Patents

Literature

1610 results about "Metallic coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A metallic coating forms a corrosion resistant protective layer that can withstand harsh environmental conditions by changing the surface properties of the material on which it is applied.

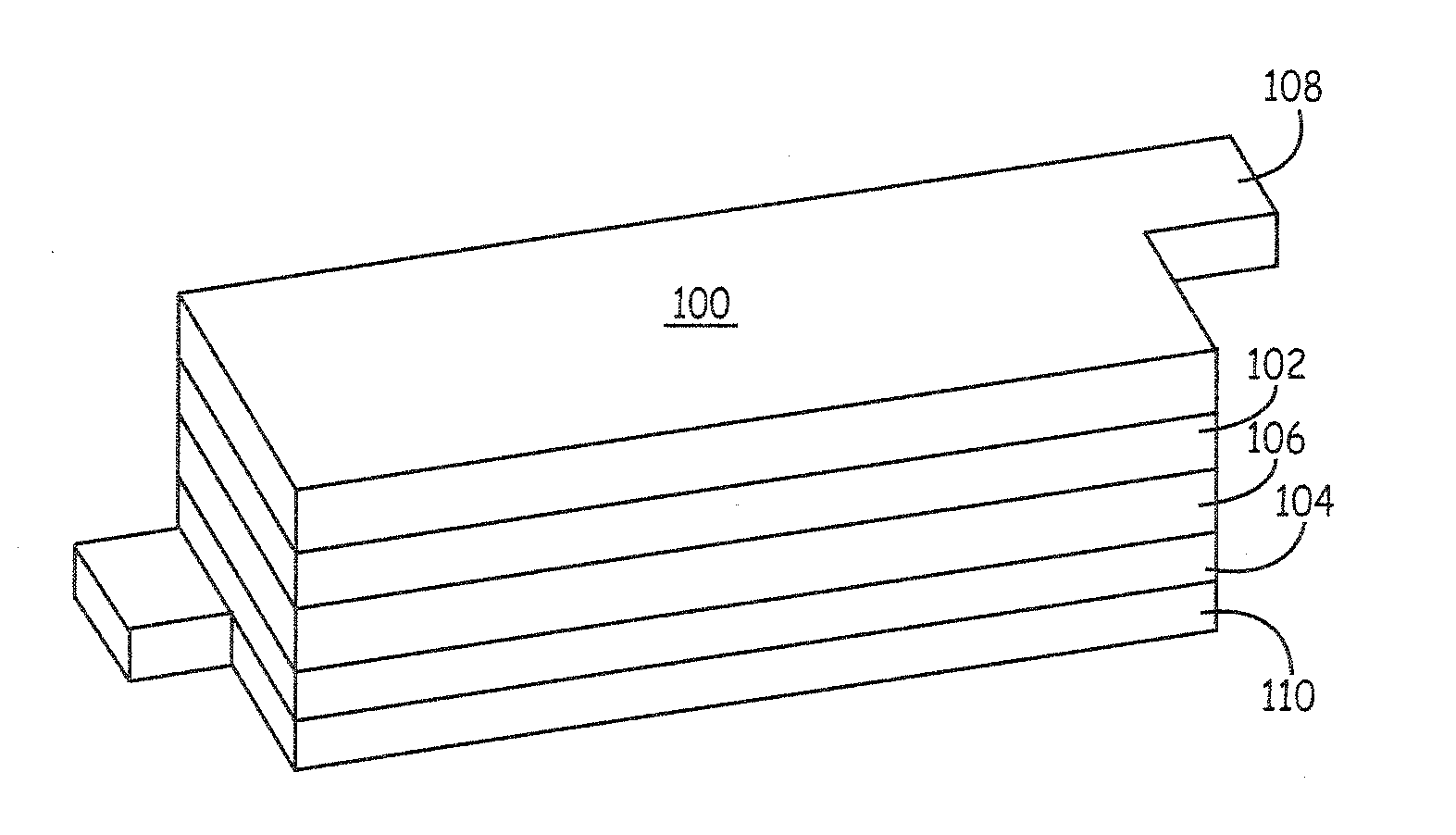

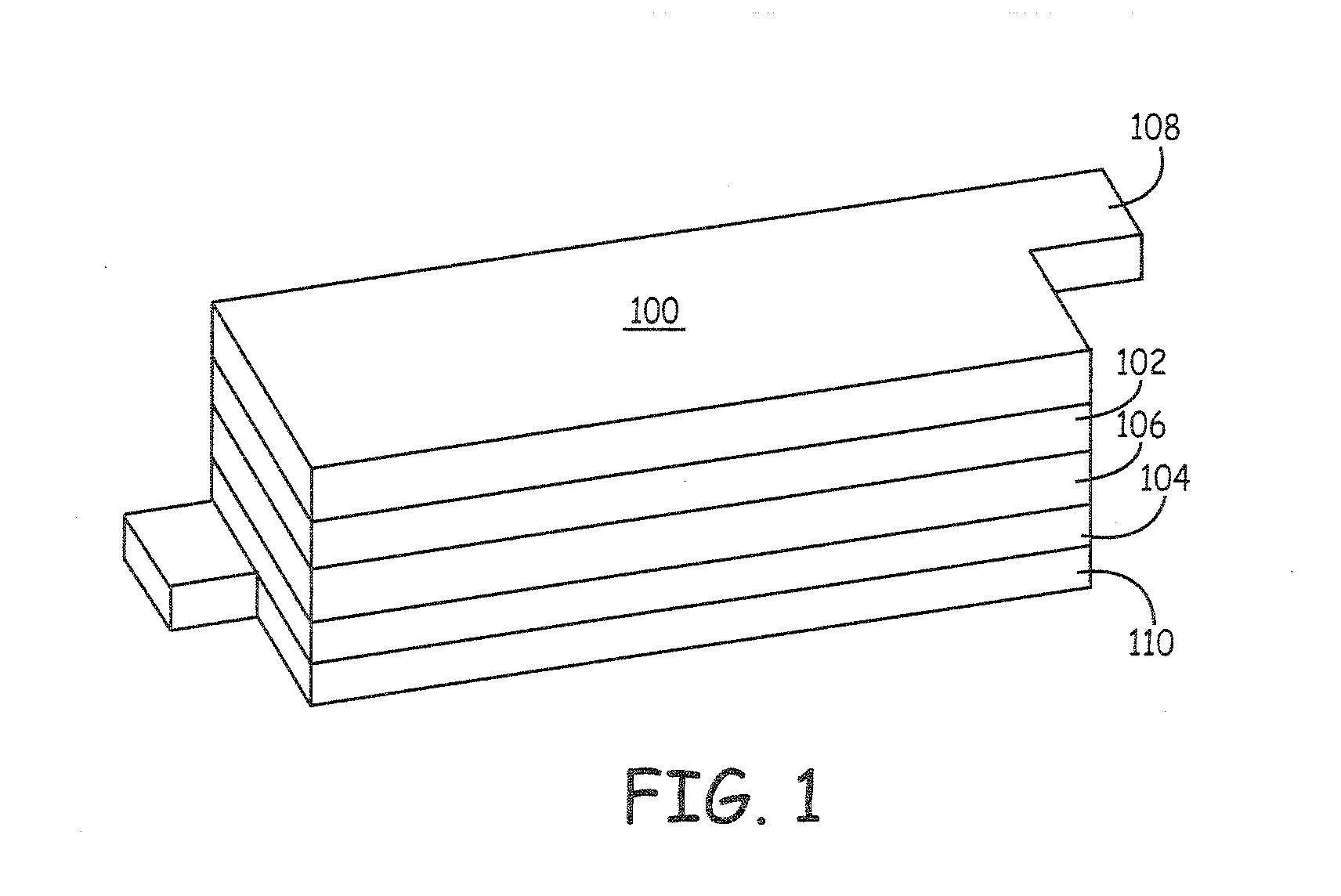

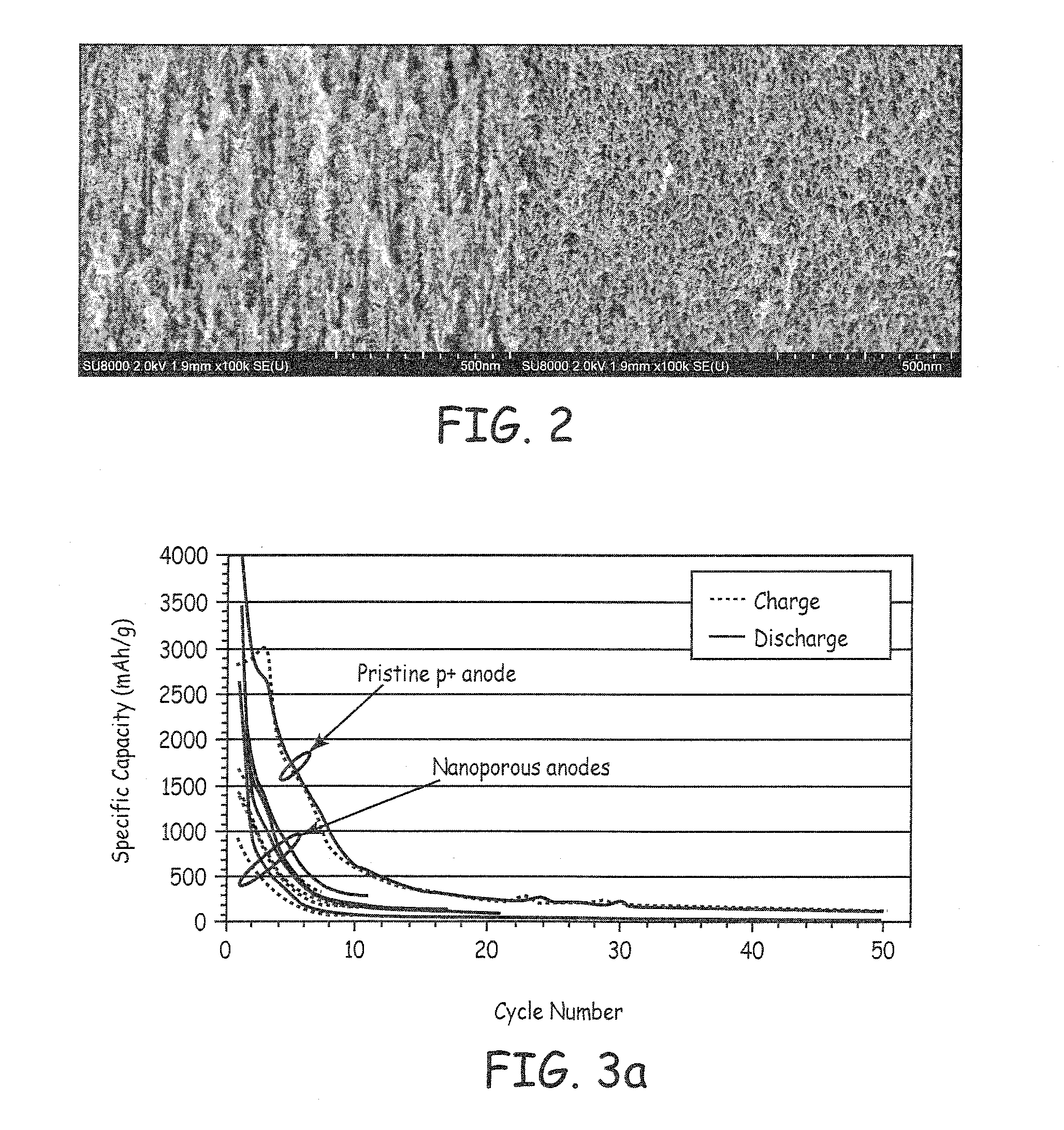

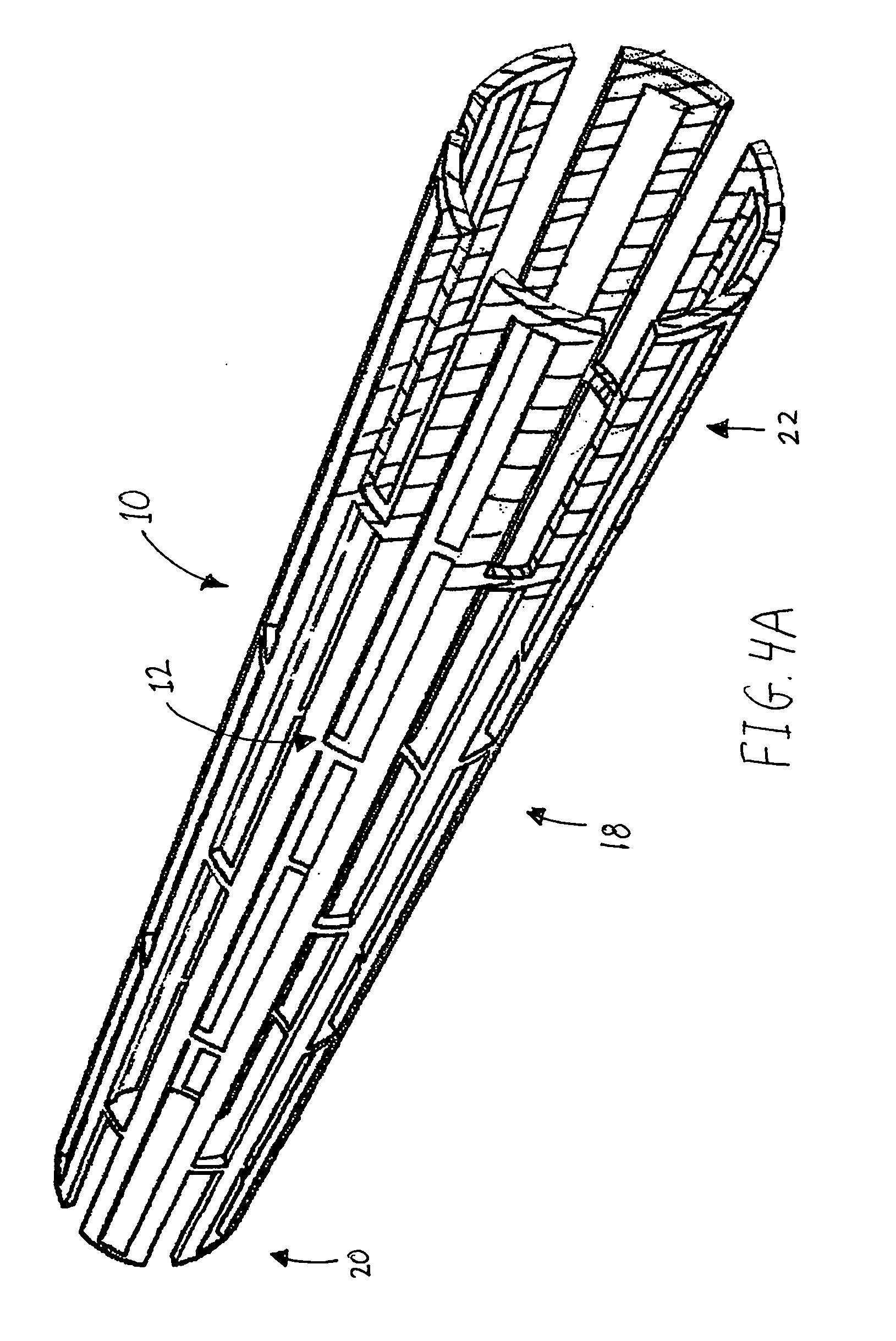

High Capacity Anode Materials for Lithium Ion Batteries

High capacity silicon based anode active materials are described for lithium ion batteries. These materials are shown to be effective in combination with high capacity lithium rich cathode active materials. Supplemental lithium is shown to improve the cycling performance and reduce irreversible capacity loss for at least certain silicon based active materials. In particular silicon based active materials can be formed in composites with electrically conductive coatings, such as pyrolytic carbon coatings or metal coatings, and composites can also be formed with other electrically conductive carbon components, such as carbon nanofibers and carbon nanoparticles. Additional alloys with silicon are explored.

Owner:IONBLOX INC

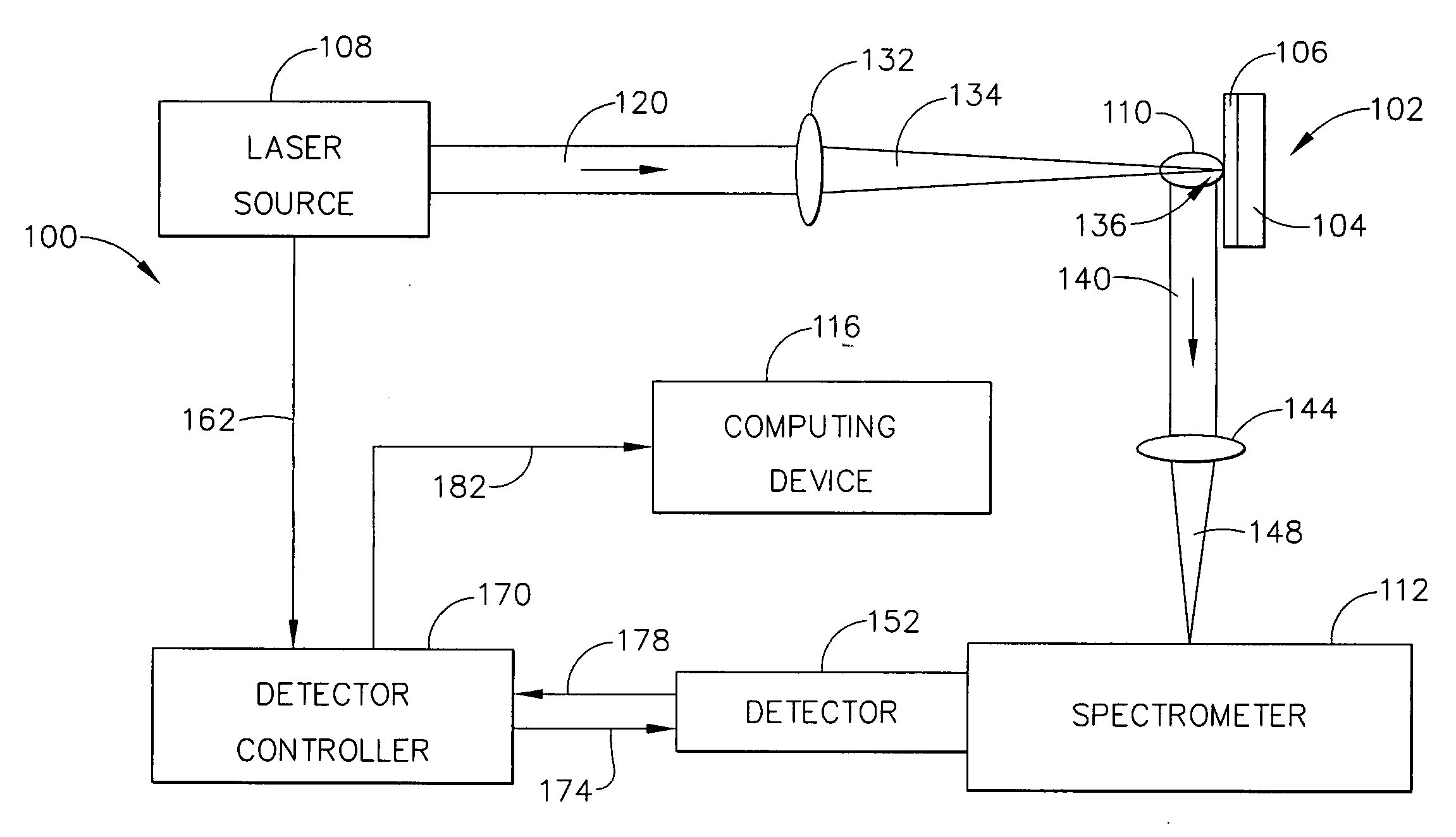

Analysis of component for presence, composition and/or thickness of coating

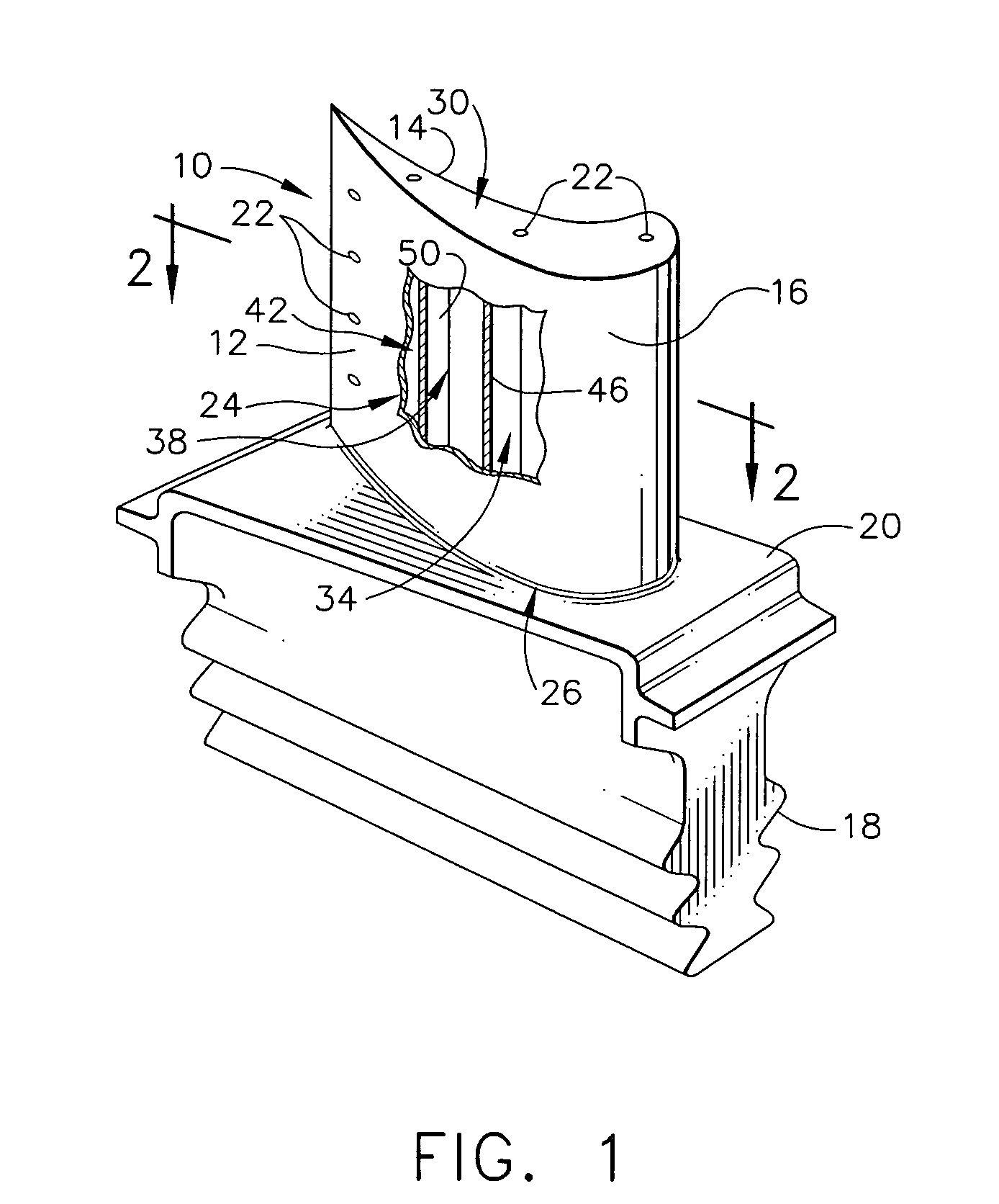

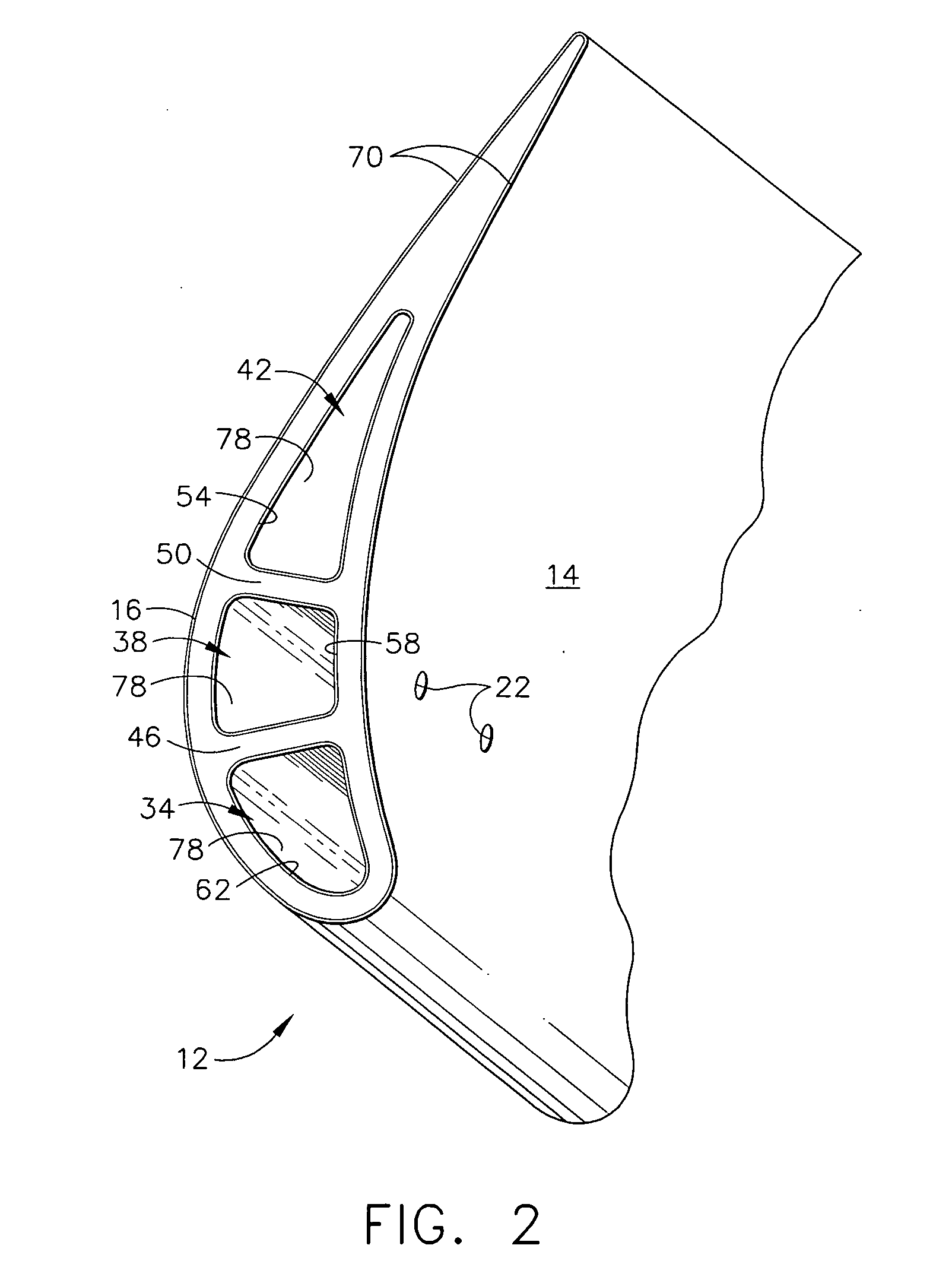

A method comprising the following steps: (a) providing a turbine component comprising a metal substrate having an external surface; and (b) analyzing the external surface by laser plasma spectroscopy to determine whether a metallic coating is present on or absent from the external surface. If a metallic coating is determined to be present on the external surface, the elemental composition, elemental concentration and / or thickness of the metallic coating present on the external surface may be determined (qualitatively and / or quantitatively) by laser plasma spectroscopy. Another method comprises the following steps: (a) providing a turbine component comprising a metal substrate having an external surface which has been subjected to treatment to remove a metallic coating applied to the external surface; and (b) analyzing the treated external surface by laser plasma spectroscopy to determine the degree of removal of the metallic coating from the treated external surface.

Owner:GENERAL ELECTRIC CO

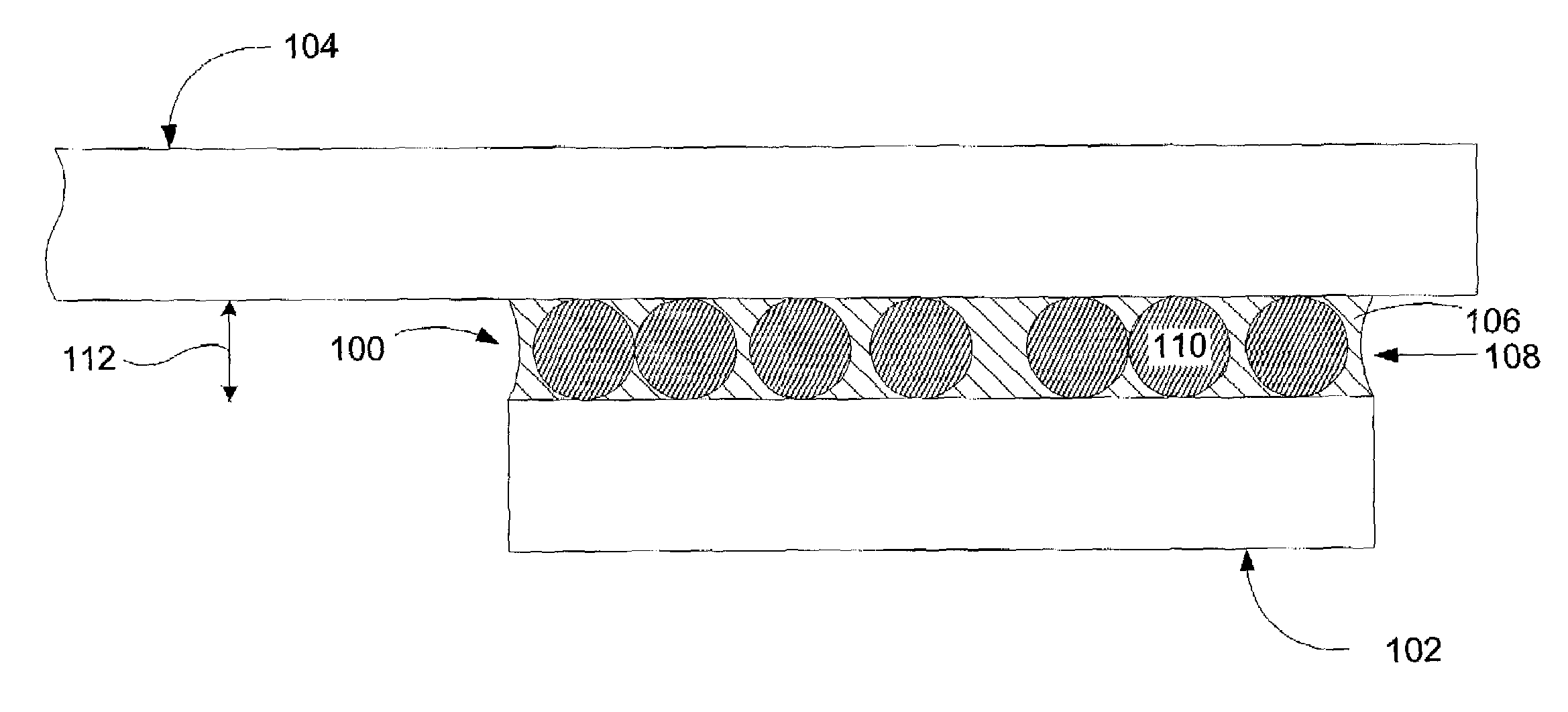

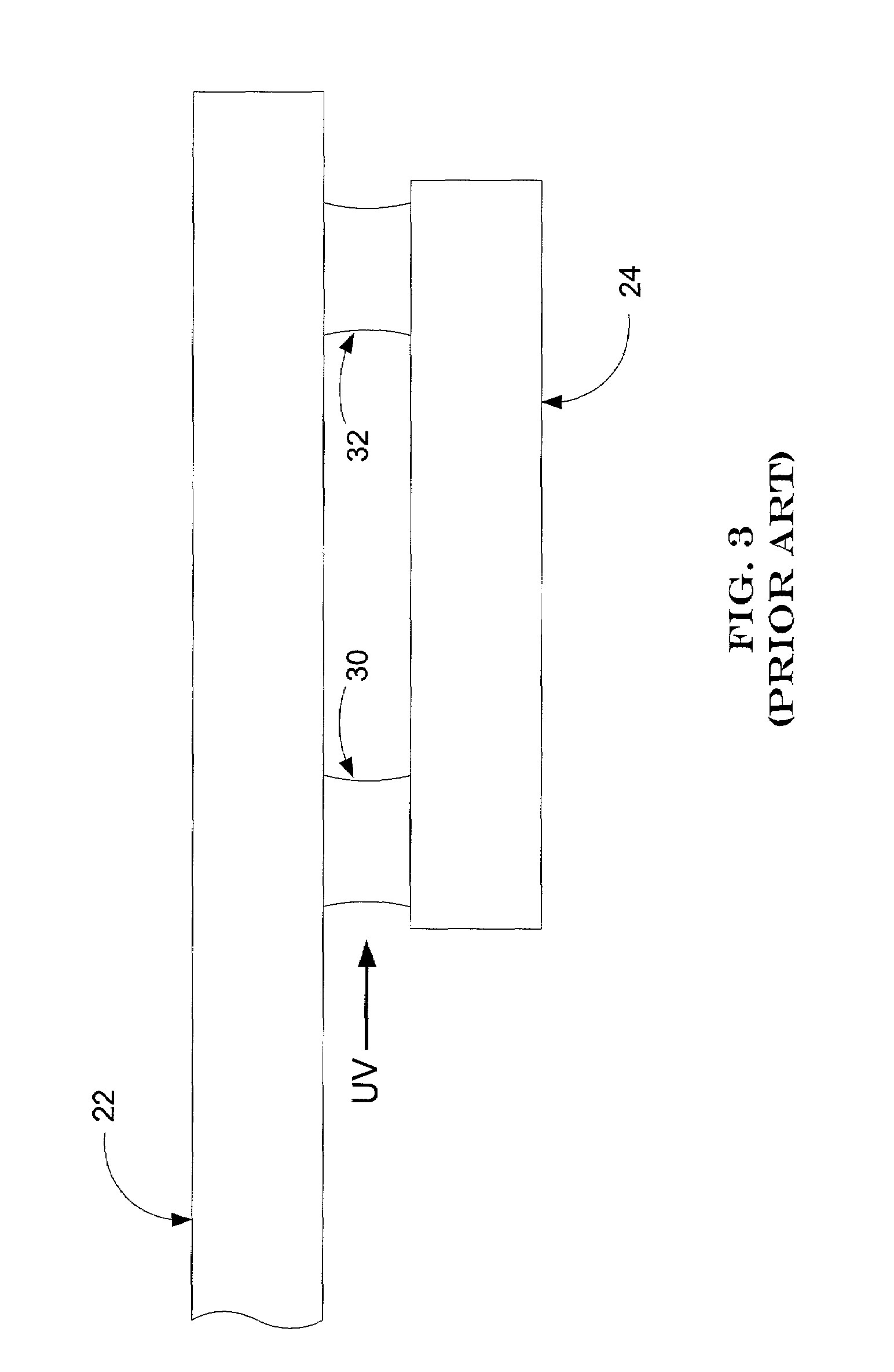

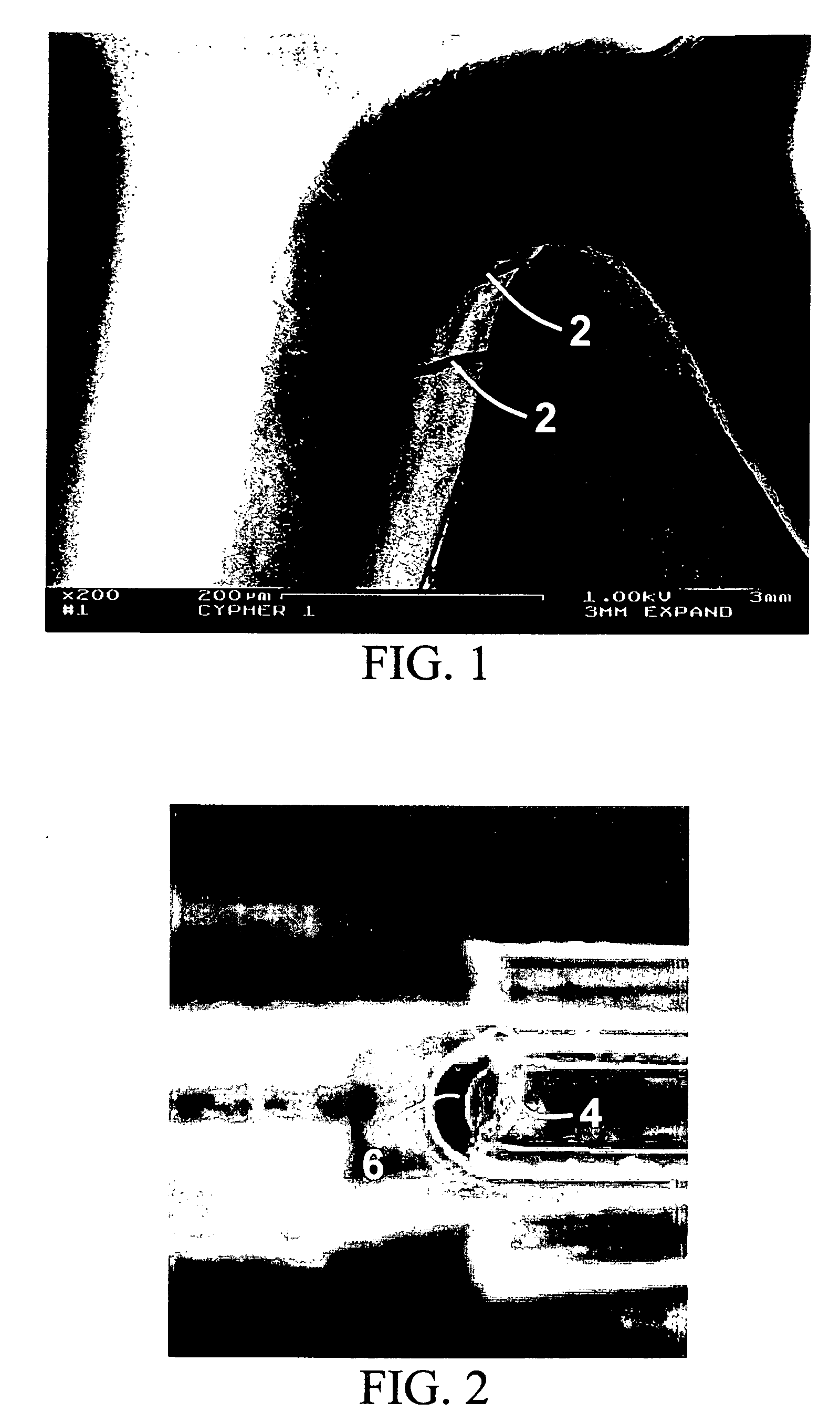

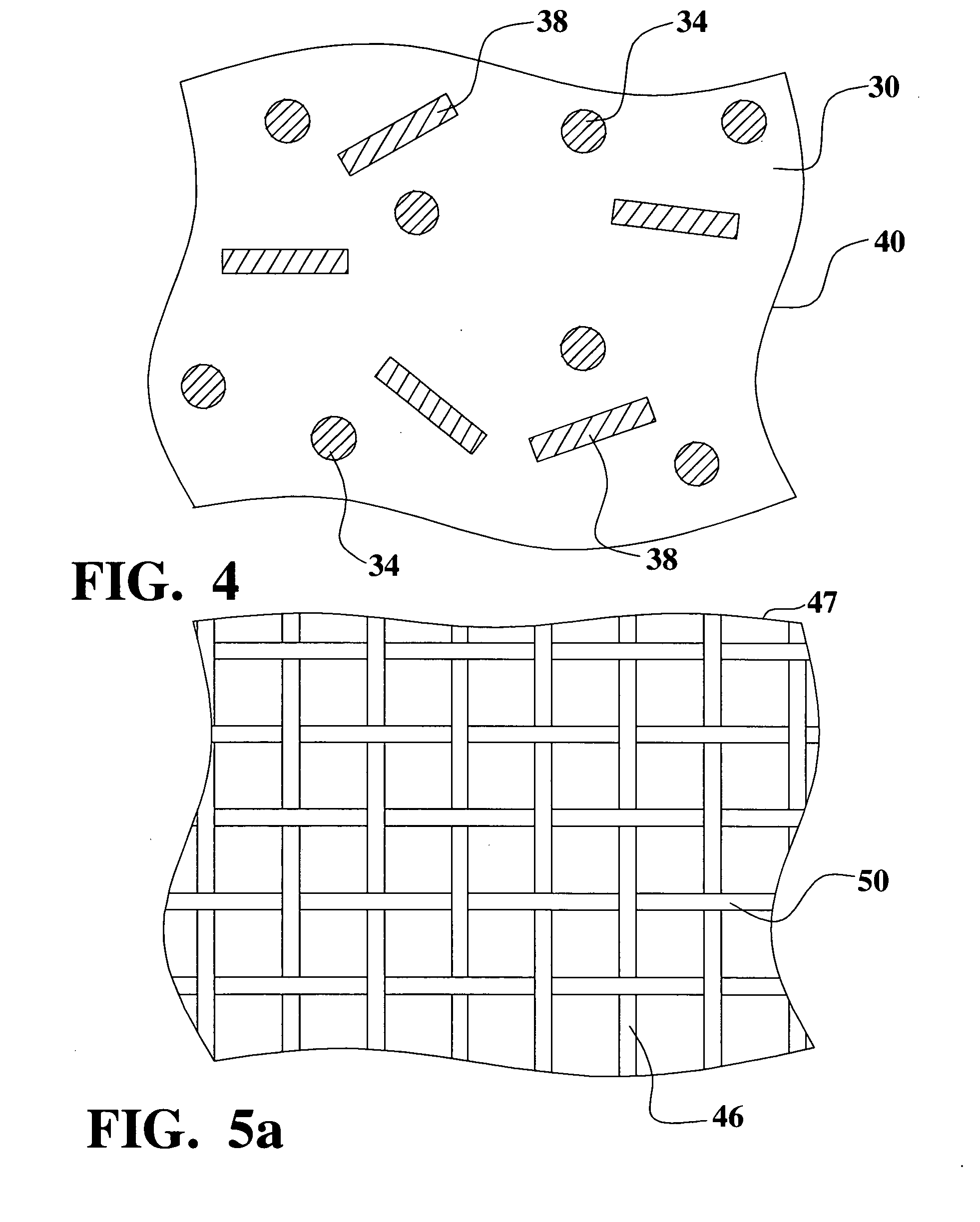

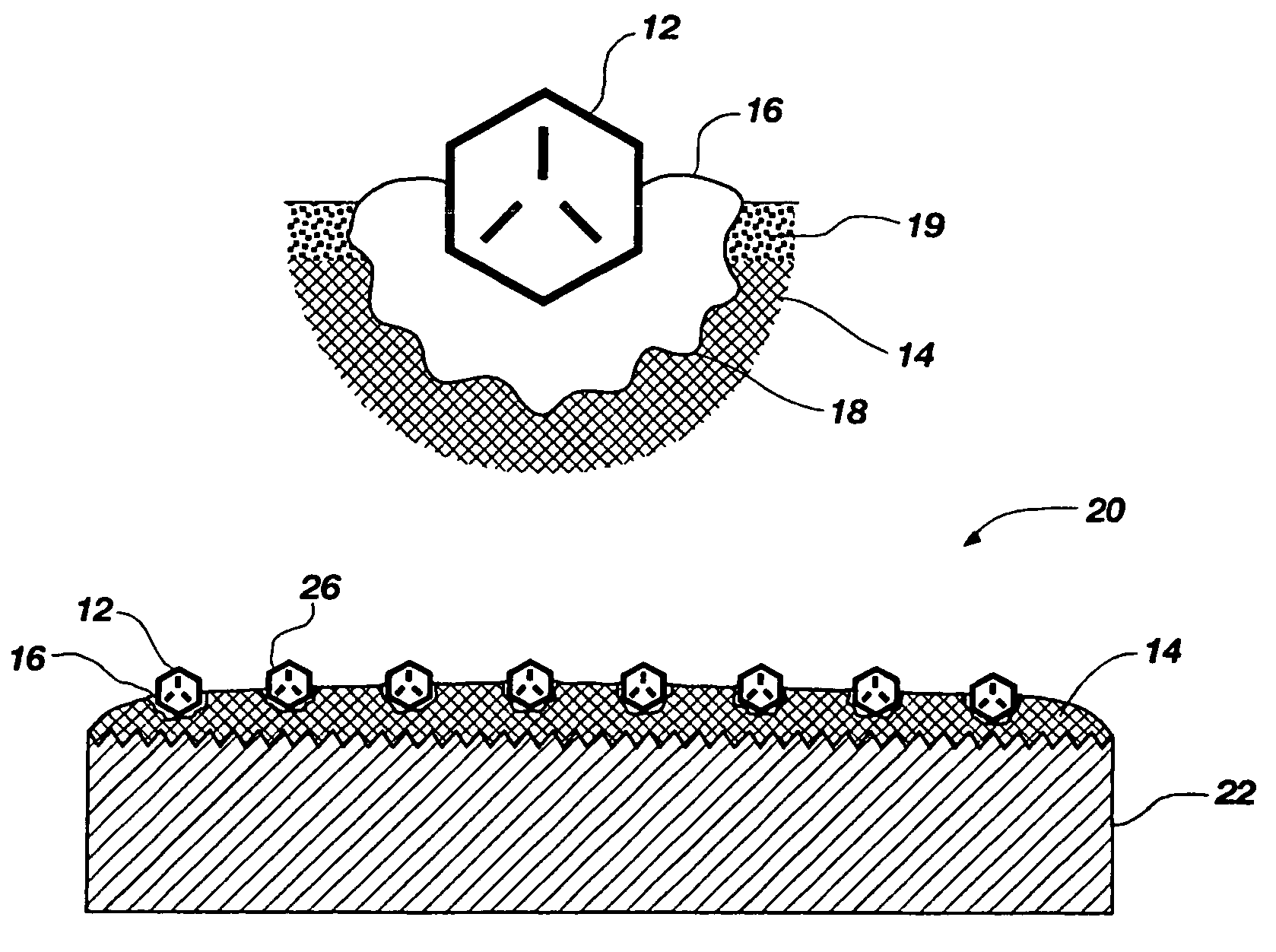

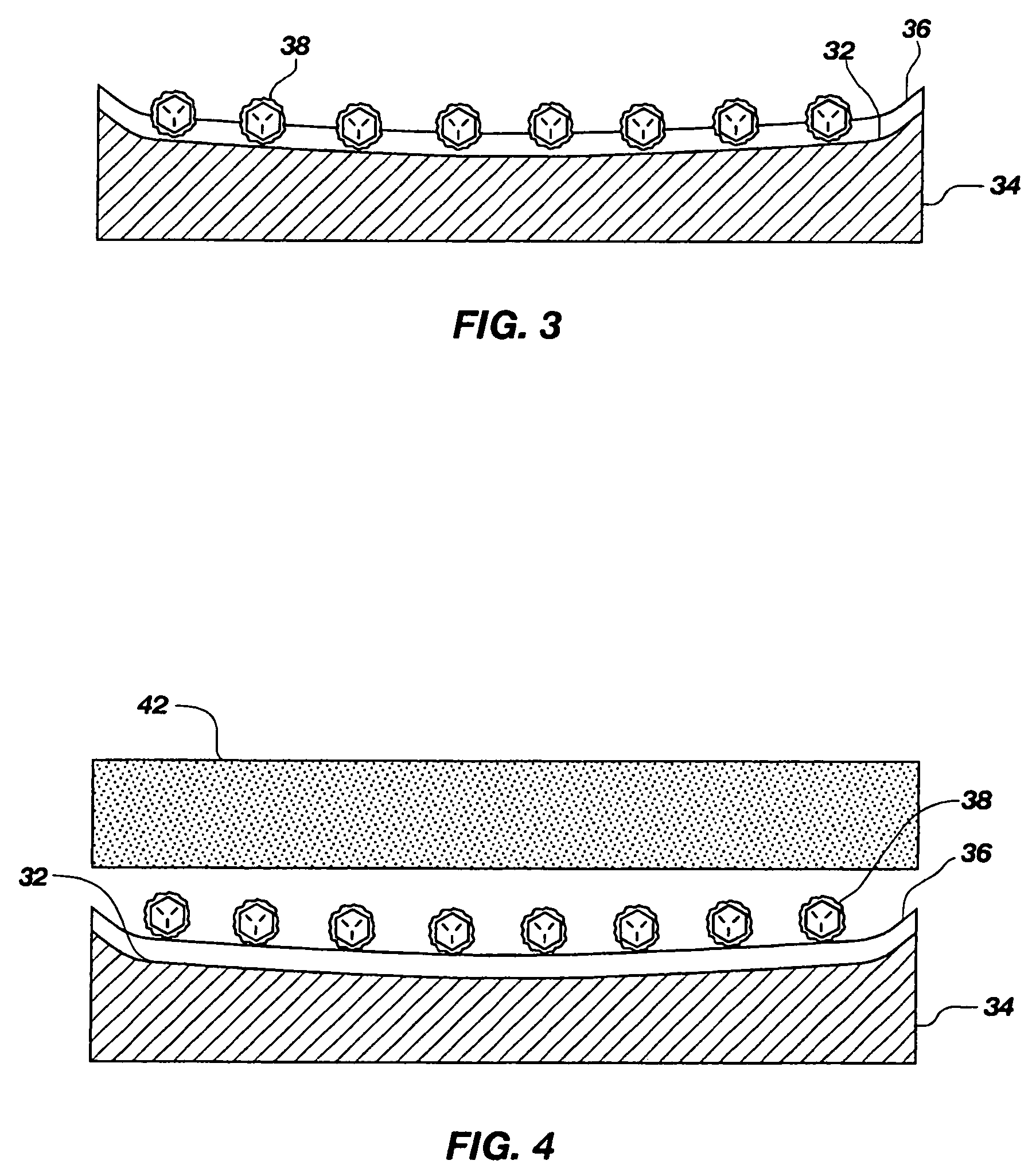

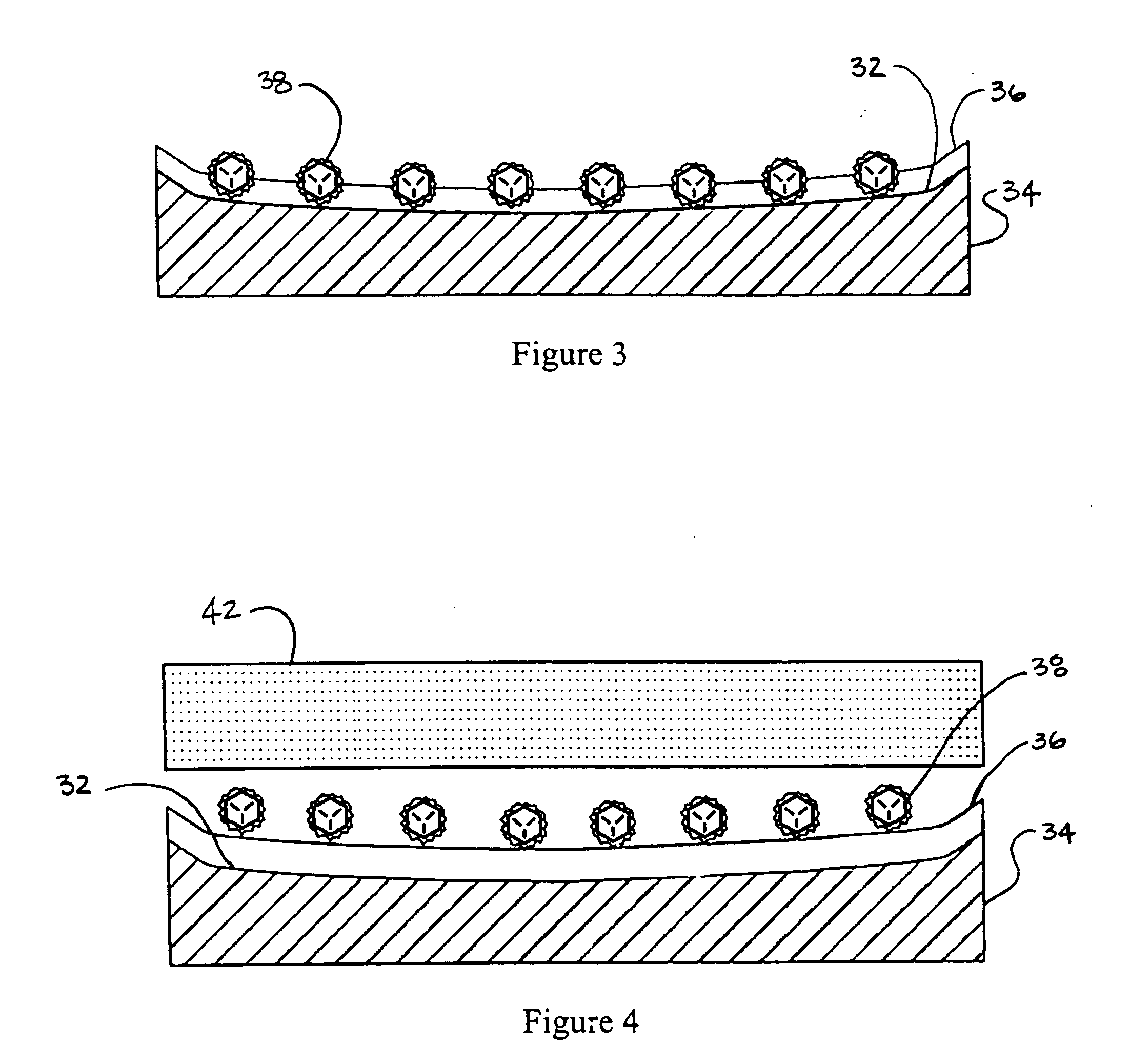

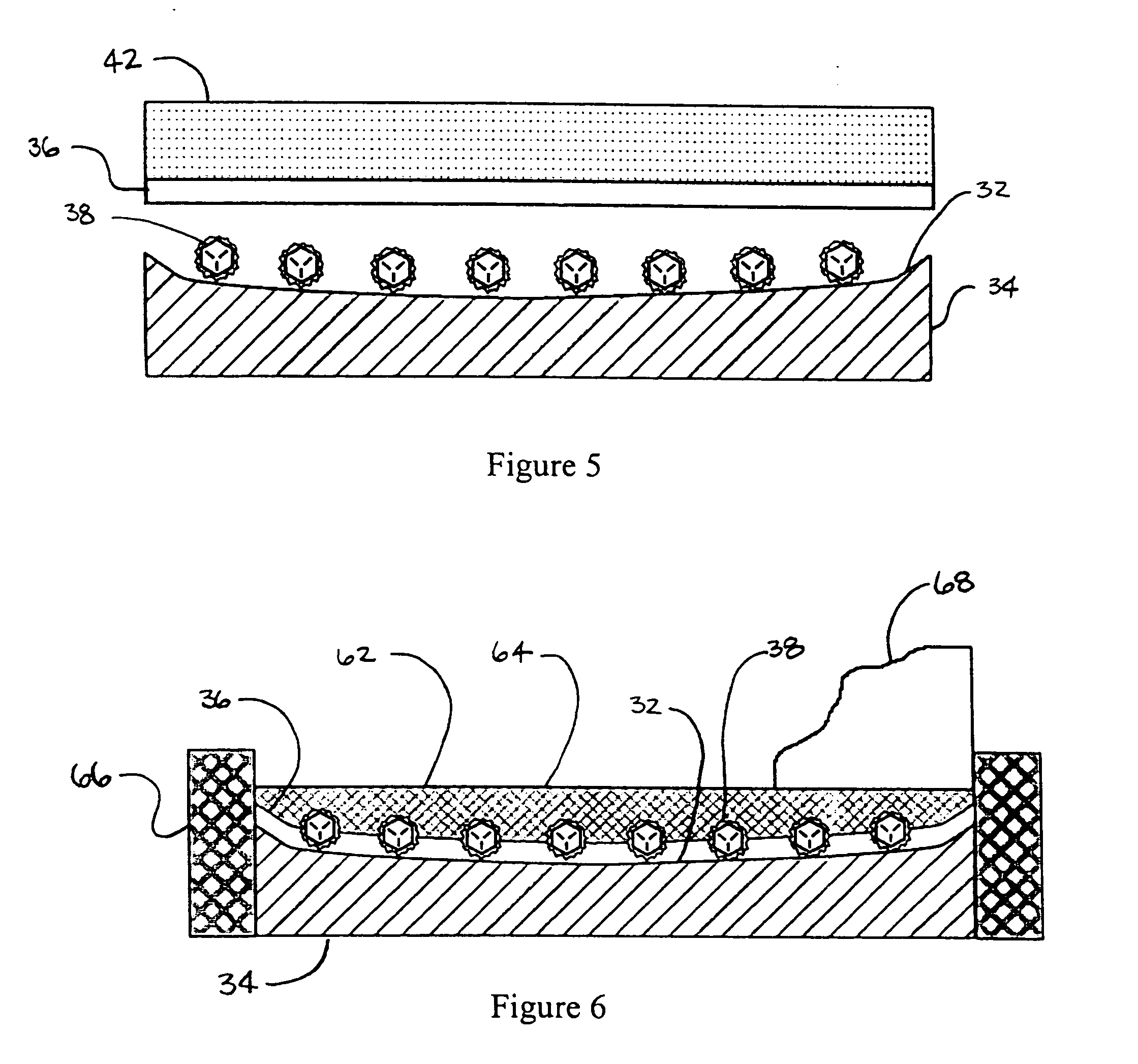

UV curable and electrically conductive adhesive for bonding magnetic disk drive components

An electrically conductive adhesive includes a resin component, a photoinitiator, and metal-coated polymer beads. The beads have an average diameter and a very narrow size distribution around the average diameter. The adhesive is applied between a read / write head and a suspension to attach the two, and the adhesive is cured by exposure to an illumination and / or heat. A pad spacer is included between the read / write head and the suspension to define a spacing and parallelism therebetween. The beads in the adhesive can form one or more layers between the read / write head and the suspension or can be disordered. The metal coating of the beads provide electrical conductivity between the read / write head and the suspension.

Owner:WESTERN DIGITAL TECH INC

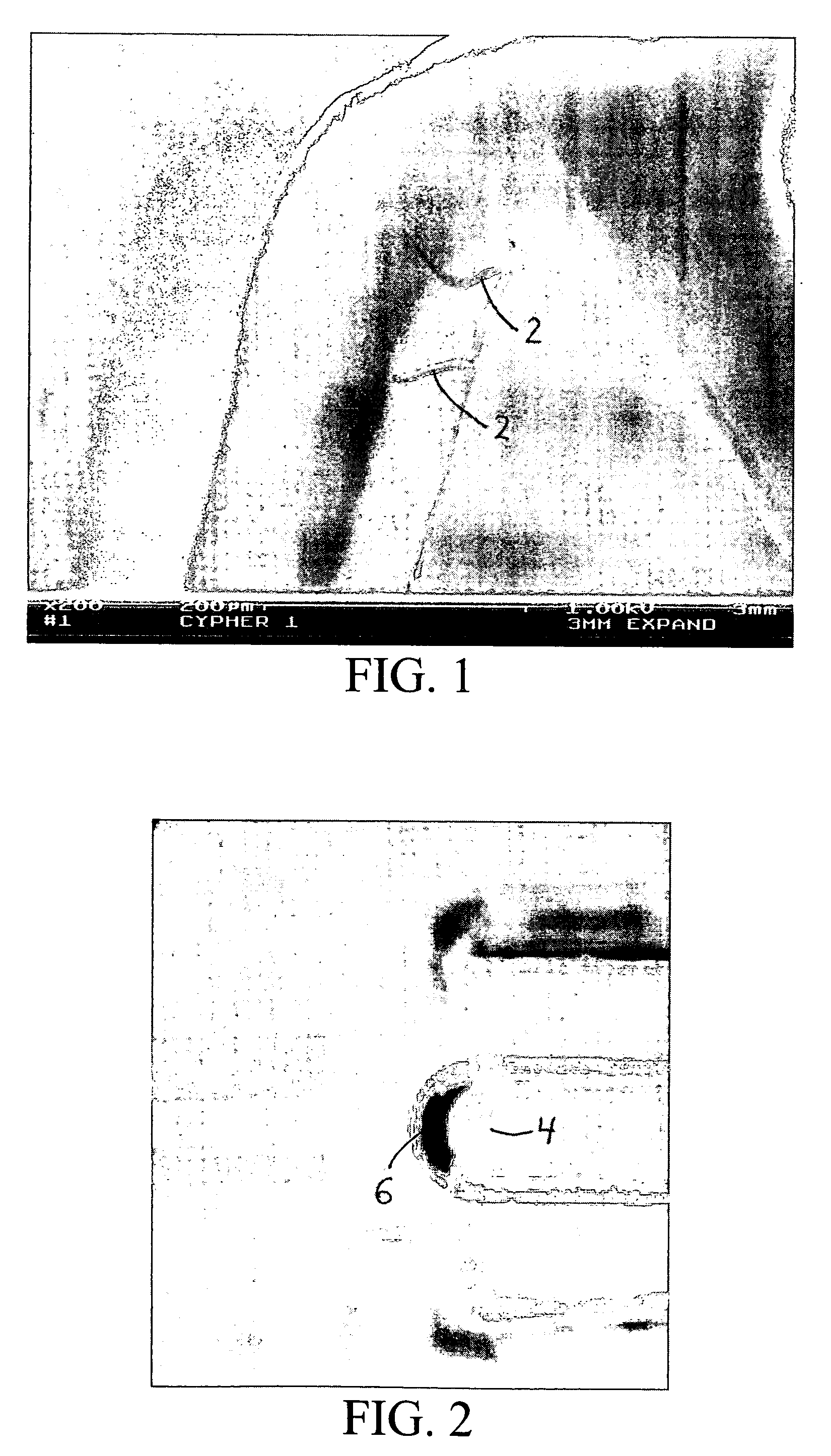

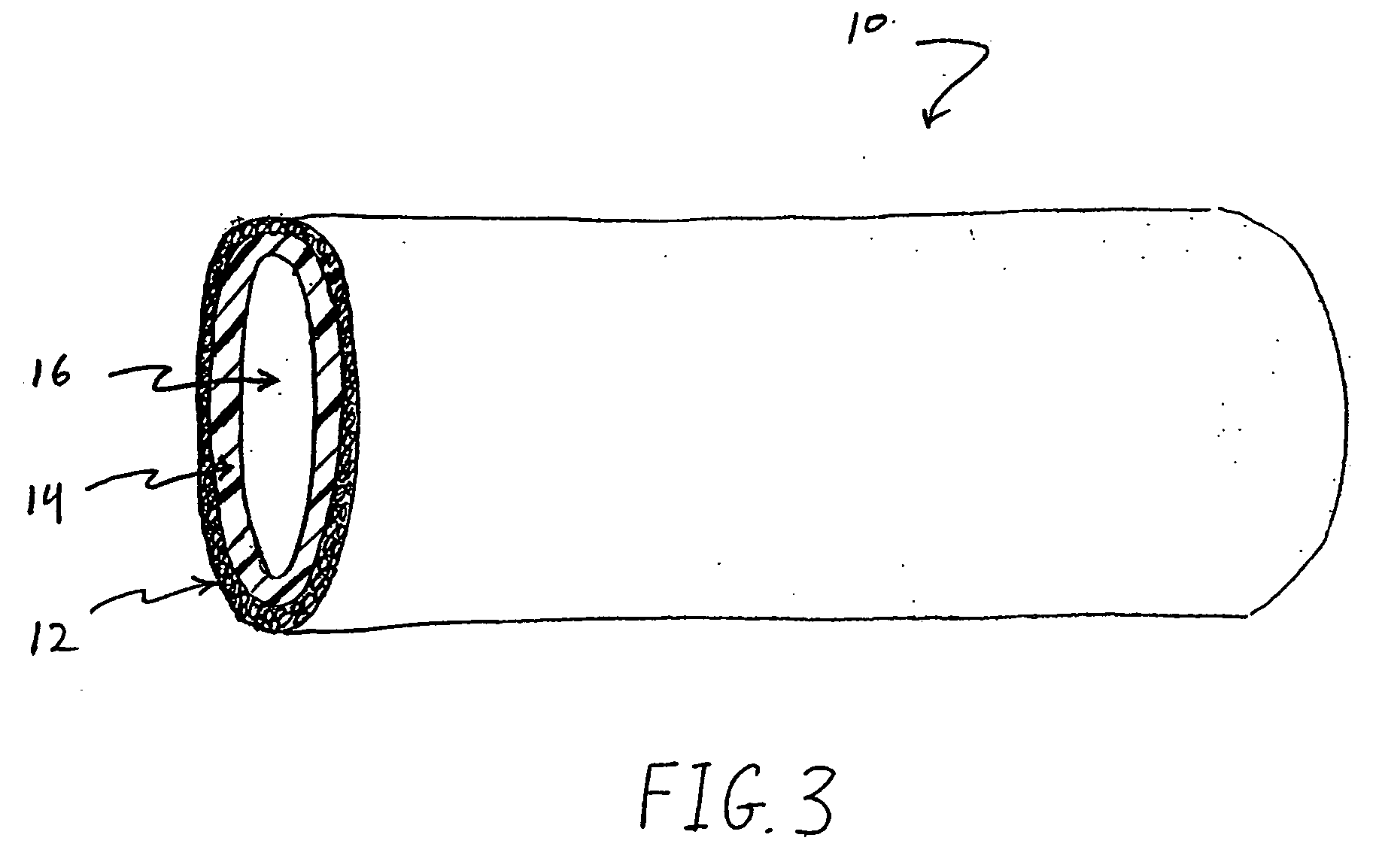

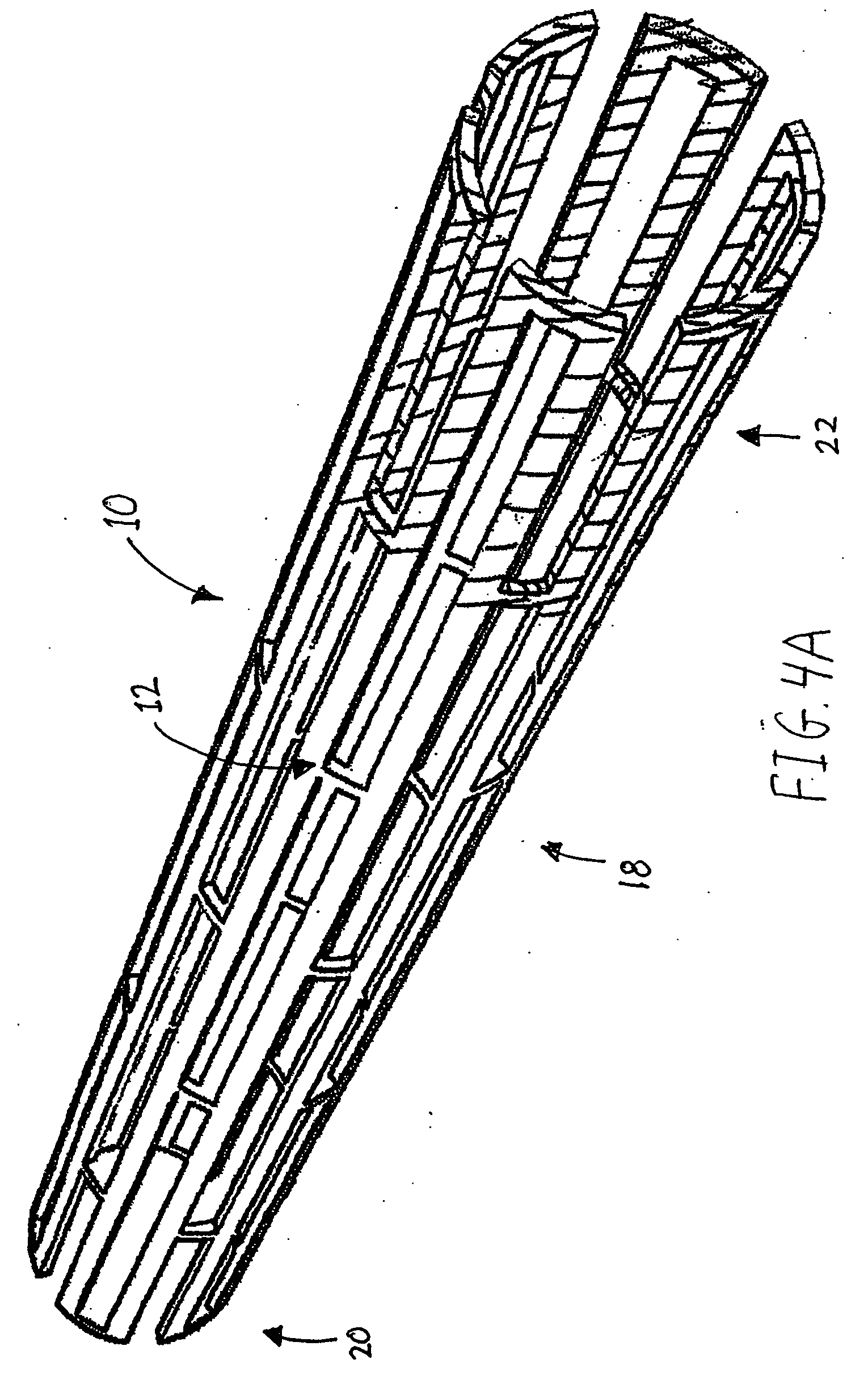

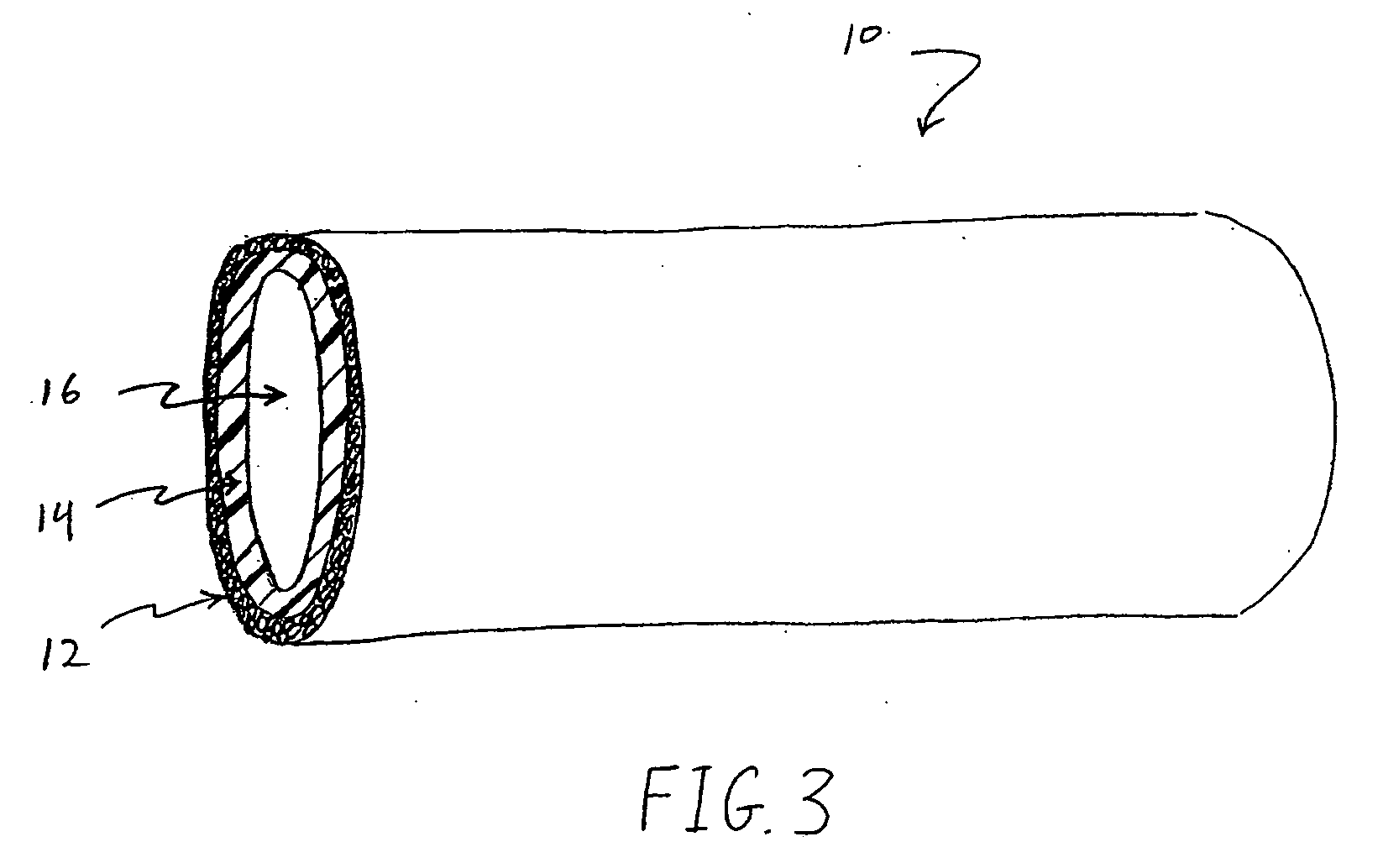

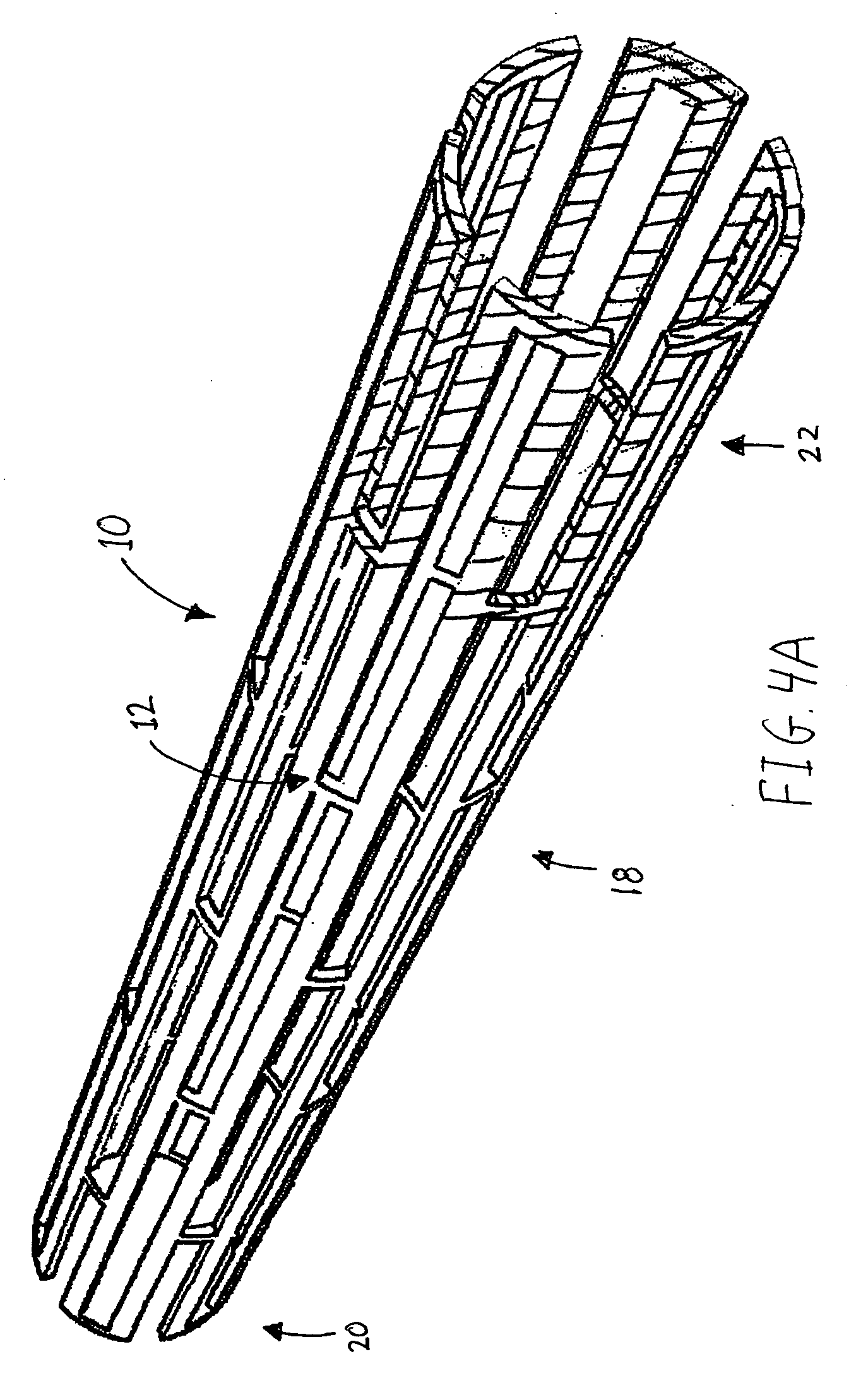

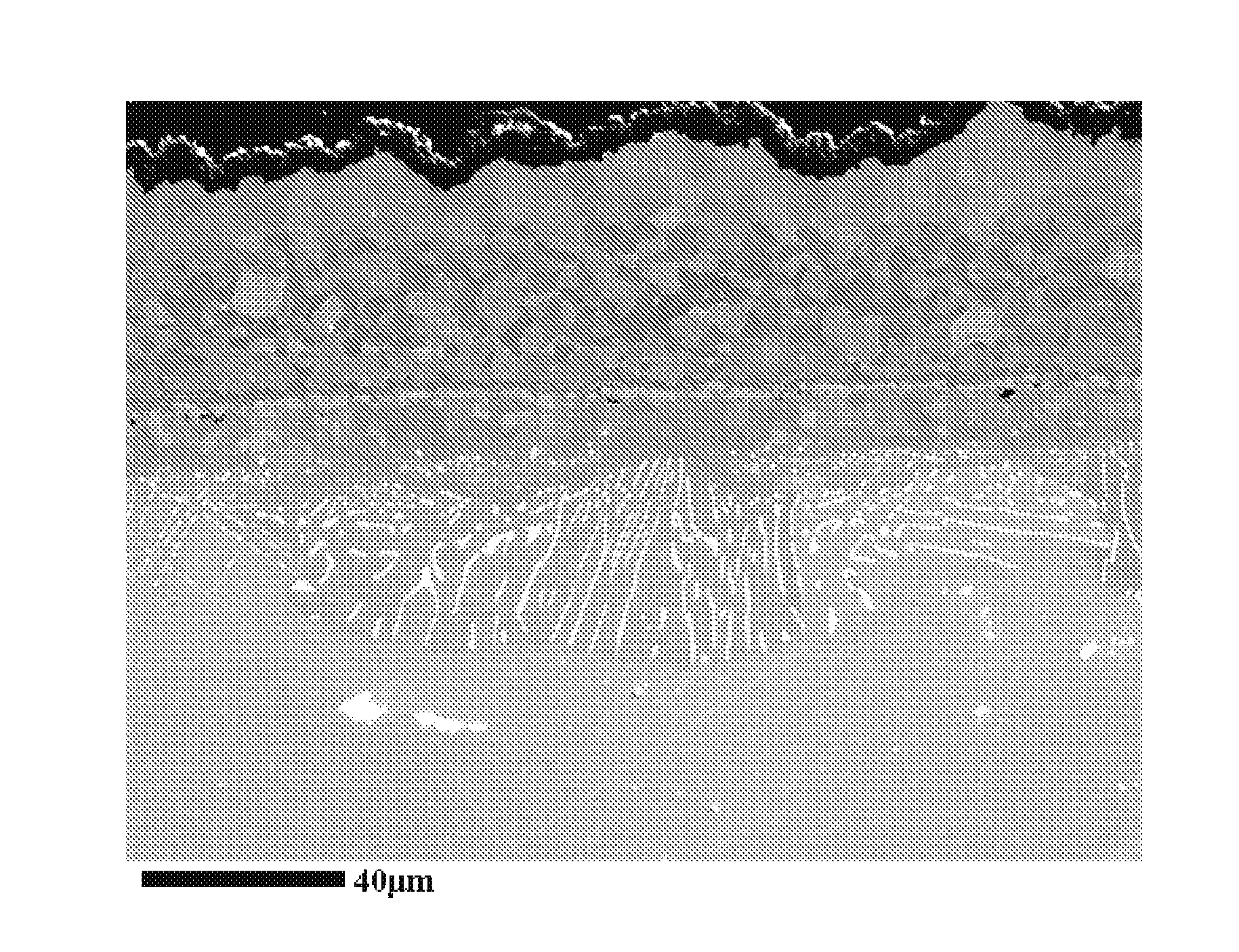

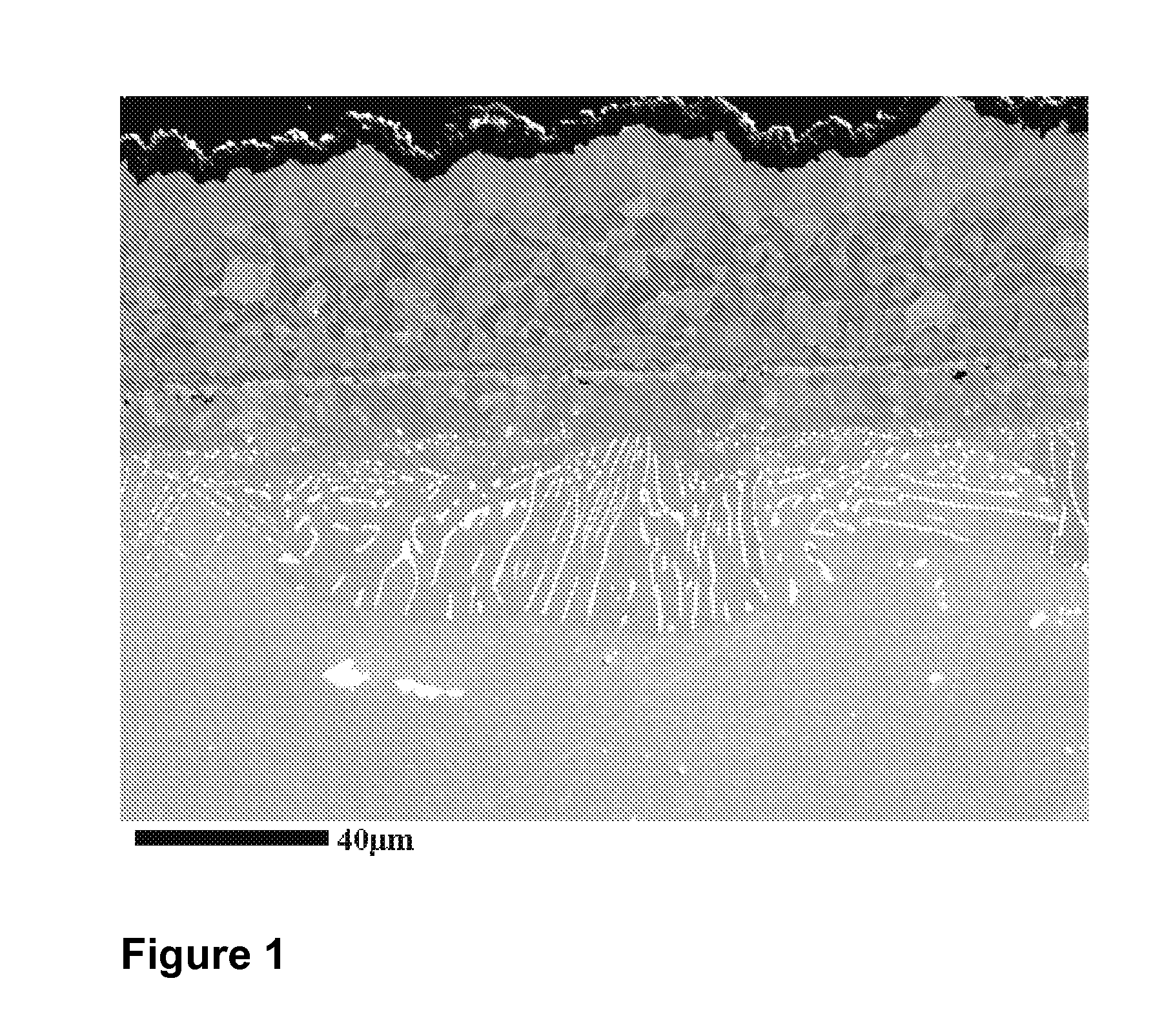

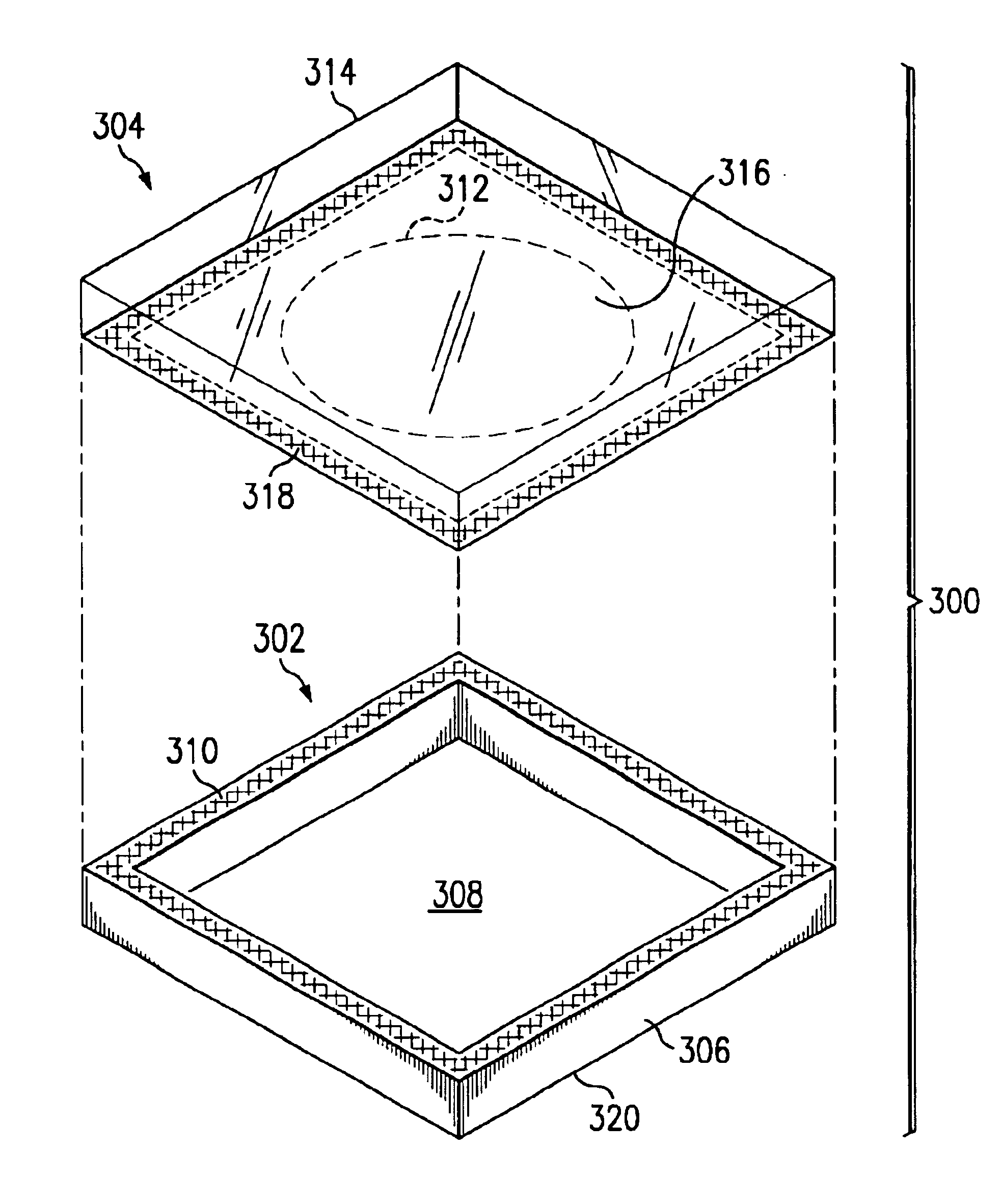

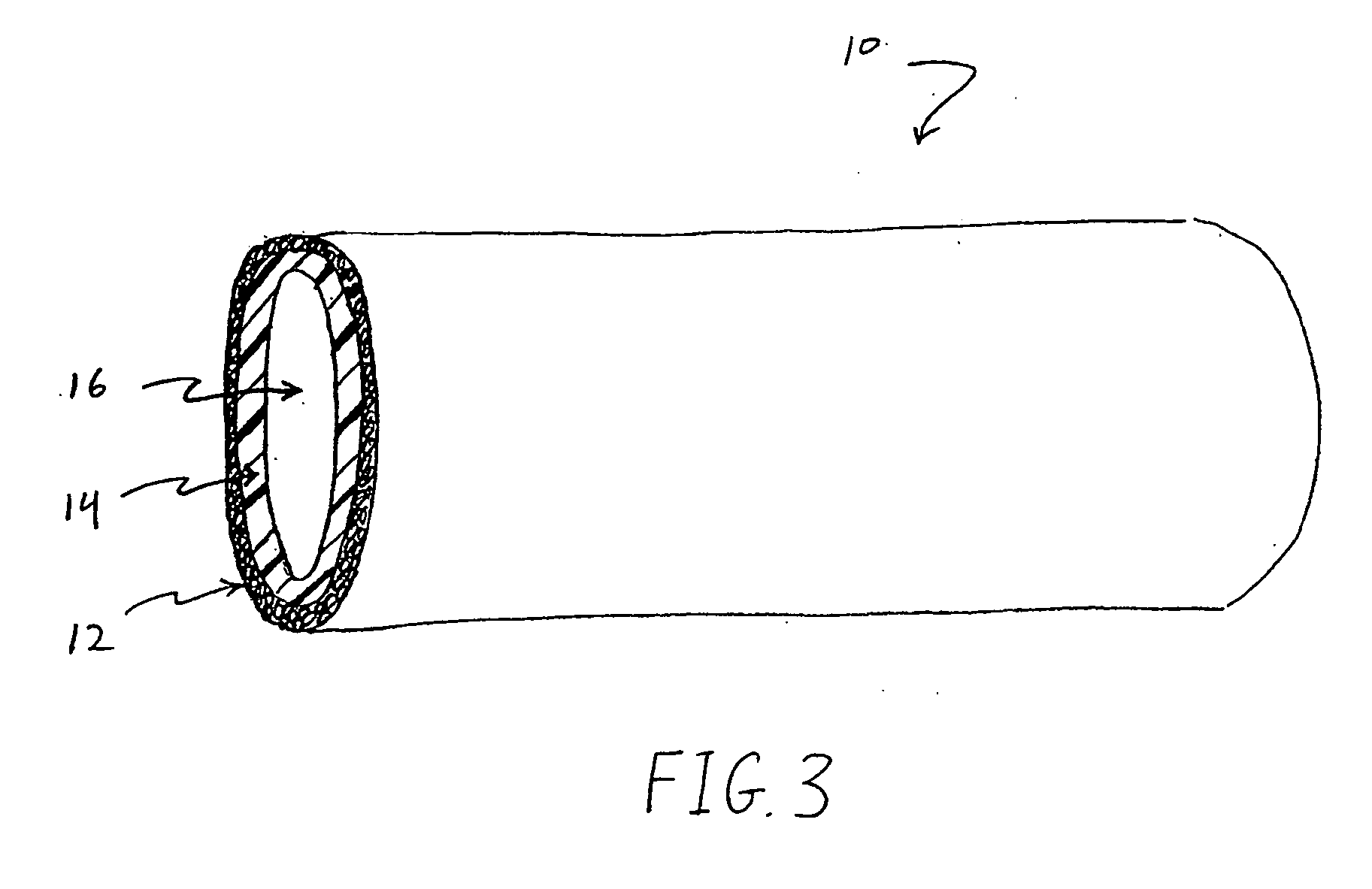

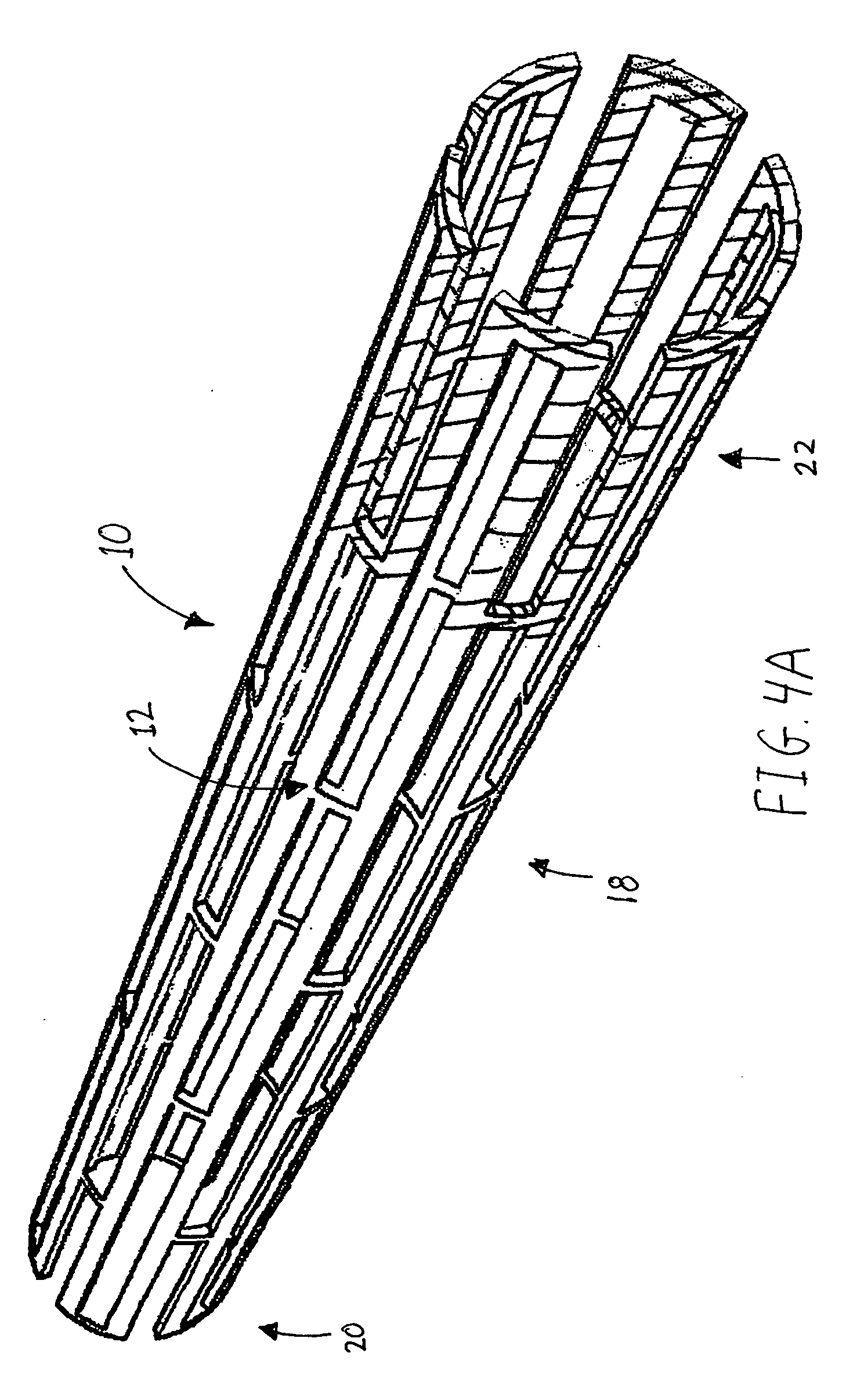

Medical devices with nanoporous layers and topcoats

The present invention relates generally to medical devices with therapy eluting components and methods for making same. More specifically, the invention relates to implantable medical devices having at least one porous layer, and methods for making such devices, and loading such devices with therapeutic agents. A mixture or alloy is placed on the surface of a medical device, then one component of the mixture or alloy is generally removed without generally removing the other components of the mixture or alloy. In some embodiments, a porous layer is adapted for bonding non-metallic coating, including drug eluting polymeric coatings. A porous layer may have a random pore structure or an oriented or directional grain porous structure. One embodiment of the invention relates to medical devices, including vascular stents, having at least one porous layer adapted to resist stenosis or cellular proliferation without requiring elution of therapeutic agents. The invention also includes methods, devices, and specifications for loading of drugs and other therapeutic agents into nanoporous coatings.

Owner:MEDTRONIC VASCULAR INC +1

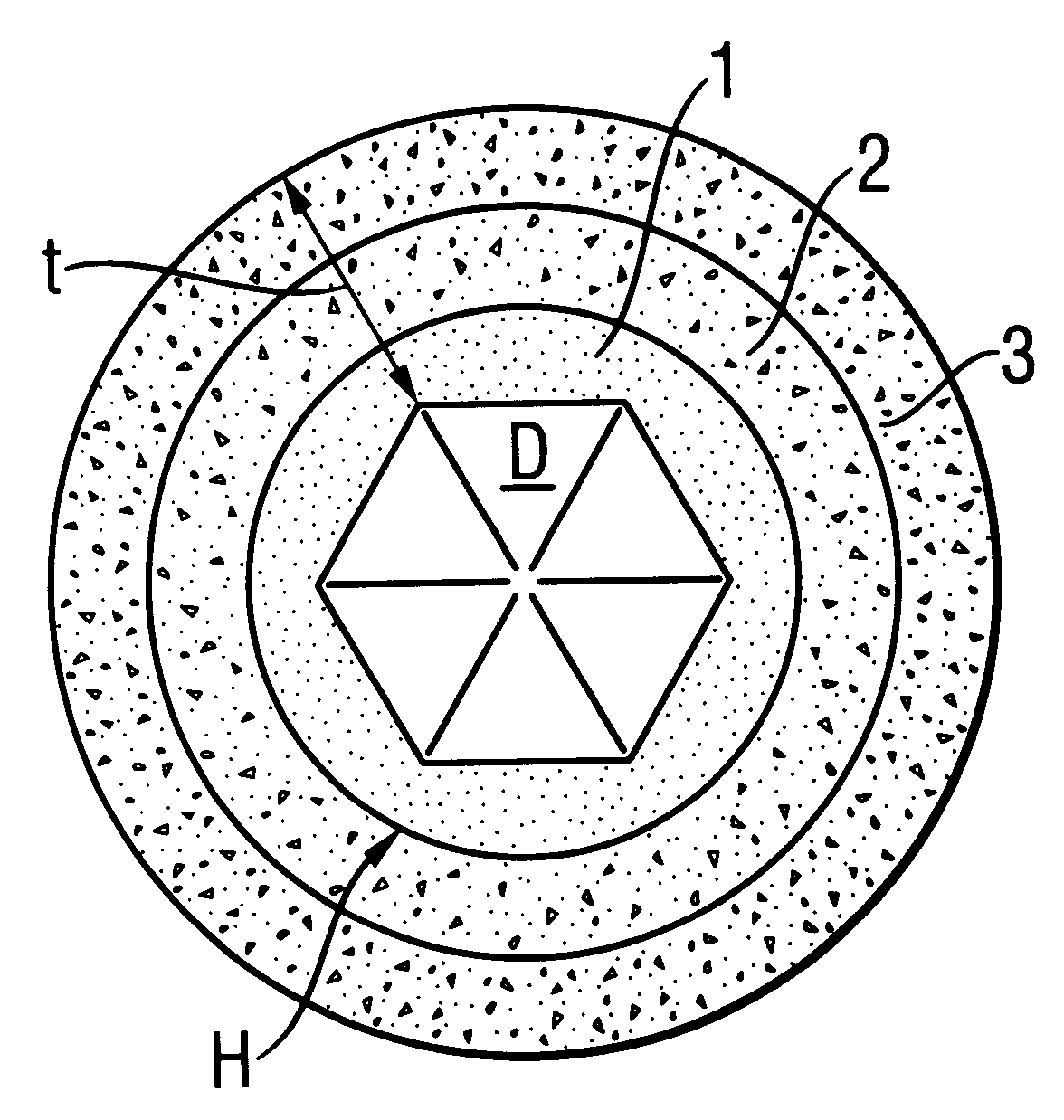

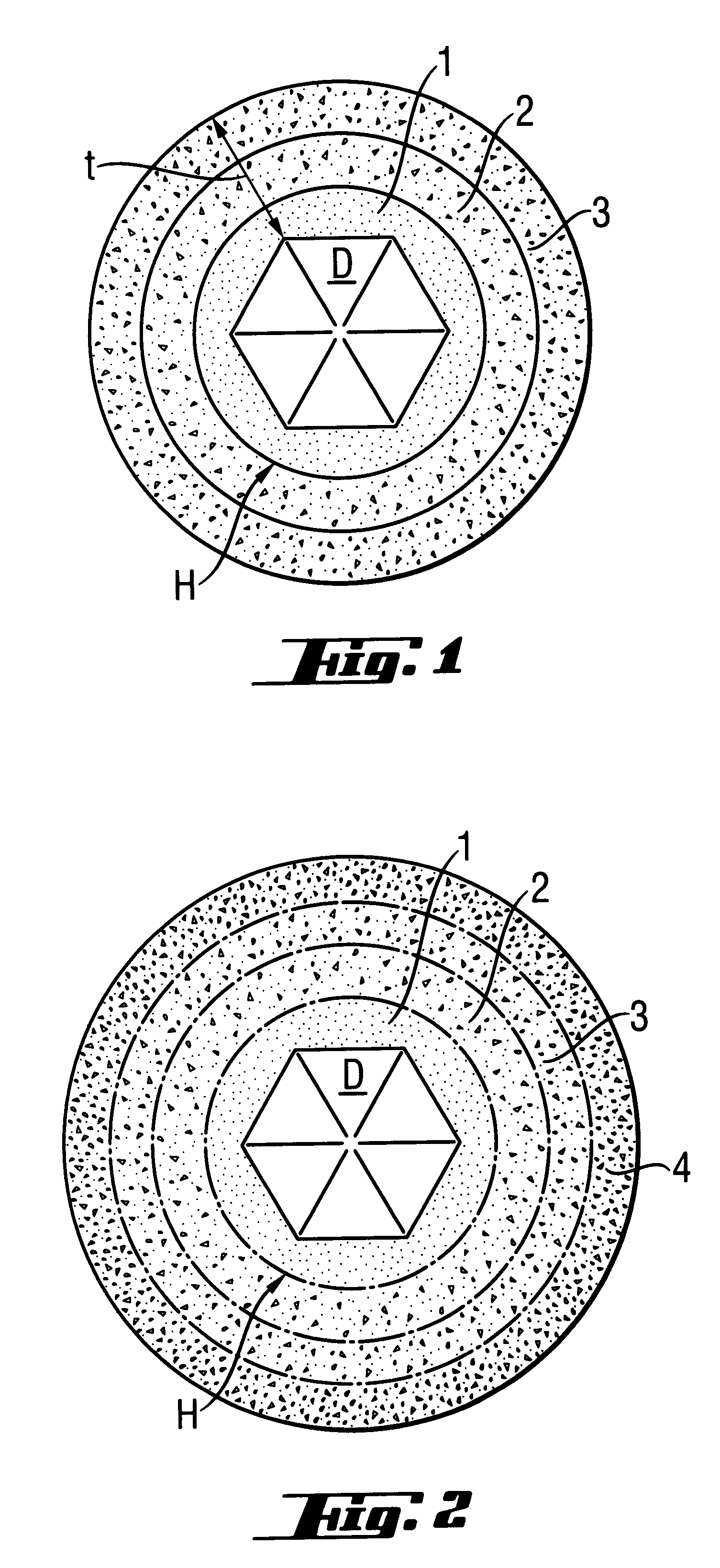

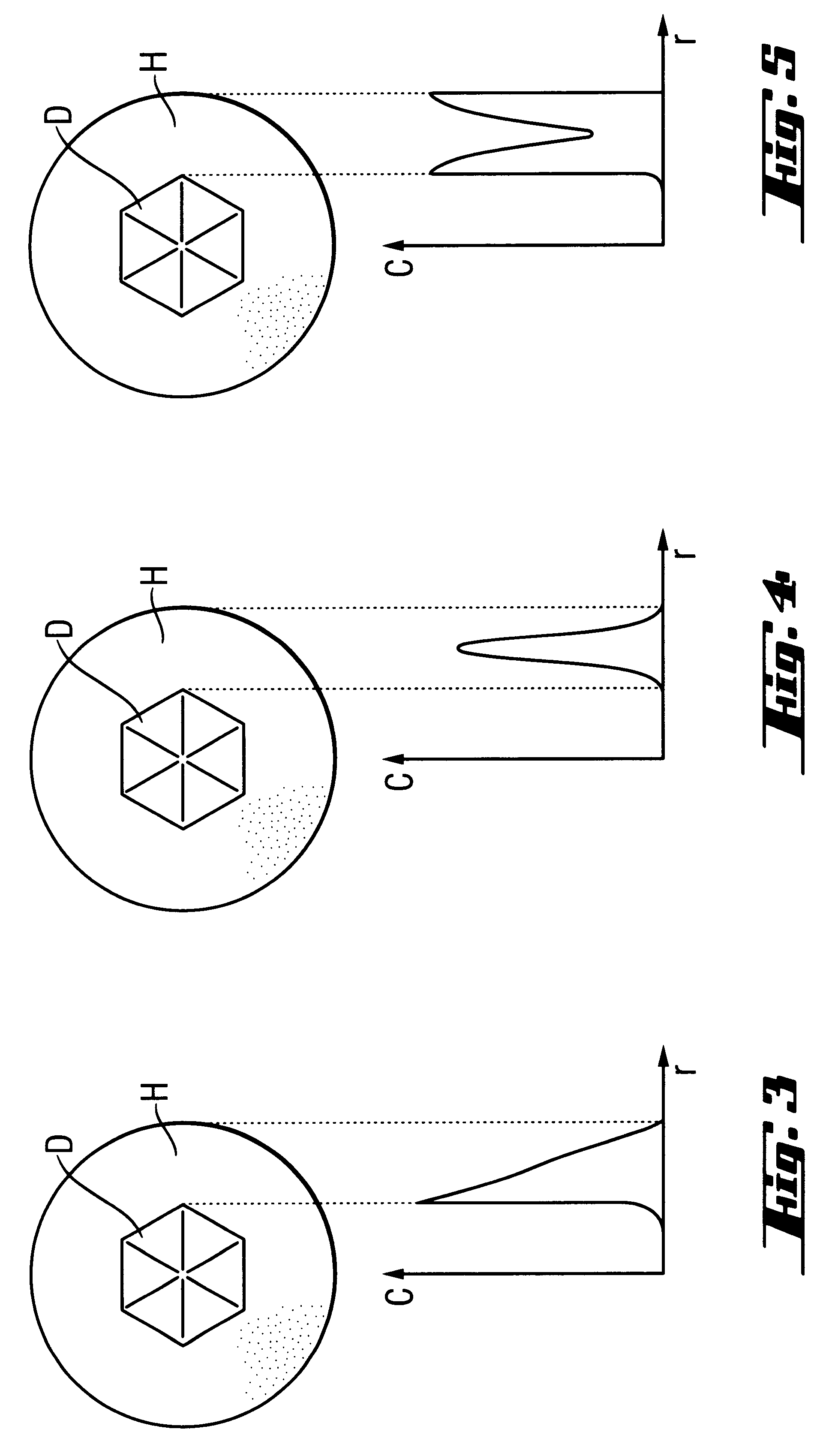

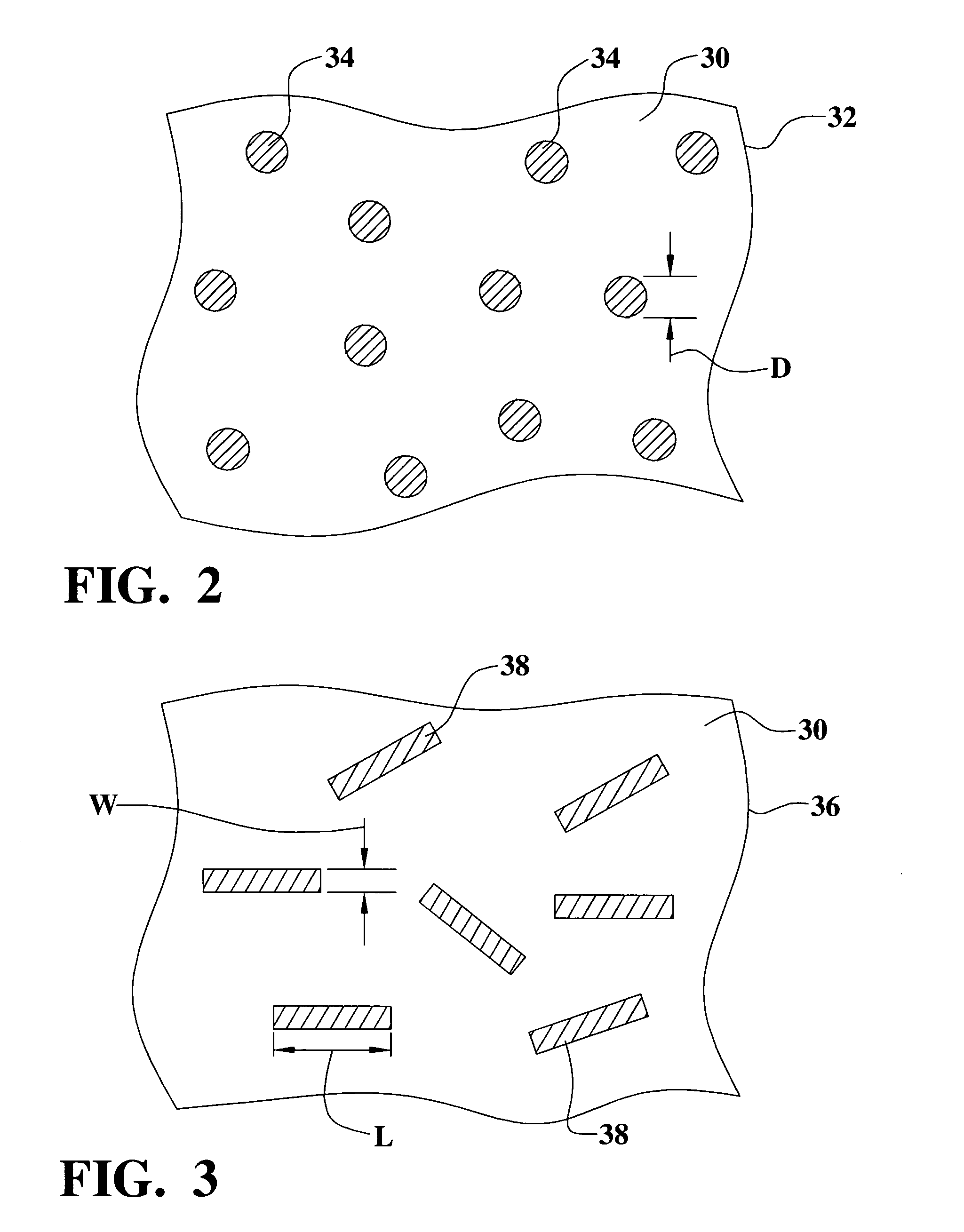

Abrasive cutter containing diamond particles and a method for producing the cutter

InactiveUS6238280B1Eliminate disadvantagesAvoid attenuationRevolution surface grinding machinesBonded abrasive wheelsMetal coatingDiamond crystal

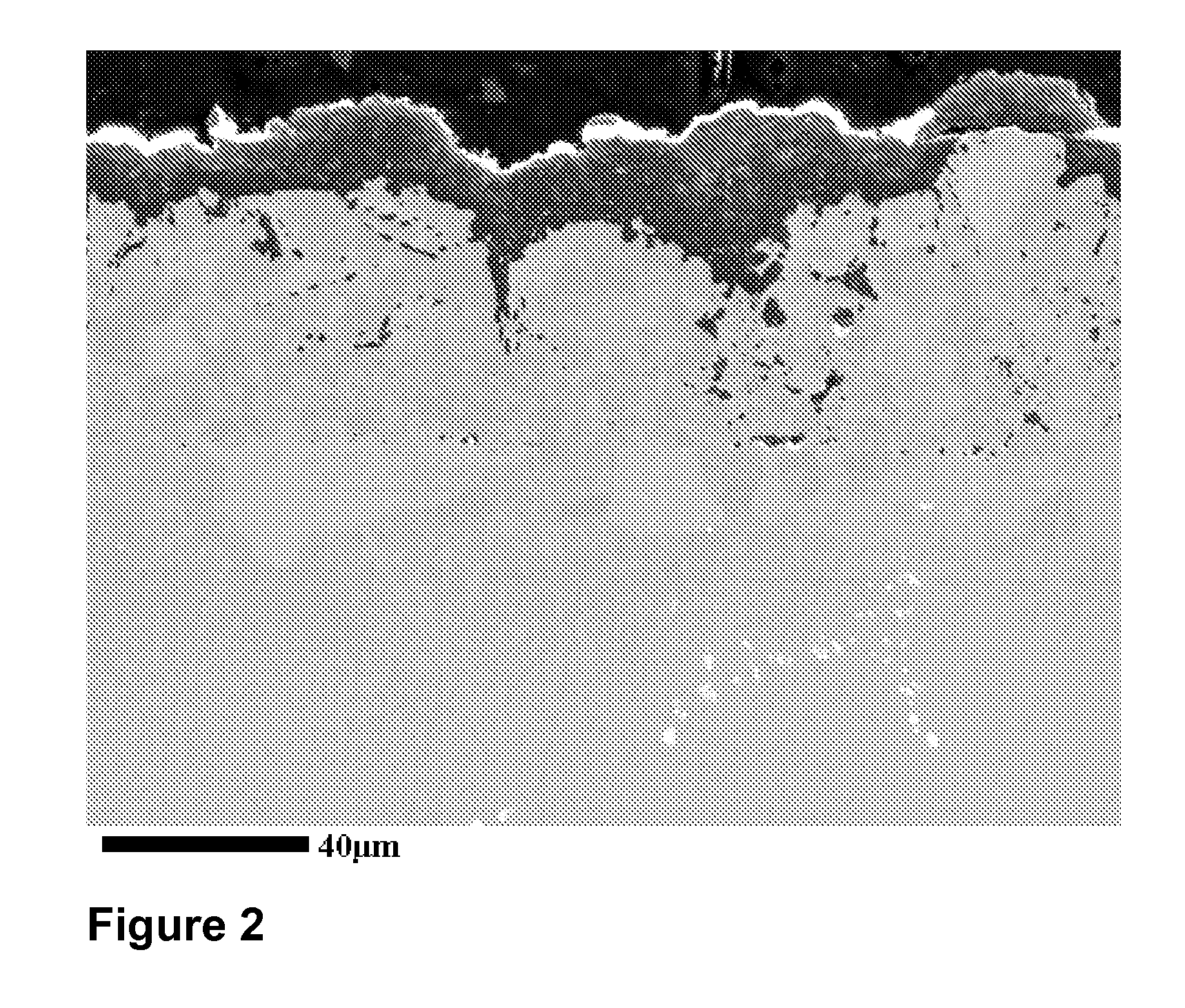

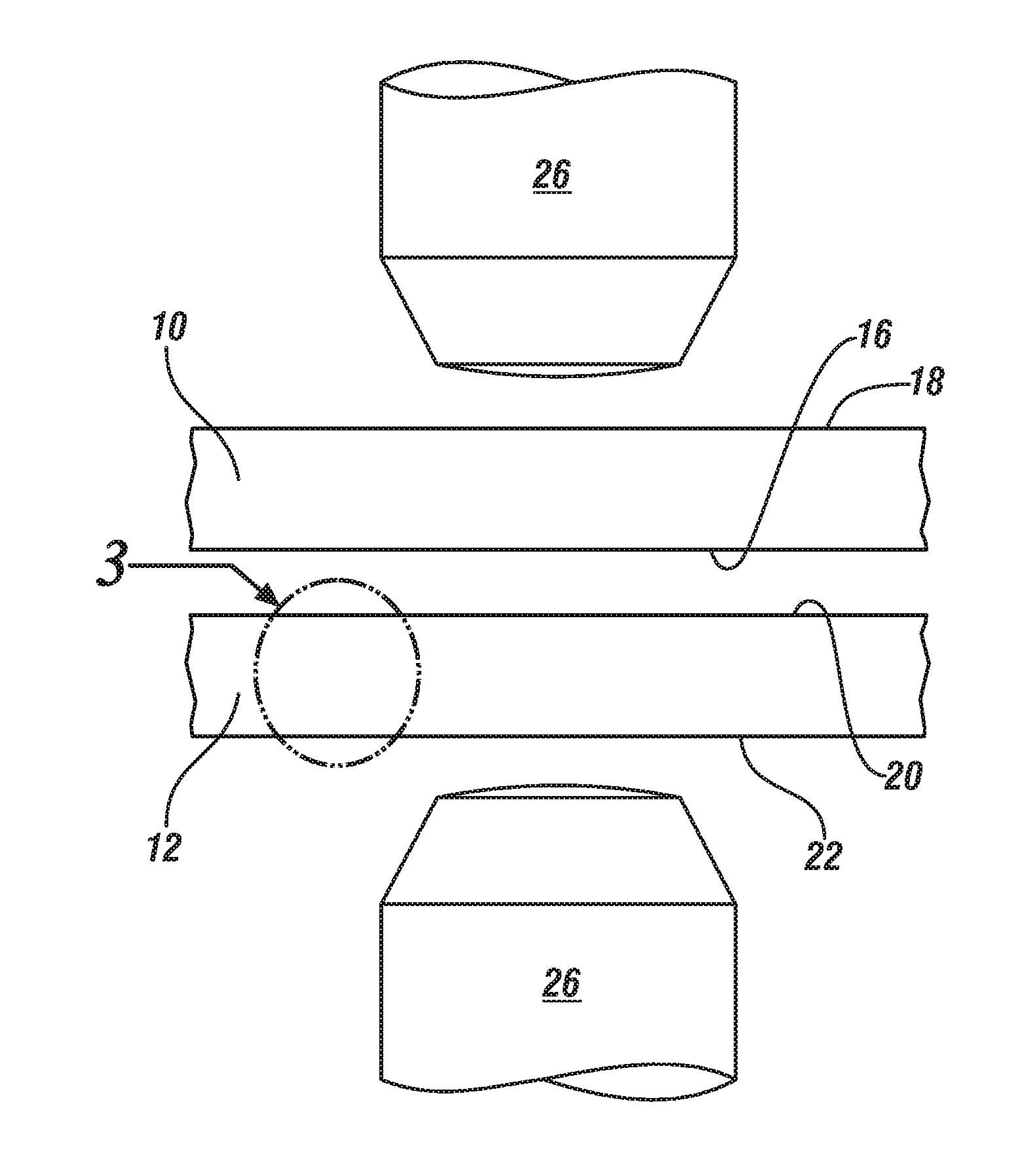

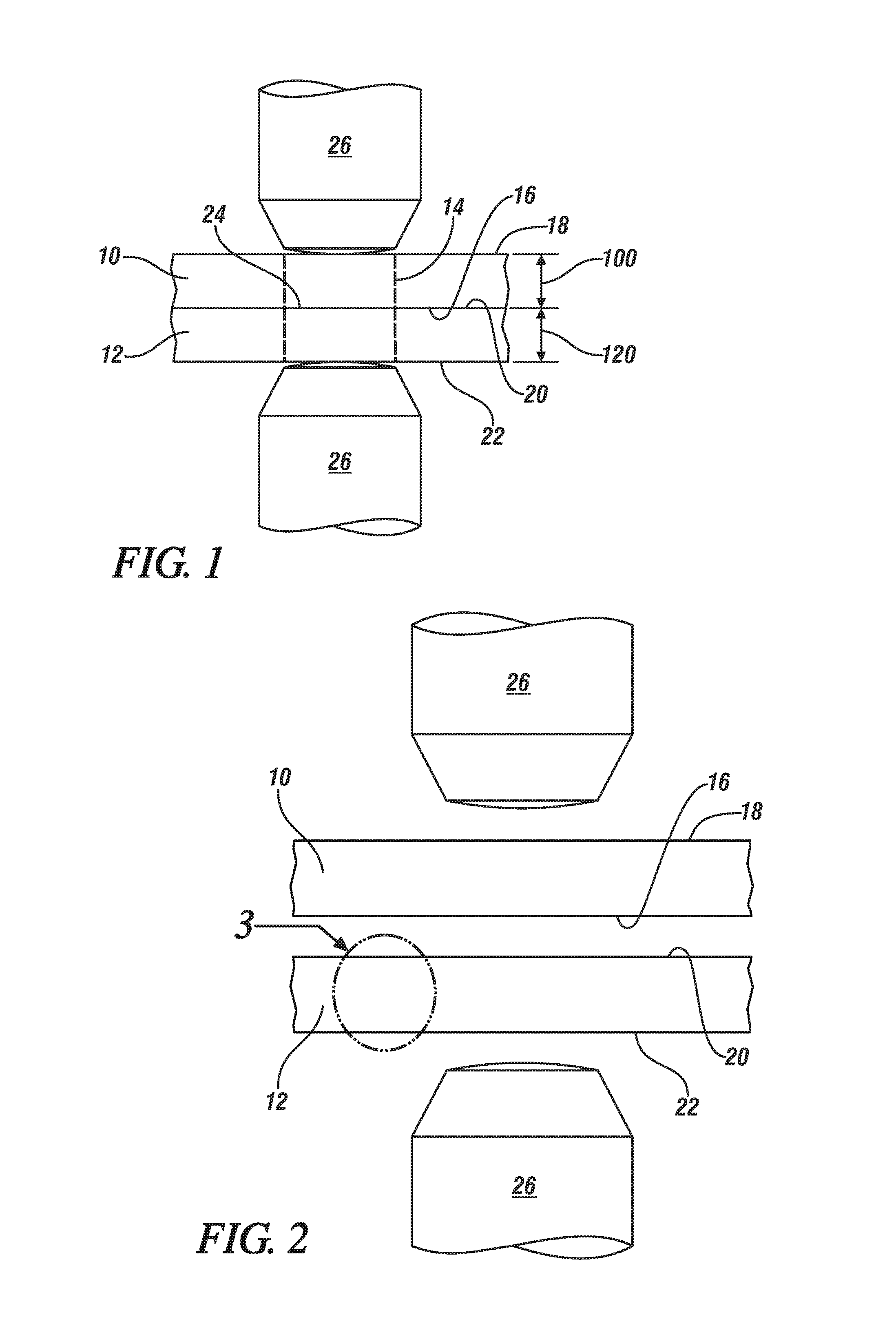

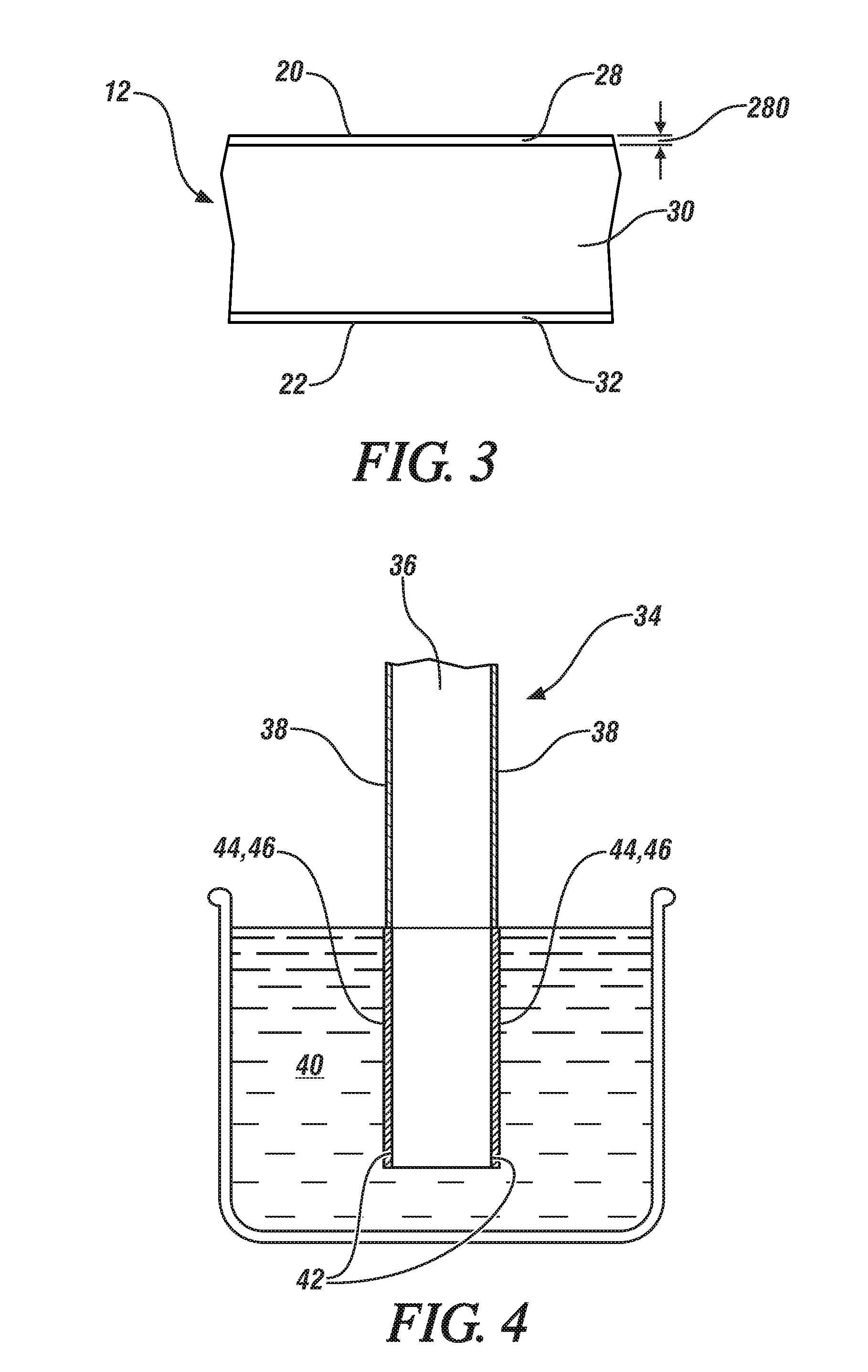

An abrasive cutter formed of at least one diamond particle, preferably at least one mono-diamond crystal and metallic binder material distinguished by the fact that the diamond particle (D) has a size of about 50 mum to about 500 mum and each diamond particle (D) is enclosed by a coating (H) produced in a fluidized bed with the coating having a wall thickness of about 10 mum to about 200 mum. The volume of the coating (H) constitutes at least 30% of the volume of the diamond particles (D) in the fully consolidated state following individual sintering of the coated diamond particles (D, H). The abrasive cutters can be applied directly onto an abrasive tool. Further they can be processed to form composite cutters or cutting segments. In the method of forming the abrasive cutter, the diamond particle (D) is brought into a fluidized bed reactor and enclosed in a metallic coating (H). Coated diamond particle (D, H) can be processed into larger cutters or segments in each case individually sintered and fixed directly on an abrasive tool.

Owner:HILTI AG

Method for loading nanoporous layers with therapeutic agent

The present invention relates generally to medical devices with therapy eluting components and methods for making same. More specifically, the invention relates to implantable medical devices having at least one porous layer, and methods for making such devices, and loading such devices with therapeutic agents. A mixture or alloy is placed on the surface of a medical device, then one component of the mixture or alloy is generally removed without generally removing the other components of the mixture or alloy. In some embodiments, a porous layer is adapted for bonding non-metallic coating, including drug eluting polymeric coatings. A porous layer may have a random pore structure or an oriented or directional grain porous structure. One embodiment of the invention relates to medical devices, including vascular stents, having at least one porous layer adapted to resist stenosis or cellular proliferation without requiring elution of therapeutic agents. The invention also includes methods, devices, and specifications for loading of drugs and other therapeutic agents into nanoporous coatings.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND +1

Metallic coating for single crystal alloys

InactiveUS20110256421A1Polycrystalline material growthMolten spray coatingSingle crystal superalloySingle crystal

A metallic coating for use in a high temperature application is created from a nickel base alloy containing from 5.0 to 10.5 wt % aluminum, from 4.0 to 15 wt % chromium, from 2.0 to 8.0 wt % tungsten, from 3.0 to 10 wt % tantalum, and the balance nickel. The metallic coating has particular utility in protecting single crystal superalloys used in high temperature applications such as turbine engine components.

Owner:UNITED TECH CORP

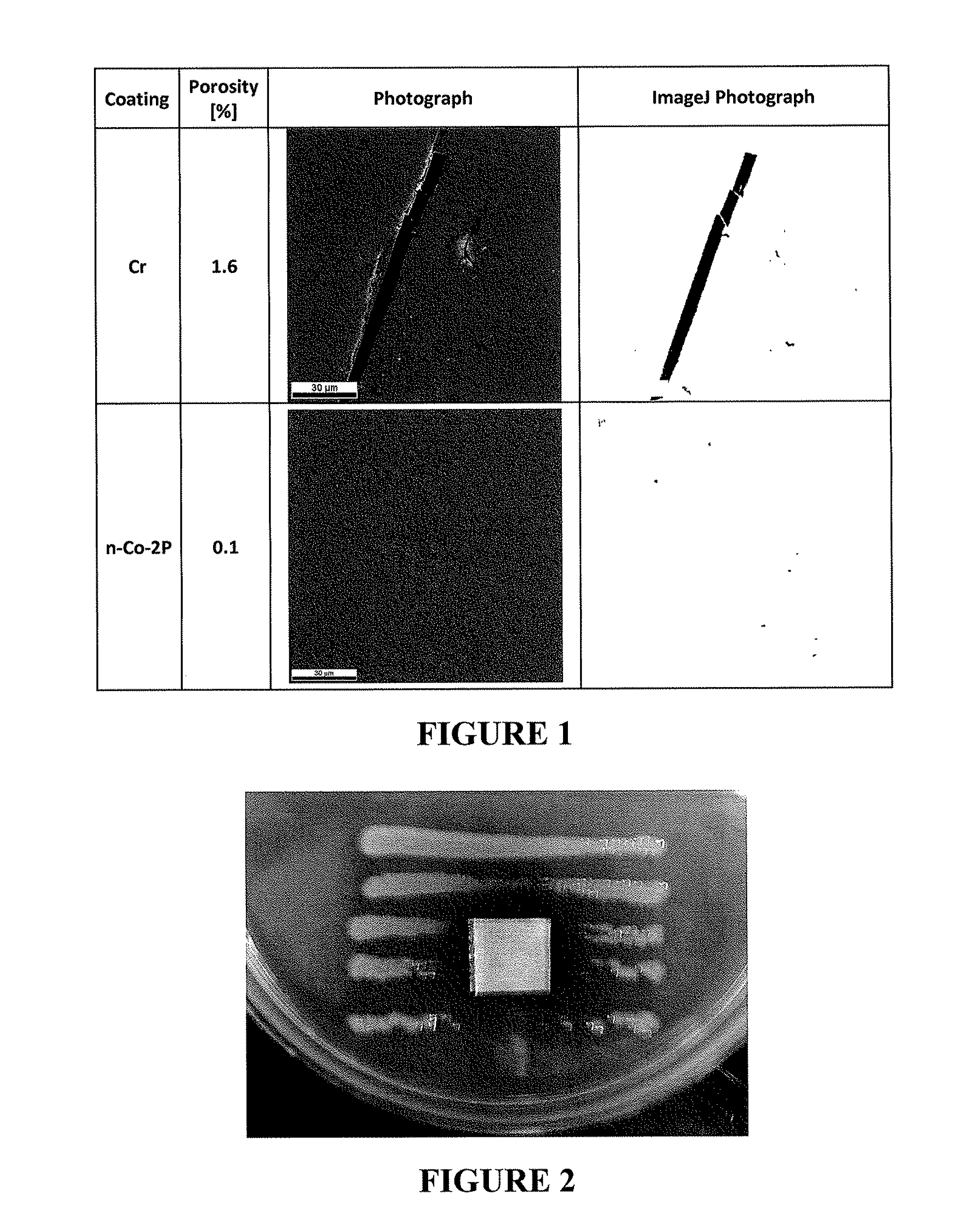

Fine-grained metallic coatings having the coefficient of thermal expansion matched to the one of the substrate

ActiveUS7320832B2Good thermal cycle performanceHigh strengthMaterial nanotechnologyRodsParticulatesChemical composition

Owner:INTEGRAN TECH

Resistance spot welding of steel to pre-coated aluminum

ActiveUS20140360986A1Low melting pointImprove the immunityWelding/soldering/cutting articlesResistance welding apparatusTitanium zirconiumConversion coating

Resistance spot welding of a steel workpiece to an aluminum or an aluminum alloy workpiece can be facilitated by replacing the refractory aluminum oxide-based layer(s) on at least the faying surface of the aluminum or aluminum alloy workpiece with a protective coating that is more conducive to the spot welding process. The protective coating may be a metallic coating or a metal oxide conversion coating. In a preferred embodiment, the protective coating is a coating of zinc, tin, or an oxide of titanium, zirconium, chromium, or silicon.

Owner:GM GLOBAL TECH OPERATIONS LLC

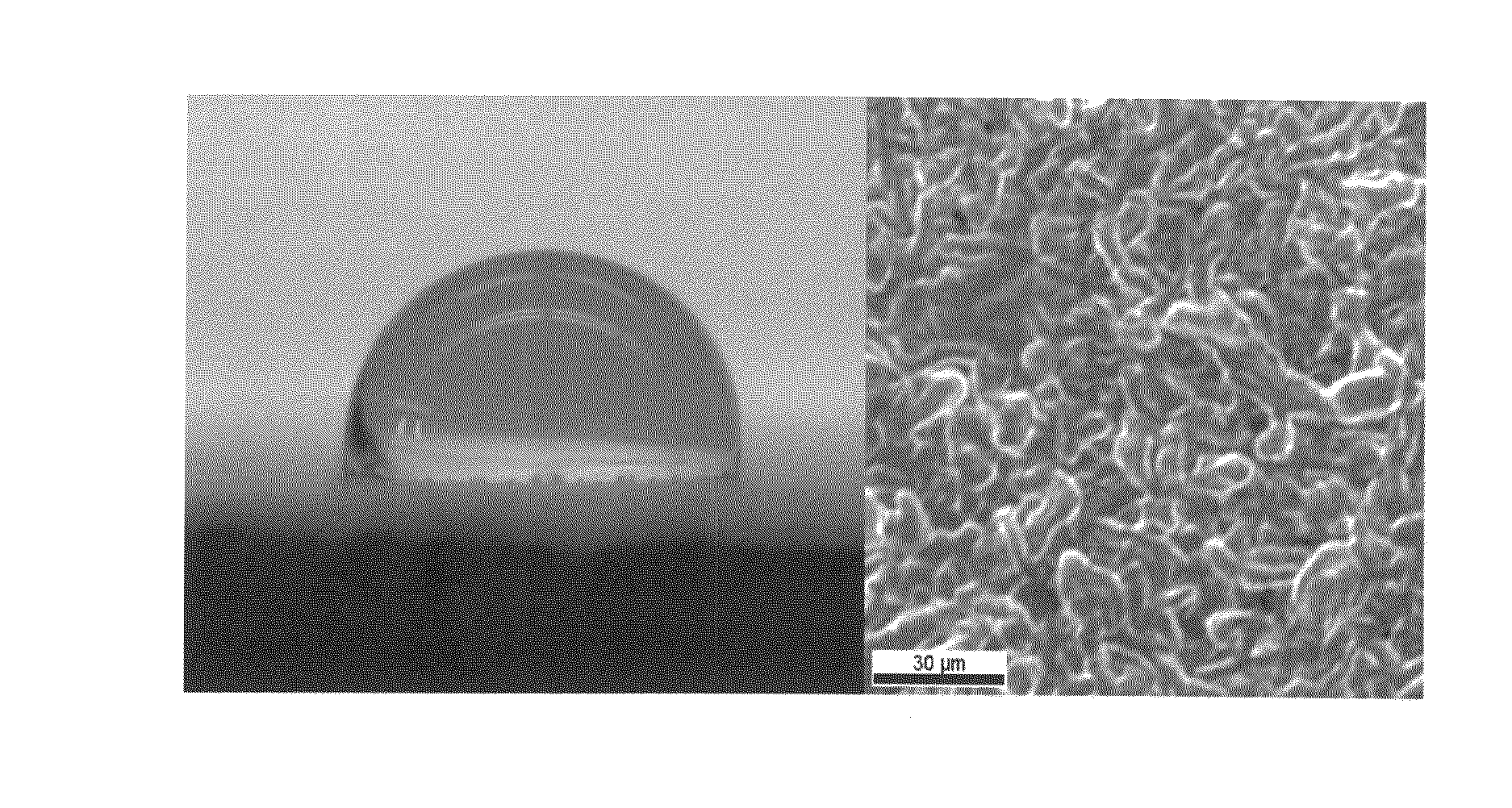

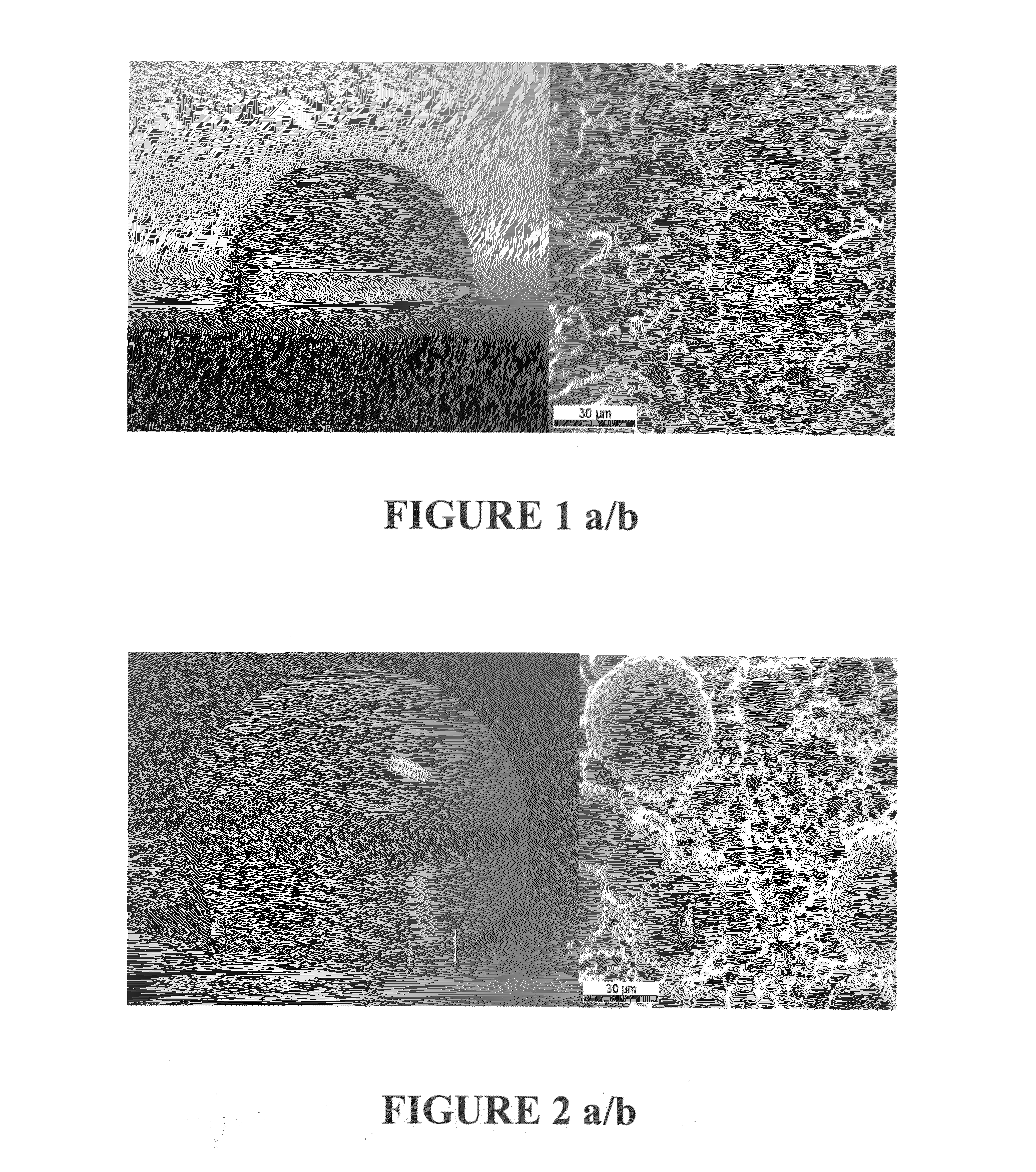

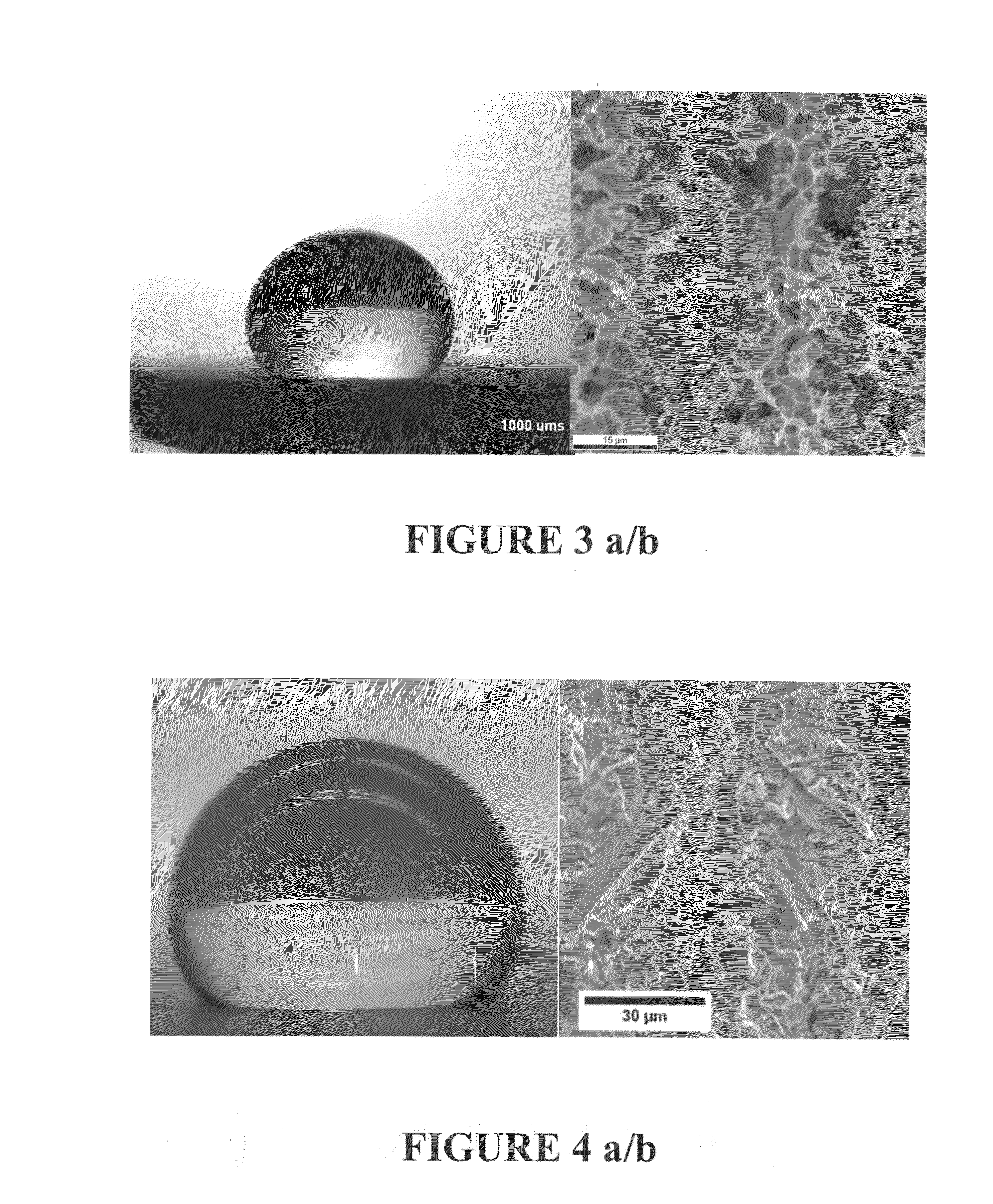

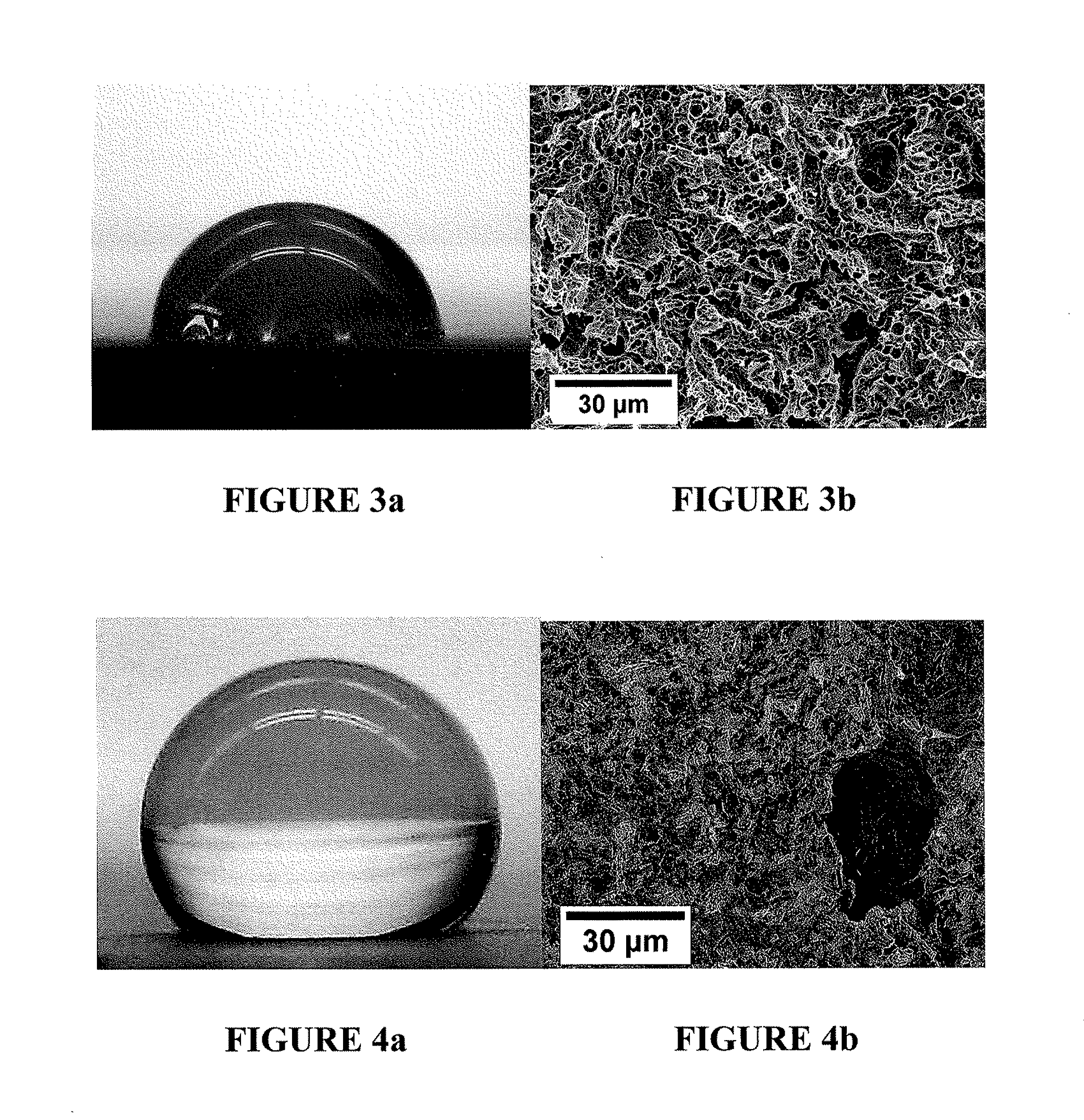

Metallic articles with hydrophobic surfaces

ActiveUS20110287223A1Lower contact angleLarge scaleElectrolysis componentsPretreated surfacesMetal coatingMetallic materials

Articles containing fine-grained and / or amorphous metallic coatings / layers on at least part of their exposed surfaces are imprinted with surface structures to raise the contact angle for water in the imprinted areas at room temperature by equal to or greater than 10°, when compared to the flat and smooth metallic material surface of the same composition.

Owner:INTEGRAN TECH

Dealloyed nanoporous stents

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND +1

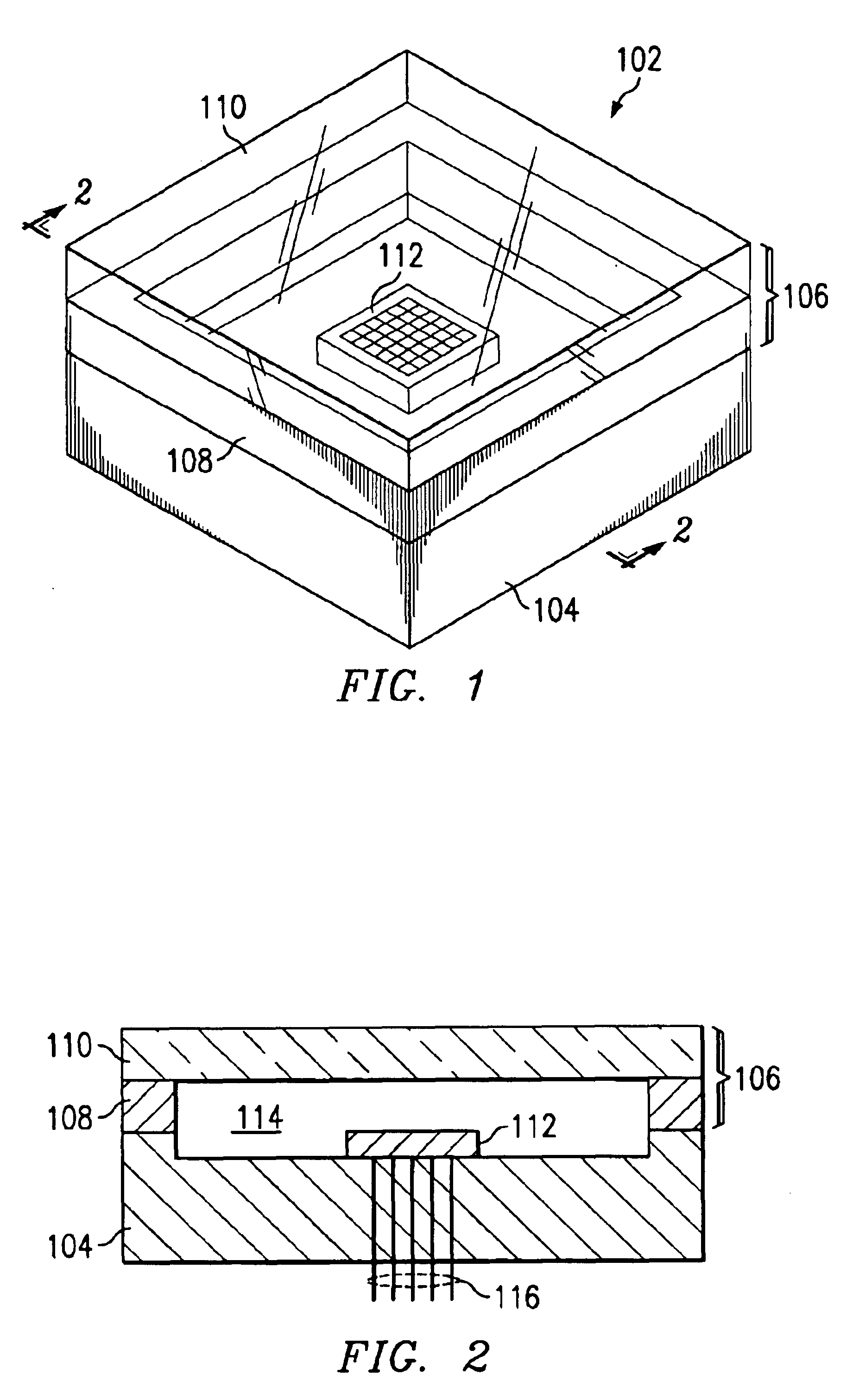

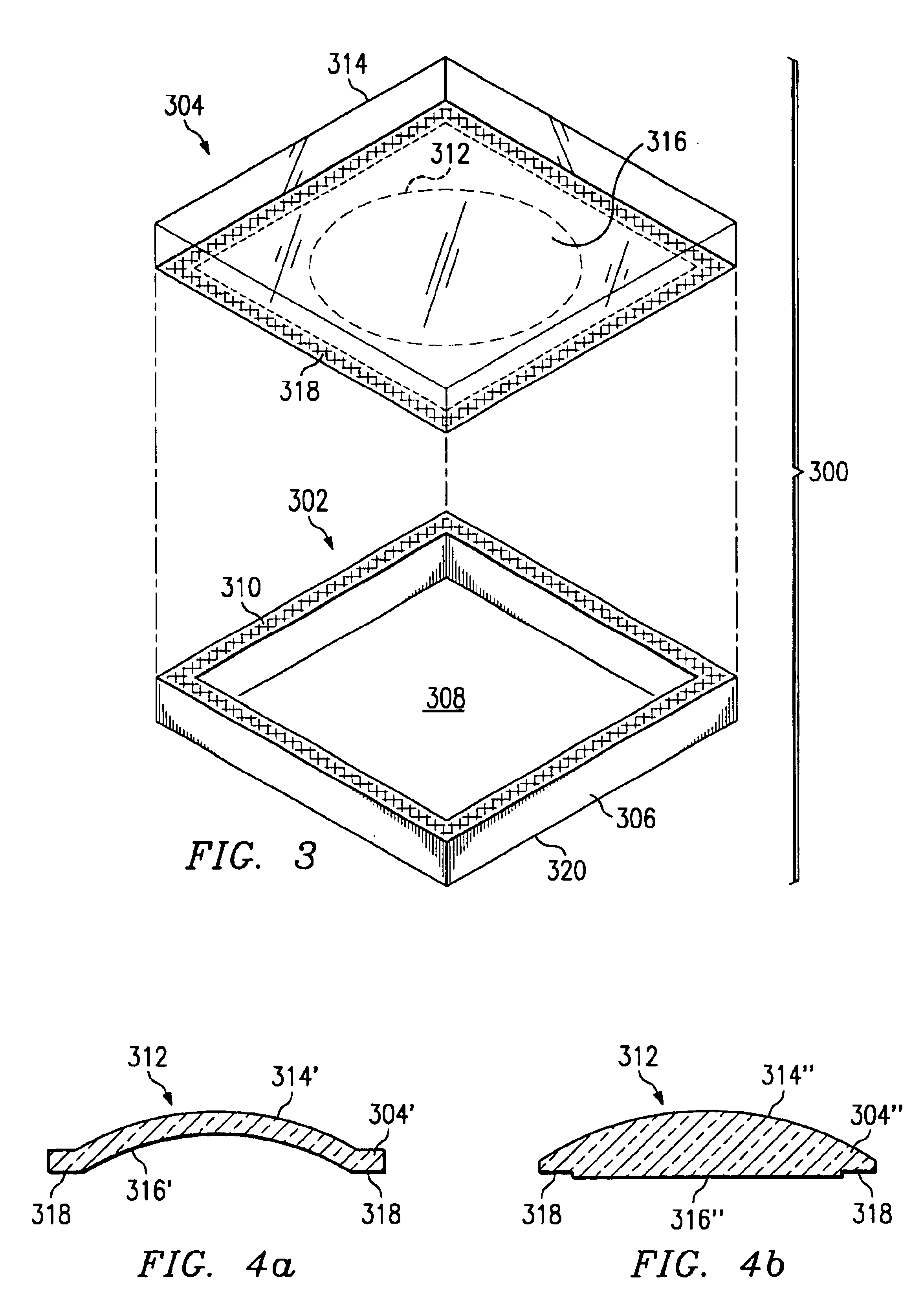

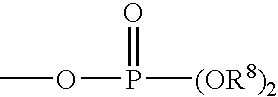

Hermetically sealed micro-device package using cold-gas dynamic spray material deposition

InactiveUS6924974B2Digital data processing detailsSemiconductor/solid-state device detailsMetal coatingMetal framework

A cover assembly for welding to a package base to form a hermetically sealed micro-device package. The cover assembly includes a sheet of a transparent material having a window portion. A built-up metallic frame adheres to the sheet and circumscribes the window portion, the frame having been deposited as follows: First, powdered metal particles are sprayed onto a prepared area of the sheet using a gas jet at a temperature below the fusing temperature of the particles, the jet having a velocity sufficient to cause the particles to merge with one another upon impact with the sheet and with one another to form an initial continuous metallic coating adhering to the prepared area of the sheet. Next, successive metal particles are applied over the initial coating using the jet to form the frame incorporating the initial continuous metallic coating as its base and having an predetermined overall thickness.

Owner:ASTRAVAC GLASS INC

Nanoporous layers using thermal dealloying

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND +1

Medical devices having nanoporous bonding layers

The present invention relates generally to medical devices with therapy eluting components and methods for making same. More specifically, the invention relates to implantable medical devices having at least one porous layer, and methods for making such devices, and loading such devices with therapeutic agents. A mixture or alloy is placed on the surface of a medical device, then one component of the mixture or alloy is generally removed without generally removing the other components of the mixture or alloy. In some embodiments, a porous layer is adapted for bonding non-metallic coating, including drug eluting polymeric coatings. A porous layer may have a random pore structure or an oriented or directional grain porous structure. One embodiment of the invention relates to medical devices, including vascular stents, having at least one porous layer adapted to resist stenosis or cellular proliferation without requiring elution of therapeutic agents. The invention also includes methods, devices, and specifications for loading of drugs and other therapeutic agents into nanoporous coatings.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND +1

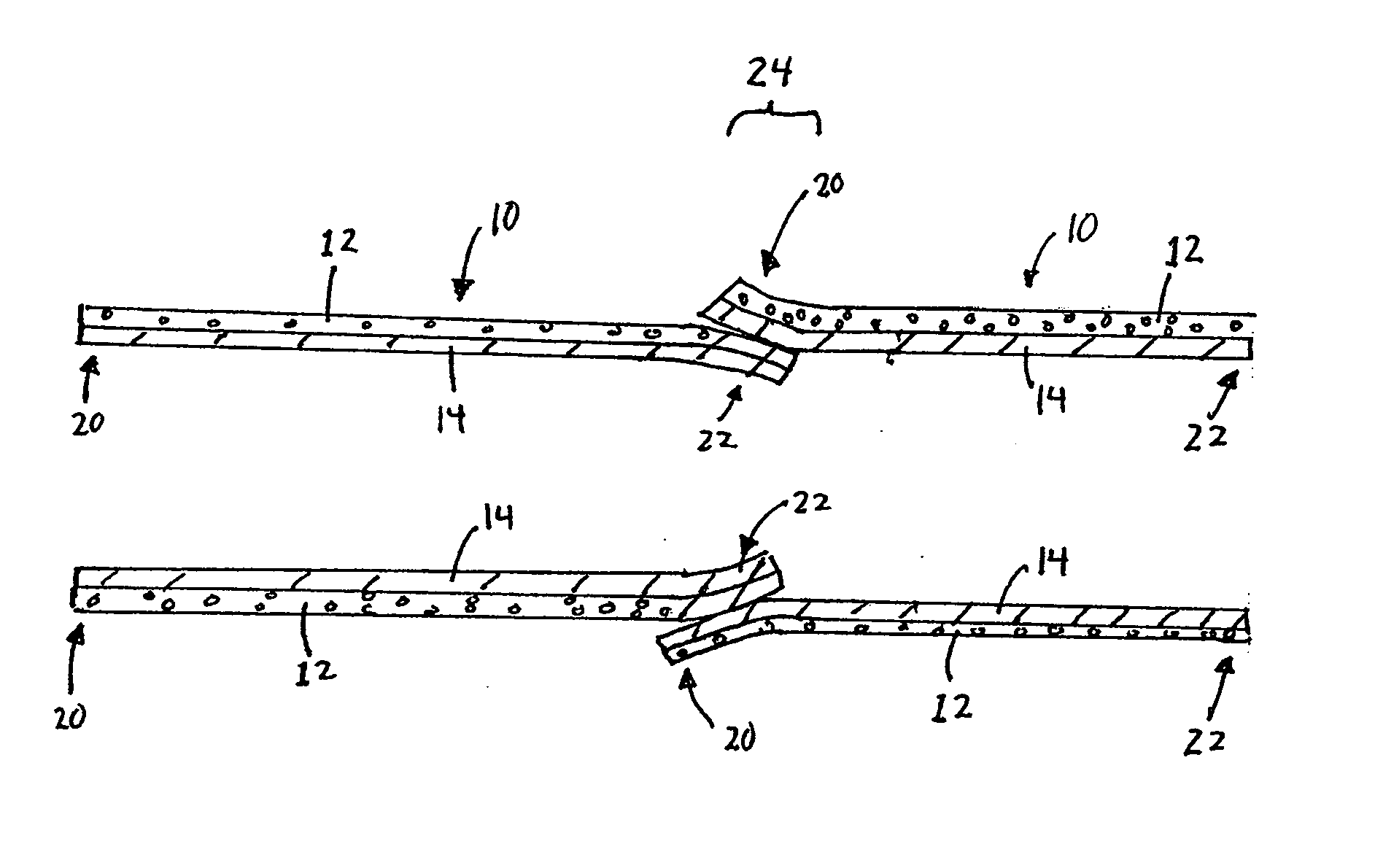

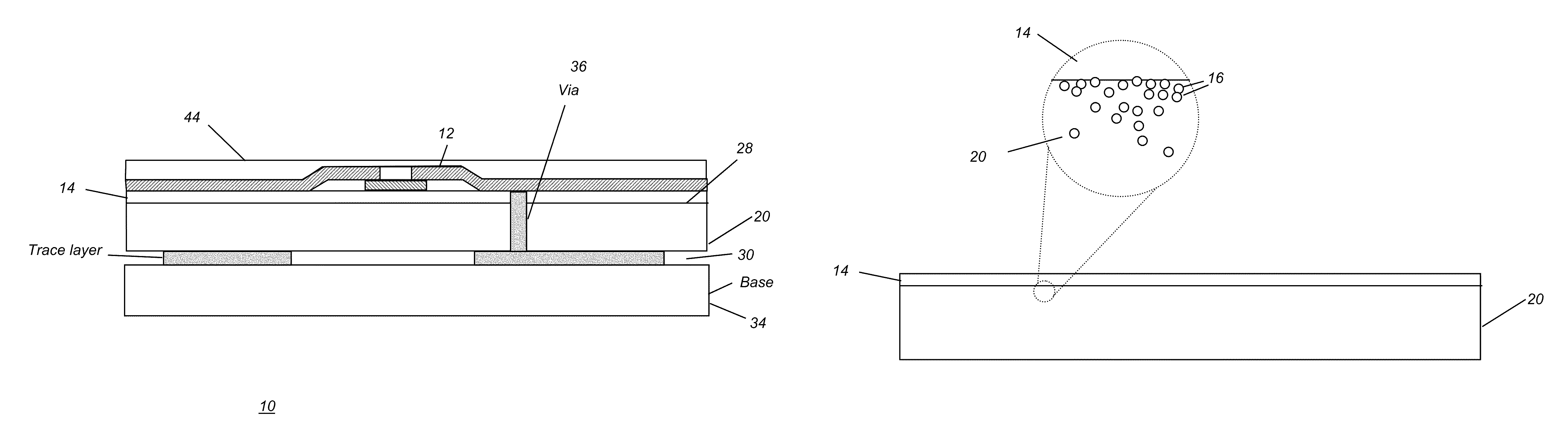

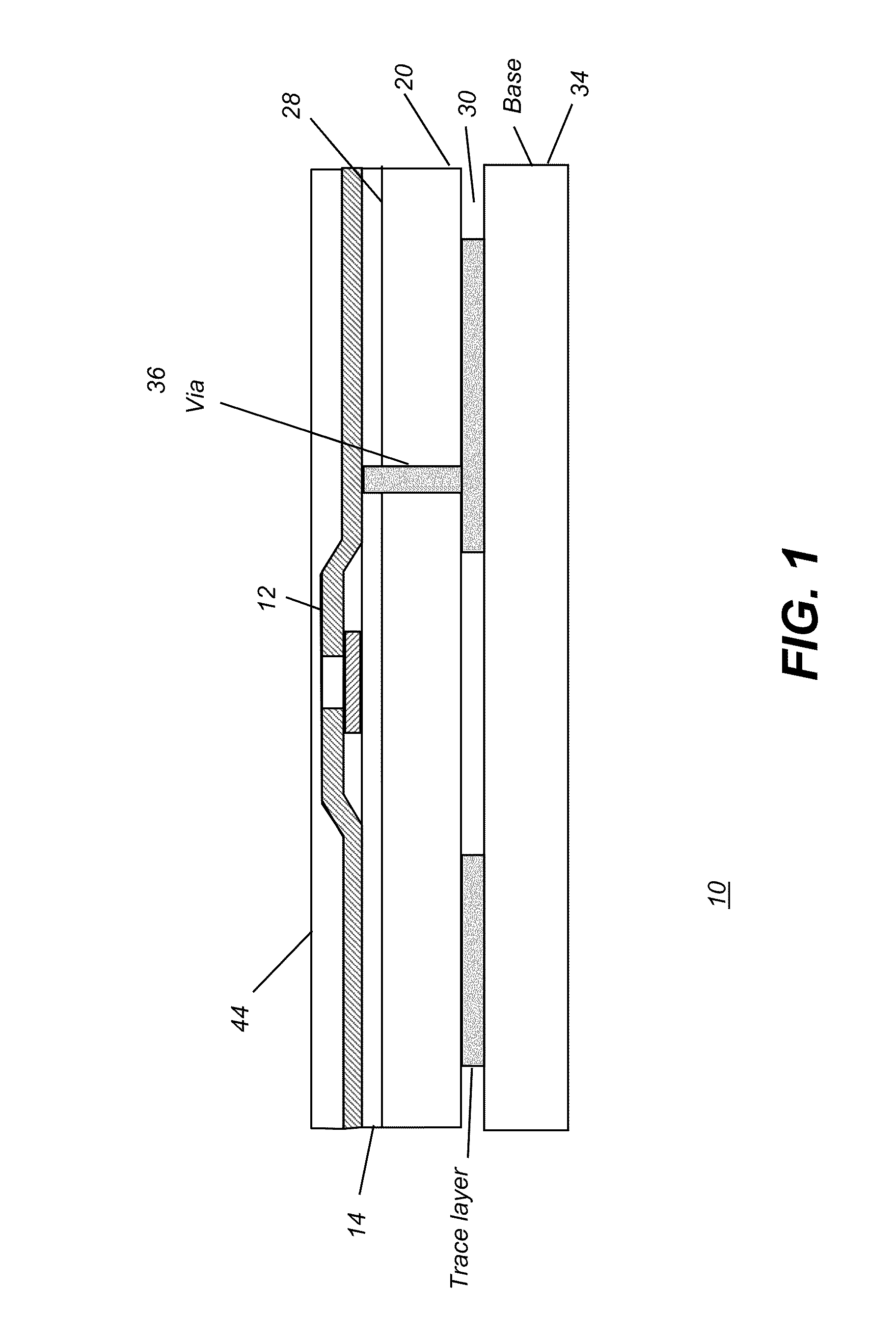

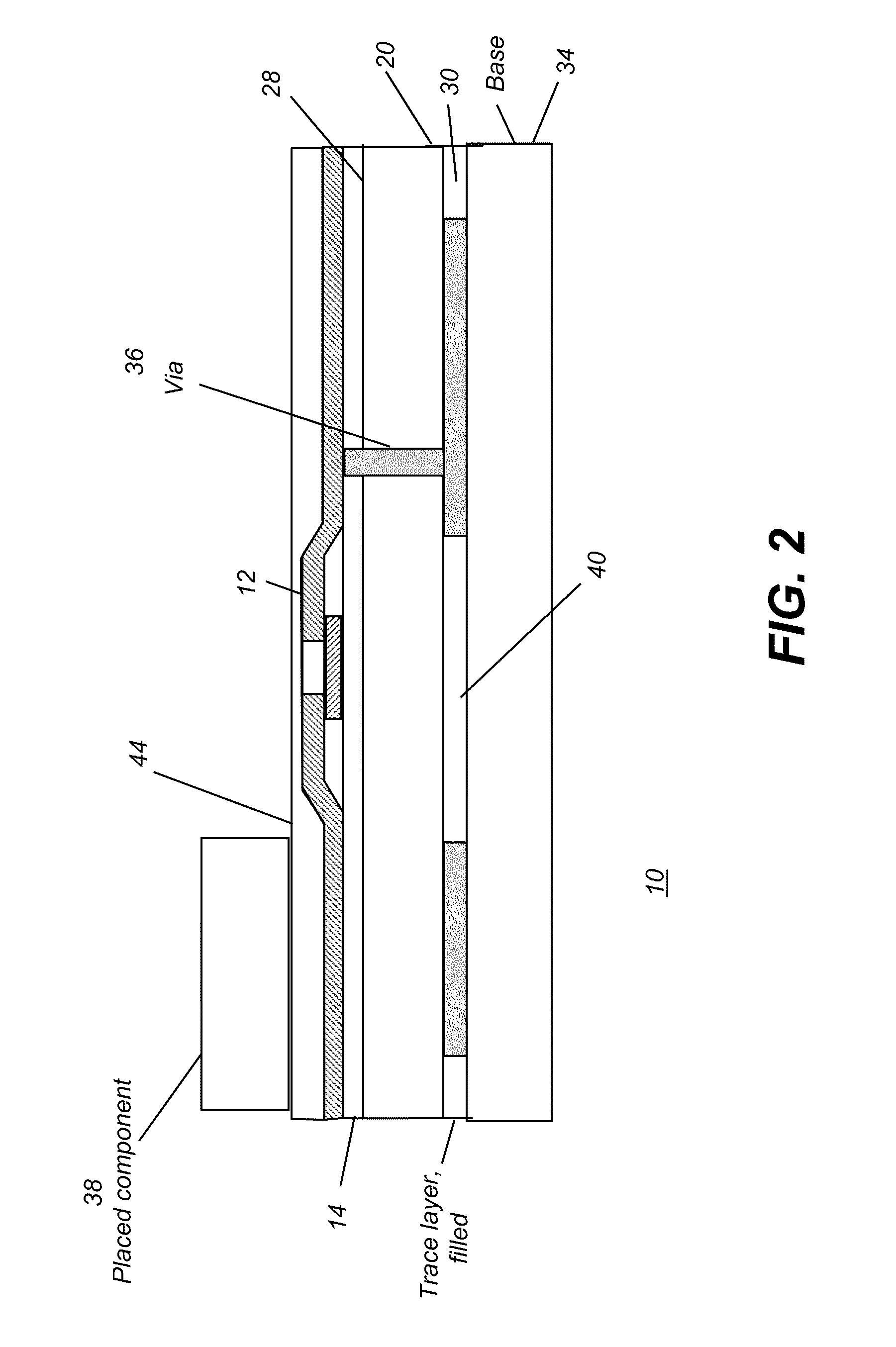

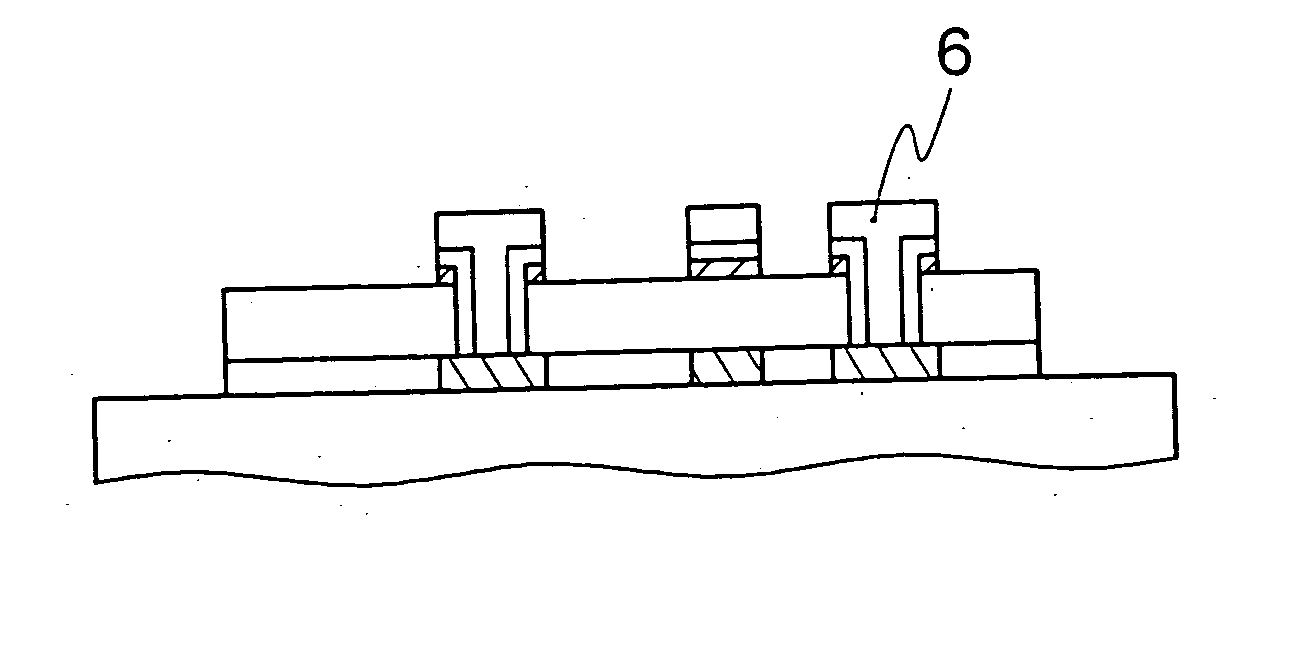

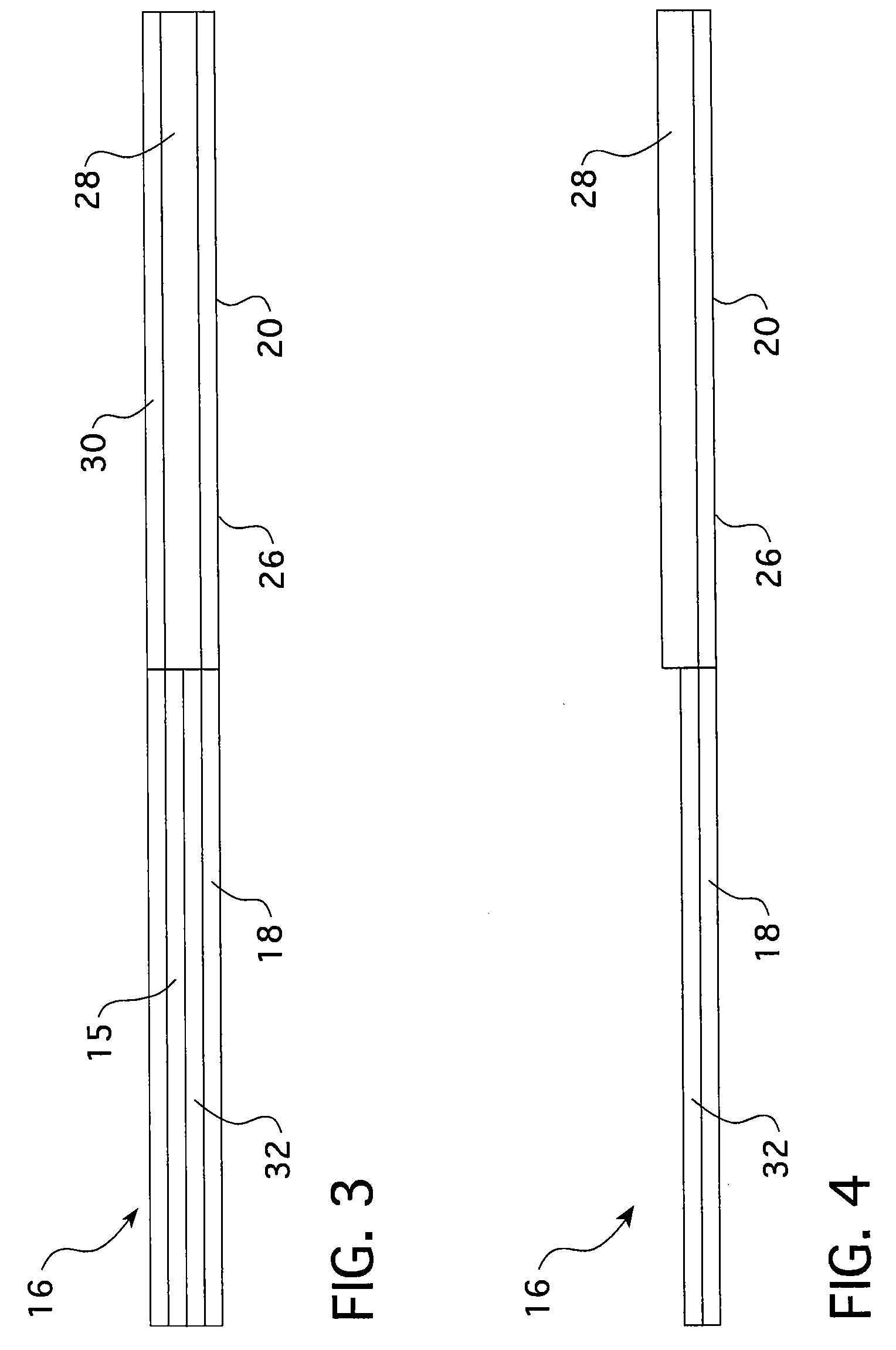

Flexible substrate with electronic devices and traces

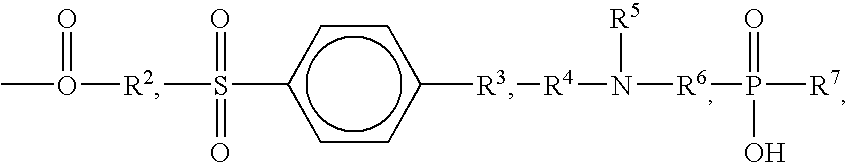

InactiveUS7977170B2Improved laminationSolid-state devicesSemiconductor/solid-state device manufacturingPlastic materialsMetallic coating

A method of manufacturing an electronic device (10) provides a substrate (20) that has a plastic material and has a metallic coating on one surface. A portion of the metallic coating is etched to form a patterned metallic coating. A particulate material (16) is embedded in at least one surface of the substrate. A layer of thin-film semiconductor material is deposited onto the substrate (20).

Owner:EASTMAN KODAK CO

Bipolar plate for fuel cell and method for production thereof

InactiveUS20040247978A1Low costSimple structureFinal product manufactureDecorative surface effectsFuel cellsMetal alloy

In a bipolar plate for a fuel cell including a metal substrate and a metallic coating formed on at least part of a surface of the metal substrate, the durability or the resilience is elevated by suitably selecting a material or a shape of the metal substrate and / or the metallic coating. The material of the metal substrate includes one or more of metals or metal alloys selected from a group consisting of iron, nickel, alloys thereof and stainless steel; and the metallic coating includes a combination of conductive platinum-group metal oxides. The metal substrate may be a thermally oxidized substrate, and the metallic coating may be a conductive oxide. Further, the metallic coating may be a metallic porous element or a metallic porous element having a passivity prevention layer on the surface thereof.

Owner:FURUYA KINZOKU KK

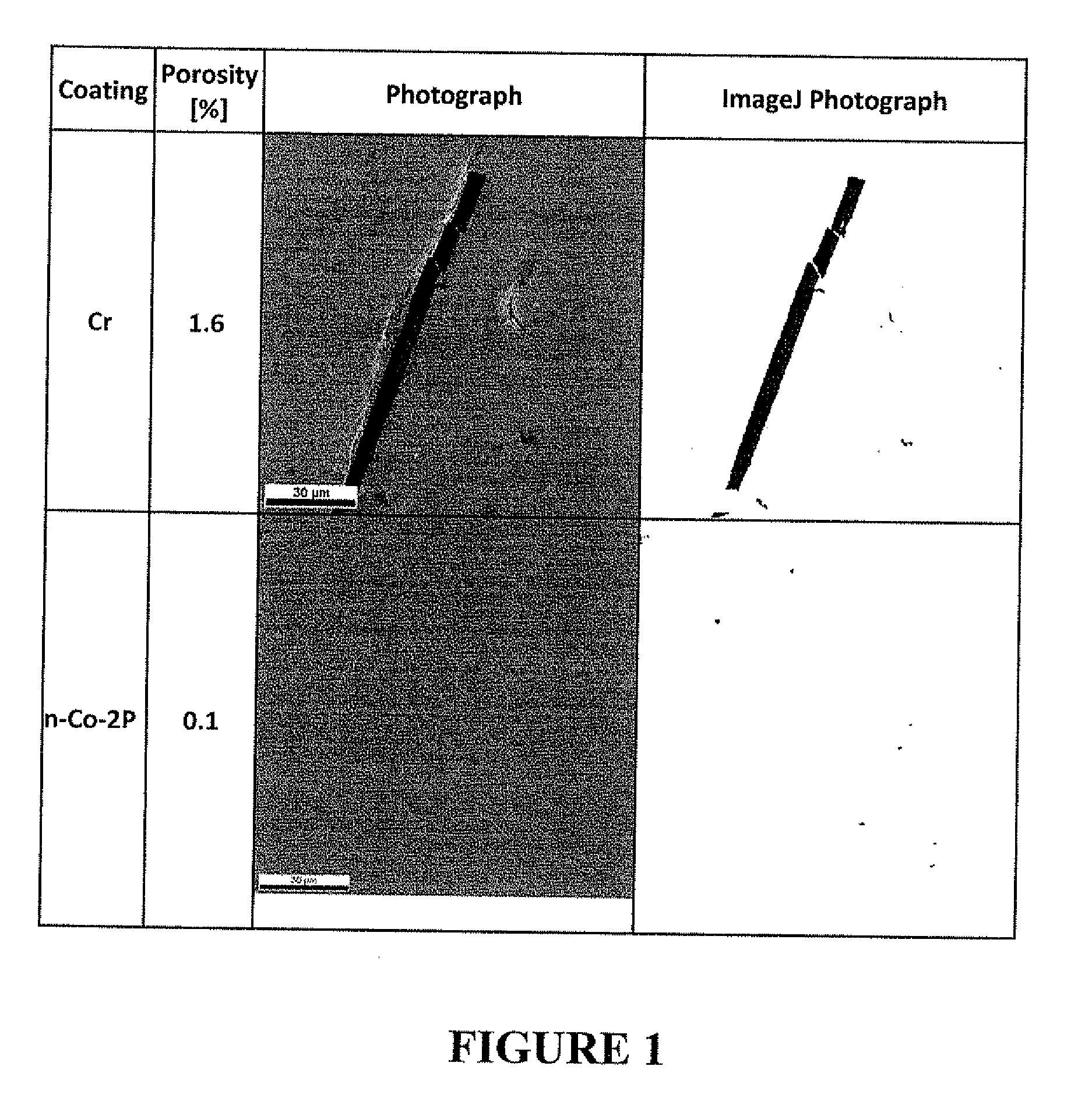

Electrodeposited metallic materials comprising cobalt

ActiveUS20100304179A1Reduce resistanceEliminate security concernsPig casting plantsElectrolytic coatingsMetal coatingMetallic materials

Free standing articles or articles at least partially coated with substantially porosity free, fine-grained and / or amorphous Co-bearing metallic materials optionally containing solid particulates dispersed therein, are disclosed. The electrodeposited metallic layers and / or patches comprising Co provide, enhance or restore strength, wear and / or lubricity of substrates without reducing the fatigue performance compared to either uncoated or equivalent thickness Cr coated substrate. The fine-grained and / or amorphous metallic coatings comprising Co are particularly suited for articles exposed to thermal cycling, fatigue and other stresses and / or in applications requiring anti-microbial and hydrophobic properties.

Owner:INTEGRAN TECH

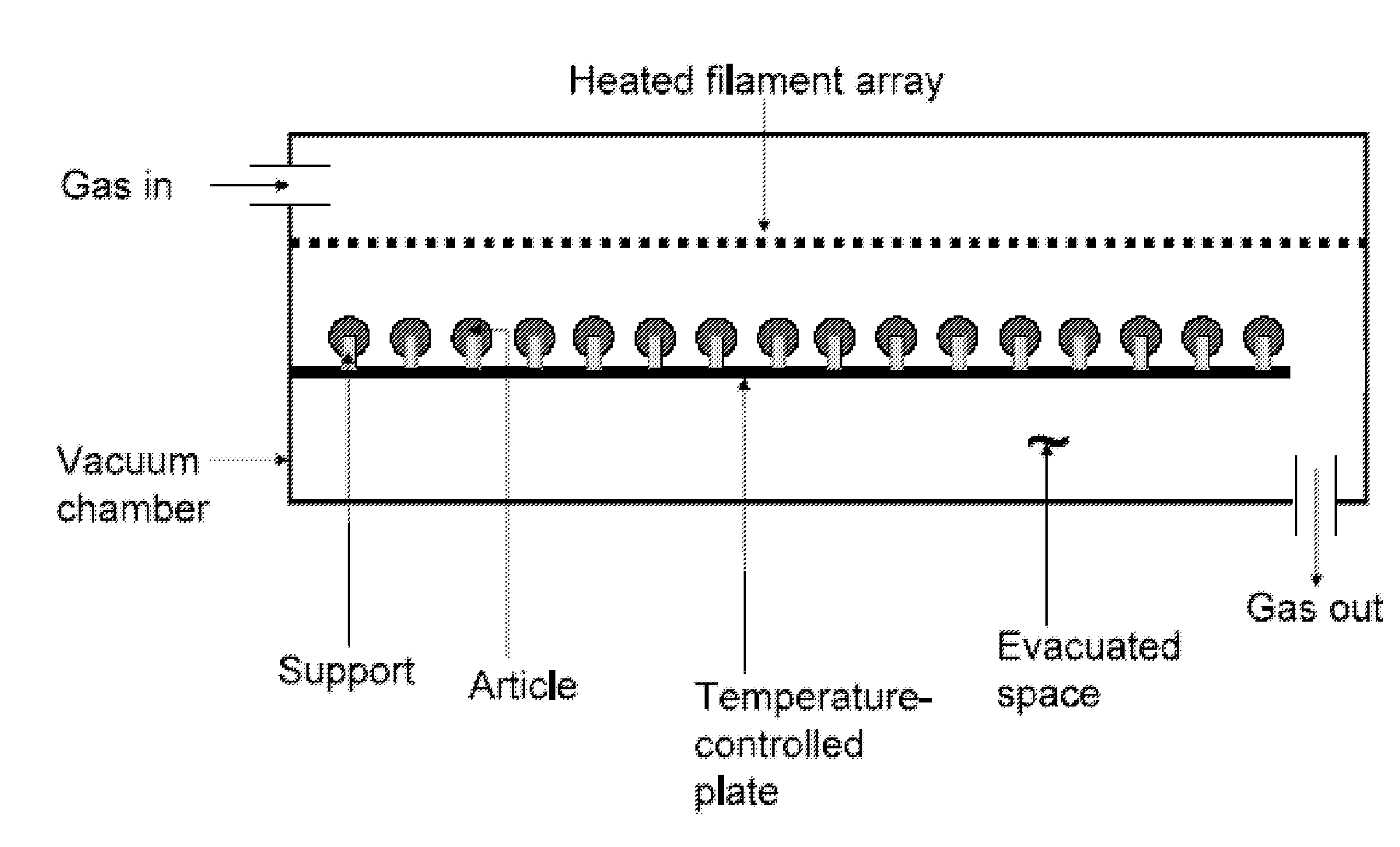

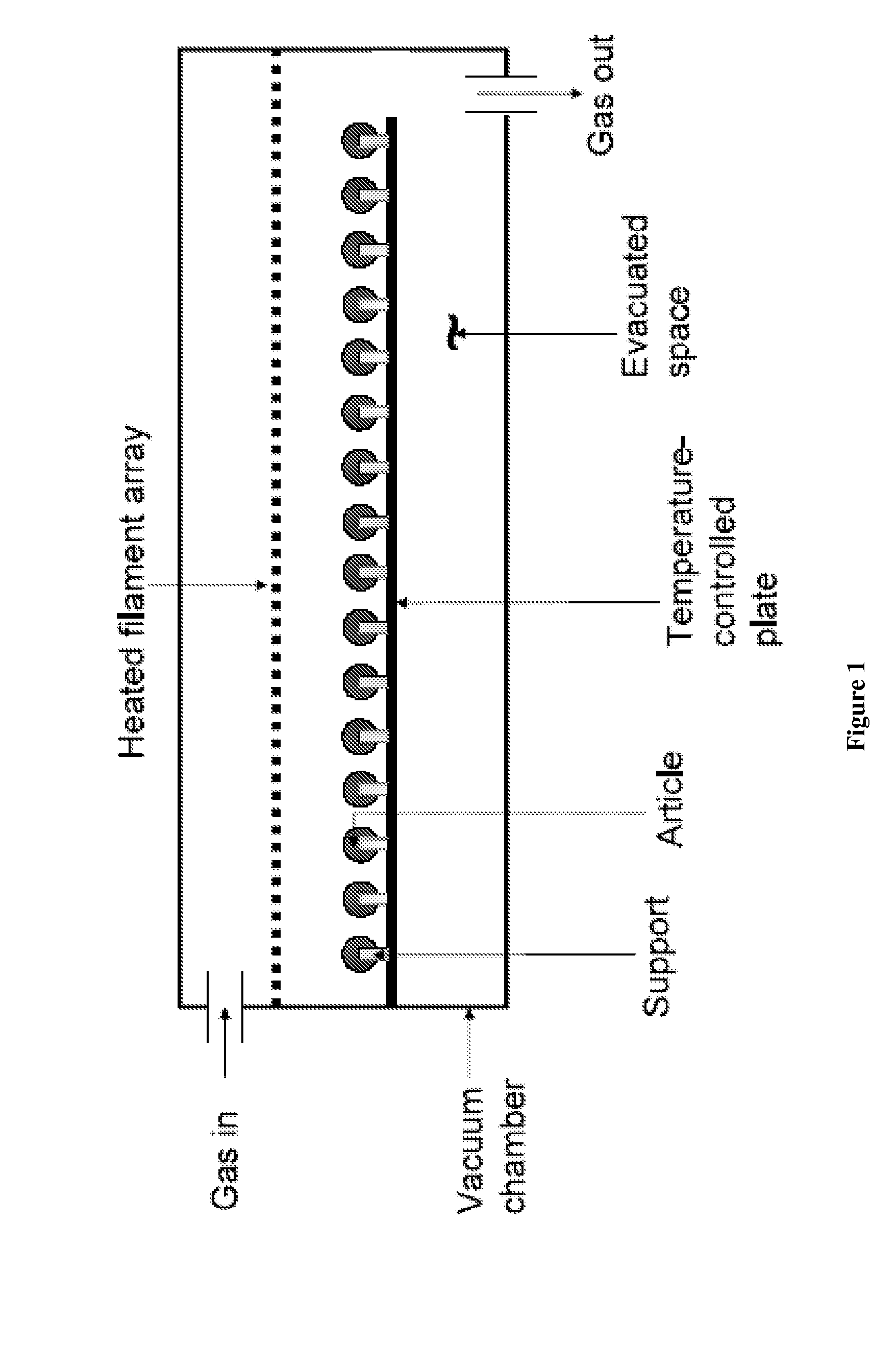

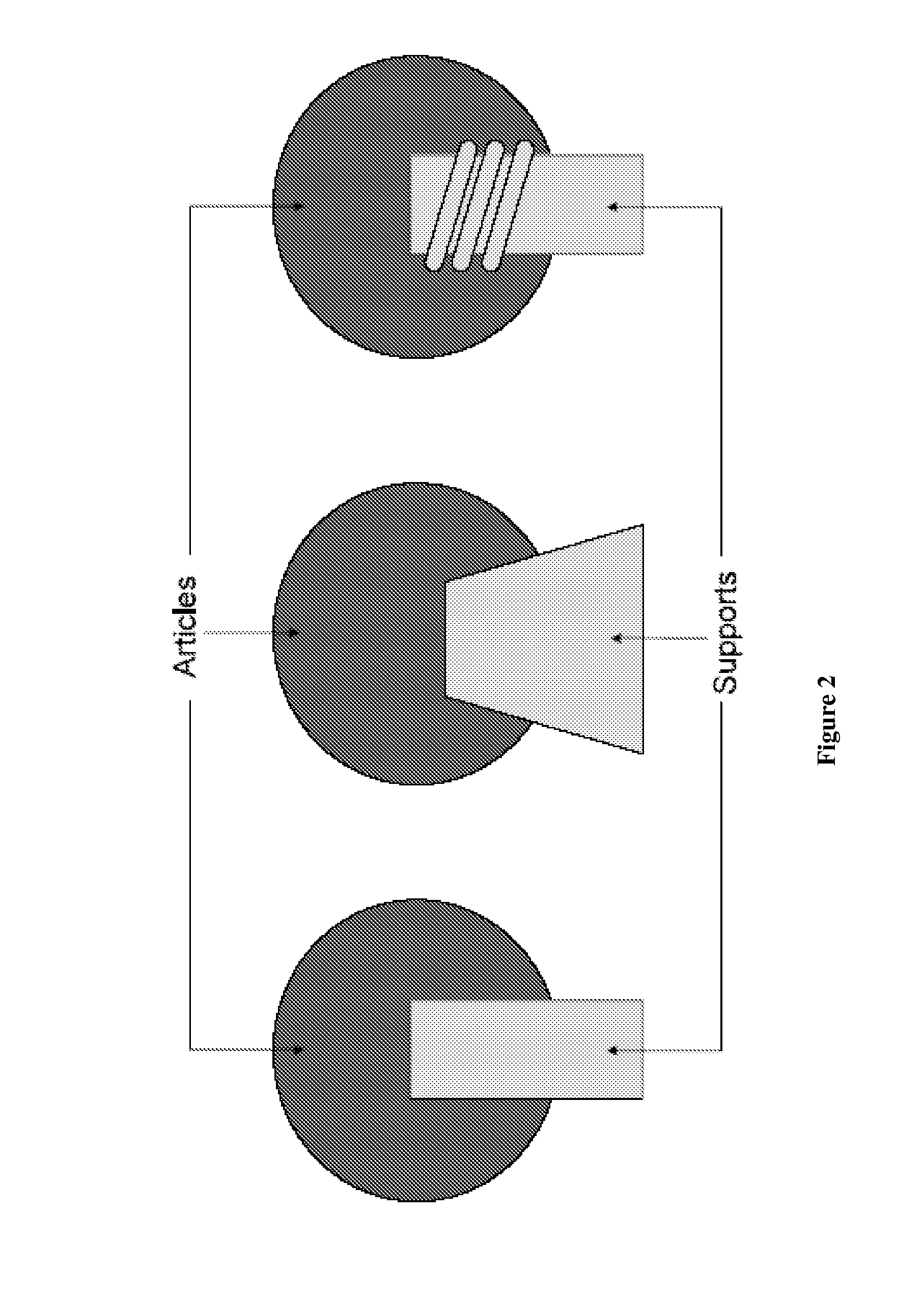

Coating methods, systems, and related articles

ActiveUS20120003497A1Adequate backside coolingEfficient transportVacuum evaporation coatingPretreated surfacesEnergy transferPolymer science

Coated articles and methods and systems for coating the articles are described herein. The methods and systems described herein include, but are not limited to, steps for actively or passively controlling the temperature during the coating process, steps for providing intimate contact between the substrate and the support holding the substrate in order to maximize energy transfer, and / or steps for preparing gradient coatings. Methods for depositing high molecular weight polymeric coatings, end-capped polymer coatings, coatings covalently bonded to the substrate or one another, metallic coatings, and / or multilayer coatings are also disclosed. Deposition of coatings can be accelerated and / or improved by applying an electrical potential and / or through the use of inert gases.

Owner:GVD CORP

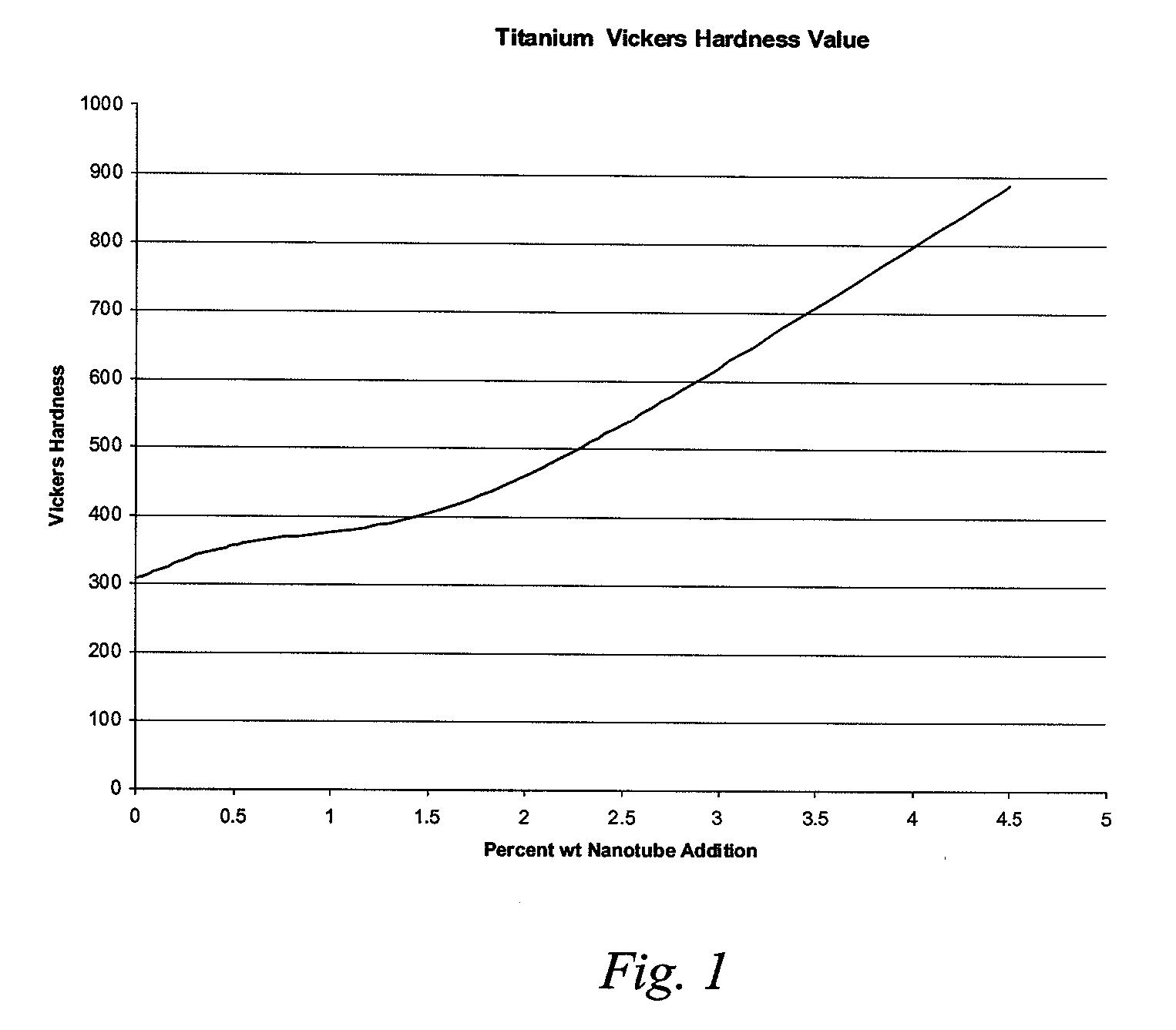

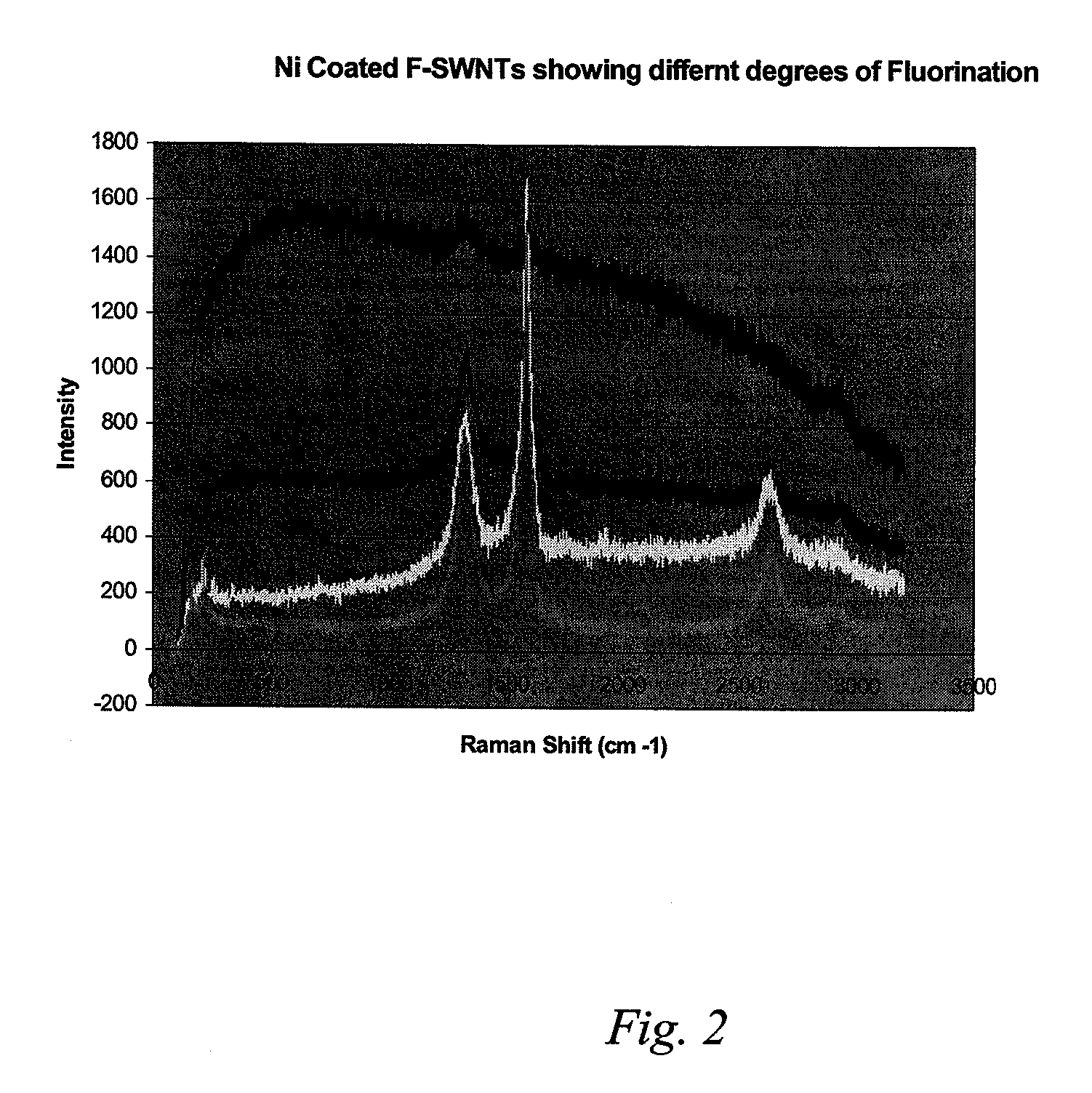

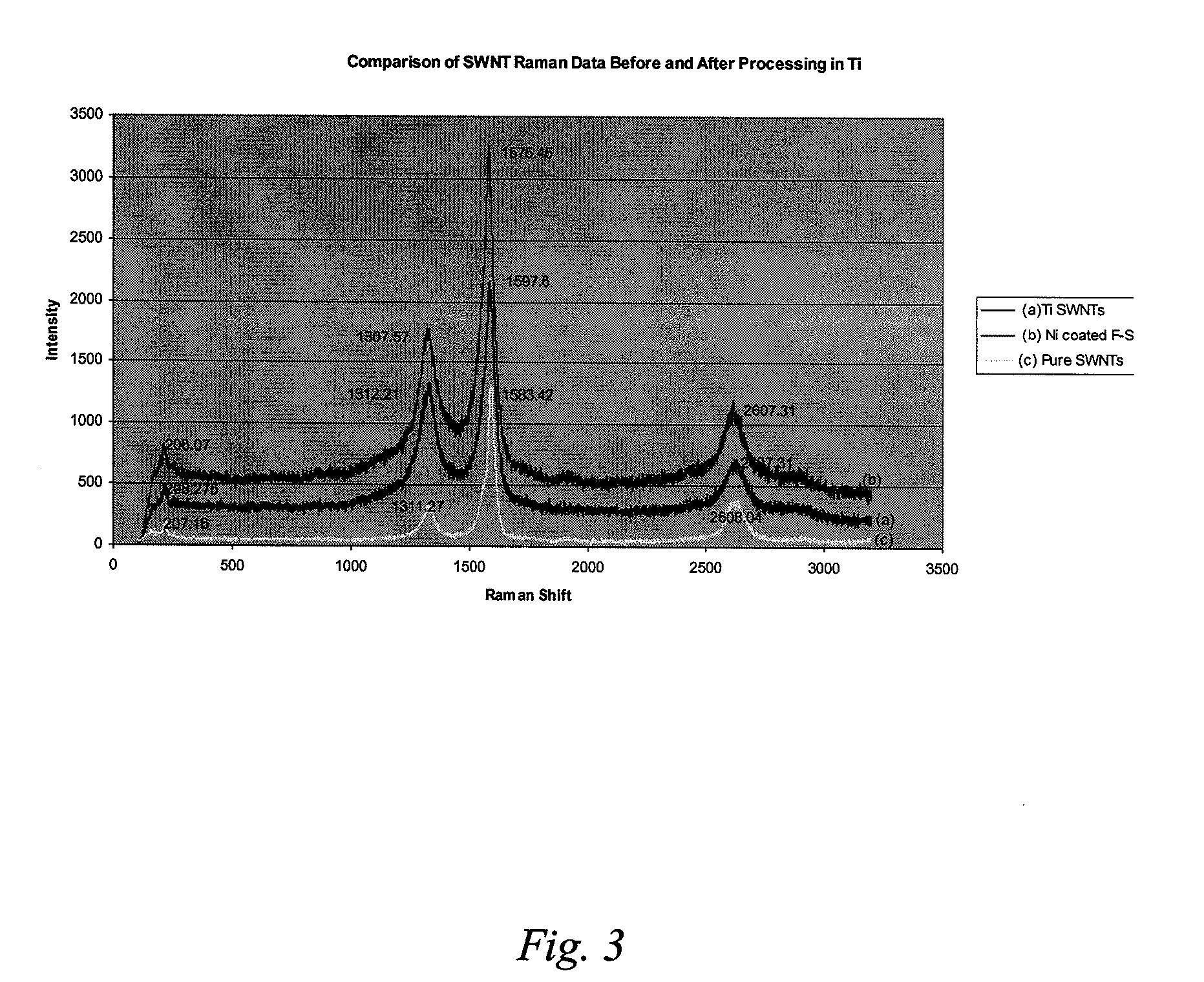

Processing of Single-Walled Carbon Nanotube Metal-Matrix Composites Manufactured by an Induction Heating Method

In some embodiments, the present invention is directed to a new composition of matter. Such a composition generally comprises a functionalized single-wall carbon nanotube (SWNT) which is coated with a metal that would not react with carbon at elevated temperatures. The metal-coated tube is incorporated into a metal matrix that could potentially form carbides. In some or other embodiments, the present invention is directed to methods of making such compositions.

Owner:RICE UNIV

Electrodeposited metallic-materials comprising cobalt

ActiveUS20100304182A1Reduce resistanceEliminate security concernsEnvelopes/bags making machineryRecord information storageParticulatesPorosity

Free standing articles or articles at least partially coated with substantially porosity free, fine-grained and / or amorphous Co-bearing metallic materials optionally containing solid particulates dispersed therein, are disclosed. The electrodeposited metallic layers and / or patches comprising Co provide, enhance or restore strength, wear and / or lubricity of substrates without reducing the fatigue performance compared to either uncoated or equivalent thickness chromium coated substrate. The fine-grained and / or amorphous metallic coatings comprising Co are particularly suited for articles exposed to thermal cycling, fatigue and other stresses and / or in applications requiring anti-microbial properties.

Owner:INTEGRAN TECH

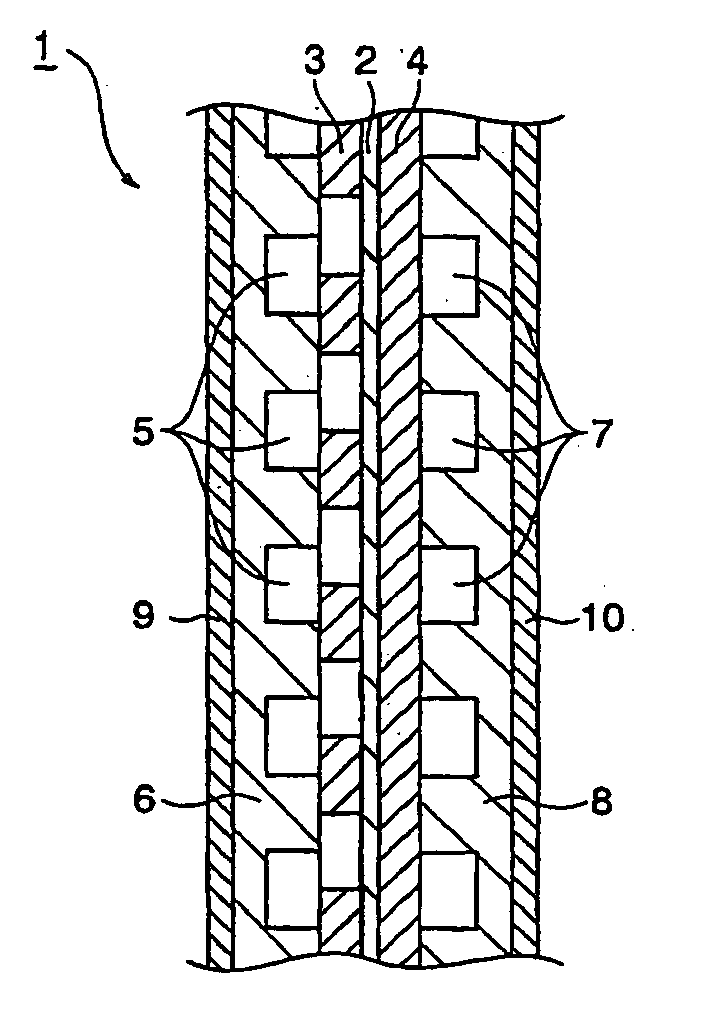

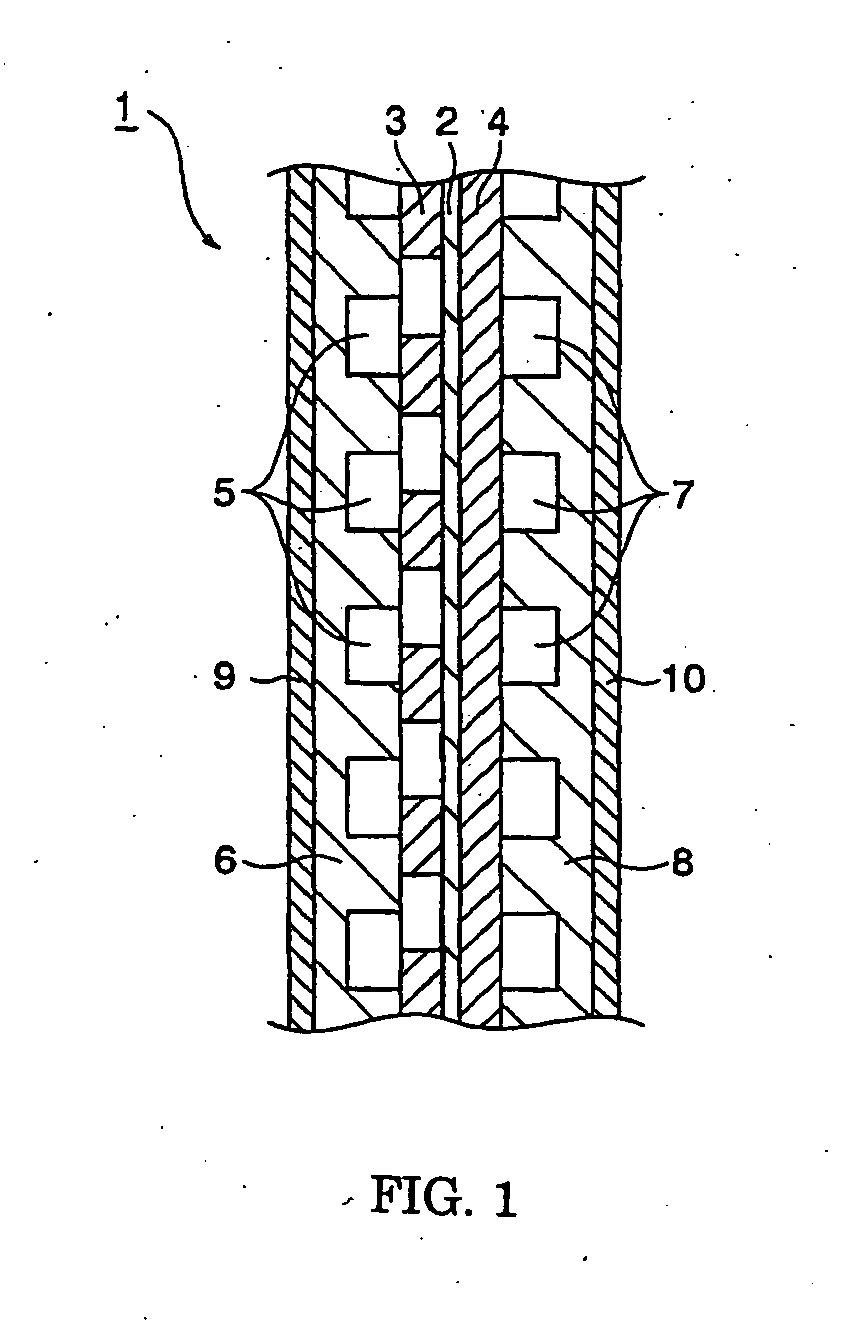

Laminate and its producing method

InactiveUS20040231141A1Improve surface smoothnessImprove adhesionPrinted circuit assemblingInsulating substrate metal adhesion improvementMetal coatingHigh density

A laminate is prepared by forming metal layer A on one face of a polymer film by dry plating method. When circuit is formed by using the laminate according to the semi-additive method, a high-density printed wiring board having excellent circuit shape, insulating property between the circuits and adhesion with the substrate can be obtained. By forming an adhesive layer on the other side of the polymer film of the laminate, an interlayer adhesive film is prepared. By thermally fusing or curing the adhesive layer after laminating the interlayer adhesive film on the inner layer circuit board, a multi-layer printed wiring board can be prepared. When preparing the circuit board by etching the first metal coating, an etchant which selectively etches the first metal coating is preferably used.

Owner:KANEKA CORP

Low cost electrically conductive tapes and films manufactured from conductive loaded resin-based materials

Electrically conductive tapes and films are formed of a conductive loaded resin-based material. The conductive loaded resin-based material comprises micron conductive powder(s), conductive fiber(s), or a combination of conductive powder and conductive fibers in a base resin host. The percentage by weight of the conductive powder(s), conductive fiber(s), or a combination thereof is between about 20% and 50% of the weight of the conductive loaded resin-based material. The micron conductive powders are formed from non-metals, such as carbon, graphite, that may also be metallic plated, or the like, or from metals such as stainless steel, nickel, copper, silver, that may also be metallic plated, or the like, or from a combination of non-metal, plated, or in combination with, metal powders. The micron conductor fibers preferably are of nickel plated carbon fiber, stainless steel fiber, copper fiber, silver fiber, aluminum fiber, or the like.

Owner:INTEGRAL TECHNOLOGY INC

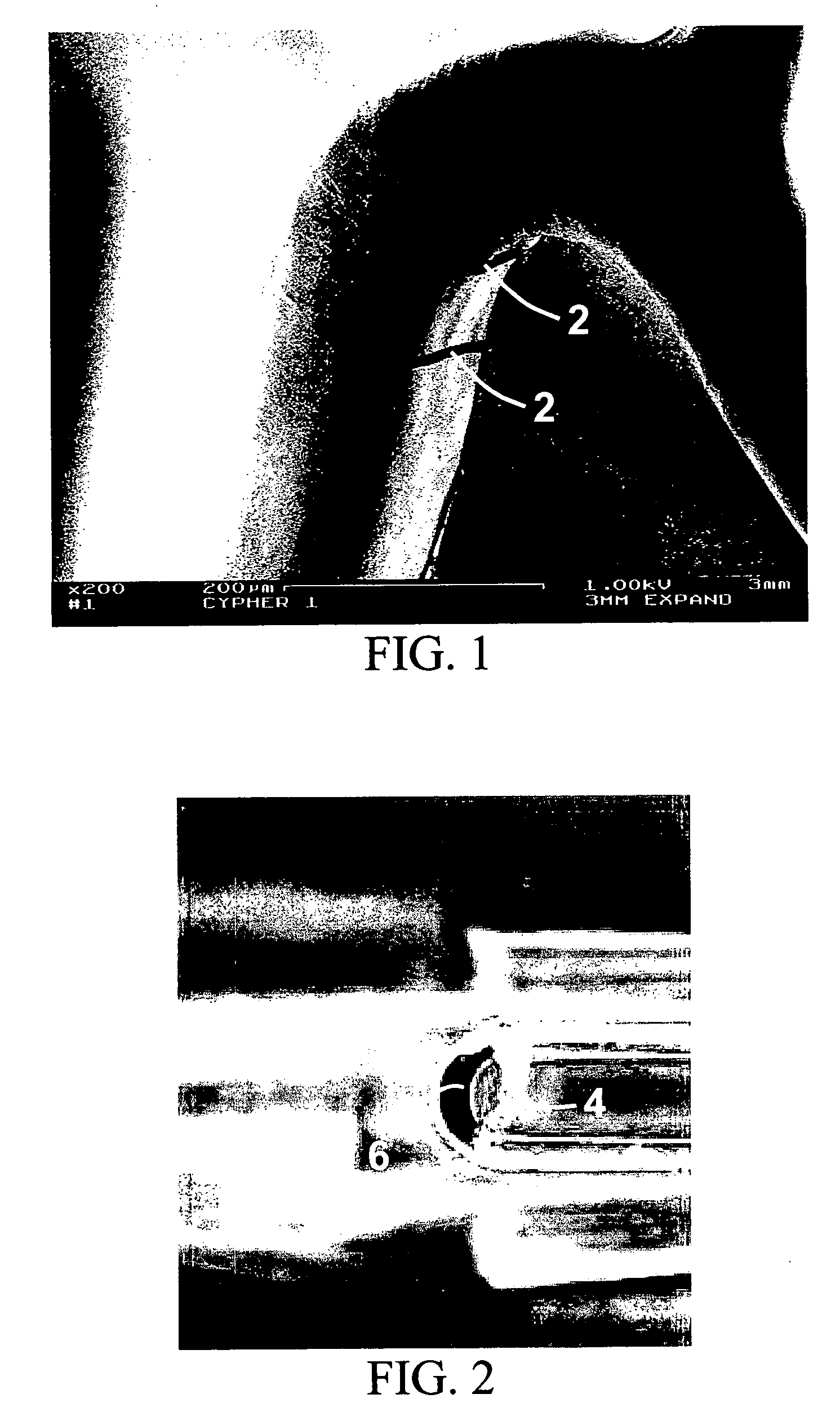

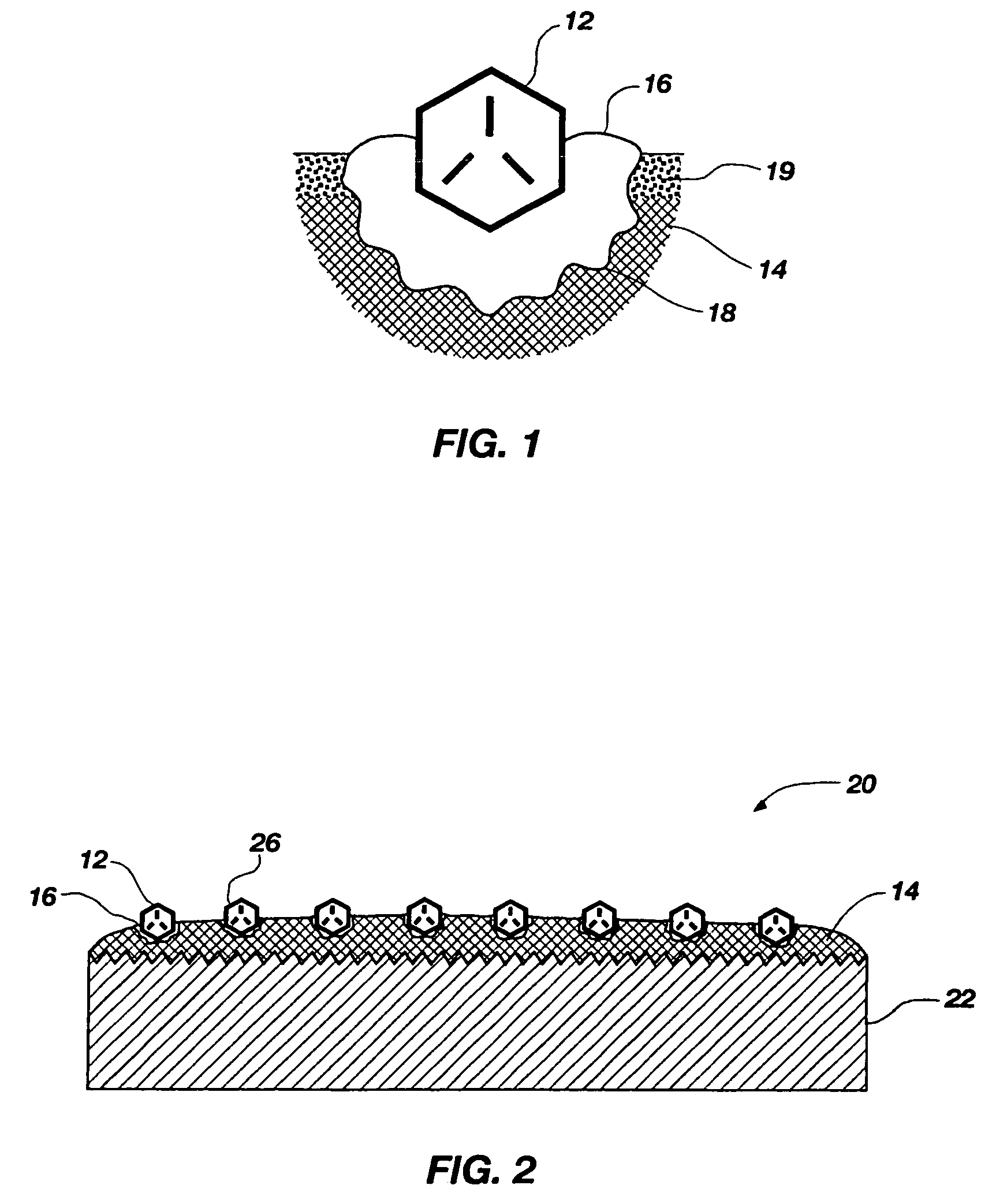

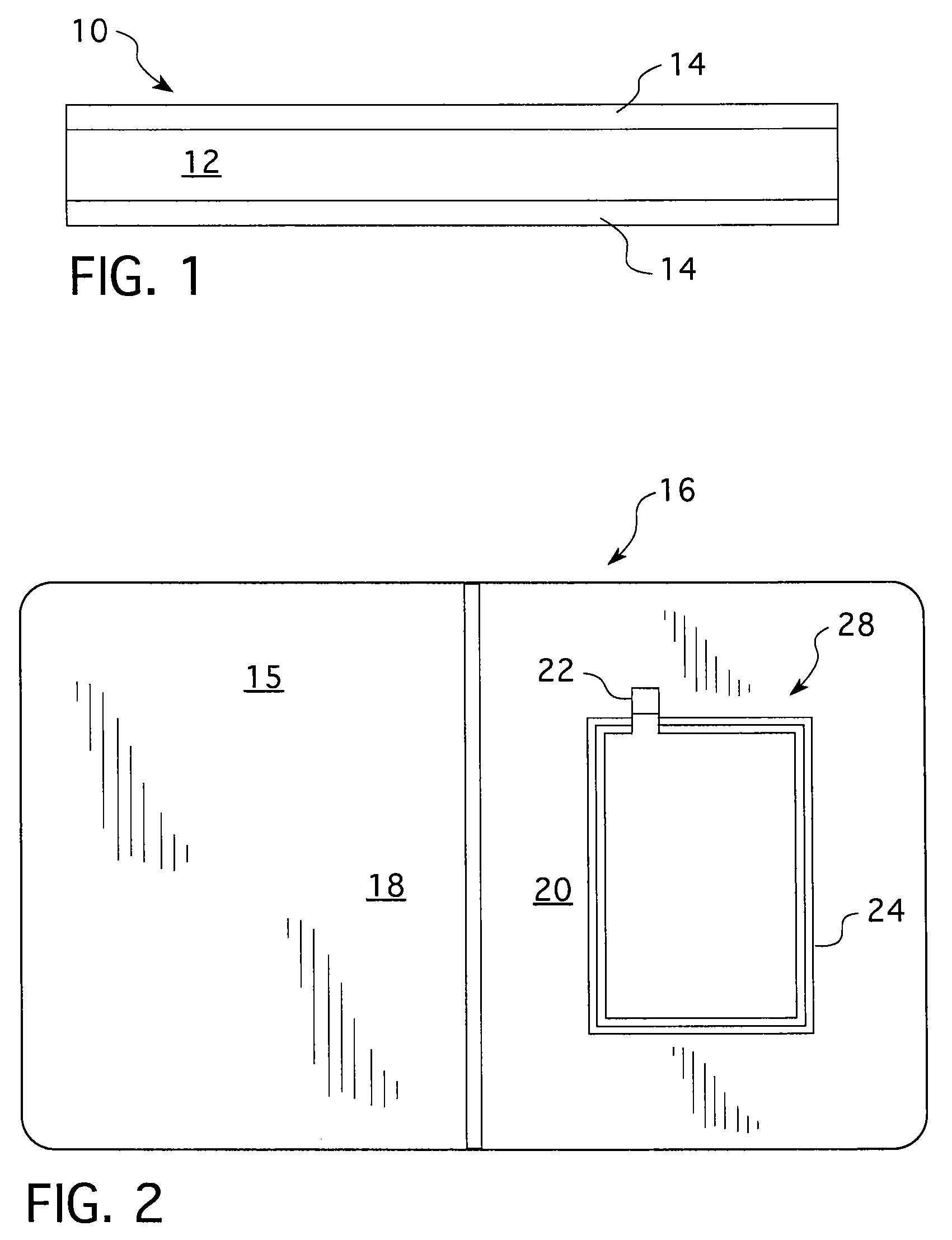

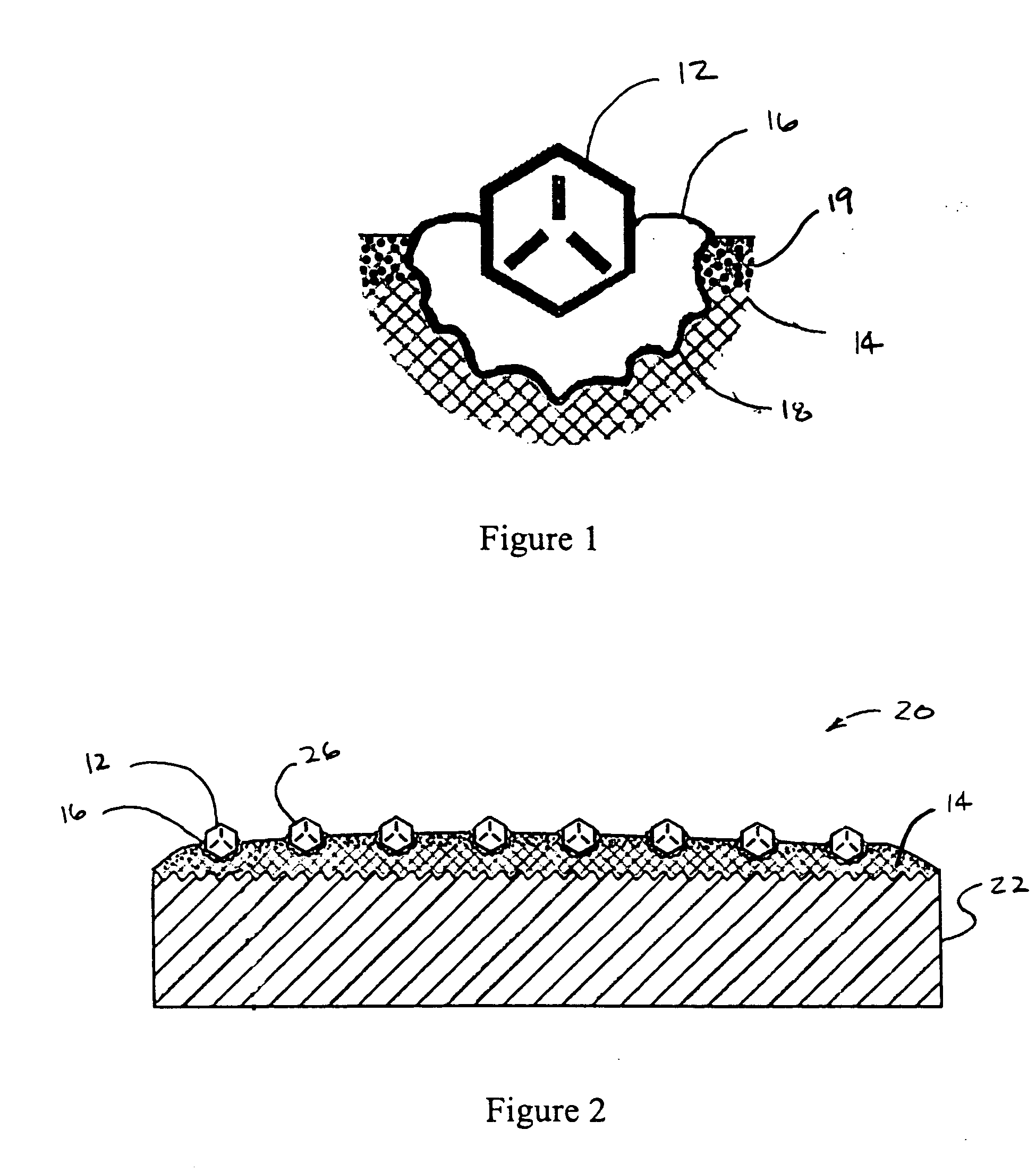

Chemical mechanical polishing pad dresser

ActiveUS7258708B2Enhance layeringHigh retention ratePigmenting treatmentOther chemical processesMetal coatingMetallic coating

CMP pad dressers and their methods of manufacture are disclosed. One aspect of the present invention provides a CMP pad dresser having improved superabrasive grit retention in a resin layer. The CMP pad includes a resin layer, superabrasive grit held in the resin layer such that an exposed portion of each superabrasive grit protrudes from the resin layer, and a metal coating layer disposed between each superabrasive grit and the resin layer, where the exposed portions are substantially free of the metal coating layer. The metal coating layer acts to increase the retention of the superabrasive grit in the resin layer as compared to superabrasive grit absent the metal coating layer.

Owner:KINIK

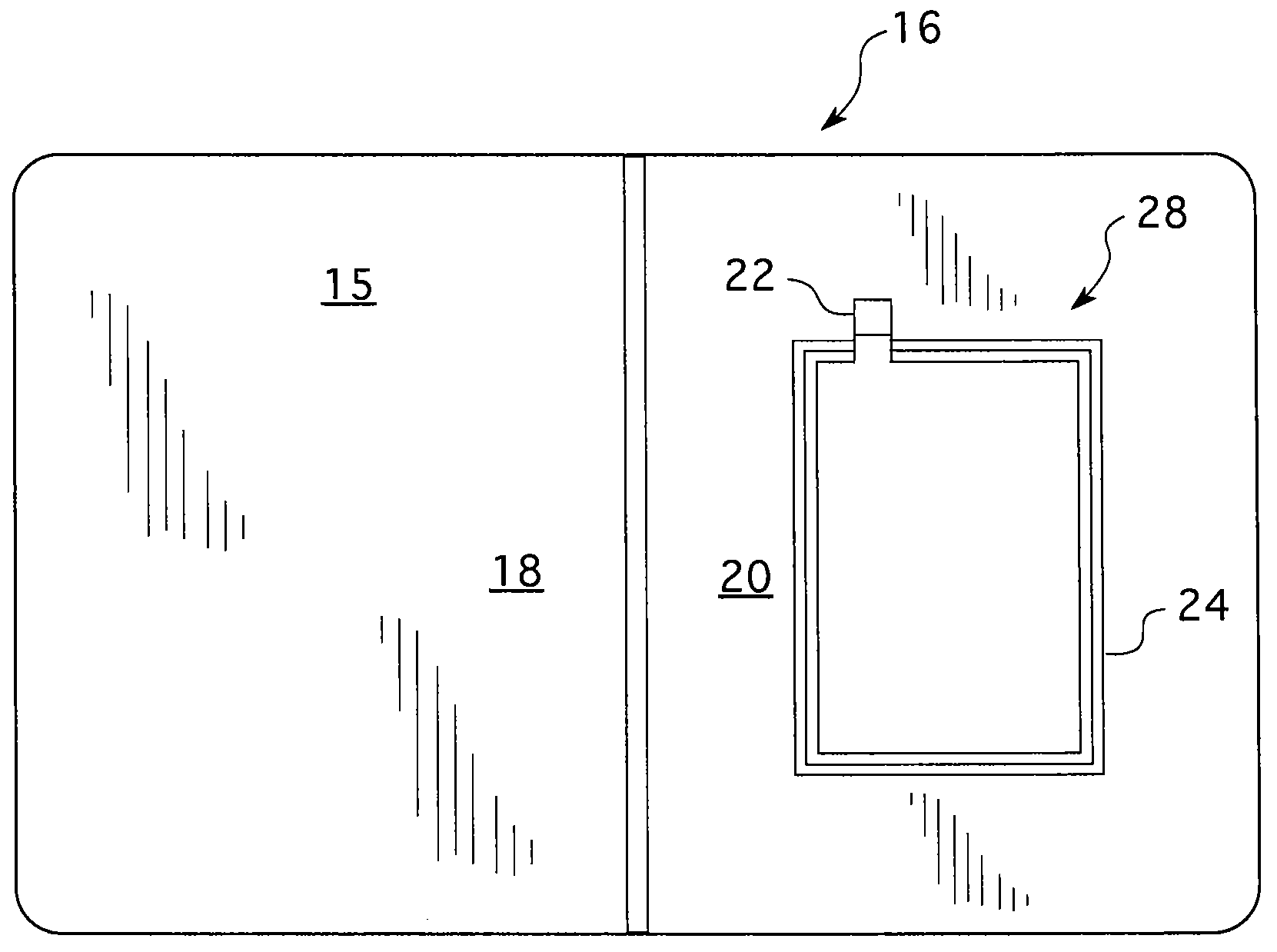

Apparatus and method for selectively permitting and resisting reading of radio frequency chips

InactiveUS20080186186A1Record carriers used with machinesBurglar alarm by hand-portable articles removalEngineeringRadio frequency

A shield for use in resisting reading of radio frequency chips includes a flexible non-metallic substrate having a metallic coating. The shield may be incorporated into a book such as a passport, an envelope, a folder, or removably adhered to an article having a radio frequency chip disposed thereon.

Owner:OPSEC SECURITY GROUP

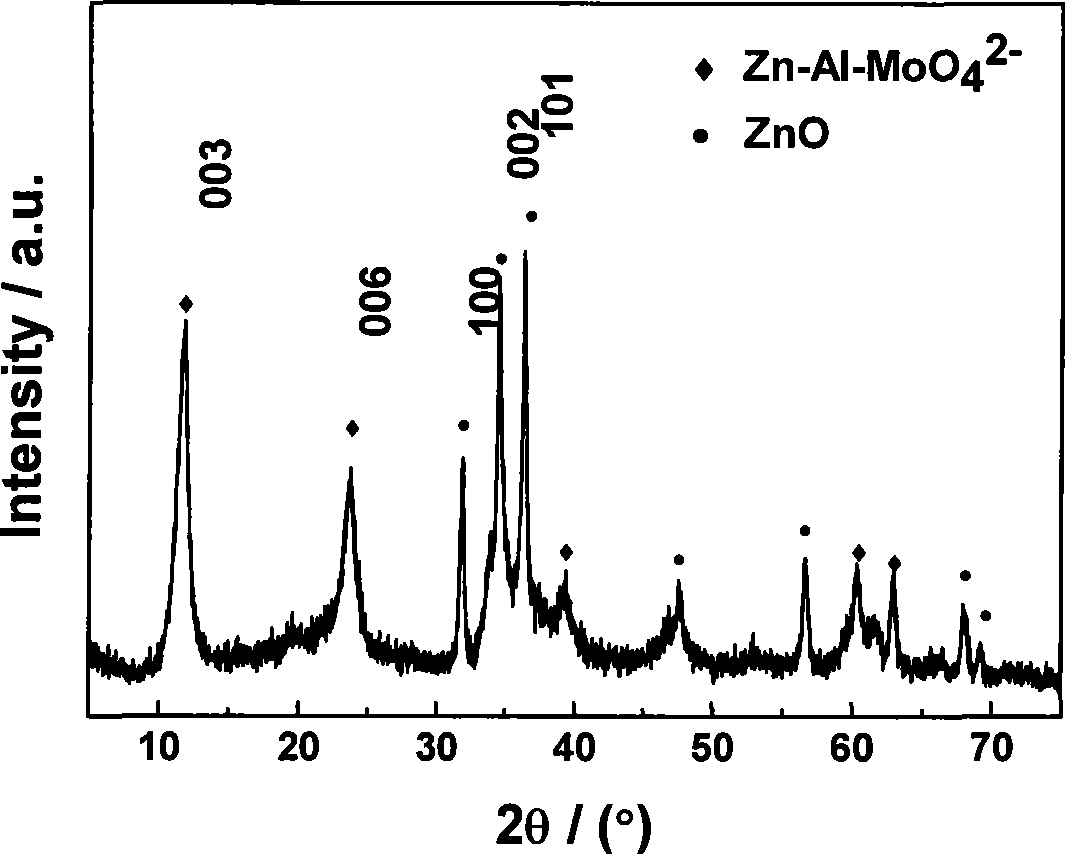

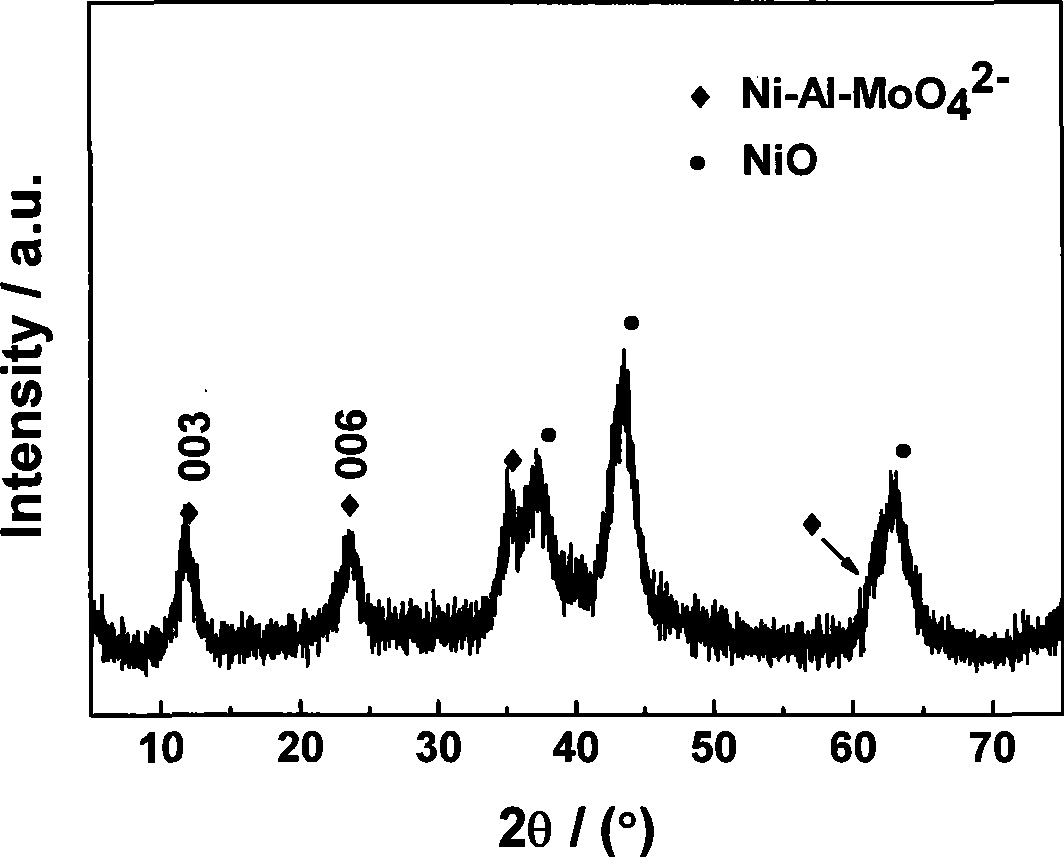

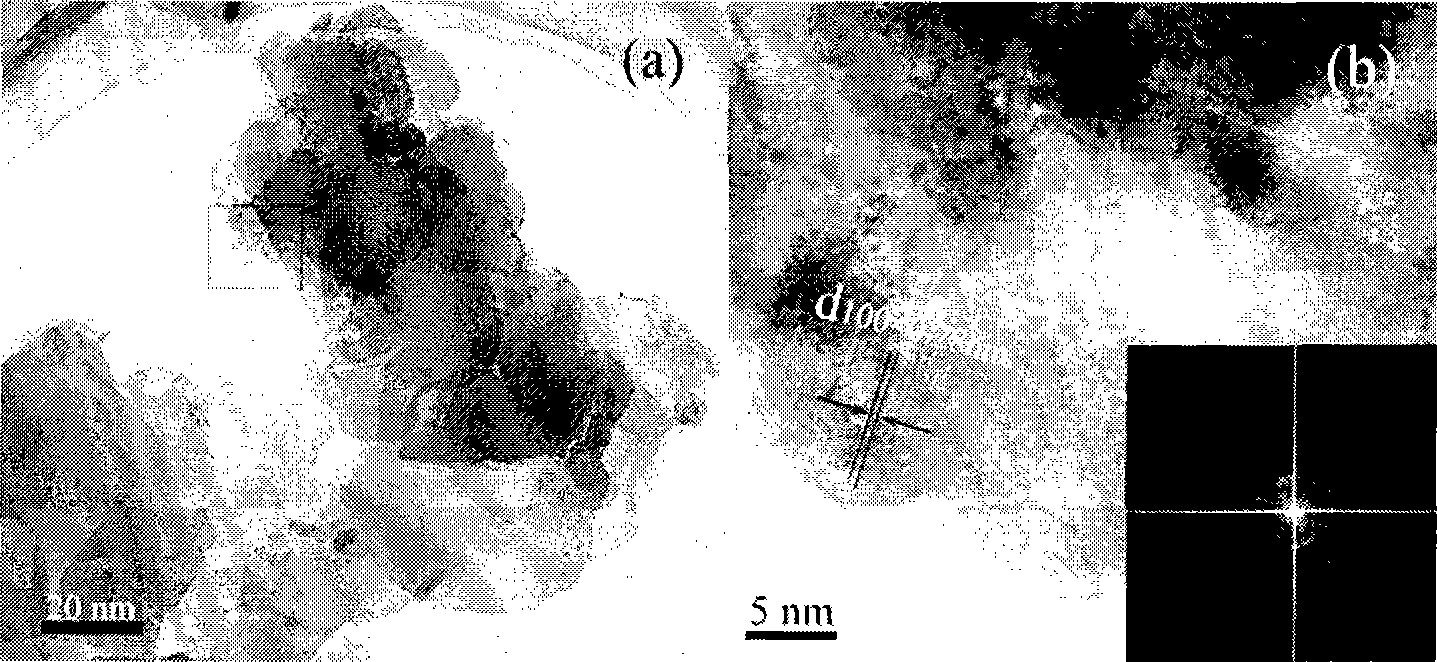

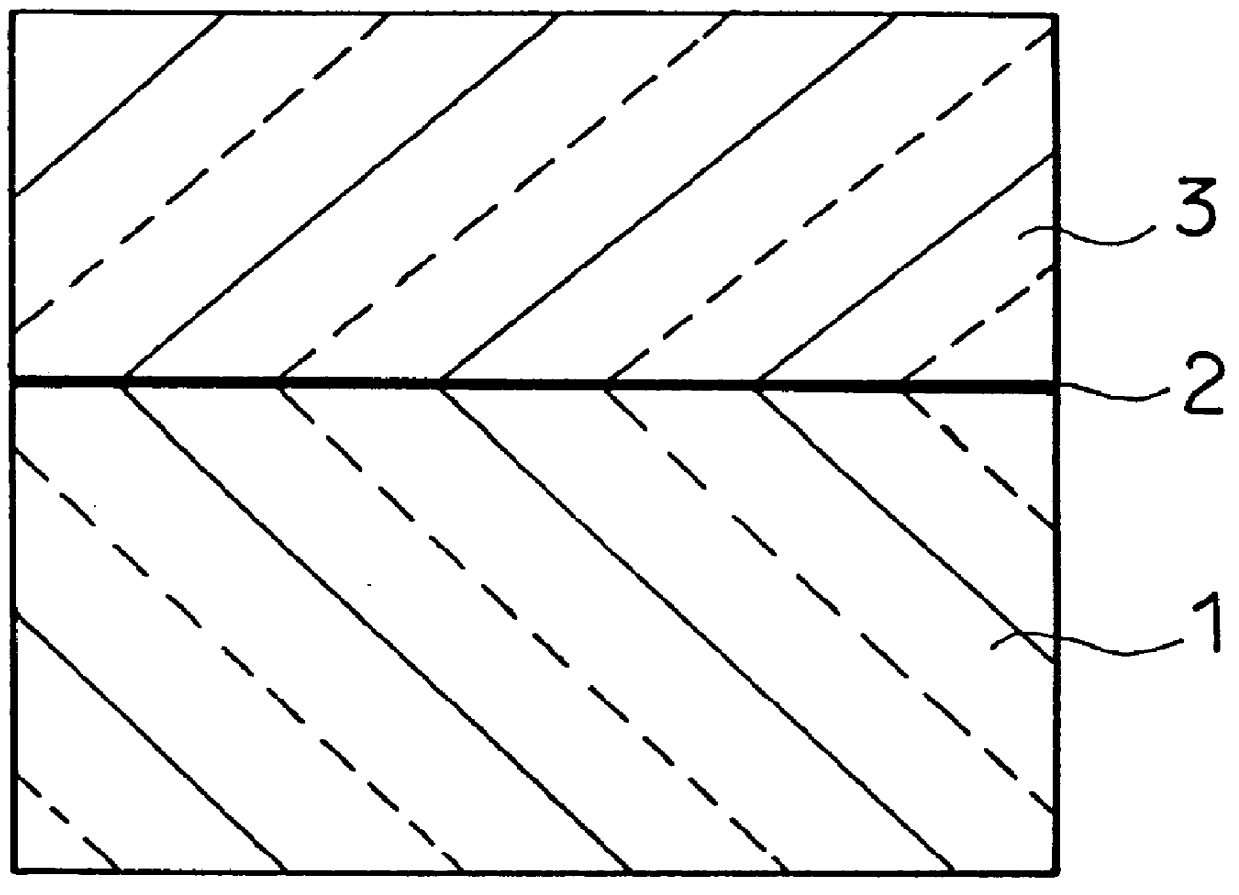

Method for preparing corrosion inhibition anion intercalated layered double hydroxides/oxide composite material and application

InactiveCN101418154AFacilitated releaseImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsOxide compositeReaction temperature

The invention provides a corrosion-inhibiting anionic intercalated hydrotalcite / nano oxide composite material, a preparation method thereof and application of the corrosion-inhibiting anionic intercalated hydrotalcite / nano oxide composite material. The preparation method is as follows: corrosion-inhibiting anions are directly inserted between hydrotalcite layers by the one-step coprecipitation method and the roasting restoring method; the nano oxide is generated by means of in situ synchronization during the process of generation of hydrotalcite crystals by controlling the mixture ratio of divalent metal ions to trivalent metal ions, the pH value of a reaction solution and the reaction temperature; and the corrosion-inhibiting anionic intercalated hydrotalcite / nano oxide composite material with the anti-corrosive function is prepared. The invention is mainly characterized in that the in situ preparation method for the hydrotalcite / oxide composite material provided with a nano lamellar structure improves the release amount of a corrosion inhibitor and reduces the water absorption of a coating by leading into the corrosion inhibitor with the anti-corrosive function and the nano oxide which is generated in situ during the reaction process. The composite material can be used to be pigment of an anti-corrosive metallic coating system, and particularly has potential application value in improving the anti-corrosive performance of a magnesium alloy anti-corrosive coating.

Owner:HARBIN ENG UNIV

Metallic coating composition and method for forming a multilayer coating

A metallic coating composition is disclosed which contains bright pigments in the form of metal flakes produced by finely dividing a vapor-deposited metal layer. The metallic coating composition may be applied over a base coating layer. A clear topcoating layer may further be applied over the metallic coating layer.

Owner:NIPPON PAINT AUTOMOTIVE COATINGS

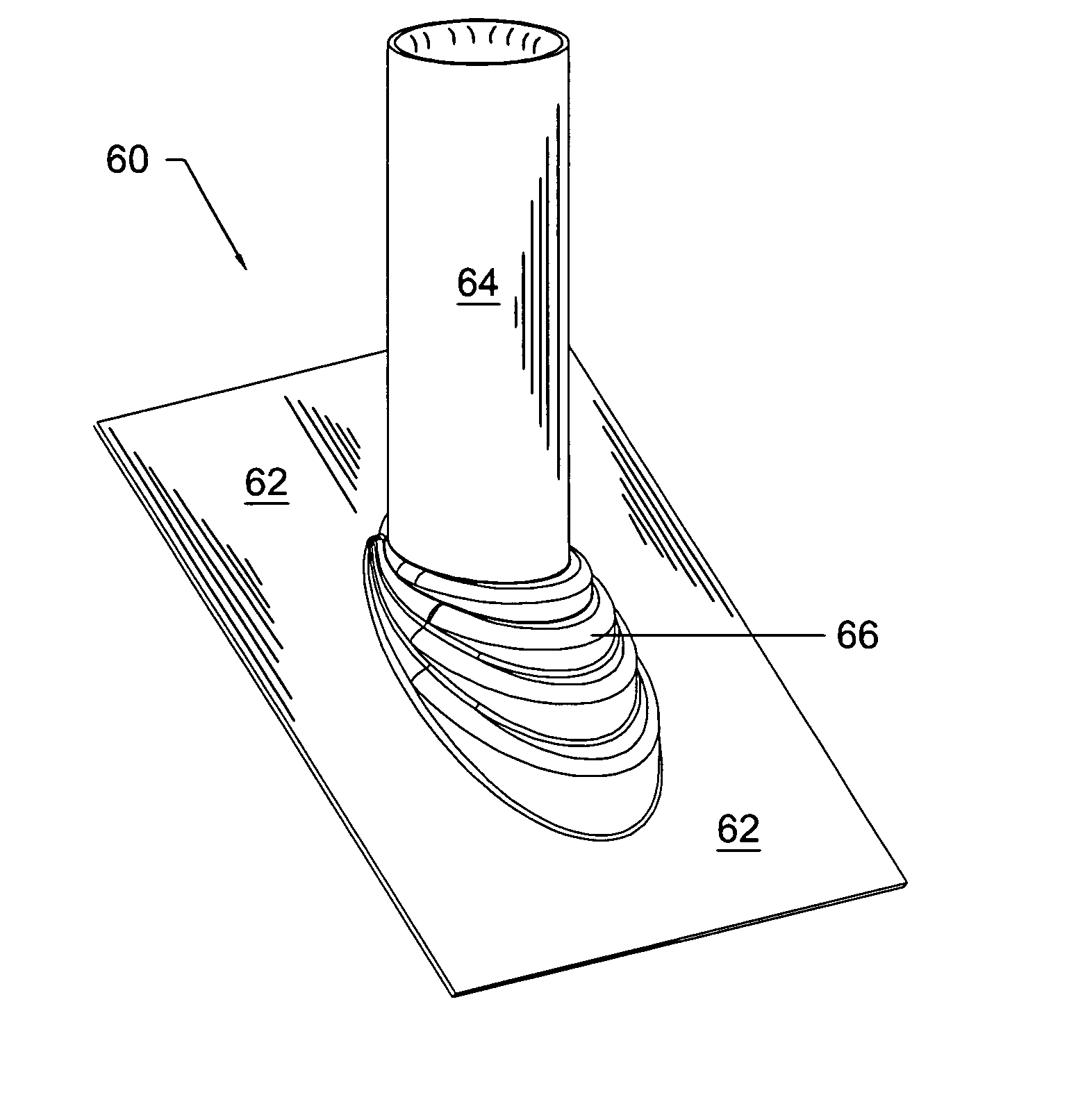

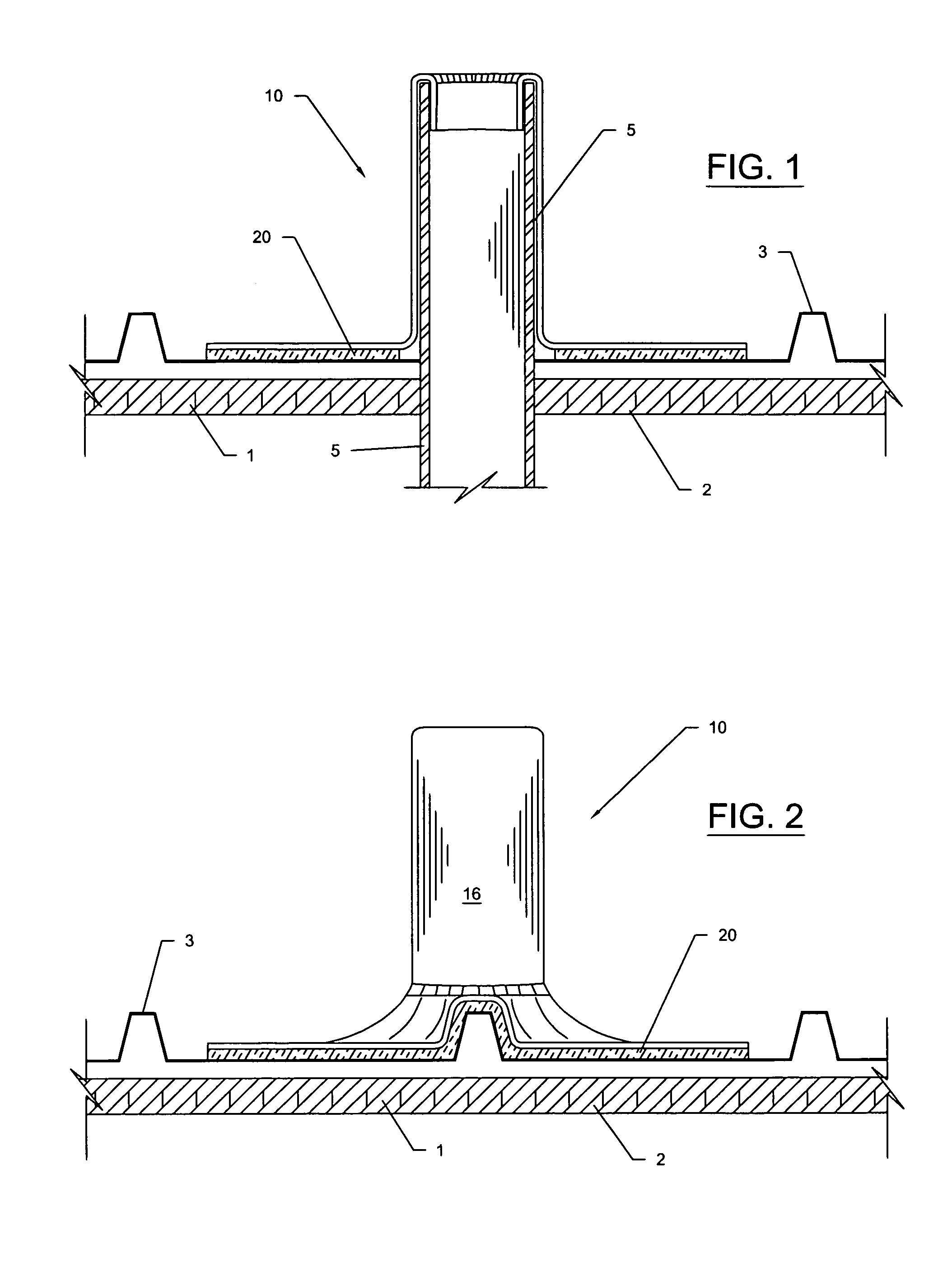

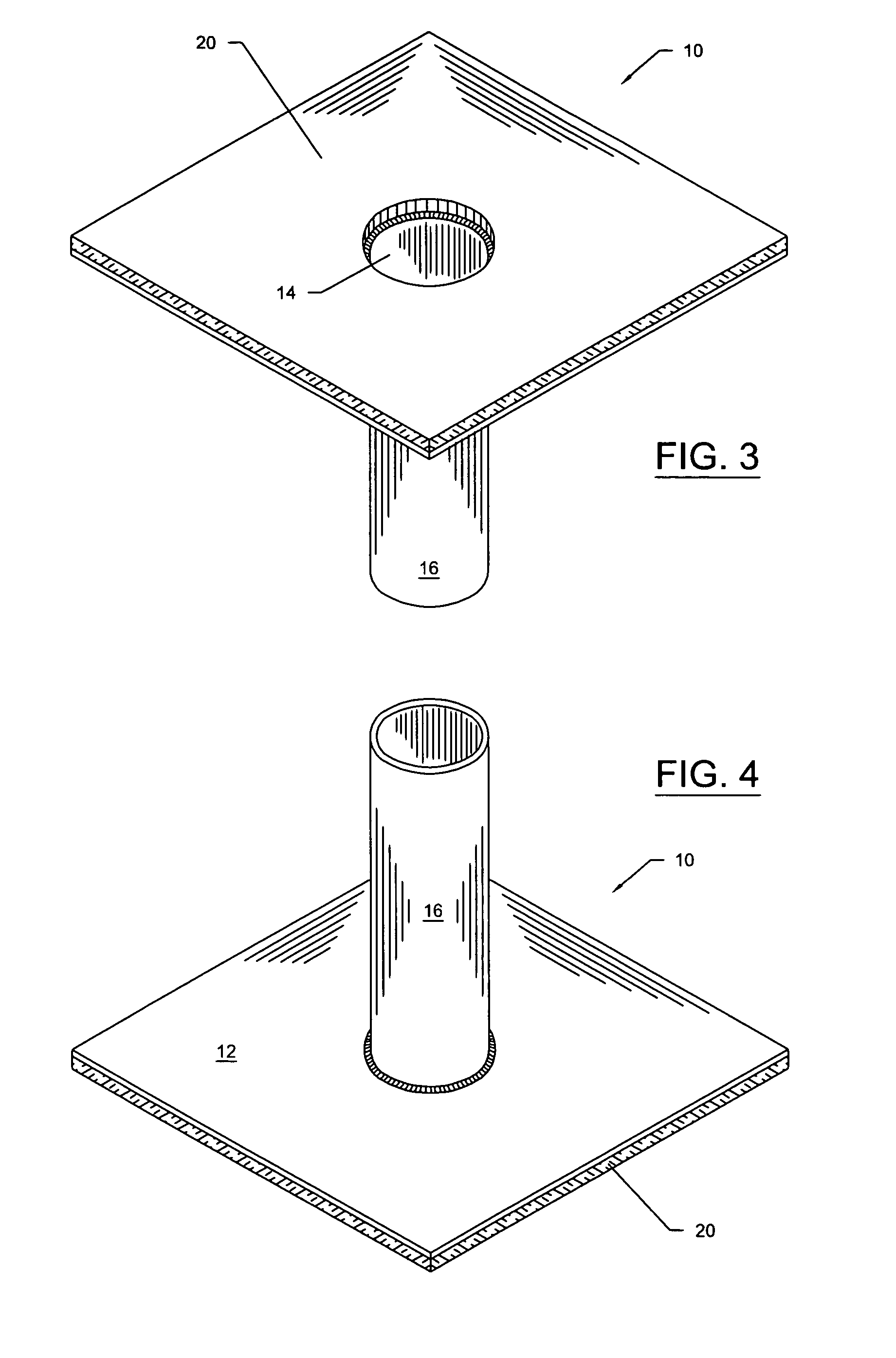

Flashing boots for roof penetrations

Improved flashing systems are disclosed for use with metal and non-metal roof systems. A lead flashing apparatus is provided comprising a generally planar lead base defining an aperture, a generally cylindrical structure attached to the base in surrounding relation with the aperture and projecting upward therefrom, and an adhesive sealing membrane attached to the bottom of the base for connecting the flashing to a roof The adhesive sealing membrane is not only effective in securing the flashing to the underlying roof, but further functions as a gasket separating the lead flashing base from a metal roof In a second embodiment, lead flashing having a generally planar base and upwardly projecting stack is adapted with a non-metallic coating. In a third embodiment, a flashing structure is fabricated from plastic, and preferably includes a sloped base with a tapered stack and is suitable for use on virtually any roof system. In any of the various embodiments disclosed herein, the base may be angled relative to the stack such that the flashing structure is suitable for use on pitched roofs. In a fourth embodiment, flashing is formed of a resilient material having a stepped accordion base that allows for the stack to be angularly adjusted relative to the base. In a fifth embodiment, the stepped accordion base is configured in a partial circumferential configuration on the downward portion of a sloped base, which partial circumferential configuration allows for the stack to be angularly adjusted relative to the base. In a sixth embodiment, a flashing system is provided with mating top and bottom flashings, each of which includes a stepped accordion base. In a seventh embodiment, a one-size-fits-all flashing system is disclosed wherein a flashing base is provided with an elongated triangular stack, for installation on a variety of pitched roofs.

Owner:HEARTLAND METALS

Fine-grained metallic coatings having the coefficient of thermal expansion matched to the one of the substrate

ActiveUS20070281176A1Cost-effective and convenient processIncrease stiffnessMaterial nanotechnologyRodsThermal dilatationMetal coating

Fine-grained (average grain size 1 nm to 1,000 nm) metallic coatings optionally containing solid particulates dispersed therein are disclosed. The fine-grained metallic materials are significantly harder and stronger than conventional coatings of the same chemical composition due to Hall-Petch strengthening and have low linear coefficients of thermal expansion (CTEs). The invention provides means for matching the CTE of the fine-grained metallic coating to the one of the substrate by adjusting the composition of the alloy and / or by varying the chemistry and volume fraction of particulates embedded in the coating. The fine-grained metallic coatings are particularly suited for strong and lightweight articles, precision molds, sporting goods, automotive parts and components exposed to thermal cycling. The low CTEs and the ability to match the CTEs of the fine-grained metallic coatings with the CTEs of the substrate minimize dimensional changes during thermal cycling and prevent premature failure.

Owner:INTEGRAN TECH

Chemical mechanical polishing pad dresser

ActiveUS20060143991A1Enhance layeringHigh retention ratePigmenting treatmentOther chemical processesMetal coatingMetallic coating

CMP pad dressers and their methods of manufacture are disclosed. One aspect of the present invention provides a CMP pad dresser having improved superabrasive grit retention in a resin layer. The CMP pad includes a resin layer, superabrasive grit held in the resin layer such that an exposed portion of each superabrasive grit protrudes from the resin layer, and a metal coating layer disposed between each superabrasive grit and the resin layer, where the exposed portions are substantially free of the metal coating layer. The metal coating layer acts to increase the retention of the superabrasive grit in the resin layer as compared to superabrasive grit absent the metal coating layer.

Owner:KINIK

Metallized films

InactiveUS6033786AImprove propertiesImprove adhesionSynthetic resin layered productsGlass/slag layered productsButeneMetal coating

A biaxially oriented, heat-set, multilayer film includes a core layer, a bonding layer having a surface adhered to the core layer and a flame treated surface opposite the surface adhered to the core layer. A metal coating for providing oxygen and moisture barrier properties deposited on the flame treated surface and a protective plastic film adhered to said metal coating. The core layer and bonding layer either are free of void-creating additives or include only a quantity of such additives that does not create a matte surface adversely affecting the barrier properties of the metal coating. The bonding layer comprising a mixture including 40 to 100% by weight of propylene / butene-1 copolymer containing up to about 14% by weight of butene-1 (PBC), 0 to 60% of an isotactic polypropylene (PP) and 0 to 50% of a copolymer of ethylene and propylene wherein propylene is the predominant component by weight (EPC).

Owner:APPLIED EXTRUSION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com