Patents

Literature

329 results about "Dovetail joint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

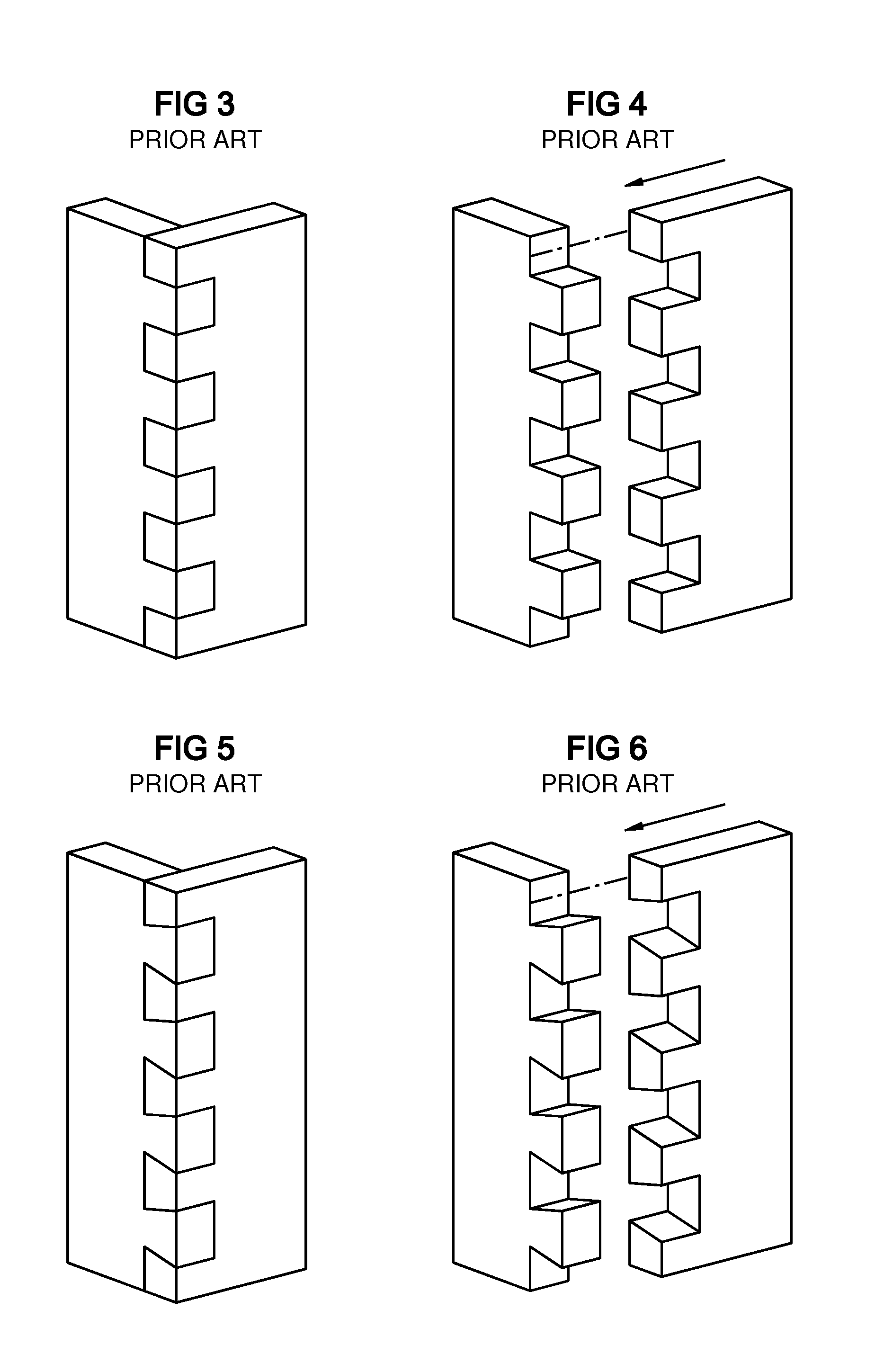

A dovetail joint or simply dovetail is a joinery technique most commonly used in woodworking joinery (carpentry) including furniture, cabinets. log buildings and traditional timber framing. Noted for its resistance to being pulled apart (tensile strength), the dovetail joint is commonly used to join the sides of a drawer to the front. A series of 'pins' cut to extend from the end of one board interlock with a series of 'tails' cut into the end of another board. The pins and tails have a trapezoidal shape. Once glued, a wooden dovetail joint requires no mechanical fasteners.

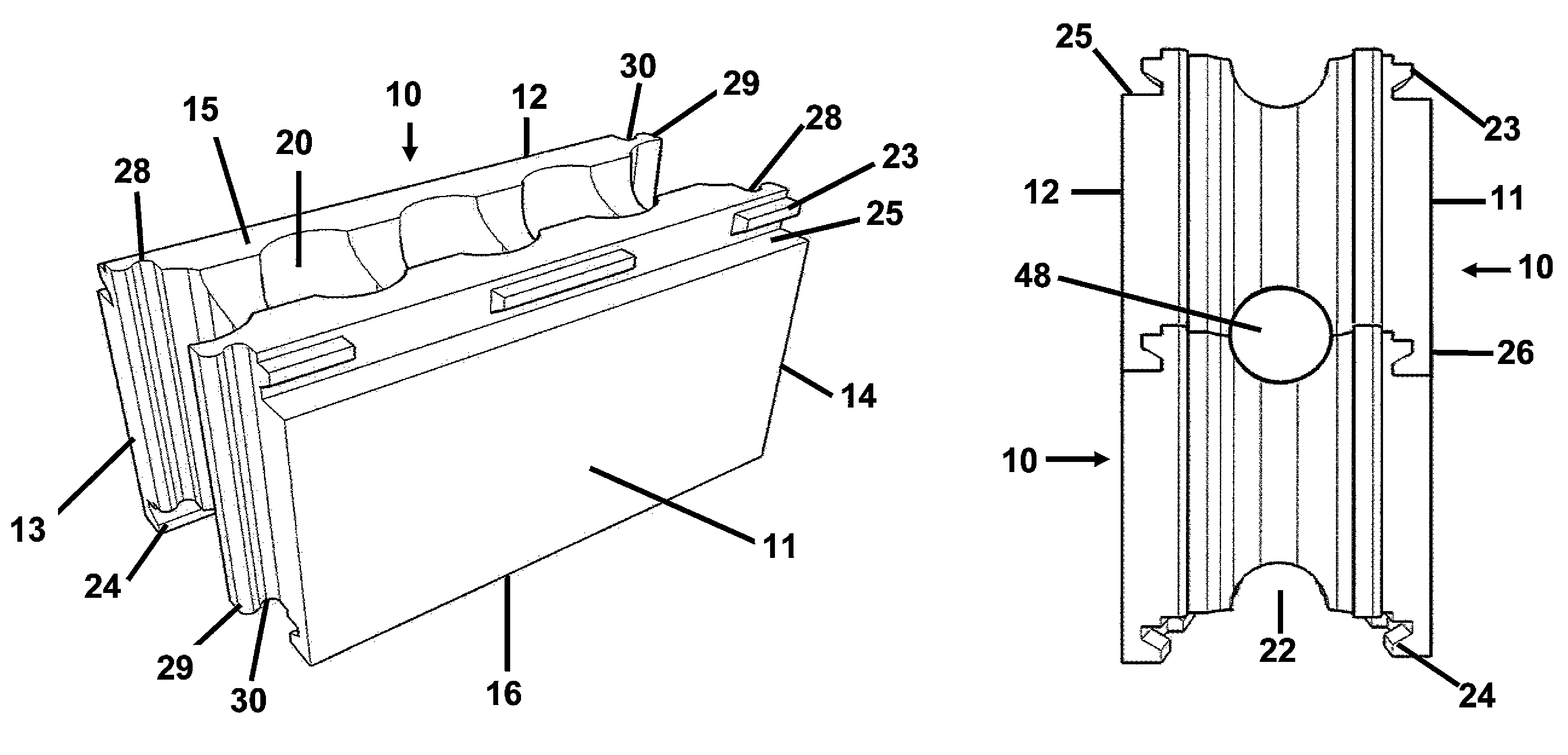

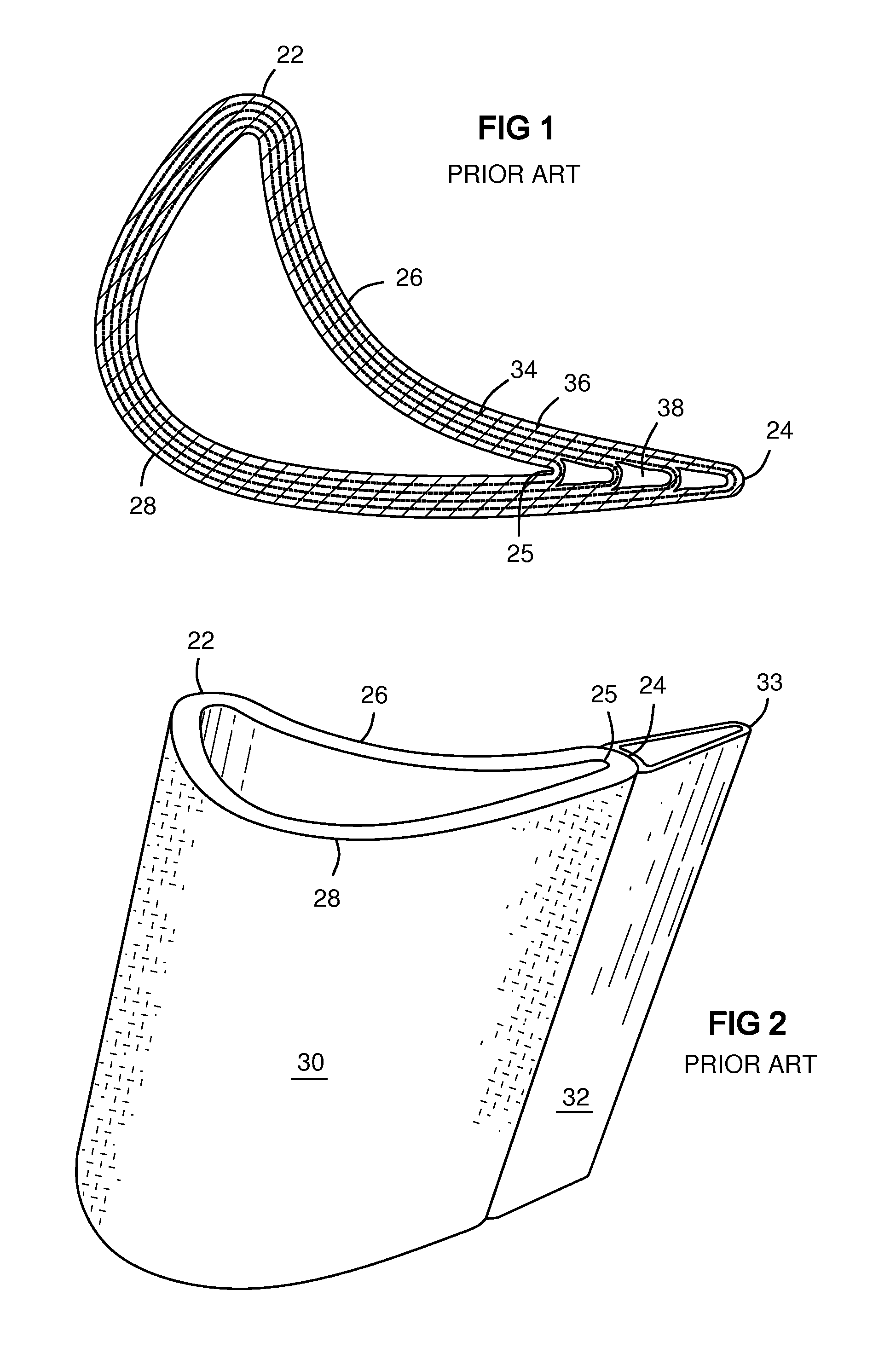

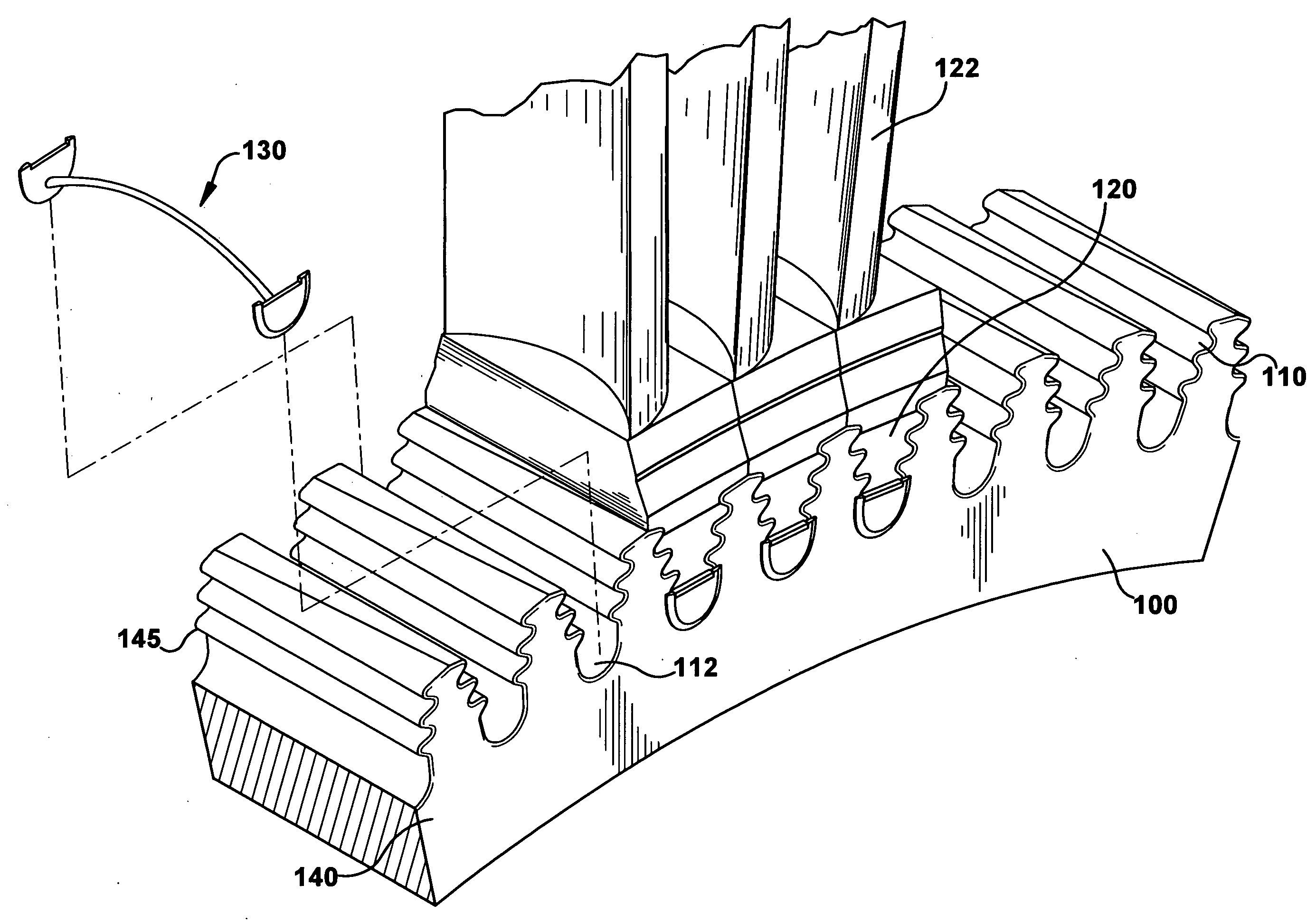

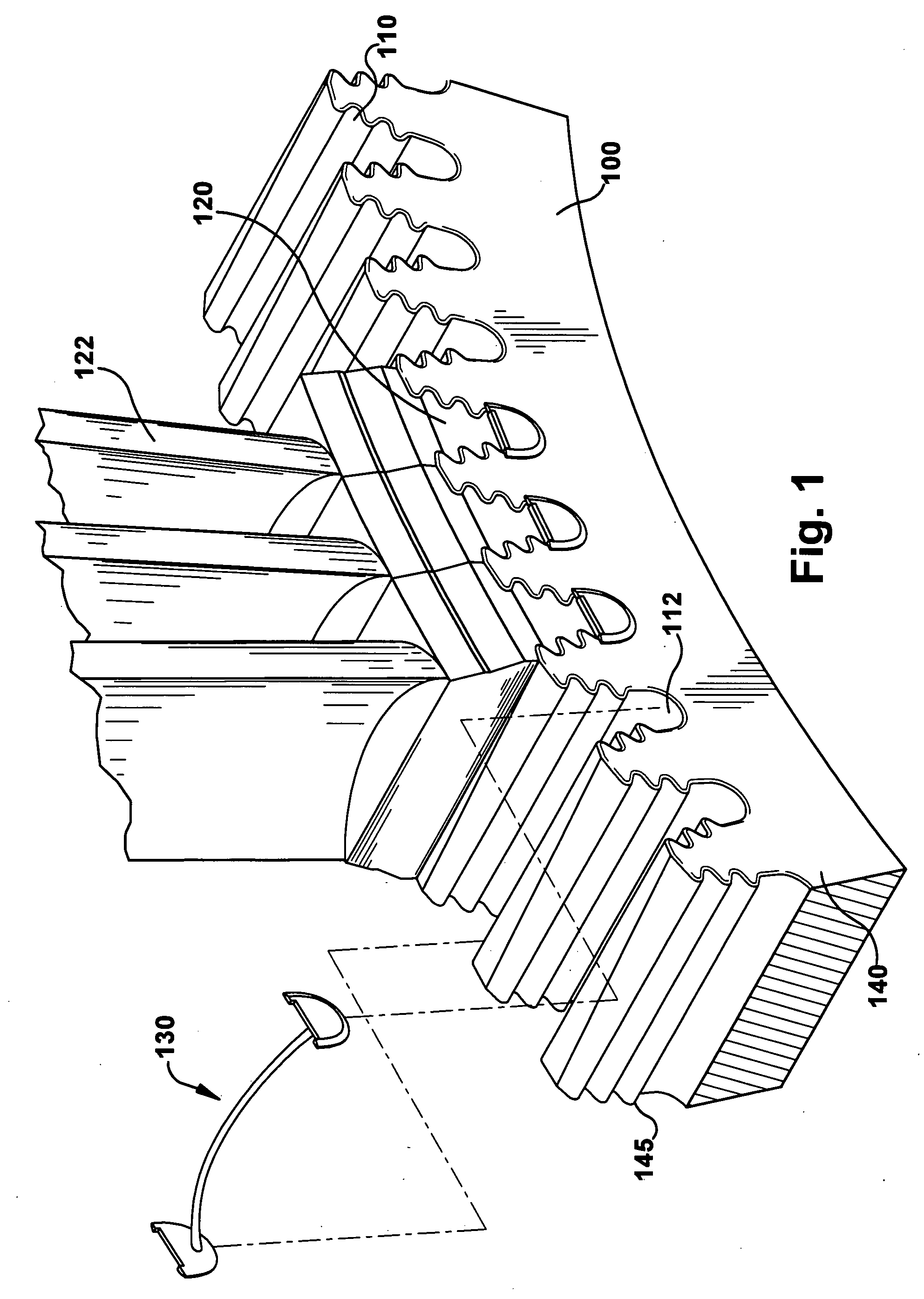

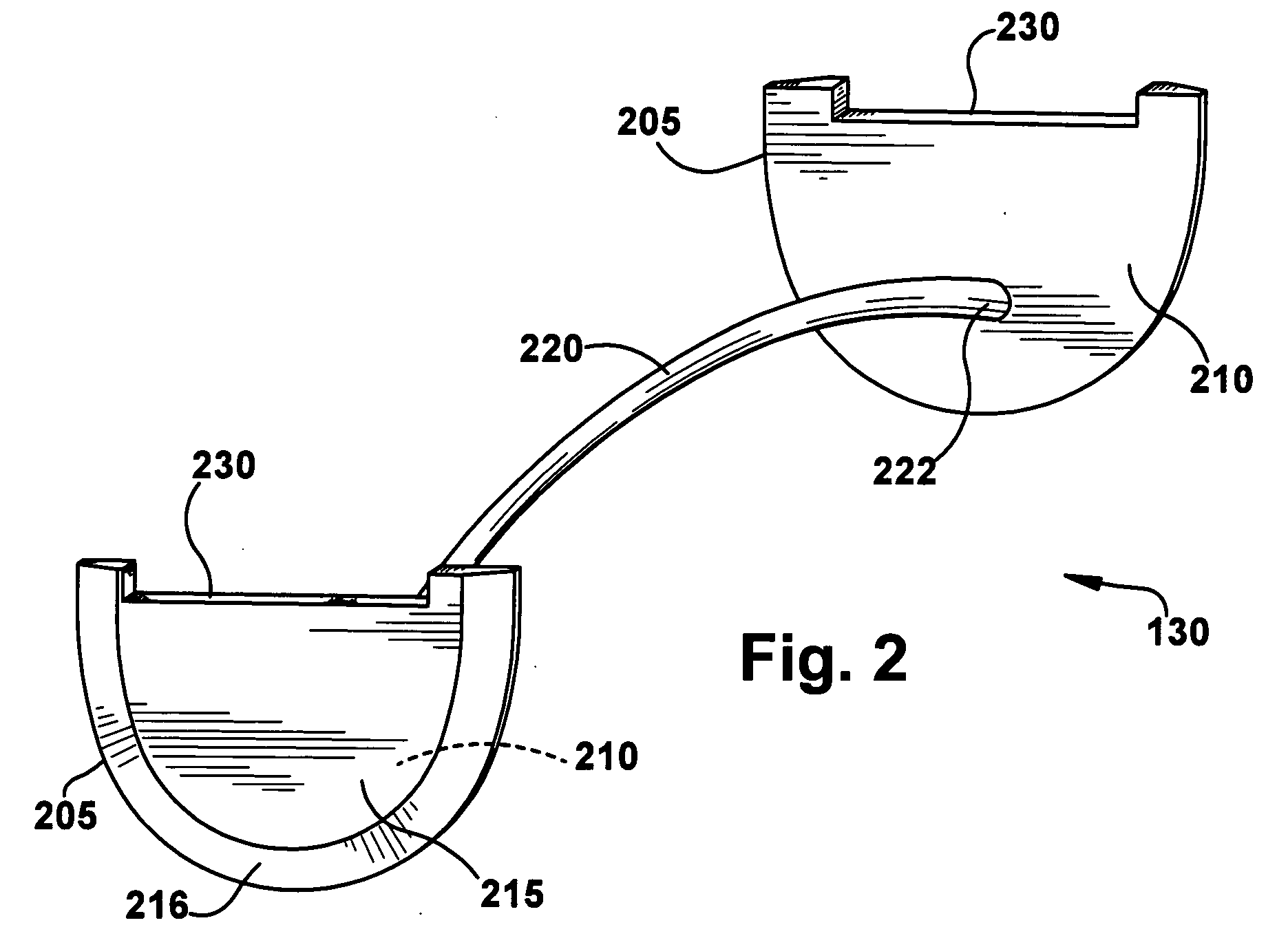

Allograft implant

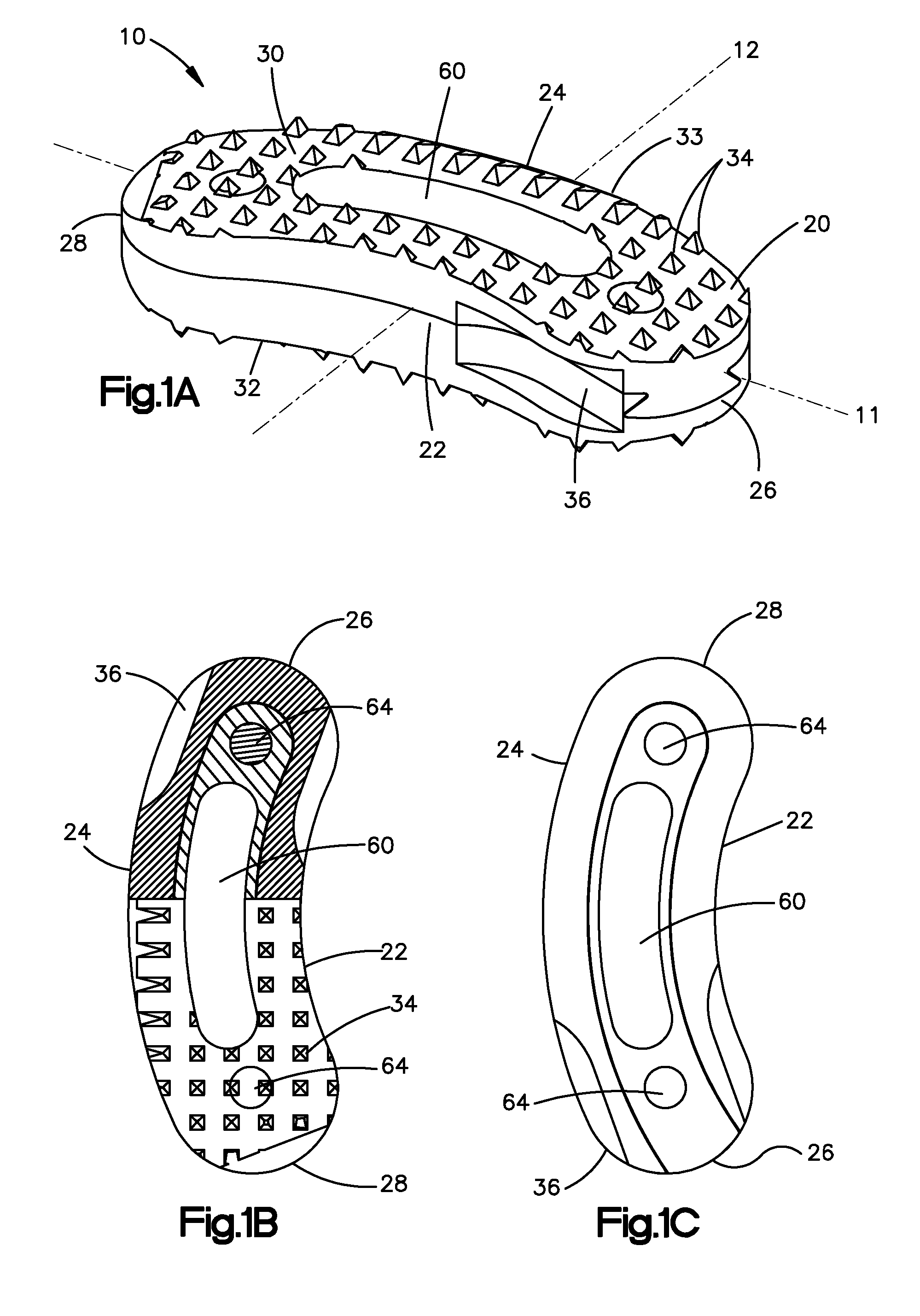

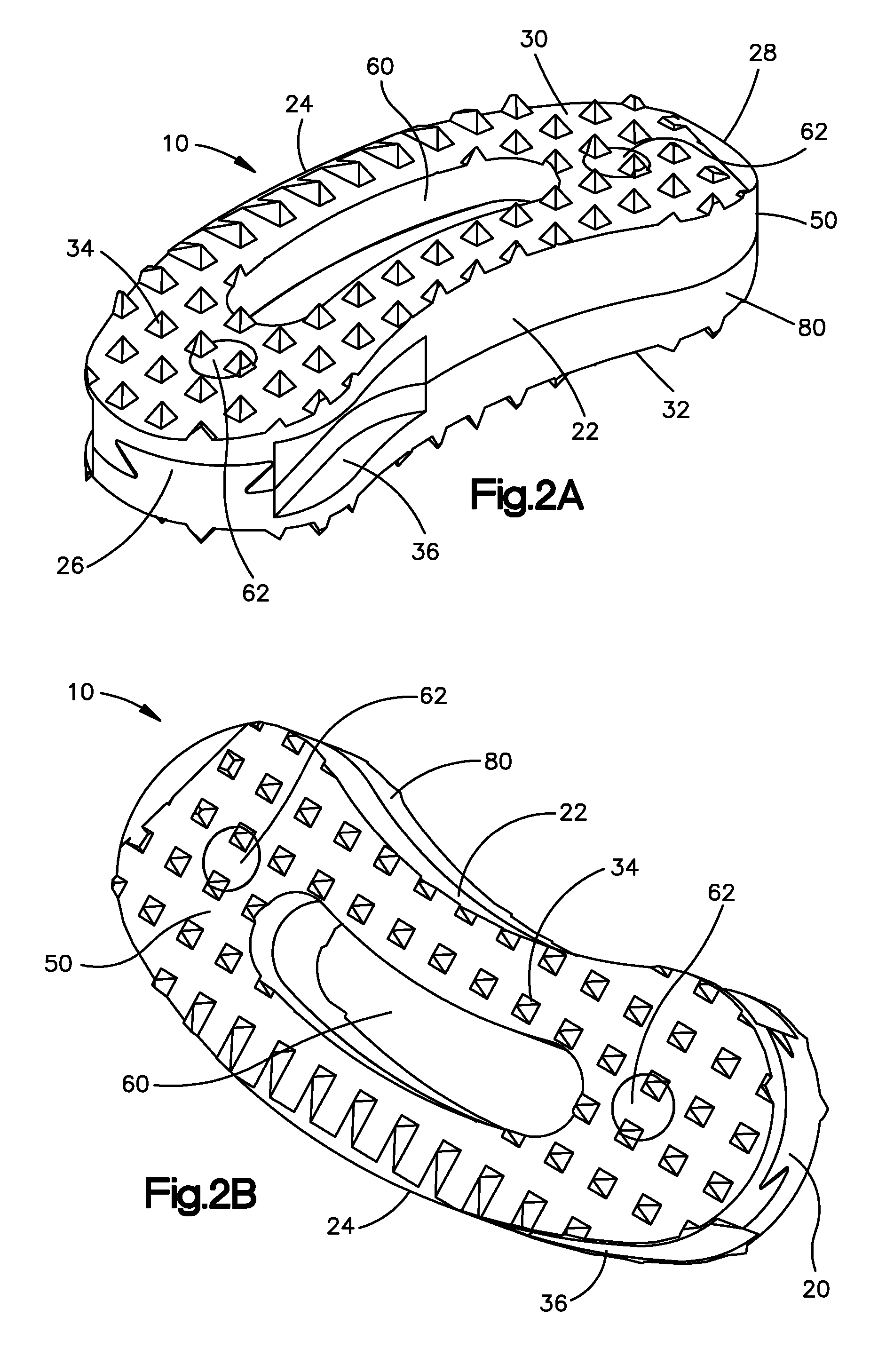

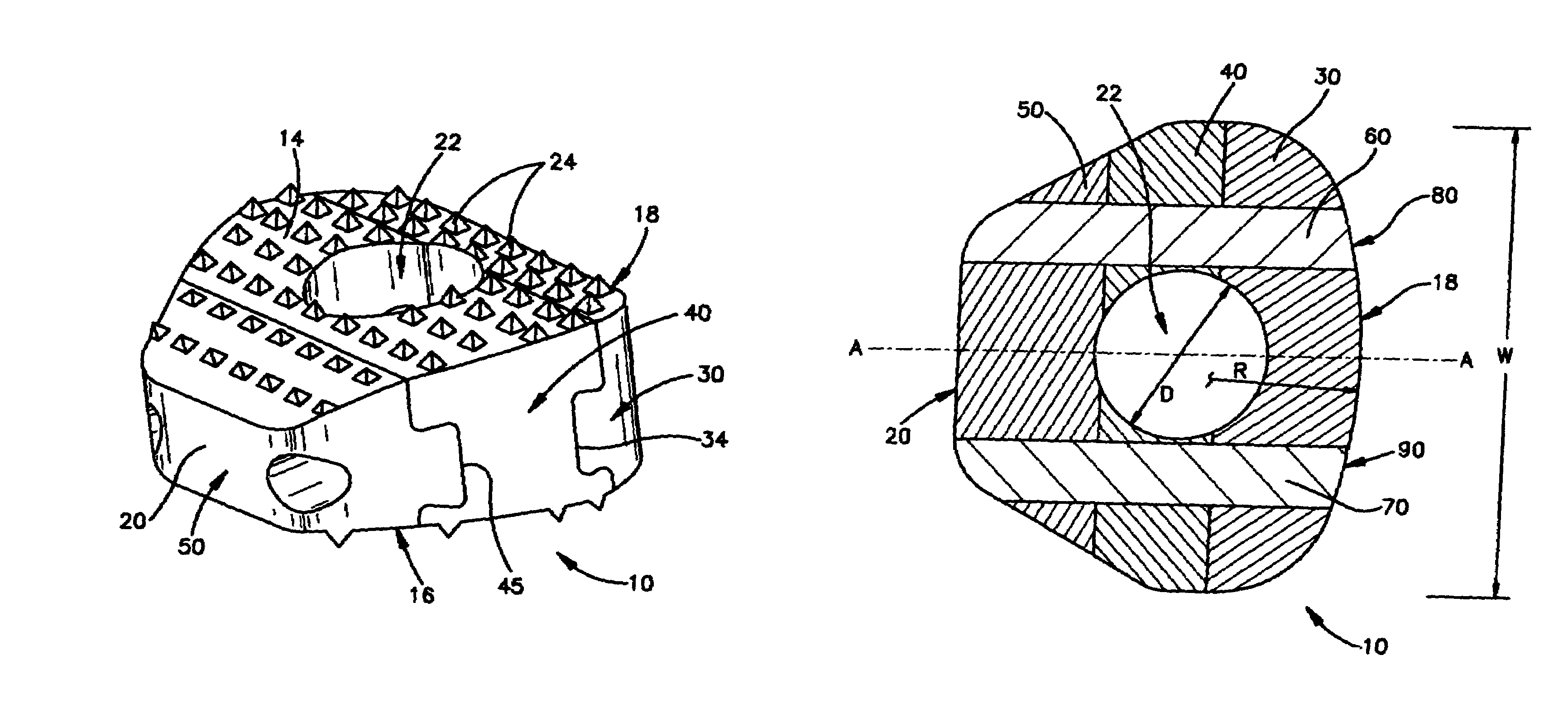

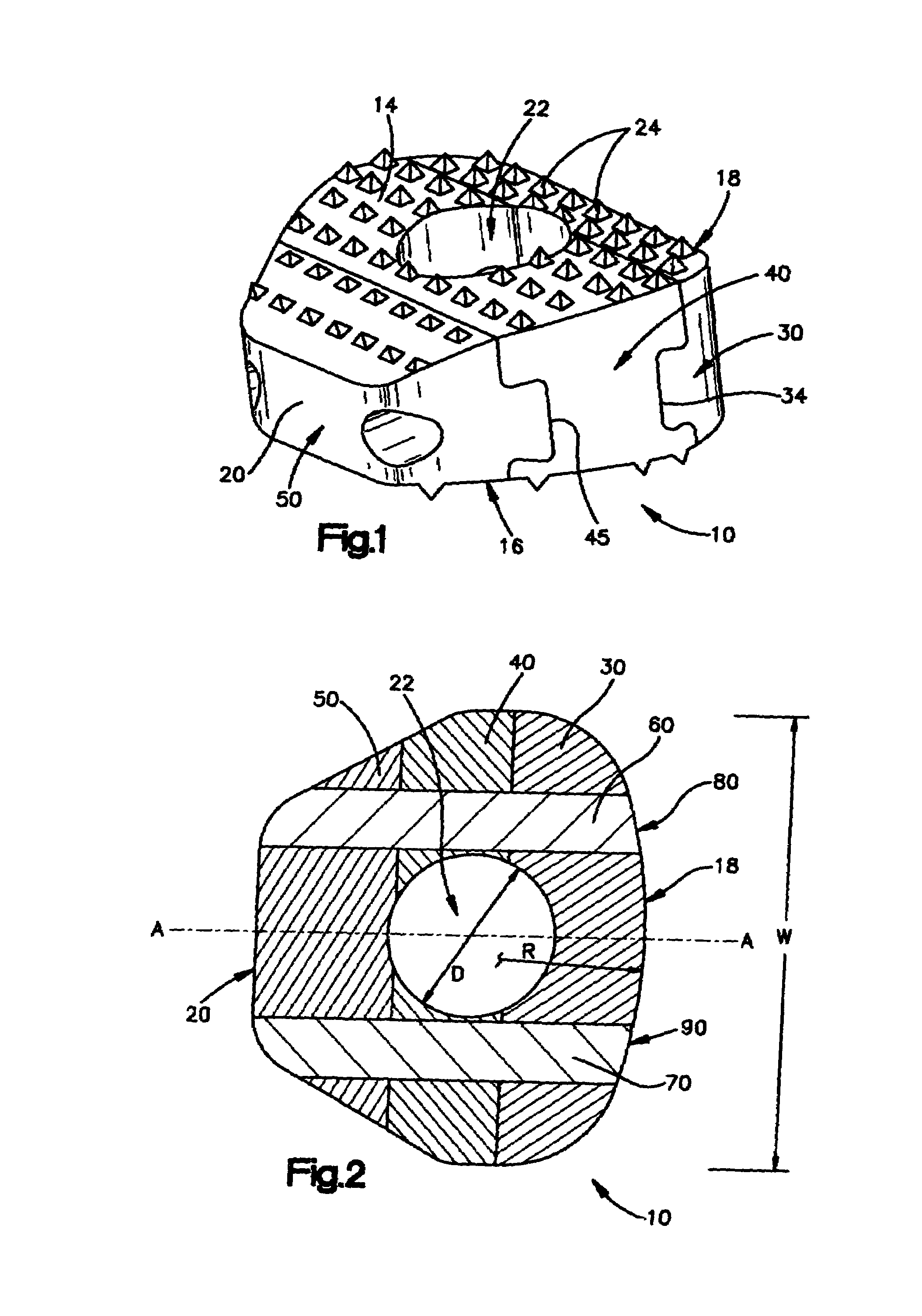

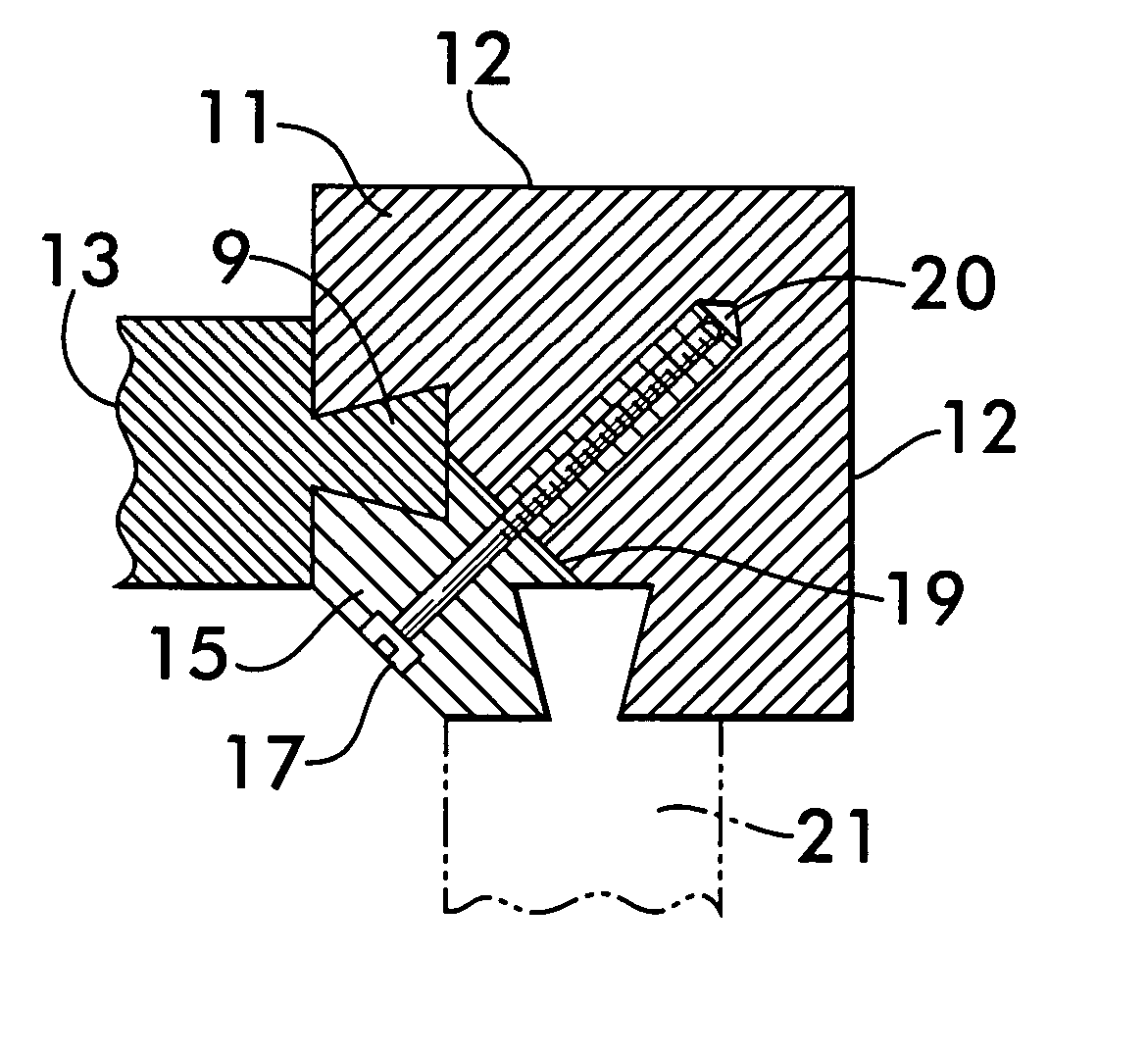

ActiveUS20050240267A1Maximize sizeInhibit migrationBone implantJoint implantsBone CortexCortical bone

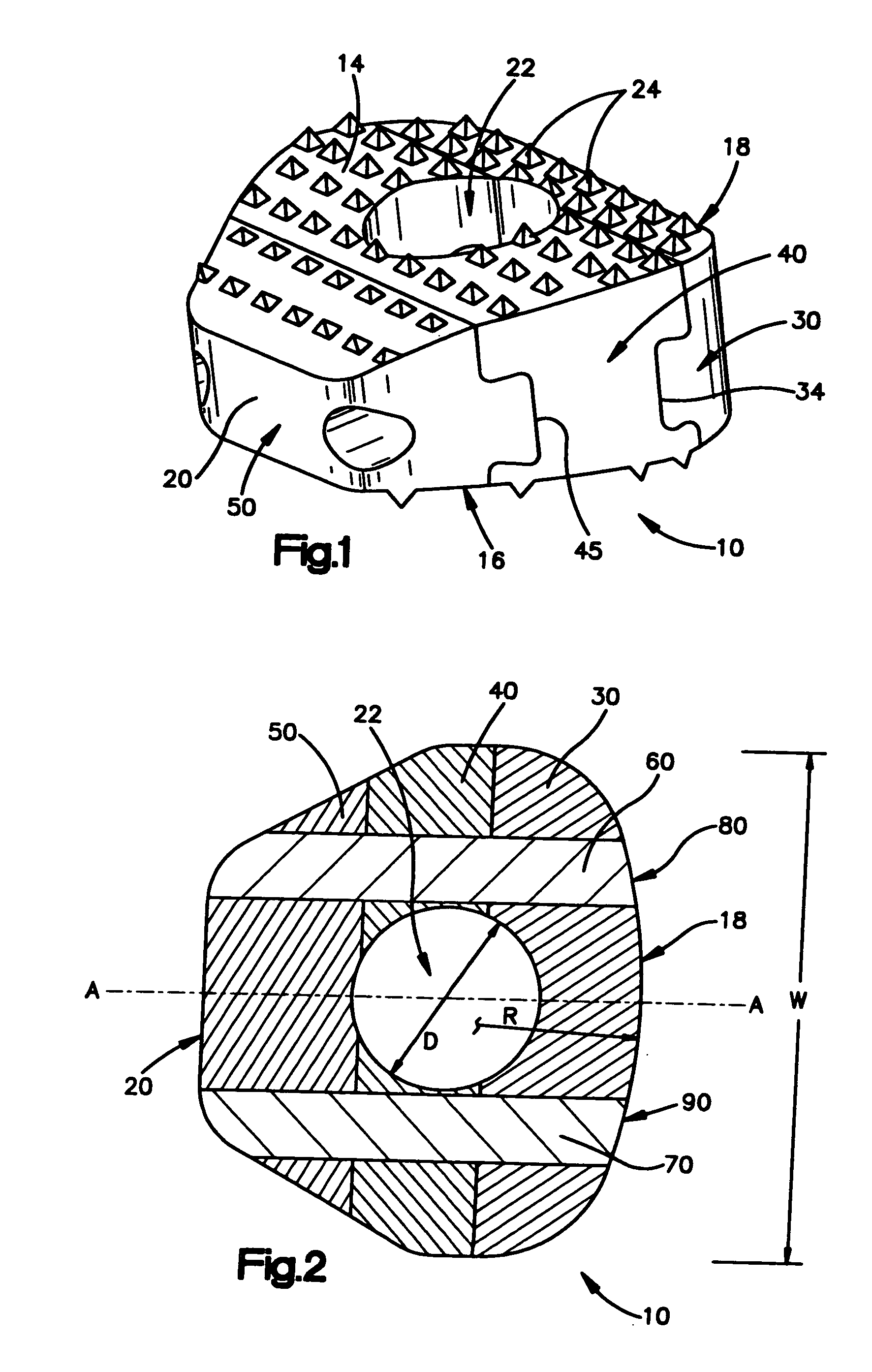

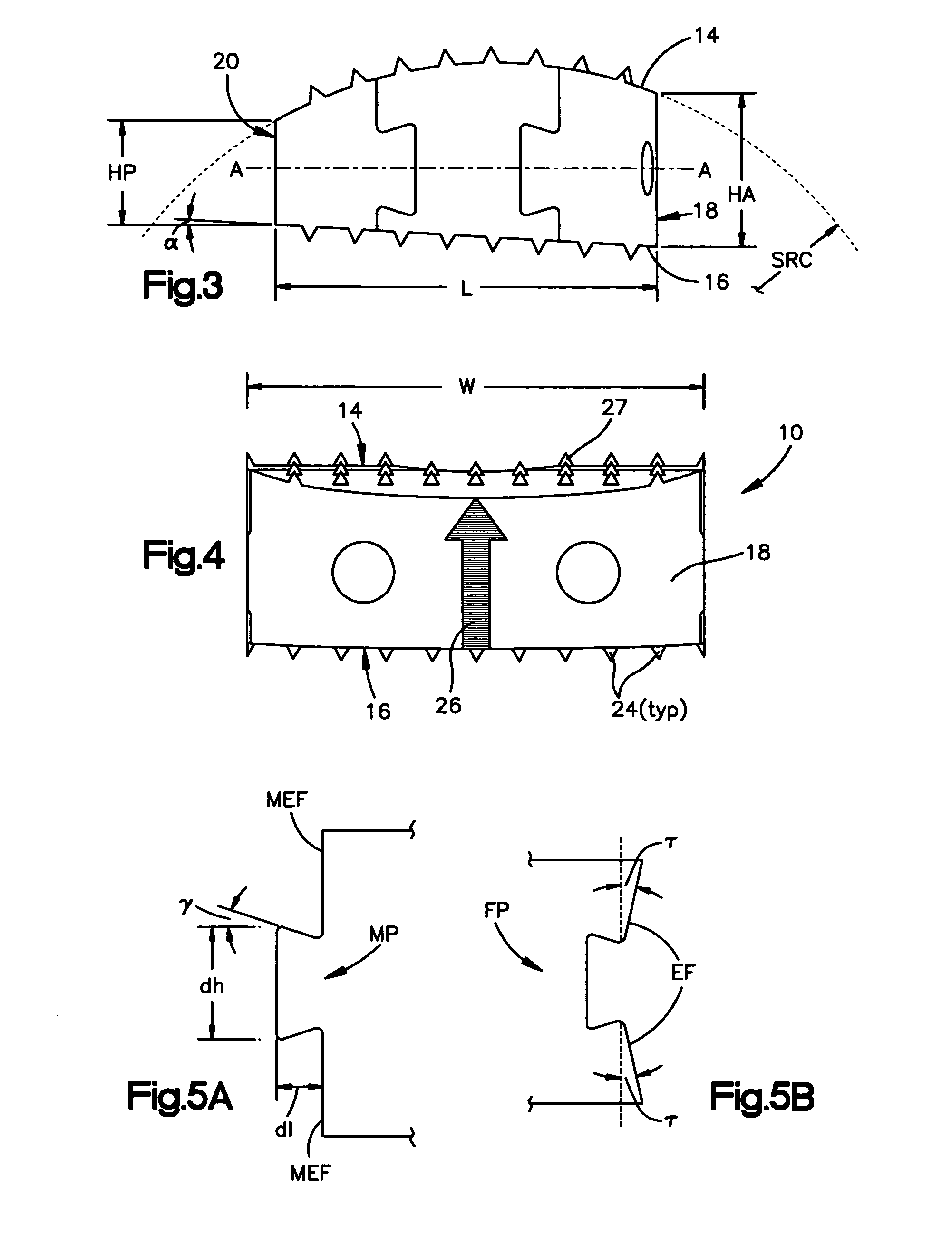

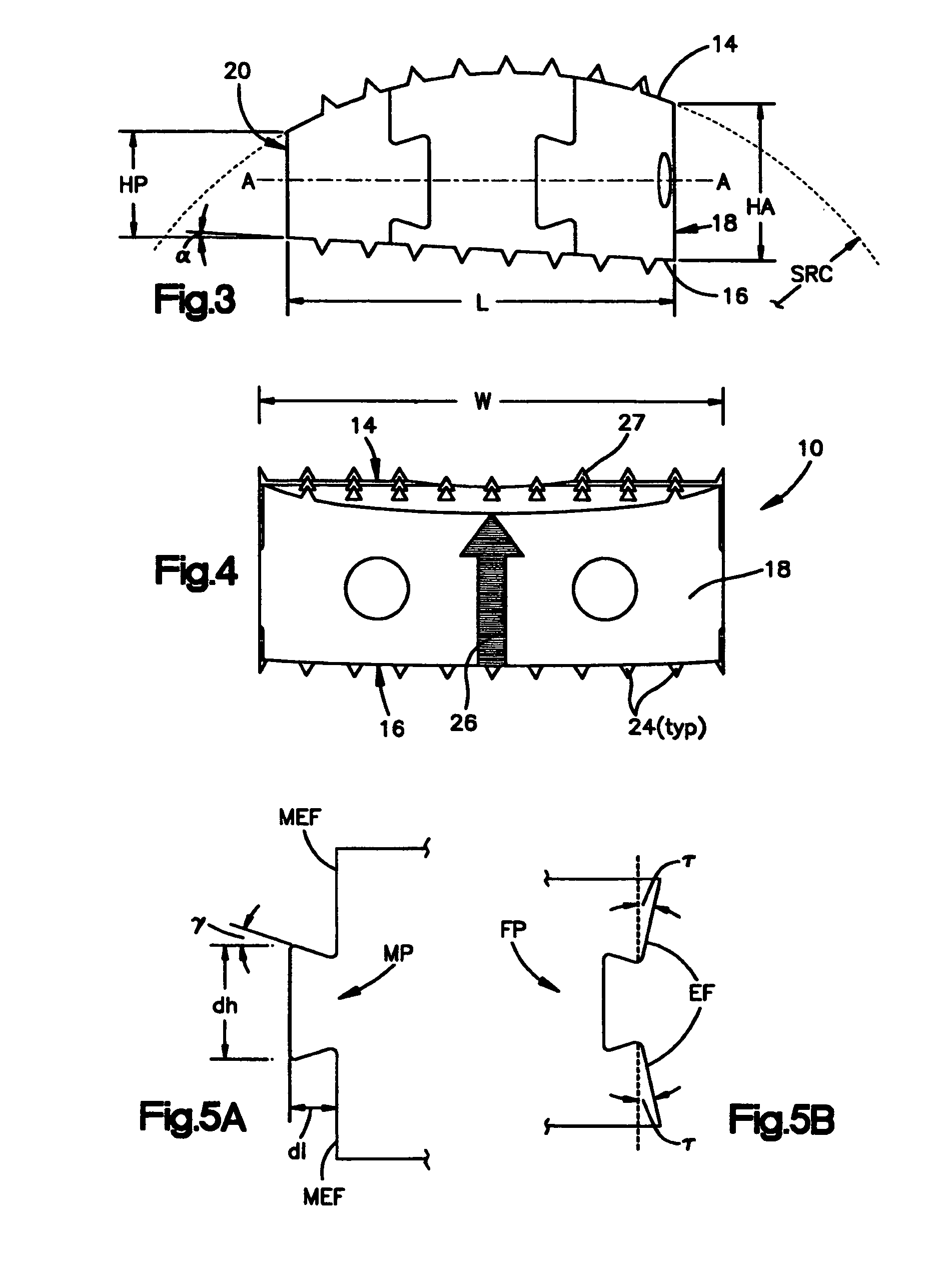

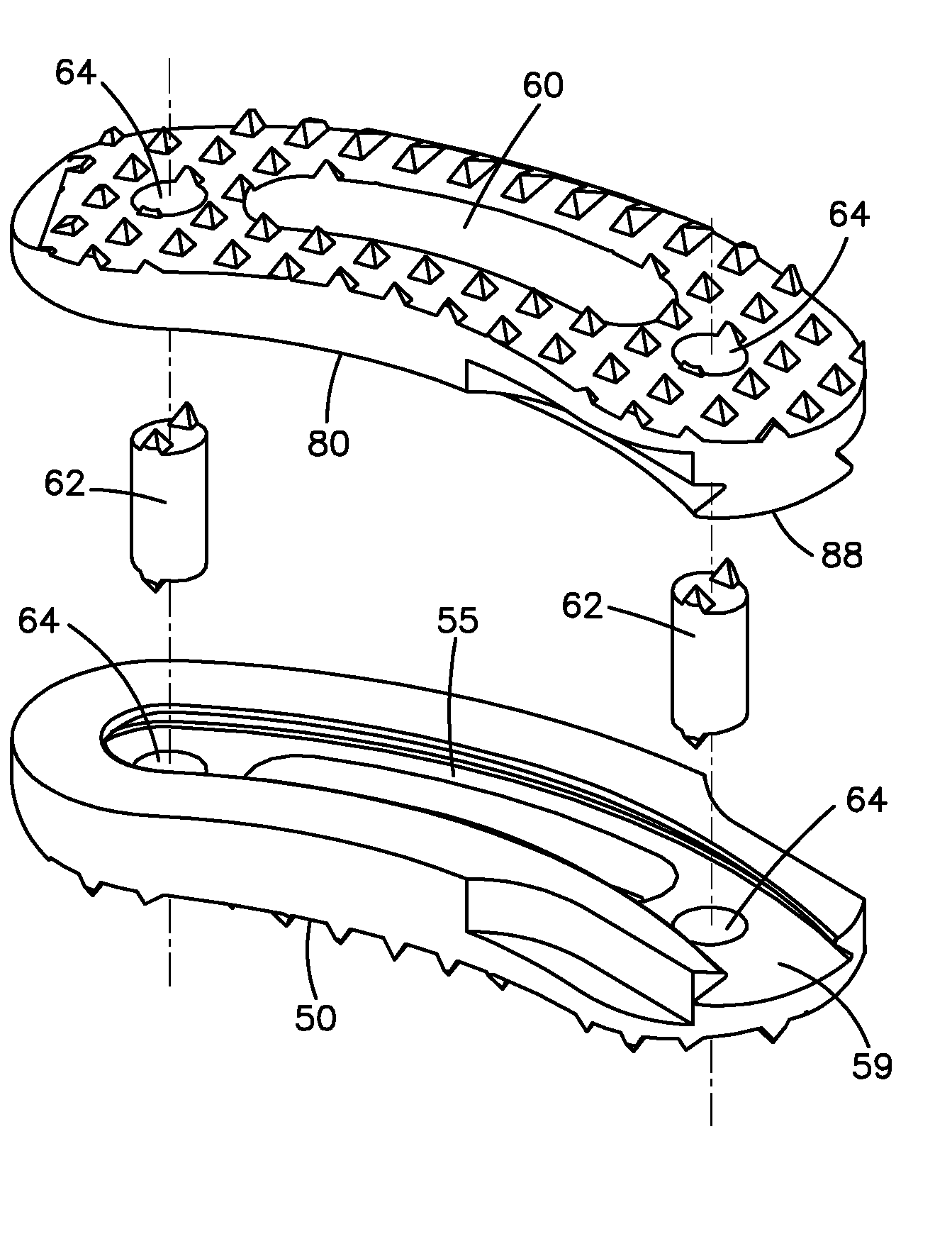

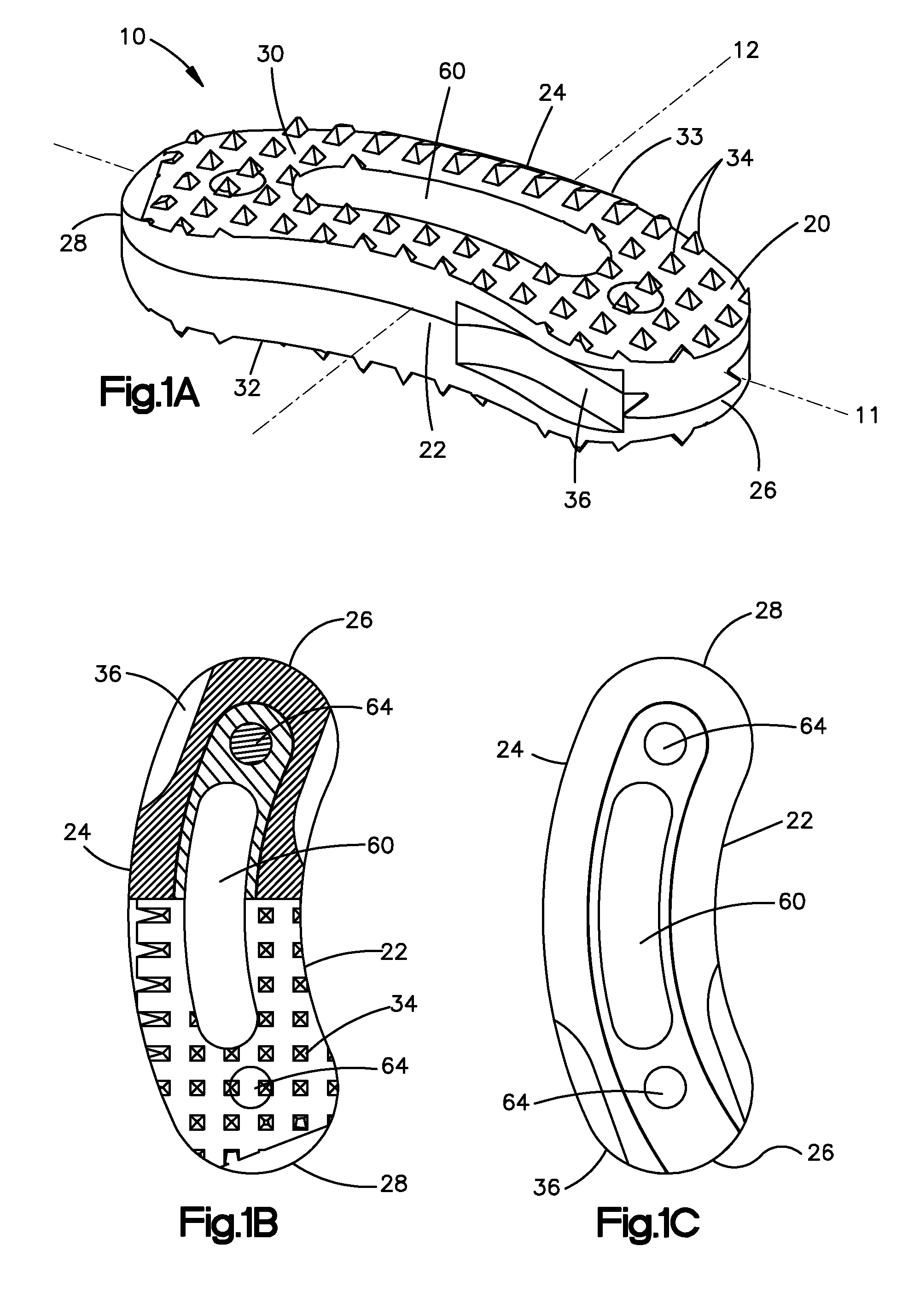

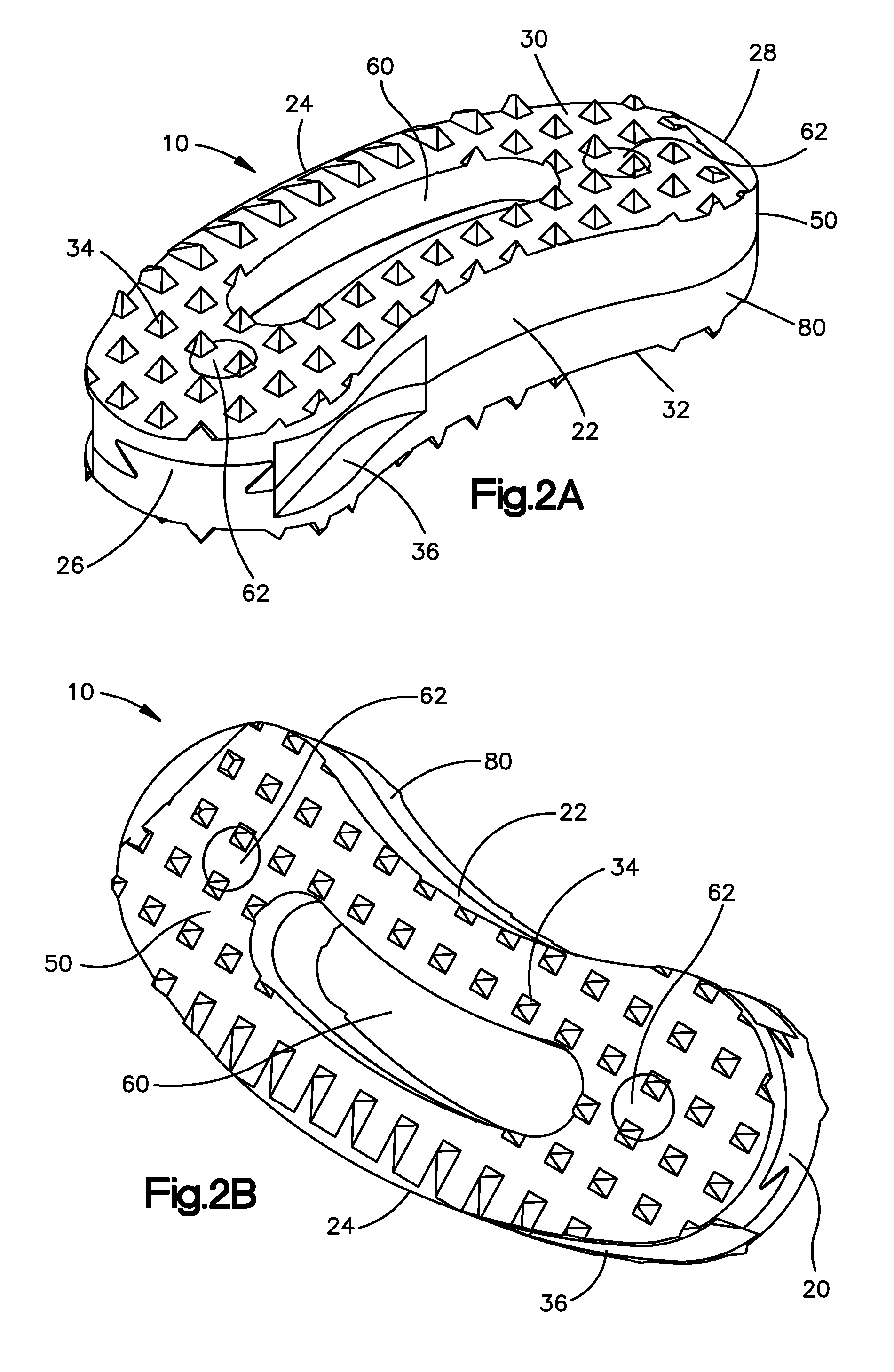

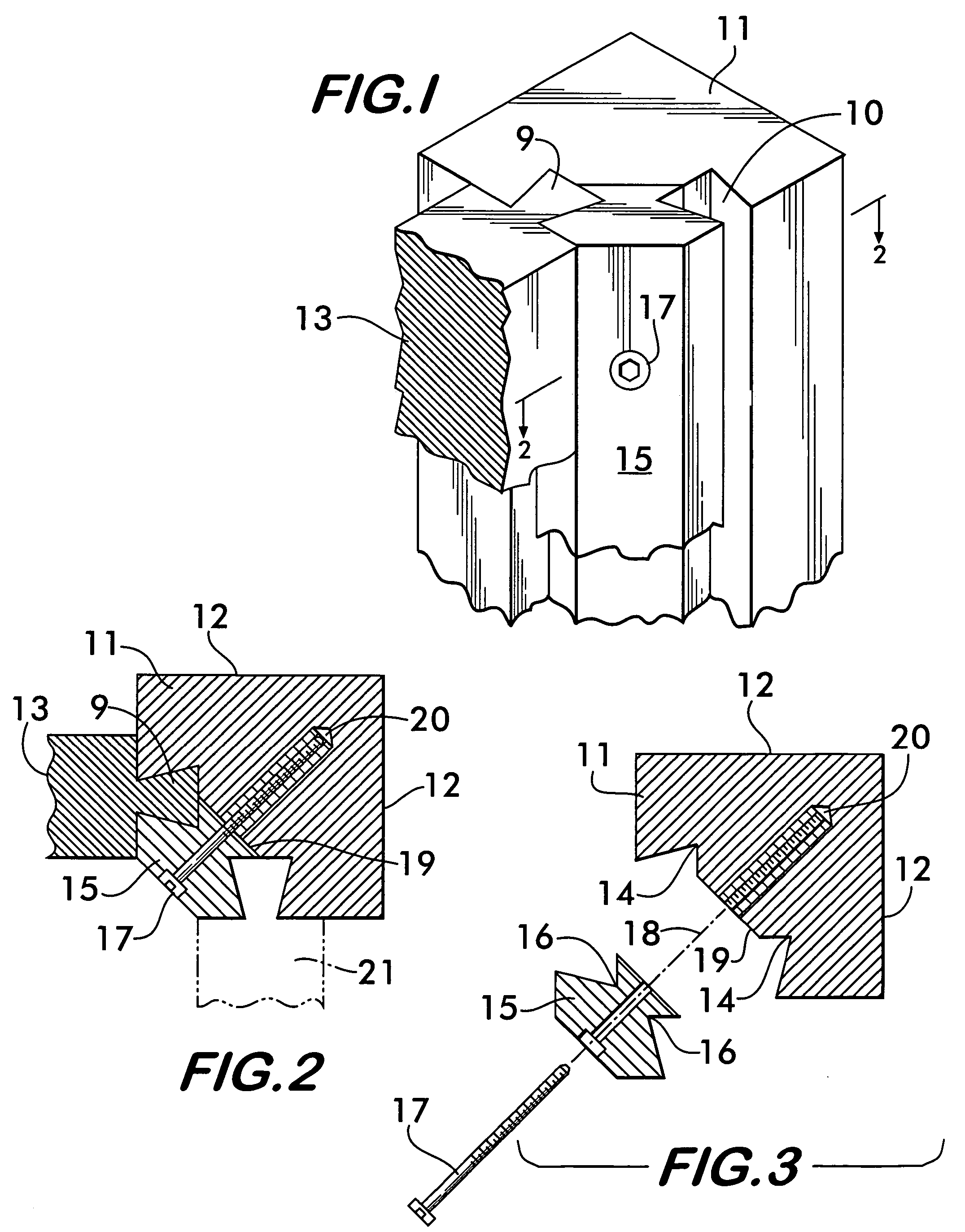

An allogenic implant for use in intervertebral fusion is formed from one or more two pieces. The pieces are made from bone, and are joined together to form an implant having sufficient strength and stability to maintain a desired distance between first and second vertebrae in a spinal fusion procedure. The implant pieces may be formed of cortical bone and connected by dovetail joints, and at least one cortical bone pin may be provided to lock the pieces together and to add strength to the implant. Teeth are formed on the vertebra engaging surfaces of the implant prevent short-term slippage of the implant.

Owner:SYNTHES USA

Allograft intervertebral implant and method of manufacturing the same

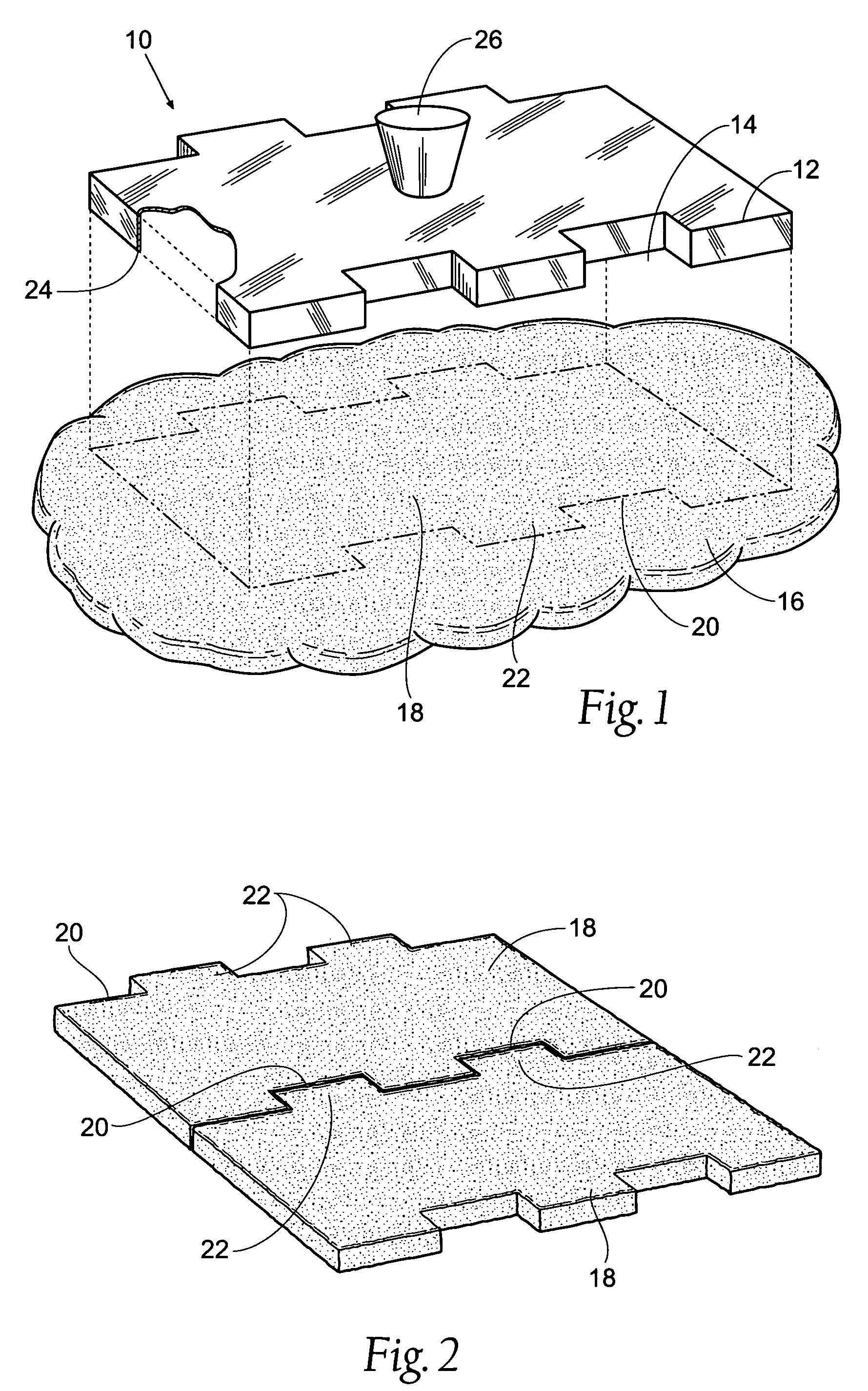

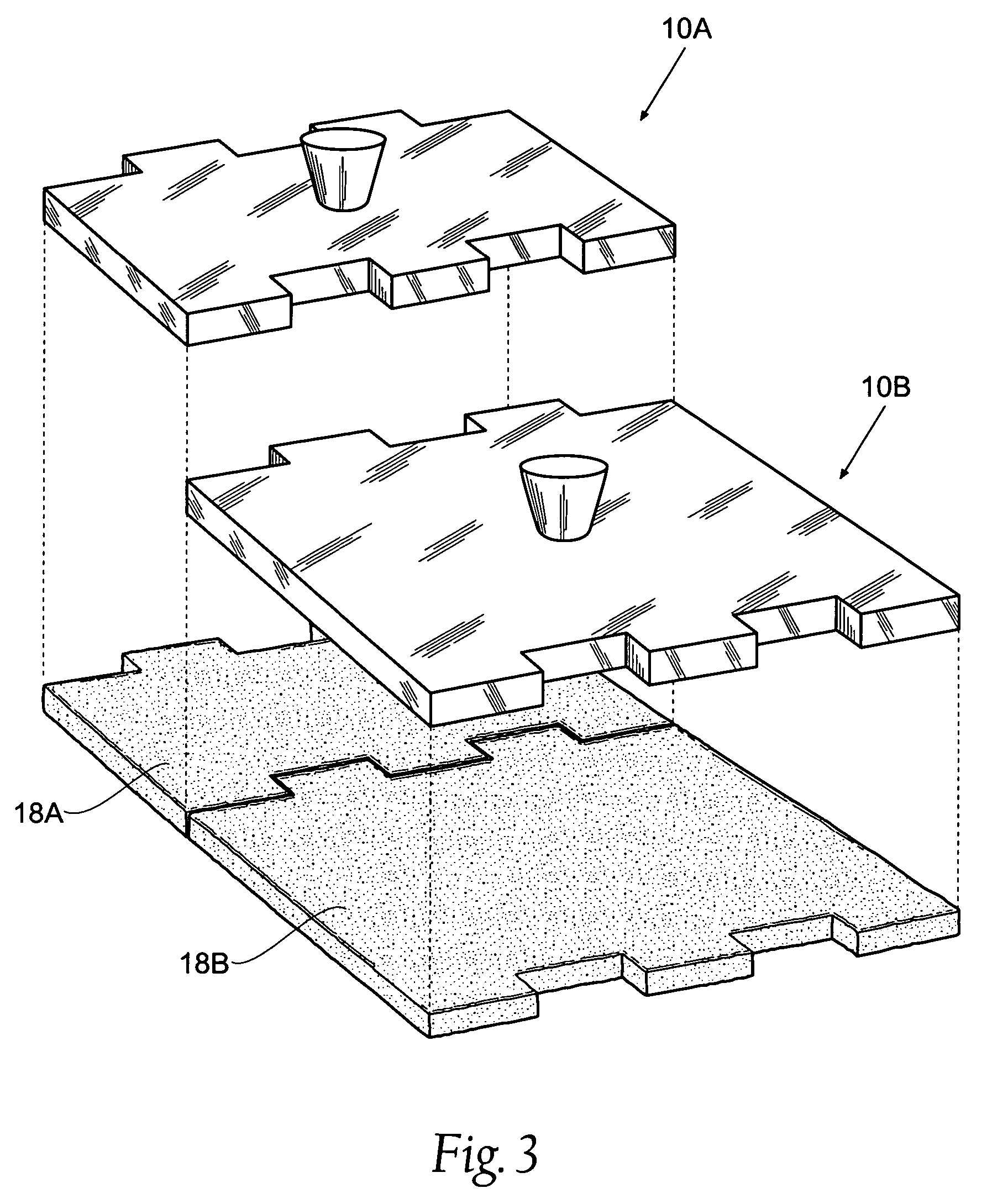

ActiveUS20080082173A1Facilitating spinal fusionBone implantSpinal implantsSacroiliac jointAllograft bone

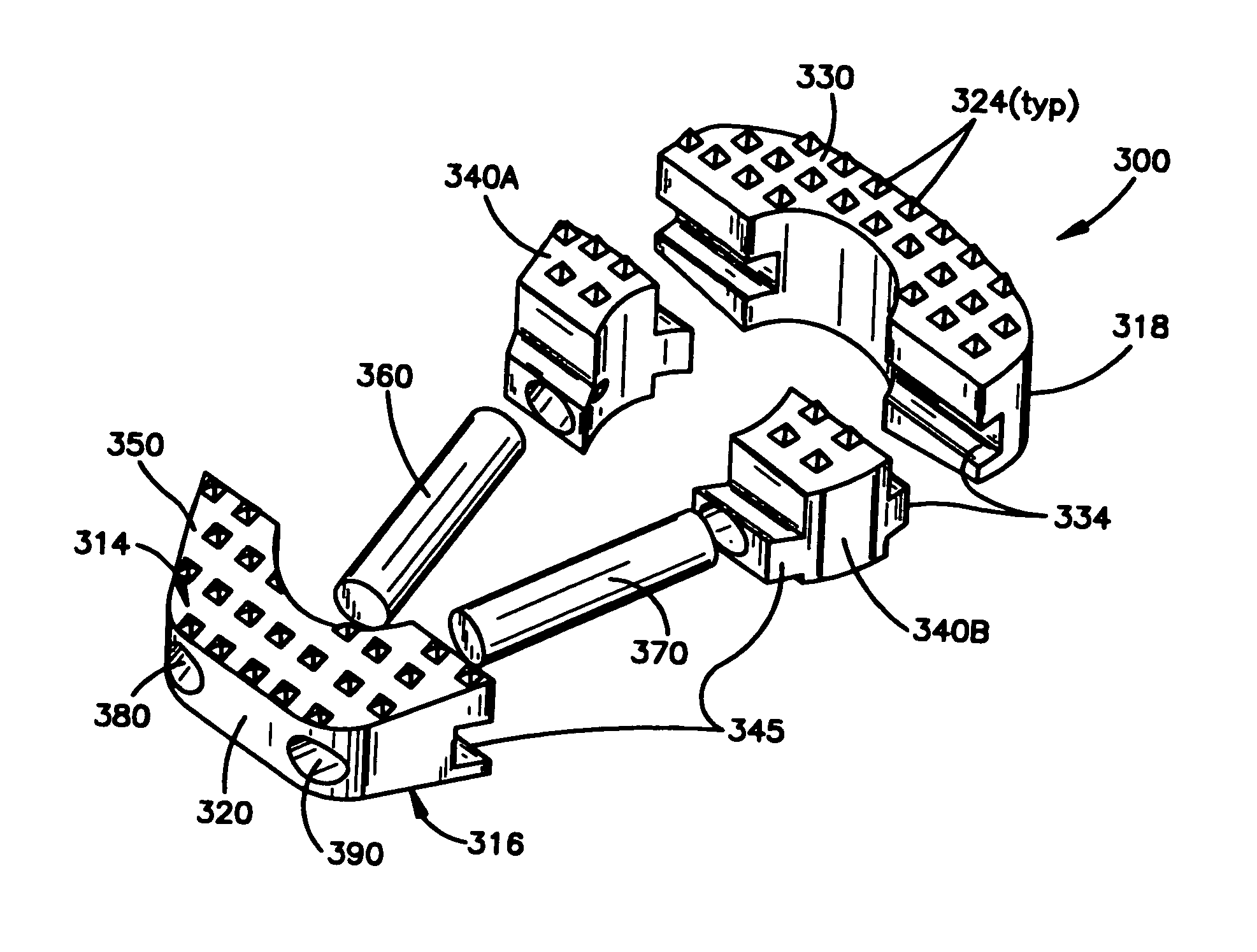

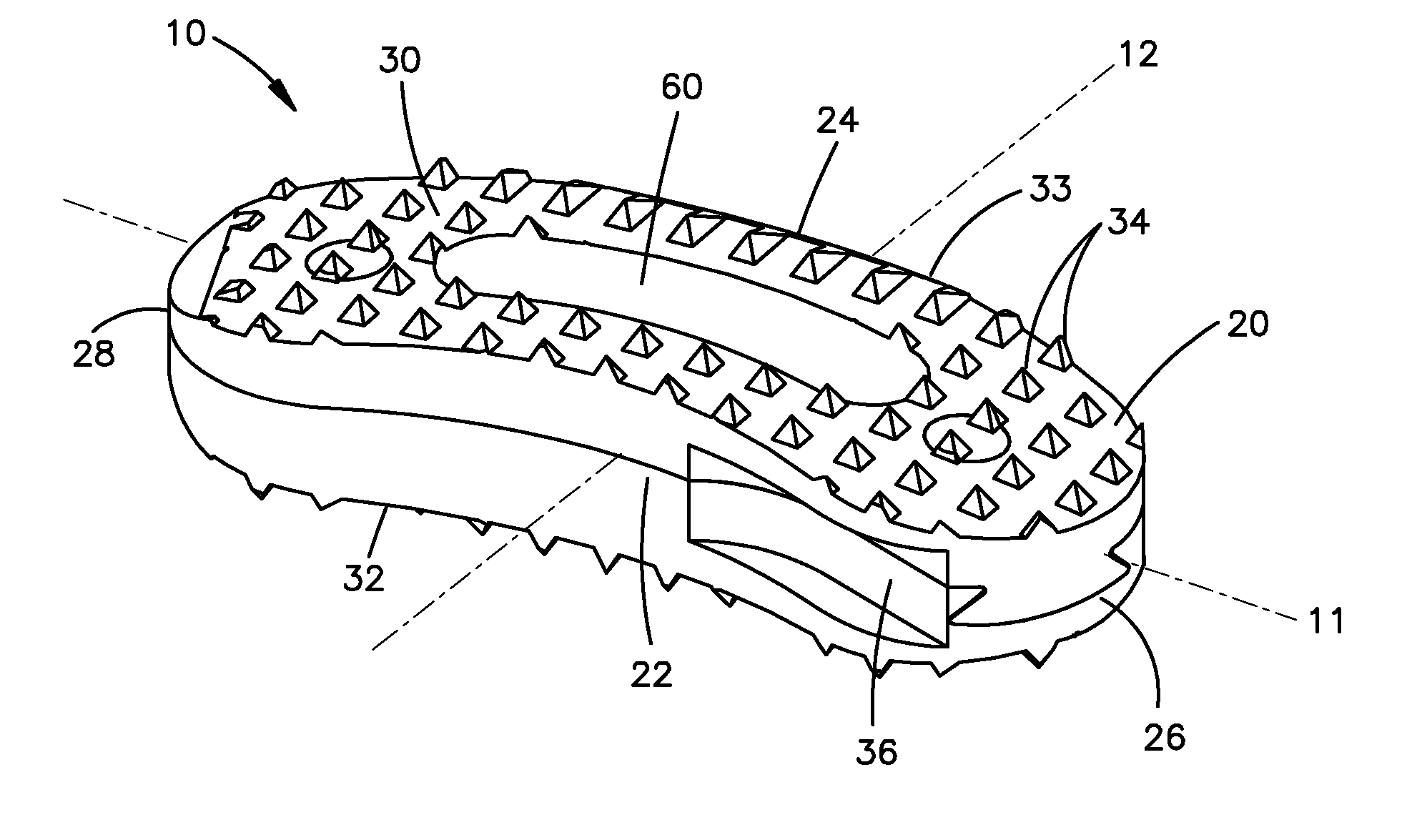

The present invention is directed to an allograft intervertebral implant sized and configured for insertion between adjacent vertebral bodies in a spinal fusion surgery. The implant is preferably manufactured from two or more pieces of allograft bone joined together by a joint, more preferably a dovetail joint. The dovetail joint being sized and configured to substantially follow the exterior shape or surface (e.g. perimeter) of the intervertebral implant. The intervertebral implant may also include one or more bone pins for joining the allograft pieces, the pins being inserted into the implant at an angle substantially perpendicular with respect to the dovetail joint. The intervertebral implant may also include one or more through-bores for receiving ostegenic or bone graft material. The intervertebral implant is preferably sized and configured for insertion during a T-PLIF or PLIF procedure.

Owner:SYNTHES USA

Allograft implant

ActiveUS7491237B2Inhibit migrationMaximize sizeBone implantJoint implantsBone CortexIntervertebral fusion

Owner:SYNTHES USA

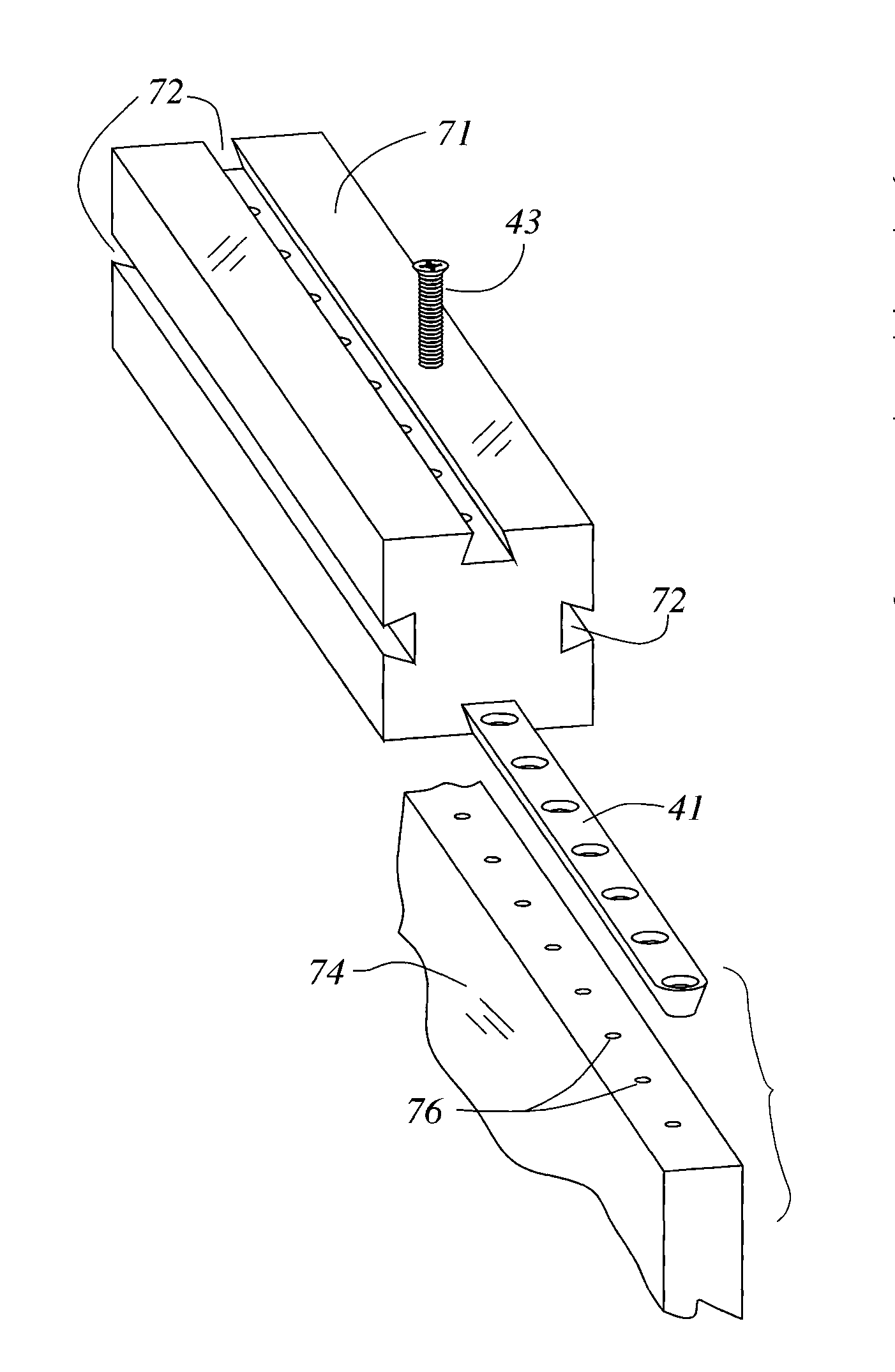

Furniture component joining system

InactiveUS20140294498A1Easy to cutEasy to modifyFurniture joining partsRod connectionsEngineeringMechanical engineering

A dovetail joining system for furniture provides hardware components that embody the male and / or female components of the dovetail joint, and these components are secured to structural components using standard screws. Male dovetail fittings have a cross-sectional profile complementary to a dovetail groove, and are secured to furniture components with screws, and range in length from a bar with a large plurality of screw holes, to a short component having a single screw hole. A block fitting comprises a rectangular solid tube with each surface having a female dovetail channel dimensioned to receive a male dovetail fitting. A male right angle dovetail fitting has orthogonal arms, each arm slidably secured in a dovetail channel formed in a separate furniture component.

Owner:LOGAN WILLIAM ROBERT

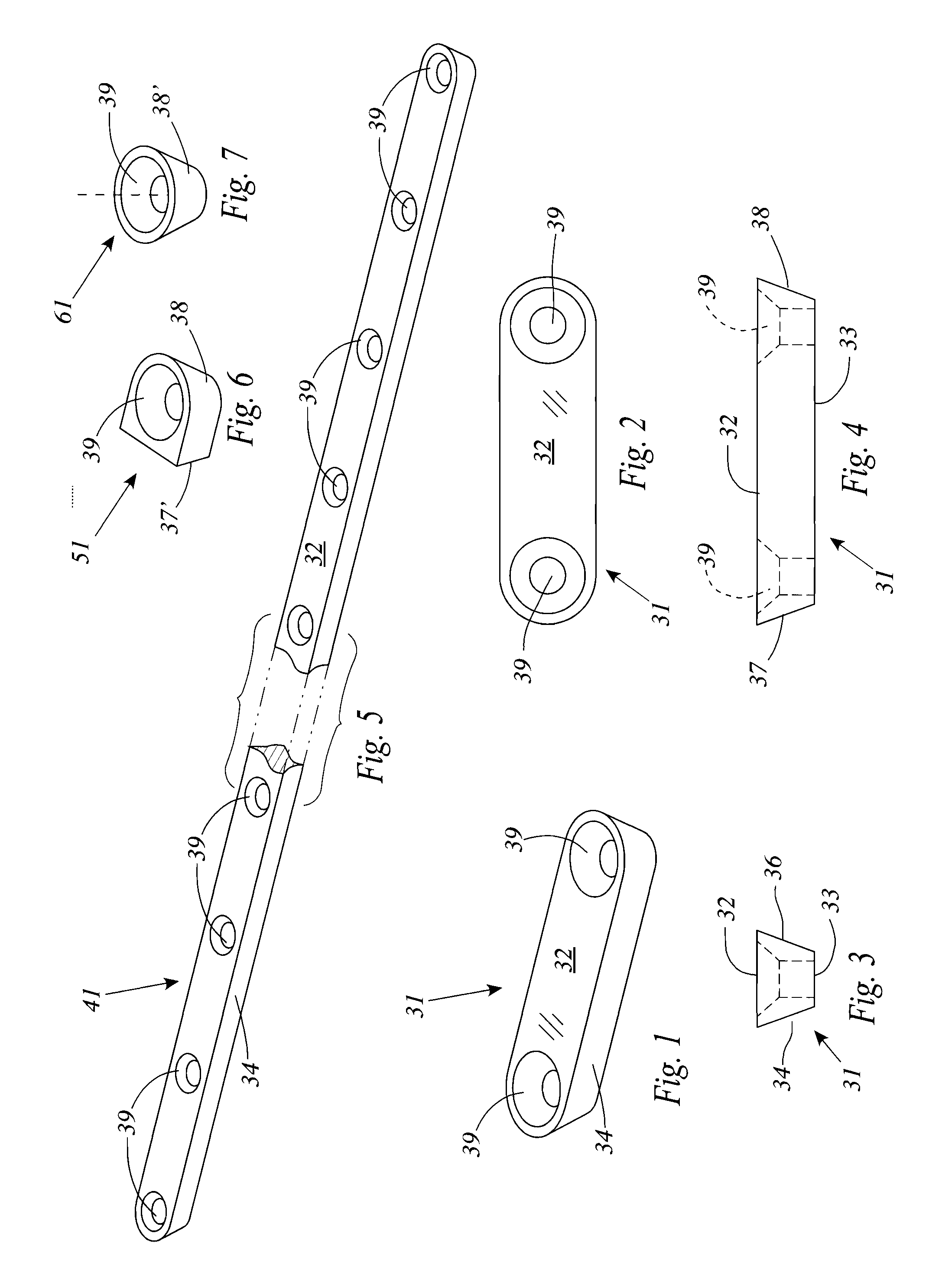

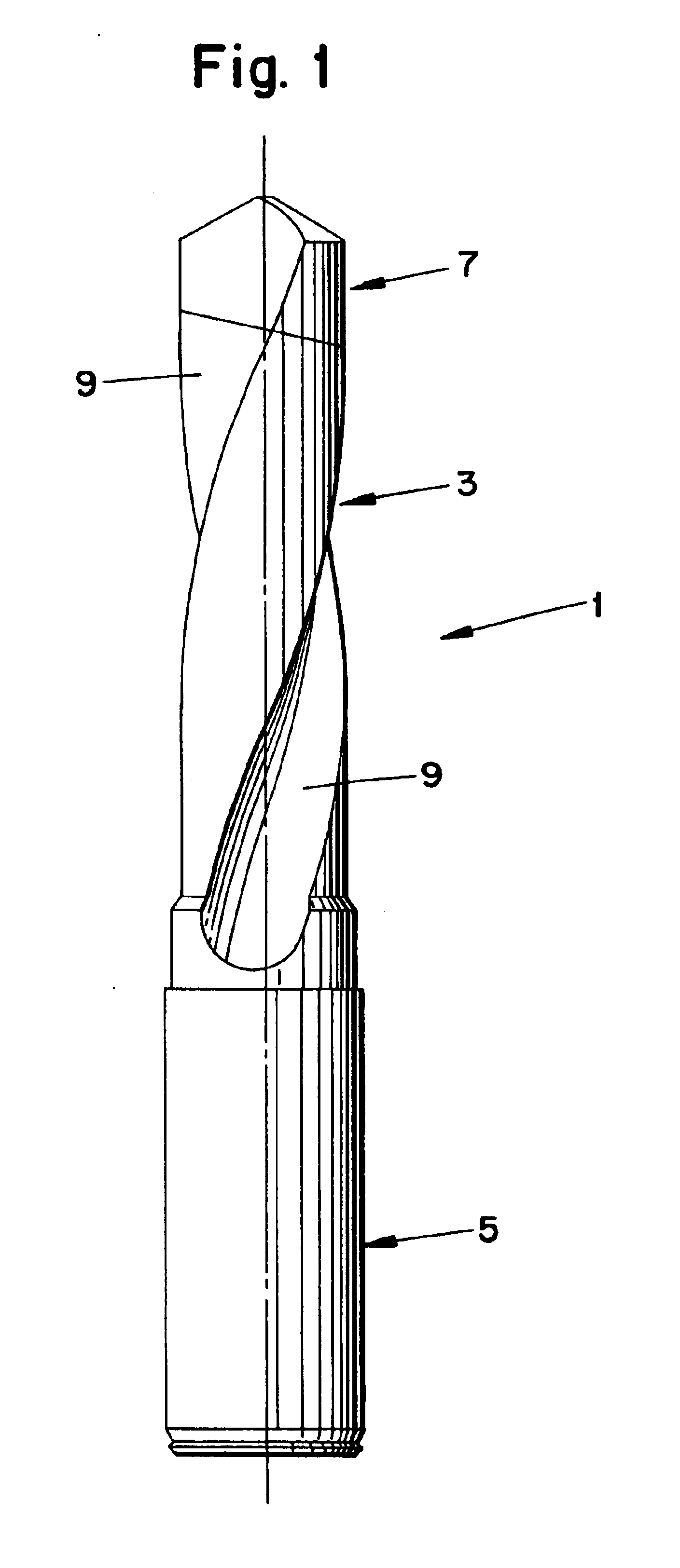

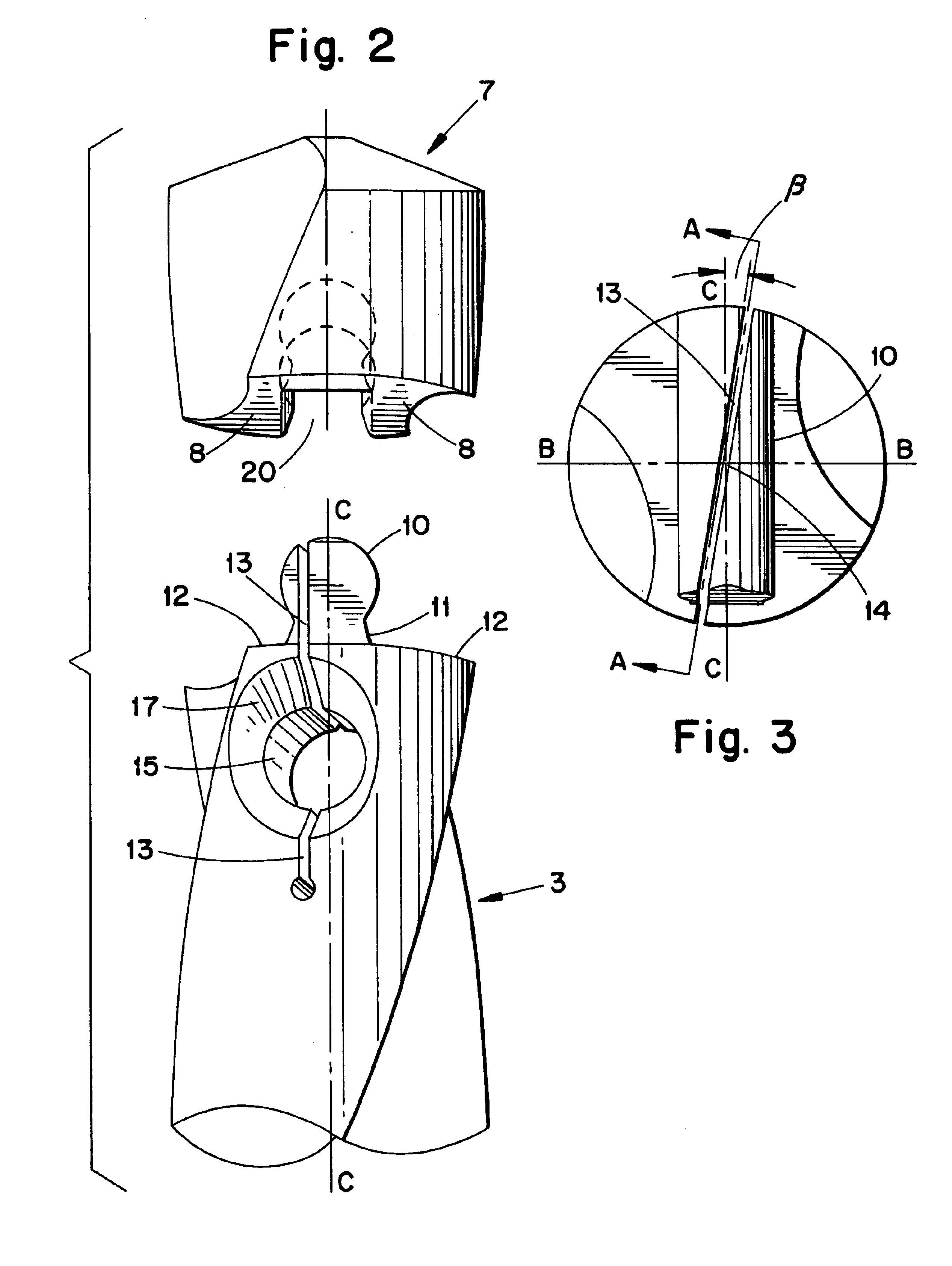

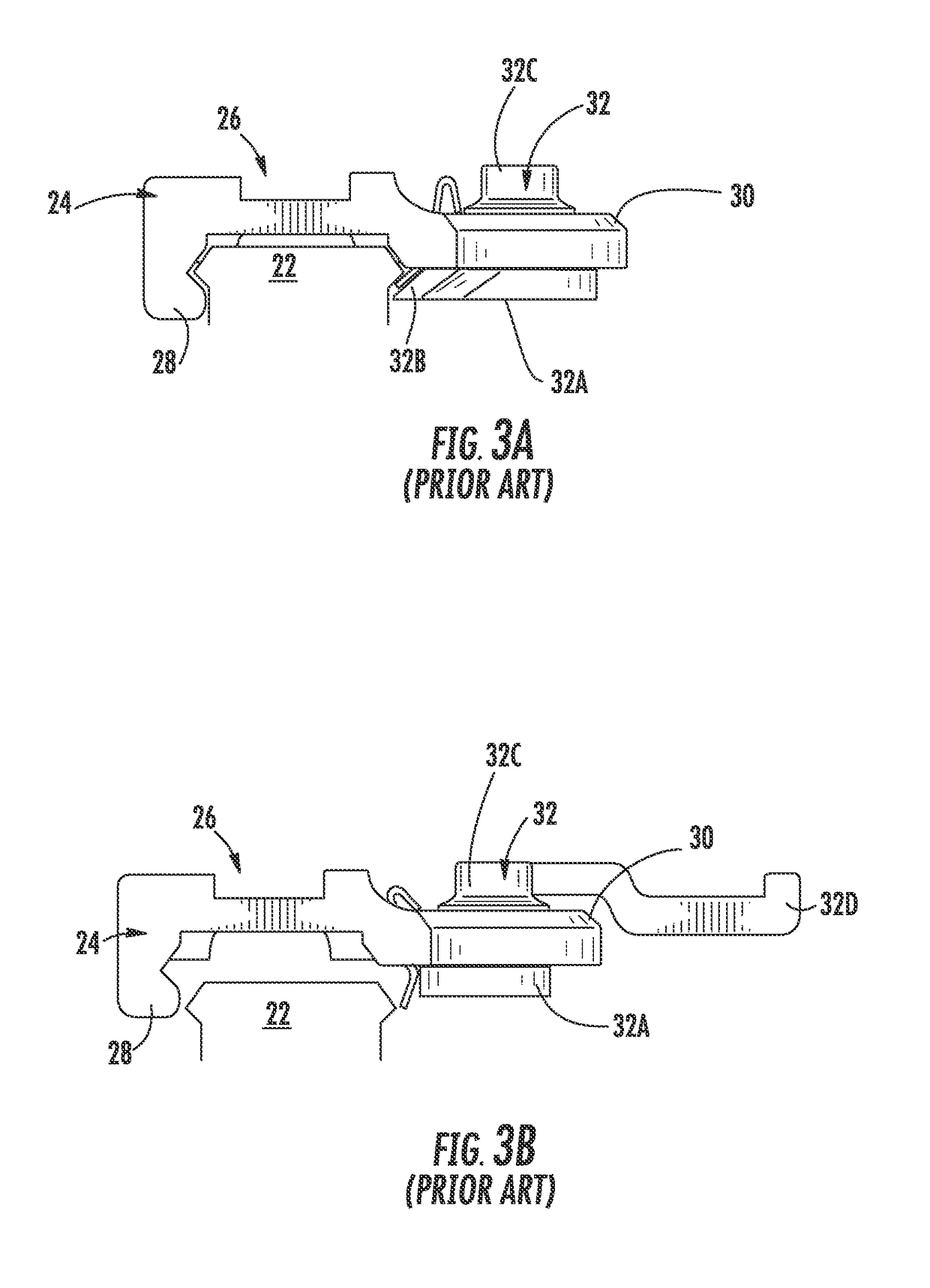

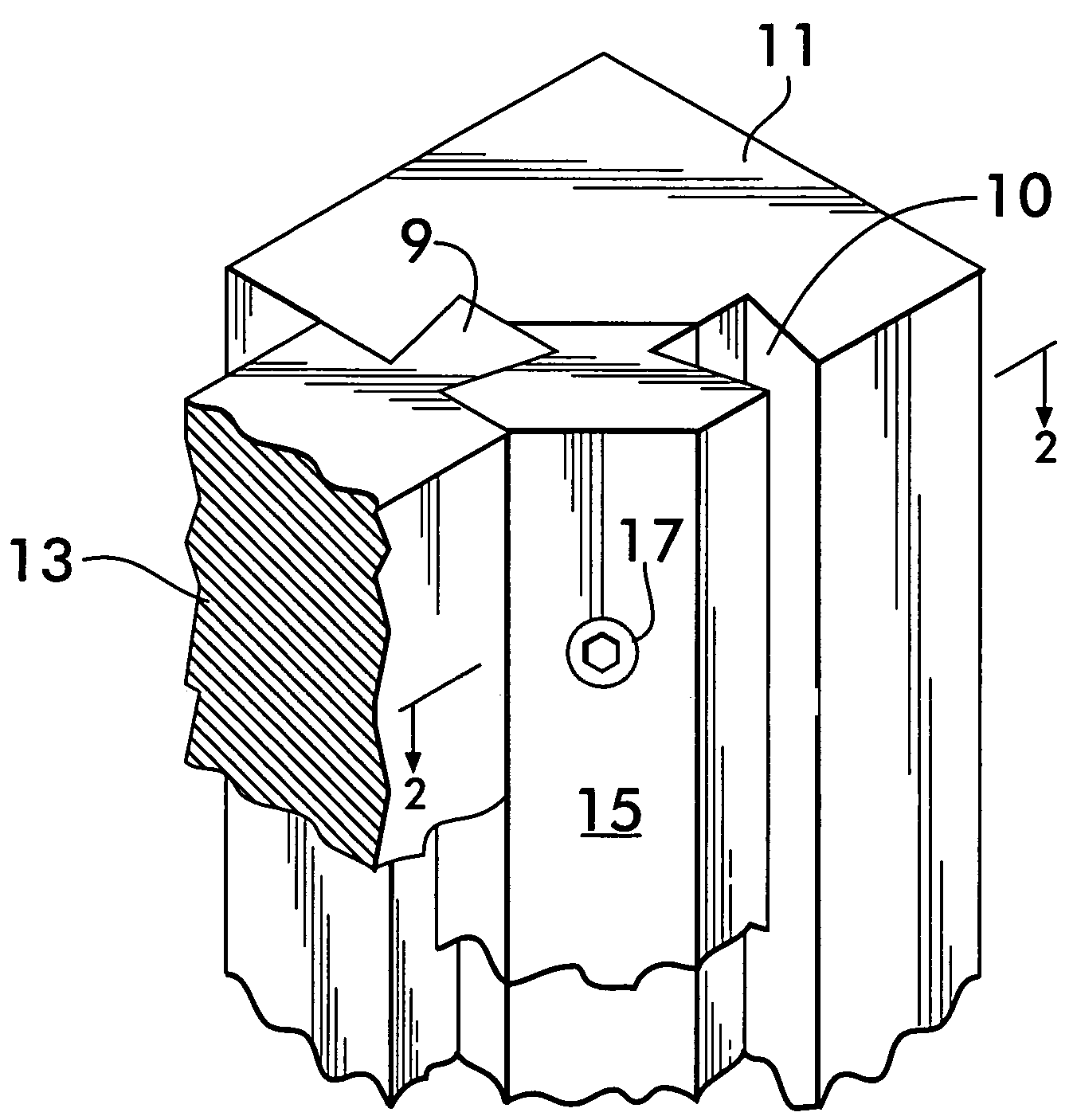

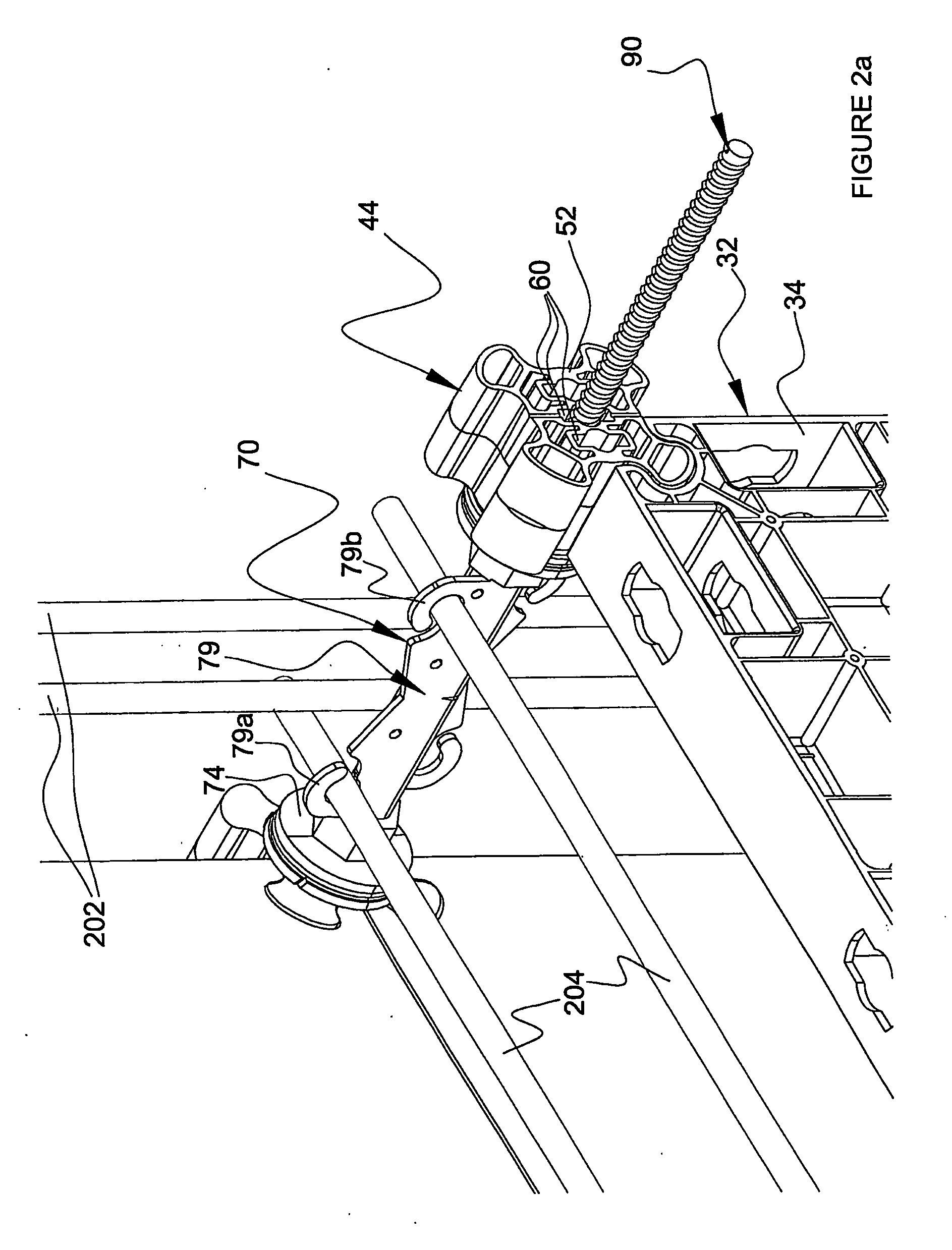

Rotatable tool having a replaceable cutting tip secured by a dovetail coupling

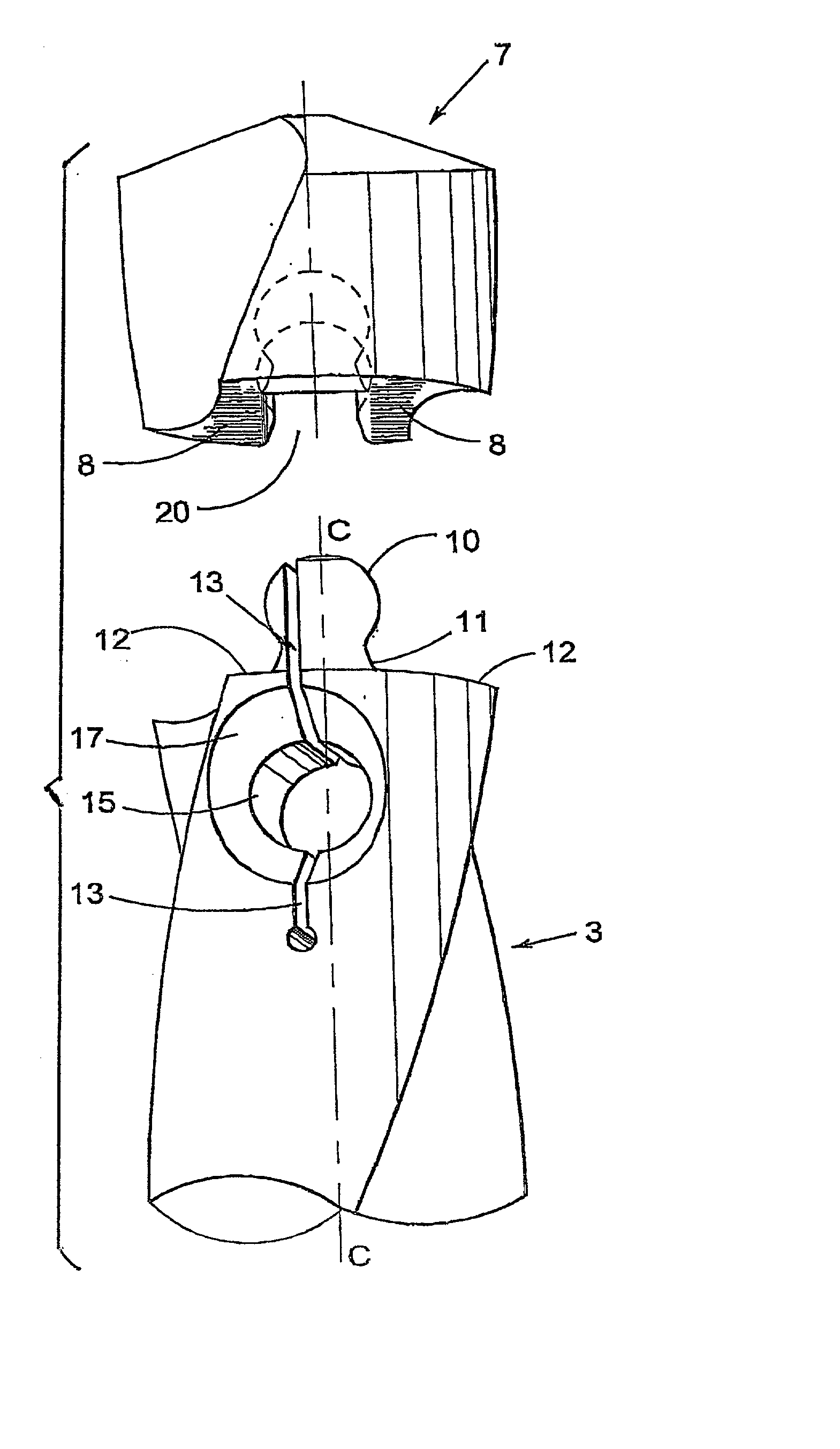

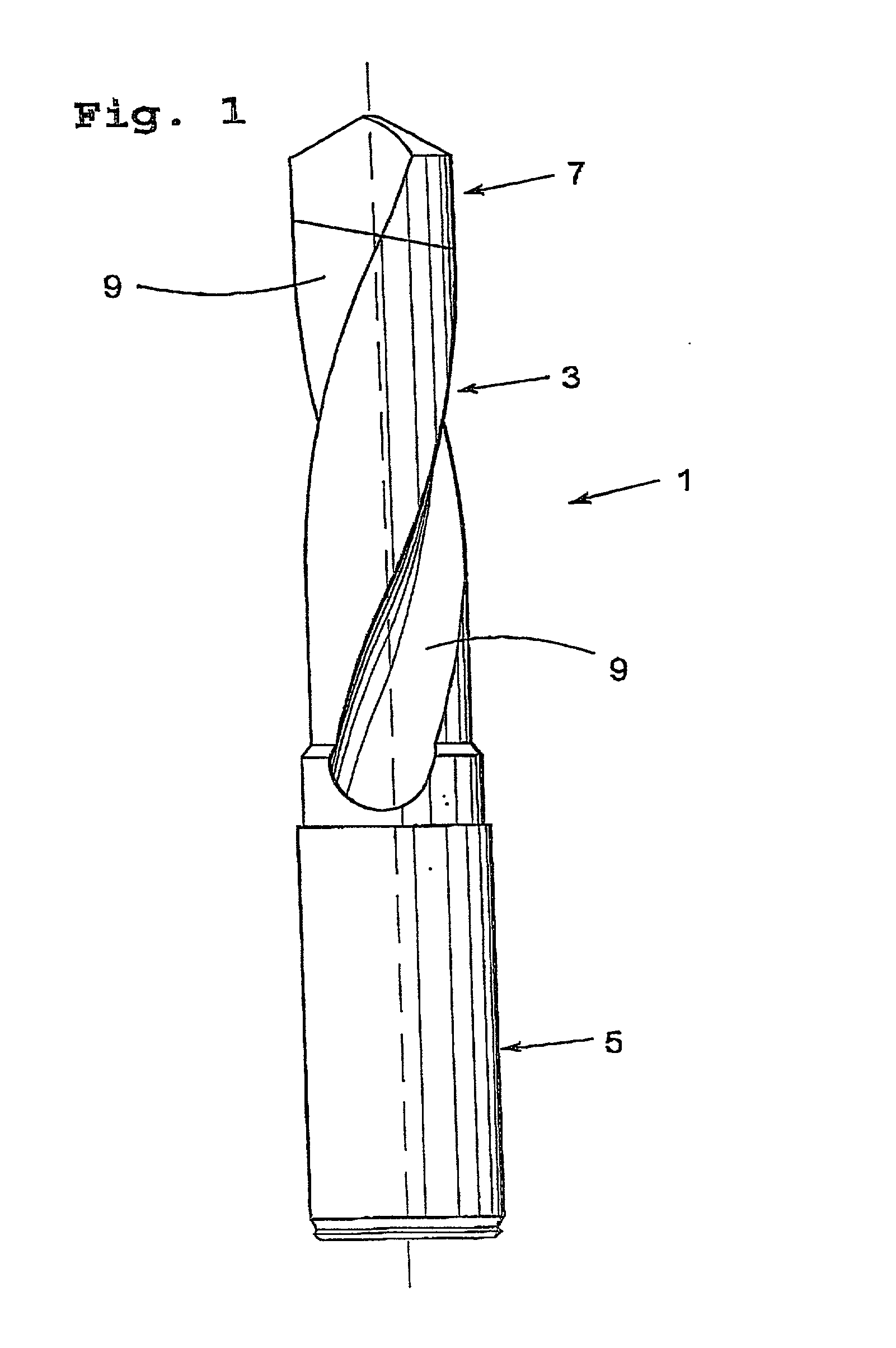

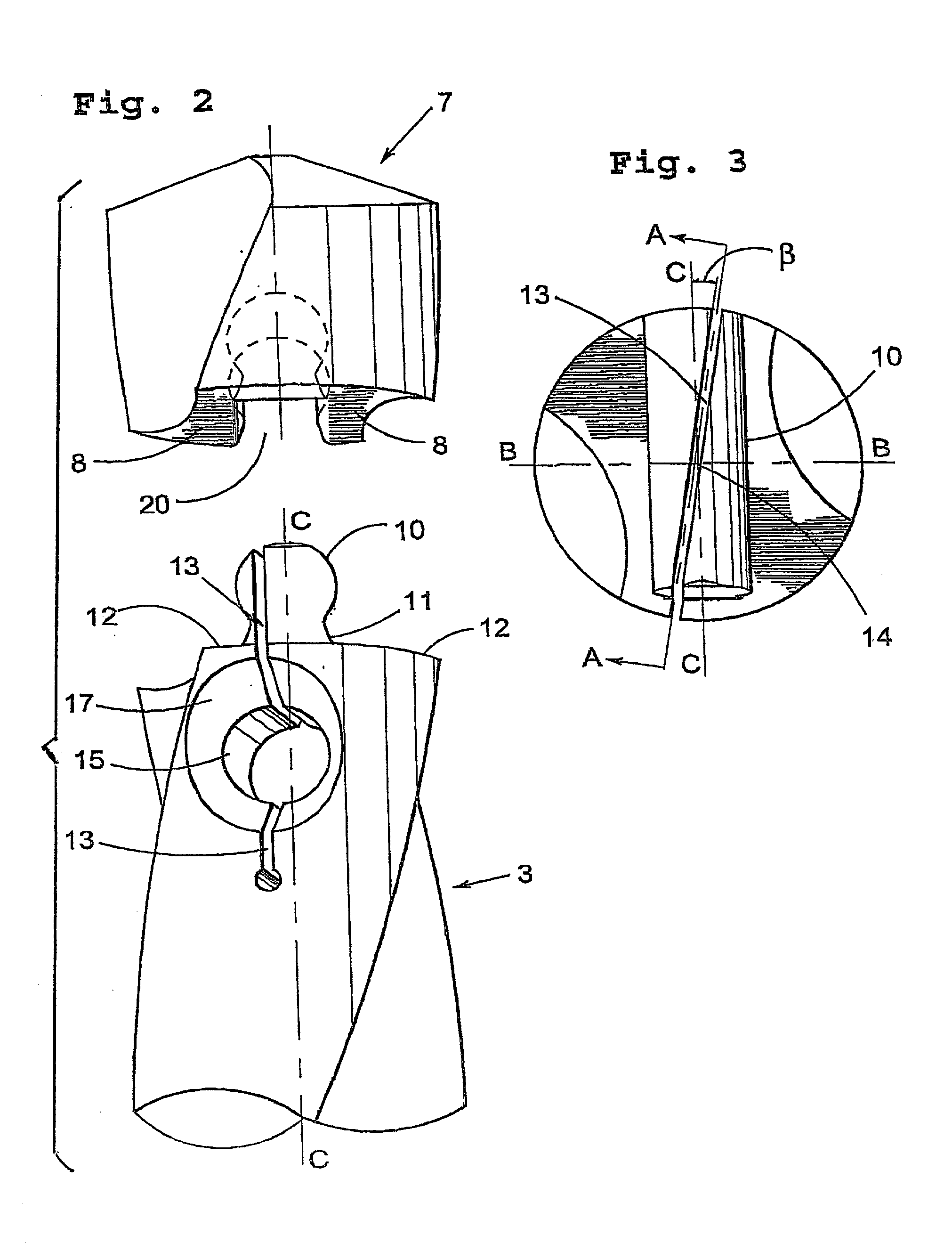

A rotatable cutting tool includes a rotatable tool body and a replaceable cutting tip for chip removing machining. The tool body includes a forward free end having a first dovetail coupling part formed thereon. The cutting tip includes a front cutting end and a rear mounting end. The mounting end includes a second dovetail coupling part joined to the first dovetail coupling part. An actuator, such as a screw, is provided which is arranged for elastically deforming one of the dovetail coupling parts to create a tightly clamped relationship between the first and second dovetail coupling parts. Insertion of a replacement cutting tip is performed by laterally mating the dovetail coupling parts until one of the coupling parts abuts a laterally facing stop surface of the other coupling part.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

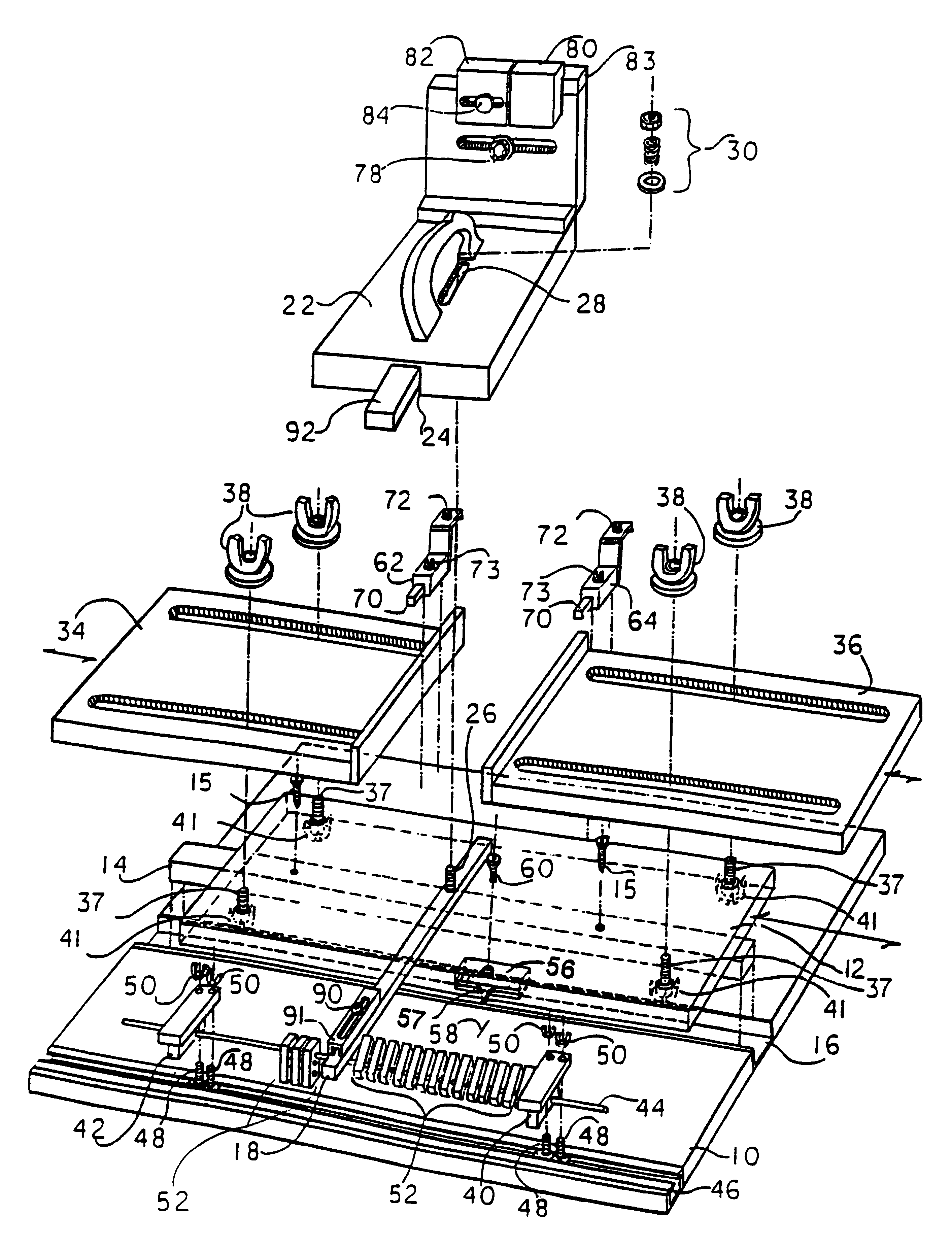

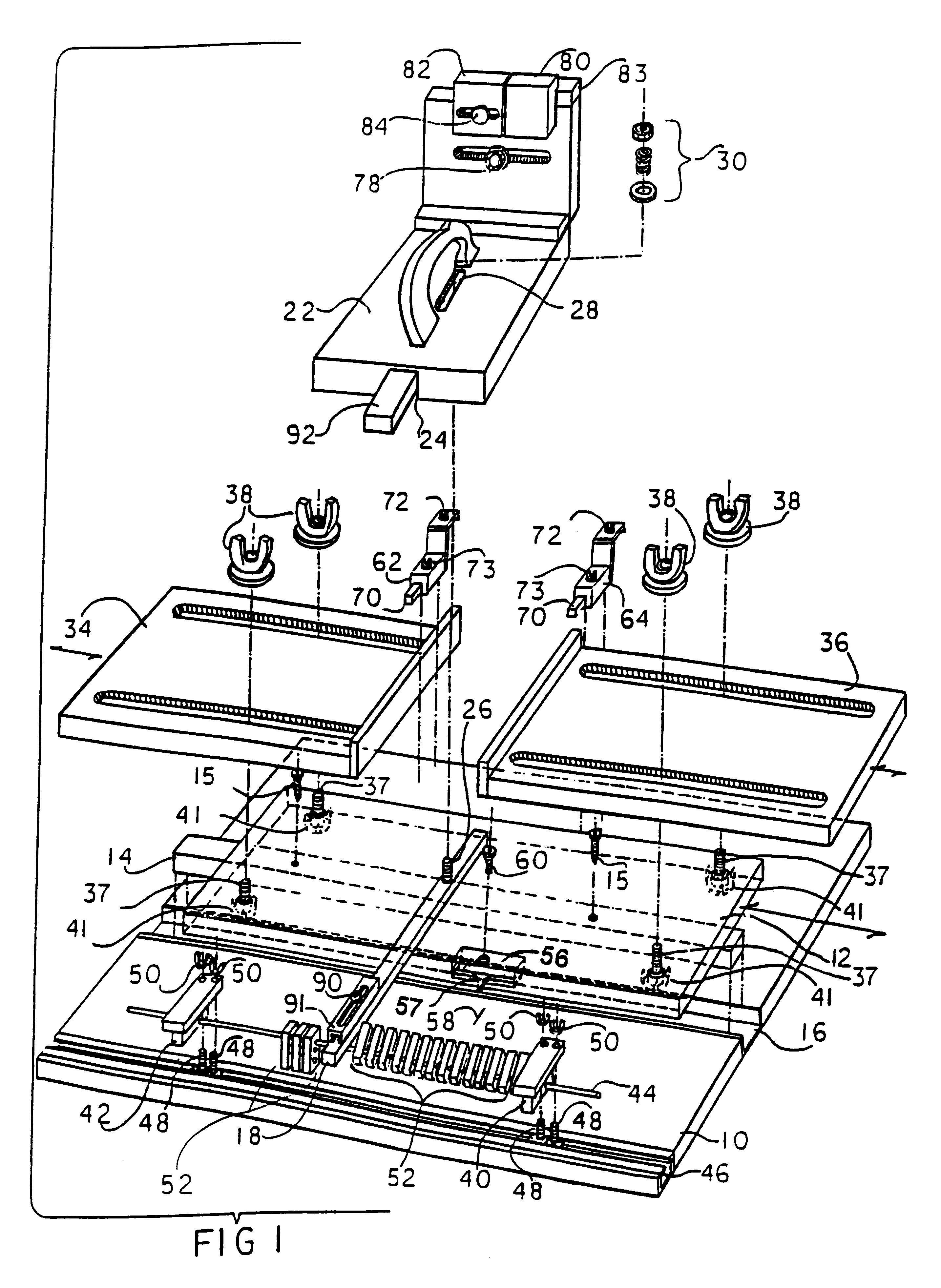

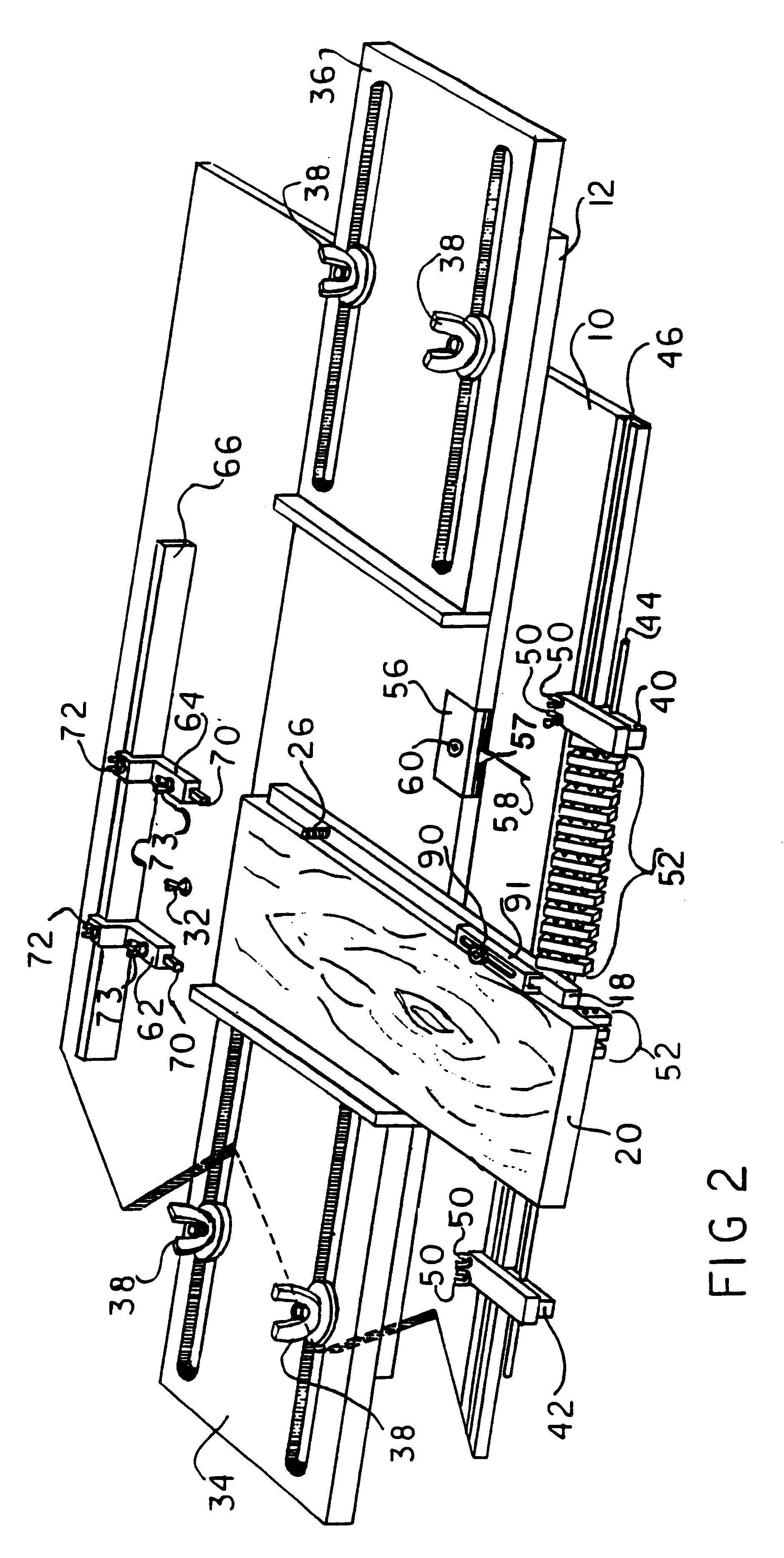

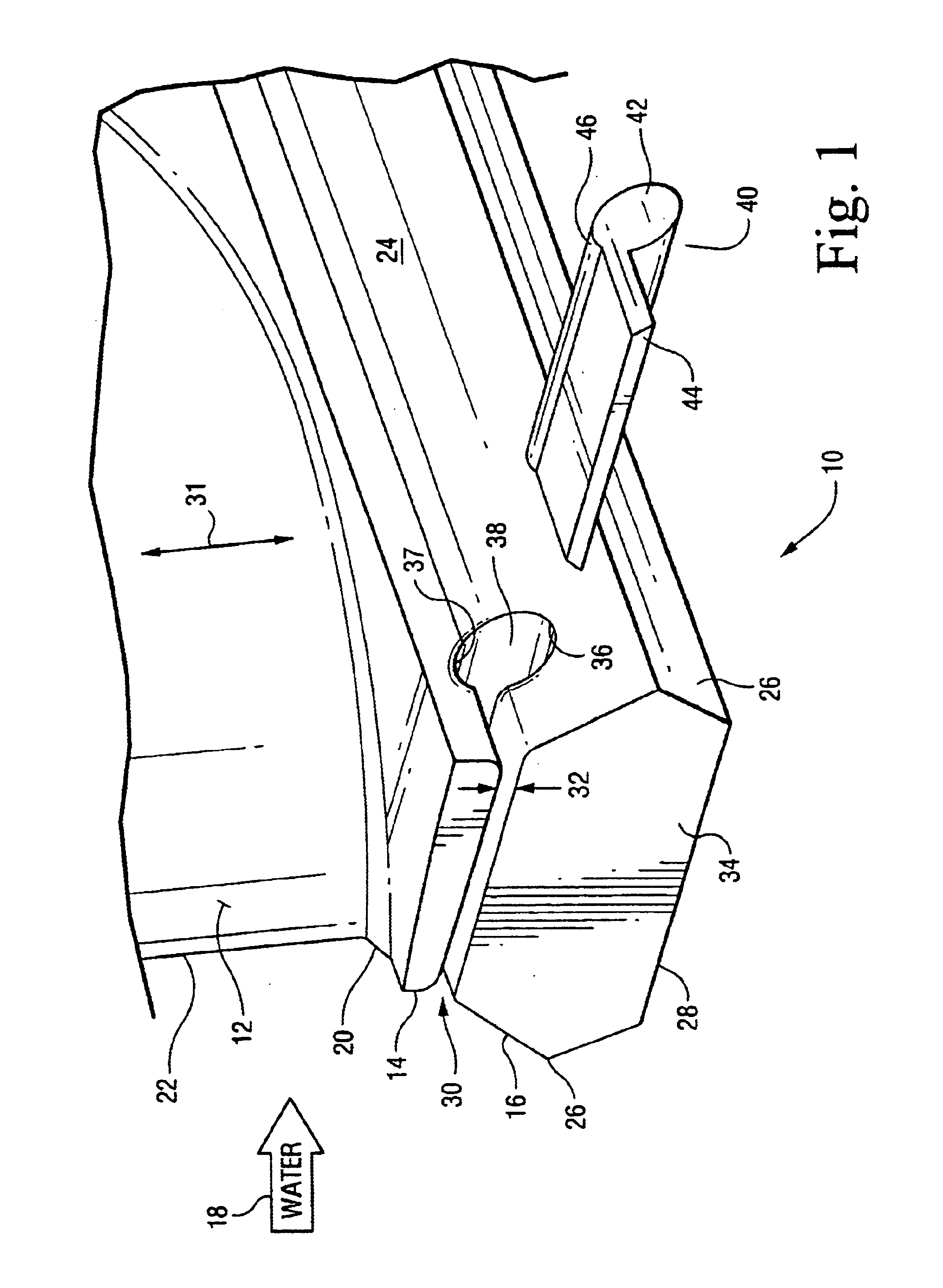

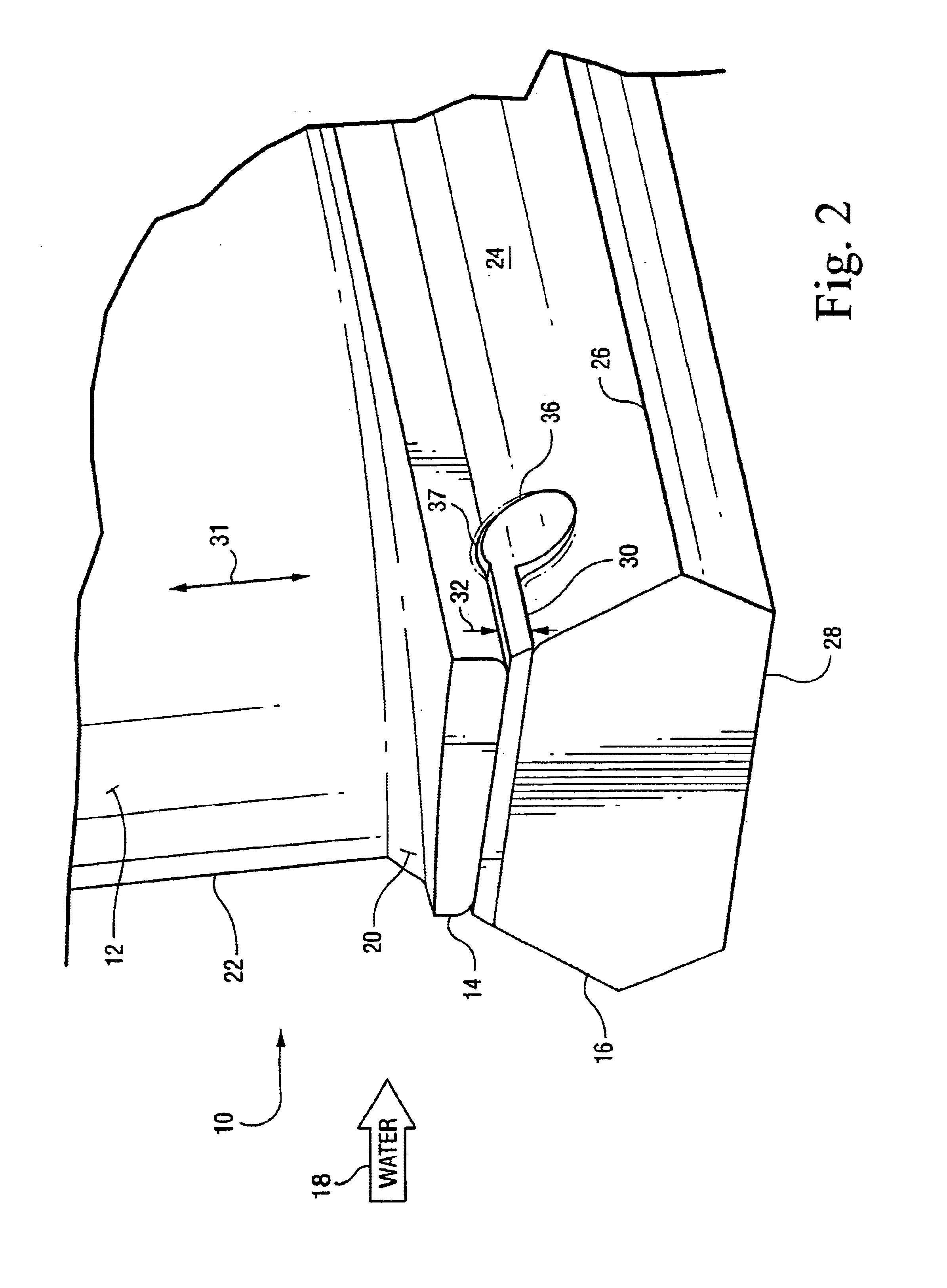

Jig system for positioning the placement of multiple cuts in a workpiece

InactiveUS6206060B1Reduce lateral movementGreat accuracy positioningDrilling/boring measurement devicesTongue/grooves making apparatusEngineeringDovetail joint

The present invention is a jig system for precisely positioning the placement of multiple cuts such as in the placement of dovetail or box joints cut in a wood panel. A row of multi-use adjustable spacers controls the indexing of a workpiece and can be used with a stationary and / or a portable cutting tool. The movability of the spacers permits a workpiece to be cut on both sides of a guide bar fence thereby assuring that the first cut will always be made on the same side of a drawer and will be esthetically pleasing regardless of the width of the workpiece. Additionally, the adjustability of the spacers accommodates any desired cutting tool height, angle and / or size. The jig system comprises: a stationary fixture; a spacer bar; a plurality of spacers engaged with the spacer bar, the spacers are adapted for lateral and rotational movement along the spacer bar thereby providing an engaged and non-engaged working mode; a sliding member adapted for lateral movement on the stationary fixture and for engaging at least one of the spacers in the engaged working mode; and means for holding the spacer bar and connecting the spacer bar to the stationary fixture while engaging with at least one of the spacers during the engaged working mode.

Owner:BLAKE F RICHARD

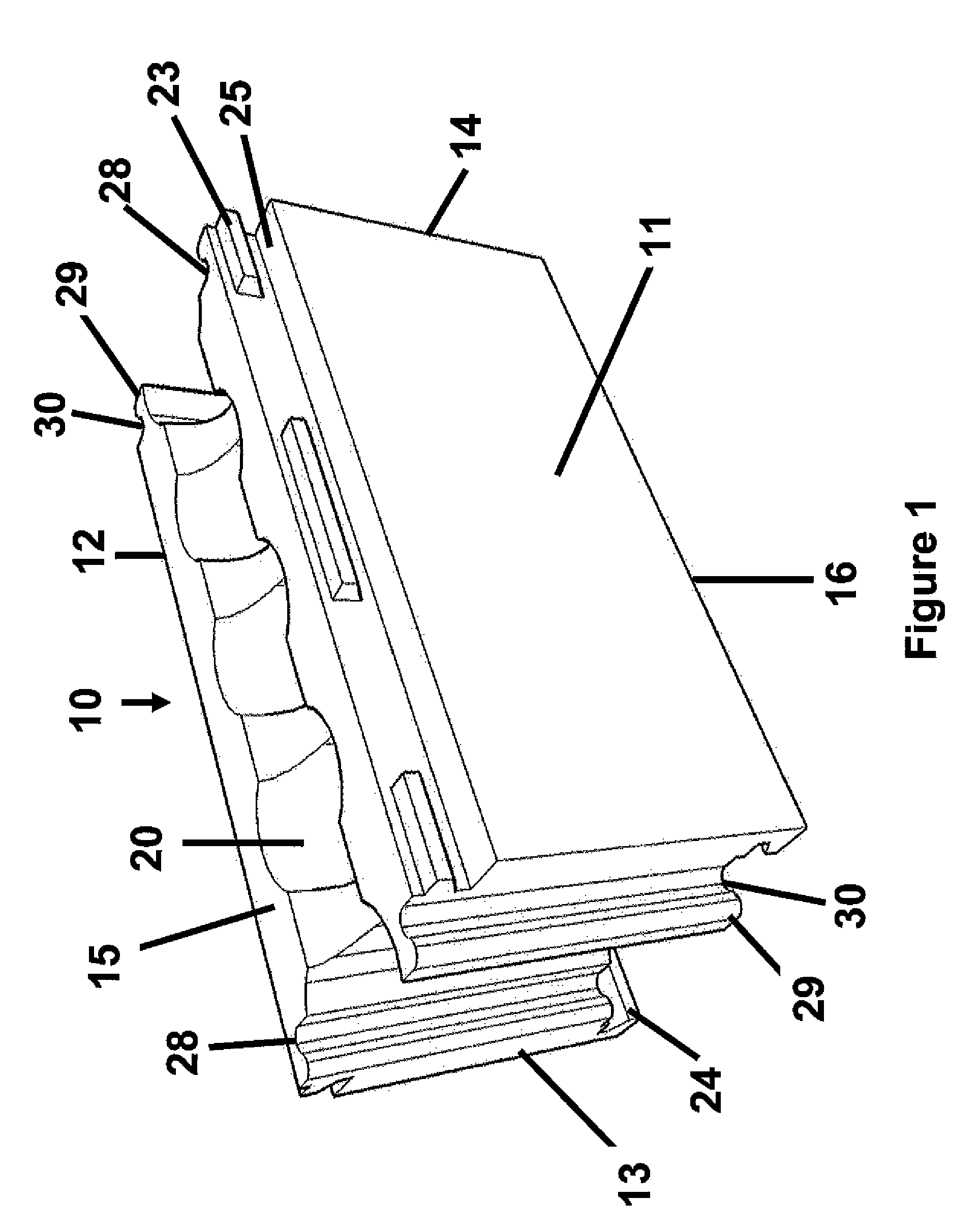

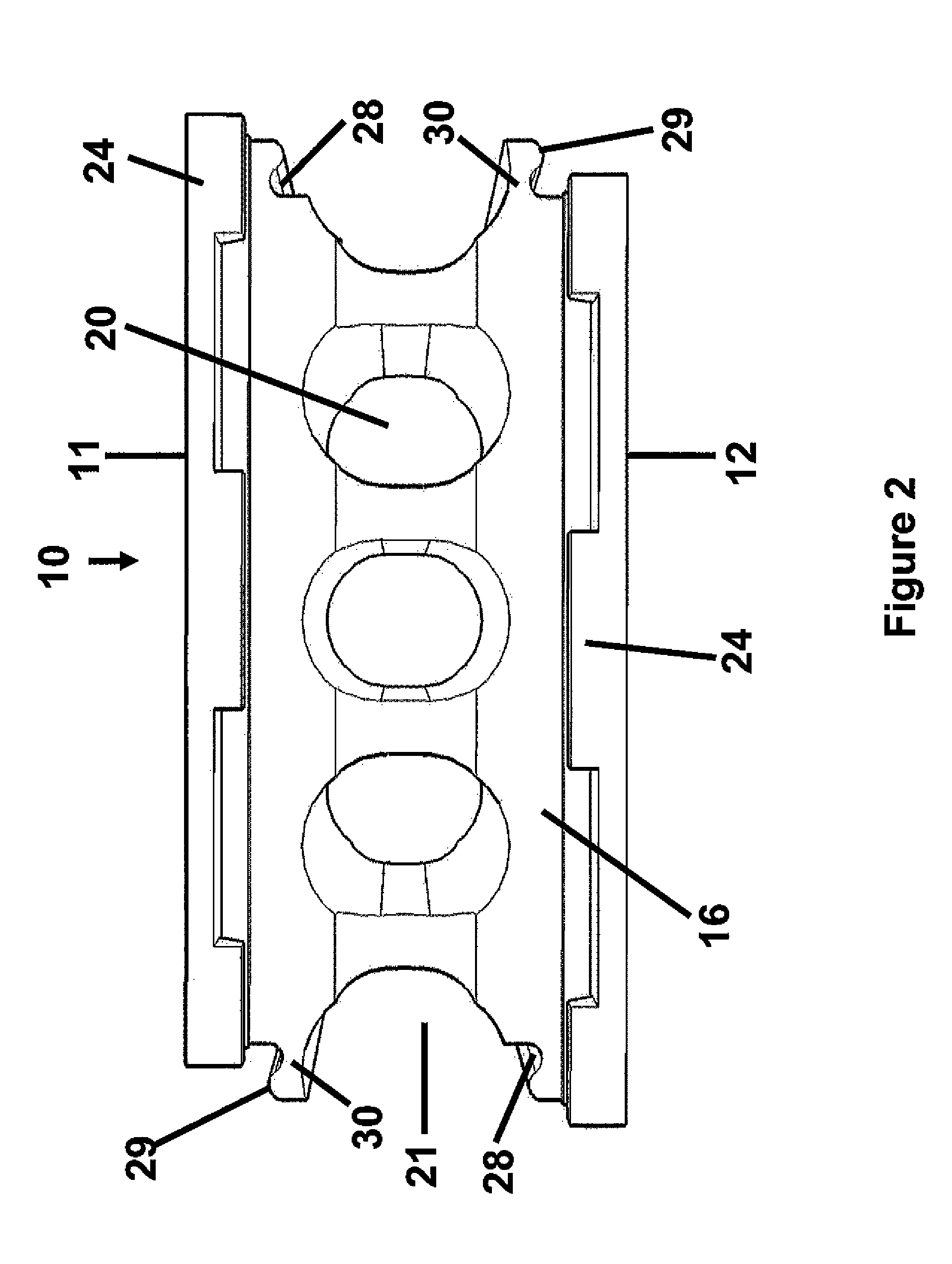

Unbonded non-masonry building block components

Non-masonry building block components, including a standard hollow-bodied block component with horizontal and vertical locking capabilities which removes the need for bonding material such as glue, mortar or other adhesives. Modified dovetails on the upper and lower surface of the building components prevent vertical movement while resistance locks on each end of the block prevent horizontal movement. Typically, use of the non-masonry building components would allow for constructing permanent or temporary structures having vertical and horizontal channels in which to allow plumbing or electrical conduit. The incorporation of materials, such as sand or similar substance, would form a bullet-resistant barrier for use in military operations. Additionally, structures formed from the block components could easily be assembled or disassembled on site without the need for skilled labor, specialized tools, demolition and clean up.

Owner:HUMPHRESS DAVID L +1

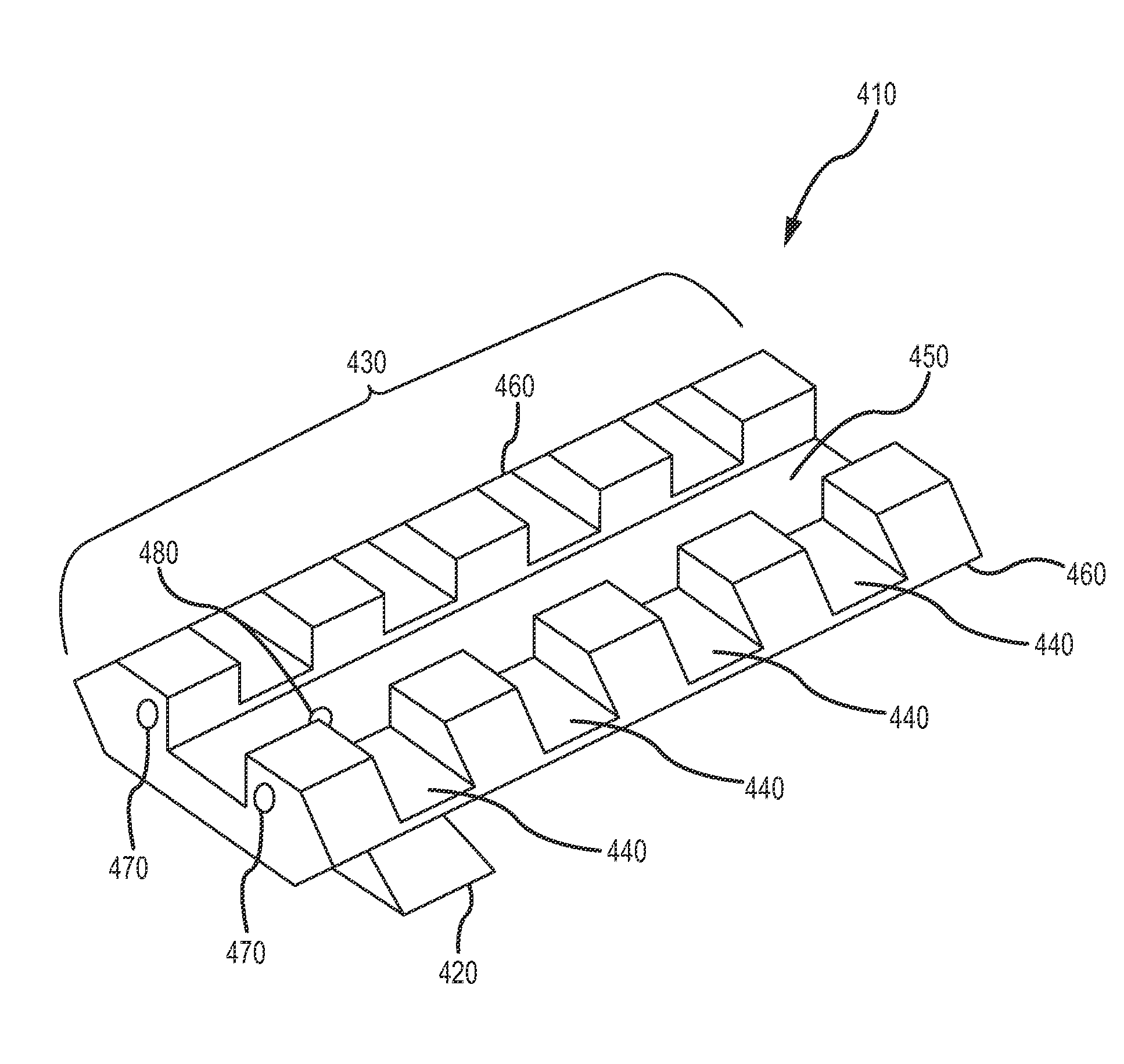

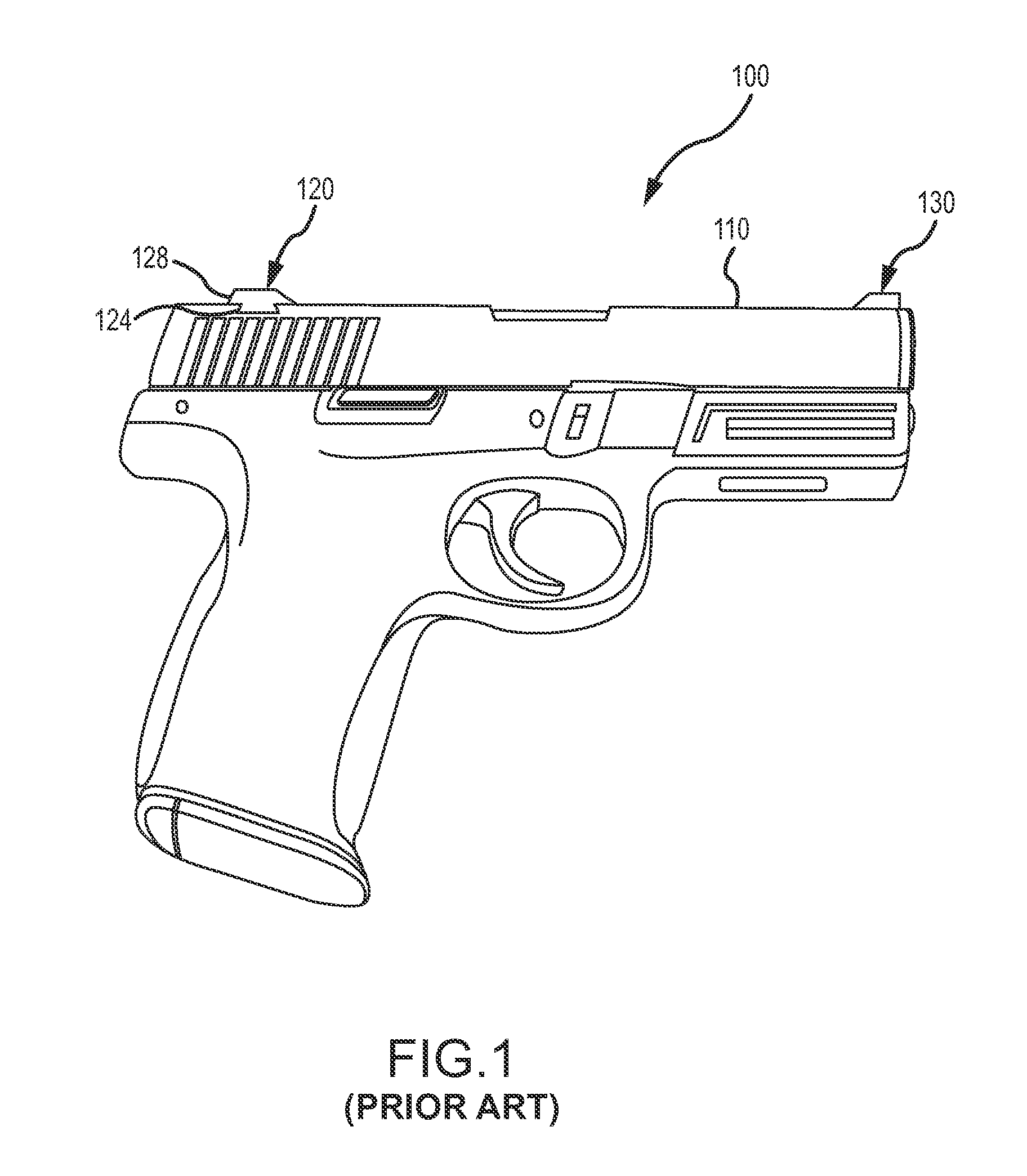

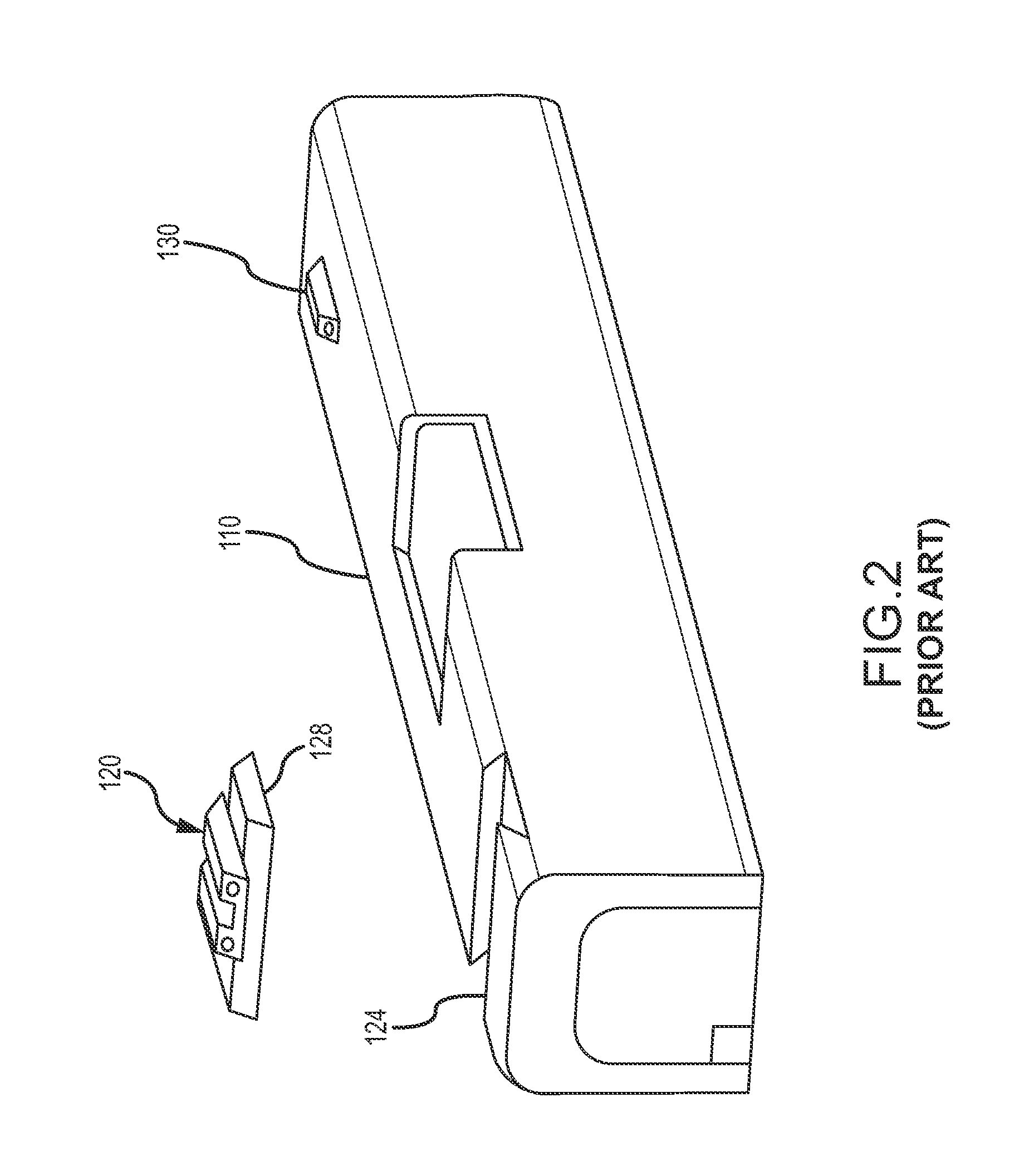

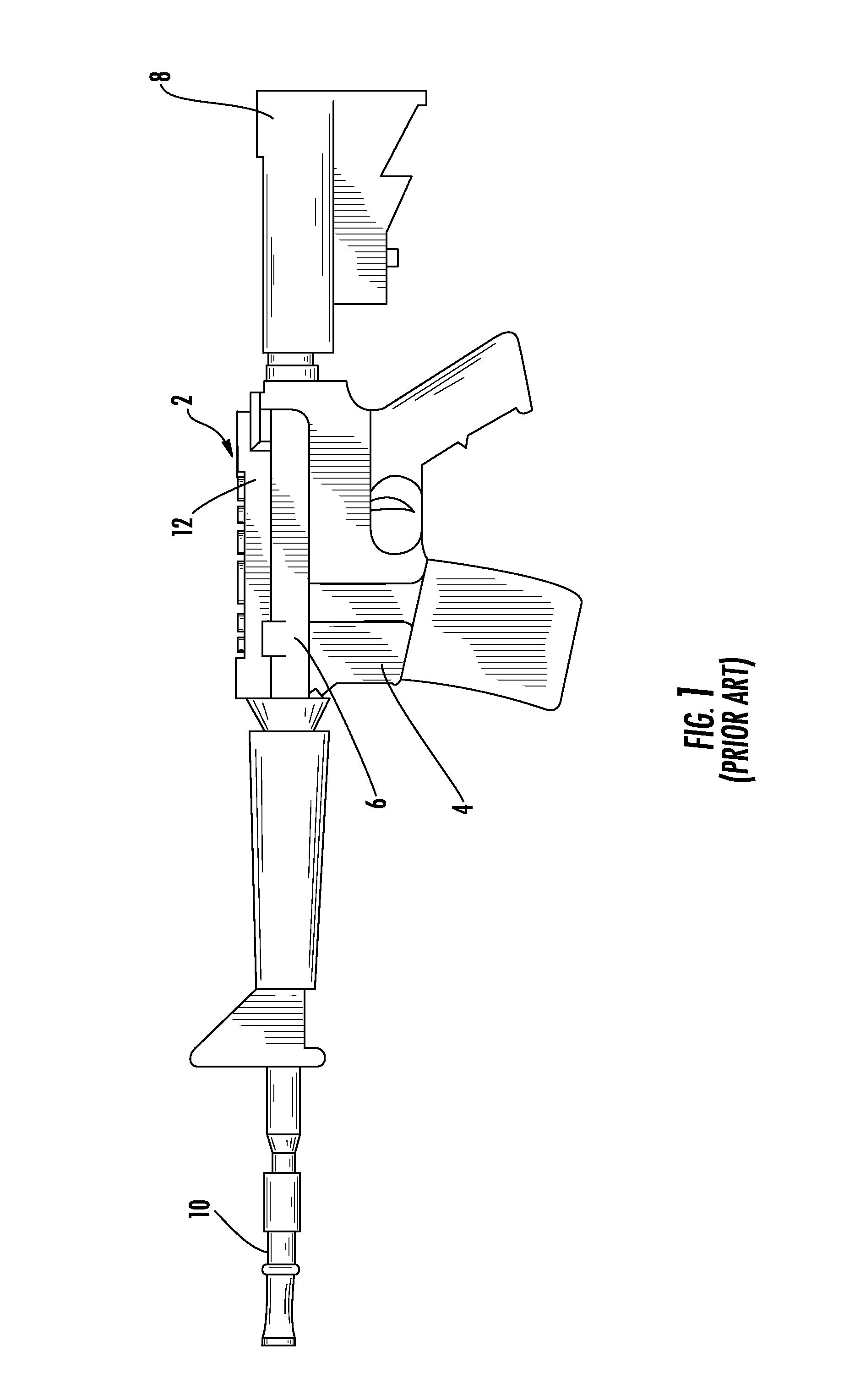

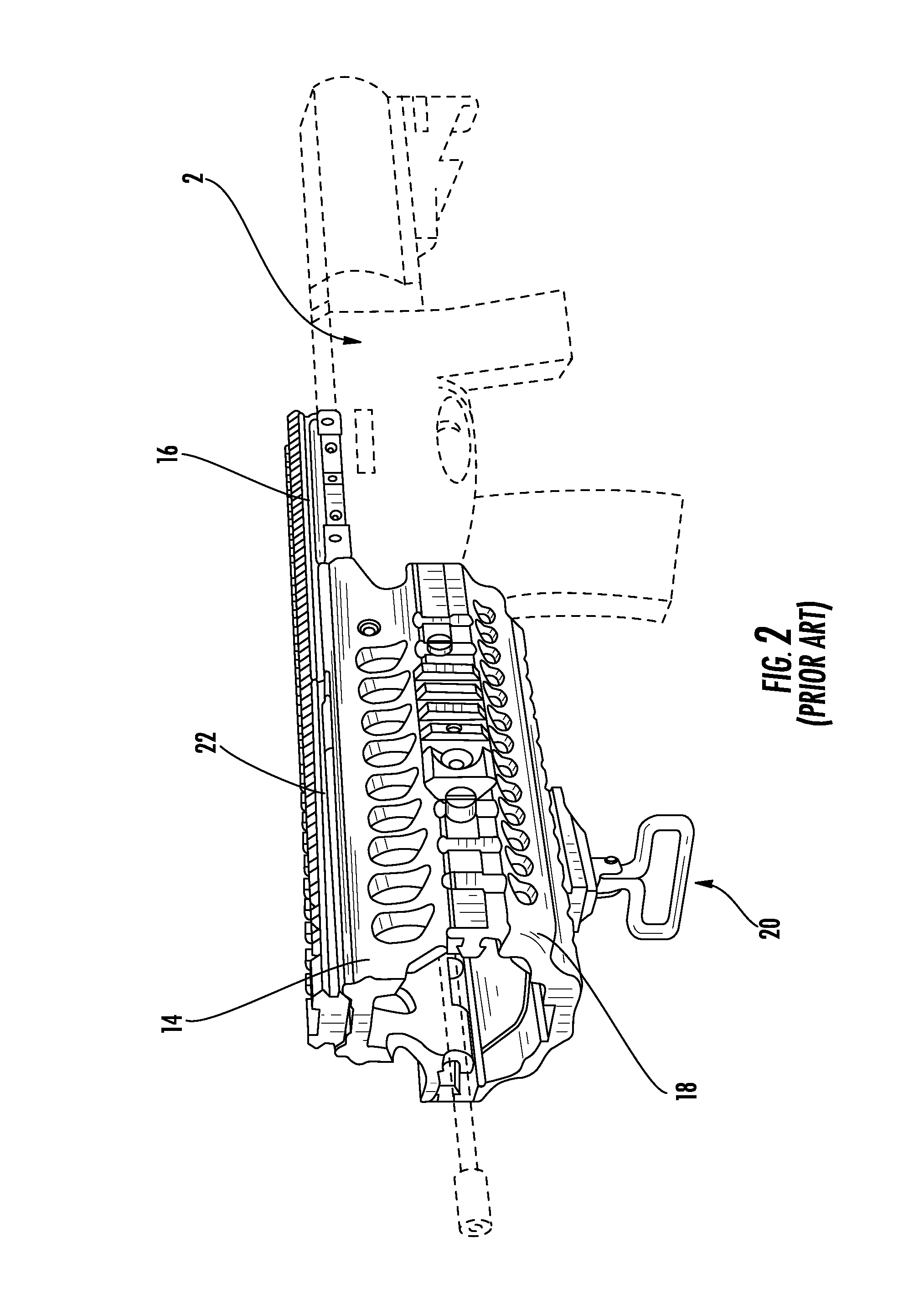

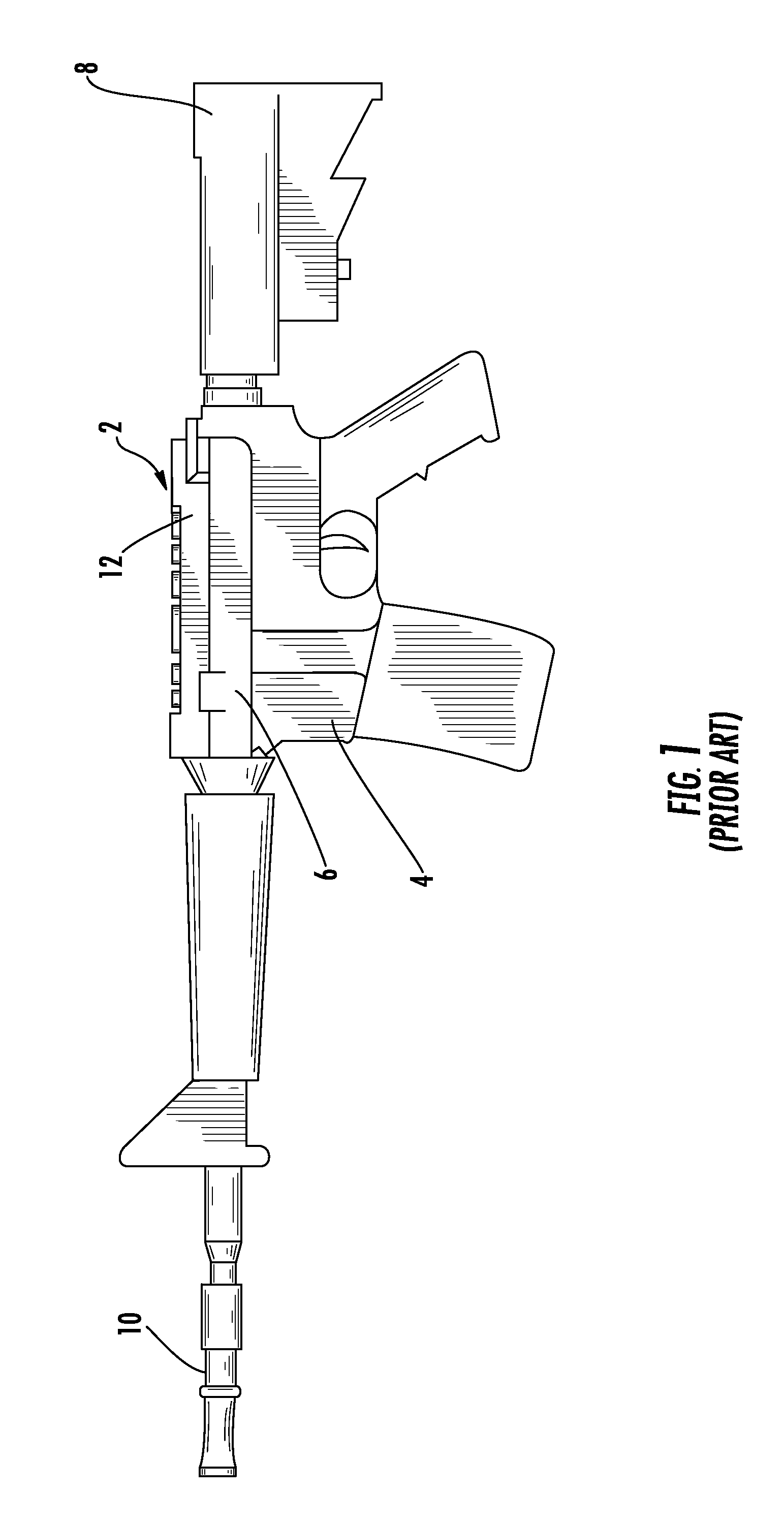

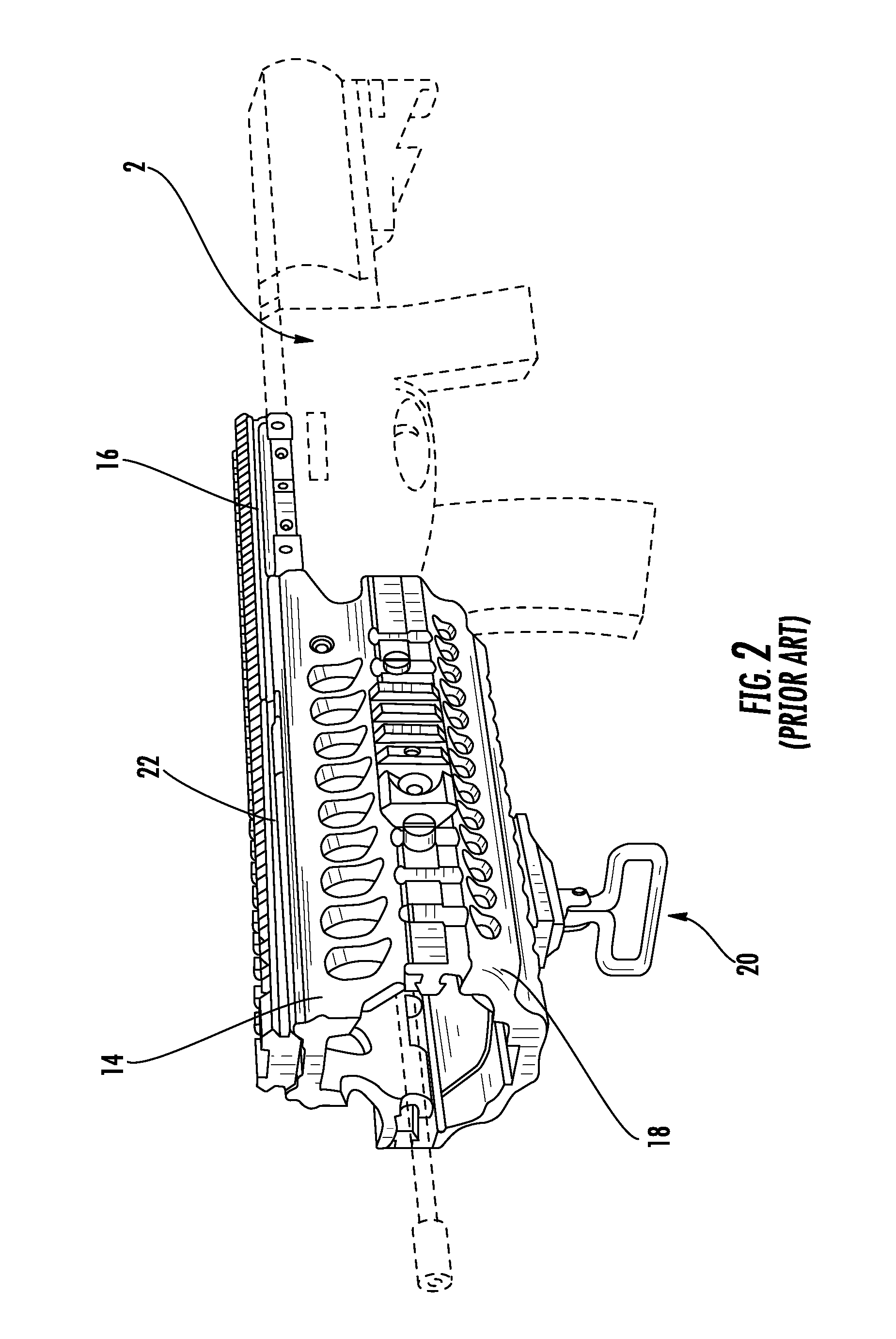

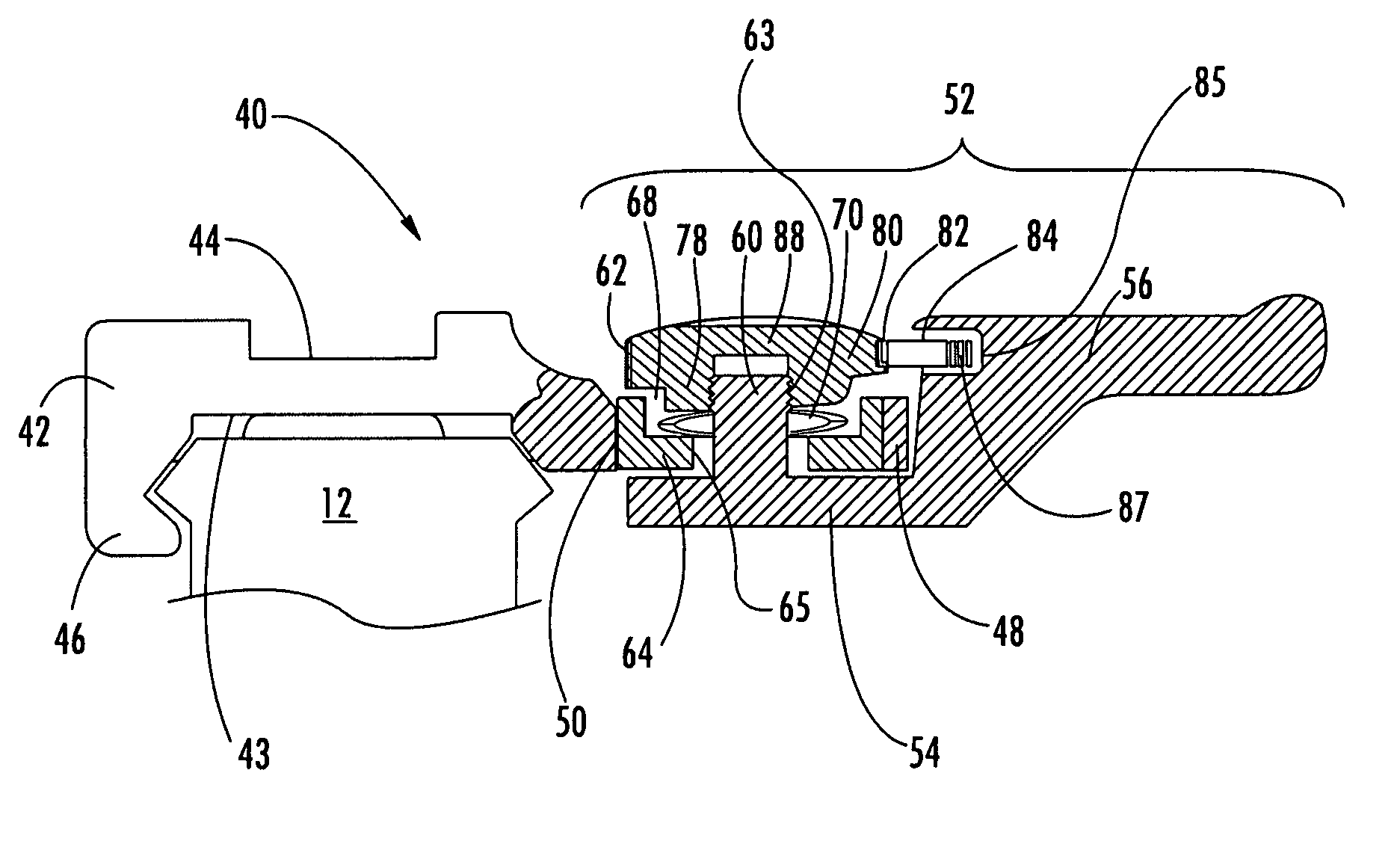

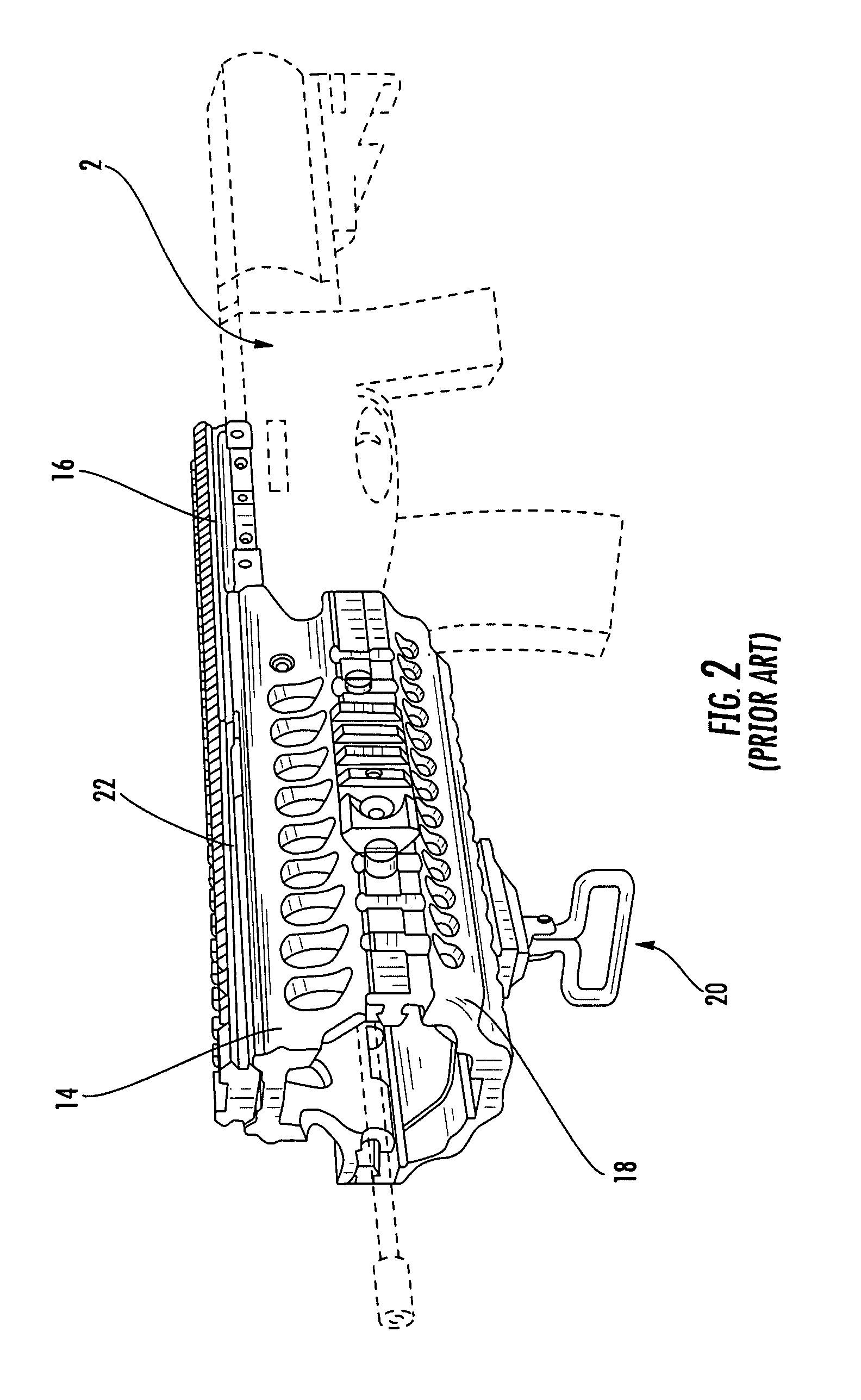

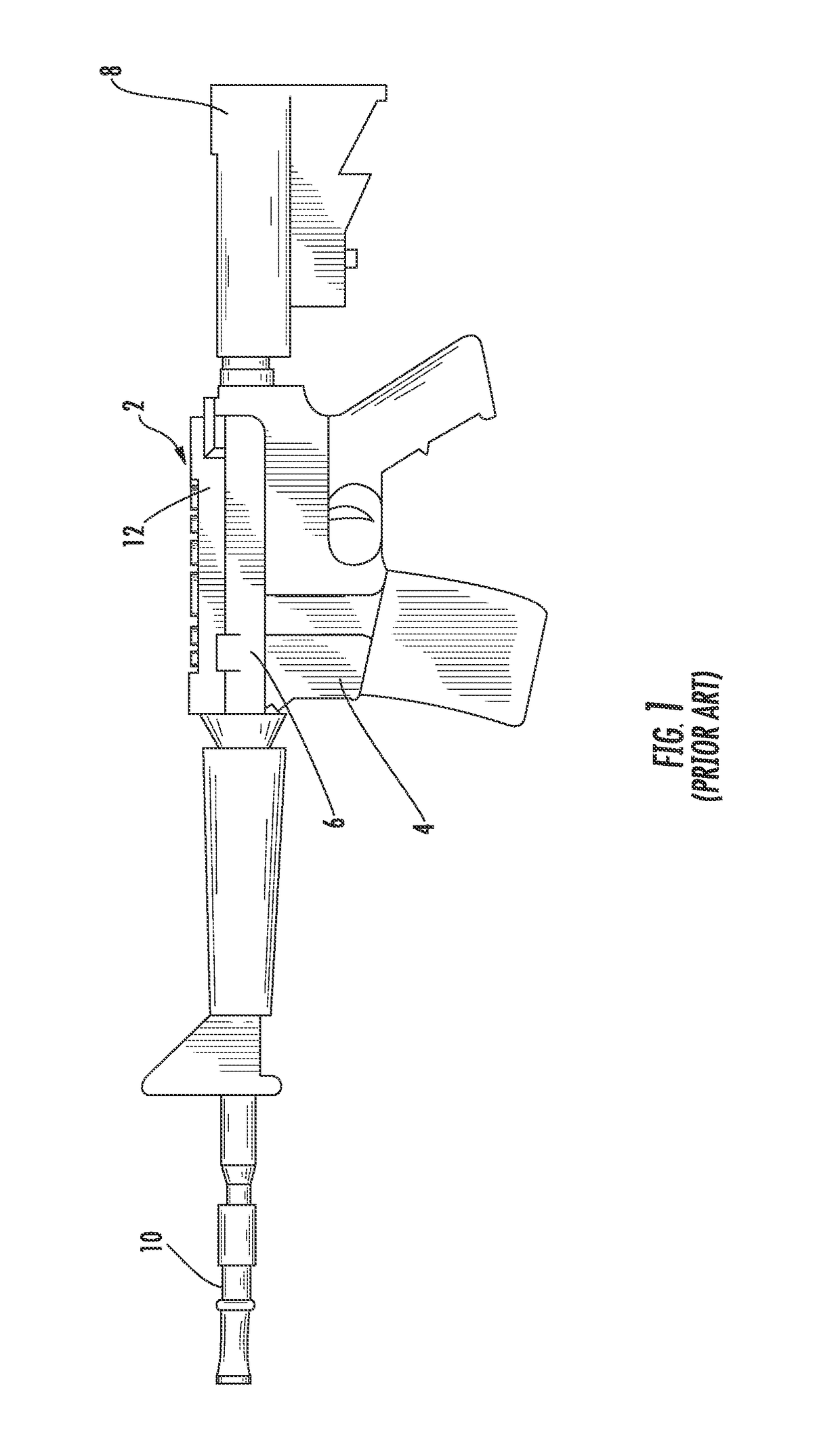

Universal firearm mount

A system for coupling a red dot sight to a handgun is provided. The system may include a mounting unit made from a single piece of material. The piece may include a male dovetail and a longitudinal rail thereon. The male dovetail may be disposed in a female dovetail of a rear sight portion of the handgun. The longitudinal rail may be configured to receive the red dot sight. The longitudinal rail may define a plurality of lateral slots on the top of the longitudinal rail, and a longitudinal slot extending across the entirety of, and laterally centered on, the top of the longitudinal length of the longitudinal rail. Two visual markers may be located on the back of the longitudinal rail, to the left and right of the longitudinal slot. A tapped aperture may extend through the male dovetail, and a set screw may be disposed therein.

Owner:RED DOT MOUNTS

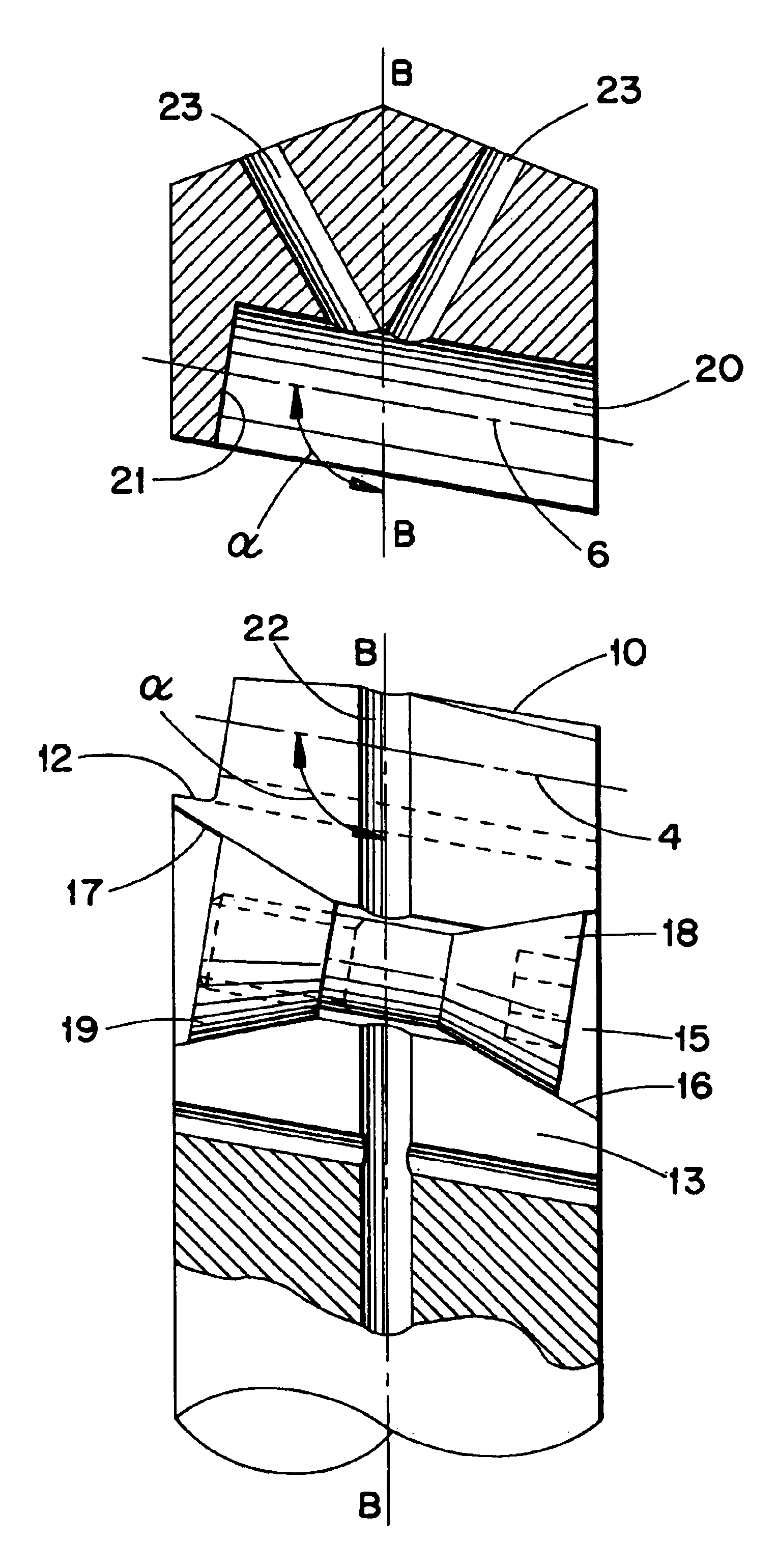

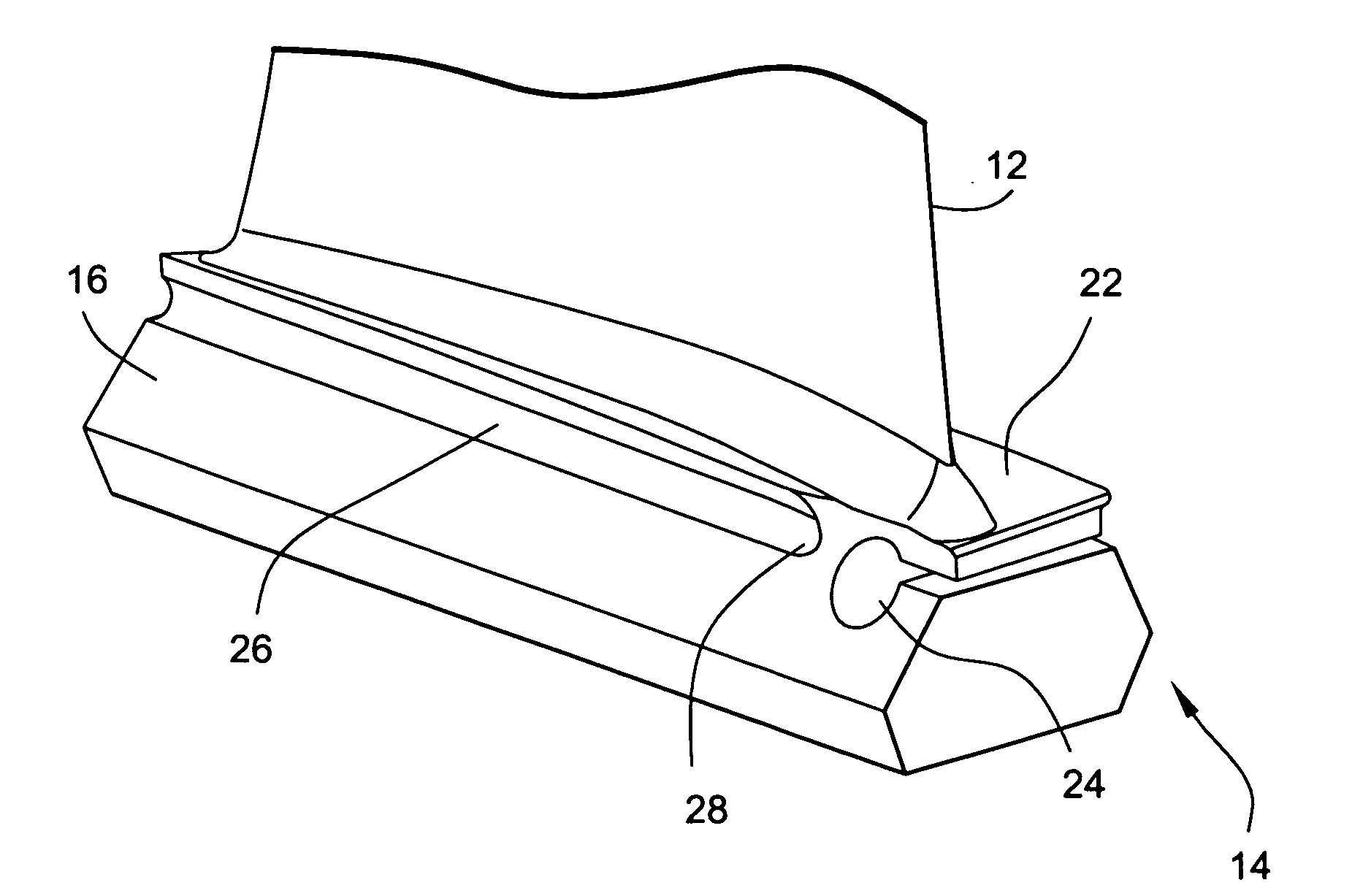

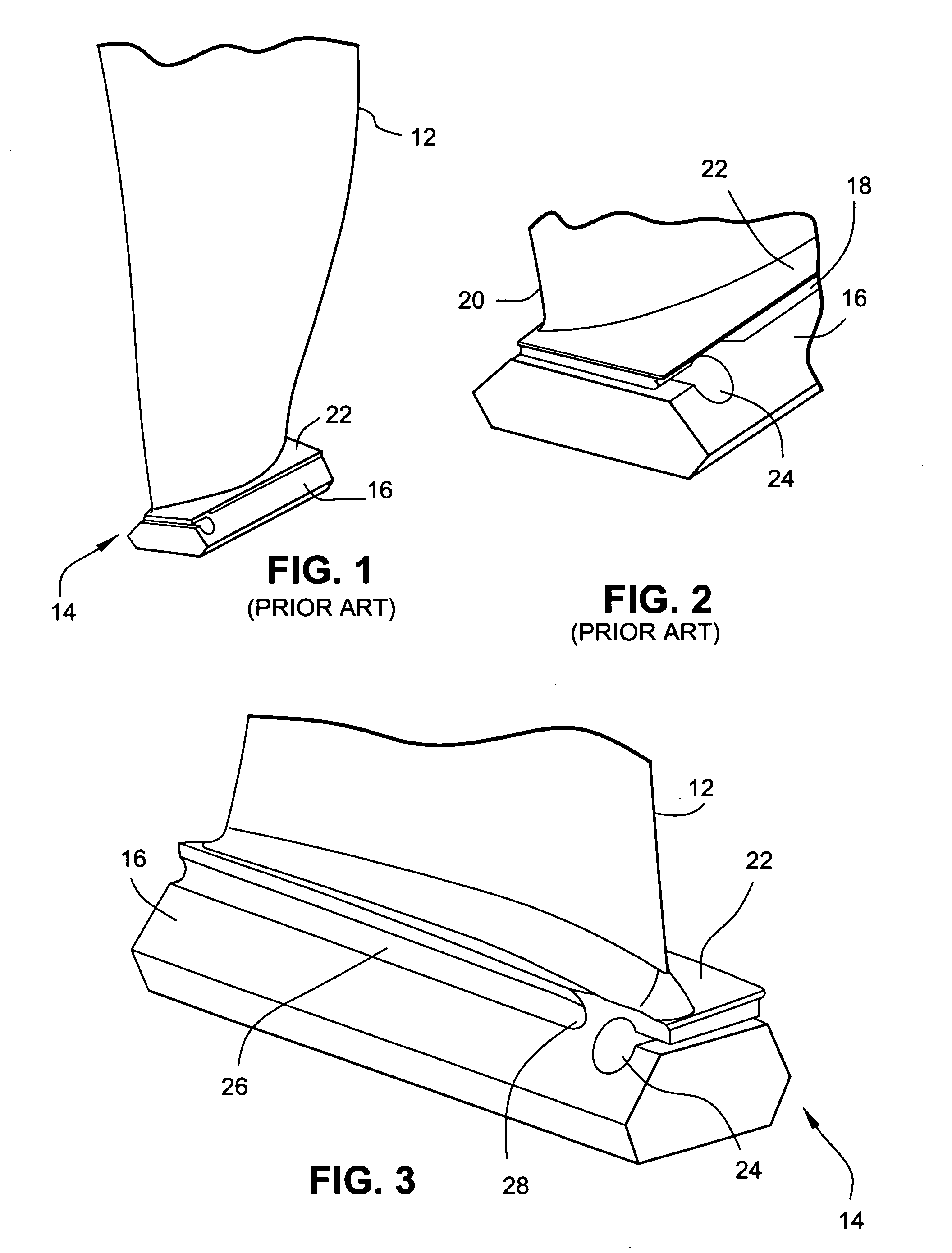

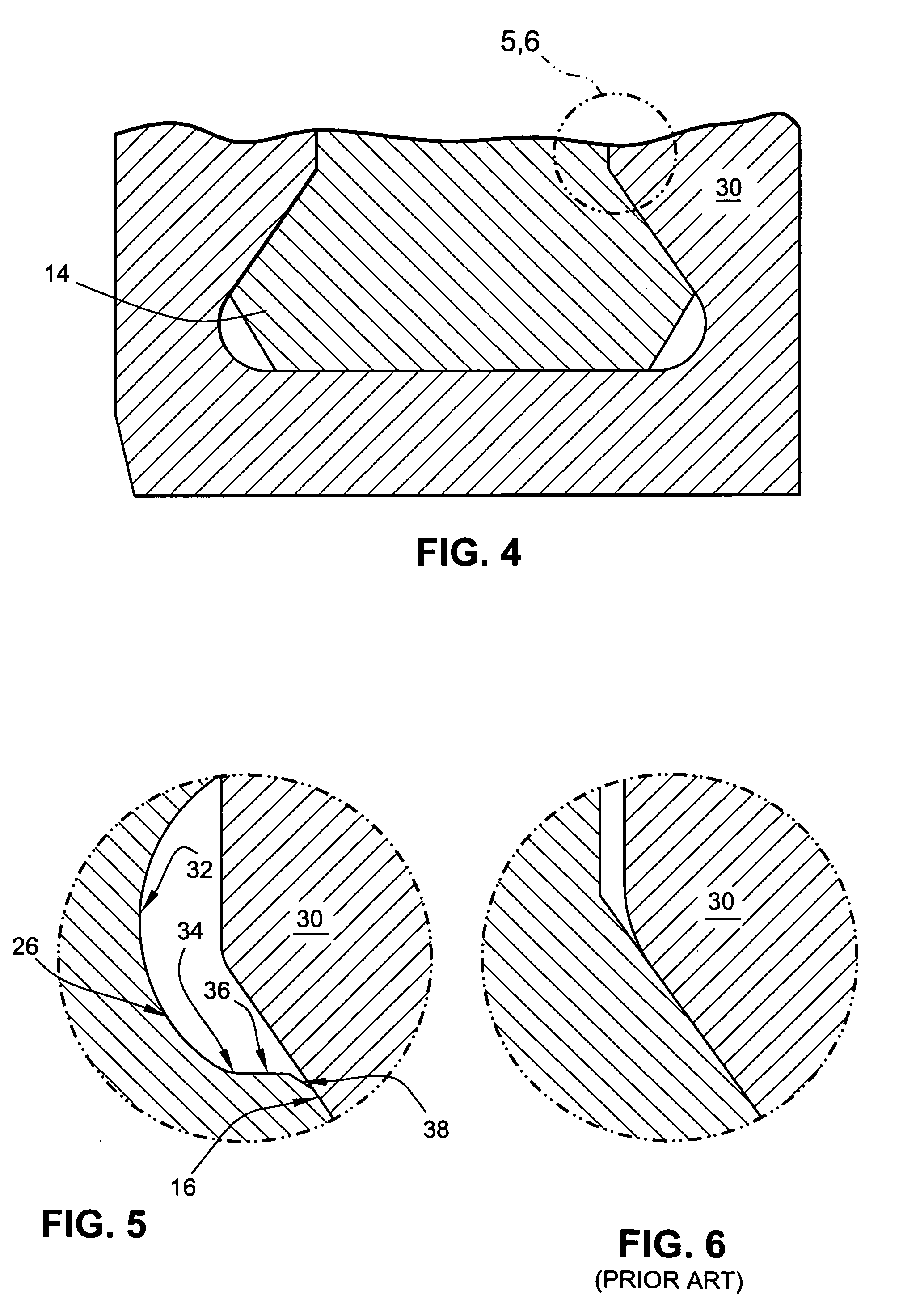

Undercut fillet radius for blade dovetails

A turbine or compressor blade assembly includes a blade fixed to a dovetail section attachable to a wheel. The dovetail section has a dovetail shaped to fit in a correspondingly shaped slot in the wheel. A dovetail platform serves as an interface between the blade and the dovetail. An undercut fillet radius is formed at an intersection of the dovetail platform and a dovetail pressure surface, where the undercut radius has a multi-part profile shape configured to attenuate edge of contact stresses. An additional feature is the area where the undercut radius transitions into the P-cut area at the forward end (leading edge) of the dovetail.

Owner:GENERAL ELECTRIC CO

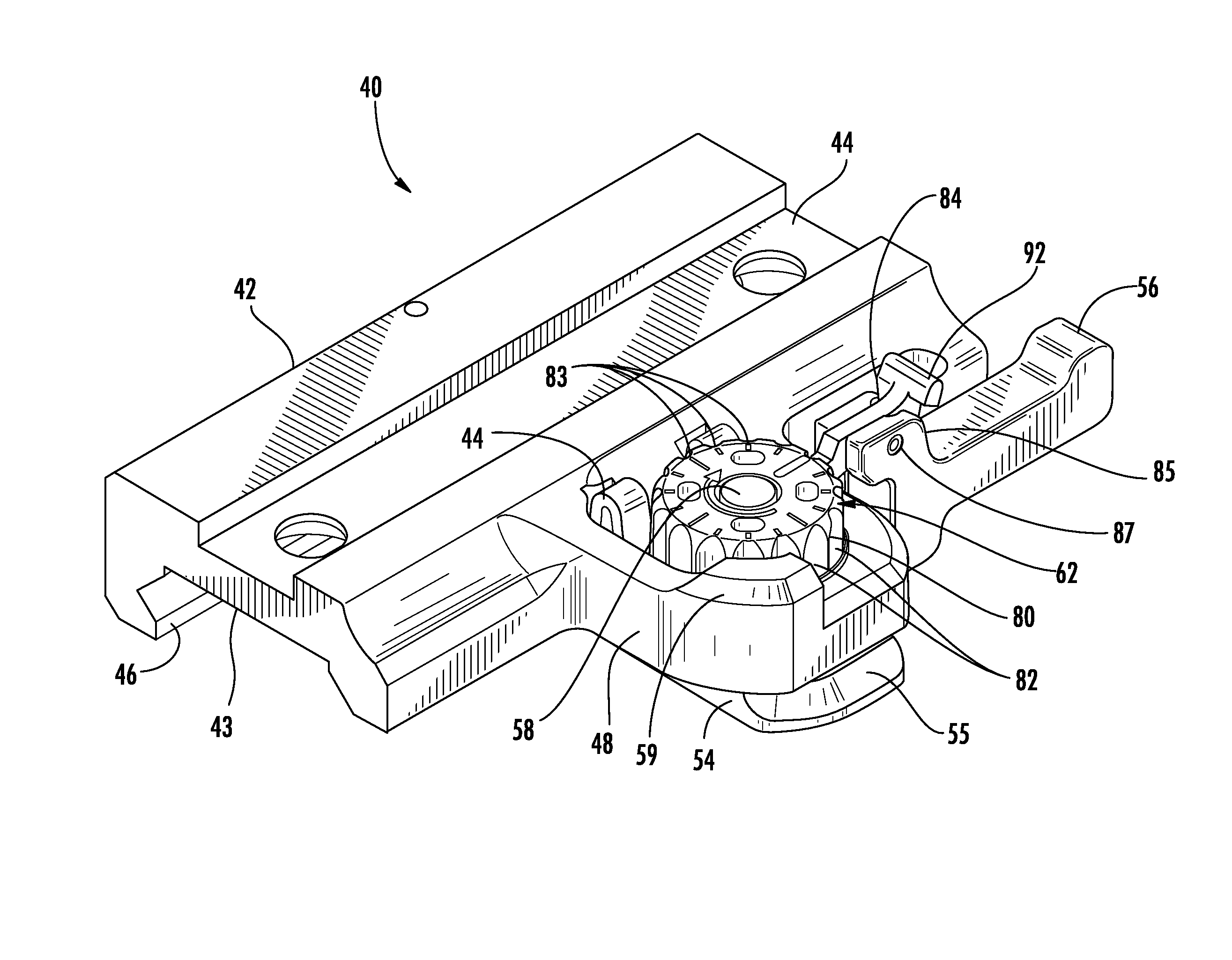

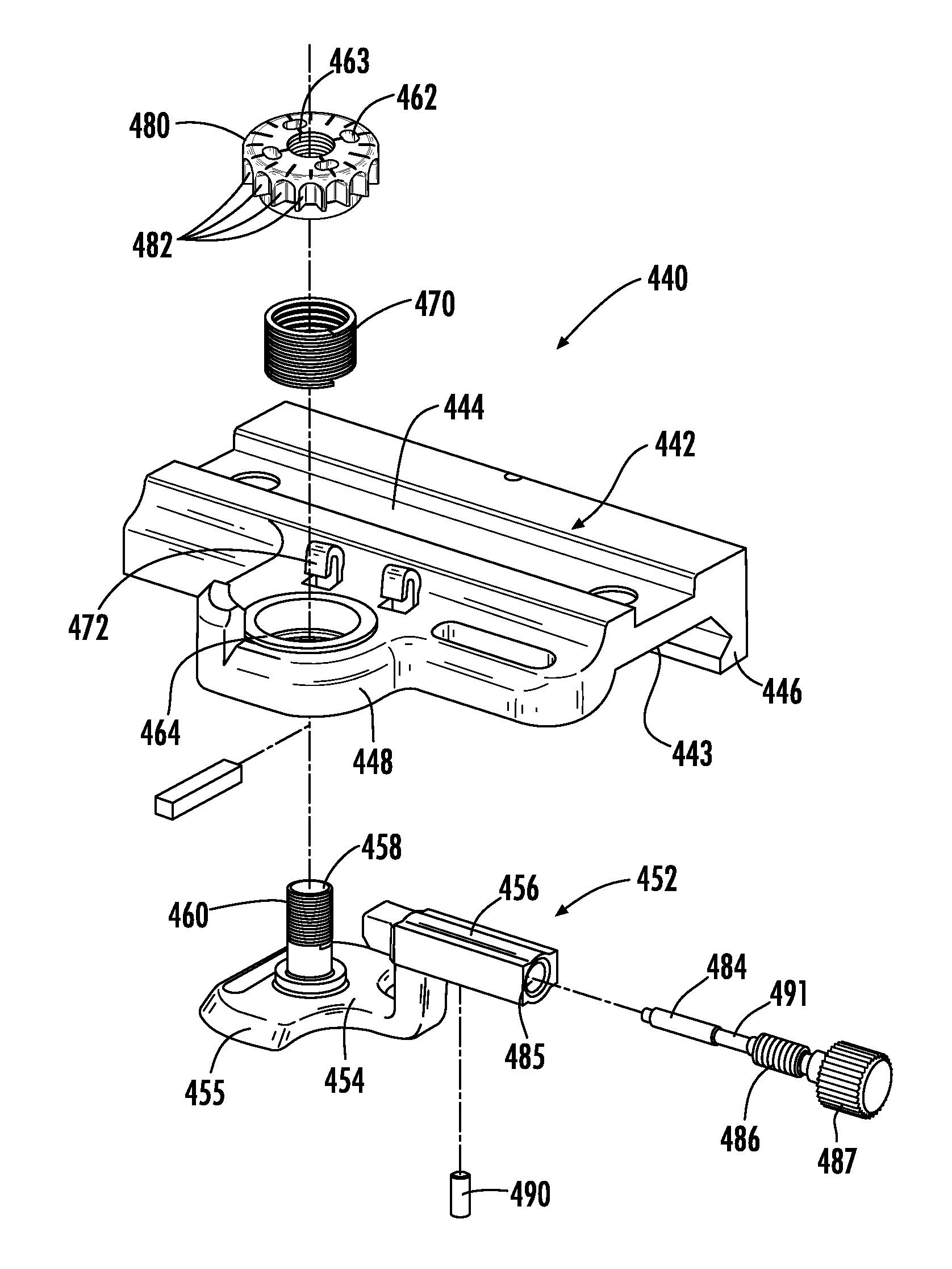

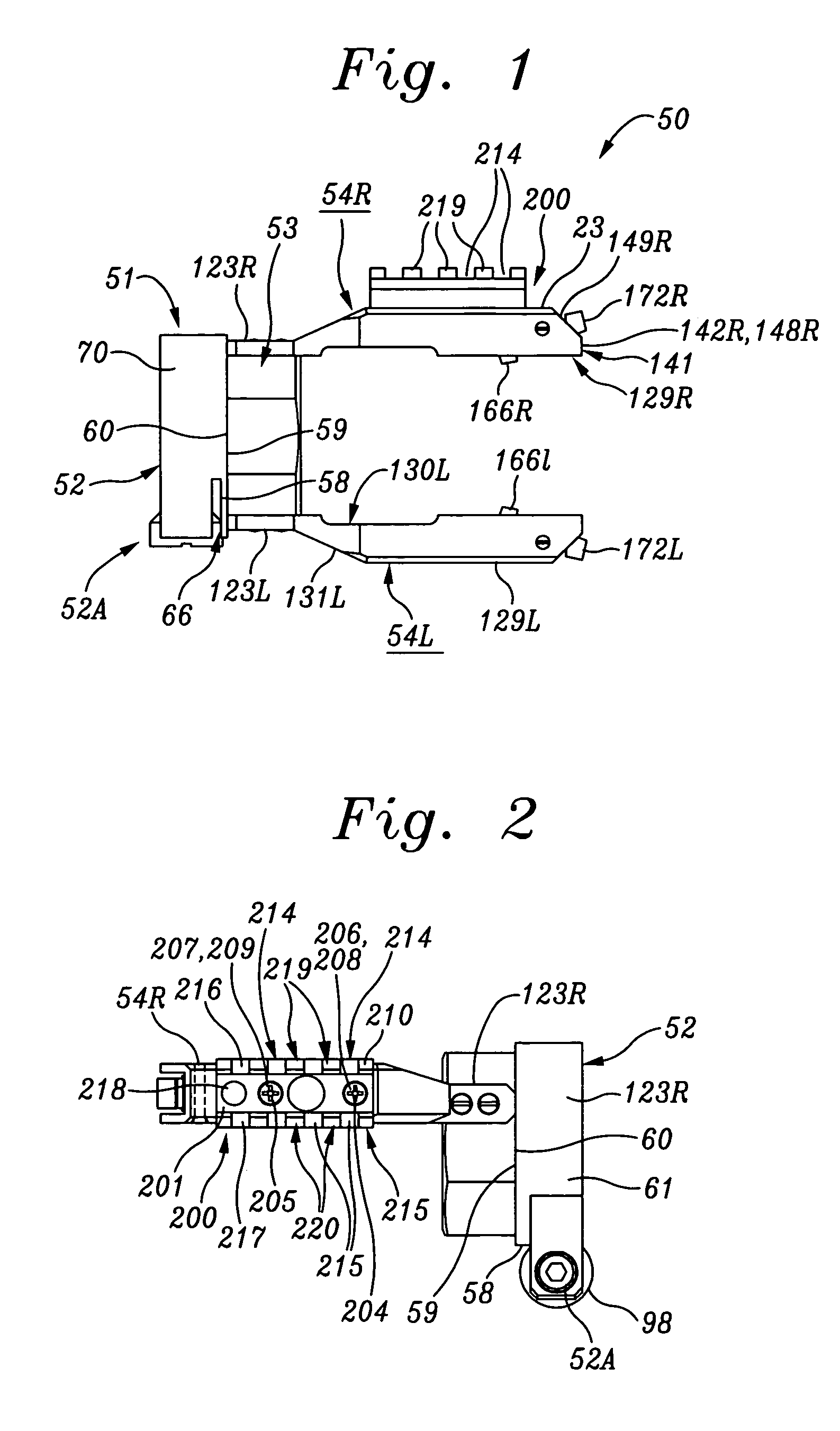

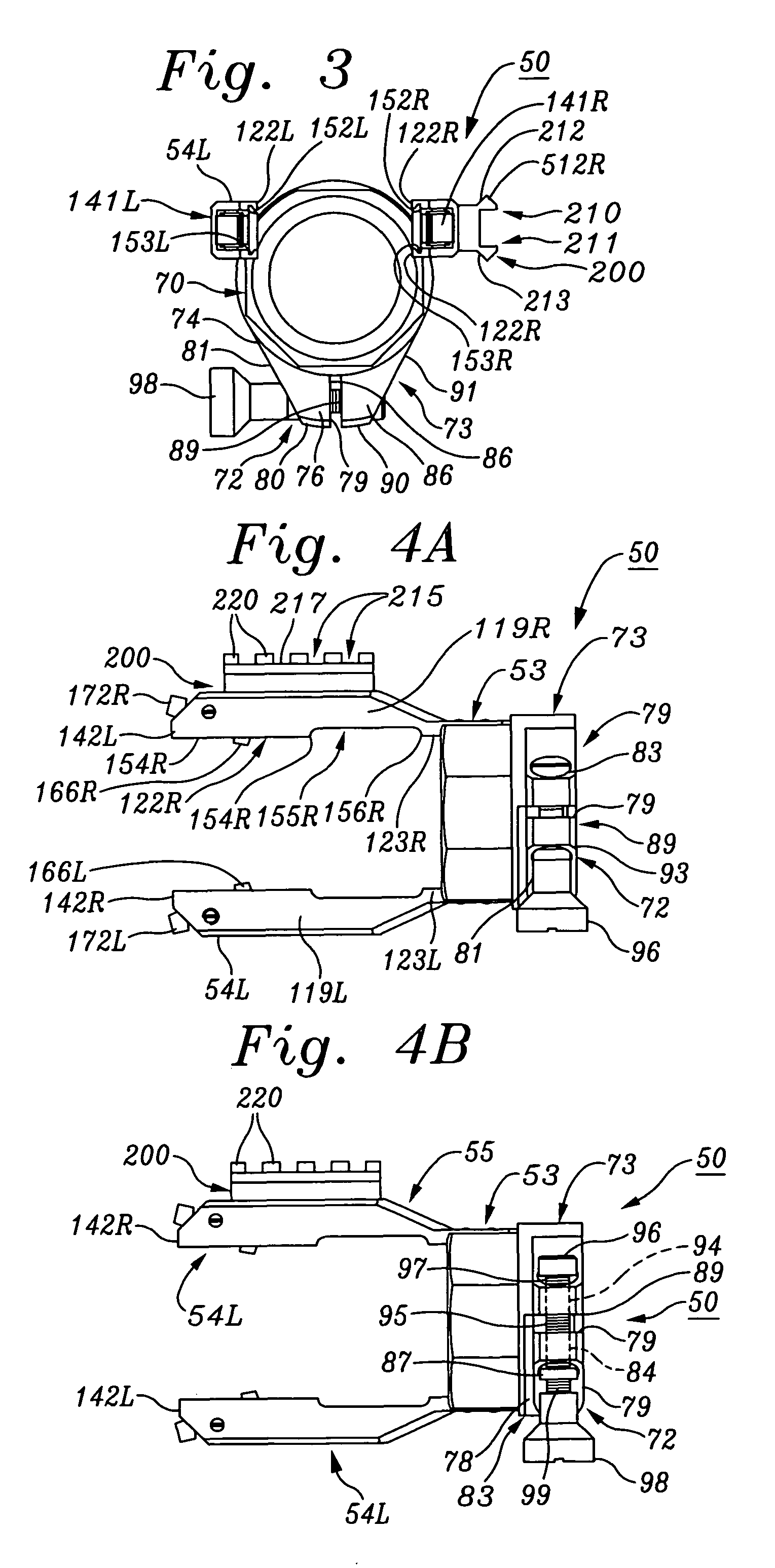

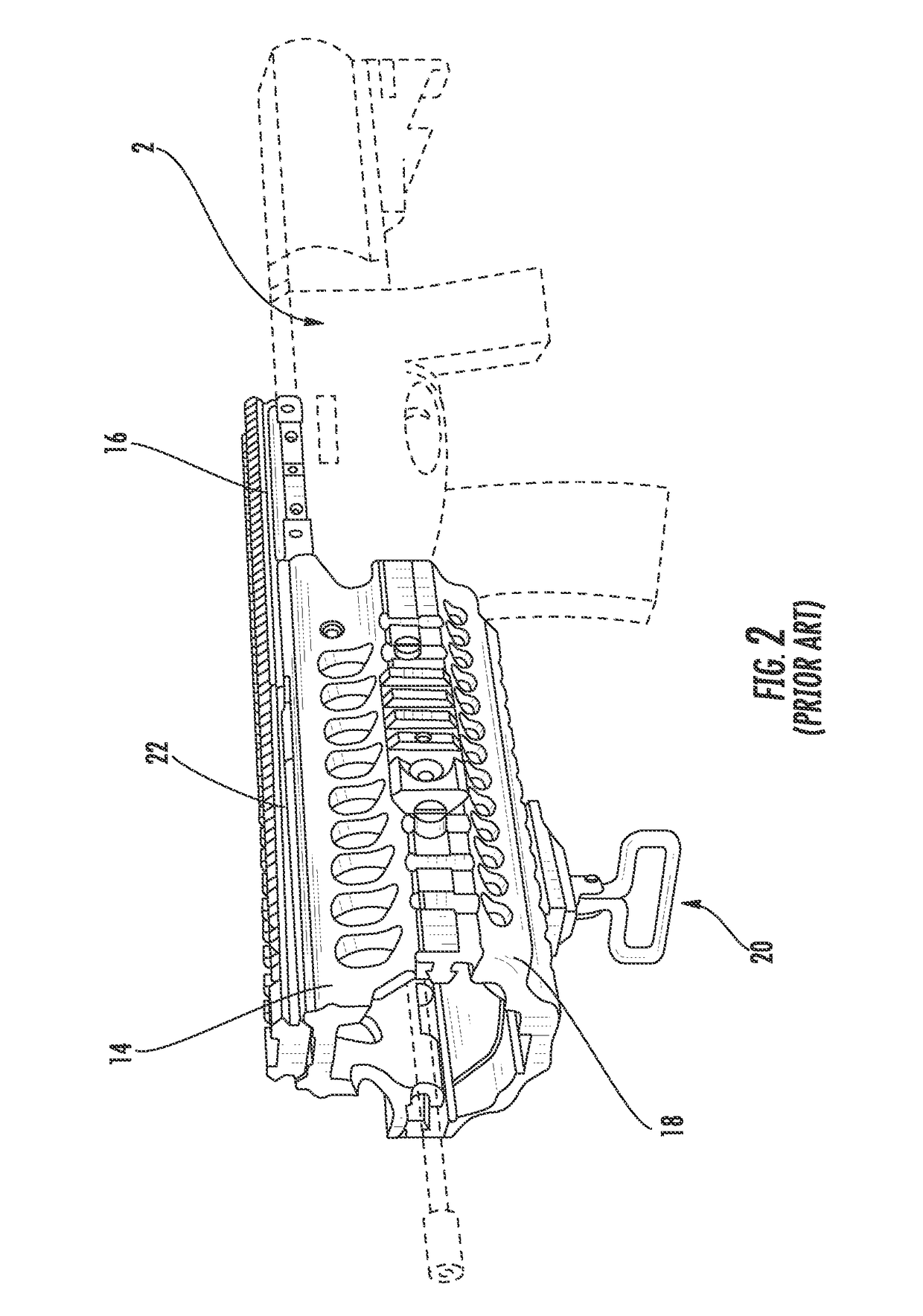

Mounting assembly with adjustable spring tension and pivoting lock lever

InactiveUS8112933B1Easy to installControl tensionSighting devicesRod connectionsRail profileEngineering

An improved mounting assembly is provided that is configured to be releasably attached to a standard dovetail rail profile, wherein the initial clamping tension of a clamping assembly is adjustable. The mounting assembly includes a main body having a lower portion that is configured to engage a standard dovetail and an upper portion accessory receiving formation. The lower portion of the mounting assembly has a first engagement member extending downwardly along one side thereof for engaging one side of the dovetail rail and a clamping assembly to engage the opposing side of the dovetail rail. At least one spring and a retention nut are provided as part of the clamping assembly such that retention nut controls the preset spring tension thereby controlling the clamping force applied by the clamping assembly. A lock lever connected to the actuator arm selectively locks the position of the retention nut on the threaded shaft.

Owner:SWAN RICHARD E

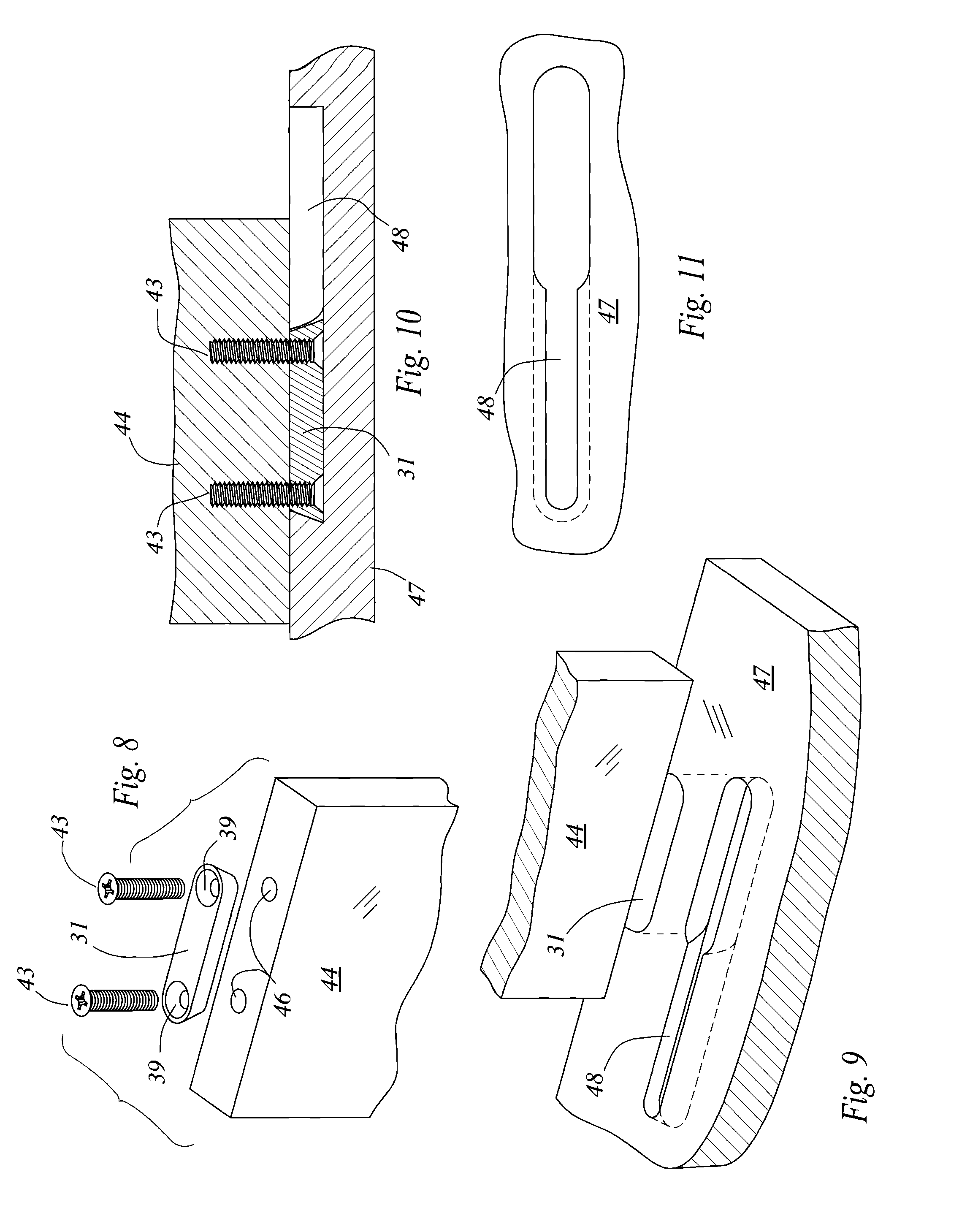

Releasable dovetail corner joint

InactiveUS20060188325A1Increases joint spaceEasy to adjustSecuring devicesBranching pipesEngineeringMirror image

A corner leg assembly comprises two grooved mating elements divided longitudinally which when held together form the female groove portion of two dovetail joints, one on each side facing laterally 90 degrees apart. One of the corner elements is a substantially triangular corner leg having perpendicular outside surfaces and parallel lengthwise L-shaped grooves on a 45 degree inside surface. The second element is a clamp block which includes opposite-facing L-shaped side grooves corresponding (being the mirror image thereof) to the grooves on the corner leg. The clamp block is affixed down the middle of the corner leg along the inside surface by one or more clamping fasteners such as a screw or bolt which passes through the clamp block. By turning the fastener(s), the clamp block may be loosened or removed to vertically adjust a laterally-extending panel or rail member.

Owner:DOLAN KEVIN P

Mounting assembly with adjustable spring tension

ActiveUS7757422B1Easy to installControl spring tensionSighting devicesRod connectionsRail profileEngineering

An improved mounting assembly is provided that is configured to be releasably attached to a standard dovetail rail profile, wherein the initial clamping tension of the clamping actuator is adjustable. The mounting assembly generally includes a main body having a lower portion that is configured to engage a standard dovetail and an upper portion accessory receiving formation. The lower portion of the mounting assembly has a first engagement member extending downwardly along one side thereof for engaging one side of the dovetail rail and a clamping assembly to engage the opposing side of the dovetail rail. At least one spring and a retention nut are provided as part of the clamping assembly such that a retention nut, which is locked relative to the clamping assembly, controls the preset spring tension thereby controlling the clamping force applied by the clamping assembly.

Owner:SWAN RICHARD E

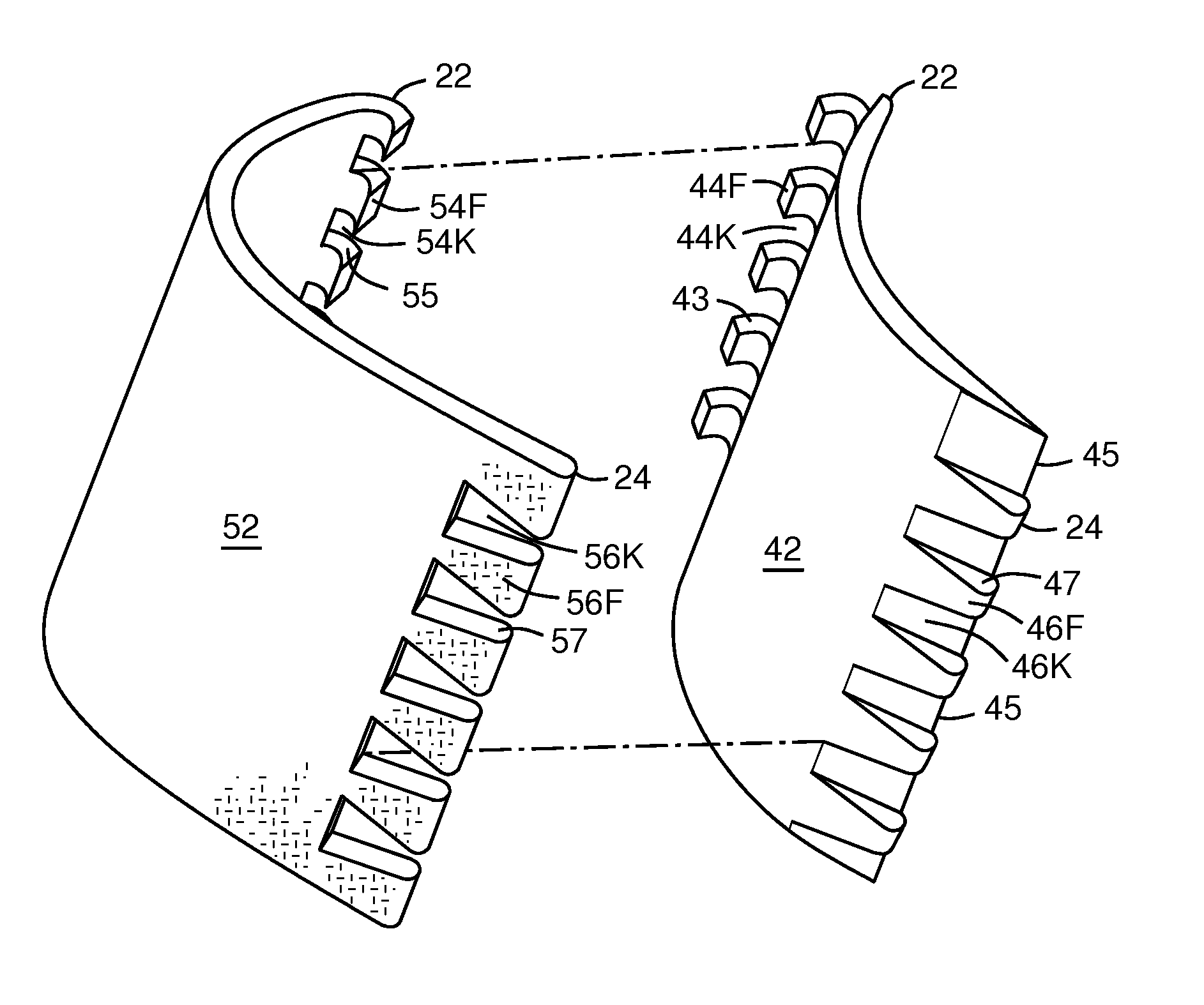

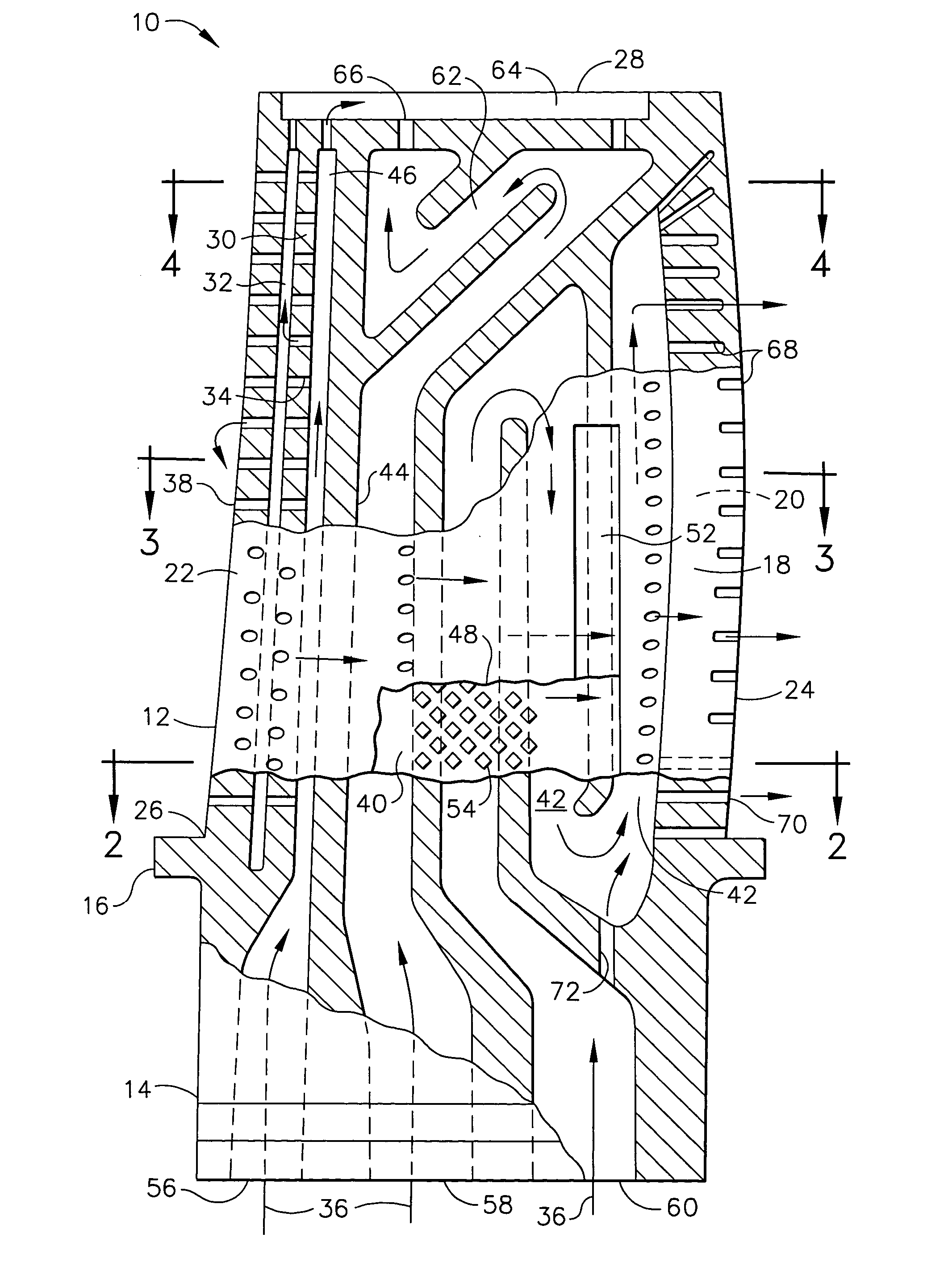

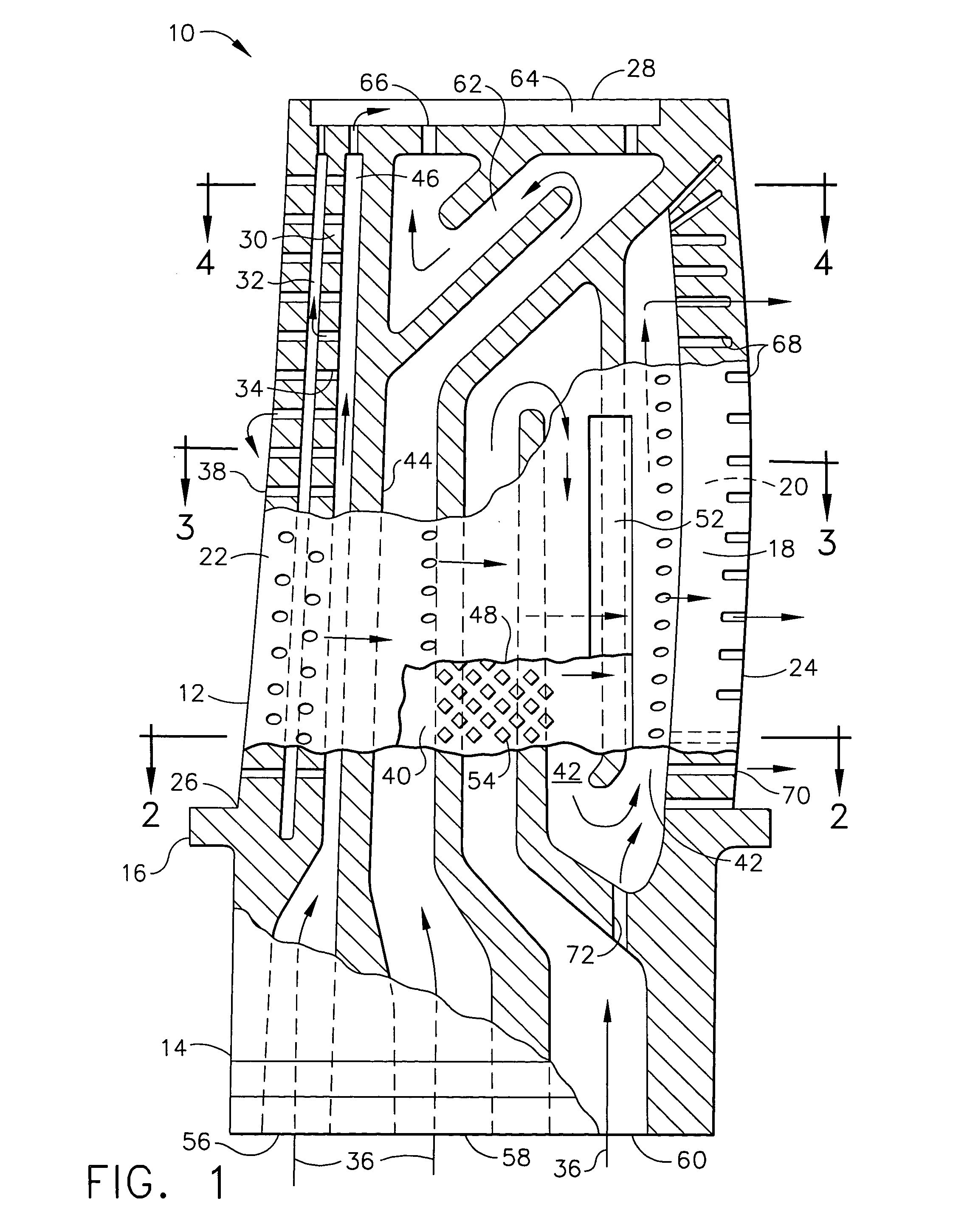

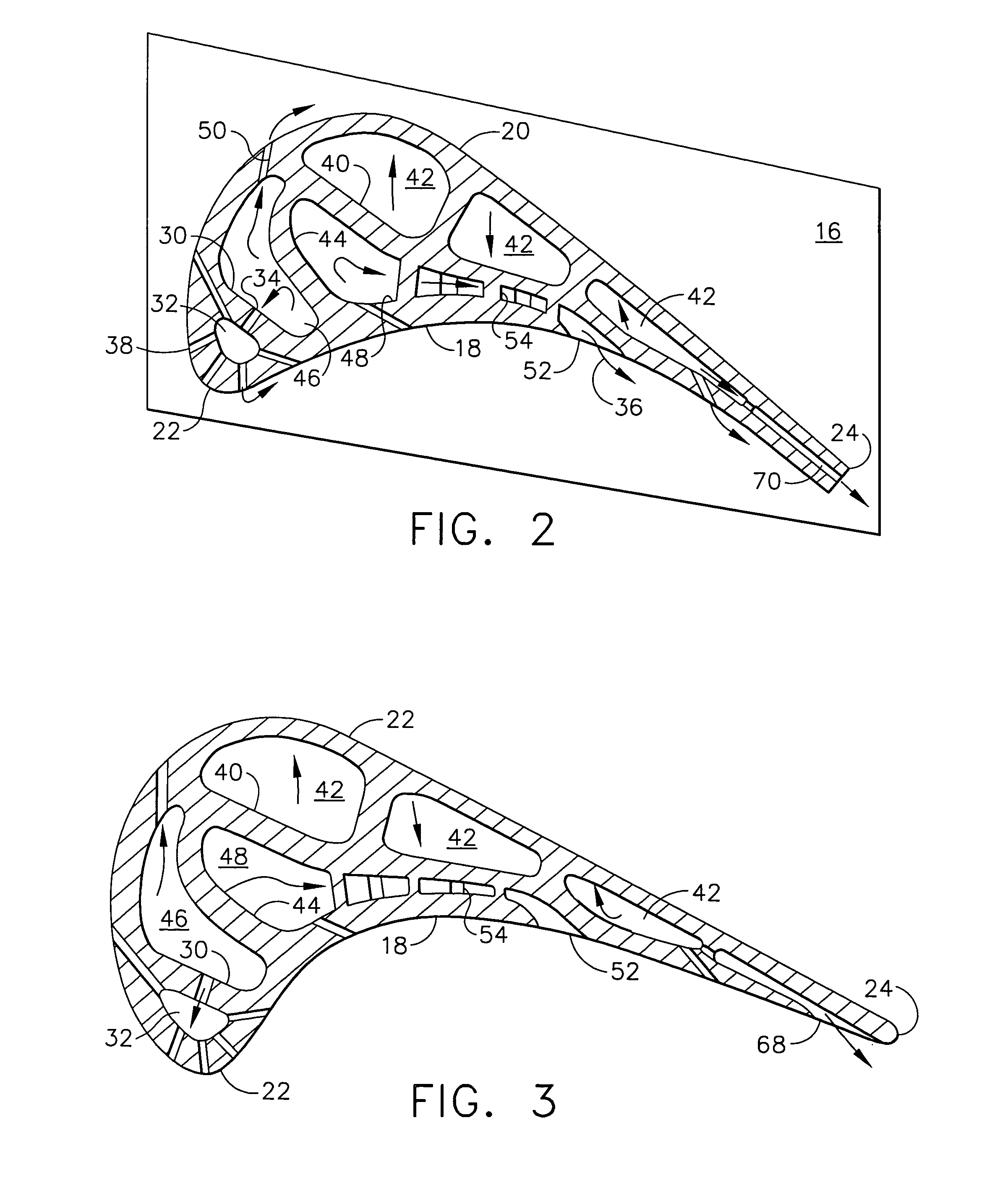

Interlocked CMC airfoil

A ceramic matrix composite (CMC) airfoil assembled from a pressure side wall (42) and a suction side wall (52) joined by interlocking joints (18, 19) at the leading and trailing edges (22, 24) of the airfoil to produce a tapered thin trailing edge. The trailing edge (24) is thinner than a combined thicknesses of the airfoil walls (42, 52). One or both of the interlocking joints (18, 19) may be formed to allow only a single direction of assembly, as exemplified by a dovetail joint. Each joint (18, 19) includes keys (44F, 54F, 56F, 46F) on one side and respective keyways (44K, 54K, 56K, 46K) on the other side. Each keyway may have a ramp (45) that eliminates indents in the airfoil outer surface that would otherwise result from the joint.

Owner:SIEMENS ENERGY INC

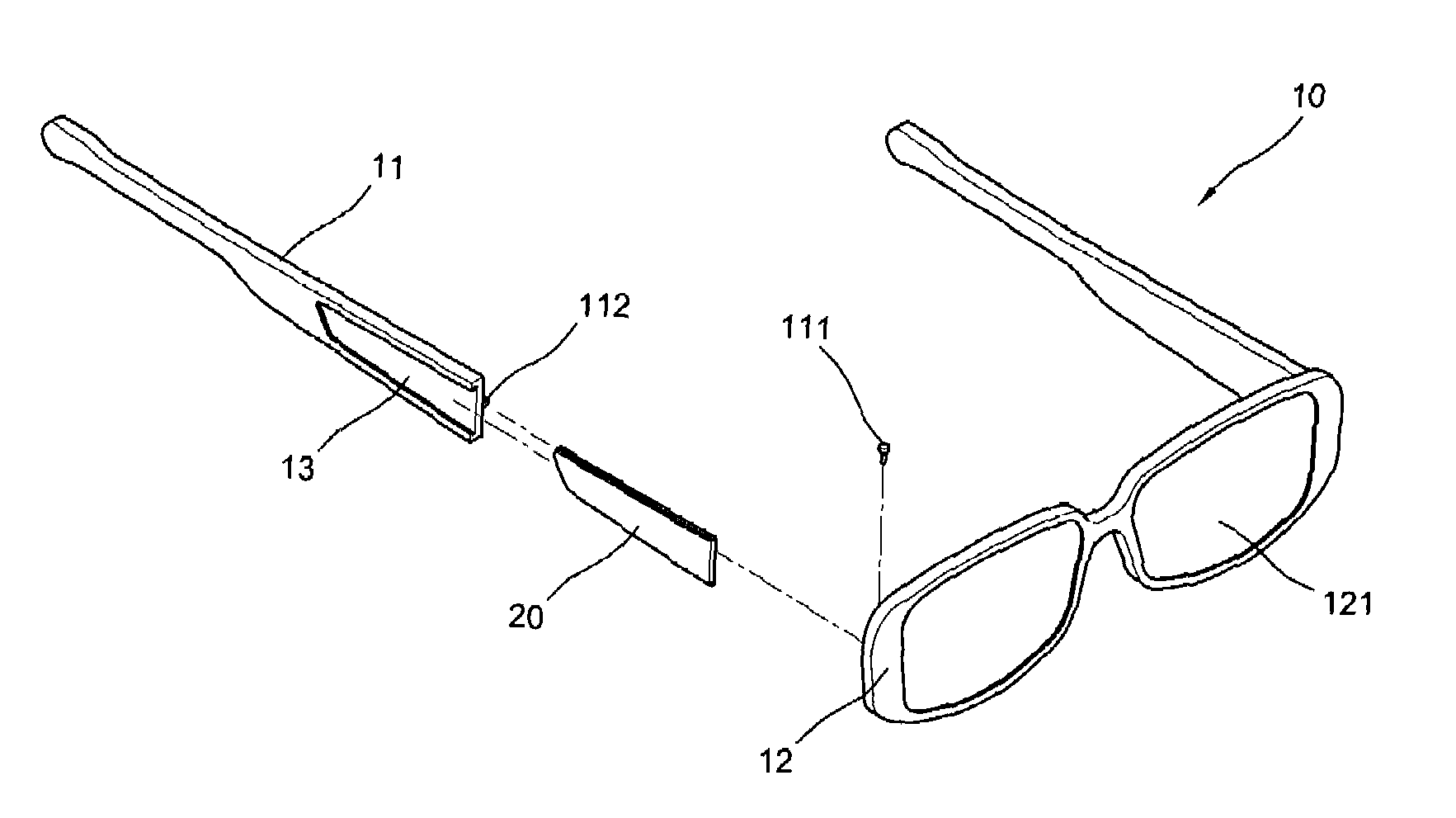

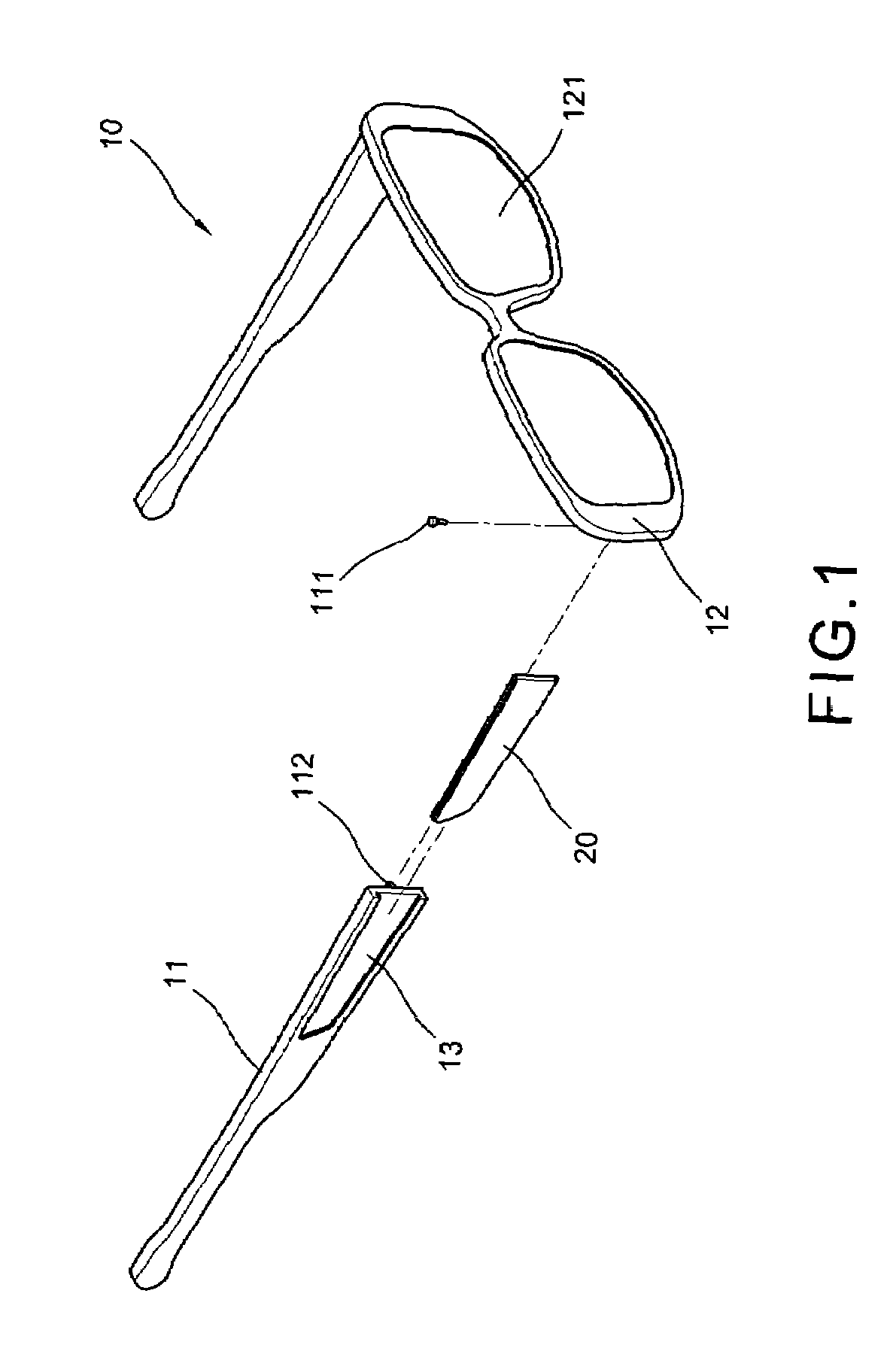

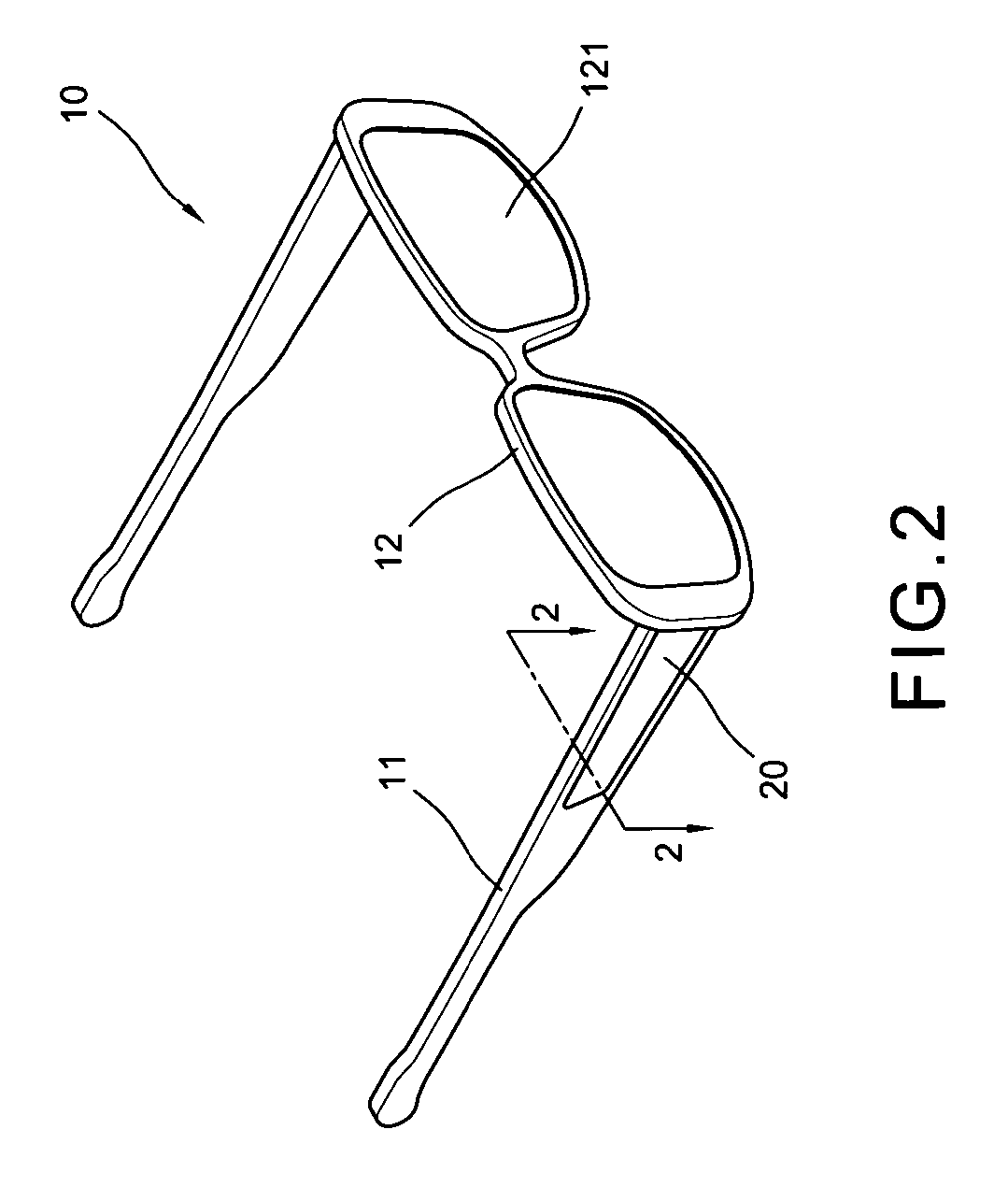

Spectacles for attaching decorative labels

Owner:CHAO KUO LUNG

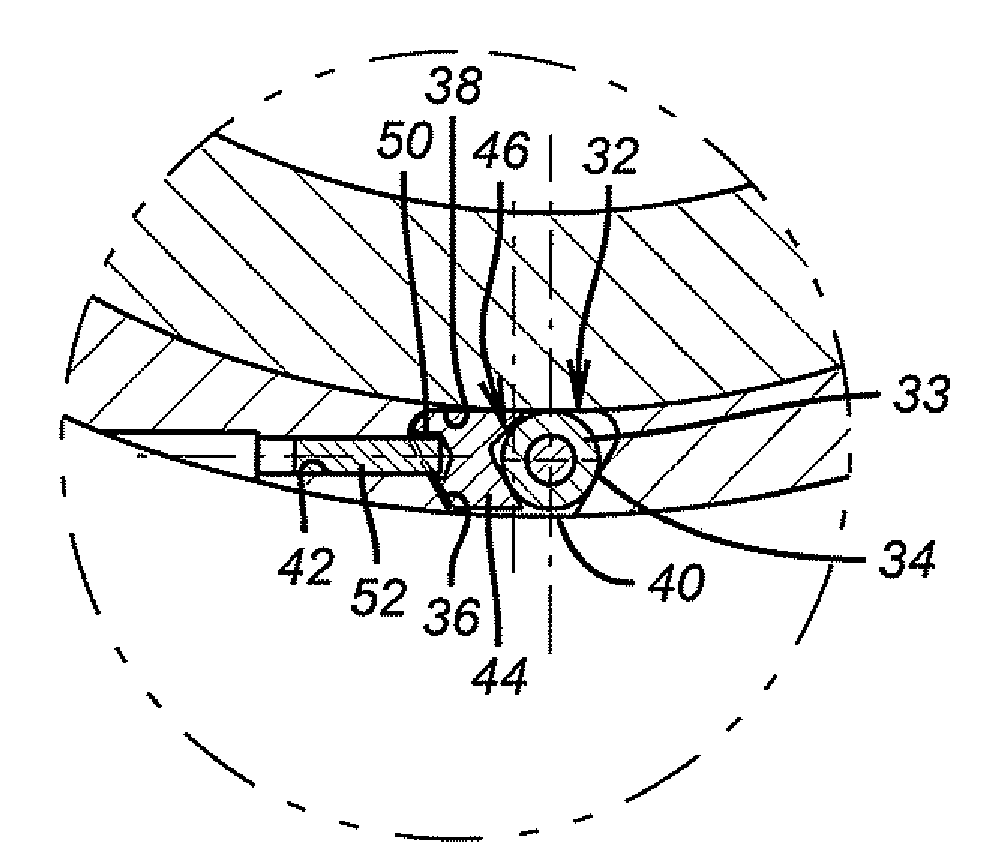

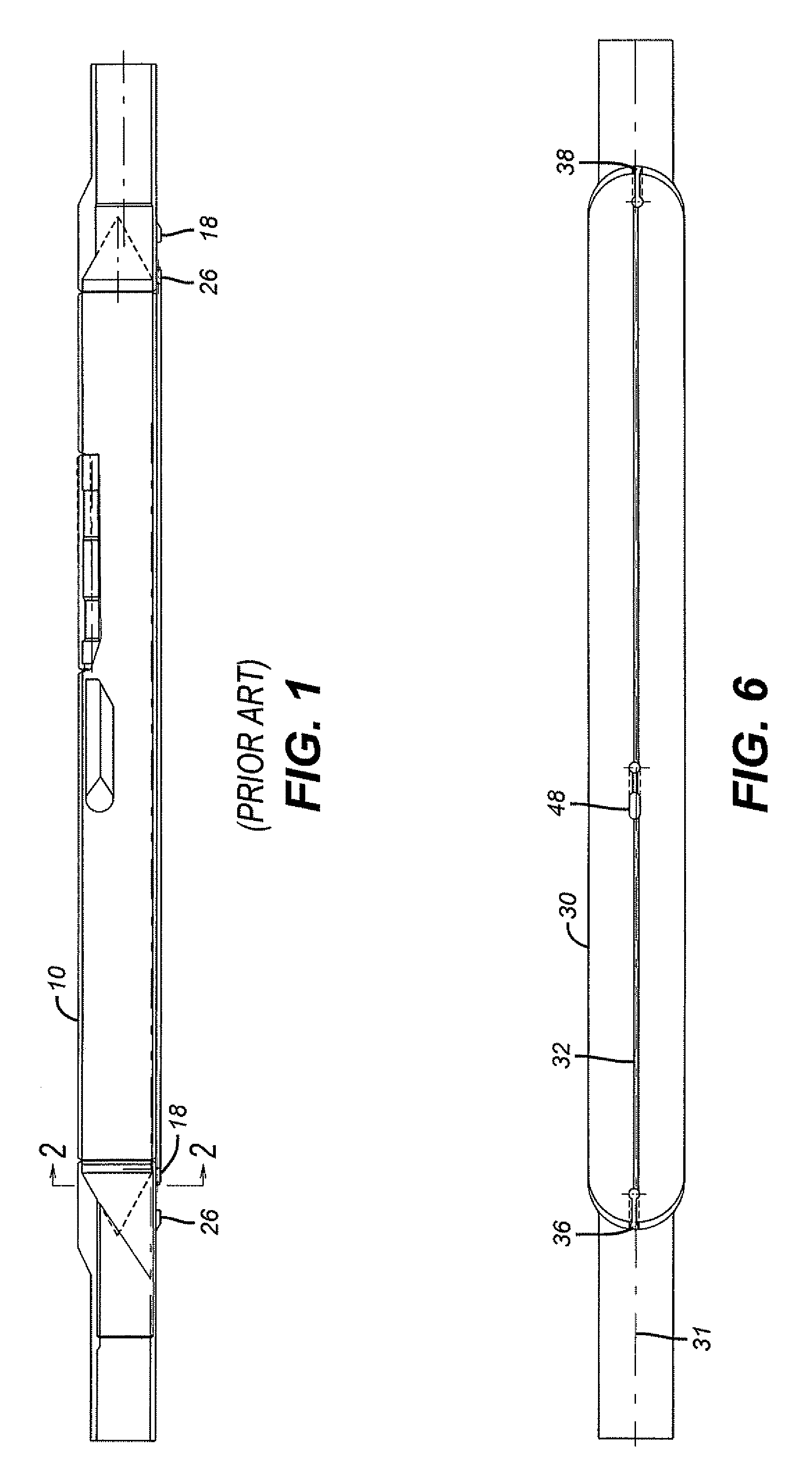

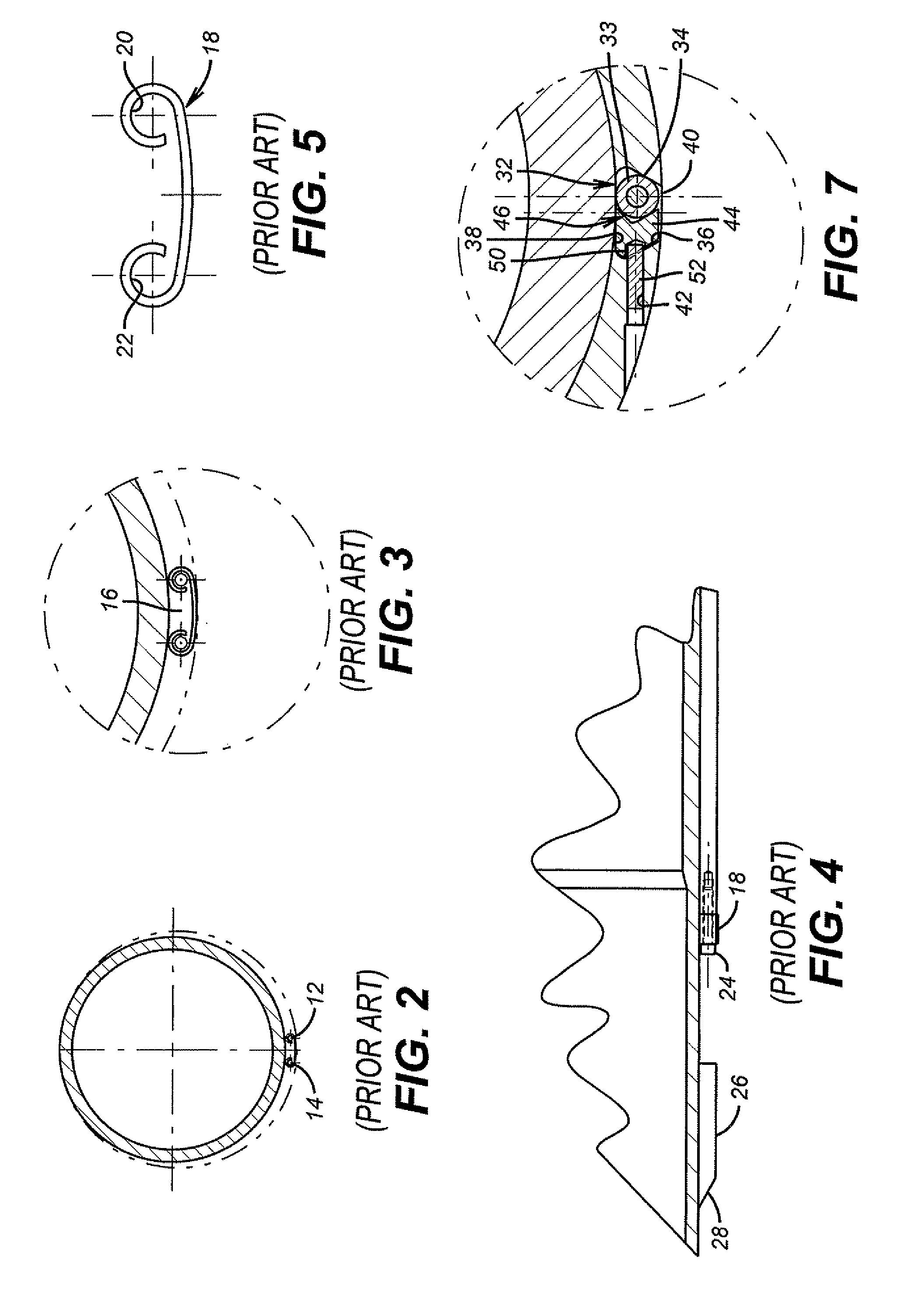

Retaining lines in bypass groove on downhole equipment

Owner:BAKER HUGHES INC

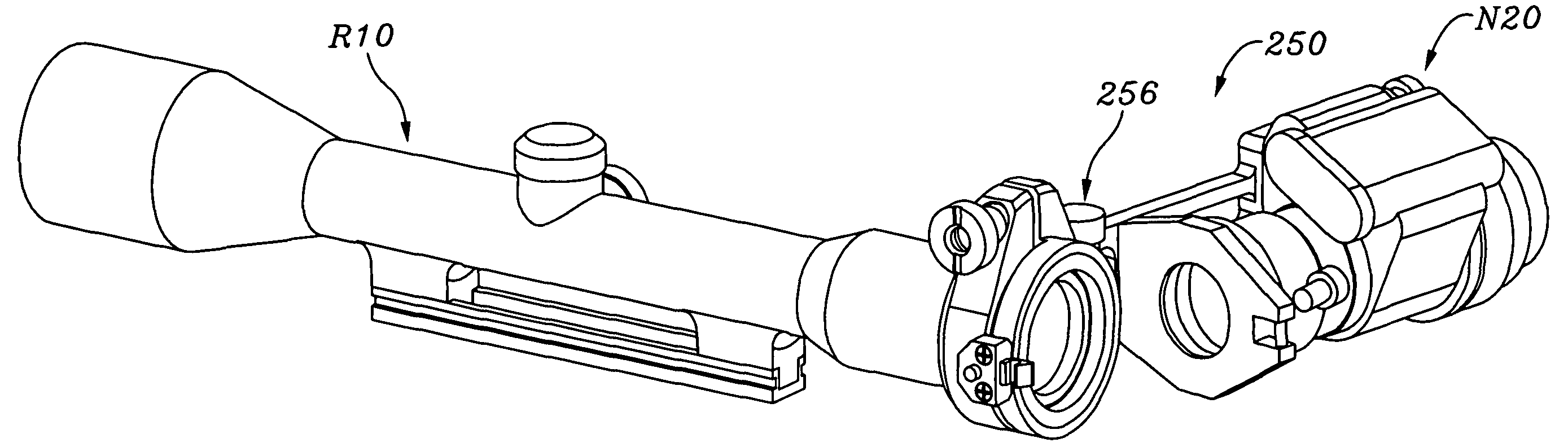

Clamping device for coaxially coupling optical devices

InactiveUS7870688B1Reduce the overall diameterCandle holdersLighting support devicesEngineeringDovetail joint

A clamping device for coupling optical devices in coaxial, tandem alignment includes a front clamp assembly that has elastically deformable split collar halves tightenable onto a front optical device by a screw tightenable into bores disposed transversely through a pair of arms extending radially from the split collar halves. A rear optical device support protrudes rearward from the front clamp assembly, and has a releasable fastener such as a screw or dovetail joint for supporting a rear optical device in coaxial alignment with the front optical device. Preferably, the arm is mounted to the front clamp assembly by means of a pivotable joint which is latchable in a first, rearward position, and a second, forward position in which the rear optical device is positioned along the side of the front optical device, so that the front device may be used independently of the rear device.

Owner:BUSHNELL

Mounting assembly with adjustable spring tension

InactiveUS7757423B1Prevents over tighteningPrevents loosening of the nut once installedSighting devicesRod connectionsRail profileActuator

An improved mounting assembly is provided that is configured to be releasably attached to a standard dovetail rail profile, wherein the initial clamping tension of the clamping actuator is adjustable. The mounting assembly generally includes a main body having a lower portion that is configured to engage a standard dovetail and an upper portion accessory receiving formation. The lower portion of the mounting assembly has a first engagement member extending downwardly along one side thereof for engaging one side of the dovetail rail and a clamping assembly to engage the opposing side of the dovetail rail. At least one spring and a retention nut are provided as part of the clamping assembly such that retention nut controls the preset spring tension thereby controlling the clamping force applied by the clamping assembly.

Owner:SWAN RICHARD E

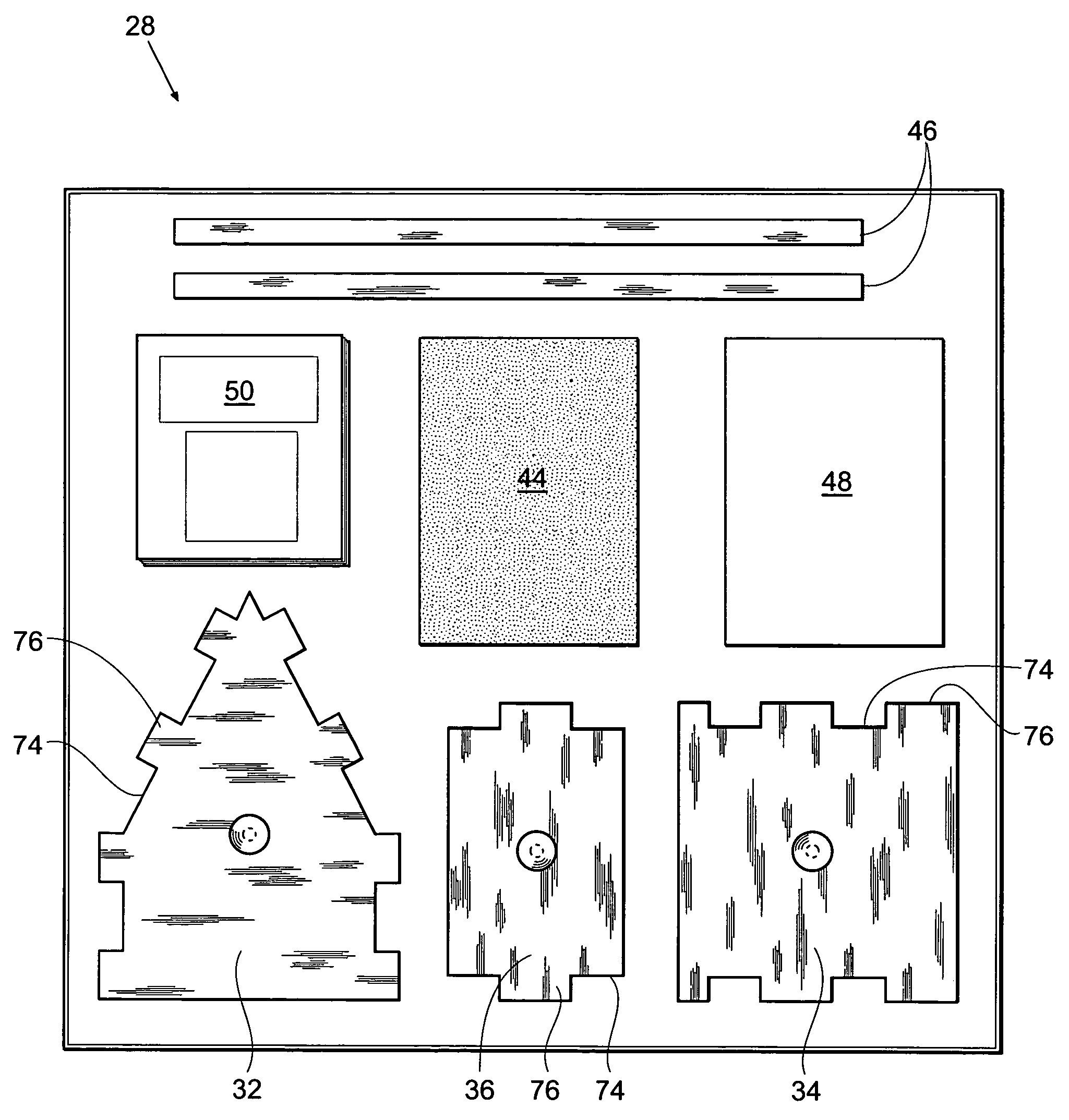

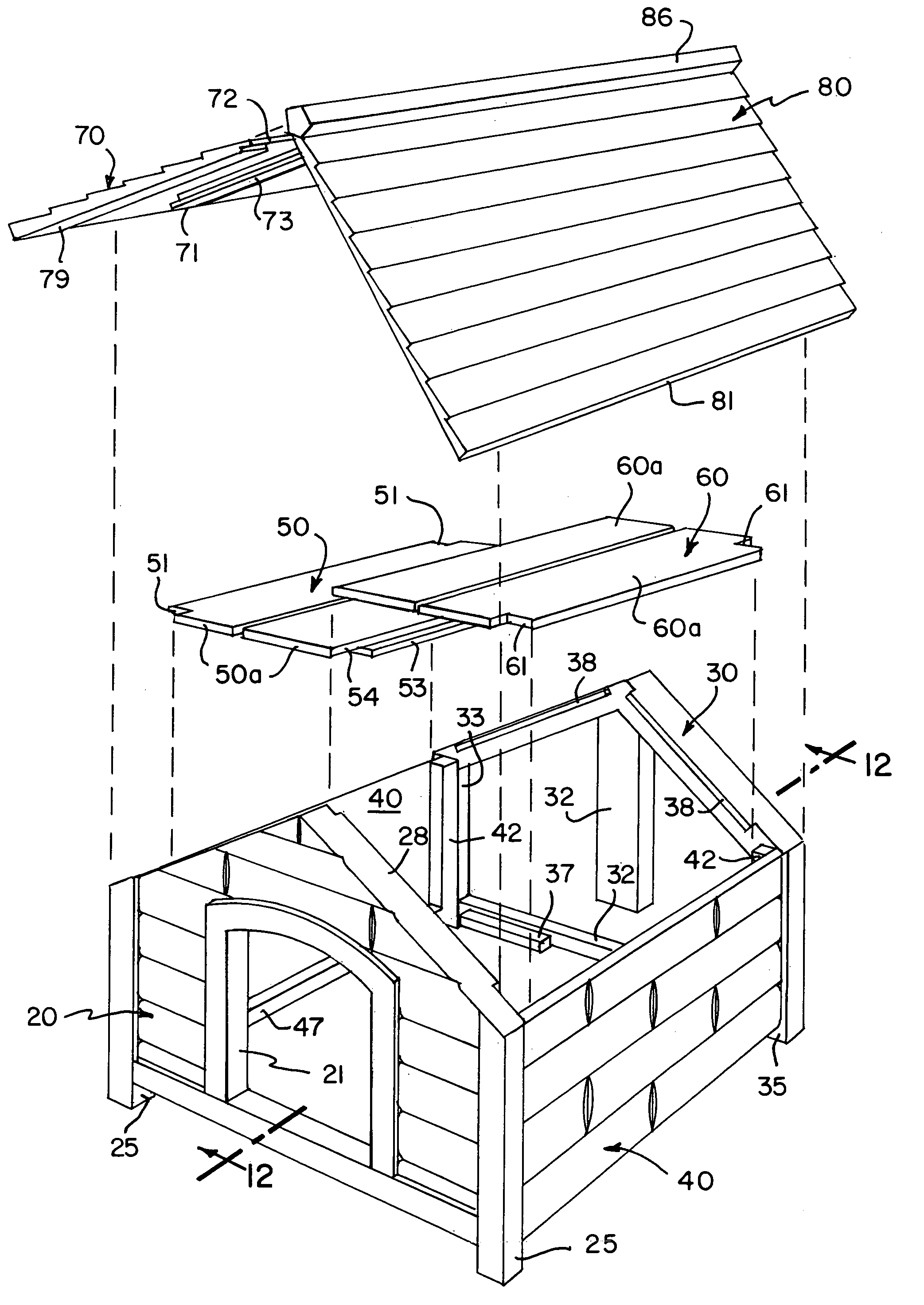

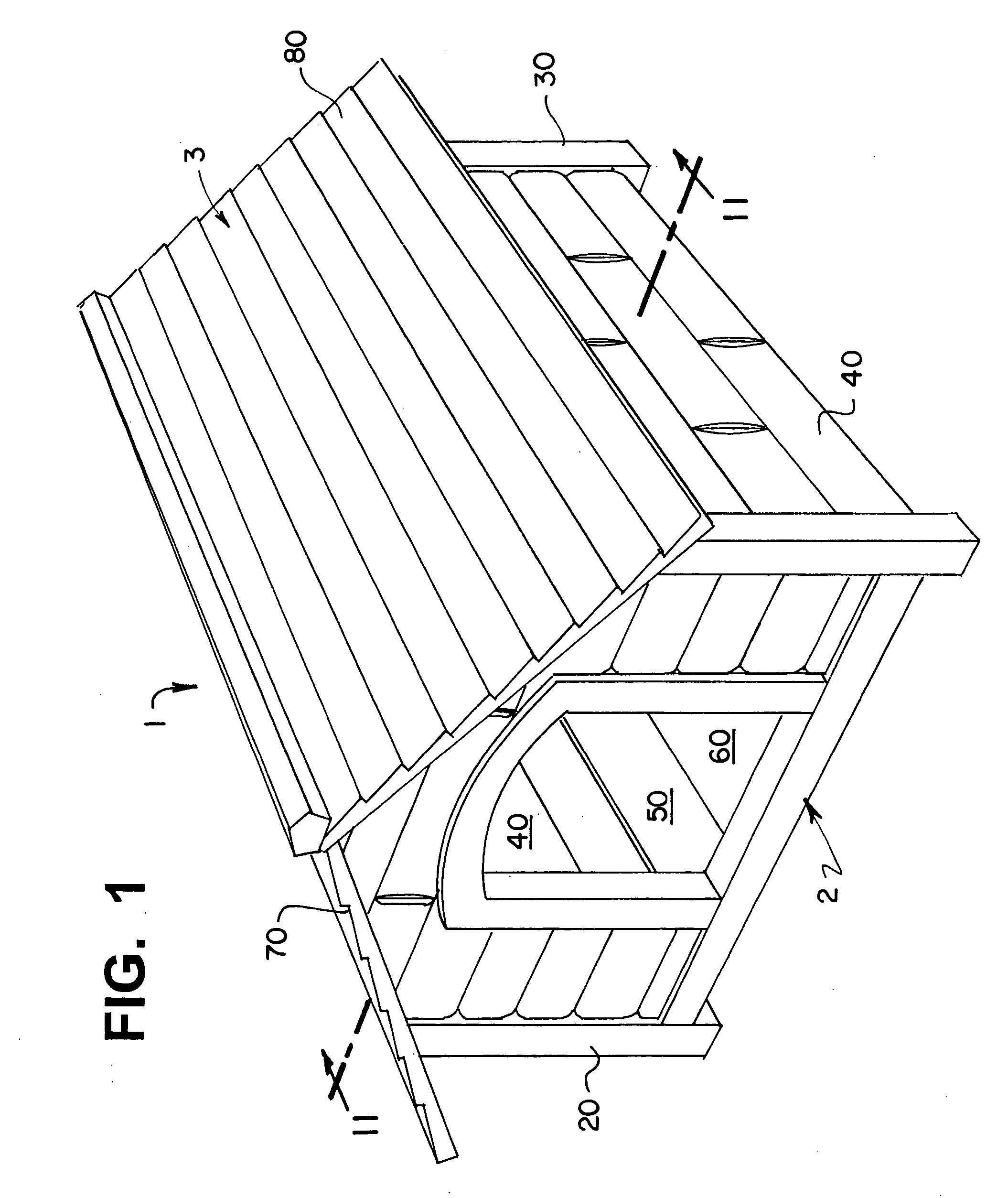

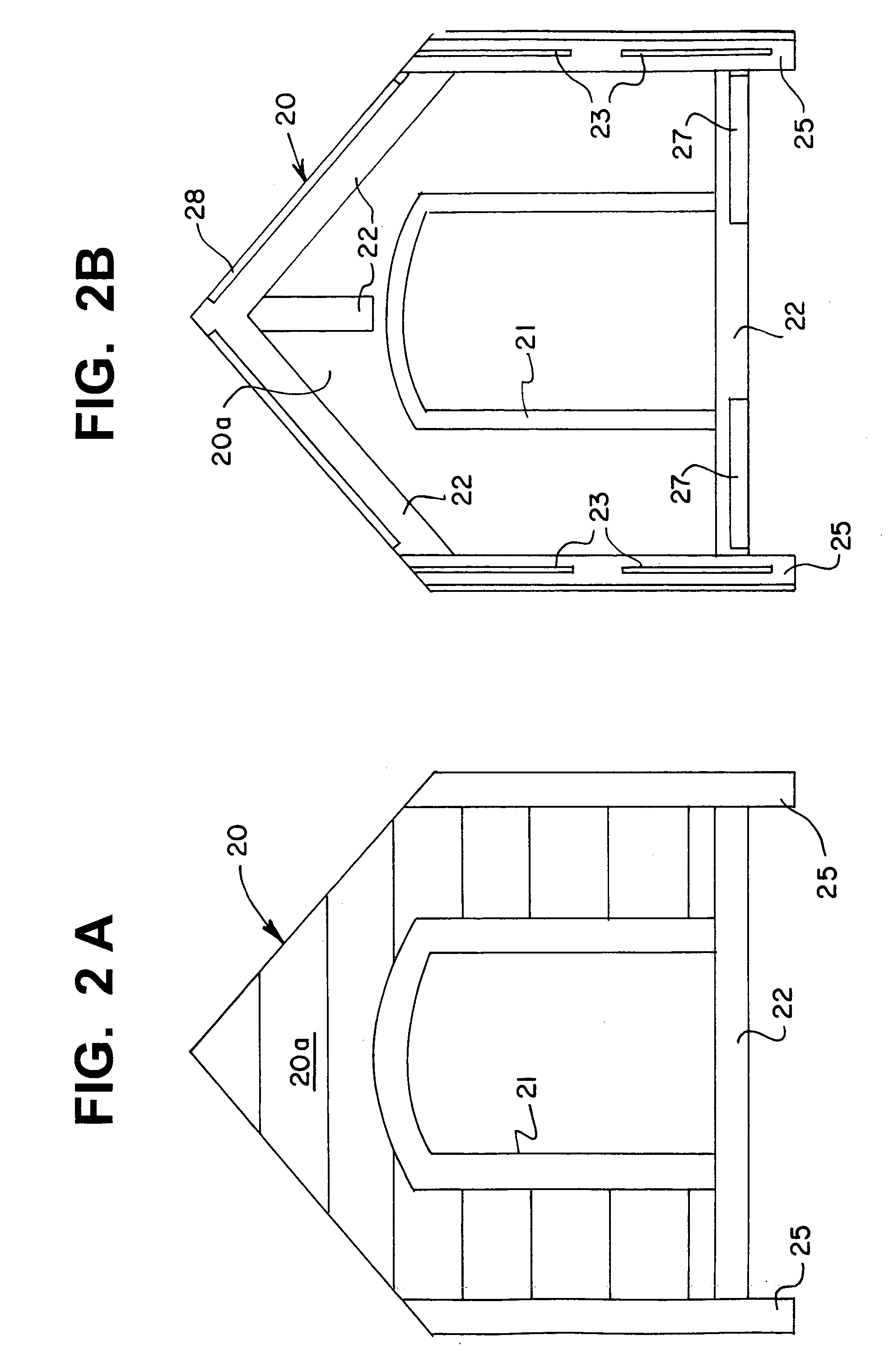

Systems and methods for building an interlocking decorative house

InactiveUS7210920B2Acceptable degree of stabilityFit tightlyMouldsFrozen sweetsEngineeringDovetail joint

A special tabbed pattern is integrated into a series of forms. The forms may be cookie cutters adapted to cut baked dough or other material set to desired density to provide a series of panels corresponding to the cutters. Alternatively, the forms may be molds, e.g, adapted to receive melted chocolate which is allowed to cool and set to form a series of panels corresponding to the molds. The panels are adapted to be joined together to form a decorative structure. The tabs are sized and positioned to provide a dovetail joint along each edge of the structure. The protruding tabs or ends are of a slightly smaller dimension than the notches that they fit inside of to provide a secure fit. This self-interlocking design allows each individual piece of the structure to be fitted together, one at a time, while maintaining an acceptable degree of stability throughout the assembly process.

Owner:KOLZ DEBRA A

Mounting assembly with adjustable spring tension

InactiveUS7905045B1Easy to installControl spring tensionSighting devicesRod connectionsRail profileEngineering

An improved mounting assembly is provided that is configured to be releasably attached to a standard dovetail rail profile, wherein the initial clamping tension of the clamping actuator is adjustable. The mounting assembly generally includes a main body having a lower portion that is configured to engage a standard dovetail and an upper portion accessory receiving formation. The lower portion of the mounting assembly has a first engagement member extending downwardly along one side thereof for engaging one side of the dovetail rail and a clamping assembly to engage the opposing side of the dovetail rail. At least one spring and a retention nut are provided as part of the clamping assembly such that retention nut controls the preset spring tension thereby controlling the clamping force applied by the clamping assembly.

Owner:SWAN RICHARD E

Compressor blade with dovetail slotted to reduce stress on the airfoil leading edge

InactiveUS6902376B2Reducing centrifugalReducing vibratory loadPropellersOther chemical processesLeading edgeAxial compressor

A blade of an axial compressor comprising: an airfoil is disclosed that has a leading edge and a root; a platform attached to the root of the airfoil; a dovetail attached to a side of the platform opposite to the airfoil; a neck of the dovetail adjacent the platform, and a slot in the neck and generally parallel to the platform, and the slot extends from a front of the neck to position in the neck beyond a line formed by the leading edge of the blade.

Owner:GENERAL ELECTRIC CO

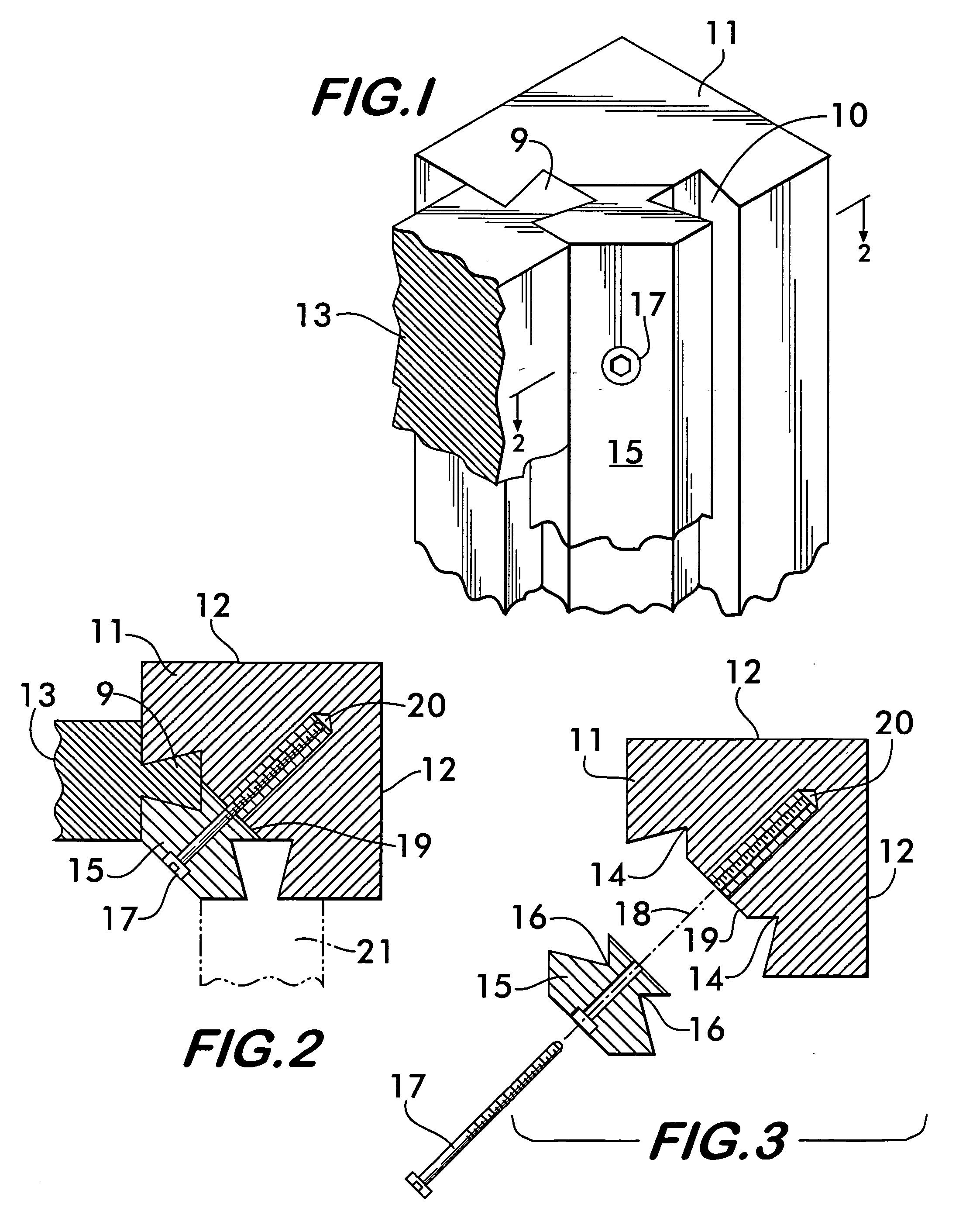

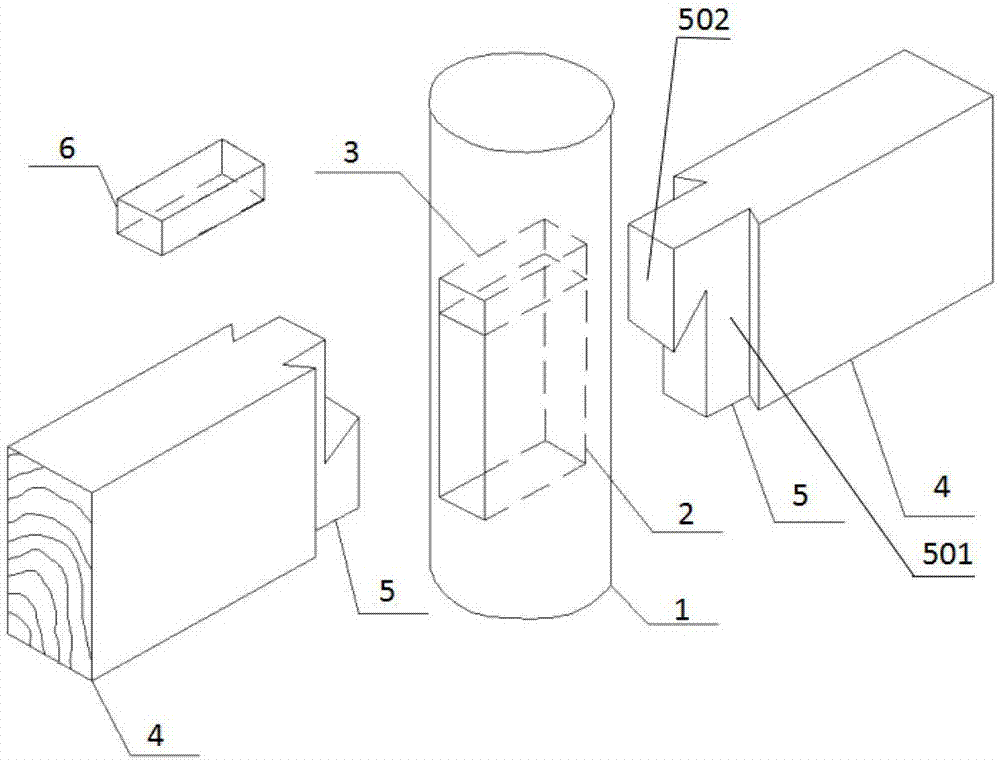

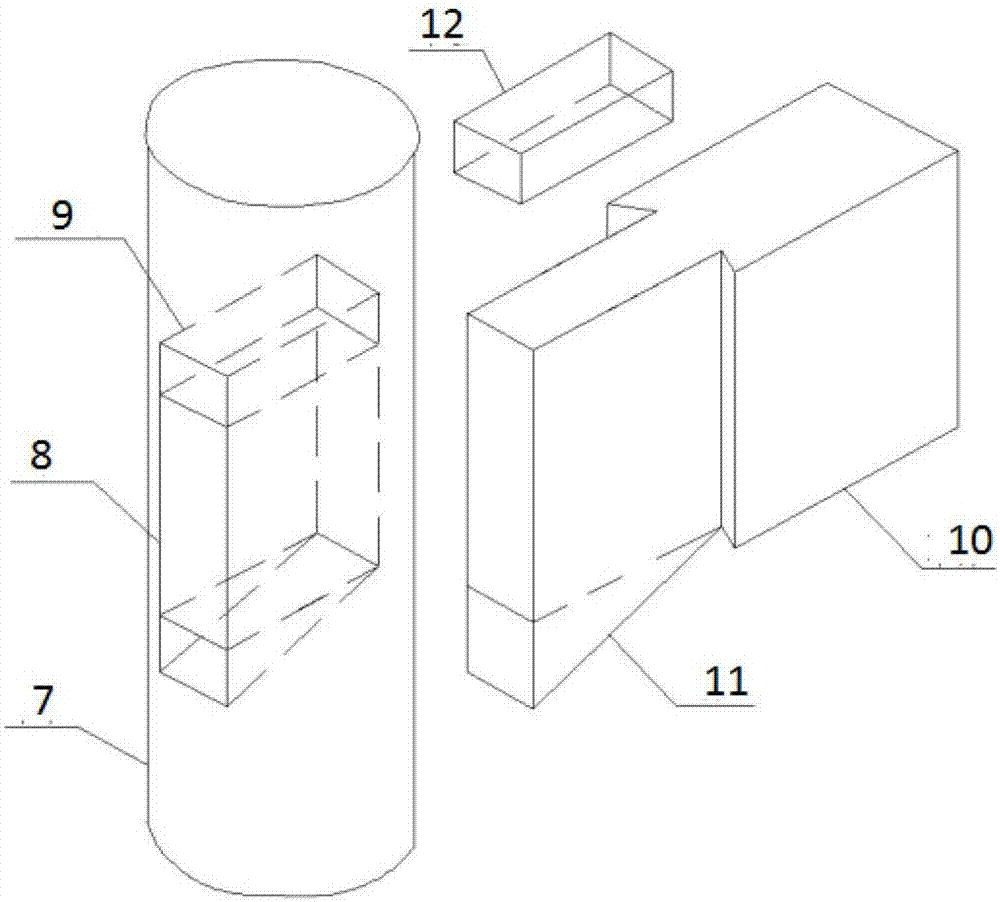

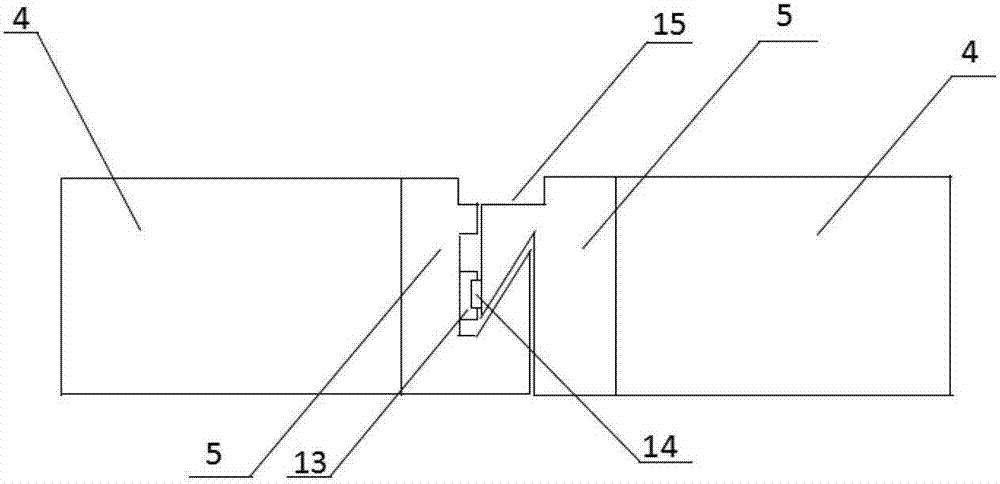

Vertical semi-dovetail tenon node connection structure for wood structure building beam column

InactiveCN106906906AReduce decreaseIncrease stiffnessBuilding constructionsMortise and tenonEngineering

The invention discloses a vertical semi-dovetail tenon node connection structure for a wood structure building beam column. In the wood structure building, the connection between a middle column and a wood beam or a side column and the wood beam adopts the vertical semi-dovetail tenon node connection structure, and knotting to each other is conducted through the tenon vertical semi-dovetail on the wood beam structure, so that the seismic horizontal bearing tensile strength of a frame is improved. Meanwhile, the vertical semi-dovetail tenon node has strong bending resistance ability. The vertical semi-dovetail tenon node is connected and applied to a wood structure farm house or a civil mixed structure, so that the seismic bearing ability of the wood structure farm house or the civil mixed structure is greatly improved; and the vertical semi-dovetail tenon node connection form makes a slight change on the basis of inheriting a traditional mortise and tenon node connection form, a nail and an iron are still not needed, the vertical semi-dovetail tenon node connection form is more suitable for drawing materials and constructing houses locally of remote mountainous areas, and the construction progress and construction quality are improved in a large degree; and meanwhile, cost of vertical semi-dovetail tenon node is low, and the cost of engineering structure can be reduced.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Integrated bridge turbine blade

InactiveUS20050008487A1Improve rendering capabilitiesIncrease temperaturePump componentsRotary propellersLeading edgeTurbine blade

A turbine blade includes a hollow airfoil integrally joined to a dovetail. The airfoil includes a perforate first bridge defining a flow channel behind the airfoil leading edge. A second bridge is spaced behind the first bridge and extends from a pressure sidewall of the airfoil short of the airfoil trailing edge. A third bridge has opposite ends joined to the pressure sidewall and the second bridge to define with the first bridge a supply channel for the leading edge channel, and defines with the second bridge a louver channel extending aft along the second bridge to its distal end at the pressure sidewall.

Owner:GENERAL ELECTRIC CO

Collapsible doghouse

Owner:FOUR PAWS PRODS

Releasable dovetail corner joint

InactiveUS7255511B2Facilitates adjustment and assemblyIncrease spacingScaffold connectionsDoors/windowsEngineeringMirror image

Owner:DOLAN KEVIN P

Rotatable tool having a replaceable cutting tip secured by a dovetail coupling

A rotatable cutting tool includes a rotatable tool body and a replaceable cutting tip for chip removing machining. The tool body includes a forward free end having a first dovetail coupling part formed thereon. The cutting tip includes a front cutting end and a rear mounting end. The mounting end includes a second dovetail coupling part joined to the first dovetail coupling part. An actuator, such as a screw, is provided which is arranged for elastically deforming one of the dovetail coupling parts to create a tightly clamped relationship between the first and second dovetail coupling parts. Insertion of a replacement cutting tip is performed by laterally mating the dovetail coupling parts until one of the coupling parts abuts a laterally facing stop surface of the other coupling part.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

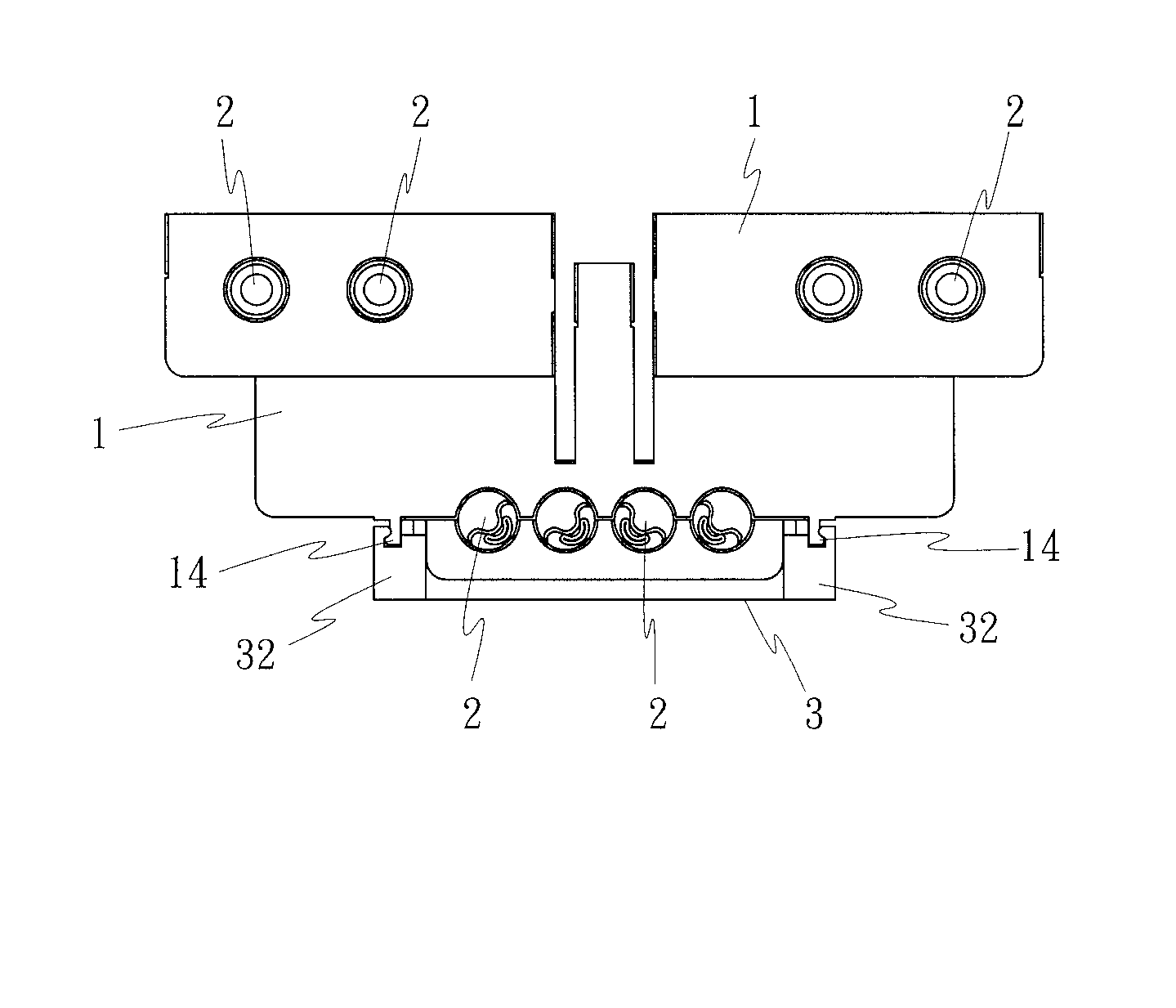

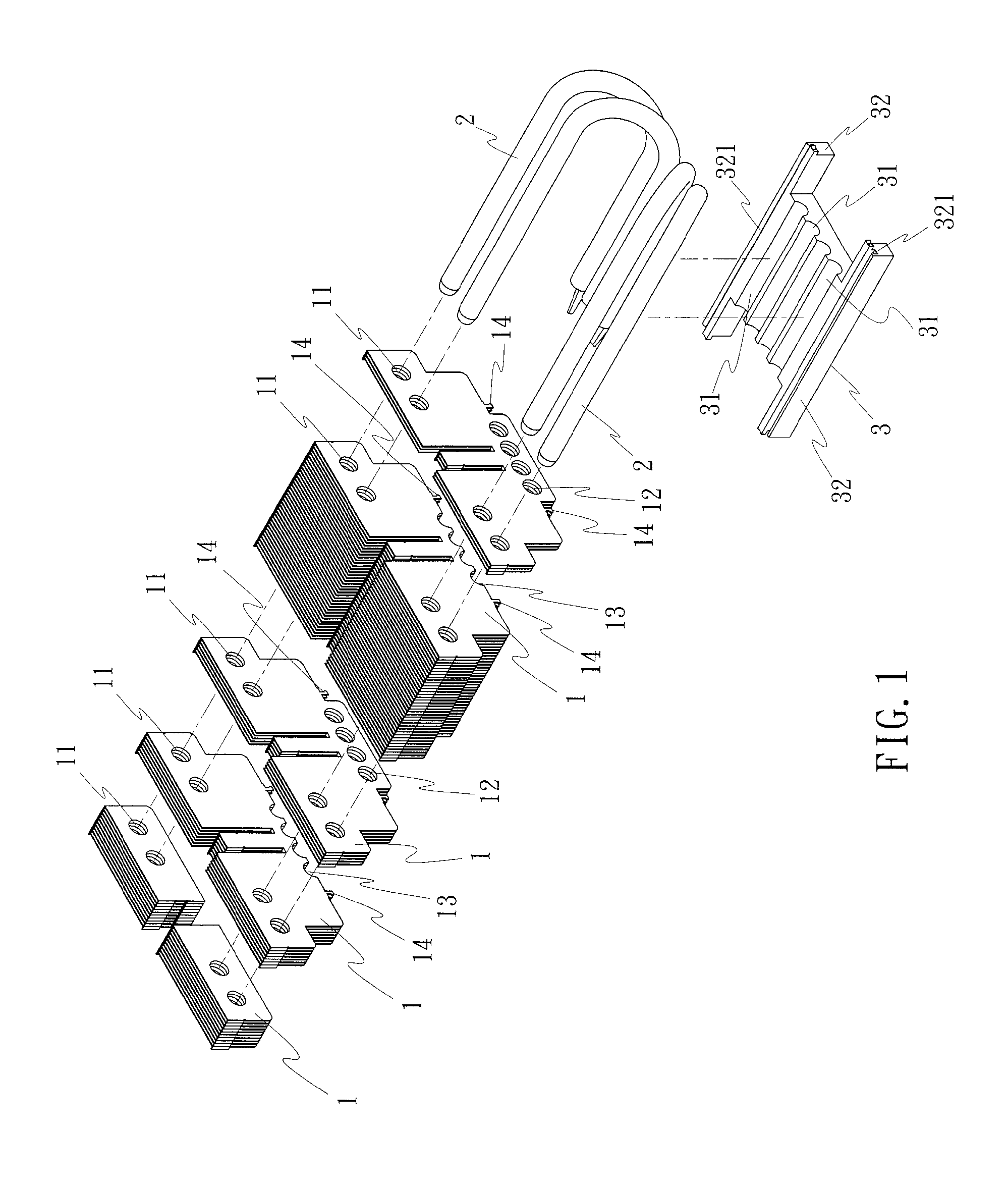

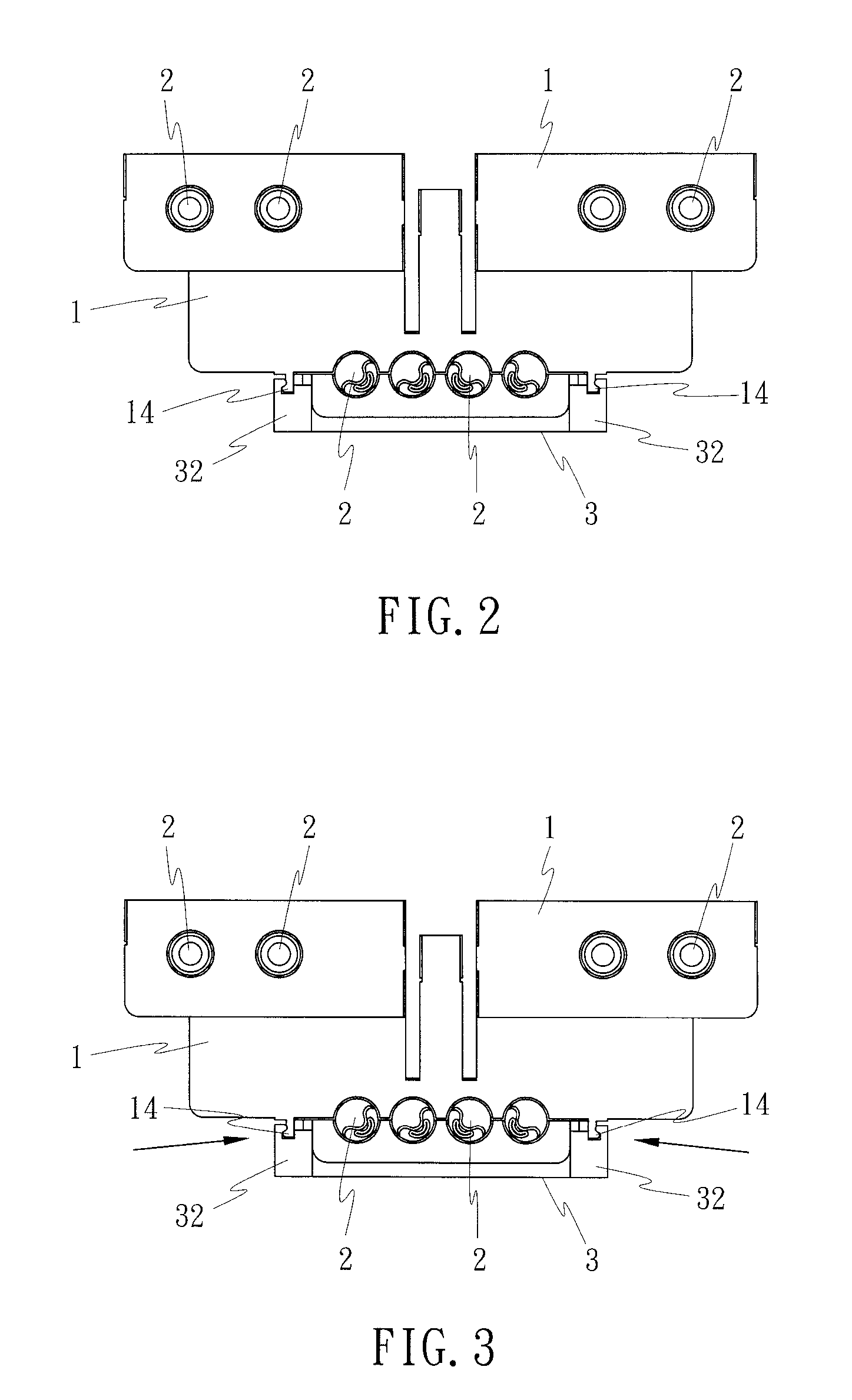

Combination cooler module

A combination cooler module is disclosed, which includes a plurality of radiating fins that are arranged in a stack, a plurality of heat tubes inserted through the radiating fins, and a heat conductive base affixed to the radiating fins by means of a dovetail joint, hook or scarf joint and disposed in contact with the heat tubes.

Owner:KUO HUA SHOU

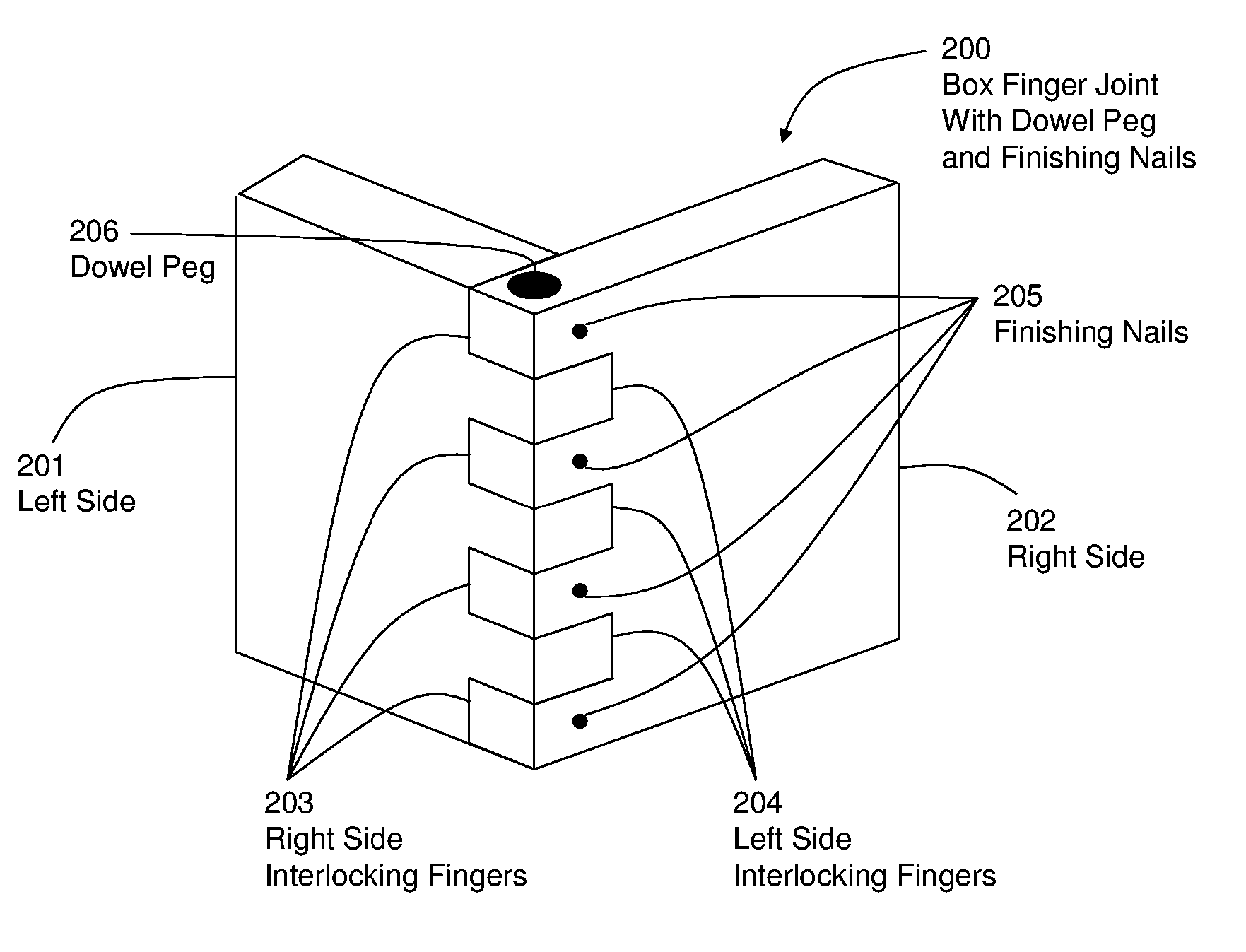

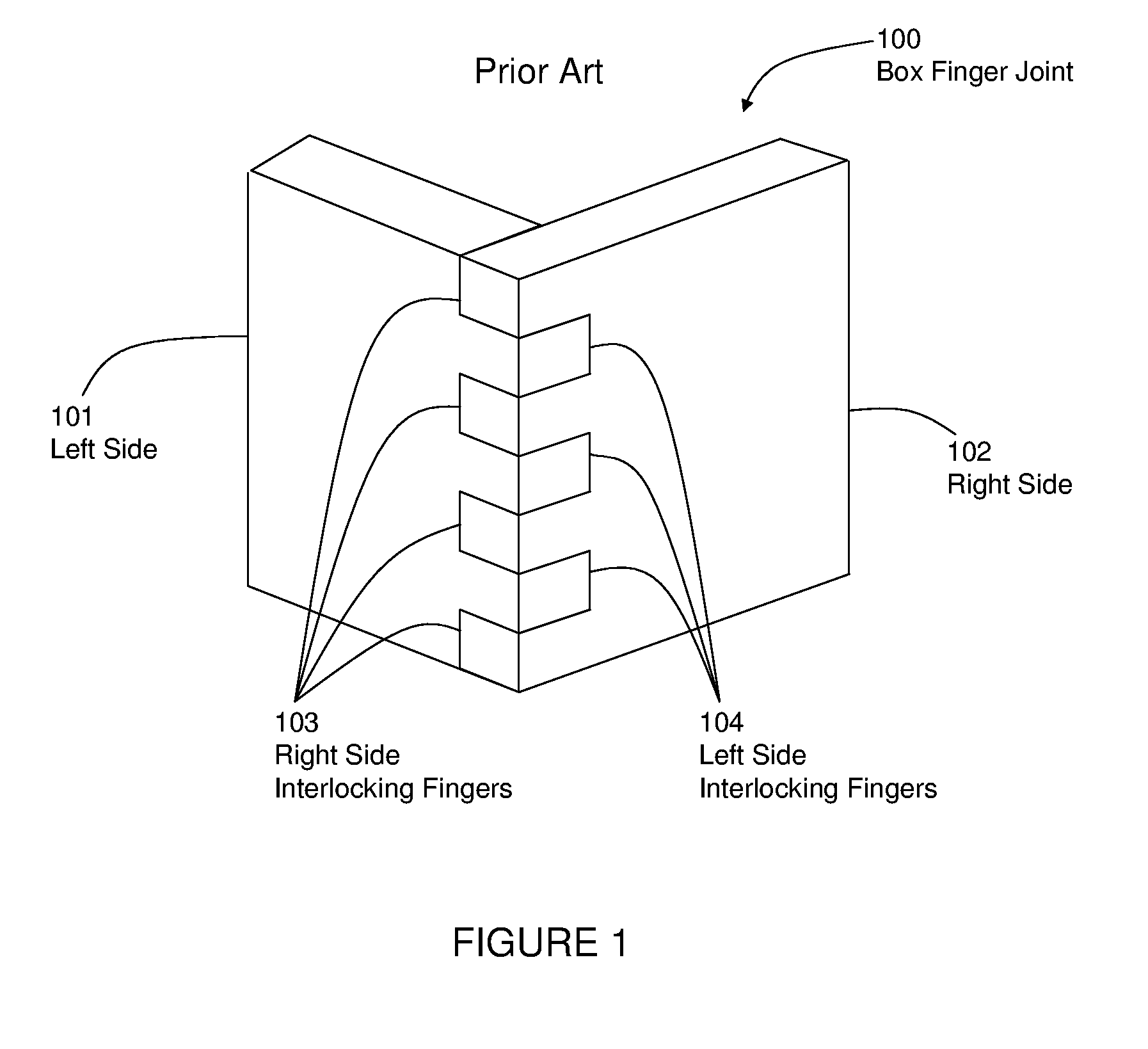

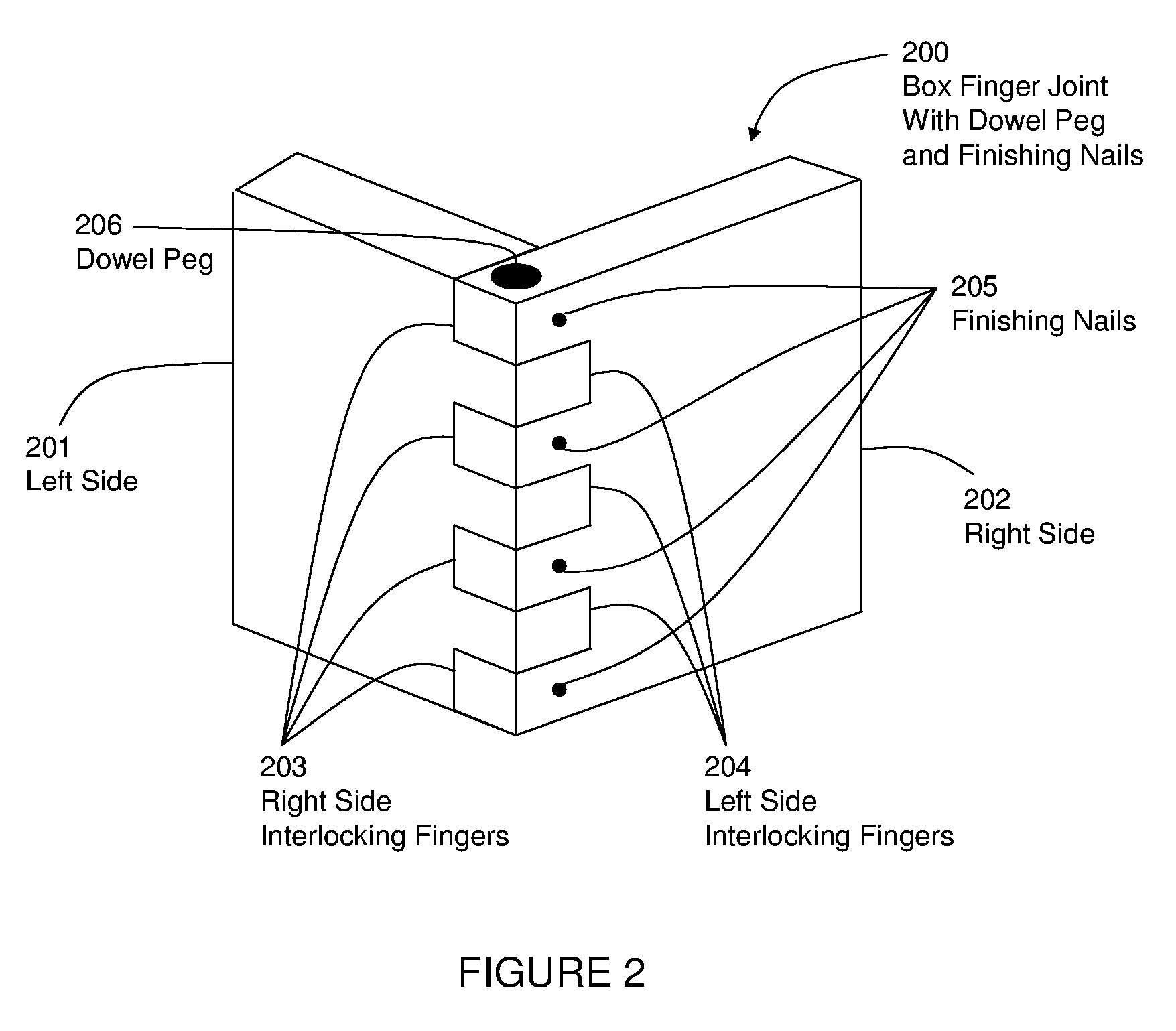

Interlocking Corner Joint

InactiveUS20060162277A1Increase the bonding surface areaImprove reliabilityBuilding repairsBuilding material handlingFinger jointEngineering

A method of constructing an interlocking corner joint by combining fixed or variable sized interlocking fingers from at least two sides, full or partial feed though dowel pegs or other geometrically shaped pegs, finishing nails, pins or screws and glue or epoxy at the interface of the interlocking fingers and pegs and pins. The resulting interlocking corner joint is much stronger than a standard dovetail joint or box finger joint due to the increased surface area created by the holes, pegs and pins. Due to the interlocking fingers, holes, pegs and pins, the interlocking corner joint will not pull apart in any one dimension x,y,z in the event that the glue joint fails.

Owner:SCHULTZ RICHARD THOMAS

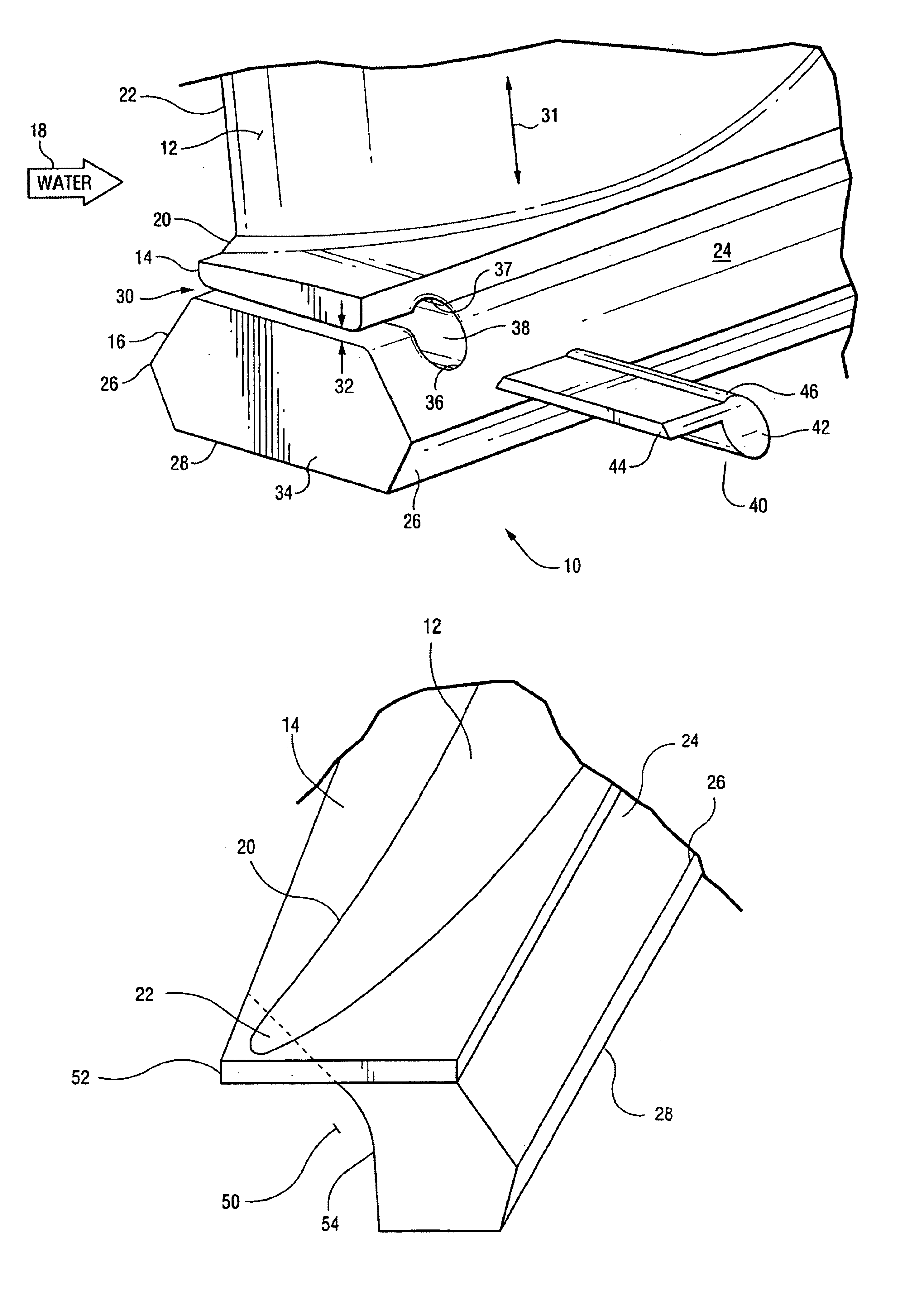

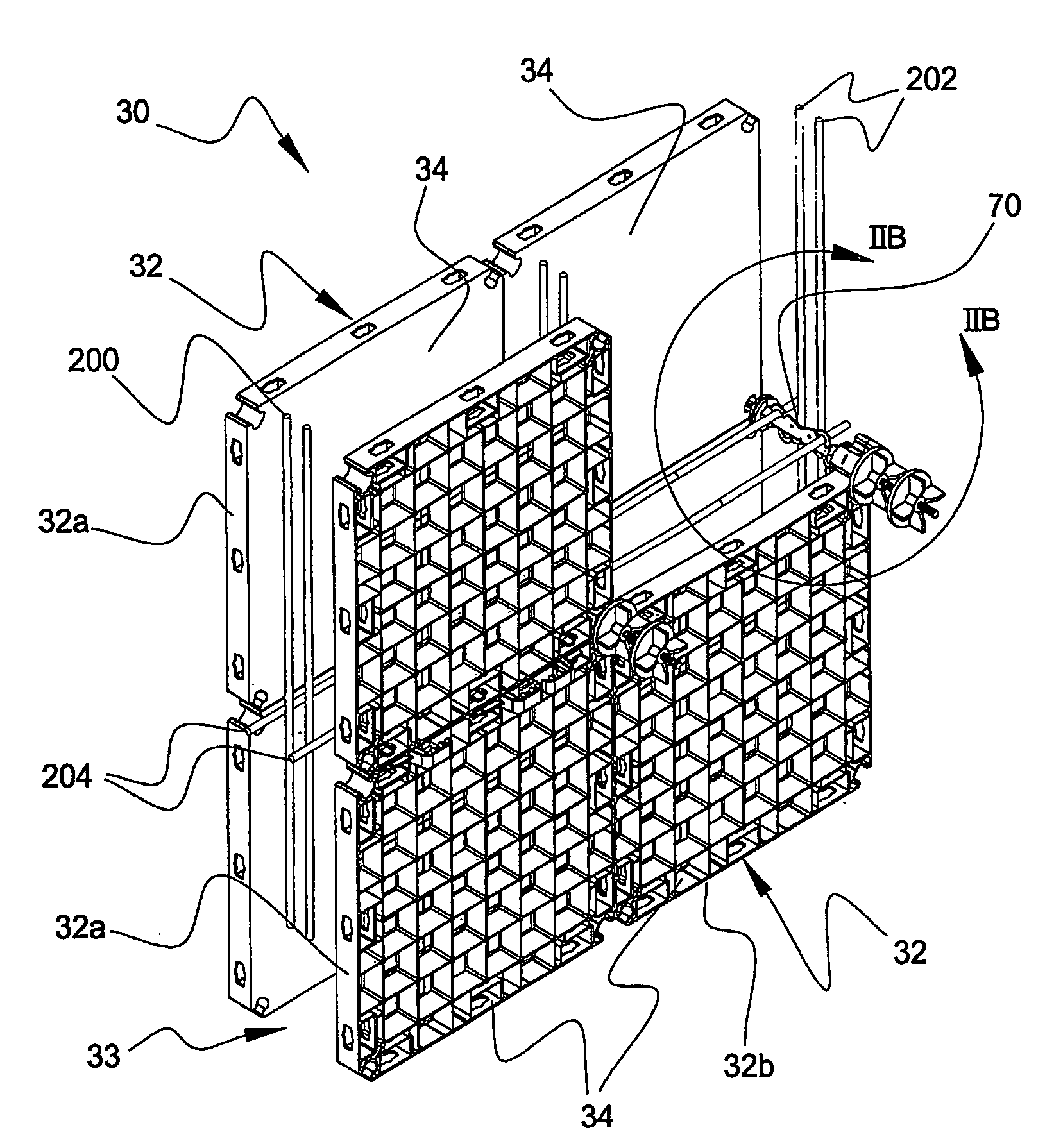

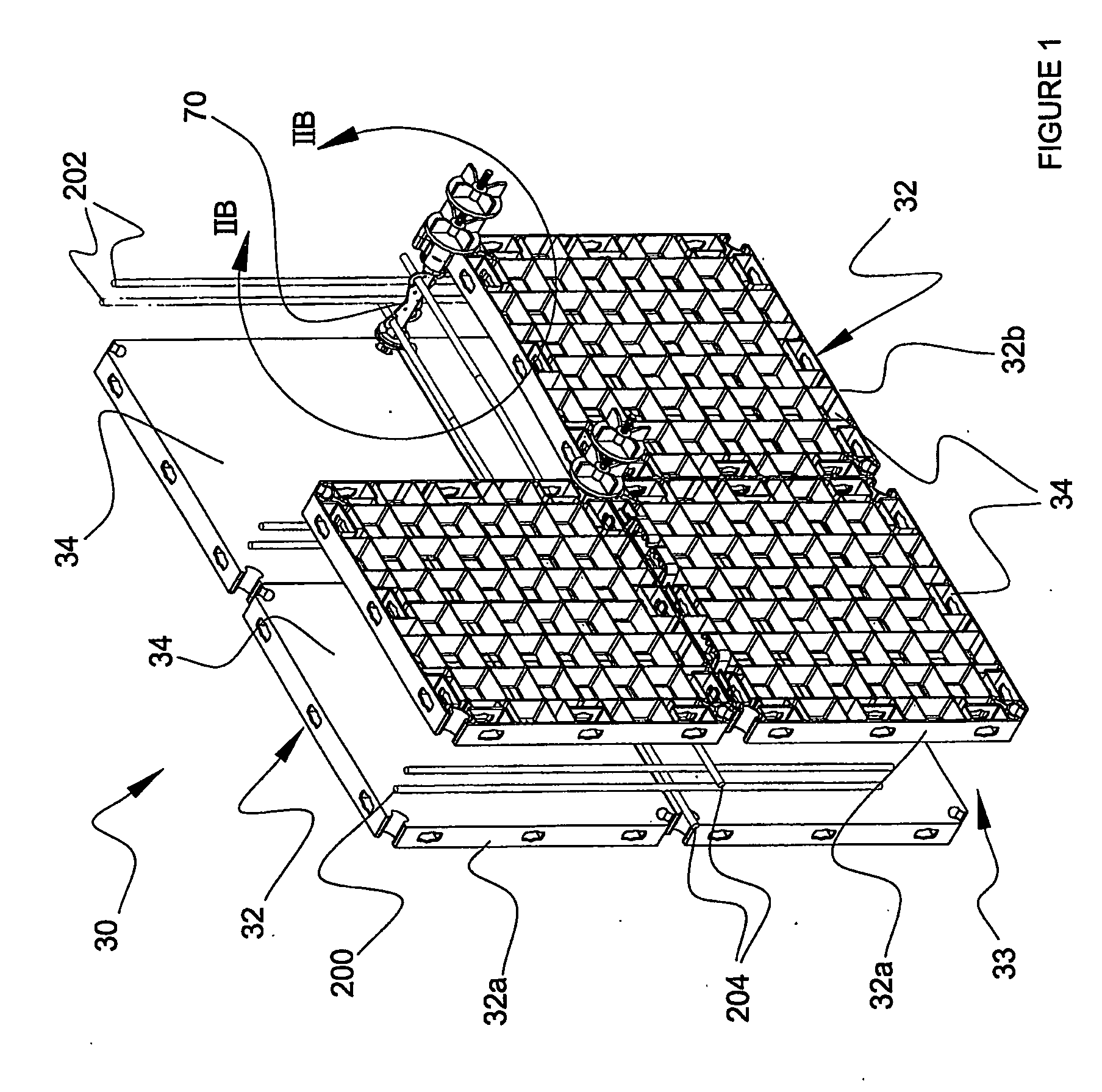

Modular formwork wall with dovetail joint connectors

InactiveUS20090272876A1Forms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksEngineeringDovetail joint

A formwork assembly for casting a concrete structure. The formwork assembly comprises a support member which may support a conventional armature grid if any, and further comprises at least one liquid-tight and load-bearing formwork wall connected to the support member. The formwork wall includes at least two panels each defining a peripheral edging, each one of the panels having at least one first dovetail joint means about its peripheral edging. Each formwork wall also comprises a panel connector having at least two second dovetail joint means, each second dovetail joint means being complementary to the first dovetail joint means of a corresponding panel; wherein each second dovetail joint means of the connector is interlocked with the first dovetail joint means of a corresponding panel to form a dovetail joint therewith, in order for the connector to hold the panels in an edgewisely juxtaposed fashion to form a continuous formwork wall. The formwork assembly further includes a securing member for securing the connector and the panels together, and a supporting structure for supporting the formwork wall in the desired position.

Owner:MCNAMARA BERNARD

Clamped plate seal

ActiveUS20090022592A1Reducing cooling flow leakageReduce cooling flow leakagePropellersPump componentsEngineeringMechanical engineering

A seal for a dovetail joint in a turbomachine is provided. The seal includes an arcuate member having a first end, a middle portion and a second end. The seal also includes sealing means, which include at least one sealing member. The sealing member can comprise a first sealing member connected to the first end and / or a second sealing member connected to the second end. The dovetail joint is the interface between a bucket dovetail and a rotor dovetail groove, and the seal reduces the amount of cooling flow leakage from the dovetail joint.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com