Patents

Literature

60803 results about "Extrusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Extrusion is a process used to create objects of a fixed cross-sectional profile. A material is pushed through a die of the desired cross-section. The two main advantages of this process over other manufacturing processes are its ability to create very complex cross-sections, and to work materials that are brittle, because the material only encounters compressive and shear stresses. It also forms parts with an excellent surface finish.

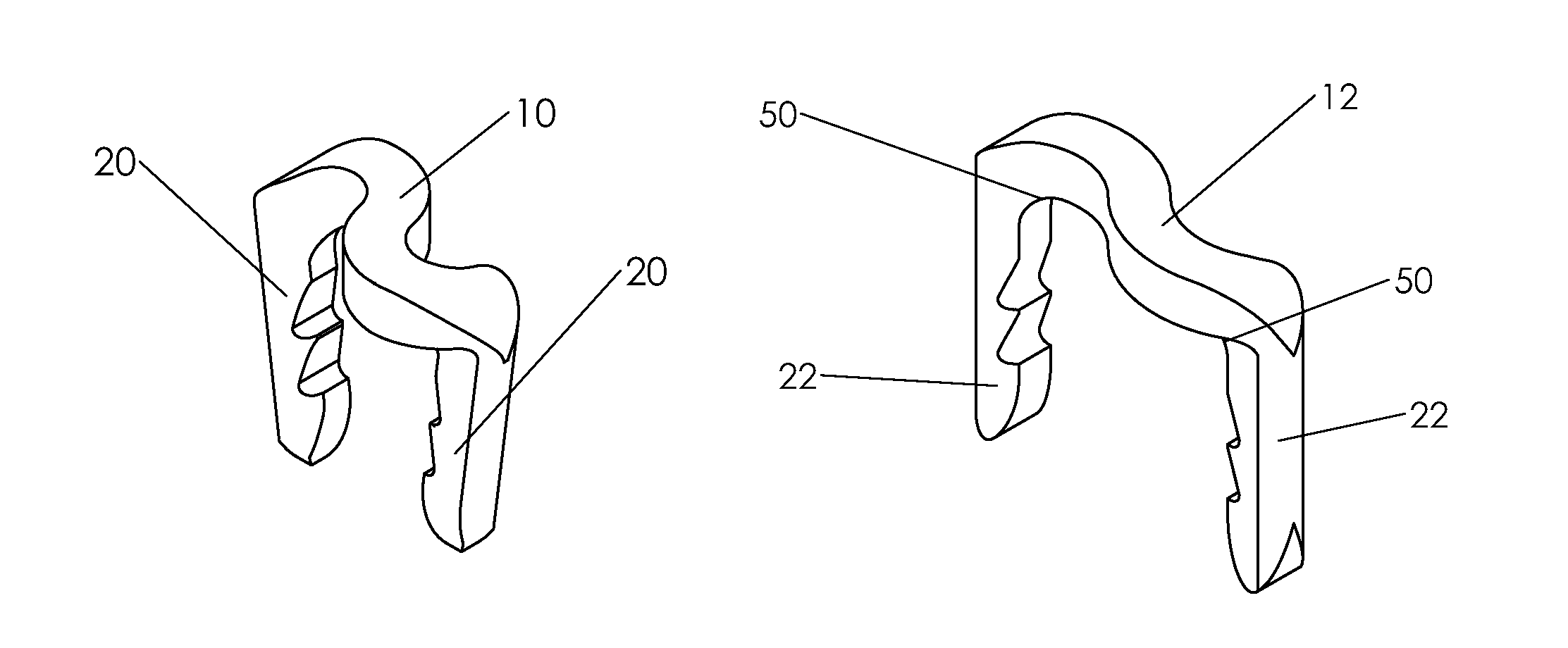

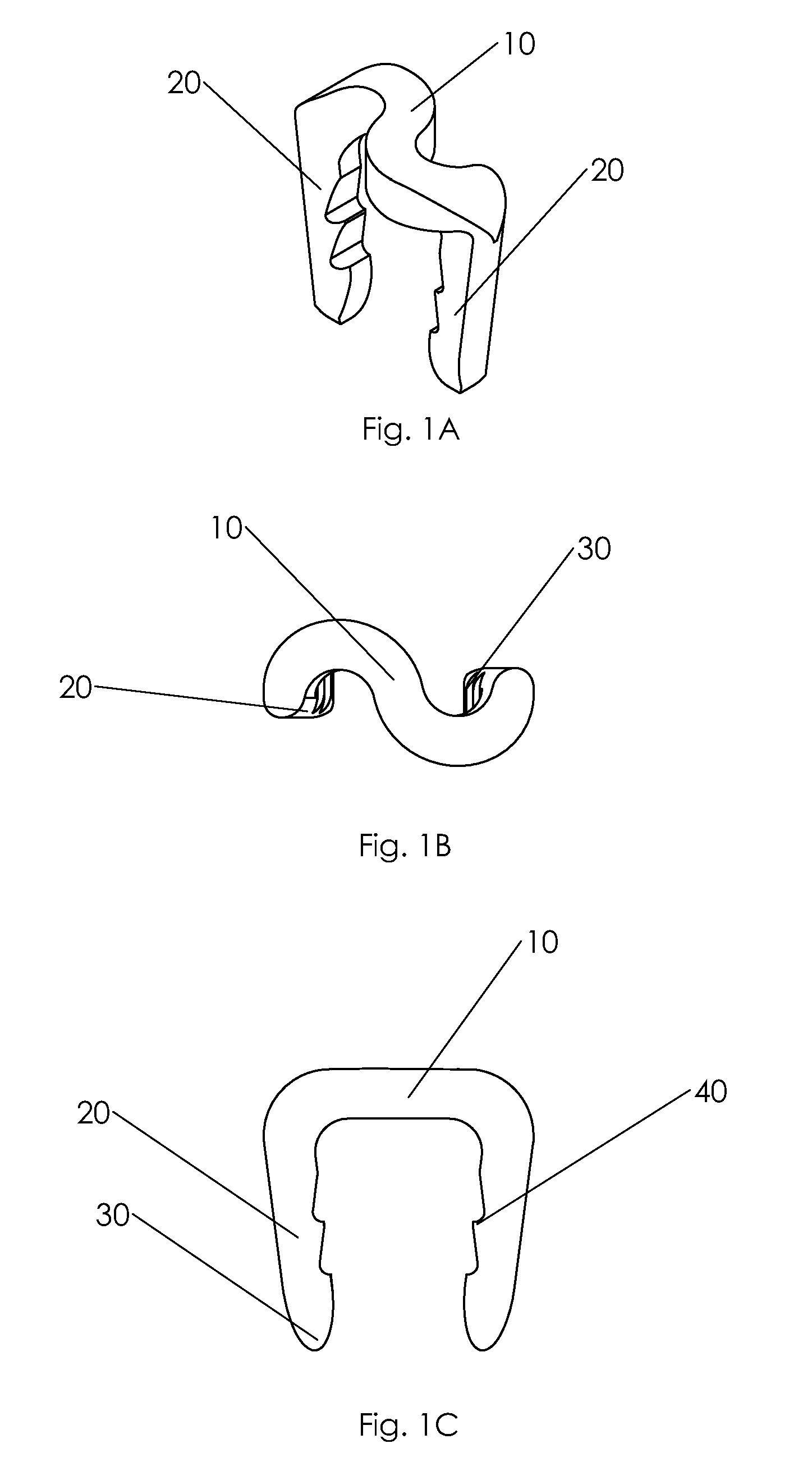

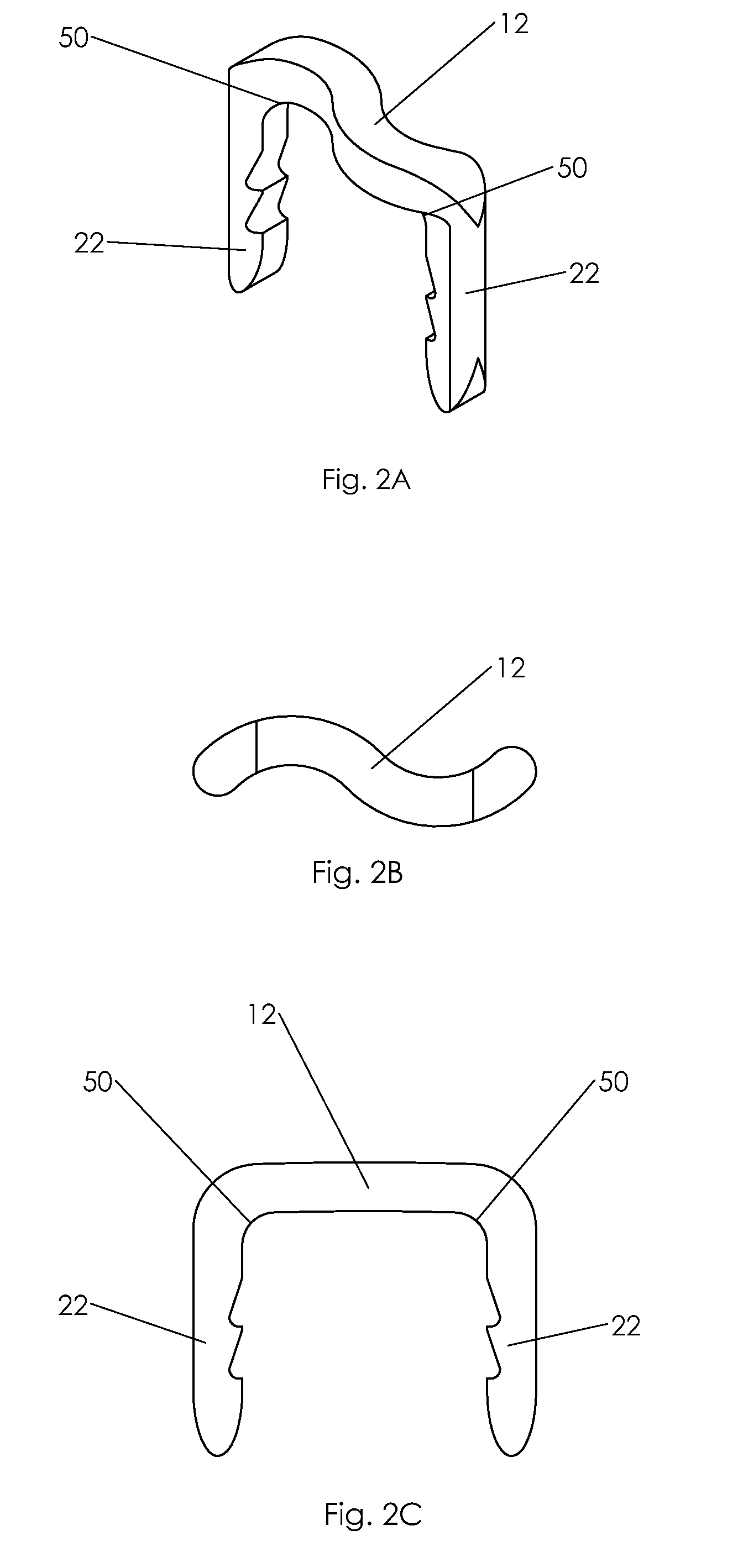

Bone staple, instrument and method of use and manufacturing

ActiveUS9017331B2Stores recoverable mechanical energyEasy to implantPinsInternal osteosythesisShape changeMechanical energy

Owner:FOX WILLIAM CASEY

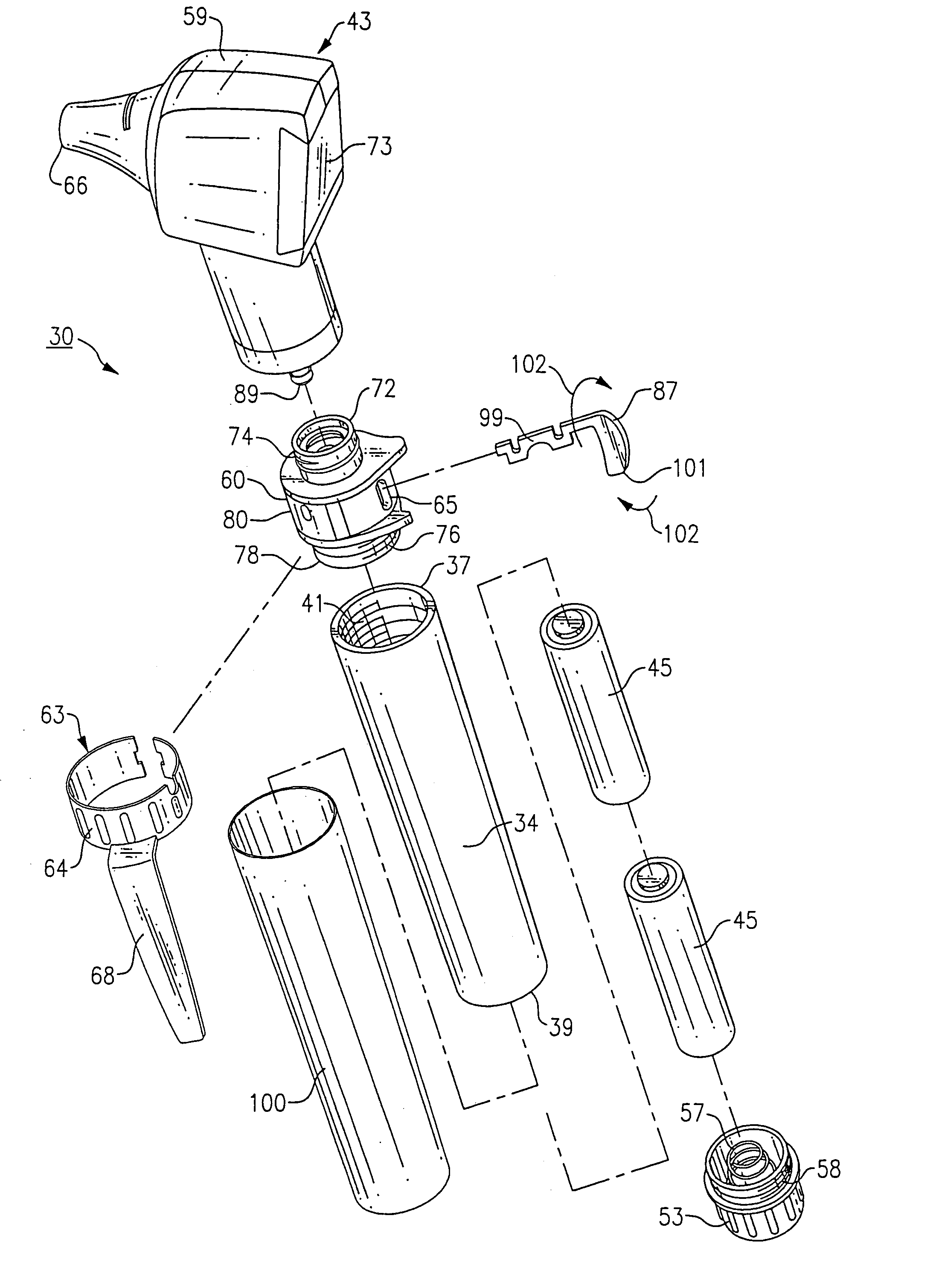

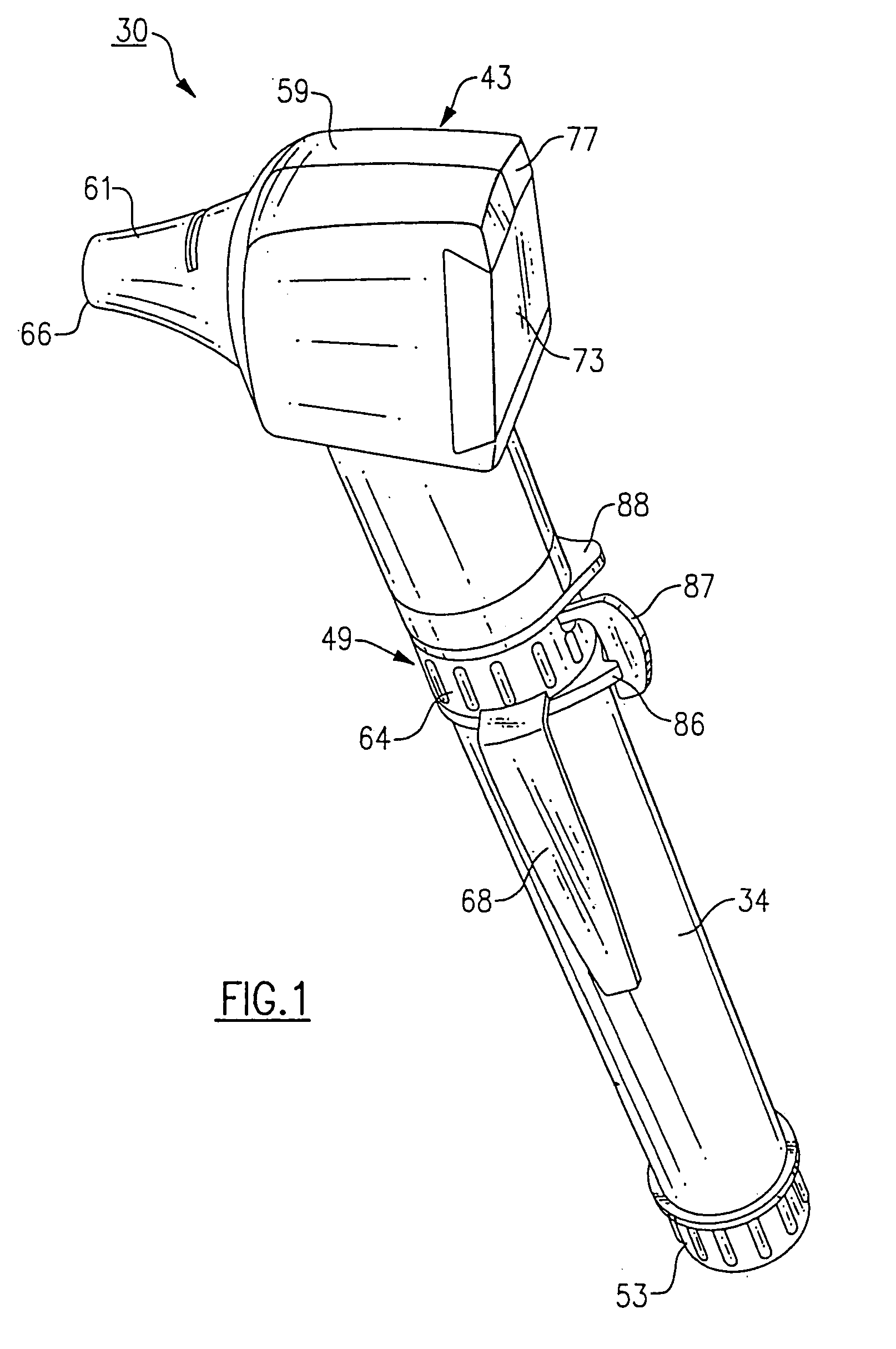

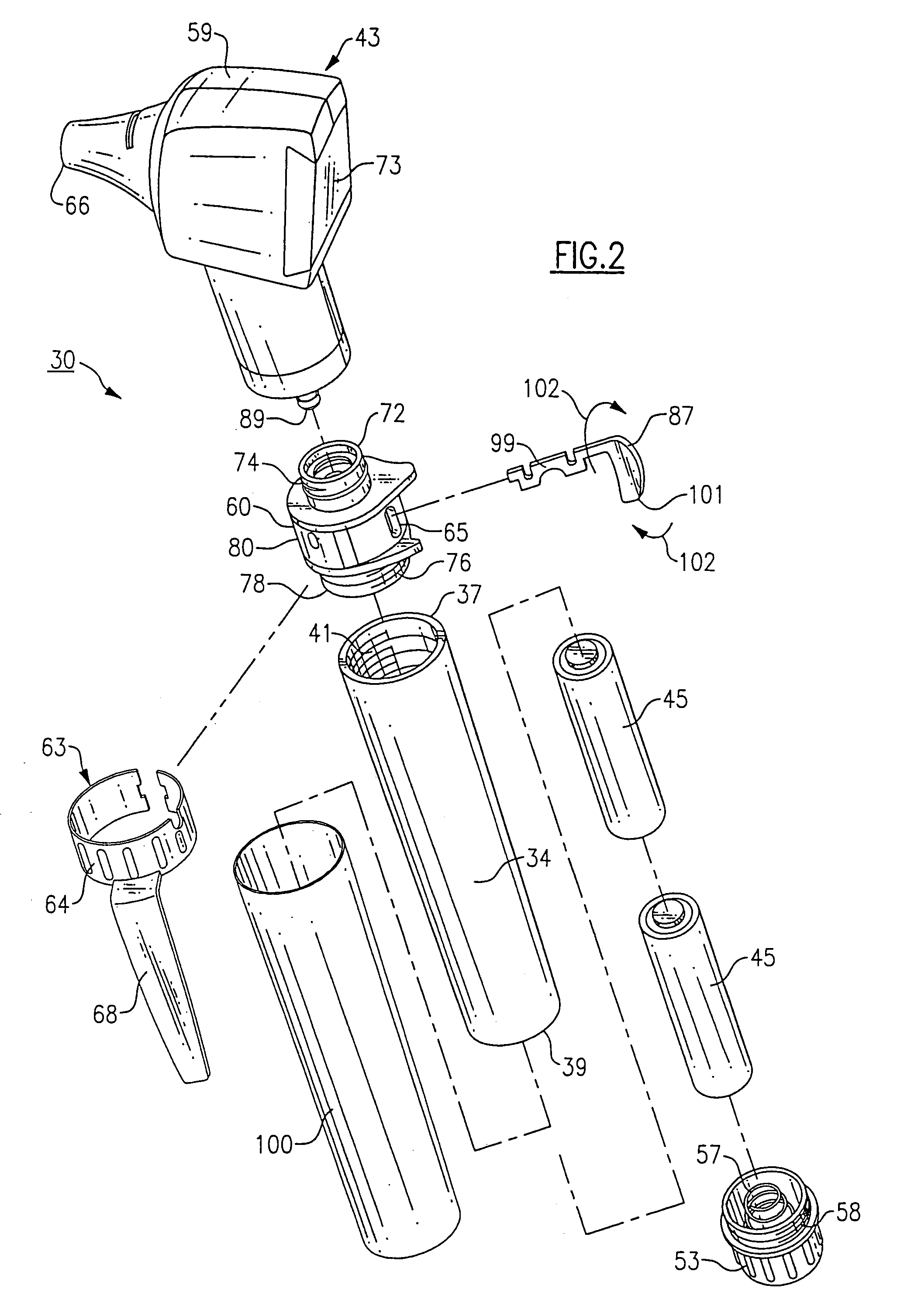

Medical diagnostic instrument

InactiveUS7029439B2Easy to manufactureImprove versatilityBronchoscopesLaryngoscopesElectricityElectrical connection

A medical diagnostic instrument includes a housing containing at least one battery and a light source, such as a lamp, for illuminating a medical target. A switch includes a movable member that selectively moves at least one of the battery and the lamp into and out of electrical connection with the other. The instrument is preferably fabricated from a diecast or an extrusion process wherein a thin plastic sleeve member having text and / or graphic materials can be shrink fitted onto an extruded handle.

Owner:WELCH ALLYN INC

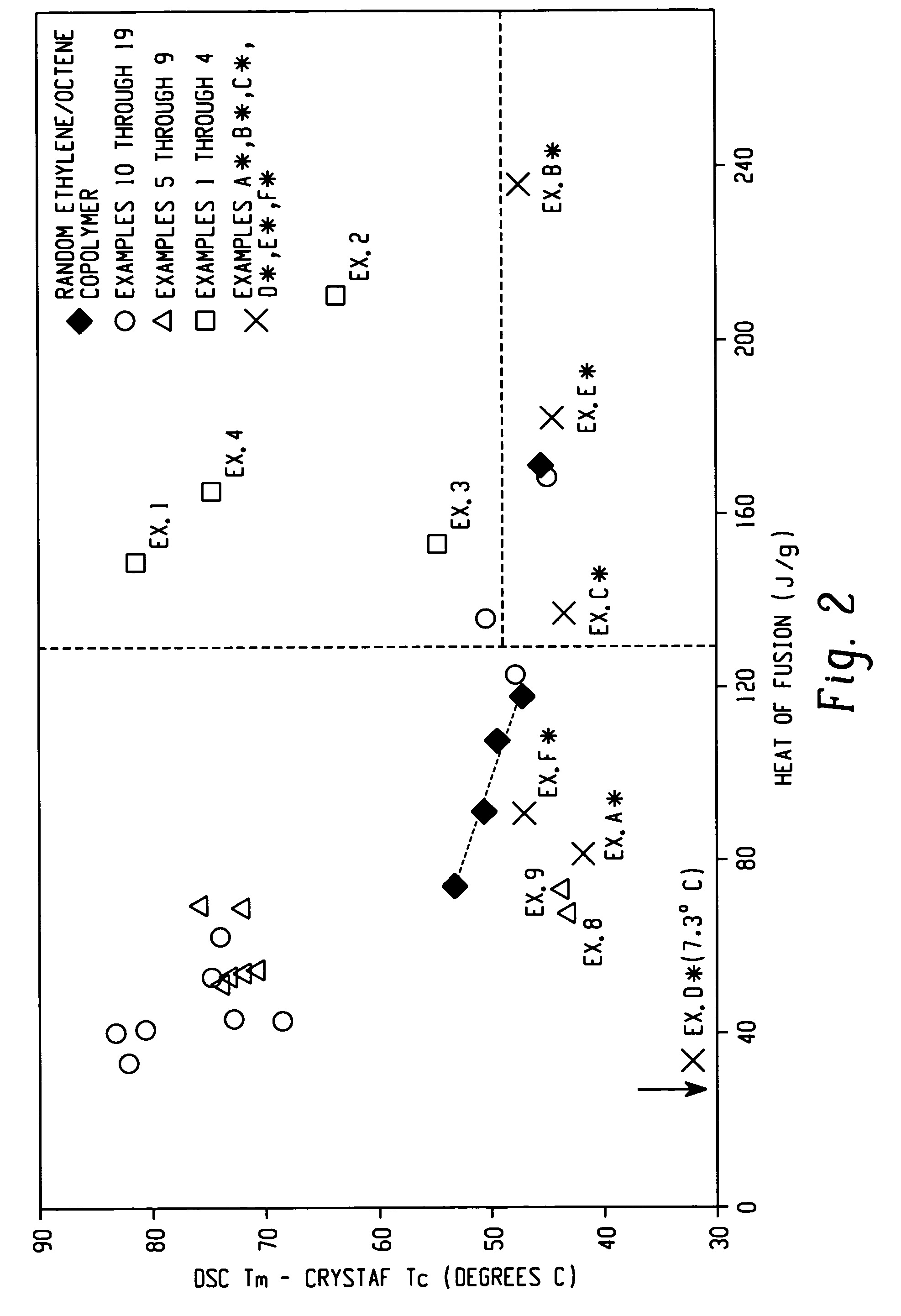

Compositions of ethylene/alpha-olefin multi-block interpolymer for elastic films and laminates

Owner:DOW GLOBAL TECH LLC

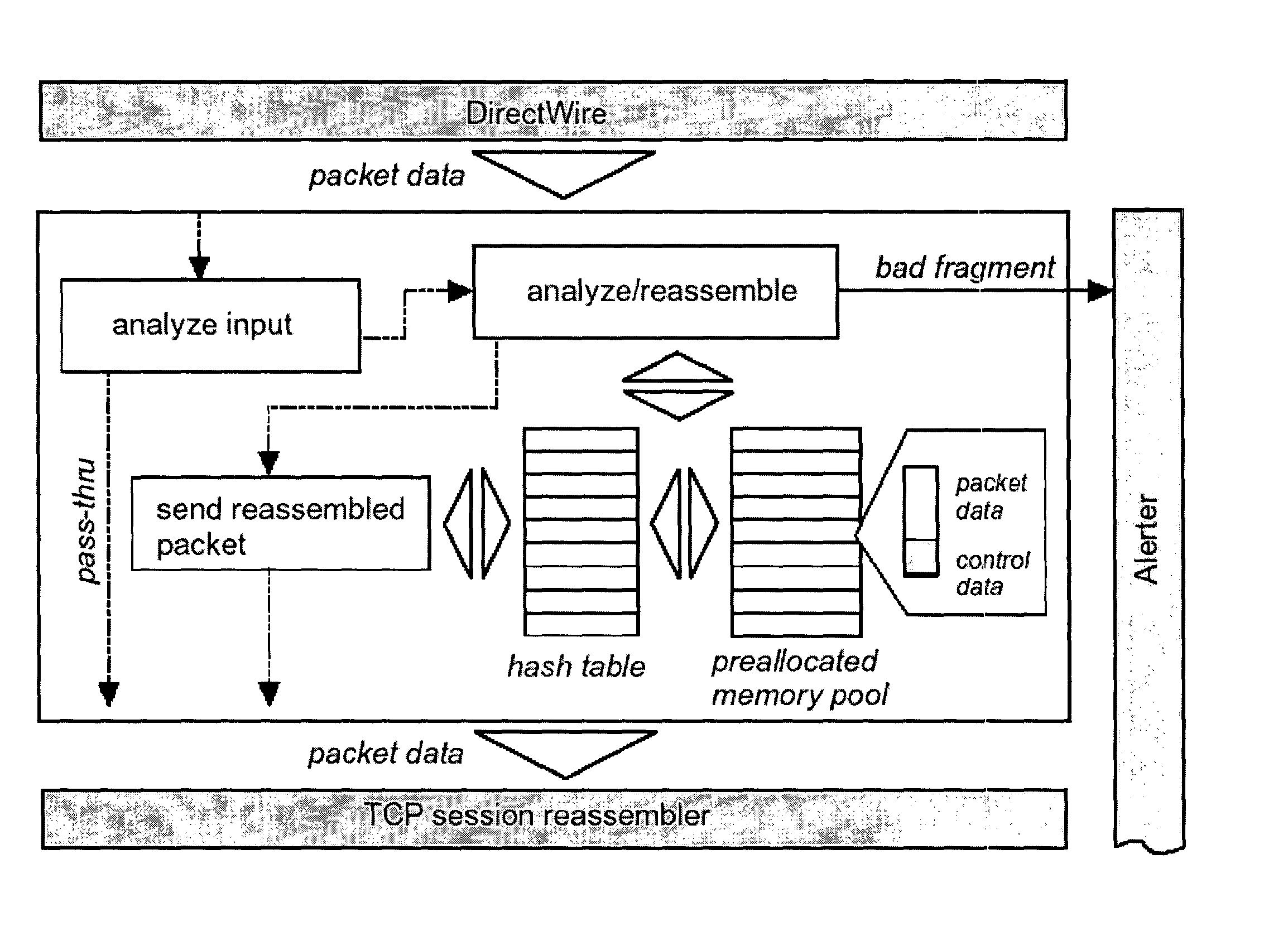

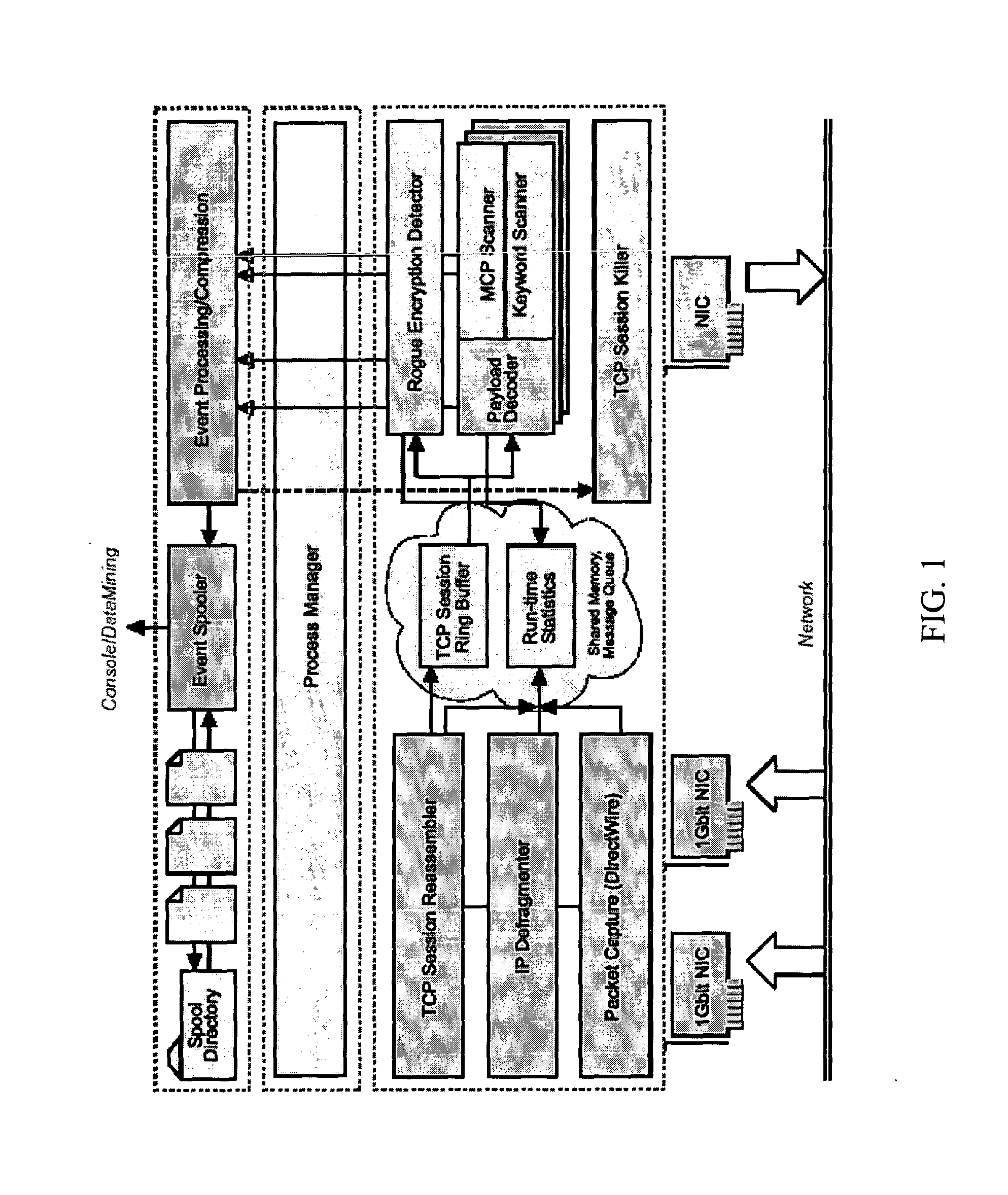

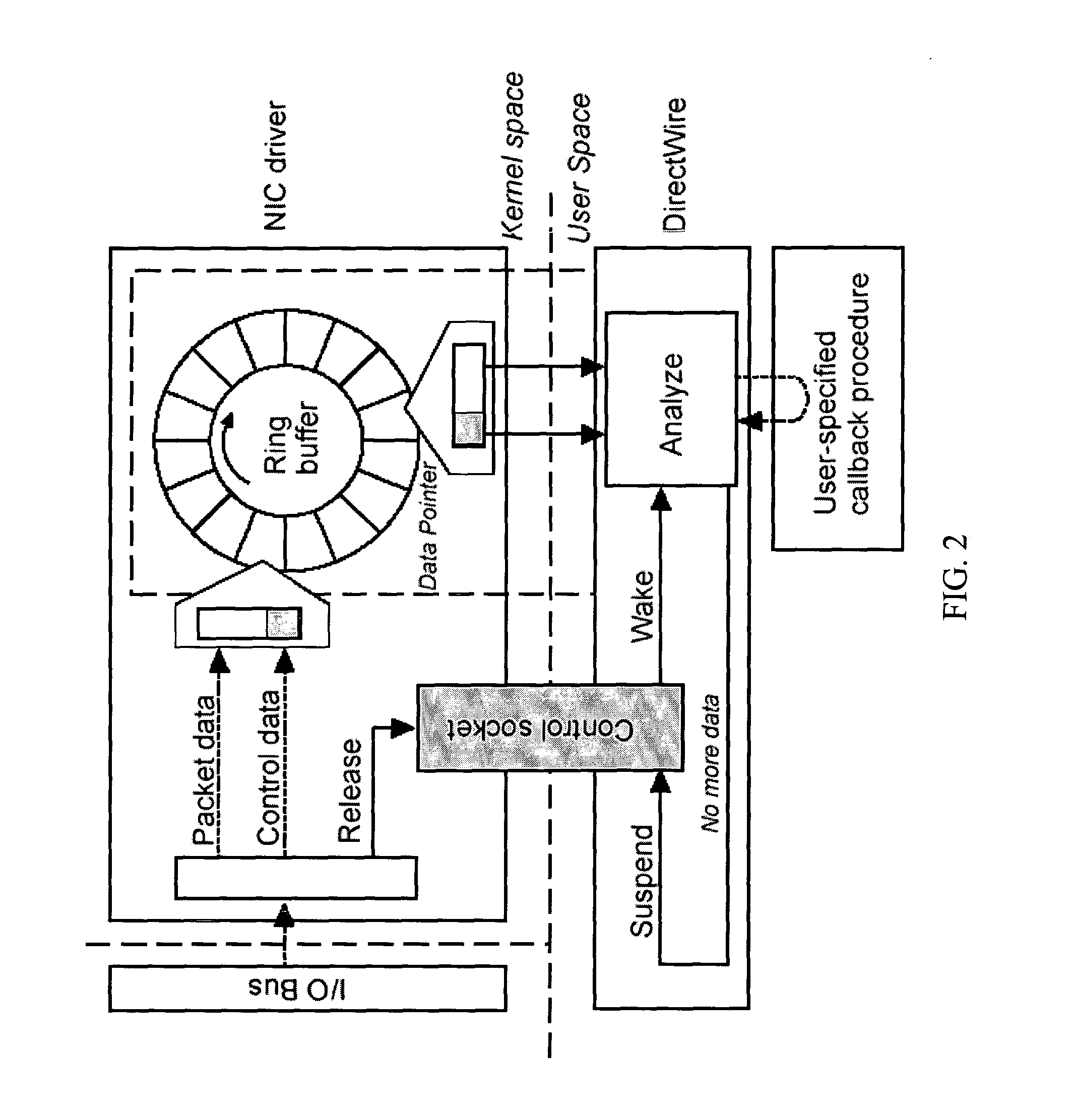

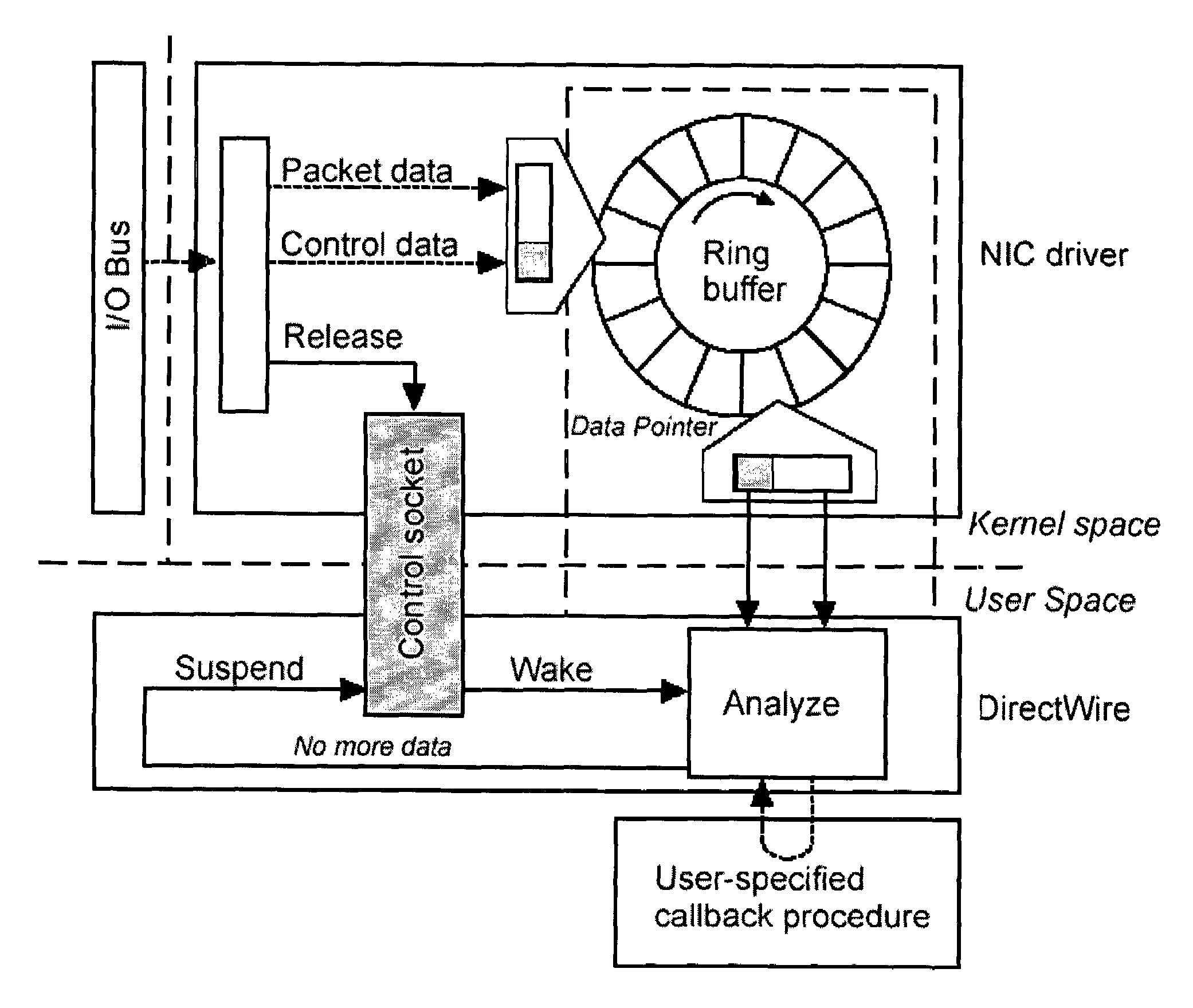

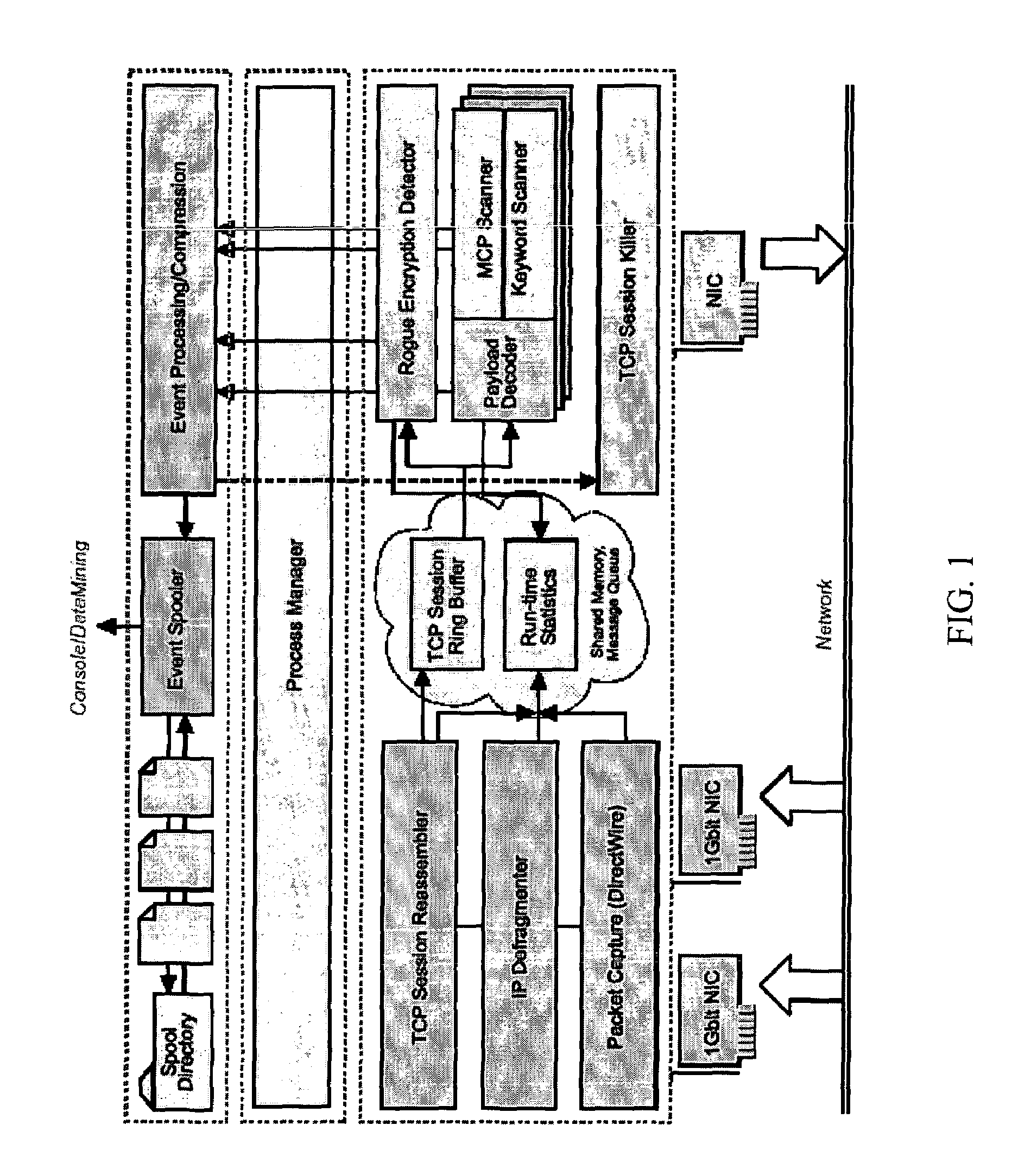

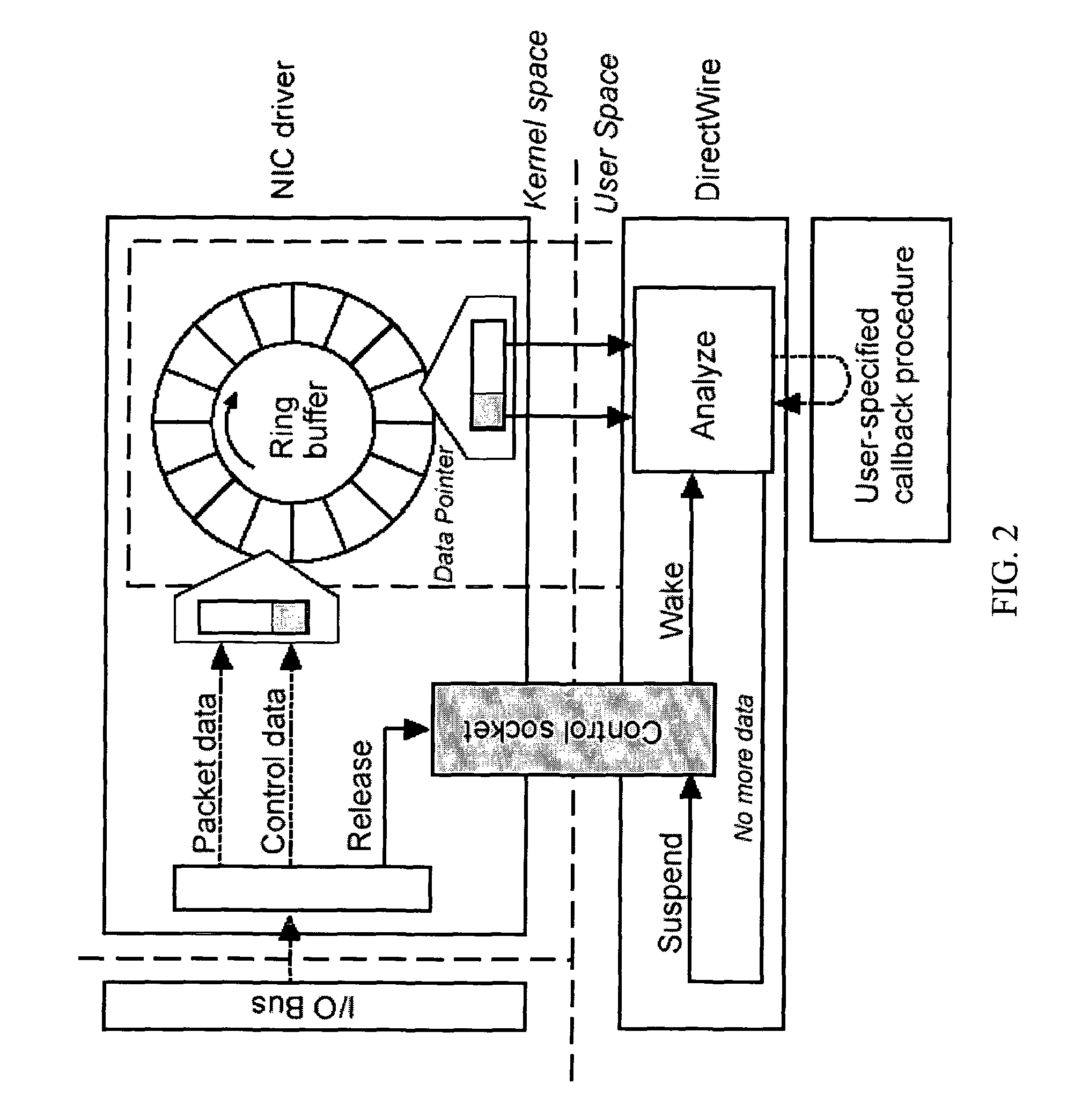

High-performance network content analysis platform

ActiveUS20050055399A1Prevent leakageDigital data processing detailsAnalogue secracy/subscription systemsData streamEmail attachment

One implementation of a method reassembles complete client-server conversation streams, applies decoders and / or decompressors, and analyzes the resulting data stream using multi-dimensional content profiling and / or weighted keyword-in-context. The method may detect the extrusion of the data, for example, even if the data has been modified from its original form and / or document type. The decoders may also uncover hidden transport mechanisms such as, for example, e-mail attachments. The method may further detect unauthorized (e.g., rogue) encrypted sessions and stop data transfers deemed malicious. The method allows, for example, for building 2 Gbps (Full-Duplex)-capable extrusion prevention machines.

Owner:FIDELIS SECURITY SYSTEMS

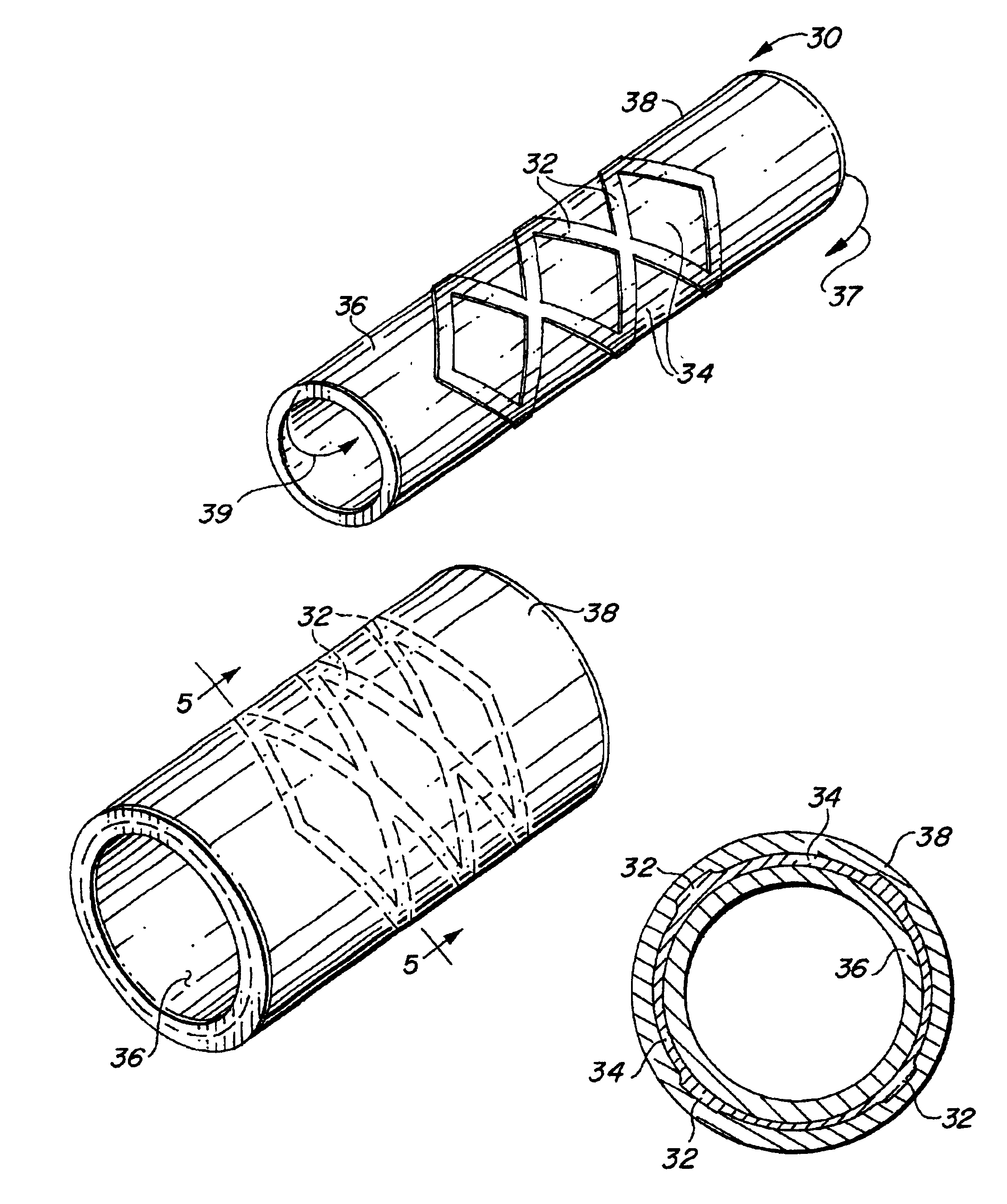

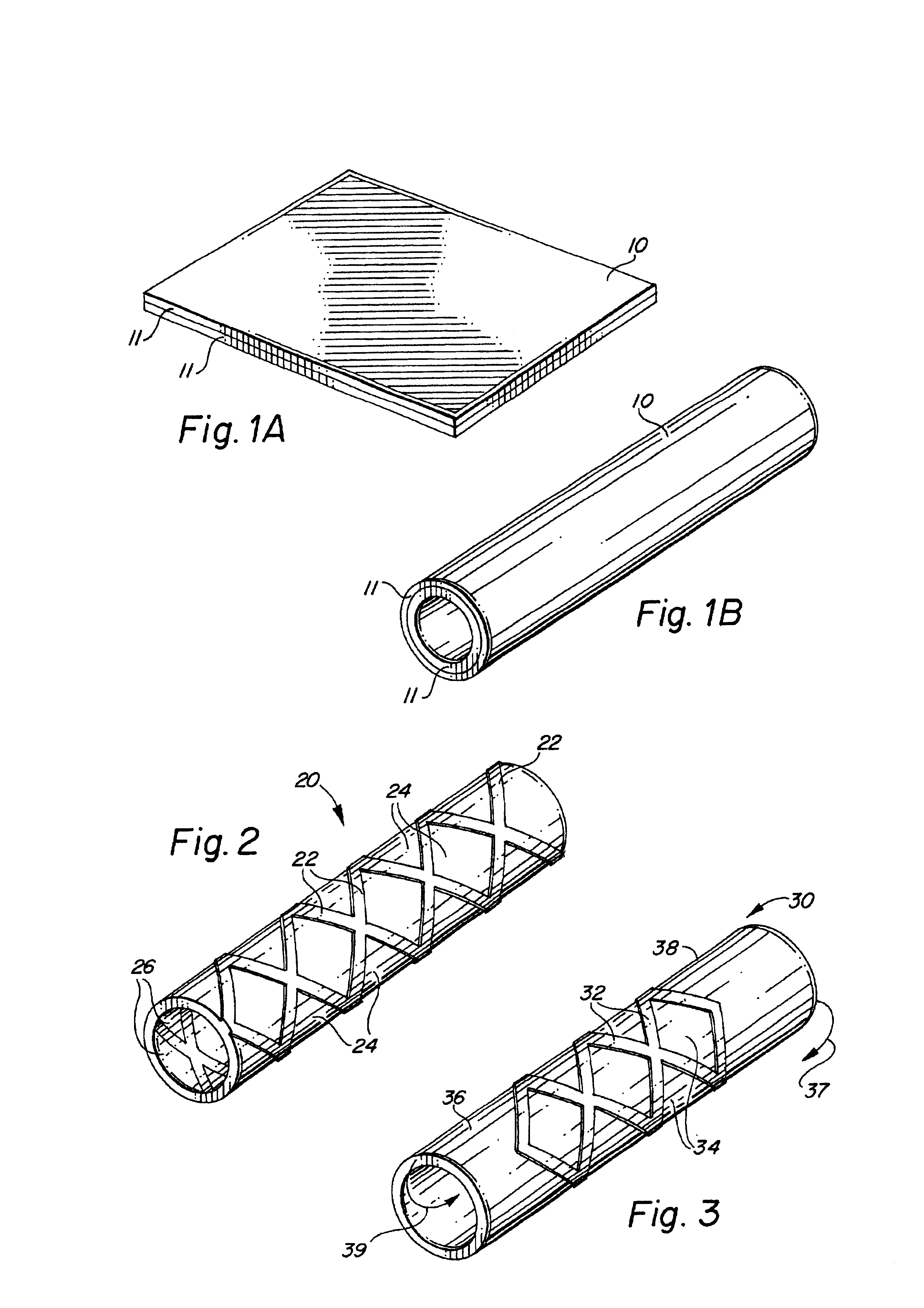

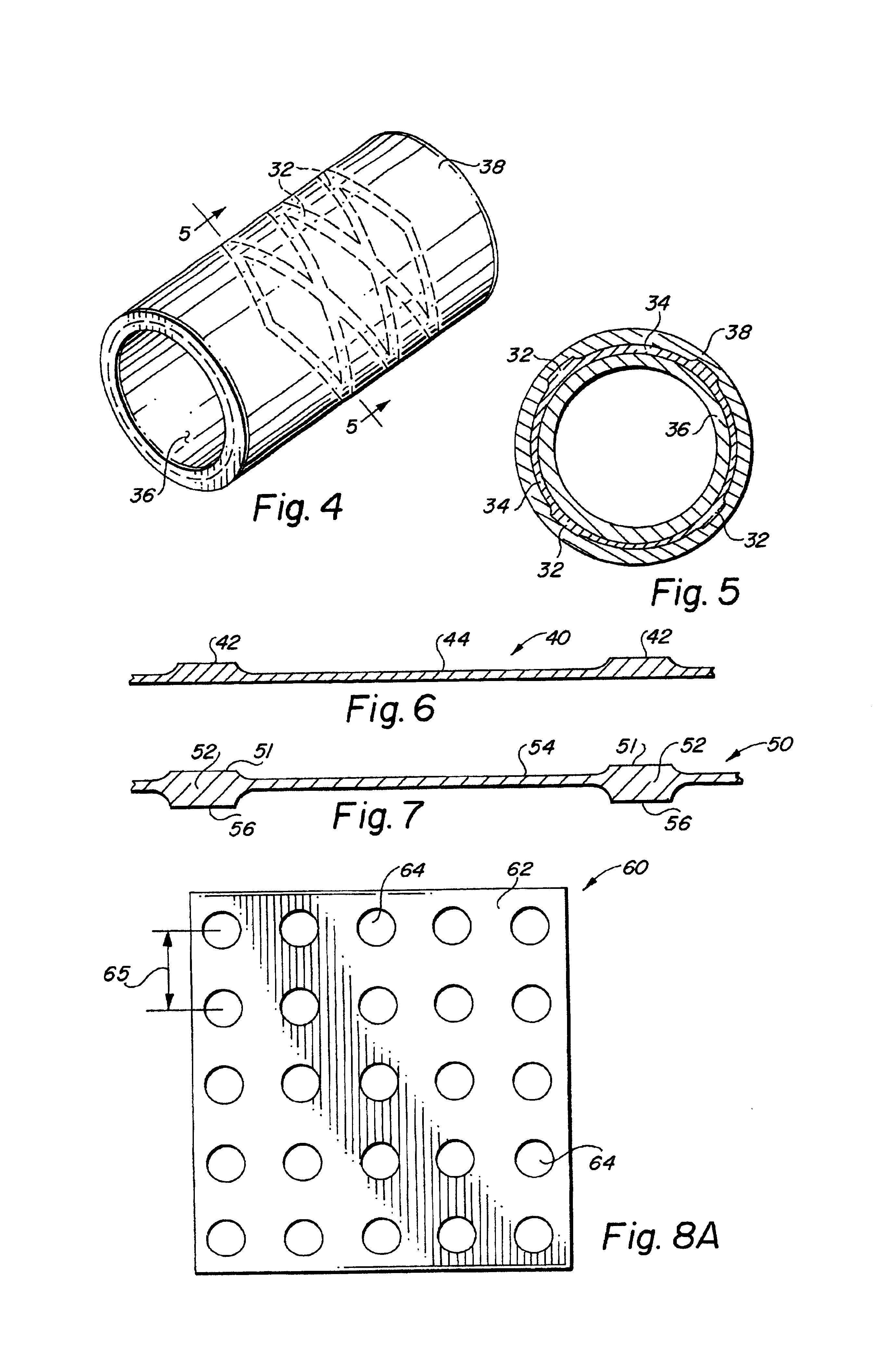

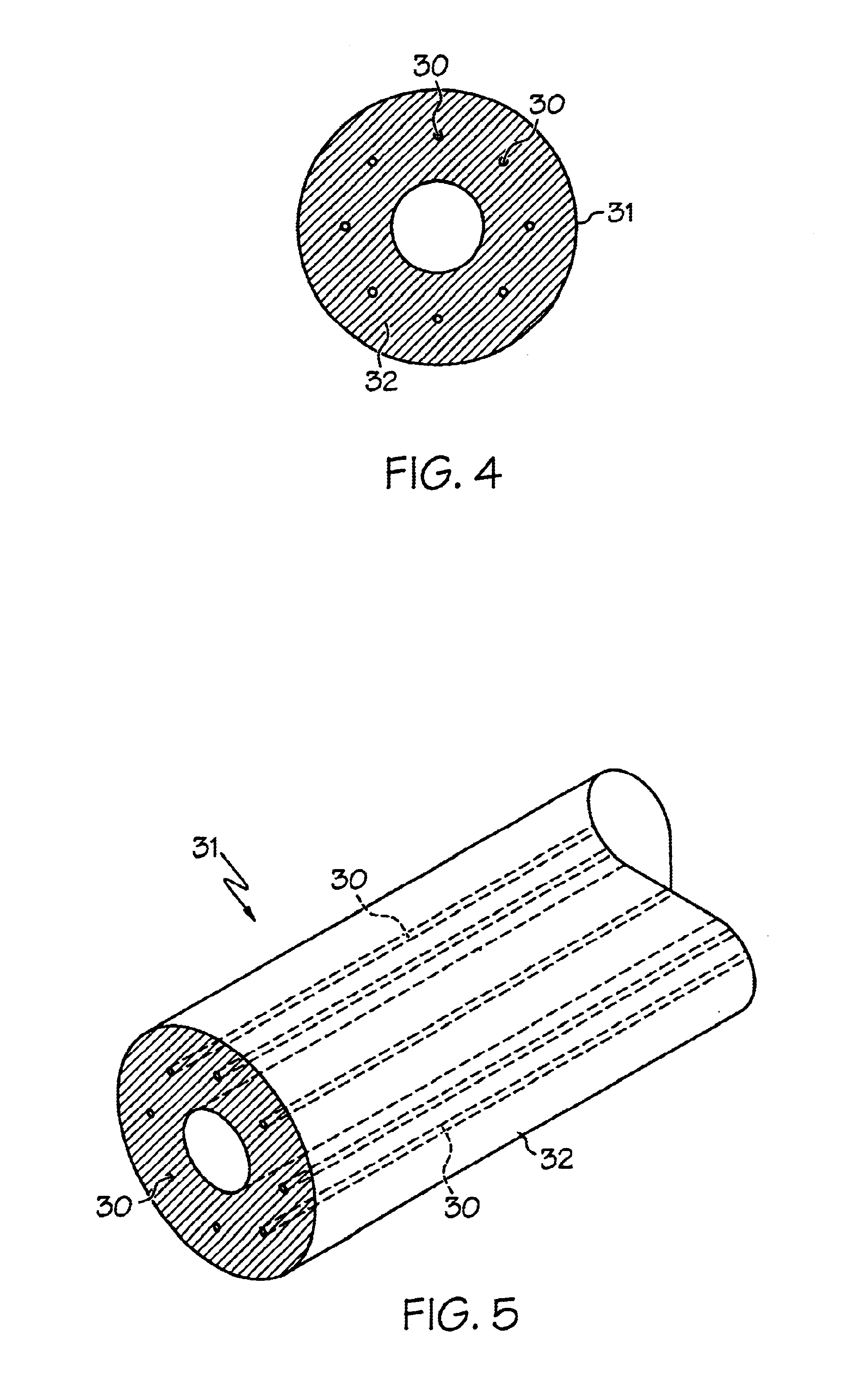

Self-supporting laminated films, structural materials and medical devices manufactured therefrom and methods of making same

Metal foils, wires, and seamless tubes with increased mechanical strength are provided. As opposed to wrought materials that are made of a single metal or alloy, these materials are made of two or more layers forming a laminate structure. Laminate structures are known to increase mechanical strength of sheet materials such as wood and paper products and are used in the area of thin films to increase film hardness, as well as toughness. Laminate metal foils have not been used or developed because the standard metal forming technologies, such as rolling and extrusion, for example, do not lend themselves to the production of laminate structures. Vacuum deposition technologies can be developed to yield laminate metal structures with improved mechanical properties. In addition, laminate structures can be designed to provide special qualities by including layers that have special properties such as superelasticity, shape memory, radio-opacity, corrosion resistance etc. Examples of articles which may be made by the inventive laminate structures include implantable medical devices that are fabricated from the laminated deposited films and which present a blood or body fluid and tissue contact surface that has controlled heterogeneities in material constitution. An endoluminal stent-graft and web-stent that is made of a laminated film material deposited and etched into regions of structural members and web regions subtending interstitial regions between the structural members. An endoluminal graft is also provided which is made of a biocompatible metal or metal-like material. The endoluminal stent-graft is characterized by having controlled heterogeneities in the stent material along the blood flow surface of the stent and the method of fabricating the stent using vacuum deposition methods.

Owner:VACTRONIX SCI LLC

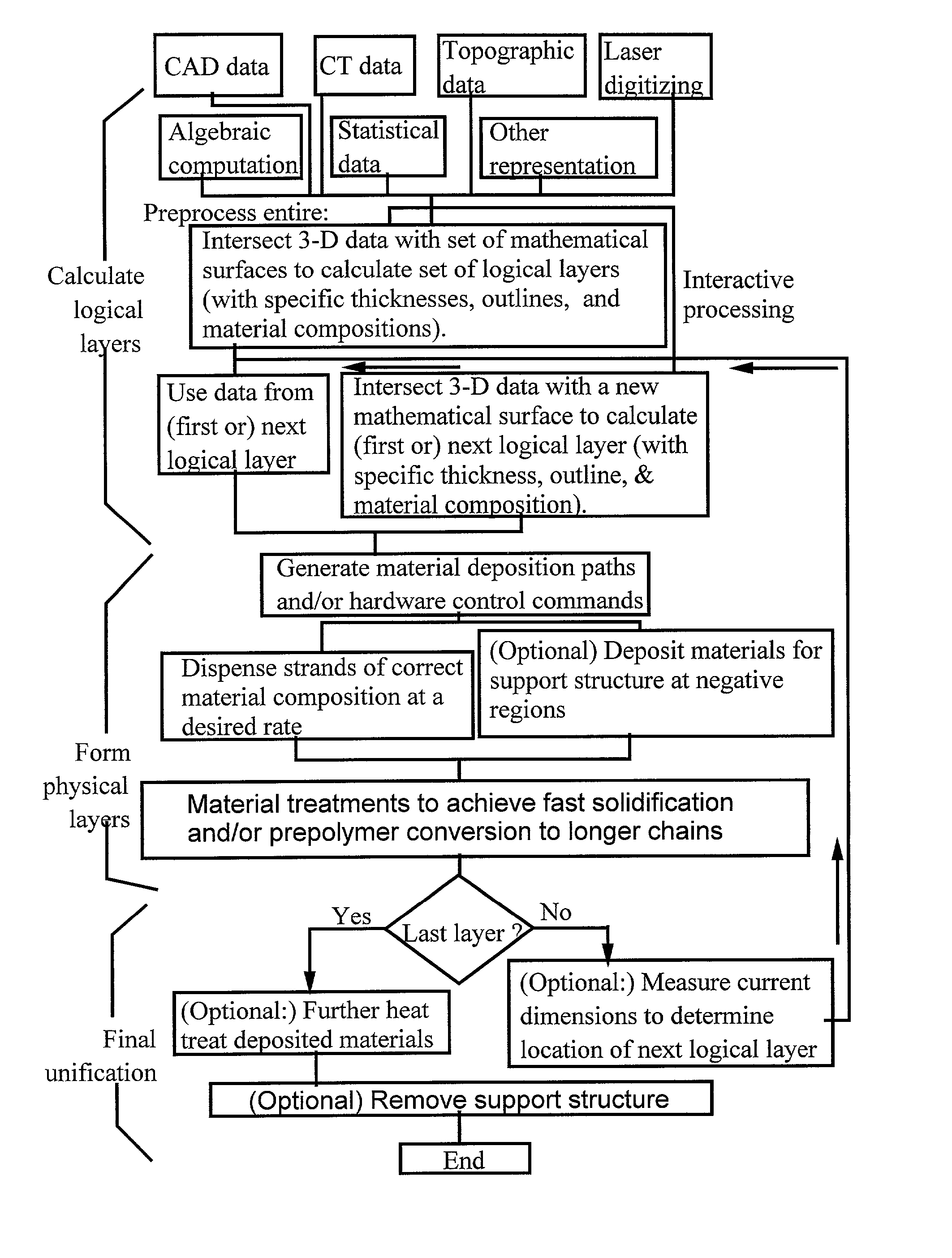

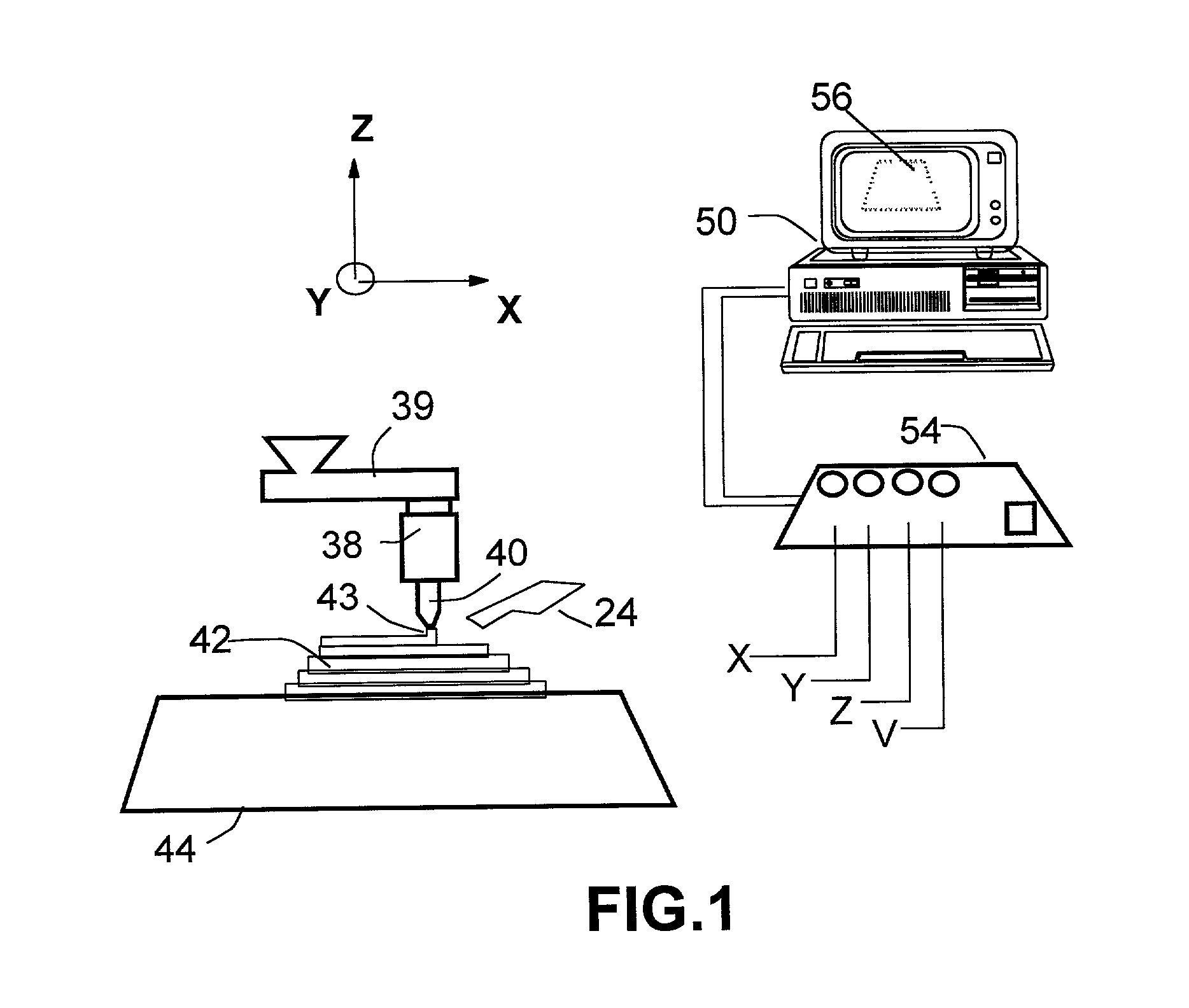

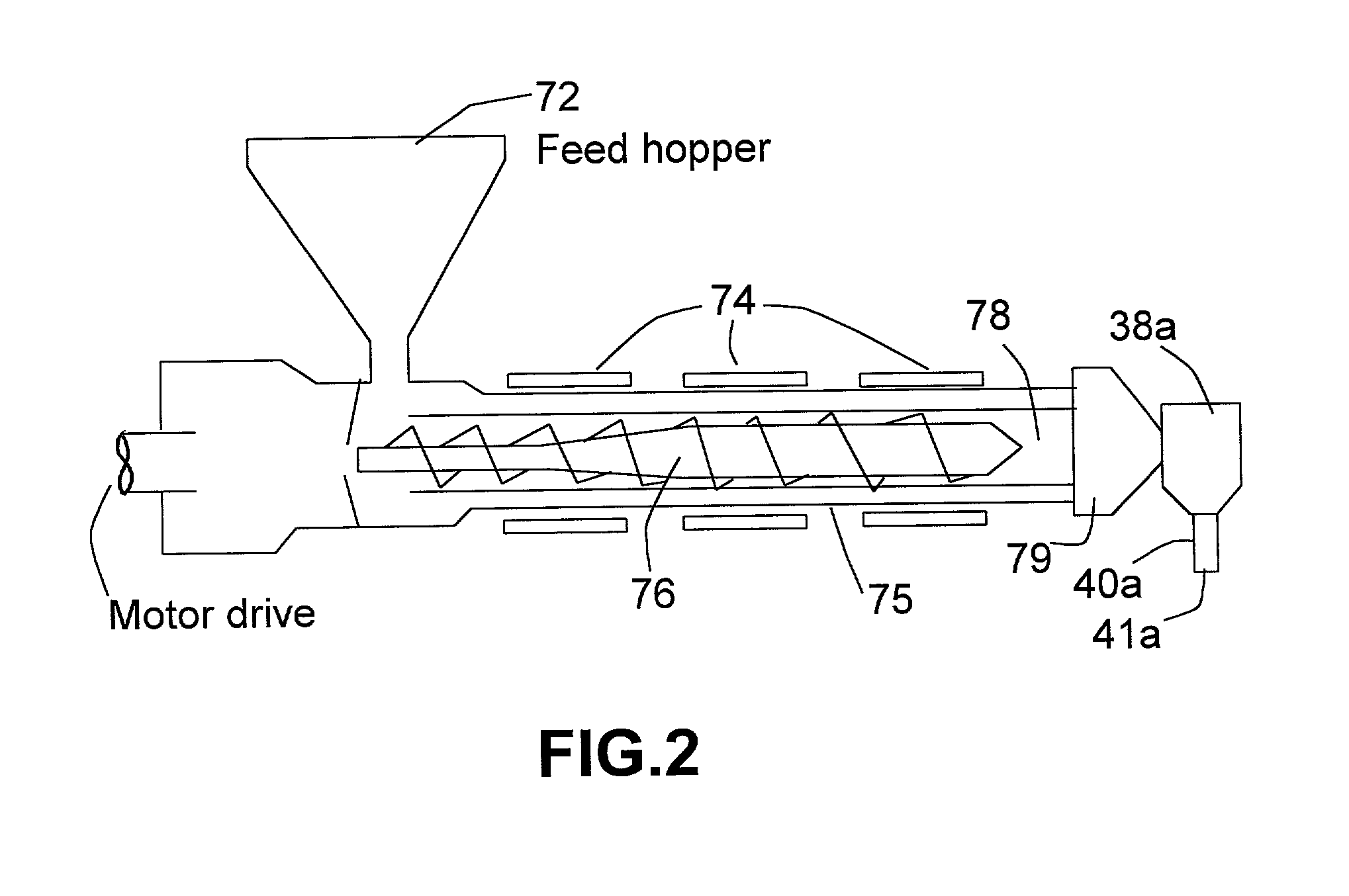

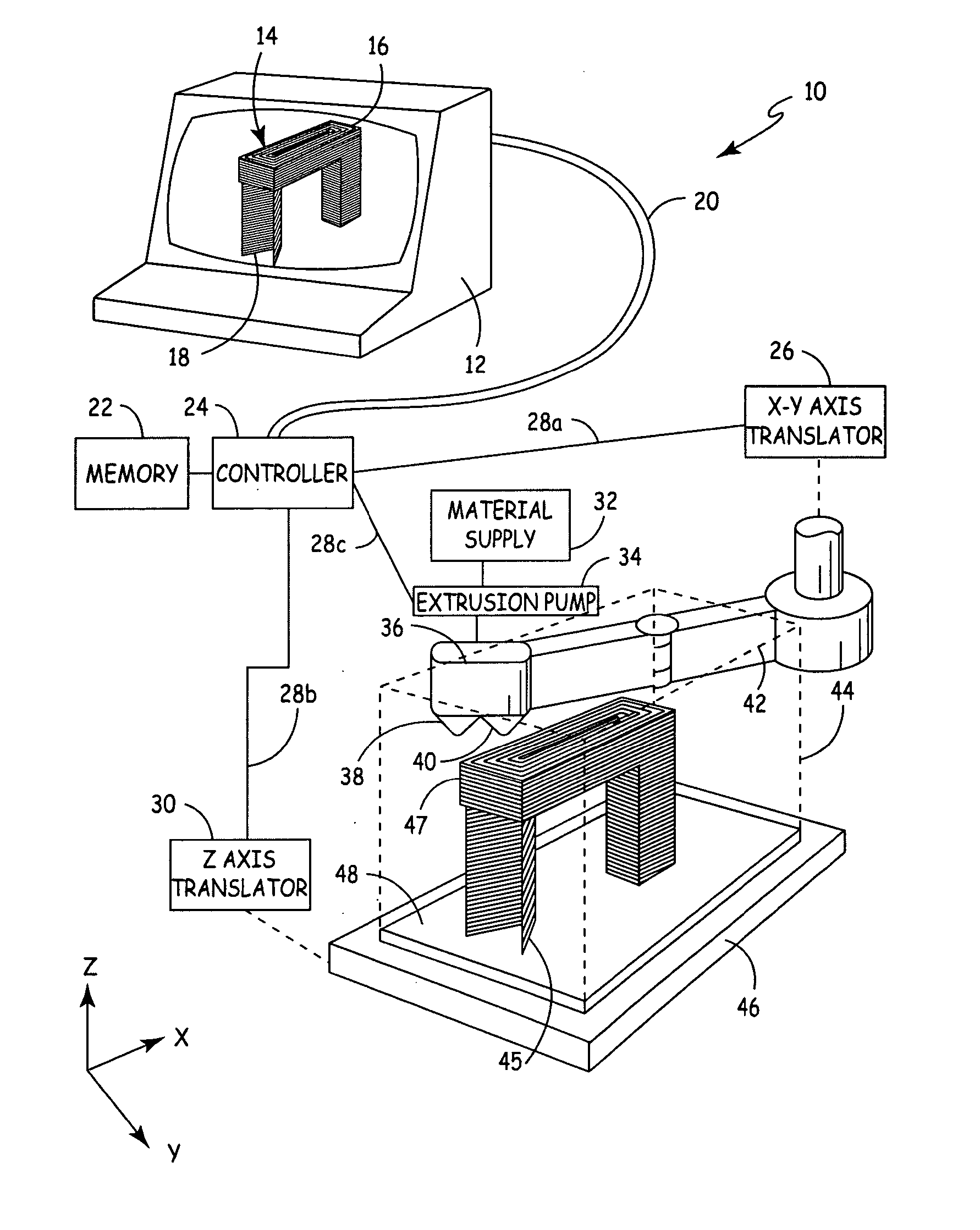

Freeform fabrication method using extrusion of non-cross-linking reactive prepolymers

InactiveUS20020113331A1Fast formingDifficult to prepareProgramme controlComputer controlCross-linkThermoplastic

An extrusion-based freeform fabrication method for making a three-dimensional object from a design created on a computer, including (a) providing a support member; (b) operating a dispensing head having at least one dispensing nozzle with a discharge orifice for dispensing continuous strands of a material composition in a fluent state at a first temperature onto the support member, the material composition including a reactive prepolymer with a melting point above 23° C. and the first temperature being greater than the prepolymer melting point; (c) operating material treatment devices for causing the dispensed strands of material composition to rapidly achieve a rigid state in which the material composition is substantially solidified to build up the 3-D object, the material treatment devices also working to convert the reactive prepolymer to a higher molecular weight thermoplastic resin; and (d) operating control devices for generating control signals in response to coordinates of the object design to control the movement of the dispensing nozzle relative to the support member and for controlling the strand dispensing of the material composition to construct the 3-D object.

Owner:ZHANG TAN +3

PVC nanocomposite manufacturing technology and applications

InactiveUS20080194736A1Material nanotechnologyPigmenting treatmentPolymer scienceManufacturing technology

The present invention relates to a process and a product of forming polymer (especially PVC) nanocomposites with a variety of nanofillers. The present invention provides a method for forming a polymer nanocomposite, comprising powder mixing a composition comprising polymer resin, a nanofiller, and a coupling agent for a residence time of about 4 to about 8 minutes to form a dry blend and extruding the dry blend in an extrusion process. Additionally, the present invention relates to a polymer nanocomposite formed by a process, comprising powder mixing a polymer resin, a nanofiller, and a coupling agent for a residence time of about 4 to about 8 minutes to form a dry blend and extruding the dry blend in an extrusion process to achieve homogeneous dispersion of nanofillers in the polymer matrix.

Owner:FORMOSA PLASTICCS CORP

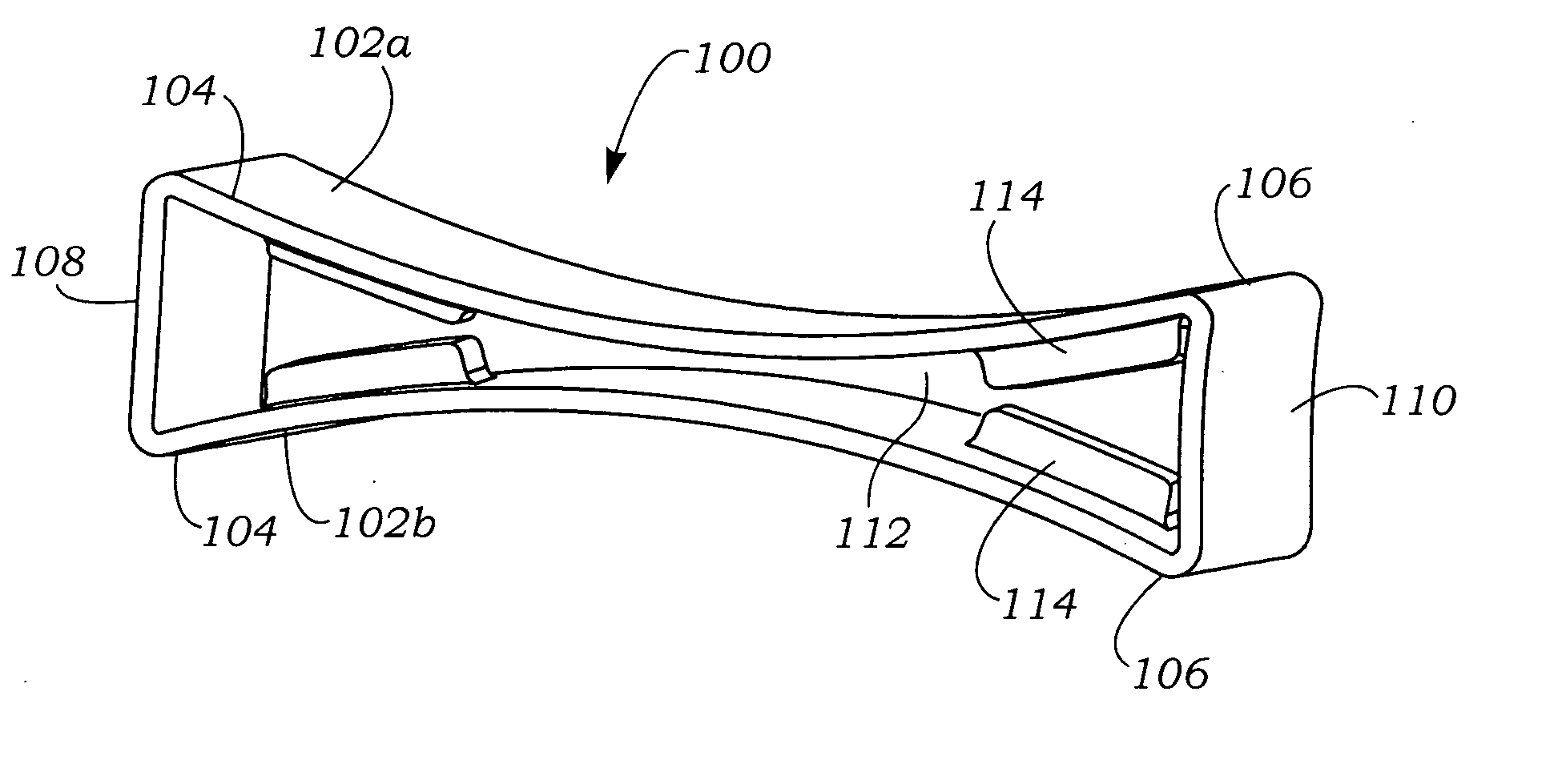

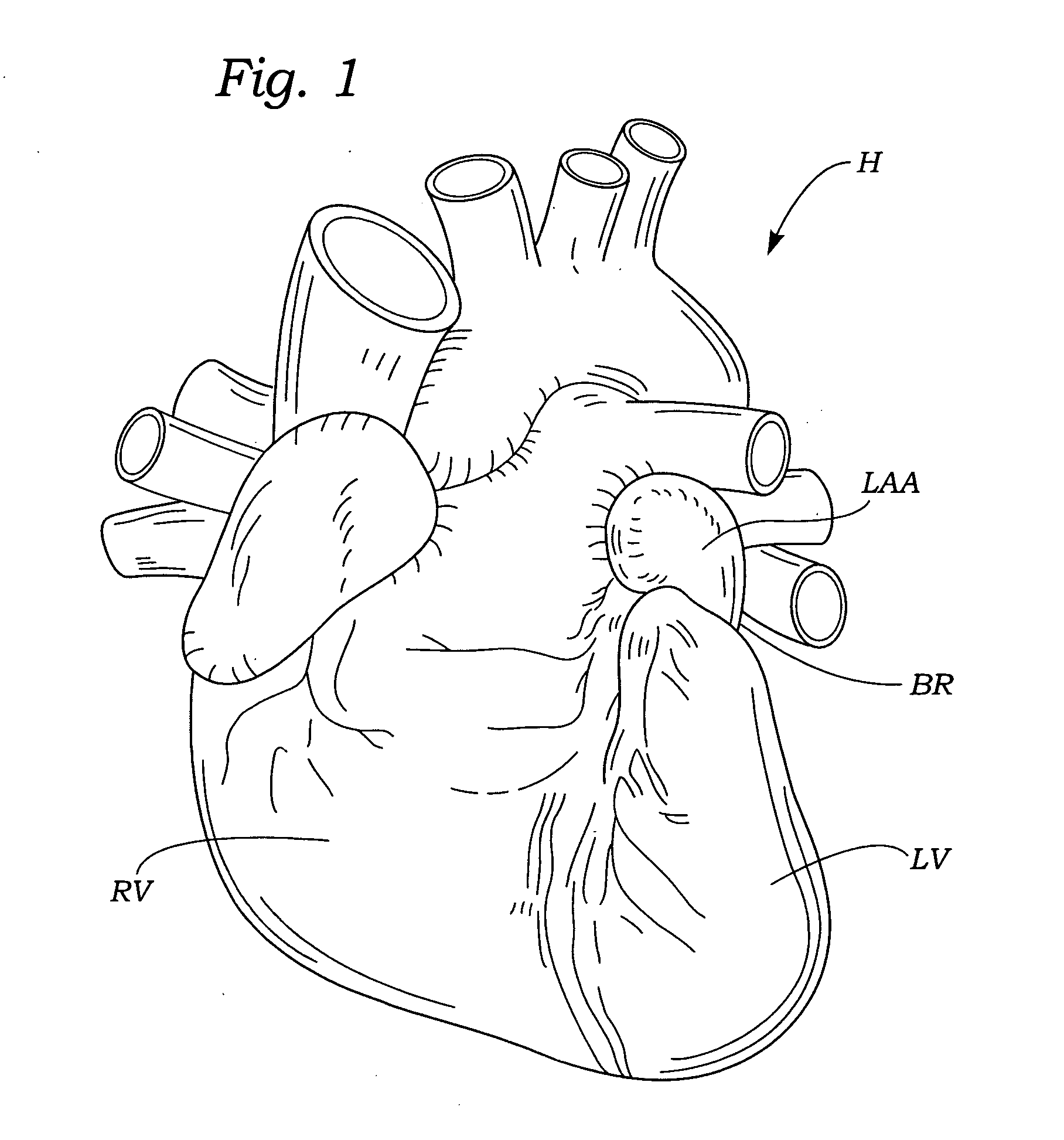

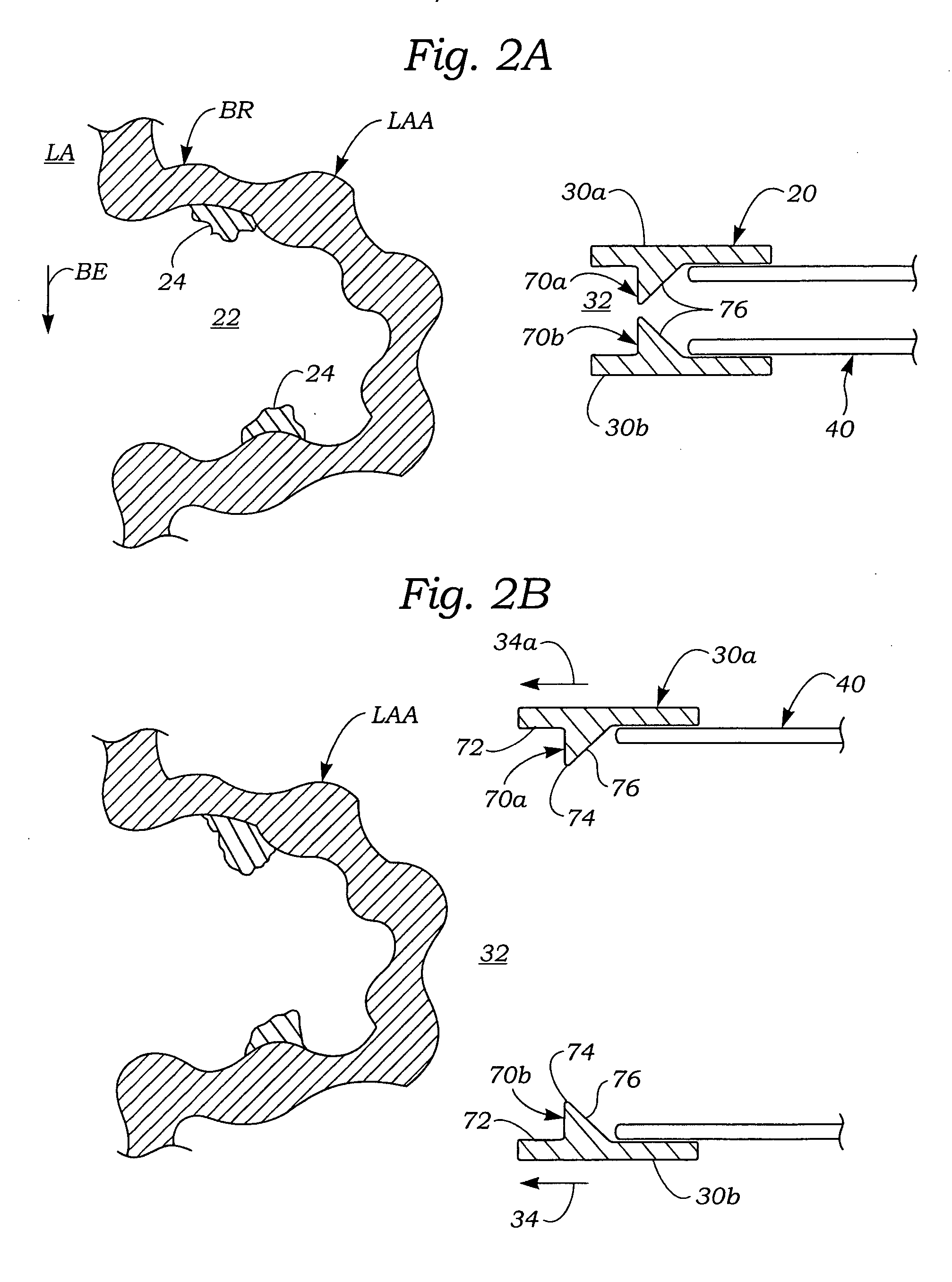

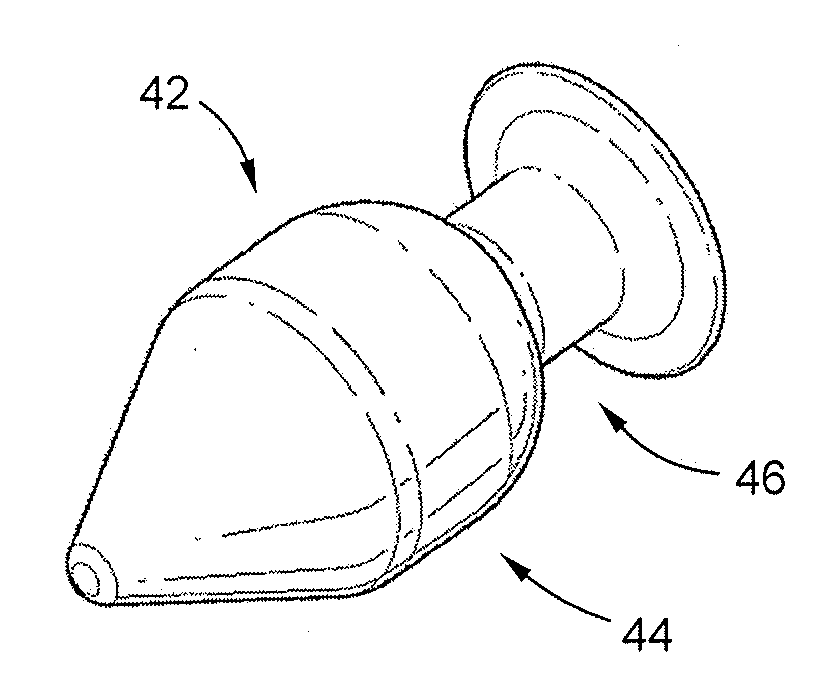

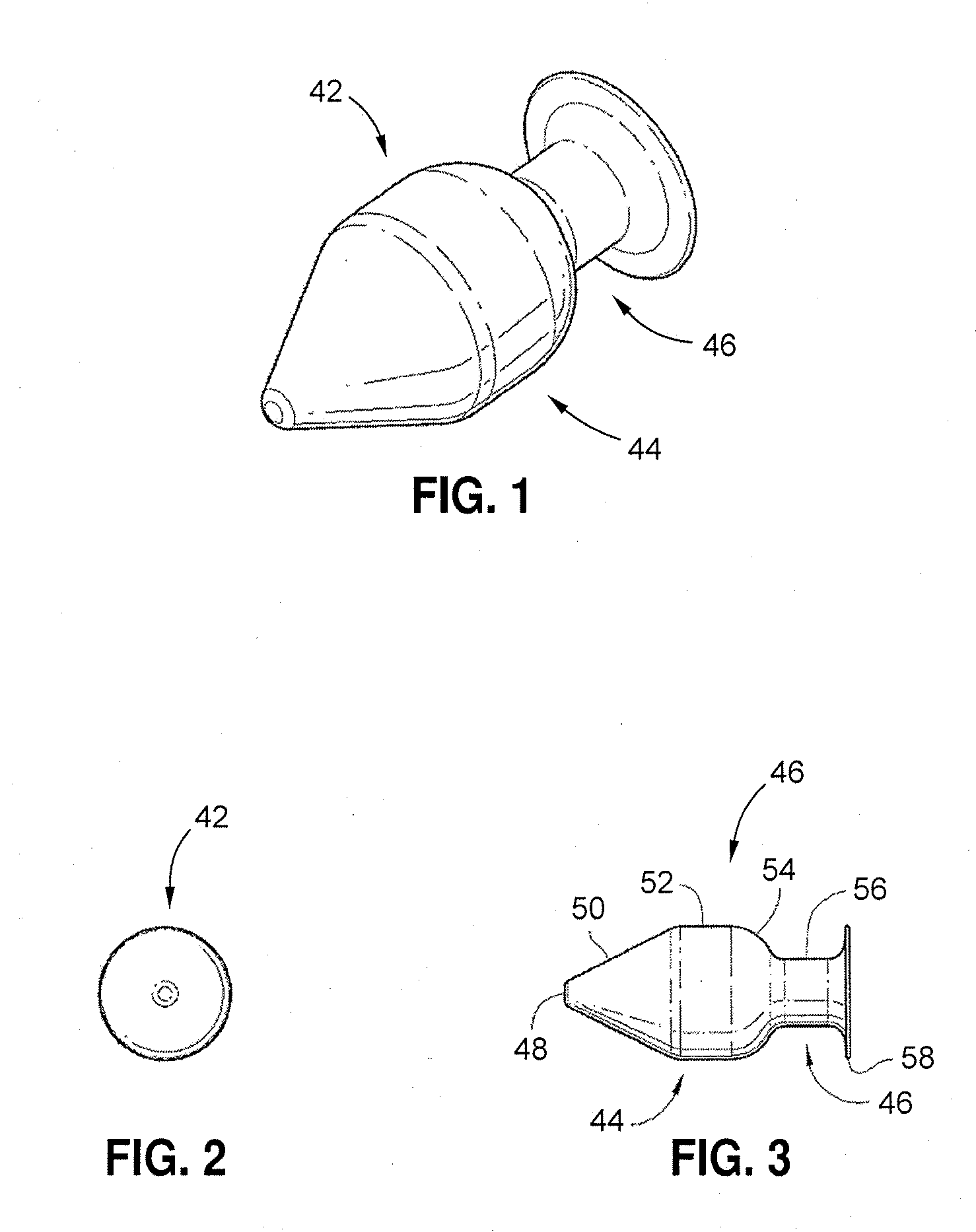

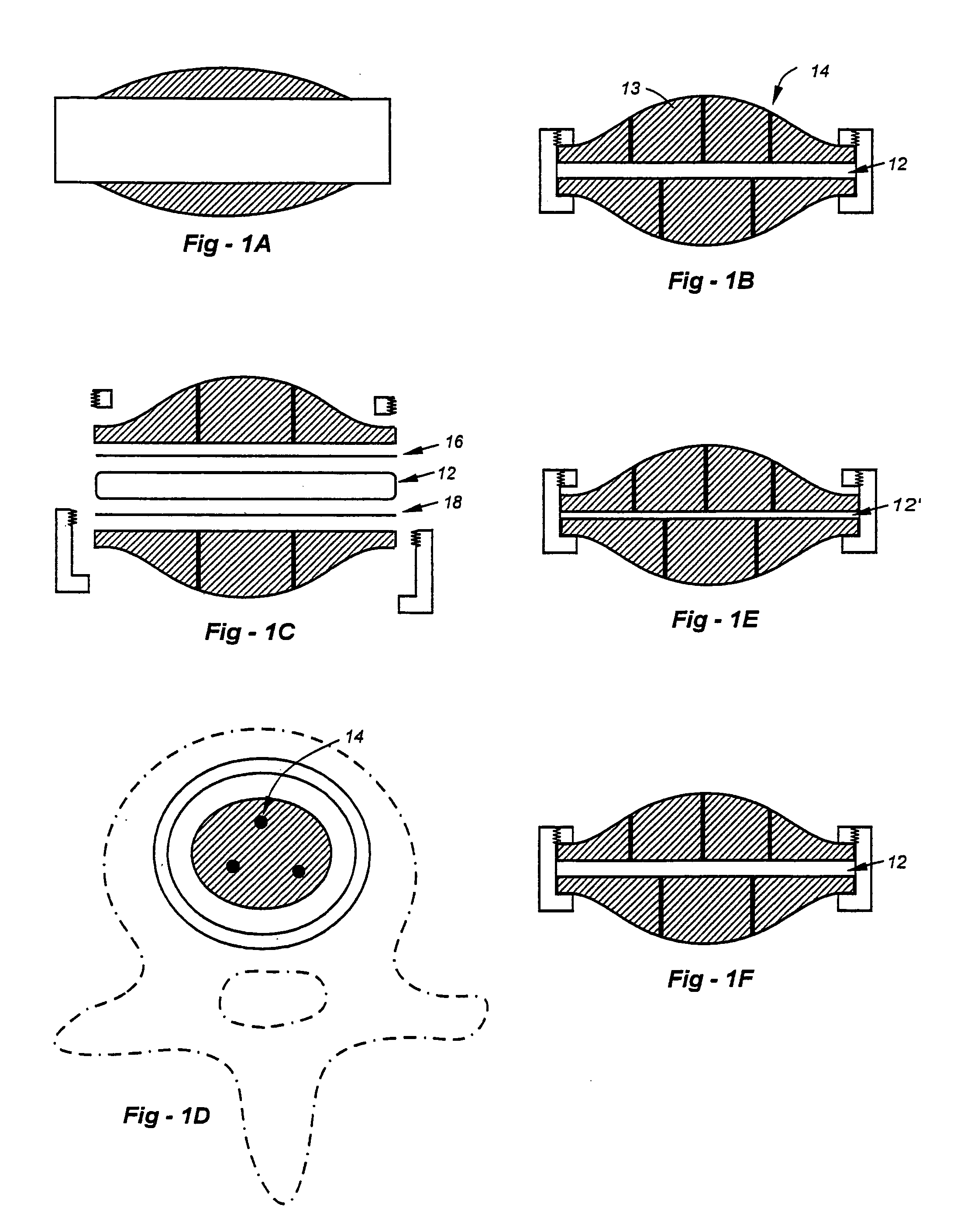

Left atrial appendage exclusion device

A device for excluding the inner cavity of the left internal appendage (LAA) from the interior of the left atrium LA may include a pair of compression members spaced apart and defining a closed periphery. The closed periphery has a variable-sized opening therein that can be enlarged to surround the LAA and then closed to compress and exclude the LAA. The closed periphery may be generally rectangular or lenticular, and may be a solid, contiguous periphery or separable at a closure. Inner protrusions or ribs may be provided on the compression members to help anchor the exclusion device in place. Needles may also be provided to pierce the LAA tissue and trap blood clots therein. The device may be non-linear in plan view so as to conform to the shape of the external left atrium. Deployment techniques or structures may be provided that squeeze the LAA in a direction starting adjacent the left atrium and then moving away from the left atrium. This squeezing motion helps prevent extrusion of any thrombus deposit within the LAA cavity into the left atrium.

Owner:EDWARDS LIFESCIENCES CORP

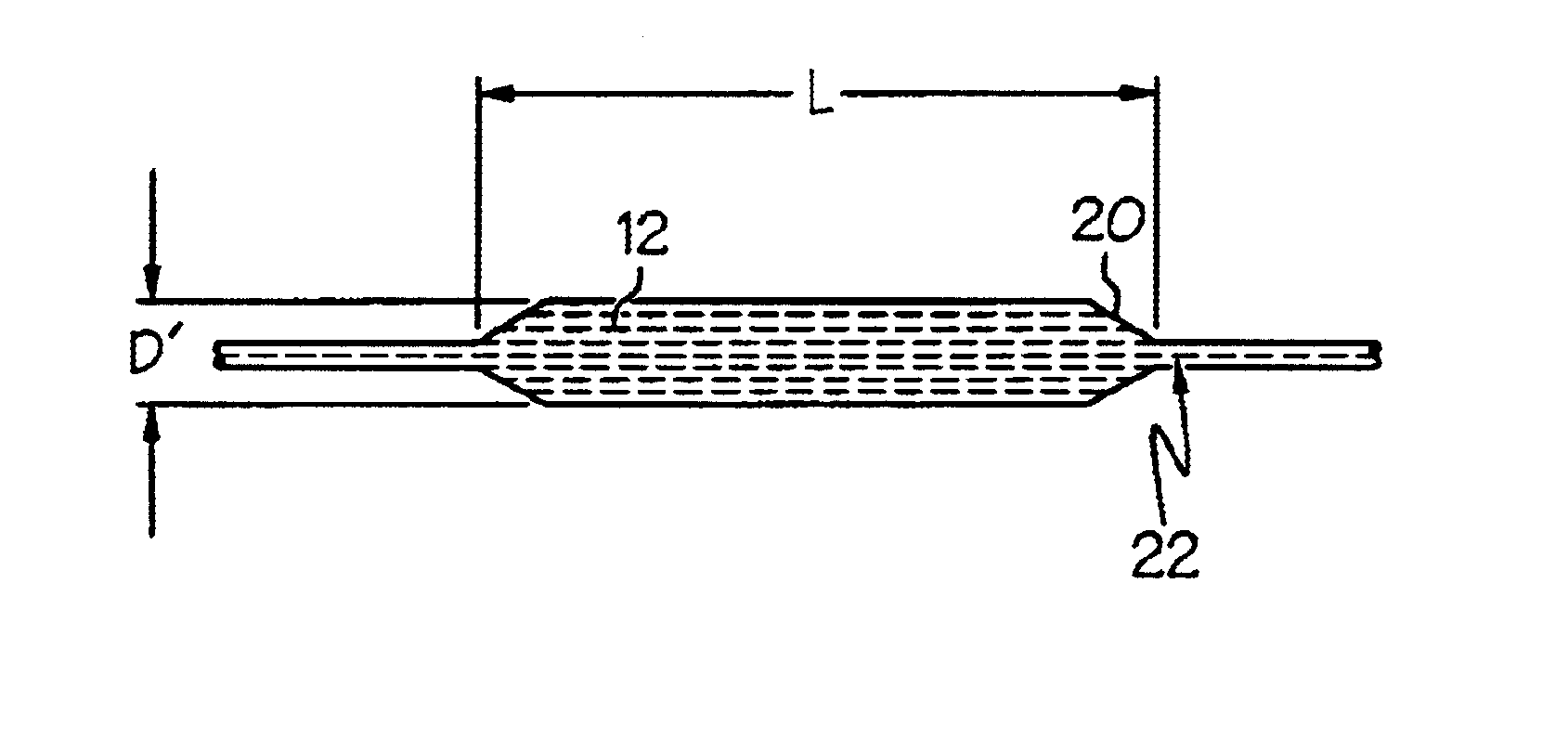

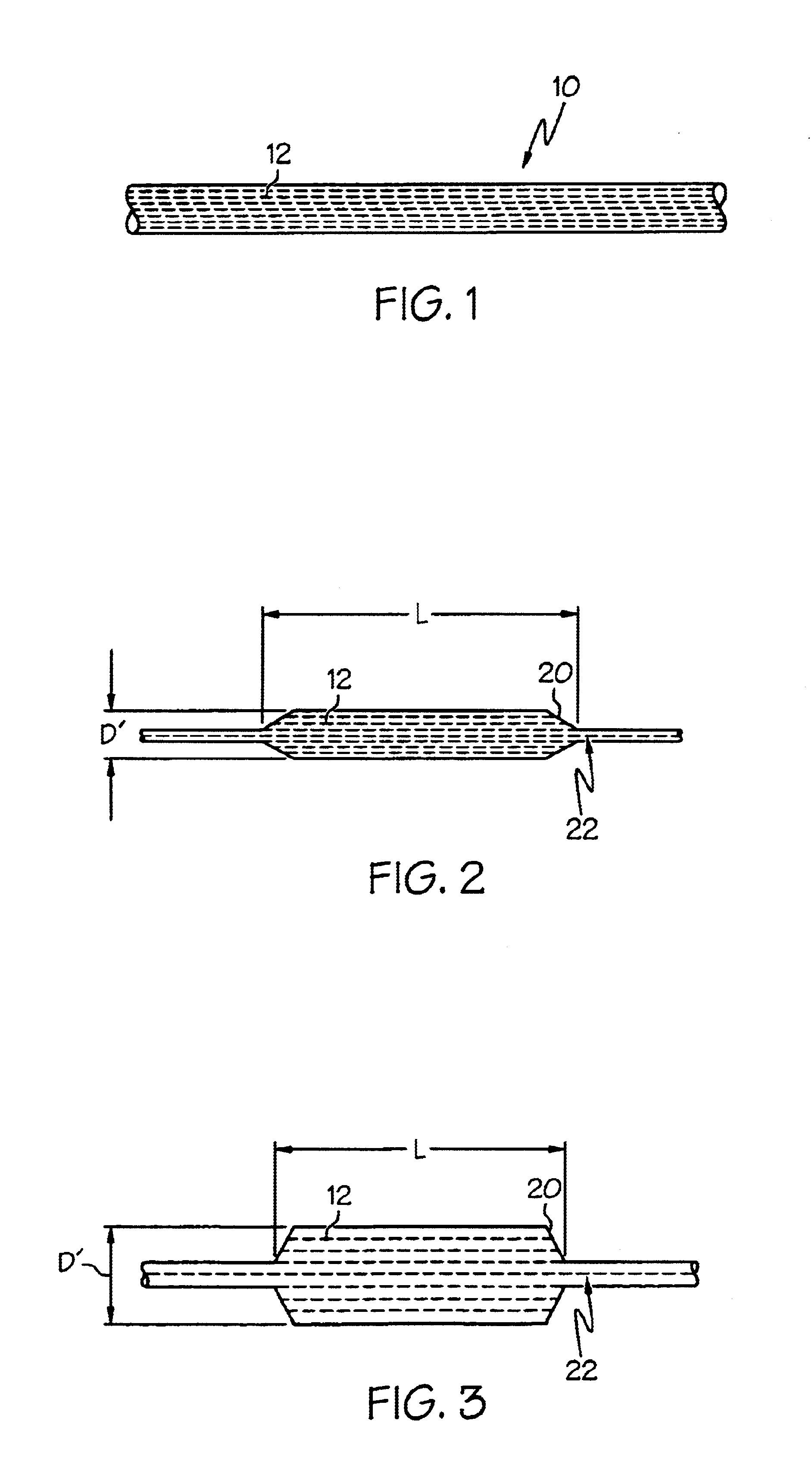

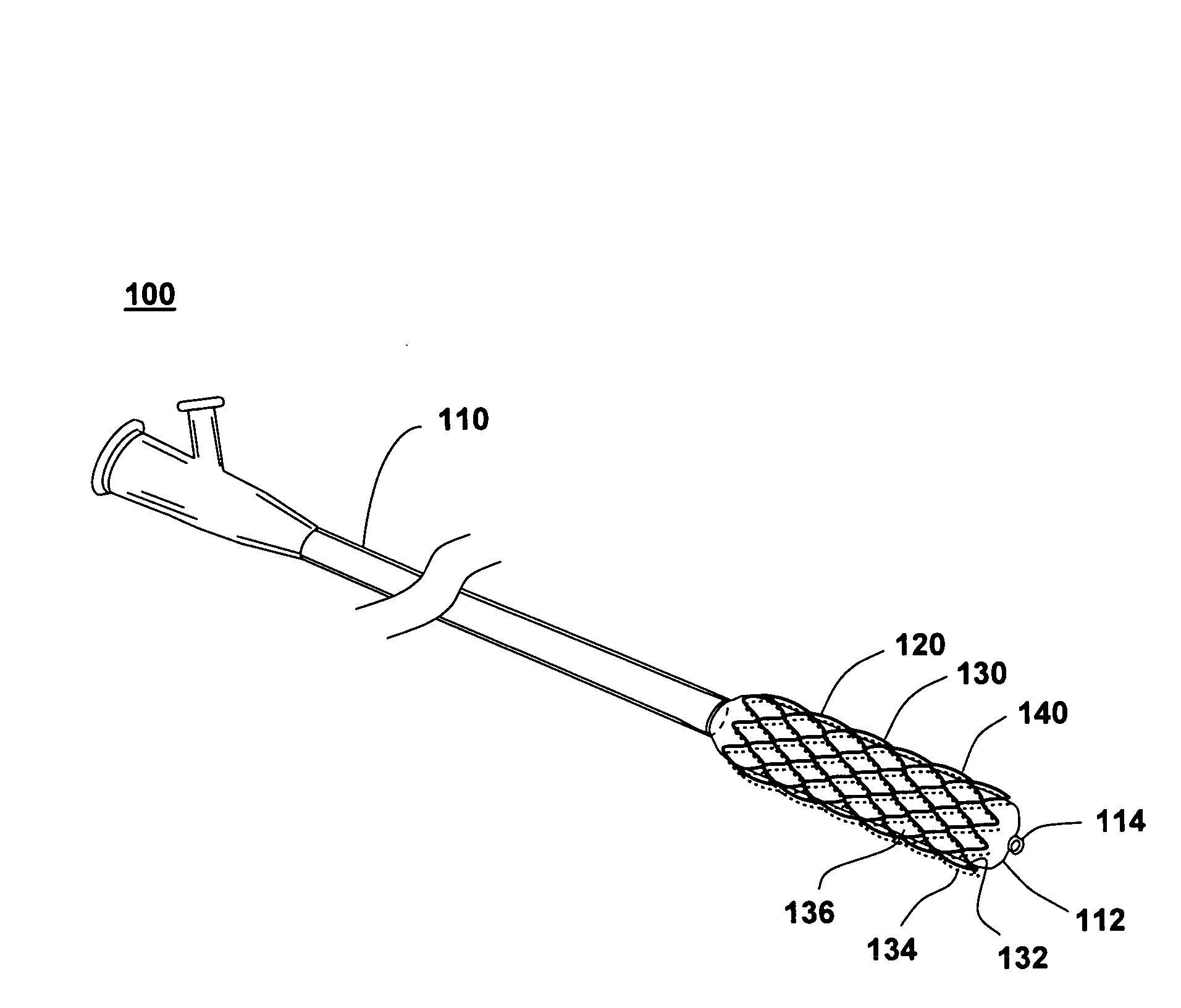

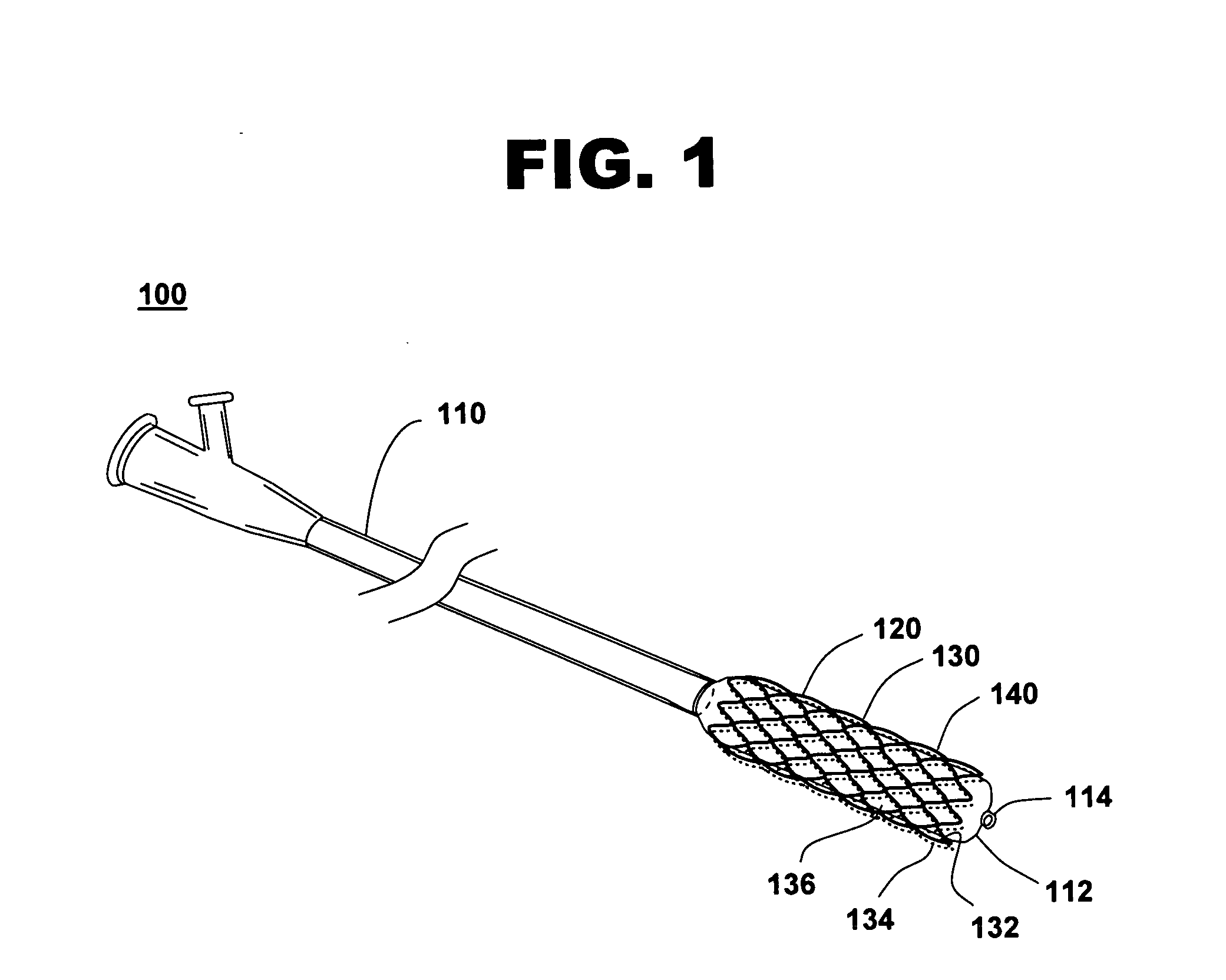

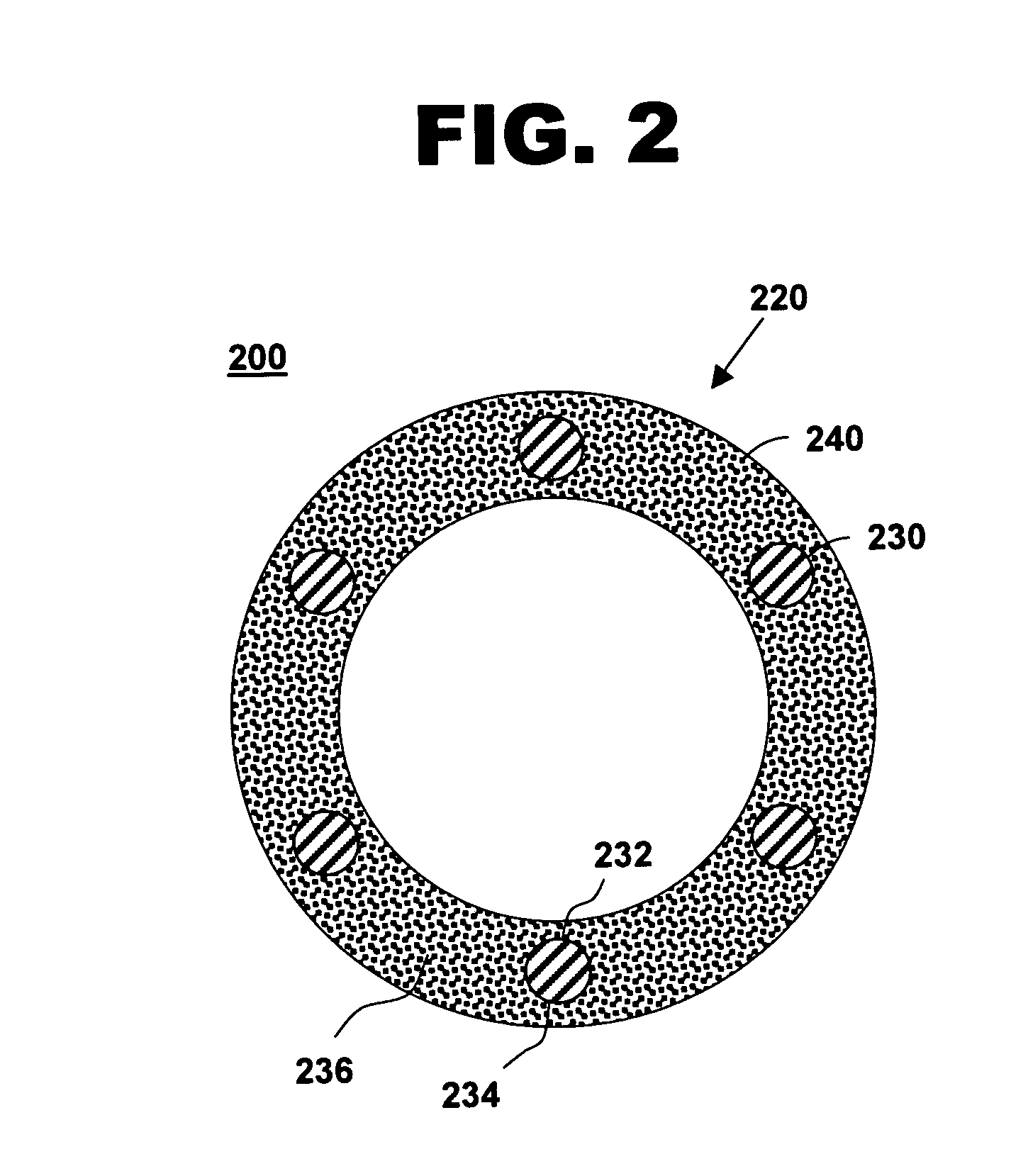

Dimensionally stable balloons

A medical balloon composed of a micro-composite material which provides for radial expansion of a balloon to a predetermined extent, but which has minimal longitudinal growing during balloon inflation. The micro-composite material includes a fibril component, a matrix component, and optionally, a compatibilizer. The fibril component may preferably be liquid crystal polymer fibers randomly scattered through out the balloon material. The liquid crystal polymers are created by extrusion at high speed. An alternative fibril component may be a PET fibers which are uniformly spaced about the balloon material and extend through out the length of the balloon material tube.

Owner:BOSTON SCI SCIMED INC

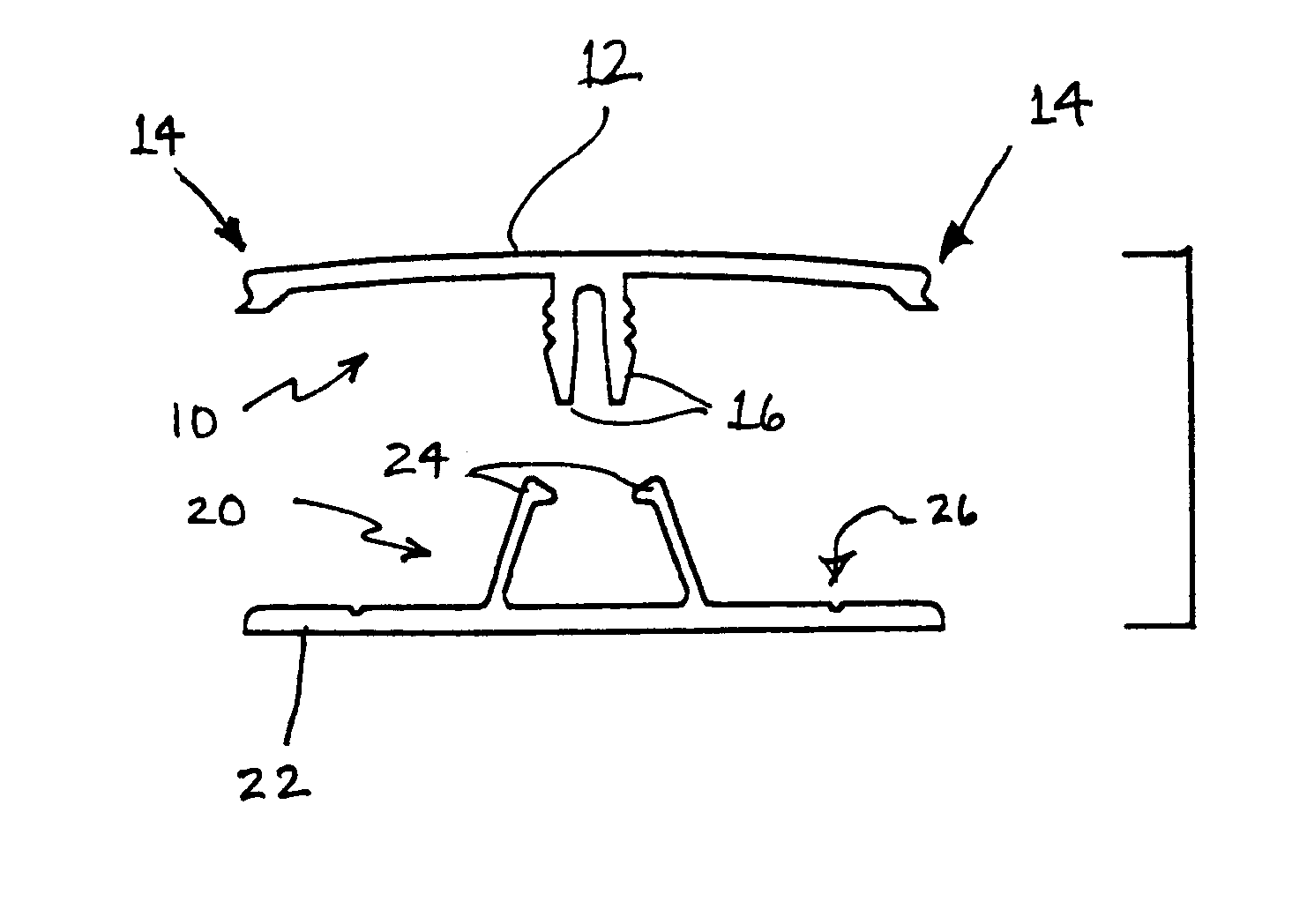

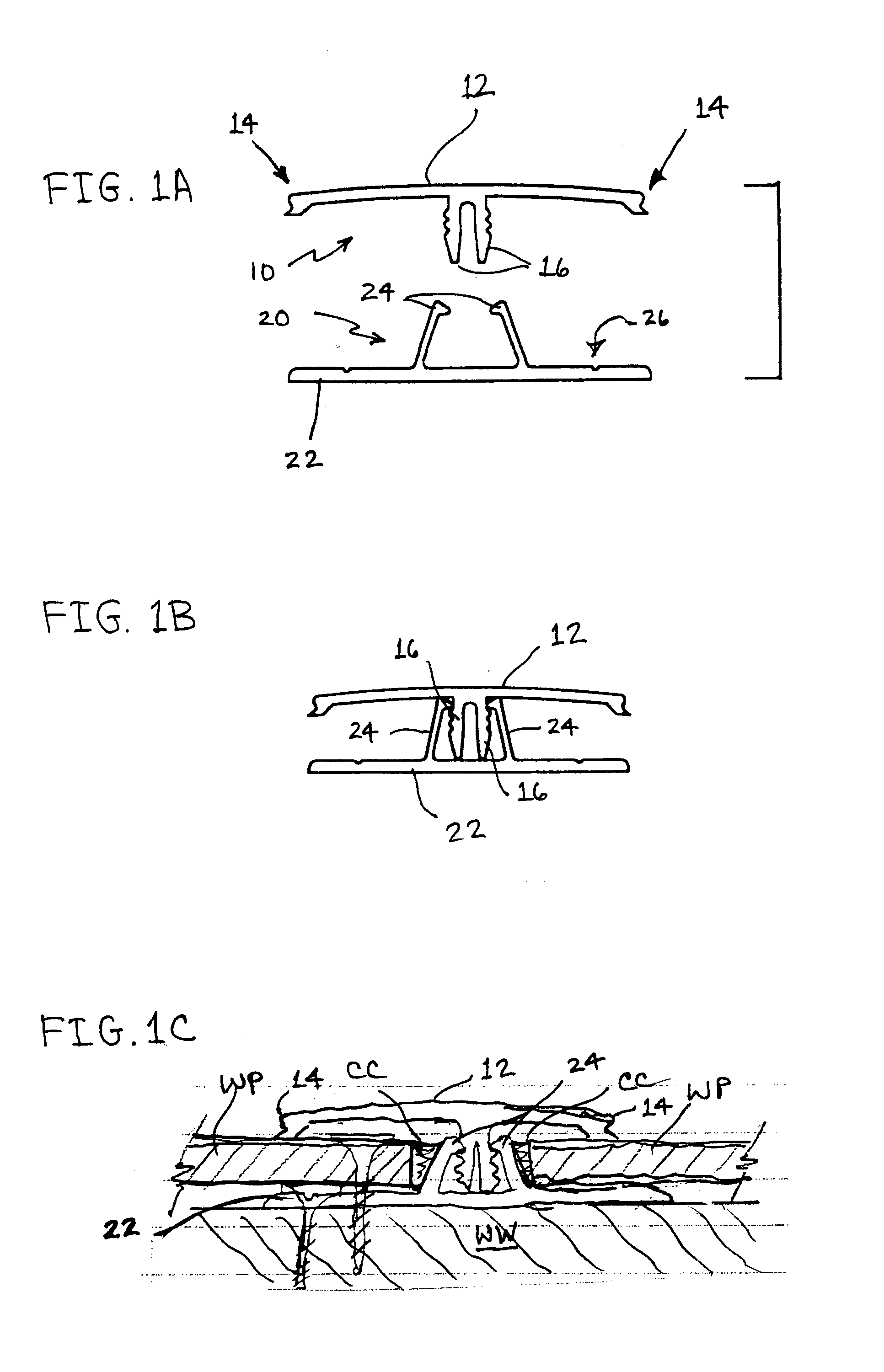

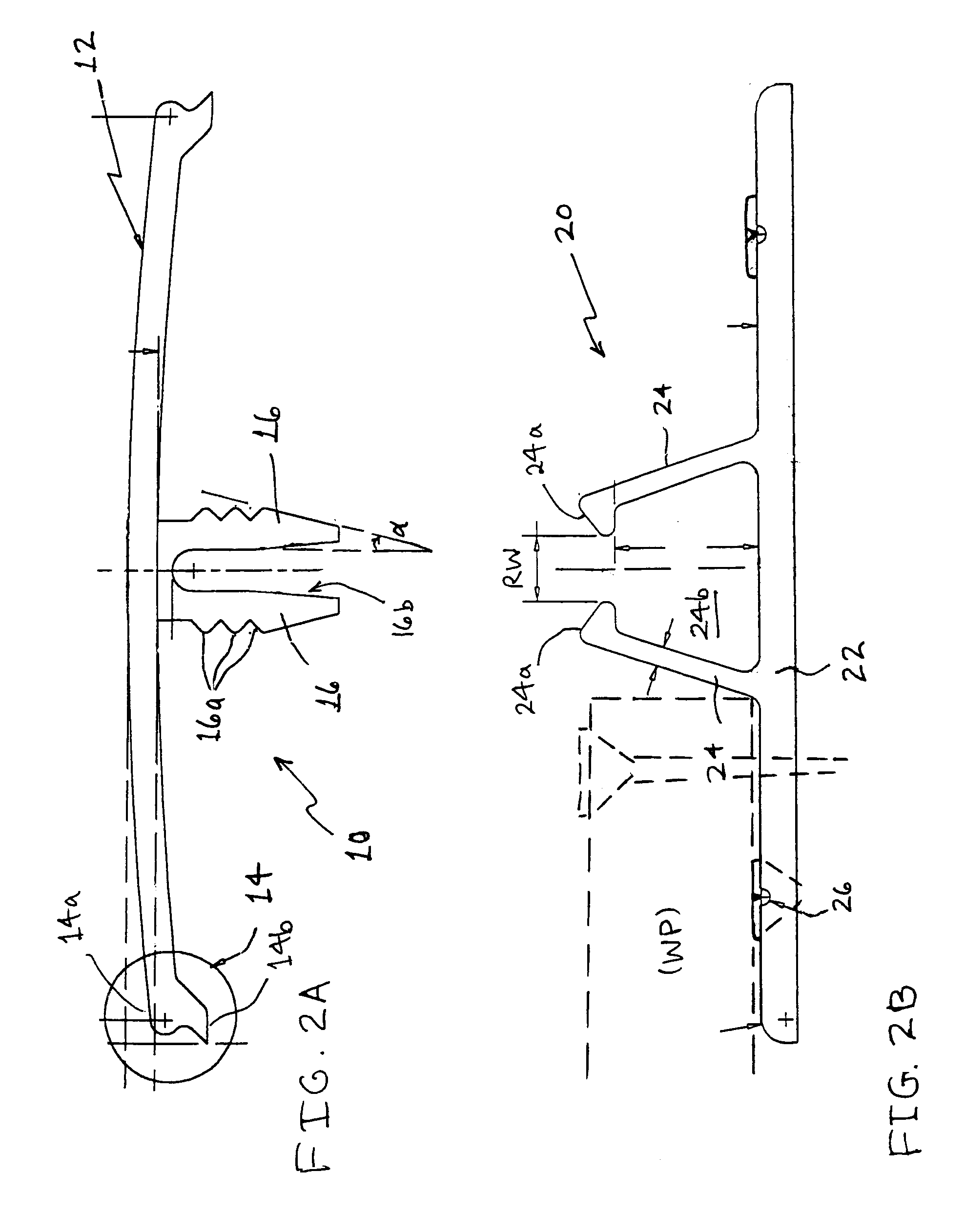

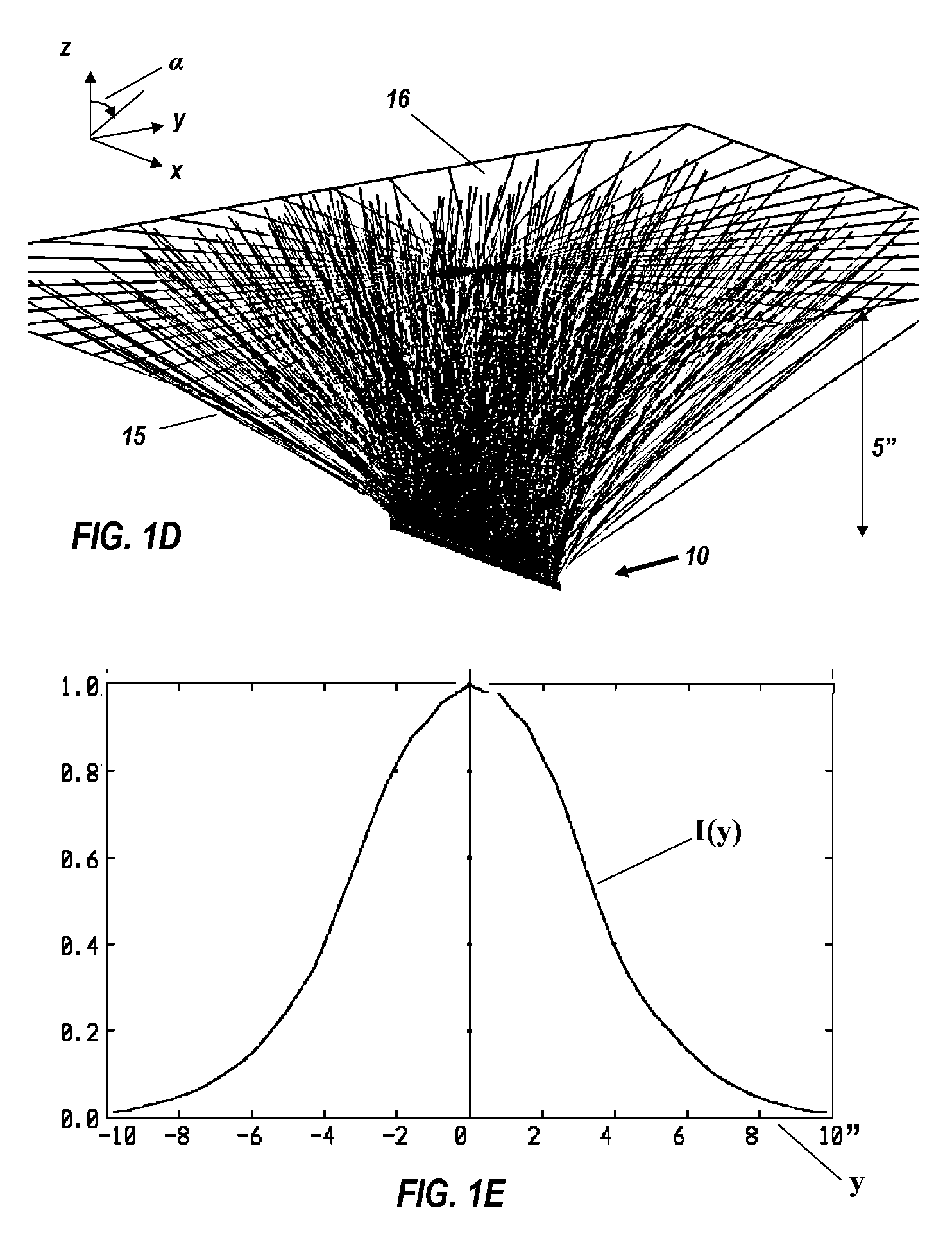

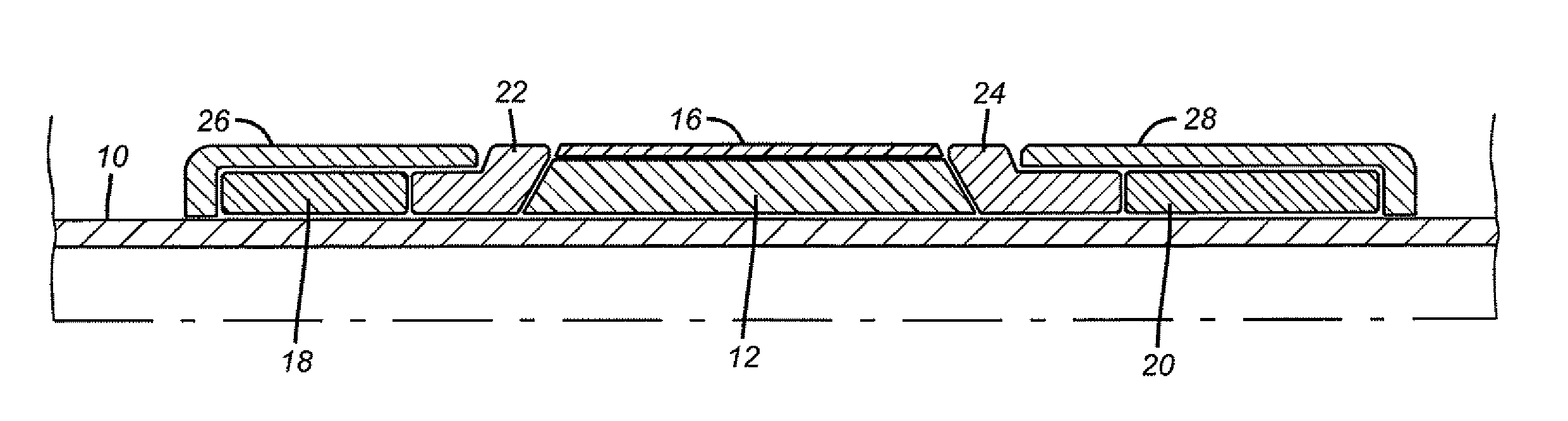

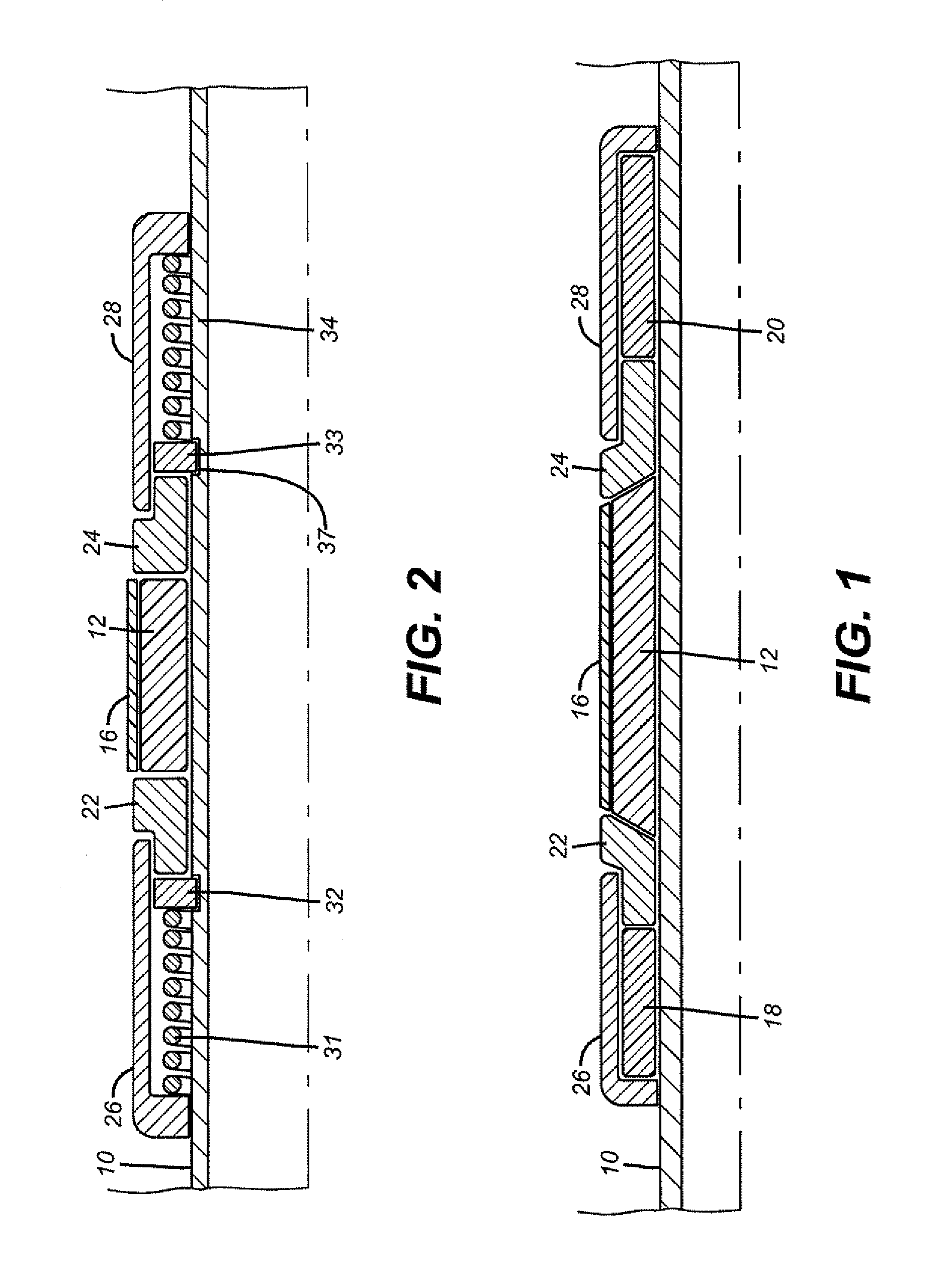

Extrusion devices for mounting wall panels

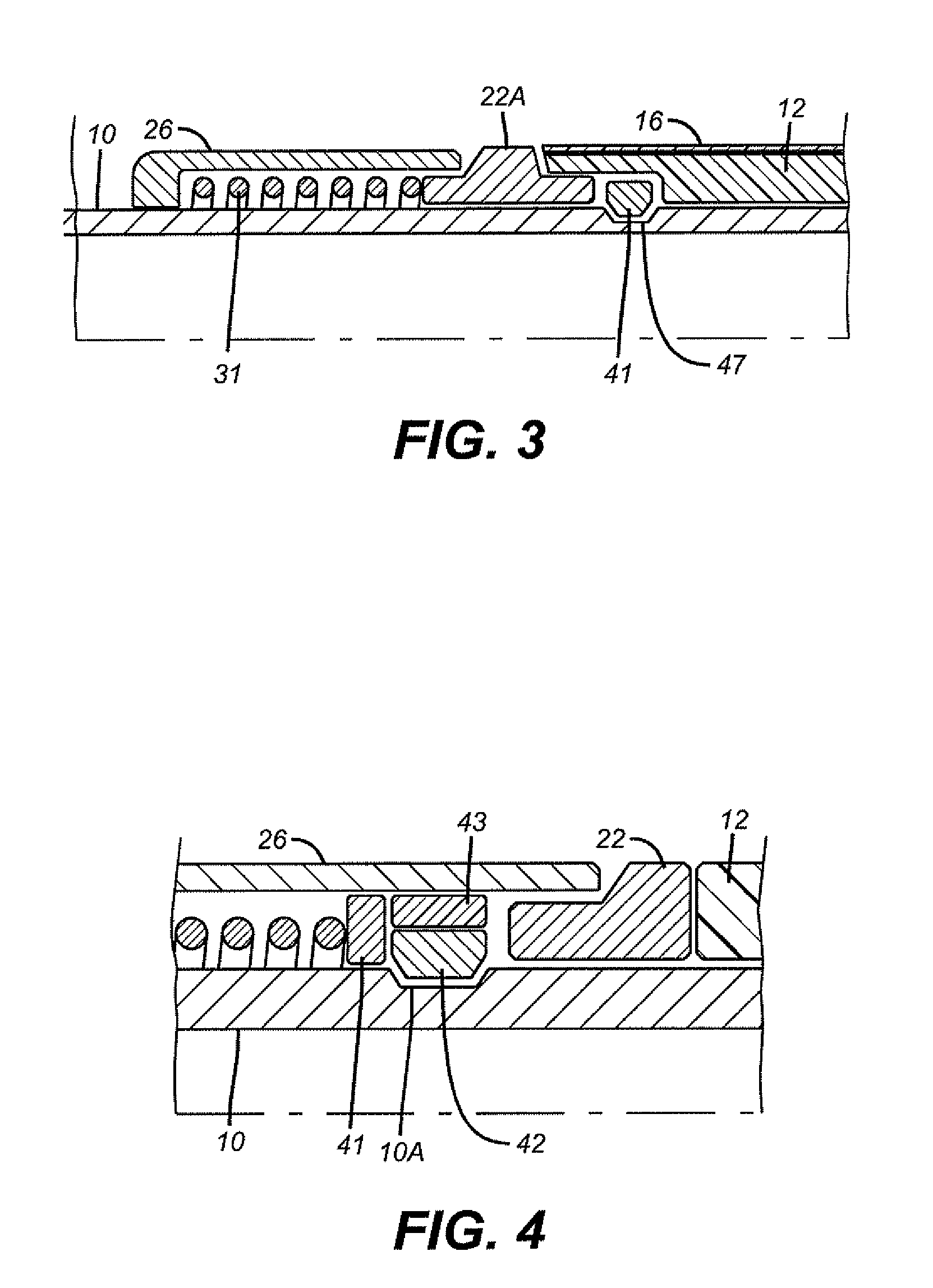

InactiveUS6588165B1Easy to insertImprove grip strengthCeilingsRoof covering using tiles/slatesEngineeringEdge space

An extrusion device for mounting a wall panel has an outer cap extending to an edge on at least one side which is positioned against an outer surface of a wall panel, having a pair of spaced-apart insertion fingers, and a receiver base having a planar mounting portion and a pair of angled receiver flanges projecting upwardly to receive the insertion fingers therein. The two-piece extrusion permits wall panels to be mounted or removed from the underlying wall structure in on-sequential order. The receiver base and cap can be provided on both sides to form an "H" type extrusion, or on only one side in a "J" type extrusion. Preferably, the outer cap is made of metal, and the tips of the insertion fingers are beveled at a slight angle of about 7° to 14° to allow easy insertion into the receiver flanges. The cap has compound water-shedding edges formed with a rounded rain-drip edge spaced in close proximity to a sharply inclined knife edge. In another variation, a one-piece extrusion device has a rear base portion and a front cover portion forming a pocket therewith, and a ramp formed on the base portion within the width of the front cover portion for gradually forcing the edge of a wall panel inserted in the pocket toward the front cover portion clear of the heads of screws used to mount the base portion to the underlying wall structure. The base portion is formed with a hook indentation on a back side of the ramp on a rear surface of the base portion, and interconnects with a "Z" type extrusion having a hook end to form a right angle connection. The one-piece extrusion may be formed as a "J" (one-sided), "H" (two sided), "C" (corner), or other suitable types.

Owner:WRIGHT JOHN T

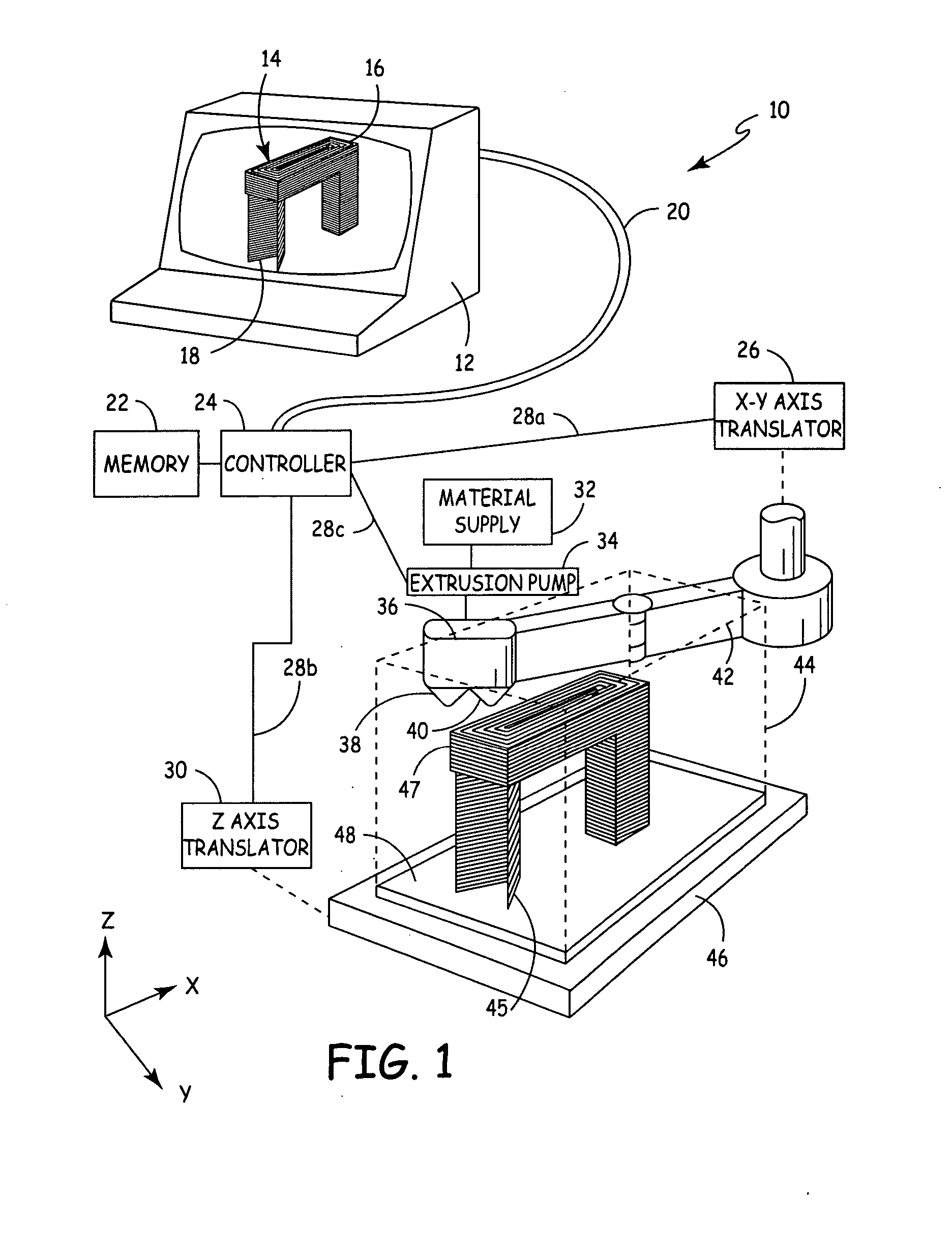

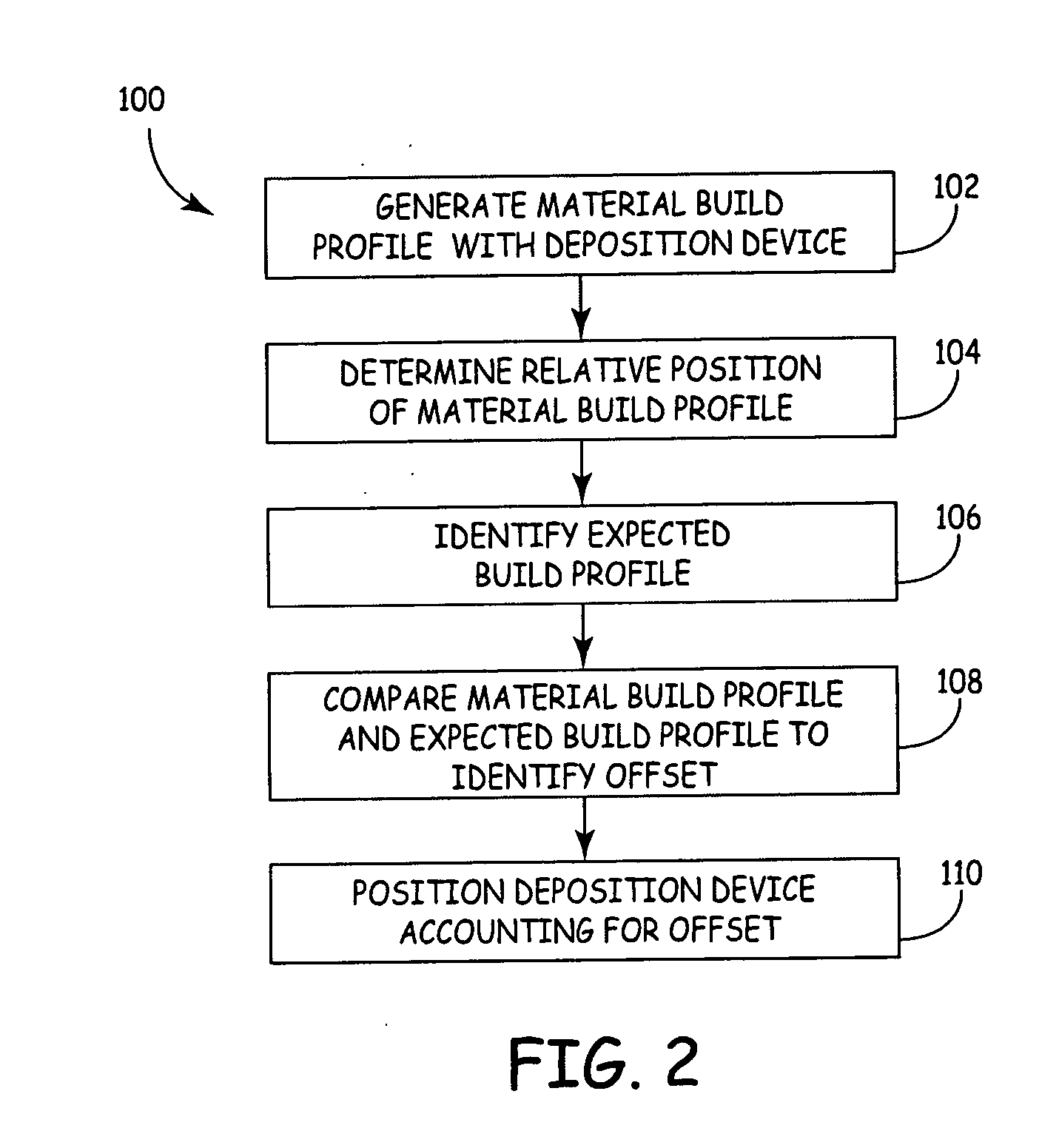

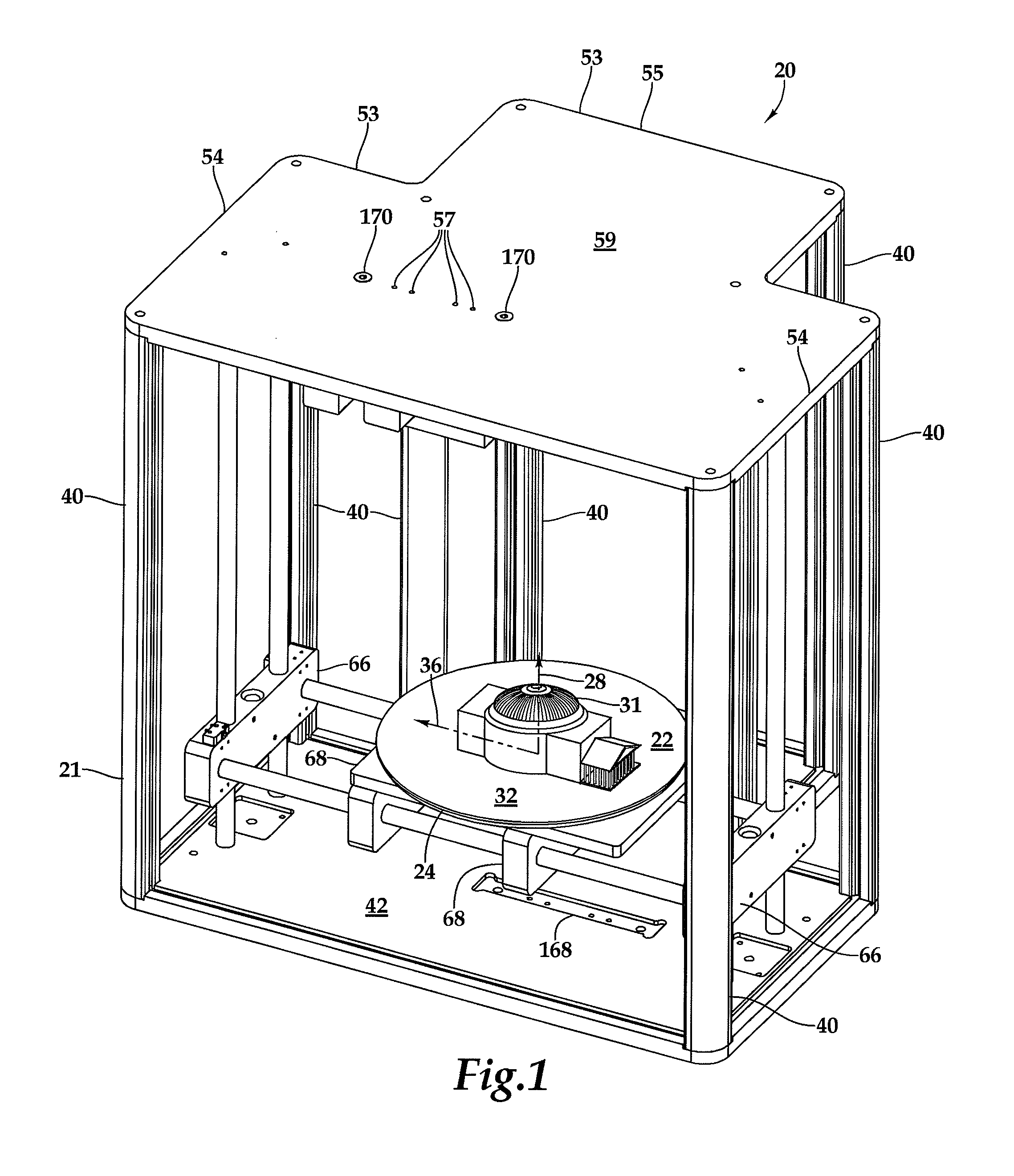

Auto tip calibration in an extrusion apparatus

The present invention is a method for performing a calibration routine of a deposition device in a three-dimensional modeling machine that deposits a material to build up three-dimensional objects as directed by a controller on a substrate mounted on a platform. The method comprises generating a material build profile, which represents a three-dimensional structure at defined locations. A relative position of the material build profile is then determined. An expected build profile is identified and then compared to the determined relative position of the material build profile to identify any difference which represents an offset. The modeling system then positions the deposition device based upon the offset.

Owner:STRATSYS INC

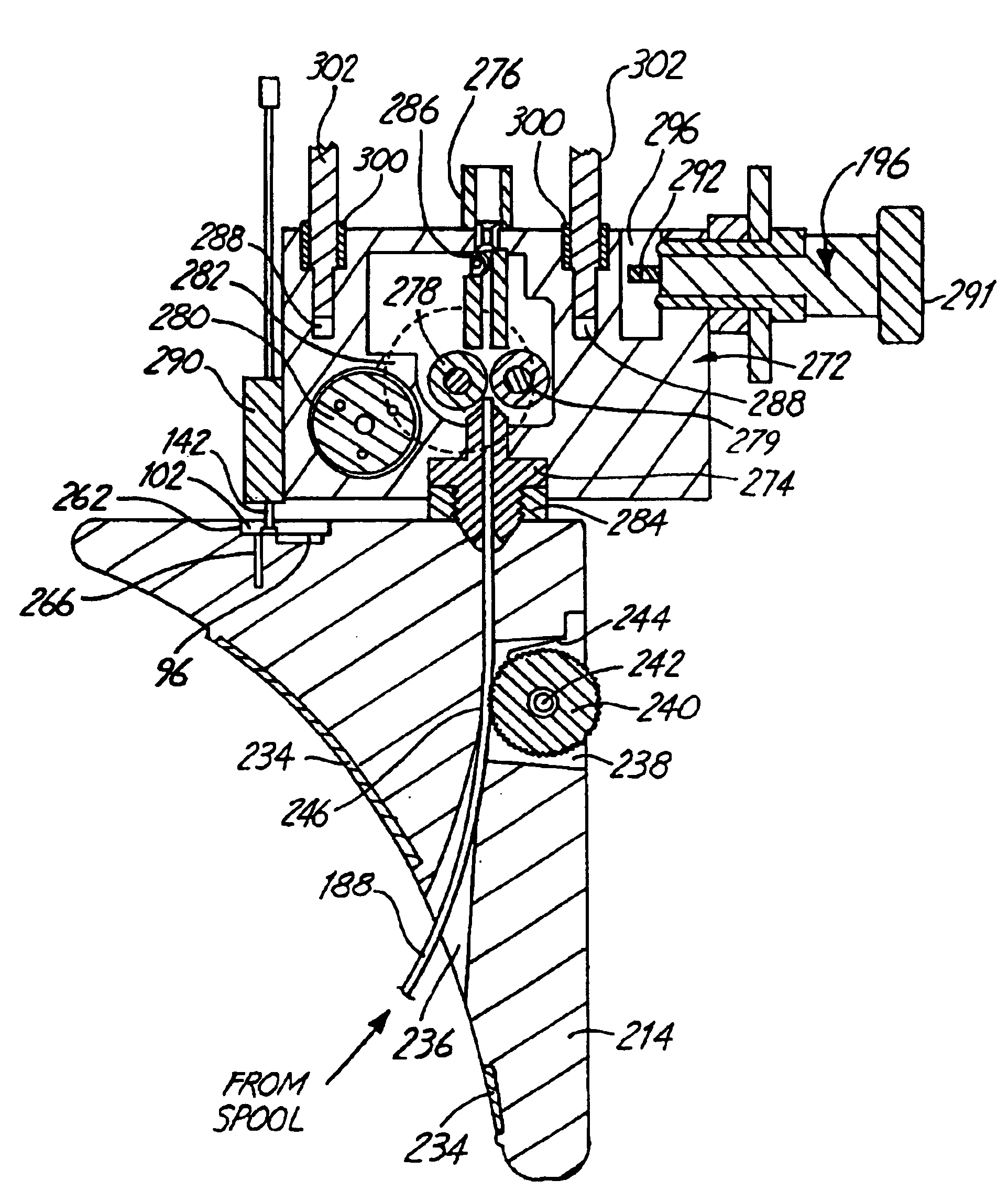

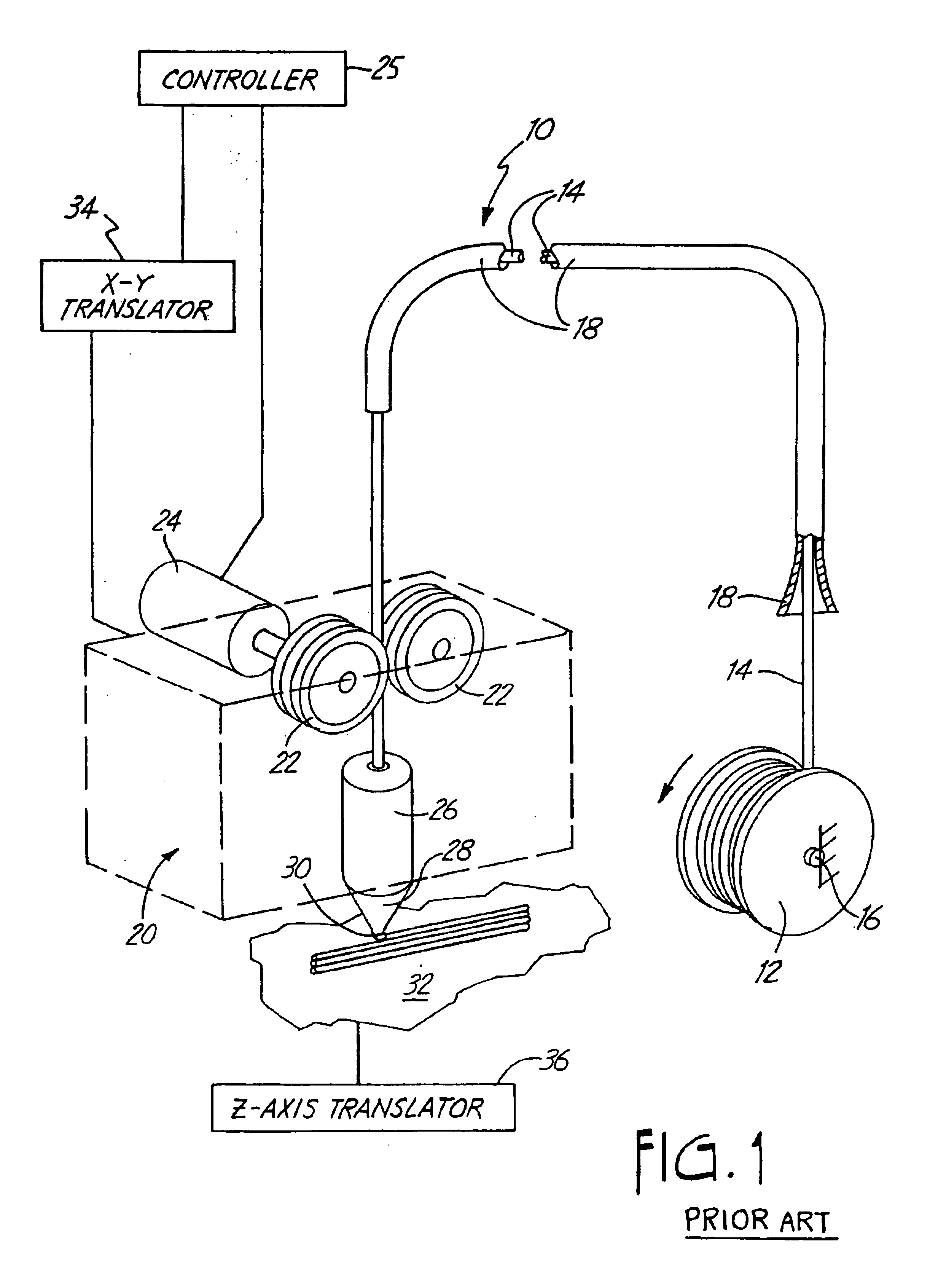

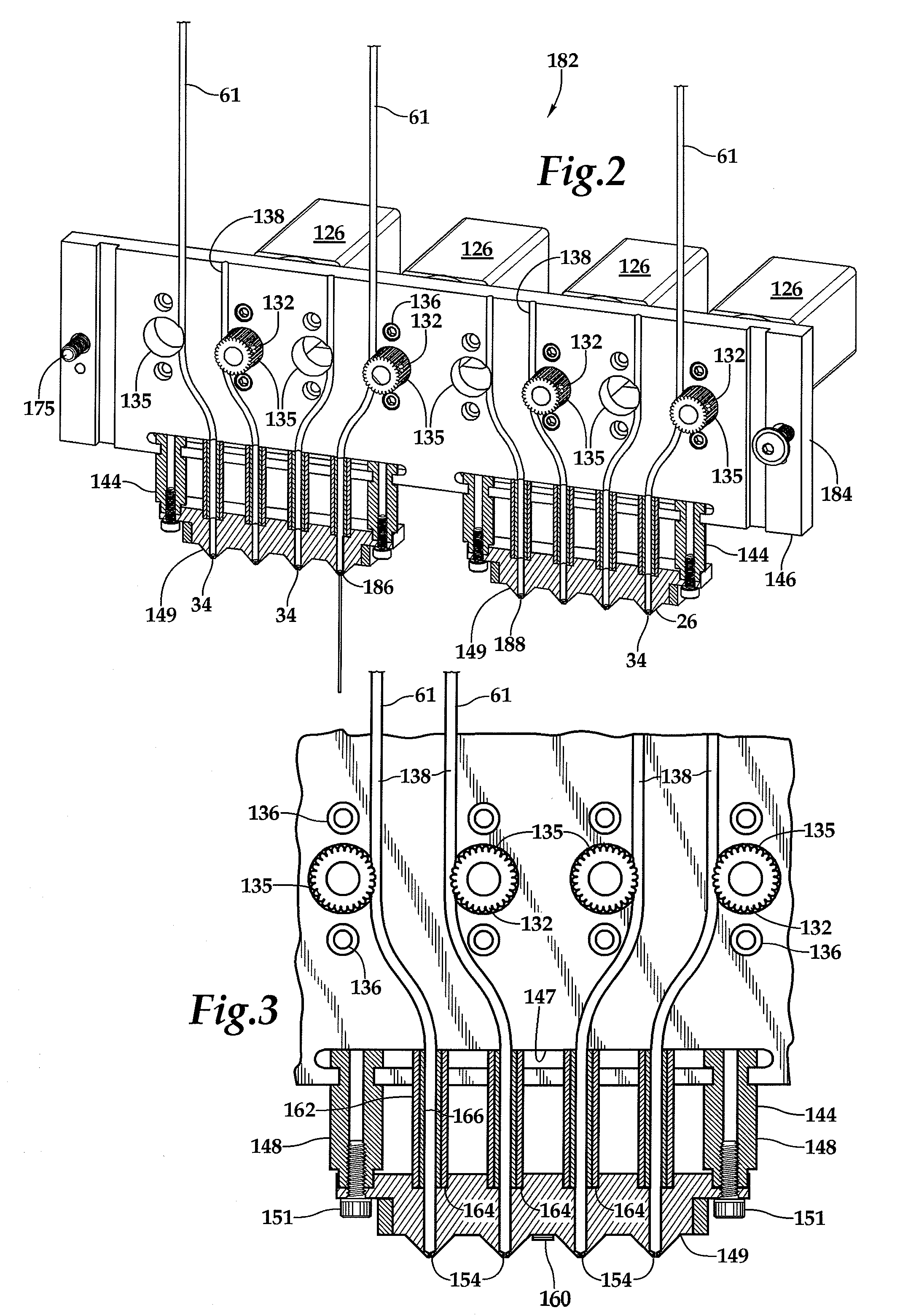

Filament loading system in an extrusion apparatus

InactiveUS6923634B2Protect environmentEasy loadingConfectionerySweetmeatsDrive wheelDimensional modeling

An apparatus which extrudes flowable material from a liquifier includes a system for loading filament supplied in a cassette. The cassette is loaded into a loading bay of the apparatus. A strand of filament from the cassette is engaged and advanced along a path to the liquifier using a drive wheel or roller pair. A conduit having an entrance in the loading bay guides the filament as it is advanced. The filament loading system of the present invention provides a convenient manner of loading and unloading filament in a three-dimensional modeling machine, and can be implemented in a manner that protects the filament from environmental moisture.

Owner:STRATSYS INC

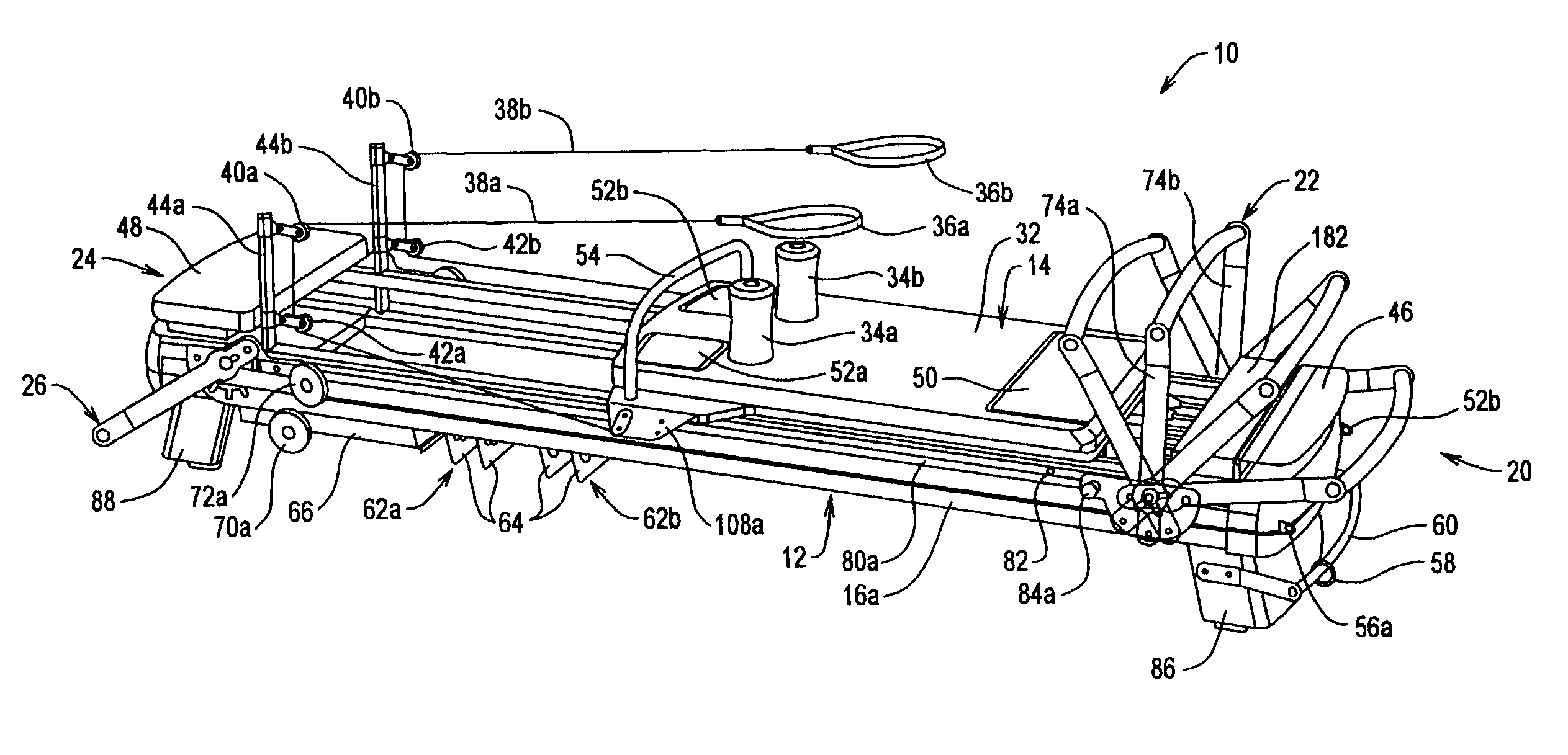

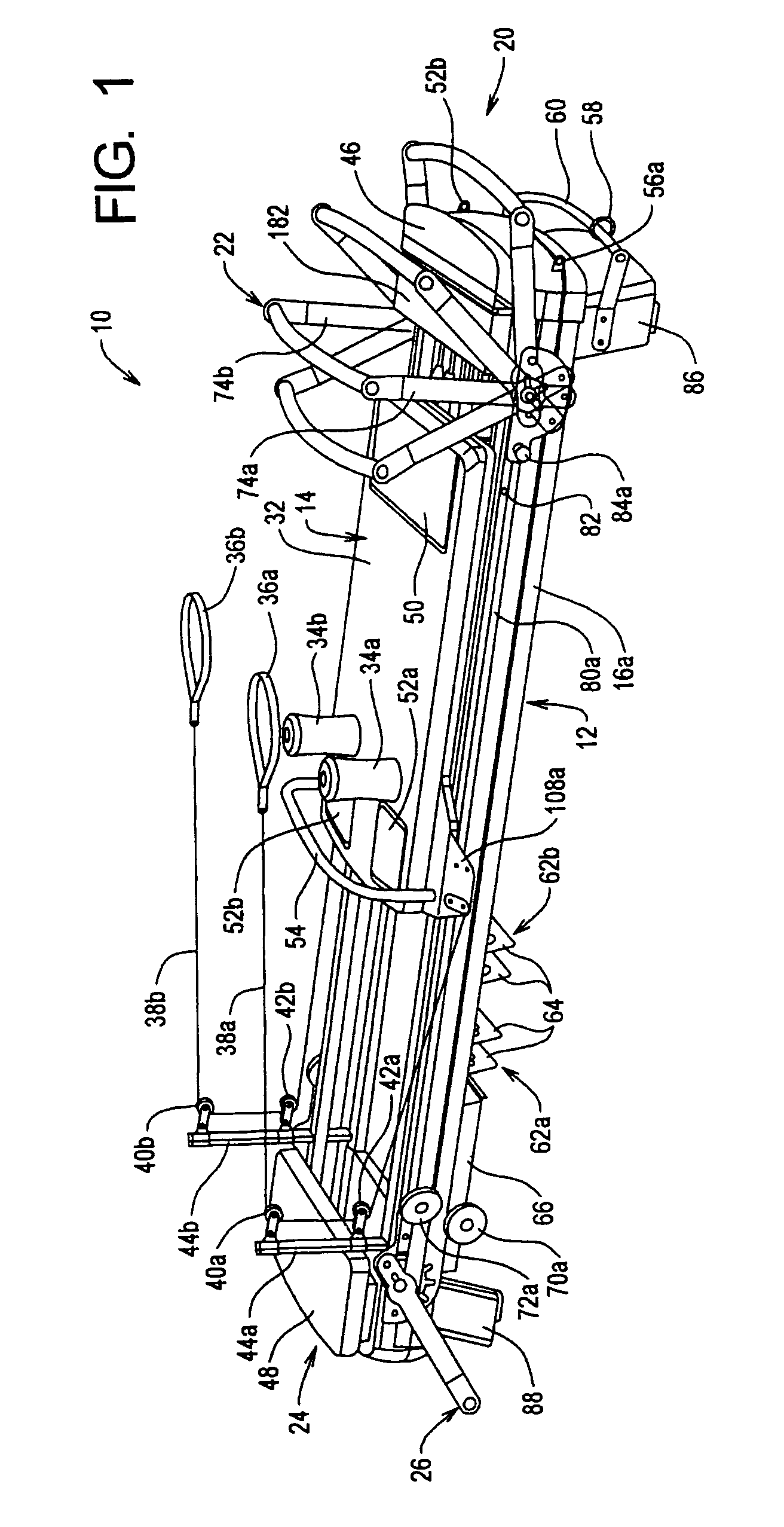

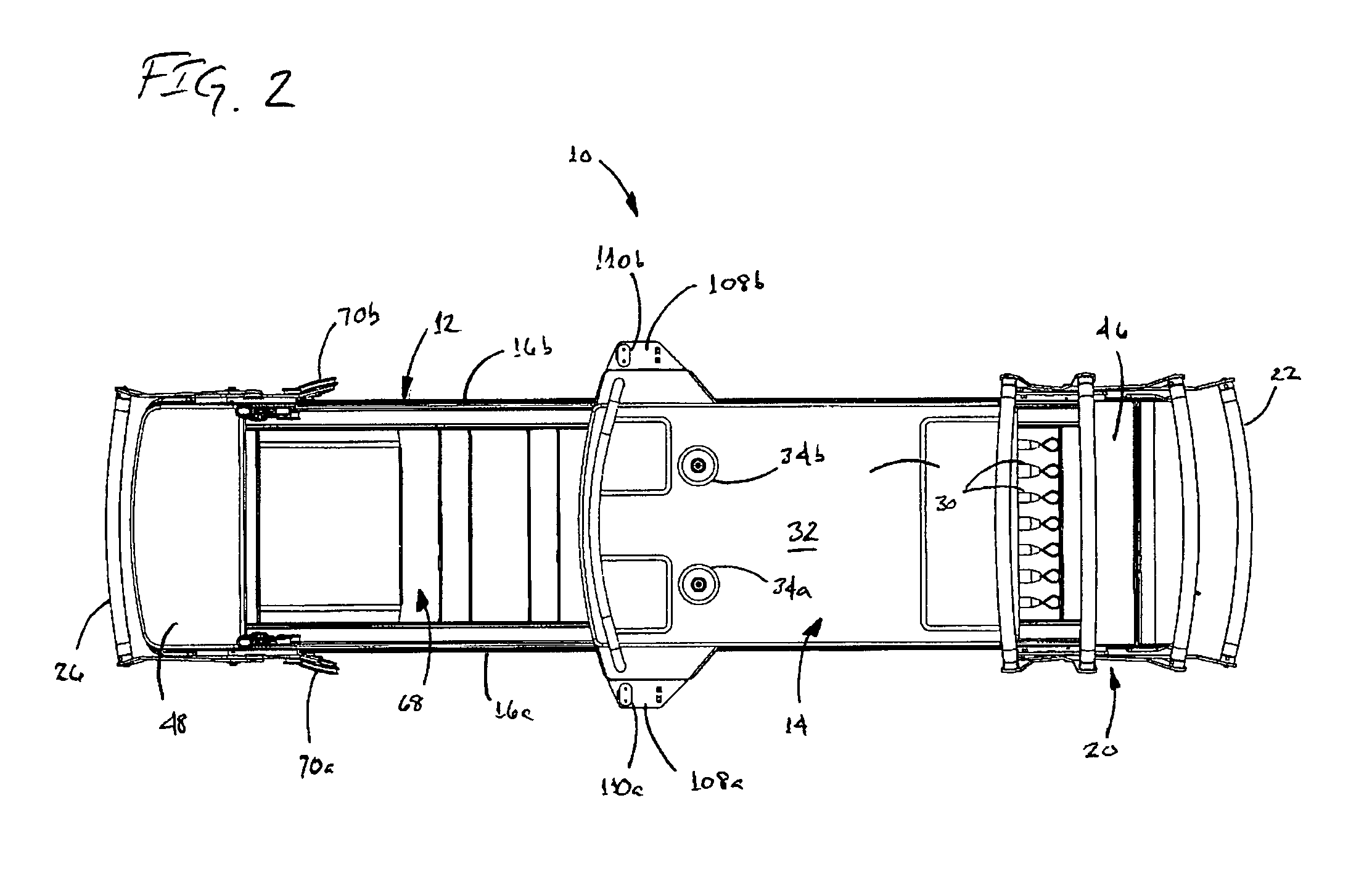

Exercise machine

Owner:LAGREE TECH INC

Effervescent granules and methods for their preparation

InactiveUS6071539AMinimize degradationMelt and soften binderPowder deliveryPill deliveryPlasticizerHot melt

According to the present invent, effervescent granules having a controllable rate of effervescence are provided. Such granules comprise an acidic agent, an alkaline agent, a hot-melt extrudable binder capable of forming a eutectic mixture with the acidic agent and, optionally, a plasticizer. The effervescent granules are made by a hot-melt extrusion process.

Owner:ETHYPHARM SA

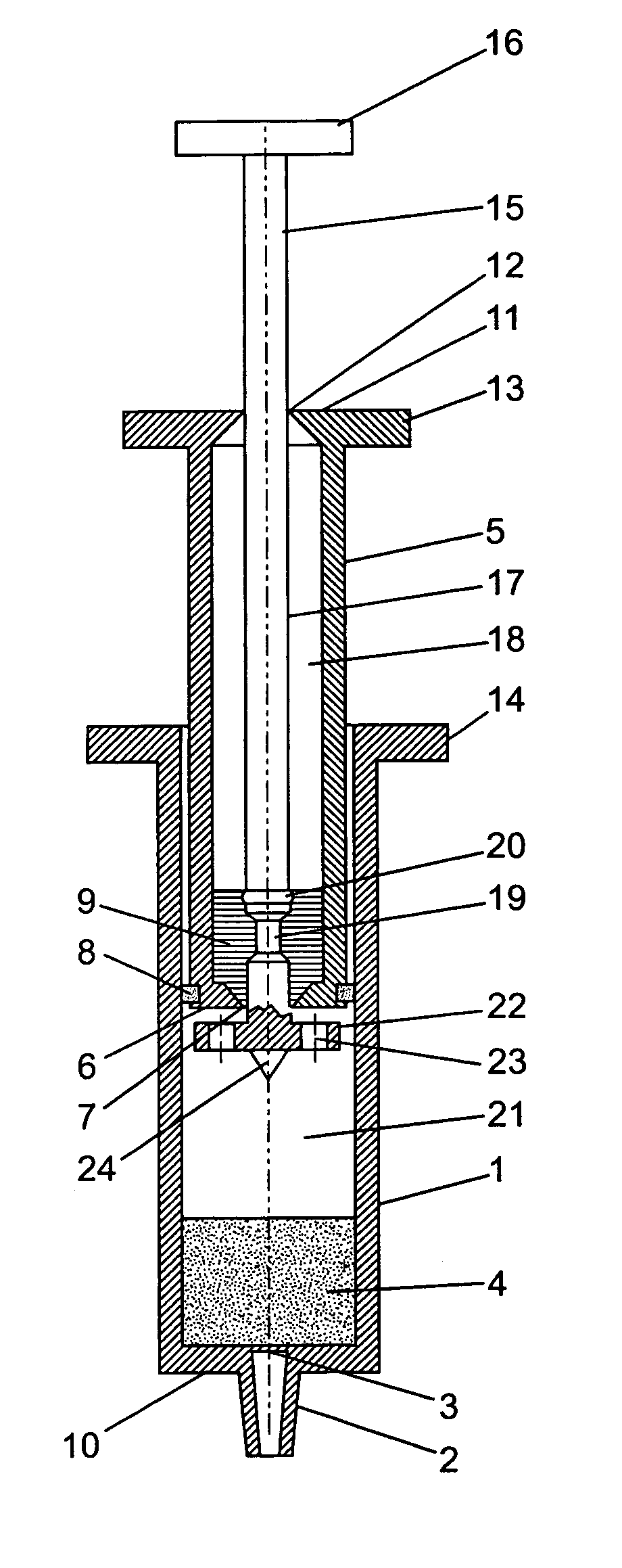

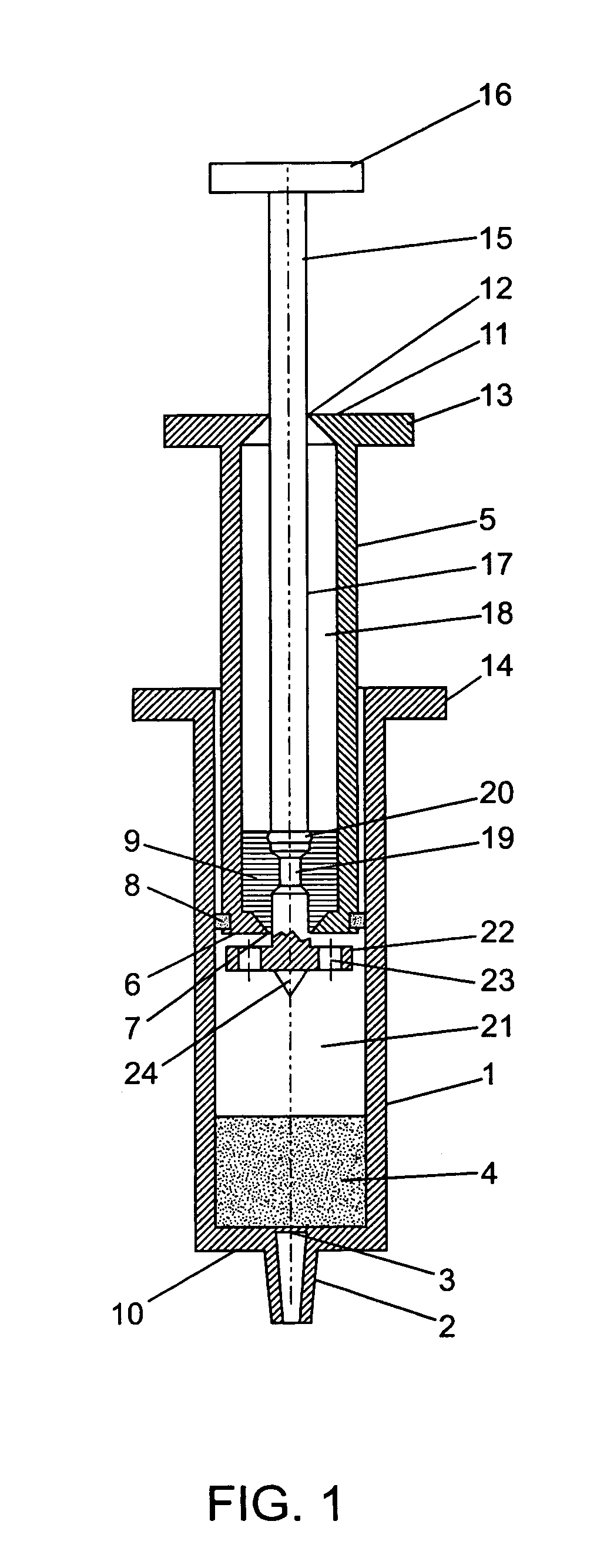

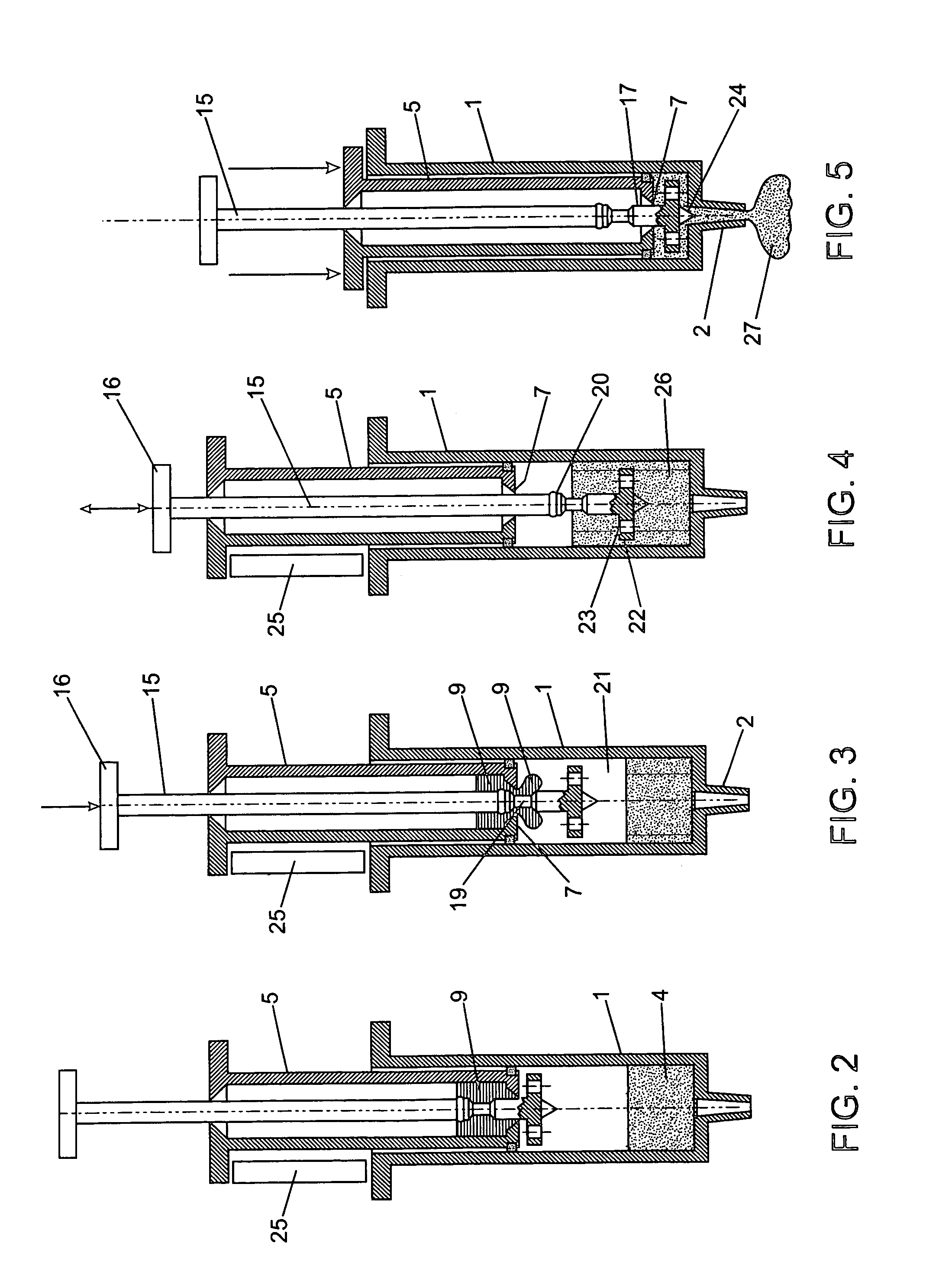

Apparatus and methods for mixing two components

ActiveUS7018089B2Solve the lack of spaceShaking/oscillating/vibrating mixersInfusion syringesEngineeringExtrusion

The apparatus for production of mixtures from two components has a container for each and devices to combine the components in the mixing space and for extrusion of the mixture. The powdered component (4) is situated in the lower part of the inner space (21), which is sealed by a bottom (10). This carries a nozzle (2) with closure membrane (3). The inner space (21) is closed on the top by the lower wall (6) and the sliding seal (8). The liquid component (9) is situated in the inner space (18) of the inner hollow cylinder (5). This is closed on the top by the upper wall (11). The lower and upper wall (6) and (11) each have an opening with sealing lips (7) and (12) that are closed by parts of the mixing rod (15). A torus (20), a section with smaller diameter (19), a mixing disk (22), as well as a mandrel (24), are present on the lower part of the mixing rod (15).

Owner:KYPHON

High-performance network content analysis platform

ActiveUS7467202B2Prevent leakageDigital data processing detailsAnalogue secracy/subscription systemsData streamKeyword analysis

One implementation of a method reassembles complete client-server conversation streams, applies decoders and / or decompressors, and analyzes the resulting data stream using multi-dimensional content profiling and / or weighted keyword-in-context. The method may detect the extrusion of the data, for example, even if the data has been modified from its original form and / or document type. The decoders may also uncover hidden transport mechanisms such as, for example, e-mail attachments. The method may further detect unauthorized (e.g., rogue) encrypted sessions and stop data transfers deemed malicious. The method allows, for example, for building 2 Gbps (Full-Duplex)-capable extrusion prevention machines.

Owner:FIDELIS SECURITY LLC

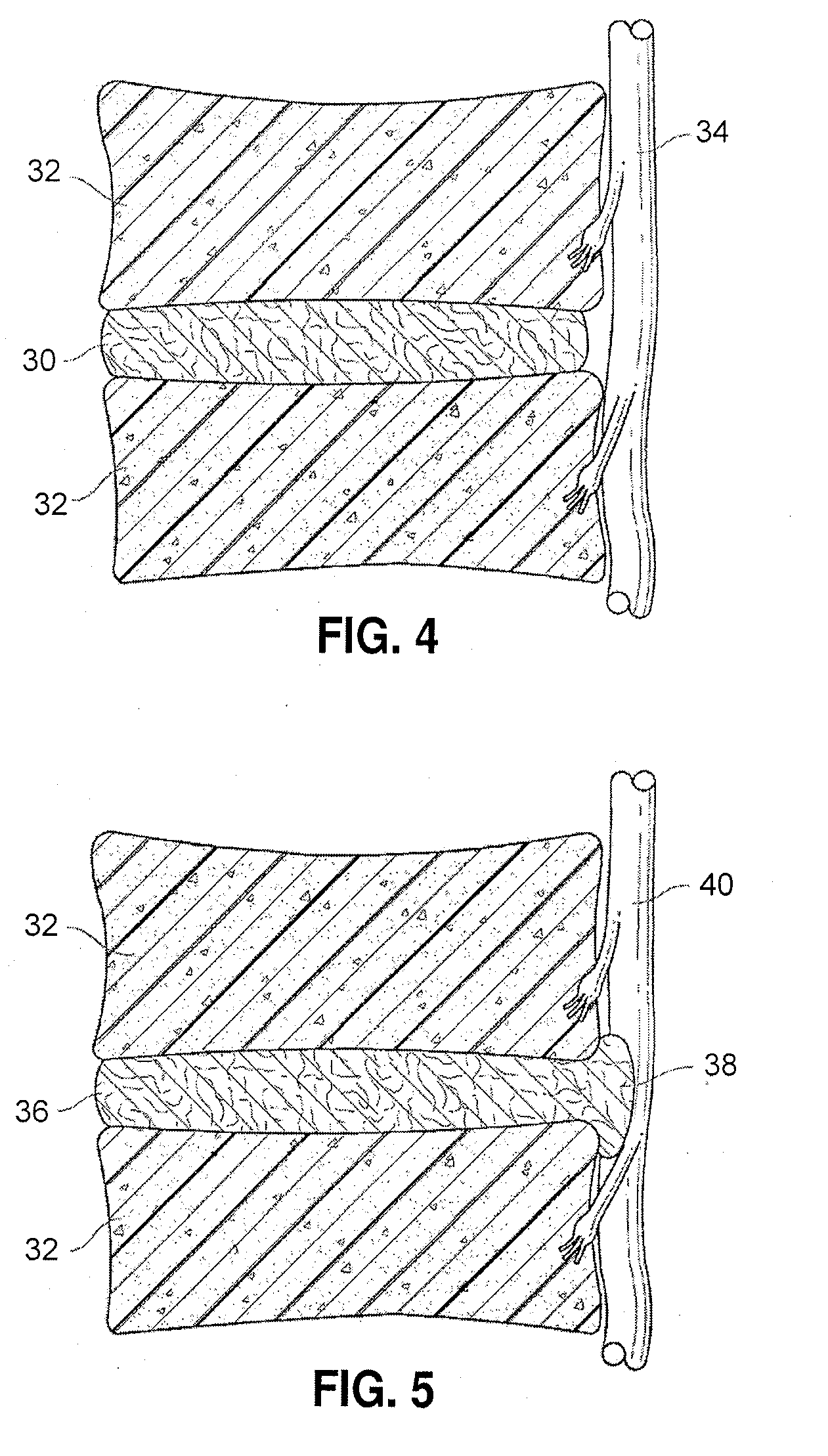

Spinal implants and methods

InactiveUS20090149959A1Reduce relative motionSmooth motionDiagnosticsBone implantPosterior regionIntervertebral disk

Owner:MAGELLAN SPINE TECH

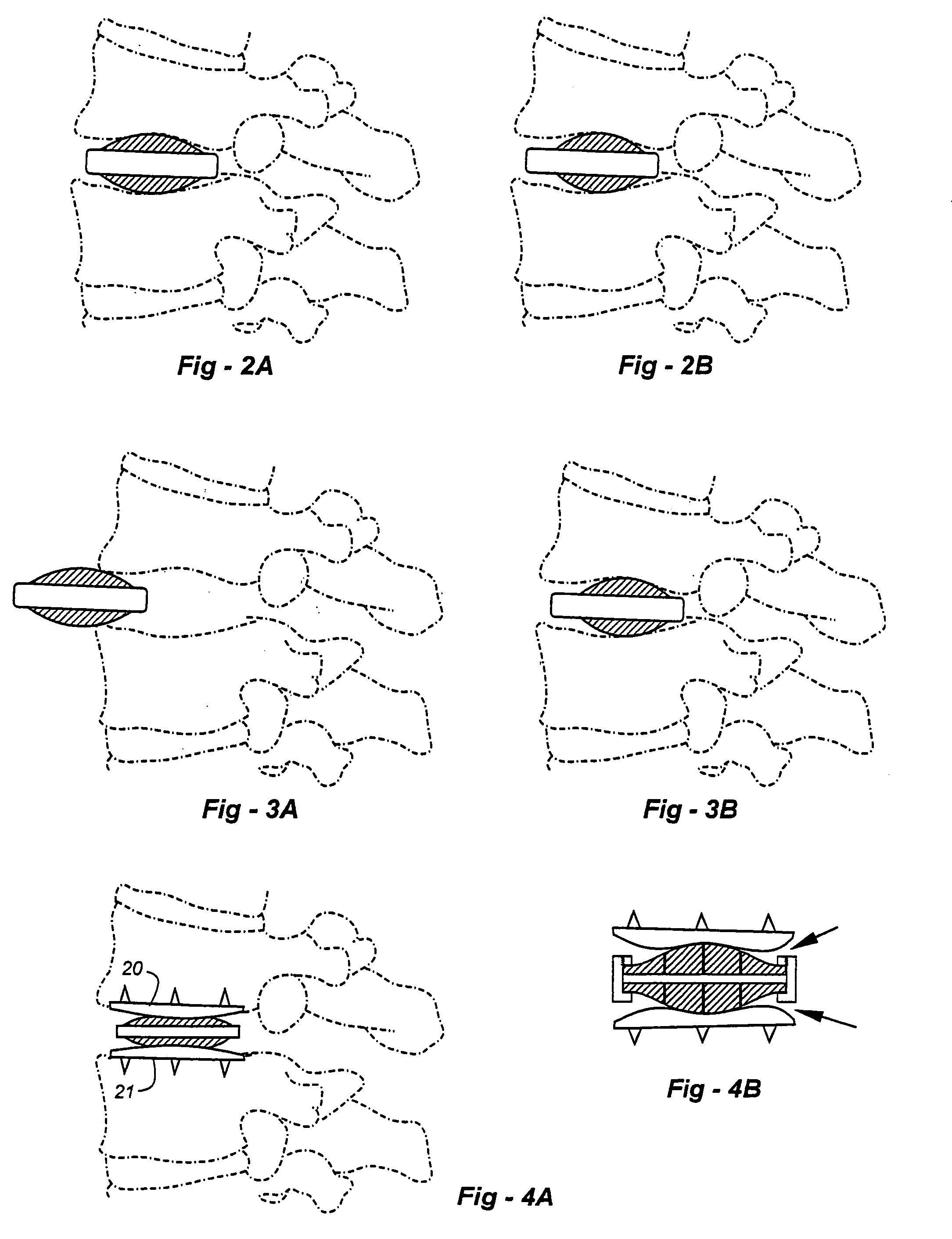

Prosthetic components with partially contained compressible resilient members

InactiveUS7066958B2Improve protectionEliminate shear stressJoint implantsSpinal implantsElastomerShape-memory alloy

One or more rigid components associated with an articulating bone are used to encase, encapsulate, contain, or otherwise protect a compressible / resilient member. The embodiments are applicable not only to artificial disc replacement (ADR) devices, but also to joint situations including total knee and hip arthroplasty. The cushion elements in the preferred embodiments include synthetic rubbers, hydrogels, elastomers, and other polymeric materials such as viscoelastic polymers and foam polyurethanes. The invention effectively combines the advantages of such materials (cushioning, shape memory, and expansion after insertion in the case of hydrogels), while providing increased protection, particularly the elimination of shear stresses. When applied to an ADR, the invention also minimizes the risk of extrusion.

Owner:FERREE BRET A

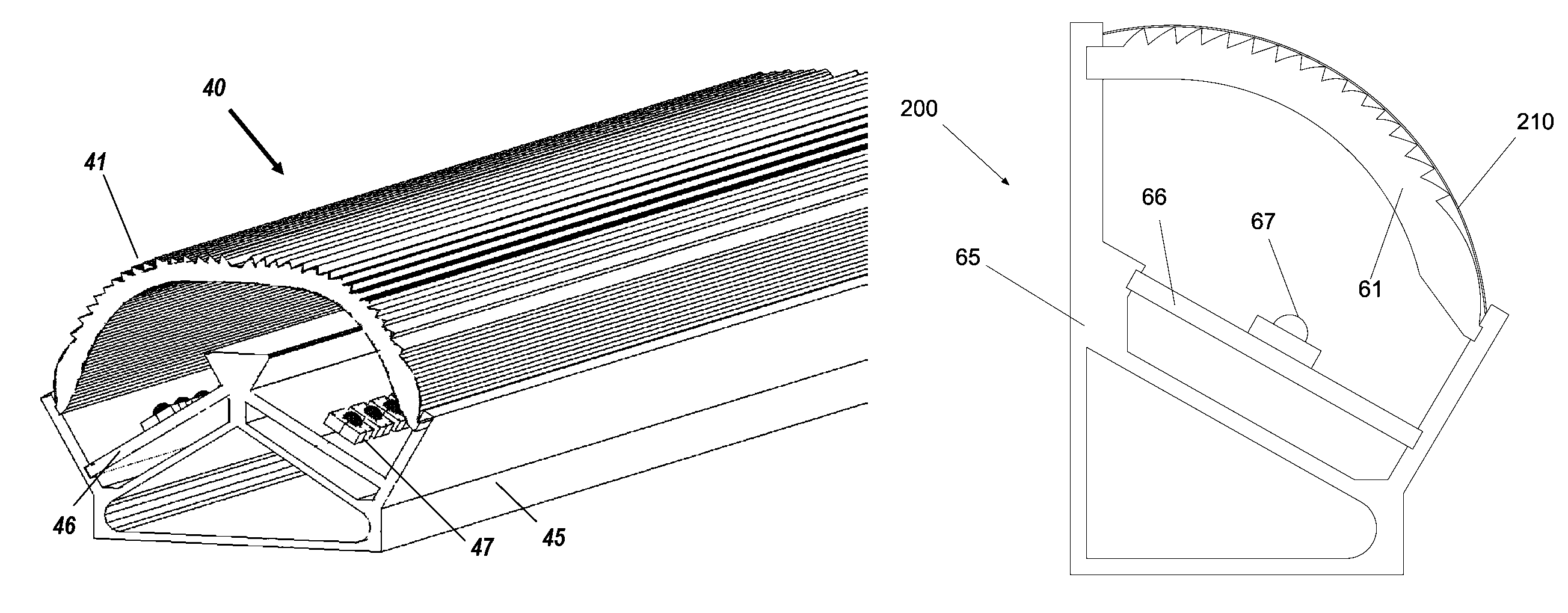

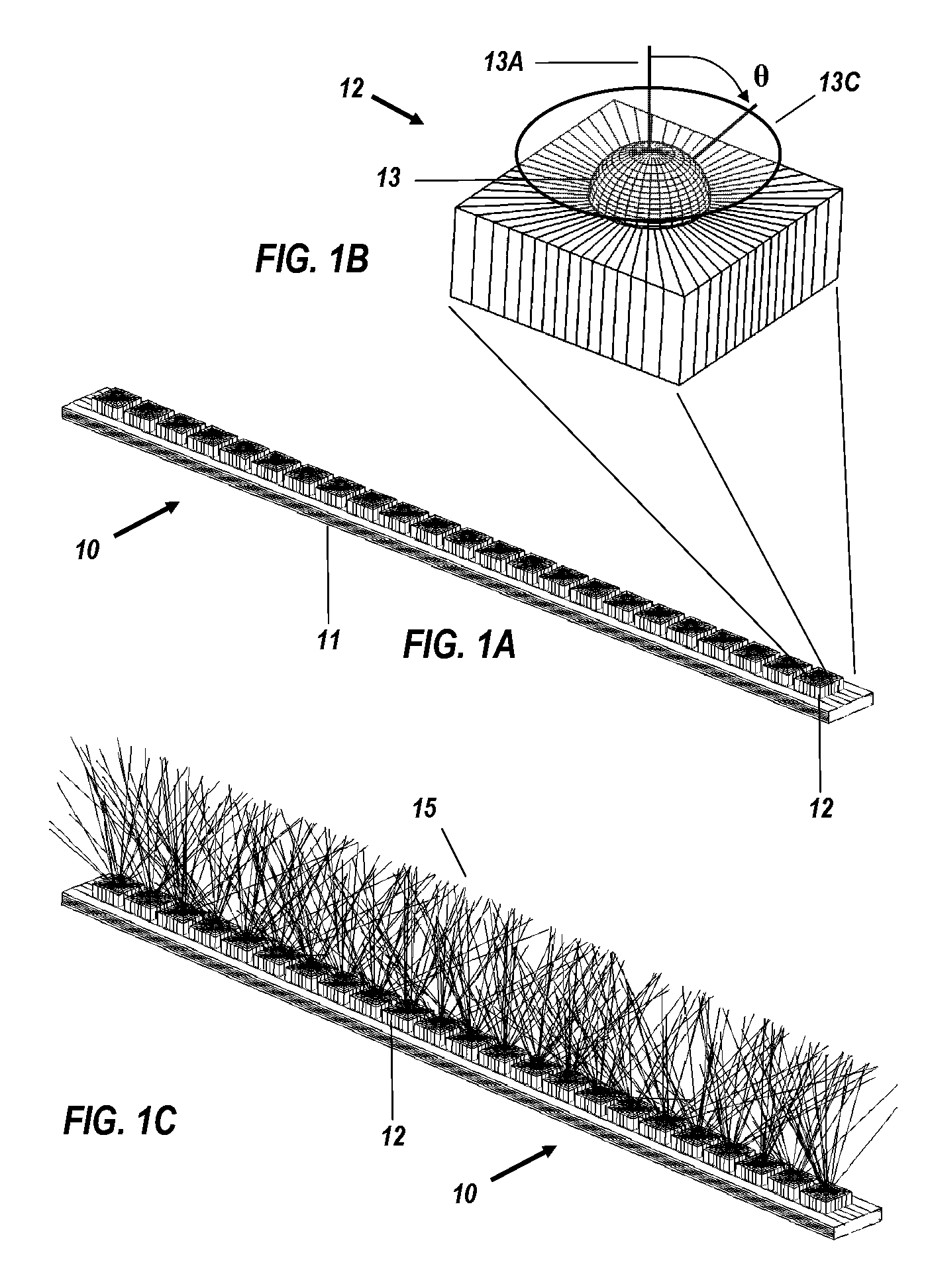

Linear illumination lens with Fresnel facets

ActiveUS7559672B1Large amount of processingImprove efficacyMechanical apparatusFurnace componentsCamera lensFresnel lens

A linear Fresnel lens for LED illumination is configured initially by using a meridional flux-assignment method and is then corrected by assessing the three-dimensional flux distribution of individual facets. The facet angles are slightly altered as required to produce uniformity. A variety of specialized lens shapes are generated, such as for illuminating shelves in commercial refrigerator food-display cases. The lens shapes are suitably thin for economical production by extrusion.

Owner:SEOUL SEMICONDUCTOR

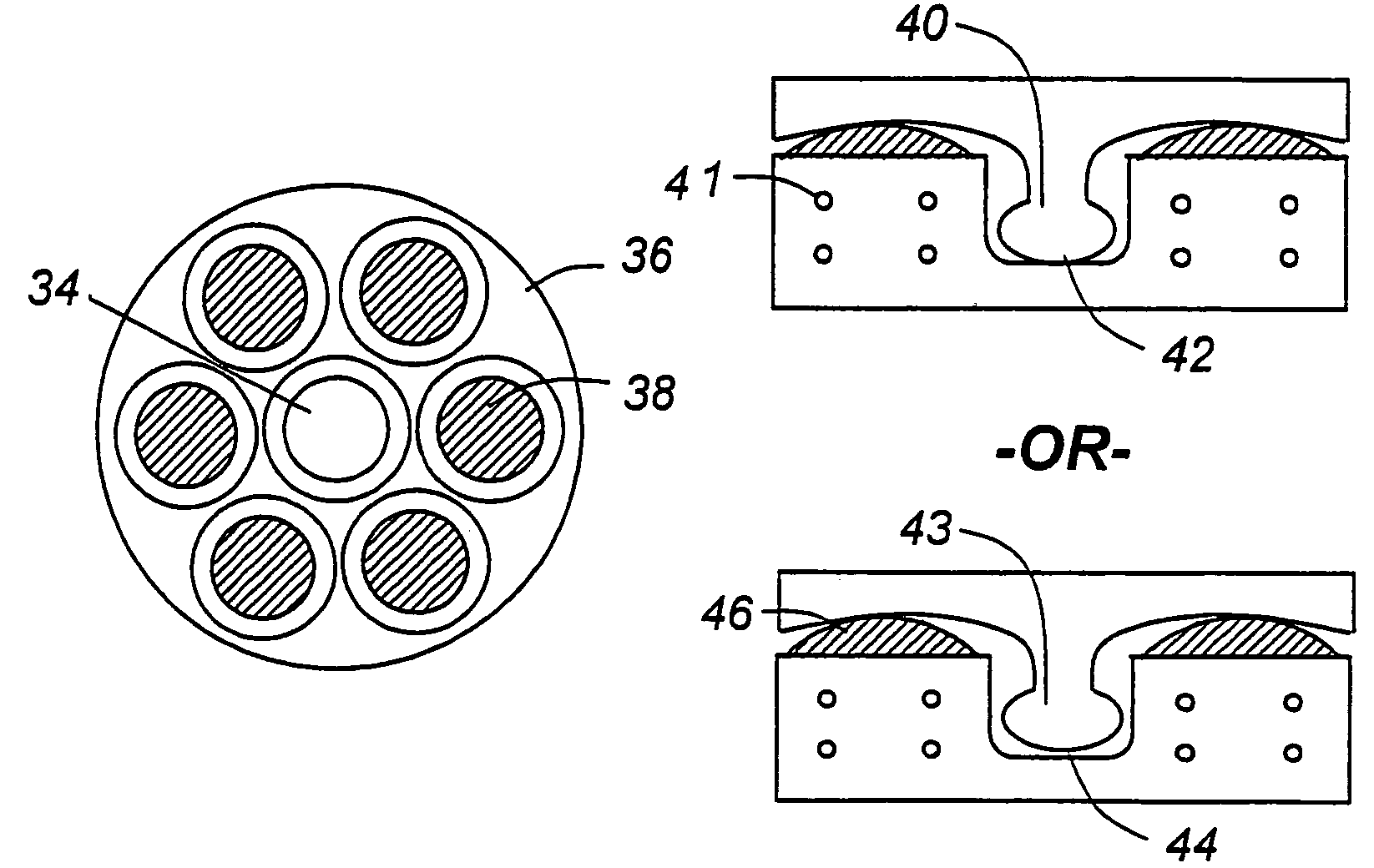

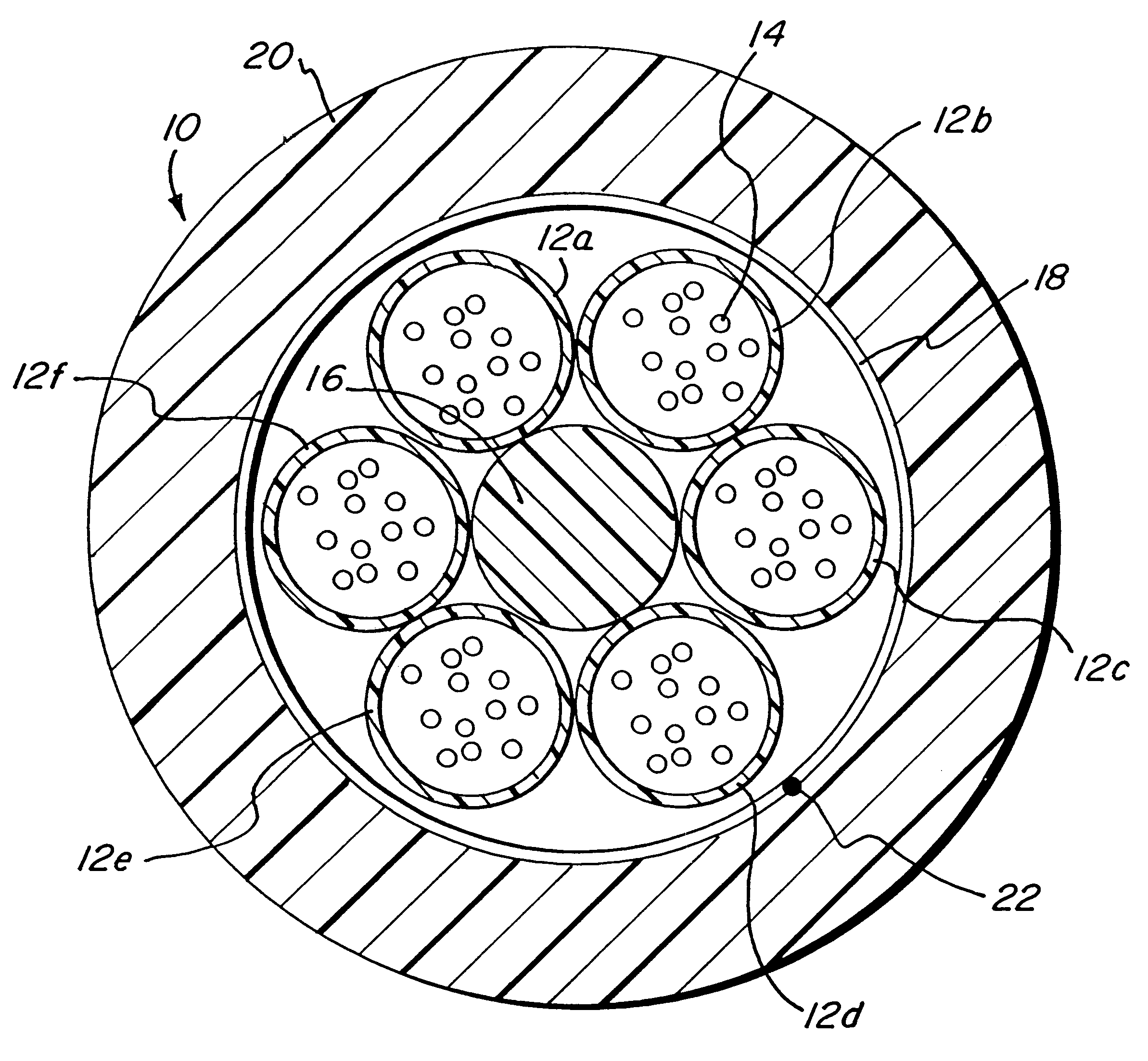

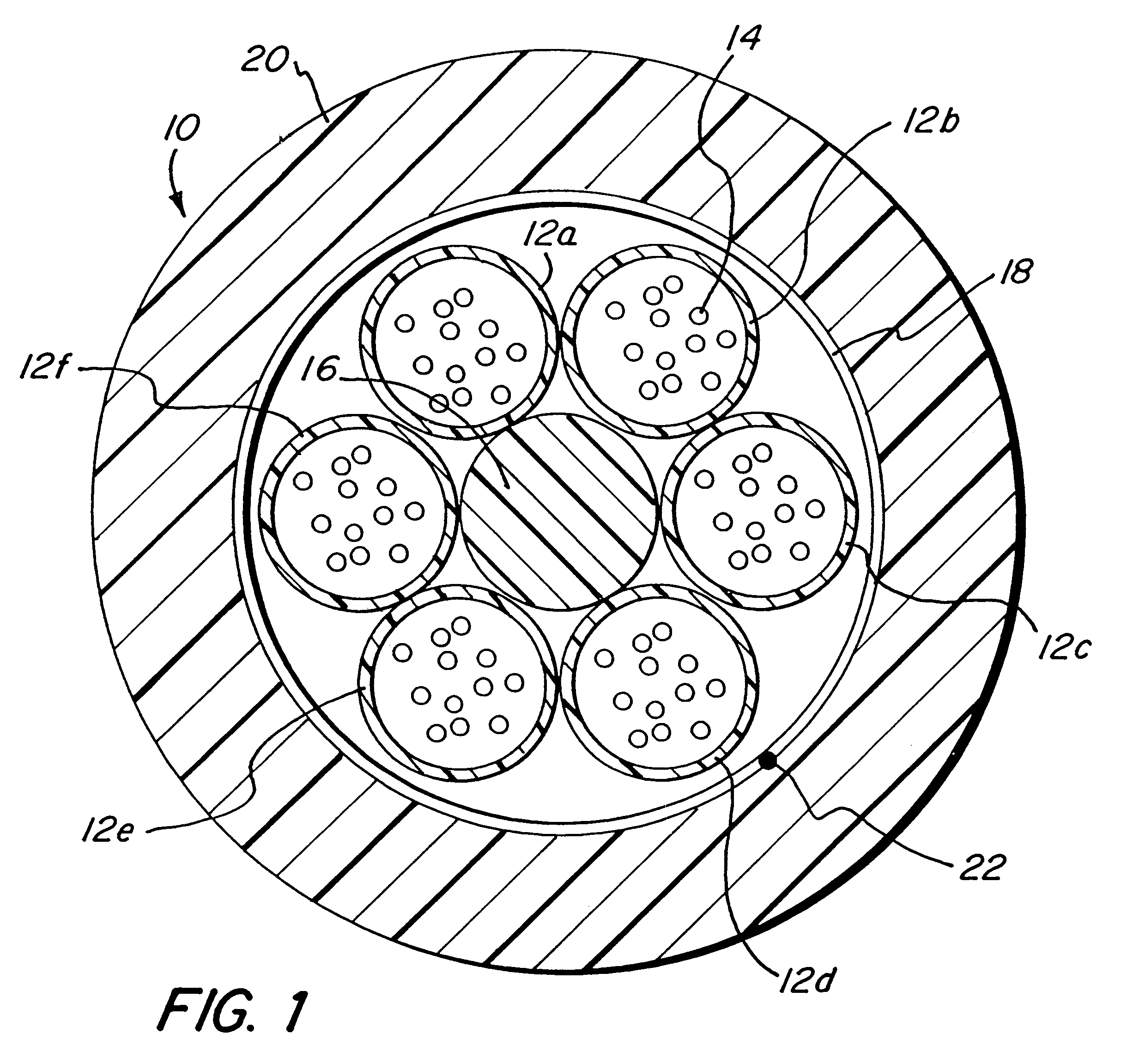

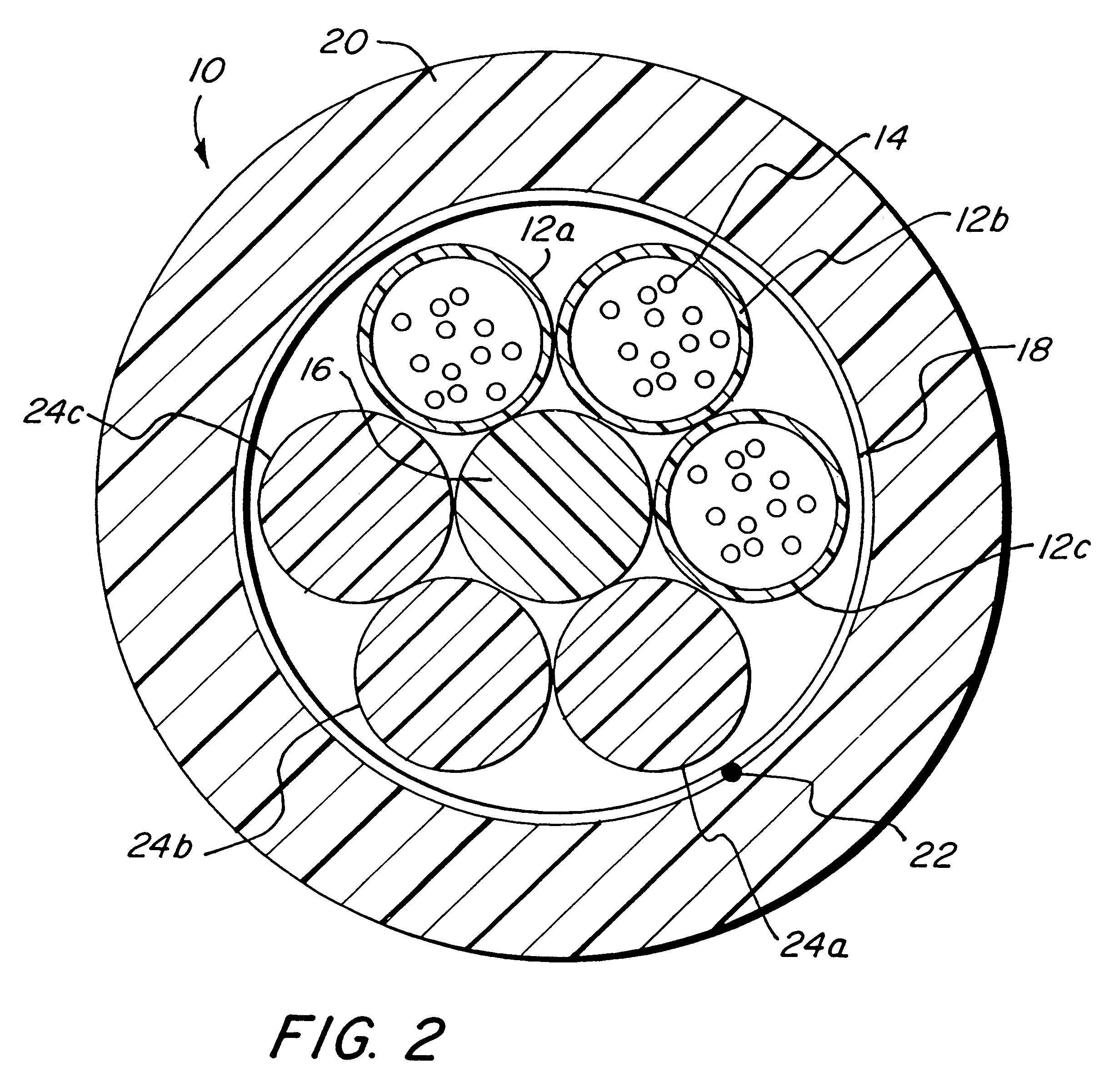

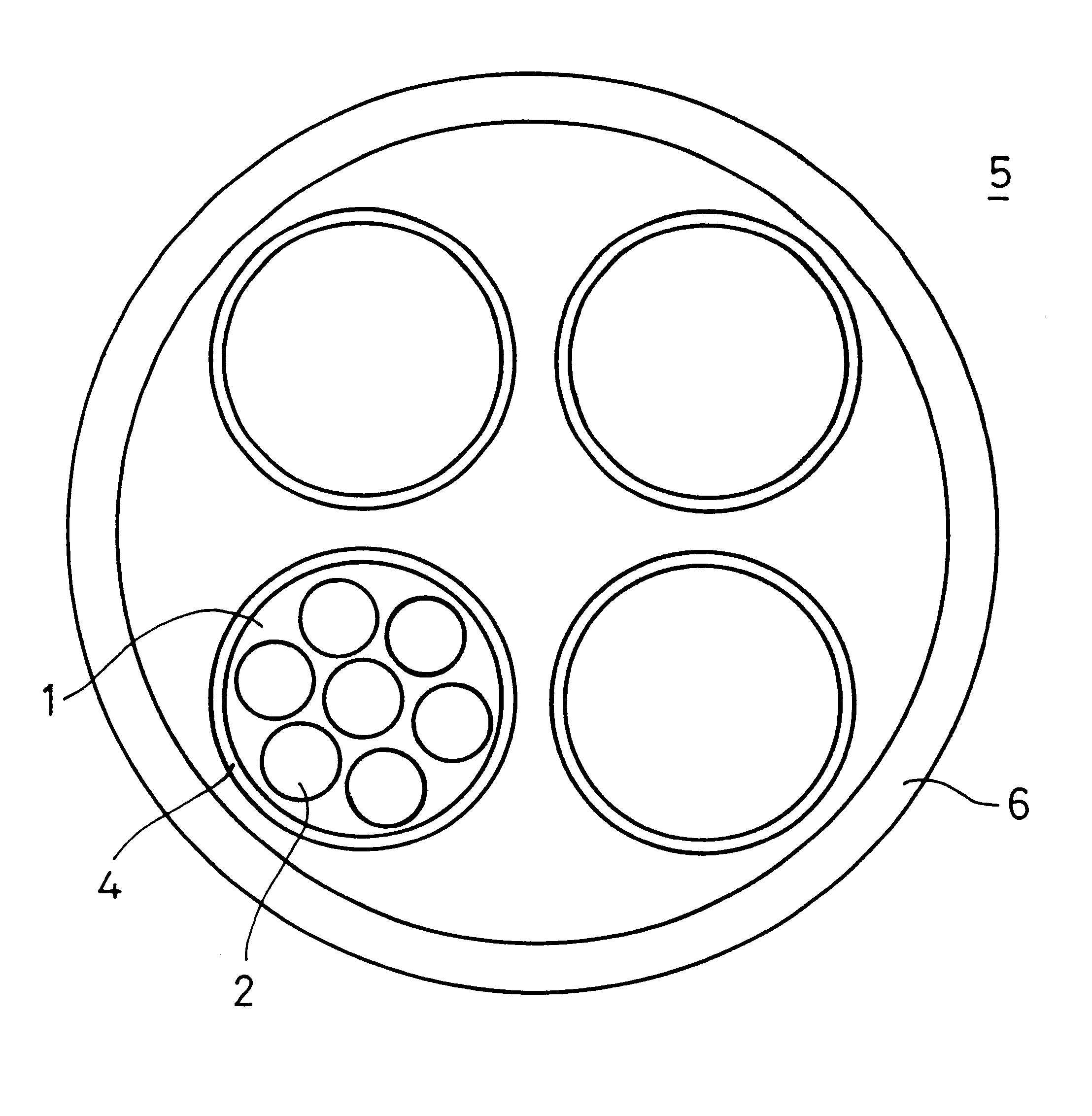

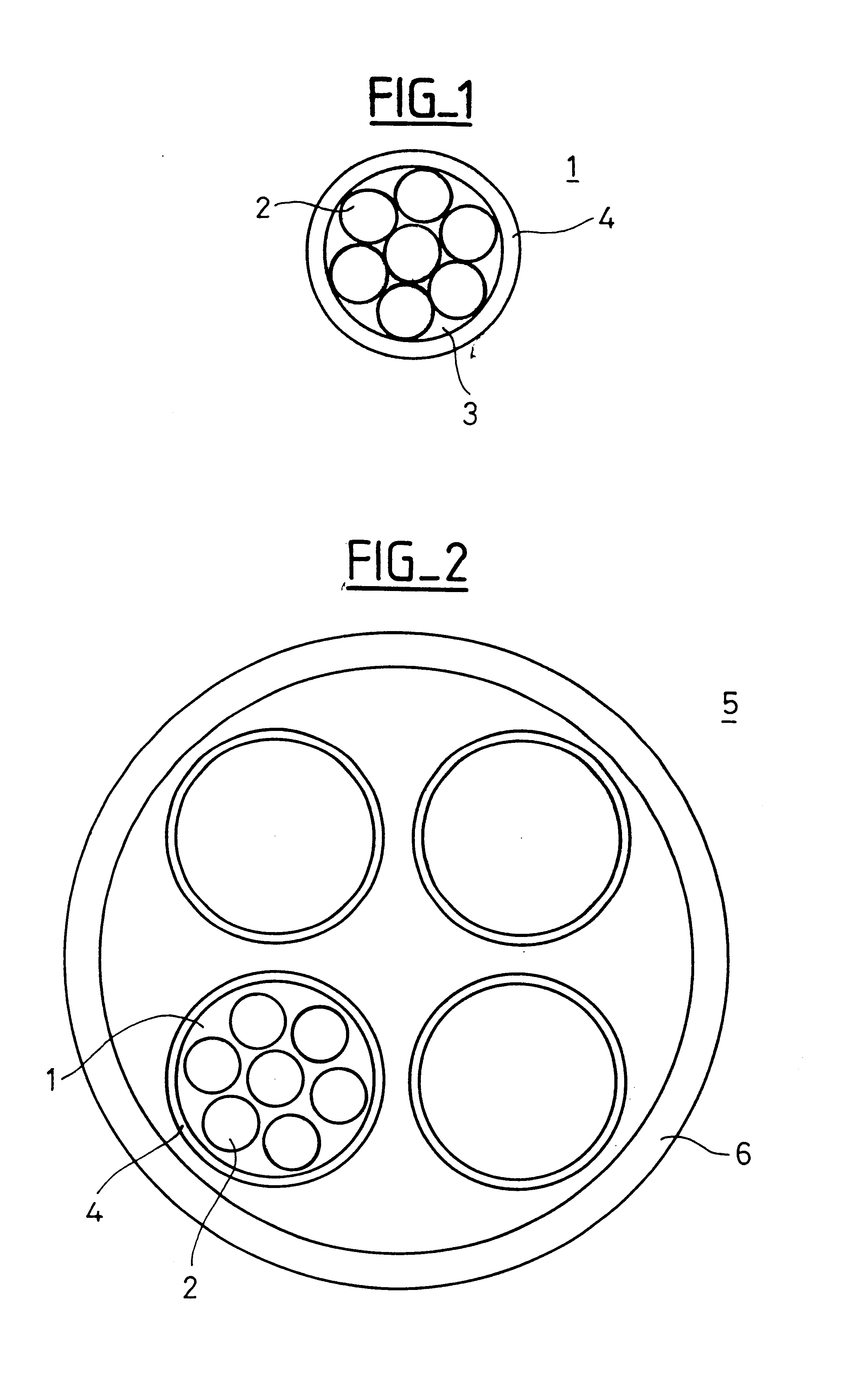

Polypropylene filler rods for optical fiber communications cables

InactiveUS6210802B1Synthetic resin layered productsFibre mechanical structuresLow-density polyethyleneEngineering

A filler rod for occupying space in a stranded optical fiber communications cable having at least one buffer tube containing at least one optical fiber is disclosed. The filler rod comprises an elongated rod extruded from a polypropylene homopolymer, a polypropylene-polyethylene copolymer (i-PP) resin material, or preferably, from a polypropylene-polyethylene copolymer having a nucleating agent disbursed therein. The resin material is foamed during extrusion so as to have a plurality of void spaces therein and a relative density which is less than 1 relative to the unfoamed resin material. As compared to rods made from high density polyethylene, the i-PP filler rods show a greater foaming efficiency, more efficient use of material, an improved combination of mechanical properties and density, reduced post-extrusion shrinkage and a substantial reduction in the sticking of the filler rods to the outer jacket that is experienced with high density polyethylene filler rods.

Owner:DRAKA COMTEQ BV

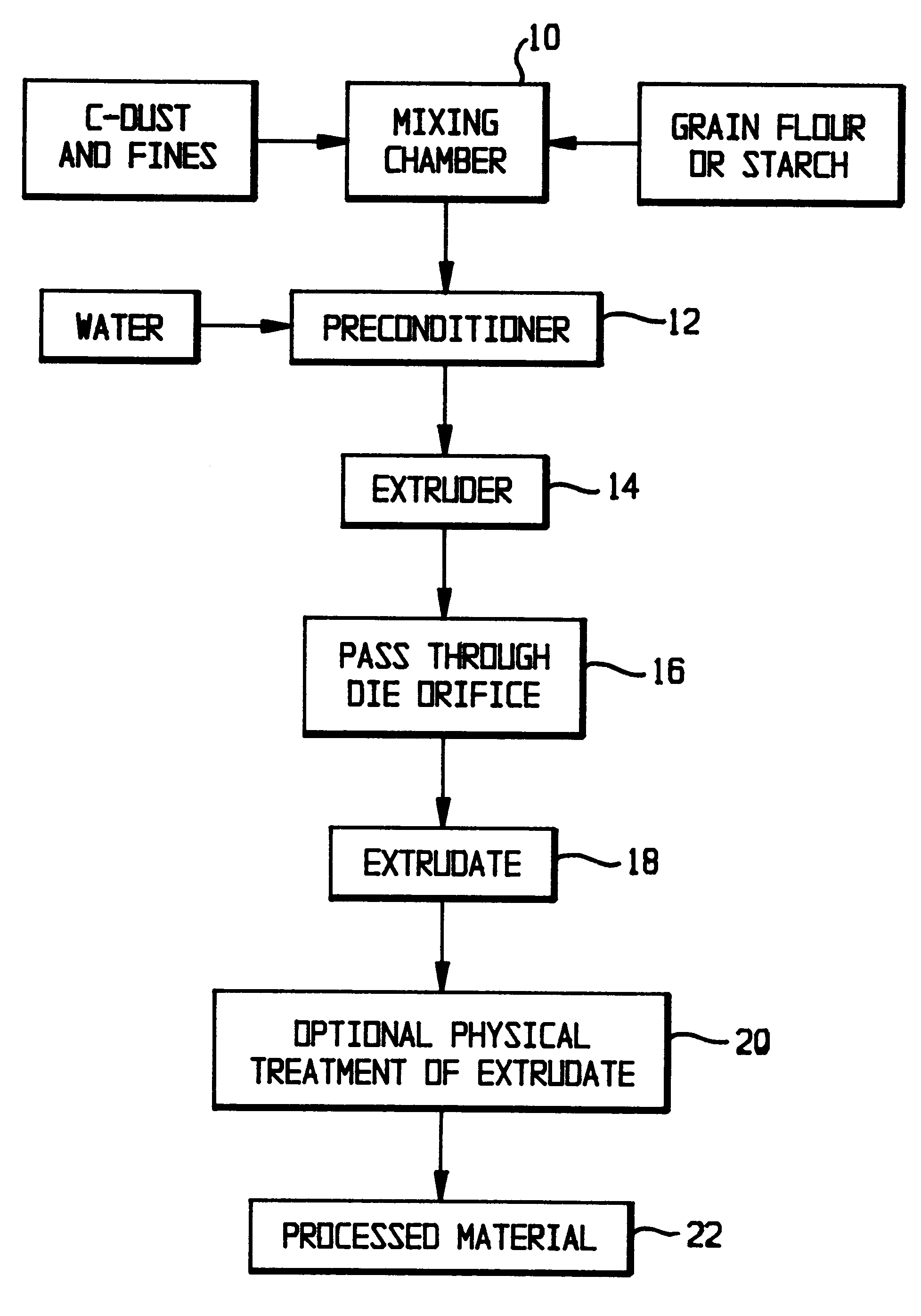

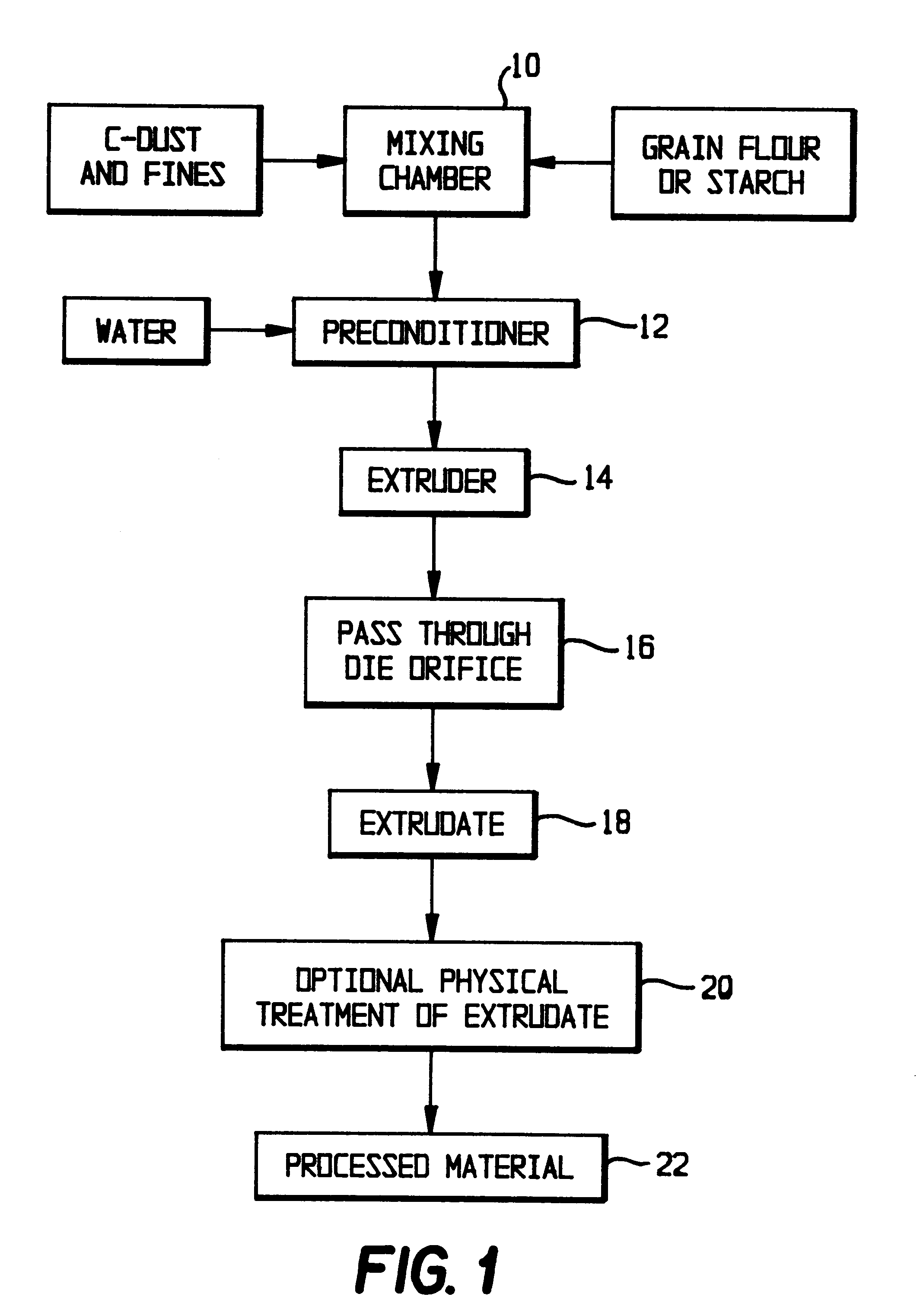

Low-density tobacco filler and a method of making low-density tobacco filler and smoking articles therefrom

InactiveUS6182670B1Pleasing tobacco odorImprove the smoke effectTobacco preparationDough treatmentSolventLow density

A low-density filler material for cigarettes from either a low-density tobacco composition or an extruded grain or starch composition. The low-density tobacco composition and a method of making the low-density tobacco composition by extruding a mixture of tobacco and flour or tobacco and starch under conditions whereby the solvent in the extruded mixture flashes into vapor upon release from the extrusion head. The low-density tobacco composition is formed without the aid of an added binder. The low-density flour or starch material and a method of making it by extruding flour or starch with a filler material such as calcium carbonate under conditions whereby the solvent in the extruded mixture flashes into vapor upon extrusion through the orifice die. The extruded composition can then be cut and used in place of cut tobacco filler.

Owner:R J REYNOLDS TOBACCO COMPANY

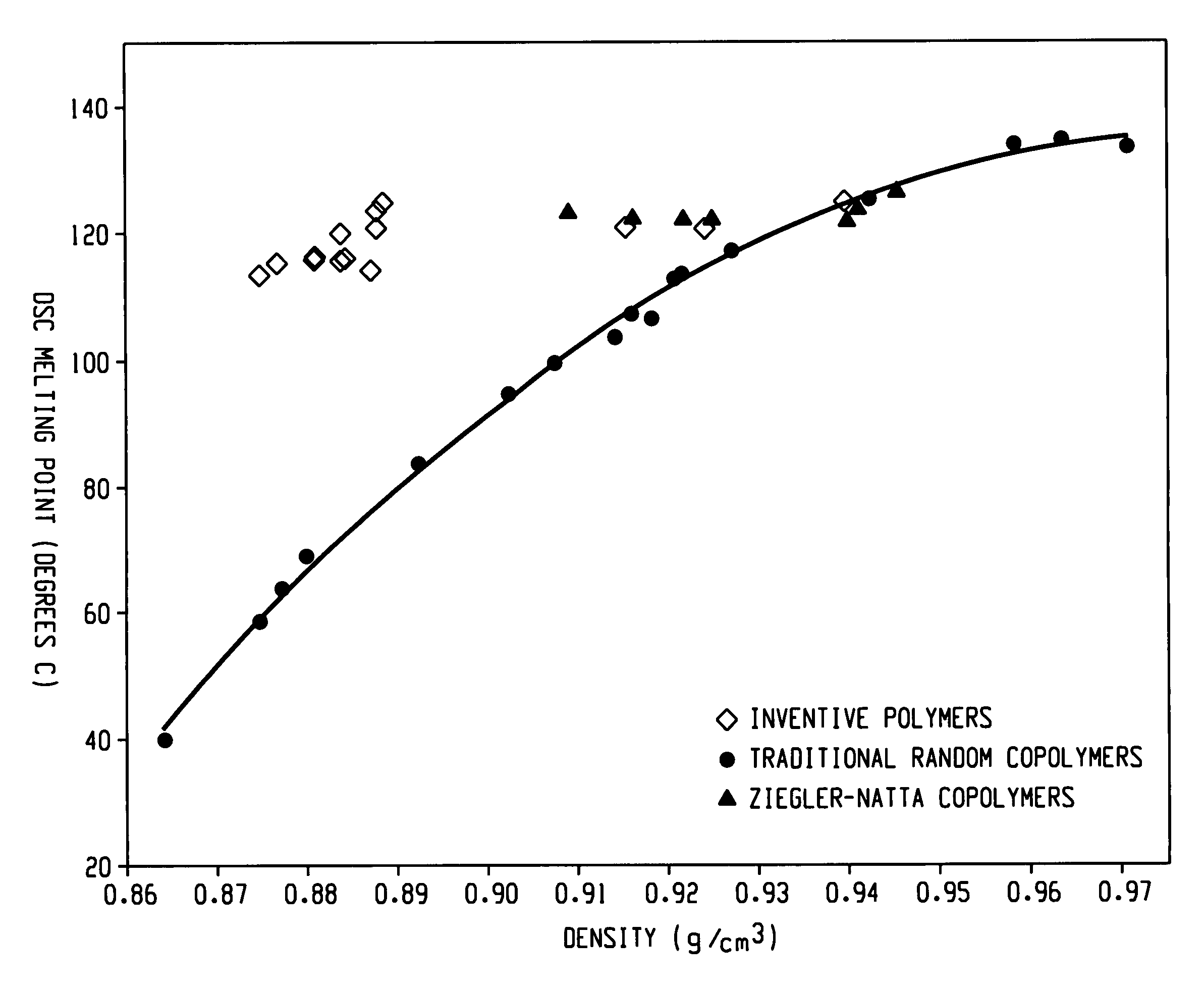

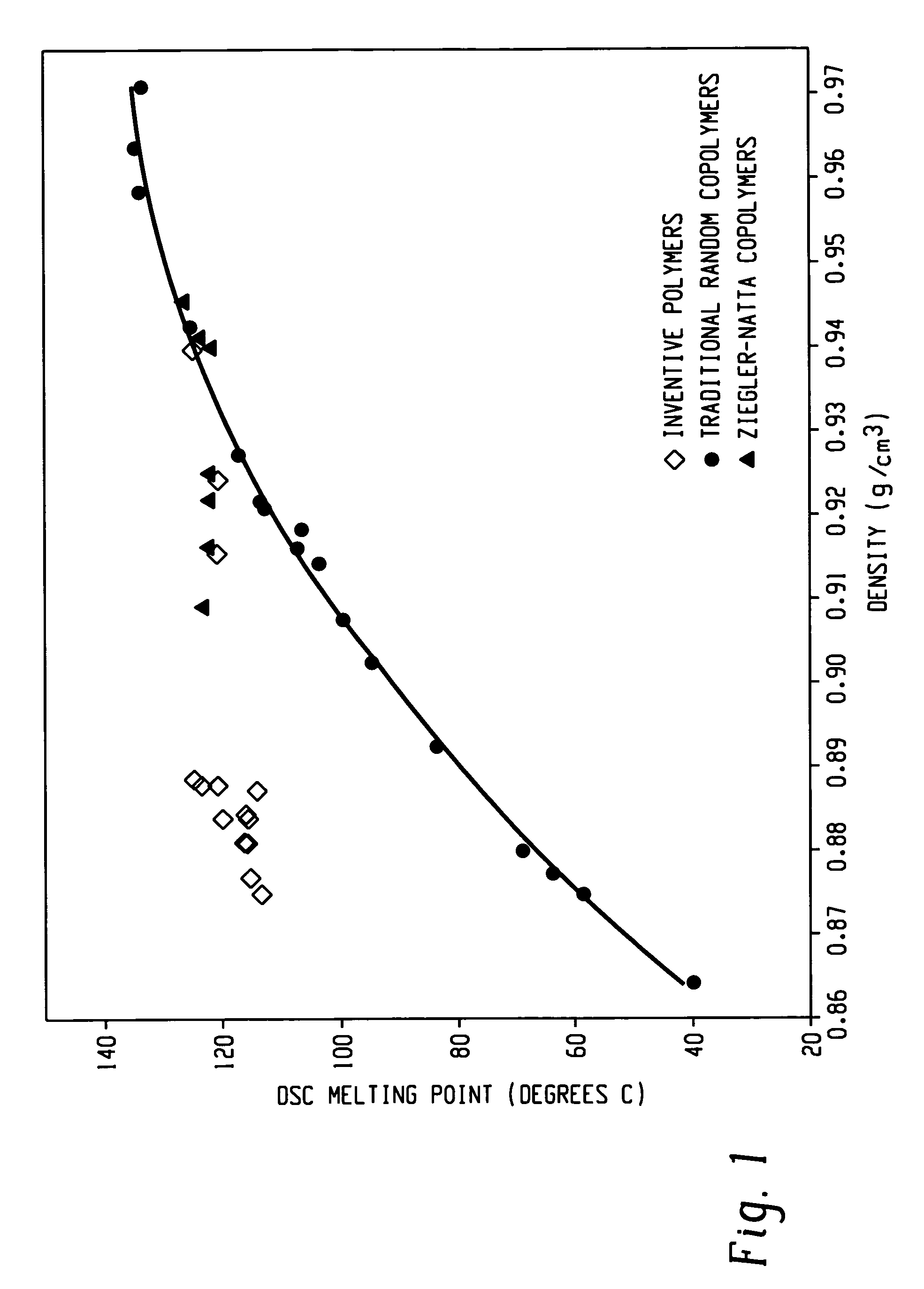

Process for preparing a simulated in situ polyethylene blend

A process comprising:(i) providing a first polyethylene, prepared independently, having a melt index in the range of about 5 to about 3000 grams per 10 minutes and a density in the range of about 0.900 to about 0.975 gram per cubic centimeter and a second polyethylene, prepared independently, having a flow index in the range of about 0.01 to about 30 grams per 10 minutes and a density in the range of about 0.860 to about 0.940 gram per cubic centimeter, the weight ratio of the first polyethylene to the second polyethylene being in the range of about 75:25 to about 25:75;(ii) blending the first polyethylene with the second polyethylene;(iii) melting the blend; and, prior to extrusion or pelletizing,(iv) passing the molten blend through one or more active screens, in the case of two or more active screens, positioned in series, each active screen having a micron retention size in the range of about 2 to about 70, at a mass flux of about 5 to about 100 pounds per hour per square inch.

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

Protective skin for optical fibers

Owner:ALCATEL LUCENT SAS

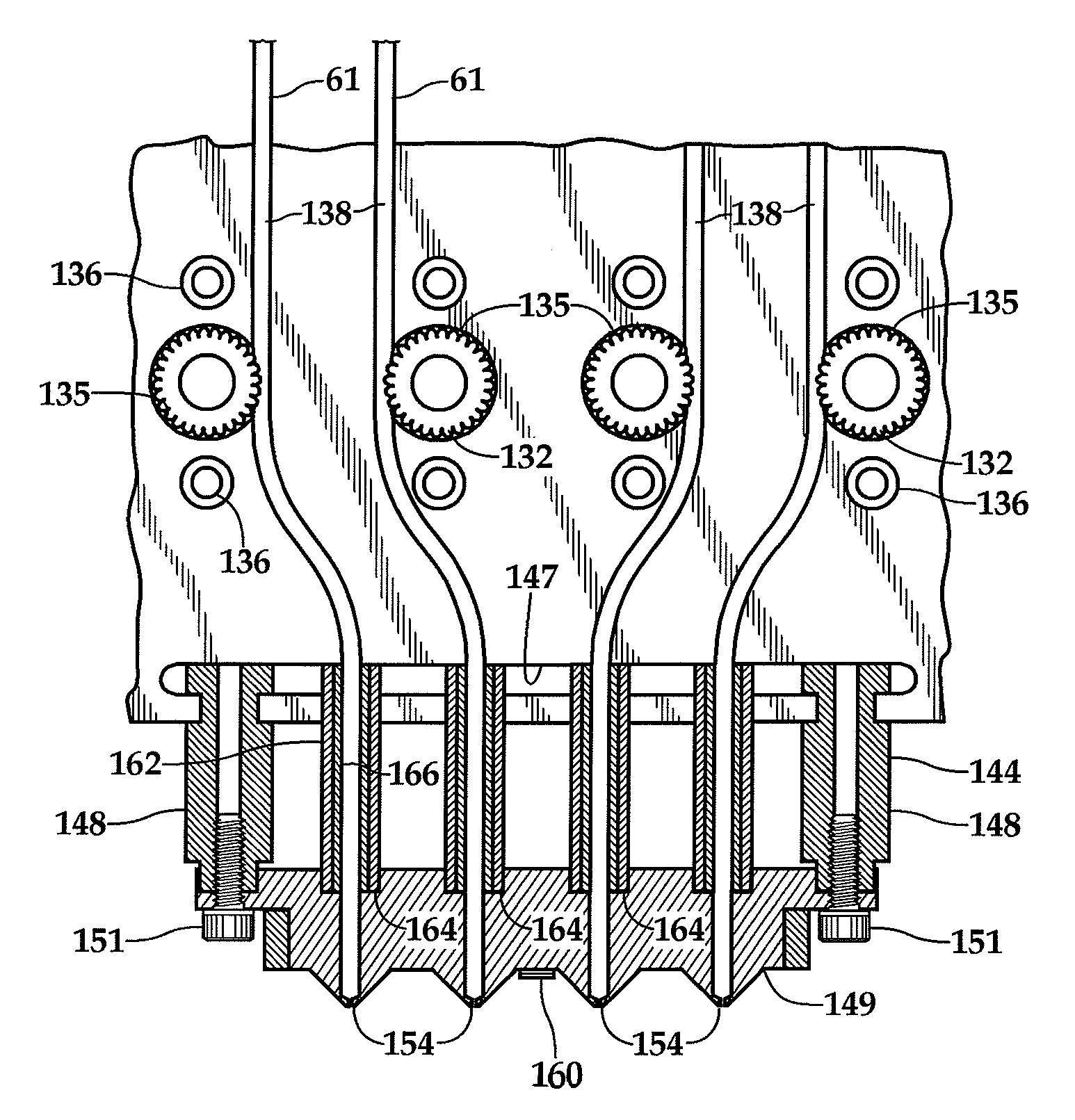

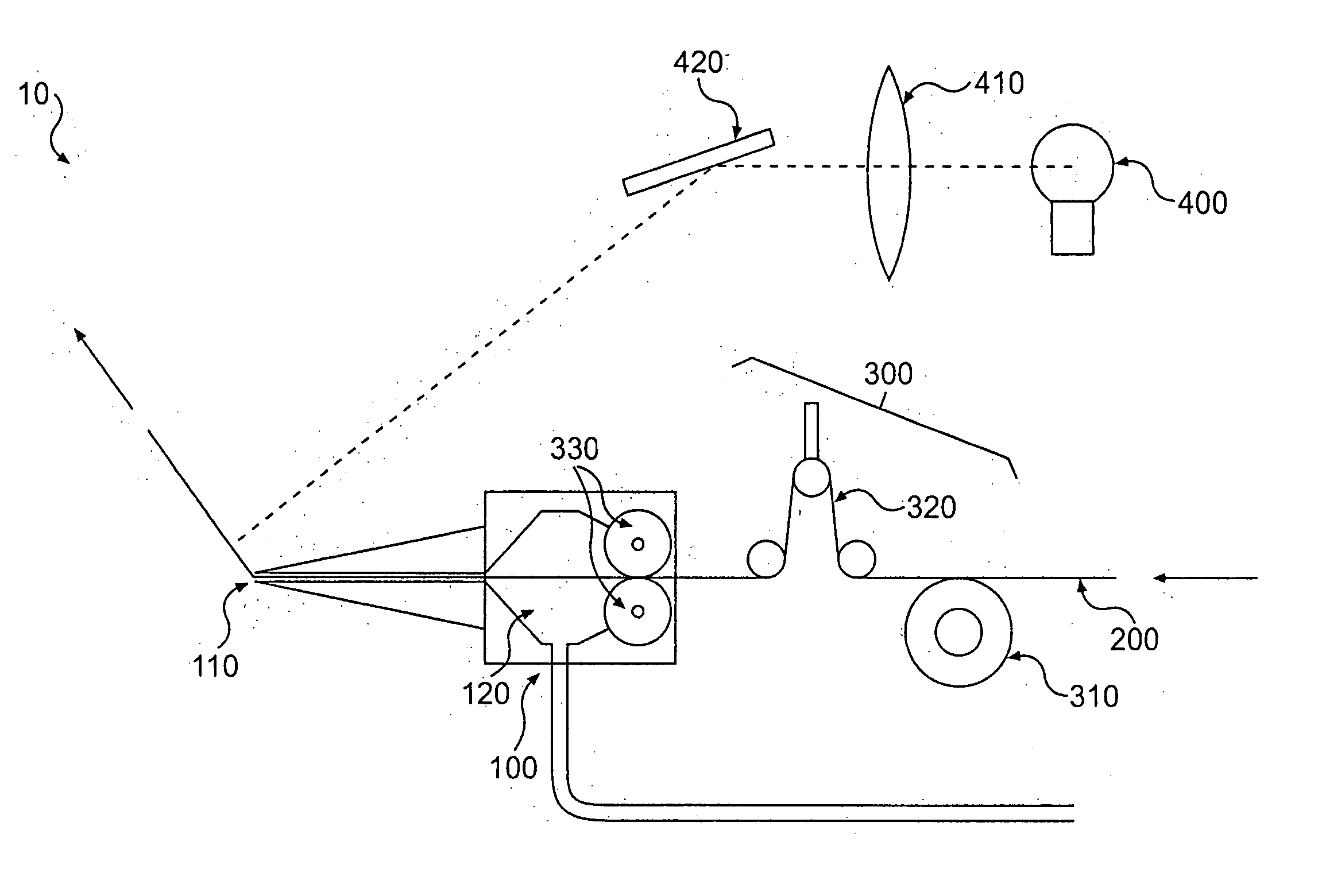

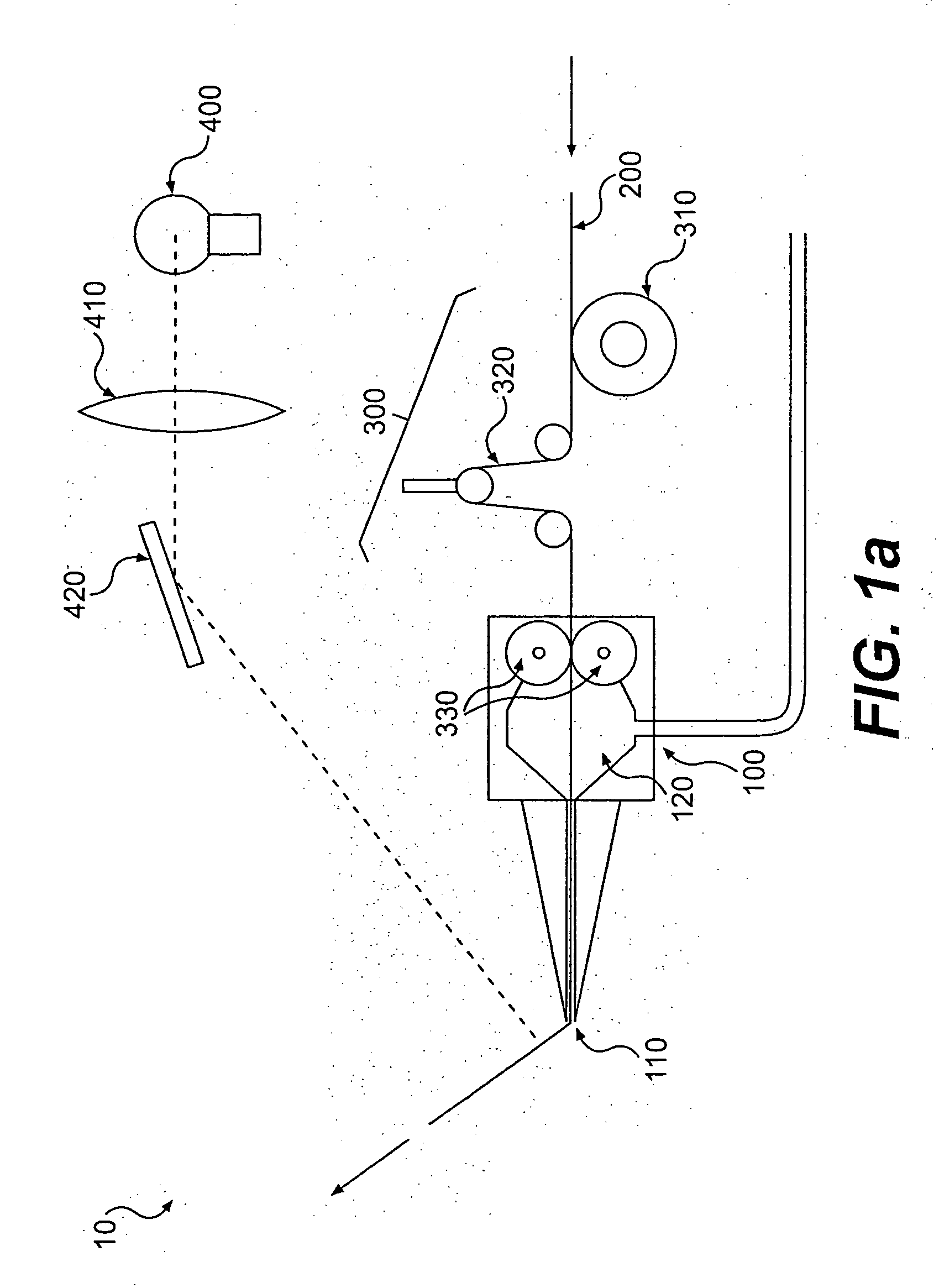

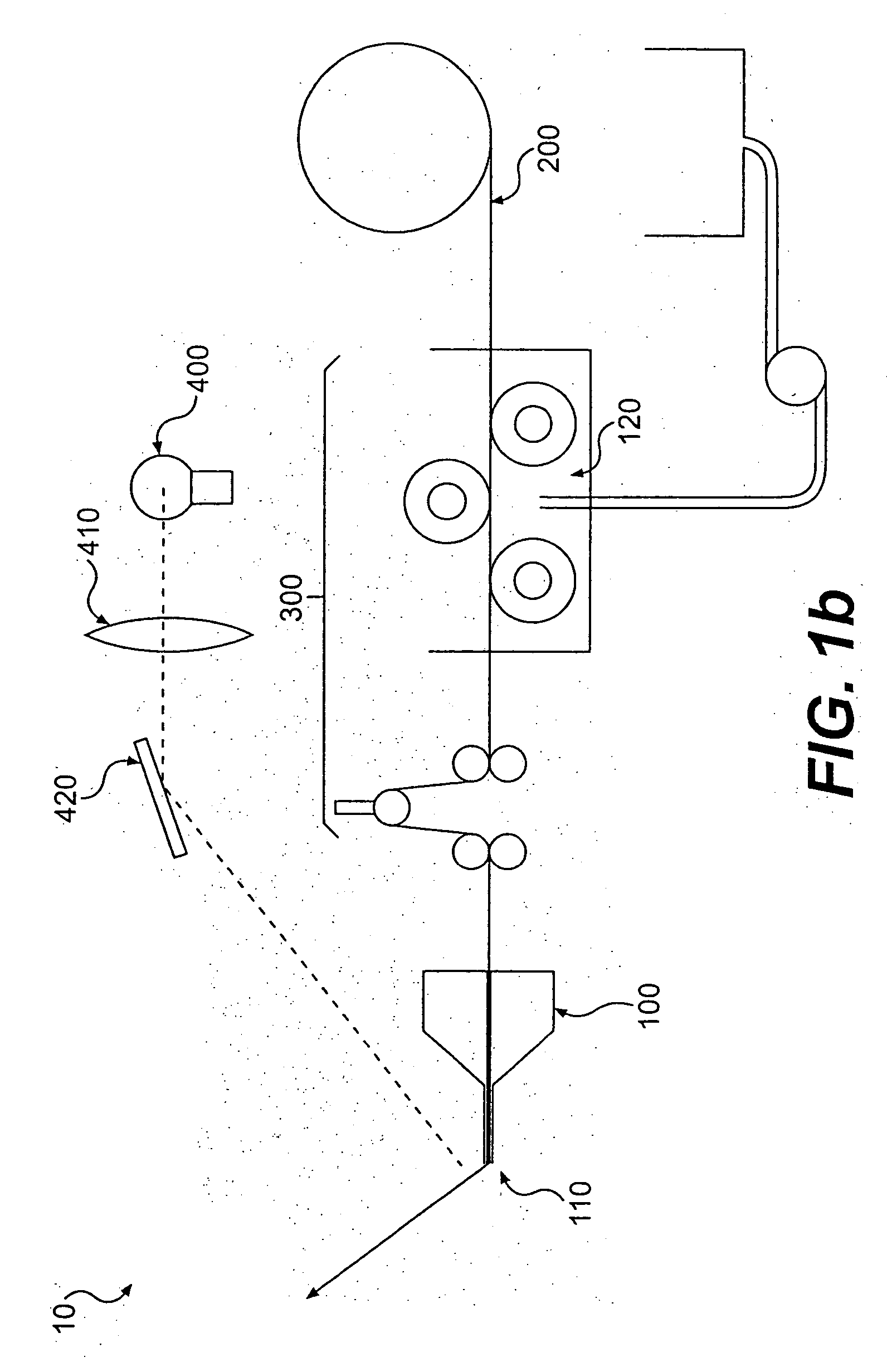

3D printer and printhead unit with multiple filaments

InactiveUS8827684B1Reduce complexityIncrease speedConfectionerySweetmeatsFused filament fabricationMetal filament

A fused filament fabrication printer has a fixed extrusion module having multiple printheads having print tips. The fixed arrangement of the printing heads allows the close spacing of multiple print tips in a printhead unit, and the simple routing of multiple plastic or metal filaments to the individual printing heads. The closely spaced print tips in the printhead unit share common components. An exemplary printhead unit has four printing heads which share a common heating block and heating block temperature sensor. The heating block incorporates a group of four print tips evenly spaced along a line. Each printing head has a separate filament which is controlled and driven by its own stepper motor through the heating block to one of the print tips. Printing of a part is by control of individual stepper motors which drive filaments through the heating block and through one of the printing tips.

Owner:RADIANT FABTION

Apparatus for fabricating fiber reinforced plastic parts

InactiveUS20070003650A1Fast and cost-effectiveLow costAdditive manufacturing apparatusCeramic shaping apparatusEngineeringMechanical engineering

The invention relates to an apparatus and method for fabricating FRP parts. More specifically, the invention relates to a method for forming FRP parts without the use of forms or molds. According to a preferred embodiment of the present invention, the method for fabricating an FRP part comprises the steps of: programming a readable definition of a part into a machine, wherein the machine moves an extrusion head mounted to the machine in a controlled pattern; and wherein the machine regulates the speed of extrusion from the extrusion head; feeding a fiber reinforcement to the extrusion head of the machine; impregnating the fiber reinforcement with a radiation-initiated resin; extruding the impregnated fiber reinforcement from an orifice in the extrusion head; and exposing the extruded fiber reinforcement to curing radiation.

Owner:SCHROEDER ERNEST C

Highly filled polymer composition with improved properties

InactiveUS6362252B1Reduce manufacturing costHigh tensile strengthConductive materialPlastic recyclingPolymer sciencePlasticizer

A highly filled polymer composition with improved properties comprising: a continuous matrix material; a filler material in an amount of 10 to 80 wt. % of said composition; a polymer plasticizer dispersed in said continuous matrix material in an amount of 0.5 to 15 wt. % of said filler; a filler coating material which coats said filler particles in the form of a continuous coating layer thus forming coated filler particles; a diffusion zone around said coated filler particles where said filler coating and said continuous matrix material are mutually diffused into one another wherein said filler coating material is distributed with concentration decreasing in the direction outward from said continuous coating layer. Provided also is a method of preparing the aforementioned composition which guarantees that during extrusion or similar treatment the filler particles are coated with a continuous layer of the filler coating material and that the aforementioned diffusion zone is formed around the coated filler particles. In the manufacture of various products such as pipes, sheets, profiles, etc., the composition of the invention combines high deformation capacity with sufficient strength. Furthermore, the composition of the invention possesses high anticorrosive properties, has low shrinkage, and has high adhesion to metals, wood, plastics, etc.

Owner:NEXT GENERATIONS TECH

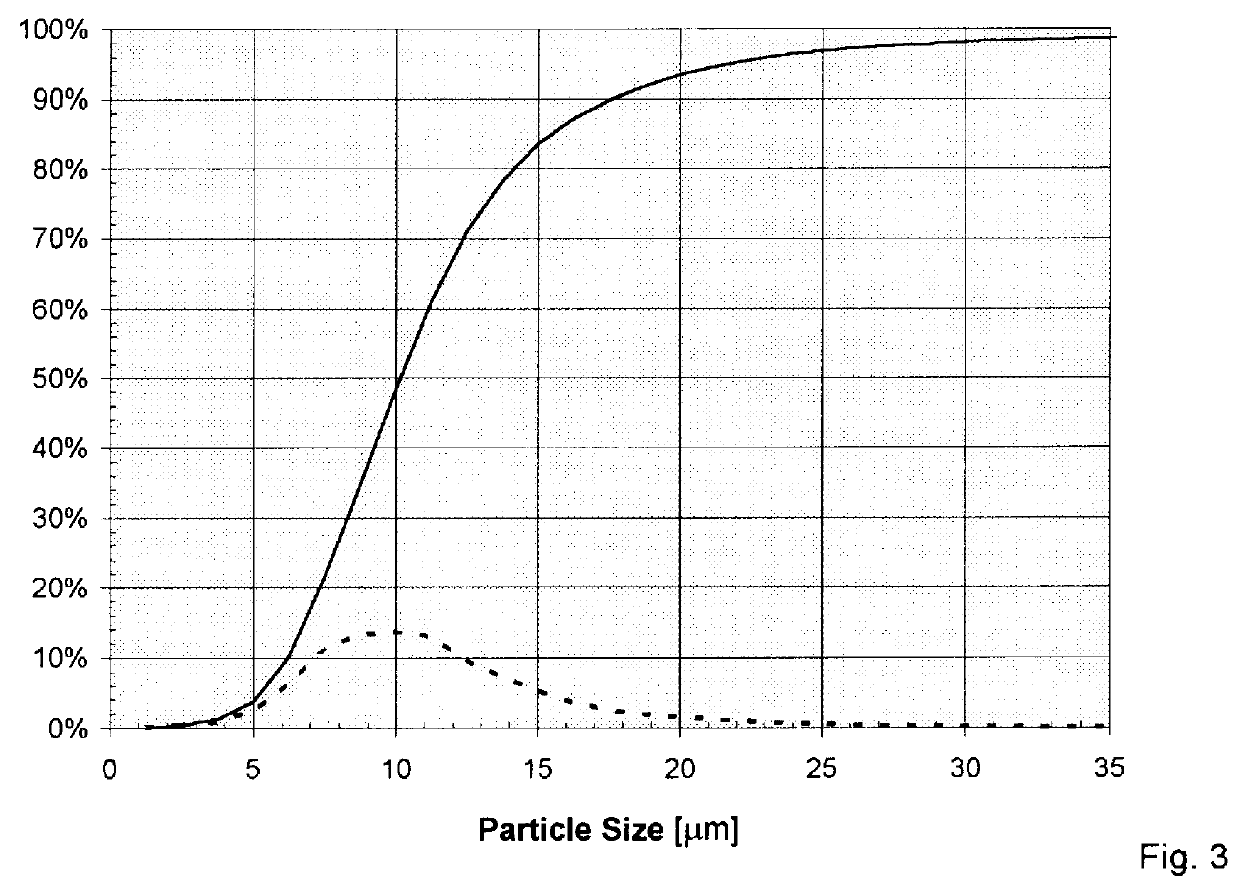

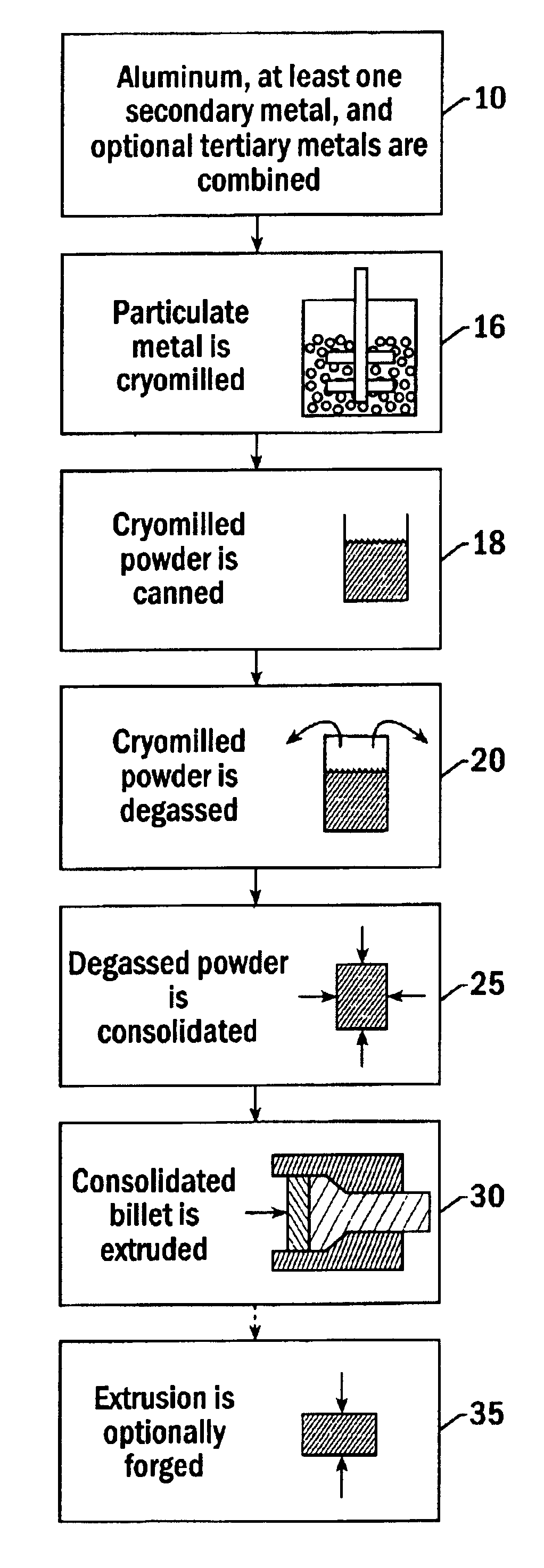

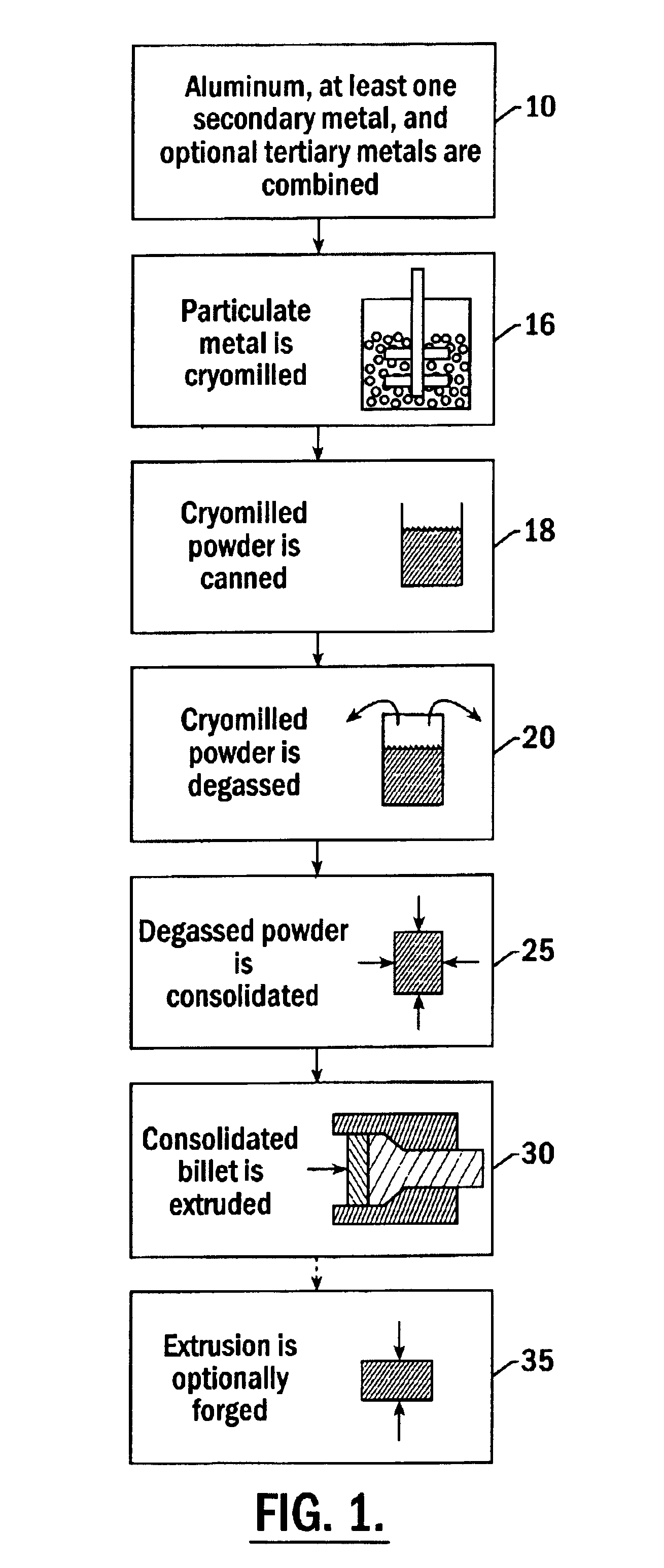

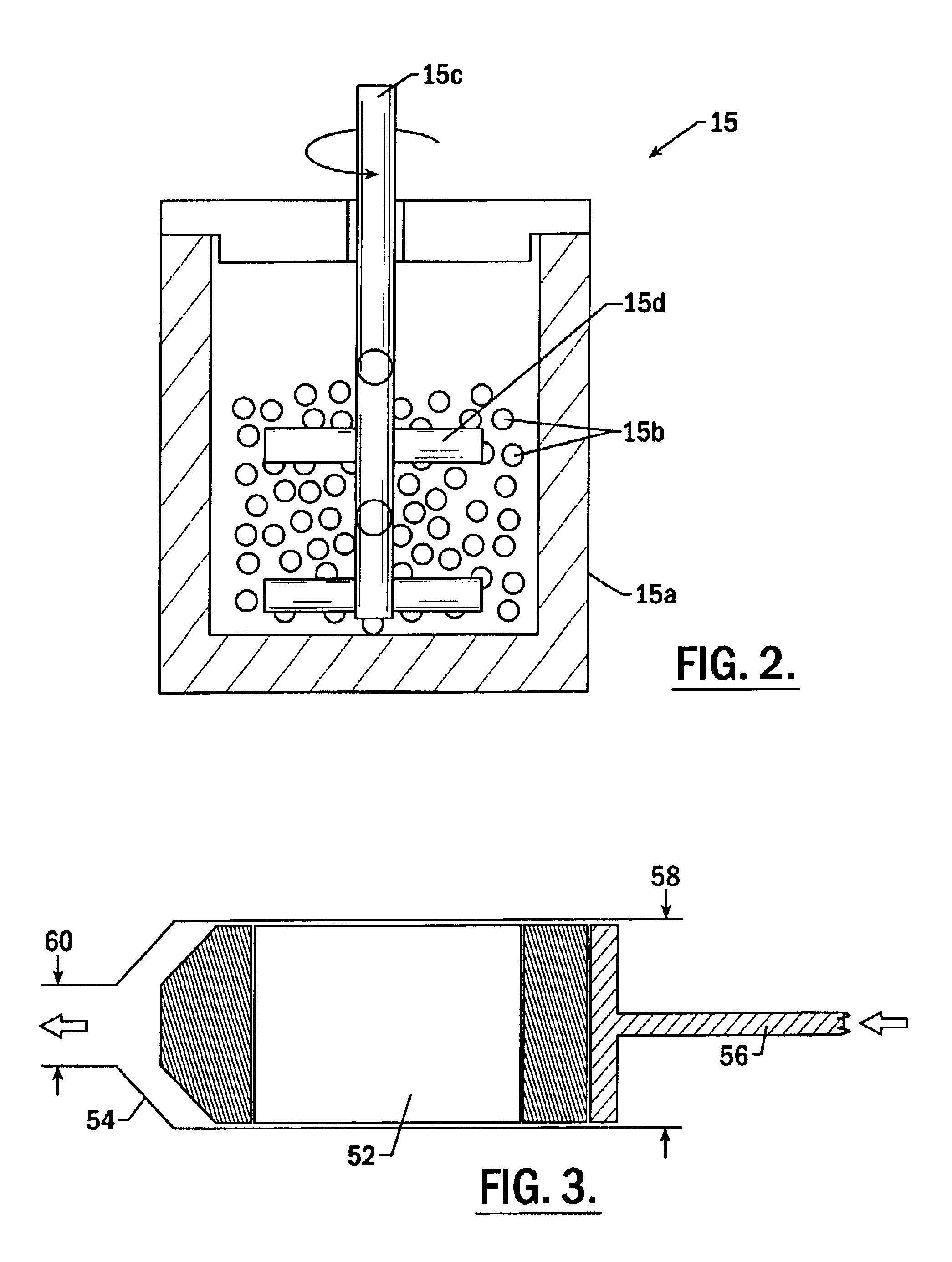

Method for preparing cryomilled aluminum alloys and components extruded and forged therefrom

InactiveUS6902699B2Stable structureHigh strengthTransportation and packagingMetal-working apparatusNanostructureAluminium alloy

High strength aluminum alloy powders, extrusions, and forgings are provided in which the aluminum alloys exhibit high strength at atmospheric temperatures and maintain high strength and ductility at extremely low temperatures. The alloy is produced by blending about 89 atomic % to 99 atomic % aluminum, 1 atomic % to 11 atomic % of a secondary metal selected from the group consisting of magnesium, lithium, silicon, titanium, zirconium, and combinations thereof, and up to about 10 atomic % of a tertiary metal selected from the group consisting of Be, Ca, Sr, Ba, Ra, Sc, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Y, Nb, Mo, Tc, Ru, Rh, Pd, Ag, Cd, W, and combinations thereof. The alloy is produced by nanostructure material synthesis, such as cryomilling, in the absence of refractory dispersoids. The synthesized alloy is then canned, degassed, consolidated, extruded, and optionally forged into a solid metallic component. Grain size within the alloy is less than 0.5 μm, and alloys with grain size less than 0.1 μm may be produced.

Owner:THE BOEING CO

Self energized packer

A packer or plug features a main sealing element that swells after a delay long enough to get it into proper position. A sleeve eventually goes away to let the well fluids at the main sealing element to start the swelling process until contact with the surrounding tubular or the wellbore is established. Other sleeves that are disposed above and below the main sealing element preferably swell, but mainly in a longitudinal direction against the main sealing element to increase its contact pressure against the surrounding tubular or the wellbore. The longitudinally swelling members may also be covered to initiate their growth after the main sealing element has started or even completed its swelling action. The longitudinally swelling members can be constrained against radial growth to direct most or all of their swelling action longitudinally. Extrusion barriers above and below the main sealing element can optionally be used.

Owner:BAKER HUGHES INC

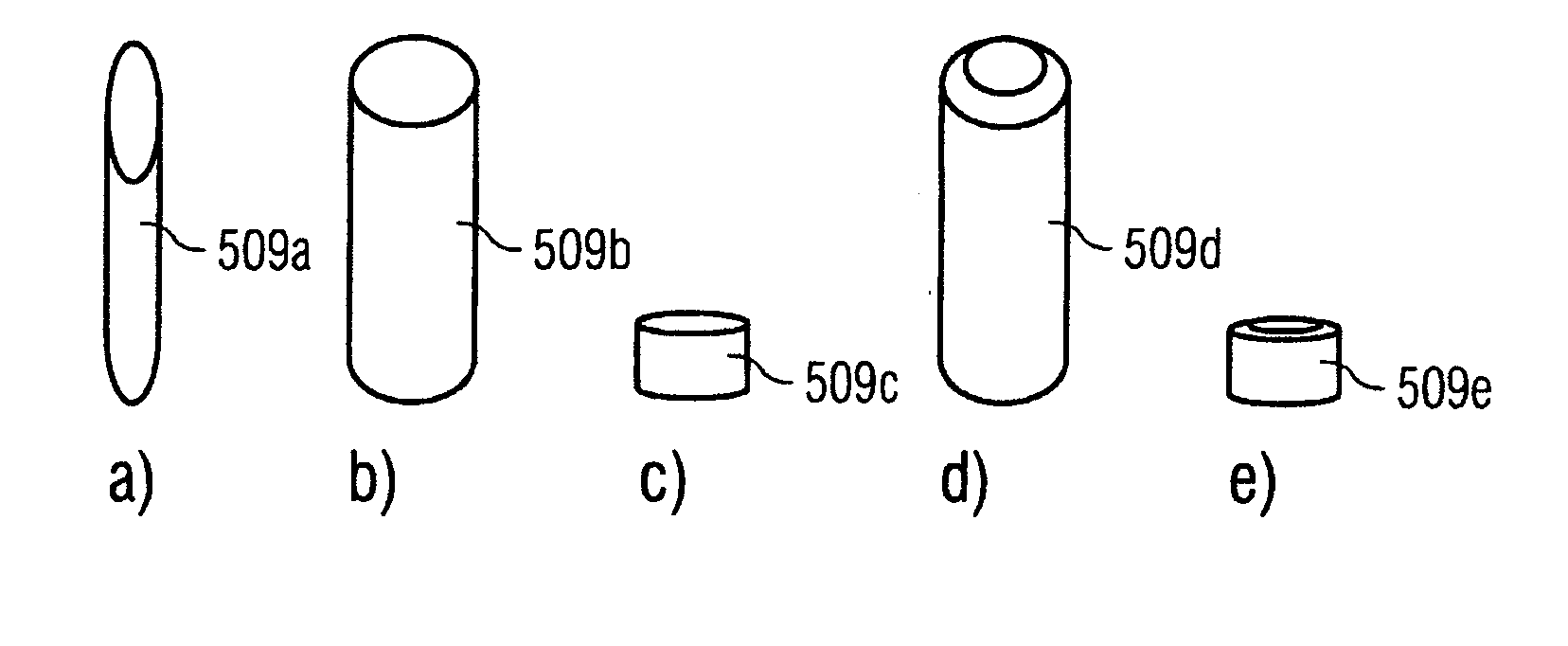

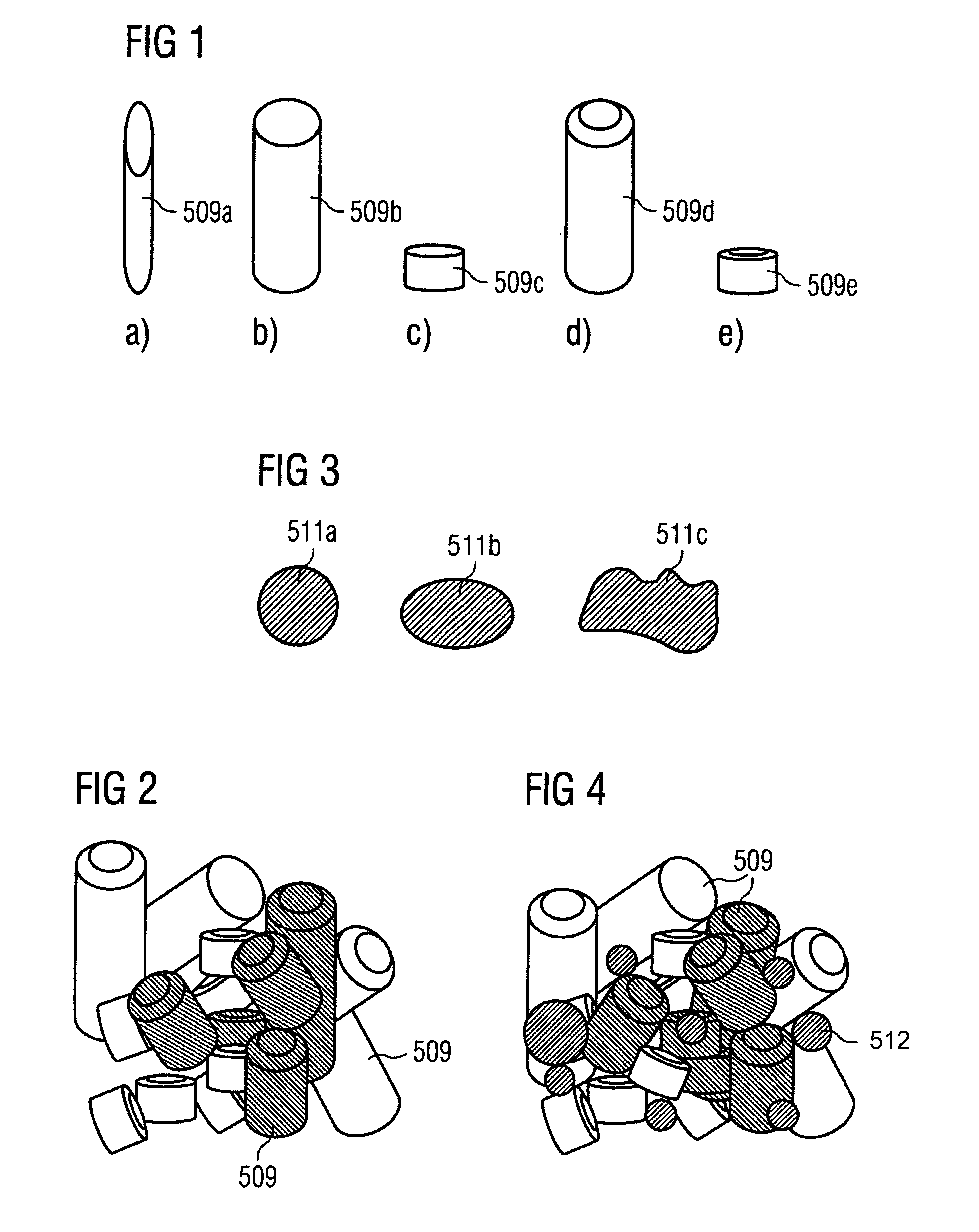

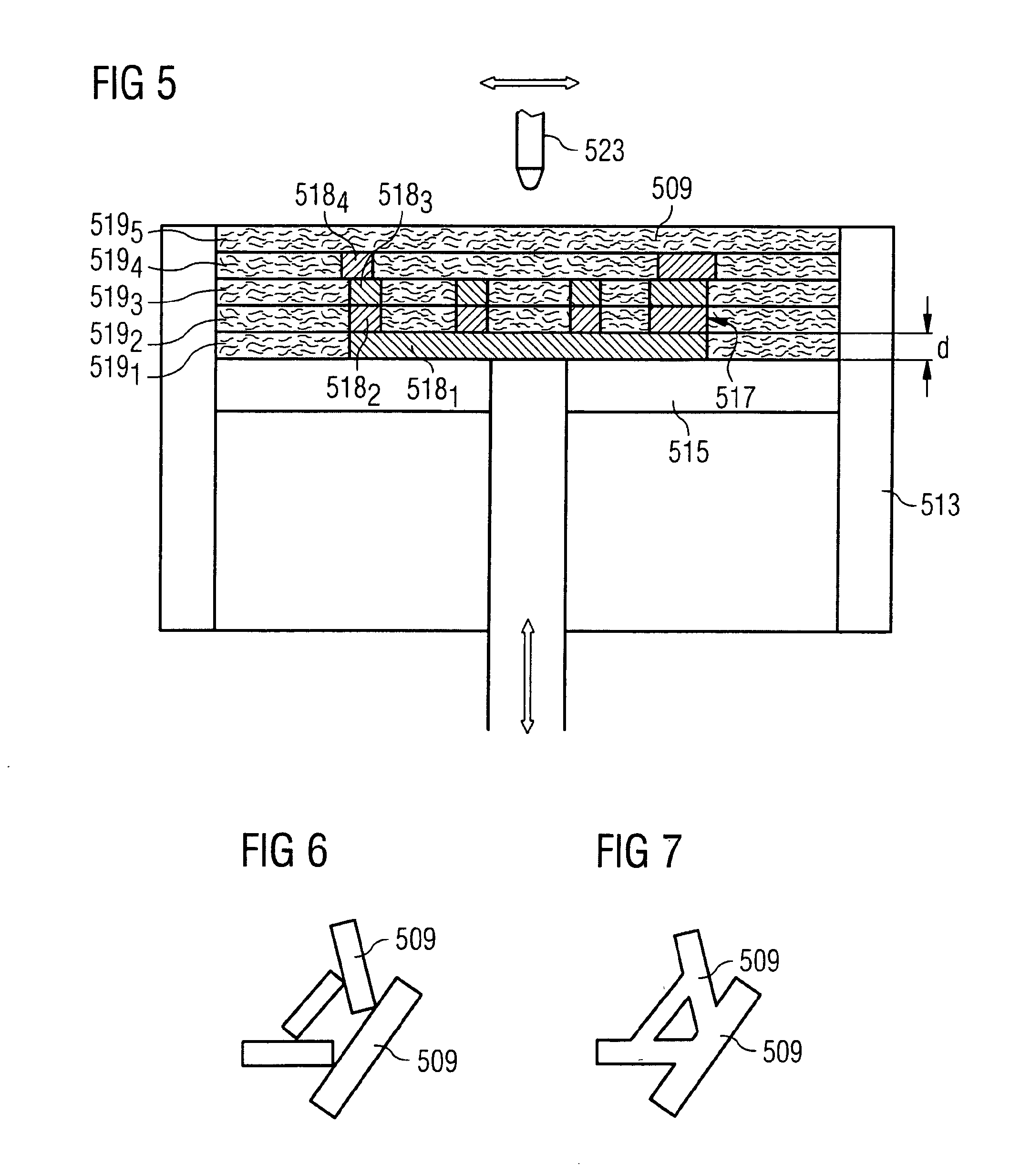

Fibers and methods for use in solid freeform fabrication

ActiveUS20110143108A1Easy to produceSpecific characteristicAdditive manufacturing apparatusSynthetic resin layered productsFiberRapid prototyping

A shaped body comprised of individual, interconnected layers may be produced from fibers in accordance with a solid freeform fabrication or rapid prototyping method. The fibers may be produced by extrusion molding a thermoplastic material.

Owner:EVONIK OPERATIONS GMBH

Extrusion process for coating stents

The present invention provides a method of coating a stent. A stent framework is provided. A polymeric mixture is injected through at least one inlet port in an extrusion die, and the polymeric mixture is extruded through a shaped orifice onto at least a portion of the stent framework to form a coated stent. A coated stent including an extruded coating disposed on at least a portion of the stent framework and a system for treating a vascular condition are also disclosed.

Owner:MEDTRONIC VASCULAR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com