Patents

Literature

449 results about "Silicon silicon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon is a chemical element (its symbol in chemical formula expressions is "Si") that is present in sand and glass and which is the best known semiconductor material in electronic components. Its atomic number is 14.

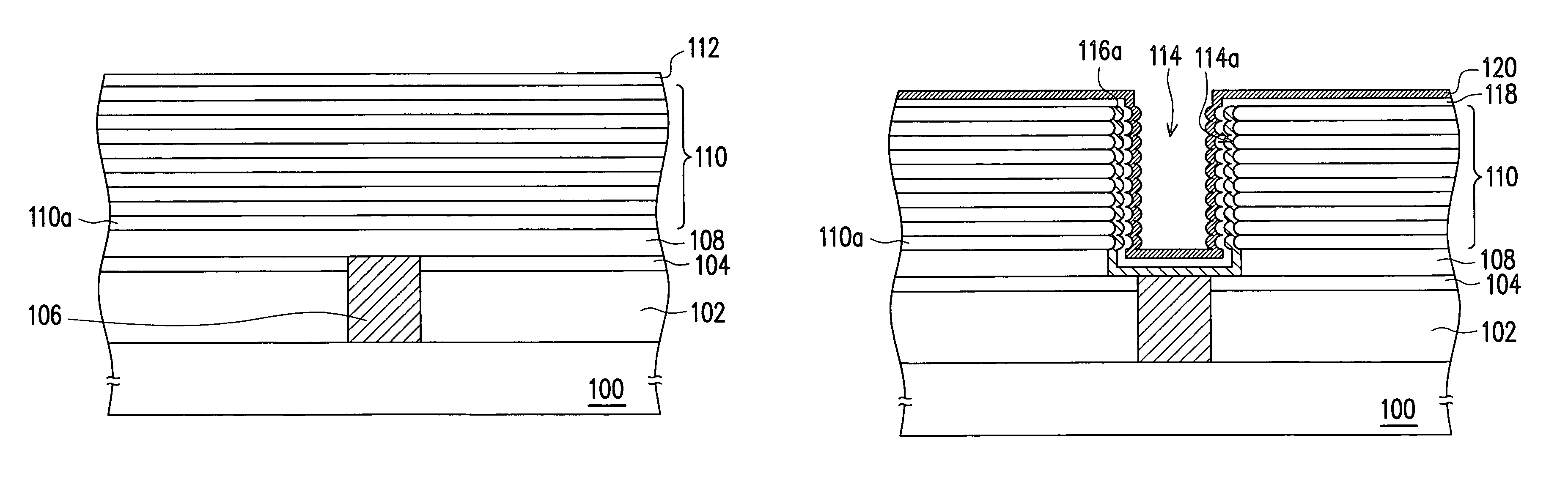

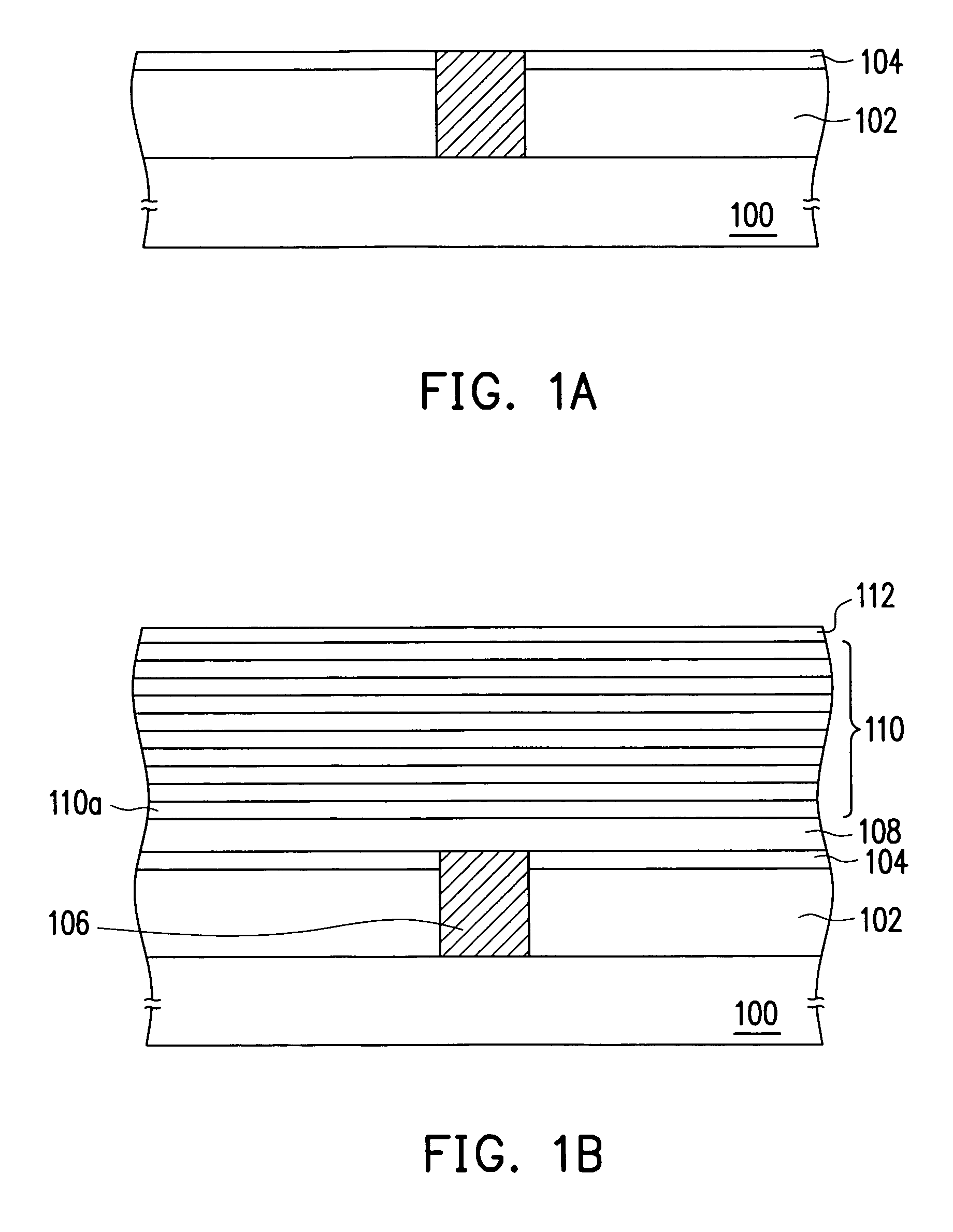

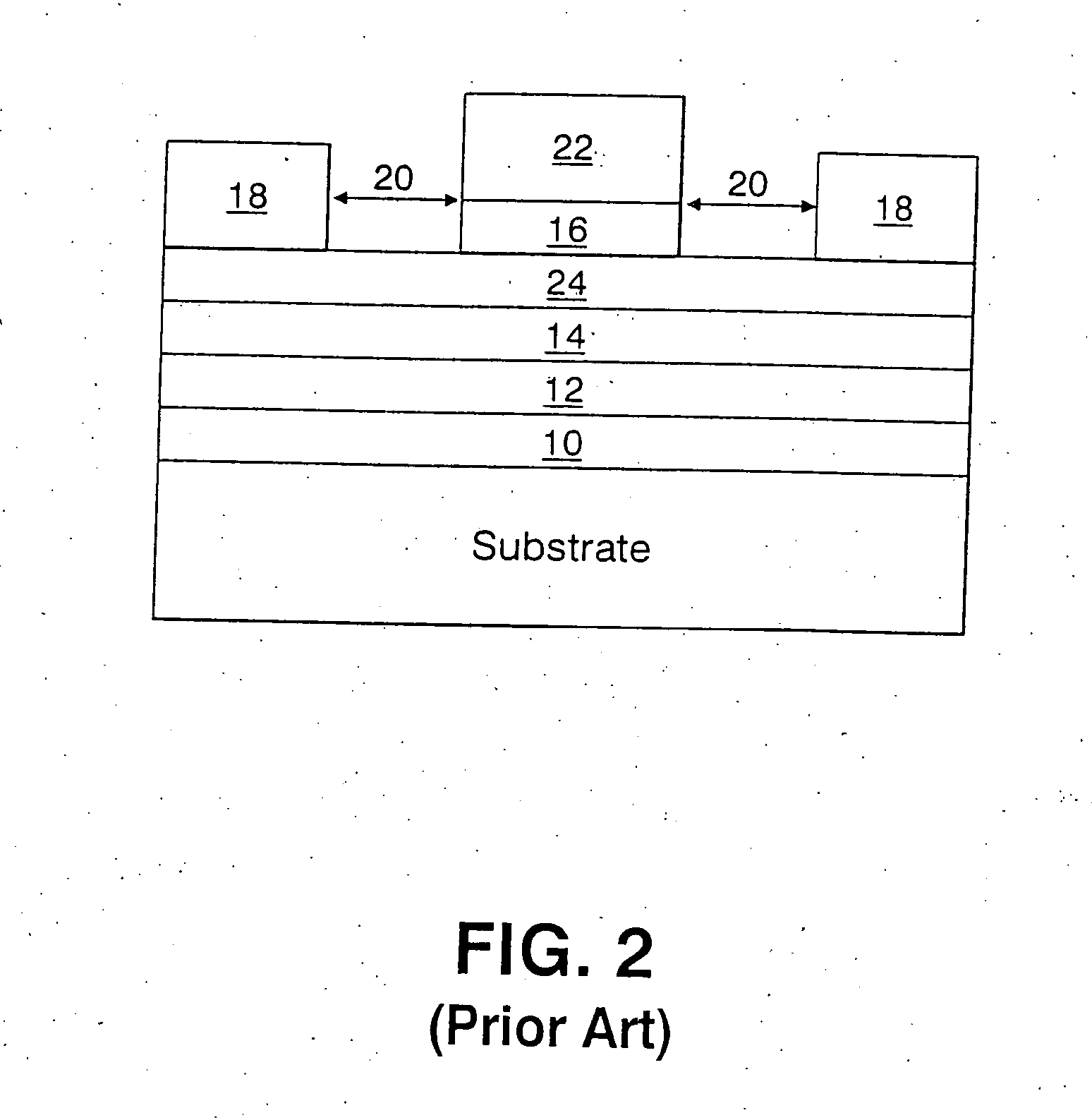

Method of manufacturing charge storage device

InactiveUS7405166B2Increase electrode areaEasy to produceSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceHydrogen fluoride

Owner:IND TECH RES INST

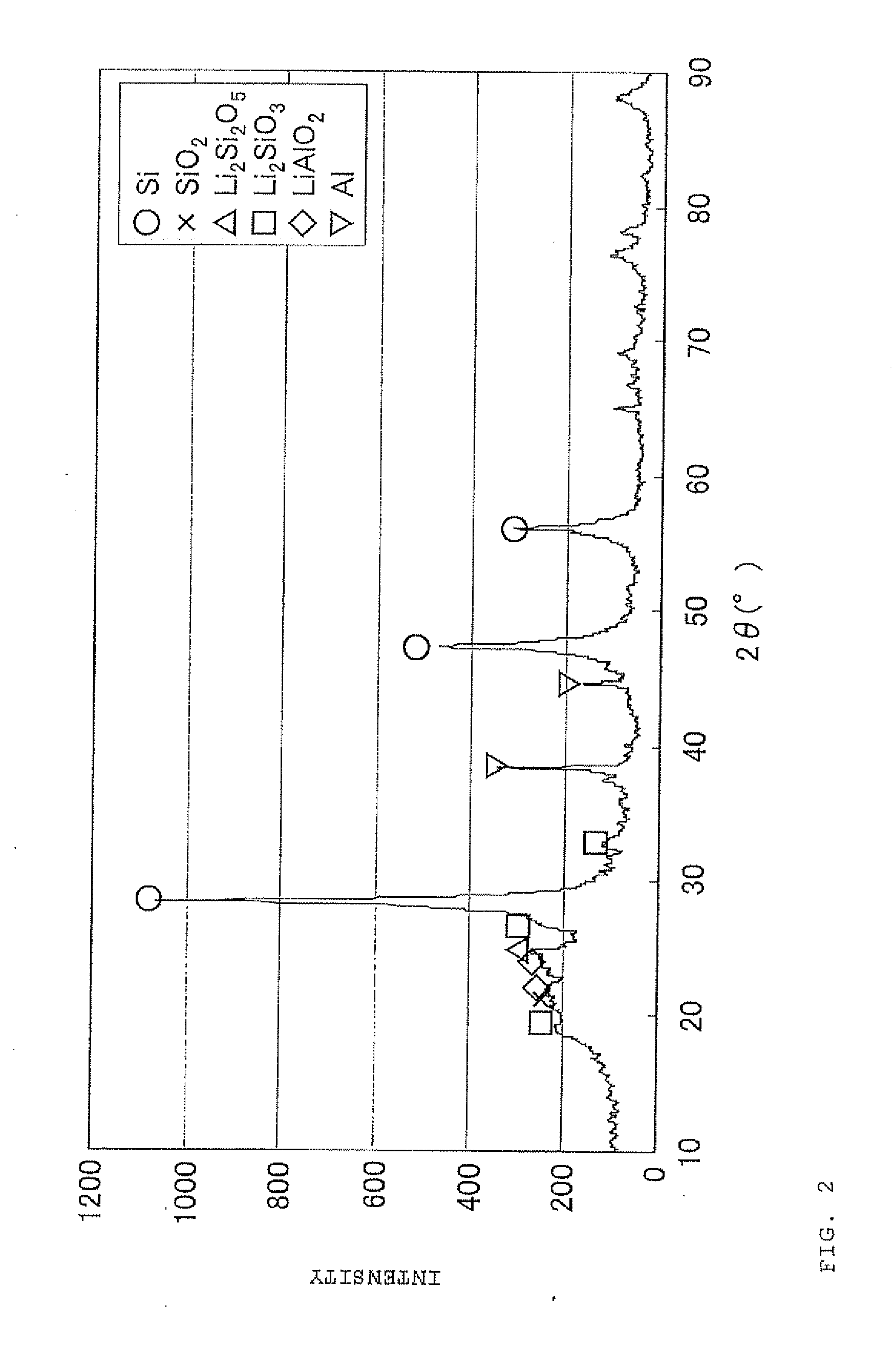

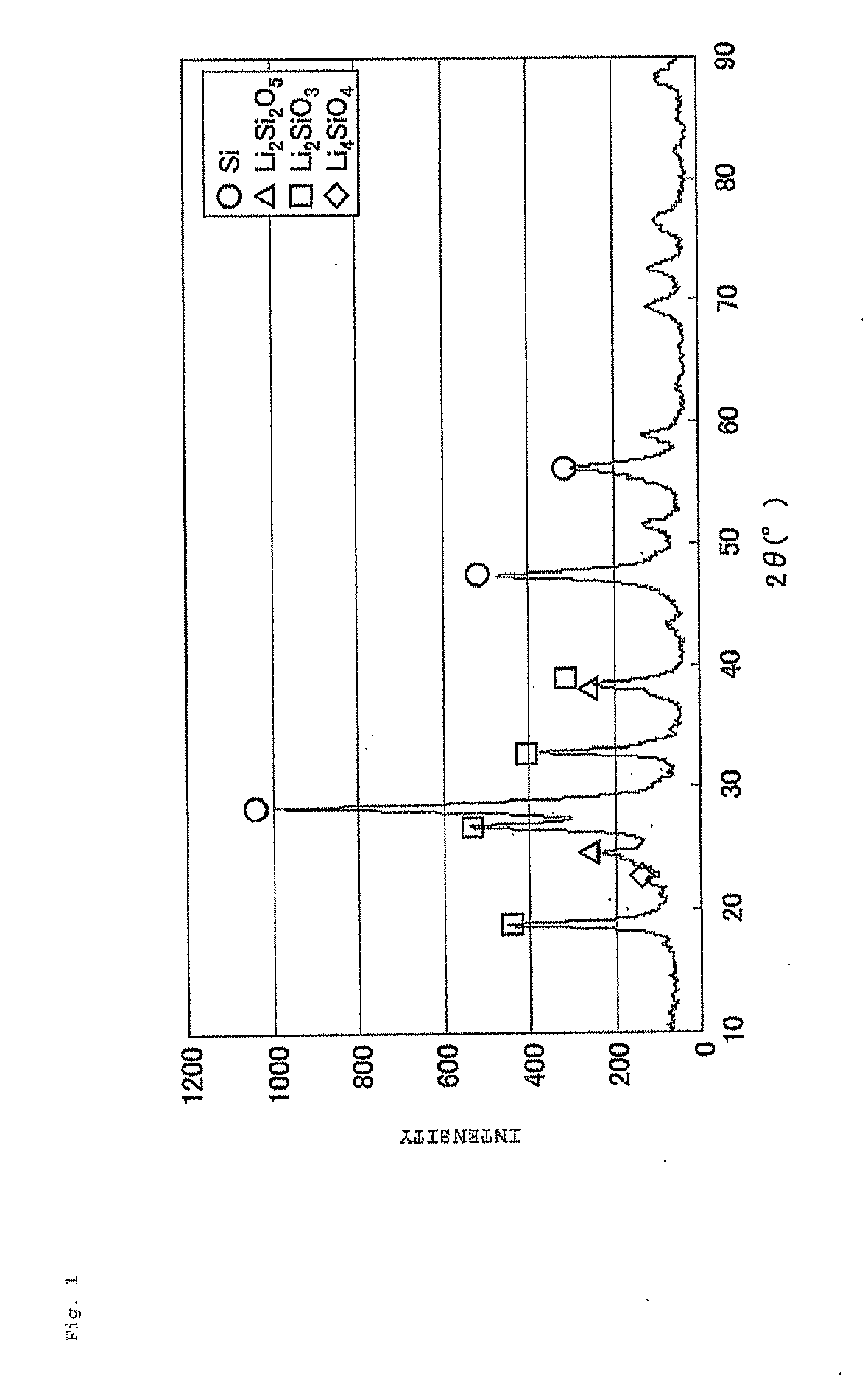

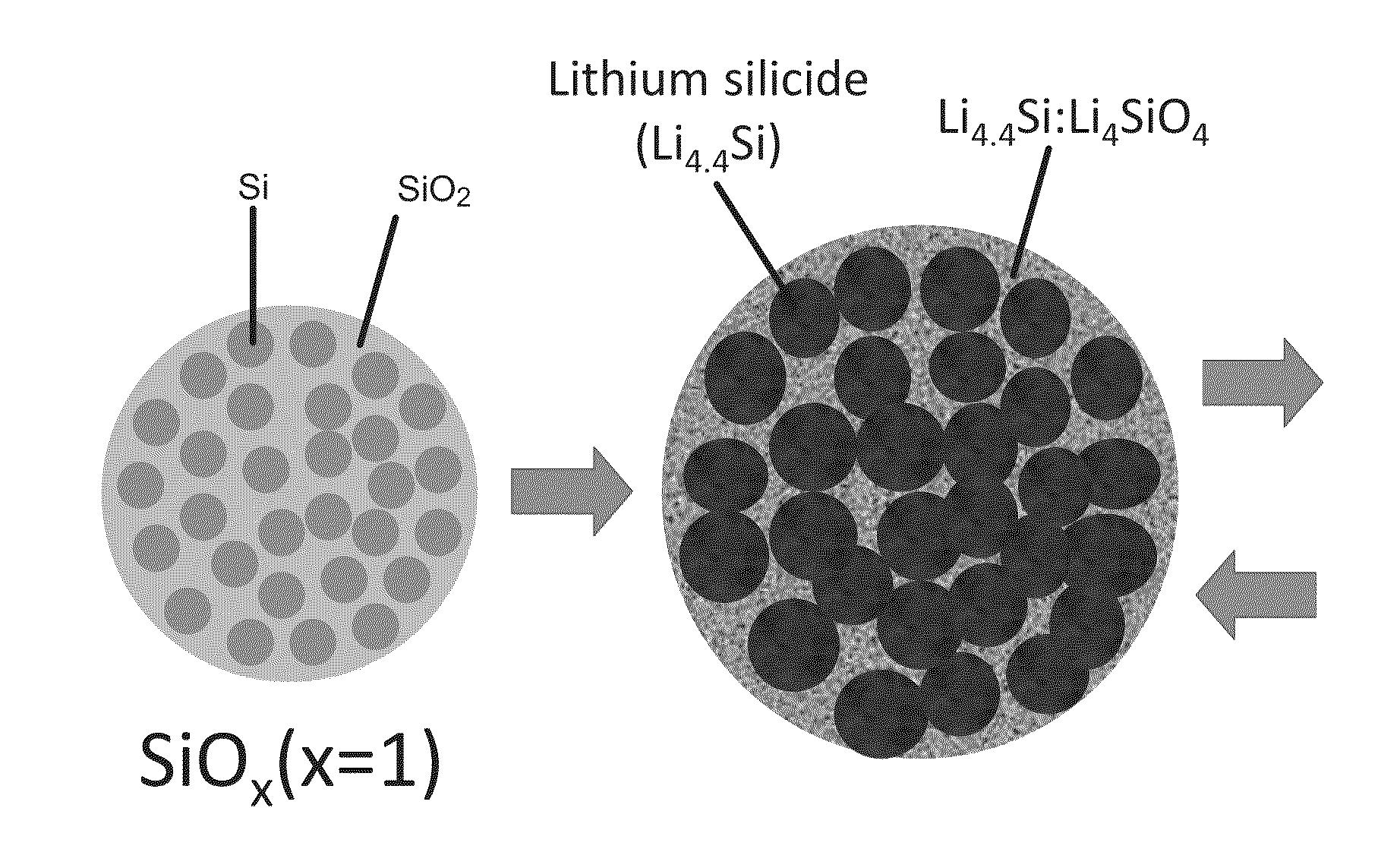

Silicon-silicon oxide-lithium composite, making method, and non-aqueous electrolyte secondary cell negative electrode material

ActiveUS20070224508A1Improve initial efficiencyImprove cycle performanceSecondary cellsNegative electrodesOxide compositeSilicon oxide

A silicon-silicon oxide-lithium composite comprises a silicon-silicon oxide composite having such a structure that silicon grains having a size of 0.5-50 nm are dispersed in silicon oxide, the silicon-silicon oxide composite being doped with lithium. Using the silicon-silicon oxide-lithium composite as a negative electrode material, a lithium ion secondary cell having a high initial efficiency and improved cycle performance can be constructed.

Owner:SHIN ETSU CHEM IND CO LTD

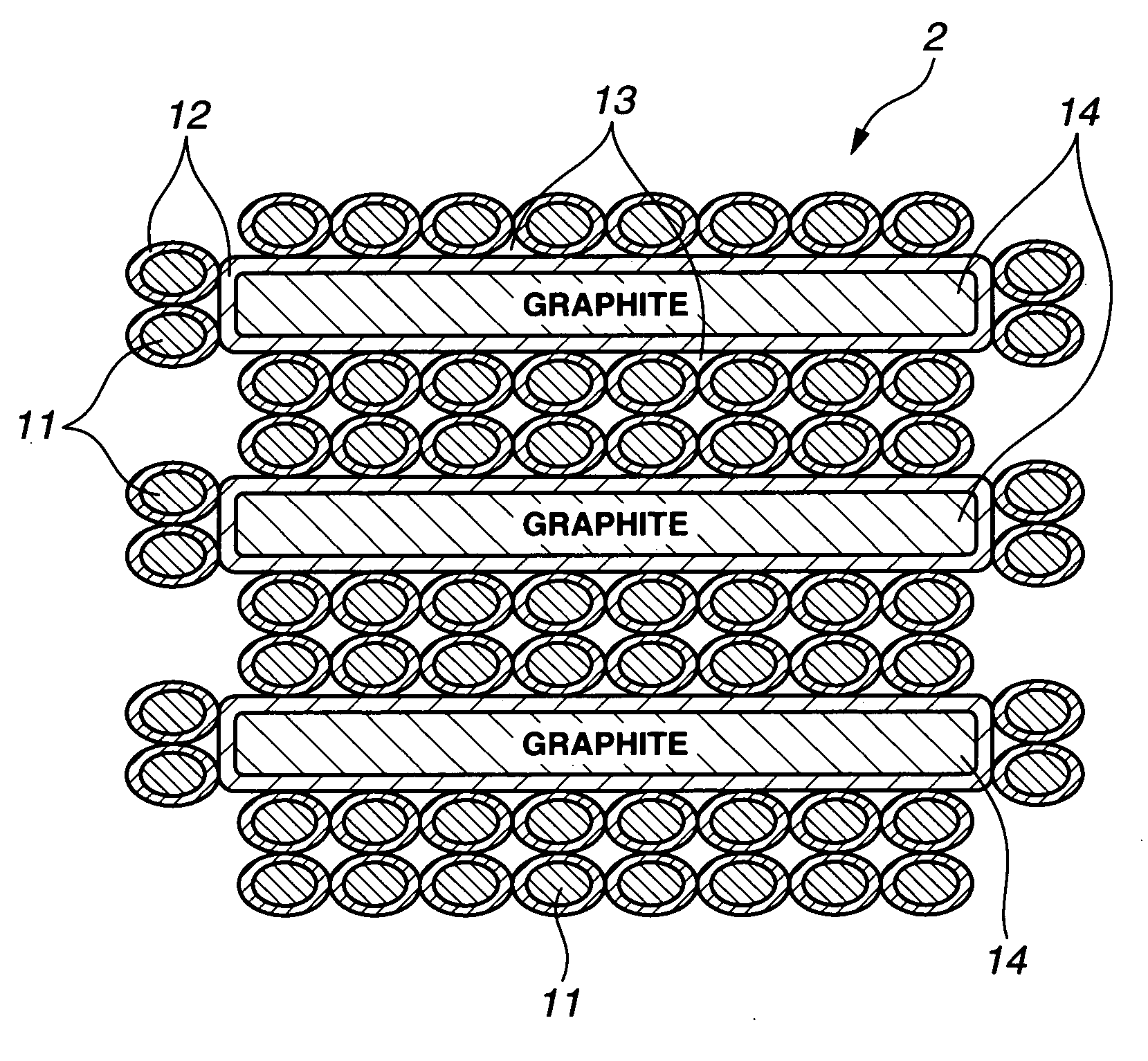

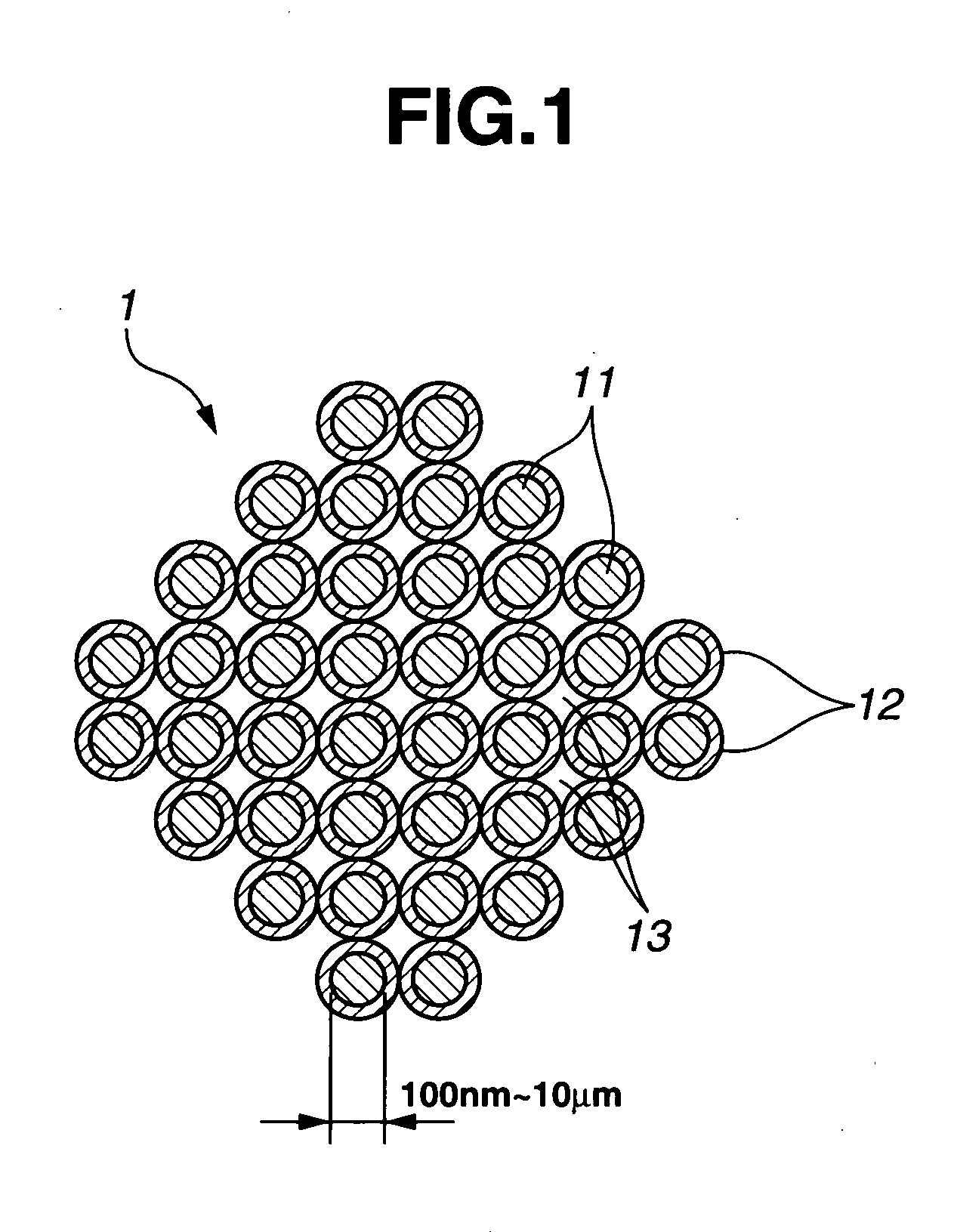

Silicon composite particles, preparation thereof, and negative electrode material for non-aqueous electrolyte secondary cell

ActiveUS20050214644A1Improve cycle performanceMinimize changesSilicaNitrogen compoundsSilicon alloyInorganic compound

Silicon composite particles are prepared by sintering primary fine particles of silicon, silicon alloy or silicon oxide together with an organosilicon compound. Sintering of the organosilicon compound results in a silicon-base inorganic compound which serves as a binder. Each particle has the structure that silicon or silicon alloy fine particles are dispersed in the silicon-base inorganic compound binder, and voids are present within the particle.

Owner:SHIN ETSU CHEM IND CO LTD

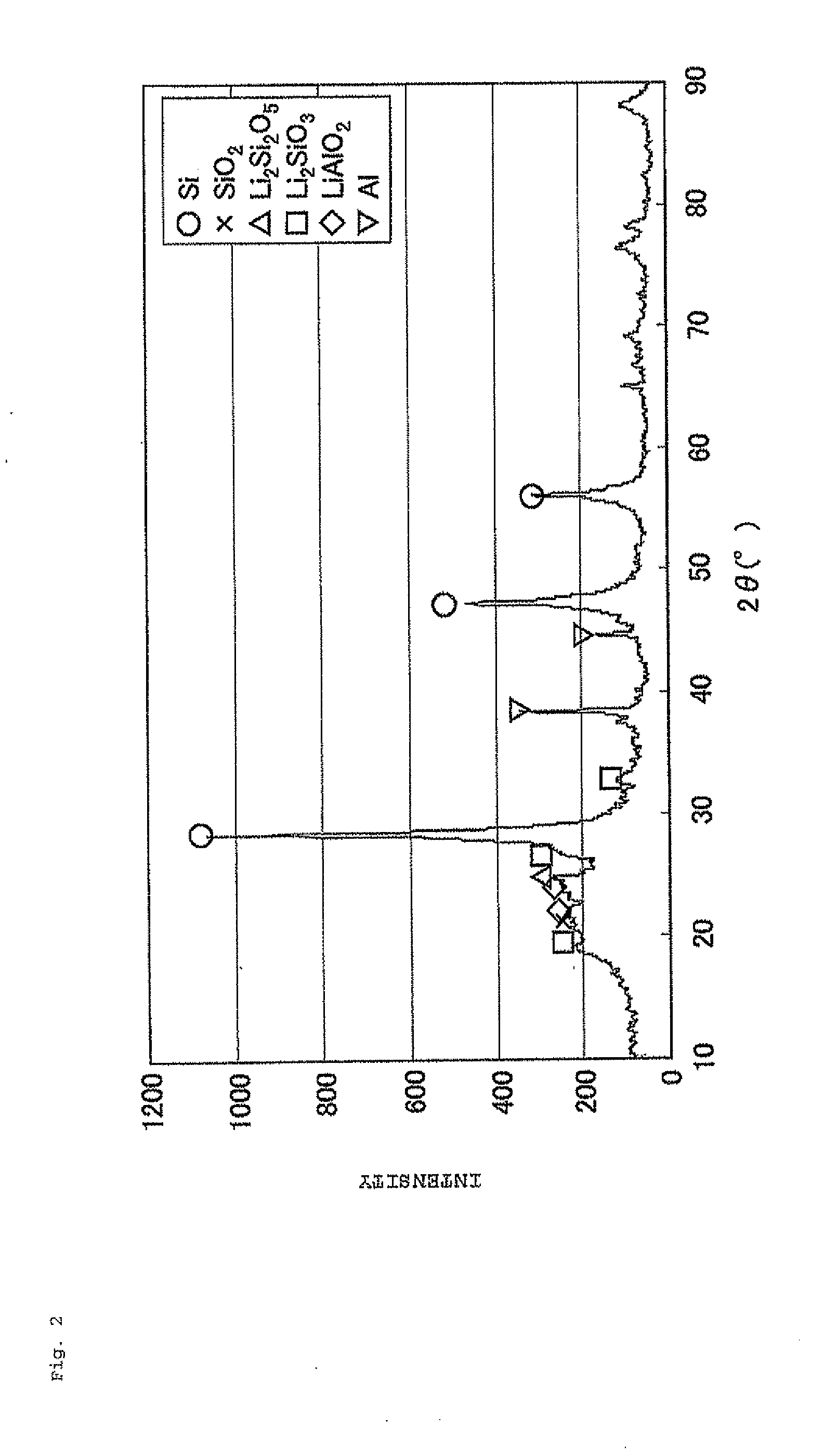

Negative electrode material for secondary battery with non-aqueous electrolyte, method for manufacturing negative electrode material for secondary battery with non-aqueous electrolyte, and lithium ion secondary battery

ActiveUS20110244333A1Cycle durability of negativeElectronic conductivity of negativeMaterial nanotechnologyElectrode thermal treatmentOxide compositeAtomic order

The present invention is a method for manufacturing a negative electrode material for a secondary battery with a non-aqueous electrolyte comprising at least: coating a surface of powder with carbon at a coating amount of 1 to 40 mass % with respect to an amount of the powder by heat CVD treatment under an organic gas and / or vapor atmosphere at a temperature between 800° C. and 1300° C., the powder being composed of at least one of silicon oxide represented by a general formula of SiOx (x=0.5 to 1.6) and a silicon-silicon oxide composite having a structure that silicon particles having a size of 50 nm or less are dispersed to silicon oxide in an atomic order and / or a crystallite state, the silicon-silicon oxide composite having a Si / O molar ratio of 1 / 0.5 to 1 / 1.6; blending lithium hydride and / or lithium aluminum hydride with the powder coated with carbon; and thereafter heating the powder coated with carbon at a temperature between 200° C. and 800° C. to be doped with lithium at a doping amount of 0.1 to 20 mass % with respect to an amount of the powder. As a result, there is provided a method for manufacturing a negative electrode material for a secondary battery with a non-aqueous electrolyte that enables a silicon oxide negative electrode material superior in first efficiency and cycle durability to conventional ones to be mass-produced (manufactured) readily and safely even in an industrial scale.

Owner:SHIN ETSU CHEM IND CO LTD

Silicon-silicon oxide-lithium composite, making method, and non-aqueous electrolyte secondary cell negative electrode material

ActiveUS7776473B2Improve efficiencyImprove cycle performanceNegative electrodesSecondary cellsOxide compositeSilicon oxide

A silicon-silicon oxide-lithium composite comprises a silicon-silicon oxide composite having such a structure that silicon grains having a size of 0.5-50 nm are dispersed in silicon oxide, the silicon-silicon oxide composite being doped with lithium. Using the silicon-silicon oxide-lithium composite as a negative electrode material, a lithium ion secondary cell having a high initial efficiency and improved cycle performance can be constructed.

Owner:SHIN ETSU CHEM CO LTD

Compound and preparation method thereof as well as negative electrode prepared by adopting compound and lithium ion battery

ActiveCN106356508AImprove consistencyImprove dispersion uniformityCell electrodesSecondary cellsElectrical batterySilicon oxygen

The invention relates to a compound and a preparation method thereof as well as a negative electrode prepared by adopting the compound and a lithium ion battery. The compound comprises silicon, silicon oxide SiOx (x is greater than 0 and is less than or equal to 2) and silicate, wherein positive ion elements of the silicate are reductant elements, and Si, O and the reductant elements in the compound are uniformly distributed. Reductants used in the compound are heated and insulated in the environment of negative pressure, so that SiO steam reacts with reductant steam in the form of a gas phase so as to condense to obtain the compound, and then the compound is further used as a raw material so as to prepare a modified silica negative electrode material. The negative electrode material is suitable for the lithium ion battery, the prepared lithium ion battery has high charge and discharge specific capacity and excellent first coulombic efficiency, the charge capacity is 1447 mAh / g or above, the discharge capacity is 1213 mAh / g or above, and the first coulombic efficiency is 83.8% or above.

Owner:BTR NEW MATERIAL GRP CO LTD

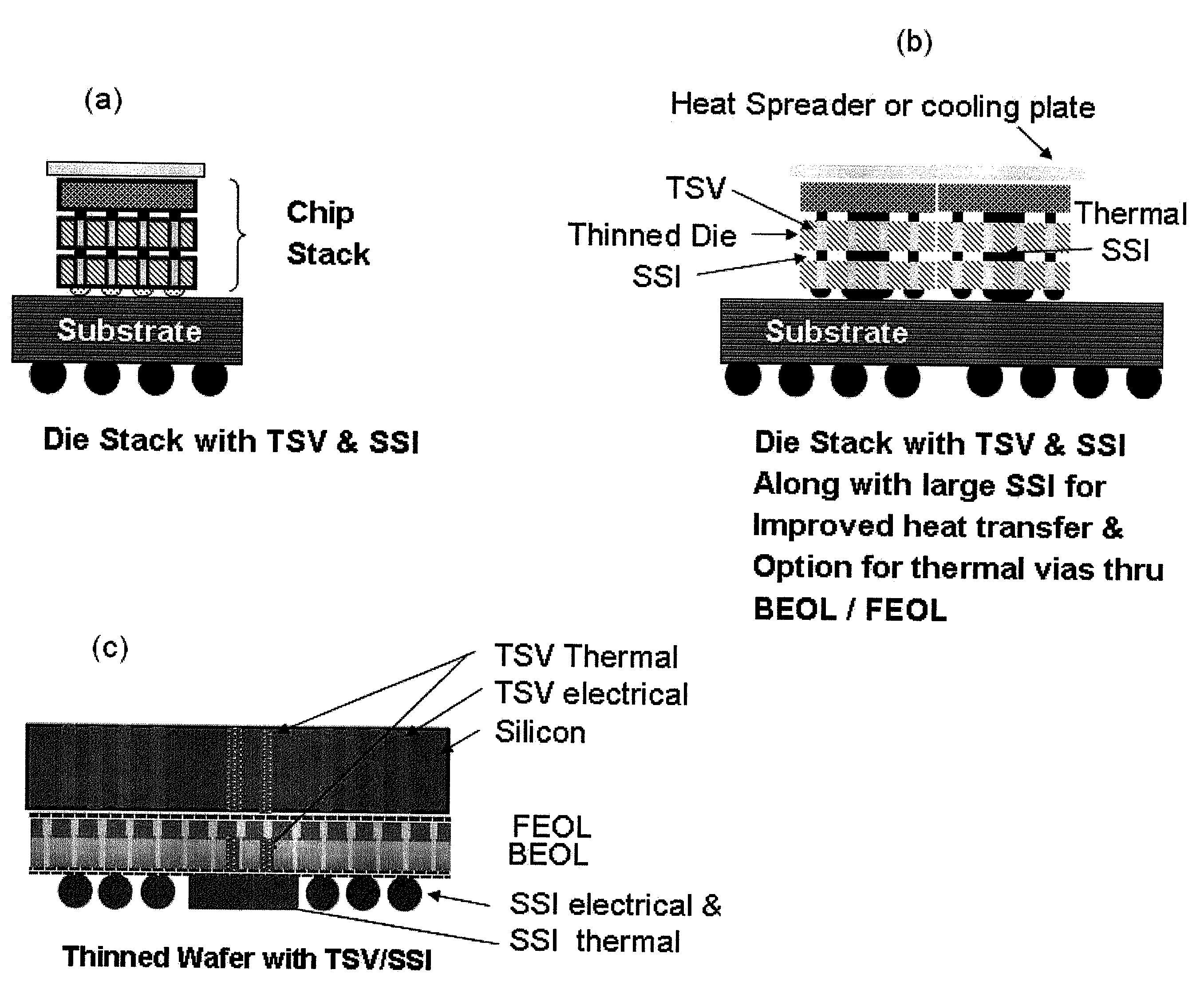

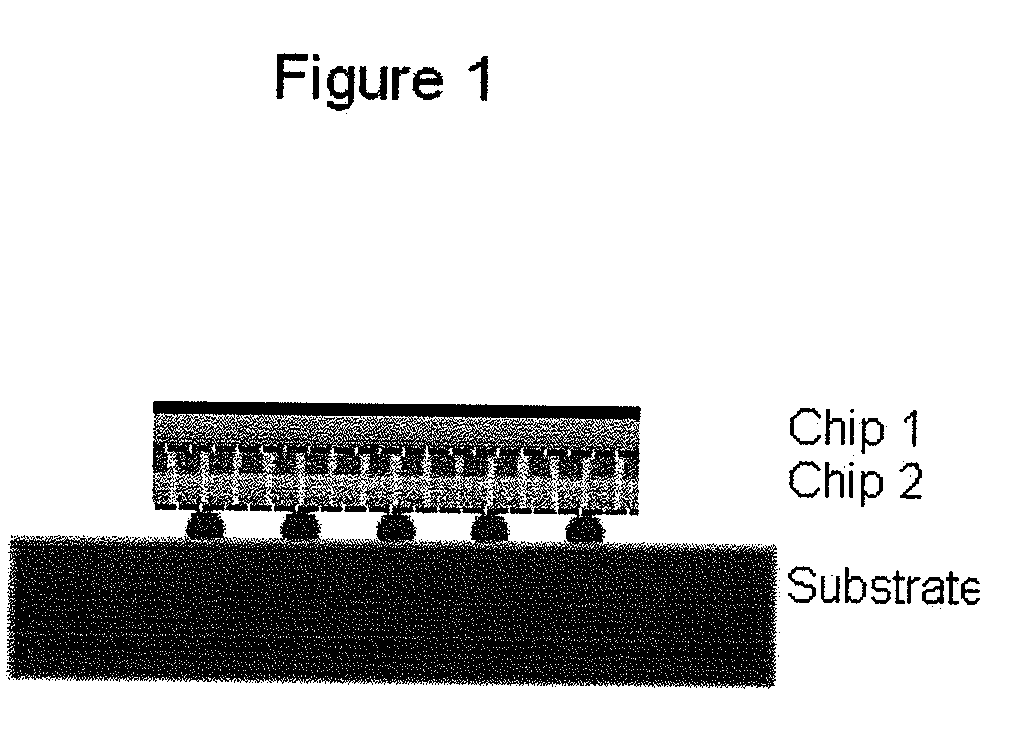

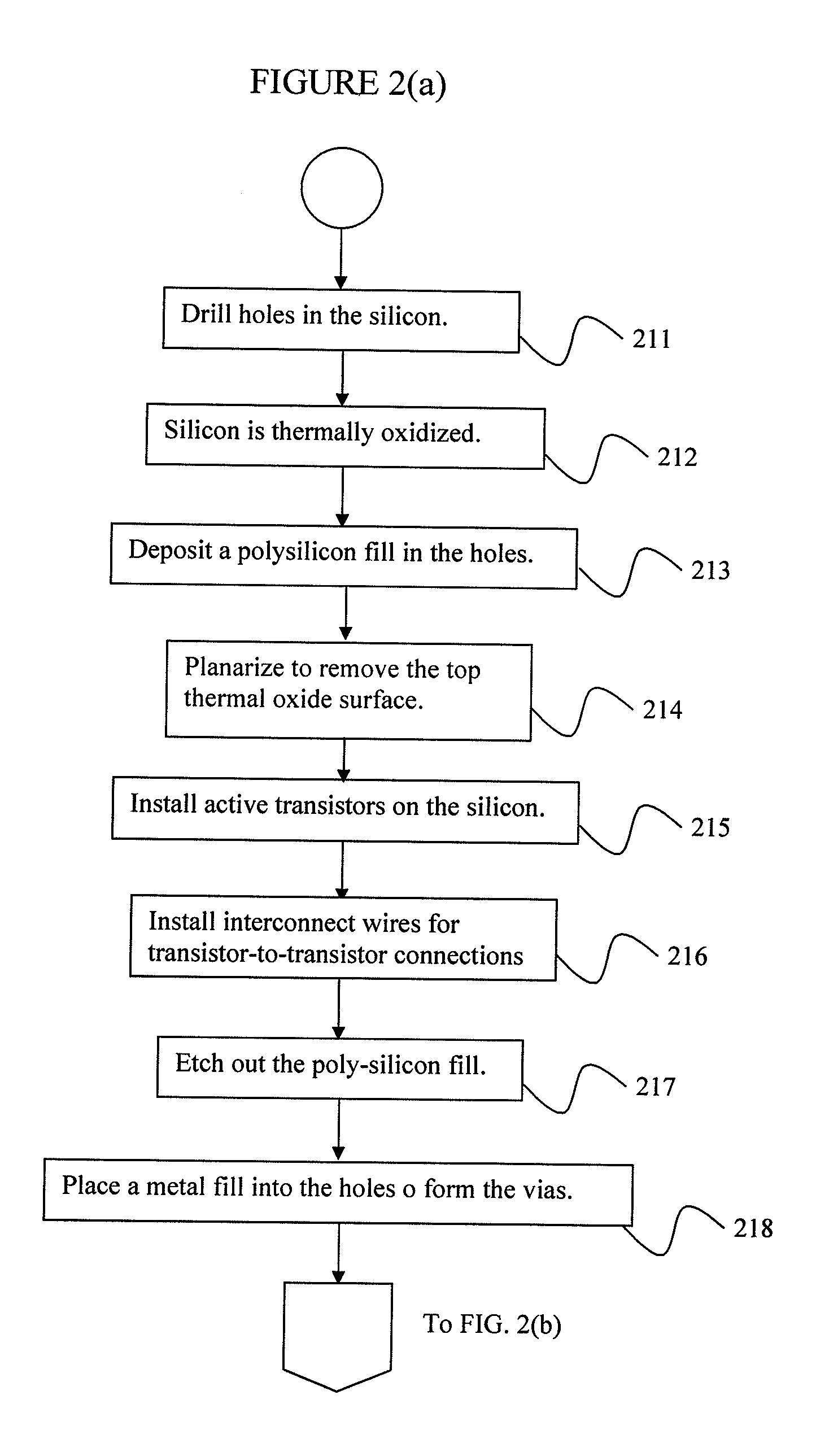

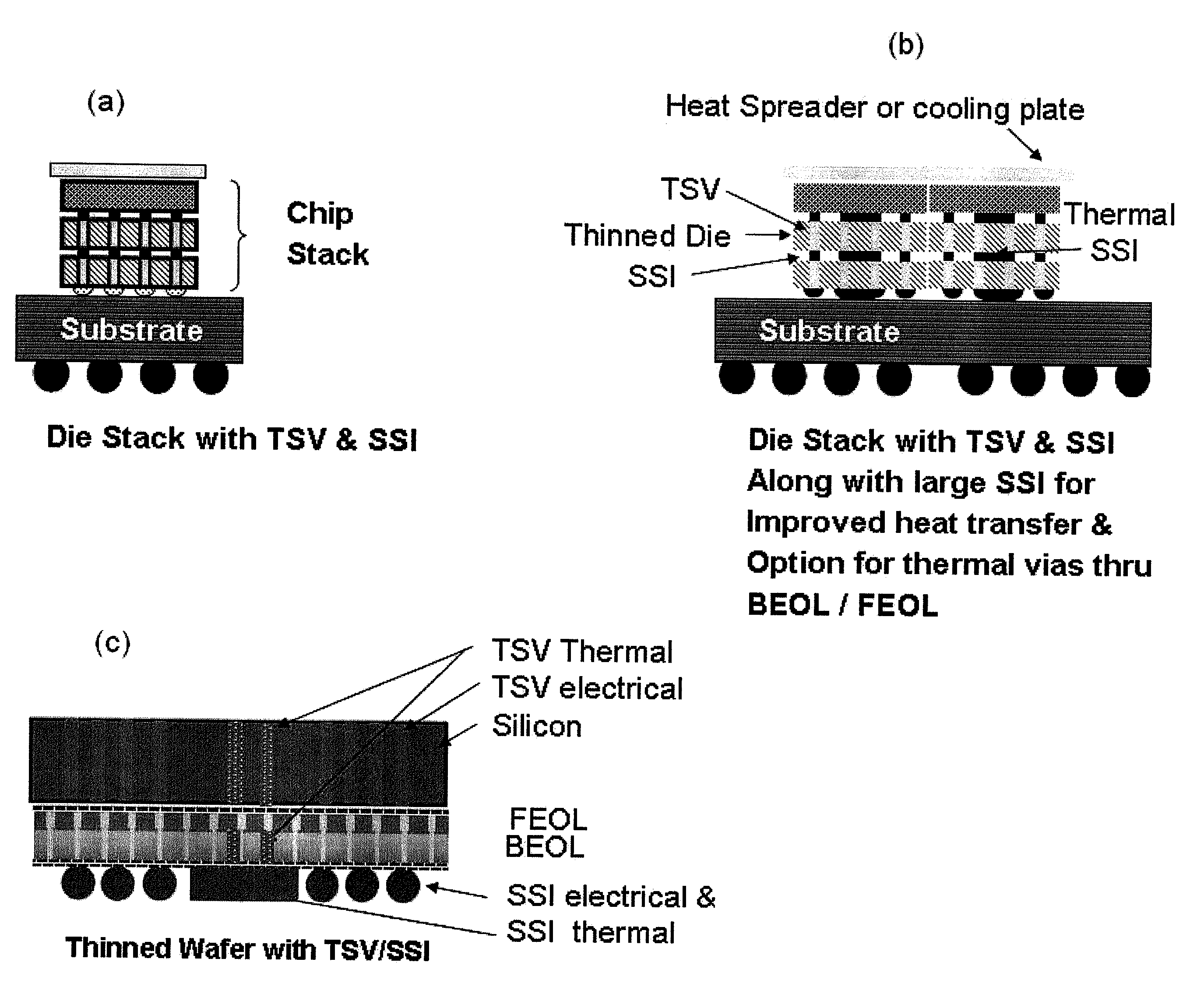

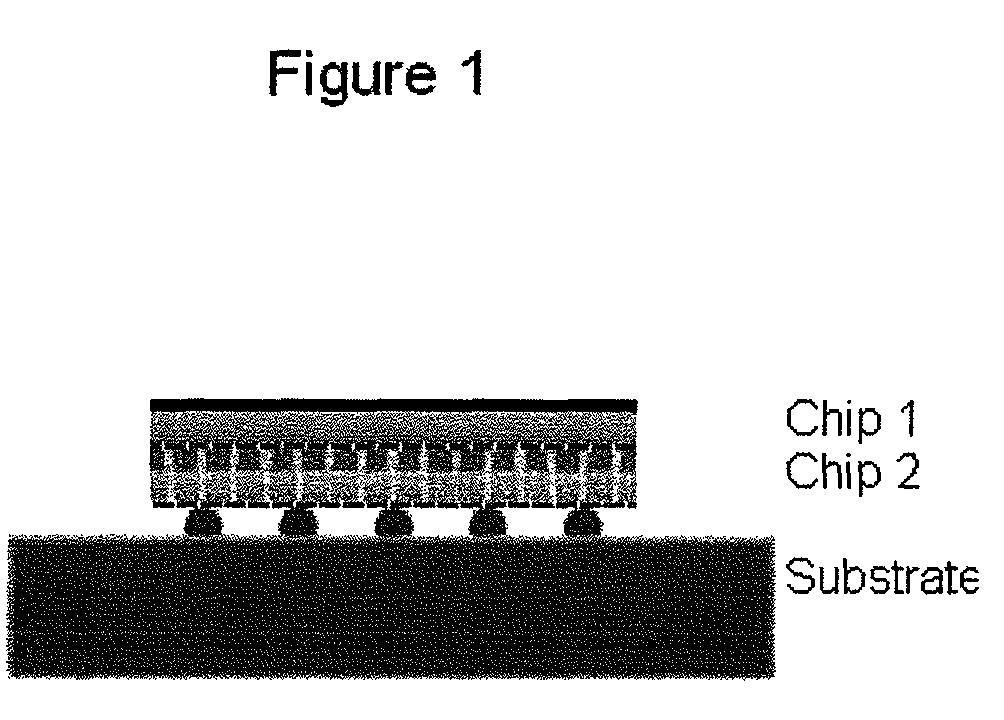

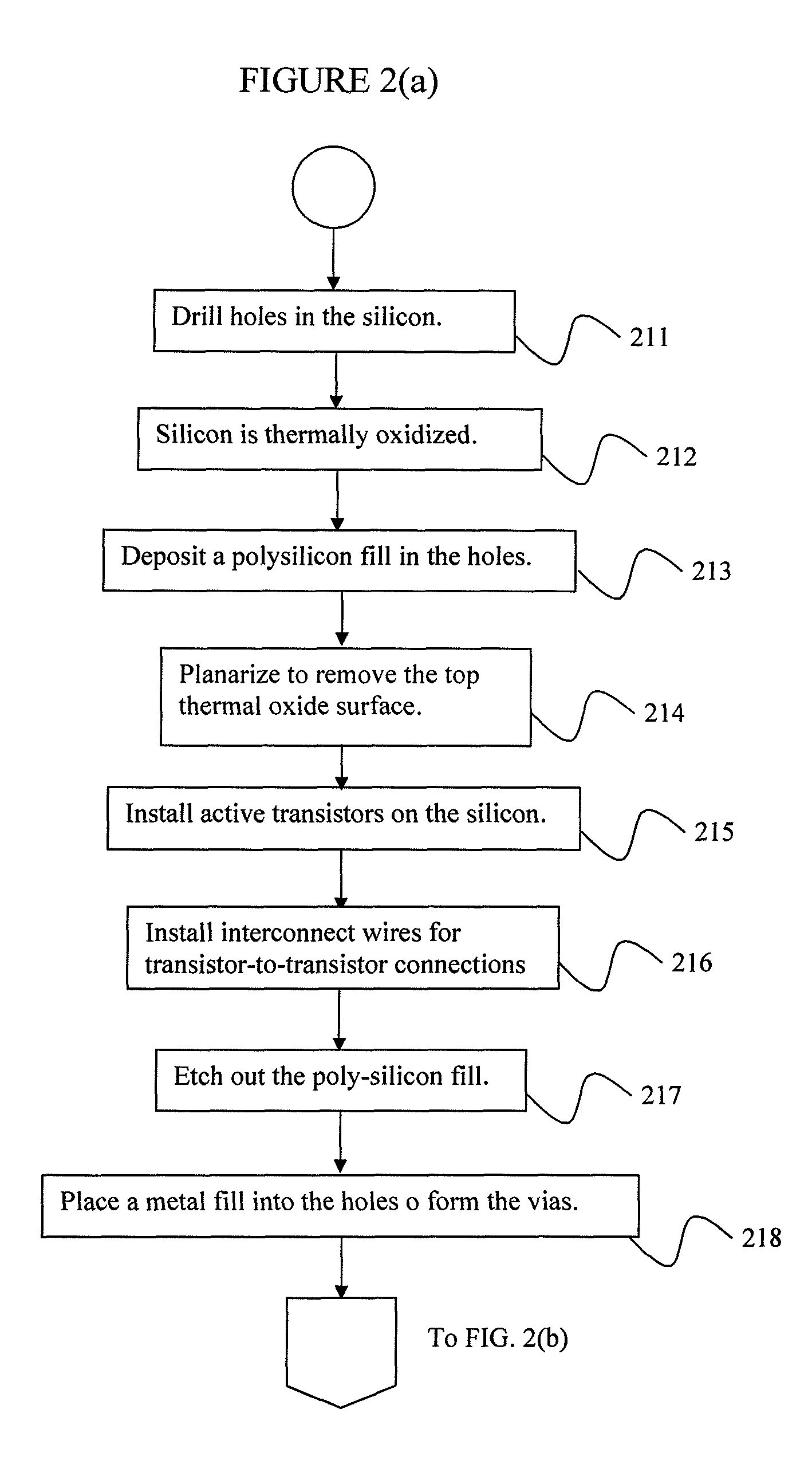

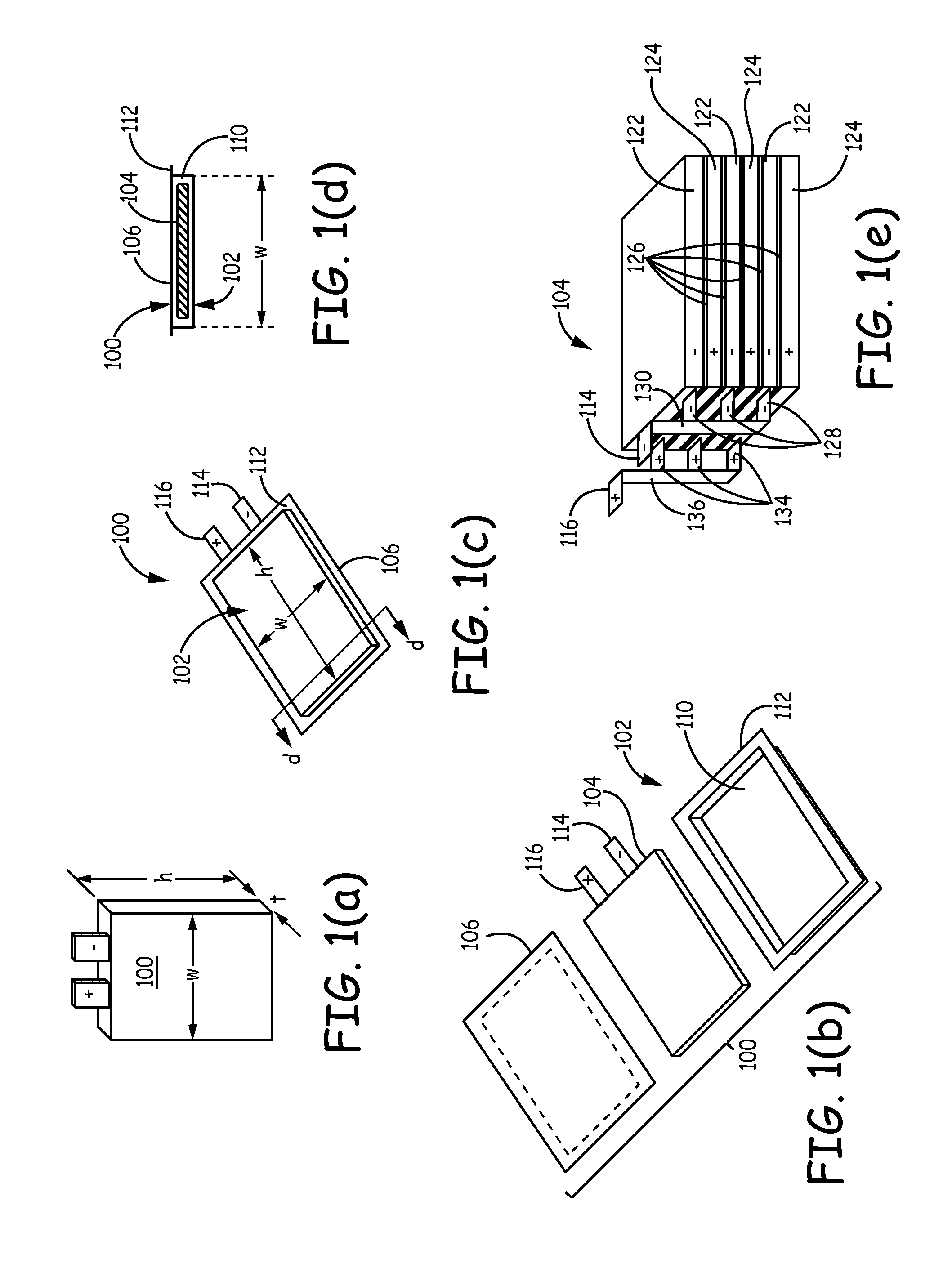

3D silicon-silicon die stack structure and method for fine pitch interconnection and vertical heat transport

InactiveUS20110042820A1Soft errorSuitable designSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsDielectricElectrical conductor

A method of fabricating a thin wafer die includes creating circuits and front-end-of-line wiring on a silicon wafer, drilling holes in a topside of the wafer, depositing an insulator on the drilled holes surface to provide a dielectric insulator, removing any excess surface deposition from the surface, putting a metal fill into the holes to form through-silicon-vias (TSV), creating back-end-of-line wiring and pads on the top surface for interconnection, thinning down the wafer to expose the insulator in from the TSVs to adapt the TSVs to be contacted from a backside of the wafer, depositing an insulating layer which contacts the TSV dielectric, thinning down the backside of the wafer, opening through the dielectric to expose the conductor of the TSV to provide a dielectric insulation about exposed backside silicon, and depositing ball limiting metallurgy pads and solder bumps on the backside of the wafer to form an integrated circuit.

Owner:GLOBALFOUNDRIES INC

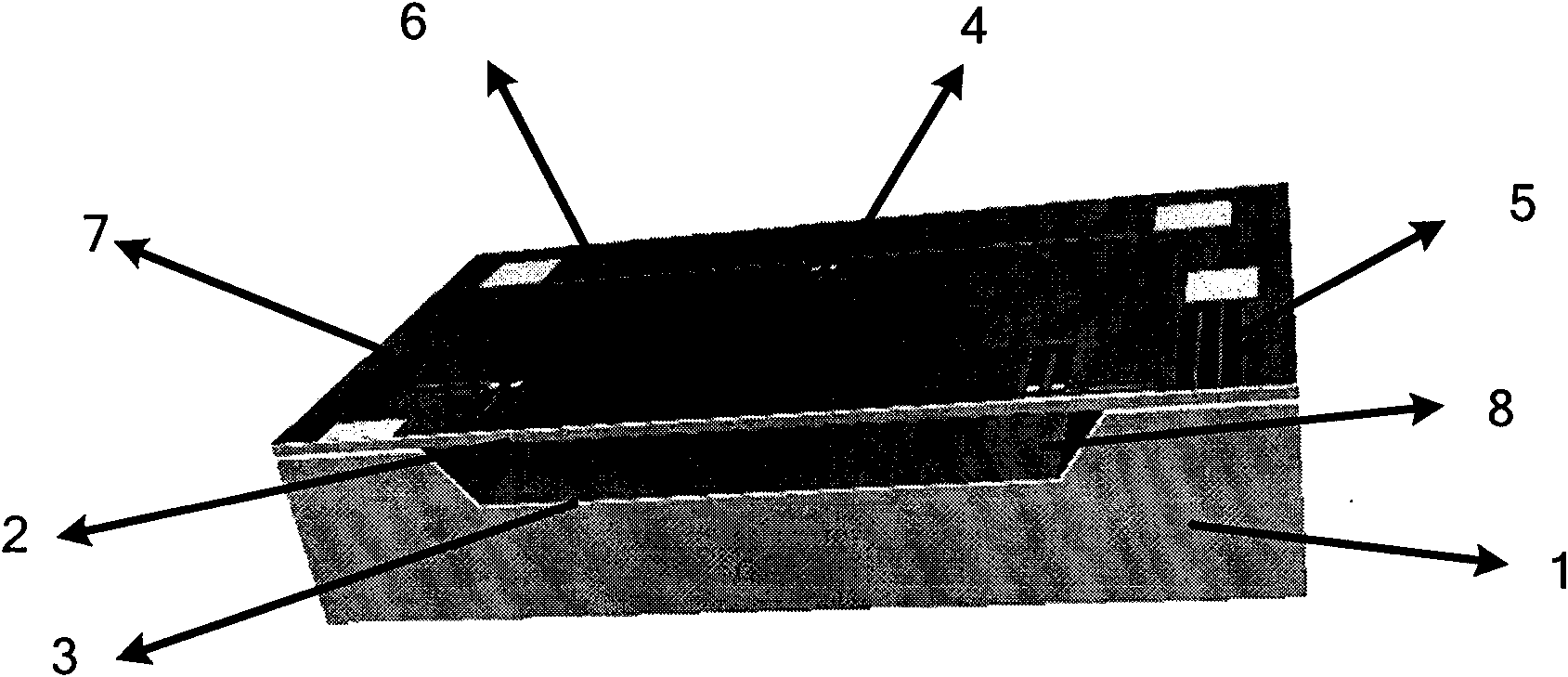

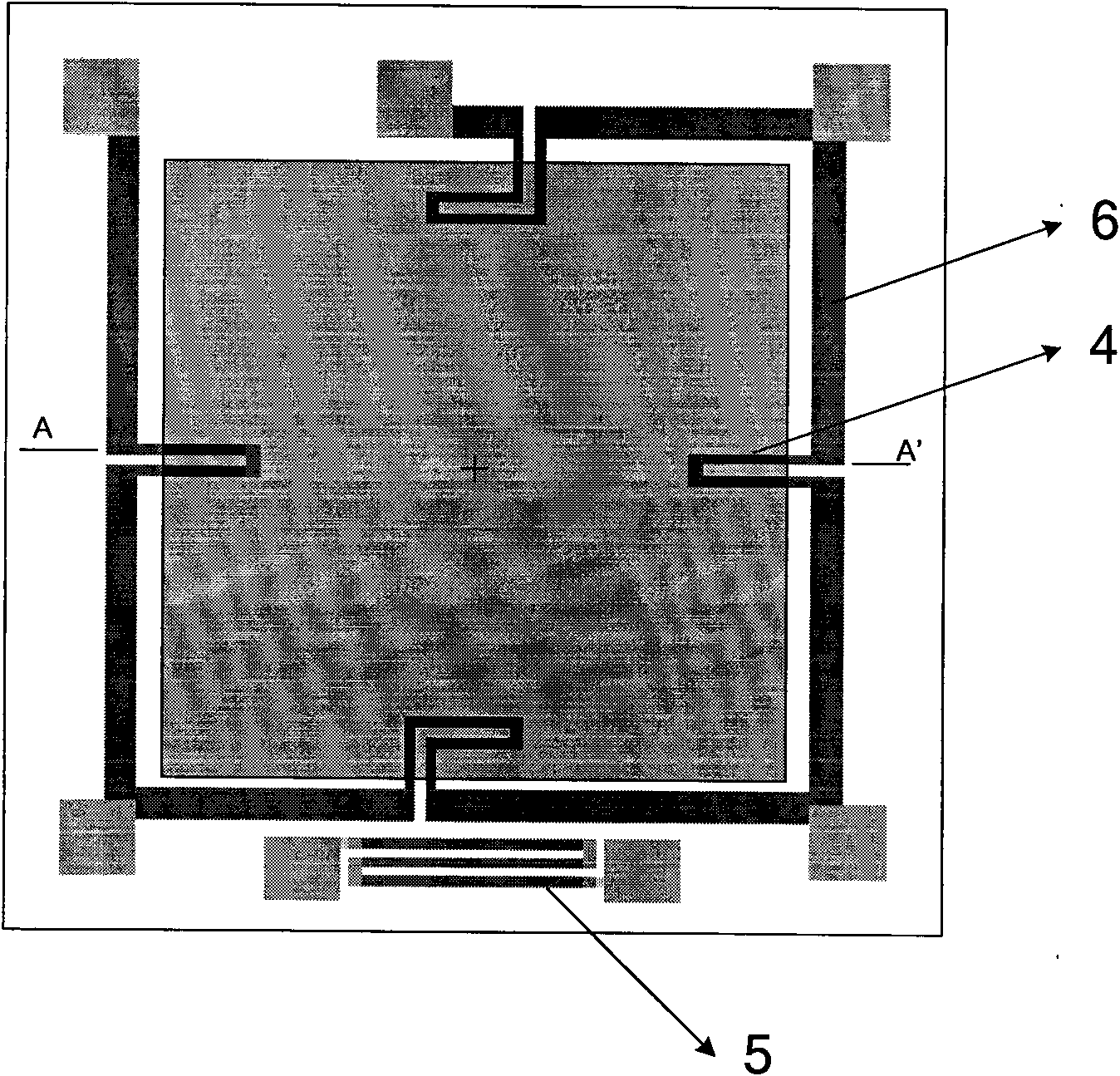

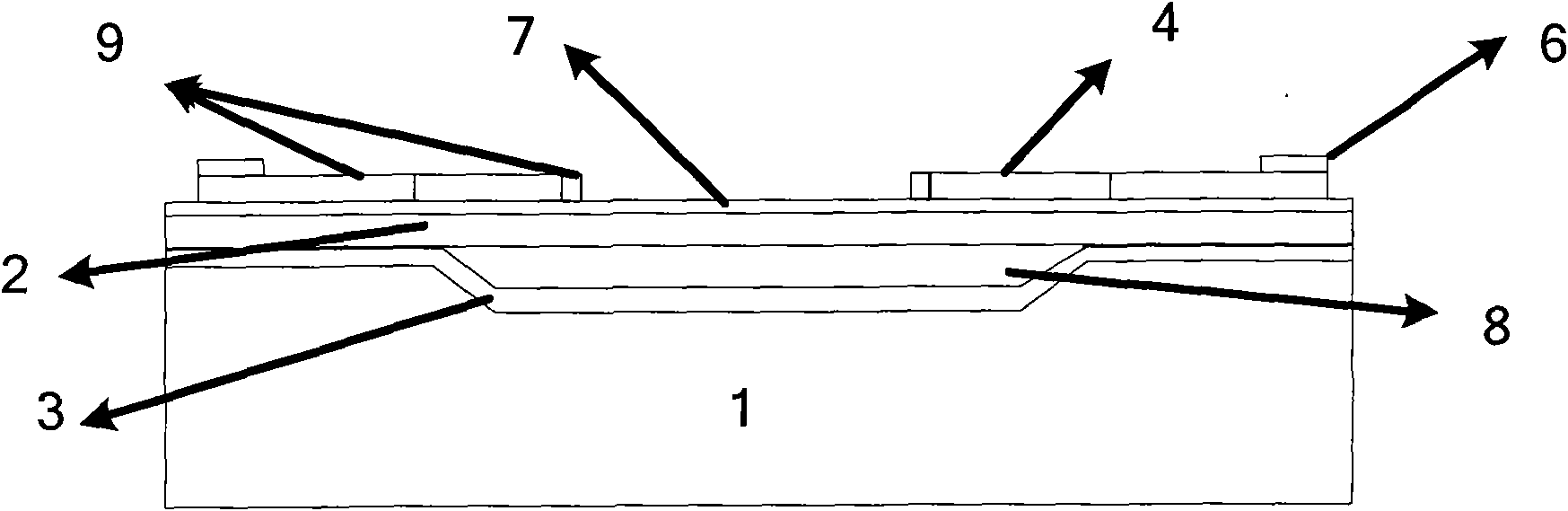

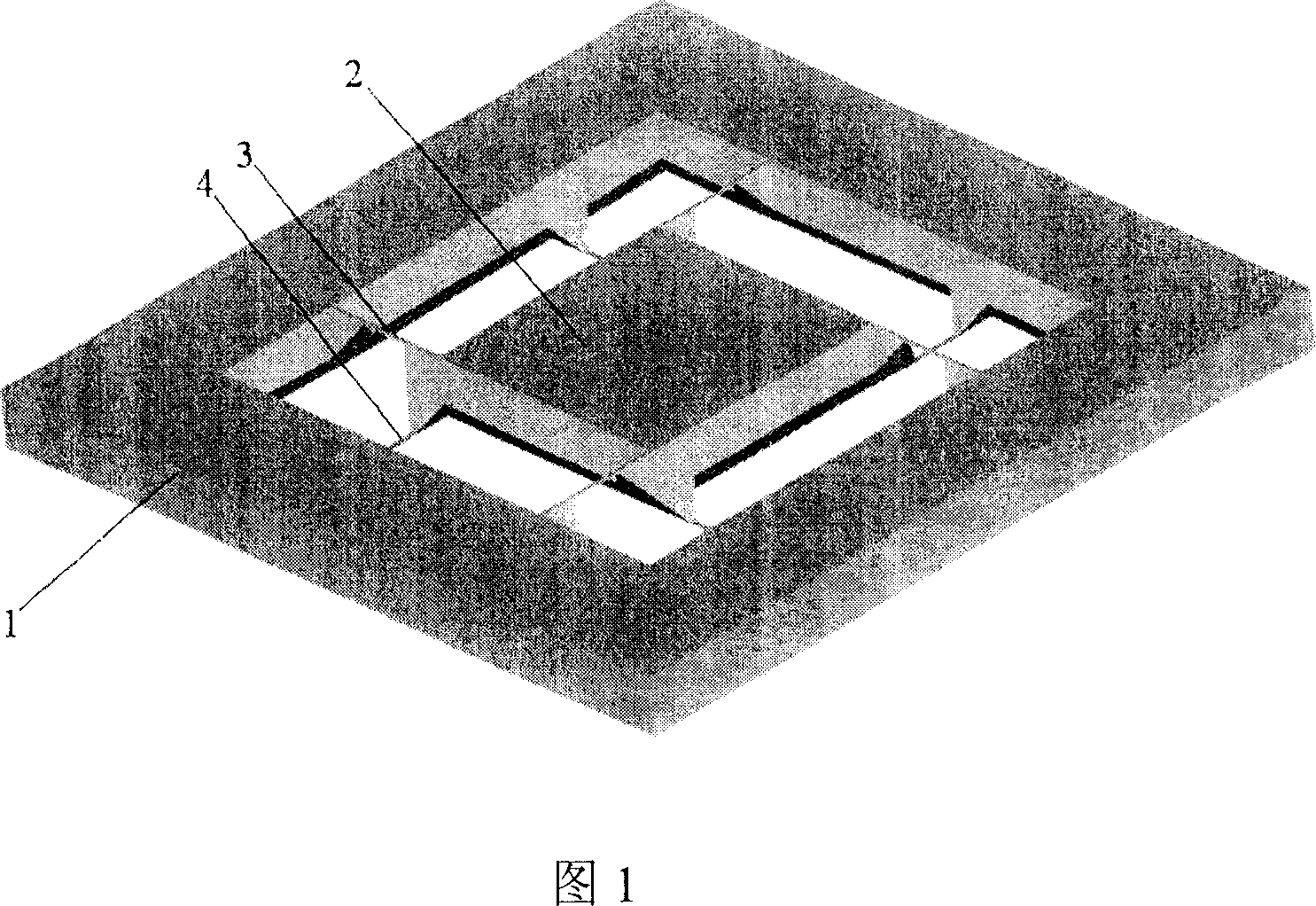

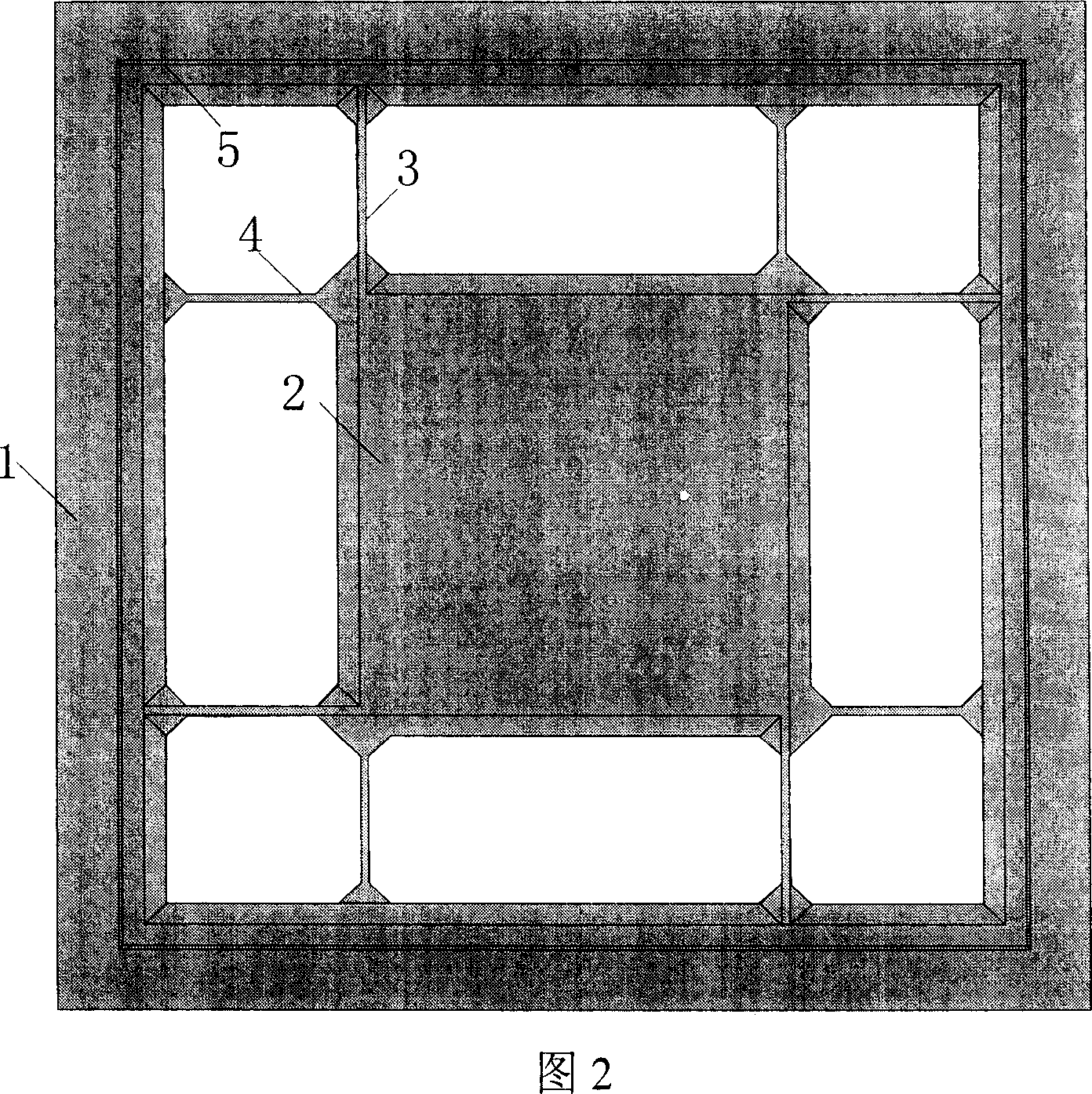

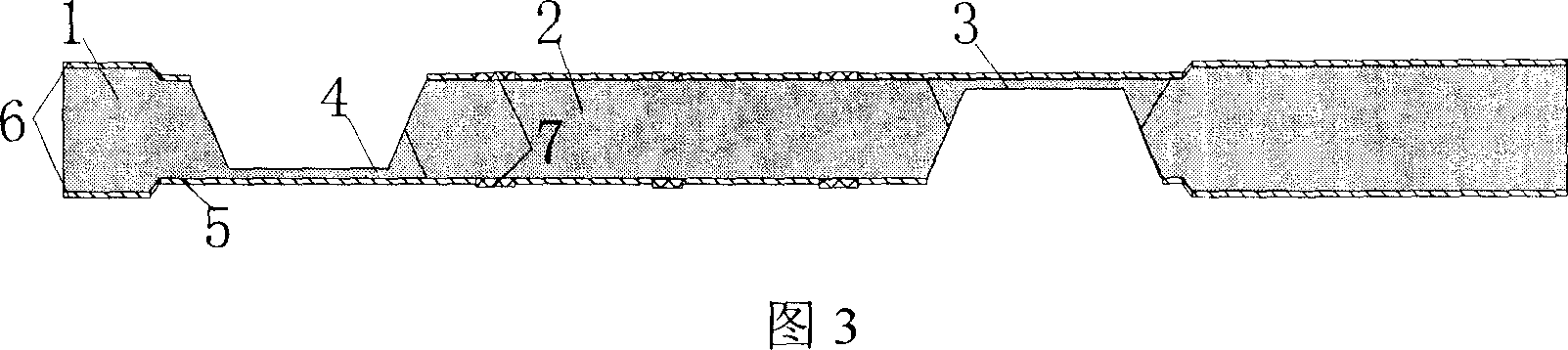

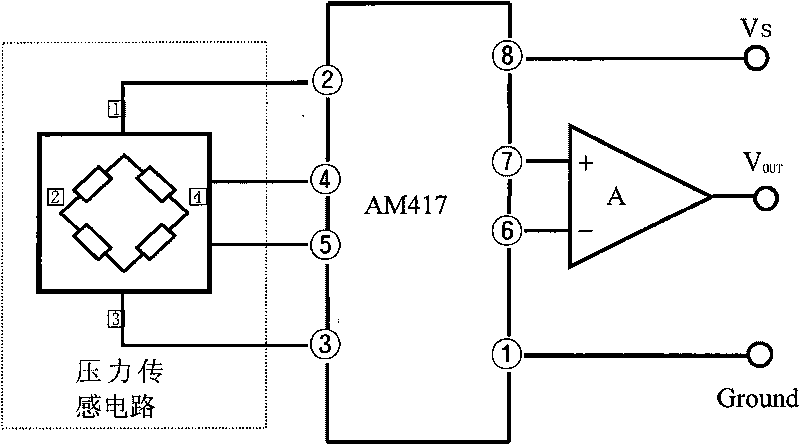

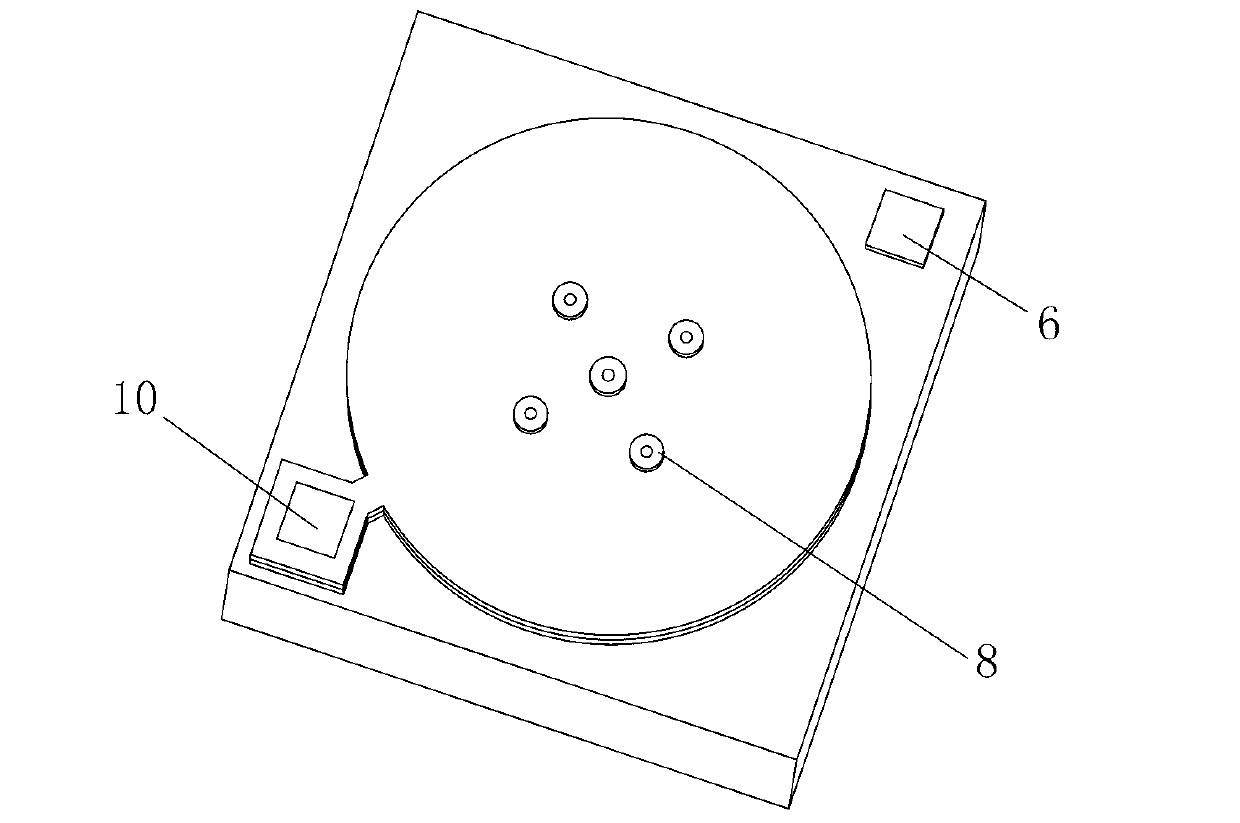

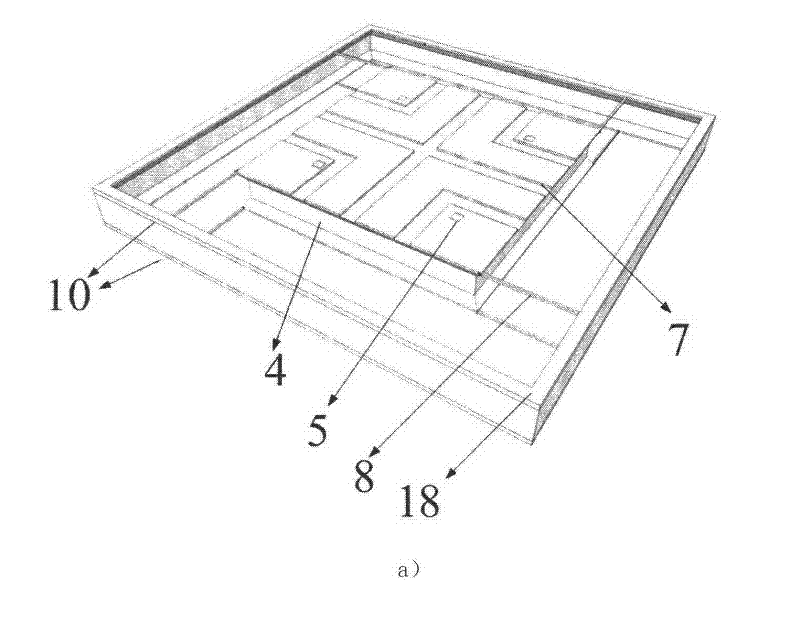

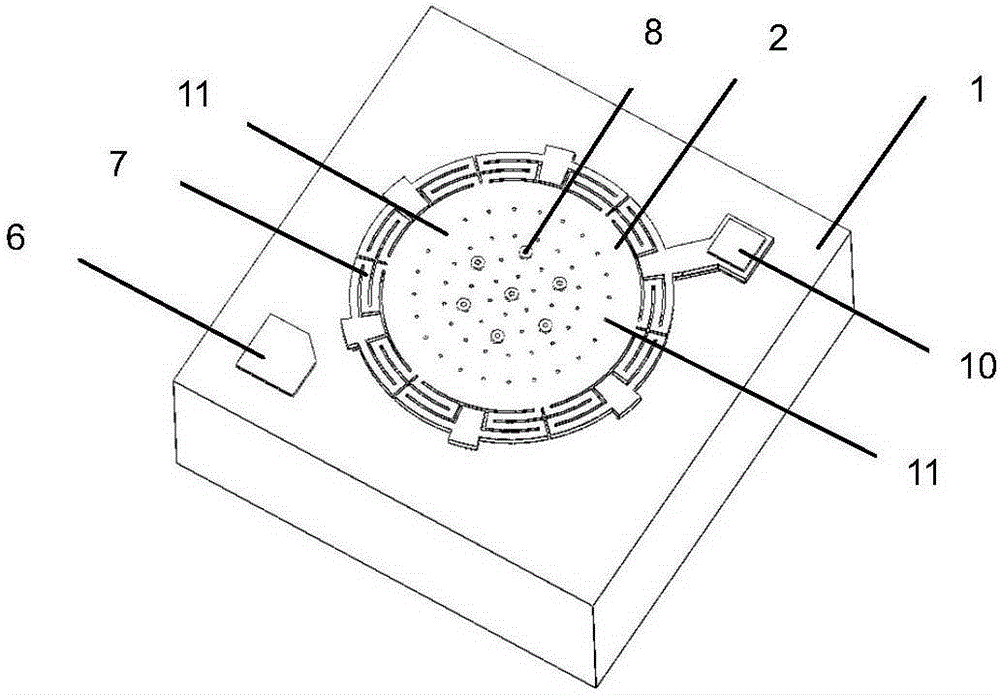

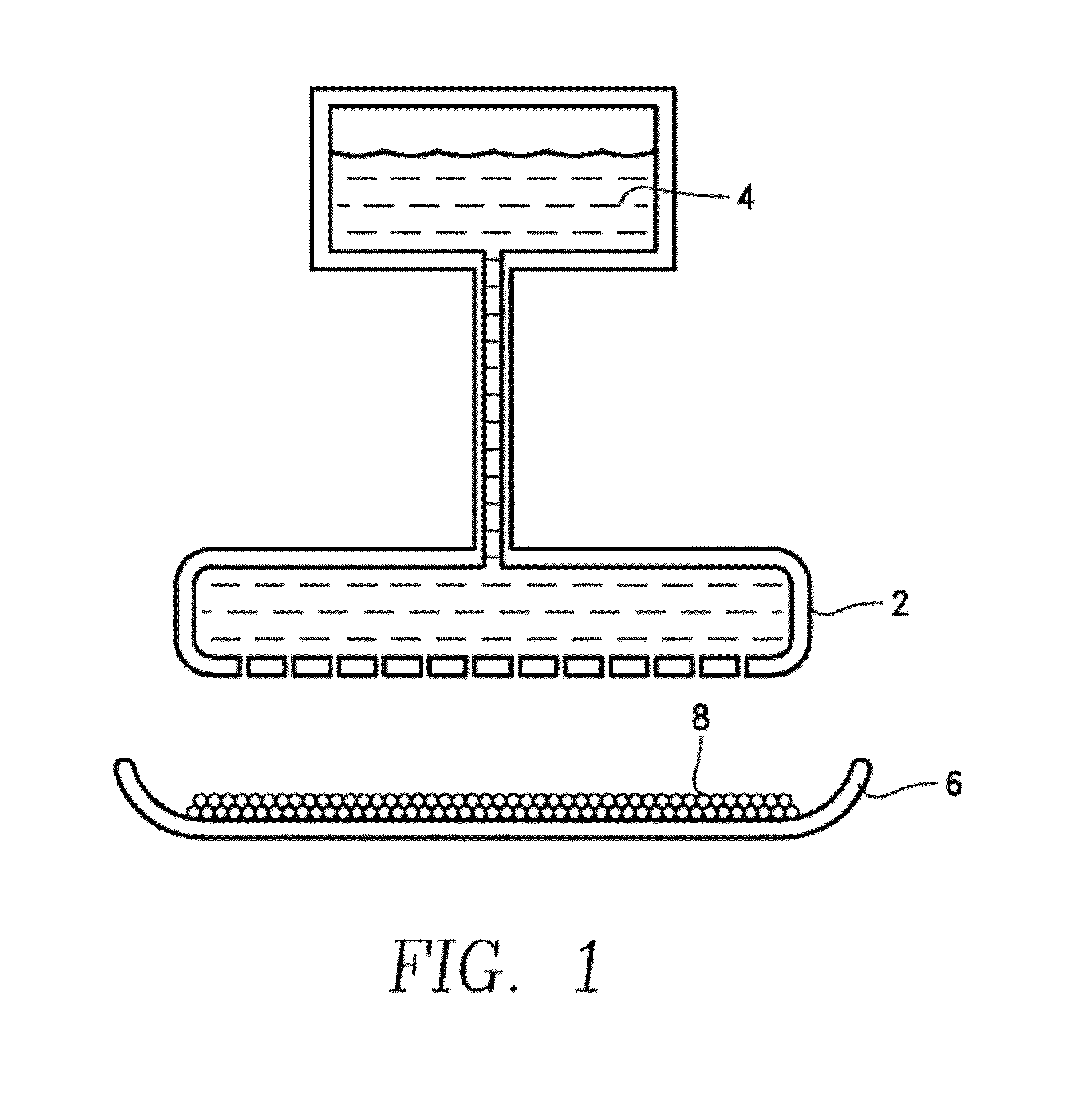

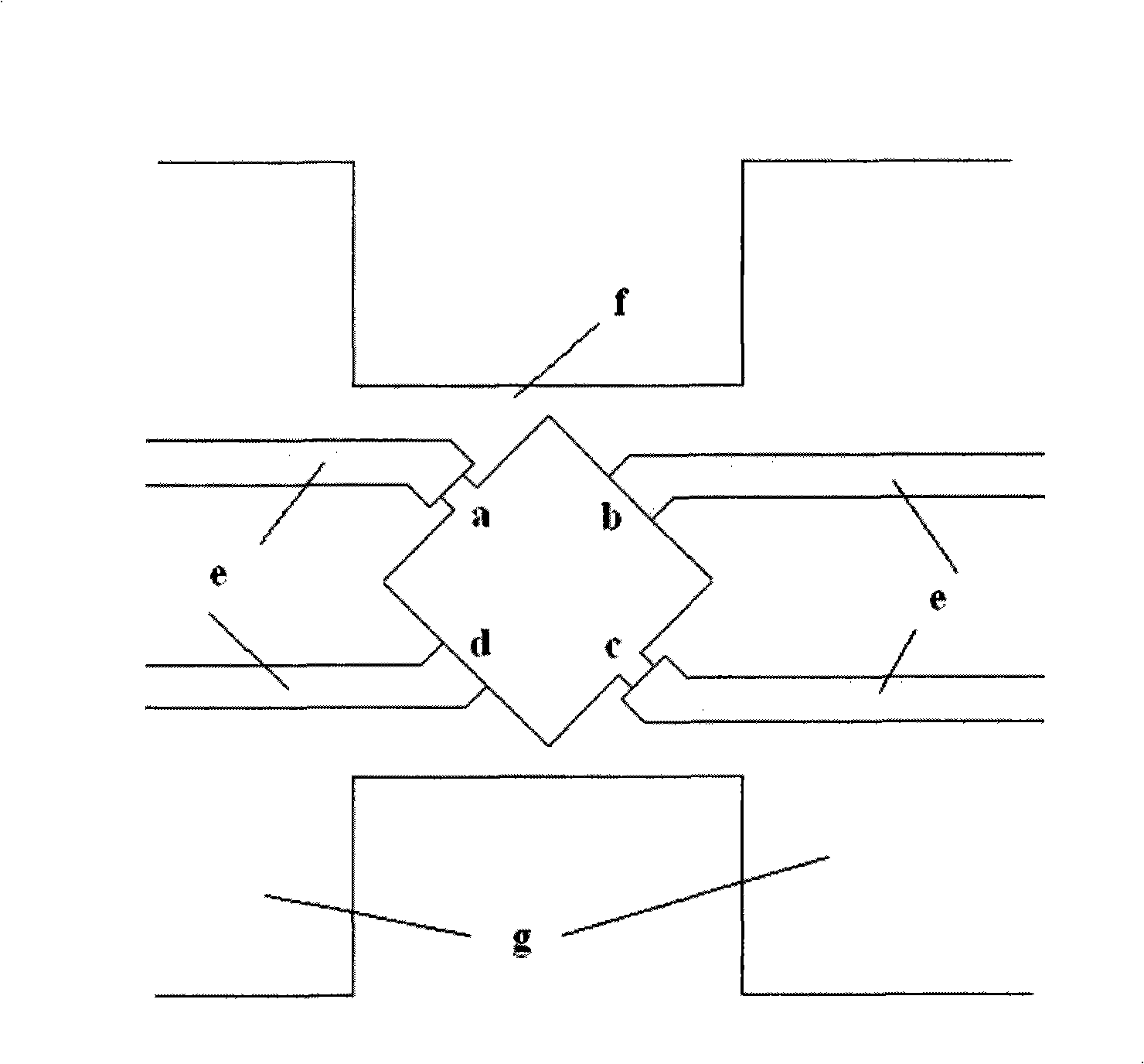

Pressure sensor based on Si-Si direct bonding and manufacturing method thereof

InactiveCN101551284APrecise size controlOvercome performance degradation flawsTelevision system detailsSemi-permeable membranesWorking temperatureBoron

The invention discloses a pressure sensor based on Si-Si direct bonding, comprising a silicon substrate (1) with a shallow groove (8); the silicon substrate (1) is provided with a single crystal silicon stress membrane (2); a silicon dioxide layer (3) is arranged between the silicon substrate (1) and the stress membrane (2); four P-type single crystal silicon piezoresistors (4) are arranged on the stress membrane (2); an insulating medium silicon dioxide layer (7) is arranged among the stress membrane (2) and the piezoresistors (4); and a Wheatstone bridge is formed among the piezoresistors (4) by utilizing concentrated boron doped silicon (9) and a golden lead (6). The pressure sensor adopts Si-Si direct bonding technology to form the stress membrane and the sealing cavity; the piezoresistors thereof adopt silicon dioxide as an insulating layer and the working temperature can be up to 300 DEG C; and the pressure sensor has firm structure and excellent performance and can meet the requirements on high-temperature pressure sensors in the fields of automobile, aerospace and the like. The invention also relates to a manufacturing method of the pressure sensor.

Owner:江苏英特神斯科技有限公司

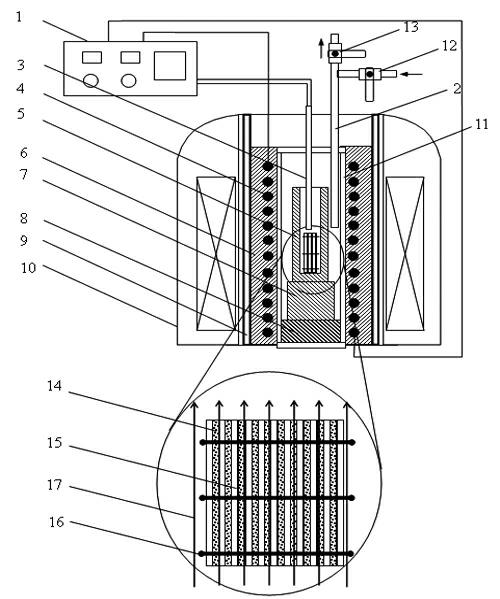

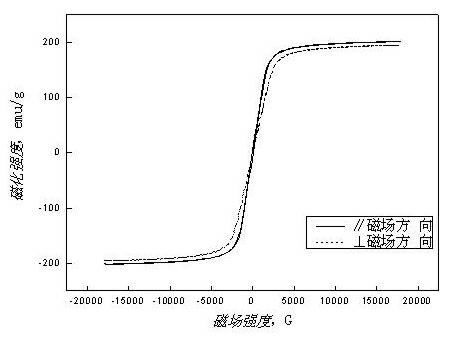

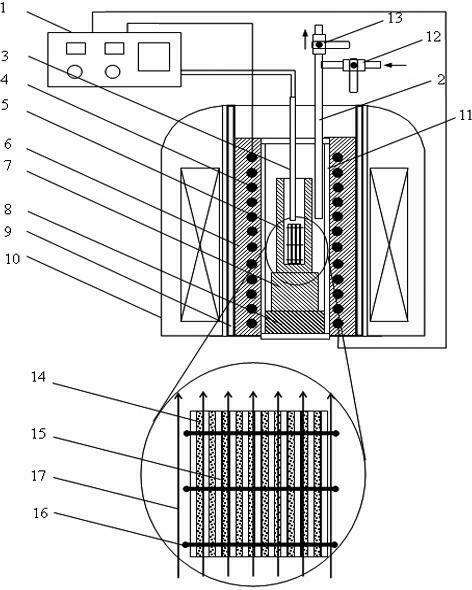

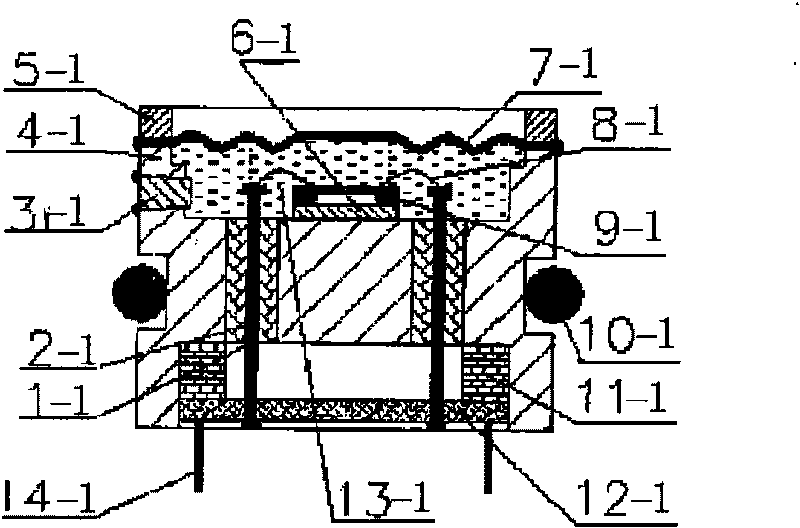

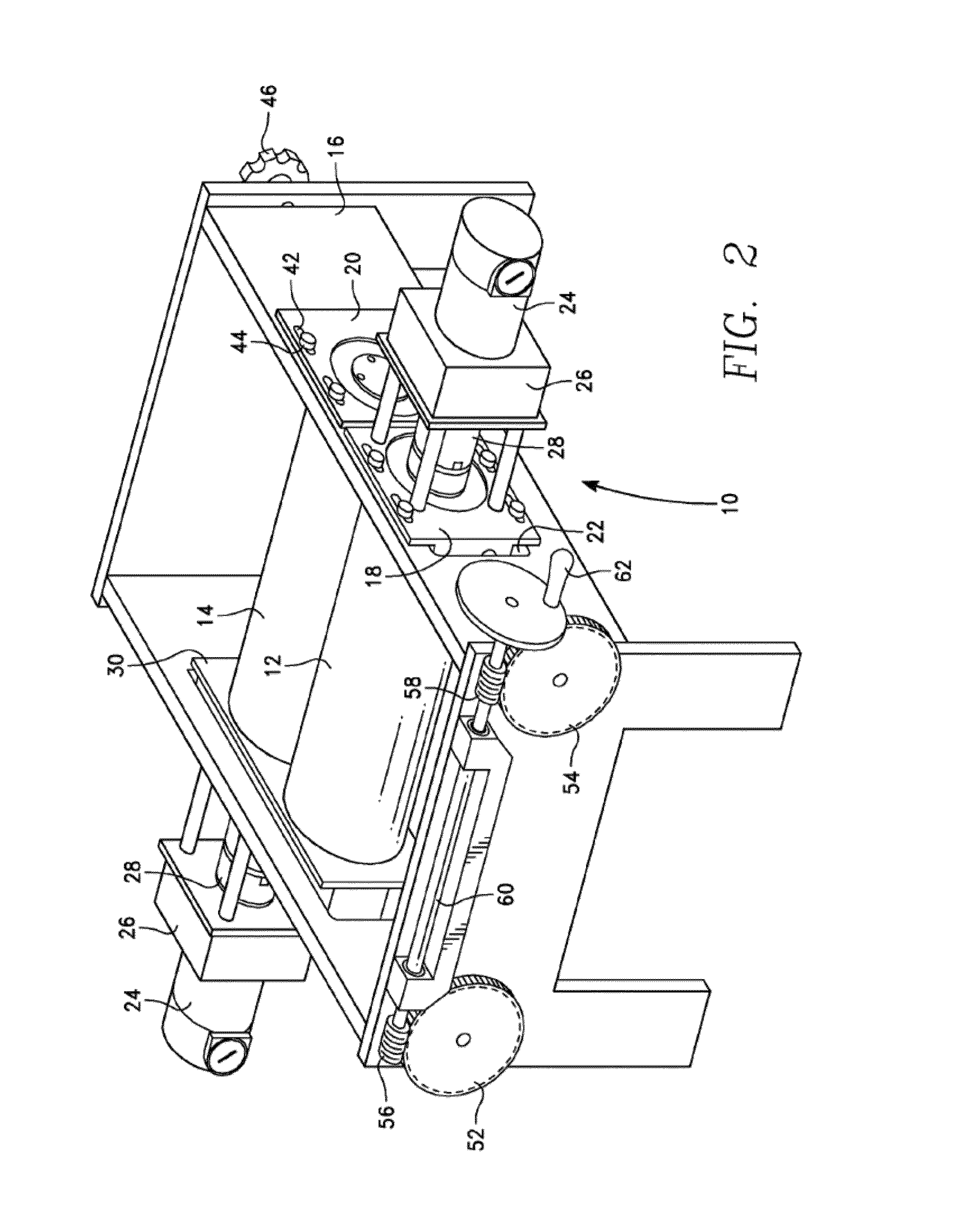

Method and device for preparing high-silicon silicon steel sheet in static magnetic field with powder sintering method

ActiveCN102658367AAccurate control of silicon contentHigh densityInorganic material magnetismInlet valveExhaust pipe

The invention relates to a method and device for preparing a silicon steel sheet in a static magnetic field with a powder sintering method. The specific process of the method consists of the following steps of: mixing Fe-Si powder; rolling into a plate blank; and sintering a Fe-6.5 weight percent Si green compact in a static magnetic field. In the method, 6.5 percent by weight of Si high-silicon steel with high density is obtained by using the influence of the magnetic field on the sintering densification and orientation process of a Fe-6.5 weight percent Si powder green compact, and an easily-magnetized axis is oriented along the magnetic field. An atmosphere / vacuum sintering device in a static magnetic field consists of a temperature control device, an exhaust pipe, a thermocouple, a heating element, a corundum crucible, a refractory fiber, a support block, a heat insulating block, a water-cooled bush, a static magnetic field generating device, a sealed corundum pipe, an inert gas inlet valve, a vacuum pumping valve, a Fe-6.5weight percent Si green compact, a thin corundum plate interlayer and a fixing molybdenum wire. The 6.5 percent Si silicon steel sheet prepared with the method has the advantages of near net molding, superior magnetic property, high orientation degree and the like, and has a remarkable industrial application prospect.

Owner:SHANGHAI UNIV

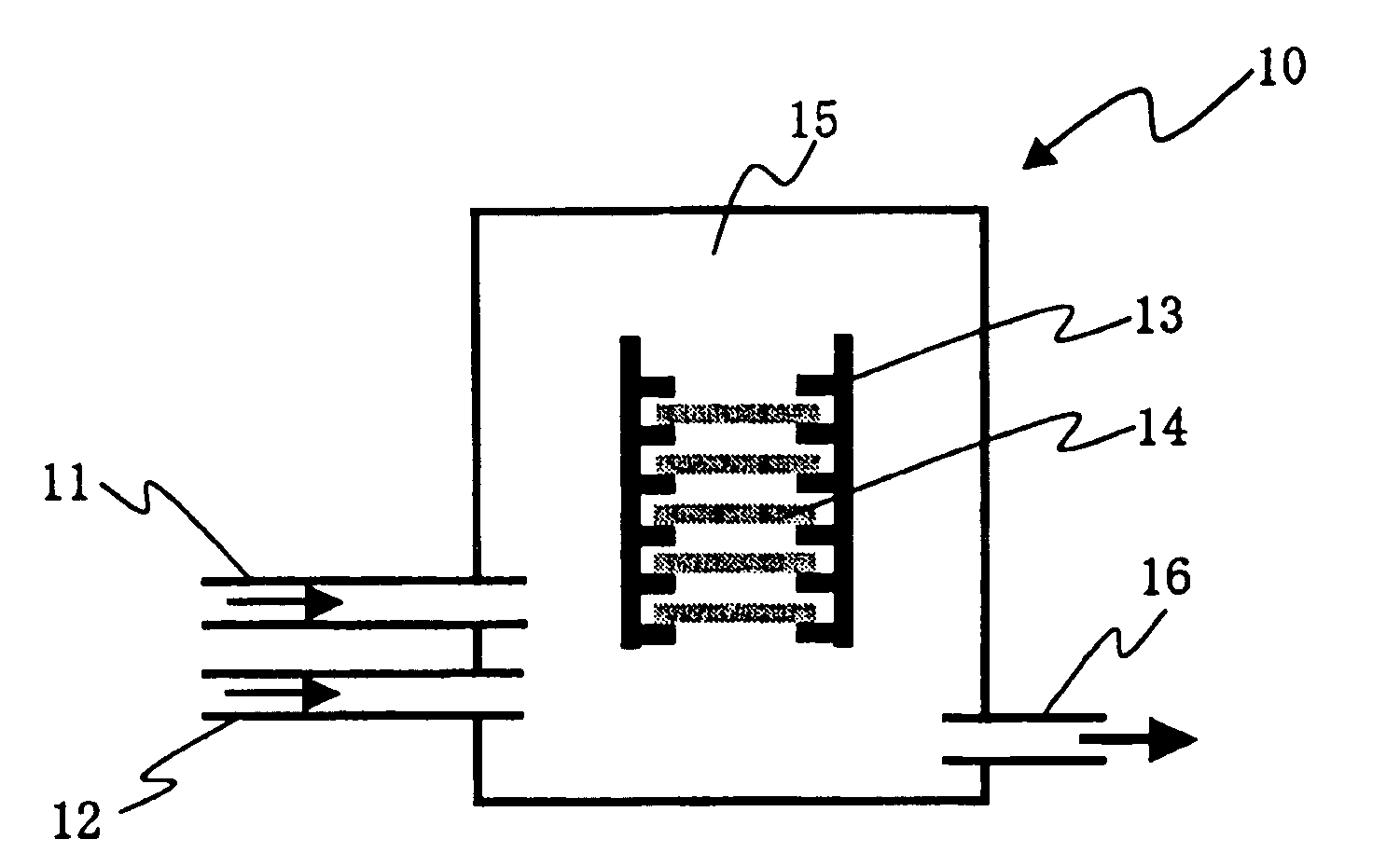

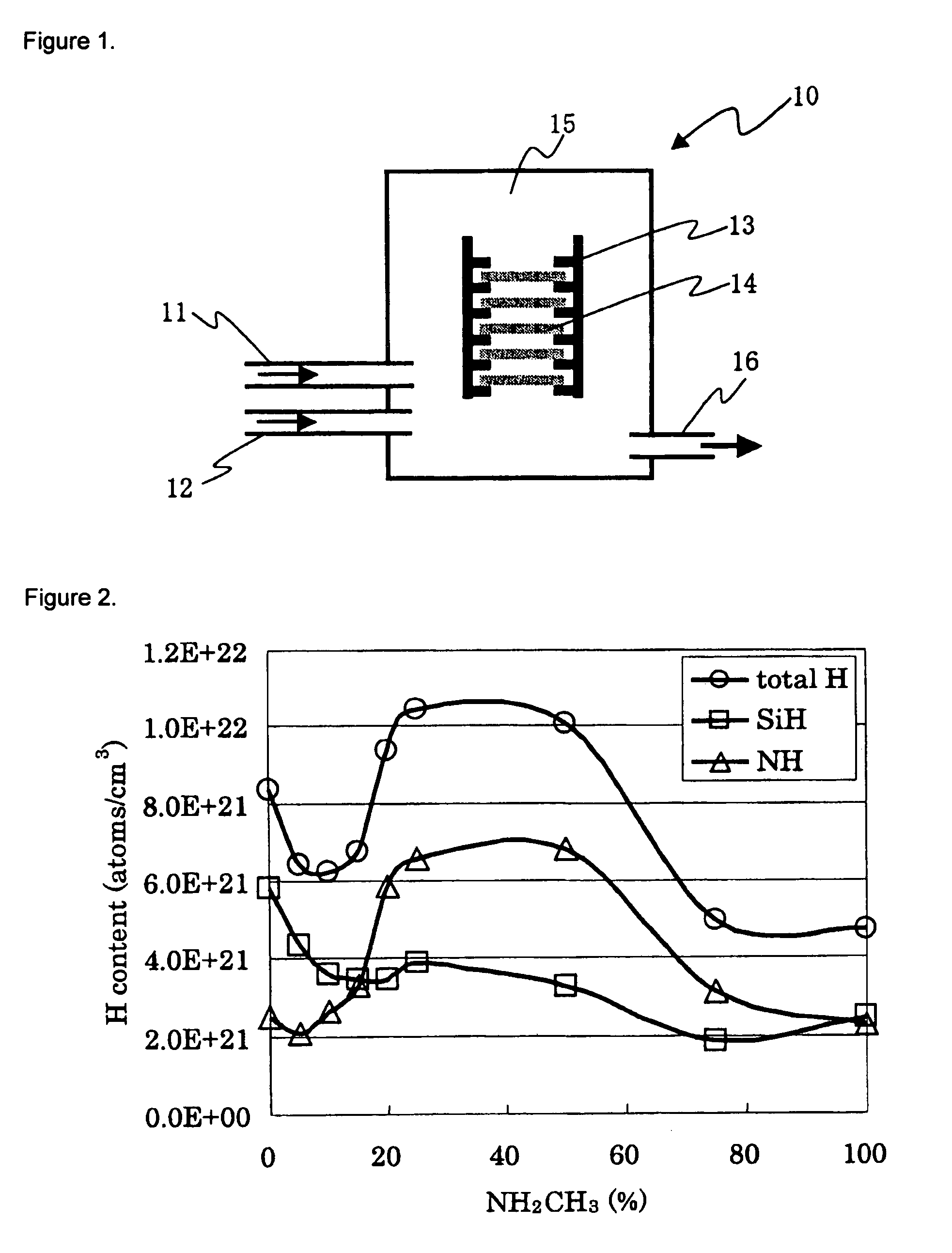

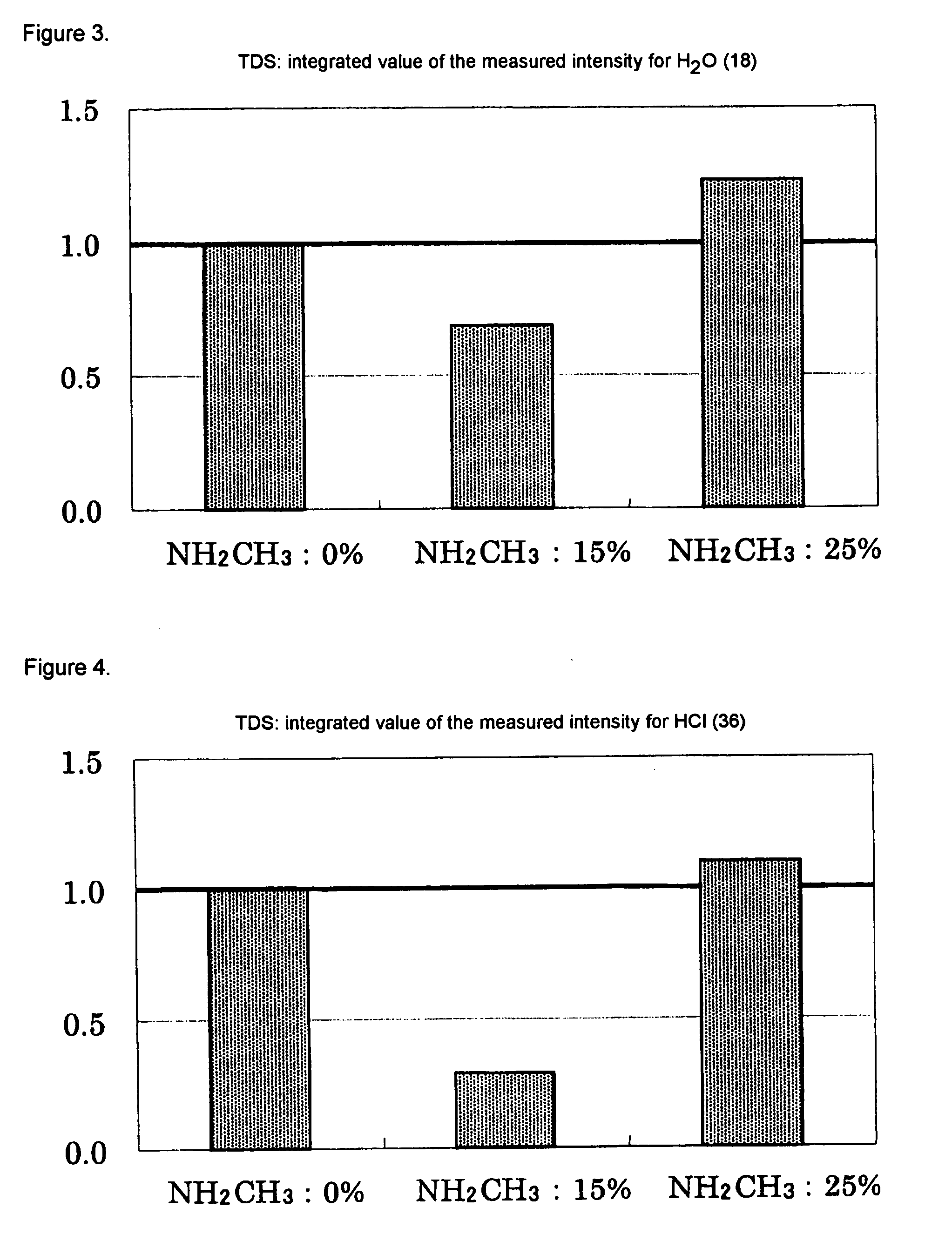

Method for producing silicon nitride films and process for fabricating semiconductor devices using said method

InactiveUS20050158983A1Reduction in thermal budgetImprove film propertiesSemiconductor/solid-state device manufacturingChemical vapor deposition coatingNitrogen sourceAmmonia

Silicon nitride film is formed on a silicon wafer mounted in a boat in an LPCVD tool by feeding a silicon source (SiH2Cl2, SiCl4, Si2Cl6, etc.) from an injector and feeding a mixed gas of monomethylamine (CH3NH2) and ammonia (NH3) as the nitrogen source from an injector. This addition of monomethylamine to the source substances for film production makes it possible to provide an improved film quality and improved leakage characteristics even at low temperatures (450-600° C.).

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

3D silicon-silicon die stack structure and method for fine pitch interconnection and vertical heat transport

InactiveUS8048794B2Improve integrityRaise transfer toSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsDielectricElectrical conductor

A method of fabricating a thin wafer die includes creating circuits and front-end-of-line wiring on a silicon wafer, drilling holes in a topside of the wafer, depositing an insulator on the drilled holes surface to provide a dielectric insulator, removing any excess surface deposition from the surface, putting a metal fill into the holes to form through-silicon-vias (TSV), creating back-end-of-line wiring and pads on the top surface for interconnection, thinning down the wafer to expose the insulator in from the TSVs to adapt the TSVs to be contacted from a backside of the wafer, depositing an insulating layer which contacts the TSV dielectric, thinning down the backside of the wafer, opening through the dielectric to expose the conductor of the TSV to provide a dielectric insulation about exposed backside silicon, and depositing ball limiting metallurgy pads and solder bumps on the backside of the wafer to form an integrated circuit.

Owner:GLOBALFOUNDRIES INC

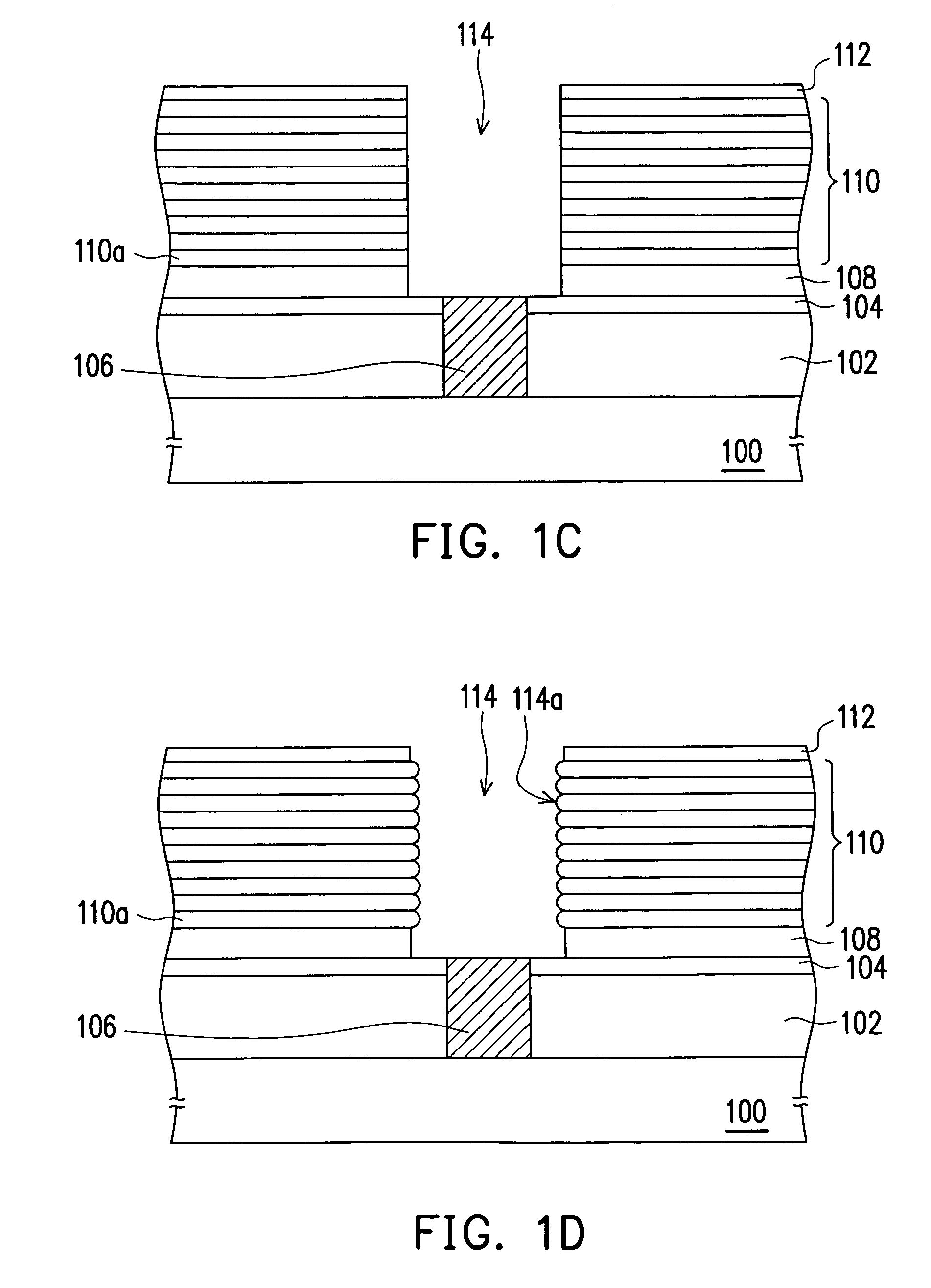

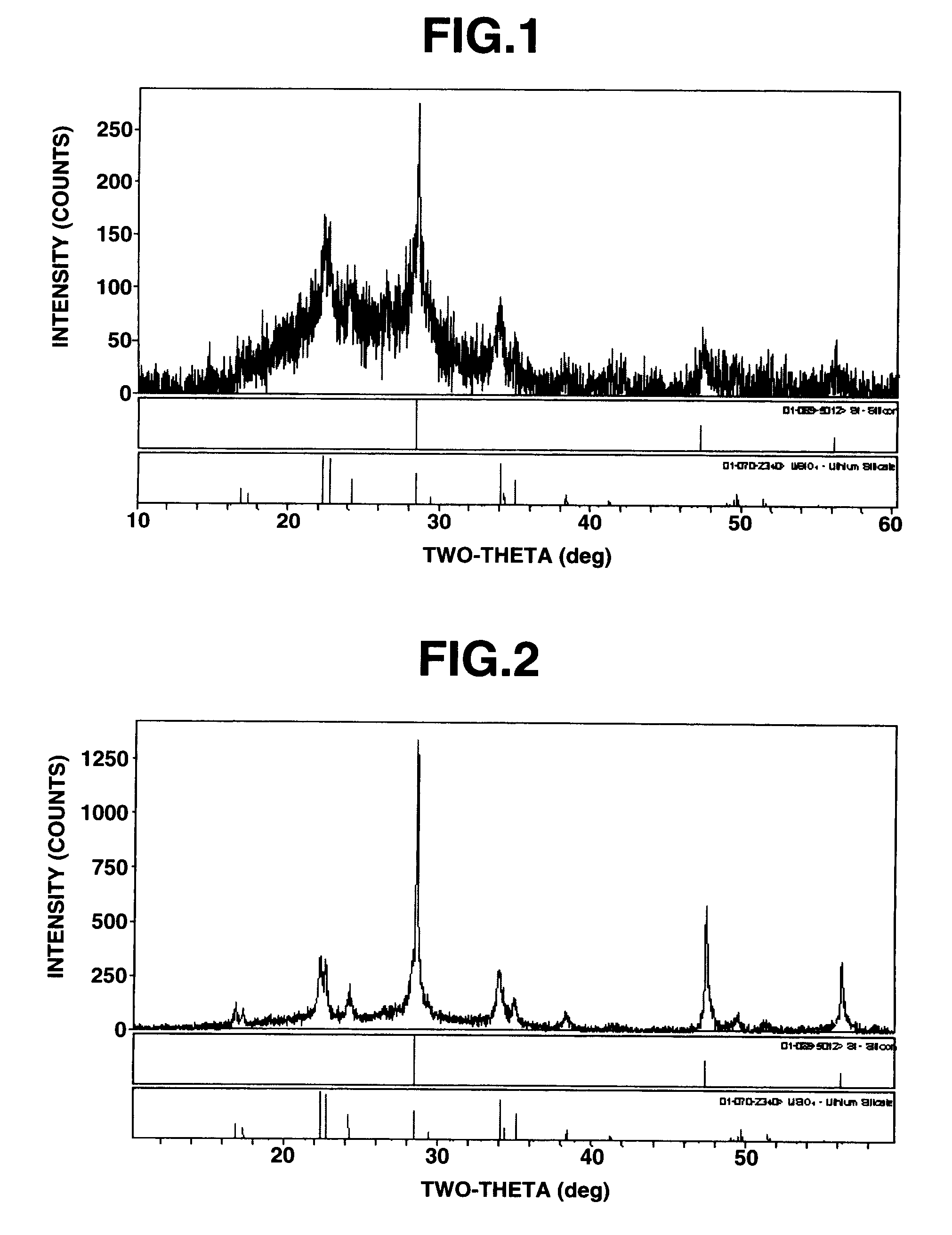

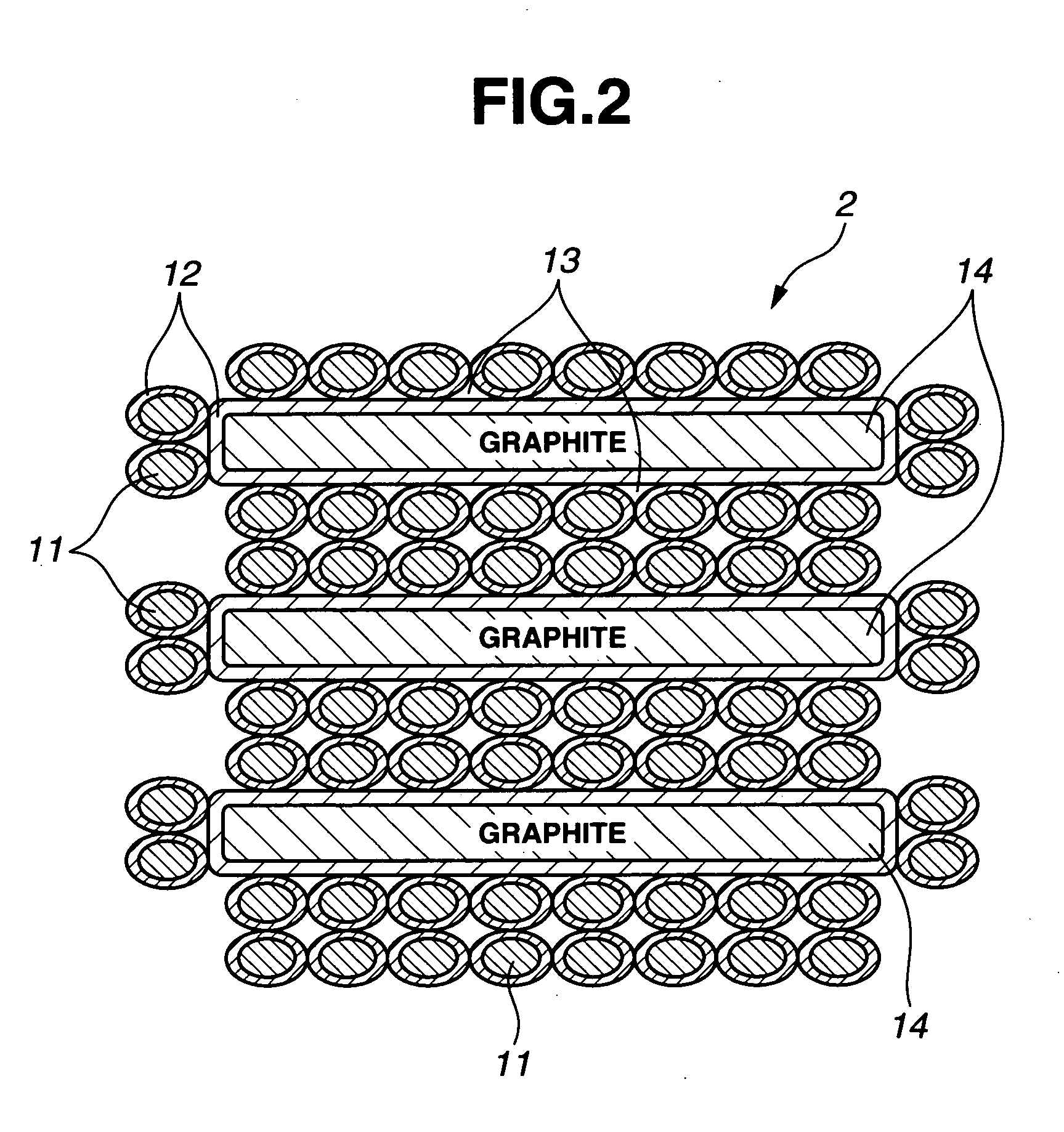

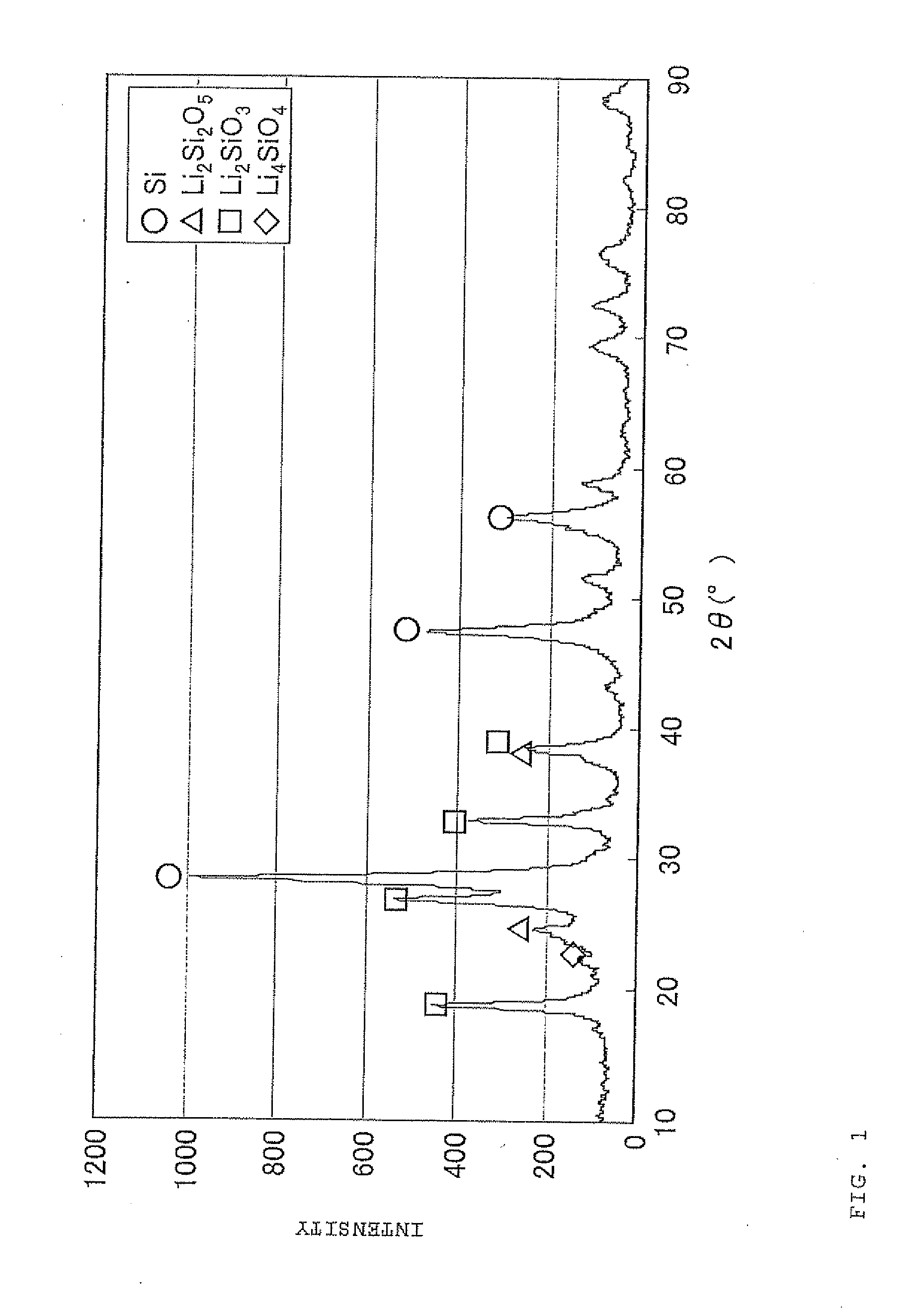

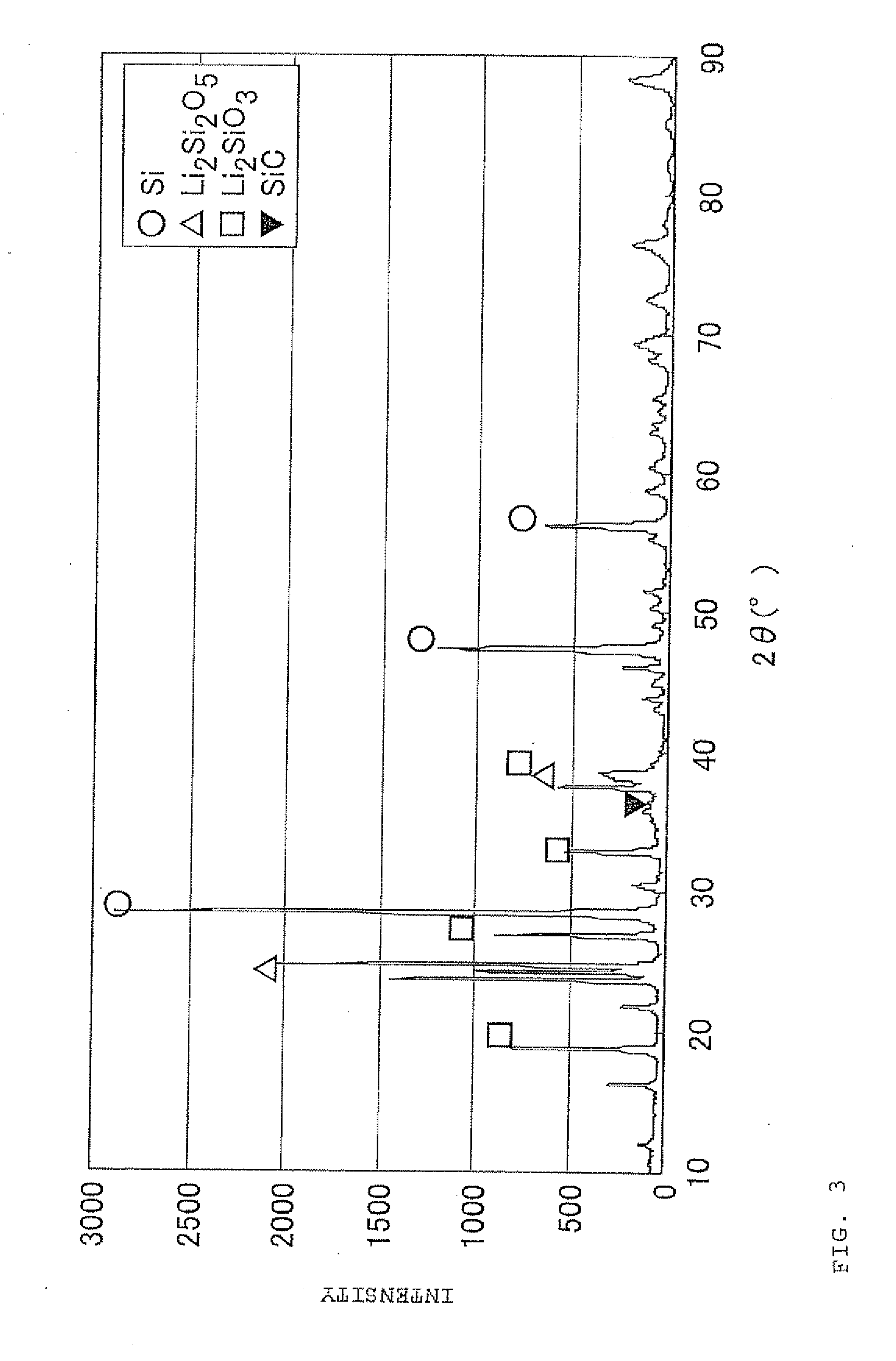

Negative electrode material for secondary battery with non-aqueous electrolyte, method for manufacturing negative electrode material for secondary battery with non-aqueous electrolyte, and lithium ion secondary battery

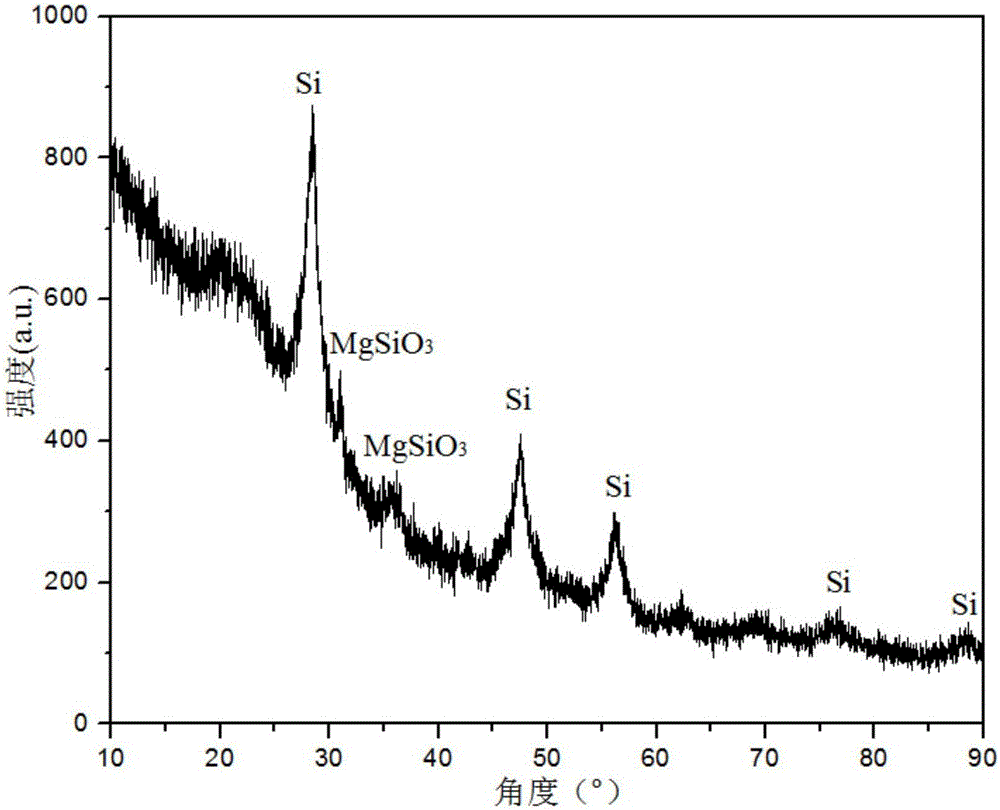

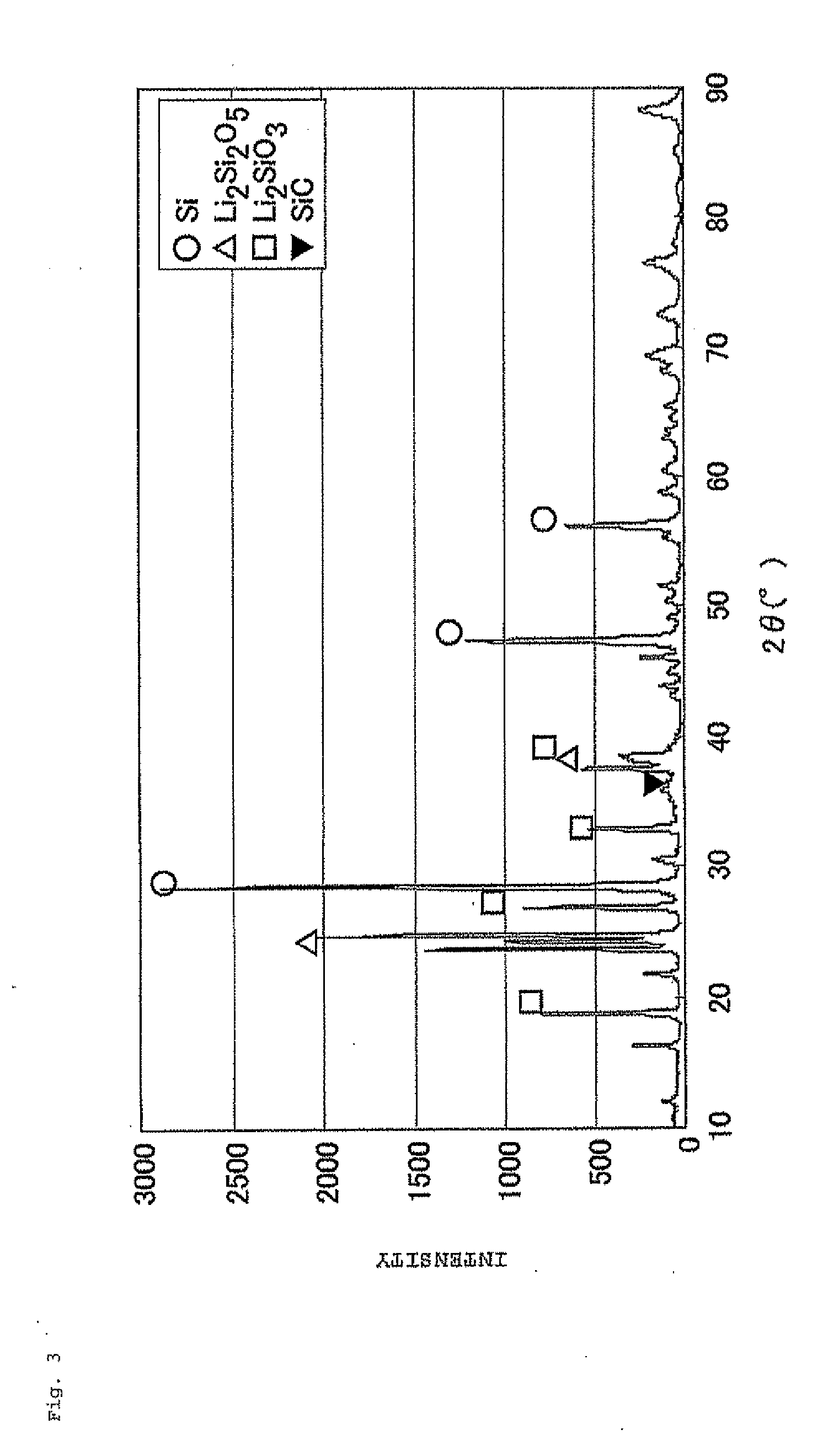

ActiveUS20110244334A1Large capacityHigh cycle durabilityFinal product manufactureLi-accumulatorsCarbon coatingX-ray

The present invention is a negative electrode material for a secondary battery with a non-aqueous electrolyte comprising at least a silicon-silicon oxide composite and a carbon coating formed on a surface of the silicon-silicon oxide composite, wherein at least the silicon-silicon oxide composite is doped with lithium, and a ratio I(SiC) / I(Si) of a peak intensity I(SiC) attributable to SiC of 2θ=35.8±0.2° to a peak intensity I(Si) attributable to Si of 2θ=28.4±0.2° satisfies a relation of I(SiC) / I(Si)≦0.03, when x-ray diffraction using Cu—Kα ray. As a result, there is provided a negative electrode material for a secondary battery with a non-aqueous electrolyte that is superior in first efficiency and cycle durability to a conventional negative electrode material.

Owner:SHIN ETSU CHEM IND CO LTD

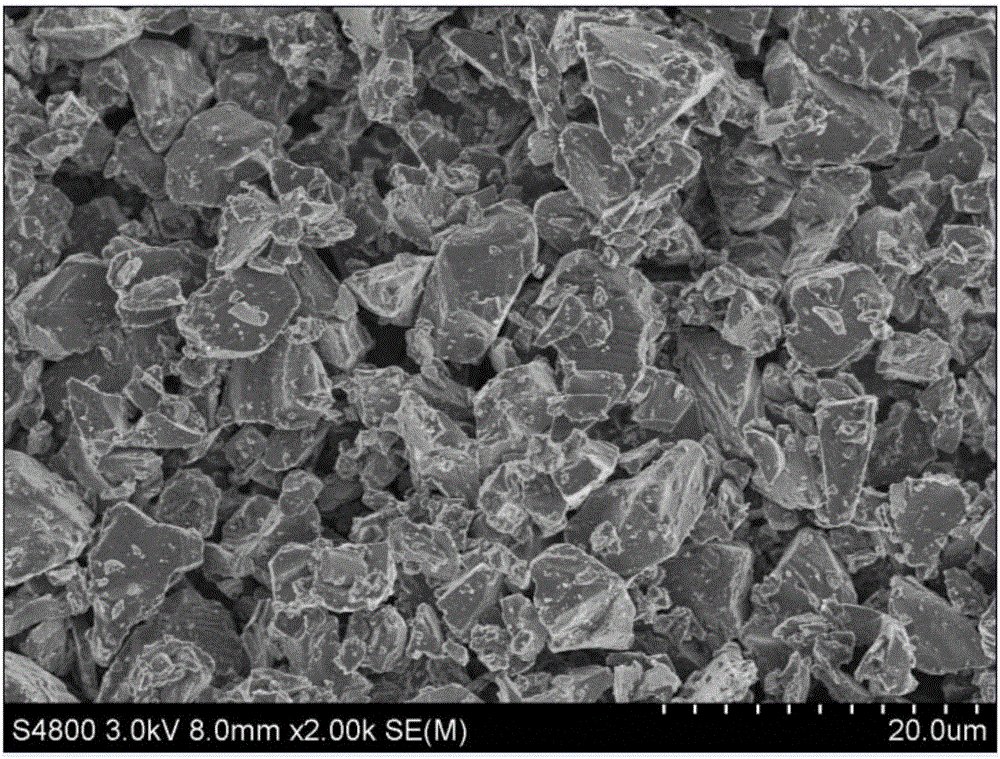

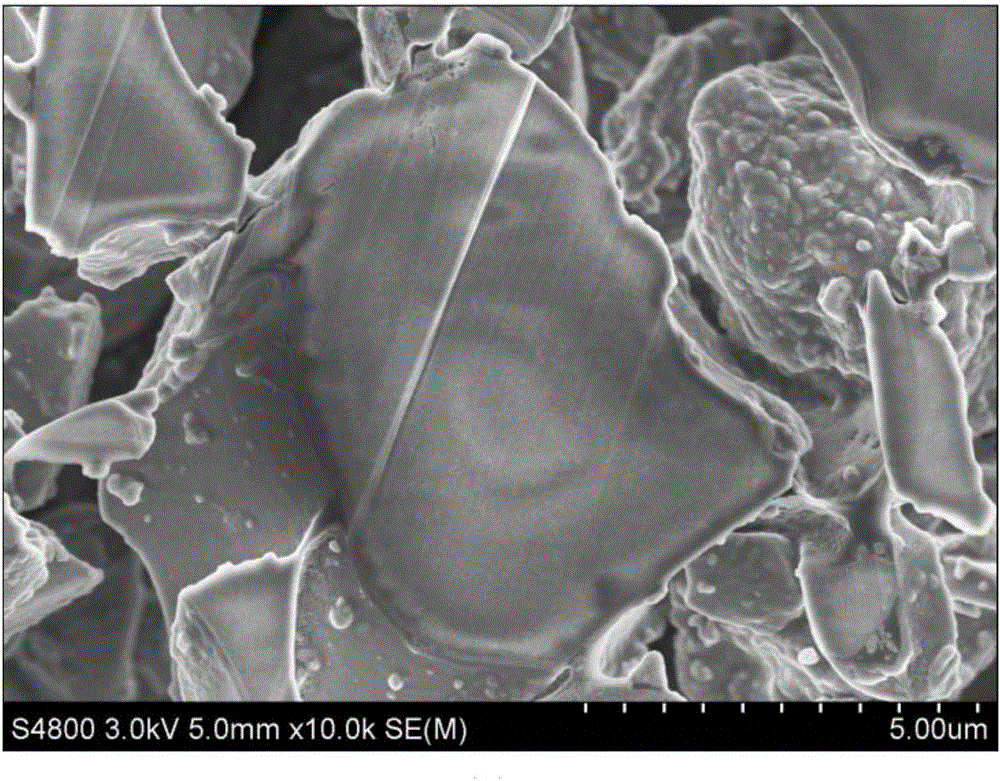

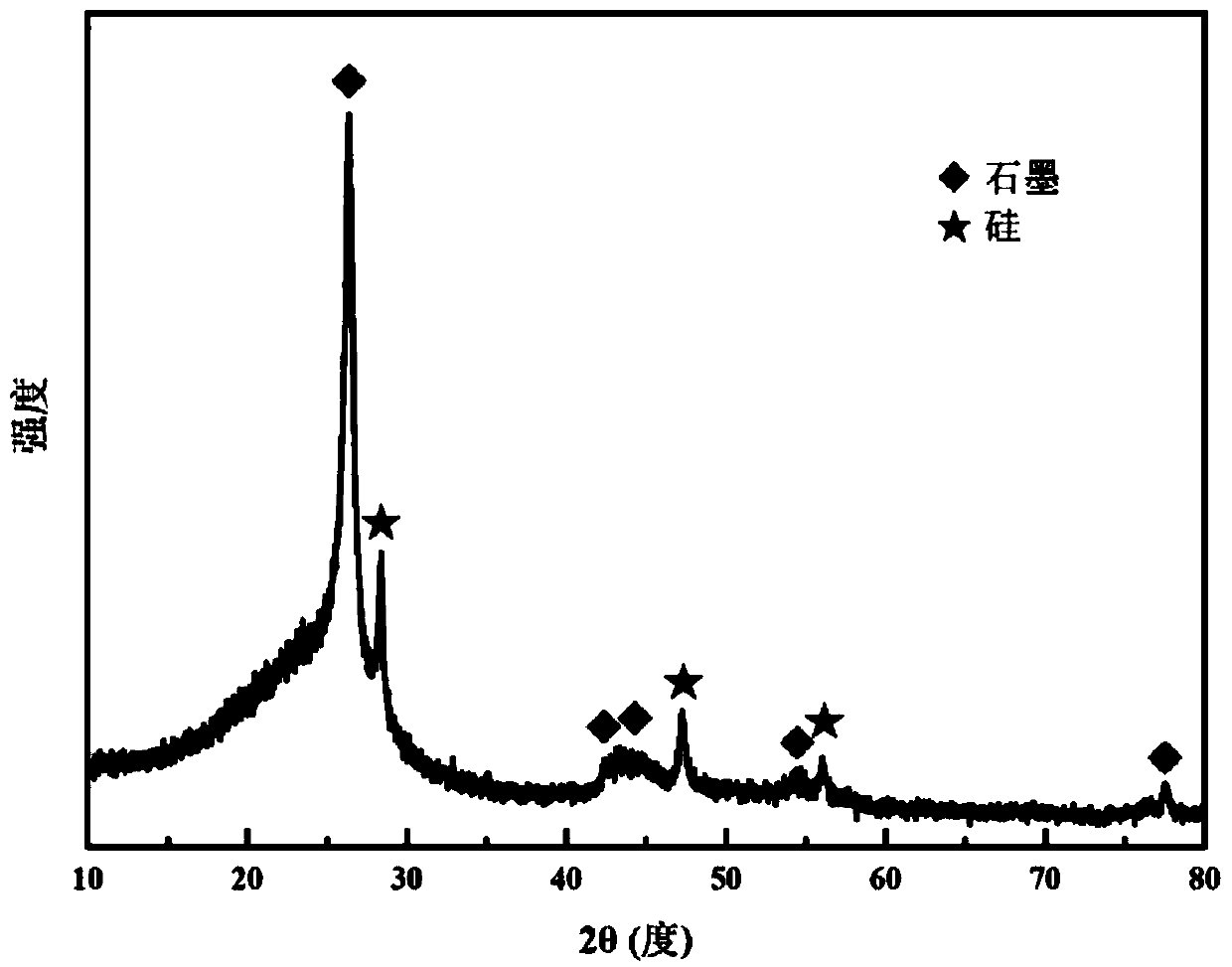

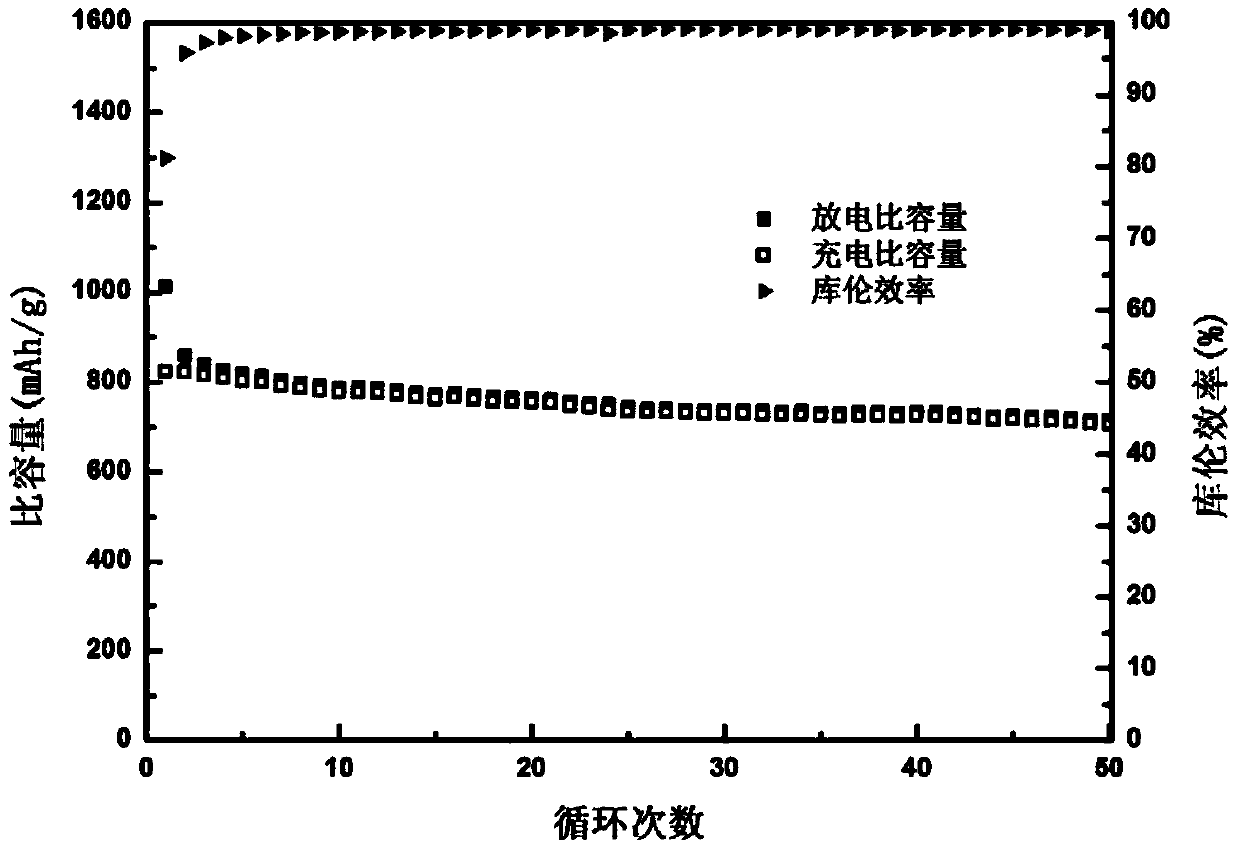

Preparation method of silicon-silicon oxide-carbon composite negative pole material of lithium ion battery

ActiveCN103730644AIncrease capacityImprove cycle lifeElectrode manufacturing processesSecondary cellsCarbon compositesSilicon oxide

The invention discloses a preparation method of a silicon-silicon oxide-carbon composite negative pole material of a lithium ion battery. Silicon oxide, silicon and graphite are mixed via ball milling, and then are blended with bitumen to form a mixture, and the mixture is subjected to high-temperature heat treatment so as to obtain the silicon-silicon oxide-carbon composite negative pole material of the lithium ion battery. According to the preparation method, the silicon is added to a silicon oxide-carbon material, can improve the reversible capacity and the initial Coulomb efficiency of the silicon oxide-carbon material, and enables a silicon oxide composite material to have excellent properties such as high capacity, better circulation performance and higher initial Coulomb efficiency. The preparation method has such advantages as low cost, simple equipment, simple and easily controlled technology condition and high yield, and is very suitable for mass industrial production.

Owner:TIANJIN B&M SCI & TECH

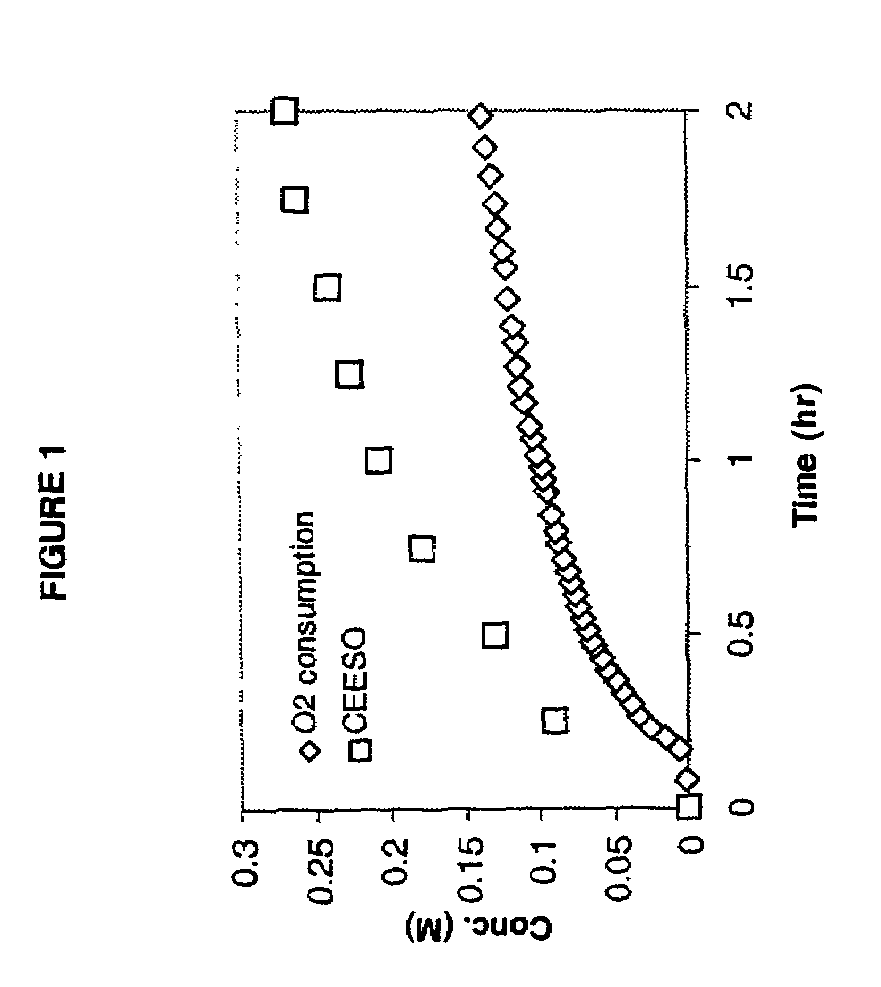

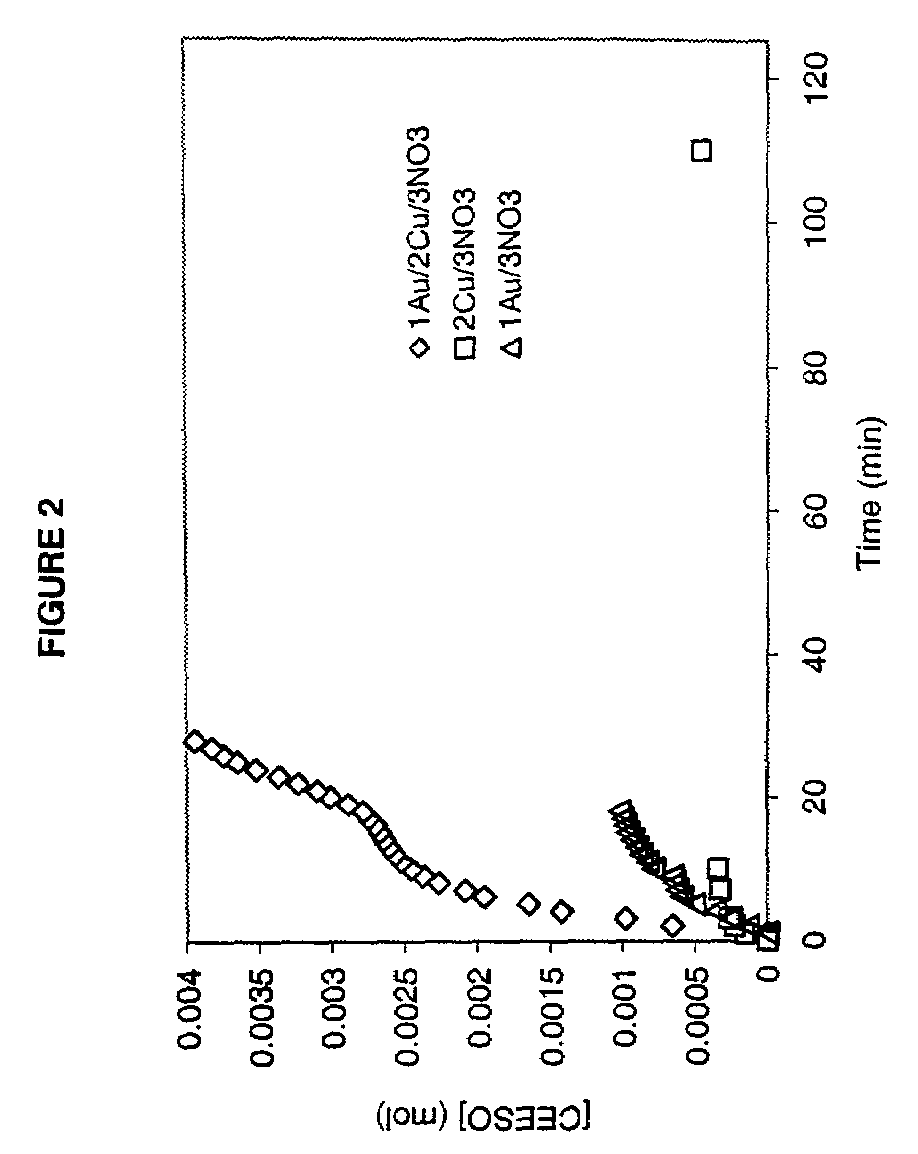

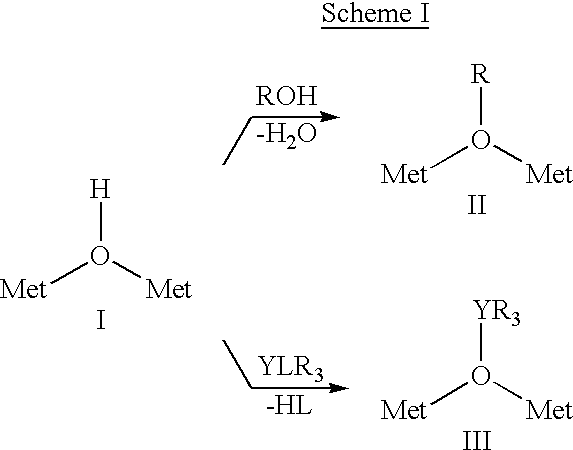

Polyoxometalate materials, metal-containing materials, and methods of use thereof

Polyoxometalate topical compositions for removing contaminants from an environment and methods of use thereof are disclosed. An embodiment of the polyoxometalate topical composition includes a topical carrier and at least one polyoxometalate, with the proviso that the polyoxometalate is not H5PV2Mo10O40; K5Si(H2O)MnIIIW11O39; K4Si(H2O)MnIVW11O39; or K5CoIIIW12O40. Another embodiment relates to a method for removing a contaminant from an environment, including contacting the polyoxometalate topical composition with the environment containing the contaminant for a sufficient time to remove the contaminant from the environment. An additional embodiment relates to a modified material for removing a contaminant from an environment, wherein the modified material includes (1) a material comprising a topical carrier, a powder, a coating, or a fabric, and (2) a metal compound including a transition metal compound, an actinide compound, a lanthanide compound, or a combination thereof, wherein the metal compound is not a polyoxometalate.

Owner:EMORY UNIVERSITY

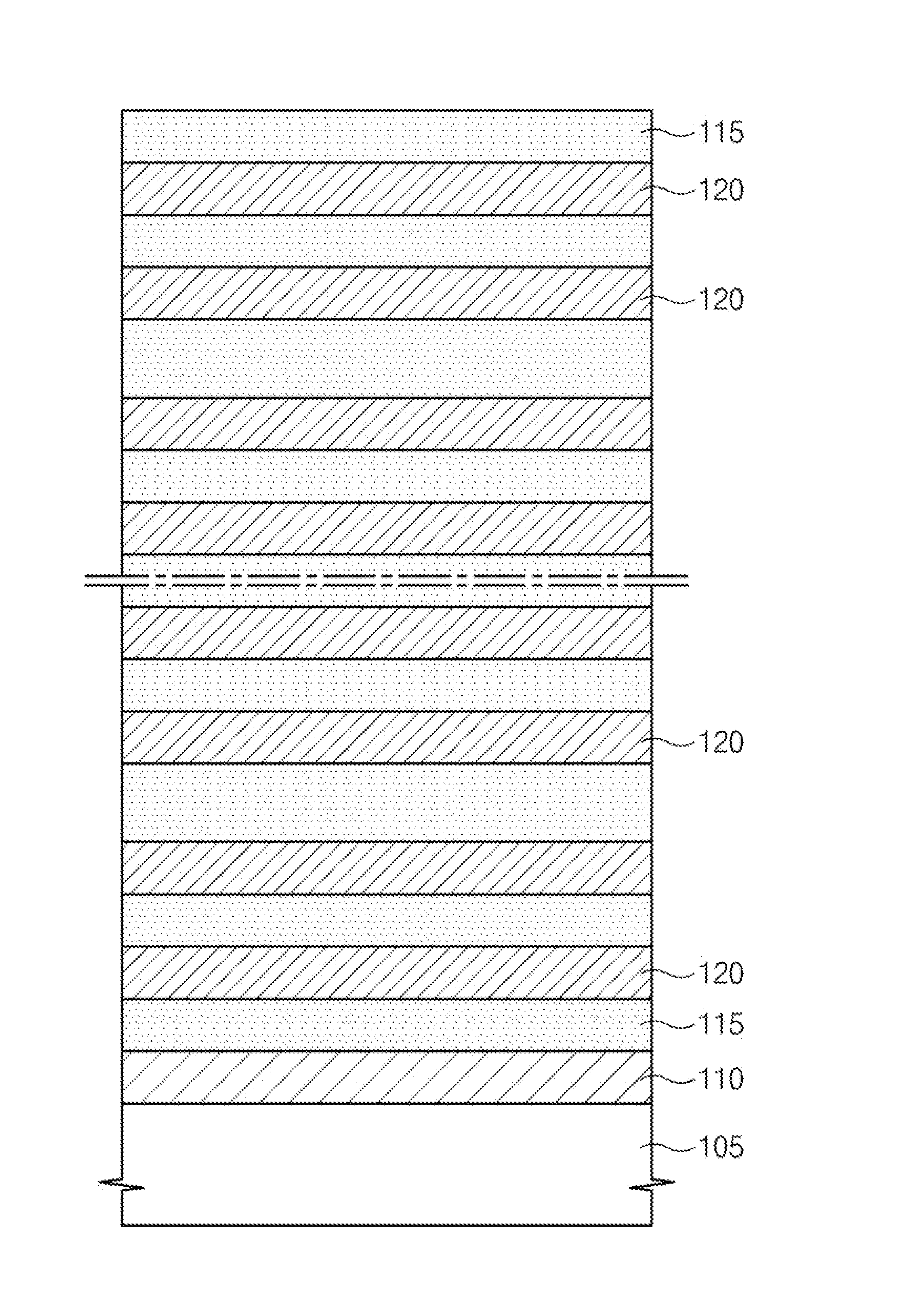

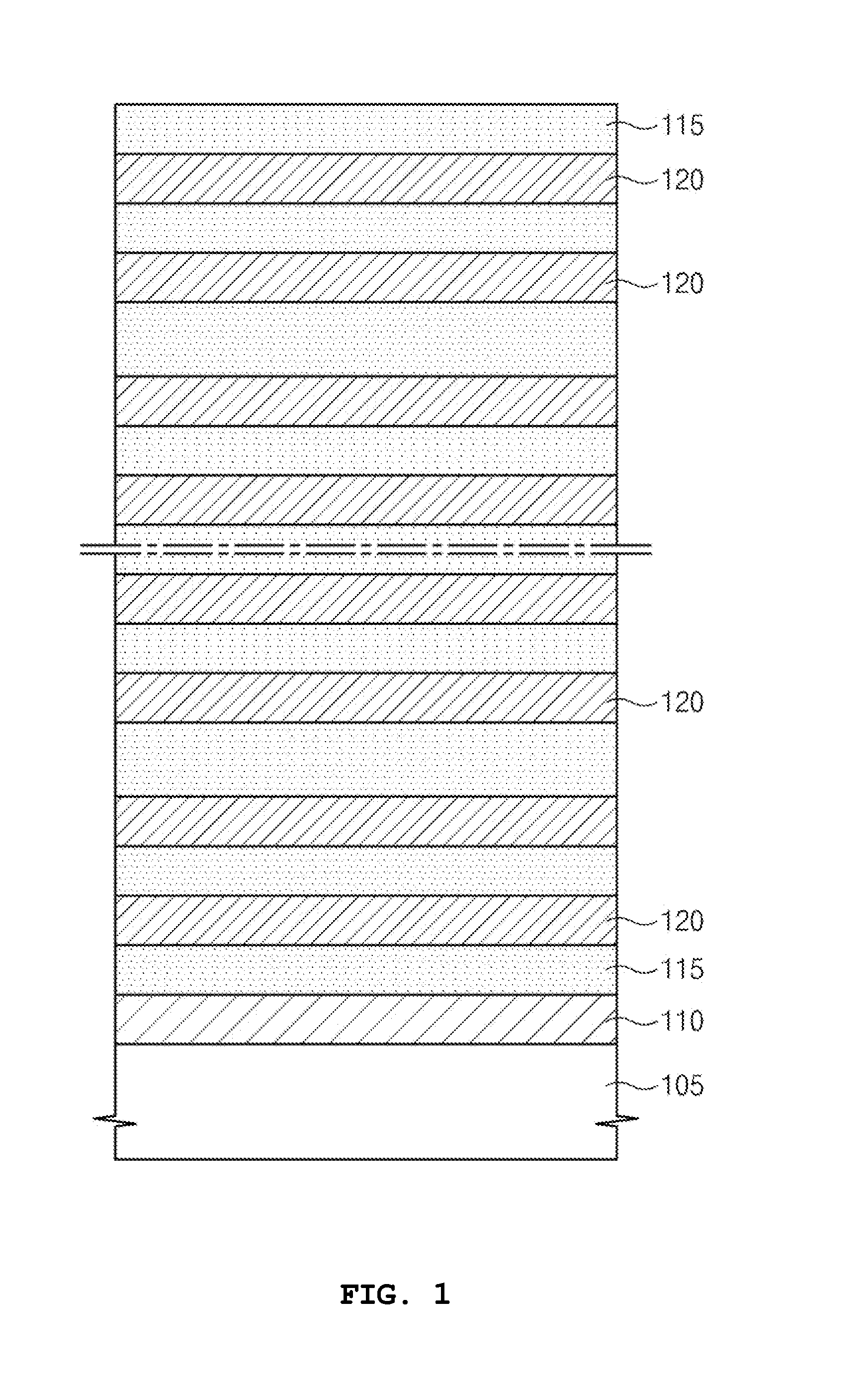

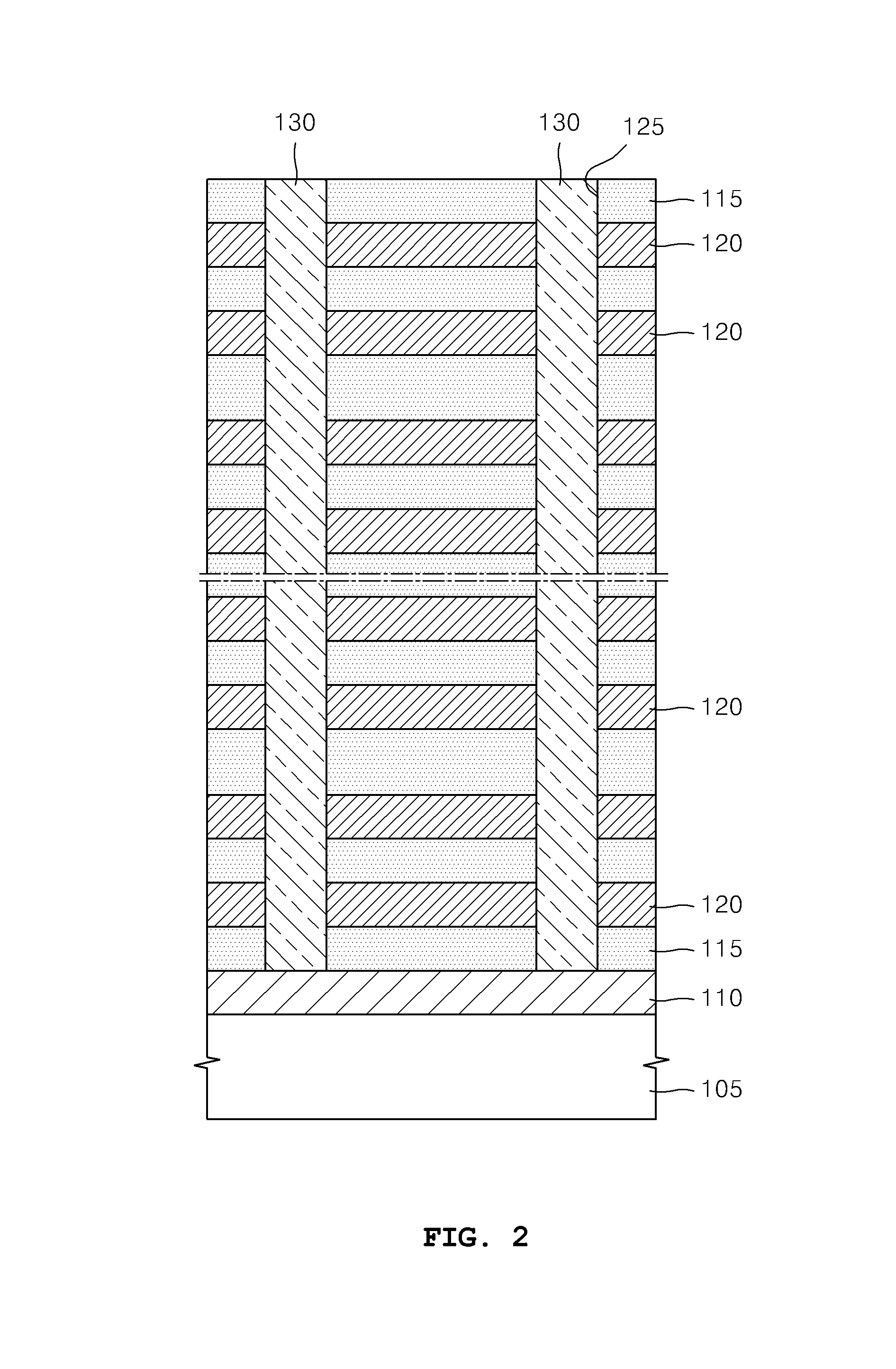

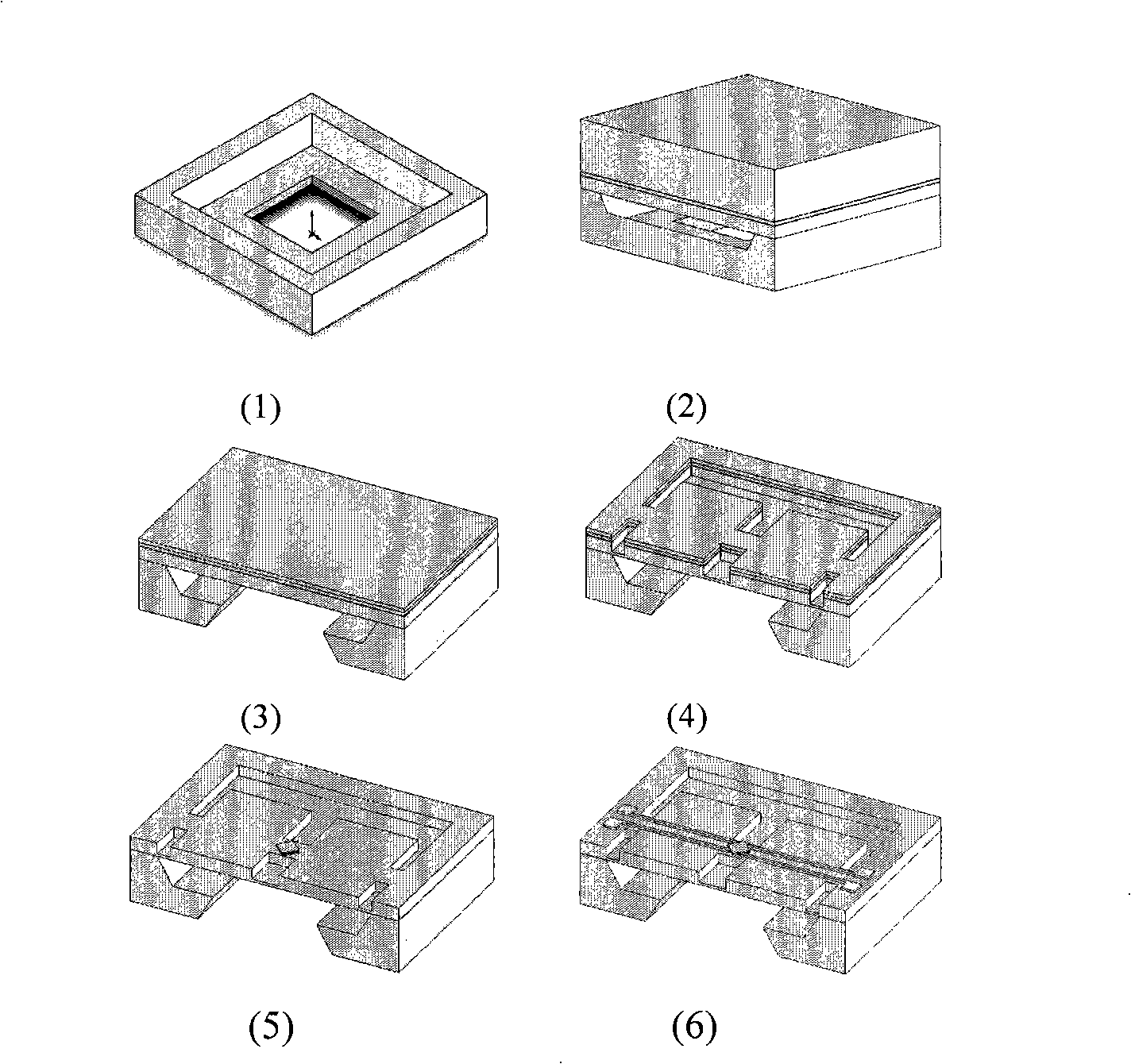

Method and apparatus for manufacturing three-dimensional-structure memory device

ActiveUS20130171827A1Lower the volumeAvoid deformationSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerSilicon monoxide

A method for manufacturing a memory device having a vertical structure according to one embodiment of the present invention comprises: a step for alternatingly laminating one or more insulation layers and one or more sacrificial layers on a substrate; a step for forming a penetration hole for penetrating the insulation layer and the sacrificial layer; a step for forming a pattern for filling up the penetration hole; a step for forming an opening for penetrating the insulation layer and the sacrificial layer; and a step for removing the sacrificial layer by supplying an etchant through the opening, wherein the step for laminating the insulation layer includes a step for depositing a first silicon oxide film by supplying to the substrate at least one gas selected from the group consisting of SiH4, Si2H6, Si3H8, Si4H10, and the step for laminating the sacrificial layer includes a step for depositing a second silicon oxide film by supplying dichlorosilane (SiCl2H2) to the substrate.

Owner:EUGENE TECH CO LTD

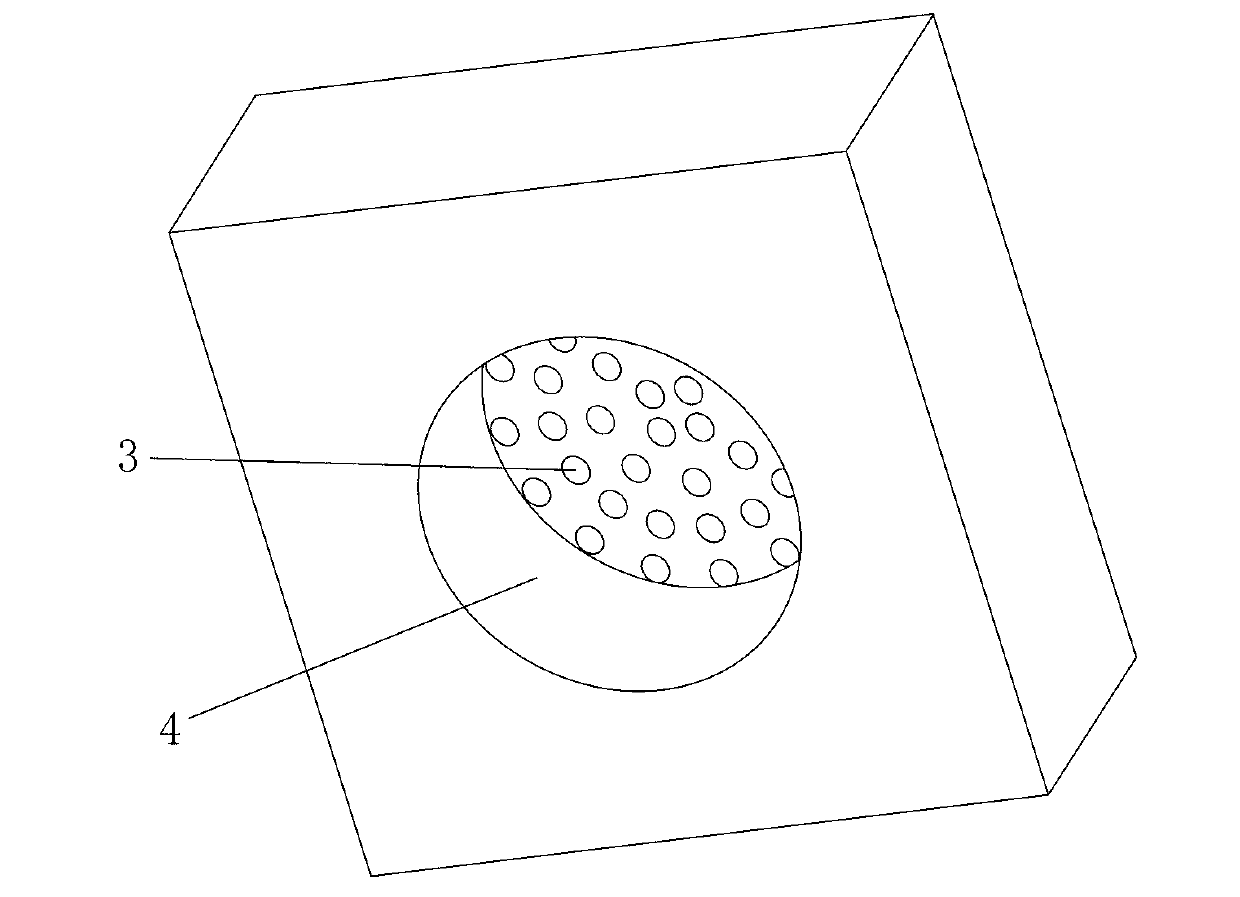

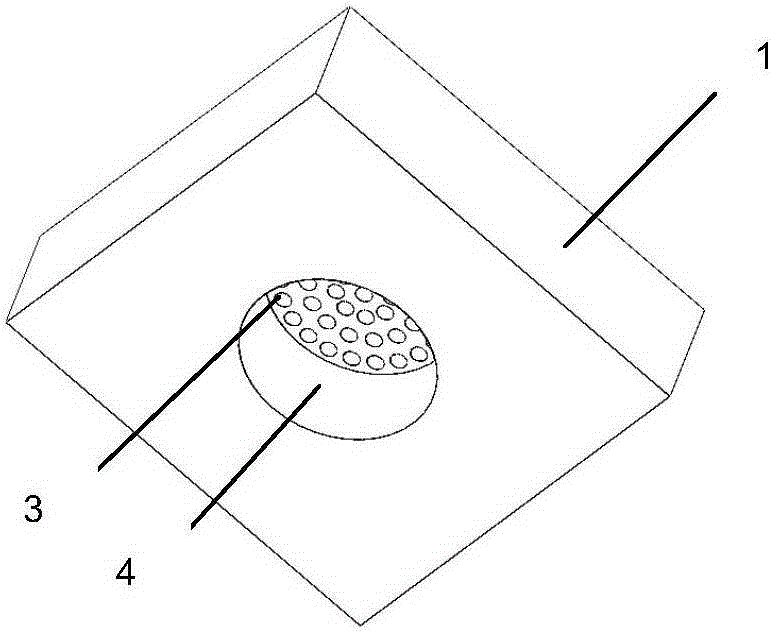

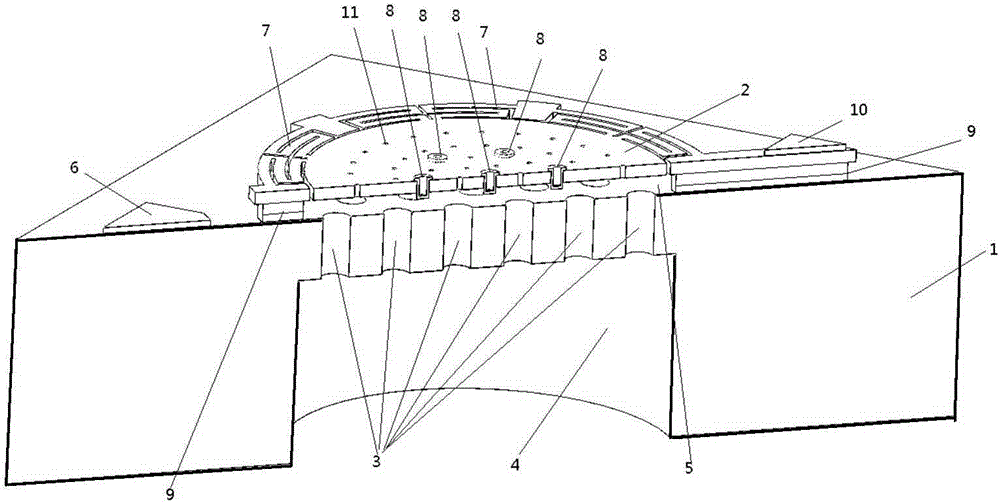

Micro mechanical capacitance type acceleration transducer, and fabricating method

A method for preparing acceleration transducer of micromechanical capacity type includes forming rectangular mass block with no lobe compensation on single crystal silicon pellet by utilizing aeolotropic corrosion technique based on elastic beams being alternatively distributed at top and bottom surfaces of active mass block, forming straight elastic beam at two said surfaces of mass block, applying silicon-silicon bond technique to realize bond of three-layers silicon pellet, depositing lead wire pad of top electrode and active electrode and realizing electric signal isolation between two said electrodes.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

MEMS pressure sensor and manufacturing method thereof

InactiveCN101738280AHigh bonding strengthLow costTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesElectrical resistance and conductanceMems pressure sensor

The invention discloses an MEMS pressure sensor and a manufacturing method thereof. The MEMS pressure sensor comprises an MEMS pressure sensing chip, wherein the MEMS pressure sensing chip is arranged at a Wheatstone bridge formed on the crystallographic orientation of a monocrystalline silicon film (110) by four polycrystalline silicon resistors, the monocrystalline silicon film comprises a lower silicon wafer, an upper silicon wafer and a purification layer, a cavity body is arranged on the lower silicon wafer, the lower silicon wafer and the upper silicon wafer are bonded together by hot melt silicon-silicon, the surface of the upper silicon wafer is provided with a passivation layer, the polycrystalline silicon resistors are arranged on the upper silicon wafer by a diffusion process, and a conducting wire of a metal film and a press welding block are etched on the upper silicon wafer. The pressure sensor adopting a silicon-silicon bonding structure can be made in a very small size, the number of chips on each silicon wafer can be increased by 50% or more, the silicon-silicon bonding strength is higher, and the air tightness is better. The cost of the sensor is greatly lowered, and the performance is more stable and reliable. The sensor belongs to a pressure sensor with low cost and high performance and has very extensive application.

Owner:HENAN POLYTECHNIC UNIV

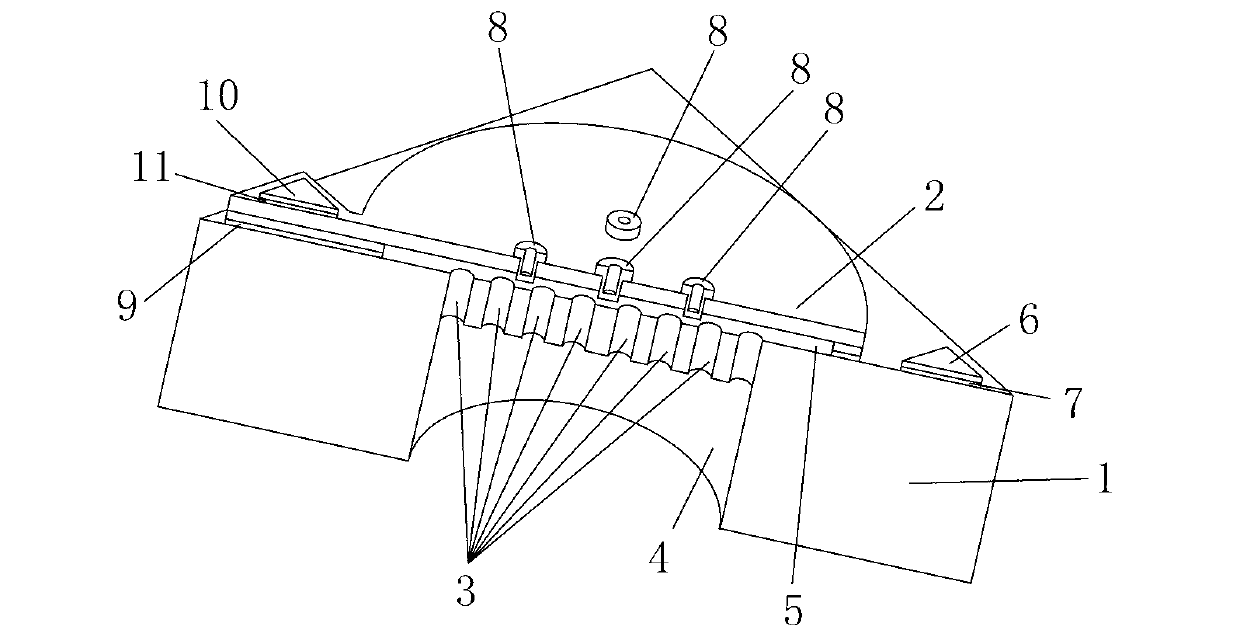

Micro-electromechanical system (MEMS) silicon microphone utilizing multi-hole signal operation instruction (SOI) silicon bonding and manufacturing method thereof

ActiveCN103139691AImprove conductivityImprove consistencyElectrostatic transducer microphonesCapacitanceBonding process

The invention provides a micro-electromechanical system (MEMS) silicon microphone utilizing multi-hole signal operation instruction (SOI) silicon bonding and a manufacturing method thereof. The MEMS silicon microphone comprises a multi-hole back pole plate silicon substrate and a single crystal silicon vibrating diaphragm placed above the multi-hole back plate silicon substrate. The MEMS silicon microphone is characterized in that the multi-hole back plate silicon substrate and the single crystal silicon vibrating diaphragm serve as two pole plates of a microphone capacitor and are integrated in a bonding mode through a silicon bonding process. The multi-hole back pole plate silicon substrate is provided with a back pole plate metal electrode, a sound aperture and a back cavity, the single crystal silicon vibrating diaphragm is provided with a metal electrode and a small protruded column, and the vibrating diaphragm electrode and the back pole plate respectively serve as output signal leading-out ends of two pole plates of the microphone capacitor to be used for being in electric connection with a complementary metal oxide semiconductor (CMOS) signal amplifying circuit. The single crystal silicon vibrating diaphragm is supported by a silicon oxide layer to be suspended above the multi-hole back plate silicon substrate, and an air gap exists between the single crystal silicon vibrating diaphragm and the multi-hole back plate silicon substrate, and the multi-hole back plate silicon substrate, the single crystal silicon vibrating diaphragm and the air gap form a capacitance structure. The MEMS silicon microphone utilizing multi-hole SOI silicon bonding and the manufacturing method thereof are simple in process, high in product sensitivity, good in consistency and high in yield rate.

Owner:华景科技无锡有限公司

Capacitive type micro-acceleration sensor with double-sided symmetrical elastic beam structure and manufacturing method

ActiveCN102495234AImprove performanceHigh sensitivityDecorative surface effectsAcceleration measurementEtchingBlock structure

The invention relates to a capacitive type micro-acceleration sensor with a double-sided symmetrical elastic beam structure and a manufacturing method. The capacitive type micro-acceleration sensor is characterized in that: (1) an SOI silicon wafer of a double-device layer is a substrate with an elastic beam-mass block structure; (2) a fixed upper electrode and a fixed lower electrode are respectively located on the upper and lower sides of the mass block; (3) the elastic beam is a straight beam of which one end is connected with the mass block, and the other end is connected with a support frame; (4) overload protection salient points are formed on the upper and lower surfaces of the mass block; (5) damping regulation grooves are formed on the upper and lower surfaces of the mass block; and (6) an electrode leading through hole of the mass block is located above the support frame. By adopting the wet etching self-stop technology, the elastic beam-mass block structure which is the most important in the acceleration sensor is processed and formed once in the wet etching; and the bonding of three layers of silicon wafers is realized by a silicon-silicon direct bonding method, and the electrode leading through hole of the mass block is formed on the fixed upper electrode through infrared aligned photoetching. According to the invention, the cross-axis sensitivity is reduced while the device sensitivity is improved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

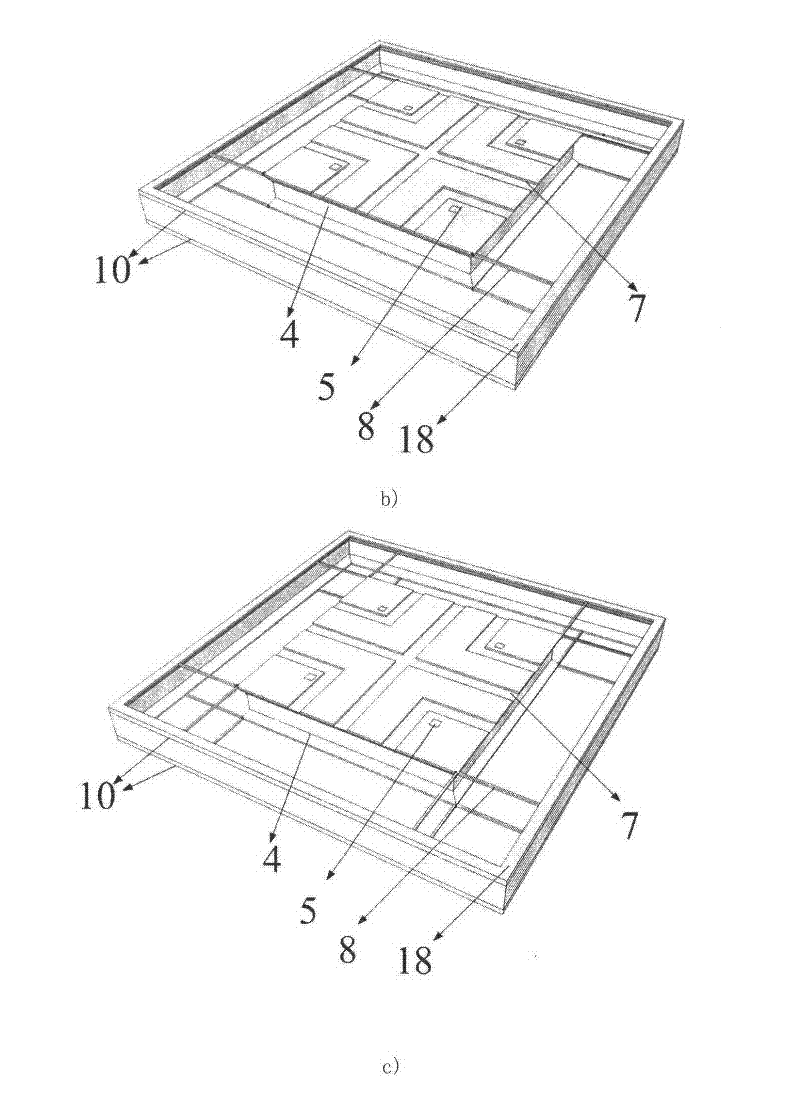

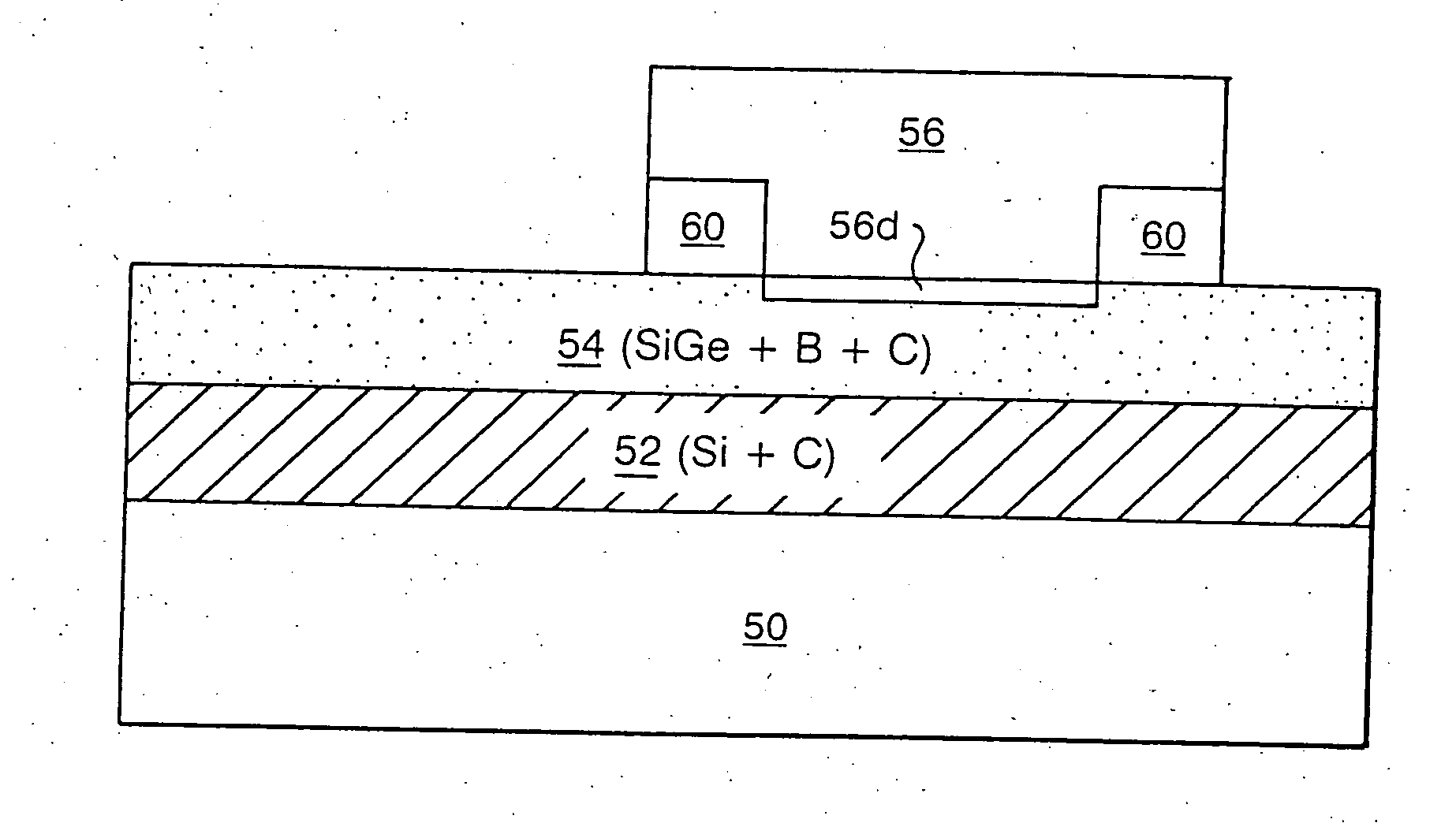

Incorporation of carbon in silicon/silicon germanium epitaxial layer to enhance yield for Si-Ge bipolar technology

InactiveUS20050054171A1Suppressed dislocationAvoid problemsSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringBoron

A SiGe bipolar transistor containing substantially no dislocation defects present between the emitter and collector region and a method of forming the same are provided. The SiGe bipolar transistor includes a collector region of a first conductivity type; a SiGe base region formed on a portion of said collector region; and an emitter region of said first conductivity type formed over a portion of said base region, wherein said collector region and said base region include carbon continuously therein. The SiGe base region is further doped with boron.

Owner:GLOBALFOUNDRIES US INC

MEMS silicon microphone and preparation method for the same

ActiveCN105721997AImprove consistencyStrong consistencyMicrophonesLoudspeakersCapacitanceEngineering

The invention relates to the silicon microphone technology field and particularly relates to an MEMS silicon microphone and a preparation method for the same. The method comprises steps of arranging a monocrystal silicon diaphragm above a silicon substrate of a porous back polar plate, performing separation by a silicon dioxide layer, bonding with the silicon substrate of the porous back pole plate through a silicon-silicon bonding method, and forming a capacitor structure of the microphone. Besides, the monocrystal silicon diaphragm is small in residual stress and good in uniformity, which can improve the sensitivity and yield of the MEMS silicon microphone; the diaphragm is provided with other structures like spring supports, projected columns, micro holes, etc, which can fast release the residual stress of the diaphragm, avoids the attraction possibility between the diaphragm and the porous back polar plate and further improves the yield and reliability of the microphone. As a result, the MEMS silicon microphone structure produced by the invention is simple in technology, high in sensitivity, good in uniformity and strong in reliability.

Owner:HUAJING SENSING TECH (WUXI) CO LTD

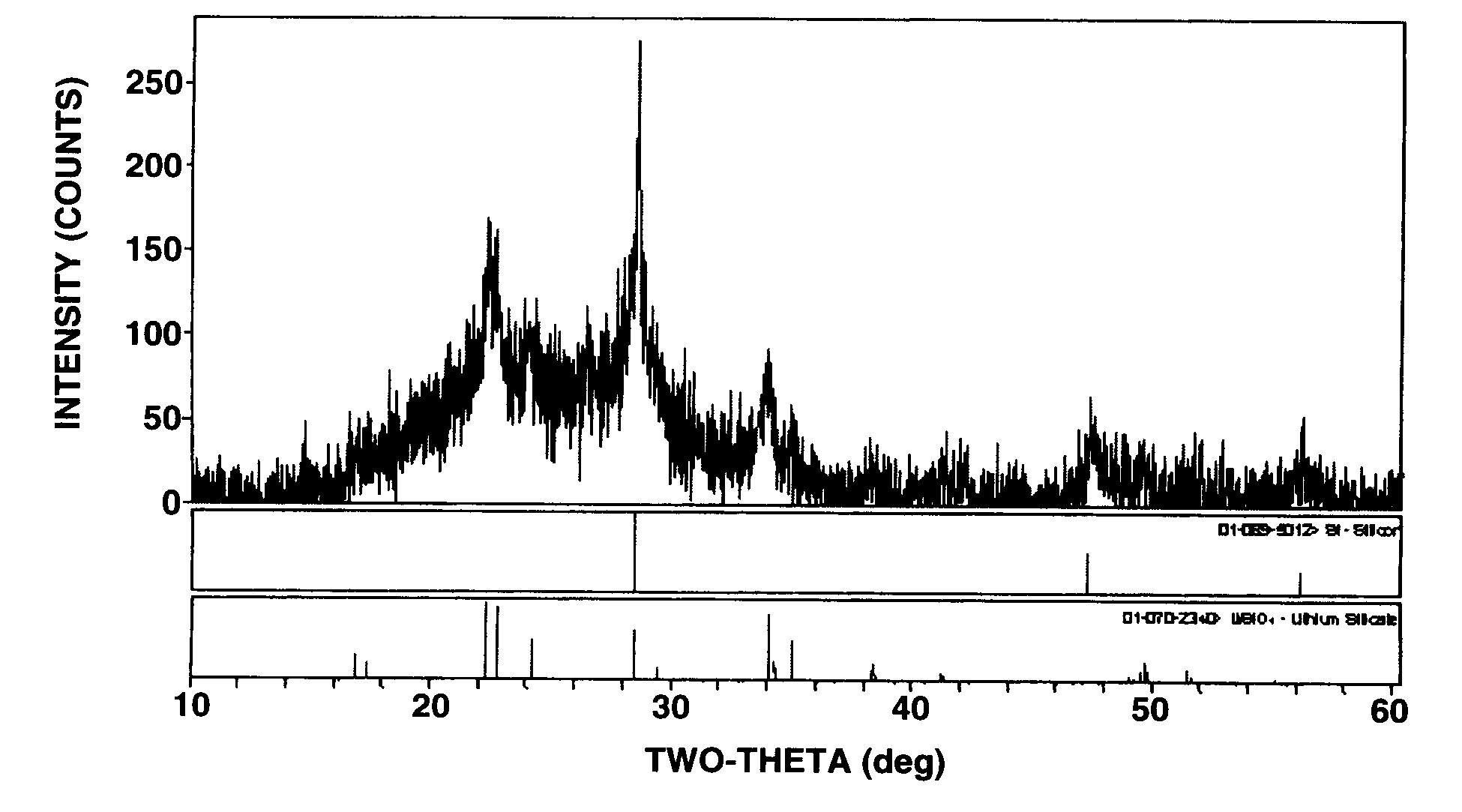

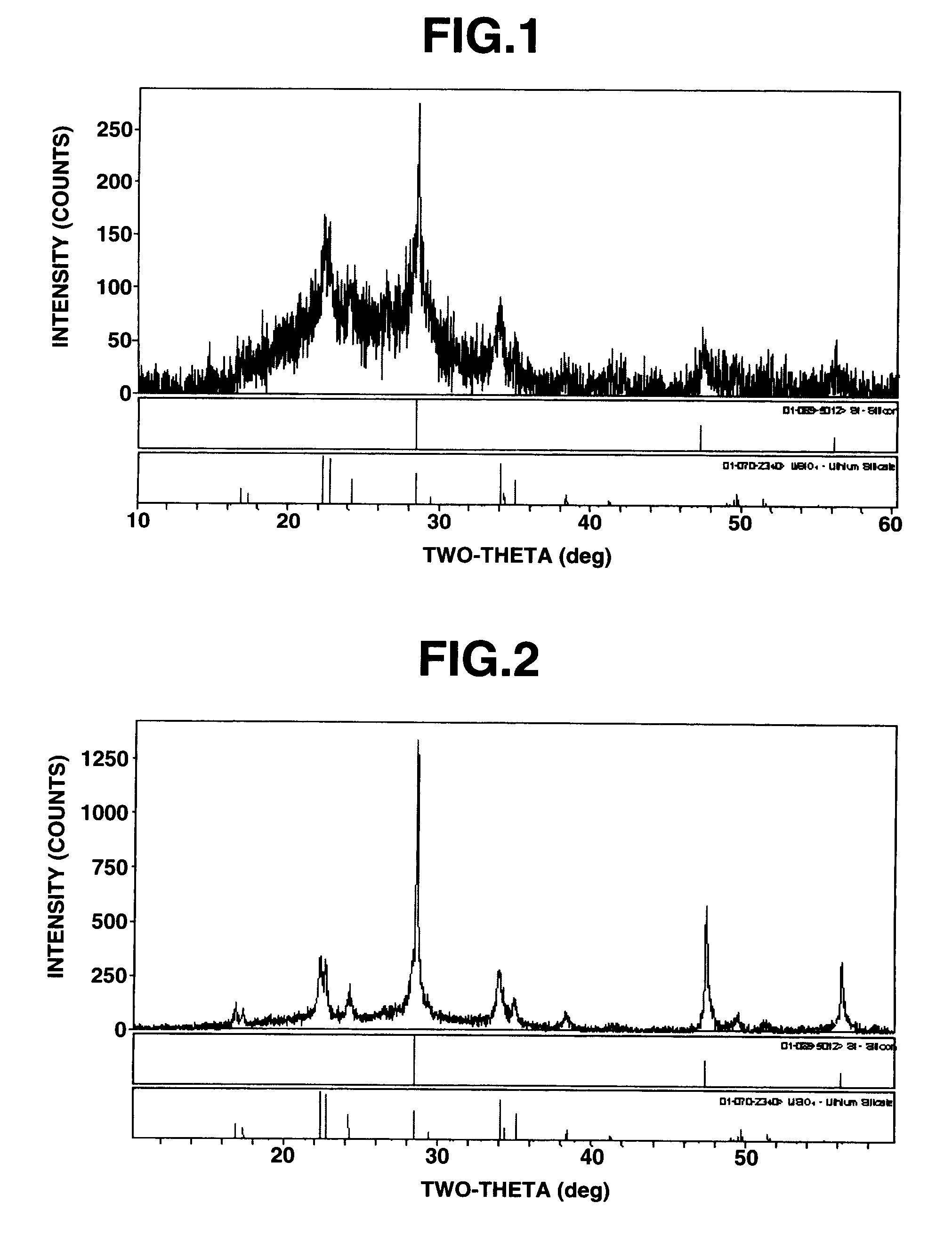

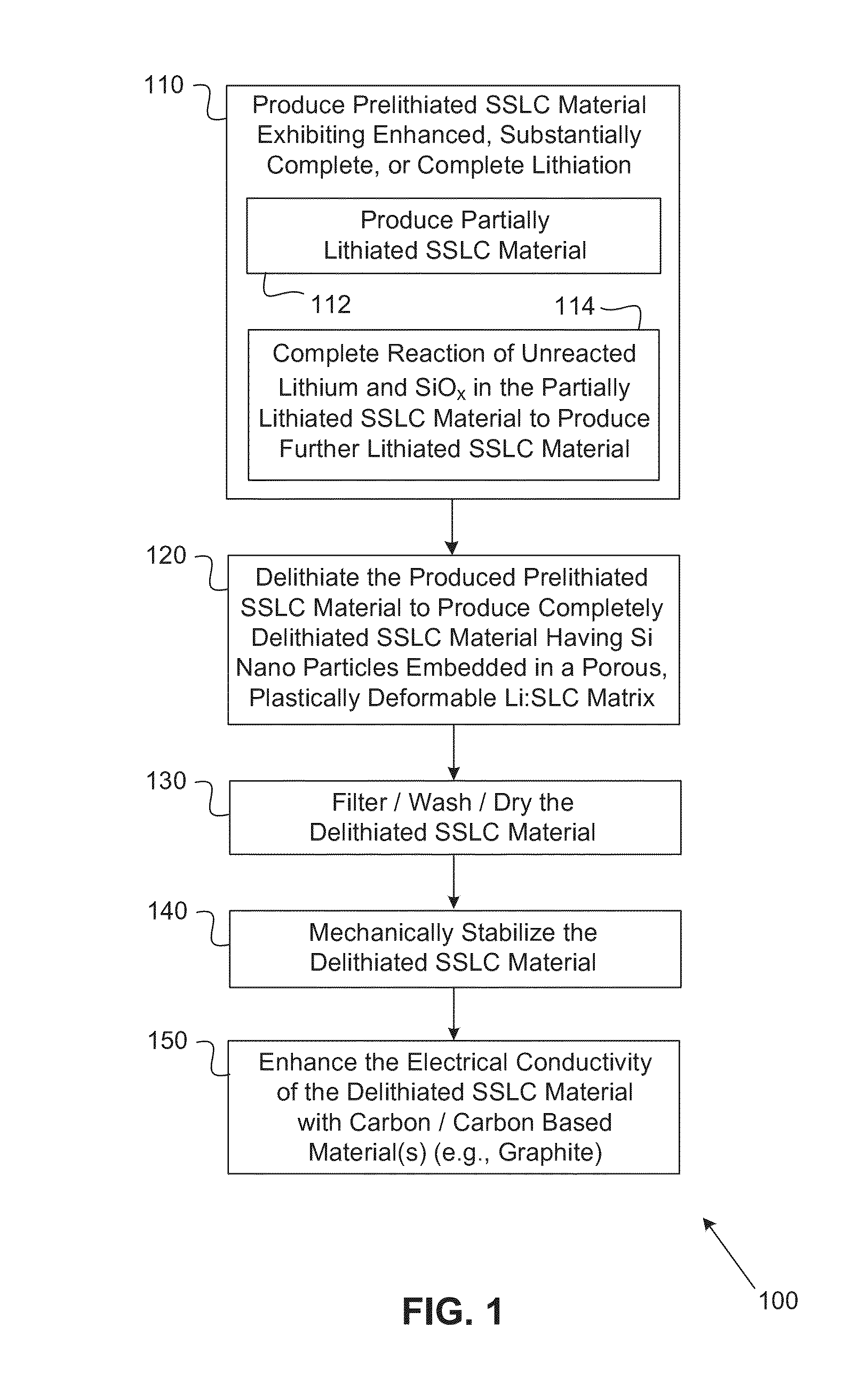

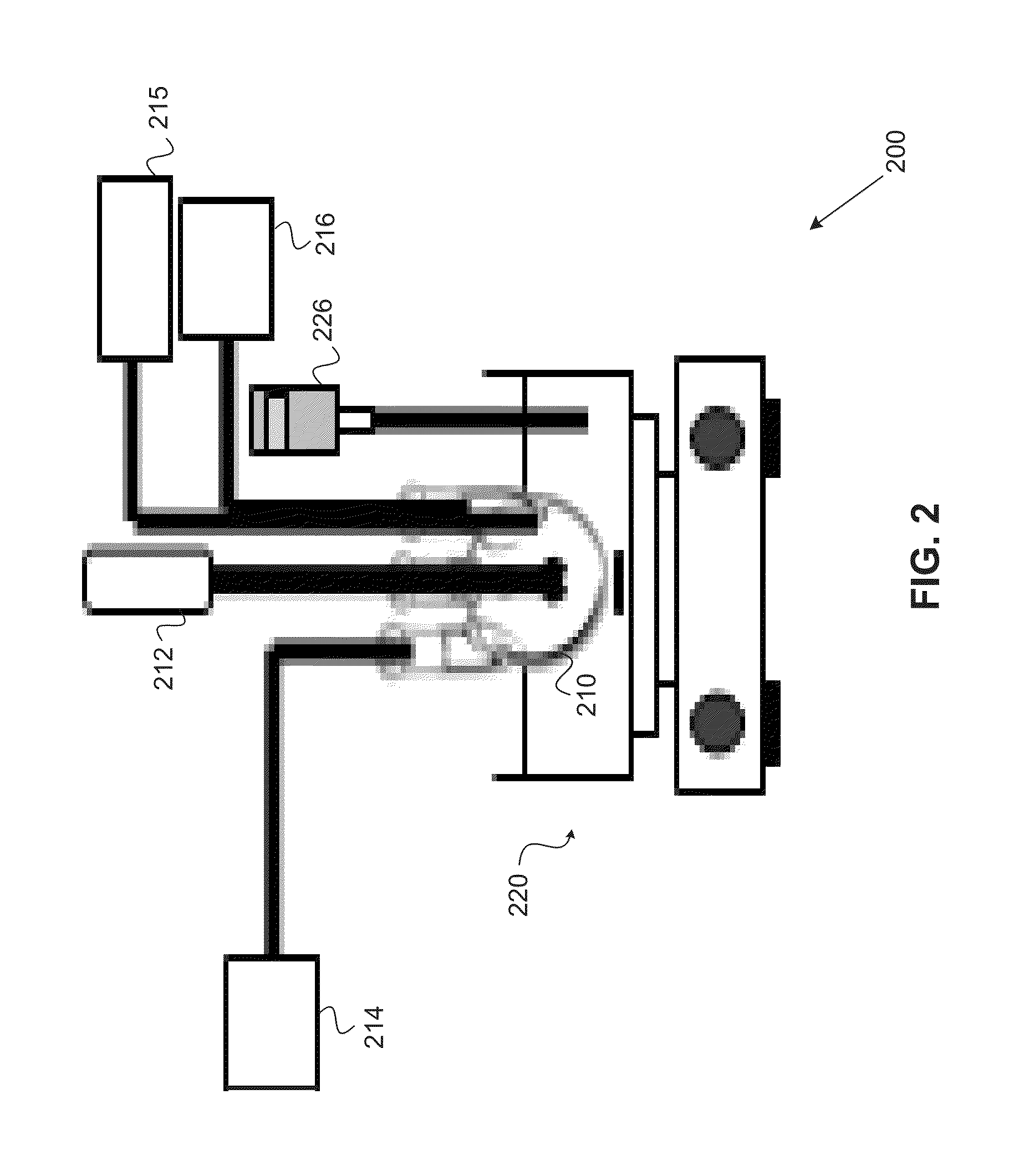

Silicon-silicon oxide-lithium composite material having NANO silicon particles embedded in a silicon:silicon lithium silicate composite matrix, and a process for manufacture thereof

ActiveUS20160260967A1Easy to useGood laminated electrode structureElectrode manufacturing processesSecondary cellsCapacity lossNano silicon

A process for producing a silicon:silicon oxide: lithium composite (SSLC) material useful as a negative electrode active material for non-aqueous battery cells includes: producing a partially lithiated SSLC material by way of mechanical mixing; subsequently producing a further prelithiated SSLC material by way of spontaneous lithiation procedure; and subsequently producing a delithiated SSLC material by way of reacting lithium silicide within the dispersed prelithiated SSLC material with organic solvent(s) to extract lithium from the prelithiated SSLC material, until reactivity of lithium silicide within the prelithiated SSLC material with the organic solvent(s) ceases. The delithiated SSLC material is a porous plastically deformable matrix having nano silicon embedded therein. The delithiated SSLC material can have a lithium silicide content of less than 0.5% by weight. A battery cell having as its negative electrode active material an SSLC material as set forth herein can exhibit an irreversible capacity loss of less than 10%.

Owner:EOCELL LTD

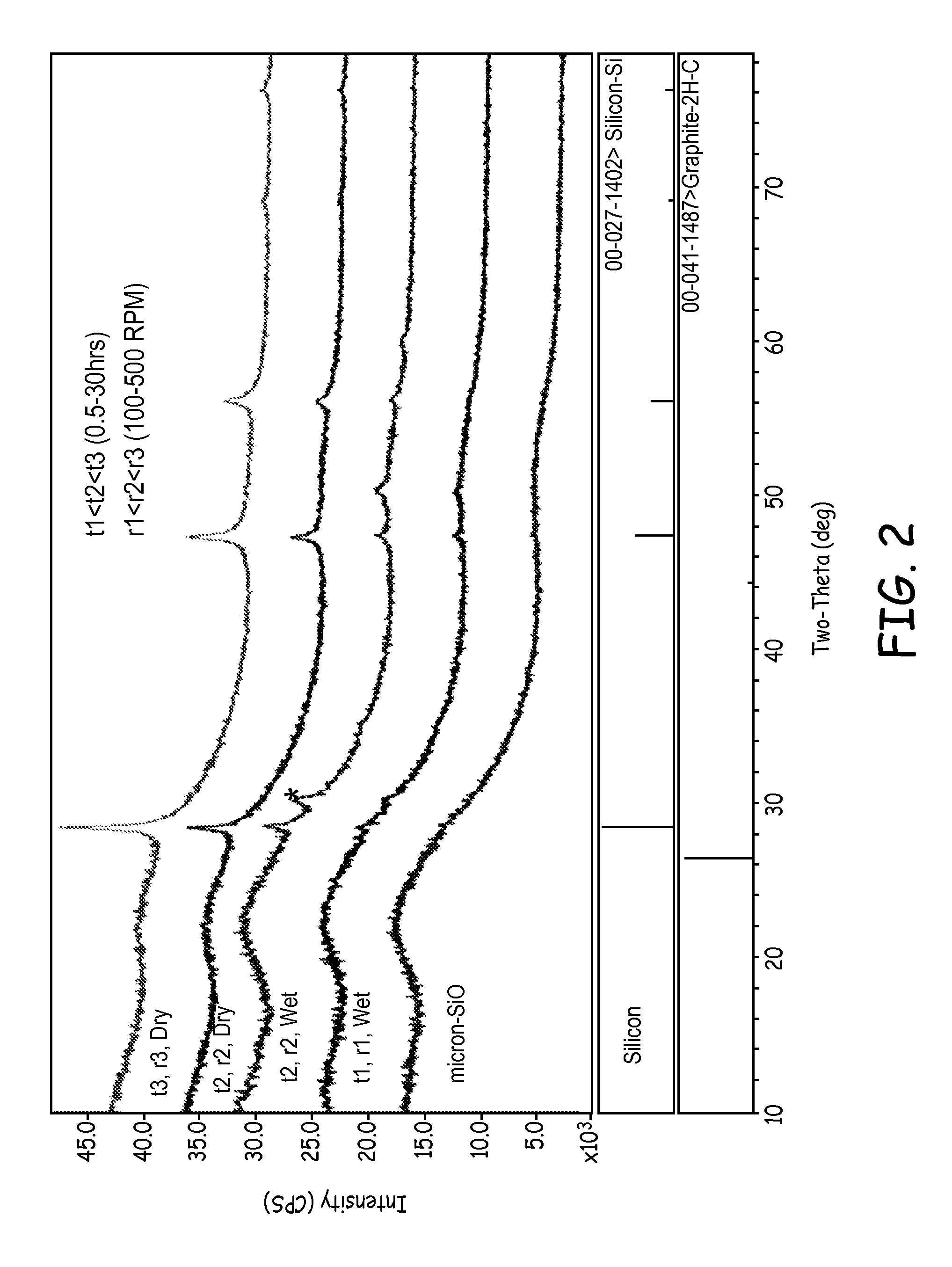

Silicon-silicon oxide-carbon composites for lithium battery electrodes and methods for forming the composites

ActiveUS20140370387A1High energyElectrode manufacturing processesLi-accumulatorsCarbon compositesHigh energy

Composite silicon based materials are described that are effective active materials for lithium ion batteries. The composite materials comprise processed, e.g., high energy mechanically milled, silicon suboxide and graphitic carbon in which at least a portion of the graphitic carbon is exfoliated into graphene sheets. The composite materials have a relatively large surface area, a high specific capacity against lithium, and good cycling with lithium metal oxide cathode materials. The composite materials can be effectively formed with a two step high energy mechanical milling process. In the first milling process, silicon suboxide can be milled to form processed silicon suboxide, which may or may not exhibit crystalline silicon x-ray diffraction. In the second milling step, the processed silicon suboxide is milled with graphitic carbon. Composite materials with a high specific capacity and good cycling can be obtained in particular with balancing of the processing conditions.

Owner:IONBLOX INC

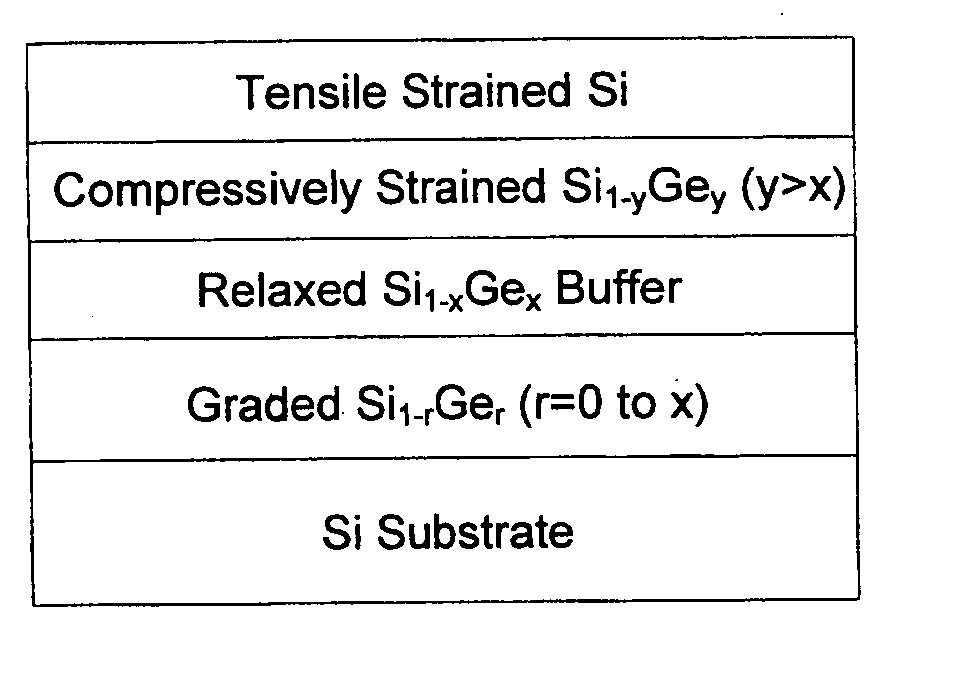

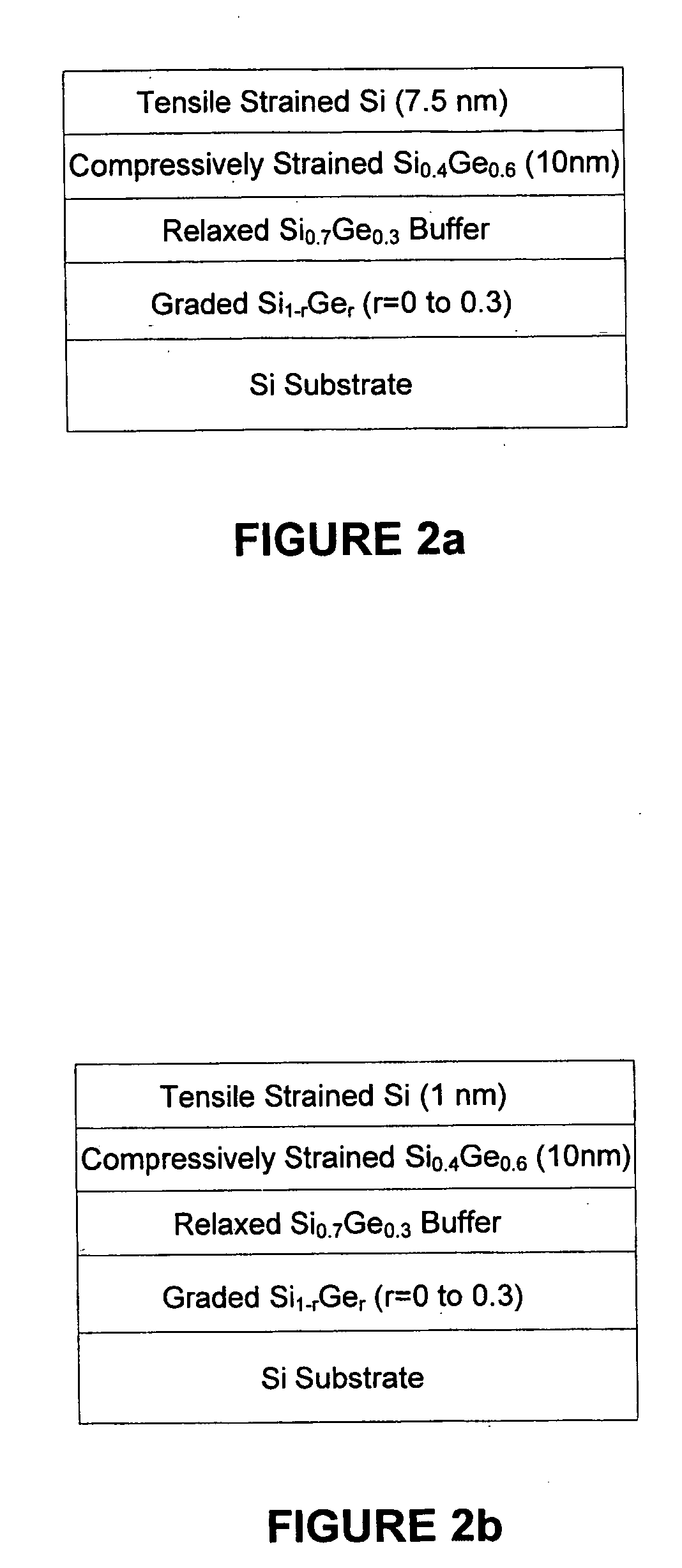

Single metal gate material CMOS using strained si-silicon germanium heterojunction layered substrate

InactiveUS20050274978A1Improve device speedEasy to transportSemiconductor/solid-state device manufacturingSemiconductor devicesHeterojunctionCMOS

Strained Si / strained SiGe dual-channel layer substrate provides mobility advantage and when used as a CMOS substrate enables single workfunction metal-gate electrode technology. A single metal electrode with workfunction of 4.5 eV produces near ideal CMOS performance on a dual-channel layer substrate that consists sequentially of a silicon wafer, an epitaxially grown 30% Ge relaxed SiGe layer, a compressively strained 60% Ge layer, and a tensile-strained Si cap layer.

Owner:MASSACHUSETTS INST OF TECH

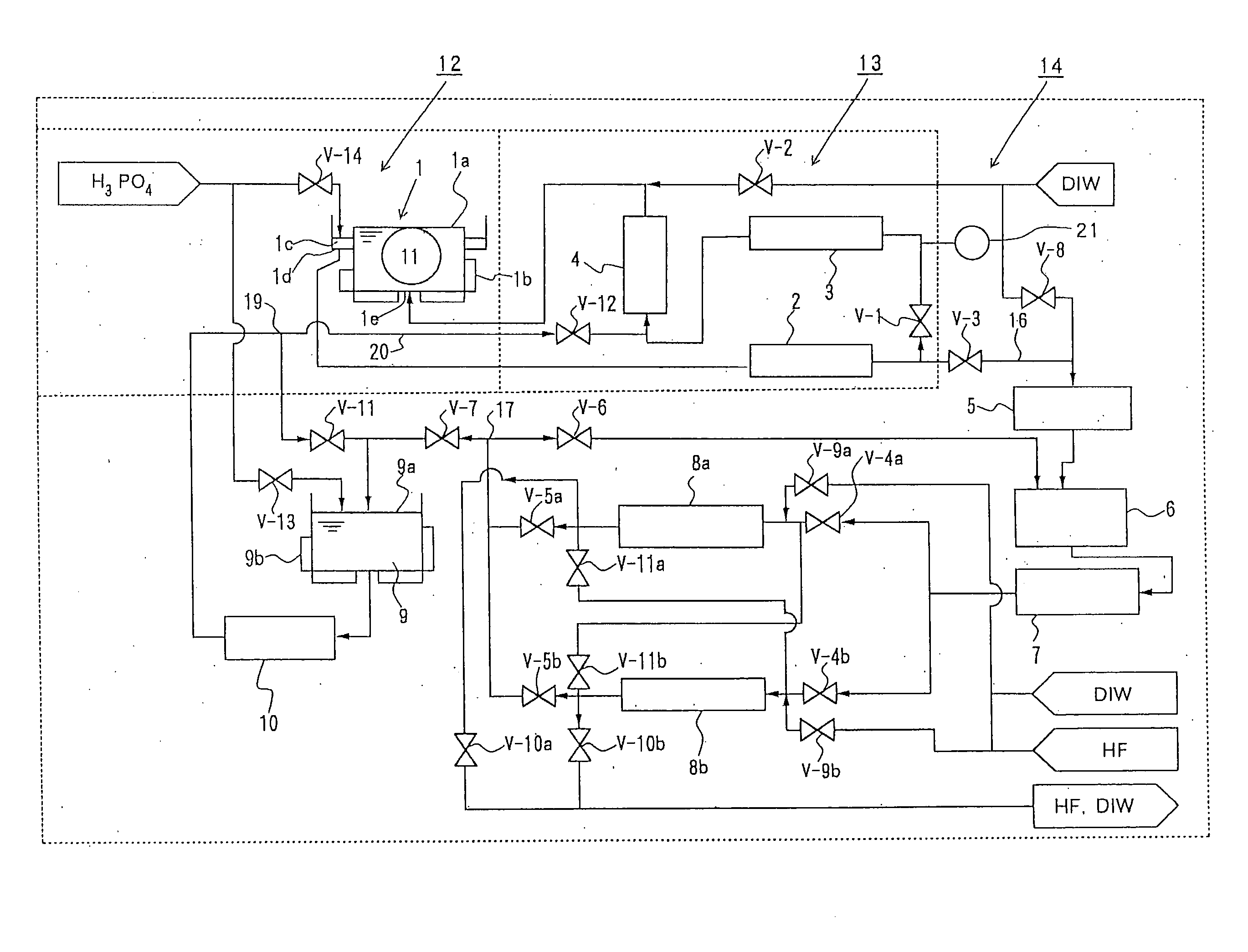

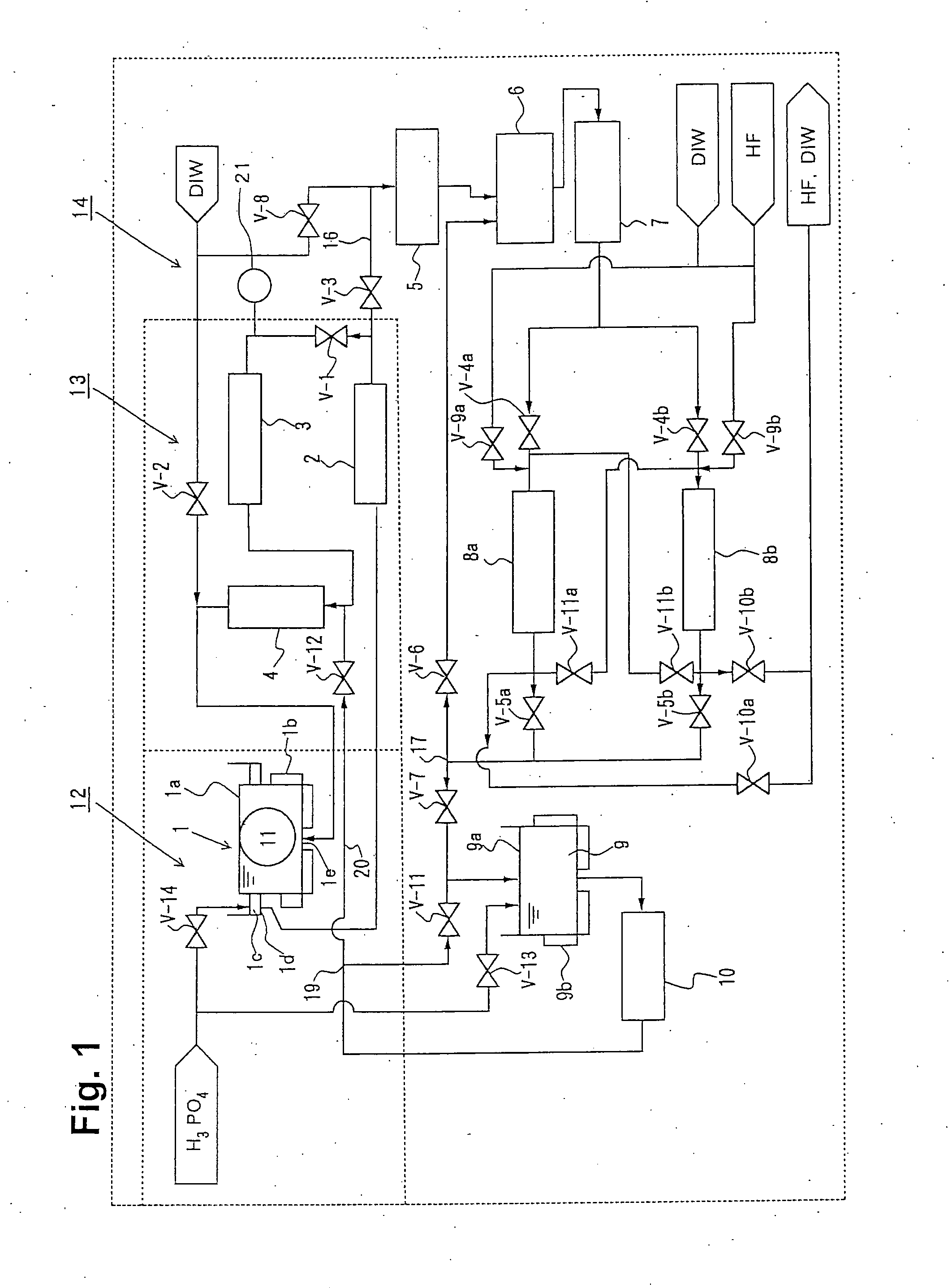

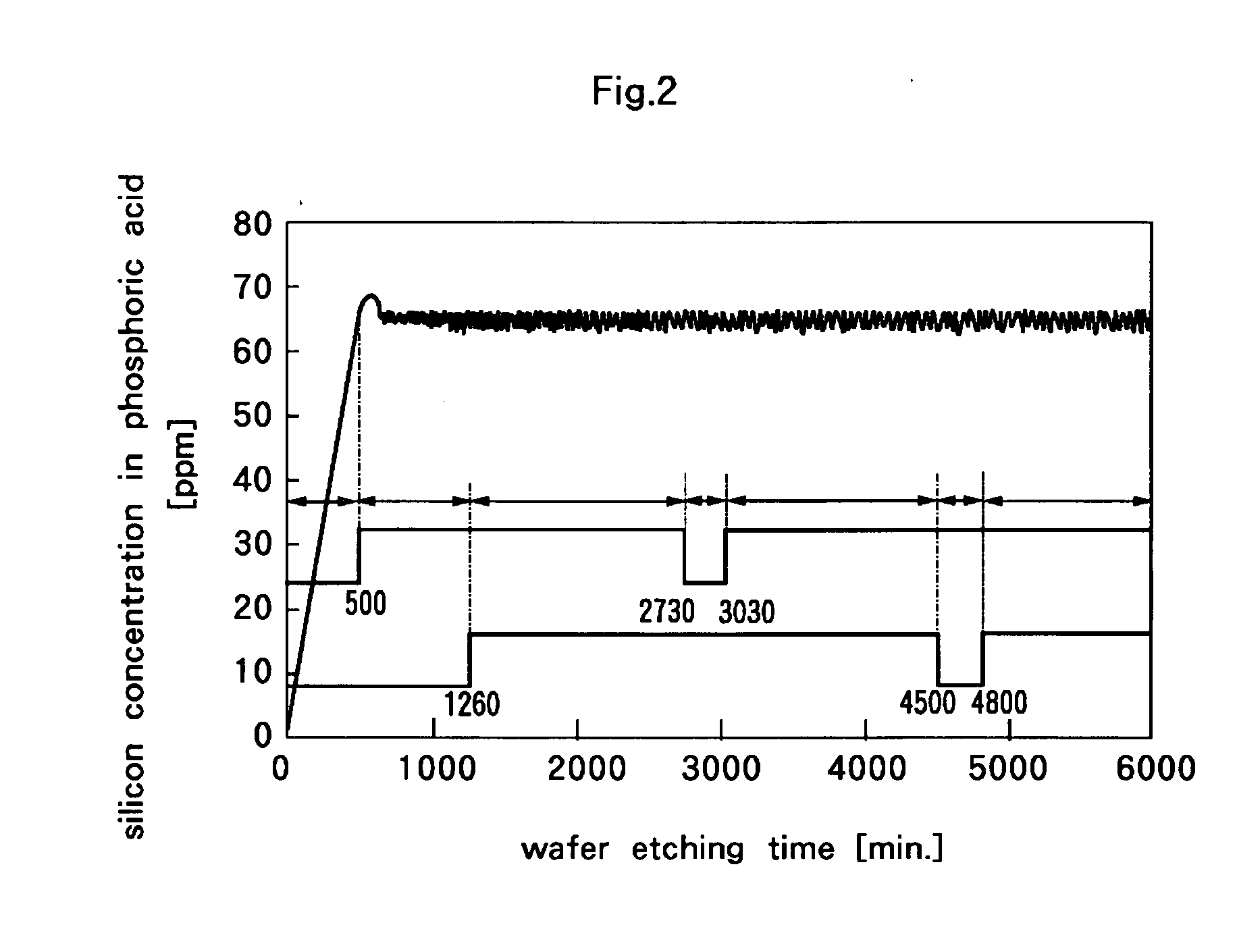

Regeneration method of etching solution, an etching method and an etching system

InactiveUS20080087645A1Low costWeak pointDecorative surface effectsSemiconductor/solid-state device manufacturingPhosphoric acidAqueous solution

The present invention provides a regeneration process of the etching solution for the silicon nitride film, applying phosphoric acid aqueous solution, wherein multiple numbers of filters are connected to the piping path of etching solution extracted from the etching tank by switching alternately in parallel or in series; in both cases that said multiple numbers of filters are connected in parallel or in series, said extracted etching solution being supplied to a filter with a filter element of a high silicon removal rate of silicon compounds with already deposited silicon compounds, thus maintaining a high silicon removal rate of silicon compounds.

Owner:APPRECIA TECH

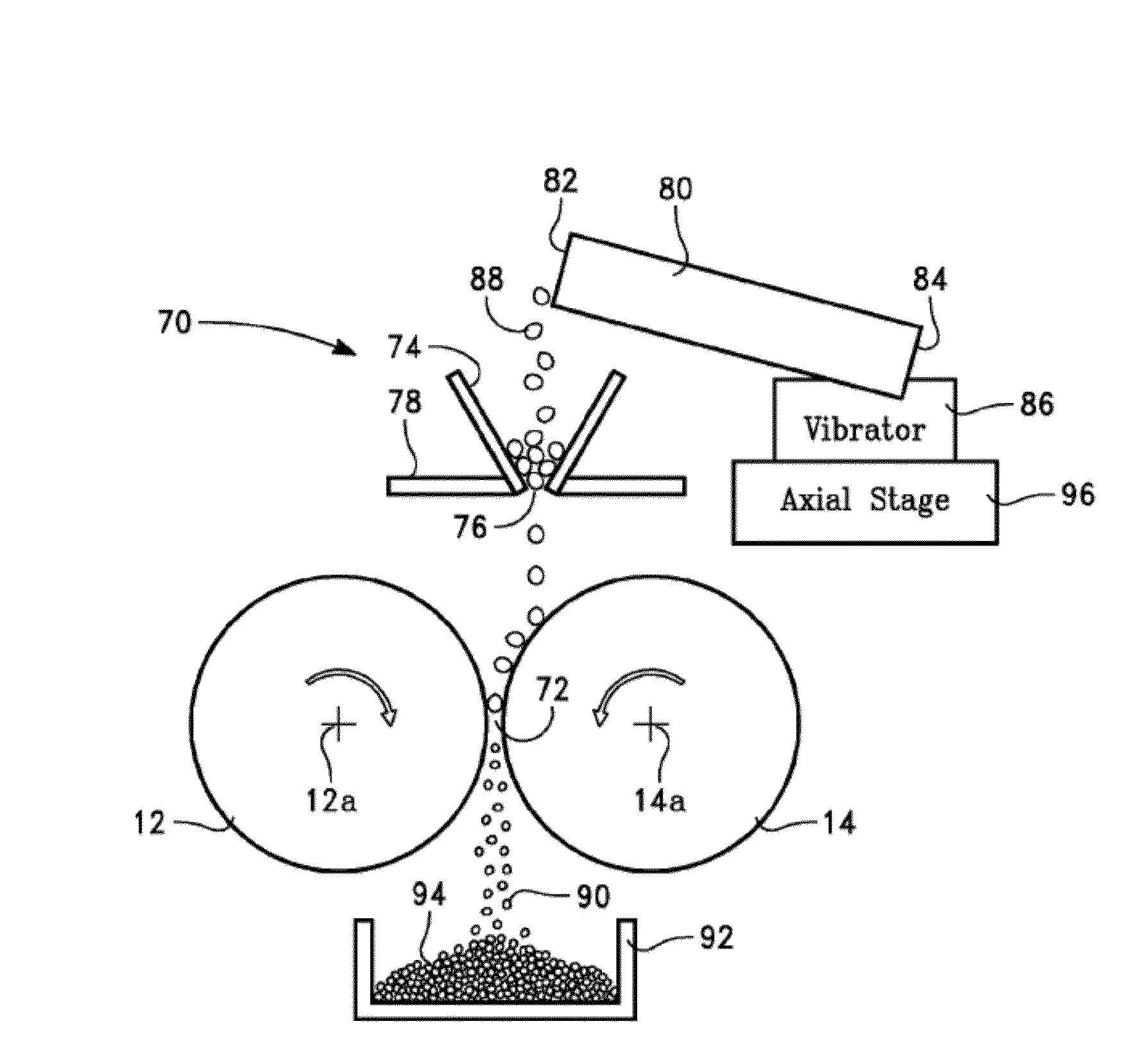

Milling of Granular Silicon

Silicon particles, including powder suitable for plasma spraying semiconductor devices, is formed by milling by a roller mill including silicon rollers and / or plates and having feed and collection systems comprising silicon and operated in a controlled ambient.

Owner:INTEGRATED PHOTOVOLTAICS

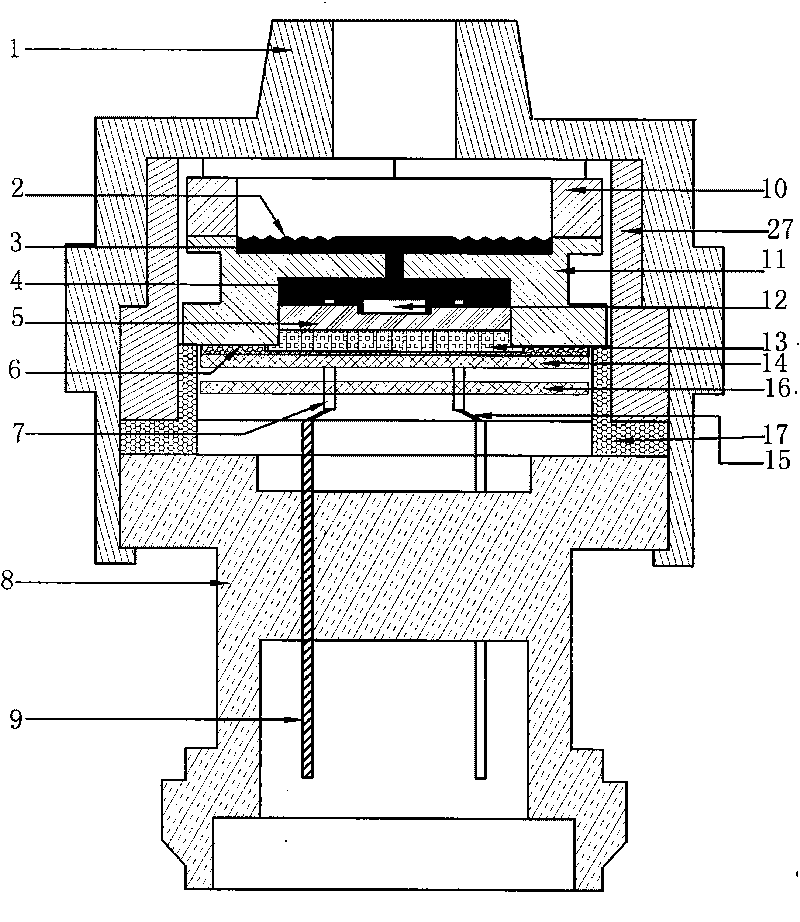

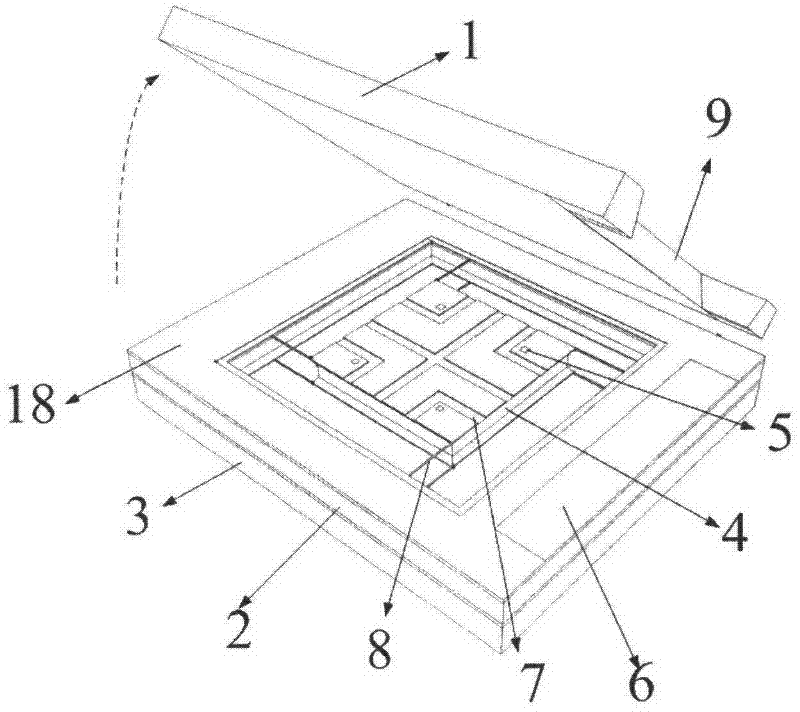

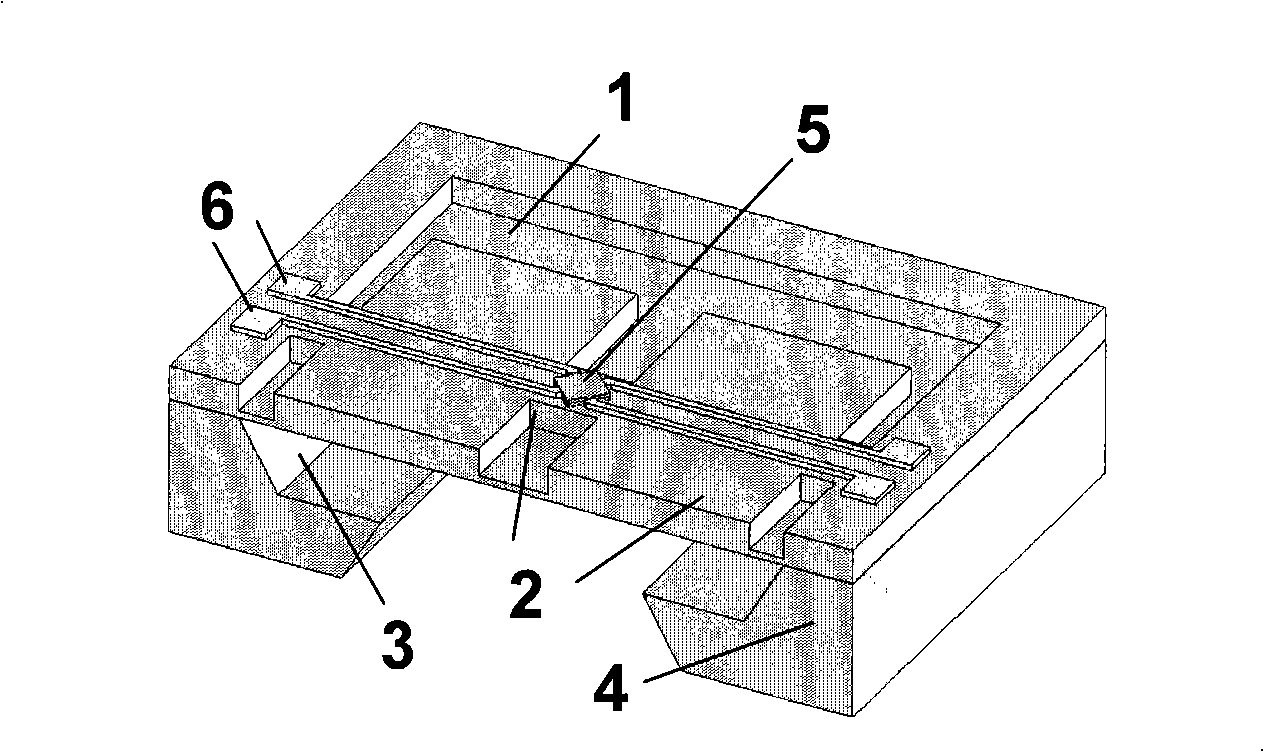

Silicon pressure transducer chip and method based on silicon-silicon linking and silicon-on-insulating layer

InactiveCN101271028AReduce residual stressImplement overvoltage protectionTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesLinearitySilicon on insulator

The invention relates to a pressure sensor chip based on silicon direction bonding and silicon on insulator and a manufacturing method thereof, and belongs to the field of sensor chips. The invention is characterized in that a shallow slot and a gas port on a supporting silicon wafer are formed through anisotropy corrosion, and appropriate shallow slot depth obtained by controlling the corrosion time can realize over pressure protection of parts. A silicon direct bonding technology bonds the supporting wafer and a reversed SOI wafer, realizes a beam-membrane structure on the SOI after lapping and polishing to improve the sensitivity and linearity of the parts; manufactures force sensing resistance elements on the processed beam; adopts the oxidation buried layer of the SOI to solve insulation and isolation of the sensing elements and elastic elements; and improves the long-termed reliability and adaptability under high temperature of the parts. The SOP high-sensitivity pressure sensor chip based on the bonding technology has the advantages of controllable process, excellent repeatability and high finished product rate.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

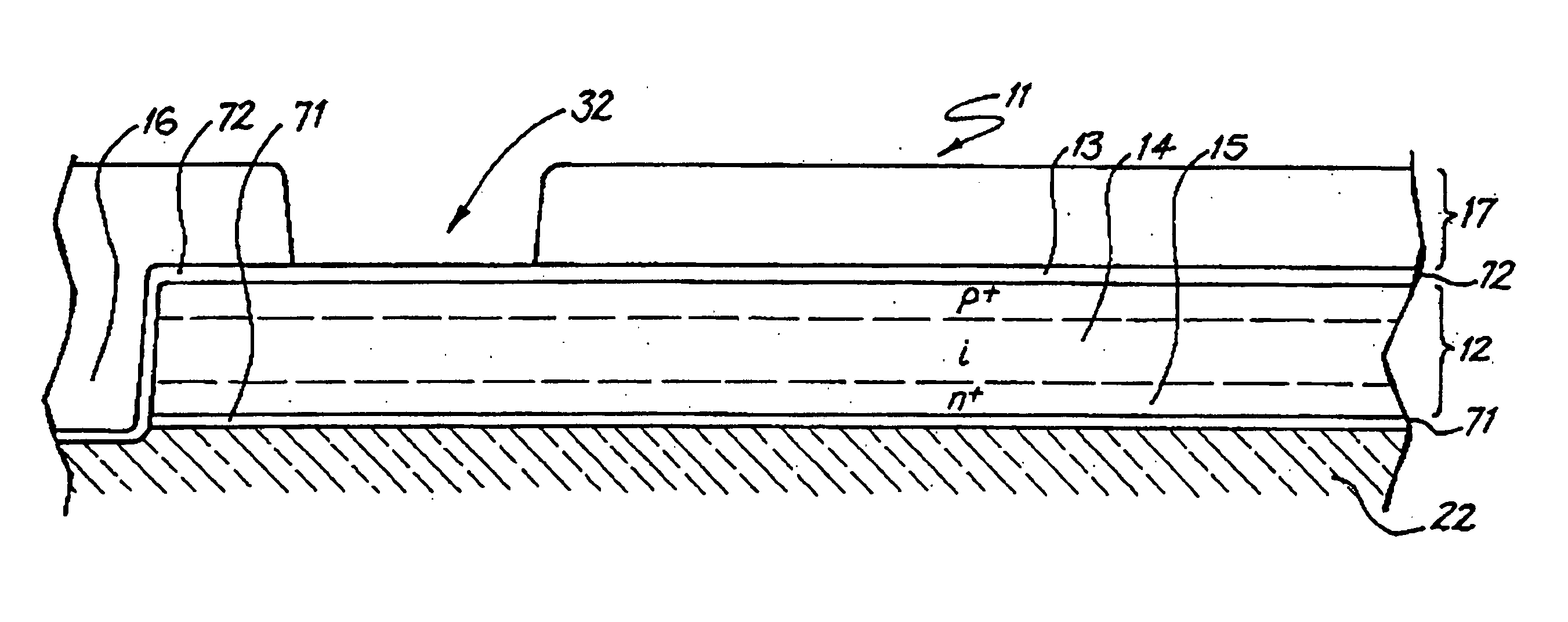

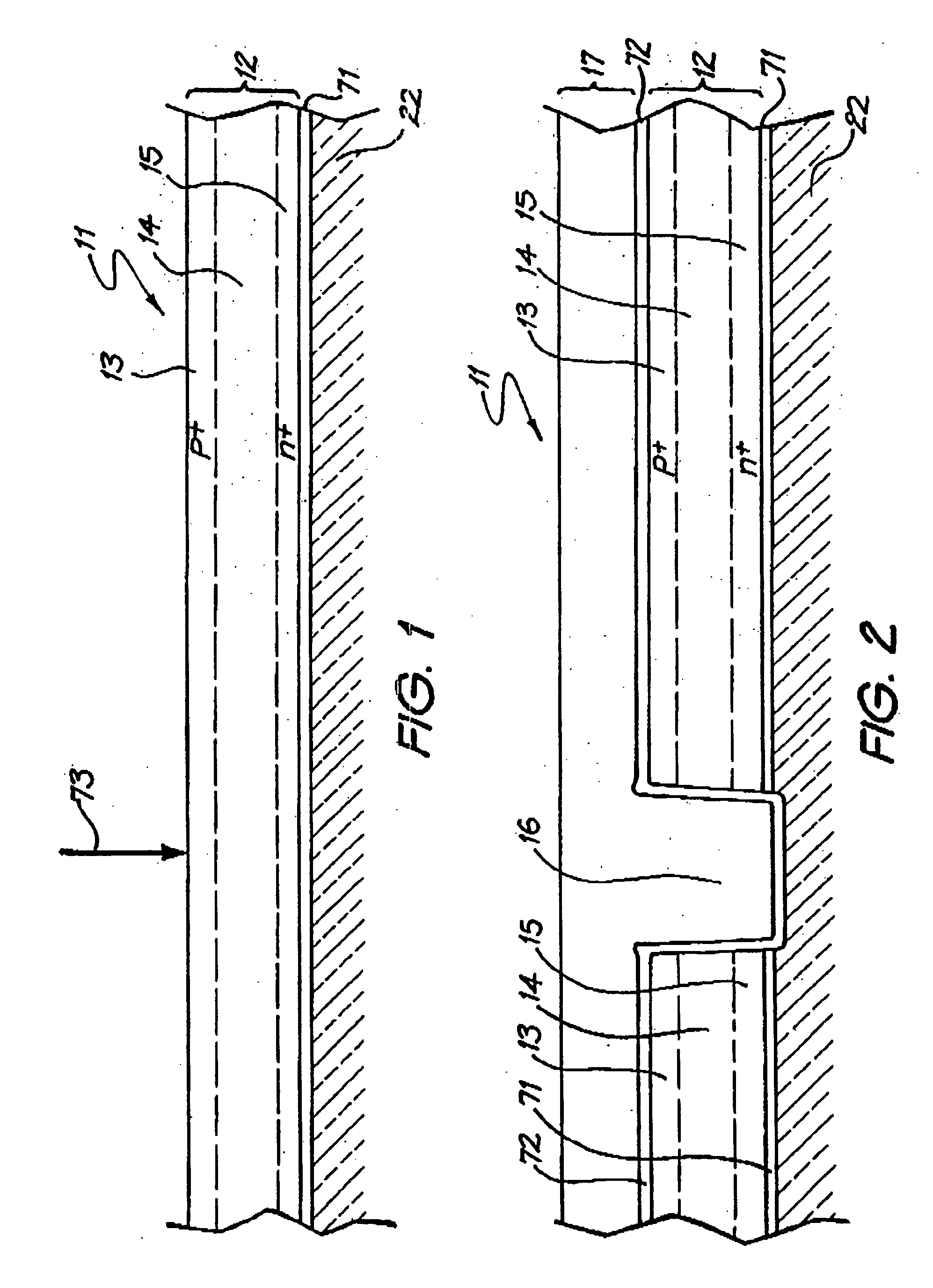

Method of etching silicon

Silicon (12) is etched through a mask (11) comprising a layer of organic resin material (such as novolac) through which openings (32) are formed in the areas to be etched. The layer of organic resin is first deposited over a free surface of the device to be etched. The openings (32) are then formed by depositing droplets of a caustic etchant such as sodium hydroxide (NaOH) or potassium hydroxide (KOH) with an inkjet printer. The etchant reacts with the resin to expose the silicon surface in areas to be etched. The etching of the silicon surface is performed by applying a dilute solution of hydrofluoric acid (HF) and potassium permanganate (KMnO4) to the exposed surface through the openings in the mask to etch the silicon to a desired depth (83).

Owner:CSG SOLAR AG

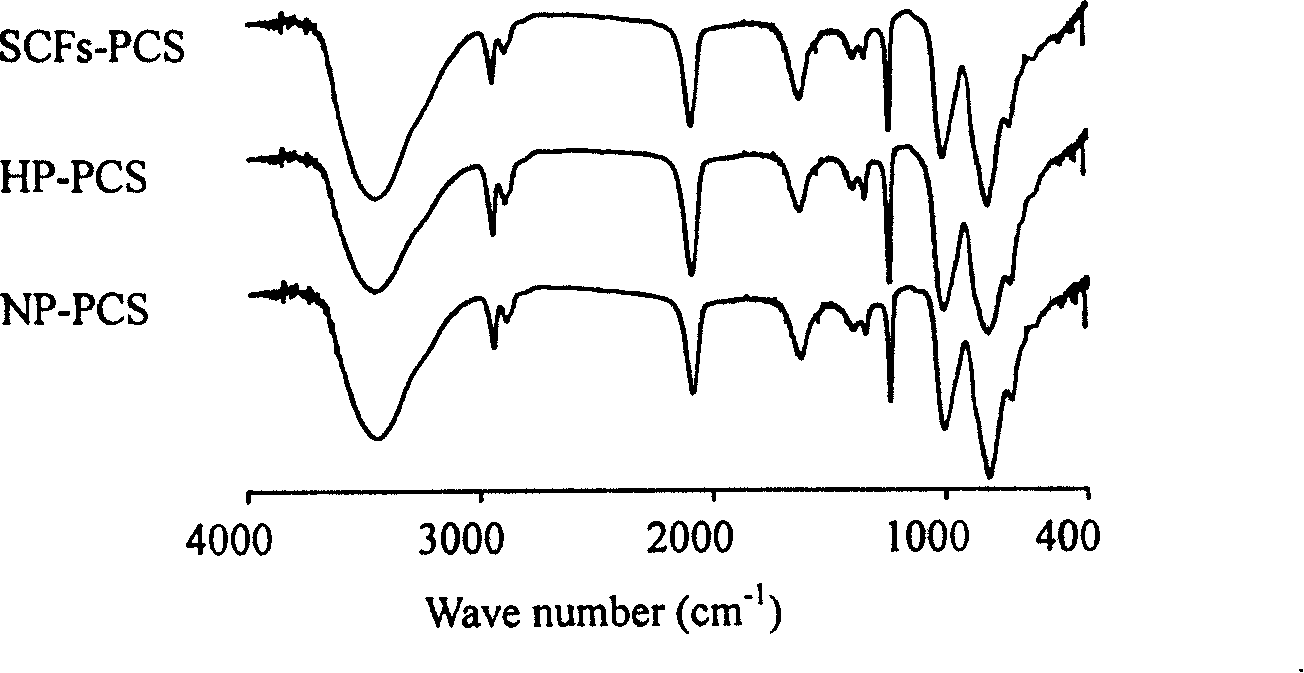

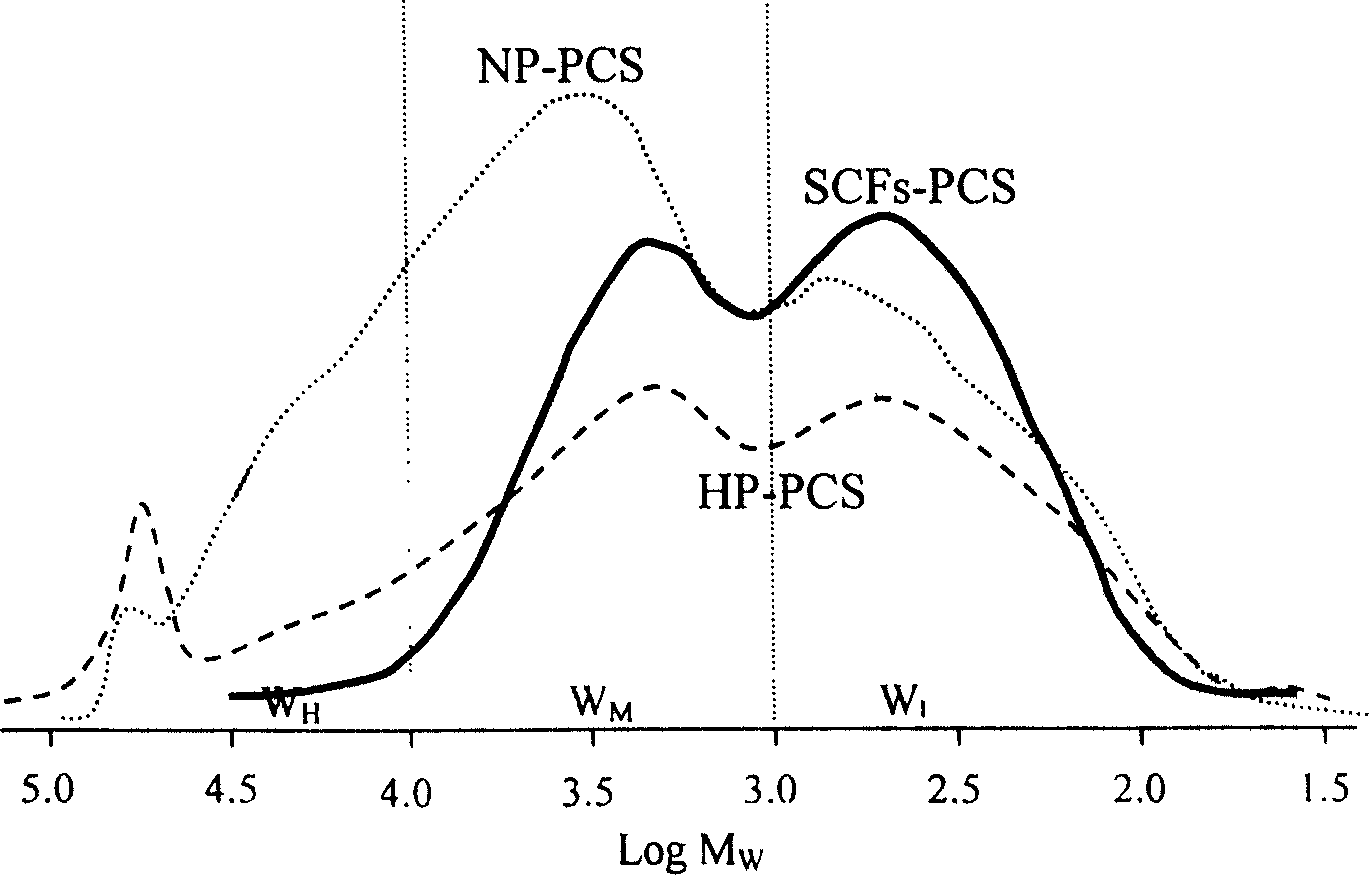

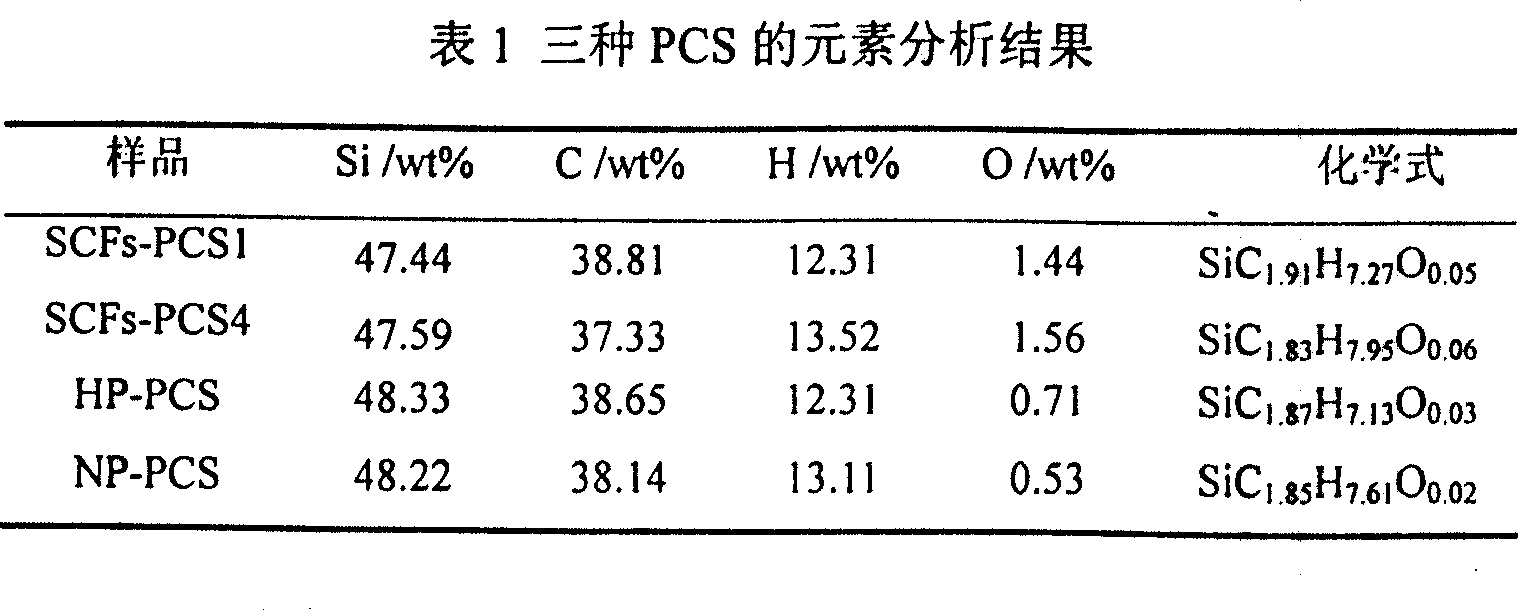

Method for synthesizing supercritical fluid of ceramic precursor polycarbosilane

InactiveCN101240070AImprove heat transfer performanceImprove uniformityBulk chemical productionHigh pressureSuperalloy

The invention discloses a organic silicon compound containing silicon-silicon bond, silicon-carbon bond, silicon-halogen bond and ceramics precursor poly carbon silicon alky synthesized under high pressure and with medium in supercritical fluid status which uses mixture of the aforementioned compound as raw material, uses solvent soluble of poly carbon silicon alky as supercritical fluid medium. Ceramics precursor poly carbon silicon alky with different molecular weight and different softening point can be obtained by controlling reaction condition of synthesis. The inventive method effectively improves uniformity of heat transfer and reaction, with short reaction time, high synthesis efficiency, high synthesis yield. The produced poly carbon silicon has a high molecular weight, high content of bonds of silicon and hydrogen and uniform distribution of molecular weight. The inventive method can be widely used in preparation of SiC fibre, SiC composite, heat resistant alloy with high strength, ceramic binder, SiC membrane, nano-wire, nano-pipe and nano-powder and so on.

Owner:NAT UNIV OF DEFENSE TECH

Lithium-silicon battery

Disclosed herein is an improved lithium-silicon battery. The anode of the battery comprises a composite comprising Group14 elements silicon and carbon. This composite comprises silicon in the preferred form for use in the lithium-silicon battery: silicon that is amorphous, nano-sized, and entrained within porous carbon. Compared to batteries found in the prior art, lithium-silicon batteries disclosed herein comprising the composite anode material disclosed herein find superior utility in various applications.

Owner:GRP 14 TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com