Patents

Literature

3432 results about "Oxide composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon-silicon oxide-lithium composite, making method, and non-aqueous electrolyte secondary cell negative electrode material

ActiveUS20070224508A1Improve initial efficiencyImprove cycle performanceSecondary cellsNegative electrodesOxide compositeSilicon oxide

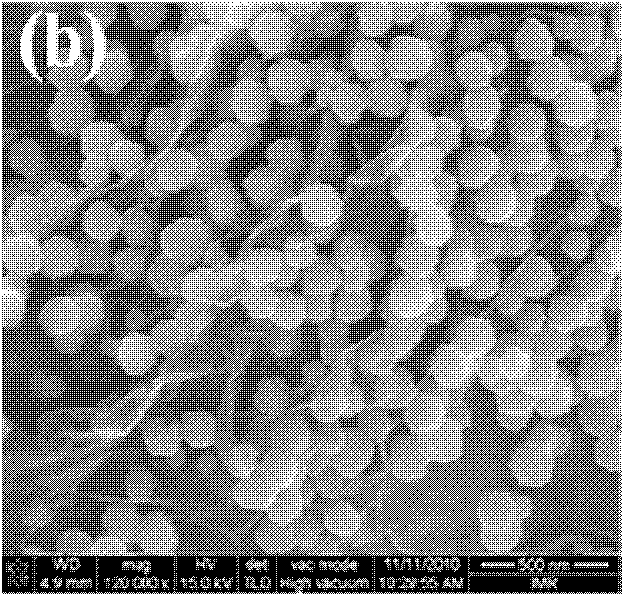

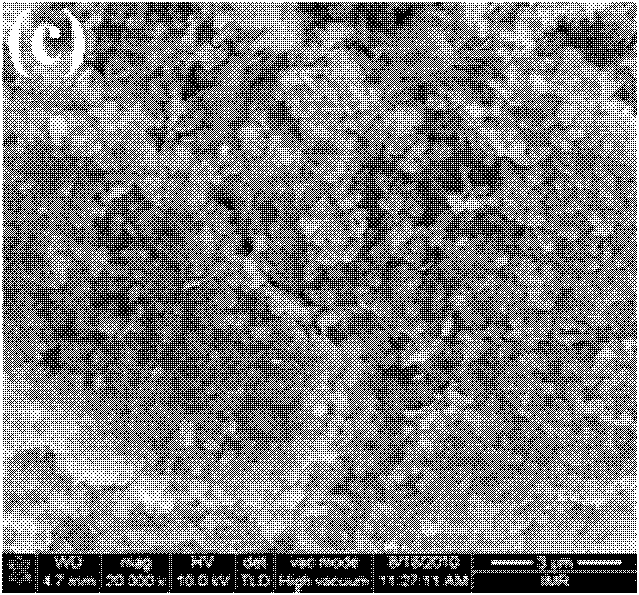

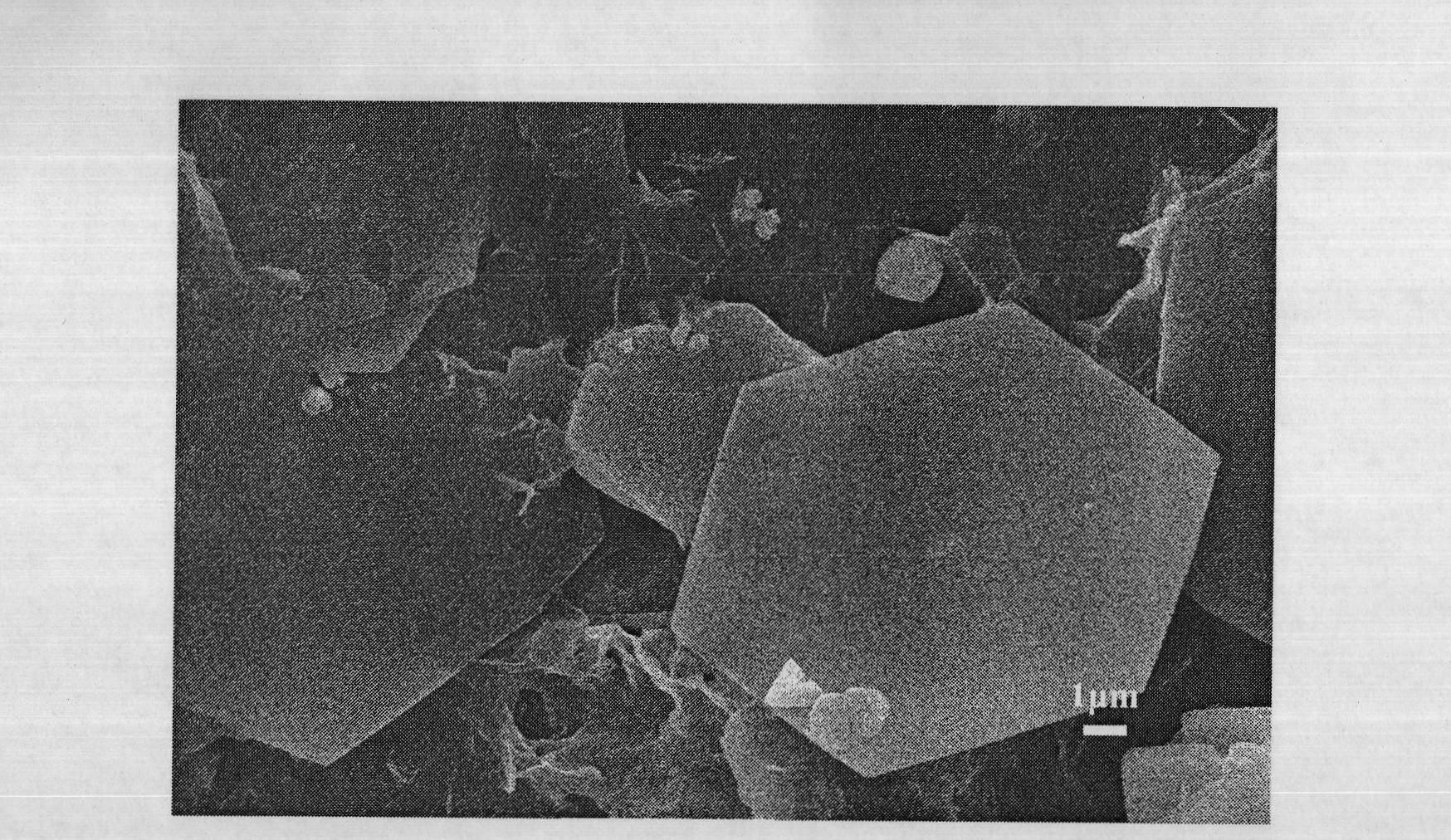

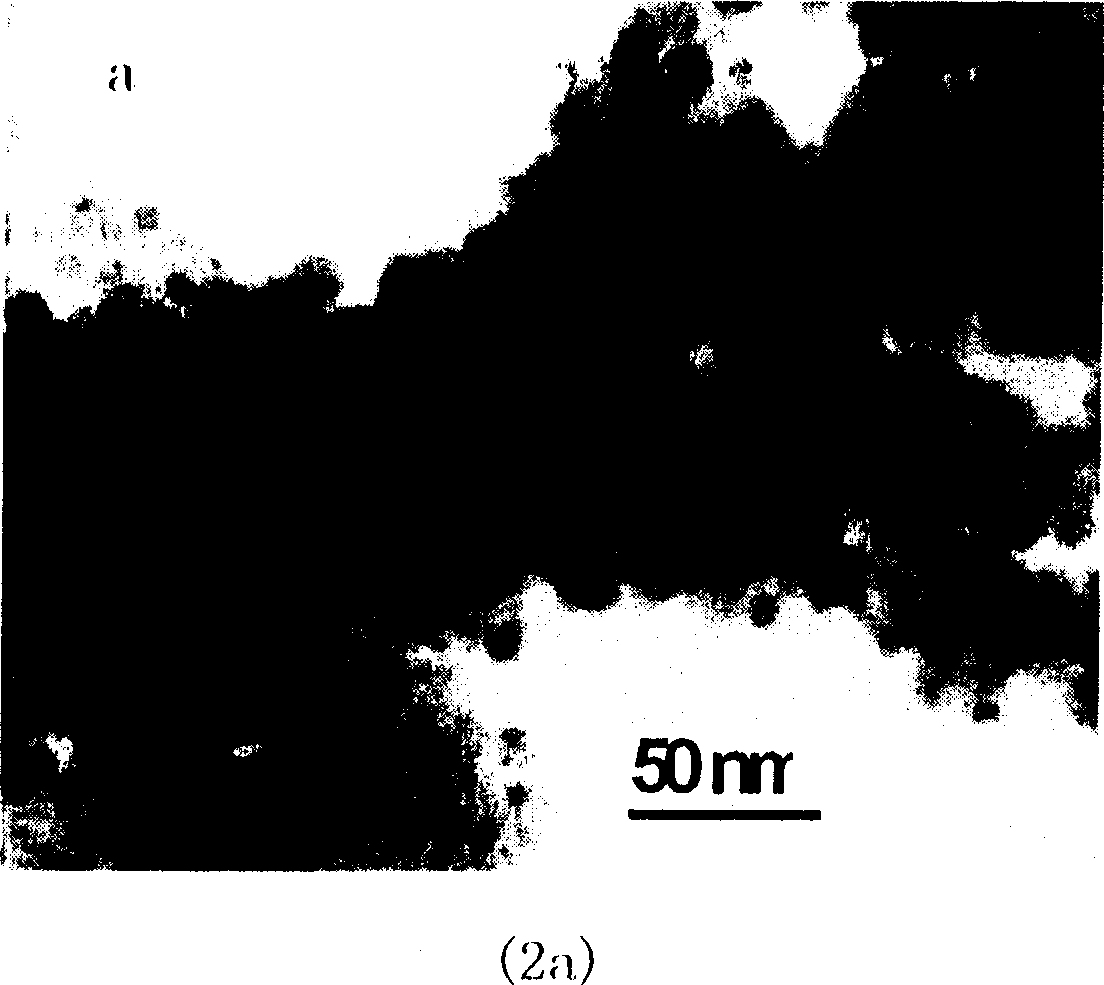

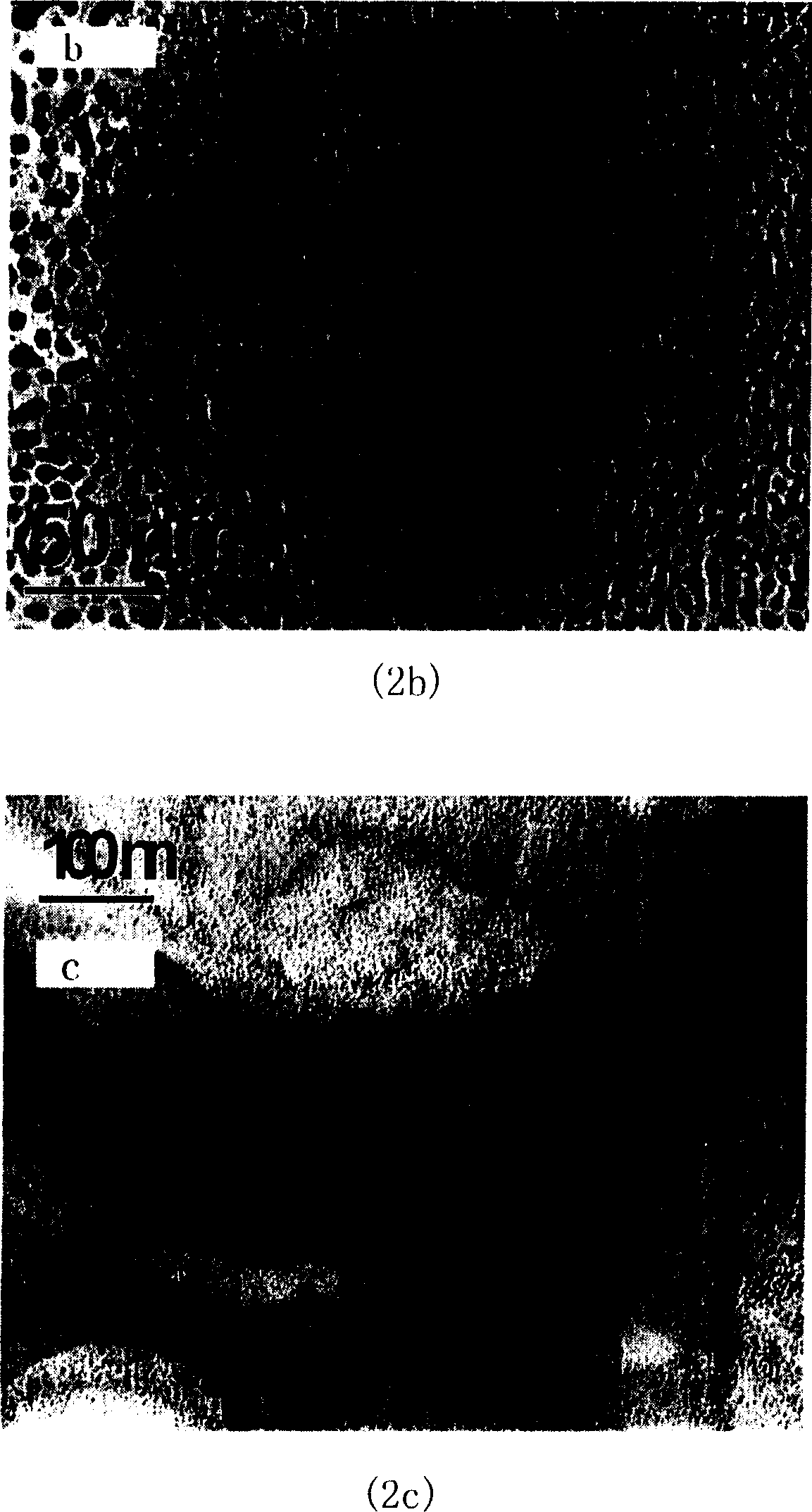

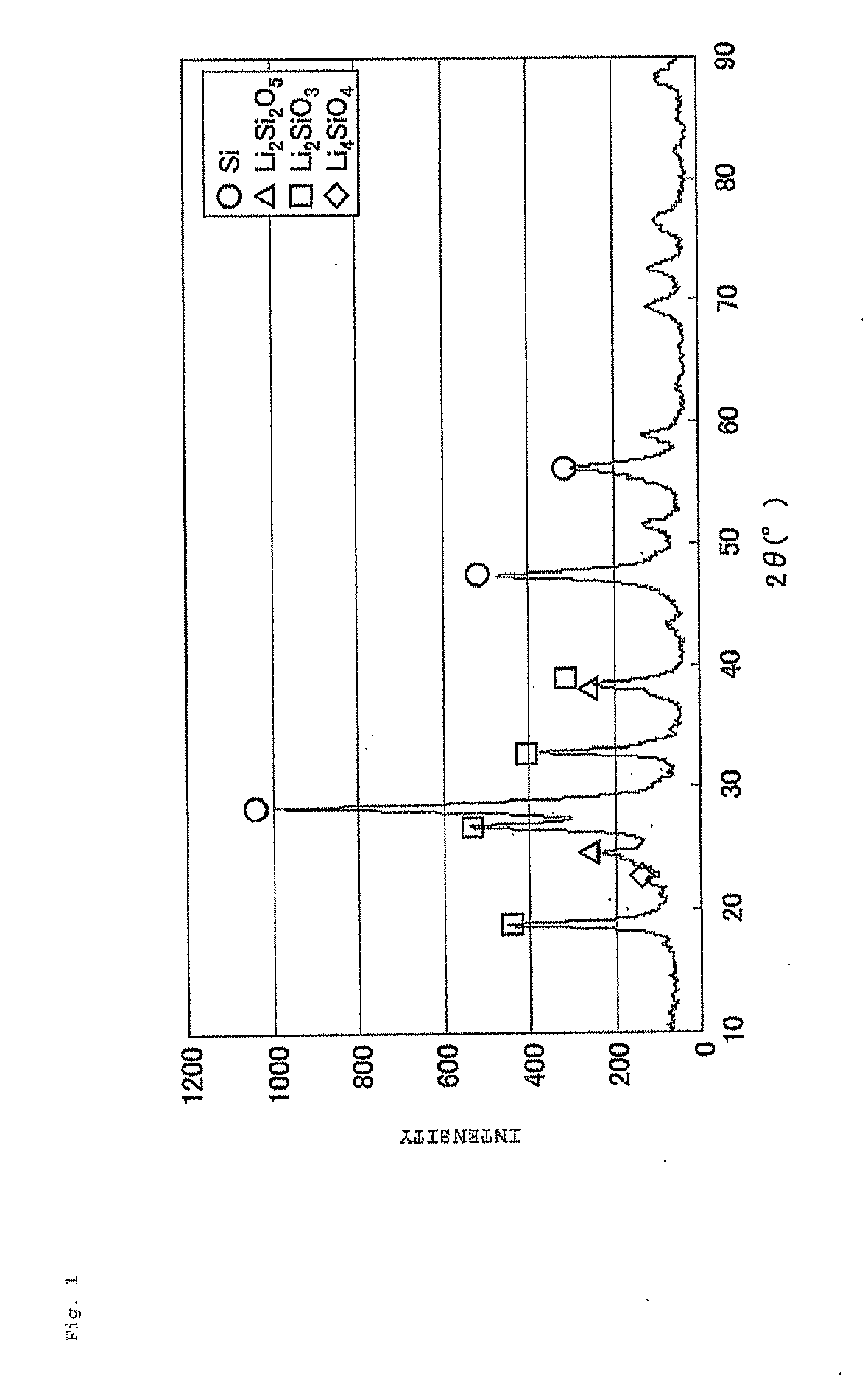

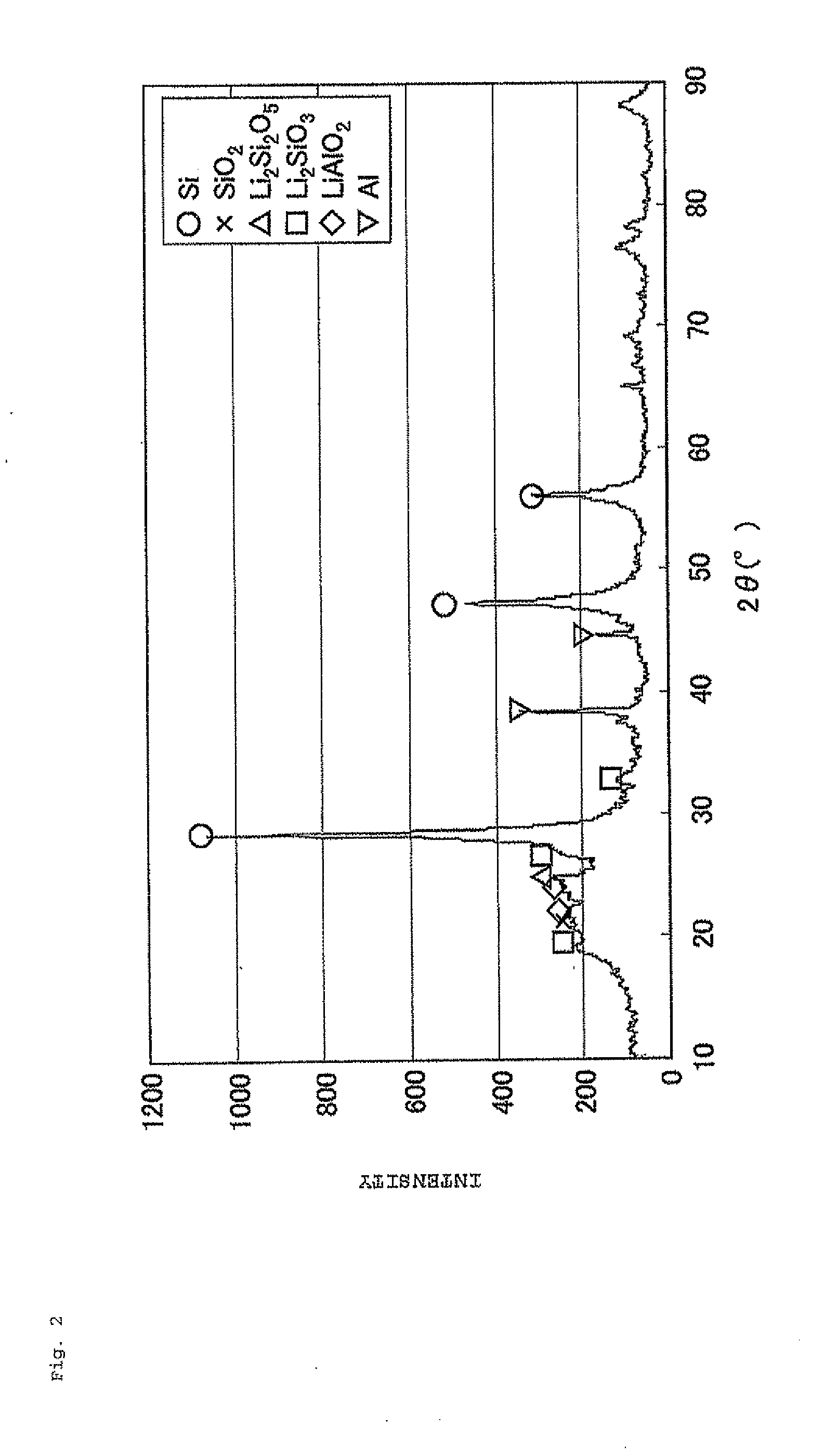

A silicon-silicon oxide-lithium composite comprises a silicon-silicon oxide composite having such a structure that silicon grains having a size of 0.5-50 nm are dispersed in silicon oxide, the silicon-silicon oxide composite being doped with lithium. Using the silicon-silicon oxide-lithium composite as a negative electrode material, a lithium ion secondary cell having a high initial efficiency and improved cycle performance can be constructed.

Owner:SHIN ETSU CHEM IND CO LTD

Graphene/metal oxide composite cathode material for lithium ion battery and preparation

InactiveCN102646817APromote circulationExcellent rate performanceCell electrodesHigh energyIn situ polymerization

The invention belongs to the fields of material synthesis and energy technology, and especially relates to a graphene / metal oxide composite cathode material for lithium ion batteries and a preparation method thereof. Grapheme is dispersed into various metal oxide precursor salt solutions; a graphene / metal oxide compound is obtained directly by a hydrothermal method, or an graphene / metal oxide compound is obtained by a liquid in-situ polymerization method or a coprecipitation process; and the graphene / metal oxide compound is obtained by heat treatment or hydrothermal treatment. In the invention, the novel three-dimensional composite cathode material of graphene-coated metal oxide or graphene-anchored metal oxide is prepared by carrying metal oxide particles with graphene as a carrier. The obtained composite material can be used as a lithium ion battery cathode, which has a high specific capacity, excellent cycle stability and rate capability, and is expected to be used as a lithium ion battery cathode material with a high energy density and a high power density.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Reduction catalysts

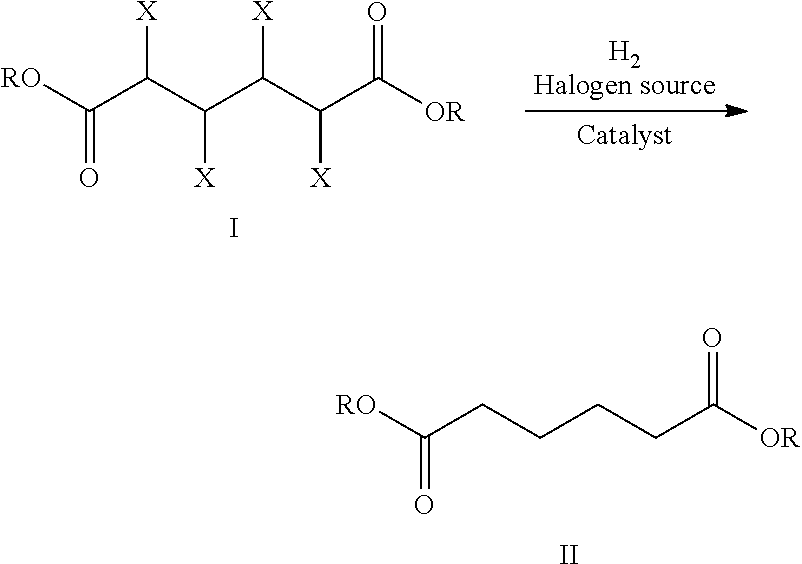

Disclosed are catalysts comprised of platinum and rhodium on a support selected from the group of zirconia, stabilized (doped) zirconia, zirconia-metal oxide composites, and mixtures thereof, wherein the outer surfaces of the support are selected from the group of zirconia, stabilized zirconia, and mixtures thereof. More particularly, the supported catalysts comprise platinum and rhodium, wherein the molar ratio of platinum to rhodium is in the range of about 3:1 to about 1:2. The average pore diameter of the catalyst supports is in the range of about 5 nm to about 70 nm and the surface area is in the range of about 15 m2 / g to about 200 m2 / g. Also disclosed are methods for the hydrodeoxygenation of carboxylic acids, mono- and / or di-lactones thereof having at least one hydroxyl group on the backbone thereof to corresponding acids where the backbone hydroxyl group has been reduced in the presence of the catalyst.

Owner:ARCHER DANIELS MIDLAND CO

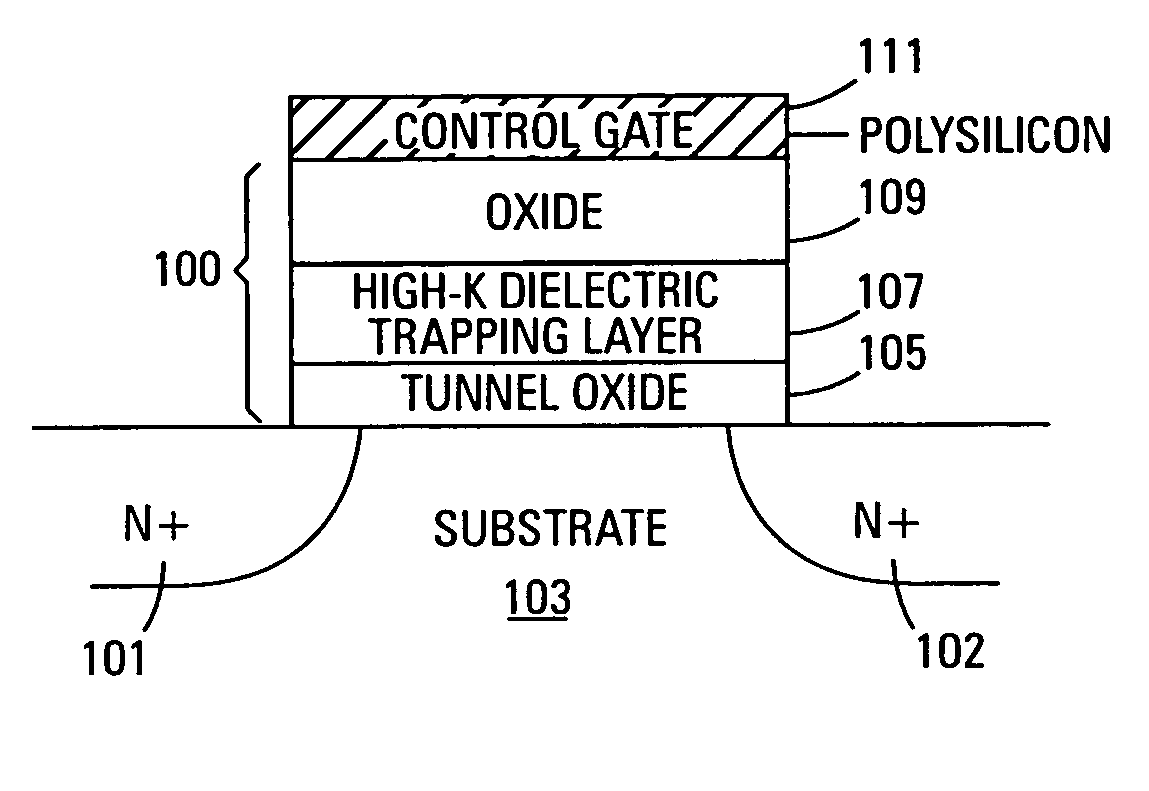

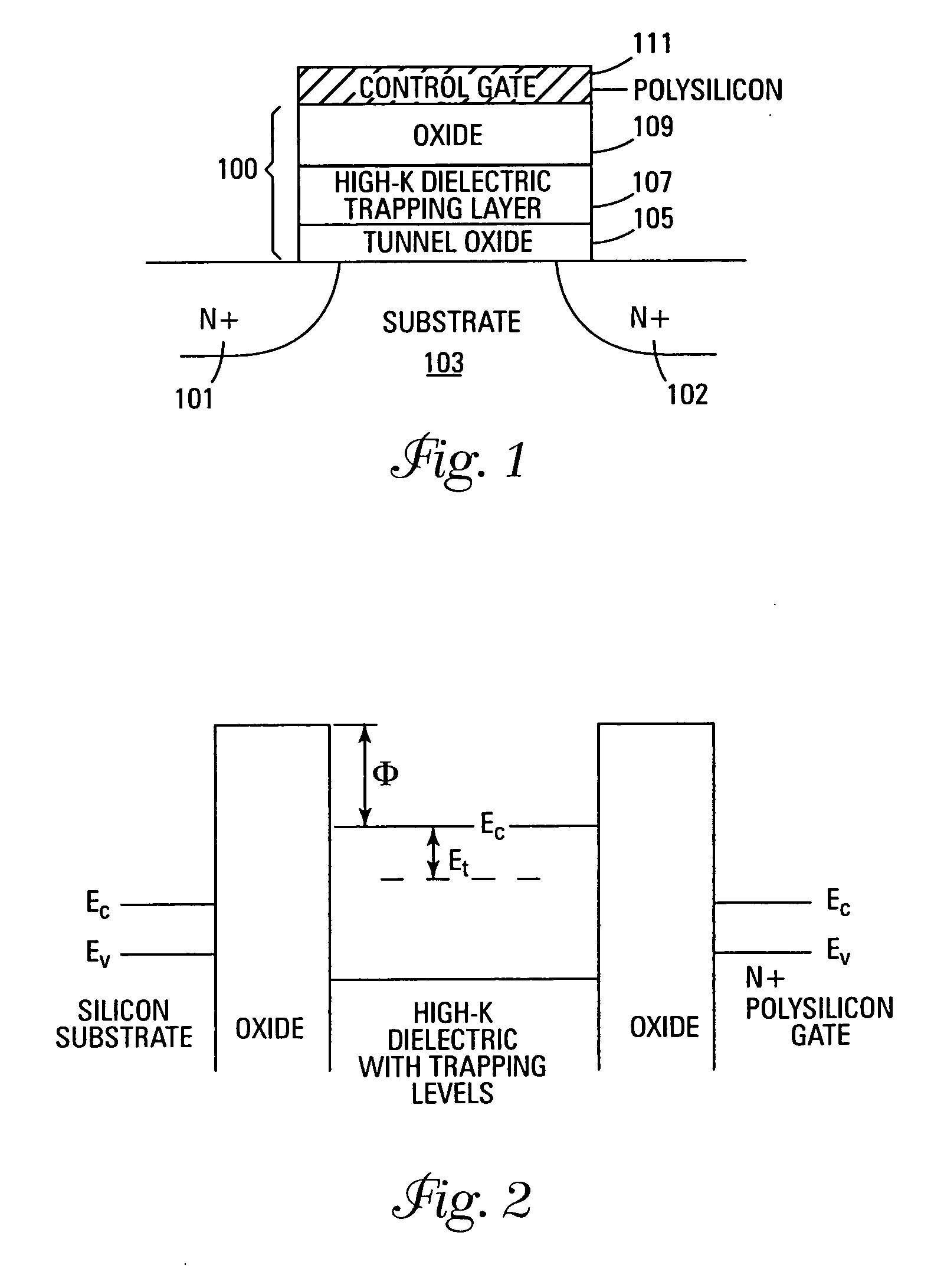

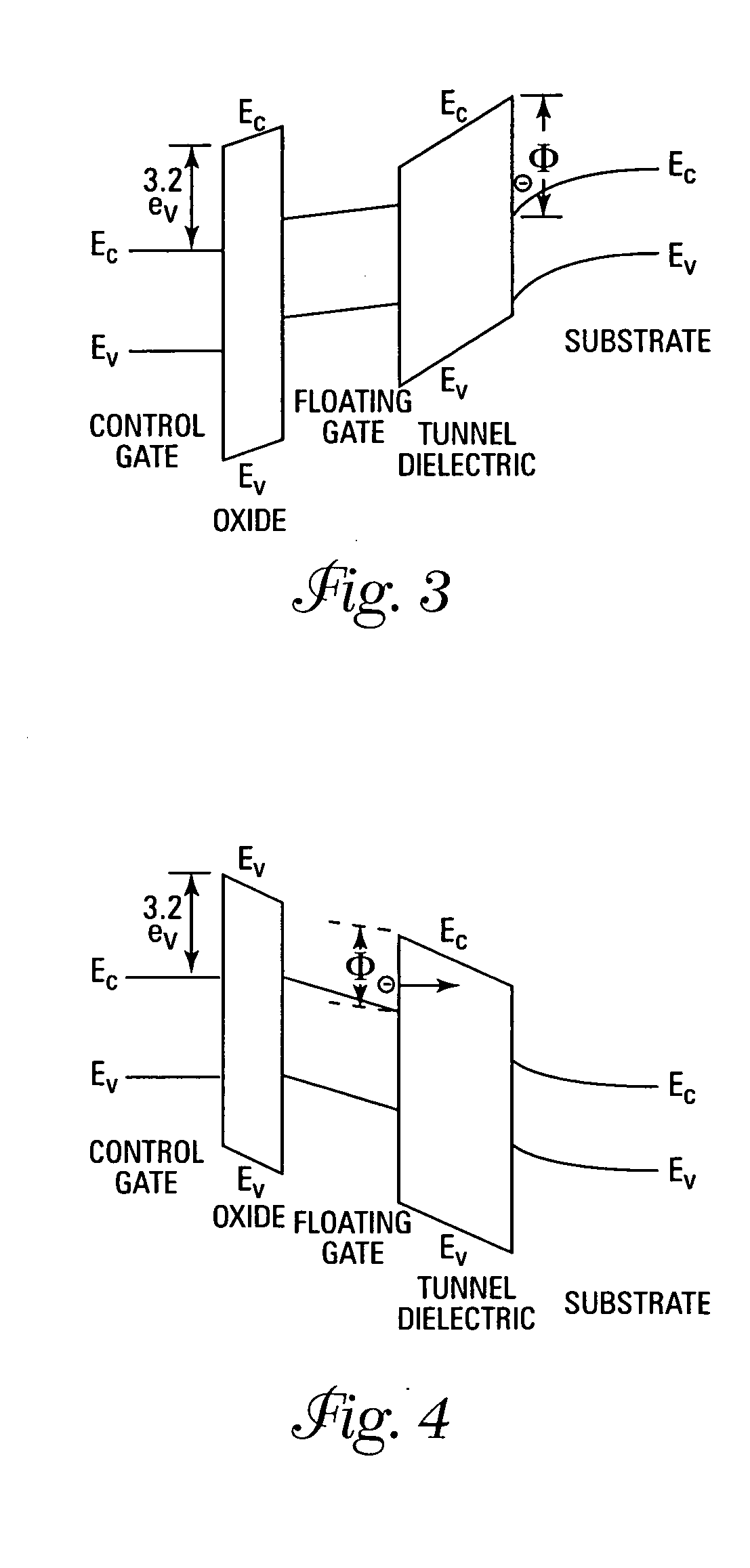

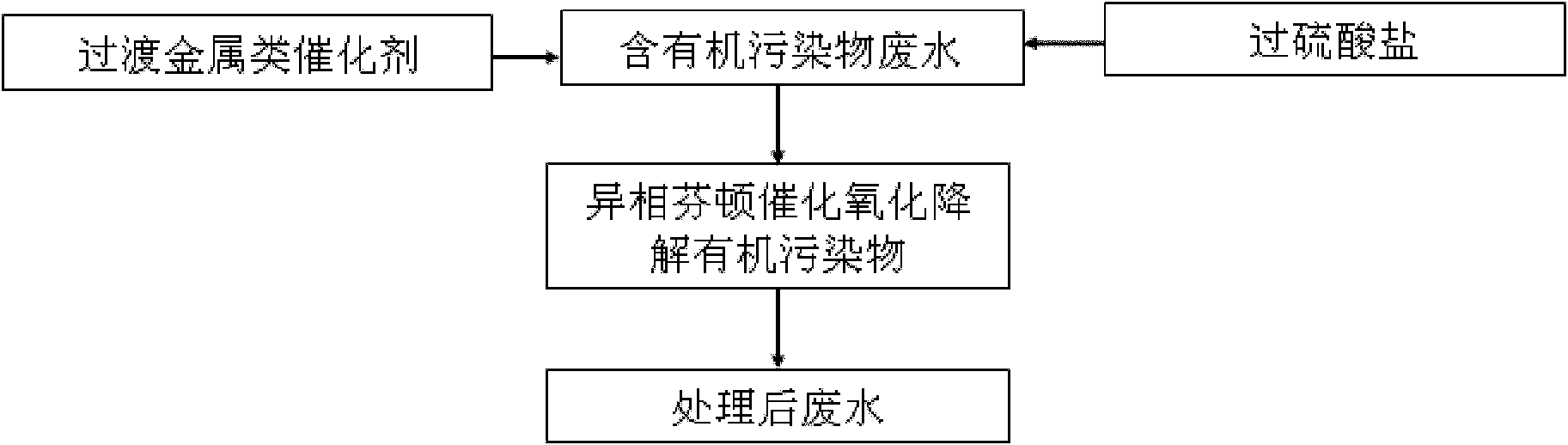

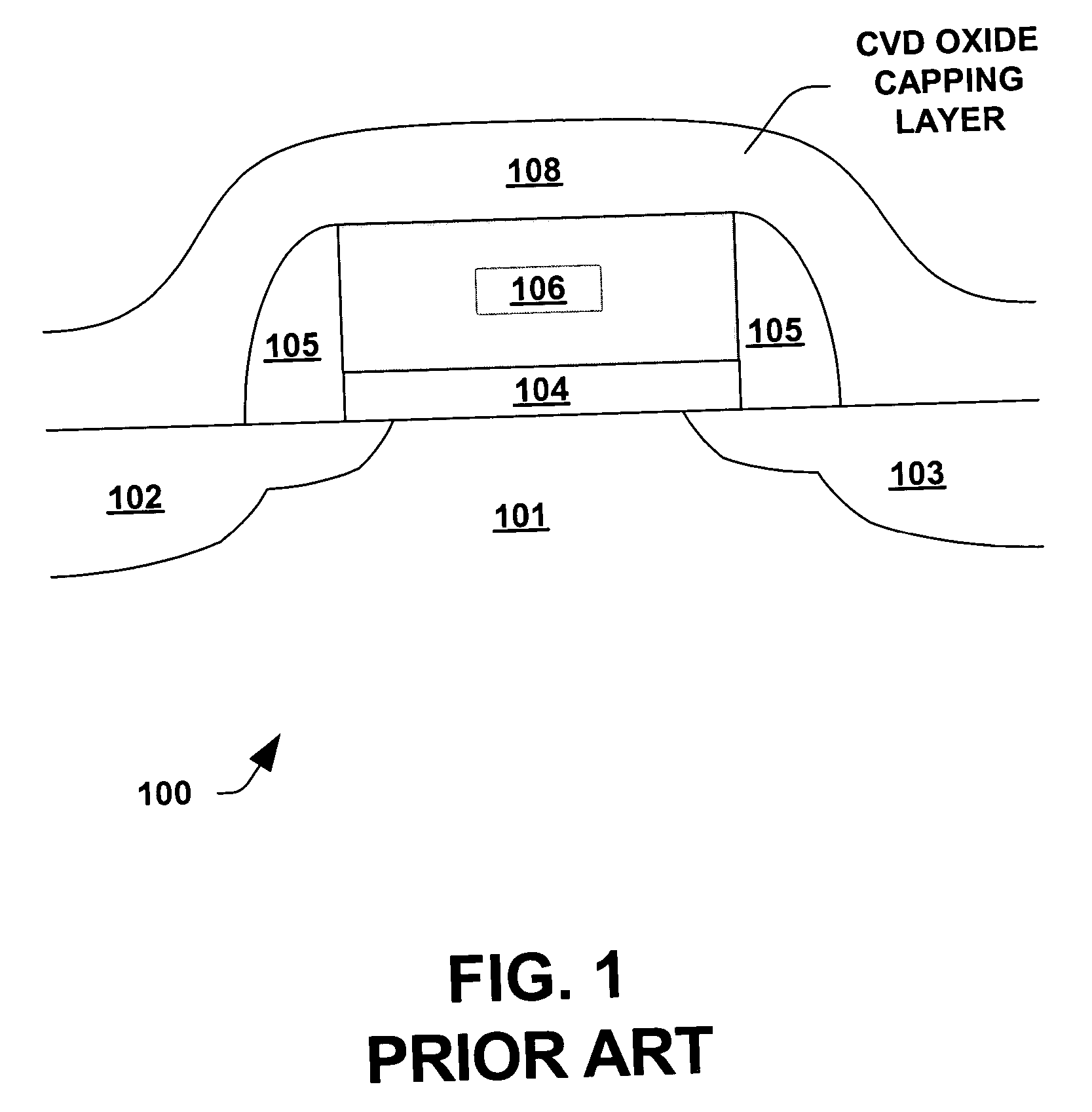

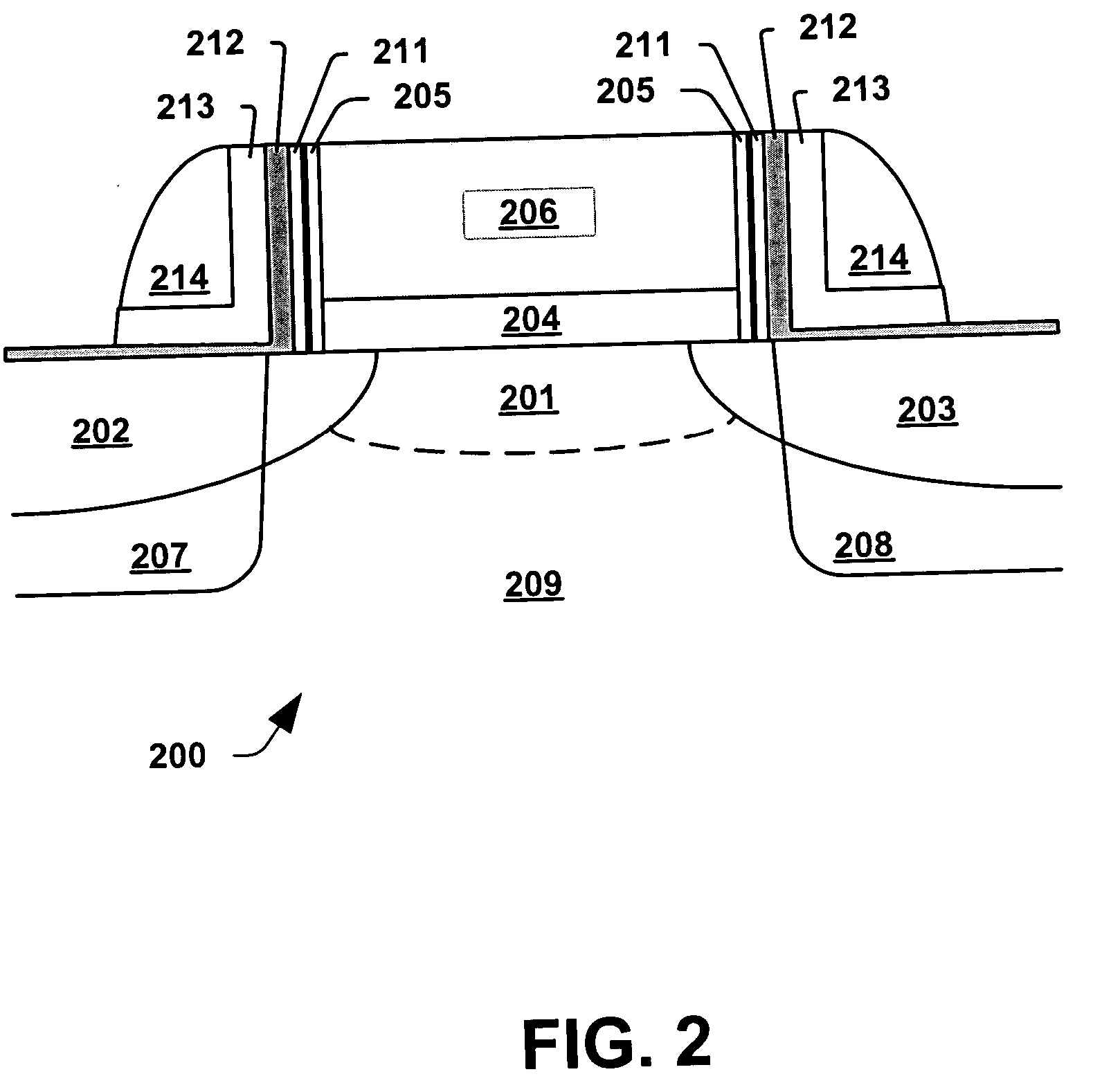

NROM flash memory with a high-permittivity gate dielectric

ActiveUS20050173755A1TransistorSemiconductor/solid-state device manufacturingGate dielectricOxide composite

A high permittivity gate dielectric is used in an NROM memory cell. The gate dielectric has a dielectric constant greater than silicon dioxide and is comprised of an atomic layer deposited and / or evaporated nanolaminate structure. The NROM memory cell has a substrate with doped source / drain regions. The high-k gate dielectric is formed above the substrate between a pair of the source / drain regions. A polysilicon control gate is formed on top of the gate dielectric. The gate dielectric can have an oxide-high-k dielectric-oxide composite structure, an oxide-nitride-high-k dielectric composite structure, or a high-k dielectric-high-k dielectric-high-k dielectric composite structure.

Owner:MICRON TECH INC

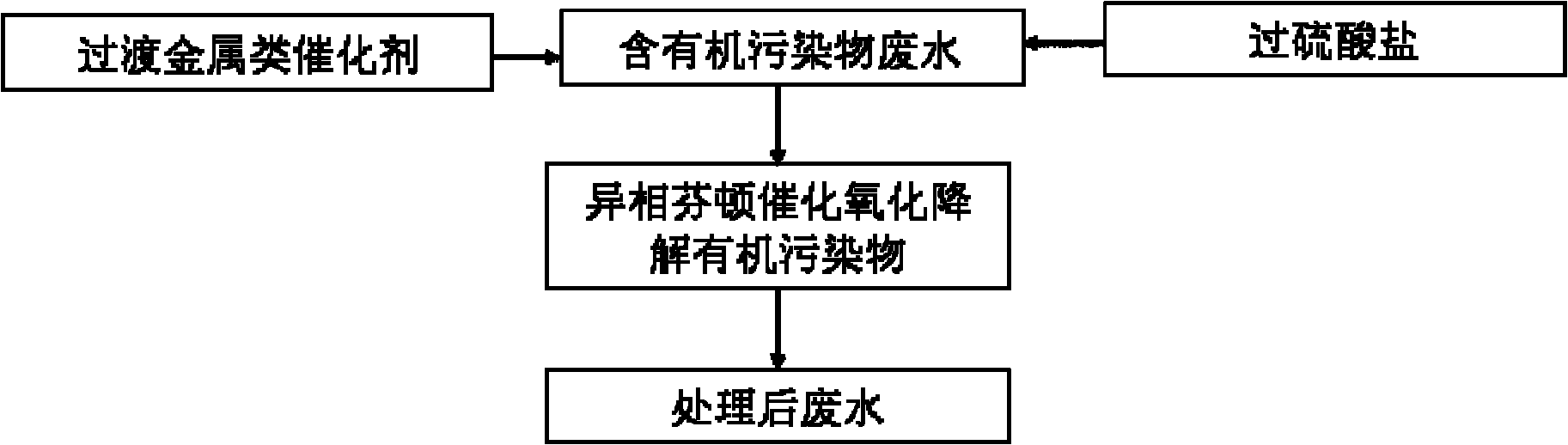

Processing method of heterocatalysis persulfate Fenton oxidation water

InactiveCN102020350ALong-lasting and efficient purificationImprove durabilityWater/sewage treatment by oxidationPersulfateFenton reagent

The invention proposes a processing technology of heterocatalysis persulfate Fenton oxidation water. In the method, transitional metal, transitional metallic oxide and a transitional metal / transitional metallic oxide composite material are used as out-phase Fenton reagents; and persulfate is catalyzed and decomposed to generate hydroxyl radical free radical, thus oxidizing to remove the organic matters in the waste water. Compared with the water treatment technique of homogeneous phase persulfate, the out-phase transitional metal and the transition metal oxide catalyst can slowly release transitional metal icons, thus ensuring that the organic matters in the water are purified lastingly and efficiently by the processing method of the heterocatalysis persulfate Fenton oxidation water. The processing technology of heterocatalysis persulfate Fenton catalyzed oxidation water built by the invention is suitable for processing various organic wastewater, has the advantages of good durability, high efficiency, environmentally friendliness, and no secondary pollution, is easy to operate, conforms to the requirements of actual water treatment units, and has great application potential in the field of environmental pollution regulation.

Owner:HUAZHONG NORMAL UNIV

Negative electrode material for secondary battery with non-aqueous electrolyte, method for manufacturing negative electrode material for secondary battery with non-aqueous electrolyte, and lithium ion secondary battery

ActiveUS20110244333A1Cycle durability of negativeElectronic conductivity of negativeMaterial nanotechnologyElectrode thermal treatmentOxide compositeAtomic order

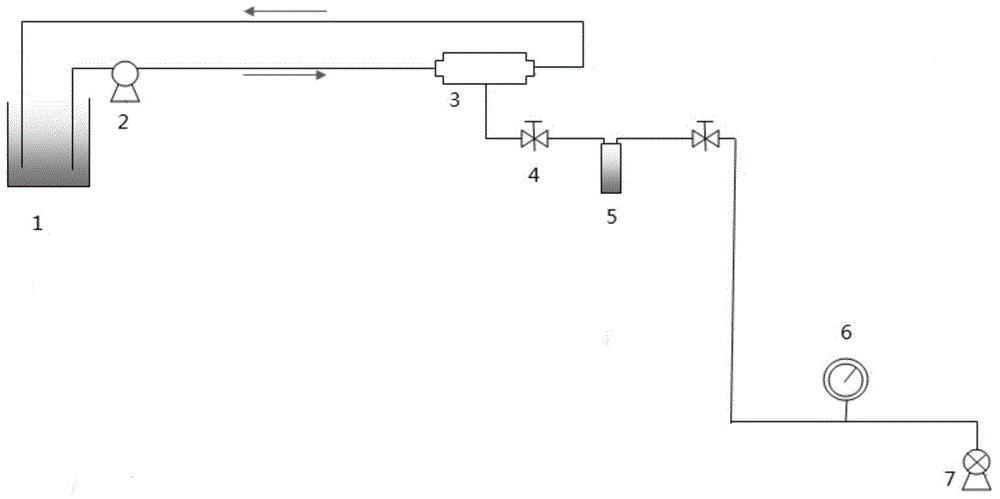

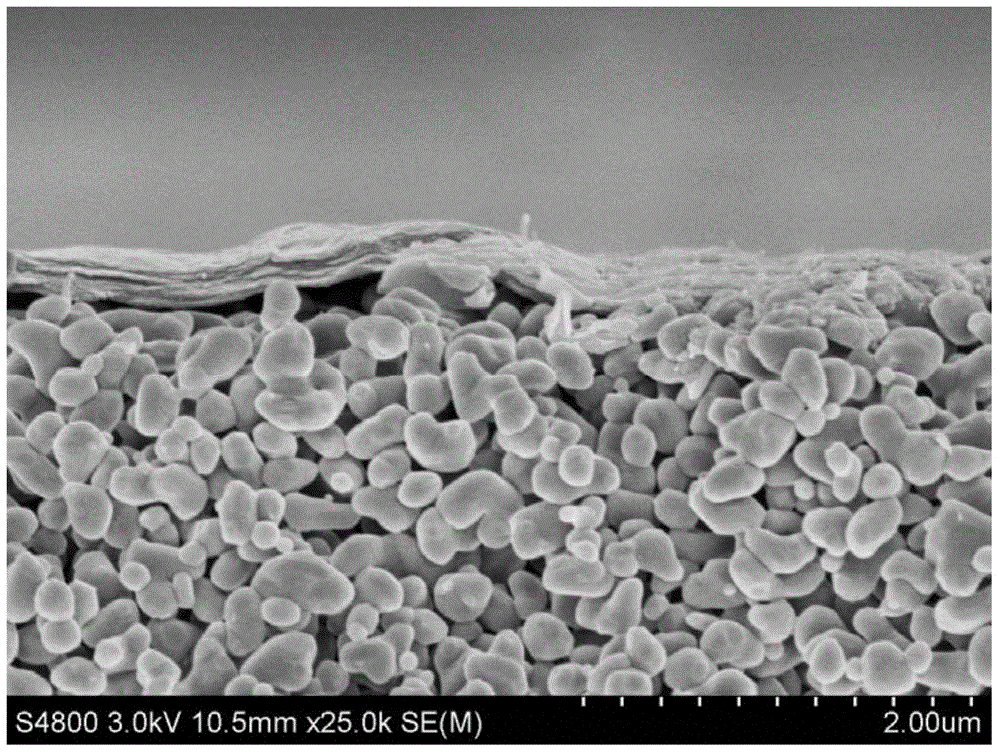

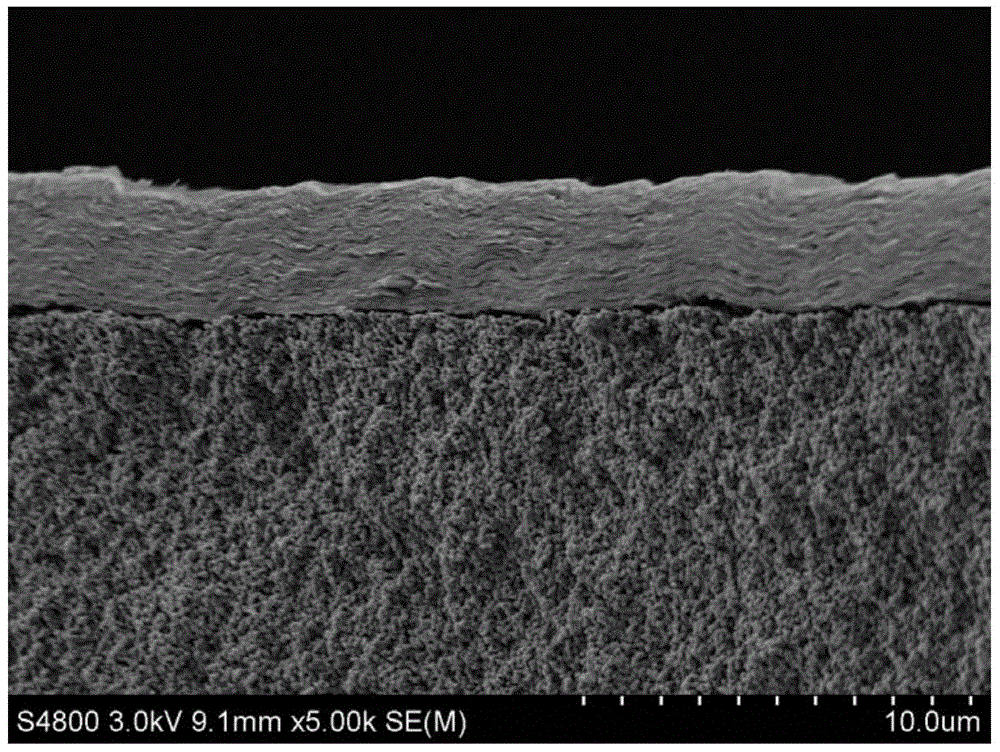

The present invention is a method for manufacturing a negative electrode material for a secondary battery with a non-aqueous electrolyte comprising at least: coating a surface of powder with carbon at a coating amount of 1 to 40 mass % with respect to an amount of the powder by heat CVD treatment under an organic gas and / or vapor atmosphere at a temperature between 800° C. and 1300° C., the powder being composed of at least one of silicon oxide represented by a general formula of SiOx (x=0.5 to 1.6) and a silicon-silicon oxide composite having a structure that silicon particles having a size of 50 nm or less are dispersed to silicon oxide in an atomic order and / or a crystallite state, the silicon-silicon oxide composite having a Si / O molar ratio of 1 / 0.5 to 1 / 1.6; blending lithium hydride and / or lithium aluminum hydride with the powder coated with carbon; and thereafter heating the powder coated with carbon at a temperature between 200° C. and 800° C. to be doped with lithium at a doping amount of 0.1 to 20 mass % with respect to an amount of the powder. As a result, there is provided a method for manufacturing a negative electrode material for a secondary battery with a non-aqueous electrolyte that enables a silicon oxide negative electrode material superior in first efficiency and cycle durability to conventional ones to be mass-produced (manufactured) readily and safely even in an industrial scale.

Owner:SHIN ETSU CHEM IND CO LTD

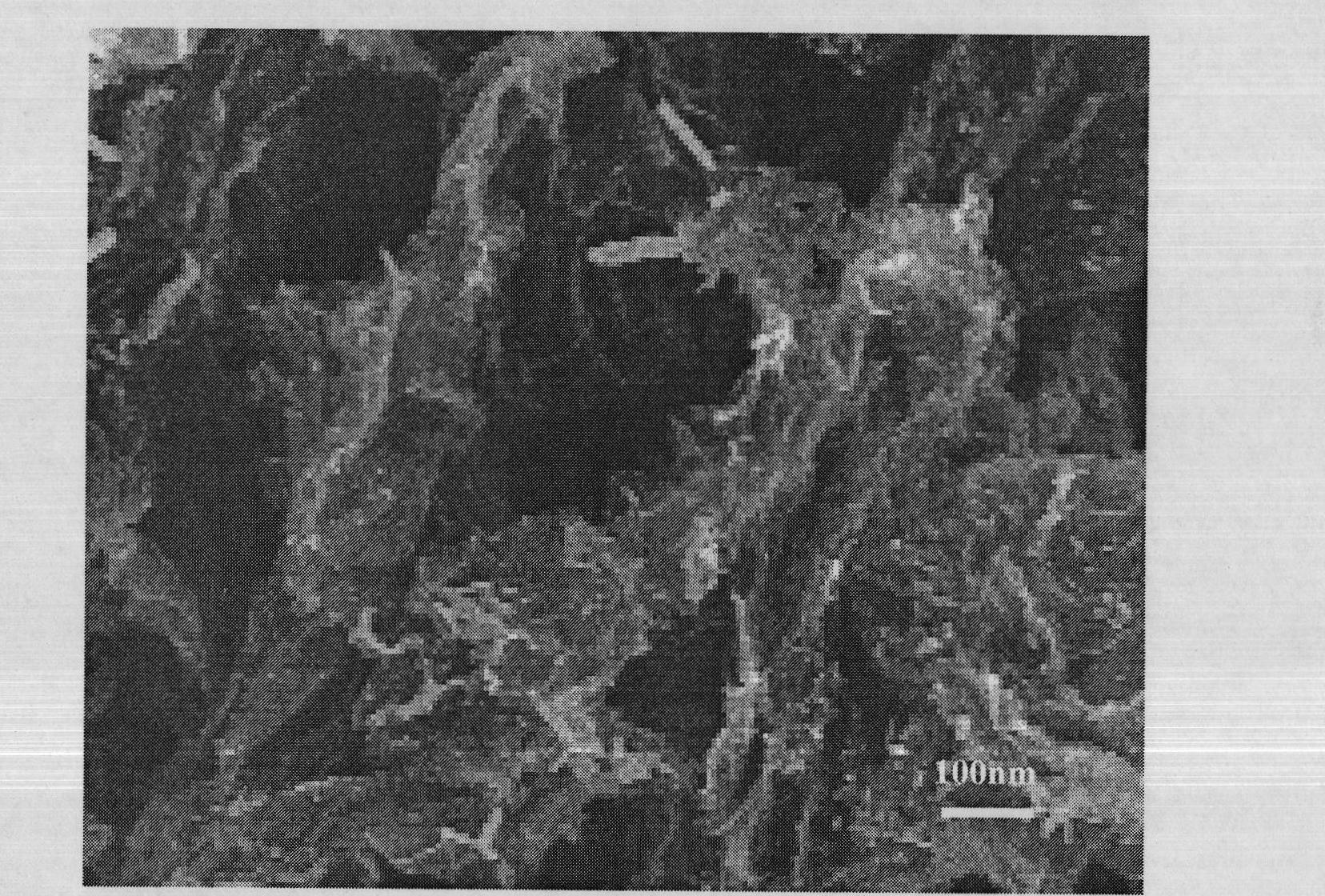

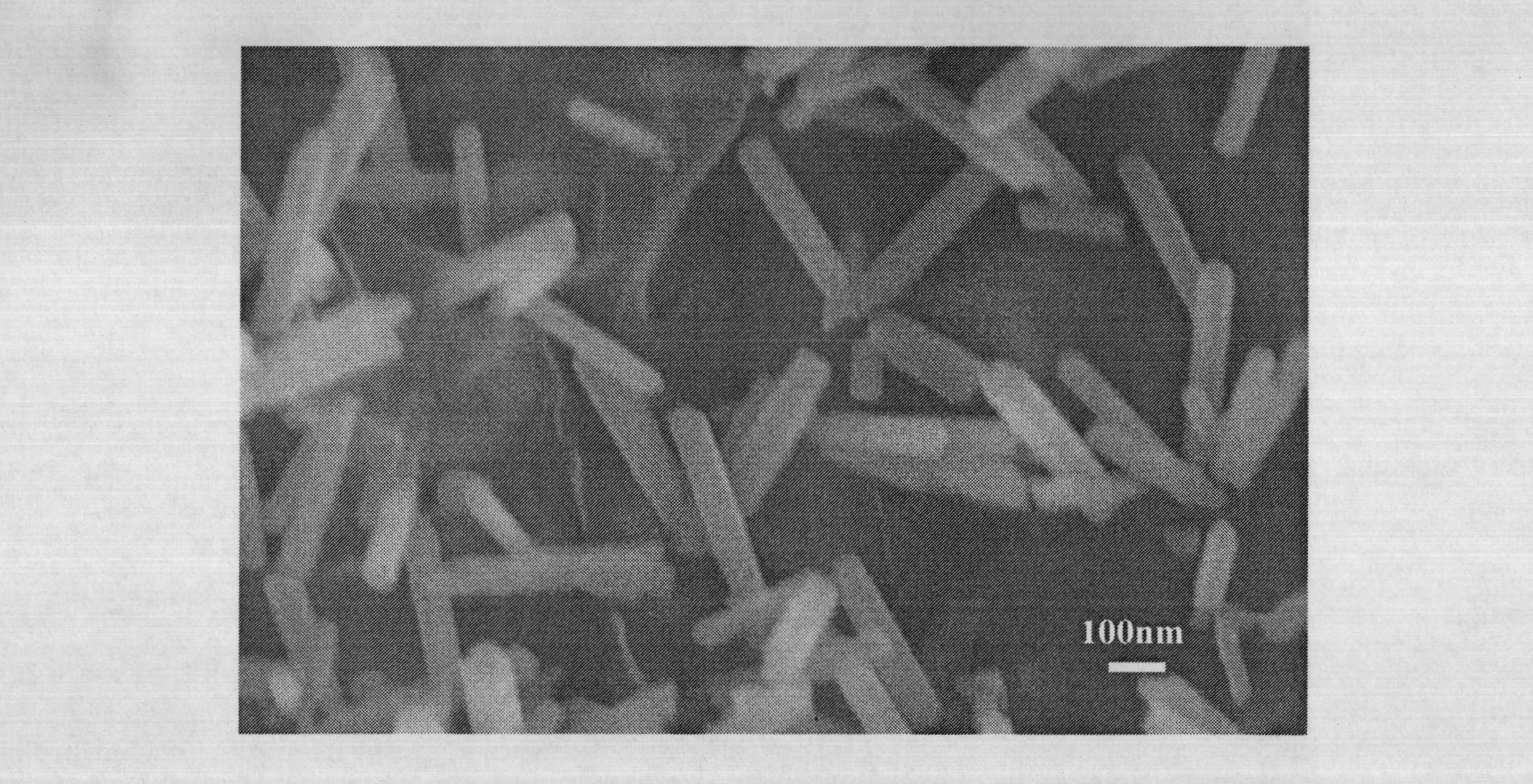

Preparation method of large-area and continuous graphen/zinc oxide composite structure

ActiveCN101857222AThickness is easy to controlSimple processZinc oxides/hydroxidesNanoparticleThree-dimensional space

The invention relates to a method for preparing continuous graphen / zinc oxide composite structure in large area, which belongs to the preparation field of the novel nanometer material, and is applicable to the fields such as sensor, solar panel, novel nanometer part and the like. The method comprises the following three steps that: first step: uniformly dispersing graphen or graphene oxide in liquid phase; second step: utilizing a hydrothermal process to ensure the zinc oxide nanometer structure and the graphen two-dimensional sheet to form a continuous structure in a three-dimensional space; third step: transferring the prepared composite structure onto a substrate to be dried. The method has simple process and low device requirement since the composite structure is synthesized in the solution; the process repeatability is strong, and the process parameter can be well controlled; the prepared graphen / zinc oxide composite structure has large area and is continuous, the generated zinc oxide nanometer sheet layer, nanometer particle and nanometer line are connected with each other and intersected with each other under the effect of the graphen so as to form a continuous porous structure in the three-dimensional space.

Owner:如东文园投资开发有限公司

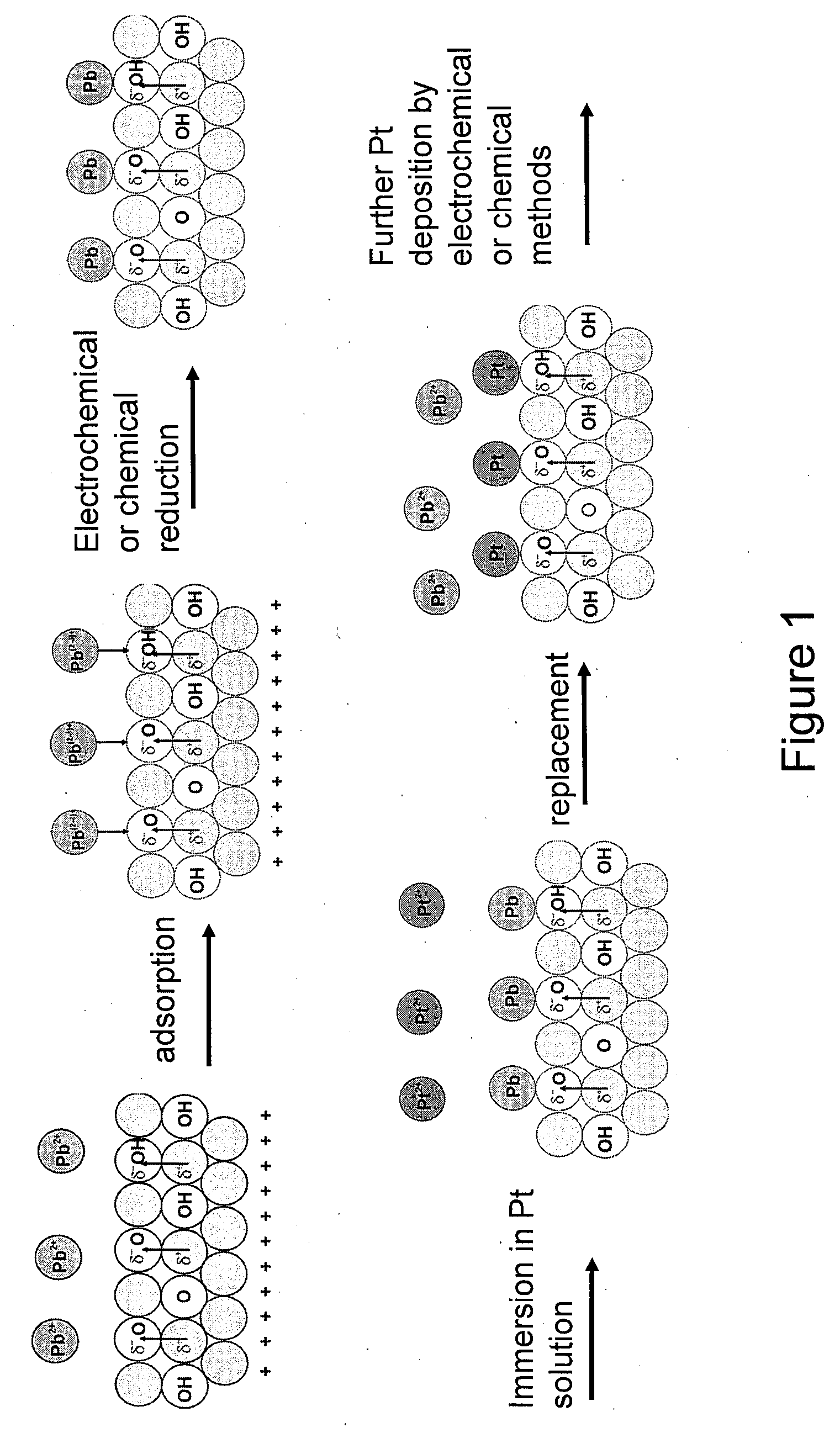

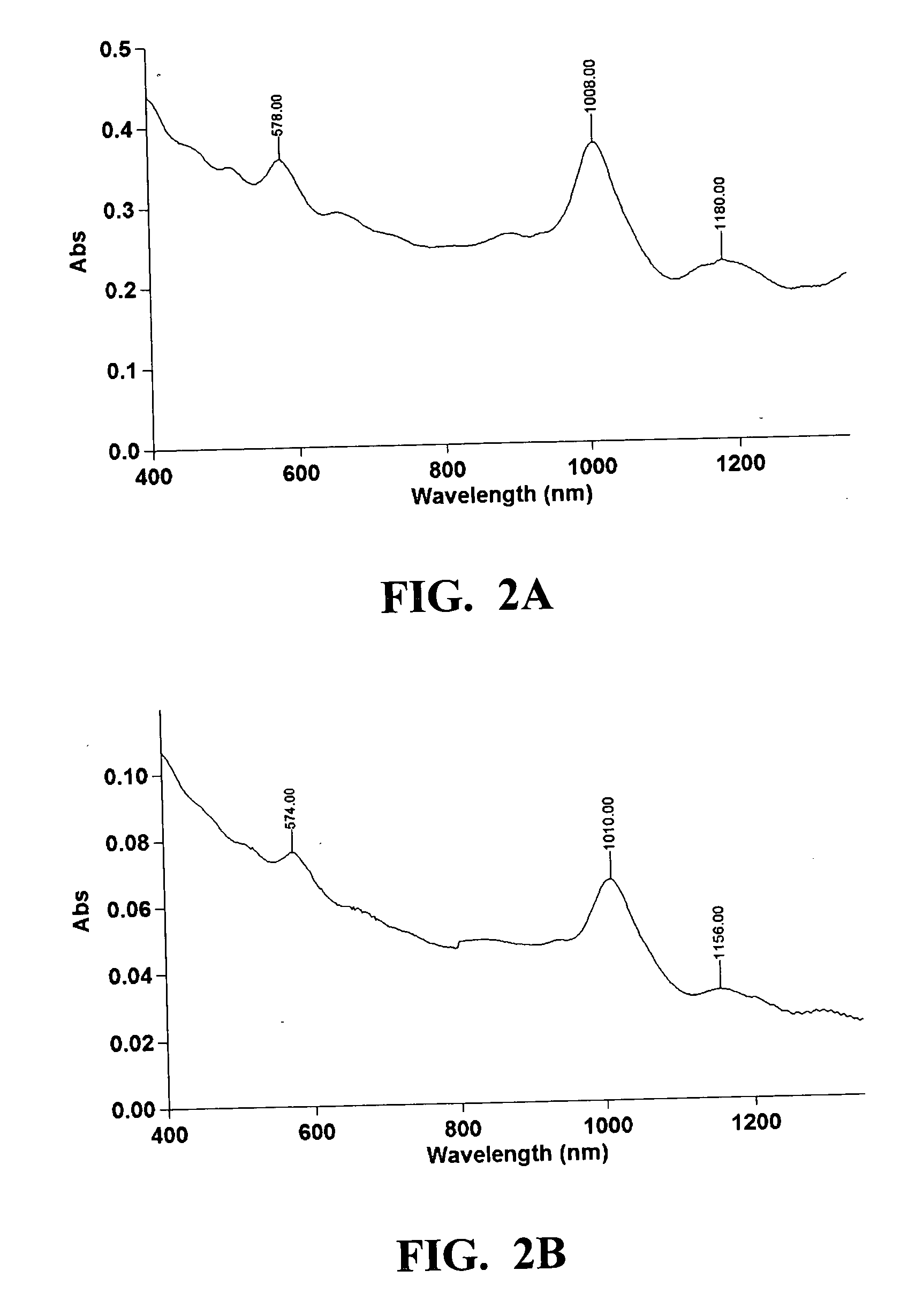

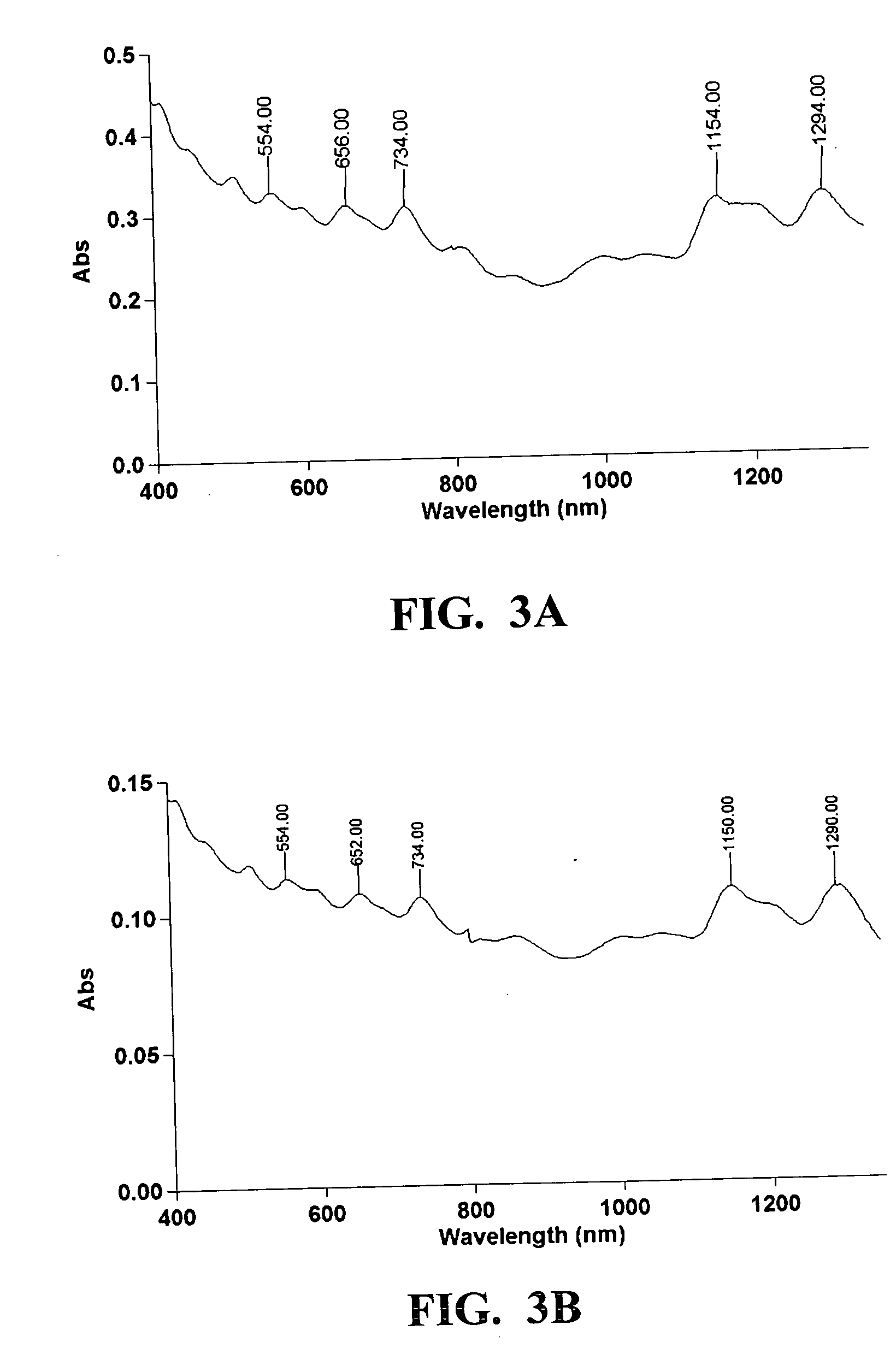

Electrocatalyst for oxygen reduction with reduced platinum oxidation and dissolution rates

InactiveUS20060263675A1Low platinum loadingImprove stabilityMaterial nanotechnologyConductive materialOxide compositeDissolution

The invention relates to platinum-metal oxide composite particles and their use as electrocatalysts in oxygen-reducing cathodes and fuel cells. The invention particularly relates to methods for preventing the oxidation of the platinum electrocatalyst in the cathodes of fuel cells by use of these platinum-metal oxide composite particles. The invention additionally relates to methods for producing electrical energy by supplying such a fuel cell with an oxidant, such as oxygen, and a fuel source, such as hydrogen.

Owner:BROOKHAVEN SCI ASSOCS

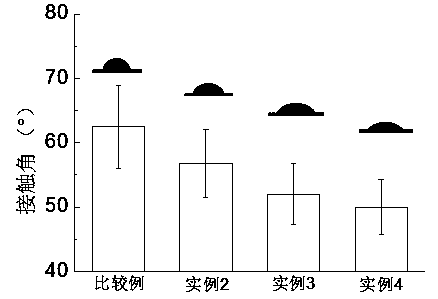

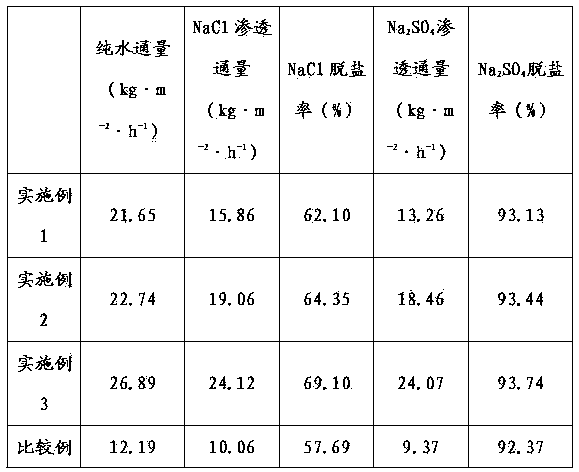

Preparation method of graphene oxide composite nano filter membrane

ActiveCN103736400AImprove throughputImprove desalination performanceSemi-permeable membranesOxide compositeMembrane surface

The invention relates to a preparation method of a graphene oxide composite nano filter membrane, and belongs to the technical field of separation membrane preparation. The preparation method of the graphene oxide composite nano filter membrane comprises the following steps: (1) preparing a graphene oxide water liquid; (2) preparing a graphene oxide cross linking liquid; and (3) preparing the graphene oxide composite nano filter membrane. The graphene oxide composite nano filter membrane provided by the invention has the characteristics that the surface of the membrane has a great deal of free carboxyl and hydroxy, the hydrophilicity is high, the flux is high, meanwhile, the charge on the surface of the membrane is negative, the salt cutting ratio is effectively improved, the flux and a desalting effect of the nano filter membrane are remarkably improved, and the graphene oxide composite nano filter membrane has the good large-scale industrialized application prospects.

Owner:OCEAN UNIV OF CHINA

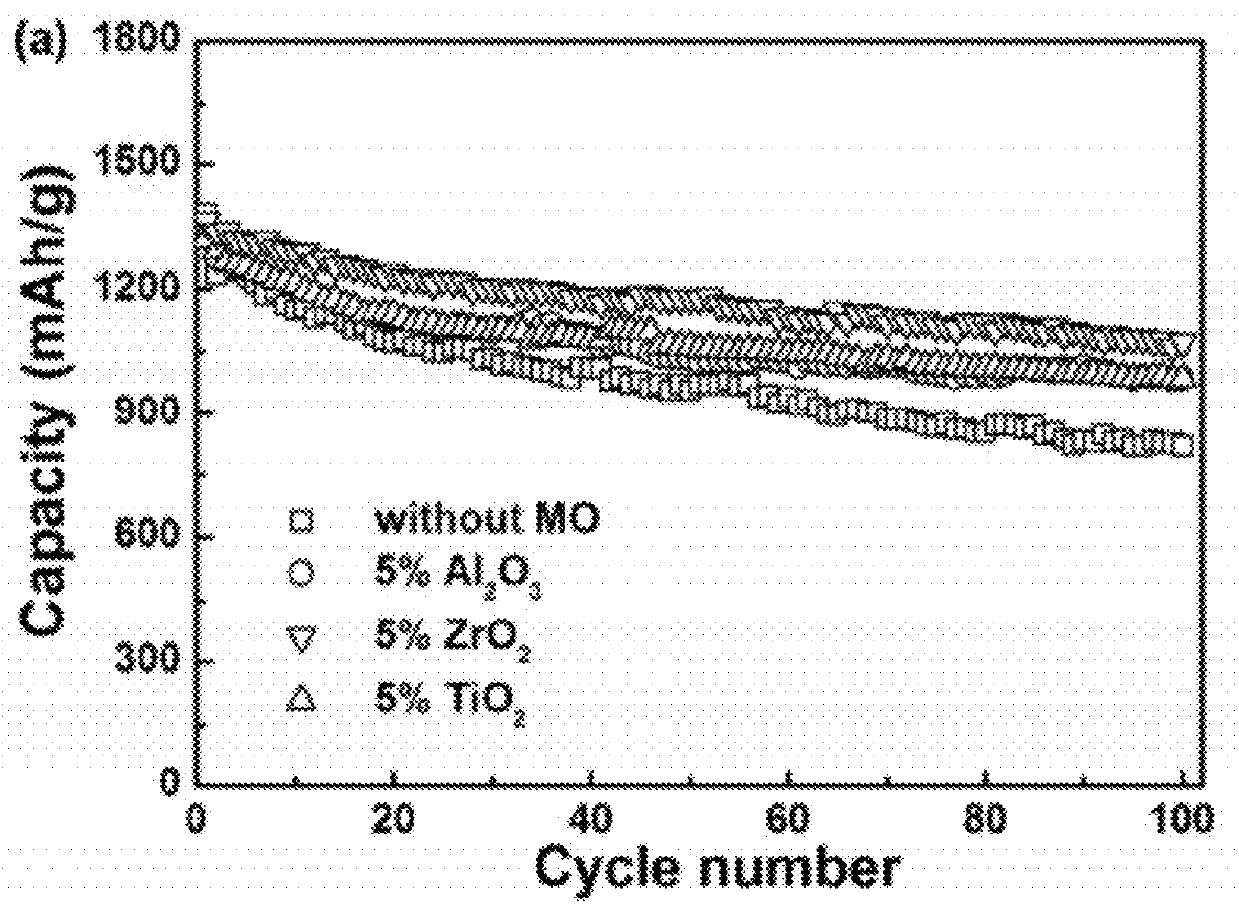

Graphene nanometer sheet-cobaltous oxide composite negative electrode material of lithium ion battery and preparation method thereof

InactiveCN101800302AImprove conductivityIncrease profitNon-aqueous electrolyte accumulator electrodesCobalt oxides/hydroxidesOxide compositeLithium-ion battery

The invention relates to a graphene nanometer sheet-cobaltous oxide composite negative electrode material of a lithium ion battery and a preparation method thereof, and belongs to the technical field of batteries. The negative electrode material consists of graphene nanometer sheets and cobaltous oxide, wherein the graphene nanometer sheets are distributed on cobaltous oxide particles in a staggering way; the mass fraction of the graphene nanometer sheets is 5 to 90 percent; the thickness of the graphene nanometer sheets is 1 to 50 nanometers; and the particle size of the cobaltous oxide is 10 to 500 nanometers. The preparation method comprises the following steps: dispersing graphite oxide in alcohol-water solution or aqueous solution with ultrasound or stirring; adding cobalt salt, alkali and a reducing agent into the mixture and pouring the mixture into a hydrothermal kettle after stirring; performing further sealing and synchronous hydrothermal reaction, washing, filtering and drying to obtain a graphene nanometer sheet-cobaltous oxide composite; and processing the graphene nanometer sheet-cobaltous oxide composite in the protective atmosphere to obtain the graphene nanometer sheet-cobaltous oxide composite negative electrode material. In the invention, when the material is charged or discharged by a current of 200mA / g, the reversible specific capacity of the material can be stabilized in a range of over 900mAh / g.

Owner:SHANGHAI JIAO TONG UNIV

Silicon-silicon oxide-lithium composite, making method, and non-aqueous electrolyte secondary cell negative electrode material

ActiveUS7776473B2Improve efficiencyImprove cycle performanceNegative electrodesSecondary cellsOxide compositeSilicon oxide

A silicon-silicon oxide-lithium composite comprises a silicon-silicon oxide composite having such a structure that silicon grains having a size of 0.5-50 nm are dispersed in silicon oxide, the silicon-silicon oxide composite being doped with lithium. Using the silicon-silicon oxide-lithium composite as a negative electrode material, a lithium ion secondary cell having a high initial efficiency and improved cycle performance can be constructed.

Owner:SHIN ETSU CHEM CO LTD

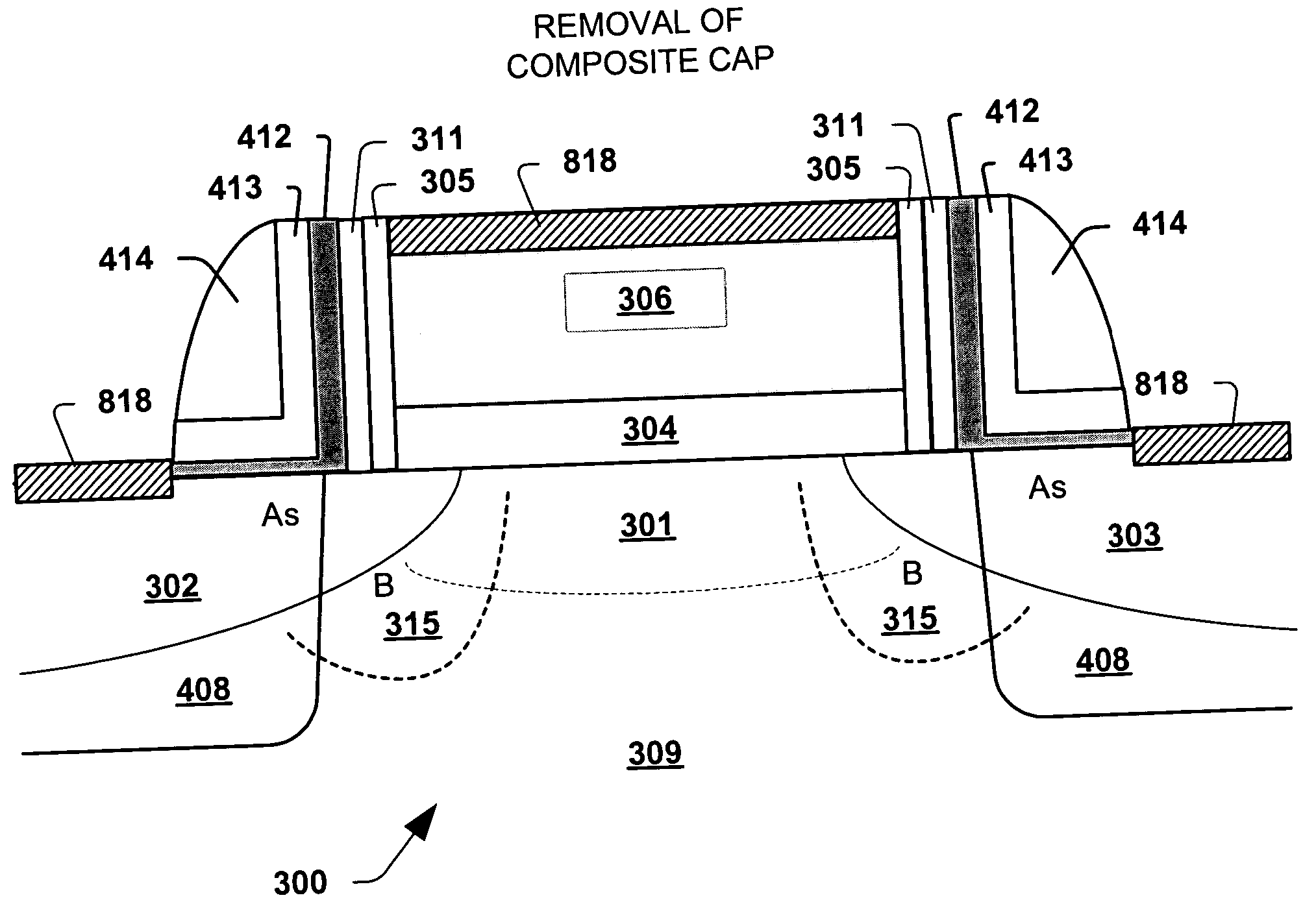

Integration of pre-S/D anneal selective nitride/oxide composite cap for improving transistor performance

ActiveUS20050059228A1Improve device performanceImprove mobilityTransistorSemiconductor/solid-state device manufacturingDopantDevice material

The present invention facilitates semiconductor device operation and fabrication by providing a cap-annealing process that improves channel electron mobility without substantially degrading PMOS transistor devices. The process uses an oxide / nitride composite-cap to alter the active dopant profile across the channel regions. During an annealing process, dopants migrate out of the Si / SiO2 in a channel region thereby altering the dopant profile of the channel region. This altered profile generally improves channel mobility thereby improving transistor performance and permitting smaller density designs.

Owner:TEXAS INSTR INC

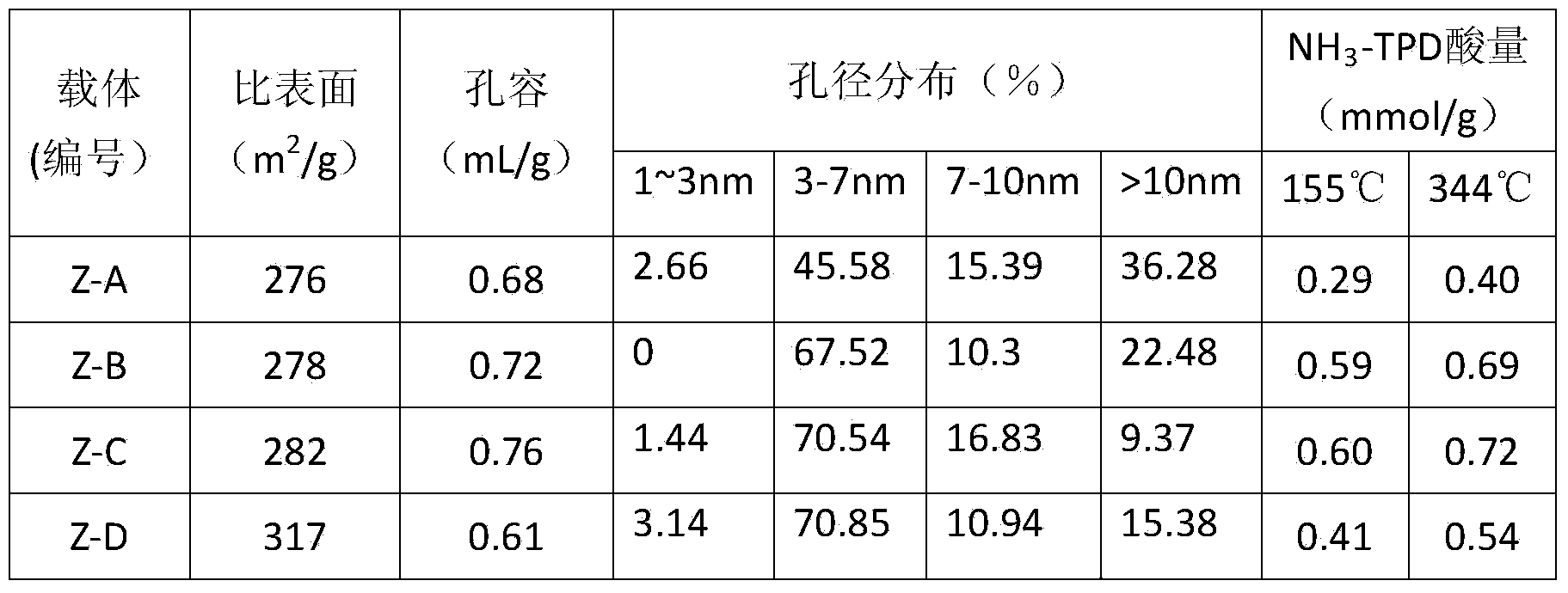

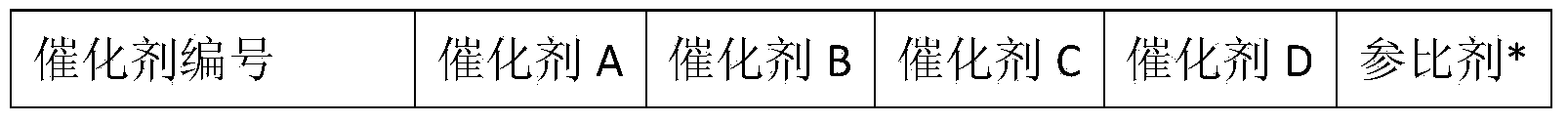

Diesel hydrodesulfurization and denitrification catalyst and preparation method thereof

InactiveCN103551162AGood dispersionIncrease profitMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHydrodesulfurizationOxide composite

The invention discloses a diesel hydrodesulfurization and denitrification catalyst. The catalyst comprises the following compositions: a carrier, an additive, and an active metal, wherein the carrier is an Al2O3-ZrO2-TiO2-SiO2 multibasic oxide composite carrier; the additive is phosphorus; nickel, cobalt, molybdenum and tungsten are taken as active components; through taking the catalyst as a benchmark, in terms of oxides, the catalyst comprises the following components in percentage by weight, 1-6wt% of cobalt oxide, 1-15wt% of nickel oxide, 2-12wt% of molybdenum oxide, 12-35wt% of tungsten oxide and 1.5-5wt% of an additive phosphorus pentoxide; and the pore volume of the catalyst is not less than 0.2 mL / g, the specific surface area of the catalyst is not less than 140 m<2> / g, and the mechanical strength of the catalyst is not less than 15N / mm; and the composite carrier comprises the following components in percentage by weight: 2-15wt% of titanium oxide, 2-20wt% of silicon oxide, 5-15wt% of zirconium oxide, and the balance of aluminum oxide.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Synthesis of Metal-Metal Oxide Catalysts and Electrocatalysts Using a Metal Cation Adsorption/Reduction and Adatom Replacement by More Noble Ones

InactiveUS20070264189A1Improve stabilityReducing and preventing oxidationCell electrodesGold compoundsHydrogenFuel cells

The invention relates to platinum-metal oxide composite particles and their use as electrocatalysts in oxygen-reducing cathodes and fuel cells. The invention particularly relates to methods for preventing the oxidation of the platinum electrocatalyst in the cathodes of fuel cells by use of these platinum-metal oxide composite particles. The invention additionally relates to methods for producing electrical energy by supplying such a fuel cell with an oxidant, such as oxygen, and a fuel source, such as hydrogen. The invention also relates to methods of making the metal-metal oxide composites.

Owner:BROOKHAVEN SCI ASSOCS

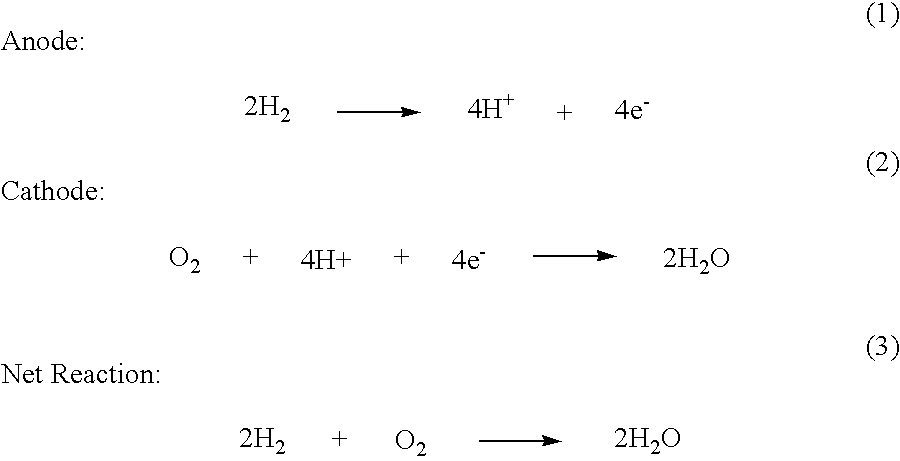

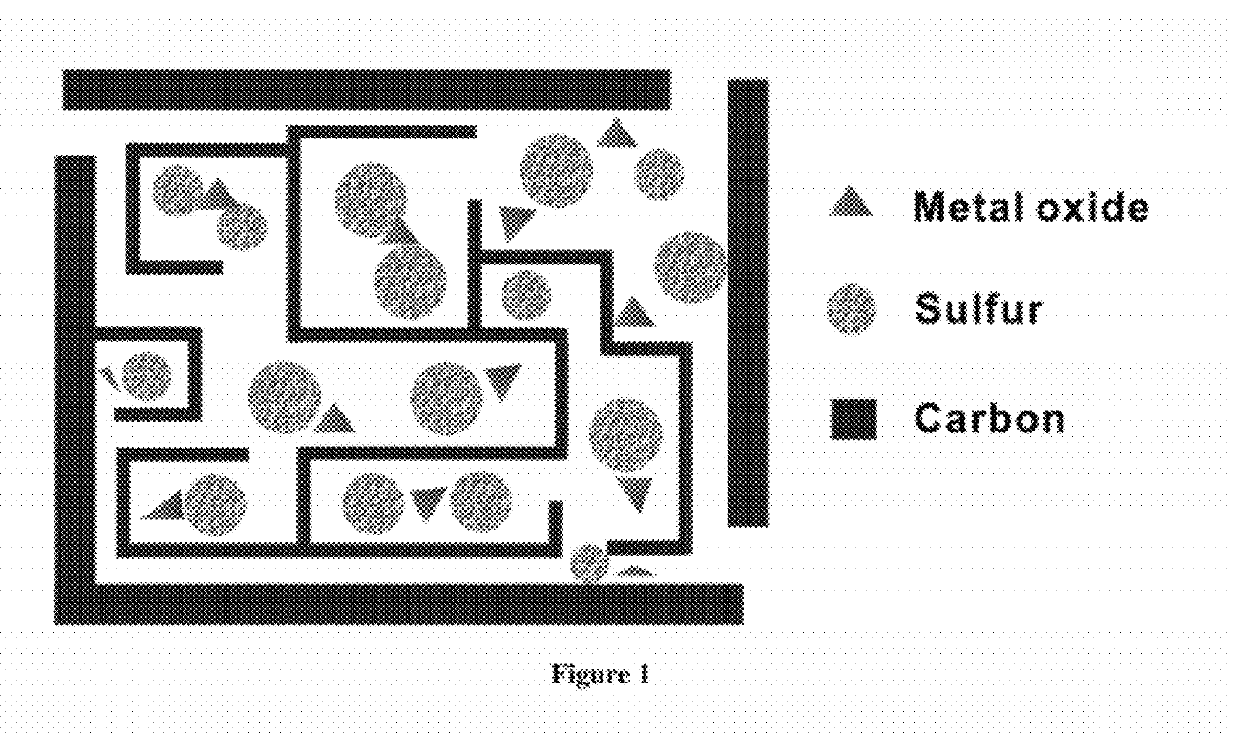

Carbon-metal oxide-sulfur cathodes for high-performance lithium-sulfur batteries

InactiveUS20120207994A1Improve performanceImprove Coulombic efficiencyNon-metal conductorsLayered productsPorous carbonLithium–sulfur battery

Embodiments presented herein provide a new approach for high-performance lithium-sulfur battery by using novel carbon-metal oxide-sulfur composites. The composites may be prepared by encapsulating sulfur particles in bifunctional carbon-supported metal oxide or other porous carbon-metal oxide composites. In this way, the porous carbon-metal oxide composite confines sulfur particles within its tunnels and maintain the electrical contact during cycling. Furthermore, the uniformly embedded metal oxides in the structure strongly adsorb polysulfide intermediates, avoid dissolution loss of sulfur, and ensure high coulombic efficiency as well as a long cycle life.

Owner:PENN STATE RES FOUND

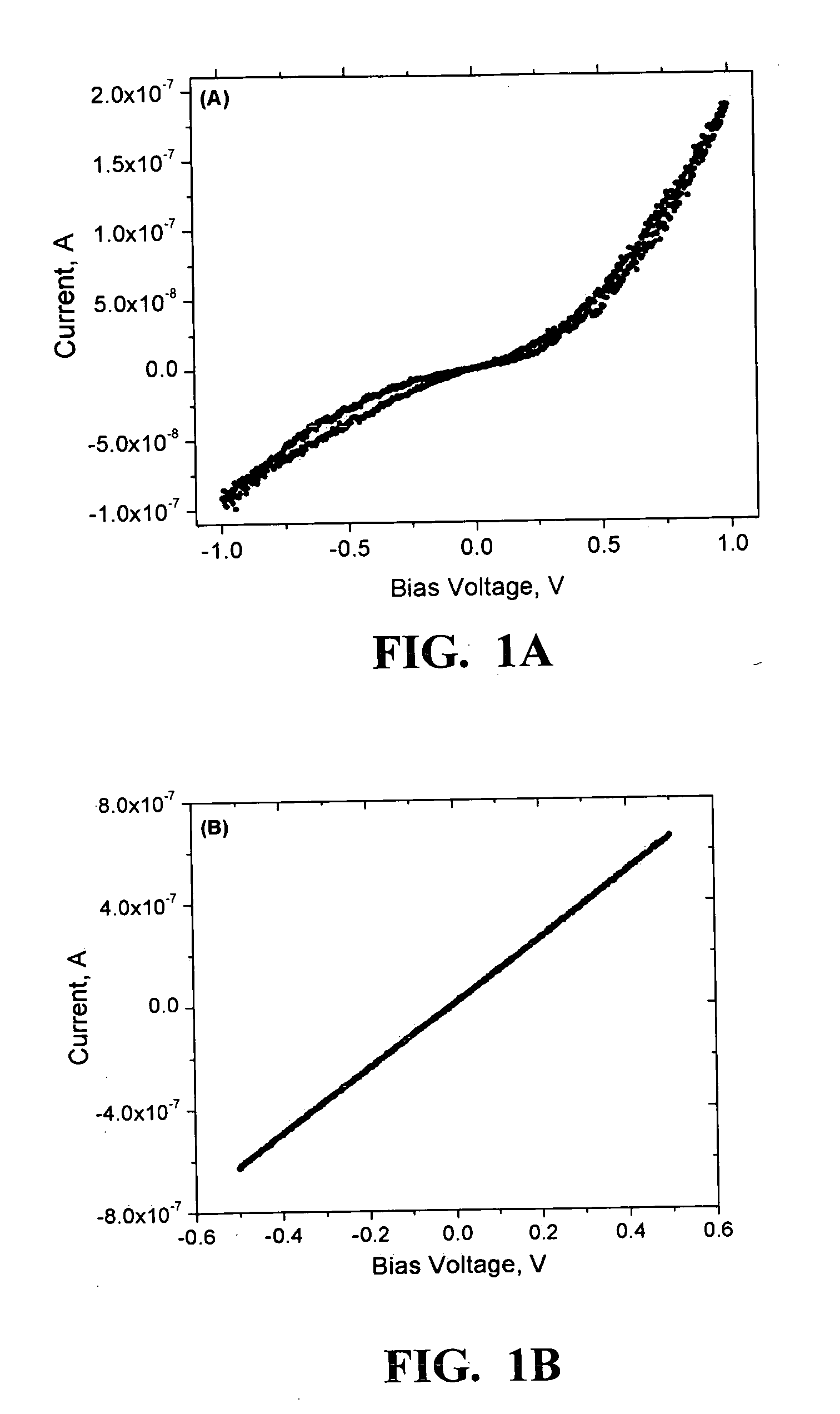

Single-walled carbon nanotube composites

InactiveUS20060240238A1Material nanotechnologyCeramic layered productsOxide compositeCarbon nanotube

Owner:EI DU PONT DE NEMOURS & CO

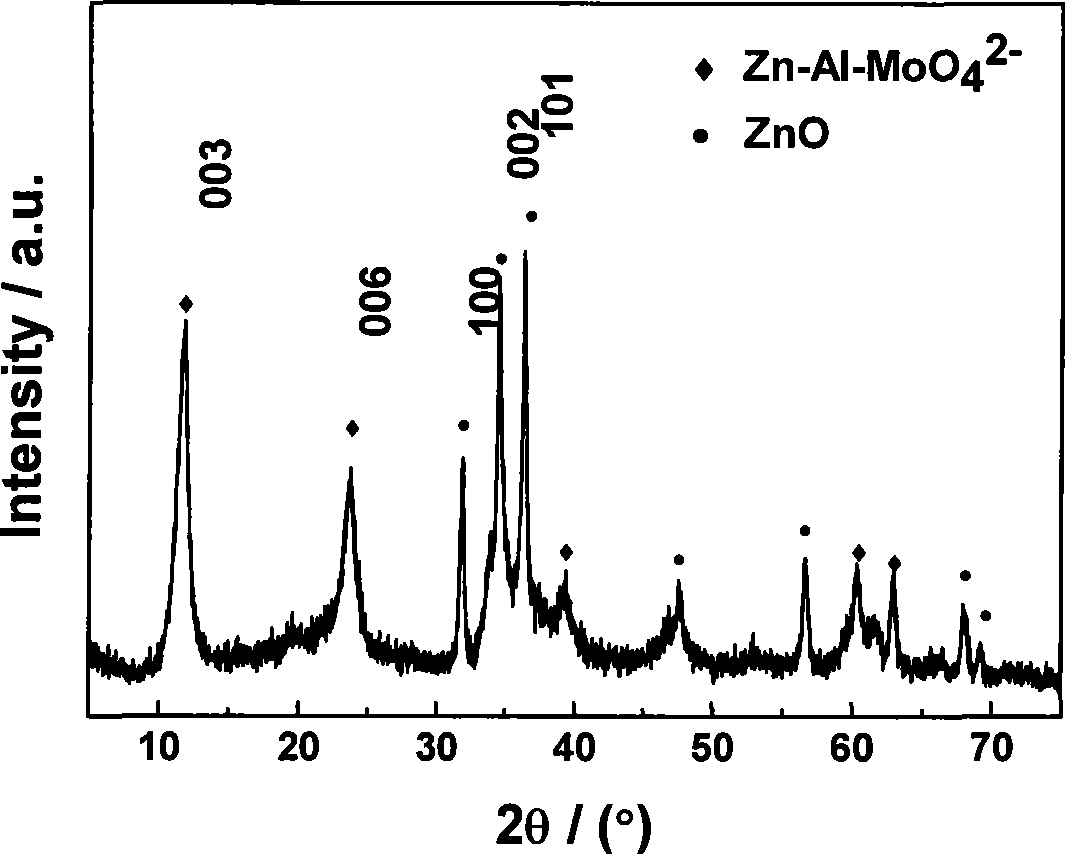

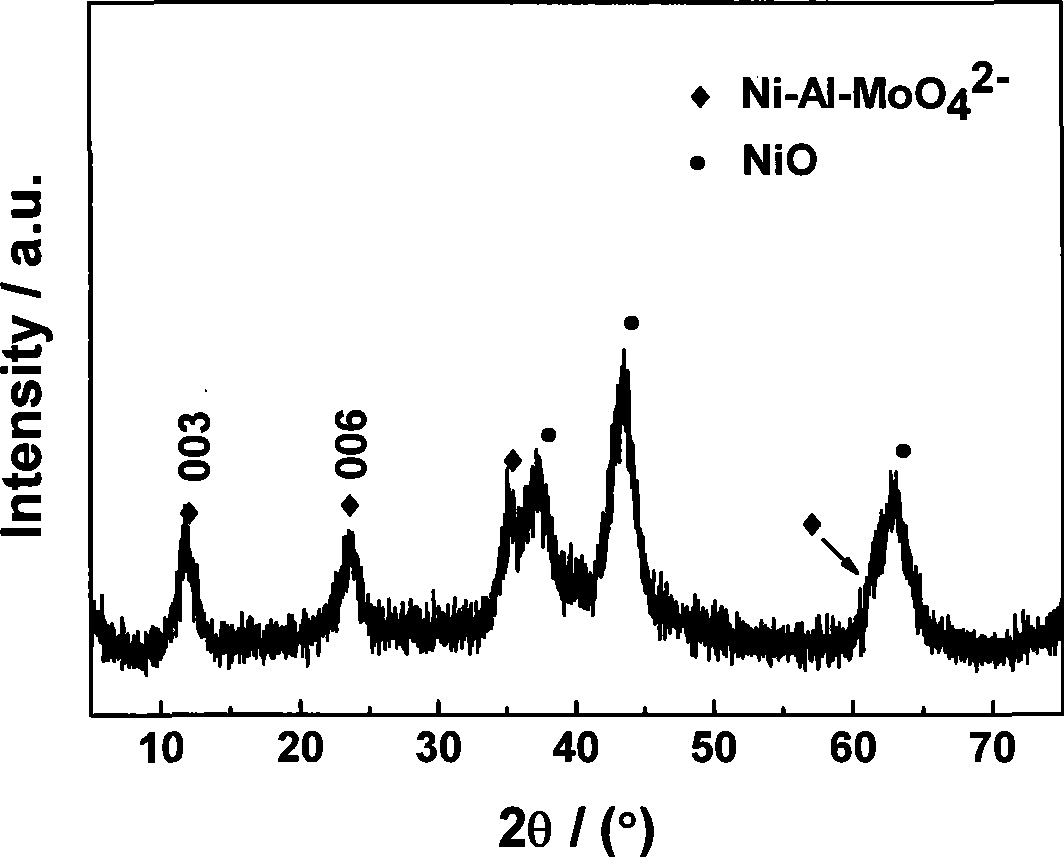

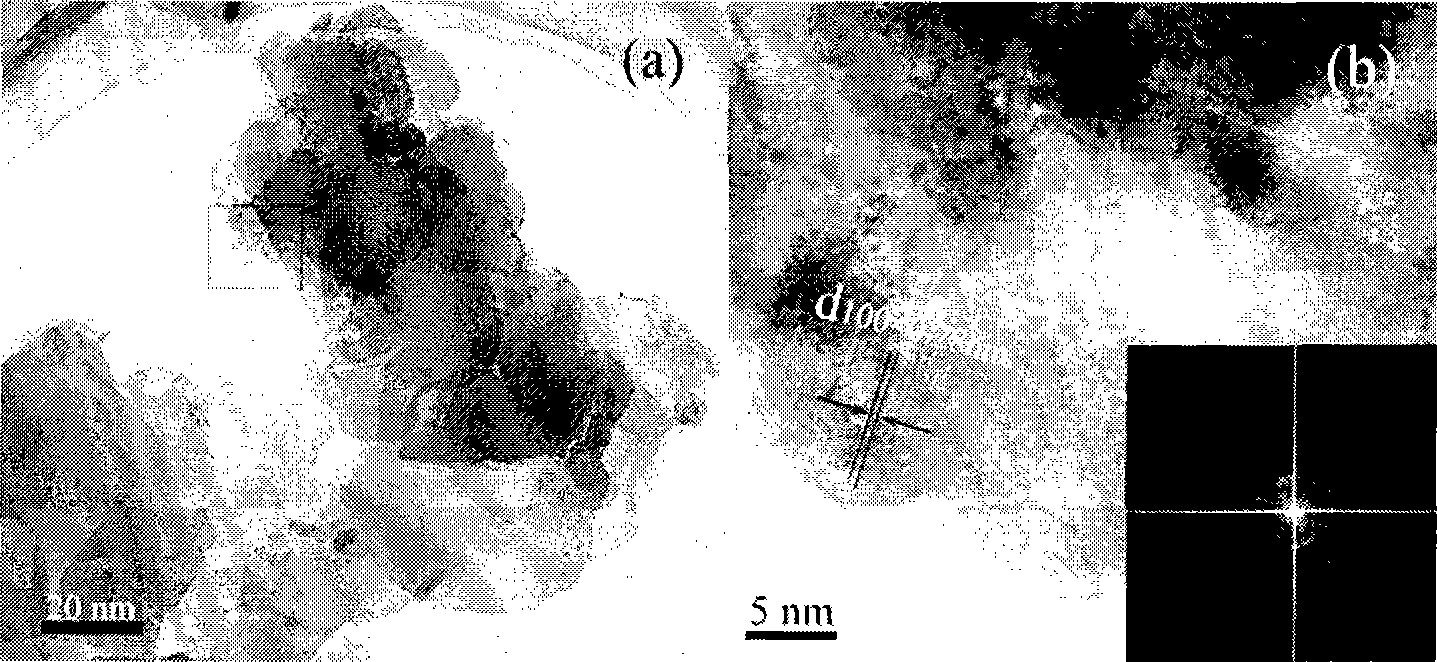

Method for preparing corrosion inhibition anion intercalated layered double hydroxides/oxide composite material and application

InactiveCN101418154AFacilitated releaseImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsOxide compositeReaction temperature

The invention provides a corrosion-inhibiting anionic intercalated hydrotalcite / nano oxide composite material, a preparation method thereof and application of the corrosion-inhibiting anionic intercalated hydrotalcite / nano oxide composite material. The preparation method is as follows: corrosion-inhibiting anions are directly inserted between hydrotalcite layers by the one-step coprecipitation method and the roasting restoring method; the nano oxide is generated by means of in situ synchronization during the process of generation of hydrotalcite crystals by controlling the mixture ratio of divalent metal ions to trivalent metal ions, the pH value of a reaction solution and the reaction temperature; and the corrosion-inhibiting anionic intercalated hydrotalcite / nano oxide composite material with the anti-corrosive function is prepared. The invention is mainly characterized in that the in situ preparation method for the hydrotalcite / oxide composite material provided with a nano lamellar structure improves the release amount of a corrosion inhibitor and reduces the water absorption of a coating by leading into the corrosion inhibitor with the anti-corrosive function and the nano oxide which is generated in situ during the reaction process. The composite material can be used to be pigment of an anti-corrosive metallic coating system, and particularly has potential application value in improving the anti-corrosive performance of a magnesium alloy anti-corrosive coating.

Owner:HARBIN ENG UNIV

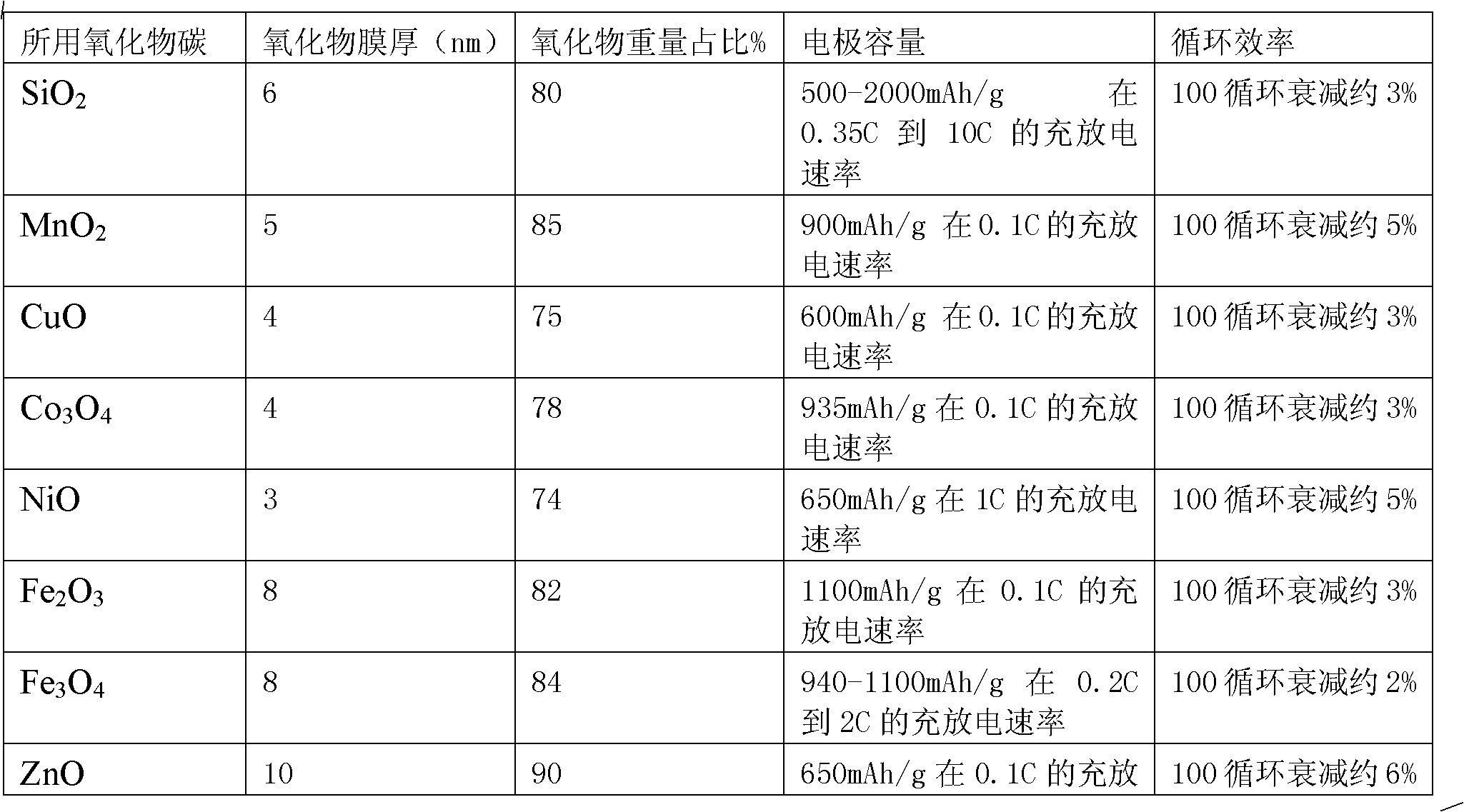

High-specific-area carbon/metallic oxide composite electrode material of lithium battery, electrode and preparation methods for high-specific-area carbon/metallic oxide composite electrode material and electrode

ActiveCN102569768AImprove structural stabilityImprove uniformityCell electrodesElectrical batteryOxide composite

The invention relates to a high-specific-area carbon / metallic oxide composite electrode material of a lithium battery, an electrode and preparation methods for the high-specific-area carbon / metallic oxide composite electrode material and the electrode. A metallic oxide is deposited on high-specific-area carbon powder by using an atomic layer deposition method, and the mass ratio of a metallic oxide film to high-specific-area carbon is between 70 percent and 90 percent. The invention also provides a method for preparing the high-specific-area carbon / metallic oxide composite electrode material by using the atomic layer deposition method, and a method for preparing the electrode by using the high-specific-area carbon / metallic oxide composite electrode material. The high-specific-area carbon / metallic oxide composite electrode material has a high-mass-ratio characteristic, and the lithium battery prepared from the high-specific-area carbon / metallic oxide composite electrode material has a long cycle life and high capacitance stability.

Owner:柔电(武汉)科技有限公司

Porous silica and metal oxide composite-based catalysts for conversion of fatty acids and oils to biodiesel

ActiveUS7790651B2Easy to separateEasy to recycleFatty oils/acids recovery from wasteNanotechMETHYL SOYATEVegetable oil

A recyclable esterification or transesterification catalyst and methods for making and using the same are provided herein. The catalyst can be used to prepare biodiesel or methyl soyate from various feedstocks, including vegetable oils and animal fats. The catalyst can both esterify free fatty acids and transesterify mono-, di-, and triglycerides. The catalyst can also be combined with a metal oxide, and optionally calcined, prior to carrying out a catalytic reaction.

Owner:IOWA STATE UNIV RES FOUND

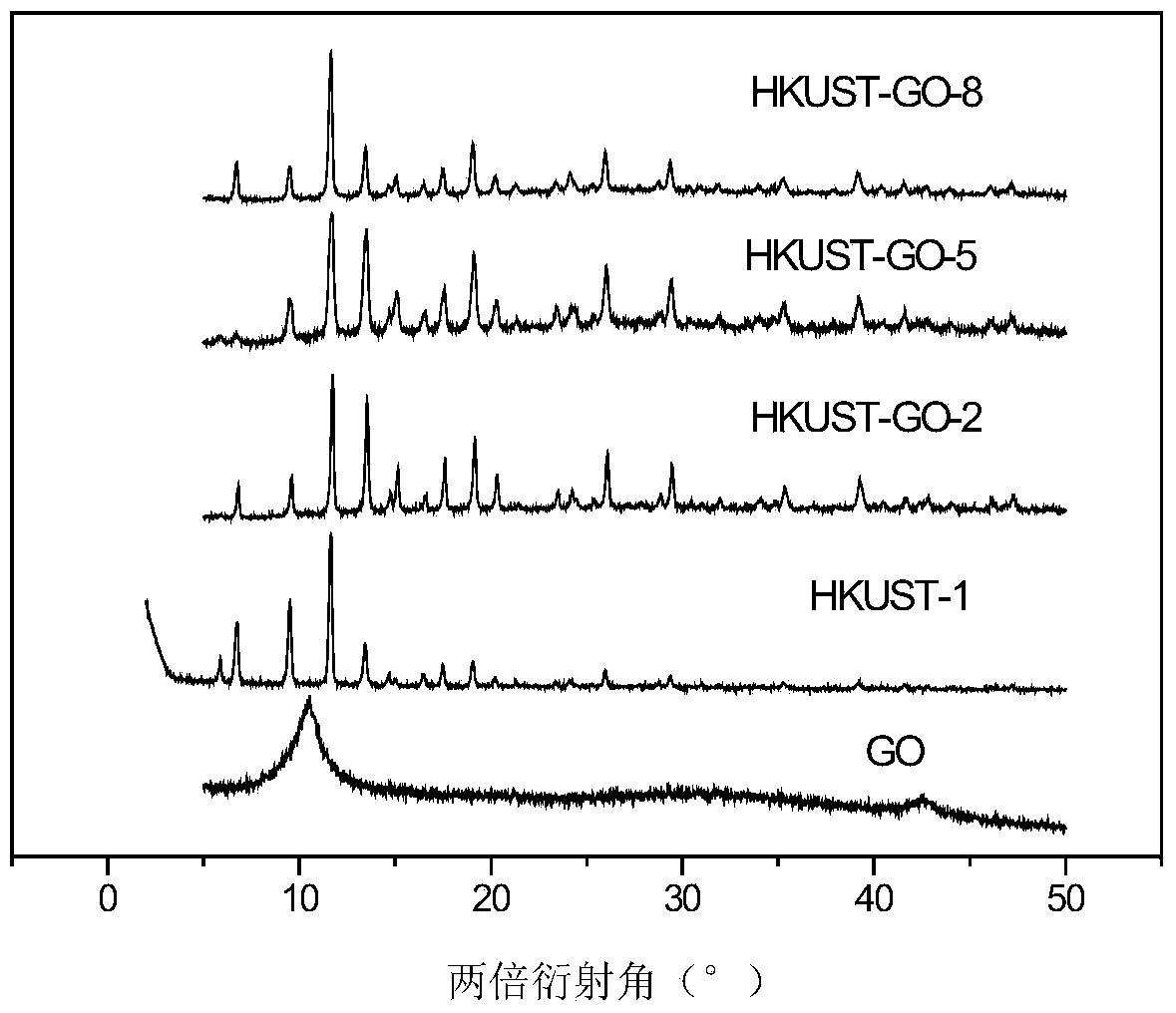

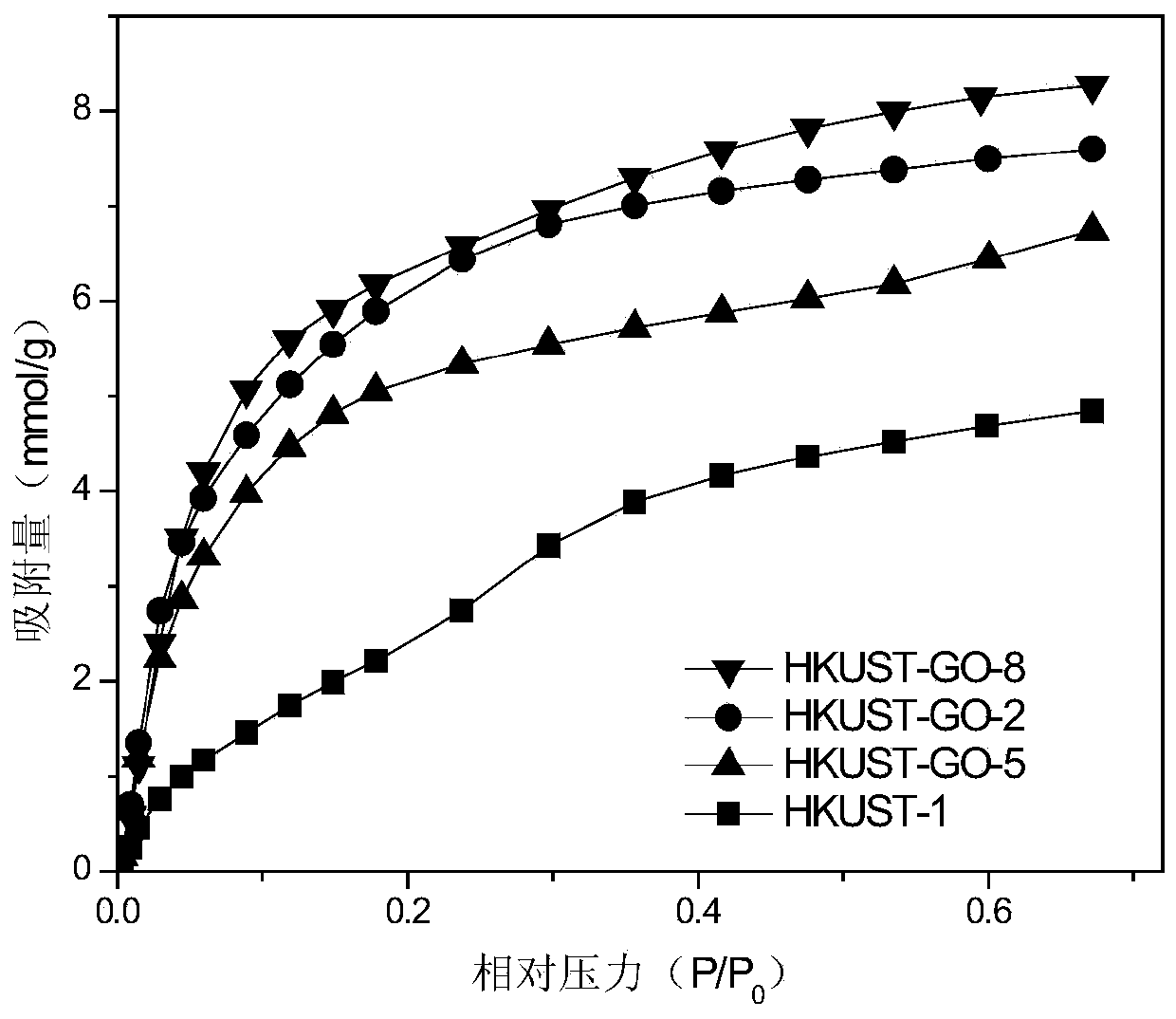

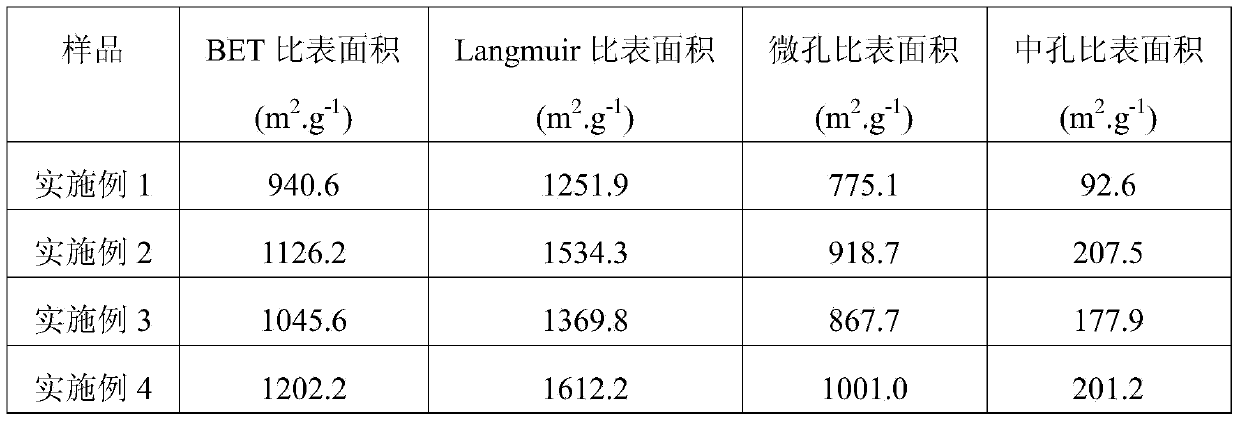

Cu-based organic skeleton-graphene oxide composite porous material and preparation method thereof

ActiveCN103432997AEasy to cleanReduce the activation energy of the interactionOther chemical processesMolecular sieveBenzene

The invention belongs to the technical field of metal organic skeletal materials, and discloses a Cu-based organic skeleton-graphene oxide composite porous material and a preparation method and application thereof. The preparation method particularly comprises the following steps of uniformly mixing copper acetate, 1,3,5-benzene tricarboxylic acid and graphene oxide; carrying out ball milling; washing; centrifugalizing; and drying to obtain the Cu-based organic skeleton-graphene oxide composite porous material. The preparation method disclosed by the invention has the advantages of short reaction time (only 30 minutes), no solvent, large preparation quantity, low energy consumption, simple operation method, and the like, is a high-efficiency, clean and environment-friendly novel green synthetic method. The obtained Cu-based organic skeleton-graphene oxide composite porous material greatly increases the adsorption capacity on hydrocarbon VOCs (Volatile Organic Compounds) and achieves the purposes that the adsorption capacity on methanol is 2.06 times of the adsorption capacity on the methanol caused by a Na-ZSM molecular sieve, 2.54 times of the adsorption capacity on the methanol caused by flexible-MOF(E), and 1.79 times of the adsorption capacity on the methanol caused by HKUST-1 under the same condition.

Owner:SOUTH CHINA UNIV OF TECH

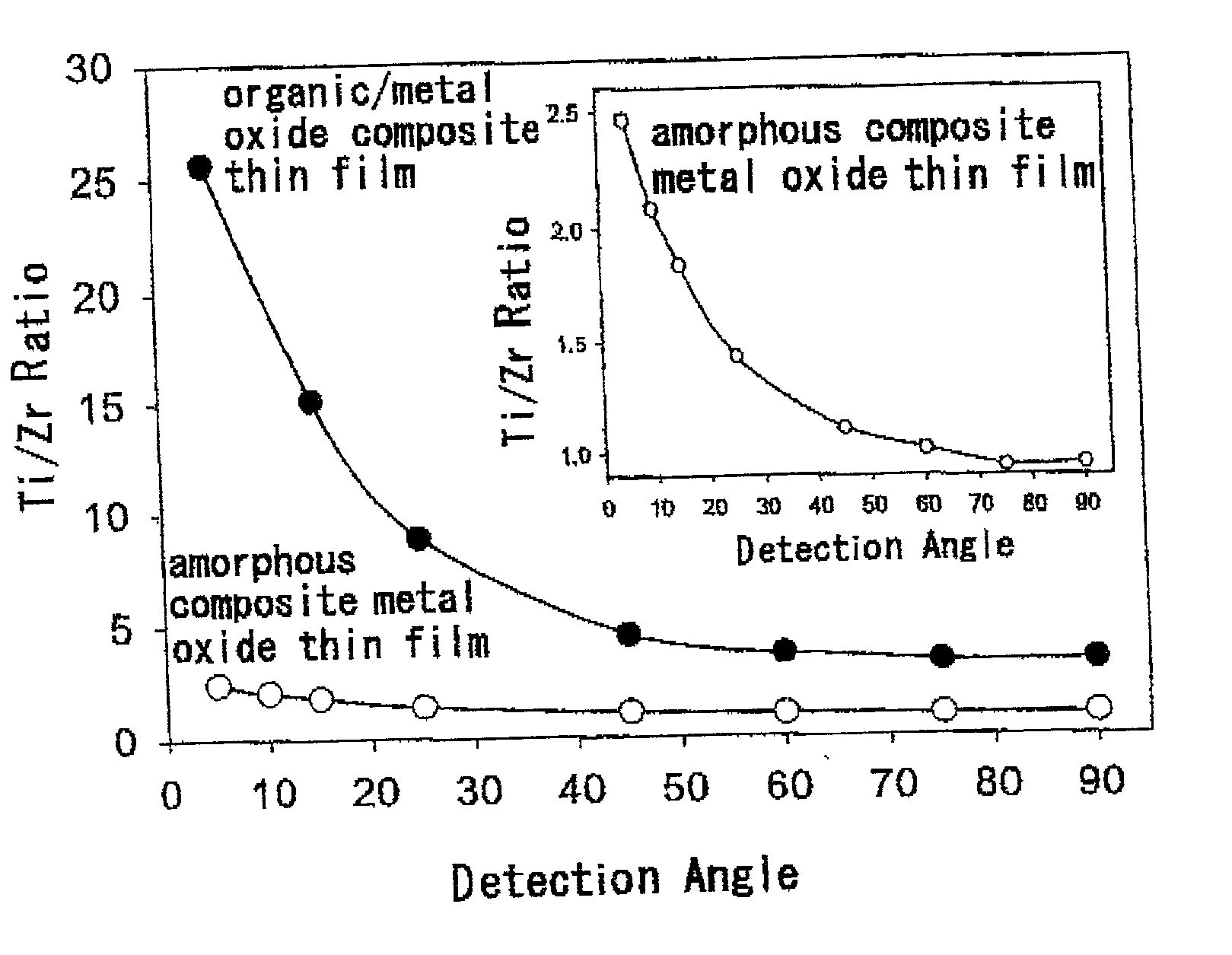

Thin film materials of amorphous metal oxides

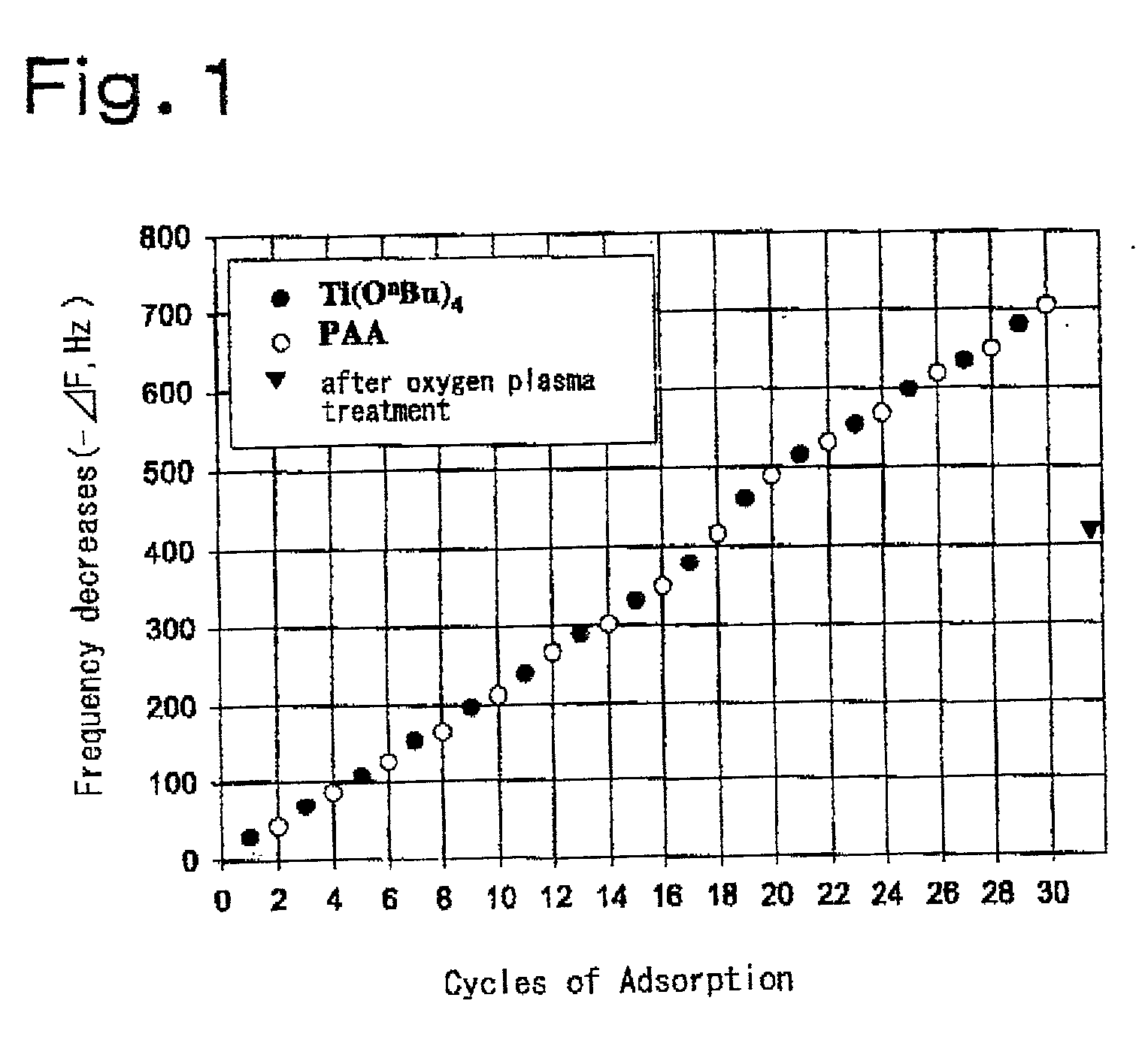

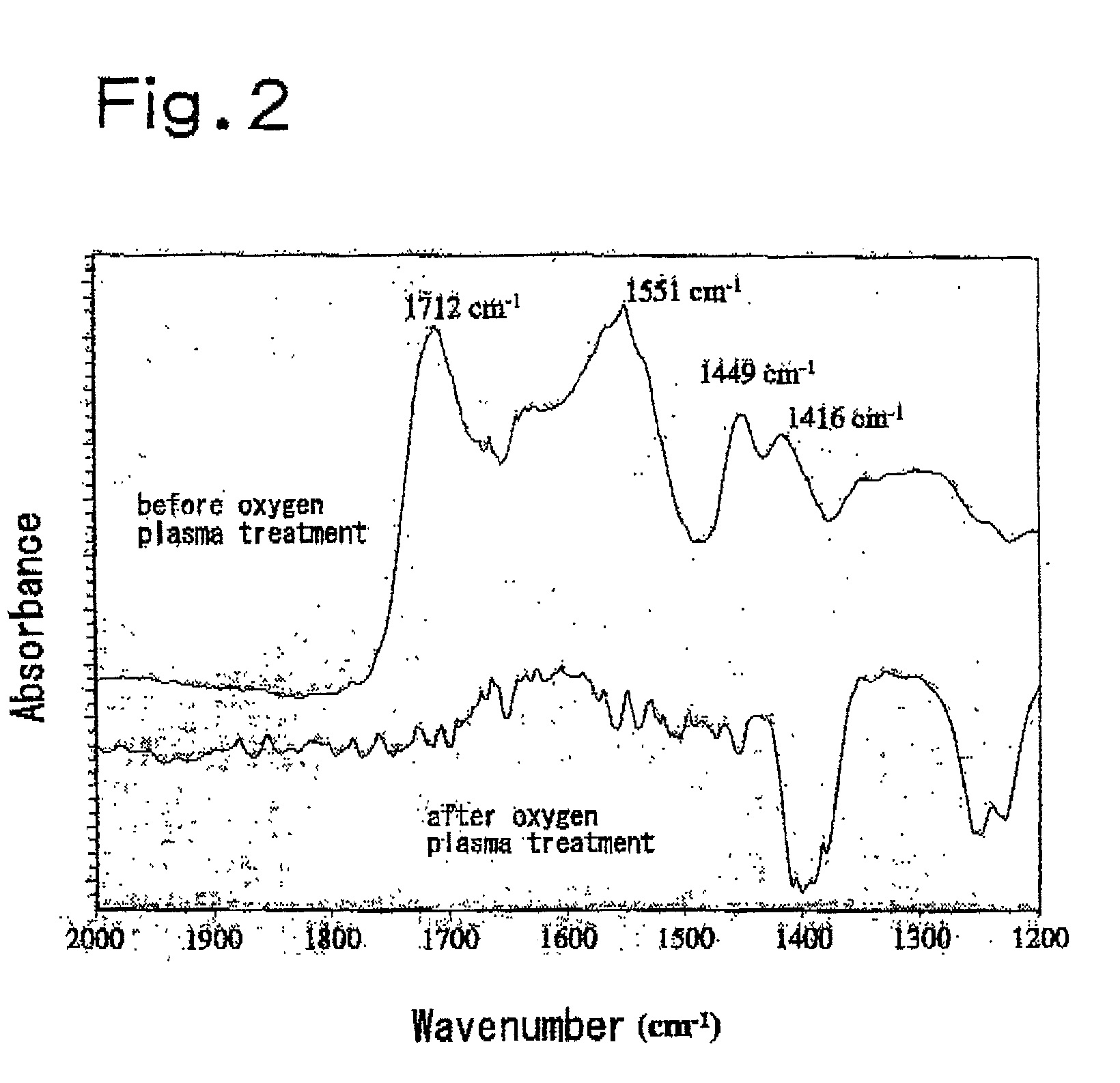

InactiveUS20020190251A1Oxide/hydroxide preparationSemiconductor/solid-state device manufacturingOxygen plasmaOxide composite

Amorphous metal oxide thin film is produced by removing through oxygen plasma treatment the organic component from an organics / metal oxide composite thin film having thoroughly dispersed therein such organic component at molecular scale. This ensures production of amorphous metal oxide thin film with low density and excellent thickness precision.

Owner:RIKEN

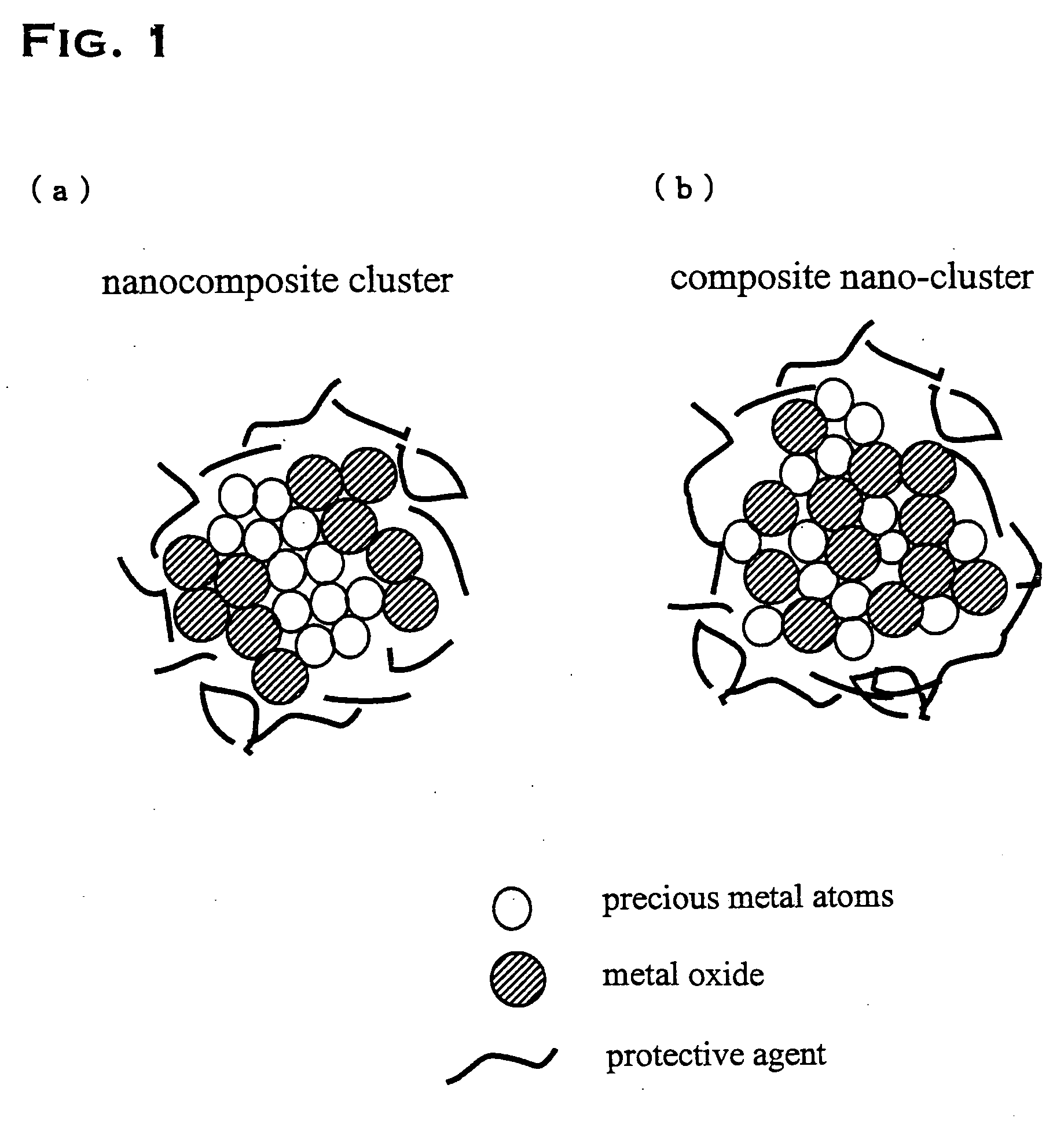

Precious metal - metal oxide composite cluster

InactiveUS20050065026A1Increase the effective surface areaSmall granularityMaterial nanotechnologyTransportation and packagingOxide compositeMaterials science

The present invention provides a precious metal—metal oxide composite cluster, wherein said cluster is formed as a single particle by combining a precious metal portion comprising a single atom or an aggregate of a plurality of atoms consisting of one or more precious metals, and a metal oxide portion comprising a single molecule or an aggregate of a plurality of molecules consisting of one or more metal oxides, and wherein said particle has a particle size between 1 and 100 nm.

Owner:TANAKA PRECIOUS METAL IND

Non-oxide composite low-carbon magnesia-carbon brick

A non-oxide compound magnesite-graphite brick containing carbon less than 6% belongs to a fire resisting material. The material contains magnesia of 75-94%, carbon of 1-5%, non-oxide such as nitride and boride of 0.4-20%, additive of 0-5%, and binder containg carbon. Such magnesite-graphite brick with low carbon has a low heat conductivity, a small acierating to the molten steel and less pollution to the low carbon steel compared to the common magnesite-graphite brick. The magnesite-graphite brick has a good slag resistance because the magnesia is the primary component. And it also has a good heat shock capacity because the carbon is one of the primary components. The carbon prevents said non-oxide from being oxidated. The brick maintains a good heat and shock resistance and slag resistance when reducing the proportion of the carbon because said non-oxide has a low heat expansion and a wet resistance to the slag.

Owner:江苏苏嘉集团新材料有限公司

Super paramagnetic ferric oxide composite nanometre particle preparation method

InactiveCN1736881AReduce nucleationReduced growth rateNanostructure manufactureFerric oxidesSal ammoniacNanoparticle

The invention discloses a preparation method for composite nano particcle of superparamagnetic ferric oxide. Wherein, adding ammonia and sodium citrate synchronously and speed controlled to make ions of Fe3+ and Fe2+ coprecipitate and form Fe3O4 nano particle with water-phase dispersion surface adsorbed by citric acid radical that can be substituted by multi chemical functional group on basic condition as crystal seed for sodium citrate-goden chloric acid reduction reaction and form SPION nano particle.

Owner:HUAZHONG UNIV OF SCI & TECH

Negative electrode material for secondary battery with non-aqueous electrolyte, method for manufacturing negative electrode material for secondary battery with non-aqueous electrolyte, and lithium ion secondary battery

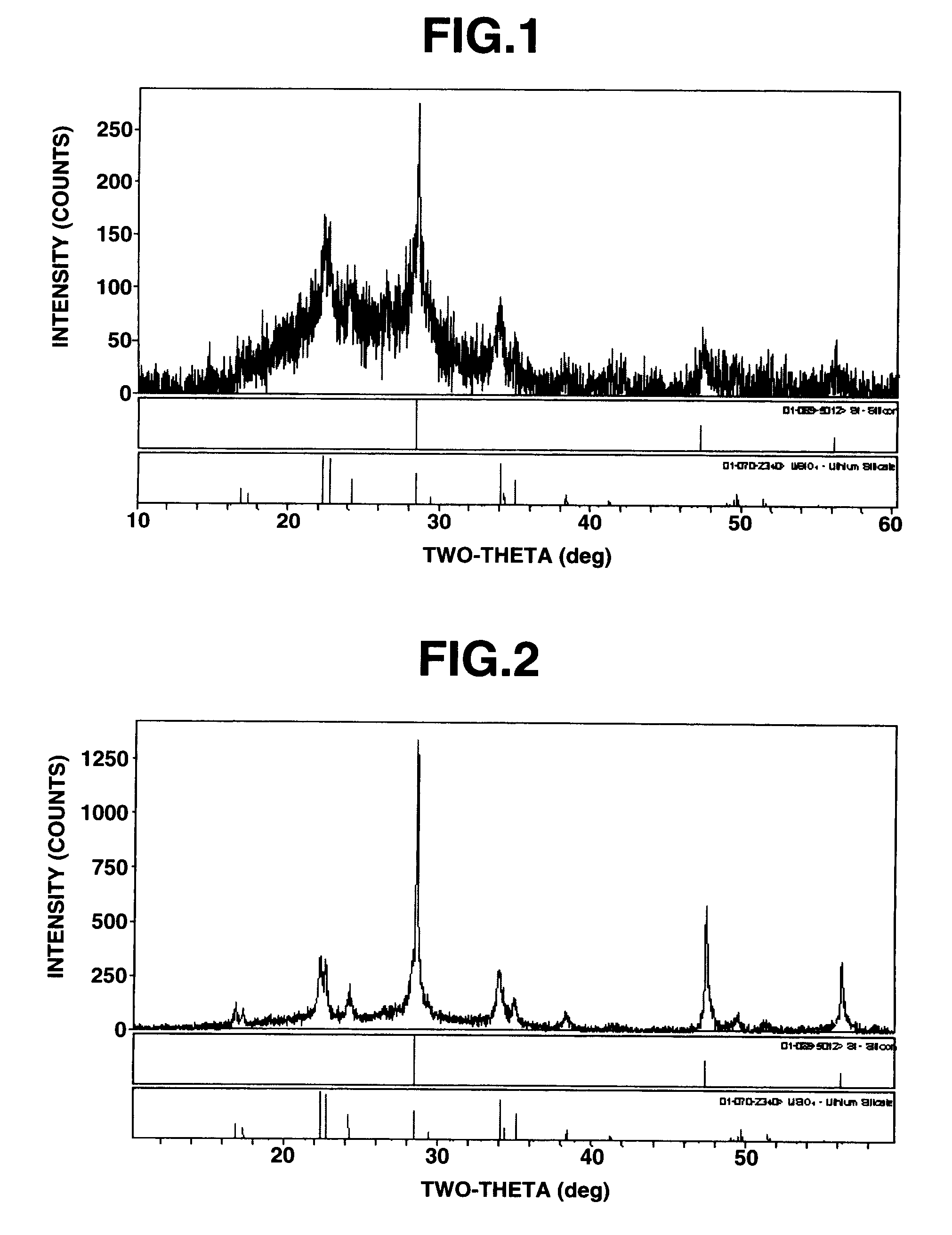

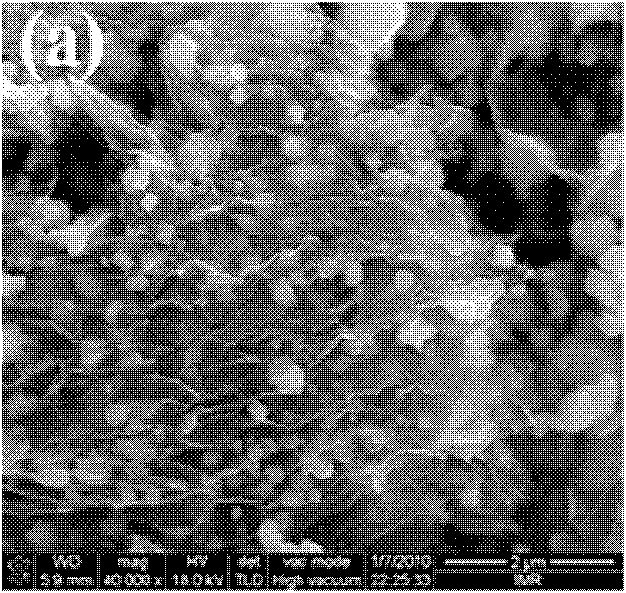

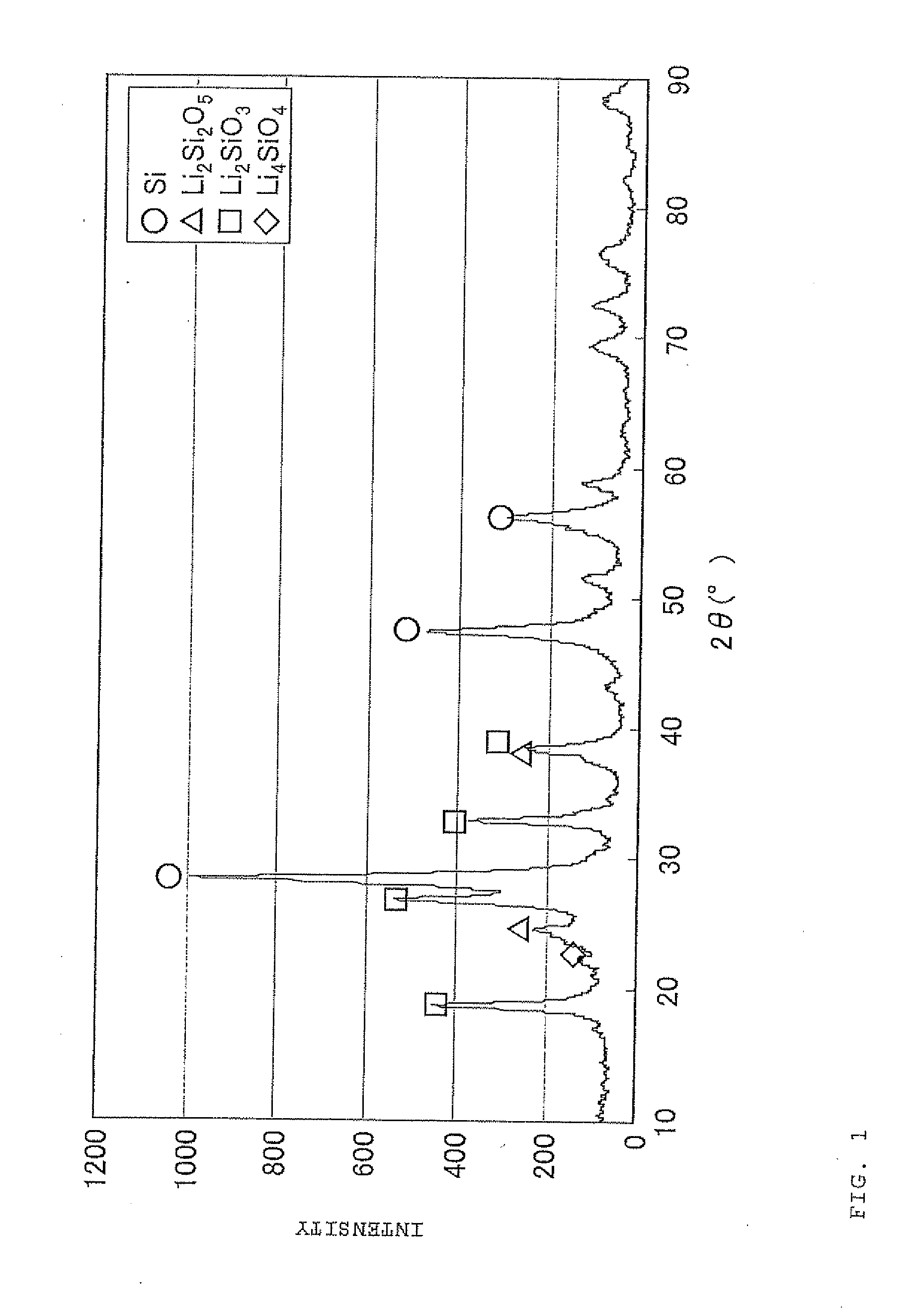

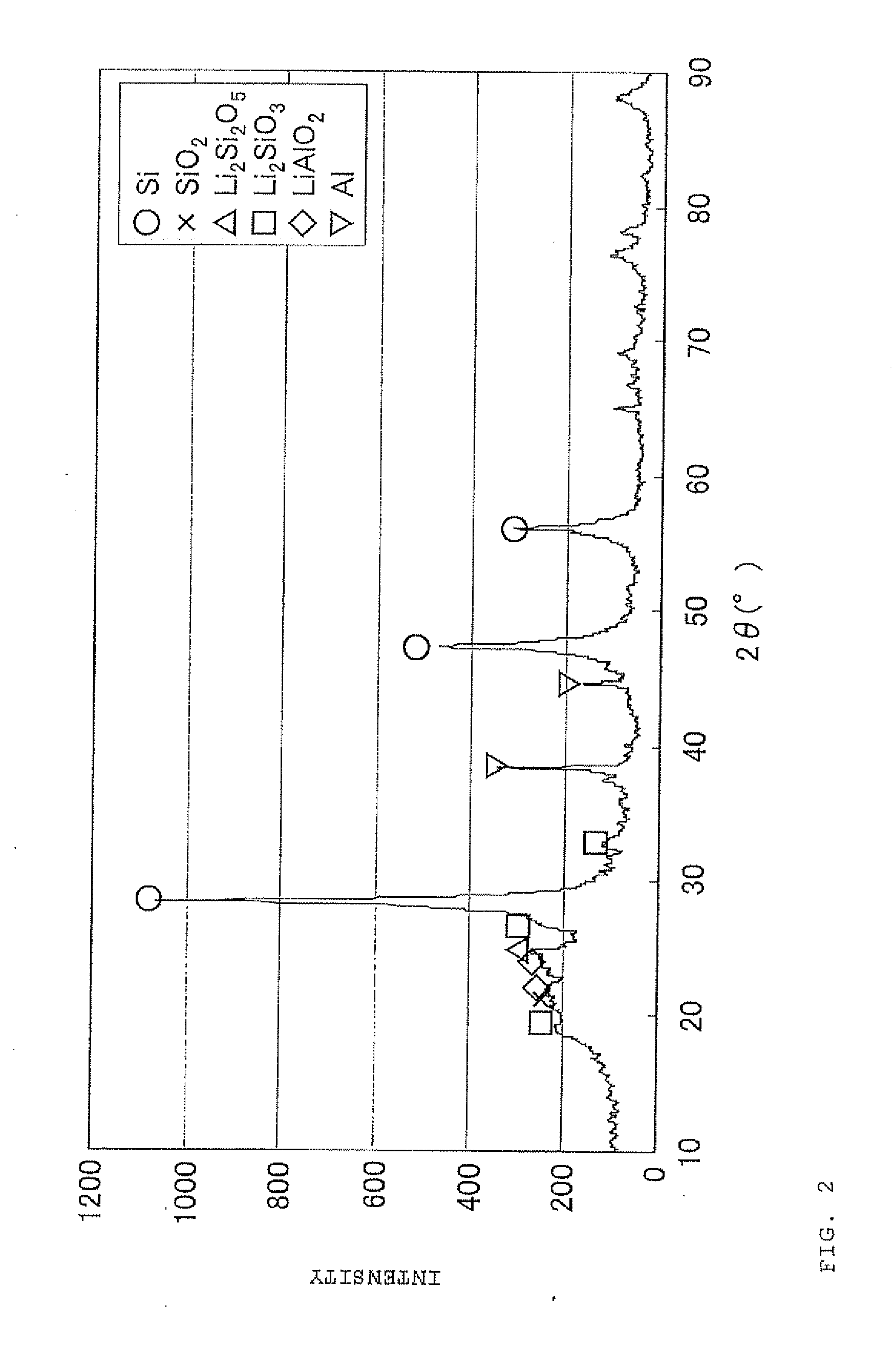

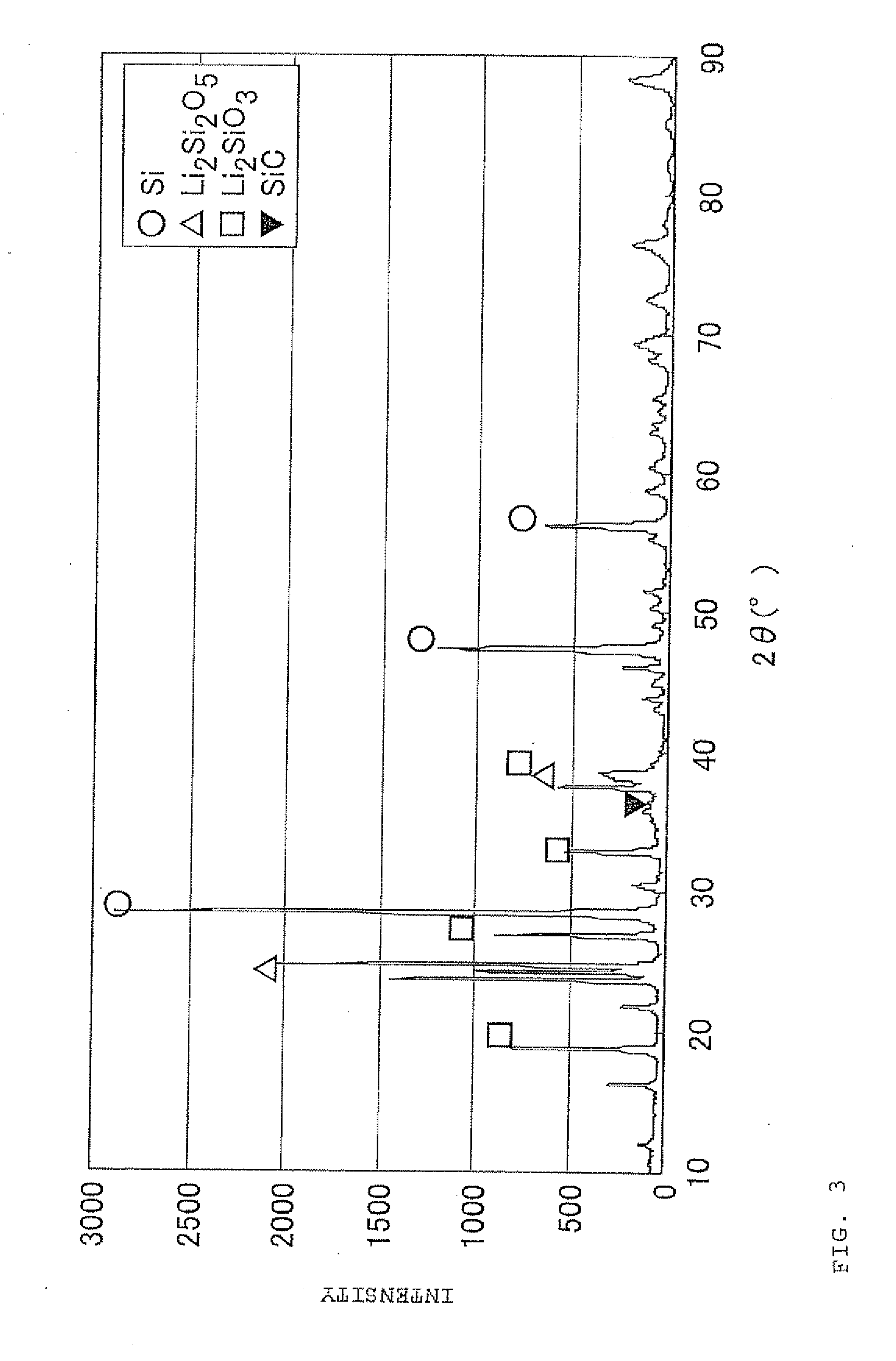

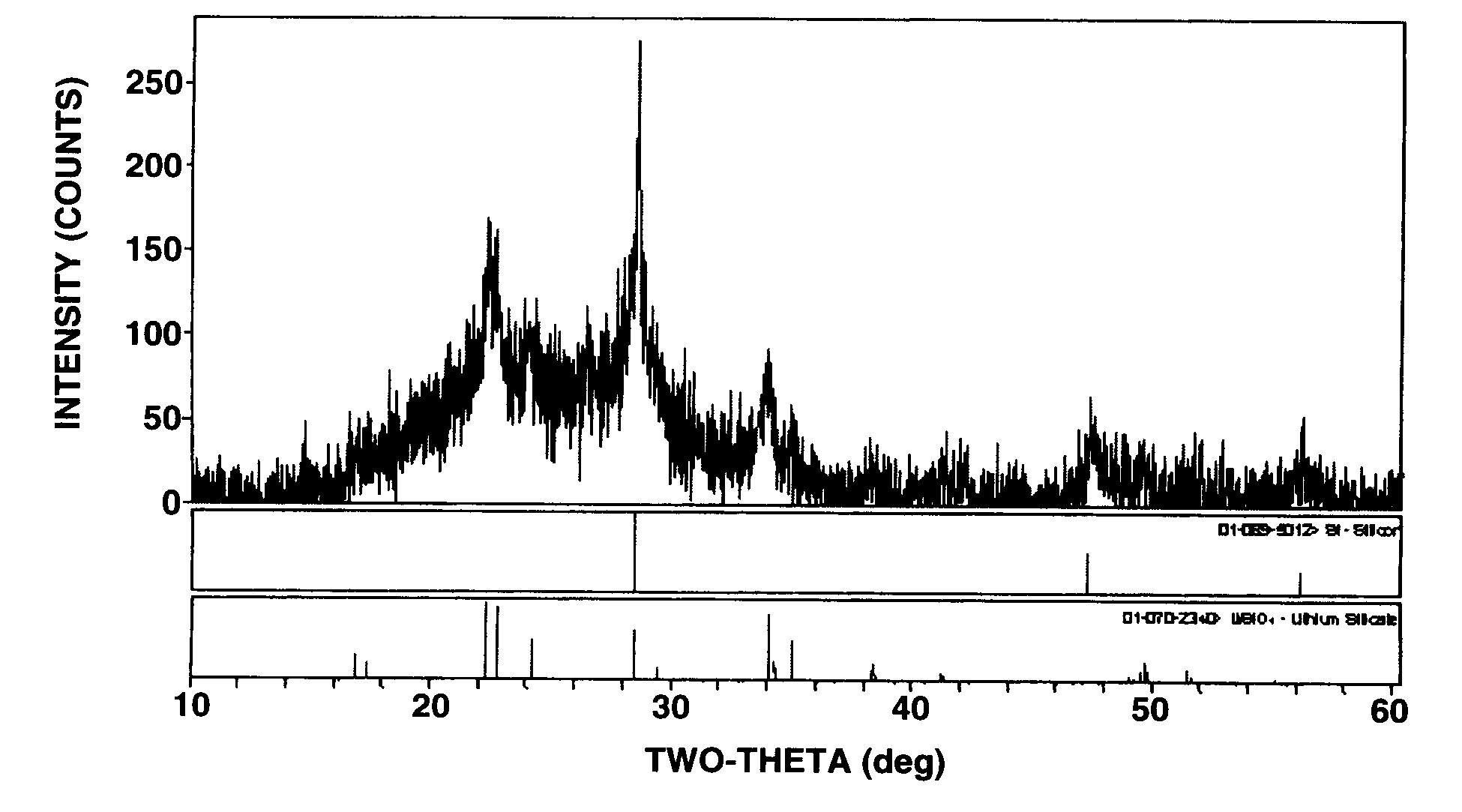

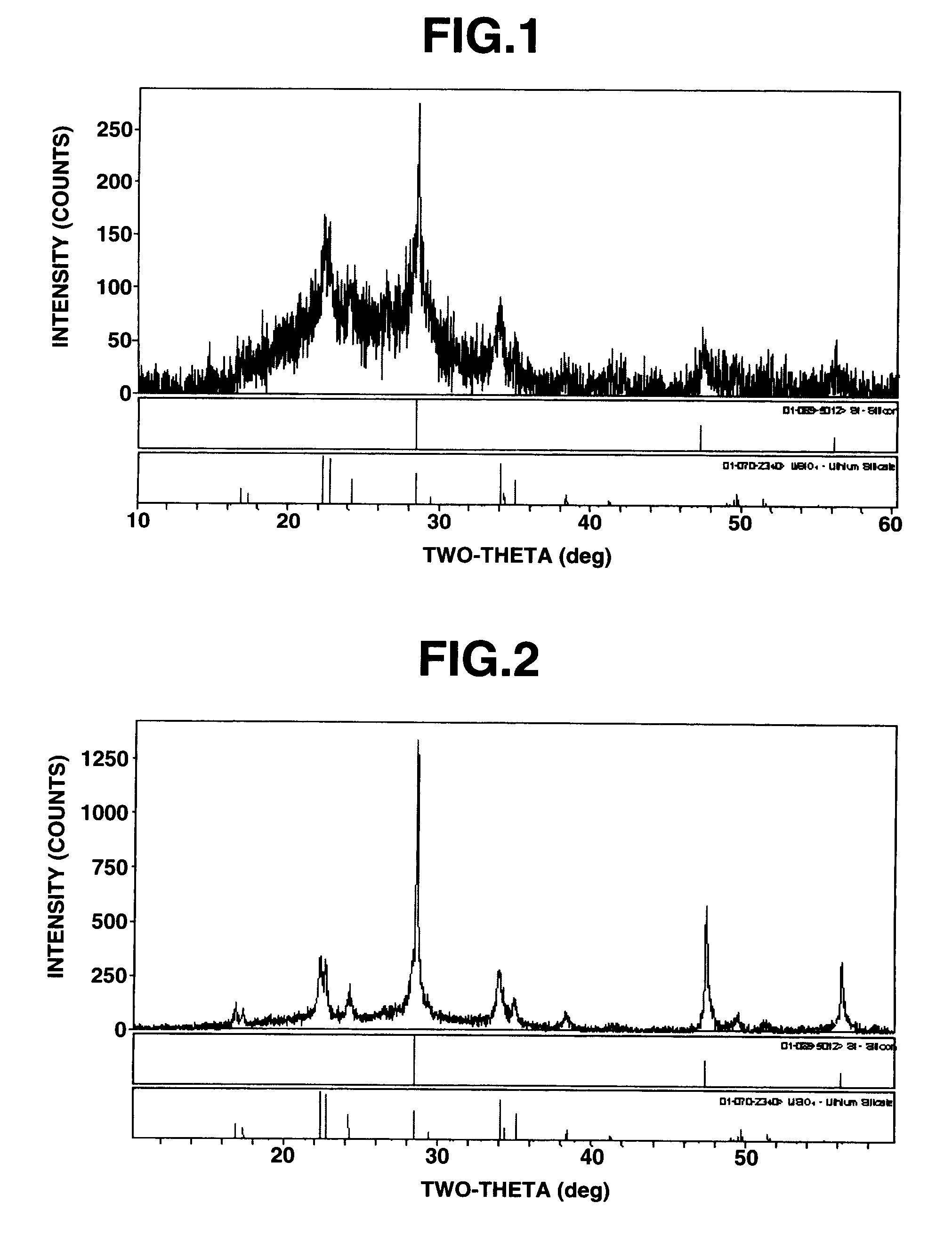

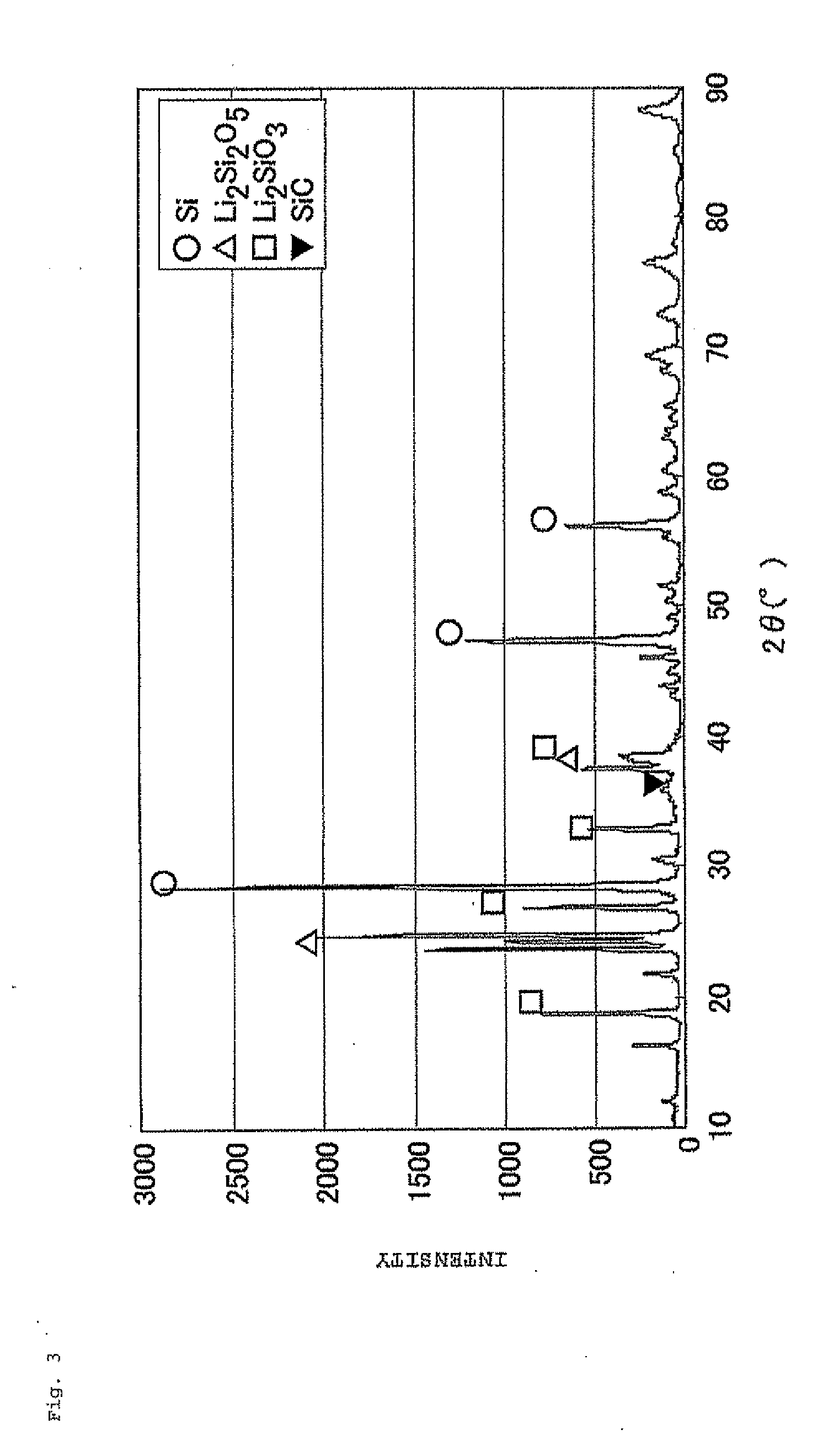

ActiveUS20110244334A1Large capacityHigh cycle durabilityFinal product manufactureLi-accumulatorsCarbon coatingX-ray

The present invention is a negative electrode material for a secondary battery with a non-aqueous electrolyte comprising at least a silicon-silicon oxide composite and a carbon coating formed on a surface of the silicon-silicon oxide composite, wherein at least the silicon-silicon oxide composite is doped with lithium, and a ratio I(SiC) / I(Si) of a peak intensity I(SiC) attributable to SiC of 2θ=35.8±0.2° to a peak intensity I(Si) attributable to Si of 2θ=28.4±0.2° satisfies a relation of I(SiC) / I(Si)≦0.03, when x-ray diffraction using Cu—Kα ray. As a result, there is provided a negative electrode material for a secondary battery with a non-aqueous electrolyte that is superior in first efficiency and cycle durability to a conventional negative electrode material.

Owner:SHIN ETSU CHEM IND CO LTD

Graphene oxide film, preparation method and applications thereof

ActiveCN104874301AHigh selectivityImprove permeabilitySemi-permeable membranesOxide compositePermeation

The present invention discloses a graphene oxide film preparation method, which comprises: 1) carrying out an oxidation treatment on graphite powder to obtain a graphite oxide, and peeling to form graphene oxide; 2) dissolving the graphene oxide in water to form a clarified graphene oxide sol; 3) carrying out washing and surface treatment on a porous carrier; and 4) forming the graphene oxide film on the porous carrier surface. The present invention further discloses the graphene oxide film prepared according to the method, and applications of the graphene oxide film in water-containing azeotrope separation. According to the present invention, the inexpensive graphite material is used to prepare the graphene oxide composite film, and the prepared graphene oxide composite film has characteristics of high water permeation selectivity and high permeation flux and can effectively separate the water-containing azeotrope so as to provide an efficient, environmentally friendly and economical way for the water-containing azeotrope separation.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Preparation method of nitrogen-rich multimode beehive carbon-sulfur composite anode material

ActiveCN103746098ALarge specific surface areaHigh nitrogen contentPositive electrodesLi-accumulatorsArgon atmosphereOxide composite

The invention relates to a preparation method of a lithium sulphur battery composite anode material. The preparation method is as follows: preparing a mixed solution of carbon tetrachloride, a nitrogen source and carbonate, heating and flowing back to obtain a nitrogen-rich polymerization / carbonic acid salt compound; high temperature pyrolyzing in a nitrogen or argon atmosphere after drying the compound, so as to form the nitrogen-rich carbon / oxide compound; adding dilute acid to remove vestigial oxide, so as to form the nitrogen-rich multimode beehive carbon material of a multilevel porthole structure; uniformly mixing the nitrogen-rich multimode beehive carbon and sublimed sulfur, heat preserving under vacuum condition, injecting sulfur gas to the nitrogen-rich multimode beehive carbon material, so that the lithium sulphur battery composite positive material can be obtained. The composite anode material provided by the invention is alveolate, and has the advantages that portholes are abundant, sulfur content is high, sulfur particle can be distributed uniformly in the nitrogen-rich multimode beehive carbon material of the multilevel porthole structure, and the carbon sulfur particles can be combined more tightly, the material mechanical stability is high, discharge specific capacity is high, cycle performance is excellent, and technological process is simple, pollution is avoided, cost is low, and the method is liable to large scale production and application.

Owner:CENT SOUTH UNIV

Nanosilver/graphene oxide composite dispersion fluid, and preparation method and application thereof

ActiveCN106391002AInhibition of agglomerationEvenly dispersedBiocideMaterial nanotechnologyAntibiosisLiquid medium

The invention discloses a nanosilver / graphene oxide composite dispersion fluid, and a preparation method and application thereof. The dispersion fluid comprises a liquid medium and a nanosilver / graphene oxide composite, wherein the nanosilver / graphene oxide composite is uniformly dispersed in the liquid medium; the concentration of the dispersion fluid is 0.01 to 10 mg / ml; and nanosilver particles in the nanosilver / graphene oxide composite are uniformly dispersed and adhered onto the surface of graphene oxide, and the sizes of the nanosilver particles are in a range of 5 to 50 nm. According to the invention, a hypergravity rotating packed bed or a micro-channel reactor is used as reaction equipment; no reducing agent is needed in the process of preparation; and the prepared nanosilver / graphene oxide composite dispersion fluid is transparent and stable and is free of precipitates after standing for six months. Compared with the prior art, the method provided by the invention is rapid, simple, efficient and applicable to large-scale industrial production. The nanosilver / graphene oxide composite dispersion fluid provided by the invention has wide application prospects in fields like catalysis, energy storage, electronics, antibiosis and surface Raman enhancement.

Owner:BEIJING UNIV OF CHEM TECH +1

Porous silica and metal oxide composite-based catalysts for conversion of fatty acids and oils to biodiesel

ActiveUS20080021232A1Easy to separateEasy to recycleFatty oils/acids recovery from wasteNanotechMETHYL SOYATEVegetable oil

A recyclable esterification or transesterification catalyst and methods for making and using the same are provided herein. The catalyst can be used to prepare biodiesel or methyl soyate from various feedstocks, including vegetable oils and animal fats. The catalyst can both esterify free fatty acids and transesterify mono-, di-, and triglycerides. The catalyst can also be combined with a metal oxide, and optionally calcined, prior to carrying out a catalytic reaction.

Owner:IOWA STATE UNIV RES FOUND

Method for preparing lithium iron phosphate composite material for lithium cells

ActiveCN102044666AImprove conductivityComposite uniformCell electrodesHydrogenLithium iron phosphate

The invention relates to a method for preparing a lithium iron phosphate composite material for lithium cells. The products prepared by the conventional method are undesirable in carbon encapsulation uniformity and purity. The method comprises: firstly, dissolving soluble lithium compound in deionized water to prepare lithium-containing solution in which the lithium ion concentration is 0.3 to 0.9mol / L, adding graphene oxide, stirring, and after the graphene oxide is dispersed, adding phosphoric acid and ferrite to form mixed solution; secondly, filling the mixed solution in a stainless reaction kettle, reacting for 1 to 4 hours at 180 to 220 DEG C, filtering reaction liquid, washing, and drying to obtain a lithium iron phosphate / graphene oxide composite material; and finally, charging hydrogen to perform a reduction reaction to obtain the lithium iron phosphate / graphene oxide composite material. In the lithium iron phosphate / graphene oxide composite nano material obtained by the method, the composition is uniform, the conductivity of lithium iron phosphate is improved greatly, the low conductivity of the lithium iron phosphate cathode material is overcome successfully, and the capacity under large-current discharge of the cells is improved.

Owner:南通丝乡丝绸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com