Patents

Literature

15555results about How to "Reduce distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

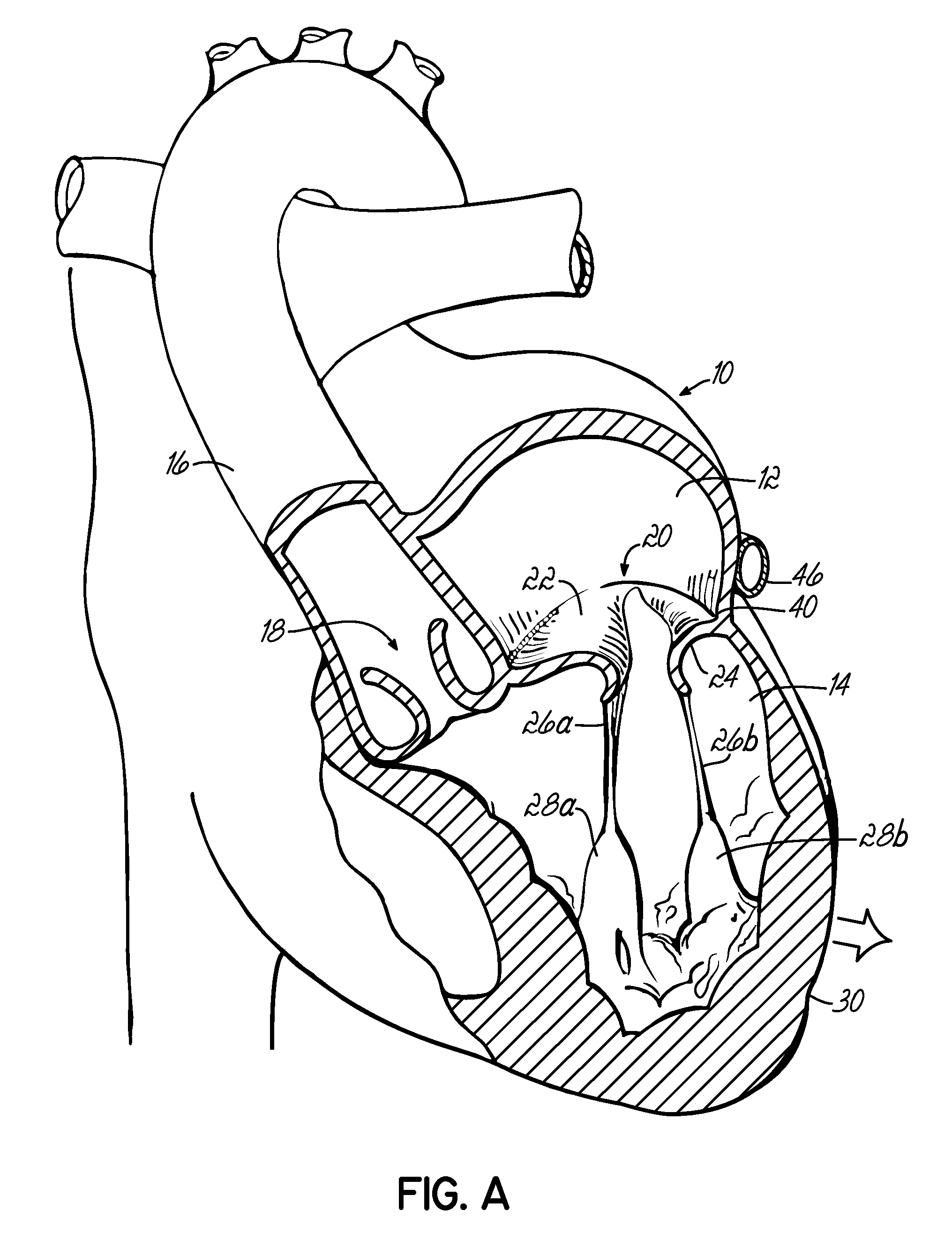

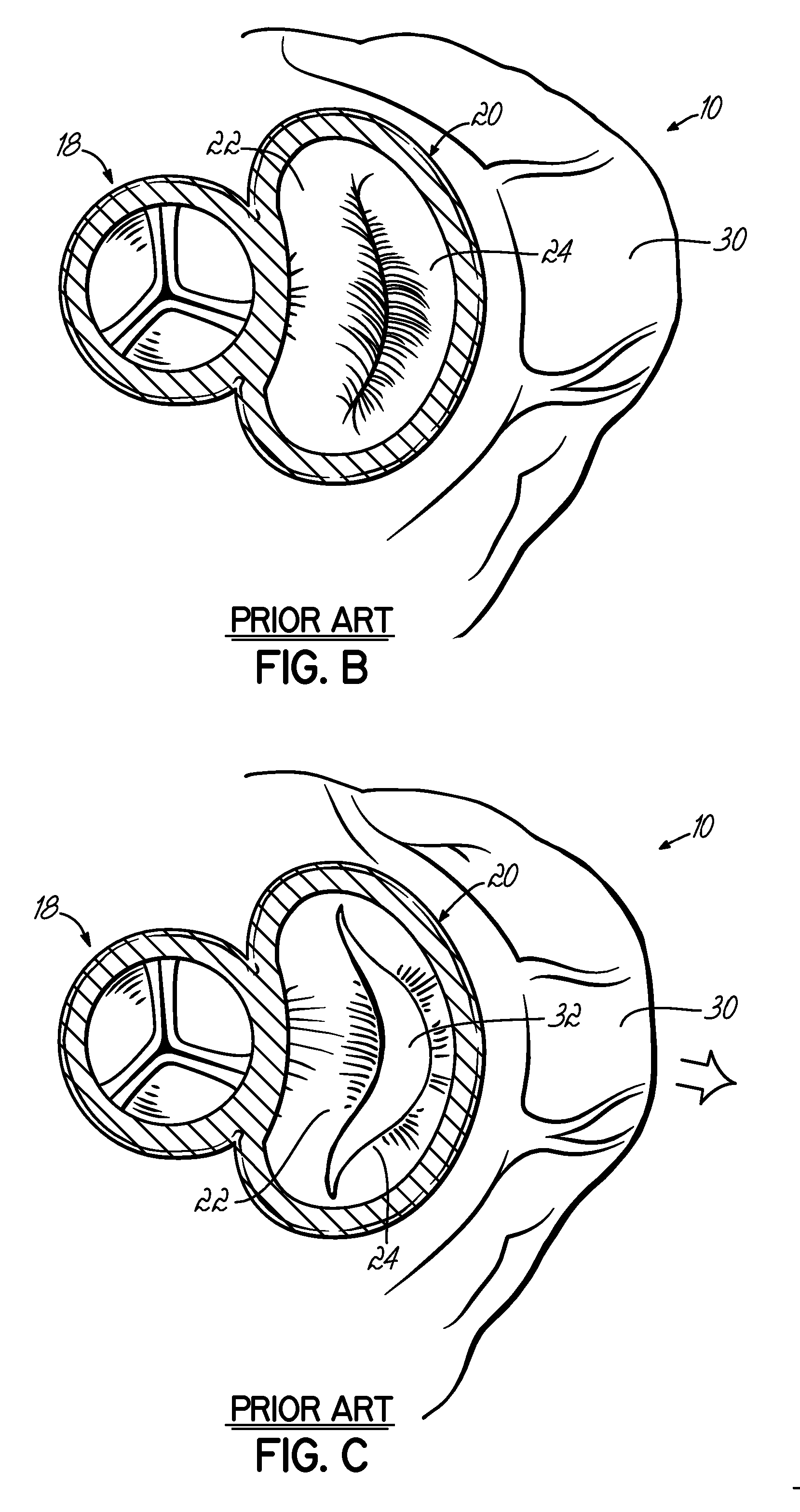

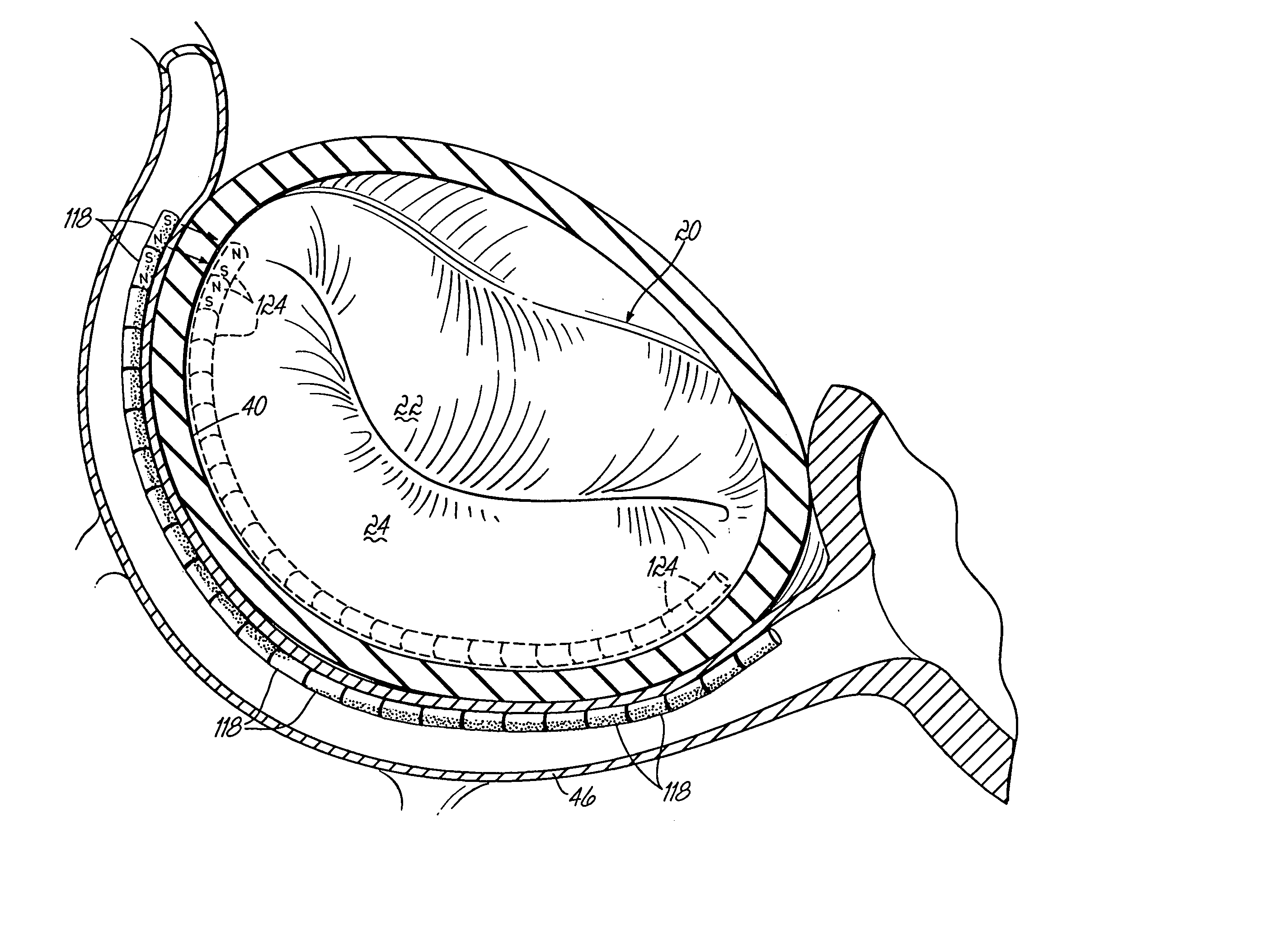

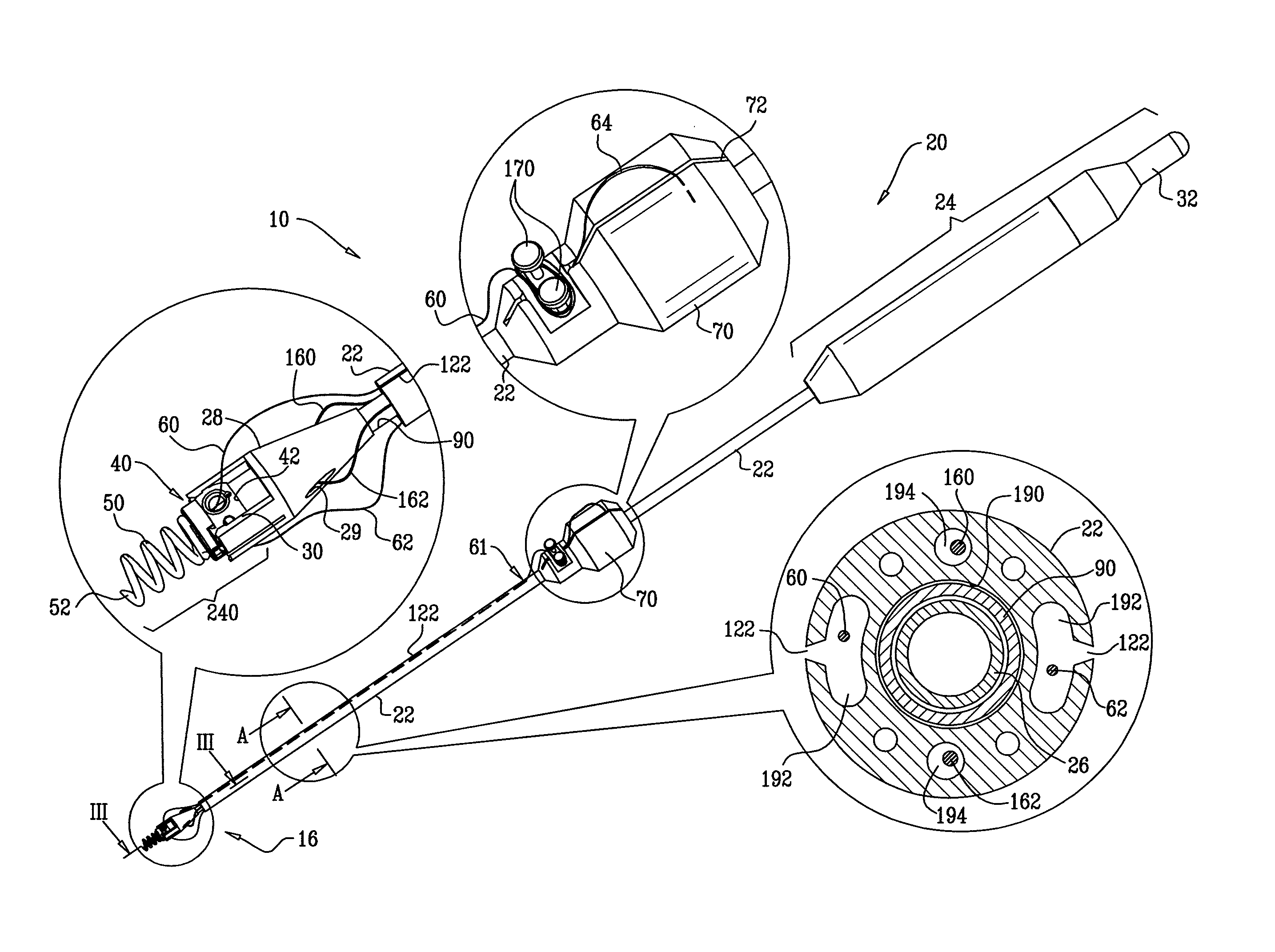

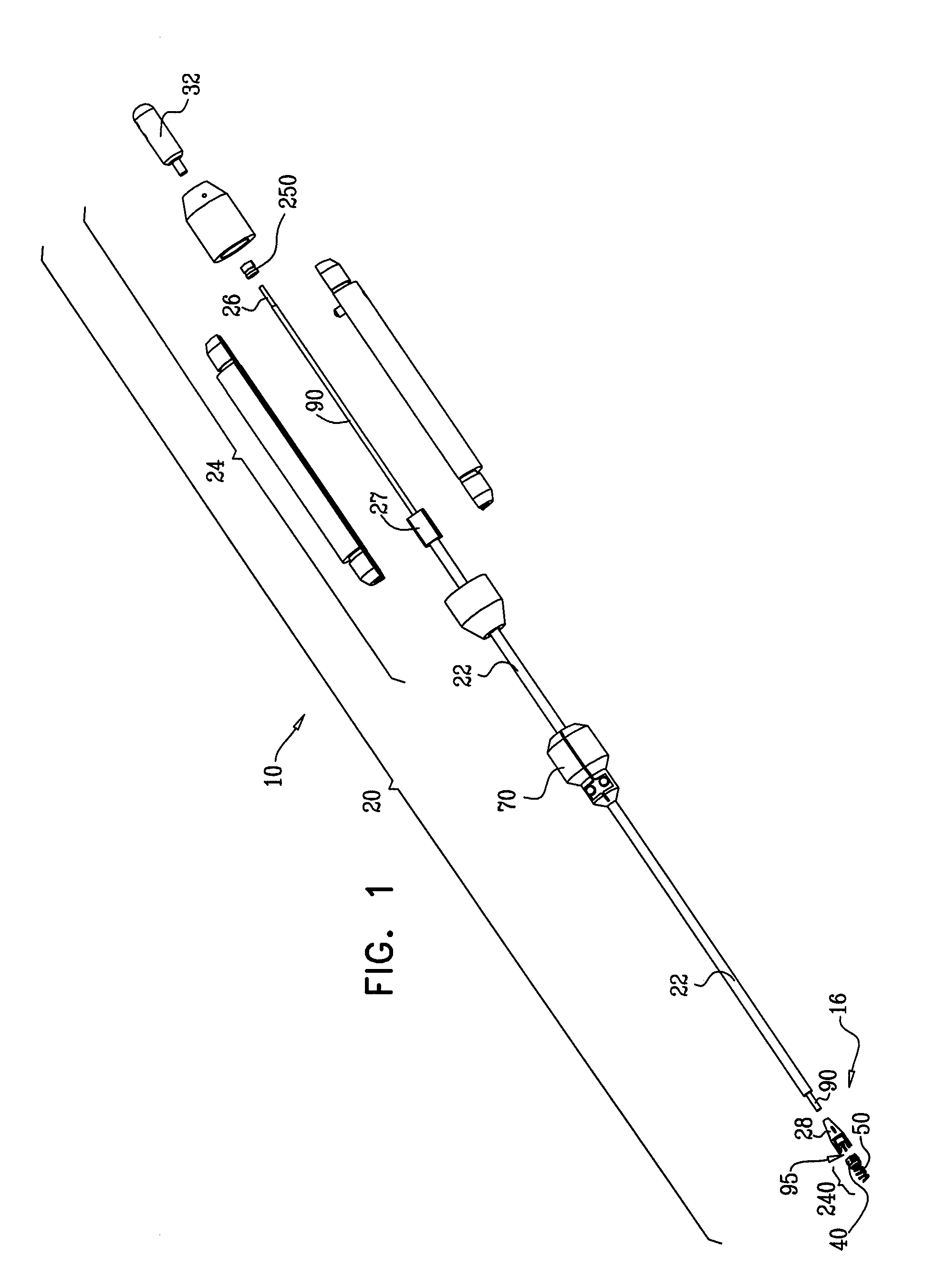

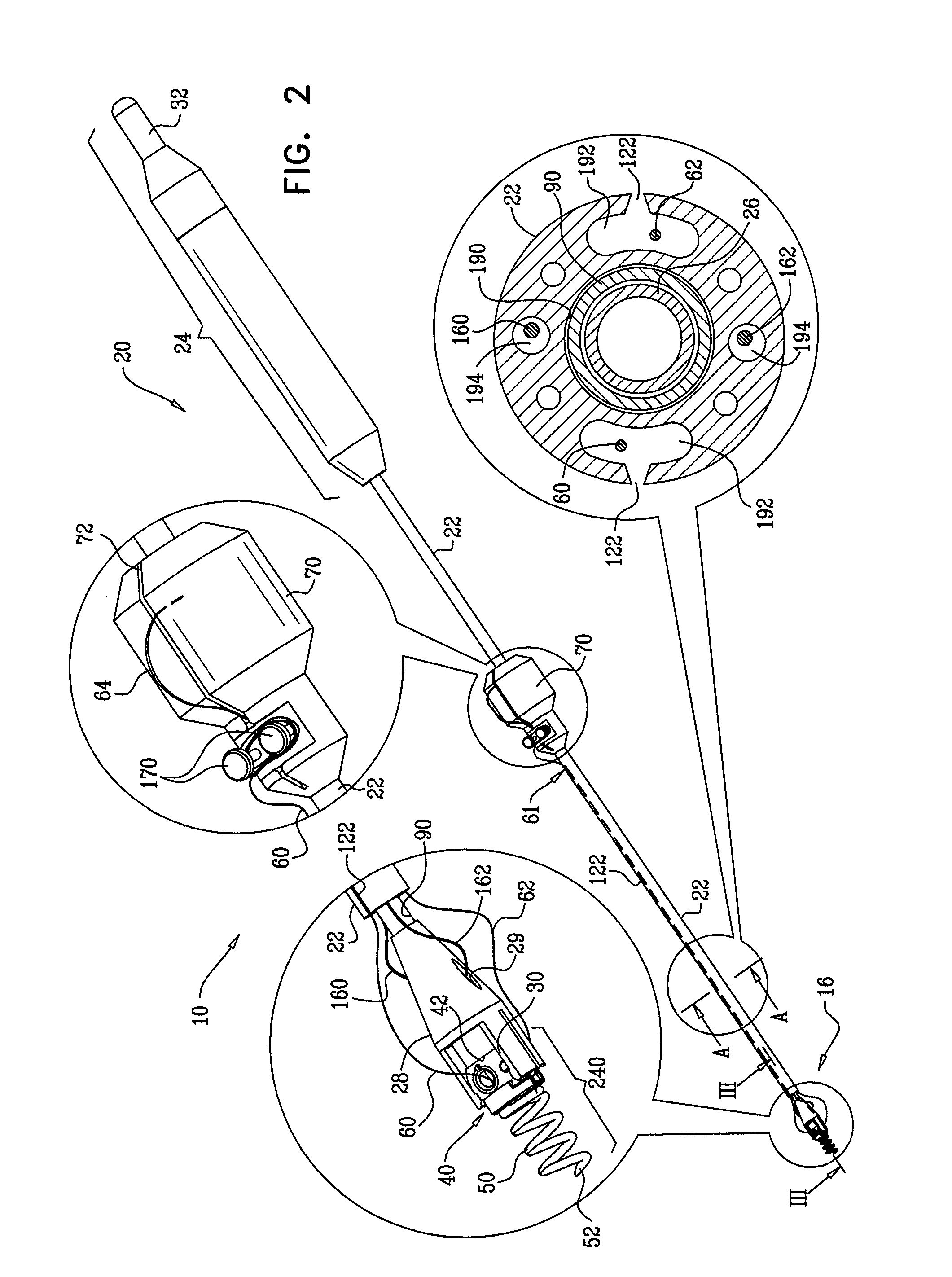

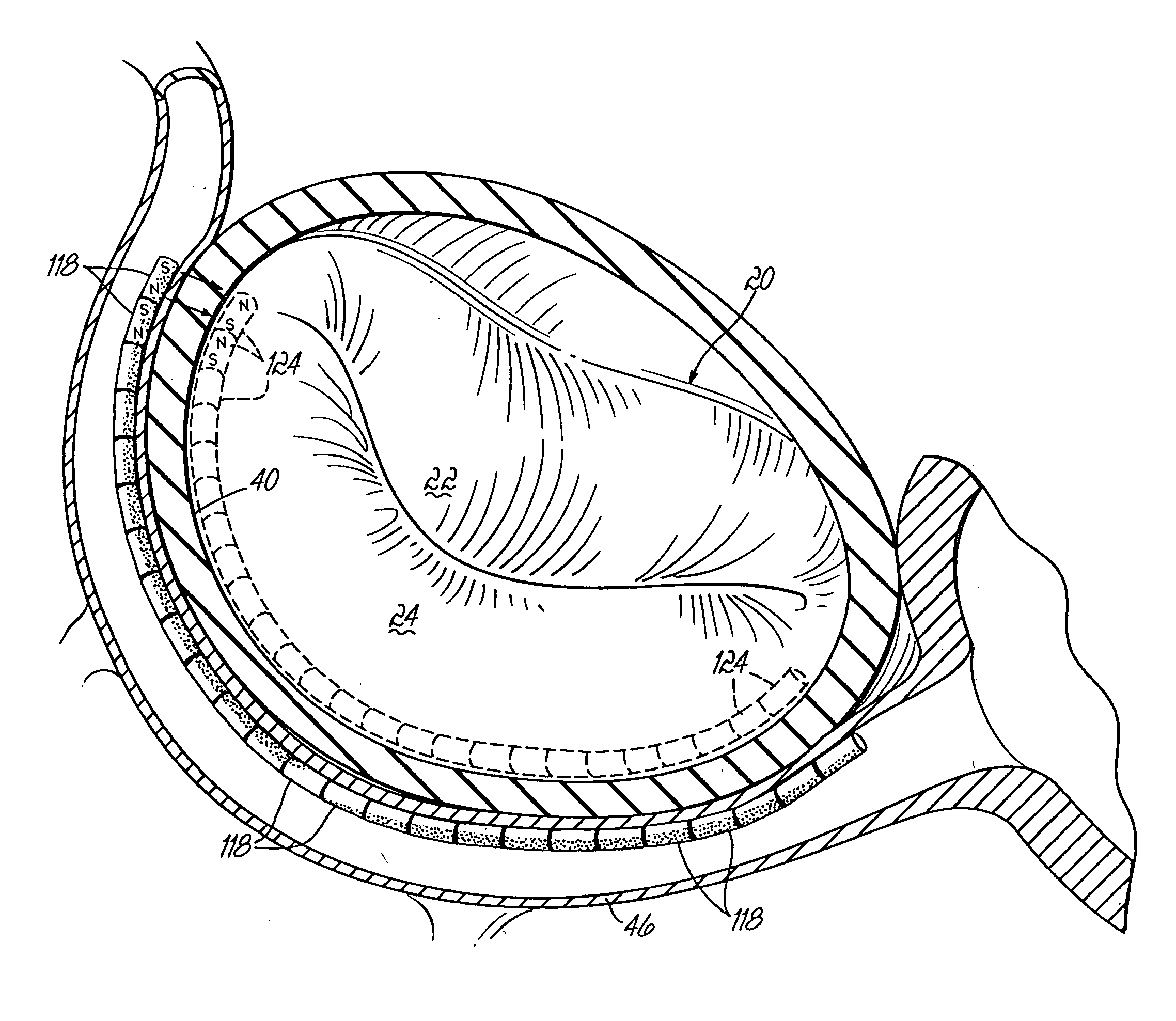

Tissue fastening systems and methods utilizing magnetic guidance

ActiveUS7166127B2Reducing circumferenceReduce distanceSuture equipmentsAnnuloplasty ringsMitral valve leafletImage guidance

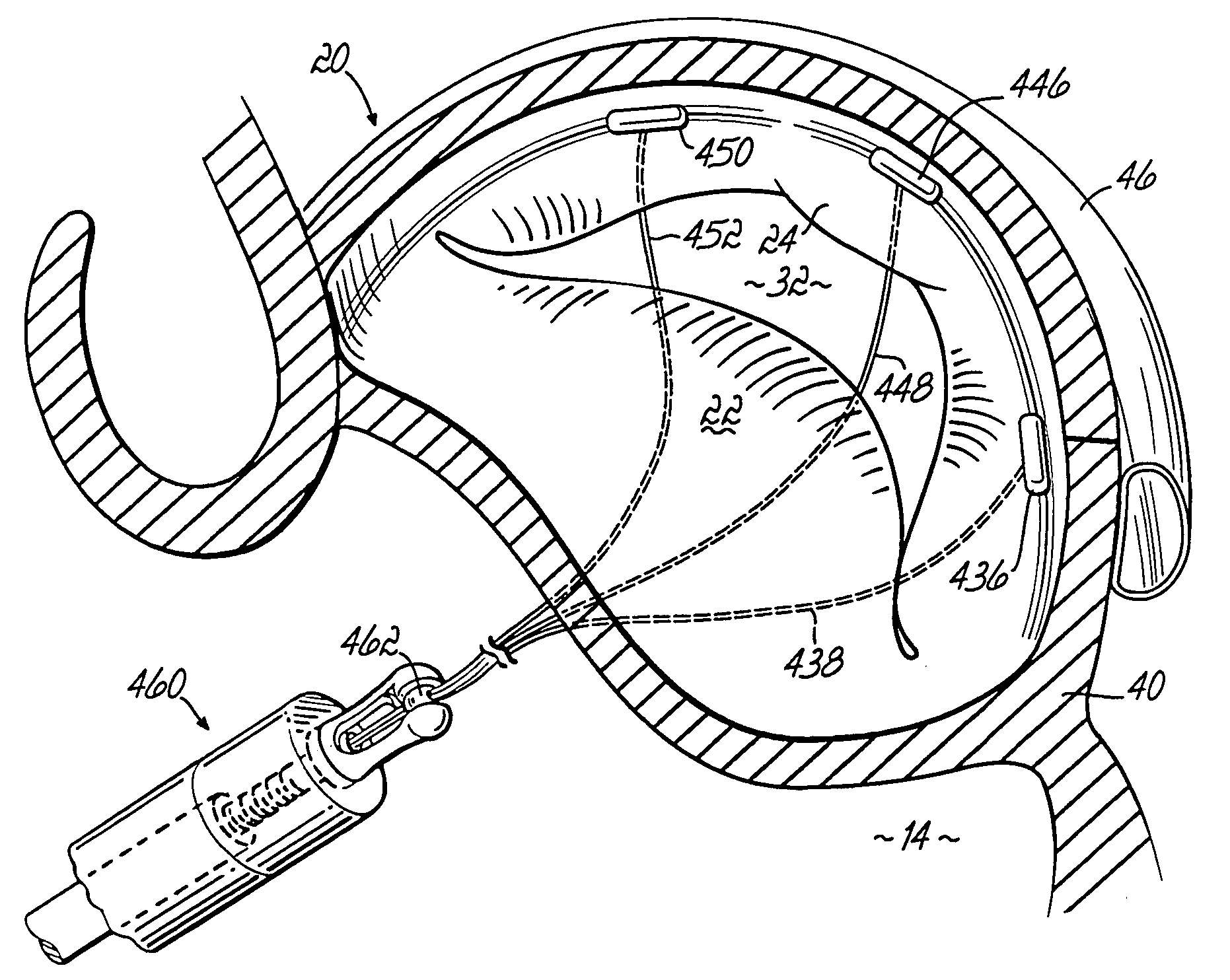

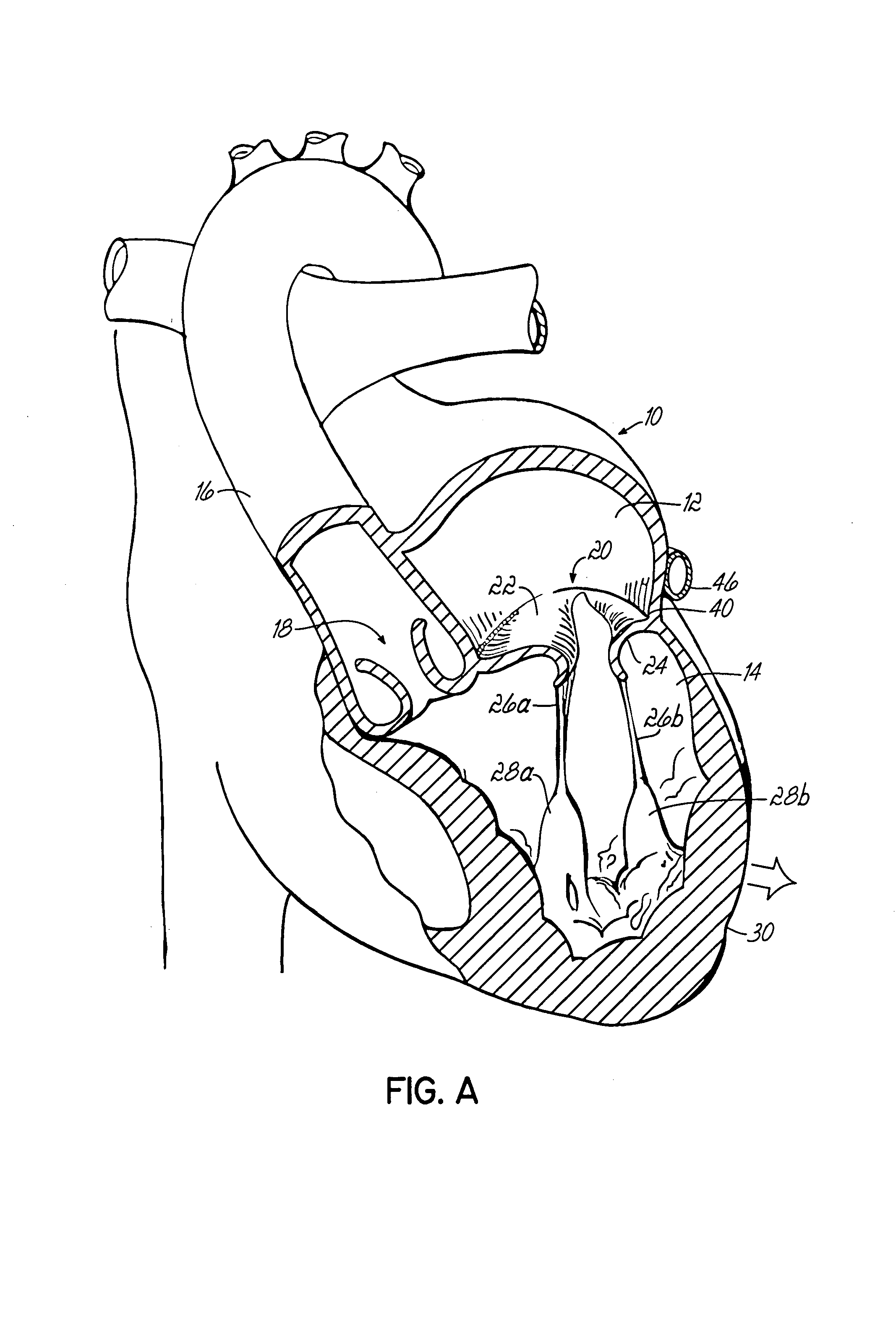

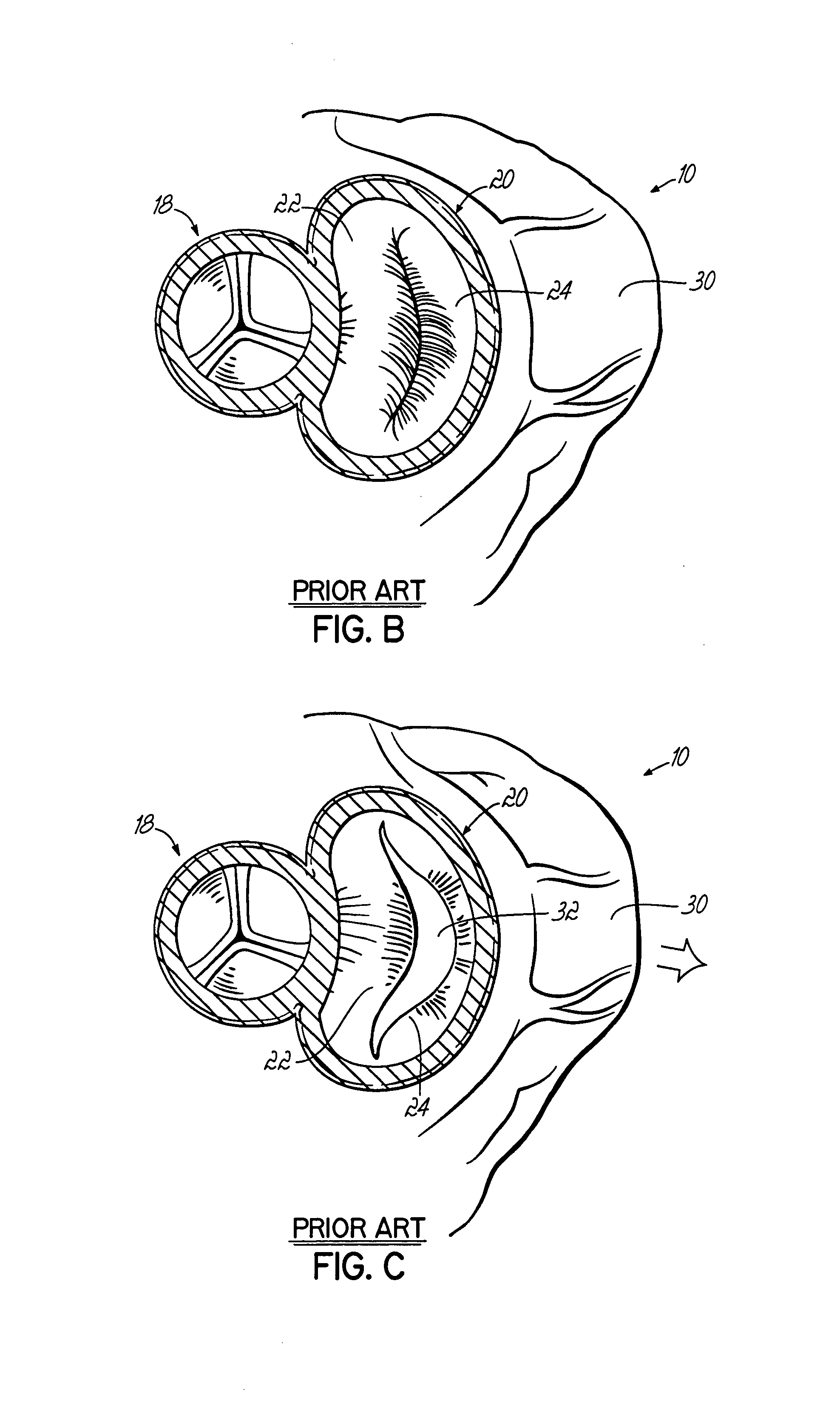

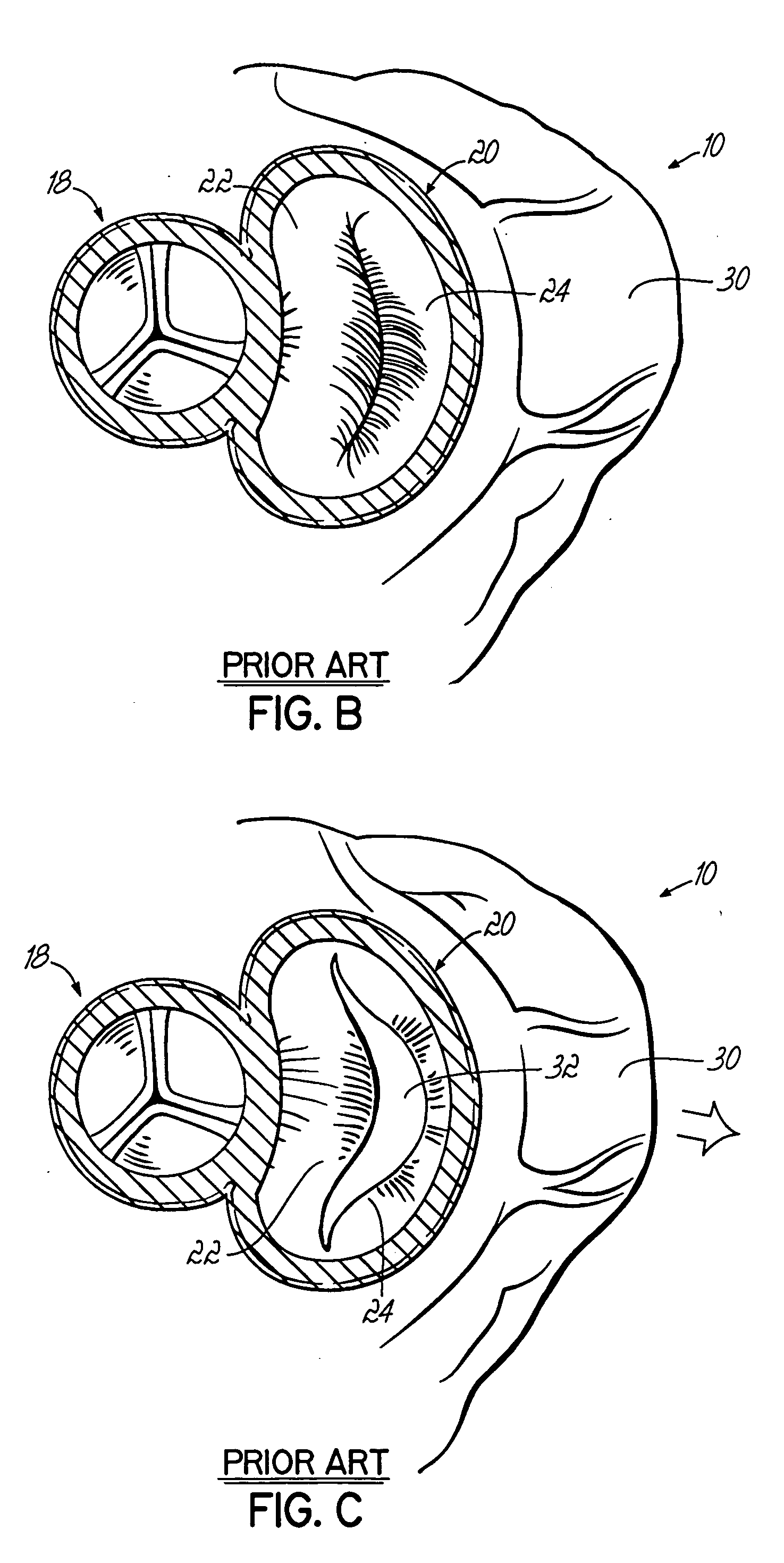

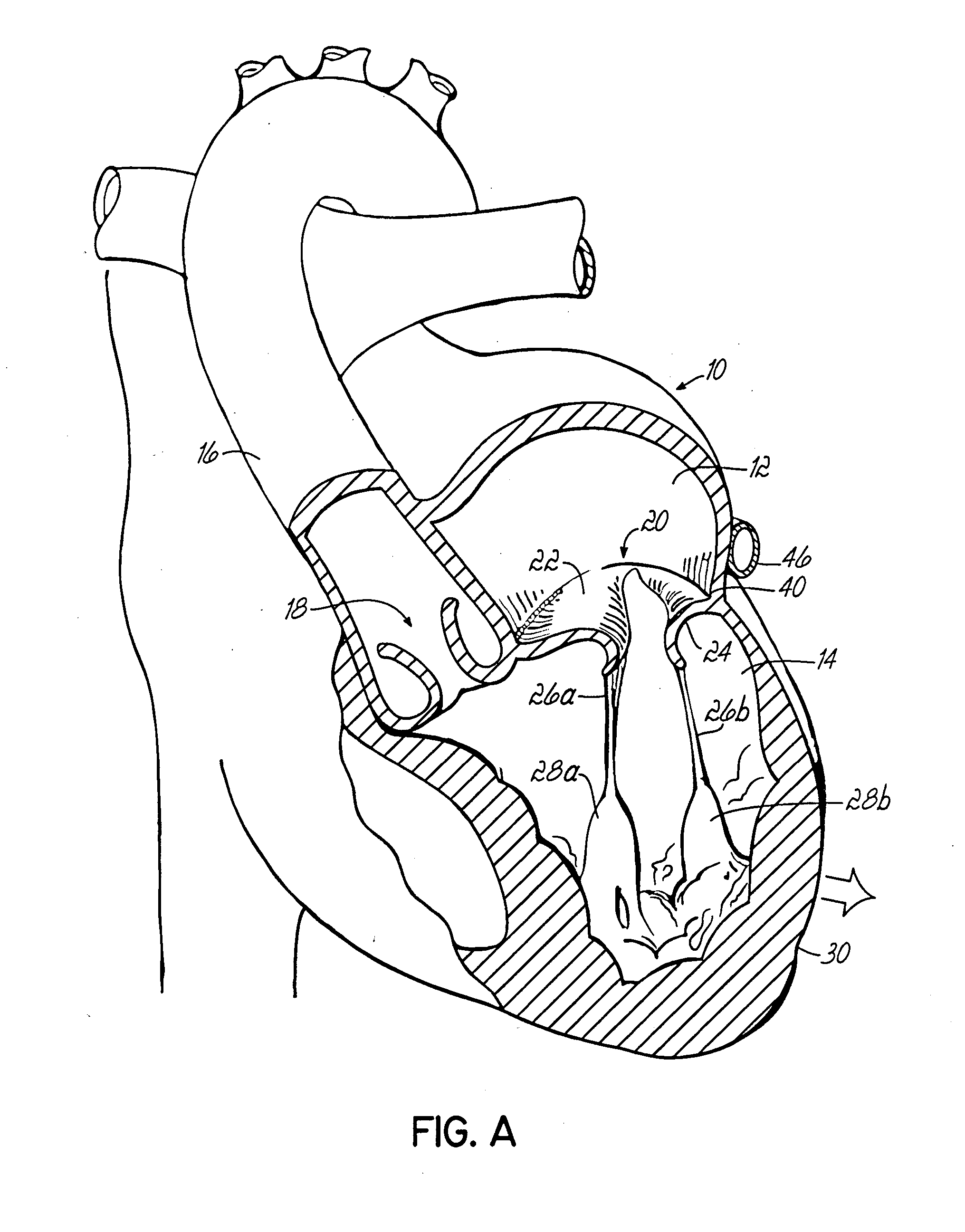

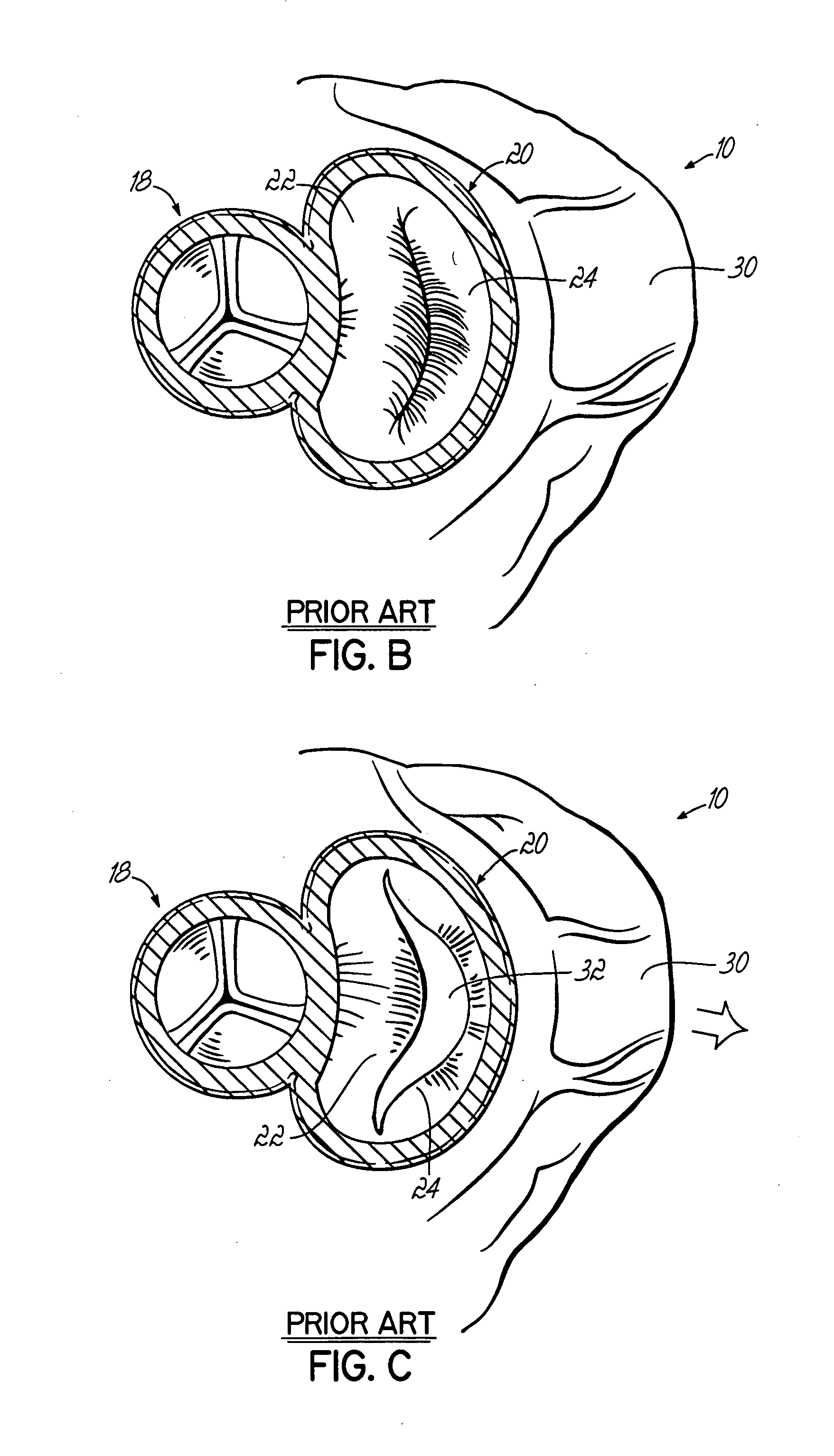

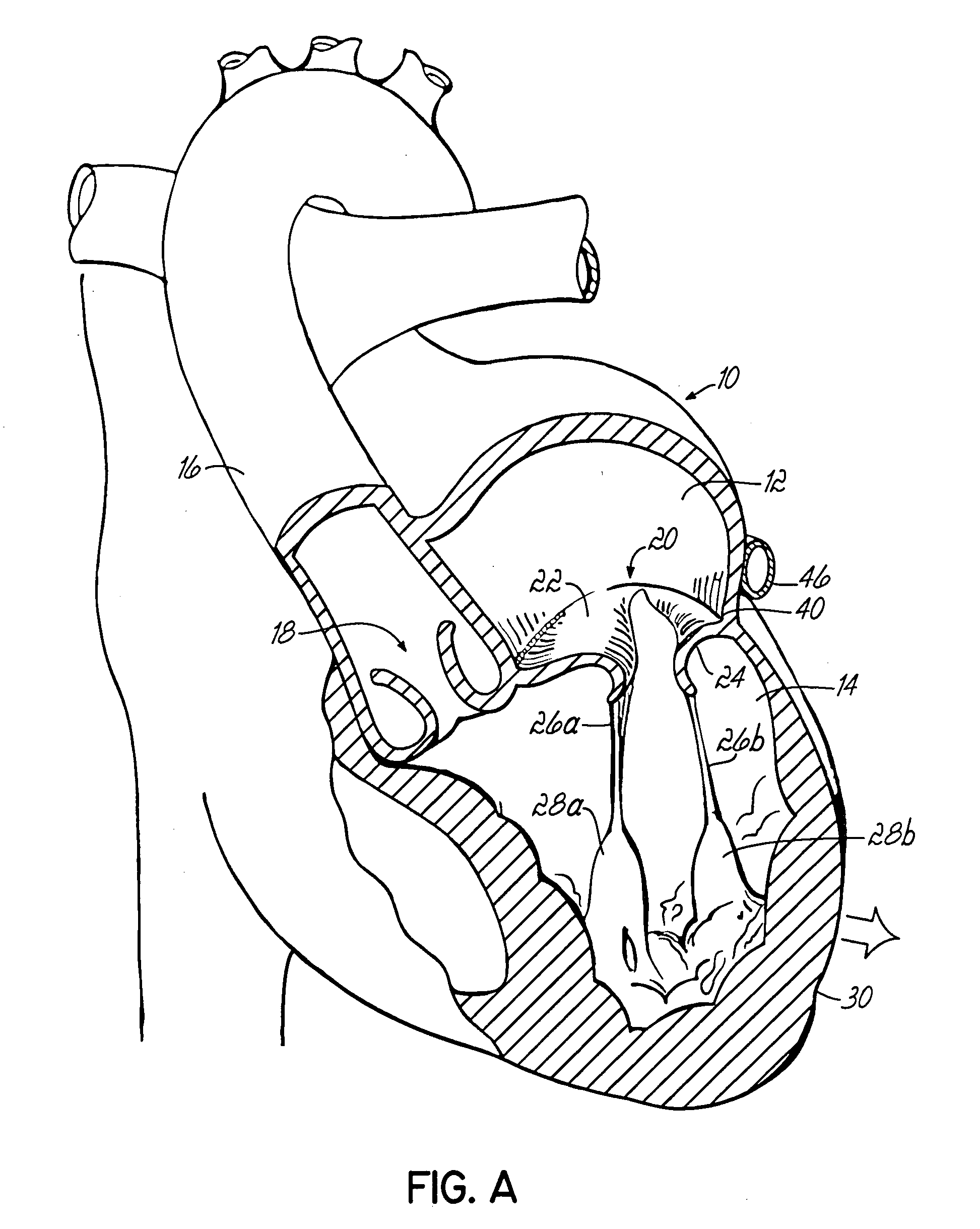

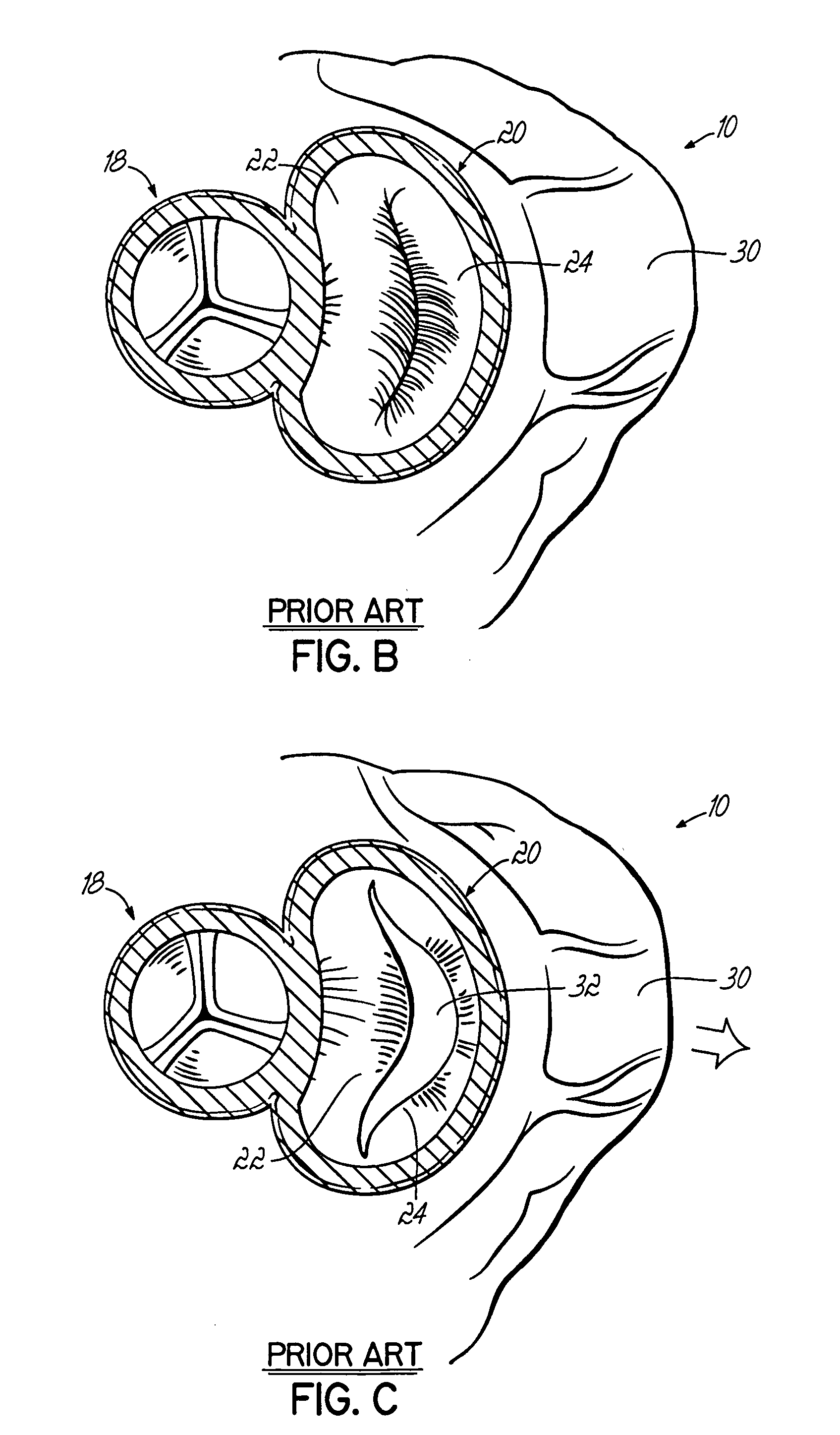

Catheter based systems and methods for securing tissue including the annulus of a mitral valve. The systems and methods employ catheter based techniques and devices to plicate tissue and perform an annuloplasty.

Owner:EDWARDS LIFESCIENCES CORP

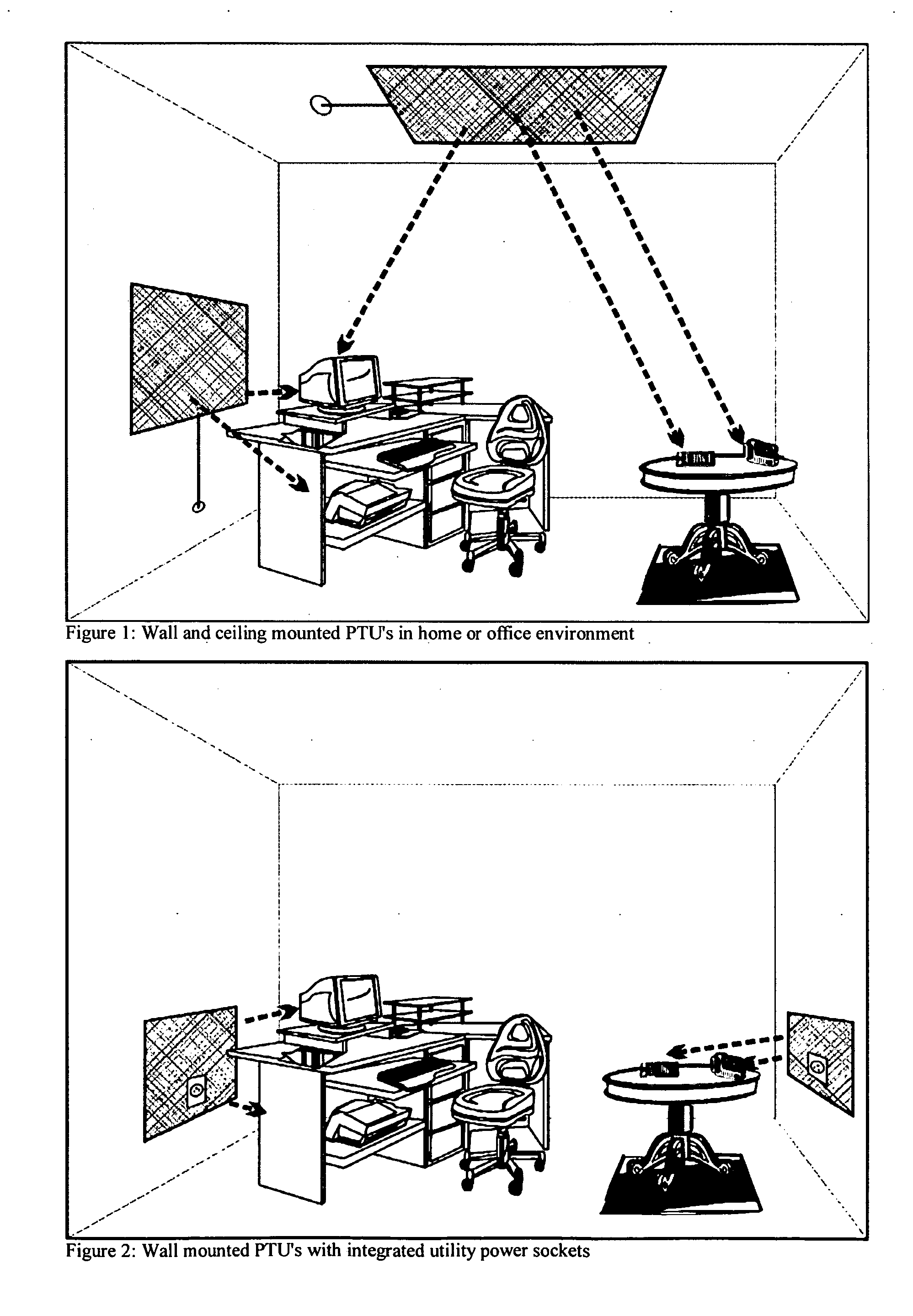

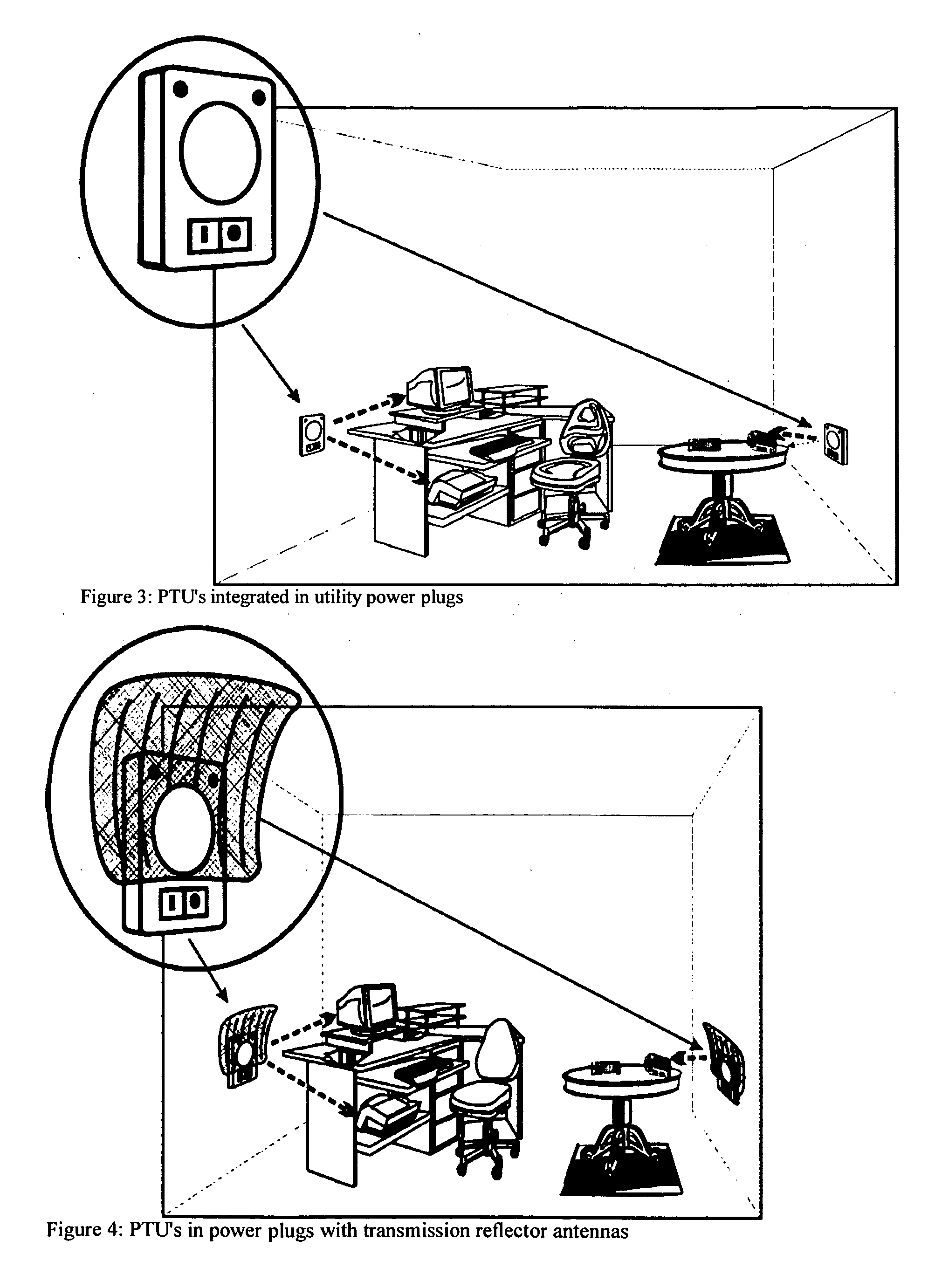

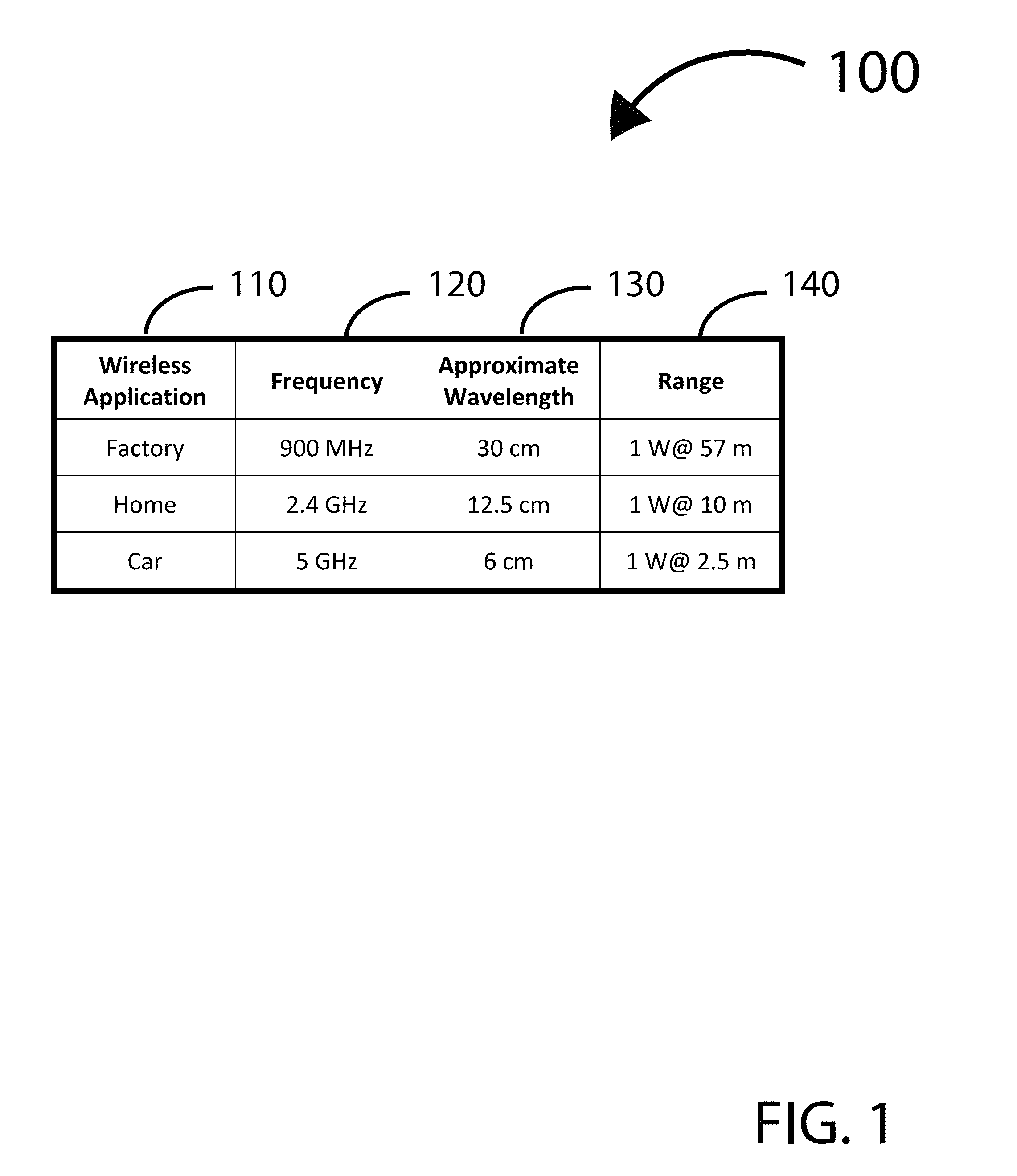

Short-range wireless power transmission and reception

InactiveUS20060238365A1Avoid the needReduce distancePower managementBatteries circuit arrangementsTransmitted powerEngineering

A short-range wireless power transmission and reception system and method are provided. Power is transmitted from the electrical utility mains power supply to electrically powered appliances via electromagnetic radiation. The appliances are capable of receiving the transmitted power, converting it into electricity and storing it for subsequent use, as well as using it directly to power the appliances.

Owner:VECCHIONE ELIO +1

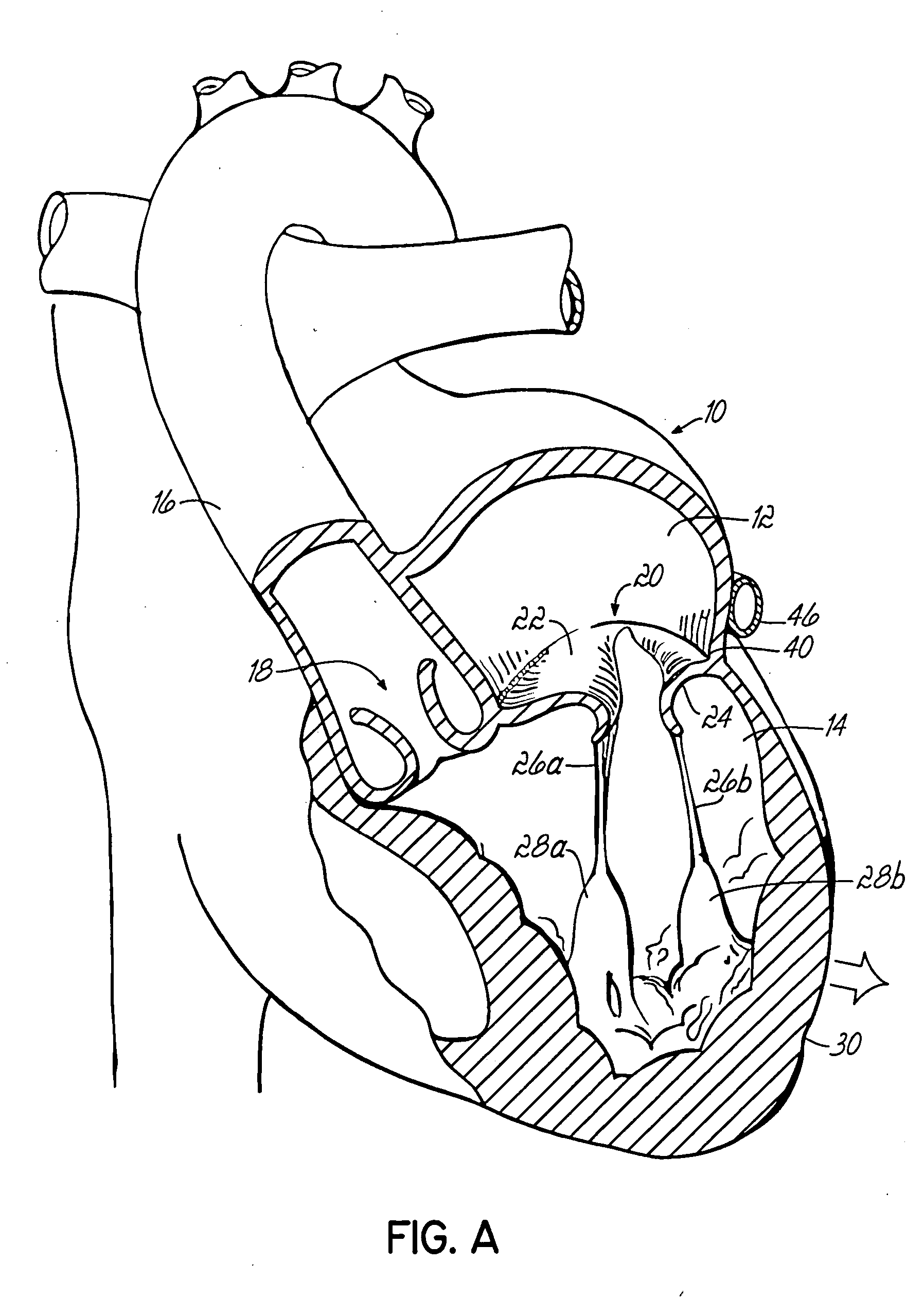

Method and device for treatment of mitral insufficiency

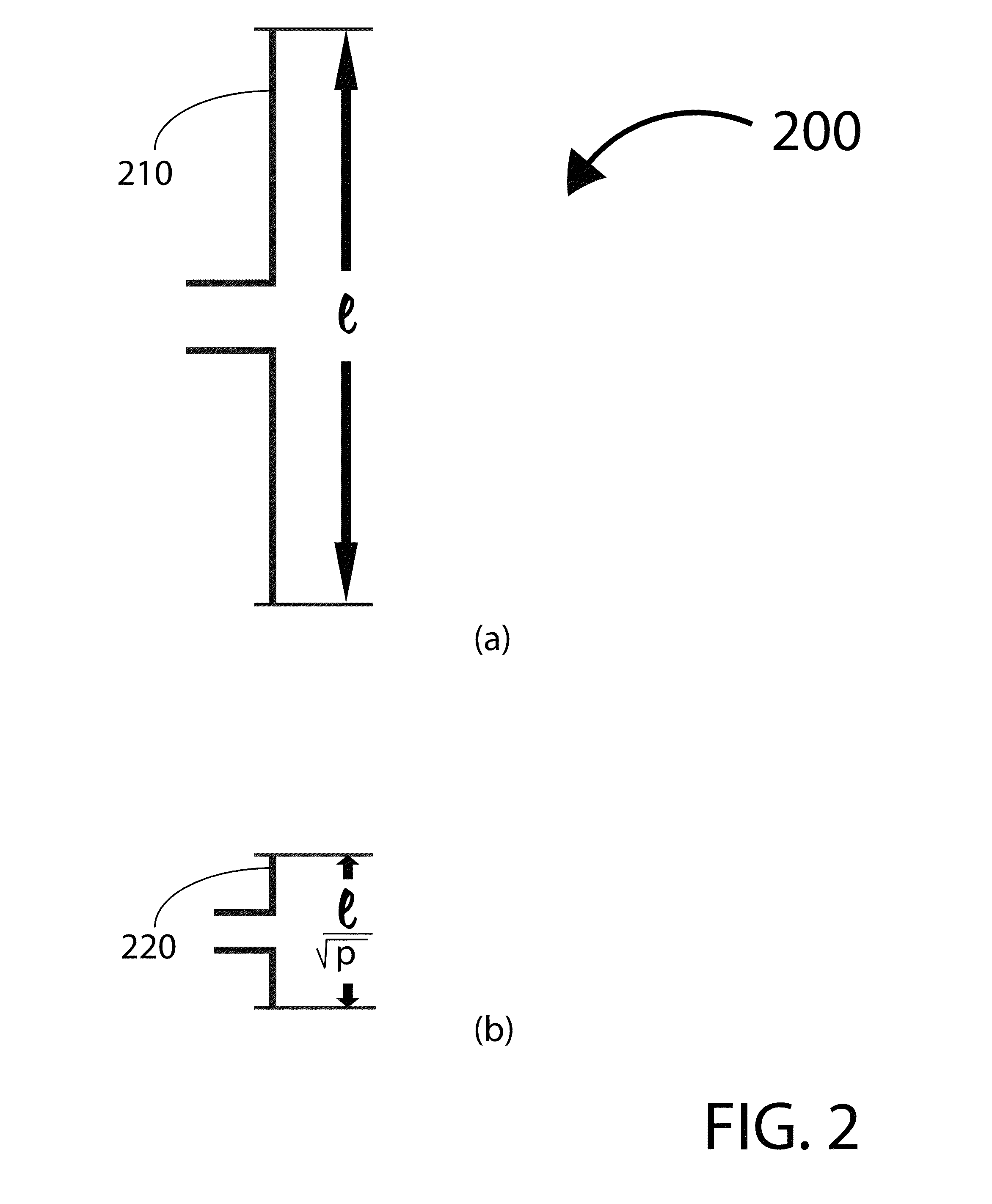

InactiveUS6997951B2Length of device can be decreasedShorten the lengthStentsBone implantCoronary sinusMitral annulus

A device for treatment of mitral annulus dilation is disclosed, wherein the device comprises two states. In a first of these states the device is insertable into the coronary sinus and has a shape of the coronary sinus. When positioned in the coronary sinus, the device is transferable to the second state assuming a reduced radius of curvature, whereby the radius of curvature of the coronary sinus and the radius of curvature as well as the circumference of the mitral annulus is reduced.

Owner:EDWARDS LIFESCIENCES AG +1

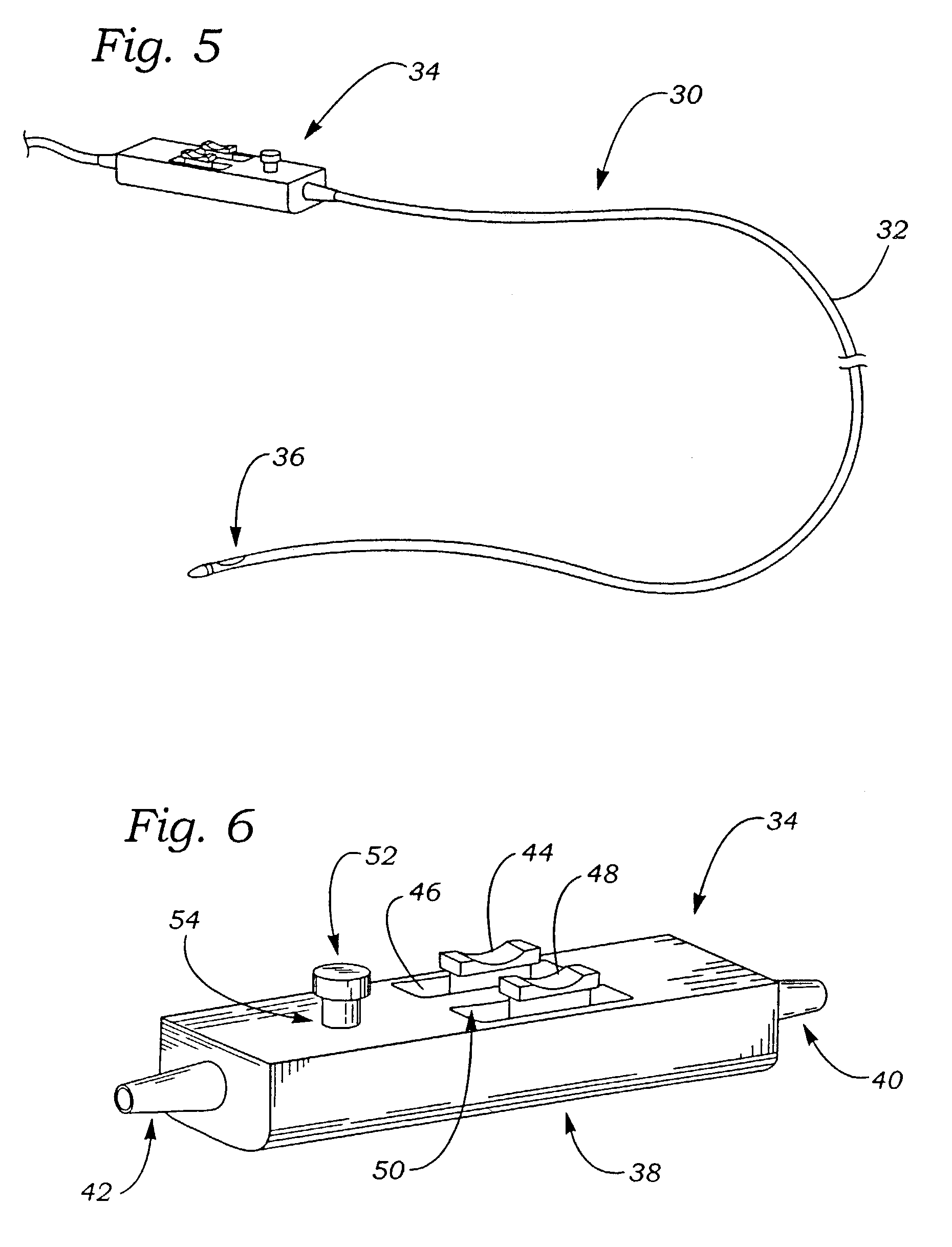

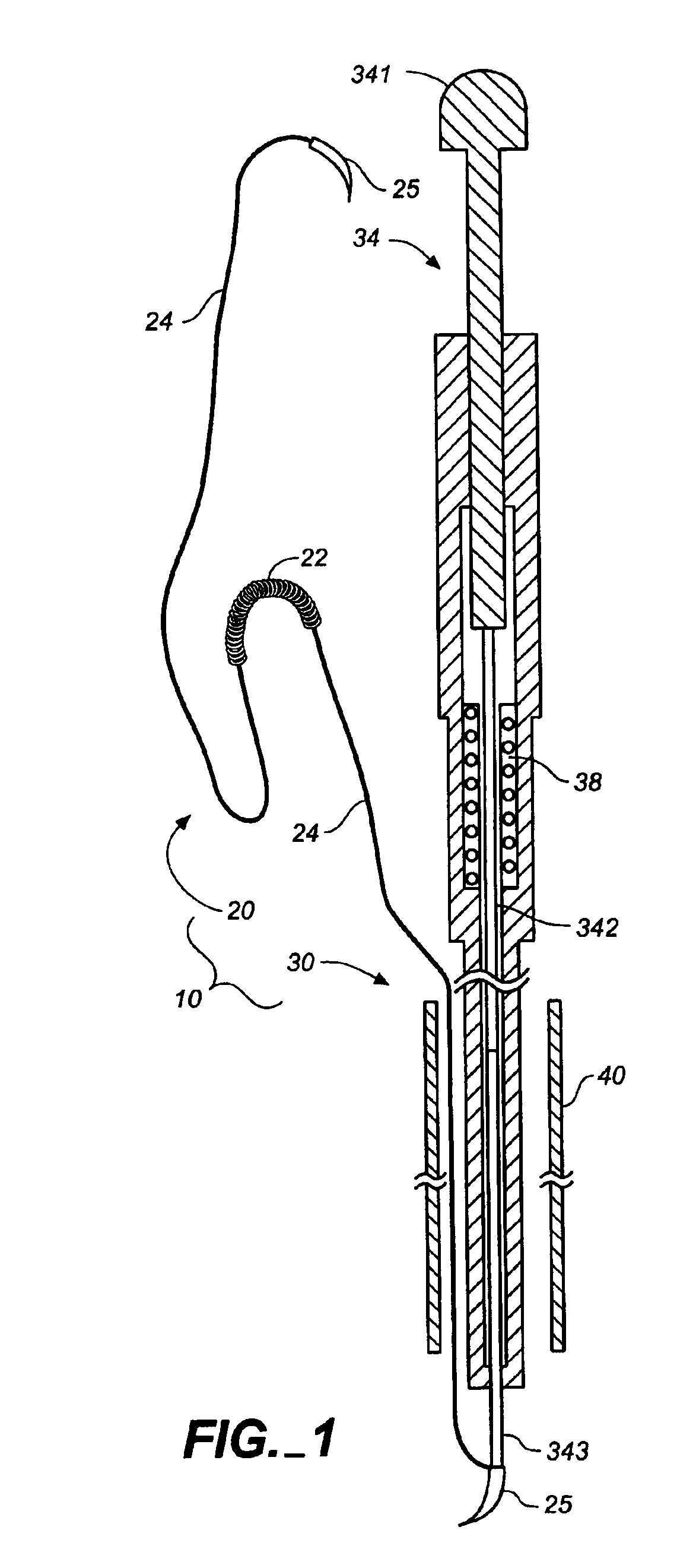

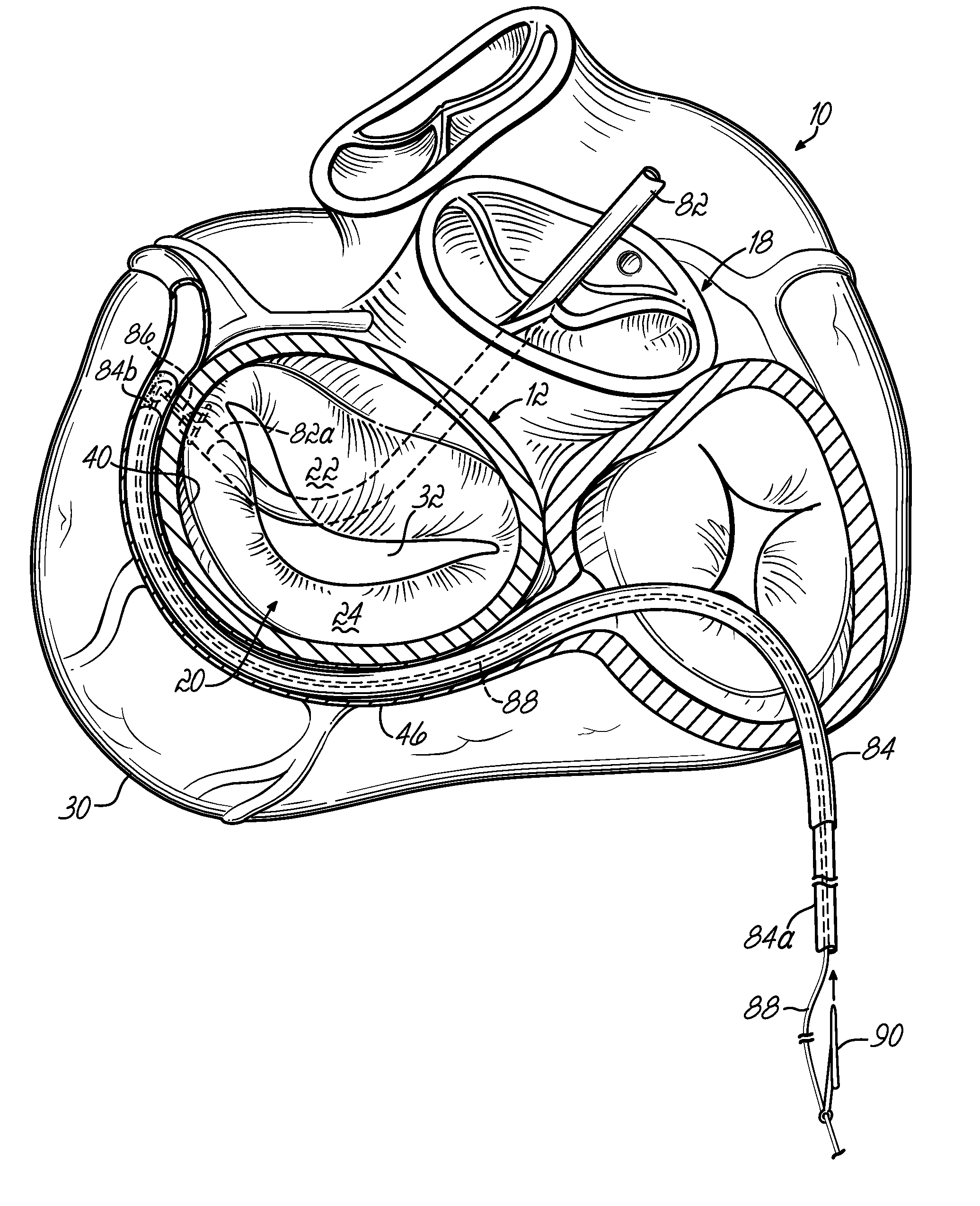

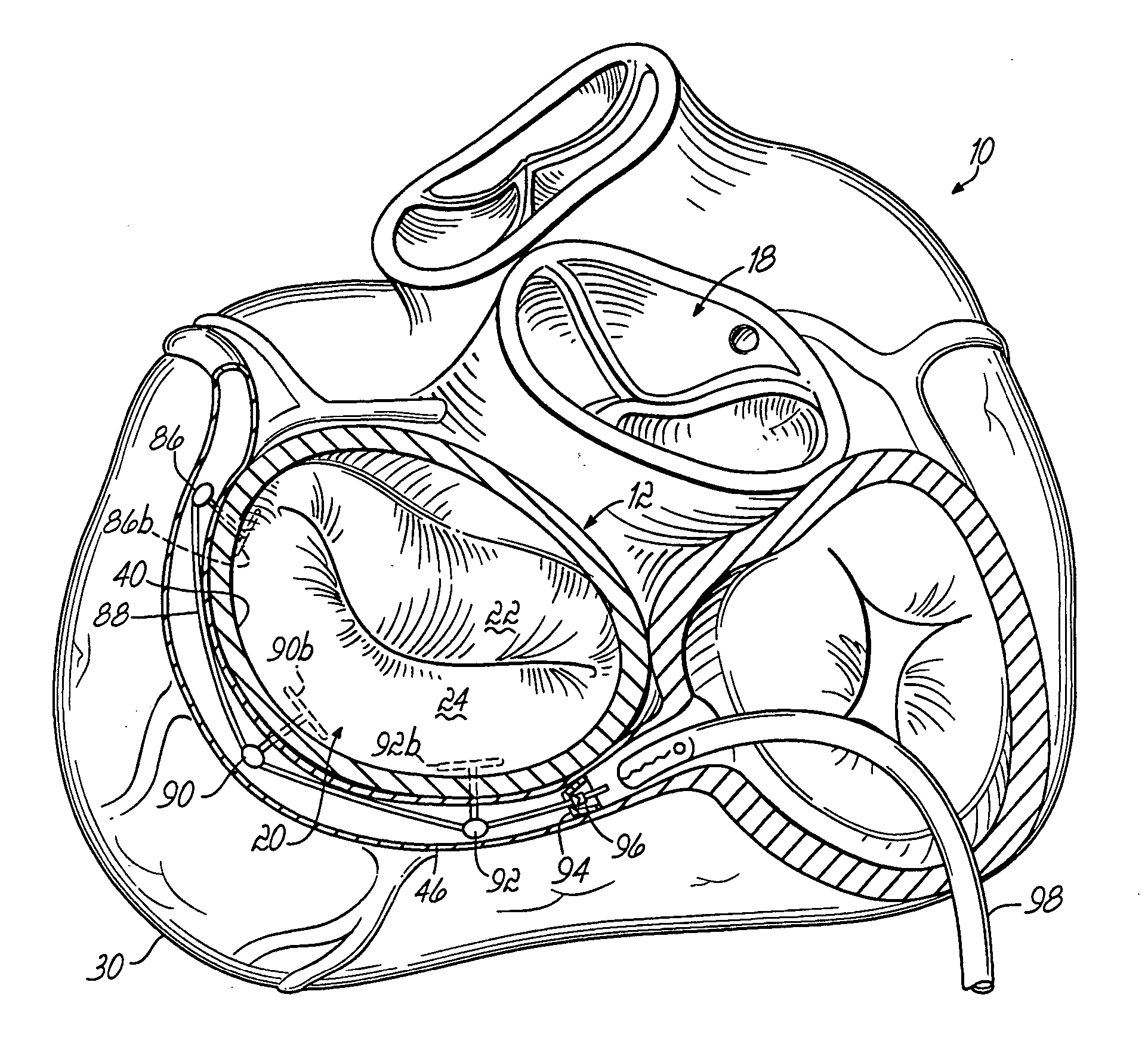

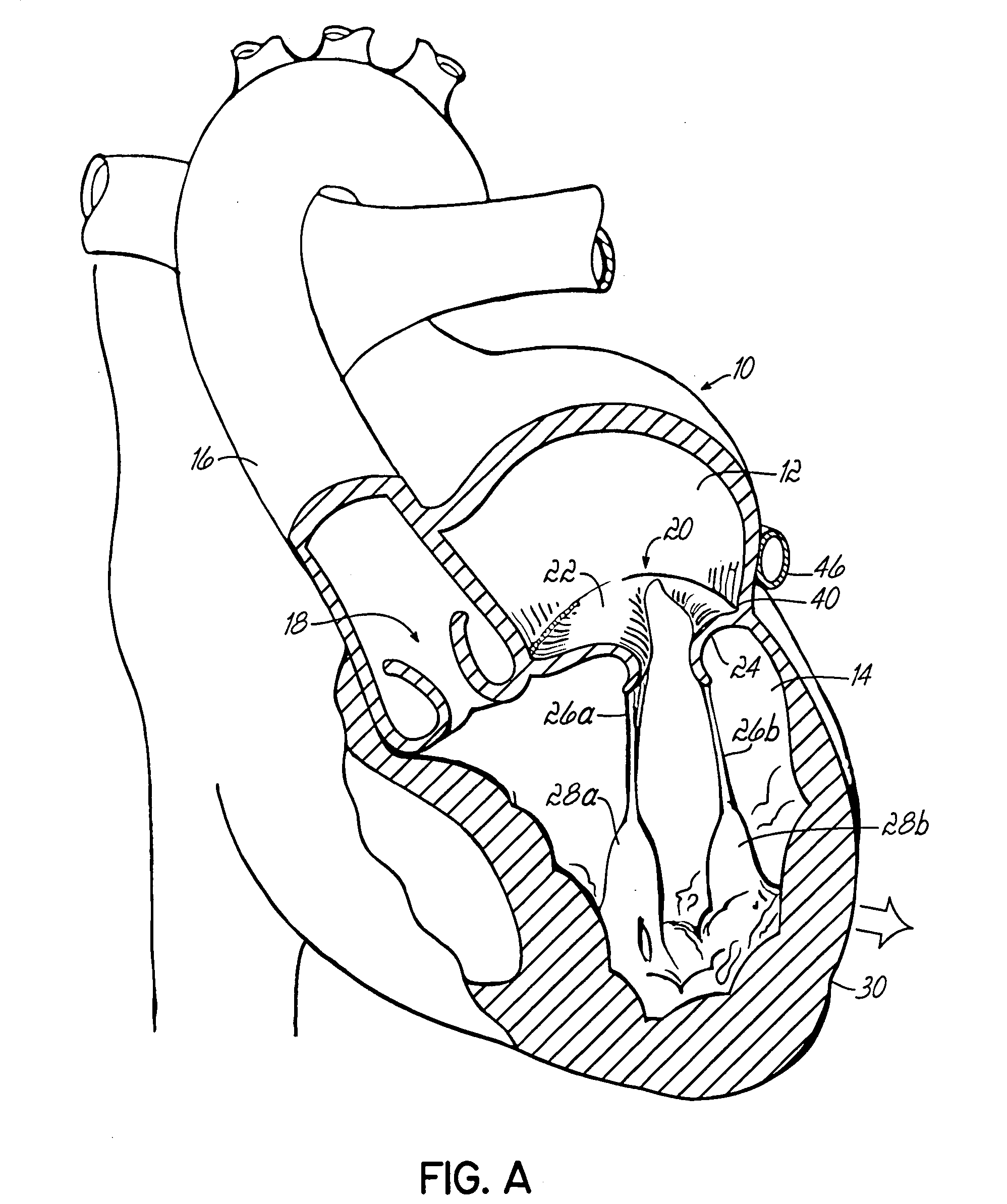

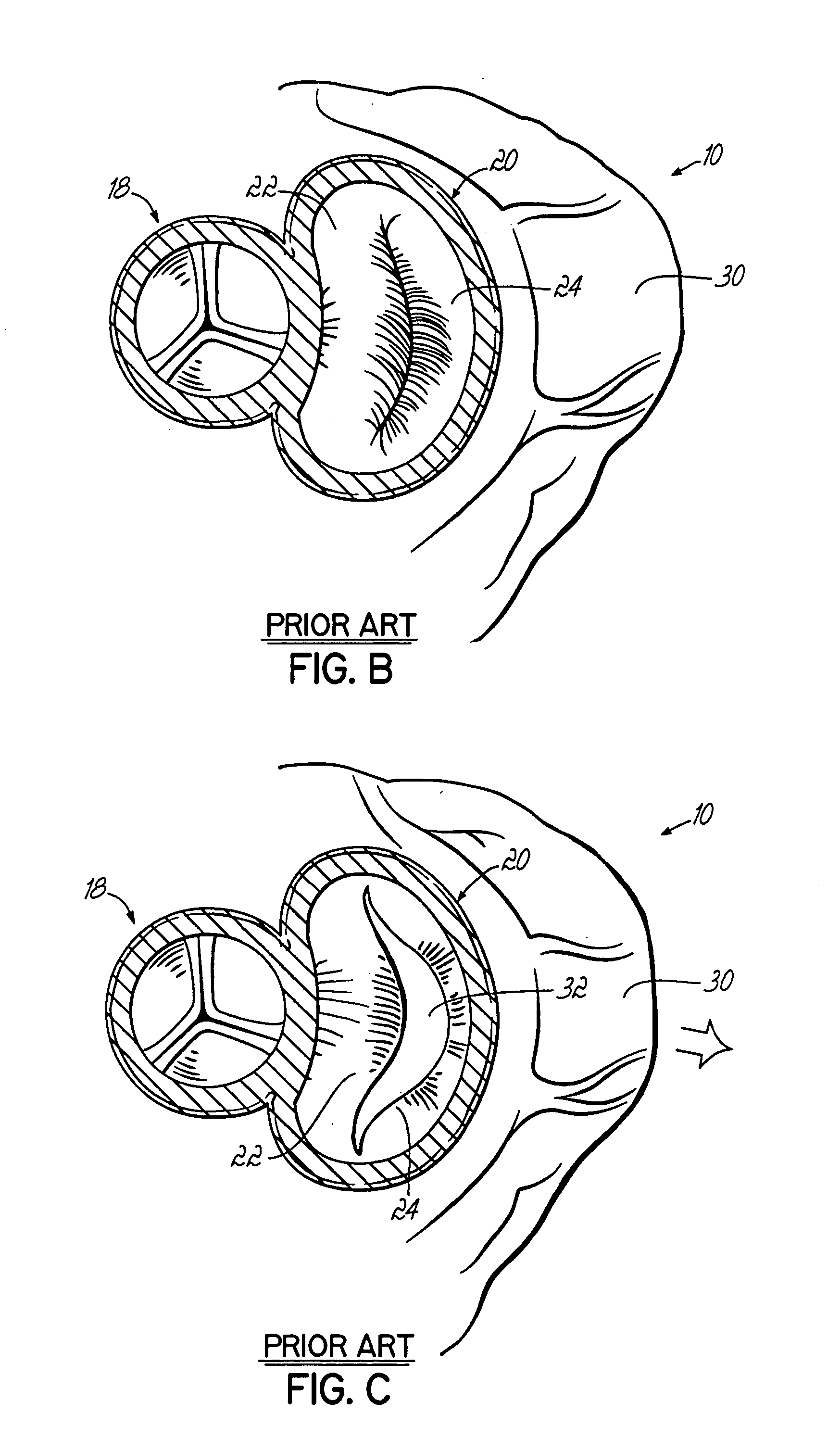

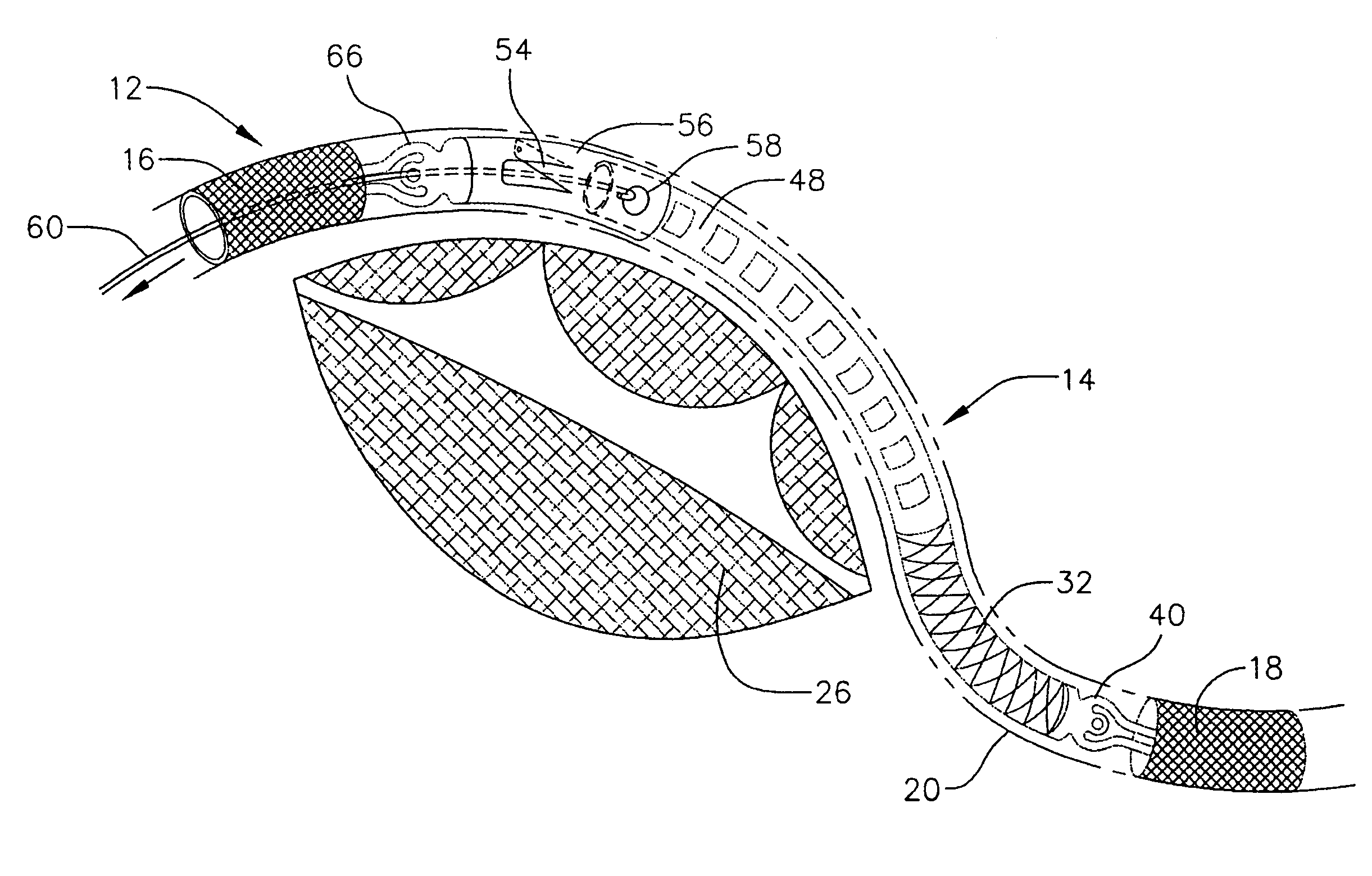

Mitral valve repair system and method for use

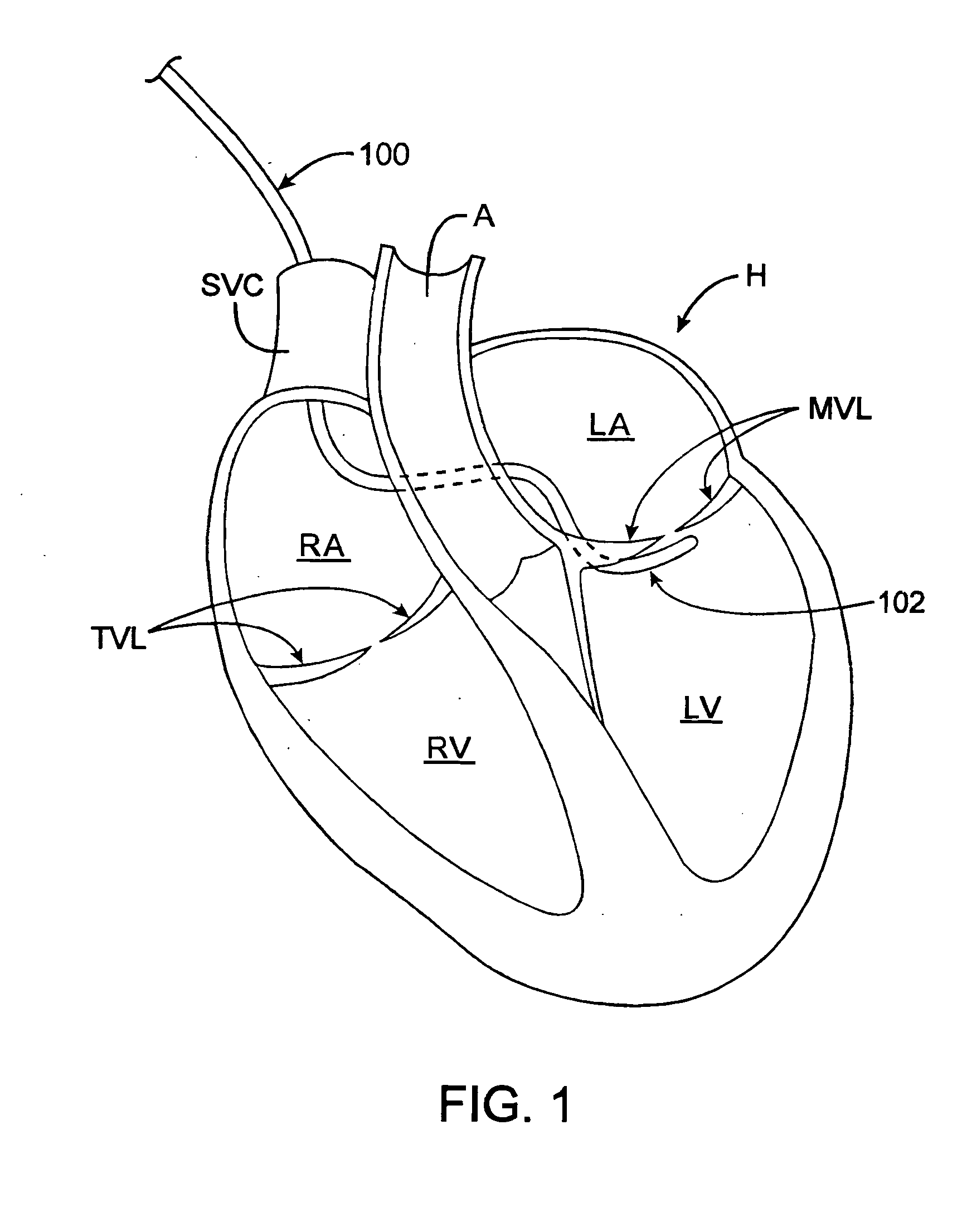

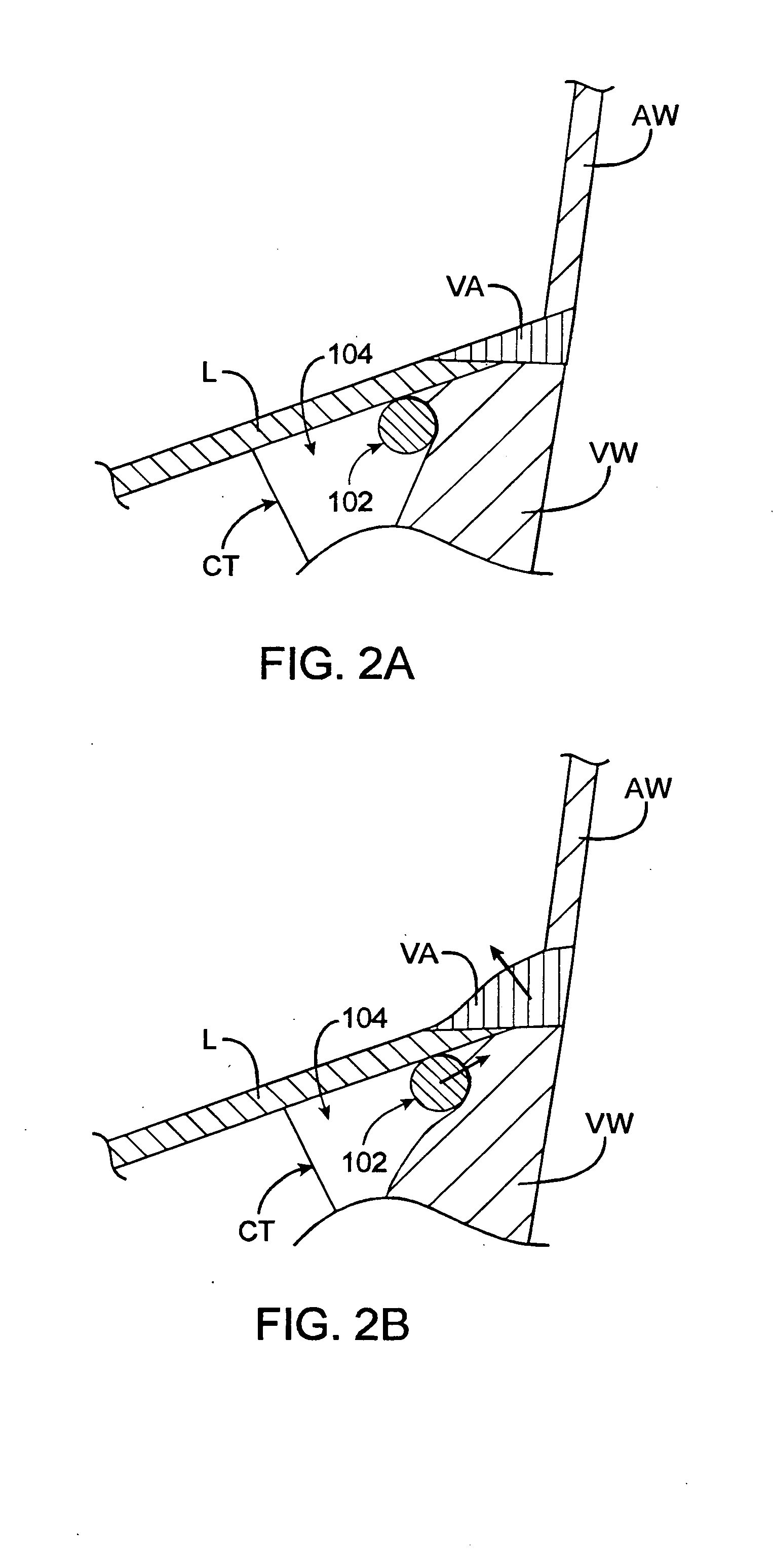

ActiveUS7381210B2Effective and stableEffectively stabilizing at least one tissue portionSuture equipmentsEar treatmentRepair tissueMitral valve operation

The present invention is directed to various systems for repairing tissue within the heart of a patient. The mitral valve repair system of the present invention comprises a guide catheter having a proximal end, a distal end, and at least one internal lumen formed therein, a therapy catheter capable of applying a suture to the tissue, and a fastener catheter capable of attaching a fastener to the suture. The therapy catheter and the fastener catheter are capable of traversing the internal lumen of the guide catheter. In addition, the present invention discloses various methods for repairing tissue within the heart of a patient.

Owner:EDWARDS LIFESCIENCES CORP

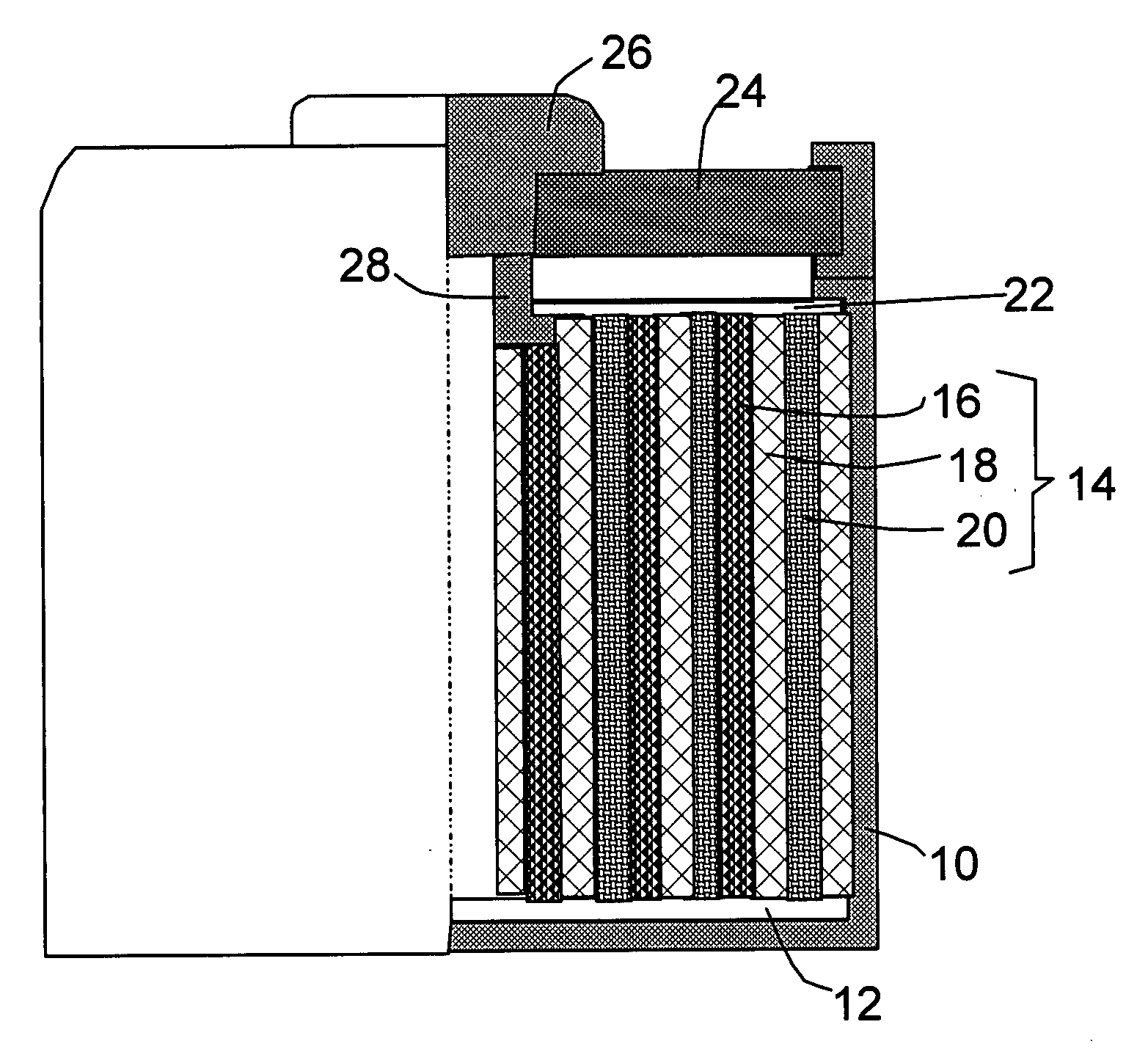

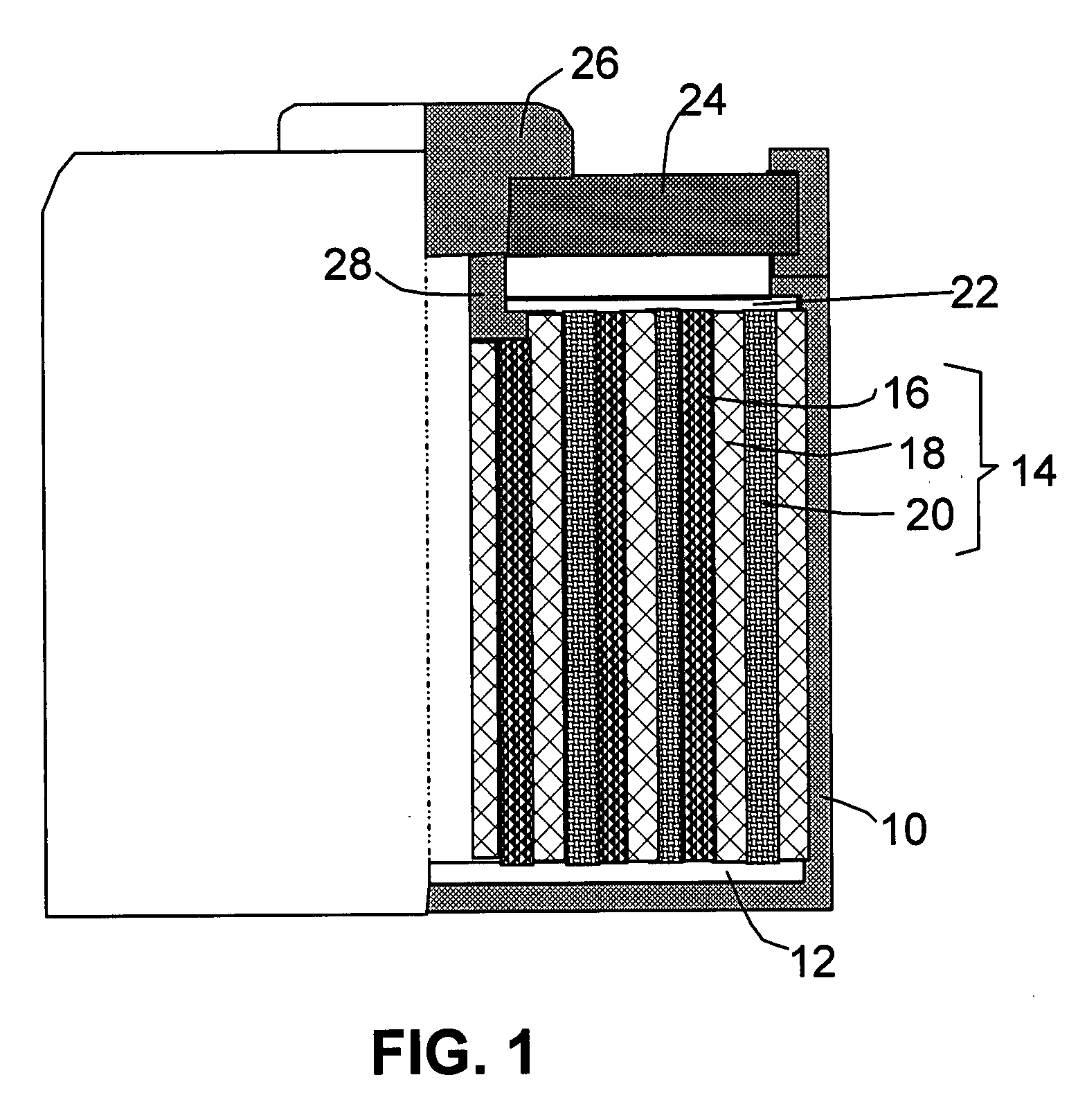

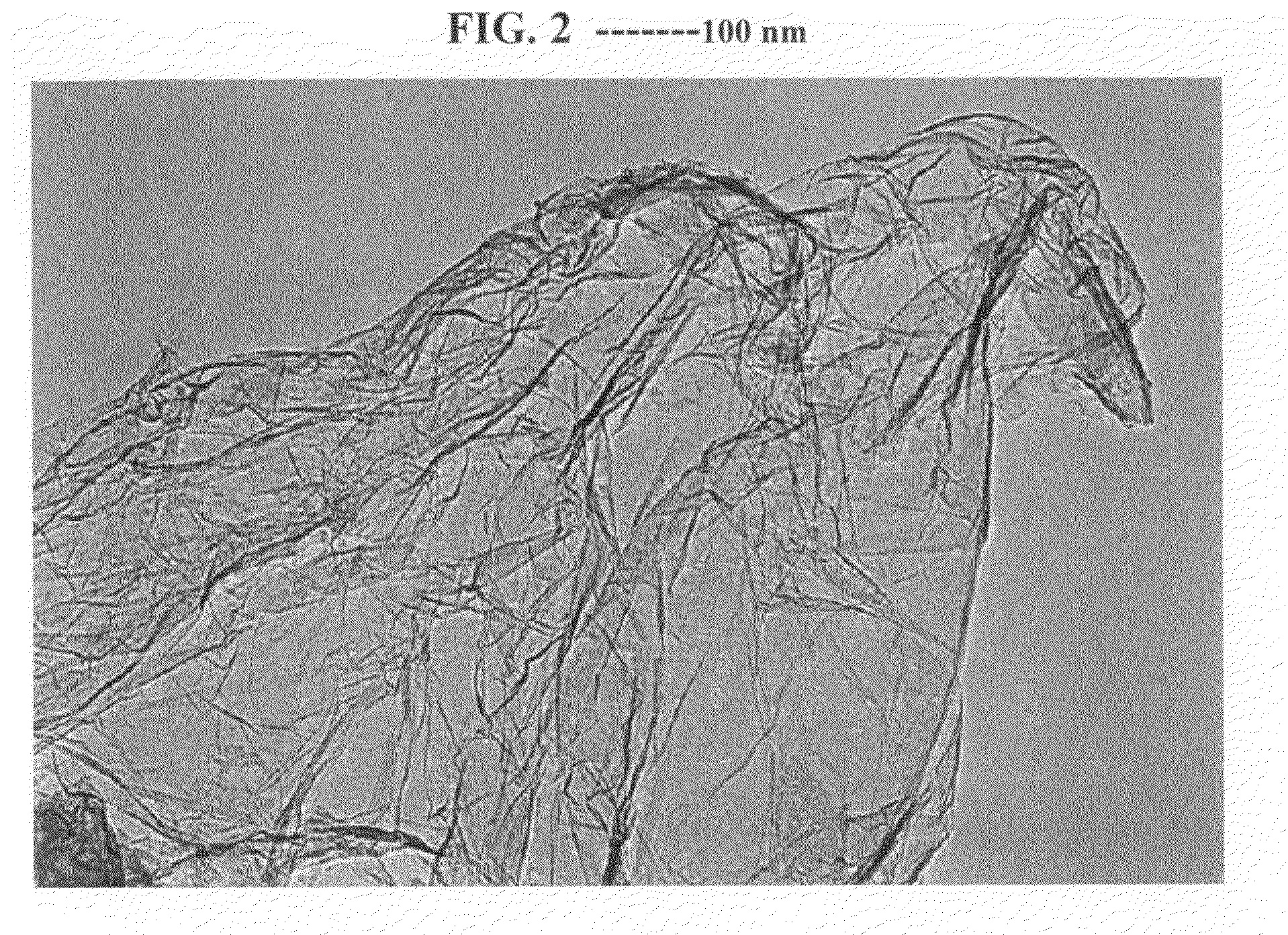

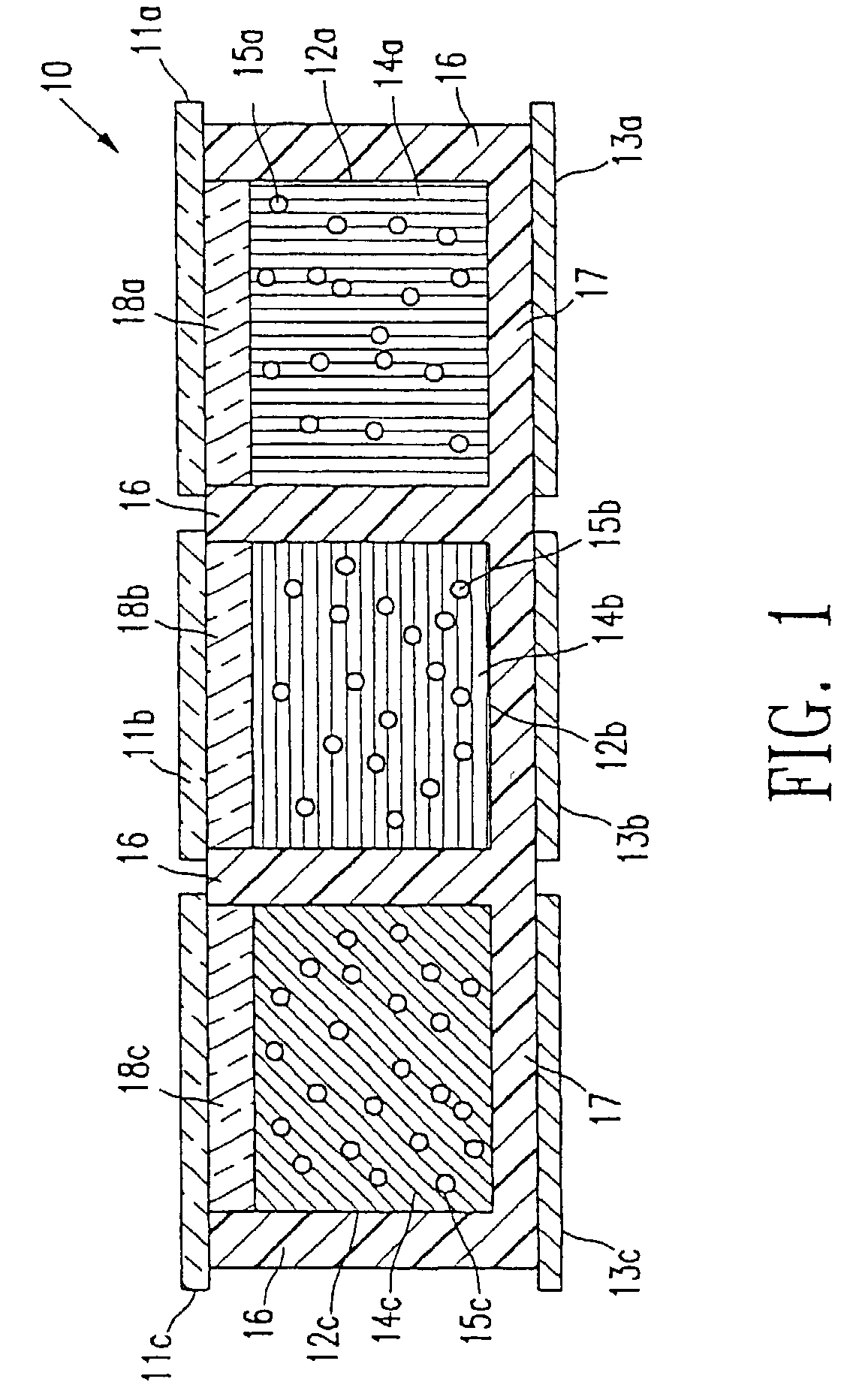

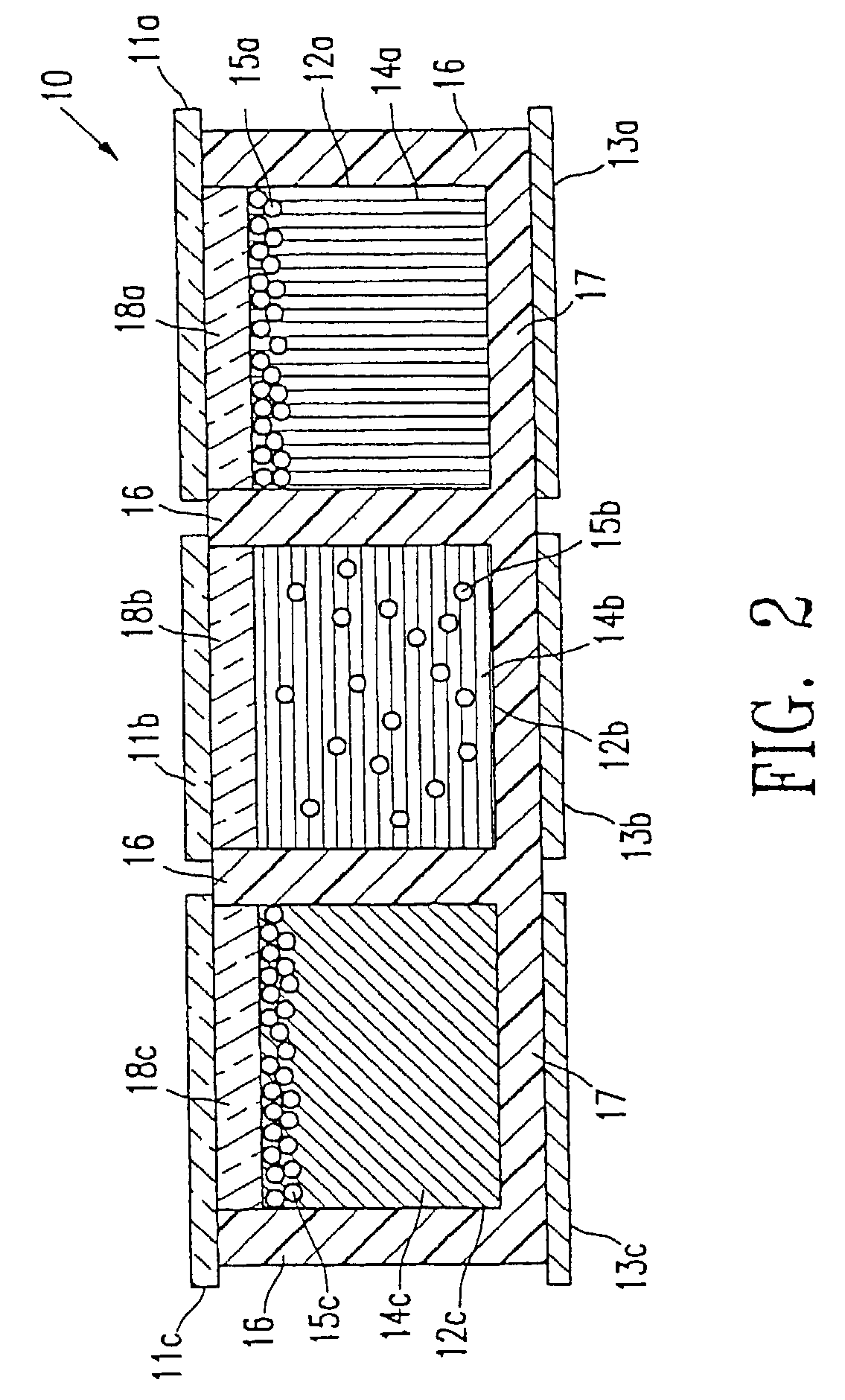

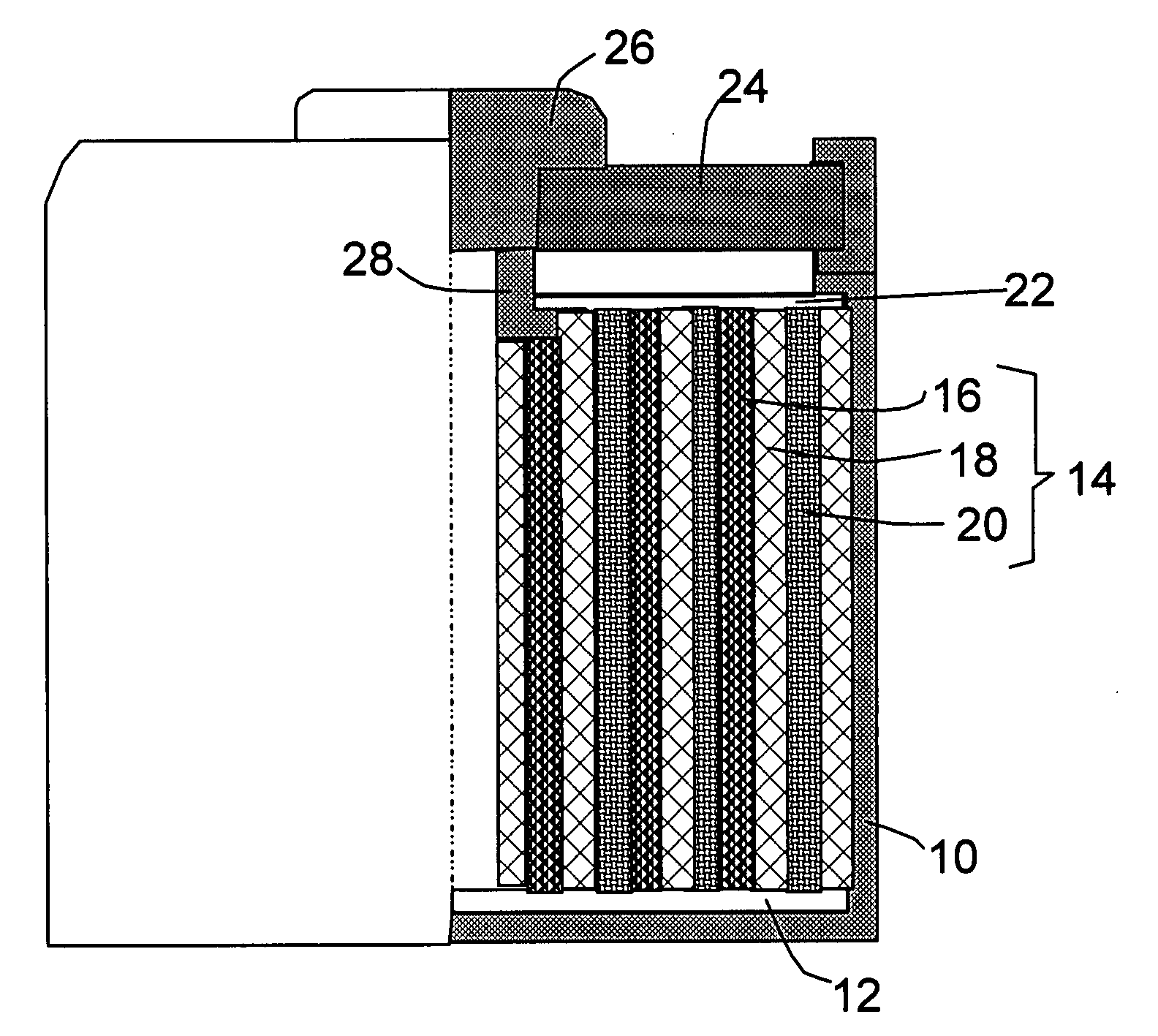

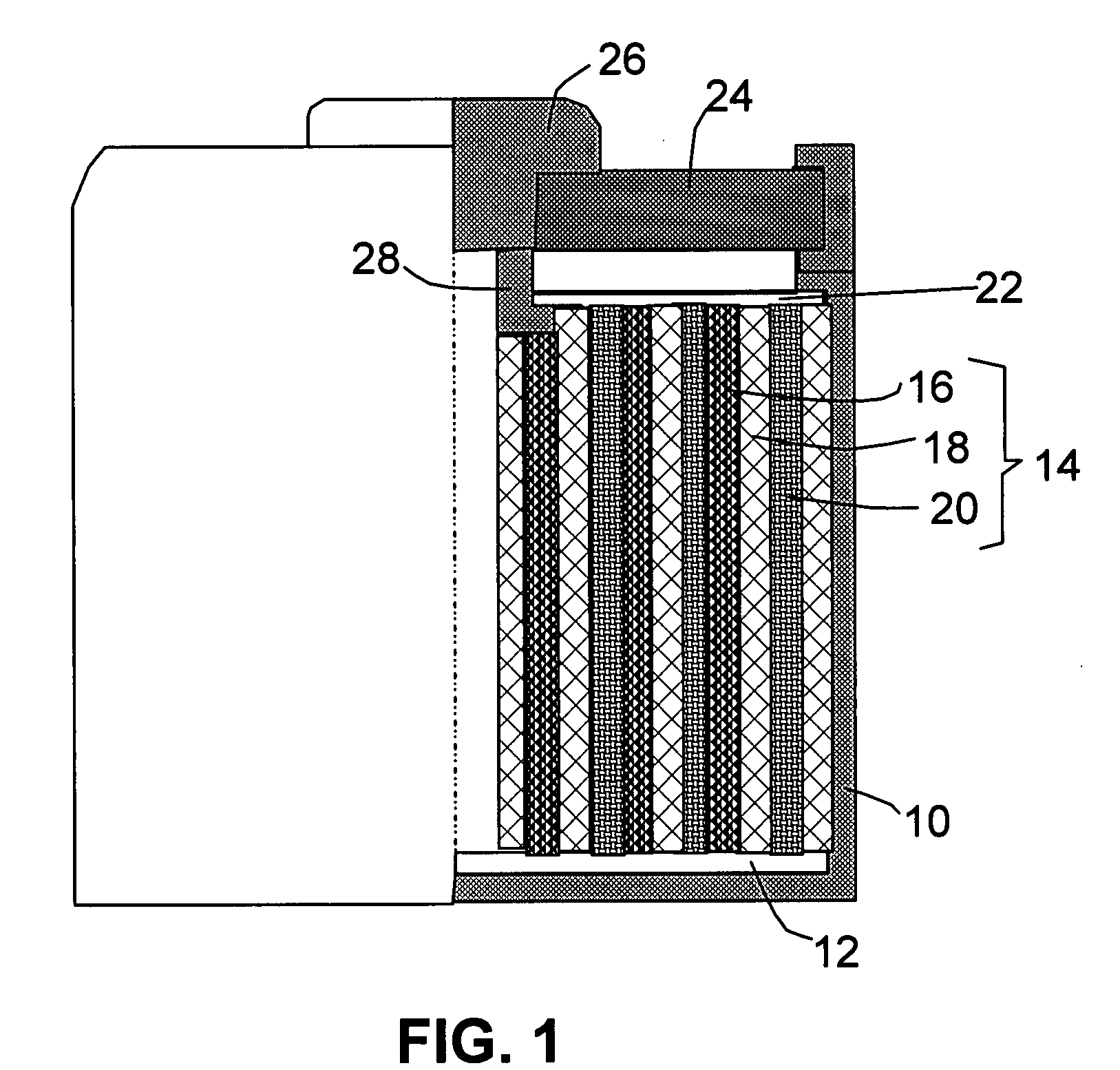

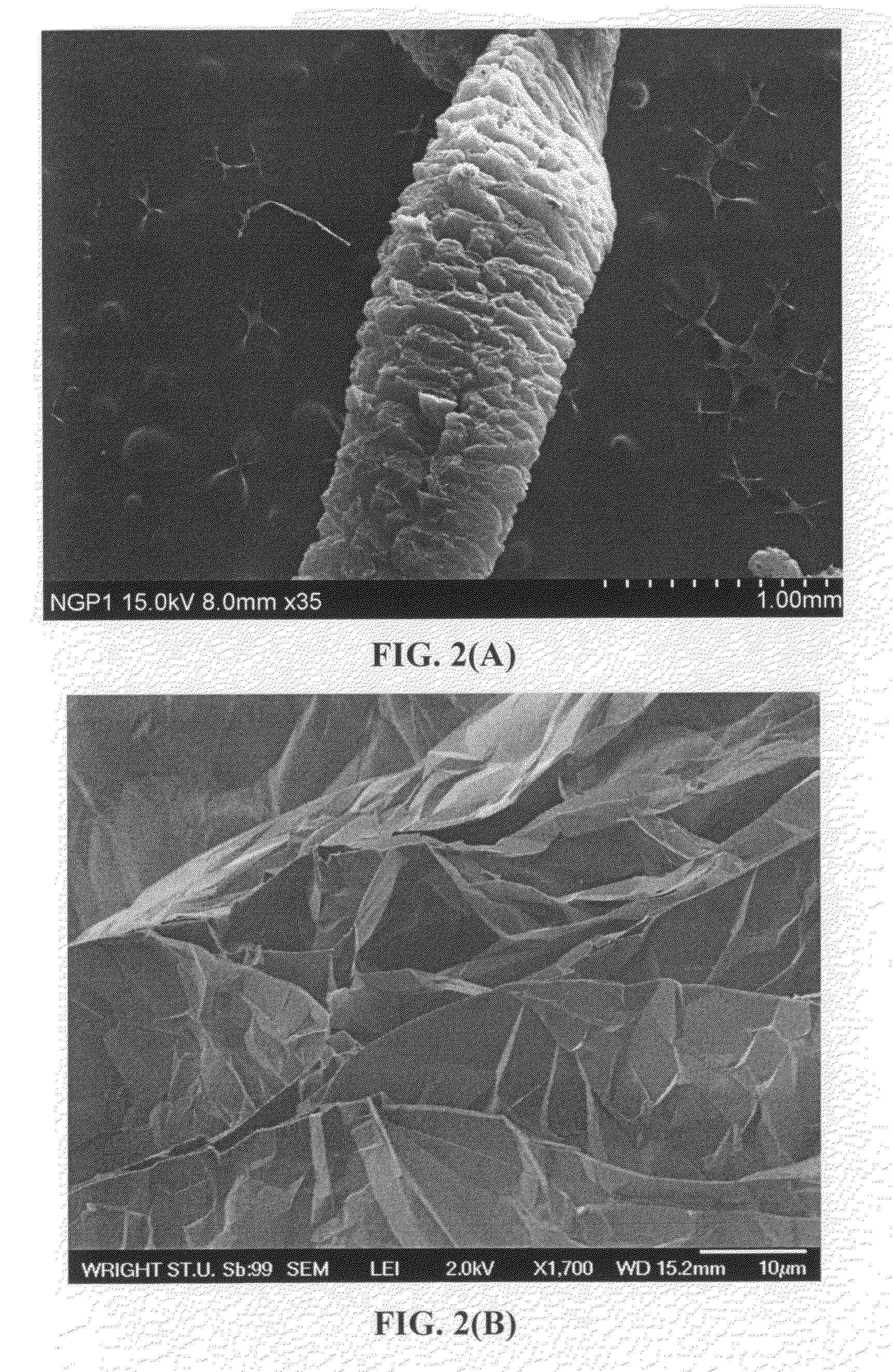

Nano graphene platelet-based composite anode compositions for lithium ion batteries

ActiveUS20090117467A1Improve conductivityLower internal resistanceElectrolytic capacitorsSecondary cellsGraphene flakeGraphite

The present invention provides a nano-scaled graphene platelet-based composite material composition for use as an electrode, particularly as an anode of a lithium ion battery. The composition comprises: (a) micron- or nanometer-scaled particles or coating which are capable of absorbing and desorbing lithium ions; and (b) a plurality of nano-scaled graphene platelets (NGPs), wherein a platelet comprises a graphene sheet or a stack of graphene sheets having a platelet thickness less than 100 nm; wherein at least one of the particles or coating is physically attached or chemically bonded to at least one of the graphene platelets and the amount of platelets is in the range of 2% to 90% by weight and the amount of particles or coating in the range of 98% to 10% by weight. Also provided is a lithium secondary battery comprising such a negative electrode (anode). The battery exhibits an exceptional specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD

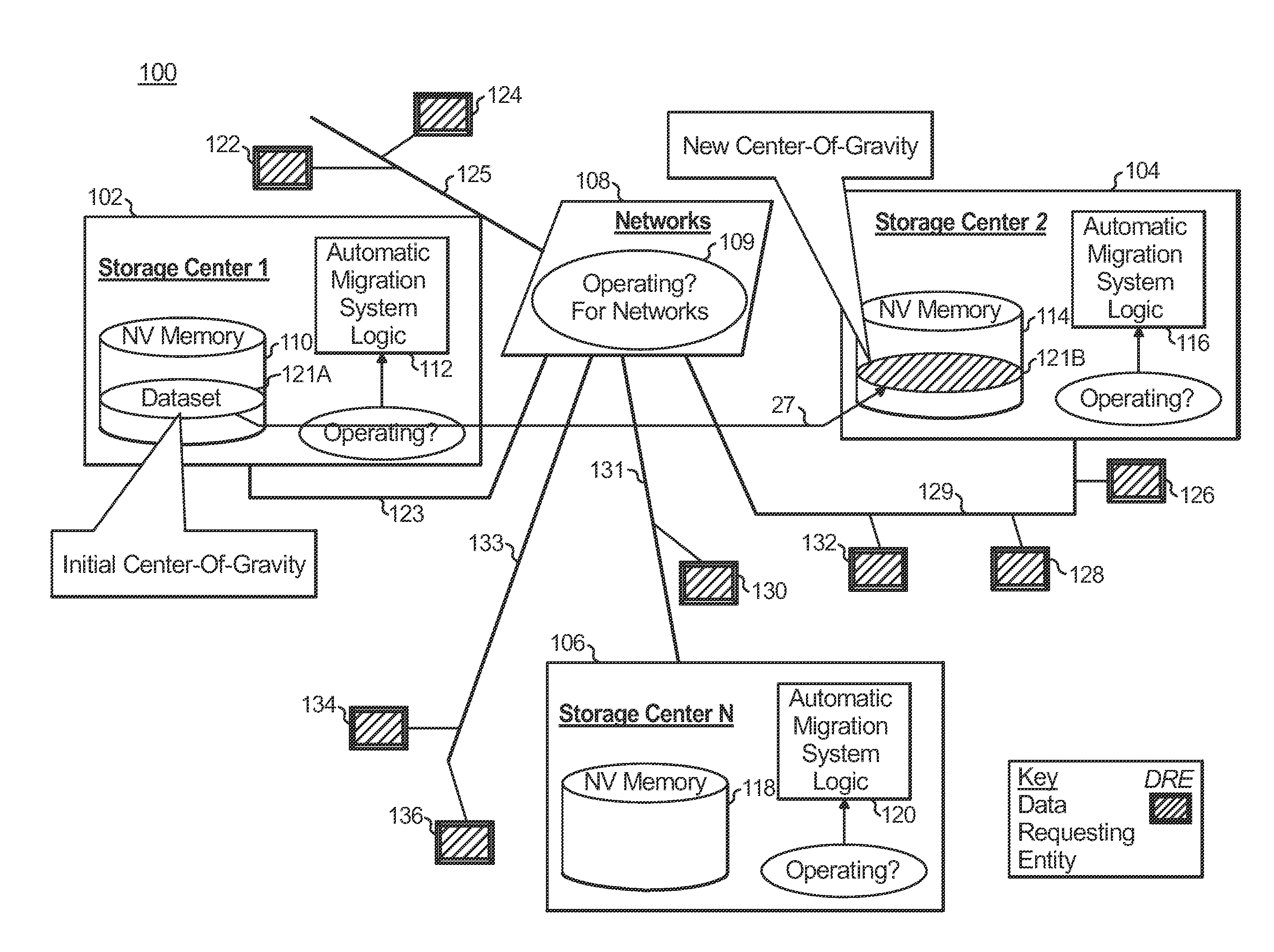

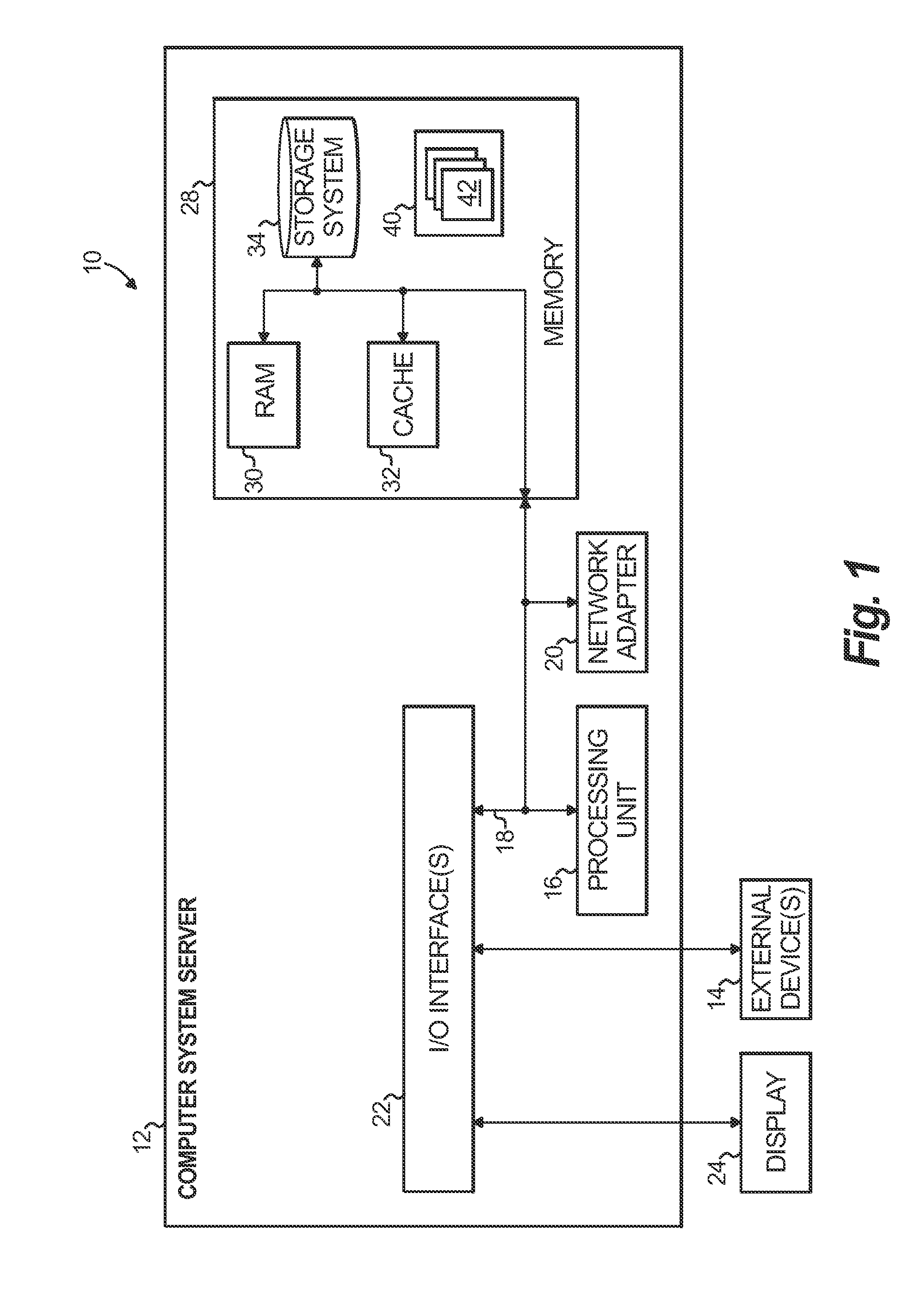

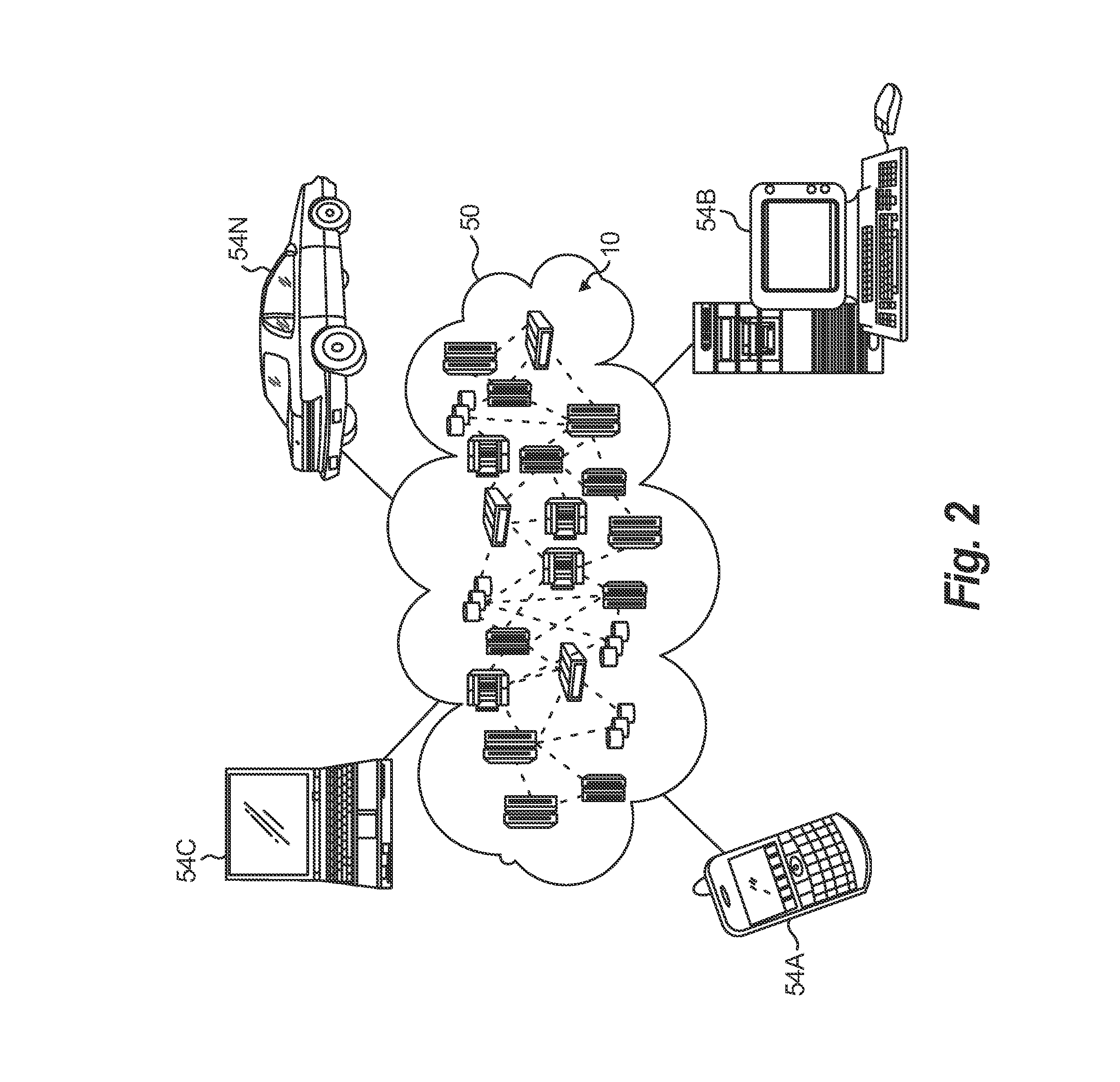

Method and Apparatus for Automated Migration of Data Among Storage Centers

InactiveUS20140173232A1Reduce data storage costsReduce deliveryInput/output to record carriersTransmissionData setData storing

A method for controlling the storage of data among multiple regional storage centers coupled through a network in a global storage system is provided. The method includes steps of: defining at least one dataset comprising at least a subset of the data stored in the global storage system; defining at least one ruleset for determining where to store the dataset; obtaining information regarding a demand for the dataset through one or more data requesting entities operating in the global storage system; and determining, as a function of the ruleset, information regarding a location for storing the dataset among regional storage centers having available resources that reduces the total distance traversed by the dataset in serving at least a given one of the data requesting entities and / or reduces the latency of delivery of the dataset to the given one of the data requesting entities.

Owner:IBM CORP

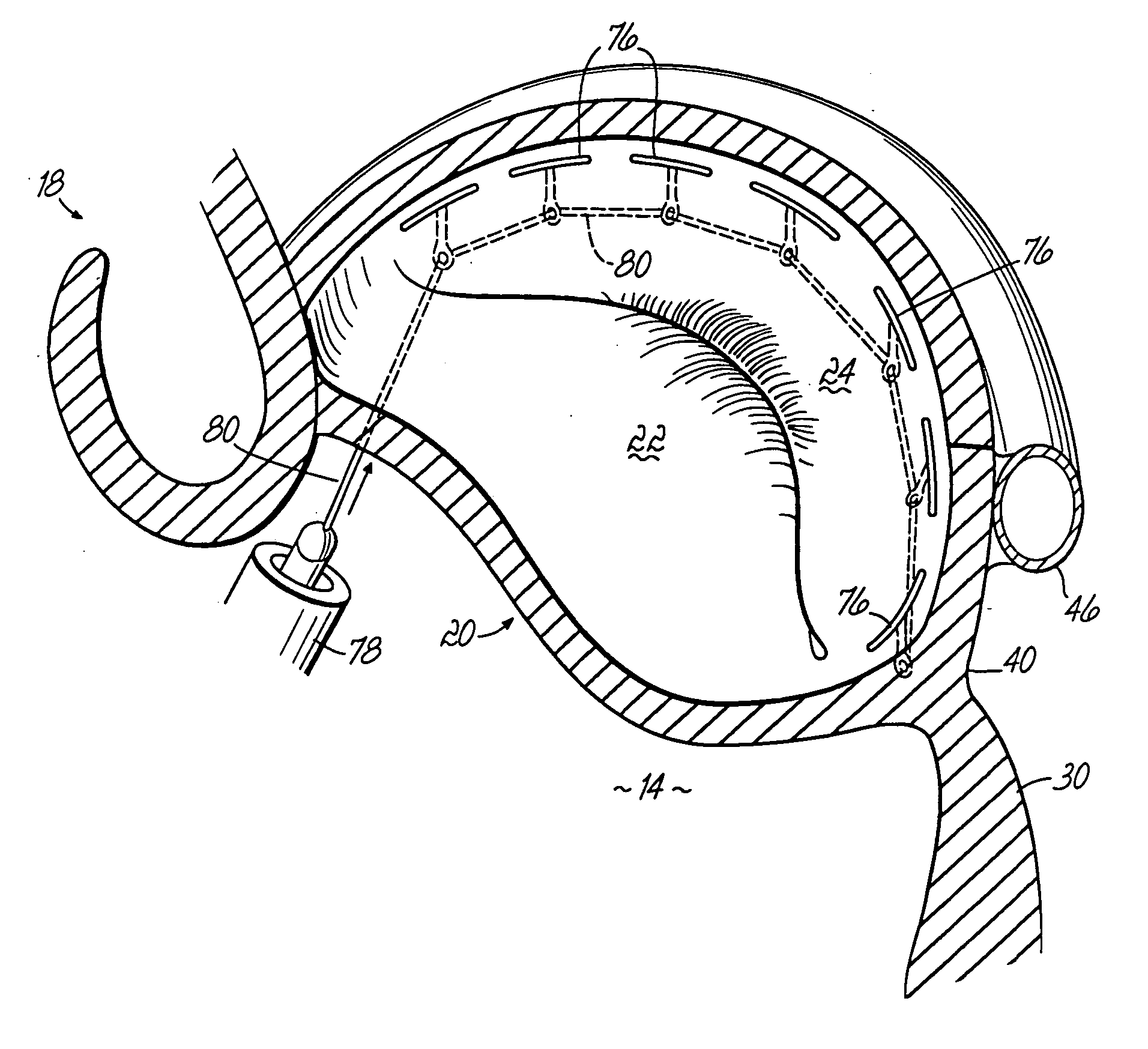

Tissue fastening systems and methods utilizing magnetic guidance

InactiveUS20060069429A1Reducing circumferenceReduce distanceSuture equipmentsStapling toolsMitral valve flowMitral anulus

Catheter based systems and methods for securing tissue including the annulus of a mitral valve. The systems and methods employ catheter based techniques and devices to plicate tissue and perform an annuloplasty.

Owner:MITRALIGN INC

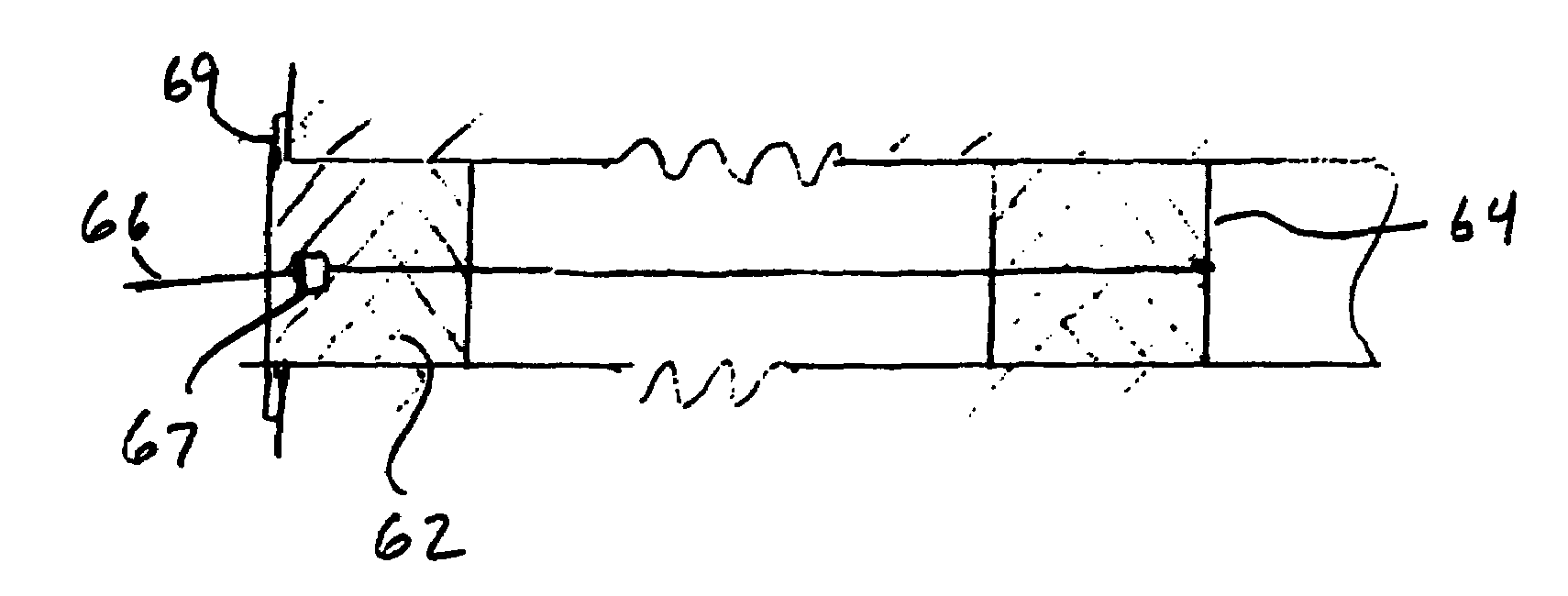

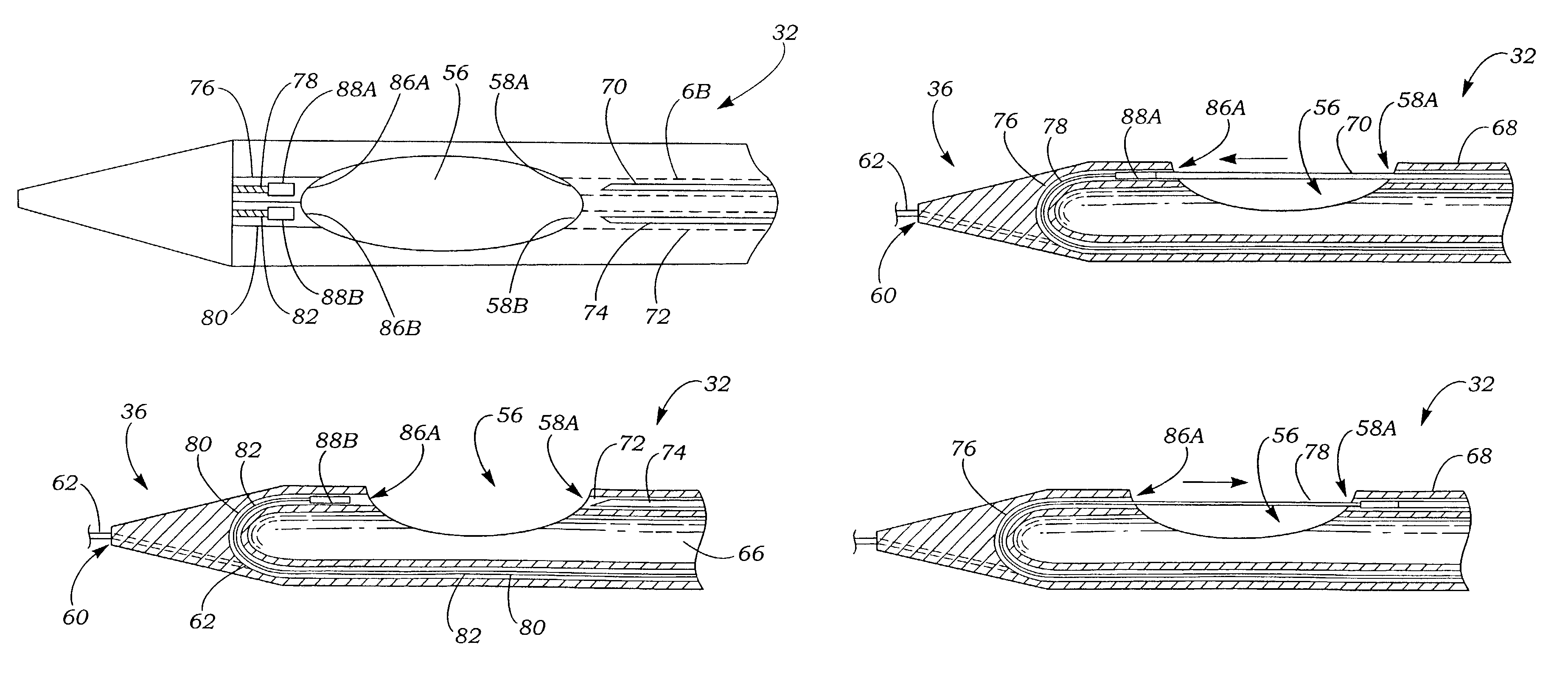

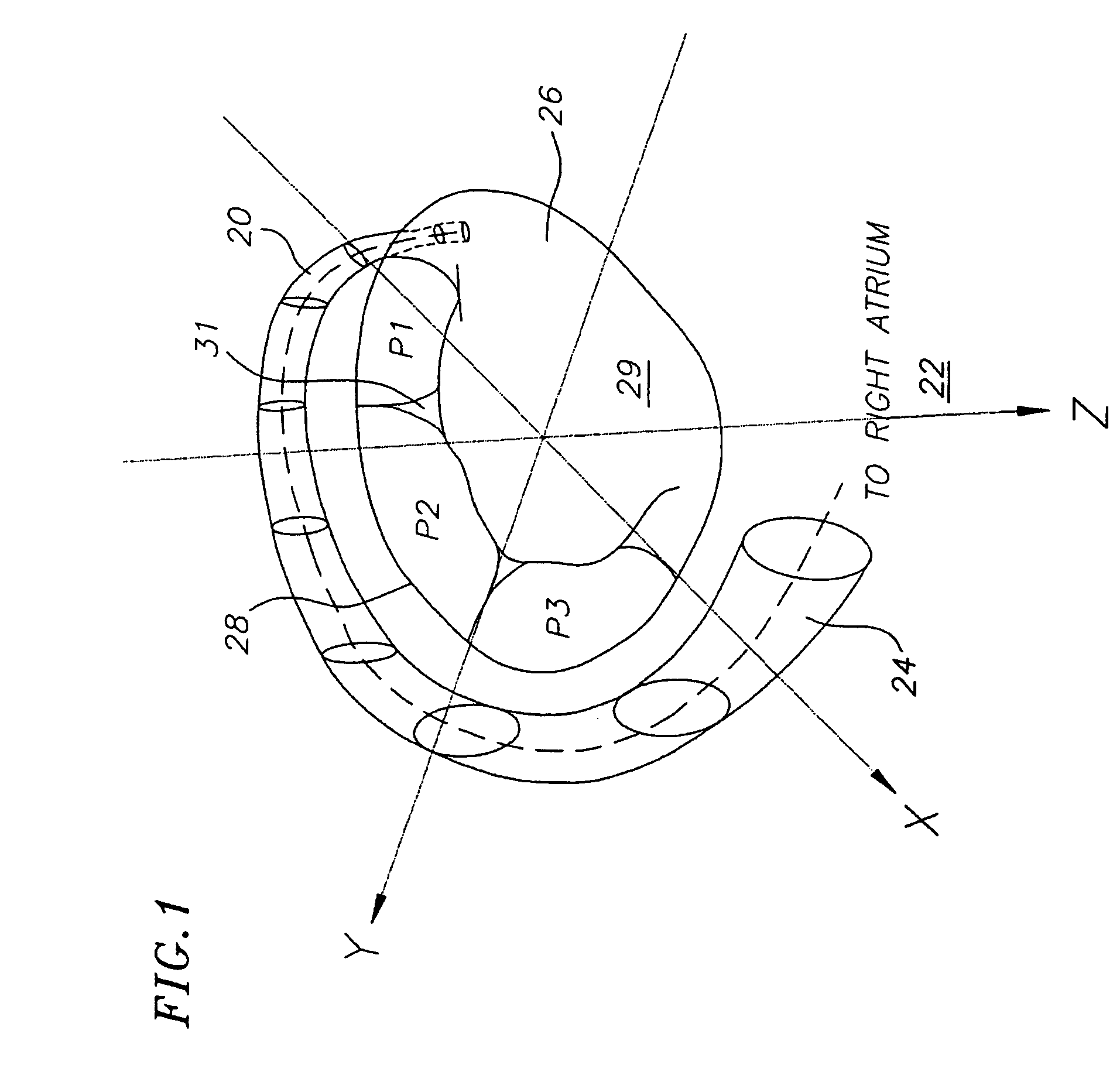

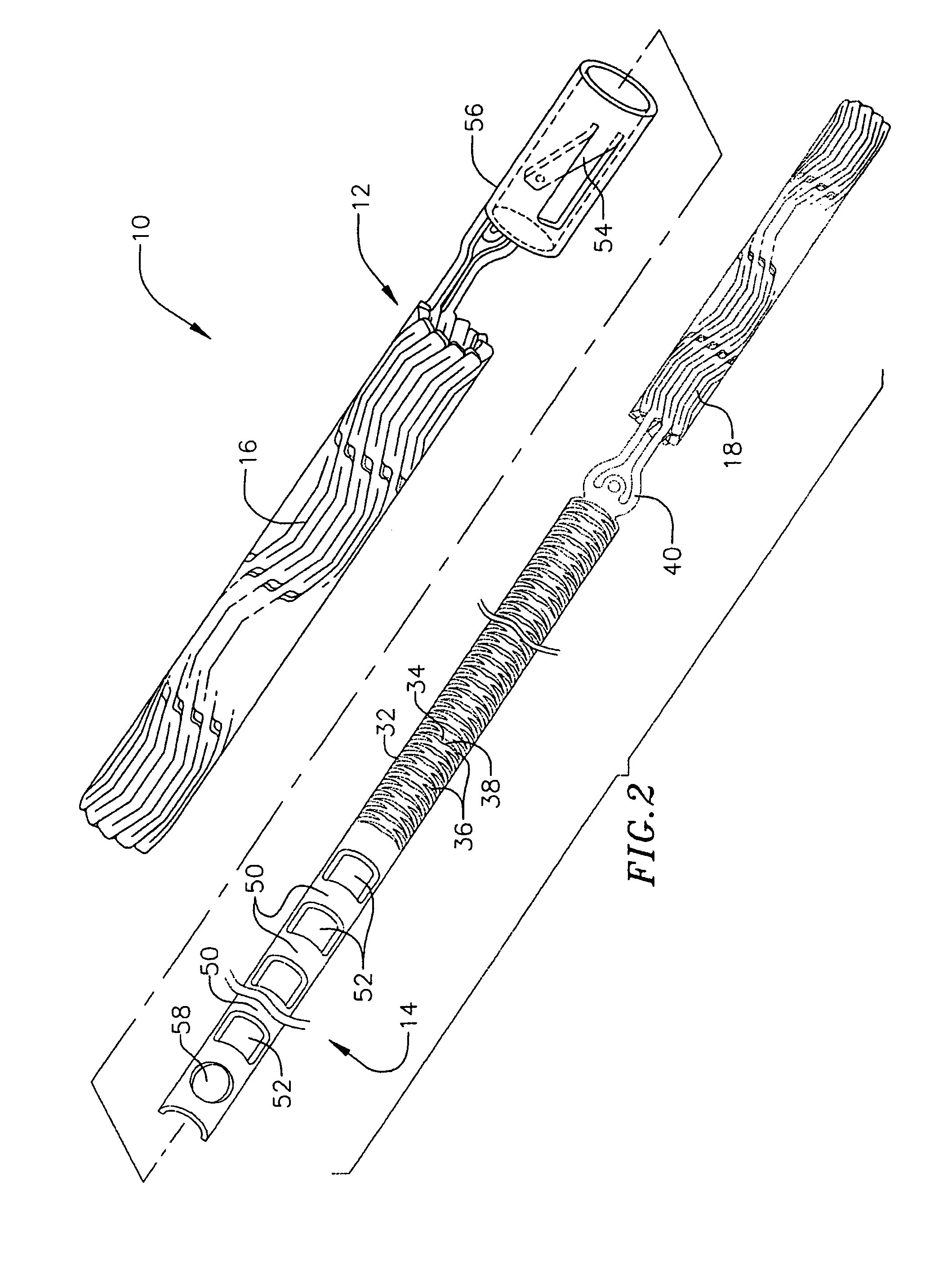

Delivery devices and methods for heart valve repair

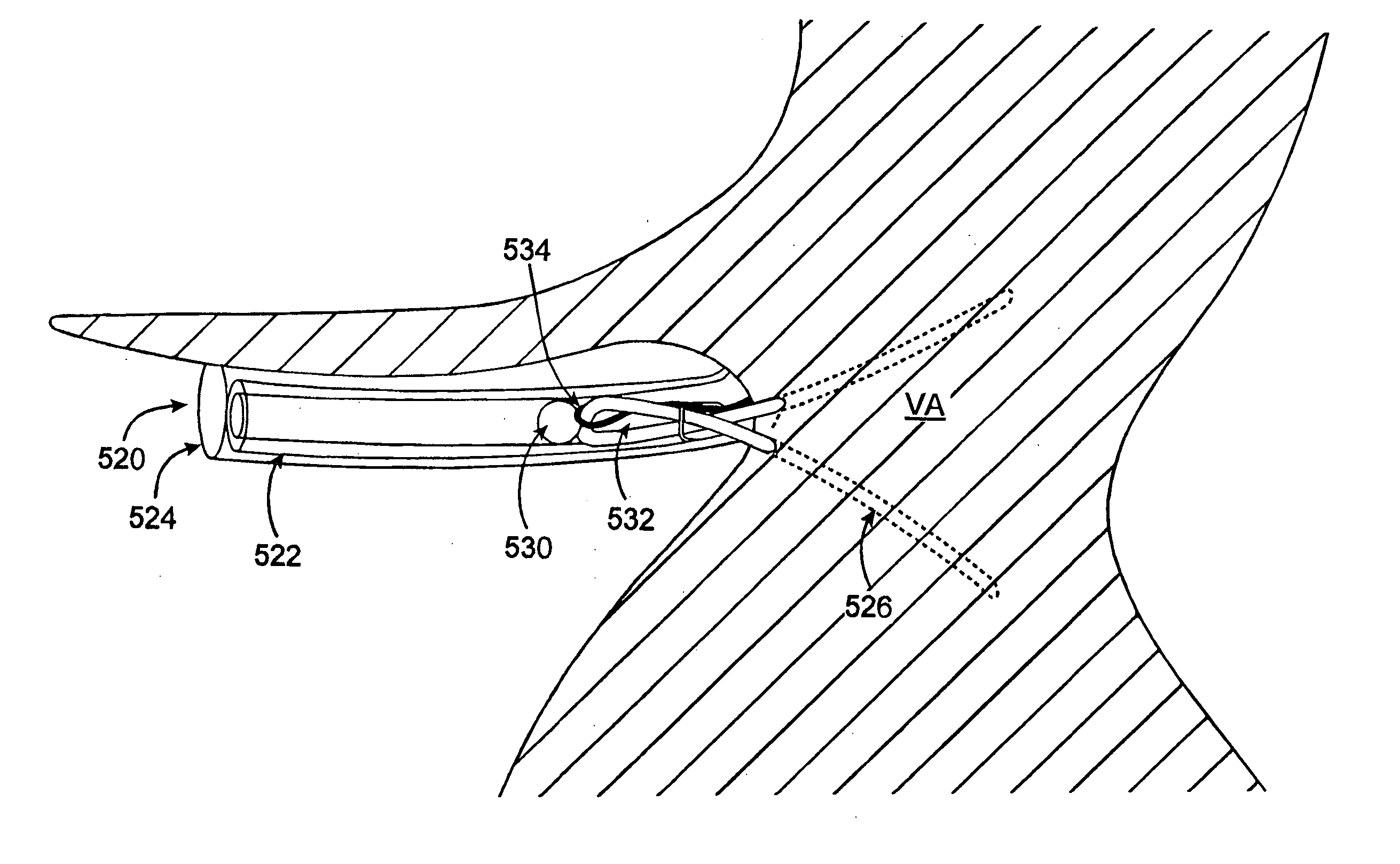

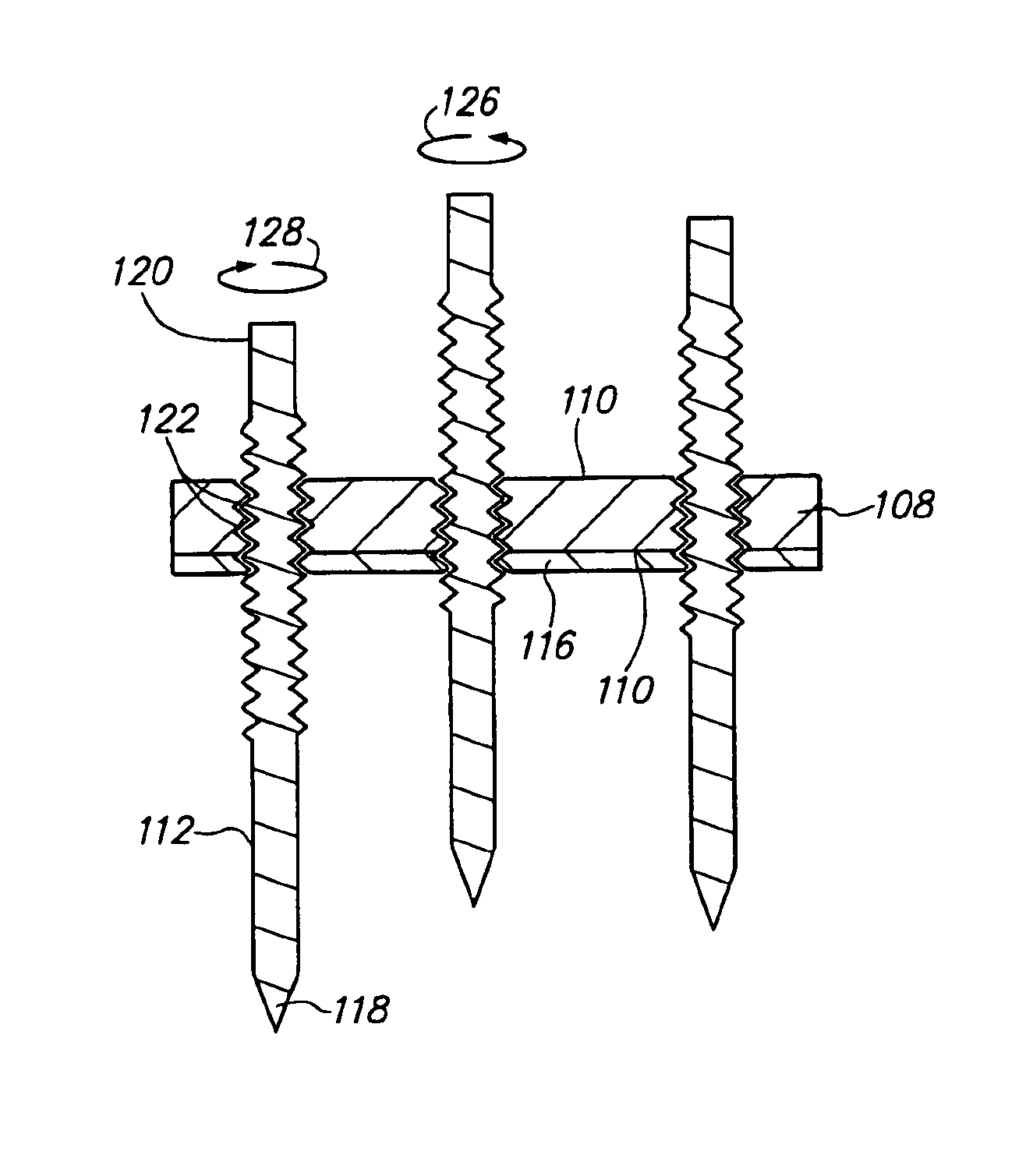

ActiveUS20050065550A1Reduce circumferential distanceReduce distanceSuture equipmentsAnnuloplasty ringsDistal portionHeart valve repair

Devices, systems and methods facilitate positioning of a cardiac valve annulus treatment device, thus enhancing treatment of the annulus. Methods generally involve advancing an anchor delivery device through vasculature of the patient to a location in the heart for treating the valve annulus, contacting the anchor delivery device with a length of the valve annulus, delivering a plurality of coupled anchors from the anchor delivery device to secure the anchors to the annulus, and drawing the anchors together to circumferentially tighten the valve annulus. Devices generally include an elongate catheter having at least one tensioning member and at least one tensioning actuator for deforming a distal portion of the catheter to help it conform to a valve annulus. The catheter device may be used to navigate a subannular space below a mitral valve to facilitate positioning of an anchor delivery device.

Owner:ANCORA HEART INC

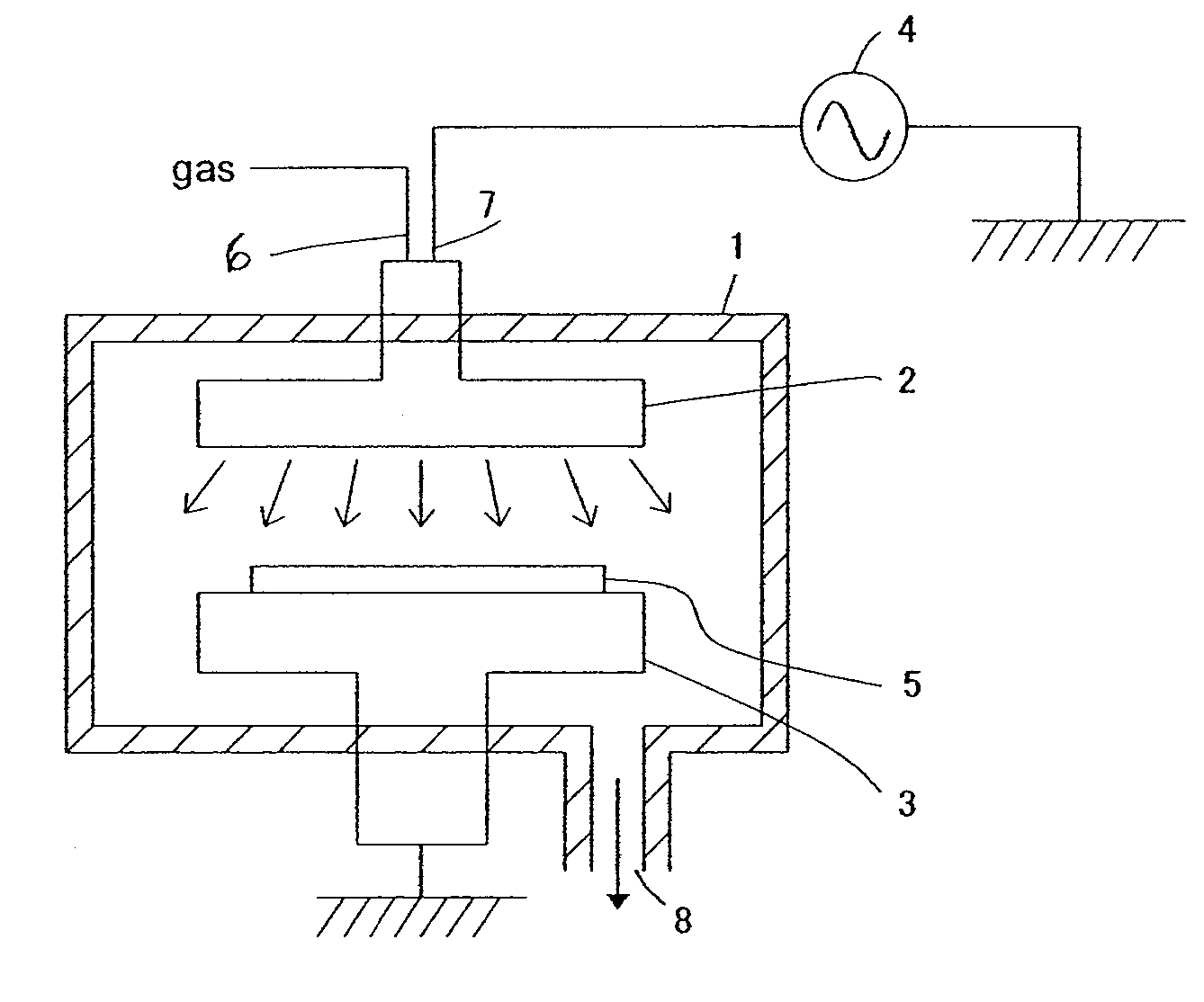

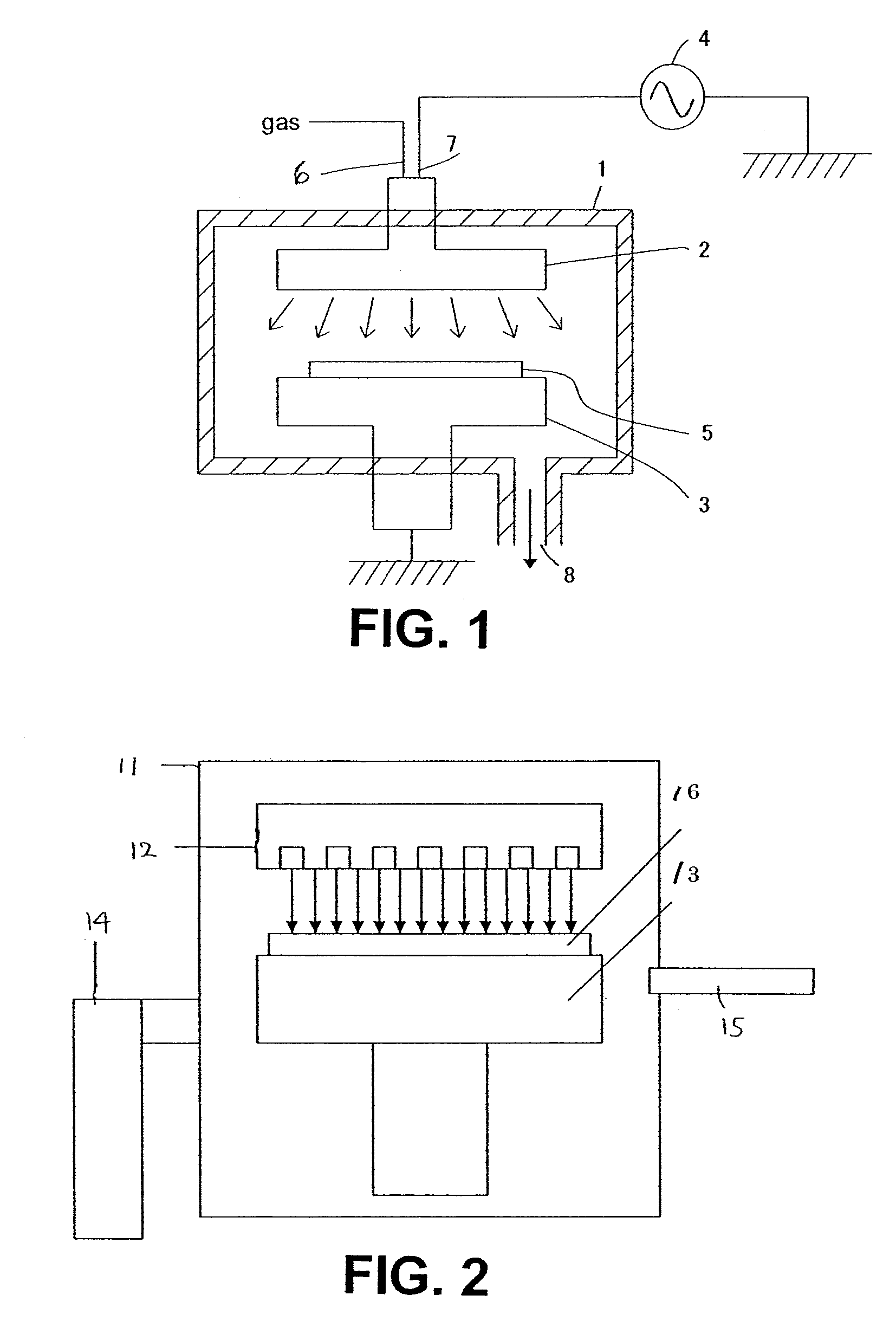

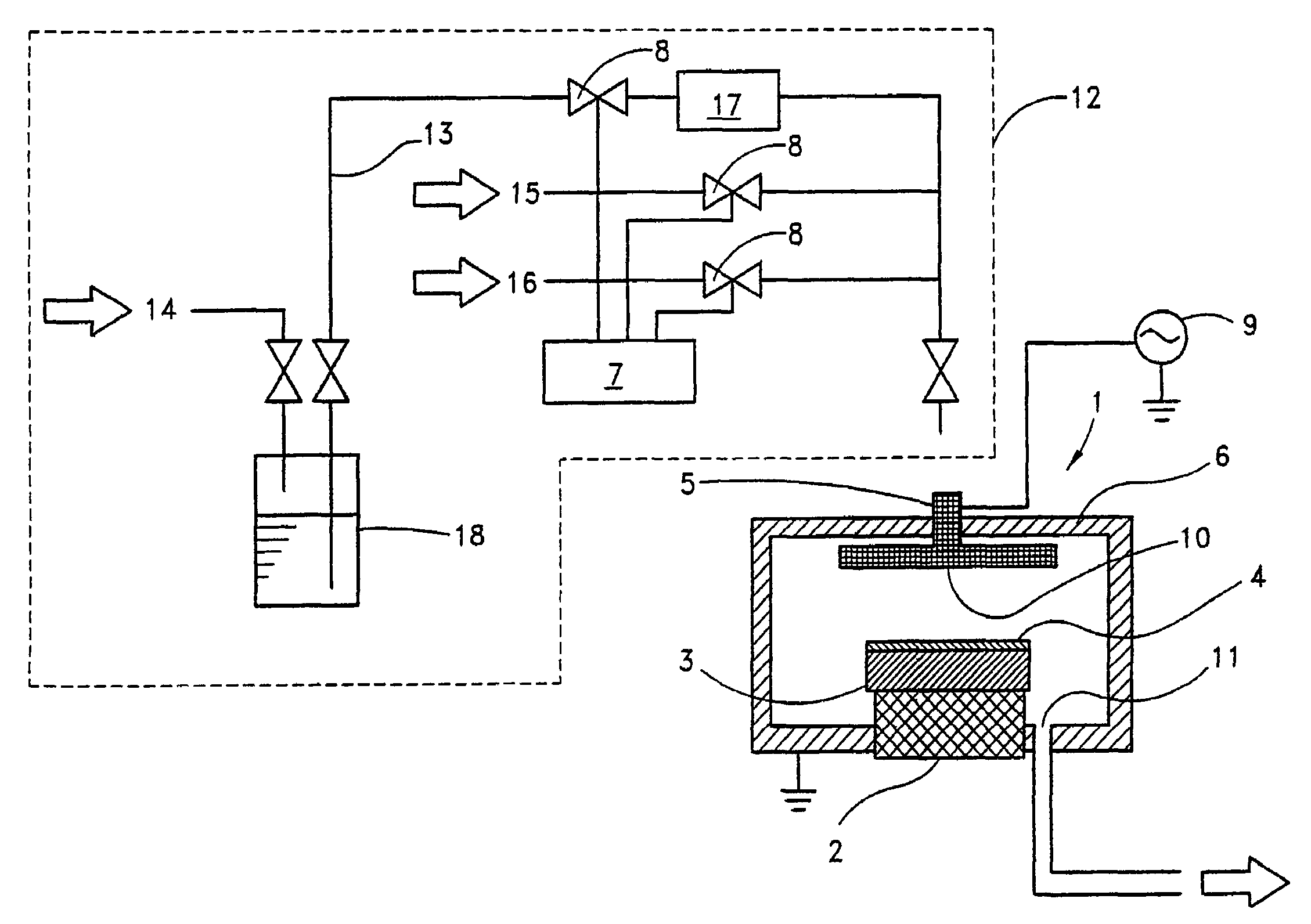

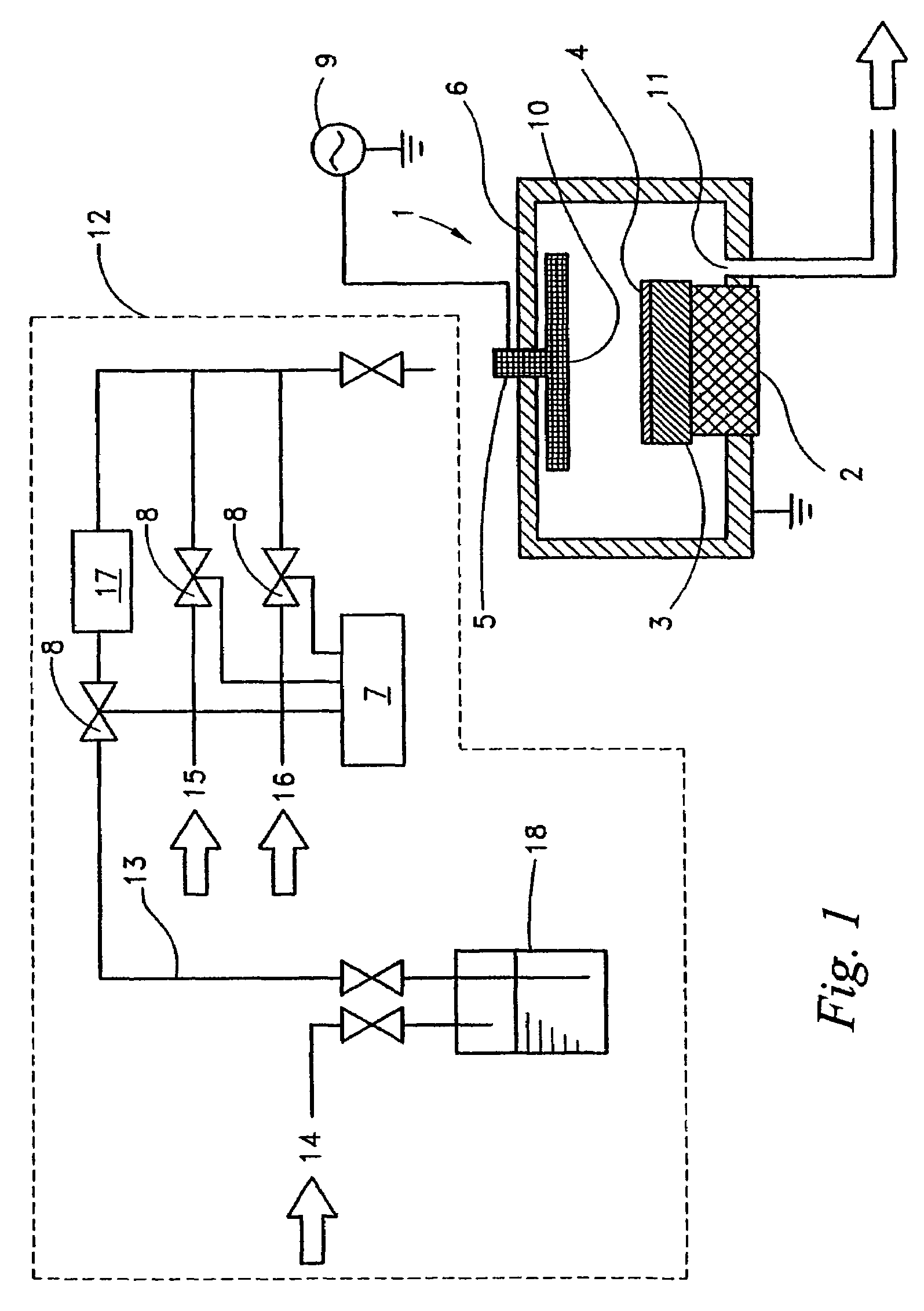

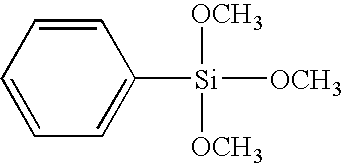

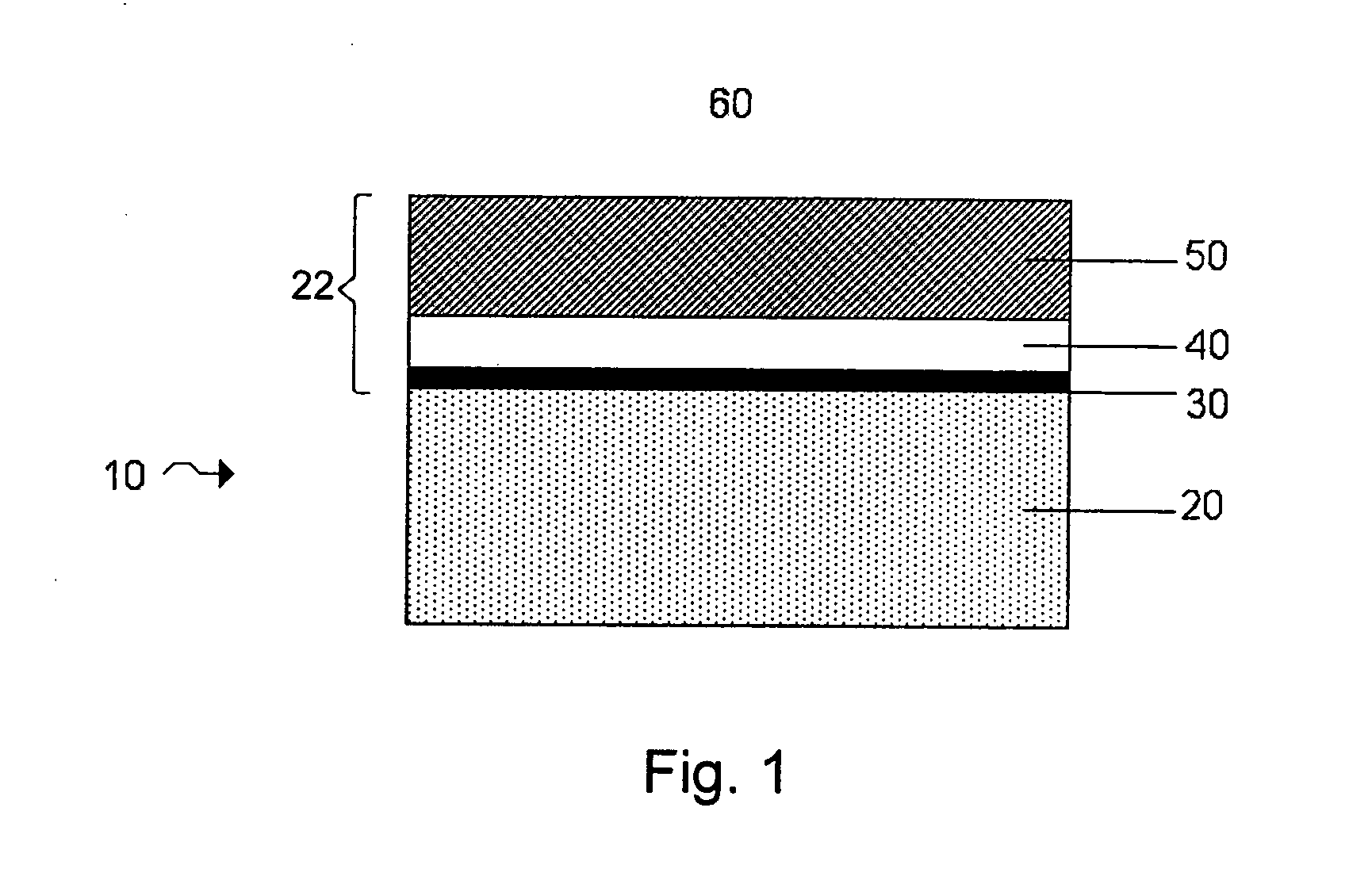

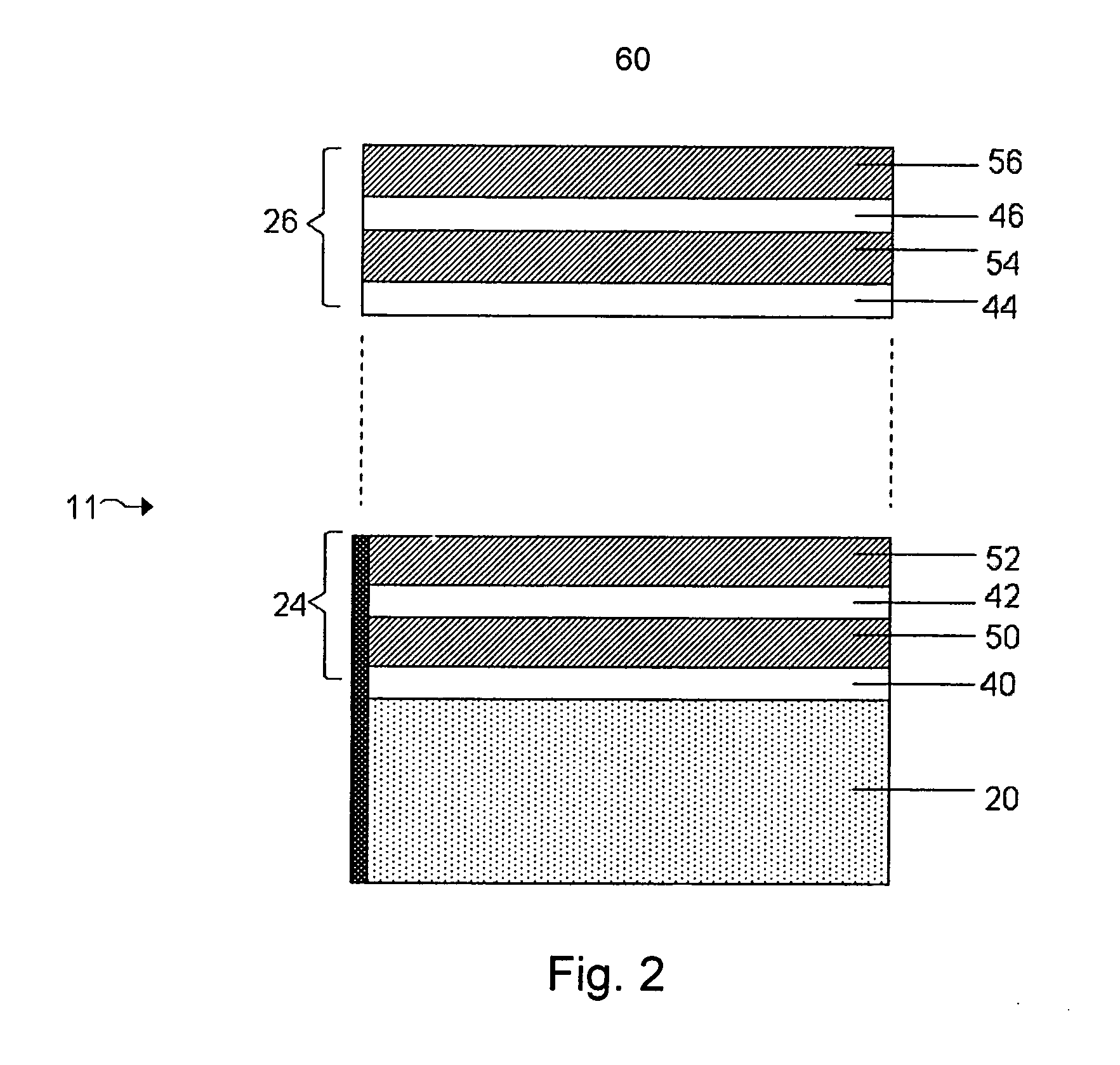

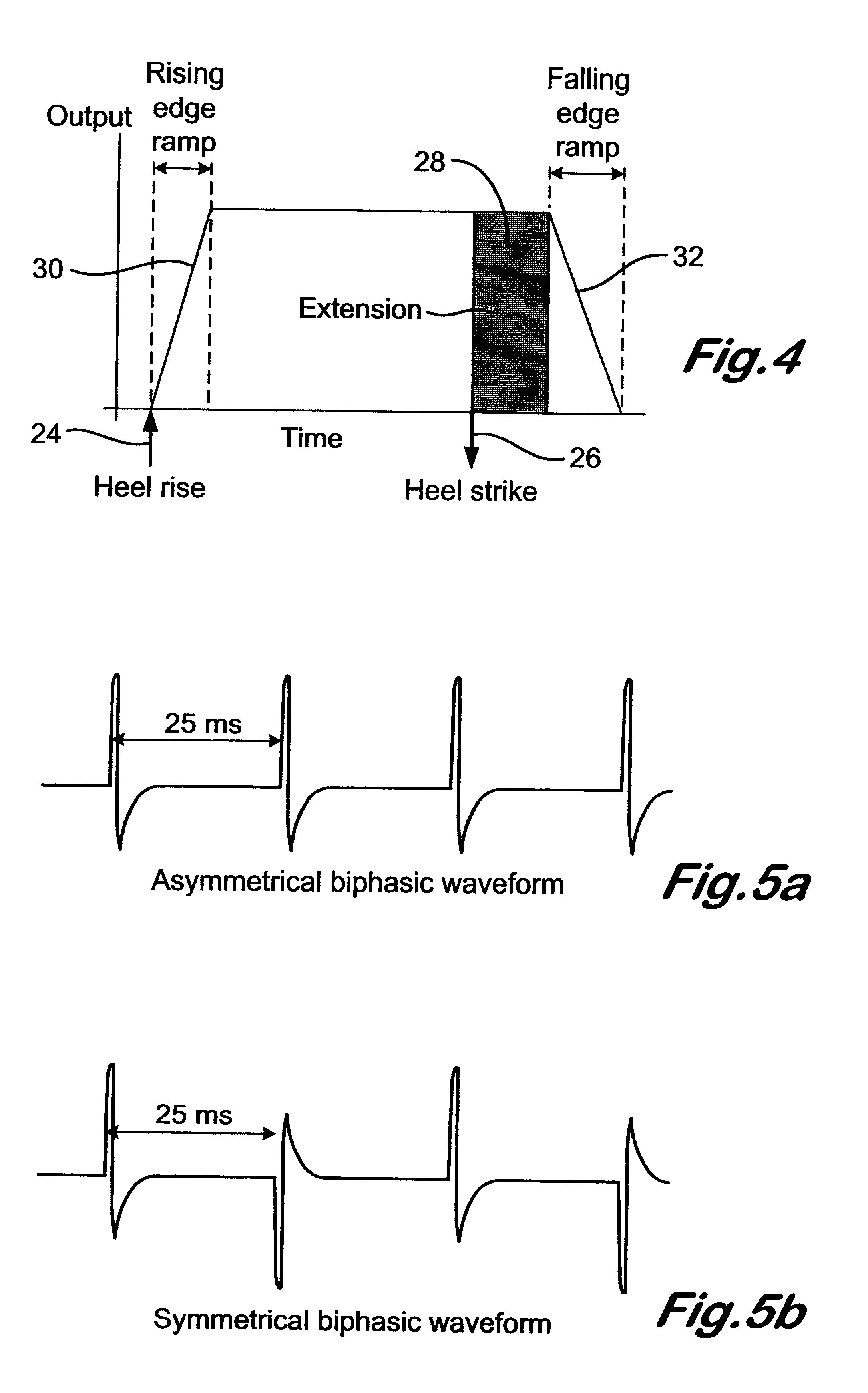

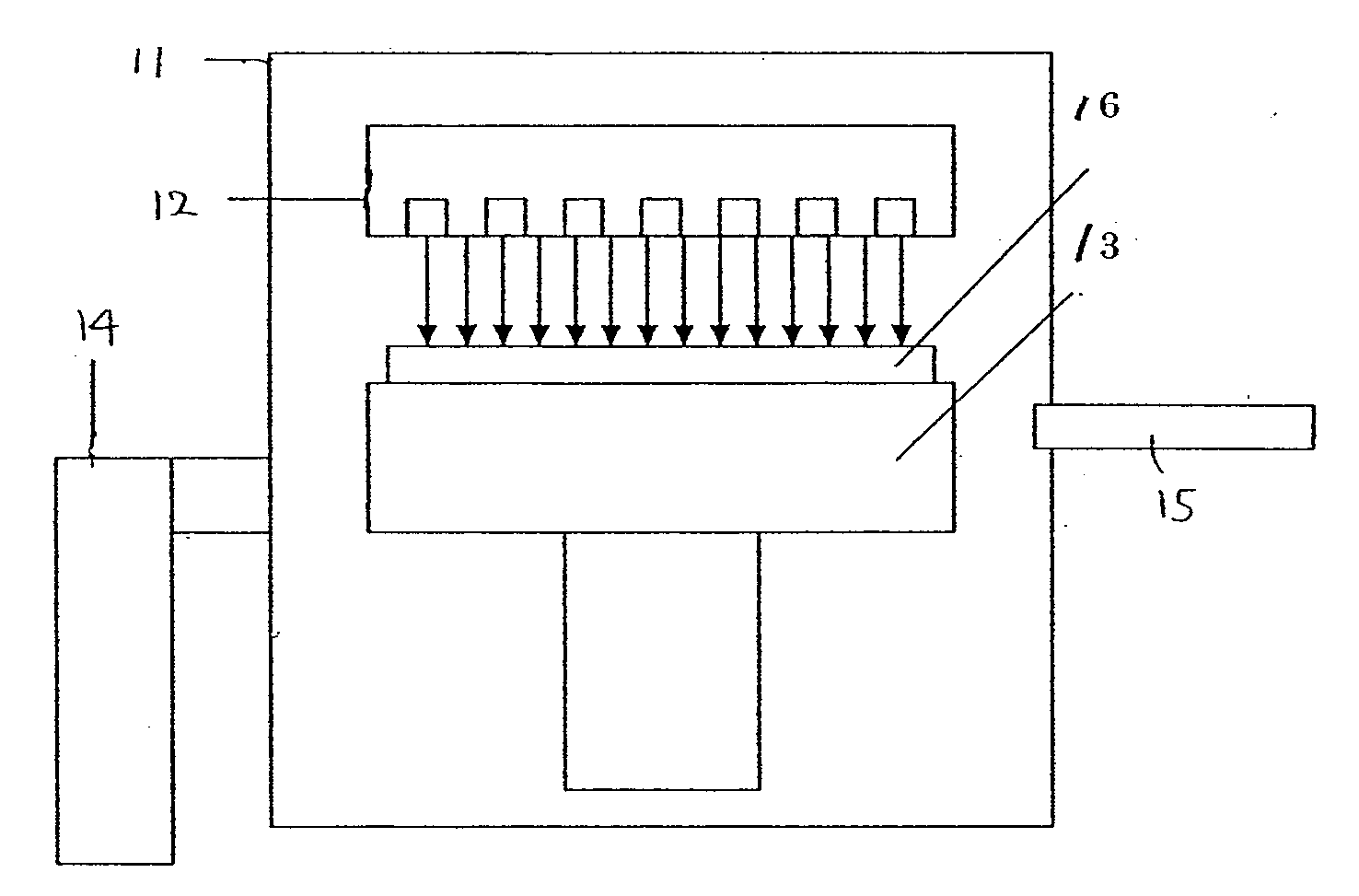

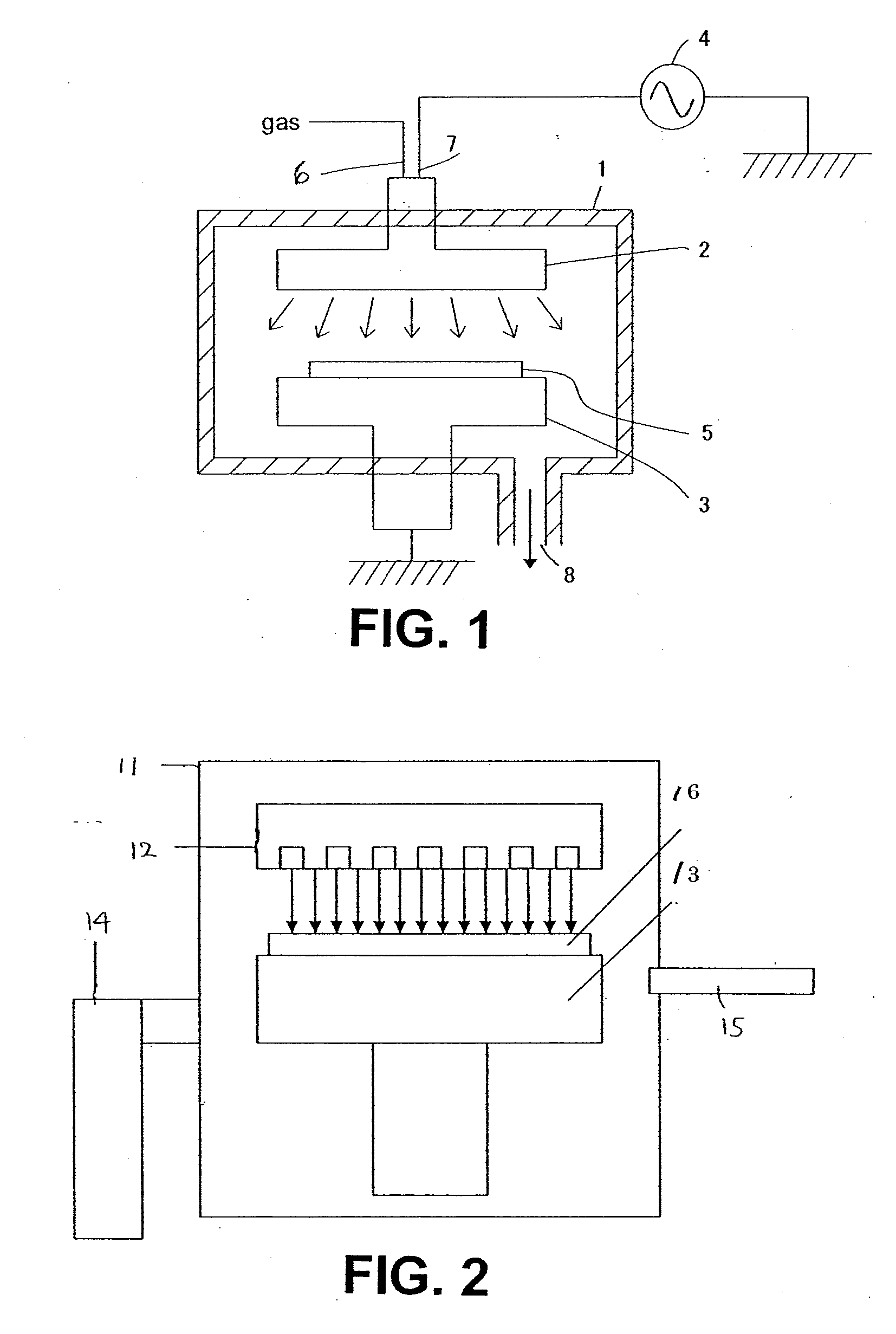

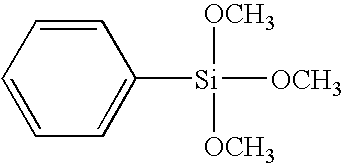

Method for forming insulation film

InactiveUS7354873B2Reduce distanceGood film densitySolid-state devicesSemiconductor/solid-state device manufacturingPlasma reactionResidence time

A method for forming an insulation film having filling property on a semiconductor substrate by plasma reaction includes: vaporizing a silicon-containing hydrocarbon having a Si—O bond compound to provide a source gas; introducing the source gas and a carrier gas without an oxidizing gas into a reaction space for plasma CVD processing; and forming an insulation film constituted by Si, O, H, and optionally C or N on a substrate by plasma reaction using a combination of low-frequency RF power and high-frequency RF power in the reaction space. The plasma reaction is activated while controlling the flow of the reaction gas to lengthen a residence time, Rt, of the reaction gas in the reaction space.

Owner:ASM JAPAN

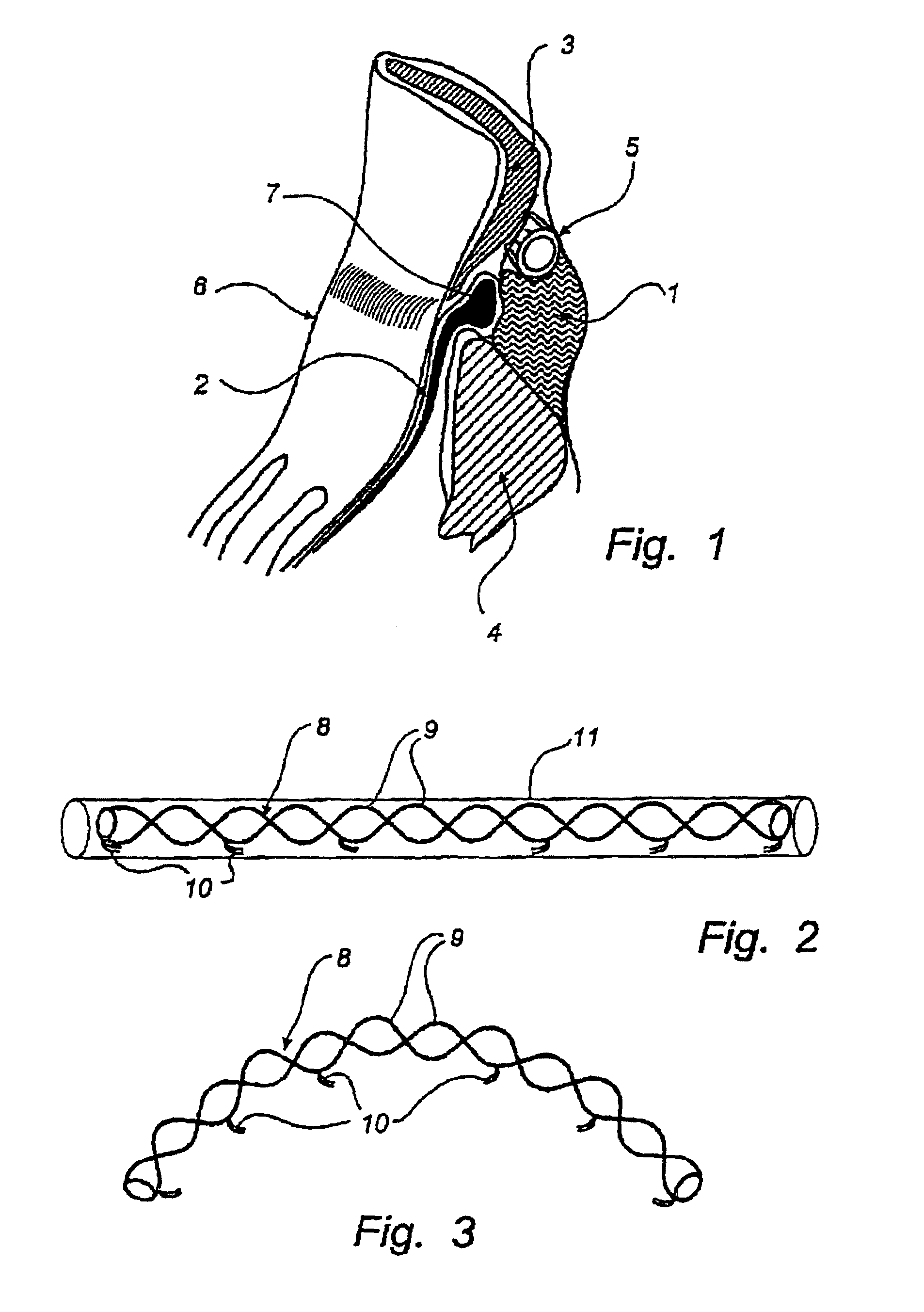

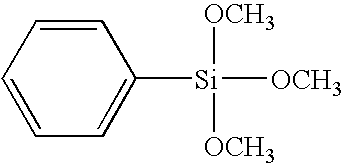

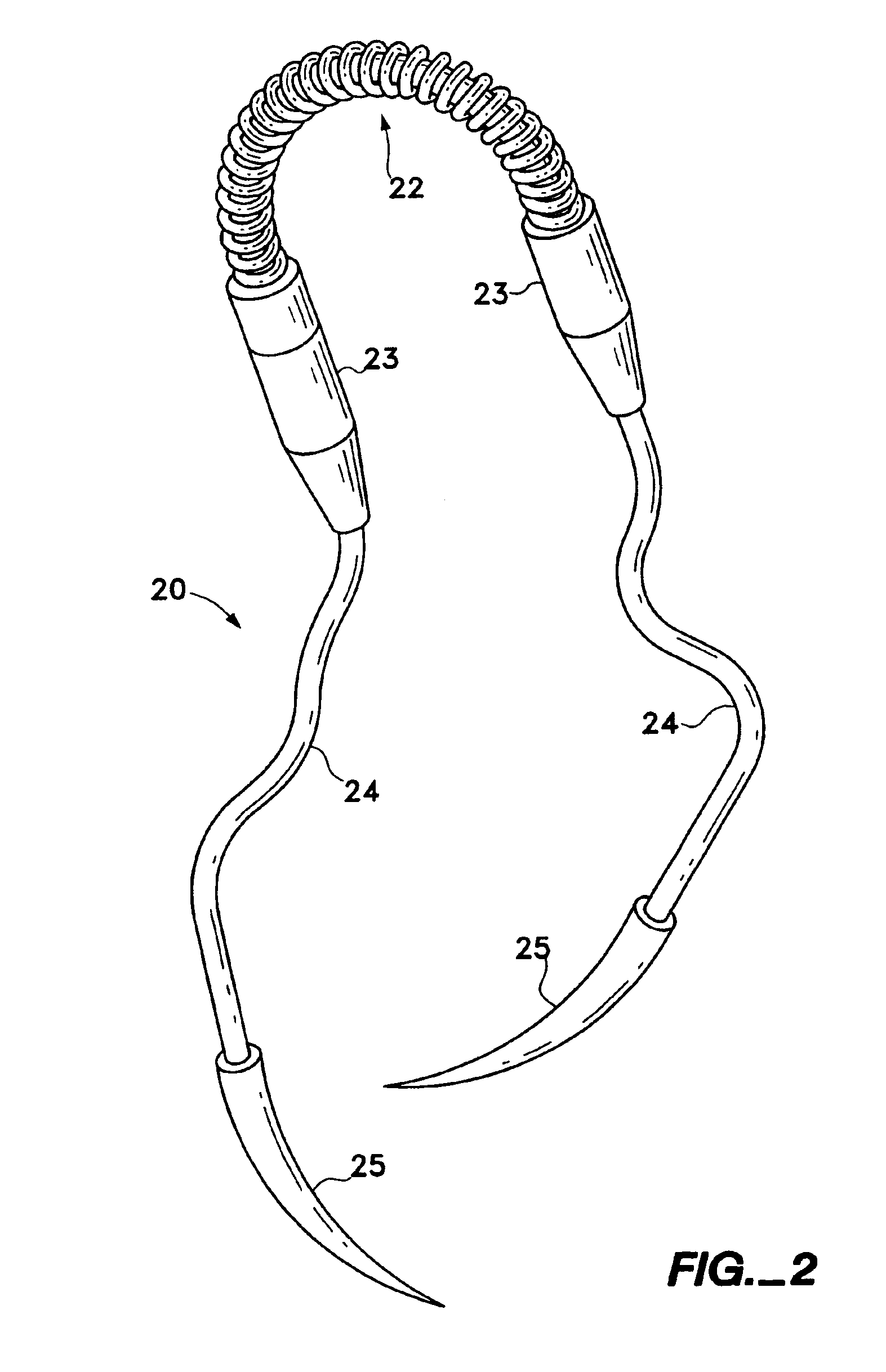

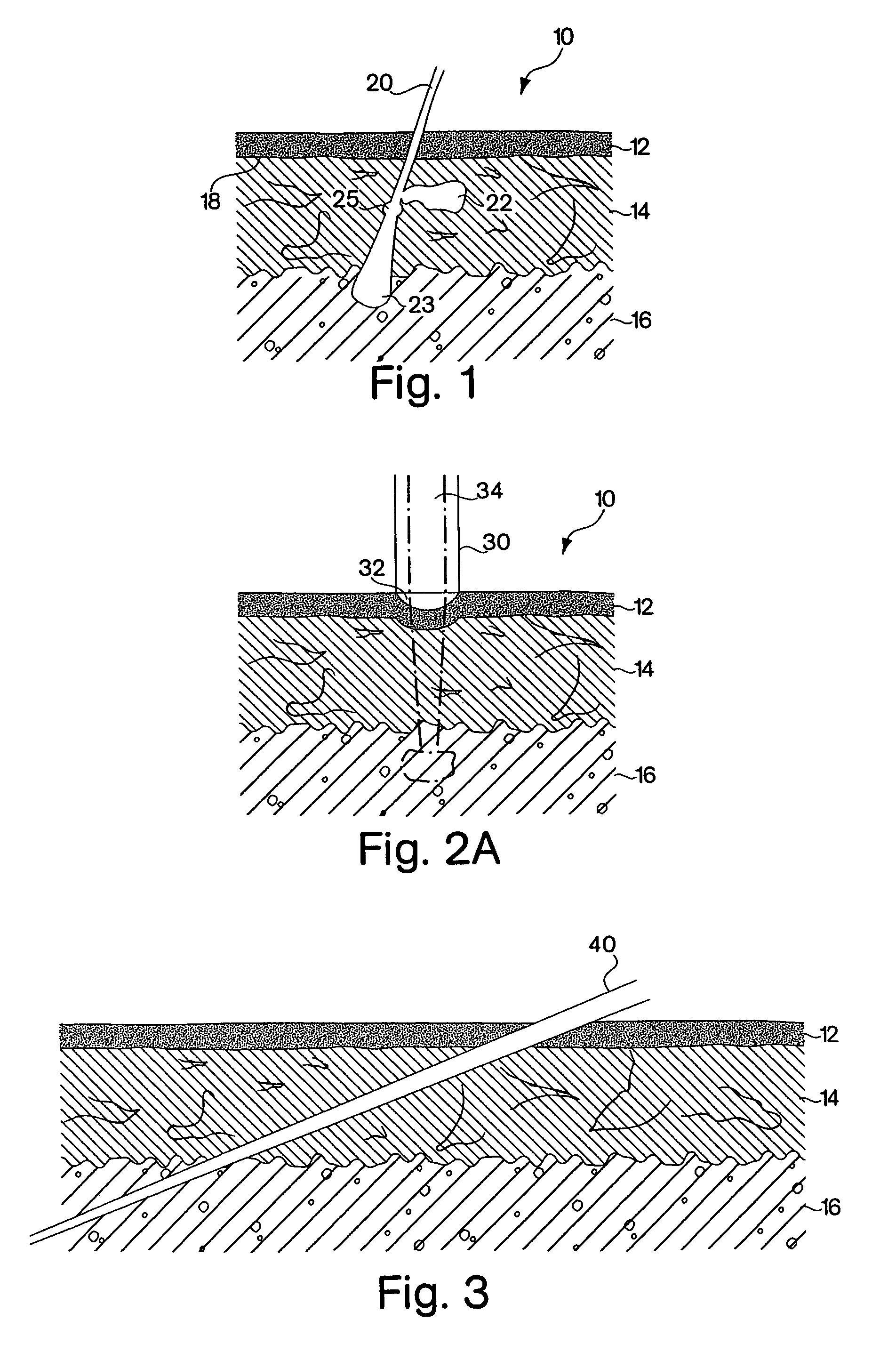

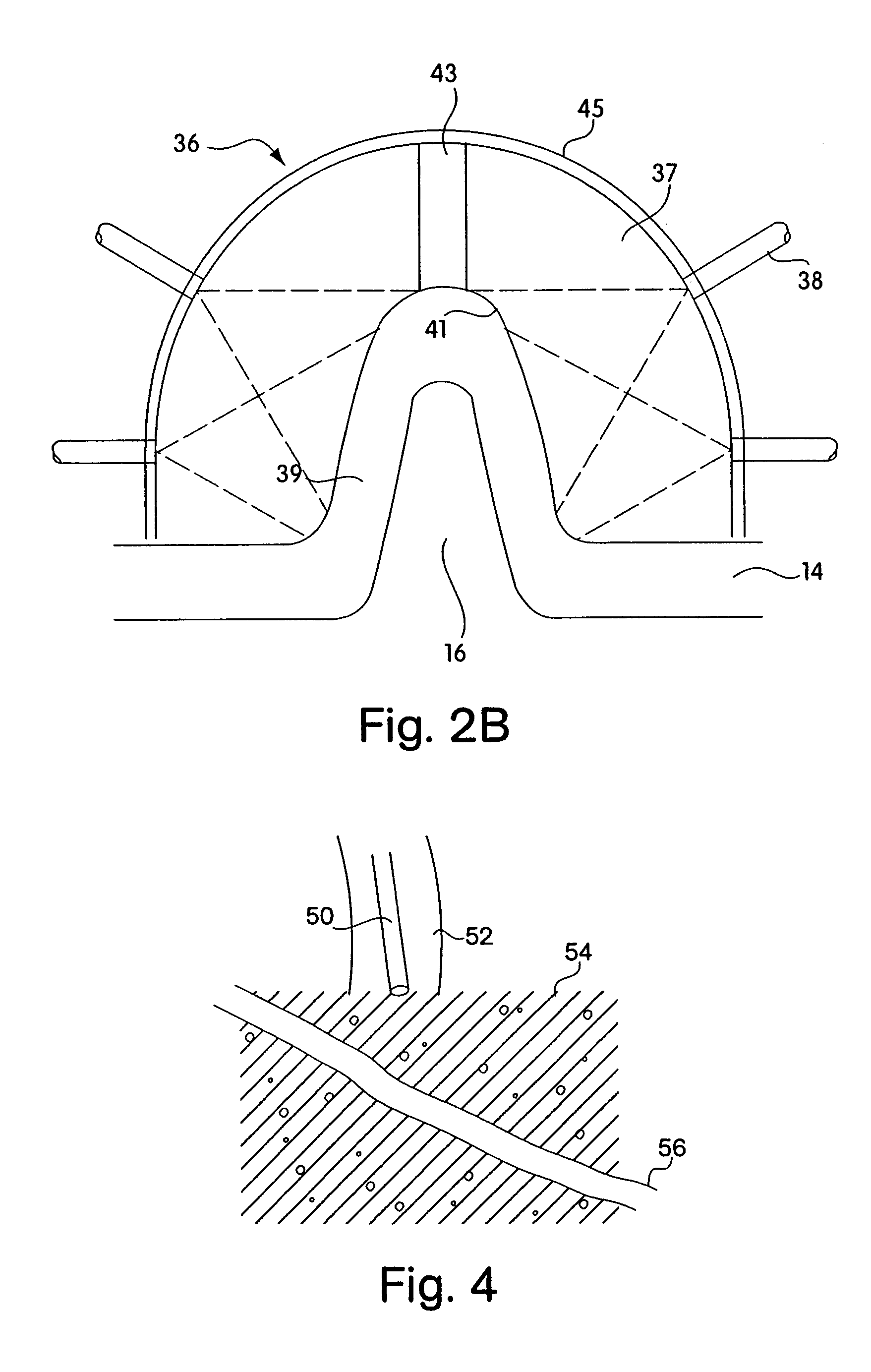

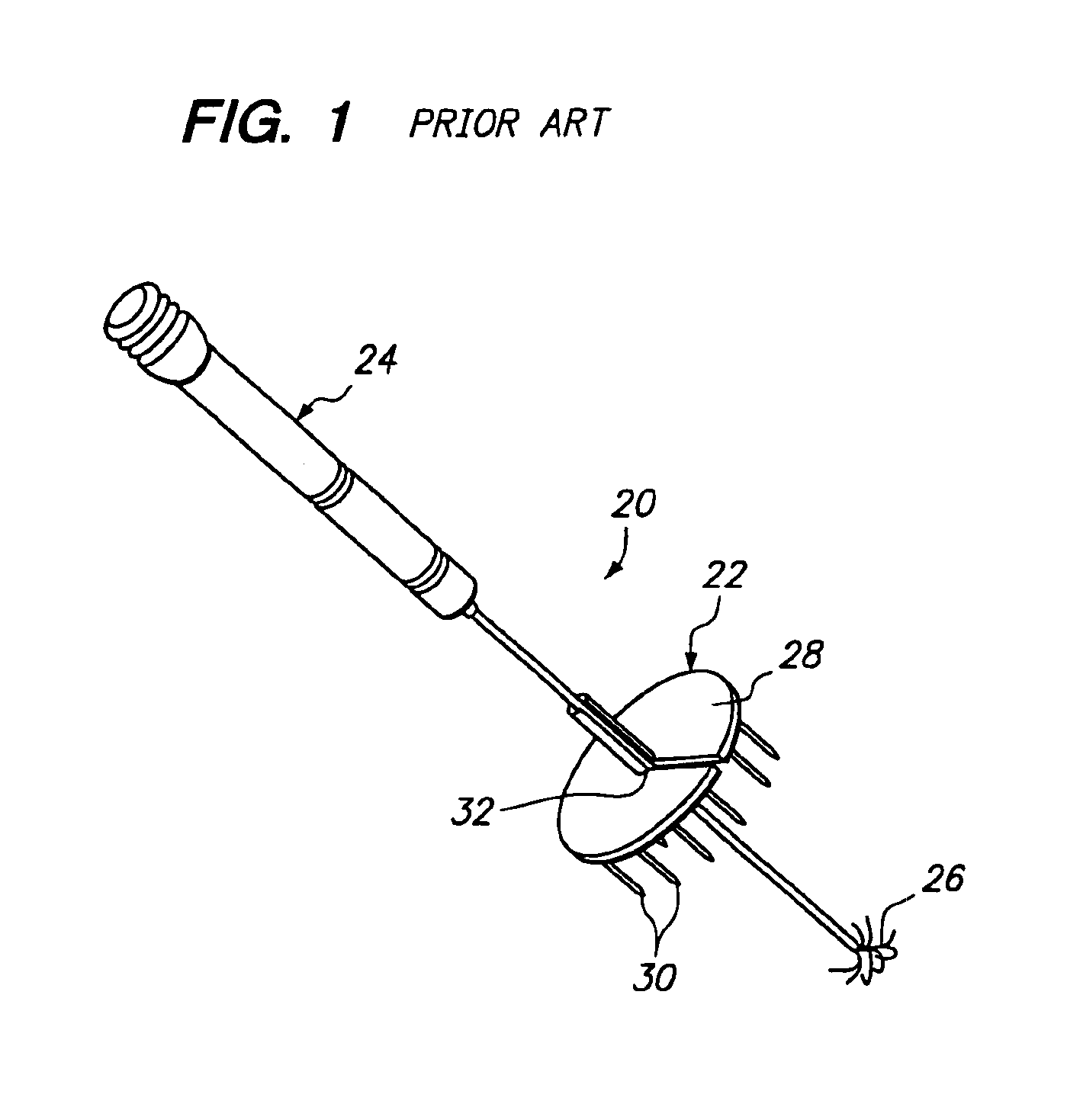

Minimally invasive valve repair procedure and apparatus

A clip of a self-closing type is used for valve repair. The clip is generally U-shaped with two end points separated from each other when it is constrained to be in an open configuration, but tends to coil up to assume its natural closed configuration if the constraint is removed. At least one end point is connected through a suture to a tissue-penetrating needle. A needle holder has an outer tube and an inner member which has a slit at the front and is slidable inside the outer tube. They are designed such that the slit can grab the needle tightly or release it as the inner member is moved backward or forward with respect to the outer tube. With the needle secured at the front, the needle holder is passed through a cannula inserted through an incision and the needle penetrates the leaflets such that the clip can be positioned with its end points hooked to the pair of leaflets to be stitched together. If the clip is released from the suture thereafter, it tends to coil up, reducing the distance between the end points and pulling the leaflets together. A double-arm clip assembly with each of the end points of the clip attached through a suture to a separate needle may be similarly used for valve repair. Such a double-arm clip assembly may contain two of such clips mutually connected by means of a flexible connector such that two leaflets are held together by the connector, with the two clips each anchored to a corresponding one of the leaflets.

Owner:MEDTRONIC INC

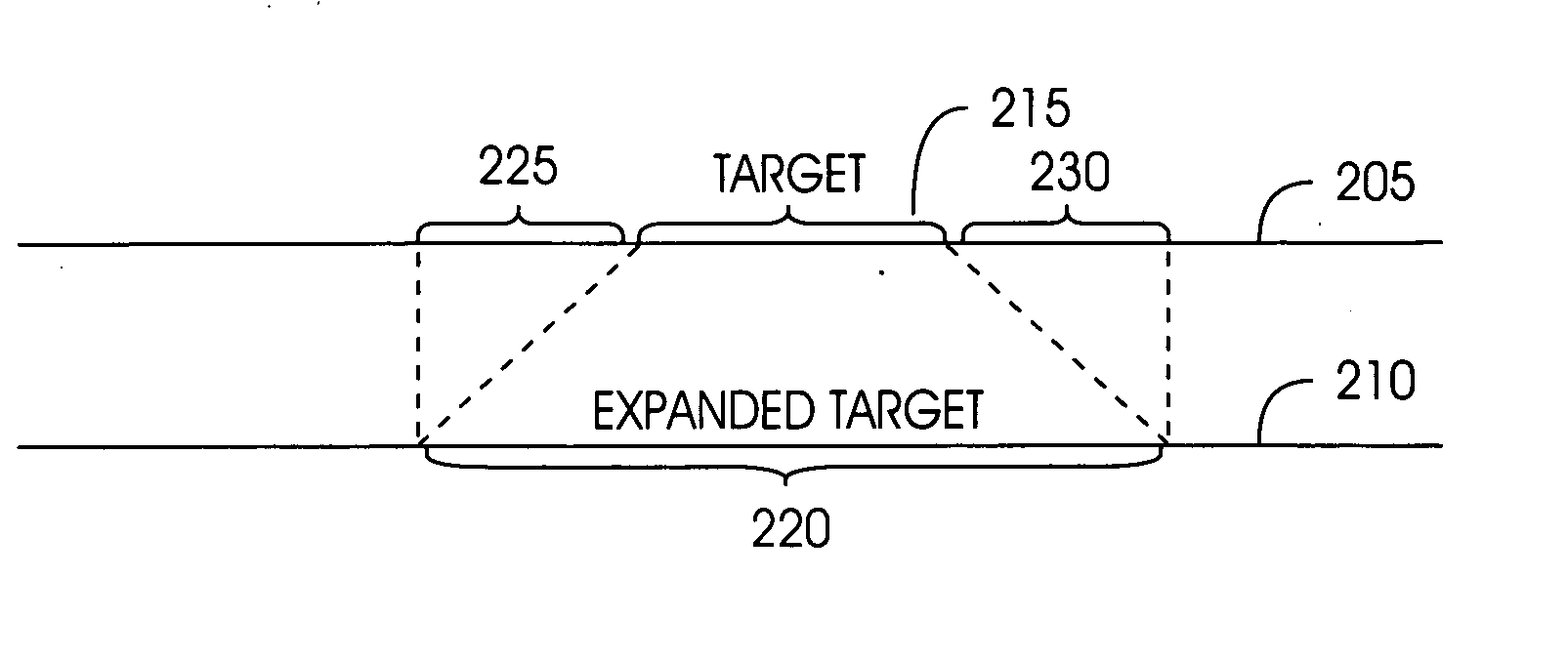

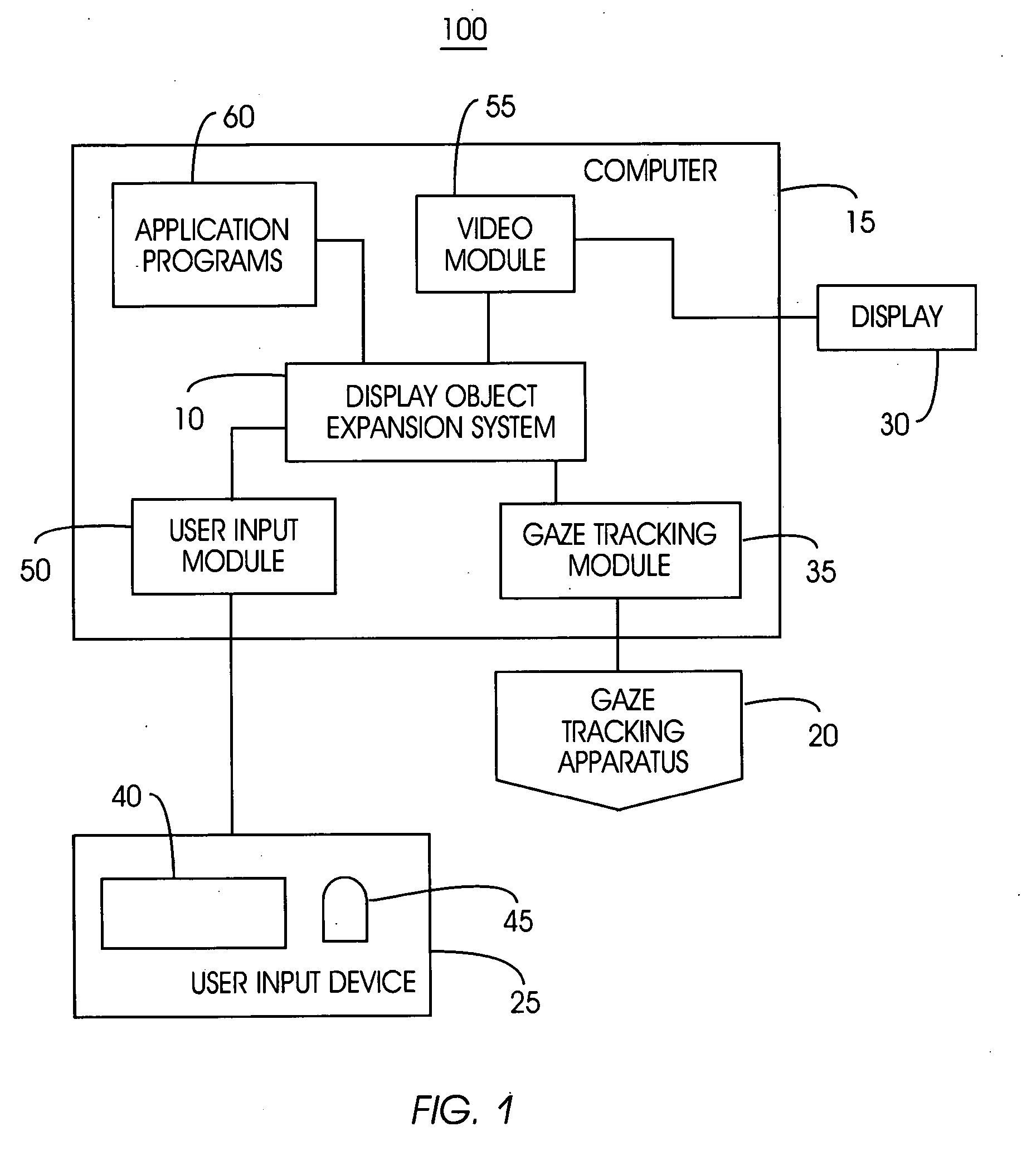

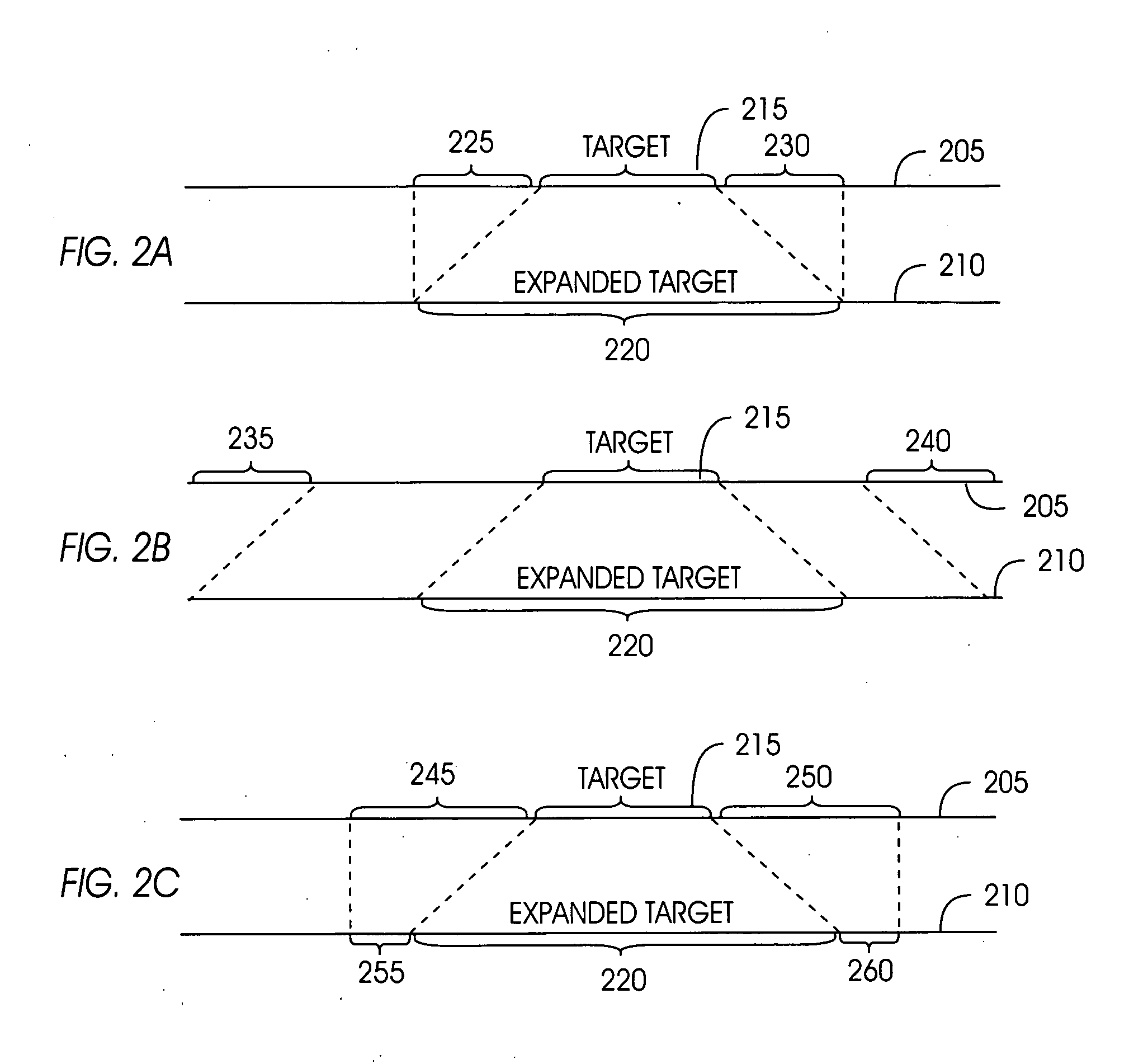

System and method for selectively expanding or contracting a portion of a display using eye-gaze tracking

InactiveUS20050047629A1Improve abilitiesMinimum of functionInput/output for user-computer interactionCharacter and pattern recognitionGraphicsVisibility

A computer-driven system amplifies a target region based on integrating eye gaze and manual operator input, thus reducing pointing time and operator fatigue. A gaze tracking apparatus monitors operator eye orientation while the operator views a video screen. Concurrently, the computer monitors an input indicator for mechanical activation or activity by the operator. According to the operator's eye orientation, the computer calculates the operator's gaze position. Also computed is a gaze area, comprising a sub-region of the video screen that includes the gaze position. The system determines a region of the screen to expand within the current gaze area when mechanical activation of the operator input device is detected. The graphical components contained are expanded, while components immediately outside of this radius may be contracted and / or translated, in order to preserve visibility of all the graphical components at all times.

Owner:IBM CORP

Method for forming insulation film

InactiveUS7582575B2Reduce trafficReduce volumeSolid-state devicesSemiconductor/solid-state device manufacturingPlasma reactionResidence time

A method for forming an insulation film on a semiconductor substrate by plasma reaction includes: vaporizing a silicon-containing hydrocarbon having a Si—O bond compound to provide a source gas; introducing the source gas and a carrier gas without an oxidizing gas into a reaction space for plasma CVD processing; and forming an insulation film constituted by Si, C, O, and H on a substrate by plasma reaction using a combination of low-frequency RF power and high-frequency RF power in the reaction space. The plasma reaction is activated while controlling the flow of the reaction gas to lengthen a residence time, Rt, of the reaction gas in the reaction space.

Owner:ASM JAPAN

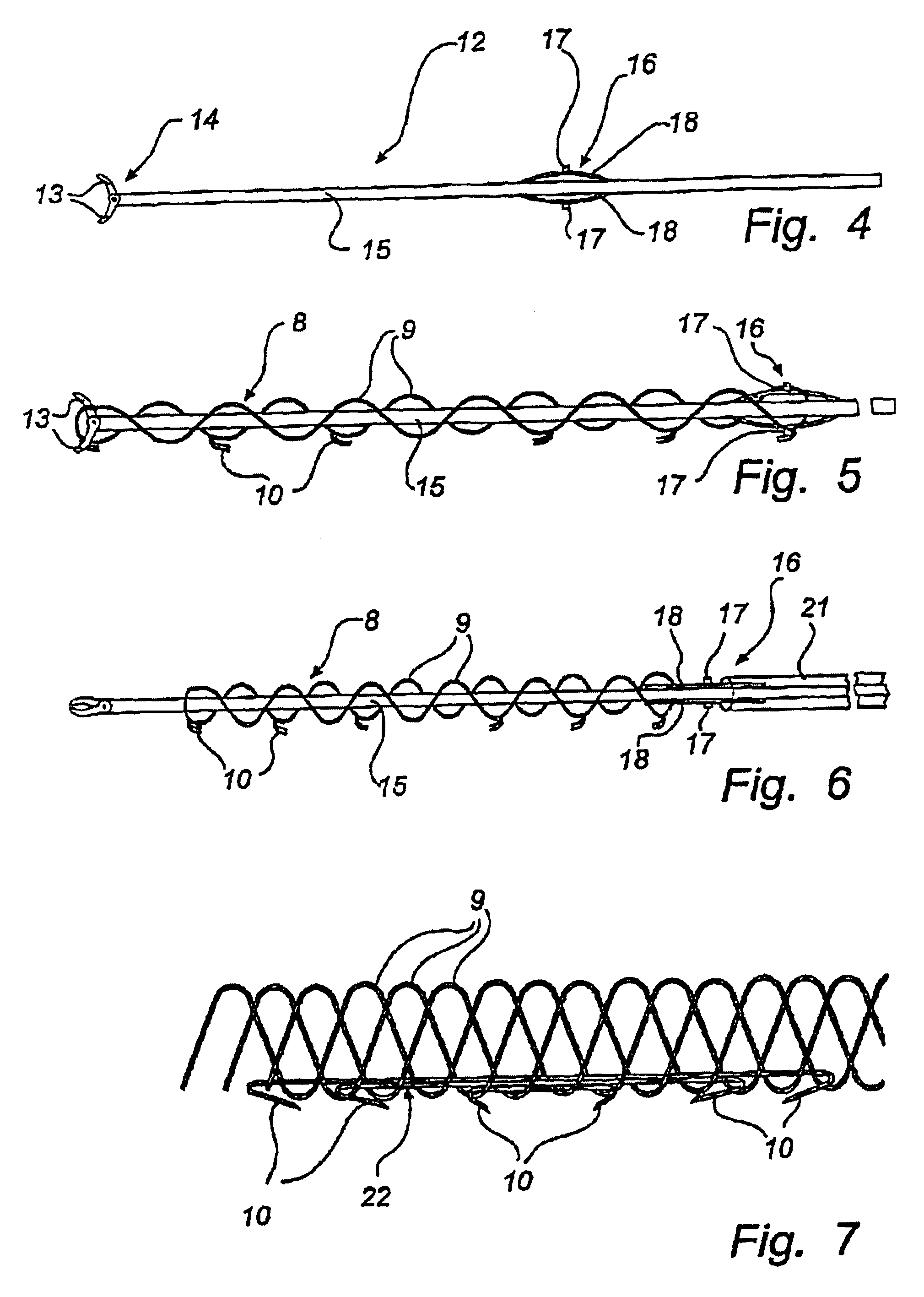

Tissue fastening systems and methods

InactiveUS20070080188A1Reducing circumferenceReduce distanceSuture equipmentsStapling toolsMitral valve leafletCatheter device

Owner:MITRALIGN INC

Tissue fastening systems and methods utilizing magnetic guidance

InactiveUS20050125011A1Prevent movementReducing circumferenceSuture equipmentsStapling toolsMitral valve leafletCatheter device

Catheter based systems and methods for securing tissue including the annulus of a mitral valve. The systems and methods employ catheter based techniques and devices to plicate tissue and perform an annuloplasty.

Owner:MITRALIGN INC

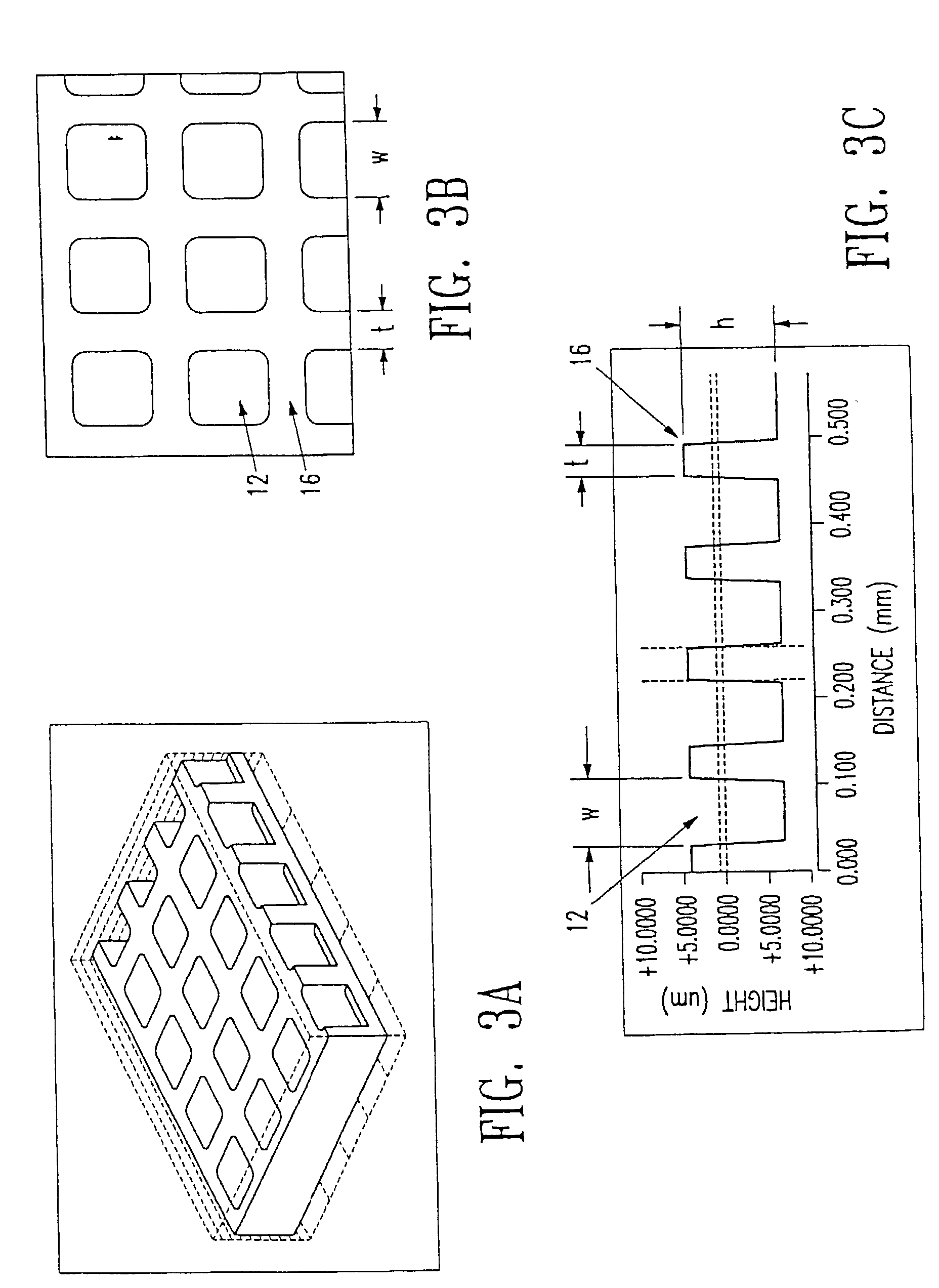

Composition and process for the sealing of microcups in roll-to-roll display manufacturing

InactiveUS7144942B2Improve adhesionQuality improvementLamination ancillary operationsLaminationCrystallographyElectrophoresis

Owner:E INK CALIFORNIA

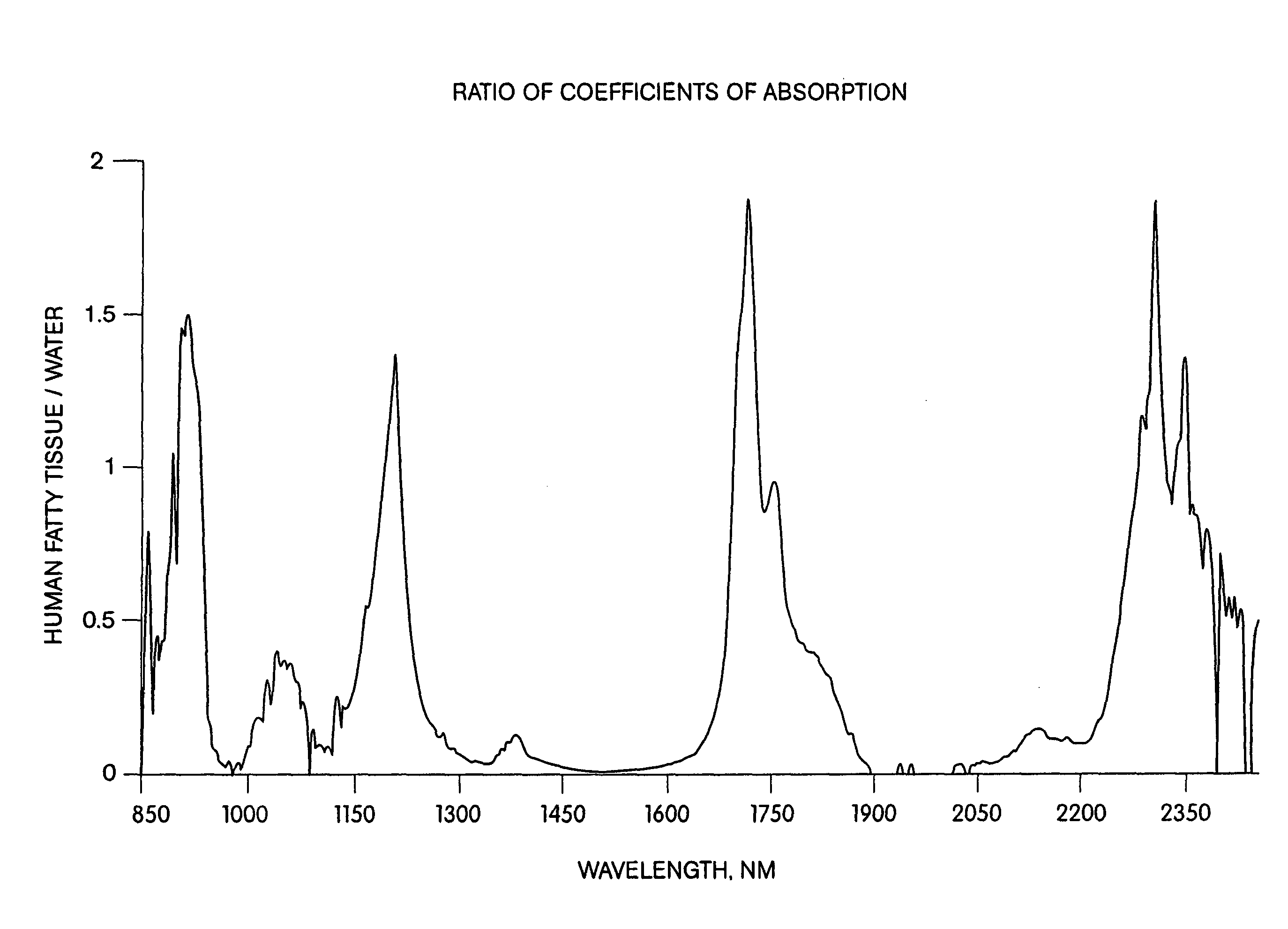

Method and apparatus for the selective targeting of lipid-rich tissues

InactiveUS7060061B2Desired treatmentSufficient durationSurgical instrument detailsSurgical pincettesHair removalLipid formation

A method and apparatus are provided for targeting lipid-rich tissue to effect a desired, the method / apparatus involving irradiating the lipid-rich tissue with energy at a wavelength preferentially absorbed by lipid cells, such wavelength being preferably in a band between 880 nm and 935 nm, 1150 nm and 1230 nm, 1690 nm to 1780 nm, or 2250 nm to 2450 nm with a fluence and duration sufficient to achieve a desired treatment. For preferred embodiments, the irradiation wavelength is between 900–930 nm, 1190–1220 nm, 1700–1730 nm, or 2280–2350 nm. The method and apparatus may for example be used to target one or more sebaceous glands for the treatment of acne or hair removal, to target subcutaneous fat for removal thereof or for targeting fat on anatomical elements for various purposes.

Owner:PALOMAR MEDICAL TECH

Implantation of repair chords in the heart

A method is provided, including positioning, at an intraventricular site of a ventricle of a patient, a spool coupled to a first end portion of a longitudinal member and coupling a second end portion of the longitudinal member to a portion of tissue facing a lumen of the ventricle. Other embodiments are also described.

Owner:VALTECH CARDIO LTD

Tissue fastening systems and methods utilizing magnetic guidance

InactiveUS20050119734A1Prevent movementReducing circumferenceSuture equipmentsAnnuloplasty ringsMitral valve leafletCatheter device

Catheter based systems and methods for securing tissue including the annulus of a mitral valve. The systems and methods employ catheter based techniques and devices to plicate tissue and perform an annuloplasty.

Owner:EDWARDS LIFESCIENCES CORP

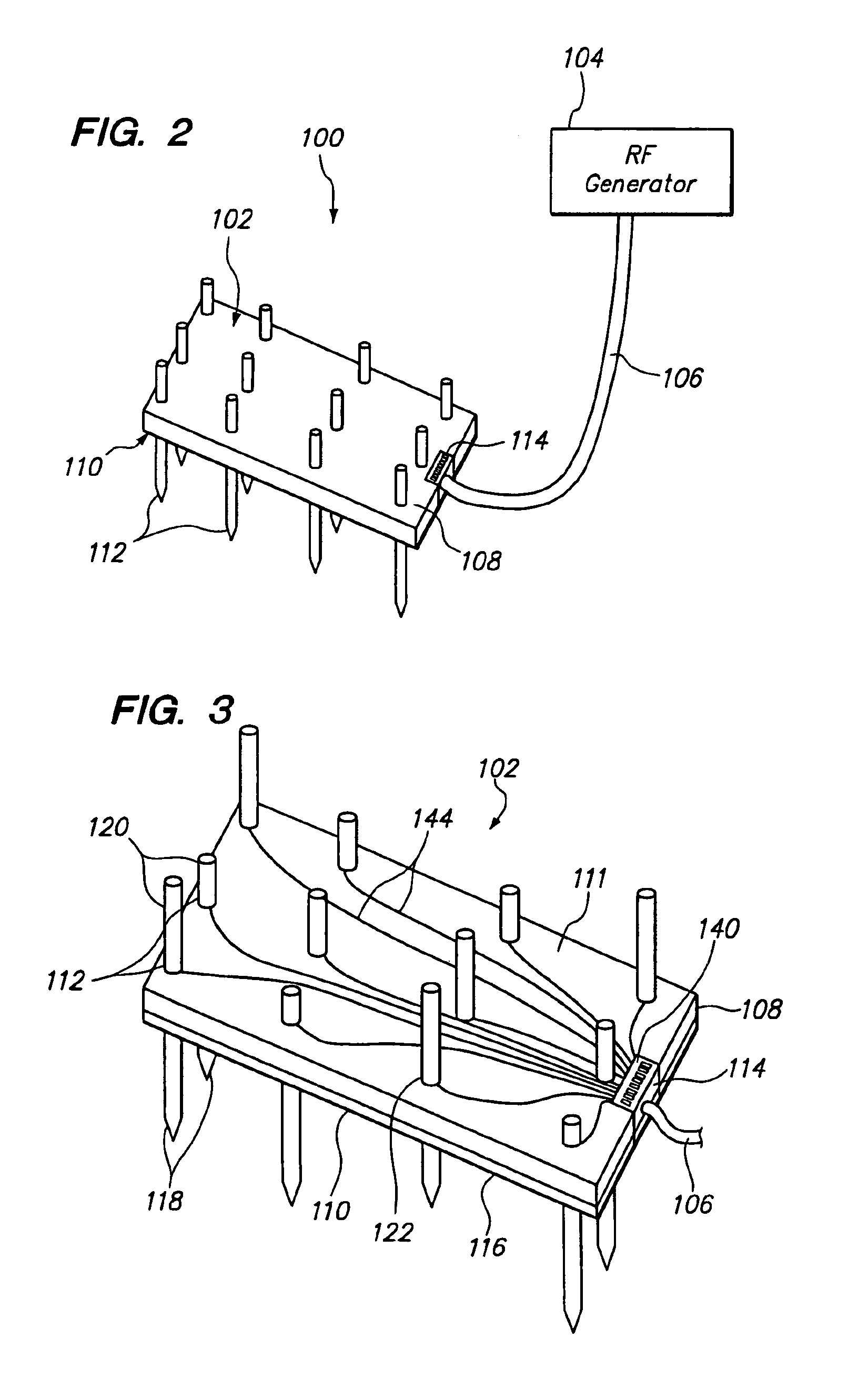

Surface electrode multiple mode operation

InactiveUS6918907B2Minimize inadvertent ablationDepth adjustableSurgical needlesJoint implantsBiomedical engineeringSurface electrode

A surface electrode for ablating tissue is provided. The surface electrode comprises a base, a plurality of tissue penetrating needle electrodes extending from the surface of the base an adjustable distance, and an electrical interface coupled to the plurality of needle electrodes. The adjustability of the needle electrodes allows the depth that the needle electrodes penetrate through tissue to be adjusted.

Owner:BOSTON SCI SCIMED INC

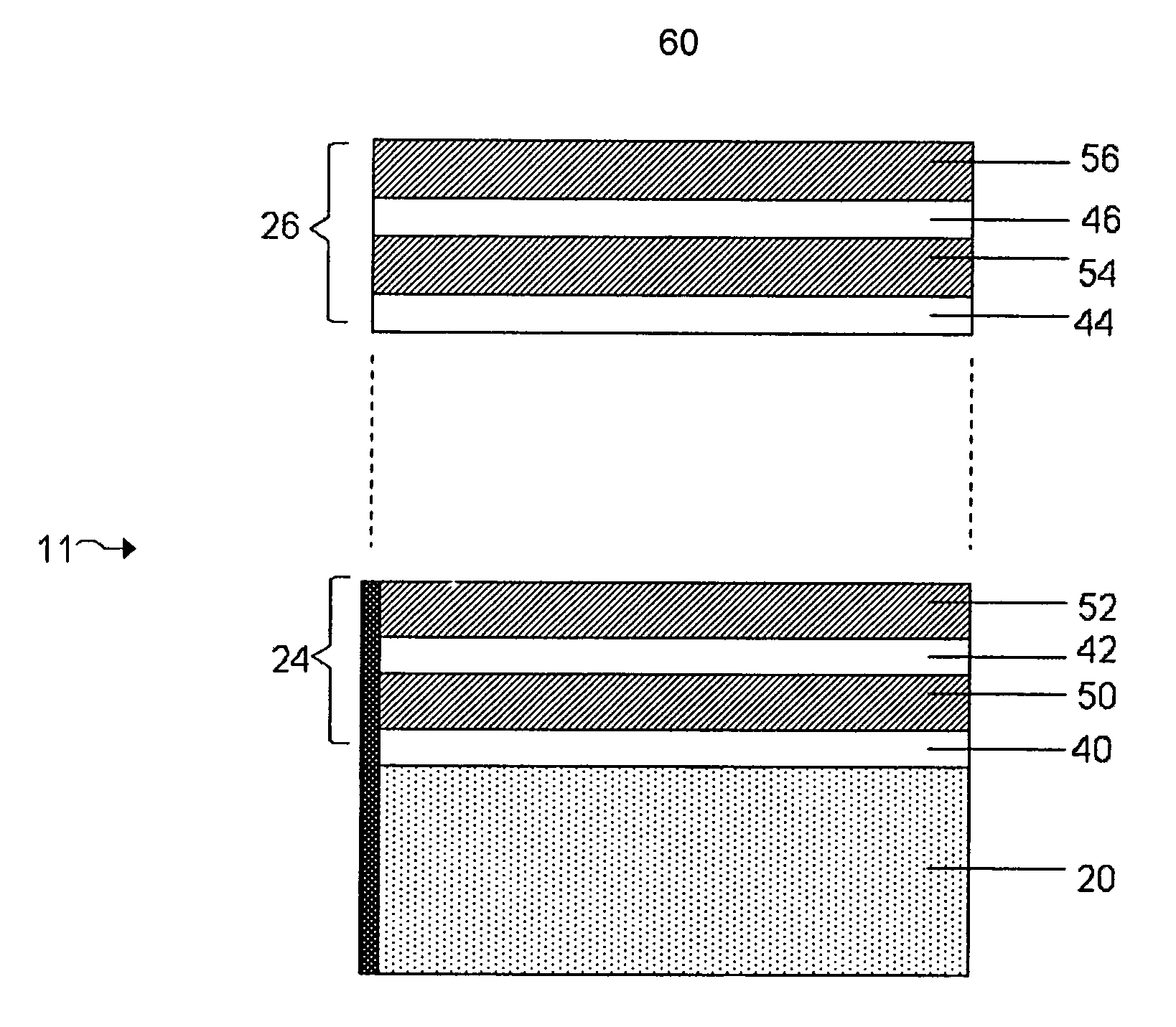

Rechargeable lithium/water, lithium/air batteries

InactiveUS20070221265A1Improve protectionEasy to controlFinal product manufacturePV power plantsHigh energyOptoelectronics

Electrochemical cells, and more specifically, rechargeable batteries comprising lithium anodes for use in water and / or air environments, as well as non-aqueous and non-air environments, are presented. In one embodiment, an electrochemical cell includes an anode comprising lithium and a multi-layered structure positioned between the anode and an electrolyte of the cell. A multi-layered structure can include at least a first single-ion conductive material layer (e.g., a lithiated metal layer), and at least a first polymeric layer positioned between the anode and the single-ion conductive material. The invention also can provide an electrode stabilization layer positioned within the electrode, i.e., between one portion and another portion of an electrode, to control depletion and re-plating of electrode material upon charge and discharge of a battery. Advantageously, electrochemical cells comprising combinations of structures described herein are not only compatible with environments that are typically unsuitable for lithium, but the cells may be also capable of displaying long cycle life, high lithium cycling efficiency, and high energy density.

Owner:SION POWER CORP

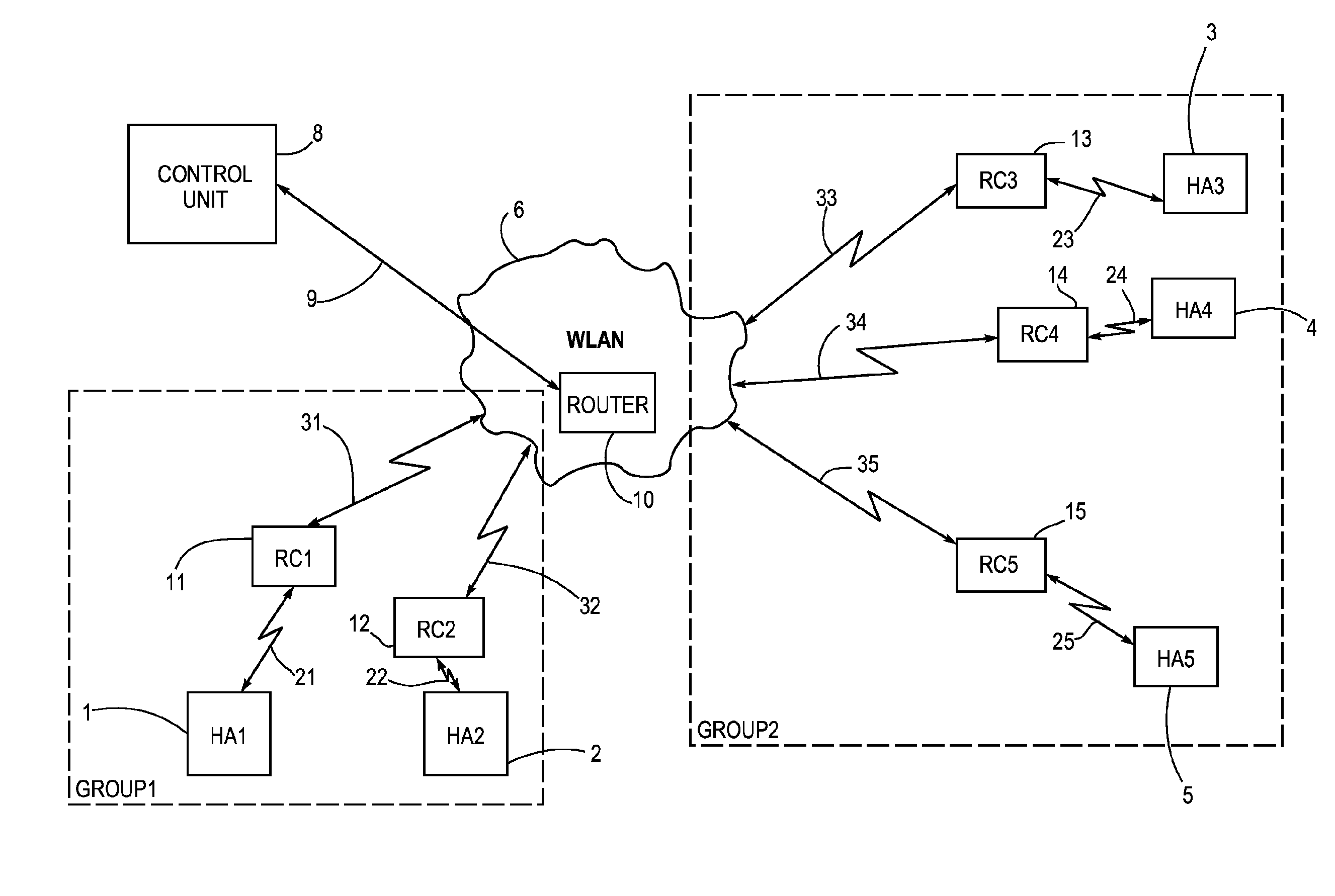

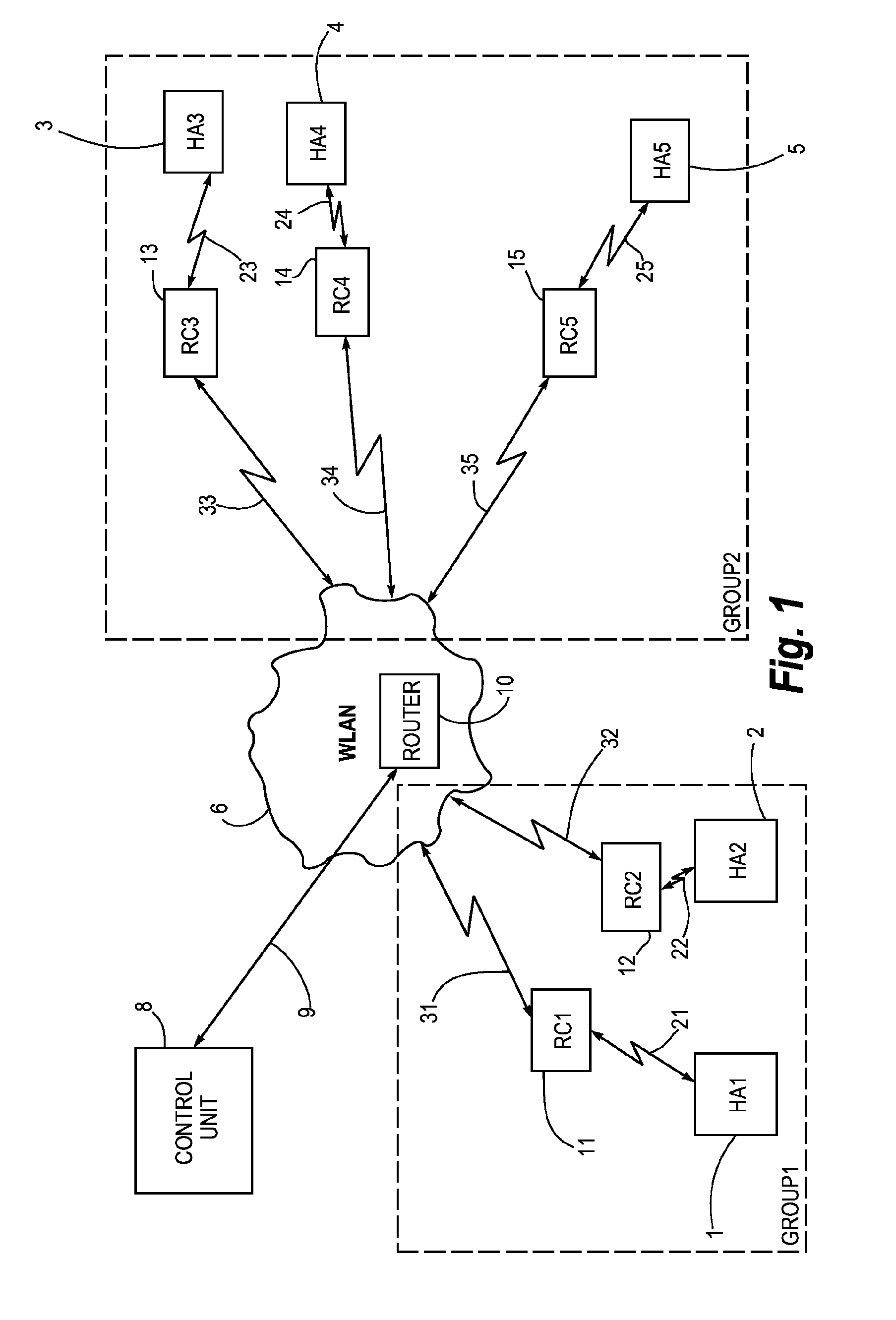

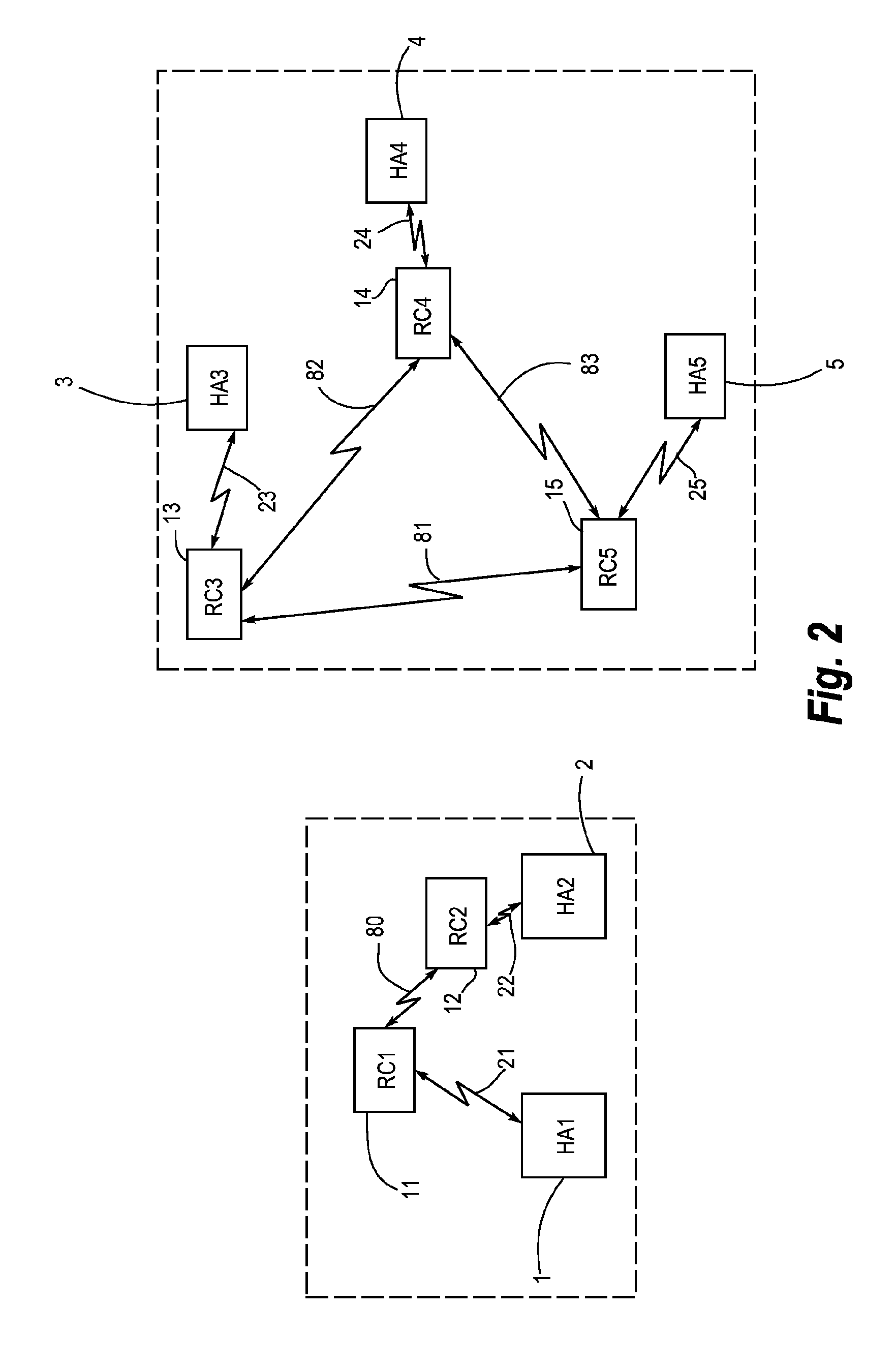

Hearing aid system for establishing a conversation group

ActiveUS20100086152A1Small sizePower transmissionFrequency-division multiplex detailsTime-division multiplexEngineeringHearing aid

A hearing aid system adapted for establishing a conversation group with other hearing aid systems used by different users, comprises a hearing aid (1, 2, 3, 4, 5) with an associated relay device (11, 12, 13, 14, 15). The relay device is (11, 12, 13, 14, 15) adapted for wireless communication (21, 22, 23, 24, 25) with said hearing aid and for wireless communication (31, 32, 33, 34, 35) with a second hearing aid system. The relay device (11, 12, 13, 14, 15) is also adapted for receiving and displaying information about said second hearing aid systems being available for participation in said conversation group, and it comprises means for selection of said other hearing aid systems for inclusion into the conversation group. The invention further provides a method for establishing a conversation group among hearing aid users.

Owner:WIDEX AS

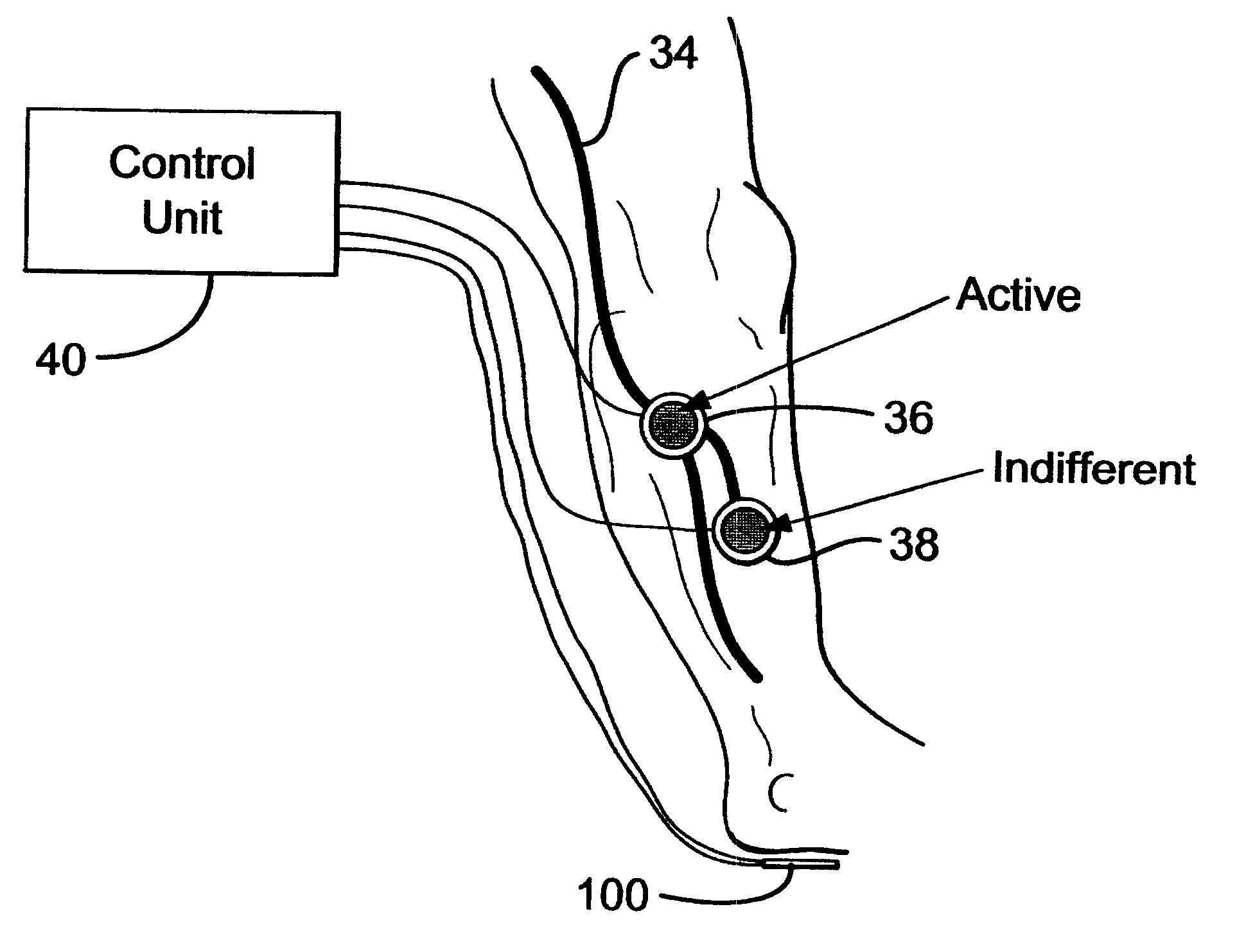

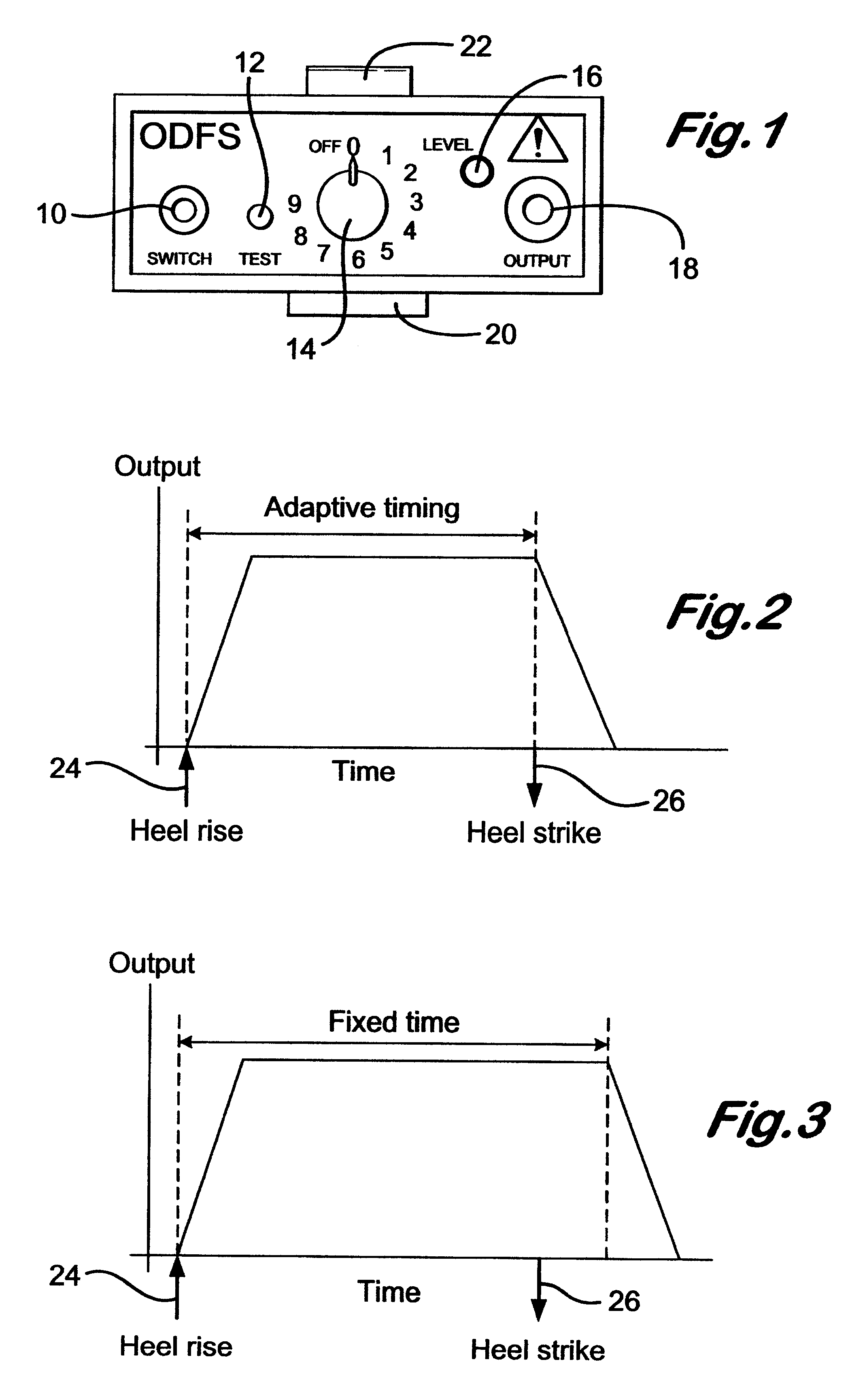

Apparatus for electrical stimulation of the body

InactiveUS6507757B1Inhibition effectReduce distanceElectrotherapyDiagnostic recording/measuringElectrical resistance and conductanceFoot strike

A stimulator for stimulating the leg or other parts of the body e.g. the leg in a patient with drop foot is provided, the stimulator being controlled by e.g a foot switch but being reliable in use and therefore commanding acceptance by users. The foot switch has to work in adverse environmental conditions and is subject to repeated use so that its characteristics vary with time. The invention provides a functional electrical stimulator for attachment to the leg that has adaptive characteristics and comprises first and second electrodes for attachment to the leg to apply an electrical stimulus, a foot switch for sensing foot rise or foot strike, a circuit responsive to said foot switch for generating stimulation pulses; and means forming part of said circuit for responding to changes in the resistance characteristics of said switch means by adjusting a corresponding response threshold of said circuit.The invention also provides a two-channel stimulator that offers various possibilities for controlling the signals to be supplied to different muscle groups. For example, means may be provided defining a signal pathway between the first and second channels so that the supply of stimulation pulses in one of said first and second channels can be controlled by the state of switch means associated with the other of said first and second channels. In a further embodiment means defining a signal pathway between the first and second channels is arranged so that the supply of stimulation pulses in one of said first and second channels can be controlled by the state of activity of the other of said first and second channels. In a yet further embodiment the first channel has means arranged to cause the stimulation pulses to time-out after a predetermined period and the second channel having no or disabled timing means so that supply of stimulation pulses is continuous in a predetermined state of limb position responsive switch means associated with that channel. The two-channel stimulator can be used e.g., to treat bilateral dropped foot.

Owner:BOURNEMOUTH UNIV HIGHER EDUCATION CORP +1

Method for forming insulation film

InactiveUS20070004204A1Reduce trafficDecrease in flow volumeSolid-state devicesSemiconductor/solid-state device manufacturingProduct gasPlasma reaction

A method for forming an insulation film having filling property on a semiconductor substrate by plasma reaction includes: vaporizing a silicon-containing hydrocarbon having a Si—O bond compound to provide a source gas; introducing the source gas and a carrier gas without an oxidizing gas into a reaction space for plasma CVD processing; and forming an insulation film constituted by Si, O, H, and optionally C or N on a substrate by plasma reaction using a combination of low-frequency RF power and high-frequency RF power in the reaction space. The plasma reaction is activated while controlling the flow of the reaction gas to lengthen a residence time, Rt, of the reaction gas in the reaction space.

Owner:ASM JAPAN

Tissue fastening systems and methods utilizing magnetic guidance

InactiveUS20050119735A1Prevent movementReducing circumferenceSuture equipmentsAnnuloplasty ringsMitral valve leafletCatheter device

Catheter based systems and methods for securing tissue including the annulus of a mitral valve. The systems and methods employ catheter based techniques and devices to plicate tissue and perform an annuloplasty.

Owner:MITRALIGN INC

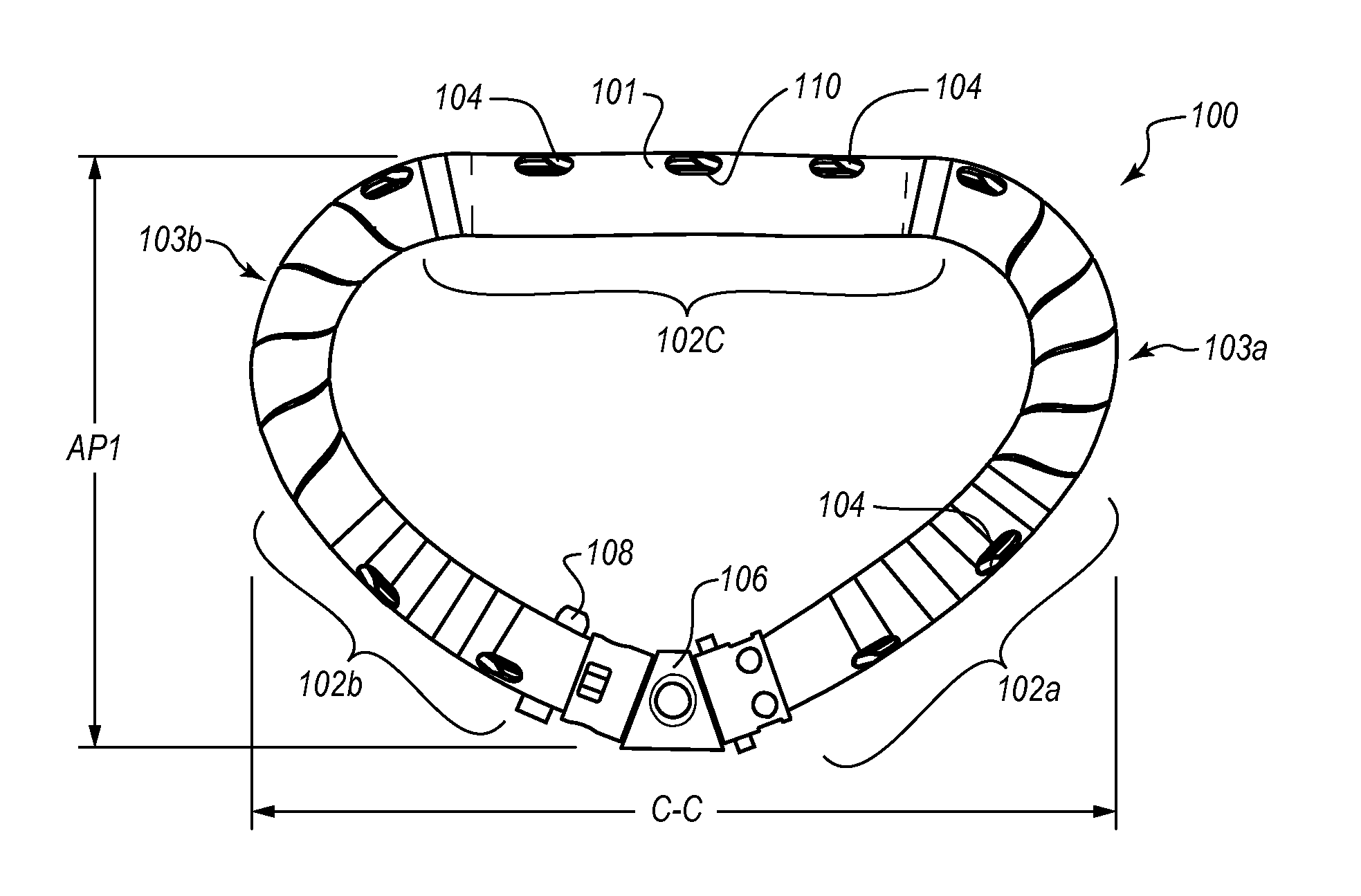

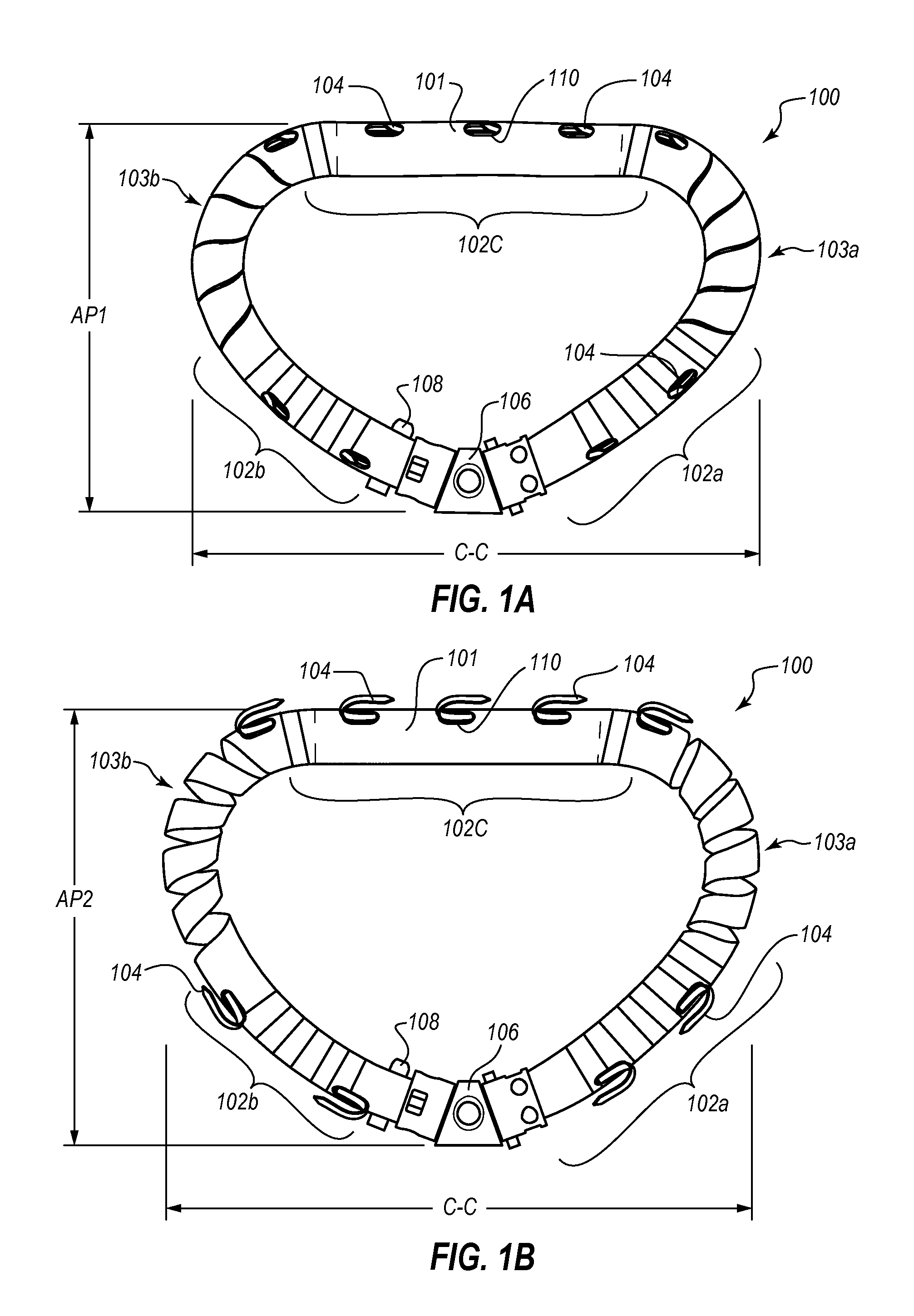

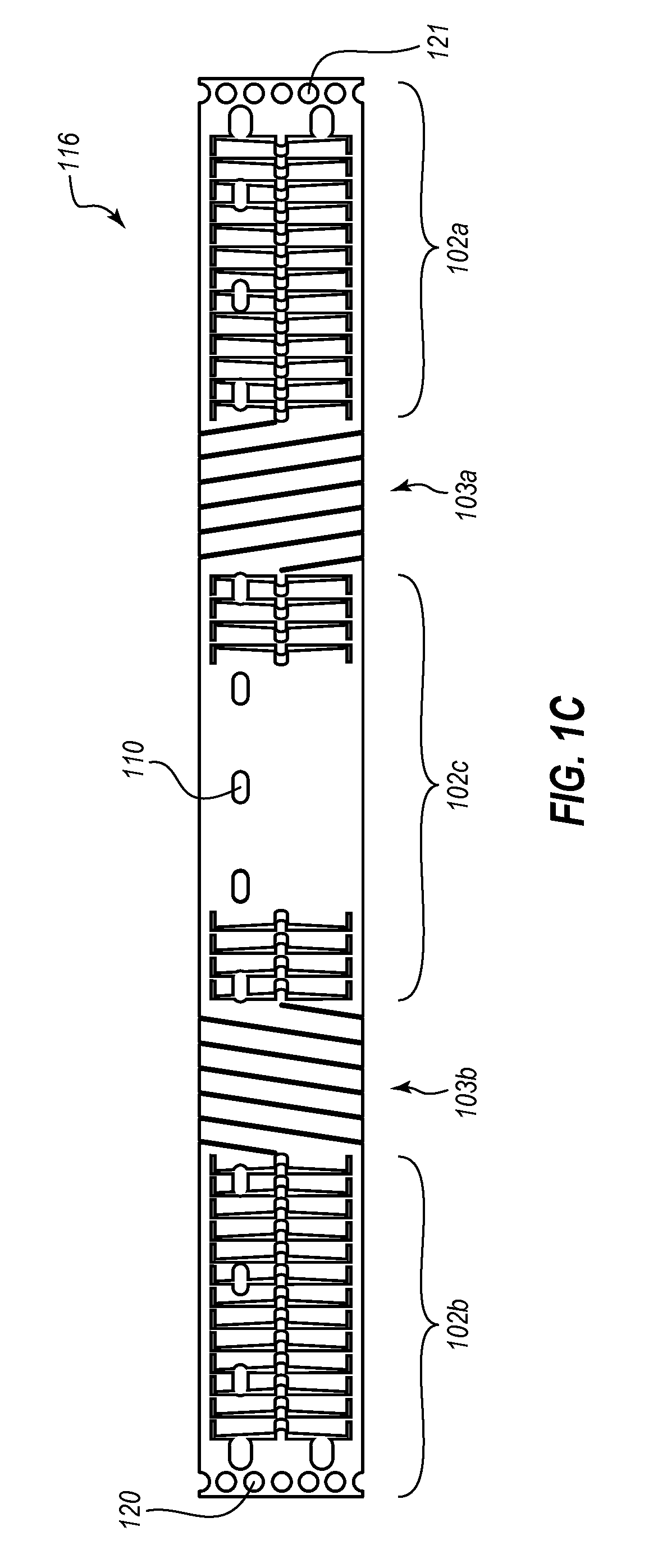

Percutaneous annuloplasty system with anterior-posterior adjustment

ActiveUS20130226289A1Improve leaflet coaptationReduce refluxAnnuloplasty ringsTubular organ implantsCouplingCatheter

Apparatus, systems, and methods are provided for repairing heart valves through percutaneous transcatheter delivery and fixation of annuloplasty rings to heart valves. An annuloplasty ring includes an outer hollow body member including a plurality of regions. Adjacent regions cooperate with one another to change the body member from an elongate insertion geometry to an annular operable geometry. Adjacent regions are coupled by a biasing element or a stepped connector to allow expansion to an expanded state and contraction to a contracted state in the annular operable geometry. The annuloplasty ring also includes an internal anchor member located at least partially within the body member and having a plurality of anchors configured to attach the annuloplasty ring to tissue of a heart valve annulus. An angled ring closure lock allows coupling of the ends of an annuloplasty ring at an apex of a D-shape annular operable geometry.

Owner:VALCARE INC

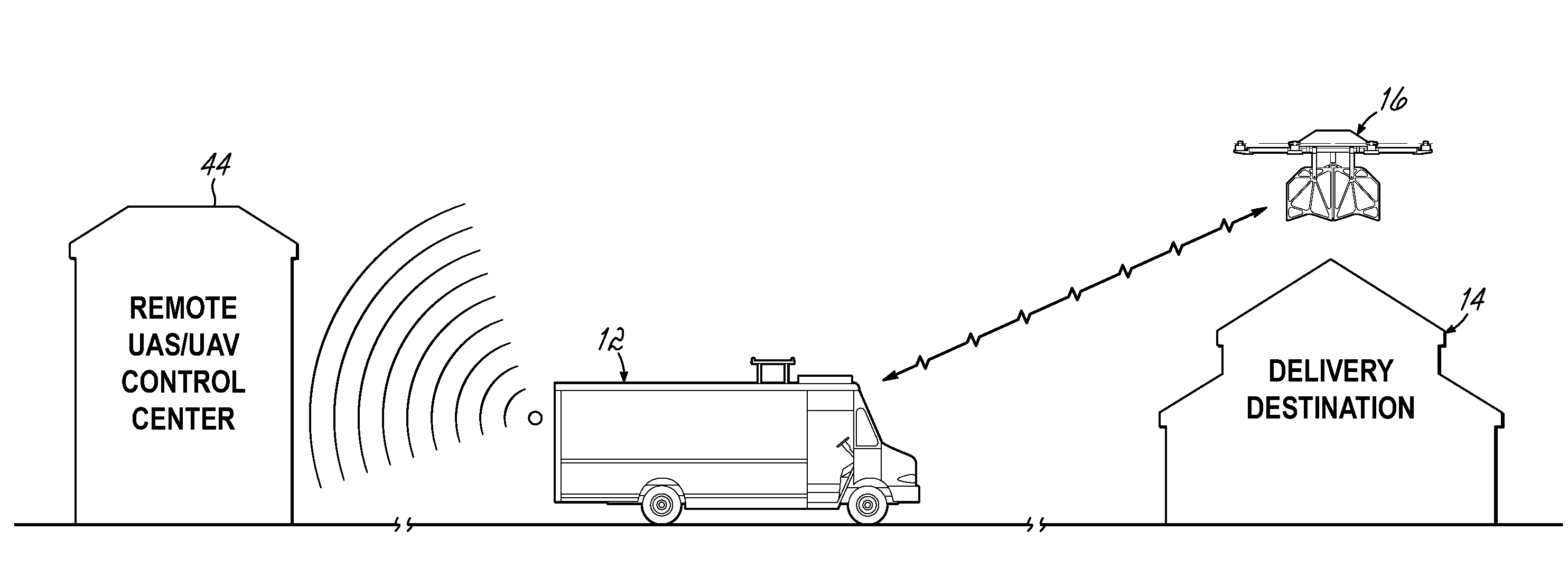

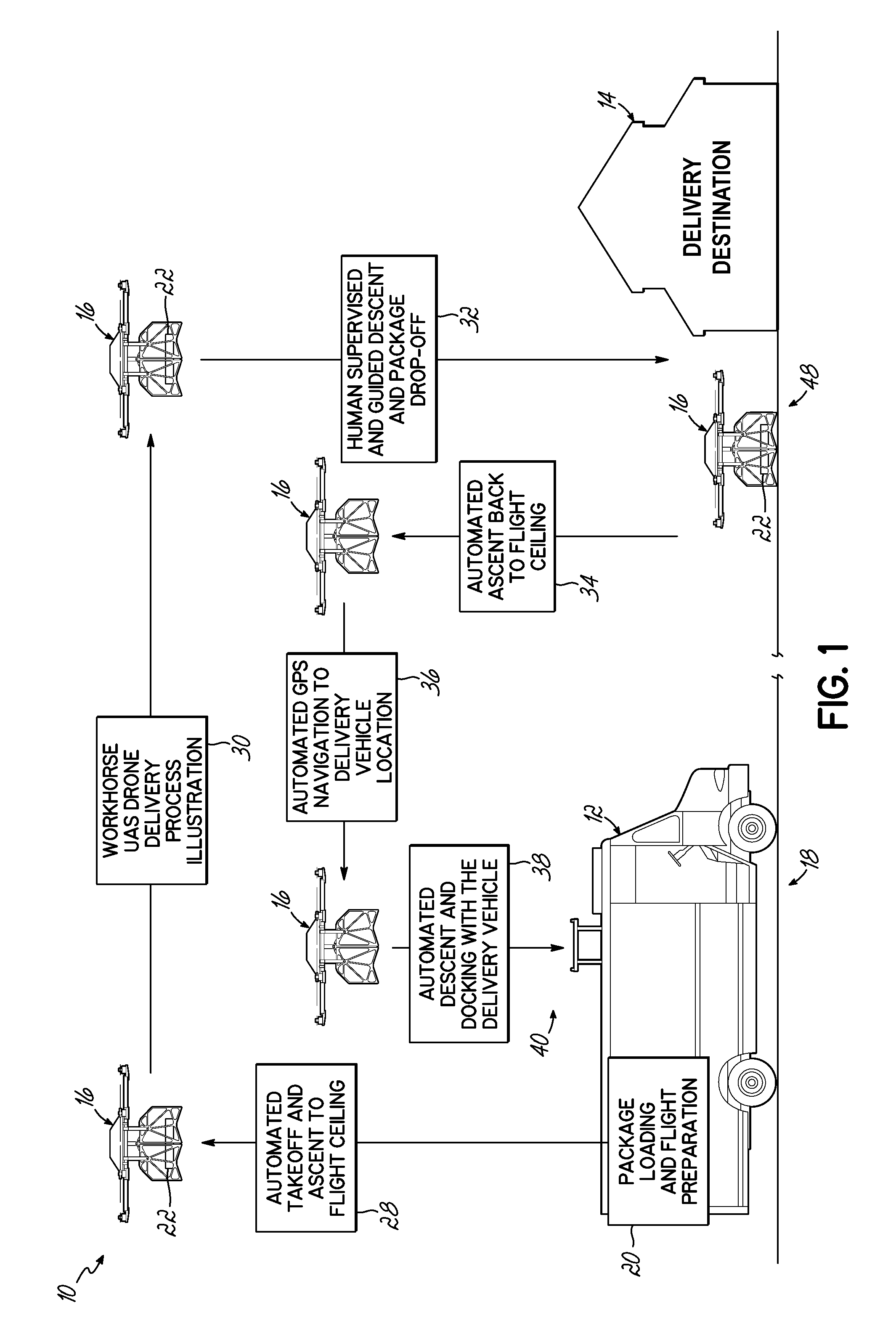

Package delivery by means of an automated multi-copter uas/uav dispatched from a conventional delivery vehicle

ActiveUS20160200438A1Substantial fuel savingReduce operating costsRemote controlled aircraftVehicular energy storageDocking stationDelivery vehicle

Methods and associated systems for autonomous package delivery utilize a UAS / UAV, an infrared positioning senor, and a docking station integrated with a package delivery vehicle. The UAS / UAV accepts a package for delivery from the docking station on the delivery vehicle and uploads the delivery destination. The UAS / UAV autonomously launches from its docked position on the delivery vehicle. The UAS / UAV autonomously flies to the delivery destination by means of GPS navigation. The UAS / UAV is guided in final delivery by means of a human supervised live video feed from the UAS / UAV. The UAS / UAV is assisted in the descent and delivery of the parcel by precision sensors and if necessary by means of remote human control. The UAS / UAV autonomously returns to the delivery vehicle by means of GPS navigation and precision sensors. The UAS / UAV autonomously docks with the delivery vehicle for recharging and preparation for the next delivery sequence.

Owner:WORKHORSE GRP INC

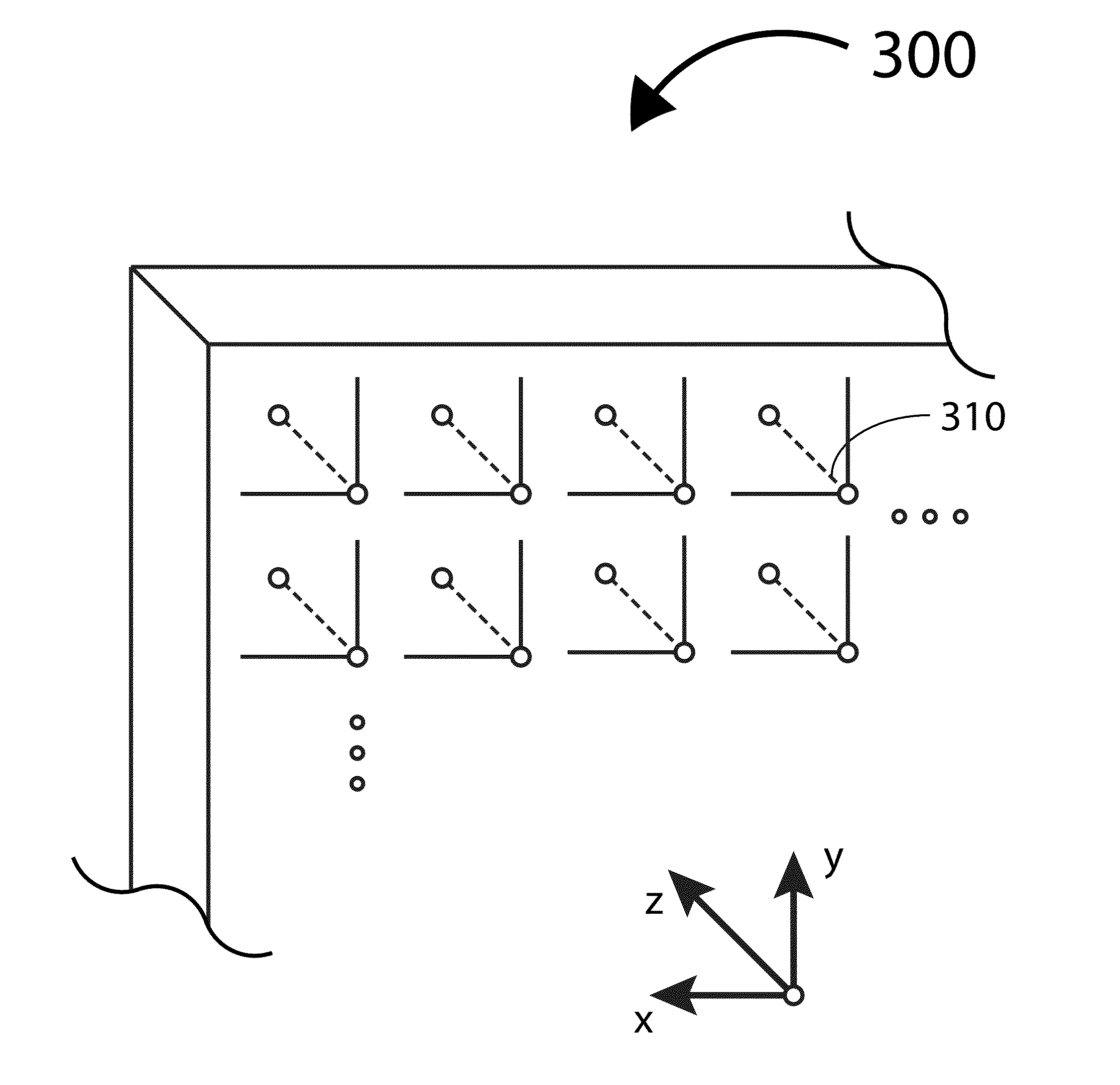

High dielectric antenna array

InactiveUS20150042526A1Small sizeReduce distanceNear-field transmissionCircuit arrangementsDielectricPhased array

A system and method for wirelessly transmitting signals via antenna phased array. In order to decrease the distance between individual antennae in the array, the antennae are submersed in a high dielectric material in addition to being arranged at right angles to one another, both features precluding one or more antennae from coupling. Furthermore, wires are covered in high dielectric material in order to refract RF signals around them, allowing antennae towards the center of the array to successfully transmit signals past other layers.

Owner:OSSIA

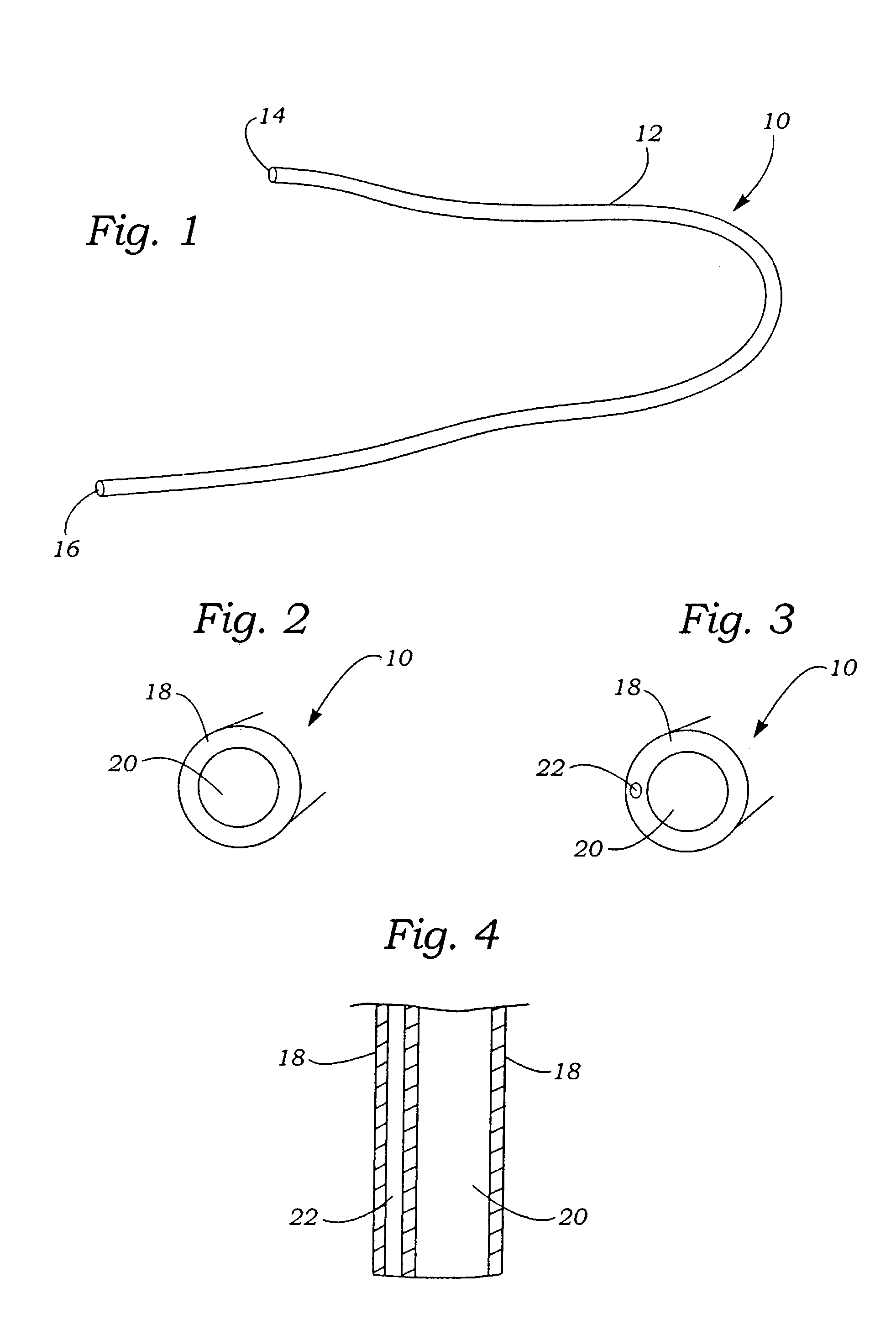

Devices and methods for percutaneous repair of the mitral valve via the coronary sinus

Devices and methods for treating mitral regurgitation by reshaping the mitral annulus in a heart. One preferred device for reshaping the mitral annulus is provided as an elongate body having dimensions as to be insertable into a coronary sinus. The elongate body includes a proximal frame having a proximal anchor and a distal frame having a distal anchor. A ratcheting strip is attached to the distal frame and an accepting member is attached to the proximal frame, wherein the accepting member is adapted for engagement with the ratcheting strip. An actuating member is provided for pulling the ratcheting strip relative to the proximal anchor after deployment in the coronary sinus. In one preferred embodiment, the ratcheting strip is pulled through the proximal anchor for pulling the proximal and distal anchors together, thereby reshaping the mitral annulus.

Owner:EDWARDS LIFESCIENCES CORP

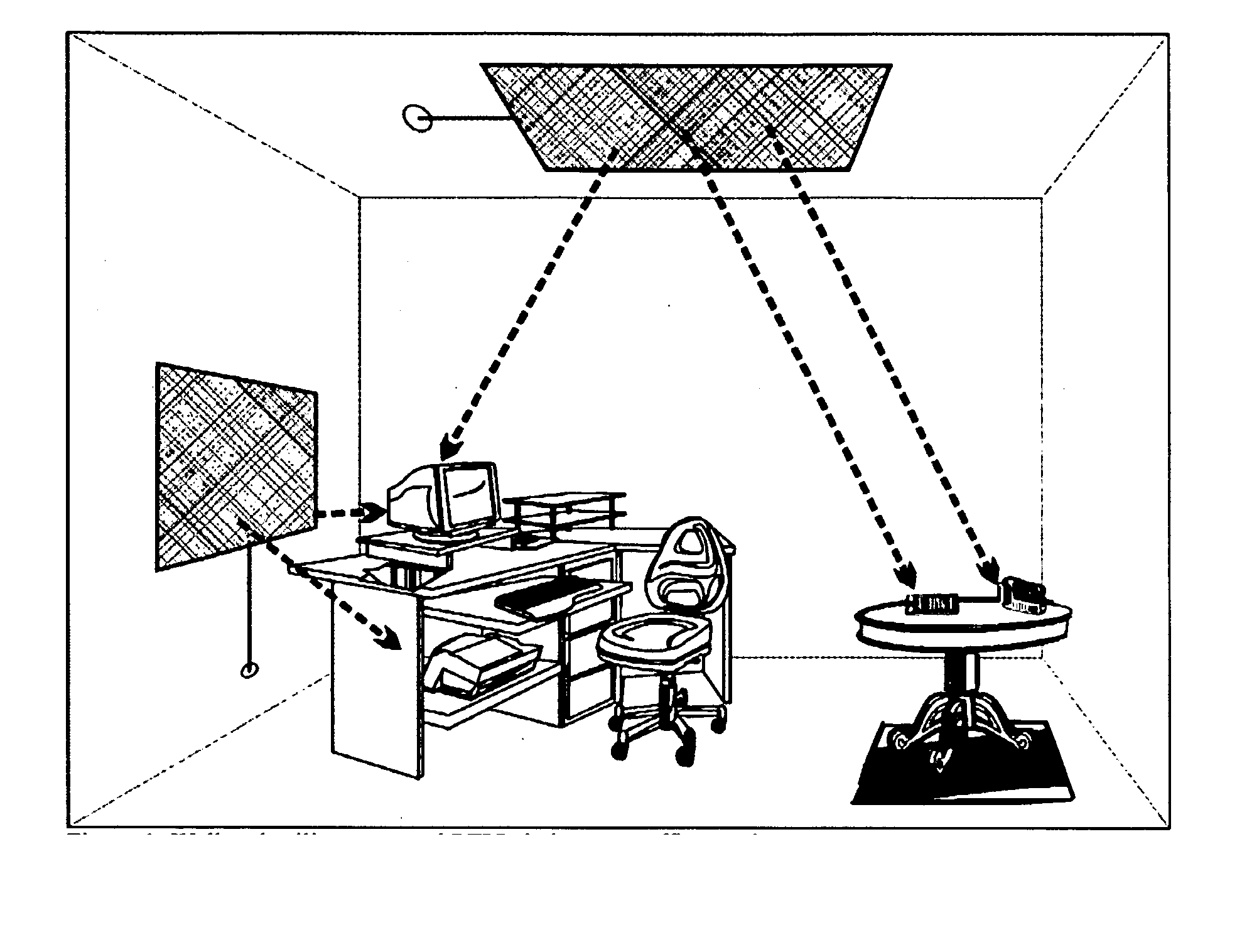

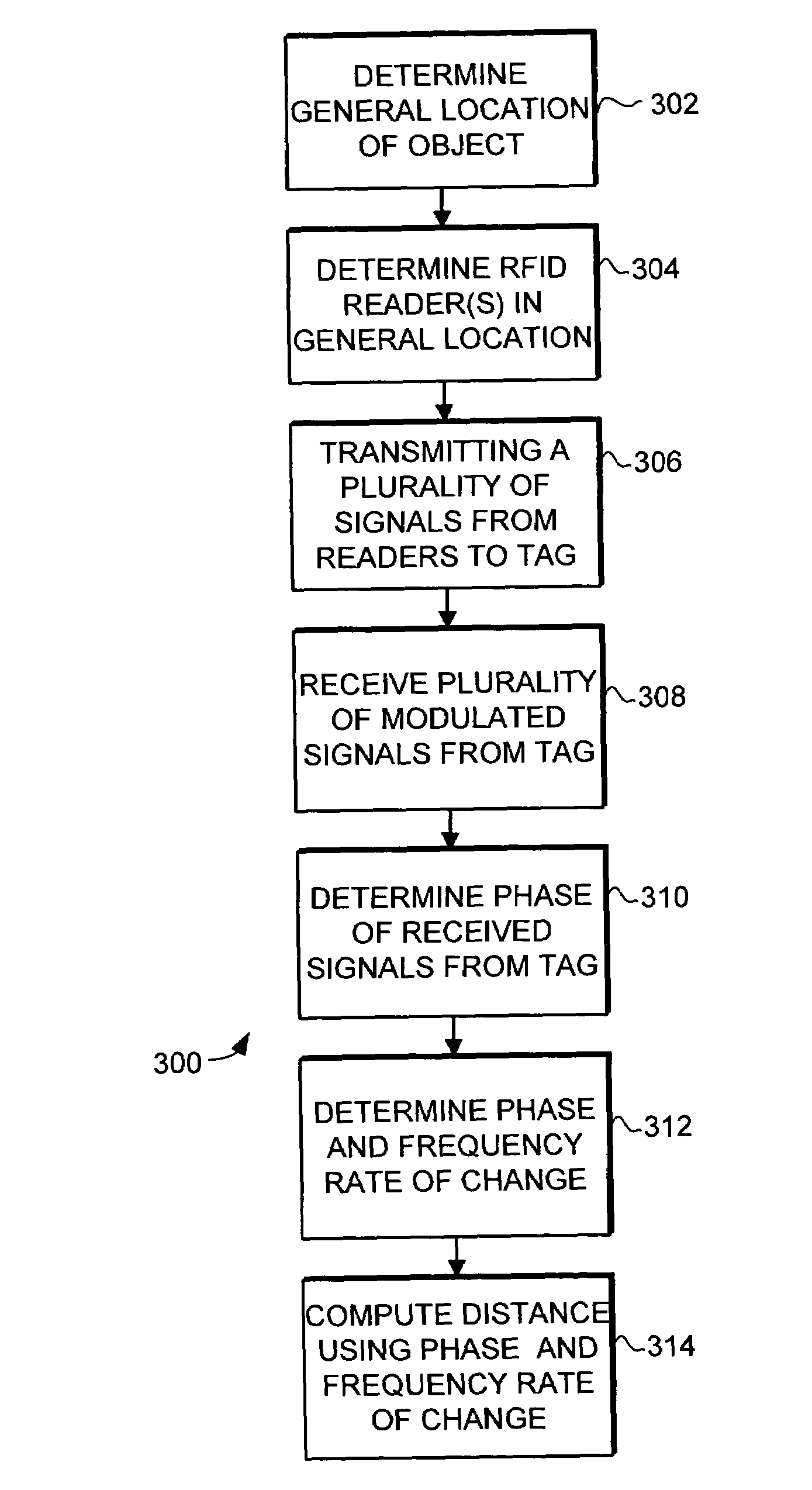

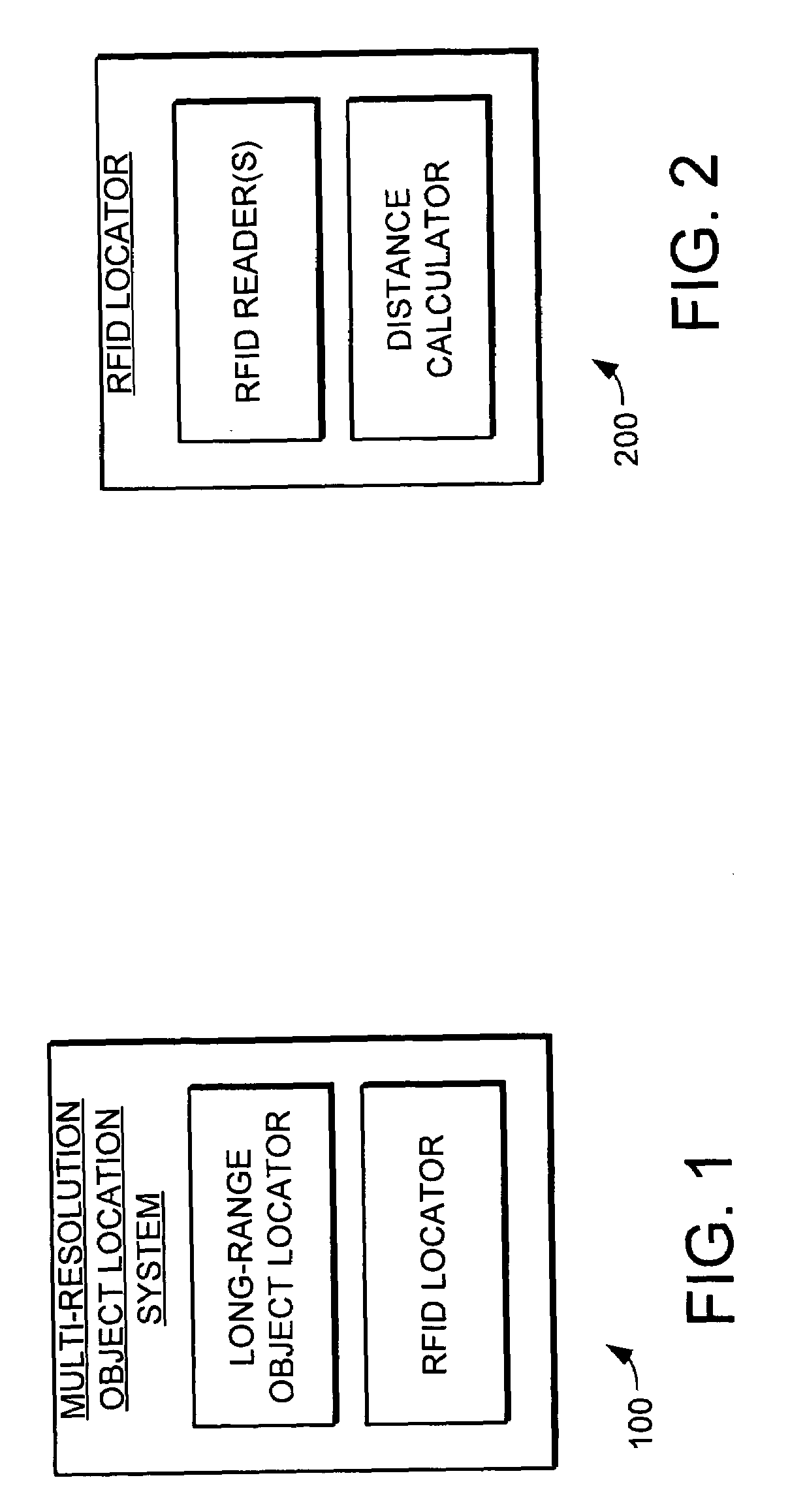

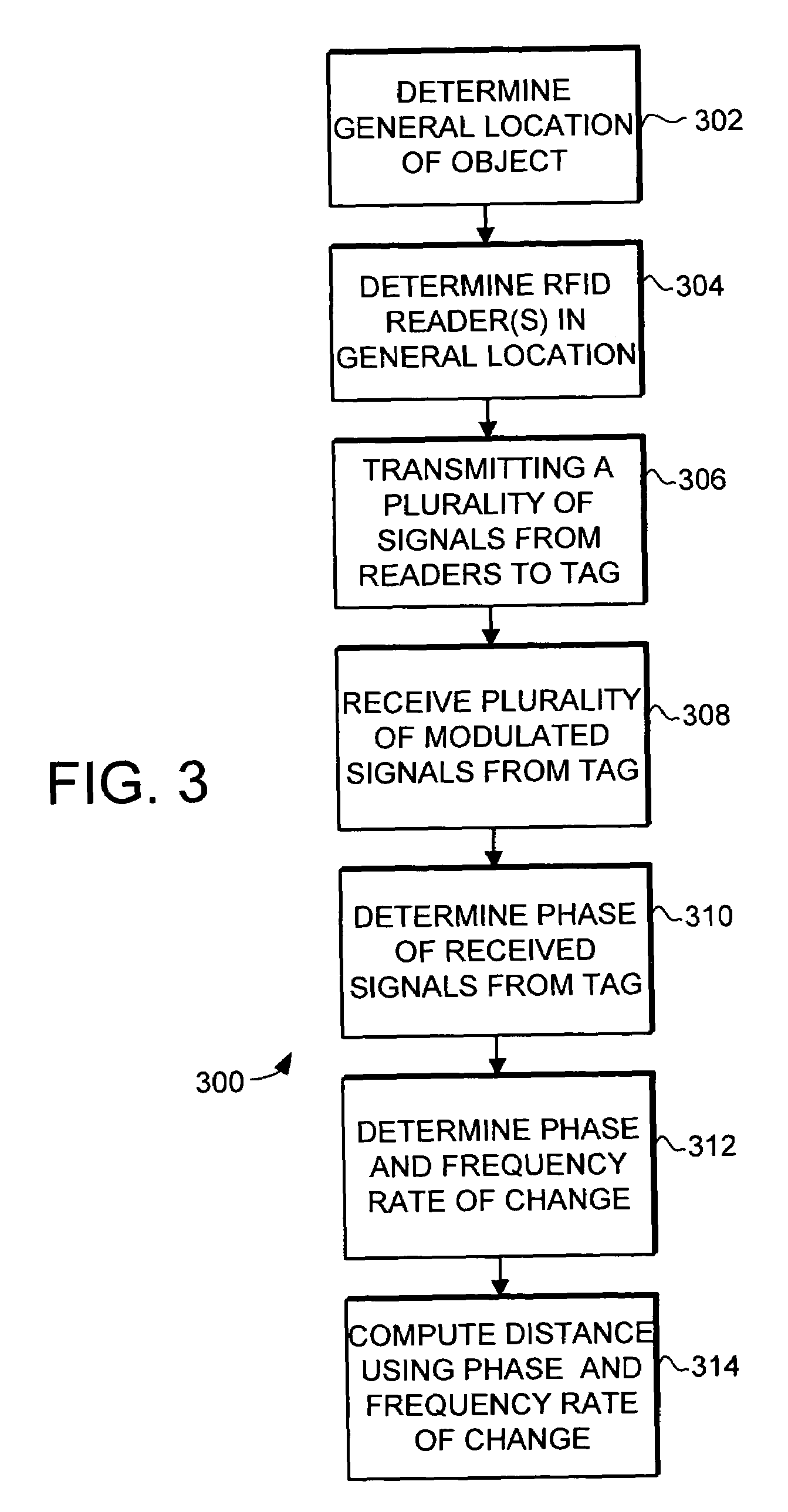

Multi-resolution object location system and method

ActiveUS7030761B2Efficiently and accurately determineLong rangeFrequency-division multiplex detailsTelephonic communicationImage resolutionMulti resolution

A multi-resolution object location system and method for locating objects is provided. The multi-resolution system and method uses a long-range object locator together with a more precise RFID locator to efficiently and accurately determine the location of objects that include an RFID tag. The long-range object locator has a relatively longer range and can cover a relatively large area to determine the general location of the object within the large area. The RFID locator has a relatively shorter range, but is able to locate the object more precisely. The object location system uses the long-range locator to first determine the general location of the object, and then the RFID locator is used to determine a more accurate location of the object. Thus, the multi-resolution object location system is able to provide both a long range location of objects over a large area and a precise location of objects.

Owner:SYMBOL TECH LLC

Hybrid anode compositions for lithium ion batteries

ActiveUS20090117466A1Superior multiple-cycle behaviorSmall capacity fadeAlkaline accumulatorsConductive materialHybrid materialSodium-ion battery

The present invention provides an exfoliated graphite-based hybrid material composition for use as an electrode, particularly as an anode of a lithium ion battery. The composition comprises: (a) micron- or nanometer-scaled particles or coating which are capable of absorbing and desorbing alkali or alkaline metal ions (particularly, lithium ions); and (b) exfoliated graphite flakes that are substantially interconnected to form a porous, conductive graphite network comprising pores, wherein at least one of the particles or coating resides in a pore of the network or attached to a flake of the network and the exfoliated graphite amount is in the range of 5% to 90% by weight and the amount of particles or coating is in the range of 95% to 10% by weight. Also provided is a lithium secondary battery comprising such a negative electrode (anode). The battery exhibits an exceptional specific capacity, excellent reversible capacity, and long cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com