Patents

Literature

5869results about "Rotary propellers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

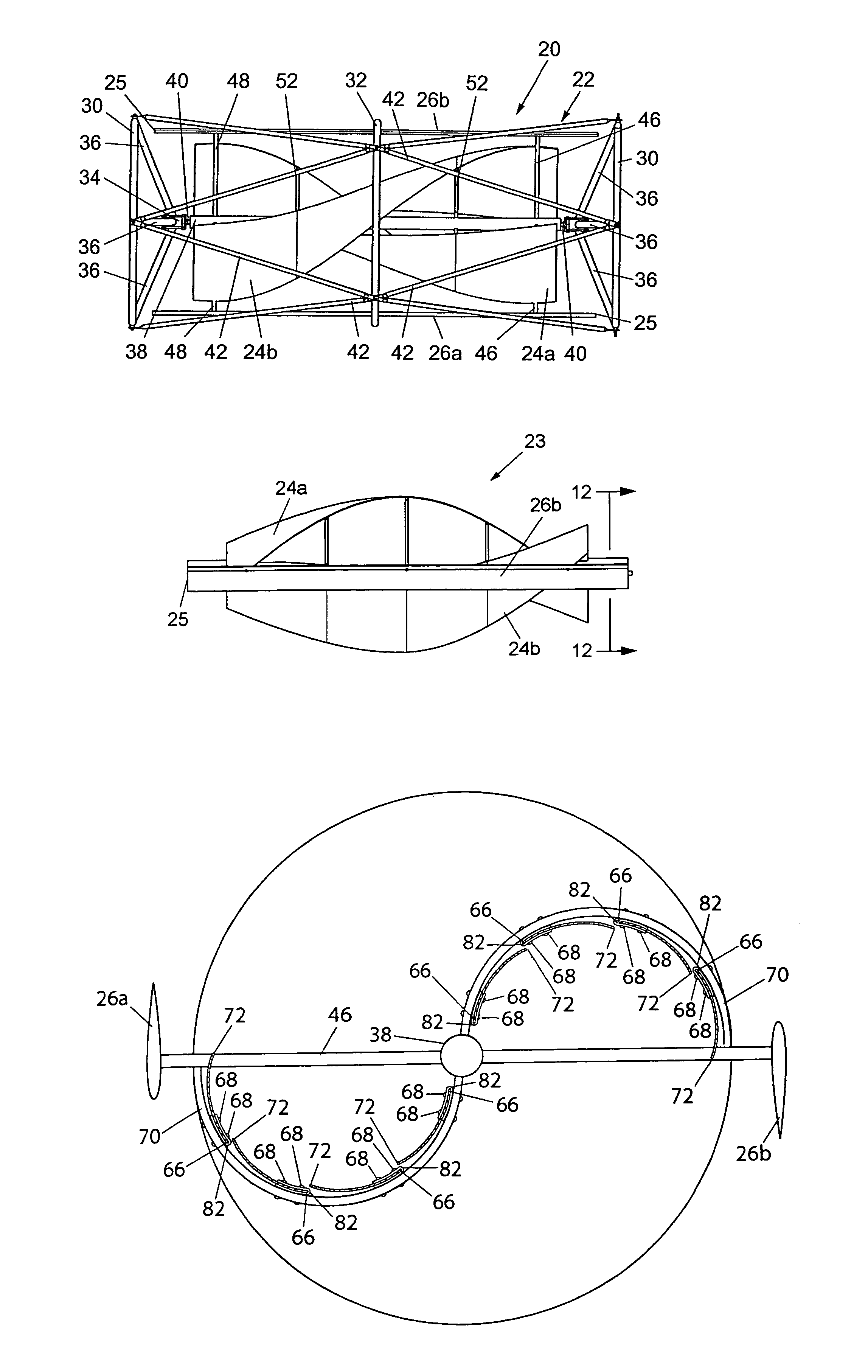

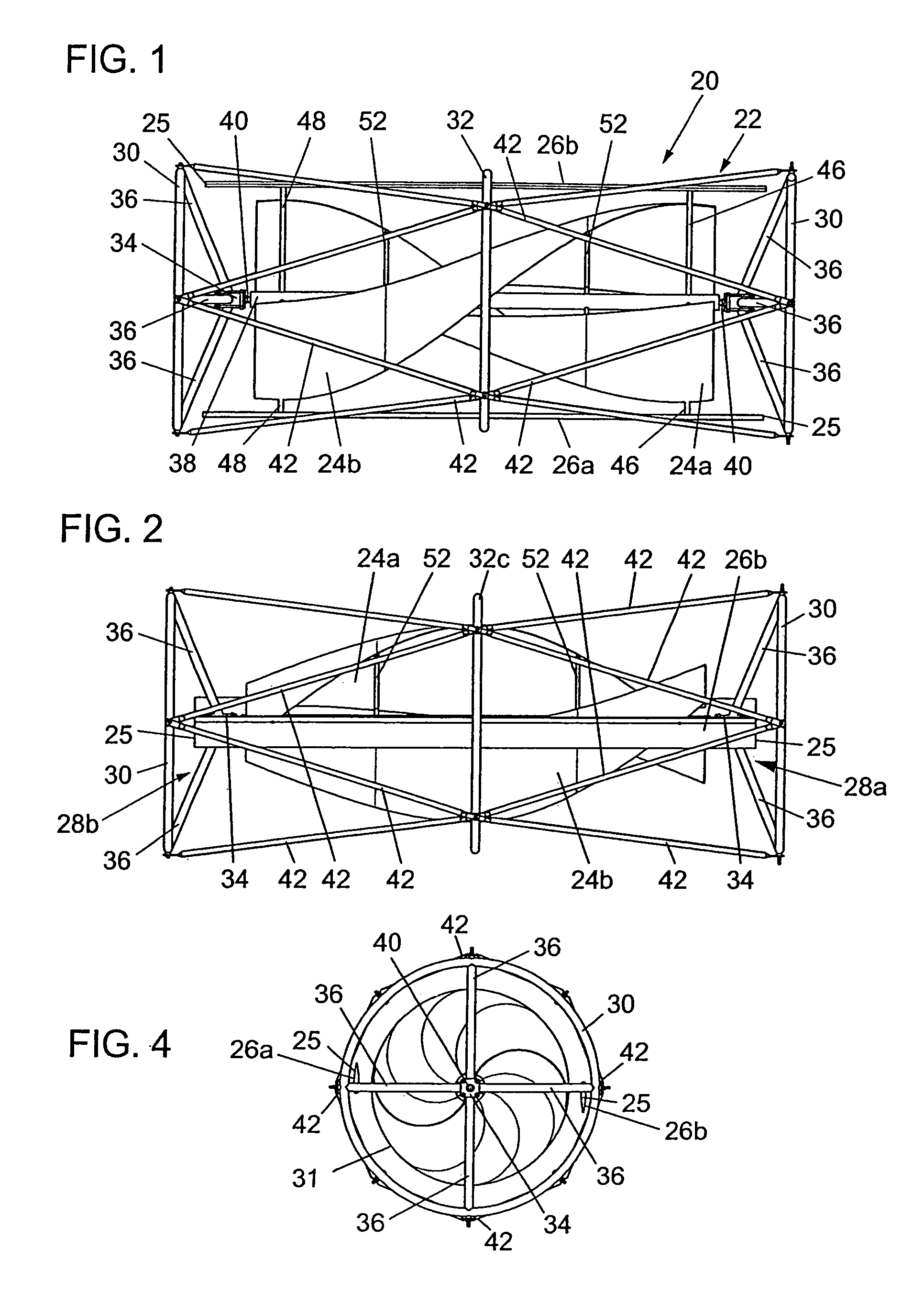

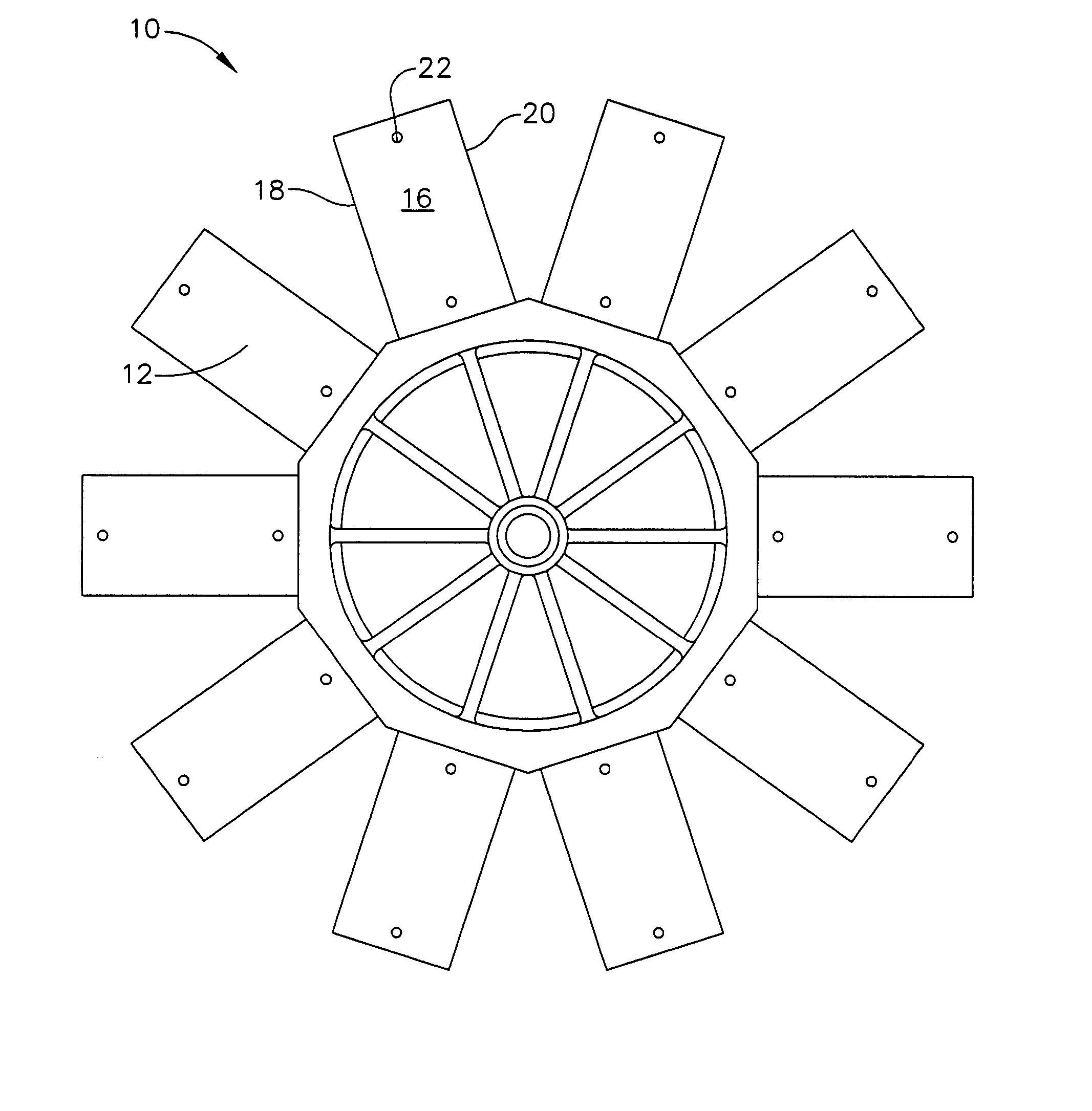

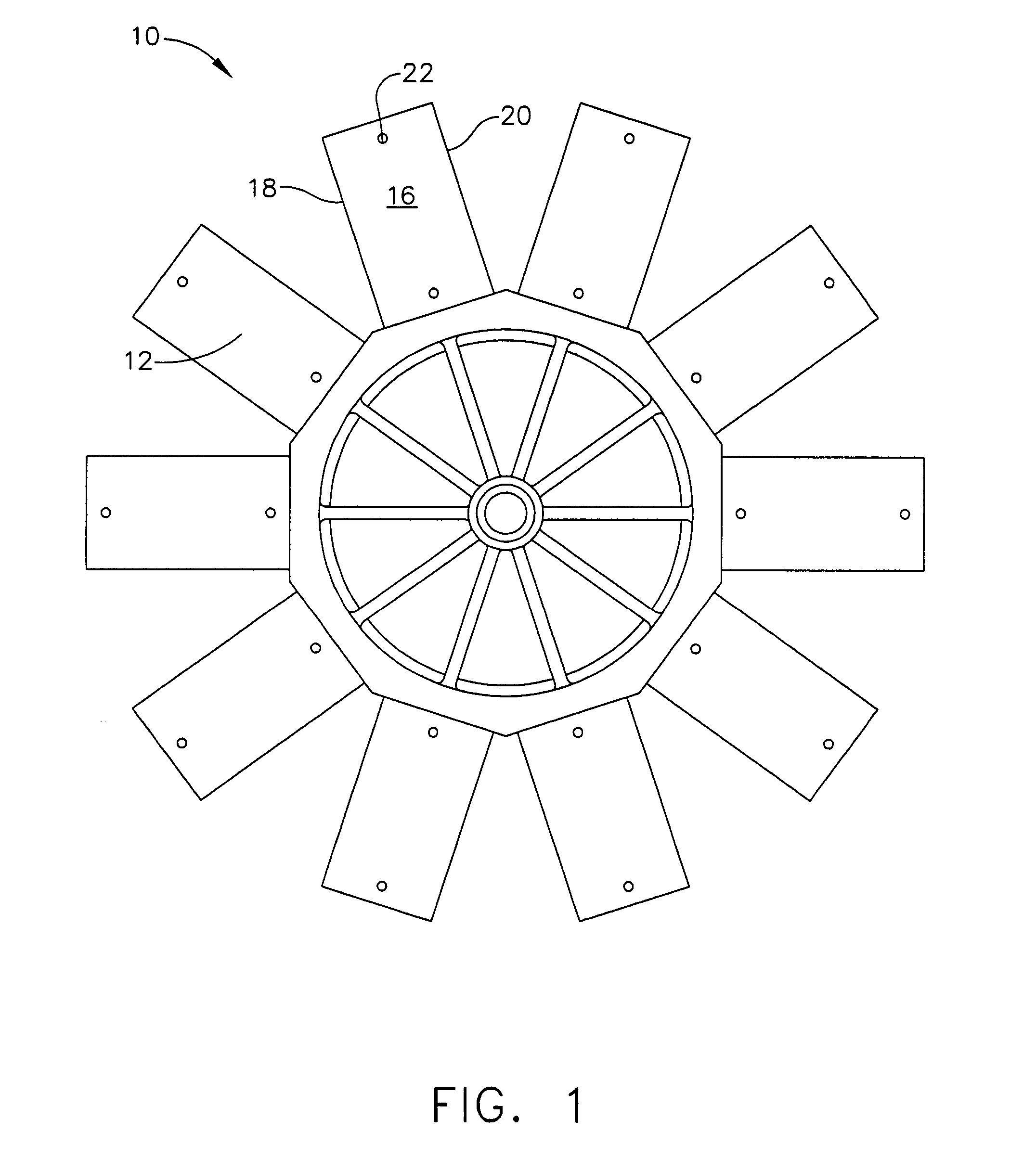

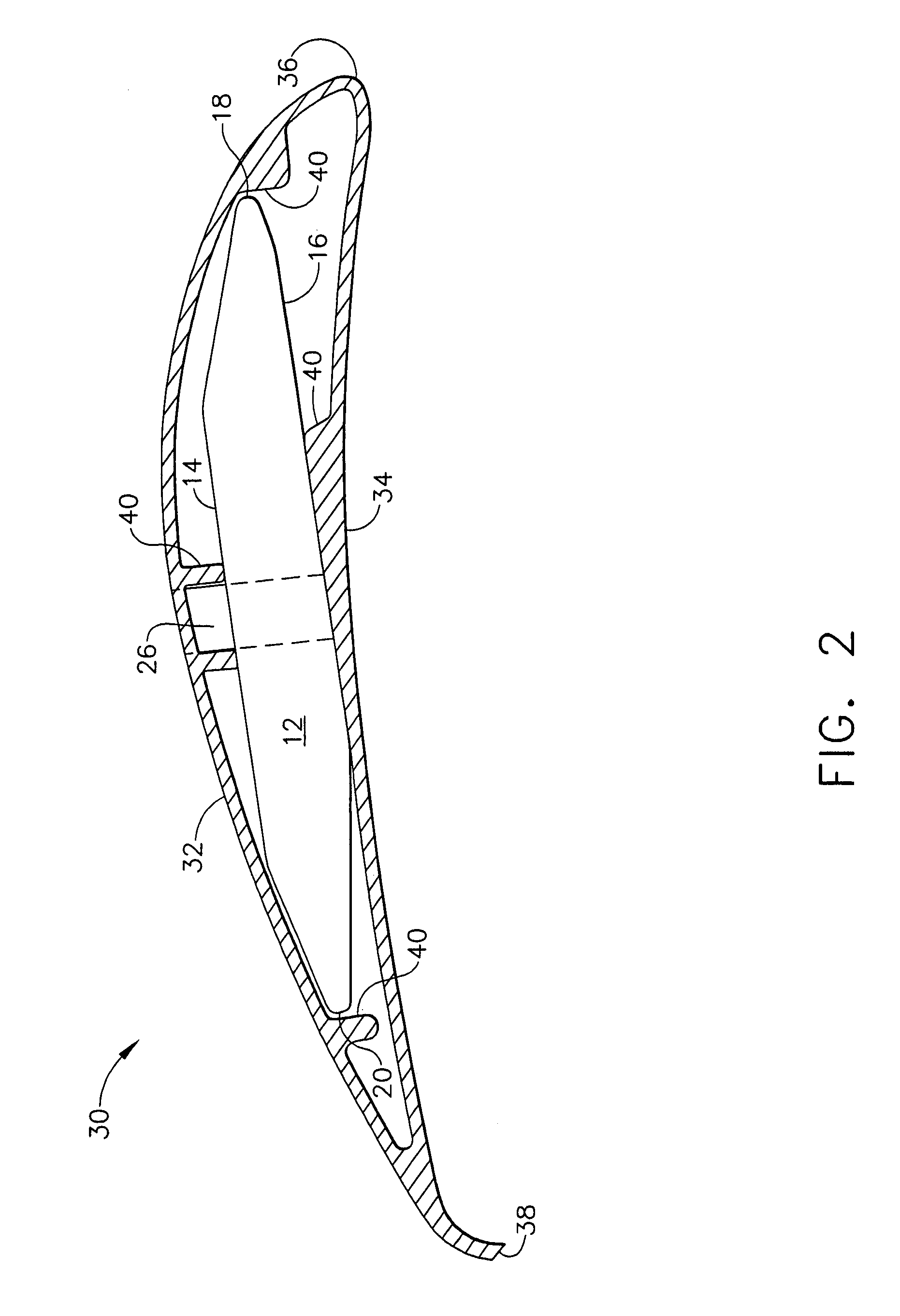

Expandable impeller pump

ActiveUS7393181B2Easy to compressReduced form requirementsPropellersEngine manufactureImpellerEngineering

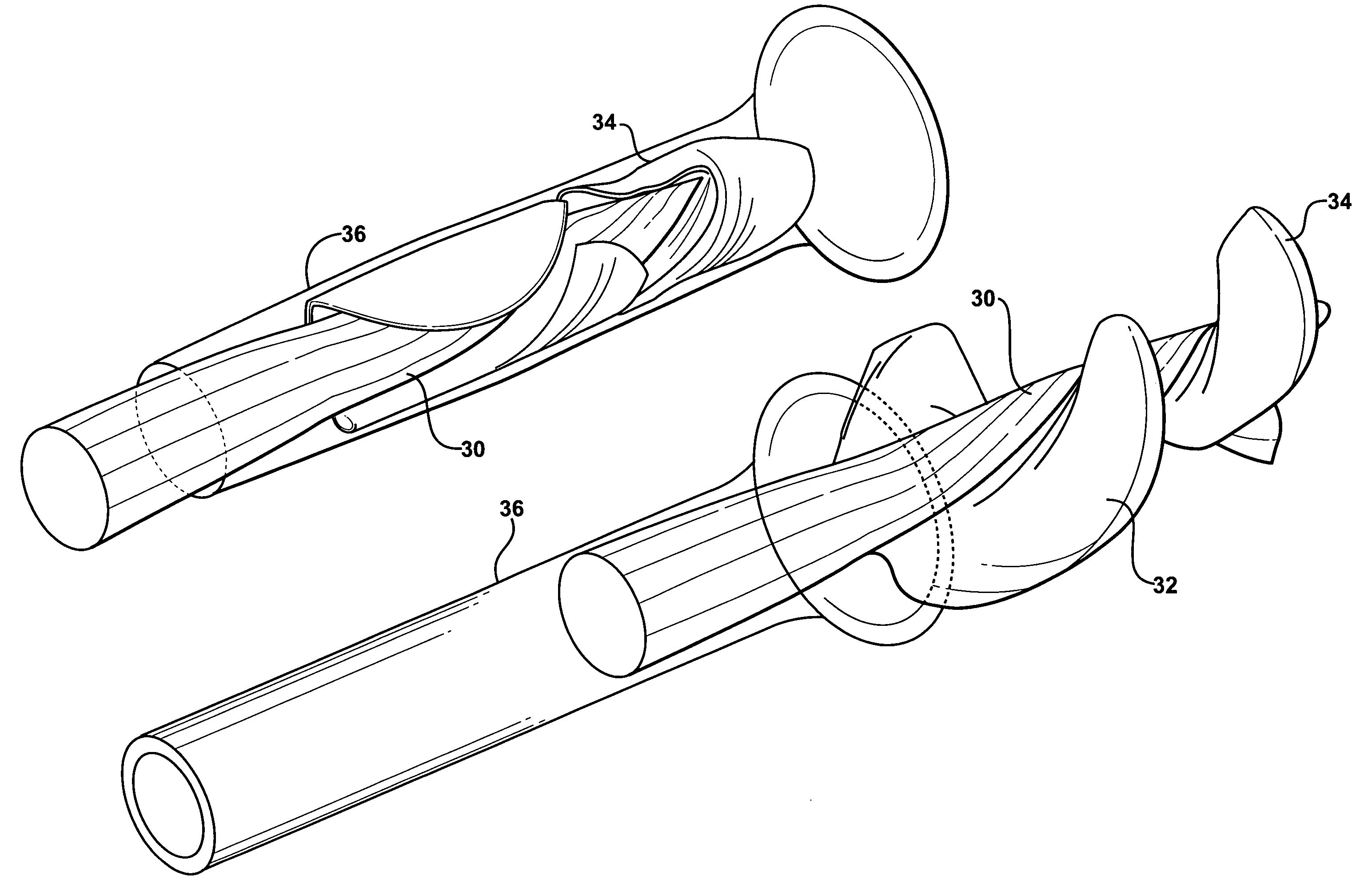

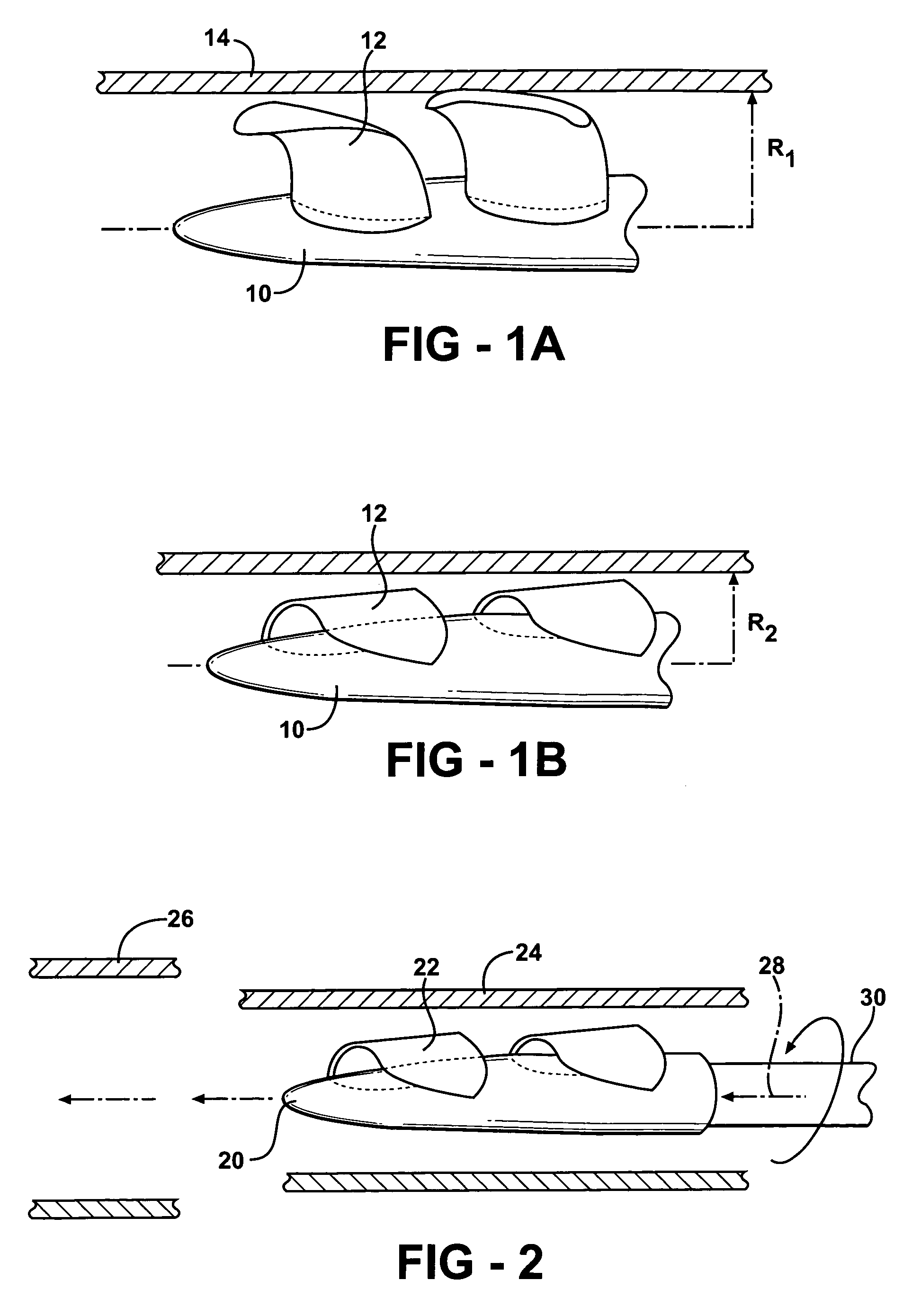

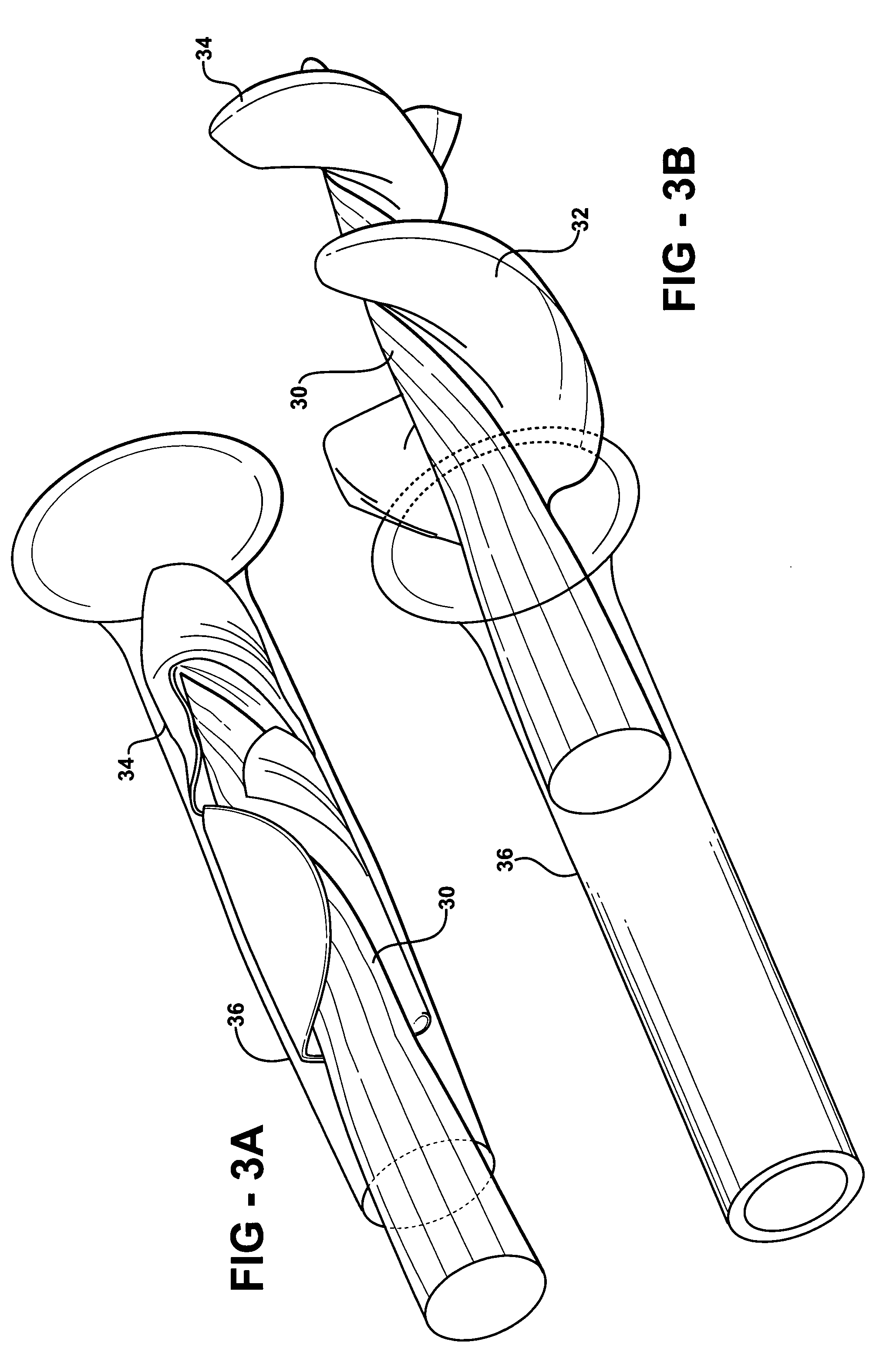

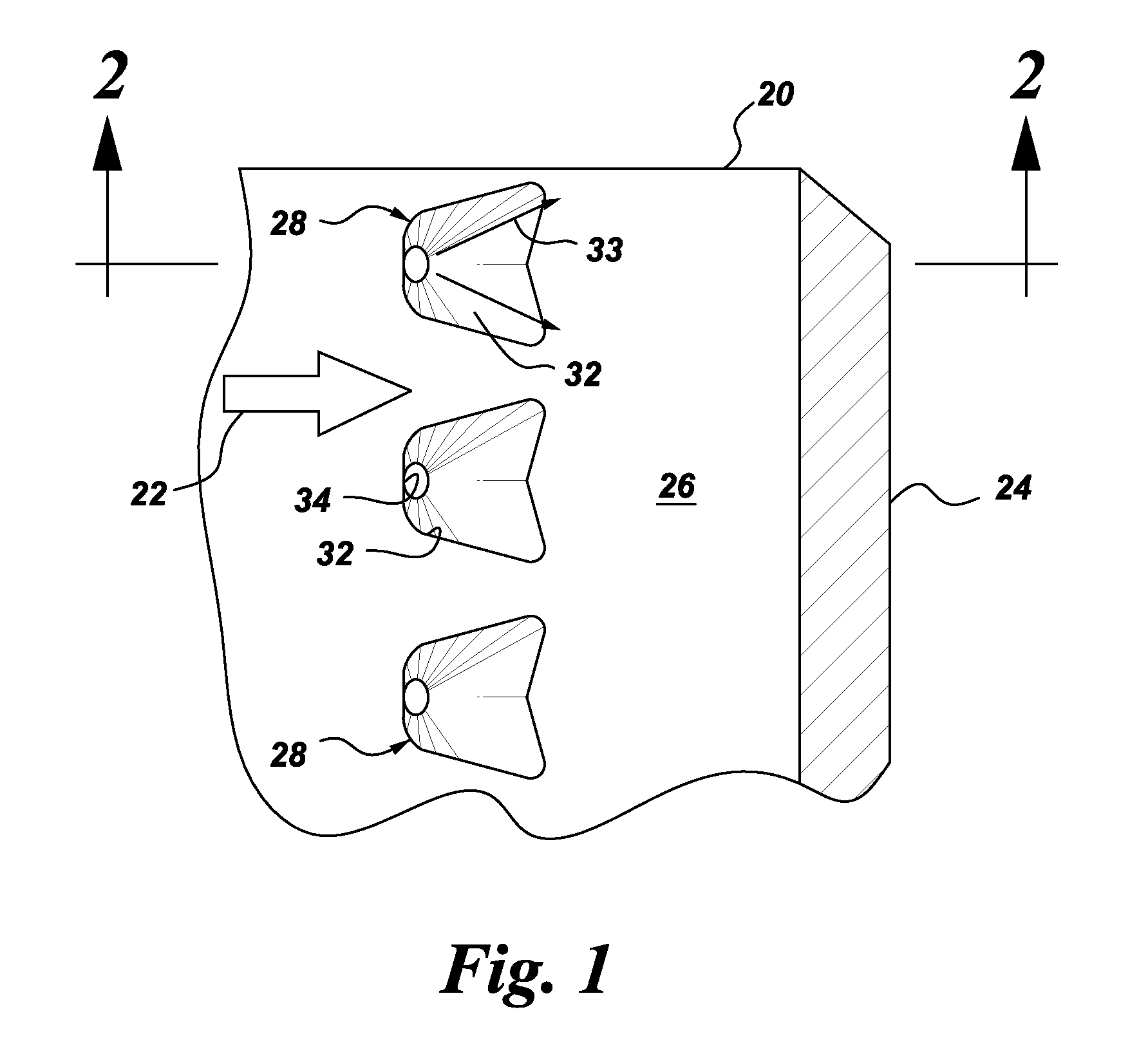

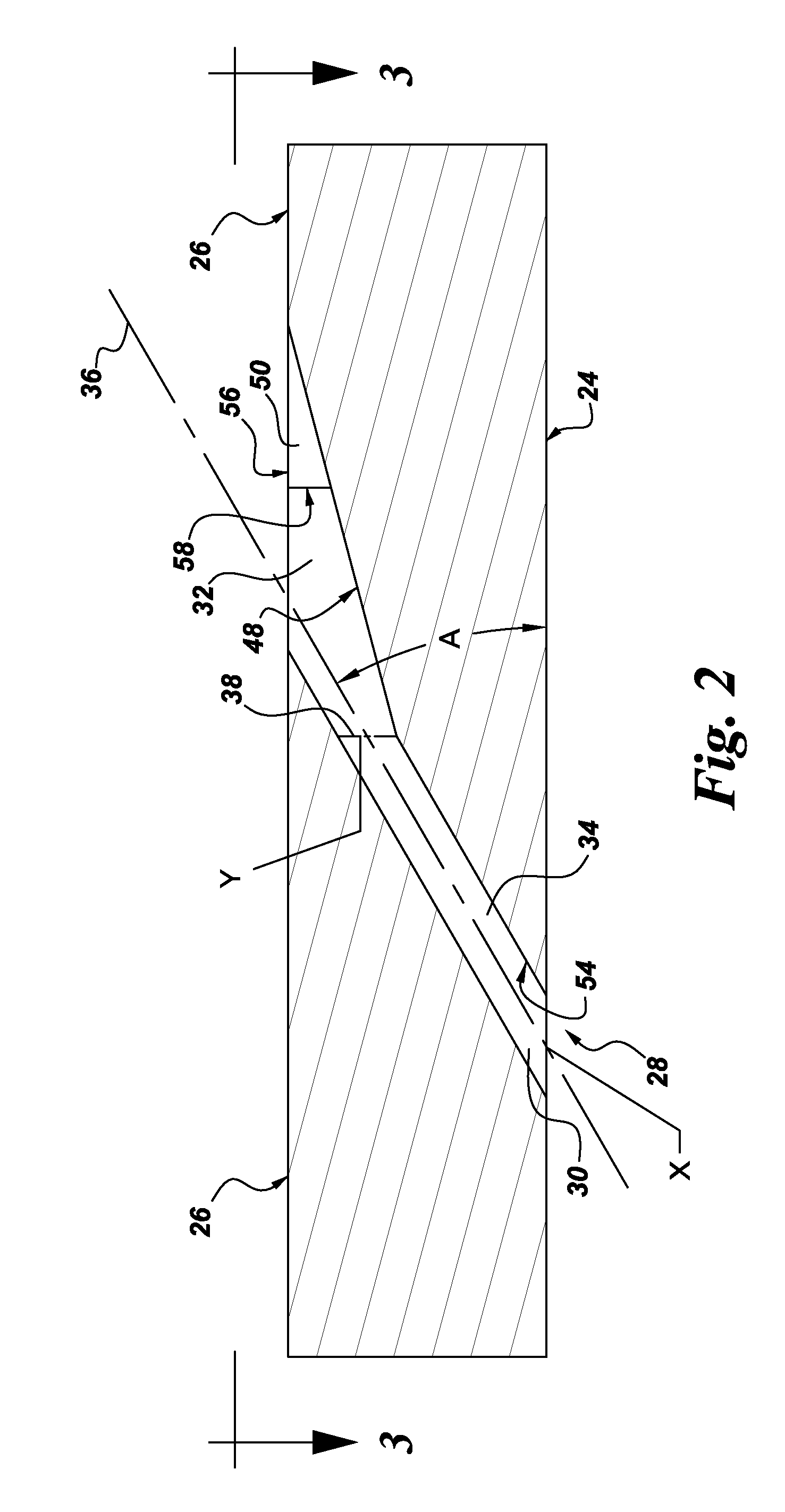

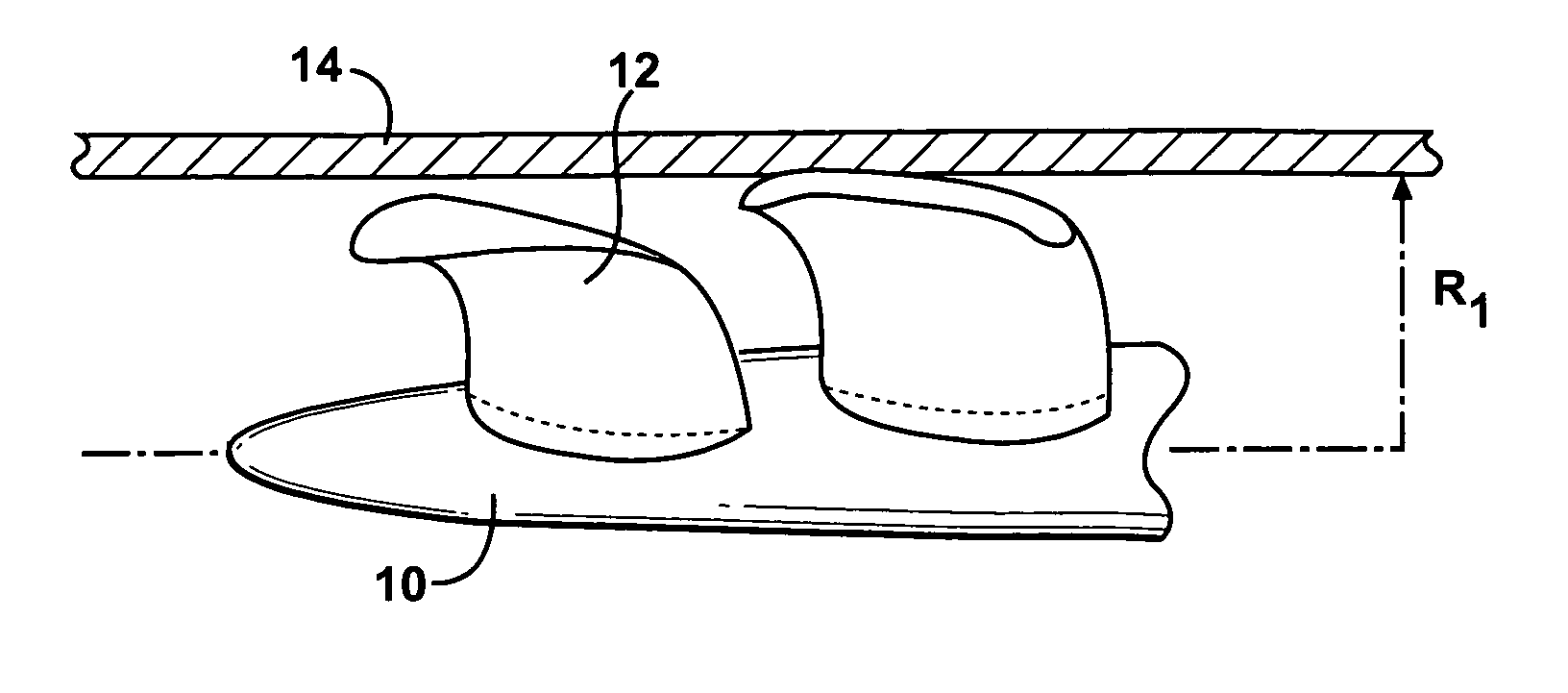

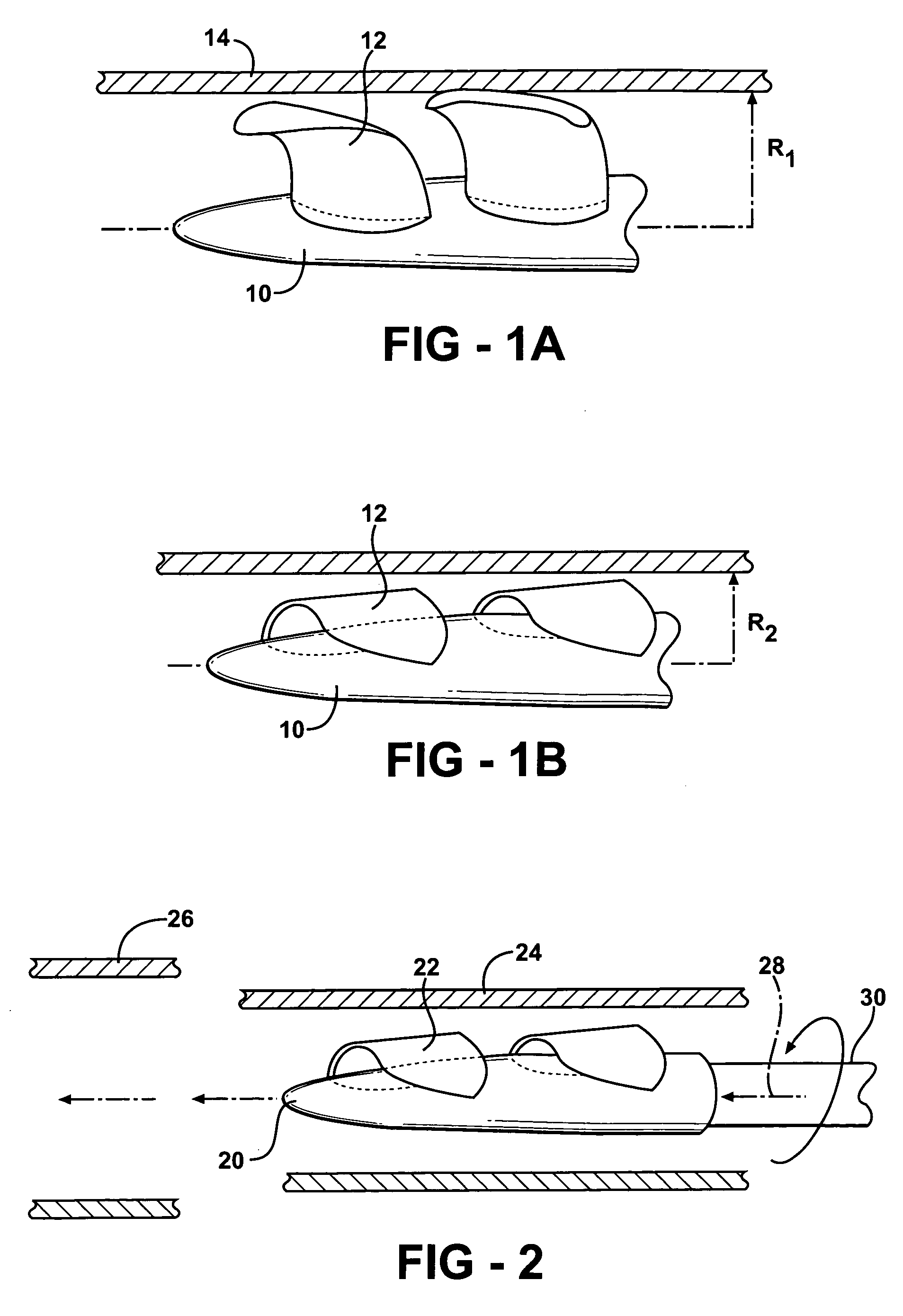

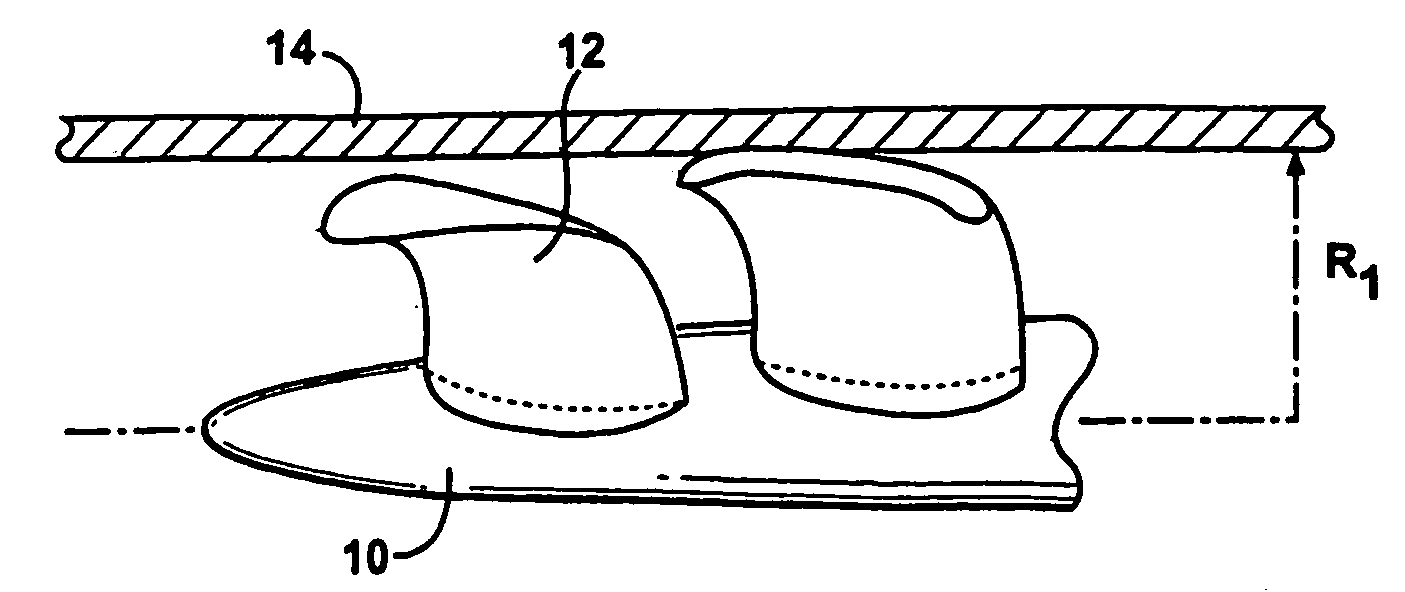

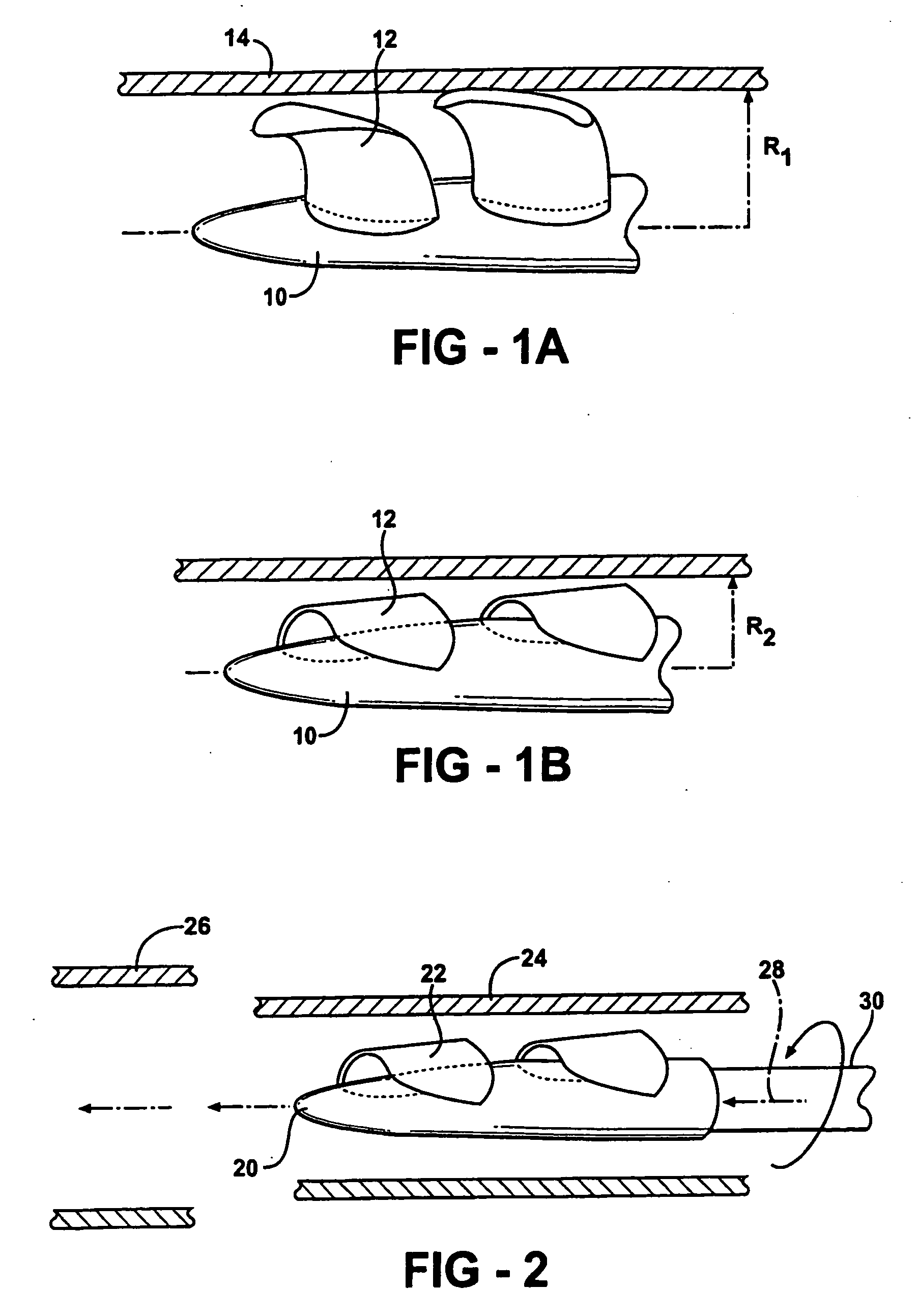

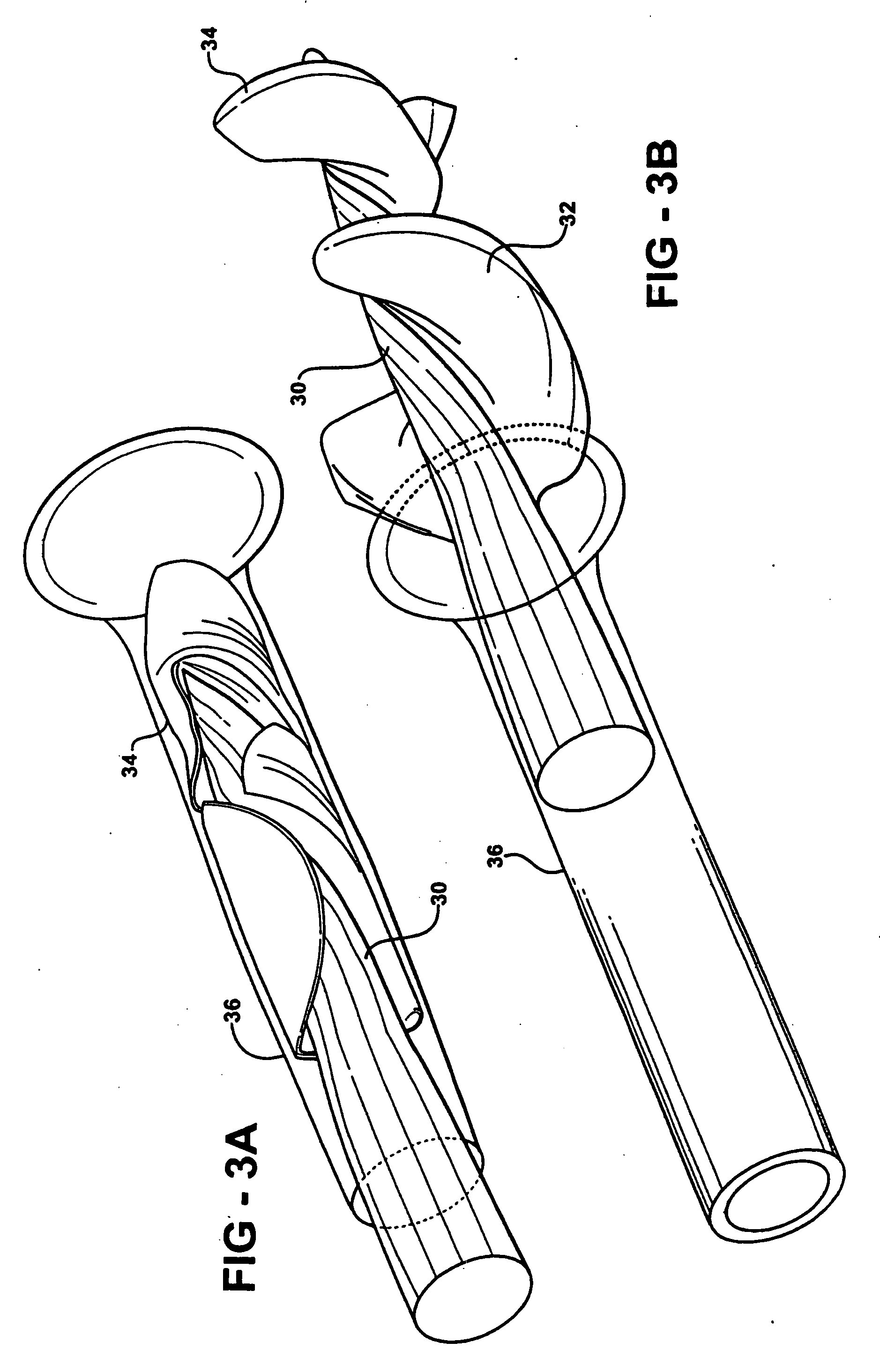

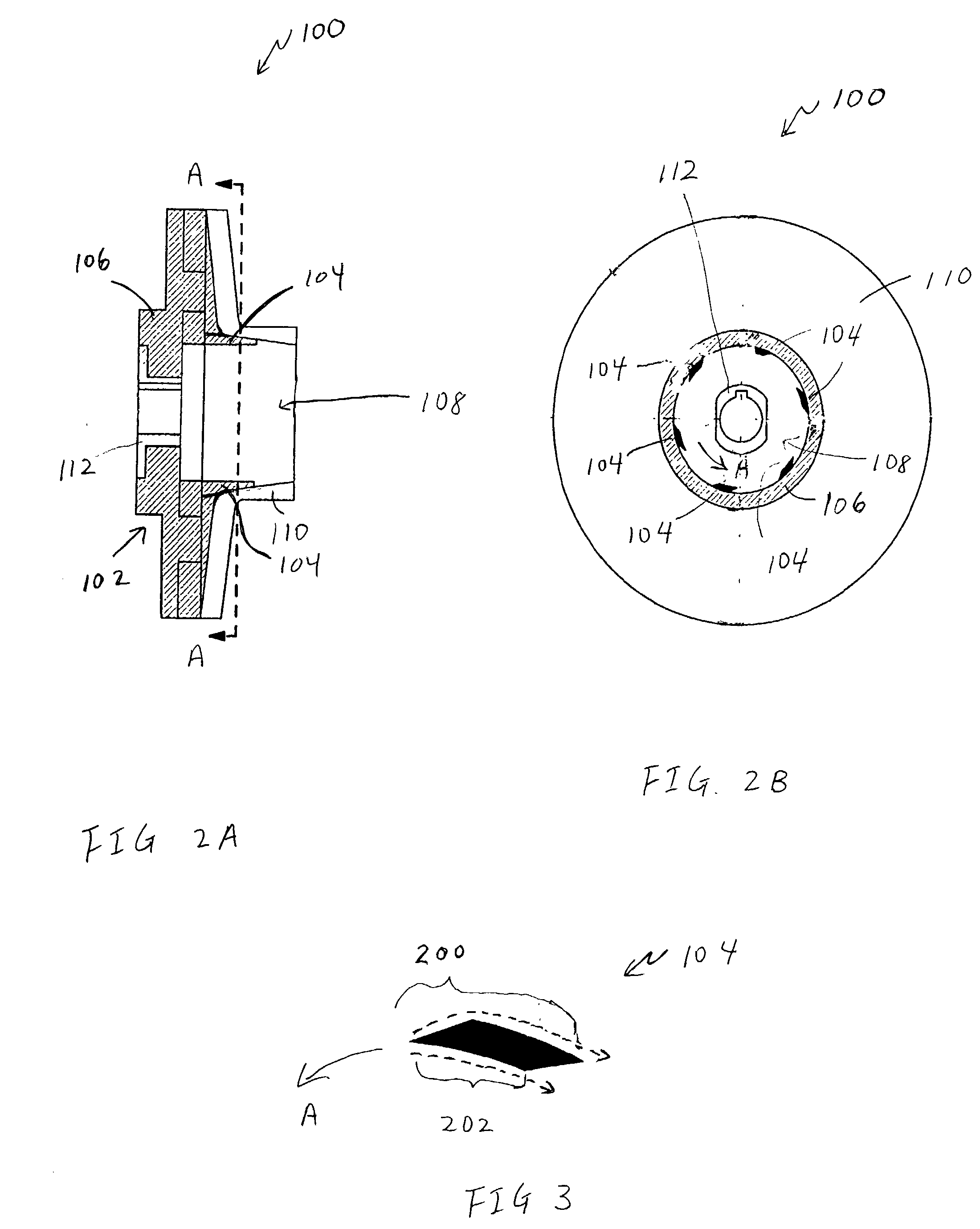

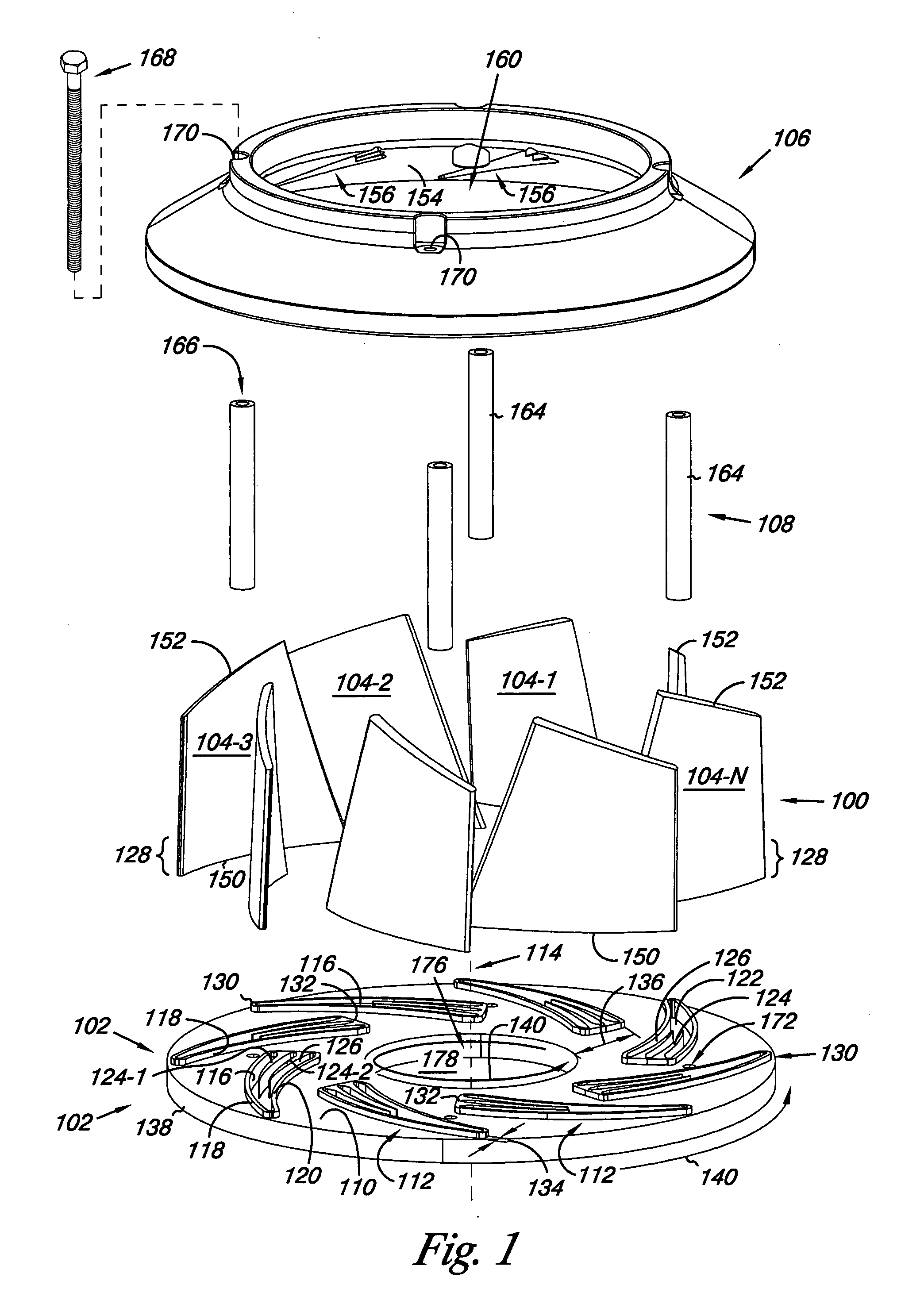

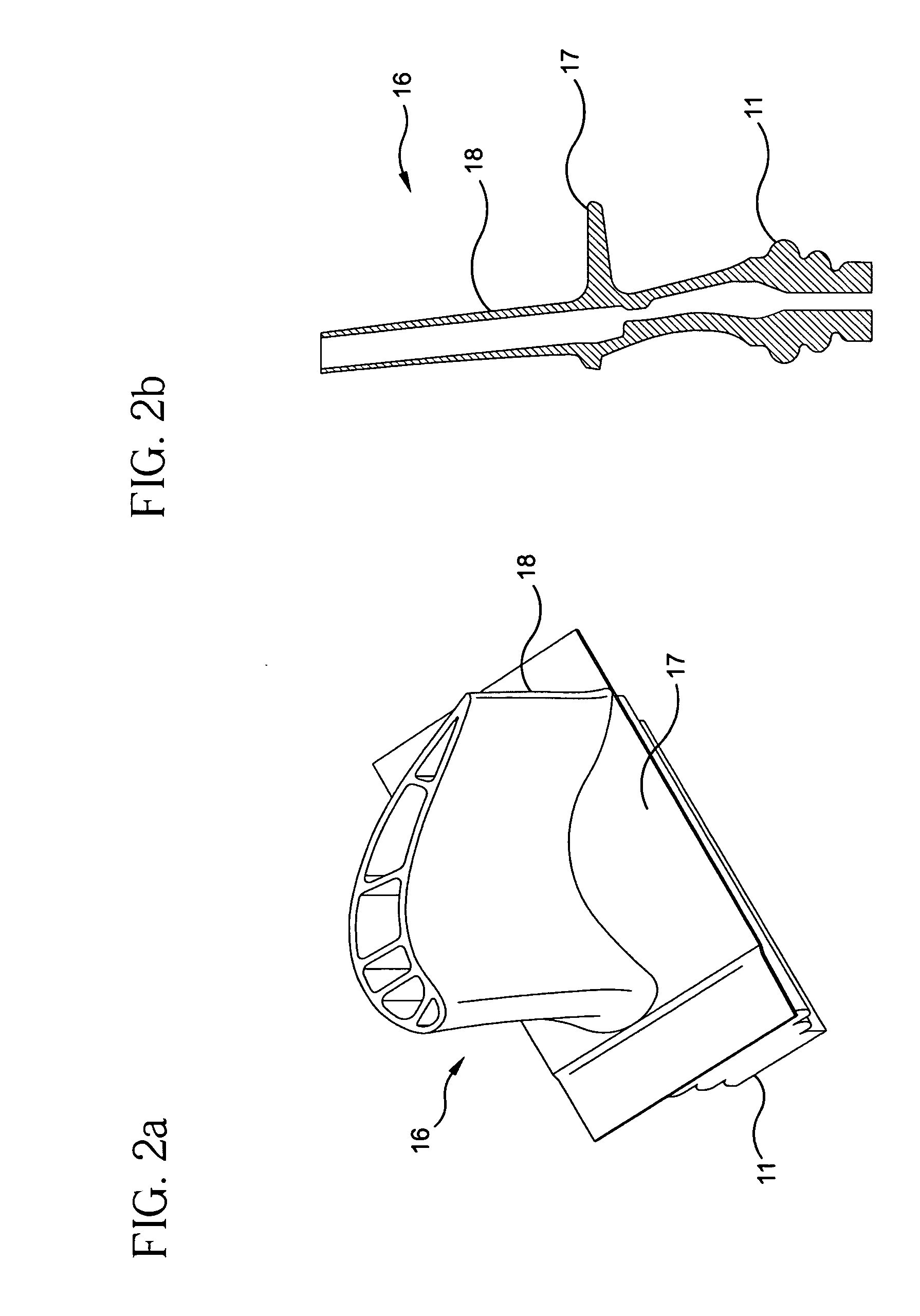

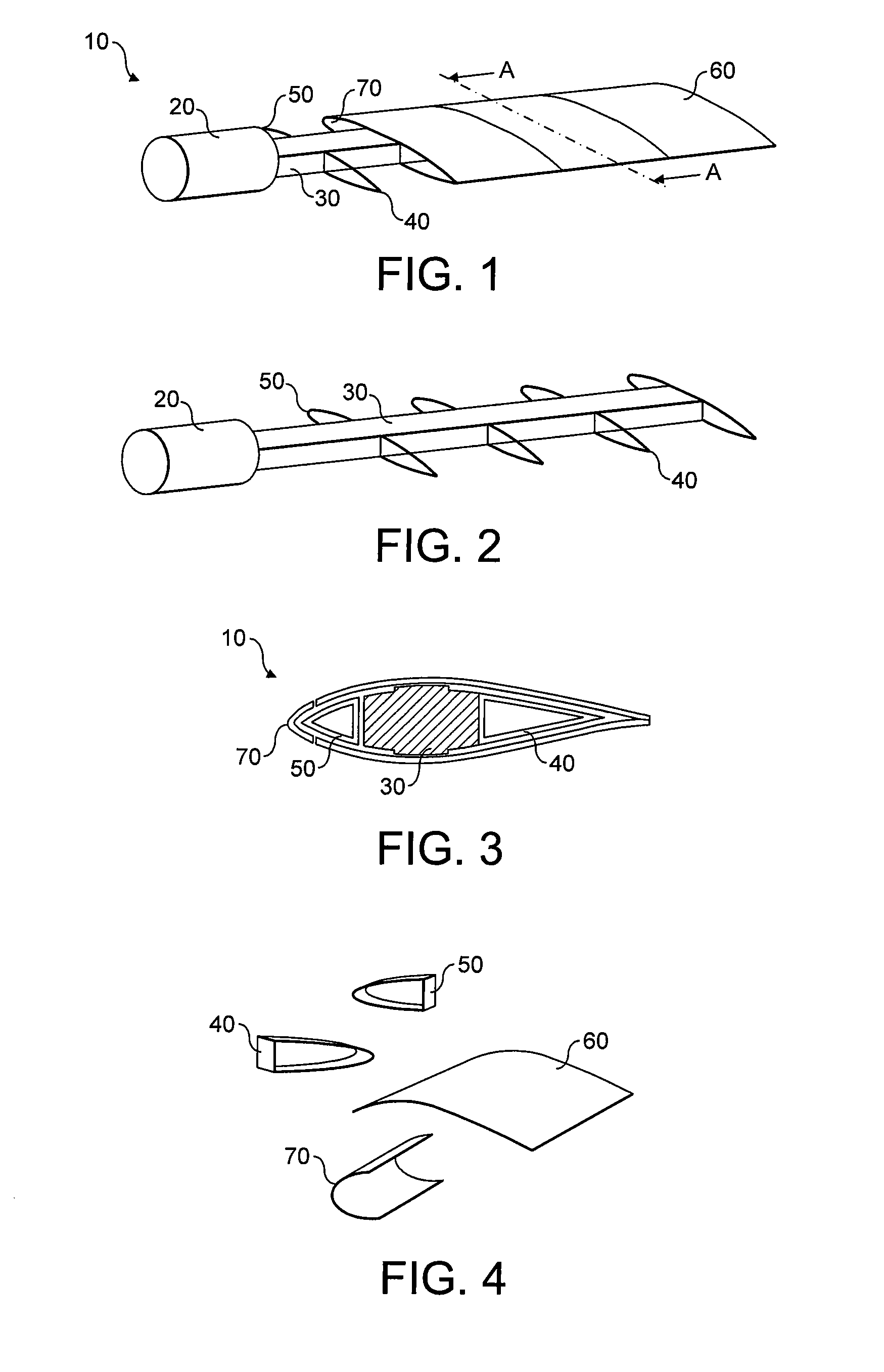

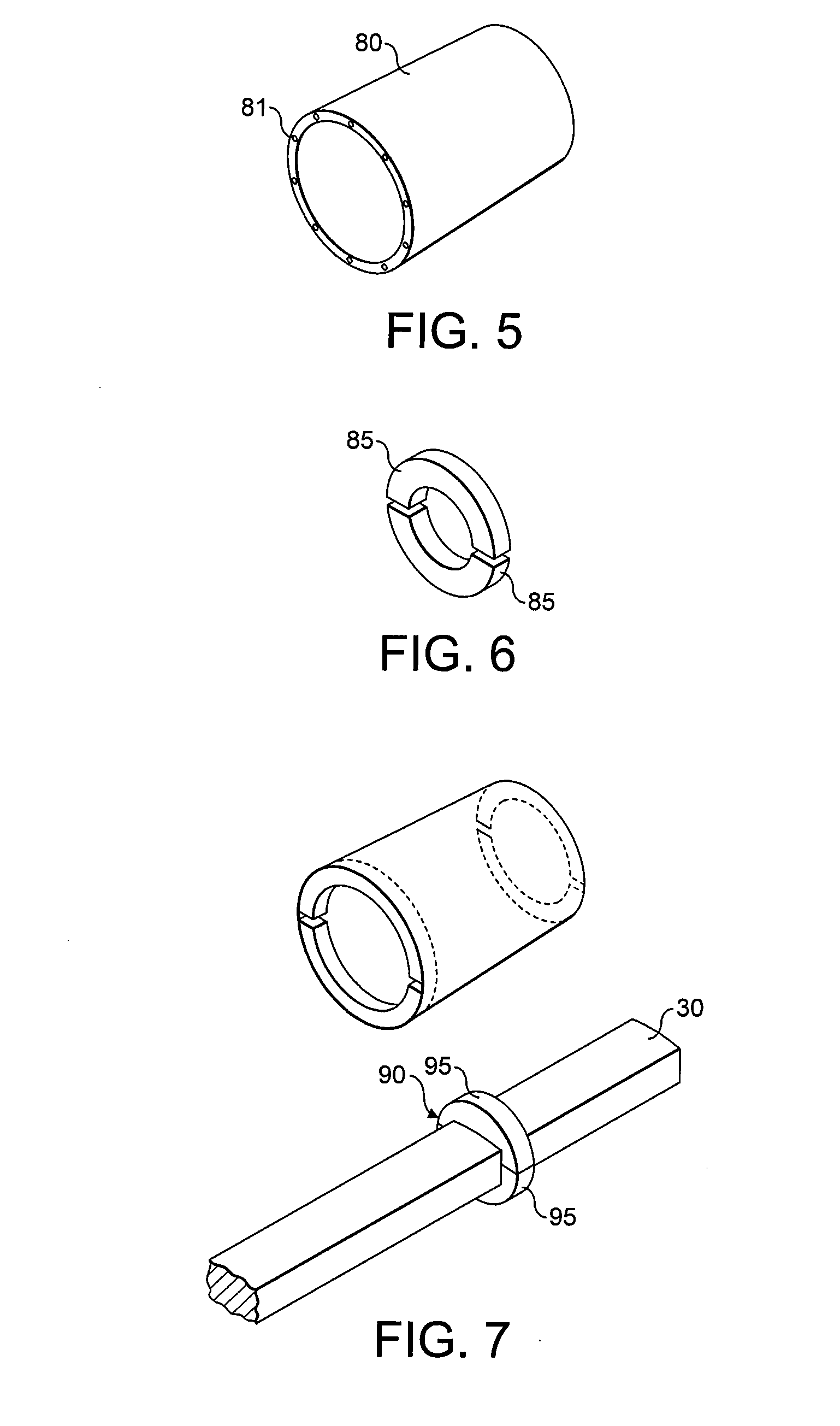

An impeller according to an example of the present invention comprises a hub, and at least one blade supported by the hub. The impeller has a deployed configuration in which the blade extends away from the hub, and a stored configuration in which the impeller is radially compressed, for example by folding the blade towards the hub. The impeller may comprise a plurality of blades, arranged in blade rows, to facilitate radial compression of the blades. The outer edge of a blade may have a winglet, and the base of the blade may have an associated indentation to facilitate folding of the blade.

Owner:PENN STATE RES FOUND +2

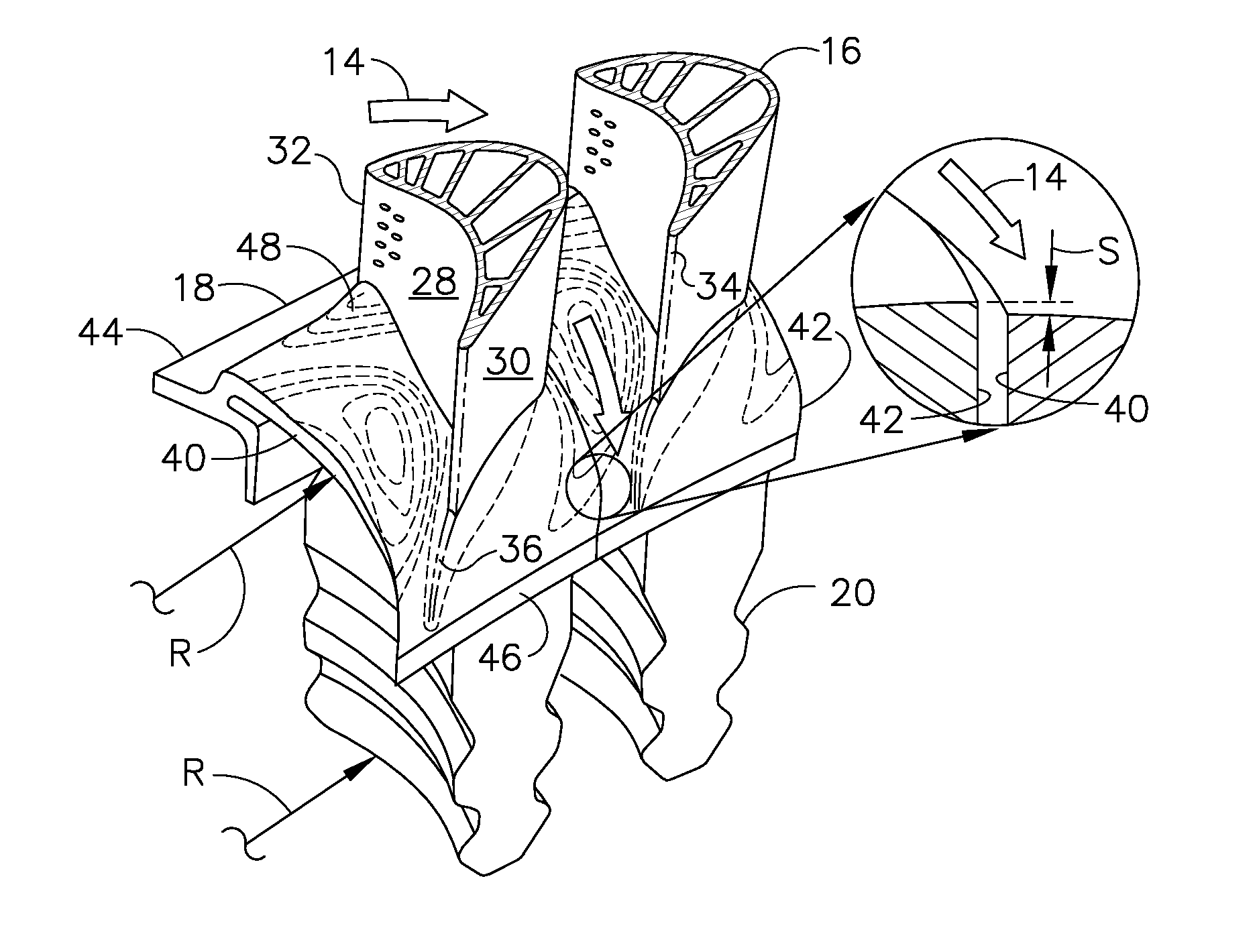

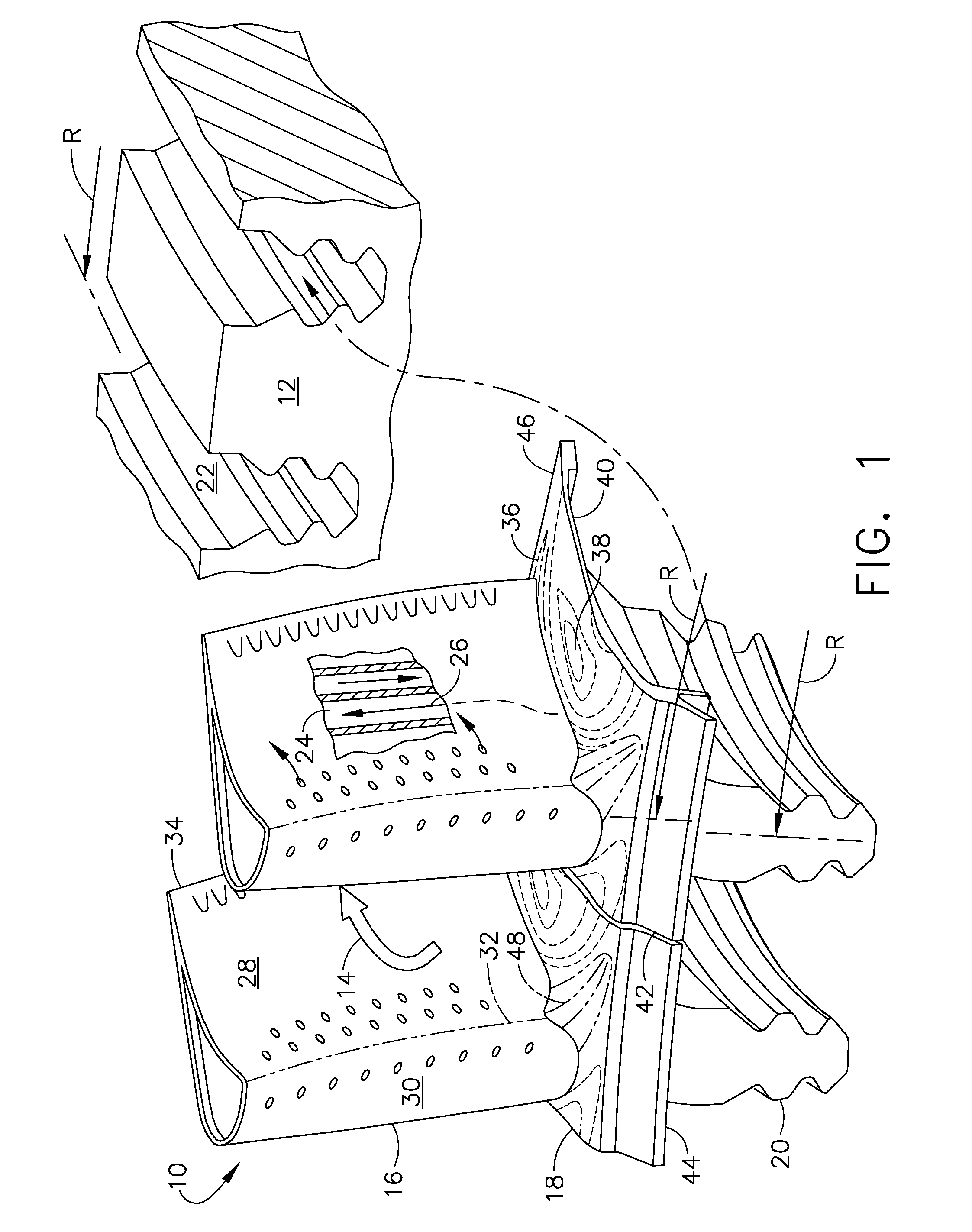

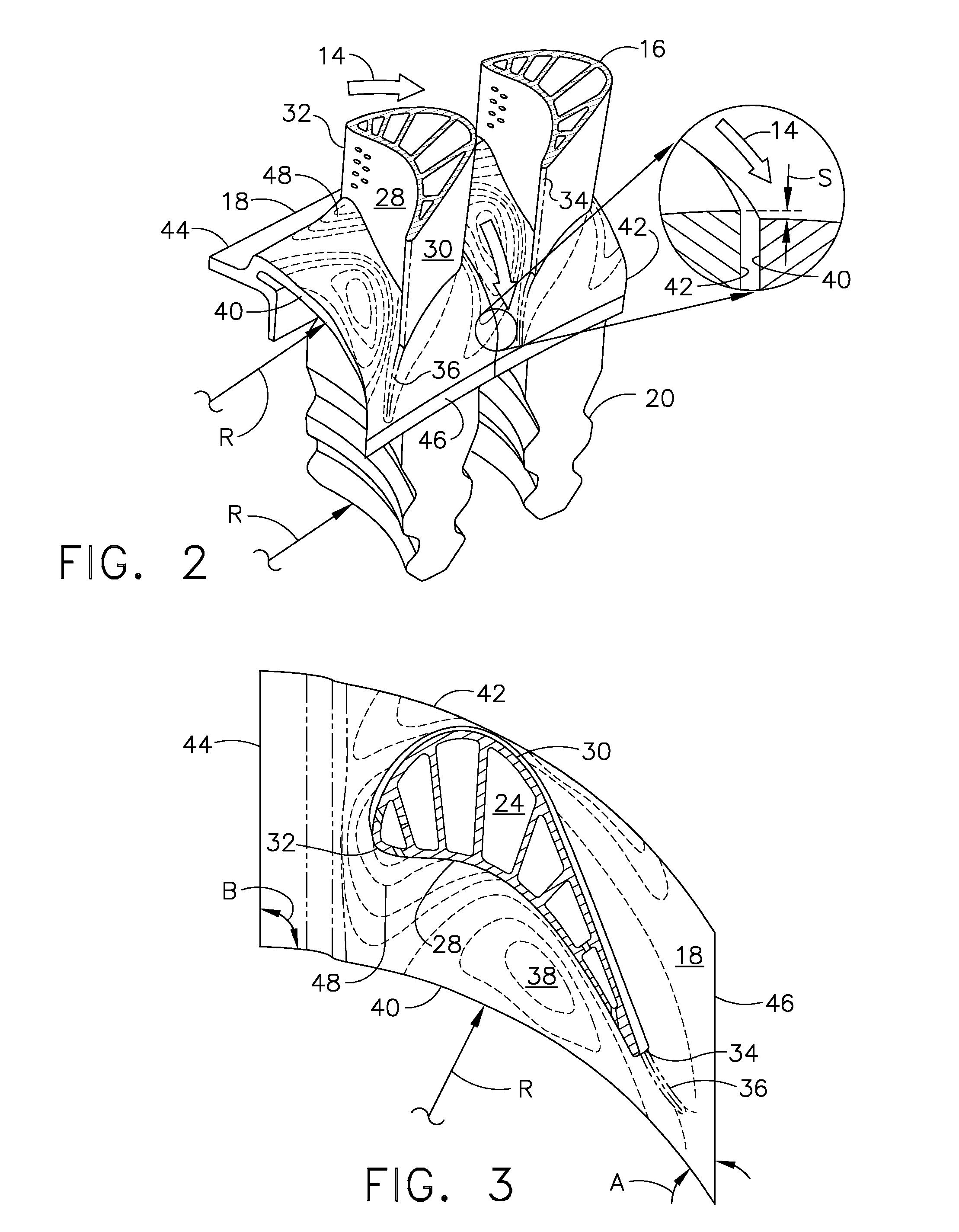

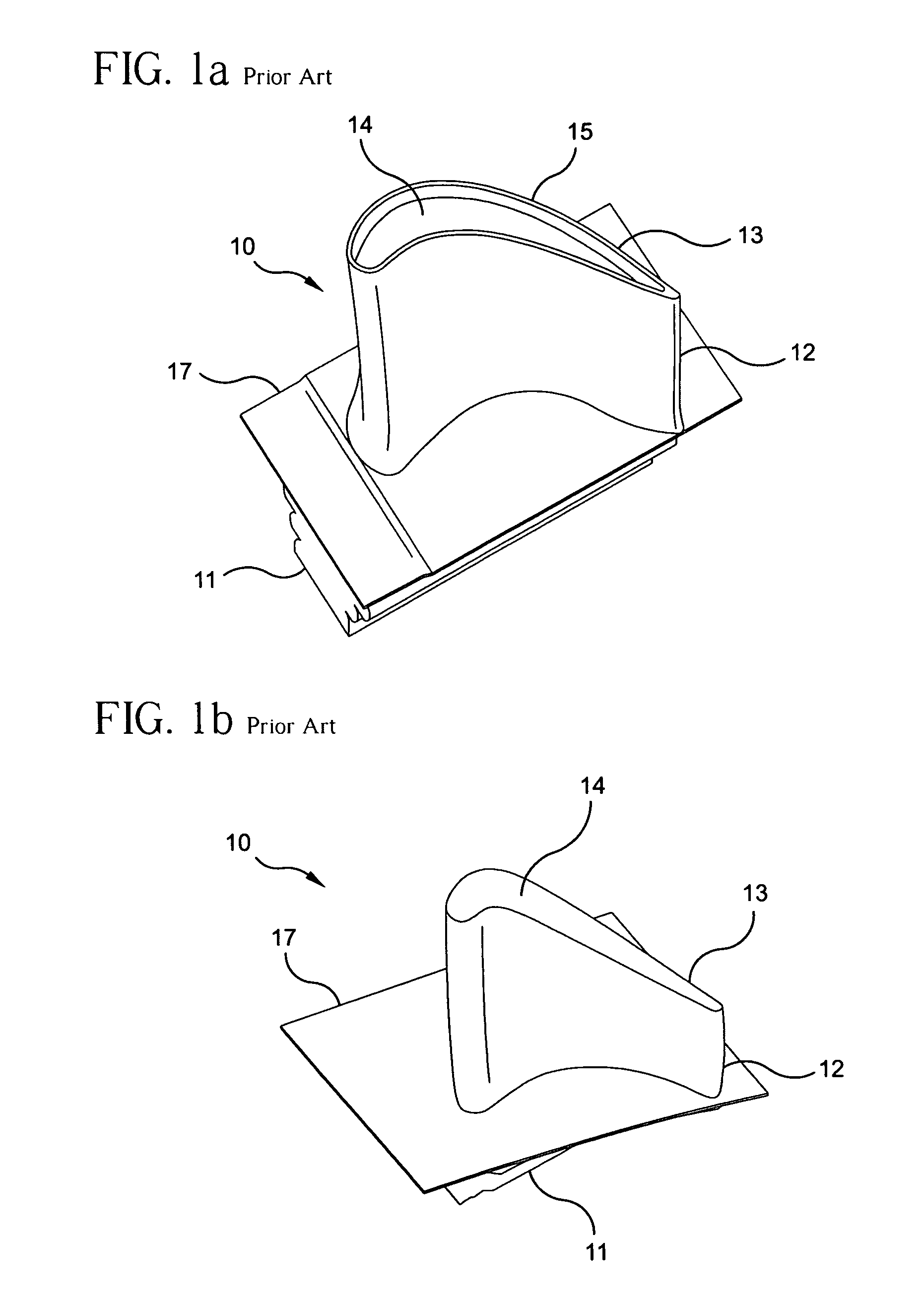

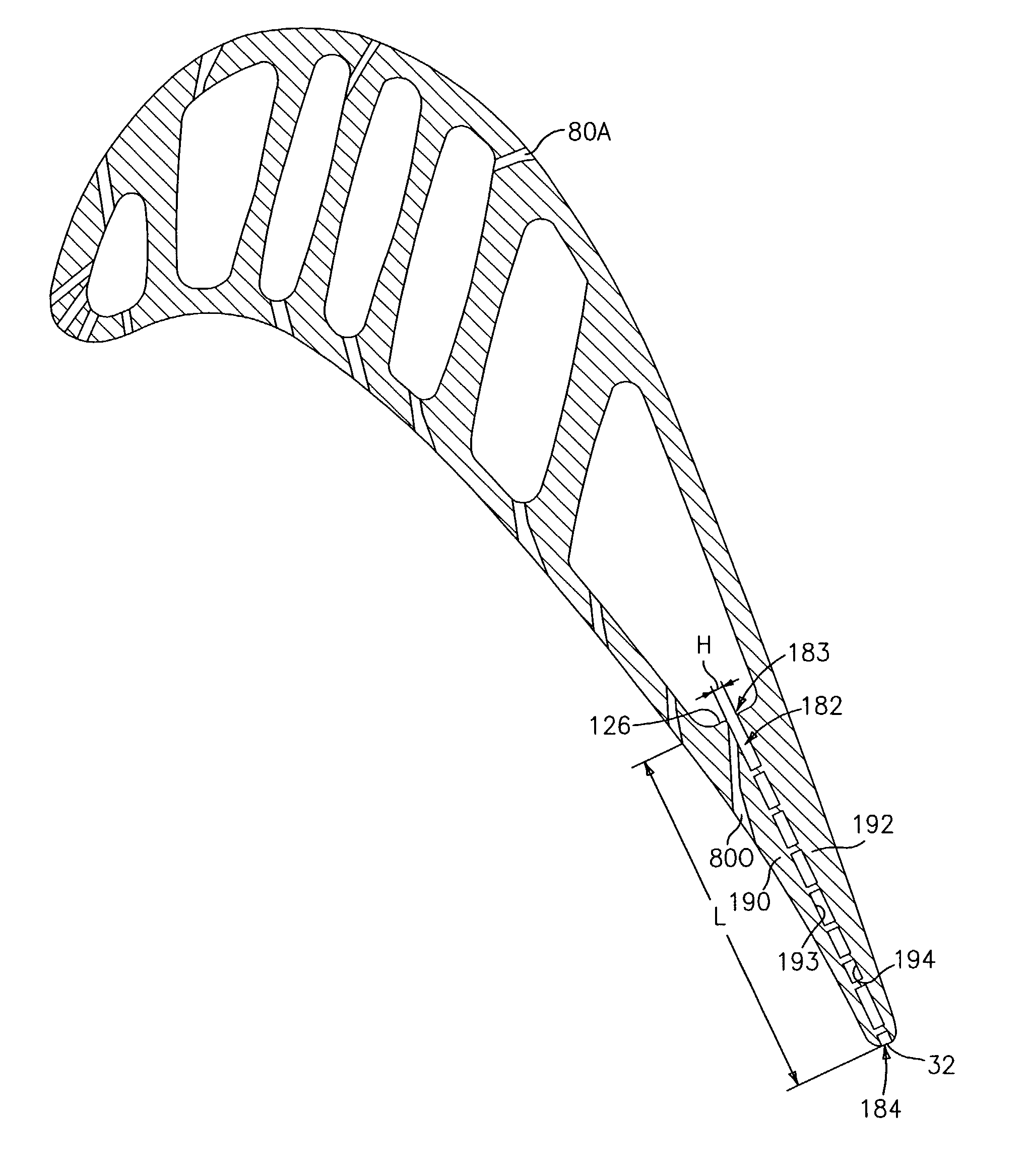

Articles which include chevron film cooling holes, and related processes

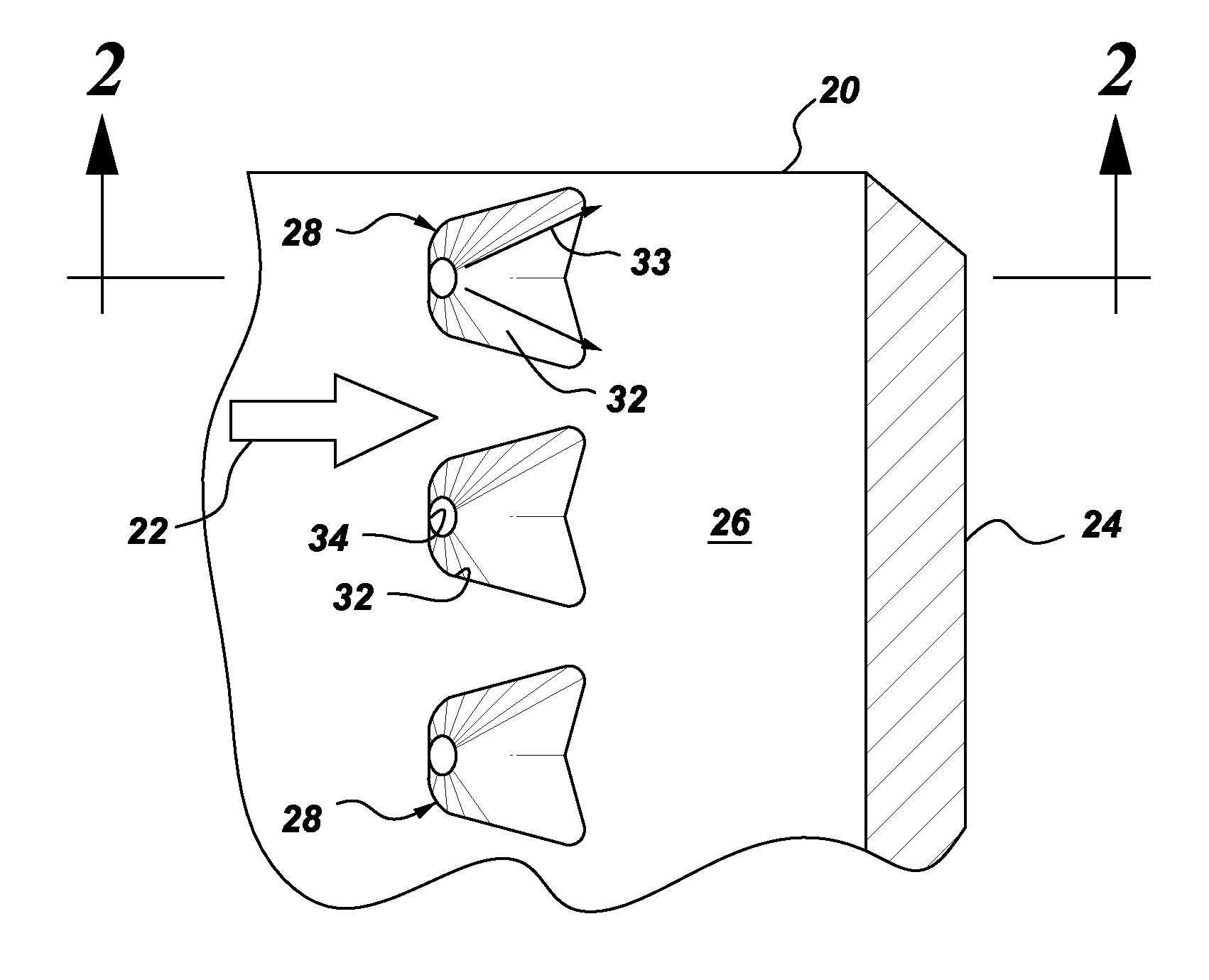

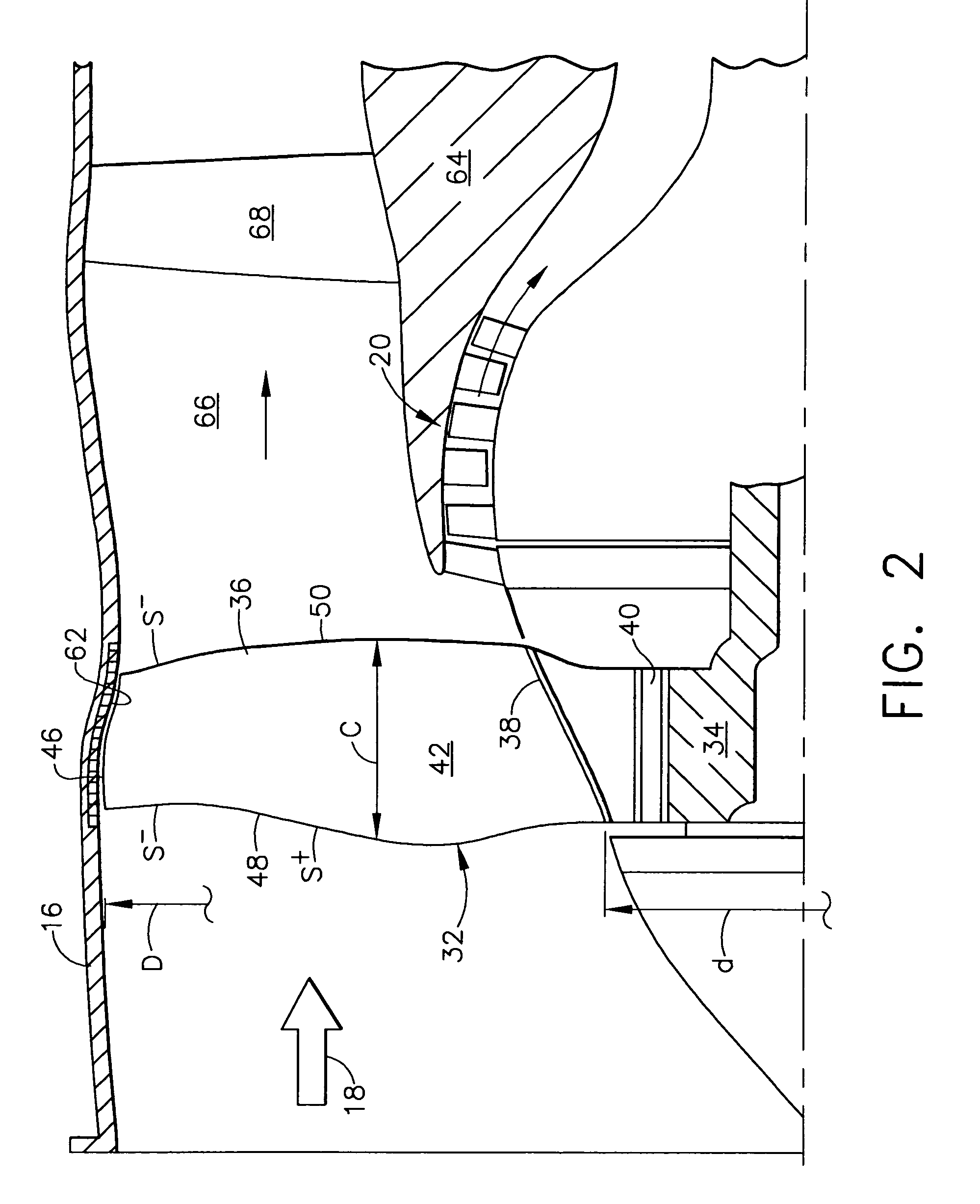

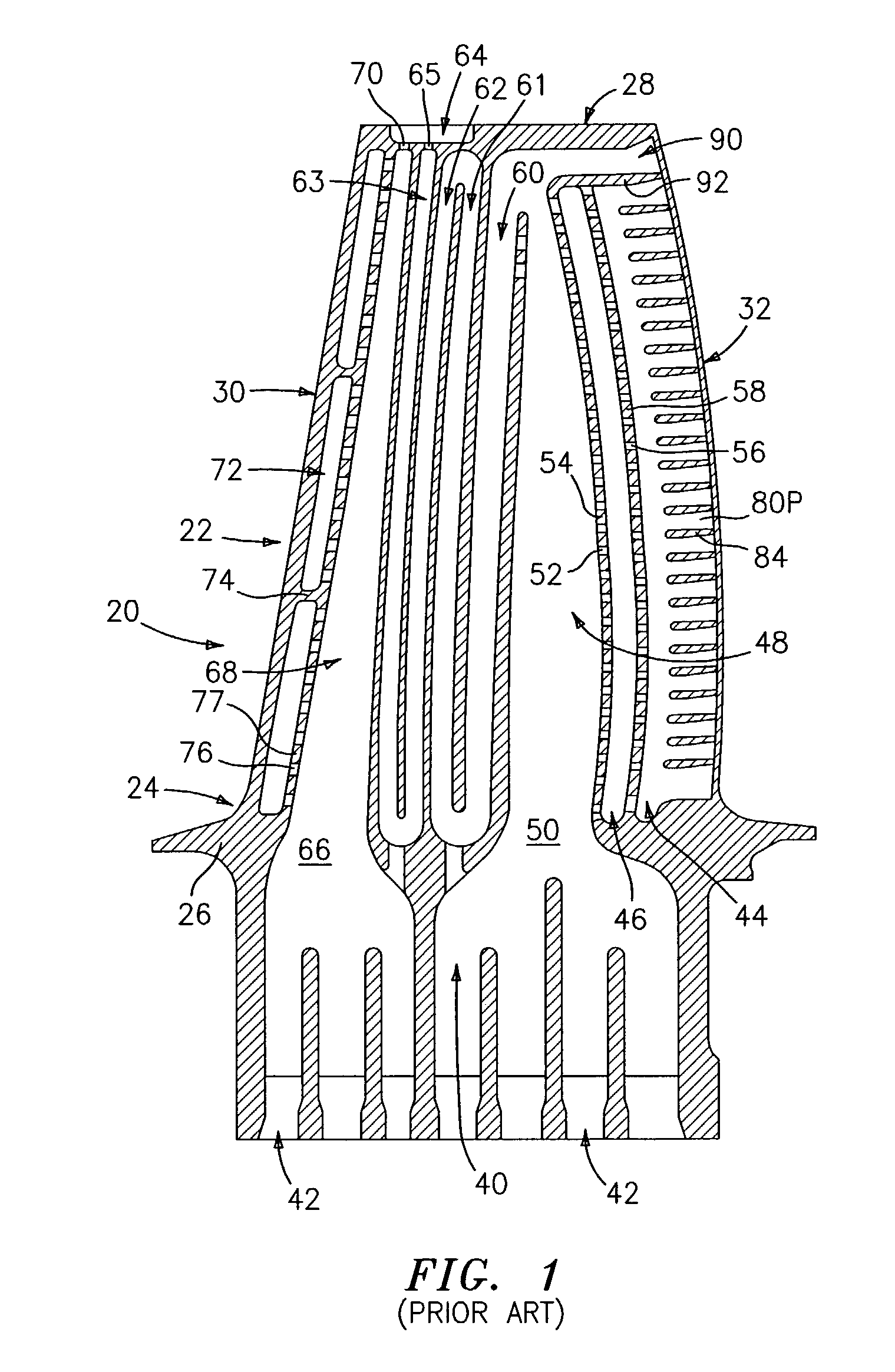

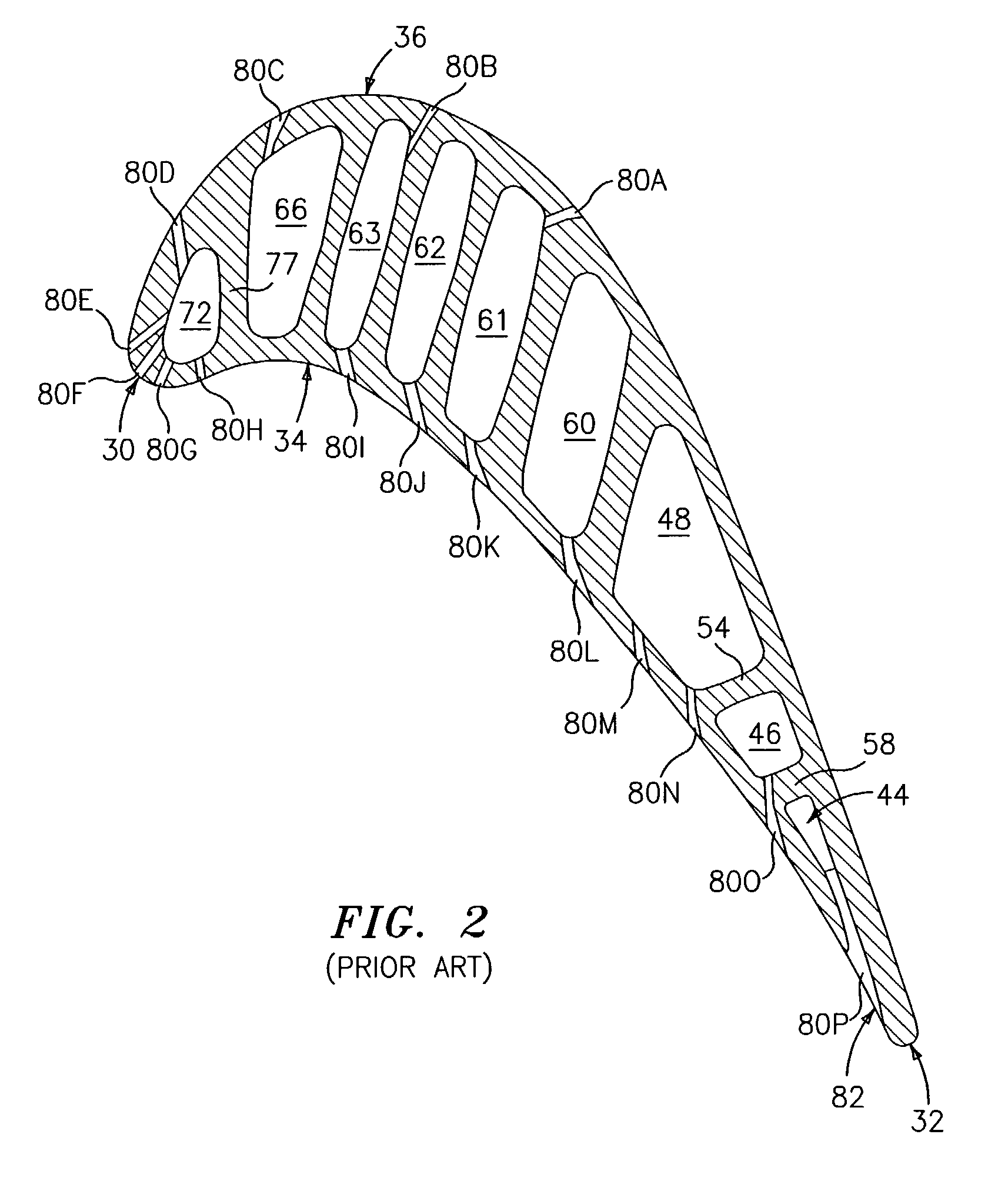

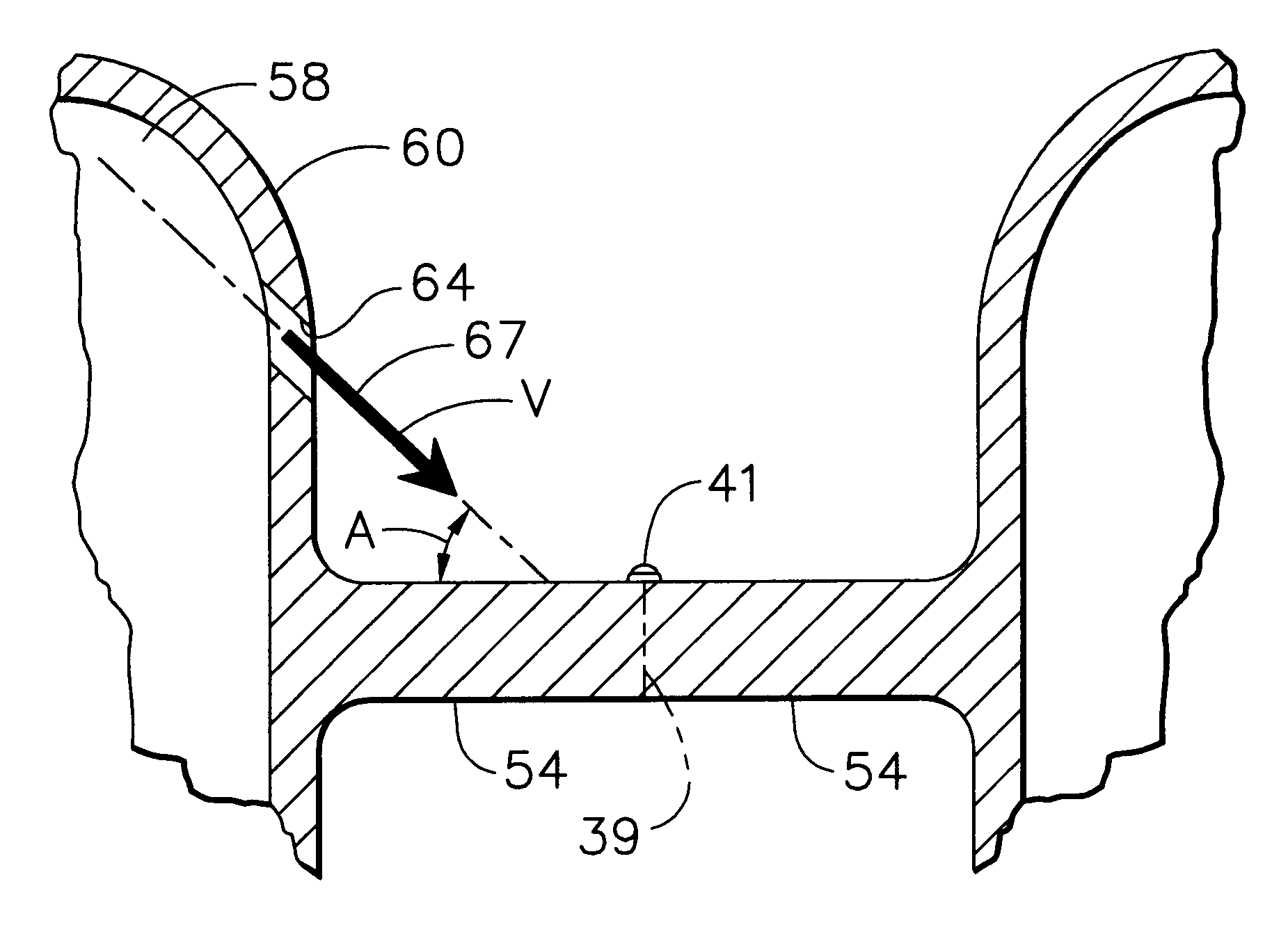

An article is described, including an inner surface which can be exposed to a first fluid; an inlet; and an outer surface spaced from the inner surface, which can be exposed to a hotter second fluid. The article further includes at least one row or other pattern of passage holes. Each passage hole includes an inlet bore extending through the substrate from the inlet at the inner surface to a passage hole-exit proximate to the outer surface, with the inlet bore terminating in a chevron outlet adjacent the hole-exit. The chevron outlet includes a pair of wing troughs having a common surface region between them. The common surface region includes a valley which is adjacent the hole-exit; and a plateau adjacent the valley. The article can be an airfoil. Related methods for preparing the passage holes are also described.

Owner:GENERAL ELECTRIC CO

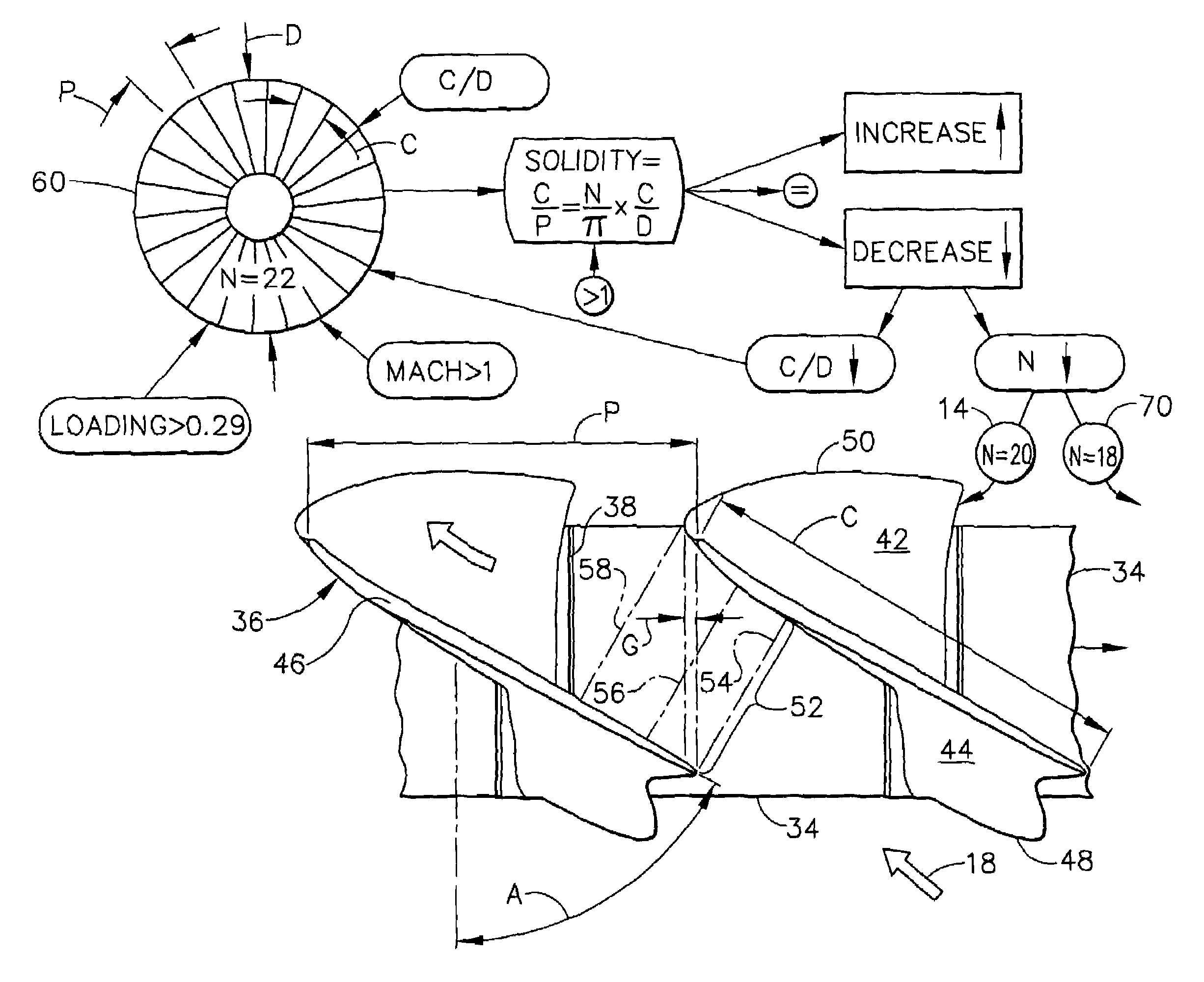

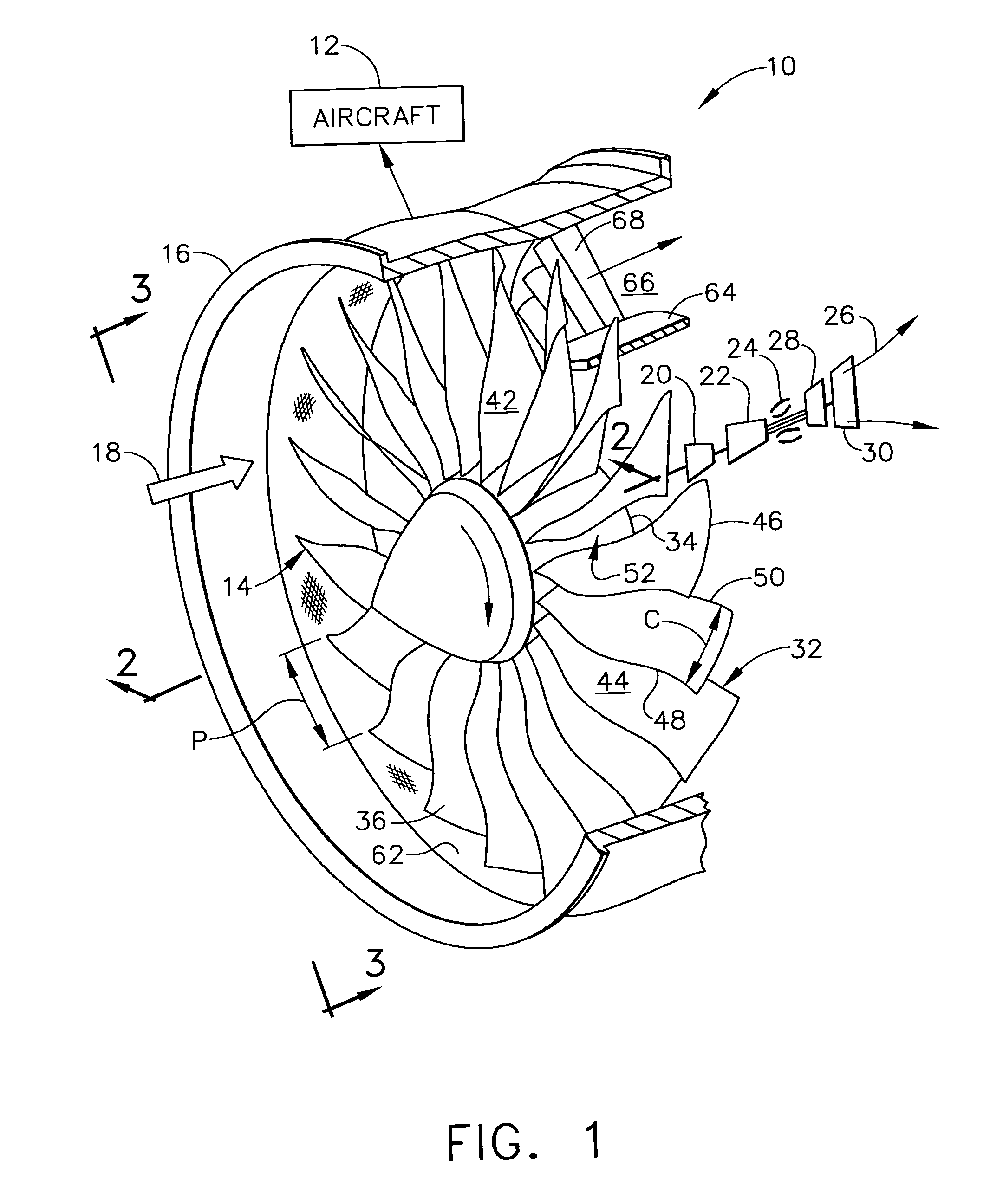

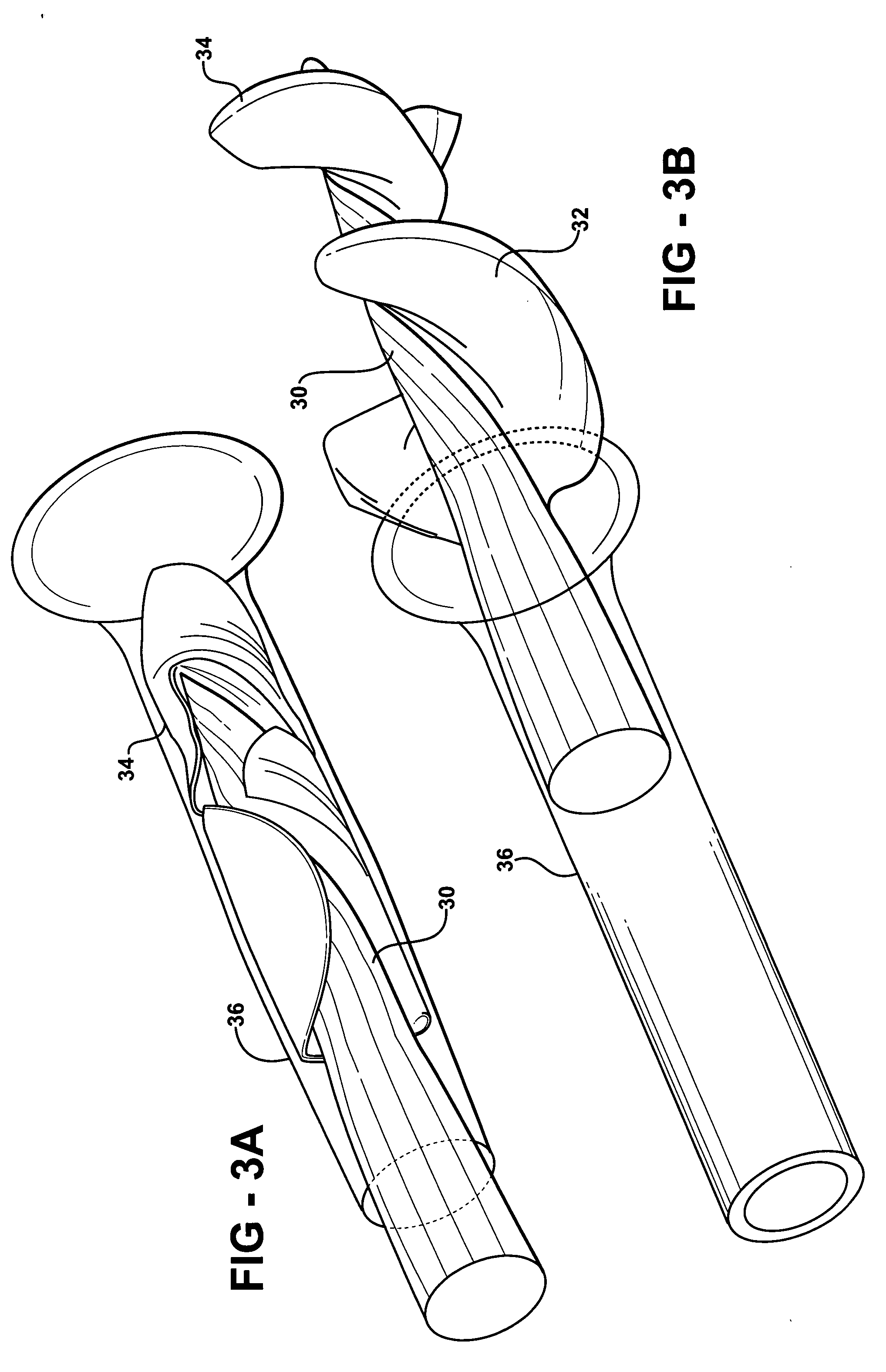

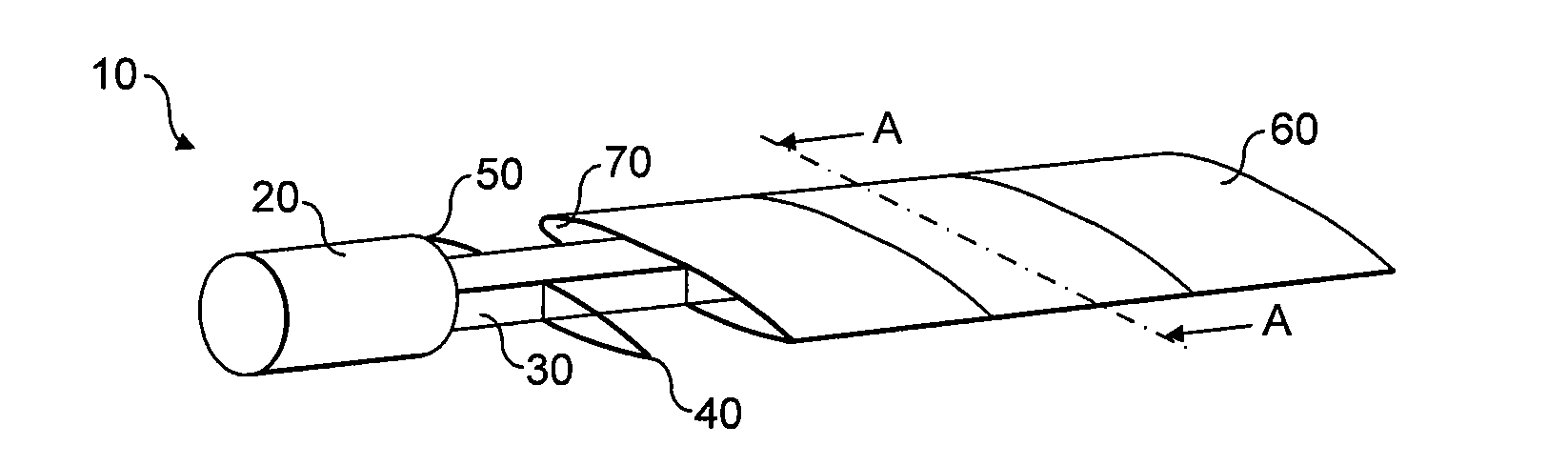

Low solidity turbofan

A turbofan includes a row of fan blades extending from a supporting disk inside an annular casing. Each blade includes an airfoil having opposite pressure and suction sides extending radially in span between a root and tip and axially in chord between leading and trailing edges. Adjacent airfoils define corresponding flow passages therebetween for pressurizing air. Each airfoil includes stagger increasing between the root and tip, and the flow passage has a mouth between the airfoil leading edge and the suction side of an adjacent airfoil and converges to a throat aft from the mouth. The row includes no more than twenty fan blades having low tip solidity for increasing the width of the passage throat.

Owner:GENERAL ELECTRIC CO

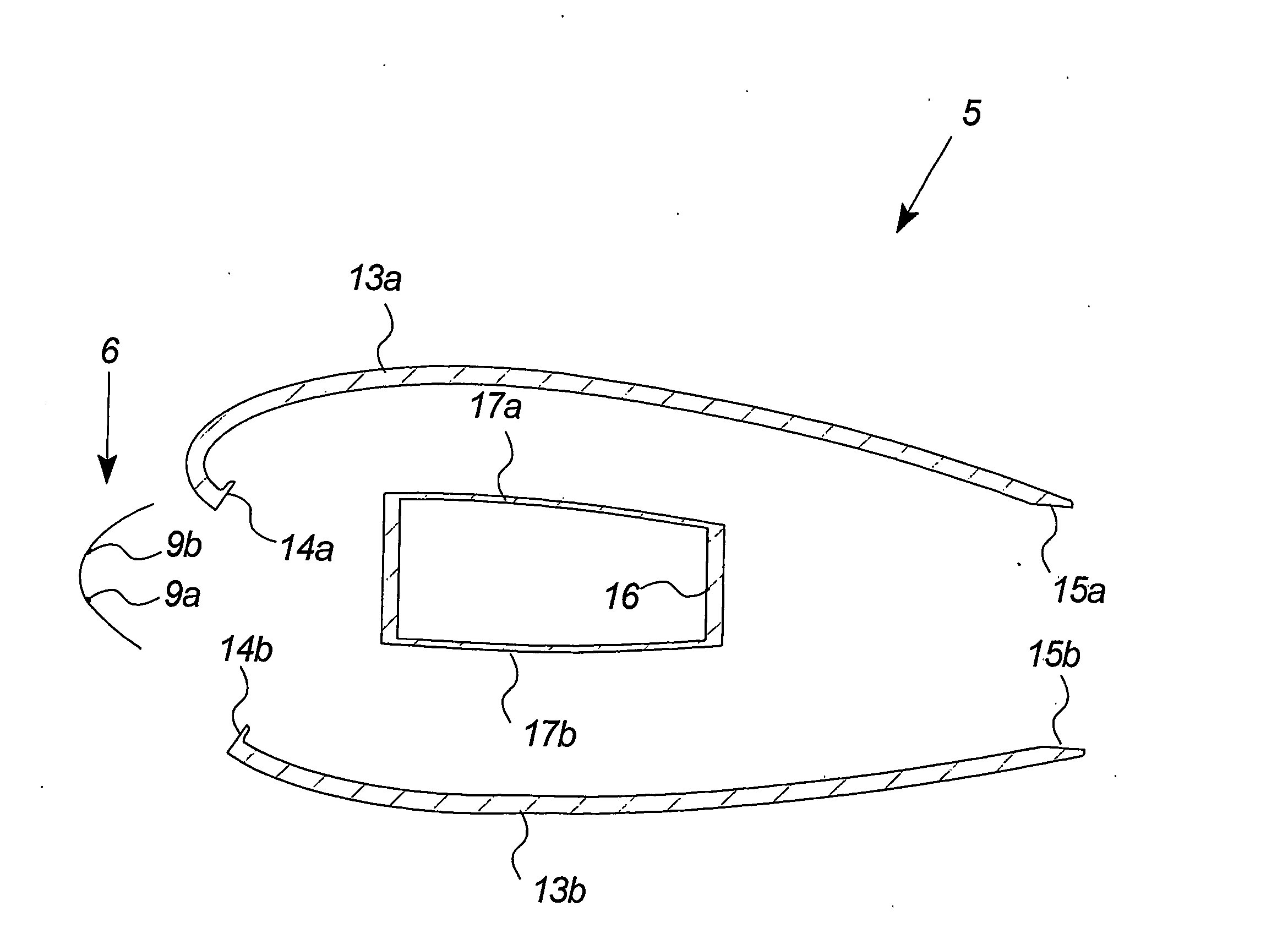

Expandable impeller pump

An impeller according to an example of the present invention comprises a hub, and at least one blade supported by the hub. The impeller has a deployed configuration in which the blade extends away from the hub, and a stored configuration in which the impeller is radially compressed, for example by folding the blade towards the hub. The impeller may comprise a plurality of blades, arranged in blade rows, to facilitate radial compression of the blades. The outer edge of a blade may have a winglet, and the base of the blade may have an associated indentation to facilitate folding of the blade.

Owner:PENN STATE RES FOUND +2

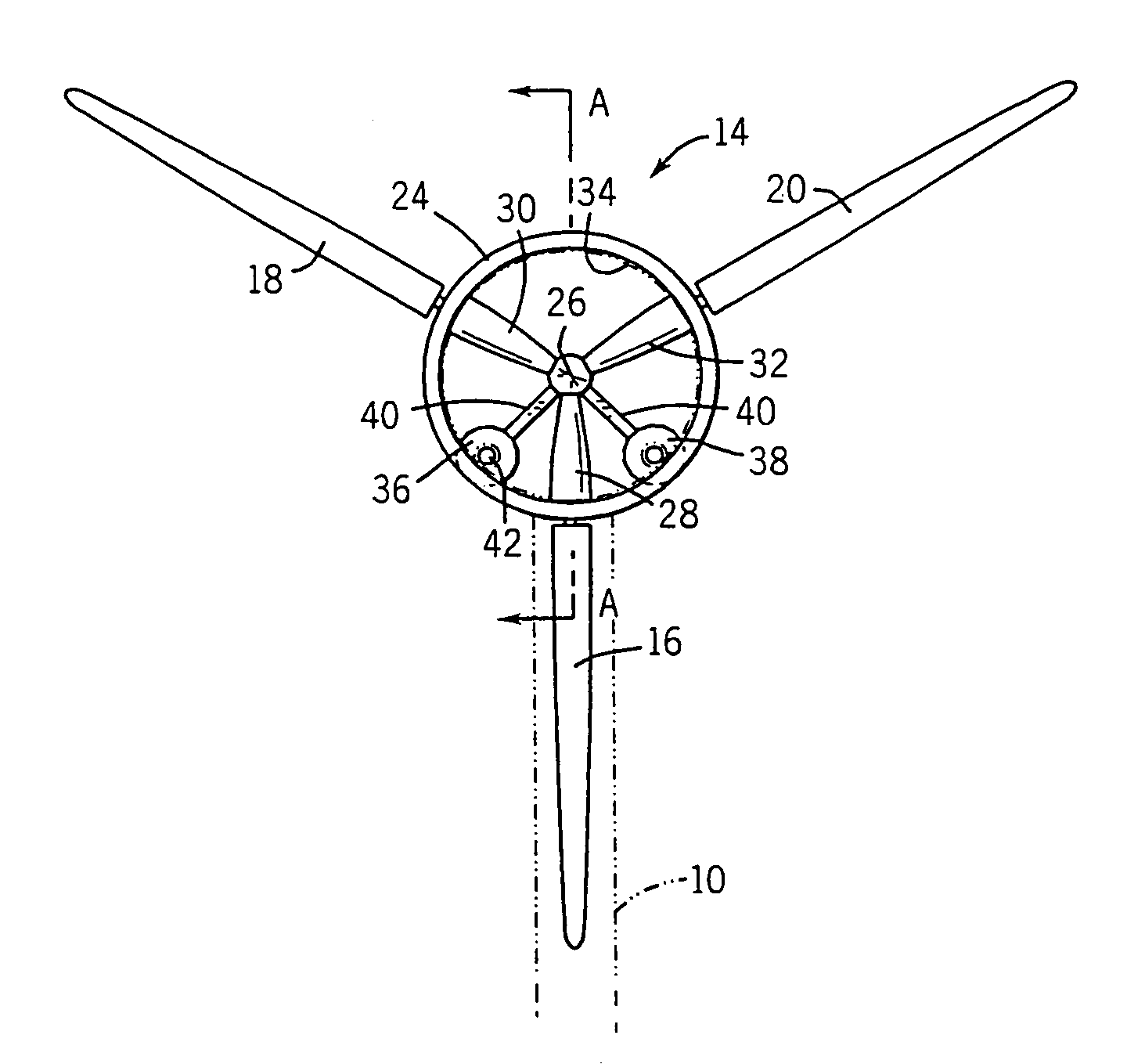

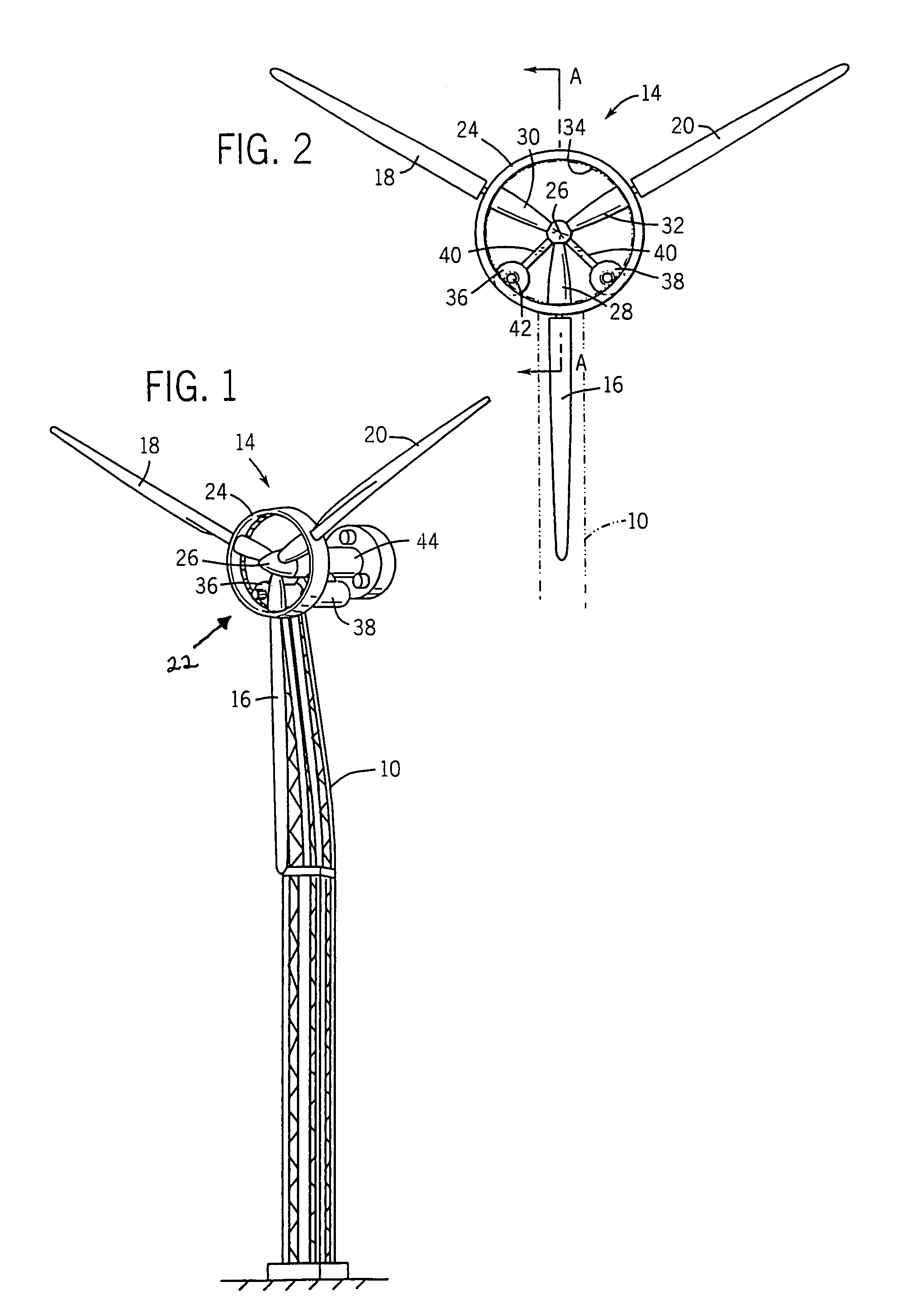

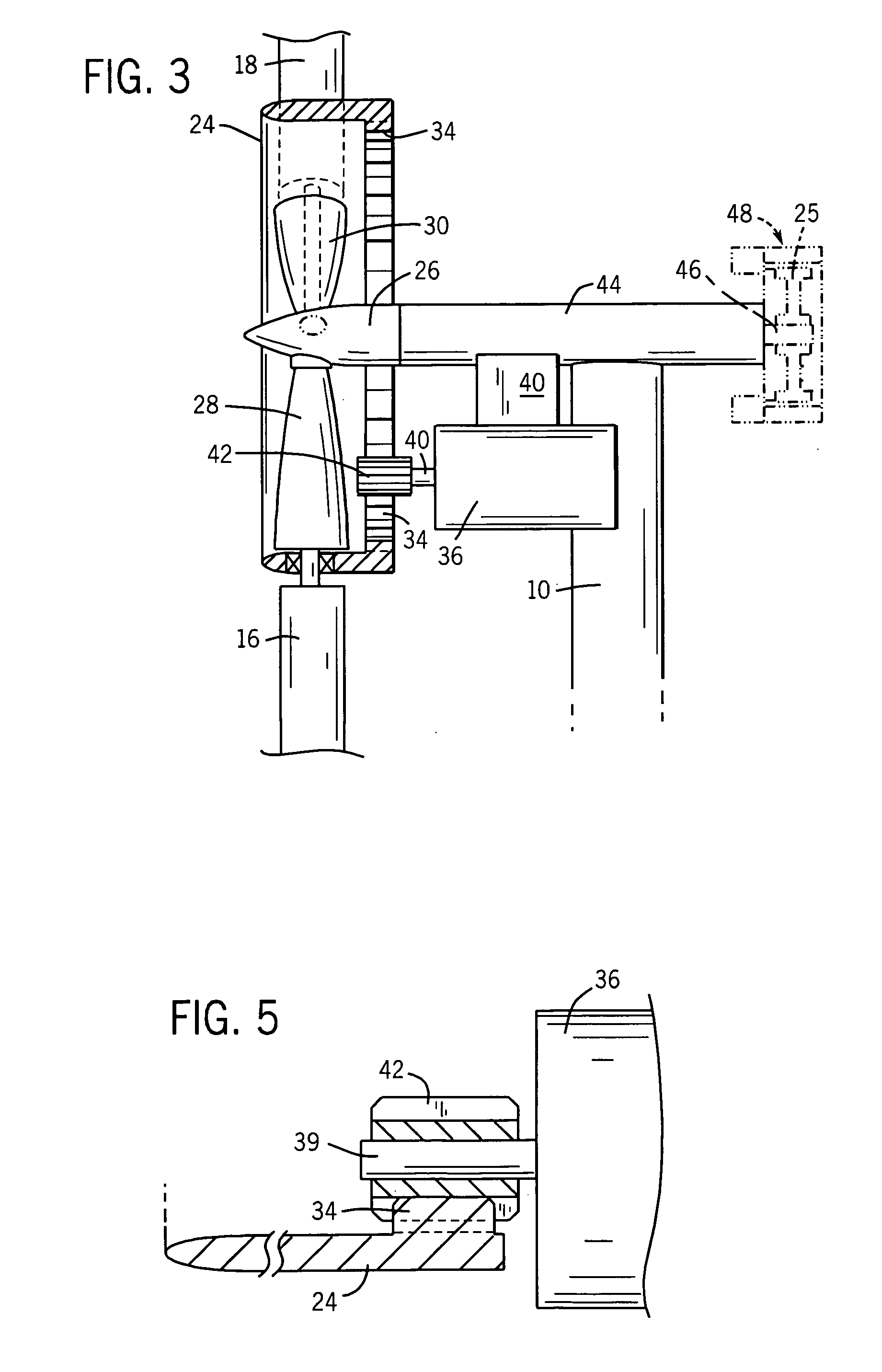

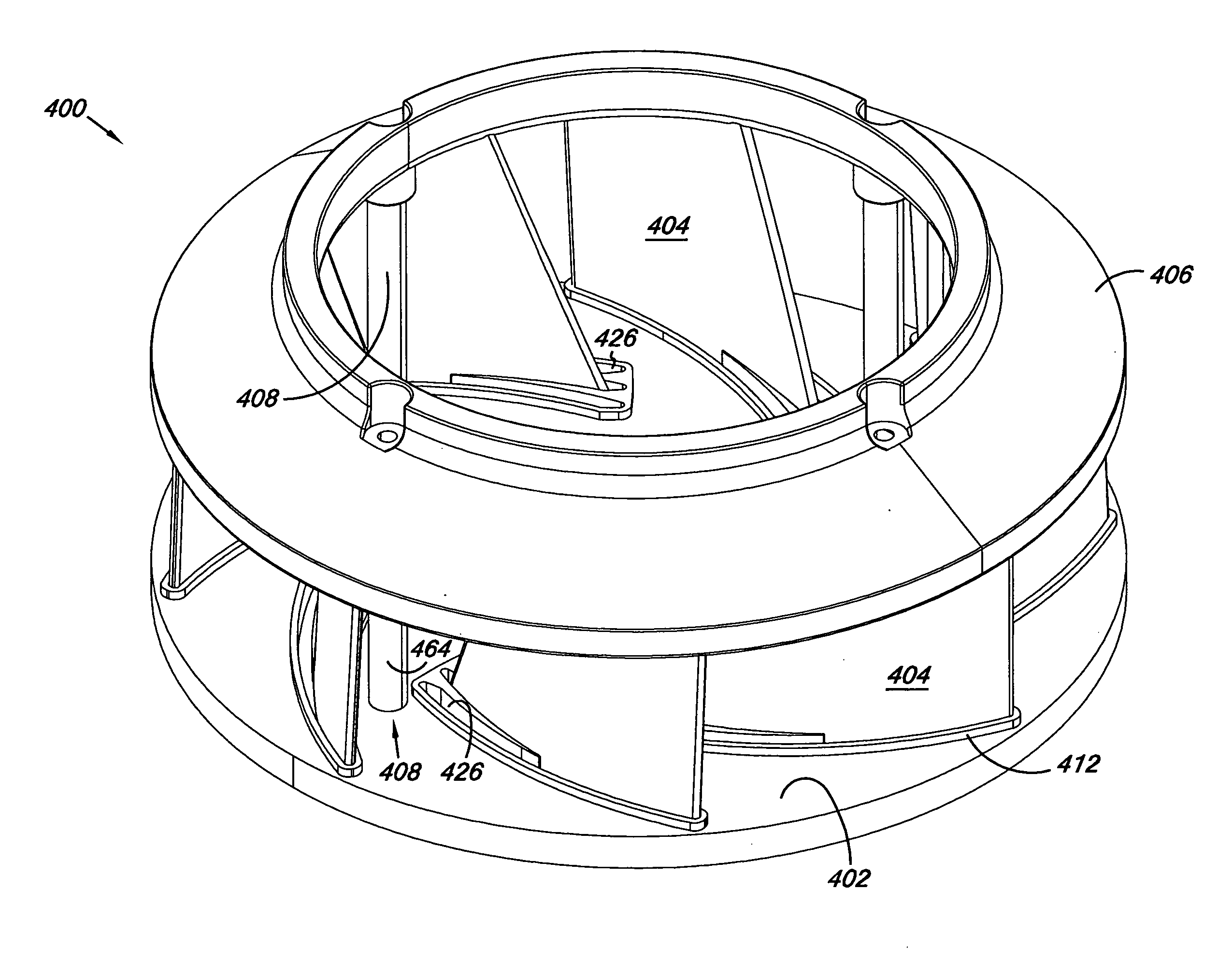

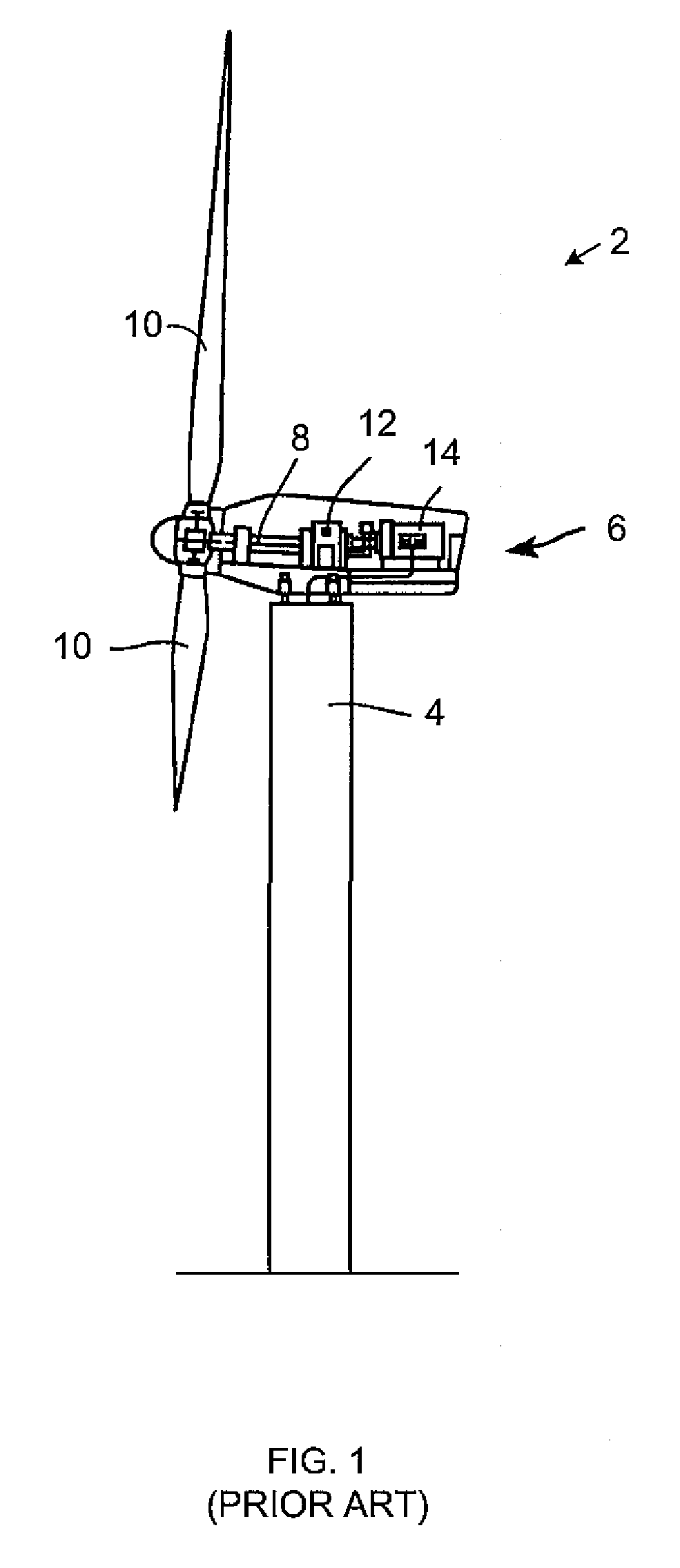

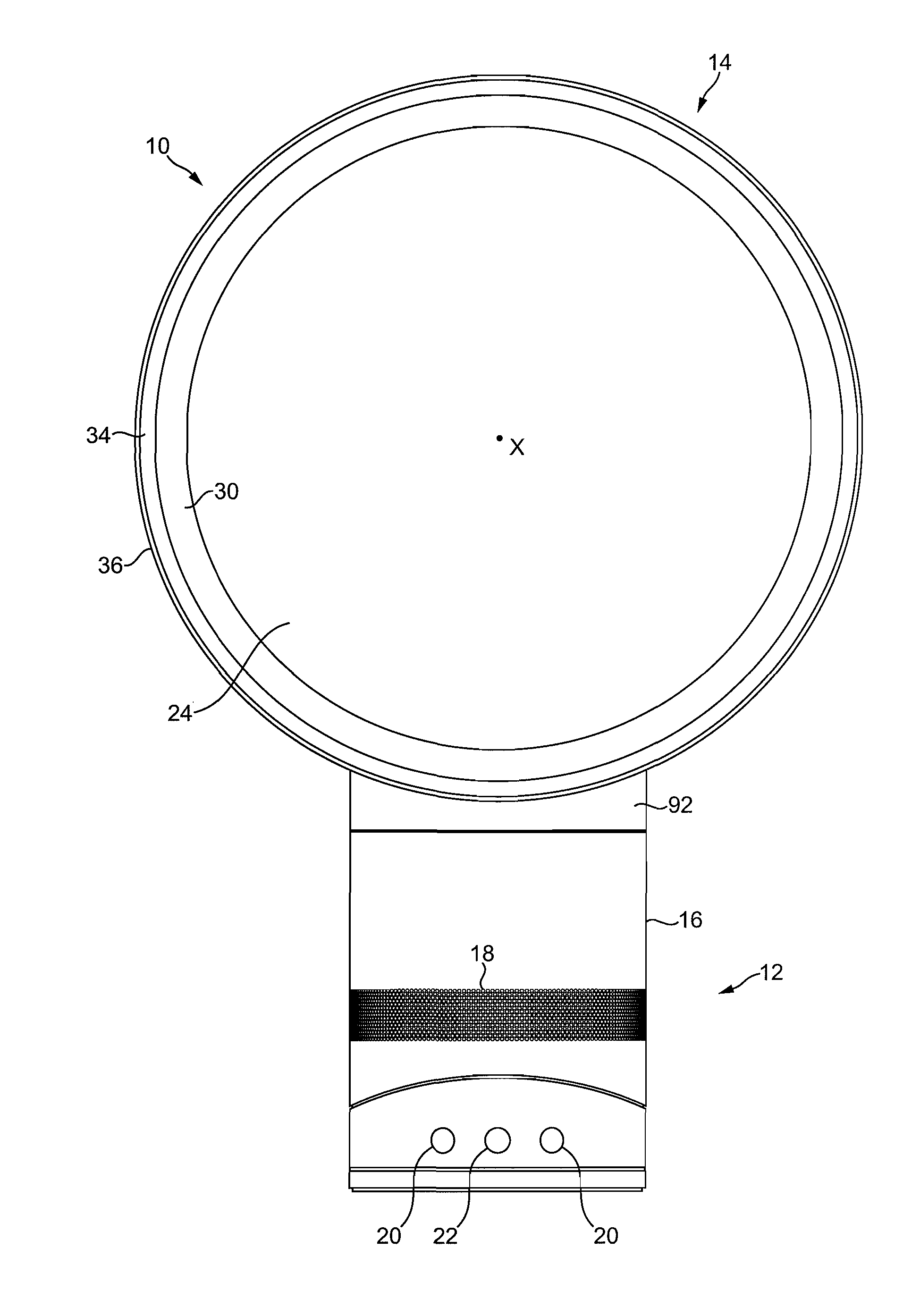

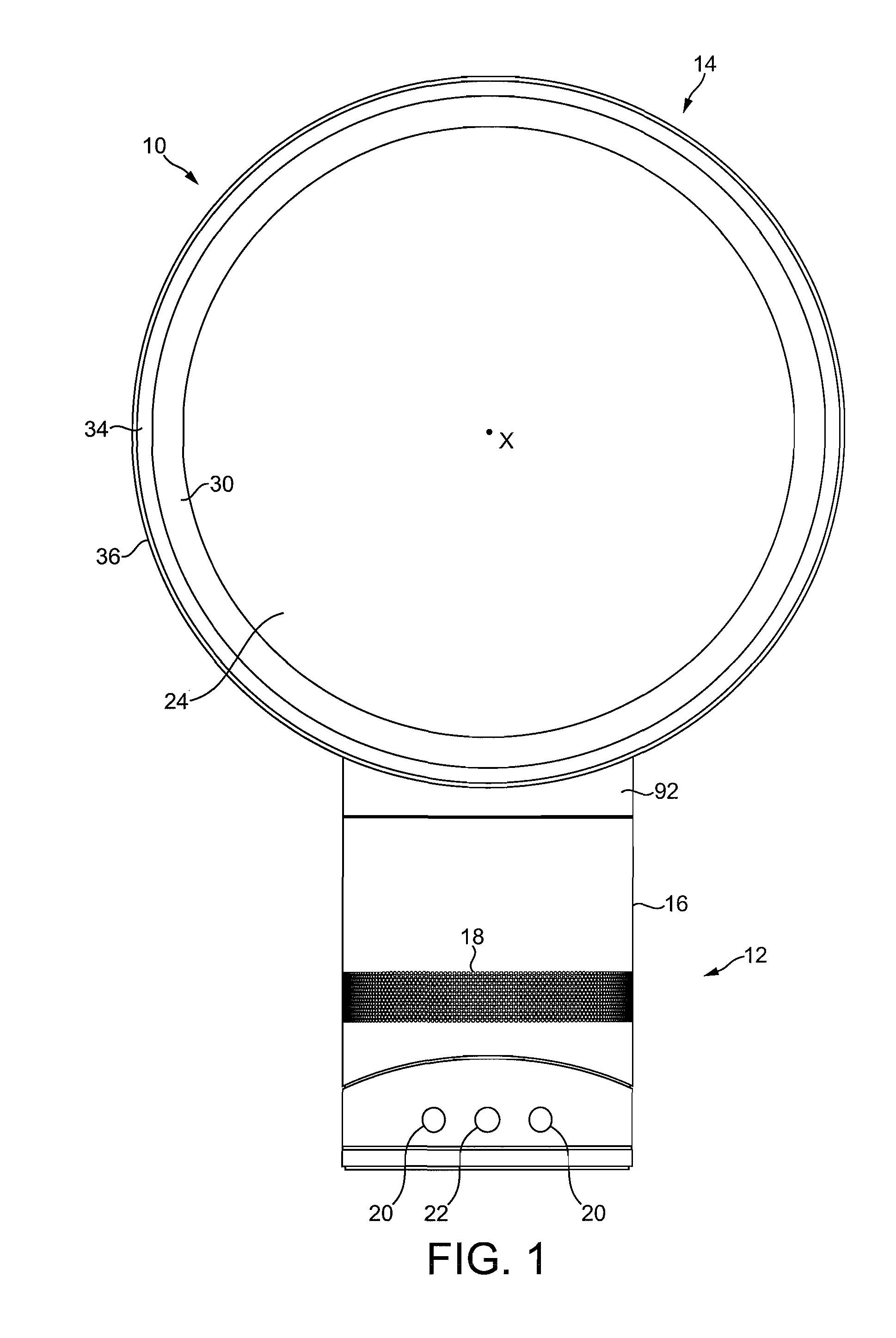

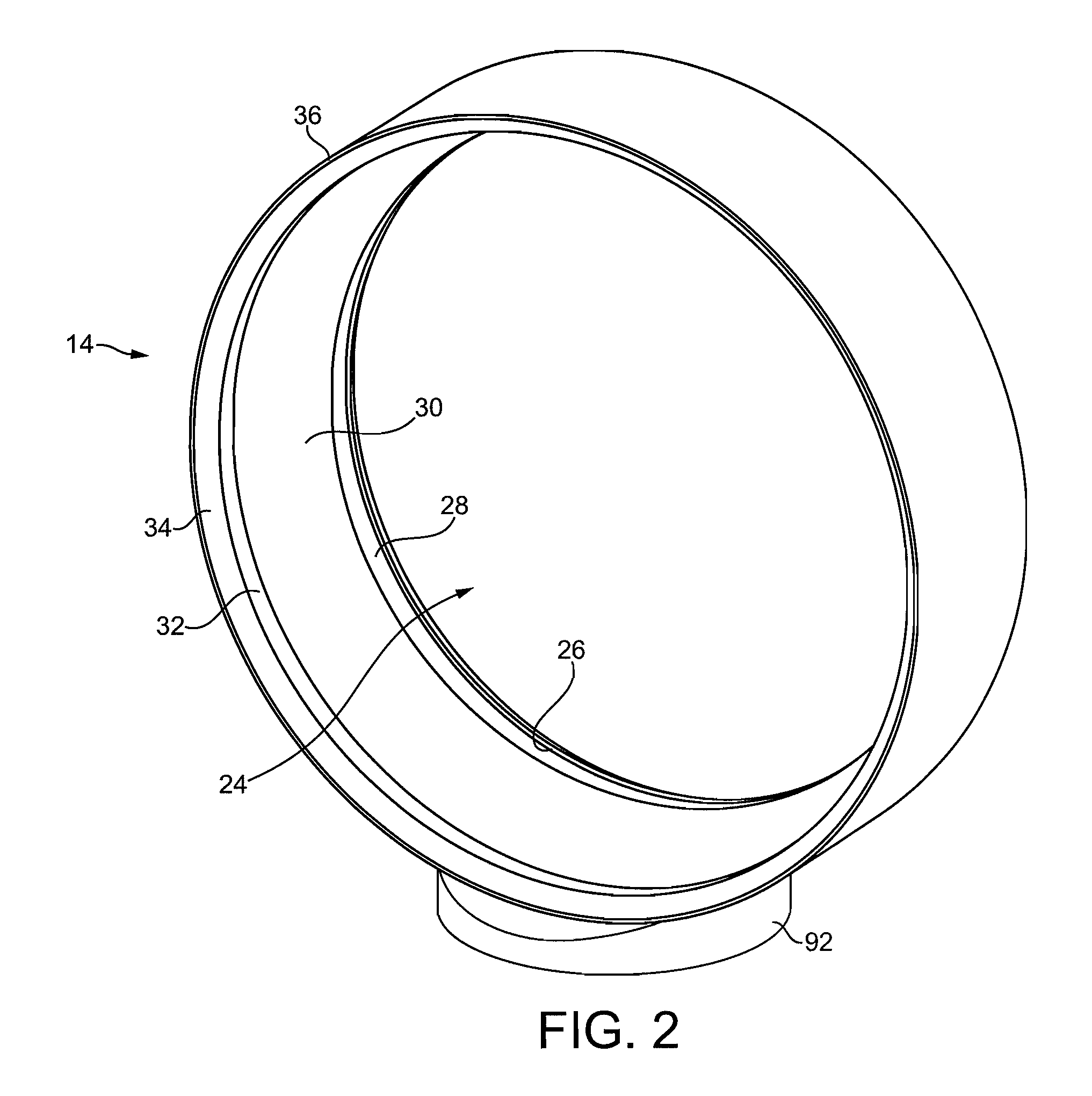

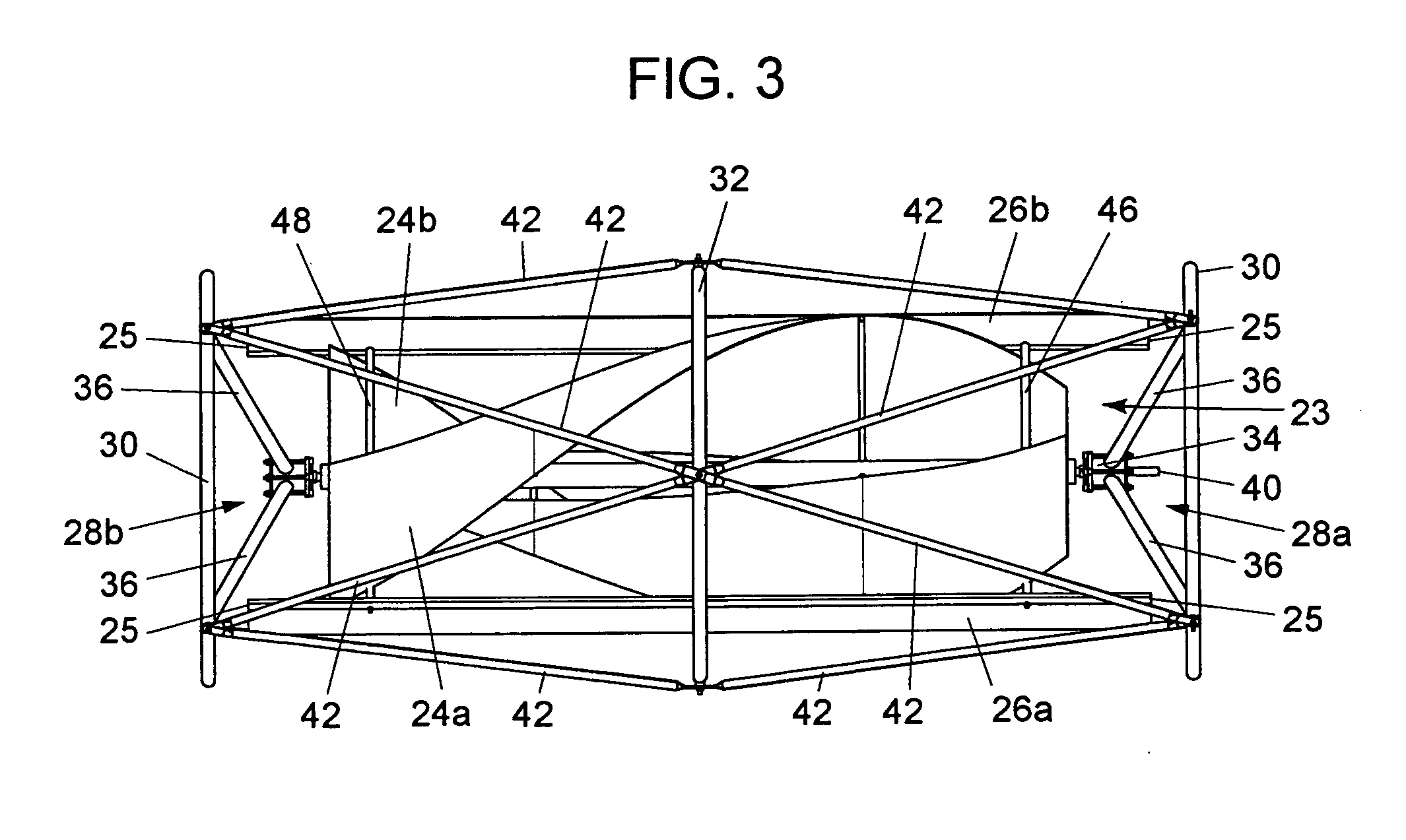

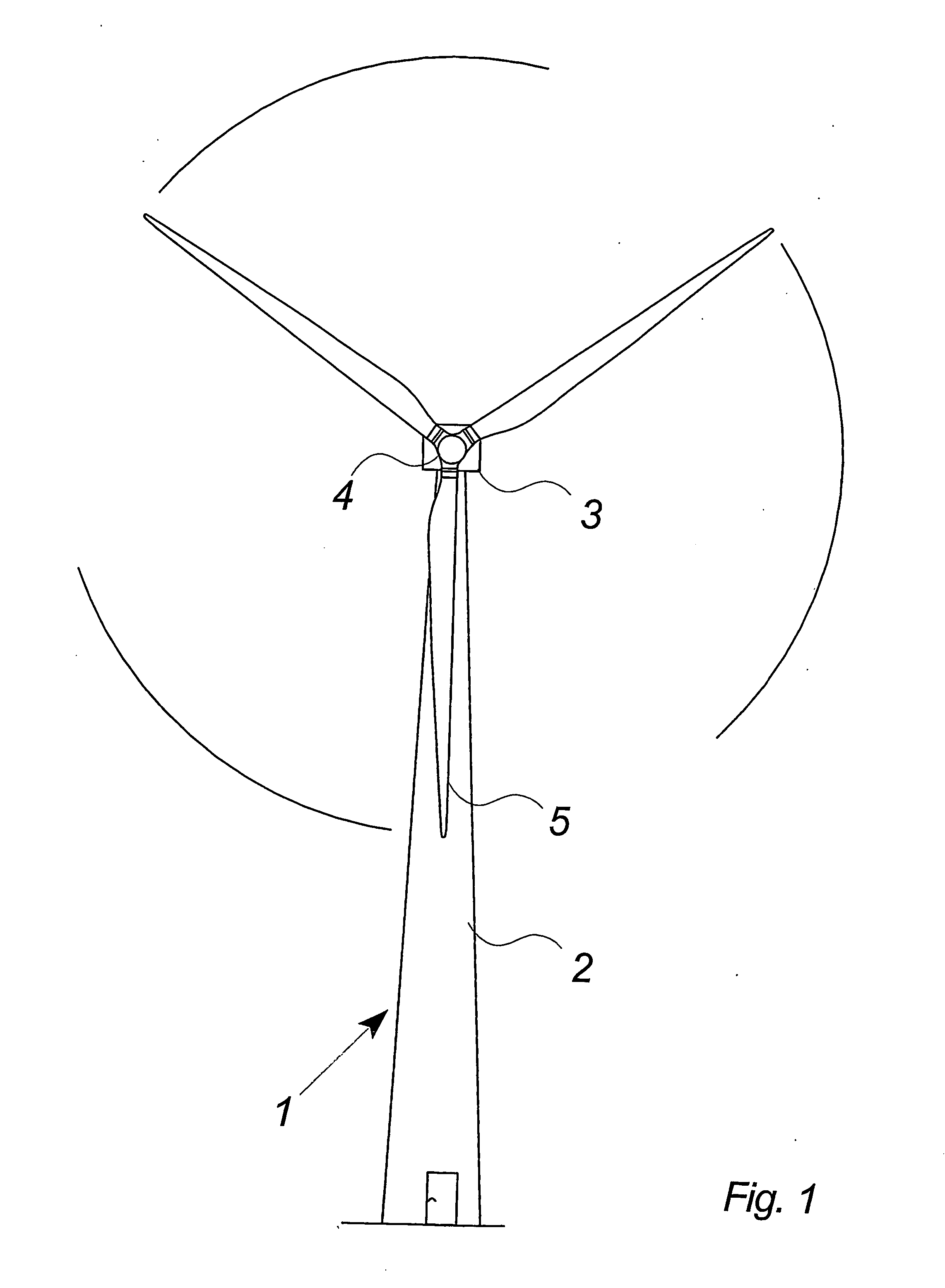

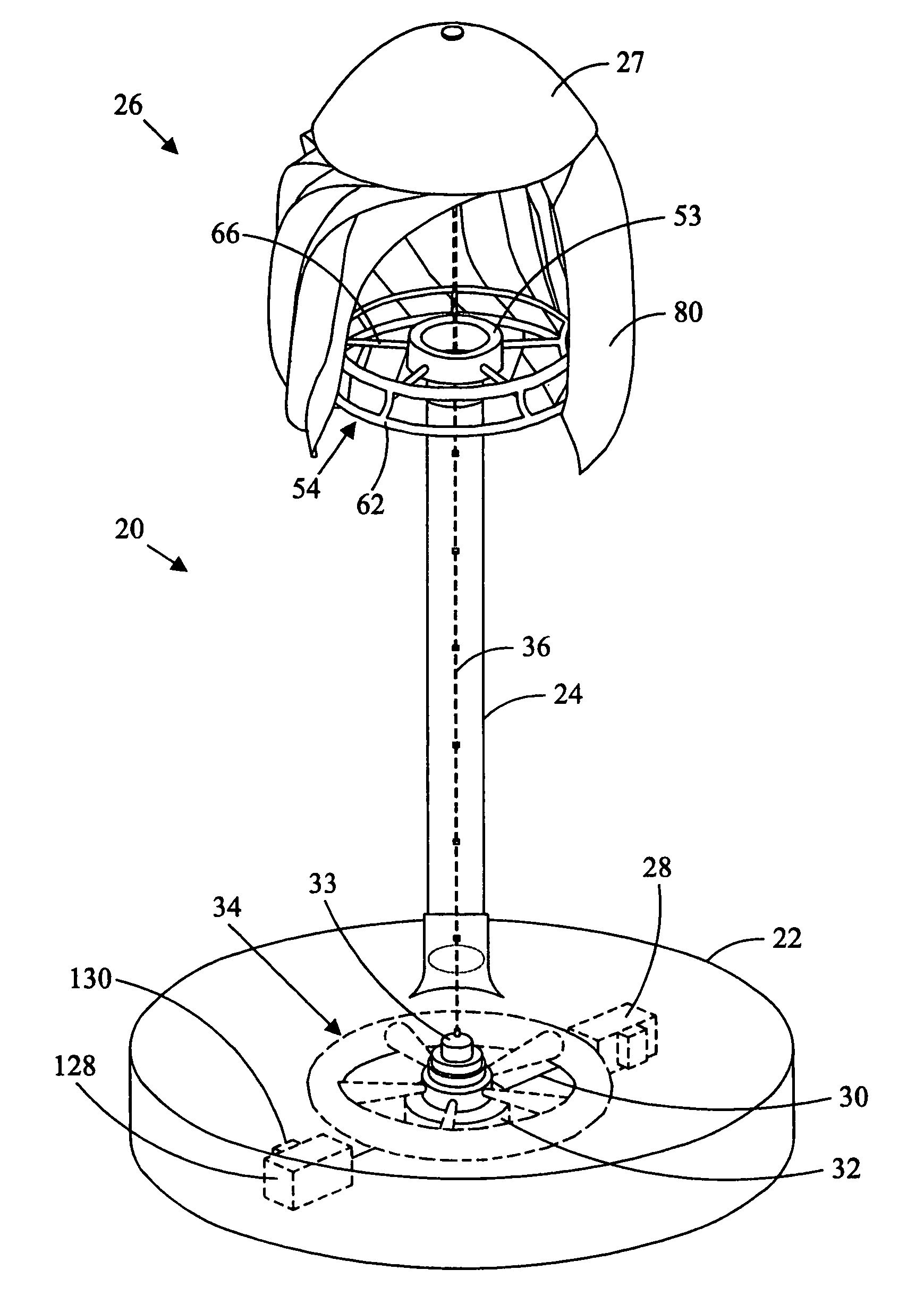

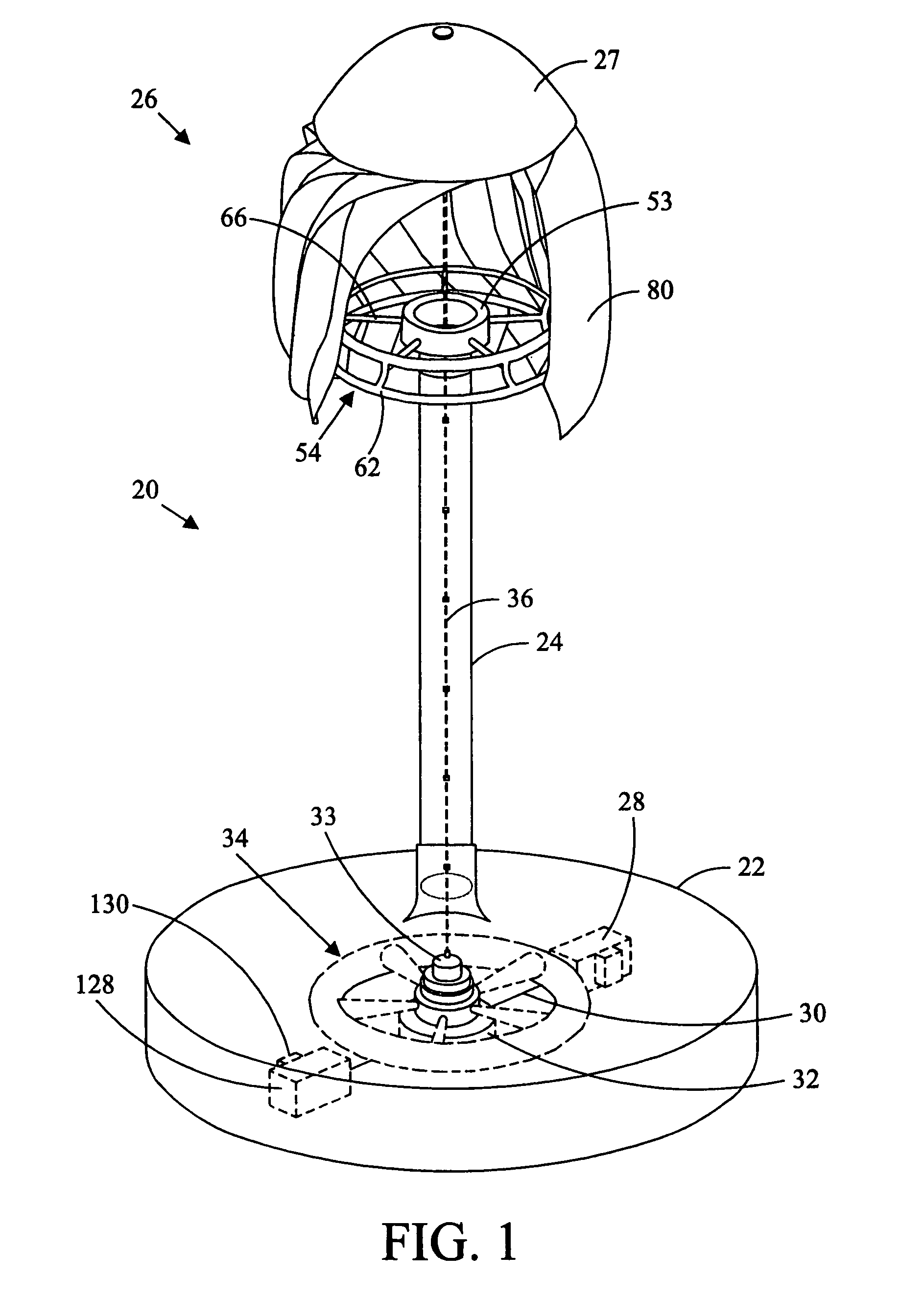

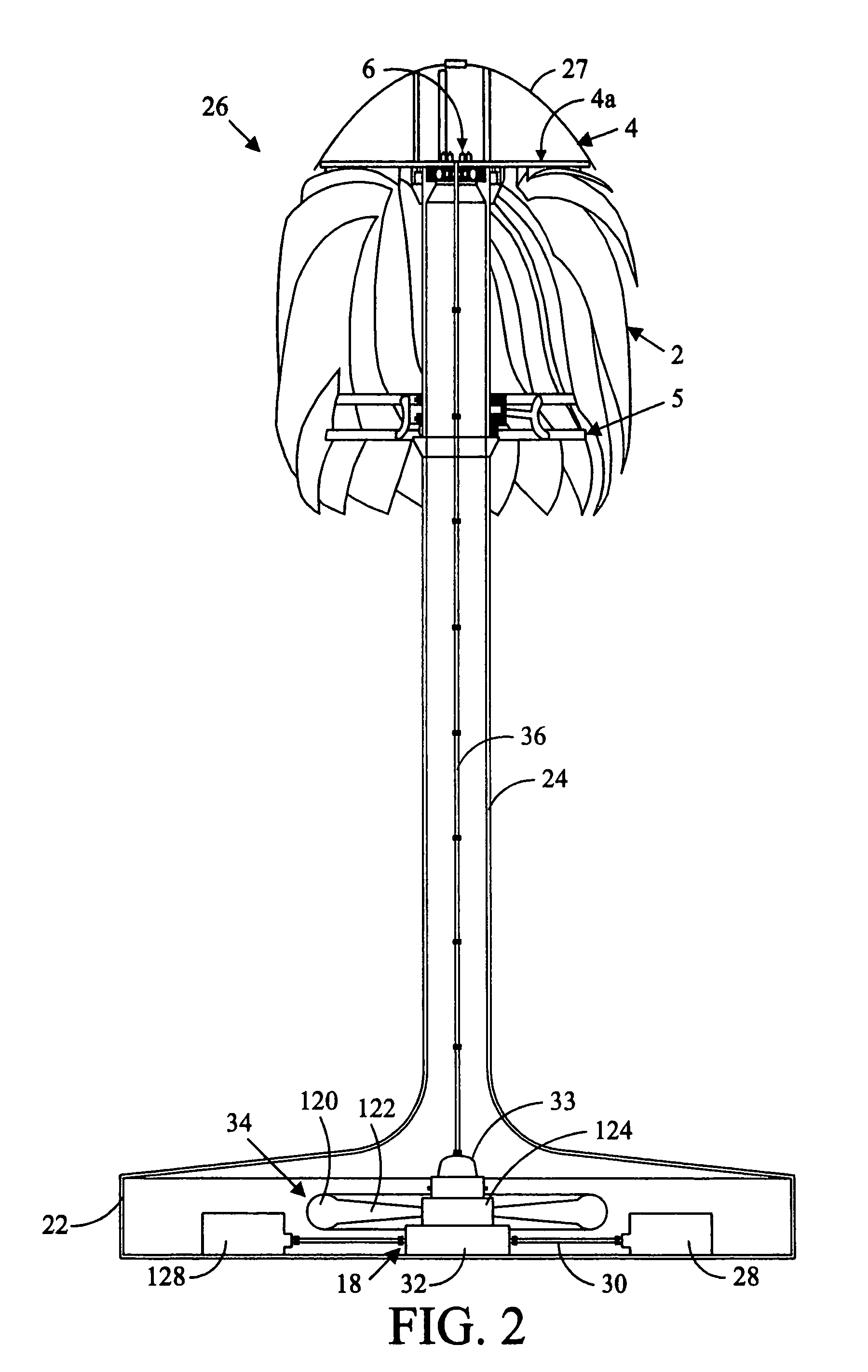

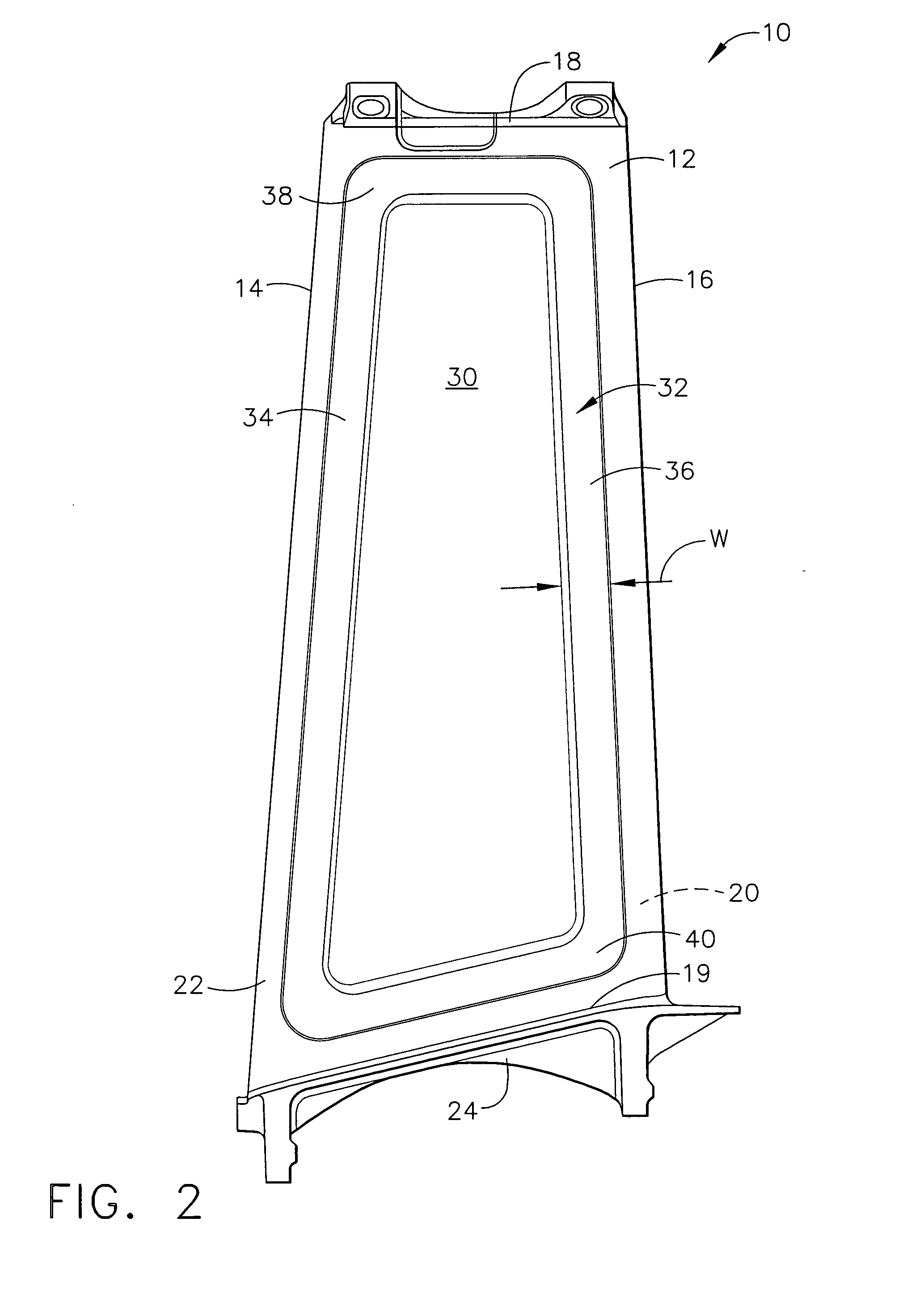

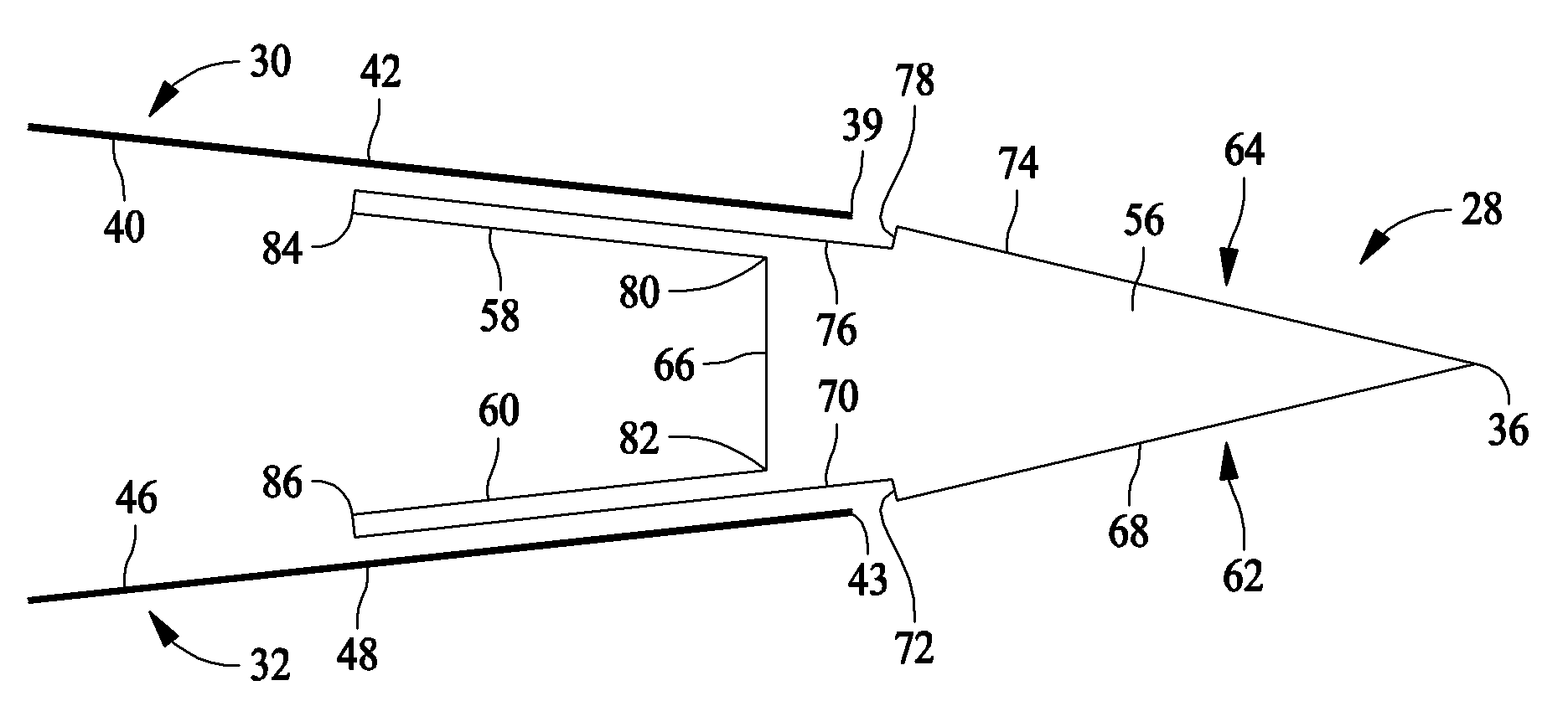

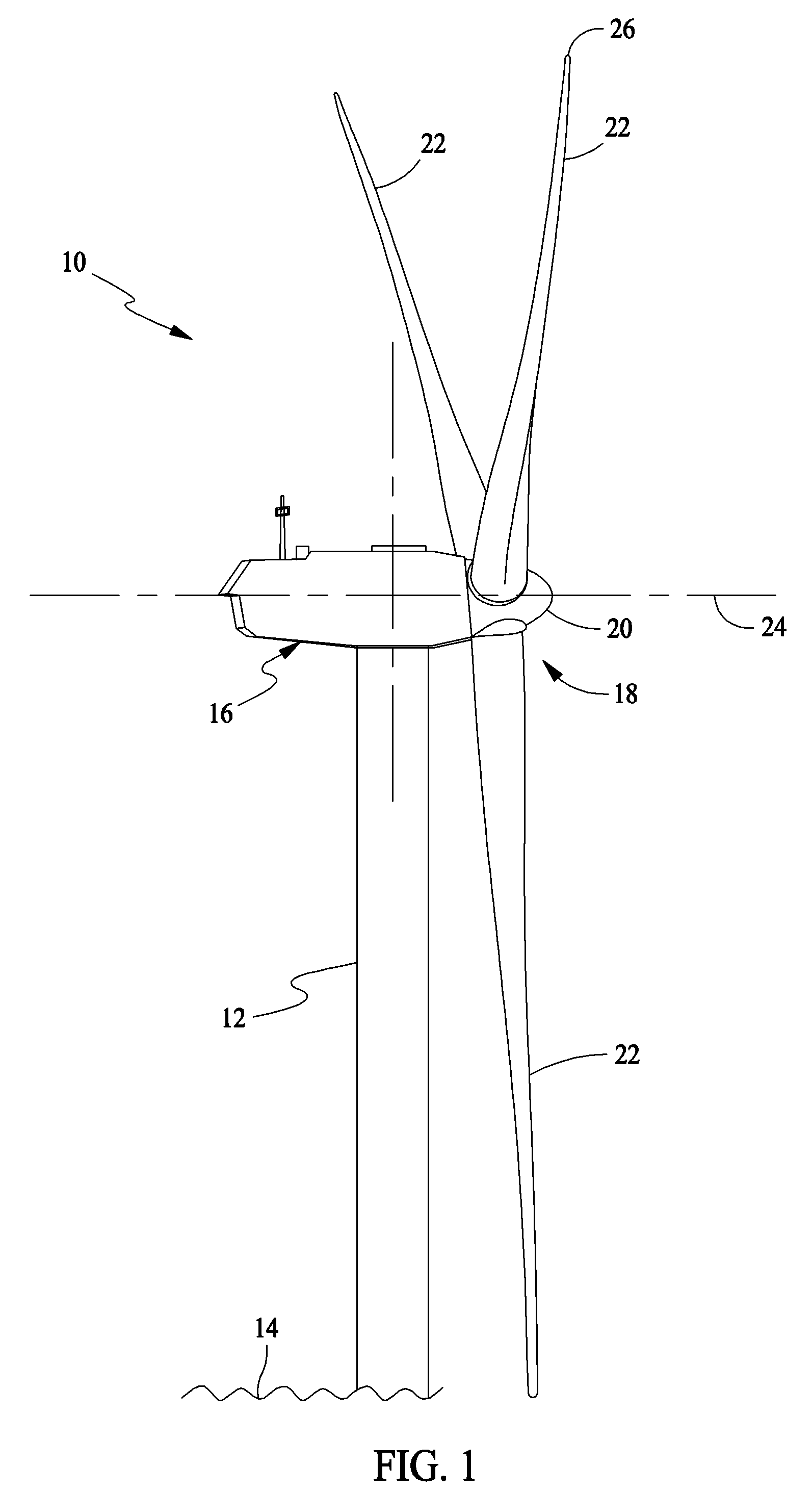

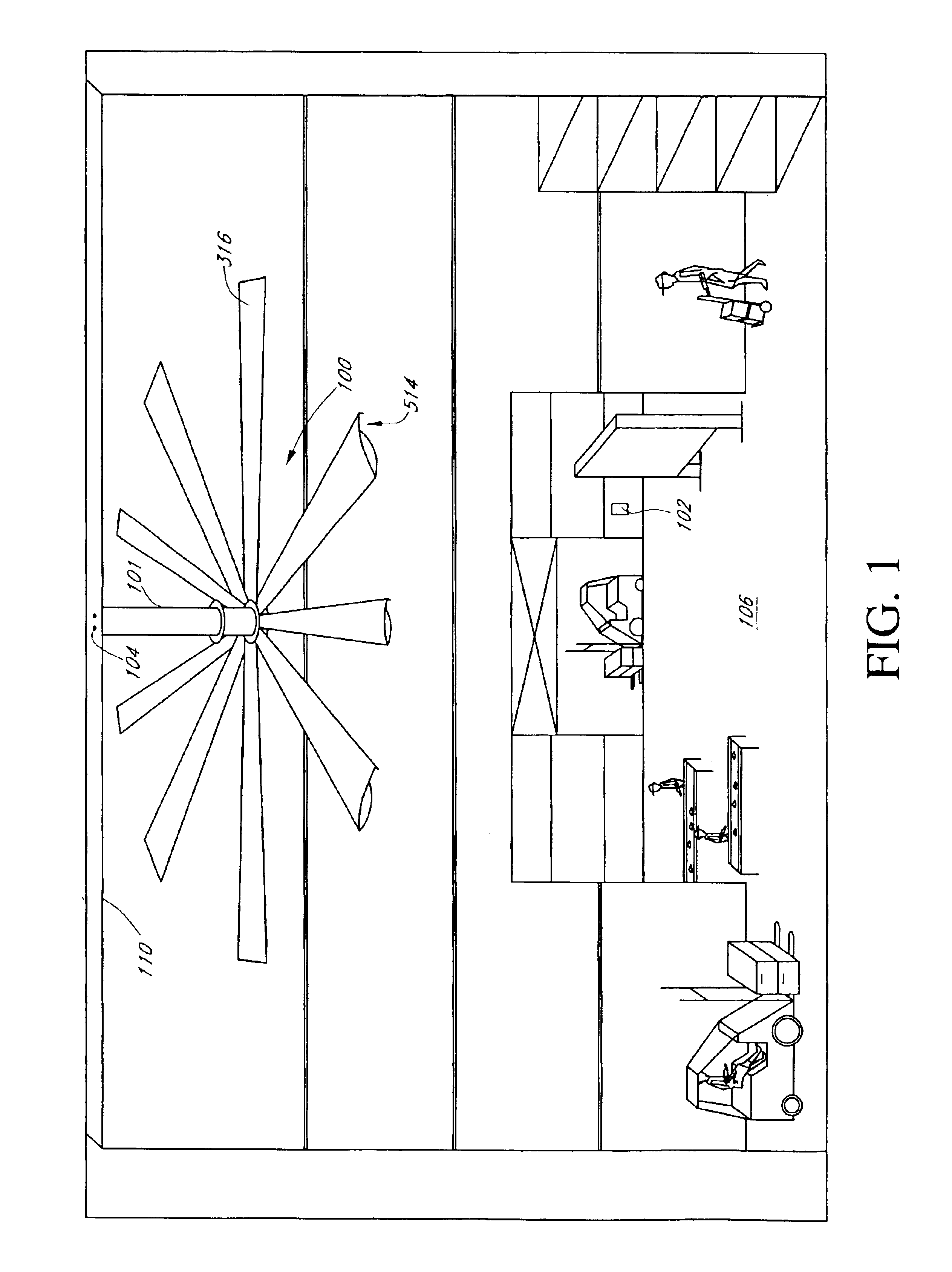

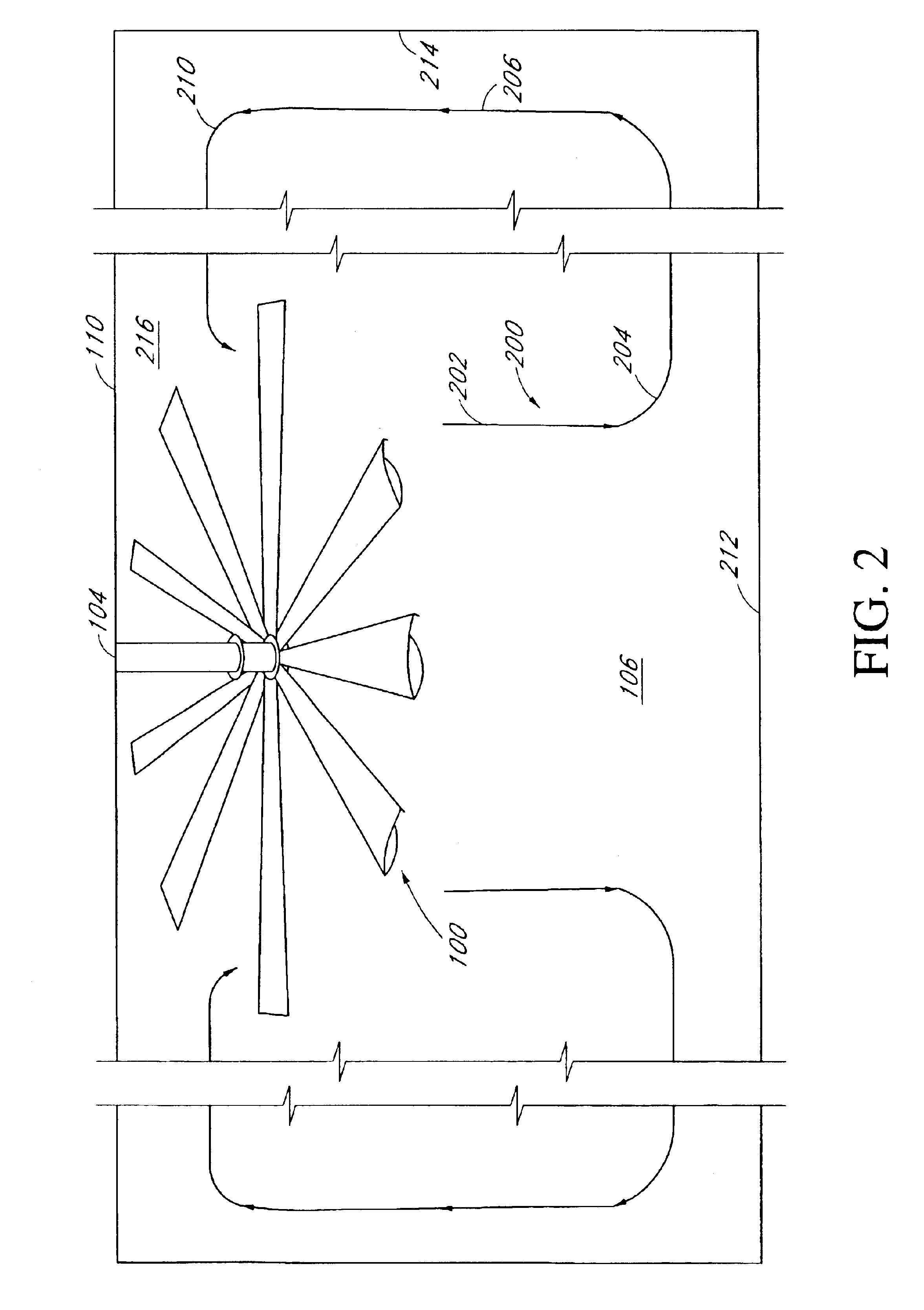

Wind turbine ring/shroud drive system

InactiveUS6951443B1Easy to adaptEliminate structureWind motor controlPump componentsNacelleGear drive

A wind turbine capable of driving multiple electric generators having a ring or shroud structure for reducing blade root bending moments, hub loads, blade fastener loads and pitch bearing loads. The shroud may further incorporate a ring gear for driving an electric generator. In one embodiment, the electric generator may be cantilevered from the nacelle such that the gear on the generator drive shaft is contacted by the ring gear of the shroud. The shroud also provides protection for the gearing and aids in preventing gear lubricant contamination.

Owner:GENERAL ELECTRIC CO

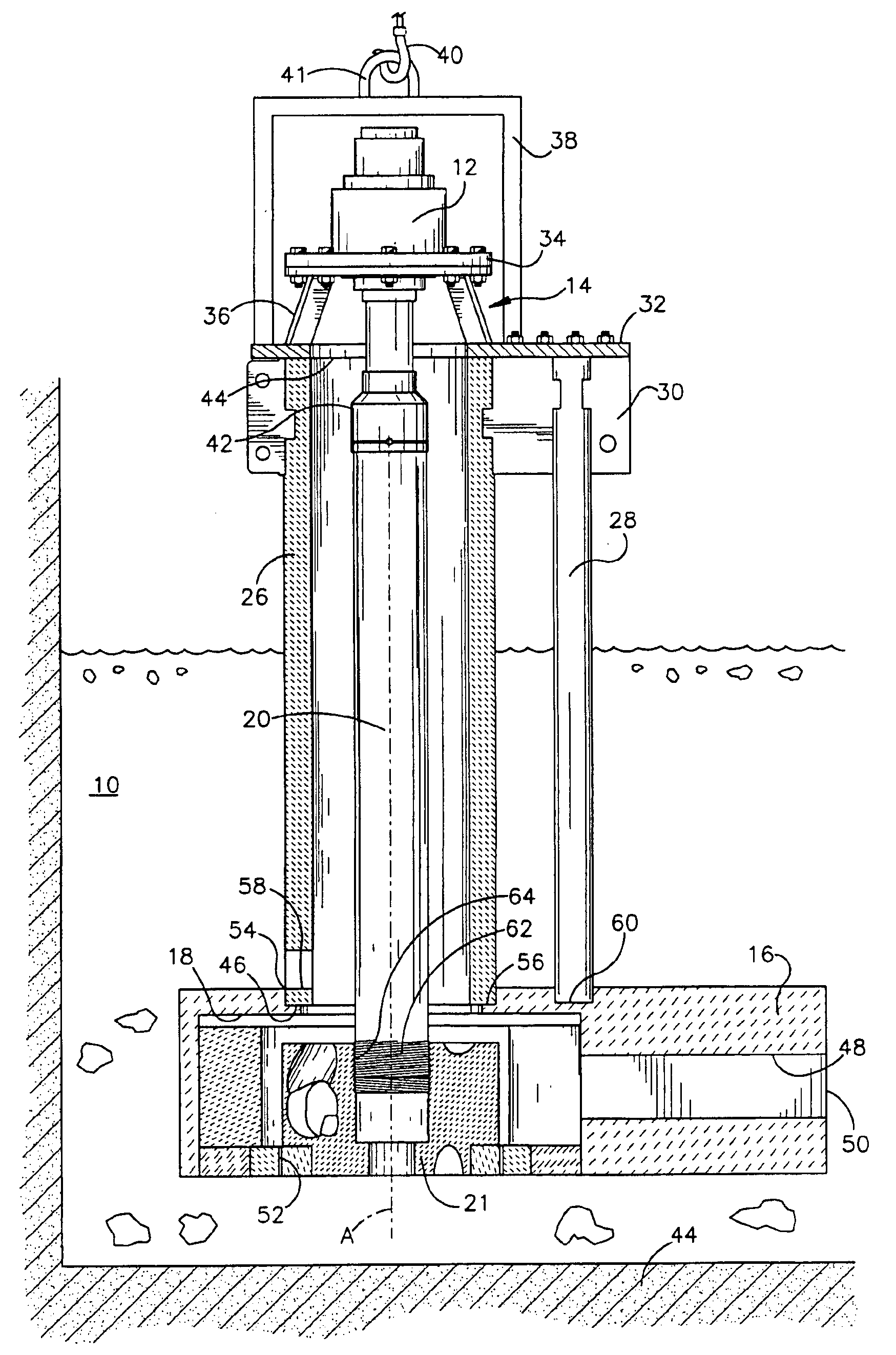

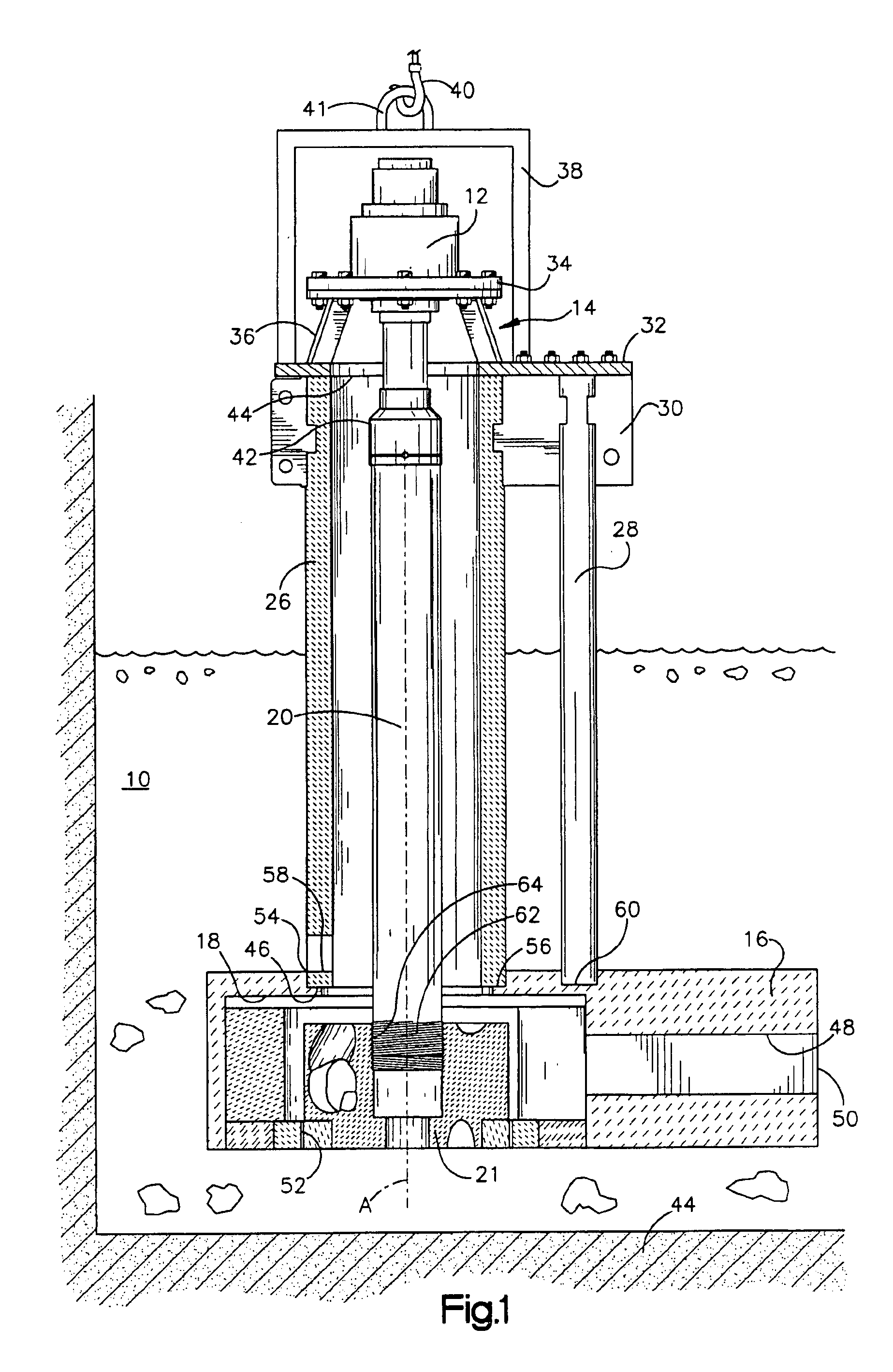

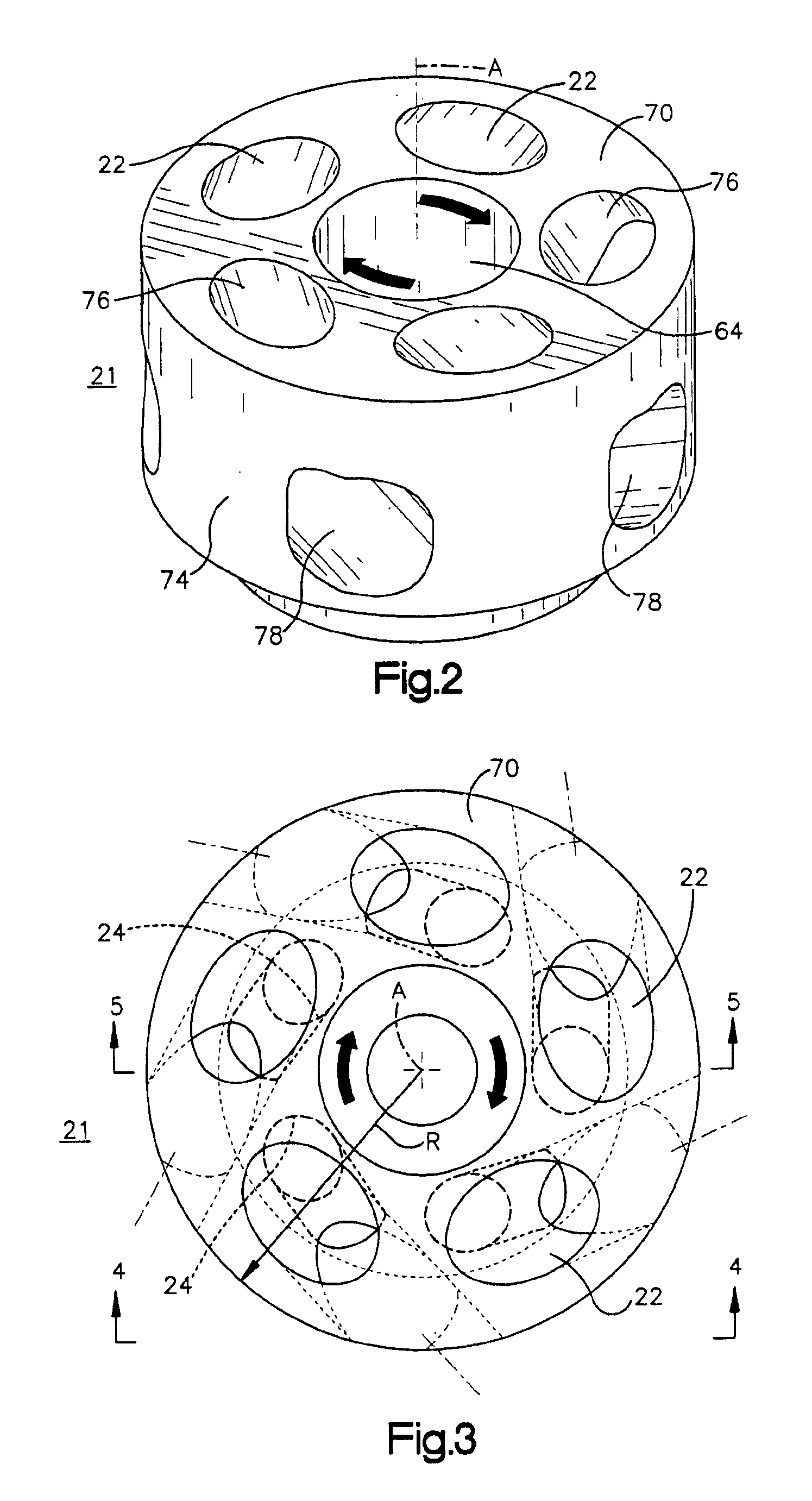

Expandable impeller pump

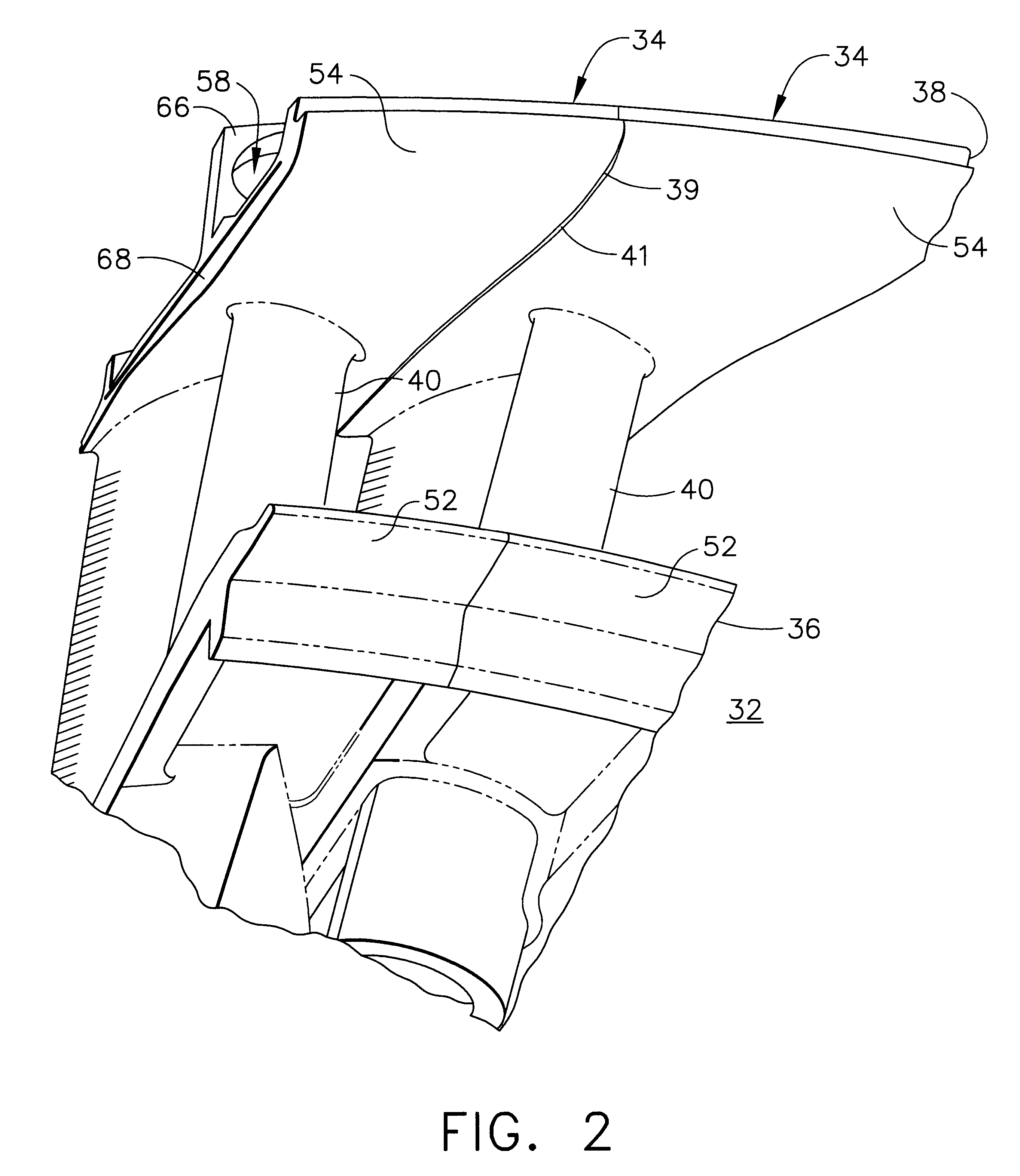

An impeller includes a hub, and a plurality of blades supported by the hub, the blades being arranged in at least two blade rows. The impeller has a deployed configuration in which the blades extend away from the hub, and a stored configuration in which at least one of the blades is radially compressed, for example by folding the blade towards the hub. The impeller may also have an operational configuration in which at least some of the blades are deformed from the deployed configuration upon rotation of the impeller when in the deployed configuration. The outer edge of one or more blades may have a winglet, and the base of the blades may have an associated indentation to facilitate folding of the blades.

Owner:TC1 LLC +2

Impeller assembly for centrifugal pumps

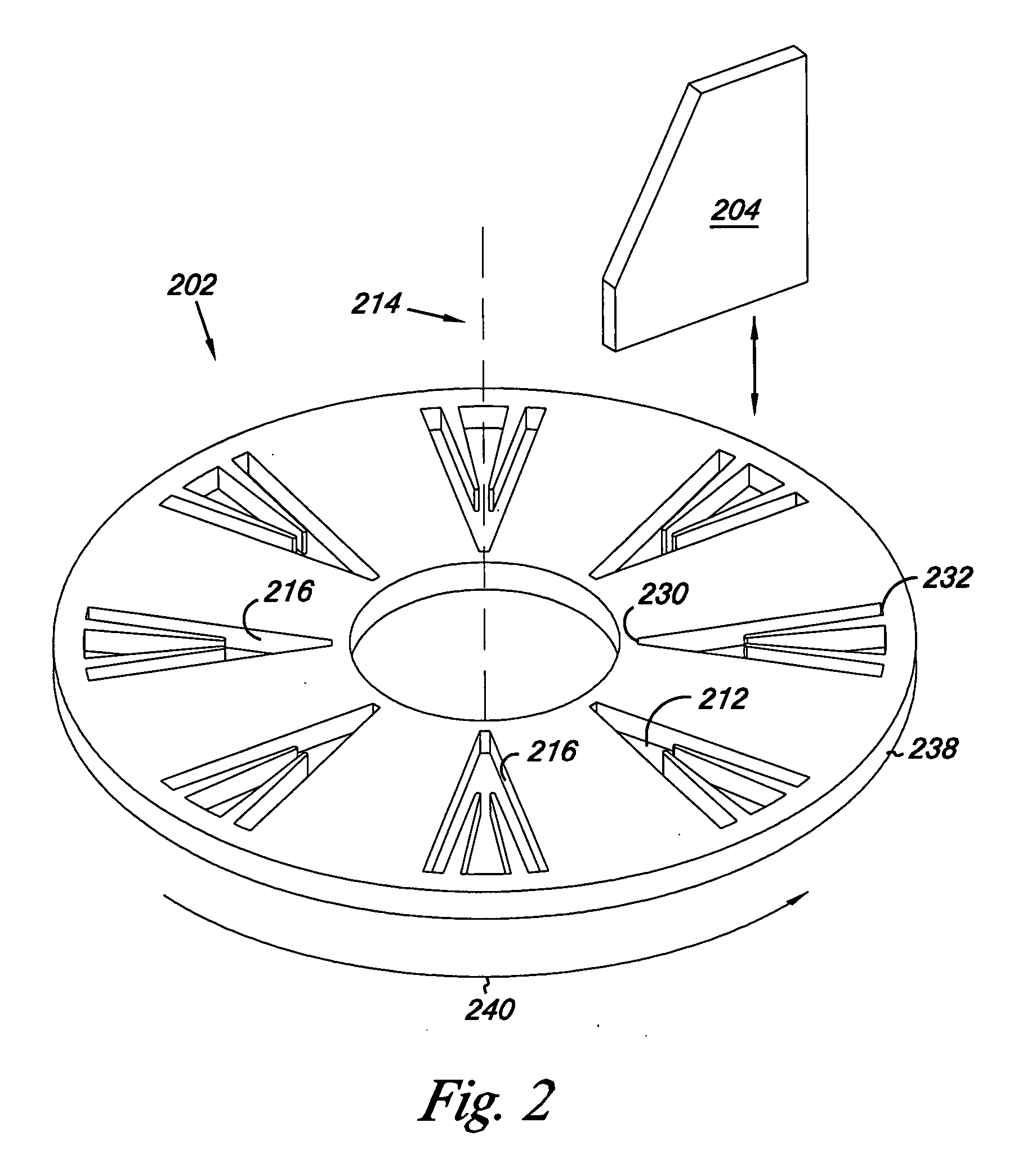

InactiveUS20030231959A1Shorten the time periodExpedite evacuationPropellersRotary propellersEngineeringEye opening

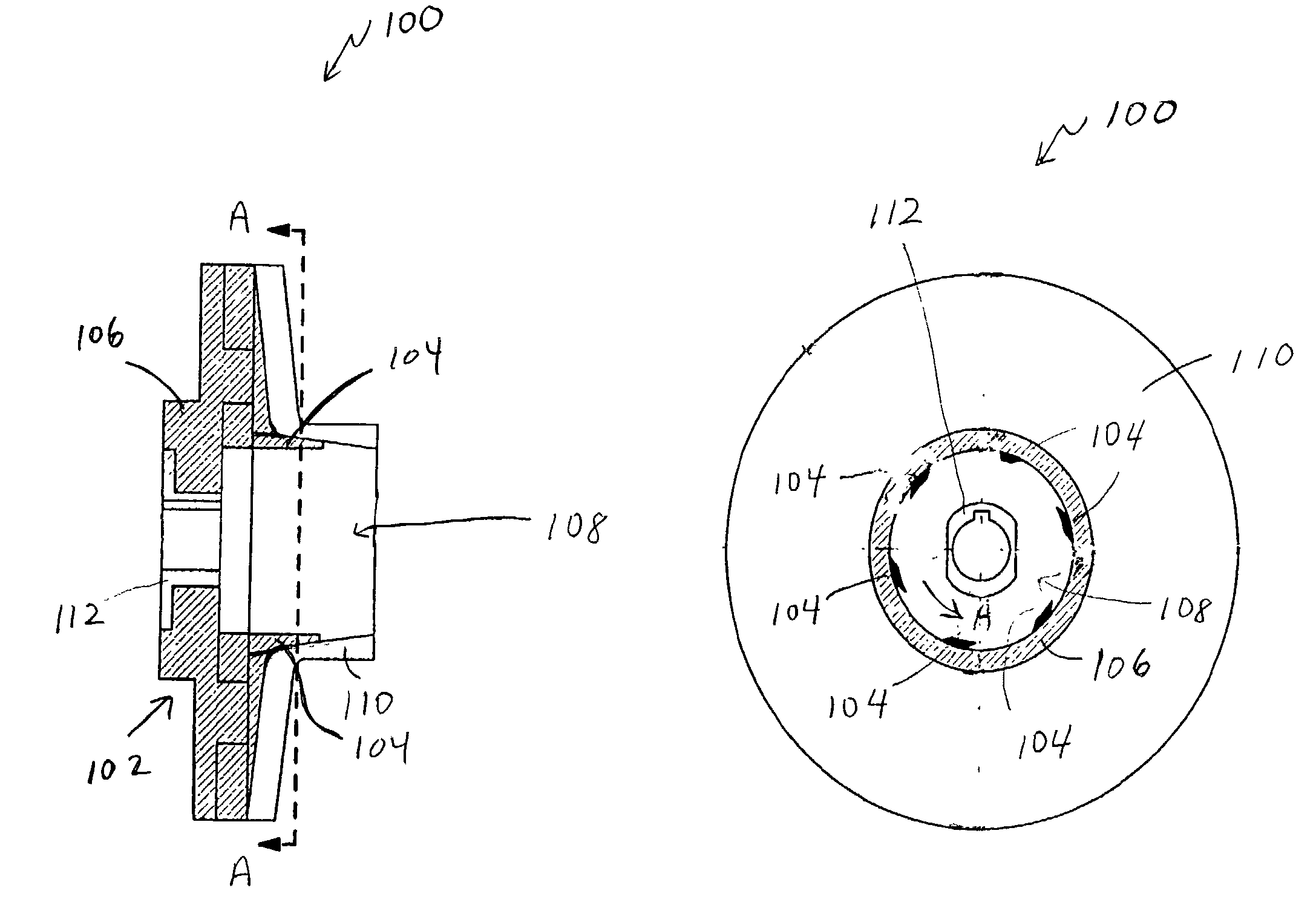

An impeller assembly for centrifugal pumps that enables self-priming in a relatively short time period includes an impeller and at least one winglet (e.g., six winglets with a trapezium cross-sectional shape). The impeller includes an impeller body with an eye opening therein. The eye opening is configured for the passage of a fluid (e.g., water) therethrough when the impeller assembly is in use. The impeller body also includes at least one vane, with a leading end, disposed about the eye opening. The at least one winglet is positioned to protrude into the eye opening of the impeller body and may, for example, be coupled to the leading end of the vane.

Owner:HACKETT WILLIAM FRANKLIN JR

Fan impeller

A fan impeller having fan blades, a base plate, a support ring and fasteners to releasably hold the fan blades between the base plate and the support ring. The base a plate includes channels each having two or more sockets that receive and releasably seat at least a portion of the fan blade. The position of the fan blade relative the axis of rotation of the impeller can be selected from the two or more sockets. The support ring includes grooves in which at least a portion of the fan blade releasably seats to hold the fan blades static relative the base plate and the support ring. The fasteners can extend between the base plate and the support ring to releasably hold the two or more blades.

Owner:KURZ KASCH

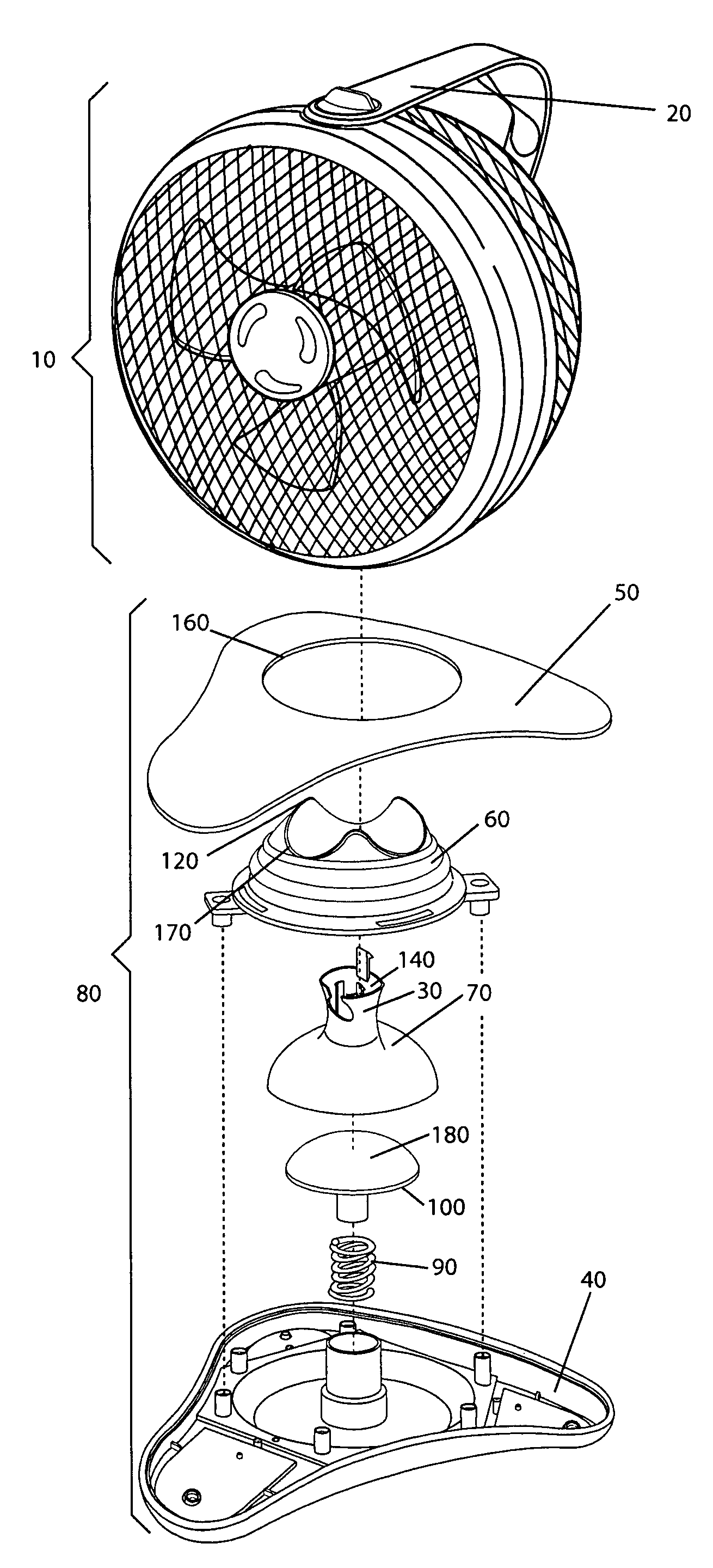

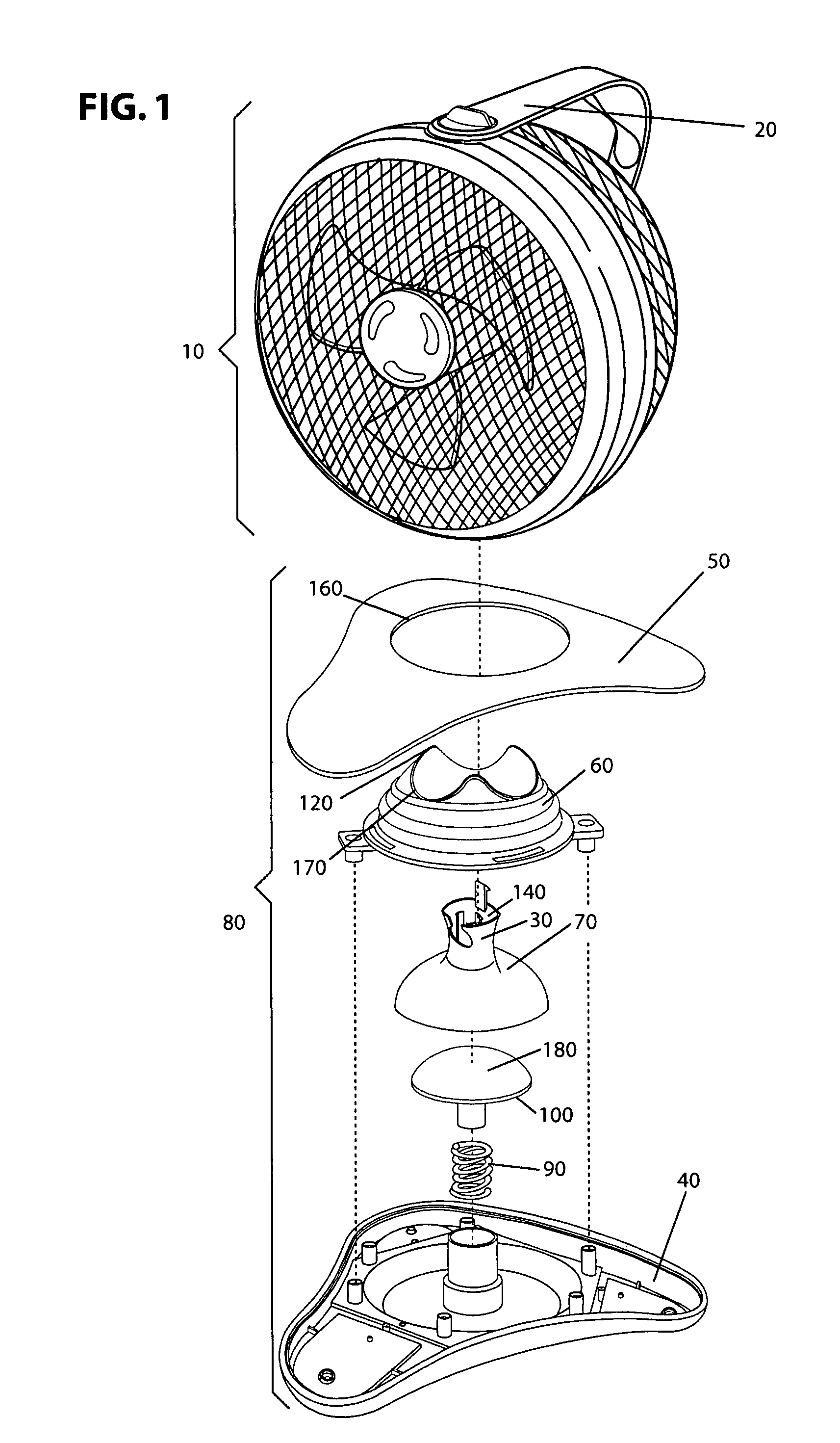

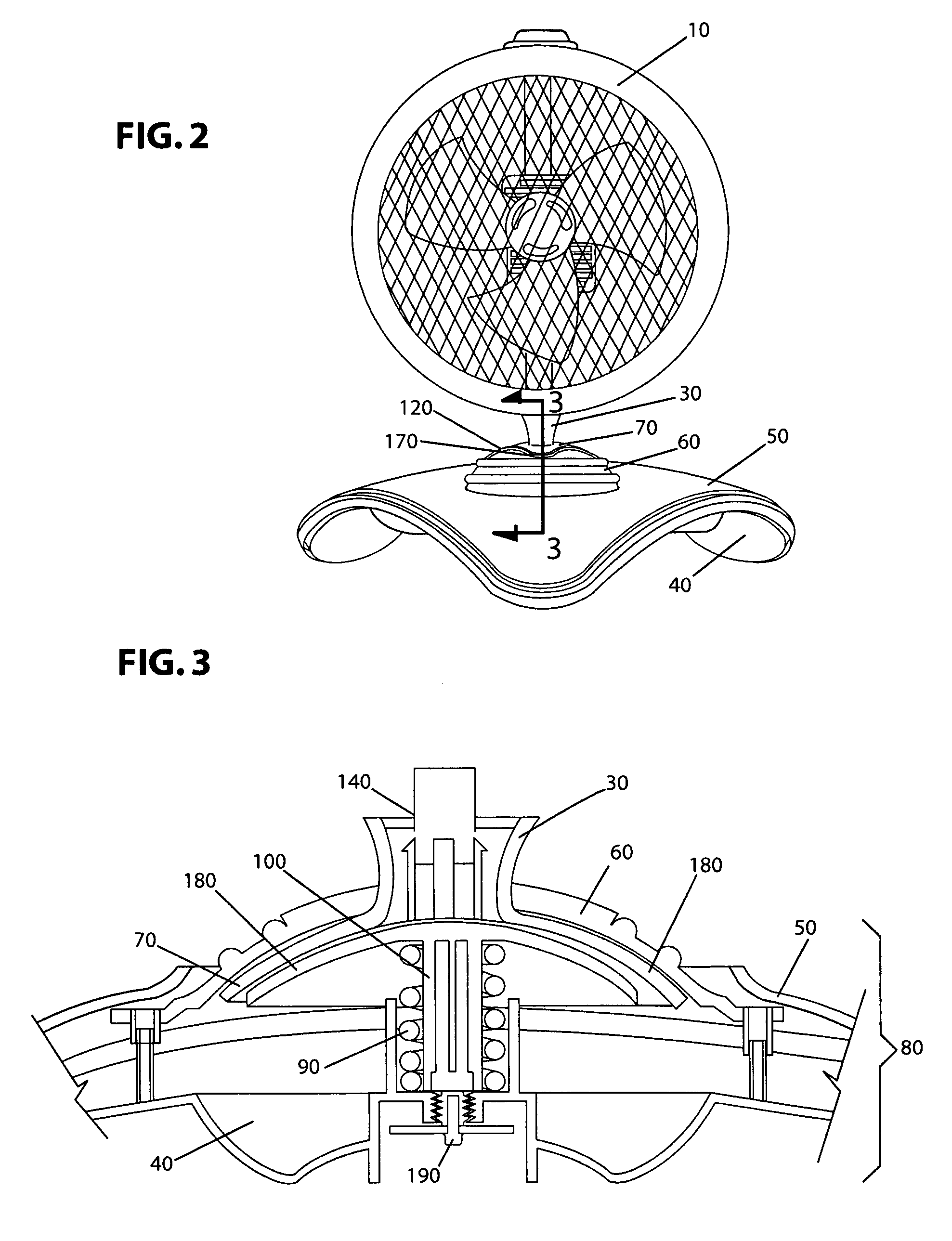

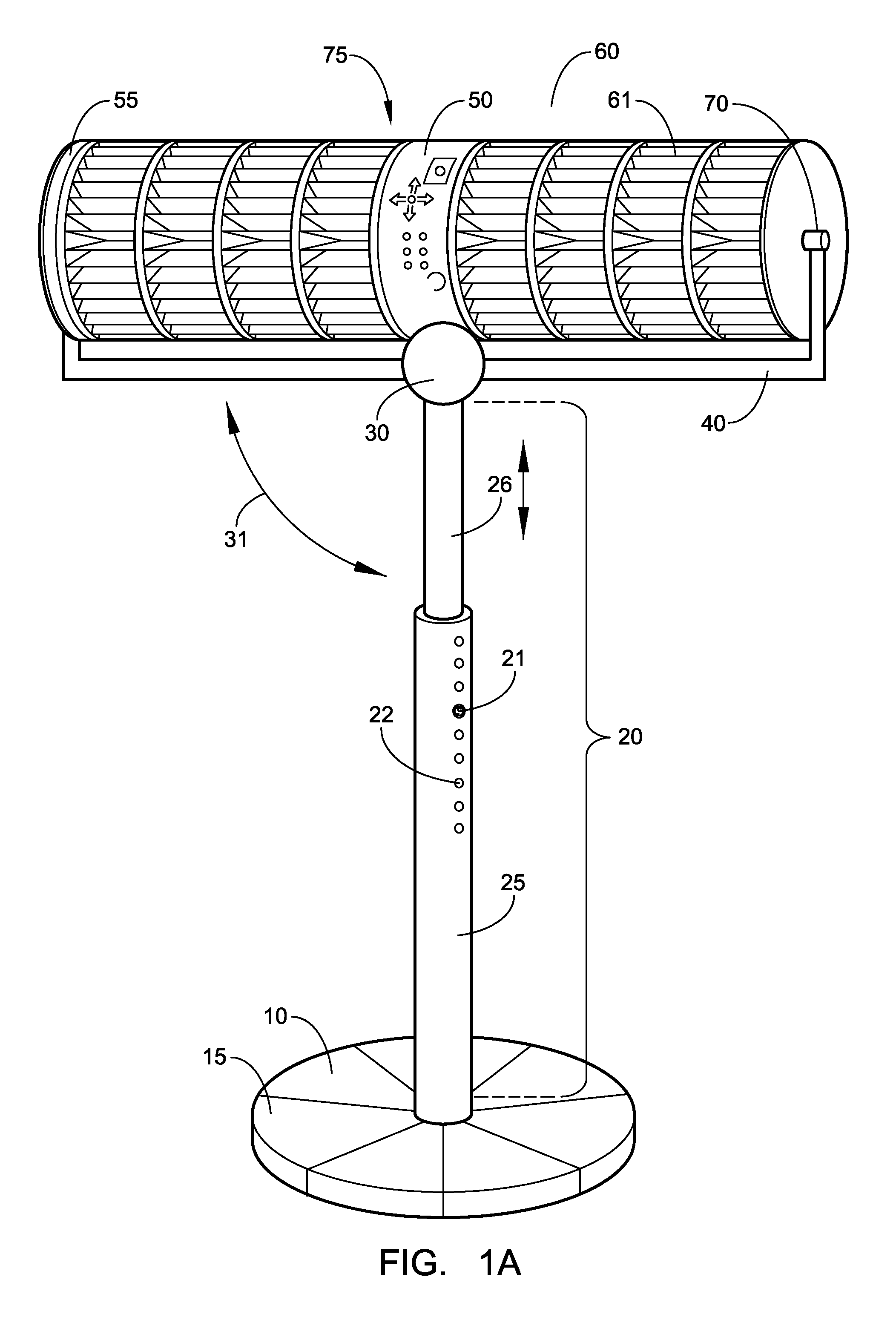

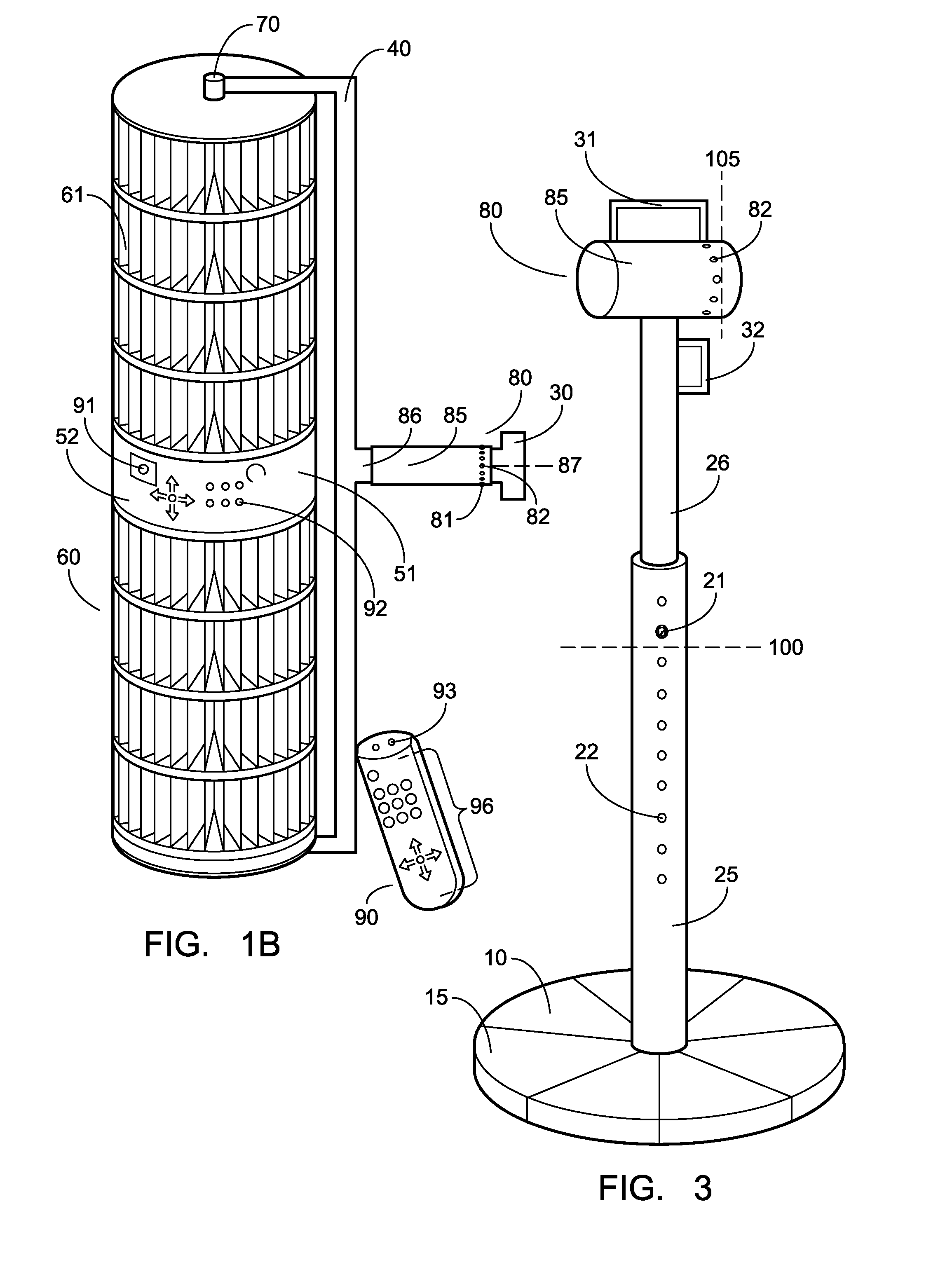

Rotatable pivot mount for fans and other appliances

ActiveUS20070166160A1Easy to adjustAccurate directionPropellersPump componentsThree degrees of freedomEngineering

A pivot assembly that can be used with various appliances. The pivot assembly provides up to three degrees of freedom when positioning the appliance. The pivot may be used, for example, with a fan that is mounted on a base such that direction of the airflow generated can be adjusted about three coordinate axes by manipulating a single rotatable pivot mount. The fan assembly includes a base unit and an arm to which an appliance may be detachably coupled. The opposite end of the arm is provided with a spherical cap which is received by the base unit. Any adjustments to the positioning of the rotatable pivot mount are maintained by the friction within the rotatable pivot mount. Additionally, the pivot mount may include a pivot guide to restrict the degree of rotation about the pivot, thereby increasing stability.

Owner:HELEN OF TROY LIMITED

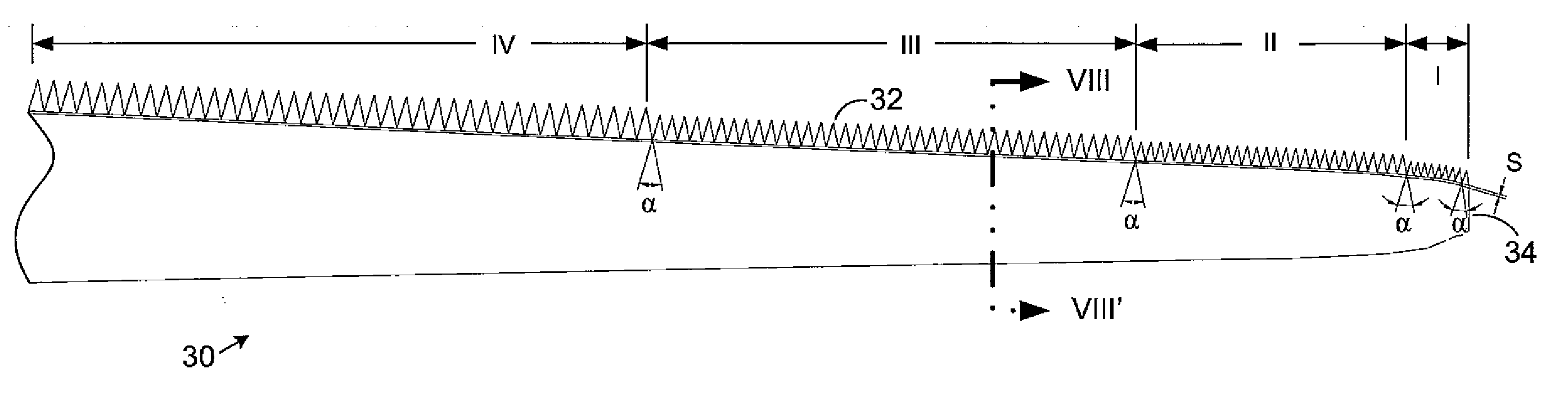

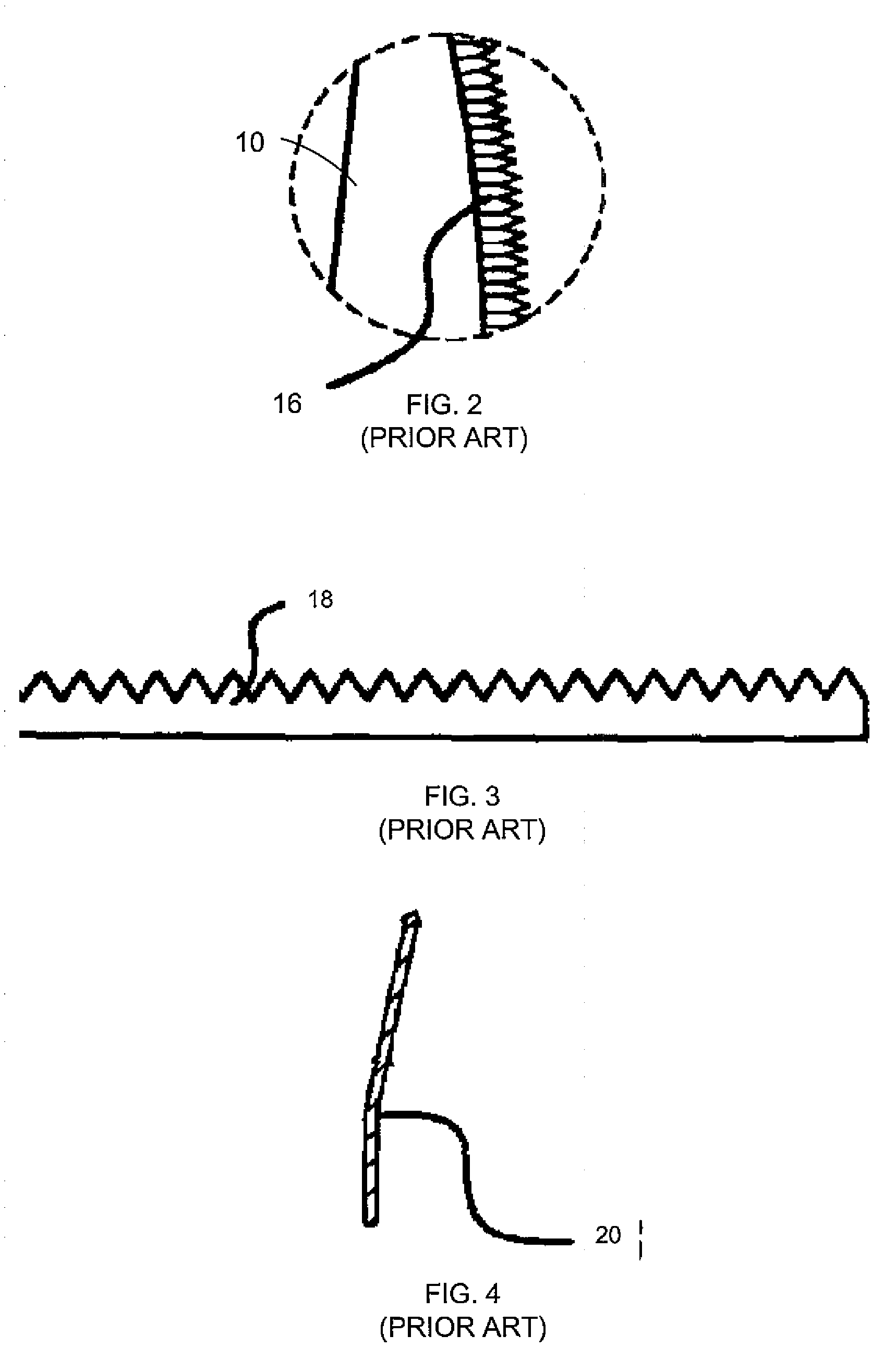

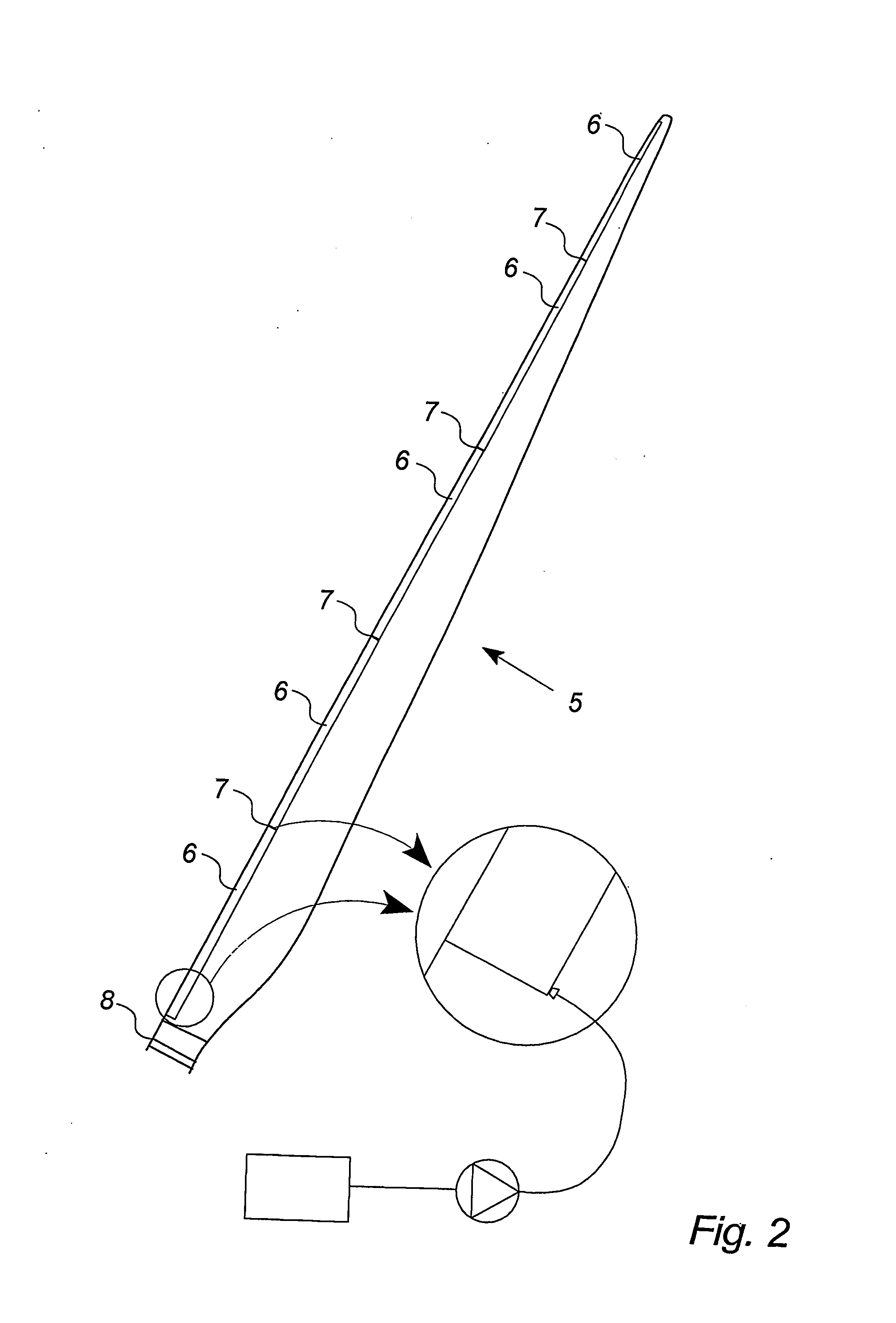

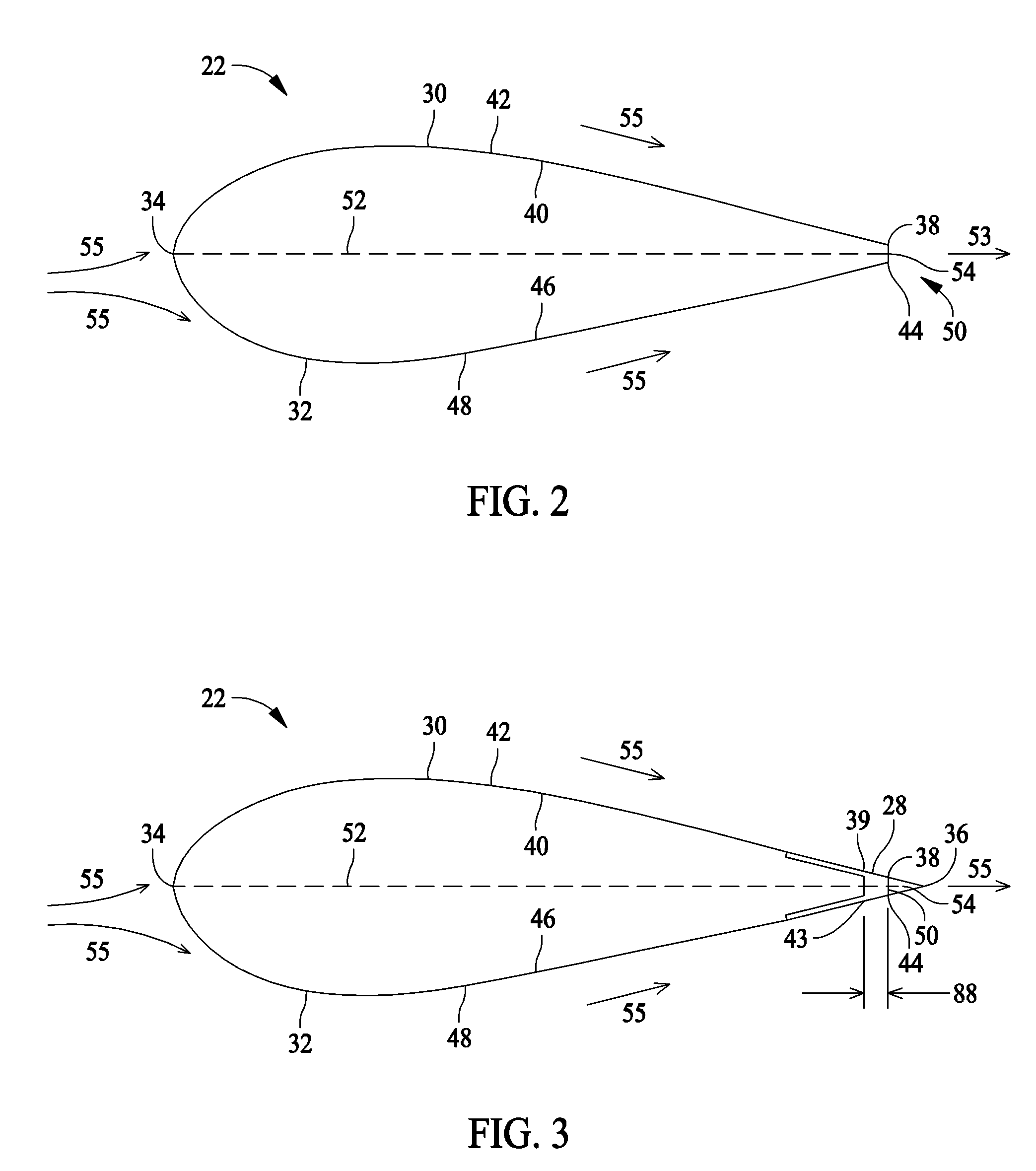

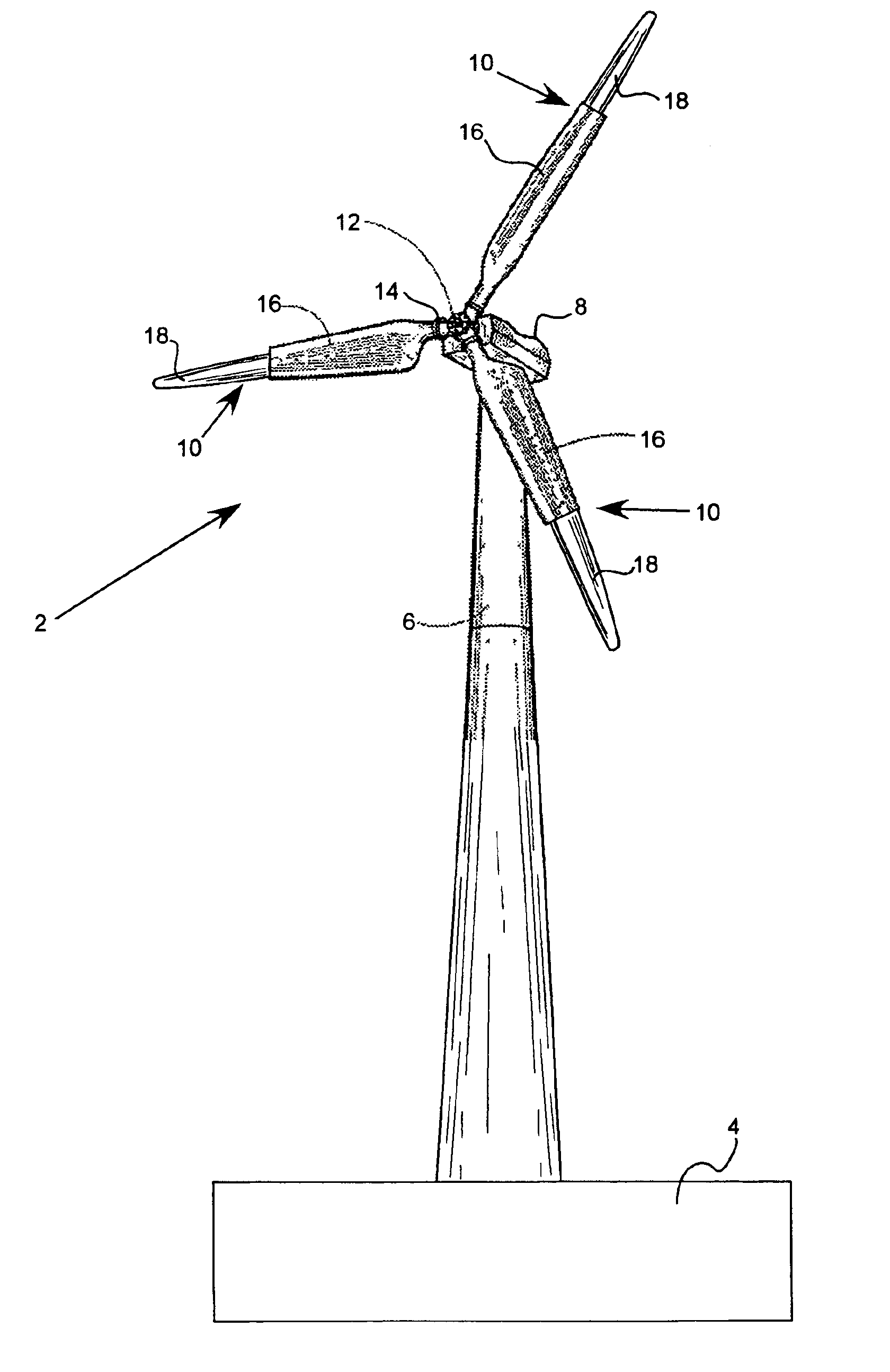

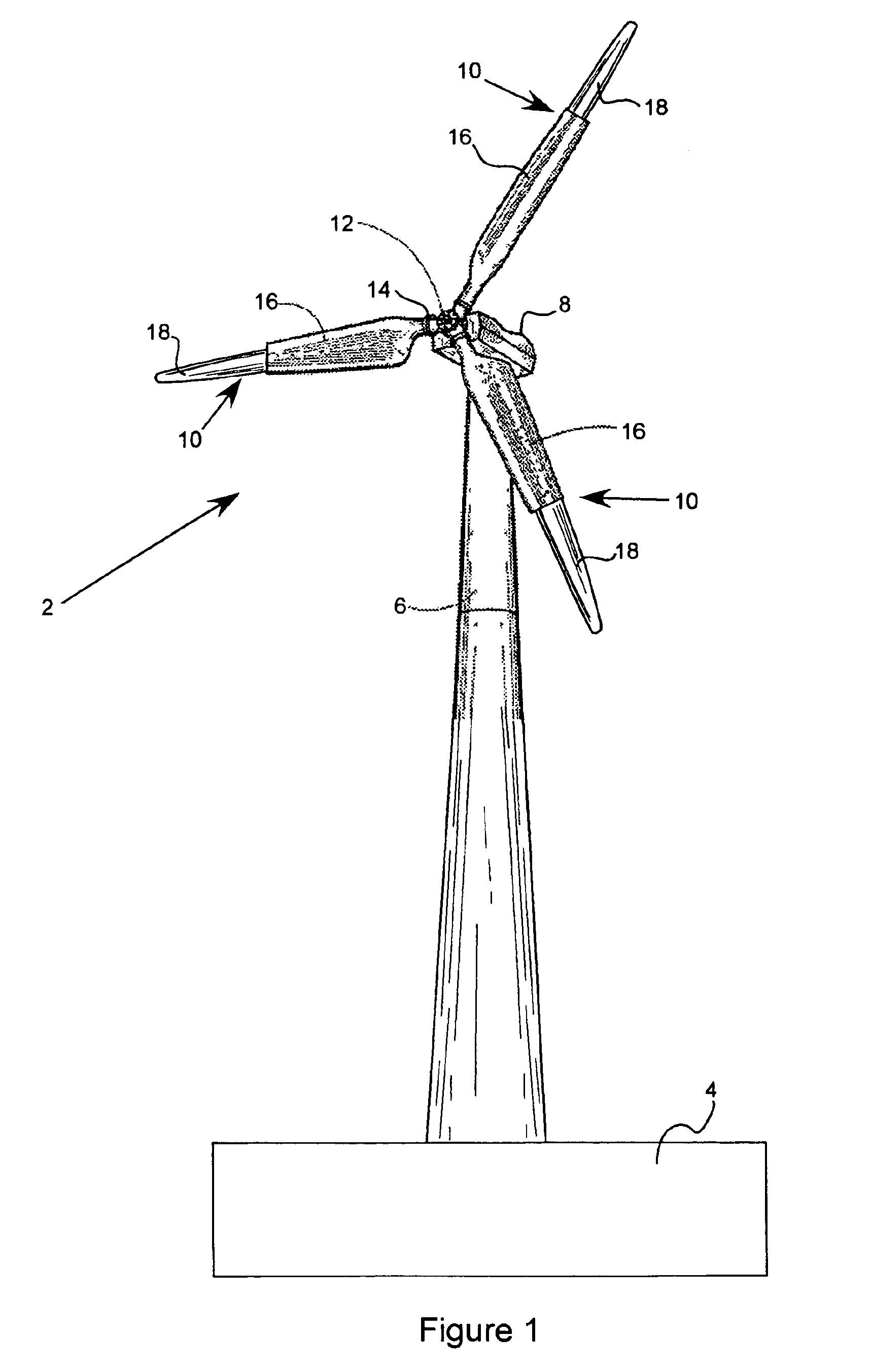

Wind turbine blades with trailing edge serrations

A wind generator and turbine blade includes a trailing edge having several serrations, a length of the serrations in each of a plurality of sections of the trailing edge is between approximately 10% and 40% of a mean chord for the corresponding section; and a length to width ratio of each of the serrations is between approximately 1:1 to 4:1.

Owner:GENERAL ELECTRIC CO

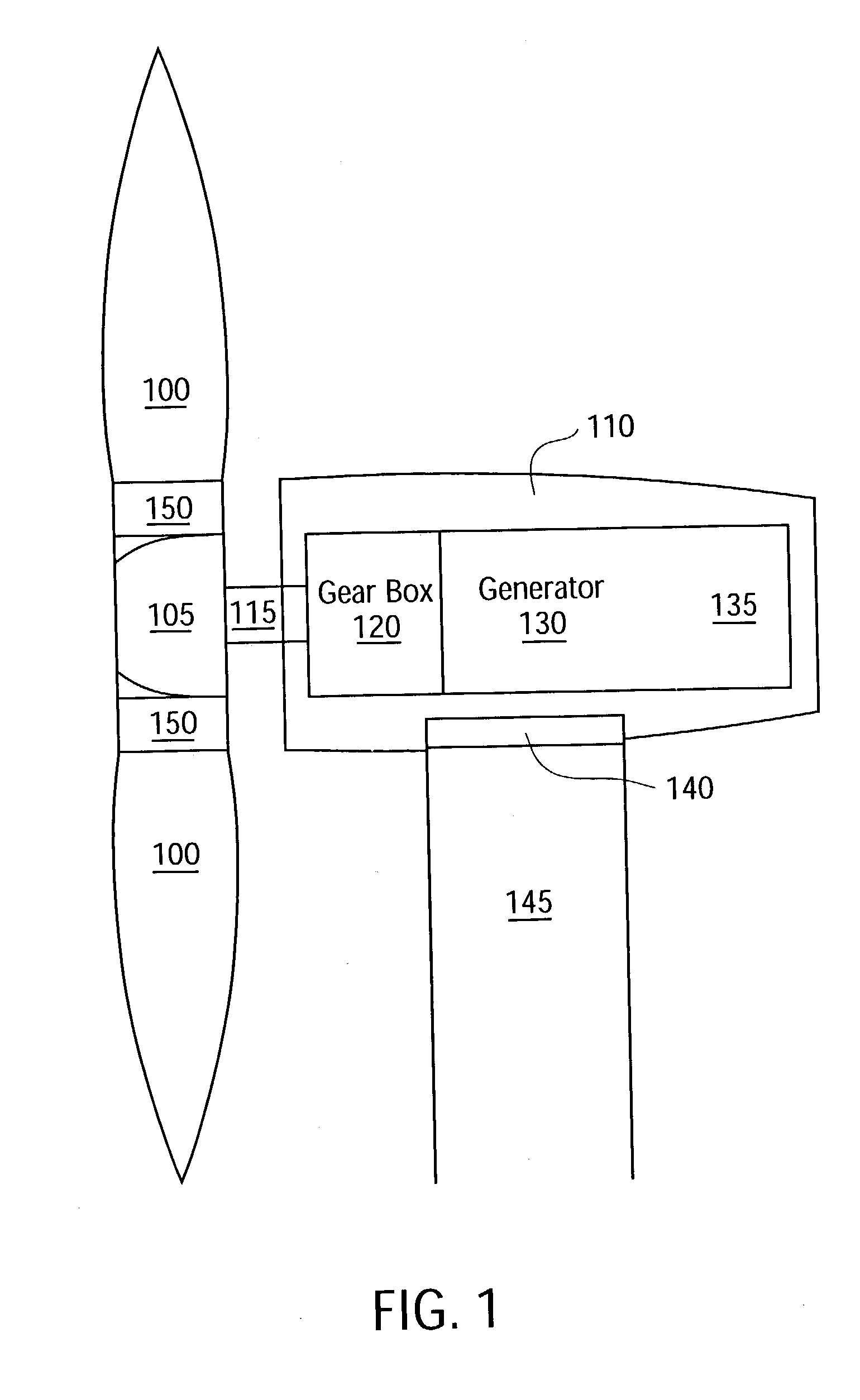

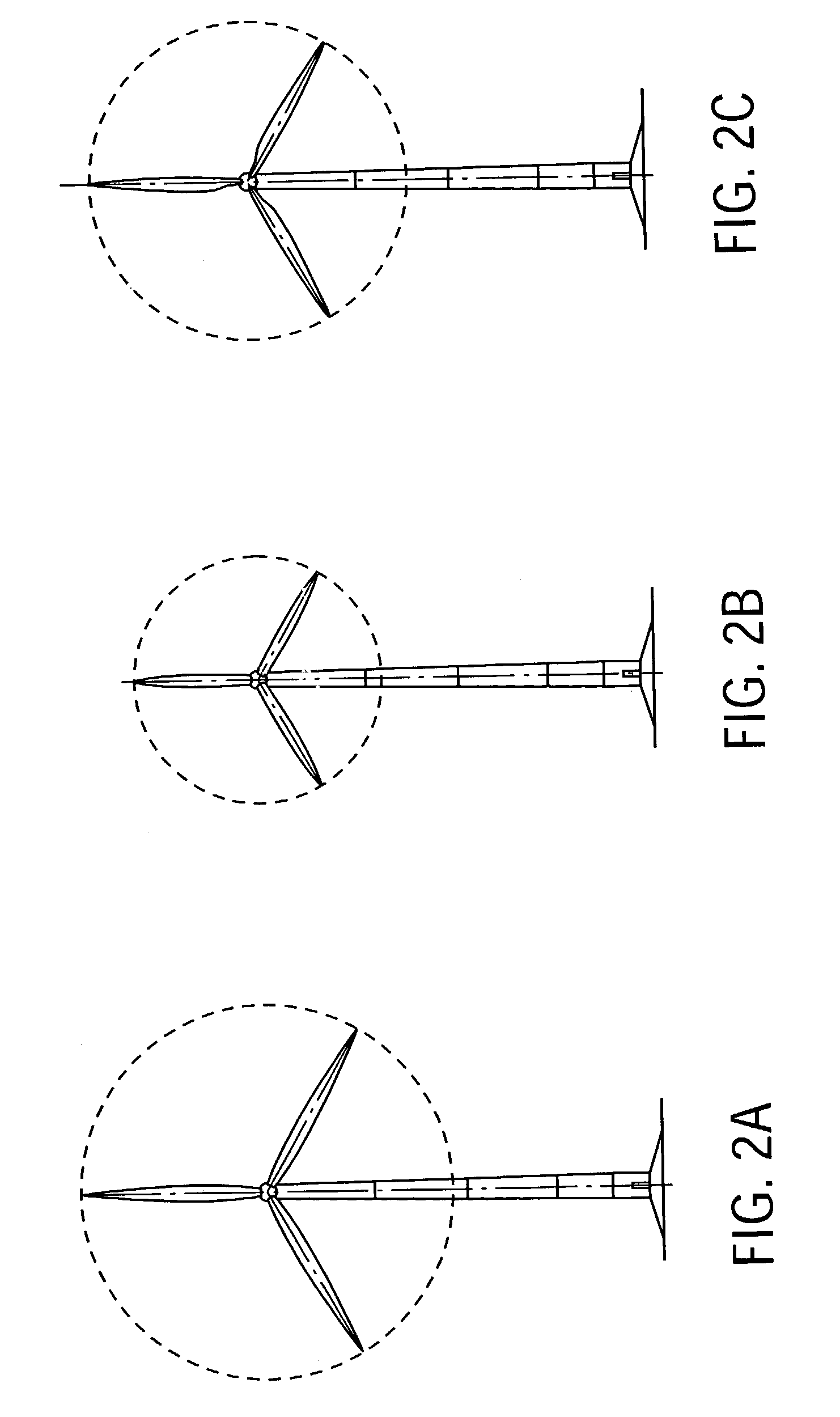

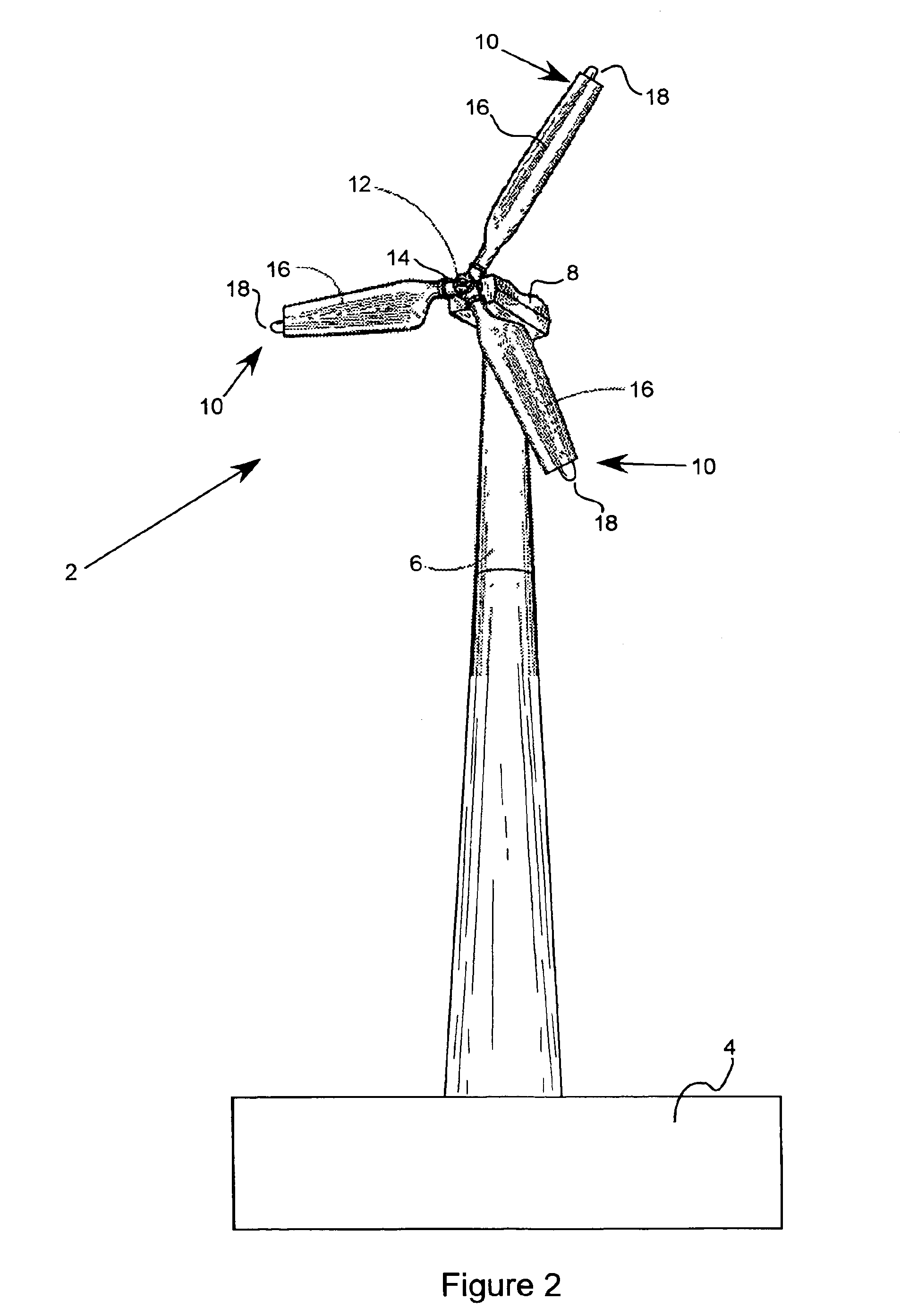

Variable diameter wind turbine rotor blades

A system and method for changing wind turbine rotor diameters to meet changing wind speeds and control system loads is disclosed. The rotor blades on the wind turbine are able to adjust length by extensions nested within or containing the base blade. The blades can have more than one extension in a variety of configurations. A cable winching system, a hydraulic system, a pneumatic system, inflatable or elastic extensions, and a spring-loaded jack knife deployment are some of the methods of adjustment. The extension is also protected from lightning by a grounding system.

Owner:GENERAL ELECTRIC CO

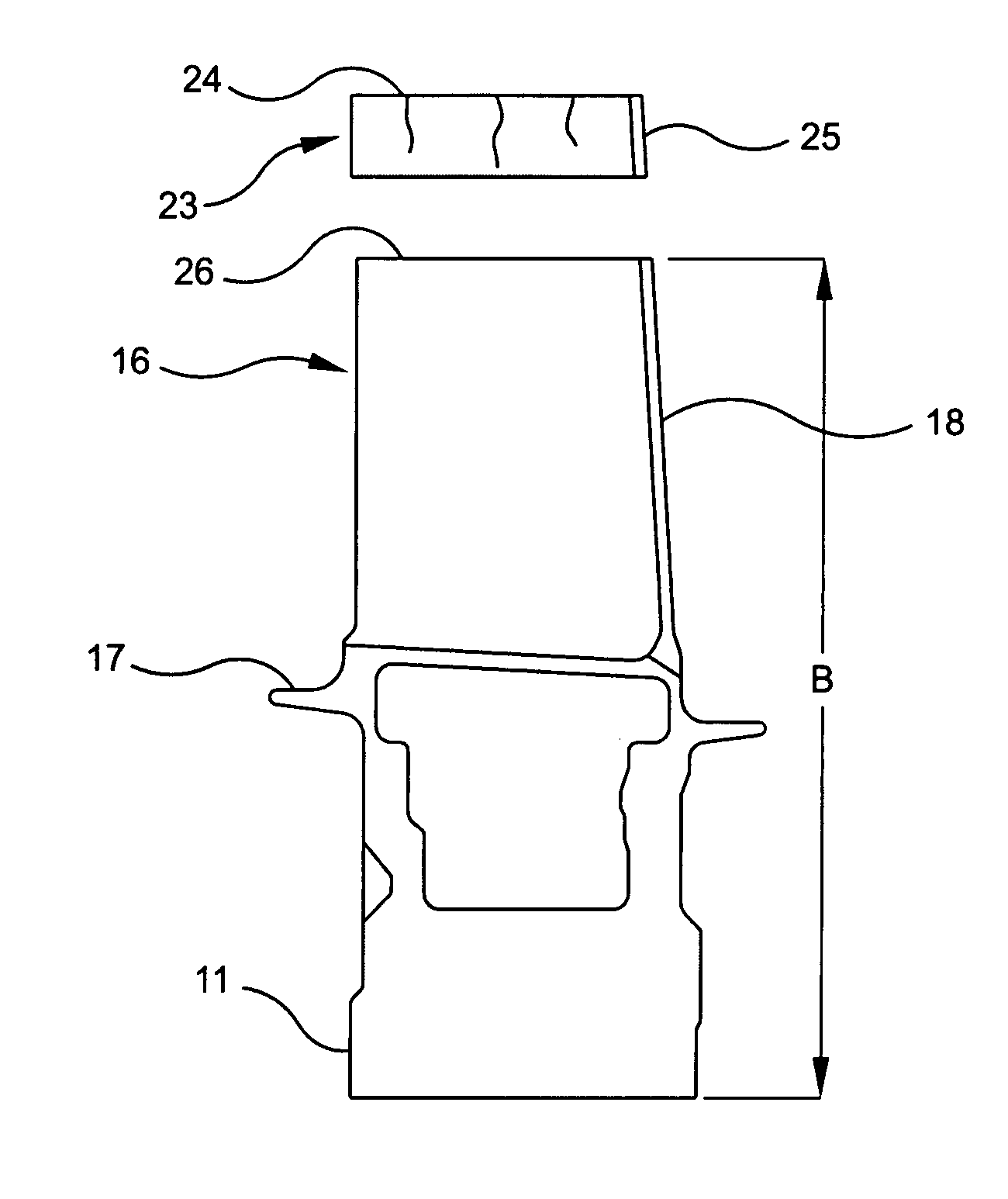

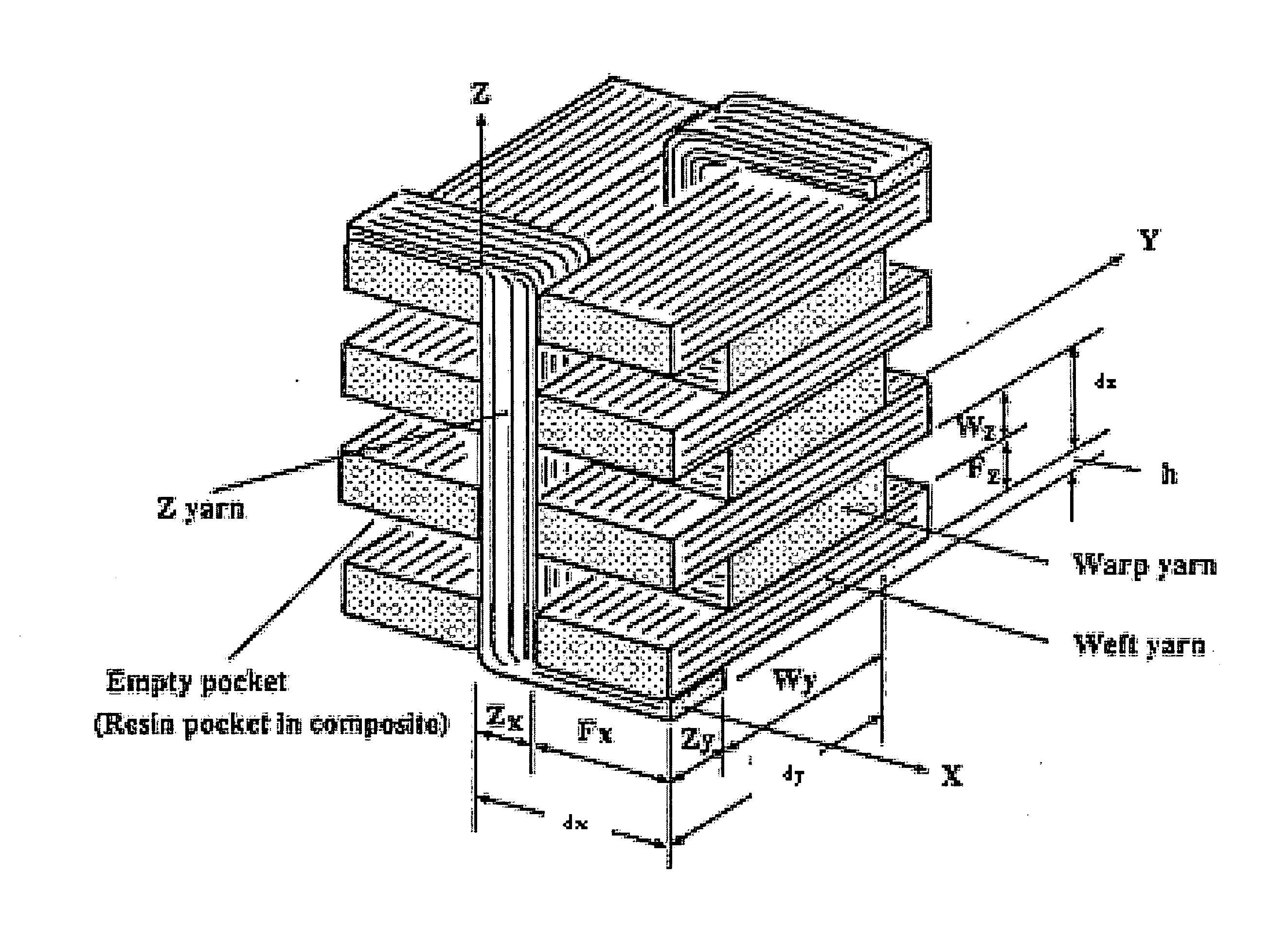

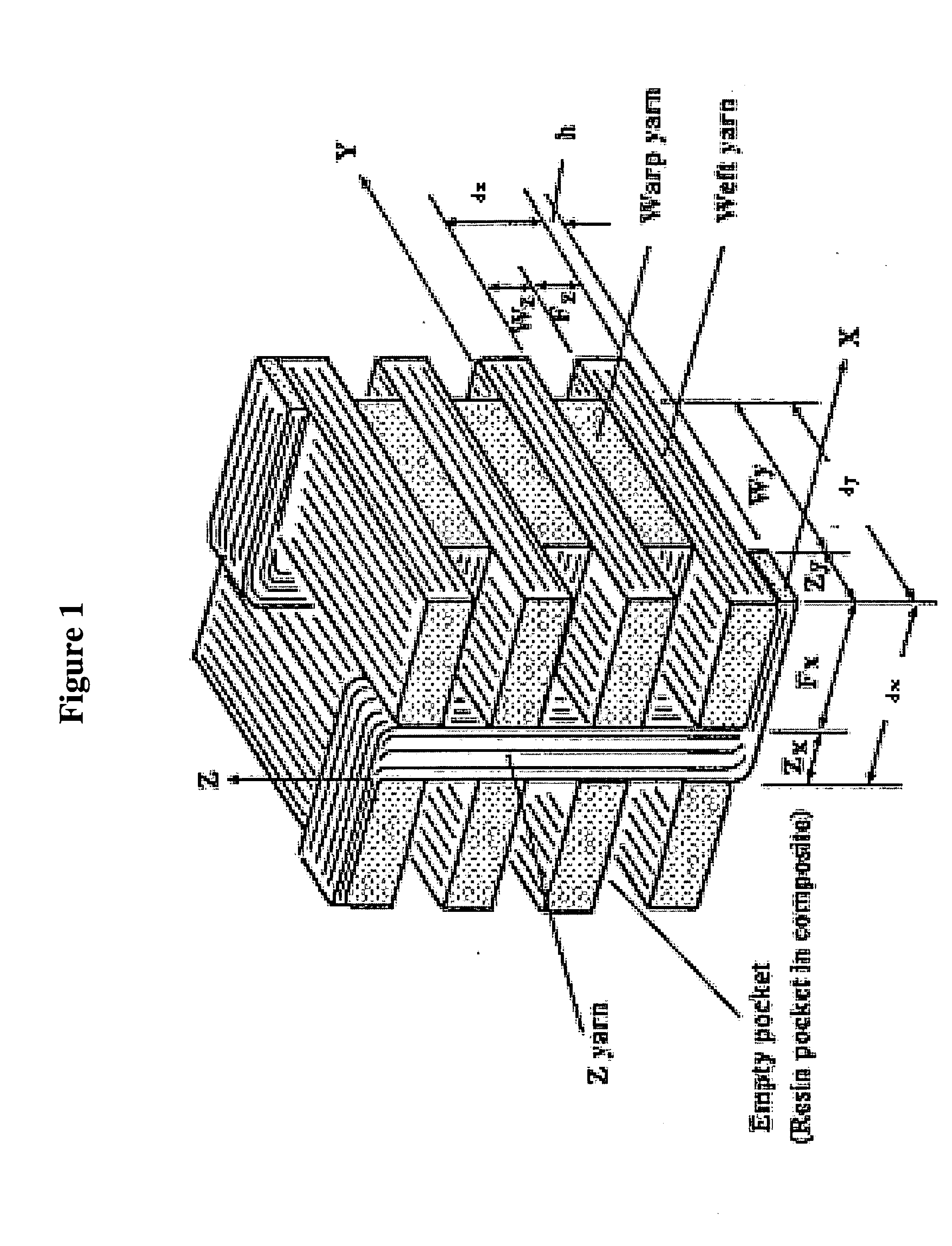

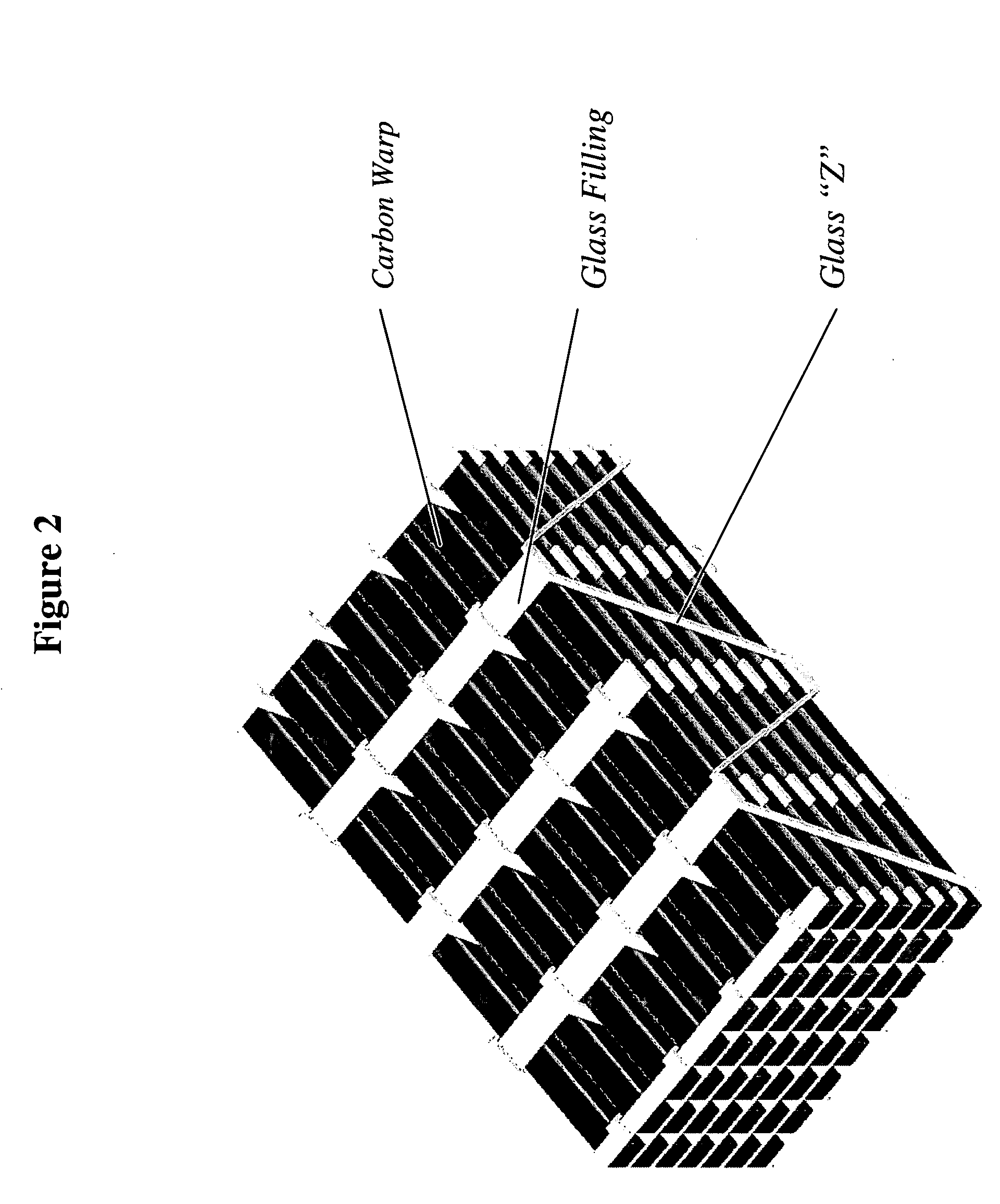

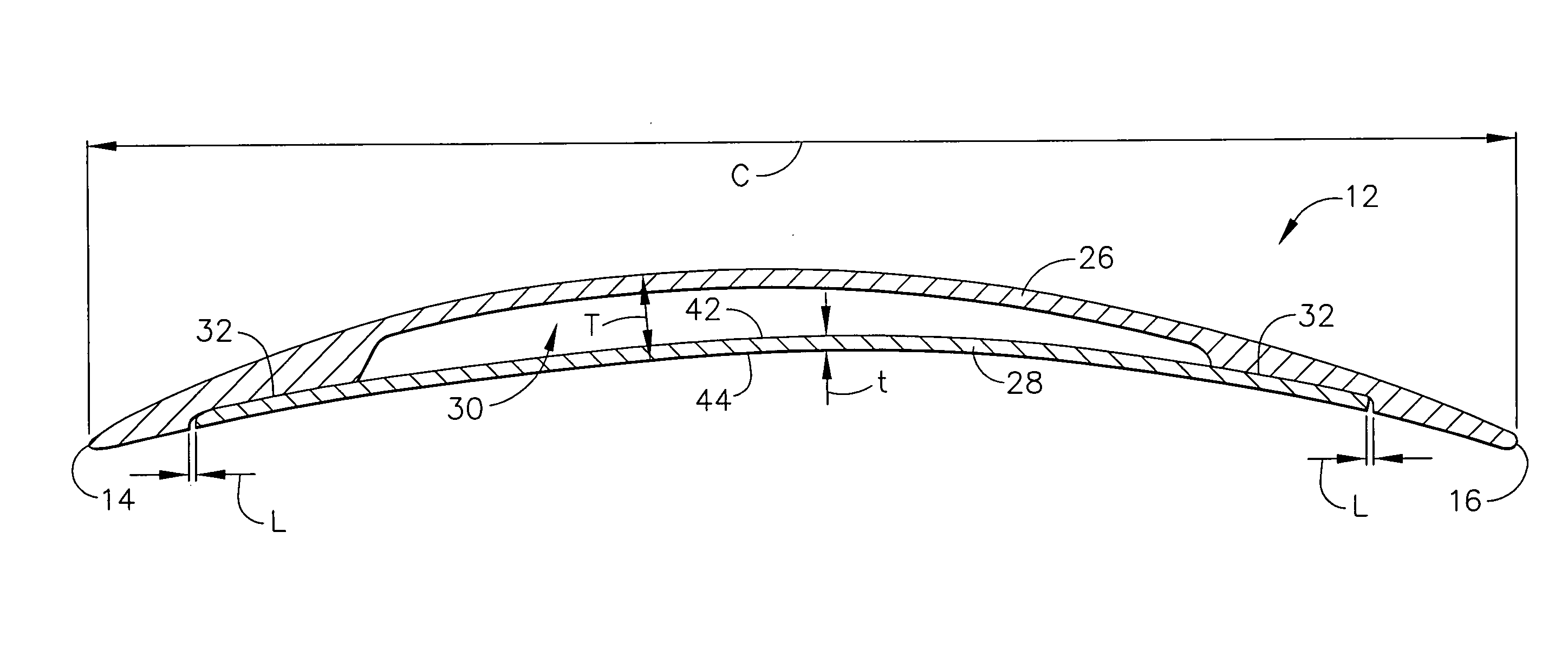

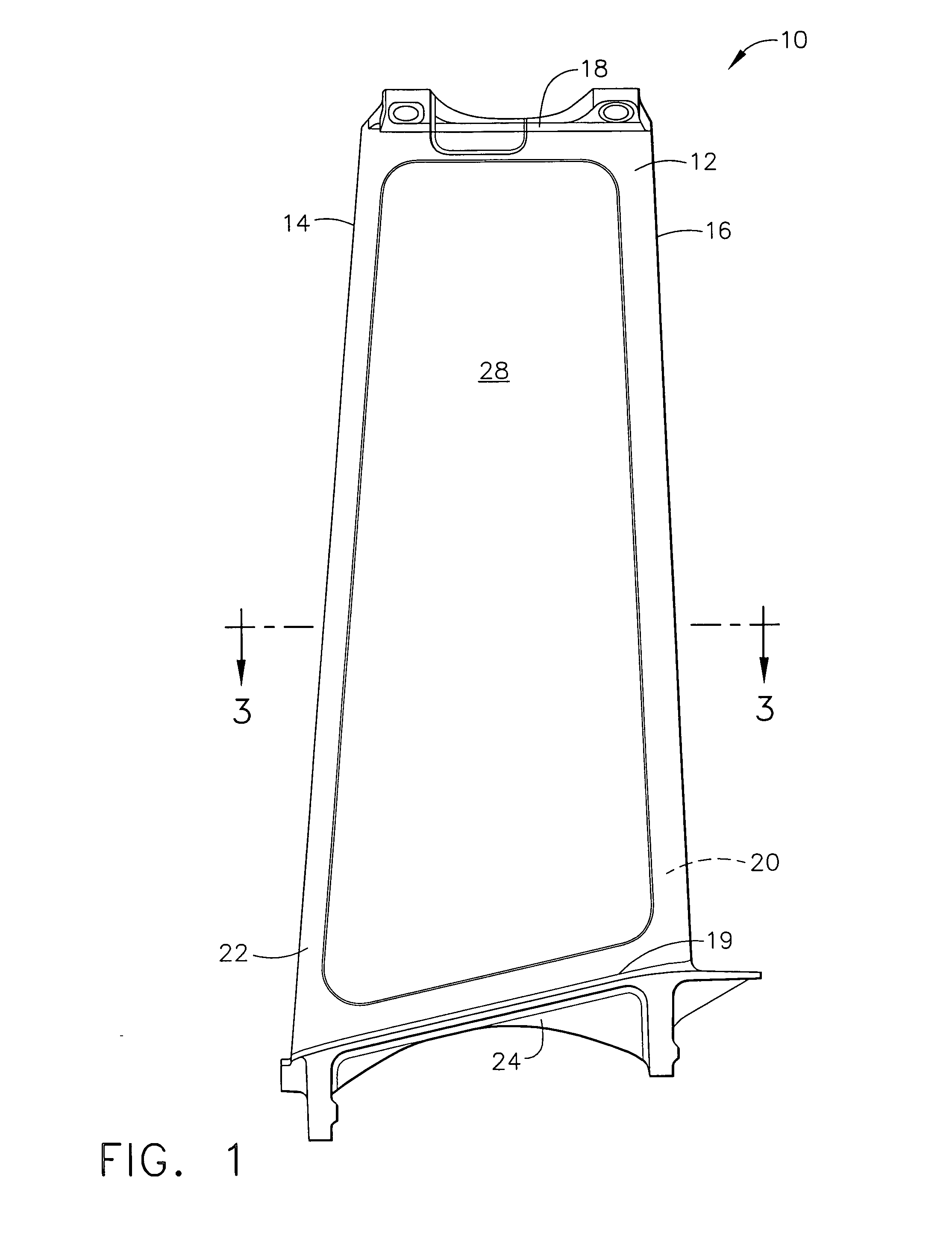

Turbomachine blade, in particular a fan blade, and its method of manufacture

The composite turbomachine blade of the present invention comprises a preform made of yarns or fibers woven in three dimensions and a binder maintaining the relative disposition between the yarns of the preform. Said preform is made up of warp yarns and of weft yarns, the direction of the warp yarns forming the longitudinal direction of the preform. In characteristic manner, said preform comprises at least a first portion made using a first weave forming the airfoil of the blade, and a second portion made using a second weave forming the root of the blade, and the first and second portions are united by a transition zone in which the first weave is progressively modified to end up with the second weave, thereby obtaining a reduction at least in the thickness of the blade between the second portion and the first portion. The invention is applicable to making a fan blade for a turbojet.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Fan assembly

ActiveUS20100226750A1Optimize locationTravel efficientlyPropellersPump componentsEngineeringGravity center

A fan assembly for creating an air current includes an air outlet mounted on a stand. The stand includes a base and a body tiltable relative to the base. The fan assembly has a centre of gravity located so that when the base is located on a substantially horizontal support surface, the projection of the centre of gravity on the support surface is within the footprint of the base when the body is in a fully tilted position.

Owner:DYSON TECH LTD

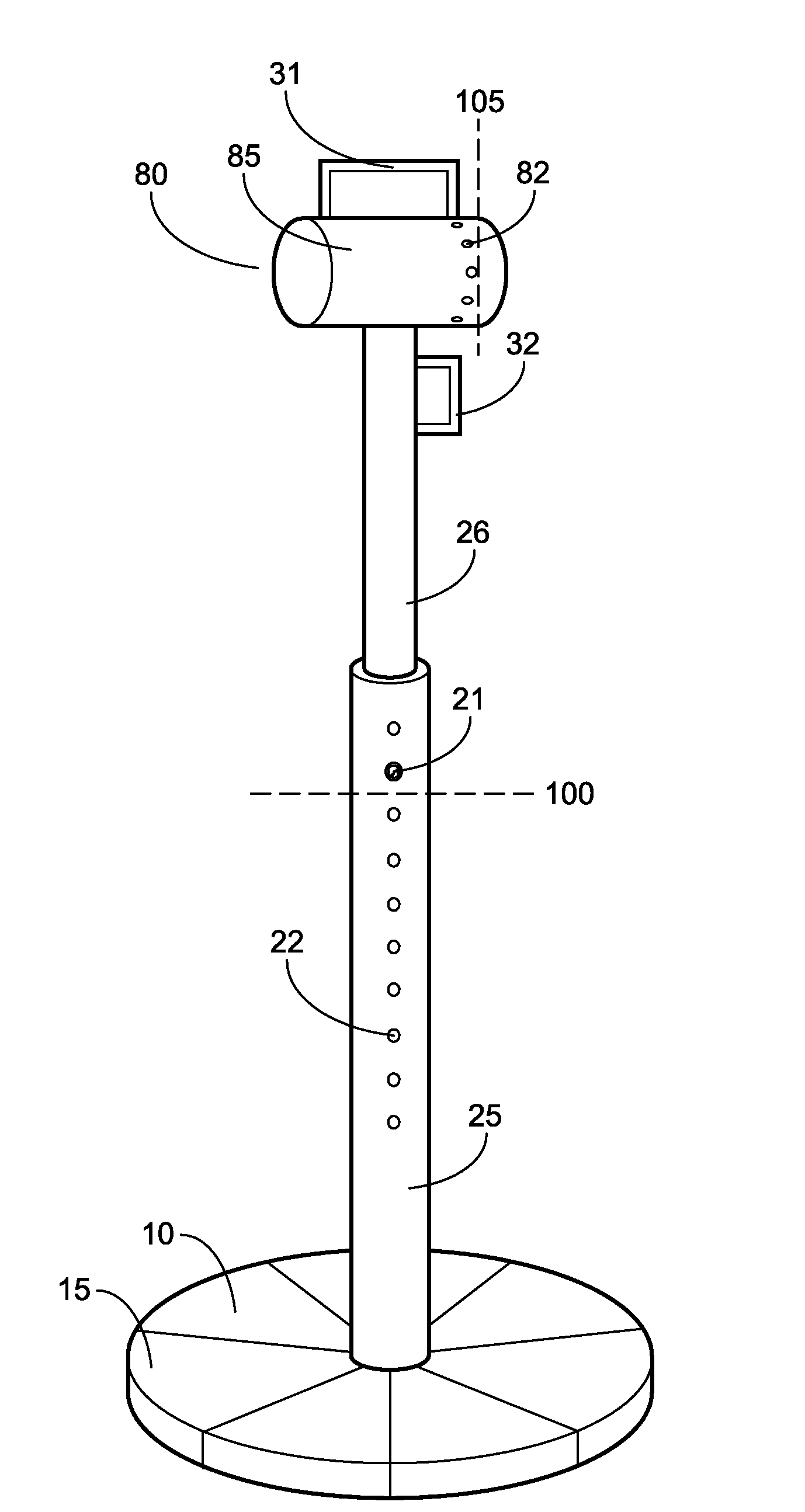

Rotatable axial fan

InactiveUS20090214341A1Increase fan speedReduce fan speedPropellersRotary propellersHorizontal axisEngineering

The present disclosure provides a novel apparatus for the movement of air. Specifically, the apparatus is an axial fan assembly which is rotatable about a horizontal axis to orient the axial fan in a vertical position, a horizontal position, or positions in between. The axial fan can be adjusted and selectively fixed in a particular orientation. The height of the axial fan is also adjustable. The vertical support member comprises a telescoping mechanism whereby the length of the vertical support member is adjustable and can be selectively fixed at a particular length.

Owner:CRAIG TREVOR

Wind turbine device

ActiveUS7132760B2Reduce blade dragConvenient lengthPropellersRotary propellersDevice formOperational capabilities

Owner:BECKER WILLIAM S

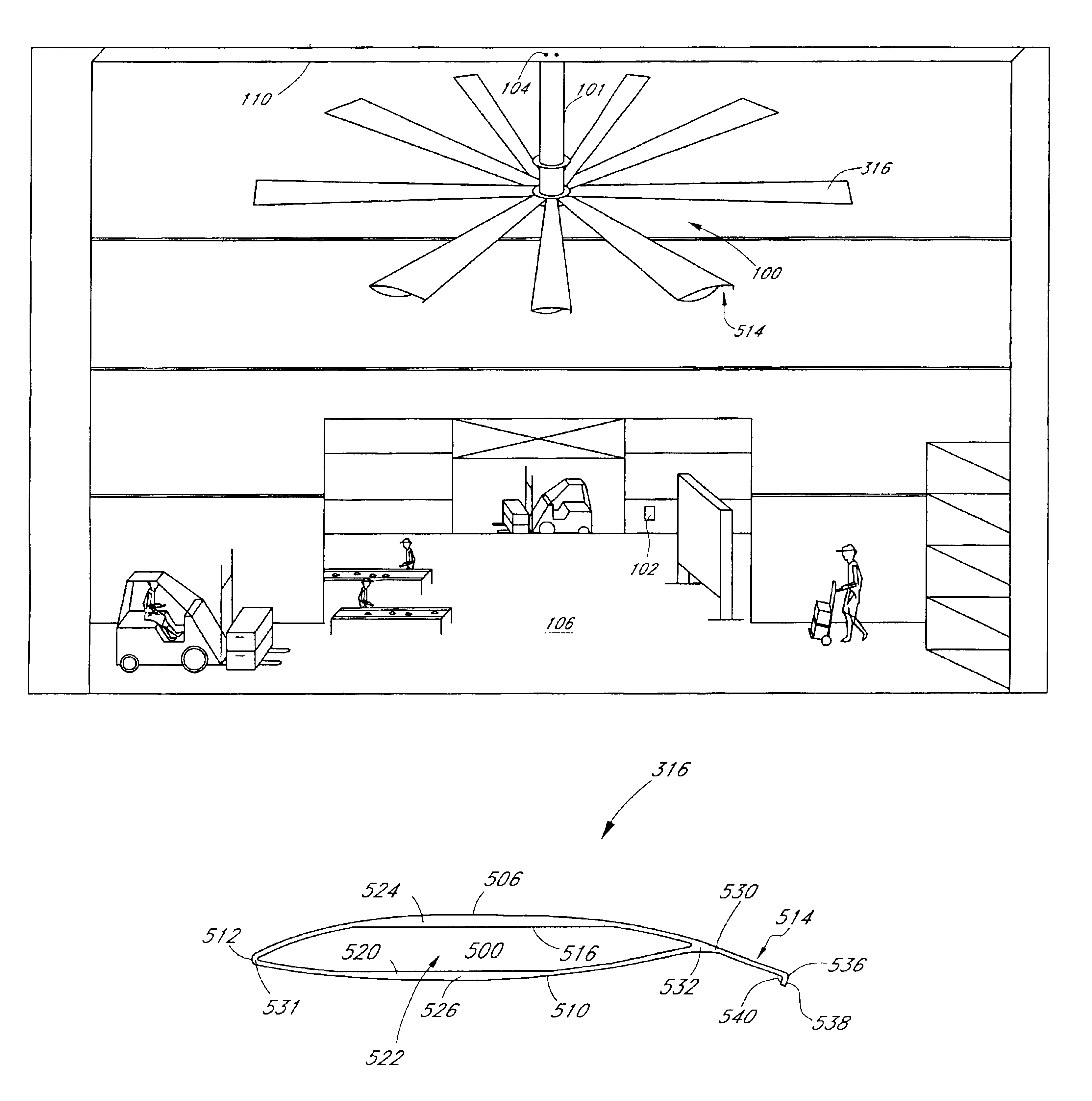

Fan blade modifications

Owner:DELTA T

Method of manufacturing a wind turbine blade, wind turbine blade, front cover and use of a front cover

The invention relates to a method of manufacturing a wind turbine blade, said method comprising the steps of: casting at least two wind turbine shells and preferably one or more load bearing structures, forming a wind turbine blade structure including at least two longitudinal joints by adhering said at least two wind turbine shells and said one or more load bearing structures together, forming one or more front covers to a shape substantially corresponding to said wind turbine blade structure or sections hereof, positioning said one or more front covers in relation to said wind turbine blade structure, and fastening said one or more front covers to said wind turbine blade structure with adhering means. The invention also relates to a wind turbine blade, front cover and the use of a front cover as a unit for supplementary mounting on a wind turbine blade.

Owner:VESTAS WIND SYST AS

Turbine blade and a method of manufacturing and repairing a turbine blade

A turbine blade and a process for manufacture of turbine blades is provided comprising: casting as one piece a blade body and a first portion of an airfoil; forming a tip section having a tip cap and a second portion of an airfoil which is sized to fit on the first portion of the airfoil; and attaching the first portion of the airfoil to the second portion of the airfoil. A process for repairing turbine blades is provided which comprises: removing the tip cap and a portion of the airfoil from the blade to form a repair surface on the airfoil; forming a replacement tip section comprising a replacement tip cap and a replacement portion of the airfoil sized to fit onto the repair surface; and attaching the replacement tip section to the repair surface.

Owner:CHROMALLOY GAS TURBINE

Wind blade spar cap and method of making

InactiveUS20050186081A1Rapid infusionImprove permeabilityRotary propellersFinal product manufactureEngineeringMechanical engineering

Owner:MOHAMED MANSOUR H

Method for producing titanium alloy turbine blades and titanium alloy turbine blades

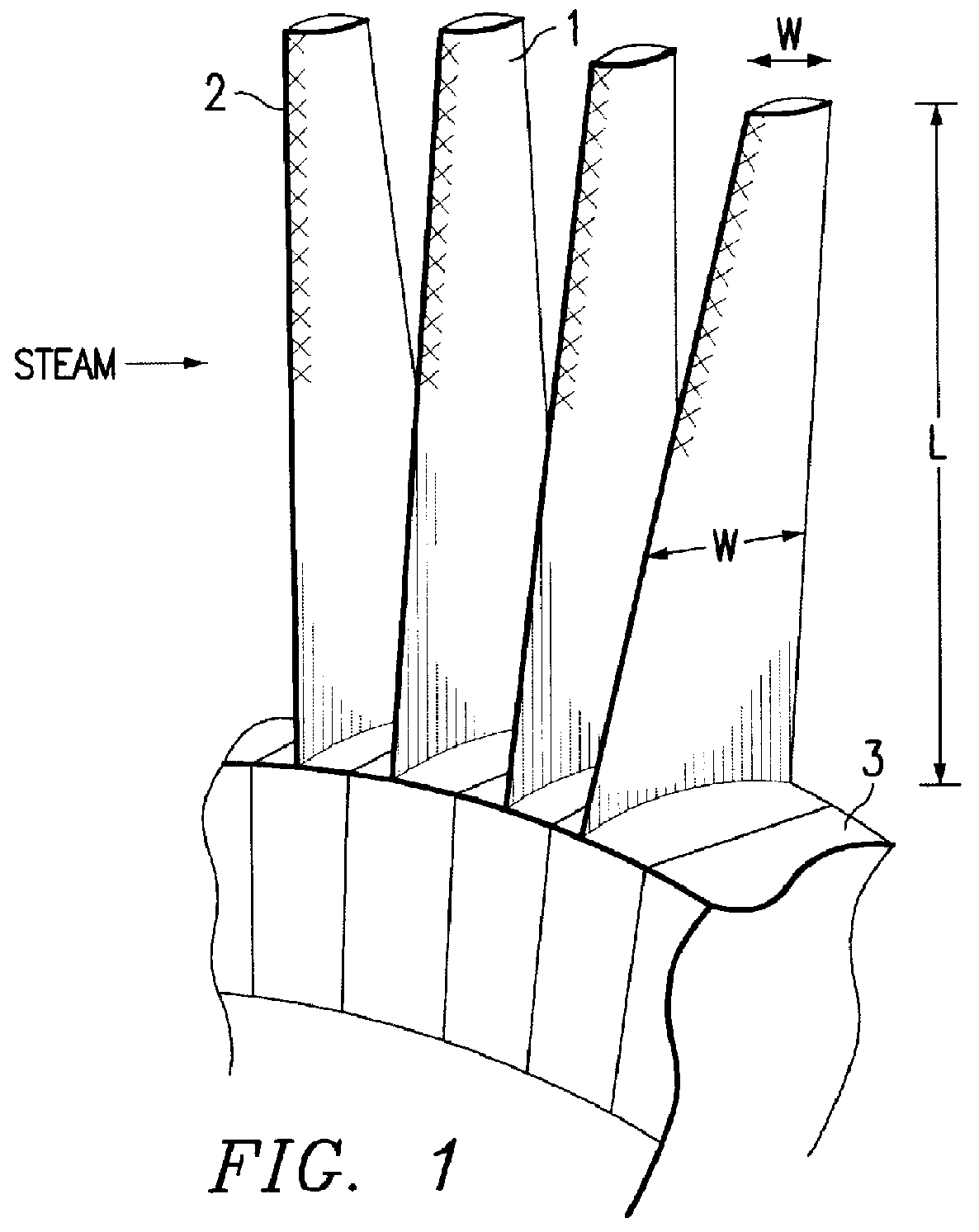

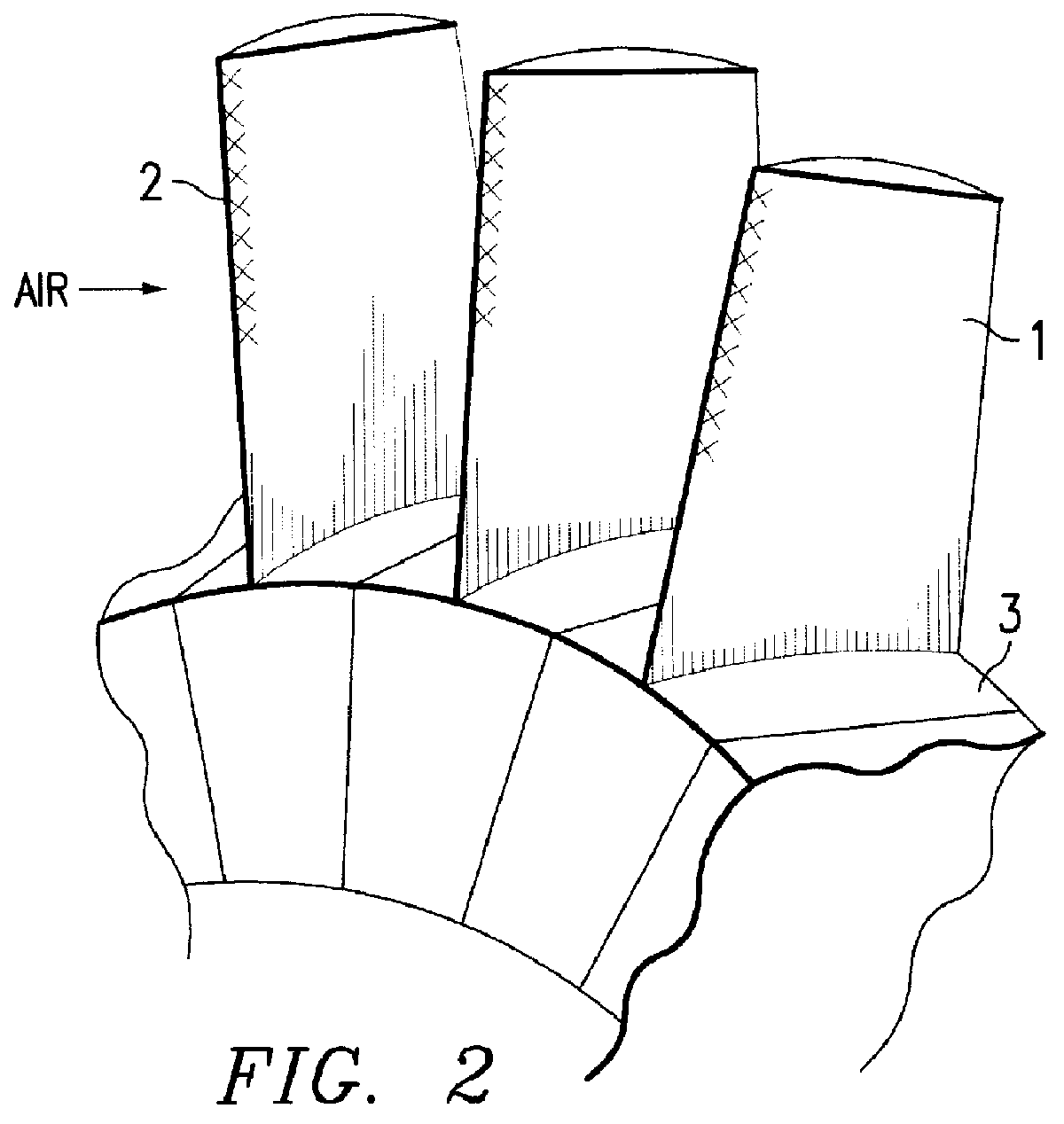

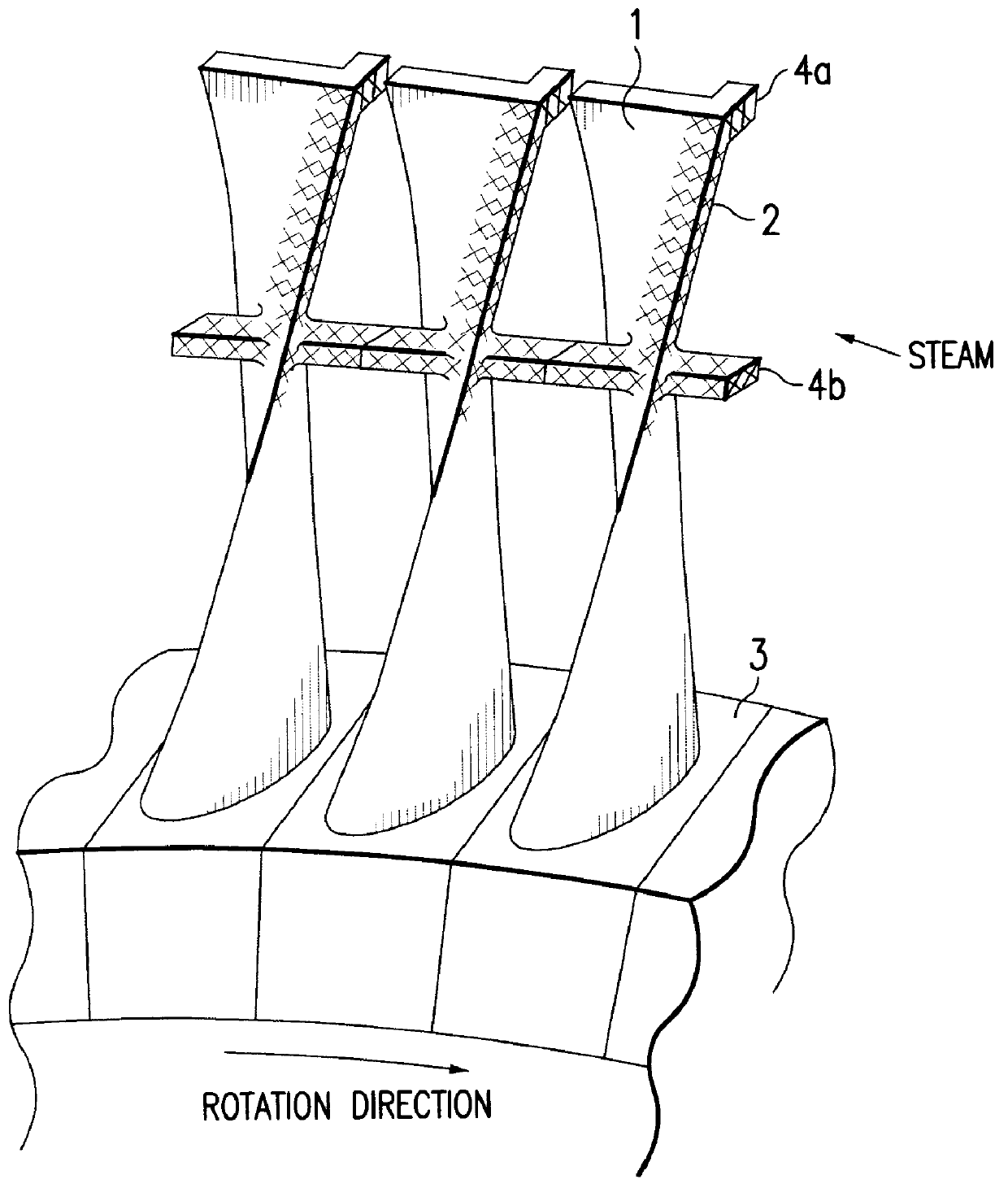

InactiveUS6127044ALess abrasionSuperior in water droplet erosion resistancePropellersEngine manufactureLeading edgeTurbine blade

PCT No. PCT / JP95 / 01817 Sec. 371 Date Jun. 2, 1998 Sec. 102(e) Date Jun. 2, 1998 PCT Filed Sep. 13, 1995 PCT Pub. No. WO97 / 10066 PCT Pub. Date Mar. 20, 1997A method for producing titanium alloy turbine blades comprising the steps of (a) forming turbine blades of titanium alloy through hot forging or machining, (b) cooling leading edges on tip portions of the turbine blades including covers thereof formed through hot forging or machining faster than blade main body after final hot forging or solid solution treatment, and (c) heat treating the cooled turbine blades. With this method, it is possible to manufacture titanium turbine blades in an economical fashion and obtain titanium alloy turbine blades superior in reliability by preventing erosion.

Owner:KK TOSHIBA +1

Turbine element

A turbine element airfoil has a cooling passageway network with a slot extending from a trailing passageway toward the trailing edge. A number of discrete posts span the slot between pressure and suction sidewall portions.

Owner:RTX CORP

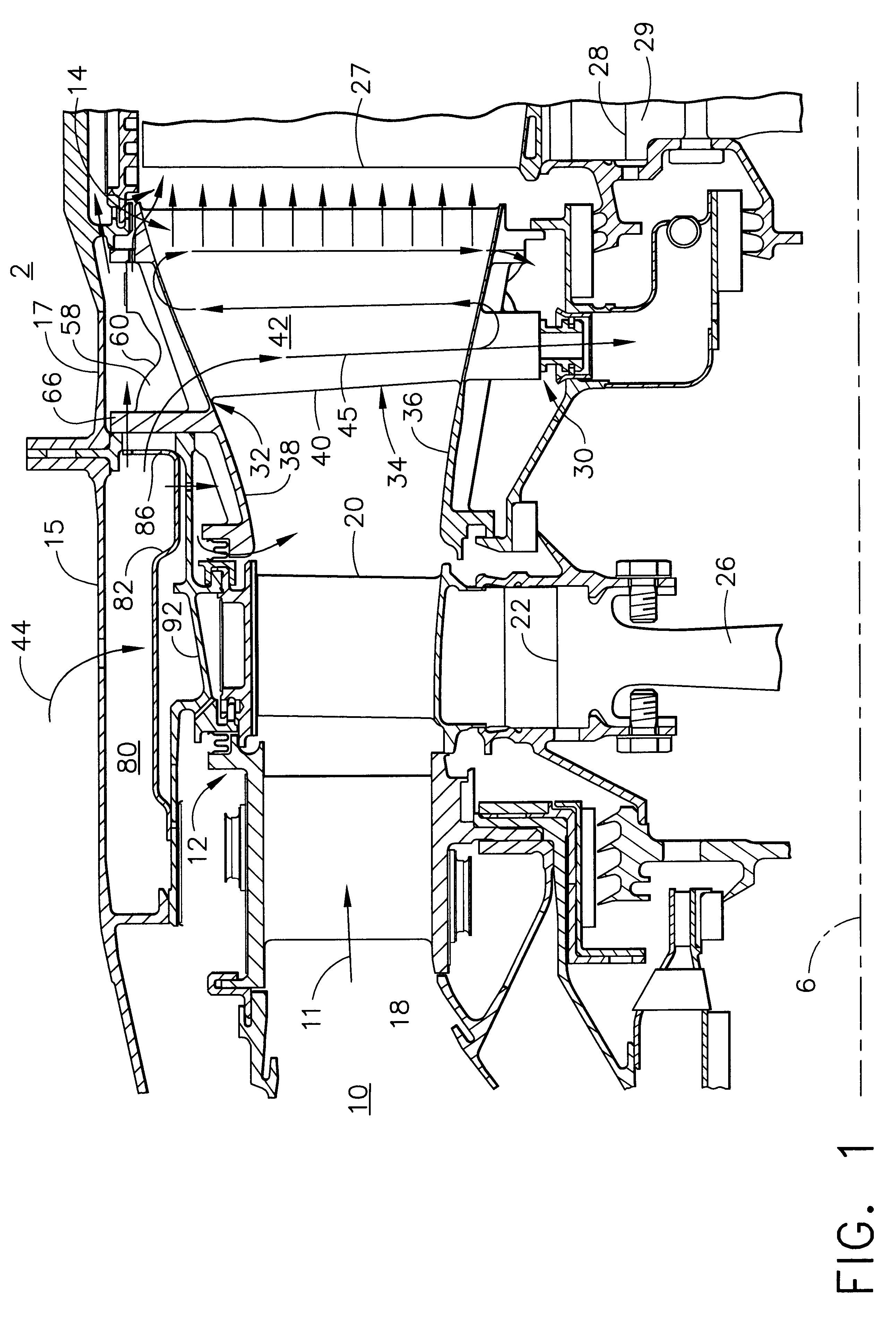

Turbine nozzle segment band cooling

A gas turbine engine nozzle segment includes at least two circumferentially adjacent vanes joined together along an interface between the vanes. Each of the vanes includes a hollow airfoil disposed between radially inner and outer band panels and a cooling air intake duct leading to a hollow interior of the airfoil for directing cooling air into the hollow interior. The intake duct has a duct wall protruding radially outward from the outer band panel and at least one impingement cooling hole disposed through the intake duct wall and circumferentially and radially inwardly angled. A flange portion extends circumferentially along the outer band panel and an opening in the flange portion is in fluid communication with the intake duct. The hollow airfoil, radially inner and outer band panels, intake duct wall, and flange portion are integrally formed and, preferably, integrally cast such that the vane is a single piece integrally cast vane.

Owner:GENERAL ELECTRIC CO

Wind turbine

A wind turbine operable as either a vertical axis wind turbine or a horizontal axis wind turbine is disclosed.

Owner:KANE VIC

Impeller for molten metal pump with reduced clogging

InactiveUS6881030B2Improve impeller efficiencyAvoid cloggingSpecific fluid pumpsPropellersImpellerEngineering

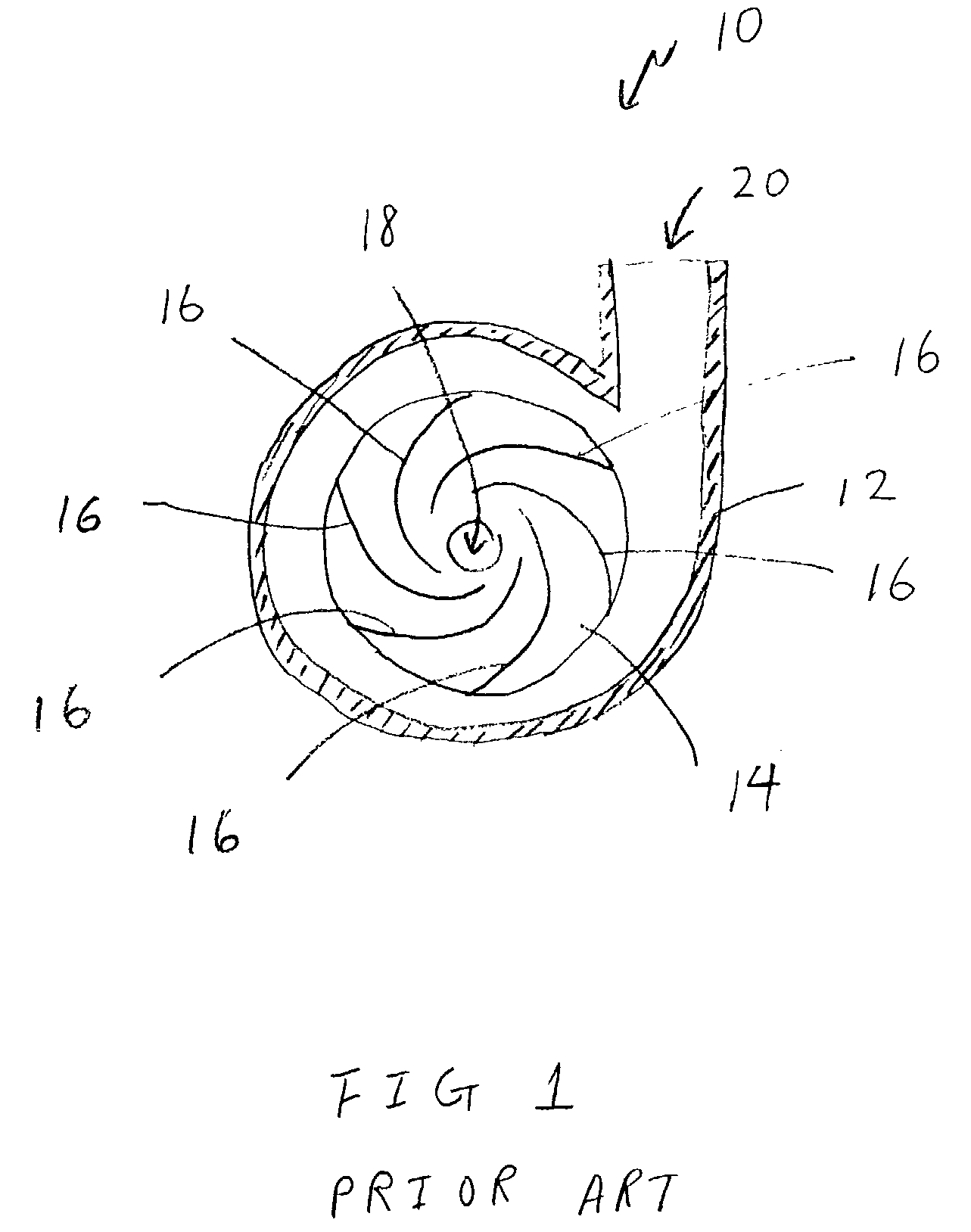

One aspect of the invention is directed to an impeller made of a non-metallic, heat resistant material, comprising a generally cylindrical shaped body, first and second generally planar end faces and a side wall extending between the first and second faces. A plurality of passages have inlets circumferentially spaced apart from each other on the first face, outlets at the impeller sidewall, and connecting portions extending between the inlets and the outlets transverse to the central axis. Another aspect of the invention is directed to an impeller comprising a central hub portion and first and second impeller bases, including end faces, transverse to a central axis. Vanes extend from the central hub portion between the impeller bases. Cavities are formed between the impeller bases and between adjacent vanes. Molten metal inlets on the end faces for molten metal to reach the cavities. Pumps are also disclosed using the inventive impellers.

Owner:THUT BRUNO H

Wind turbine blade

ActiveUS20090068017A1Low production costComplex shapePropellersEngine manufactureTurbine bladeEngineering

Owner:BLADE DYNAMICS LTD

Friction stir welded hollow airfoils and method therefor

A hollow component for gas turbine engine, for example an outlet guide vane, is assembled from a body having at recessed pocket formed therein, and an aerodynamic cover bonded over the pocket. Both the cover and the body are constructed from materials which are not readily fusion weldable. The cover is attached to the body by a solid state bonding process, for example friction stir welding. The hollow component may also be built up from multiple individual components which are bonded to each other by a solid state bonding process such as friction stir welding.

Owner:GENERAL ELECTRIC CO

Rotor blade trailing edge assembly and method of use

A method of assembling a rotor blade for a turbine is provided that includes forming a rotor blade trailing edge by coupling a suction side terminus to a pressure side terminus and positioning a trailing edge assembly between the suction side terminus and the pressure side terminus, the trailing edge assembly having a varying cross-section.

Owner:GENERAL ELECTRIC CO

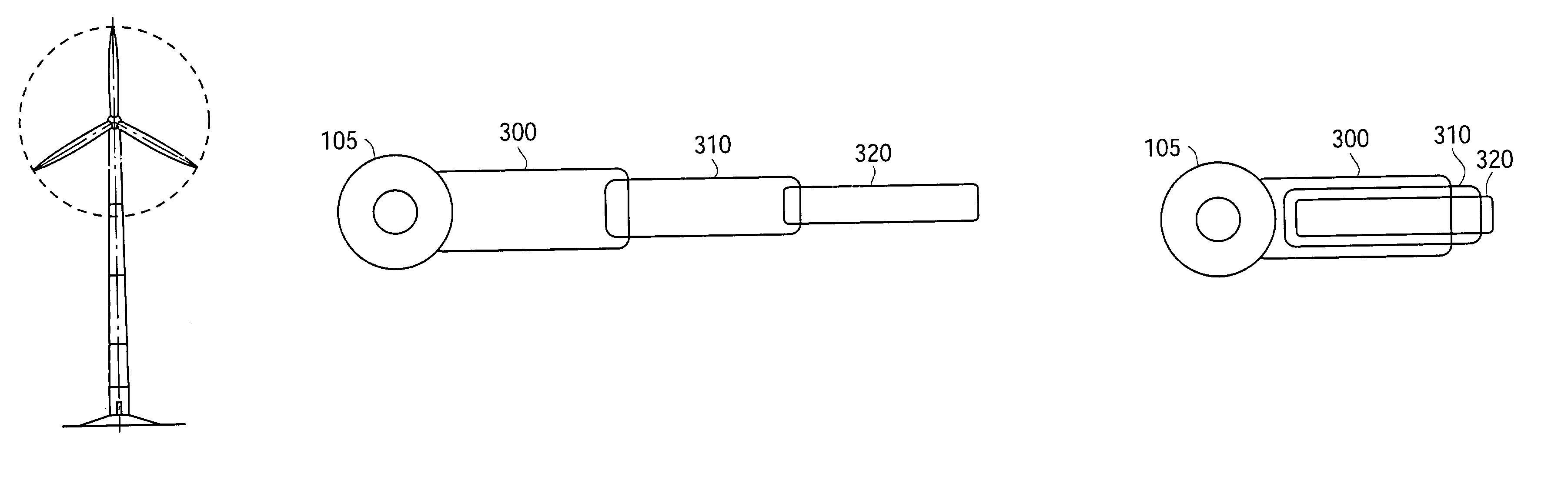

Telescoping wind turbine blade

A wind turbine blade made of a fixed blade section with an integral mounting flange for attachment to a wind turbine hub. A moveable blade section is attached to the fixed blade section and is free to move in a longitudinal direction relative to the fixed blade section. A positioning device controllably positions the moveable blade section to vary the overall length of the blade. This allows the wind turbine's rotor diameter to be adjusted. The rotor diameter can be increased in order to provide high power output in low wind conditions and it can be decreased in order to minimize loads in high wind conditions.

Owner:FRONTIER WIND LLC

Cooling fan with reinforced blade

InactiveUS6939108B2Simple structureIncreased downward thrustPropellersPump componentsTrailing edgeFan blade

A circulatory device comprising a large diameter fan having reinforced fan blades with a tapered airfoil shape is disclosed. The fan blades may be formed using an extrusion method of fabrication, wherein each fan blade may comprise a reinforced trailing edge with a downwardly extending flange. The benefit of forming each fan blade with a reinforced trailing edge of the present invention results in improved structural characteristics such that the trailing edge of each fan blade may be fabricated longer so as to improve aerodynamic performance. Also, the reinforced trailing edge resists tearing that may occur during extrusion by adding the bent flanged region to at least one distal end of the trailing edge. For example, the bent portion of the trailing edge tends to rigidly orient the extruded material in a stabilized position more readily during formation. Also, the bent portion provides added strength by providing supporting forces in two dimensions that relatively parallel and perpendicular to its length so as to neutralize the adverse effects of pressure forces acting on the trailing edge of the fan blade during extrusion.

Owner:DELTA T

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com