Patents

Literature

8637 results about "Metal substrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The most popular steel substrates in the metal roofing and siding industry are Galvanized and Galvalume. Galvanized substrates are coated in zinc, while Galvalume substrates are coated with an alloy of zinc plus aluminum. Both Galvalume and Galvanized are good substrates for metal panels.

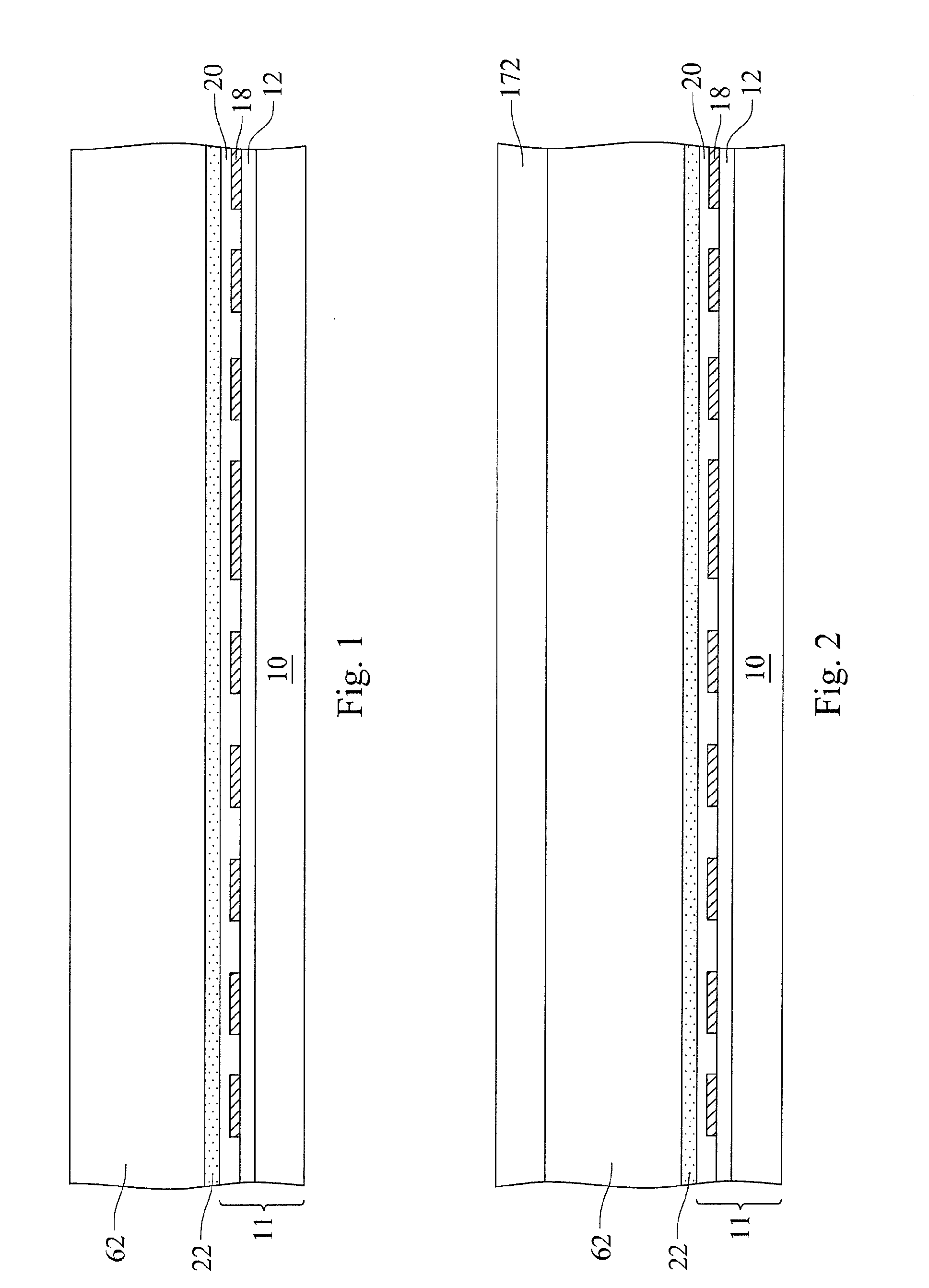

LED retrofit lamp

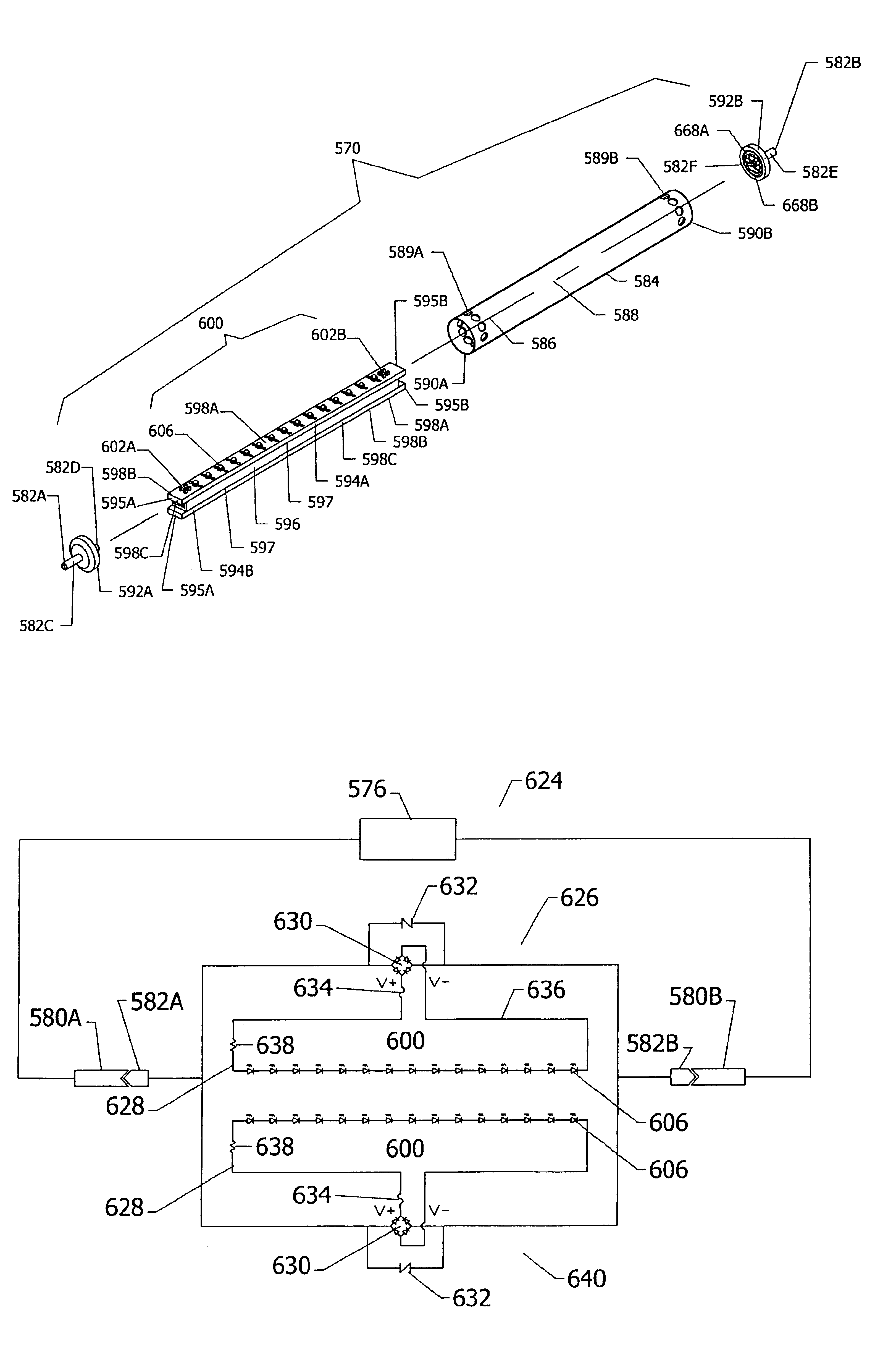

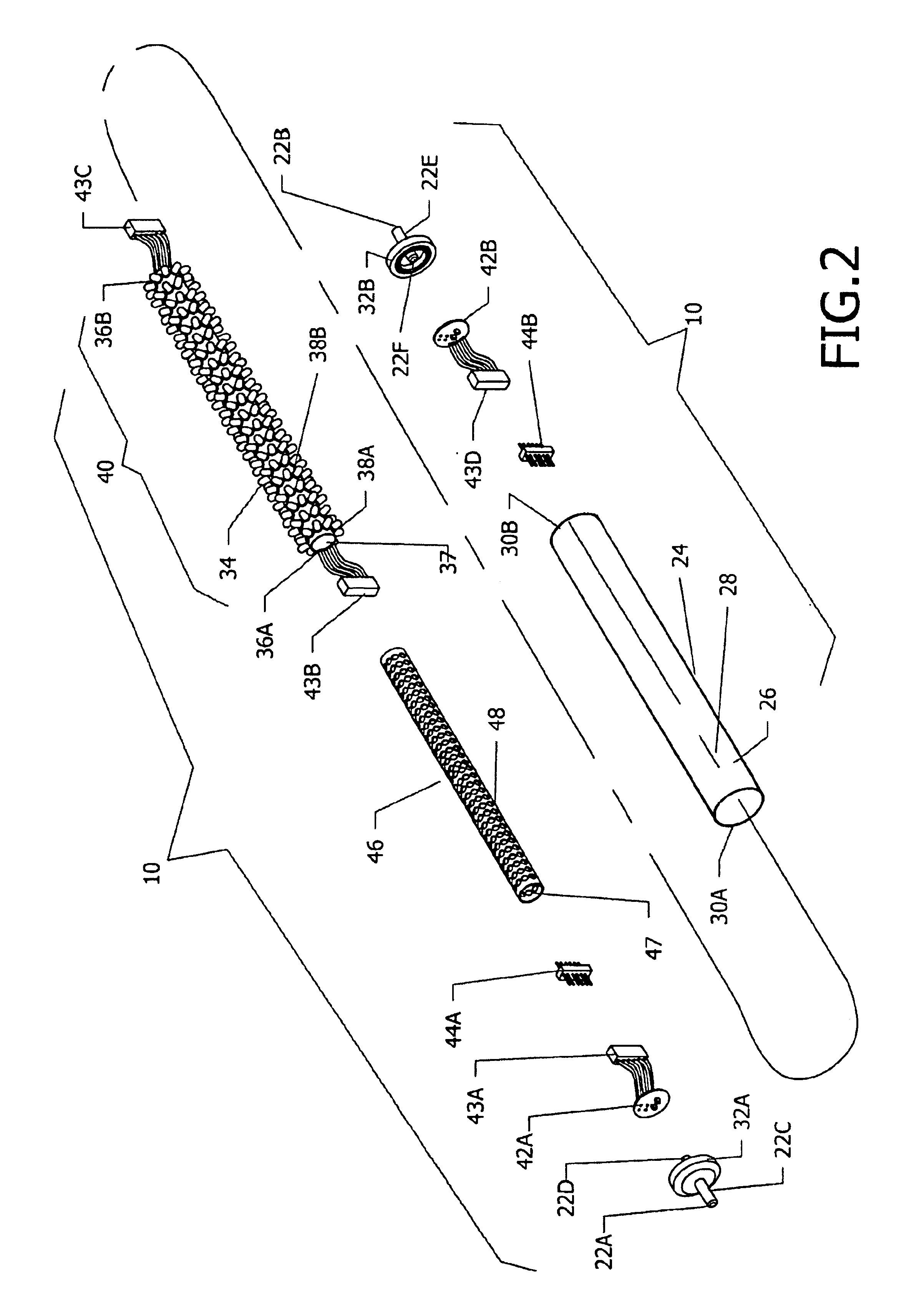

InactiveUS6853151B2Reduce materialReduce power consumptionPoint-like light sourceElongate light sourcesElectrical connectionLED lamp

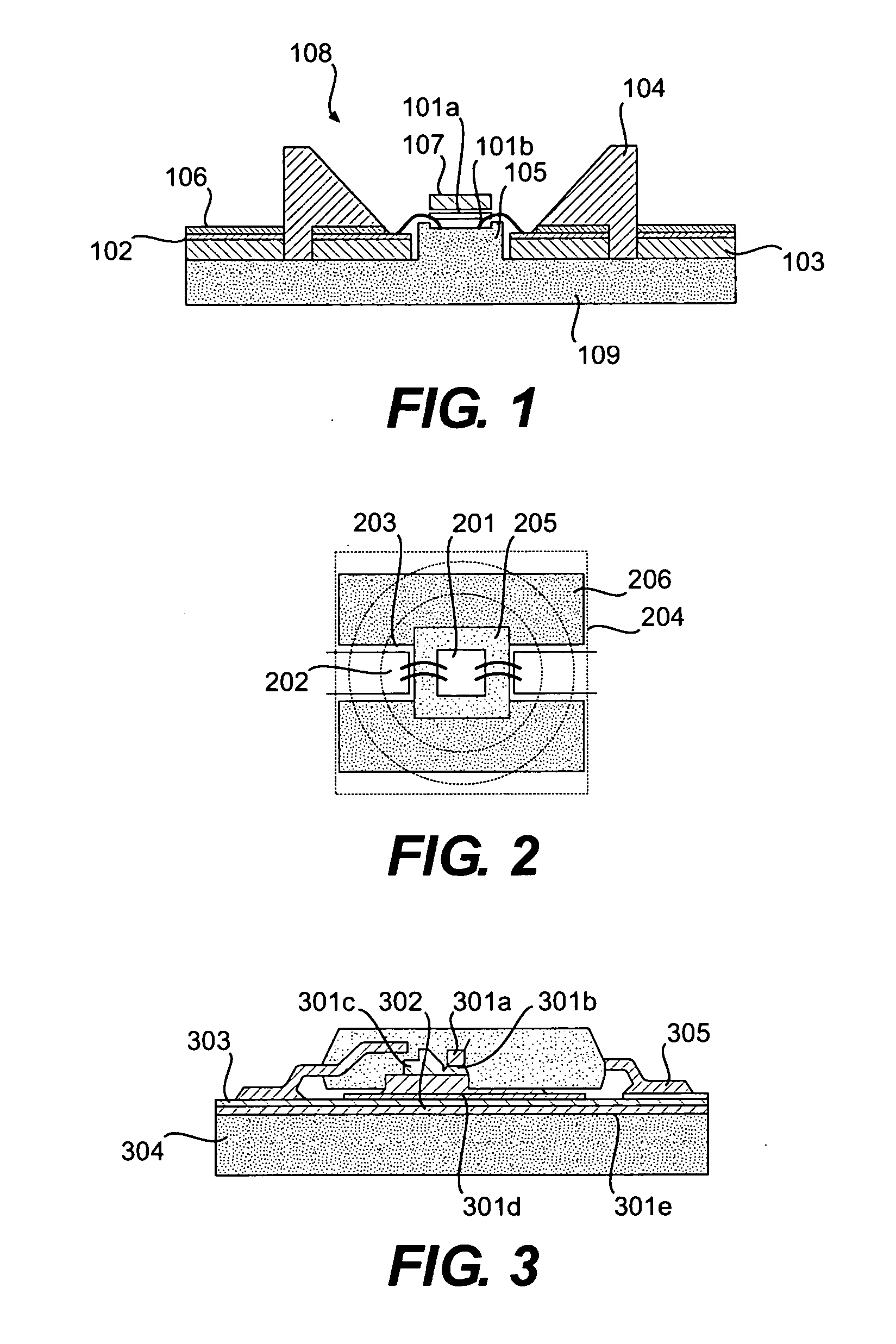

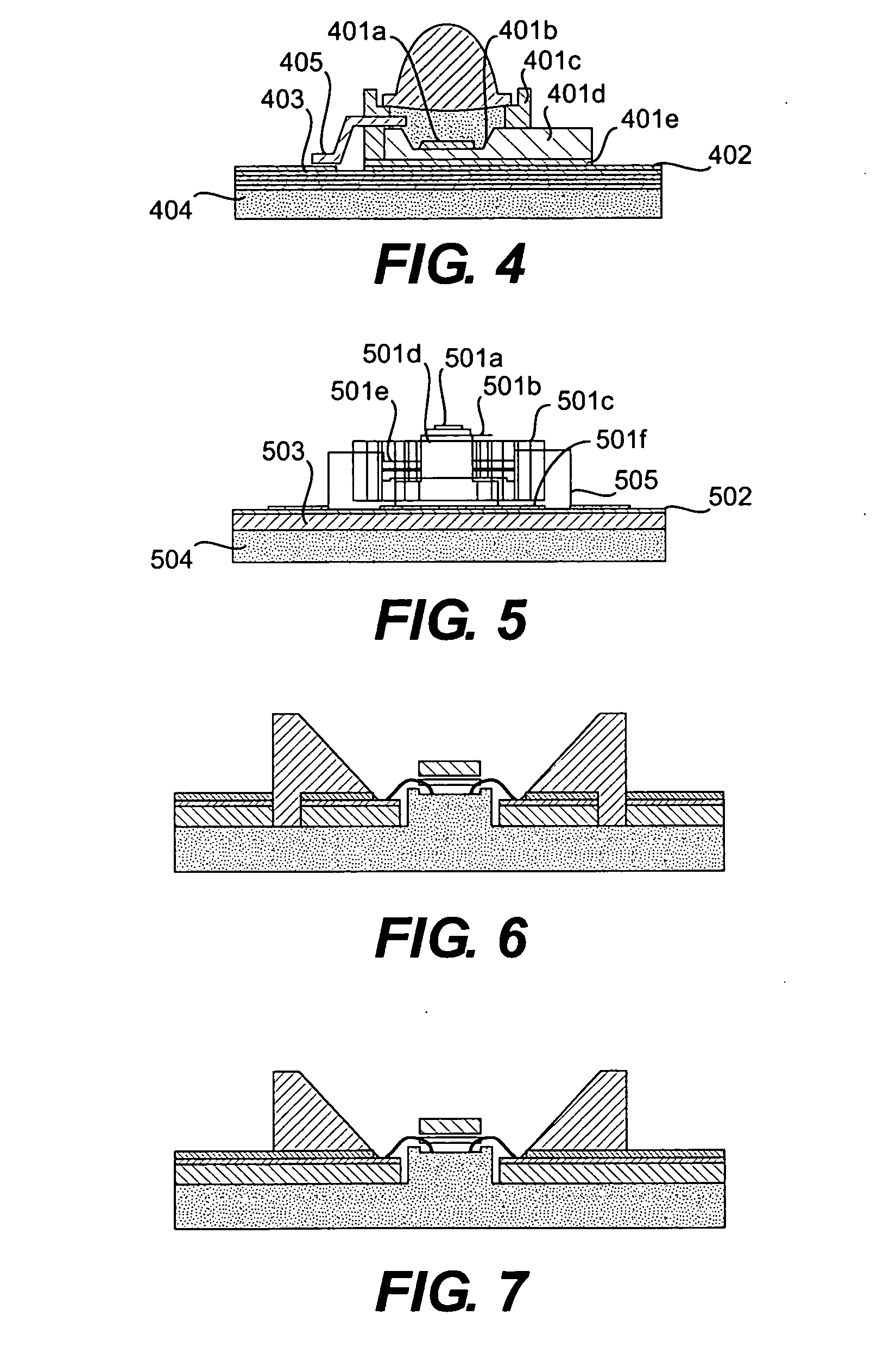

An LED lamp for mounting to an existing fluorescent lamp fixture having a ballast assembly including ballast opposed electrical contacts, comprising a tubular wall generally circular in cross-section and having tubular wall ends with one or more LEDs positioned within the tubular wall between the tubular wall ends. An electrical circuit provides electrical power from the ballast assembly to the LED(s). The electrical circuit includes at least one metal substrate circuit board and means for electrically connecting the electrical circuit with the ballast assembly. The electrical circuit includes an LED electrical circuit including opposed electrical contacts. Each metal substrate circuit board supports and holds the one or more LEDs and the LED electrical circuit. Each metal substrate circuit board is positioned within the tubular wall between the tubular wall ends. At least one electrical string is positioned within the tubular wall and generally extends between the tubular wall ends. One or more LEDs are in electrical connection with at least one electrical string and are positioned to emit light through the tubular wall. Means for suppressing ballast voltage is included. The metal substrate circuit board includes opposed means for connecting the metal substrate circuit board to the tubular wall ends, which include means for mounting the means for connecting, and the one or more metal substrate circuit boards.

Owner:SIGNIFY HLDG BV

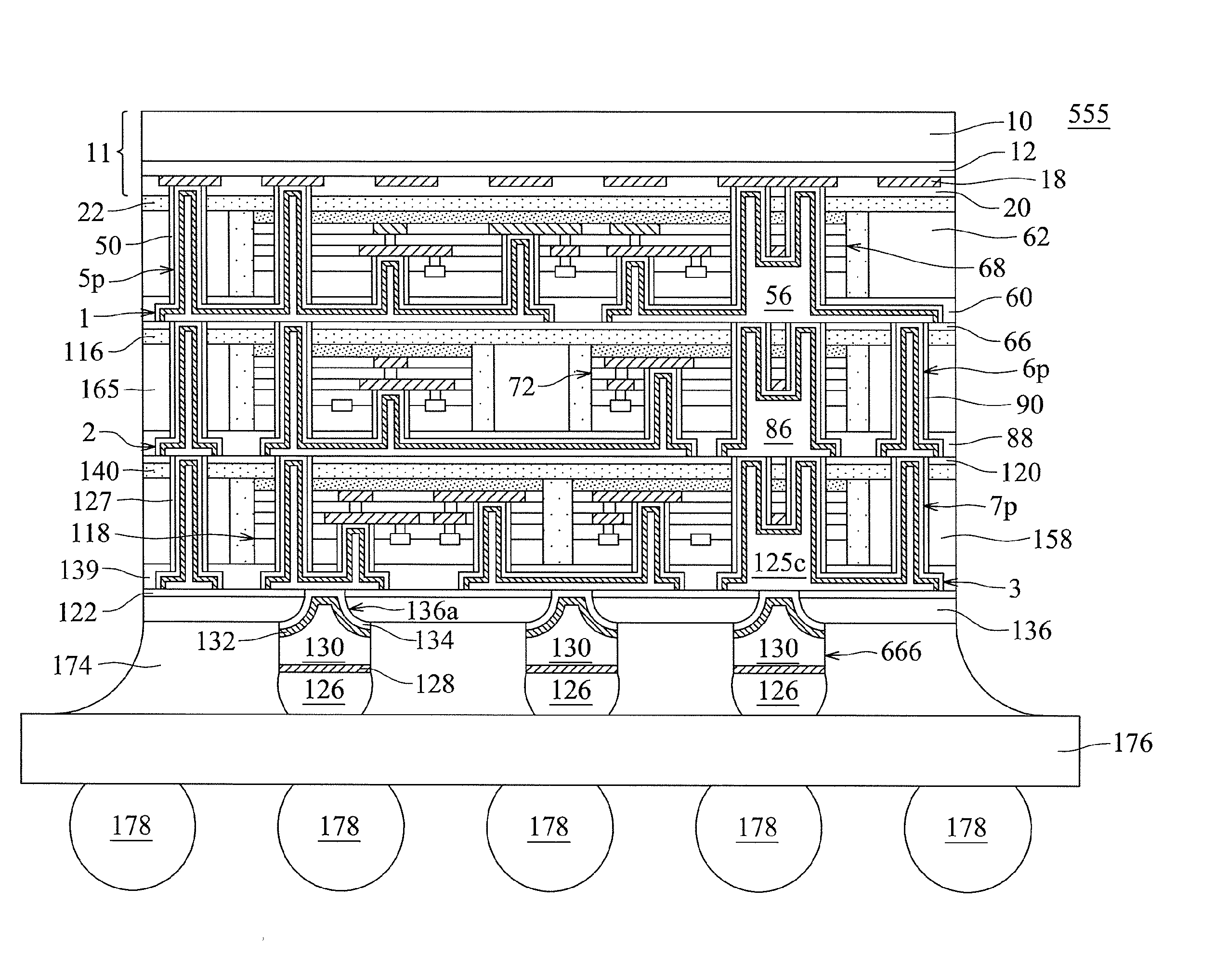

System-in packages

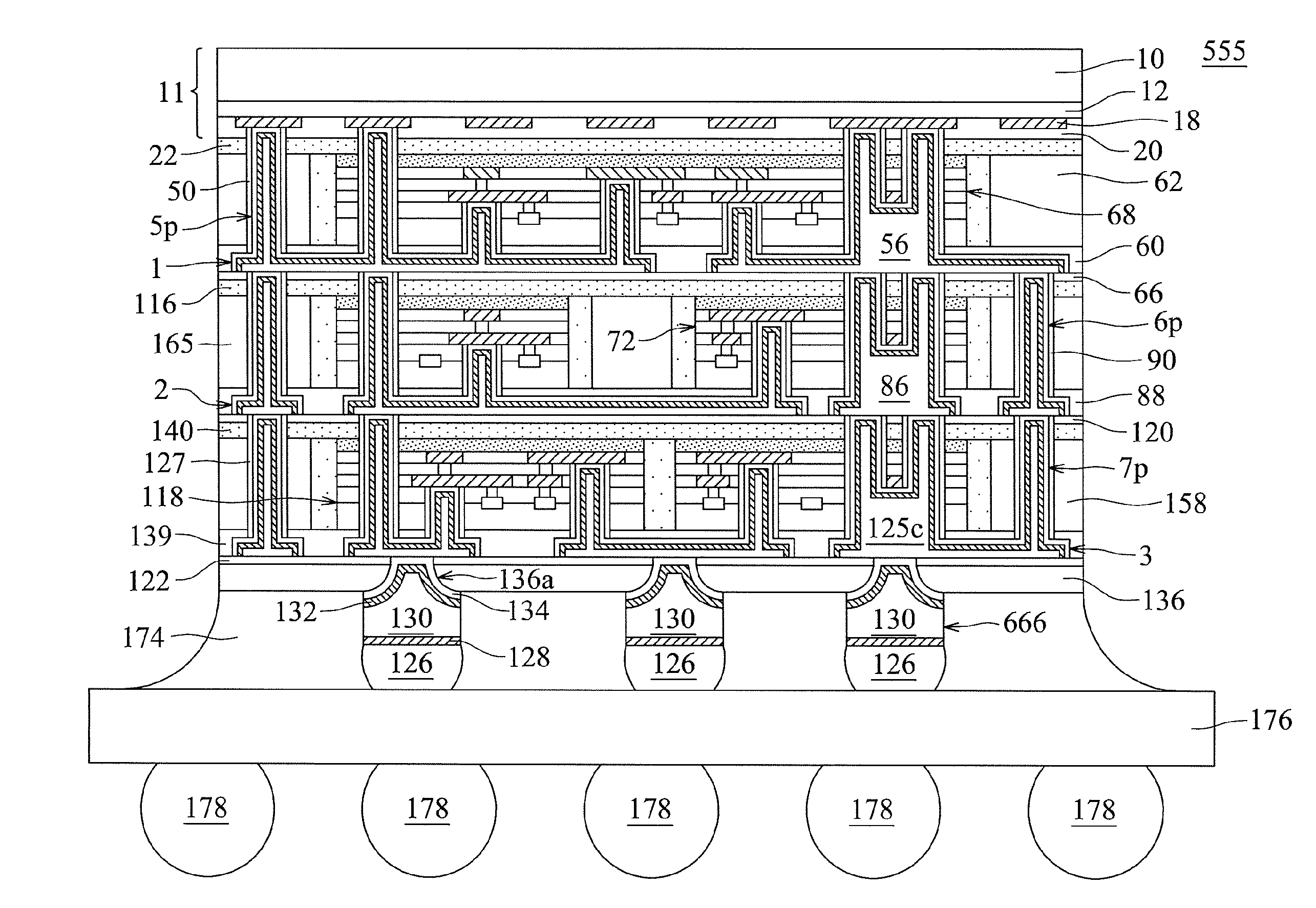

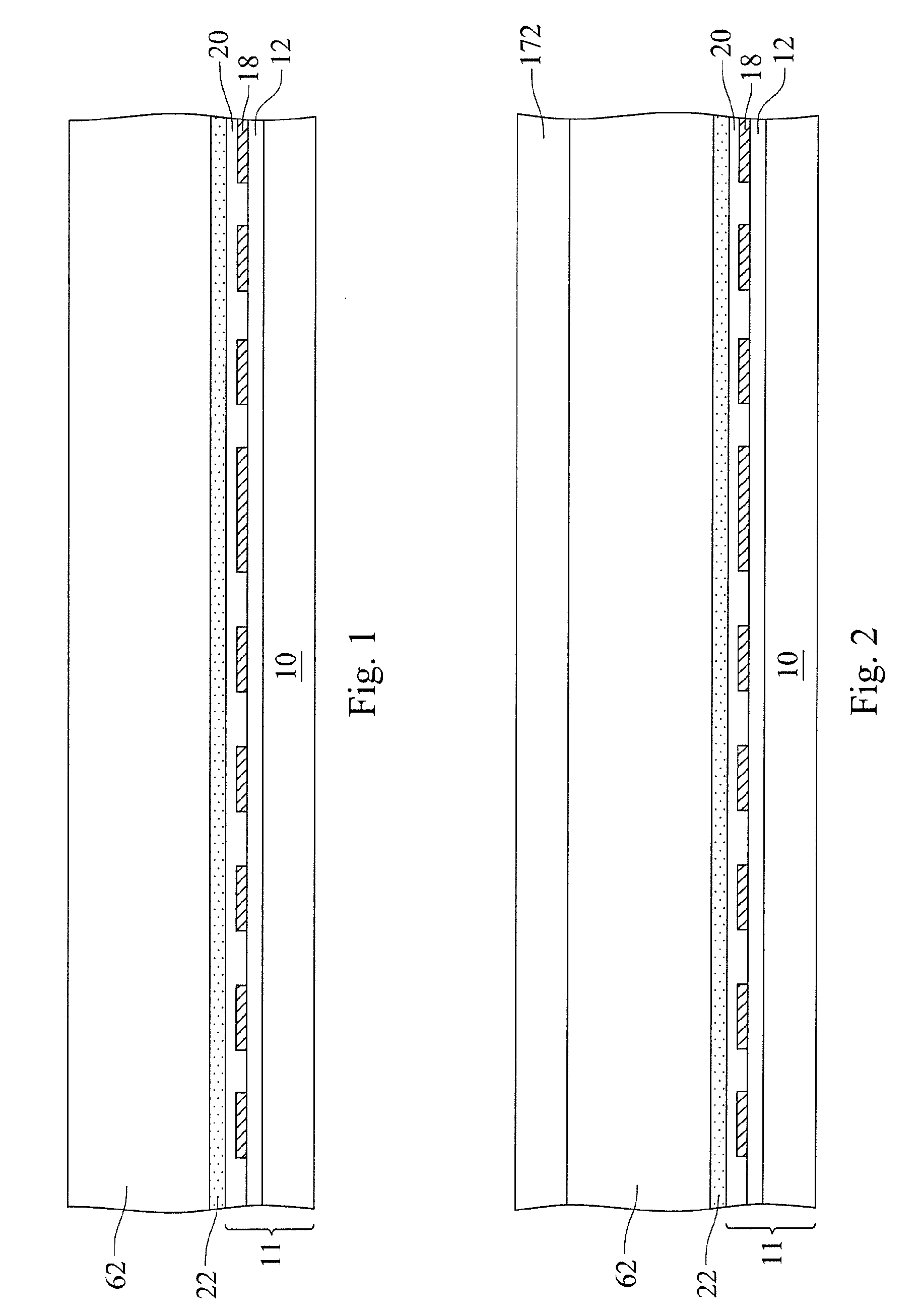

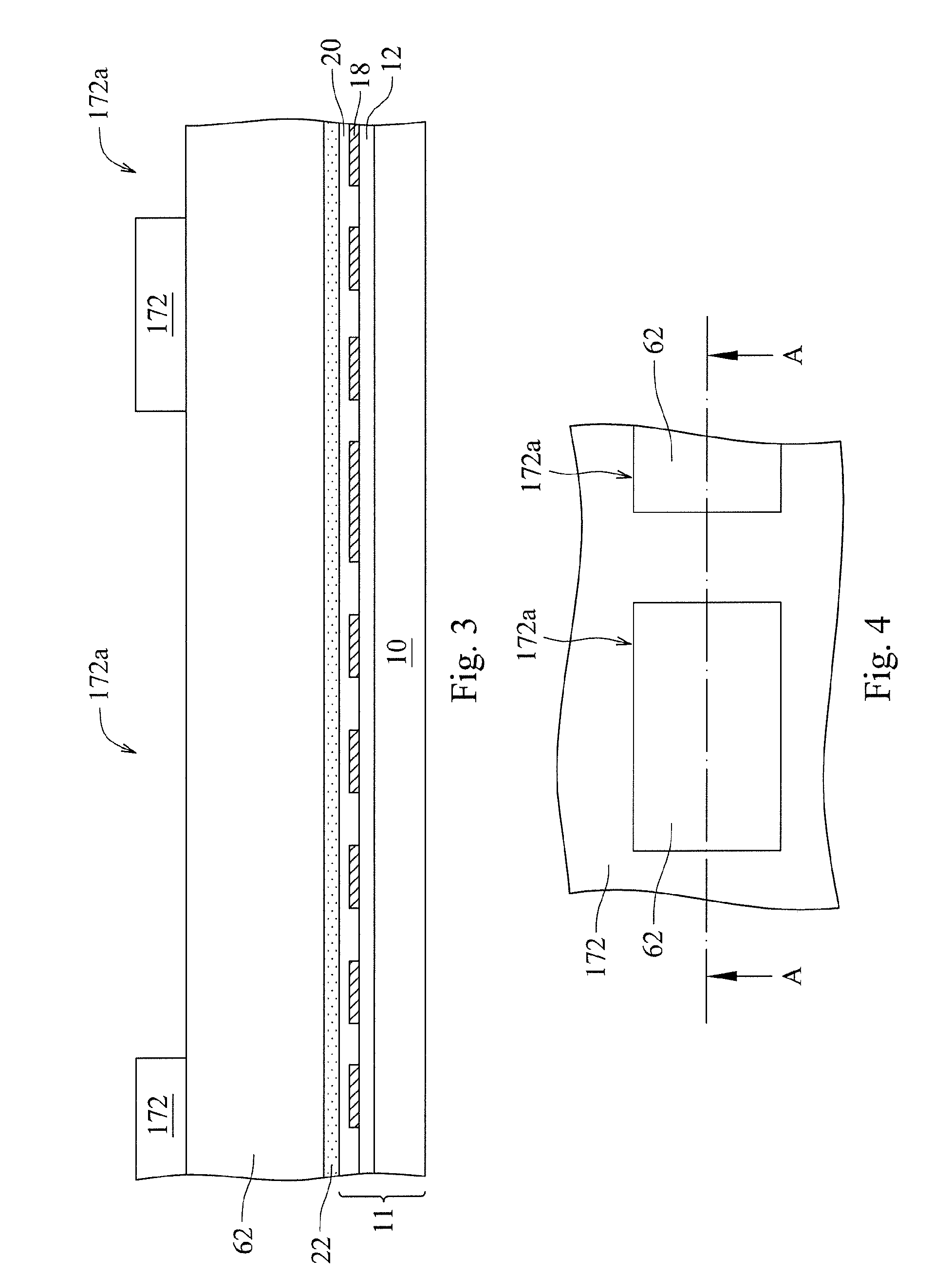

ActiveUS20110026232A1Improve uniformitySemiconductor/solid-state device detailsCircuit arrangements on support structuresMetal interconnectSystem in package

System-in packages, or multichip modules, are described which can include multi-layer chips and multi-layer dummy substrates over a carrier, multiple through vias blindly or completely through the multi-layer chips and completely through the multi-layer dummy substrates, multiple metal plugs in the through vias, and multiple metal interconnects, connected to the metal plugs, between the multi-layer chips. The multi-layer chips can be connected to each other or to an external circuit or structure, such as mother board, ball grid array (BGA) substrate, printed circuit board, metal substrate, glass substrate, or ceramic substrate, through the metal plugs and the metal interconnects.

Owner:QUALCOMM INC

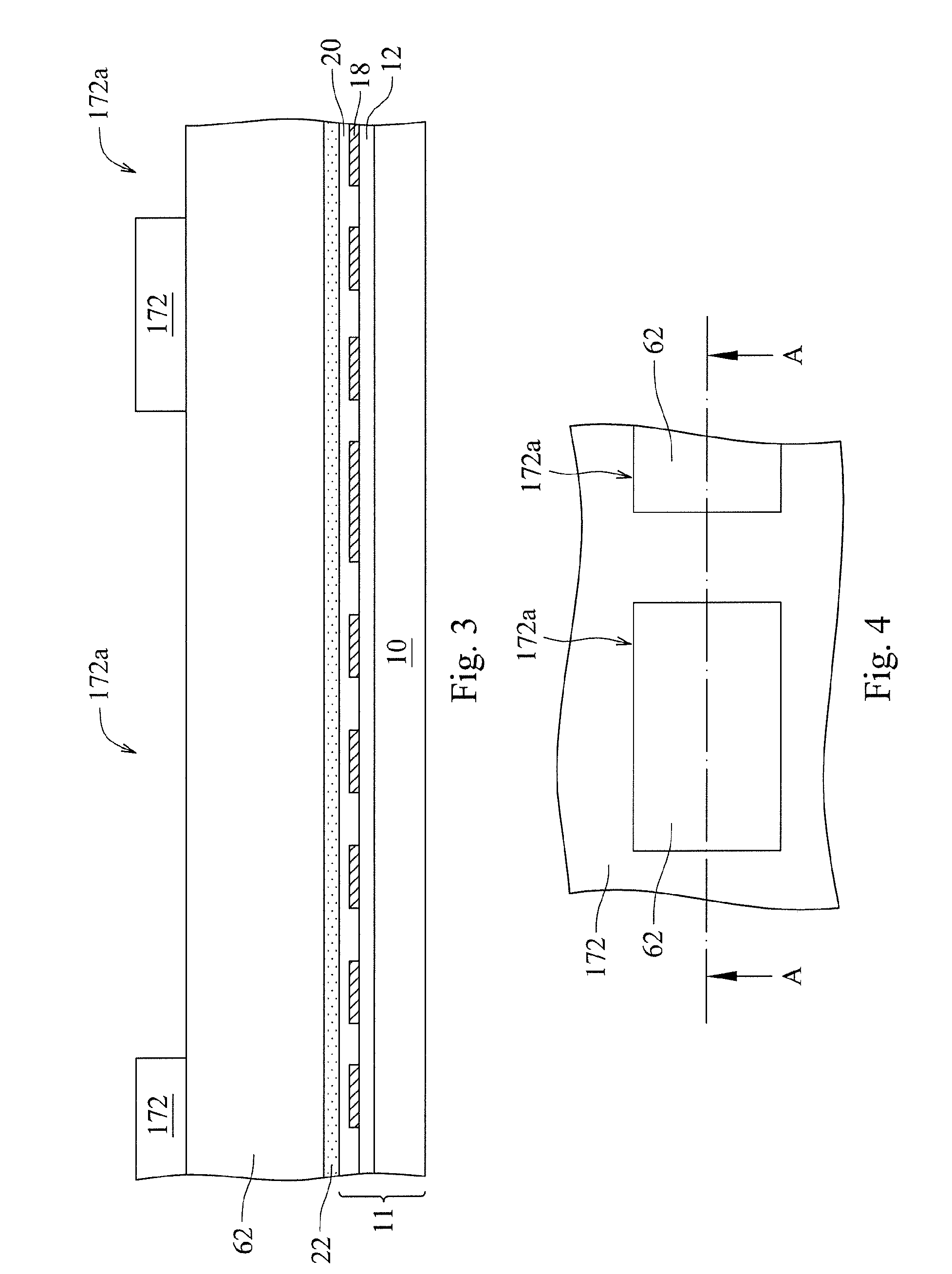

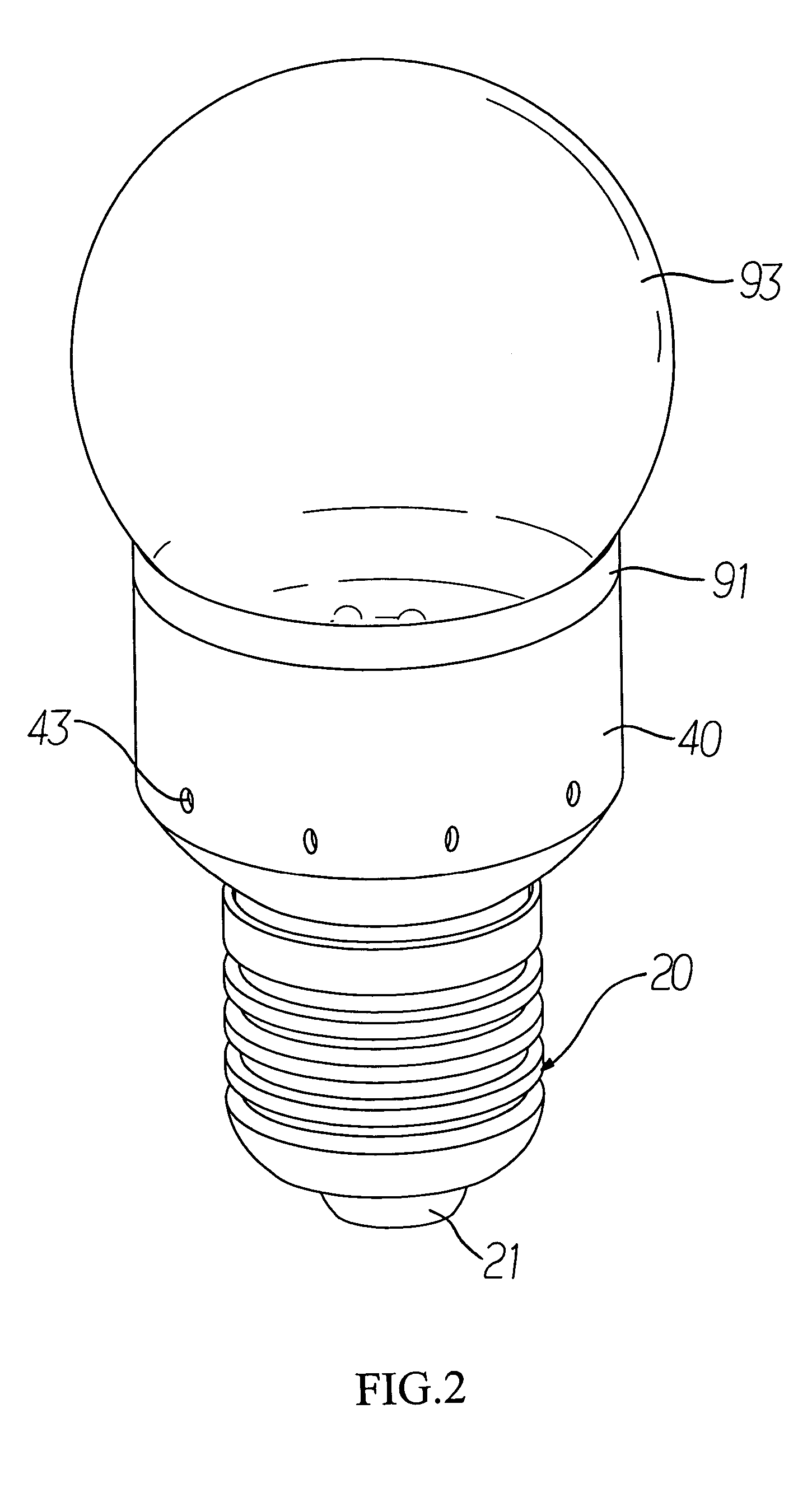

Light emitting diode illumination apparatus

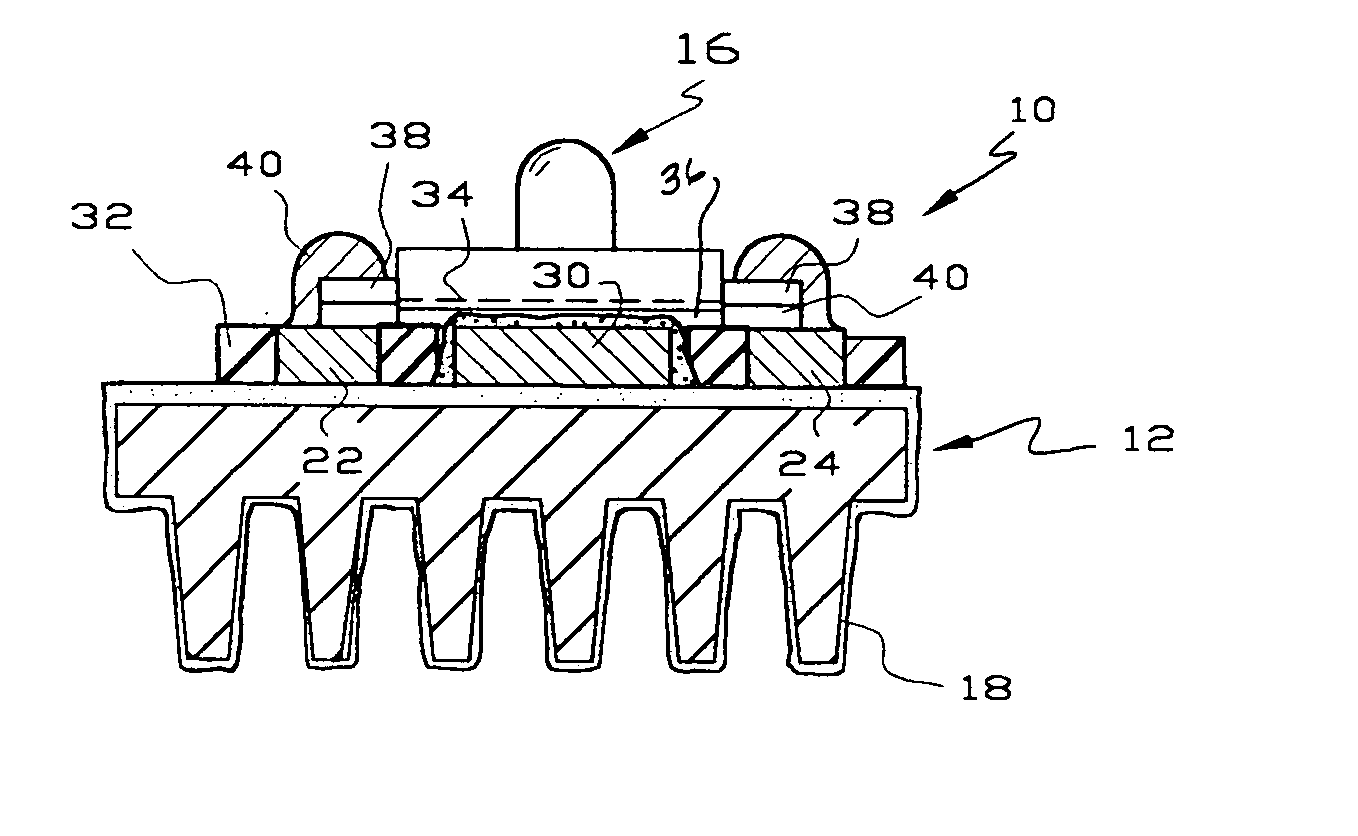

ActiveUS7226189B2Effective lightingEfficient heatingCoupling device connectionsPoint-like light sourceLight-emitting diodeMetal substrate

The present invention describes a light emitting diode illumination apparatus made of a light bulb base, a heat dissipating device, a plastic lid, a drive substrate, a metal substrate, a circular insulated base and a casing, and the heat dissipating device is in contact with the metal substrate in normal conditions, such that the heat source produced by each light emitting diode is conducted to the heat dissipating device through the metal substrate and then conducted from the heat dissipating device to the light bulb base for effectively dispersing the heat source and maintaining the light emitting efficiency of each light emitting diode.

Owner:TAIWAN OASIS TECH CO LTD

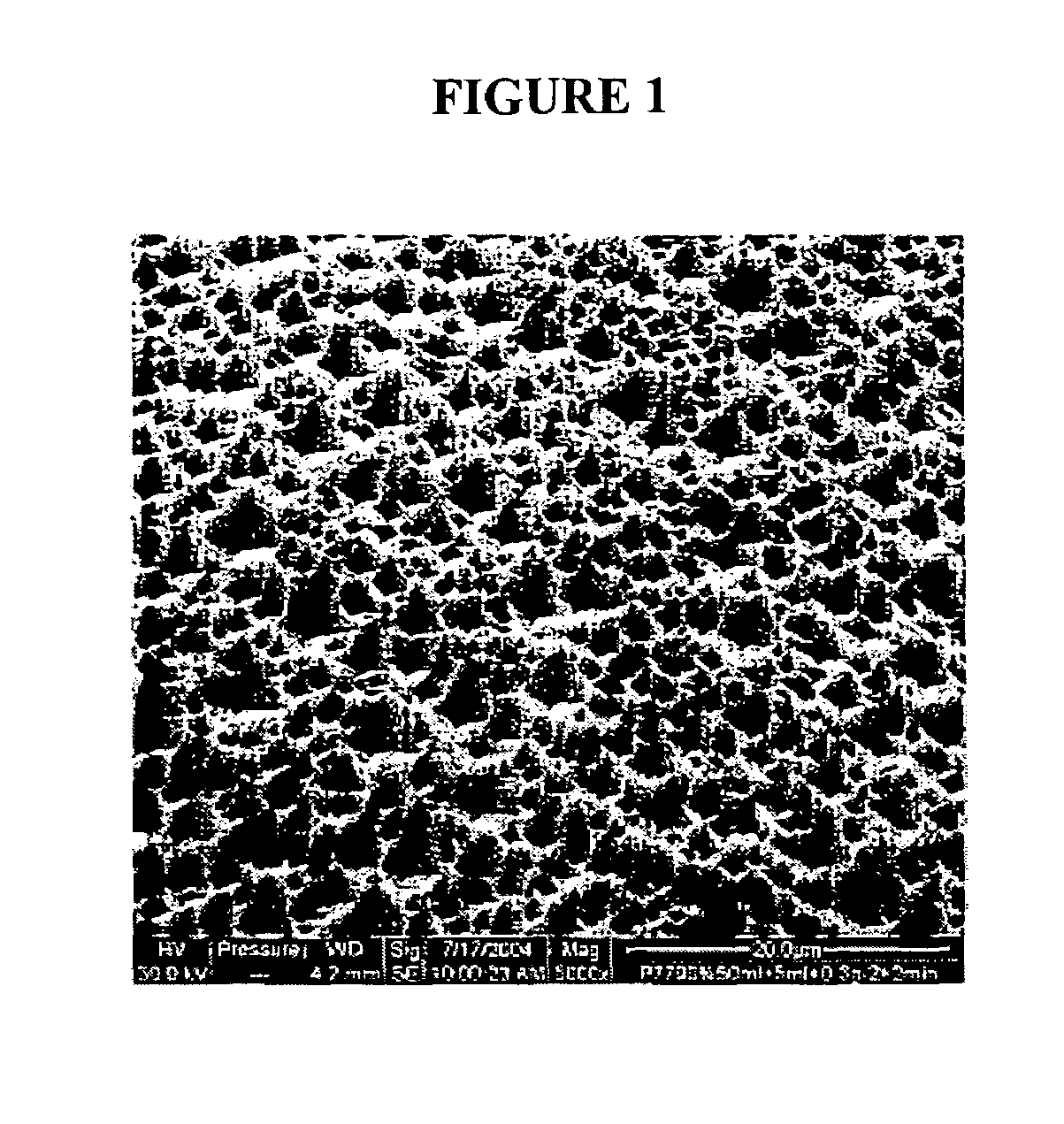

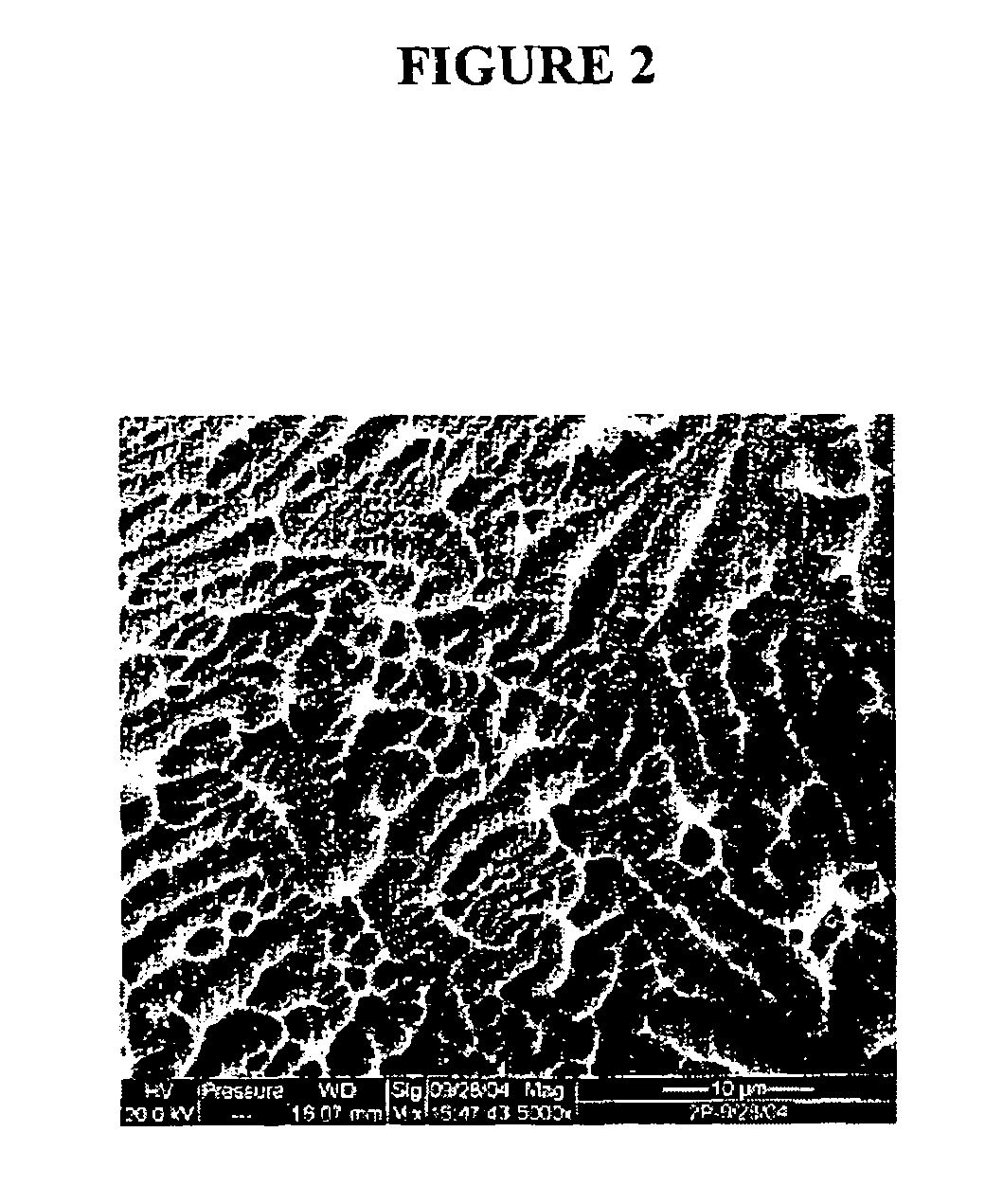

Nanotube/metal substrate composites and methods for producing such composites

InactiveUS20050238810A1Simplified and advantageous mannerReduce productionMaterial nanotechnologyIndirect heat exchangersHydrogen fuel cellChemical vapor deposition

Carbon nanotubes are grown directly on metal substrates using chemical vapor deposition. Metal substrates are comprised of catalysts which facilitate or promote the growth of carbon nanotubes. The nanotube coated metal substrates have applications including, but not limited to, heat transfer and thermal control, hydrogen storage, fuel cell catalytic reformers, electronics and semiconductors, implantable medical devices or prostheses, and tribological wear and protective coatings.

Owner:MAINSTREAM ENG

System-in packages

ActiveUS8503186B2Improve uniformityCircuit arrangements on support structuresSemiconductor/solid-state device detailsMetal interconnectSystem in package

Owner:QUALCOMM INC

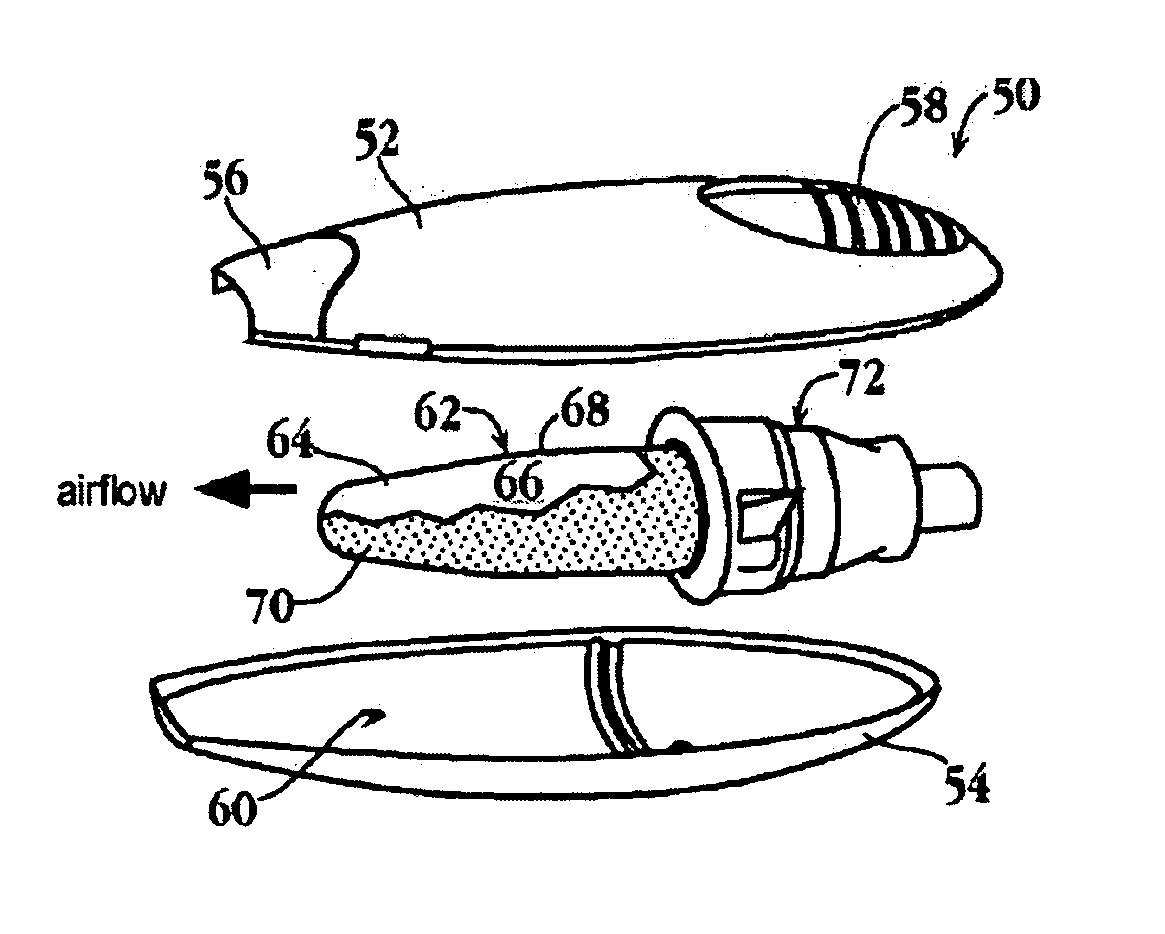

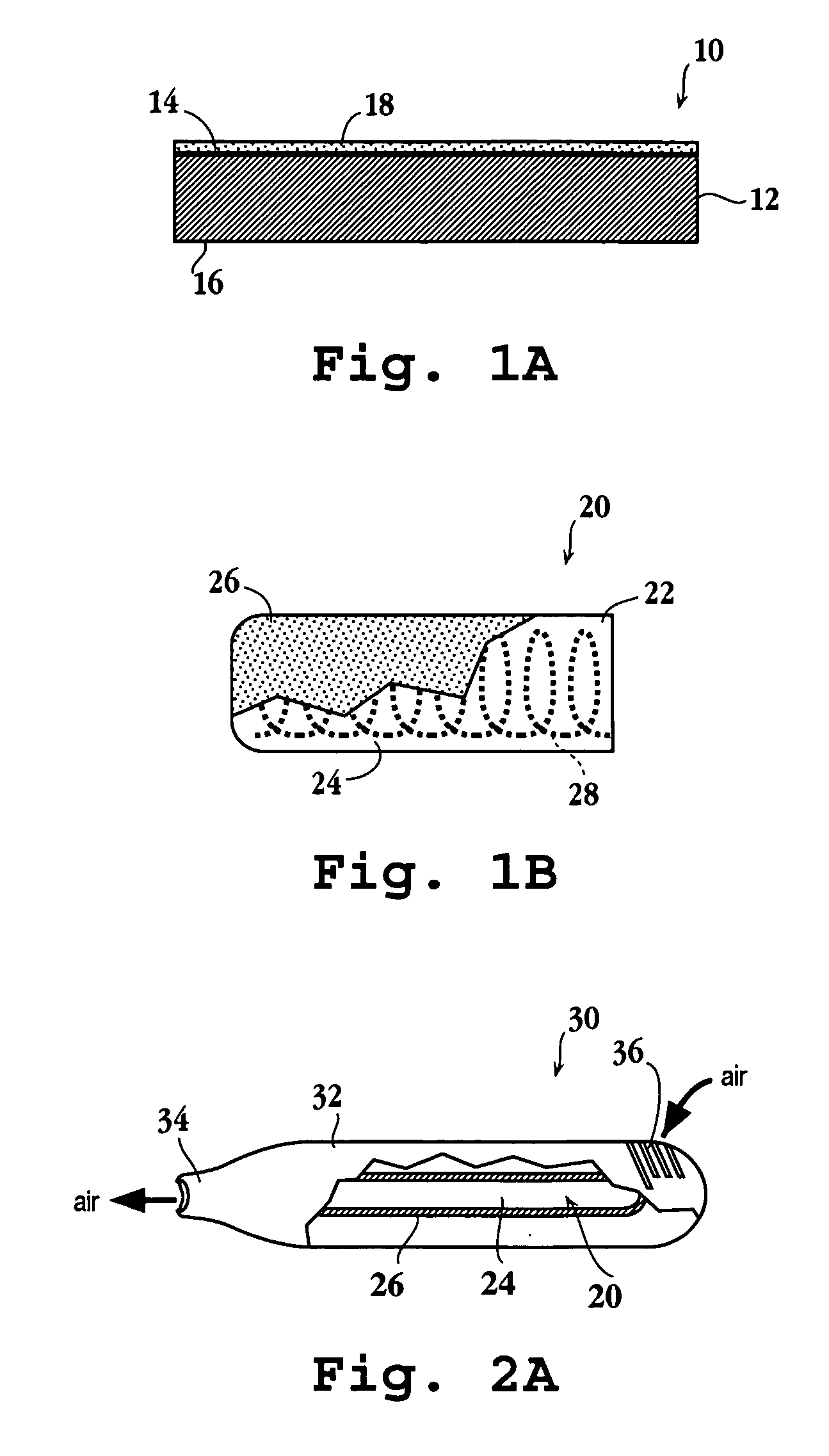

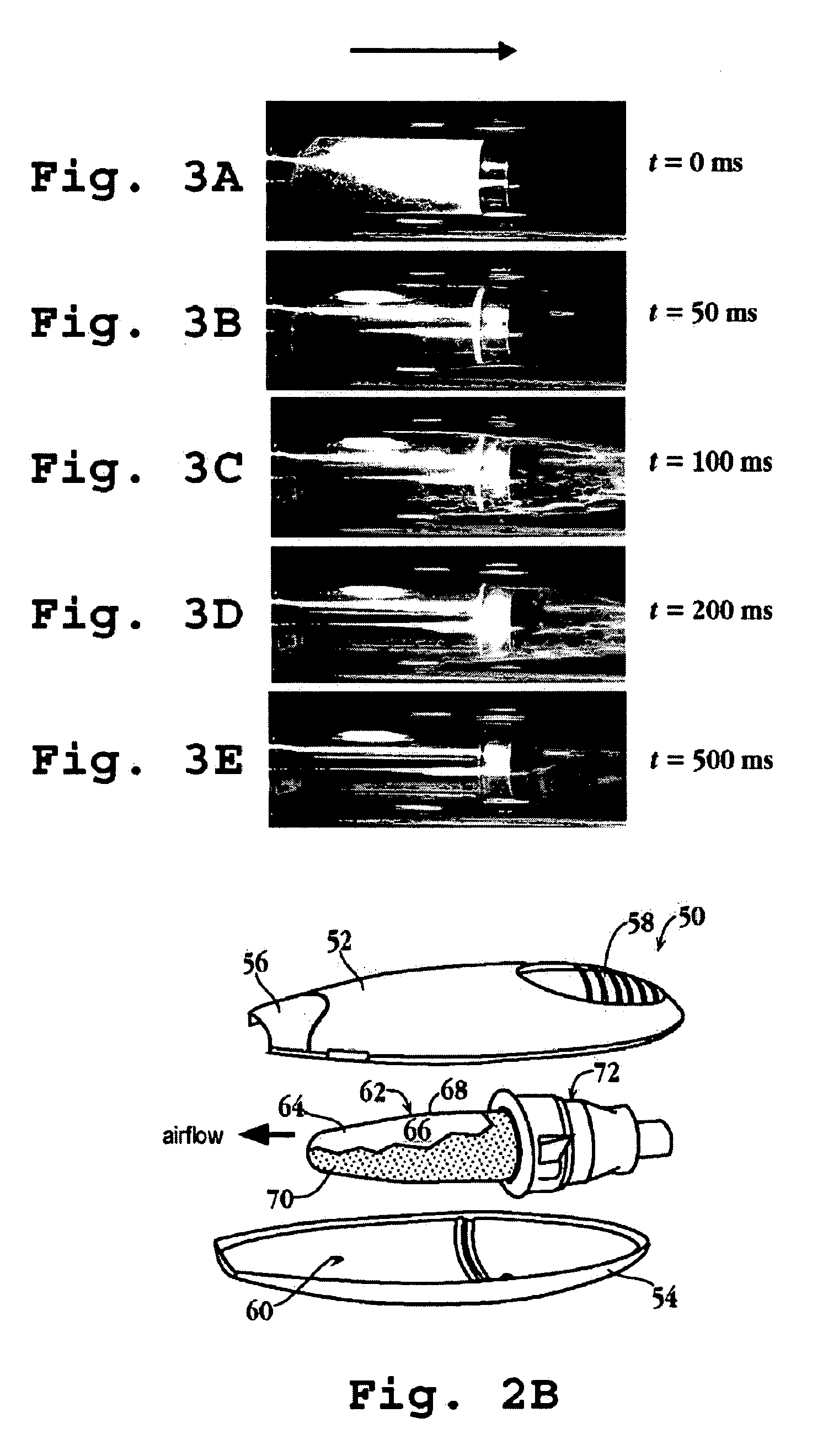

Substrates for drug delivery device and methods of preparing and use

An assembly and method for producing a condensation aerosol are disclosed. The assembly includes a heat-conductive metal substrate with an oxidation resistant exterior surface and a drug composition film on the exterior surface and is for use in an aerosol device. The thickness of the film and the surface of the substrate is such that the aerosol formed by vaporizing and condensing the drug composition the aerosol contain 10% by weight or less drug-degradation products and at least 50% of the total amount of the drug composition in the film. The methods for treating the exterior surface include heat and chemical treatment and formation of a protective overcoat.

Owner:ALEXZA PHARMA INC

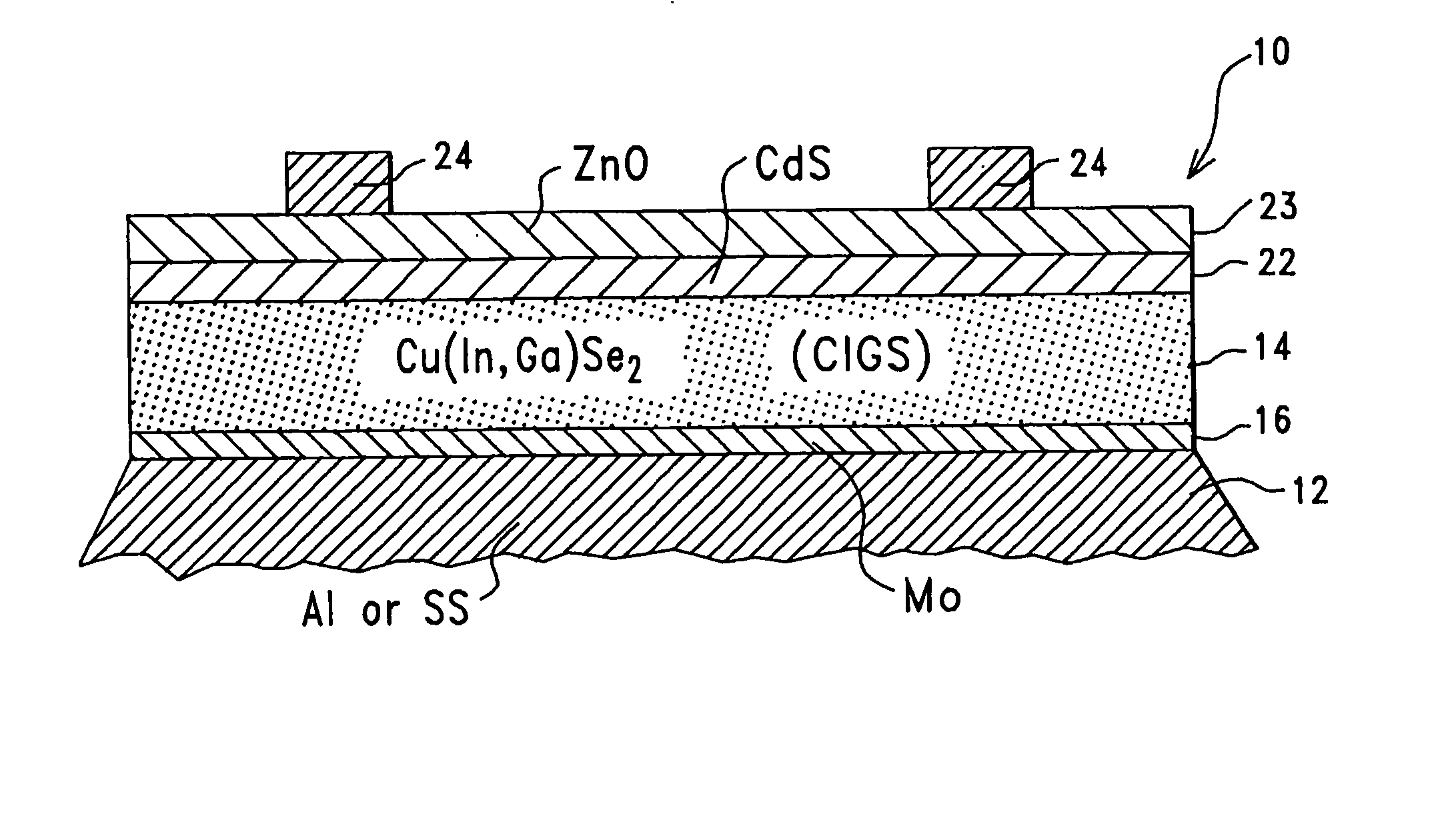

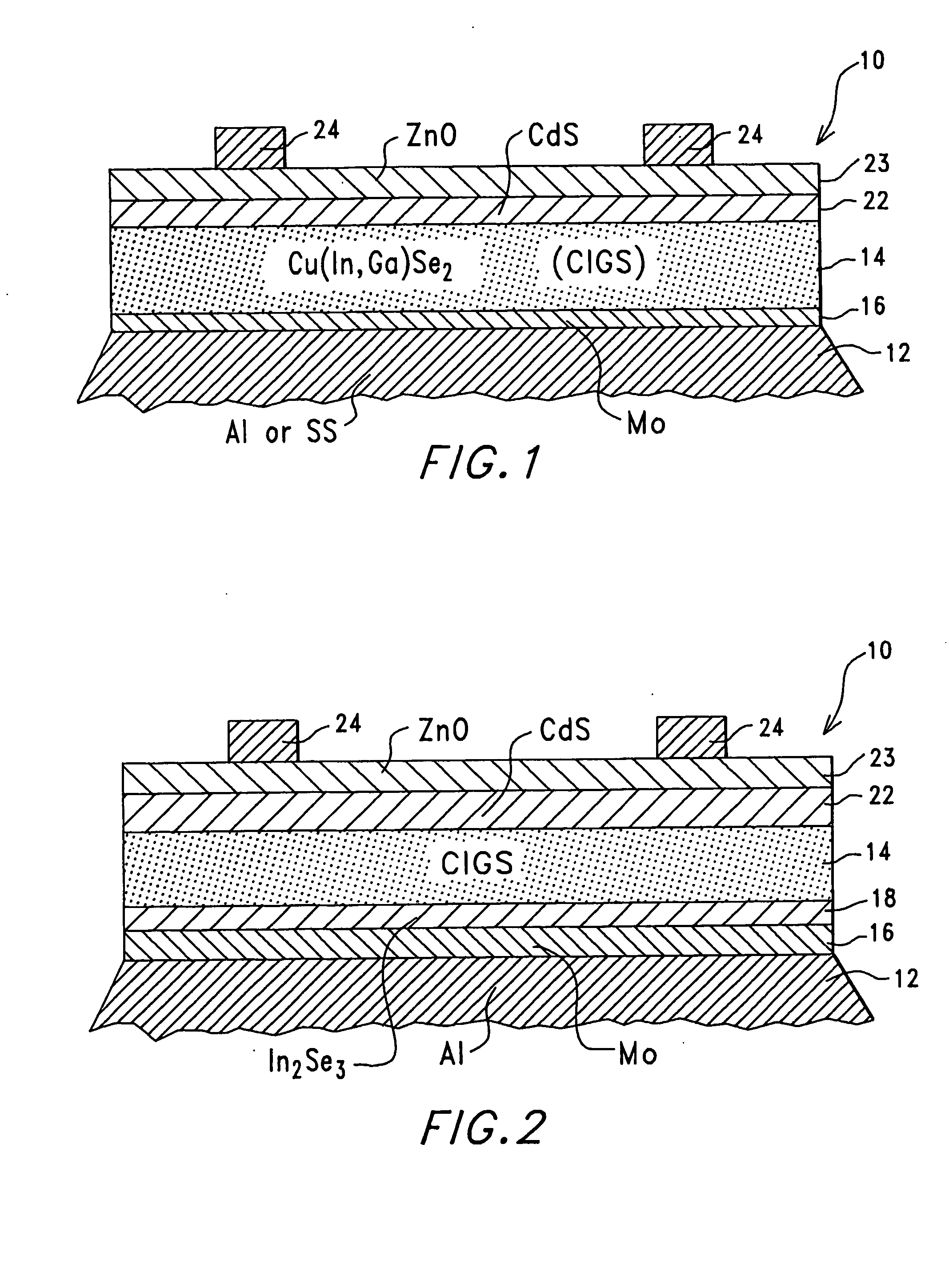

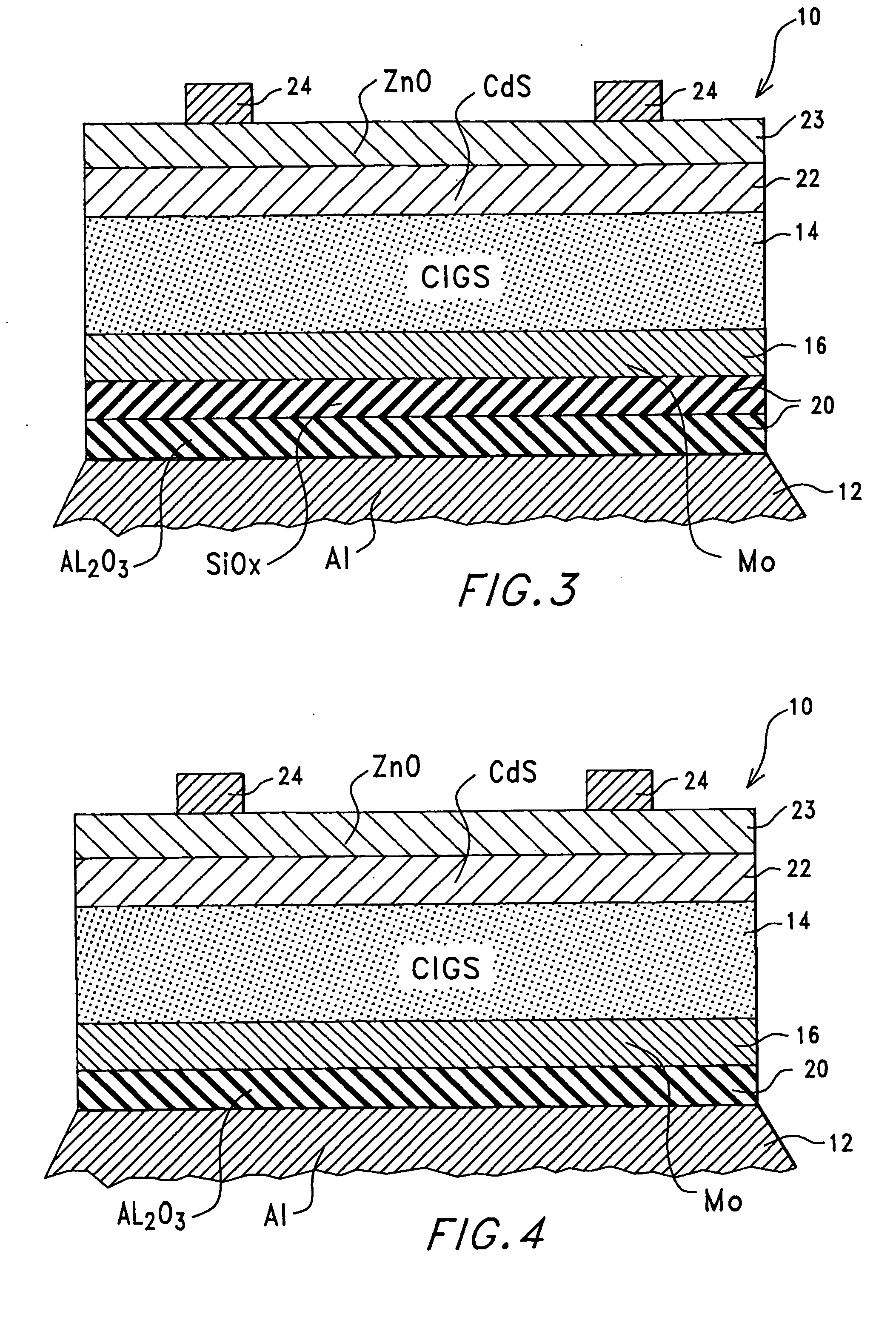

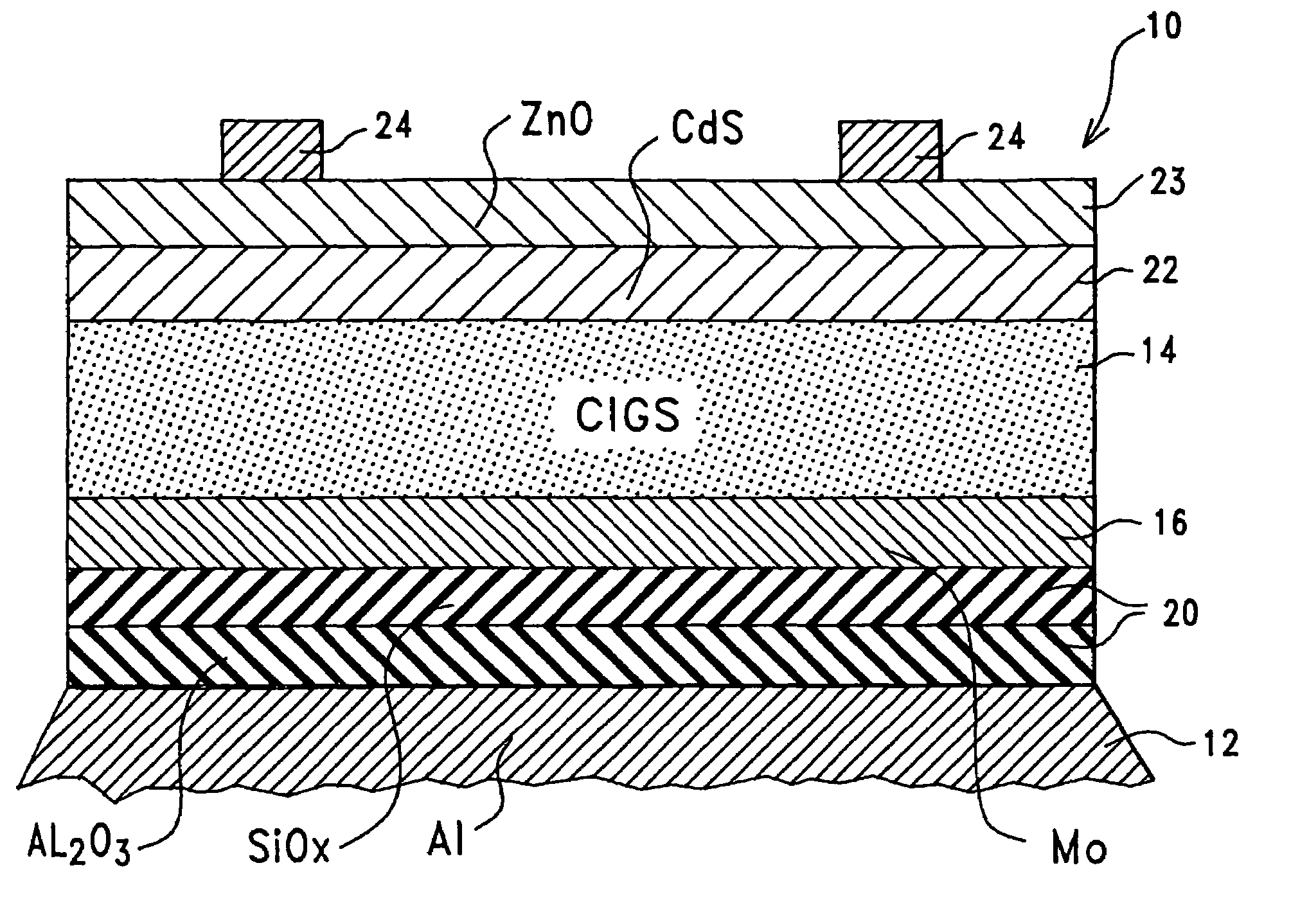

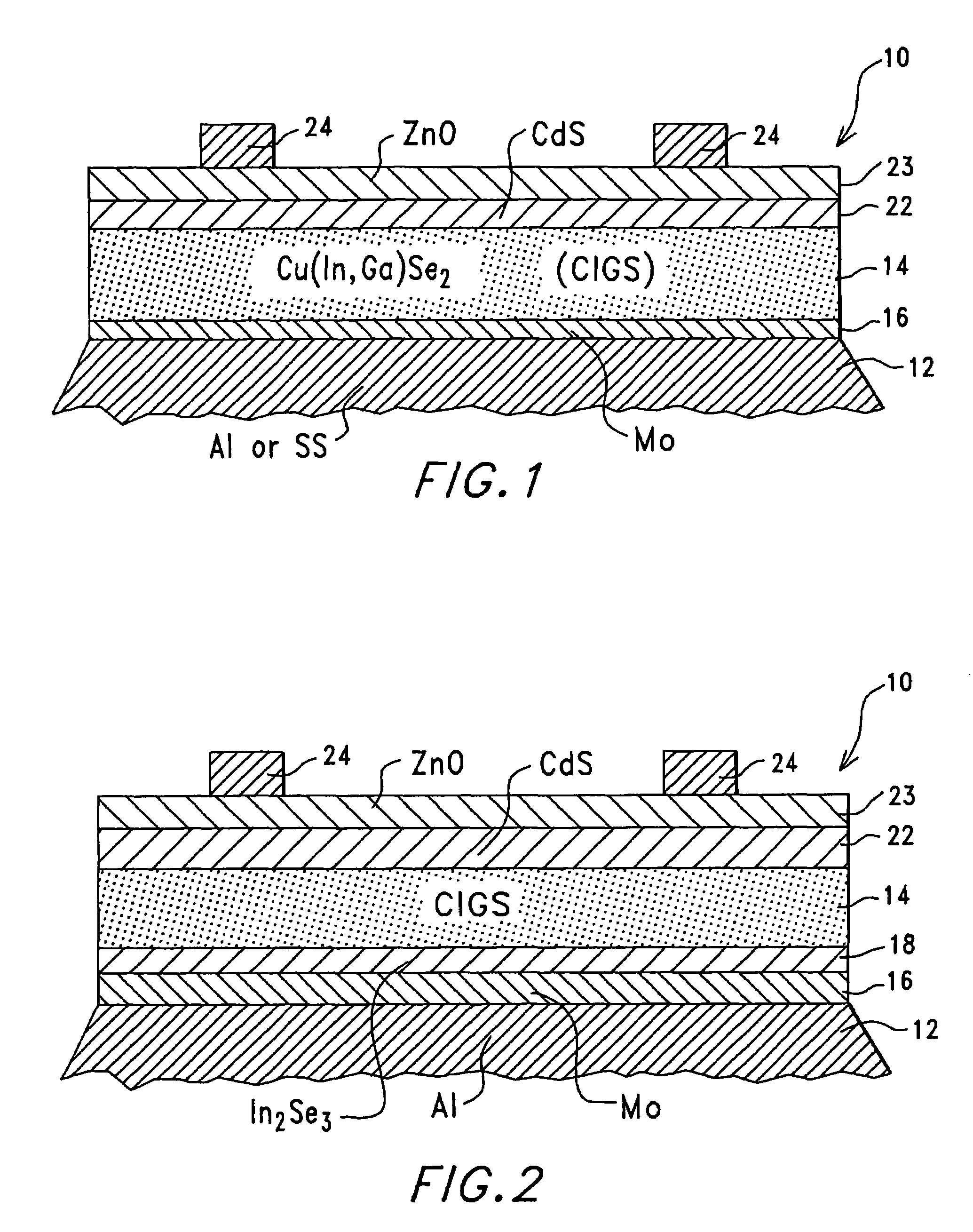

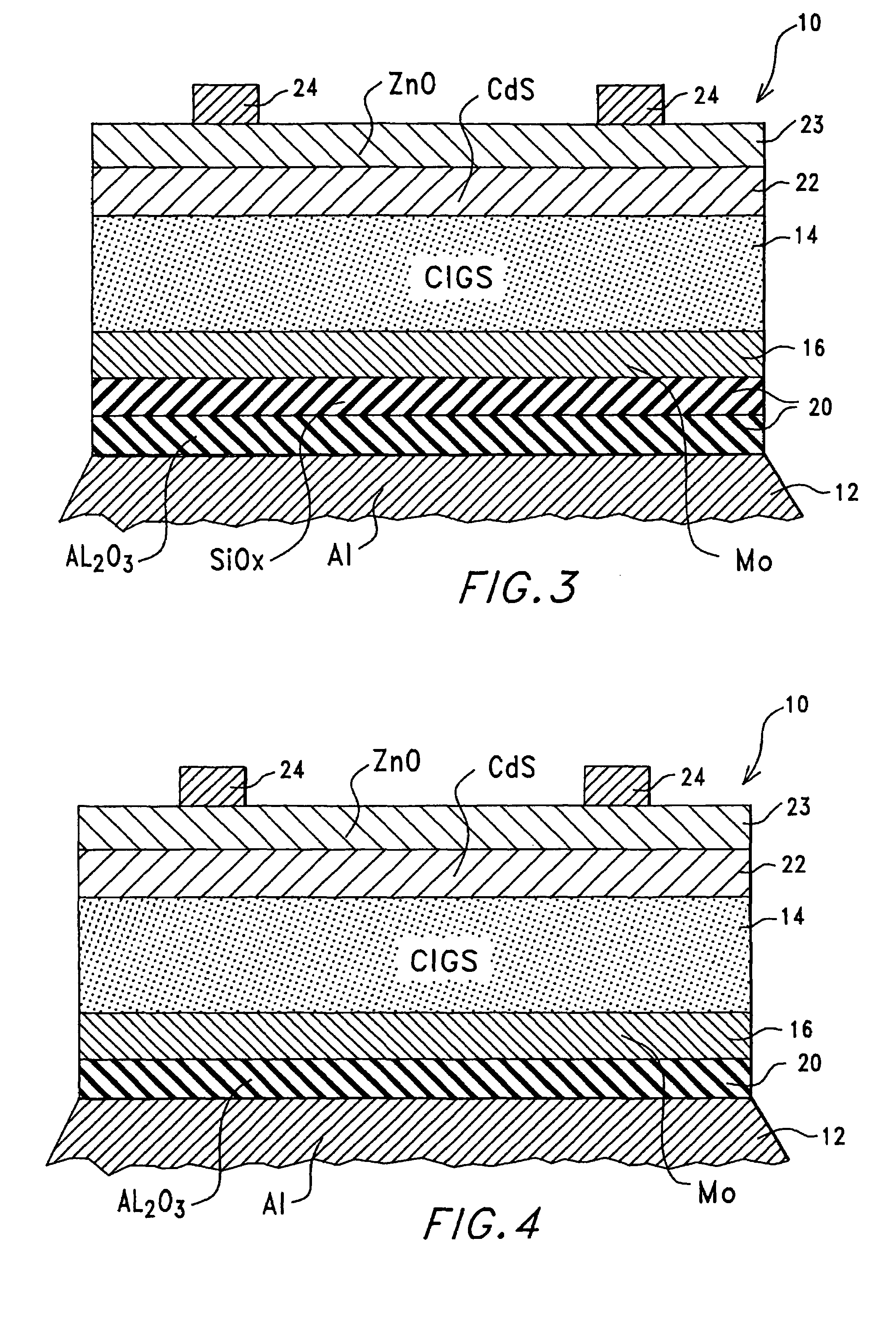

Thin-film solar cell fabricated on a flexible metallic substrate

A thin-film solar cell (10) is provided. The thin-film solar cell (10) comprises a flexible metallic substrate (12) a having a first surface and a second surface. A back metal contact layer (16) is deposited on the first surface of the flexible metallic substrate (12). A semiconductor absorber layer (14) is deposited on the back metal contact. A photoactive film deposited on the semiconductor absorber layer (14) forms a heterojunction structure and a grid contact (24) deposited on the heterjunction structure. The flexible metal substrate (12) can be constructed of either aluminium or stainless steel. Furthermore, a method of constructing a solar cell is provided. The method comprises providing an aluminum substrate (12), depositing a semiconductor absorber layer (14) on the aluminum substrate (12), and insulating the aluminum substrate (12) from the semiconductor absorber layer (14) to inhibit reaction between the aluminum substrate (12) and the semiconductor absorber layer (14).

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

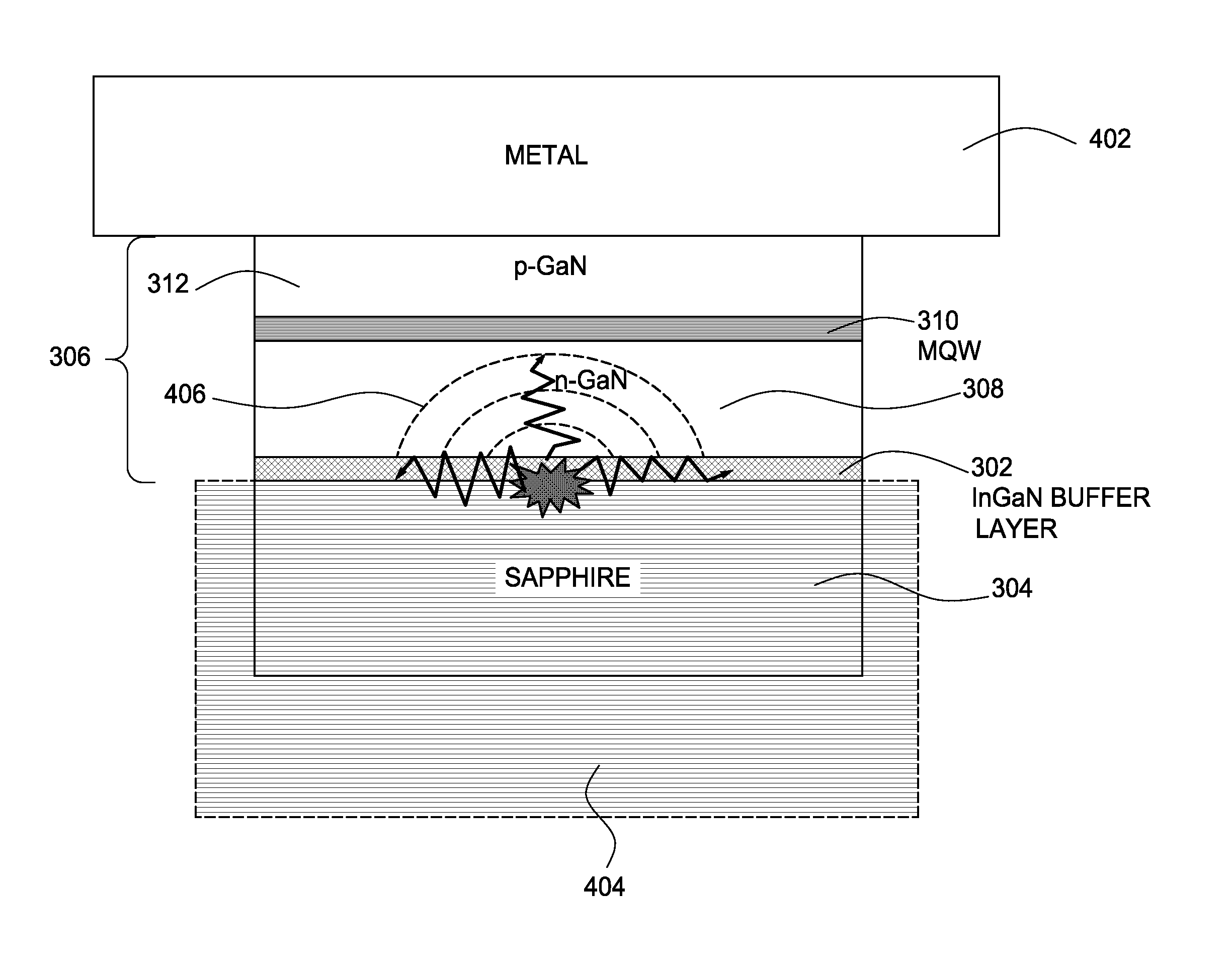

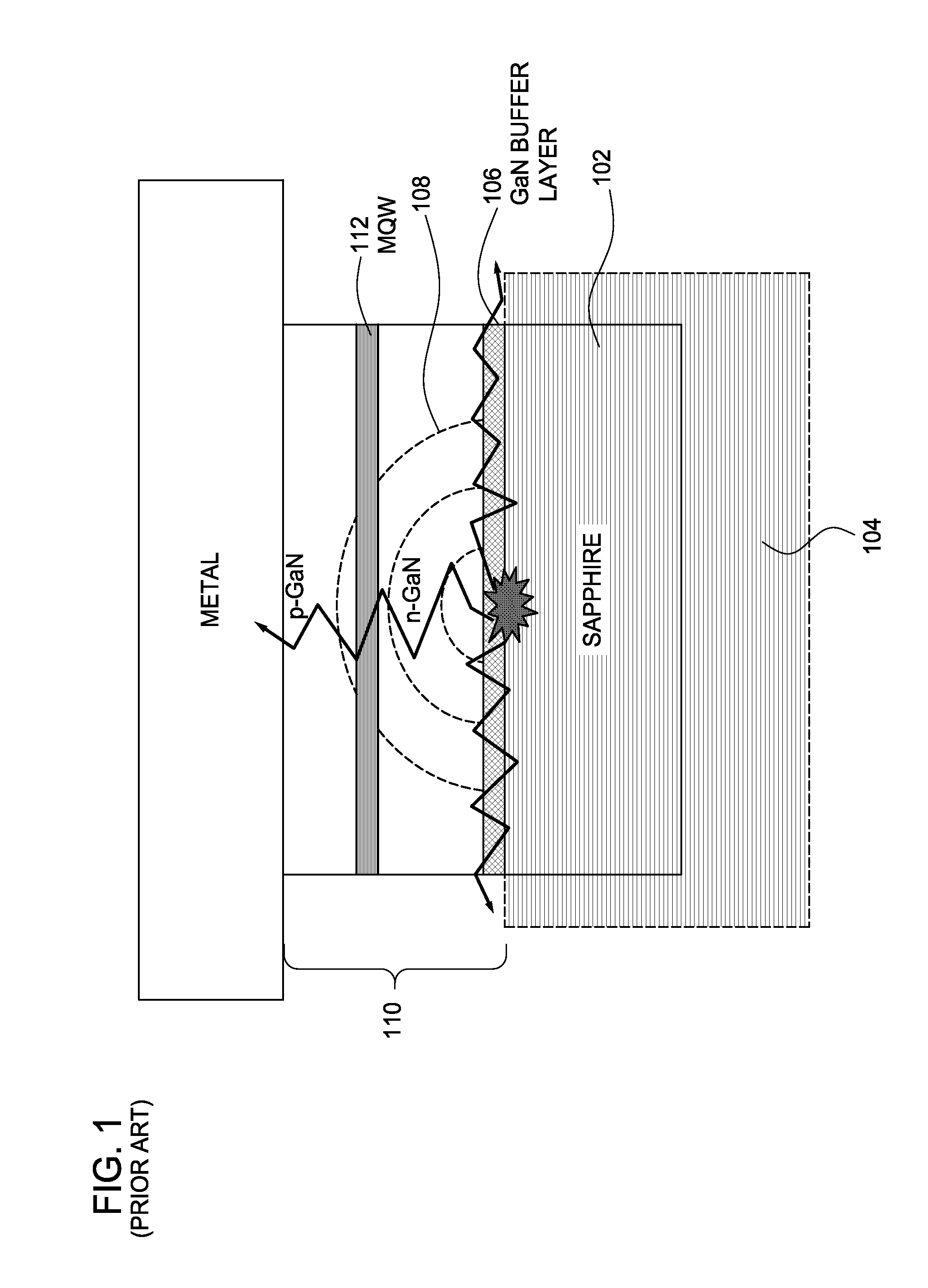

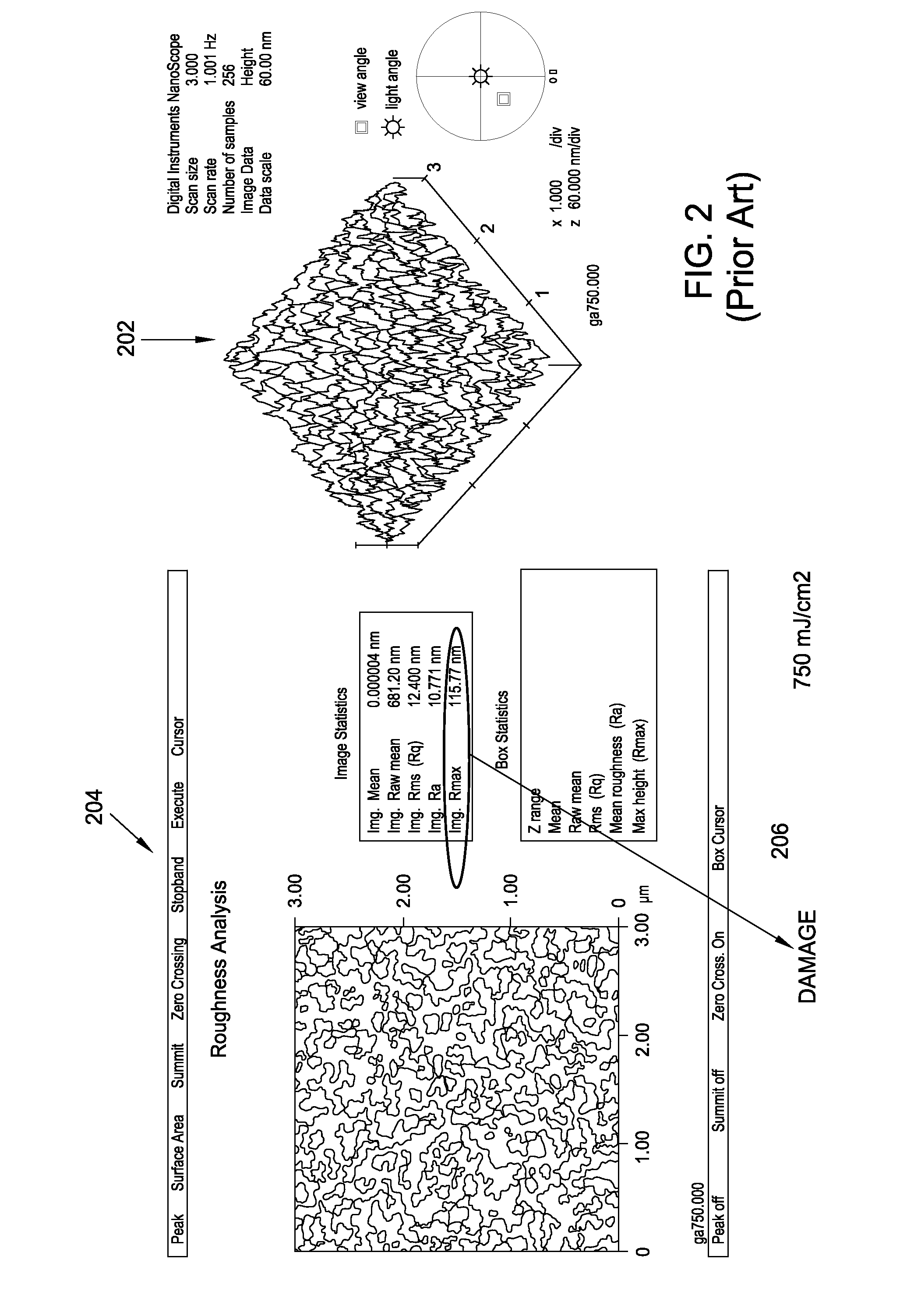

Method for producing group iii - group v vertical light-emitting diodes

ActiveUS20080099780A1Semiconductor/solid-state device manufacturingSemiconductor devicesInterface layerLight-emitting diode

A method of producing one or more vertical light-emitting diode (VLED) dies having a light-emitting diode (LED) stack comprising Group III-Group V combinations of elements (e.g., GaN, AlN, InN, AlGaN, InGaN, and InAlGaN) and a metal substrate is provided. The techniques include forming an InGaN or InAlGaN interface layer above a suitable growth-supporting substrate, such as sapphire or silicon carbide (SiC), and forming the LED stack above the interface layer. Such an interface layer may absorb a majority of the energy from a laser pulse used during laser lift-off of the growth-supporting substrate in an effort to prevent damage to the light emitting layers of the LED stack, which may result in improved brightness performance over VLED dies produced with conventional buffer layers.

Owner:SEMILEDS OPTOELECTRONICS CO LTD

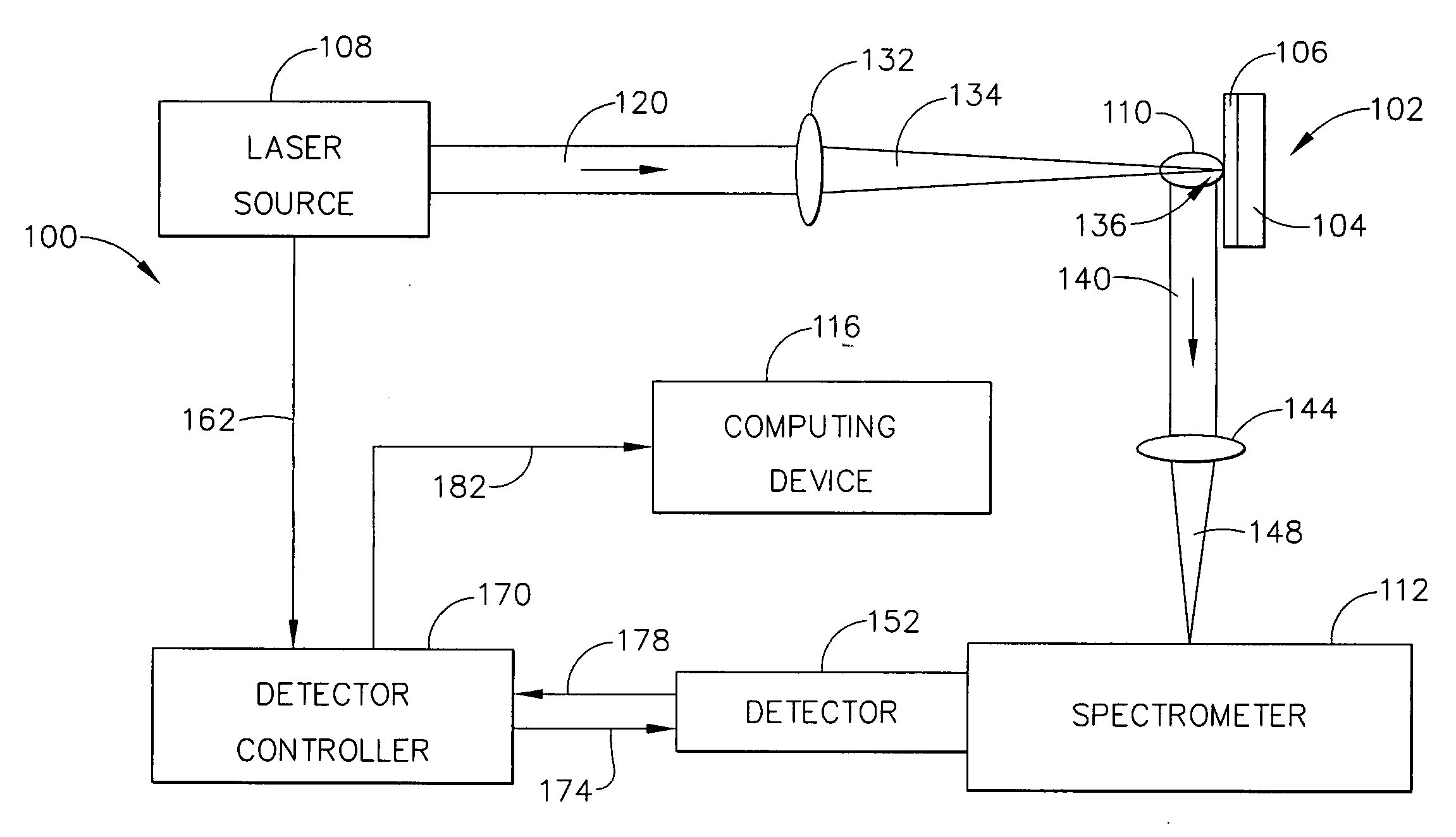

Analysis of component for presence, composition and/or thickness of coating

A method comprising the following steps: (a) providing a turbine component comprising a metal substrate having an external surface; and (b) analyzing the external surface by laser plasma spectroscopy to determine whether a metallic coating is present on or absent from the external surface. If a metallic coating is determined to be present on the external surface, the elemental composition, elemental concentration and / or thickness of the metallic coating present on the external surface may be determined (qualitatively and / or quantitatively) by laser plasma spectroscopy. Another method comprises the following steps: (a) providing a turbine component comprising a metal substrate having an external surface which has been subjected to treatment to remove a metallic coating applied to the external surface; and (b) analyzing the treated external surface by laser plasma spectroscopy to determine the degree of removal of the metallic coating from the treated external surface.

Owner:GENERAL ELECTRIC CO

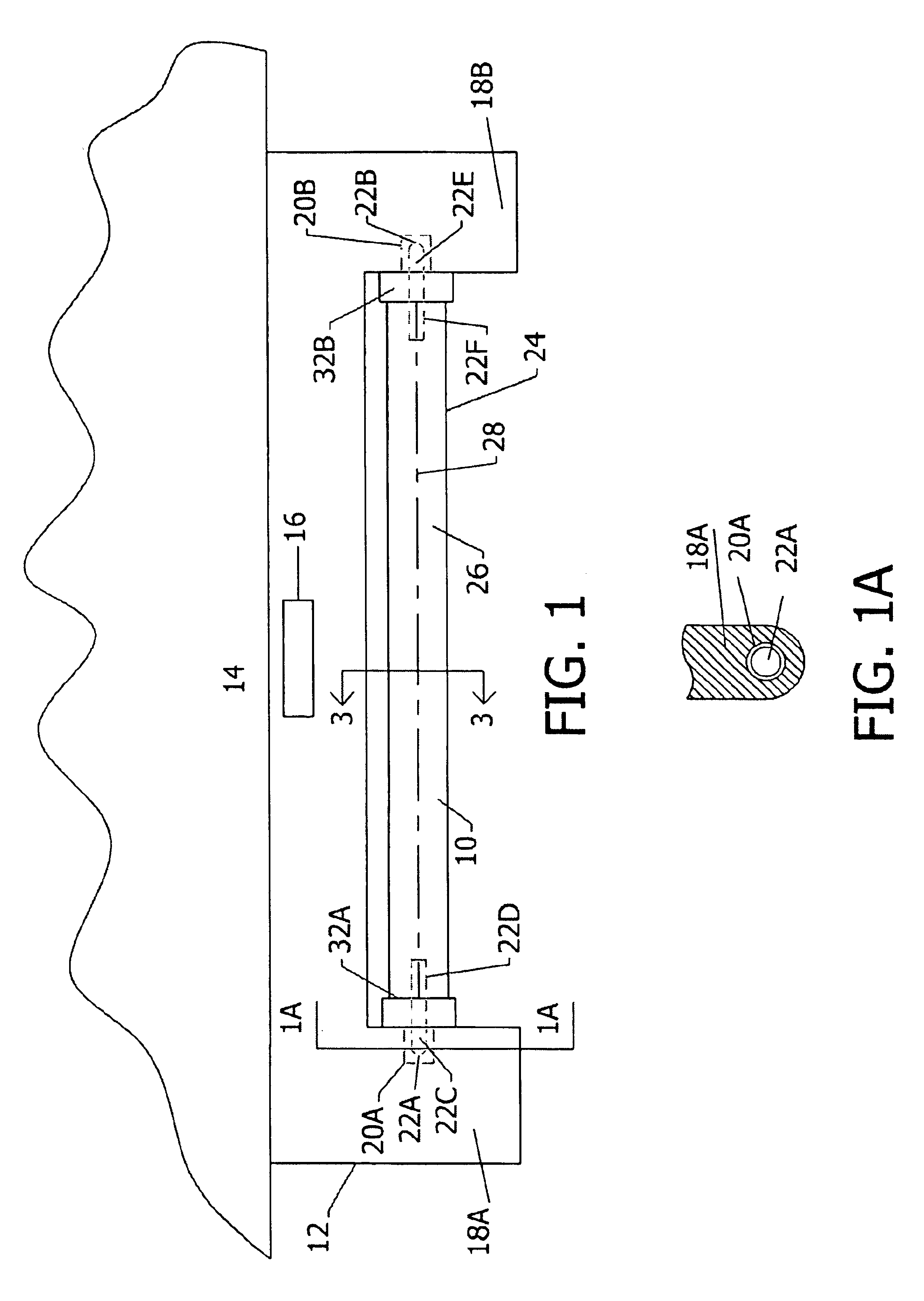

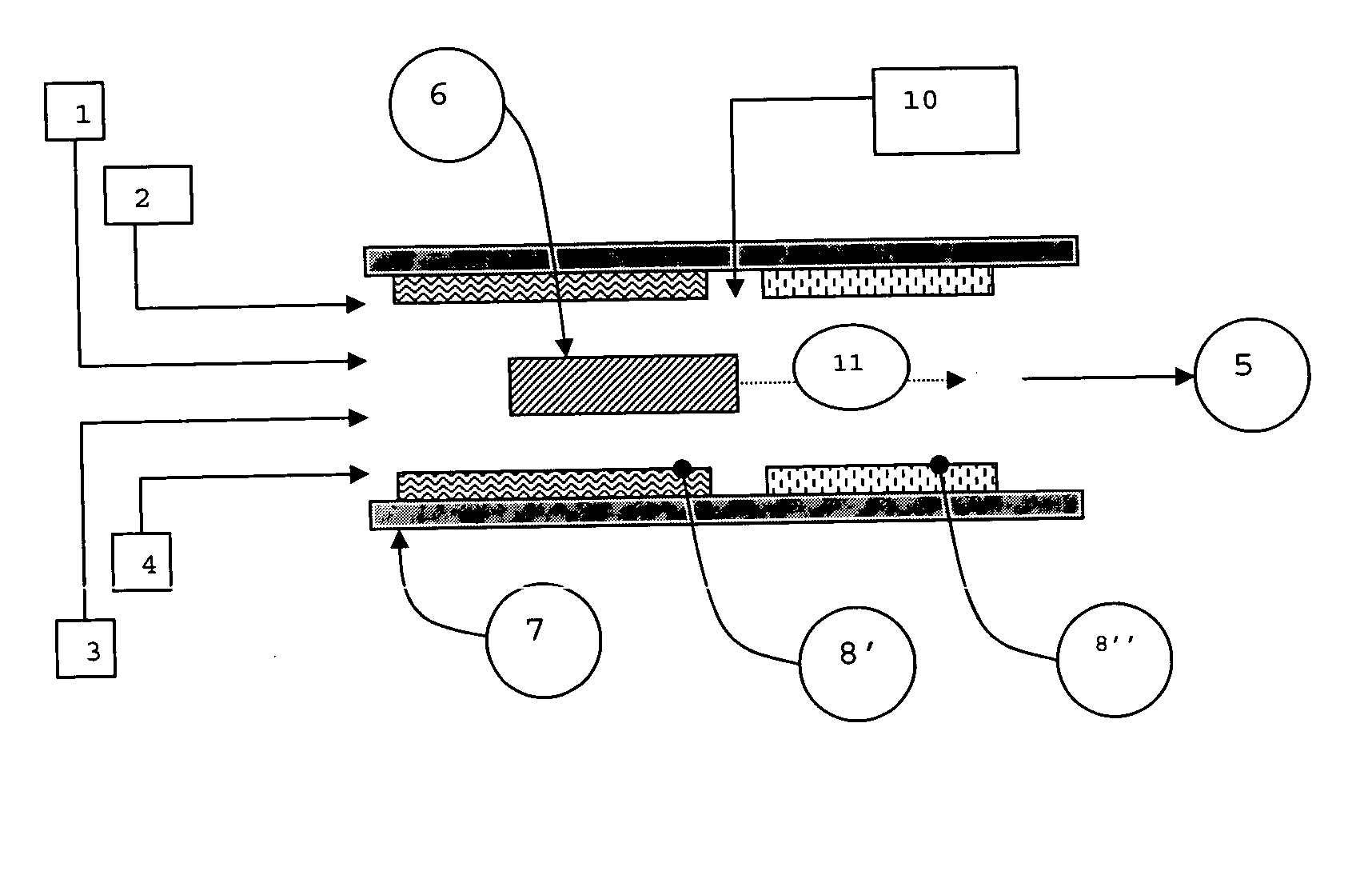

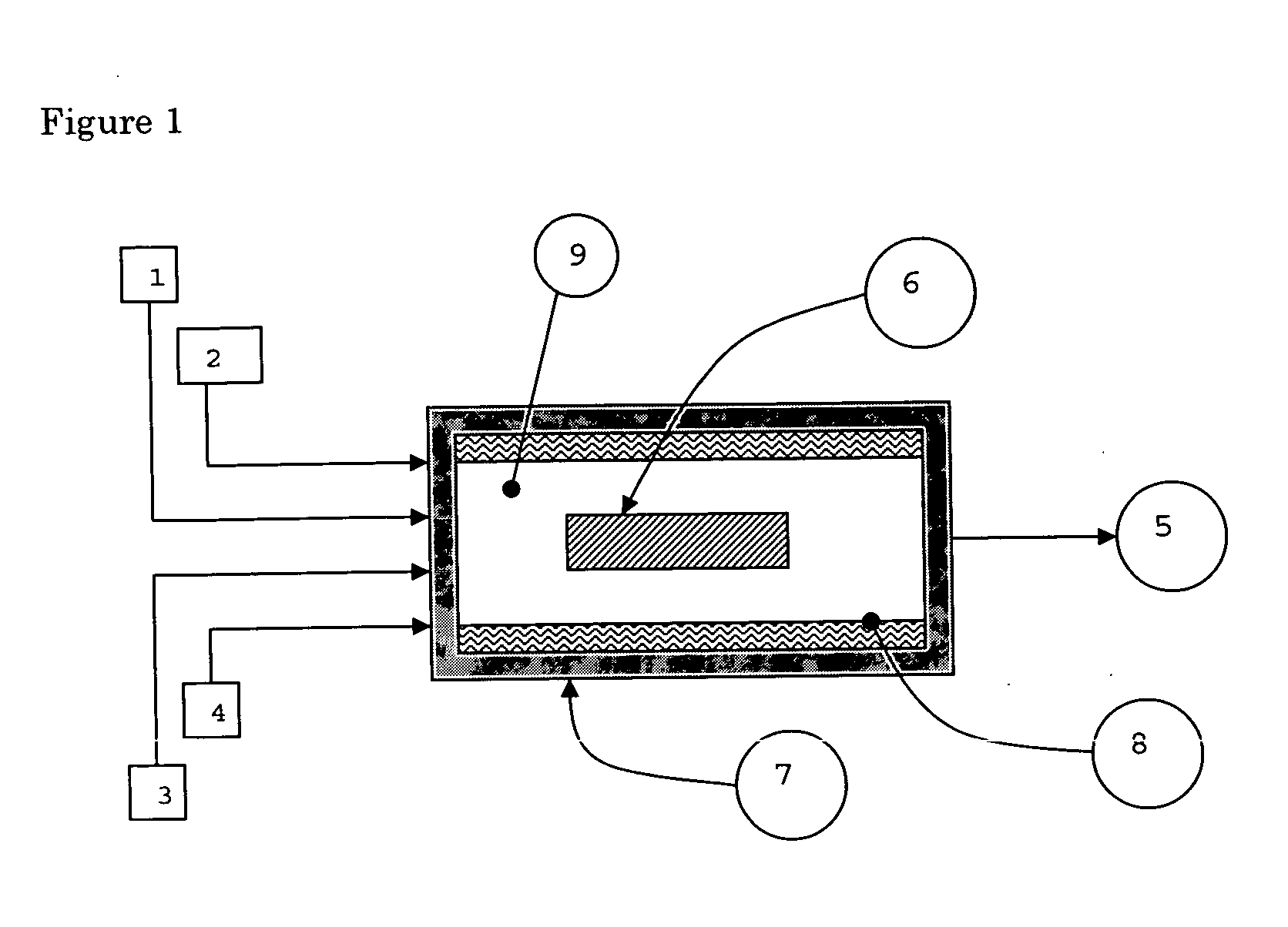

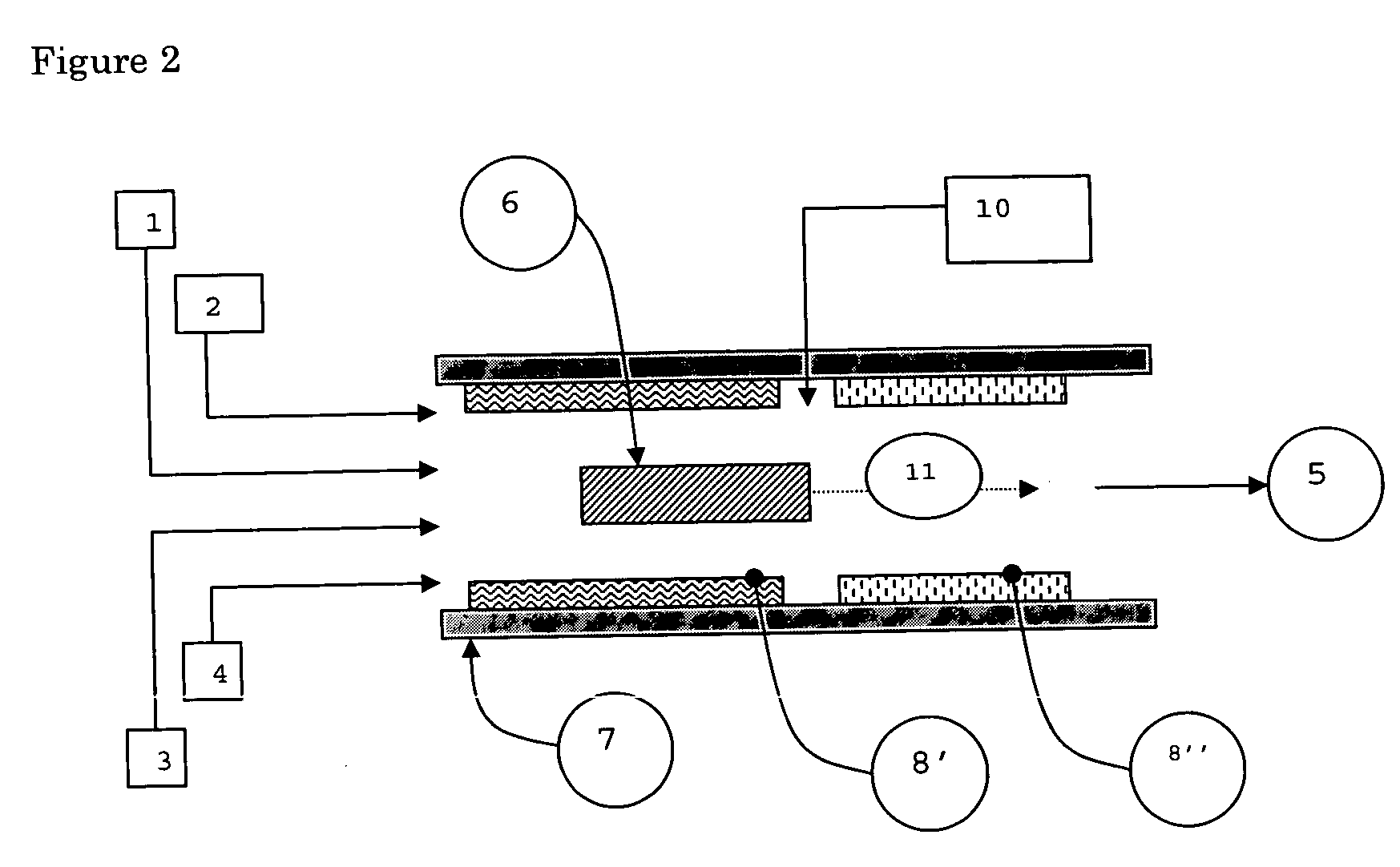

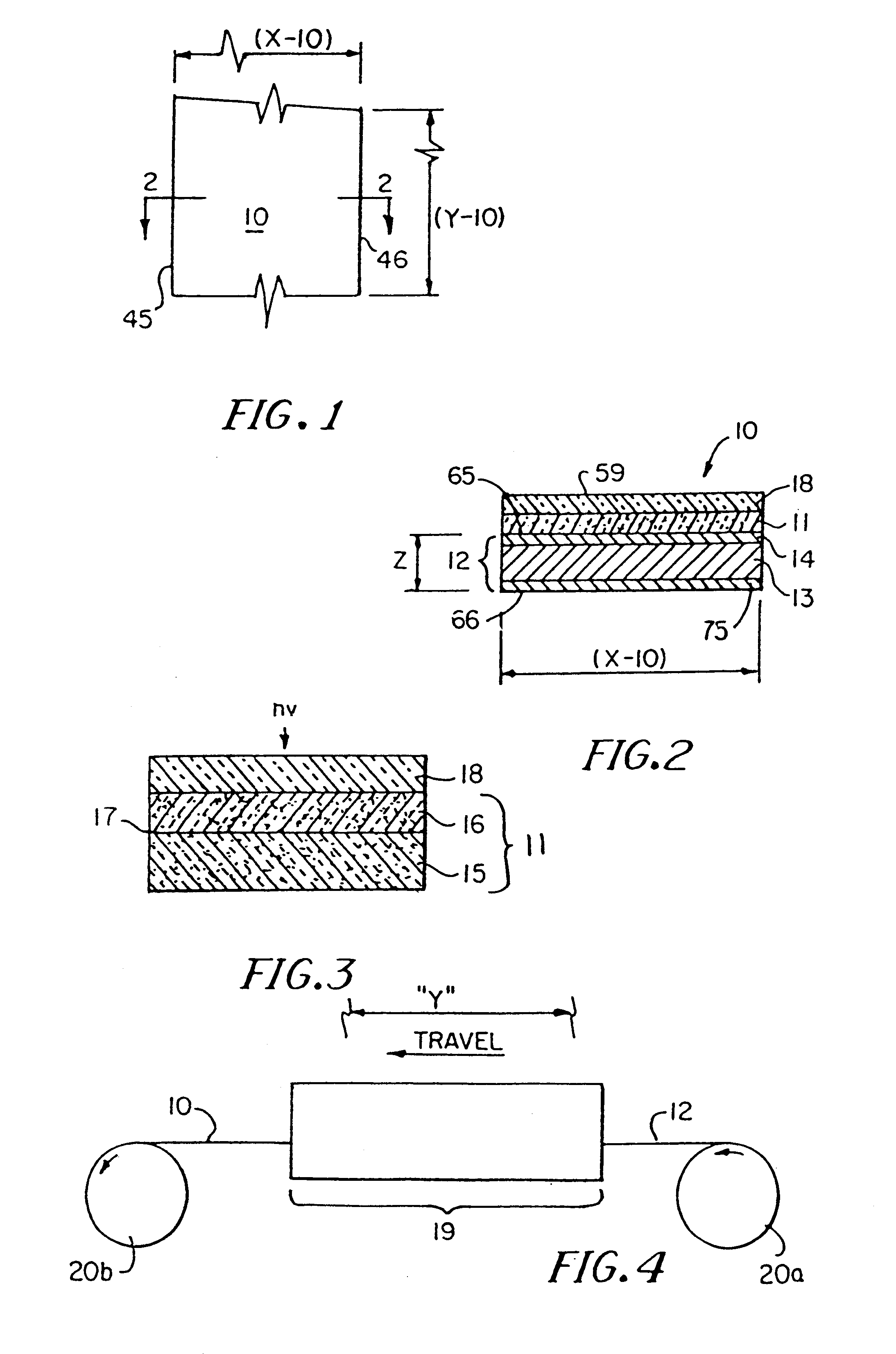

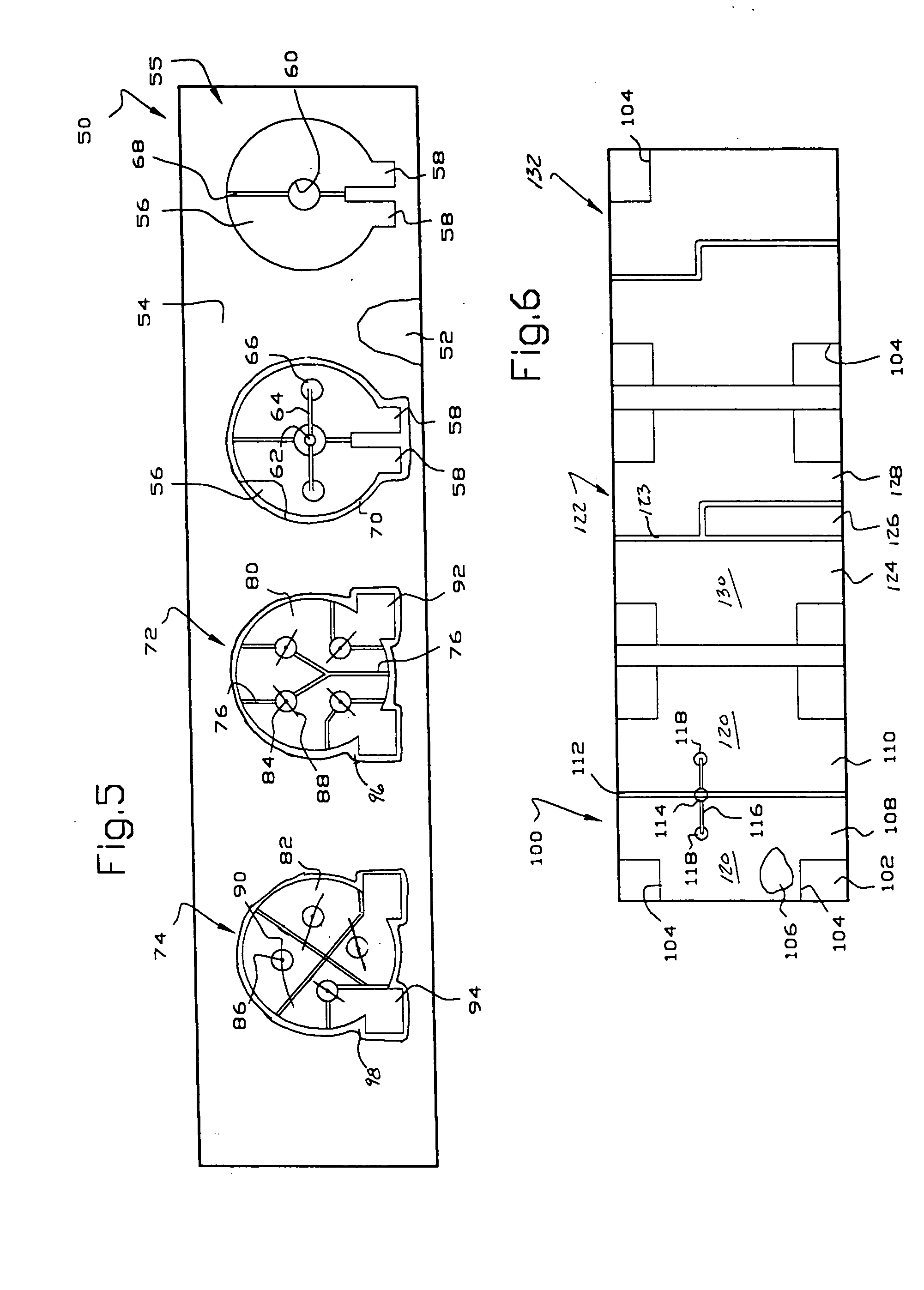

Substrate and collector grid structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

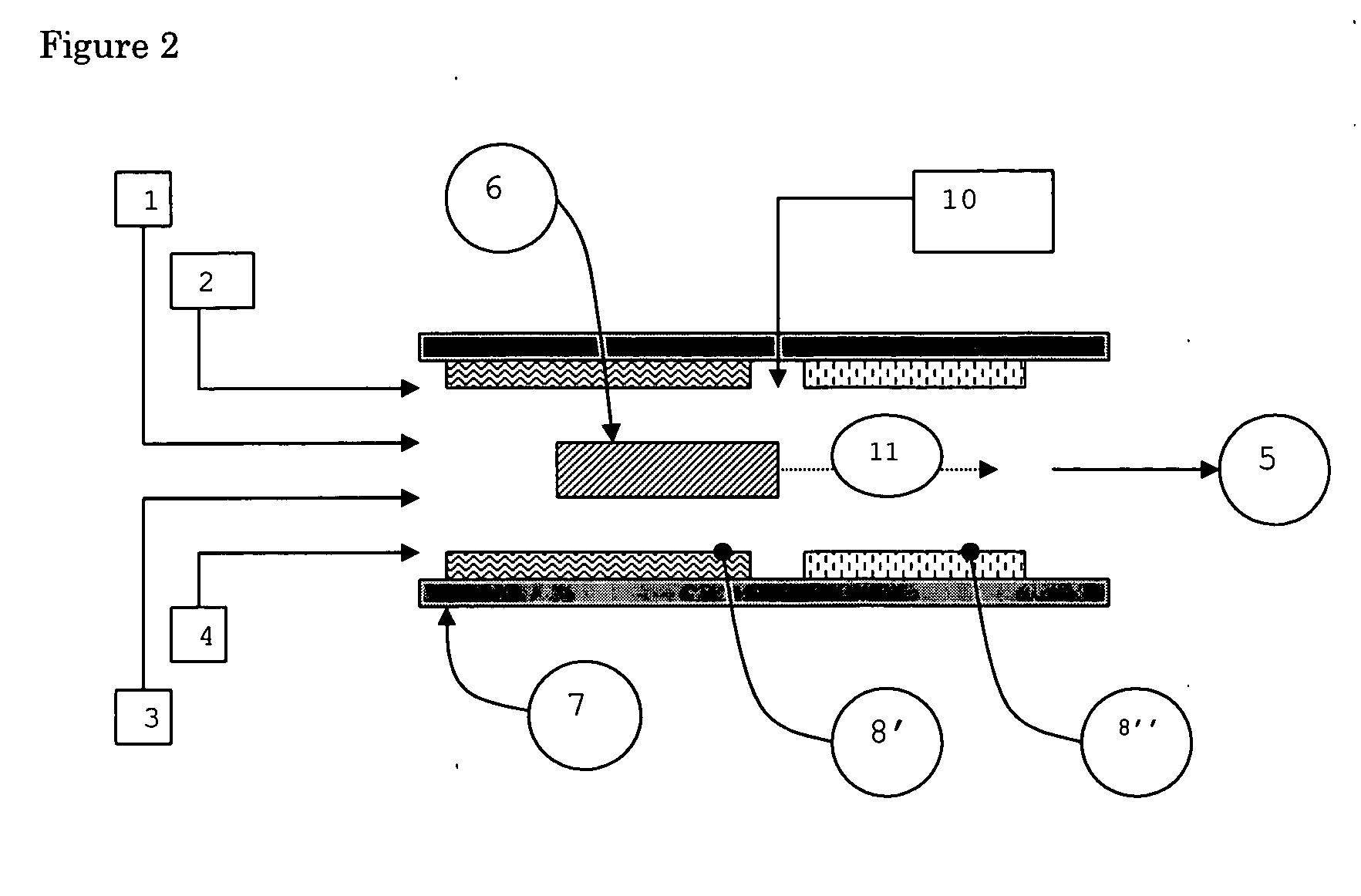

InactiveUS6414235B1Eliminate deficienciesCheap productionPV power plantsElectrode carriers/collectorsRoll-to-roll processingMetal foil

This invention comprises deposition of thin film photovoltaic junctions on metal substrates which can be heat treated following deposition in a continuous fashion without deterioration of the metal support structure. In a separate operation an interconnection substrate structure is produced in a continuous roll-to-roll fashion. In this way the interconnection substrate structure can be uniquely formulated from polymer-based materials since it does not have to endure high temperature exposure. Cells comprising the metal foil supported photovoltaic junctions are then laminated to the interconnection substrate structure. Conductive interconnections are deposited to complete the array. The conductive interconnections can be accomplished with a separately prepared interconnection component. The interconnected array is produced using continuous roll-to-roll processing which avoids the need to use the expensive and intricate material removal operations currently taught in the art to achieve electrical interconnections among arrays of photovoltaic cells.

Owner:SOLANNEX

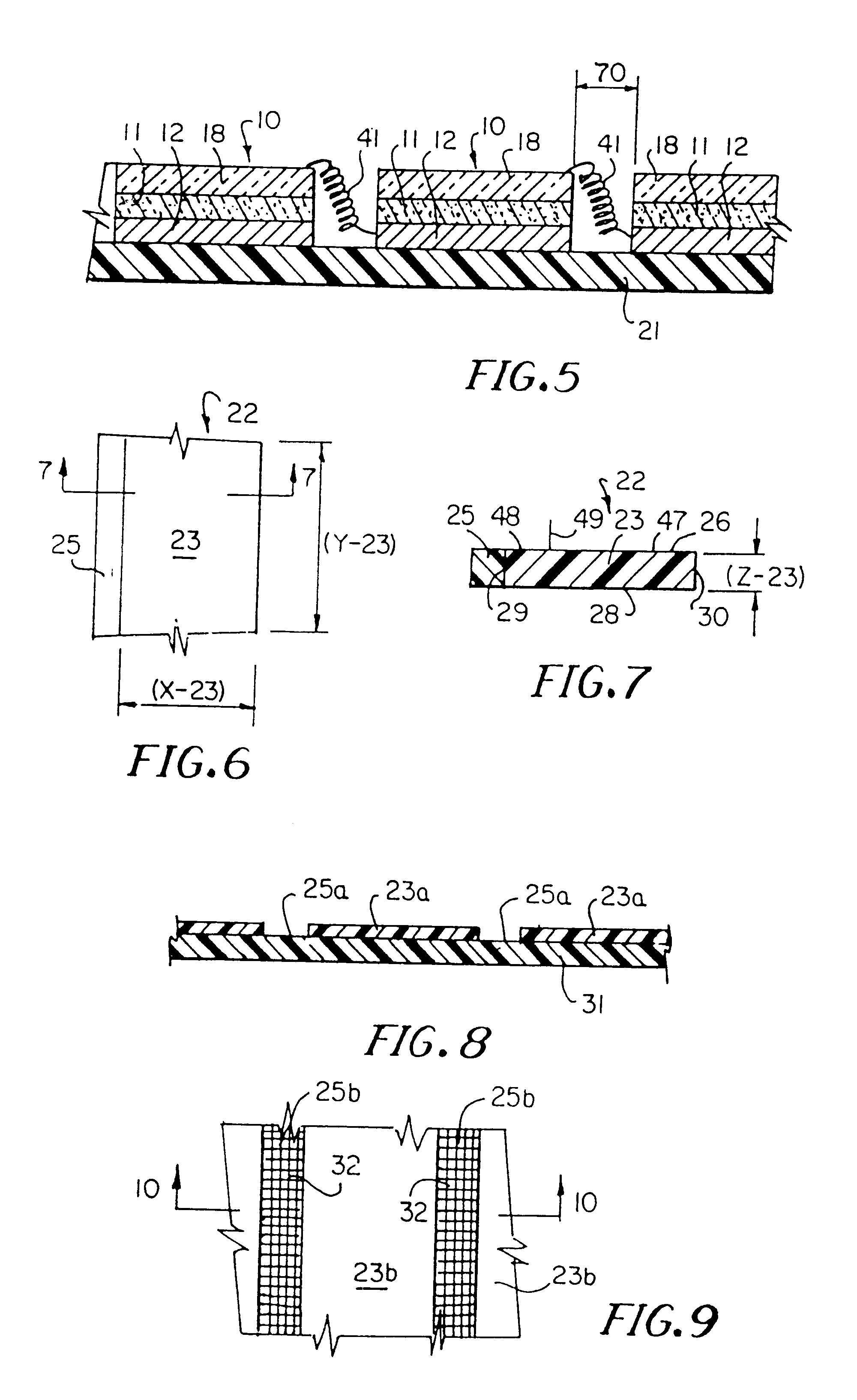

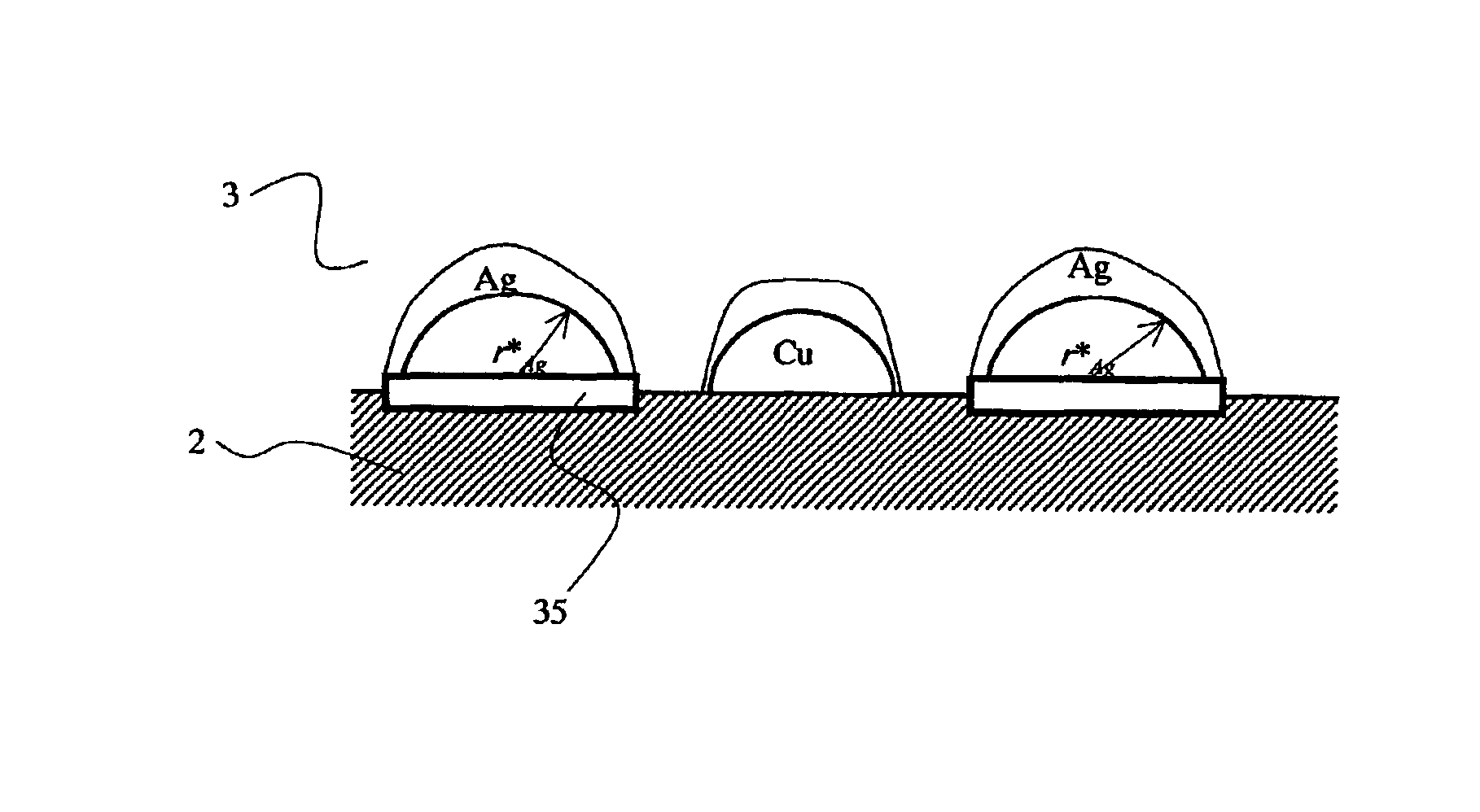

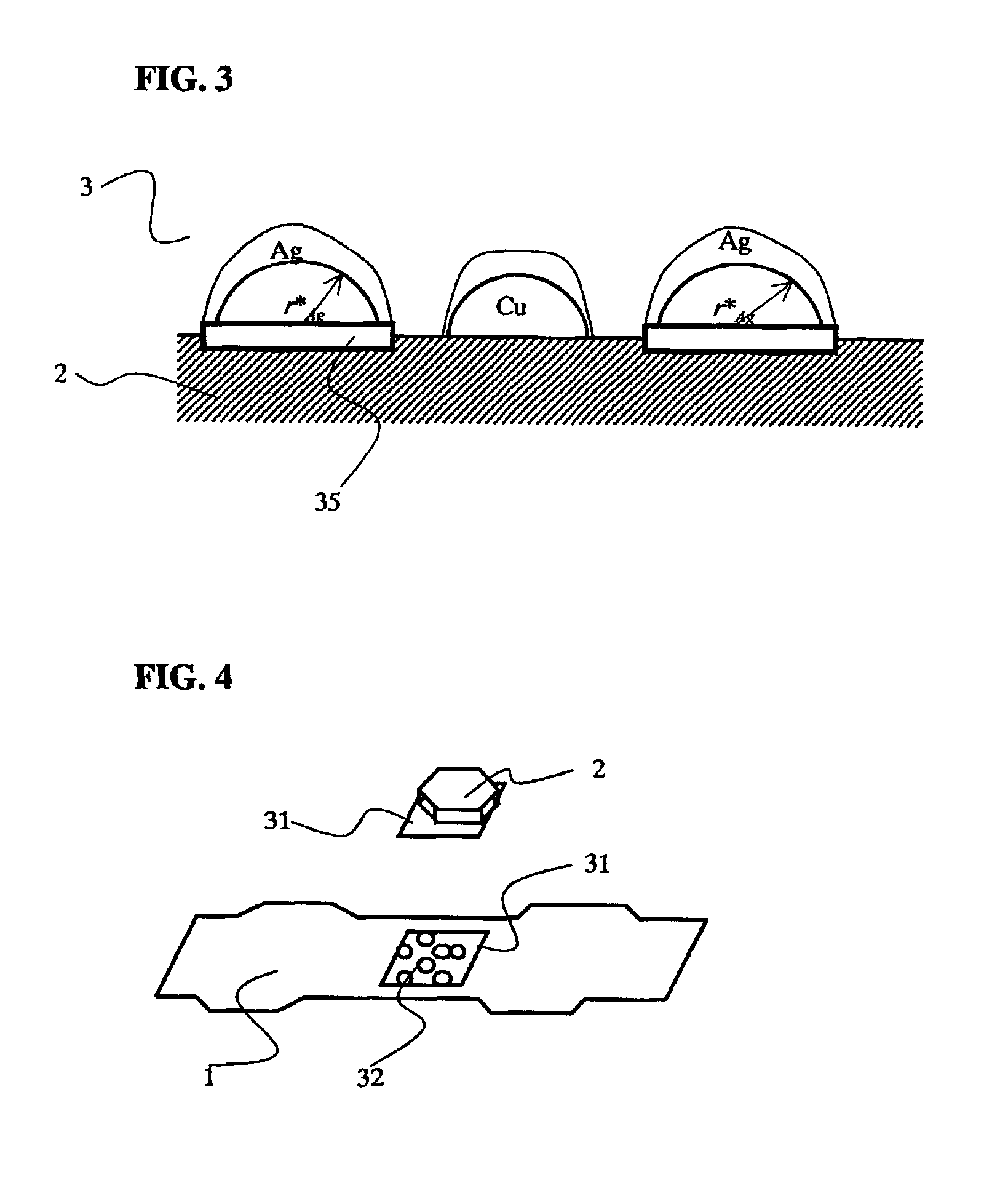

Brazing-filler material and method for brazing diamond

InactiveUS6889890B2Beautiful sceneryStable joint strengthLayered productsOther manufacturing equipments/toolsFilling materialsCopper

When a diamond is brazed to a metal substrate, while obtaining a stable joining strength, a joined interface of the diamond is not eroded to provide a good joint with a beautiful view. A brazing-filler material containing at least one selected from a group consisting of gold and silver, and copper as principal components, and further containing 0.001 to 5 mass % of vanadium is used. Preferably, a vanadium content is not more than 2.0 mass %, and more preferably not more than 0.5 mass %. Using this brazing-filler material, unidirectional solidification is performed from a side of diamond to form vanadium carbide in a joined interface in a shape of islands, and thereby an interface having a beautiful view with stable joining strength can be obtained. In addition, strong joining is possible also by a usual solidification method.

Owner:HOHOEMI BRAINS INC

Thin-film solar cell fabricated on a flexible metallic substrate

A thin-film solar cell (10) is provided. The thin-film solar cell (10) comprises a flexible metallic substrate (12) having a first surface and a second surface. A back metal contact layer (16) is deposited on the first surface of the flexible metallic substrate (12). A semiconductor absorber layer (14) is deposited on the back metal contact. A photoactive film deposited on the semiconductor absorber layer (14) forms a heterojunction structure and a grid contact (24) deposited on the heterjunction structure. The flexible metal substrate (12) can be constructed of either aluminium or stainless steel. Furthermore, a method of constructing a solar cell is provided. The method comprises providing an aluminum substrate (12), depositing a semiconductor absorber layer (14) on the aluminum substrate (12), and insulating the aluminum substrate (12) from the semiconductor absorber layer (14) to inhibit reaction between the aluminum substrate (12) and the semiconductor absorber layer (14).

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

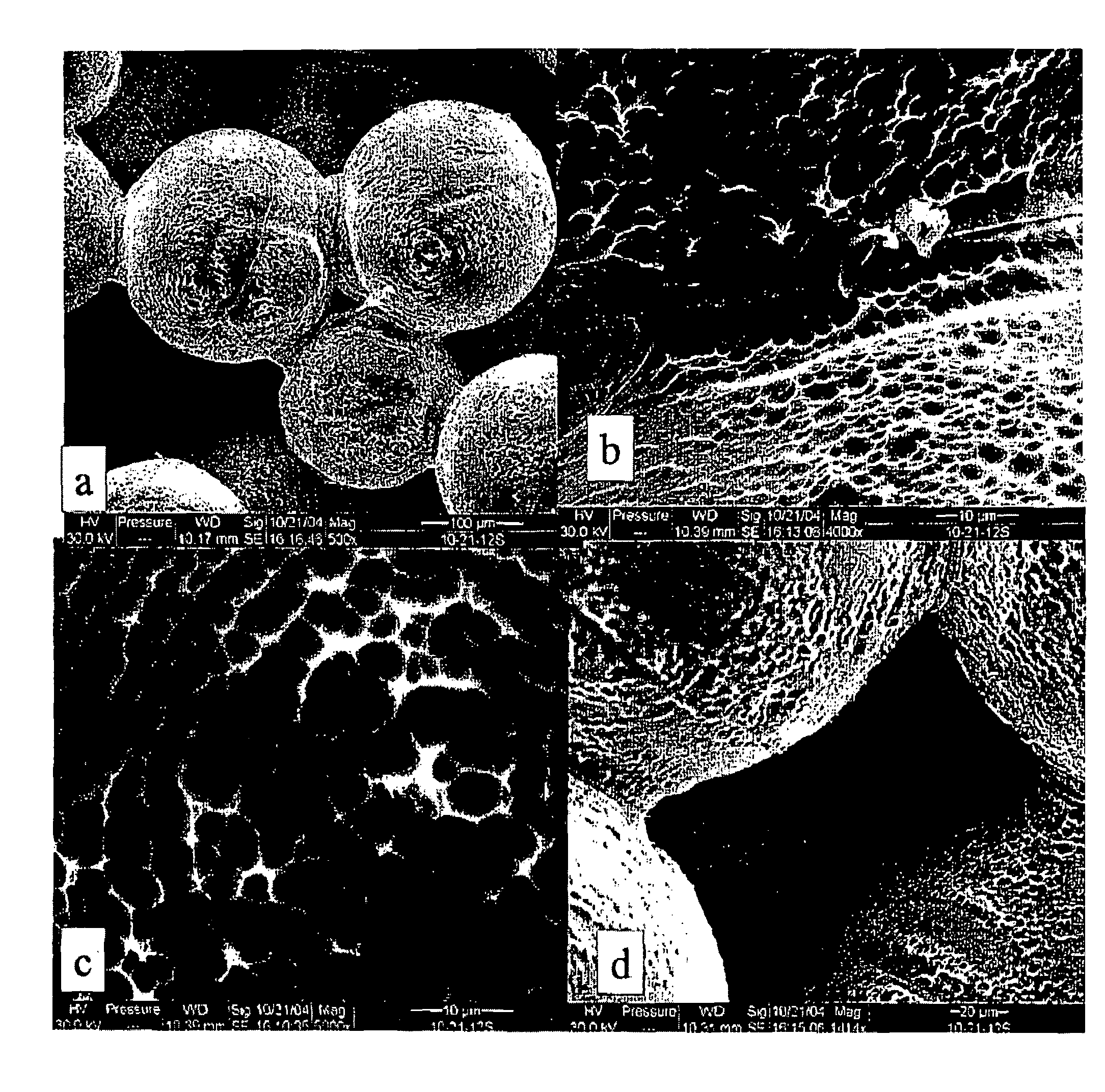

Implants with textured surface and methods for producing the same

ActiveUS7368065B2High retention rateConvenient coatingImpression capsDecorative surface effectsMicrometerChloride

Compositions and methods are provided for preparing a metal substrate having a uniform textured surface with a plurality of indentations with a diameter in the nanometer and micrometer range. The textured surface is produced by exposing the substrate to an etching fluid comprising a hydrohalic acid and a mixture of a hydrohalic acid and an oxyacid, a chloride containing compound, and an oxidant. The etching solution can be used at ambient temperature. This textured surface enhances adherence of coatings or cells onto the textured surface, improves the retention of proteins on the surface, and encourages bone in-growth.

Owner:DEPUY PROD INC

Methods for coating a metal substrate and related coated substrates

ActiveUS7749368B2Volume/mass flow measurementFluid pressure measurement by electric/magnetic elementsElectrogalvanizationMetallic substrate

Owner:PPG IND OHIO INC

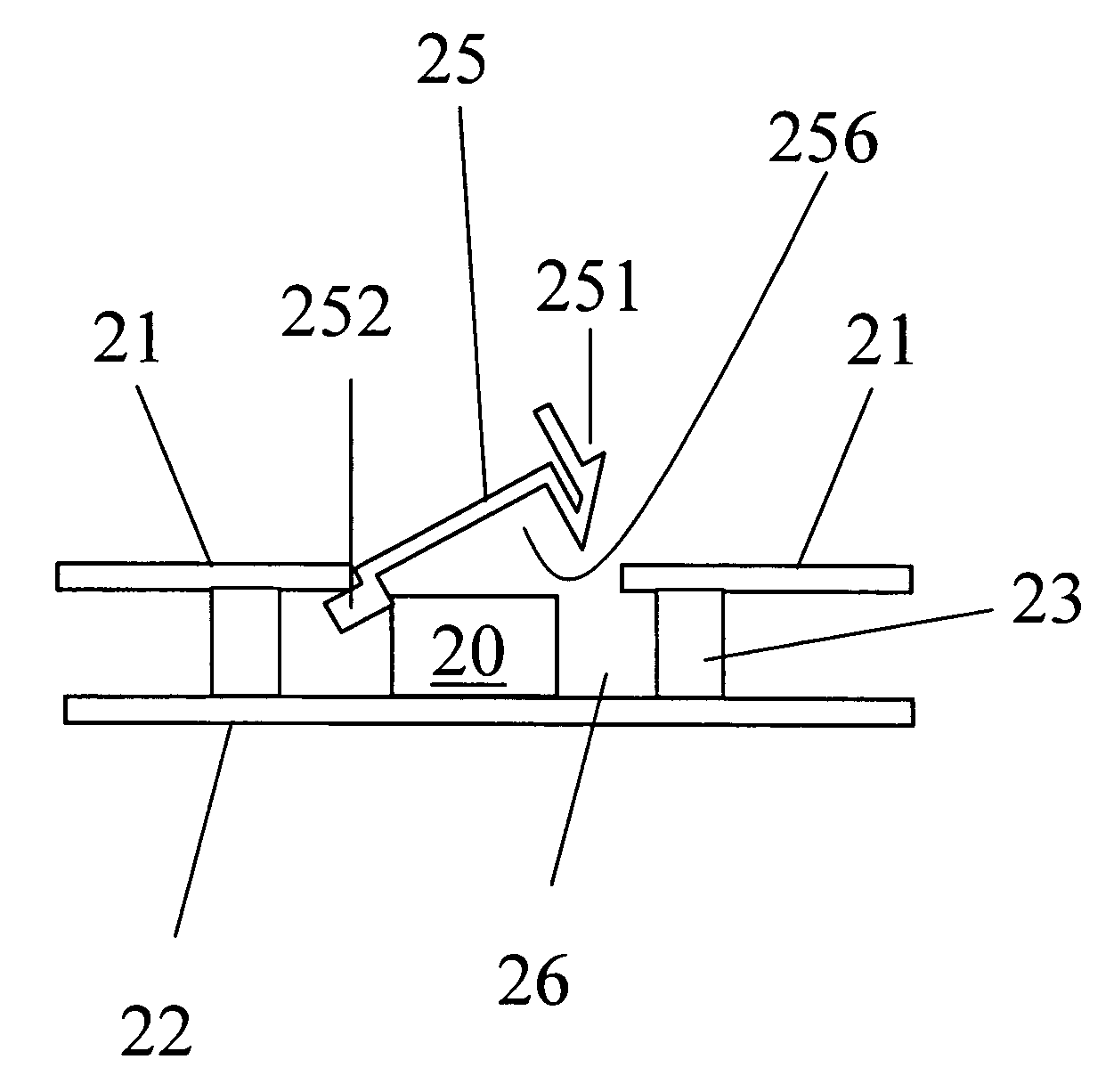

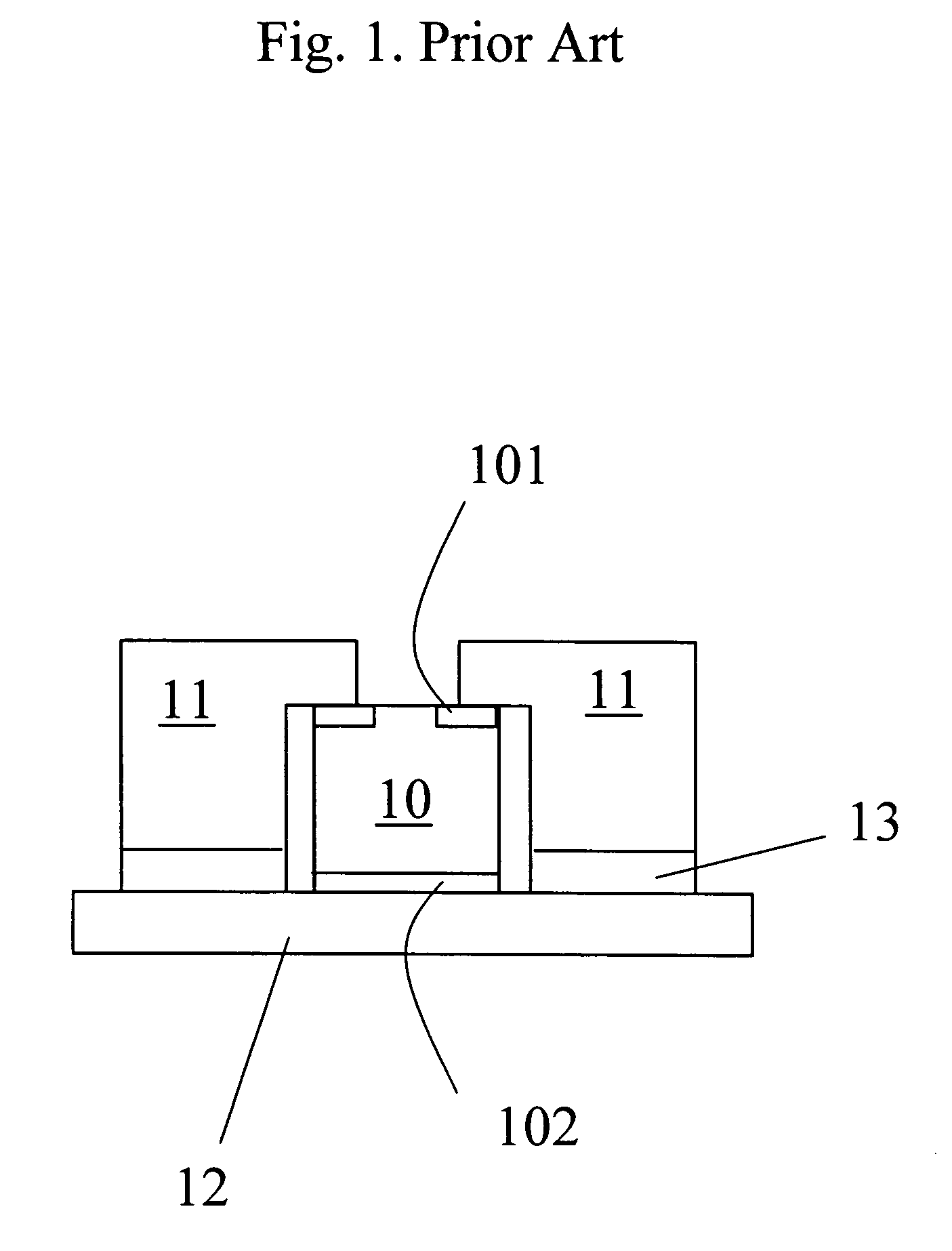

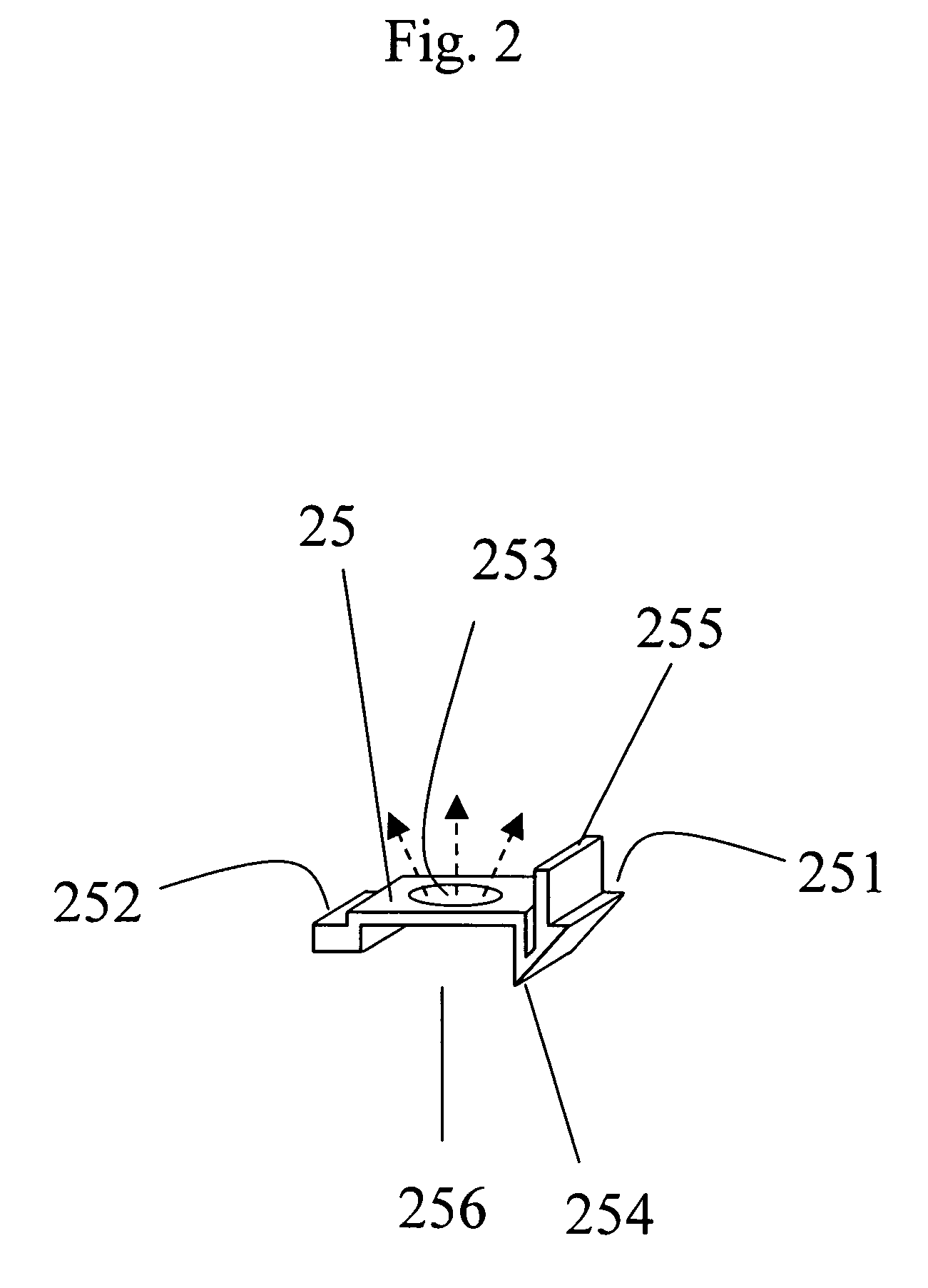

High power light-emitting diode package comprising substrate having beacon

InactiveUS20080019133A1Reduce heat resistance requirementsDecreasing junction temperatureSemiconductor/solid-state device detailsLighting heating/cooling arrangementsCo-fired ceramicPrinted circuit board

Disclosed herein is a package structure including at least one high power light-emitting diode to exhibit excellent heat release properties. In the package structure, a light-emitting diode chip which generates heat is directly attached to a beacon processed to protrude from part of a heat spreader having high heat conductivity, whereby an electrical wiring portion is separated from a heat release portion, thus maximizing heat release properties and realizing high luminance and reliability. The package structure is composed of a beacon formed on a metal or non-metal substrate having high heat conductivity to mount a high power light-emitting diode chip, to increase heat release properties; a wiring portion provided on the same line as the diode to input and output power and signals; and a reflection cup having a cavity, which may be inserted into or attached to the heat spreader or the wiring substrate, including a low temperature co-fired ceramic substrate, a high temperature co-fired ceramic substrate, or a printed circuit board.

Owner:KOREA PHOTONICS TECH INST

Pretreatment compositions and methods for coating a metal substrate

Disclosed are methods for treating metal substrates, including ferrous substrates, such as cold rolled steel and electrogalvanized steel. The methods include contacting the substrate with a pretreatment composition that includes: (a) a group IIIB and / or IVB metal; (b) free fluorine; (c) a metal fluoride salt formed from a metal which forms a fluoride salt having a pKsp of at least 11; and (d) water.

Owner:PPG IND OHIO INC

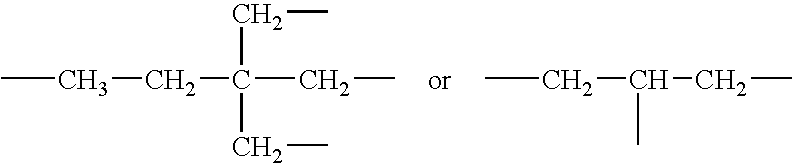

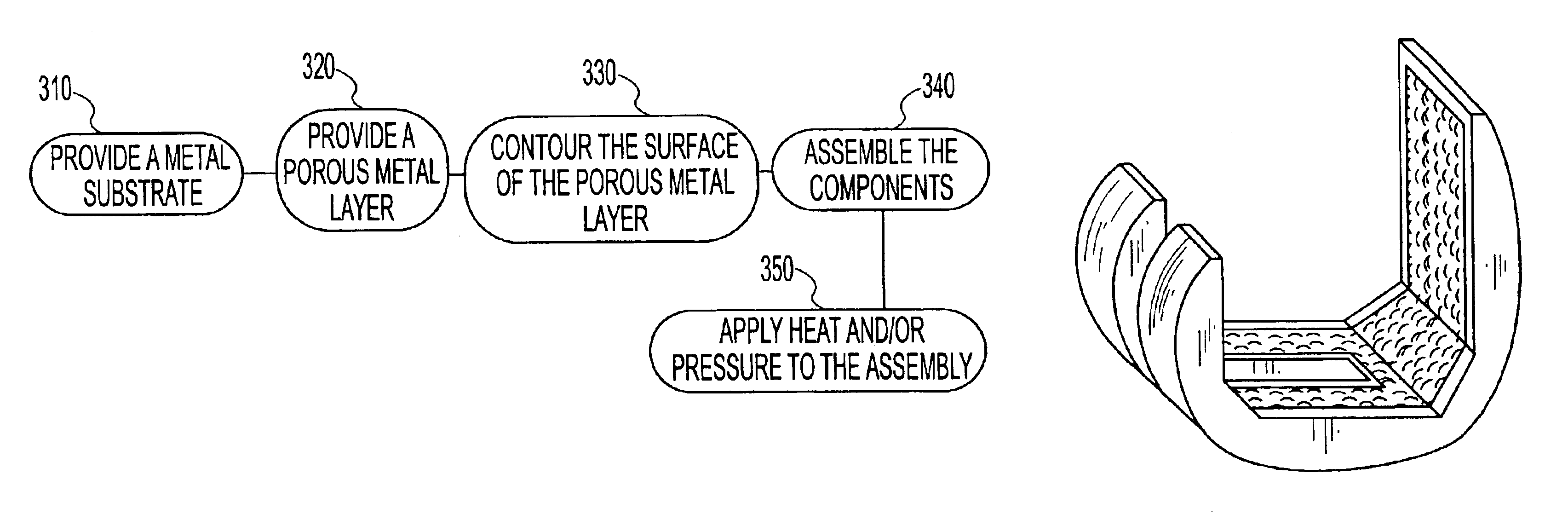

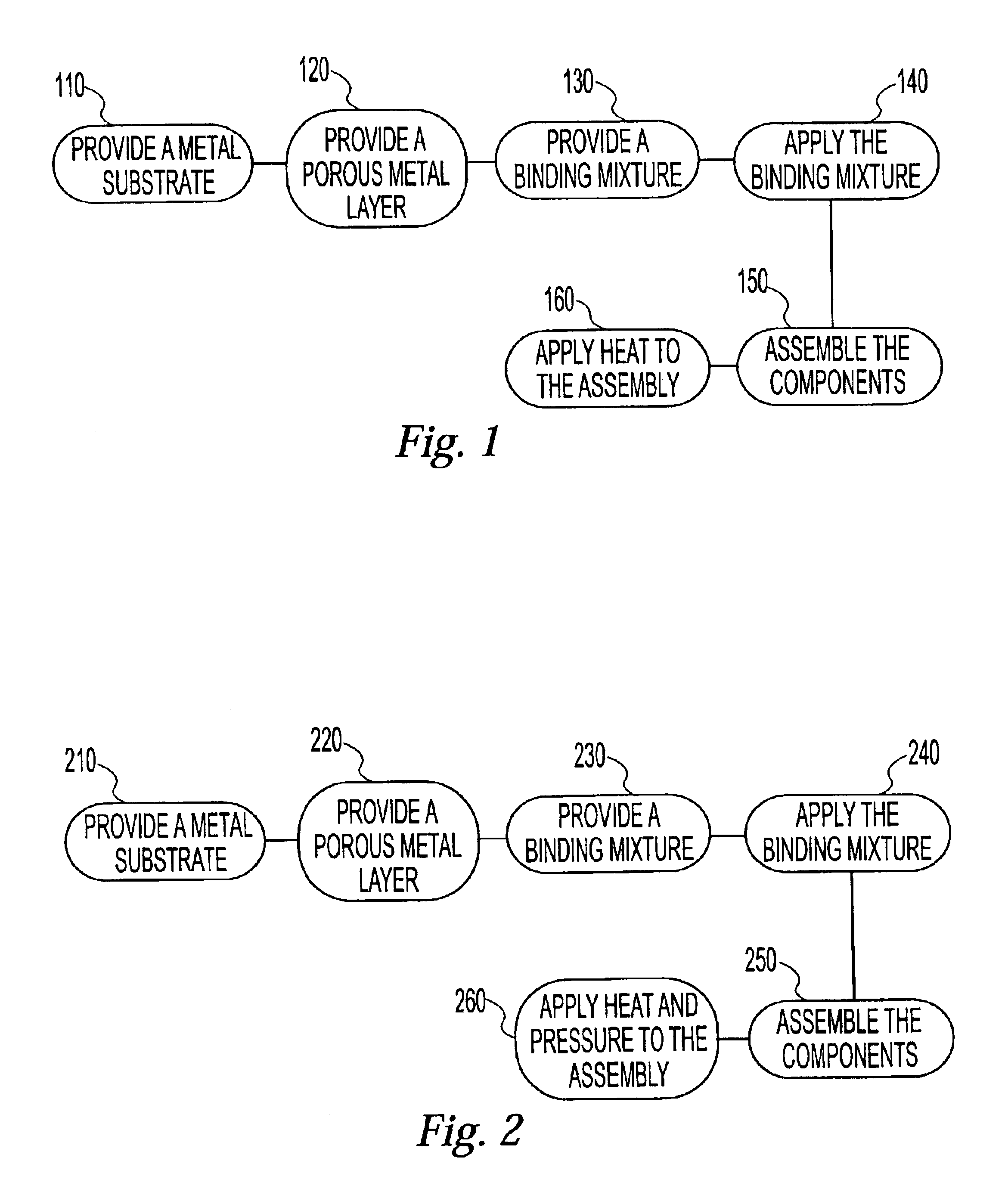

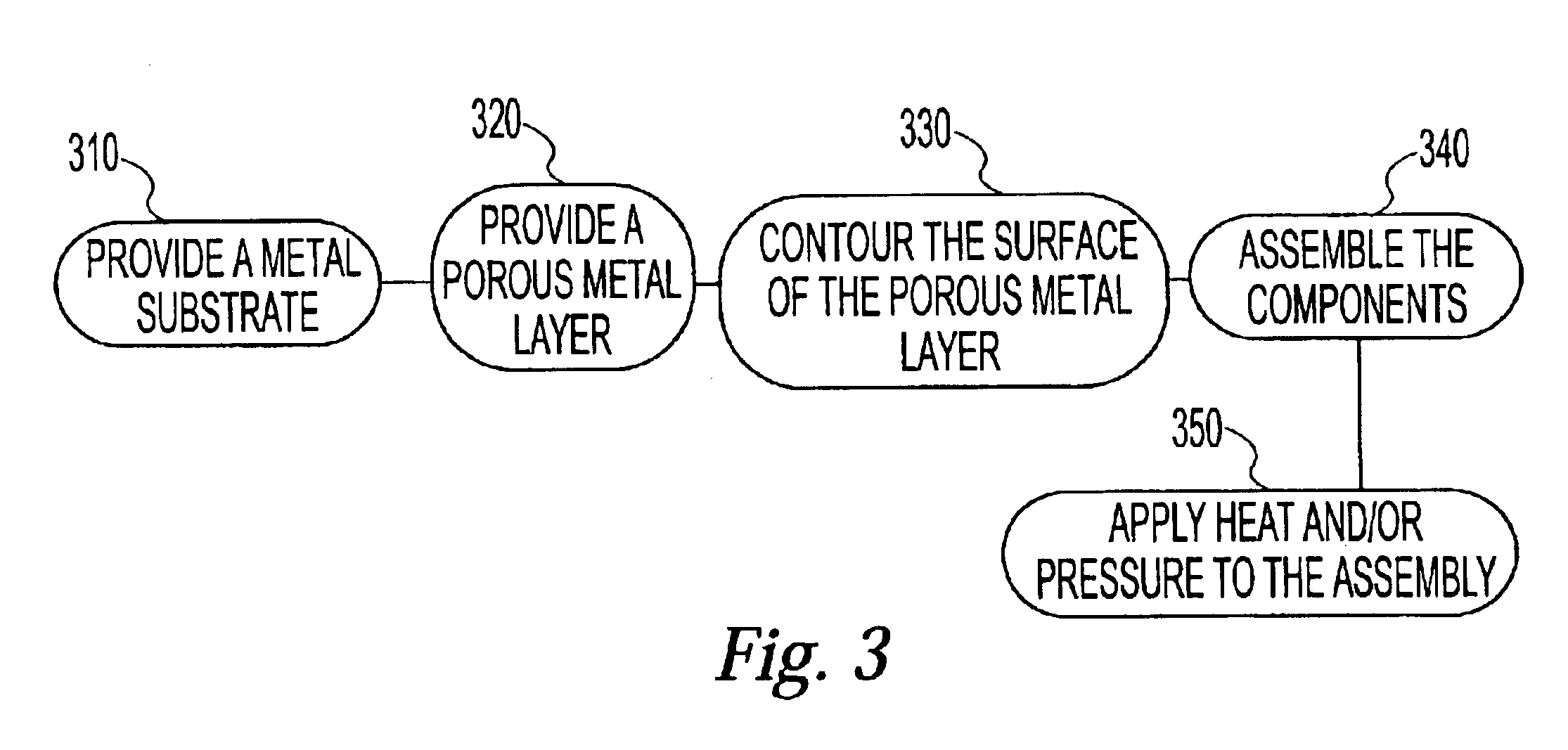

Method for attaching a porous metal layer to a metal substrate

InactiveUS6945448B2Increase resistanceHigh strengthImpression capsPretreated surfacesPorous layerSurgical implant

A method for attaching a porous metal layer to a dense metal substrate, wherein the method is particularly useful in forming orthopedic implants such as femoral knee components or acetabular cups. The method, in one embodiment thereof, comprises providing a structured porous layer; providing a dense metal substrate; providing a binding mixture; applying the binding mixture to the exterior of the substrate; placing the porous layer against the substrate such that the binding mixture is disposed there between forming an assembly; and heat treating the assembly to metallurgically bond the porous layer to the substrate.

Owner:ZIMMER TECH INC

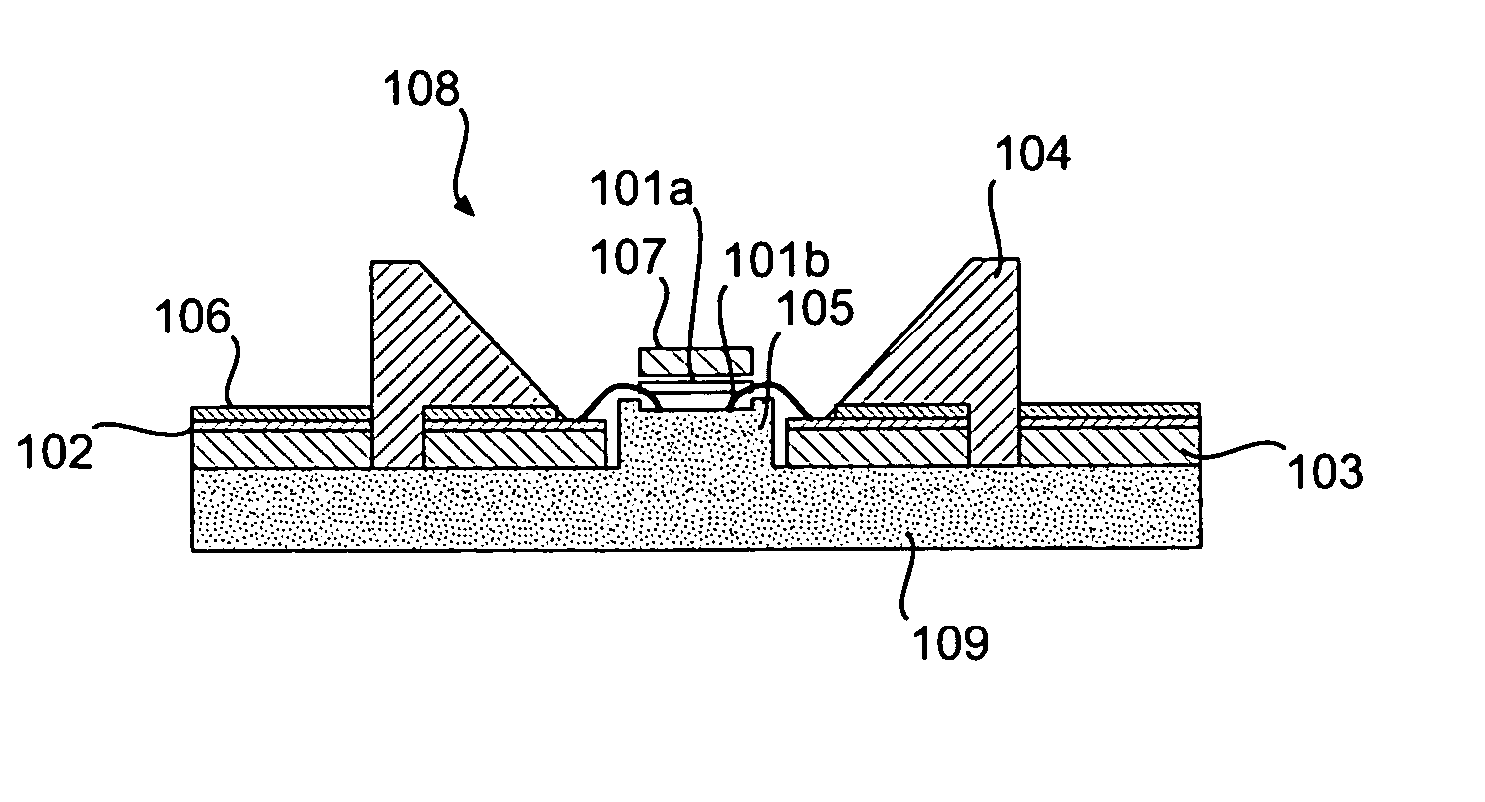

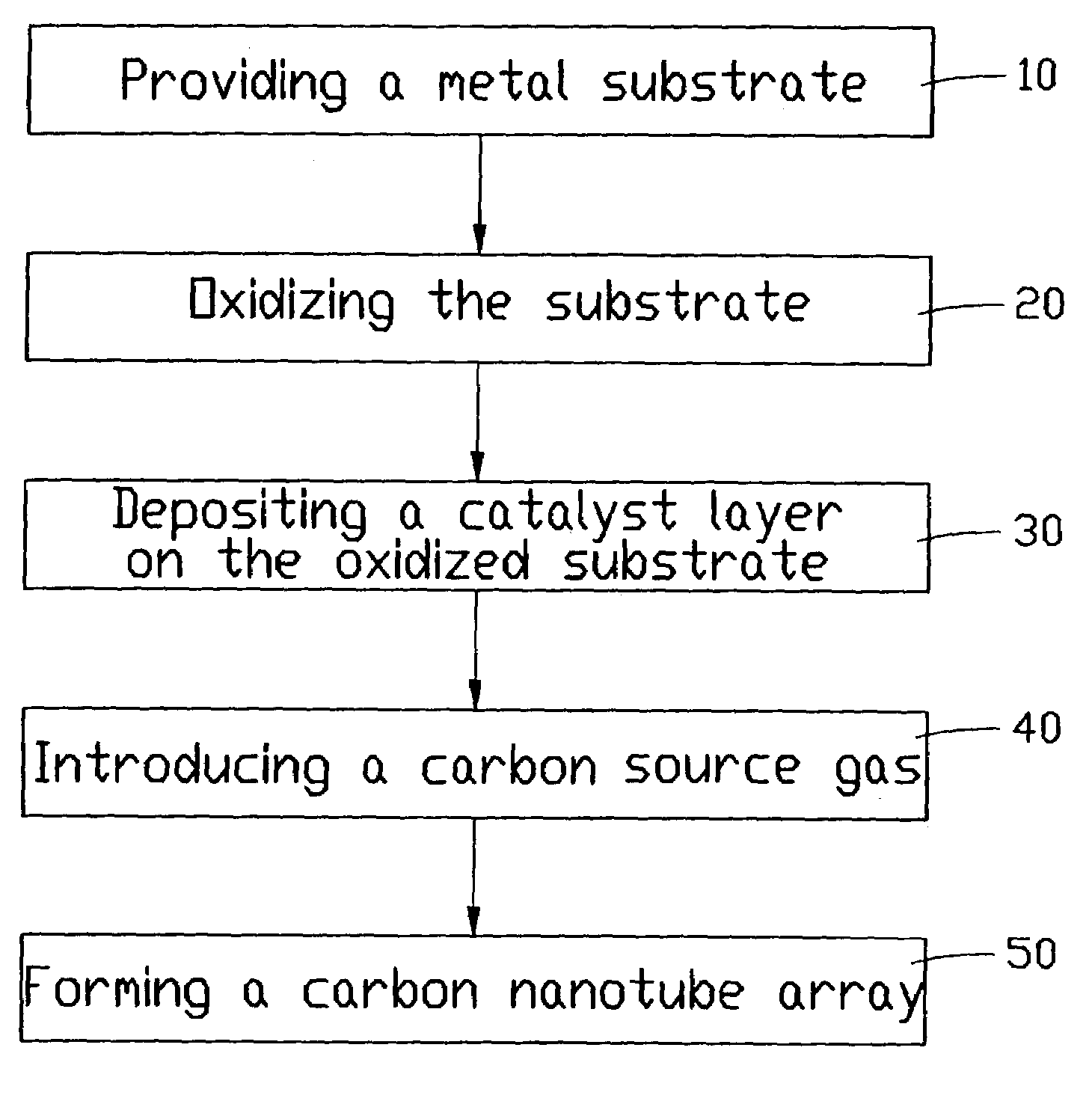

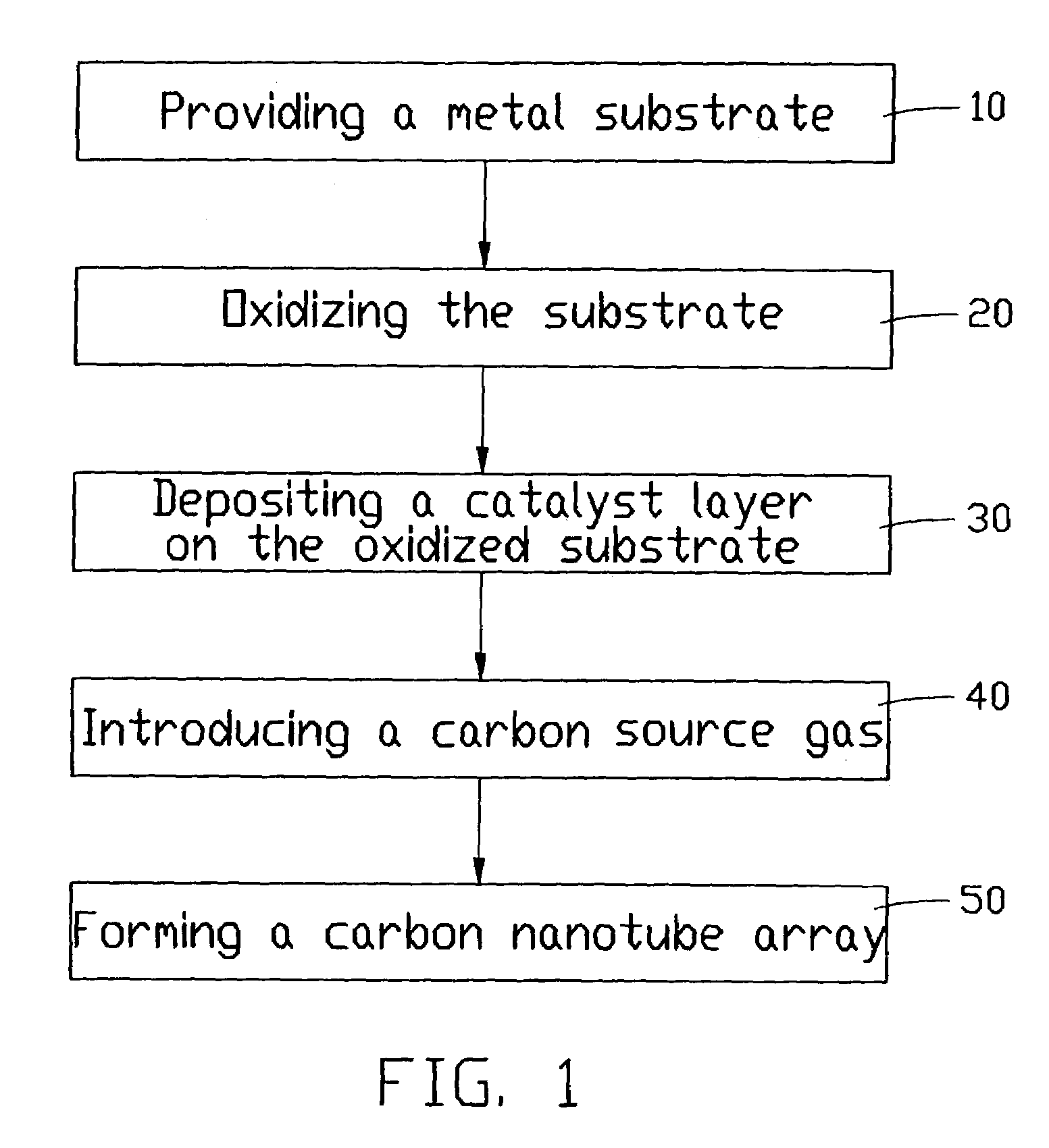

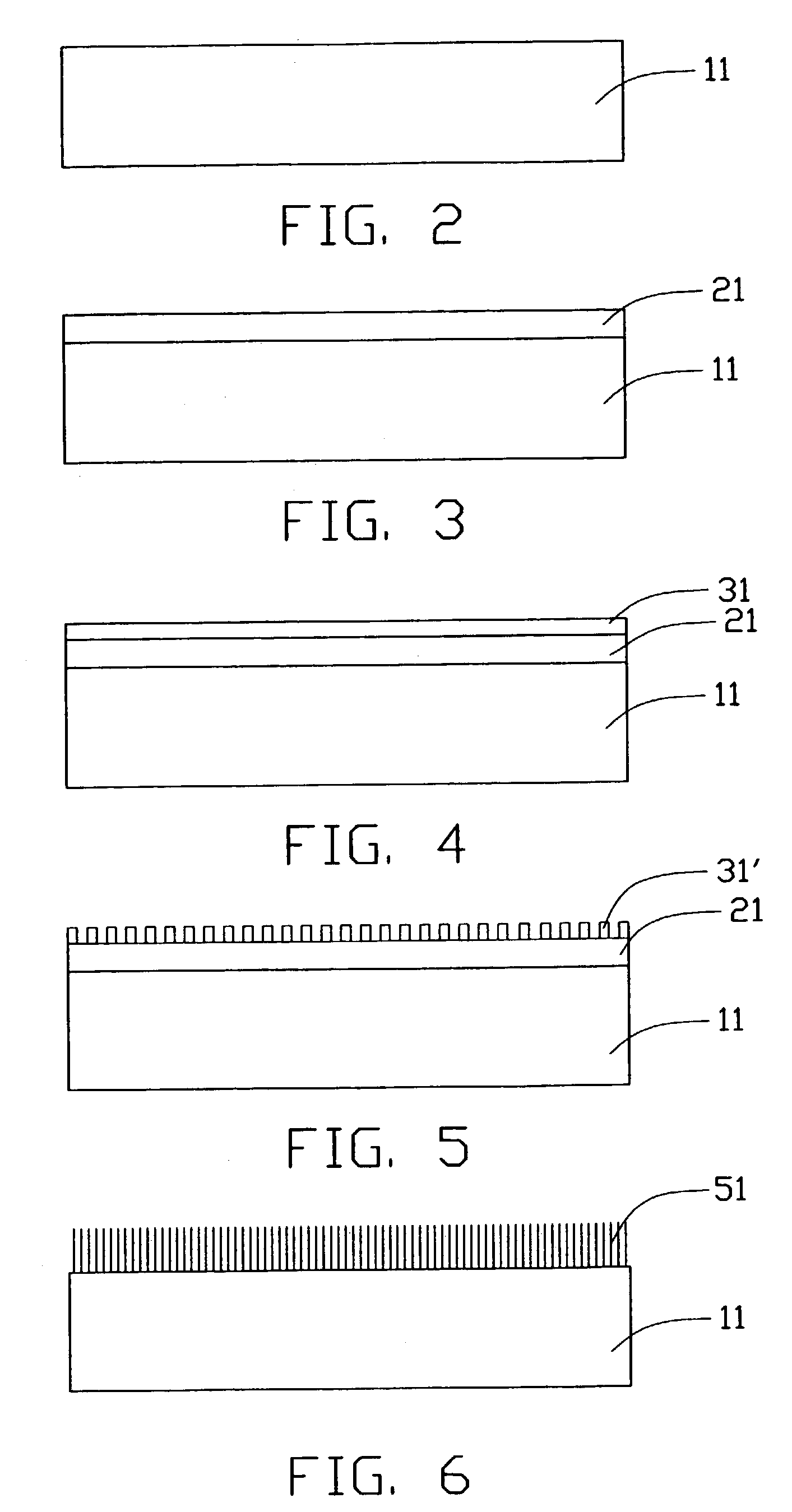

Carbon nanotube array and method for forming same

ActiveUS7160532B2Damage formationInhibition formationMaterial nanotechnologyFibre chemical featuresField emission deviceCarbon nanotube

A method for forming a carbon nanotube array using a metal substrate includes the following steps: providing a metal substrate (11); oxidizing the metal substrate to form an oxidized layer (21) thereon; depositing a catalyst layer (31) on the oxidized layer; introducing a carbon source gas; and thus forming a carbon nanotube array (61) extending from the metal substrate. Generally, any metallic material can be used as the metal substrate. Various carbon nanotube arrays formed using various metal substrates can be incorporated into a wide variety of high power electronic device applications such as field emission devices (FEDs), electron guns, and so on. Carbon nanotubes formed using any of a variety of metal substrates are well aligned, and uniformly extend in a direction substantially perpendicular to the metal substrate.

Owner:TSINGHUA UNIV +1

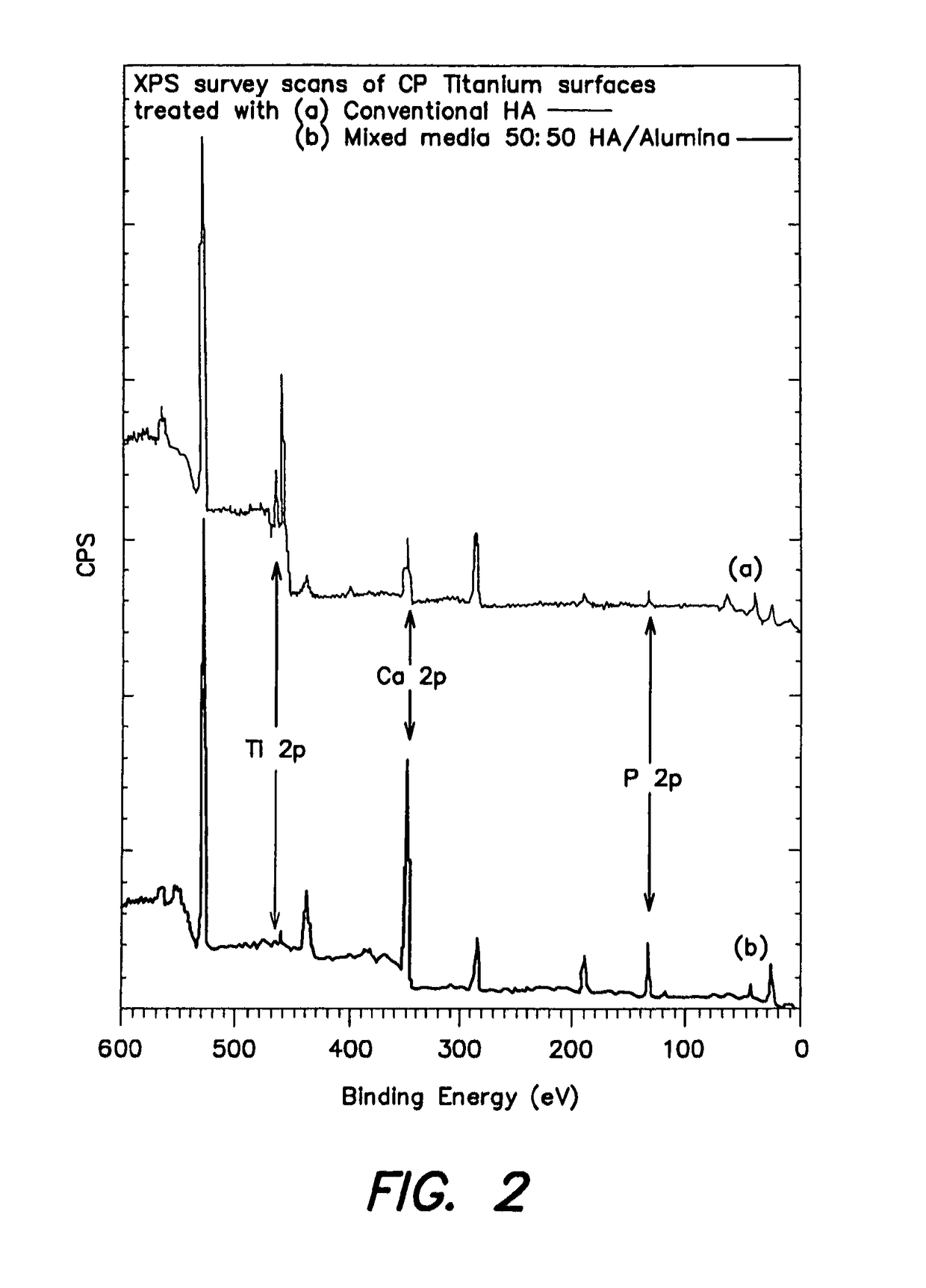

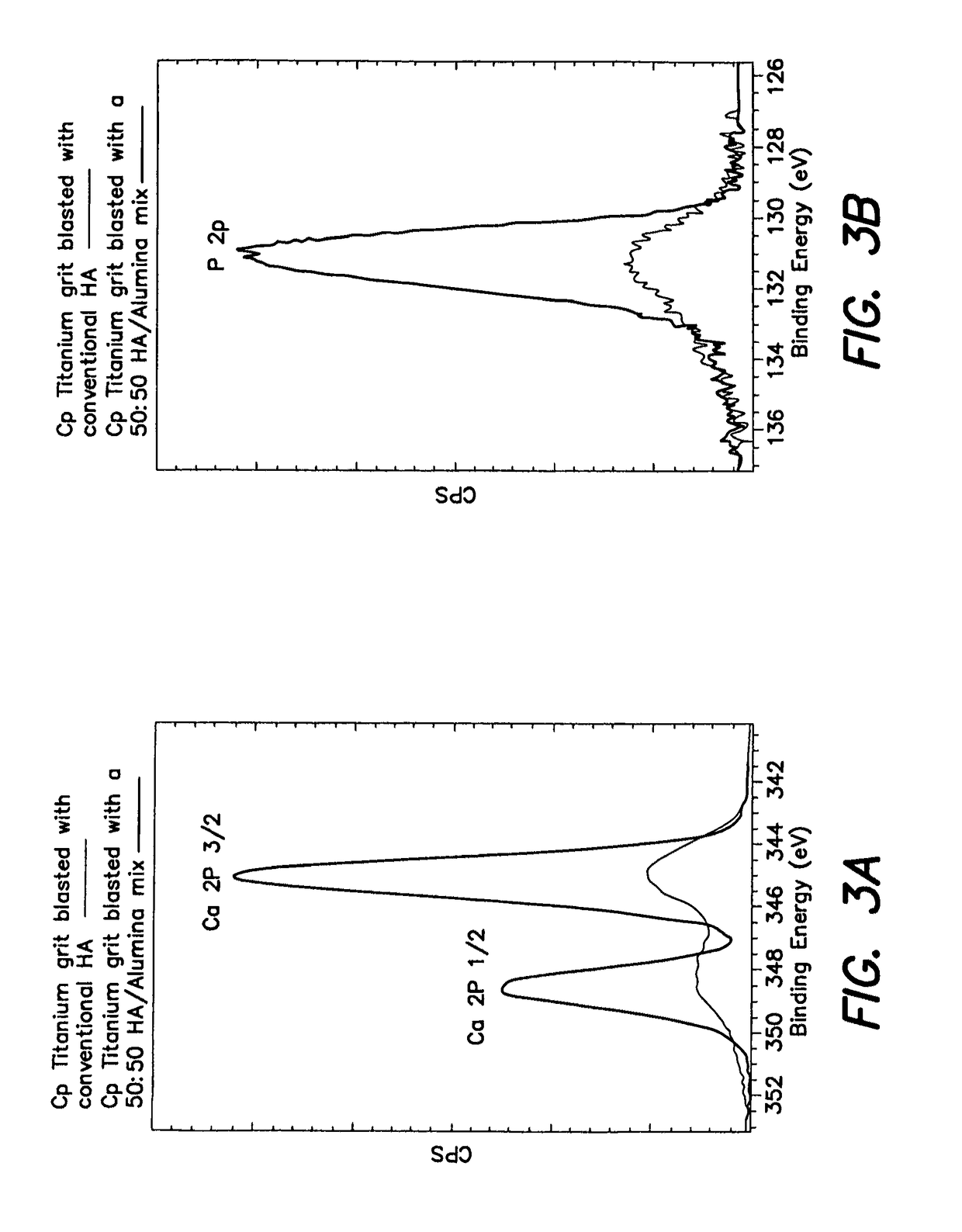

Method of doping surfaces

Disclosed herein are methods of treating an article surface. The method comprises removing a metal oxide surface from the metal substrate to expose a metal surface; and delivering particles comprising a dopant from at least one fluid jet to the metal surface to impregnate the surface of the article with the dopant. The method also comprises delivering substantially simultaneously a first set of particles comprising a dopant and a second set of particles comprising an abrasive from at least one fluid jet to a surface of an article to impregnate the surface of the article with the dopant.

Owner:ENBIO

Nanotube/metal substrate composites and methods for producing such composites

InactiveUS20060233692A1Simplified and advantageous mannerReduce productionSolar heating energyMaterial nanotechnologyHydrogen fuel cellChemical vapor deposition

Carbon nanotubes are grown directly on metal substrates using chemical vapor deposition. Metal substrates are comprised of catalysts which facilitate or promote the growth of carbon nanotubes. The nanotube coated metal substrates have applications including, but not limited to, heat transfer and thermal control, hydrogen storage, fuel cell catalytic reformers, electronics and semiconductors, implantable medical devices or prostheses, and tribological wear and protective coatings.

Owner:MAINSTREAM ENG

Light emitting assembly with heat dissipating support

InactiveUS20050122018A1Low costImprove cooling effectPoint-like light sourceDischarge tube main electrodesLight reflectionEngineering

A light emitting assembly includes a metal substrate for dissipating heat from the assembly. The metal substrate includes an electrically insulating layer or coating on at least one side. Circuit traces are applied to the electrically insulating layer using either thick or thin film techniques. At least the ends of the circuit traces include a metallic section to which leads of light emitting elements are soldered or wire-bonded. A metallic section is provided adjacent the light emitting element to transfer heat to the underlying substrate and / or to reflect light from the element away from the substrate. A clear finish retards tarnishing of the reflecting metallic section.

Owner:INT RESISTIVE OF TEXAS

Bisphenol a and aromatic glycidyl ether-free coatings

ActiveUS20070036903A1Good metal substrateGood inter-coat adhesionLiquid surface applicatorsSynthetic resin layered productsPolyesterMeth-

Disclosed are Bisphenol A (BPA), Bisphenol F, Bisphenol A diglycidyl ether (BADGE), and Bisphenol F diglycidyl ether (BFDGE)-free coating compositions for metal substrates including an under-coat composition containing a polyester (co)polymer, and an under-coat cross-linker; and an over-coat composition containing a poly(vinyl chloride) (co)polymer dispersed in a substantially nonaqueous carrier liquid, an over-coat cross-linker, and a functional (meth)acrylic (co)polymer. Also provided is a method of coating a metal substrate using the BPA, BPF, BADGE and BFDGE-free coating system to produce a hardened protective coating useful in fabricating metal storage containers. The coated substrate is particularly useful in fabricating multi-part foodstuffs storage containers with “easy-open” end closures.

Owner:SWIMC LLC

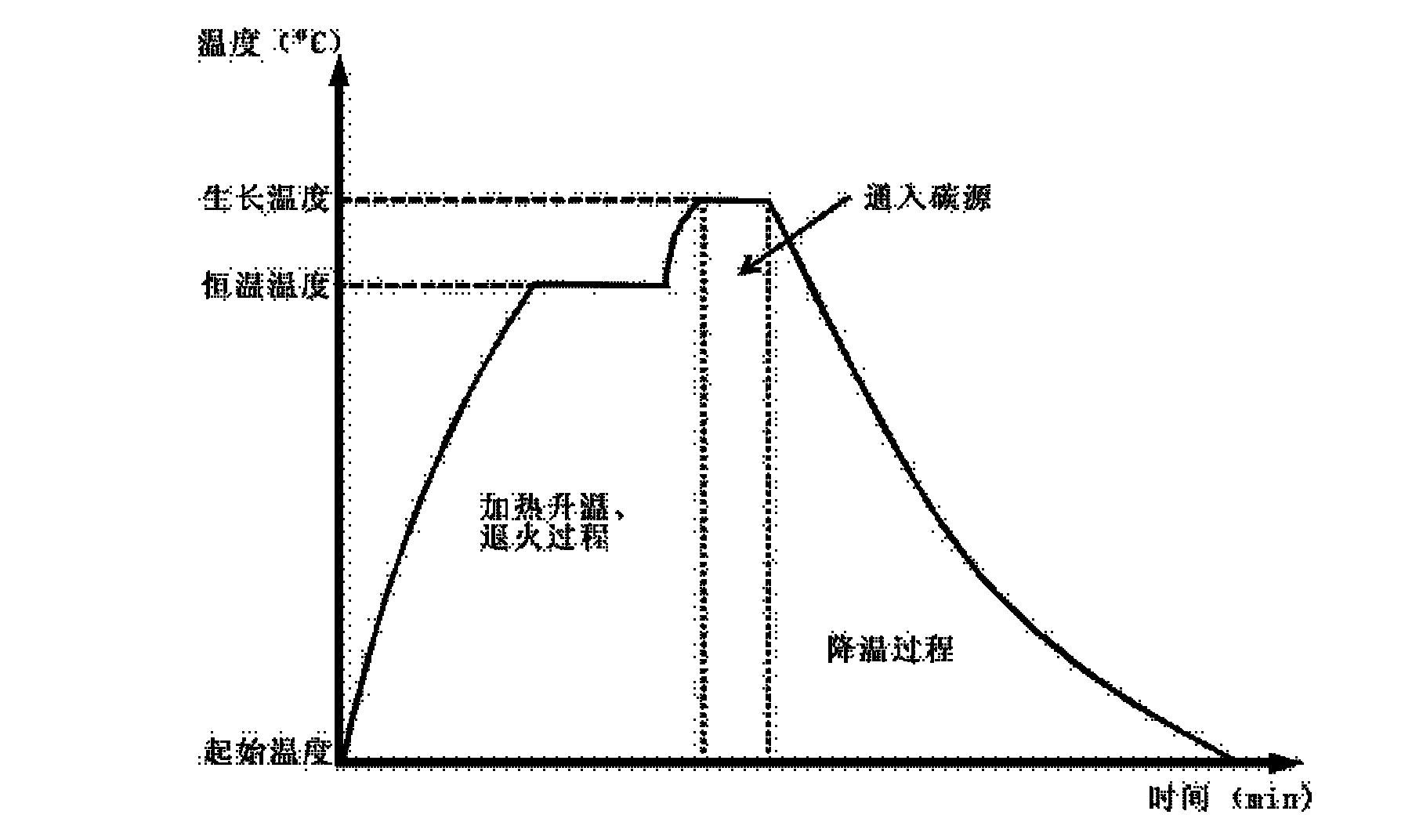

Method for preparing single-layer graphene

The invention discloses a method for preparing single-layer graphene. The method comprises the following steps of: 1) preparing an alloy substrate; and 2) in the hydrogen and inert atmosphere, catalyzing to grow graphene on the surface of the alloy substrate obtained in the step 1) by a chemical vapor deposition method, thereby finishing the preparation of the single-layer graphene. The method makes use of the characteristics of two or more alloy metals in the alloy substrate, realizes control on the decomposition, diffusion and precipitation processes of a carbon source, simply and efficiently restrains the precipitation process of carbon dissolved in the metal substrate to enable the graphene to be capable of growing in a surface catalytic manner to obtain the single-layer graphene withuniform layer distribution, and is suitable for industrial production and particularly for the controllable preparation of single-layer or few-layer graphene.

Owner:PEKING UNIV

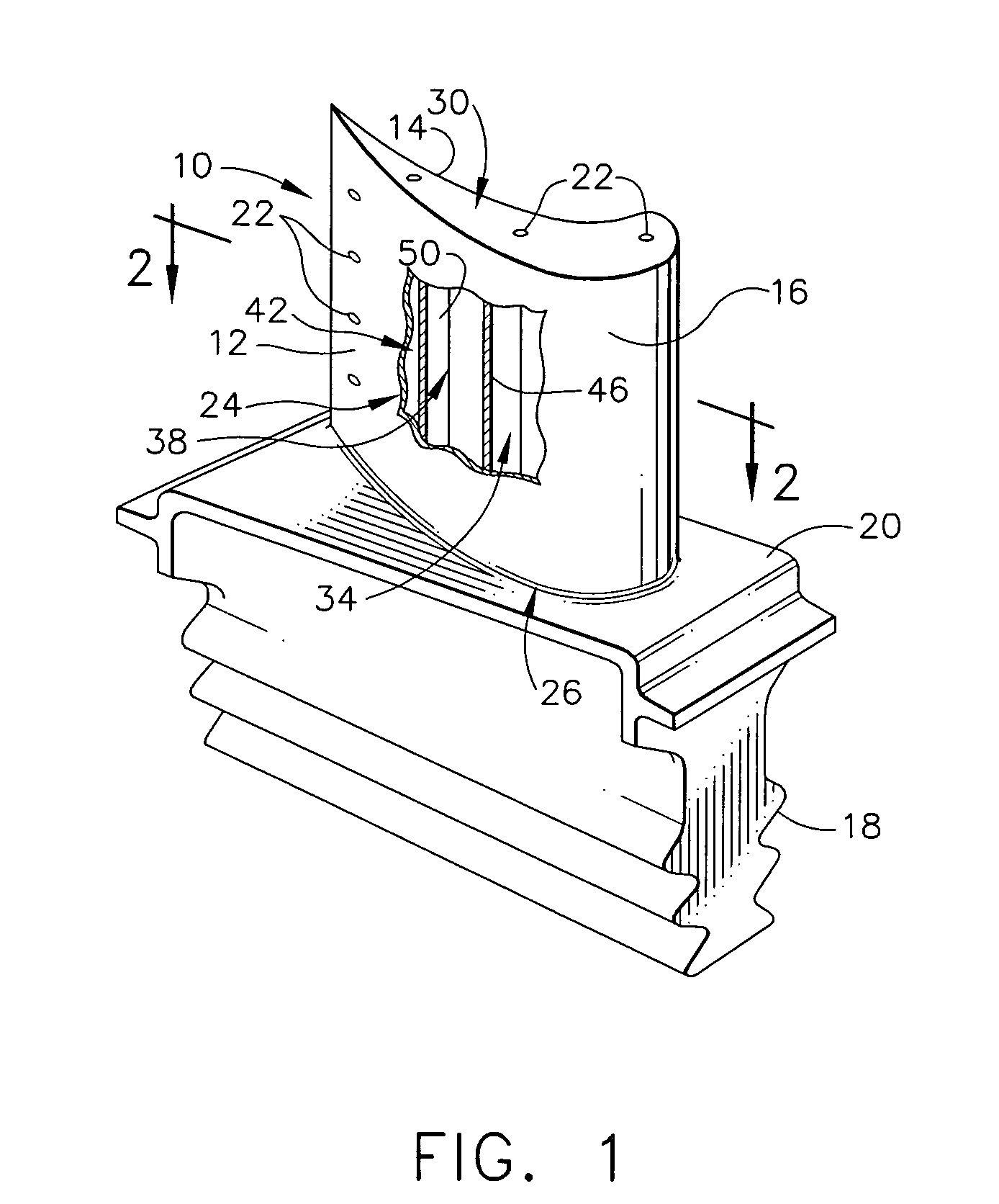

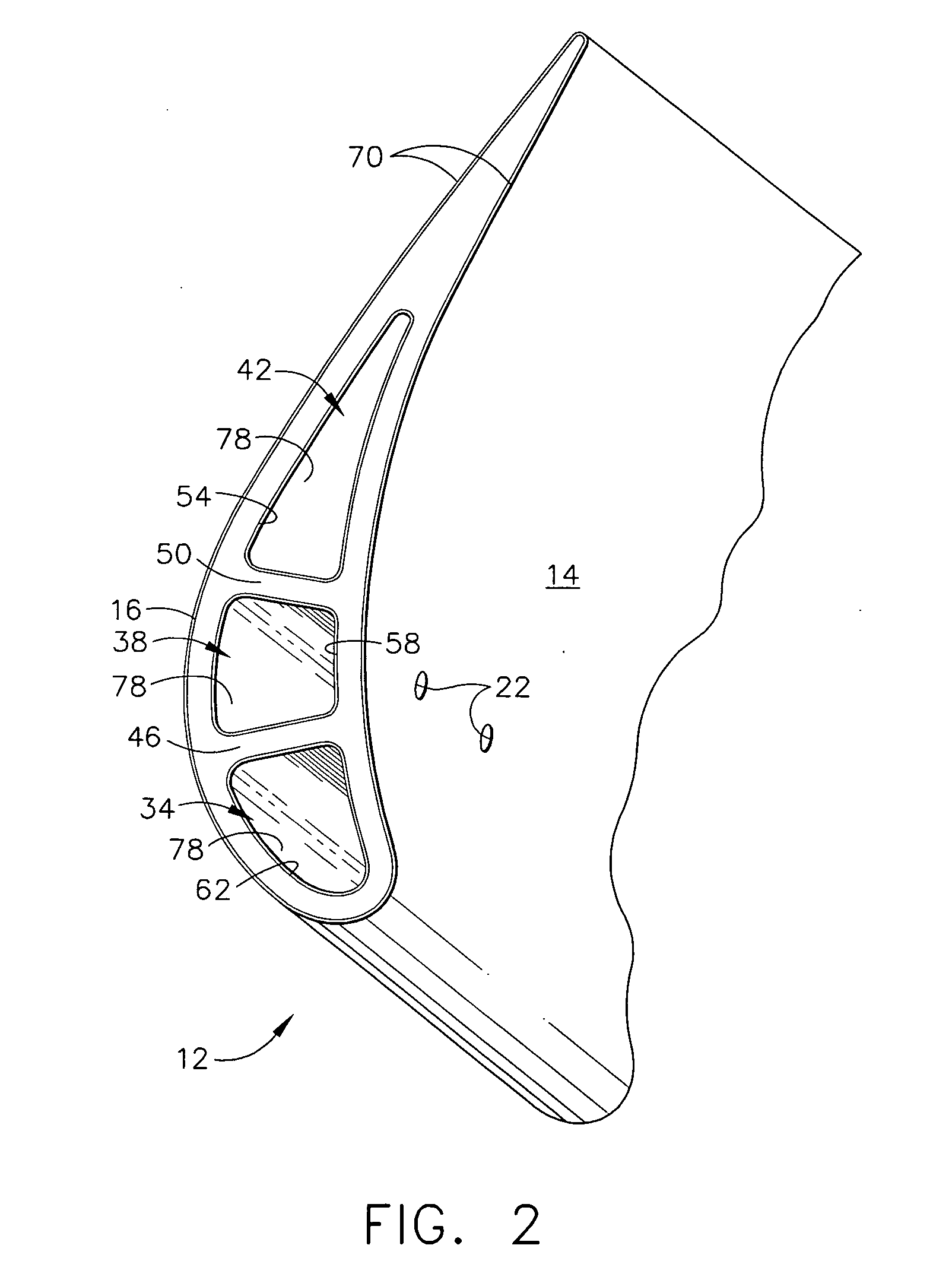

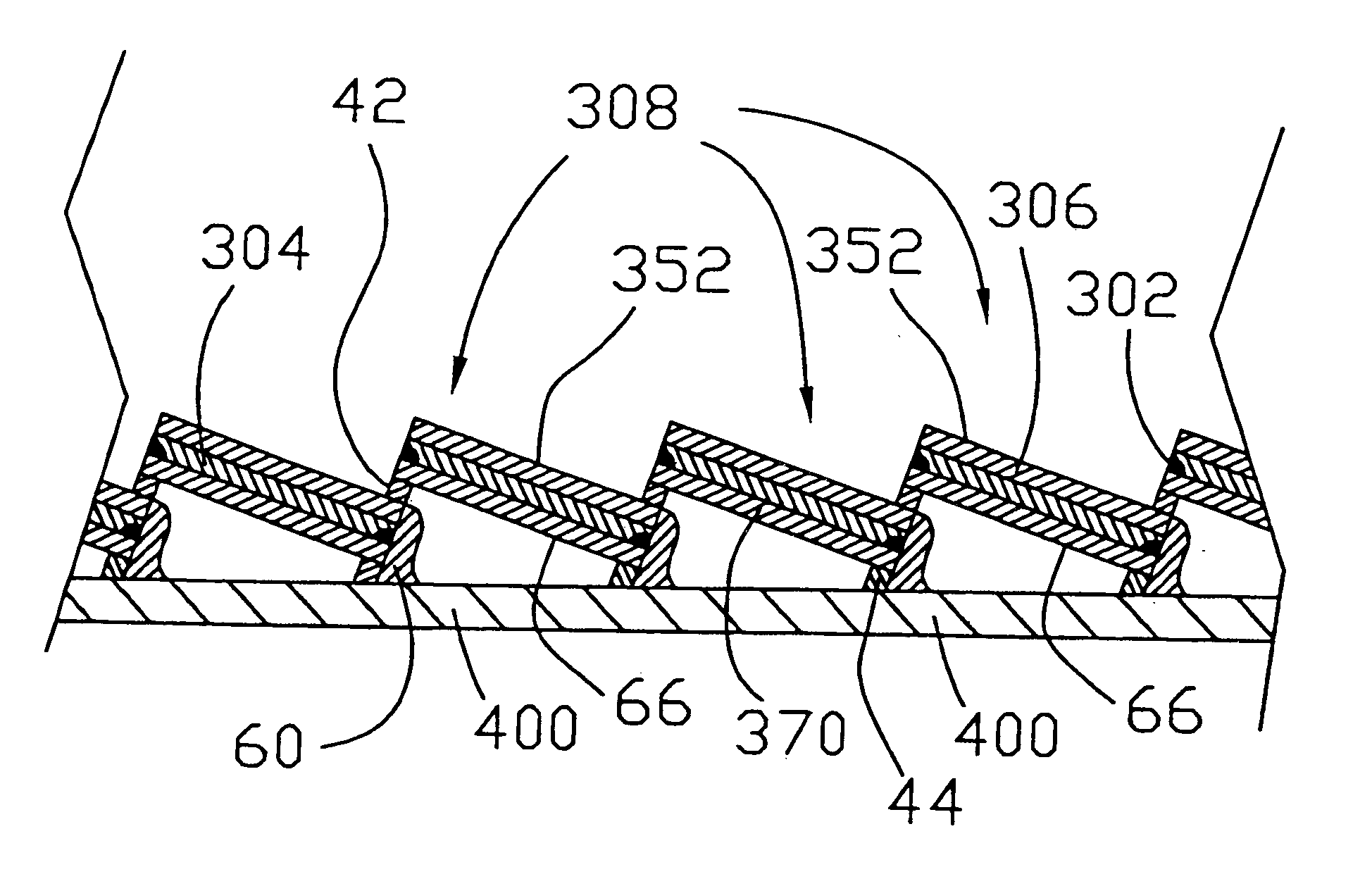

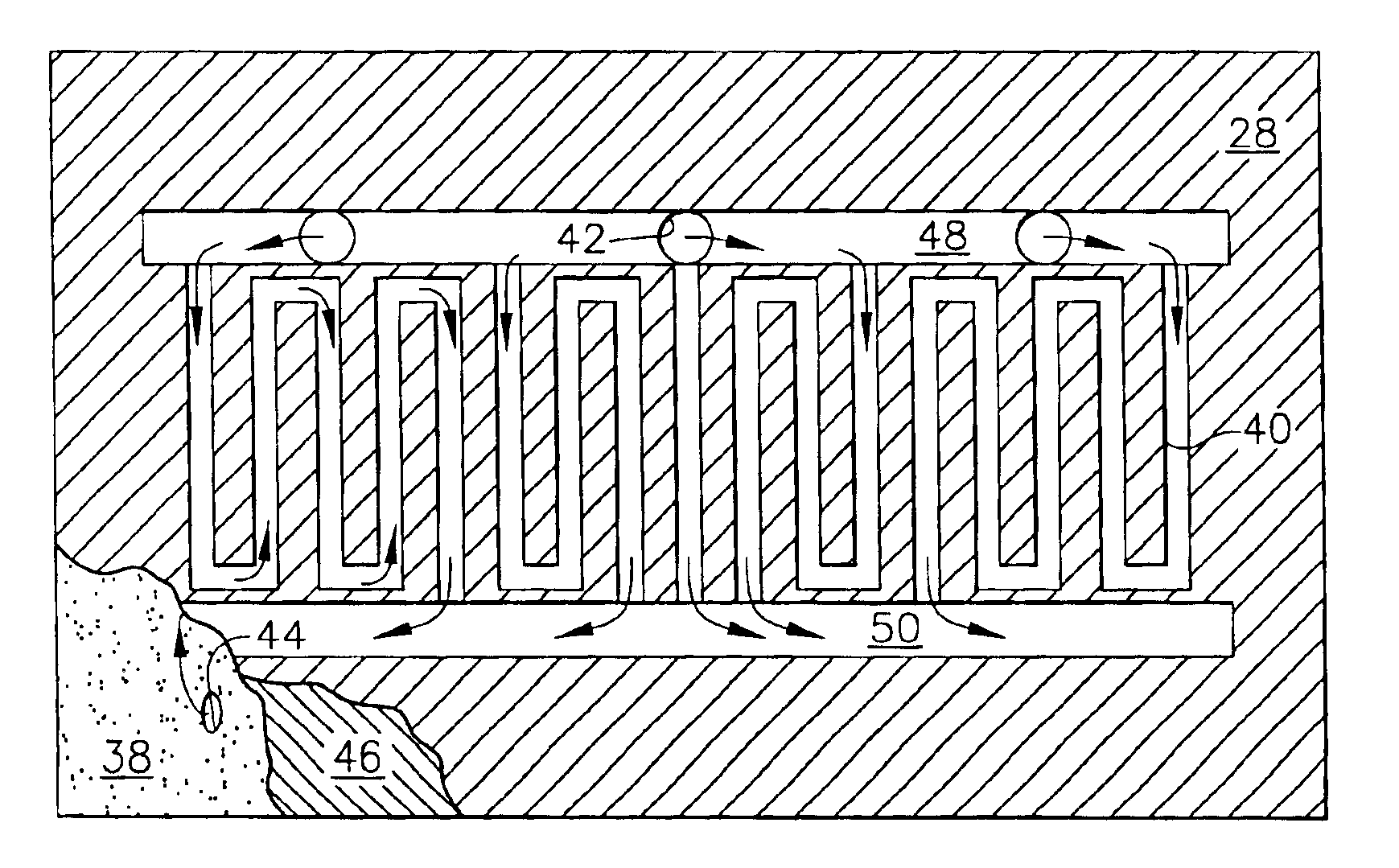

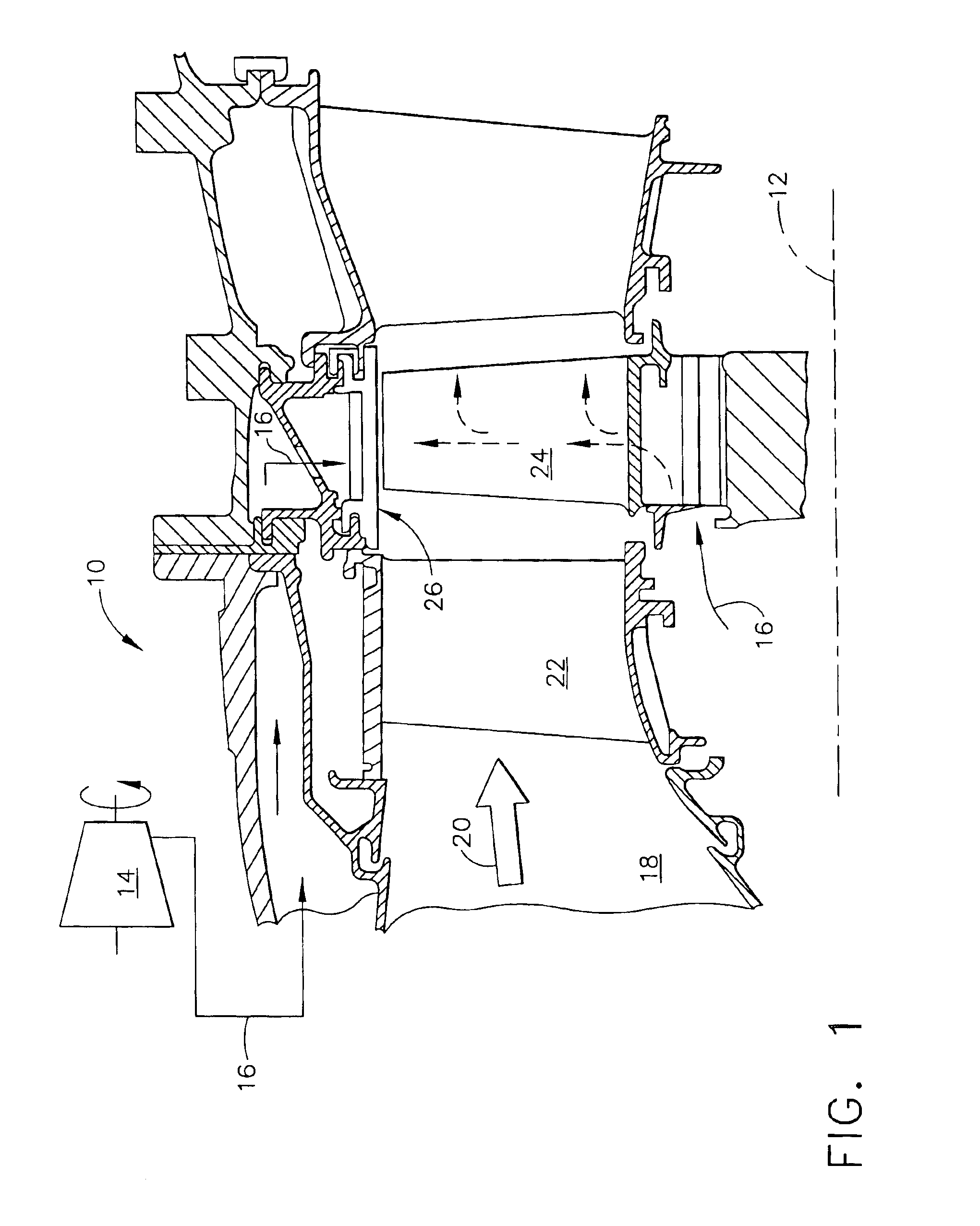

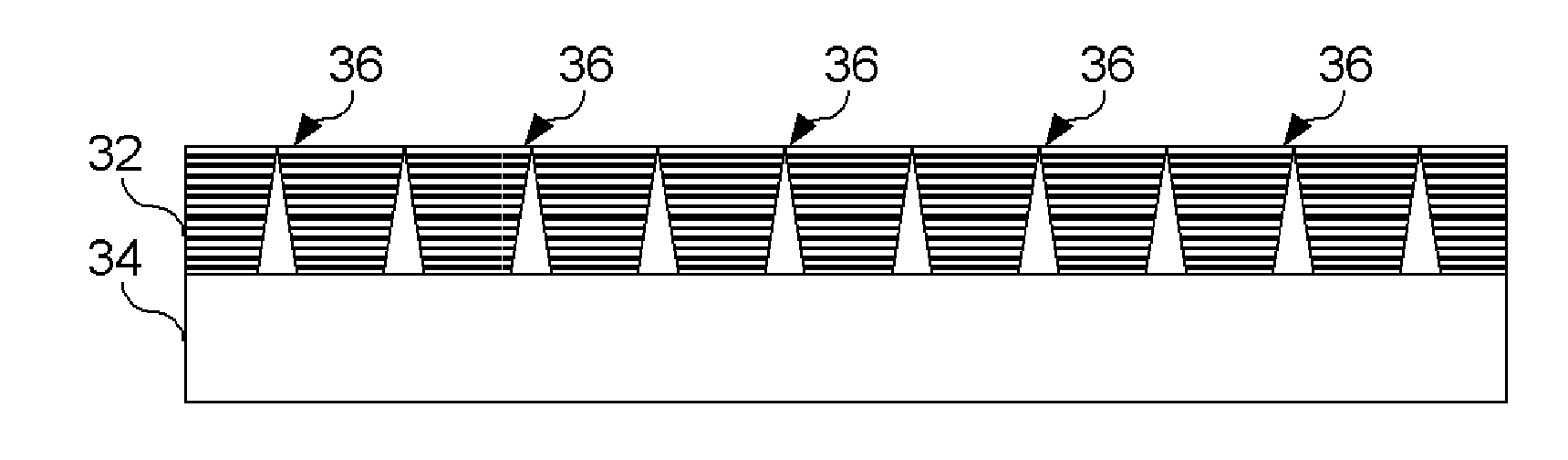

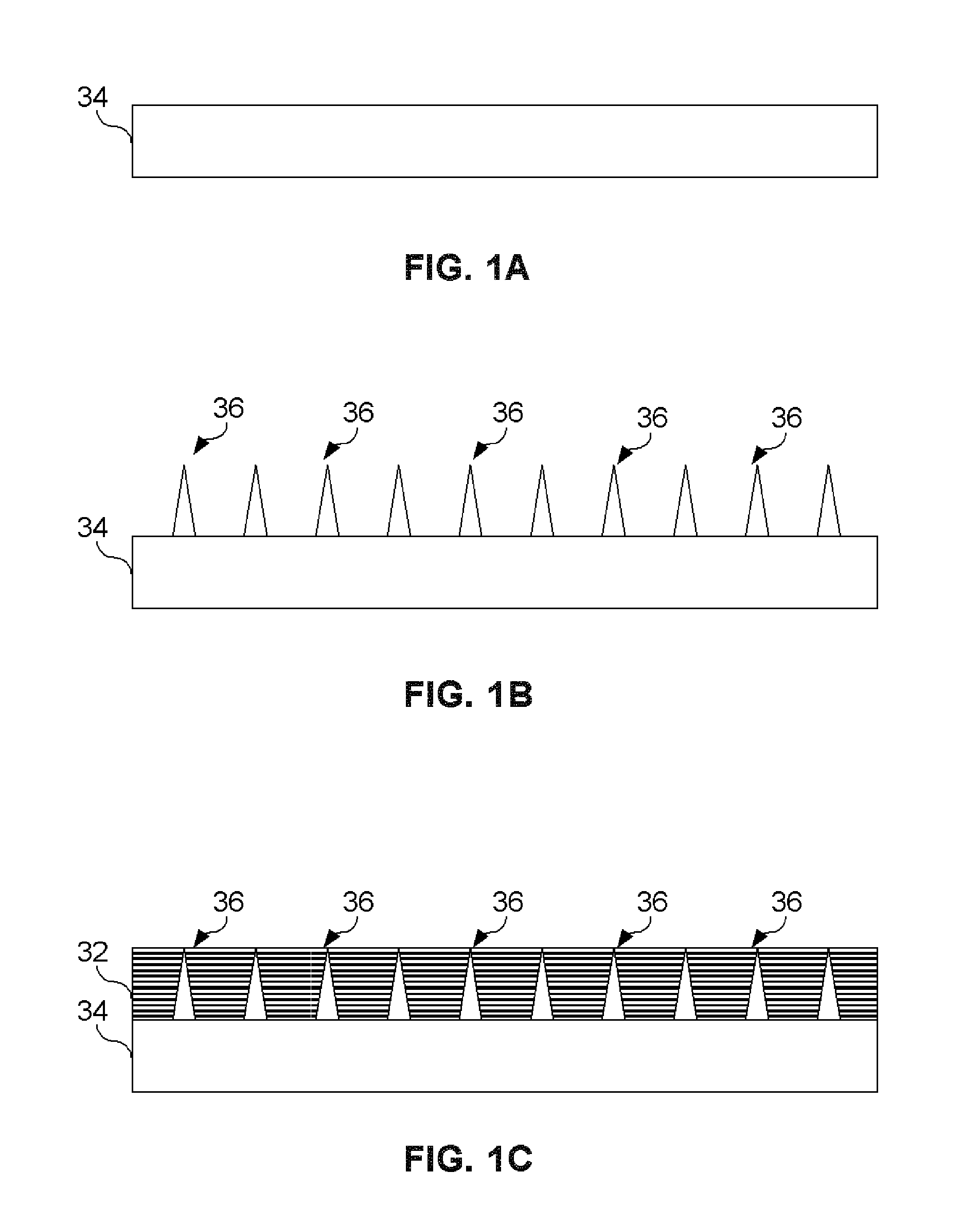

Network cooled coated wall

A turbine wall includes a metal substrate having front and back surfaces. A thermal barrier coating is bonded atop the front surface. A network of flow channels is laminated between the substrate and the coating for carrying an air coolant therebetween for cooling the thermal barrier coating.

Owner:GENERAL ELECTRIC CO

Pretreatment compositions and methods for coating a metal substrate

ActiveUS20090032144A1Sufficient amountElectrophoretic coatingsSolid state diffusion coatingPre treatmentMetal substrate

Disclosed are methods for treating metal substrates, including ferrous substrates, such as cold rolled steel and electrogalvanized steel. The methods include contacting the substrate with a pretreatment composition that includes: (a) a group IIIB and / or IVB metal; (b) free fluorine; (c) a metal fluoride salt formed from a metal which forms a fluoride salt having a pKsp of at least 11; and (d) water.

Owner:PPG IND OHIO INC

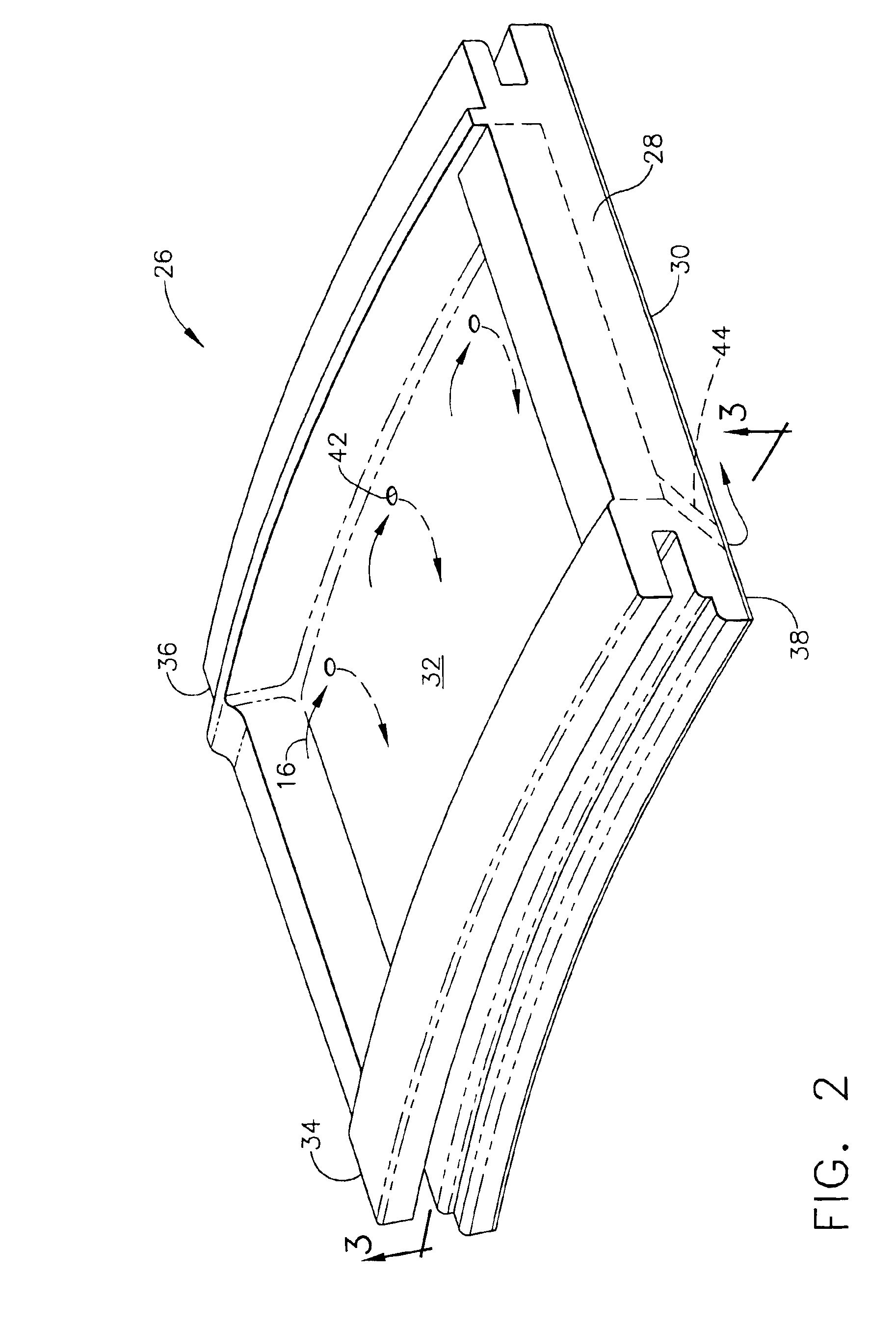

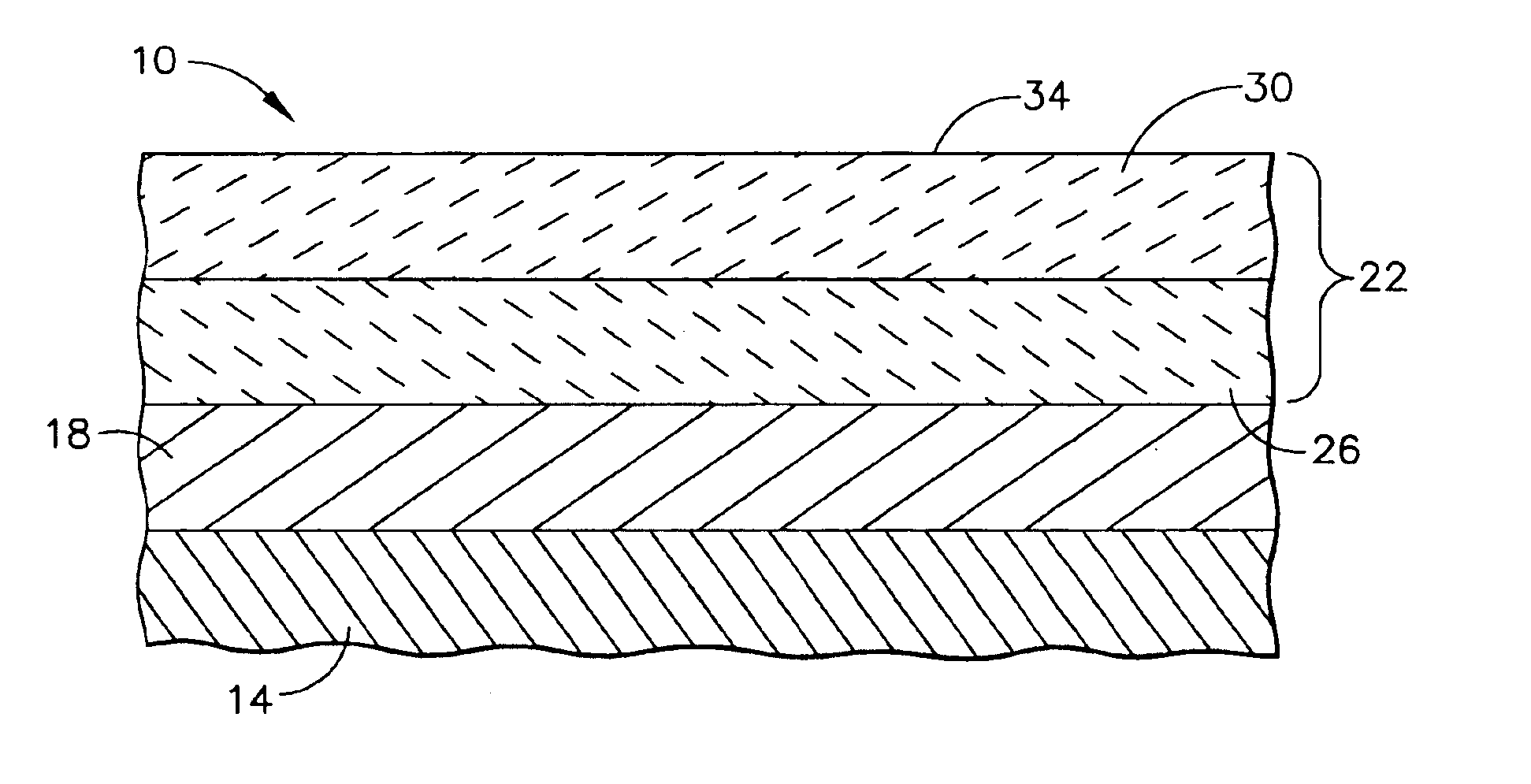

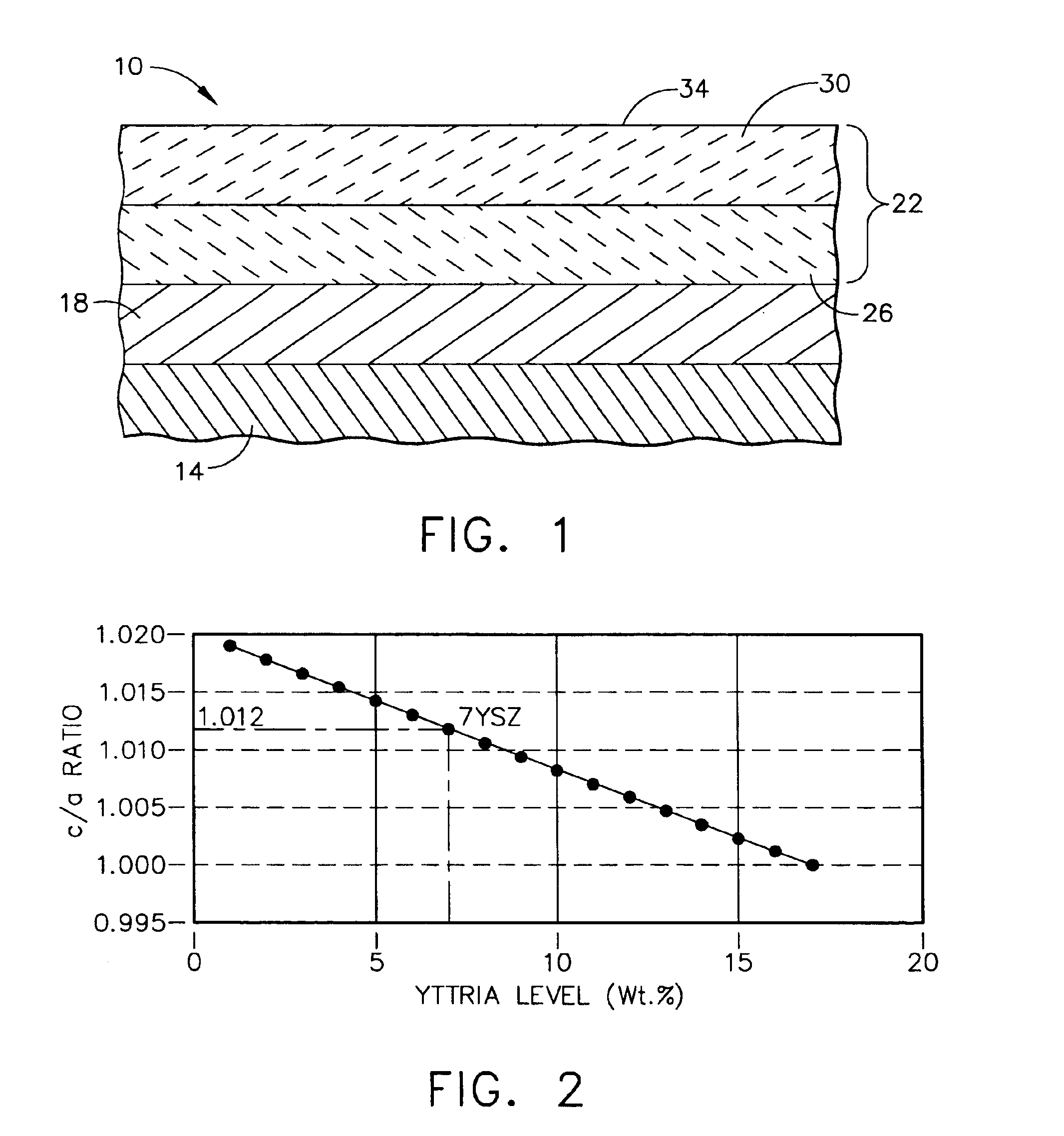

Thermal barrier coatings with protective outer layer for improved impact and erosion resistance

InactiveUS6875529B1Improve erosion resistanceImprove impact resistanceMolten spray coatingVacuum evaporation coatingBond coatMetallic substrate

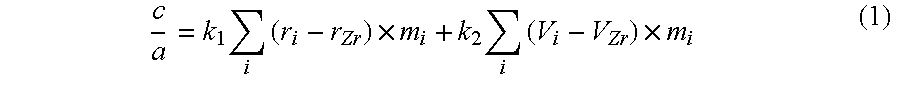

A reduced thermal conductivity thermal barrier coating having improved impact and erosion resistance for an underlying metal substrate of articles that operate at, or are exposed to, high temperatures. This coating comprises an inner layer nearest to the underlying metal substrate comprising a ceramic thermal barrier coating material, as well as a protective outer layer adjacent to and overlaying the inner layer and having an exposed surface. The outer layer has a thickness up to about 5 mils (127 microns) sufficient to impart impact and erosion resistance to the thermal barrier coating, and comprises a zirconia-containing ceramic composition having a c / a ratio of the zirconia lattice in the range of from about 1.011 to about 1.016 and stabilized in the tetragonal phase by a stabilizing amount of a stabilizing metal oxide selected from the group consisting of yttria, calcia, ceria, scandia, magnesia, india, ytterbia and mixtures thereof. This coating can be used to provide a thermally protected article having a metal substrate and optionally a bond coated layer adjacent to and overlaying the metal substrate. The thermal barrier coating can be prepared by forming the inner layer comprising the ceramic thermal barrier coating material, followed by forming on the inner layer the protective outer layer.

Owner:GENERAL ELECTRIC CO

Replaceable light emitting diode module

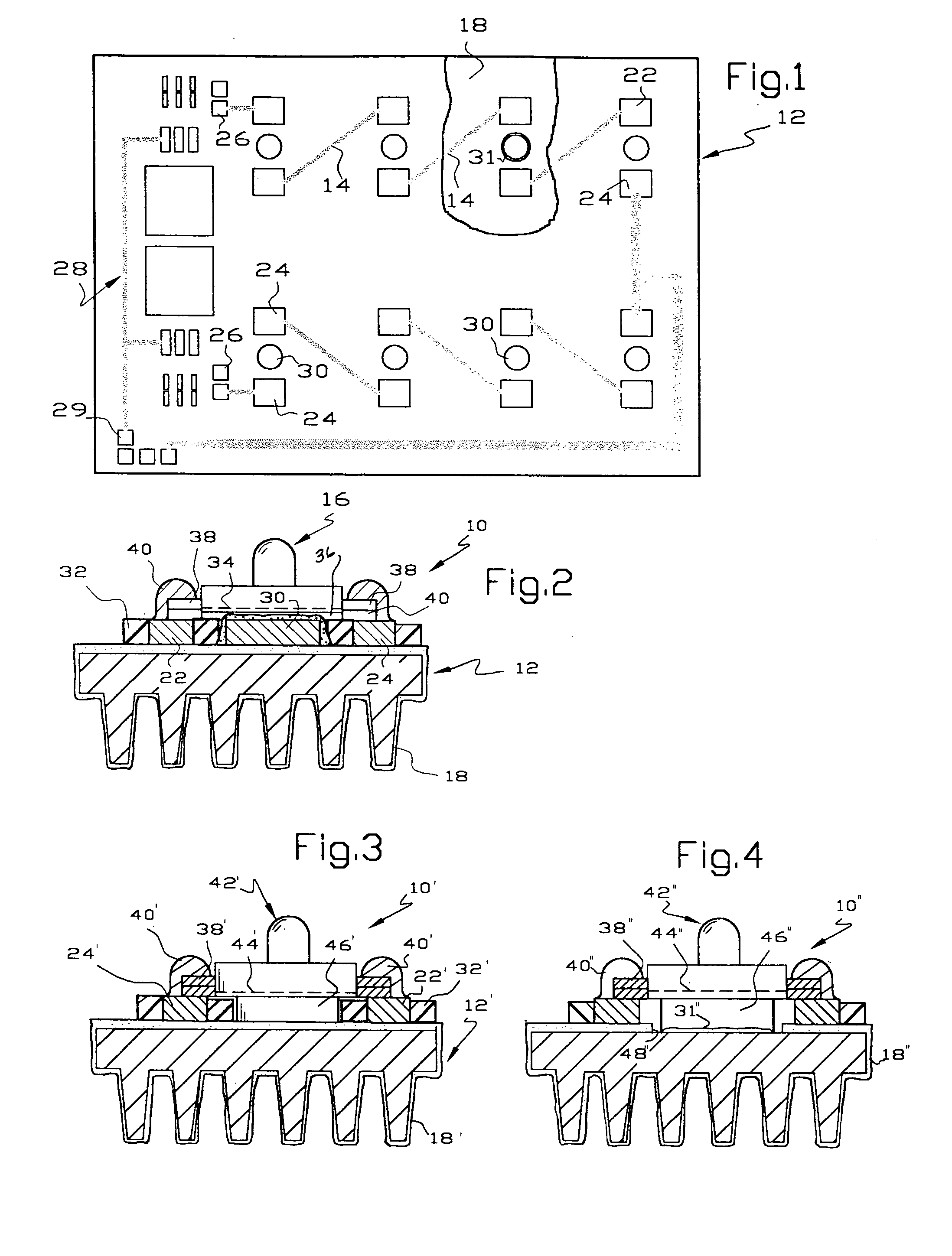

ActiveUS6998650B1Easy to replaceEasy to liftBus-bar/wiring layoutsPoint-like light sourceCouplingEngineering

A clip is used to clamp a LED in place in a LED module. The clip has pliable conducting cover and can be latched to the upper lead metal of the LED module. The clip can be lifted for replacing a defective or color LED. A plurality of replaceable LEDs can be mounted a common metal substrate to form a display panel, and each LED can be clamped in position with clips straddling between parallel upper lead metal for electrical coupling to the top electrodes of the LED.

Owner:CHENG KUNG CAPITAL LLC

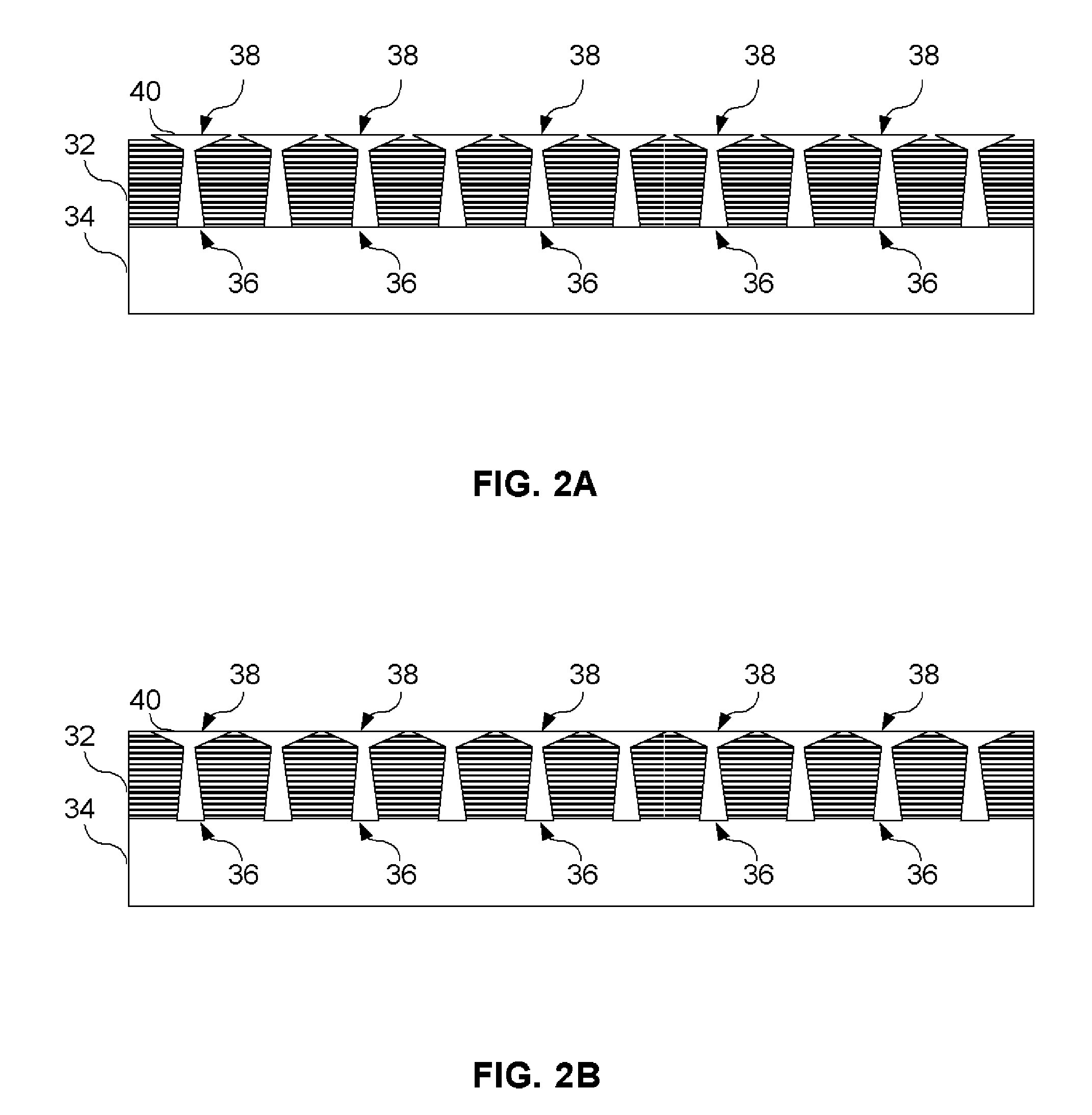

Metallic mini hooks for joining of metallic and composites

InactiveUS20080003401A1Bonding strengthGood mechanical bondLayered productsSheet joiningMetallic substrateMetal substrate

A method for joining a first structural member and a metallic substrate is provided. This method involves drawing projections from a metallic substrate using a Co-Meld or other like process. Individual plies of composite materials may be laid upon the metallic substrate and projections. These projections penetrate the individual ply or layers of the composite material. A mechanical feature that serves as a retaining device may be located at the distal end of the projections in order to prevent separation of the composite materials from the metallic substrate. The composite materials may be infused with a resin or other material to complete the formation of the composite material. Additionally, other layers of composite material may be placed over the mechanical features located at the distal ends.

Owner:LOCKHEED MARTIN CORP

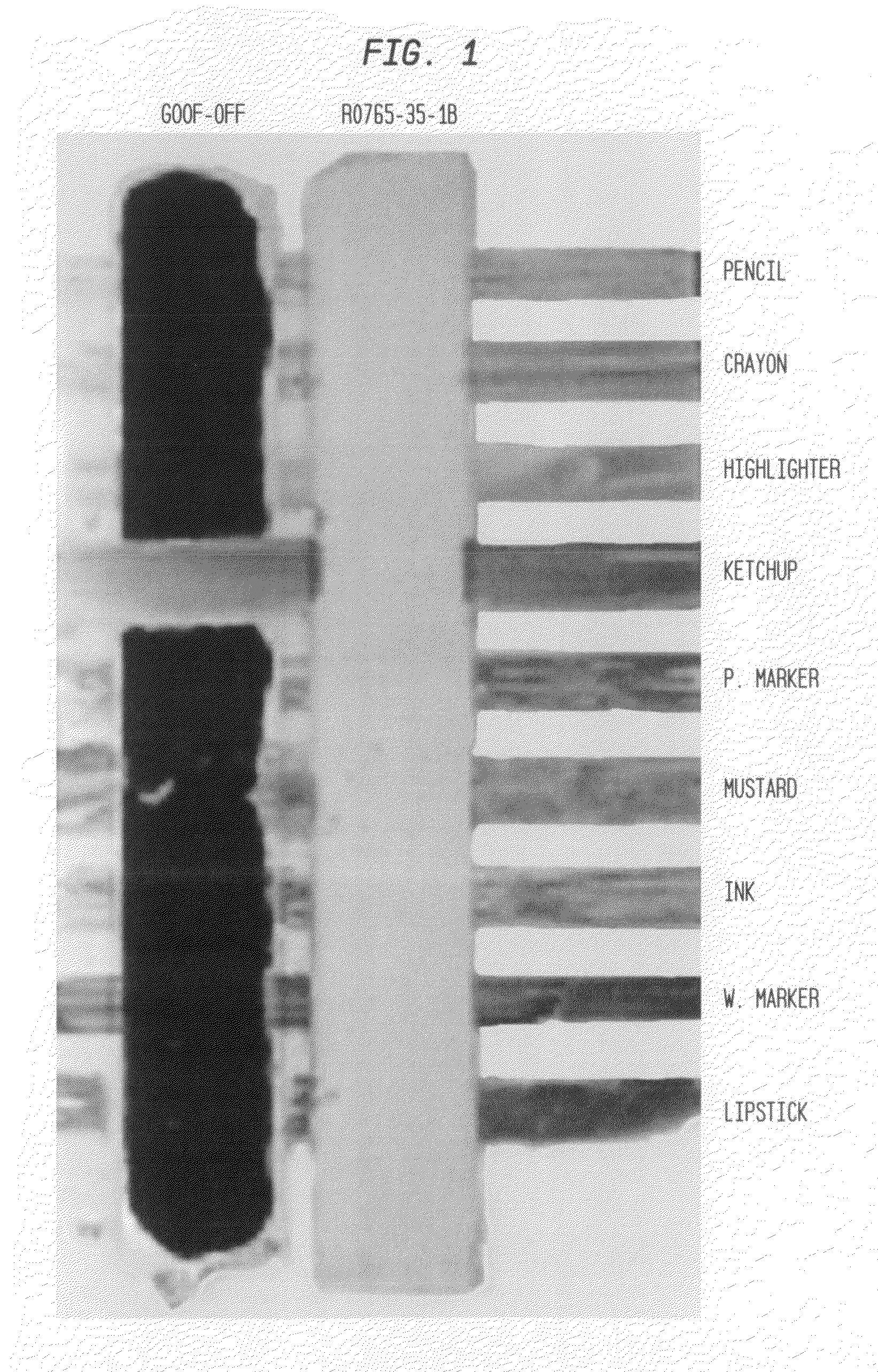

Cleaning compositions incorporating green solvents and methods for use

ActiveUS20090281012A1High flash pointLow vapor pressureOrganic detergent compounding agentsDetergent mixture composition preparationGlutaric acidActive agent

An environmentally-friendly cleaning composition for industrial and consumer applications comprising (a) a blend of dibasic esters, (b) one or more surfactants (c) and, optionally, (d) water or a solvent. The dibasic esters are be derived from a blend of adipic, glutaric, and succinic diacids, and, in one particular embodiment, the blend comprises dialkyl adipate, dialkyl methylglutarate and dialkyl ethylsuccinate, wherein the alkyl groups individually comprise a C1-C12 hydrocarbon group. The one or more surfactants are typically chosen from alcohol alkoxylate, an alkyl phenol ethoxylate, a terpene, a terpene alkoxylate or any derivates thereof. Optionally, additional components or additives including delaminates such as pinene and d-limonene, fragrances, whiteners, stabilizers, thickeners and the like can be added to the composition. The industrial or consumer application selected from the group consisting of a graffiti cleaner, a painted-substrate cleaner, an ink cleaner, a metal substrate cleaner, a plastic substrate cleaner, an environmentally friendly cleaner, a stain-spot cleaner, an industrial hand cleaner, a resin cleaner, a tar resin cleaner, a textile cleaner, a paint stripper and any combination thereof.

Owner:RHODIA OPERATIONS SAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com