Patents

Literature

141 results about "Bonded interface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

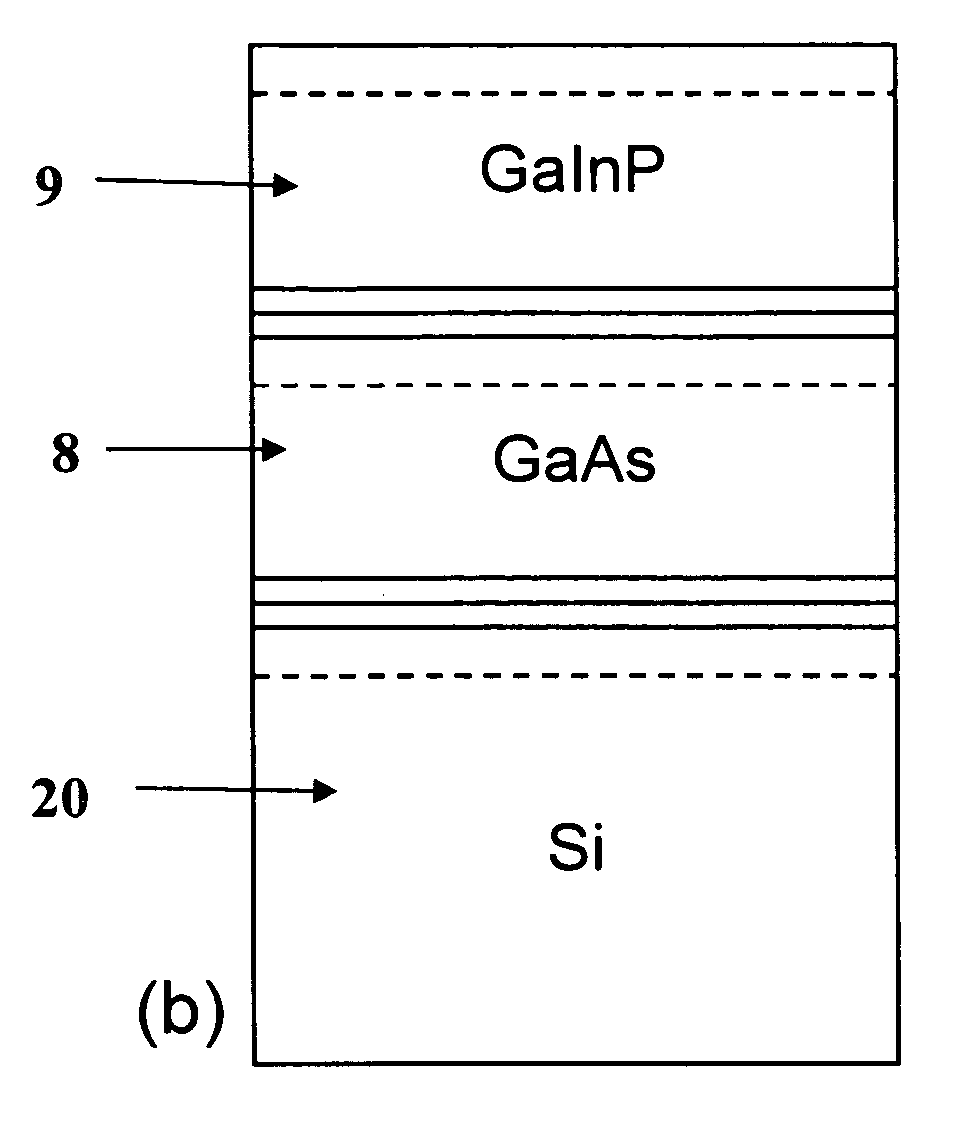

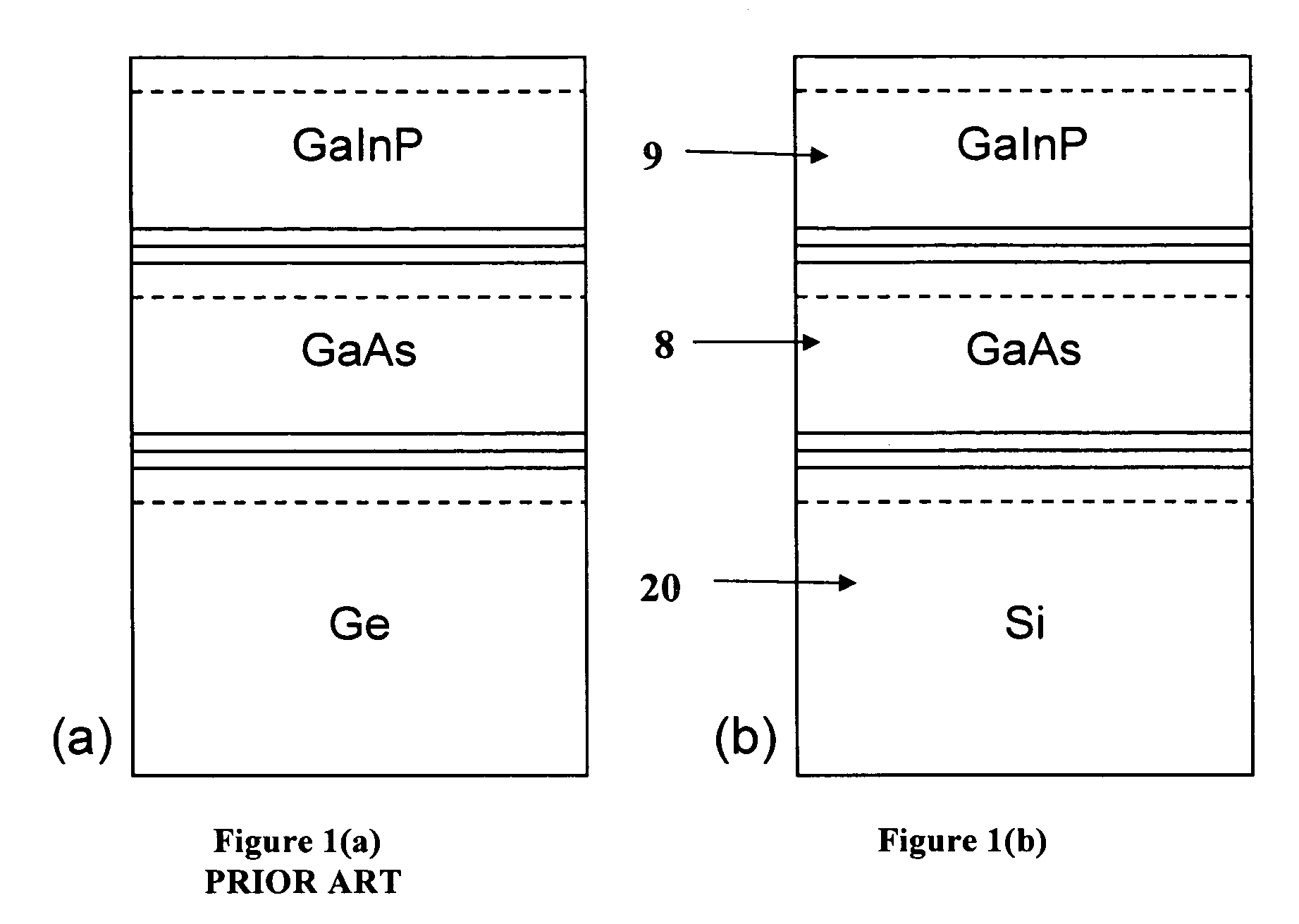

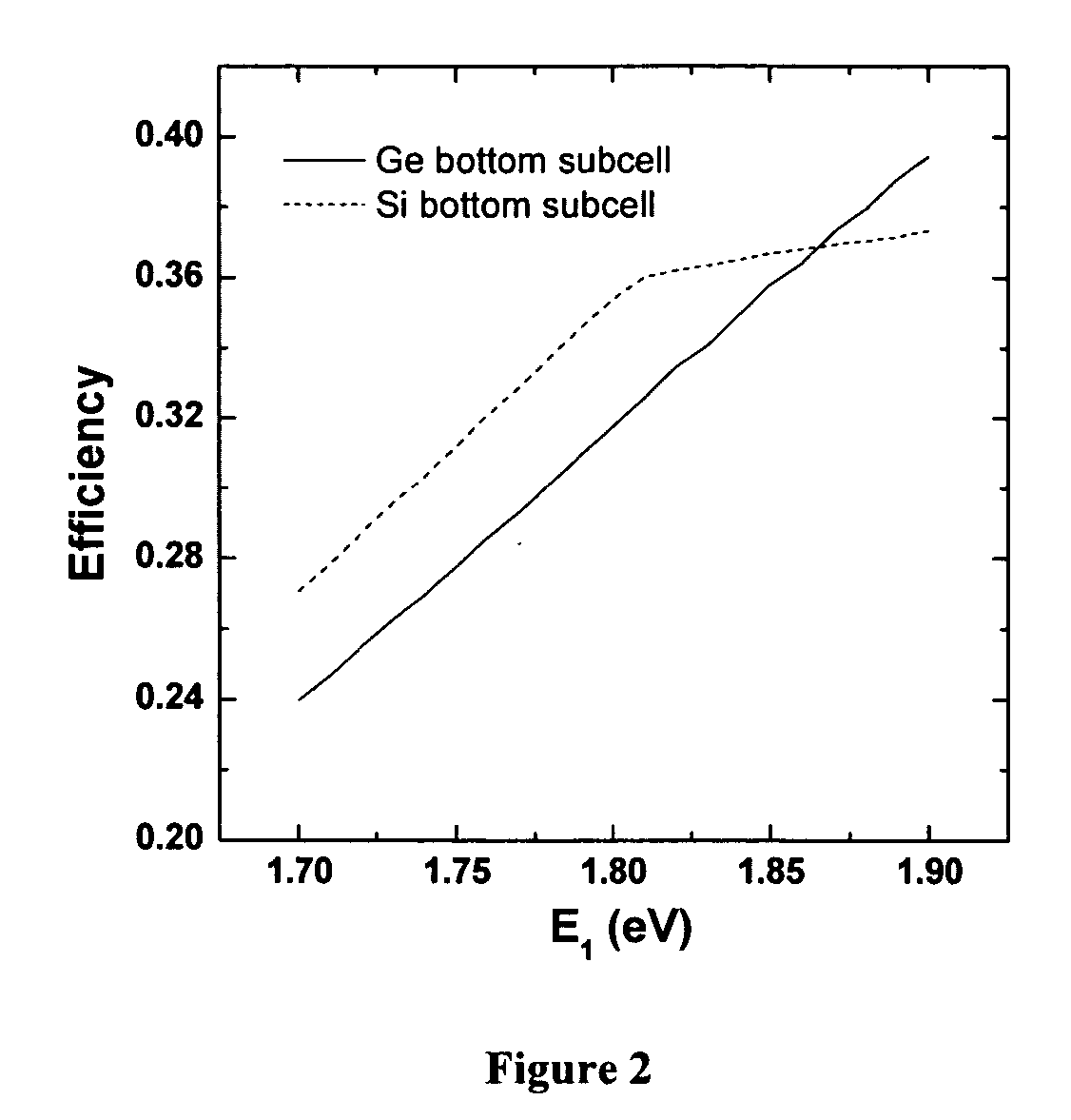

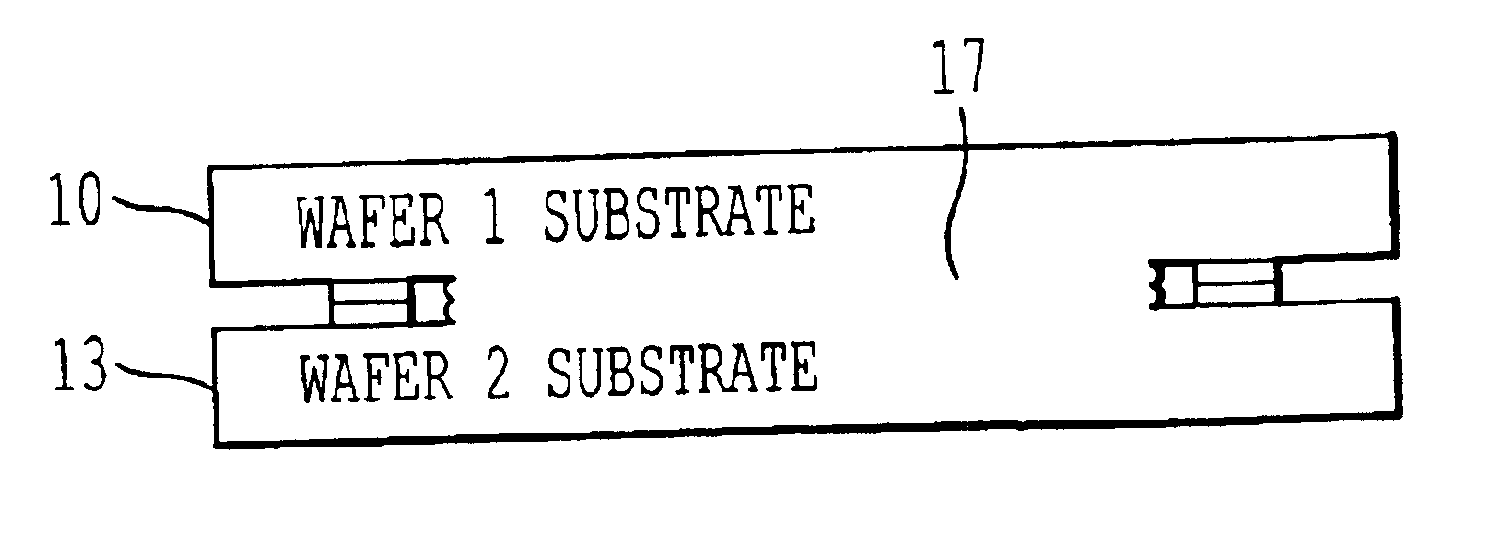

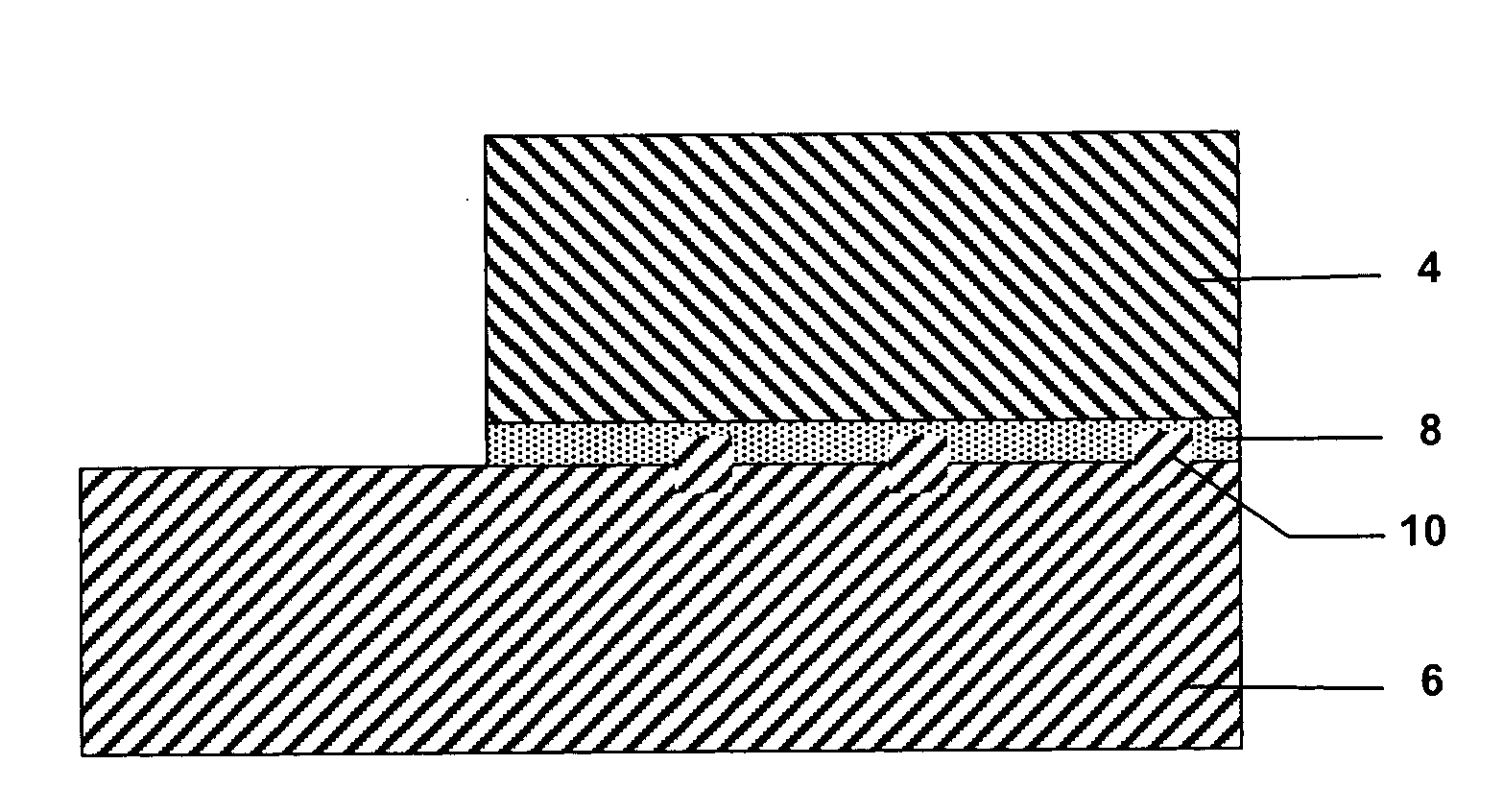

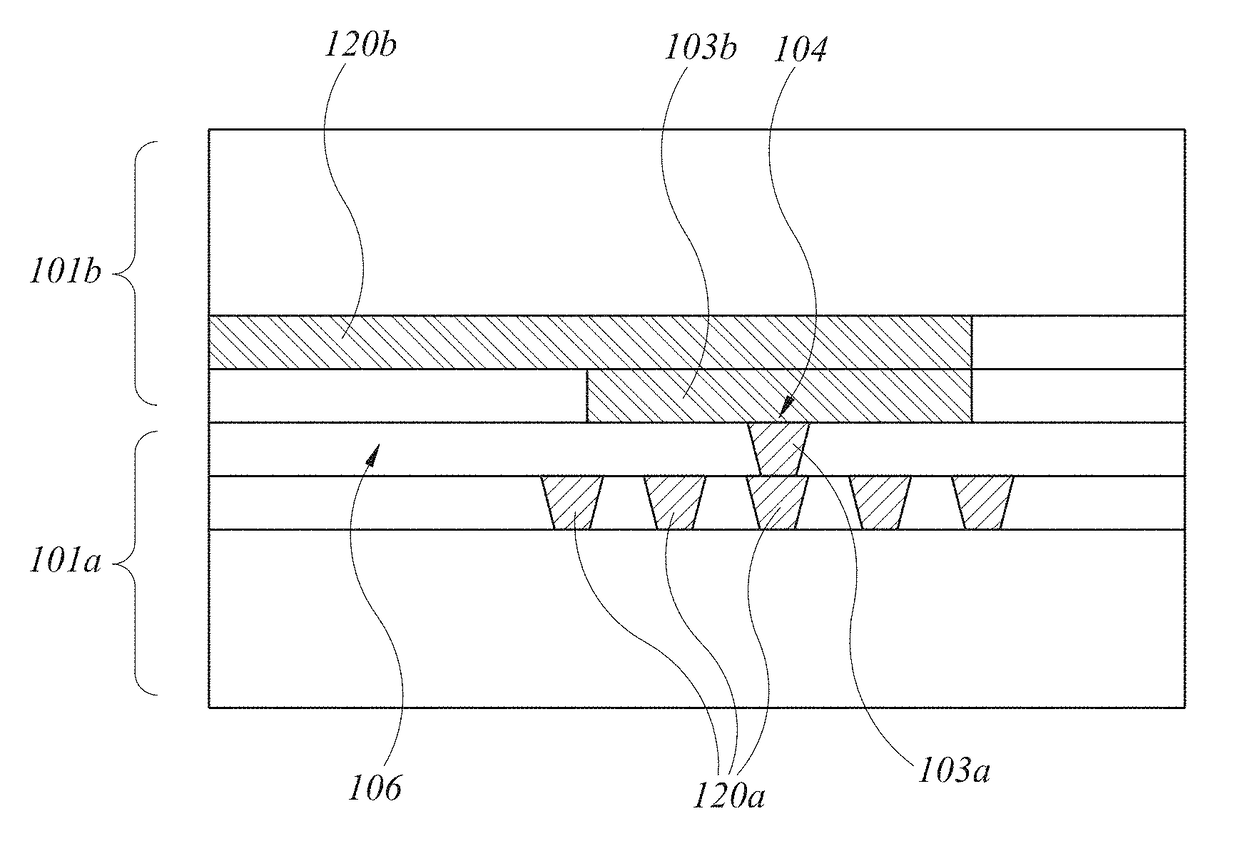

GaInP / GaAs / Si triple junction solar cell enabled by wafer bonding and layer transfer

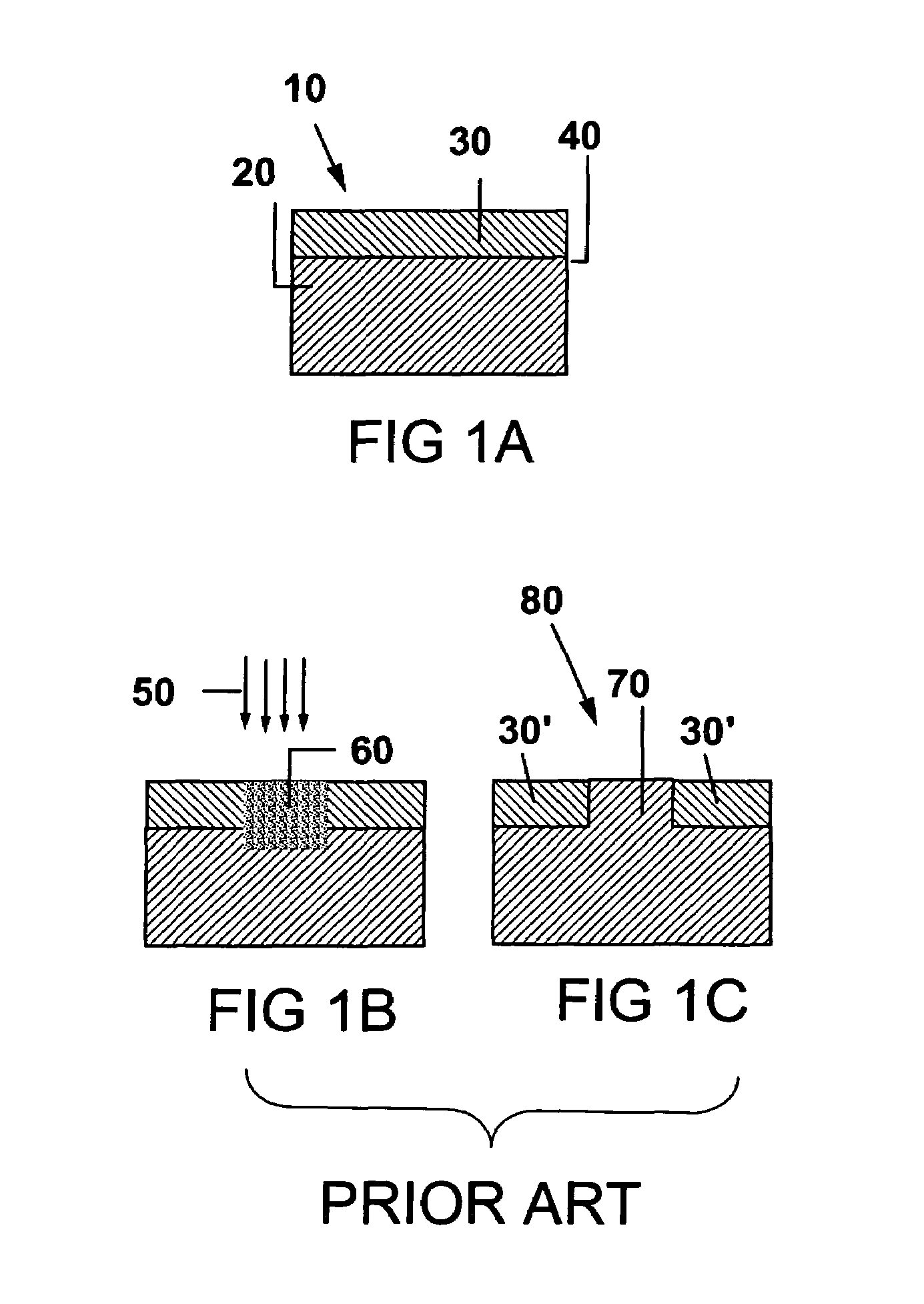

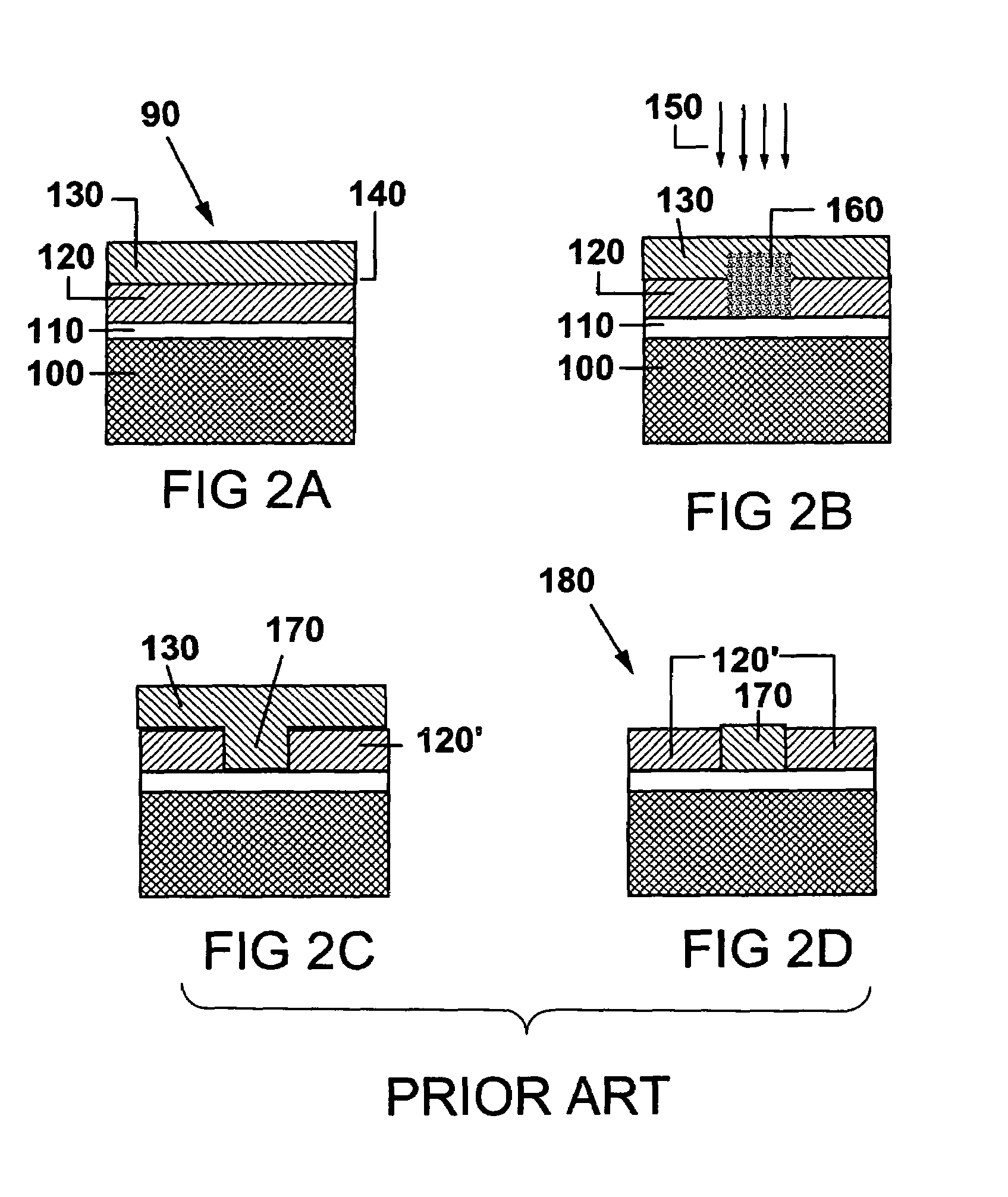

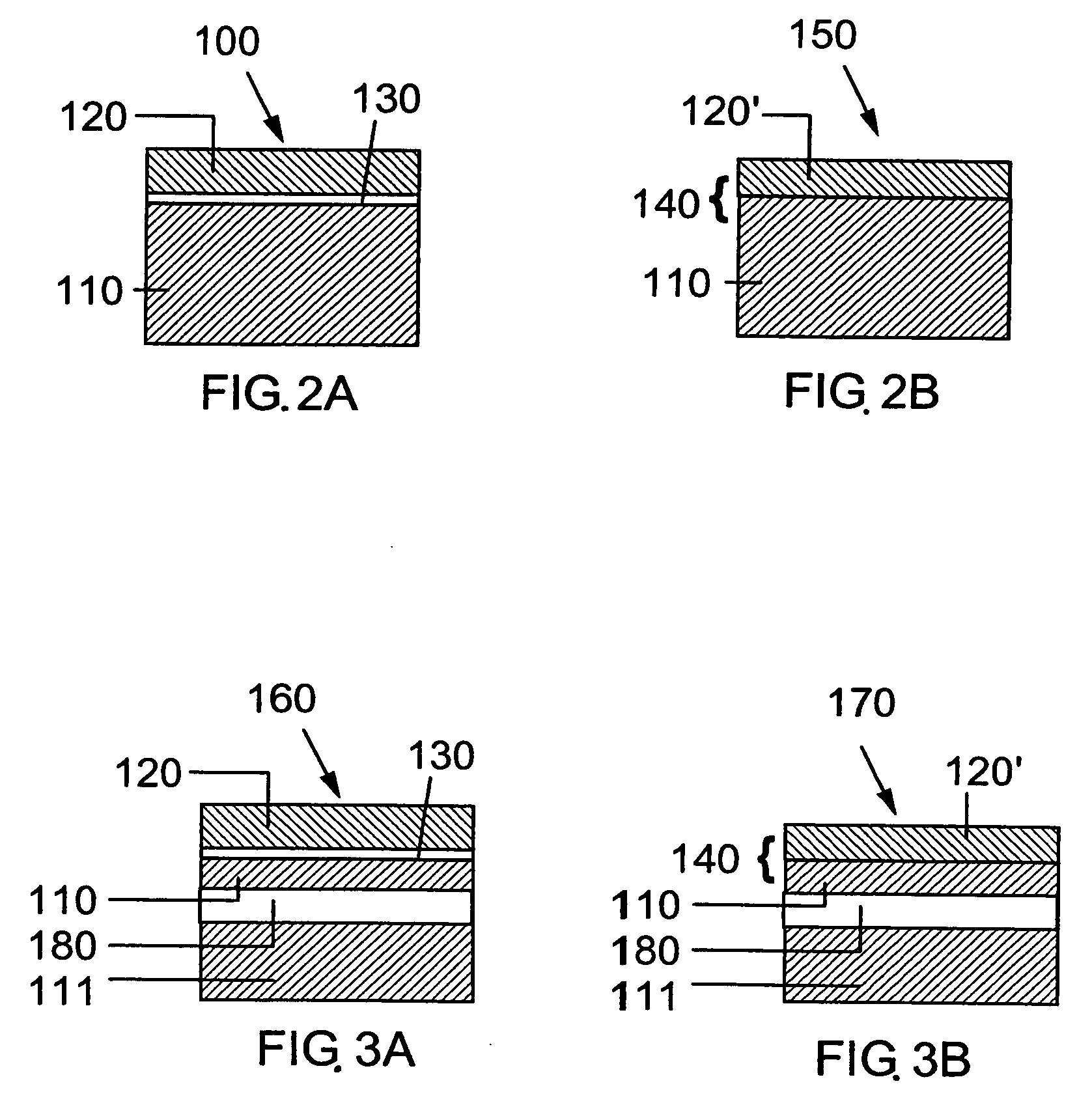

InactiveUS20060021565A1Polycrystalline material growthFinal product manufactureBond interfaceWafer bonding

A multi-junction solar cell includes a silicon solar subcell, a GaInP solar subcell, and a GaAs solar subcell located between the silicon solar subcell and the GaInP solar subcell. The GaAs solar subcell is bonded to the silicon solar subcell such that a bonded interface exists between these subcells.

Owner:AONEX TECH

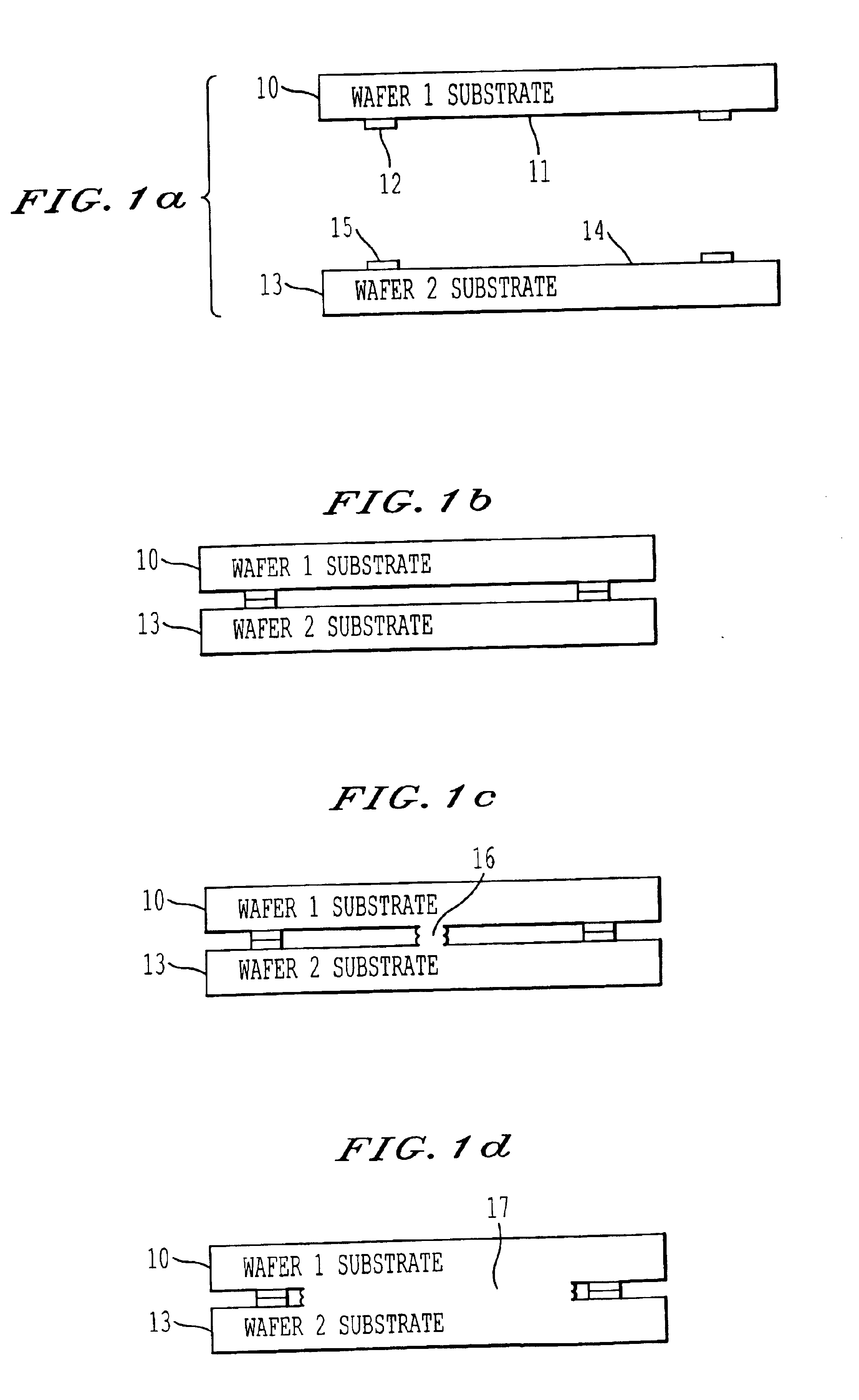

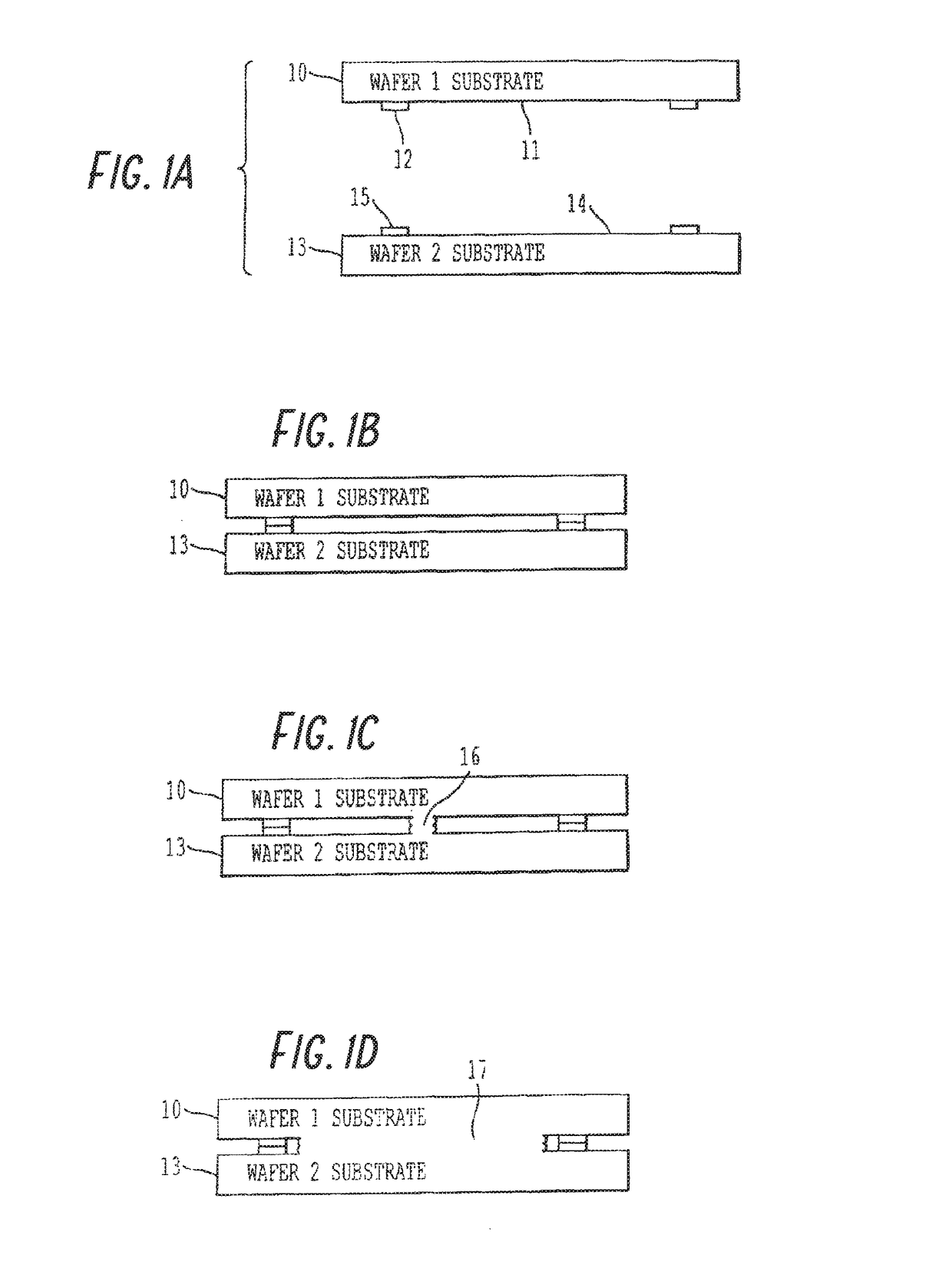

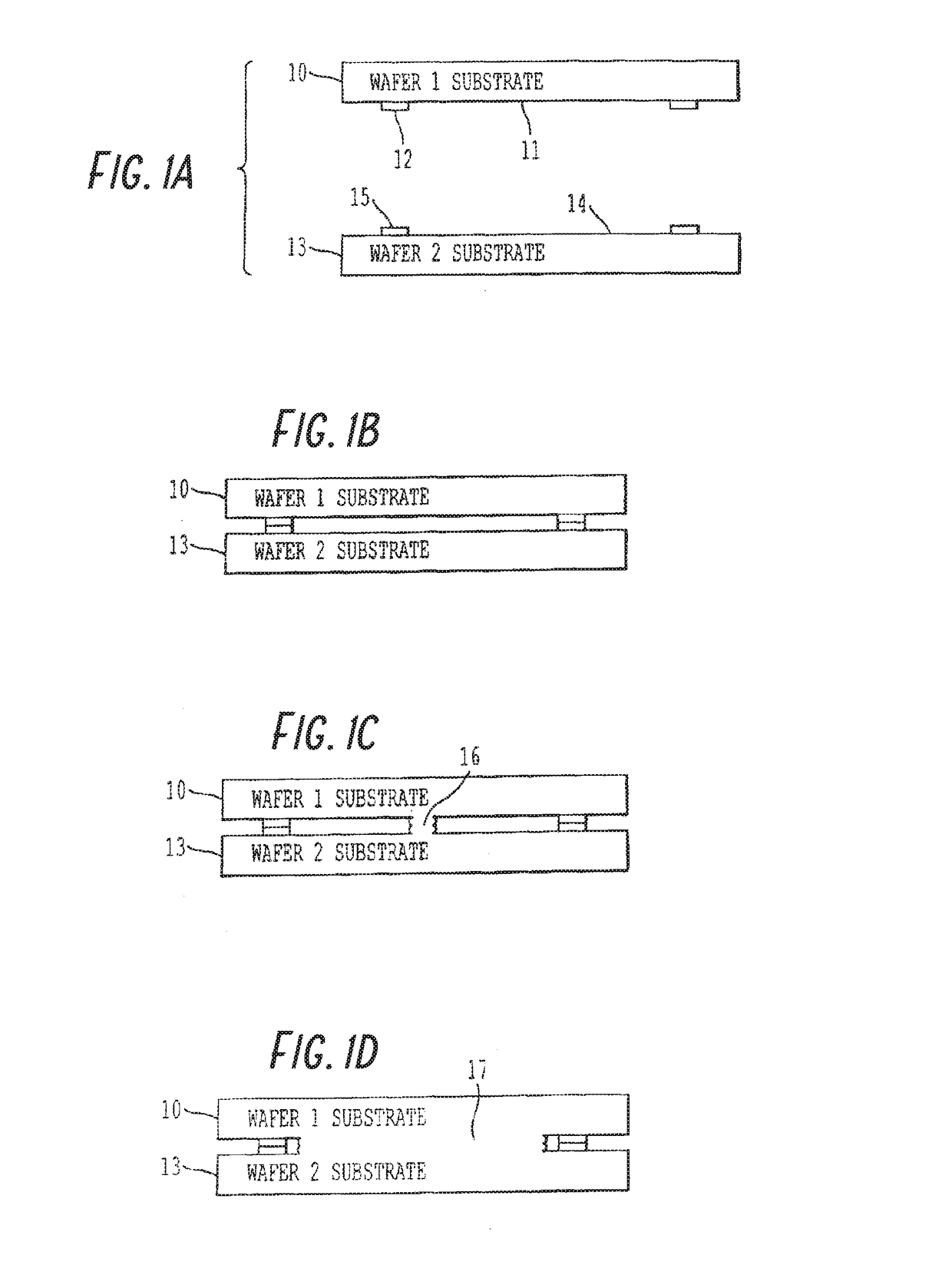

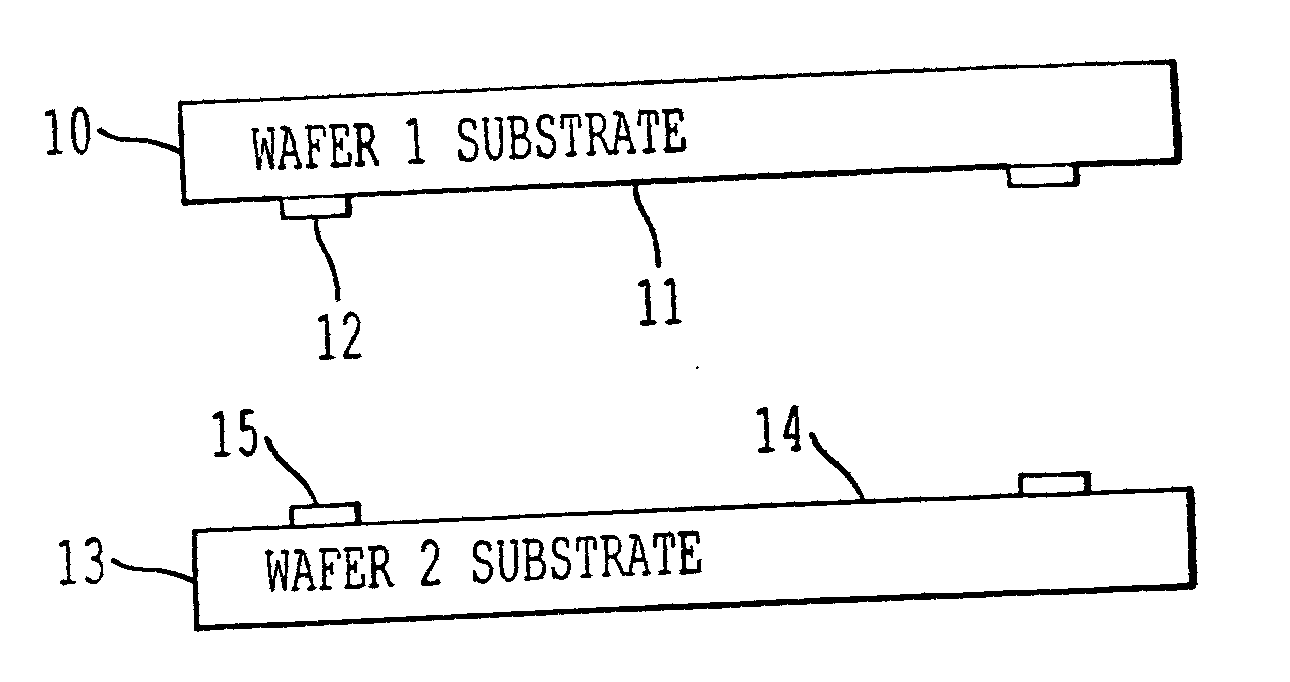

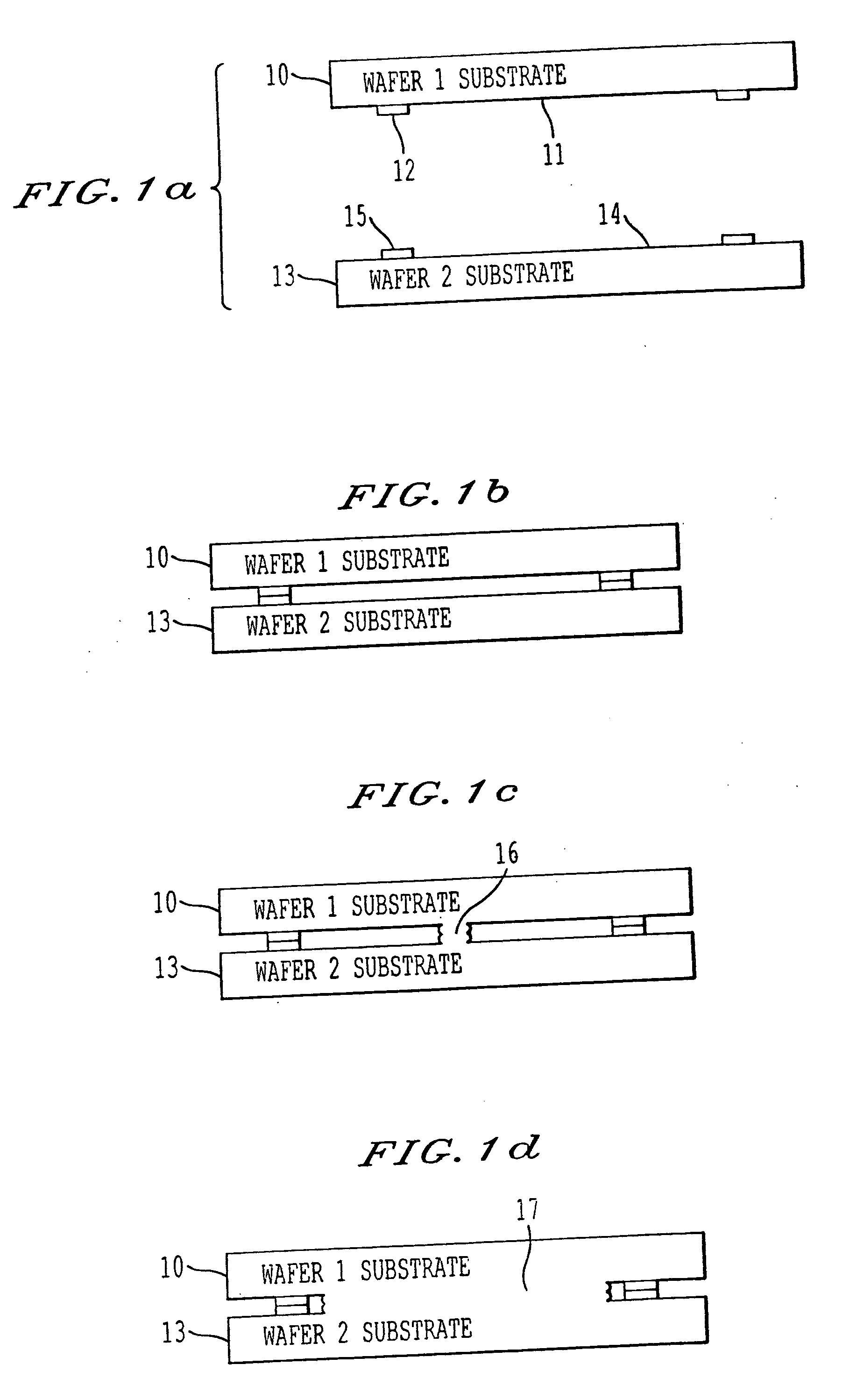

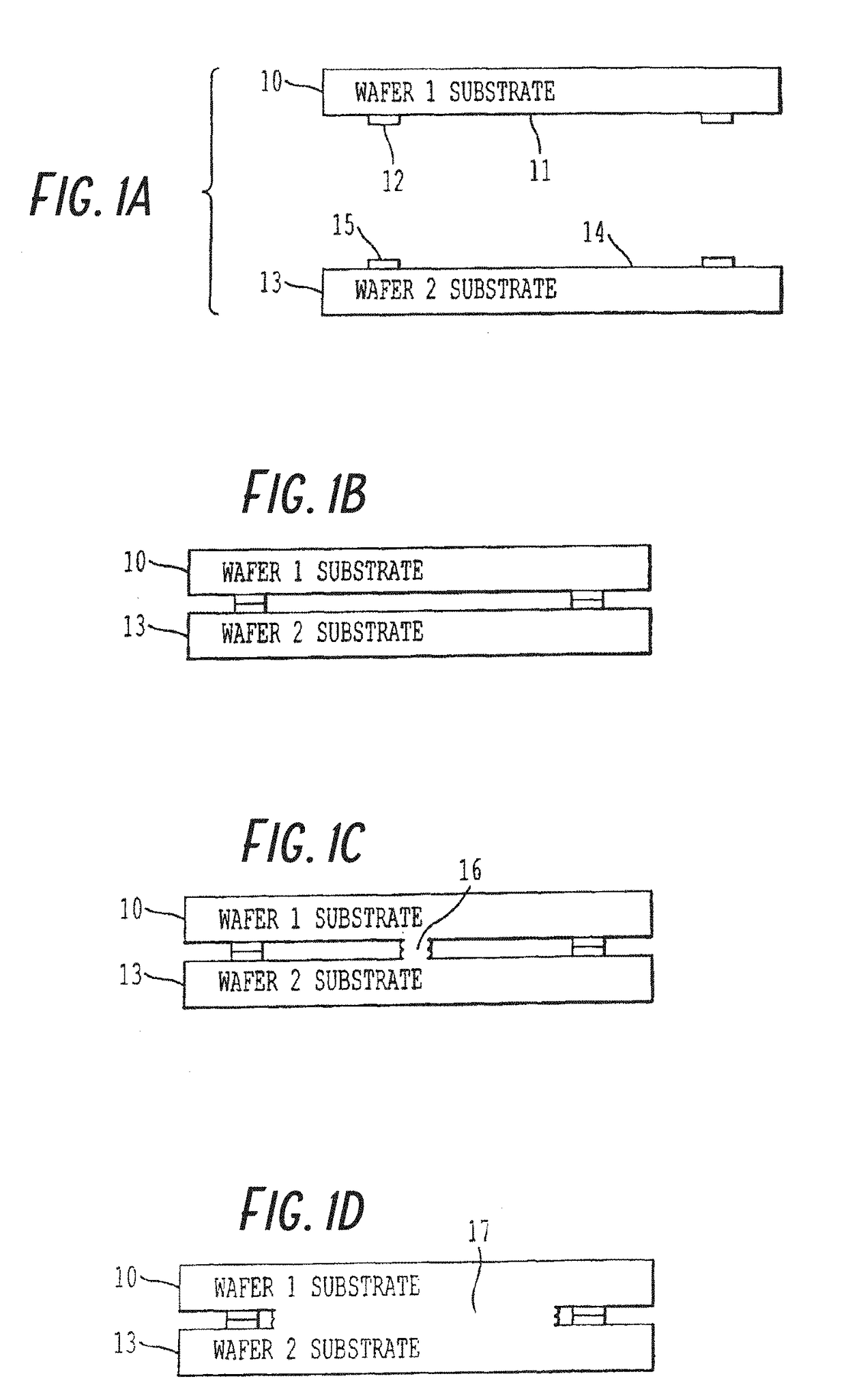

Method for room temperature metal direct bonding

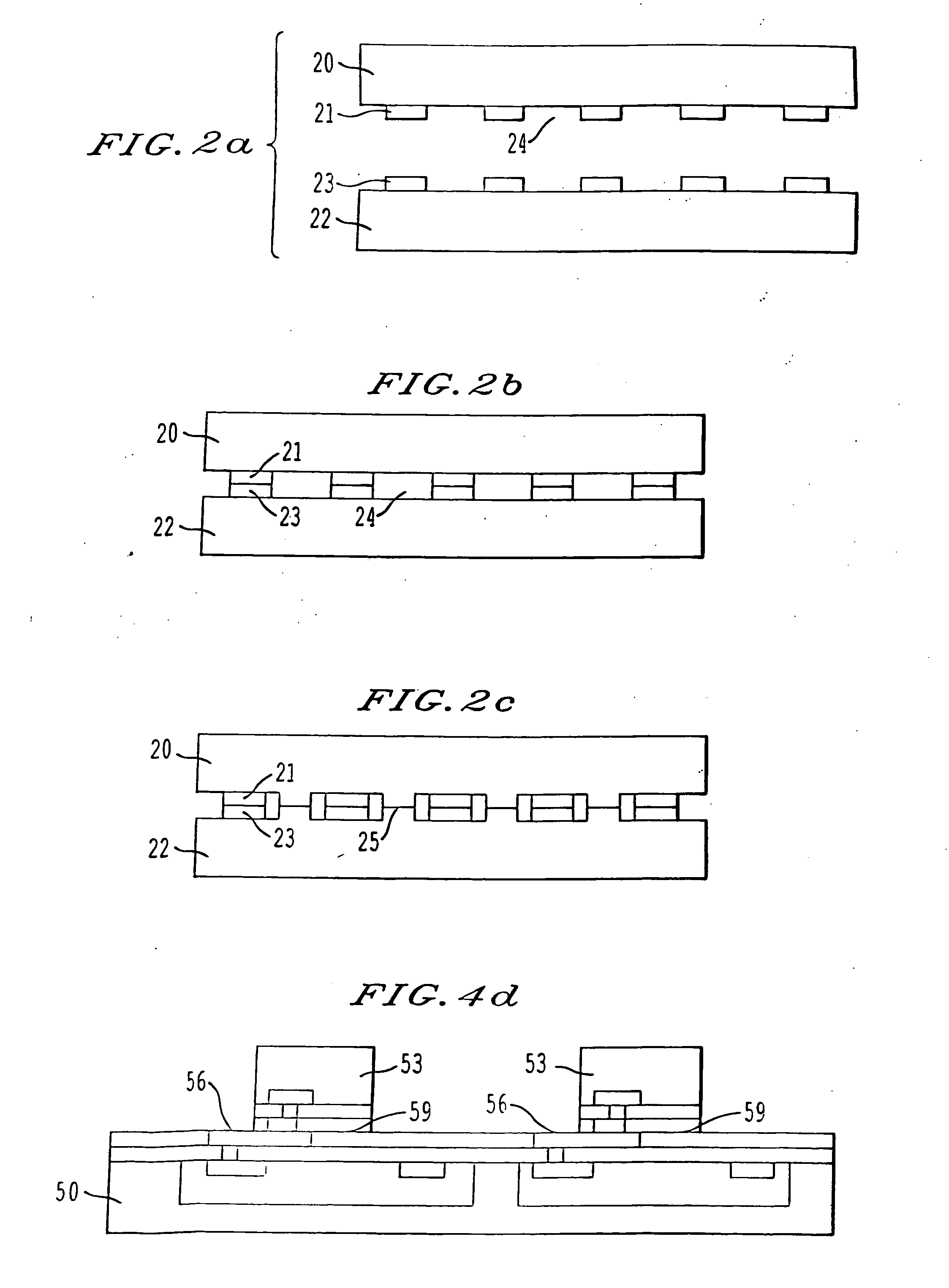

InactiveUS6962835B2Solid-state devicesSemiconductor/solid-state device manufacturingBond interfaceRoom temperature

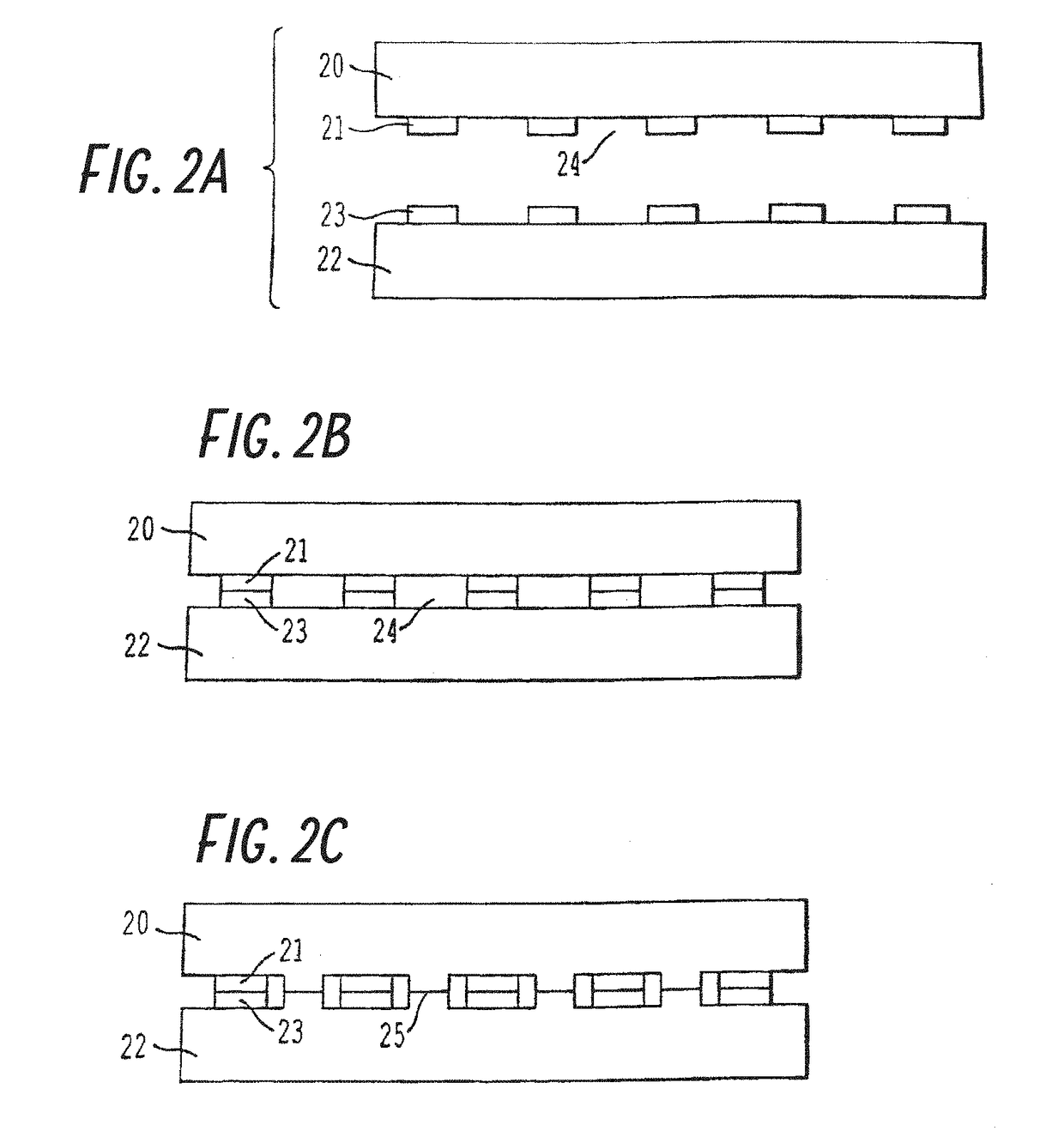

A bonded device structure including a first substrate having a first set of metallic bonding pads, preferably connected to a device or circuit, and having a first non-metallic region adjacent to the metallic bonding pads on the first substrate, a second substrate having a second set of metallic bonding pads aligned with the first set of metallic bonding pads, preferably connected to a device or circuit, and having a second non-metallic region adjacent to the metallic bonding pads on the second substrate, and a contact-bonded interface between the first and second set of metallic bonding pads formed by contact bonding of the first non-metallic region to the second non-metallic region. At least one of the first and second substrates may be elastically deformed.

Owner:INVENSAS BONDING TECH INC

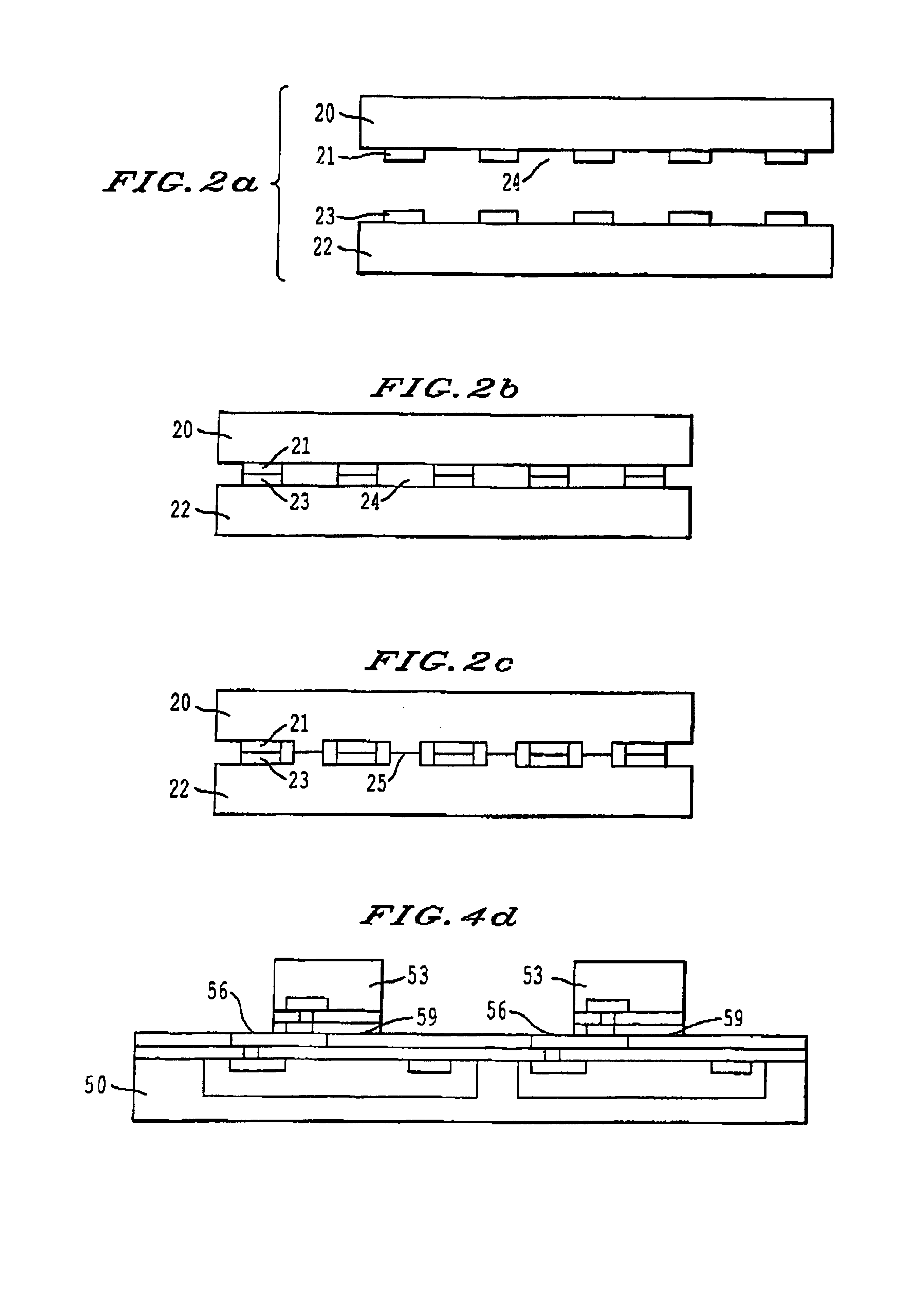

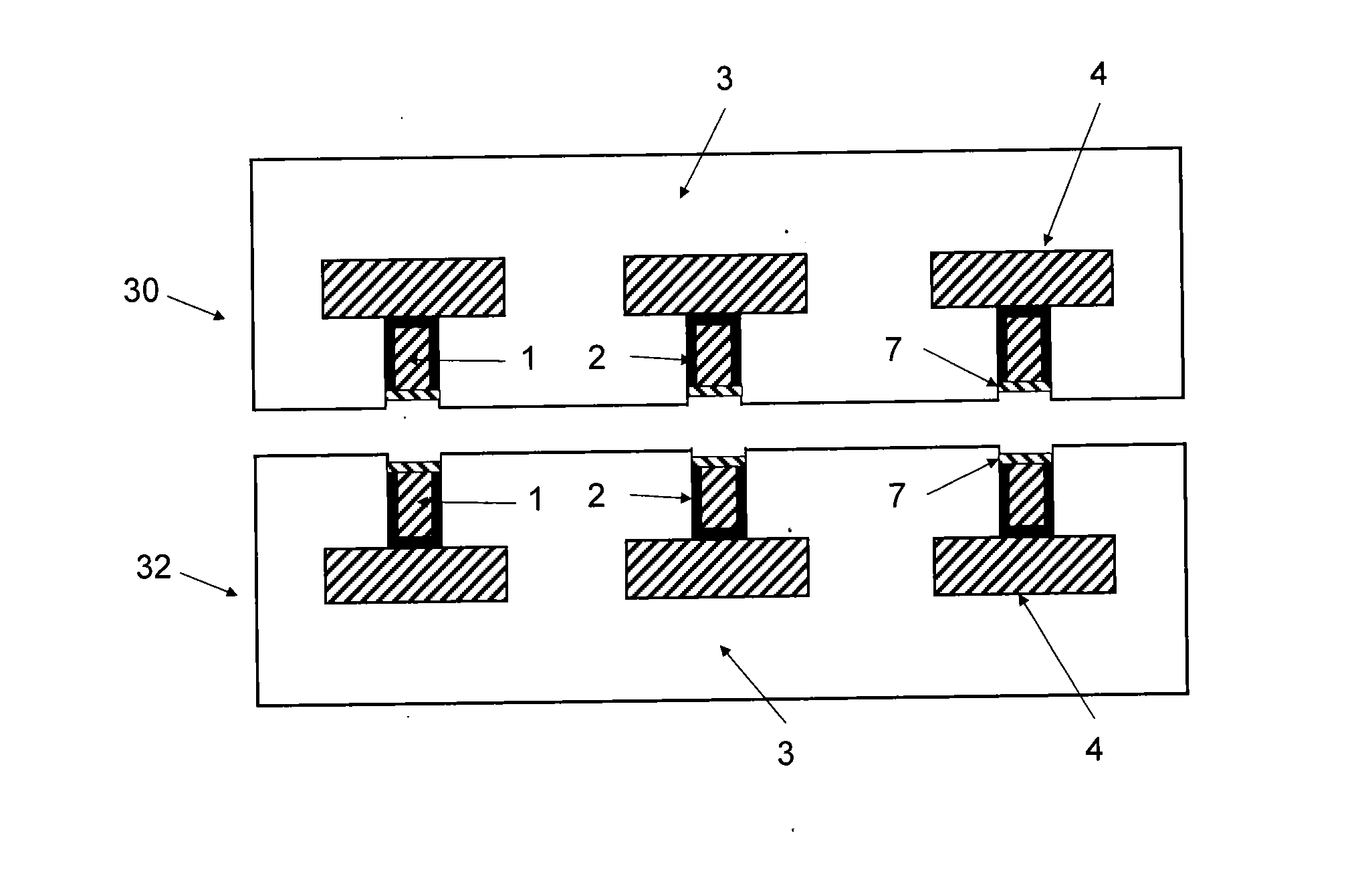

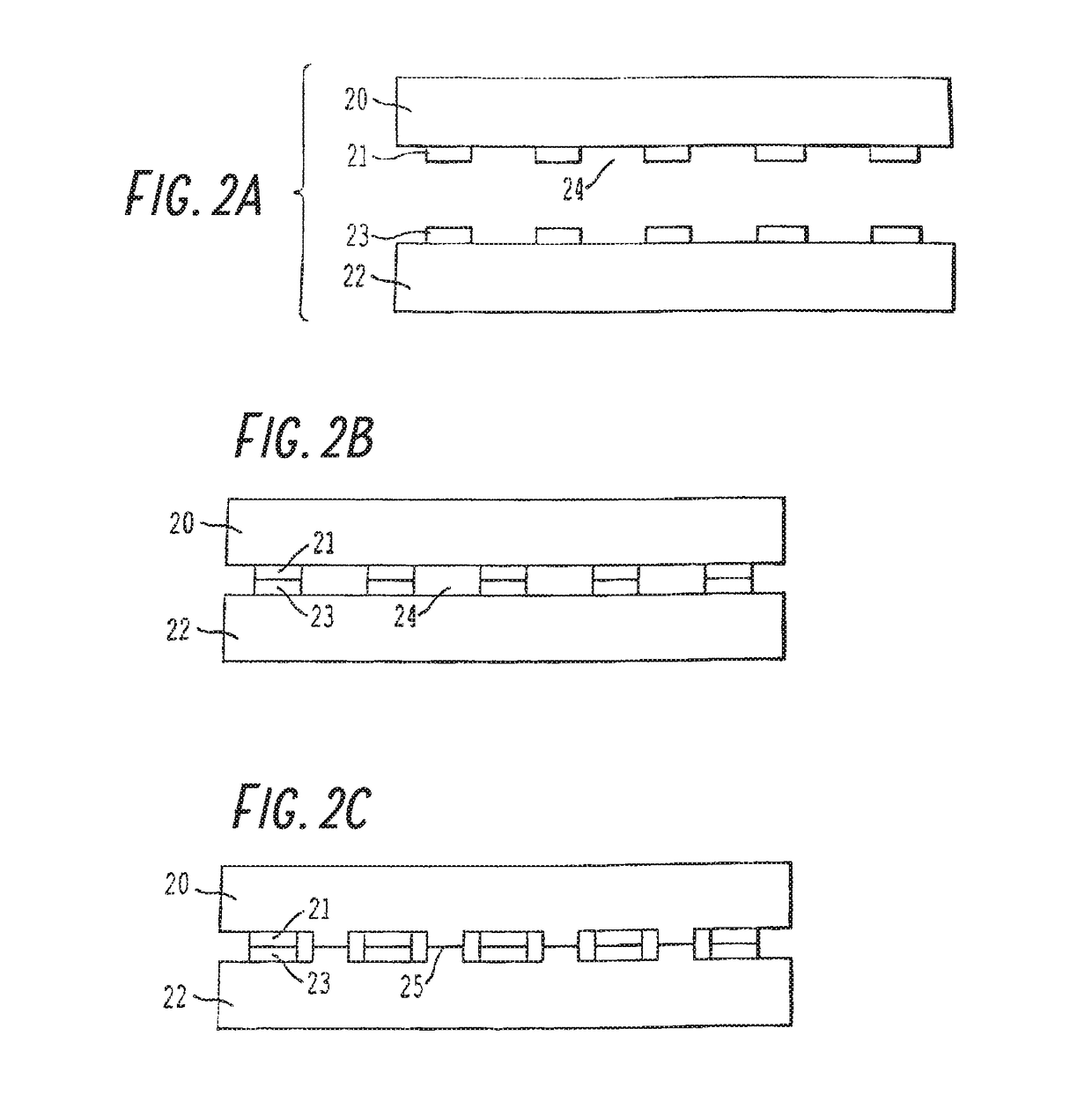

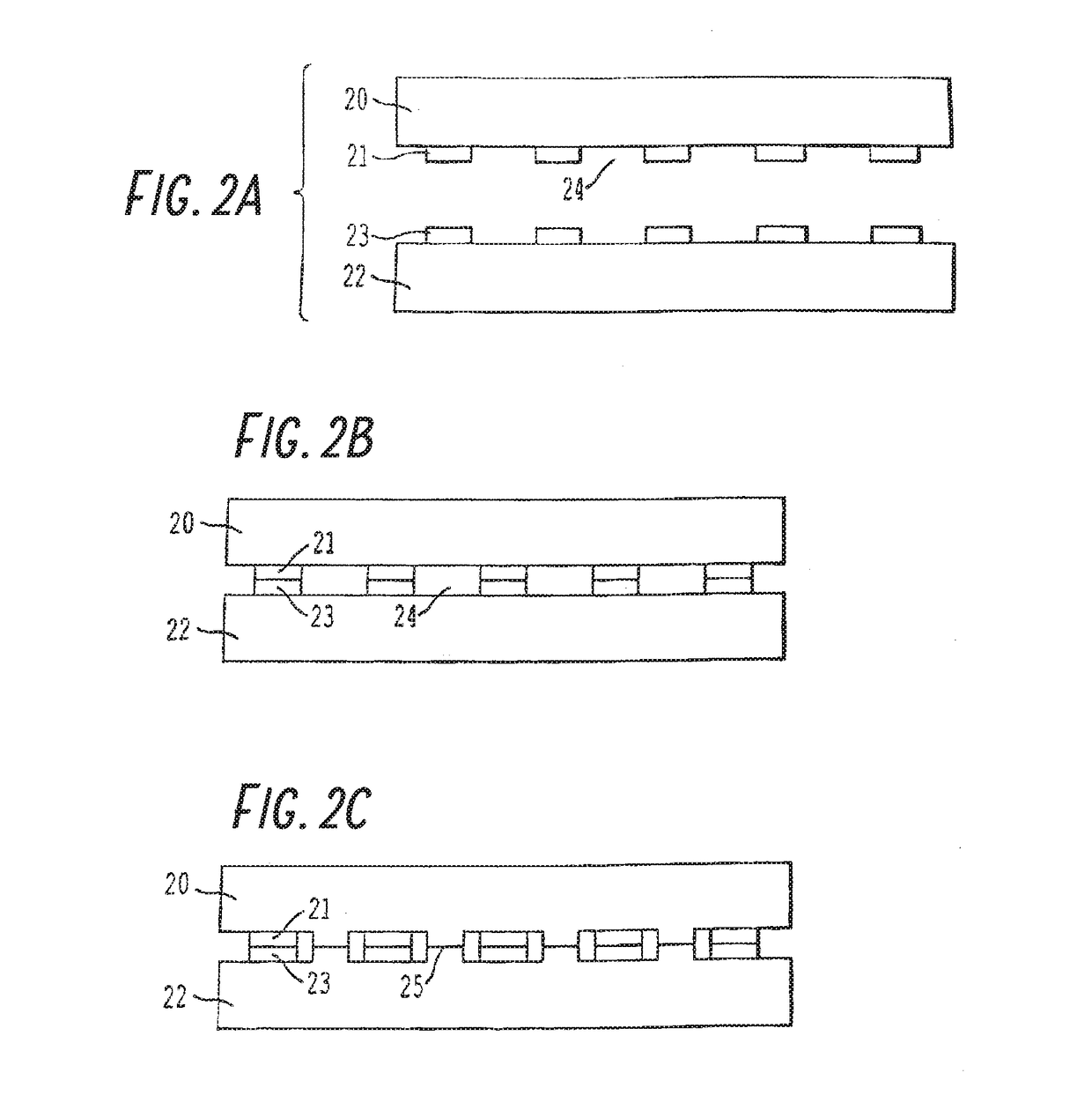

Conductive barrier direct hybrid bonding

ActiveUS20170062366A1Semiconductor/solid-state device detailsSolid-state devicesBond interfaceMetallic bonding

A method for forming a direct hybrid bond and a device resulting from a direct hybrid bond including a first substrate having a first set of metallic bonding pads, preferably connected to a device or circuit, capped by a conductive barrier, and having a first non-metallic region adjacent to the metallic bonding pads on the first substrate, a second substrate having a second set of metallic bonding pads capped by a second conductive barrier, aligned with the first set of metallic bonding pads, preferably connected to a device or circuit, and having a second non-metallic region adjacent to the metallic bonding pads on the second substrate, and a contact-bonded interface between the first and second set of metallic bonding pads capped by conductive barriers formed by contact bonding of the first non-metallic region to the second non-metallic region.

Owner:INVENSAS BONDING TECH INC

Conductive barrier direct hybrid bonding

ActiveUS9953941B2Semiconductor/solid-state device detailsSolid-state devicesBond interfaceMetallic bonding

Owner:INVENSAS BONDING TECH INC

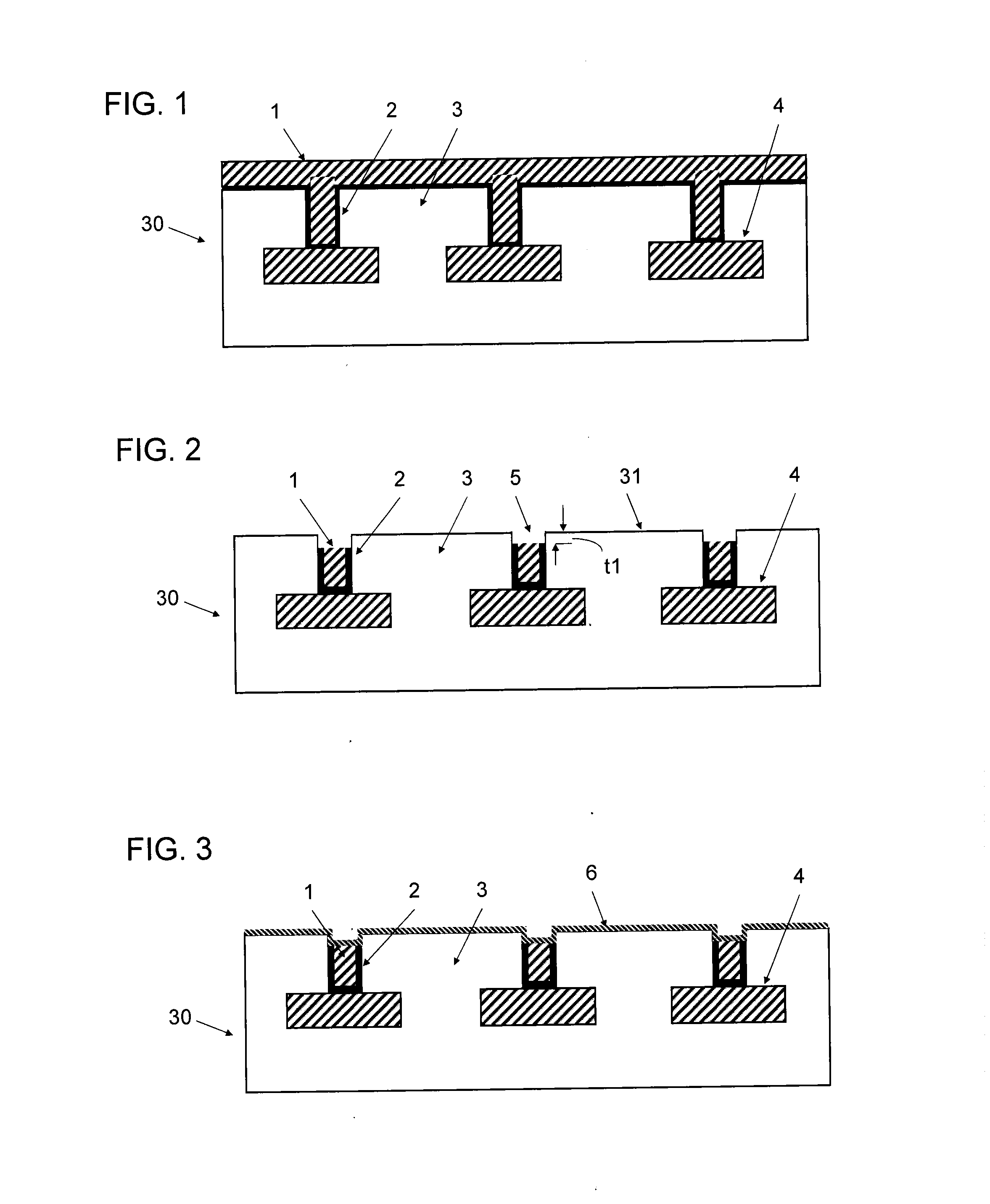

Increased contact alignment tolerance for direct bonding

ActiveUS9852988B2Easy temperatureSemiconductor/solid-state device detailsSolid-state devicesBond interfaceParasitic capacitance

Owner:INVENSAS BONDING TECH INC

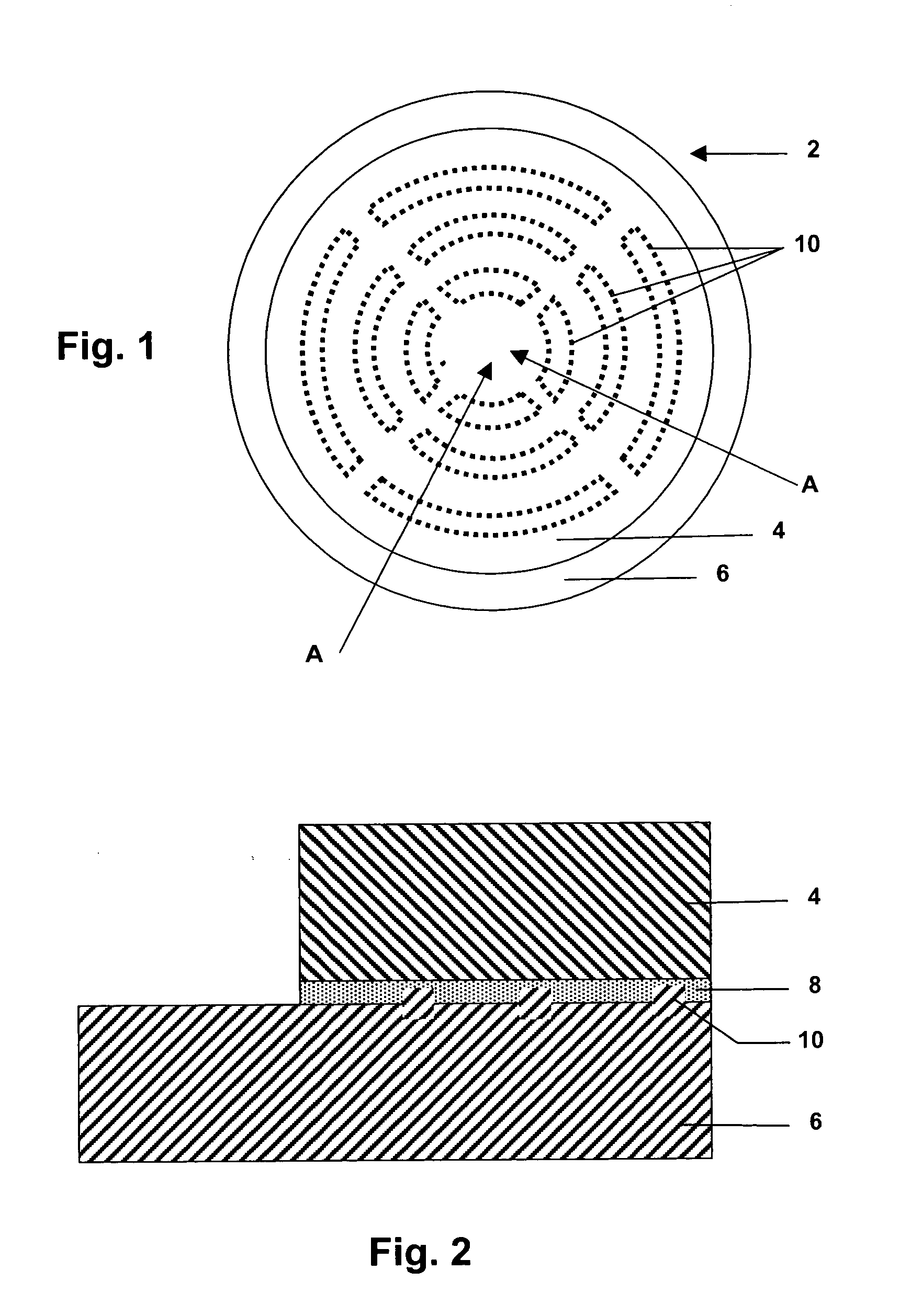

Hybrid orientation substrates by in-place bonding and amorphization/templated recrystallization

InactiveUS7060585B1Free from damageClear interfaceSemiconductor/solid-state device manufacturingBond interfaceElectrical conductor

A method utilizing in-place bonding and amorphization / templated recrystallization (ATR) is provided for making bulk and semiconductor-on-insulator substrates having coplanar semiconductor layers of different crystallographic orientations. First and second semiconductor layers having different orientations are bonded to opposite sides of a sacrificial spacer layer. Selected areas in one of the semiconductor layers are amorphized; in-place bonding is then performed in a wet etch solution to remove the sacrificial layer and leave the semiconductor layers bonded to each other. The amorphized regions are recrystallized across the bonded interface, using the semiconductor on the non-amorphized side of the bonded interface as a template.

Owner:IBM CORP

Quasi-hydrophobic Si-Si wafer bonding using hydrophilic Si surfaces and dissolution of interfacial bonding oxide

InactiveUS20060154442A1Thinning and removing materialSemiconductor/solid-state device manufacturingInterfacial oxideSemiconductor materials

The present invention provides a method for removing or reducing the thickness of ultrathin interfacial oxides remaining at Si—Si interfaces after silicon wafer bonding. In particular, the invention provides a method for removing ultrathin interfacial oxides remaining after hydrophilic Si—Si wafer bonding to create bonded Si—Si interfaces having properties comparable to those achieved with hydrophobic bonding. Interfacial oxide layers of order of about 2 to about 3 nm are dissolved away by high temperature annealing, for example, an anneal at 1300°-1330° C. for 1-5 hours. The inventive method is used to best advantage when the Si surfaces at the bonded interface have different surface orientations, for example, when a Si surface having a (100) orientation is bonded to a Si surface having a (110) orientation. In a more general aspect of the invention, the similar annealing processes may be used to remove undesired material disposed at a bonded interface of two silicon-containing semiconductor materials. The two silicon-containing semiconductor materials may be the same or different in surface crystal orientation, microstructure (single-crystal, polycrystalline, or amorphous), and composition.

Owner:GLOBALFOUNDRIES INC

Coefficient of thermal expansion adaptor

InactiveUS20080160274A1Improve accuracyAfter-treatment detailsLamination ancillary operationsBond interfaceThermal expansion

In designing a precision monolithic structure having all discrete components with different Coefficient of Thermal Expansion (CTE) permanently bonded together, to avoid internal stress caused by changing of temperature: The Coefficient of Thermal Expansion (CTE) Adaptor must be bonded between two components having different Coefficient of Thermal Expansion (CTE); the Bonding Interfaces must be parallel; the Coefficient of Thermal Expansion (CTE) Adaptor is made of material having varied CTE, the variation must be gradual and in only one direction, which is perpendicular to the said Bonding Interfaces; at each Bonding Interface, the CTE of the CTE Adaptor must match the CTE of bonding component in certain degree.

Owner:DANG CHI HUNG

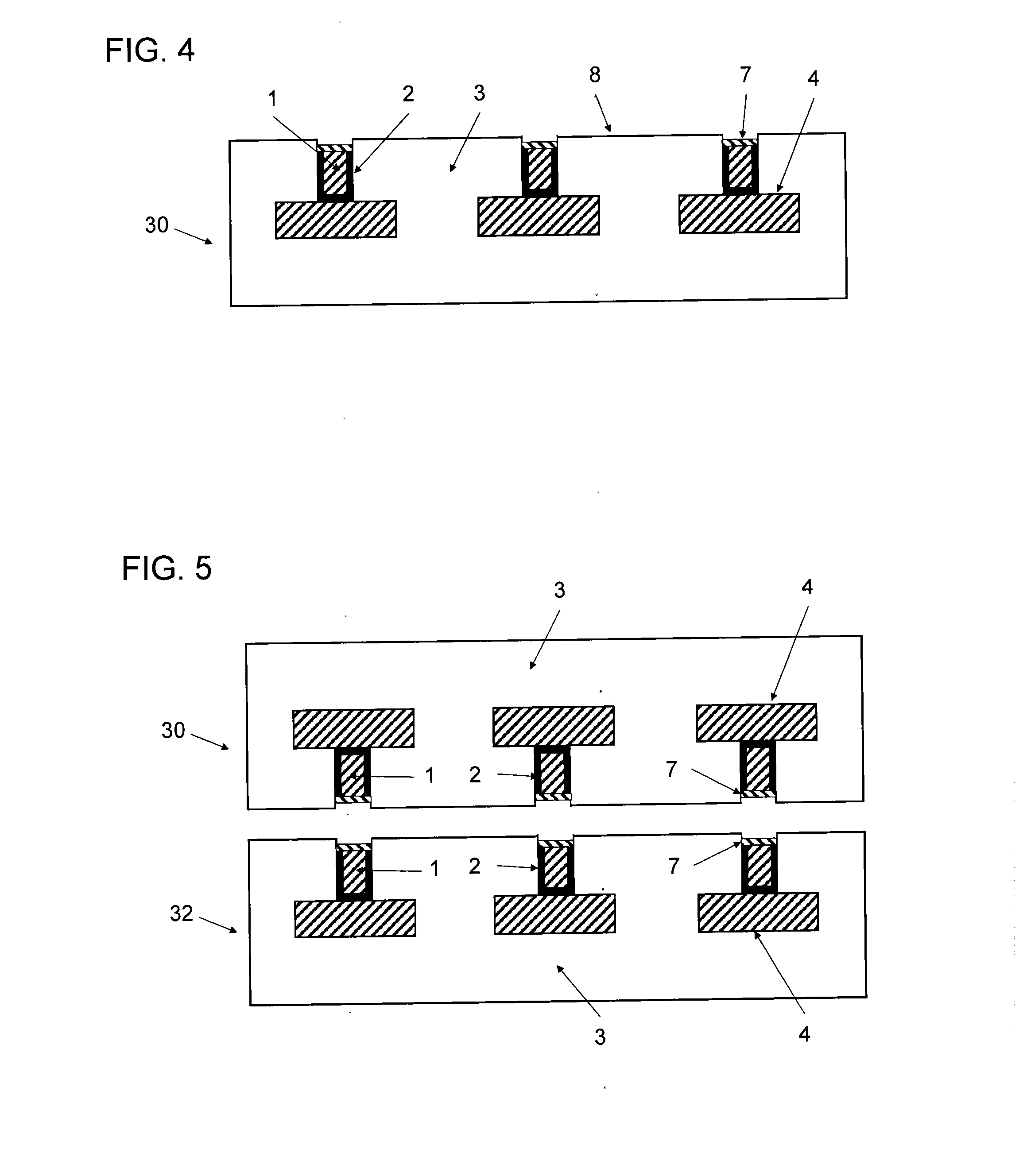

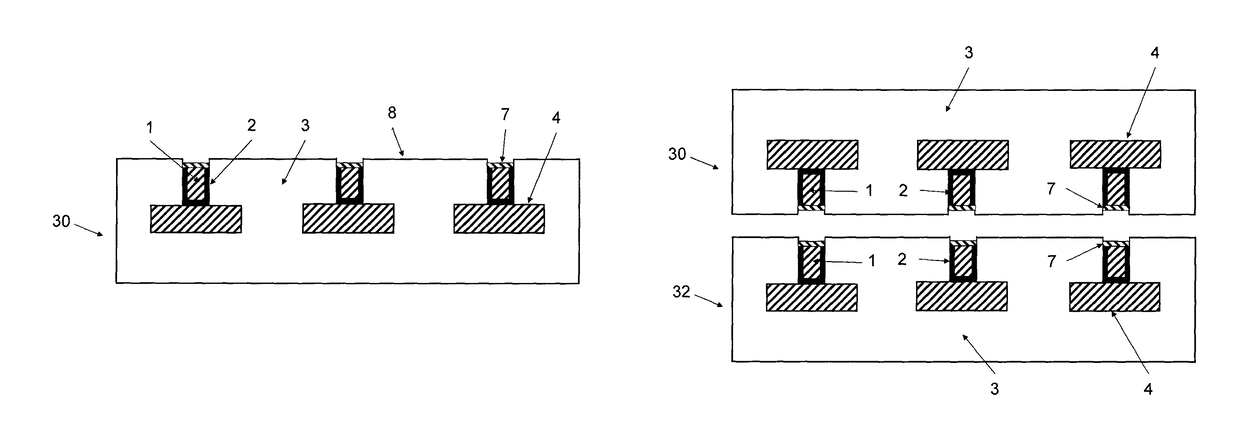

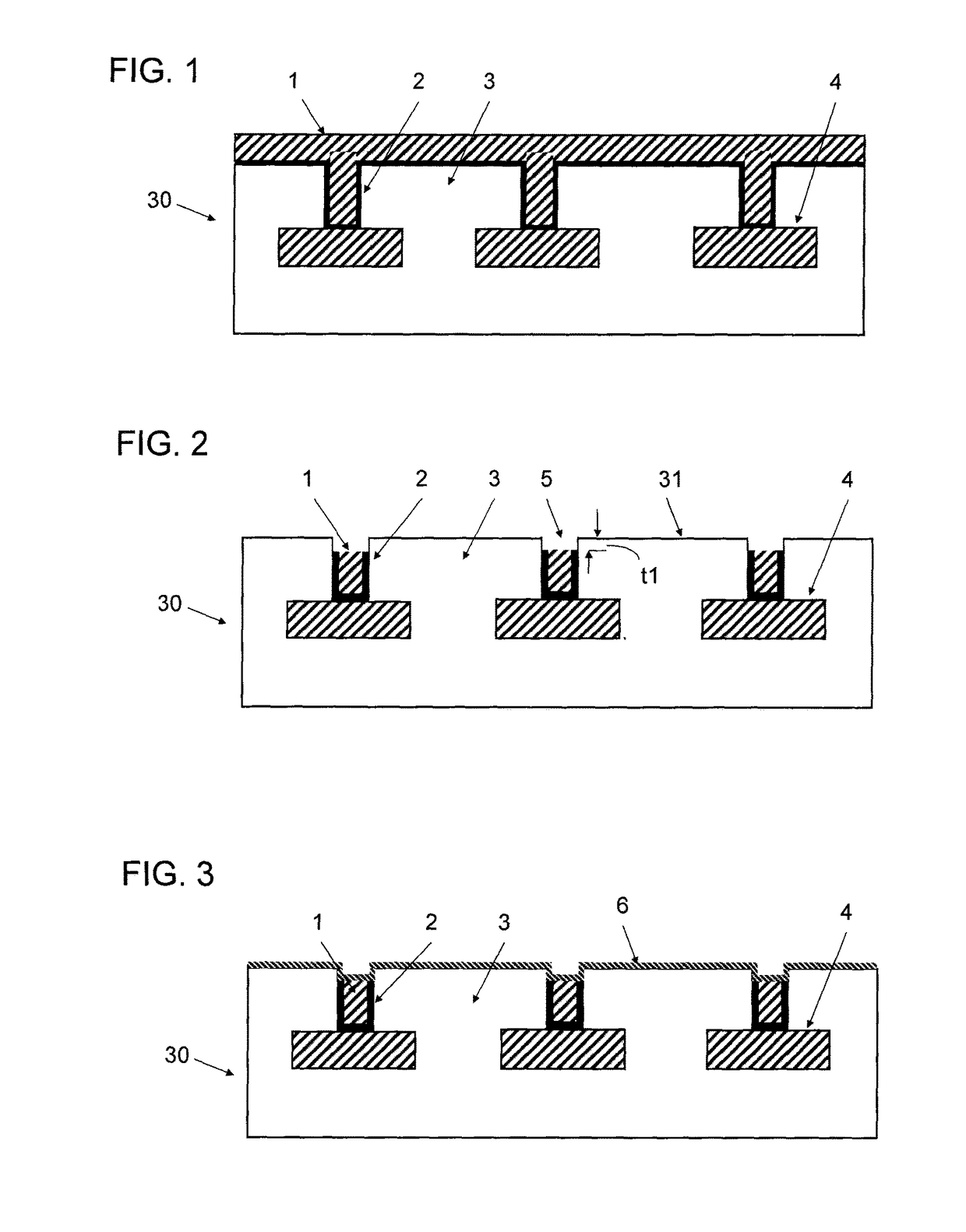

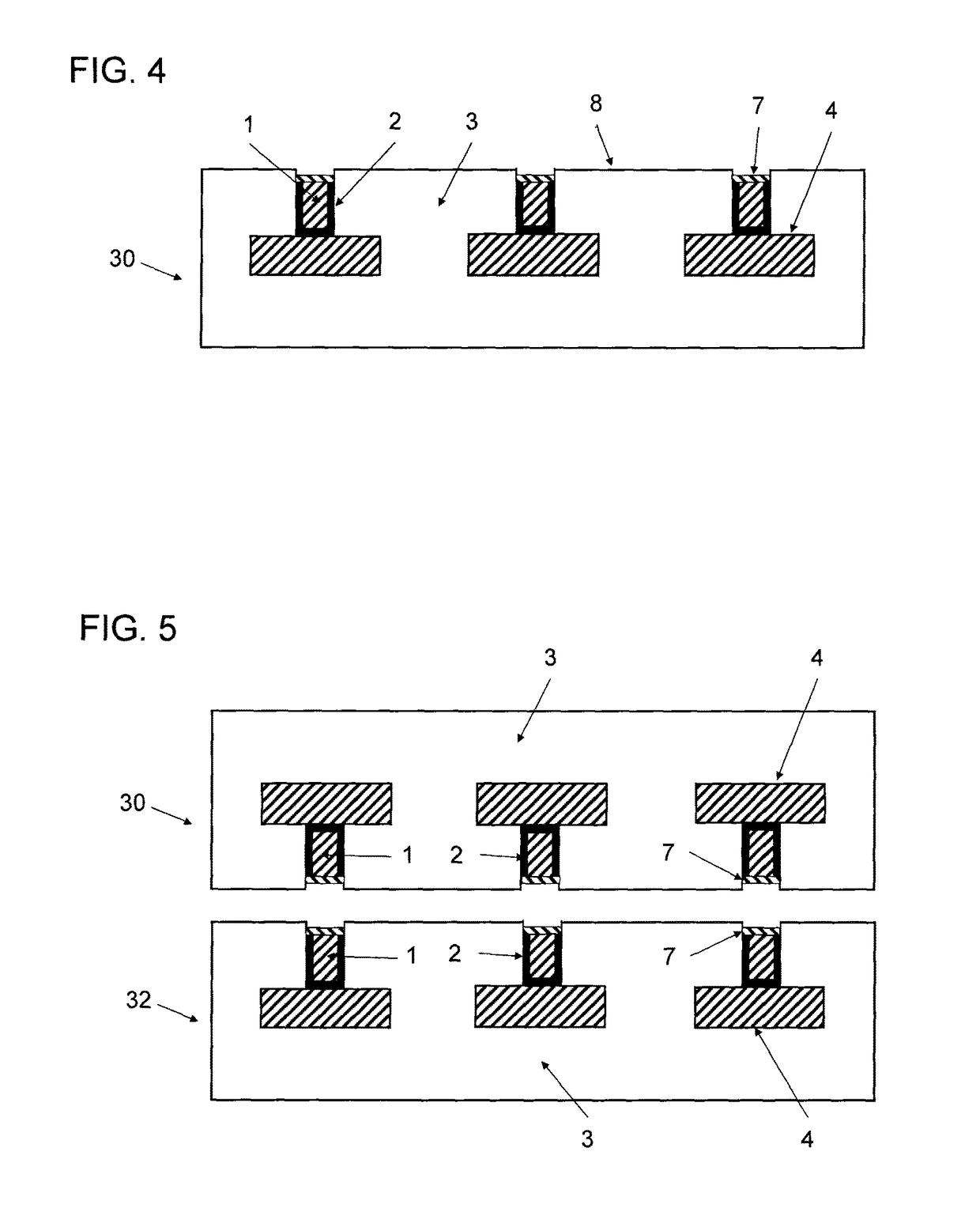

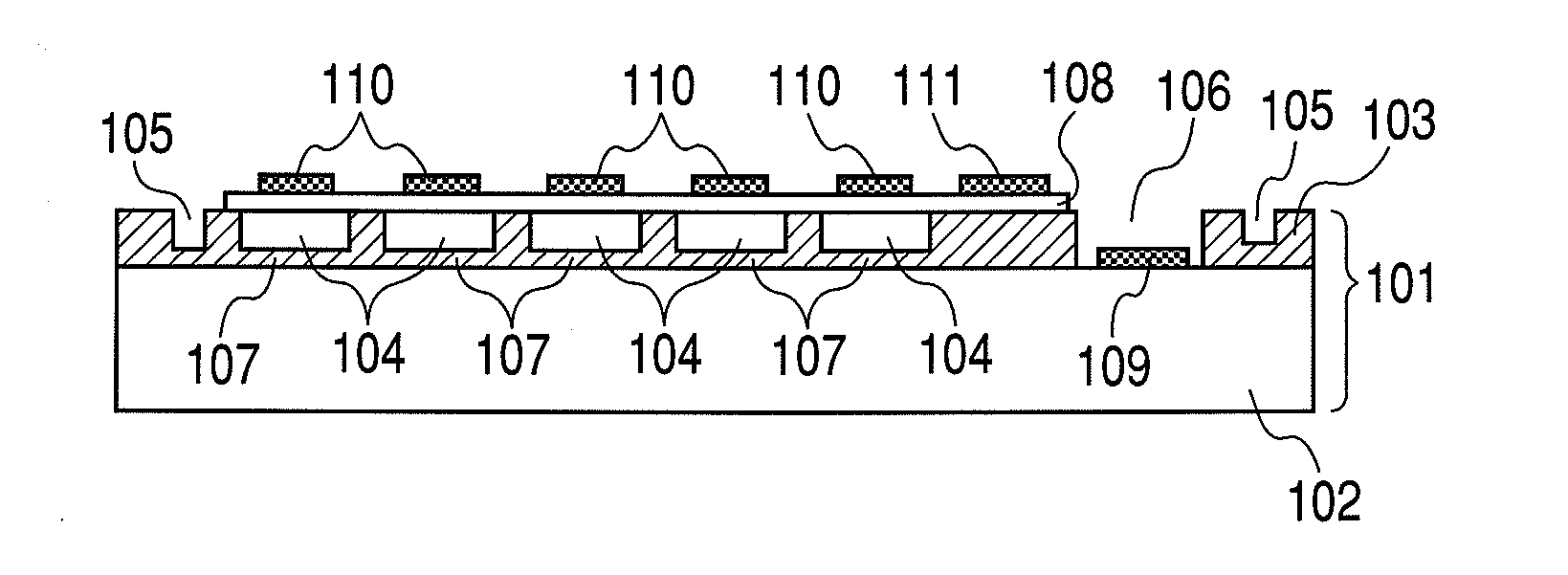

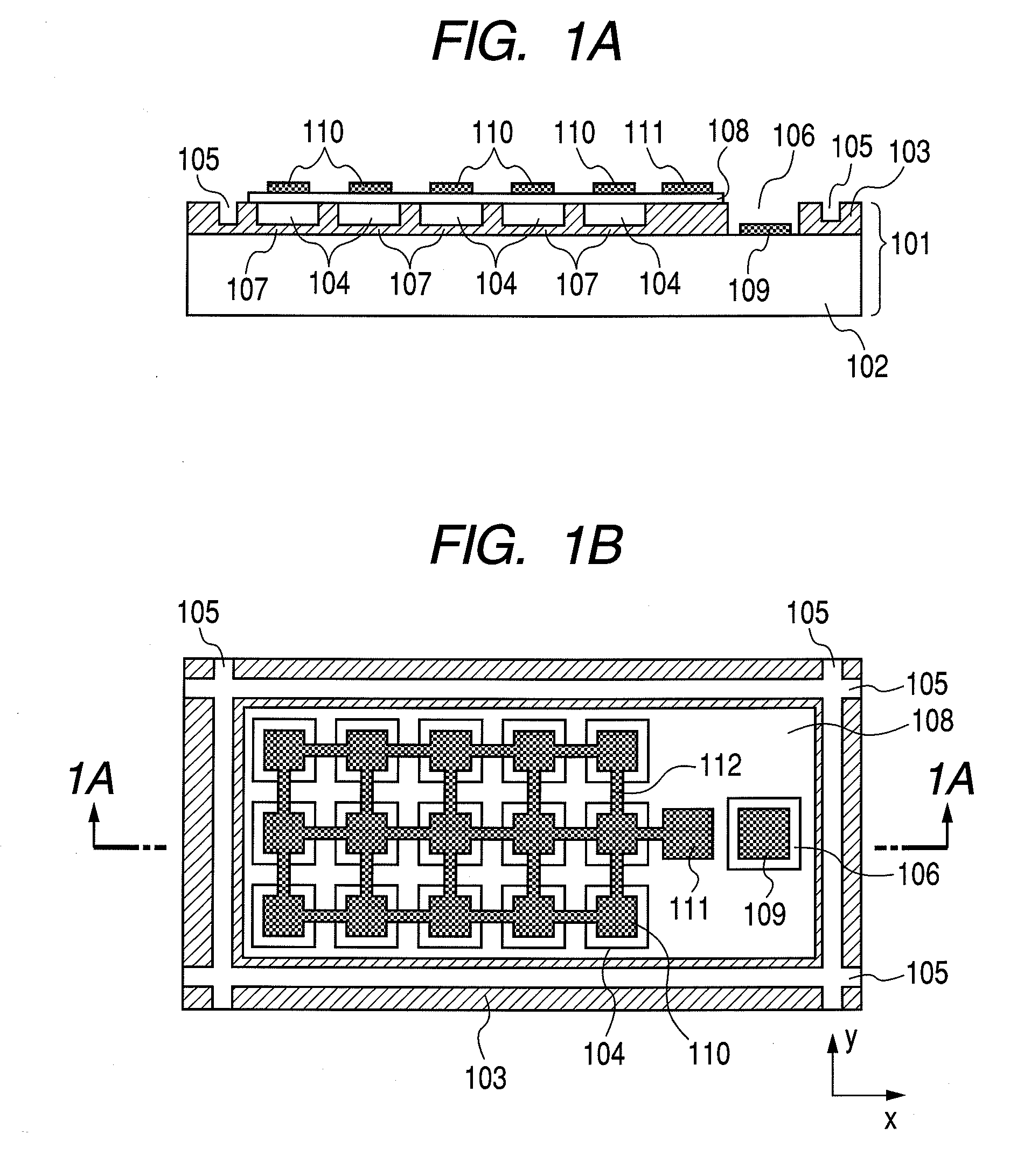

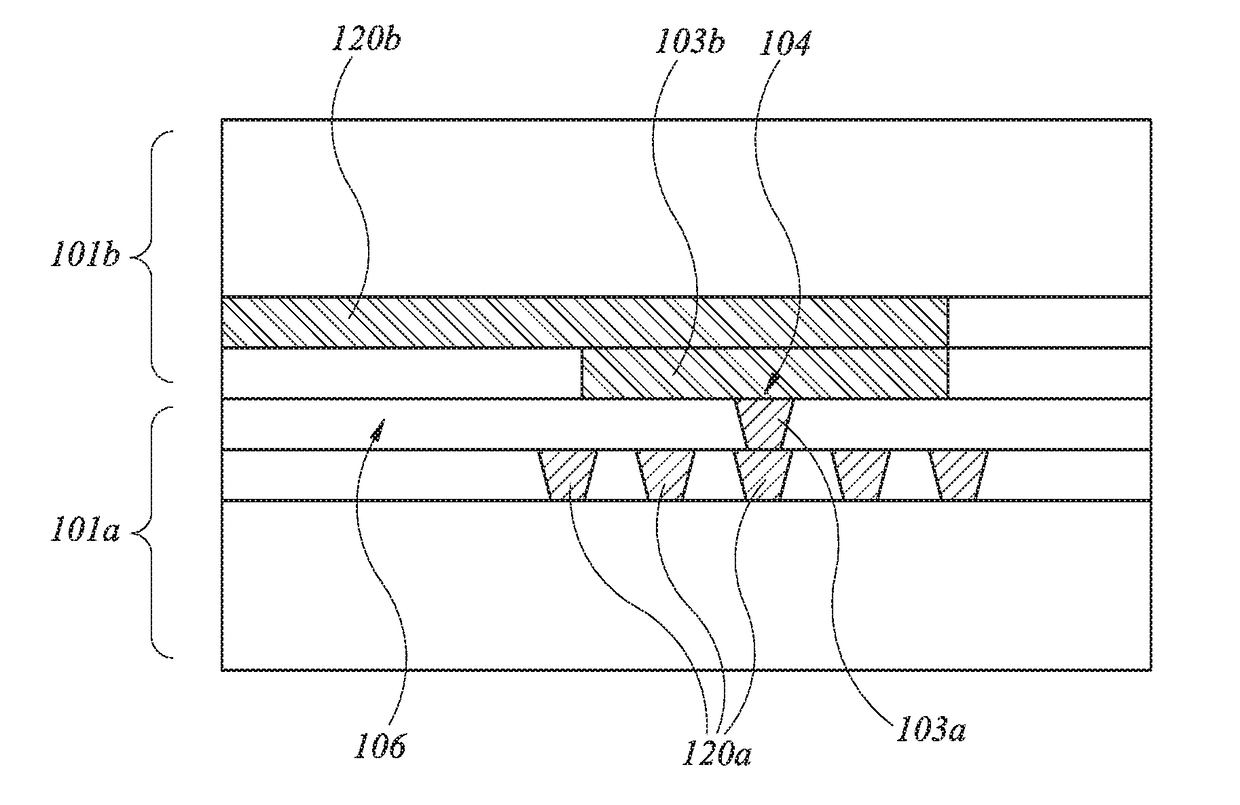

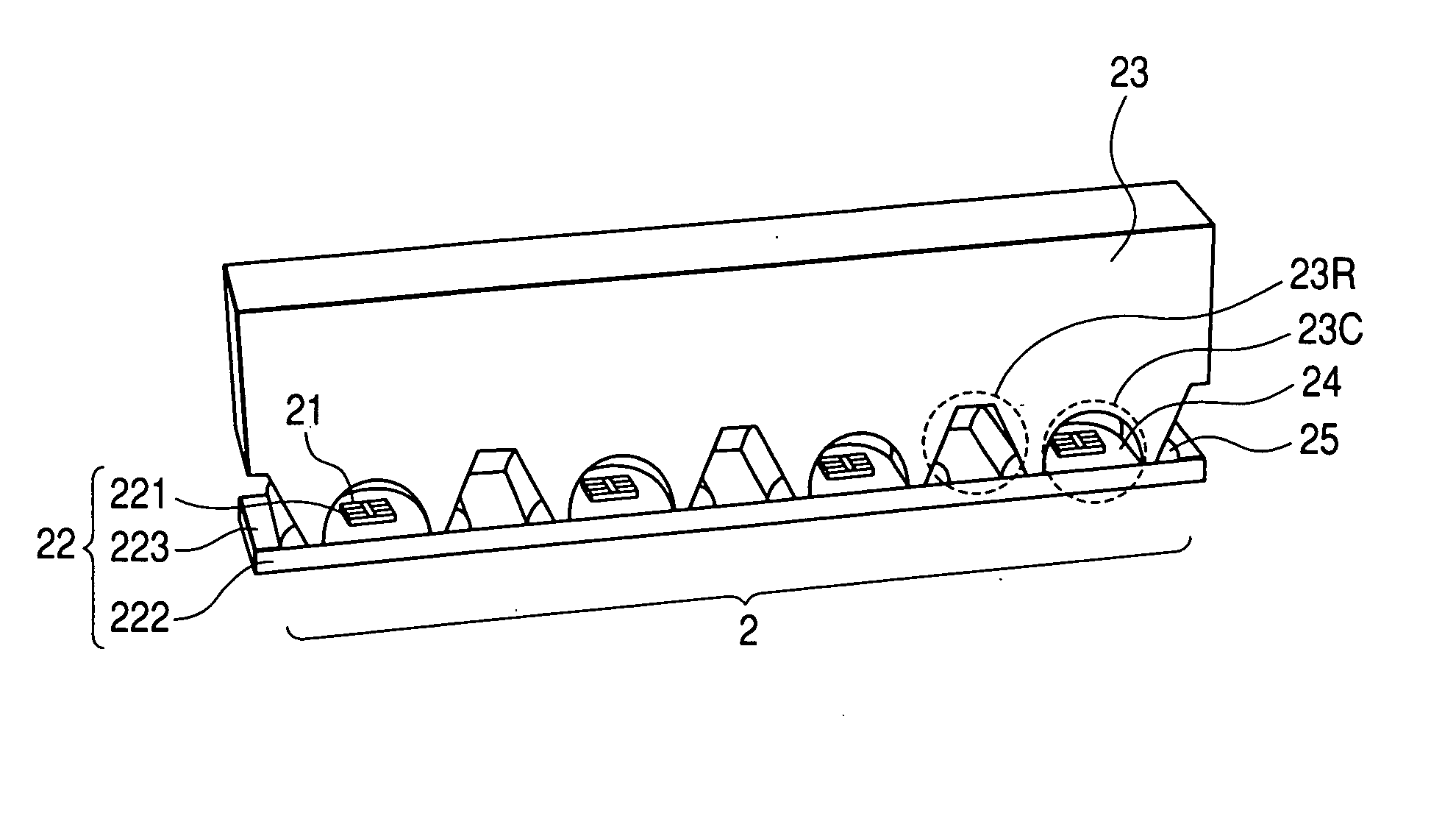

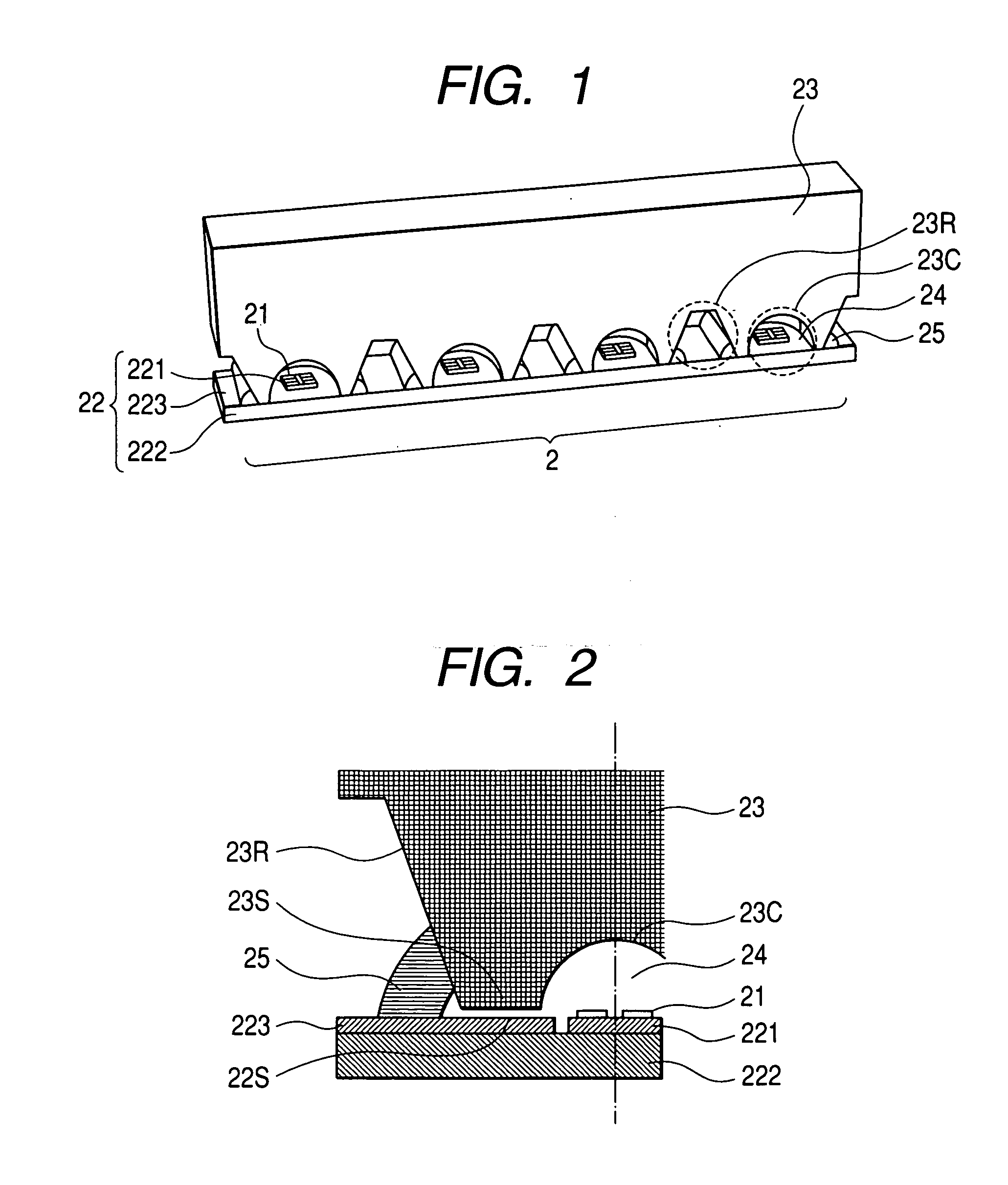

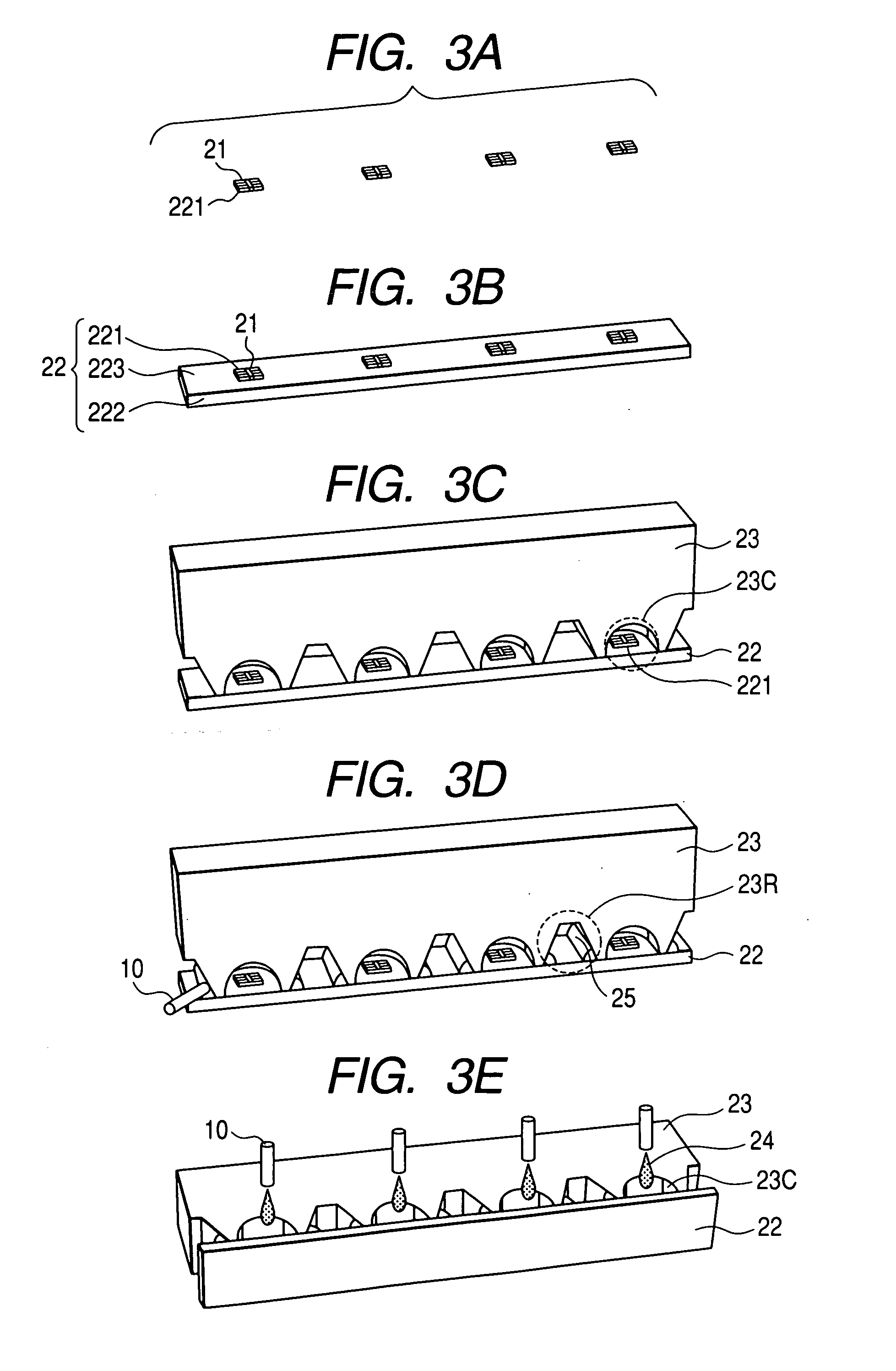

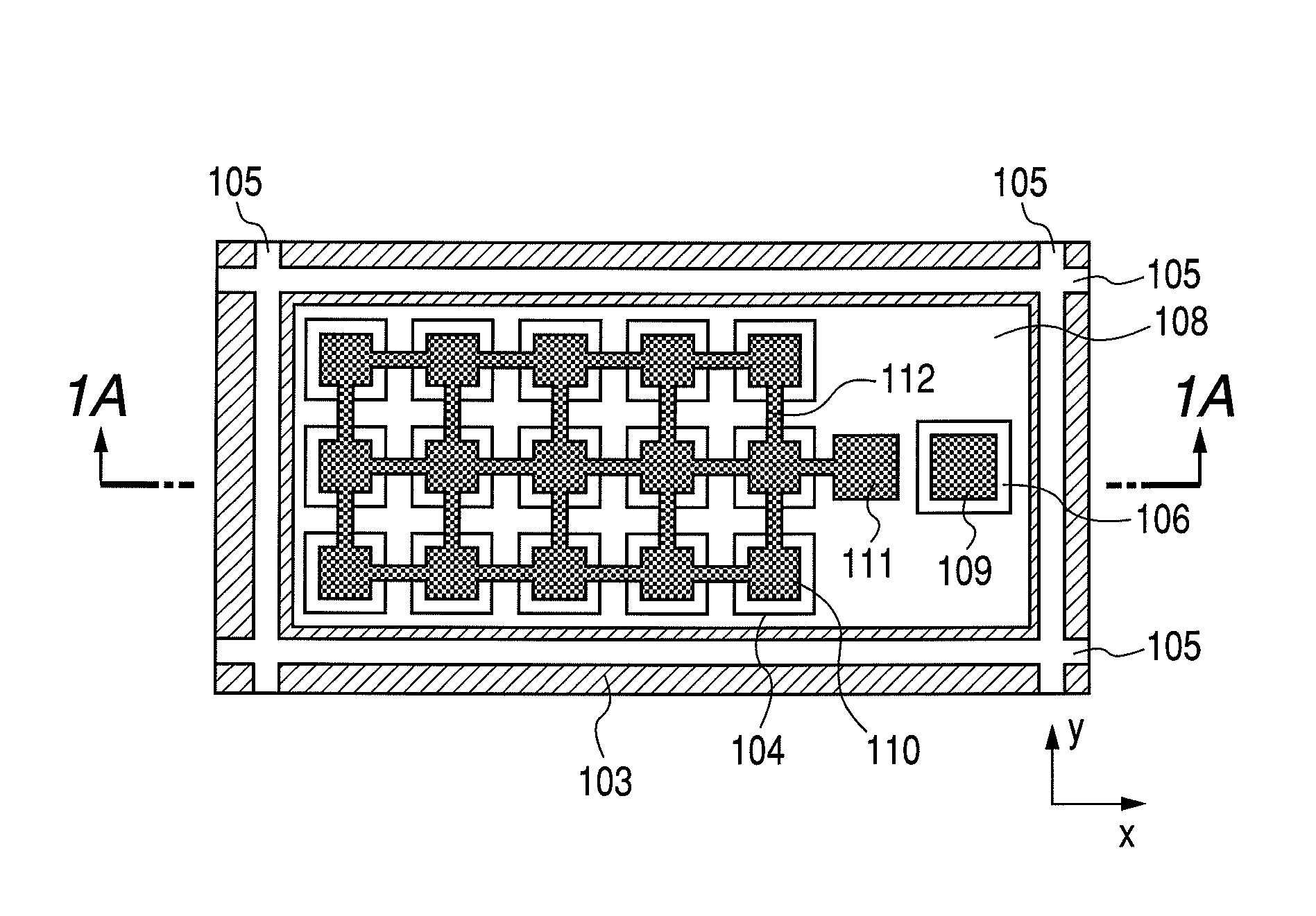

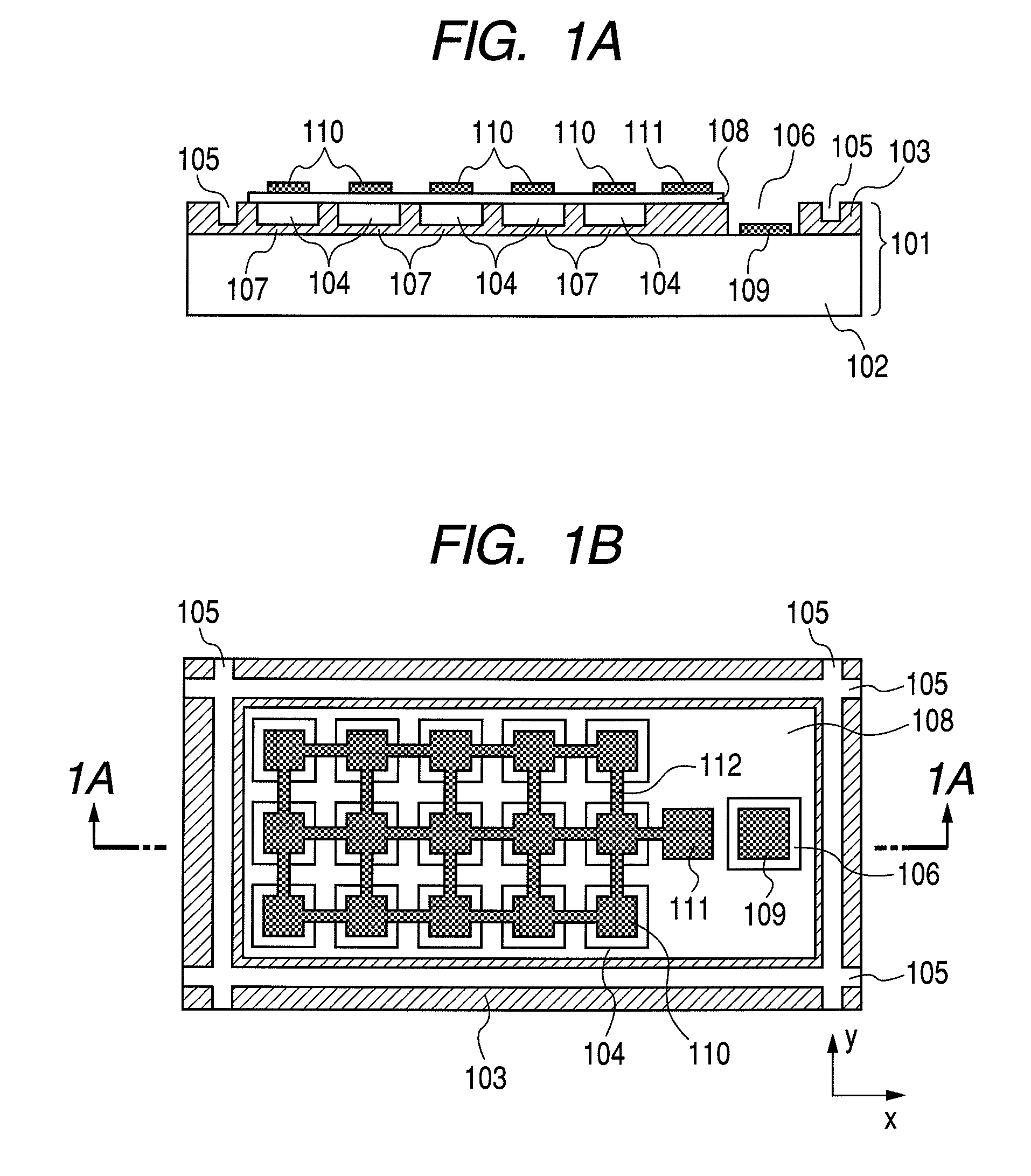

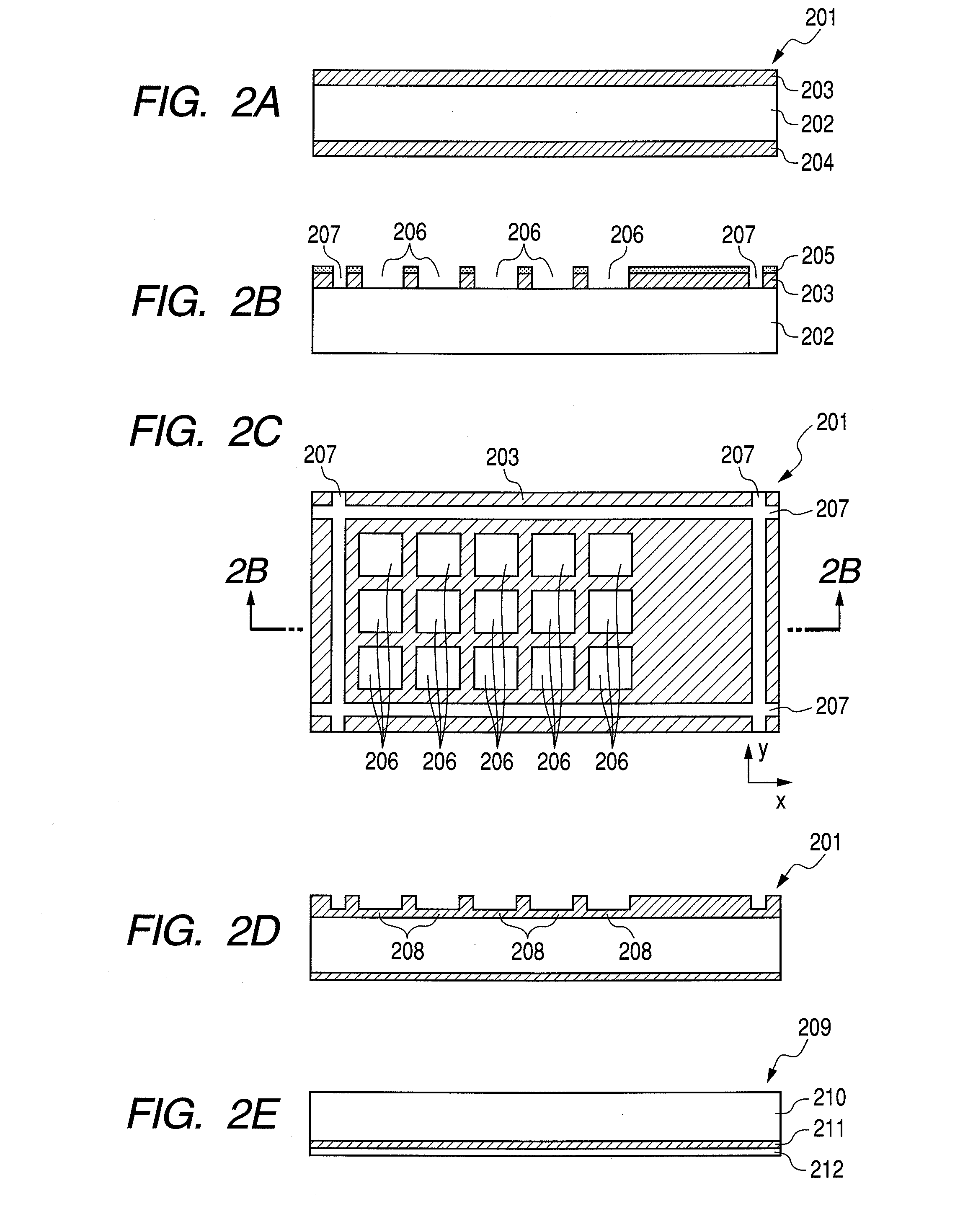

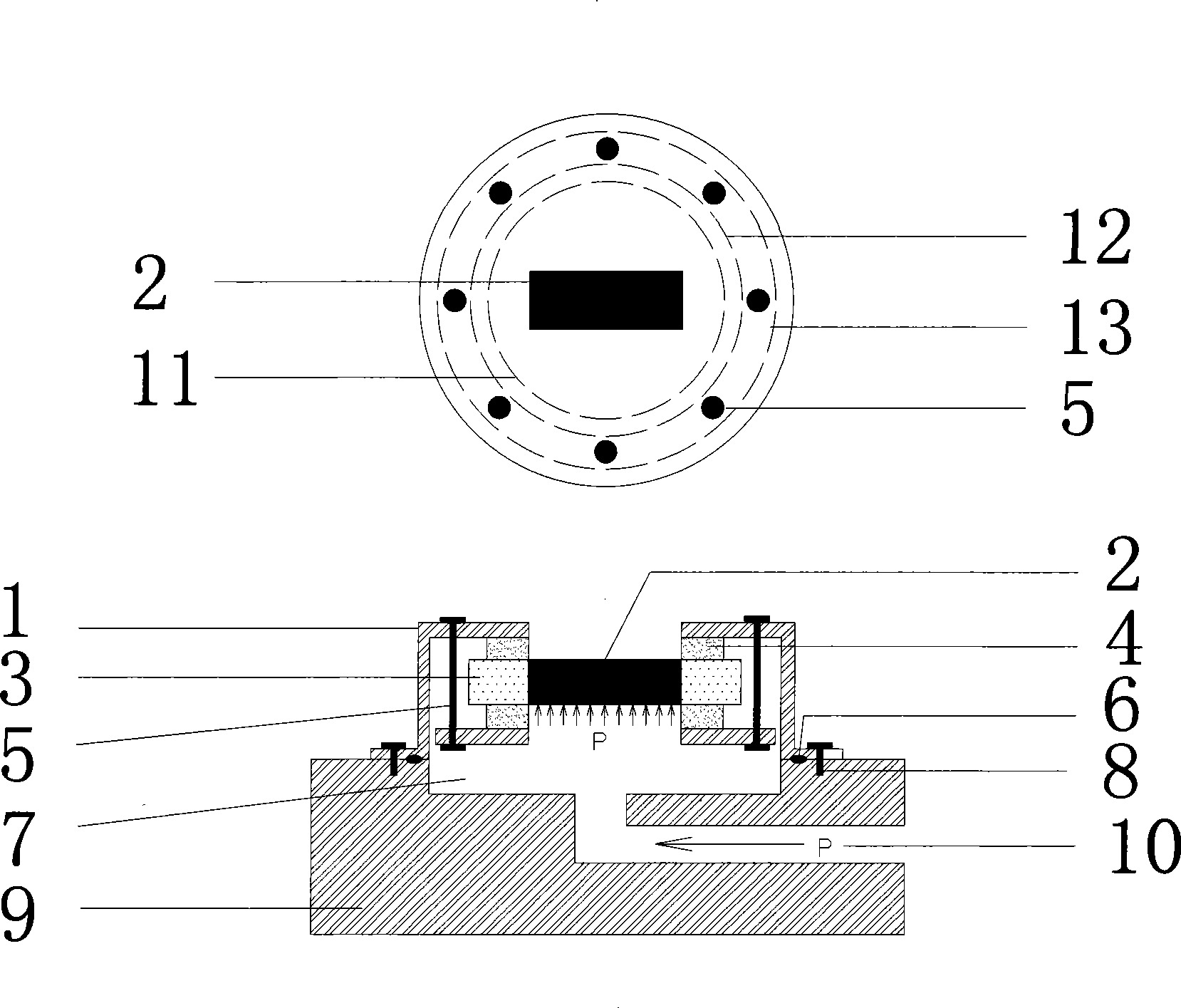

Process for producing capacitive electromechanical conversion device, and capacitive electromechanical conversion device

InactiveUS20110084570A1Poor bondingBeacon systems using ultrasonic/sonic/infrasonic wavesWave amplification devicesBond interfaceEngineering

A process for producing a capacitive electromechanical conversion device by bonding together a substrate and a membrane member to form a cavity sealed between the substrate and the membrane member, the process for producing a capacitive electromechanical conversion device comprises the steps of: providing a gas release path penetrating from a bonded interface between the substrate and the membrane member to the outside, and forming the cavity by bonding the membrane member with the substrate with the gas release path provided; the gas release path being provided at a location where the path does not communicate with the cavity.

Owner:CANON KK

Low temperature sputter target/backing plate method and assembly

InactiveUS7146703B2Firmly connectedSolve the lack of resistanceCellsElectric discharge tubesBond interfaceBond strength

A sputtering target and a backing plate are diffusion-bonded with or without an insert or inserts interposed there-between so as to have a solid phase diffusion-bonded interface. The sputtering target substantially maintains its metallurgical characteristic and properties even though it has been diffusion-bonded to the backing plate. The solid-diffusion bonding of the target and backing plate, is achieved at a low temperature and pressure and results in interdiffusion of constituent atoms to attain high adhesion and bond strength without attendant deterioration or large deformation of the target material, while inhibiting the crystal growth in the target material. The bond undergoes no abrupt decrease in bond strength upon elevation of the service temperature. One hundred percent bonding is achieved with non-bonded portions such as pores left along the interface.

Owner:TOSOH SMD

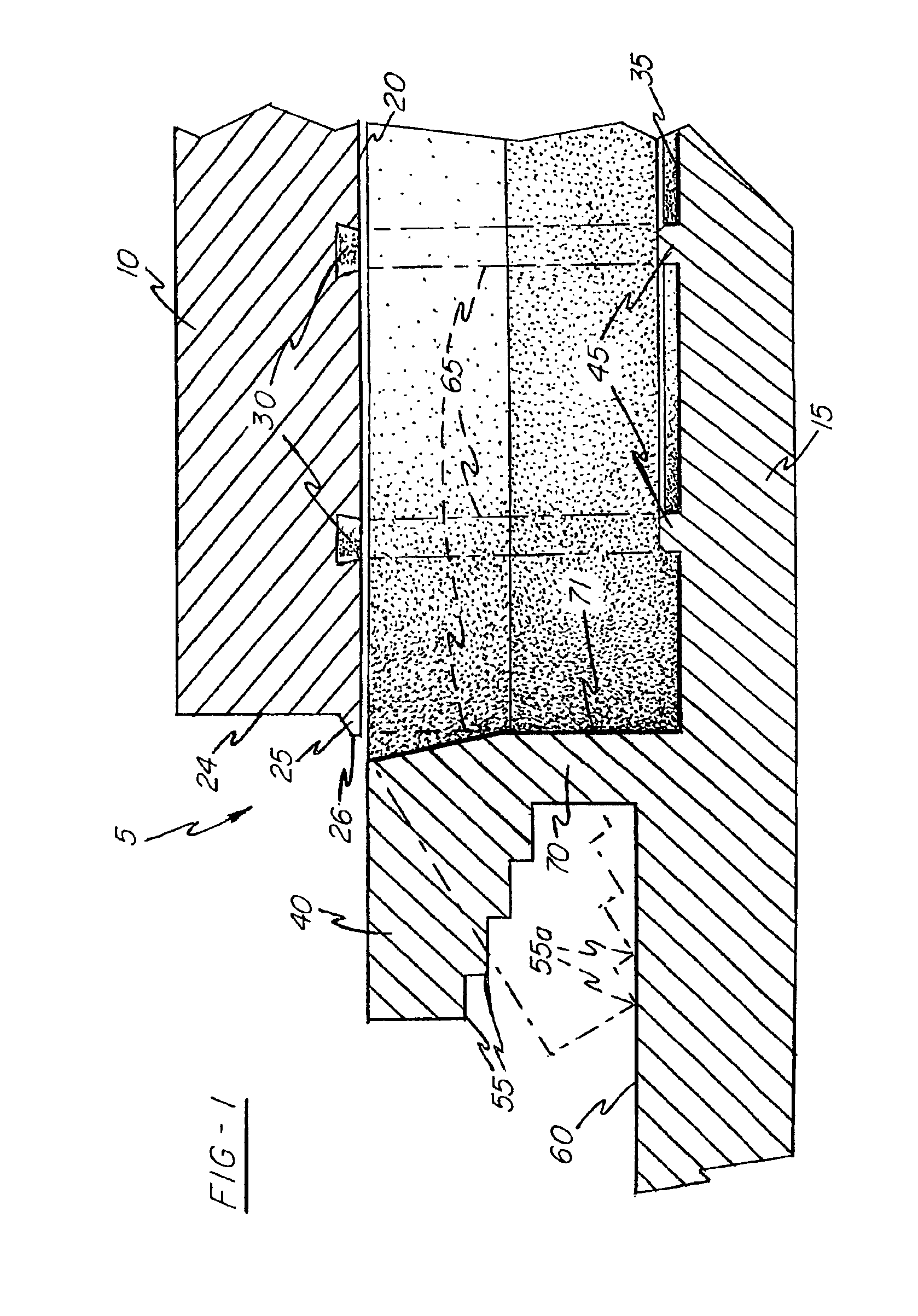

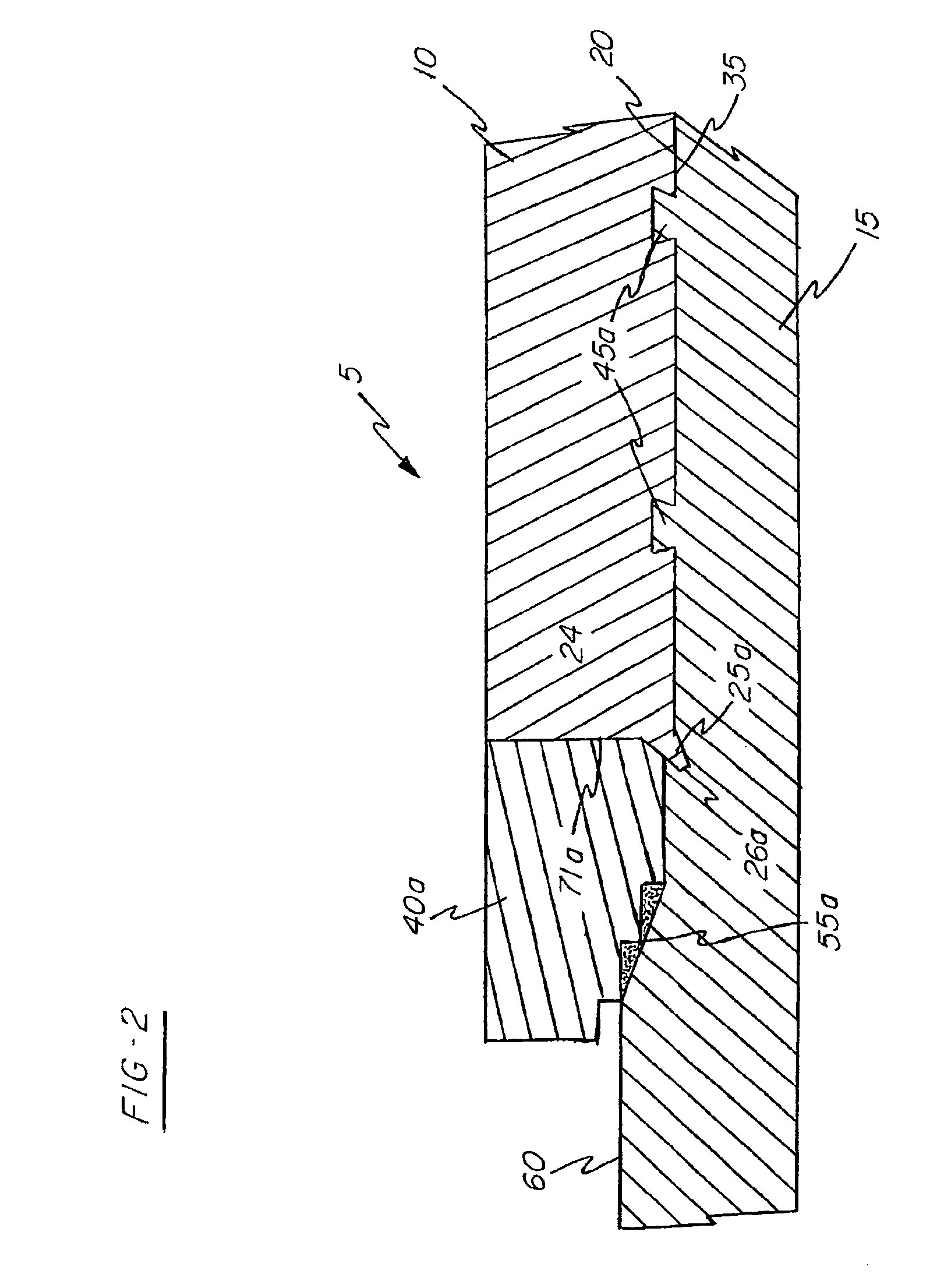

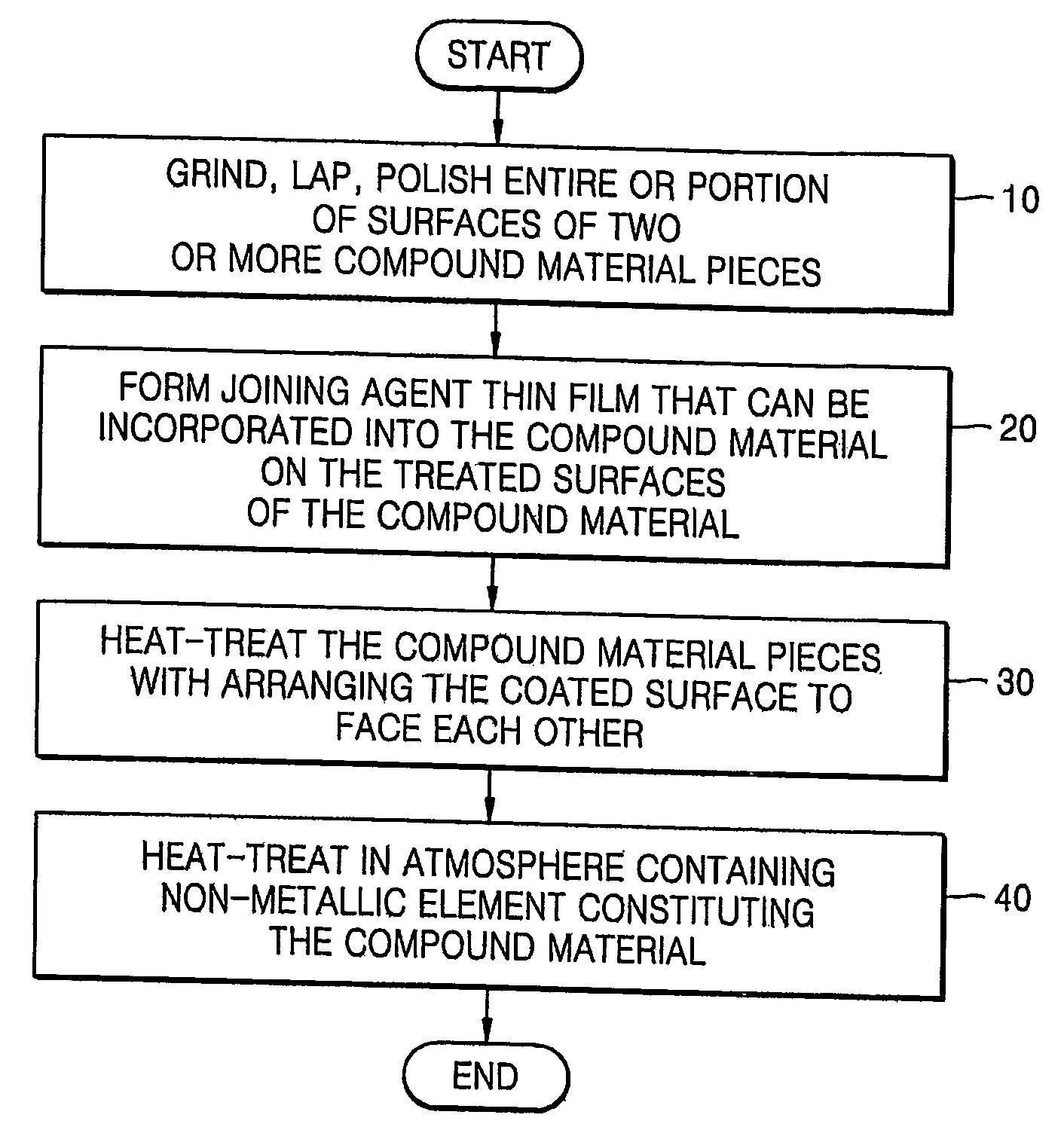

Method of joining ceramics: reaction diffusion-bonding

InactiveUS20060162849A1Suitable characteristicMaintain structural integrityAfter-treatment detailsLamination ancillary operationsBond interfaceSolid solution

Provided is a method of joining compound materials such as ceramics. The method is a combination of diffusion bonding and reaction bonding, which is called reaction diffusion bonding (RDB). The method includes: grinding, lapping, or polishing entire or portions of surfaces to be joined of two or more pieces of a compound material; forming a thin film of a joining agent on one or more of the ground, lapped, or polished surfaces by one of inserting, spreading, depositing, plating, and coating, the joining agent being able to transform into the compound material by being incorporated into the compound material or by forming a solid solution with the compound material upon heat treating; and forming a directly bonded interface without a second phase by heat treating the pieces of the compound material with the to-be-joined surfaces on which the joining agent film is formed arranged to face each other, wherein the joining agent thin film is composed of a material selected from the group consisting of metals, metal organics, and metal compounds.

Owner:CERAWEL

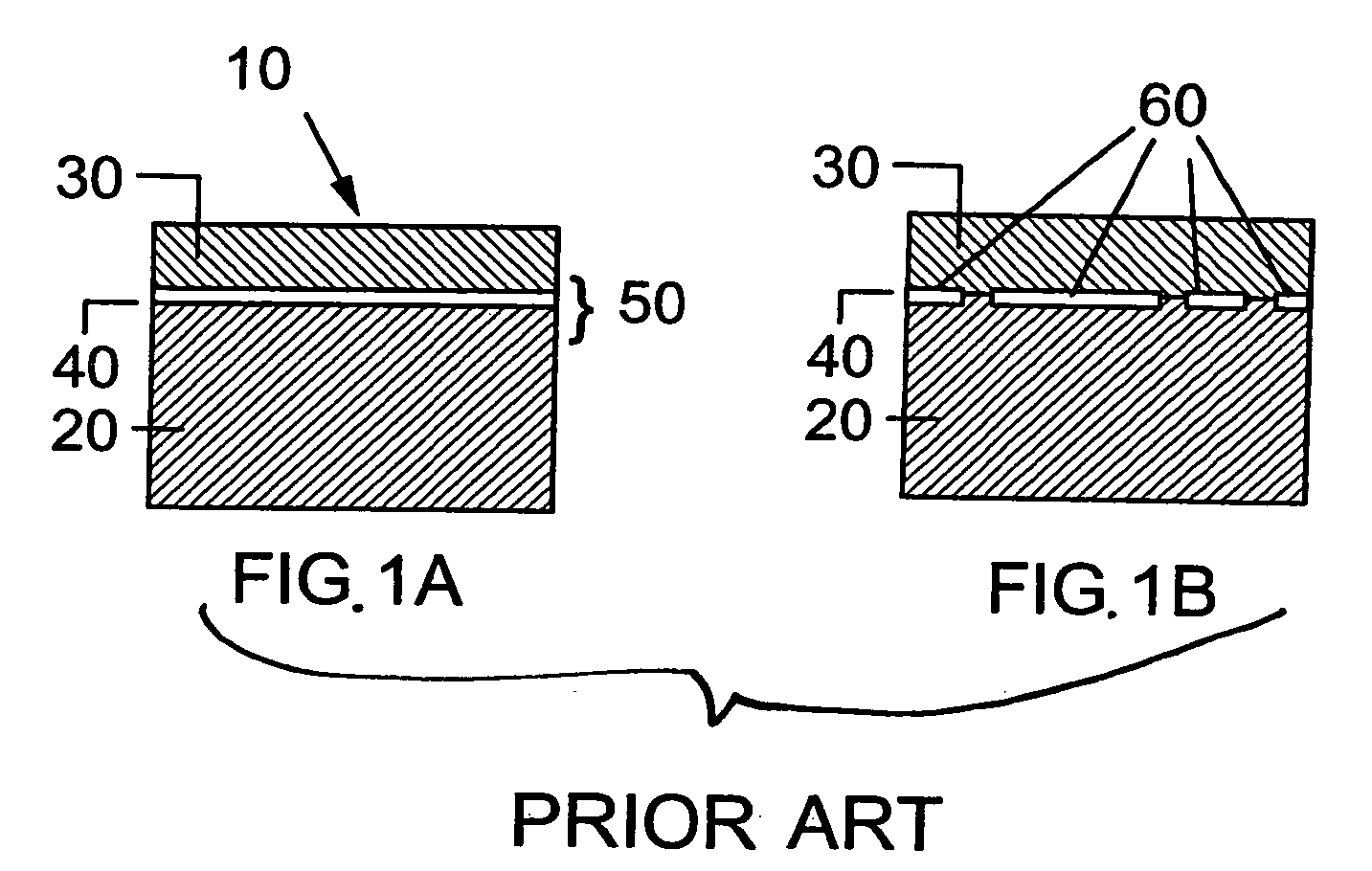

Increased contact alignment tolerance for direct bonding

ActiveUS20170179029A1Easy temperatureSemiconductor/solid-state device detailsSolid-state devicesBond interfaceParasitic capacitance

A bonded device structure including a first substrate having a first set of conductive contact structures, preferably connected to a device or circuit, and having a first non-metallic region adjacent to the contact structures on the first substrate, a second substrate having a second set of conductive contact structures, preferably connected to a device or circuit, and having a second non-metallic region adjacent to the contact structures on the second substrate, and a contact-bonded interface between the first and second set of contact structures formed by contact bonding of the first non-metallic region to the second non-metallic region. The contact structures include elongated contact features, such as individual lines or lines connected in a grid, that are non-parallel on the two substrates, making contact at intersections. Alignment tolerances are thus improved while minimizing dishing and parasitic capacitance.

Owner:INVENSAS BONDING TECH INC

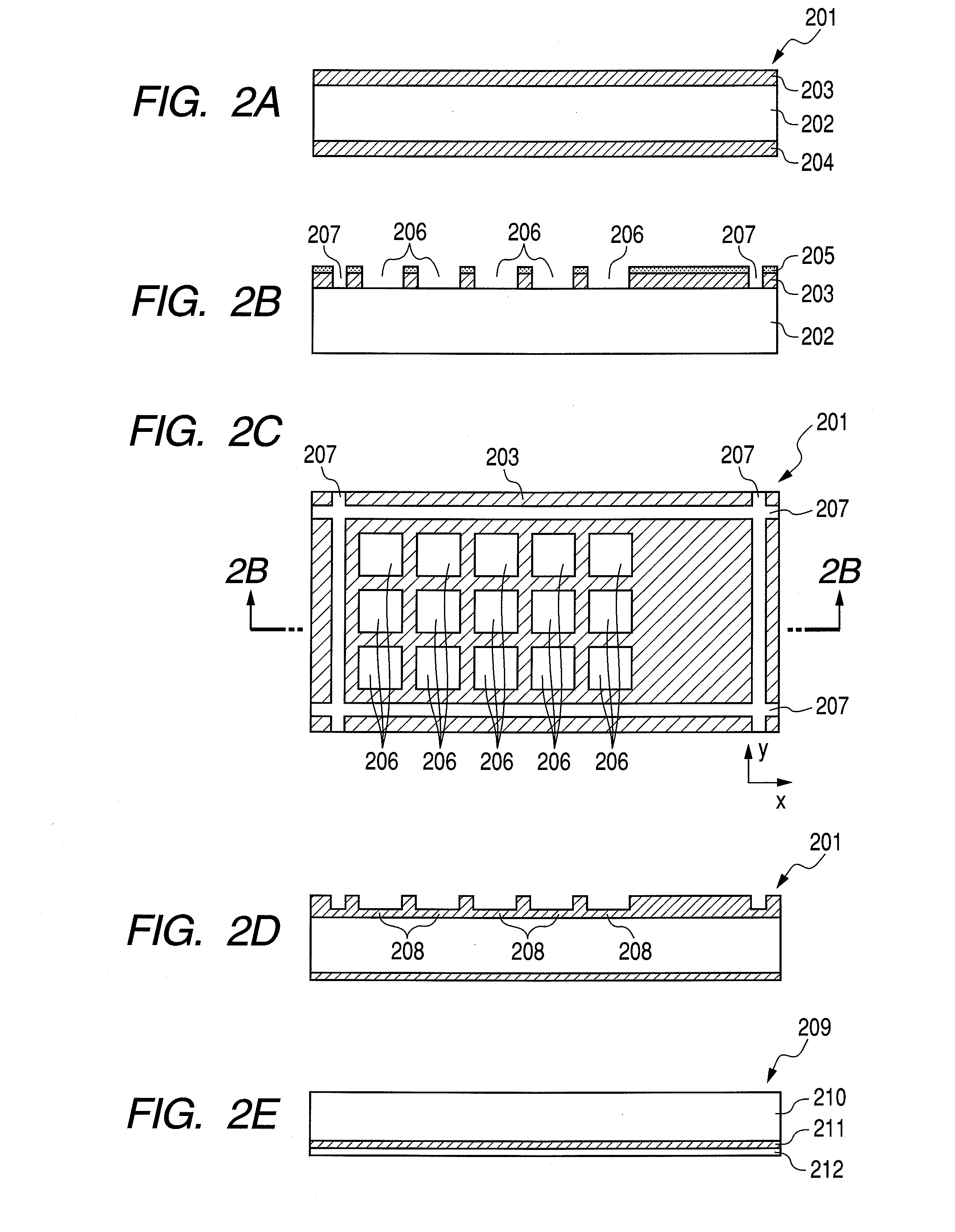

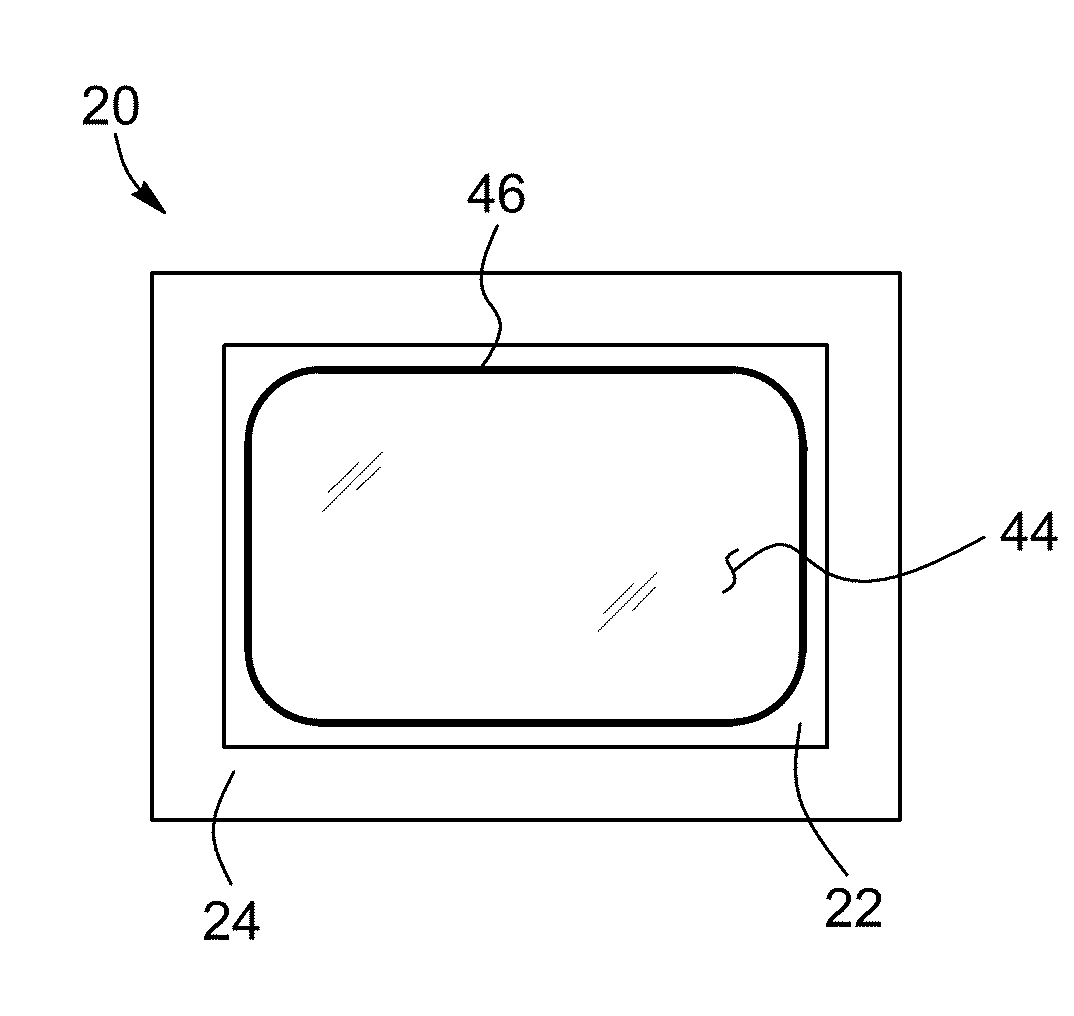

Liquid crystal display, illuminant module and its manufacturing method

InactiveUS20070076433A1Improve image qualityImprove extraction efficiencyDischarge tube luminescnet screensPoint-like light sourceBond interfaceLiquid-crystal display

When a long illuminant module is constructed, debonding of a bonded interface or bending occurs due to a difference in a magnitude of thermal deformation between a lens material and a metal substrate. In an illuminant module including light emitting elements, a substrate on which the light emitting elements are mounted, a transparent encapsulating resin which encapsulates the light emitting elements, and a lens material having cavities formed therein, in which the respective light emitting elements and transparent encapsulating resin are stored, notches are formed in a surface of the lens material on the side of the substrate, and the notch surfaces of the notches and the surface of the substrate are bonded using a bonding material.

Owner:HITACHI LIGHTING

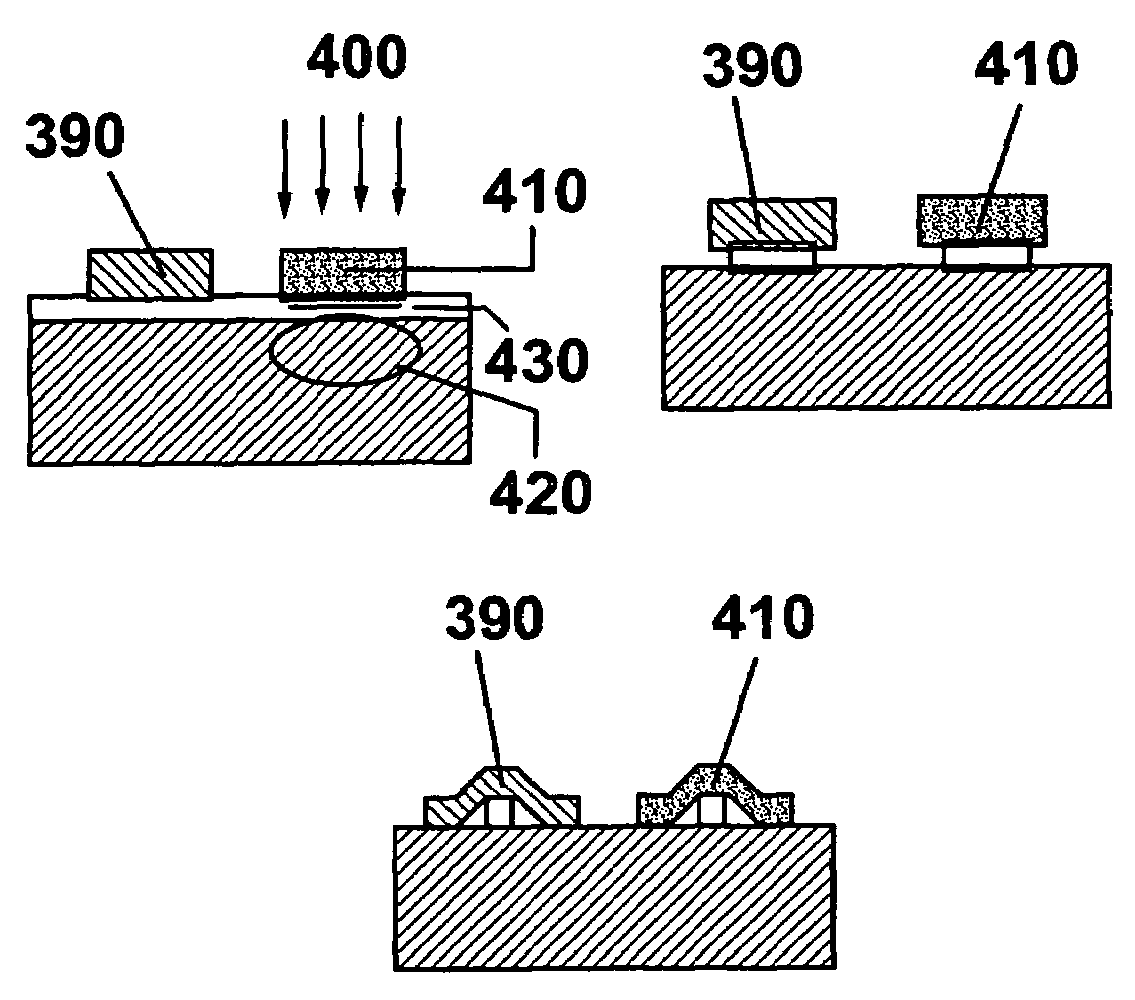

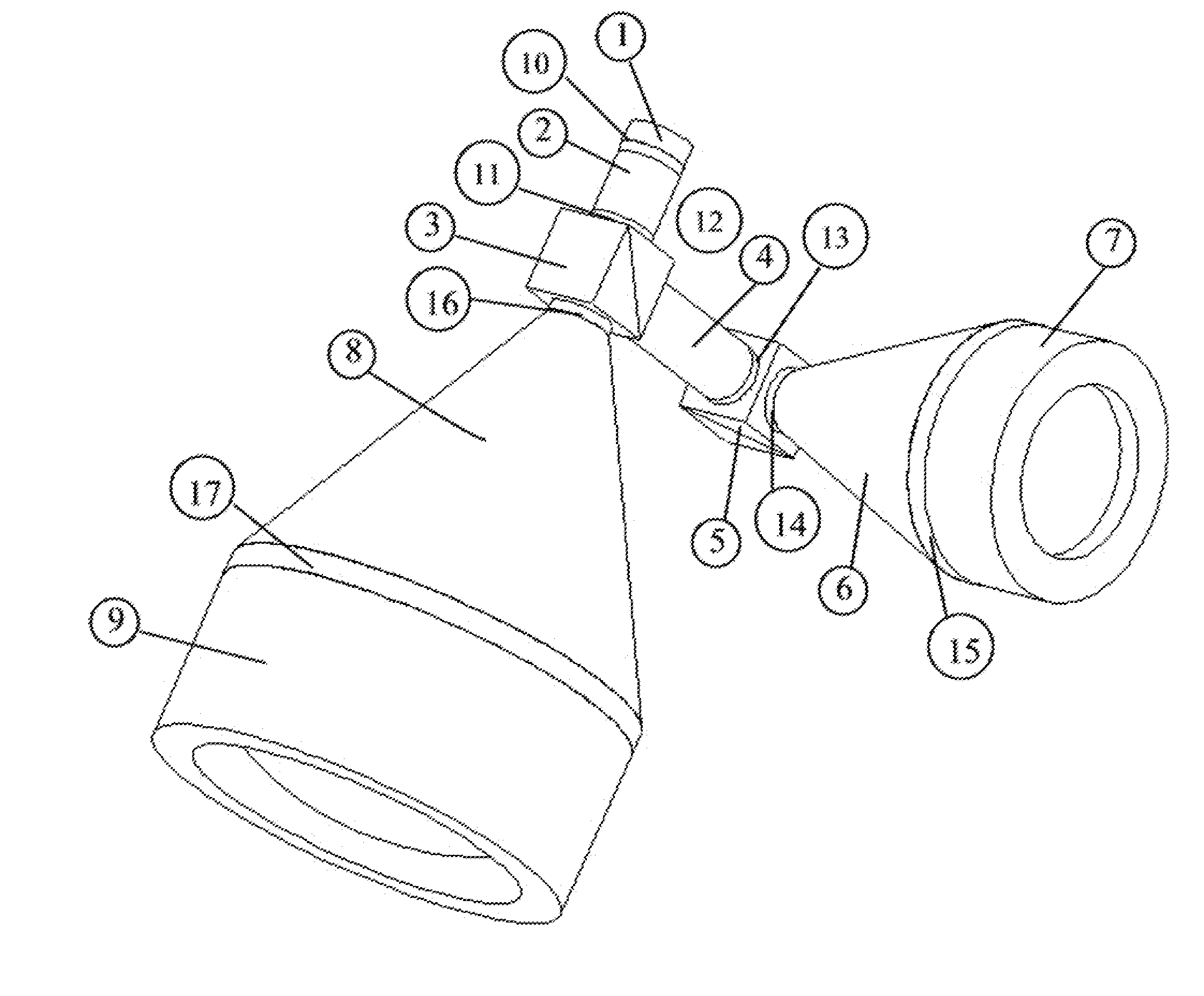

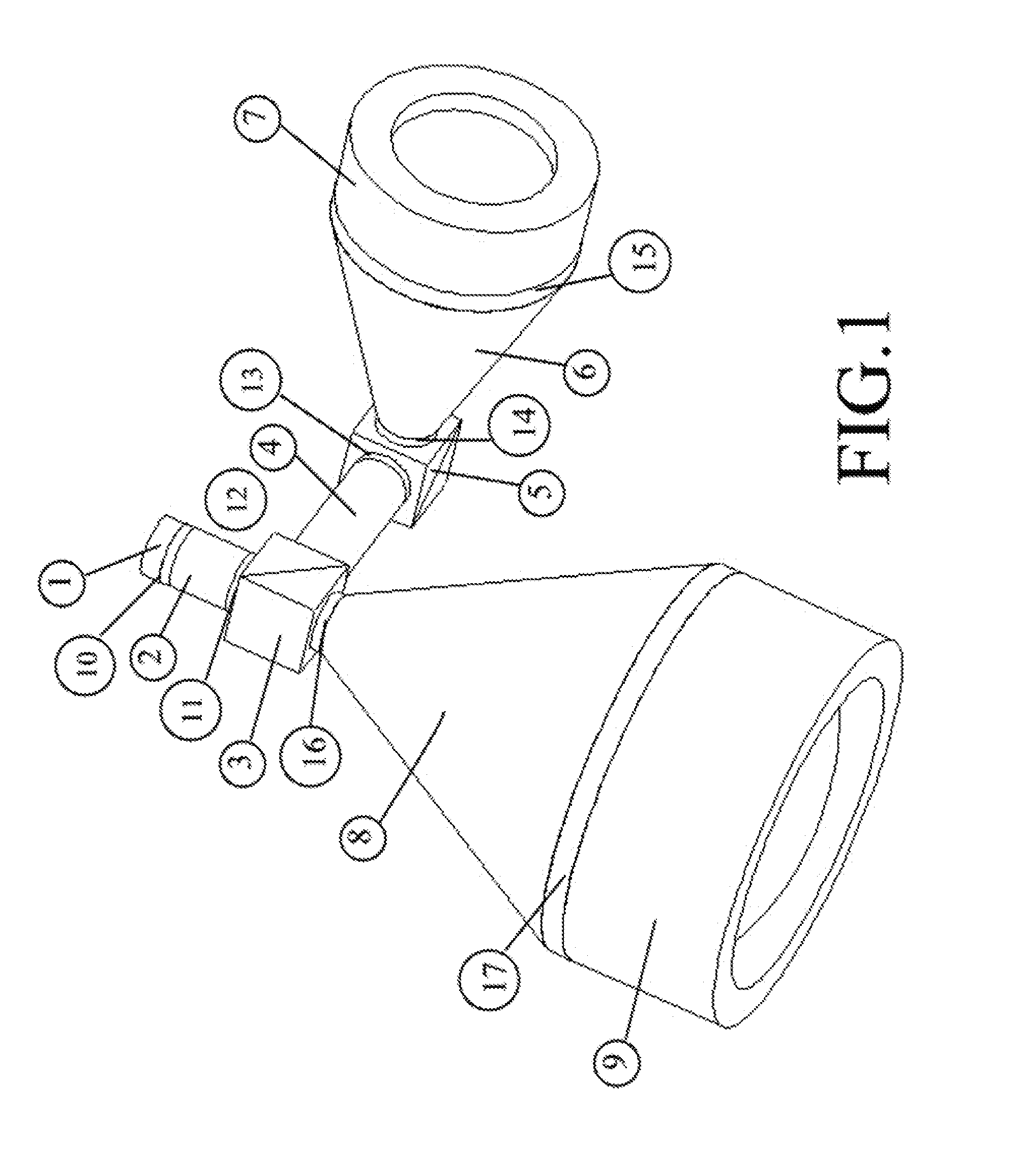

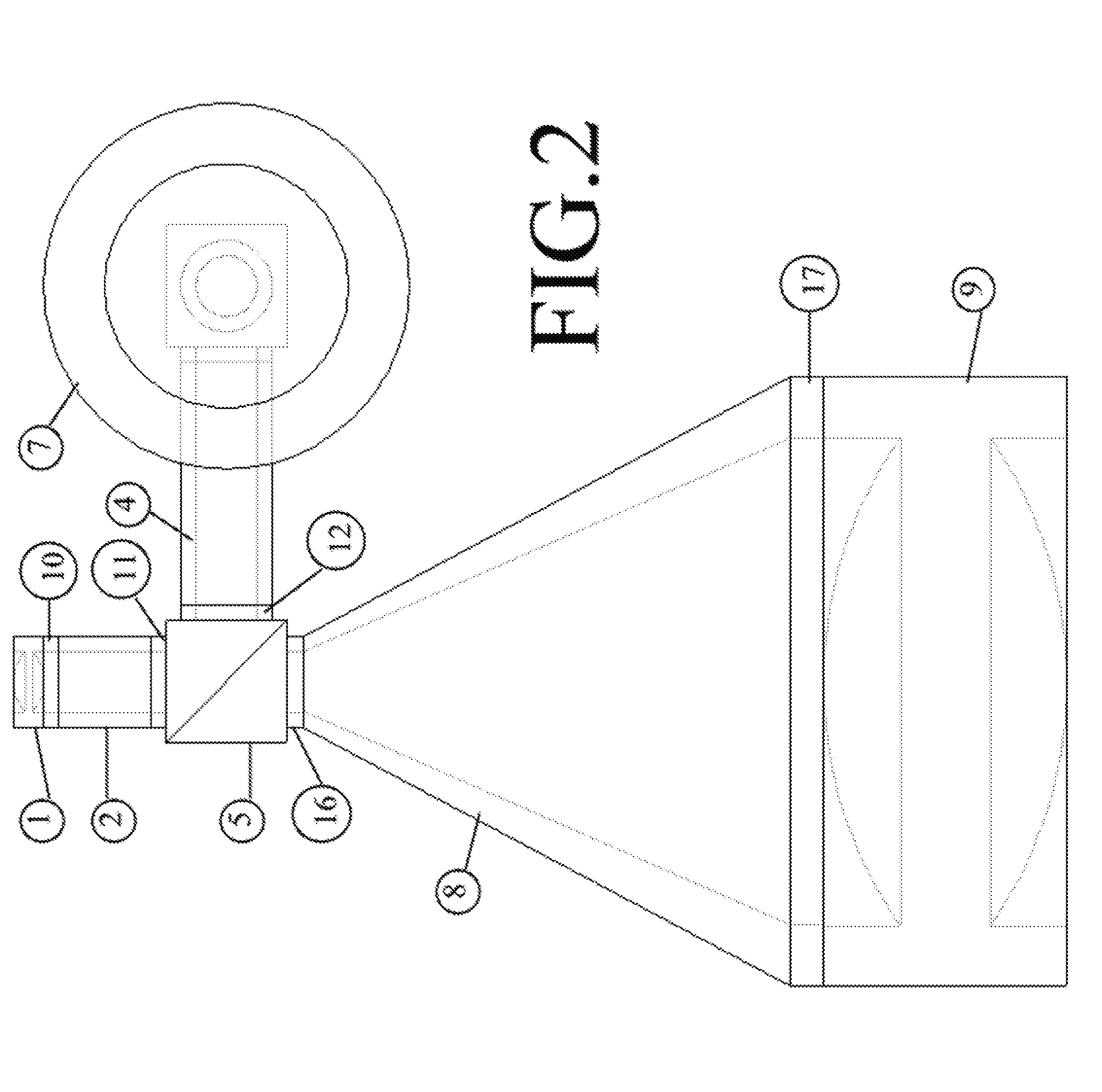

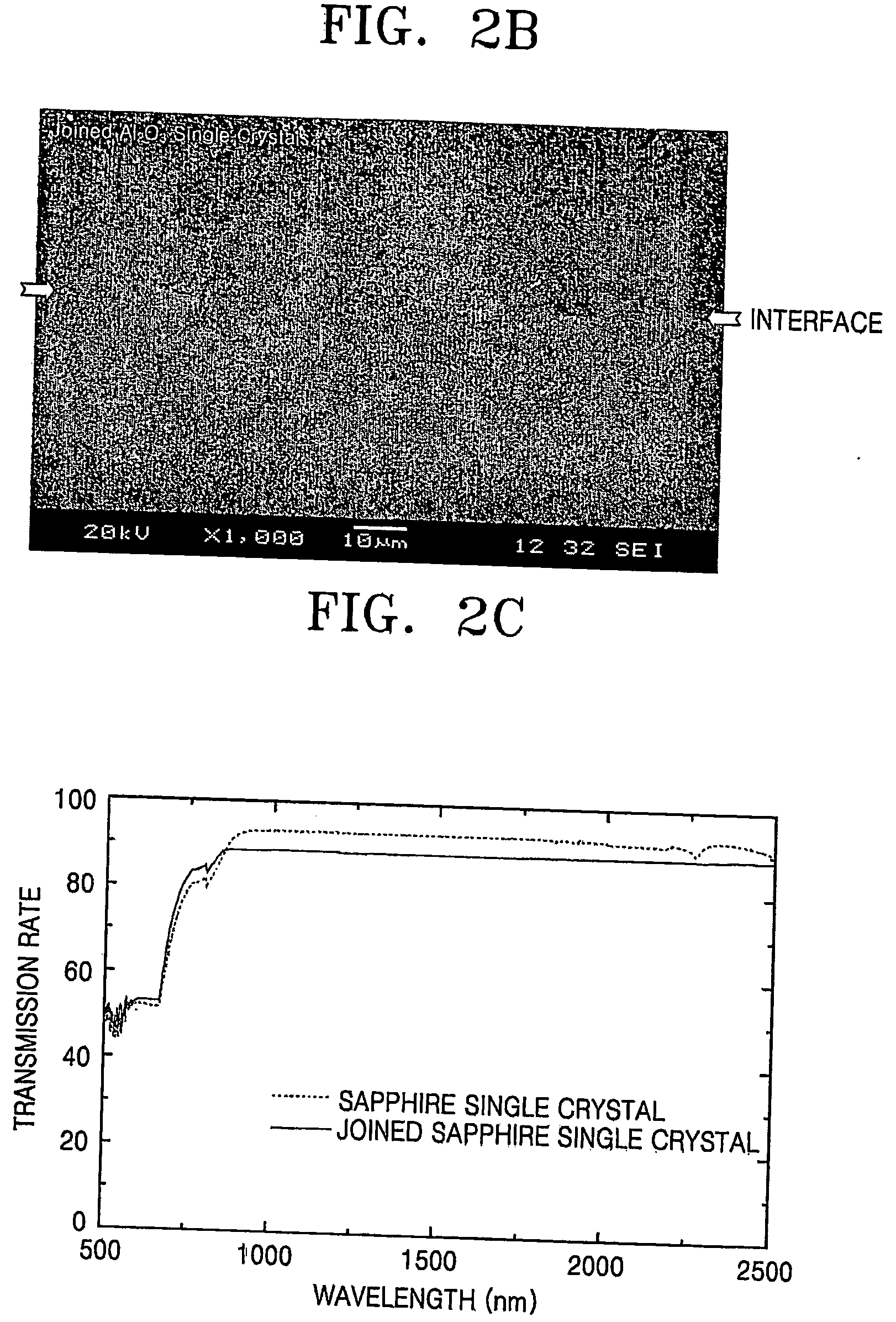

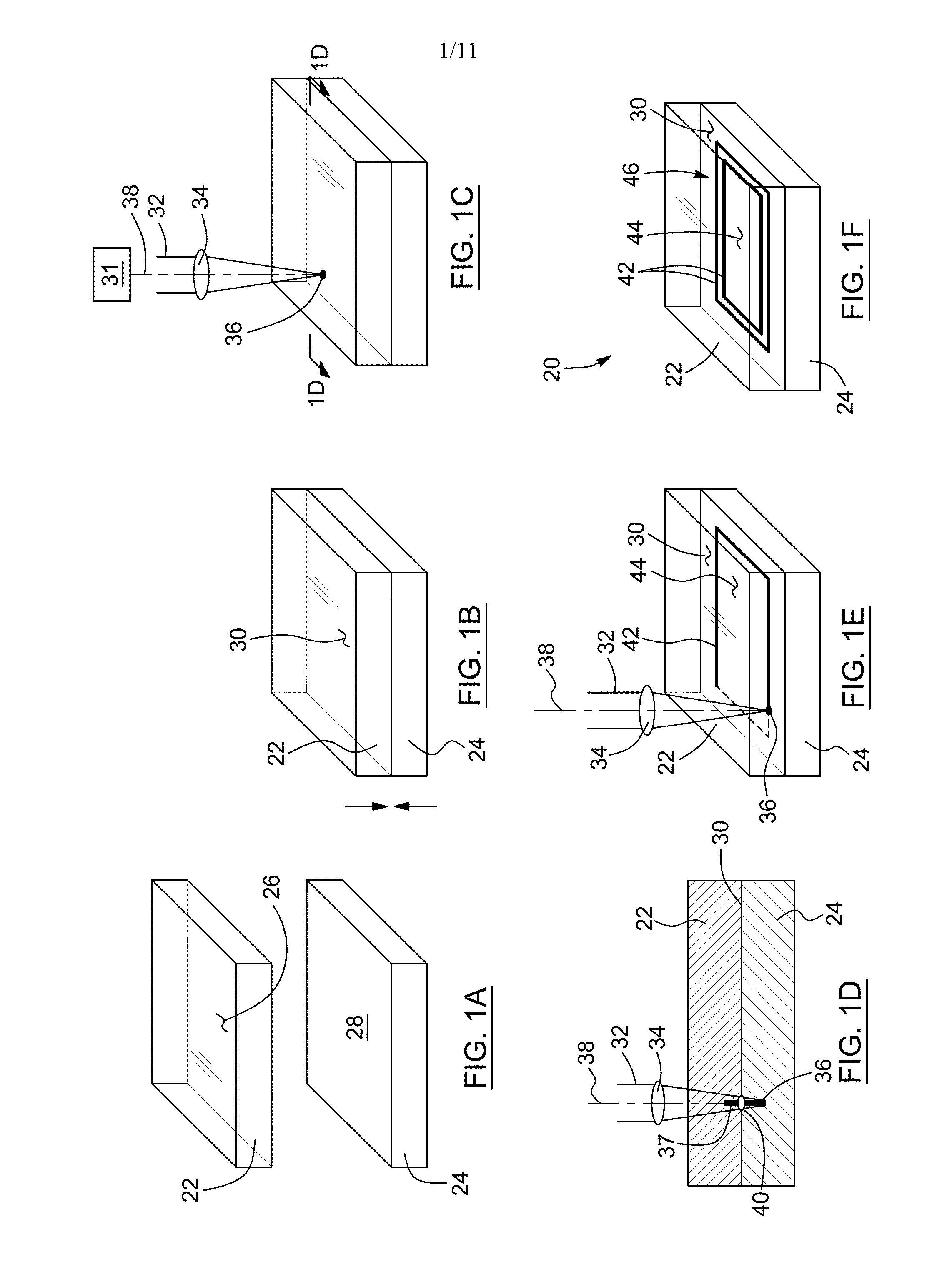

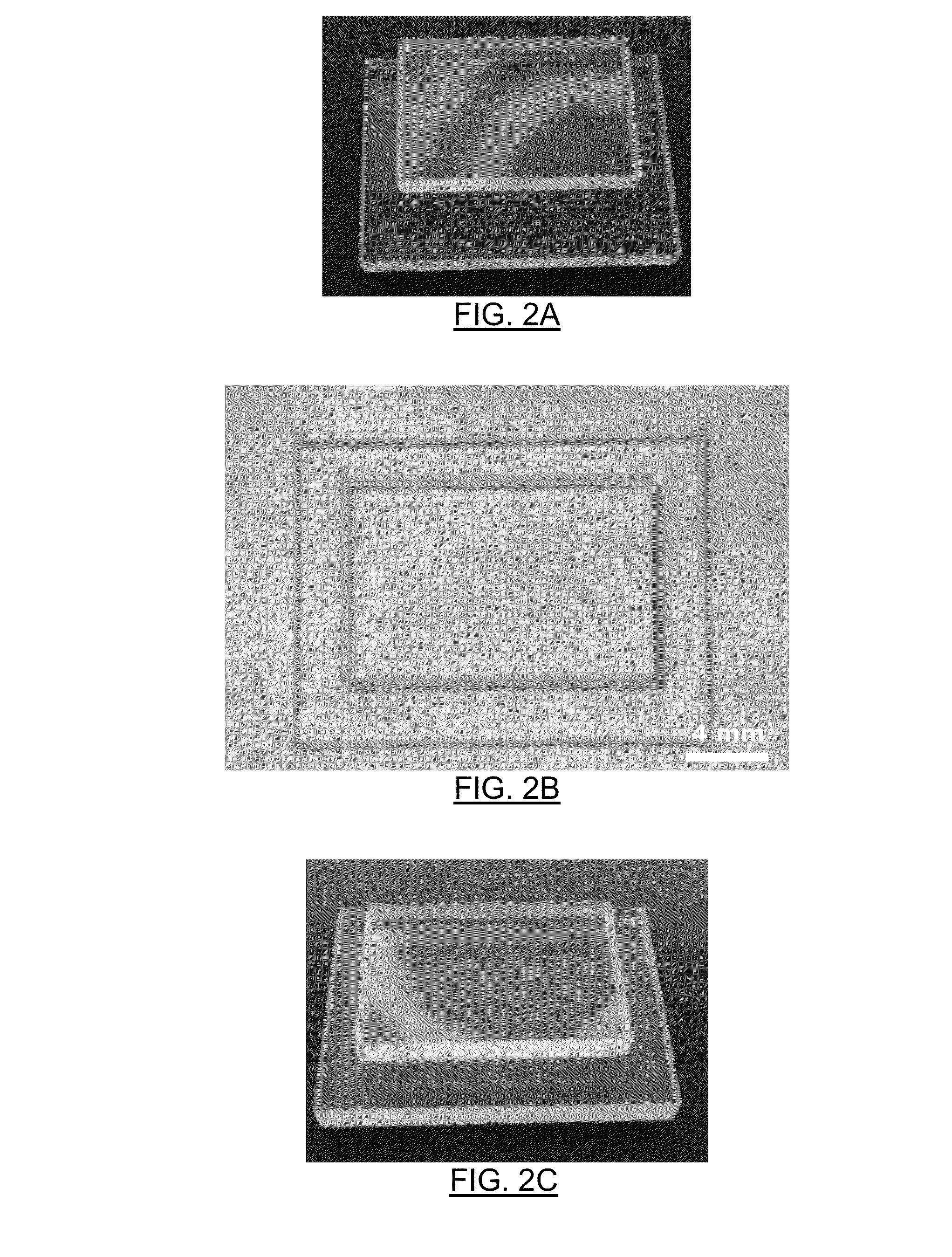

Laser reinforced direct bonding of optical components

ActiveUS20130344302A1Negligible alterationEasy to assembleLamination ancillary operationsDecorative surface effectsEngineeringUltrashort laser

A method for the laser reinforced direct bonding of two optical components having a respective bonding surface and a reinforced optical assembly made thereby are provided. The method includes a first step of assembling the two optical components by direct bonding of their respective bonding surface together, thereby defining a direct-bonded interface therebetween. The method further includes a second step of reinforcing the direct-bonded interface with a weld seam including at least one substantially continuous reinforcing weld line forming a dosed shape enclosing a sealed direct-bonded region. Each weld line is inscribed by focusing ultrashort laser pulses at the direct-bonding interface so as to generate non-linear optical phenomena inducing a localized junction between the two optical components. Advantageously, embodiments of the present invention provide reinforced optical assemblies exhibiting hermetic and mechanically resistant bonds over a large area as well as negligible alteration of their optical transmission properties.

Owner:UNIV LAVAL

Room temperature metal direct bonding

InactiveUS20050161795A1Semiconductor/solid-state device detailsSolid-state devicesBond interfaceRoom temperature

A bonded device structure including a first substrate having a first set of metallic bonding pads, preferably connected to a device or circuit, and having a first non-metallic region adjacent to the metallic bonding pads on the first substrate, a second substrate having a second set of metallic bonding pads aligned with the first set of metallic bonding pads, preferably connected to a device or circuit, and having a second non-metallic region adjacent to the metallic bonding pads on the second substrate, and a contact-bonded interface between the first and second set of metallic bonding pads formed by contact bonding of the first non-metallic region to the second non-metallic region. At least one of the first and second substrates may be elastically deformed.

Owner:INVENSAS BONDING TECH INC

Method for bonding a sputter target to a backing plate and the assembly thereof

InactiveUS20050061857A1Electric discharge tubesVacuum evaporation coatingBond interfaceBonded interface

A method for solder bonding a sputter target to a backing plate having a plurality of spaced-apart ridges on its bonding surface to provide a uniform spacing and a uniform solder bonded interface; and the sputter target / backing plate assembly so produced.

Owner:PRAXAIR ST TECH INC

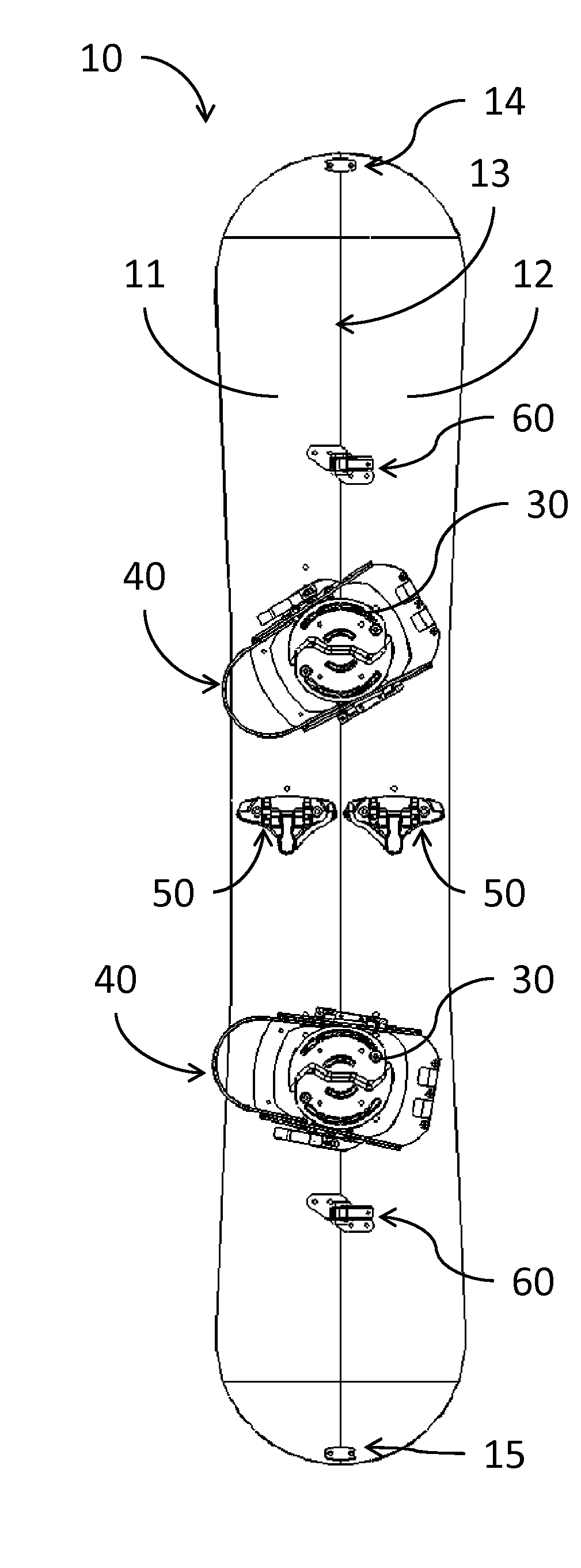

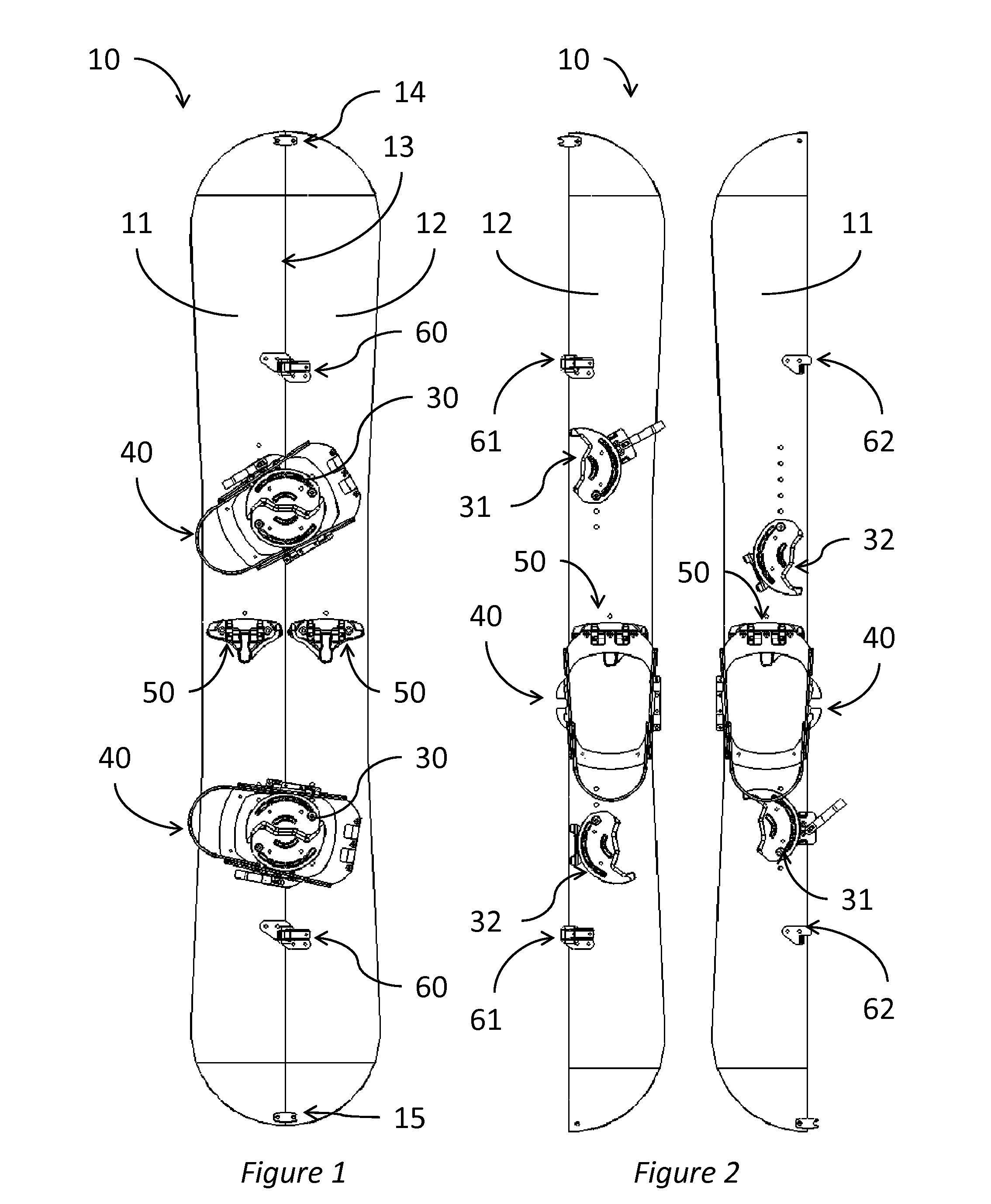

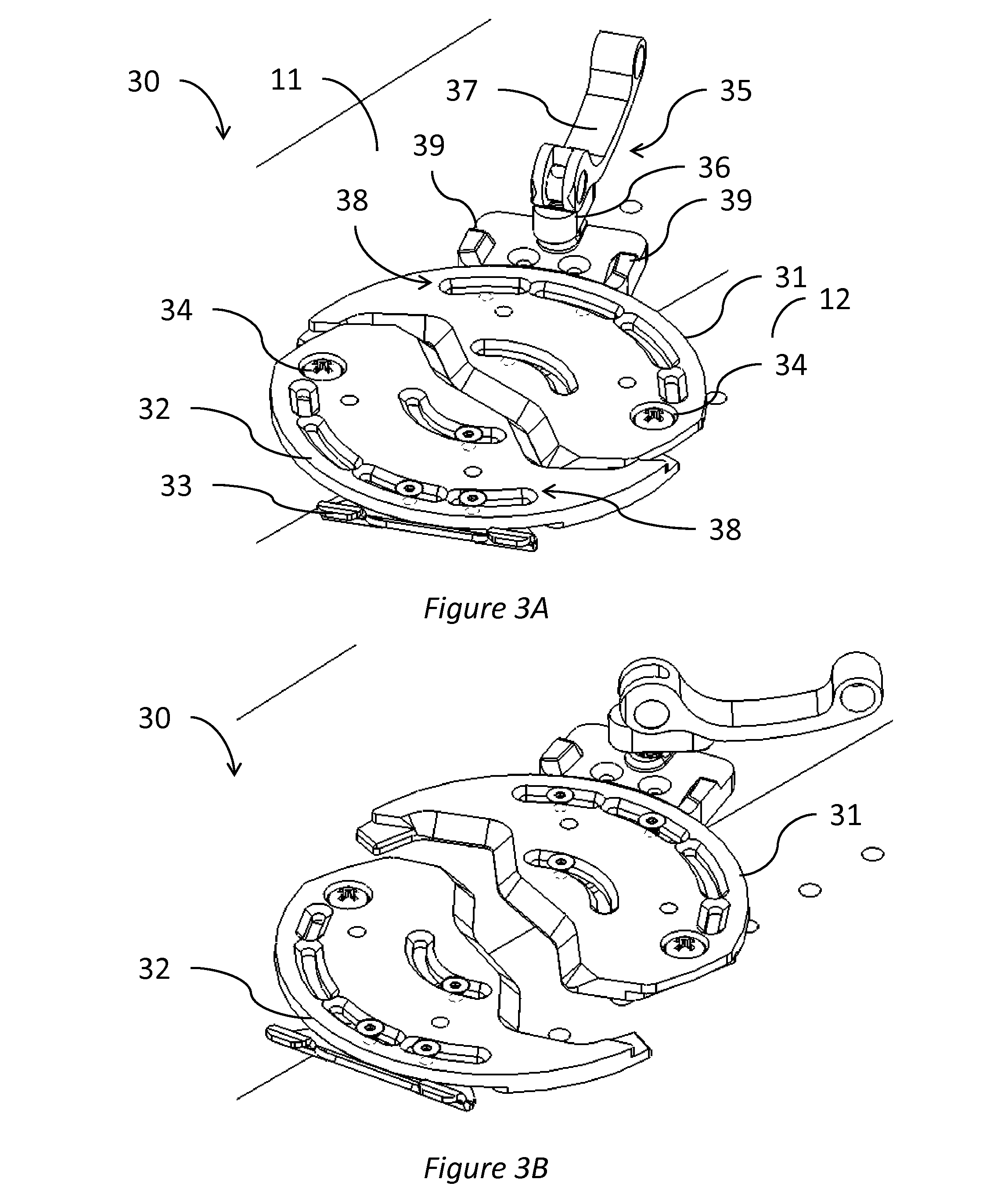

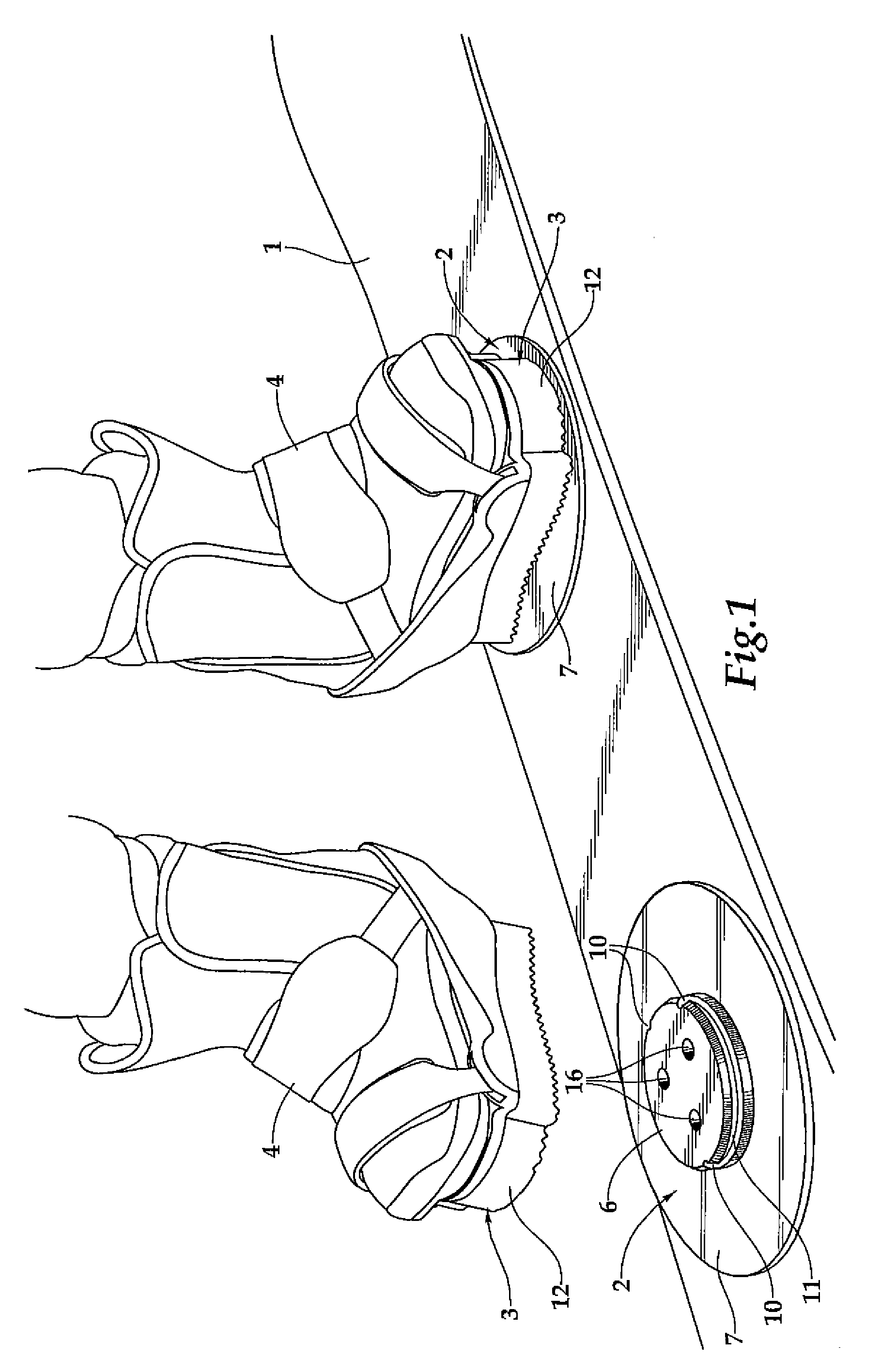

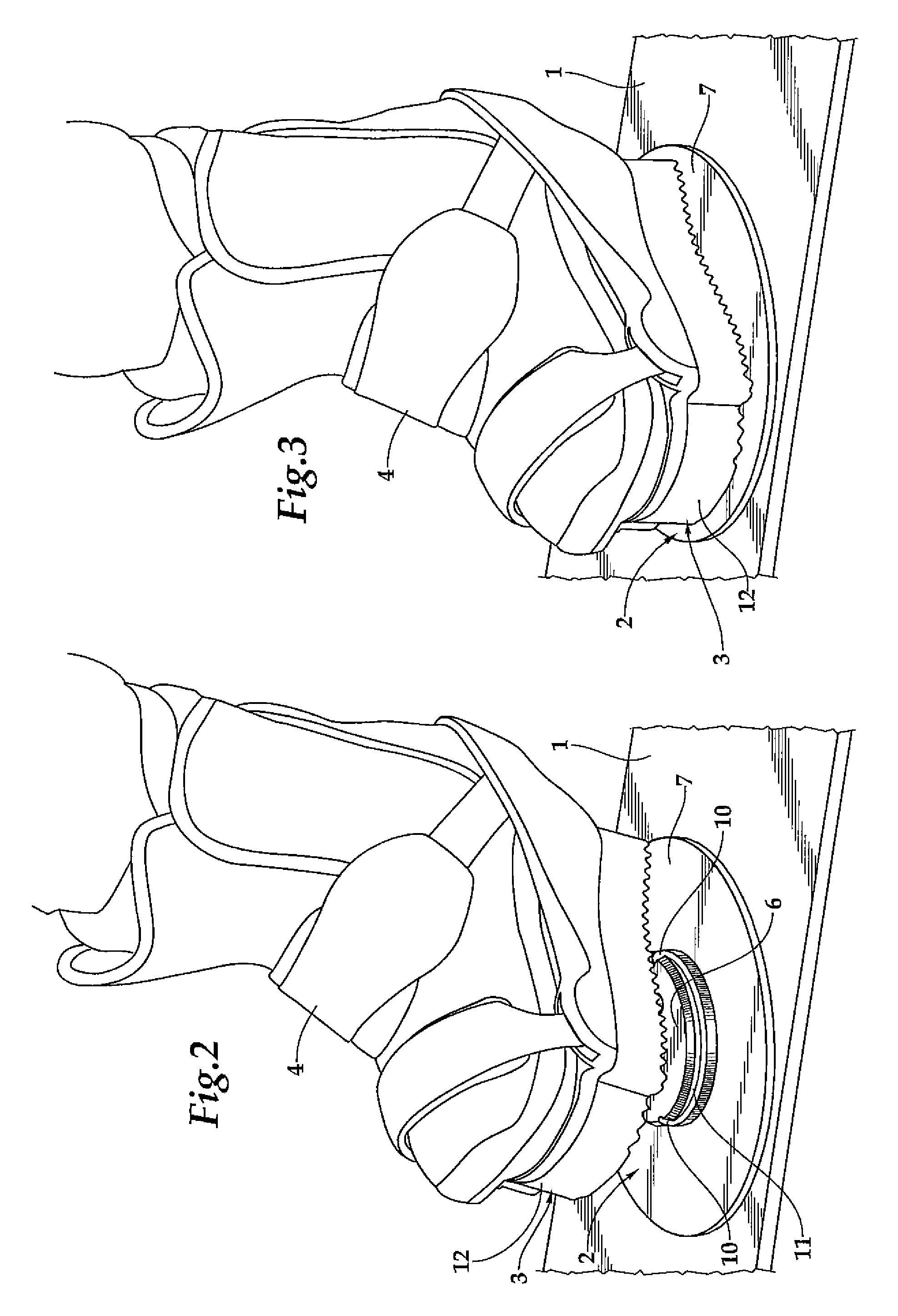

Splitboard binding apparatus

Owner:KLOSTER BRYCE M +1

Process for producing capacitive electromechanical conversion device, and capacitive electromechanical conversion device

InactiveUS8665672B2Poor bondingBeacon systems using ultrasonic/sonic/infrasonic wavesWave amplification devicesBond interfaceEngineering

Owner:CANON KK

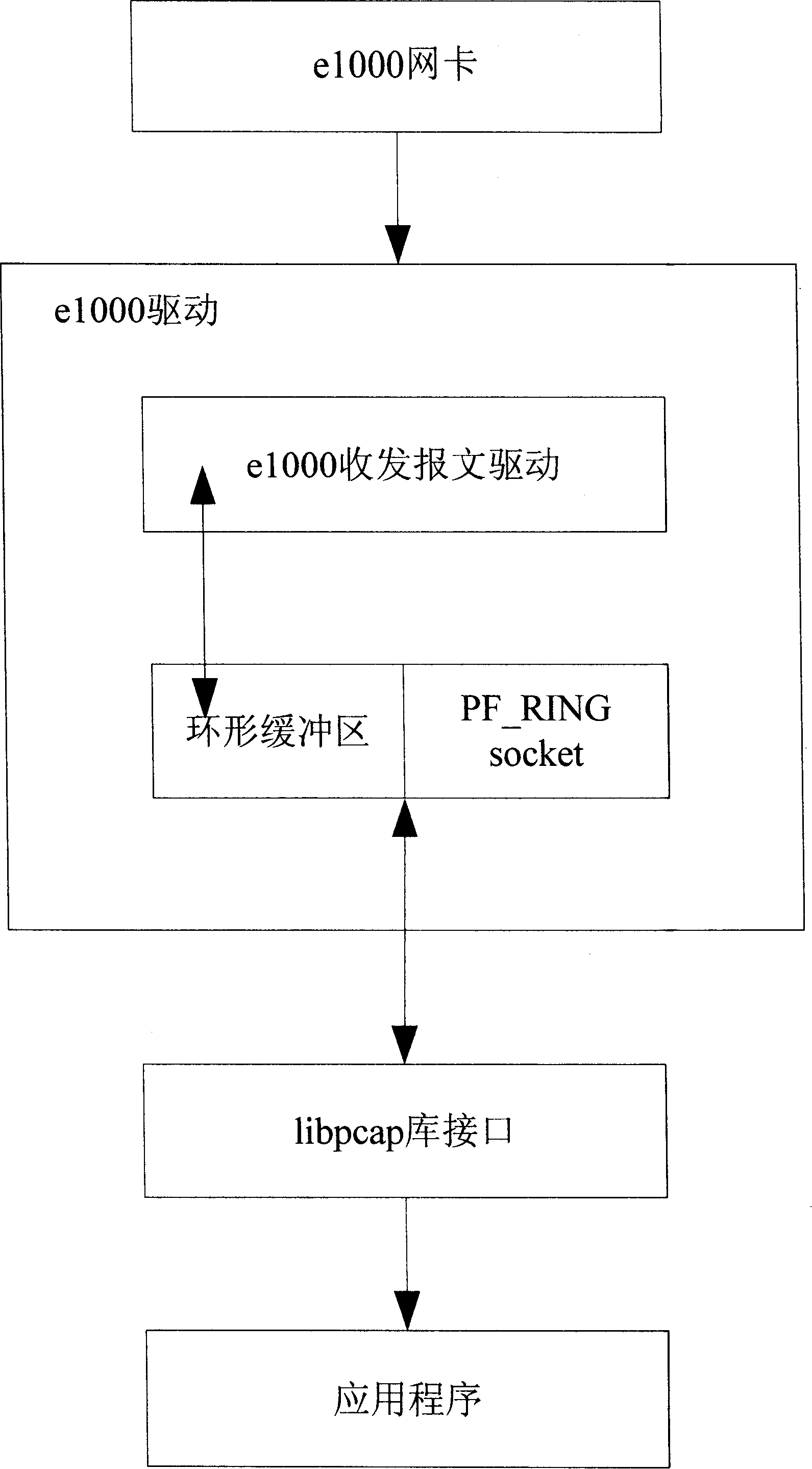

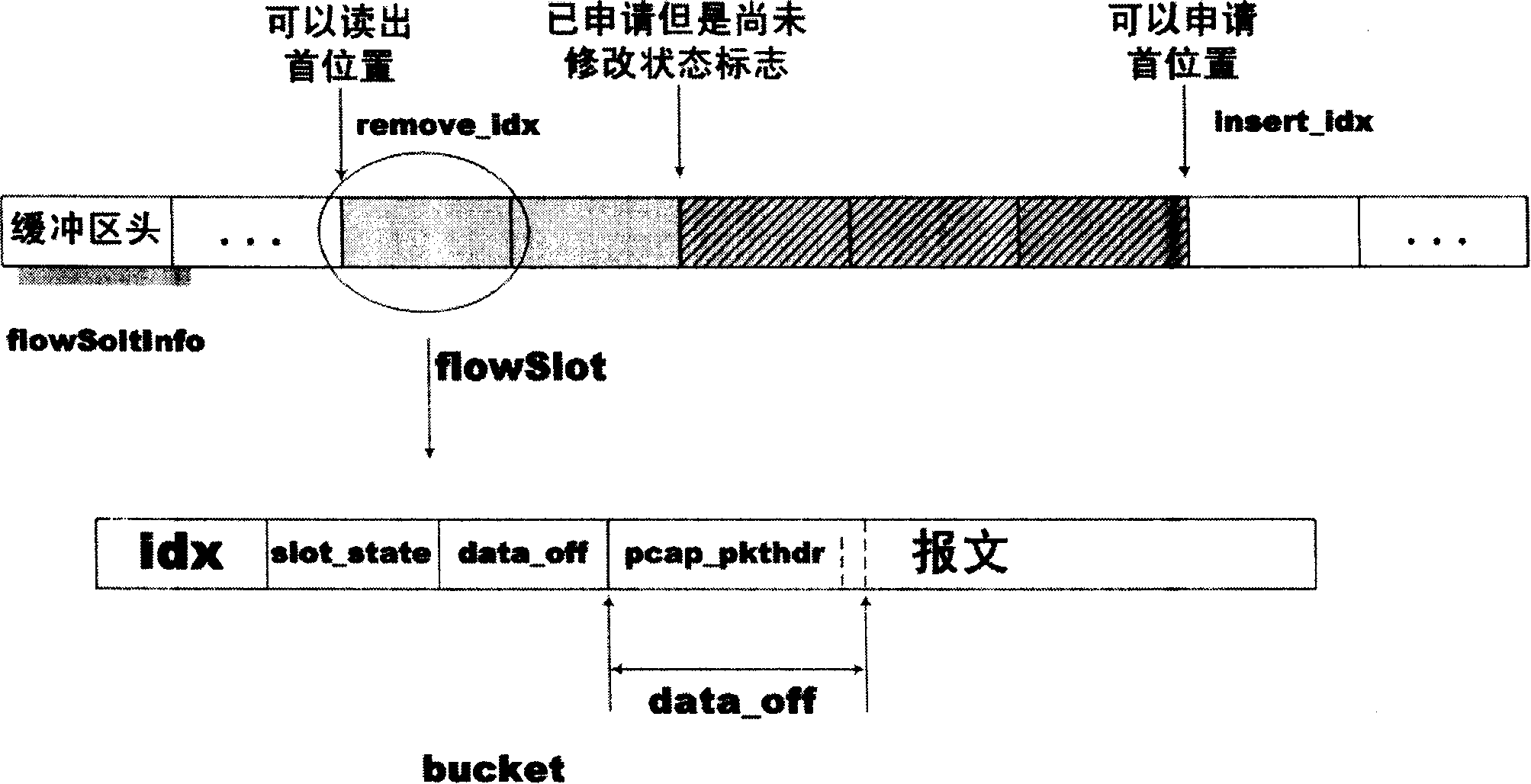

Intel e1000 zero copy method

The invention relates to a transmitting method of the data communication in a computer and is a method of direct communication through the user applying procedure and network card hardware driving procedure. The kernel and the applying layer procedure commonly share one ring-shaped memory buffering district, the memory buffering district is divided into a number of slots (can also be regarded as array which can buffer store a number of messages), and each slot buffer stores one message. The network card driving adopts a DMA method to write message into a buffering district; and the applying layer space reads data from the buffering district. When a socket connector is used for controlling the connector using zero copying mechanism, e1000 receiving message driving starts to write date into the ring-shaped buffering district, the up layer applying can directly visit the data in the ring-shaped buffering district after the socket mechanism binding the connector and getting the mapped memory.

Owner:莱克斯科技(北京)有限公司

Method for preparing tungsten carbide abrasion resistant composite coating by penetration brazing method

ActiveCN101637838AHigh bonding strengthFast heat conductionSoldering apparatusWelding/soldering/cutting articlesEpoxyBond interface

The invention relates to a method for preparing tungsten carbide abrasion resistant composite coating by a penetration brazing method, belonging to the field of coating preparation in materials processing engineering. The invention comprises the following steps: (1) pasting coating metal powder cloth containing tungsten carbide-cobalt (WC-Co), nickle (Ni) and chromium (Cr) mixed powder on a metalsubstrate by using epoxy resin bonding agent; (2) preparing welding material metal powder cloth from BNi-2 brazing material and pasting the welding material metal powder cloth on the coating metal powder cloth obtained in the step (1); and (3) carrying out penetration brazing in a vacuum furnace to form a metallurgical bonded interface. The tungsten carbide abrasion resistant composite coating canbe applicable to protection of mechanical elements in the field of generating plant, petroleum, aviation, food, plastics and the like.

Owner:JIANGXI HENGDA HI TECH CO LTD

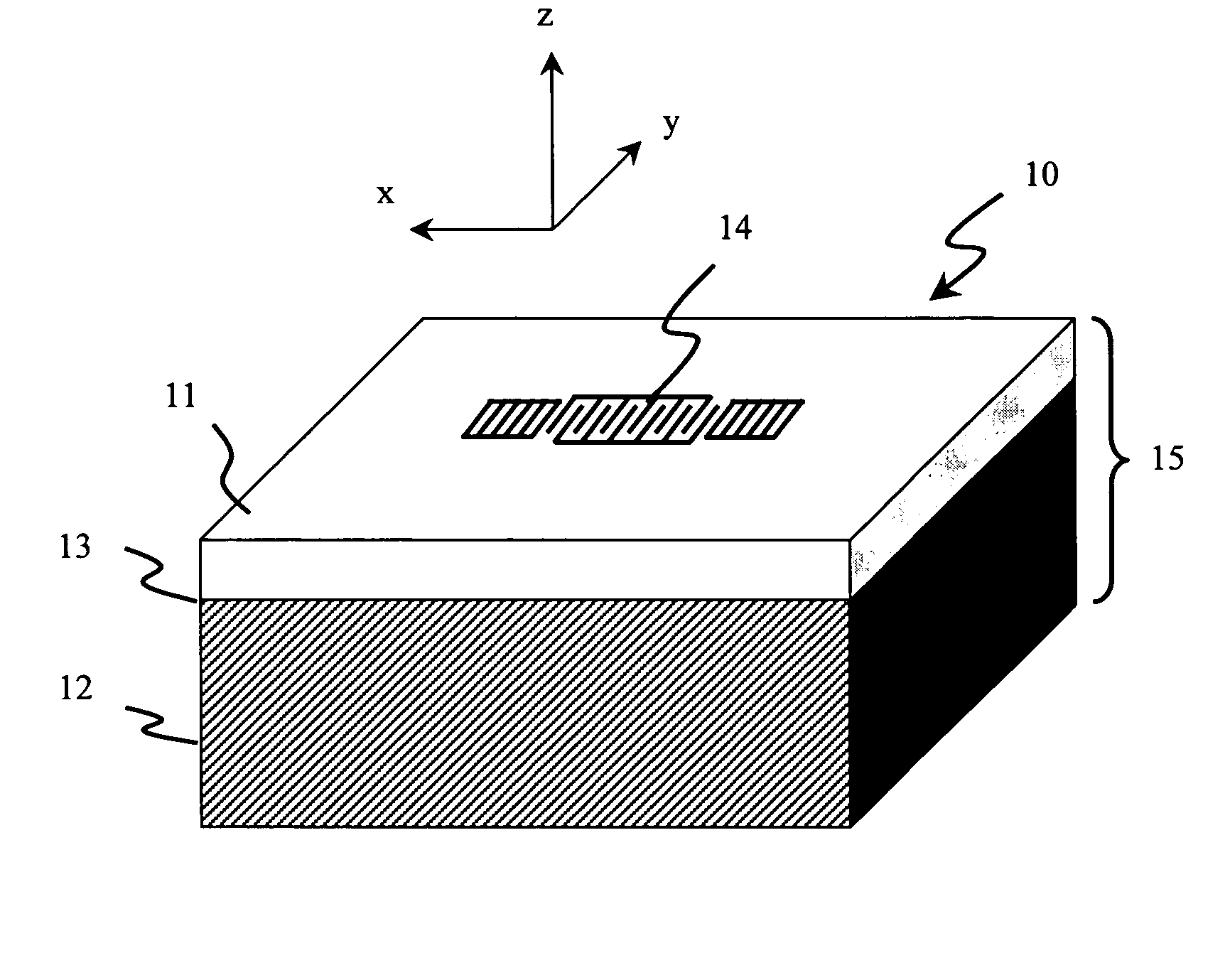

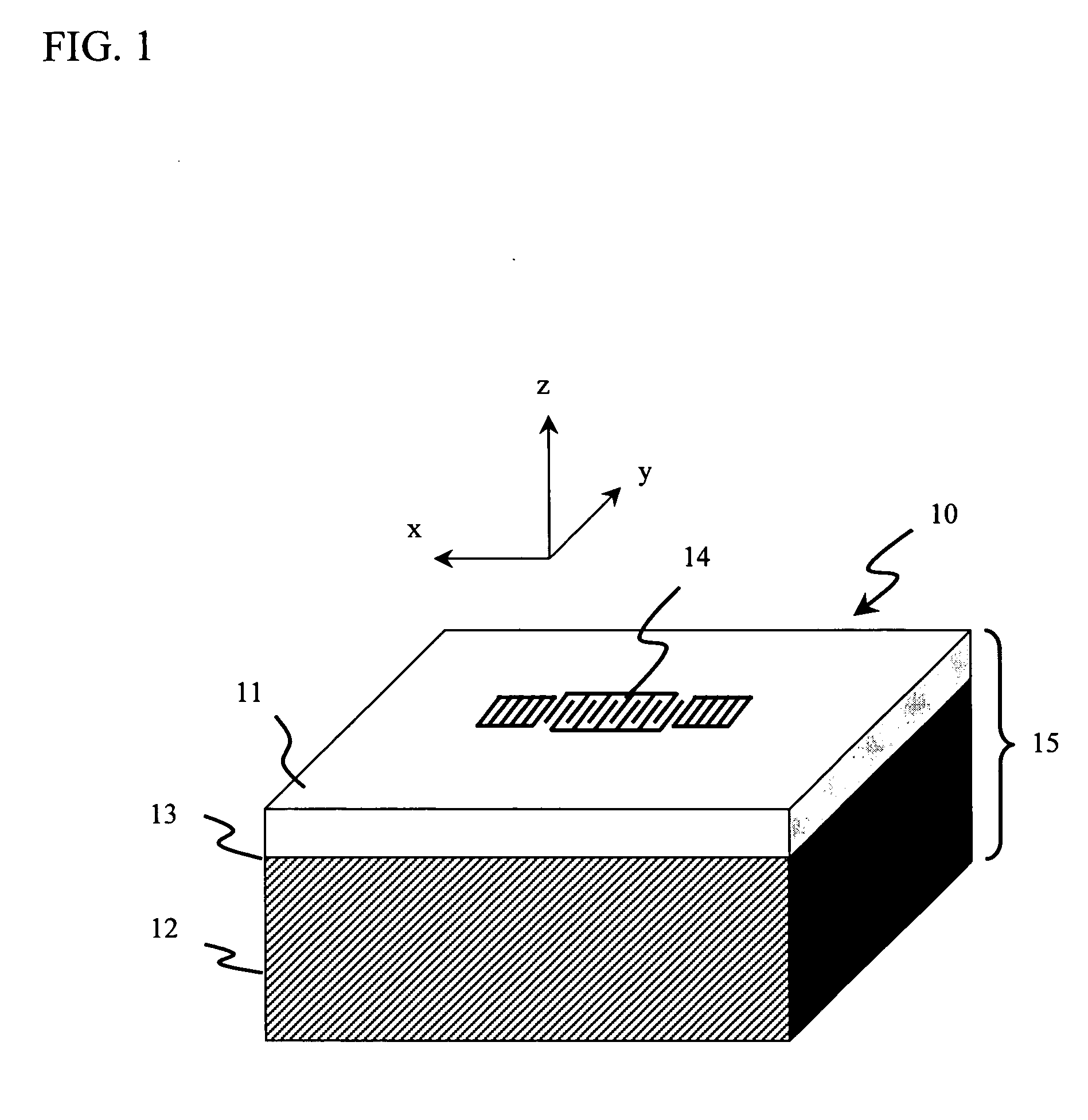

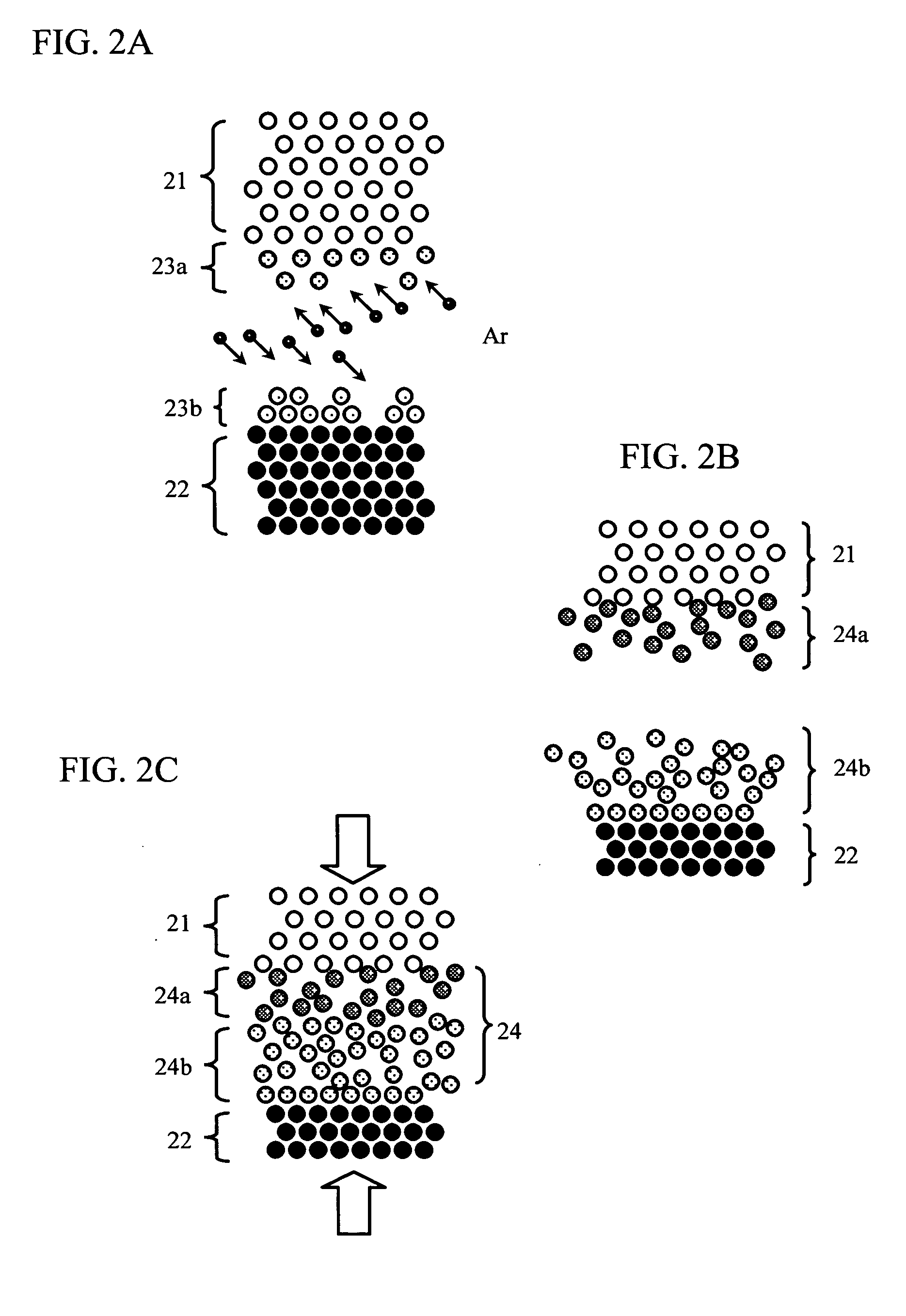

Bonded substrate, surface acoustic wave chip, and surface acoustic wave device

ActiveUS20050194864A1High bonding strengthSmall distortionPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesBond interfaceOxygen

A bonded substrate includes a lithium tantalate substrate and a sapphire substrate to which the lithium tantalate substrate is bonded, a bonded interface of the lithium tantalate and the sapphire substrate includes a bonded region in an amorphous state having a thickness of 0.3 nm to 2.5 nm. The bonded region in the amorphous state is formed by activating at least one of the lithium tantalate substrate and the sapphire substrate in the bonded interface with neutralized atom beams, ion beams or plasma of inert gas or oxygen. It is possible to bond the piezoelectric substrate to the supporting substrate having different lattice constants without the high-temperature thermal treatment and realize the bonded substrate having an excellent bonding strength and being less warped.

Owner:TAIYO YUDEN KK

Method for making self-supporting structure of nano fluid system based on SU-8 photoresist

InactiveCN102012633AIncrease the areaLow production weekDecorative surface effectsPhotomechanical apparatusBond interfacePolyethylene terephthalate

The invention discloses a method for making a self-supporting structure of a nano fluid system based on a SU-8 photoresist, which is characterized by comprising the following steps of: firstly processing and making a PDMS (Polydimethylsiloxane) flexible template, making a SU-8 nano channel substrate by utilizing the PDMS flexible template, simultaneously making a SU-8 bonding layer comprising a sample pond by utilizing ultraviolet exposure development, realizing the bonding sealing of the SU-8 nano channel substrate and the bonding layer by utilizing a bonding technique, and finally removing PDNS and PET (Polyethylene Terephthalate) flexible substrates to obtain the self-supporting structure of the nano fluid system. The method has the advantages of simple operation, low making cost and low equipment requirement. The making result shows that the system has no delamination and blockage, the bonded interface can be hardly seen, and the outline of a channel is clear and visible so that the self-supporting structure of the nano fluid system has good quality.

Owner:HEFEI UNIV OF TECH

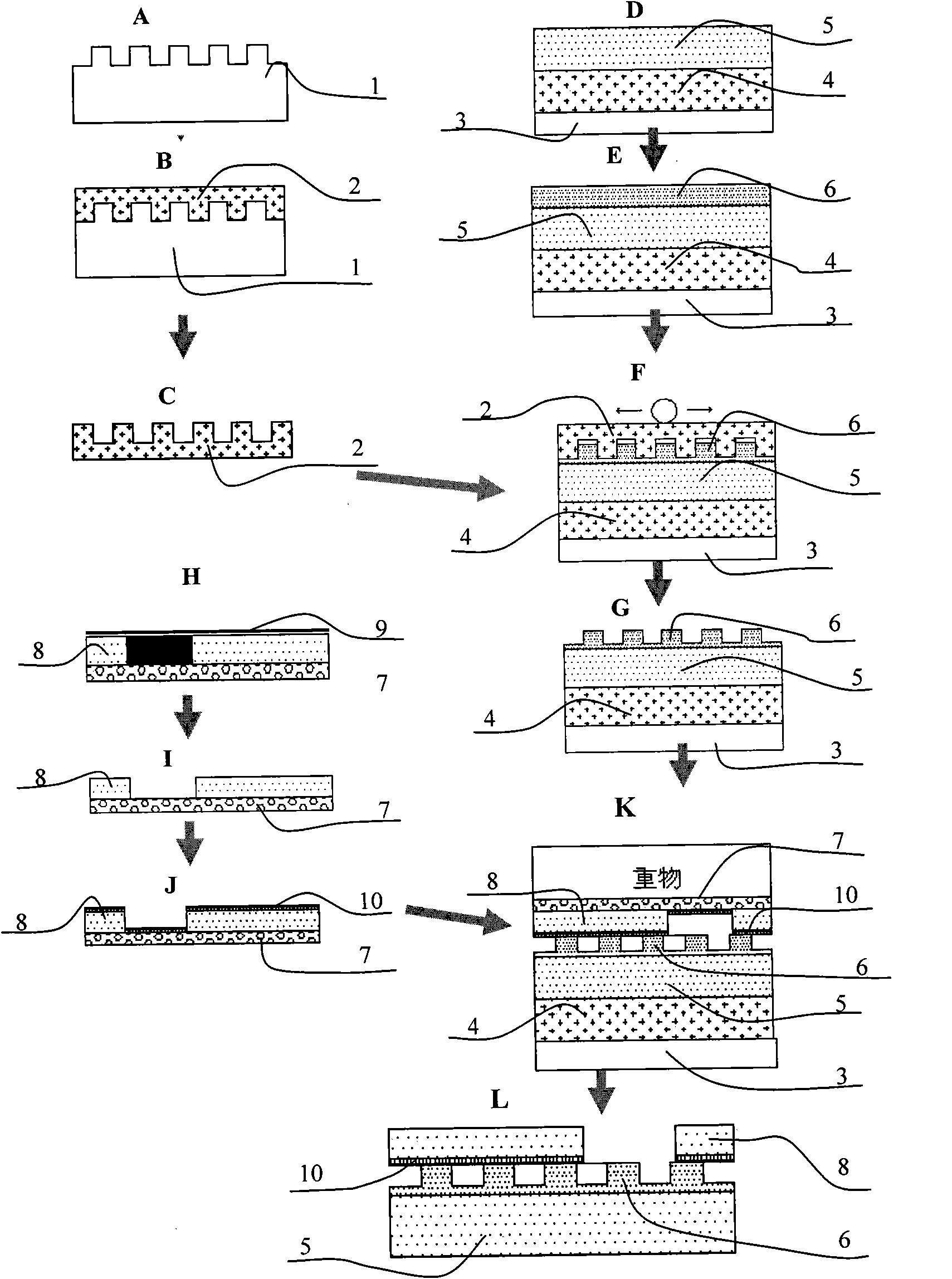

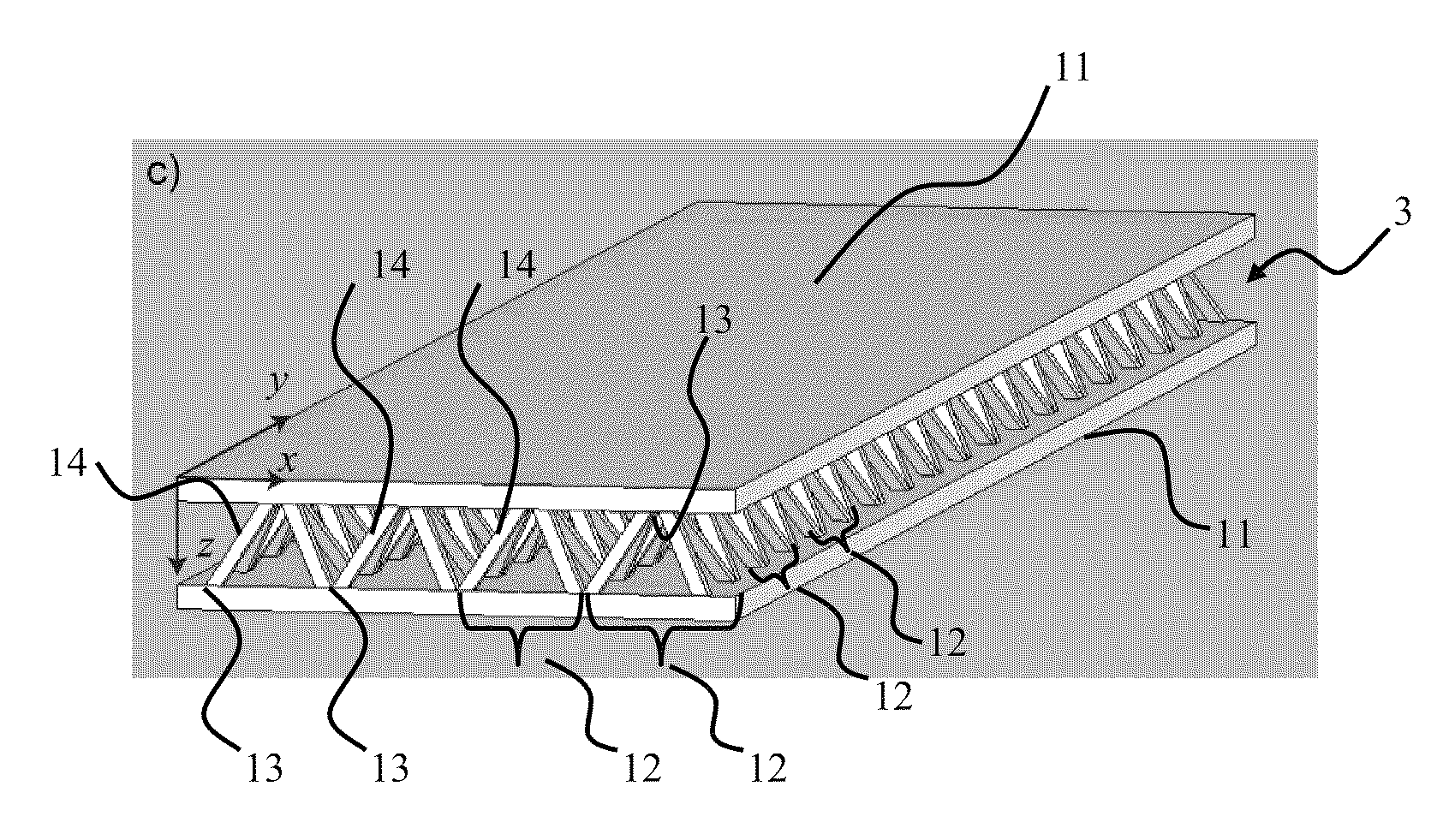

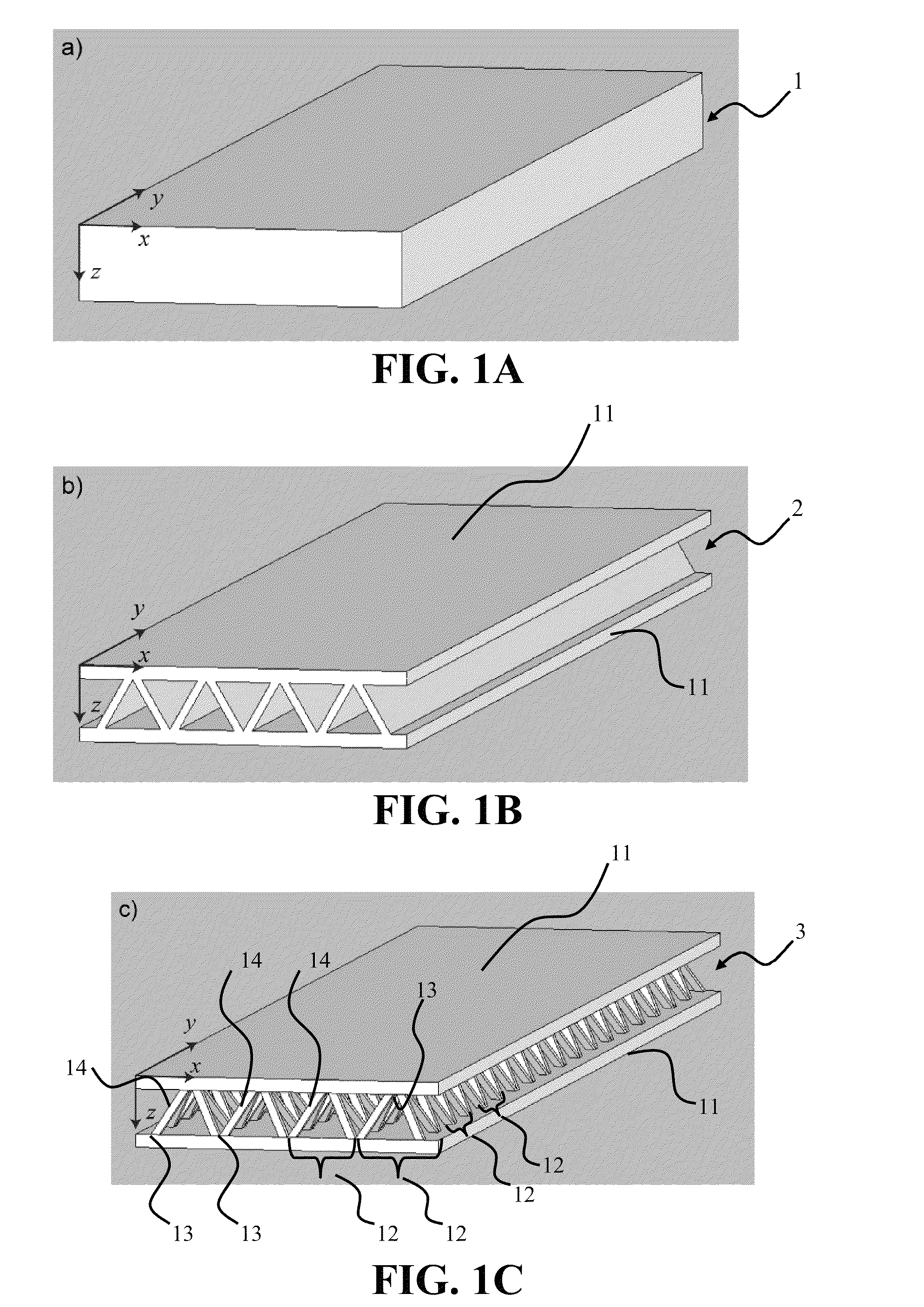

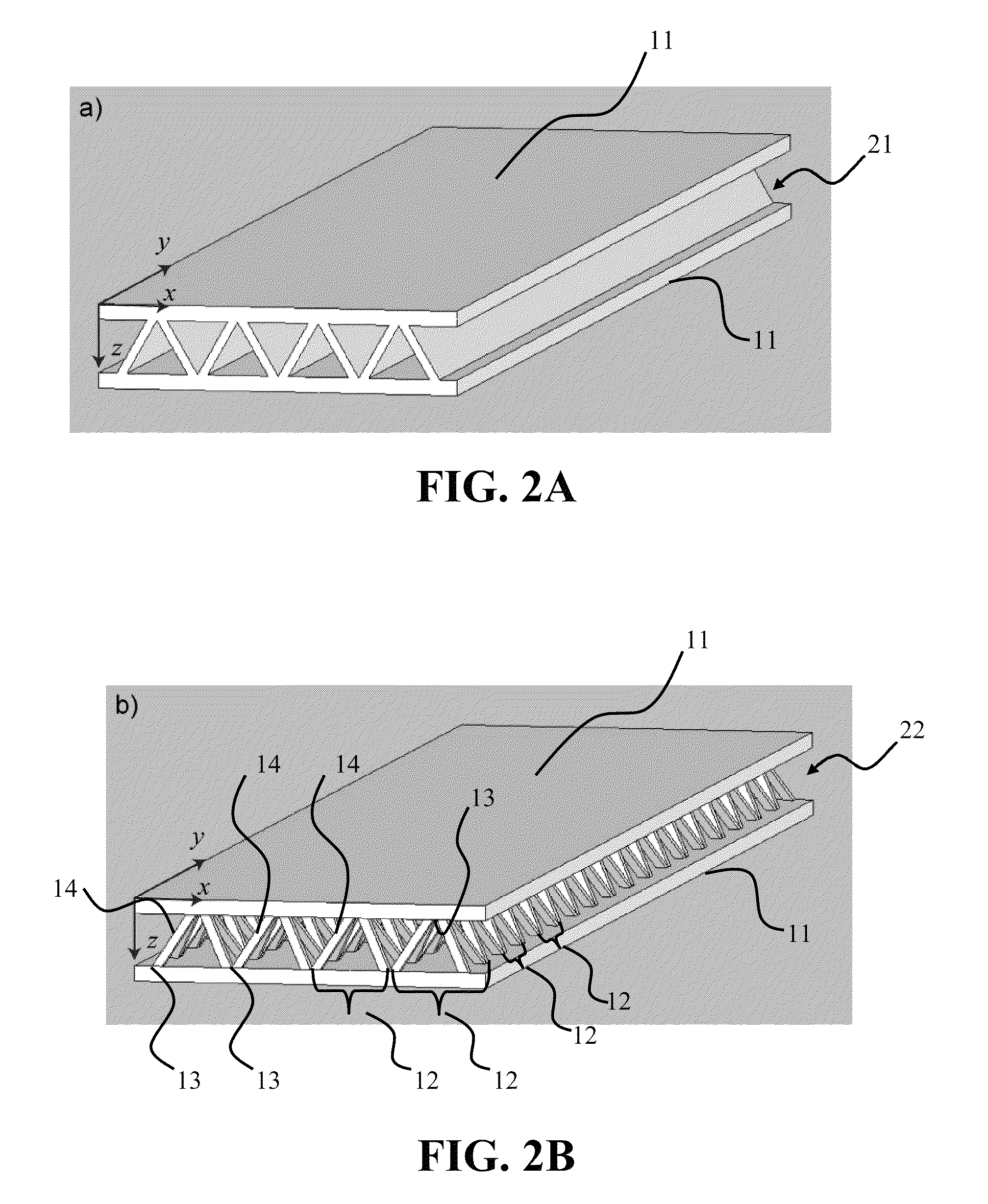

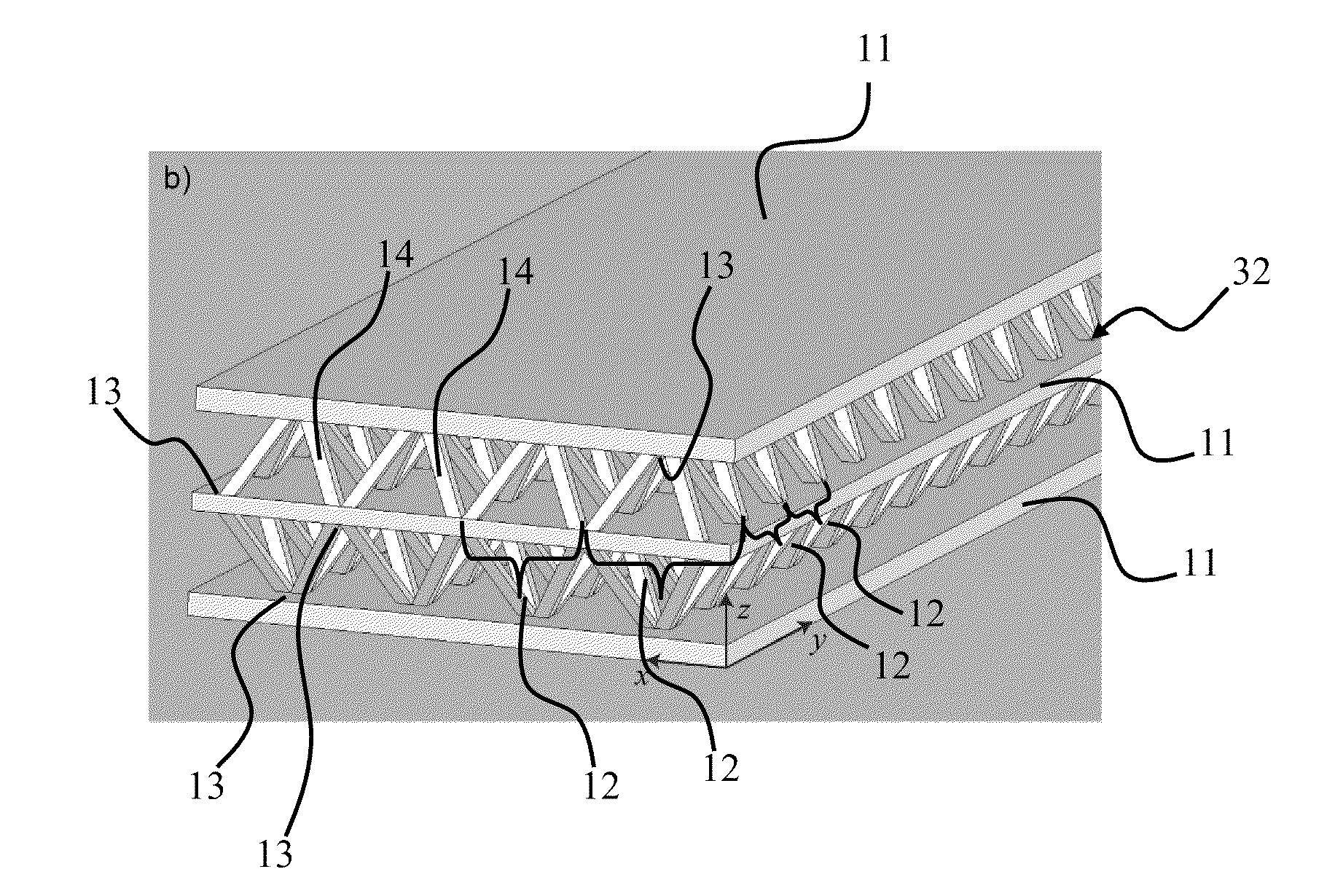

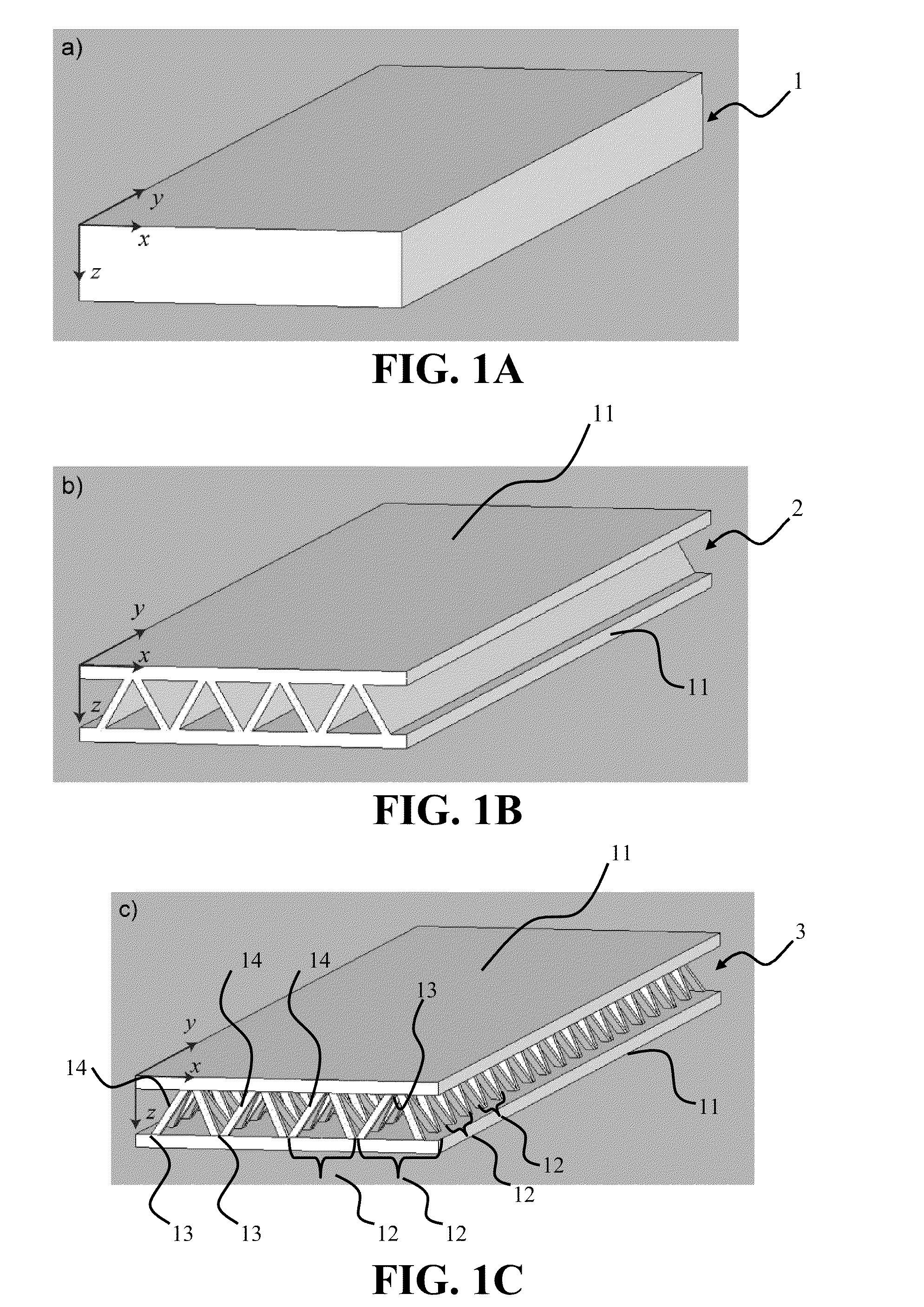

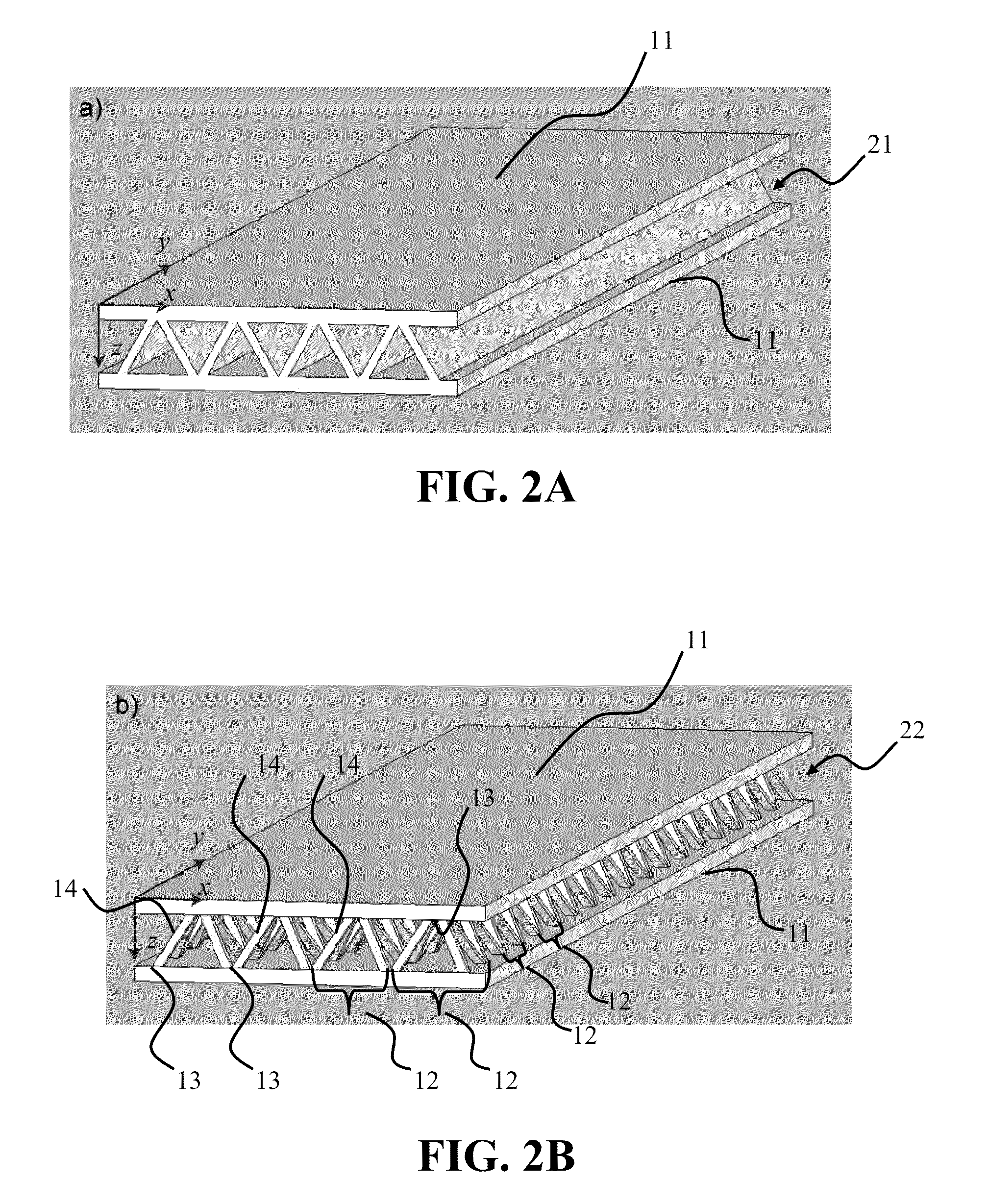

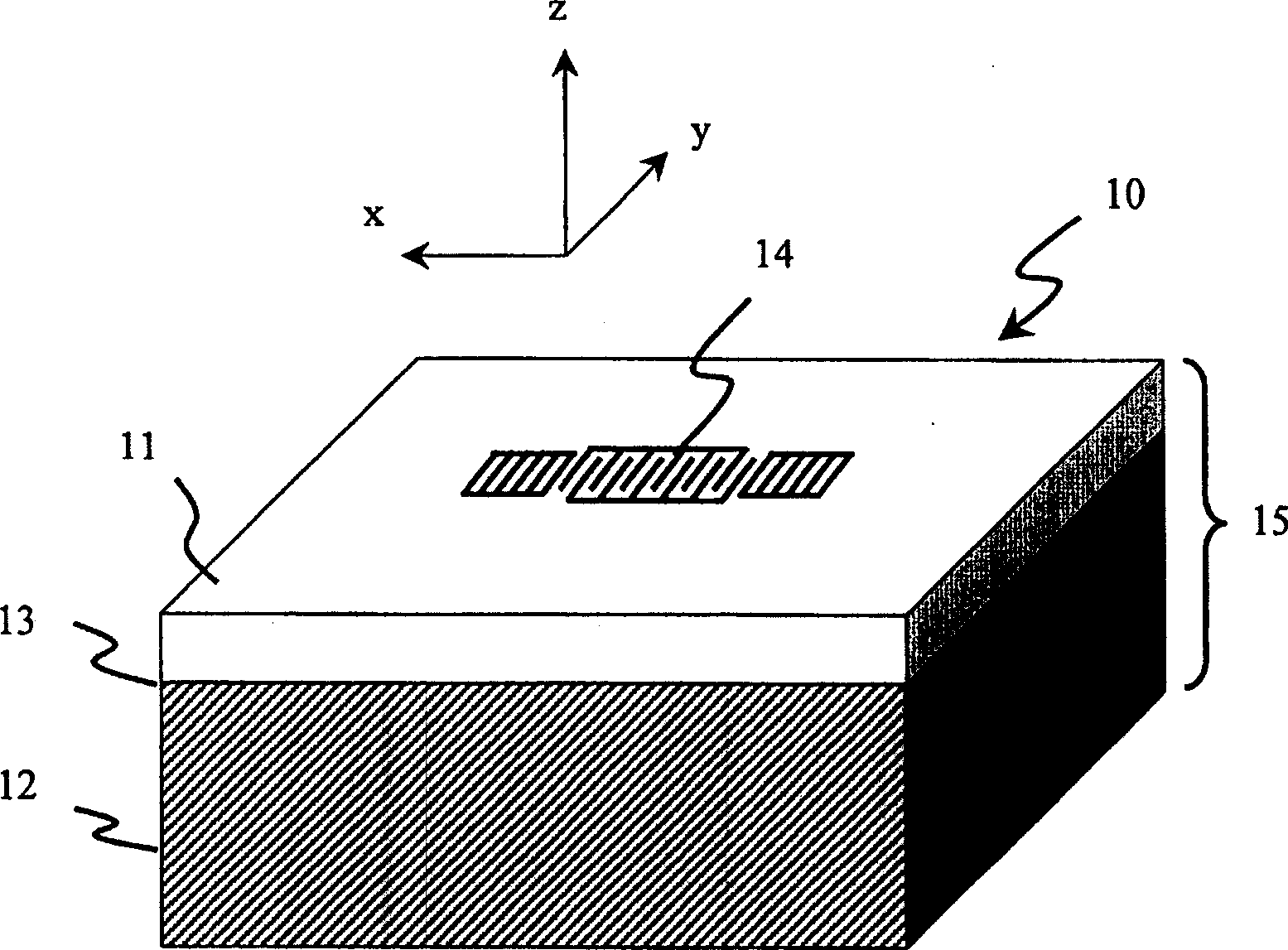

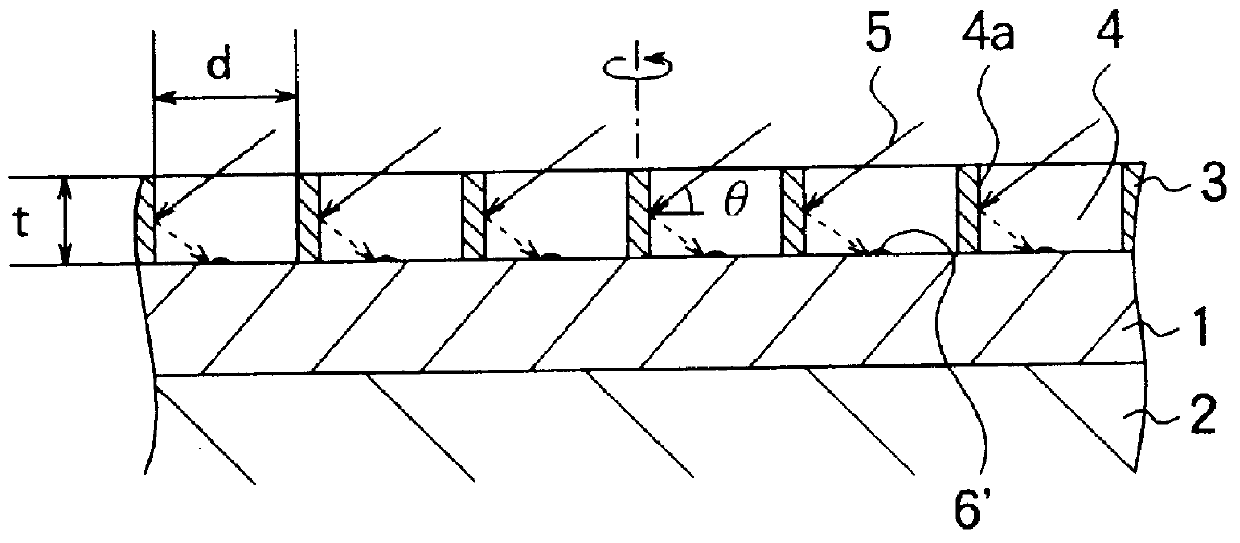

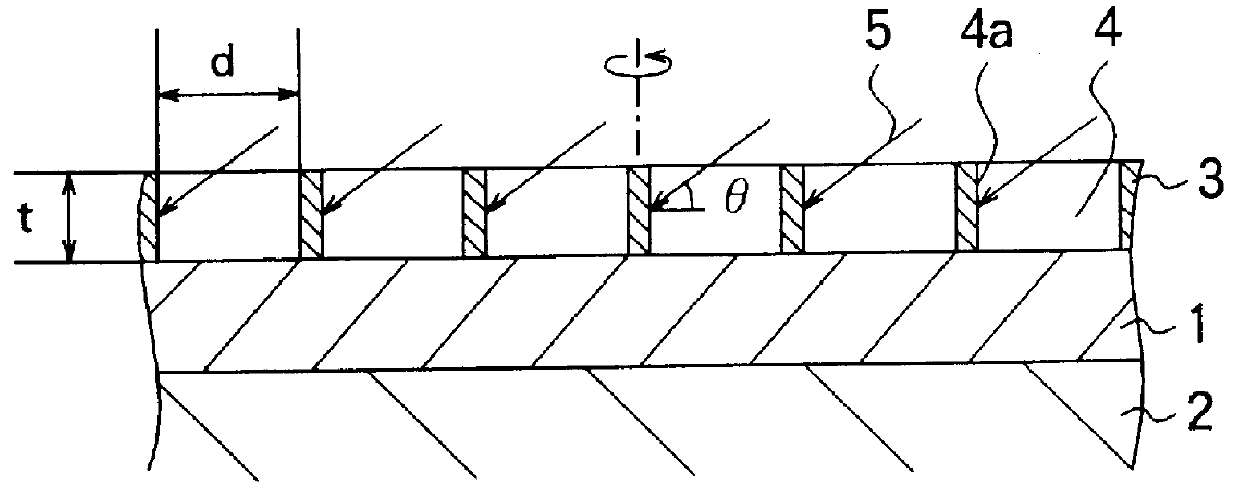

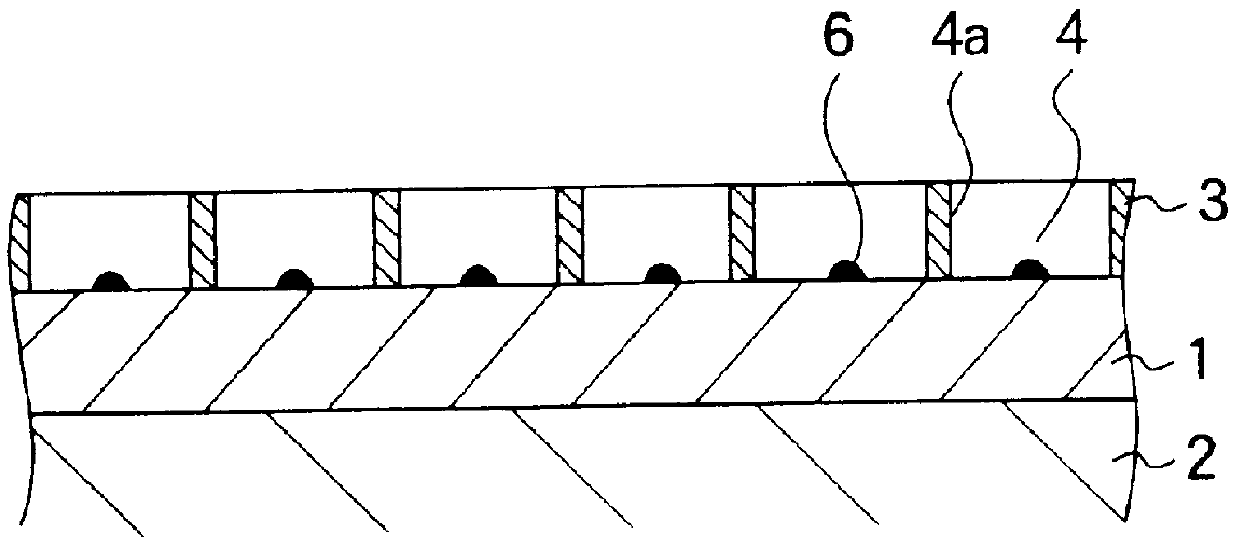

Manufacture of lattice truss structures from monolithic materials

ActiveUS8176635B2Low densityImprove stress resistanceDecorative surface effectsFloorsBond interfaceBonding process

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

Manufacture of Lattice Truss Structures from Monolithic Materials

ActiveUS20090282773A1Low densityImprove stress resistanceDecorative surface effectsFloorsBond interfaceBonding process

Methods and systems to manufacture lattice-based sandwich structures from monolithic material. Such methods and systems eliminate the bonding process which is conventionally used to join lattice based truss cores to facesheets to form sandwich structures. This bonded interface is a key mode of failure for sandwich structures which are subjected to shear or bending loads because the nodes transfer forces from the face sheets to the core members while the topology for a given core relative density dictates the load carrying capacity (assuming adequate node-bond strength exists). An aspect comprises a core and related structures that provide very low density, good crush resistance and high in-plane shear resistance. An aspect of the truss structures may include sandwich panel cores and lattice truss topology that may be designed to efficiently support panel bending loads while maintaining an open topology that facilitates multifunctional applications.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

Bonded substrate, surface acoustic wave chip, and surface acoustic wave device

ActiveCN1665131APiezoelectric/electrostrictive device manufacture/assemblyImpedence networksBond interfaceOxygen

A bonded substrate includes a lithium tantalate substrate and a sapphire substrate to which the lithium tantalate substrate is bonded, a bonded interface of the lithium tantalate and the sapphire substrate includes a bonded region in an amorphous state having a thickness of 0.3 nm to 2.5 nm. The bonded region in the amorphous state is formed by activating at least one of the lithium tantalate substrate and the sapphire substrate in the bonded interface with neutralized atom beams, ion beams or plasma of inert gas or oxygen. It is possible to bond the piezoelectric substrate to the supporting substrate having different lattice constants without the high-temperature thermal treatment and realize the bonded substrate having an excellent bonding strength and being less warped.

Owner:TAIYO YUDEN KK

Test method for anti-permeability performance of fluid sealant and substrate bonding sample interface

InactiveCN101482470AEasy to operateEasy to useMaterial strength using tensile/compressive forcesBond interfaceSealant

The invention discloses a method for testing interface impervious strength of the sample bonded by sealant and base material. The method comprises: reserving a seam cavity of a certain size in the middle of the bonded base material sample, filling sealant into the seam cavity to bond the base material and the sealant into an integral body to obtain a impervious sample of the size matching the water pressure chamber; maintaining the impervious sample in the environment with temperature of 20+ / -2 degrees centigrade and relative humidity of 65+ / -5% for 28 days; fixing the tested cylindrical impervious sample into a steel sample jacket mould; placing upon the water pressure chamber of impervious instrument ensuring that the bonded interface of the sealant and base material is the only channel of the pressure water; increasing the water pressure of the permeability instrument at regular intervals for 0.1MPa each time from 0.1MPa until water seeps from the impervious sample surface; and determining the previous water pressure as the impervious strength of the interface of base material and sealant. The invention has simple operation, need not adding other equipments, it can test the impervious strength of various composite material structure.

Owner:NORTHWEST A & F UNIV

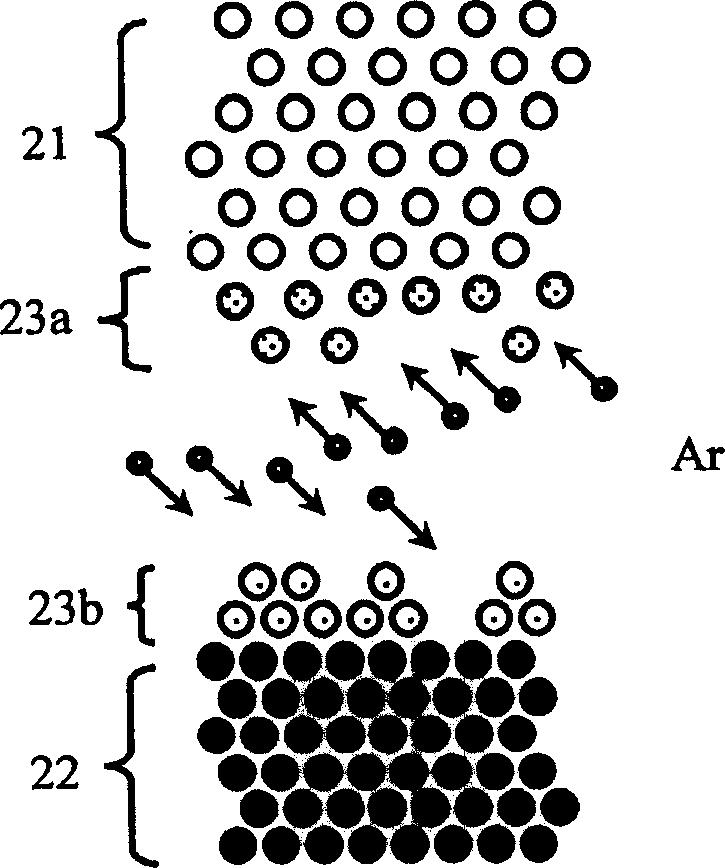

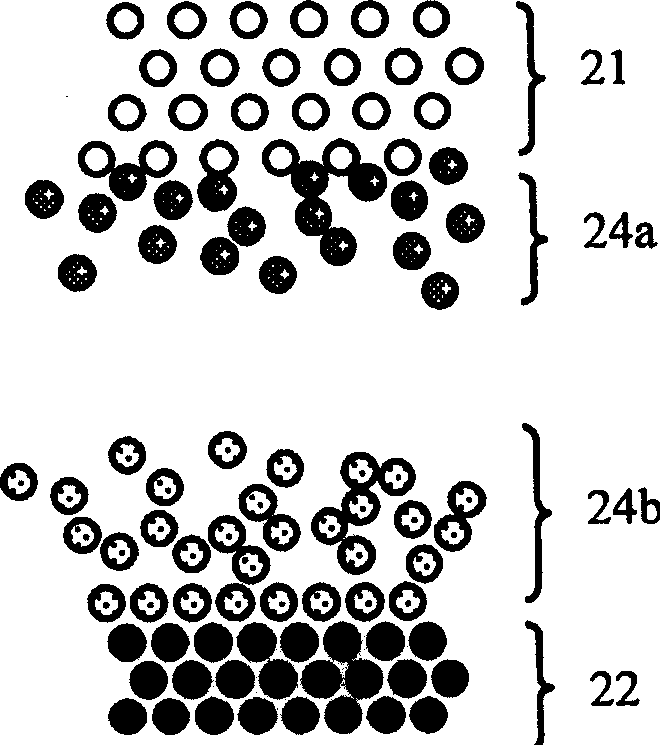

Ultrafine particle and production method thereof, production method of ultrafine particle bonded body, and fullerene and production method thereof

InactiveUS6017630AHigh propertyEasy to getMaterial nanotechnologyFullerenesBond interfaceSingle crystal

A target material having pores is disposed on a substrate. A high energy beam is irradiated to the inner walls of the pores of the target material in a slanting direction. Constituent atoms or molecules of the target material are detached from it to obtain a single or plurality of ultrafine particles separated as a unit substance. The superfine particles are formed at desired positions corresponding to the pores of the target material. Besides, by using an amorphous carbon substrate as the substrate, fullerenes such as an onion-like graphite are formed with the ultrafine particles as nucleation points. When the high energy beam is irradiated to at least two neighboring metal ultrafine particles, these metal ultrafine particles are bonded mutually. When the obtained metal ultrafine particle bonded body has a corresponding grain boundary, the high energy beam is further irradiated to lower value SIGMA of the corresponding grain boundary of the bonded interface. Besides, the metal ultrafine particle bonded body can also be made into a monocrystal grain or a polycrystal grain. Such a metal ultrafine particle bonded body is stable.

Owner:RES DEVMENT OF JAPAN +1

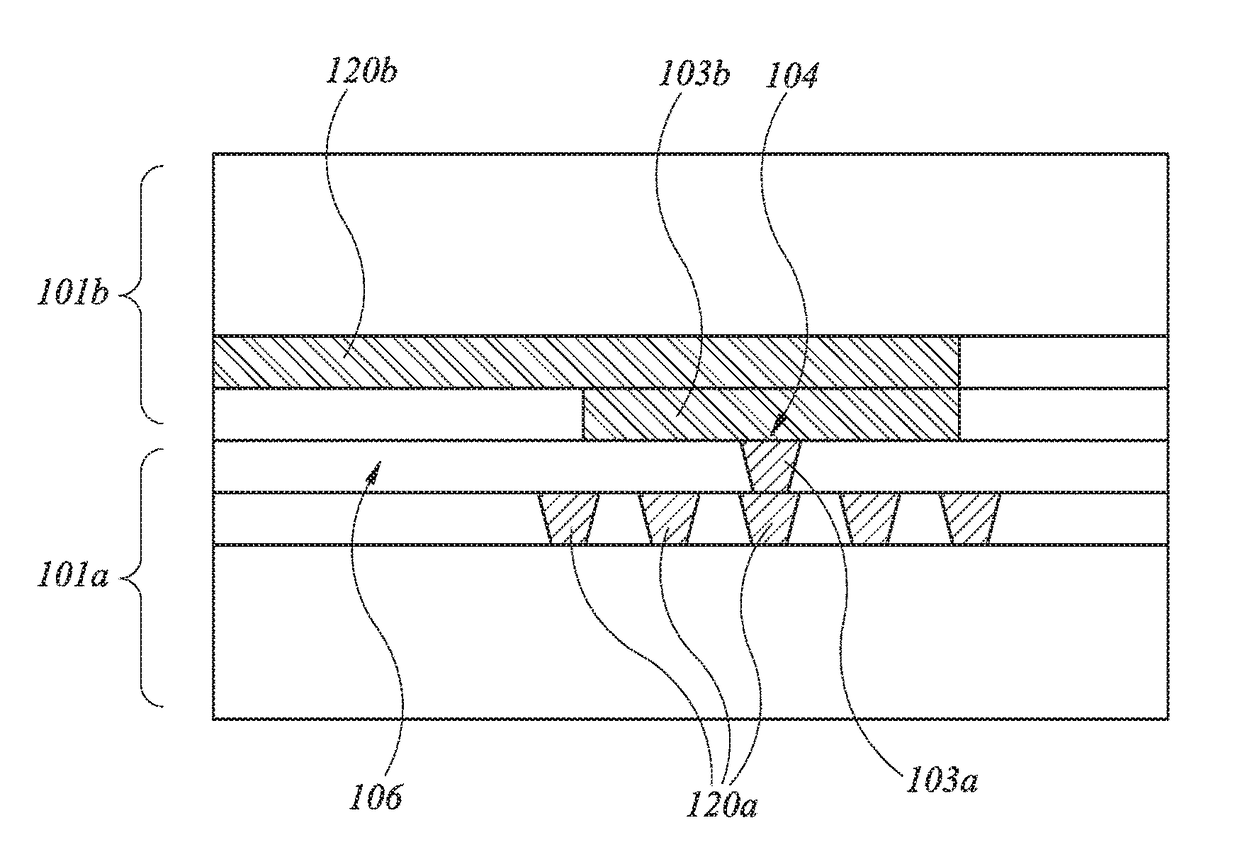

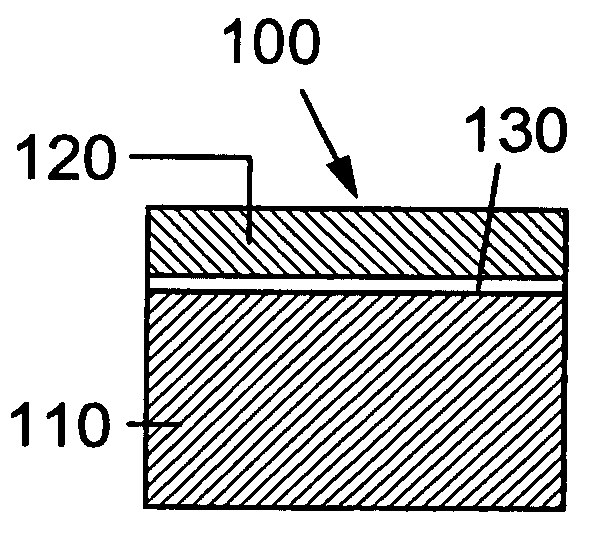

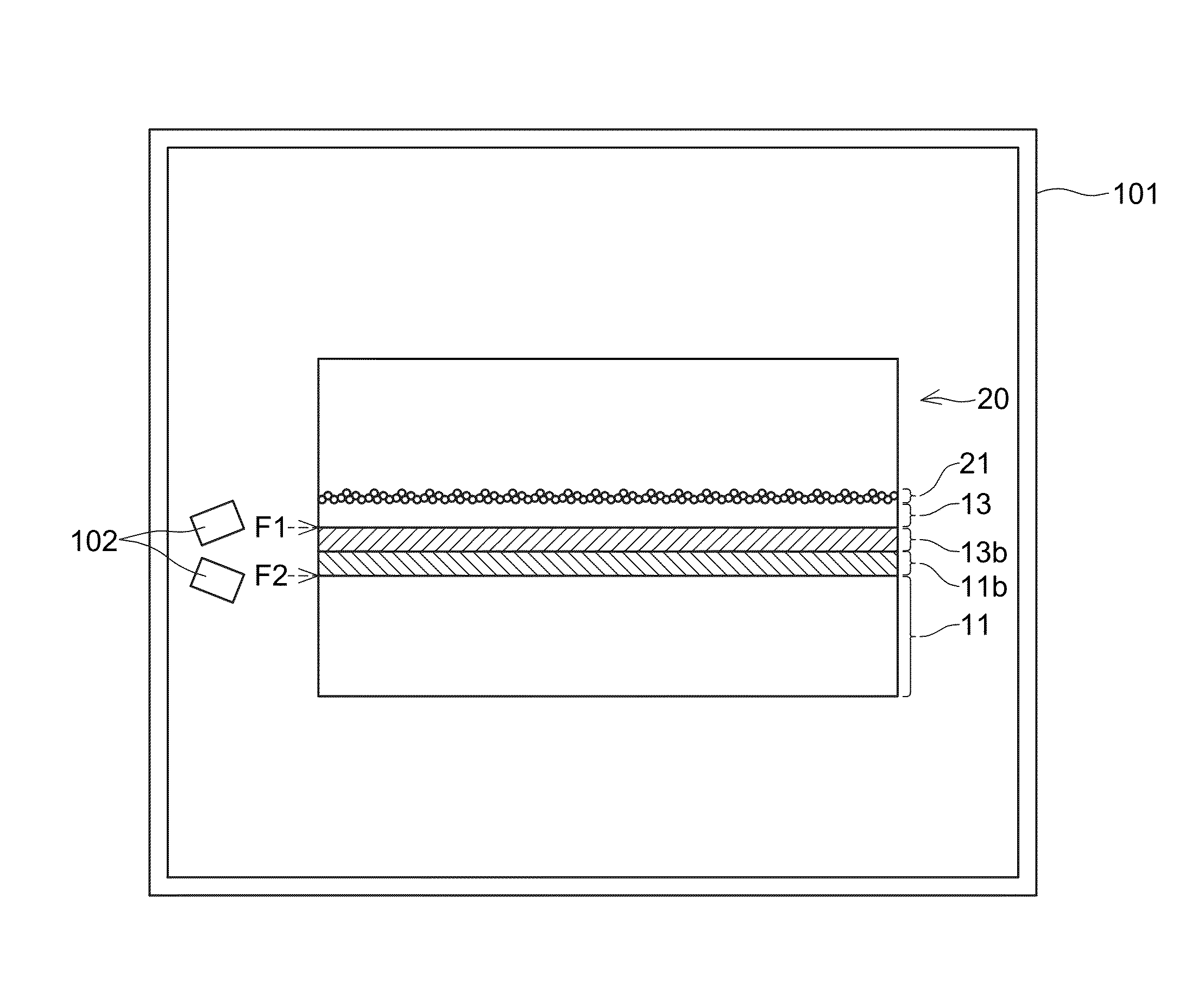

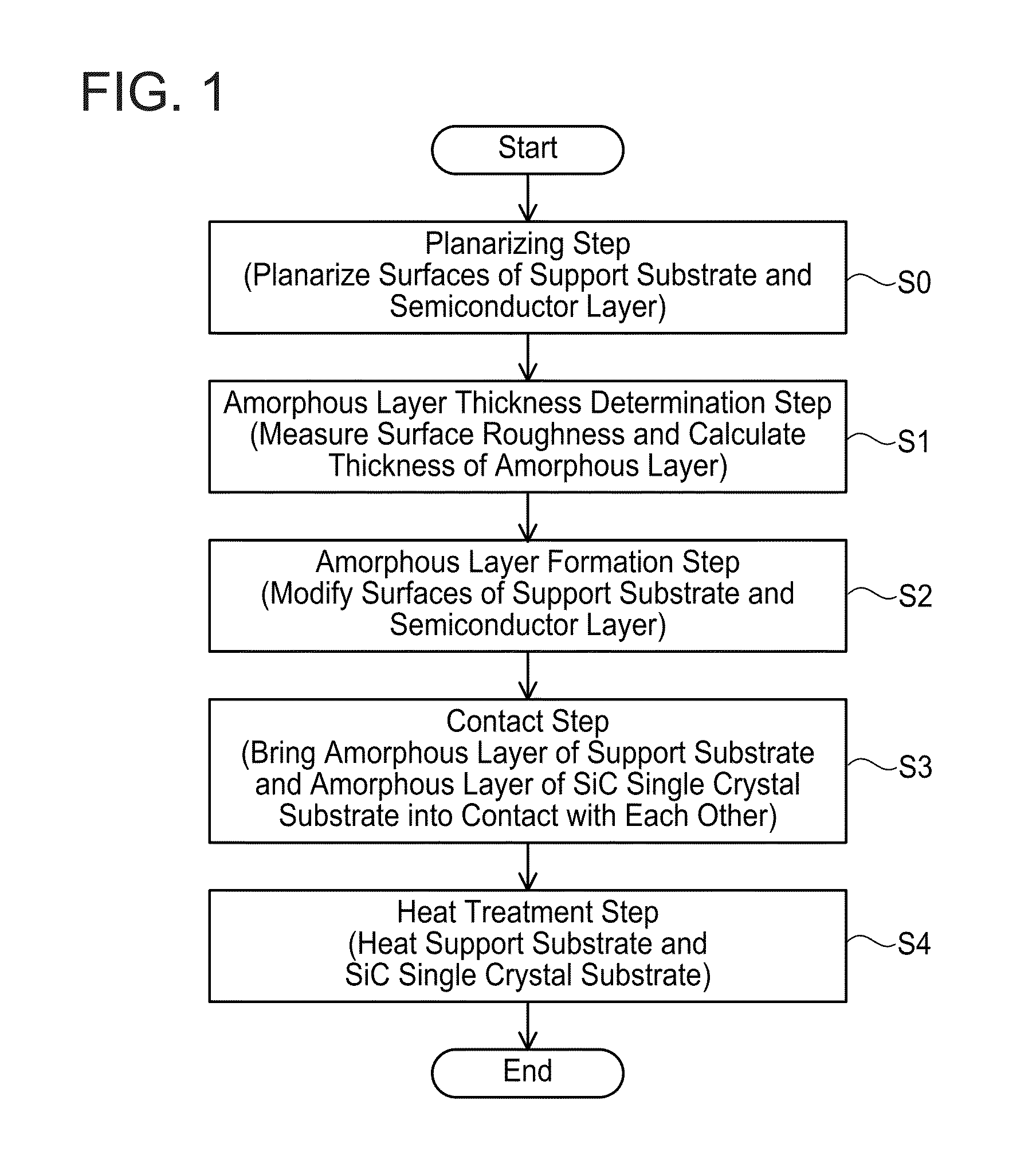

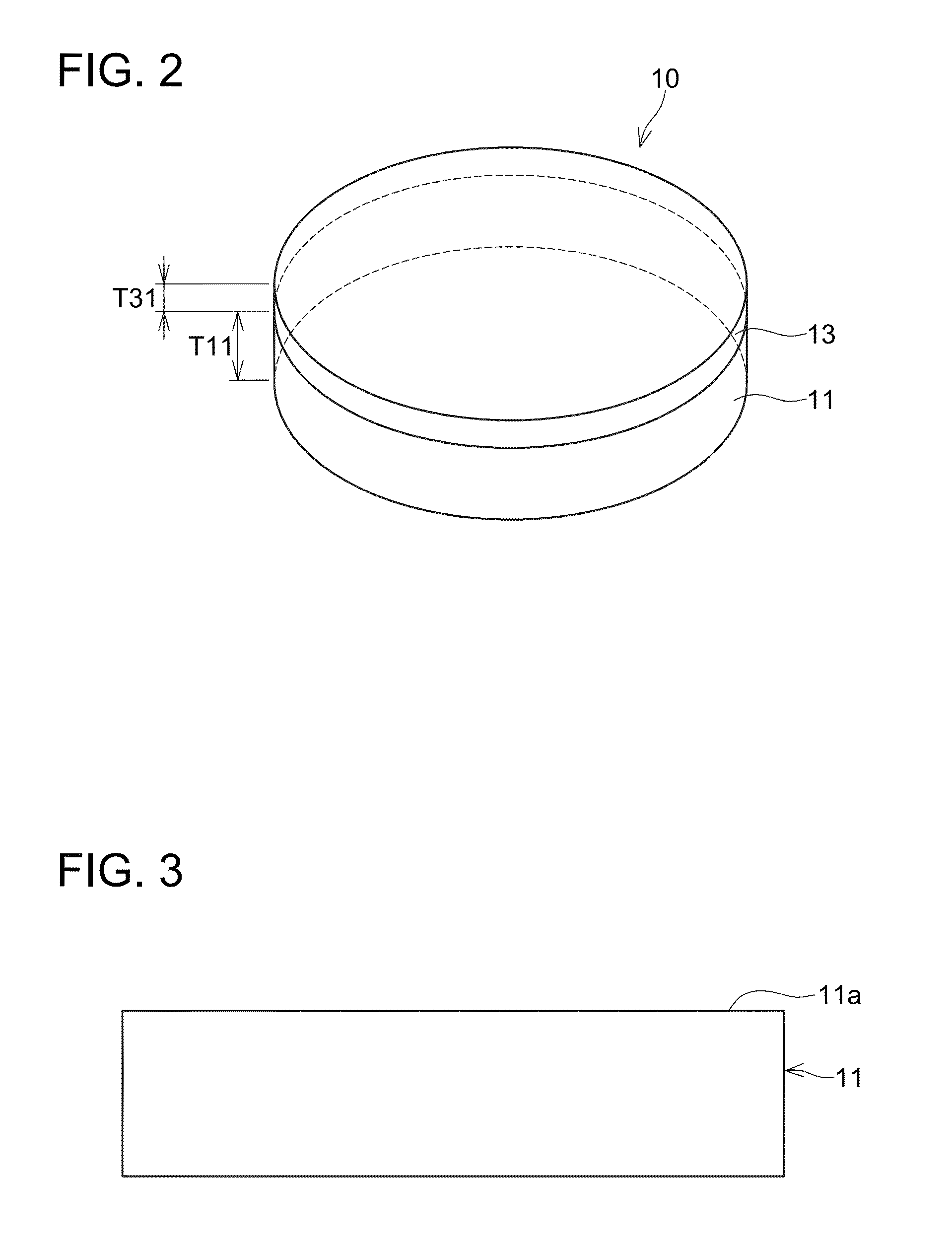

Manufacturing method for semiconductor substrate

ActiveUS20160204023A1High bonding strengthSemiconductor/solid-state device manufacturingSemiconductor devicesBond interfaceSingle crystal

A technique disclosed herein relates to a manufacturing method for a semiconductor substrate having the bonded interface with high bonding strength without forming an oxide layer at the bonded interface also for the substrate having surface that is hardly planarized. The manufacturing method for the semiconductor substrate may include an amorphous layer formation process in which a first amorphous layer is formed by modifying a surface of a support substrate and a second amorphous layer is formed by modifying a surface of a single-crystalline layer of a semiconductor. The manufacturing method may include a contact process in which the first amorphous layer and the second amorphous layer are contacted with each other. The manufacturing method may include a heat treatment process in which the support substrate and single-crystalline layer are heat-treated with the first amorphous layer and the second amorphous layer being in contact with each other.

Owner:SICOXS +1

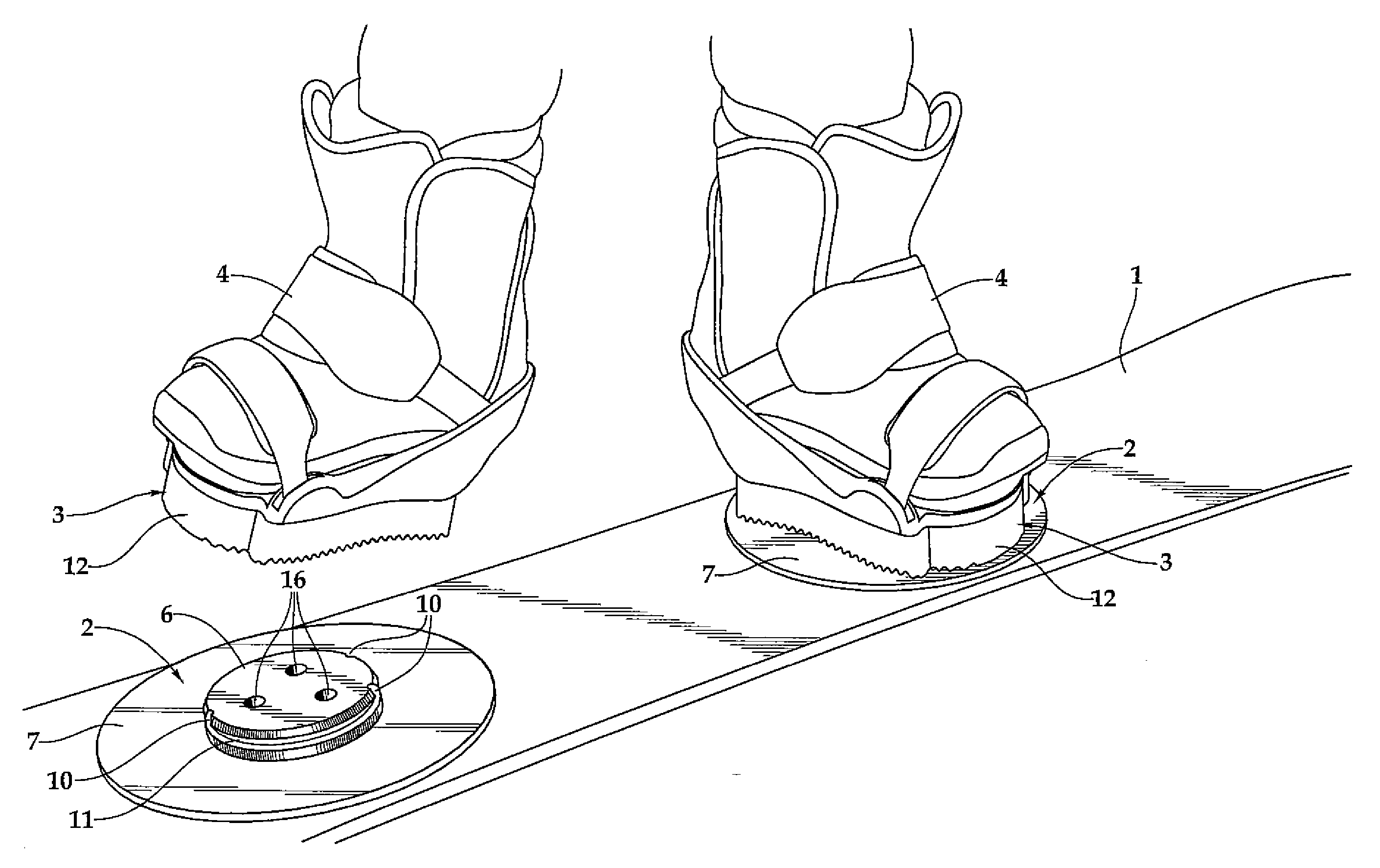

Snowboard binding accessory

InactiveUS20100109289A1Enhanced couplingDisrupting smooth rotationSki bindingsSnowboard bindingsEngineeringBonded interface

Owner:WISCHHUSEN RENE +1

Increased contact alignment tolerance for direct bonding

ActiveUS20180204798A1Easy temperatureSemiconductor/solid-state device detailsSolid-state devicesBond interfaceParasitic capacitance

A bonded device structure including a first substrate having a first set of conductive contact structures, preferably connected to a device or circuit, and having a first non-metallic region adjacent to the contact structures on the first substrate, a second substrate having a second set of conductive contact structures, preferably connected to a device or circuit, and having a second non-metallic region adjacent to the contact structures on the second substrate, and a contact-bonded interface between the first and second set of contact structures formed by contact bonding of the first non-metallic region to the second non-metallic region. The contact structures include elongated contact features, such as individual lines or lines connected in a grid, that are non-parallel on the two substrates, making contact at intersections. Alignment tolerances are thus improved while minimizing dishing and parasitic capacitance.

Owner:INVENSAS BONDING TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com