Patents

Literature

1972results about "Silicon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for Polycrystalline film silicon growth

InactiveUS6281098B1Widely distributedQuality improvementPolycrystalline material growthLiquid surface applicatorsVapor barrierProduct gas

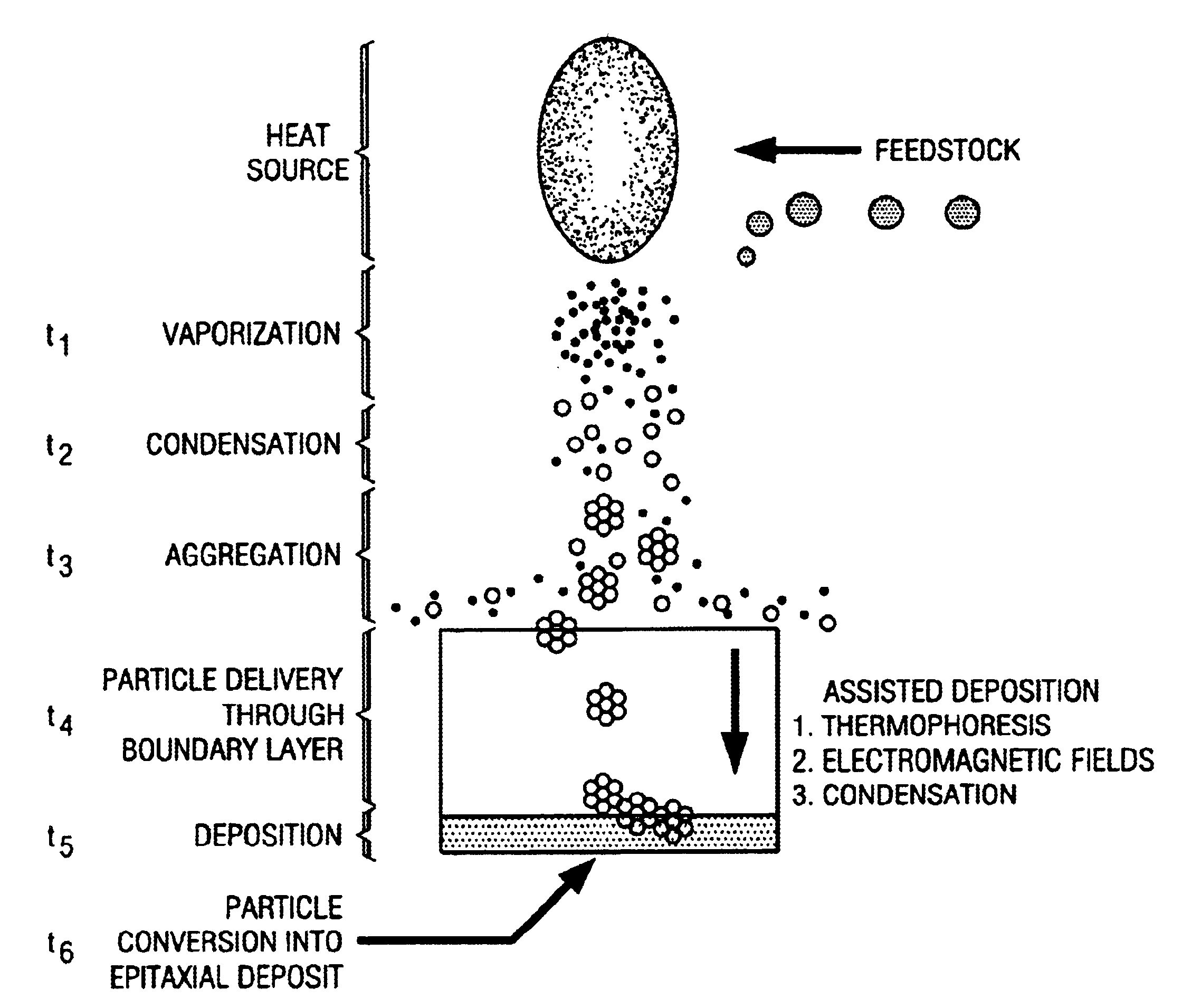

A process for depositing polycrystalline silicon on substrates, including foreign substrates, occurs in a chamber at about atmospheric pressure, wherein a temperature gradient is formed, and both the atmospheric pressure and the temperature gradient are maintained throughout the process. Formation of a vapor barrier within the chamber that precludes exit of the constituent chemicals, which include silicon, iodine, silicon diiodide, and silicon tetraiodide. The deposition occurs beneath the vapor barrier. One embodiment of the process also includes the use of a blanketing gas that precludes the entrance of oxygen or other impurities. The process is capable of repetition without the need to reset the deposition zone conditions.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

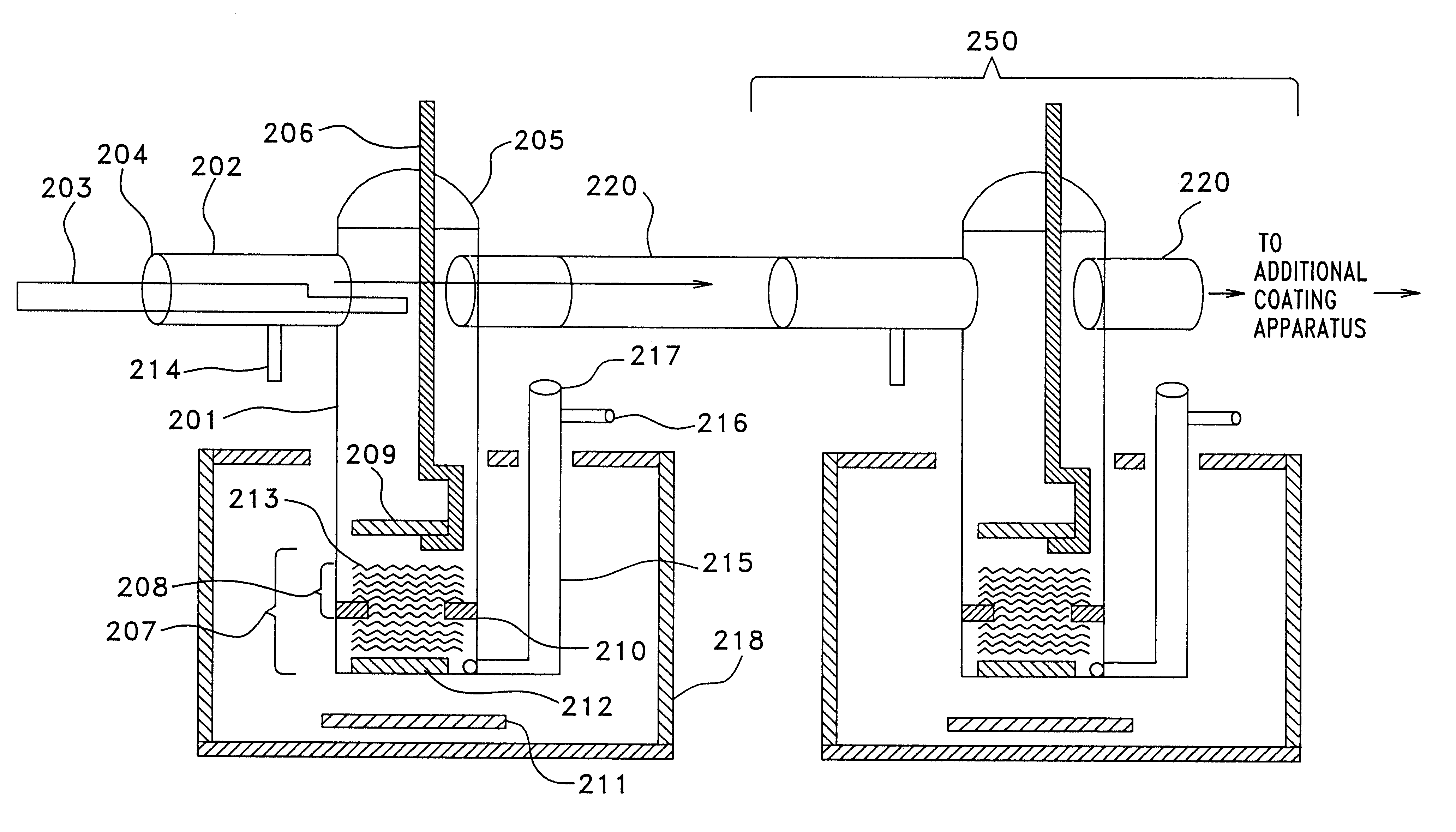

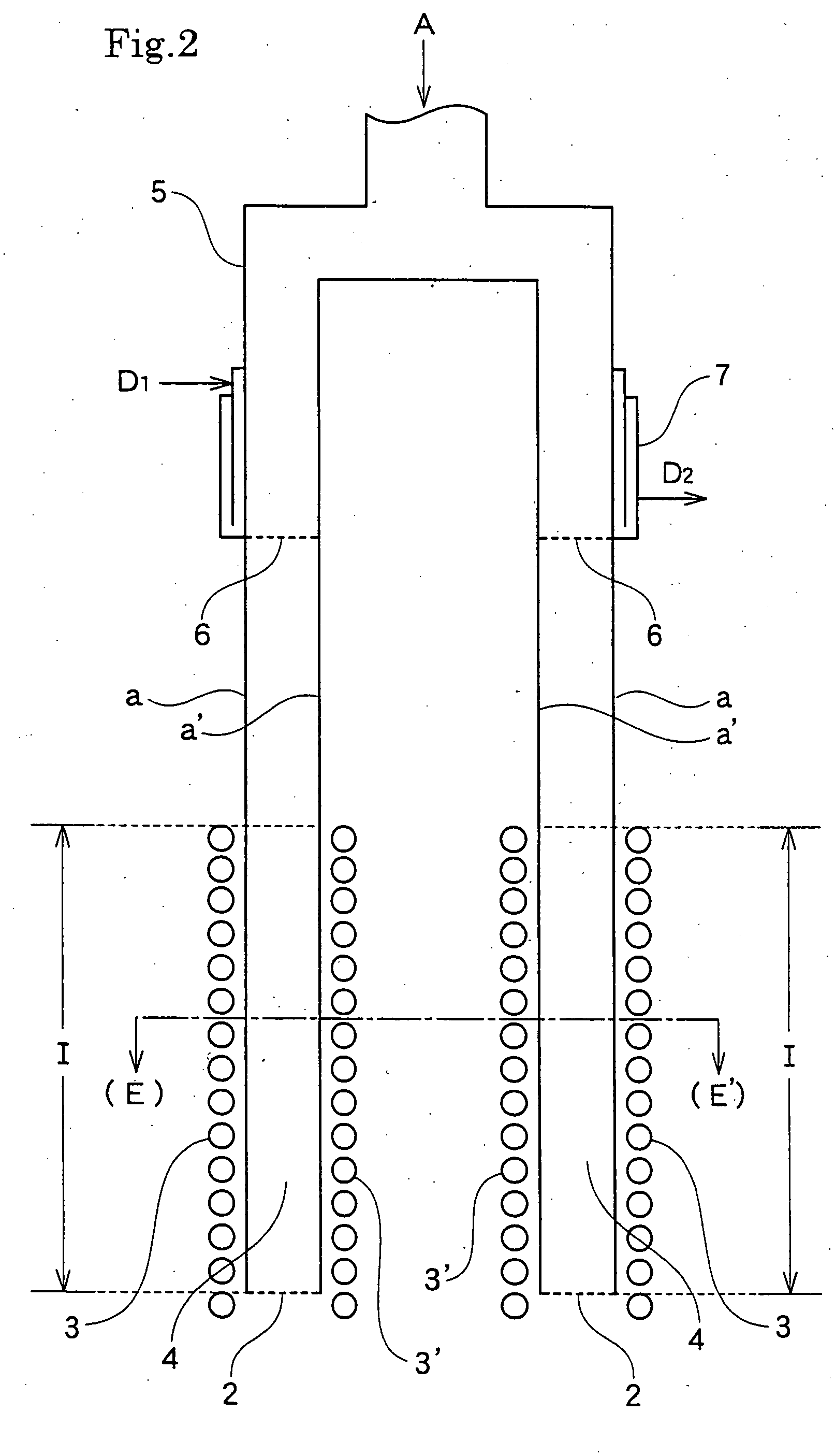

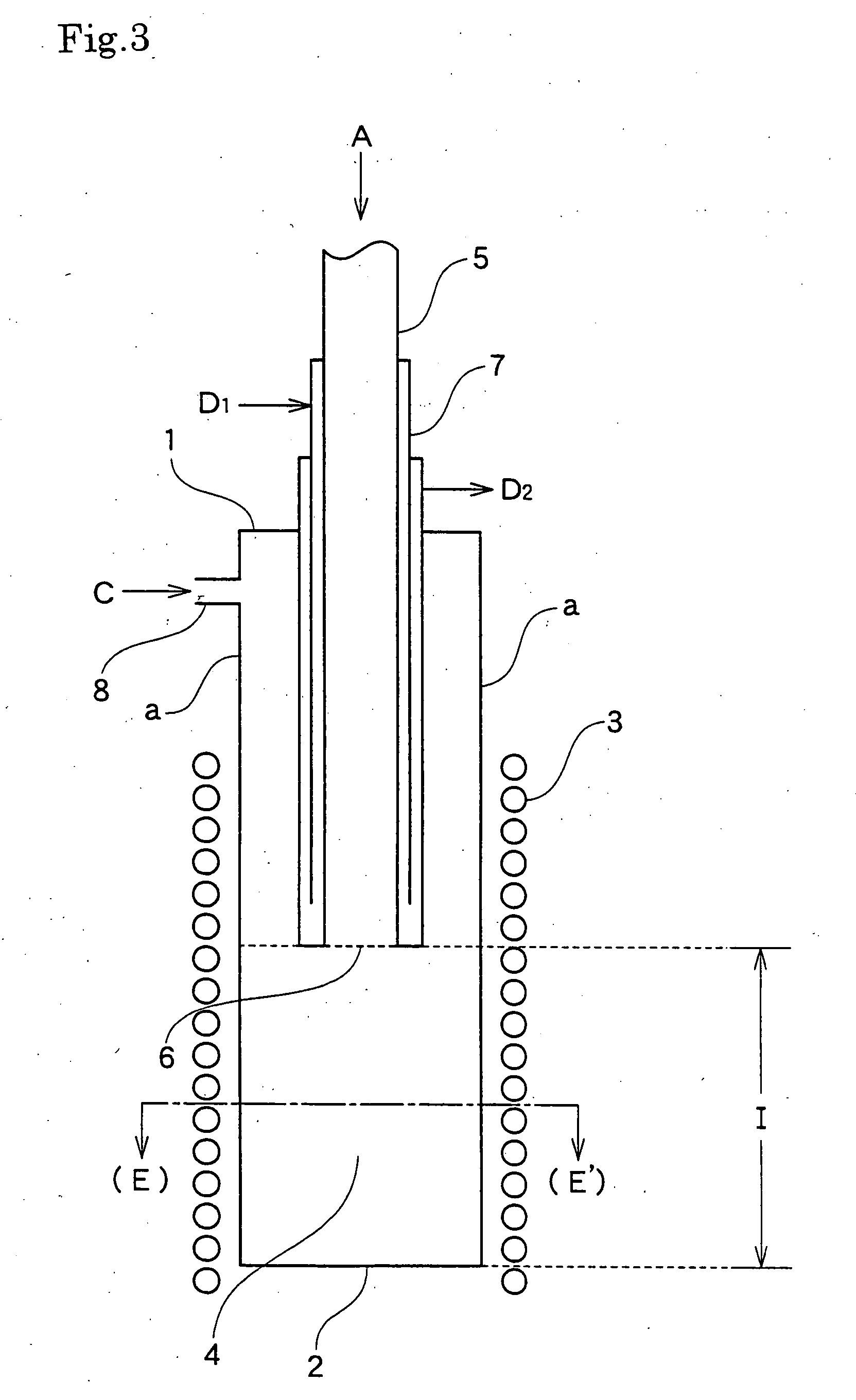

Reaction apparatus for producing silicon

ActiveUS20050201908A1Reduce spacingReduce distanceAfter-treatment apparatusSiliconProcess engineeringSilicon

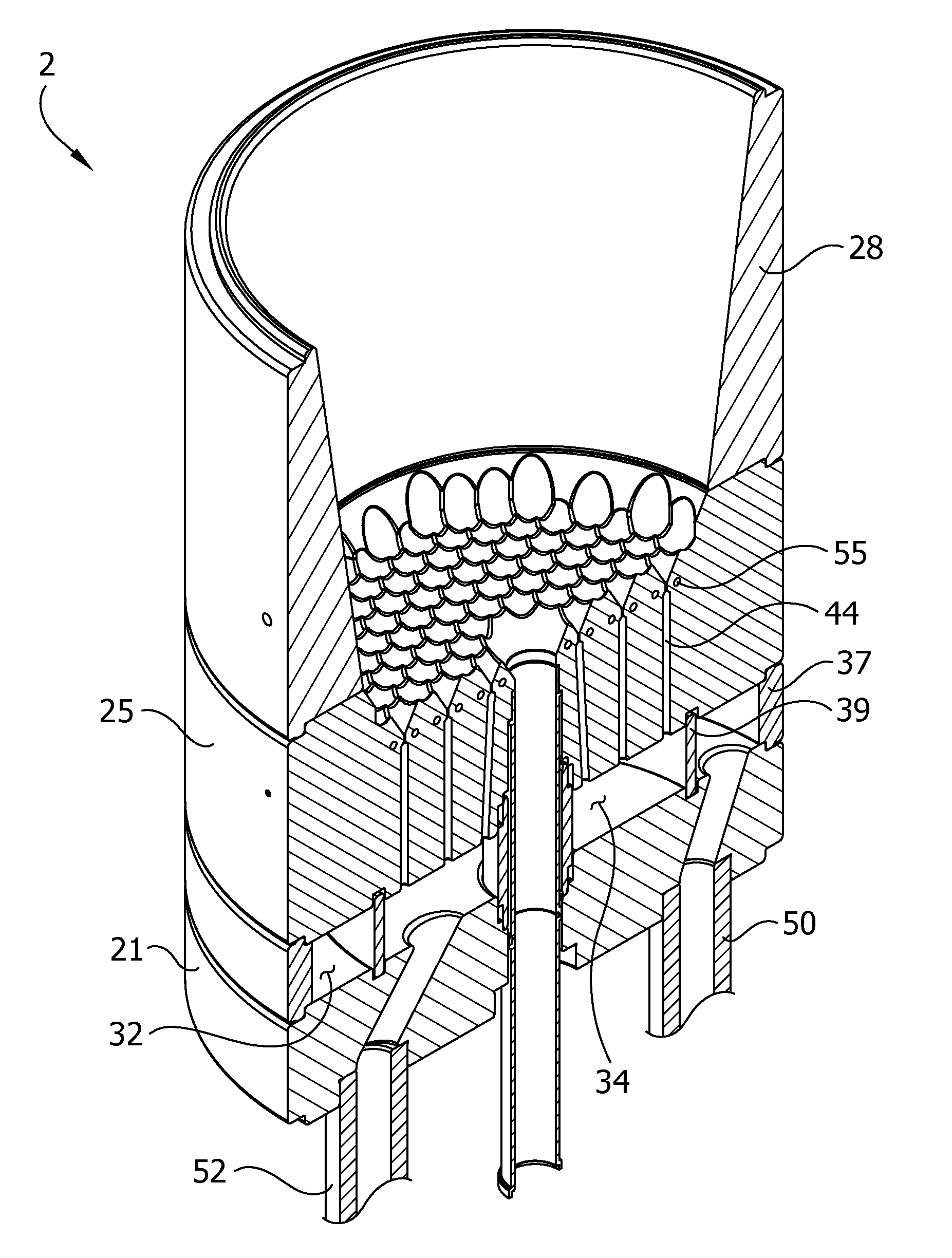

A silicon production reactor comprising a reaction vessel and heating means, said reaction vessel comprising a vertically extending wall and a space surrounded by the wall, said heating means being capable of heating at least a part, including lower end portion, of the wall's surface facing the space to a temperature of not lower than the melting point of silicon, said silicon production reactor being adapted to flow raw gas for silicon deposition from an upper part of the space of the reaction vessel toward a lower part thereof, characterized in that the space of the reaction vessel is of slit form in cross-sectional view. This silicon production reactor is capable of attaining improvement with respect to problems encountered at apparatus scaleup, such as decrease of reactivity of raw gas and generation of by-products, thereby accomplishing a striking enhancement of production efficiency.

Owner:TOKUYAMA CORP

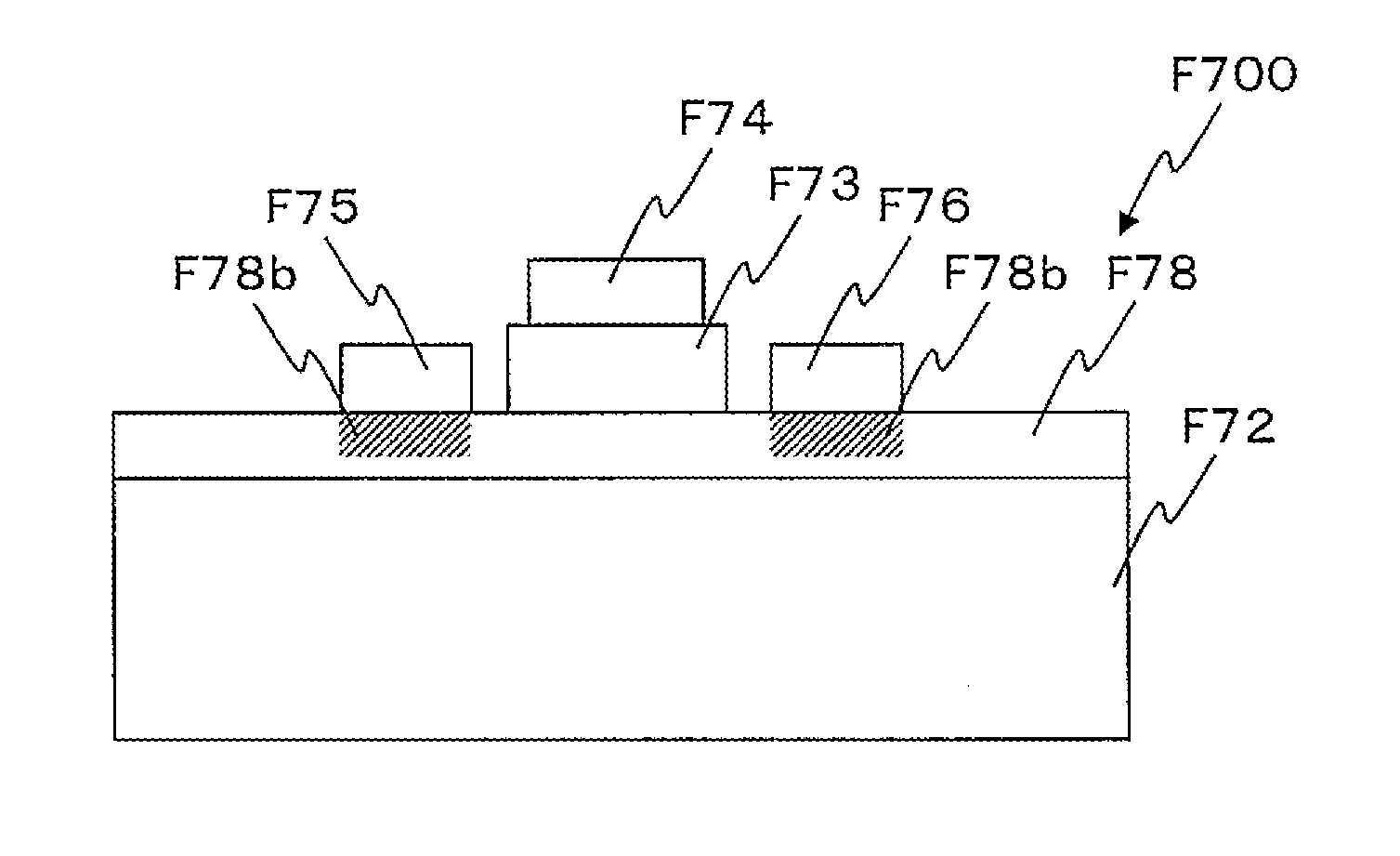

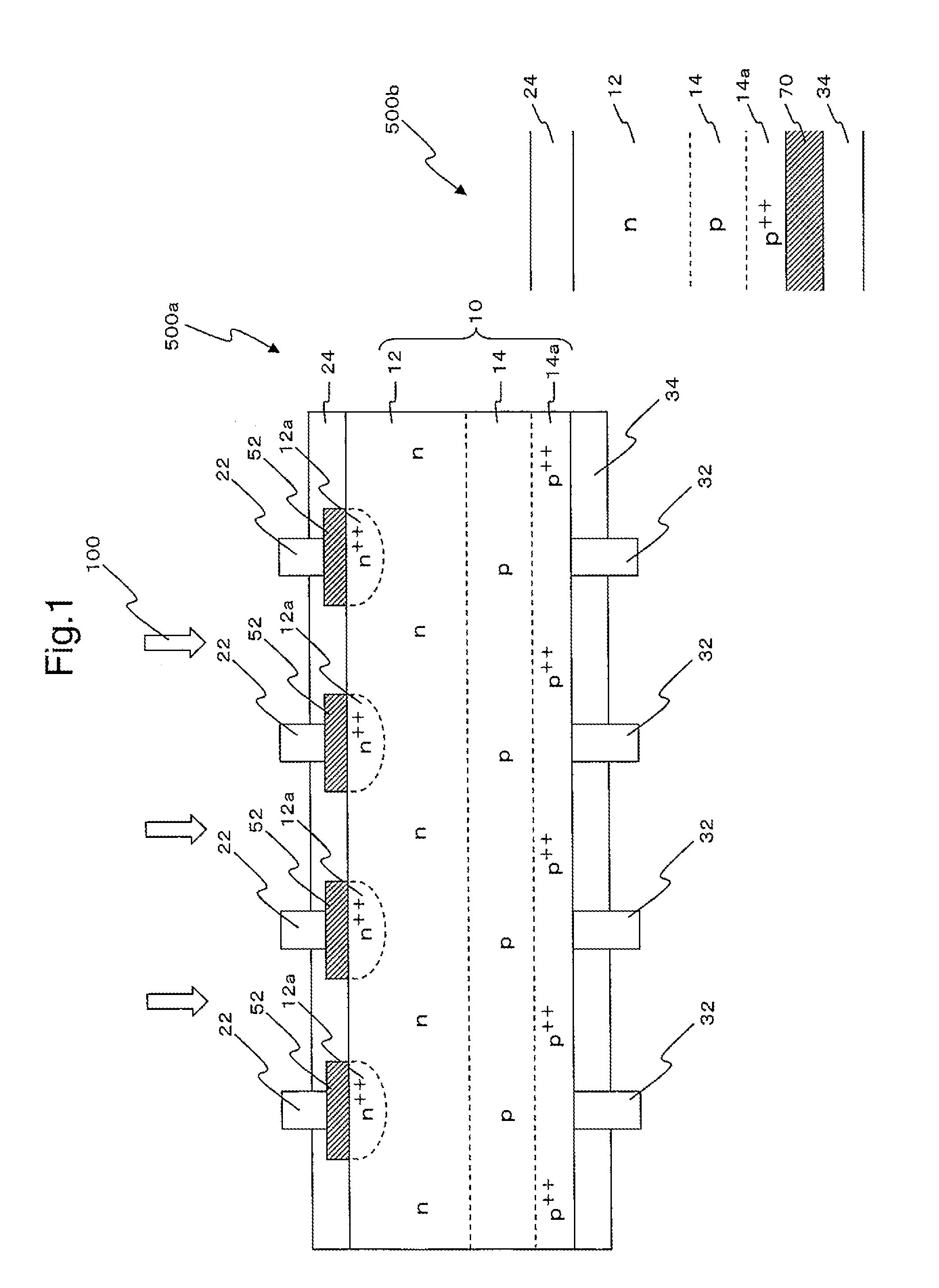

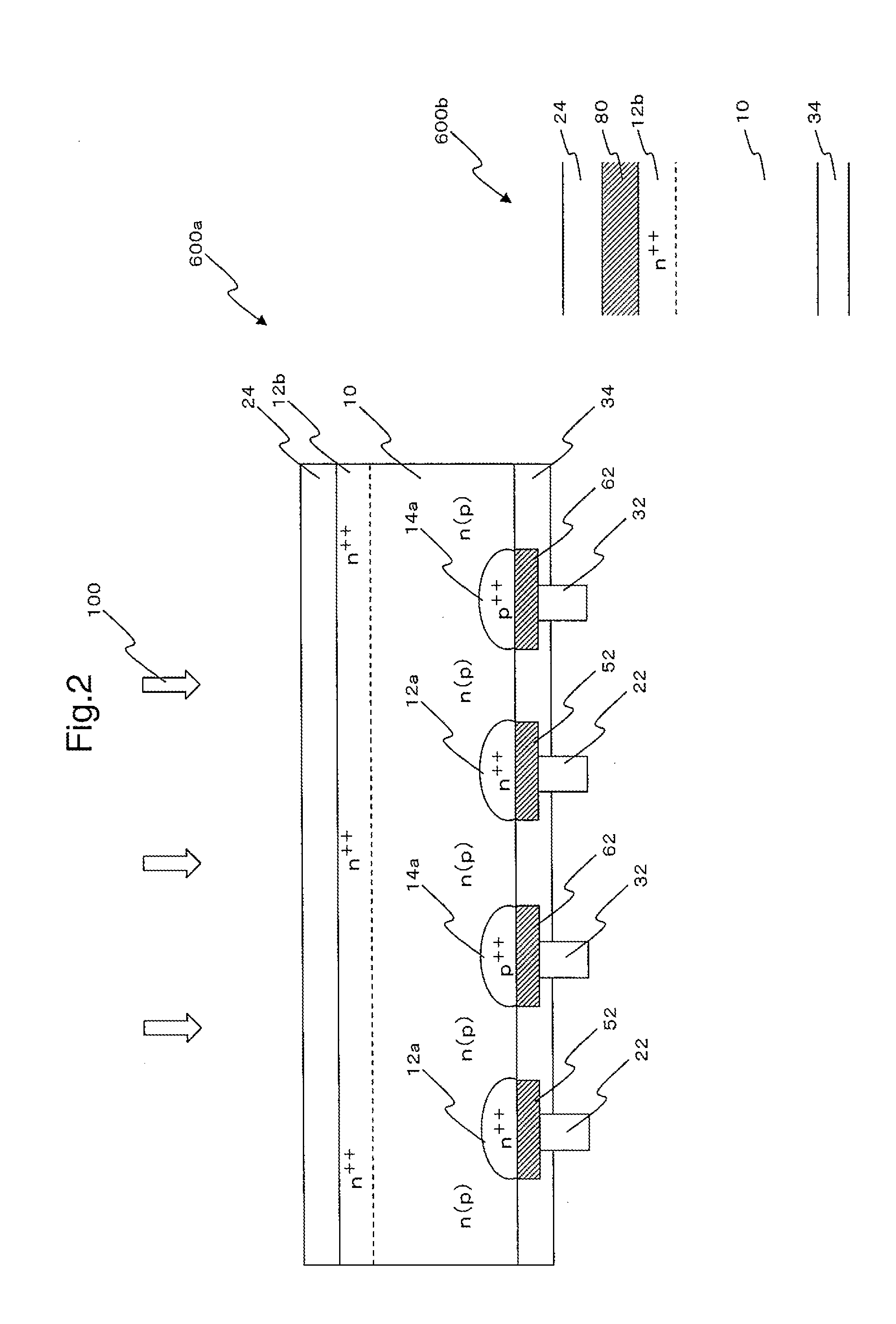

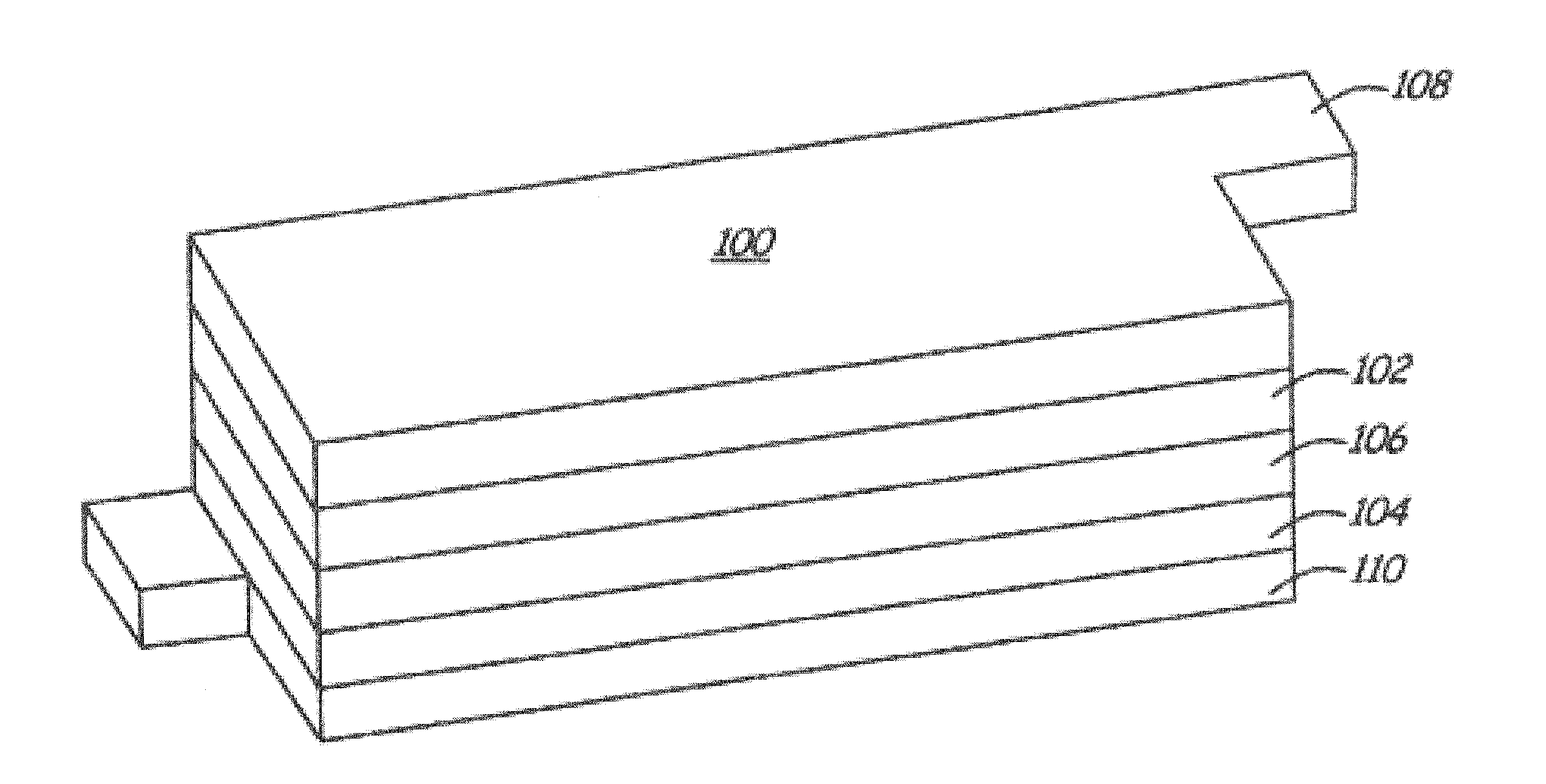

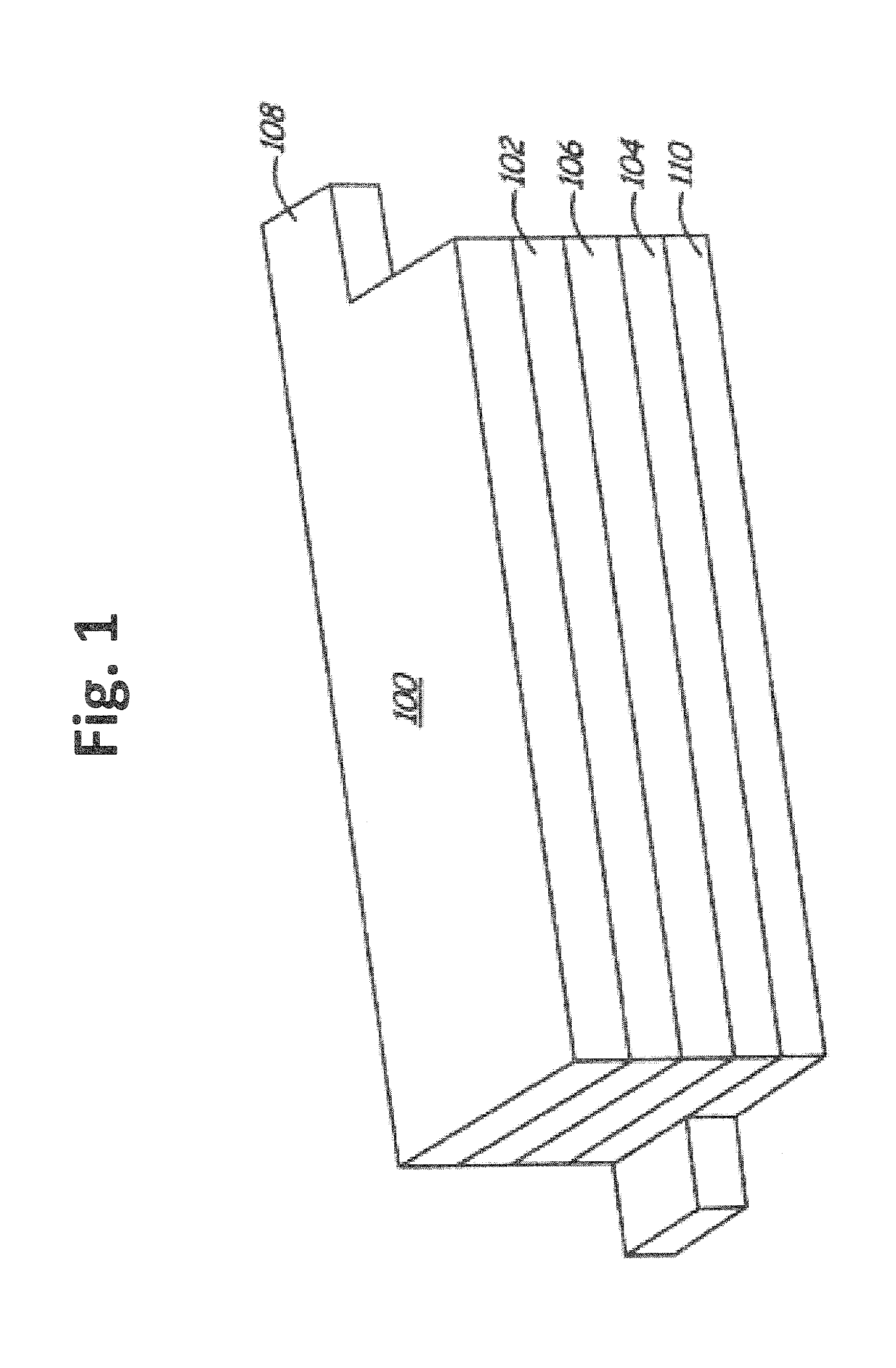

Semiconductor laminate, semiconductor device, and production method thereof

InactiveUS20130228902A1Avoid entrapmentLight absorptionSiliconFinal product manufactureDopantCrystal orientation

Provided is a method for manufacturing a semiconductor device. Also provided are: a semiconductor device which can be obtained by the method; and a dispersion that can be used in the method. A method for manufacturing a semiconductor device (500a) of the present invention comprises the steps (a)-(c) described below and is characterized in that the crystal orientation of a first dopant implanted layer (52) is the same as the crystal orientation of a semiconductor layer or a base (10) that is formed of a semiconductor element. (a) A dispersion which contains doped particles is applied to a specific part of a layer or a base. (b) An unsintered dopant implanted layer is obtained by drying the applied dispersion. (c) The specific part of the layer or the base is doped with a p-type or n-type dopant by irradiating the unsintered dopant implanted layer with light, and the unsintered dopant implanted layer is sintered, thereby obtaining a dopant implanted layer that is integrated with the layer or the base.

Owner:TEIJIN LTD

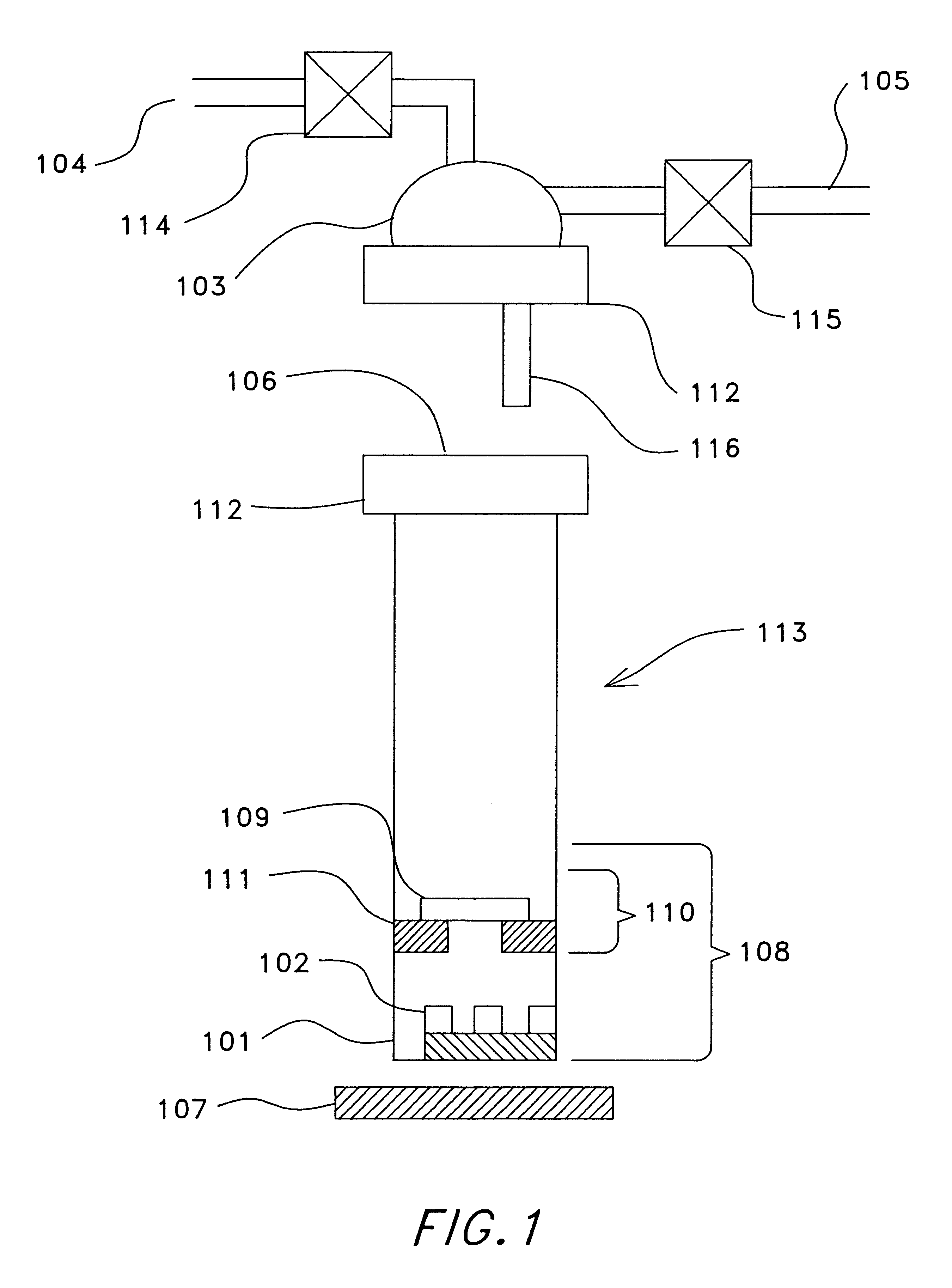

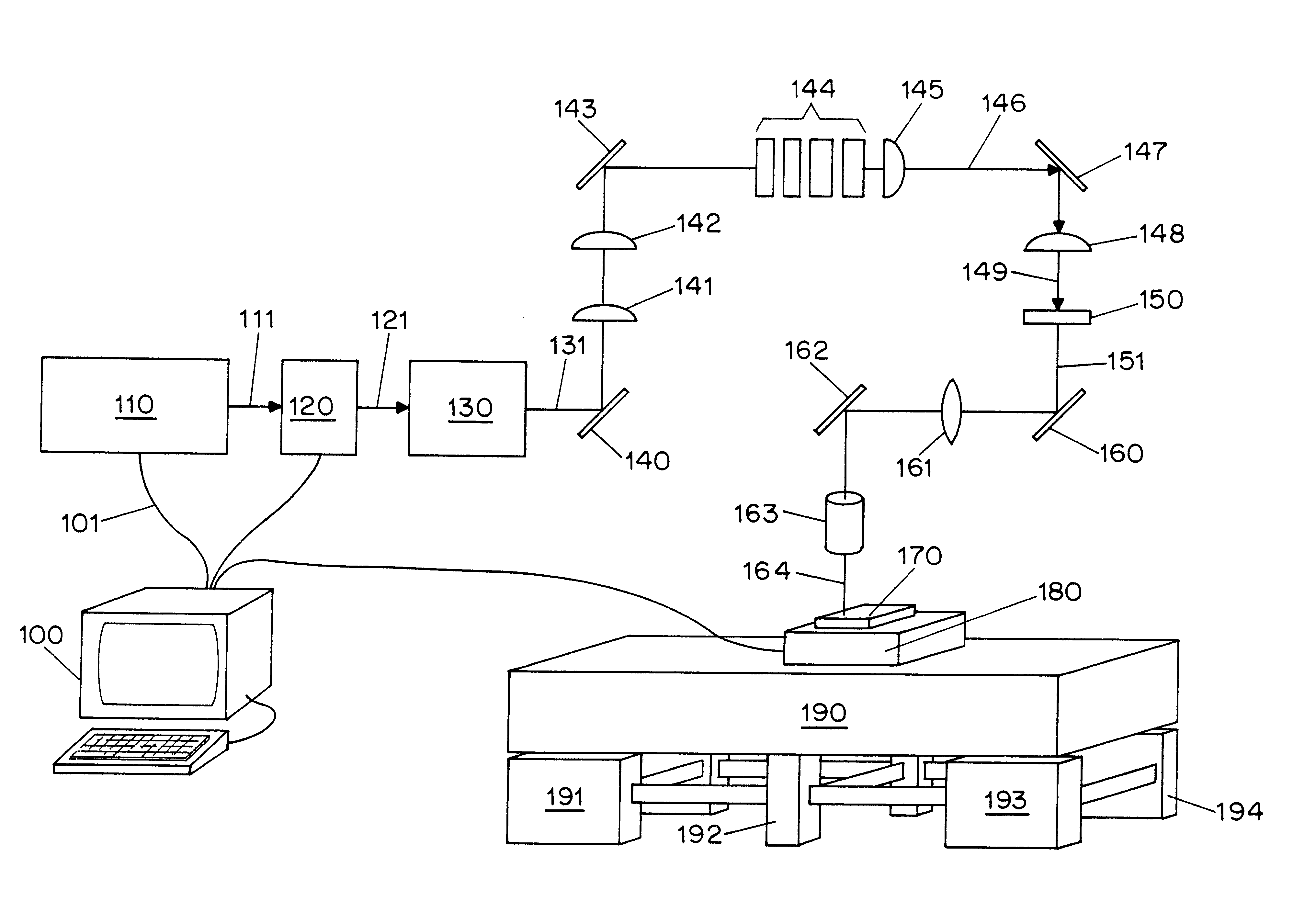

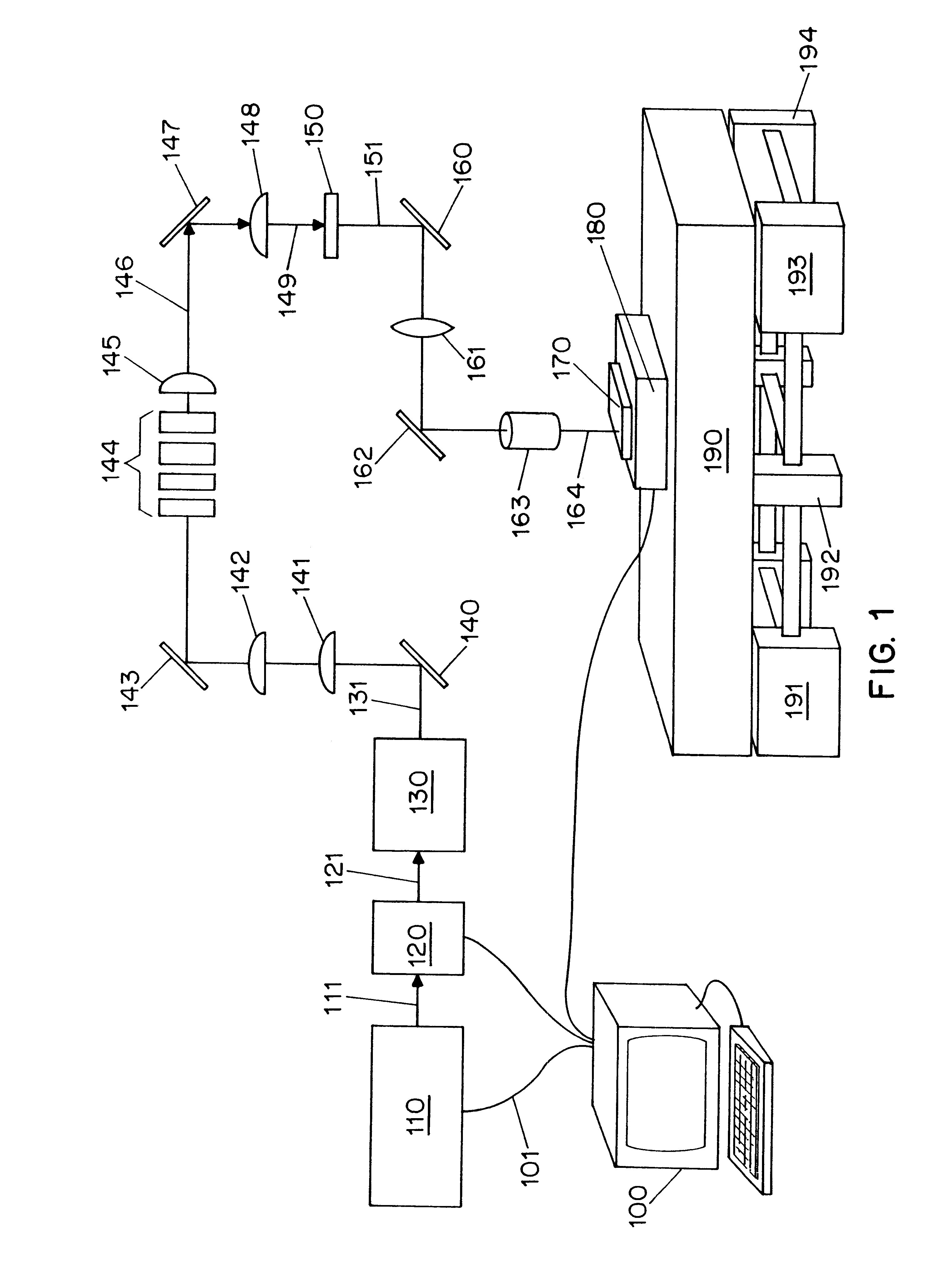

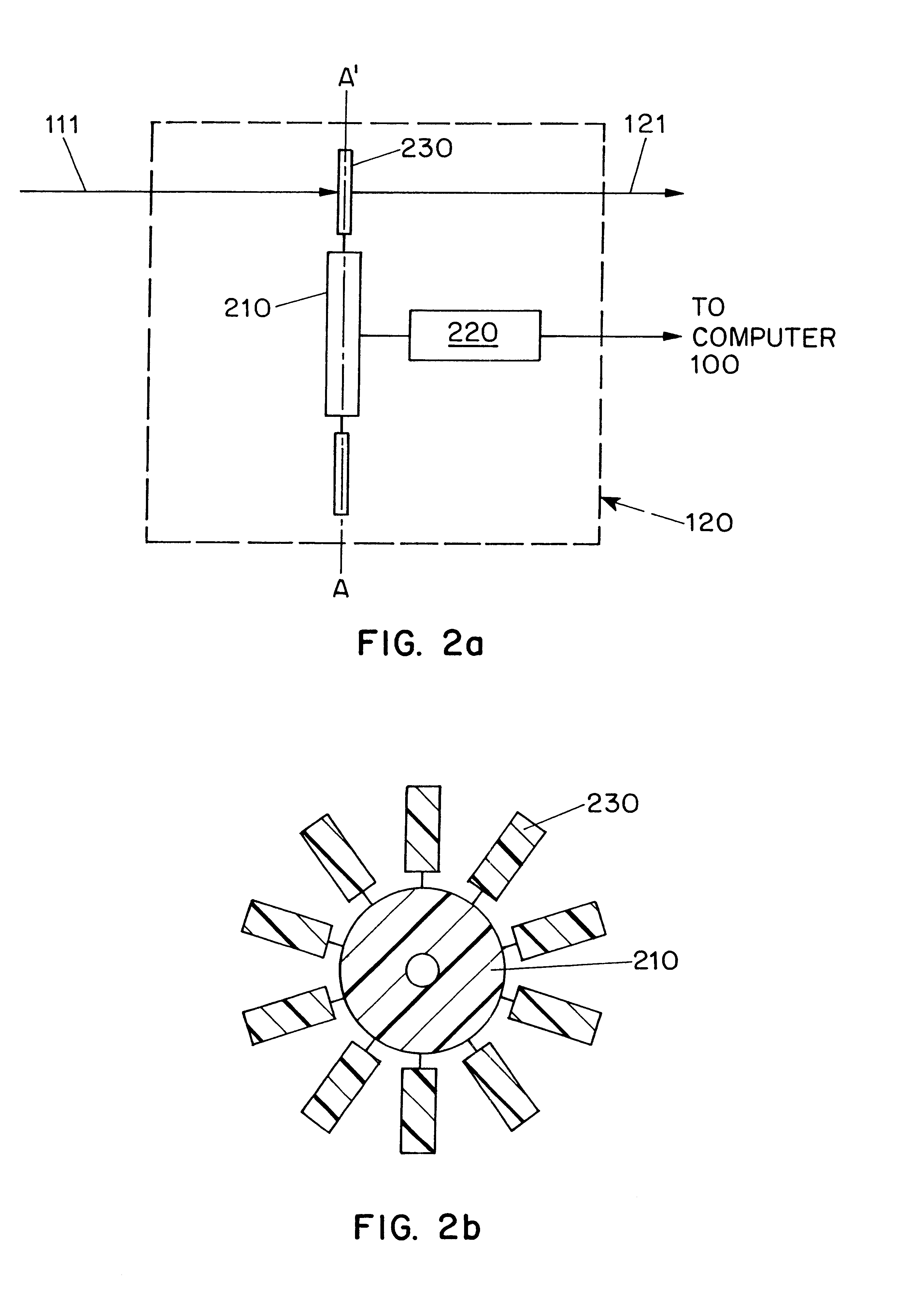

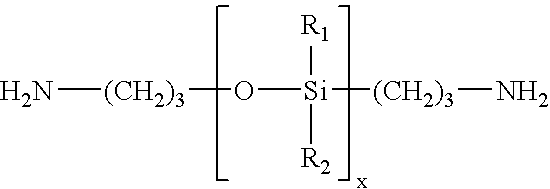

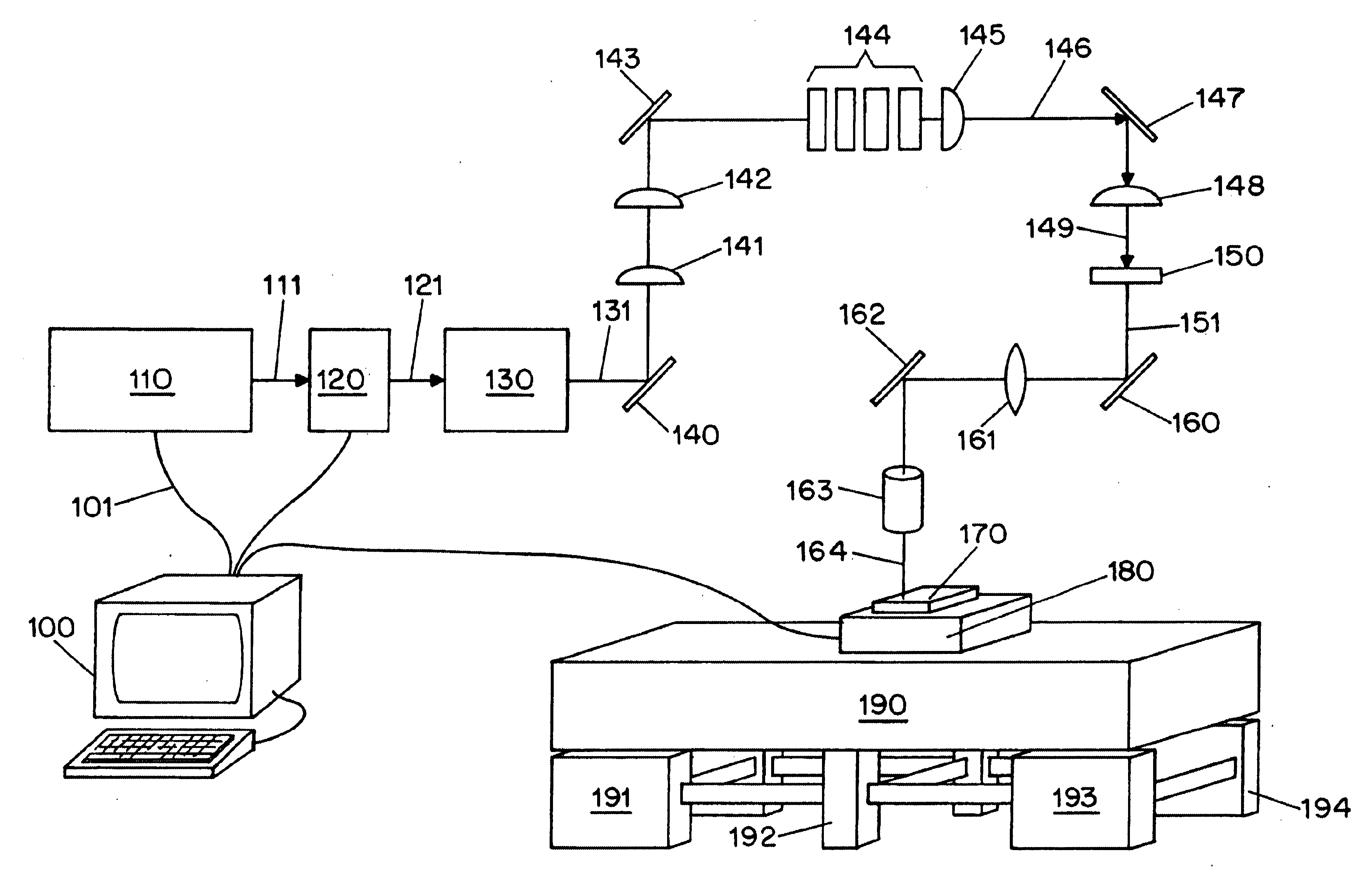

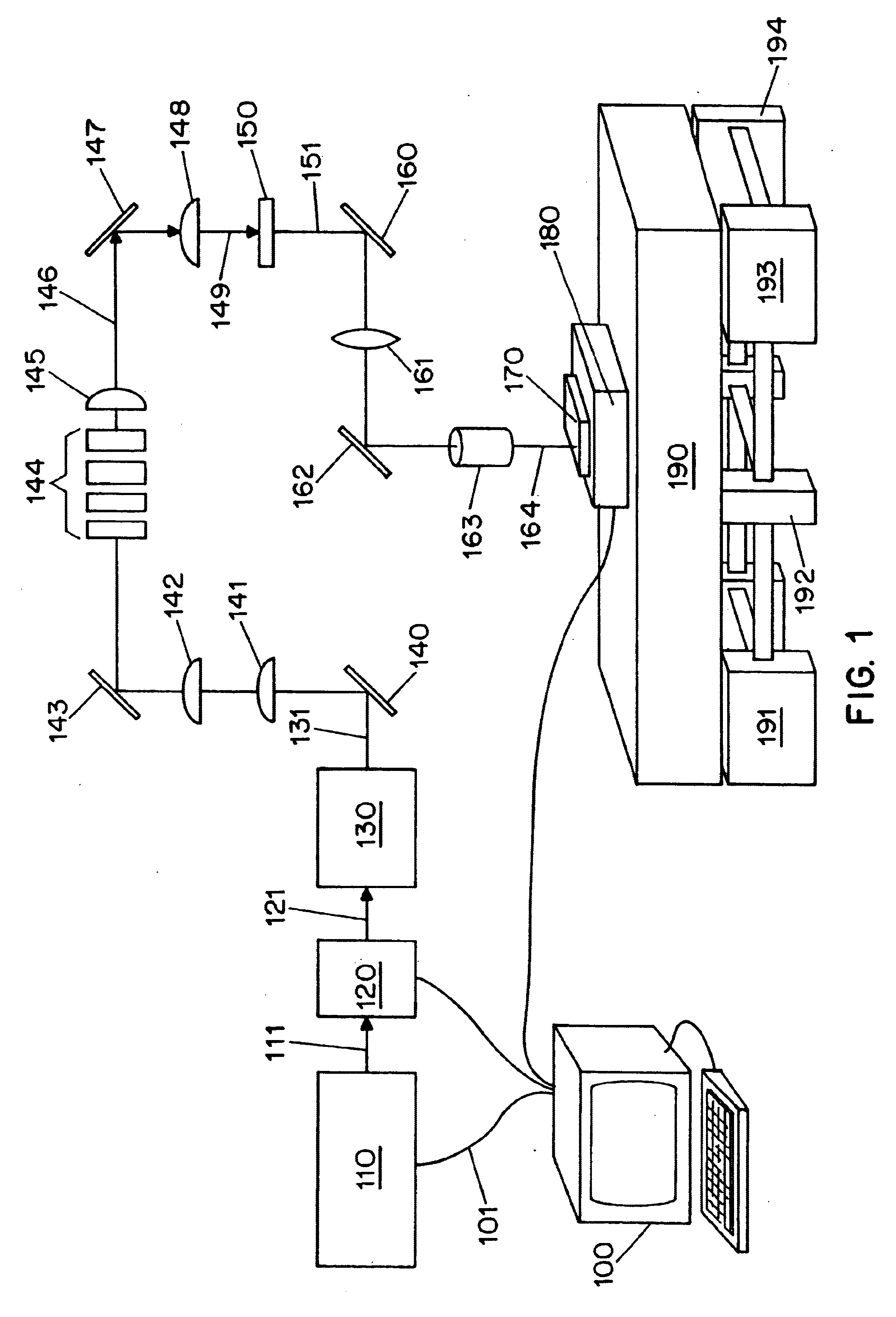

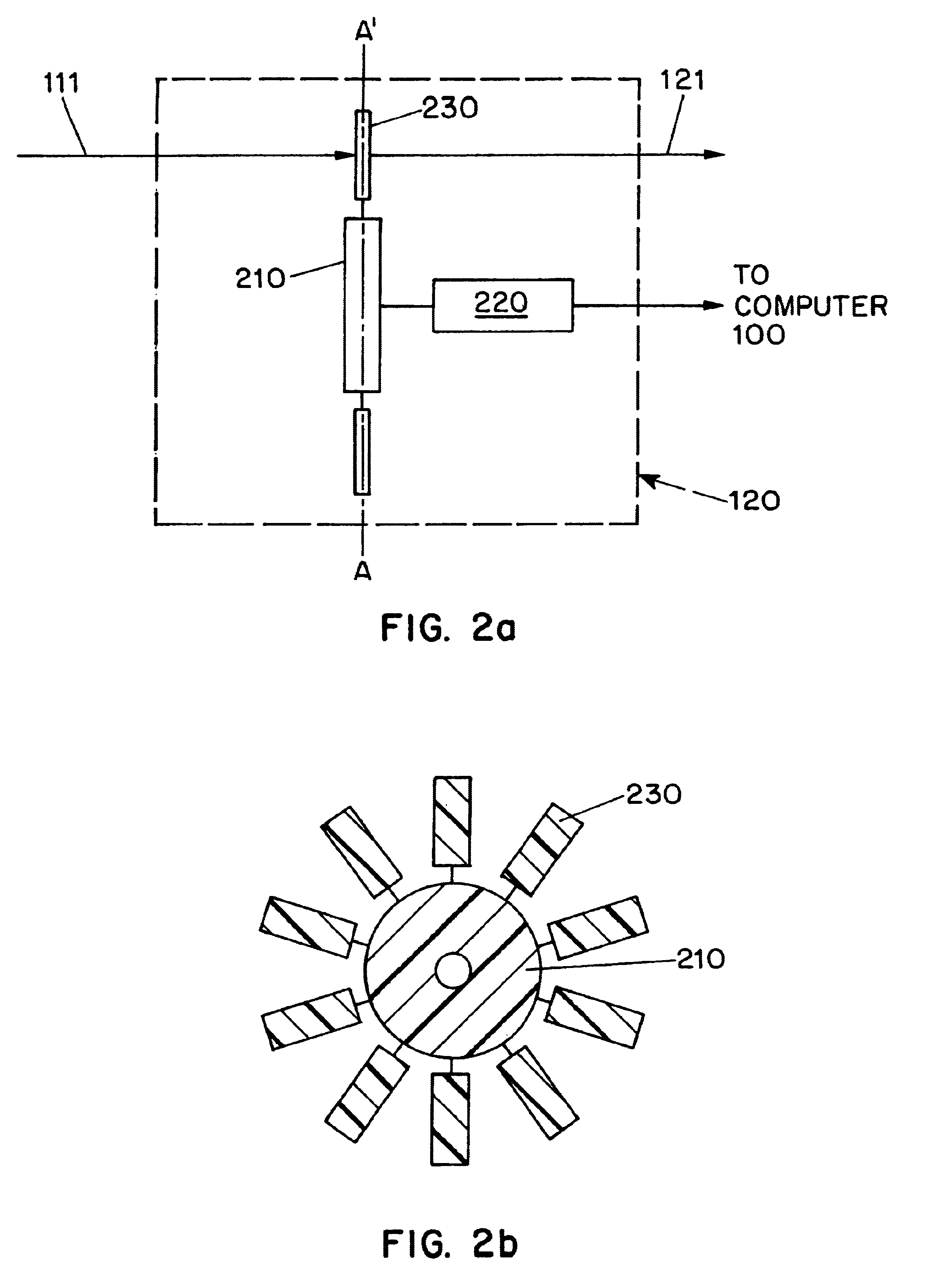

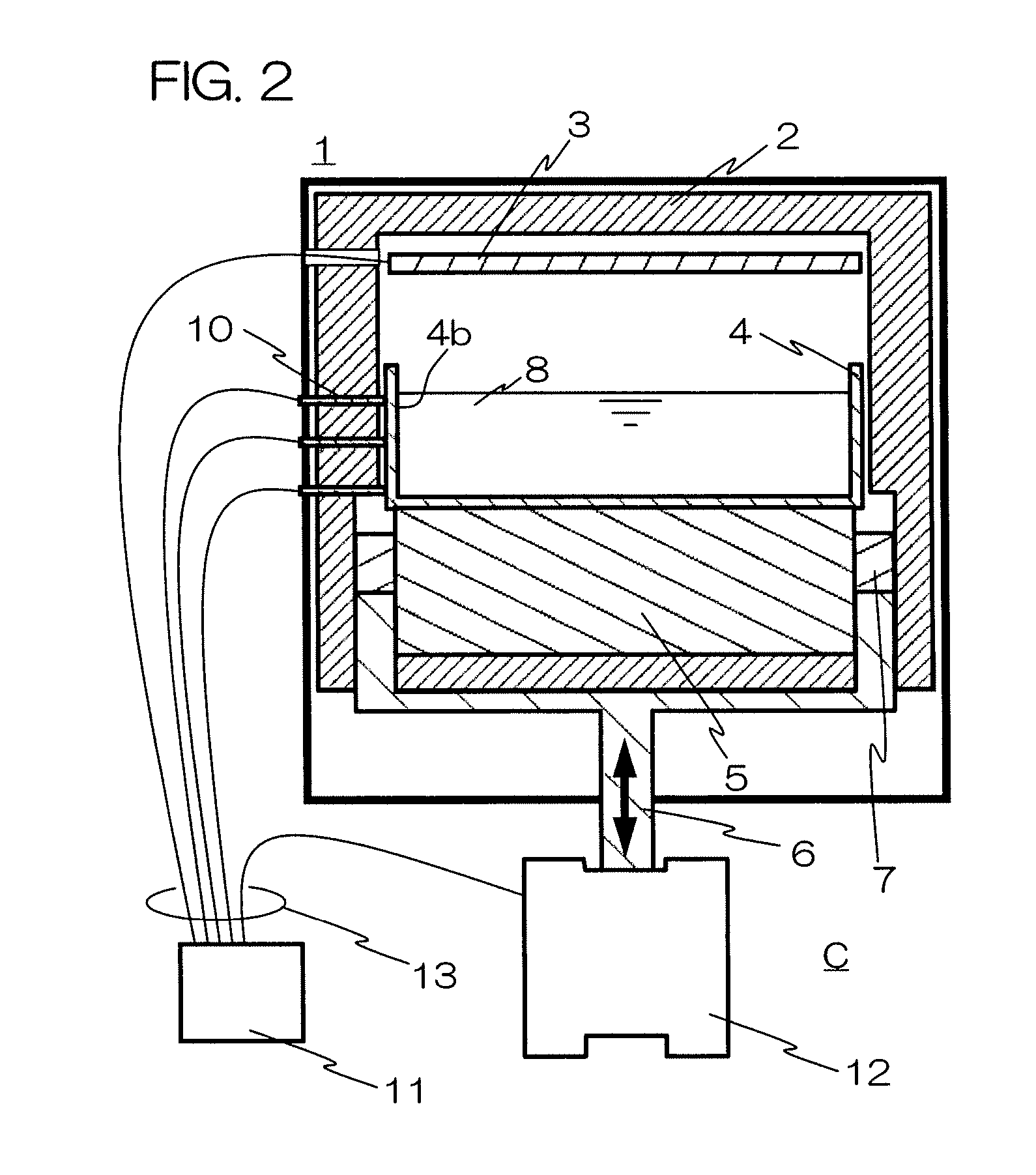

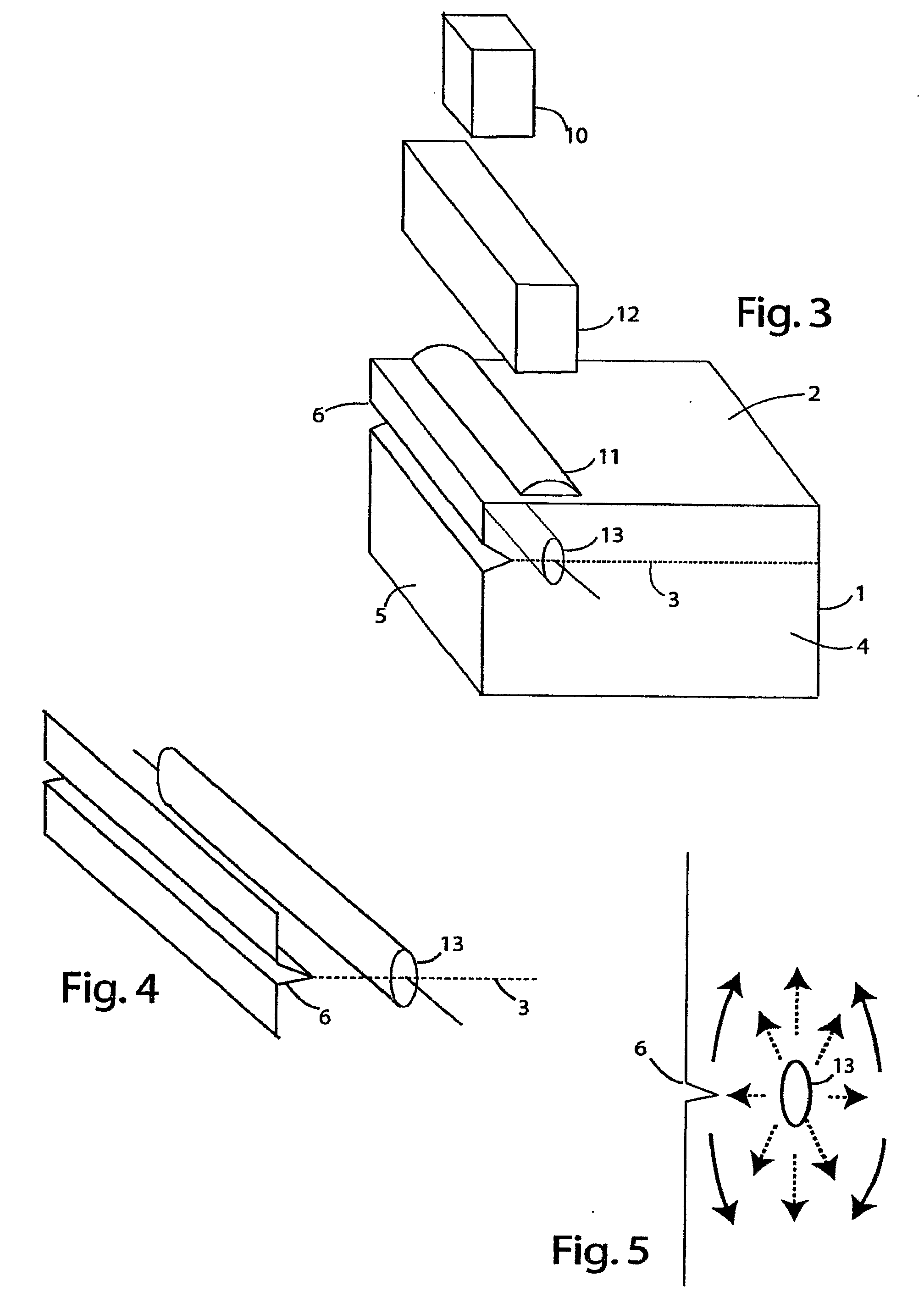

Systems and methods using sequential lateral solidification for producing single or polycrystalline silicon thin films at low temperatures

System and methods for processing an amorphous silicon thin film sample into a single or polycrystalline silicon thin film are disclosed. The system includes an excimer laser for generating a plurality of excimer laser pulses of a predetermined fluence, an energy density modulator for controllably modulating fluence of the excimer laser pulses, a beam homoginizer for homoginizing modulated laser pulses in a predetermined plane, a mask for masking portions of the homoginized modulated laser pulses into patterned beamlets, a sample stage for receivingthe patterned beamlets to effect melting of portions of any amorphous silicon thin film sample placed thereon corresponding to the beamlets, translating means for controllably translating a relative position of the sample stage with respect to a position of the mask and a computer for controlling the controllable fluence modulation of the excimer laser pulses and the controllable relative positions of the sample stage and mask, and for coordinating excimer pulse generation and fluence modulation with the relative positions of the sample stage and mask, to thereby process amorphous silicon thin film sample into a single or polycrystalline silicon thin film by sequential translation of the sample stage relative to the mask and irradiation of the sample by patterned beamlets of varying fluence at corresponding sequential locations thereon.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

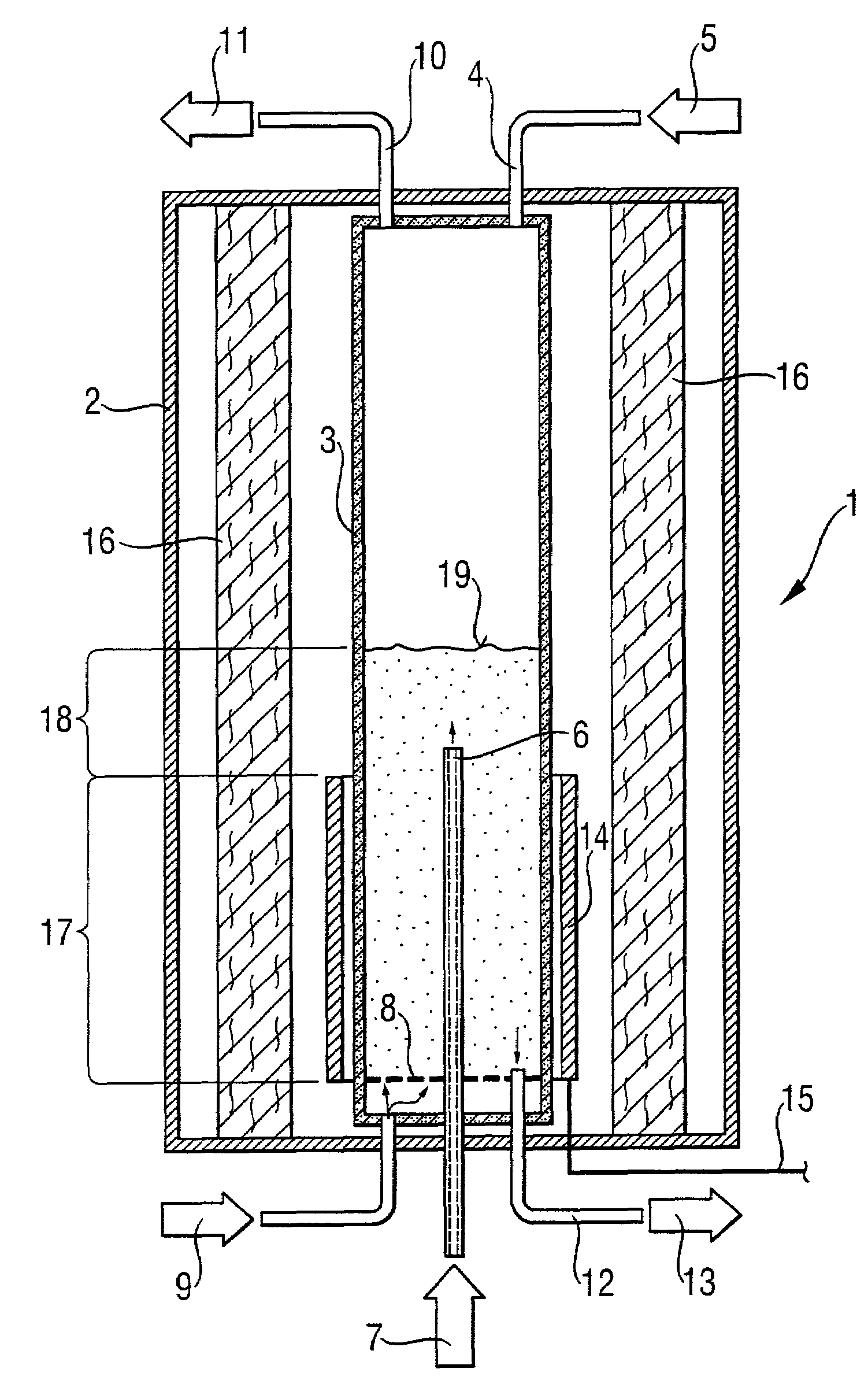

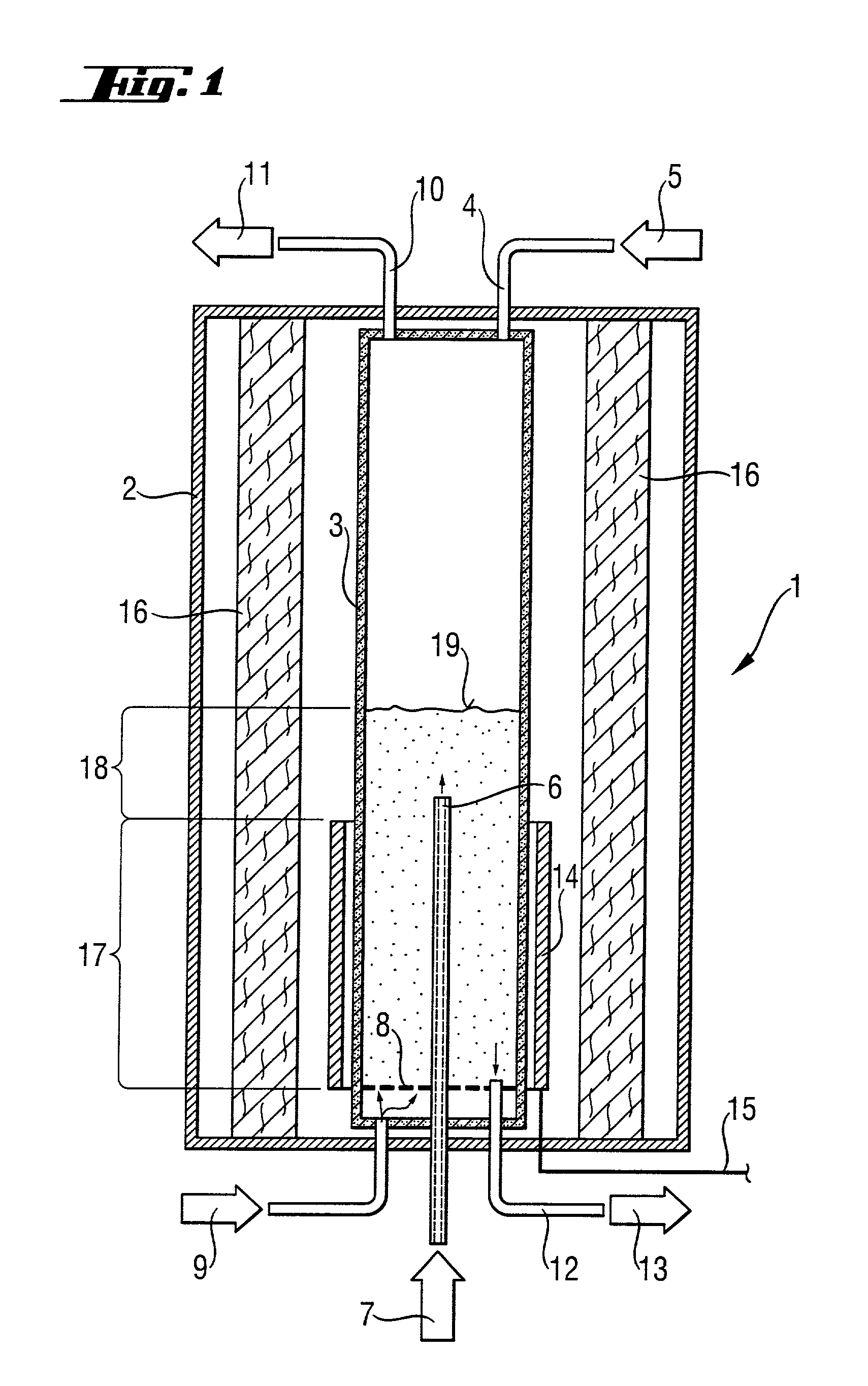

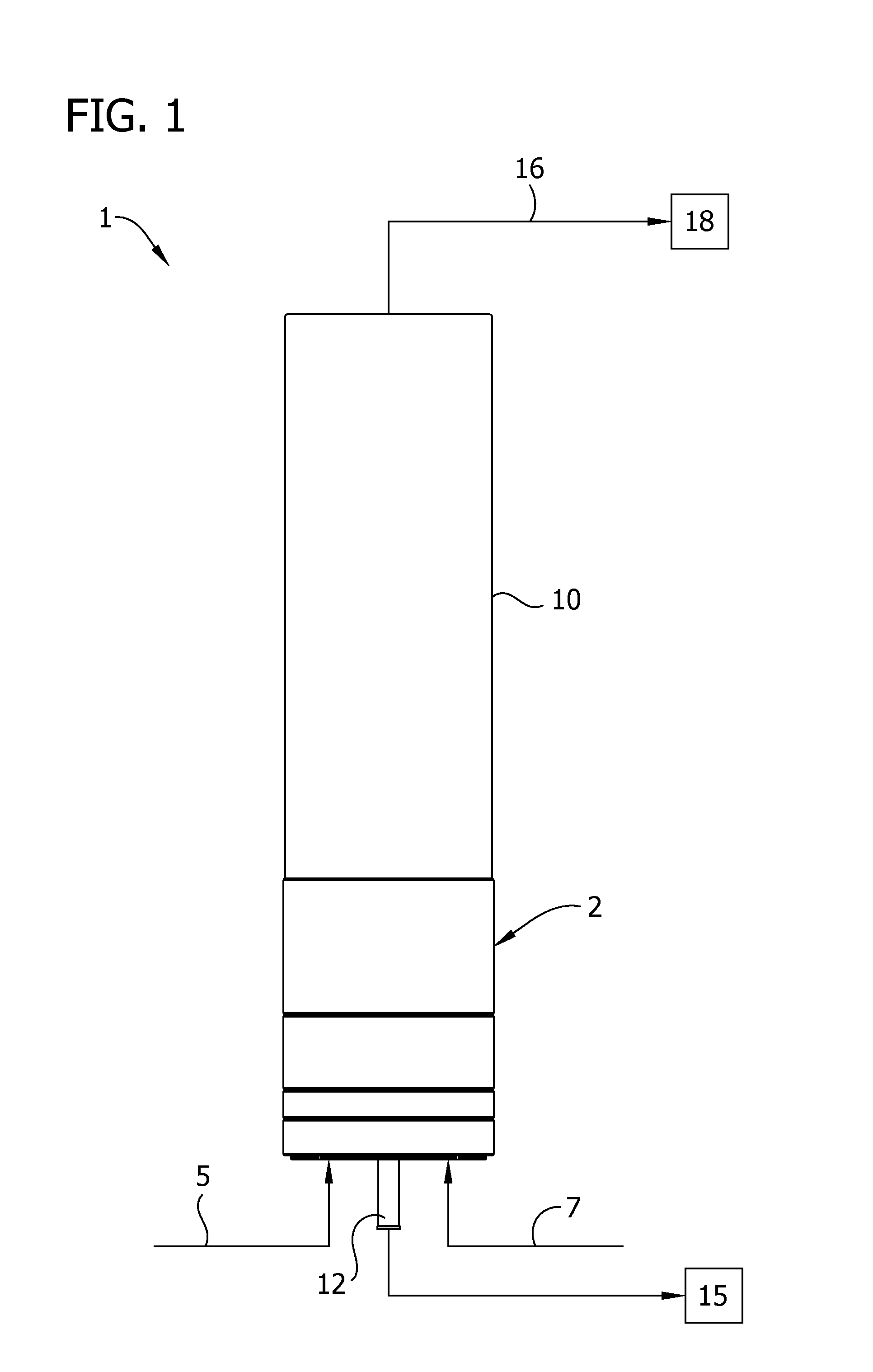

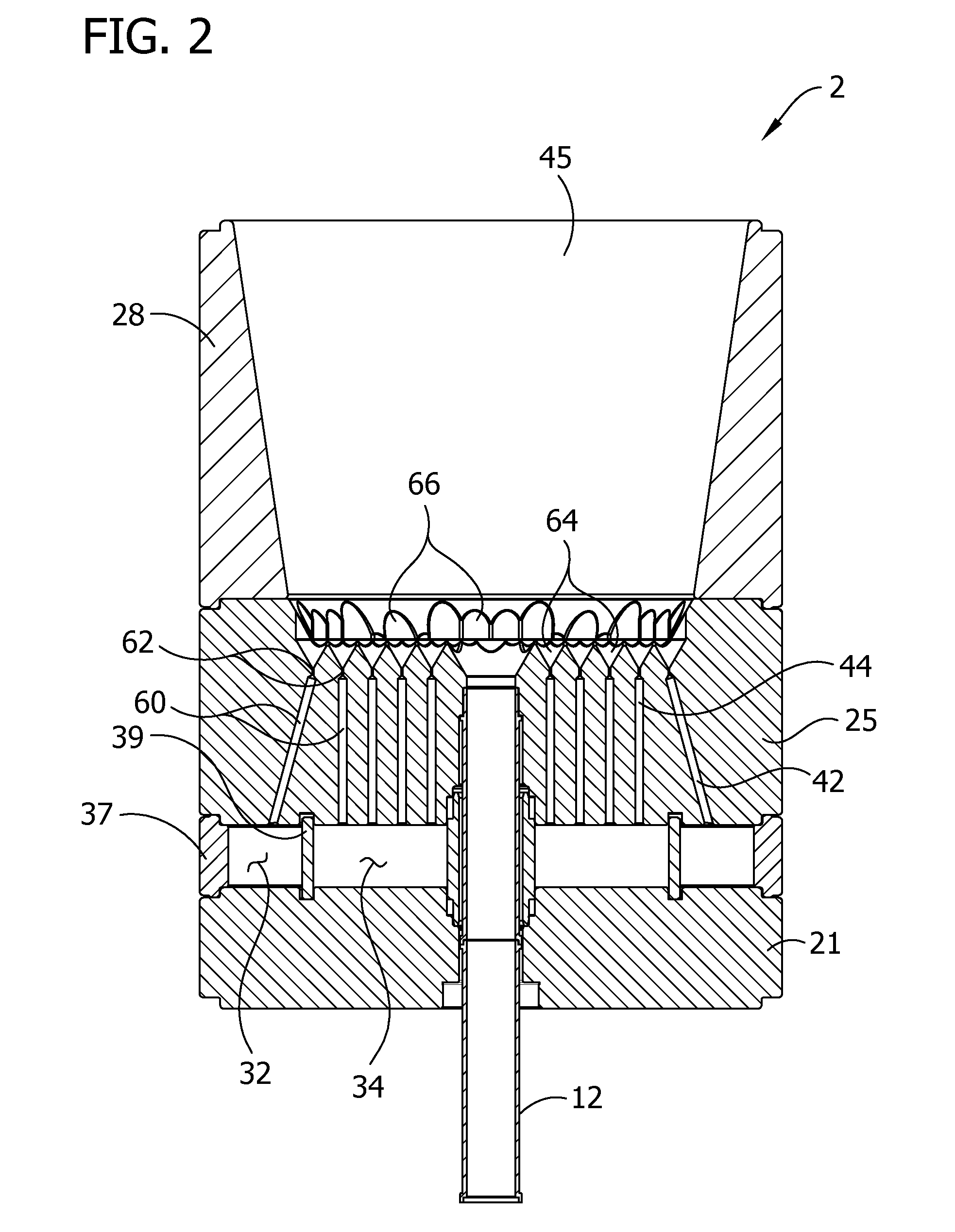

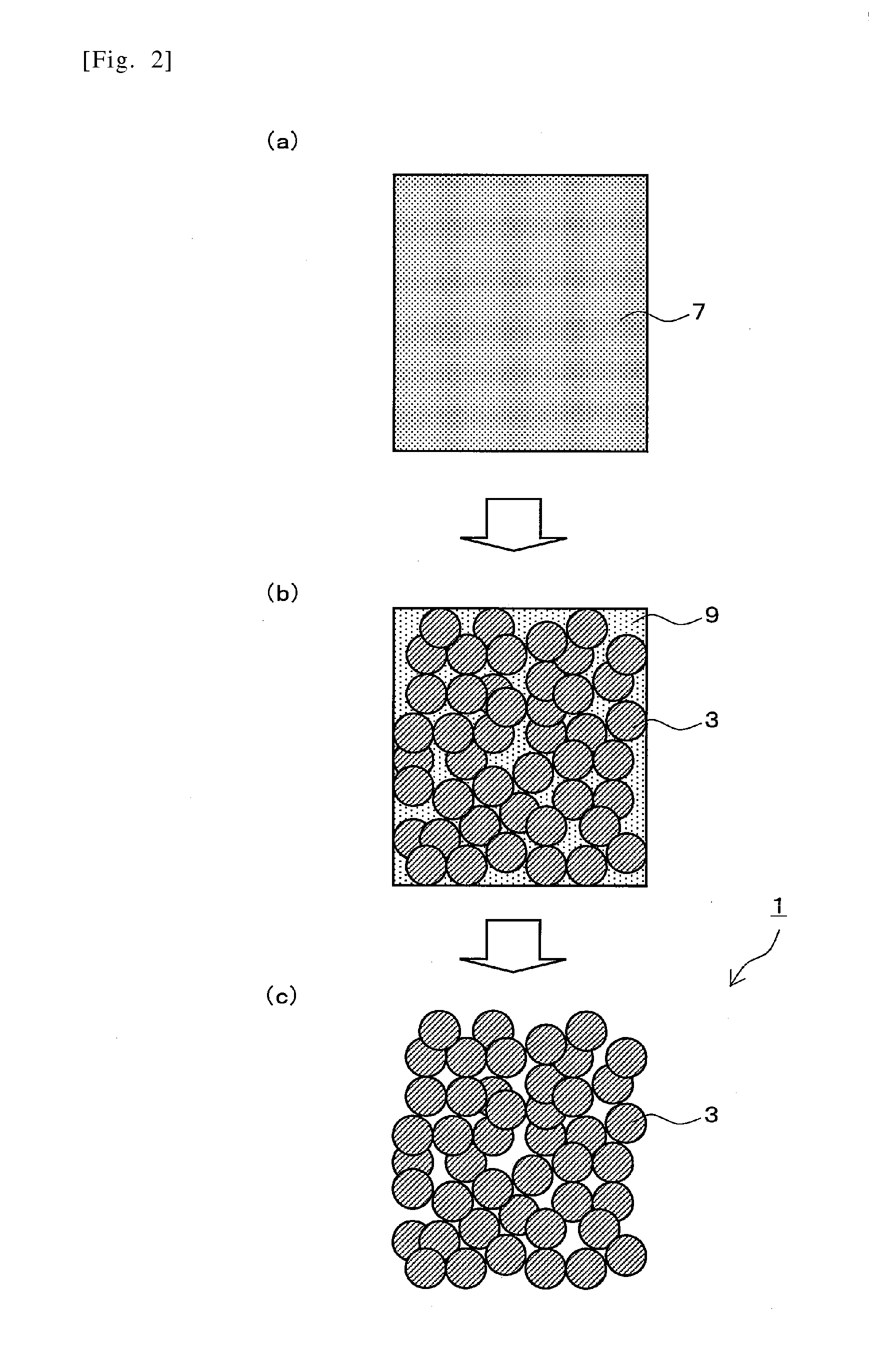

Radiation-heated fluidized-bed reactor

InactiveUS7029632B1Low levelHigh puritySiliconFluidised-bed furnacesFluidized bedReaction temperature

A radiation-heated fluidized-bed reactor and a process for producing high-purity polycrystalline silicon by using this reactor are provided. In this reactor, a heater device (14) is a radiation source for thermal radiation which is arranged outside the inner reactor tube and as a cylinder around the heater zone, without being in direct contact with the inner reactor tube. The inner reactor tube is designed in such a manner that it uses thermal radiation to heat the silicon particles in the heating zone to a temperature which is such that the reaction temperature is established in the reaction zone.

Owner:WACKER CHEM GMBH

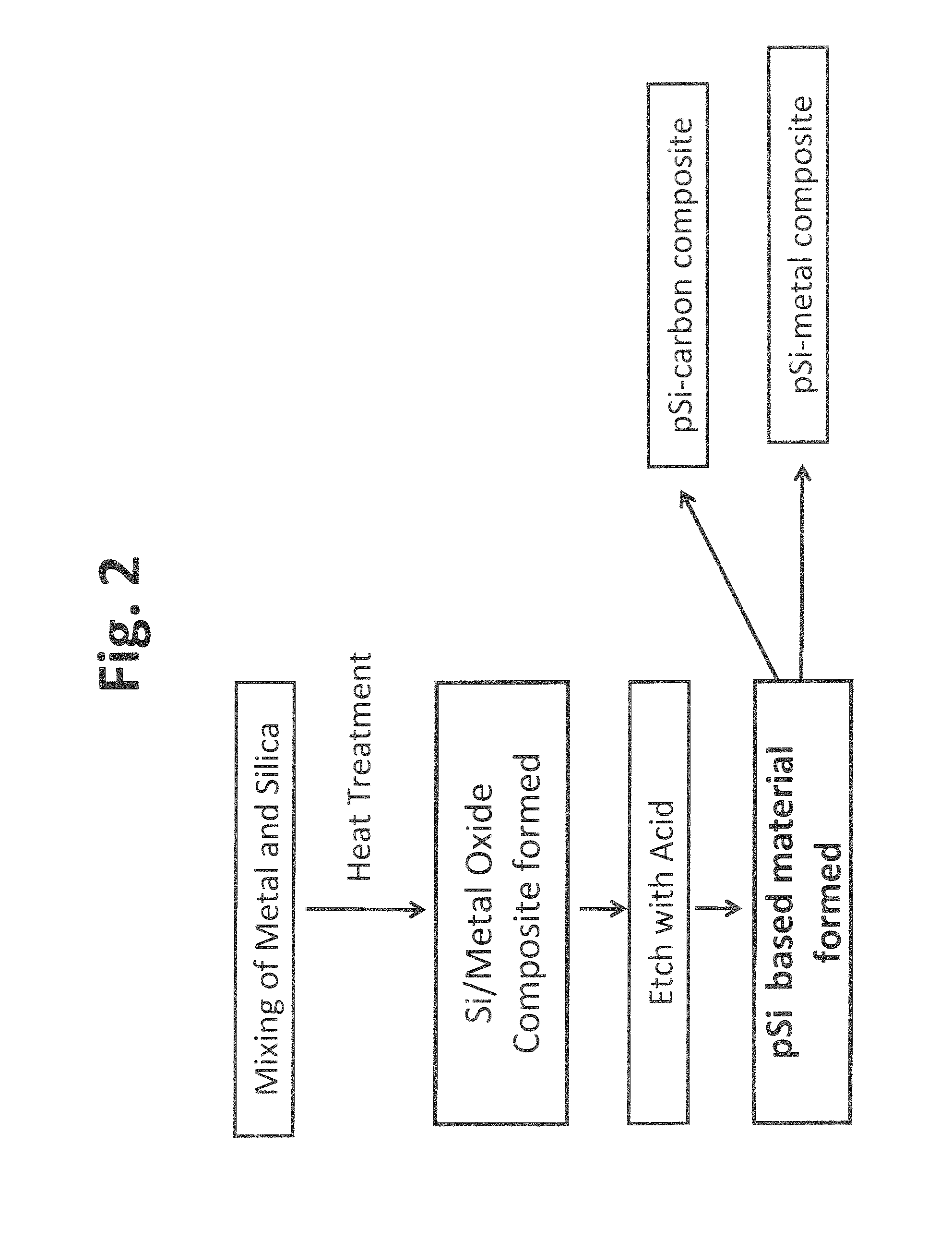

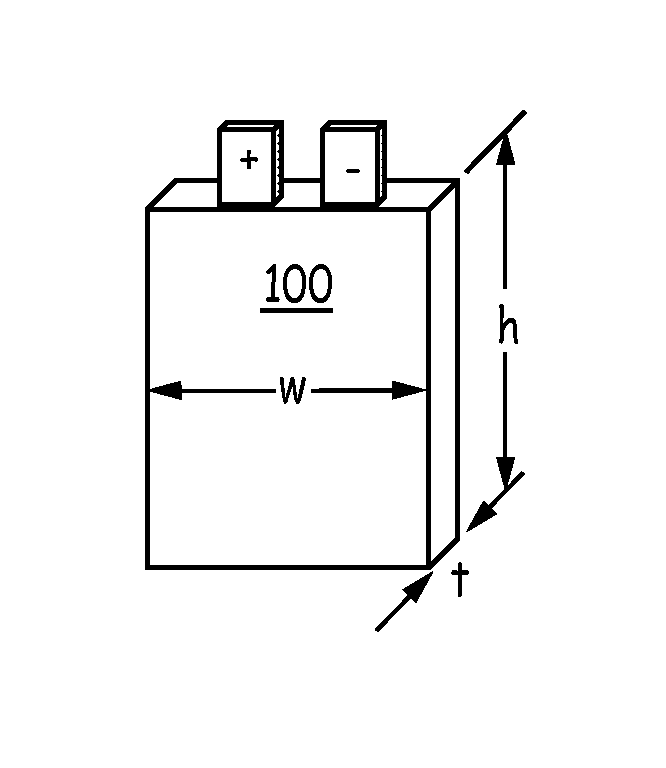

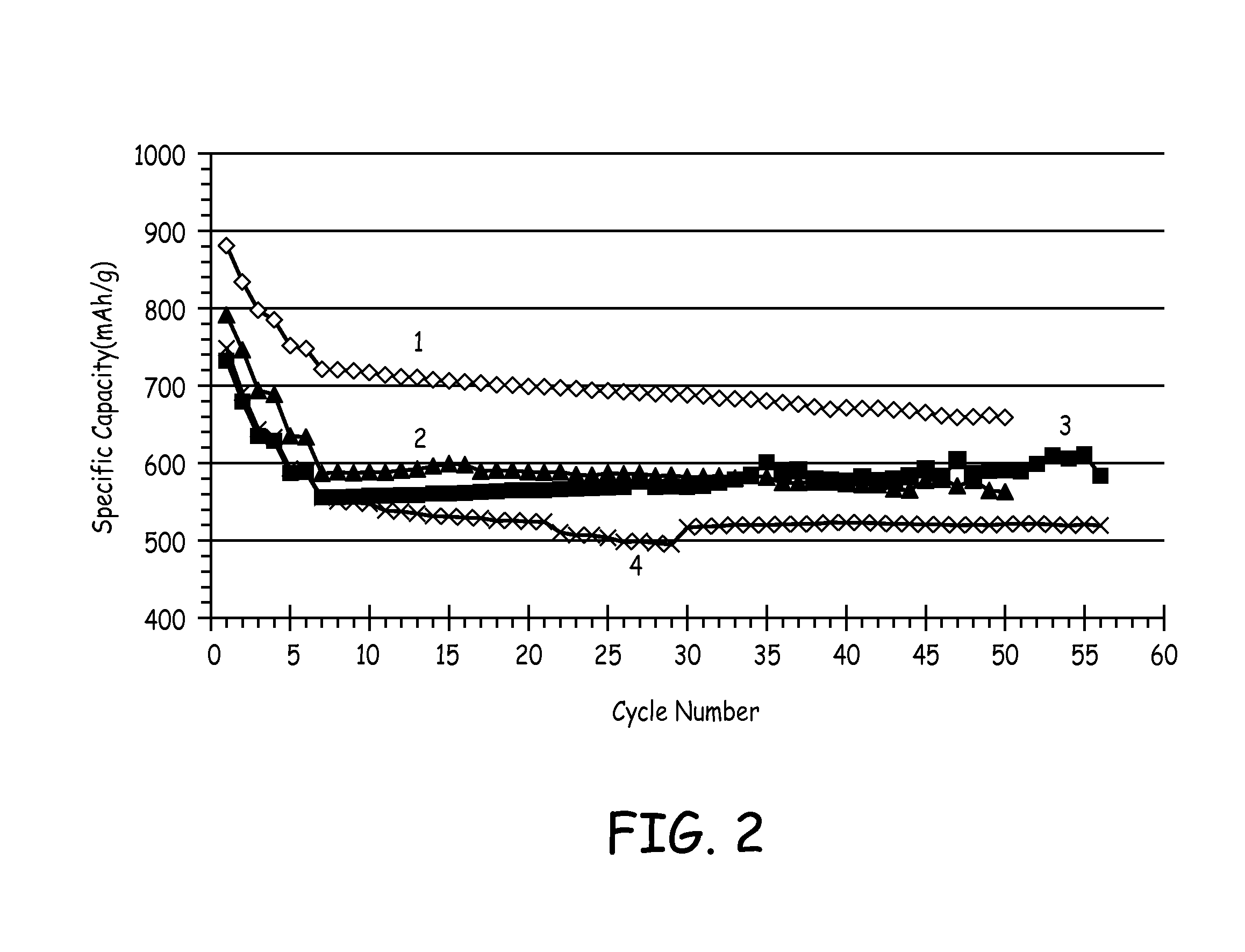

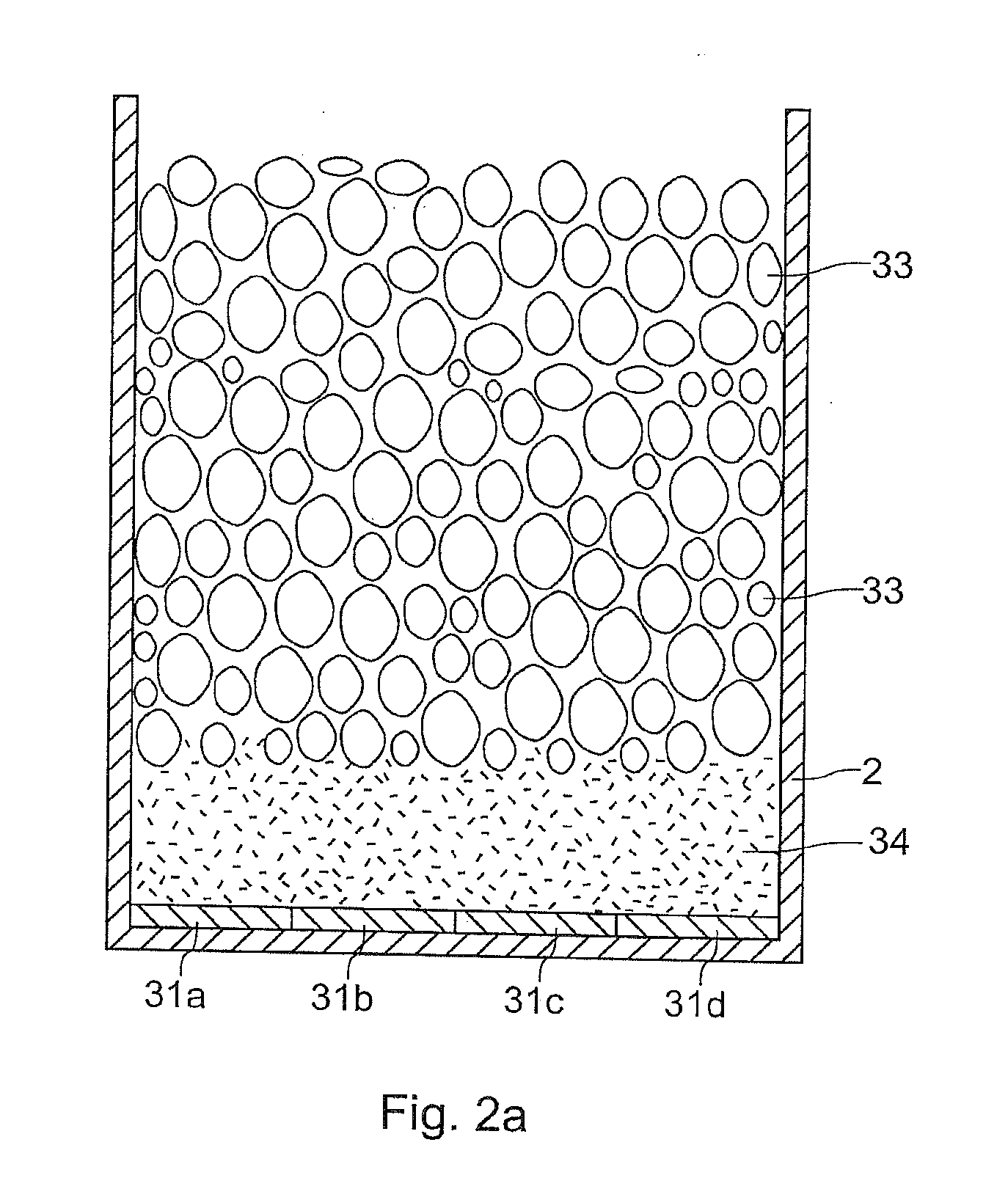

Porous silicon based anode material formed using metal reduction

A porous silicon based material comprising porous crystalline elemental silicon formed by reducing silicon dioxide with a reducing metal in a heating process followed by acid etching is used to construct negative electrode used in lithium ion batteries. Gradual temperature heating ramp(s) with optional temperature steps can be used to perform the heating process. The porous silicon formed has a high surface area from about 10 m2 / g to about 200 m2 / g and is substantially free of carbon. The negative electrode formed can have a discharge specific capacity of at least 1800 mAh / g at rate of C / 3 discharged from 1.5V to 0.005V against lithium with in some embodiments loading levels ranging from about 1.4 mg / cm2 to about 3.5 mg / cm2. In some embodiments, the porous silicon can be coated with a carbon coating or blended with carbon nanofibers or other conductive carbon material.

Owner:IONBLOX INC

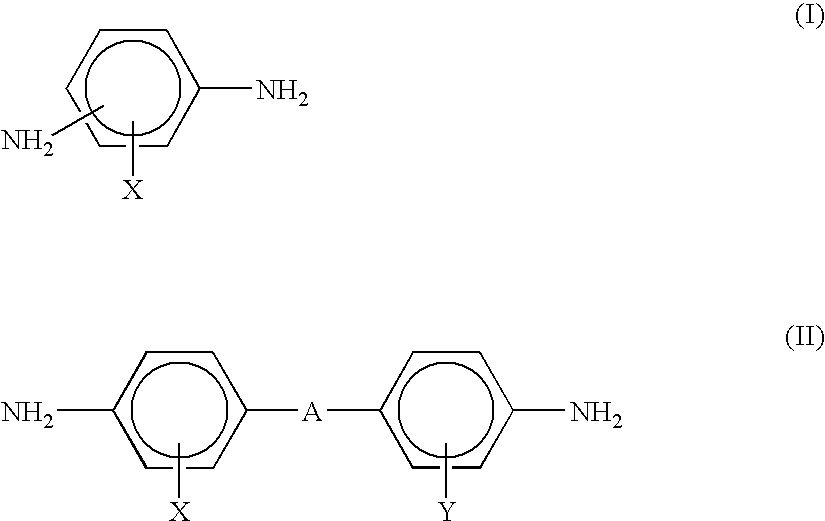

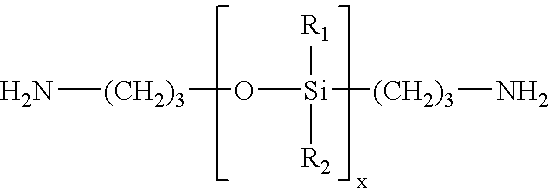

Polyimide aerogels, carbon aerogels, and metal carbide aerogels and methods of making same

InactiveUS20040132845A1Reduce nitrogen contentSuperior physical and electrical propertyMaterial nanotechnologySiliconPolymer scienceCarbide

A preparation process of polyimide aerogels that composed of aromatic dianhydrides and aromatic diamines or a combined aromatic and aliphatic diamines is described. Also descried is a process to produce carbon aerogels derived from polyimide aerogel composed of a rigid aromatic diamine and an aromatic dianhydride. Finally, the processes to produce carbon aerogels or xerogel-aerogel hybrid, both of which impregnated with highly dispersed transition metal clusters, and metal carbide aerogels, deriving from the polyimide aerogels composed of a rigid aromatic diamine and an aromatic dianhydride, are described. The polyimide aerogels and the polyimide aerogel derivatives consist of interconnecting mesopores with average pore size at 10 to 30 nm and a mono-dispersed pore size distribution. The gel density could be as low as 0.008 g / cc and accessible surface area as high as 1300 m<2> / g.

Owner:ASPEN AEROGELS INC

Systems and methods using sequential lateral solidification for producing single or polycrystalline silicon thin films at low temperatures

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

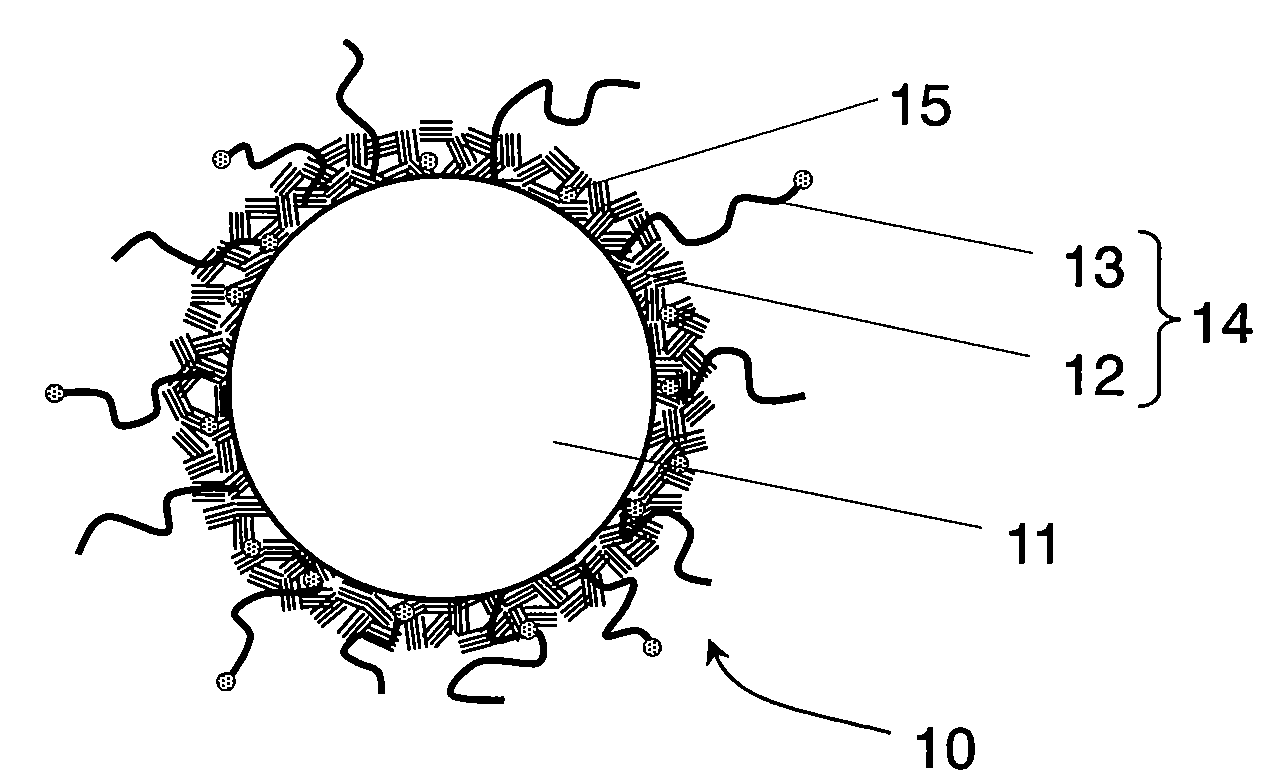

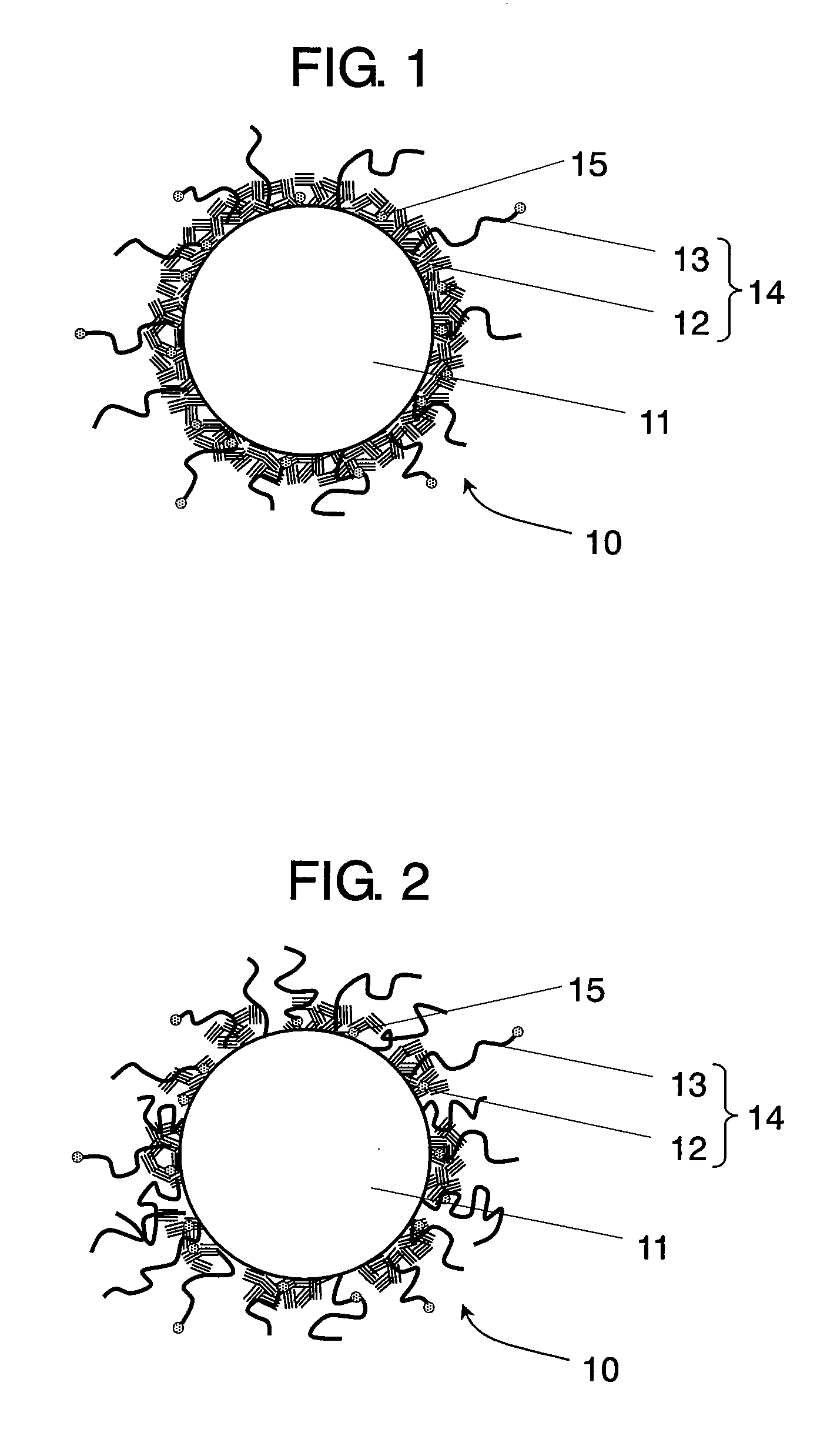

Carbon nanotube-coated silicon/metal composite particle, preparation method thereof, and anode for secondary battery and secondary battery using the same

InactiveUS20100092868A1Small volume changeImprove conductivityMaterial nanotechnologySiliconPhysical chemistryNanotube

Disclosed are a carbon nanotube-coated silicon / metal composite particle, a preparation method thereof, an anode for a secondary battery comprising the carbon nanotube-coated silicon / metal composite particle, and a secondary battery comprising the anode, wherein the carbon nanotube-coated silicon / metal composite particle characterized in comprising: a composite particle of silicon and metal; and a carbon nanotube coated on the surface of the composite particle of silicon and metal, wherein the carbon nanotube-coated silicon / metal composite particle may be prepared by preparing composite particle of silicon and metal, followed by treating the composite particles of silicon and metal with heat under a mixed gas atmosphere of an inert gas and a hydrocarbon gas.

Owner:KOREA INST OF SCI & TECH

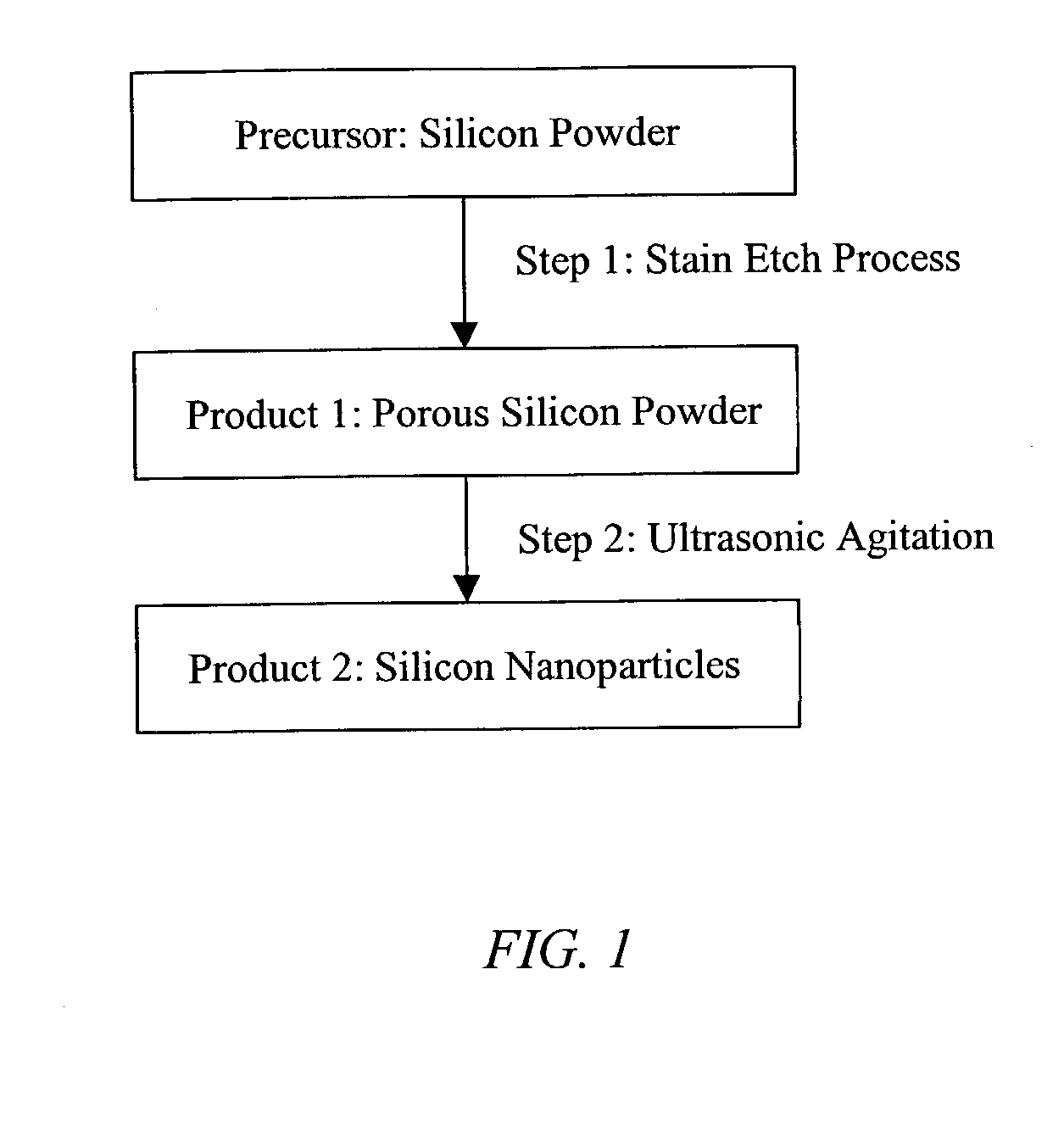

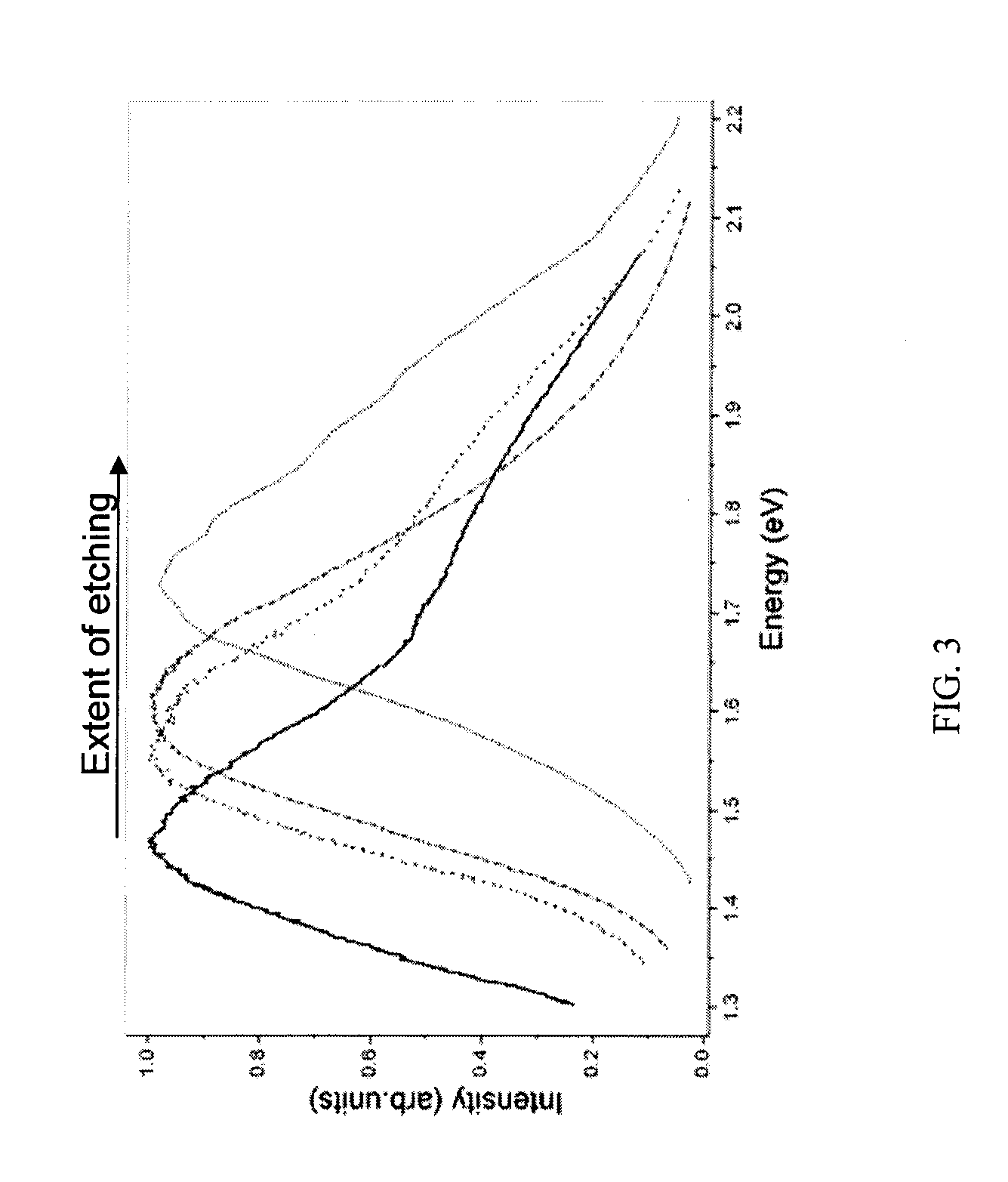

Method of producing silicon nanoparticles from stain-etched silicon powder

The present invention is for a porous silicon powder comprising silicon particles wherein the outermost layers of said particles are porous. The present invention is also directed to a method of making this porous silicon powder using a stain etch method. The present invention is also directed to a method of making silicon nanoparticles from the porous silicon powders using a process of ultrasonic agitation. The present invention also includes methods of processing these silicon nanoparticles for use in a variety of applications.

Owner:SI DIAMOND TECH

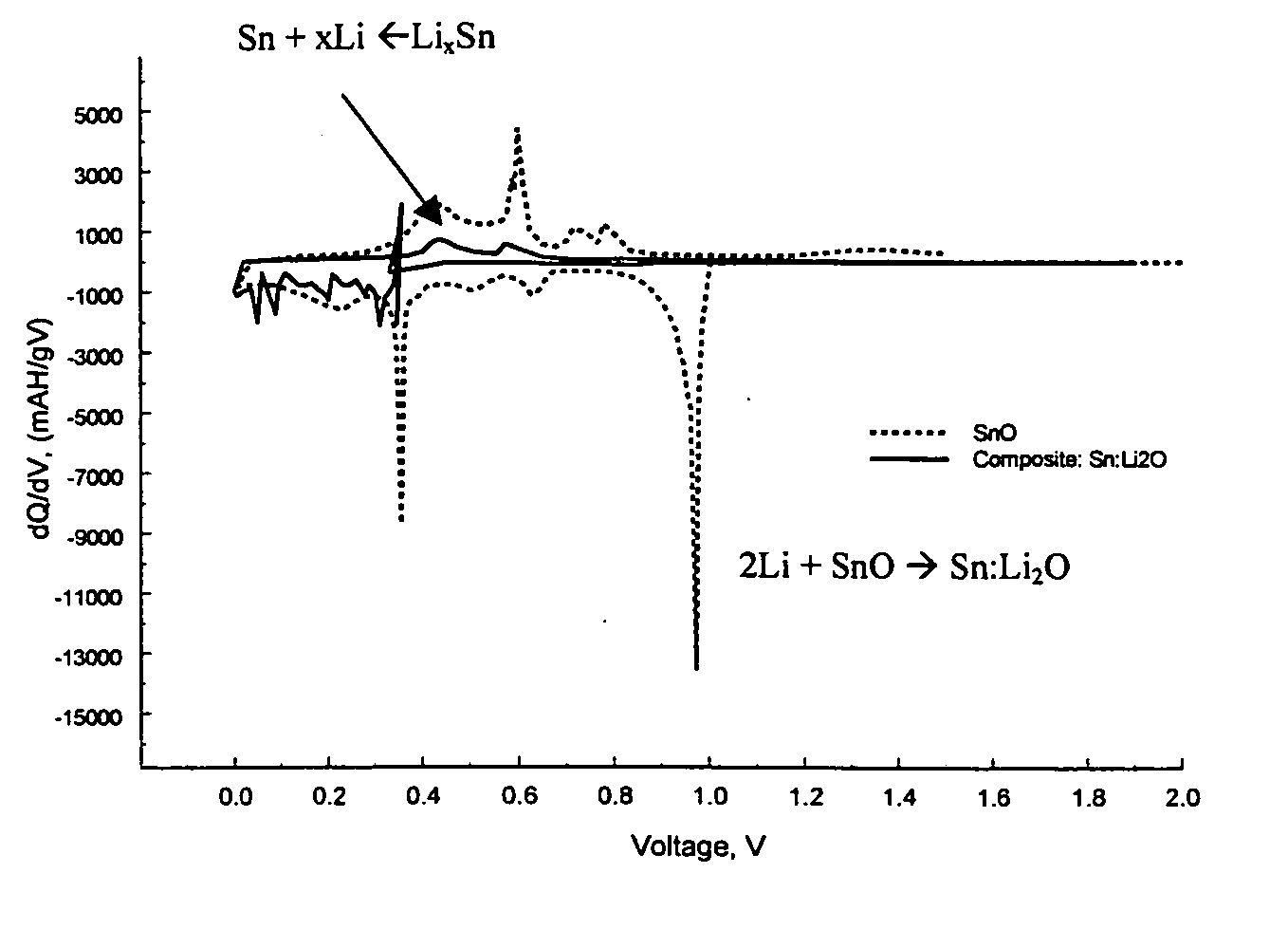

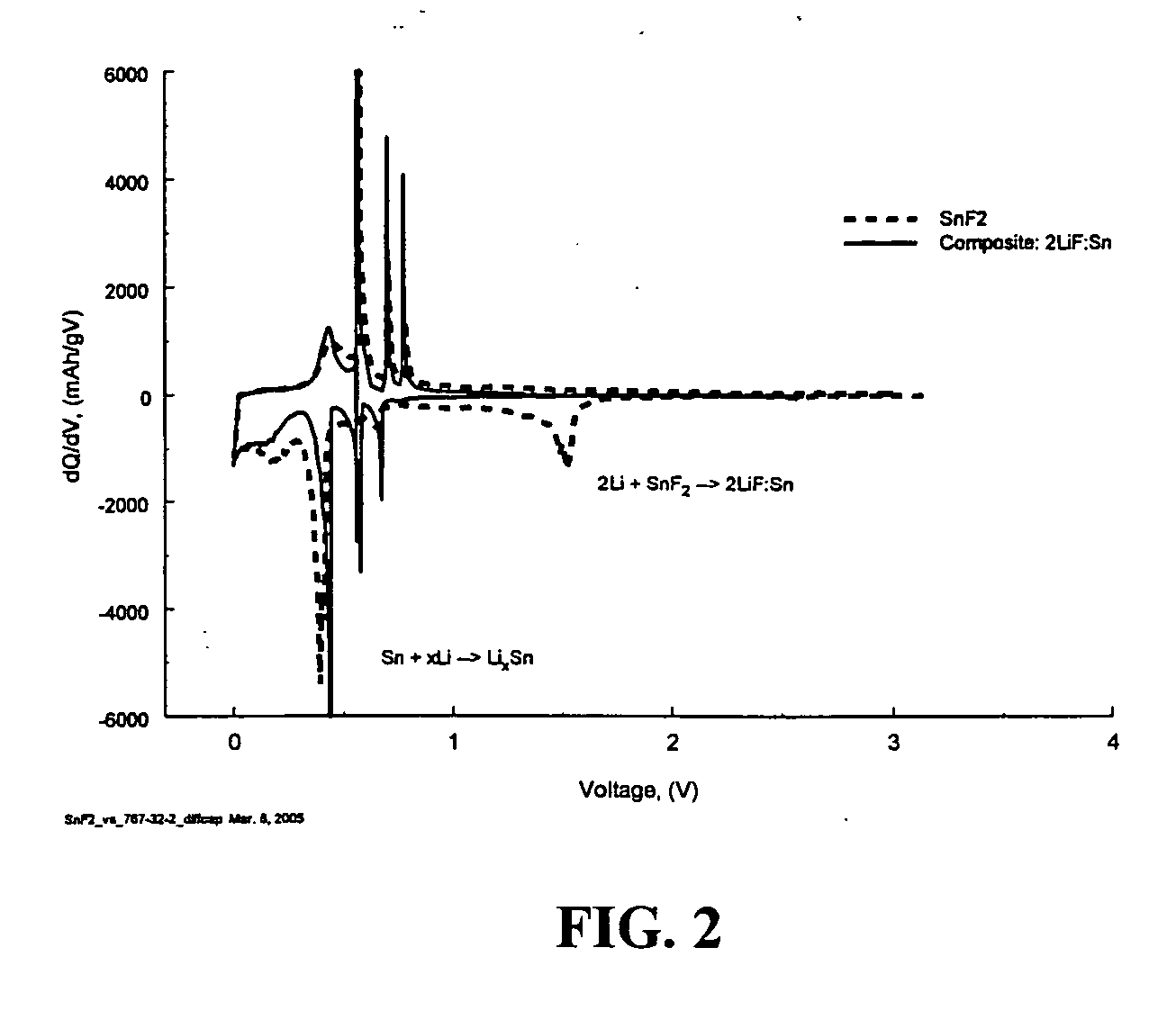

Composite materials of nano-dispersed silicon and tin and methods of making the same

Composite compounds of tin and lithium, silicon and lithium, or tin, silicon, and lithium having tin and silicon nano-dispersed in a lithium-containing matrix may be used as electrode materials and particularly anode materials for use with rechargeable batteries. Methods of making the composite compounds include the oxidation of alloys, the reaction of stabilized lithium metal powder with tin and silicon oxides, and the reaction of inorganic salts of lithium with tin and silicon containing compounds.

Owner:LIVENT USA CORP

Non-aqueous electrolyte secondary cell negative electrode material and metallic silicon power therefor

InactiveUS20060051670A1Improve cycle performanceLow costSiliconSynthetic resin layered productsImpuritySilicon

A metallic silicon powder is prepared by effecting chemical reduction on silica stone, metallurgical refinement, and metallurgical and / or chemical purification to reduce the content of impurities. The powder is best suited as a negative electrode material for non-aqueous electrolyte secondary cells, affording better cycle performance.

Owner:SHIN ETSU CHEM IND CO LTD

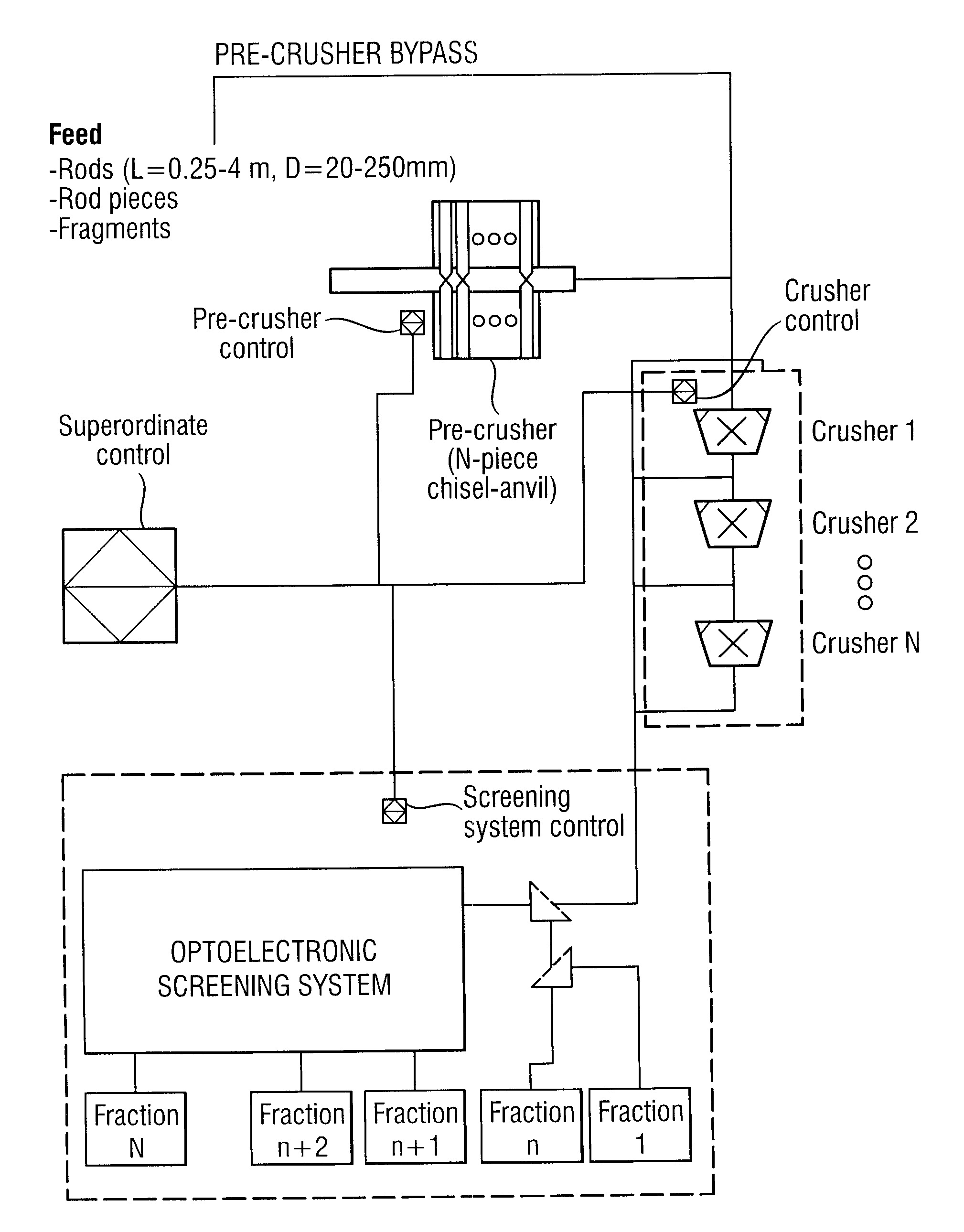

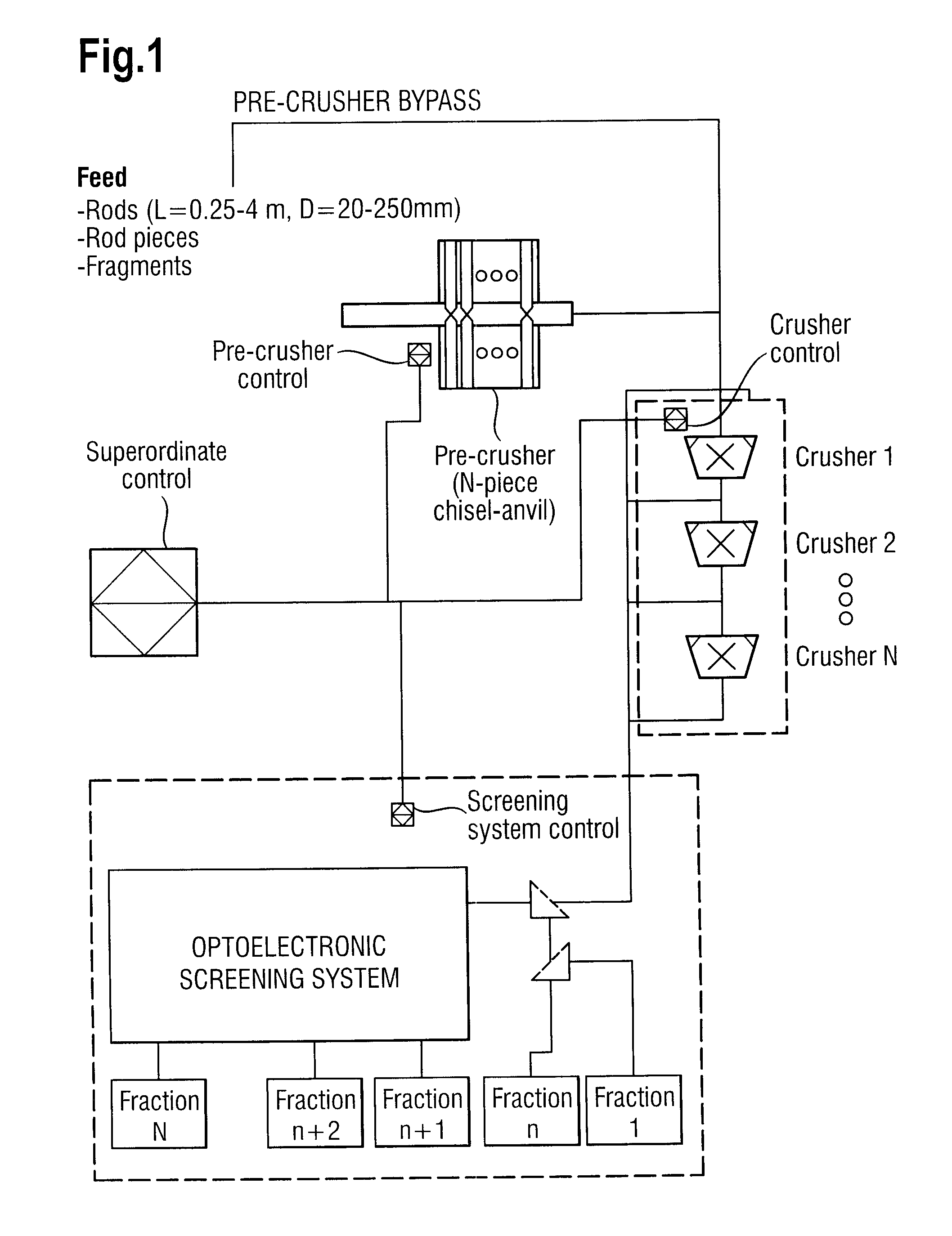

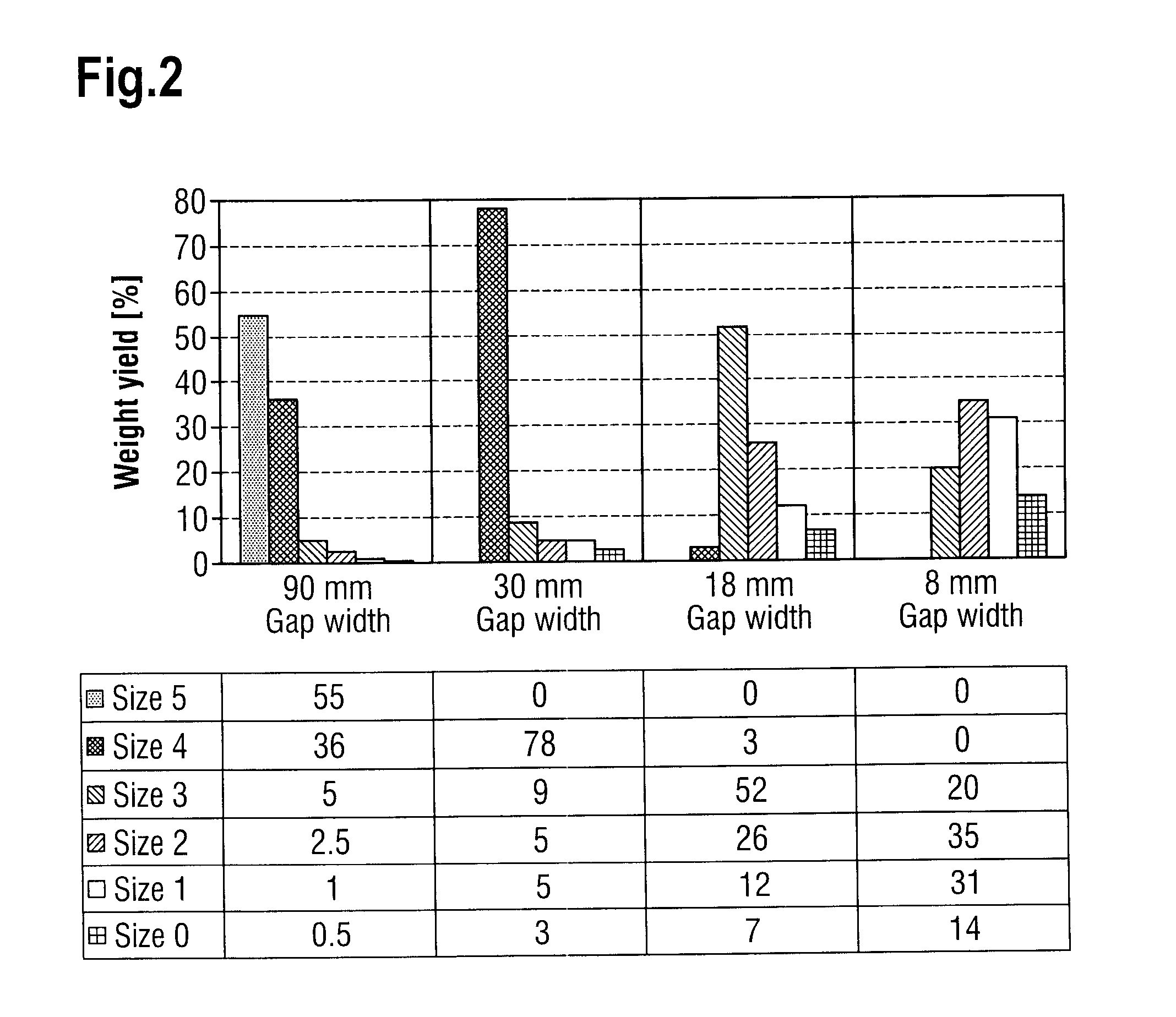

Method and Device For Comminuting and Sorting Polysilicon

ActiveUS20070235574A1Increase productionPolycrystalline material growthSiliconEngineeringPolycrystalline silicon

The invention relates to a device for comminuting and sorting polycrystalline silicon, comprising an instrument for feeding a coarse polysilicon fraction into a crushing system, the crushing system associated with a sorting system for classifying the polysilicon fraction, wherein the device is provided with a controller which allows variable adjustment of at least one crushing parameter in the crushing system and / or at least one sorting parameter in the sorting system.

Owner:WACKER CHEM GMBH

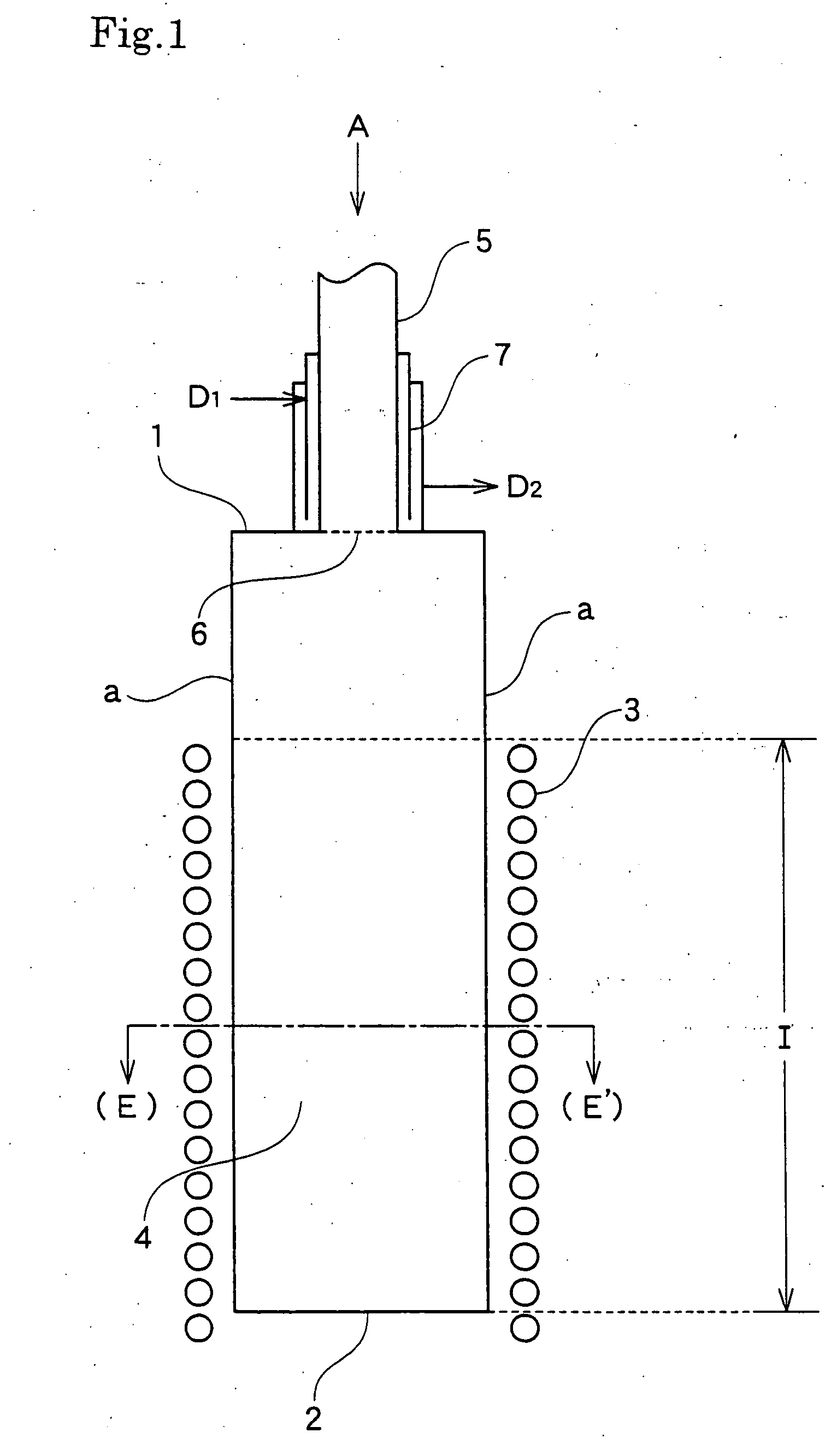

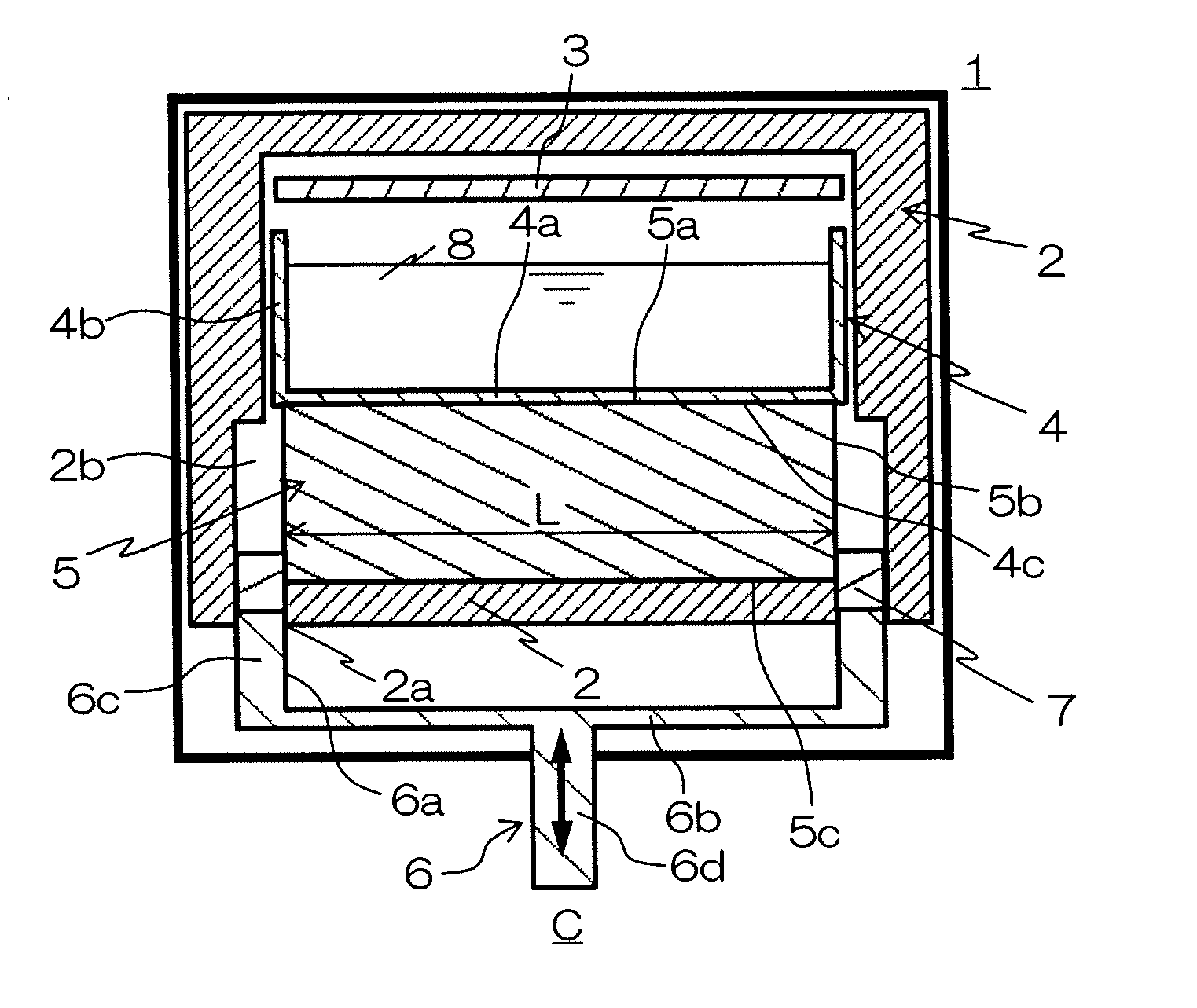

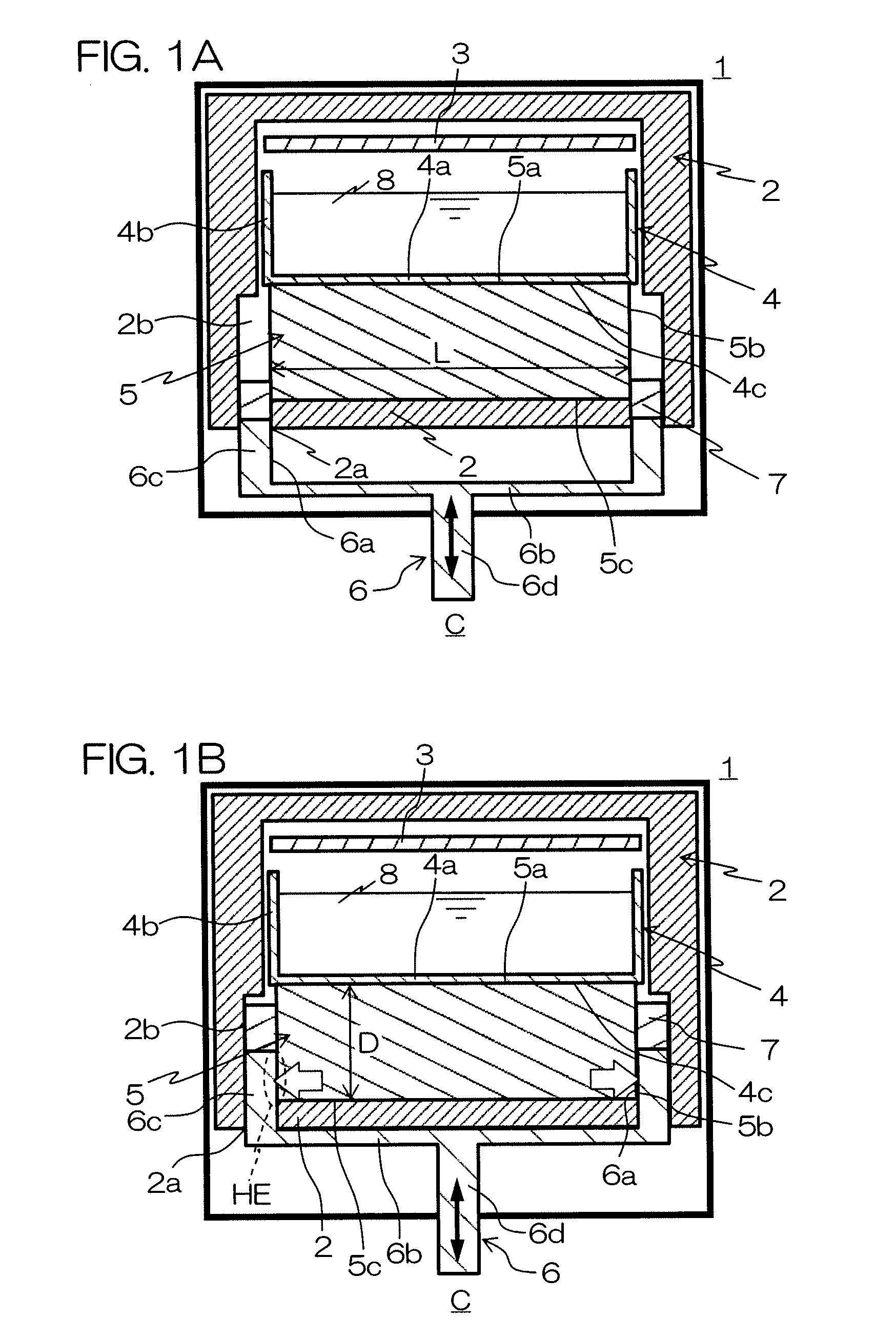

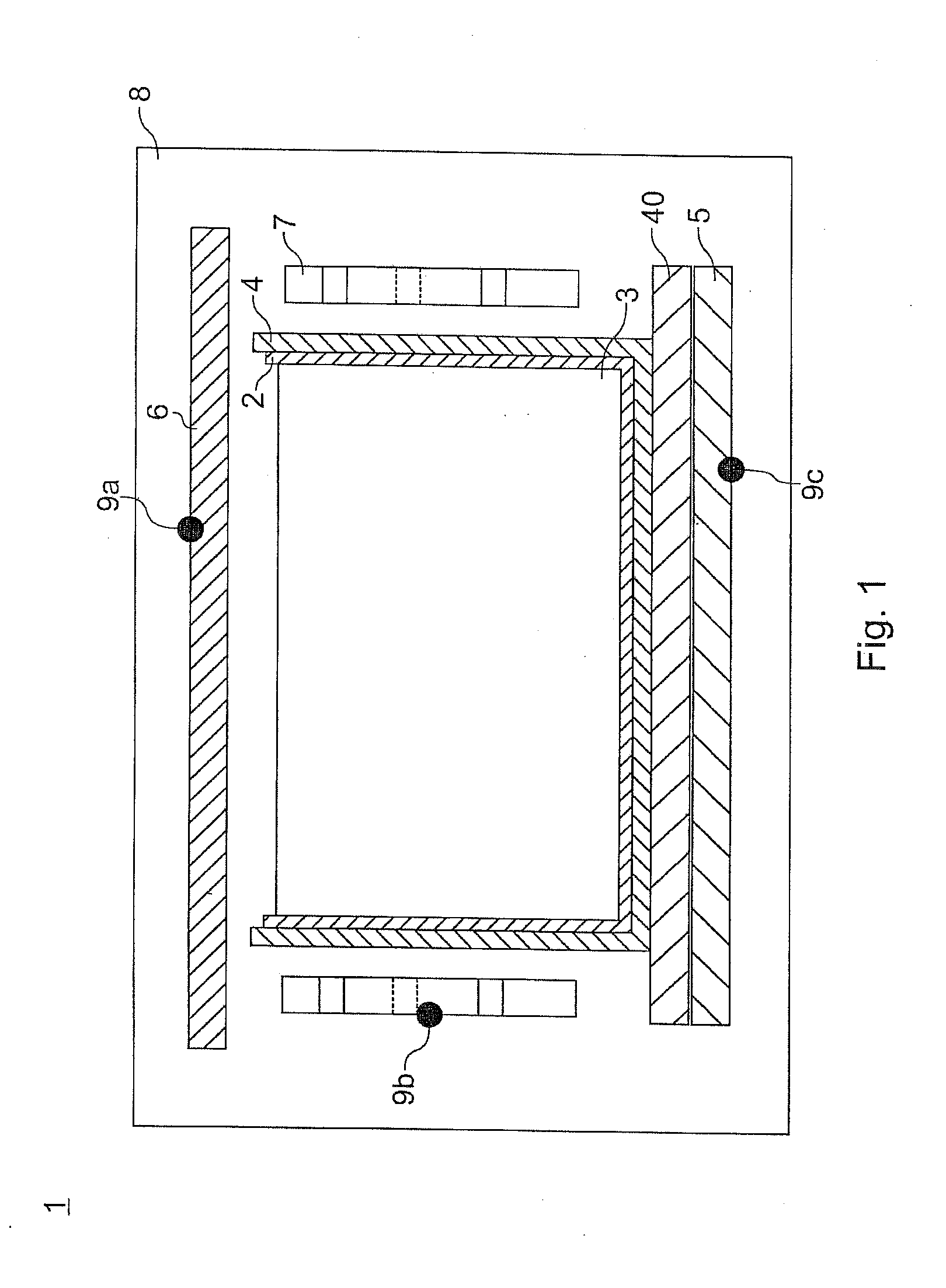

Silicon Casting Apparatus and Method of Producing Silicon Ingot

InactiveUS20070227189A1Good reproducibilityLow costFinal product manufactureGlass drawing apparatusIngotTemperature gradient

A silicon casting apparatus for producing polycrystal silicon ingot by heating a silicon melt (8) held in a mold (4) from above by a heater (3) and cooling it from below while changing the heat exchange area of a heat exchange region (HE), defined between a pedestal (5) having the mold (4) placed thereon and a bottom cooling member (6), in such a manner as to keep pace with the rise of the solid-liquid interface of the silicon melt (8), thereby causing unidirectional solidification upward along the mold (4); and a method of producing polycrystal silicon ingot using such apparatus. According to this production method, the temperature gradient given to the silicon melt (8) can be maintained at constant by adjusting the heat exchange area, so that polycrystal silicon ingot having good characteristics can be produced with good reproducibility.

Owner:KYOCERA CORP

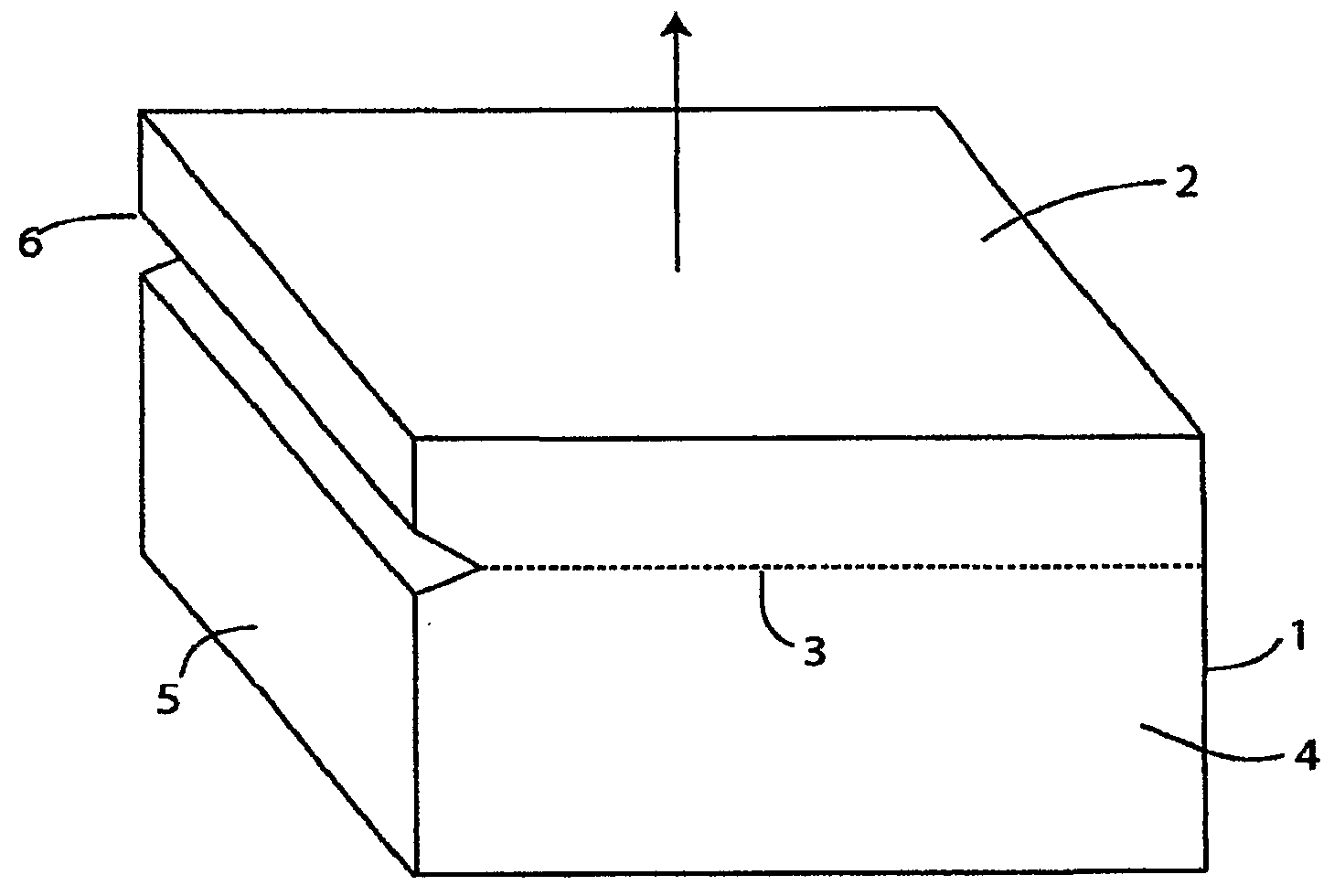

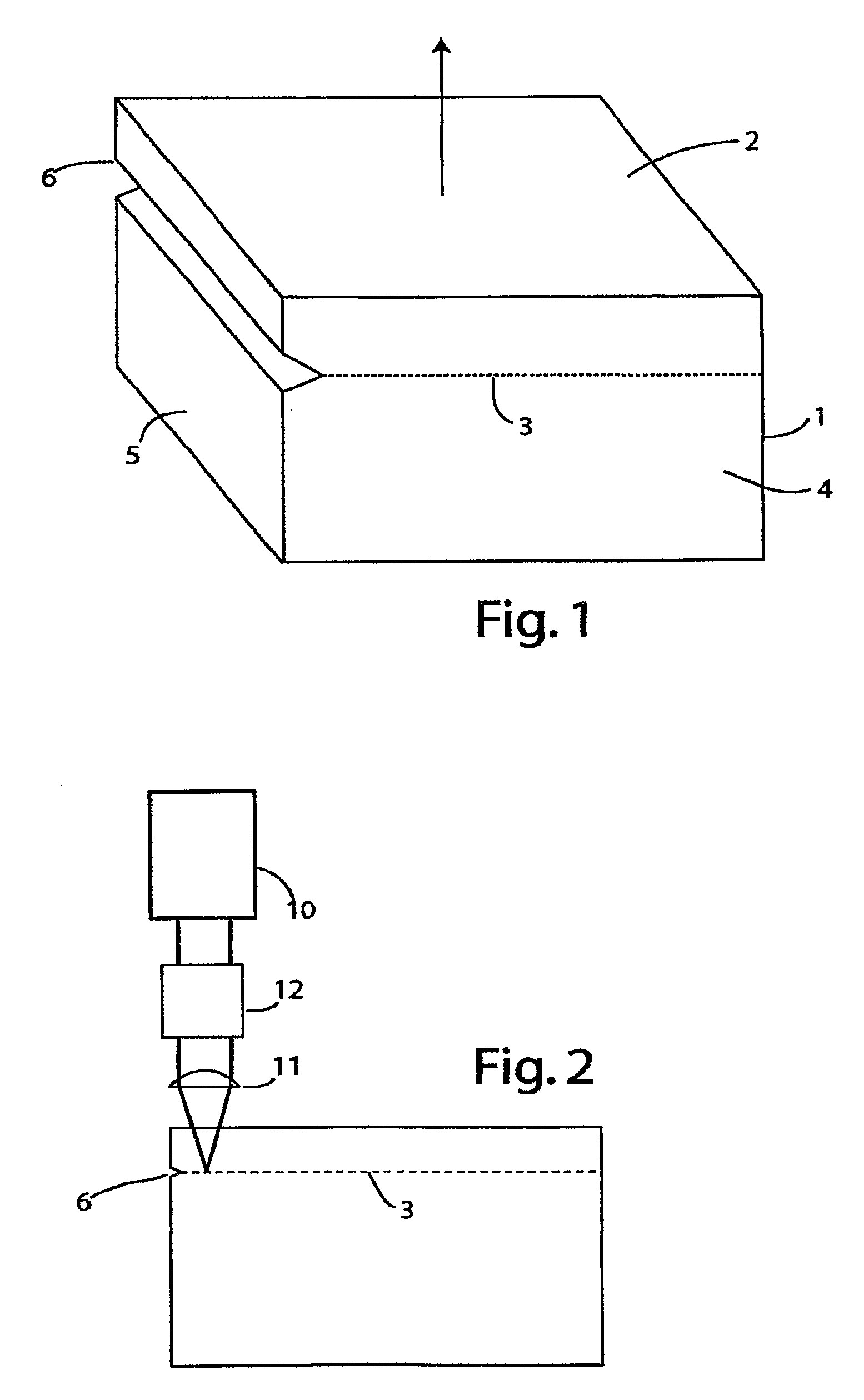

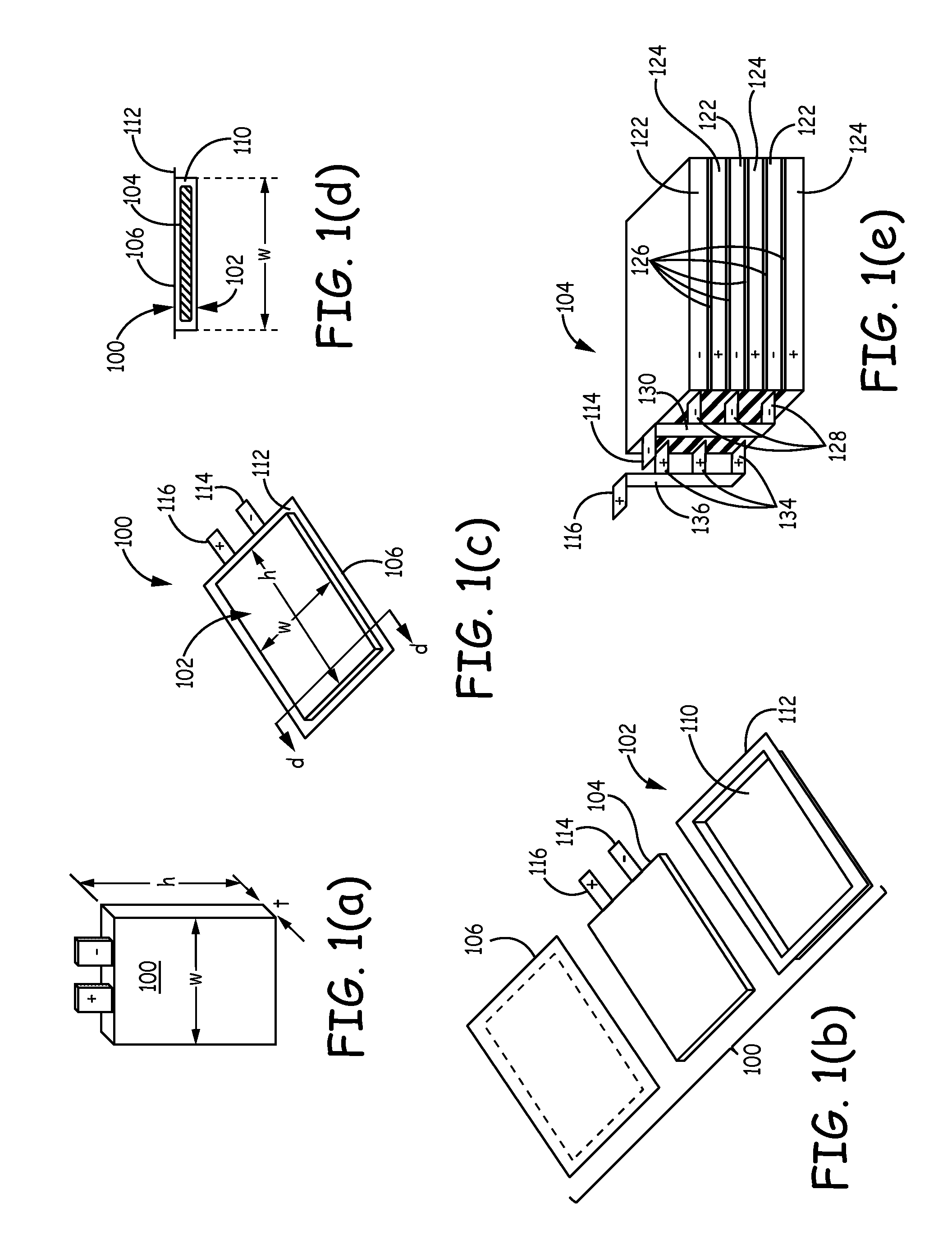

Cleaving Wafers from Silicon Crystals

ActiveUS20090056513A1Effective absorptionIncrease the areaAutomatic control devicesPolycrystalline material growthShortest distanceIngot

A method of creating thin wafers of single crystal silicon wherein an ingot of single-crystal silicon with a (111) axis is flattened and polished at one end normal to the axis, and a notch with a vertex in the (111) plane is produced on a side or edge of the ingot, such that the distance between this vertex and said end is the desired thickness of a wafer to be cleaved from the ingot and such this vertex is in the desired plane of cleavage. Light of a wavelength able to penetrate into the silicon crystal without significant absorption, when the intensity of the beam is low, but is efficiently absorbed and converted to heat when the intensity of the beam is high, is focused to an elongated volume with an axis of elongation in the desired cleavage plane, parallel to and a short distance from said notch edge. Heating and the resulting transient local expansion of the silicon in this illuminated volume causes tensile stress at the vertex of said notch, substantially normal to the desired cleavage plane, thereby causing fracture of the crystal in the chosen cleavage plane. Movement of the illuminated volume relative to the ingot allows the fracture to propagate across the desired cleavage plane, thereby completely severing the wafer from the rest of the ingot.

Owner:BAER

Silicon-based active materials for lithium ion batteries and synthesis with solution processing

Silicon based anode active materials are described for use in lithium ion batteries. The silicon based materials are generally composites of nanoscale elemental silicon with stabilizing components that can comprise, for example, silicon oxide-carbon matrix material, inert metal coatings or combinations thereof. High surface area morphology can further contribute to the material stability when cycled in a lithium based battery. In general, the material synthesis involves a significant solution based processing step that can be designed to yield desired material properties as well as providing convenient and scalable processing.

Owner:IONBLOX INC

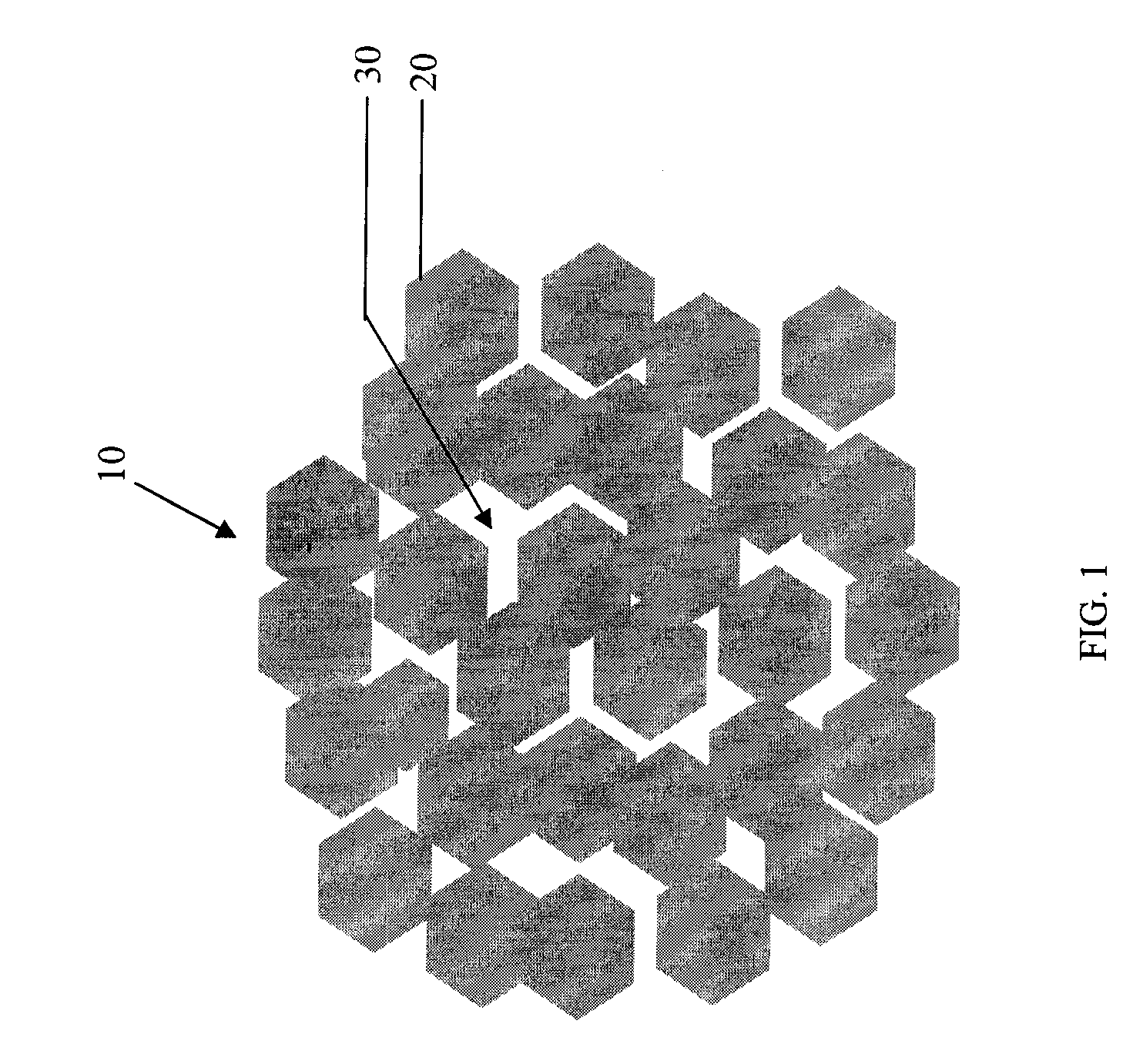

Condensed phase conversion and growth of nanorods instead of from vapor

Compositions, systems and methods are described for condensed phase conversion and growth of nanorods and other materials. A method includes providing a condensed phase matrix material; and activating the condensed phase matrix material to produce a plurality of nanorods by condensed phase conversion and growth from the condensed chase matrix material instead of from vacor. The compositions are very strong. The compositions and methods provide advantages because they allow (1) formation rates of nanostructures necessary for reasonable production rates, and (2) the near net shaped production of component structures.

Owner:UT BATTELLE LLC

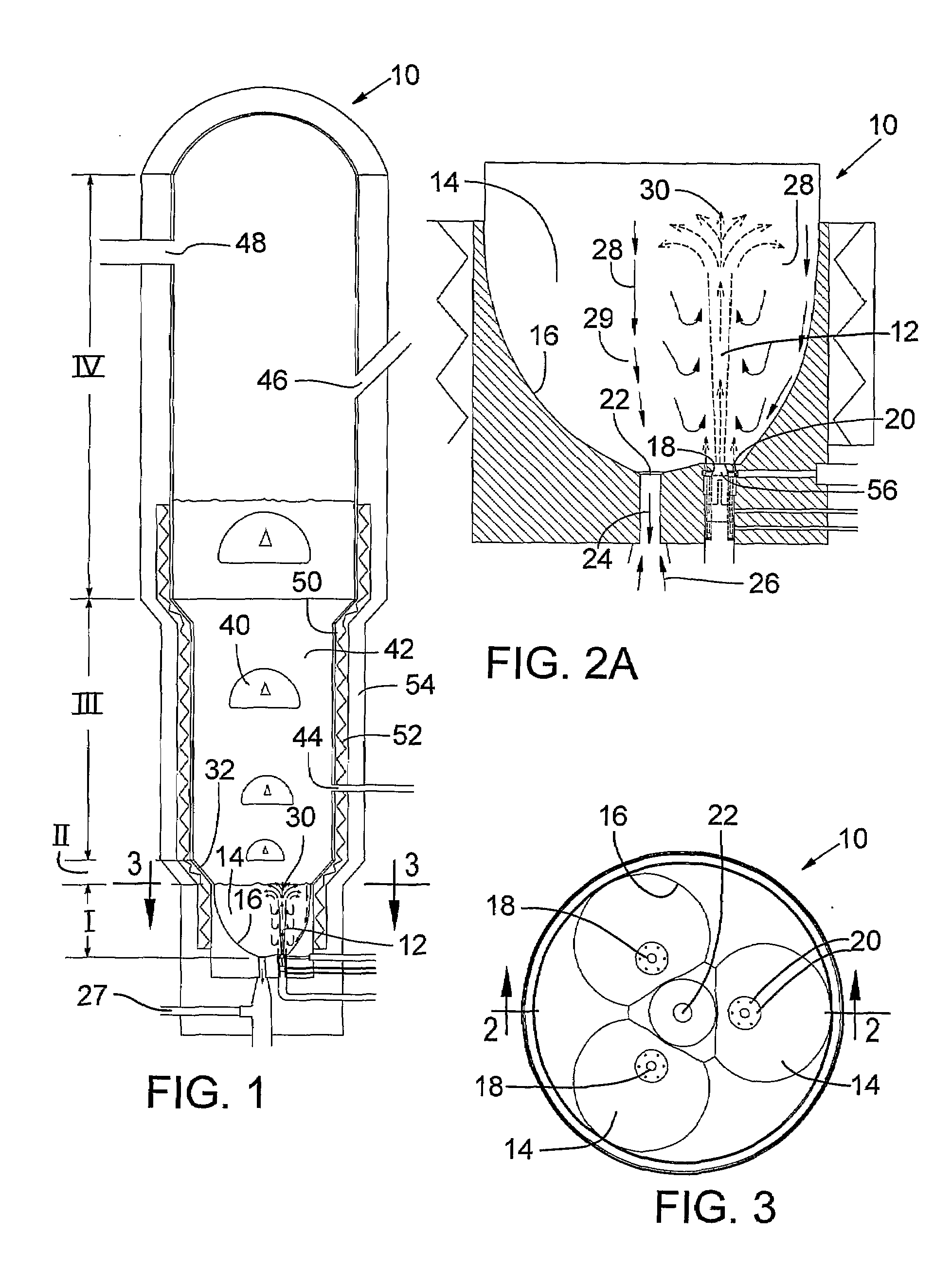

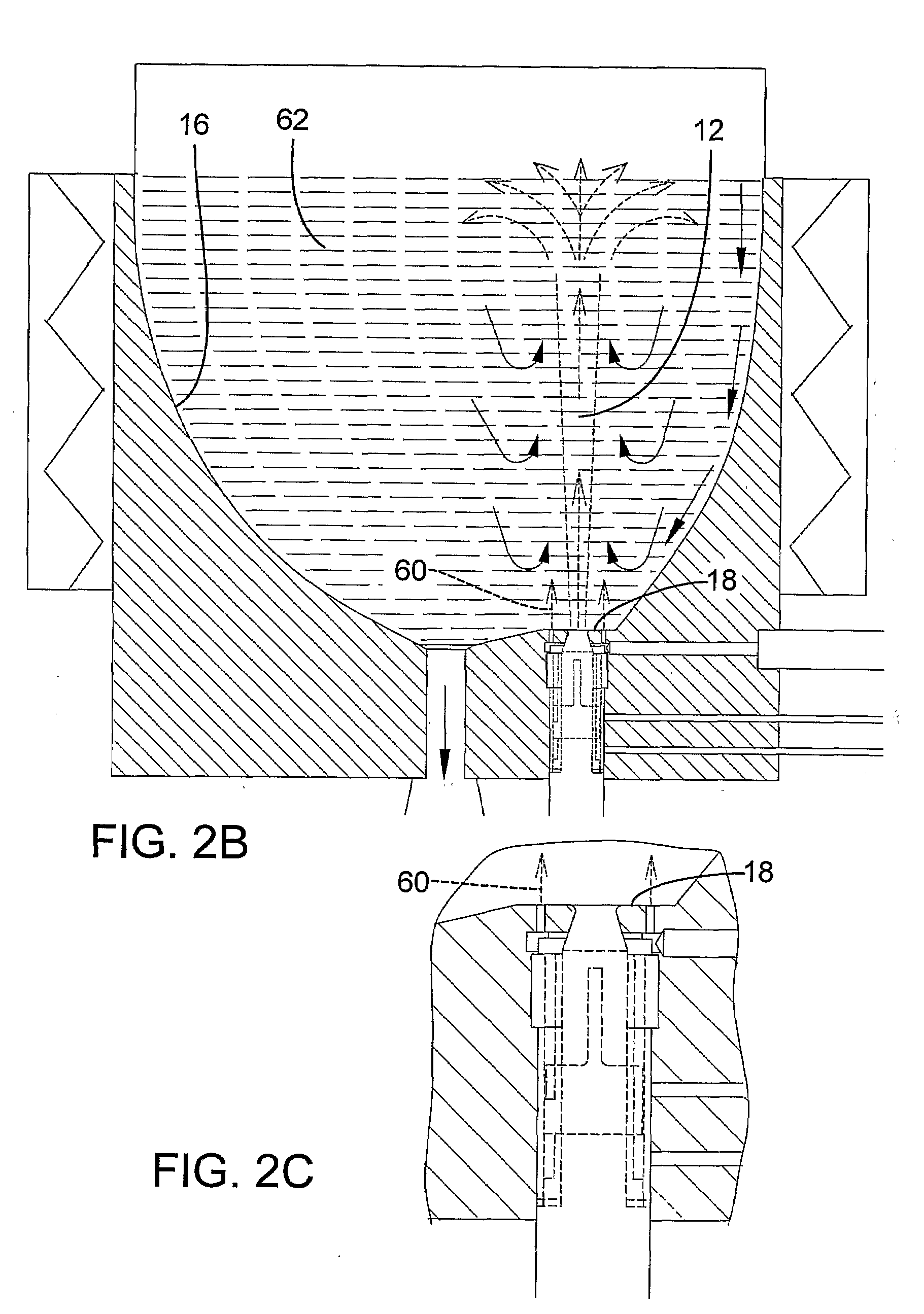

Fluidized bed reactor systems and methods for reducing the deposition of silicon on reactor walls

ActiveUS20090324479A1Reduce the amount requiredIncrease in sizeSiliconFluidised-bed furnacesReactor systemFluidized bed

Gas distribution units of fluidized bed reactors are configured to direct thermally decomposable compounds to the center portion of the reactor and away from the reactor wall to prevent deposition of material on the reactor wall and process for producing polycrystalline silicon product in a reactor that reduce the amount of silicon which deposits on the reactor wall.

Owner:CORNER STAR LTD

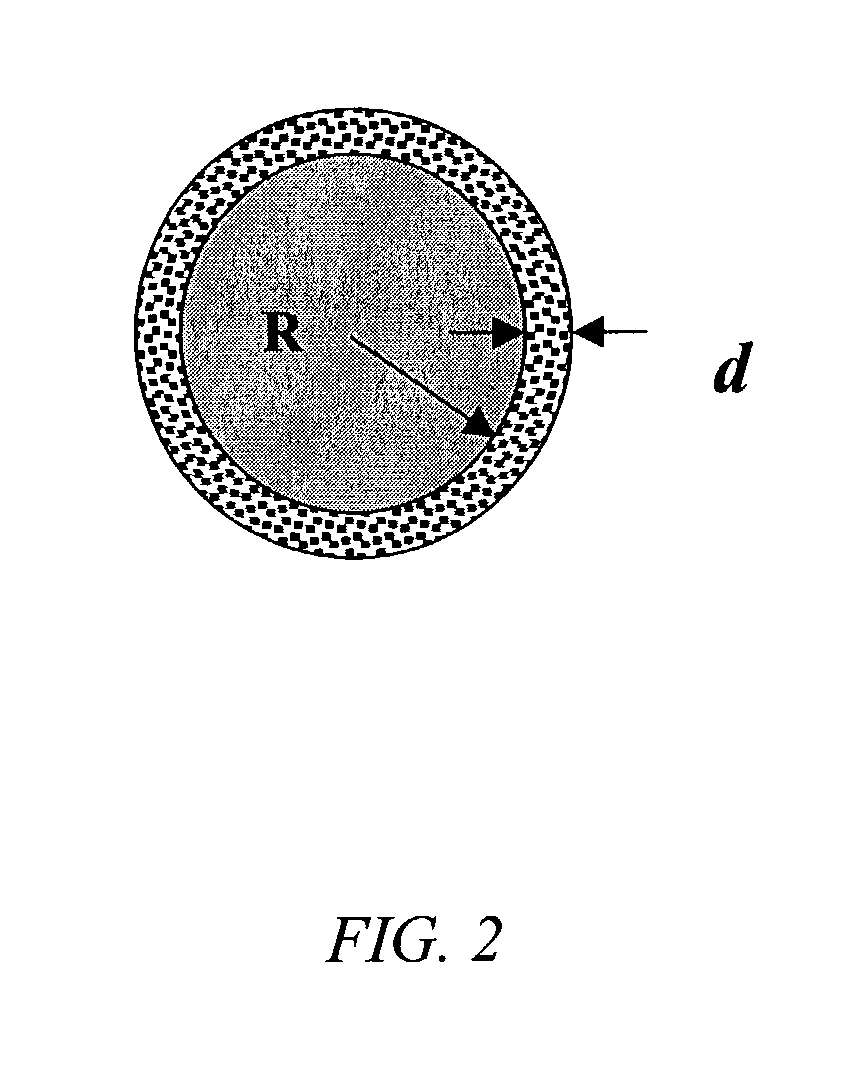

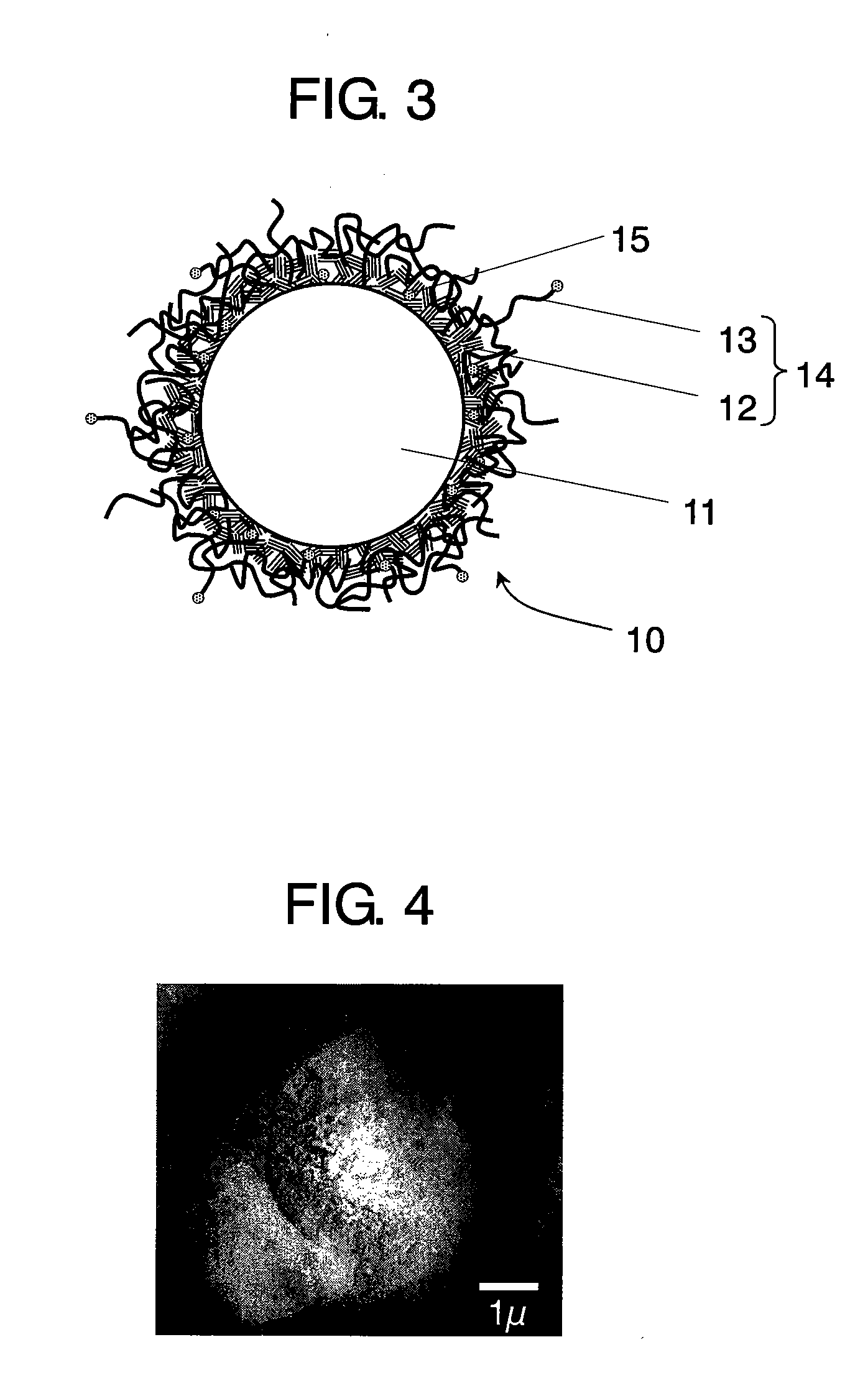

Silicon Nanosponge Particles

Silicon nanosponge particles prepared from a metallurgical grade silicon powder having an initial particle size ranging from about 1 micron to about 4 microns is presented. Each silicon nanosponge particle has a structure comprising a plurality of nanocrystals with pores disposed between the nanocrystals and throughout the entire nanosponge particle.

Owner:VESTA RES

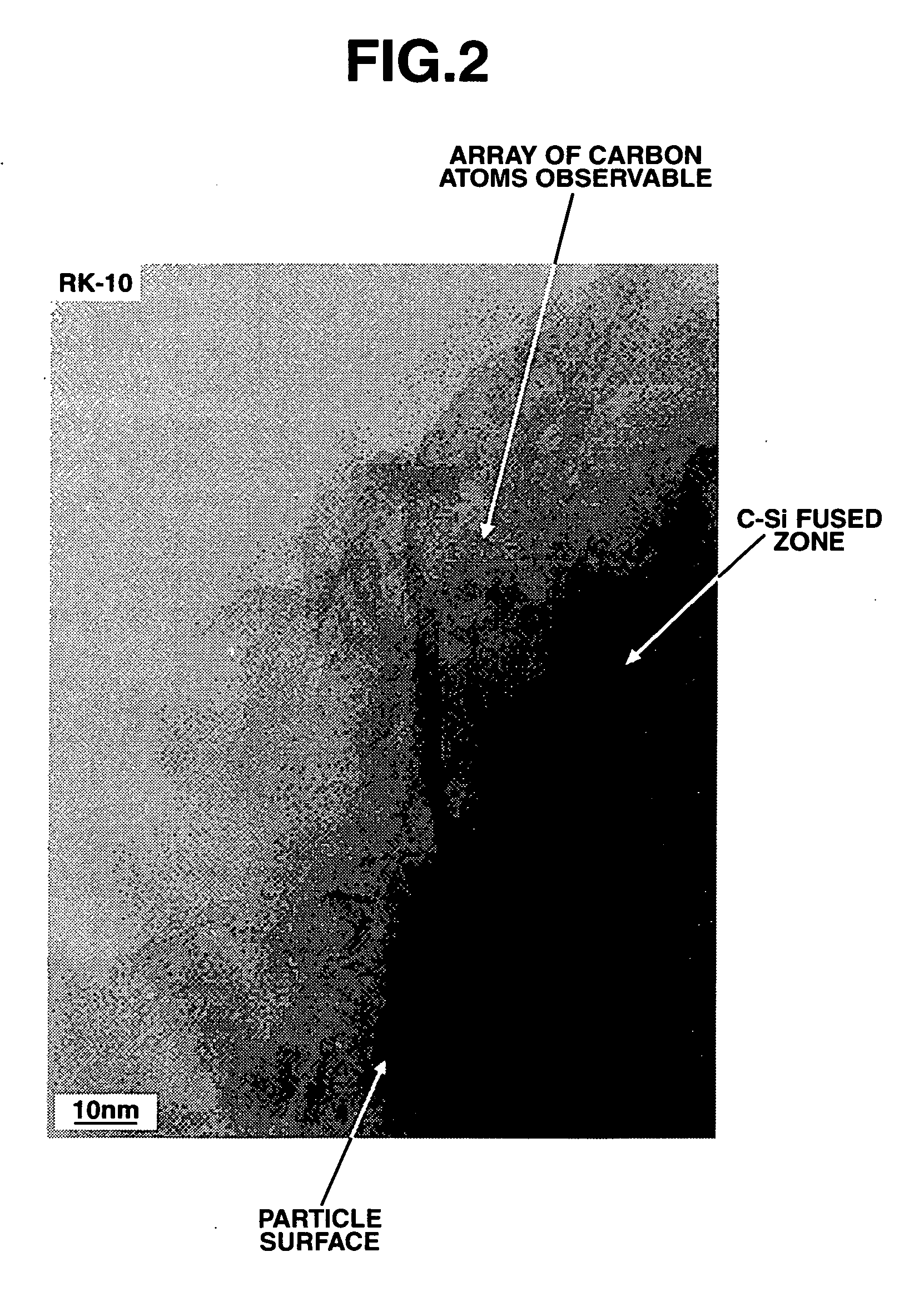

Conductive composite particle, method of manufacturing the same, electrode using the same, lithium ion secondary battery

In a manufacturing method of a conductive composite particle, a conductive composite particle is manufactured that is formed of an active material particle having a region capable of electrochemically inserting and desorbing lithium and a carbon layer joined to the particle surface. In the carbon layer, fine metal particles are dispersed. This method has the following three steps. In the first step, a polymer material containing the metal element composing the fine metal particles is prepared. In the second step, the active material particle surface is coated with the polymer material containing the metal element. In the third step, a carbon layer having a porous structure including a fibrous structure is formed as the surface layer section from the polymer material by a treatment where the active material particle coated with the polymer containing the metal element is heated in an inert atmosphere to carbonize the polymer material.

Owner:PANASONIC CORP

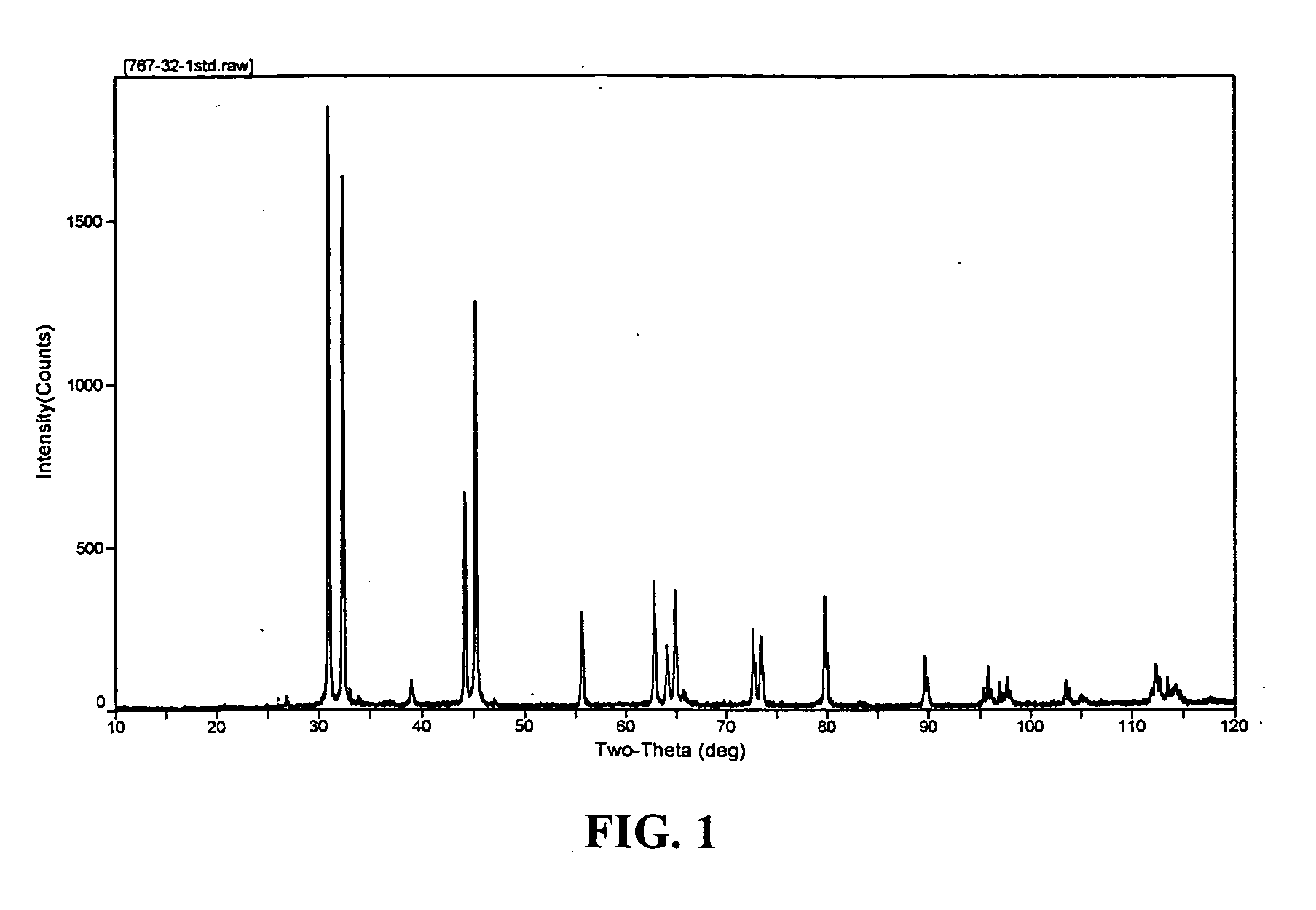

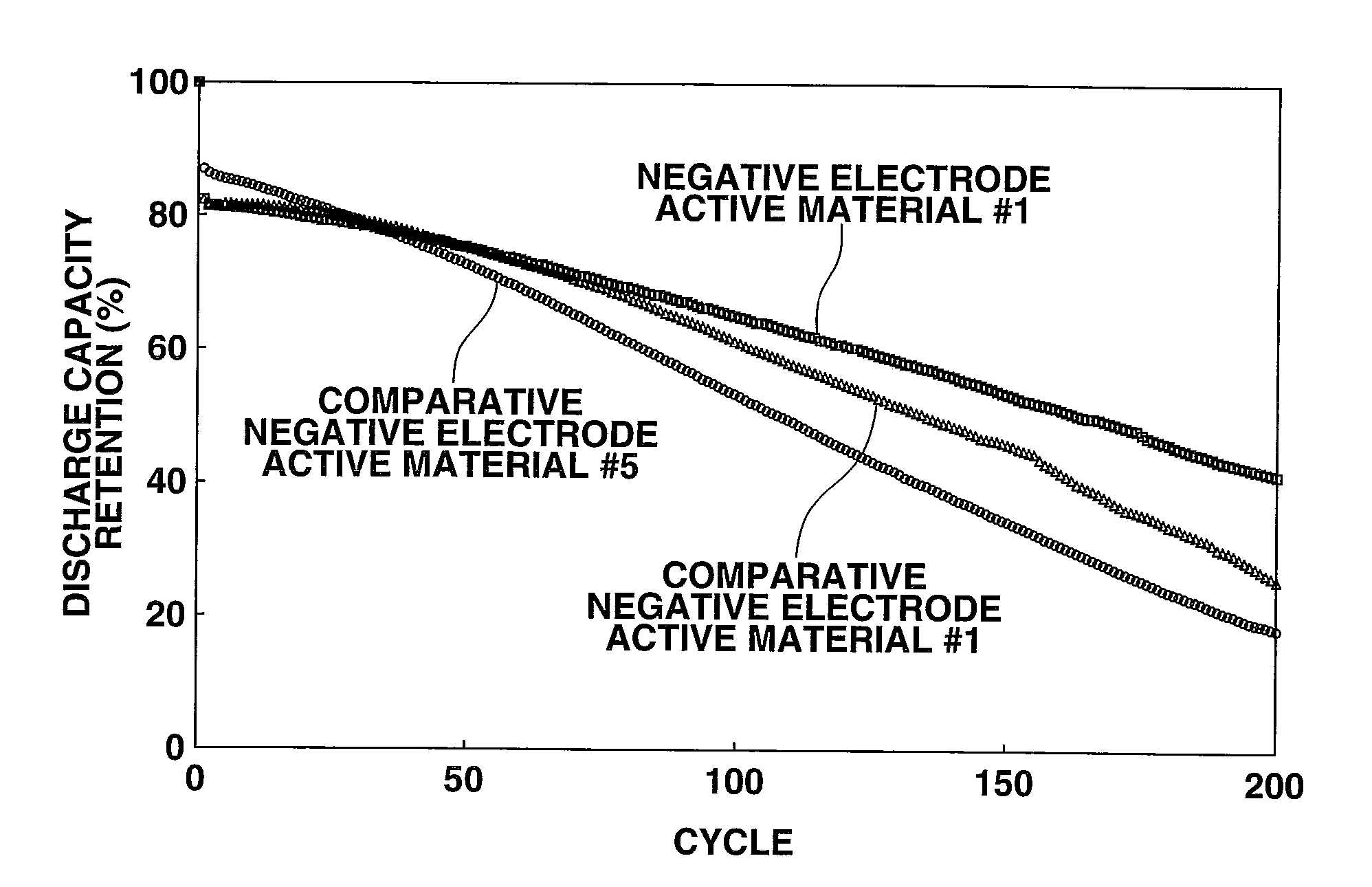

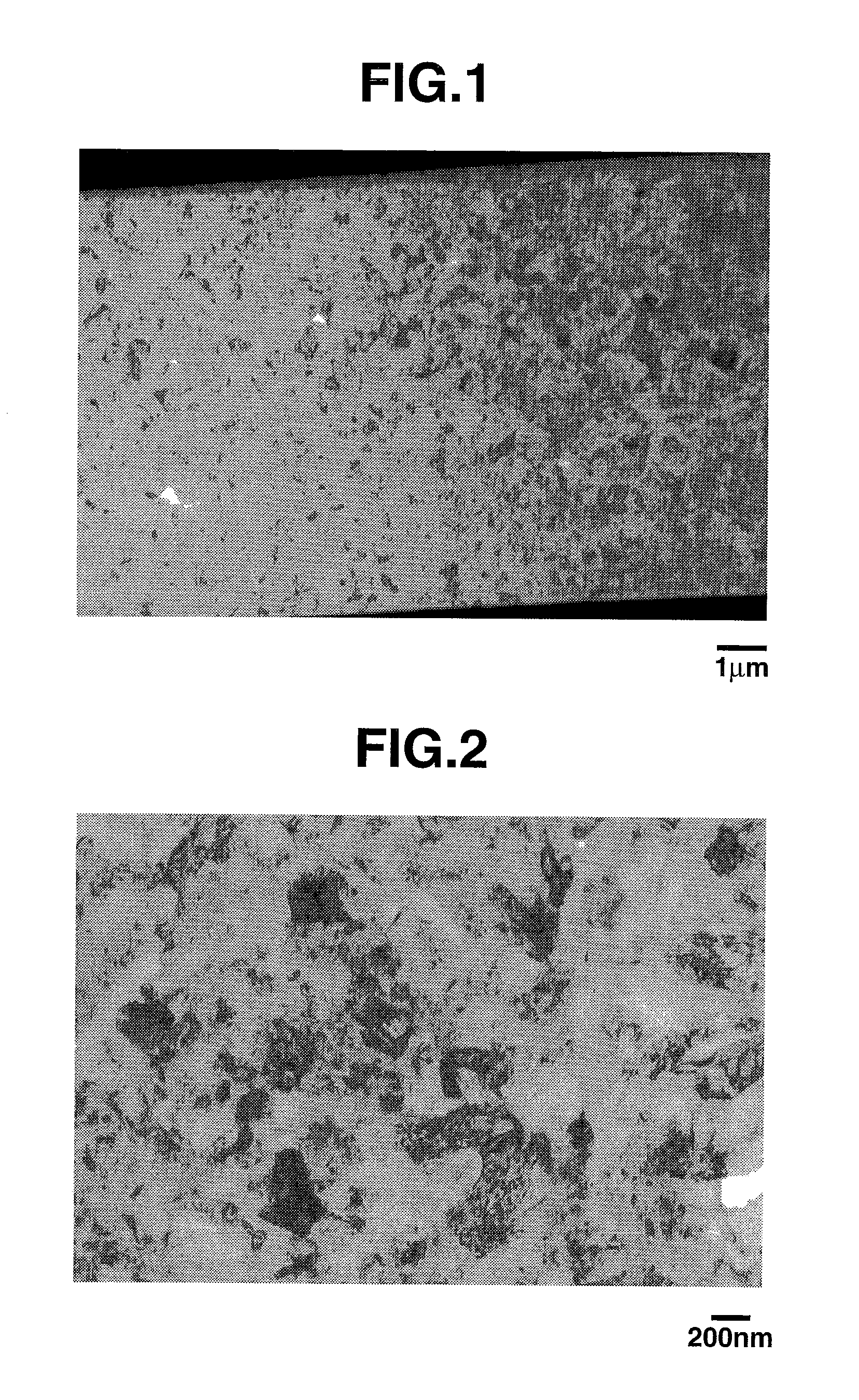

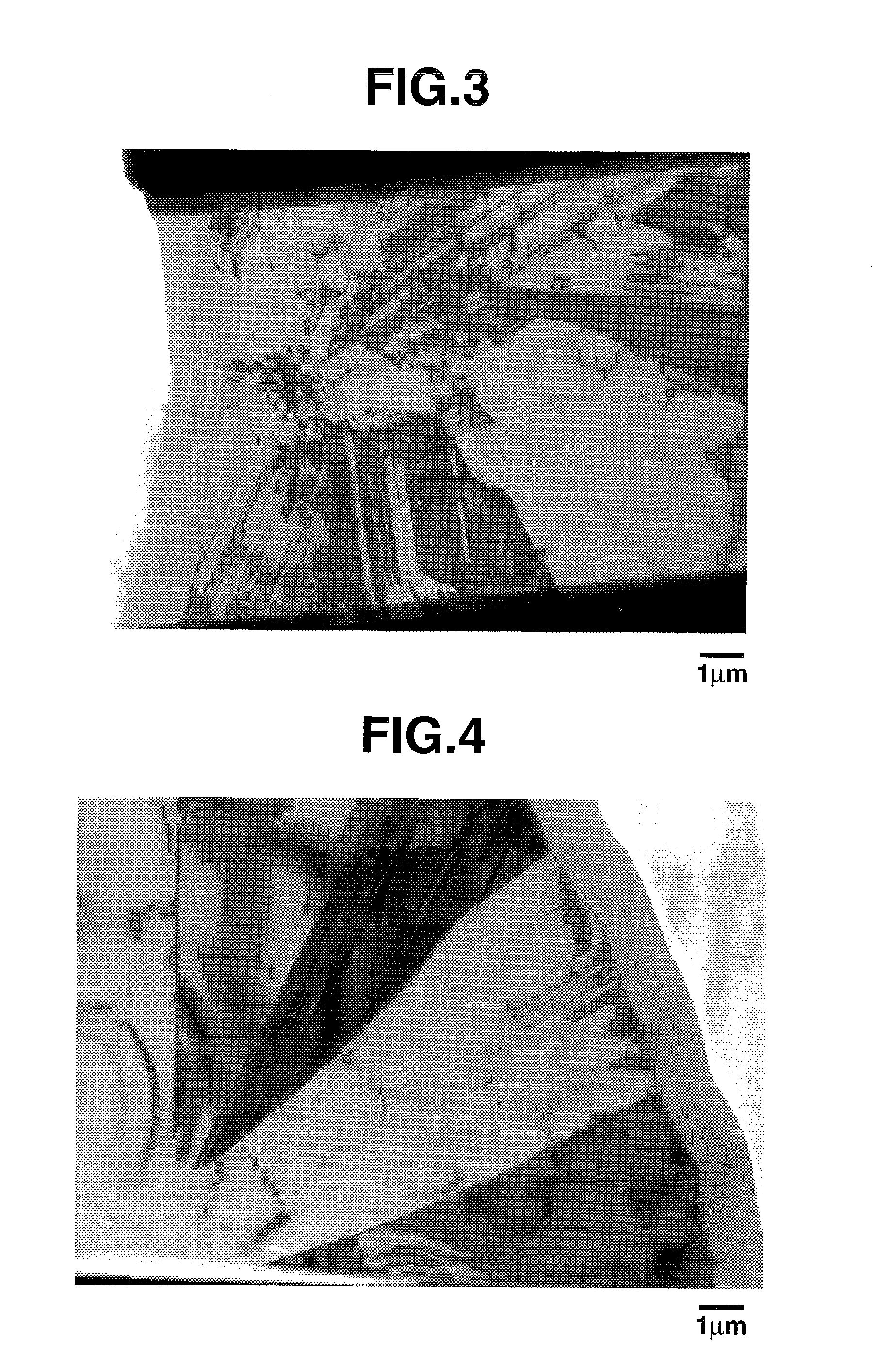

Negative electrode material for rechargeable battery with nonaqueous electrolyte, negative electrode for rechargeable battery with nonaqueous electrolyte, rechargeable battery with nonaqueous electrolyte, and process for producing polycrystalline silicon particles for active material for negative electrode material for rechargeable battery with nonaqueous electrolyte

ActiveUS20100266902A1Increase capacityImprove efficiencyMaterial nanotechnologySiliconX-rayFull width at half maximum

This invention provides a negative electrode material for a rechargeable battery with a nonaqueous electrolyte, characterized in that the negative electrode material contains polycrystalline silicon particles as an active material, the particle diameter of crystallites of the polycrystalline silicon is not less than 20 nm and not more than 100 nm in terms of a crystallite size determined by the Scherrer method from the full width at half maximum of a diffraction line attributable to Si (111) around 2θ=28.4° in an x-ray diffraction pattern analysis, and the true specific gravity of the silicon particles is 2.300 to 2.320.

Owner:PANASONIC ENERGY CO LTD +1

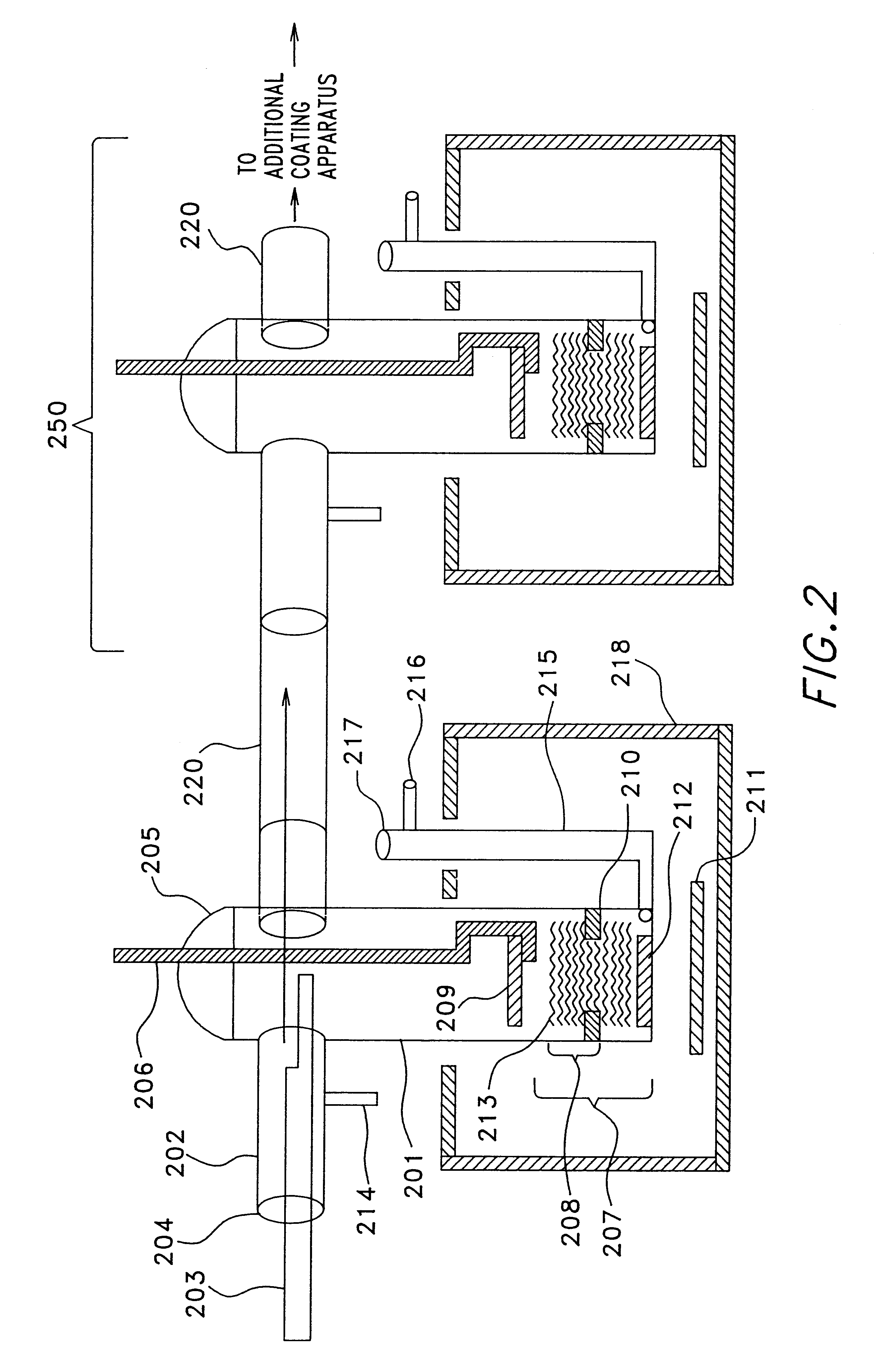

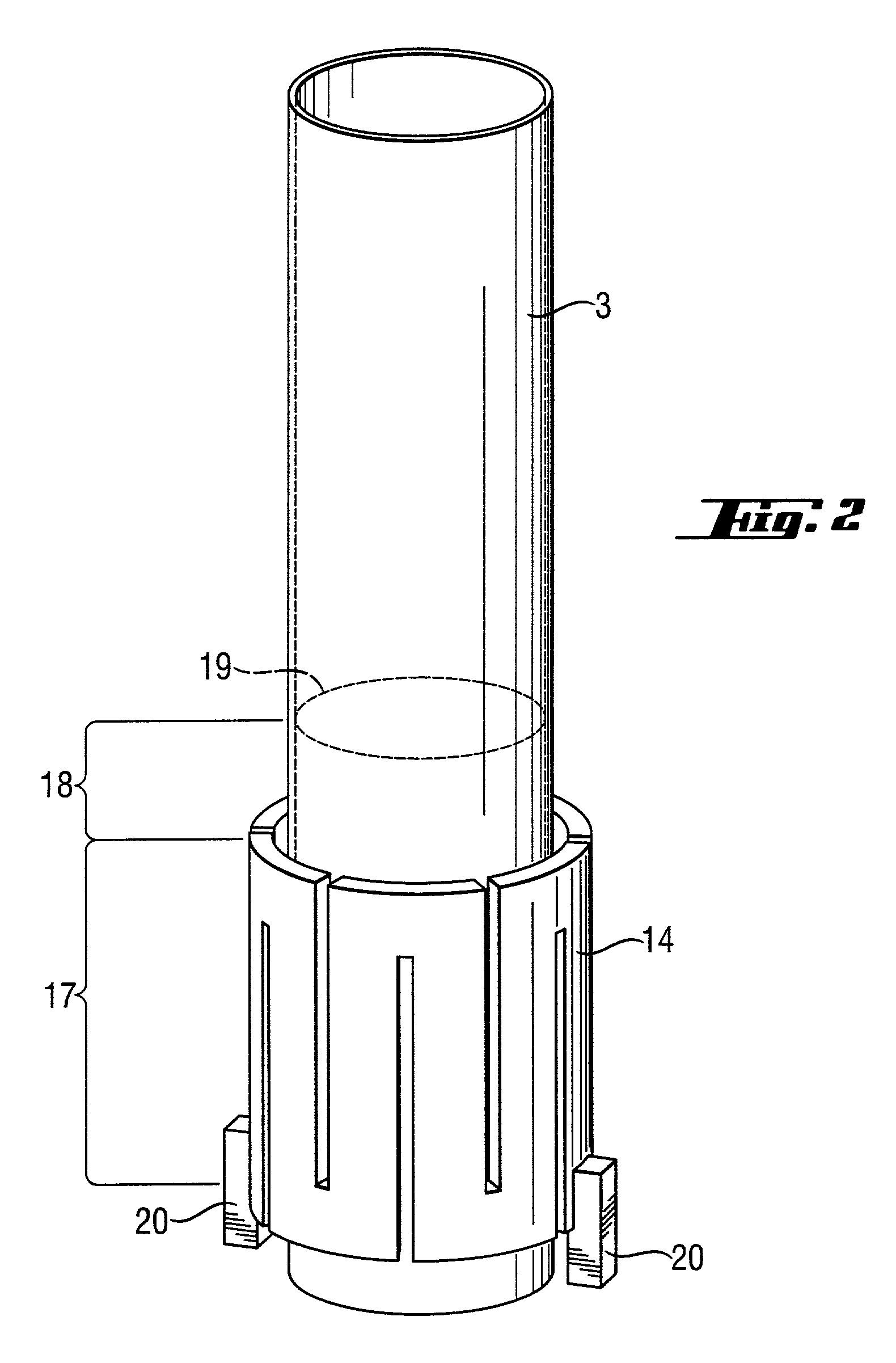

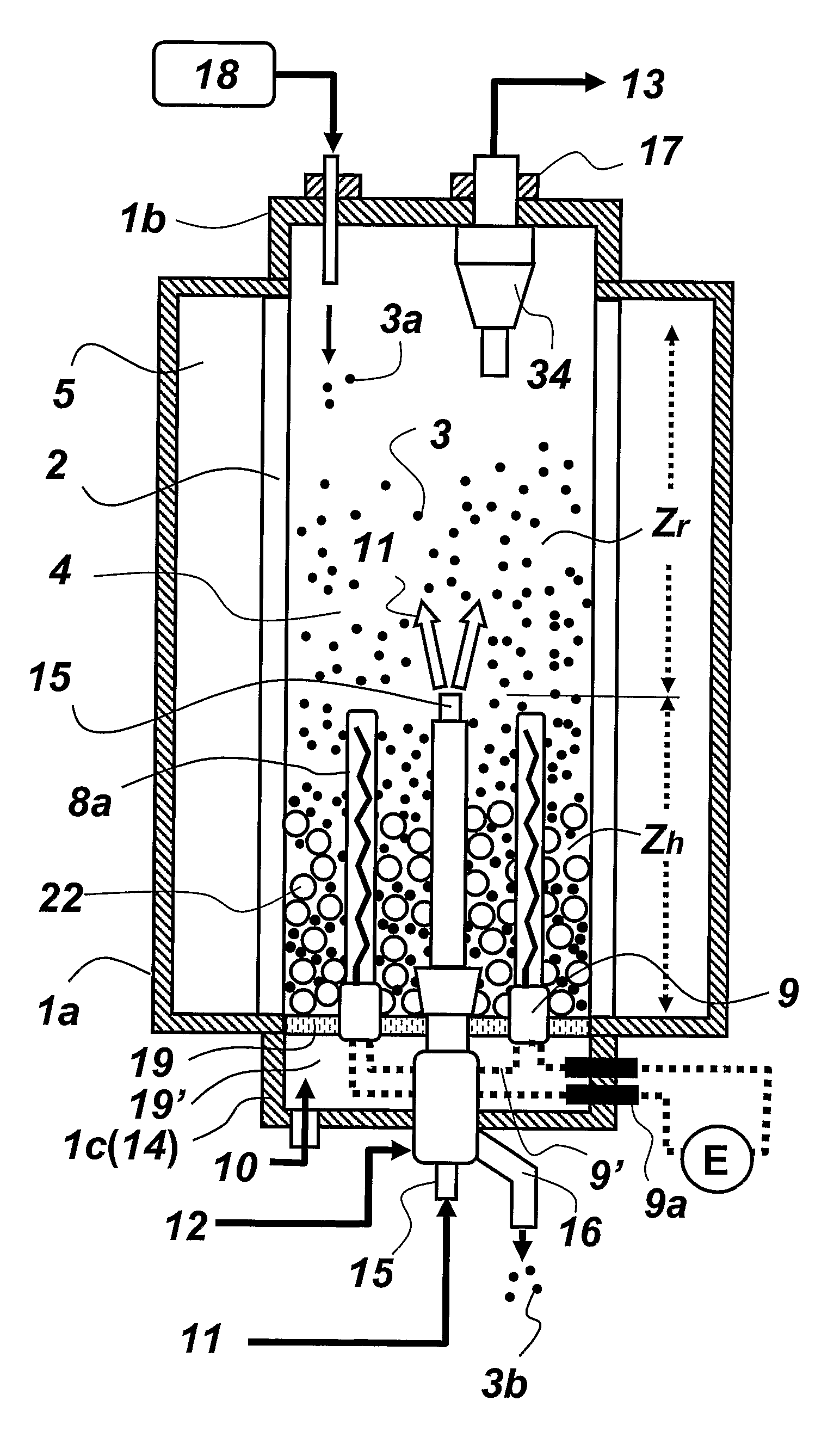

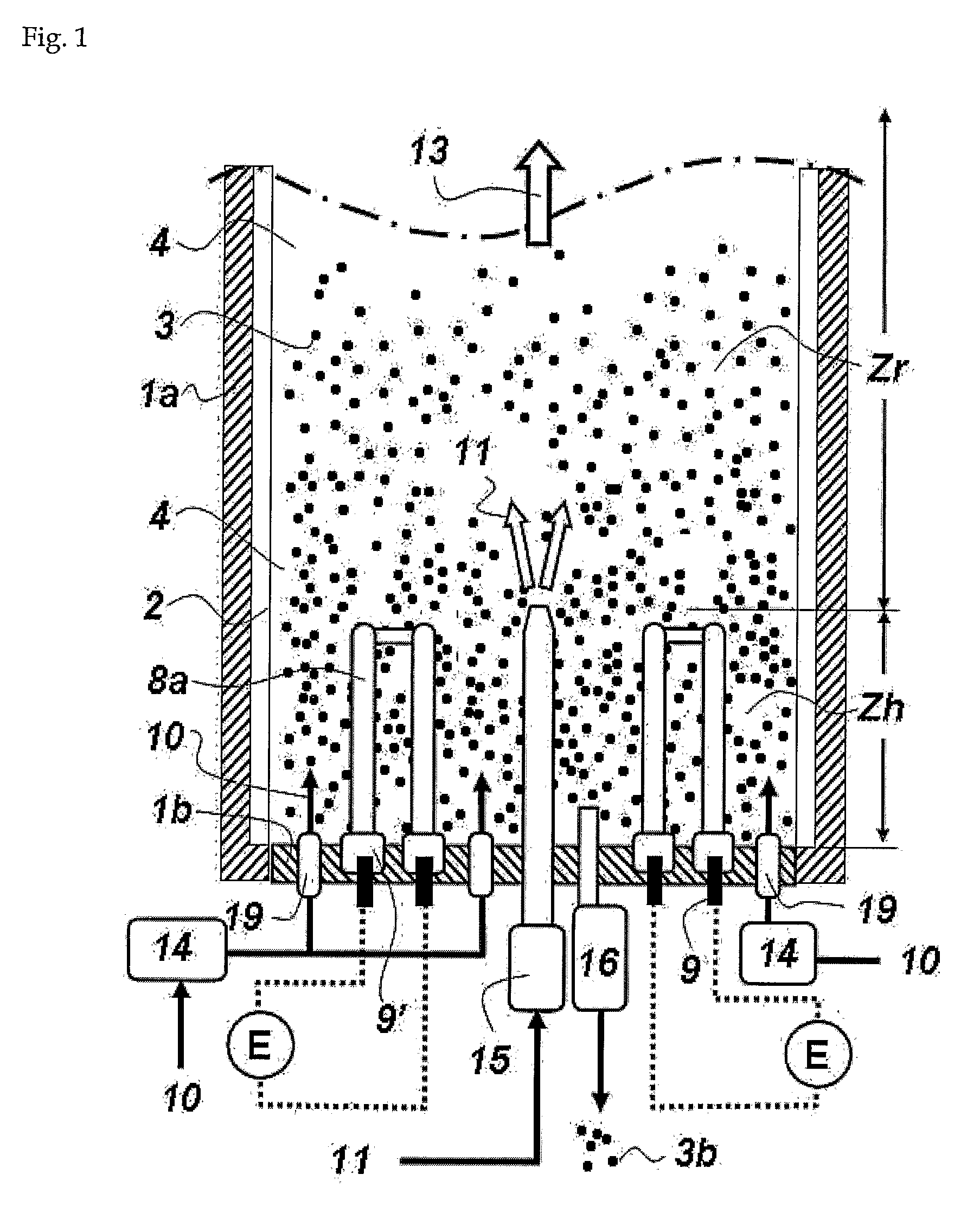

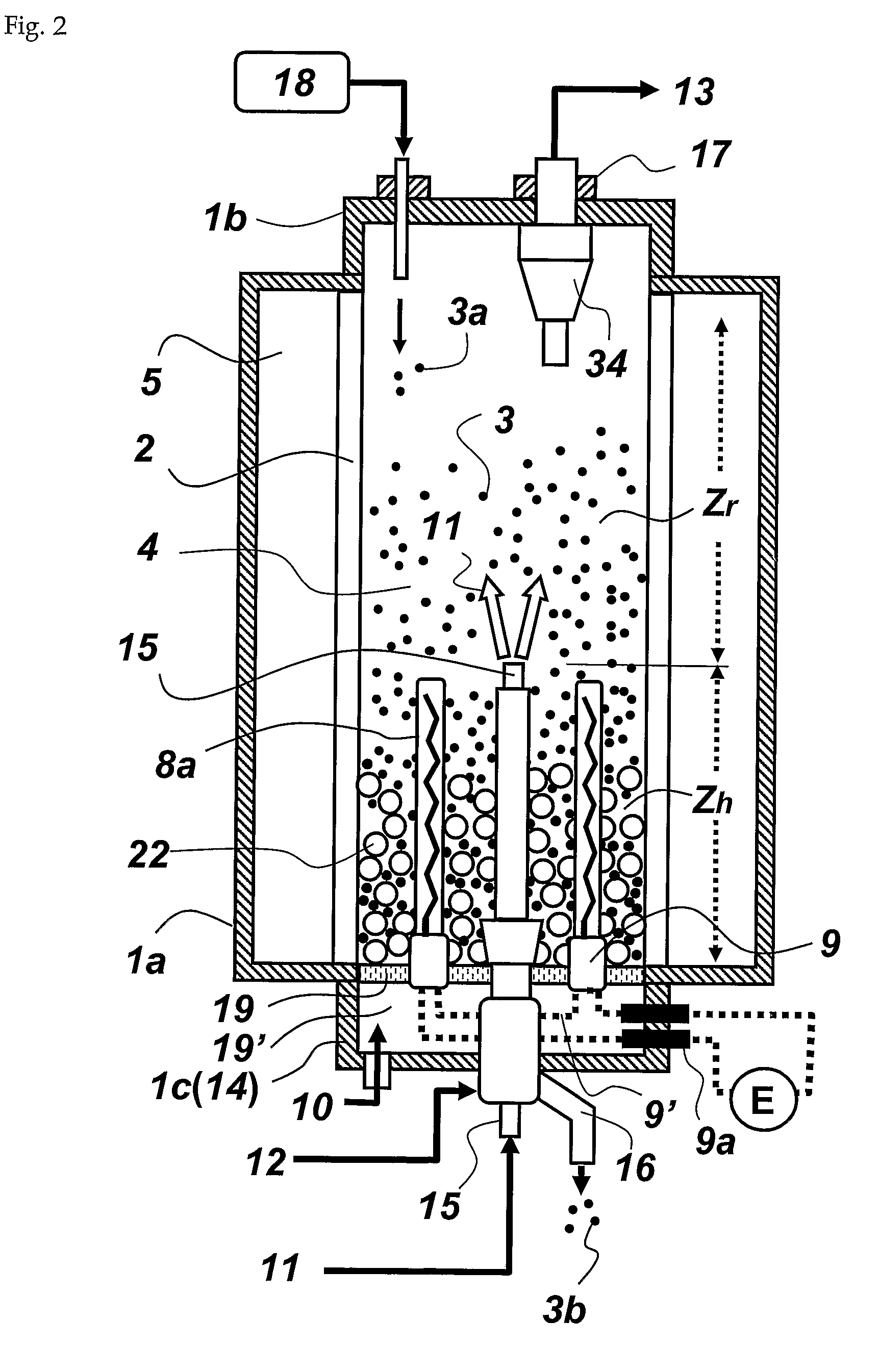

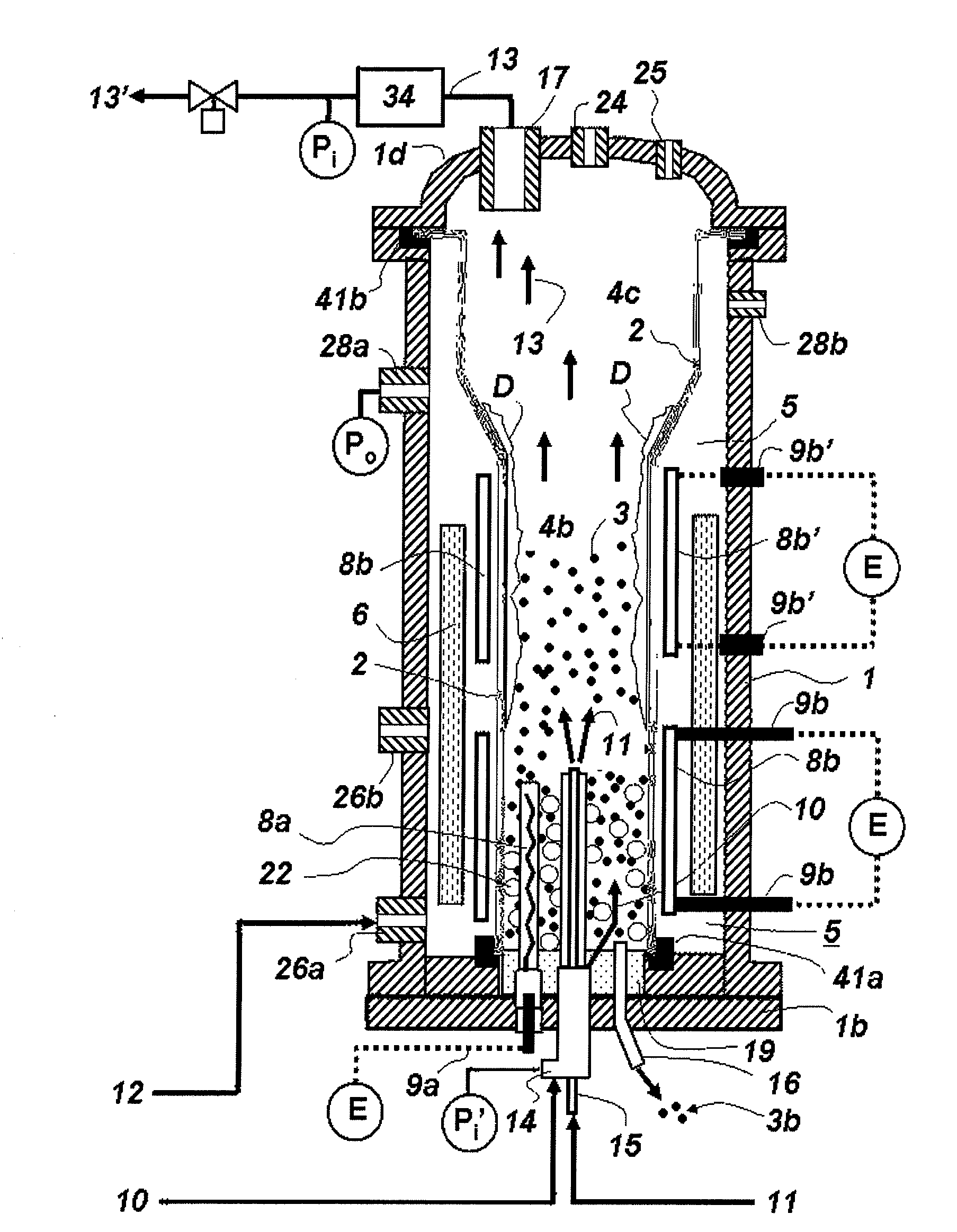

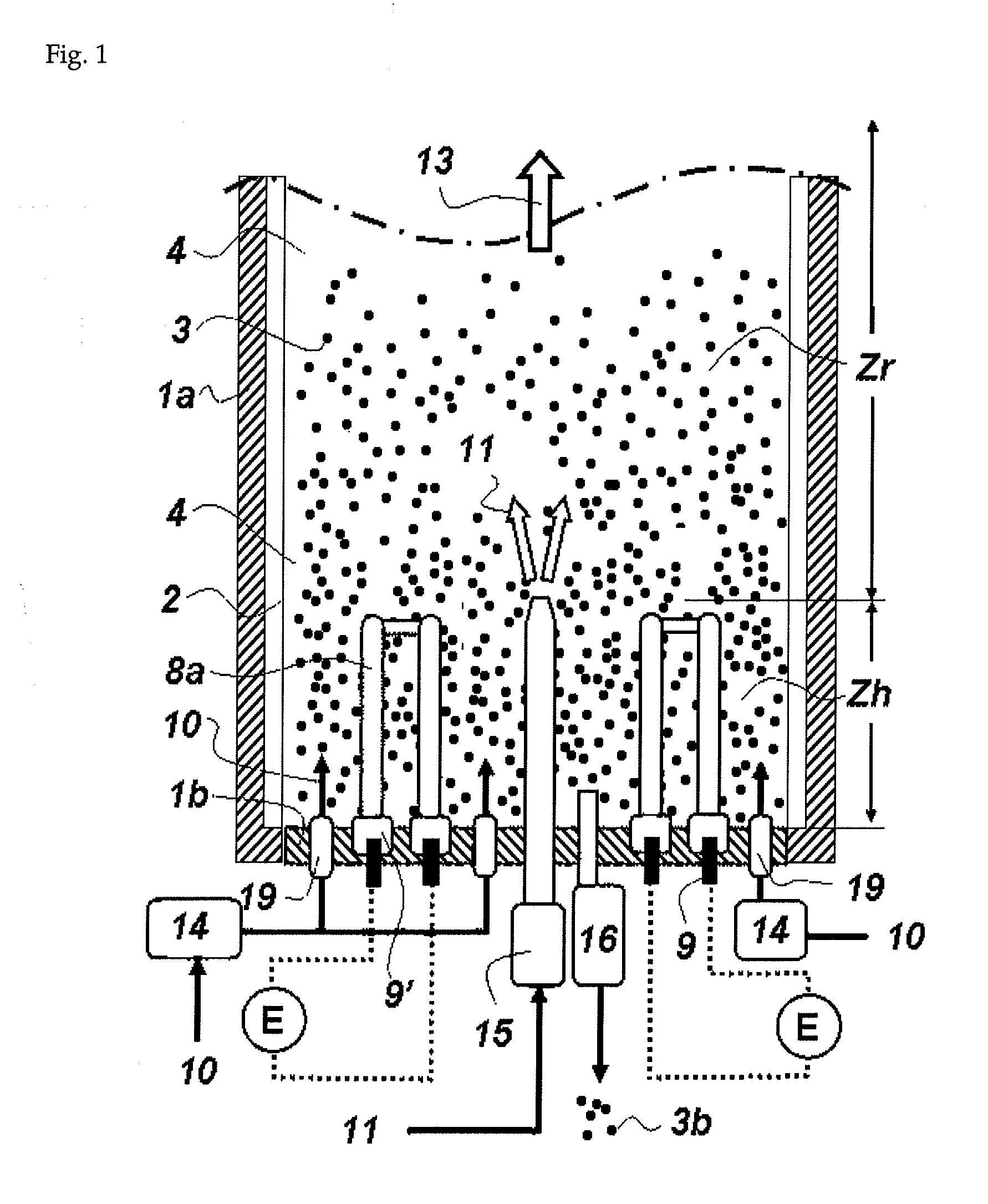

Method and Apparatus for Preparation of Granular Polysilicon

InactiveUS20090047204A1Reduce stepsPolycrystalline material growthSiliconProduction rateElectrical resistance and conductance

A process for preparing granular polysilicon using a fluidized bed reactor is disclosed. The upper and lower spaces of the bed are defined as a reaction zone and a heating zone, respectively, with the height of the reaction gas outlet being selected as the reference height. The invention maximizes the reactor productivity by sufficiently providing the heat required and stably maintaining the reaction temperature in the reaction zone, without impairing the mechanical stability of the fluidized bed reactor. This is achieved through electrical resistance heating in the heating zone where an internal heater is installed in a space in between the reaction gas supplying means and the inner wall of the reactor tube, thereby heating the fluidizing gas and the silicon particles in the heating zone. The heat generated in the heating zone is transferred to the reaction zone by supplying the fluidizing gas at such a rate that the silicon particles can be intermixed between the reaction zone and the heating zone in a continuous, fluidized state.

Owner:KOREA RES INST OF CHEM TECH

Lithium ion secondary battery negative electrode material and its preparation

InactiveUS20050031958A1Large capacityImprove cycle performanceSiliconElectrode thermal treatmentLithiumDesorption

A metallic silicon-containing composite in which metallic silicon nuclei are coated with an inert material which does not contribute to adsorption and desorption of lithium ions is a useful negative electrode material for lithium ion secondary batteries. Using the composite as a negative electrode active material, a lithium ion secondary battery having a high capacity and excellent cycle performance can be fabricated.

Owner:SHIN ETSU CHEM IND CO LTD

Method for producing monocrystalline metal or semi-metal bodies

InactiveUS20090047203A1Cheap methodCost effective productionPolycrystalline material growthSiliconVertical gradientCrucible

Owner:SCHOTT AG

Method and apparatus for preparation of granular polysilicon

InactiveUS20100068116A1Reduce stepsPolycrystalline material growthSiliconProduction rateElectrical resistance and conductance

A process for preparing granular polysilicon using a fluidized bed reactor is disclosed. The upper and lower spaces of the bed are defined as a reaction zone and a heating zone, respectively, with the height of the reaction gas outlet being selected as the reference height. The invention maximizes the reactor productivity by sufficiently providing the heat required and stably maintaining the reaction temperature in the reaction zone, without impairing the mechanical stability of the fluidized bed reactor. This is achieved through electrical resistance heating in the heating zone where an internal heater is installed in a space in between the reaction gas supplying means and the inner wall of the reactor tube, thereby heating the fluidizing gas and the silicon particles in the heating zone. The heat generated in the heating zone is transferred to the reaction zone by supplying the fluidizing gas at such a rate that the silicon particles can be intermixed between the reaction zone and the heating zone in a continuous, fluidized state.

Owner:KOREA RES INST OF CHEM TECH

Method for producing silicon for use in solar cells

InactiveUS6090361AAvoid energy wasteAvoid material lossPolycrystalline material growthSiliconElectrical batteryZone melting

Method for producing highly purified silicon for use in solar cells by a single solidification purification, pouring silicon into a mold and gradually fractionally solidifying it while solidifying the liquid surface, followed by purifying the solidified silicon by zone melting or continuous casting using an electromagnetic mold, or by zone melting in combination with continuous casting, and optionally causing directional solidification to concentrate impurities, leaching and recycling.

Owner:KAWASAKI STEEL CORP

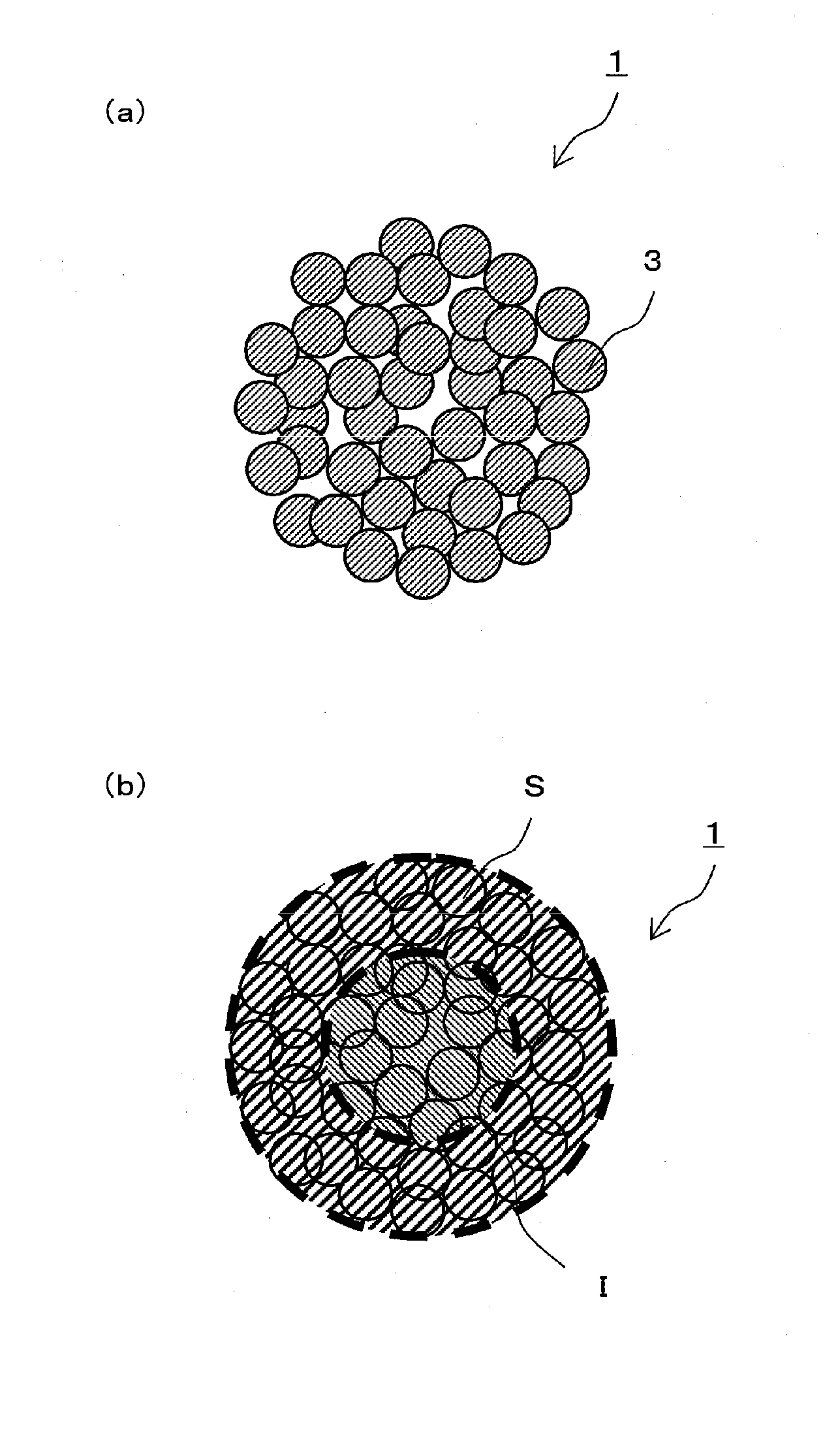

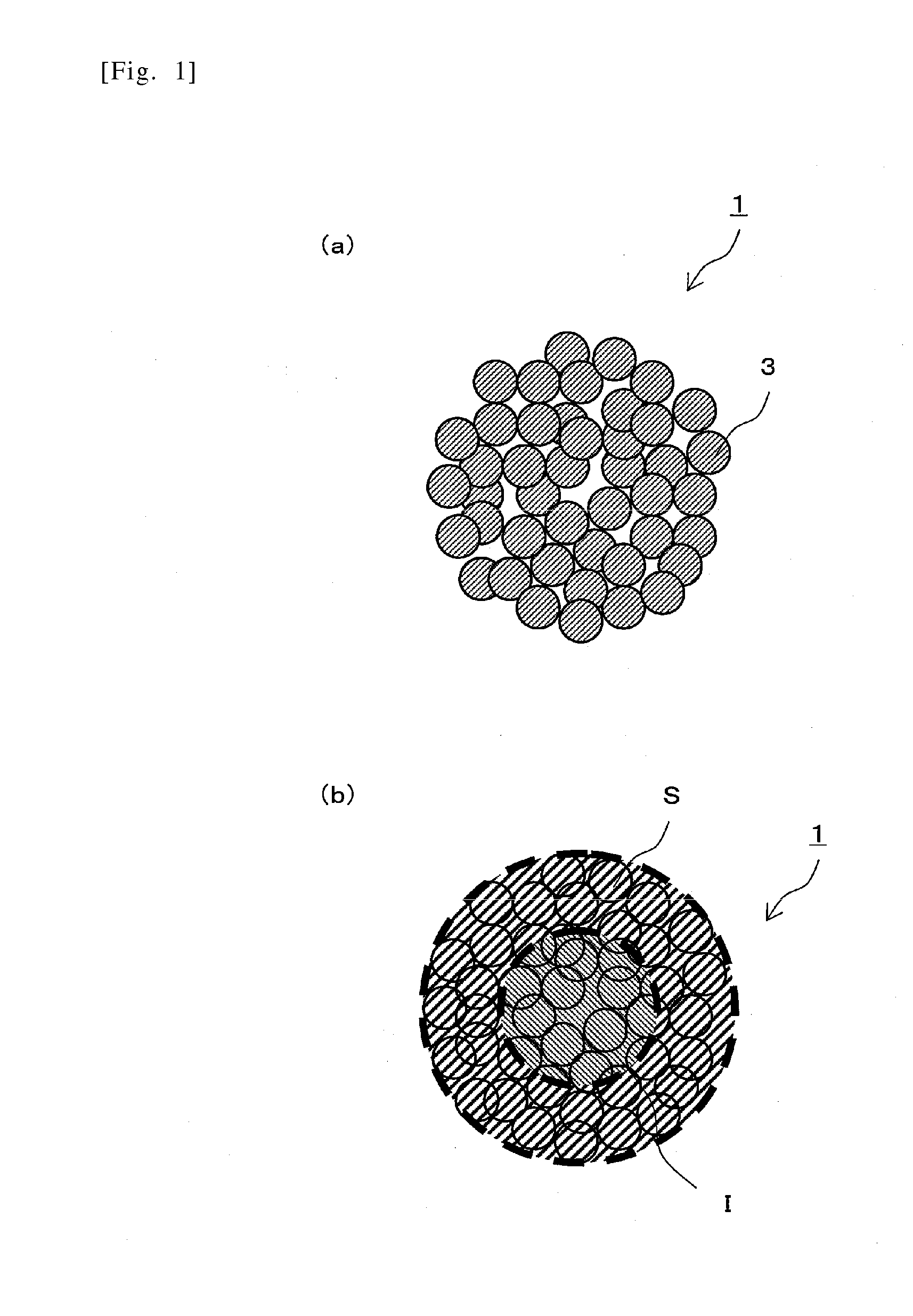

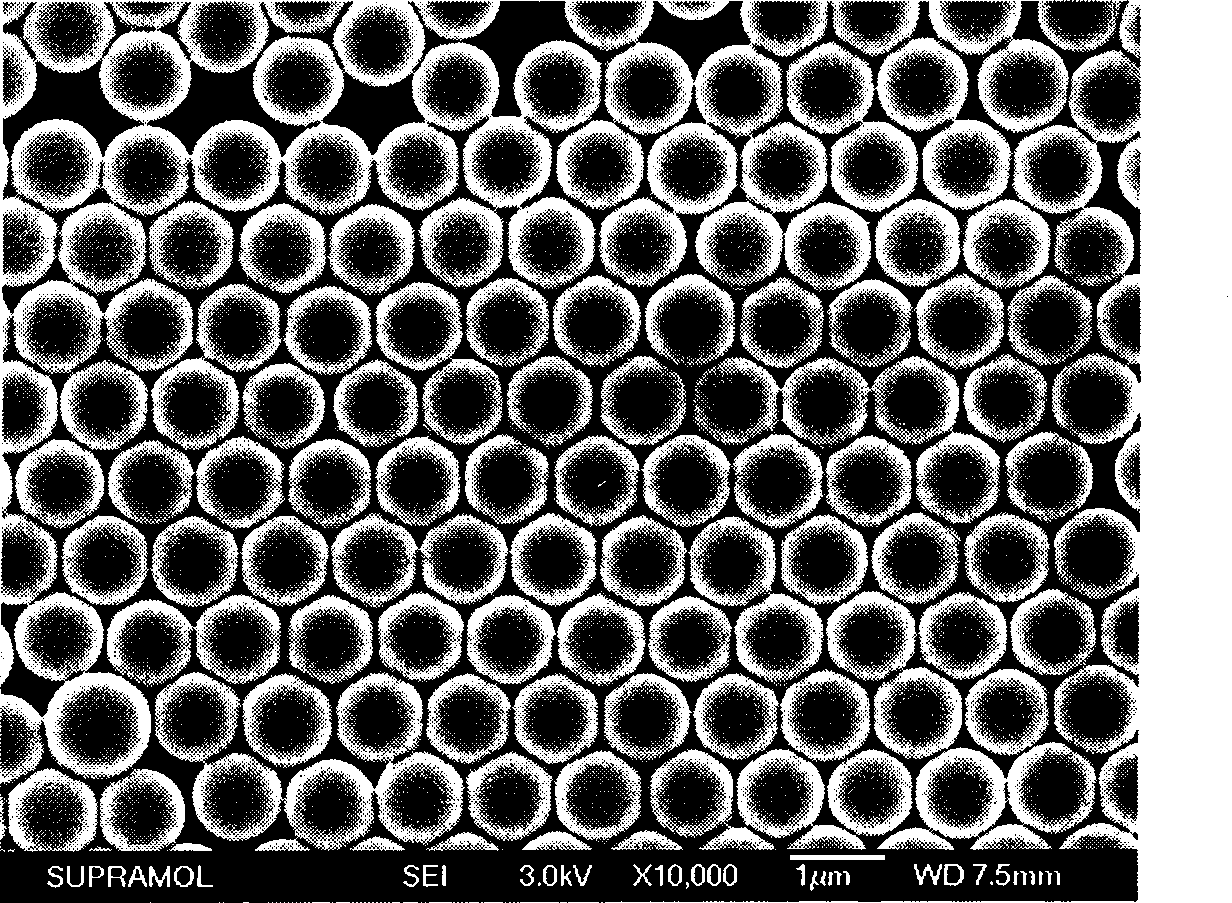

Porous silicon particles and complex porous silicon particles, and method for producing both

ActiveUS20130196158A1Large capacityImprove featuresElectrode manufacturing processesSiliconNetwork structureMicroparticle

Porous silicon particles and complex porous silicon particles suitable for negative electrode materials etc. for lithium-ion batteries, which achieve high capacity and good cycling characteristics, are provided. Porous silicon particles formed by the joining of a plurality of silicon microparticles, and having an average particle diameter of 0.1 μm to 1000 μm, a three-dimensional network structure having continuous gaps, an average porosity of 15 to 93%, and a structure in which the particles of a whole particle are uniform. Complex porous silicon particles formed by the joining of a plurality of silicon microparticles and a plurality of silicon compound particles, and characterized by containing a compound of silicon and composite elements, having an average particle diameter of 0.1 μm to 1000 μm, and having a three-dimensional network structure having continuous gaps.

Owner:FURUKAWA ELECTRIC CO LTD +1

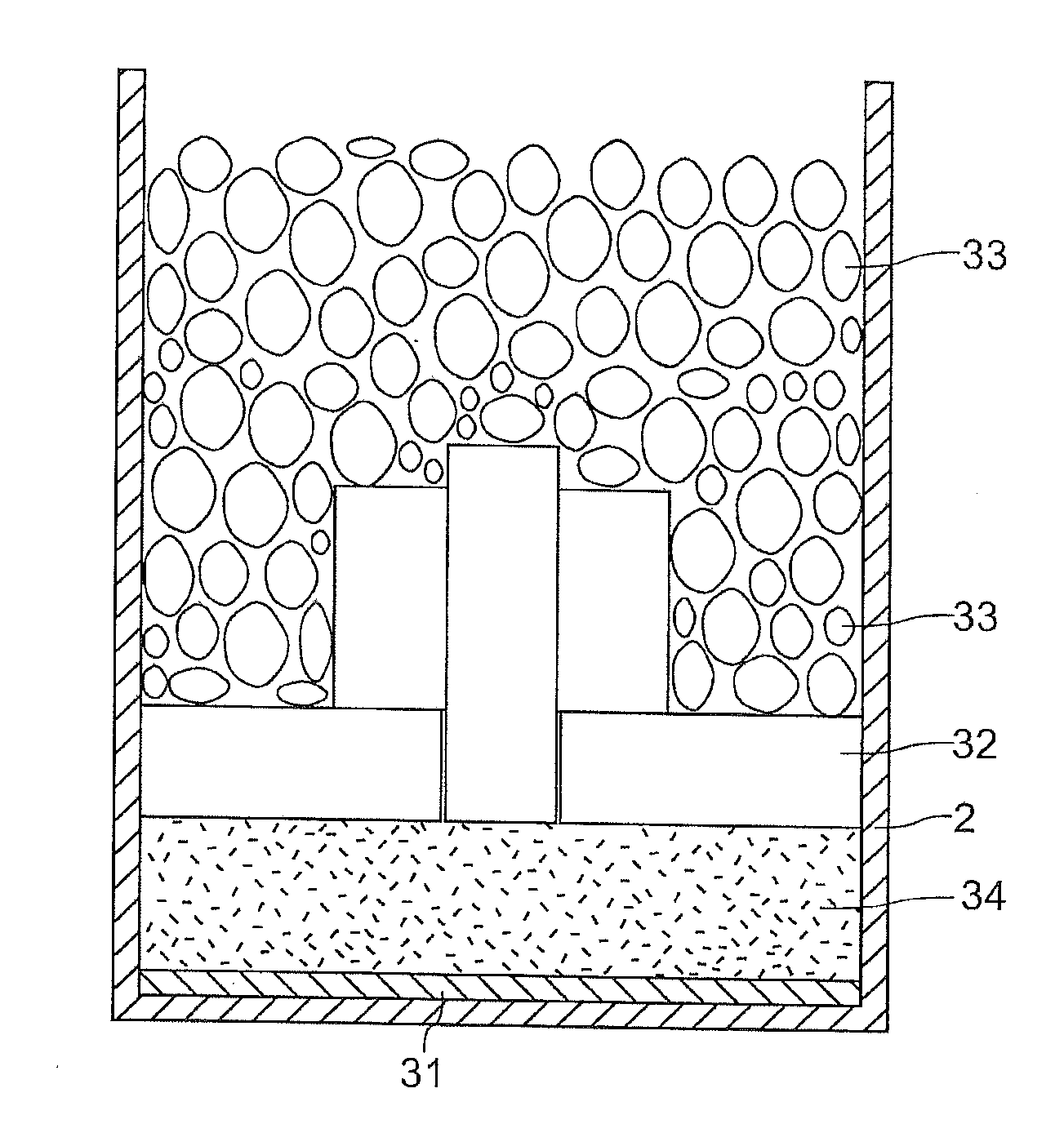

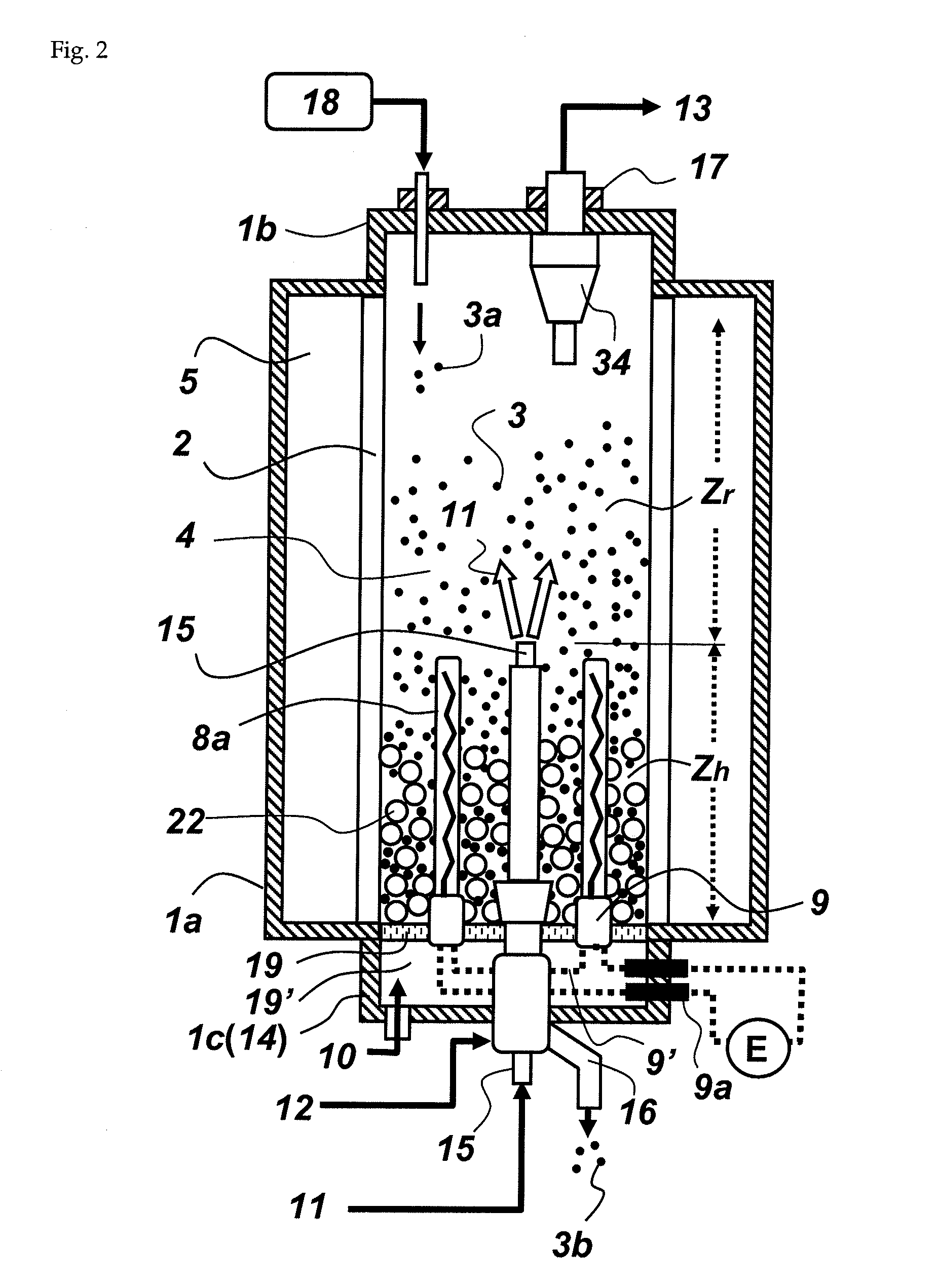

Silicon Spout-Fluidized Bed

InactiveUS20080220166A1Improve usabilityImprove productivitySiliconChemical/physical/physico-chemical nozzle-type rreactorsFluidized bedEngineering

Polysilicon is formed by pyrolytic decomposition of a silicon-bearing gas and deposition of silicon onto fluidized silicon particles. Multiple submerged spout fluidized bed reactors and reactors having secondary orifices are disclosed.

Owner:REC SILICON

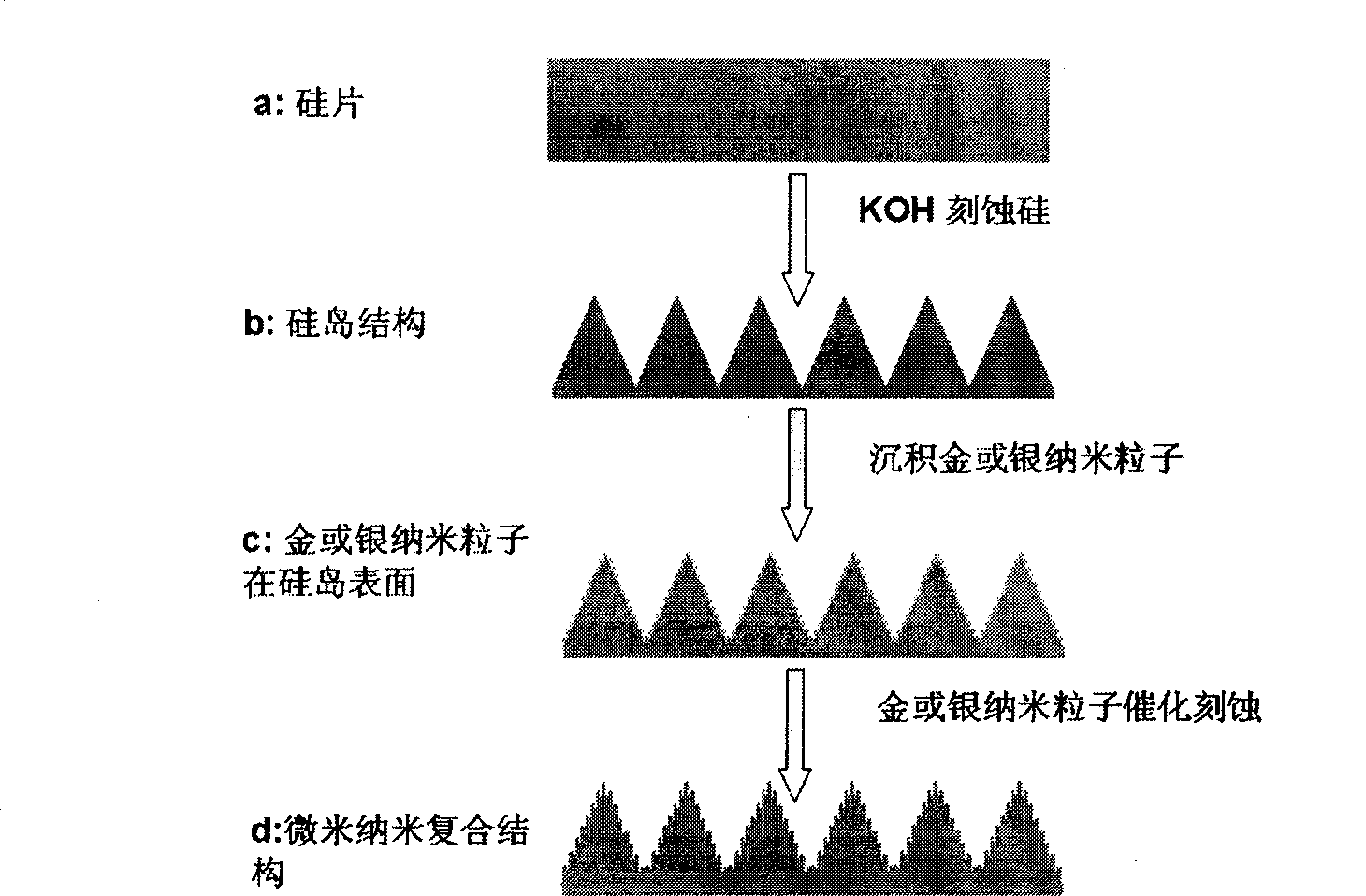

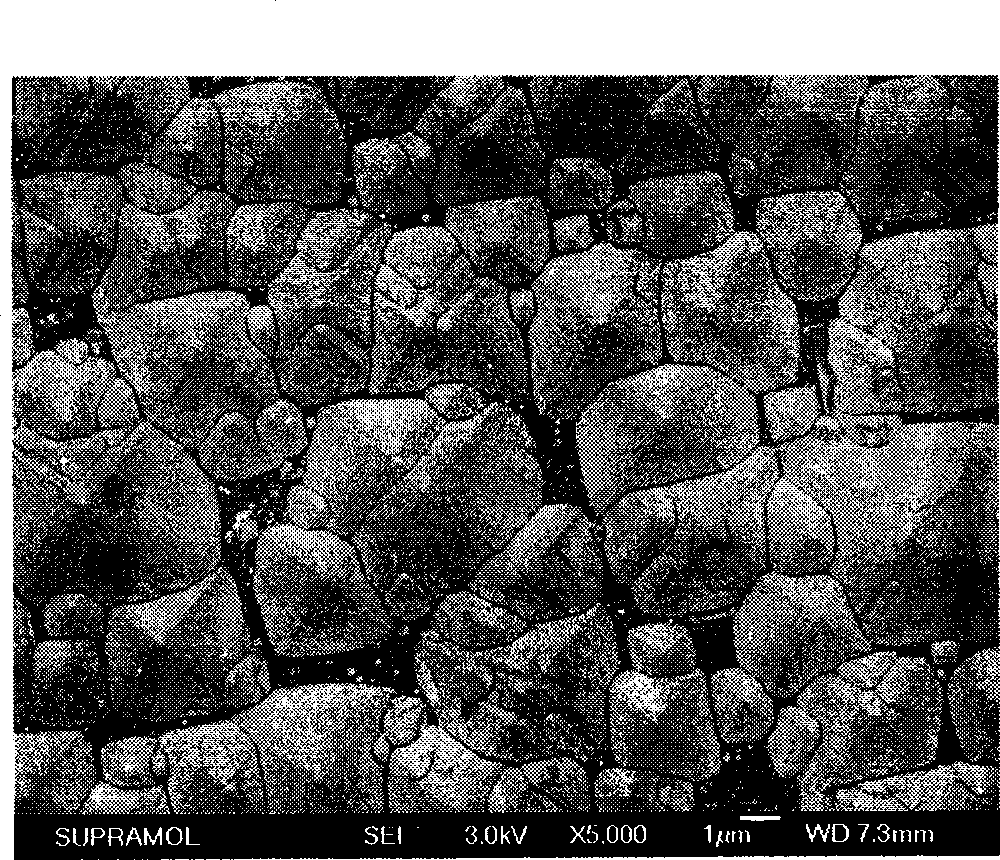

Method for preparing super-hydrophobic antireflex micron and nano composite structure surface

The invention belongs to the technical field of preparing the surface of a composite structure, and in particular relates to a method for preparing super-hydrophobic antireflective silicon surface with a micron and nanometer composite structure. The method comprises the following steps: cleaning a silicon chip; preparing a micron-level silicon island and a gridding structure on the surface of the silicon chip; carrying out catalytic etching taking silver or aurum nanoparticles as blockage; obtaining the surface of the micron and nanometer composite structure; and carrying out chemical modification of the surface of the composite structure. A static contact angle between the super-hydrophobic antireflective material surface prepared by the method and water is more than 150 degrees, and a static rolling angle of water is less than 3 degrees. The surface has superior antireflective performance, and in particular, the light reflectivity within the wavelength range between 800 and 1,100 nm is less than 3 percent. With application of the method, the super-hydrophobic antireflective silicon surface of the micron and nanometer composite structure can be produced on scale, can be widely applied to a solar cell, a microfluidic chip, a photoelectric device, and the like, and has good industrial application prospect.

Owner:JILIN UNIV

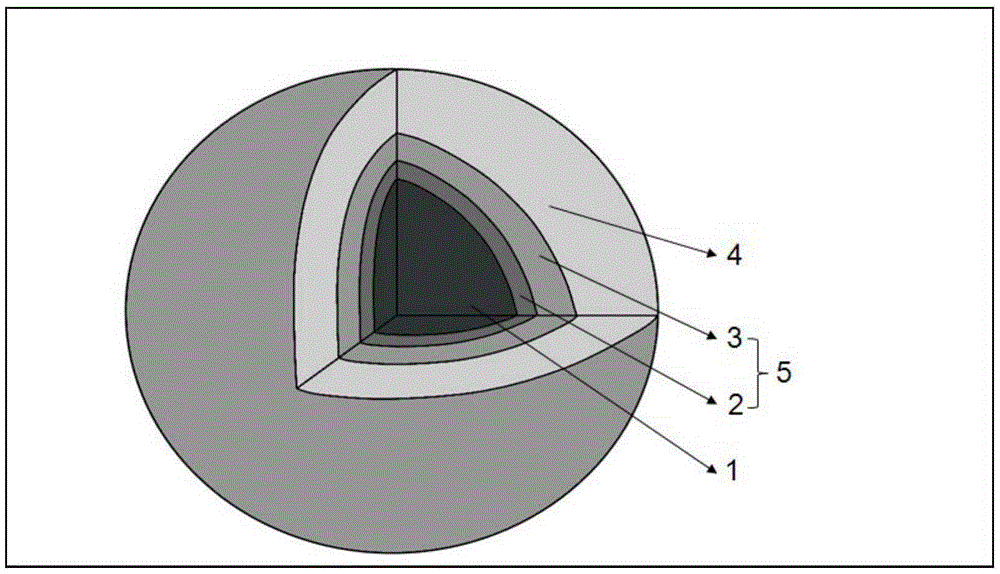

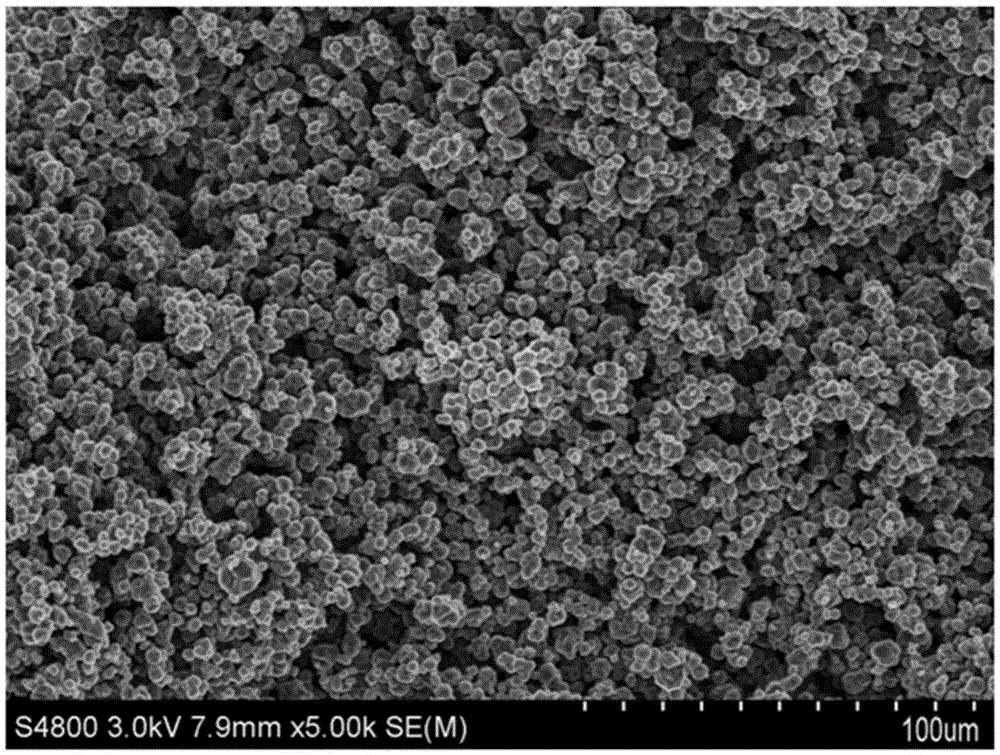

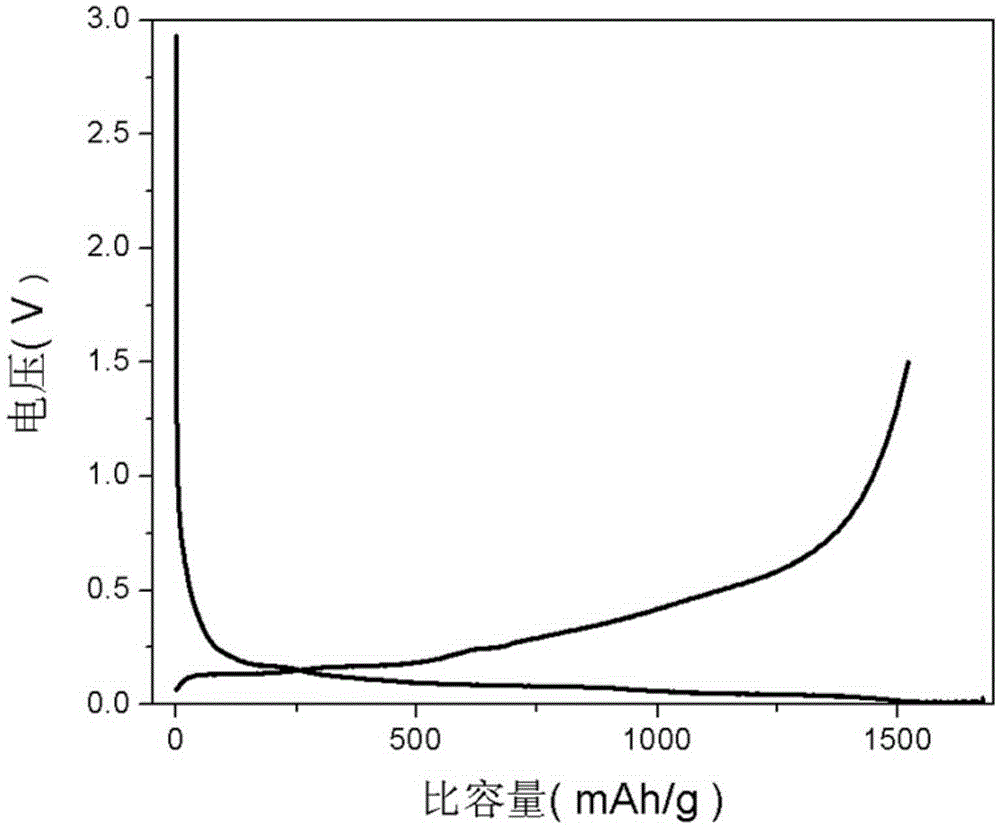

Composite silicon negative electrode material, and preparation method and application thereof

ActiveCN105406050AGood electrical conductivityIncrease capacitySiliconElectrode thermal treatmentCarbon layerLithium

The invention relates to a composite silicon negative electrode material. The composite silicon negative electrode material comprises nanometer silicon, a nanometer composite layer coating the surface of nanometer silicon and a conductive carbon layer uniformly coating the nanometer composite layer, wherein the nanometer composite layer is silicon oxide and metal alloy. According to the composite silicon negative electrode material with a three-layer structure, the nanometer composite layer composed of the silicon oxide and the metal alloy coating the surface of the silicon oxide effectively reduces volume expansion of the nanometer silicon, maintains the characteristic of high conductivity of the silicon material, improves mobility of lithium ions, prevents direct contact between a silicon negative electrode and an electrolyte, and can form a hard SEI film on the surface of the composite silicon negative electrode material, thereby allowing the cycle performance of the material to be substantially enhanced. The composite silicon negative electrode material has the characteristics of high capacity (greater than 1500 mAh / g), long cycle life (with a capacity retention ratio of more than 90% after 300 cycles) and high conductivity. The preparation method for the composite silicon negative electrode material is simple, easily controllable, and applicable to industrial production.

Owner:DINGYUAN NEW ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com