Patents

Literature

234 results about "Metallic bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metallic bonding is a type of chemical bonding that rises from the electrostatic attractive force between conduction electrons (in the form of an electron cloud of delocalized electrons) and positively charged metal ions. It may be described as the sharing of free electrons among a structure of positively charged ions (cations). Metallic bonding accounts for many physical properties of metals, such as strength, ductility, thermal and electrical resistivity and conductivity, opacity, and luster.

Complexes with tridentate ligands

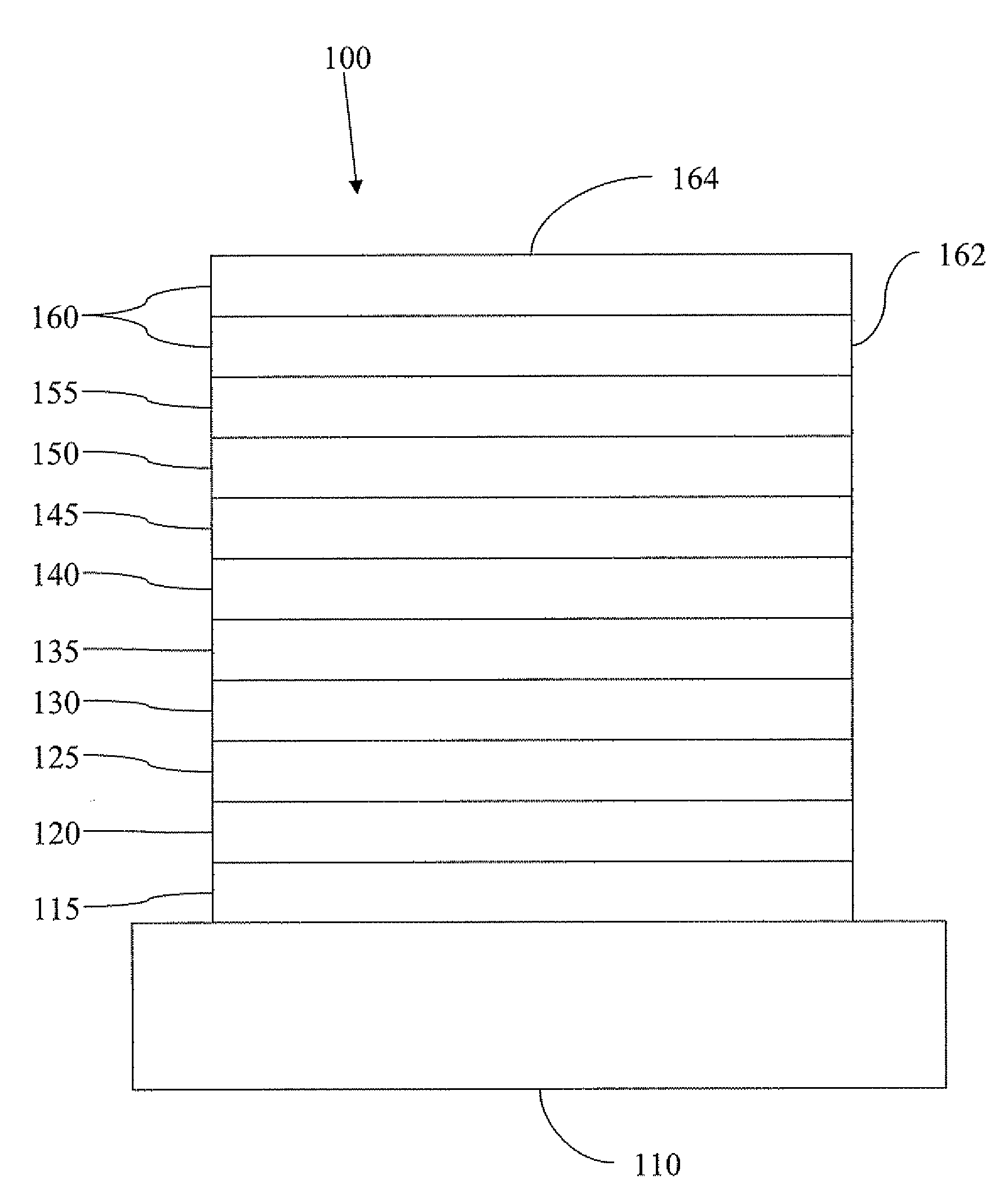

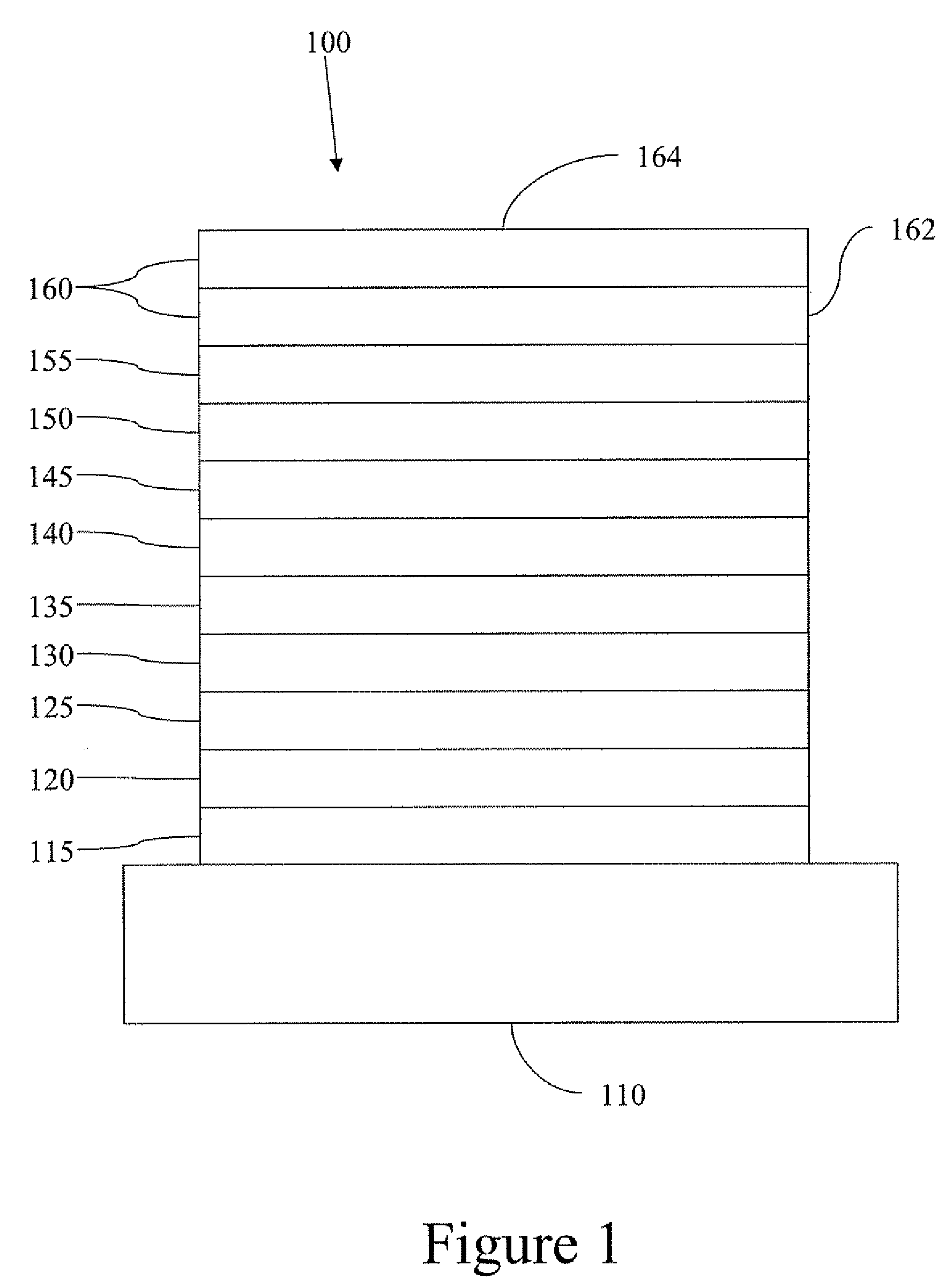

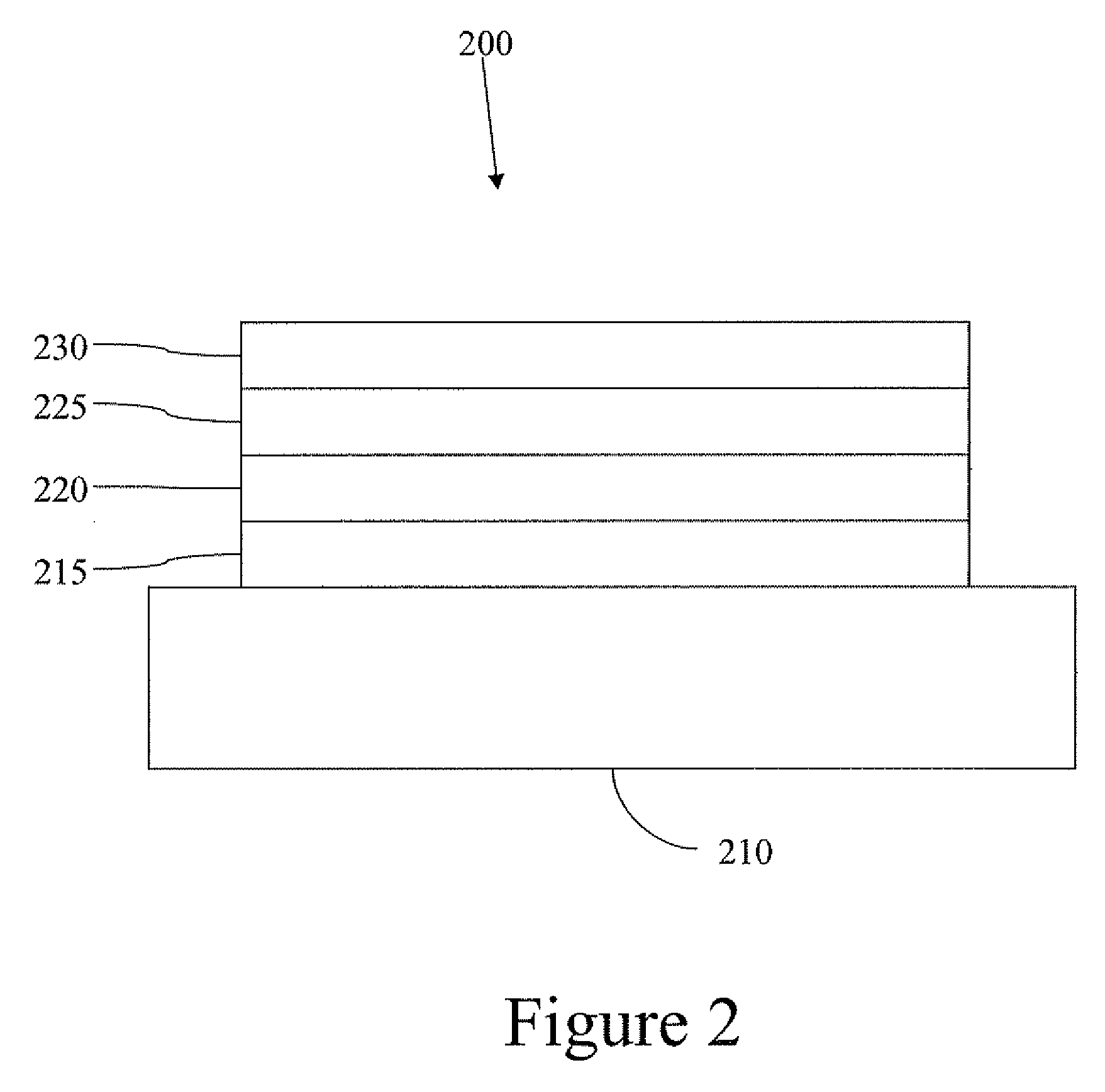

ActiveUS20090115322A1Group 5/15 element organic compoundsGroup 3/13 element organic compoundsOrganic light emitting deviceCoordination complex

The present invention relates to organic light emitting devices (OLEDs), and more specifically to phosphorescent organic materials used in such devices. More specifically, the present invention relates to emissive phosphorescent material which comprise at least one tridentate ligand bound to a metal center, wherein at least one of the bonds to the tridentate ligand is a carbon-metal bond.

Owner:UNIVERSAL DISPLAY

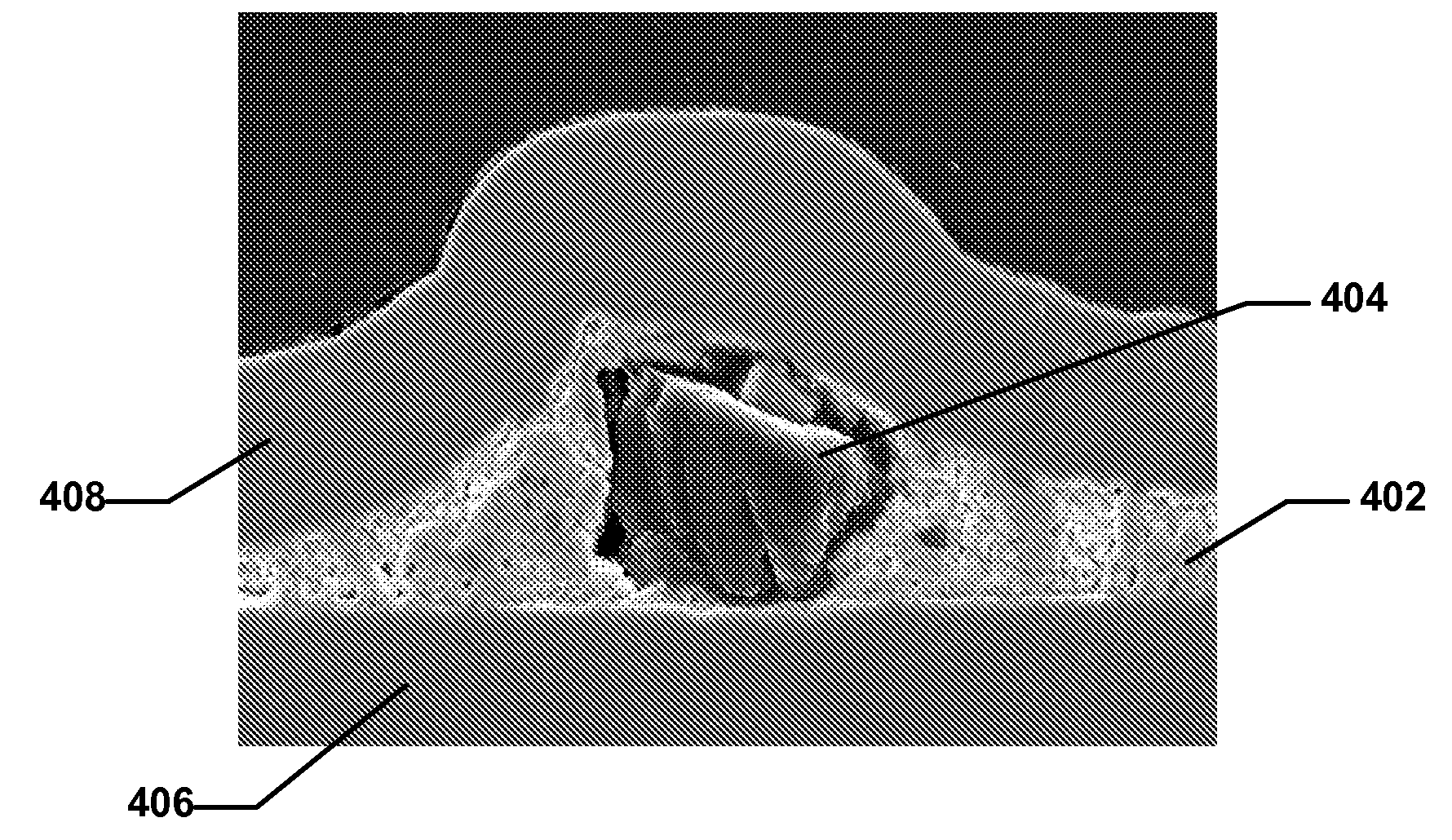

Method for room temperature metal direct bonding

InactiveUS6962835B2Solid-state devicesSemiconductor/solid-state device manufacturingBond interfaceRoom temperature

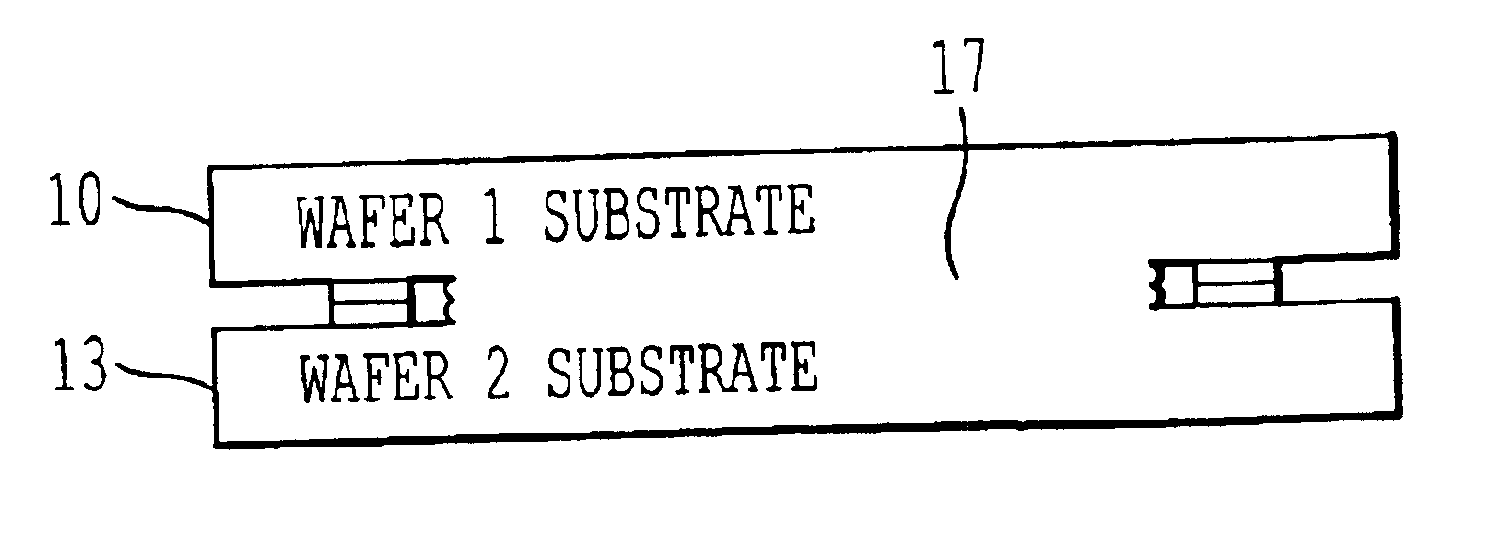

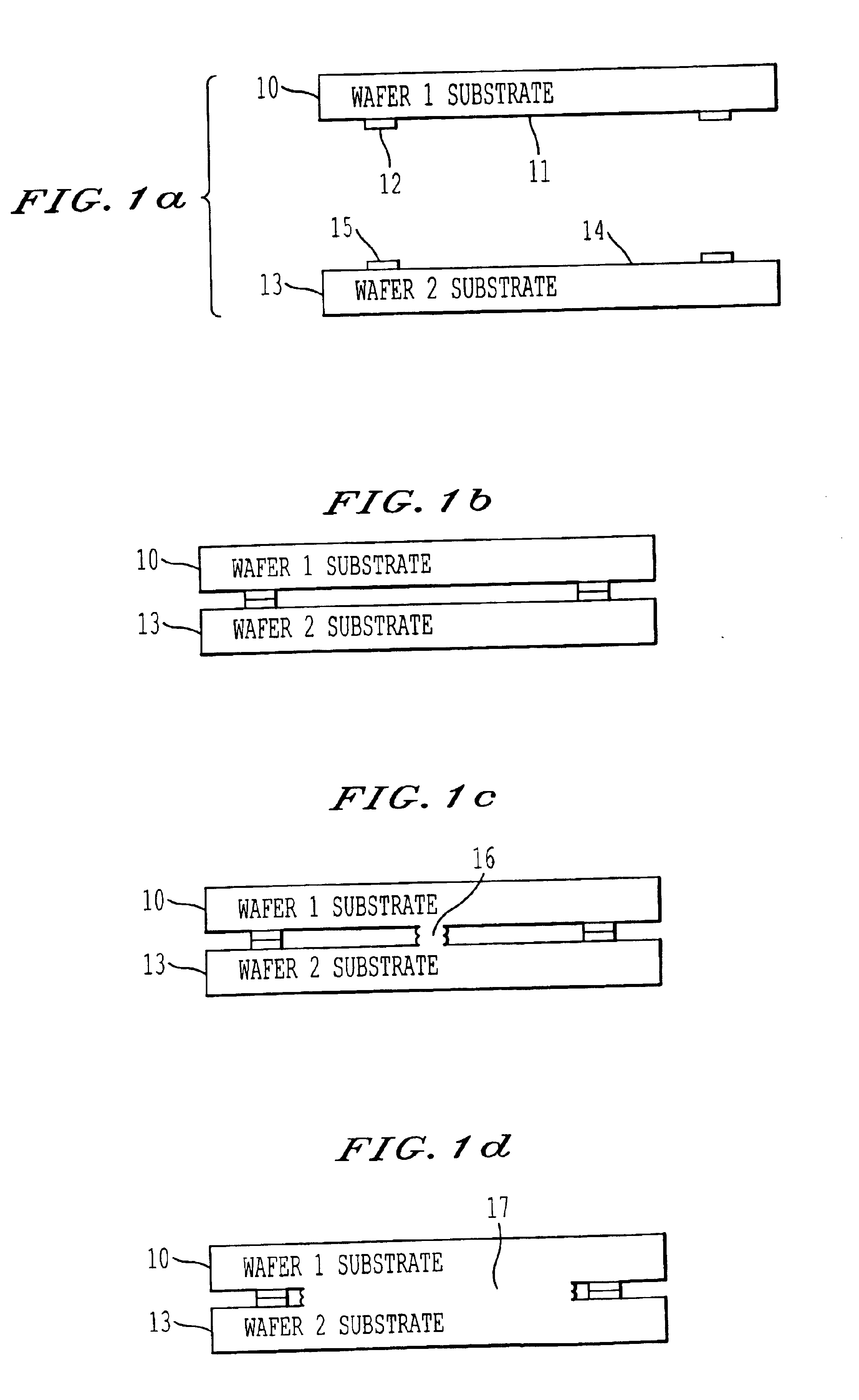

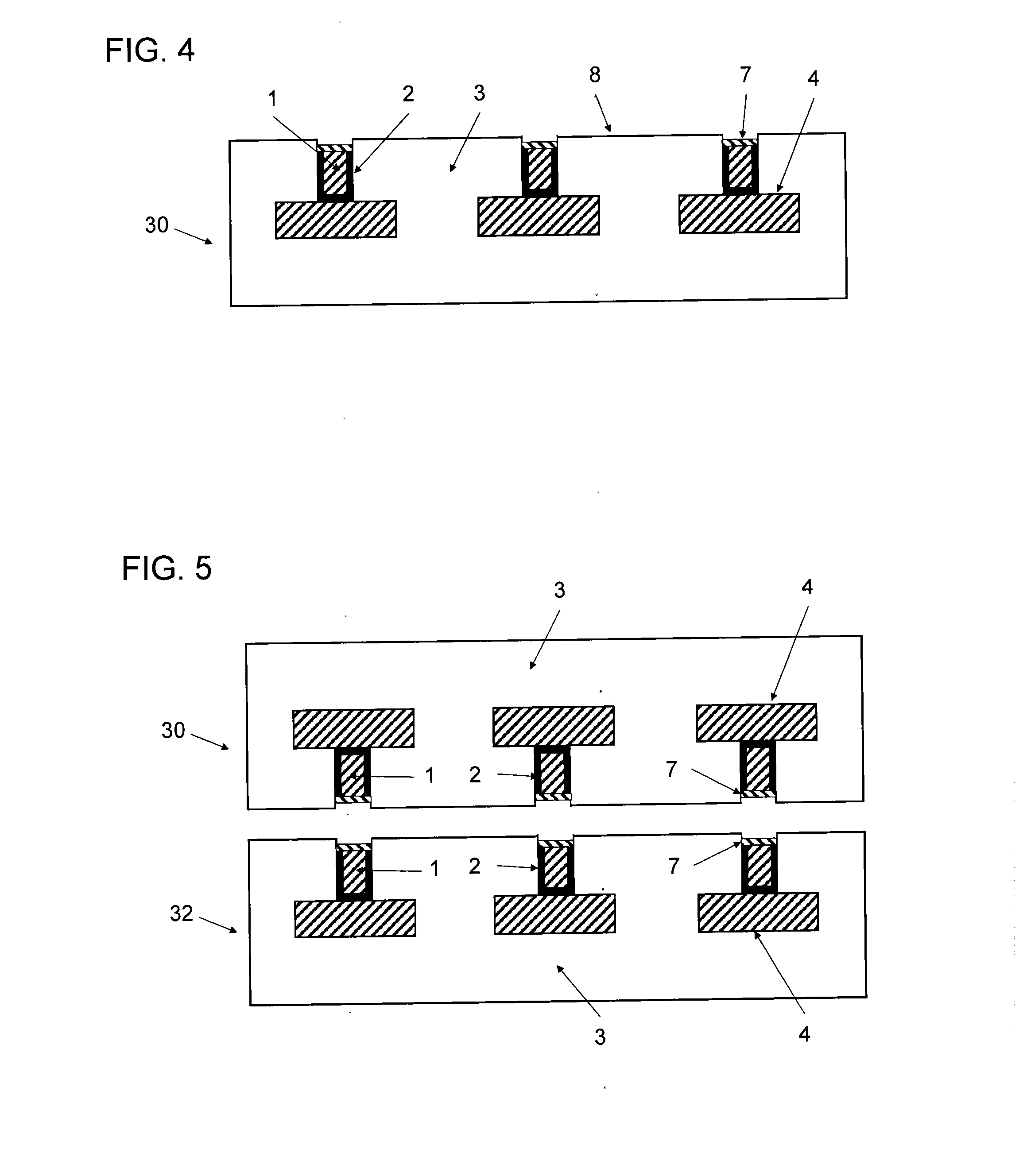

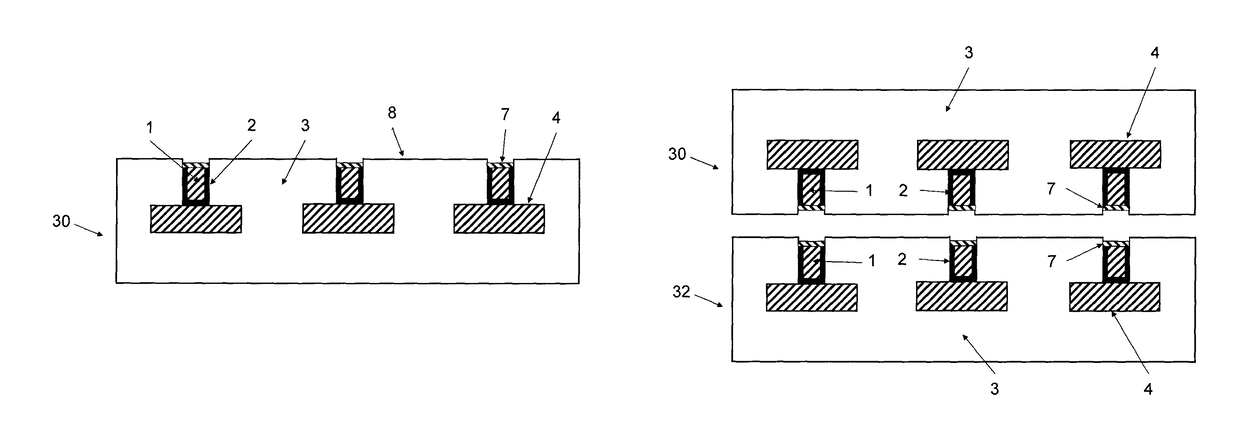

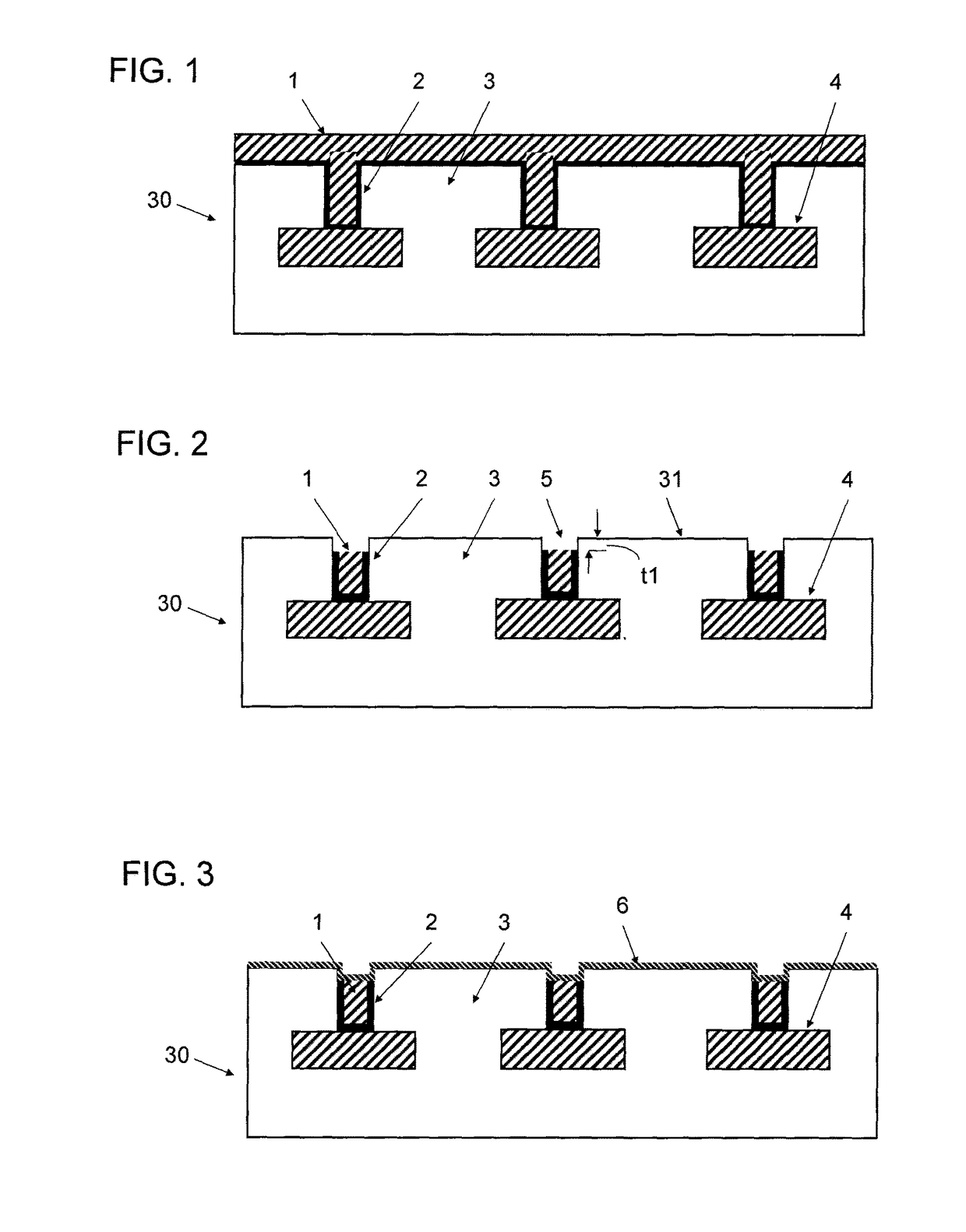

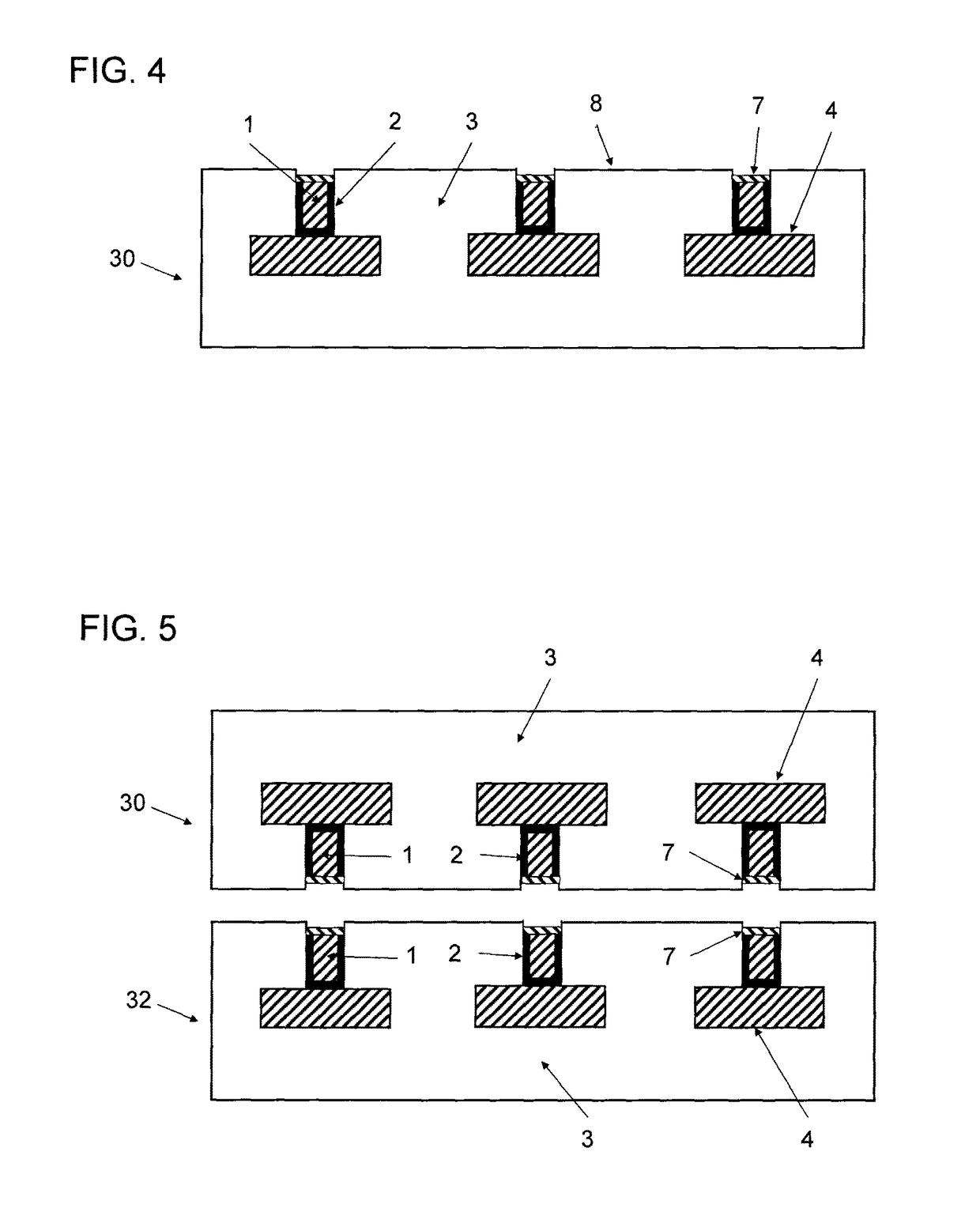

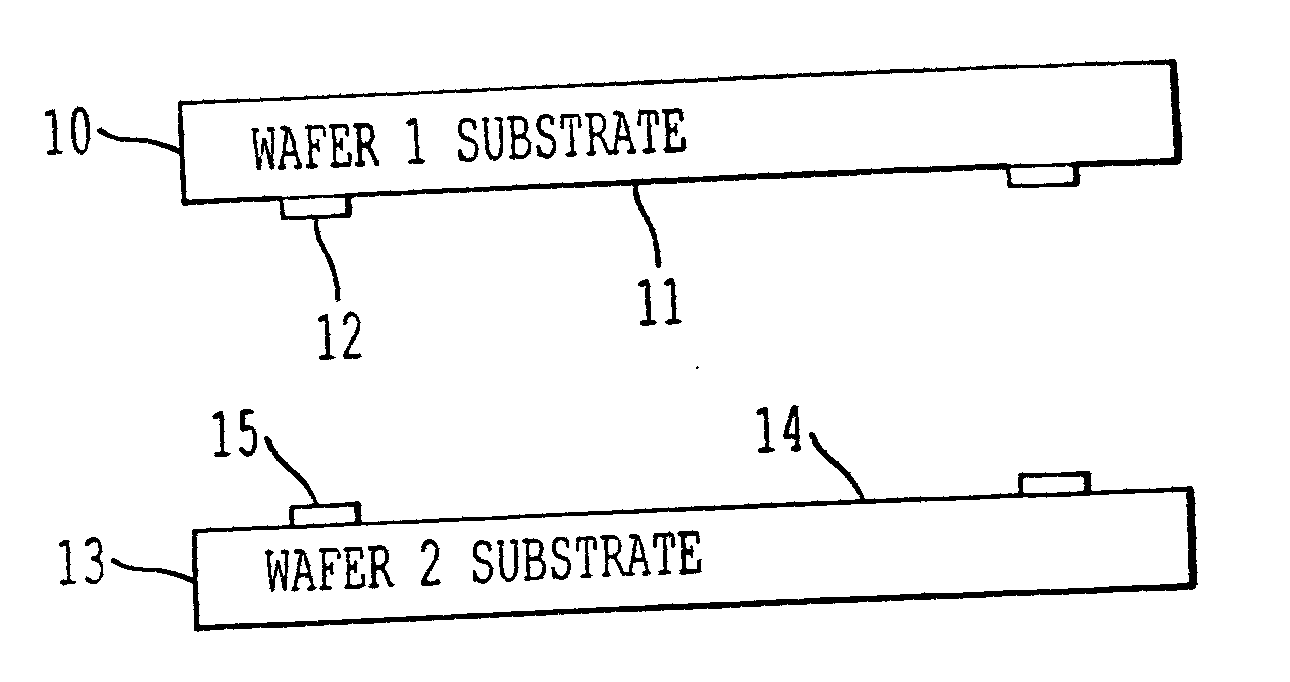

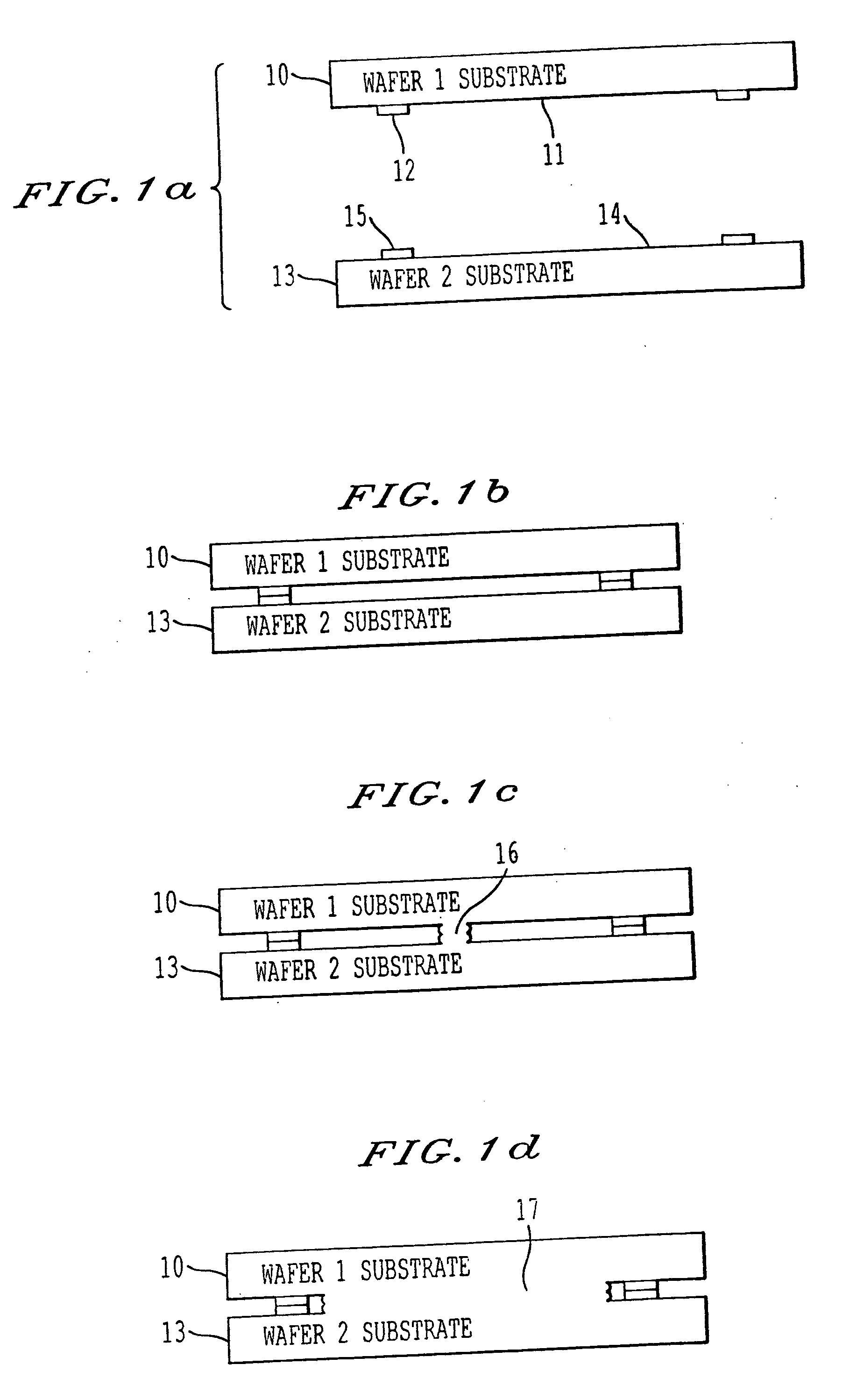

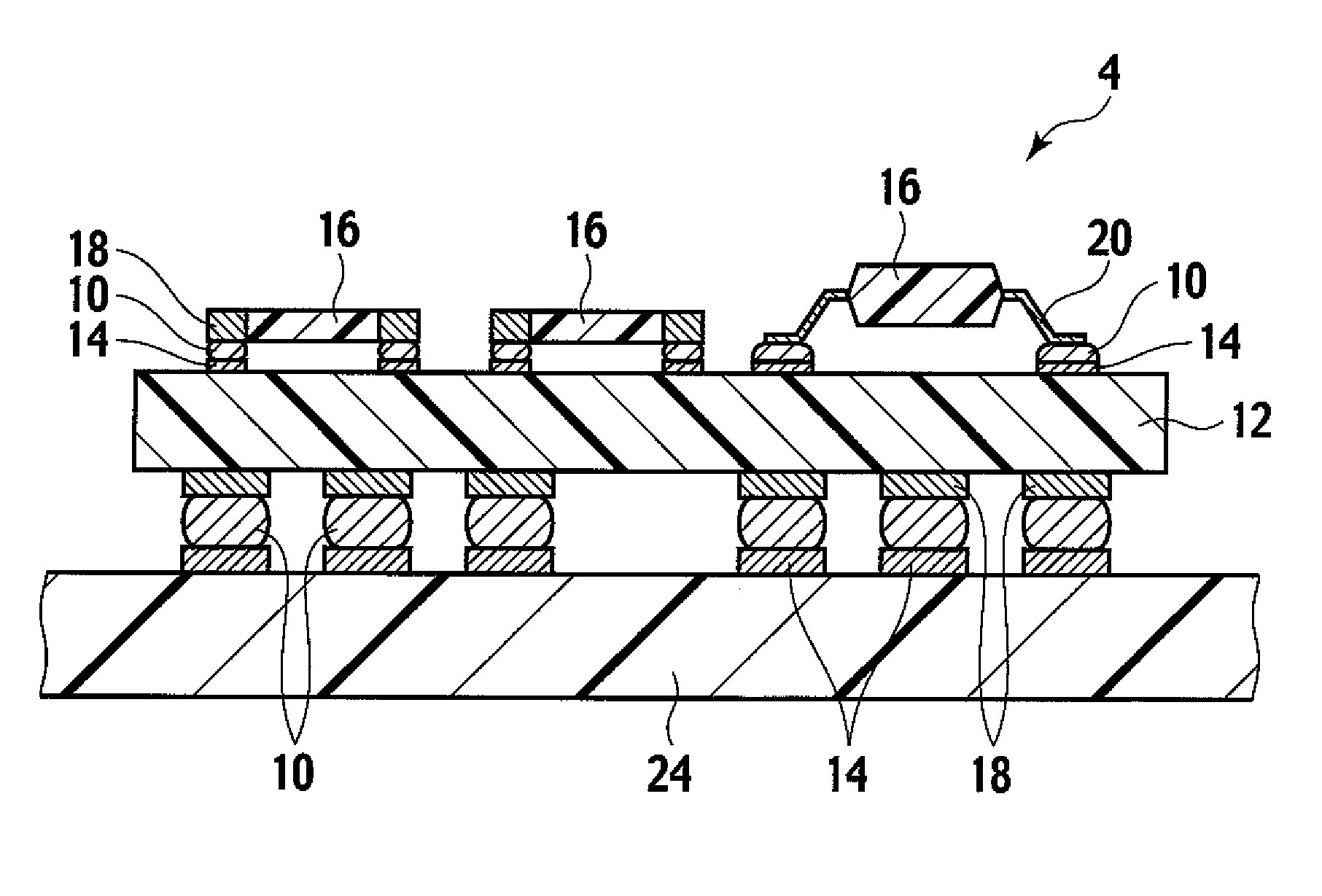

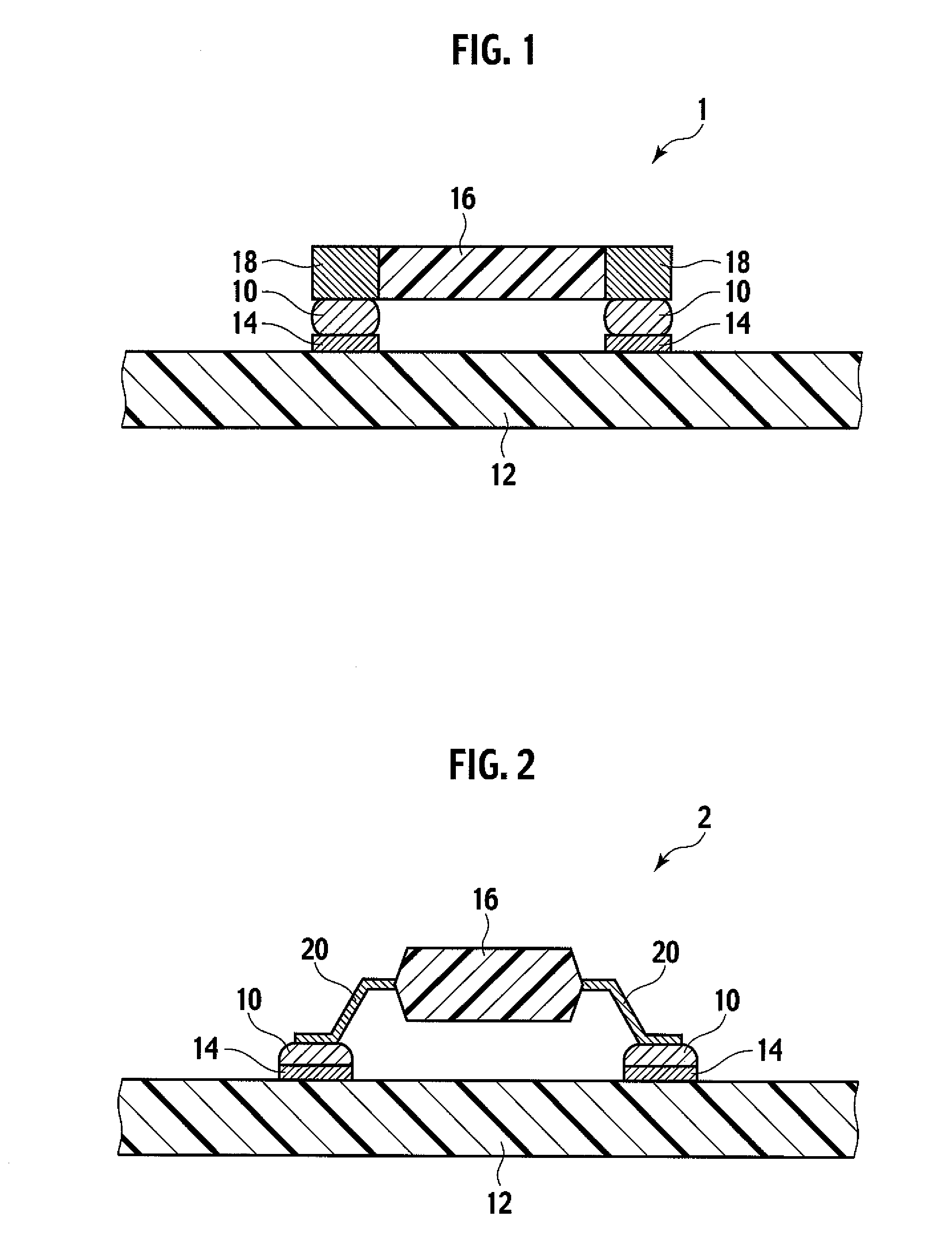

A bonded device structure including a first substrate having a first set of metallic bonding pads, preferably connected to a device or circuit, and having a first non-metallic region adjacent to the metallic bonding pads on the first substrate, a second substrate having a second set of metallic bonding pads aligned with the first set of metallic bonding pads, preferably connected to a device or circuit, and having a second non-metallic region adjacent to the metallic bonding pads on the second substrate, and a contact-bonded interface between the first and second set of metallic bonding pads formed by contact bonding of the first non-metallic region to the second non-metallic region. At least one of the first and second substrates may be elastically deformed.

Owner:INVENSAS BONDING TECH INC

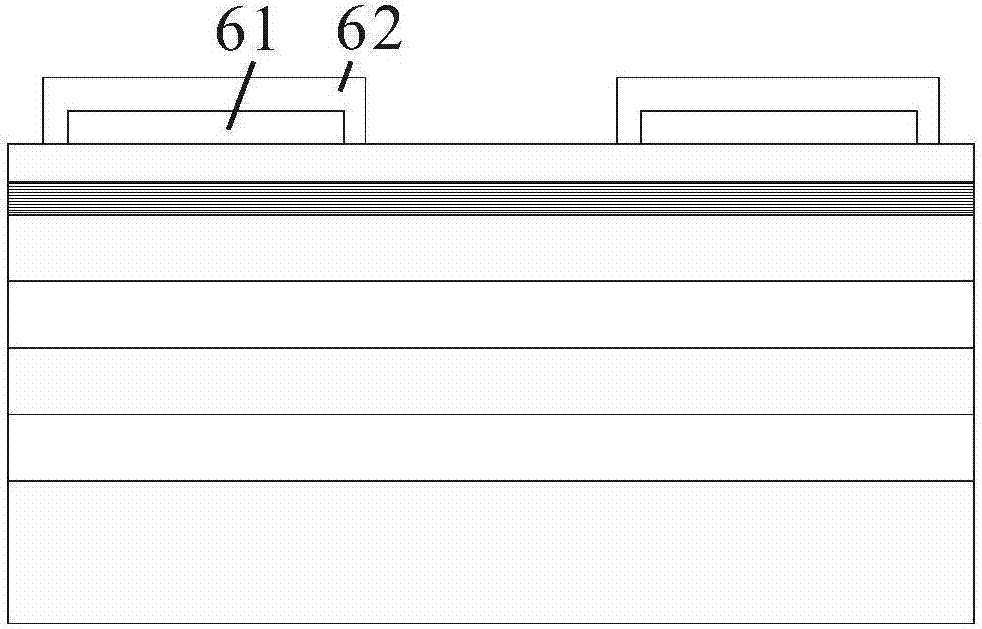

Conductive barrier direct hybrid bonding

ActiveUS20170062366A1Semiconductor/solid-state device detailsSolid-state devicesBond interfaceMetallic bonding

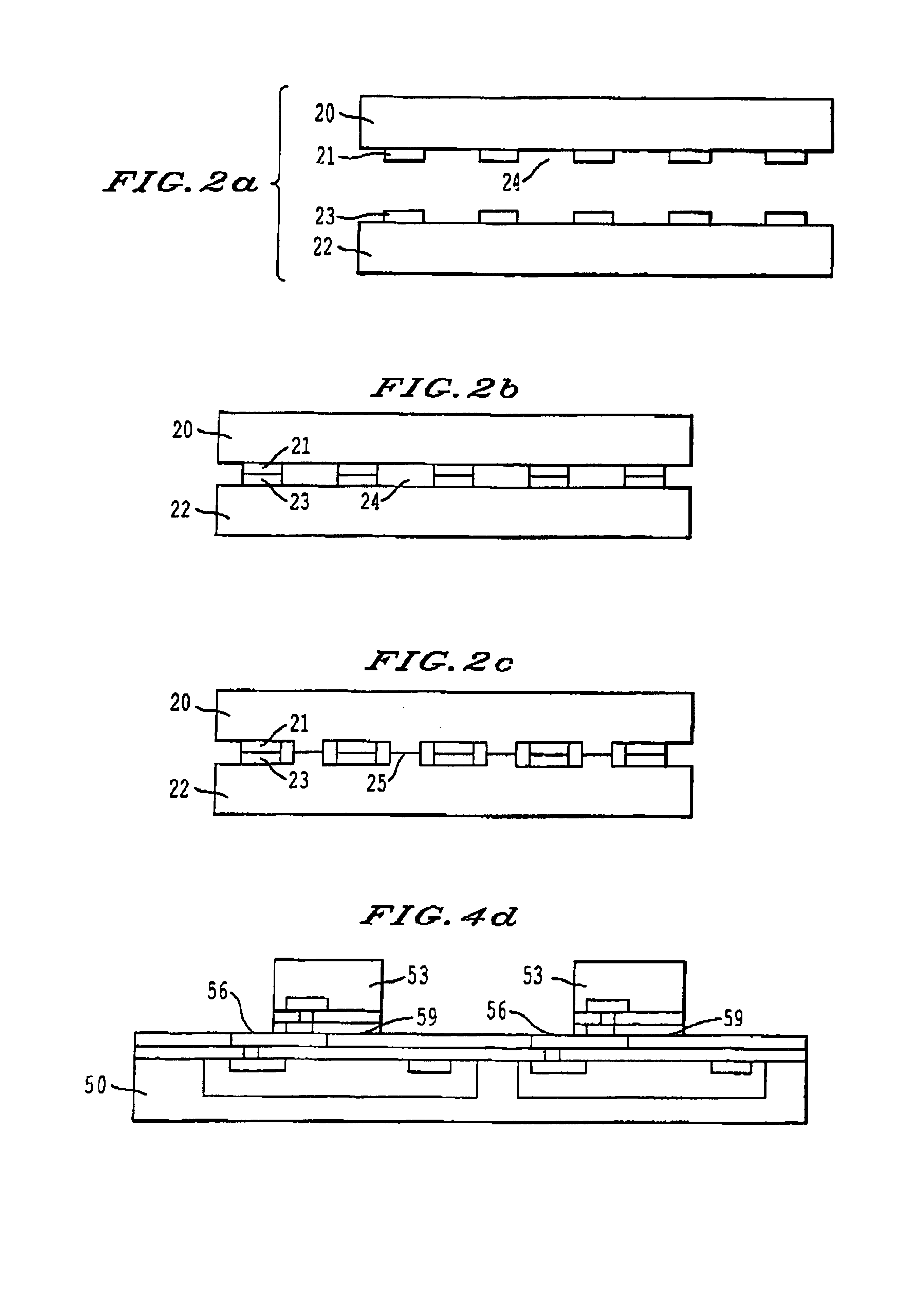

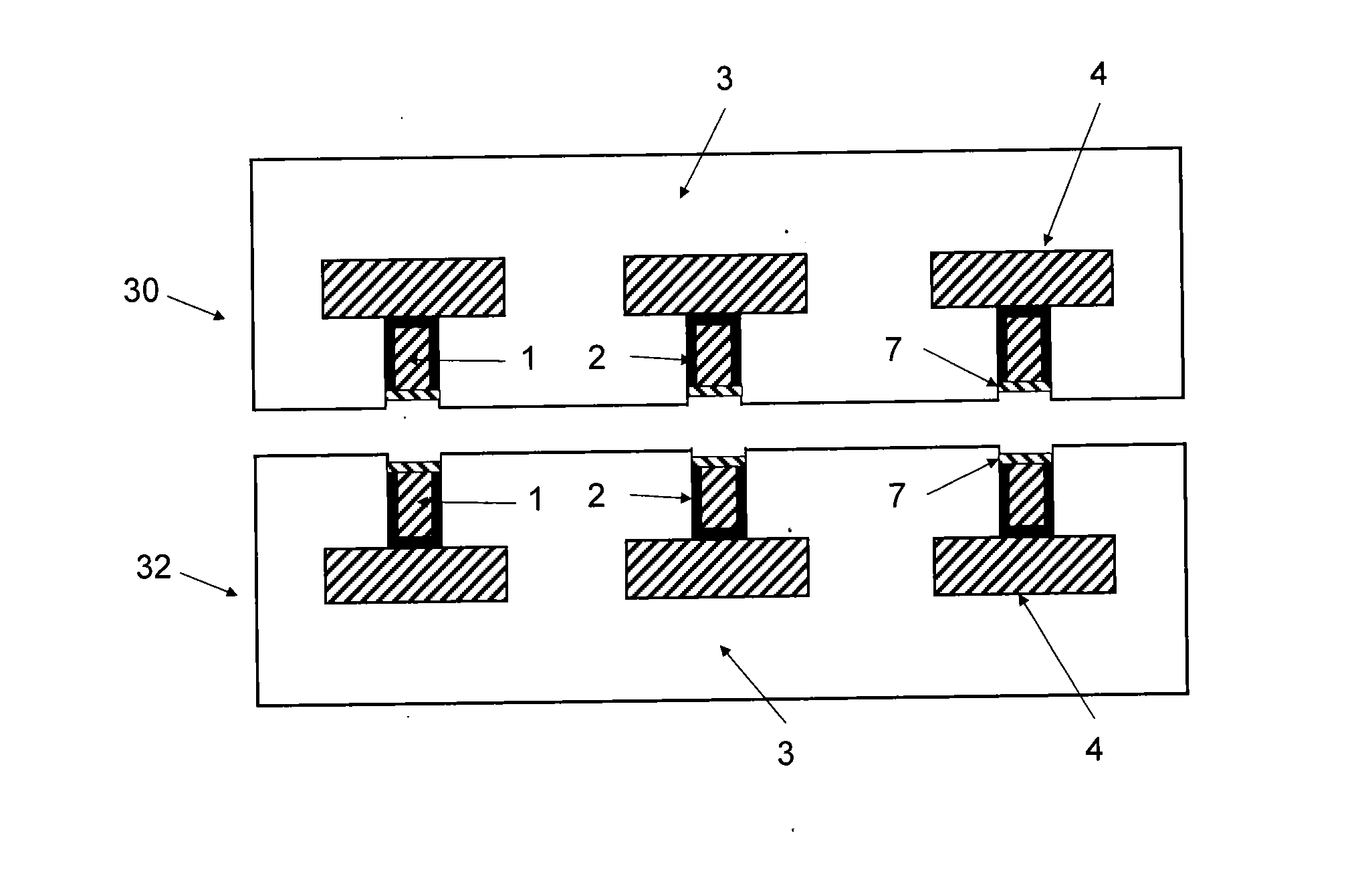

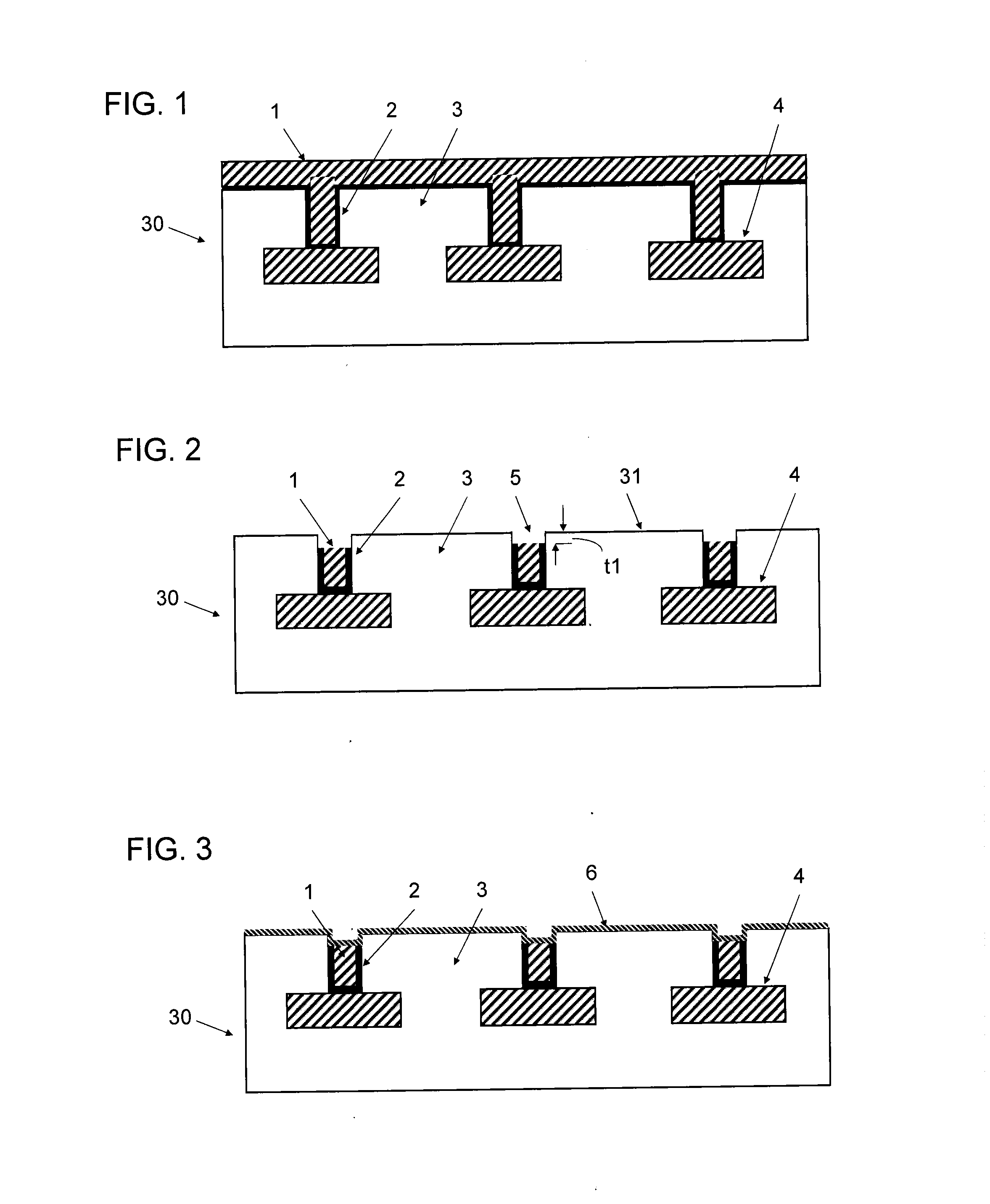

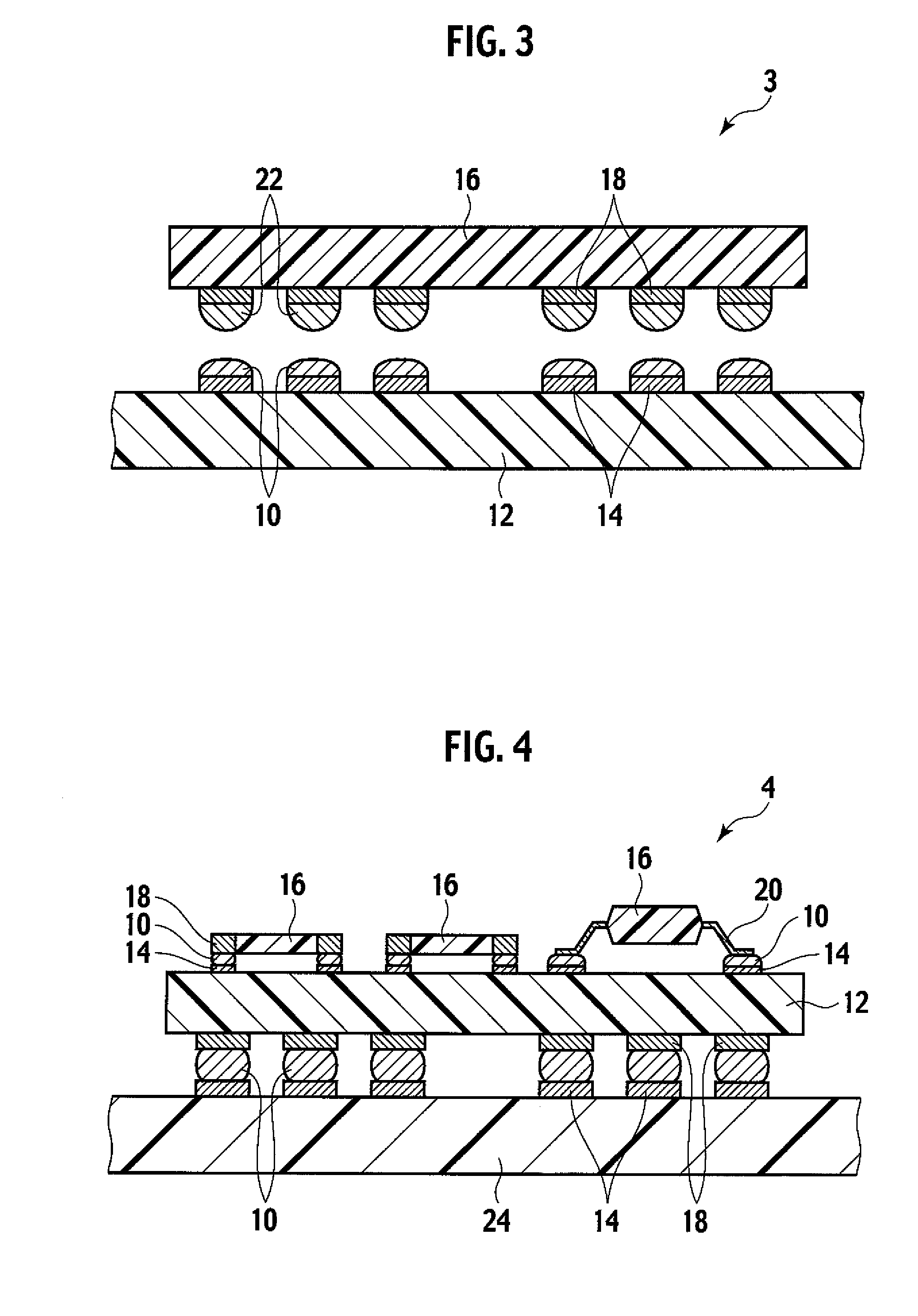

A method for forming a direct hybrid bond and a device resulting from a direct hybrid bond including a first substrate having a first set of metallic bonding pads, preferably connected to a device or circuit, capped by a conductive barrier, and having a first non-metallic region adjacent to the metallic bonding pads on the first substrate, a second substrate having a second set of metallic bonding pads capped by a second conductive barrier, aligned with the first set of metallic bonding pads, preferably connected to a device or circuit, and having a second non-metallic region adjacent to the metallic bonding pads on the second substrate, and a contact-bonded interface between the first and second set of metallic bonding pads capped by conductive barriers formed by contact bonding of the first non-metallic region to the second non-metallic region.

Owner:INVENSAS BONDING TECH INC

Conductive barrier direct hybrid bonding

ActiveUS9953941B2Semiconductor/solid-state device detailsSolid-state devicesBond interfaceMetallic bonding

Owner:INVENSAS BONDING TECH INC

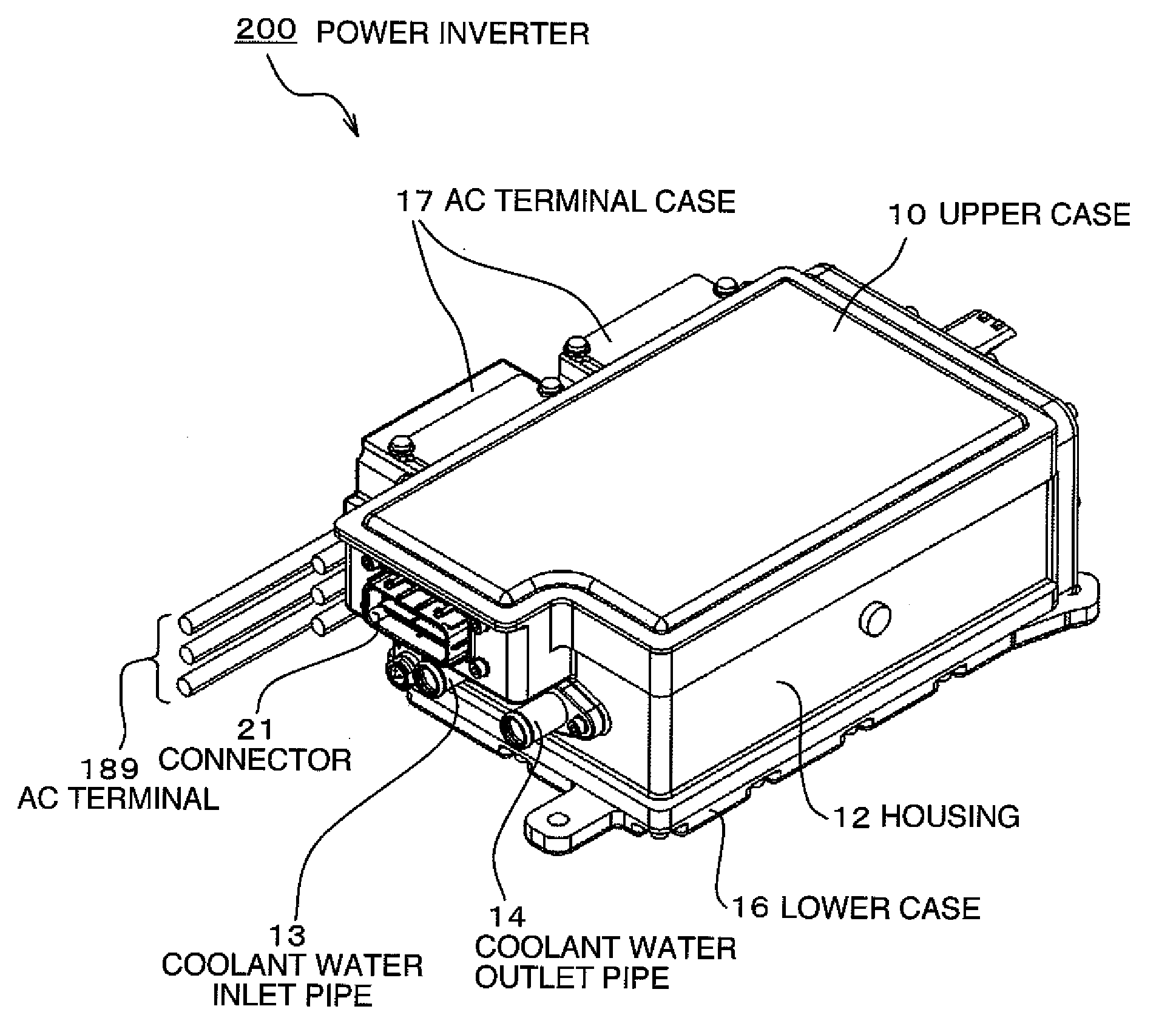

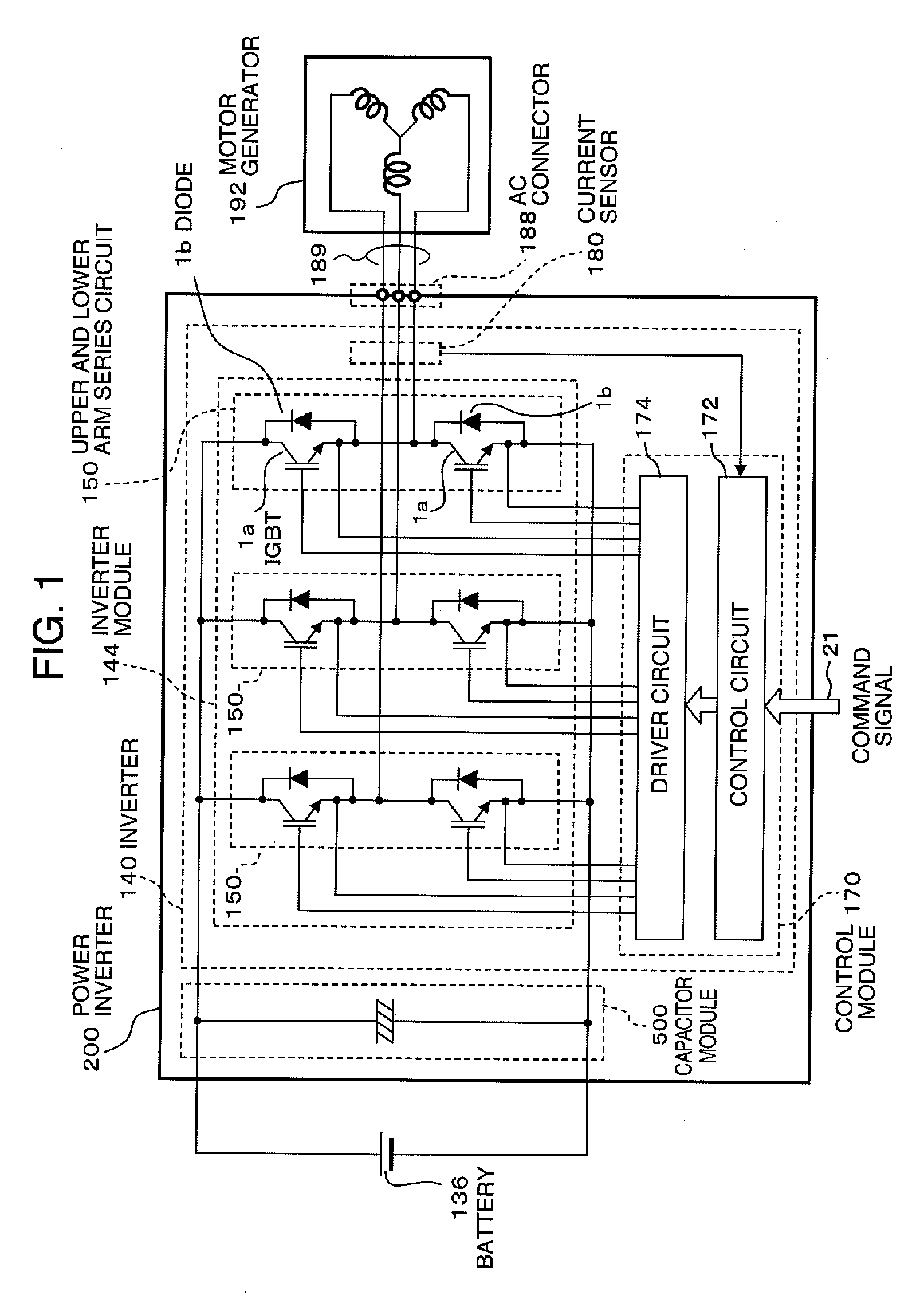

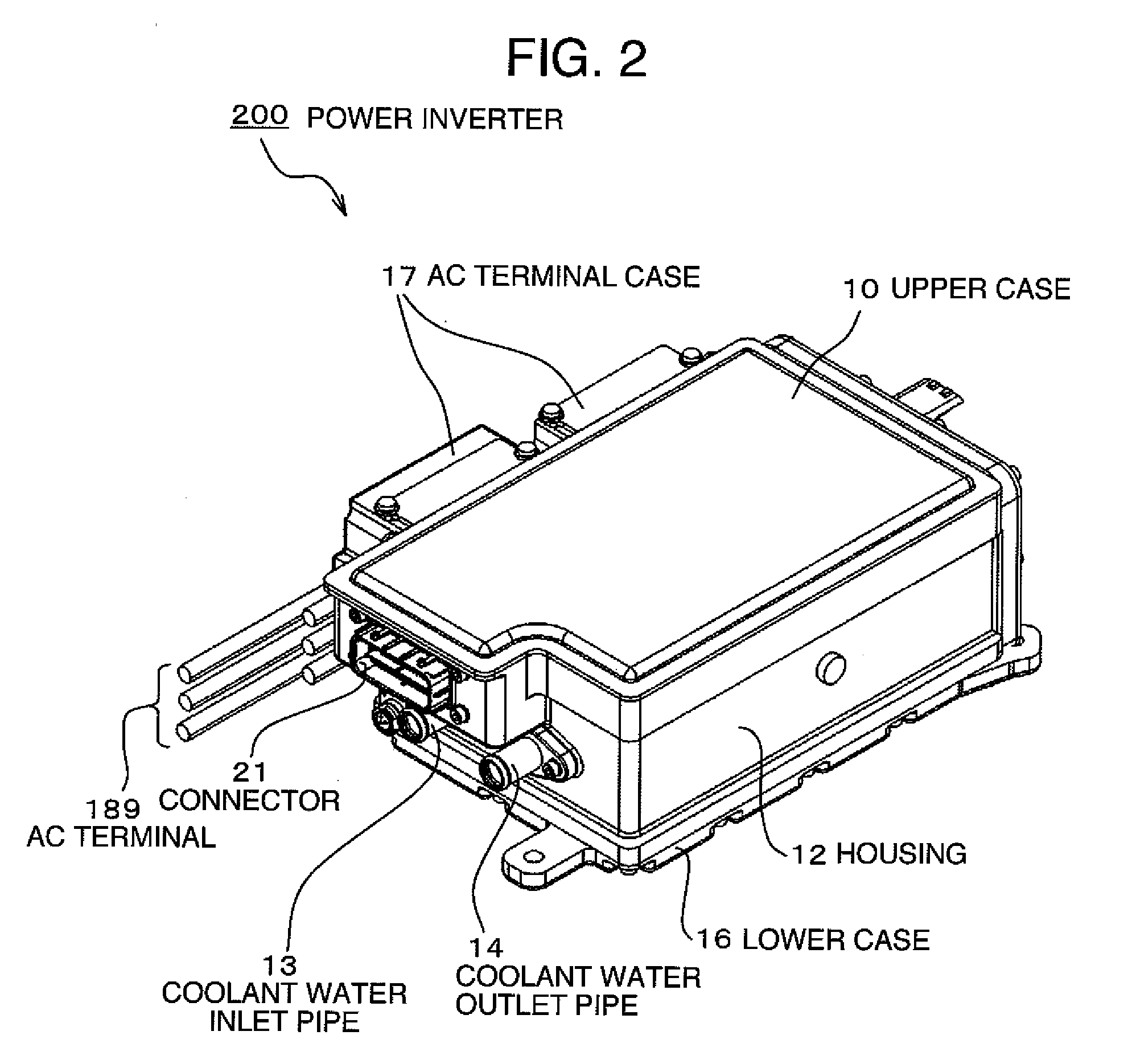

Semiconductor power module, inverter, and method of manufacturing a power module

ActiveUS20100208427A1Avoid heat dissipationAvoid bendingSolid-state devicesSemiconductor/solid-state device manufacturingPower semiconductor deviceMetallic materials

A semiconductor power module includes an insulated substrate mounting with a plurality of power semiconductor devices and a heat sink for radiating a heat generated from the plurality of power semiconductor devices, wherein the heat sink is integrally molded with a plurality of radiation fins on one surface of a planate base by forging work such that a metallic material filled into a female die of a predetermined shape is pressed by a male die of a predetermined shape, and the heat sink and the insulated substrate are bonded in metallic bonding with another surface opposite of one surface on which the radiation fins are formed with the base of the heat sink.

Owner:HITACHI POWER SEMICON DEVICE

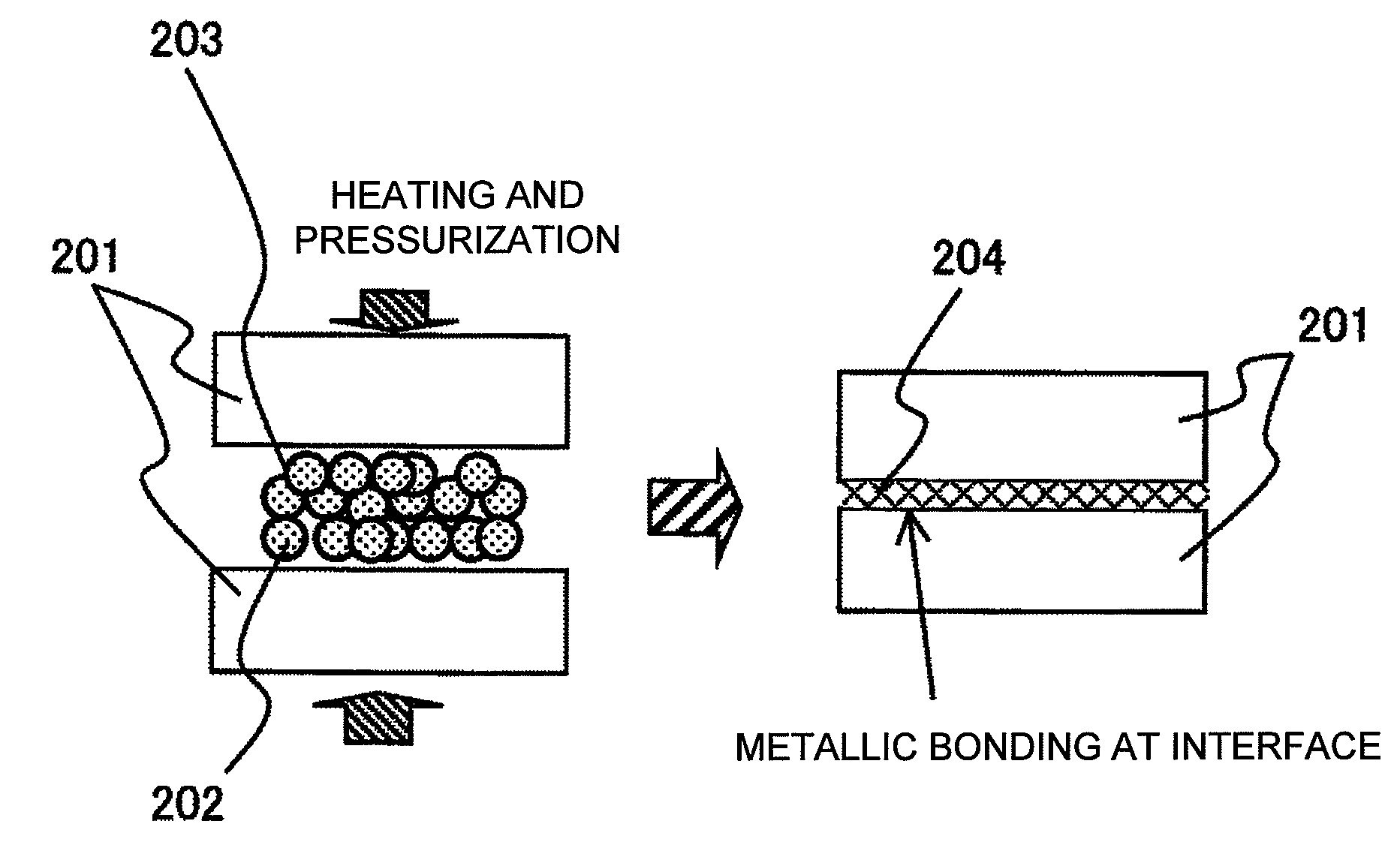

Bonding method and bonding material using metal particle

InactiveUS20080156398A1Semiconductor/solid-state device detailsSolid-state devicesBond interfaceCarboxylic salt

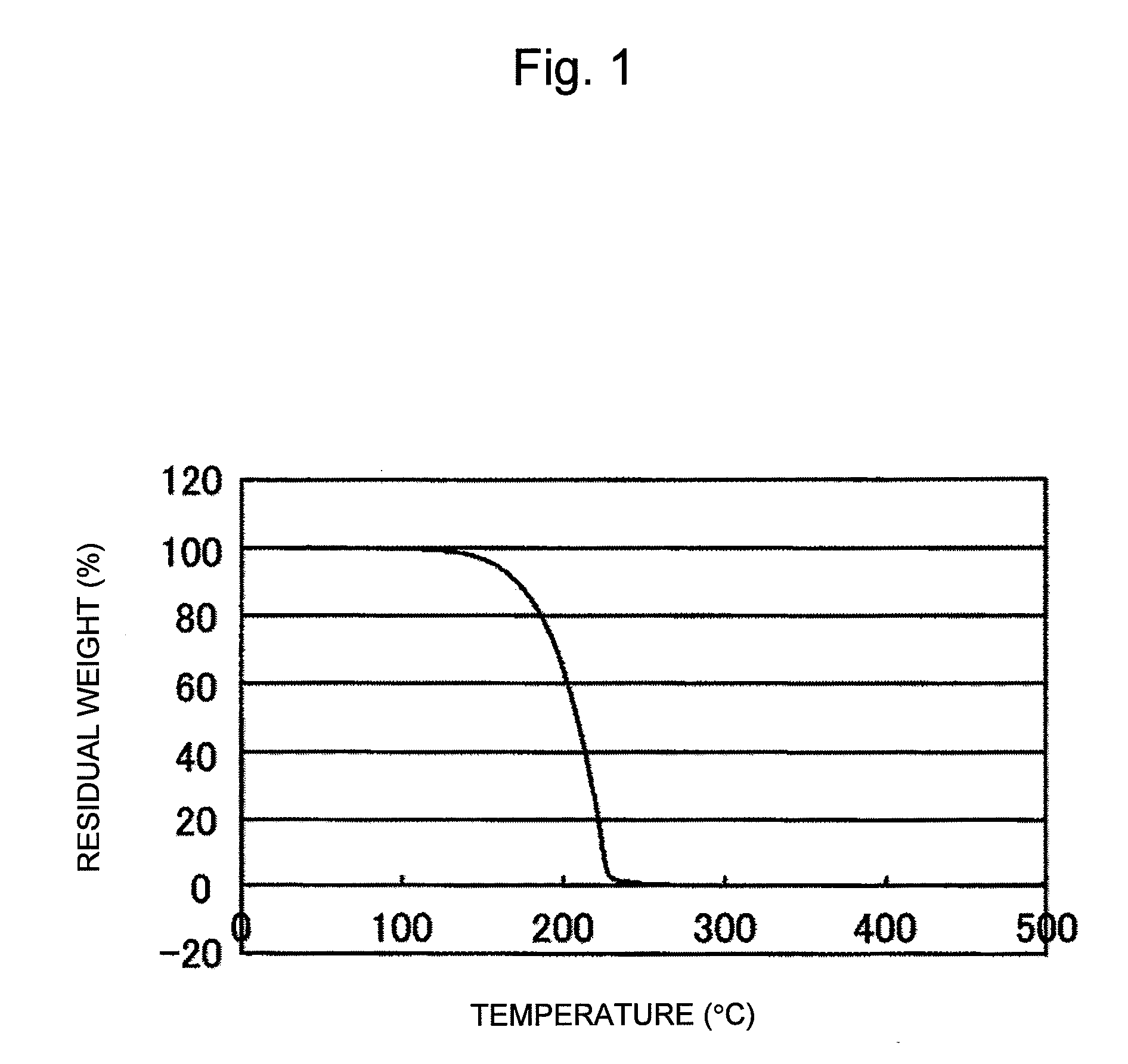

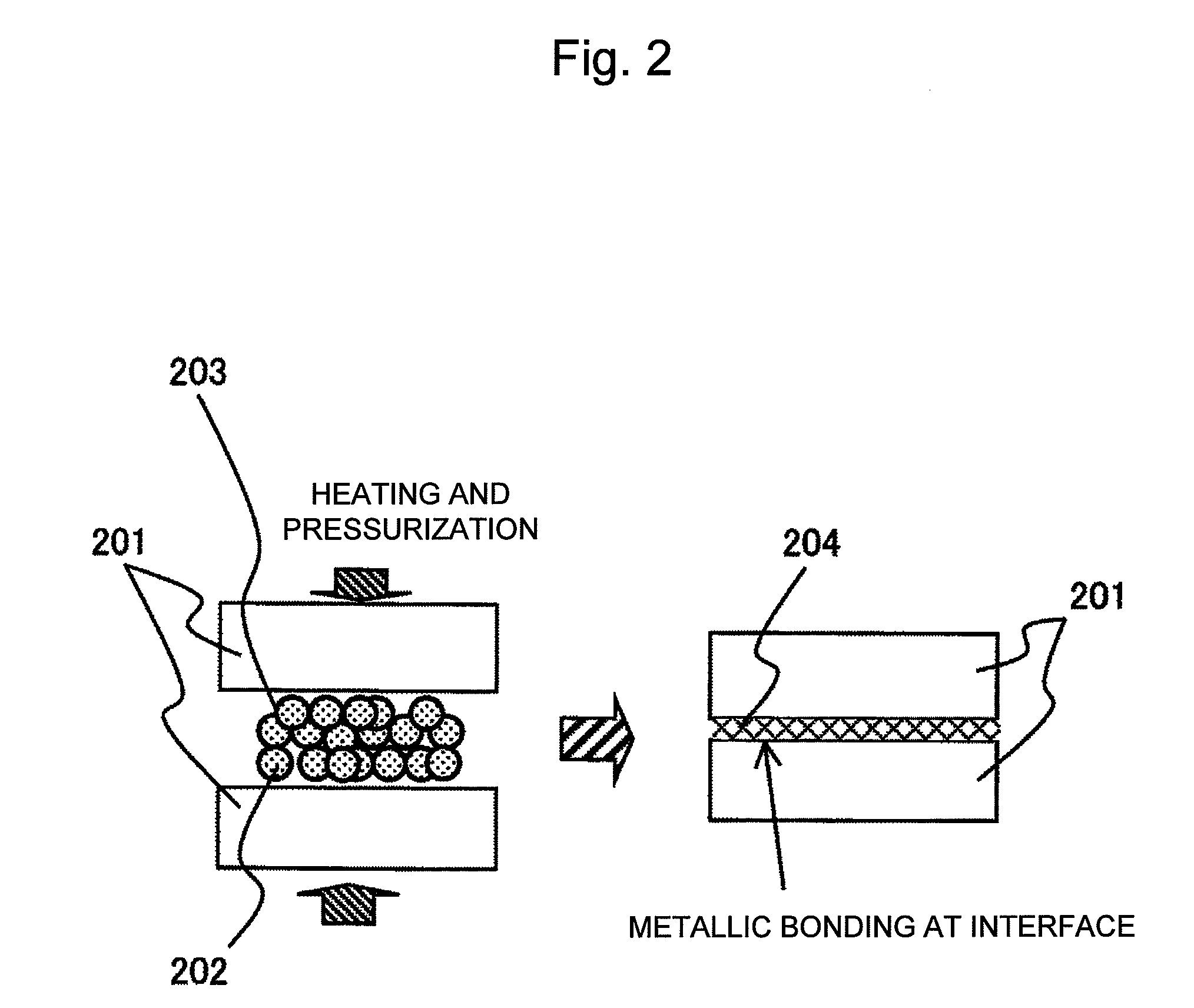

It is an object of this invention to provide a bonding material capable of realizing bonding by metallic bonding at a bonding interface at a lower temperature compared to a bonding material using a metal particle having an average particle diameter of not more than 100 nm and a bonding method. There is provided a bonding material including a metal particle precursor being at least one selected from the group consisting of a particle of a metal oxide, a particle of a metal carbonate, and a particle of a metal carboxylate and having an average particle diameter of 1 nm to 50 μm and a reducing agent composed of an organic substance, wherein the content of the metal particle precursor is more than 50 parts by mass and not more than 99 parts by mass per 100 parts by mass of the bonding material.

Owner:HITACHI LTD

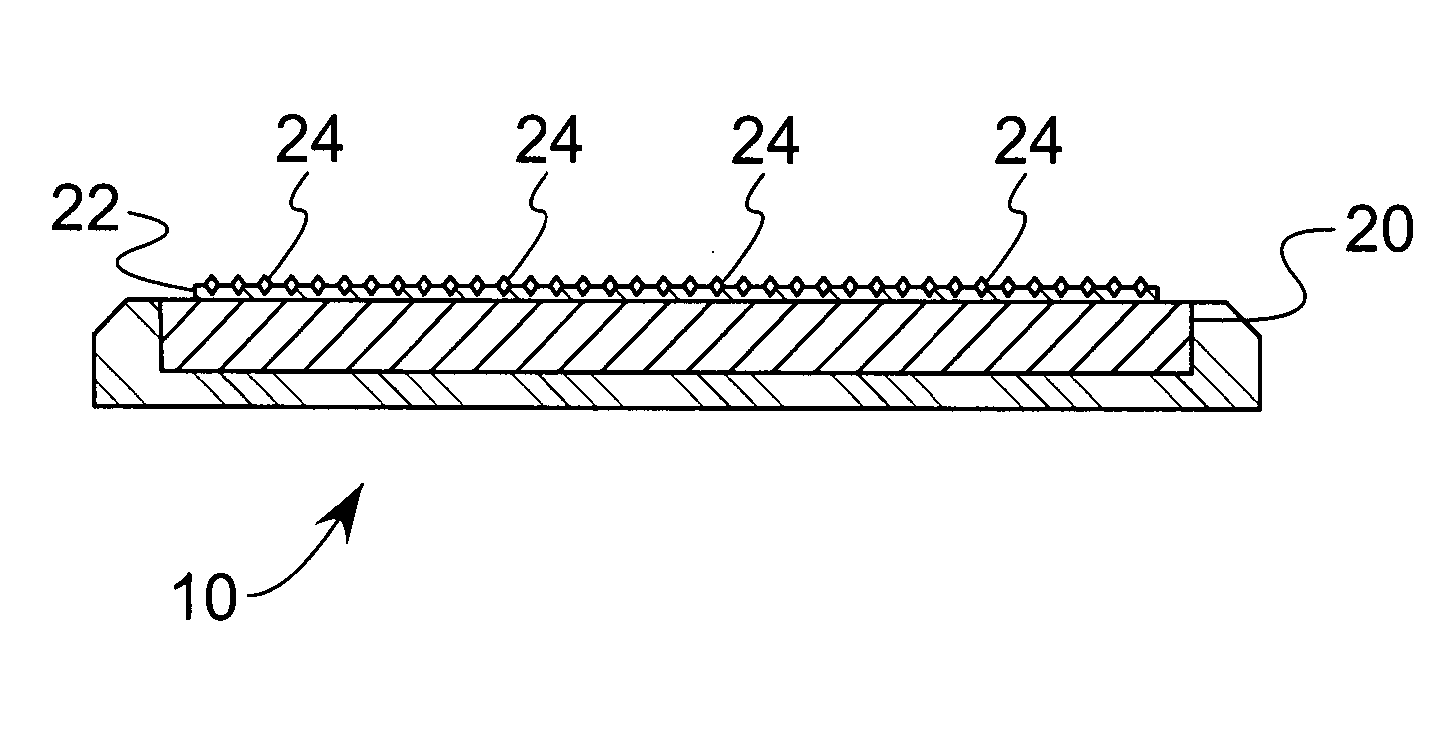

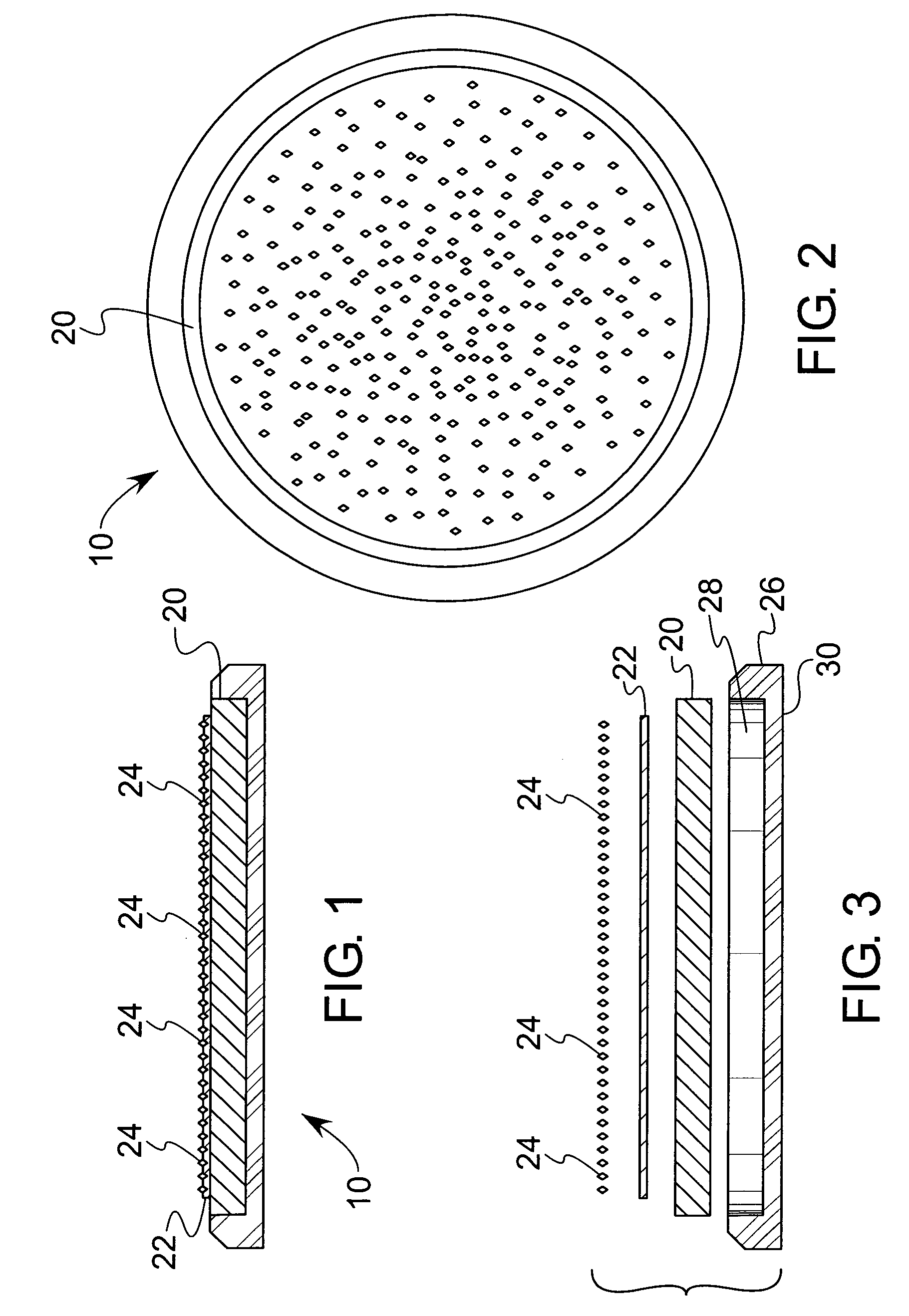

CMP diamond conditioning disk

A method of making and the resulting non-metallic CMP conditioning pad comprising a non-metallic substrate and a single layer of abrasive particles bonded to the substrate by a non-metallic bonding medium. Preferred substrates include aluminum oxide and graphite. A bonding system employing finely powdered aluminum oxide particles mixed with a suitable adhesive is employed to bond the abrasive layer to the aluminum oxide substrate. Silicon carbide particles mixed into a compatible adhesive carrier including a polymer composition is preferred for bonding the abrasive particle layer to a graphite or carbide substrate.

Owner:ABRASIVE TECH

Room temperature metal direct bonding

InactiveUS20050161795A1Semiconductor/solid-state device detailsSolid-state devicesBond interfaceRoom temperature

A bonded device structure including a first substrate having a first set of metallic bonding pads, preferably connected to a device or circuit, and having a first non-metallic region adjacent to the metallic bonding pads on the first substrate, a second substrate having a second set of metallic bonding pads aligned with the first set of metallic bonding pads, preferably connected to a device or circuit, and having a second non-metallic region adjacent to the metallic bonding pads on the second substrate, and a contact-bonded interface between the first and second set of metallic bonding pads formed by contact bonding of the first non-metallic region to the second non-metallic region. At least one of the first and second substrates may be elastically deformed.

Owner:INVENSAS BONDING TECH INC

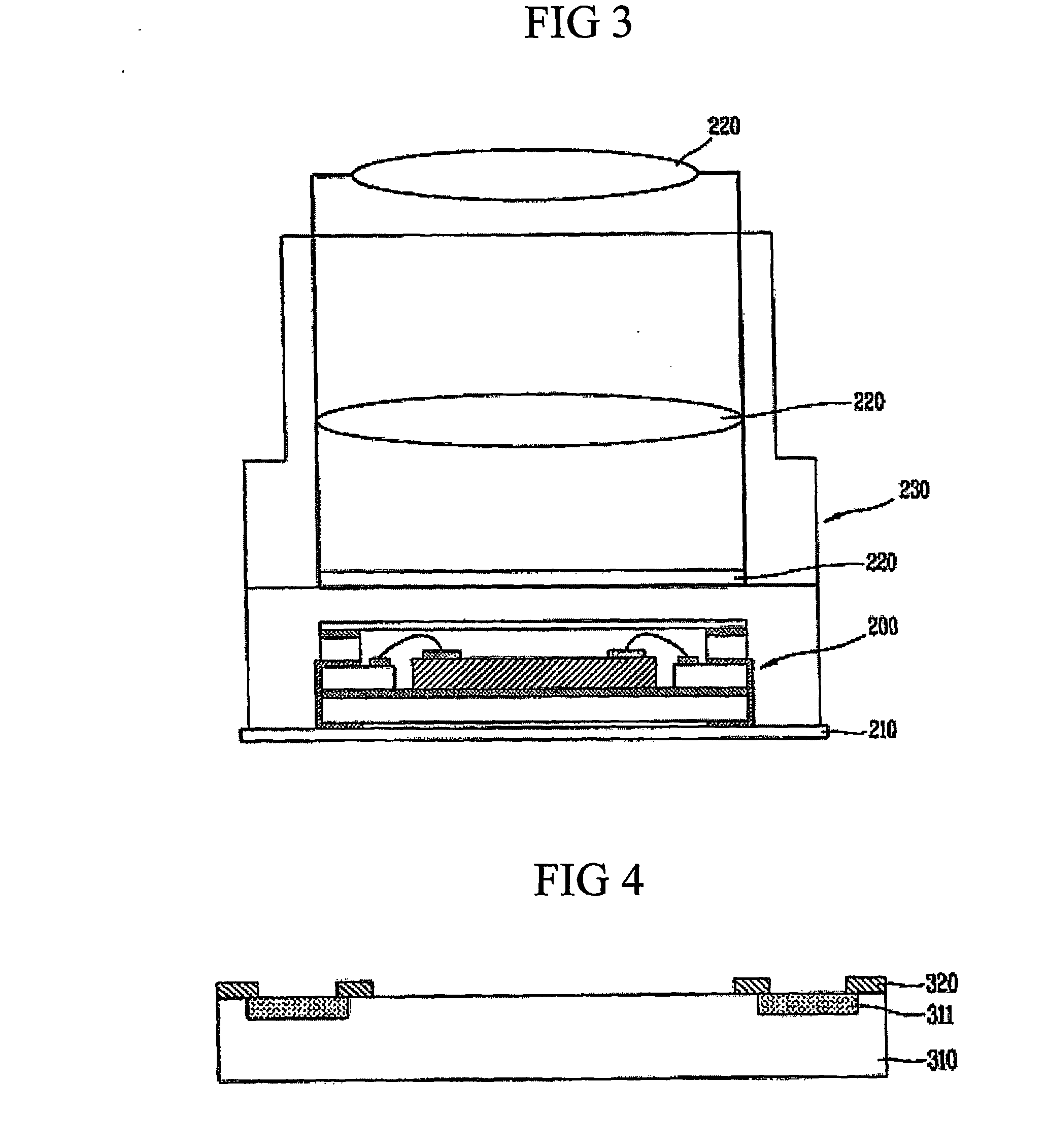

Thermoelectric device and optical module made with the device and method for producing them

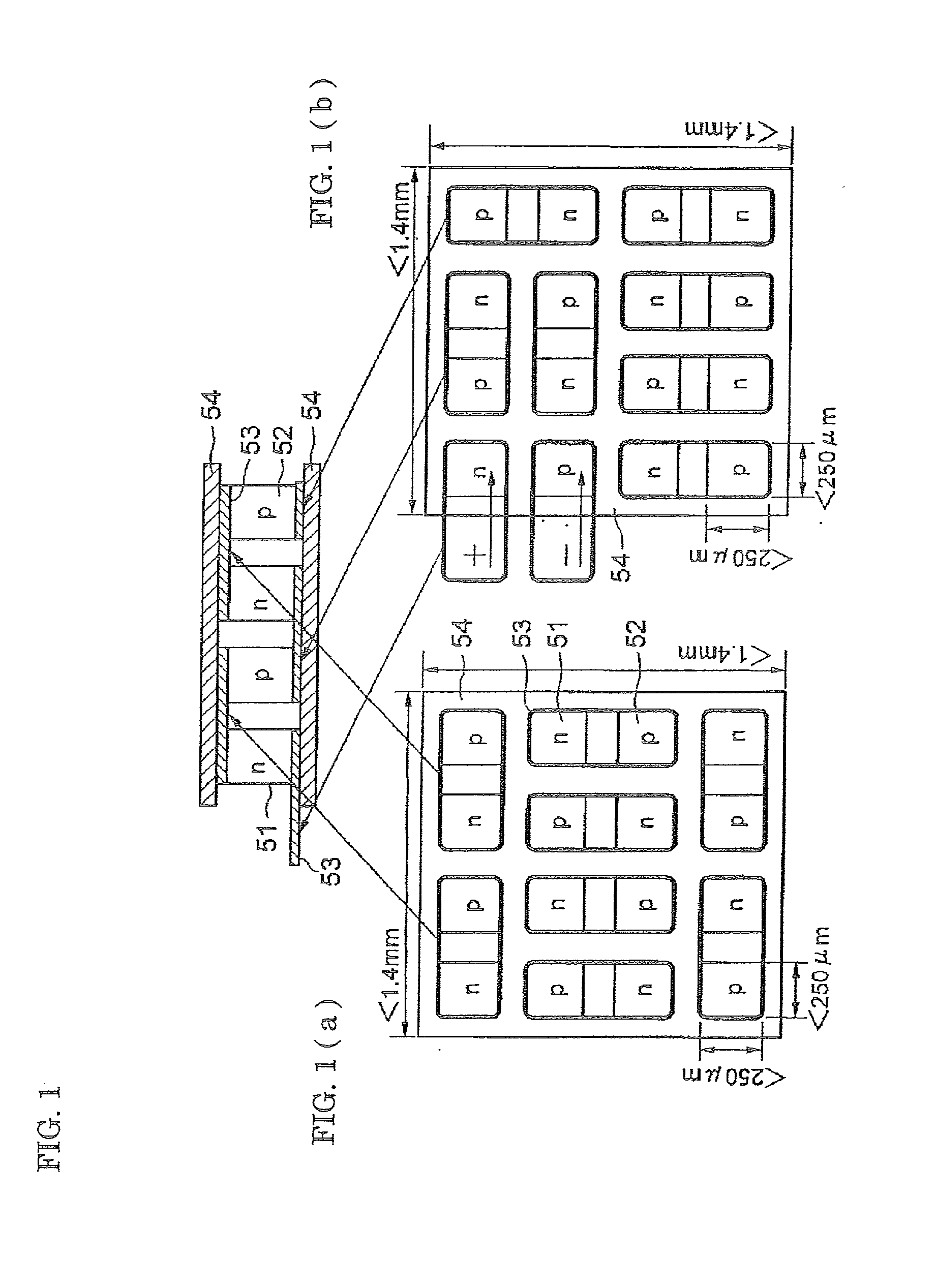

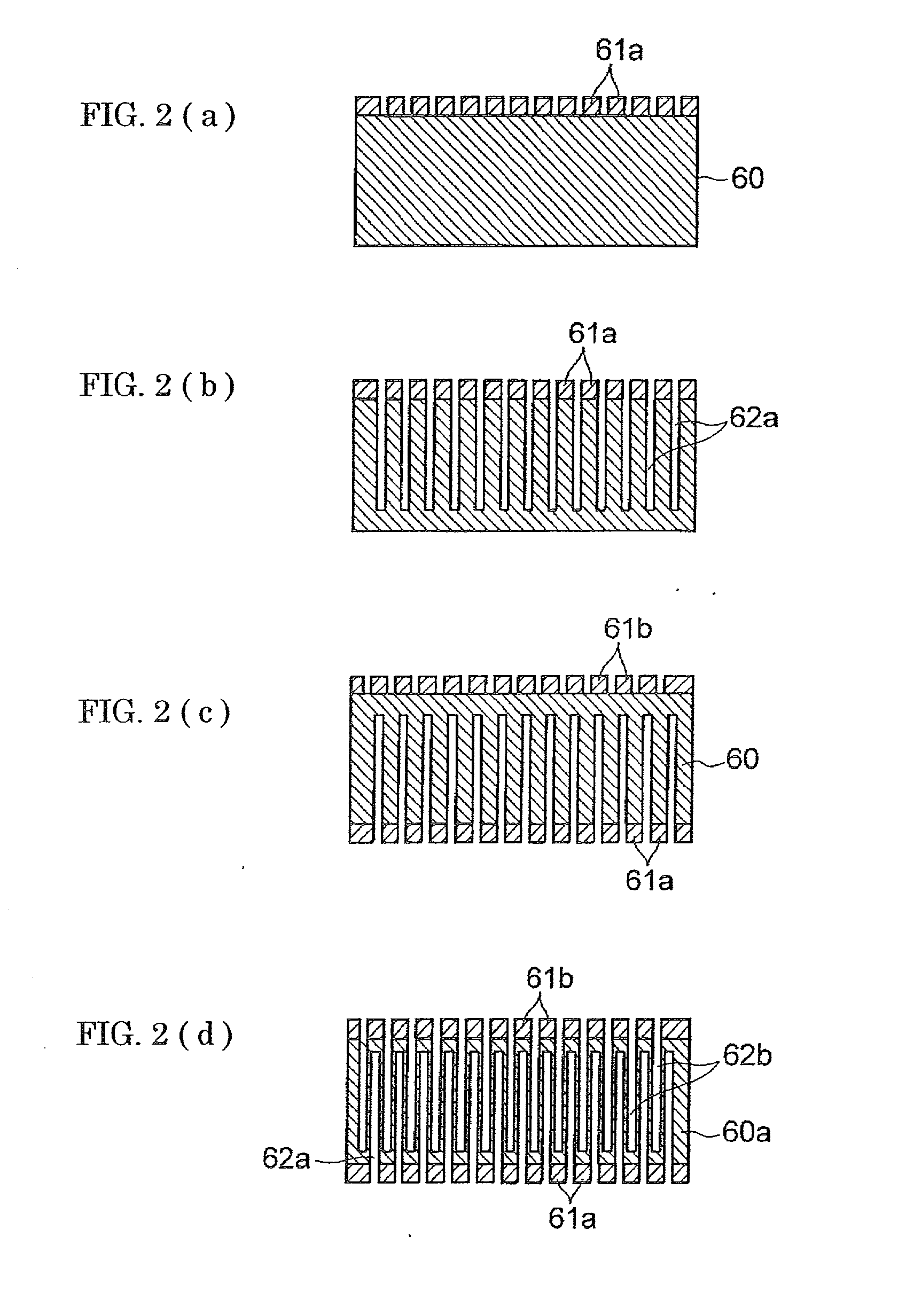

InactiveUS20030057560A1Thermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentOptical ModuleRounded Rectangle

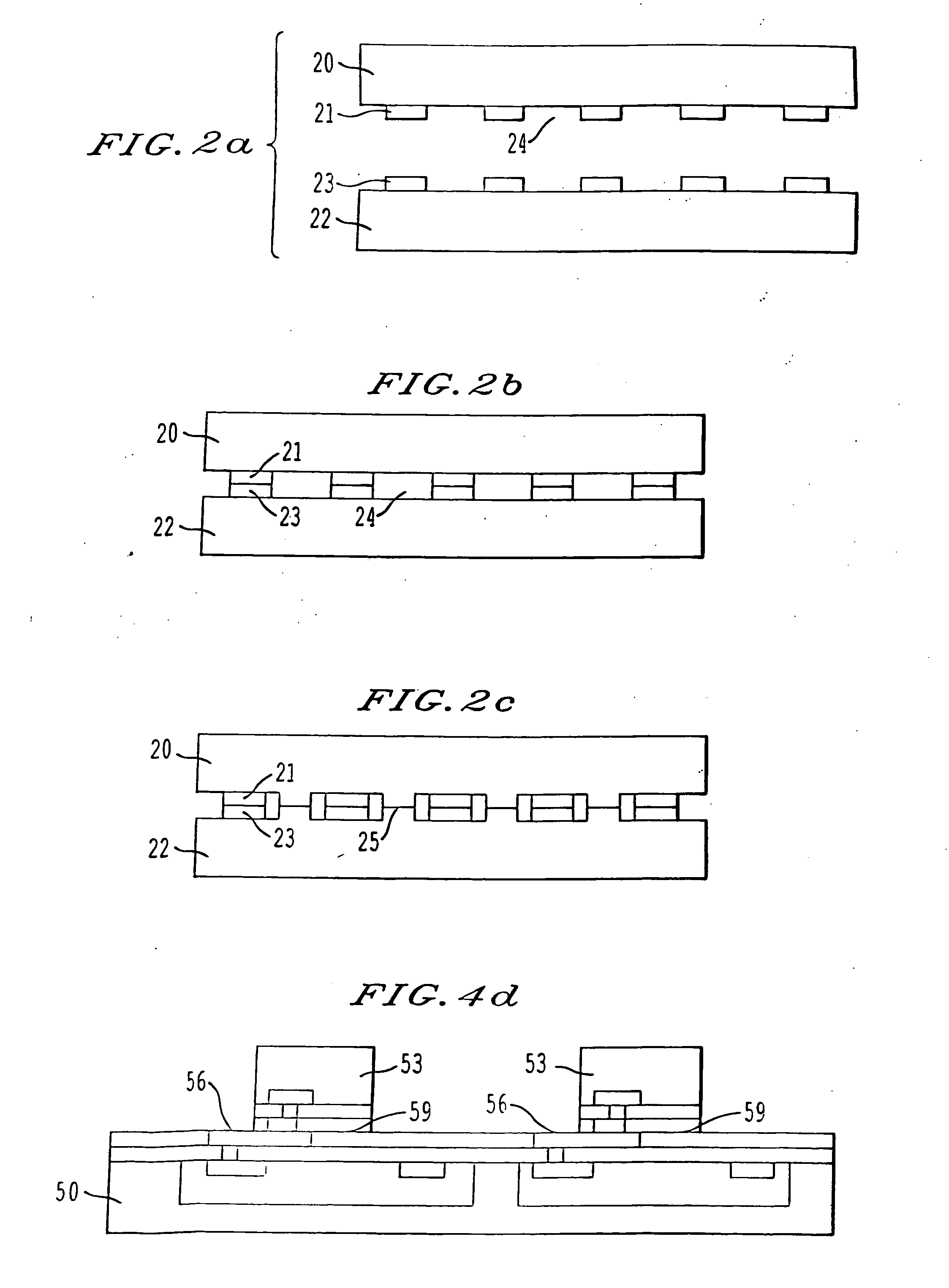

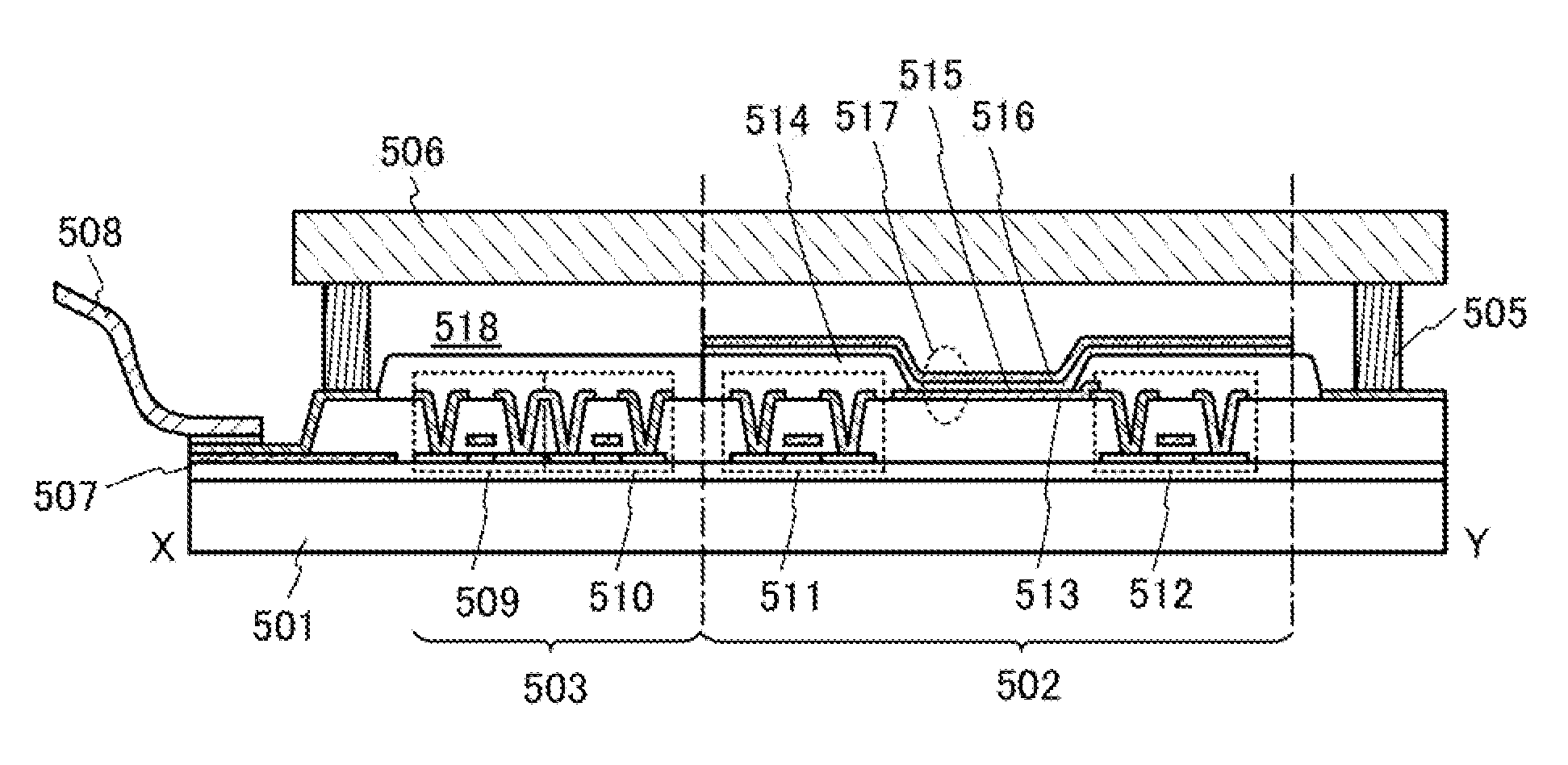

A thermoelectric device that realizes miniaturization and densification, an optical module incorporating the thermoelectric device, and their production method. N-type thermoelectric elements 51 and p-type thermoelectric elements 52 are arranged orthogonally and alternately, on the XY-plane, in a matrix consisting of at least four elements in total in a row and at least four elements in total in a column. All the thermoelectric elements 51 and 52 have a size of at most 250 mum in the X and Y directions. At most four thermoelectric elements nearest to an n-type thermoelectric element 51 are of p type, and at most four thermoelectric elements nearest to a p-type thermoelectric element 52 are of n type. The thermoelectric elements 51 and 52 are bonded through metallic bonding materials to electrodes 53 having the shape of a rectangle or a rounded rectangle formed on an insulating substrate 54.

Owner:SUMITOMO ELECTRIC IND LTD +2

Treating fluid and method for preparing vanadium-zirconium composite conversion coatings with self-repairing performance on aluminum alloy surfaces through same

ActiveCN102766862AImprove corrosion resistanceGuaranteed stabilityMetallic material coating processesMetallic bondingSodium fluoride

The invention belongs to the technical field of chemical materials, and relates to a treating fluid and a method for preparing vanadium-zirconium composite conversion coatings with self-repairing performance on aluminum alloy surfaces through the same. The method includes the steps of firstly preparing the treating fluid containing fluorozirconate, metavanadate, sodium fluoride, nitrate, an accelerate and an additive; then putting an aluminum alloy after surface pretreatment into a working fluid made of the diluted treating fluid for 2min-10min; and finally subjecting the aluminum alloy to washing, drying and cooling to obtain the vanadium-zirconium composite conversion coatings. The preparation process is simple, heavy metals such as hexavalent chromium and nickel are not contained, the environment is friendly, the conversion coatings of the aluminum alloy after a conversion coating treatment are dense and high in binding force, metal ions in the conversion coatings can bond with base metal under a corrosion environment and provided with a certain self-repairing performance, and the treating technology of vanadium-zirconium conversion coatings can effectively replace chromate treatment on aluminum alloy surfaces.

Owner:湖南松井先进表面处理与功能涂层研究院有限公司

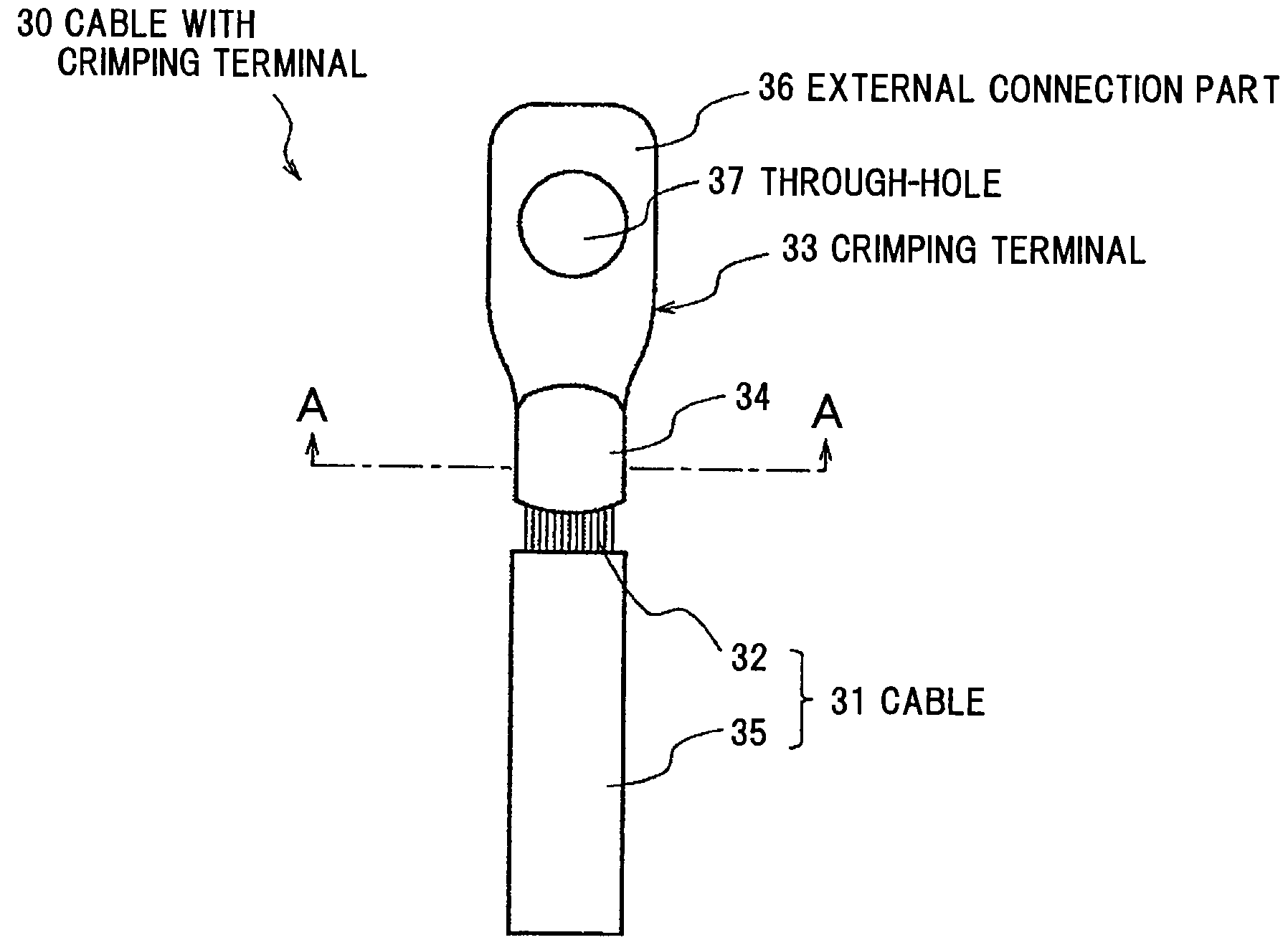

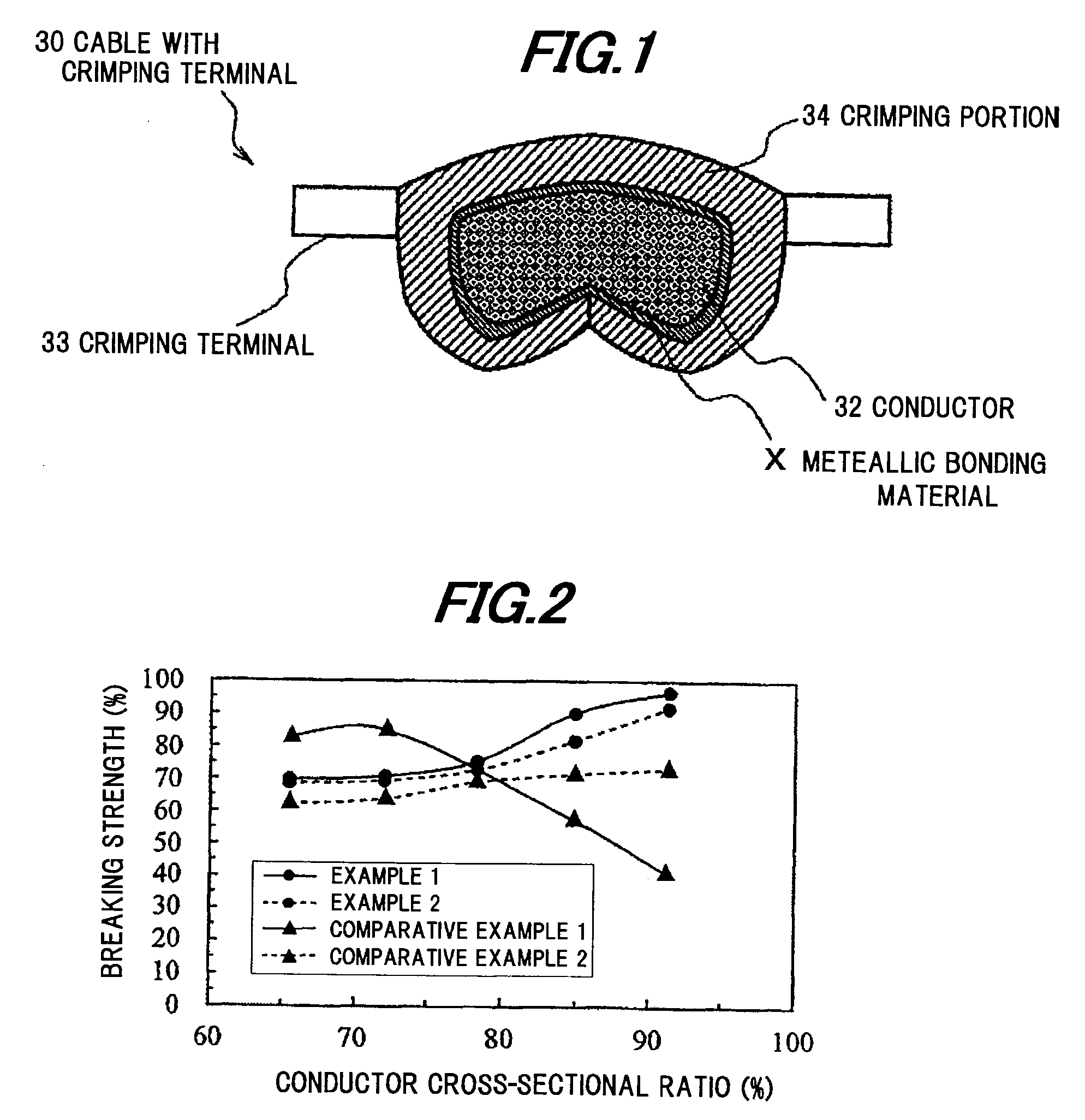

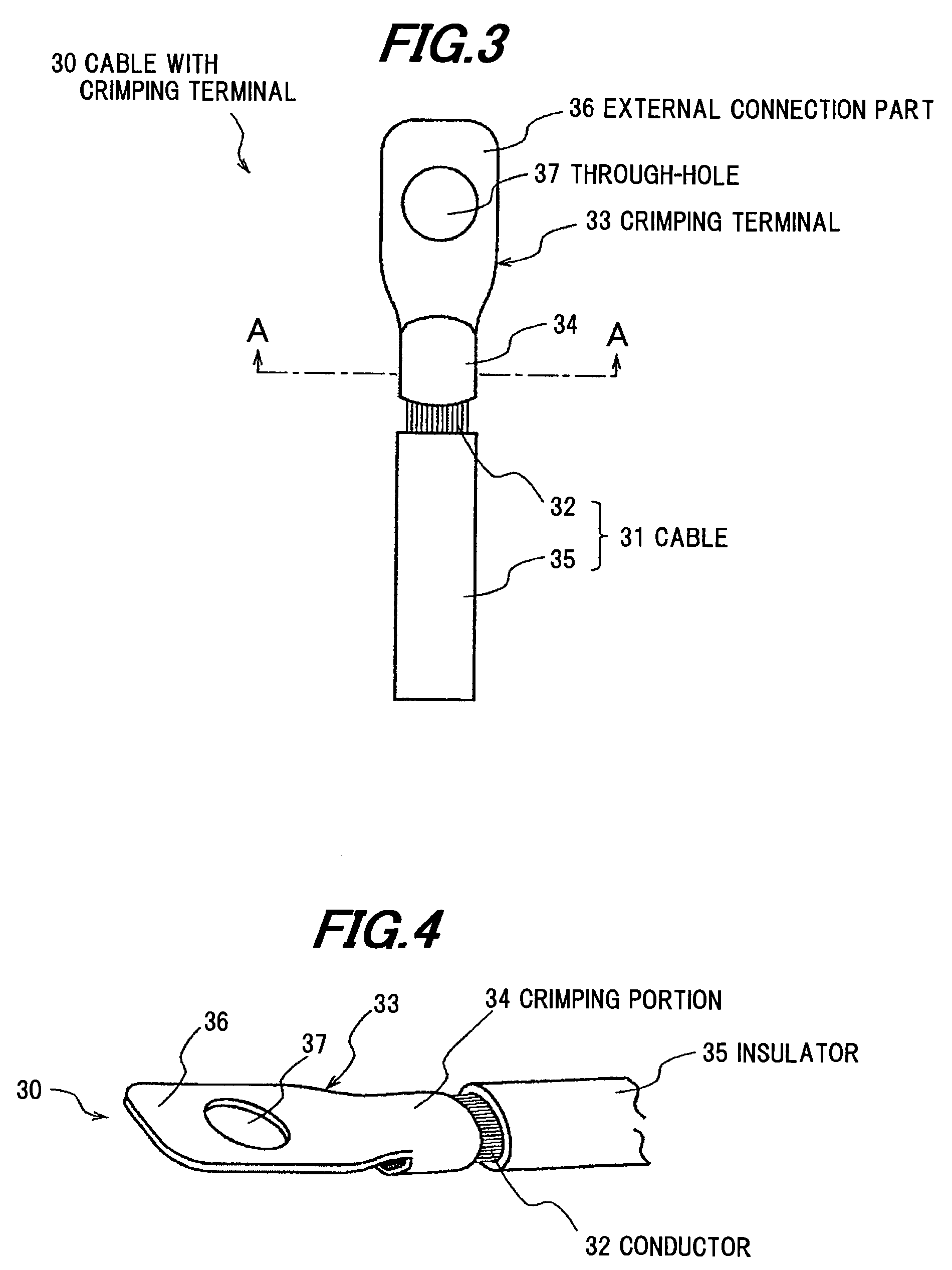

Cable with crimping terminal and method of making the same

InactiveUS20100018768A1High breaking strengthReduced breaking strengthLine/current collector detailsElectrically conductive adhesive connectionsElectrical conductorPlastic materials

A cable with a crimping terminal includes a cable including a conductor and an insulator including a plastic material, and the crimping terminal bonded to the conductor of the cable at a crimping portion by crimping connection. The conductor of the cable is bonded to the crimping terminal by a metallic bonding material at a crimping portion, and the metallic bonding material includes silver as a main component.

Owner:HITACHI CABLE

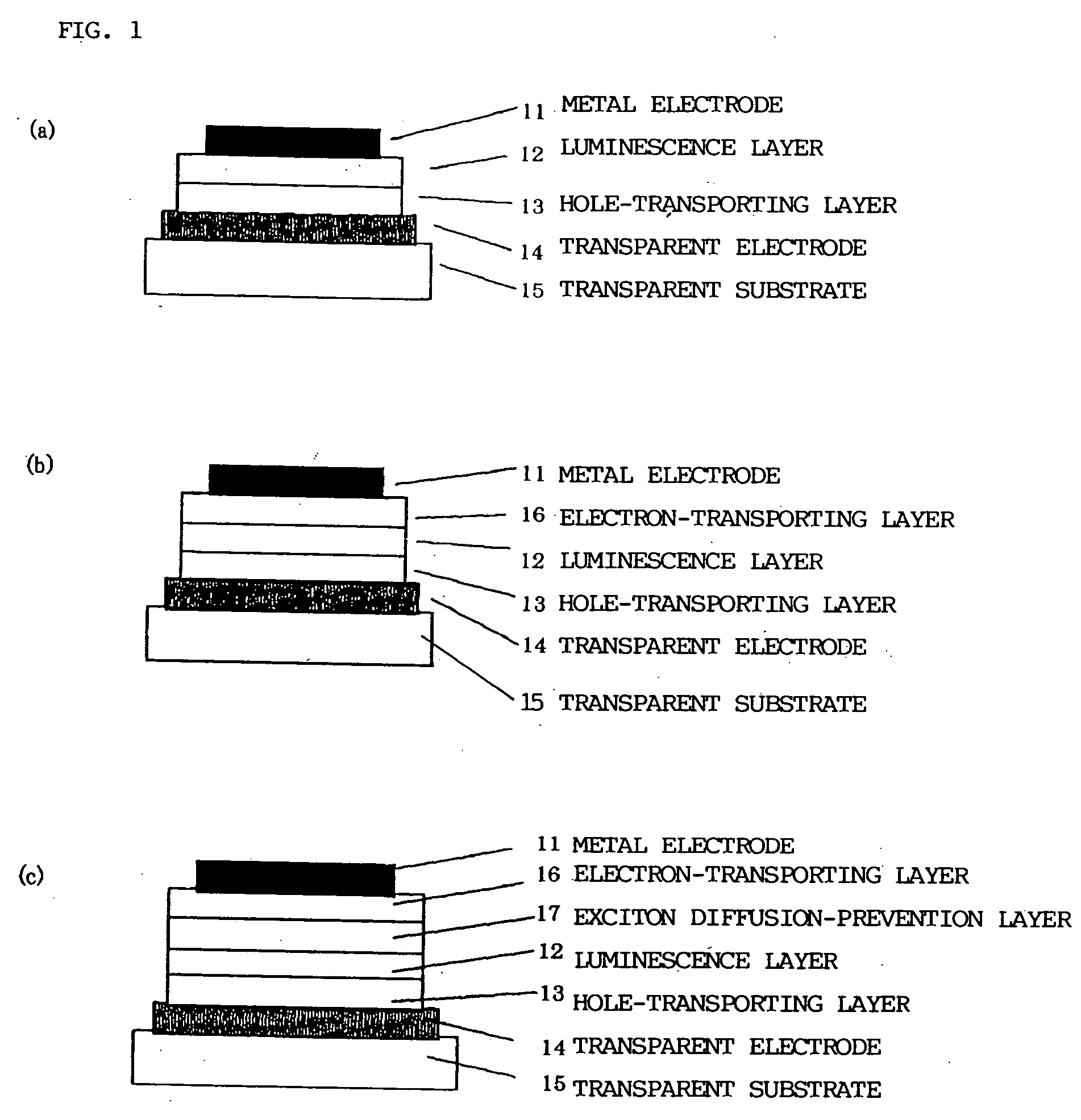

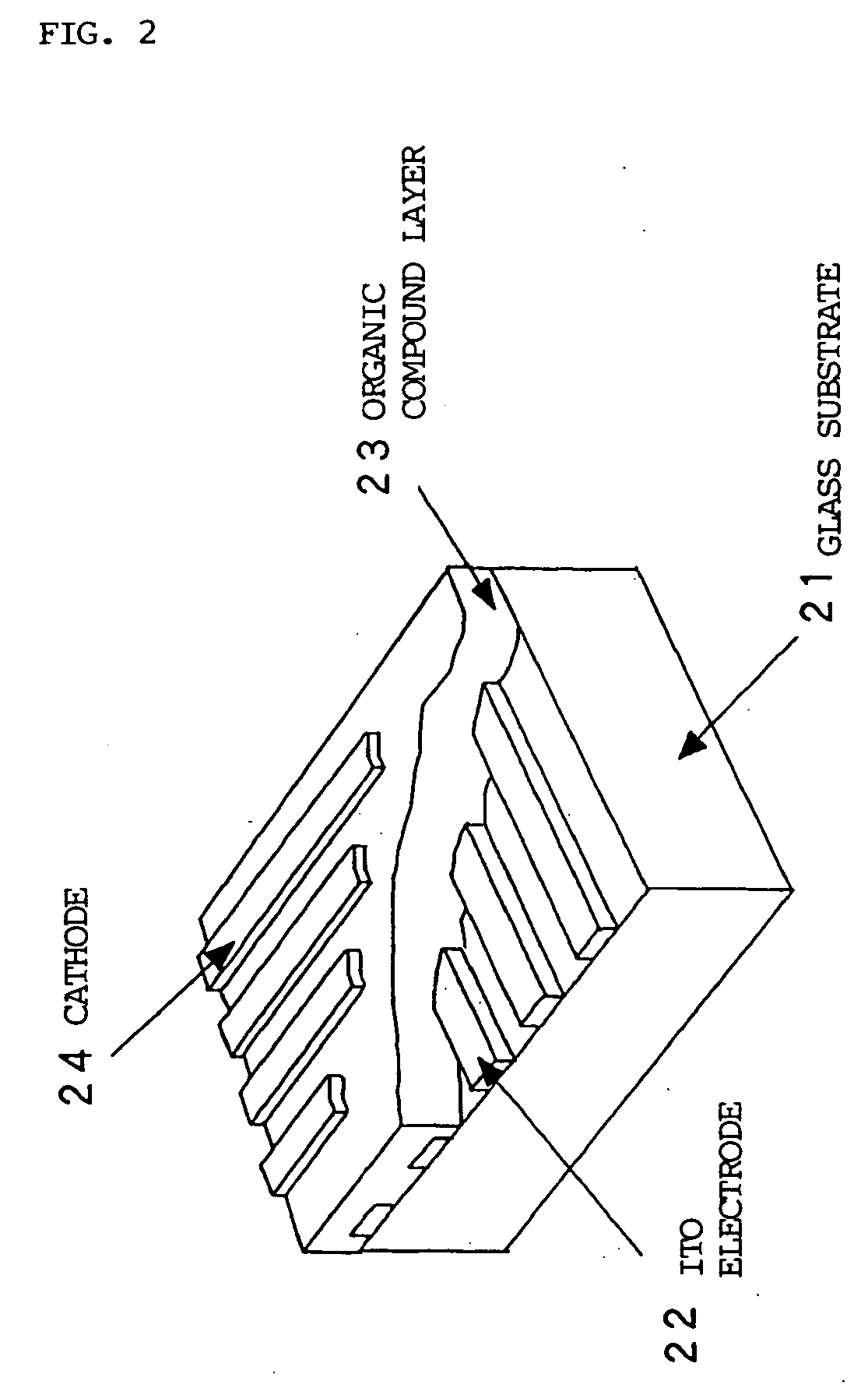

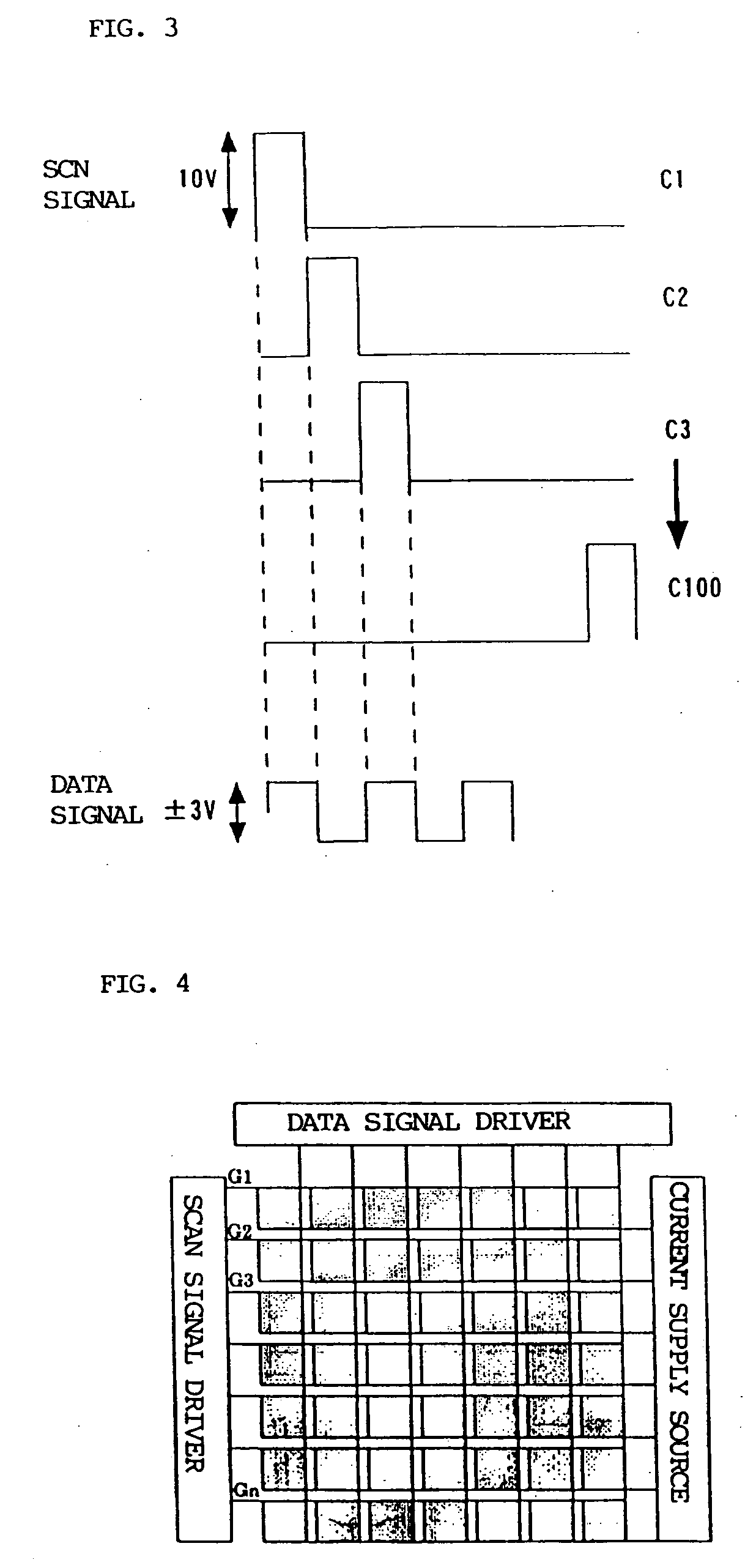

Luminescence device and display apparatus

InactiveUS20060177694A1High efficiency luminescenceExtend device lifeIndium organic compoundsDischarge tube luminescnet screensLuminescenceHigh luminance

A luminescence device having a layer containing a metal coordination compound which has a partial structure. MLm of formula (2) below and is preferably entirely represented by formula (3) below: MLmL′n (3) wherein M denotes a metal atom of Ir, Pt, Rh or Pd; represent mutually different bidentate ligands; m is 1 or 2 or 3; n is 0 or 1 or 2 with the proviso that m+n=2 or 3; the partial structure MLm is represented by formula (2) below (wherein B is an isoquinolyl group bonded to the metal M with its N and including a position-1 carbon atom bonded to a cyclic group A which includes the C bonded to the metal M), and the partial structure ML′n is represented by formula (4), (5) or (6) shown below. There is provided a luminescence device capable of high-efficiency luminescence and long-term high luminance and adapted to red luminescence.

Owner:CANON KK

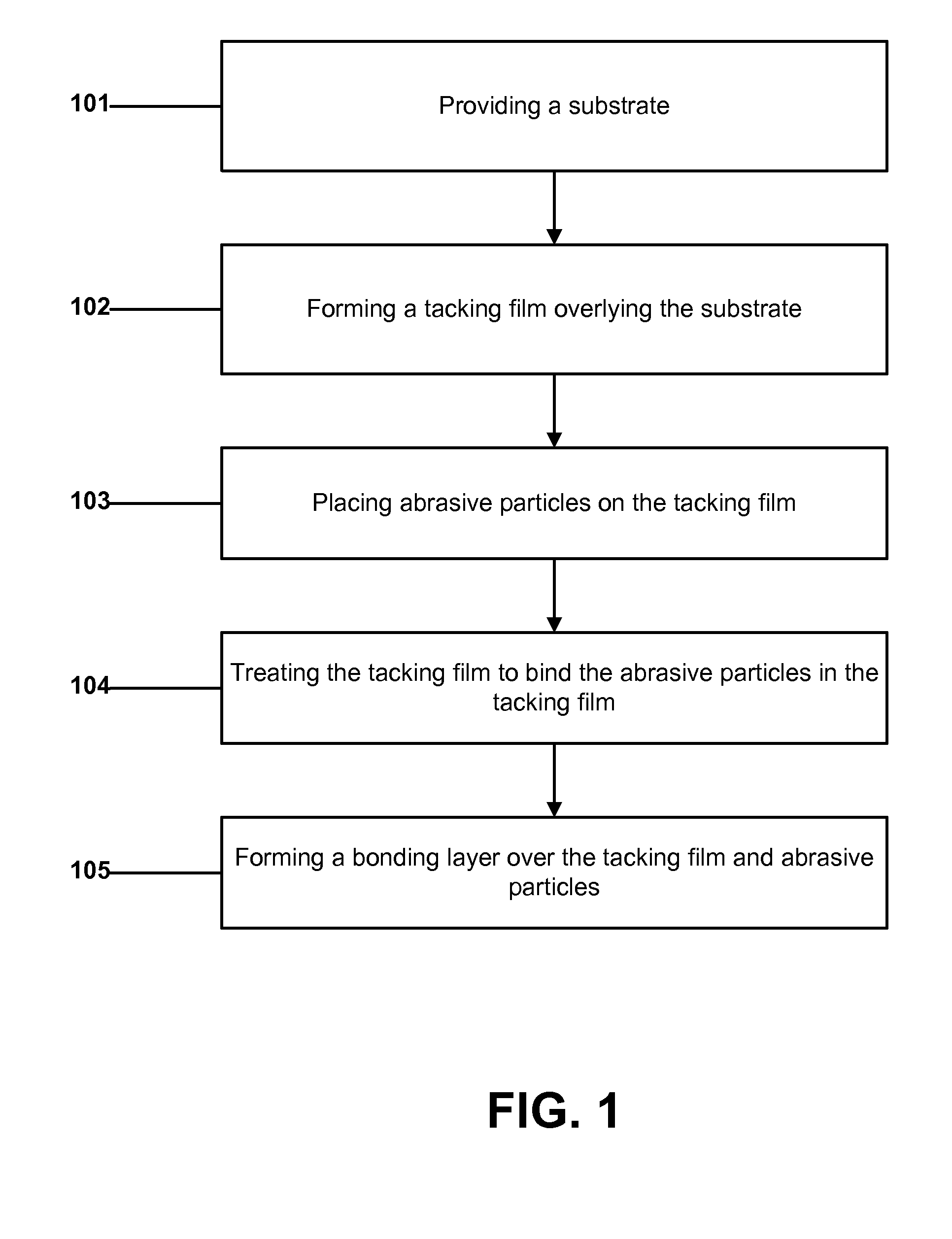

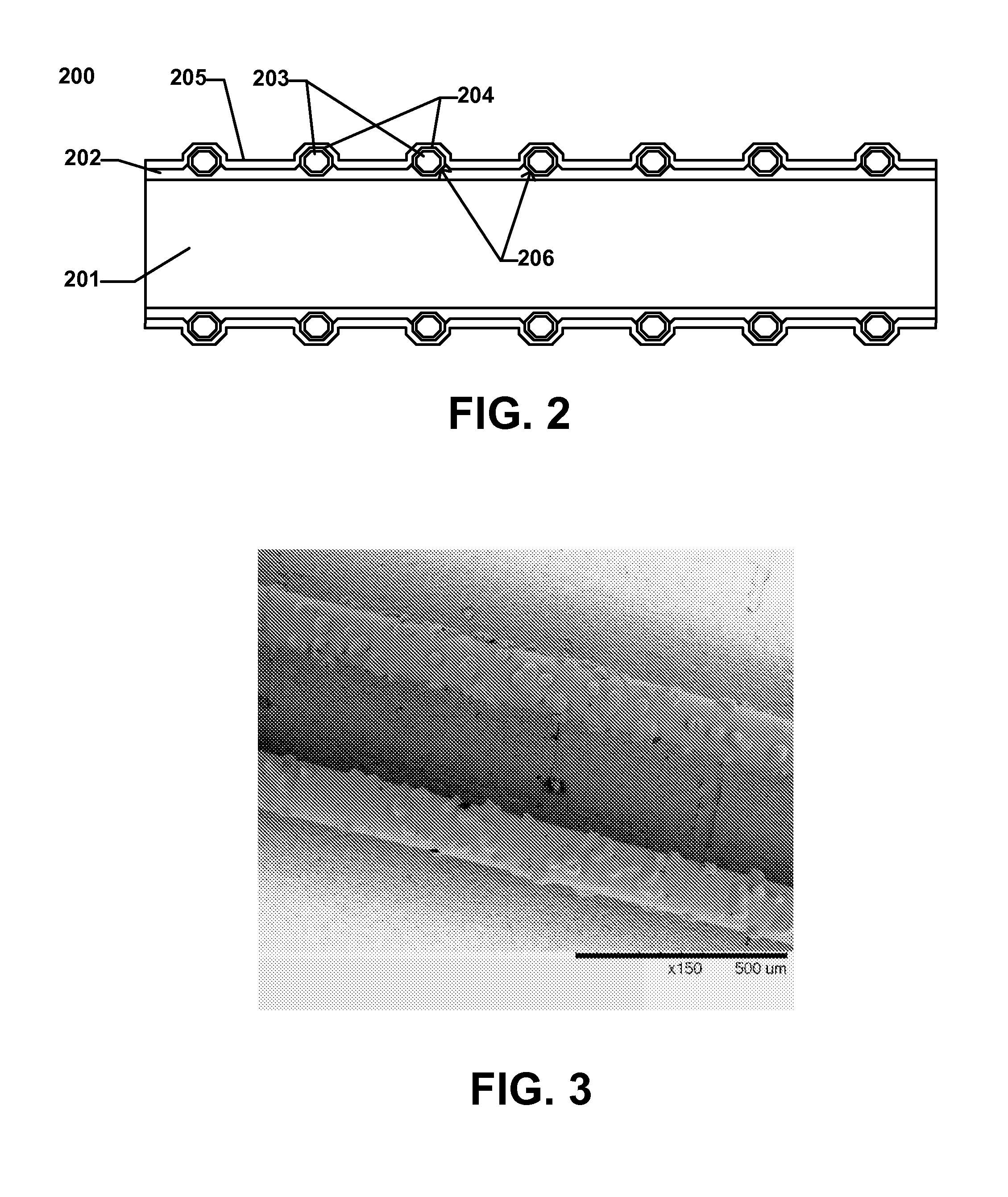

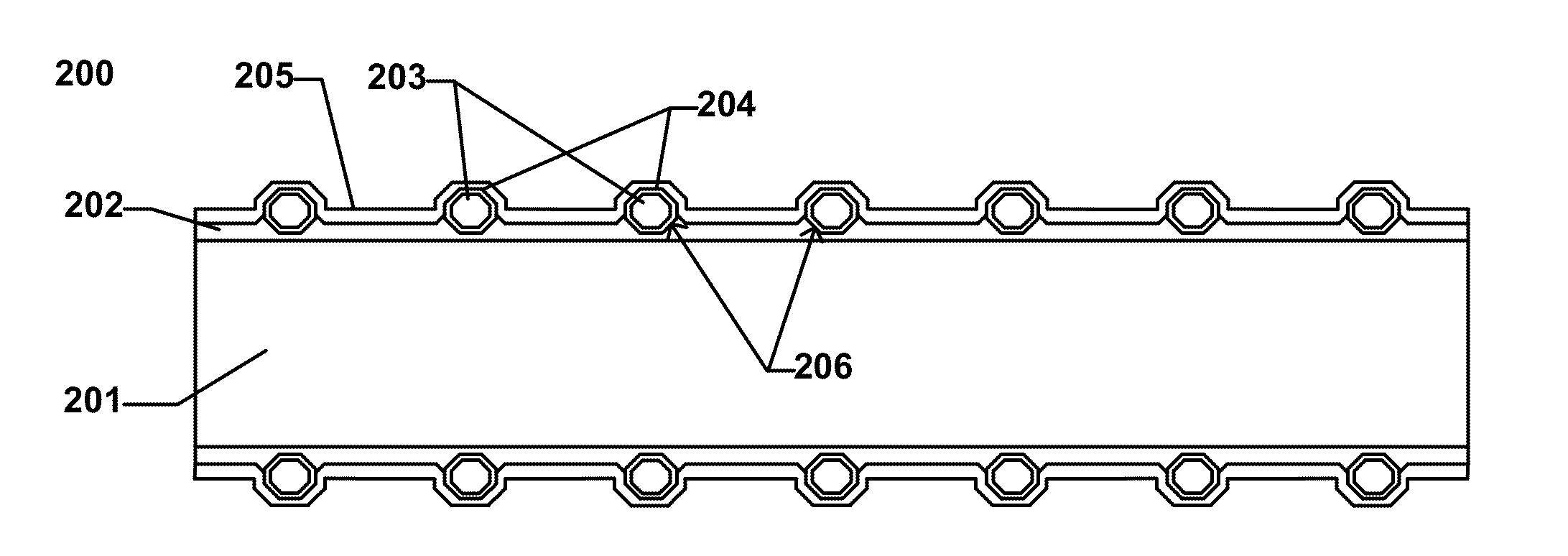

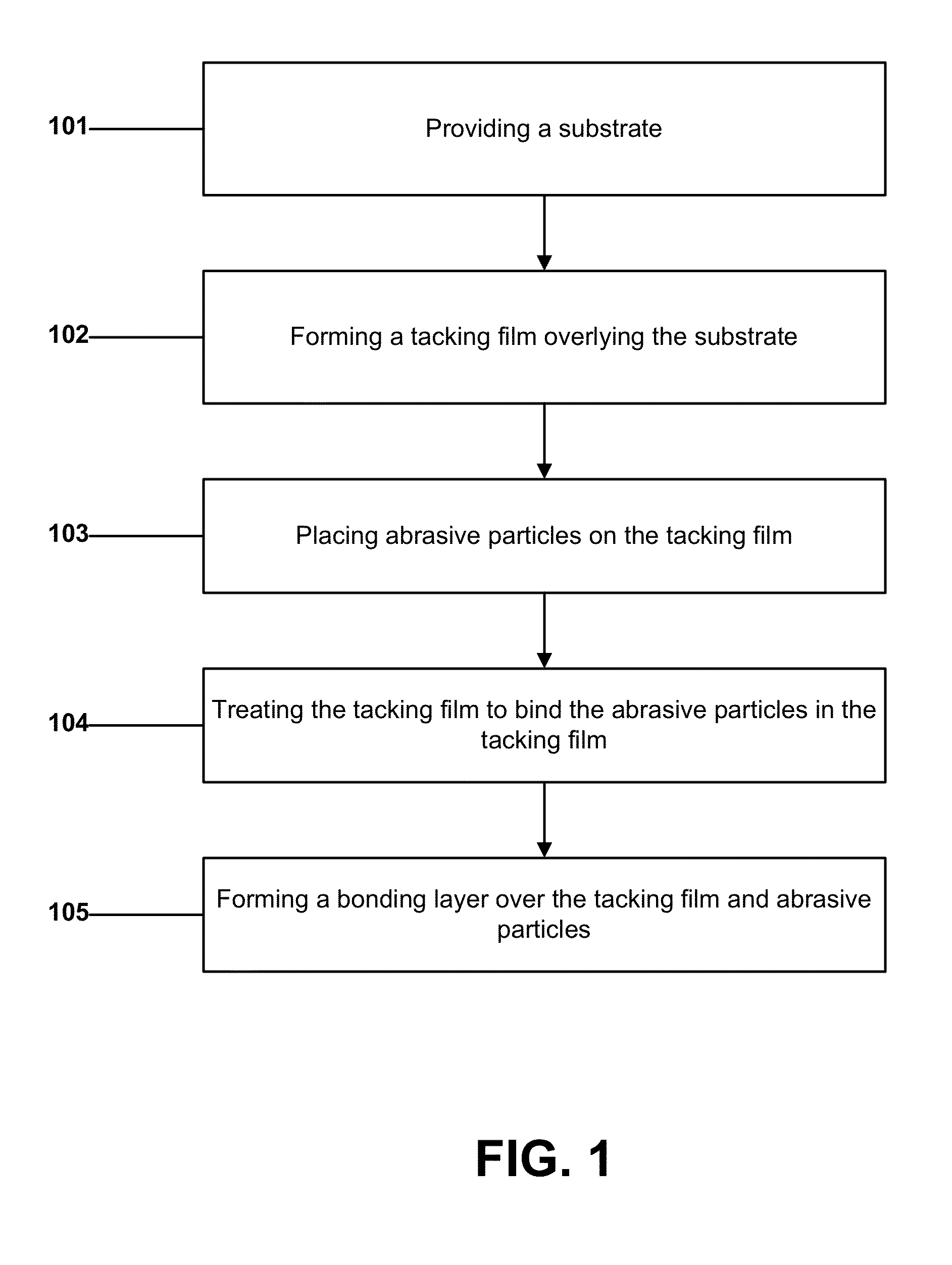

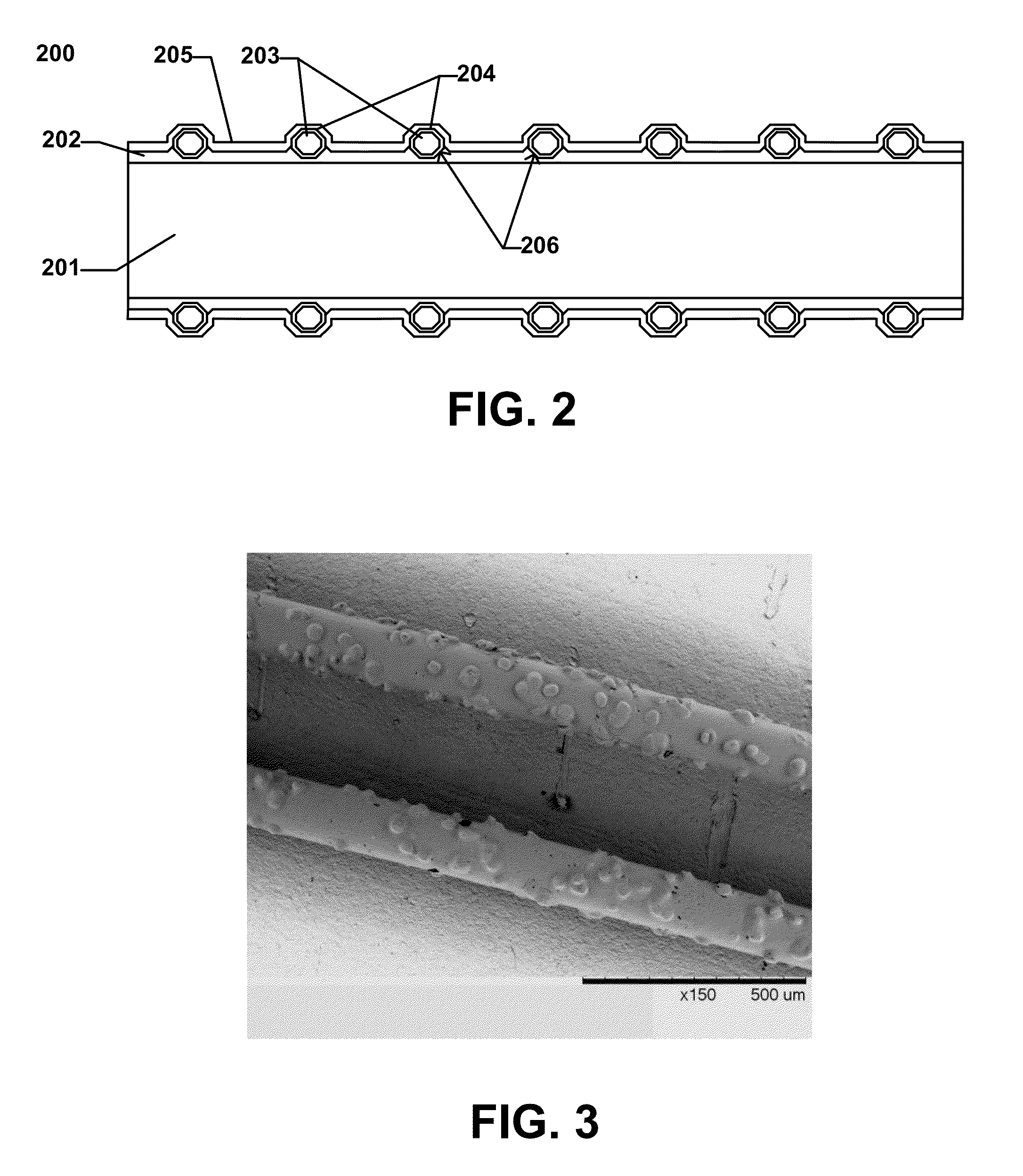

Abrasive article and method of forming

An abrasive article having a substrate, a tacking film overlying the substrate, abrasive particles comprising a coating layer bonded to the tacking film such that a bond between the coating layer and the tacking film defines a metallic bonding region, and a bonding layer overlying the abrasive particles and the tacking film,

Owner:SAINT GOBAIN ABRASIVES INC +1

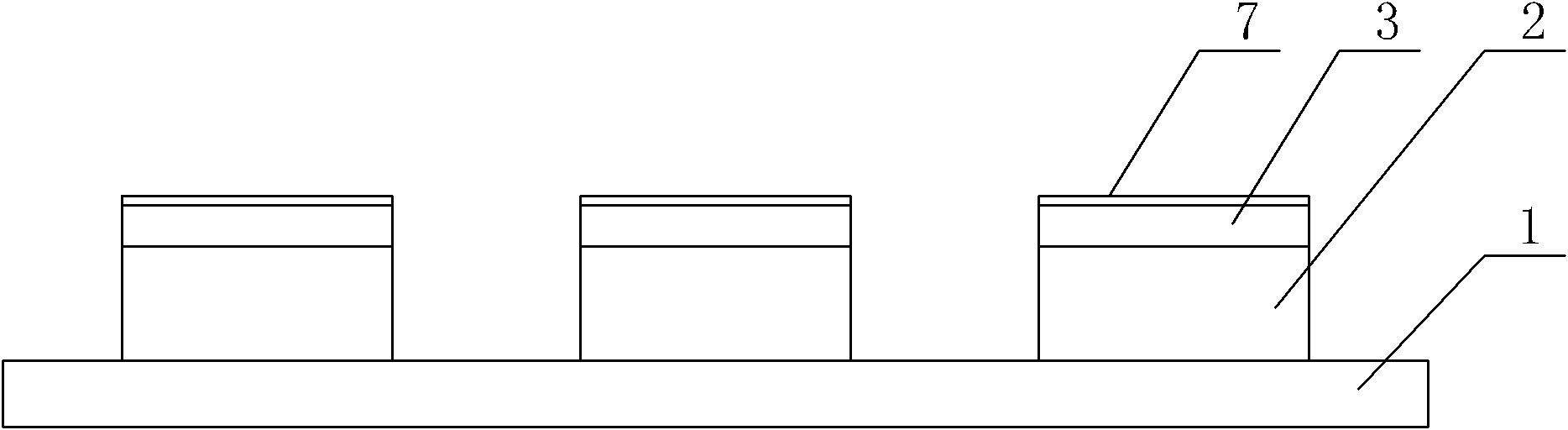

Micro-resonant cavity LED chip with substrate removed through chemical erosion and preparation method thereof

ActiveCN107369746ANo pollutionImprove reflectivityFinal product manufactureSemiconductor devicesResonant cavityQuantum well

The invention discloses a micro-resonant cavity LED chip with a substrate removed through chemical erosion and a preparation method thereof. The LED chip is an inversely installed film structure, and an epitaxial film only contains a p-GaN layer, a quantum well layer and an n-GaN layer. The lower surface of the p-GaN layer is a metallic reflection electrode with high reflectivity, a medium distributed Bragg reflection mirror is arranged on the upper surface of the n-GaN layer, a metallic reflection electrode and a medium DBR form a reflector of a resonant cavity, and the chamber length of the resonant cavity is order of magnitude of the wavelength. According to the preparation method, the substrate of an LED epitaxial wafer is removed through first photoelectric auxiliary chemical erosion and second chemical erosion, and then the LED epitaxial wafer is distributed on a heat conduction substrate through metallic bonding to obtain the micro-resonant cavity LED chip with substrate removed through chemical erosion. No extra material is introduced in the preparation method, pollution of the vacuum cavity of epitaxial growth equipment can be prevented, and the length of the resonant cavity can be reduced.

Owner:SOUTH CHINA UNIV OF TECH

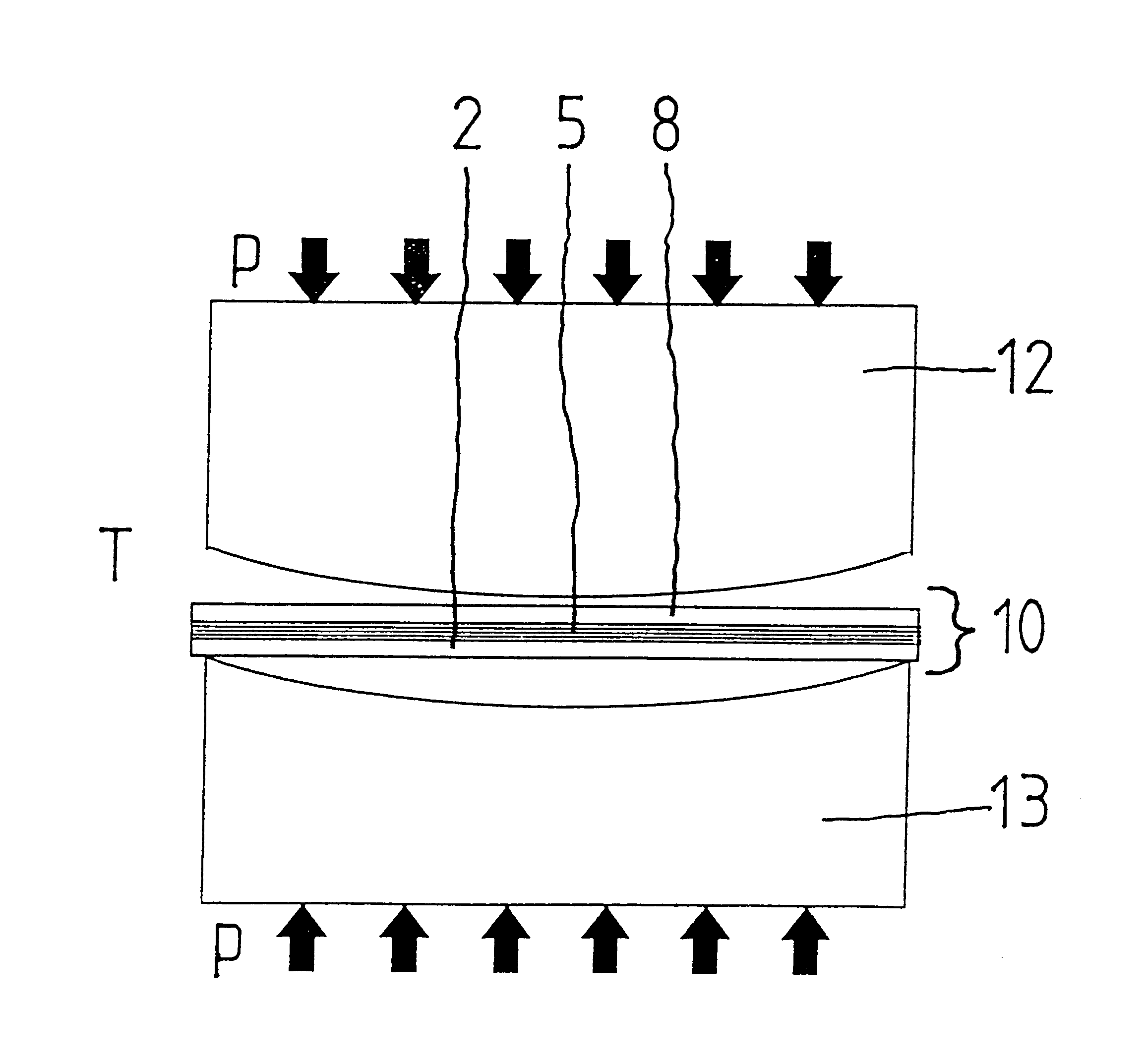

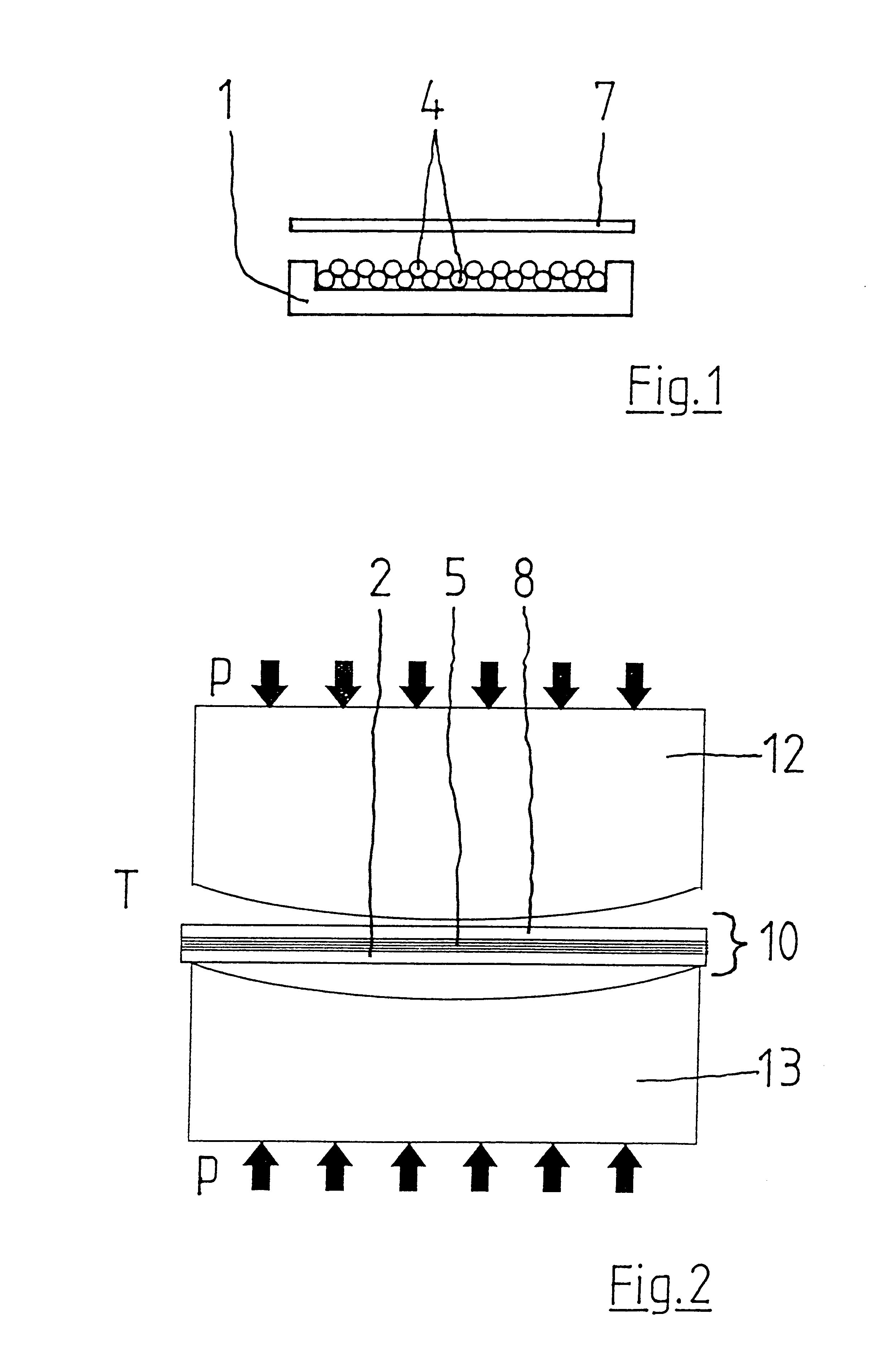

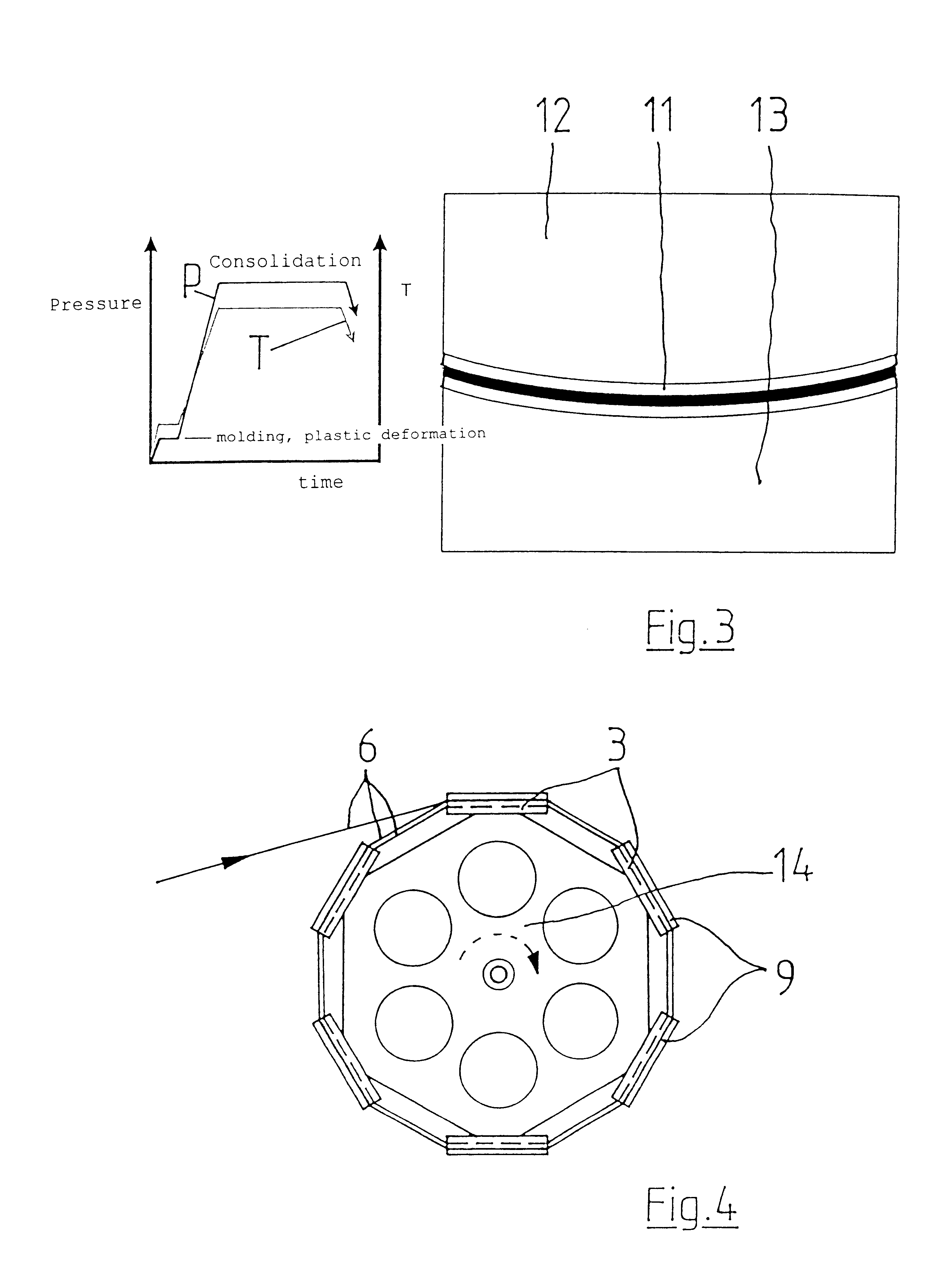

Method of producing fiber-reinforced metallic building components

A method of producing fiber-reinforced metallic building components having a complicated three-dimensional geometric shape includes the following steps. First, metal-coated SiC fibers are applied to a metallic sectional piece having a simple geometric shape, and are then held thereon without restraint by a metallic counterpart piece. Then, the unit consisting of the sectional piece, fibers and counterpart piece undergoes plastic deformation in vacuo between mold halves by applying pressure at an elevated temperature, without bonding of the fibers to one another or to the building component metal. By further increasing the pressure and / or temperature, the molded unit is compressed further between the mold halves and is consolidated to a monolithic part by metallic bonding (diffusion welding), whereby the part, either alone or bonded to other parts, forms the building component, after cooling and removing it from the mold halves.

Owner:MOTOREN UND TURBINEN UNION MUNCHEN GMBH +1

Abrasive article and method of forming

Owner:SAINT GOBAIN ABRASIVES INC +1

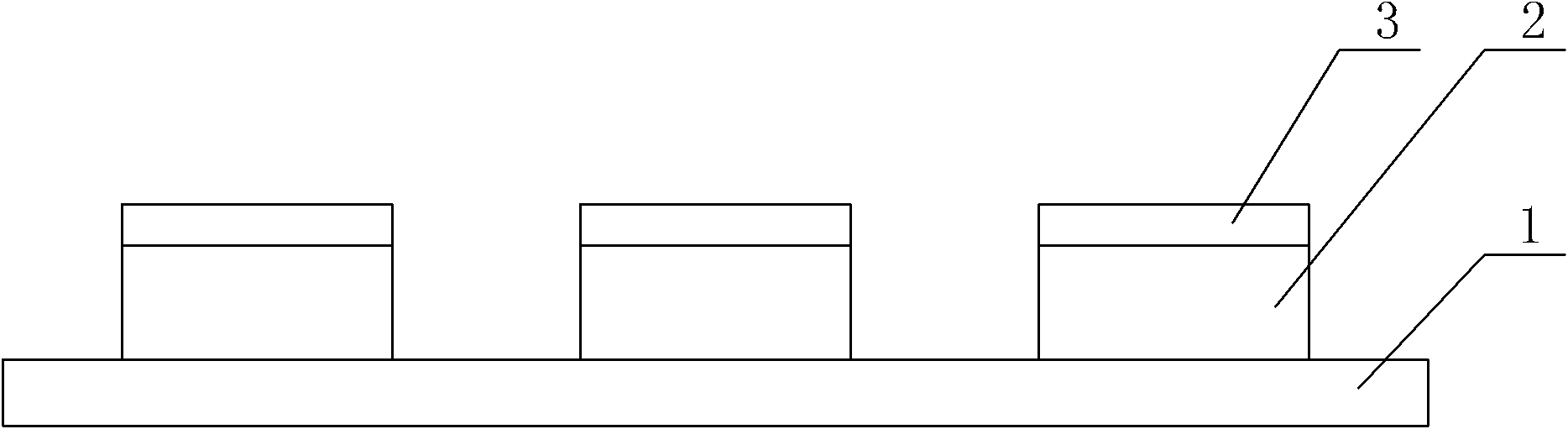

Coarsened-sidewall AlGaInP-base LED and manufacture method thereof

ActiveCN105185883AImprove light extraction efficiencyIncrease brightnessSemiconductor devicesOhmic contactMetallic bonding

The invention relates to a coarsened-sidewall AlGaInP-base LED and a manufacture method thereof and belongs to the technical field of semiconductors. The method comprises steps of: bonding an epitaxial wafer on a permanent substrate by using a metallic bonding layer on the epitaxial wafer and a metallic bonding layer on the permanent substrate in order to form a bonded semi-finished product; removing a temporary substrate, a buffer layer, and a cutoff layer on the bonded semi-finished product in order to expose an ohmic contact layer; etching and patterning the ohmic contact layer, and manufacturing a n-type expansion electrode, a main electrode, and a back electrode; and etching a cutting channel at least reaching a p-GaP window layer on the periphery of the epitaxial layer of each LED chip, coarsening the surface and the sidewall of the epitaxial layer in order that the surface and the sidewall of the epitaxial layer are coarsened. The manufacture method is simple in technology, convenient in production, and capable of increasing electro-optical conversion efficiency, prolonging the service life of the LED, enlarging a visual angle, and improving the display effect of an LED screen.

Owner:YANGZHOU CHANGELIGHT

Manufacturing method of single intermetallic compound micro-interconnecting structure of flip chip

InactiveCN102244022AWeak interfaces are reducedEliminate interfaceSemiconductor/solid-state device detailsSolid-state devicesSurface layerOptoelectronics

The invention discloses a manufacturing method of a single intermetallic compound micro-interconnecting structure of a flip chip, relating to the manufacturing method of an intermetallic compound micro-interconnecting structure of the flip chip and aiming at solving the problem that micro-interconnection welding spots of the flip chip fracture at connecting interfaces among brazing solder alloys, intermetallic compounds and metallic bonding pads. The technical scheme I comprises the following steps of: manufacturing a chip metallic basic layer (a chip metallic bonding pad) and a surface layer on a metallic surface of the chip, and manufacturing a substrate metallic basic layer (a substrate metallic bonding pad) and a surface layer on a metallic surface of a substrate, wherein the chip and the substrate metallic surface are made of pure Sn; coating a soldering flux on the metallic surface of the chip and the metallic surface of the substrate; and inverting the chip to ensure that the chip metallic bonding pad corresponds to the substrate metallic bonding pad, pressing, heating, cooling, and forming the intermetallic compound micro-interconnecting structure of the flip chip. The technical scheme II is different from the technical scheme I in the following steps of: coating the soldering flux on the metallic basic layer of the chip and the metallic basic layer of the substrate and inverting the chip, wherein the metallic basic layer of the chip is in contact with the metallic bonding pad of the substrate by a Sn foil. The single intermetallic compound micro-interconnecting structure is applied to an electronic packaging structure.

Owner:HARBIN INST OF TECH

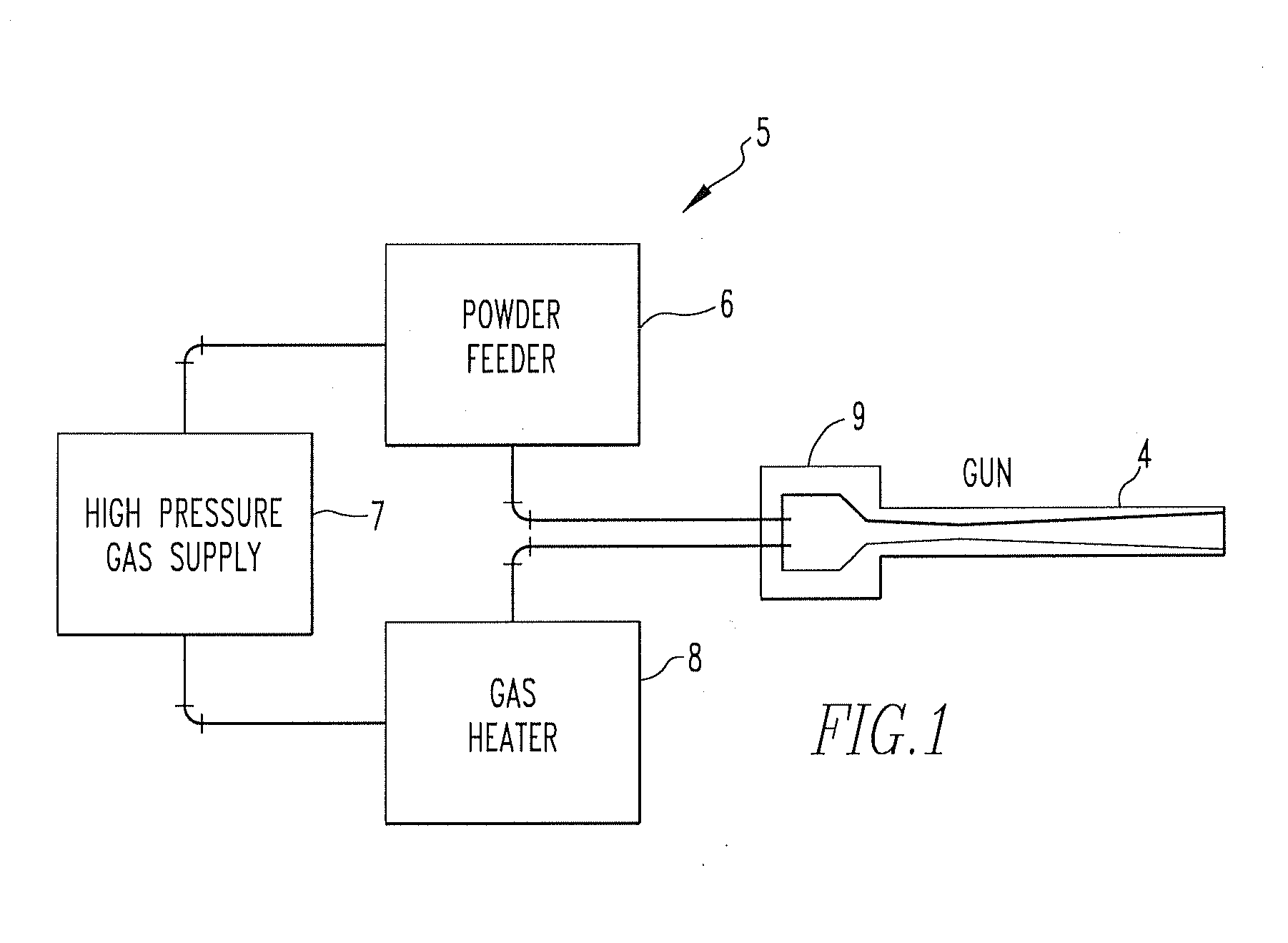

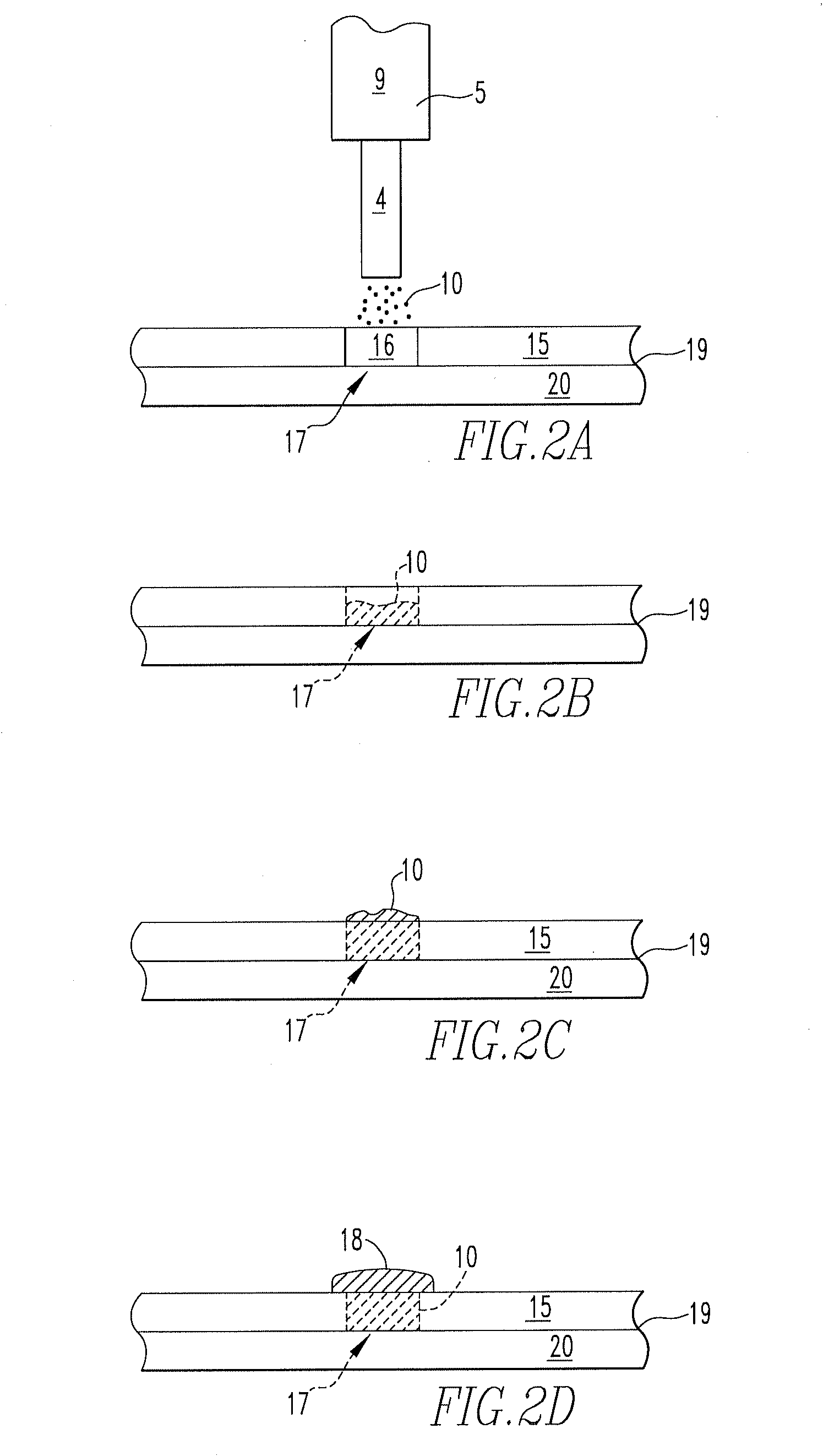

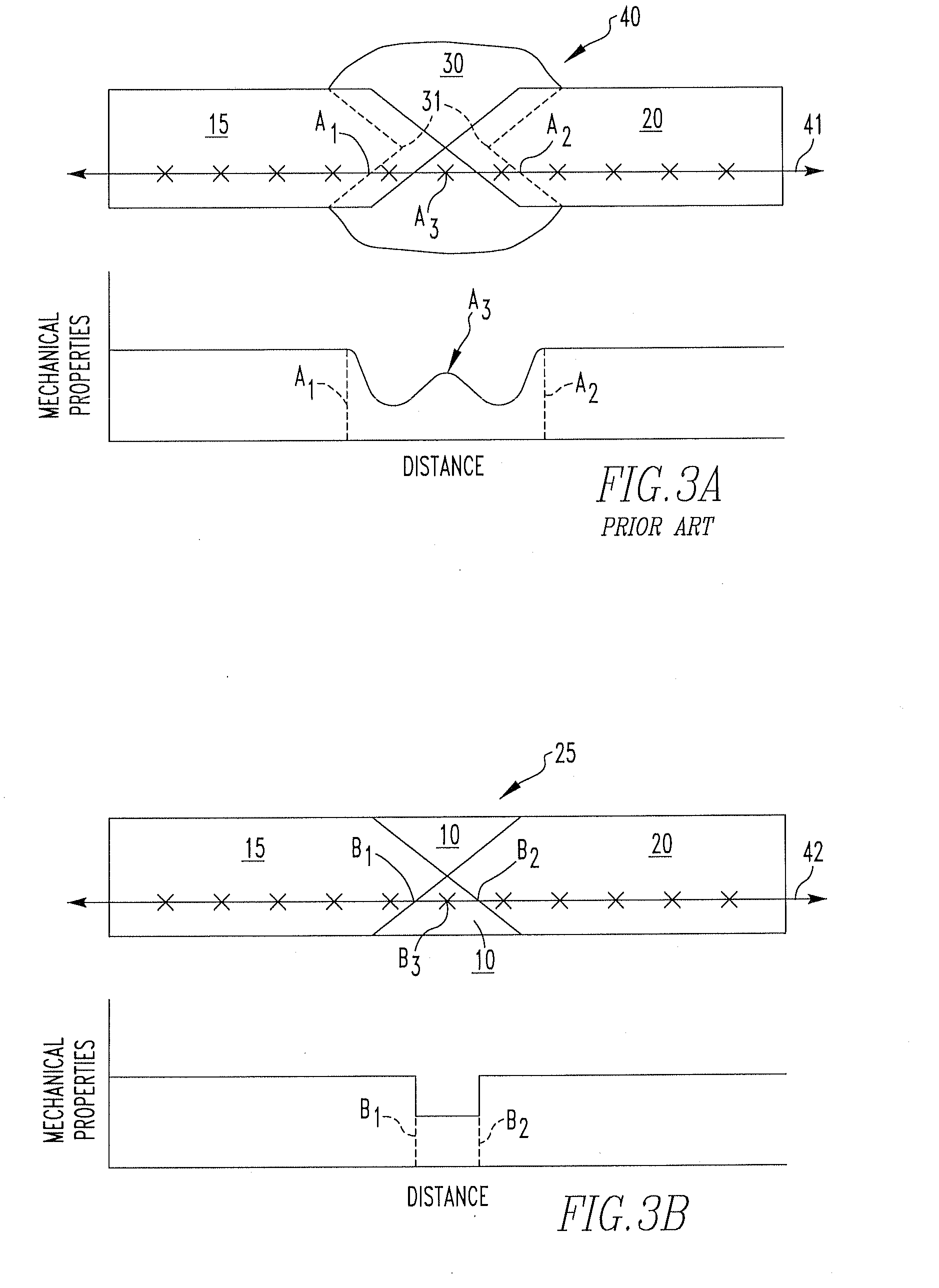

High velocity metallic powder spray fastening

InactiveUS20070194085A1Uniform mechanical propertiesCooking-vessel materialsLiquid spraying apparatusMulti materialMetallic bonding

The present invention provides a low temperature joining method that is compatible with multiple materials and results in a bond between joined structures without reducing the mechanical properties of the joined structures base materials. The method of the present invention includes the steps of contacting a first structure to a second structure; and directing particles of a metallic bonding material towards an interface between the first structure and second structure at a velocity to cause the particles of the metallic bonding material form a molecular fusion between the first structure and second structure.

Owner:ARCONIC INC

Microfluid heat radiation channel, heat radiation method and preparation method thereof

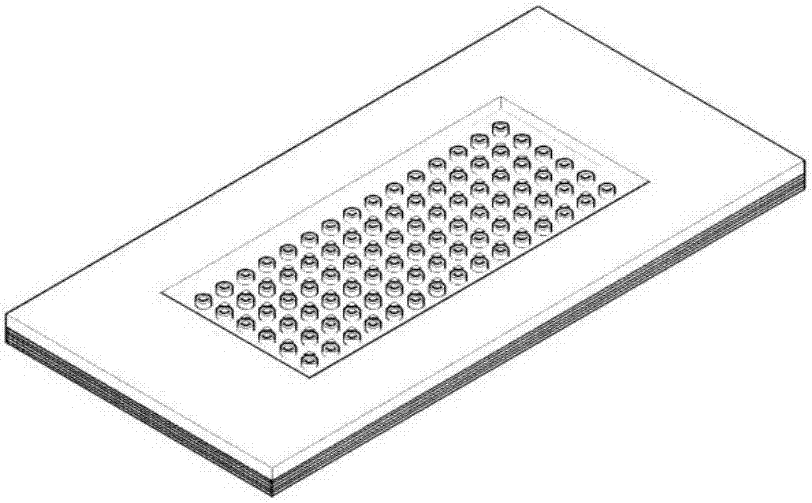

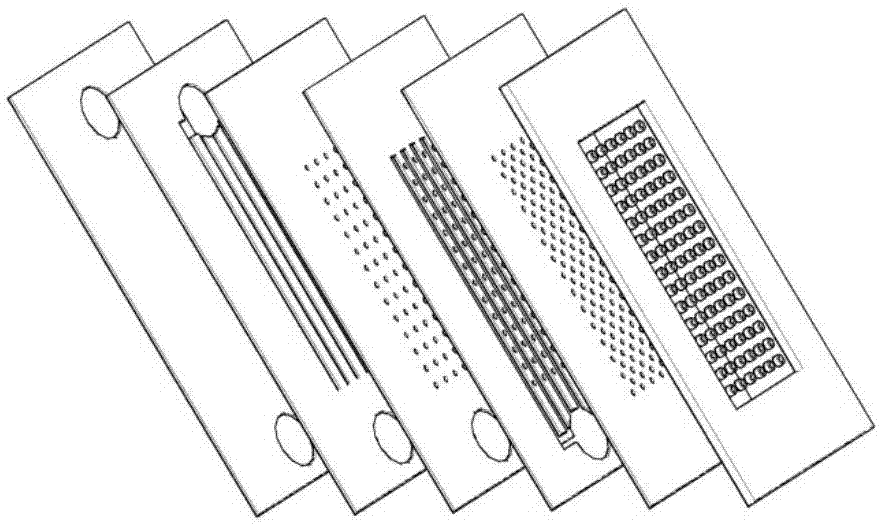

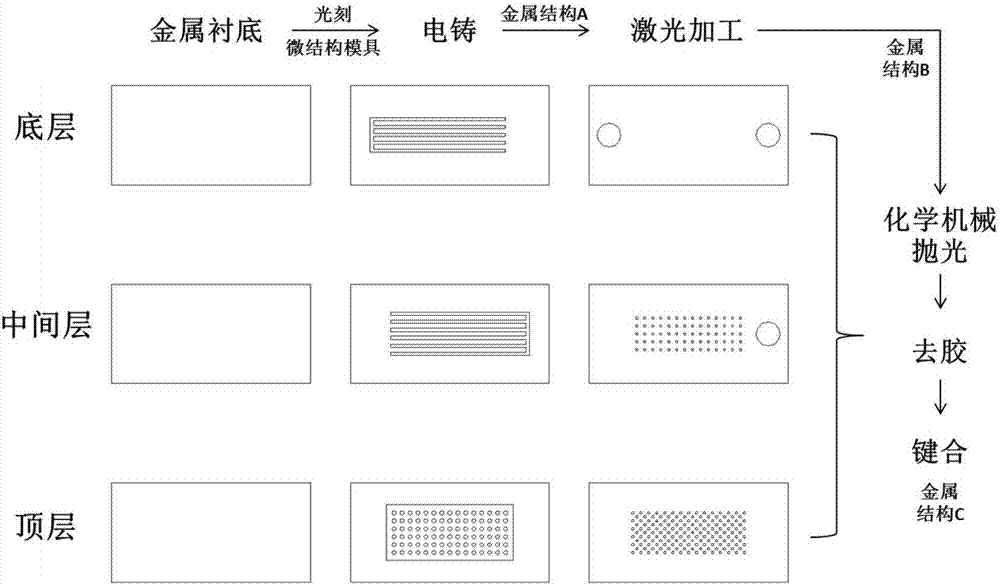

ActiveCN107275297AReduce technical difficultyReduce processing costsSemiconductor/solid-state device detailsSolid-state devicesSpray nozzleBonding process

The invention belongs to the field of microelectronic heat radiation technology. For aiming at problems in prior art, the invention provides a microfluid heat radiation channel, a heat radiation method and a preparation method. According to the preparation method, a total metal heat radiation microchannel based on a distributed nozzle structure is realized through processes of photoetching, metal micro-electroforming and metal bonding. The preparation method comprises the steps of preparing corresponding microstructure molds on a bottom layer, an intermediate layer and a top metal substrate by means of a photosensitive material; through a metal micro-electroforming process, transferring the micro-structure molds for preparing a metal microstructure A; performing hole processing on the metal microstructure A through a laser fine machining process, and forming a metal microstructure B with communicating holes; performing mechanical polishing on the metal microstructure B, and forming the microfluid heat radiation channel based on the distributed nozzle structure through a metal bonding process.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

Adhesive composition, electronic-component-mounted substrate and semiconductor device using the adhesive composition

ActiveUS20100221559A1Maintain storage stabilityExcellent in electroconductivityNon-macromolecular adhesive additivesConductive materialElectrical resistance and conductancePolymer science

There are provided are an adhesive composition that keeps storage stability and further gives a cured product wherein metallic bonds are formed in the state that the cured product wets its components and is satisfactorily spread between the components (or parts), thereby turning excellent in adhesive property, electroconductivity, and reliability for mounting such as TCT resistance or high-temperature standing resistance; an electronic-component-mounted substrate using the same; and a semiconductor device. The adhesive composition comprises electroconductive particles (A) and a binder component (B), wherein the electroconductive particles (A) include a metal (a1) having a melting point equal to or higher than the reflow temperature and containing no lead, and a metal (a2) having a melting point lower than the reflow temperature and containing no lead, and the binder component (B) includes a thermosetting resin composition (b1) and an aliphatic dihydroxycarboxylic acid (b2).

Owner:RESONAC CORP

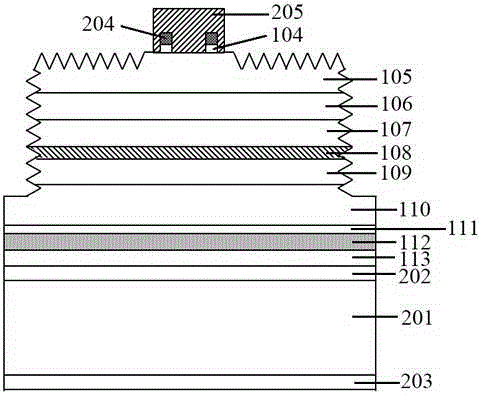

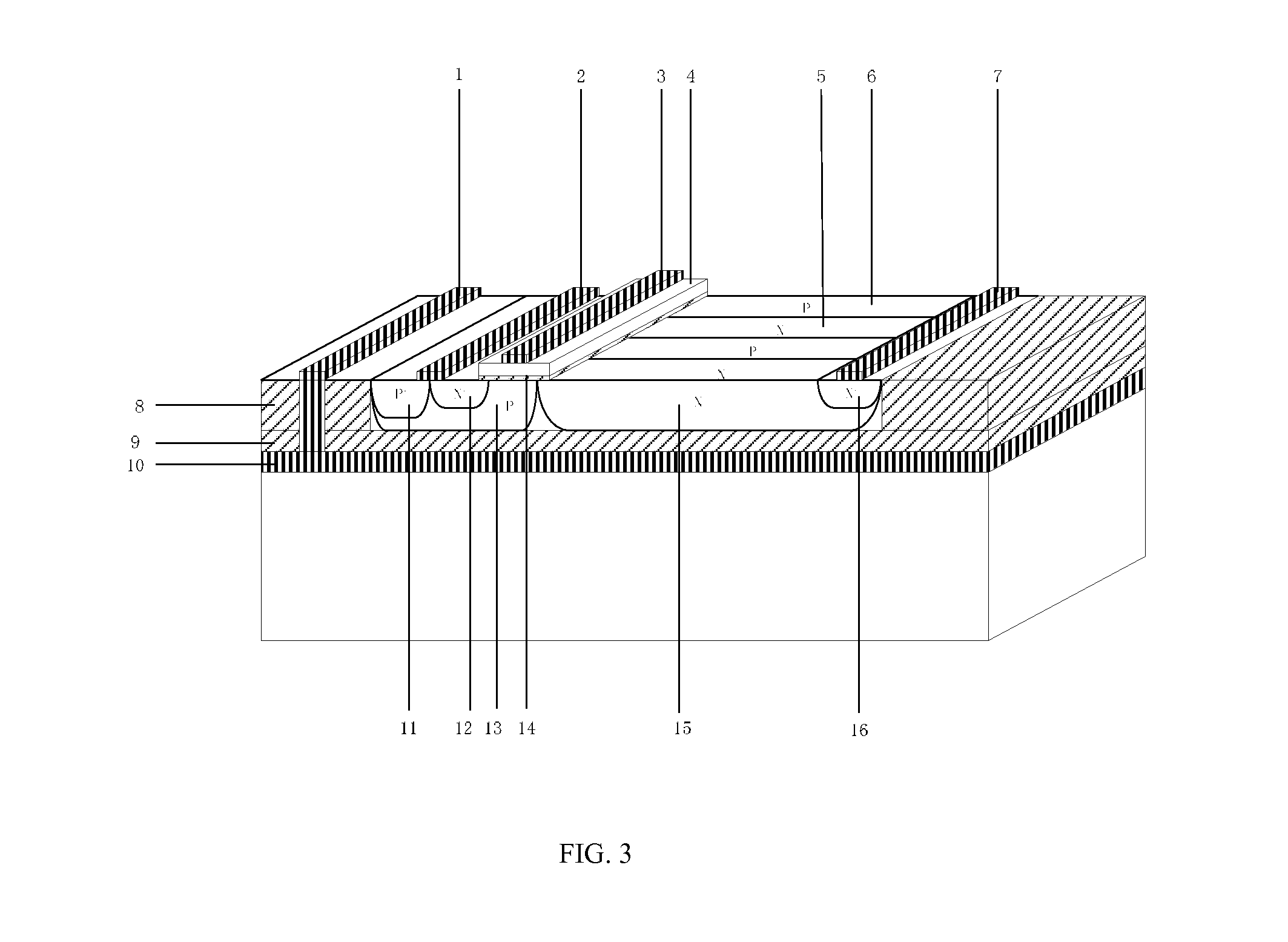

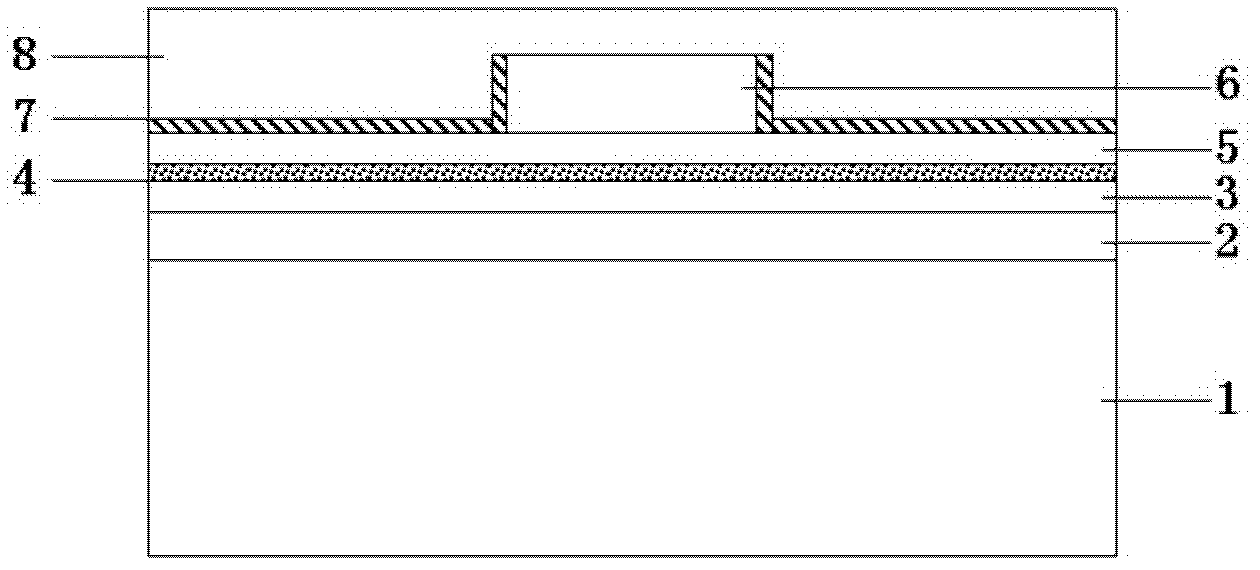

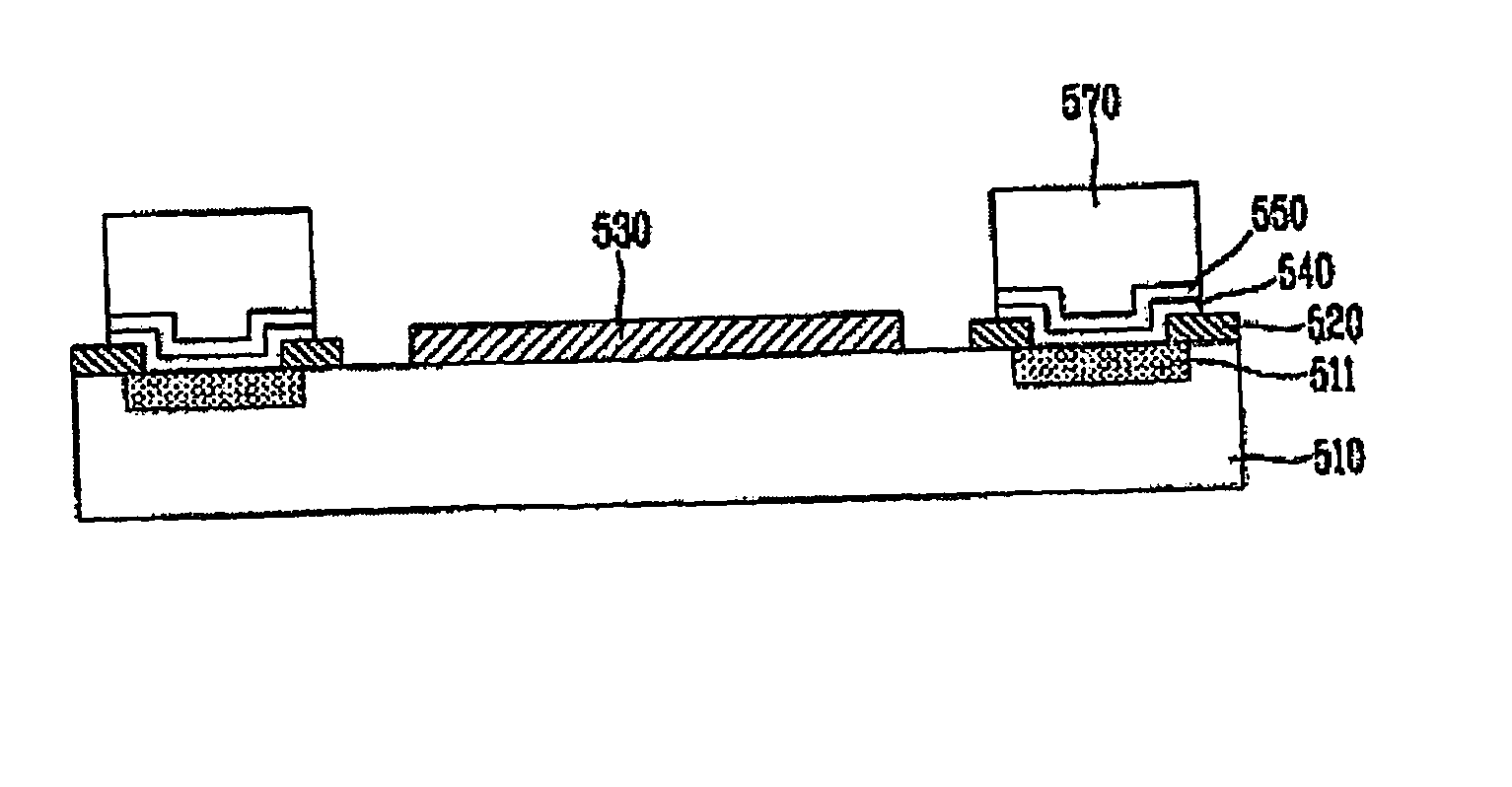

Method of fabricating soi super-junction ldmos structure capable of completely eliminating substrate-assisted depletion effects

InactiveUS20120058608A1Eliminating substrate-assisted depletion effectEliminate the effects ofSemiconductor/solid-state device manufacturingSemiconductor devicesLDMOSSoi substrate

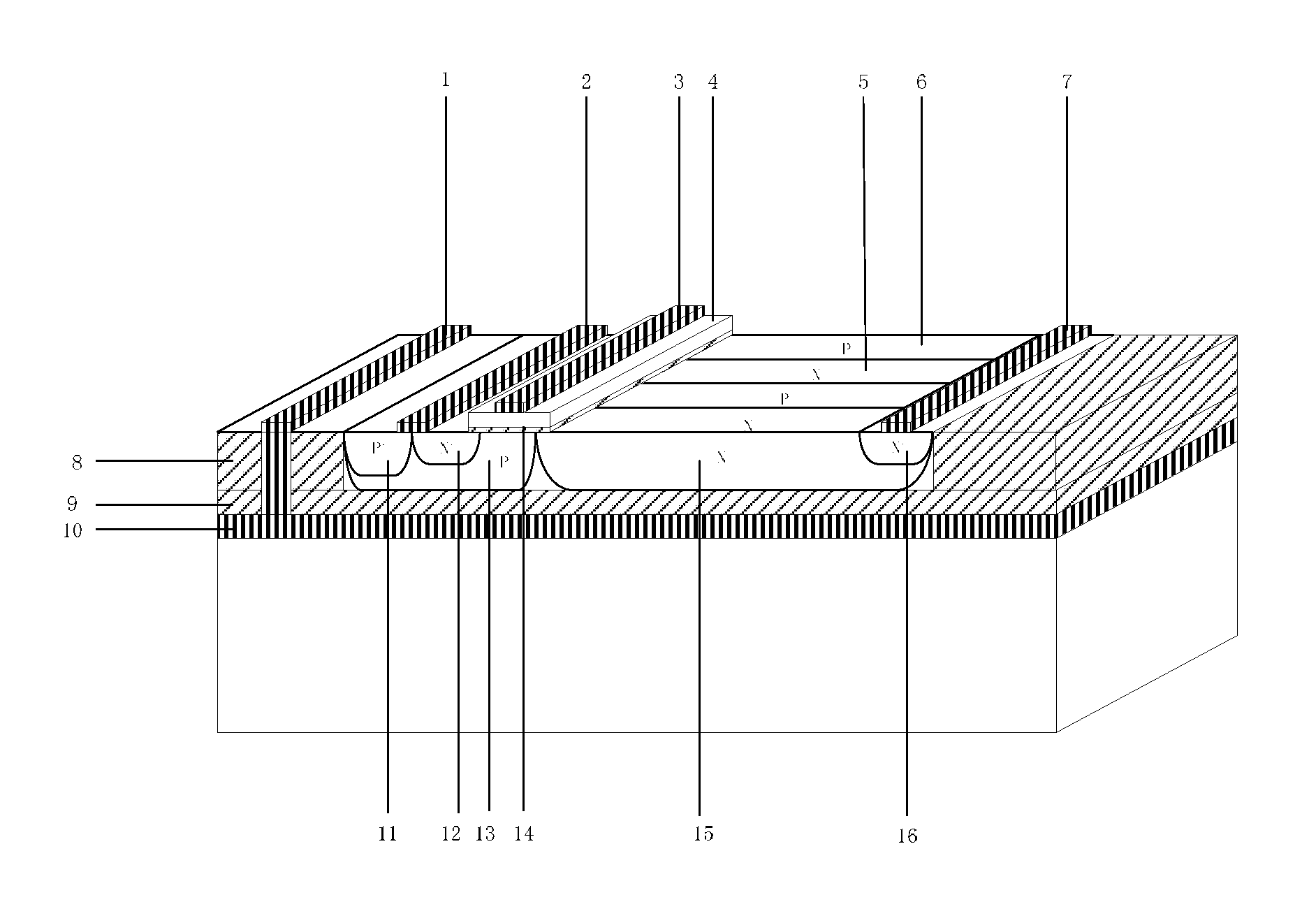

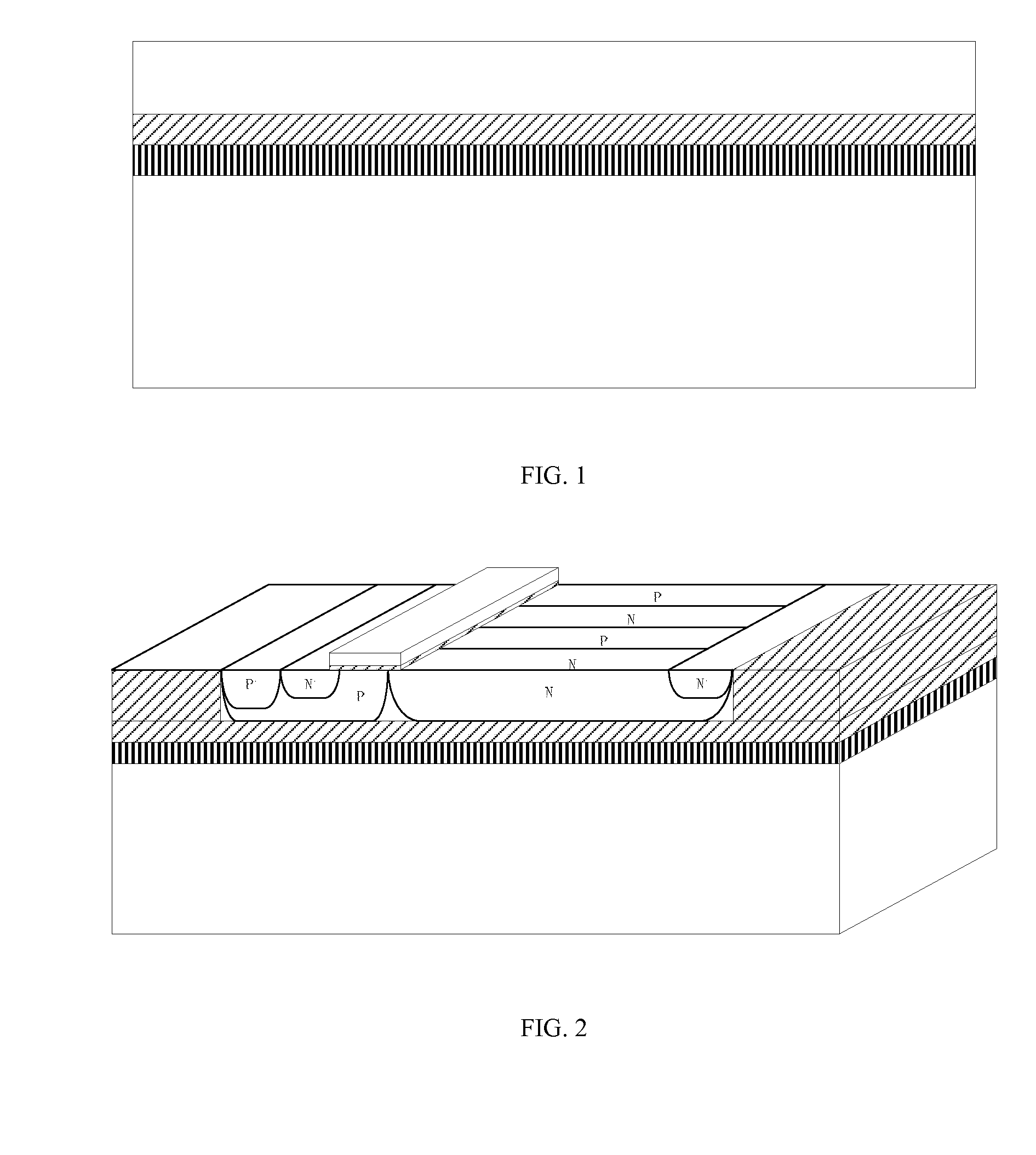

The present invention relates to a method of fabricating an SOI SJ LDMOS structure that can completely eliminate the substrate-assisted depletion effects, comprising the following steps: step one: a conducting layer is prepared below the SOI BOX layer using the bonding technique; the conducting layer is prepared in the following way: depositing a barrier layer on a first bulk silicon wafer, and then depositing a charge conducting layer, thereby obtaining a first intermediate structure; forming a silicon dioxide layer on a second bulk silicon wafer via thermal oxidation, then depositing a barrier layer, and finally depositing a charge conducting layer, thereby obtaining a second intermediate structure; bonding the first intermediate structure and the second intermediate structure using the metal bonding technology to arrange the conducting layer below the SOI BOX layer; step two: a SJ LDMOS structure is fabricated on the SOI substrate having a conducting layer. The present invention is capable of releasing the charge accumulated at the lower interface of the BOX layer, eliminating the effect of the vertical charge on the charge balance between the p-type pillar and the n-type pillar, and therefore completely eliminating the substrate-assisted depletion effects and elevating the breakdown voltage of the device.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Light emitting diode possessing transparent extended electrode structure and manufacturing method thereof

InactiveCN105914269AImprove protectionIncrease contactSemiconductor devicesGraphicsHigh volume manufacturing

The invention discloses a light emitting diode possessing a transparent extended electrode structure and a manufacturing method thereof. The light emitting diode comprises a permanent substrate, an epitaxial luminescent layer and a back electrode. Graphical processing is performed on an N-GaAs ohmic contact layer in the epitaxial luminescent layer. A back side of the permanent substrate is provided with the back electrode. On the permanent substrate, the permanent substrate is connected to the epitaxial luminescent layer through a first metal bonding layer and a second metal bonding layer. A mirror surface reflecting layer and a medium film layer are arranged between the second metal bonding layer and the epitaxial luminescent layer. An extended electrode made of a transparent material wraps an armoring layer and the N-GaAs ohmic contact layer in the whole epitaxial luminescent layer and forms electric contact with a graph on the N-GaAs ohmic contact layer. The extended electrode is provided with a main electrode. The light emitting diode and the method of the invention possess advantages that electrode shading can be avoided; current expansion uniformity is increased; luminous efficiency is improved; electrode reliability is increased; the light emitting diode is not easy to damage; reliability is good and the light emitting diode is suitable for mass production.

Owner:NANCHANG KAIXUN PHOTOELECTRIC CO LTD

Organometallic complex, light-emitting element, light-emitting device, electronic appliance, and lighting device

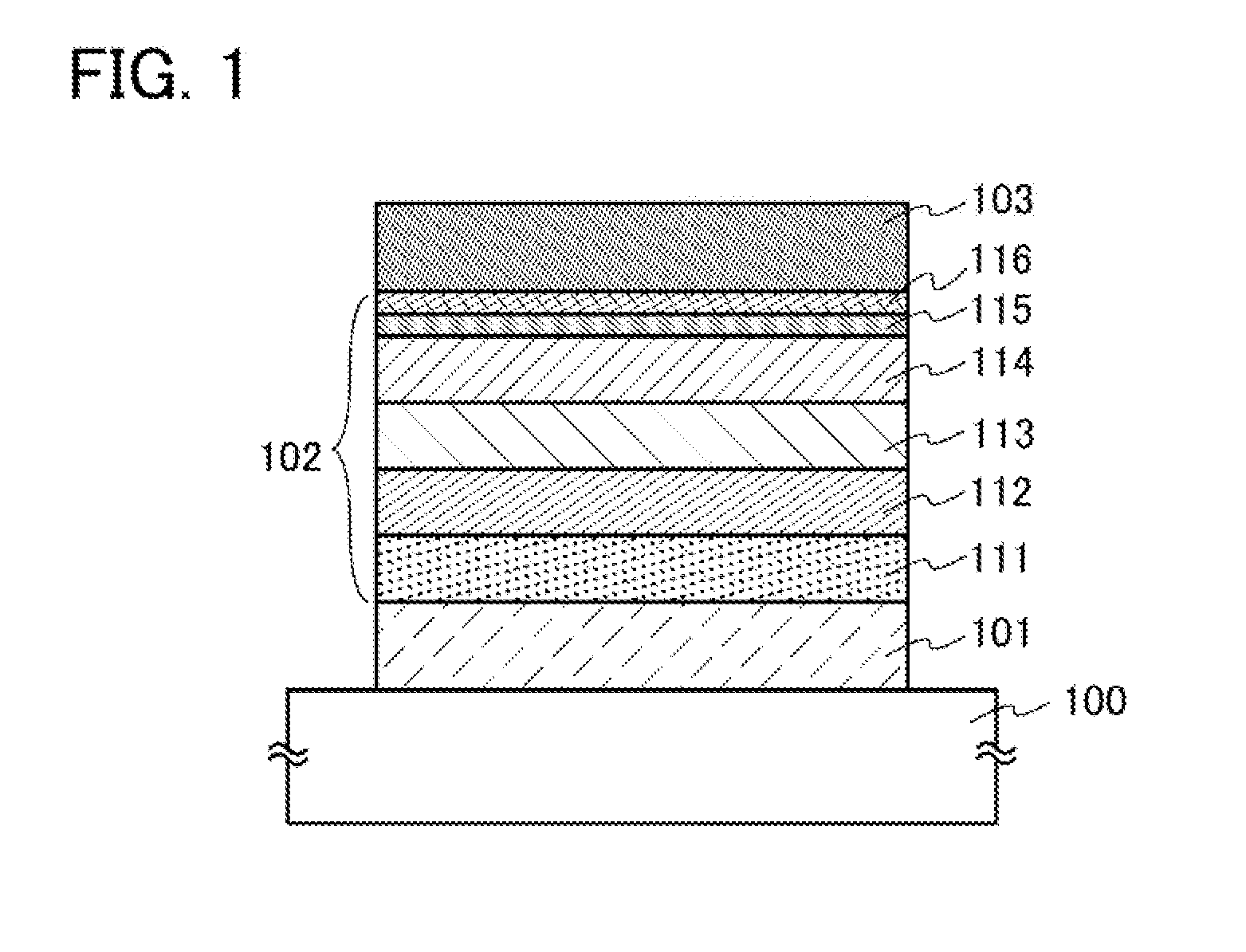

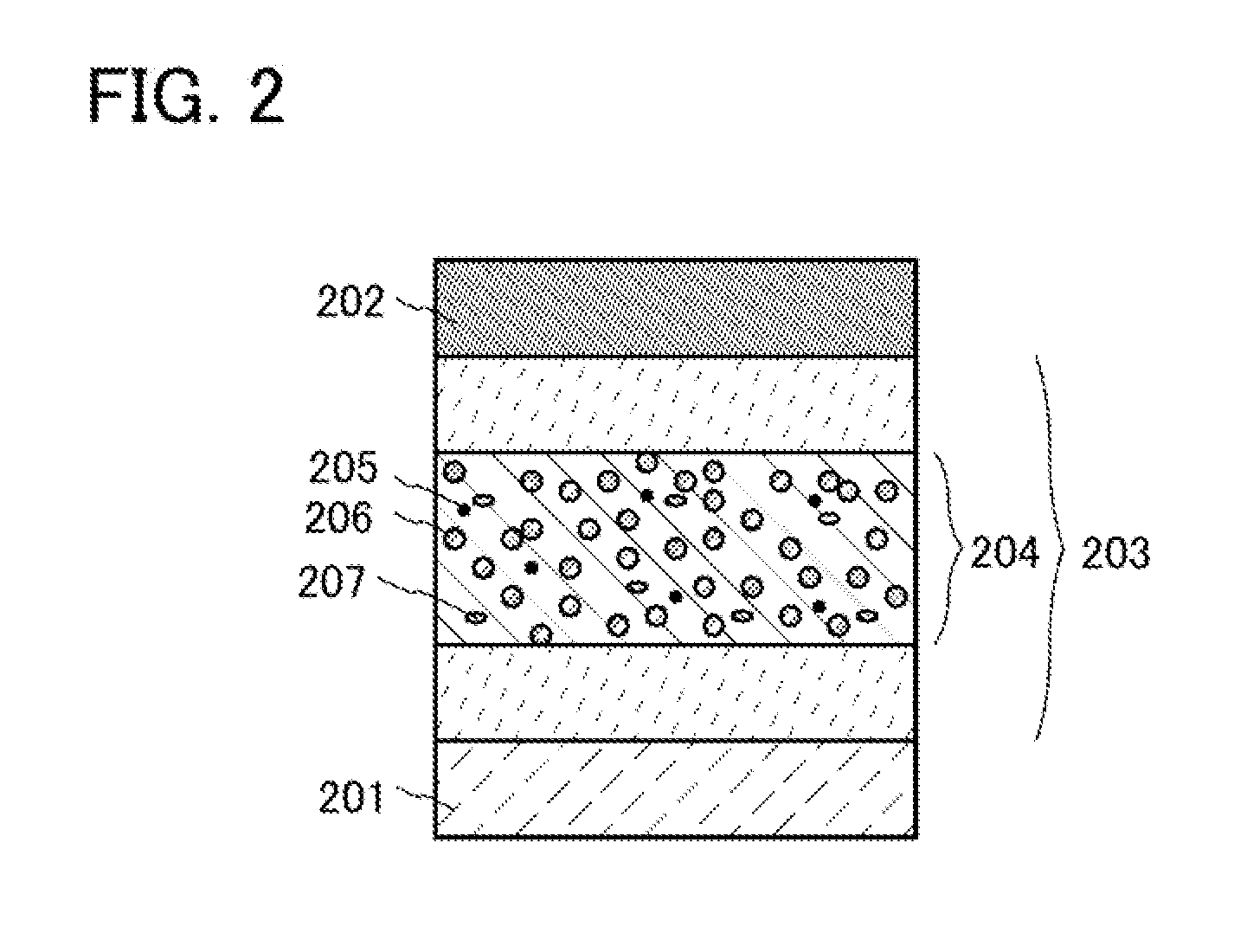

InactiveUS20140339526A1Emission efficiency be highHigh reliabilityGroup 5/15 element organic compoundsSolid-state devicesPyrimidineEmission efficiency

A light-emitting element including a phosphorescent organometallic complex is provided. The organometallic complex emits phosphorescence in the yellow green to orange wavelength range and has high emission efficiency and high reliability. Thus, the organometallic complex that exhibits phosphorescence is provided. The organometallic complex, in which nitrogen at the 3-position of a pyrimidine ring is coordinated to a metal, a carbazole skeleton is bonded to the 4-position of the pyrimidine ring, and the carbazole skeleton is bonded to the metal, is used as an emission center. The metal is preferably a Group 9 element or a Group 10 element, more preferably iridium.

Owner:SEMICON ENERGY LAB CO LTD

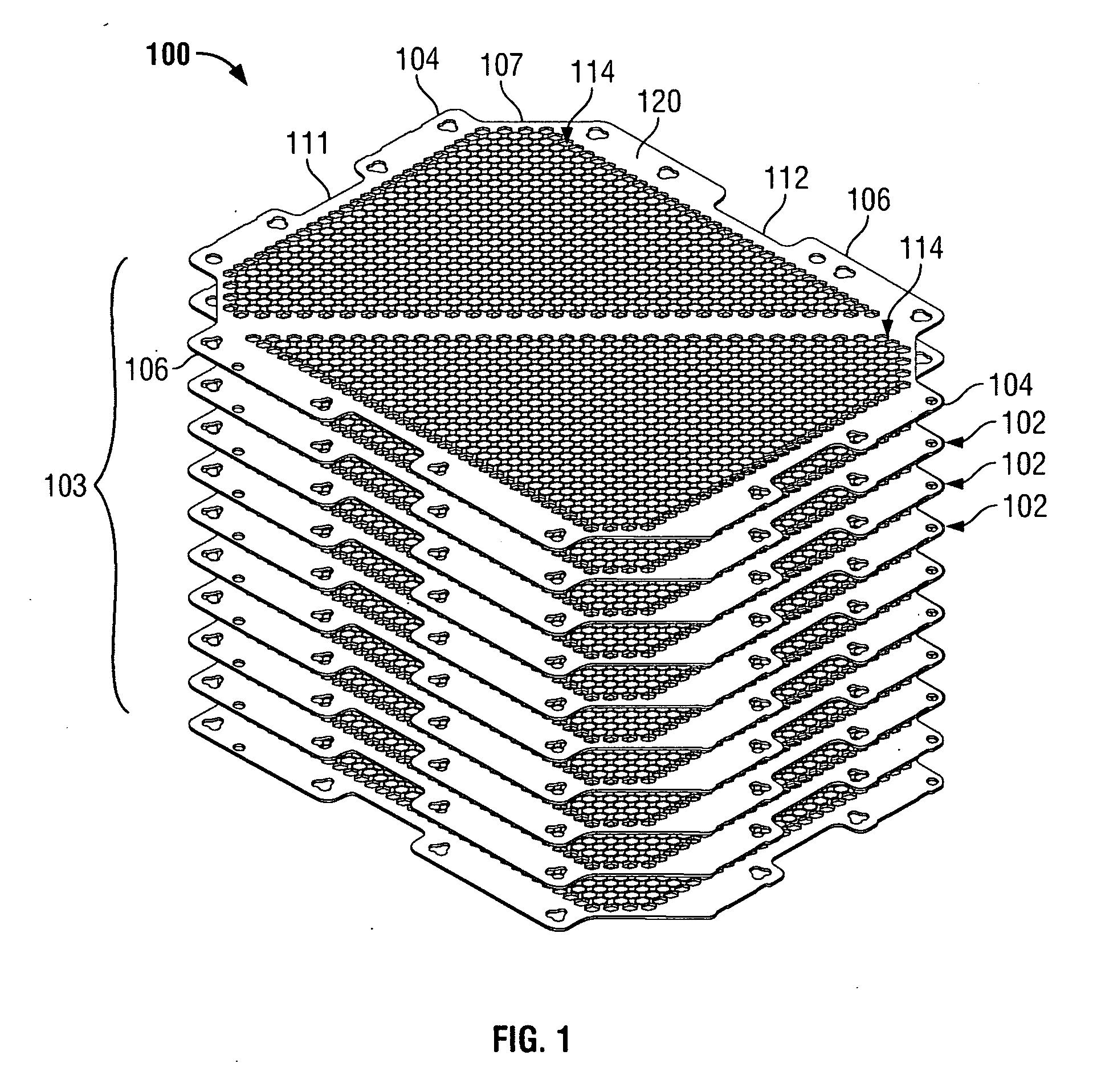

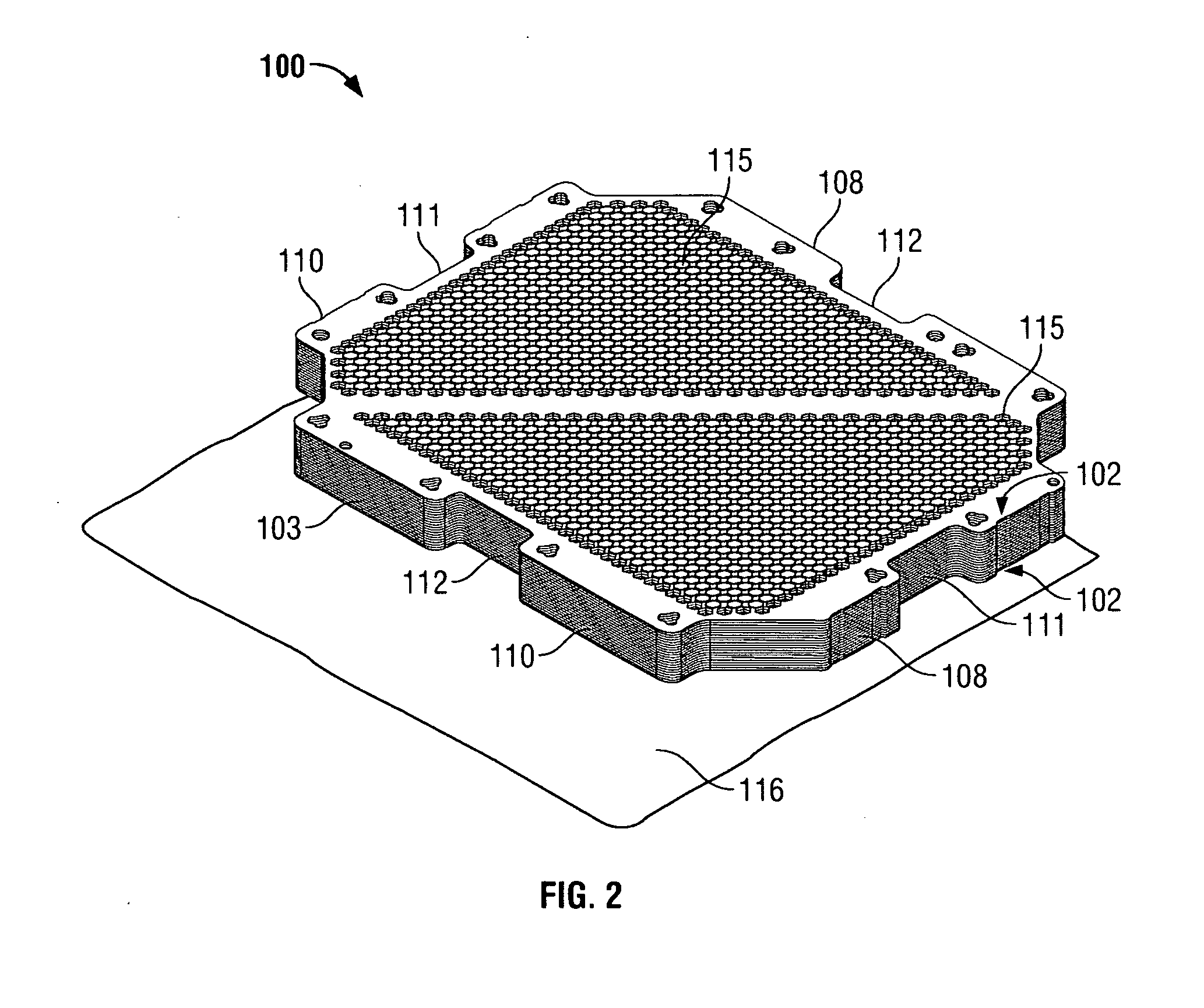

Bonded three dimensional metal laminate structure and method

InactiveUS20050221634A1Structural economyRelieving strain on wire connectionElectrically conductive connectionsMetallic bondingMaterials science

A conductive structure and method of manufacturing therefor includes a plurality of stacked metal laminates secured to one another via an intermetallic bond made from a metallic bonding agent.

Owner:TE CONNECTIVITY CORP

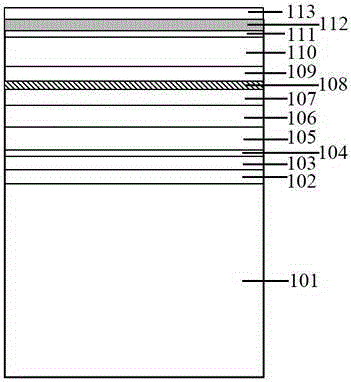

Inverted laser chip based on SiC substrate and manufacturing method of inverted laser chip

ActiveCN103001119AGood stress matchingHigh crystallinityLaser detailsSemiconductor laser structural detailsOptoelectronicsContact layer

The invention provides an inverted laser chip based on an SiC substrate and a manufacturing method of the inverted laser chip. The inverted laser chip based on the SiC substrate comprises a conventional laser chip structure and the SiC substrate. The conventional laser chip structure sequentially comprises a substrate, a buffer layer, an N limit layer, an active area, a P limit layer, a P-type ohm contact layer, a current retaining layer and a metal ohm contact layer from bottom to top. A metal ohm contact layer is plated at the bottom of the SiC substrate, and a metal bonding layer is plated on the other side. The metal ohm contact layer of the conventional laser chip is bonded with the SiC substrate through the metal bonding layer of the SiC substrate. The N electrode metal layer is evaporated on the buffer layer, with original substrate being removed, of the conventional laser chip. The pole N of the manufactured SiC substrate is at the top, and the pole P of the manufactured SiC substrate is at the bottom. Compared with conventional lasers, the inverted laser chip based on the SiC substrate has the advantages of good radiation, good stability, long service life and the like.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

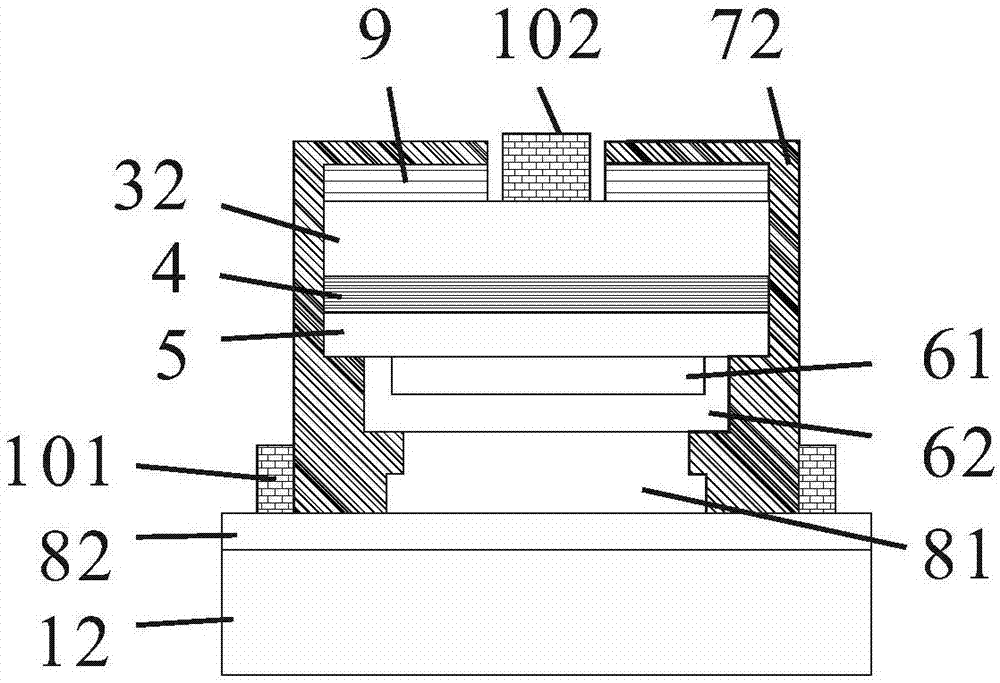

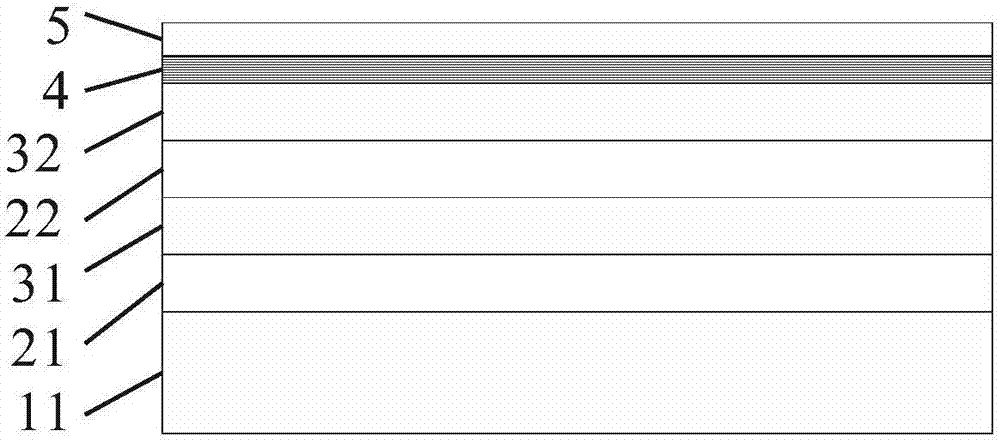

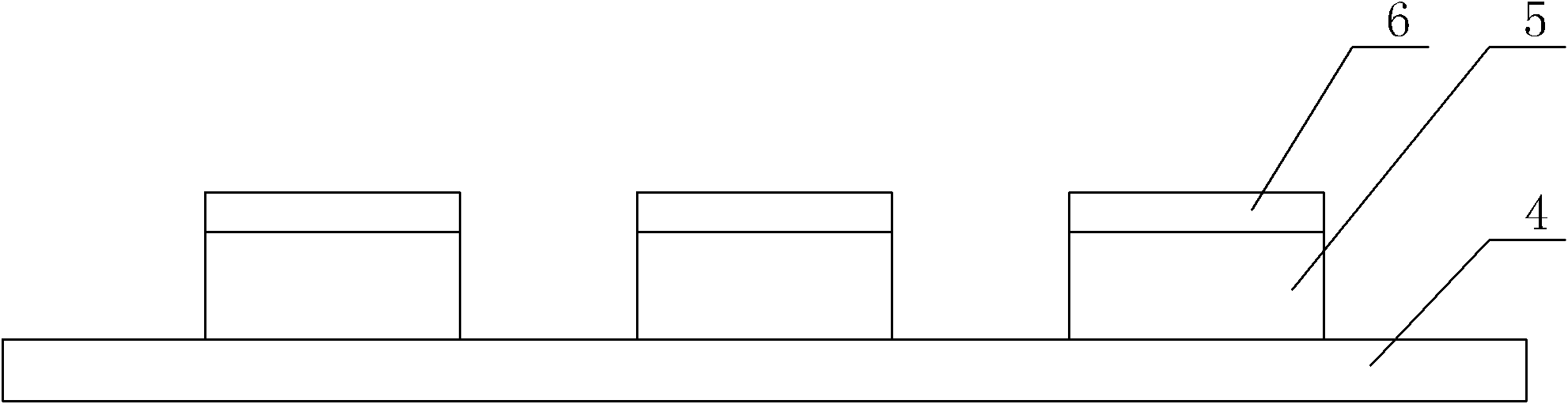

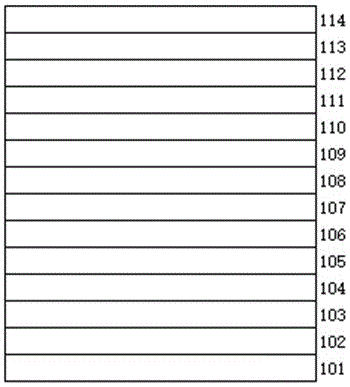

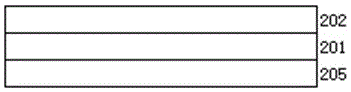

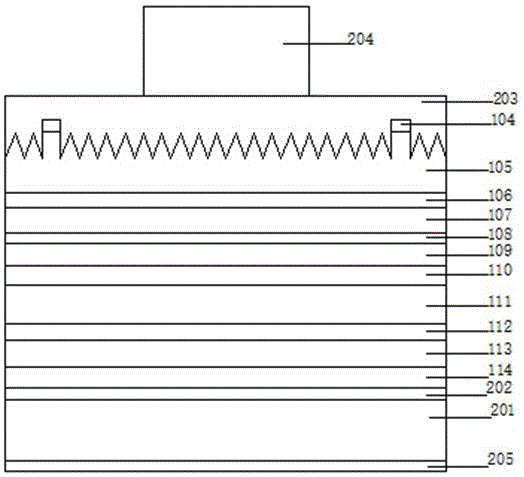

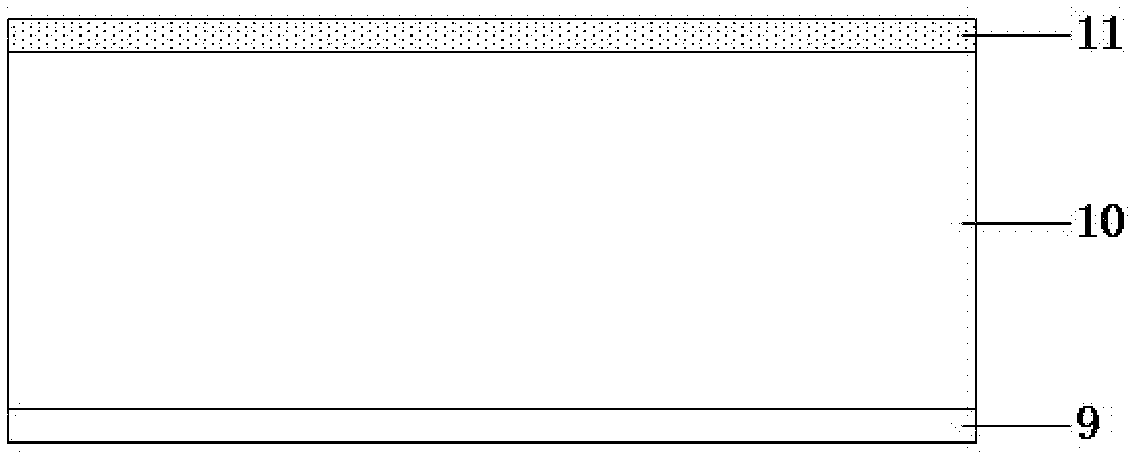

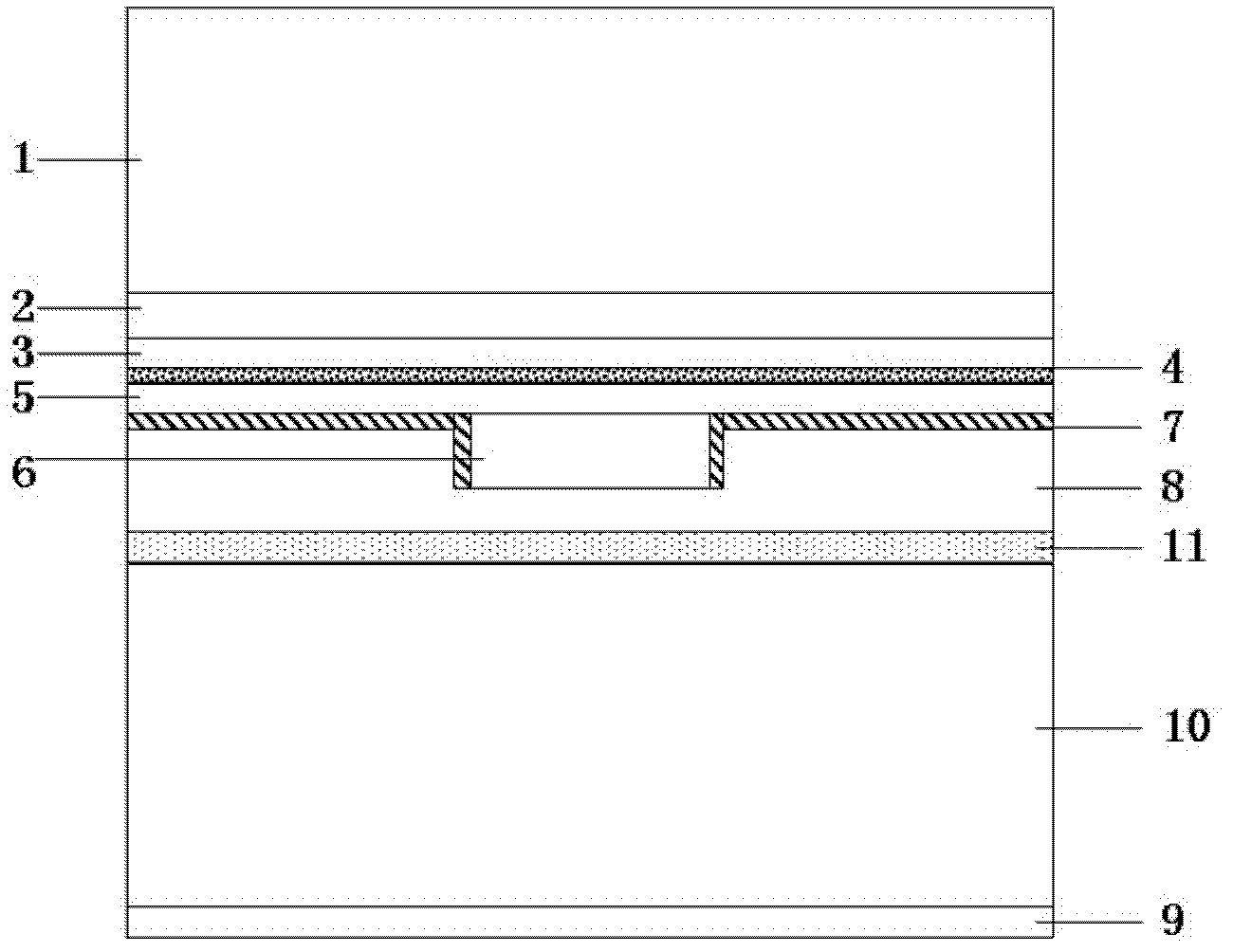

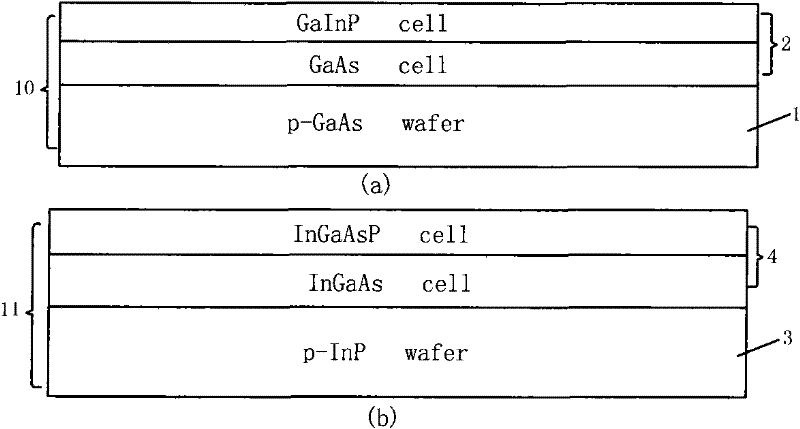

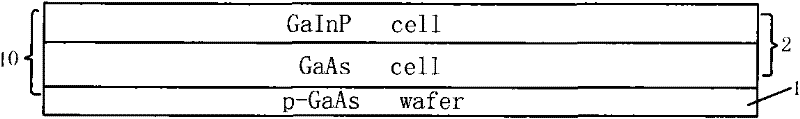

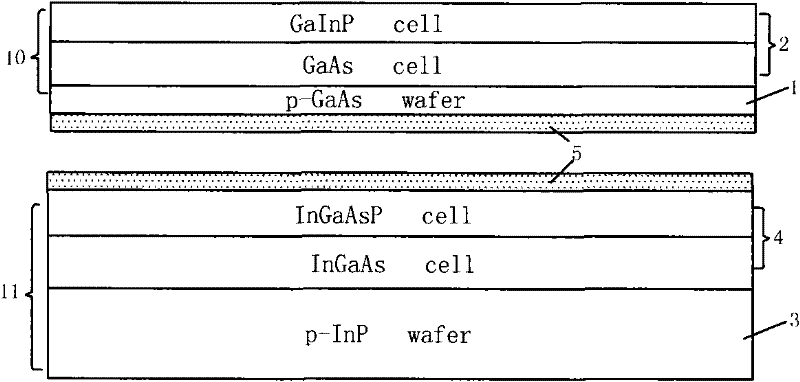

A kind of multi-junction tandem solar cell and its manufacturing method

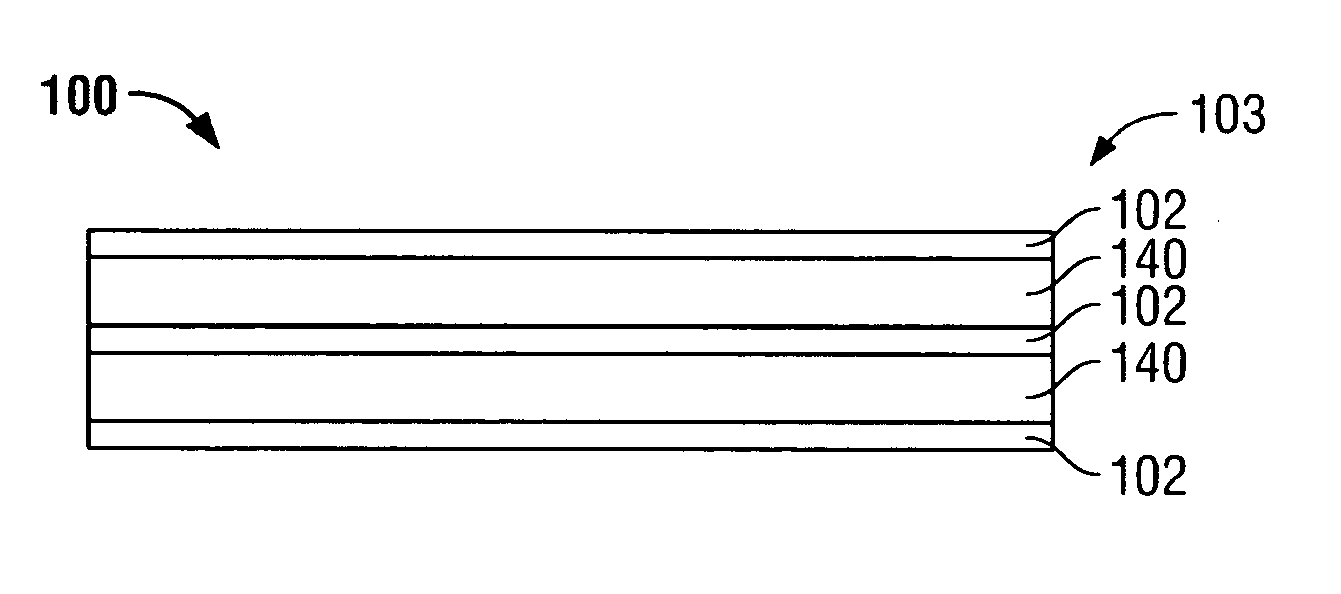

InactiveCN102270693AGood electrical conductivityImprove work efficiencyFinal product manufacturePhotovoltaic energy generationMetallic bondingEngineering

The invention relates to a multijunction laminated solar cell and a manufacturing method thereof. The multijunction laminated solar cell comprises a cell unit laminated body (A) as well as a top electrode (12) and a back electrode (13) which are arranged on the top and bottom of the cell unit laminated body (A), wherein the cell unit laminated body (A) comprises a bottom-layer cell unit (11) and at least one upper-layer cell unit (10) connected to the top of the bottom-layer cell unit (11) in a laminating manner; the bottom-layer cell unit (11) comprises a substrate (3) and an epitaxial layer(4); the upper-layer cell unit (10) at least comprises an epitaxial layer (2); and the cell unit laminated body (A) can be obtained by performing direct bonding, metallic bonding or inversed welding processes on the bottom-layer cell unit (11) and the upper-layer cell unit (10). According to the invention, not only can the problem of unmatched crystal lattice of the cell unit laminated body (A) is solved, but also the overall working efficiency of the solar cell is improved.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

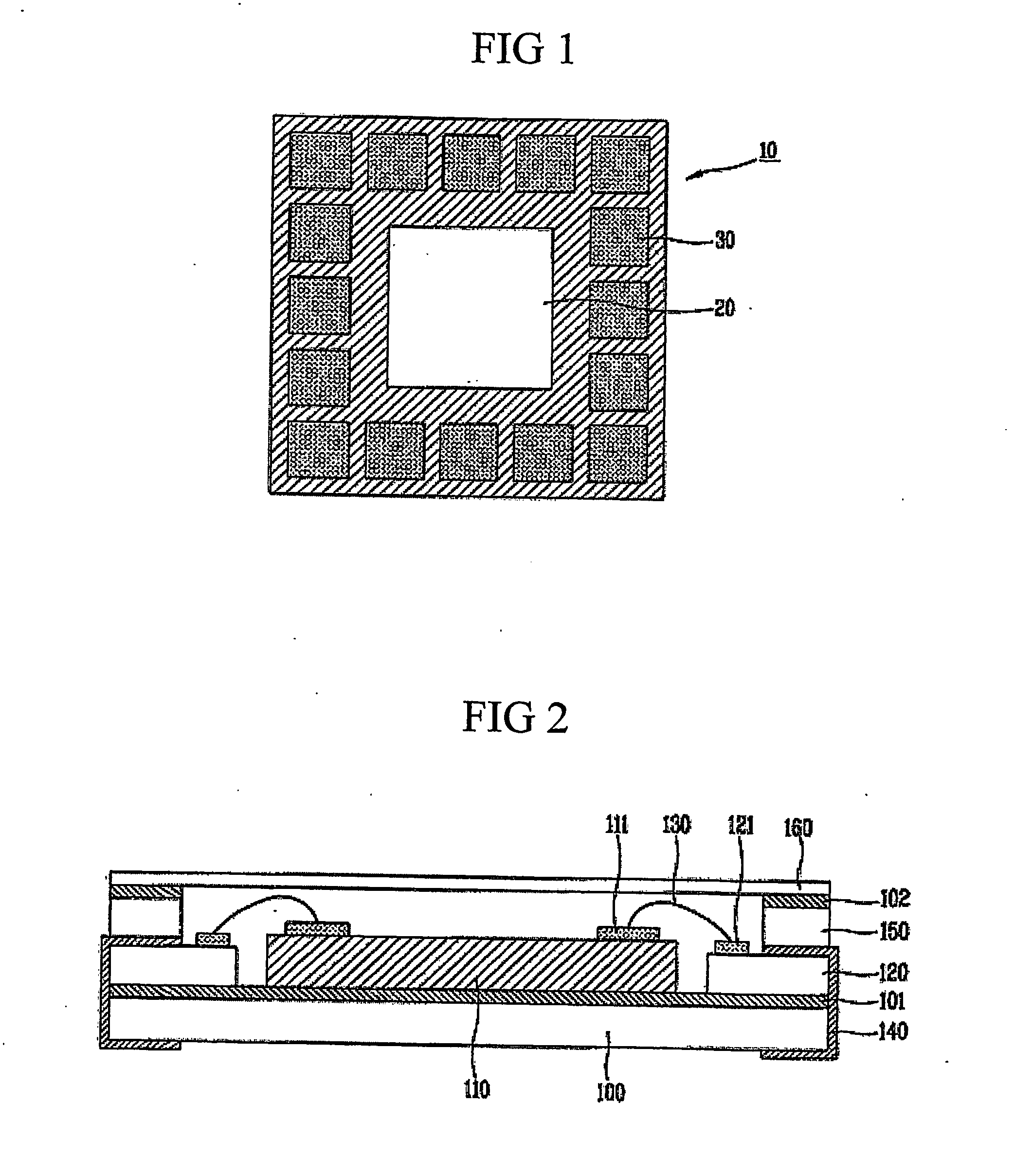

Image sensor mounted by mass reflow

InactiveUS20070085180A1Avoiding characteristicSemiconductor/solid-state device detailsSolid-state devicesRoom temperatureMetallic bonding

A package for semiconductor image pickup device is provided. The package is fabricated by using flip chip bumping. During deposition process of forming a metallic bonding layer and a metal layer for plating, a surface of a semiconductor image pickup device is maintained at the range between room temperature and 200° C. in accordance with a first embodiment. A polymer layer for preventing stress from generating can absorb stress generated during the deposition process in accordance with a second embodiment. According to the present invention, a functional polymer layer on the surface of a semiconductor image pickup device can be prevent from being deteriorated in its properties and from transforming at its surface.

Owner:NEPES CO LTD

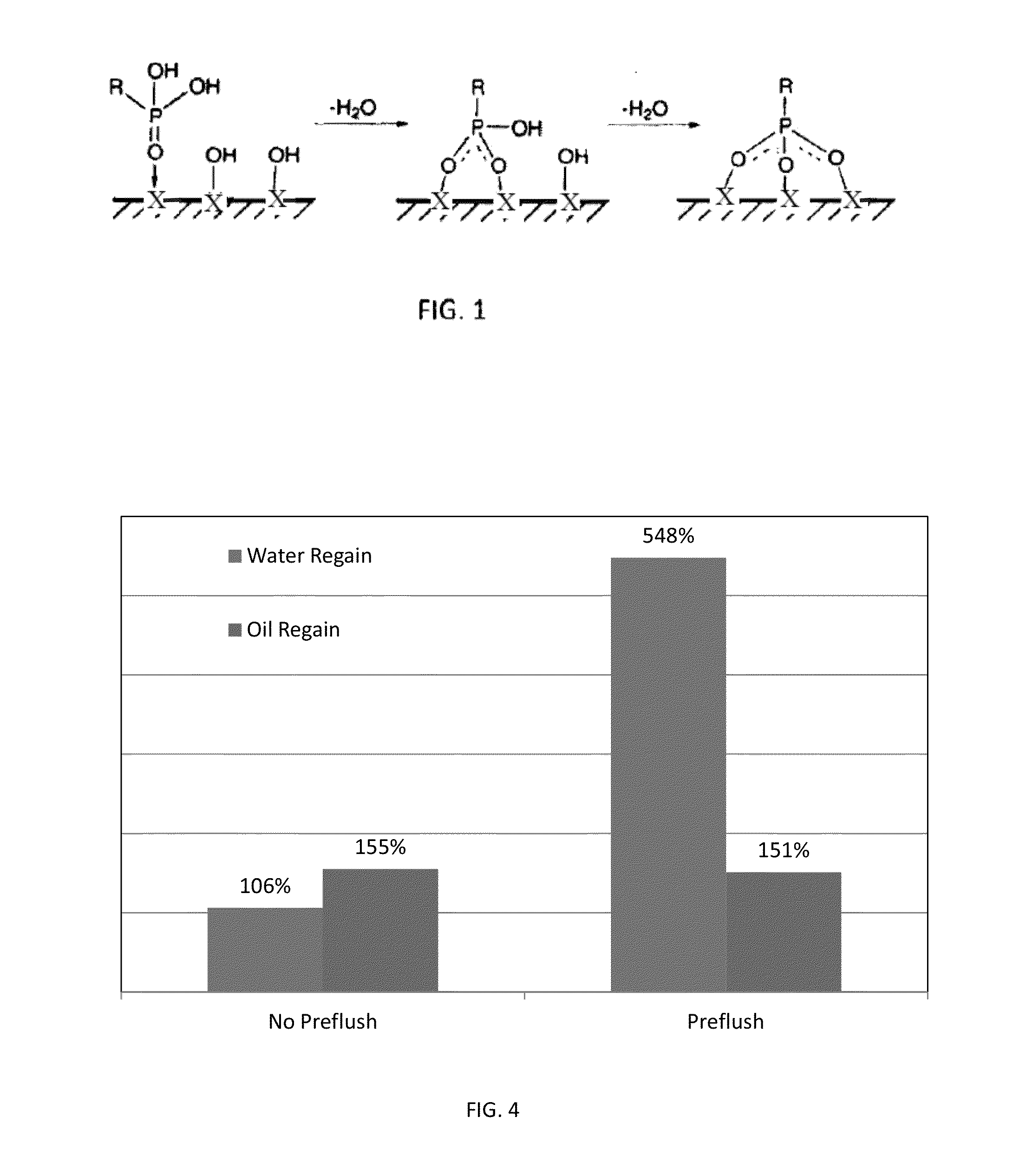

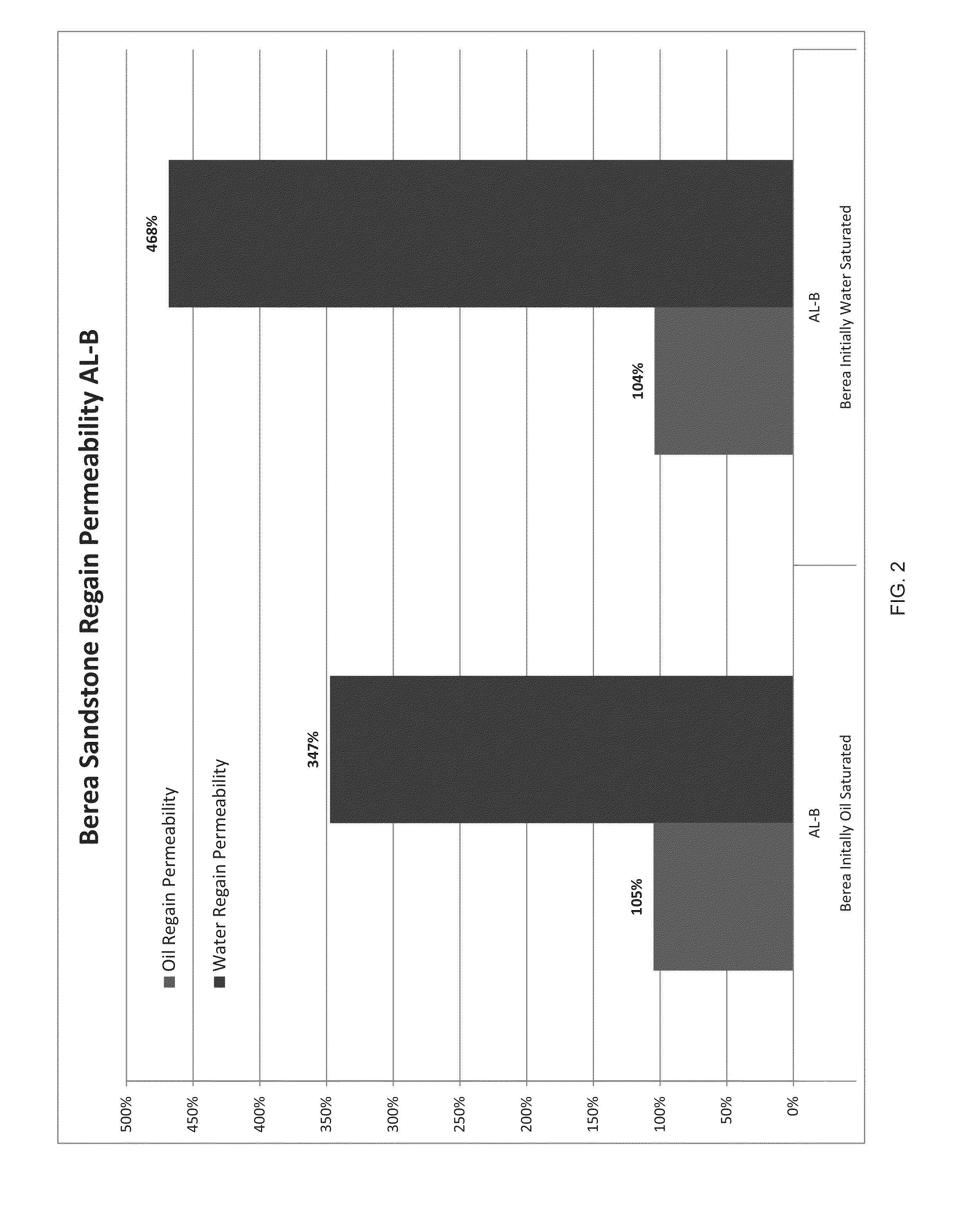

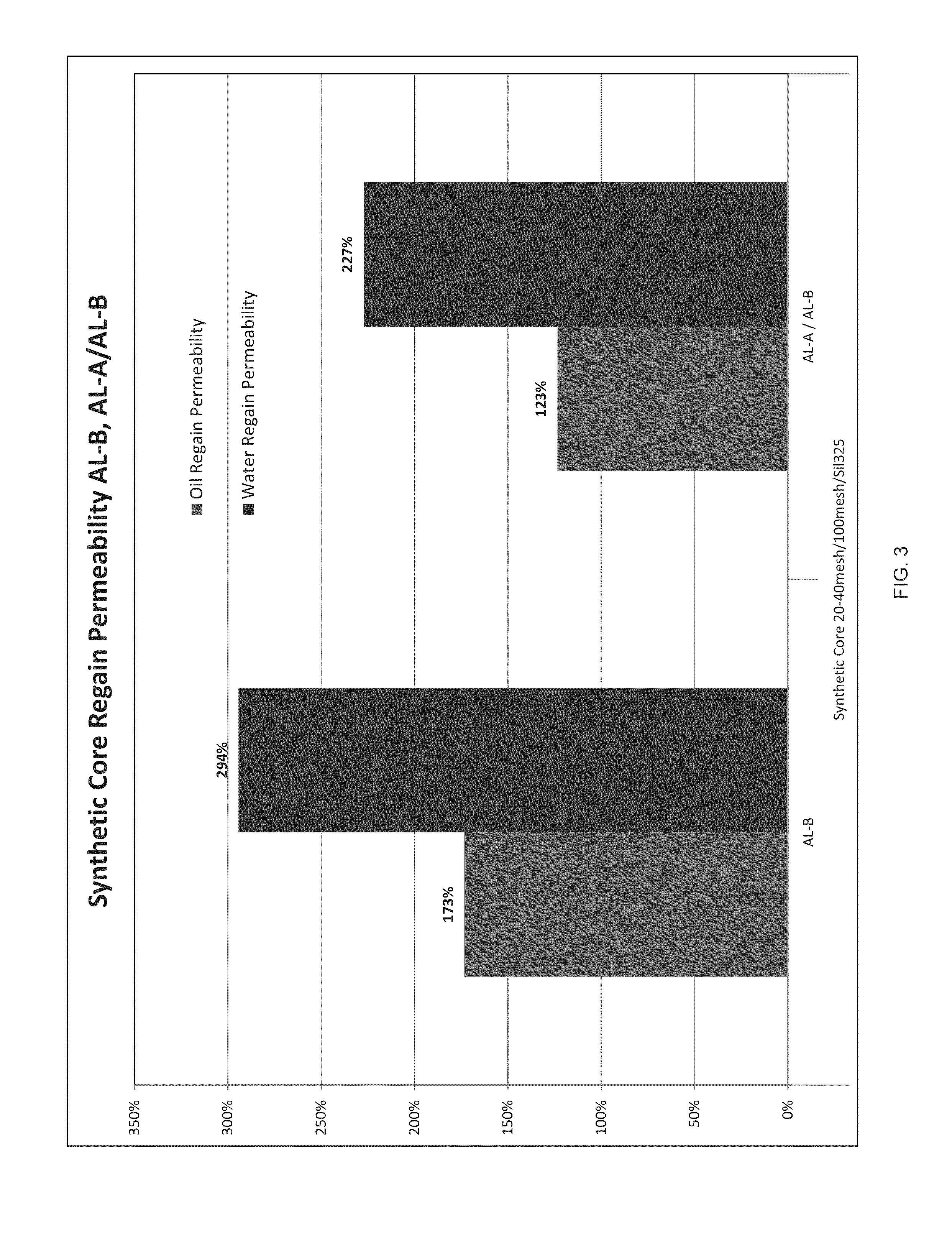

Method of using surface modifying treatment agents to treat subterranean formations

ActiveUS20150083416A1Minimize and prevent retention of waterAvoid depositionFluid removalDrilling compositionProduction rateAcid derivative

A well treatment fluid contains a surface modifying treatment agent having an anchor and a hydrophobic tail. The surface modifying treatment agent is an organophosphorus acid derivative. After the well treatment fluid is pumped into a well penetrating the subterranean formation, the anchor binds to the surface of the formation. The subterranean formation is a siliceous formation or a metal oxide-containing subterranean formation. The anchor bonds to a Si atom when the formation is a siliceous formation and to the metal of the metal oxide when the formation is a metal oxide-containing formation. After being bound to the surface of the formation, frictional drag within the well is reduced. This allows for faster recovery of formation fluids. The bonding of the surface modifying treatment agent onto the formation may further be enhanced by first pre-treating the formation with a non-aqueous fluid. By increasing the number of sites for the surface modifying treatment agent to bind onto the surface of the subterranean formation, productivity is improved.

Owner:BAKER HUGHES INC

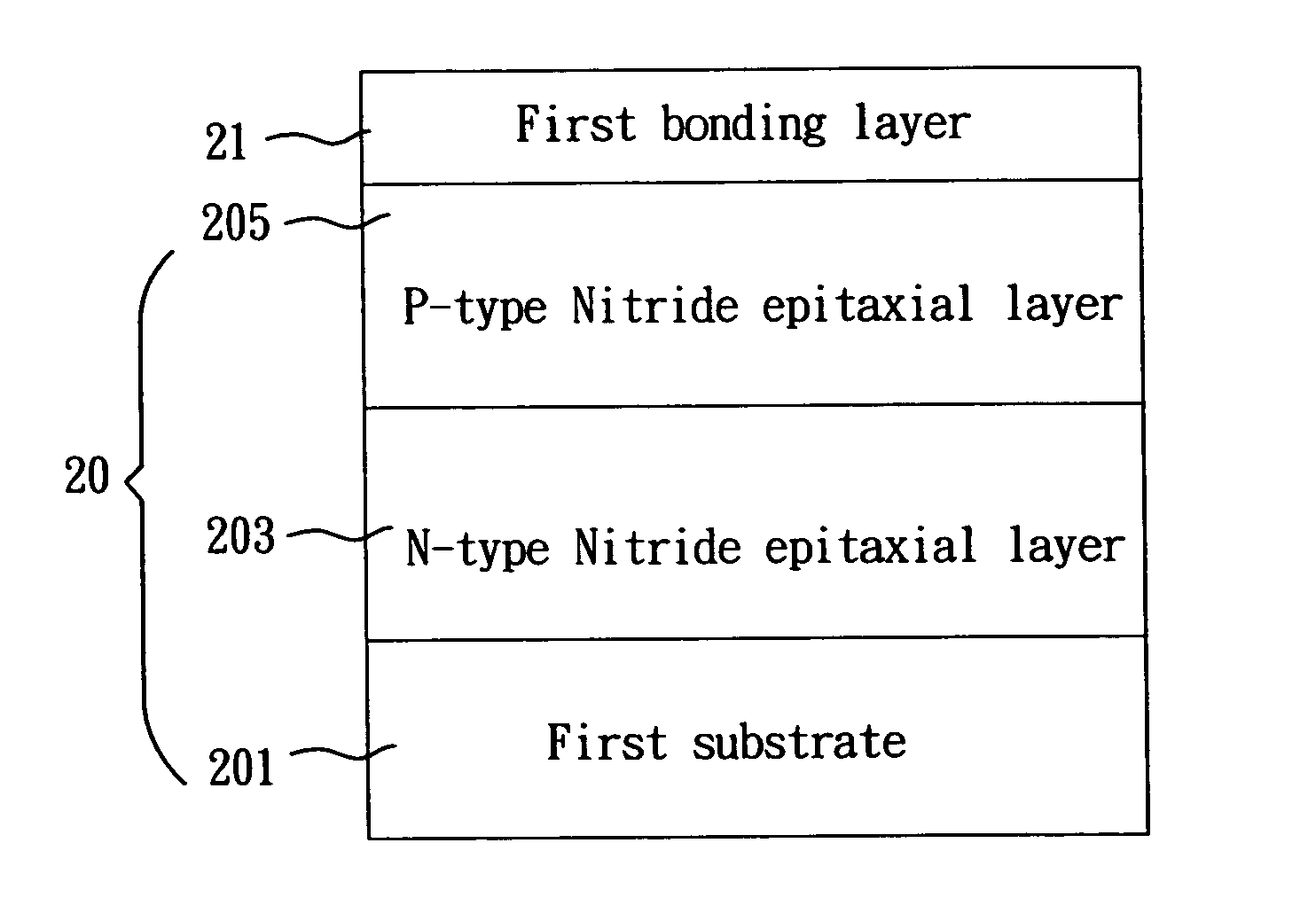

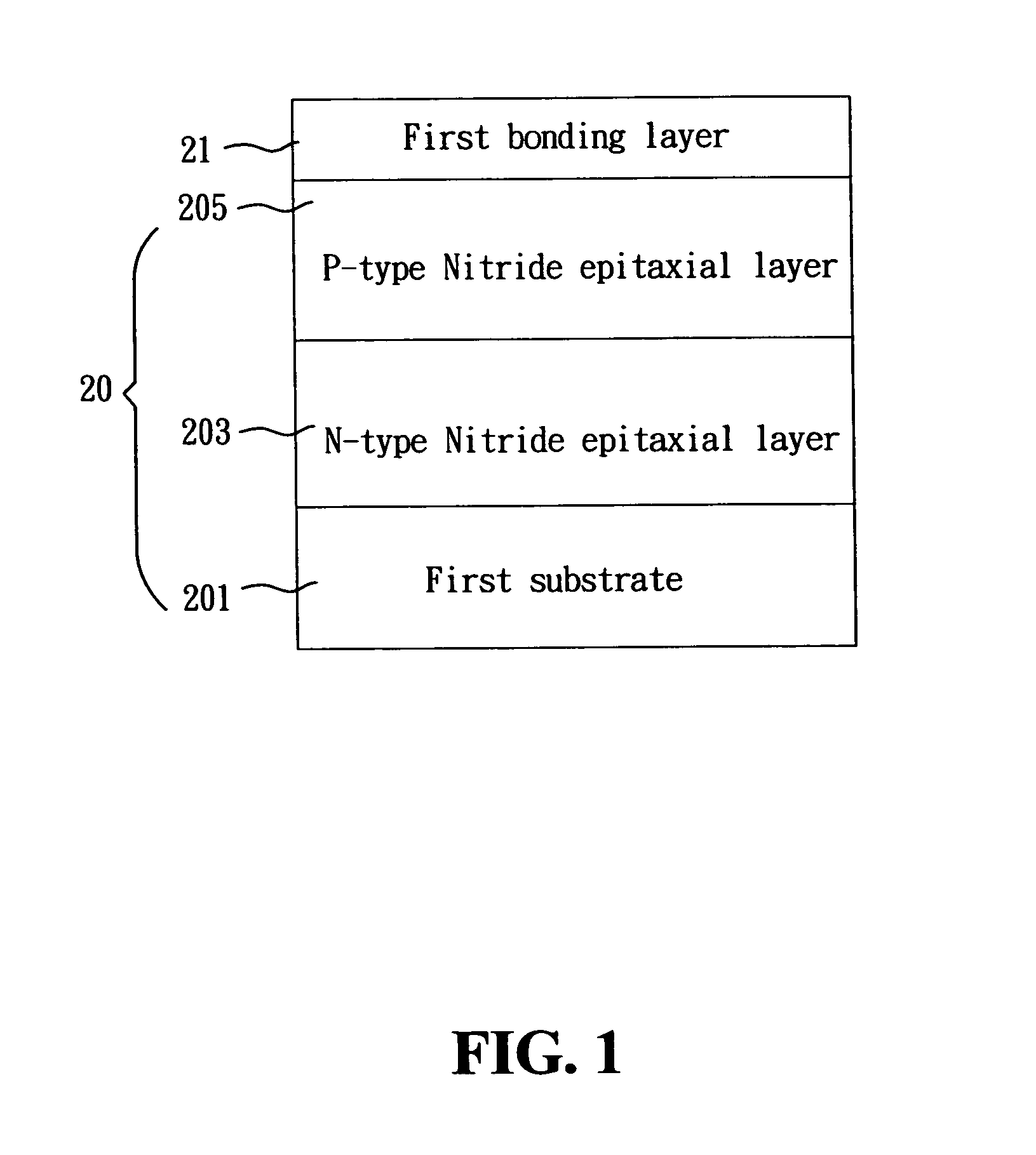

Method for manufacturing nitride light-emitting device

InactiveUS20050040212A1Reduce shading areaImproved light emissionWelding/cutting media/materialsSoldering mediaCurrent distributionOhmic contact

A method for manufacturing nitride light-emitting device is disclosed, which fixes two metallic bonding layers together in order to bond a nitride lighting structure grown on a poor thermal conductivity substrate to a high thermal conductivity substrate, then removes the poor thermal conductivity substrate by means of chemical etching, dry etching, or mechanical abrading to thereby transfer the nitride lighting structure onto that high thermal conductivity substrate. Meanwhile, by taking advantage of forming ohmic contact between a transparent conductive layer and an N-type nitride epitaxial layer, the uniformity of current distribution can be significantly improved to thereby suppress light absorption effect and heighten the lighting efficiency of the light emitting device.

Owner:FORMOSA EPITAXY INCORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com