Patents

Literature

4737 results about "High adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

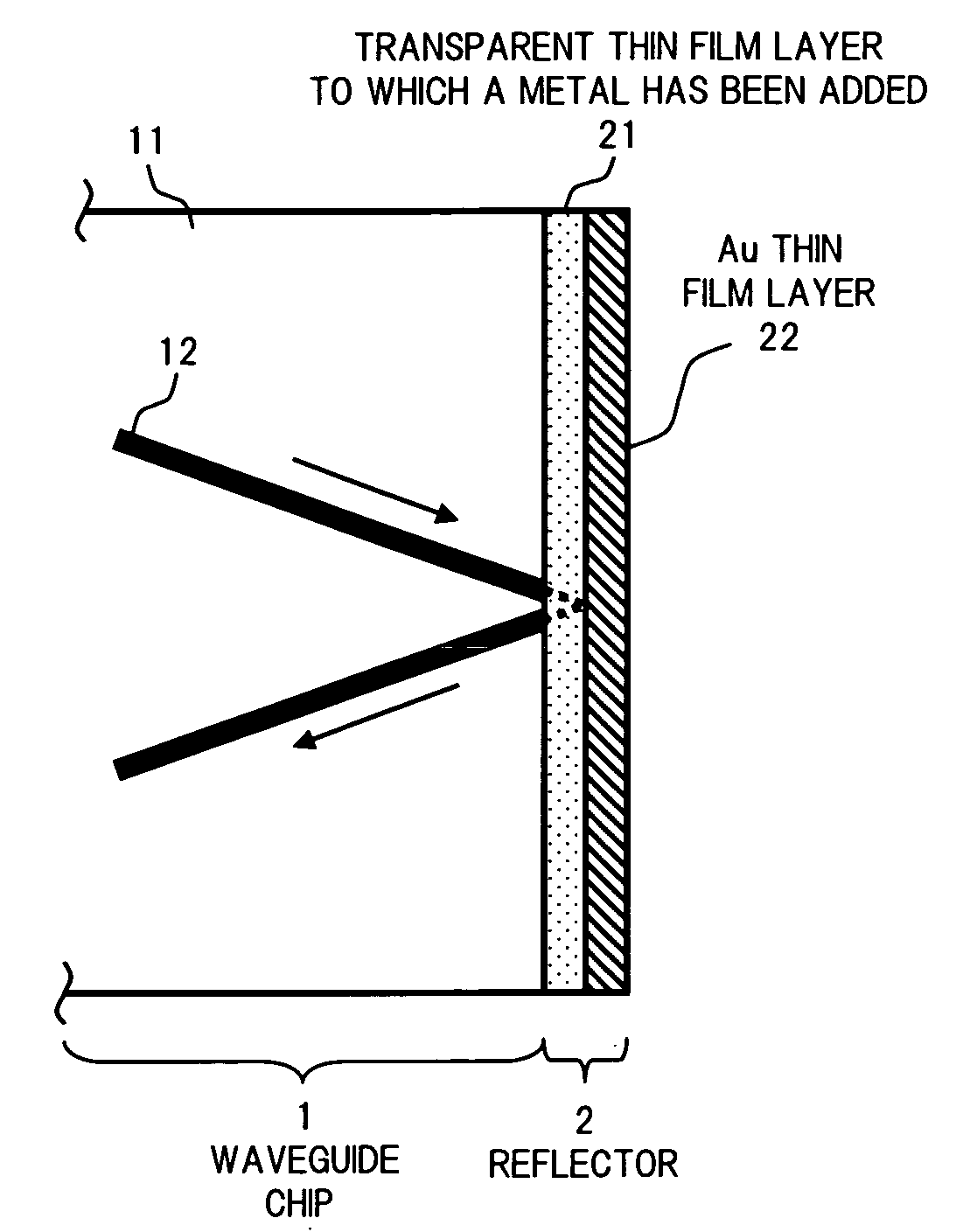

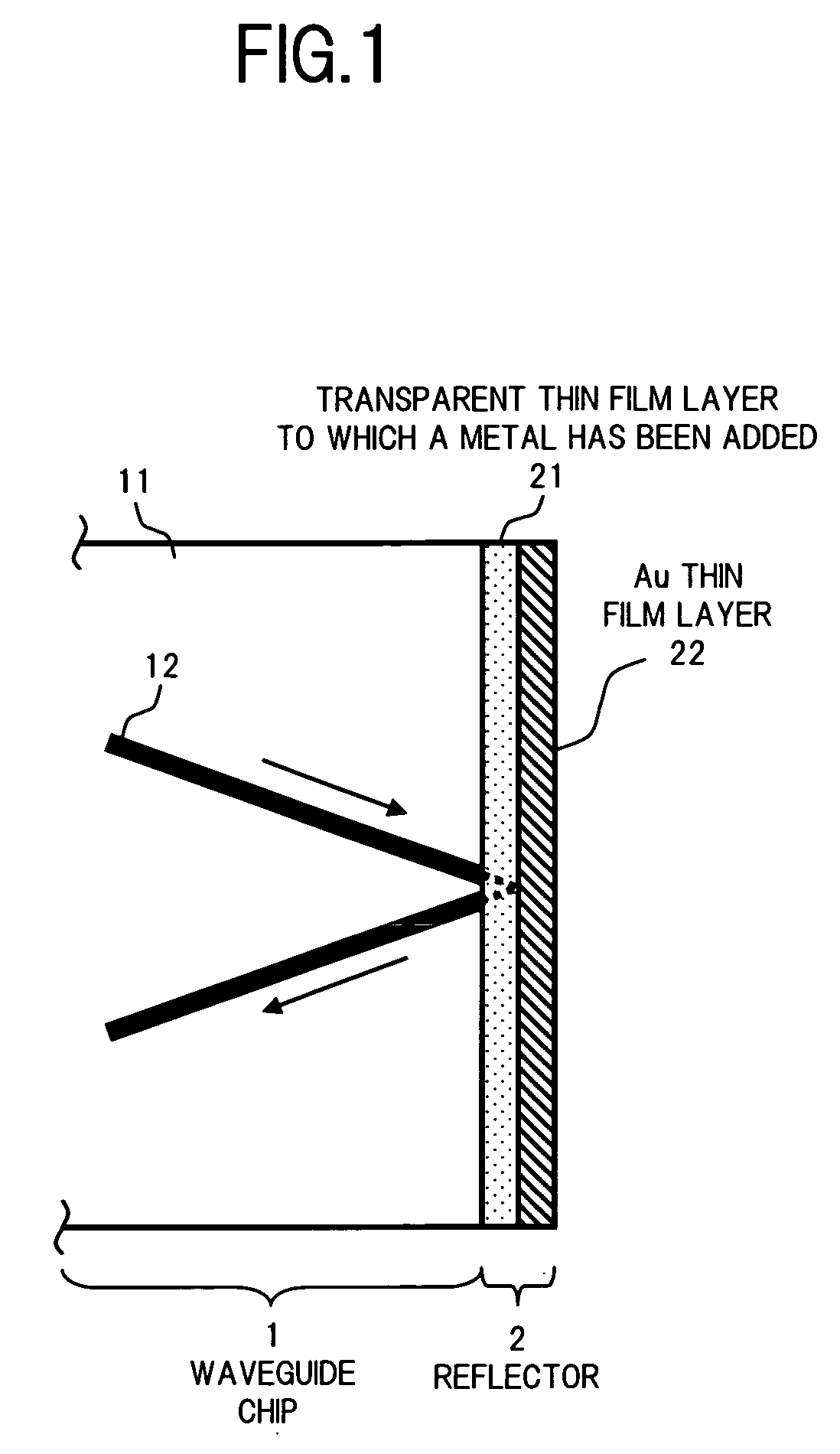

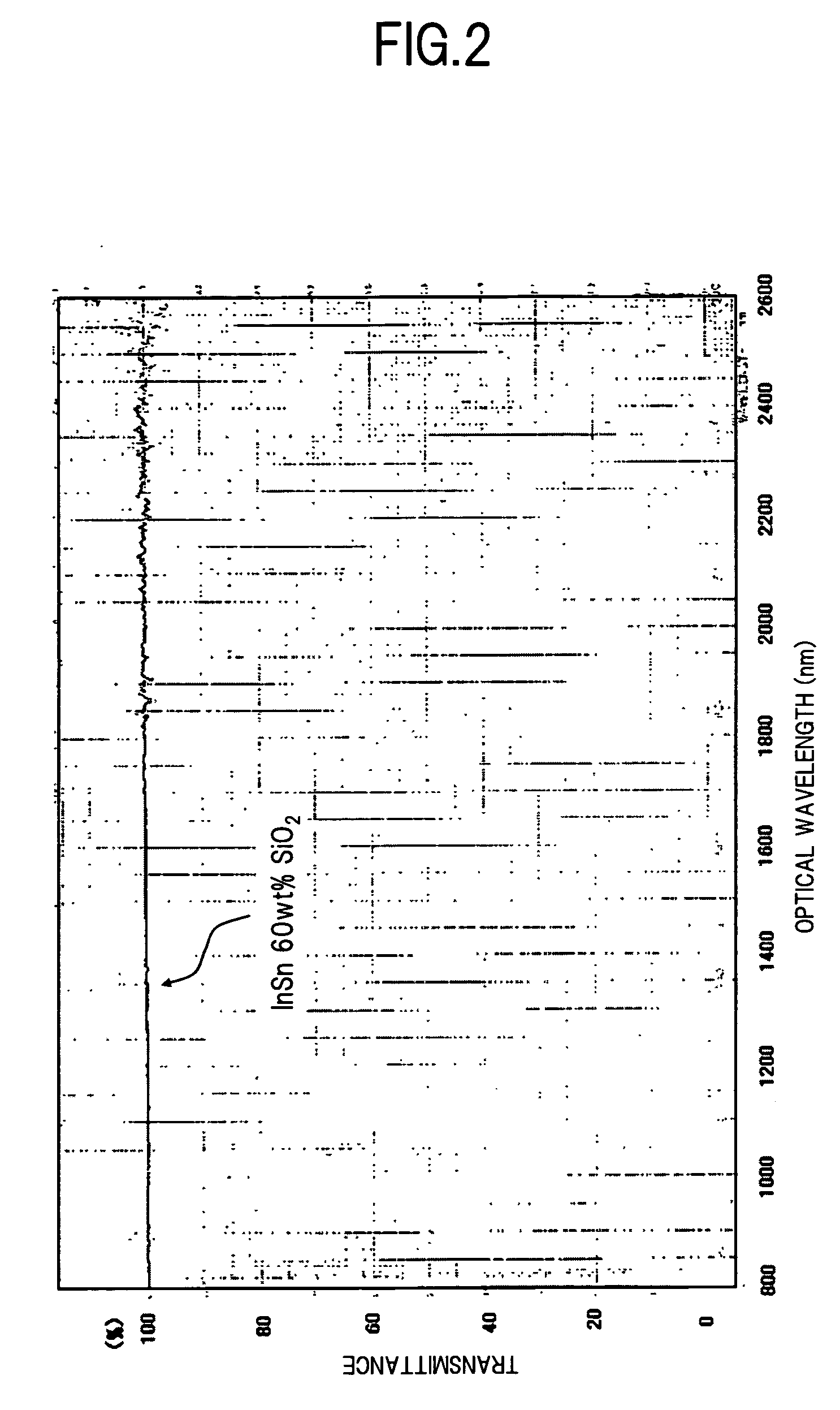

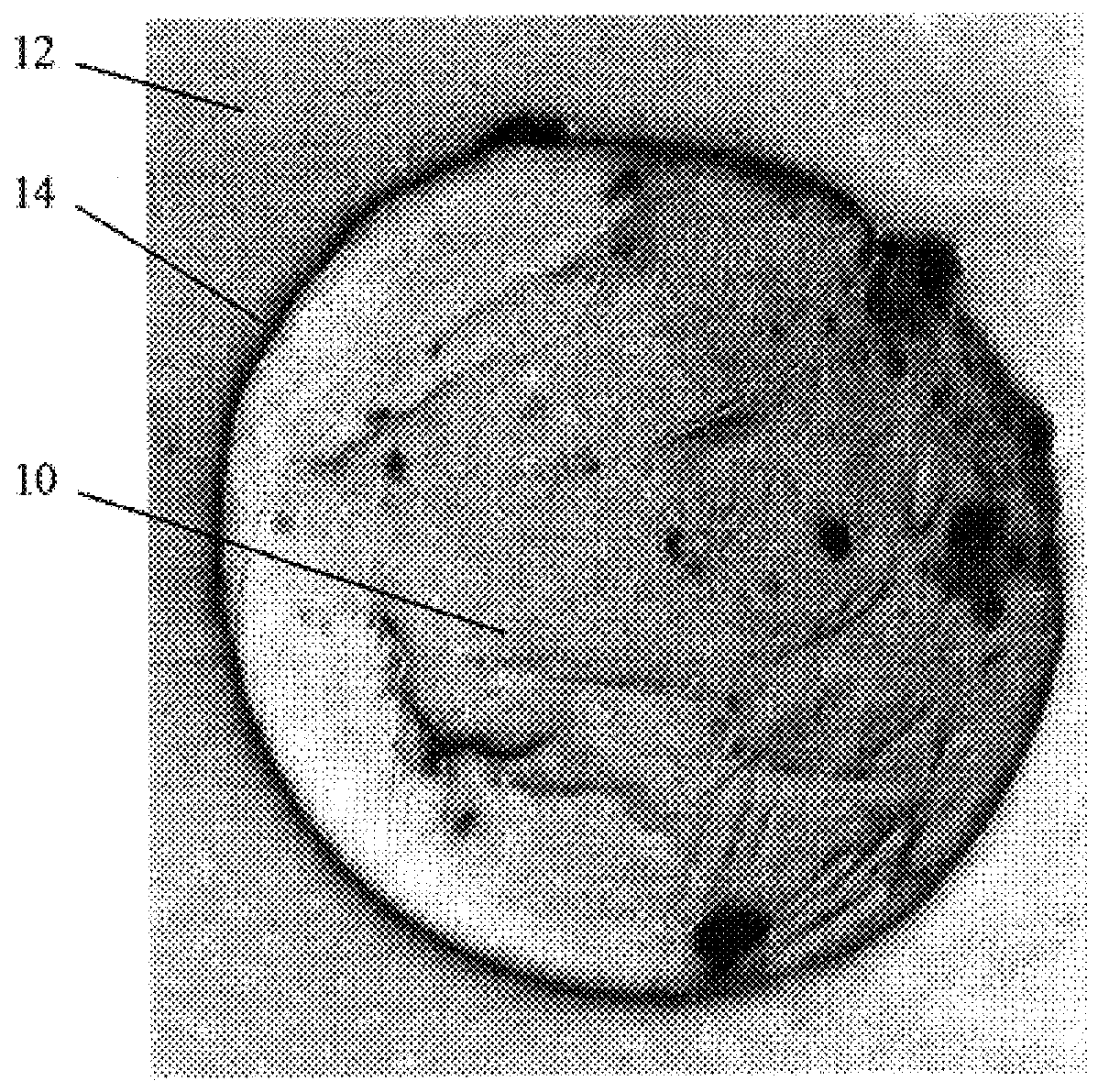

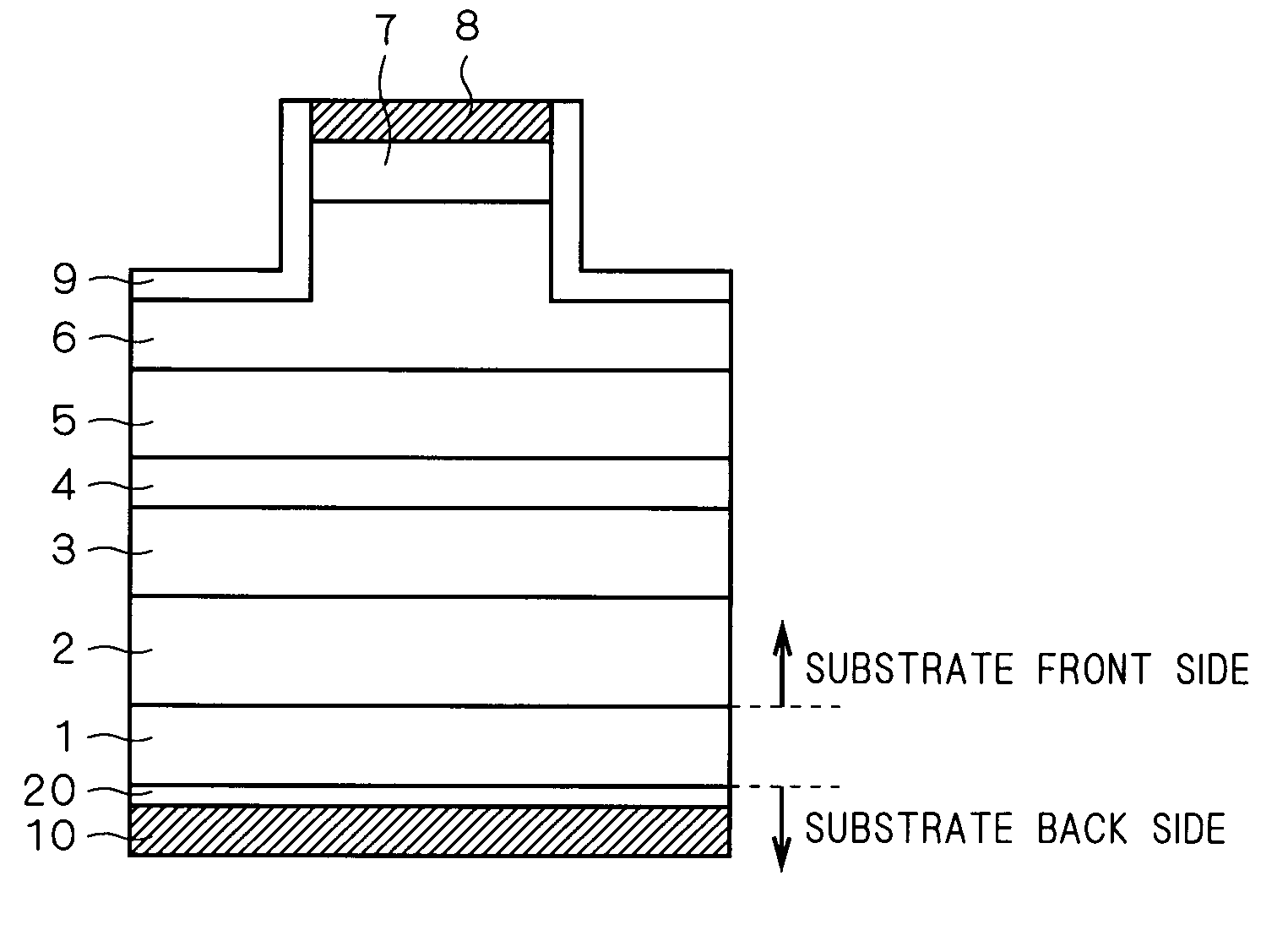

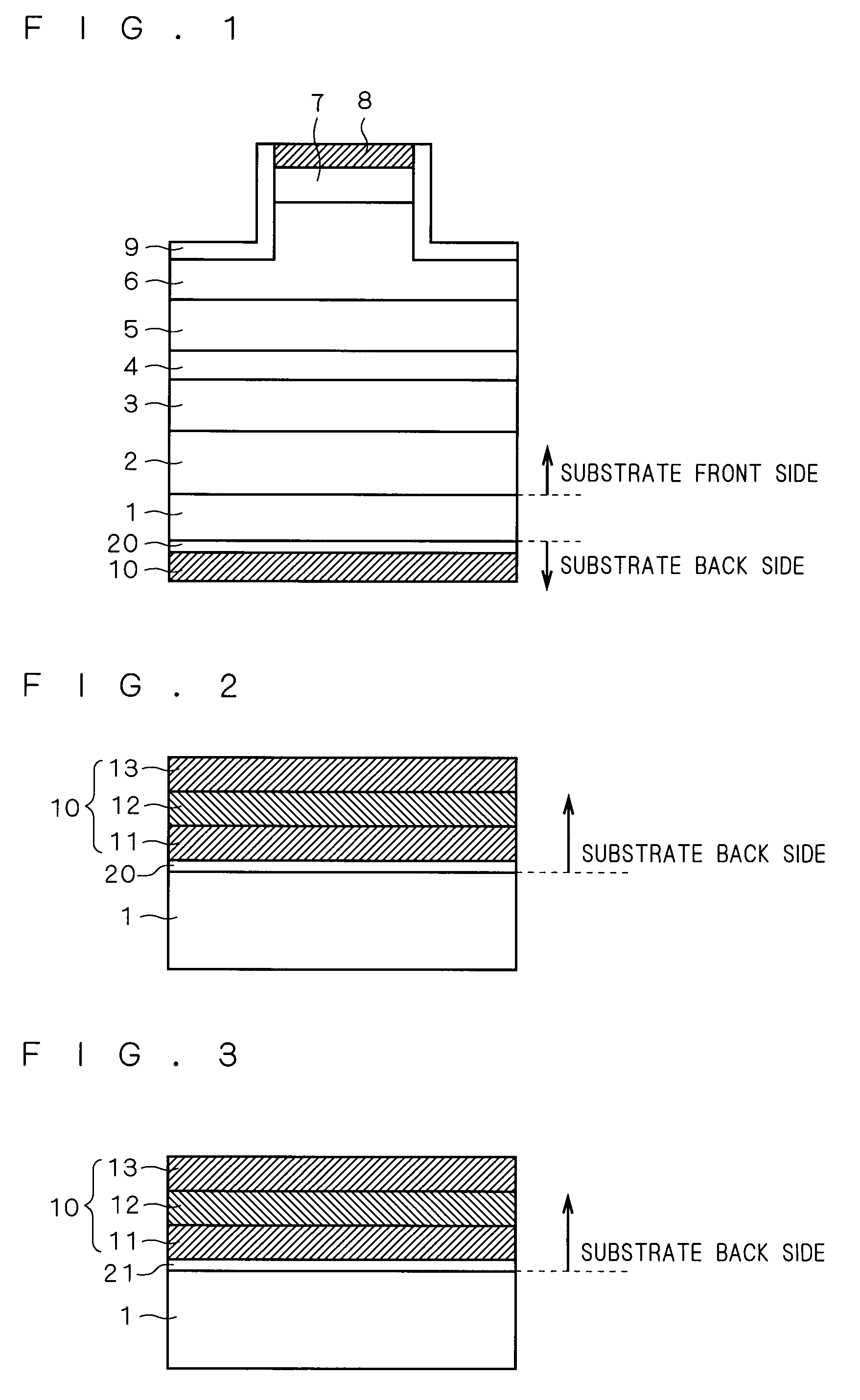

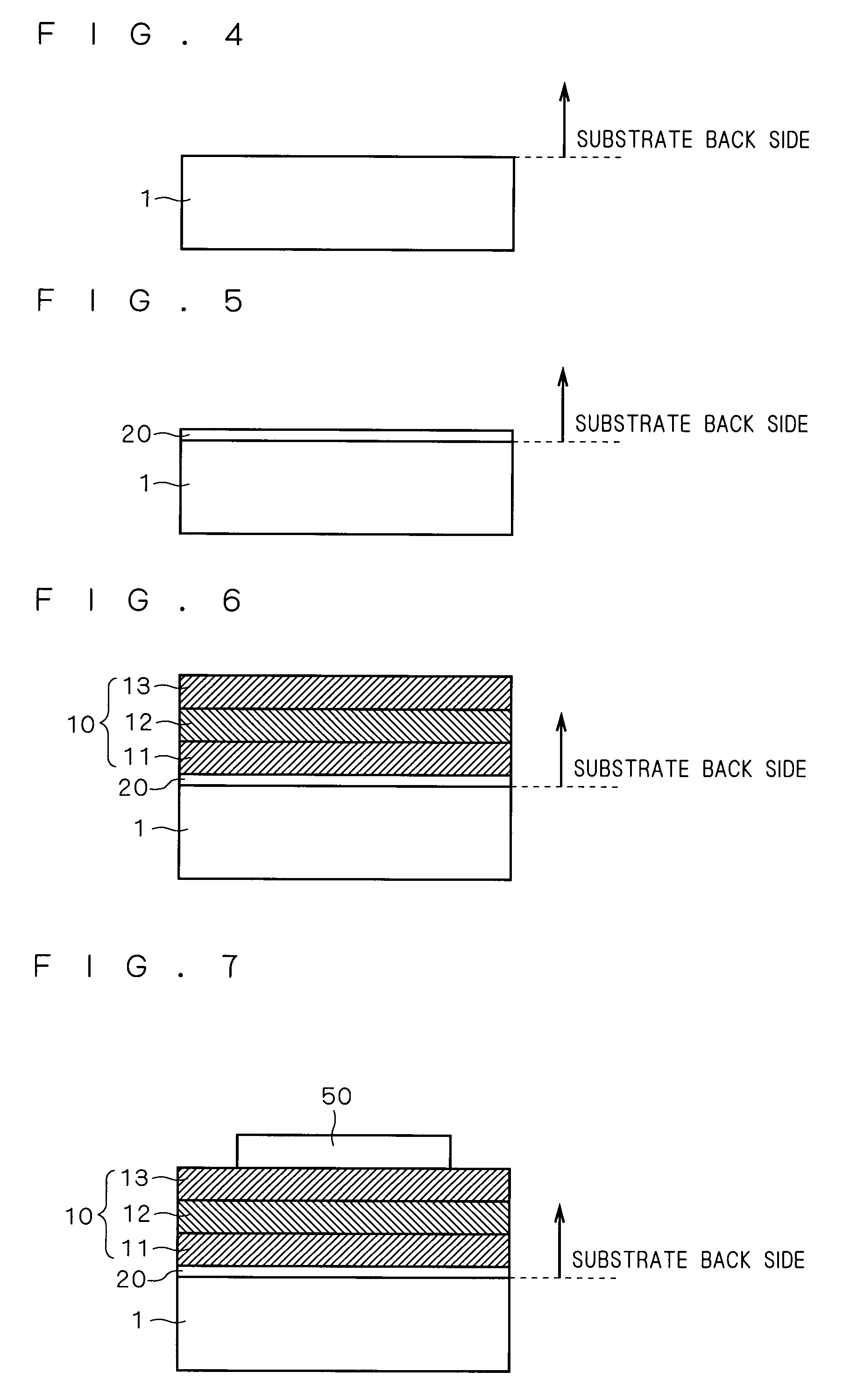

Optical communication device provided with a reflector and method for forming a reflector in an optical communication device

InactiveUS20070070490A1Small lossHigh bonding strengthMirrorsCoupling light guidesCompound (substance)Optical communication

An optical communication device of the invention includes a reflector for reflecting the light that has reached one end surface of a waveguide chip to turn the optical path of the light. The reflector includes a transparent thin film layer formed on one end surface of the waveguide chip by using a material to which a metal that forms an intermetallic compound or the like with Au is added to a substance that is transparent to the light that propagates through the waveguide, as well as an Au thin film layer formed on the front surface of the transparent thin film layer. This allows formation of a reflector having an Au thin film layer as a reflecting surface in an optical medium with high adhesion strength. Thus, an optical communication device can be provided having a high reliability with little loss.

Owner:FUJITSU LTD

Highly filled polymer composition with improved properties

InactiveUS6362252B1Reduce manufacturing costHigh tensile strengthConductive materialPlastic recyclingPolymer sciencePlasticizer

A highly filled polymer composition with improved properties comprising: a continuous matrix material; a filler material in an amount of 10 to 80 wt. % of said composition; a polymer plasticizer dispersed in said continuous matrix material in an amount of 0.5 to 15 wt. % of said filler; a filler coating material which coats said filler particles in the form of a continuous coating layer thus forming coated filler particles; a diffusion zone around said coated filler particles where said filler coating and said continuous matrix material are mutually diffused into one another wherein said filler coating material is distributed with concentration decreasing in the direction outward from said continuous coating layer. Provided also is a method of preparing the aforementioned composition which guarantees that during extrusion or similar treatment the filler particles are coated with a continuous layer of the filler coating material and that the aforementioned diffusion zone is formed around the coated filler particles. In the manufacture of various products such as pipes, sheets, profiles, etc., the composition of the invention combines high deformation capacity with sufficient strength. Furthermore, the composition of the invention possesses high anticorrosive properties, has low shrinkage, and has high adhesion to metals, wood, plastics, etc.

Owner:NEXT GENERATIONS TECH

Curing resin composition, adhesive epoxy resin paste, adhesive epoxy resin sheet, conductive connection paste, conductive connection sheet, and electronic component joined body

ActiveUS20060154078A1Adhesion reliability is highIncrease flexibilityNon-insulated conductorsSynthetic resin layered productsEpoxyHeat resistance

It is an object of the invention to provide a curable resin composition excellent in mechanical strength, heat resistance, moisture resistance, flexibility, resistance to thermal cycles, resistance to solder reflow, dimensional stability, and the like after curing and providing high adhesion reliability and conduction reliability and an adhesive epoxy resin paste, an adhesive epoxy resin sheet, a conductive connection paste, and a conductive connection sheet using the curable resin composition, and an electronic component joined body. The invention relates to a curable resin composition, which contains an epoxy resin, a solid polymer having a functional group to react with the epoxy group and a curing agent for an epoxy resin, no phase separation structure being observed in a matrix of a resin when a cured product is dyed with a heavy metal and observed with a transmission electron microscope.

Owner:SEKISUI CHEM CO LTD

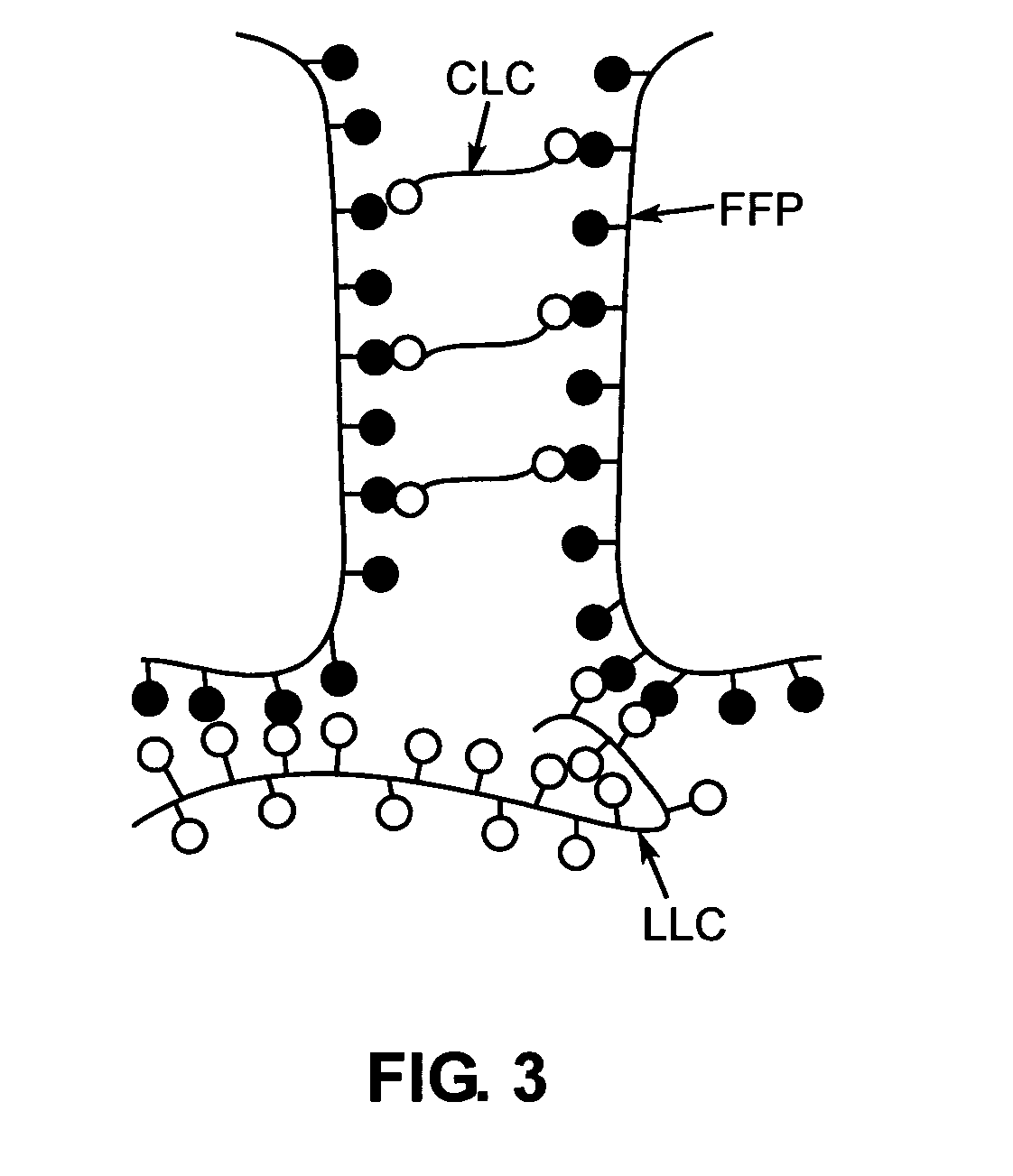

Method of preparing polymeric adhesive compositions utilizing the mechanism of interaction between the polymer components

InactiveUS20050113510A1Easy to handleReduce leakageCosmetic preparationsImpression capsPolymer scienceBioadhesive

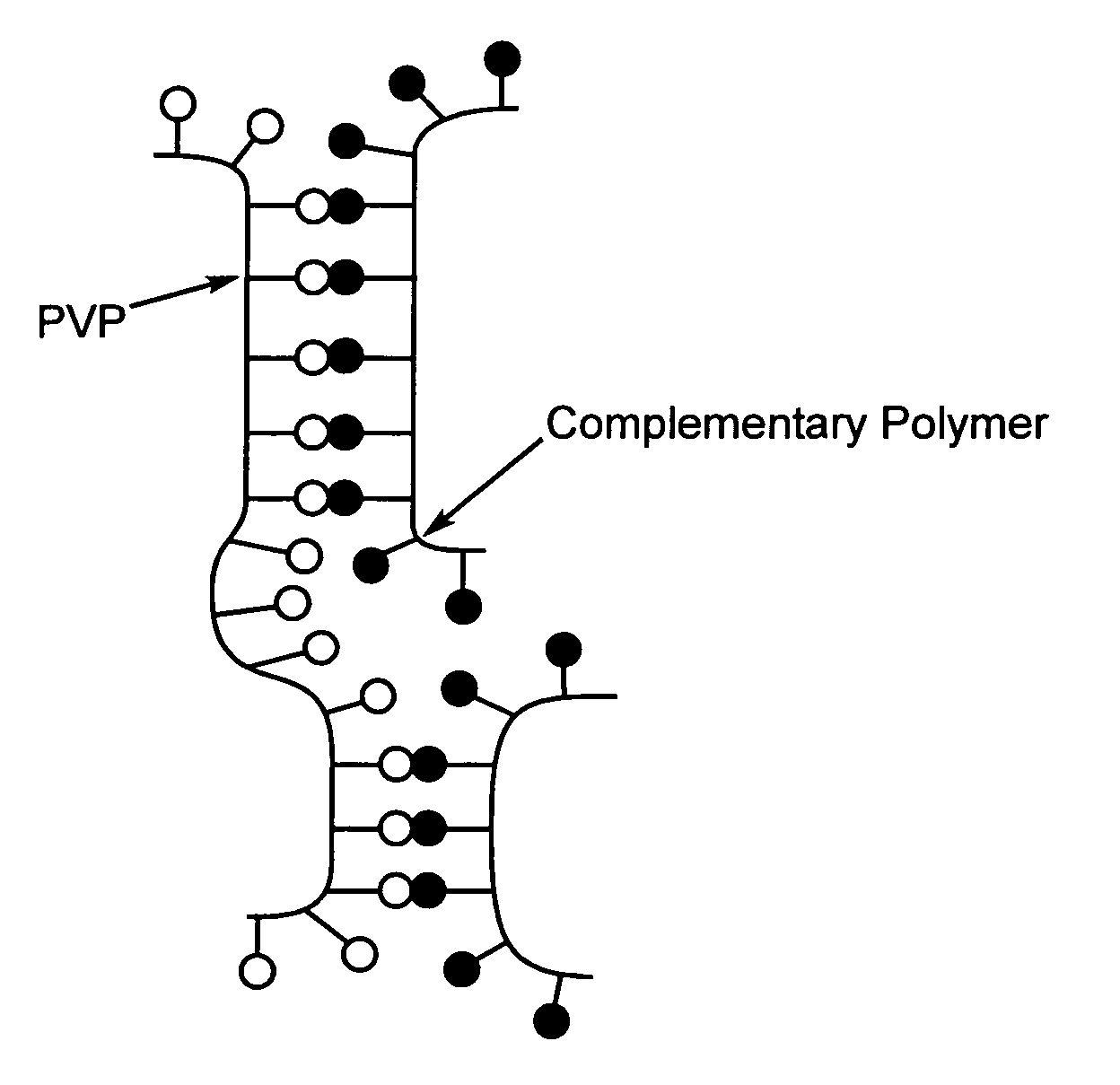

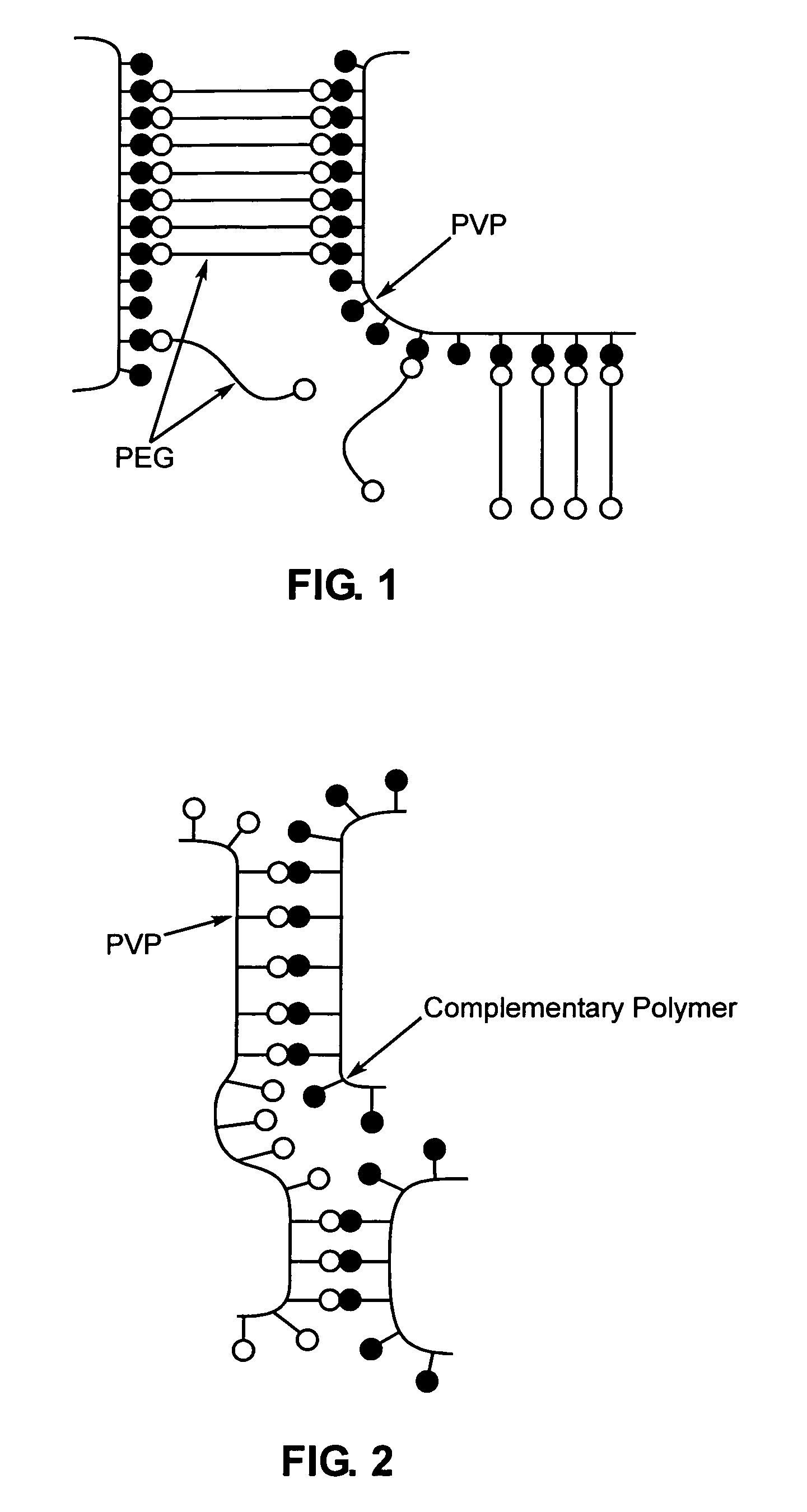

A method of selecting components for use in water-absorbing pressure-sensitive adhesive compositions is provided. The method involves selecting a film-forming polymer, a ladder-like non-covalent crosslinker that is capable of forming a ladder-like interpolymer complex with the film-forming polymer selected, and selecting a carcass-like non-covalent crosslinker that is capable of forming a carcass-like complex with at least one of the film-forming polymer selected or the ladder-like non-covalent crosslinker selected. The adhesive hydrogels provide high adhesion in a swollen state and bridge the gap between conventional pressure sensitive adhesives and bioadhesives. Methods for preparing and using the resulting compositions are also disclosed.

Owner:A V TOPCHIEV INST OF PETROCHEM +1

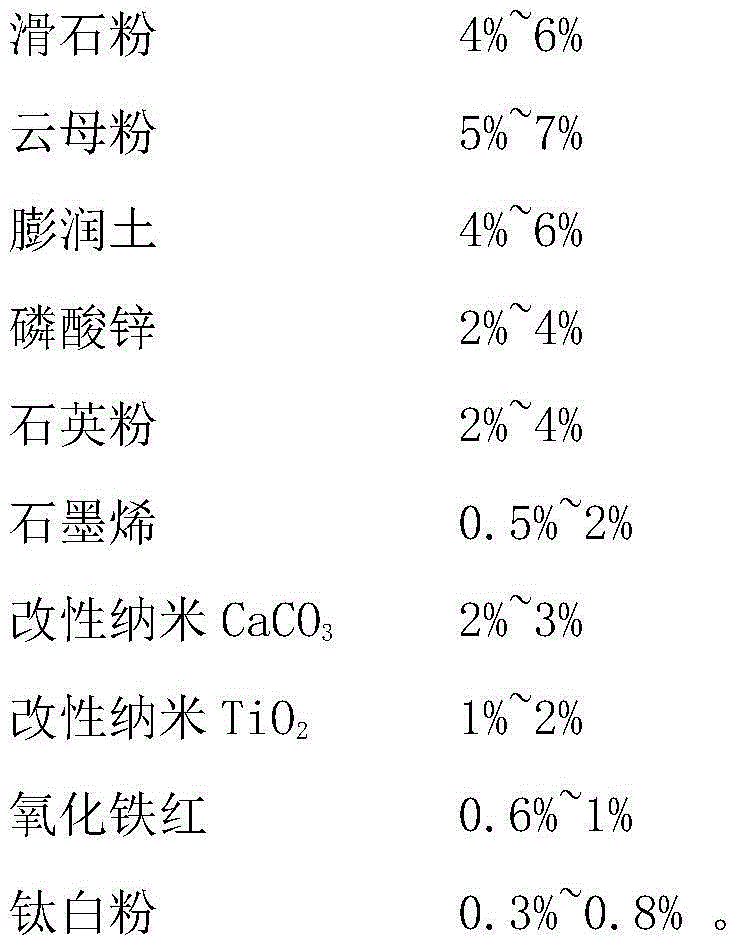

Fiber-reinforced high-temperature-resistant thermal insulation and heat preserving ceramic coating and preparation method thereof

InactiveCN102464933ADelivery barrierHigh surface strength of the coatingEpoxy resin coatingsCeramic coatingThermal insulation

The invention relates to a high-temperature-resistant thermal insulation and heat preserving ceramic coating and a preparation method thereof. The coating is prepared from the following raw materials in percentage by weight: 30-50 percent of film forming substance, 30-40 percent of high-temperature-resistant filler, 10-15 percent of hollow micro beads, 2-5 percent of thermal insulation fiber and 2-8 percent of aid and solvent. The coating has the toughness of an organic coating and the rigidity and hardness of an inorganic coating, has high adhesion, can be used at the high temperature of 400-1,200 DEG C for a long time, and is resistant to chemical reagents, acids, alkalis and oil. A coating film has high surface intensity, and can bear strong shear force without being damaged when a high-temperature pipeline is required to be connected mechanically. The coating has excellent heat preserving performance, and the surface temperature of a pipeline of 350 DEG C can be lowered to be below 100 DEG C by coating the coating outside the pipeline in the thickness of 4-6 millimeters. The coating can be widely applied to heat-resistant protection of the inner and outer surfaces of equipment such as high-temperature steam pipelines, metallurgy high-temperature furnaces, high-temperature valves, high-temperature containers and the like.

Owner:SHENYANG LIGONG UNIV

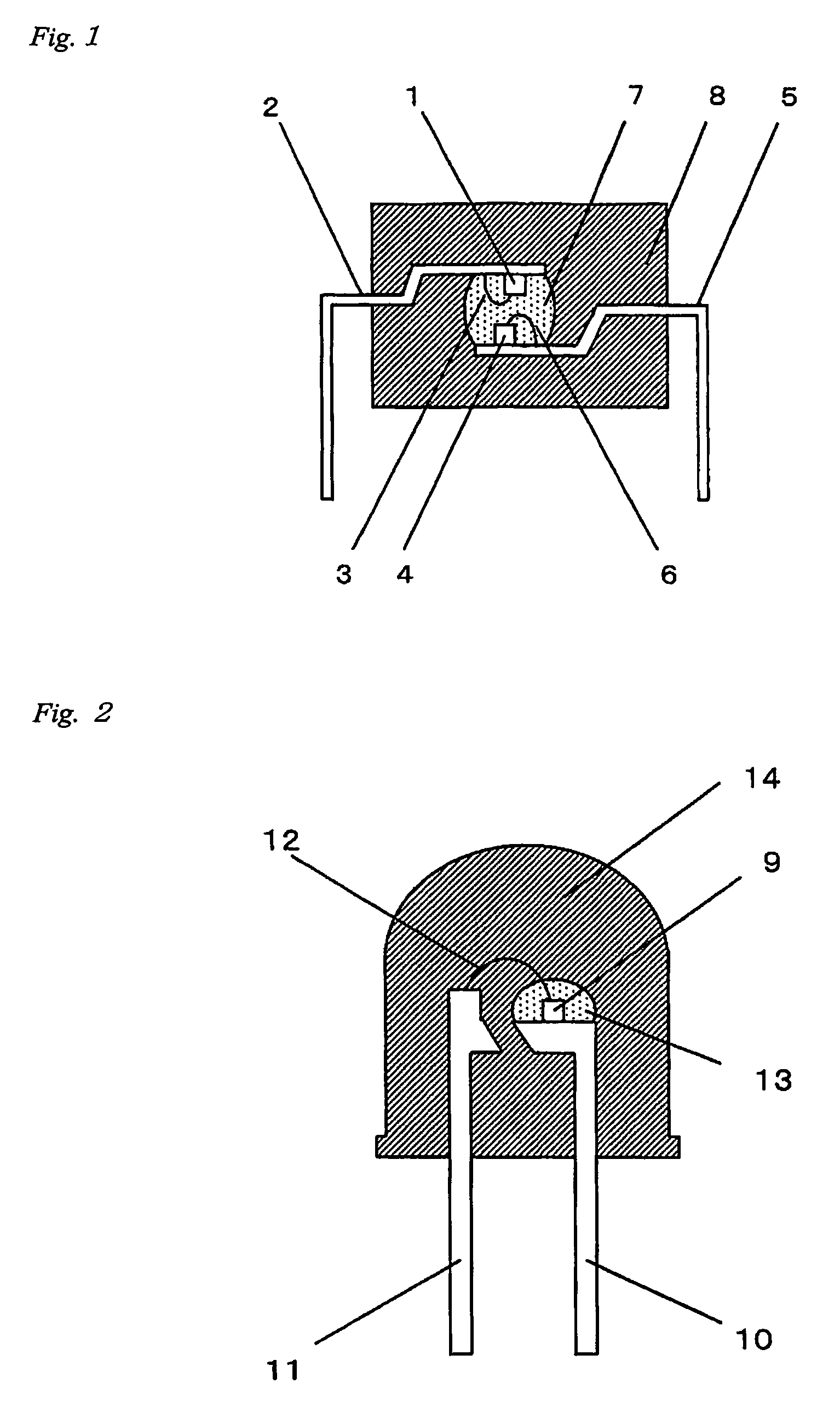

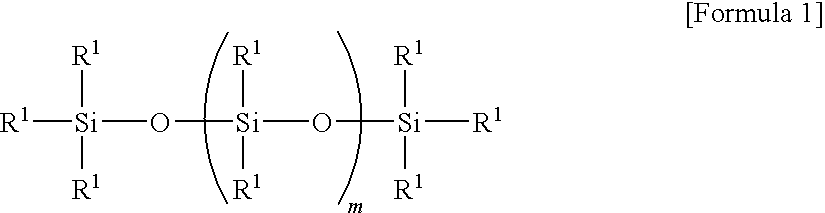

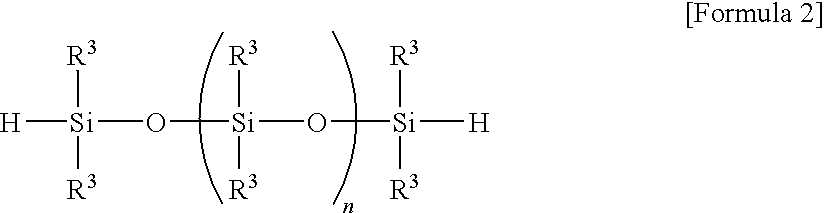

Curable organopolysiloxane composition and semiconductor device

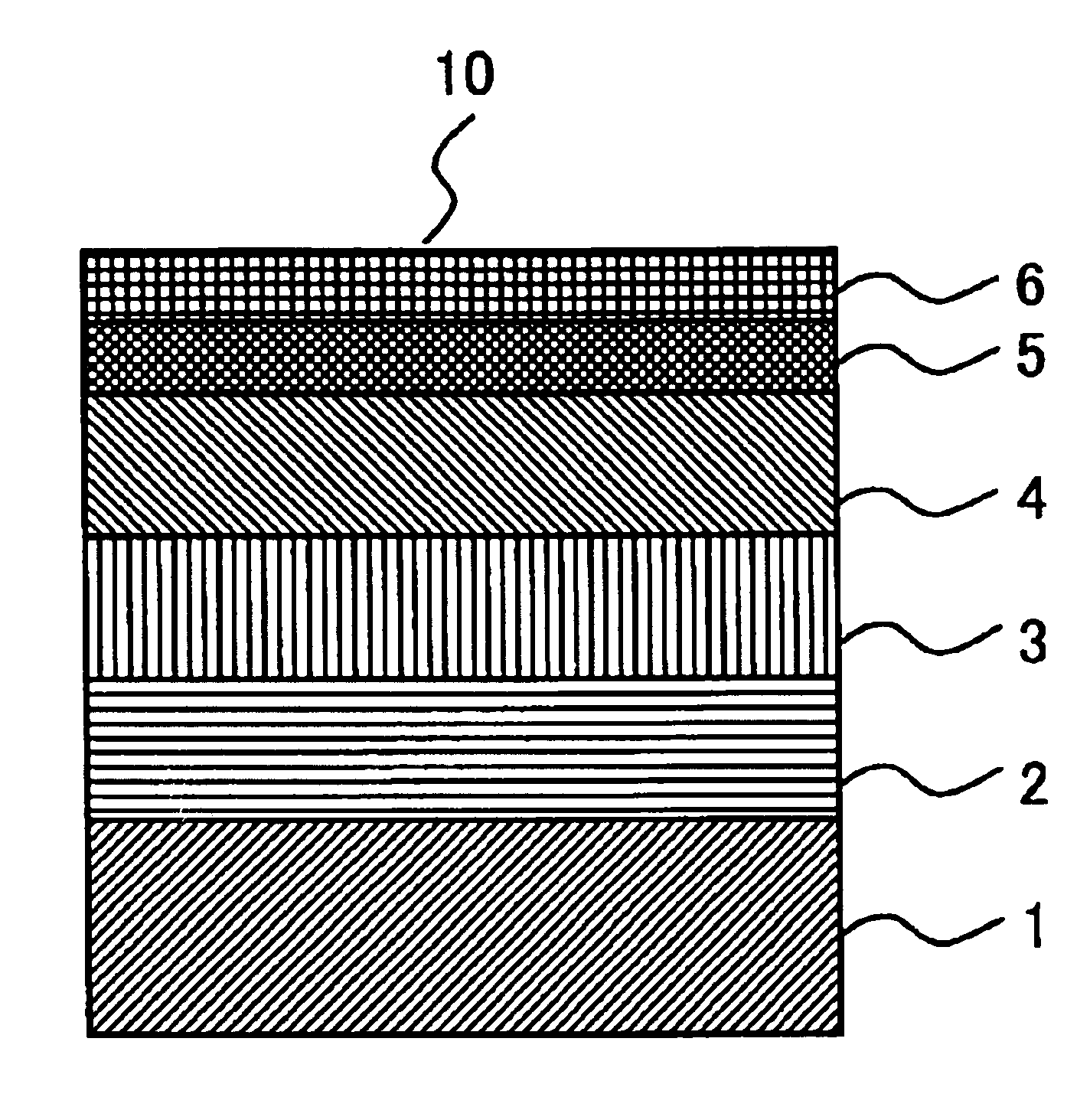

ActiveUS7527871B2Layered productsSemiconductor/solid-state device detailsDevice materialRefractive index

A curable organopolysiloxane composition comprising (A) a linear organopolysiloxane having at least two alkenyl groups and at least one aryl group per molecule, (B) a branched organopolysiloxane having at least one alkenyl group and at least one aryl group per molecule, and having siloxane units represented by the general formula: RsiO2 / 3, (C) a linear organopolysiloxane with both terminal ends of the molecular chain blocked by silicon bonded hydrogen atoms having at least one aryl group per molecule, and (D) a hydrosilation reaction catalyst, and a semiconductor device whose semiconductor elements are coated with the cured product of the above-described composition. The curable organopolysiloxane composition shows low viscosity, excellent filling properties, and excellent curability that cures to form a soft cured product of a large refractive index, high light transmittance, and high adhesion to substrates, as well as the semiconductor device shows superior reliability.

Owner:DOW CORNING TORAY CO LTD

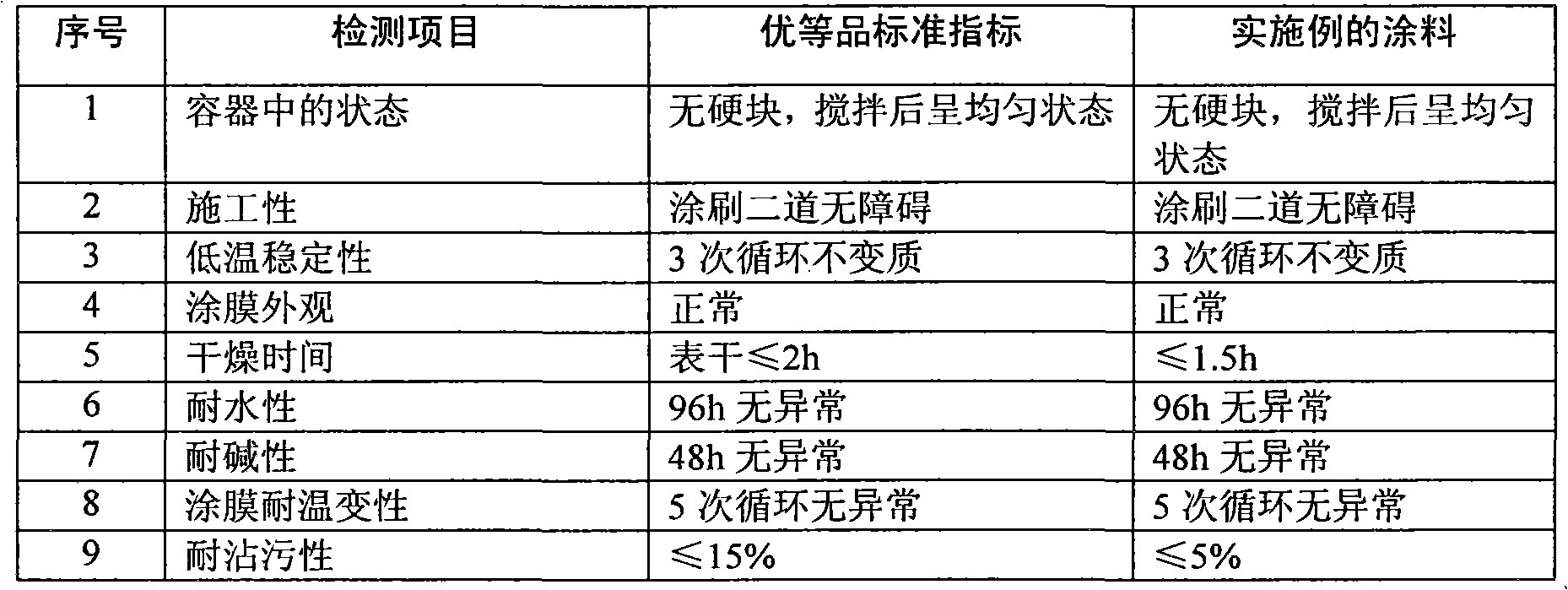

Exterior wall coating and preparation method thereof

InactiveCN101974273ASimple preparation processLow equipment requirementsAnti-corrosive paintsPolymer scienceDefoaming Agents

The invention discloses a multifunctional exterior wall coating with strong weather resistance, brushing resistance and high adhesion and a preparation method thereof. The exterior wall coating is prepared from the following raw materials in percentage by weight: 10-30% of silicone acrylic emulsion with a interpenetrating network structure, 10-40% of acrylic ester emulsion, 1-15% of hydrophobically modified inorganic nanoparticles, 10-40% of pigment and filler, 0.3-1% of a dispersing agent, 0.1-0.2% of a defoaming agent, 0.1-0.3% of a preservative, 0.3-0.6% of a flatting agent, 1-2% of a thickening agent, and the balance deionized water. The exterior wall coating of the invention has the advantages of strong weather resistance, brushing resistance, strong adhesion, long service life, simple and convenient preparation process and low equipment requirement, thus being easy for large-scale popularization and application. The exterior wall coating overcomes the defects of poor brushing resistance, poor ageing resistance and the like of the existing exterior wall coating.

Owner:广州市枫源化工有限公司

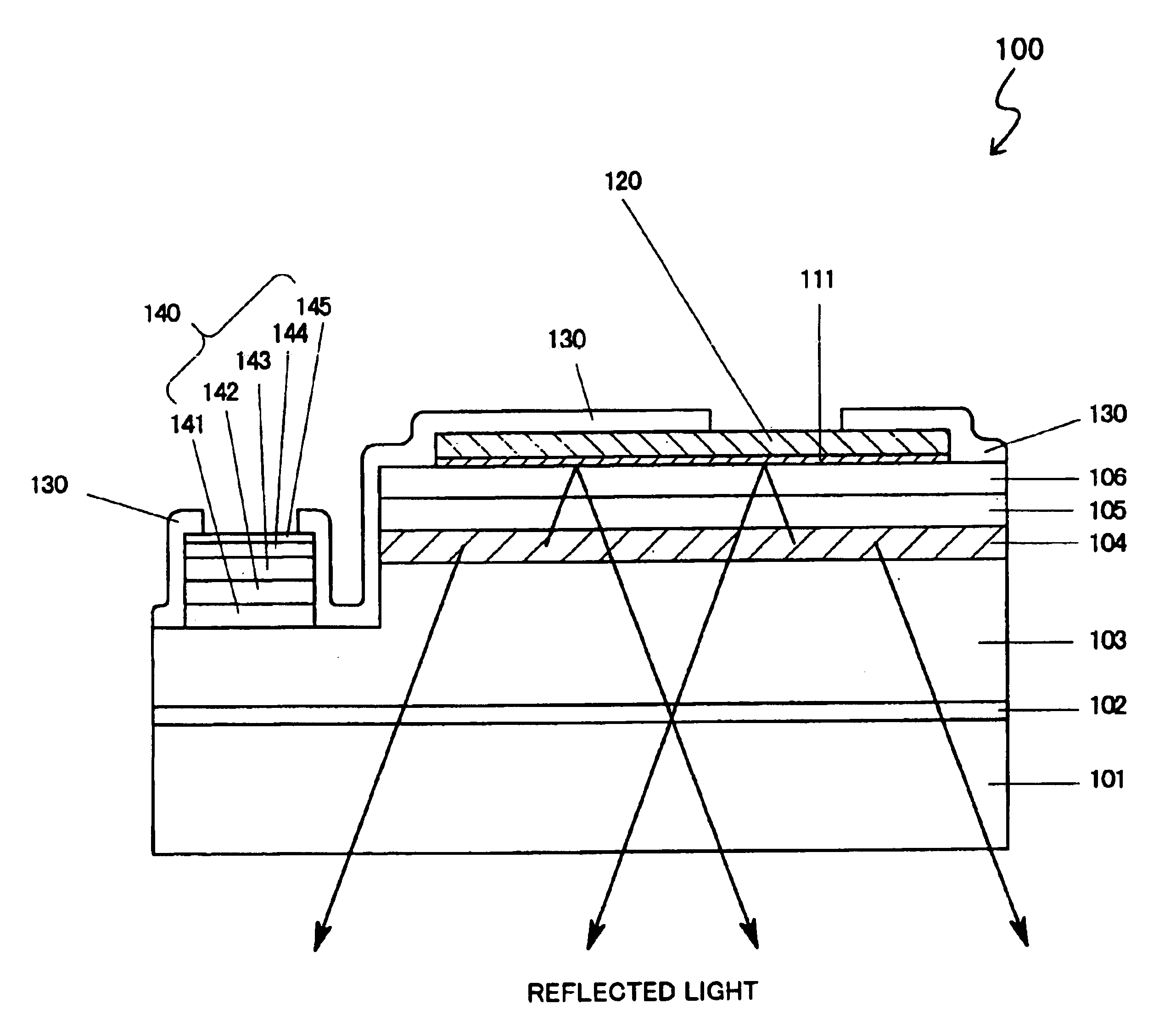

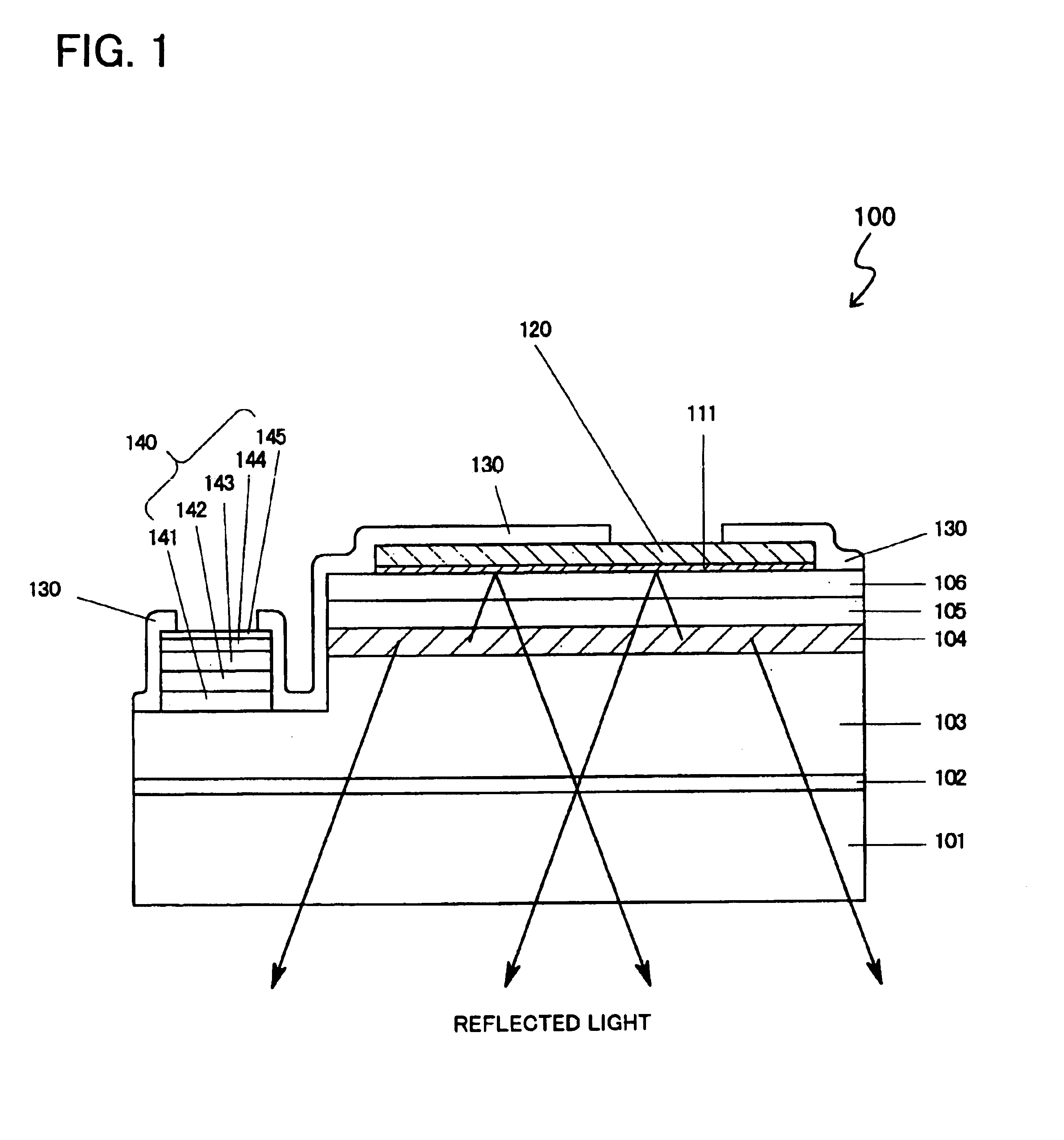

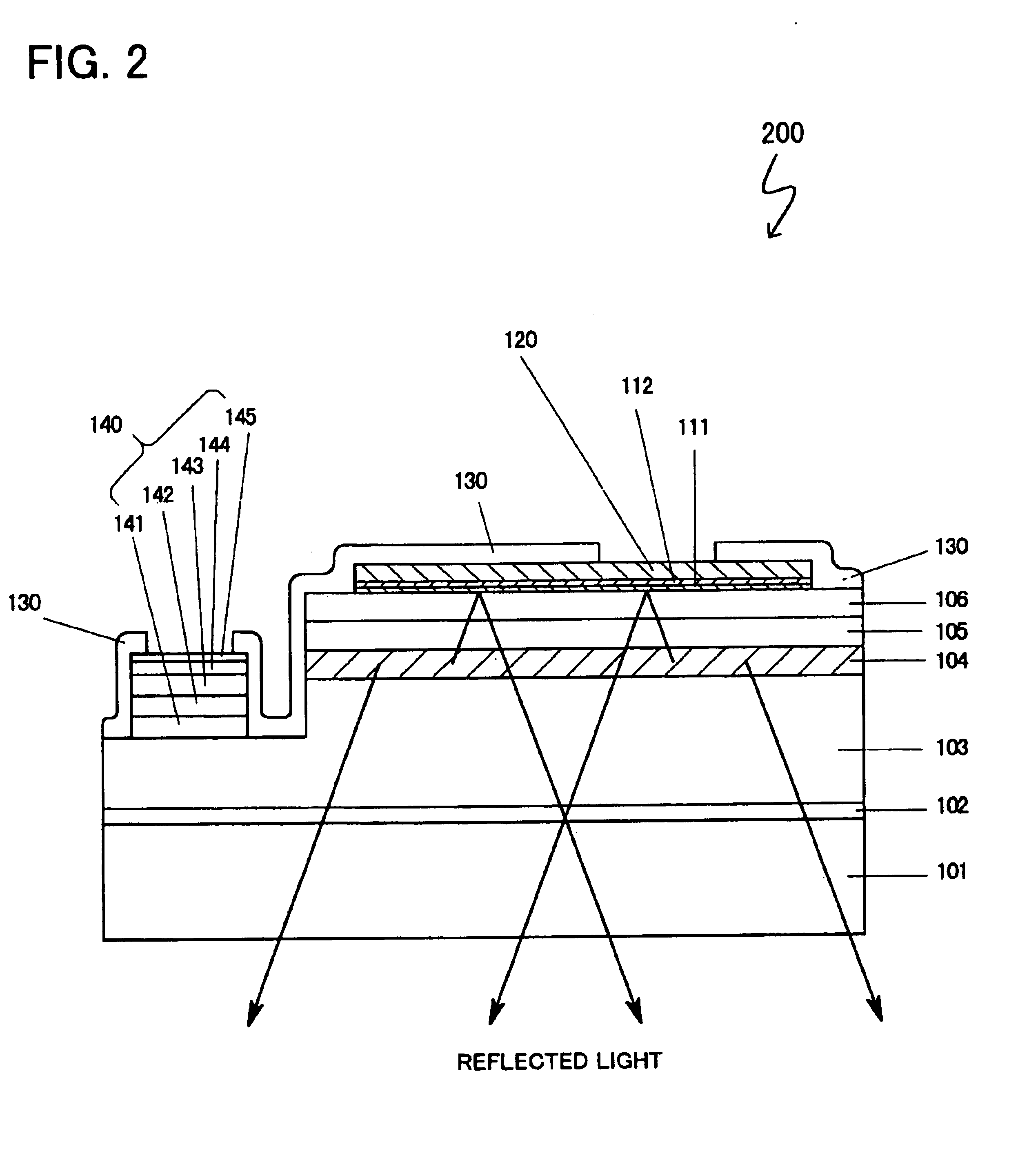

Light-emitting semiconductor device using group III nitride compound

InactiveUS6936859B1Improve reflectivityIncreased durabilitySemiconductor/solid-state device detailsSolid-state devicesAlloyContact layer

A flip chip type of light-emitting semiconductor device using group III nitride compound comprising a thick positive electrode. The positive electrode, which is made of at least one of silver (Ag), rhodium (Rh), ruthenium (Ru), platinum (Pt) and palladium (Pd), and an alloy including at least one of these metals, is adjacent to a p-type semiconductor layer, and reflect light toward a sapphire substrate. Accordingly, a positive electrode having a high reflectivity and a low contact resistance can be obtained. A first thin-film metal layer, which is made of cobalt (Co) and nickel (Ni), or any combinations of including at least one of these metals, formed between the p-type semiconductor layer and the thick electrode, can improve an adhesion between a contact layer and the thick positive electrode. A thickness of the first thin-film metal electrode should be preferably in the range of 2 Å to 200 Å, more preferably 5 Å to 50 Å. A second thin-film metal layer made of gold (Au) can further improve the adhesion.

Owner:TOYODA GOSEI CO LTD

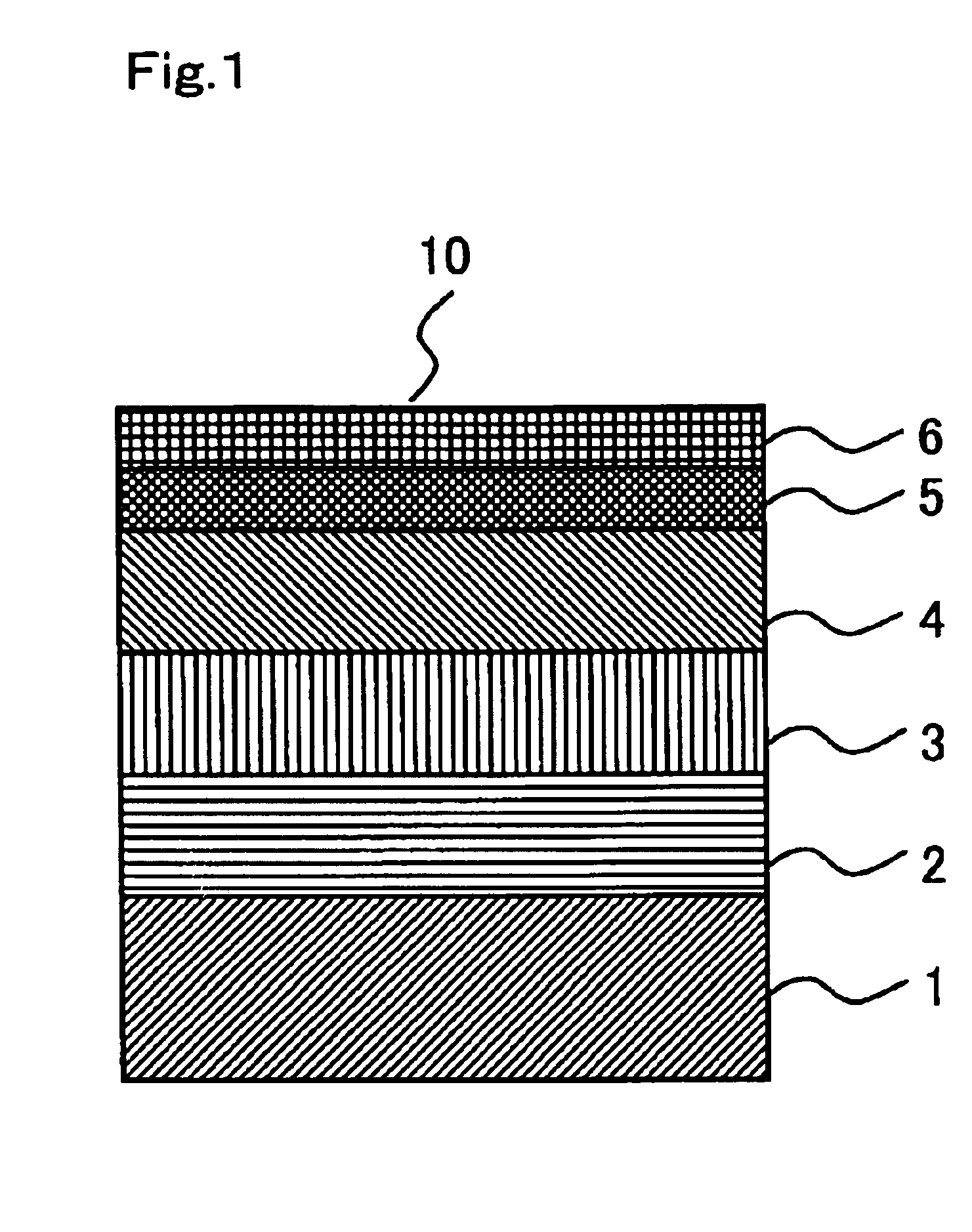

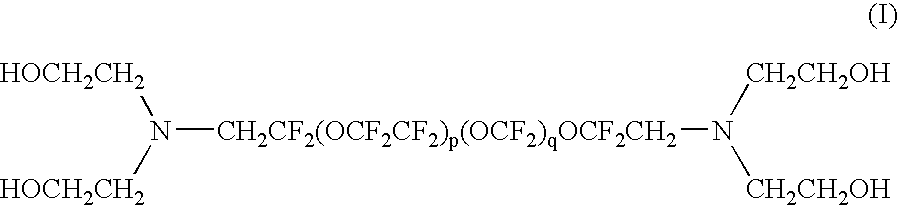

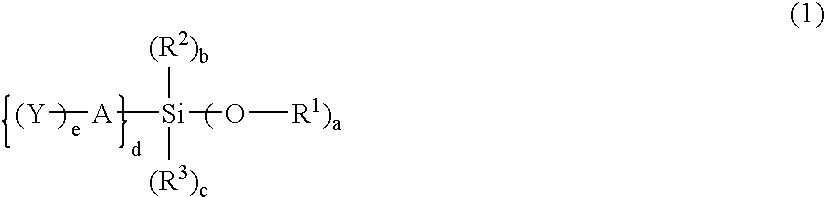

Magnetic recording disk and process for manufacture thereof

ActiveUS7045215B2Improve the lubrication effectImprove adhesionProtective coatings for layersSynthetic resin layered productsPerfluoropolyetherEther

A magnetic recording disk has a high-adhesion lubricant layer that permits an operation at an extremely low level of flying height of 12 nm or less without troubles and which is capable of preventing the migration at a high-speed rotation, and comprises a substrate, a magnetic layer formed on the substrate, a protective layer formed on the magnetic layer and a lubricant layer formed on the protective layer, the lubricant layer containing a compound (A) of the general formula (I), wherein each of p and q is an integer of 1 or more, anda compound (B) having a perfluoropolyether main chain having two end moieties each of which contains a carbon atom or an oxygen atom to which a hydroxyl-containing hydrocarbon group that optionally contains ether bond(s) is bonded, and a process for the manufacture thereof is provided.

Owner:WESTERN DIGITAL TECH INC

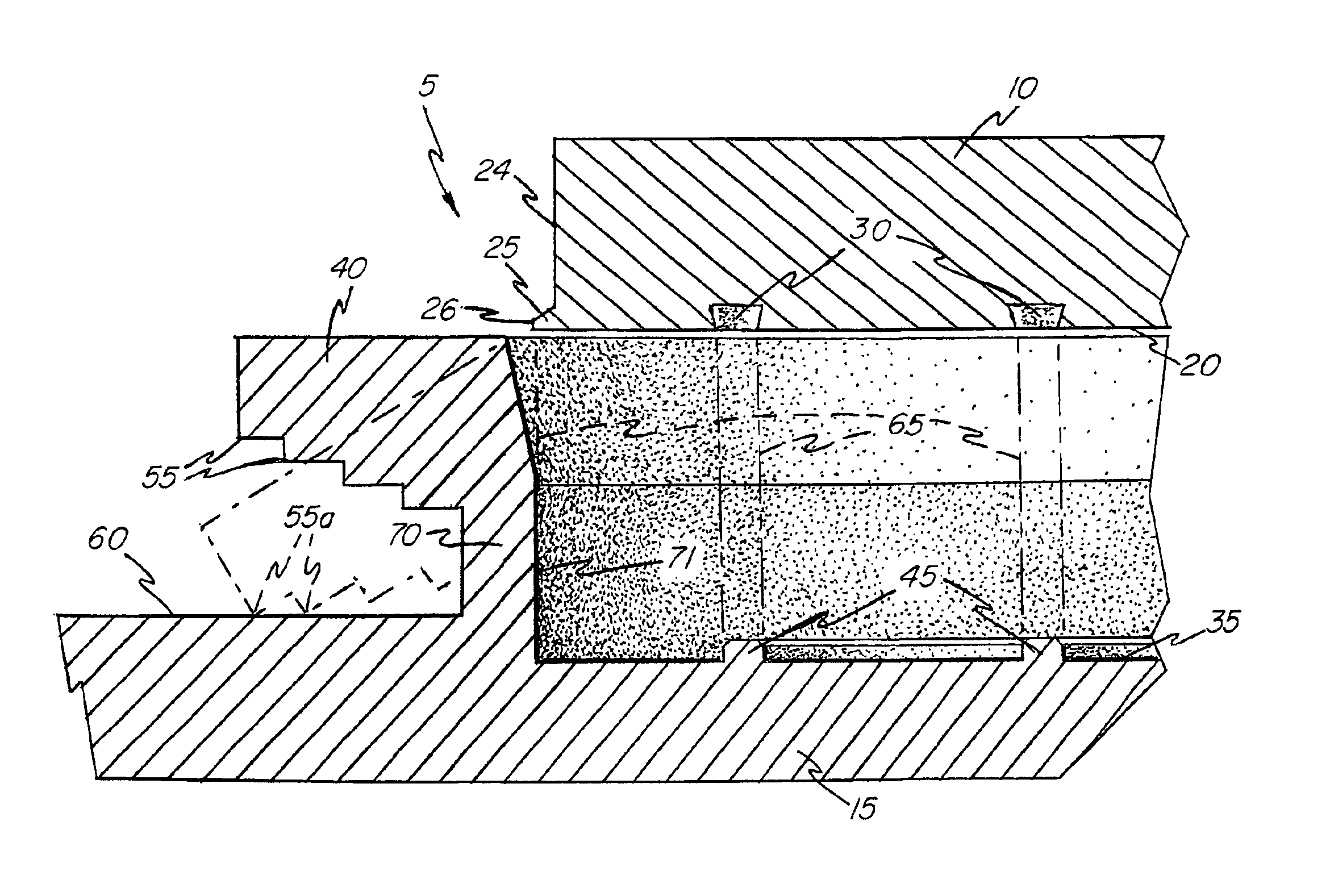

Low temperature sputter target/backing plate method and assembly

InactiveUS7146703B2Firmly connectedSolve the lack of resistanceCellsElectric discharge tubesBond interfaceBond strength

A sputtering target and a backing plate are diffusion-bonded with or without an insert or inserts interposed there-between so as to have a solid phase diffusion-bonded interface. The sputtering target substantially maintains its metallurgical characteristic and properties even though it has been diffusion-bonded to the backing plate. The solid-diffusion bonding of the target and backing plate, is achieved at a low temperature and pressure and results in interdiffusion of constituent atoms to attain high adhesion and bond strength without attendant deterioration or large deformation of the target material, while inhibiting the crystal growth in the target material. The bond undergoes no abrupt decrease in bond strength upon elevation of the service temperature. One hundred percent bonding is achieved with non-bonded portions such as pores left along the interface.

Owner:TOSOH SMD

Curable composition, cured article obtained therefrom, and photochromic optical material and process for producing the same

InactiveUS20040220292A1Improve adhesionEnhance aggregation abilityCoatingsOptical elementsMethacrylateSilylene

A curable composition which provides a coating layer having high adhesion to a substrate and a hard coat layer and extremely excellent photochromic properties such as high color development intensity, high fading speed and excellent durability. This composition comprises (1) 100 parts by weight of radically polymerizable monomers including a silyl monomer such as gamma-methacryloyloxypropyl trimethoxysilane and / or an isocyanate monomer such as 2-isocyanatoethoxy methacrylate, (2) 0.01 to 20 parts by weight of an amine compound and (3) 0.01 to 20 parts by weight of a photochromic compound. A photochromic optical material having excellent adhesion between a photochromic coating layer and a resin substrate and obtained by using this composition as a coating material and a process for producing the photochromic optical material.

Owner:TOKUYAMA CORP

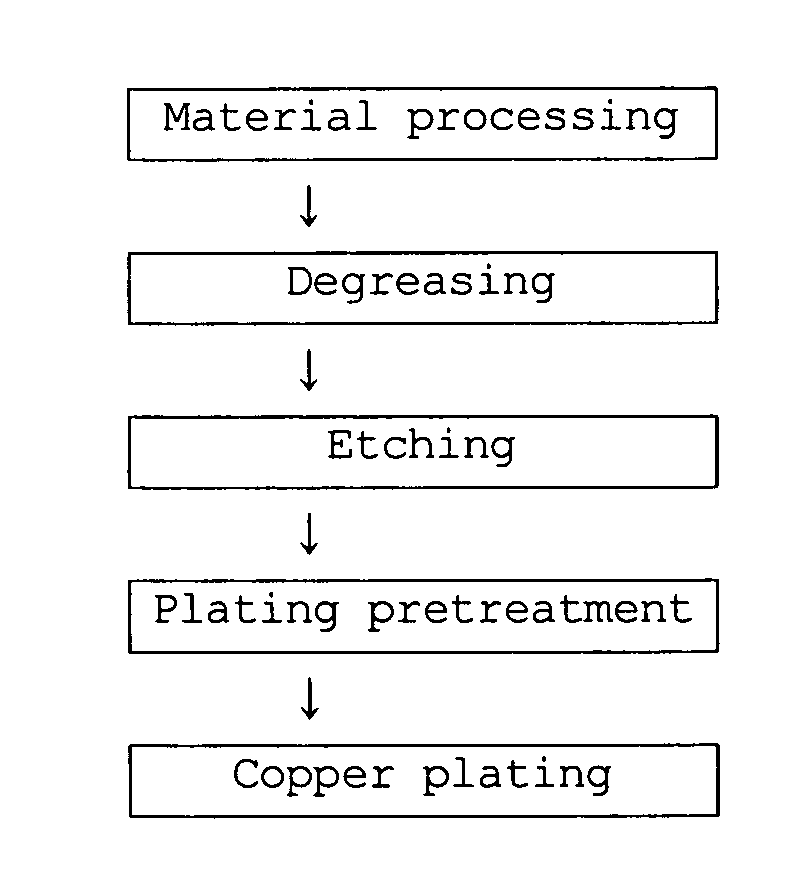

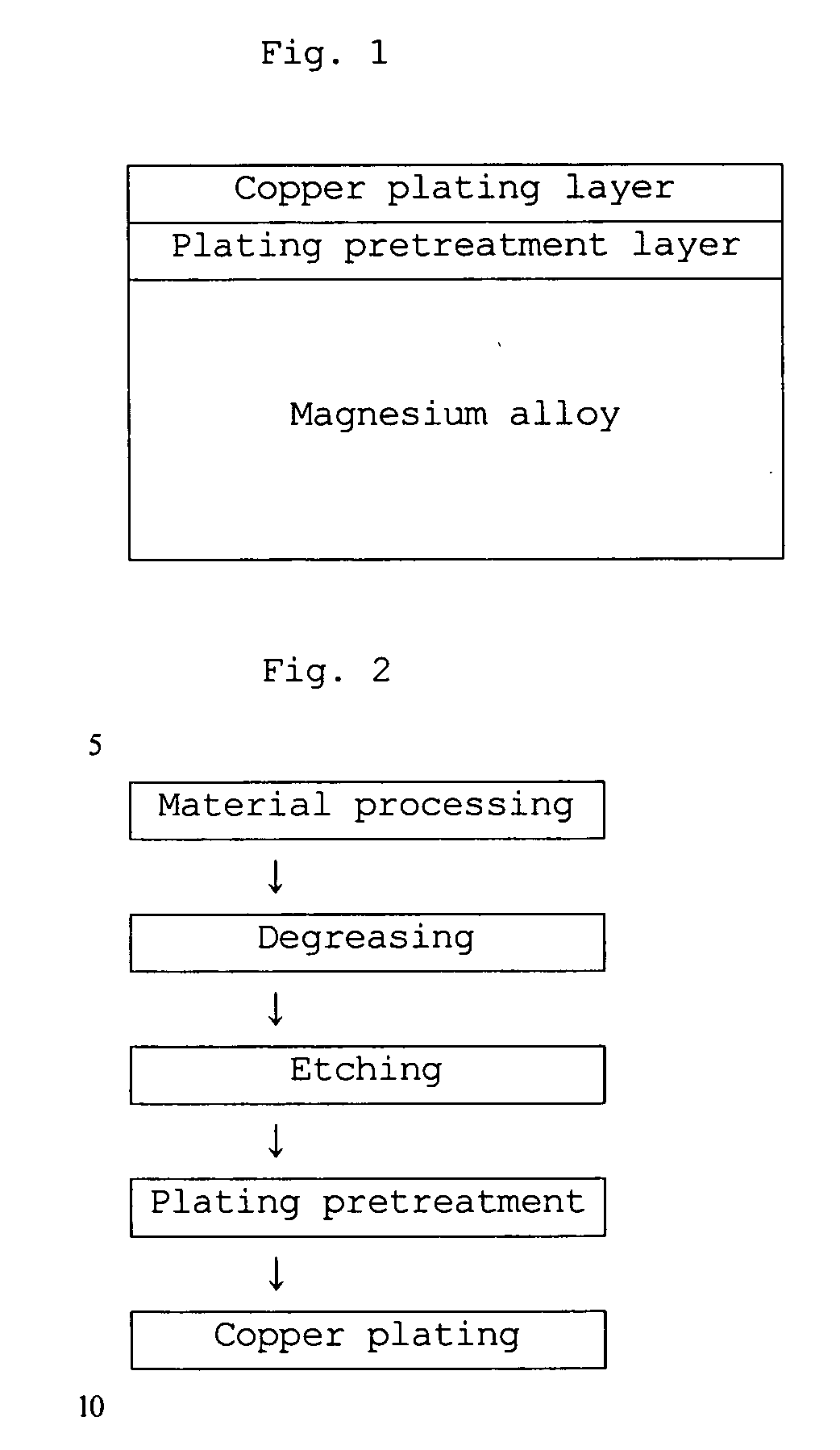

Method of preparing copper plating layer having high adhesion to magnesium alloy using electroplating

InactiveUS20070108060A1Improve adhesionImprove corrosion resistanceSuperimposed coating processCopper platingCurrent distribution

Disclosed is a method of preparing a copper electroplating layer having high adhesion to a magnesium alloy, which is advantageous because the usability of the magnesium alloy, having the highest specific strength among actually usable metals, can be increased through the development of a process of forming a uniform copper plating layer upon electroplating of the magnesium alloy. The method of preparing a copper electroplating layer having high adhesion to a magnesium alloy of this invention is characterized in that the magnesium alloy is pretreated with a plating pretreatment solution to form a film for electroplating, serving as a magnesium alloy pretreatment layer, exhibiting a uniform current distribution, which is then electroplated with copper to form the copper plating layer. According to this invention, through the pretreatment of the magnesium alloy, the adhesion of the copper plating layer to the film for electroplating formed on the magnesium alloy can be increased.

Owner:PANGRIM

High-performance jet ink

The invention relates to a high-performance jet ink. The jet ink comprises the following components by weight percent: 20-80% of solvent, 1-45% of cosolvent, 4-20% of adhesive, 0.5-20% of colorant, 0-5% of adhesion force promoter, 0.01-2% of wax powder, 0-2% of brightening agent and 0-5% of other additives. As adhesion force promoter is added in the jet ink, the adhesion performance on base materials such as glass, metal, polypropylene or polyethylene is increased. In addition, wax is added to increase wear resistance and scratch resistance, and brightening agent is added to increase the lustrousness, brilliance and definition of the ink. The product has high adhesion force, good wear resistance, high lustrousness and definition and good compatibility, thus the defects of the existing ink such as low lustrousness, poor wear resistance and low definition can be greatly improved and the jet ink has good market prospect.

Owner:王学珍

Ultraviolet cured paint for plastics and its production process

InactiveCN1772820AHigh hardnessImprove wear resistancePolyurea/polyurethane coatingsPolyester coatingsUltravioletDiluent

The present invention relates to one kind of ultraviolet cured paint for plastics and its production process. The paint includes matrix resin, active diluent, light initiator and solvent and features its antiwear hardness additive accounting for 0.1-8.0 wt% of the paint. The paint has high hardness, high antiwear performance, forms smooth paint coating through spraying, high toughness, high adhesion and high chemical corrosion resistance.

Owner:BYD CO LTD

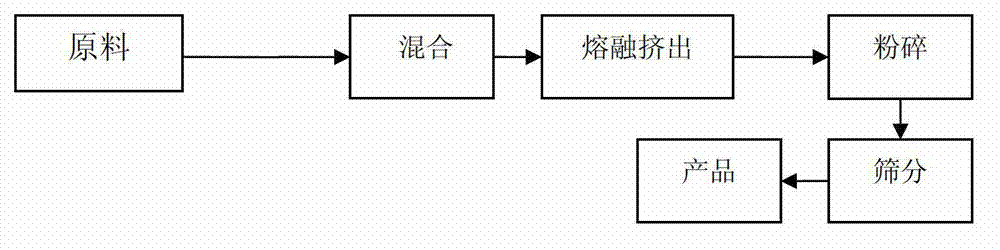

Three-dimensional printing forming material with toughness and high adhesive property and preparation method thereof

The invention discloses a three-dimensional printing forming material with toughness and high adhesive property. The three-dimensional printing forming material comprises a powder material and an adhesive material and is characterized in that the powder material comprises the following components in parts by weight: 40-85 parts of polyamide resin, 5-40 parts of pigments, 5-30 parts of filler, 1-6 parts of pigment and filler dispersing and wetting aid, 0.1-1.5 parts of flatting agent and 0.1-0.5 part of degassing agent; the adhesive material comprises the following components in parts by weight: 60-95 parts of epoxy resin, 5-40 parts of filler, 1-10 parts of toughening agent, 0.1-1.5 parts of flatting agent, 1-4 parts of pigment and filler dispersing and wetting aid, 0.1-0.5 part of degassing agent and 0.1-0.5 parts of powder flowing aid; and when the three-dimensional printing forming material is used, 1 part by weight of powder material and 0.01-0.5 part by weight of adhesive material are cooperatively used. A solid component printed by using the material disclosed by the invention has the advantages of higher adhesion strength and firmness, good flexibility and scratching resistance.

Owner:ZHONGSHAN POLYTECHNIC

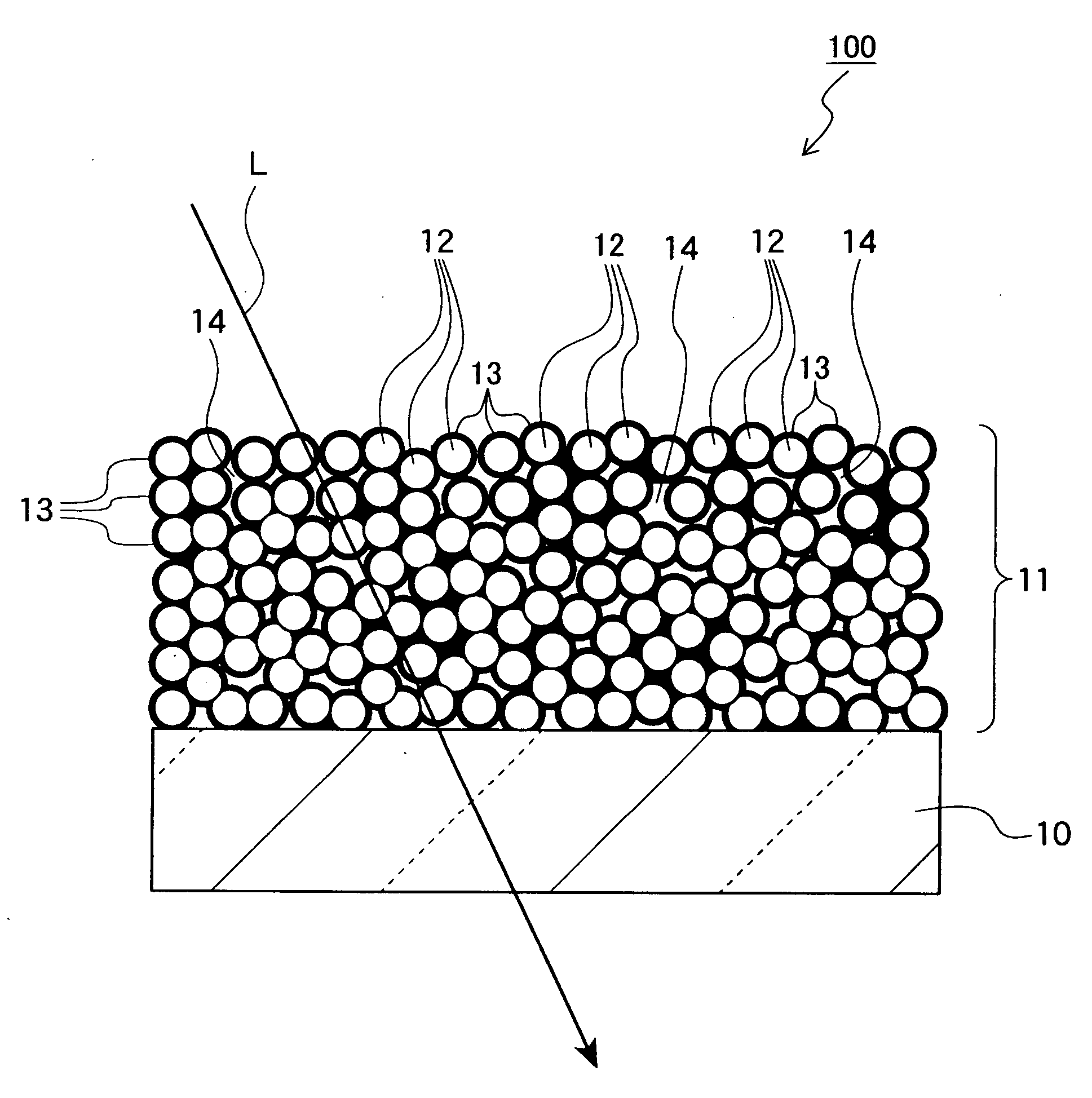

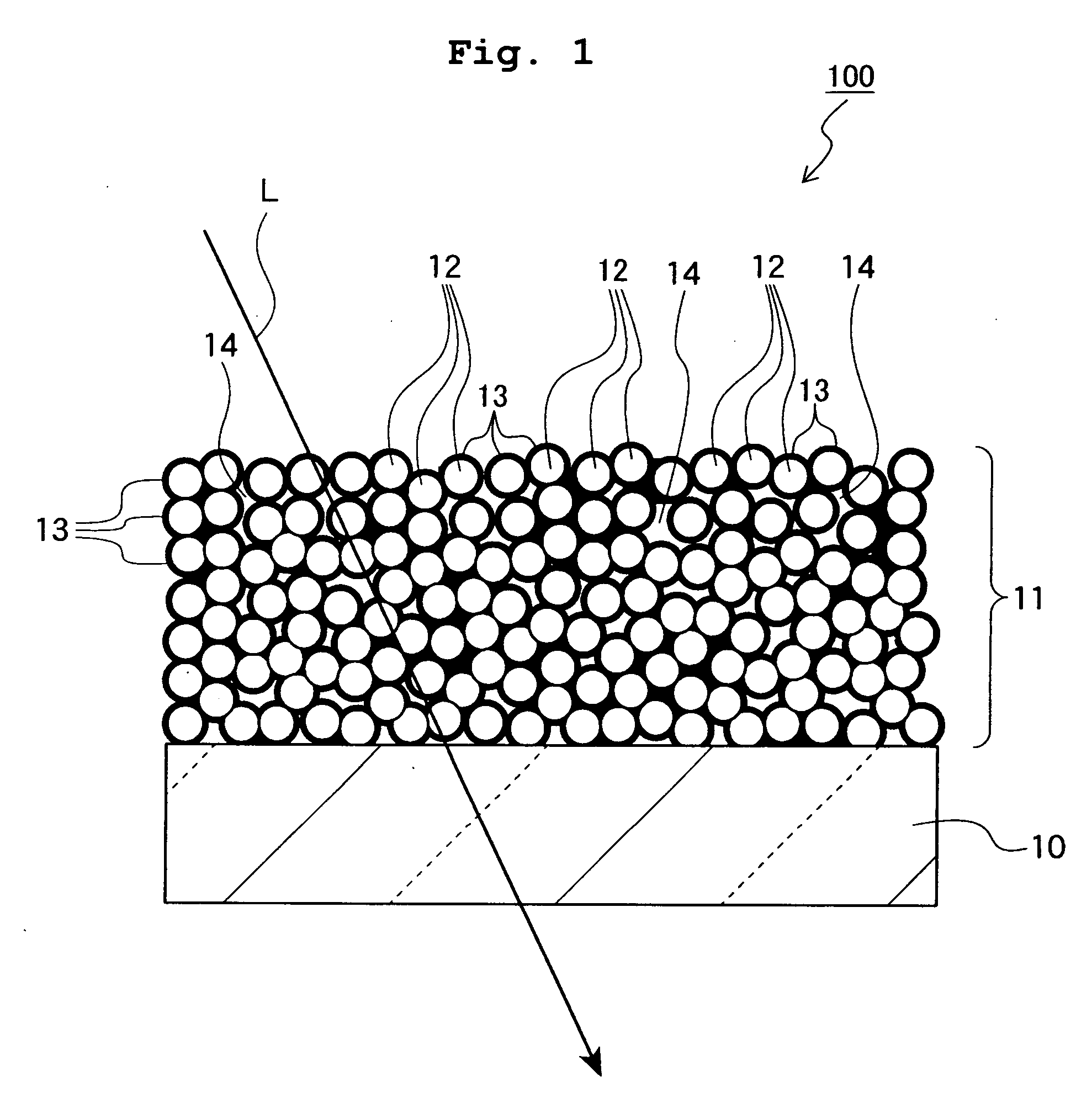

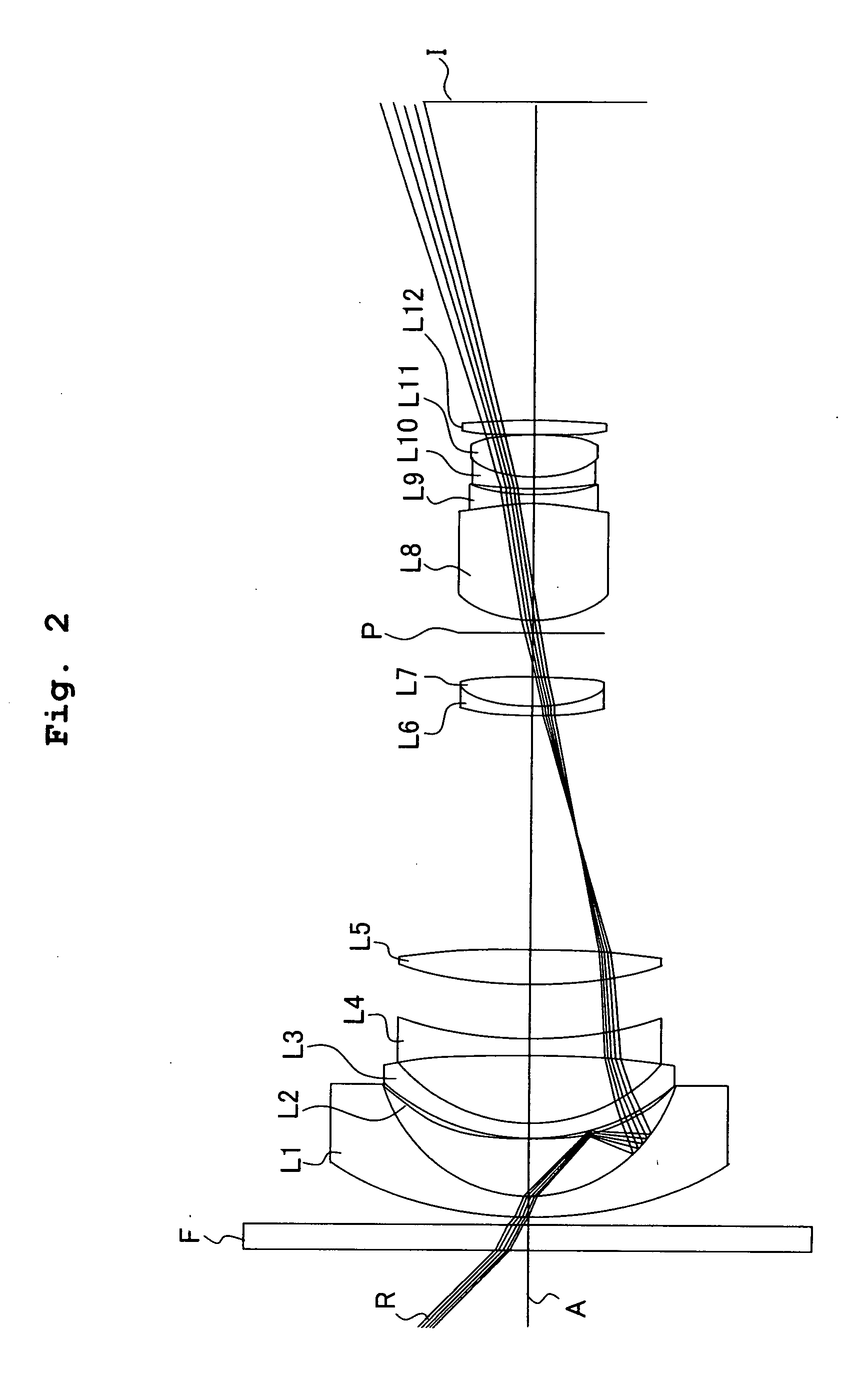

Mgf2 Optical Thin Film Including Amorphous Silicon Oxide Binder, Optical Element Provided With the Same, and Method for Producing Mgf2 Optical Thin Film

InactiveUS20080002259A1Excellent in environment resistance (durability)Secure environment resistanceMagnesium fluoridesMaterial nanotechnologyRefractive indexAmorphous silicon

An MgF2 optical thin film is formed on an optical surface of a base material. The MgF2 optical thin film includes MgF2 particles and an amorphous silicon oxide-based binder which exists on the surfaces of the MgF2 particles and between the MgF2 particles. Owing to this amorphous silicon oxide-based binder, the optical thin film can have high mechanical strength and high adhesion to the base material, while having excellent environment resistance and a lower refractive index.

Owner:NIKON CORP

Metallic carbide/adamantine (MeC/DLC) nanometer multi-layer film material and method for preparing the same

ActiveCN101081557AImprove micro-roughnessImprove the interface binding forceLayered productsVacuum evaporation coatingCarbideHardness

The present invention is nanometer multilayer metal carbide / diamond-like film material and its preparation process. The nanometer multilayer film material includes one base material layer, one transition layer and one nanometer multilayer film layer arranged successively. The transition layer consists of one metal layer, one metal nitride layer and one metal carbonitride layer; and the nanometer multilayer film layer consists of metal carbide layers and diamond-like film layers arranged alternately. The preparation process includes: bombarding with Ti, Cr, and Zr or W targets successively to clean the base material; depositing one metal layer, one metal nitride layer and one metal carbonitride layer successively; and depositing metal carbide layers and diamond-like film layers alternately. The nanometer multilayer film material has high micro hardness, low friction coefficient and high adhesion, and may be applied in improving the surface performance of metal parts.

Owner:GUANGDONG INST OF NEW MATERIALS

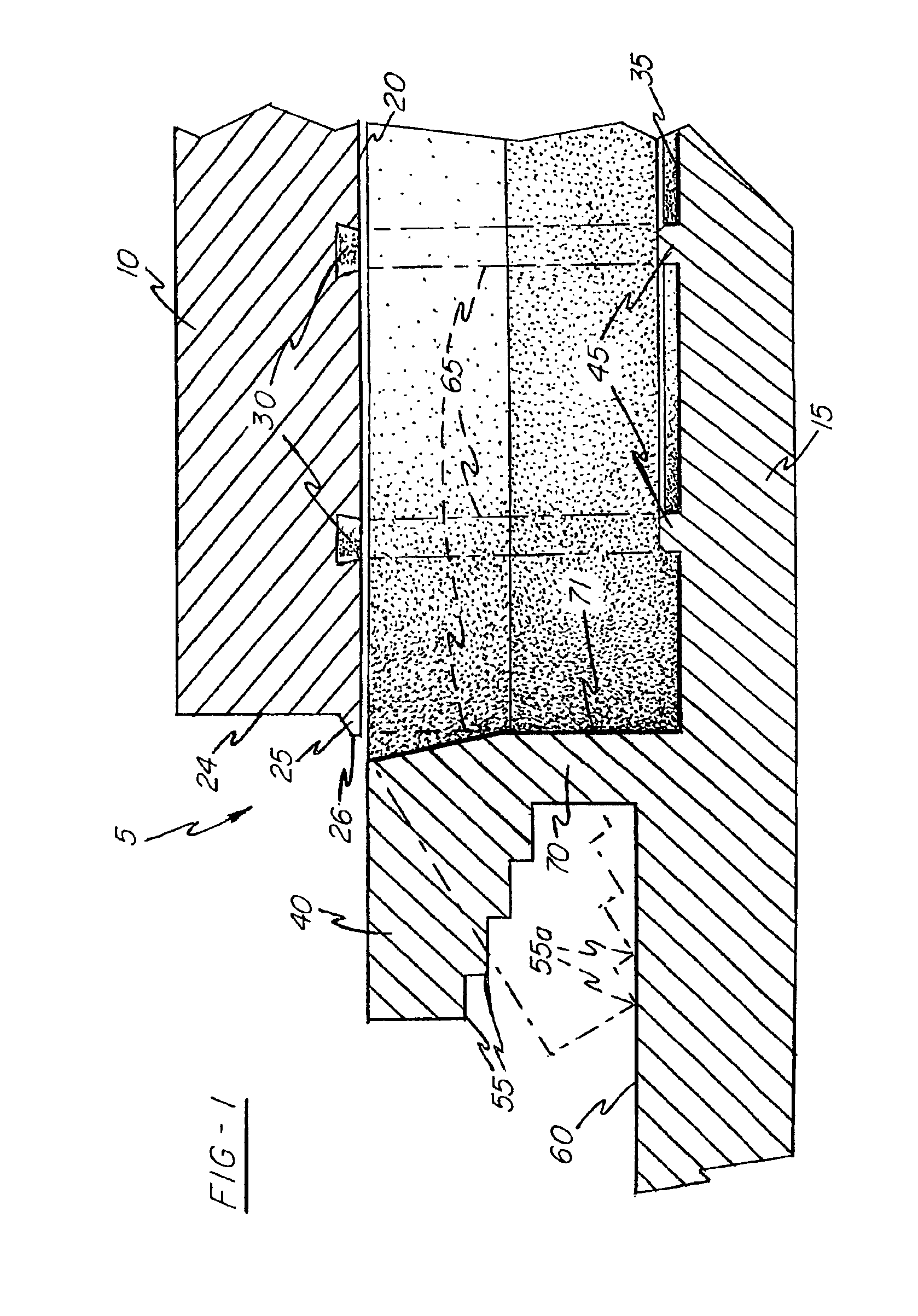

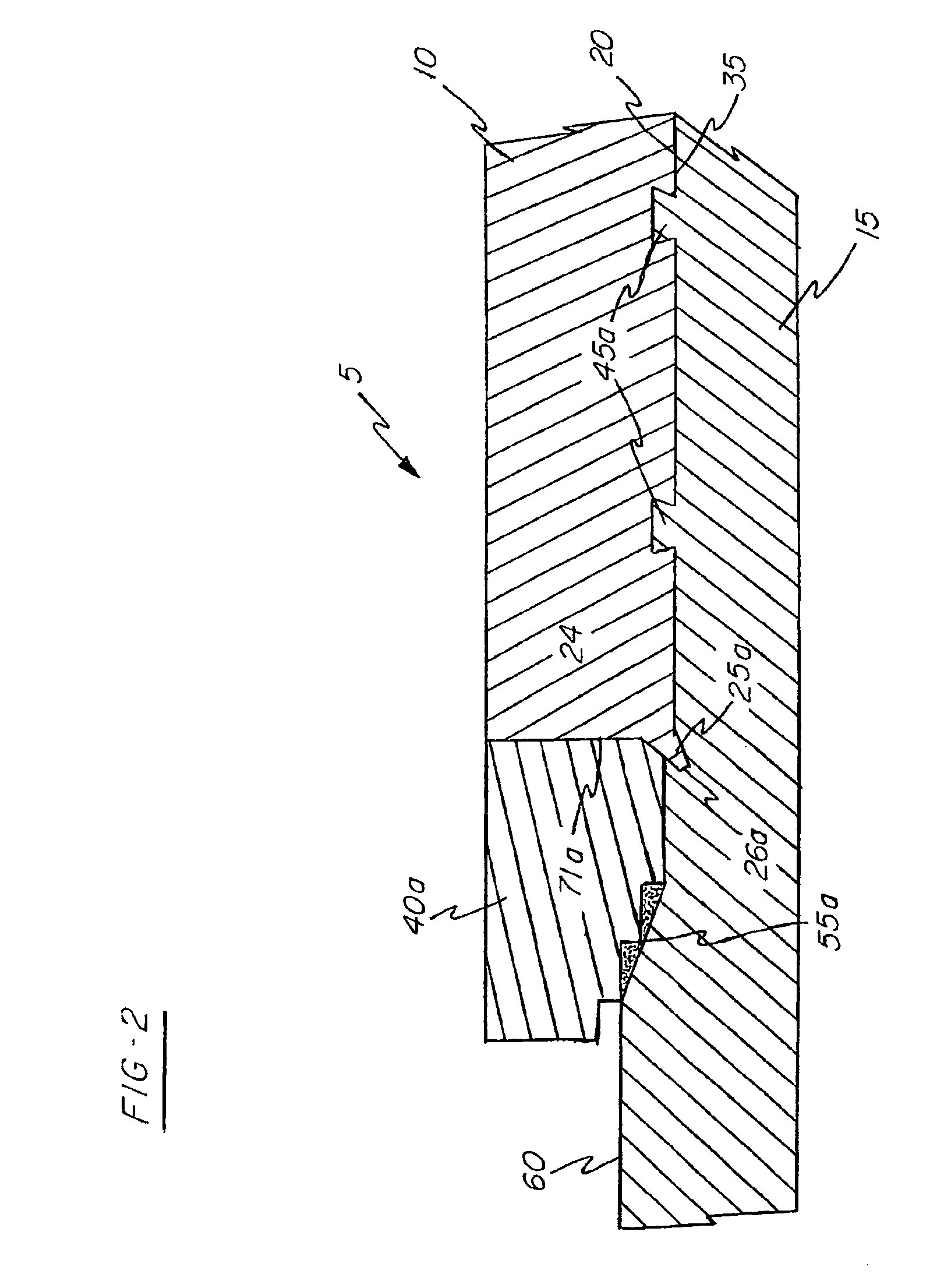

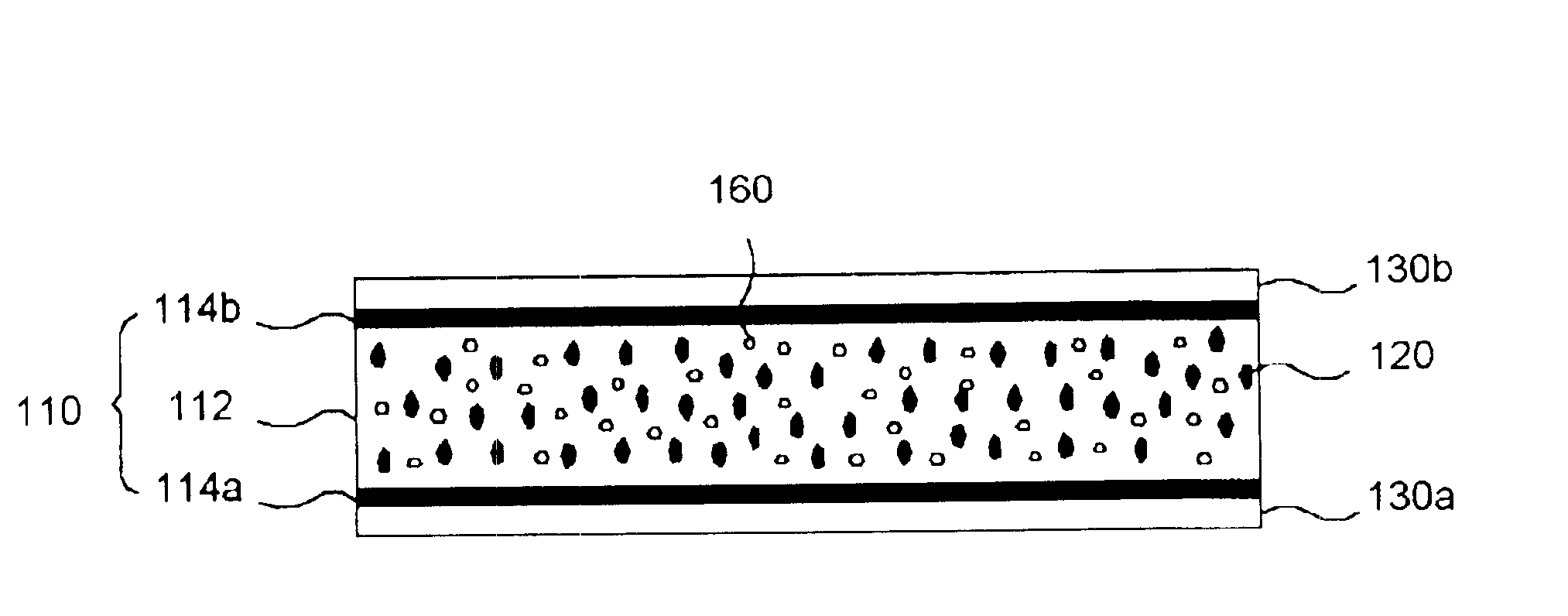

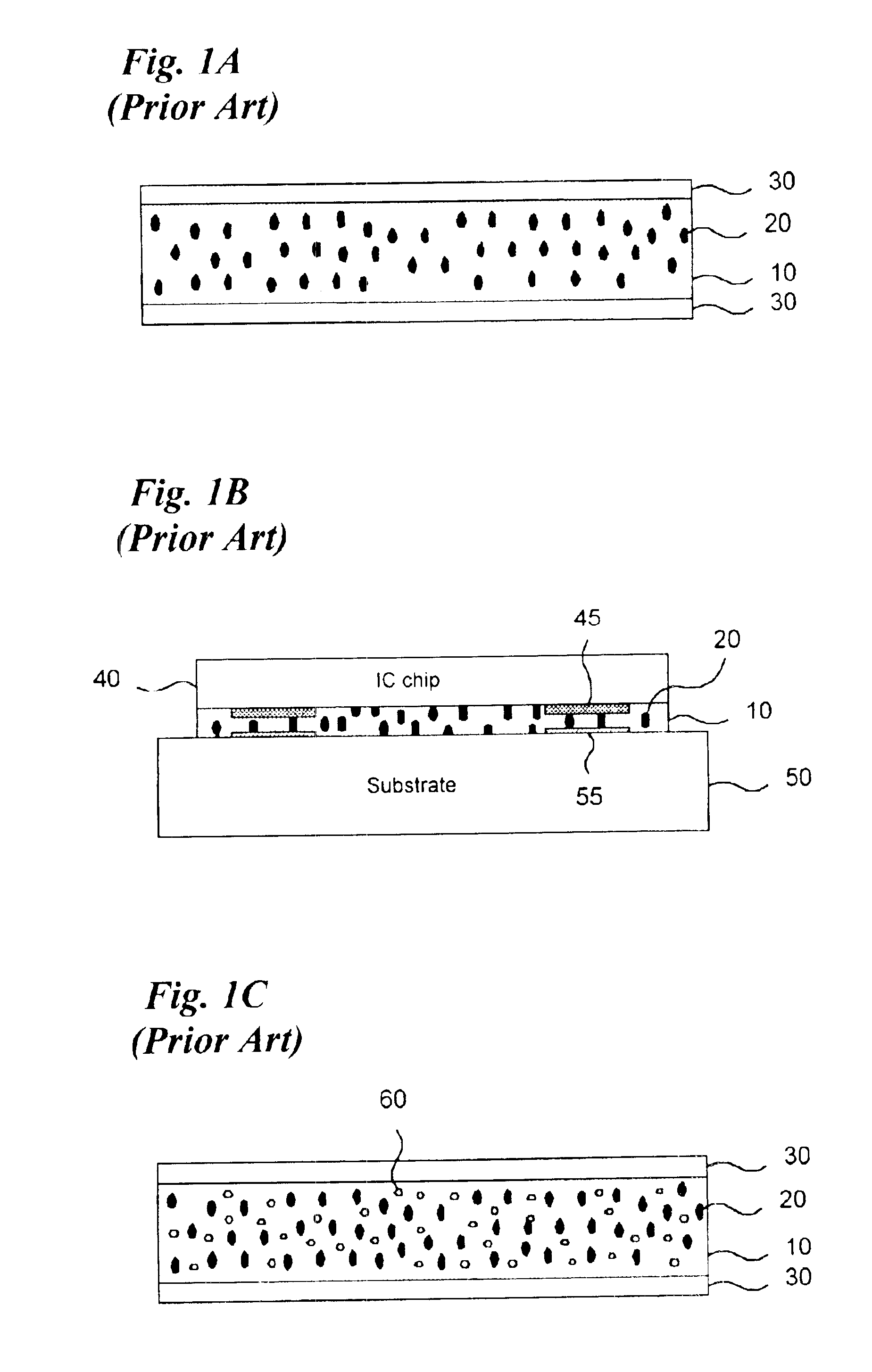

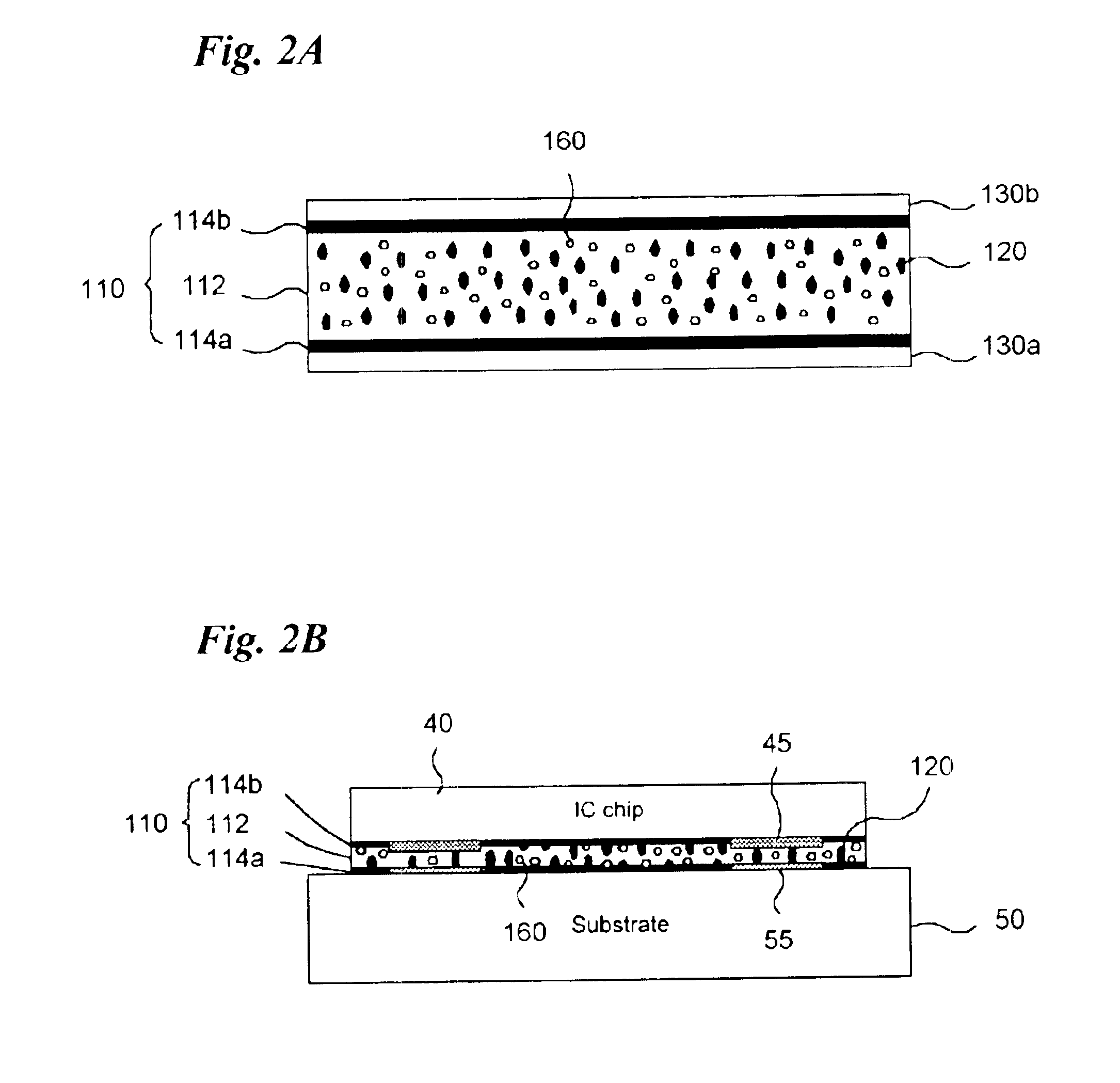

High adhesion triple layered anisotropic conductive adhesive film

InactiveUS6878435B2High bonding strengthImprove adhesionNon-insulated conductorsSolid-state devicesEpoxyAnisotropic conductive film

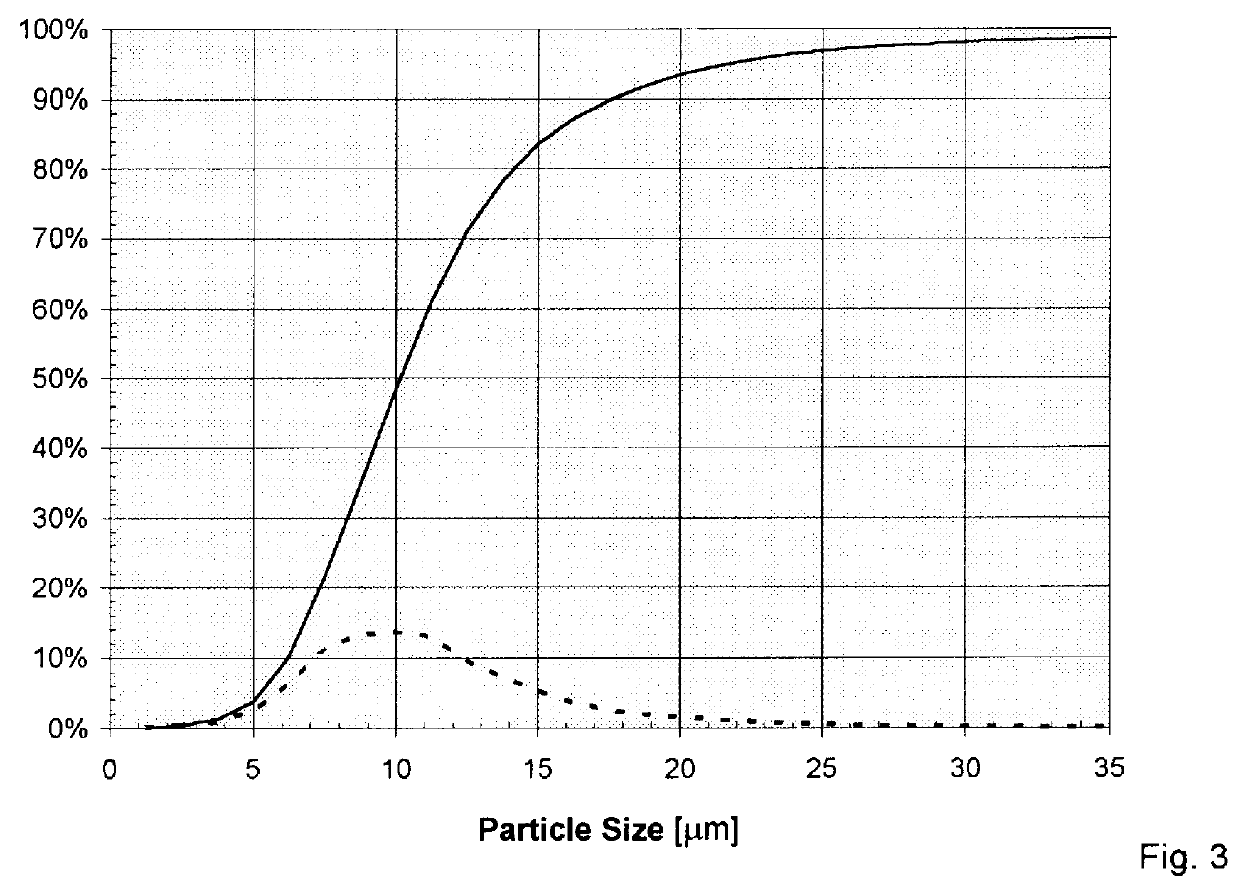

Disclosed is a triple layered ACA film adapted for enhancing the adhesion strength of a typical single layer Anisotropic Conductive Film or for enhancing the adhesion strength of the ACA film in flip chip bonding. The triple layered ACA film of the invention comprises: a main ACA film based upon epoxy resin and containing conductive particles having a particle size of 3 to 10 μm and optionally non-conductive particles having a particle size of 0.1 to 1 μm; and adhesion reinforcing layers based upon epoxy resin and formed at both sides of the main ACA film.

Owner:KOREA ADVANCED INST OF SCI & TECH

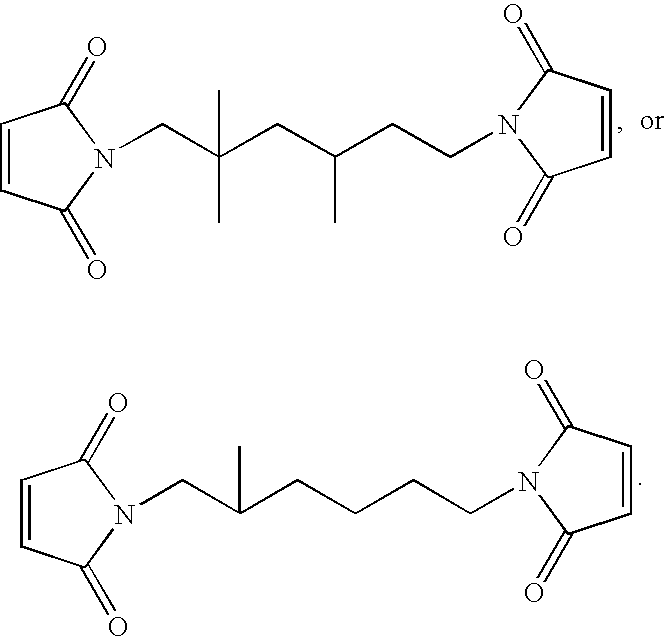

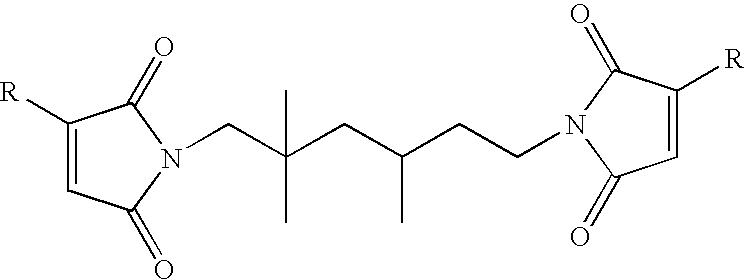

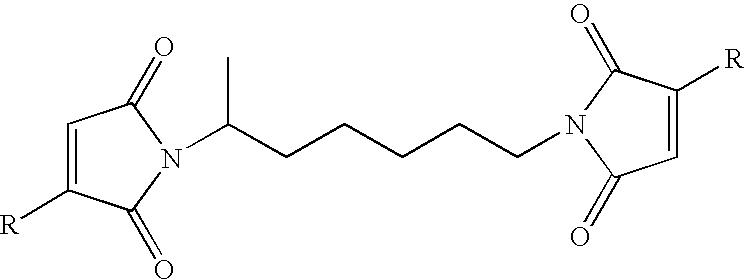

Low temperature curing acrylate and maleimide based formulations and methods for use thereof

ActiveUS20100063184A1Non-fibrous pulp additionFilm/foil adhesivesLow temperature curingElectronic packaging

The present invention is based on the discovery that certain electron poor olefins combined with nucleophiles and a base catalyst are useful as adhesive compositions for the electronic packaging industry. In particular, the adhesive formulations set forth herein are useful as low temperature curing formulations with high adhesion to a variety of substrates. Invention formulations typically cure at about 80° C. and have a potlife of about 24 hours. The formulations cure by the well-known Michael addition reaction.

Owner:DESIGNER MOLECULES

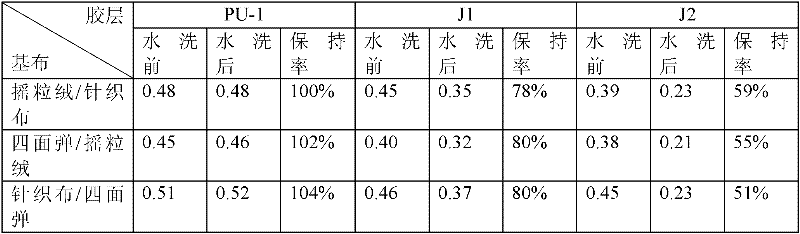

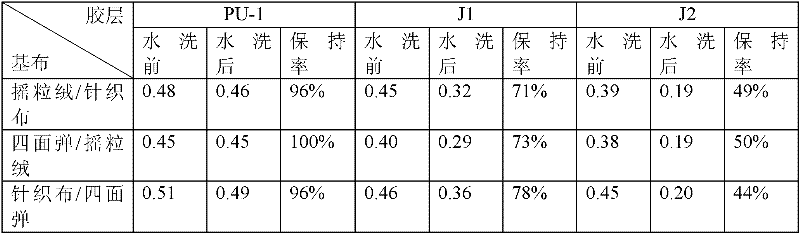

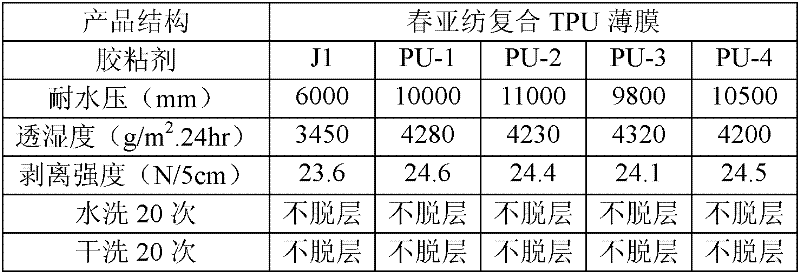

Preparation method of reactive polyurethane hot melt adhesive for fabric lamination

ActiveCN102336883AApplicable fitExcellent enzyme-resistant bacteria performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPliability

The invention relates to a preparation method of a reactive polyurethane hot melt adhesive for fabric lamination, relates to a reactive polyurethane hot melt adhesive, and belongs to the technical field of polyurethane hot melt adhesive preparation. The reactive polyurethane hot melt adhesive for fabric lamination is prepared by the following steps: heating and melting polyester polyol, polyether polyol, a chain extender, an adhesive force accelerant and an antioxidant and mixing uniformly, drying in vacuum for dewatering, adding isocyanate, a catalyst and a silane coupling agent, and reacting under nitrogen protection. The prepared reactive polyurethane hot melt adhesive for fabric lamination has the characteristics that: after being heated, the hot melt adhesive becomes molten thick state because of physical crosslinking generated under the action of hydrogen bonds, and then becomes original physical property after being cooled; the hot melt adhesive not only has excellent enzyme bacteria resistance, higher adhesion strength and good flexibility, water resistance, waterproof and moisture permeable properties and the like, but also does not contain volatile organic solvents, has excellent environmental friendliness, and is suitable for the lamination of various fabrics and the lamination of fabrics and waterproof and moisture permeable thin films.

Owner:WUXI WANLI ADHESION MATERIALS

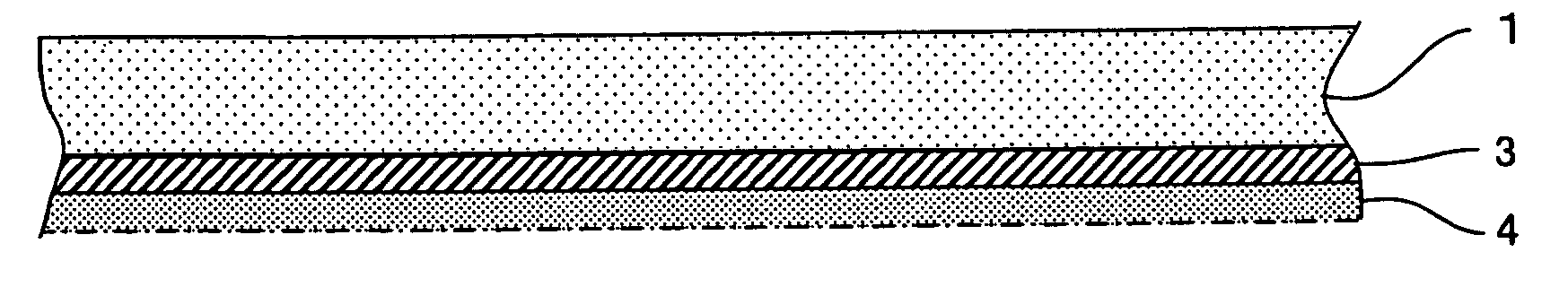

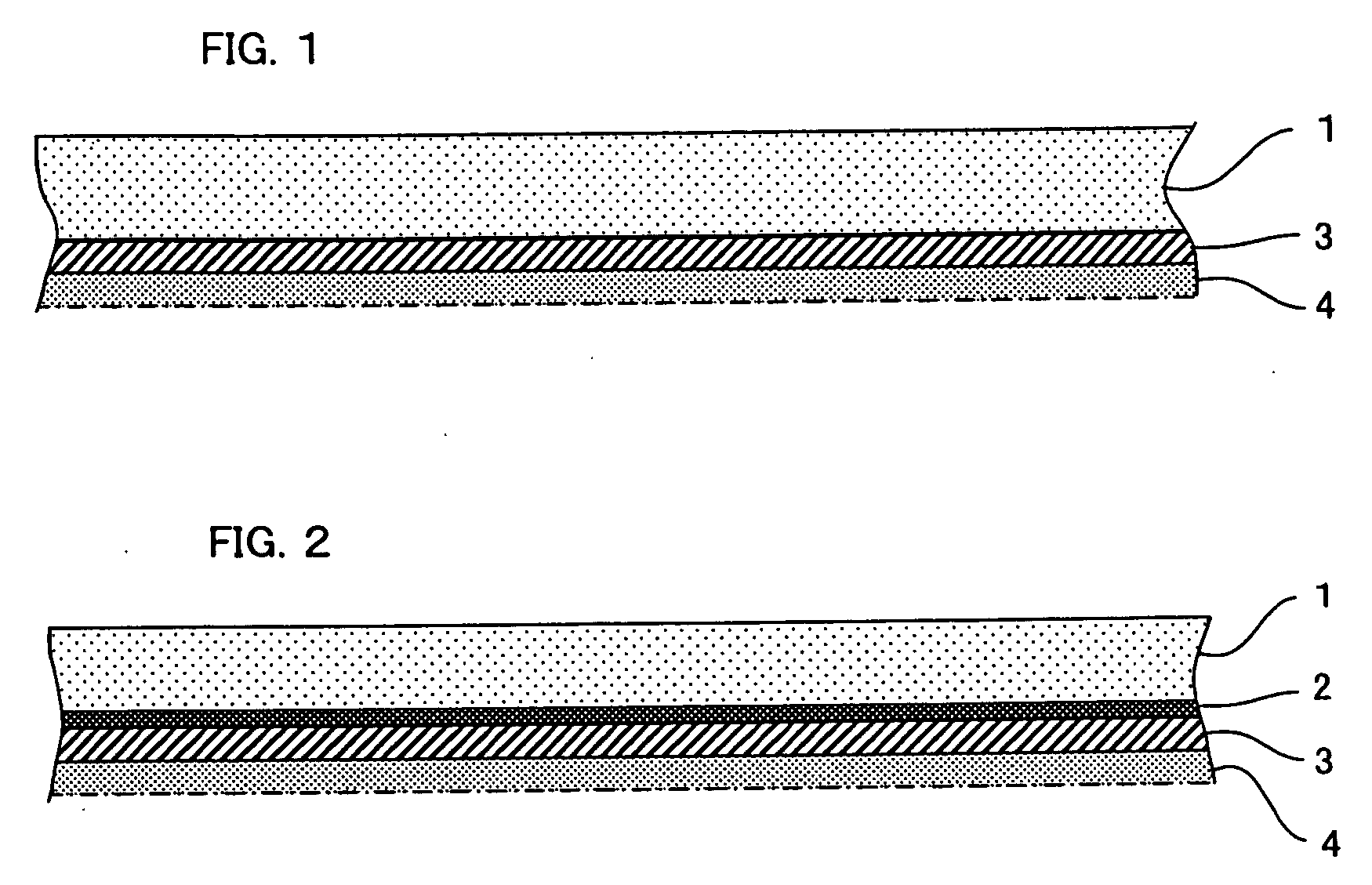

Adhesive film and image display device

InactiveUS20070031660A1Improve bindingImprove adhesionSynthetic resin layered productsLaminationAntistatic agentWater dispersible

An adhesive film prevents static charge on peeling generated when removed from an adherend and also improves adhesion between a base material and an adhesive layer, where an under coat layer containing an organometallic is formed on the base material and then an adhesive layer is formed on the base material. Alternatively, an adhesive film showing high adhesion with a glass substrate, and including an antistatic layer, which prevents static charge on peeling generated when the surface protective film is removed, and improves adhesion between a base material and an adhesive layer, where the adhesive film includes a base material, an adhesive layer made of a water dispersible adhesive including, and an antistatic layer, containing a water soluble or water dispersible conductive material, interposed between them, and the adhesive film is stuck onto an image display device.

Owner:NITTO DENKO CORP

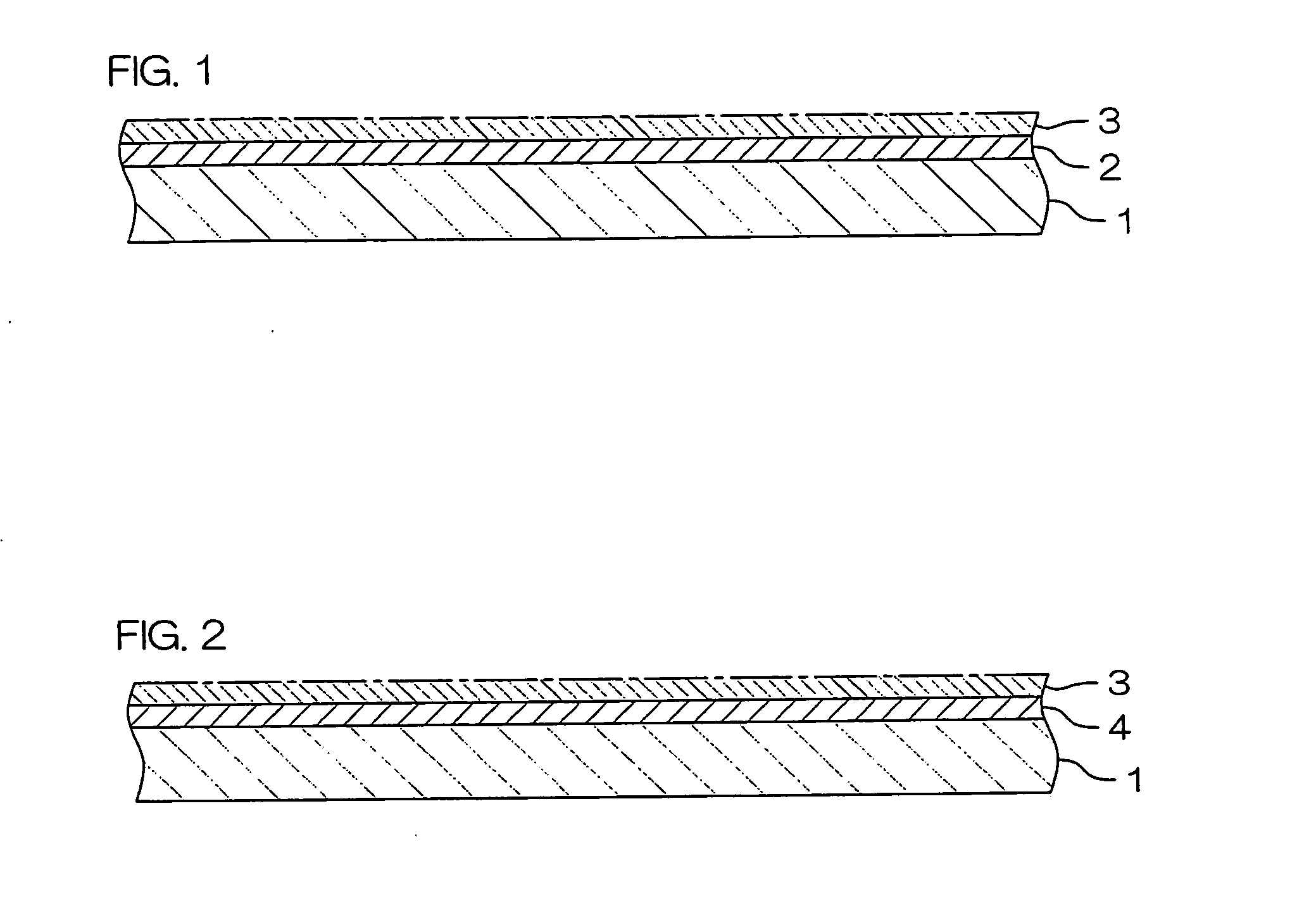

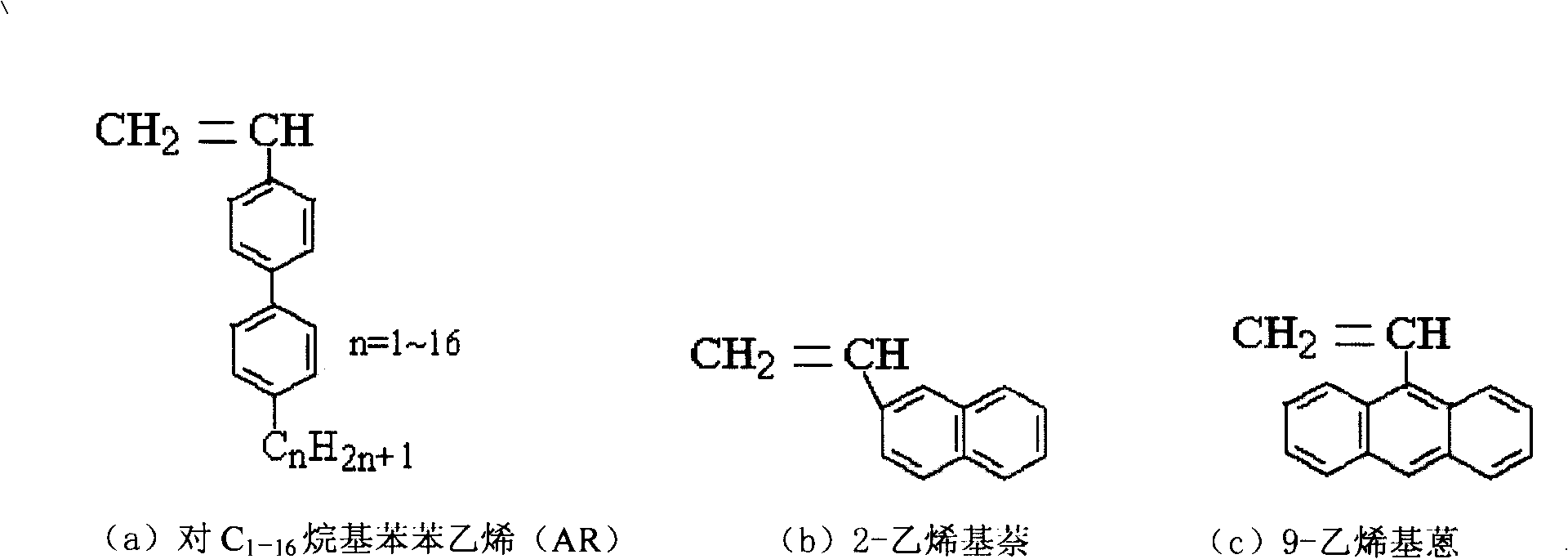

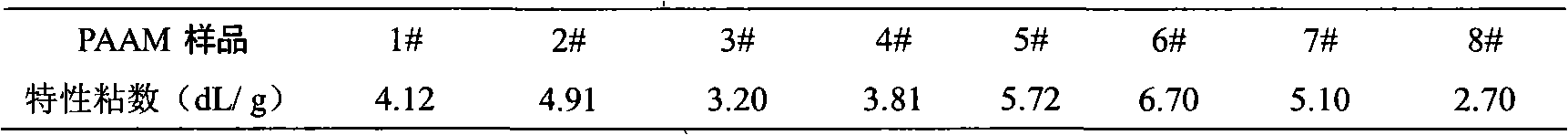

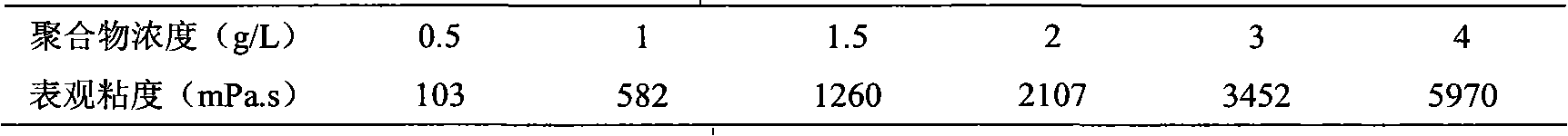

High adhesion-promotion salt resistant water-soluble copolymer, preparation method and application thereof

InactiveCN101293944AImprove salt resistanceGood viscosity increasing effectDrilling compositionPolymer scienceBottle

The invention discloses a water soluble copolymer with high viscosity and salt resistance, and a preparation method and an application thereof. The preparation method comprises the steps of: adding acrylamide 20 weight parts, an anionic monomer or / and a cationic monomer 0.1-15 weight parts,, a vinyl polycyclic aromatic hydrocarbon 0.05-4 weight parts,, a surfactant 0.5-90 weight parts,, and deionized water 70-900 weight parts, into a three-neck reaction bottle, adjusting the solution pH to 2.5-9, introducing N2 for 30min, adding an initiator persulfate 0.001-0.2 weight parts, at 20-70DEG C, and reacting for 6-36 hours to obtain a low-molecular weight water soluble copolymer with molecular association ability, high viscosity and salt resistance, which can be used in intermediate-permeability oil reservoir and low-permeability oil reservoir development. An associated water soluble polymer oil displacement agent is obtained by preparing the copolymer into an aqueous solution with copolymer concentration of 0.3-3 g / L and surfactant concentration of 0.01-4 mmol / L, adding into a mixer with a stirring device, and stirring uniformly at room temperature; and the obtained oil displacement agent has high viscosity, salt resistance, temperature resistance and shear resistance, and can be used in intermediate-permeability oil reservoir and the low-permeability oil reservoir development.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

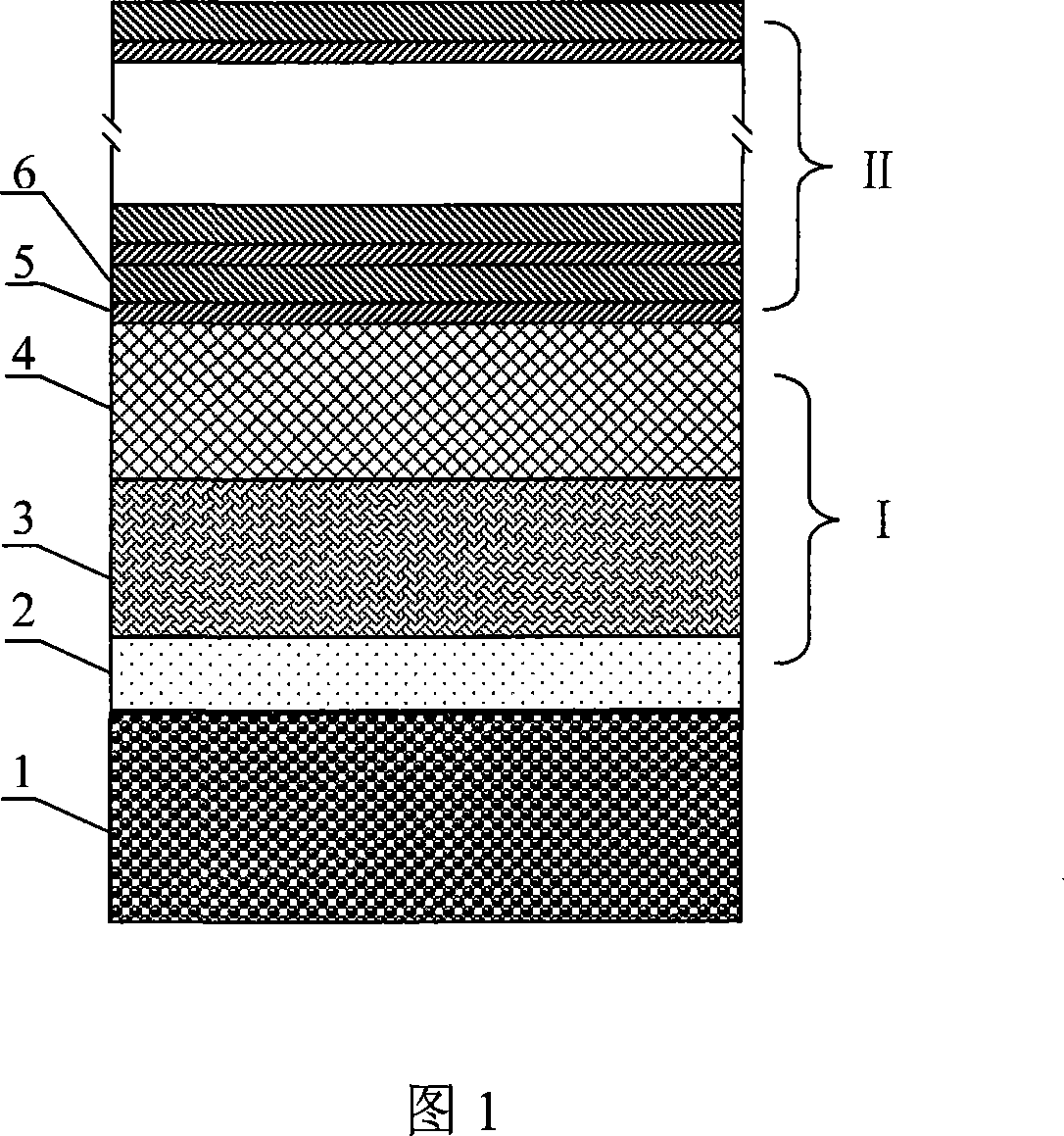

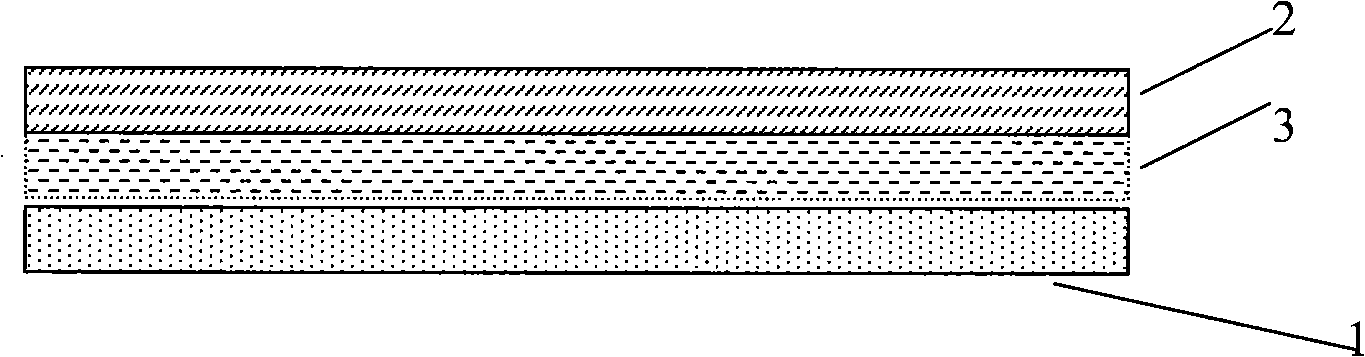

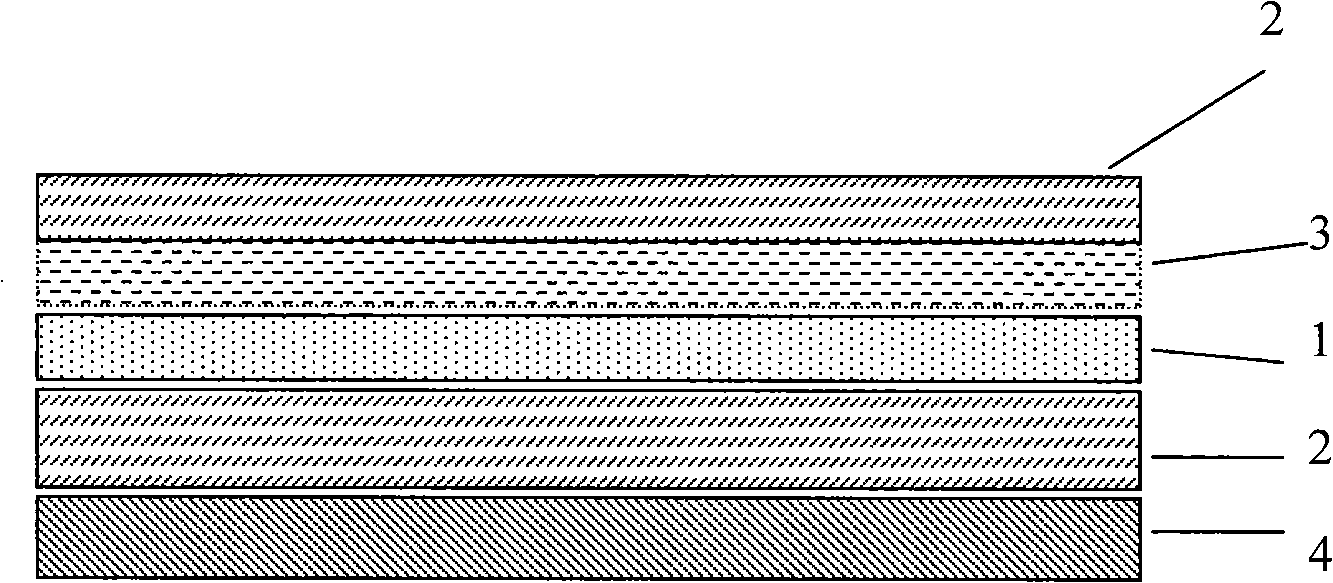

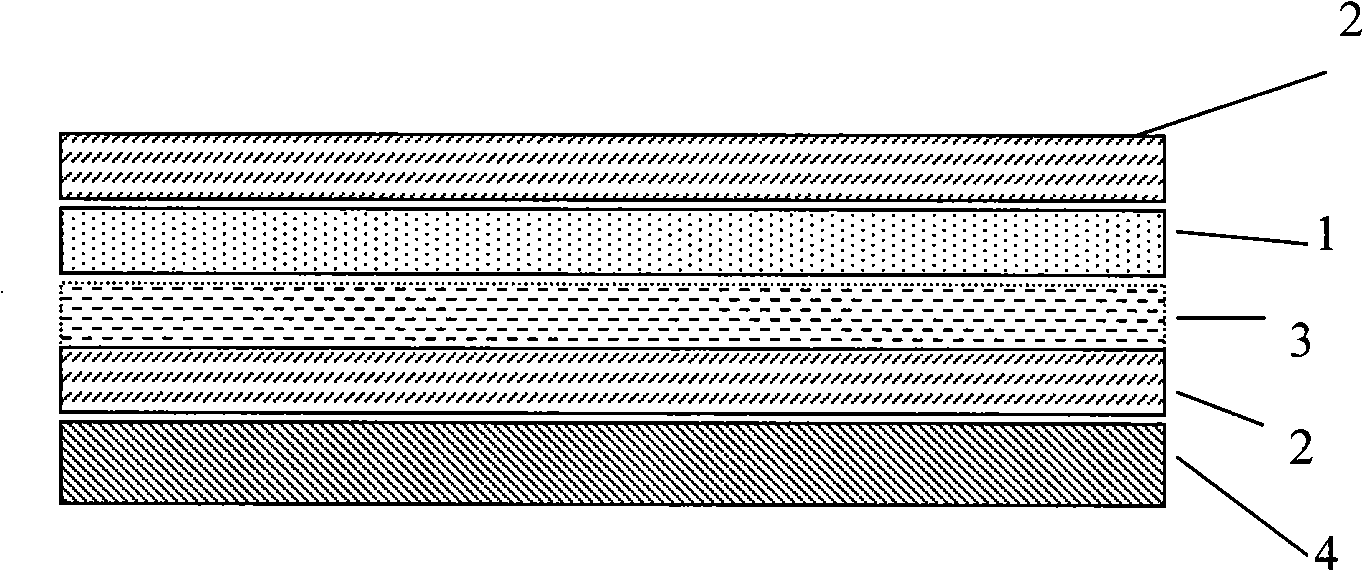

Back plate of solar cell

InactiveCN101359695AStrong weather resistanceHigh barrierSynthetic resin layered productsPhotovoltaic energy generationAdditive ingredientEngineering

Disclosed is a solar cell back panel, comprising a substrate material and a weather-resistant layer. The weather-resistant layer is at least arranged at one side of the substrate material, and a barrier film is arranged at one side of the substrate material. The weather-resistant layer contains the following ingredients (based on weight portion) 25-45 portions of fluorine resin, 1.5-3 portions of modified resin, 0.5-3 portions of polymer fillers, 0.1-1 portion of inorganic filler and 50-70 portions of solvent. The solar cell back panel is of strong weather resistance, good water barrier property and high adhesion with a solar cell package material.

Owner:CHINA LUCKY FILM CORP +1

Marine anticorrosive coating

InactiveCN104087126AImprove anti-corrosion performanceGood flexibilityAnti-corrosive paintsPolyurea/polyurethane coatingsHigh resistanceEpoxy

The invention discloses a marine anticorrosive coating. The marine anticorrosive coating consists of the following components in percentage by mass: 30-40 percent of film forming matter, 21.5-33.8 percent of pigment filler, 6.2-15.4 percent of aids and 30-42.3 percent of solvent, wherein the film forming matter consists of 16-23 mass percent of water-based phenolic epoxy resin and 14-16 mass percent of waterborne polyurethane; the pigment filler comprises graphene; the solvent is deionized water. The marine anticorrosive coating has high corrosion resistance, high flexibility, high wear resistance, high oil and aging resistance and good antirust performance. The film forming matter integrates high adhesion force, high strength, low shrinkage rate and high corrosion resistance of the water-based phenolic epoxy resin as well as high flexibility, wear resistance, oil and aging resistance and good film-forming performance of the waterborne polyurethane.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

High-temperature-resistant hot melt adhesive membrane for aluminum honeycomb boards, and preparation method thereof

ActiveCN103205210AHigh bonding strengthImprove heat resistanceFilm/foil adhesivesPolyureas/polyurethane adhesivesElastomerPolyester

The invention discloses a high-temperature-resistant hot melt adhesive membrane for aluminum honeycomb boards, and a preparation method thereof. The high-temperature-resistant hot melt adhesive membrane for aluminum honeycomb boards is made from, by weight percent, 30-50% of polyester elastomer with above 180 DEG C of melting point, 10-40% of polyolefin copolymer modified by maleic anhydride, 0-40% of polyolefin copolymer, 10-30% of tackifying resin, 0-15% of filler, and 1-3% of functional aid. The components add up to 100%. The high-temperature-resistant hot melt adhesive membrane for aluminum honeycomb boards has the advantages of high adhesion strength, instantaneous resistance to the temperature up to 170-190 DEG C, and long-term resistance to the temperature up to 130 DEG C.

Owner:JIANGSU LUSHAN PHOTOVOLTAIC TECH +1

Adhesive composition, adhesive optical film and image display device

ActiveUS20060188712A1Improve adhesionImprove heat resistanceBlast furnace componentsSynthetic resin layered productsPolymer scienceMeth-

To provide an adhesive composition which shows high adhesion with a glass substrate and has excellent heat resistance, moisture resistance and moist heat resistance, an adhesive optical film comprising an adhesive layer made of the adhesive composition, which shows high adhesion between the adhesive layer and an optical film and effectively suppresses the occurrence of adhesive residue and lack of adhesive and also has excellent heat resistance, moisture resistance and moist heat resistance, and an image display device comprising the adhesive optical film, the adhesive optical film comprises an optical film 1, an adhesive layer 3 made of a water dispersible adhesive composition comprising, as raw monomers, an alkyl(meth)acrylate ester whose alkyl group has 4 to 18 carbon atoms, a carboxyl group-containing vinyl monomer, a phosphoric acid group-containing vinyl monomer, and a copolymerizable vinyl monomer which is optionally copolymerizable with the above monomers, wherein a carboxyl group concentration is from 0.05 to 1.50 mmol / g and a phosphoric acid group concentration is from 0.01 to 0.45 mmol / g in the raw monomers, an under coat layer 2 containing an oxazoline group-containing polymer, and being interposed between the optical film 1 and the adhesive layer 3, and the adhesive optical film is applied onto an image display device.

Owner:NITTO DENKO CORP

Fuel cell ordered porous nano-fiber single electrode, membrane electrode and preparation method

InactiveCN103413947AShorten the transmission distanceIncrease profitMaterial nanotechnologyCell electrodesPorositySlurry

The invention discloses a fuel cell ordered porous nano-fiber single electrode, a membrane electrode and a preparation method. Polymer nano-fibers are deposited on one side of a gaseous diffusion material through an electro-spinning technology; metal nanoparticles with catalytic activity are deposited on the surfaces of the polymer nano-fibers by using magnetron sputtering and vacuum evaporation methods, or catalyst slurry is directly sprayed to one side of a nano-fiber thin film to form a porous single electrode; then two single electrodes and a layer of proton exchange membrane are combined into a three-in-one membrane electrode. The fuel cell ordered porous nano-fiber single electrode, the membrane electrode and the preparation method have the beneficial effects that the conventional micro-porous layer is substituted by the nano-fiber layer with high porosity and high specific surface area, prepared by electro-spinning, so that the catalytic activity area is increased and the three-phase reaction interface and the mass transfer are facilitated, and an active metal catalytic layer formed by magnetron sputtering and vacuum evaporation has high adhesion, is uniform in coating and has controllable thickness, so that the using amount of the active metal catalyst is reduced and the utilization rate of the catalyst is also greatly increased.

Owner:WUHAN UNIV OF TECH

Anti-rust treating agent for nickel-plated battery steel shell and using method thereof

ActiveCN102002698AFast film formationReduce processing timeMetallic material coating processesPolyvinyl alcoholPhytic acid

Owner:XIANGTAN UNIV

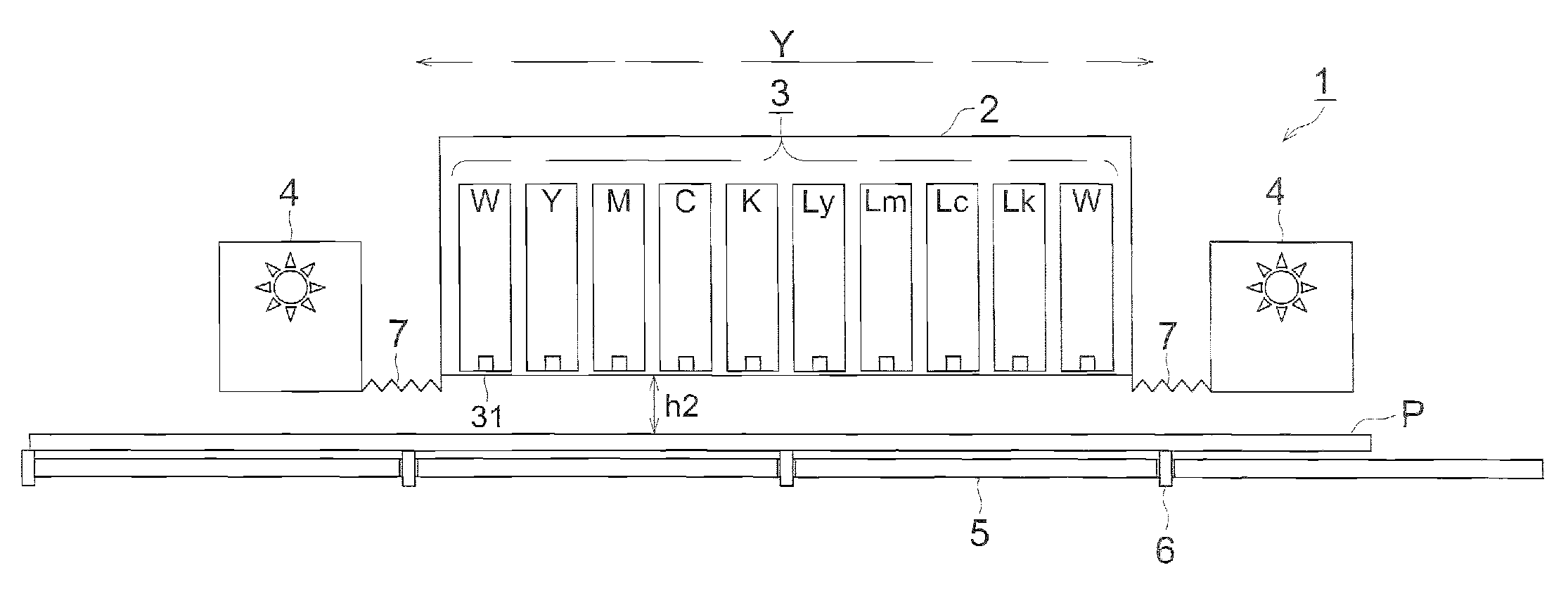

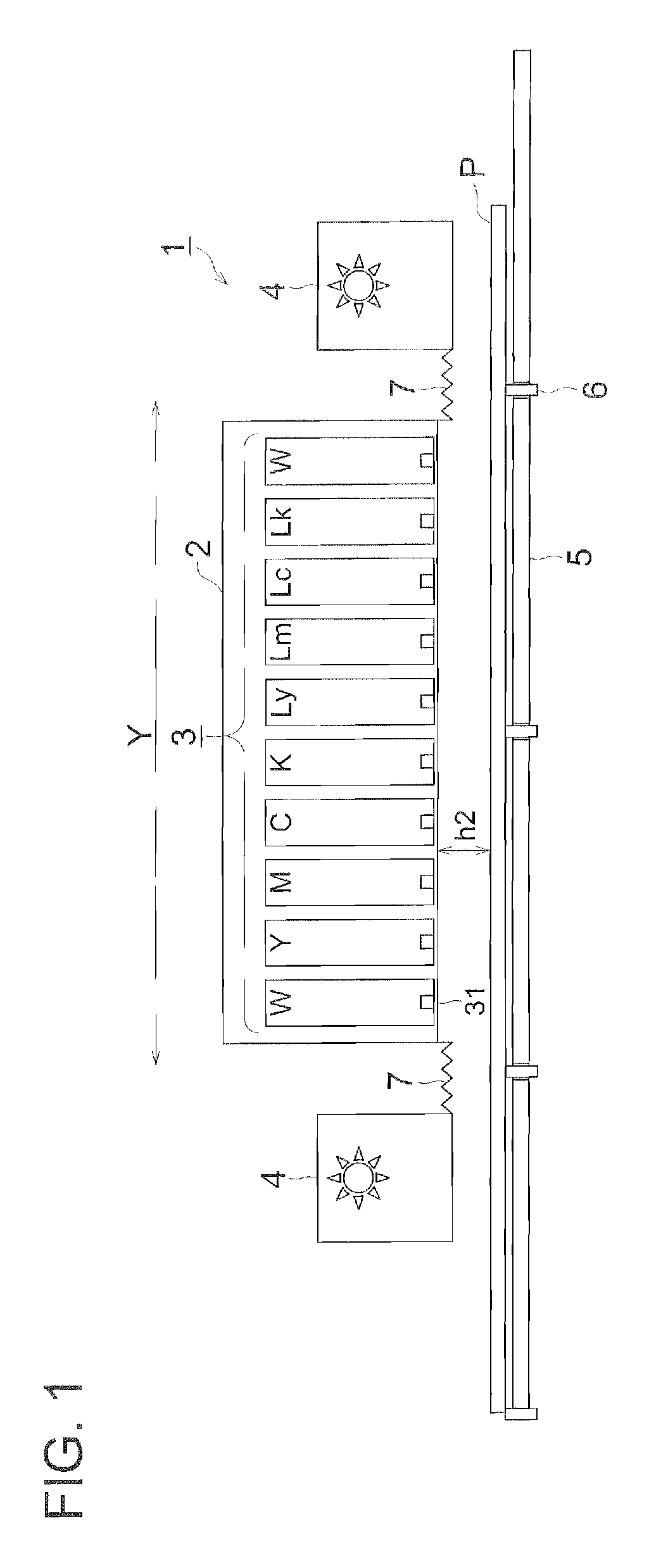

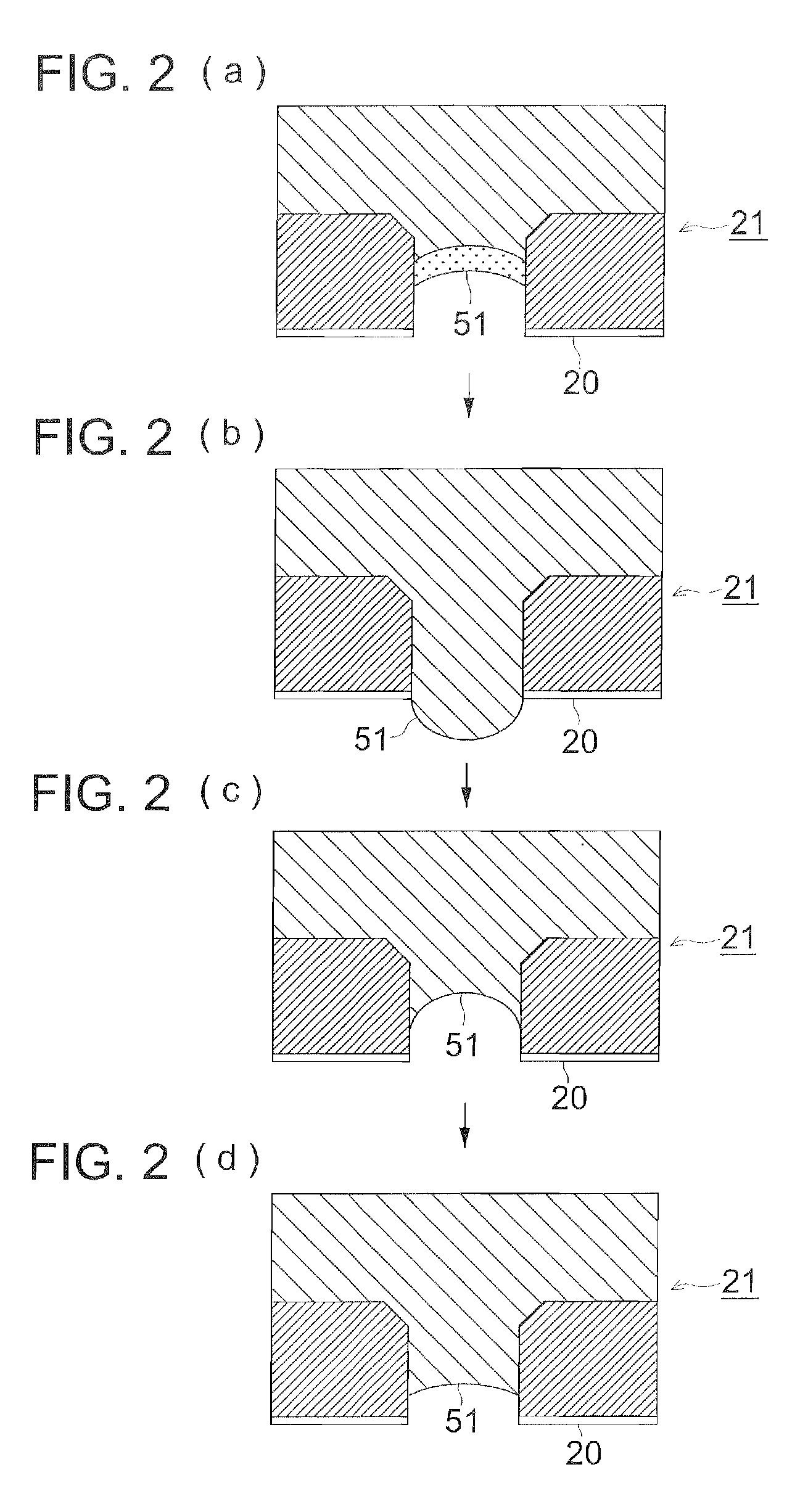

Inkjet ink, inkjet ink set, and inkjet recording method

InactiveUS20080165237A1Increase resistanceHigh degreeInksOther printing apparatusSide chainEngineering

Disclosed is an inkjet ink having printing aptitude with various recording media, excellent feathering resistance, beading resistance and bleed resistance, high adhesion to a recording medium, and high print quality. Also disclosed are an inkjet set and an inkjet recording method. Specifically disclosed is an inkjet ink containing at least a colorant, water and a polymer compound which has a plurality of side chains on a hydrophilic main chain and is cross-linkable between the side chains when irradiated with an active energy ray.

Owner:KONICA MINOLTA INC

Nitride semiconductor device and manufacturing method thereof

ActiveUS20070231978A1Low-resistance ohmic propertyImprove adhesionOptical wave guidanceSolid-state devicesMetal electrodesSilicon

A nitride semiconductor device and its manufacturing method are provided which are capable of achieving low-resistance ohmic properties and high adhesion. A nitride semiconductor device has an n-type GaN substrate over which a semiconductor element is formed and an n-electrode as a metal electrode formed over the back surface of the GaN substrate. A surface denatured layer functioning as a carrier supply layer is provided between the GaN substrate and the n-electrode. The surface denatured layer is formed by denaturing the back surface of the GaN substrate by causing it to react with a material that contains silicon.

Owner:MITSUBISHI ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com