Patents

Literature

85643results about How to "Precise positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Integrated routing/mapping information

InactiveUS6321158B1Enabling cooperationEnabling matingInstruments for road network navigationRoad vehicles traffic controlImage resolutionLevel of detail

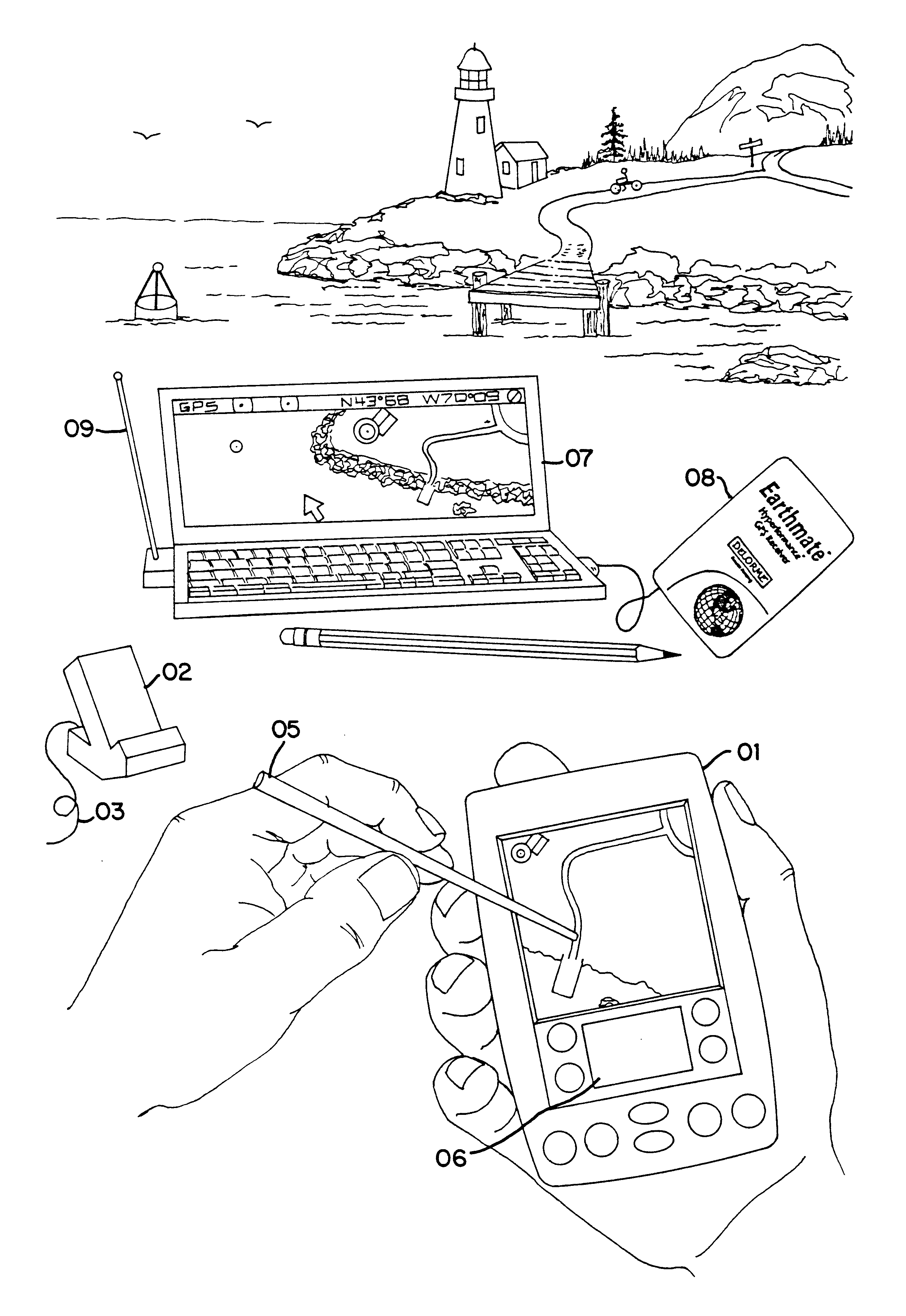

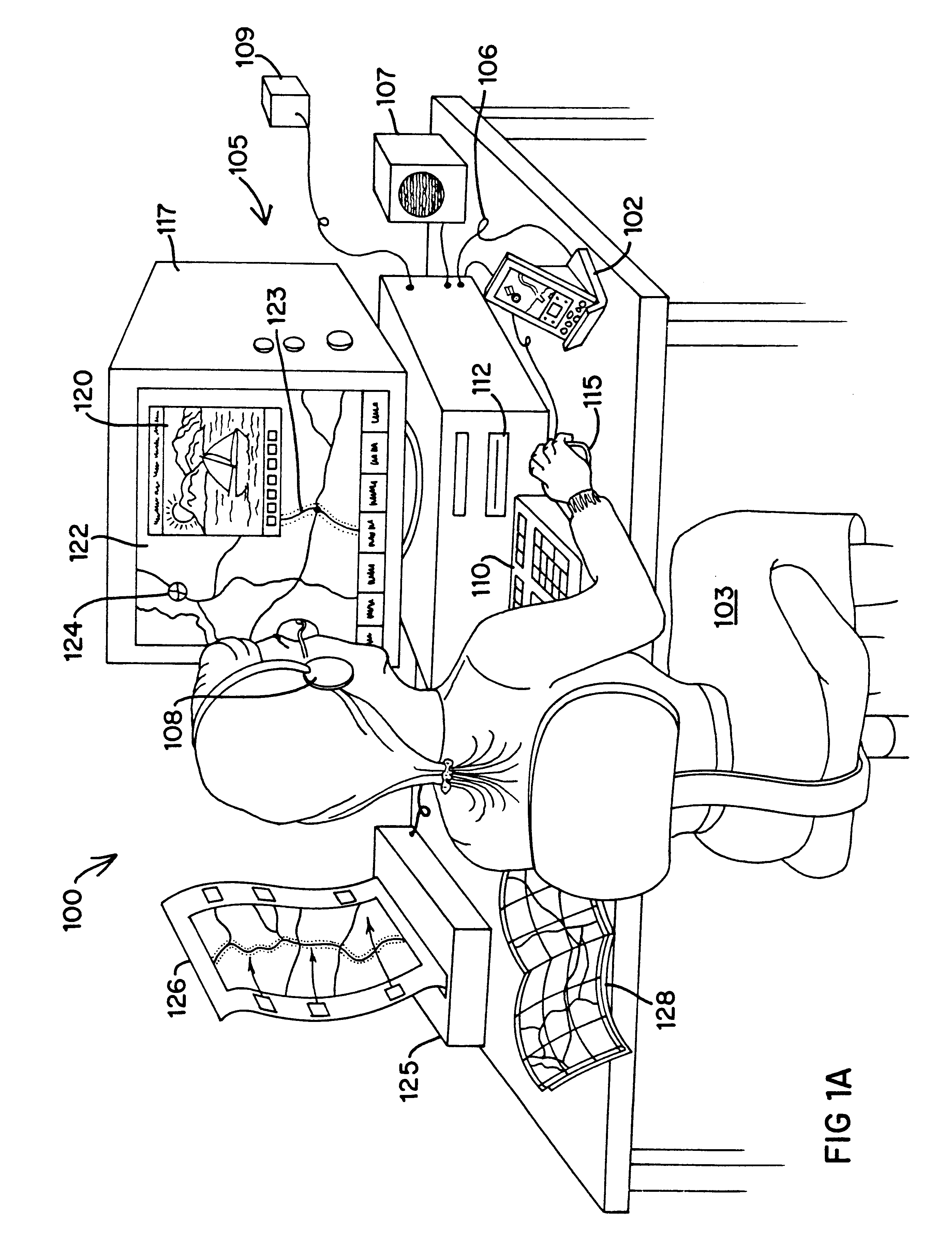

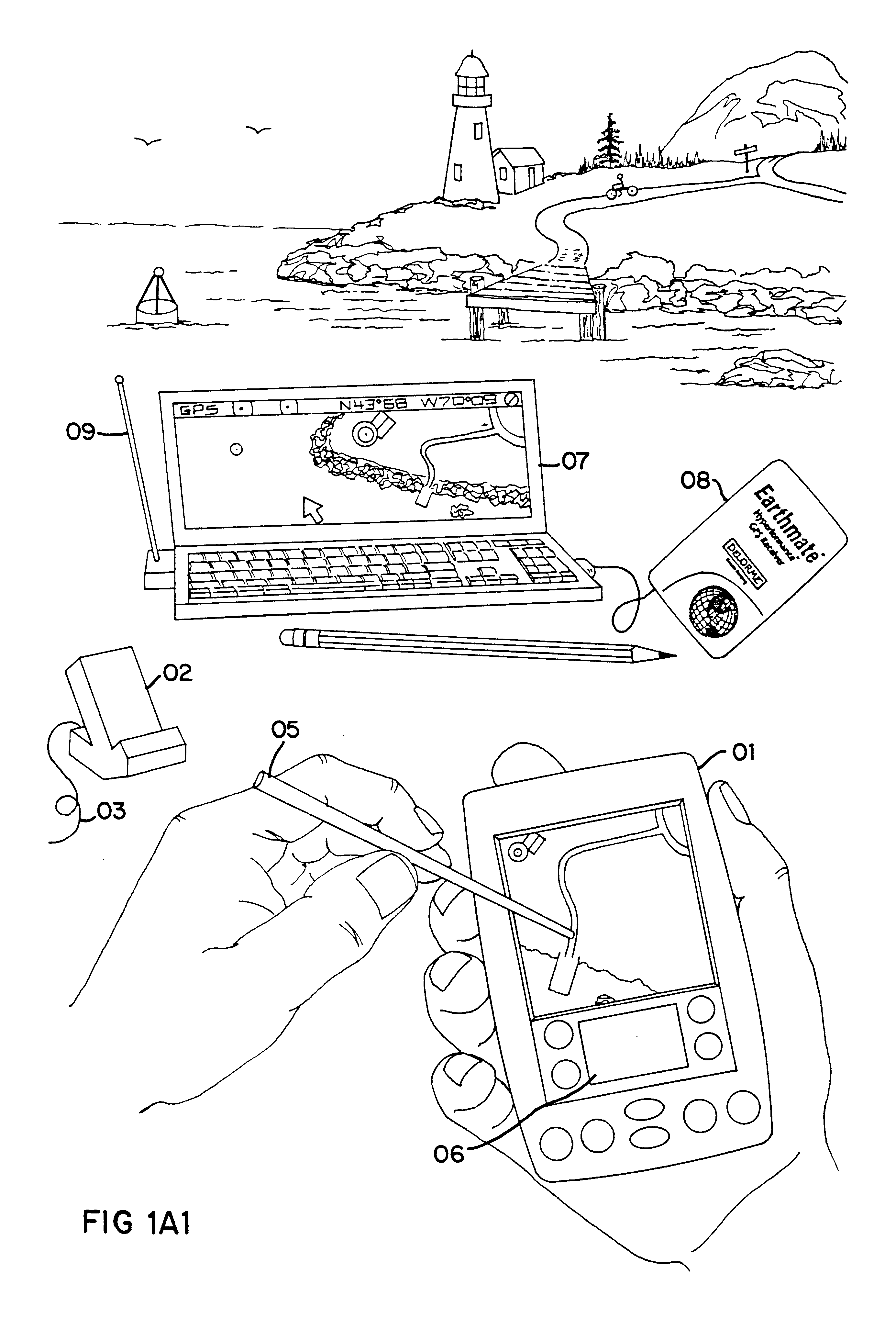

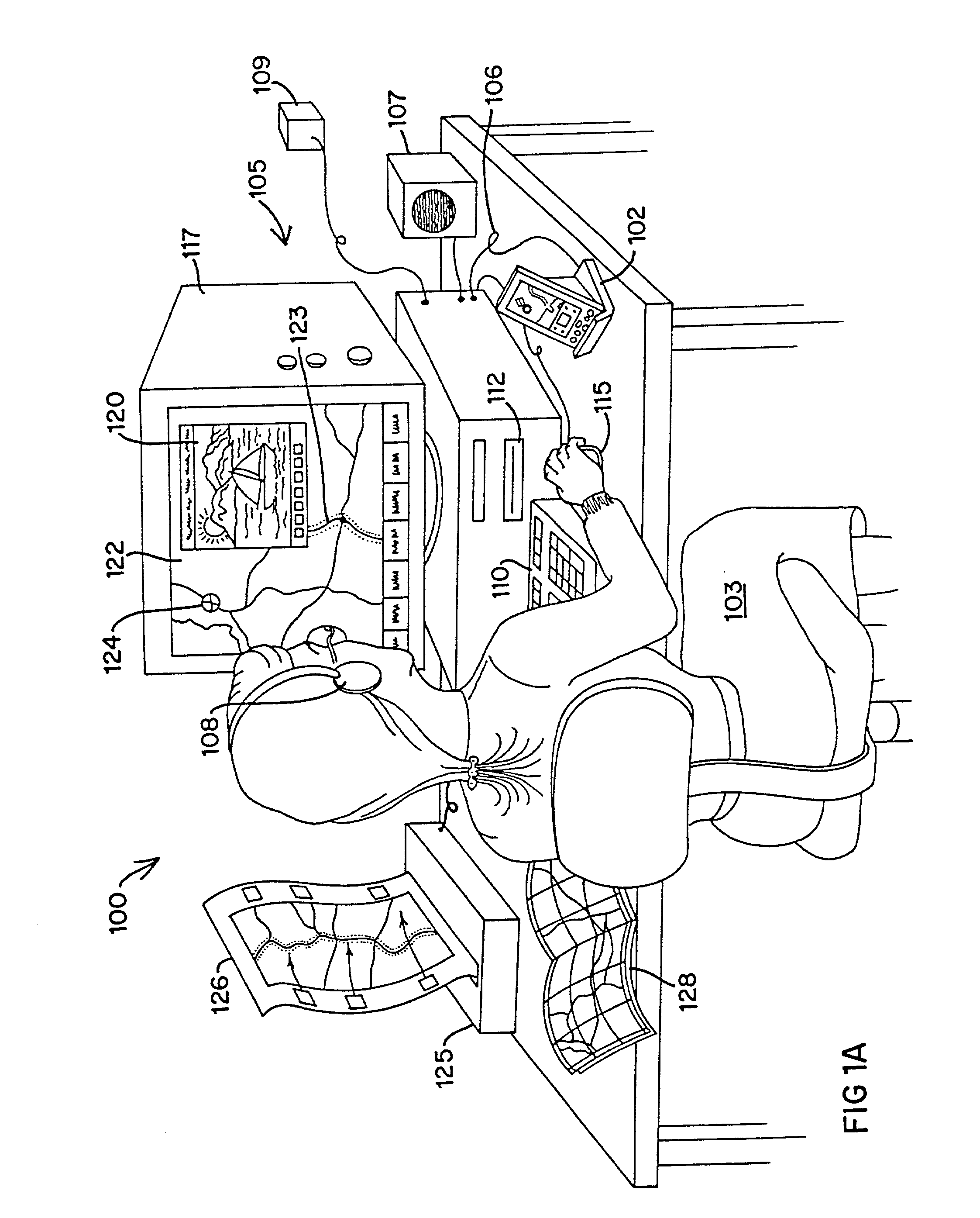

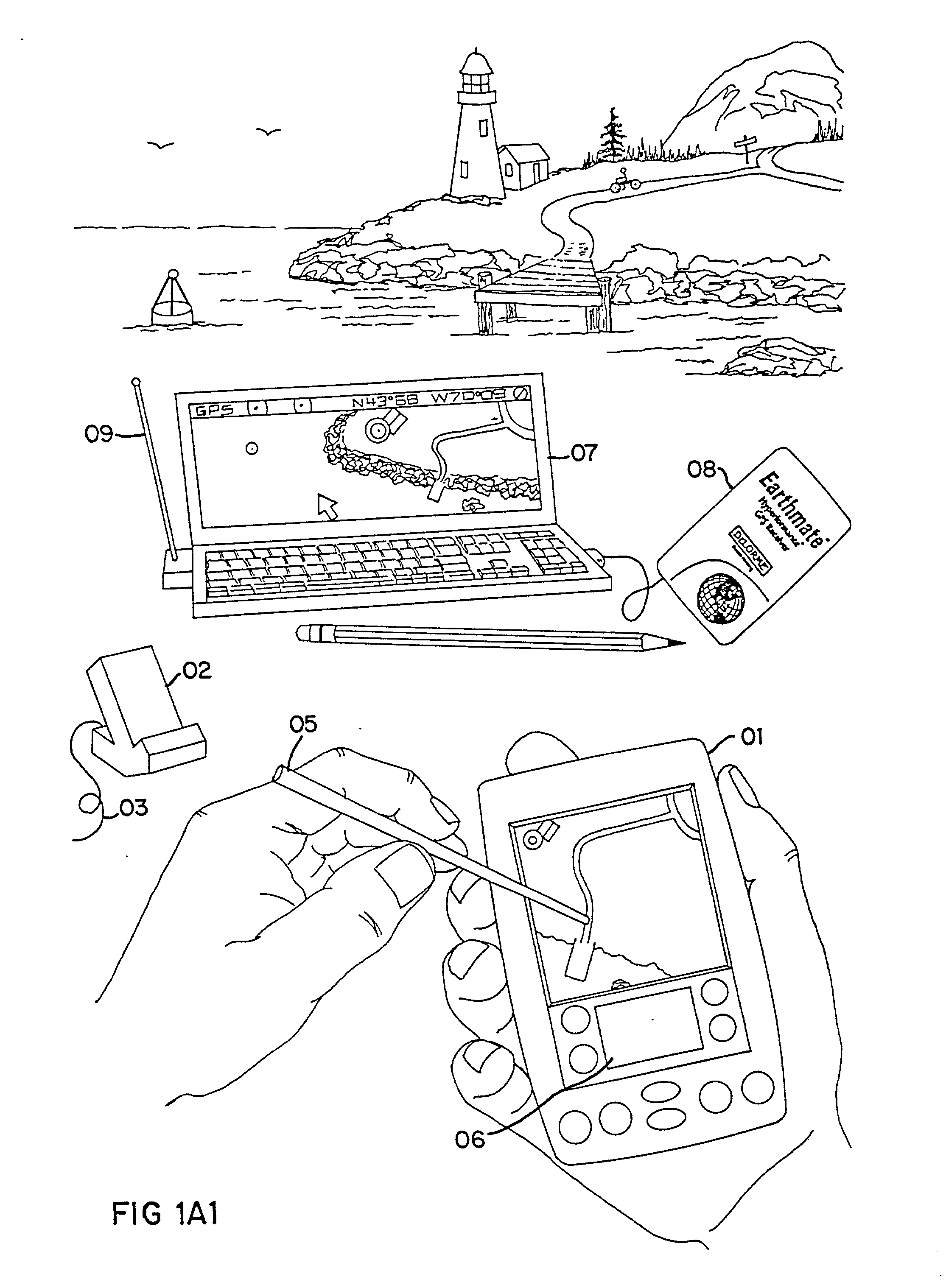

An Integrated Routing / Mapping Information System (IRMIS) links desktop personal computer cartographic applications to one or more handheld organizer, personal digital assistant (PDA) or "palmtop" devices. Such devices may be optionally equipped with, or connected to, portable Global Positioning System (GPS) or equivalent position sensing device. Desktop application facilitates user selection of areas, starts, stops, destinations, maps and / or point and / or route information. It optionally includes supplemental online information, preferably for transfer to the PDA or equivalent device. Users' options include route information, area, and route maps. Maps and related route information are configured with differential detail and levels of magnitude. Used in the field, in conjunction with GPS receiver, the PDA device is configured to display directions, text and map formats, the user's current position, heading, speed, elevation, and so forth. Audible signals identifying the next turn along the user's planned route are also provided. The user can pan across maps and zoom between two or more map scales, levels of detail, or magnitudes. The IRMIS also provides for "automatic zooming," e.g., to show greater detail or closer detail as the user approaches a destination, or to larger scale and lower resolution to show the user's overall planned route between points of interest. The IRMIS also enables the user to mark or record specific locations and / or log actual travel routes, using GPS position information. These annotated location marks and / or "breadcrumb" or GPS log data can be saved, uploaded, displayed, or otherwise processed on the user's desktop geographic information or cartographic system. The IRMIS application and data may be distributed online and / or in tangible media in limited and advanced manipulation formats.

Owner:GARMIN

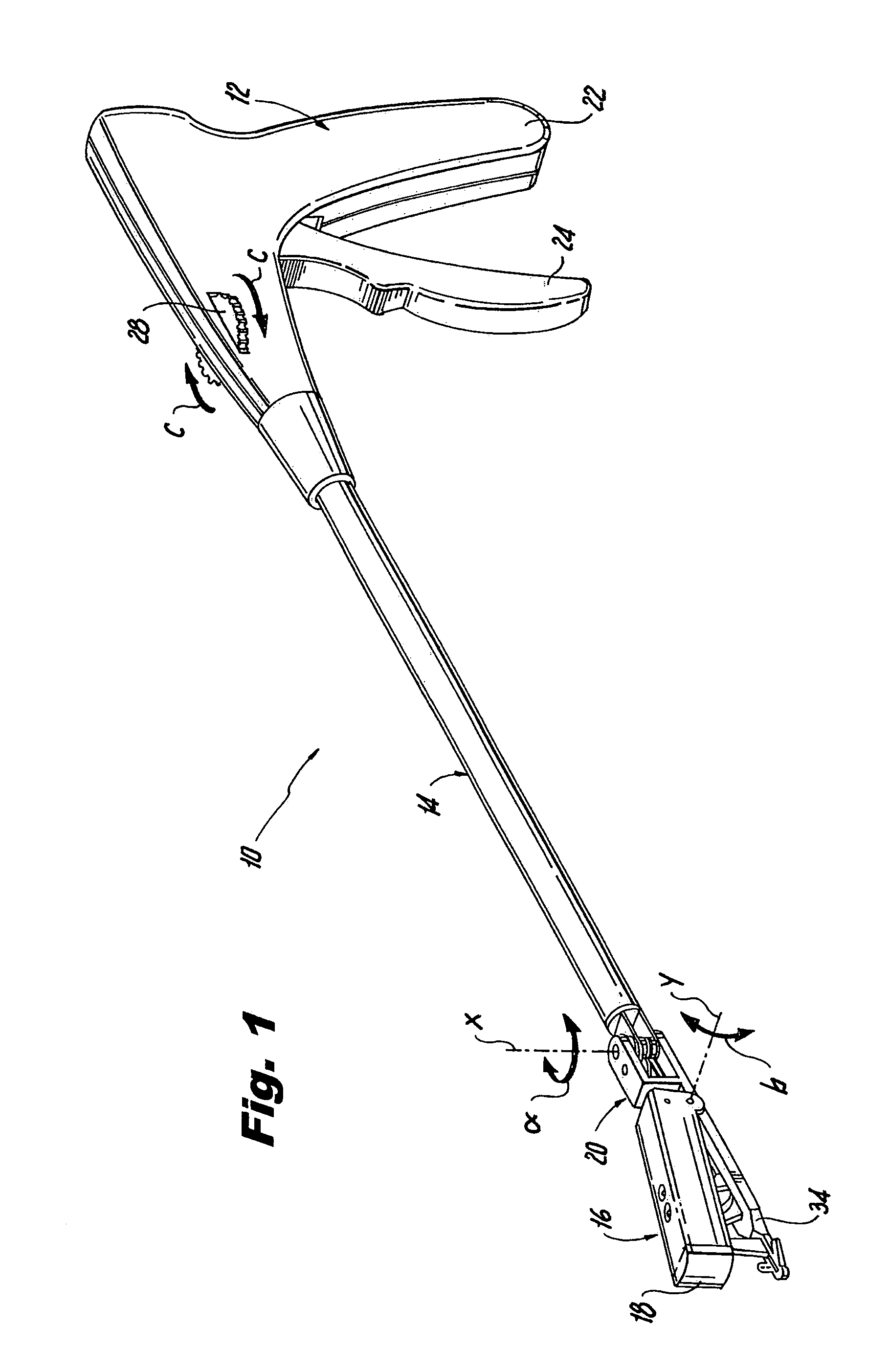

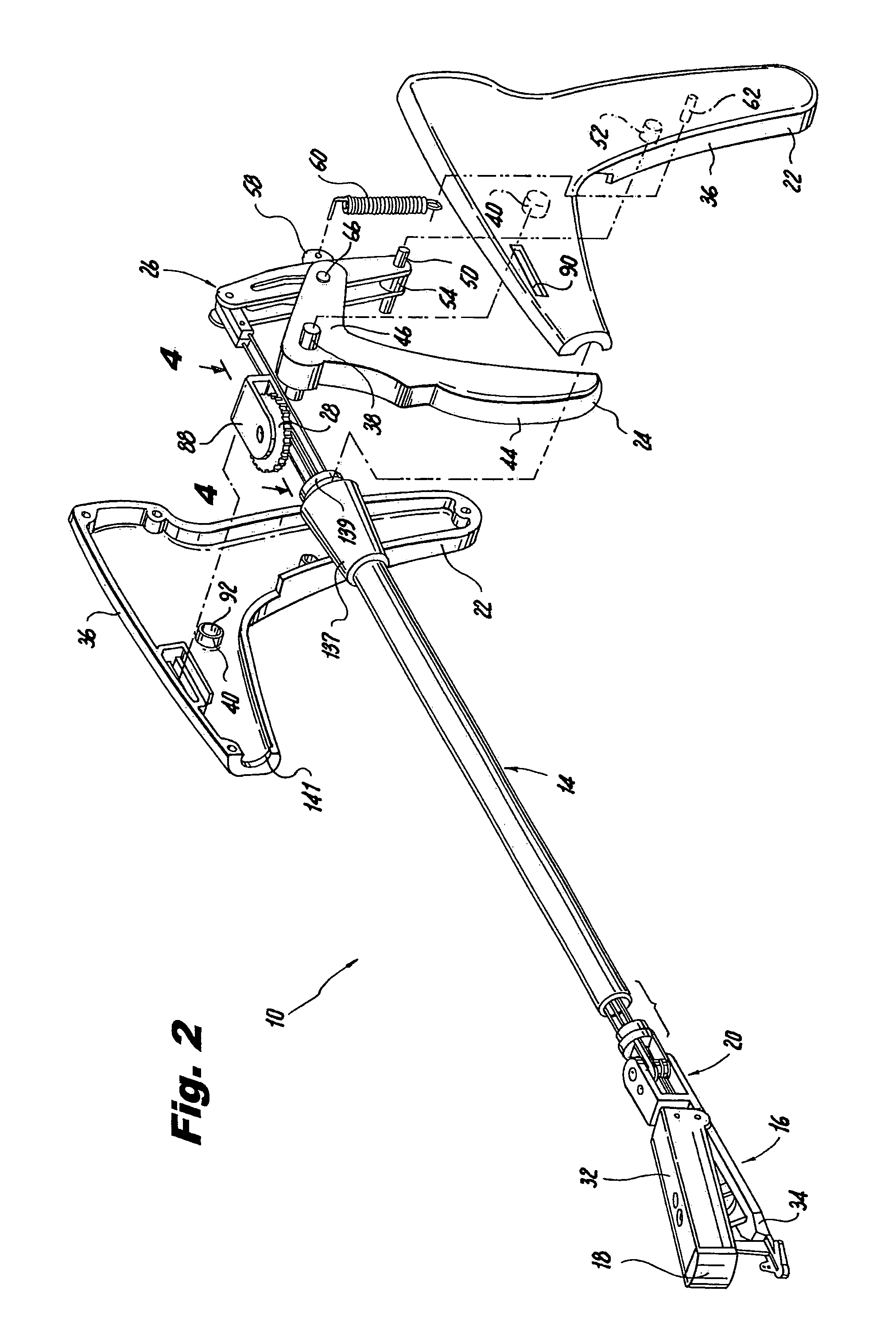

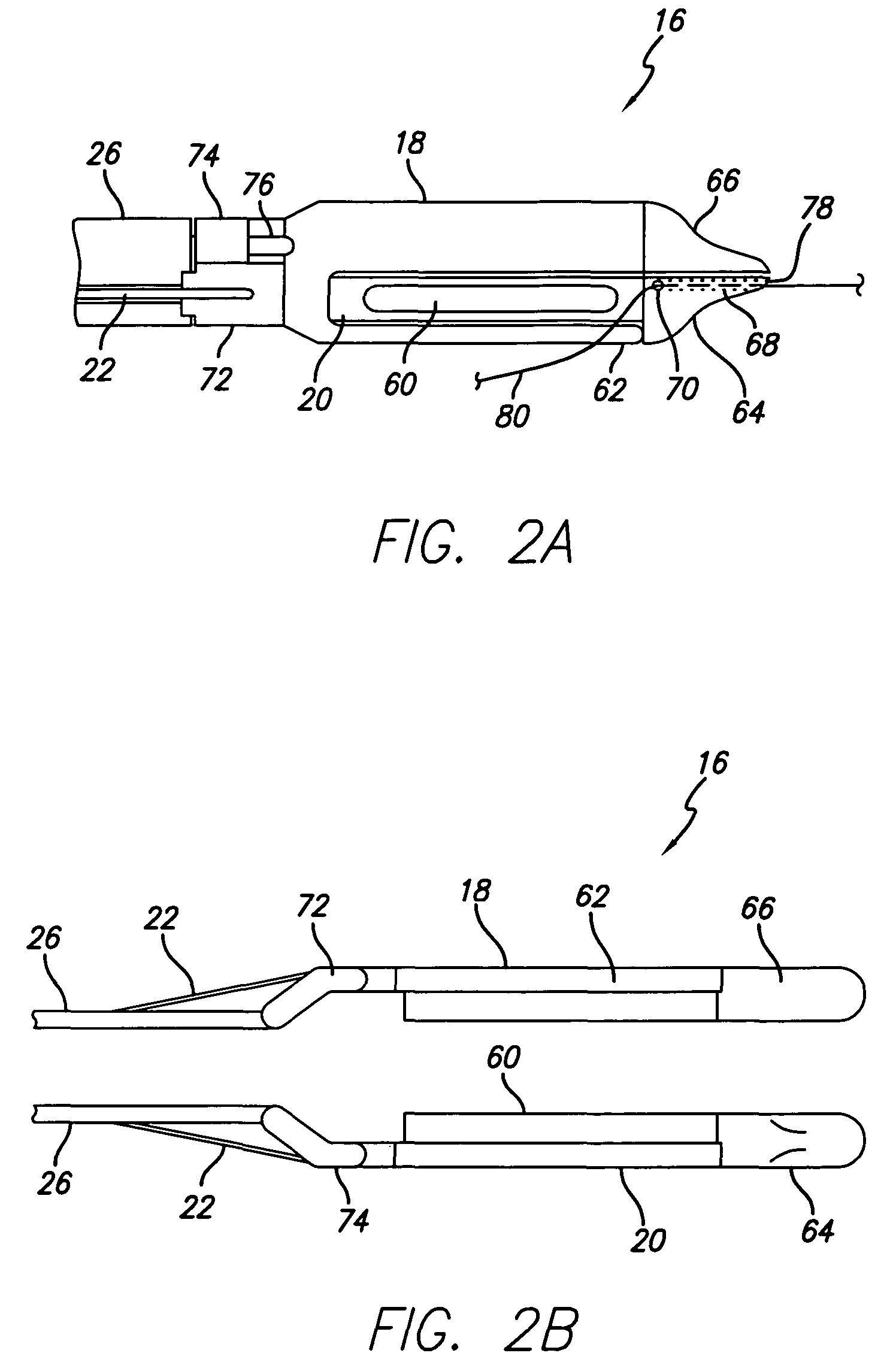

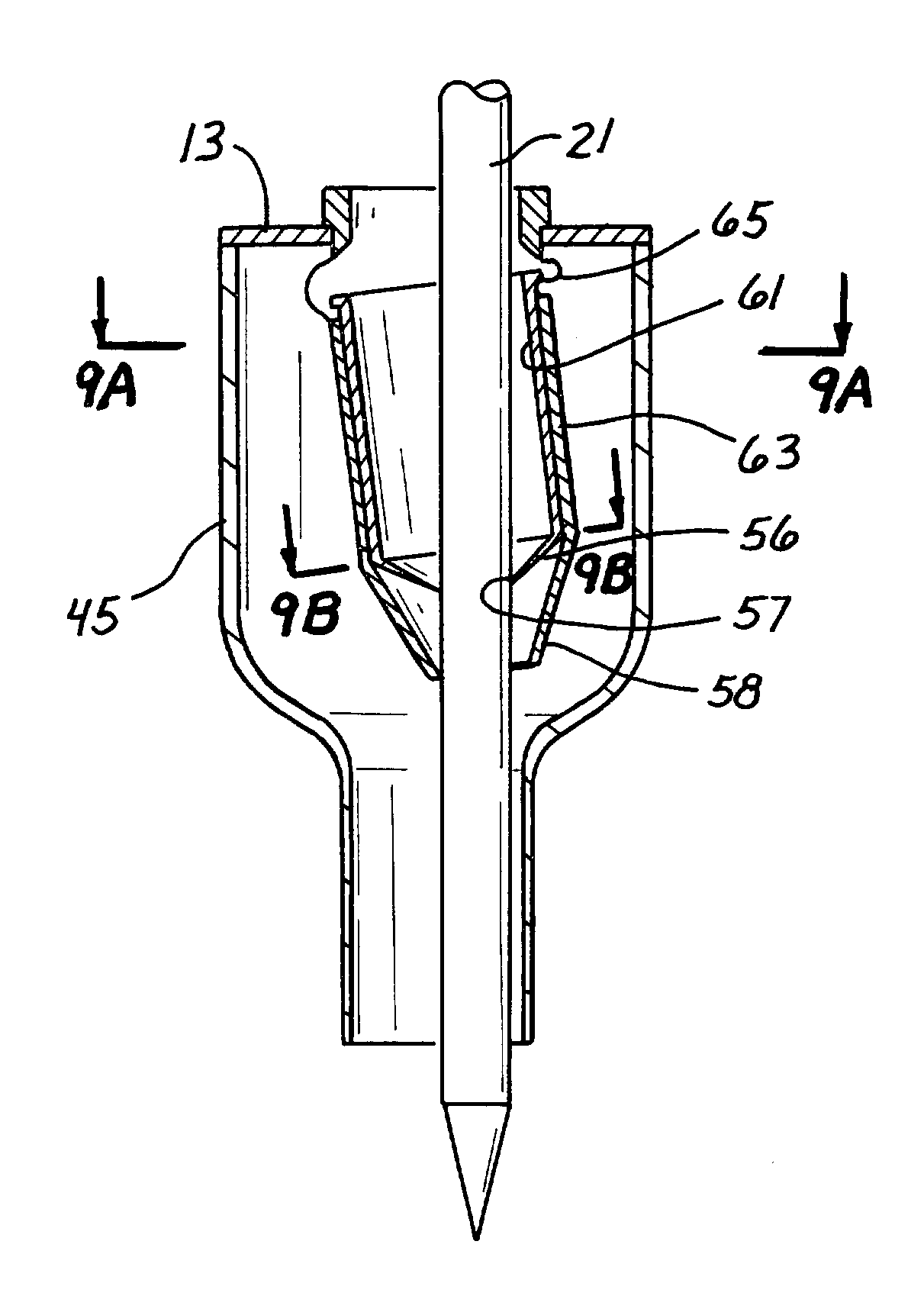

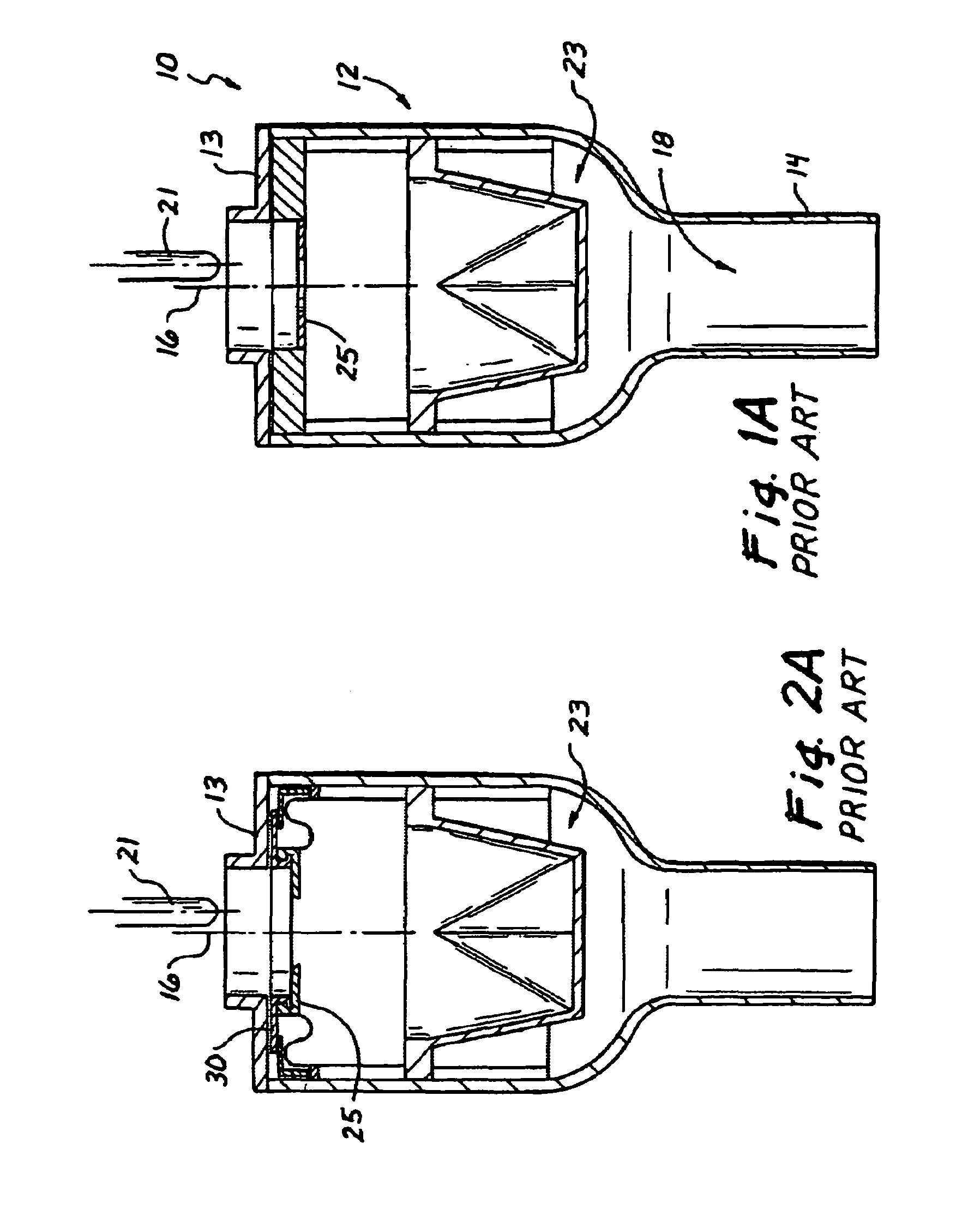

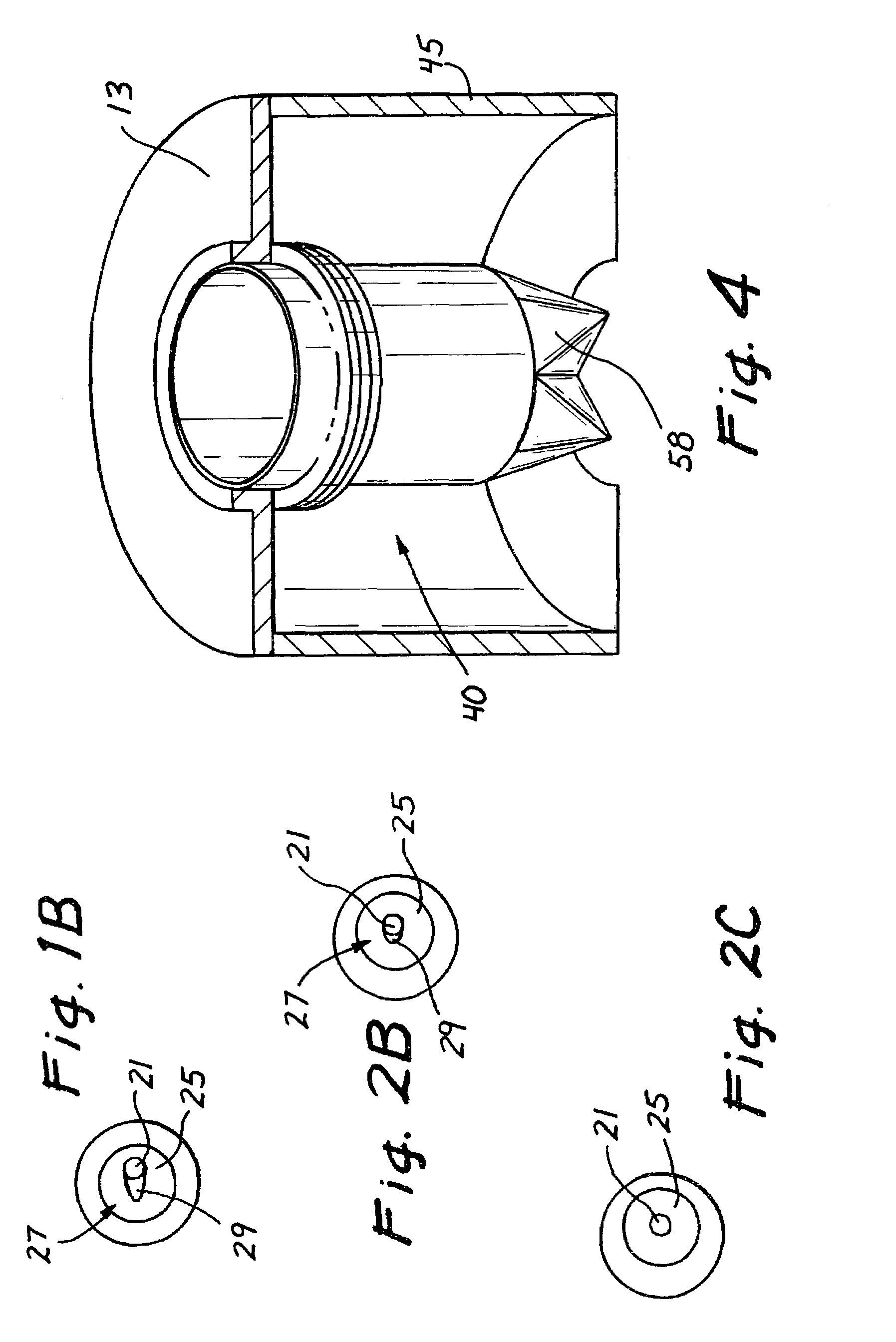

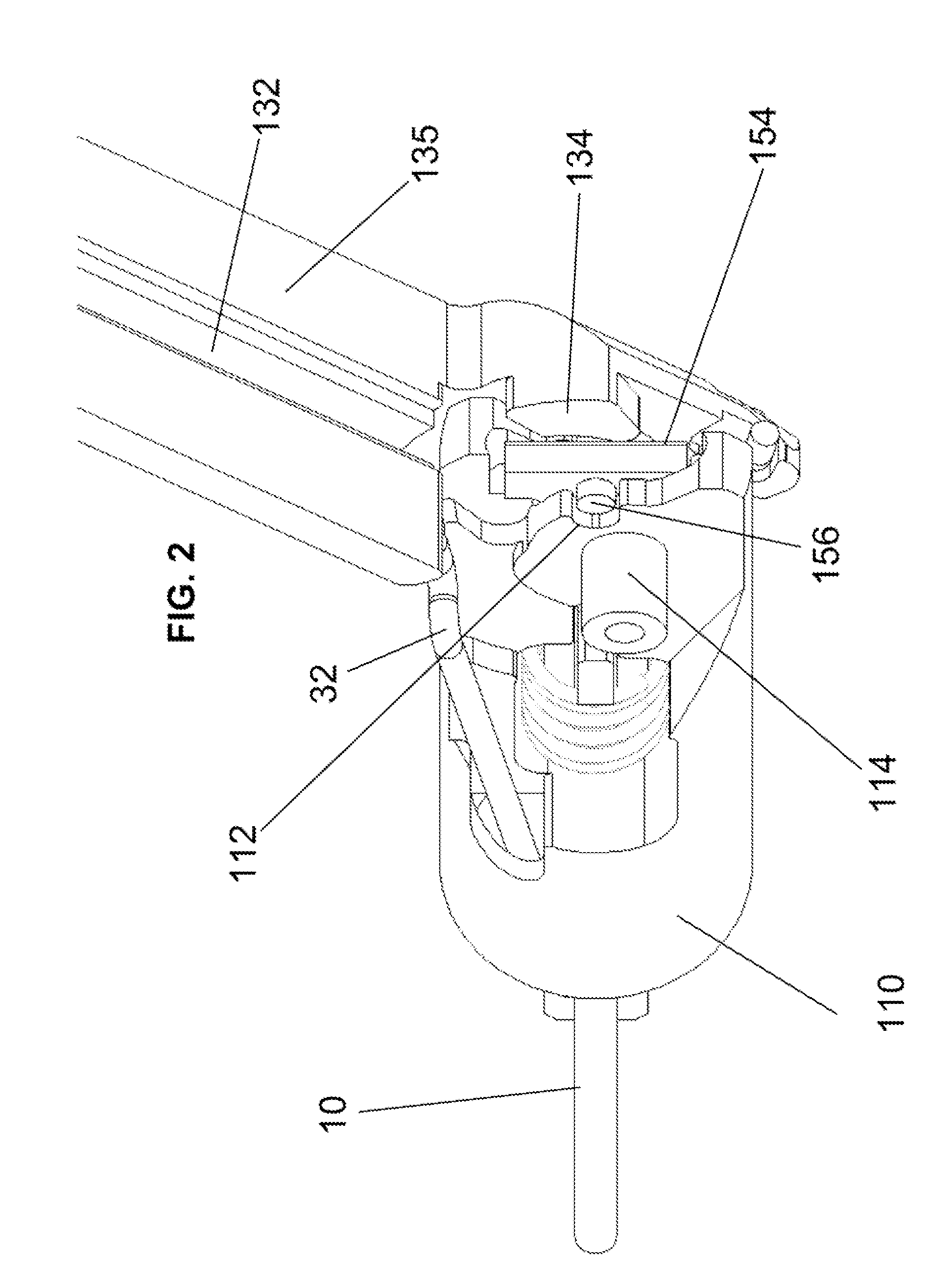

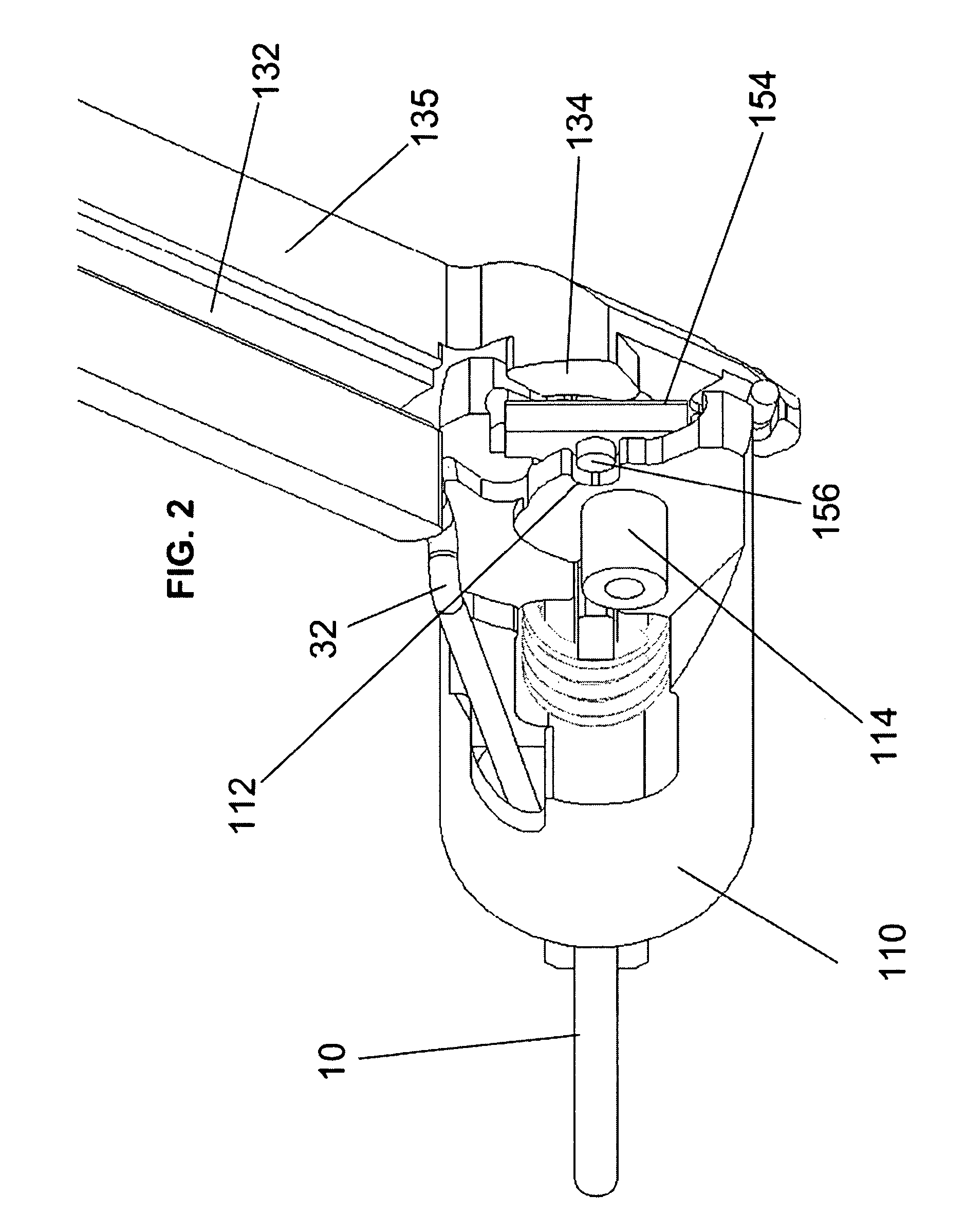

Surgical instrument for progressively stapling and incising tissue

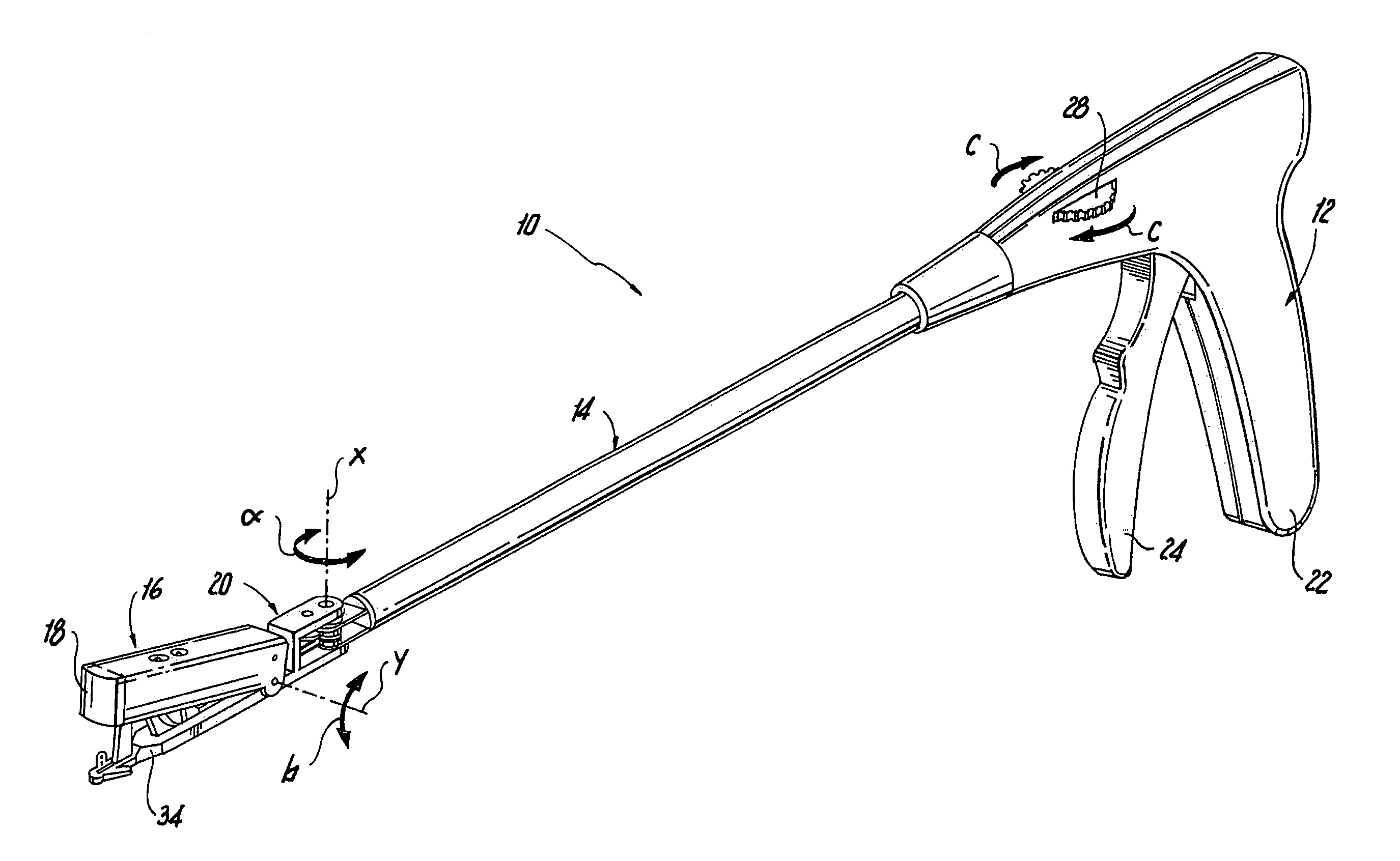

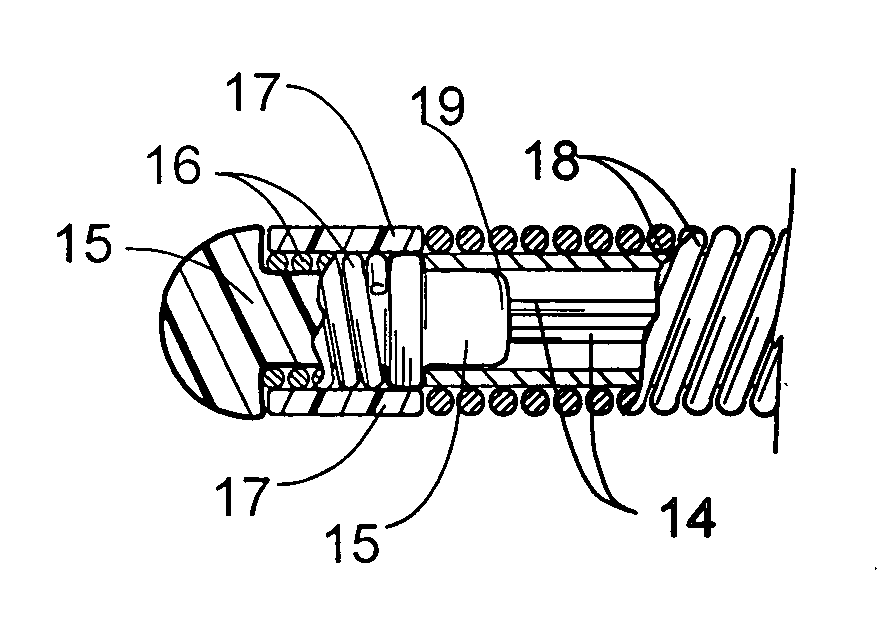

An instrument including a clamping jaw with an anvil defining an elongated slot and staple forming cups on opposing sides of the elongated slot. A housing rotatably mounts on the anvil and a pusher rotatably mounts within the housing. A handle actuates the clamping jaw from the open to the intermediate position by rotating the housing towards the clamping jaw. To move from the intermediate position to the closed position, the pusher rotates towards the anvil. A staple cartridge, disposed in the housing, includes a staple track for retaining two rows of staples on opposing sides of the elongated slot. Two staple drivers align with the distal most staples. The drivers slidably mount in the staple cartridge and couple to the pusher such that each staple driver forces a staple into the forming cups and, in turn, staples the body tissue as the pusher rotates from the intermediate to closed position. A knife rotatably mounts on the staple cartridge and couples to the pusher such that the knife passes into the elongated slot and, in turn, cuts the body tissue as the pusher rotates from the intermediate to closed position.

Owner:GREEN DAVID T

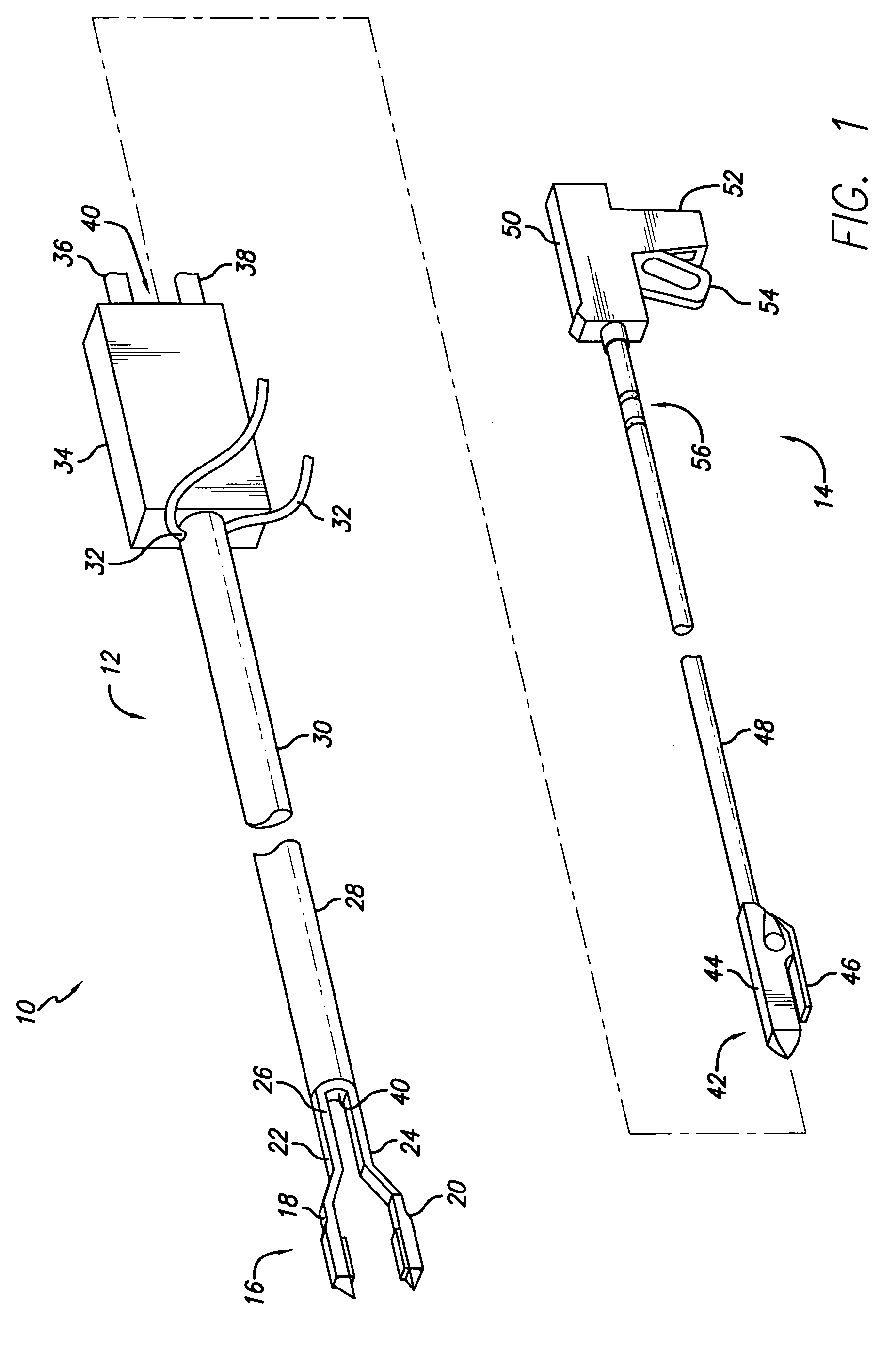

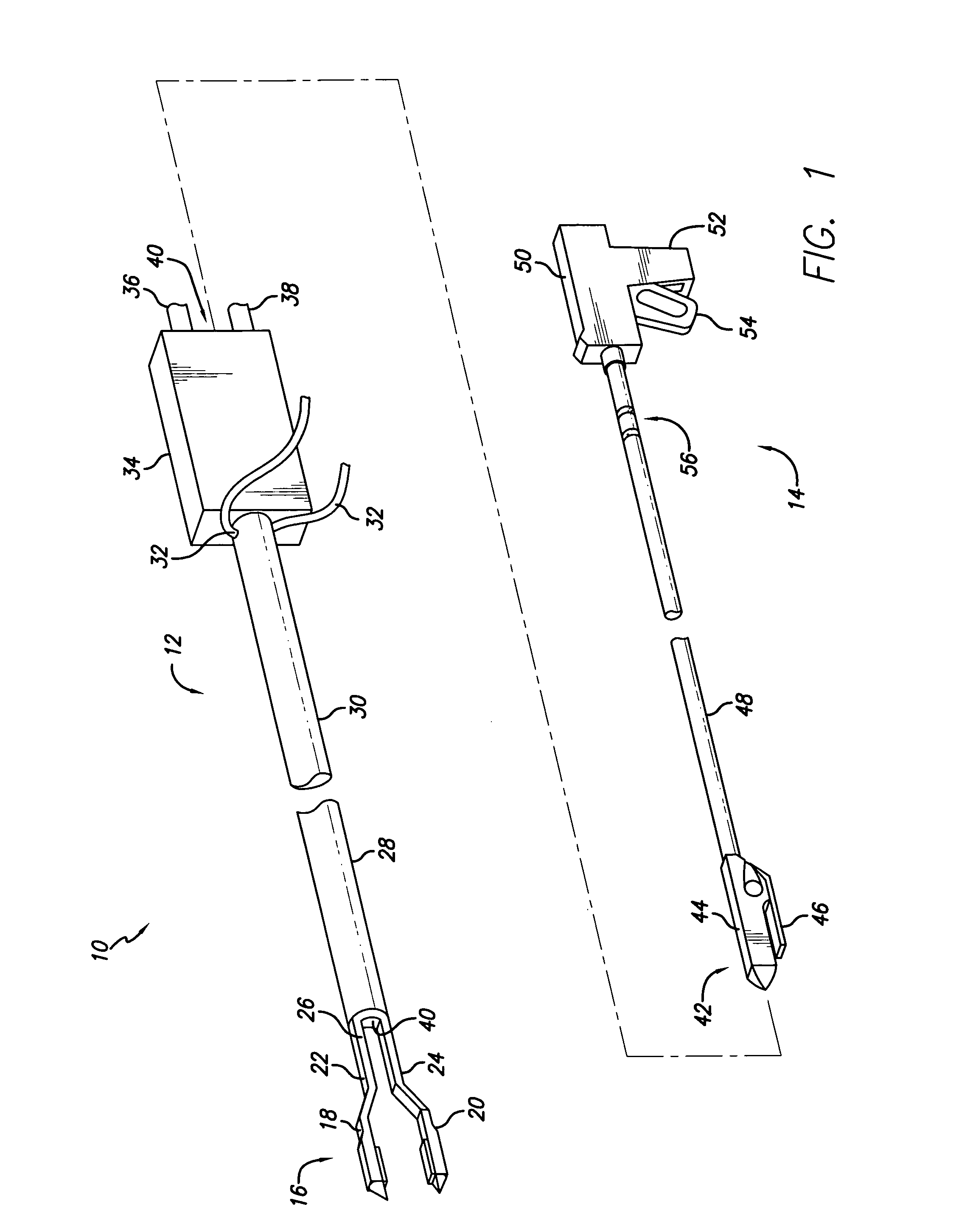

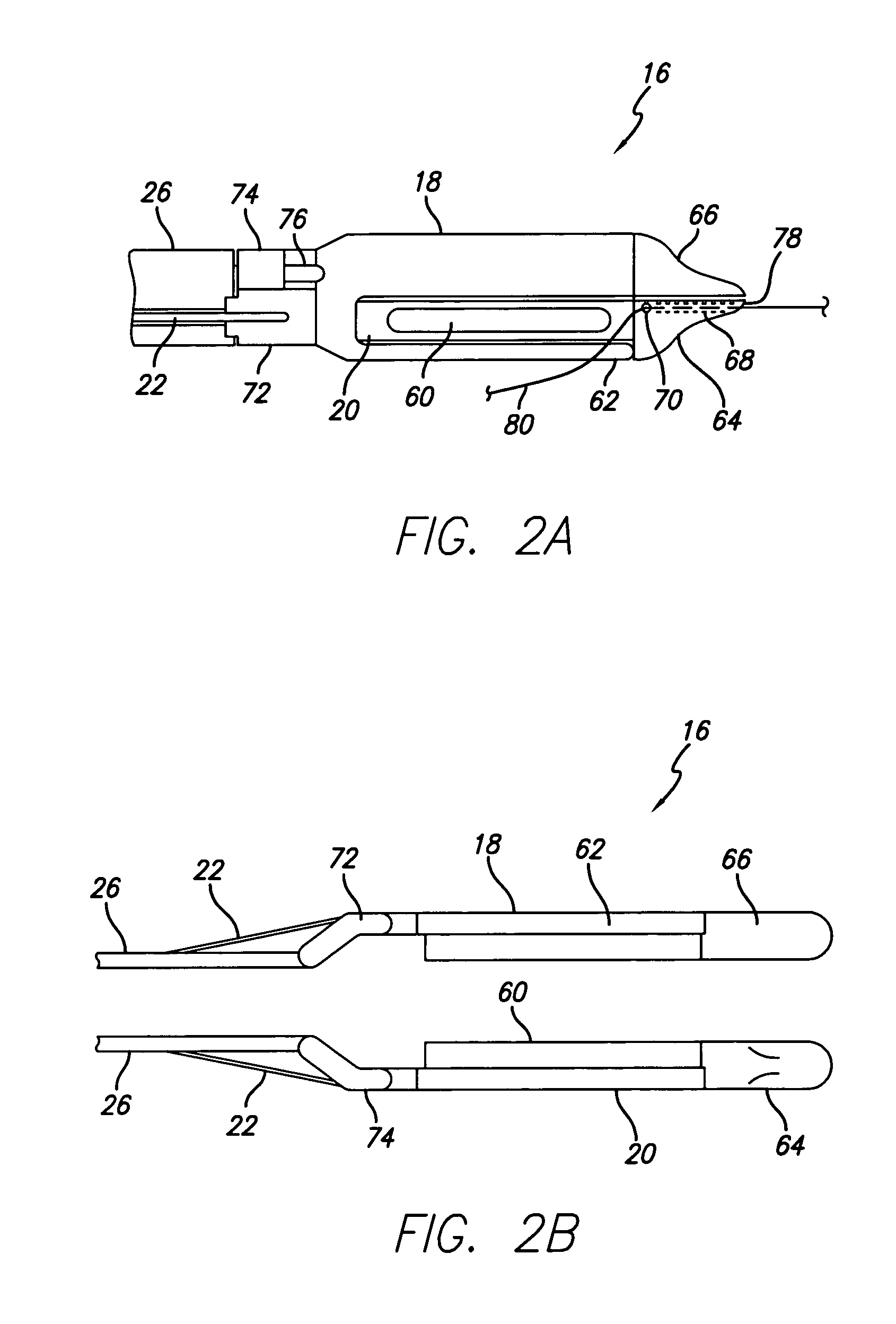

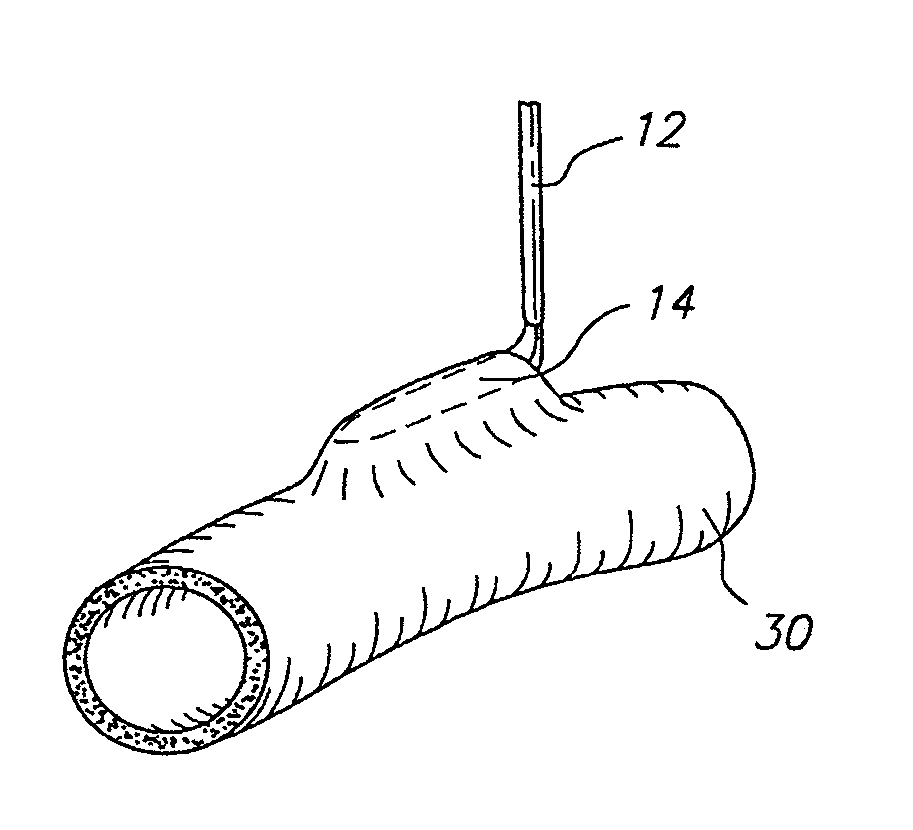

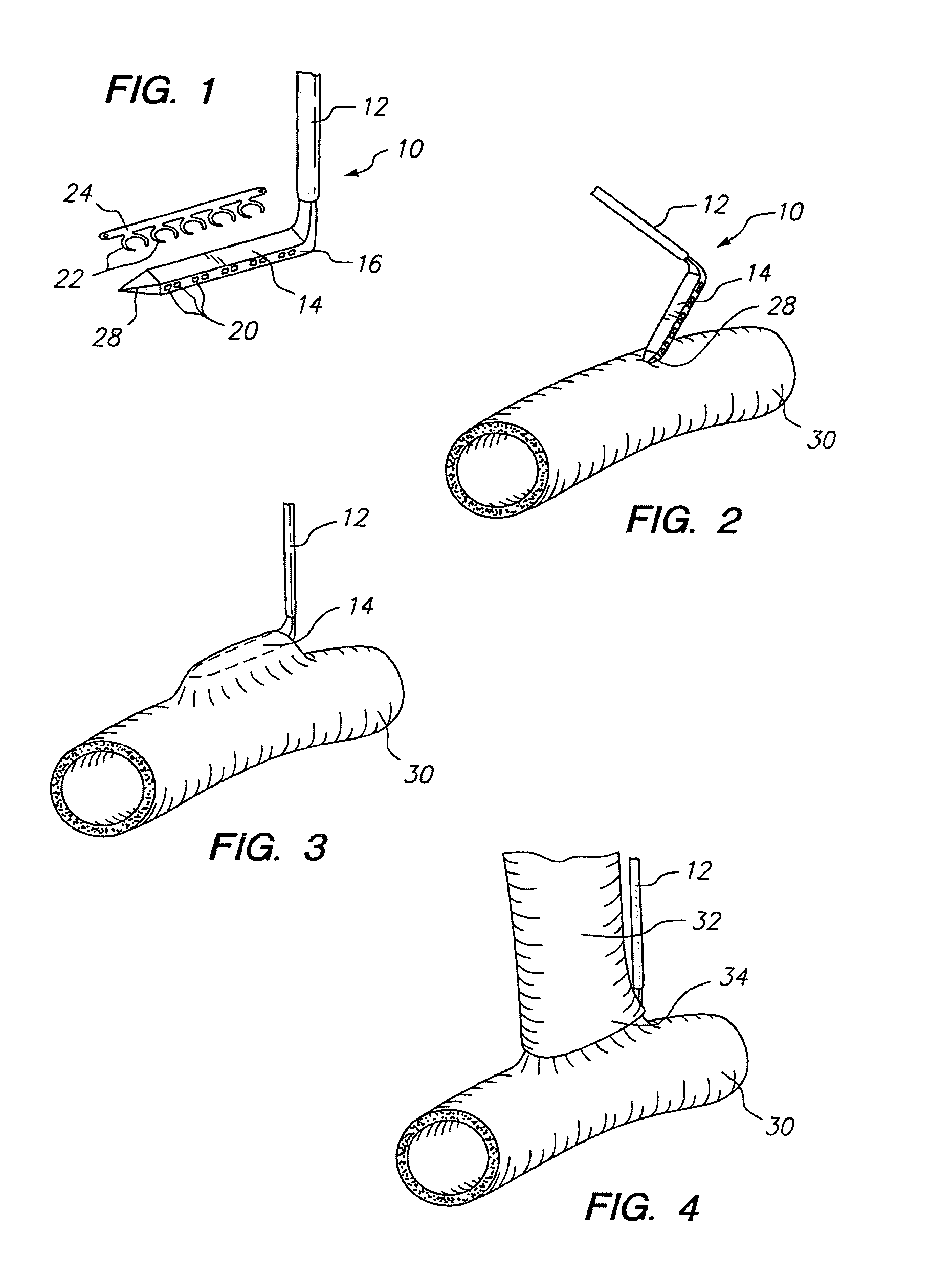

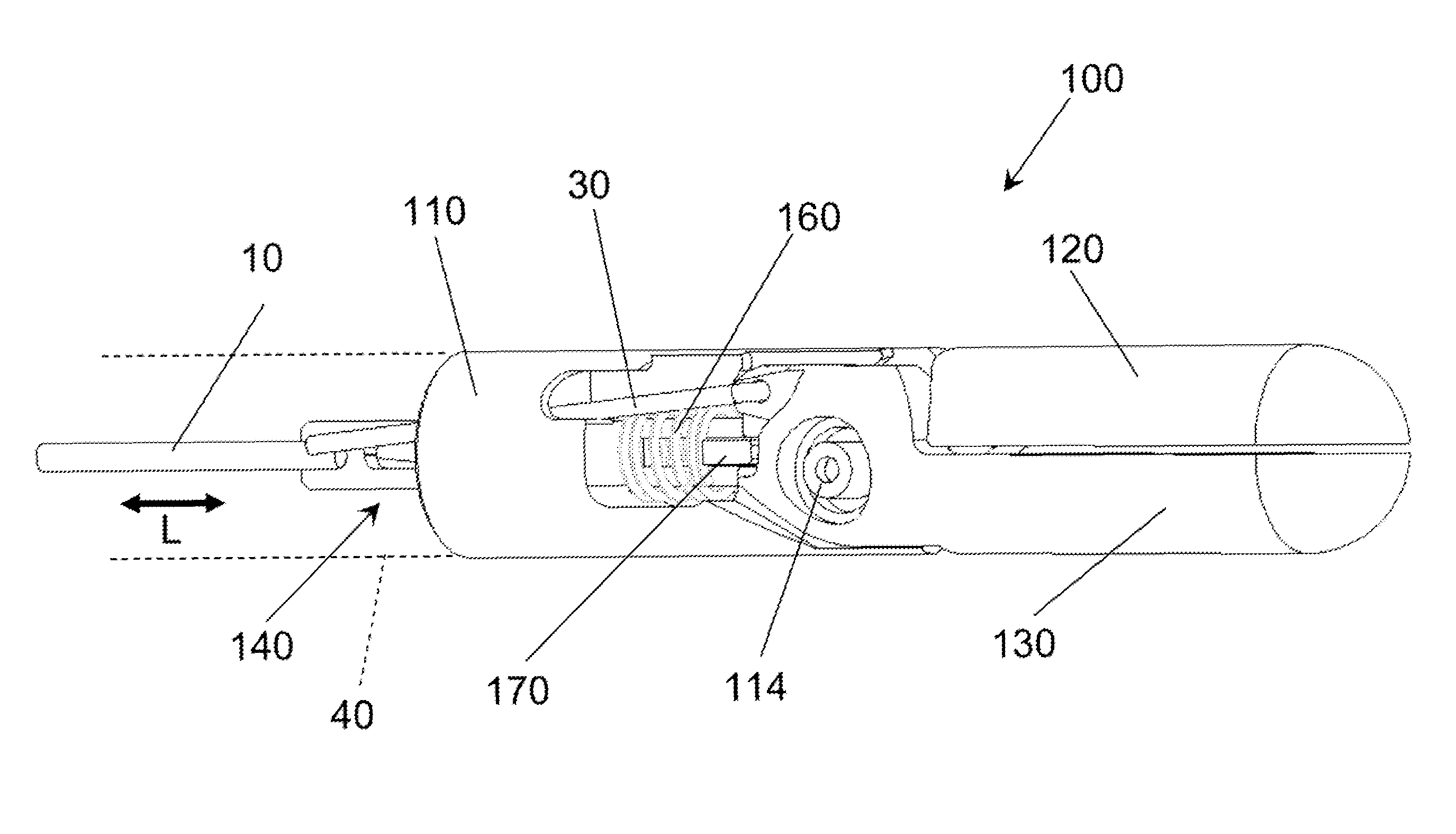

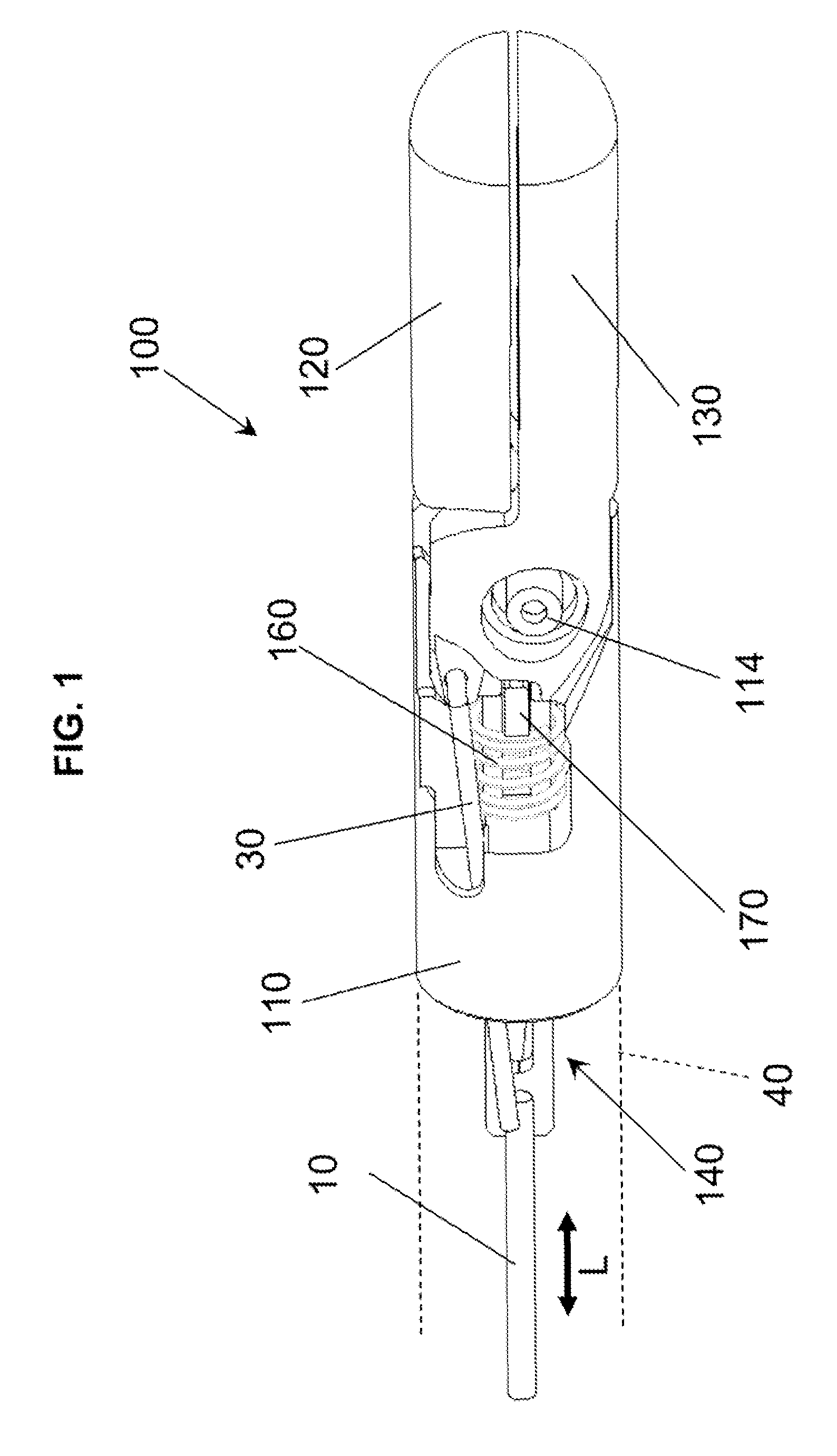

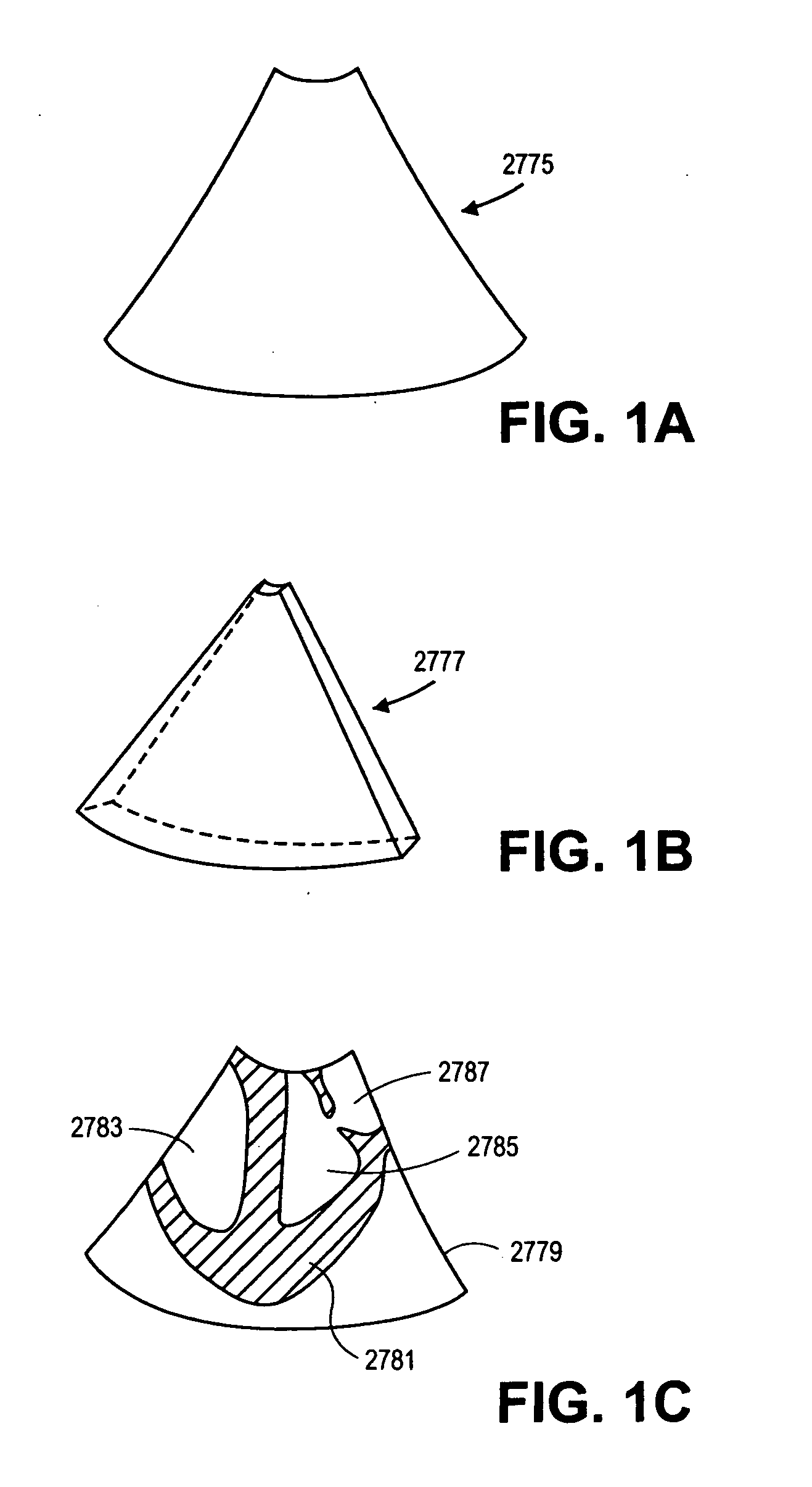

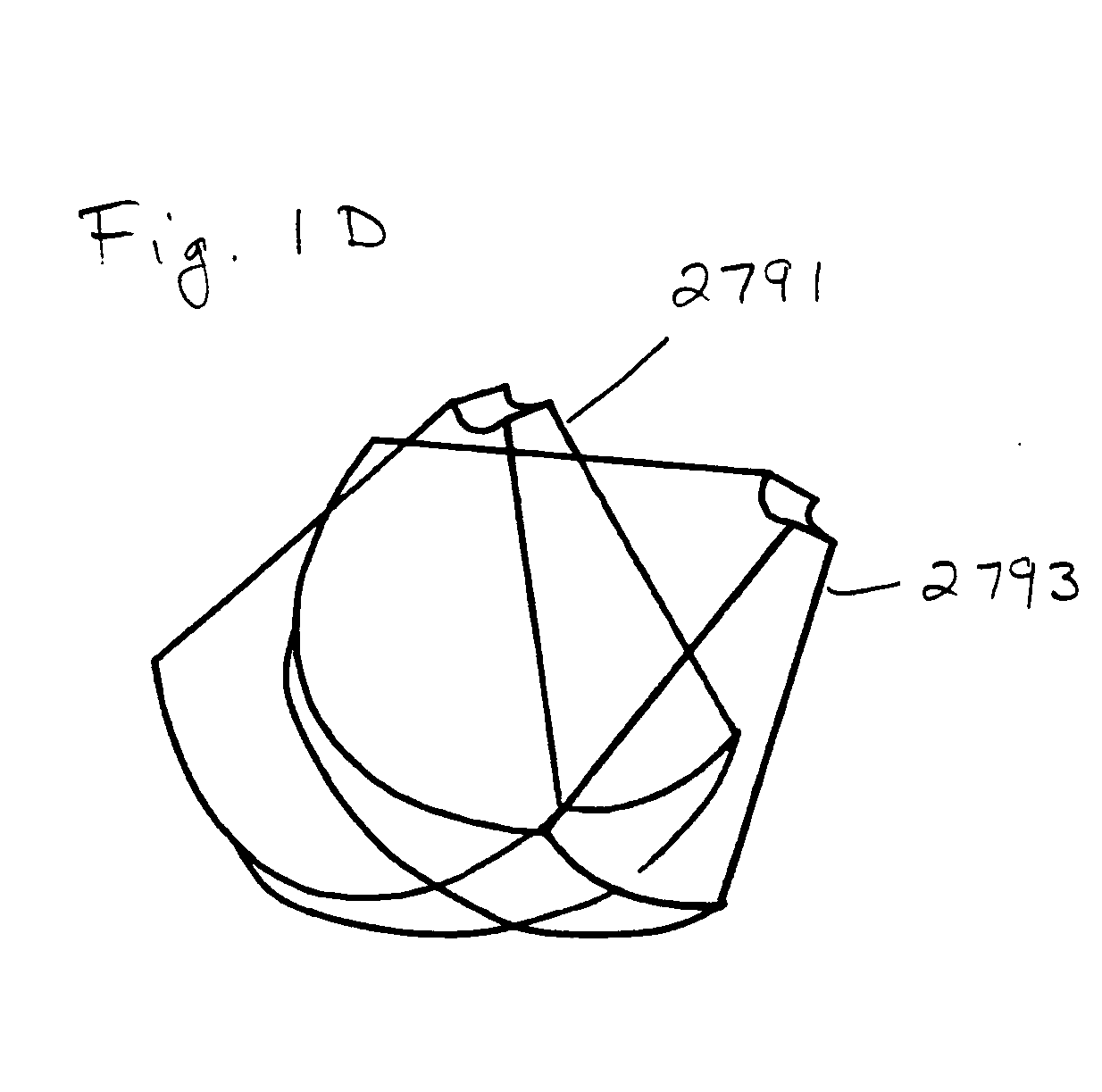

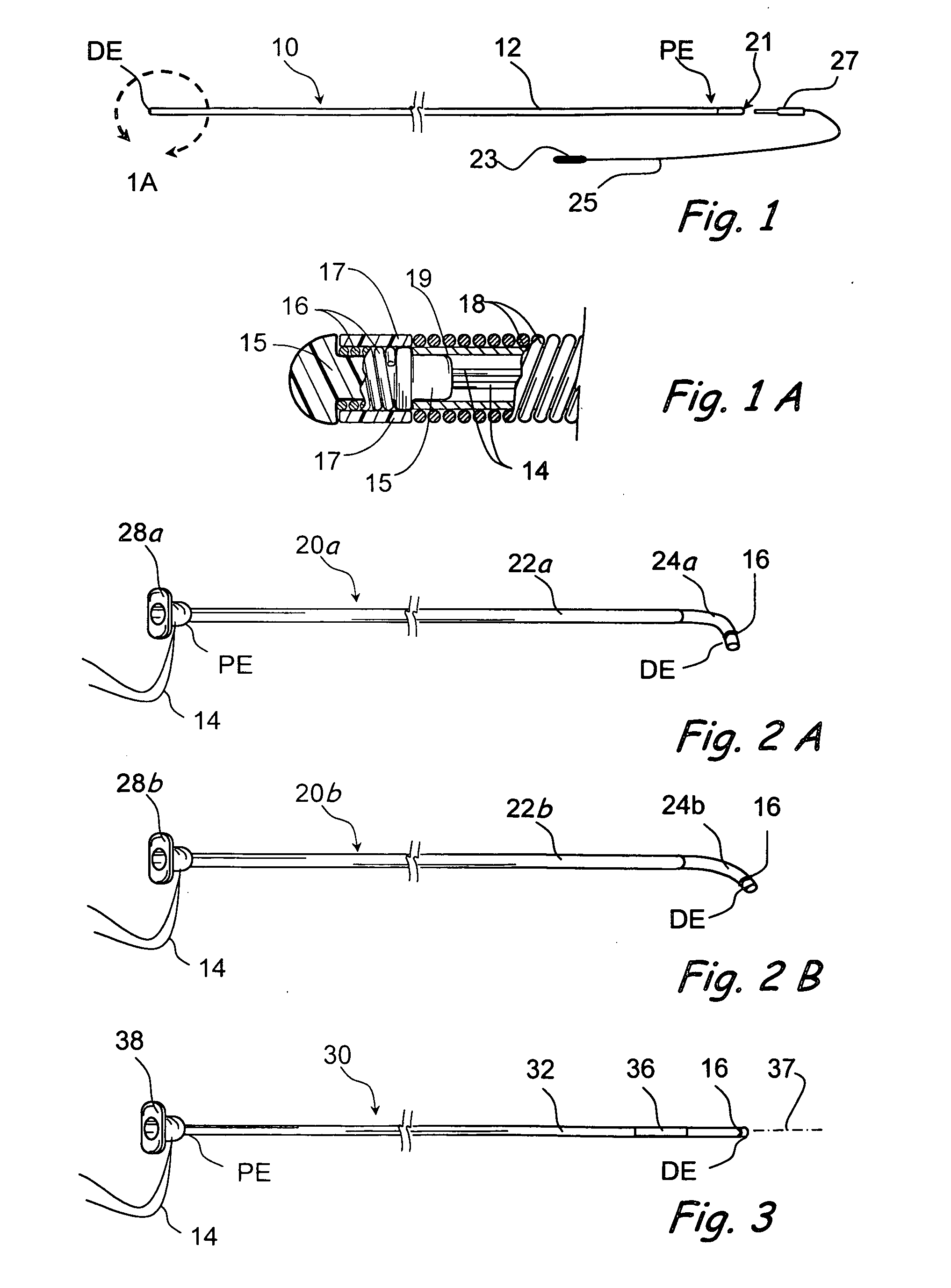

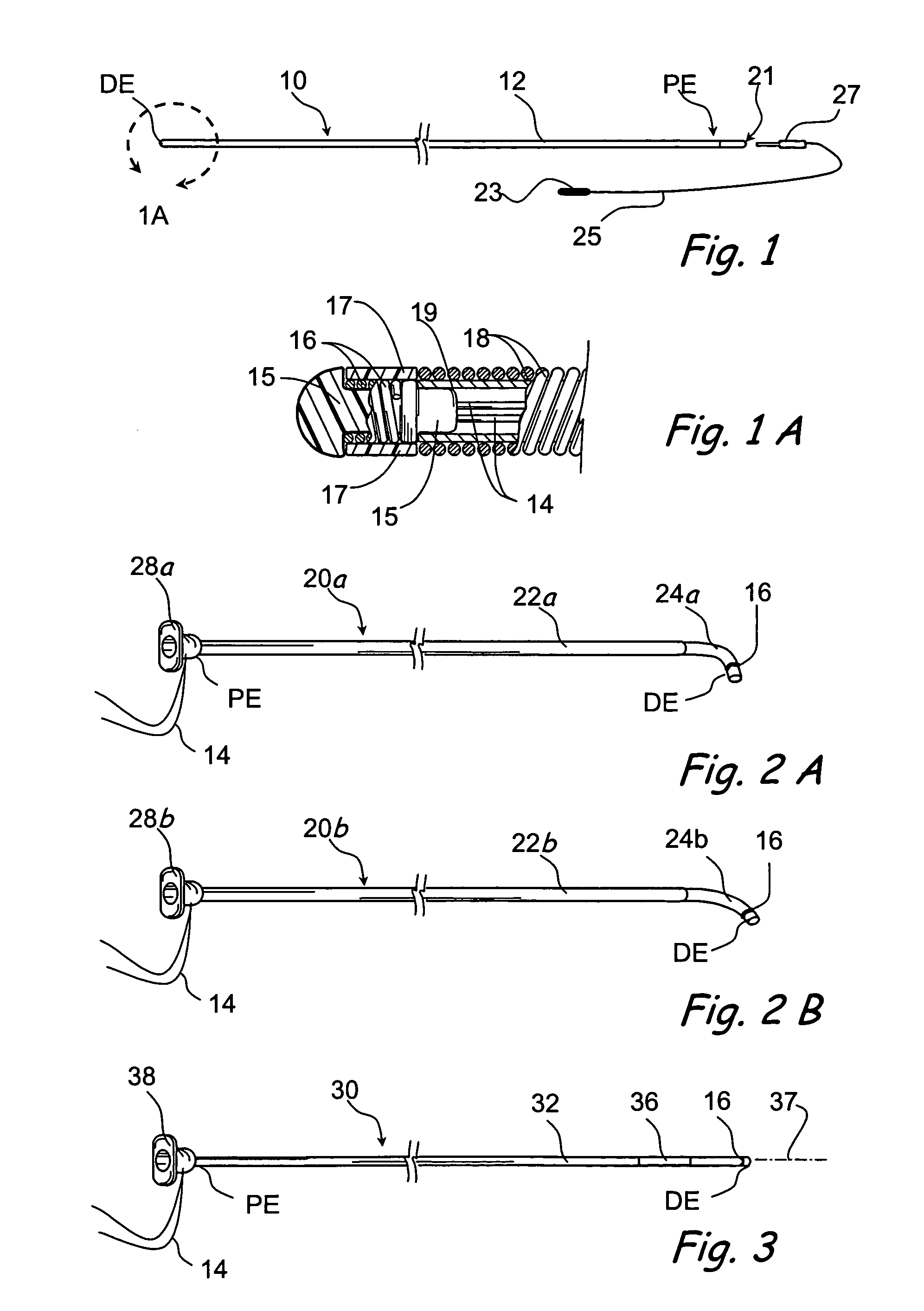

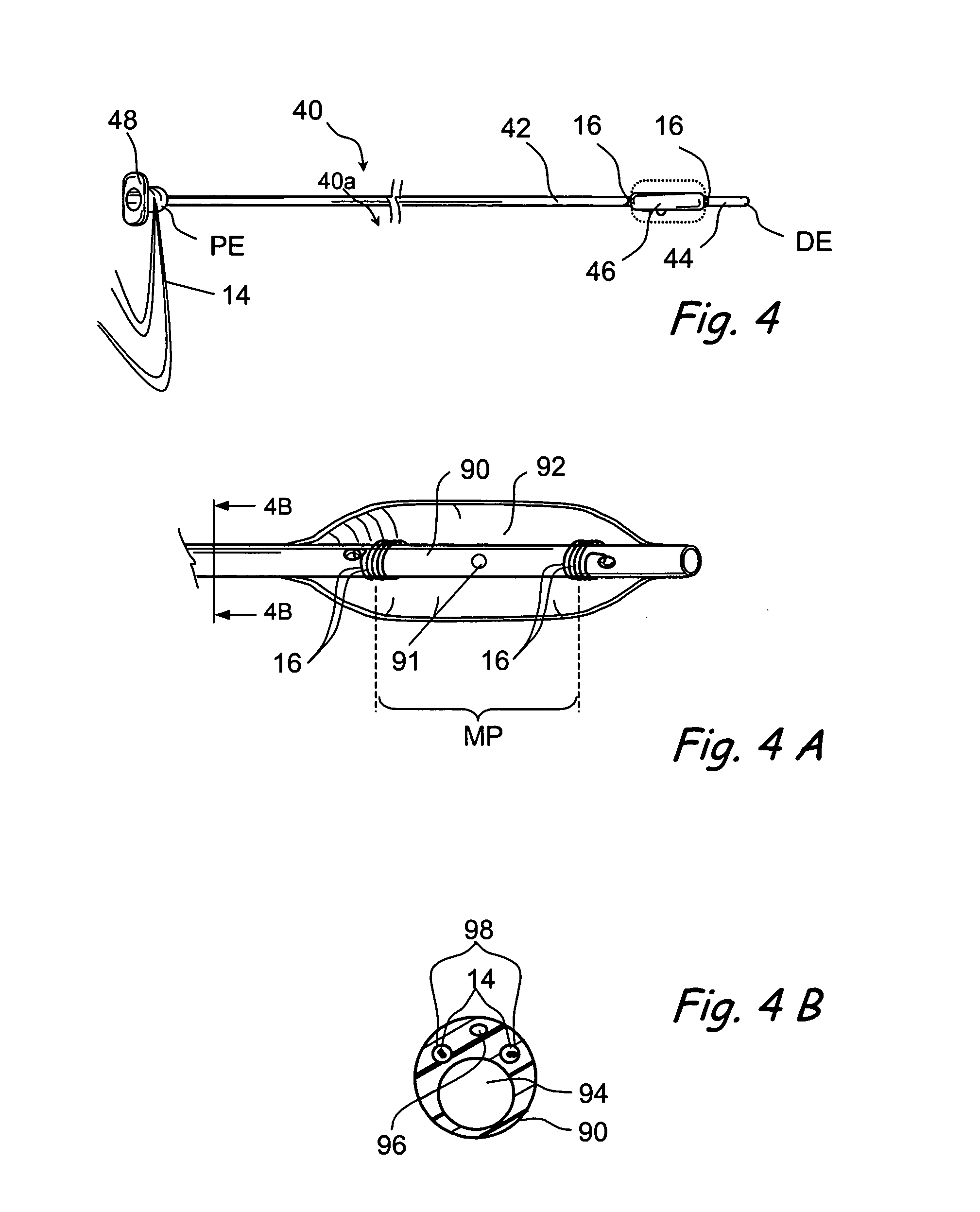

Single fold device for tissue fixation

ActiveUS7914543B2Convenient guidancePrevent kinking and pinchingSuture equipmentsStapling toolsBody organsStoma

A system for tissue approximation and fixation is described herein. A device is advanced in a minimally invasive manner within a patient's body to create one or several divisions or plications within a hollow body organ. The system comprises a stapler assembly having a tissue acquisition member and a tissue fixation member. The stapler assembly approximates tissue from within the hollow body organ with the acquisition member and then affixes the approximated tissue with the fixation member. In one method, the system can be used as a secondary procedure to reduce the size of a stoma within the hollow body organ.

Owner:ETHICON ENDO SURGERY INC

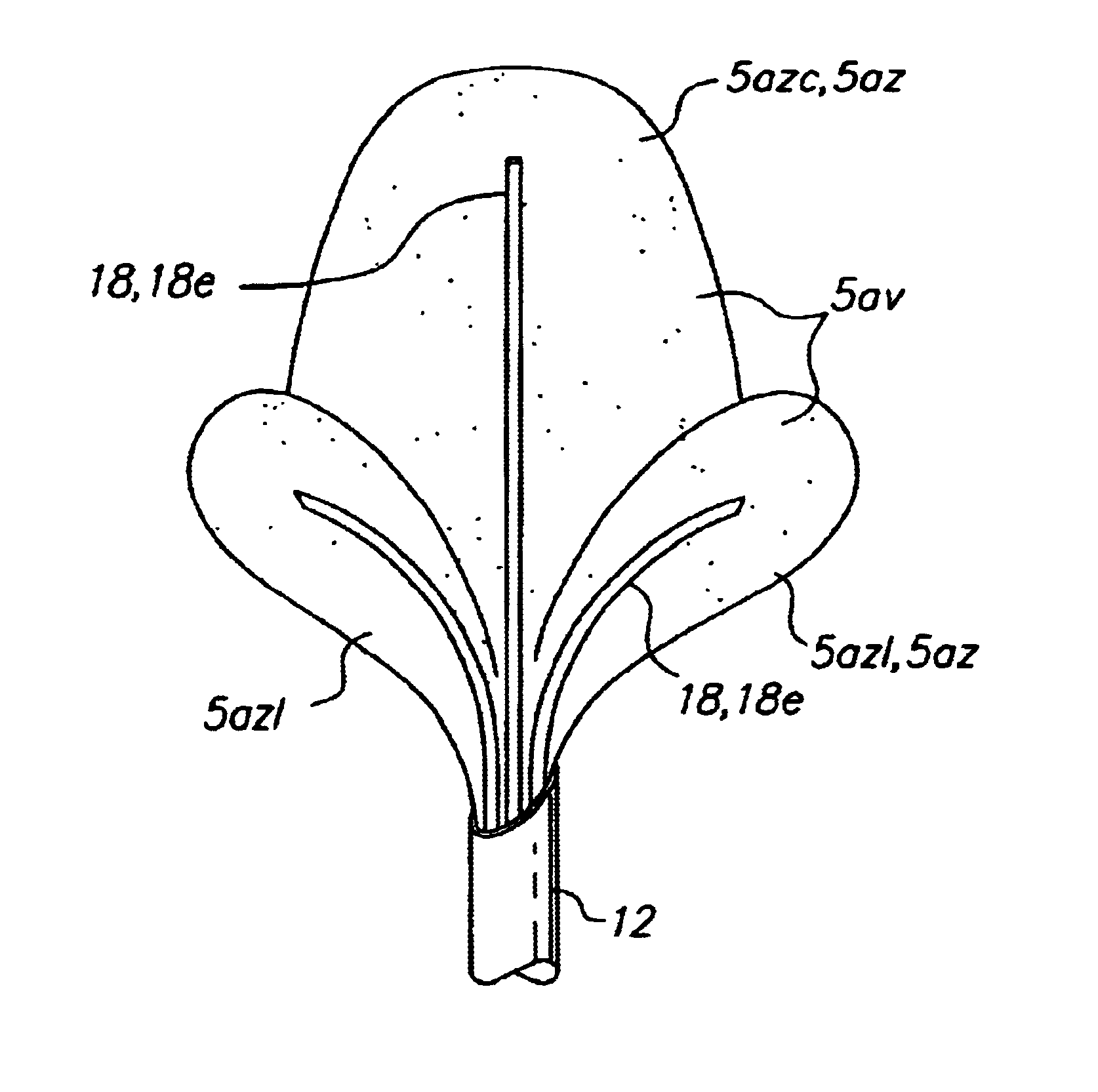

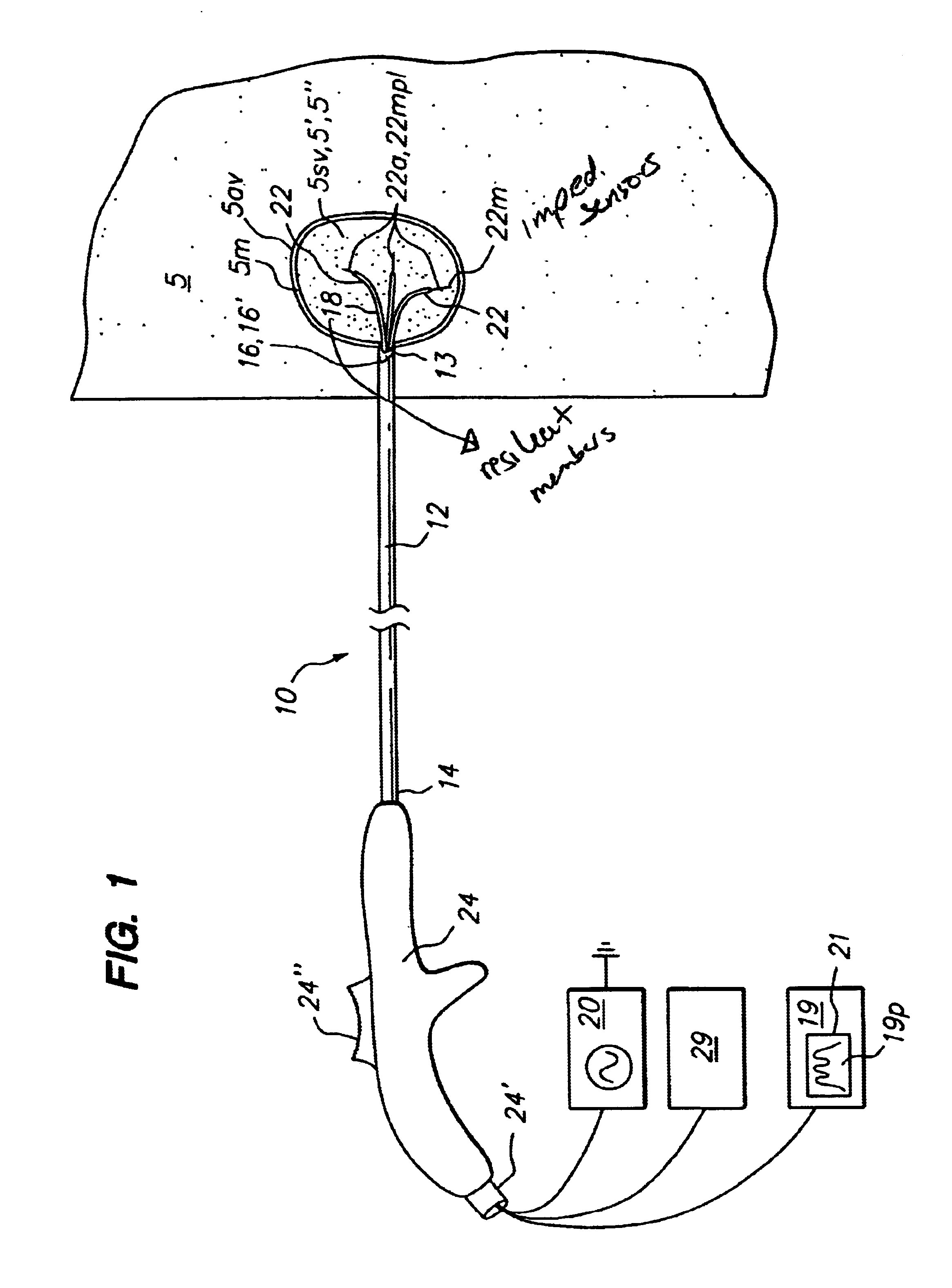

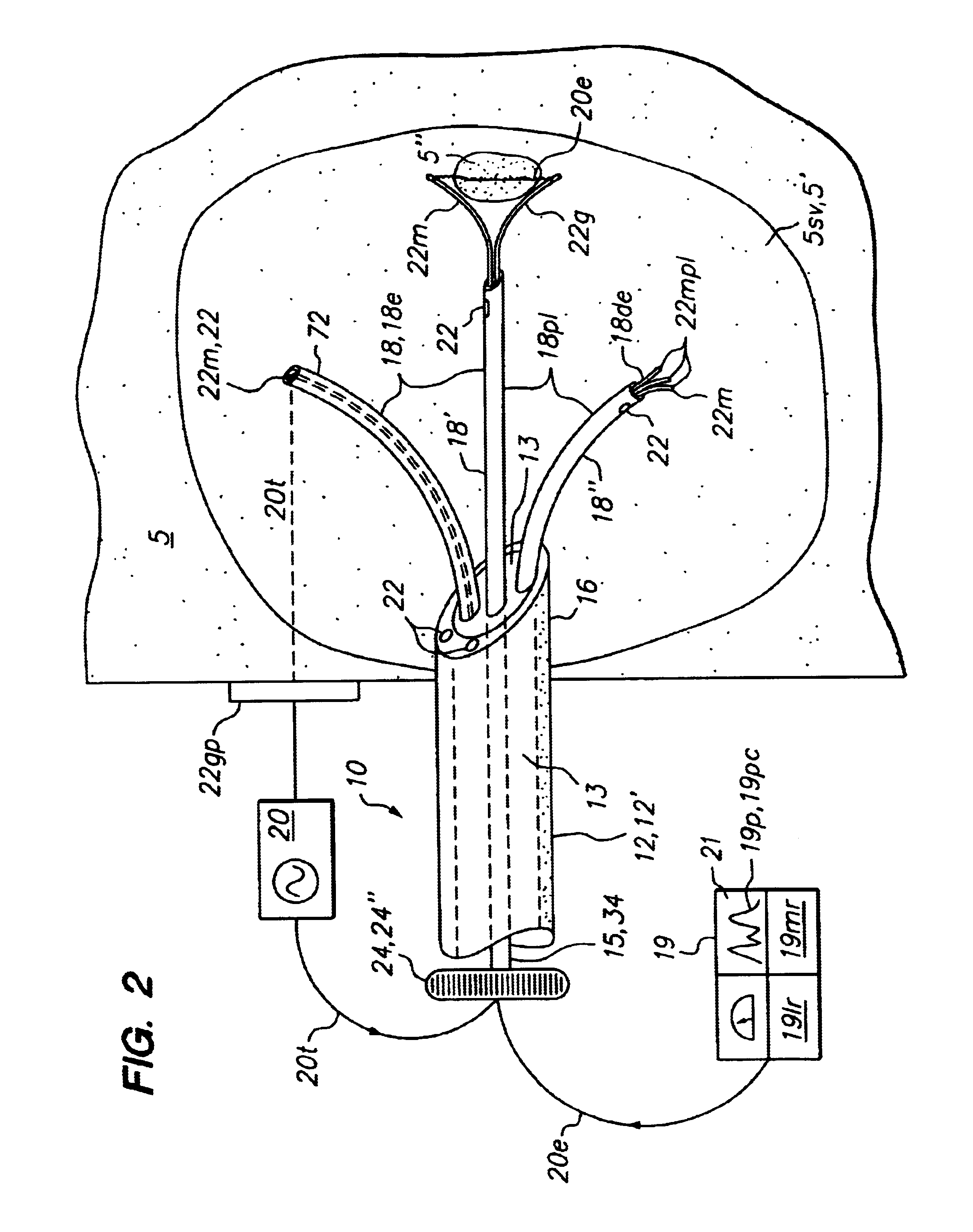

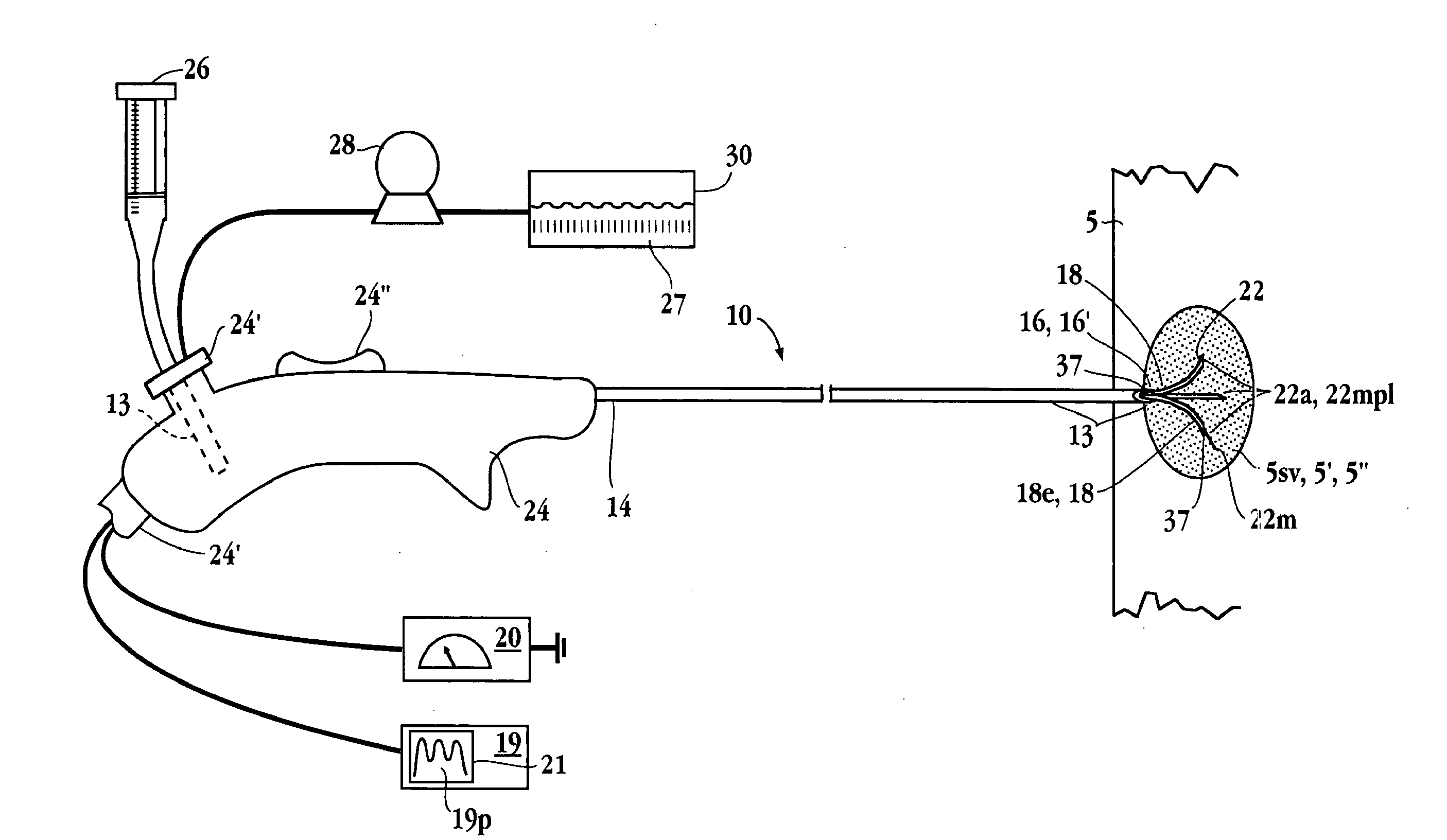

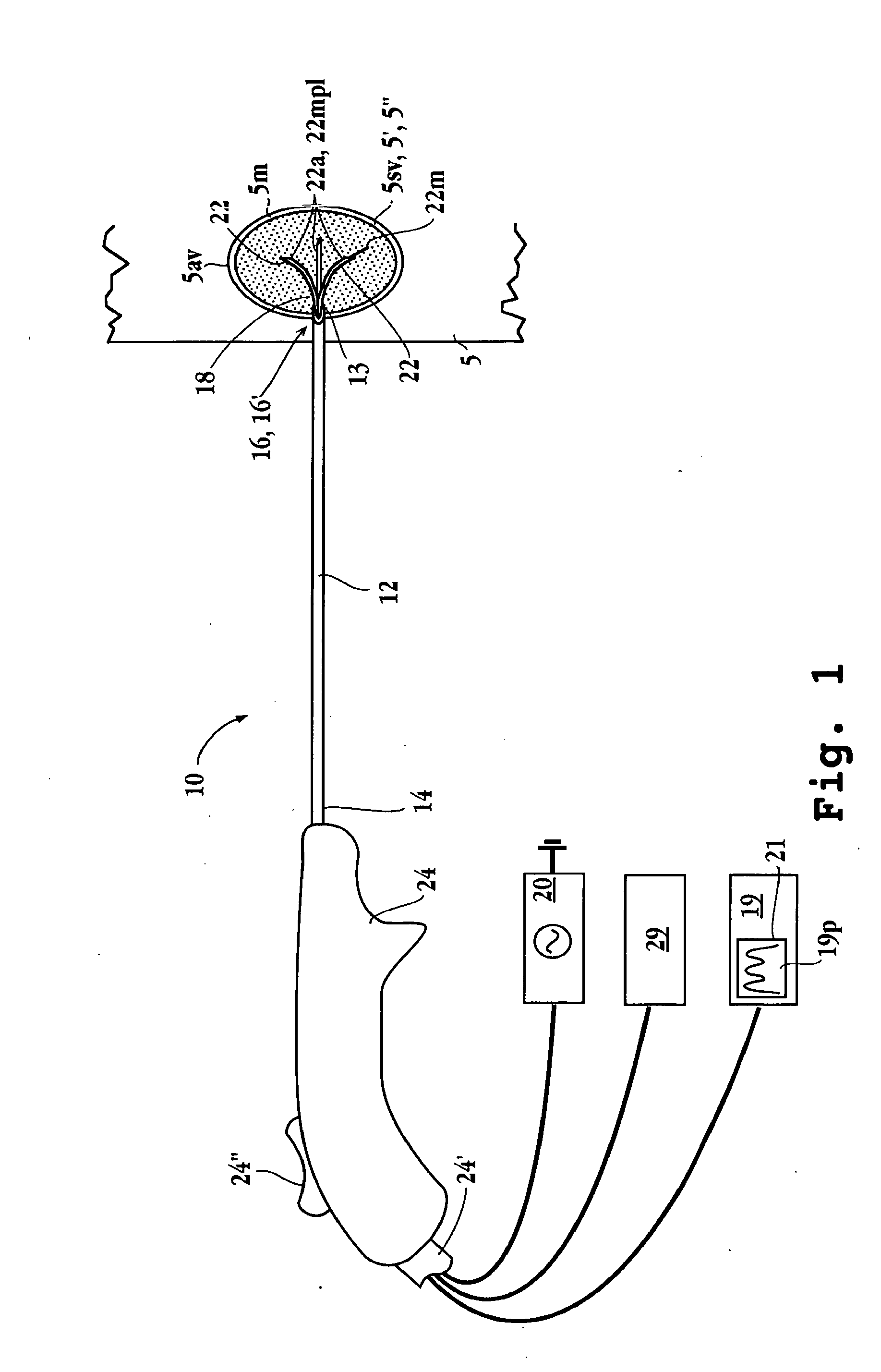

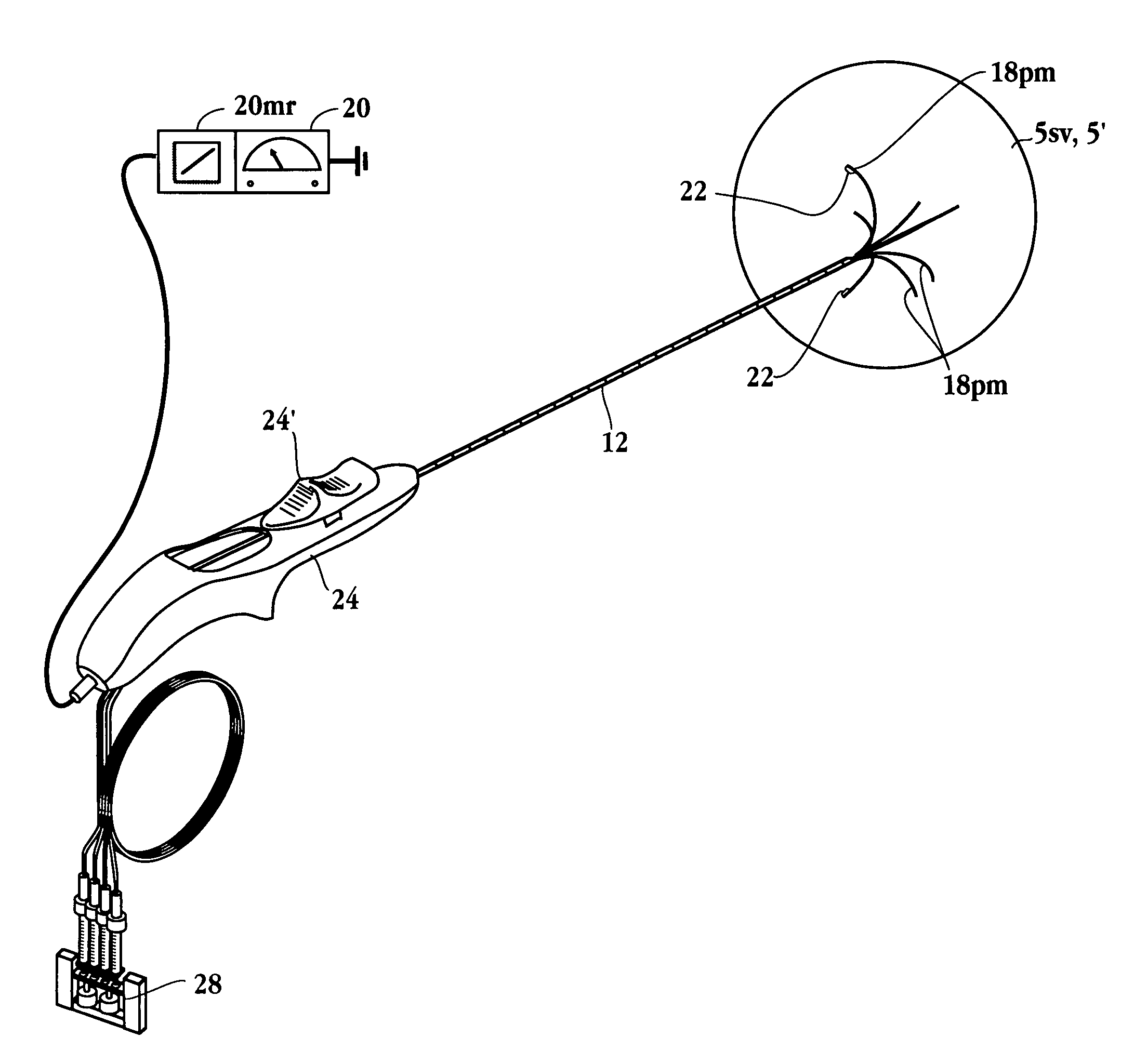

Method for detecting and treating tumors using localized impedance measurement

InactiveUS6962587B2Precise positioningEasy to monitorSurgical needlesDiagnostic recording/measuringAbnormal tissue growthEngineering

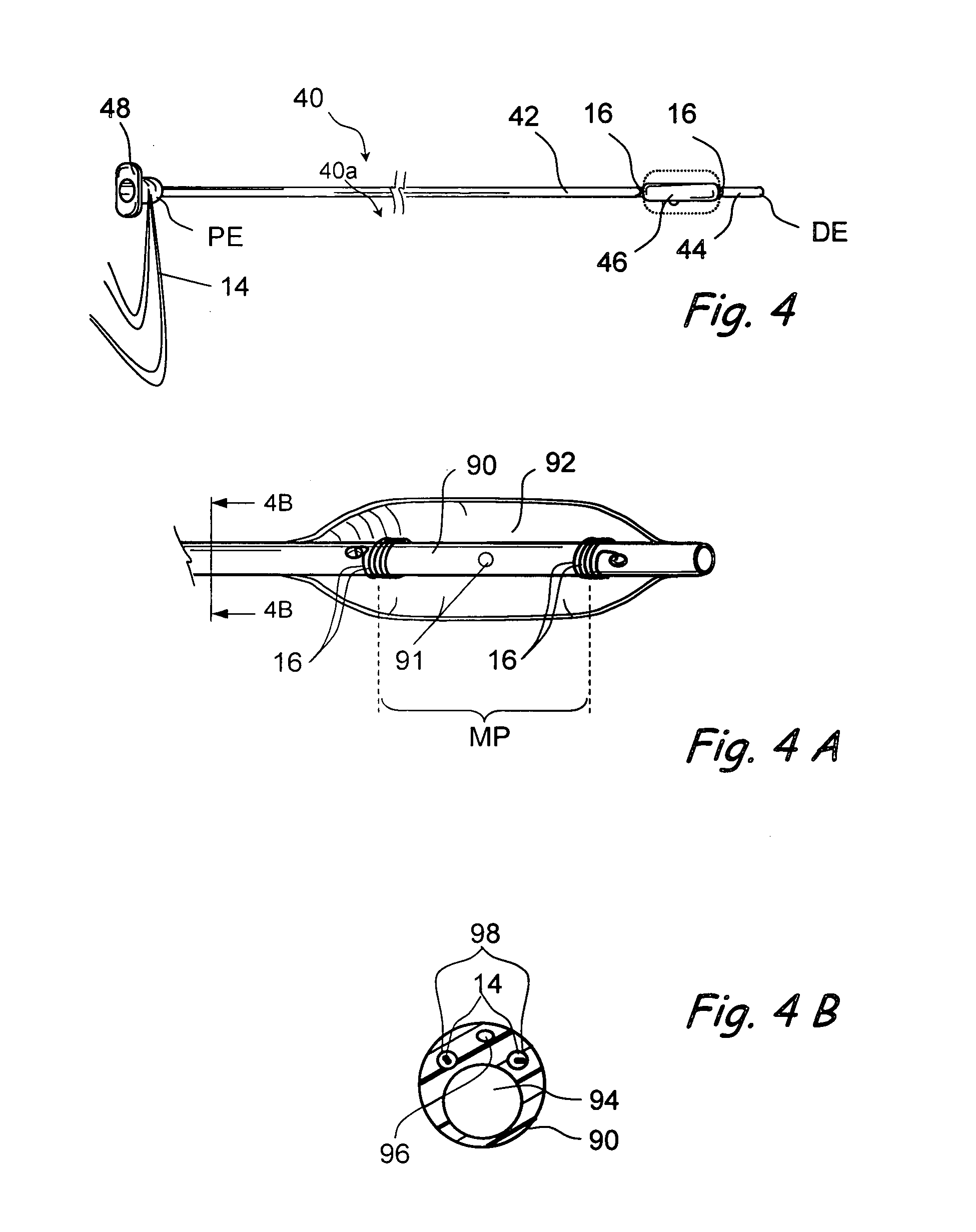

An embodiment of the invention provides a method for detecting and treating a tumor using tissue localized volumetric impedance measurement. The method includes providing an impedance measurement apparatus having a plurality of resilient members deployable with curvature and configured to sample tissue impedance through a plurality of conductive pathways. The apparatus is configured to be coupled to at least one of an energy delivery device, a power supply, a switching device or logic resources. The apparatus is then positioned at a selected tissue site and the impedance array deployed to define a sample volume. The impedance array is then utilized to make impedance measurements through a plurality of conductive pathways. Information from the impedance measurements is then utilized to determine a tissue condition of the sample volume. Energy is then delivered from the energy delivery device to ablate or necrose at least a portion of the tumor.

Owner:ANGIODYNAMICS INC

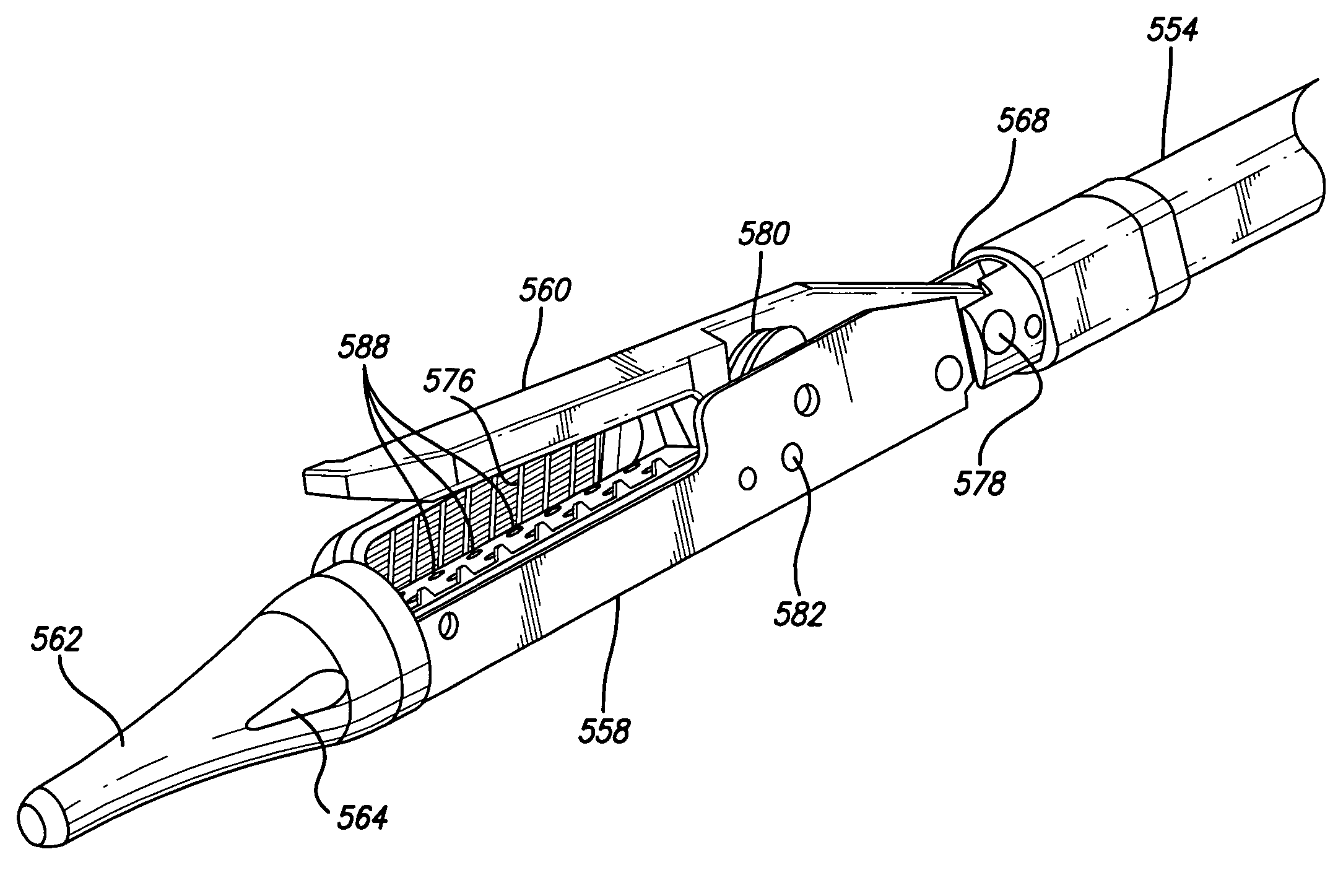

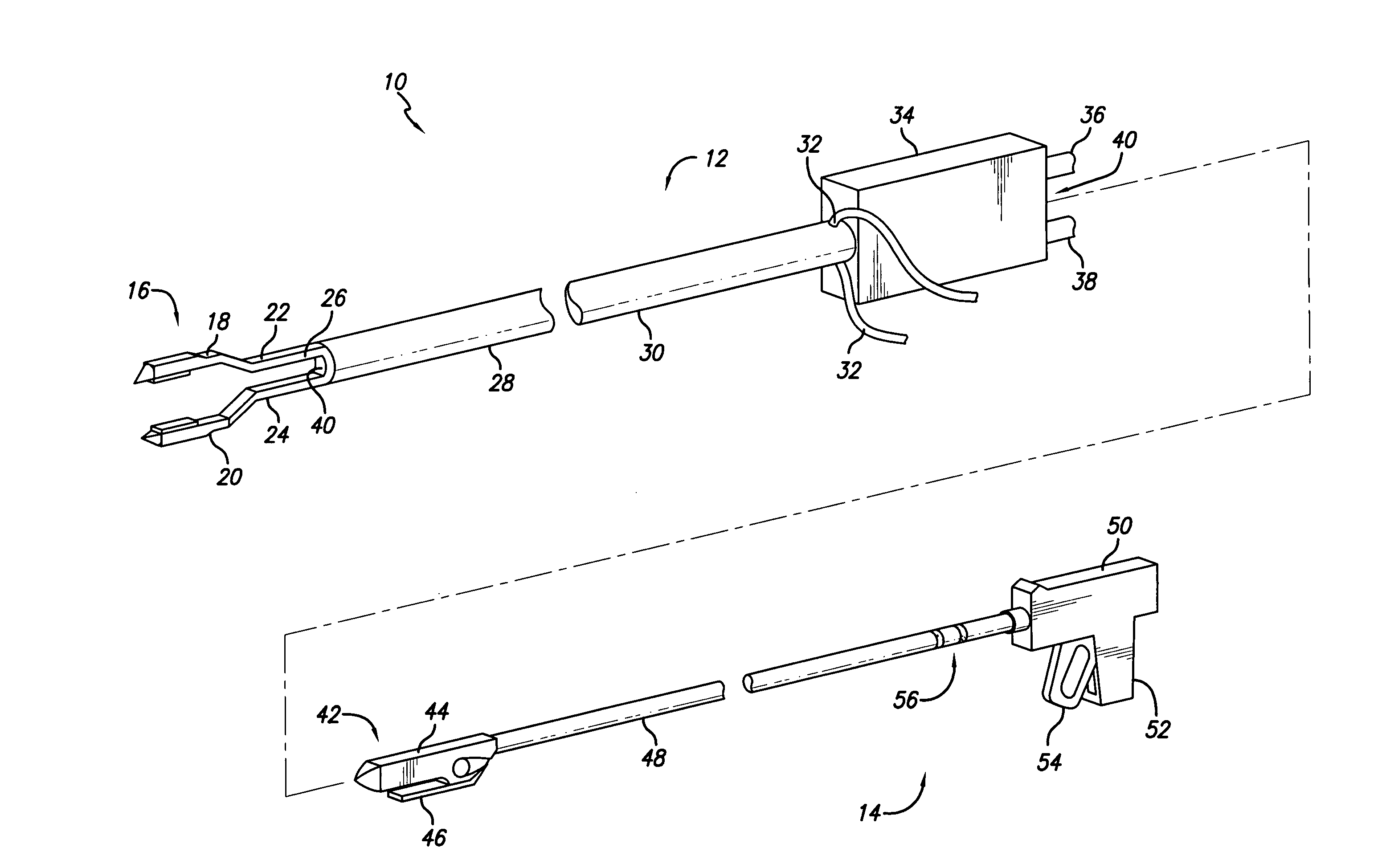

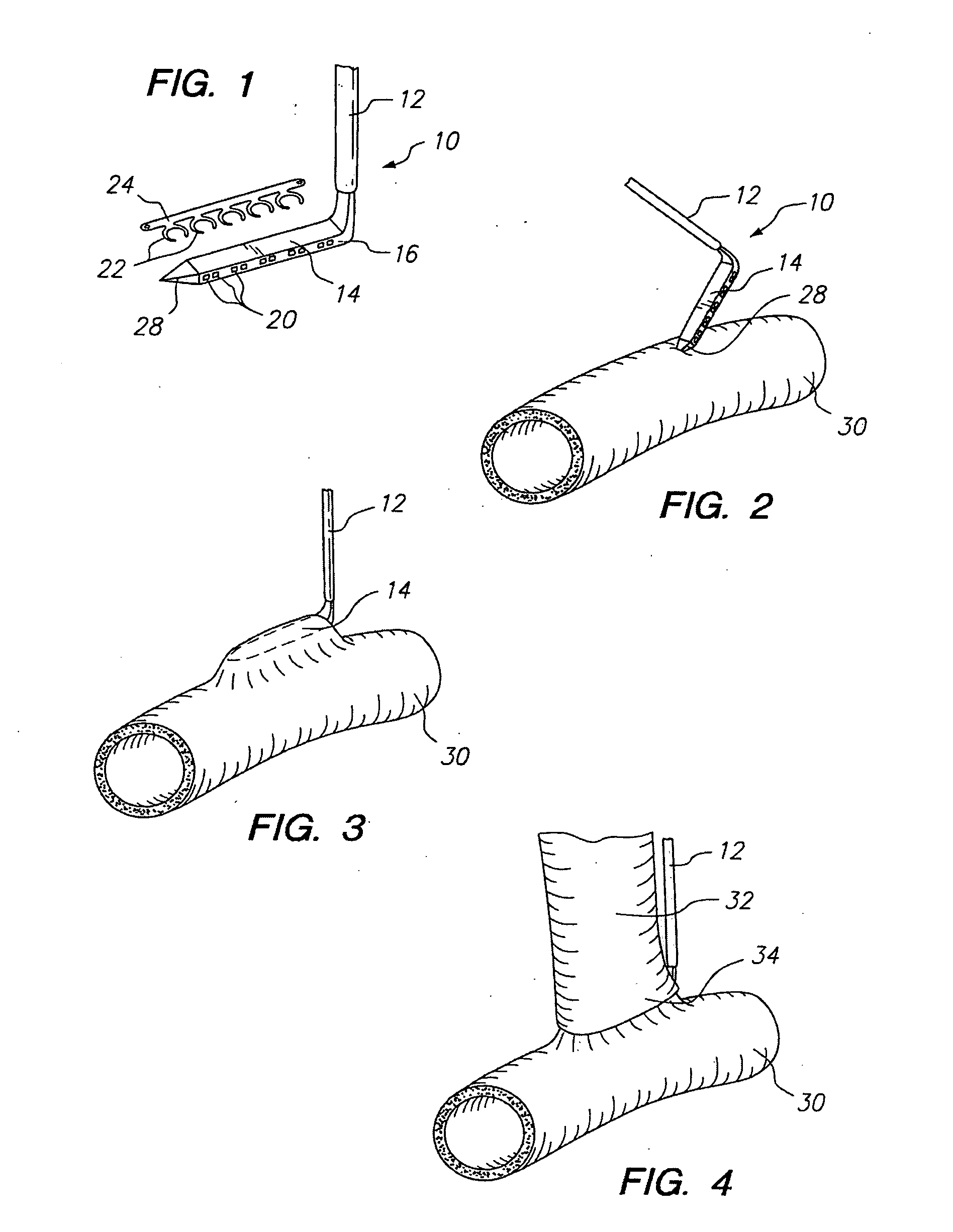

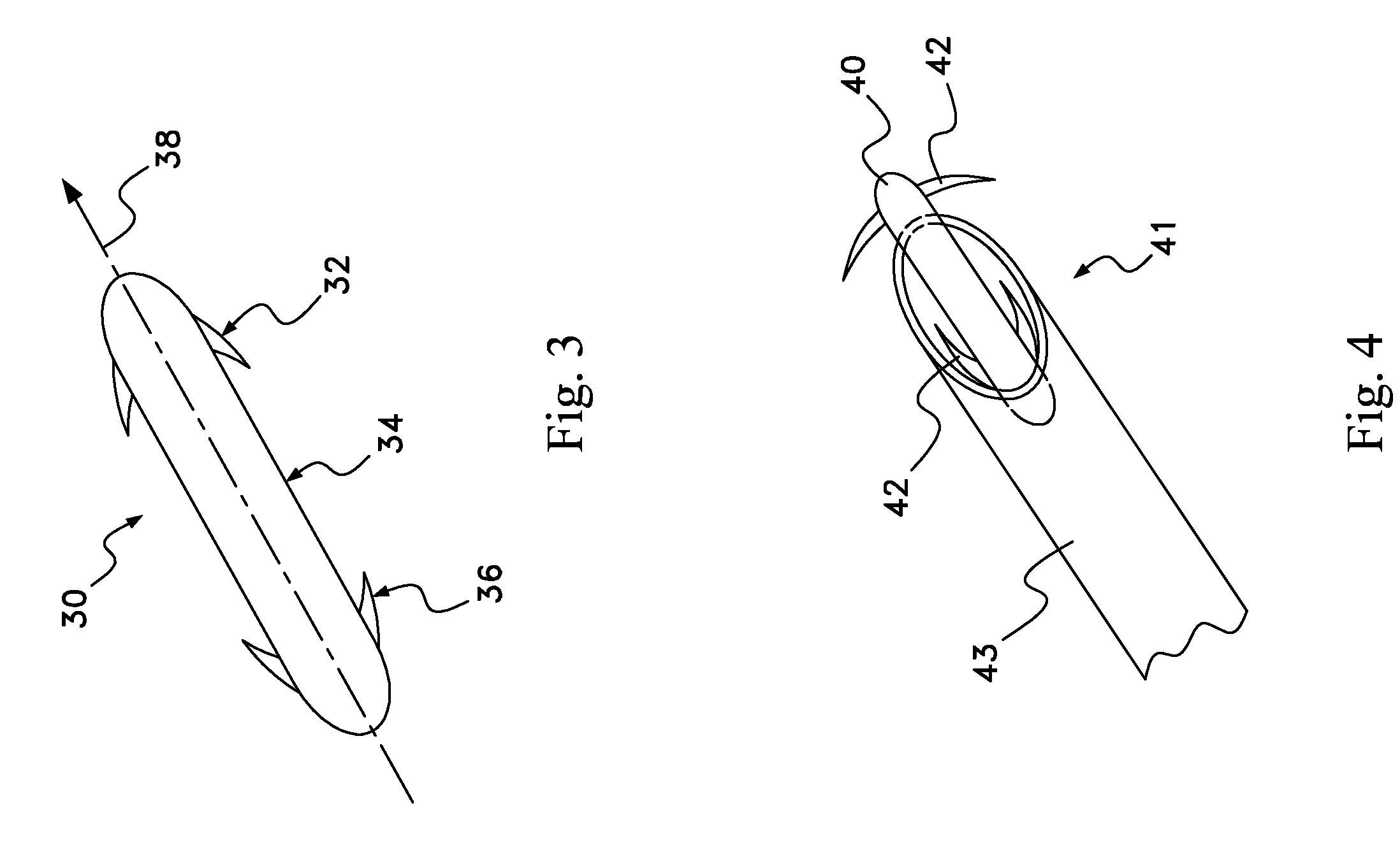

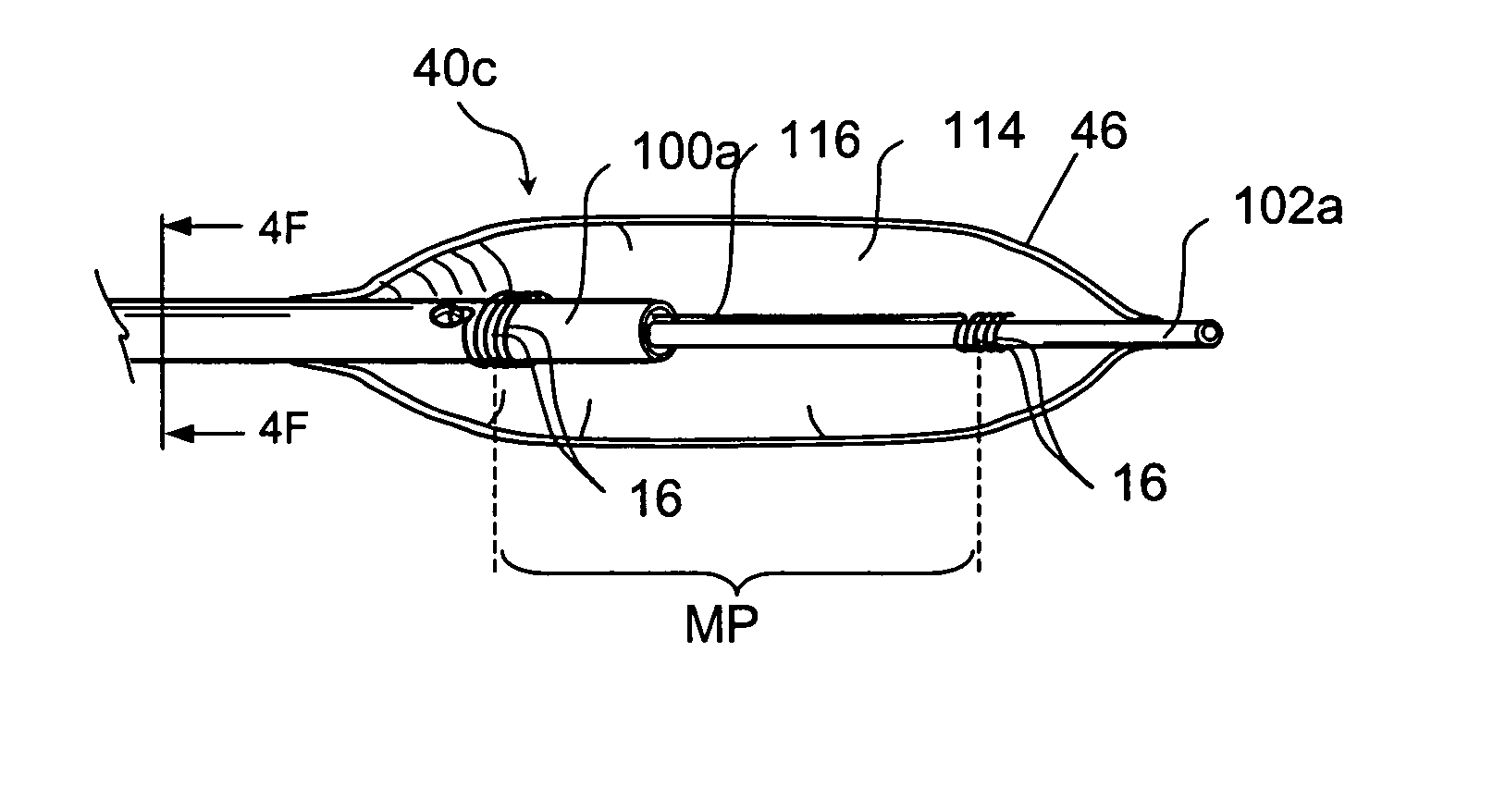

System for tissue approximation and fixation

ActiveUS7097650B2Convenient guidancePrevent kinking and pinchingSuture equipmentsStapling toolsBody organsBiomedical engineering

A system for tissue approximation and fixation is described herein. The devices are advanced in a minimally invasive manner within a patient's body to create one or several divisions or plications within a hollow body organ. The system comprises a tissue acquisition and folding device and a tissue stapling or fixation device, each of which is used together as a system. The acquisition device is used to approximate tissue regions from within the hollow body organ and the stapling device is advanced through a main lumen defined through the acquisition device and is used to affix the approximated tissue. The stapling device is keyed to maintain its rotational orientation relative to the acquisition device as well as to provide the user positional information of the stapling device. The acquisition device is also configured to provide lateral stability to the stapling device prior to the stapling device being clamped onto tissue.

Owner:ETHICON ENDO SURGERY INC

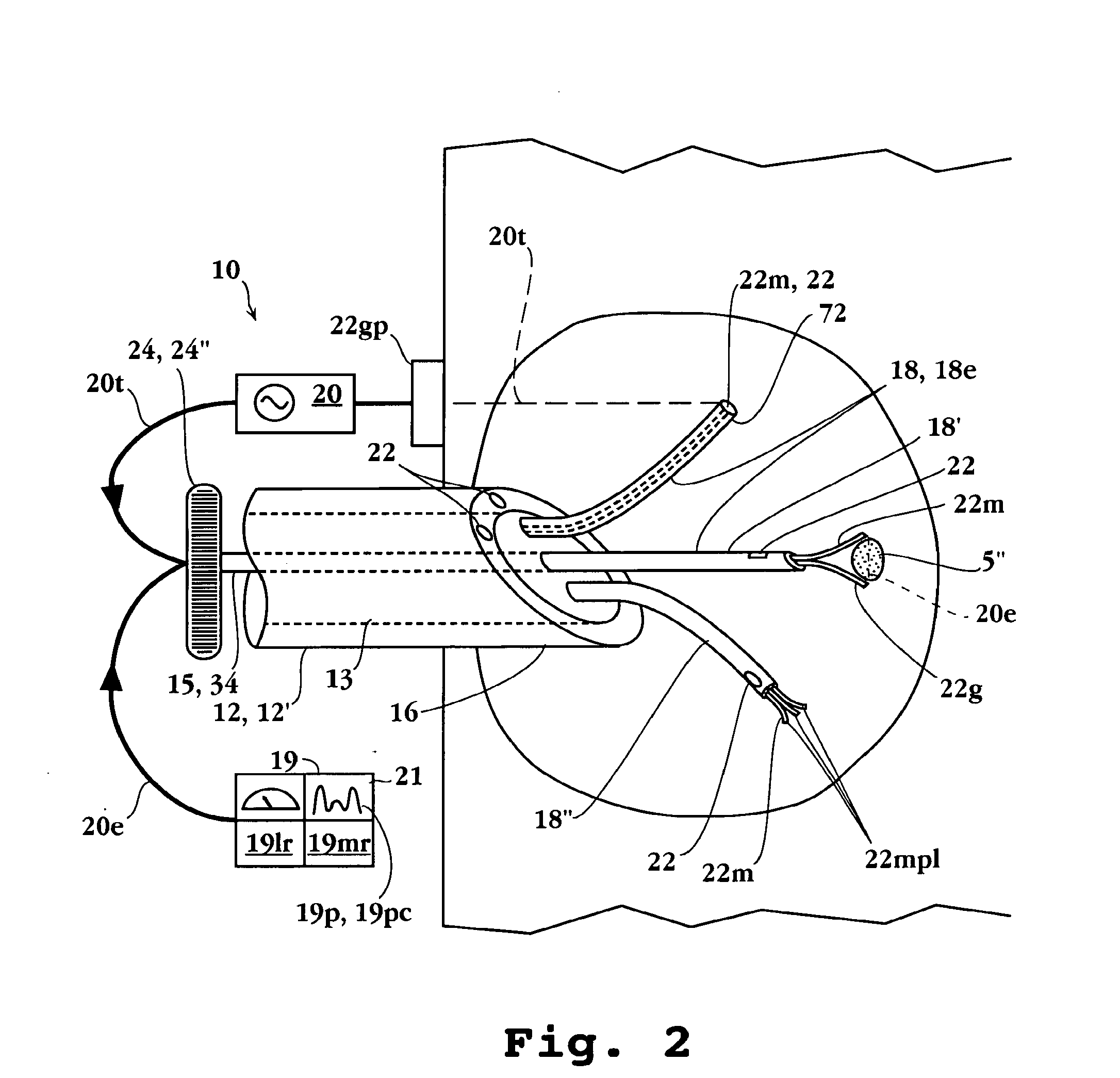

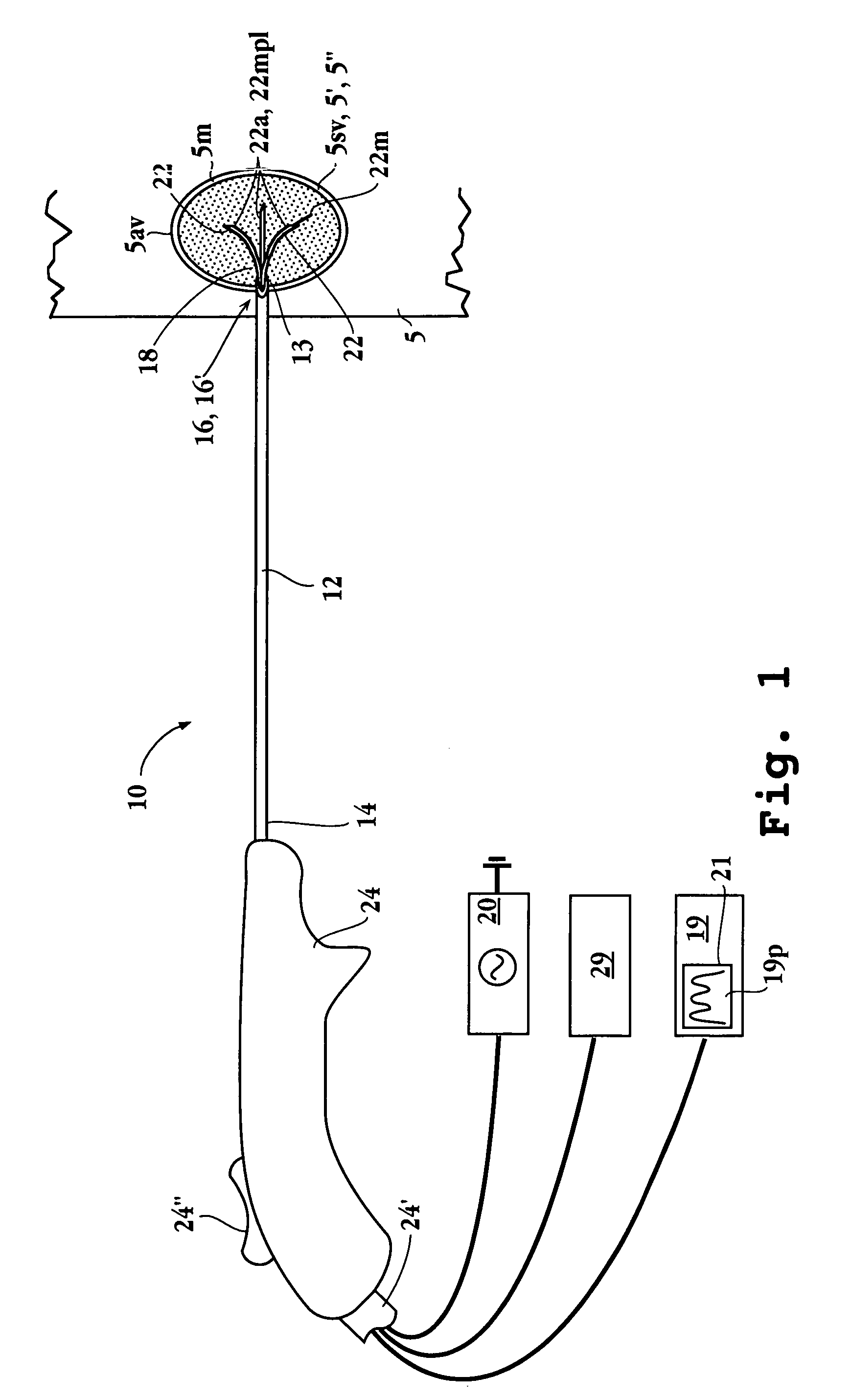

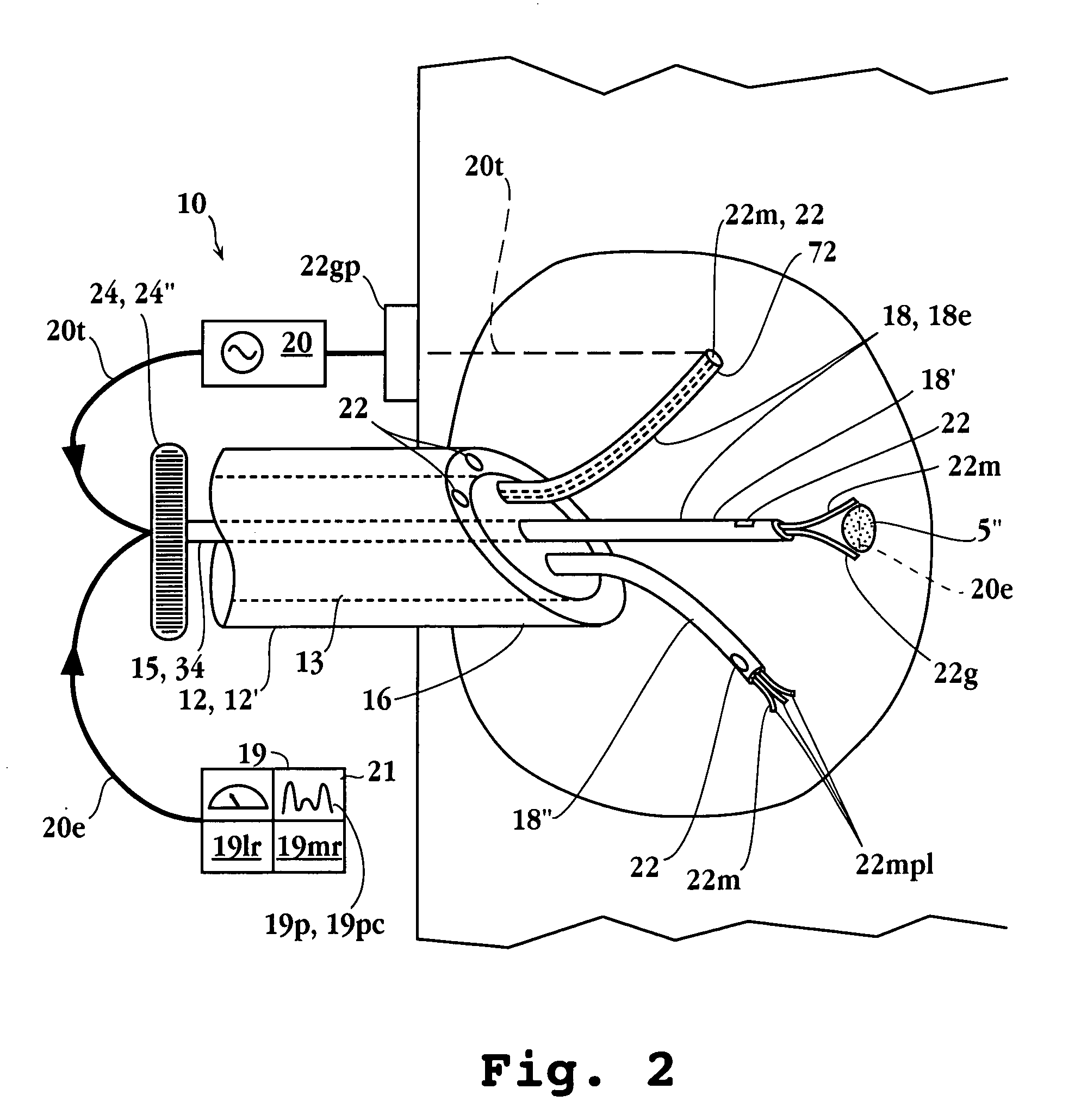

Tissue ablation apparatus and method

InactiveUS20080287944A1Improve the level ofIncrease in sizeSurgical needlesDiagnostic recording/measuringRf ablationTarget tissue

A method and apparatus for carrying our thermal ablation of target tissue is disclosed. The apparatus includes an RF ablation device having a multi-electrode electrode assembly designed to be deployed in target tissue, defining a selected-volume tissue region to be ablated, and having infusion channels for infusing a liquid into the target tissue during the ablation process. A control unit in the apparatus is operably connected to an RF energy source, for controlling the RF power level supplied to the electrodes, and to an infusion device, for controlling the rate of infusion of a liquid through the device into the tissue. During both electrode deployment and tissue ablation, impedance and or temperature measurements made within the tissue are used to control the RF source and infusion device, for optimizing the time and extent of tissue ablation.

Owner:ANGIODYNAMICS INC

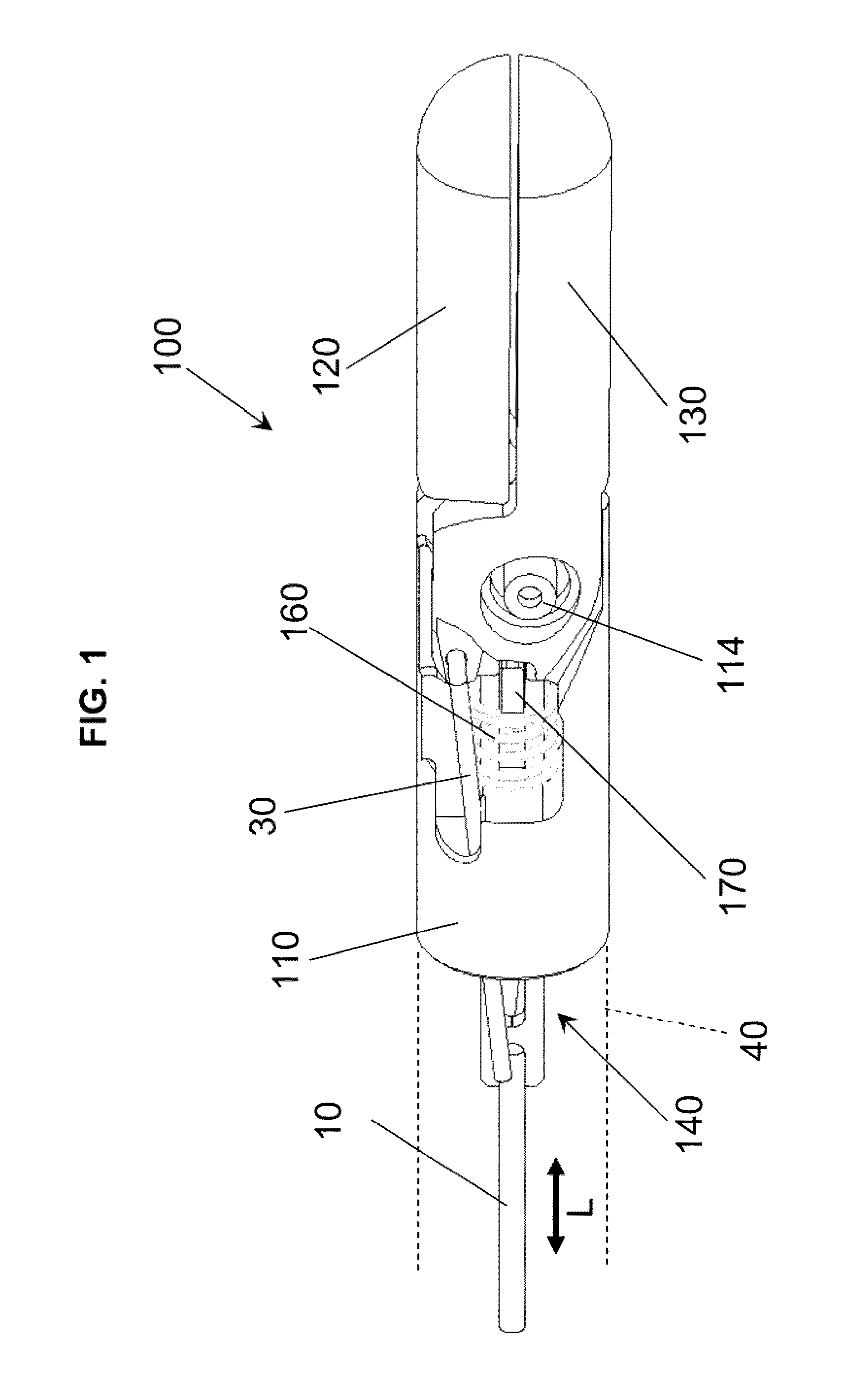

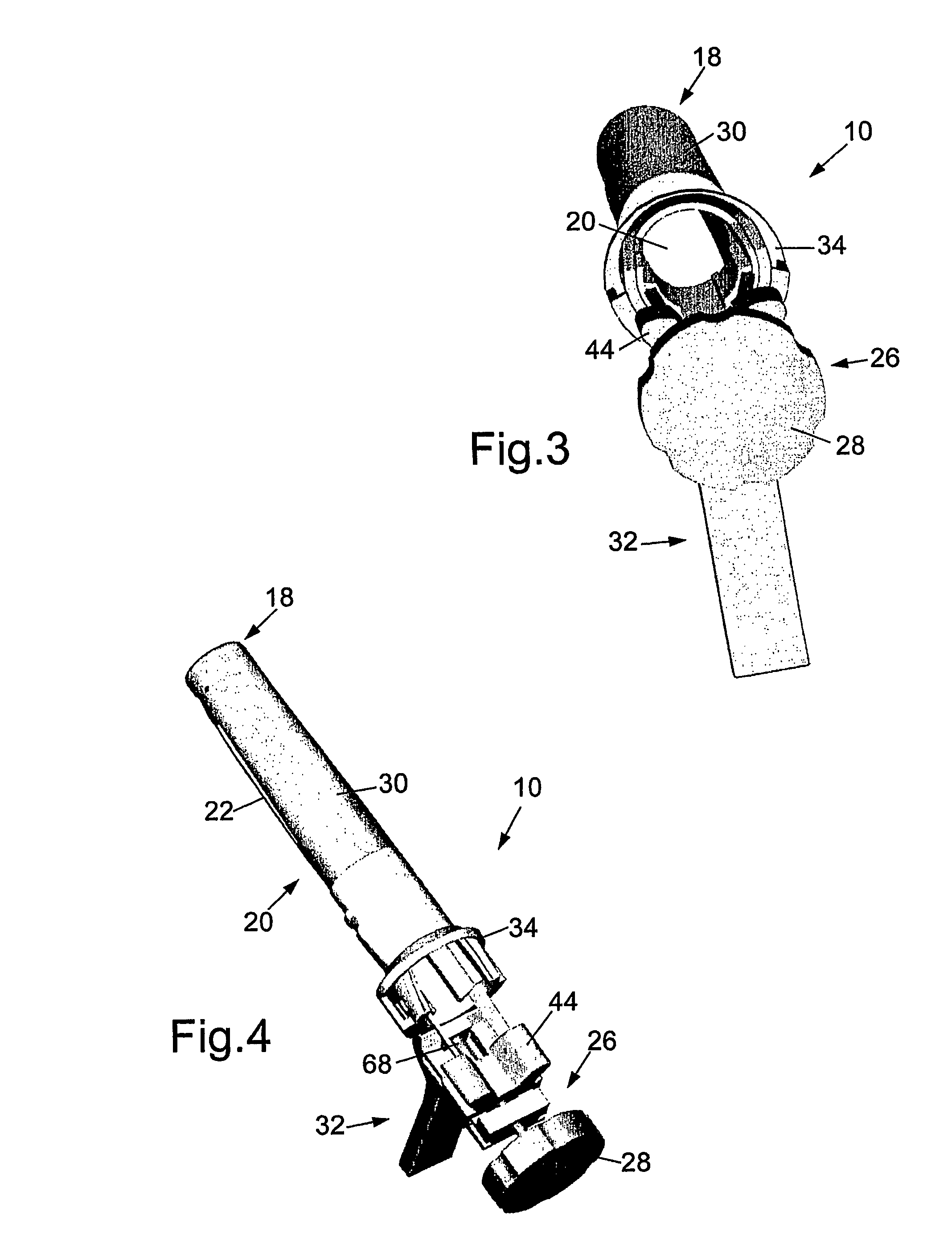

Cordless medical cauterization and cutting device

ActiveUS8328802B2Precise positioningSufficient forceSurgical instruments for heatingSurgical forcepsElectricityRadio frequency signal

A surgical device includes a radio-frequency-signal-generation assembly including a radio-frequency-signal-generation circuit operable to generate a radio-frequency signal at an output and adapted to couple to a switch-mode power supply and a surgical handle including an end effector having at least one jaw with at least one electrical contact, the end effector including at least one signal input that electrically connects to the output to provide the radio-frequency signal at the at least one electrical contact.

Owner:COVIDIEN AG

Method of performing anastomosis

InactiveUS7699859B2Precise positioningSecurely holdSuture equipmentsStapling toolsGeneral surgeryDistal anastomosis

Owner:AESCULAP AG

Impedance controlled tissue ablation apparatus and method

InactiveUS7344533B2Improve the level ofIncrease in sizeSurgical needlesDiagnostic recording/measuringRf ablationControl cell

A method and apparatus for carrying our thermal ablation of target tissue is disclosed. The apparatus includes an RF ablation device having a multi-electrode electrode assembly designed to be deployed in target tissue, defining a selected-volume tissue region to be ablated, and having infusion channels for infusing a liquid into the target tissue during the ablation process. A control unit in the apparatus is operably connected to an RF energy source, for controlling the RF power level supplied to the electrodes, and to an infusion device, for controlling the rate of infusion of a liquid through the device into the tissue. During both electrode deployment and tissue ablation, impedance and or temperature measurements made within the tissue are used to control the RF source and infusion device, for optimizing the time and extent of tissue ablation.

Owner:ANGIODYNAMICS INC

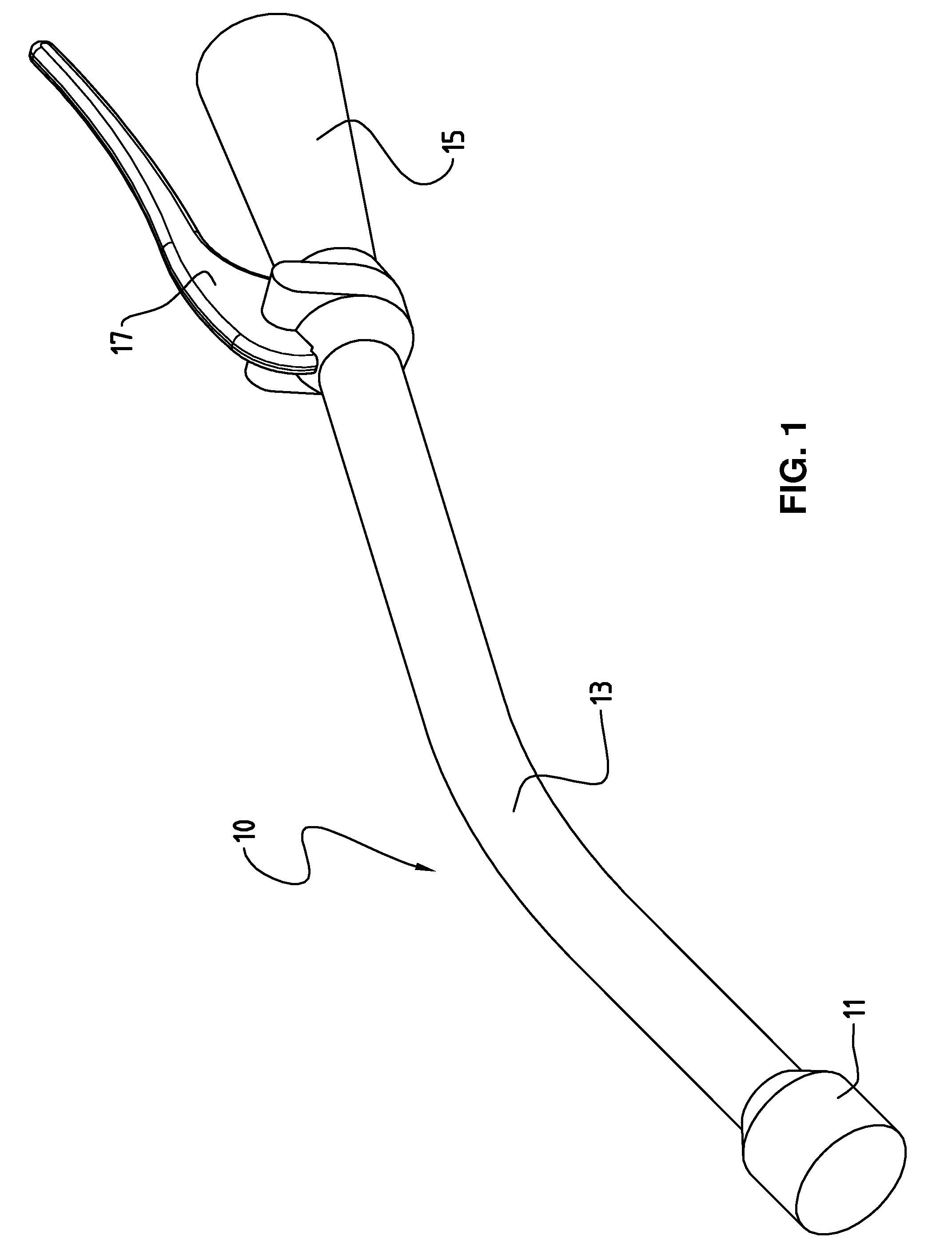

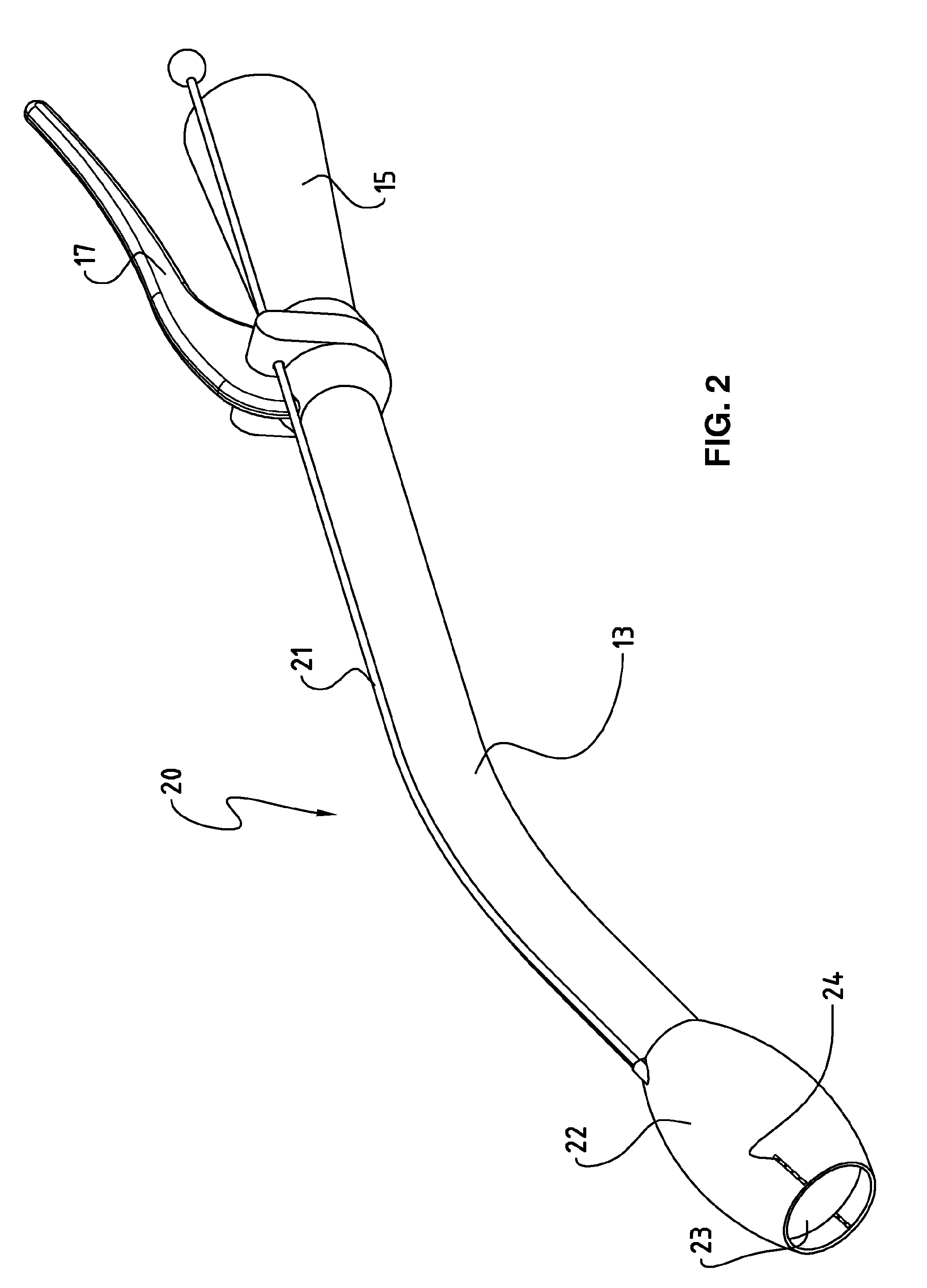

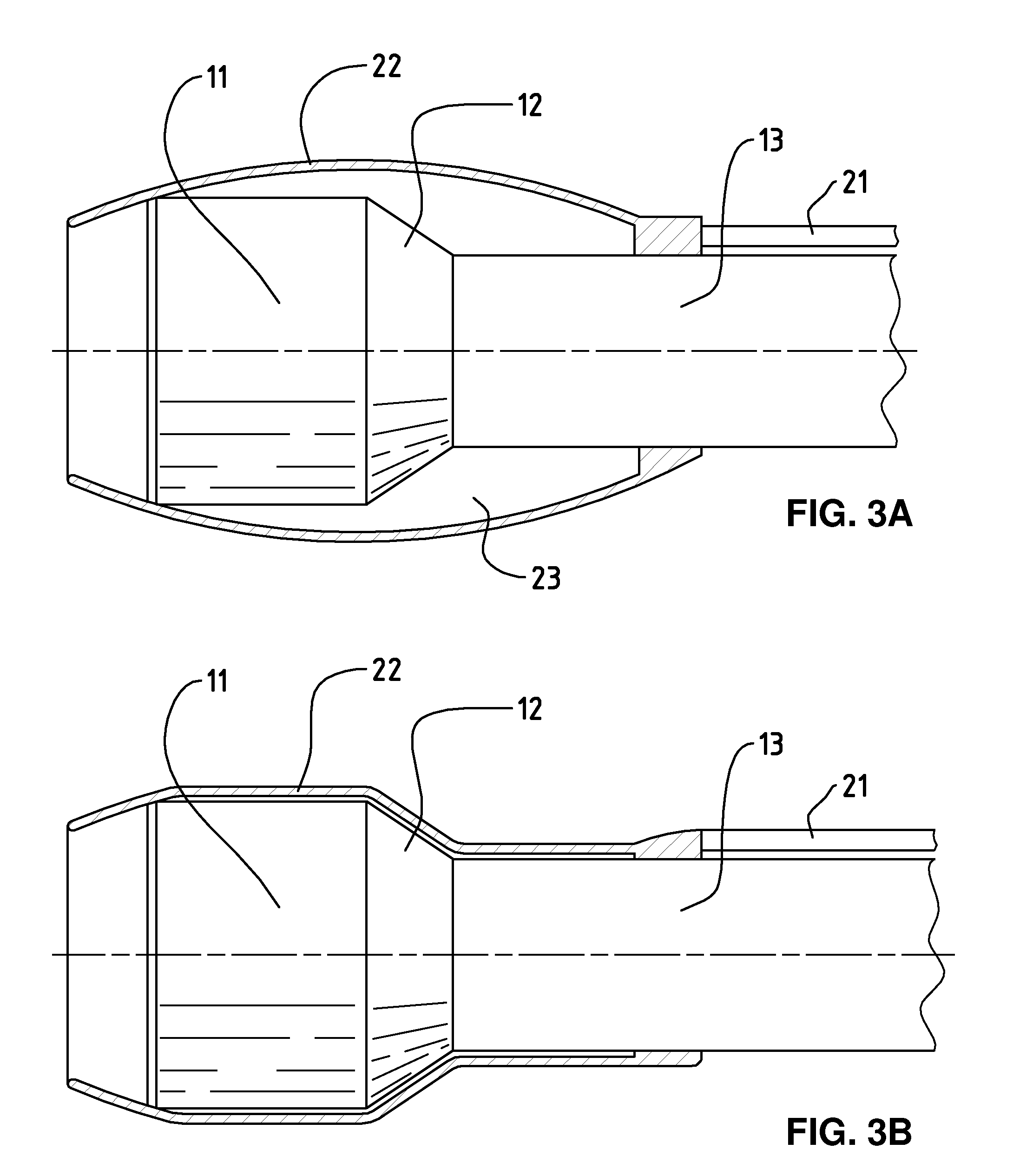

Device for introducing and positioning surgical instruments and corresponding method

InactiveUS20090204108A1Precise and simple and quick insertionPrecise positioningDiagnosticsSurgical drapesSurgical operationEngineering

This invention relates to a device (20) for inserting and positioning surgical instruments (10) in the body of a patient, with an outer cover (22), into which outer cover (22) at least a front part (11) of the surgical instrument (10) is insertable, and which outer cover (22) is removable for positioning the surgical instrument (10) at the point of application, the outer cover (22) being pulled away from the front part (11) of the surgical instrument (10) by means of a pulling device (21). In particular, the outer cover (22) is able to be pulled backwards over the front part (21) <sic. (11)> of the surgical instrument (10), and the surgical instrument (10), or respectively its front part, is able to be uncovered again, so that the function assigned to the surgical instrument (10) is able to be carried out unimpeded. The outer cover (22) can be returned to the starting position, in particular also by means of a return device. The outer cover (22) is preferably able to be controlled by means of the pulling device (21) using the handle (15) of the surgical instrument (10).

Owner:STEFFEN RUDOLF

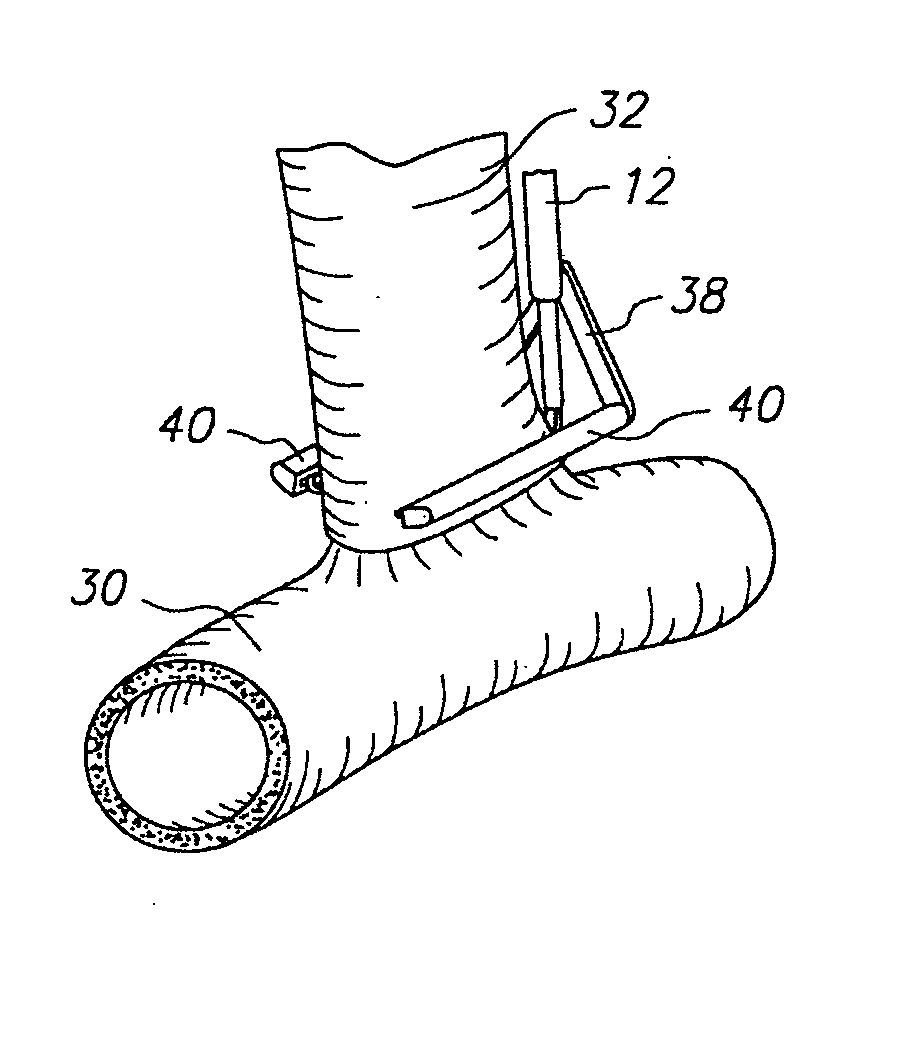

Method for anastomosing vessels

InactiveUS20050154406A1Precise positioningSecurely holdSuture equipmentsDiagnosticsSurgeryBlood vessel

A method for connecting a graft vessel to a target vessel, each vessel having a wall surrounding a lumen, may include providing a connector holder, associating an end of the graft vessel with the connector holder, positioning the connector holder outside of the lumen of the target vessel, outside the lumen of the graft vessel, and in proximity to the outer surface of the wall of the target vessel, and actuating the connector holder to secure the end of the graft vessel to the side of the target vessel.

Owner:AESCULAP AG

Drug depot implant designs

ActiveUS7727954B2Uniform drug distributionMinimal disruptionPowder deliveryPeptide/protein ingredientsSkeletal injuryChronic pain

Owner:WARSAW ORTHOPEDIC INC

Surgical access device with pendent valve

InactiveUS7083626B2Precise positioningMaximize ease and safetyEar treatmentCannulasSurgical departmentVALVE PORT

A surgical access device, such as a trocar, includes a pendent valve having an elongate structure extending from a proximal end to a septum valve disposed at a distal end. In operation, the elongate structure follows the angle of the instrument to pre-position the septum valve into the path of the instrument where it is not significantly challenged during instrument insertion or manipulation. The pendant valve can be made to float at both the proximal end and the distal end of the elongate structure, to further reduce the vulnerability of the septum valve. Since the valve is less vulnerable to instrument insertion, it can be formed to minimize friction and maximize the functional range of the access device.

Owner:APPL MEDICAL RESOURCES CORP

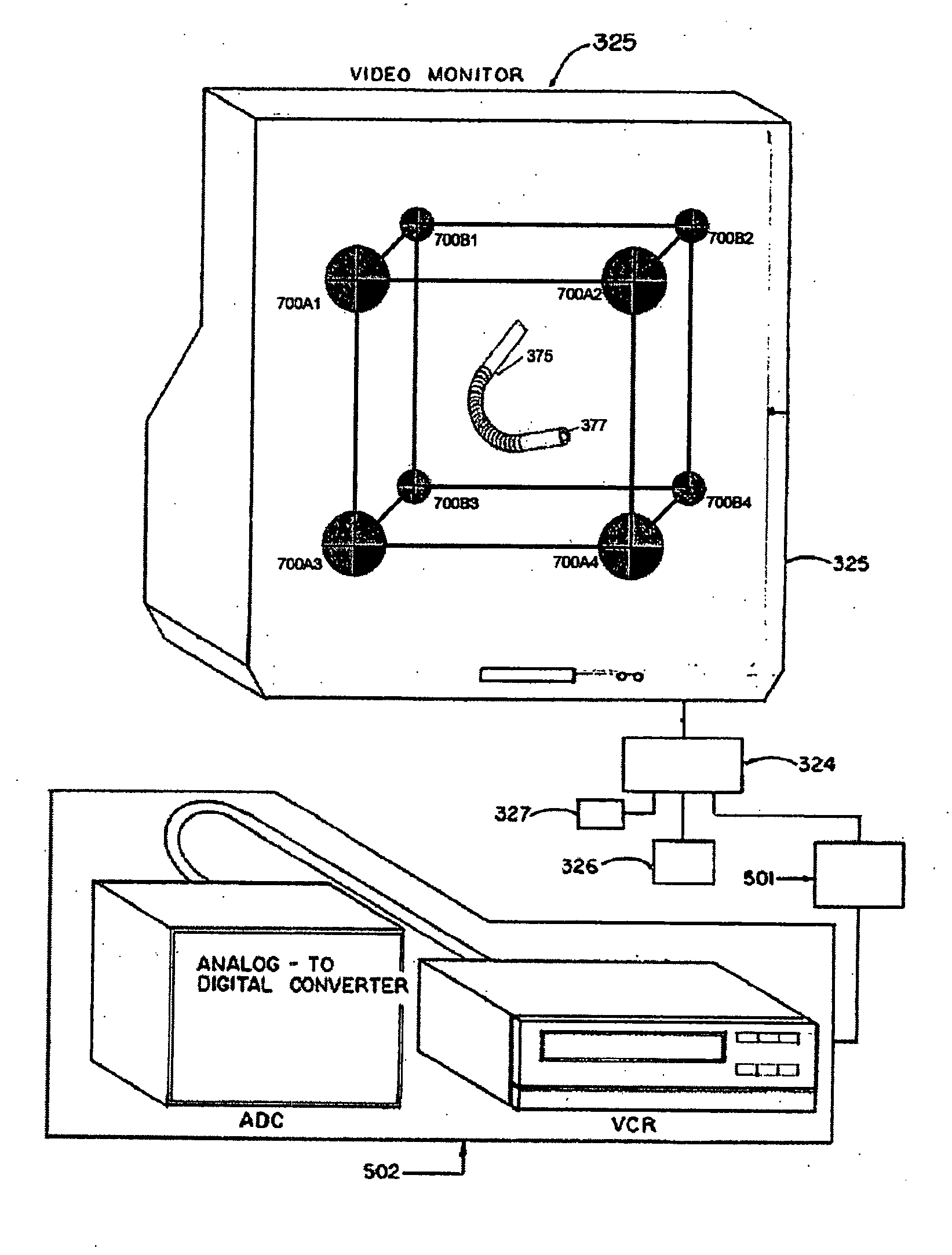

System and method for controlling movement of a surgical tool

InactiveUS20060116634A1Less trainingMinimizing x-ray and contrast material exposureSurgical navigation systemsMedical devicesEndoscopeBiopsy needles

A system whereby a magnetic tip attached to a surgical tool is detected, displayed and influenced positionally so as to allow diagnostic and therapeutic procedures to be performed rapidly, accurately, simply, and intuitively is described. The tools that can be so equipped include catheters, guidewires, and secondary tools such as lasers and balloons, in addition biopsy needles, endoscopy probes, and similar devices. The magnetic tip allows the position and orientation of the tip to be determined without the use of x-rays by analyzing a magnetic field. The magnetic tip further allows the tool tip to be pulled, pushed, turned, and forcefully held in the desired position by applying an appropriate magnetic field external to the patient's body. A Virtual Tip serves as an operator control. Movement of the operator control produces corresponding movement of the magnetic tip inside the patient's body. Additionally, the control provides tactile feedback to the operator's hand in the appropriate axis or axes if the magnetic tip encounters an obstacle. The output of the control combined with the magnetic tip position and orientation feedback allows a servo system to control the external magnetic field by pulse width modulating the positioning electromagnet. Data concerning the dynamic position of a moving body part such as a beating heart offsets the servo systems response in such a way that the magnetic tip, and hence the secondary tool is caused to move in unison with the moving body part. The tip position and orientation information and the dynamic body part position information are also utilized to provide a display that allows three dimensional viewing of the magnetic tip position and orientation relative to the body part.

Owner:NEURO KINESIS CORP

Method for powering a surgical instrument

ActiveUS8491581B2Precise positioningSufficient forceSurgical instruments for heatingSurgical forcepsRadio frequency signalEngineering

A method for powering an electrosurgical instrument includes the steps of inserting a removable battery assembly into an electrosurgical instrument and activating the power control circuit to power the electrosurgical instrument. The removable battery assembly includes a power control circuit powered by at least one energy storage cell, a radio-frequency-signal-generation assembly communicatively coupled to the power control circuit and operable to selectively produce a radio-frequency signal, and a battery assembly / instrument interface operably coupled to the radio-frequency-signal-generation assembly. The battery assembly / instrument interface includes a first plurality of connectors removably connectable with at least one corresponding connector coupled to the electrosurgical instrument, at least one of the first plurality of connectors being operable to supply the radio-frequency signal to the electrosurgical instrument.

Owner:COVIDIEN AG

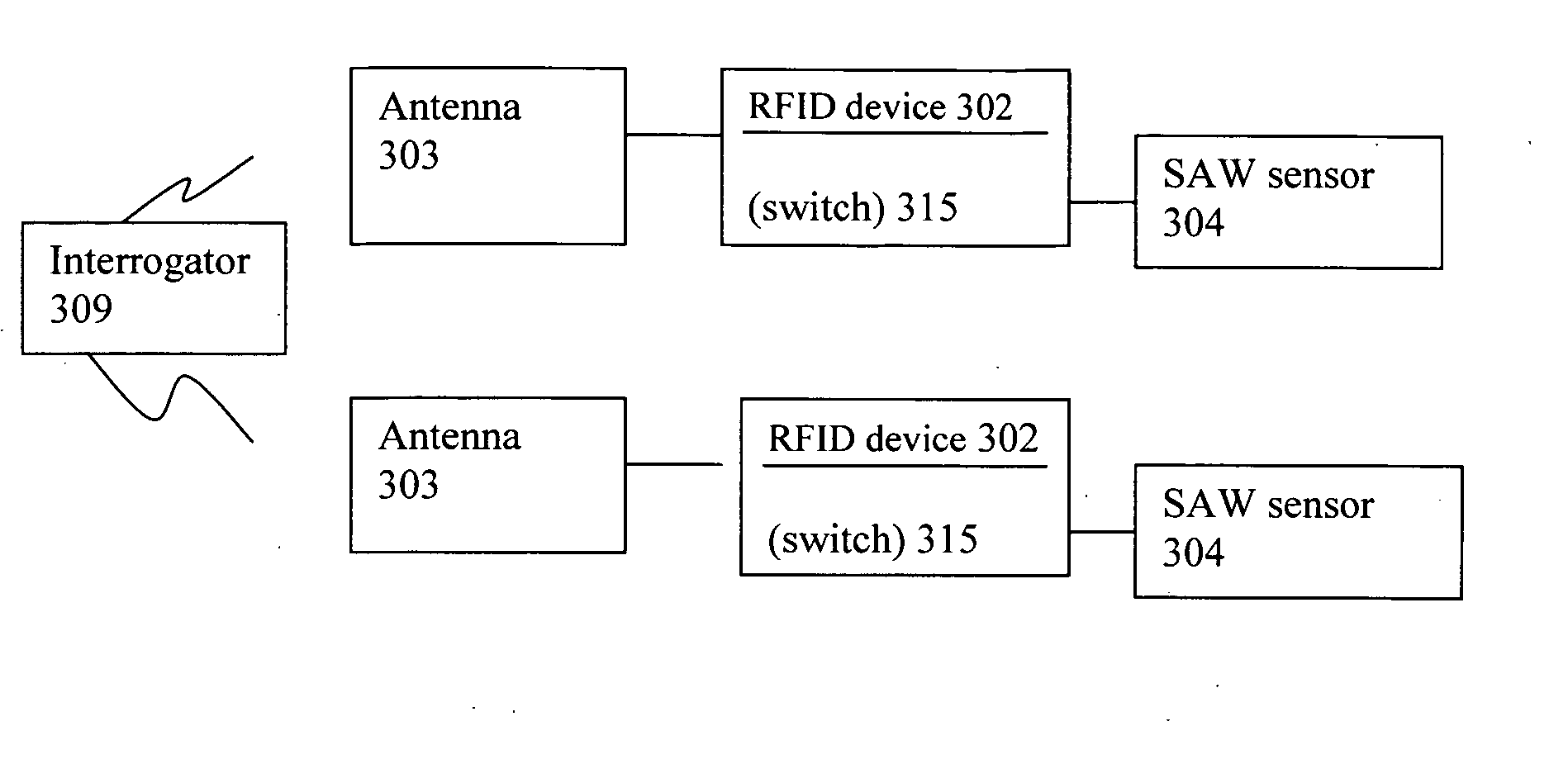

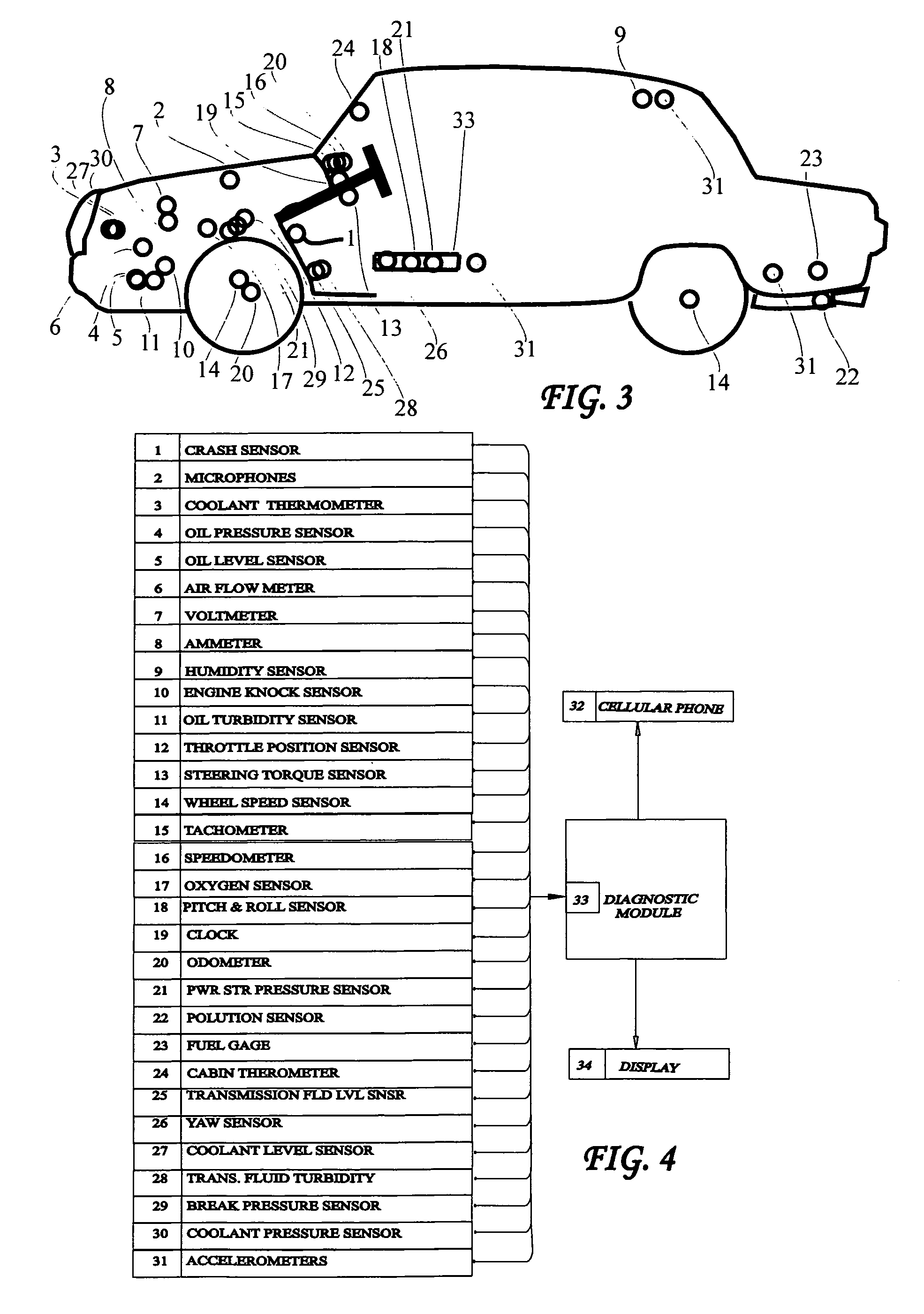

Sensor assemblies

InactiveUS20060025897A1Low costPrecise positioningVehicle testingRegistering/indicating working of vehiclesRadio frequency signalPhysical quantity

Sensor assembly capable of obtaining and providing a measurement of a physical quantity, e.g., measurement of temperature and / or pressure of a vehicular tire, includes an antenna capable of receiving a radio frequency signal, a radio frequency identification (RFID) device coupled to the antenna, a sensor coupled to the RFID device arranged to generate a measurement of the physical quantity or quantities, and a switch coupled to the RFID device and arranged to connect or disconnect the sensor from a circuit with the antenna dependent on whether the antenna receives a particular signal associated with the RFID device. When the antenna receives the particular signal associated with the RFID device, the RFID device causes the switch to close and connect the sensor in the circuit with the antenna to enable the measurement generated by the sensor to be directed to and transmitted by the antenna.

Owner:AMERICAN VEHICULAR SCI

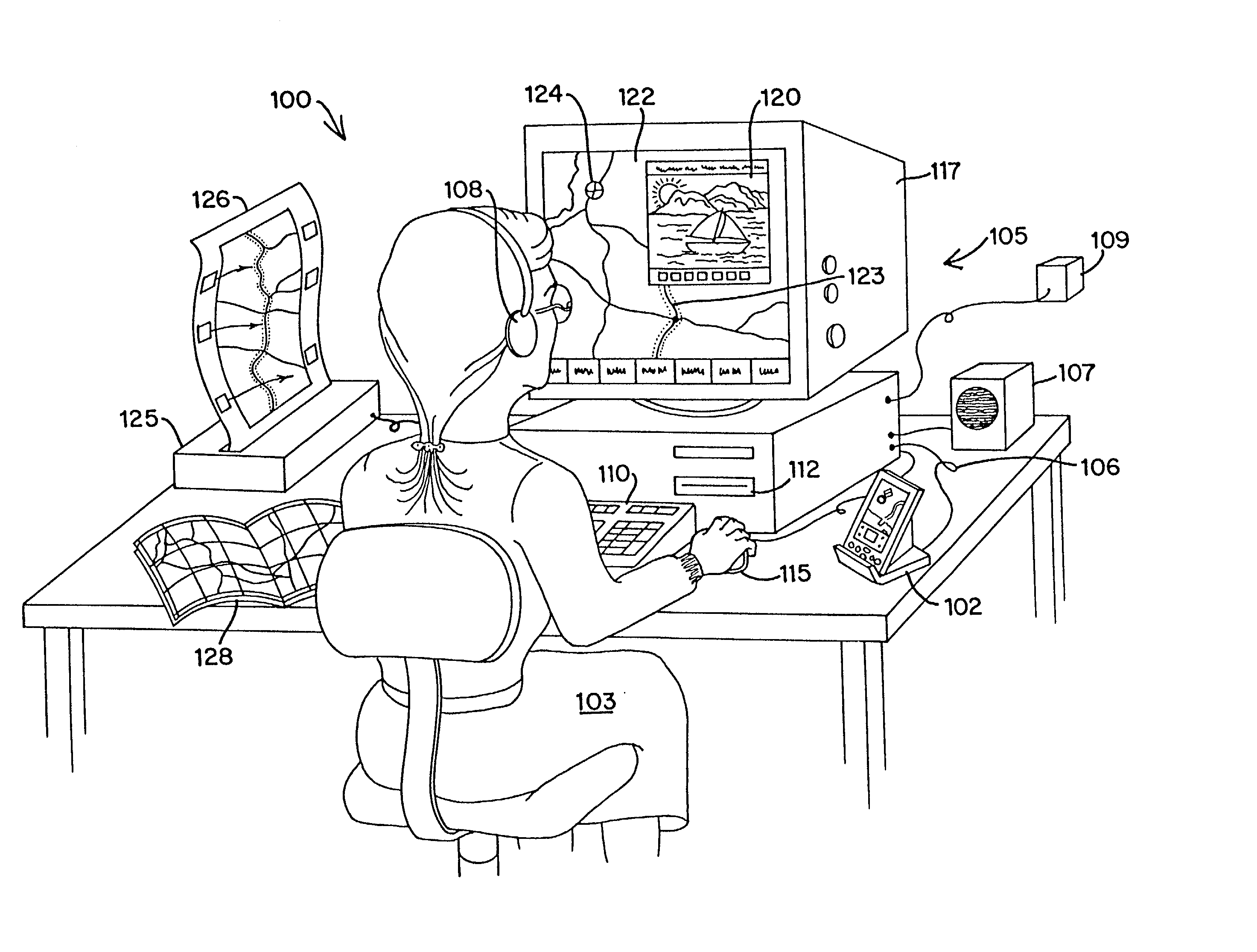

Integrated routing/mapping information system

InactiveUS20030182052A1Enabling cooperationEnabling matingInstruments for road network navigationRoad vehicles traffic controlImage resolutionLevel of detail

An Integrated Routing / Mapping Information System (IRMIS) links desktop personal computer cartographic applications to one or more handheld organizer, personal digital assistant (PDA) or "palmtop" devices. Such devices may be optionally equipped with, or connected to, portable Global Positioning System (GPS) or equivalent position sensing device. Desktop application facilitates user selection of areas, starts, stops, destinations, maps and / or point and / or route information. It optionally includes supplemental online information, preferably for transfer to the PDA or equivalent device. Users' options include route information, area, and route maps. Maps and related route information are configured with differential detail and levels of magnitude. Used in the field, in conjunction with GPS receiver, the PDA device is configured to display directions, text and map formats, the user's current position, heading, speed, elevation, and so forth. Audible signals identifying the next turn along the user's planned route are also provided. The user can pan across maps and zoom between two or more map scales, levels of detail, or magnitudes. The IRMIS also provides for "automatic zooming," e.g., to show greater detail or closer detail as the user approaches a destination, or to larger scale and lower resolution to show the user's overall planned route between points of interest. The IRMIS also enables the user to mark or record specific locations and / or log actual travel routes, using GPS position information. These annotated location marks and / or "breadcrumb" or GPS log data can be saved, uploaded, displayed, or otherwise processed on the user's desktop geographic information or cartographic system. The IRMIS application and data may be distributed online and / or in tangible media in limited and advanced manipulation formats.

Owner:KHOURI ANTHONY

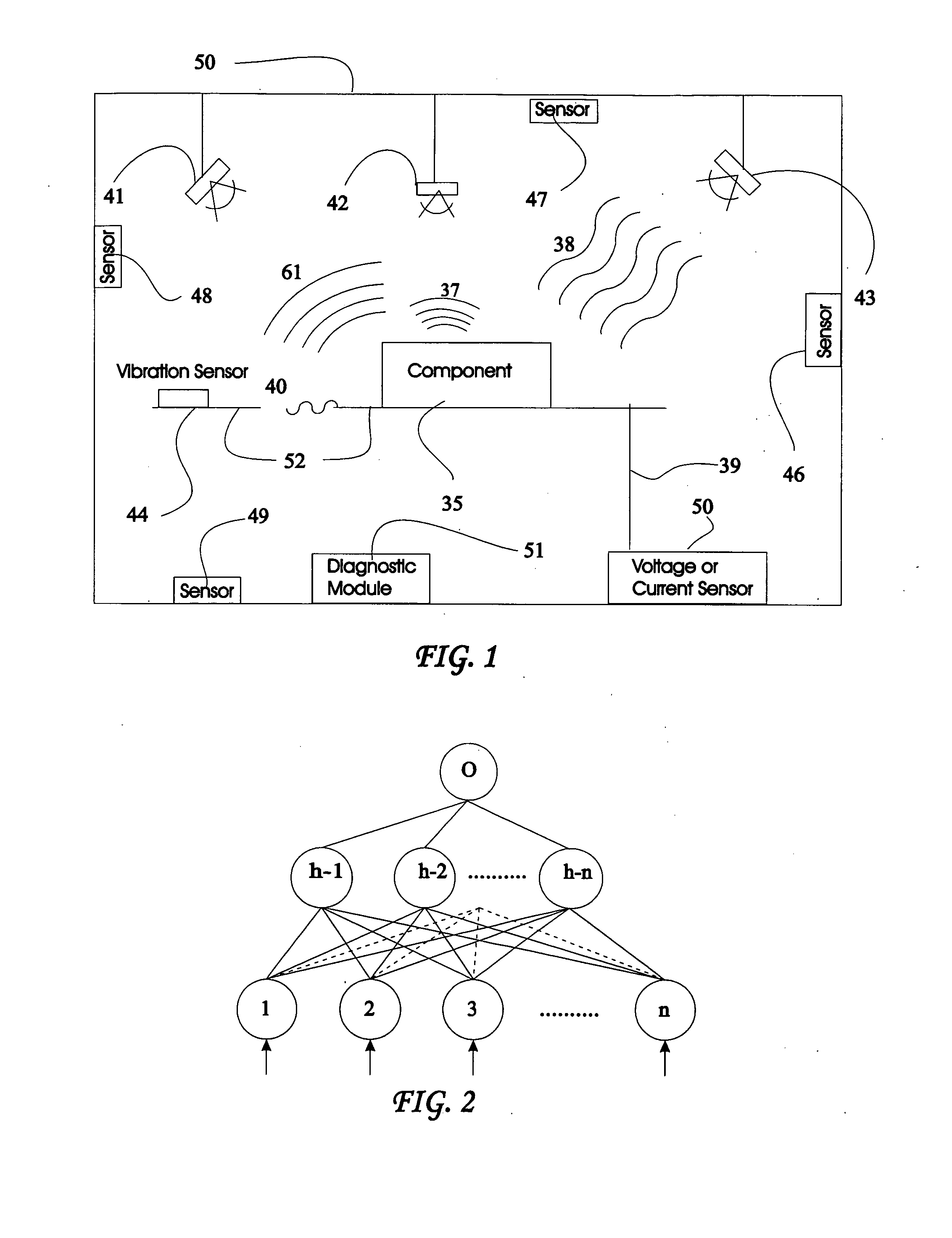

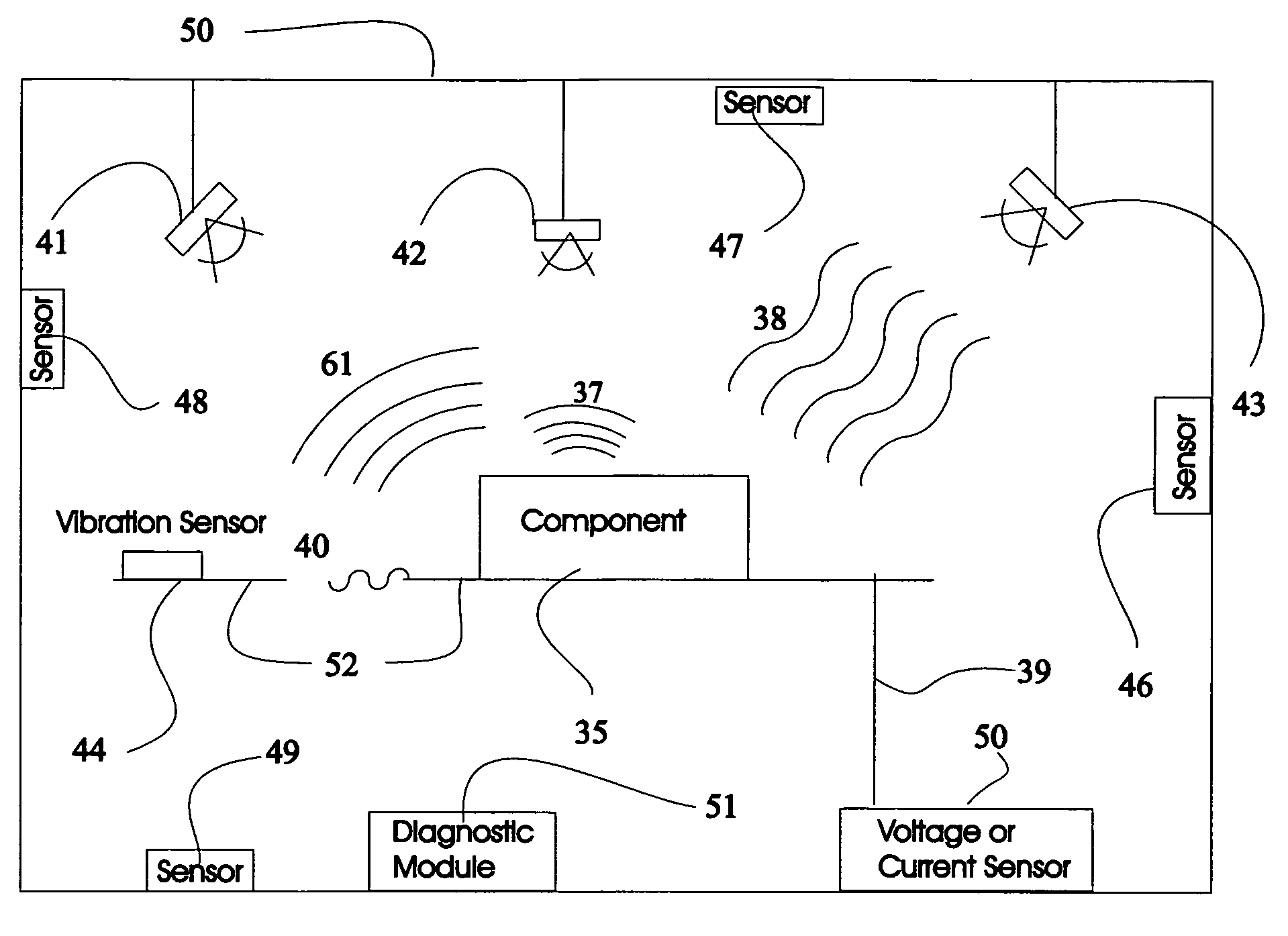

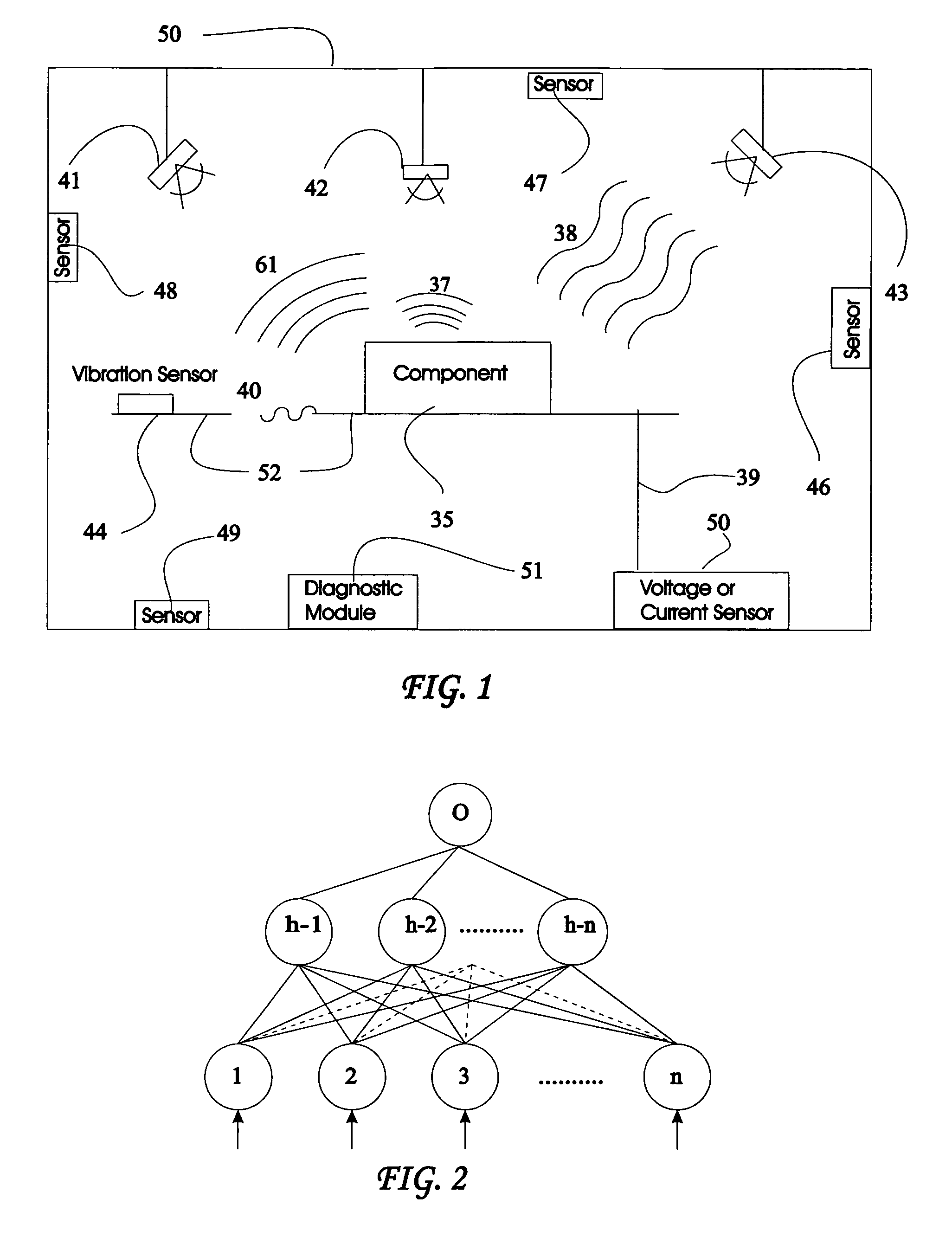

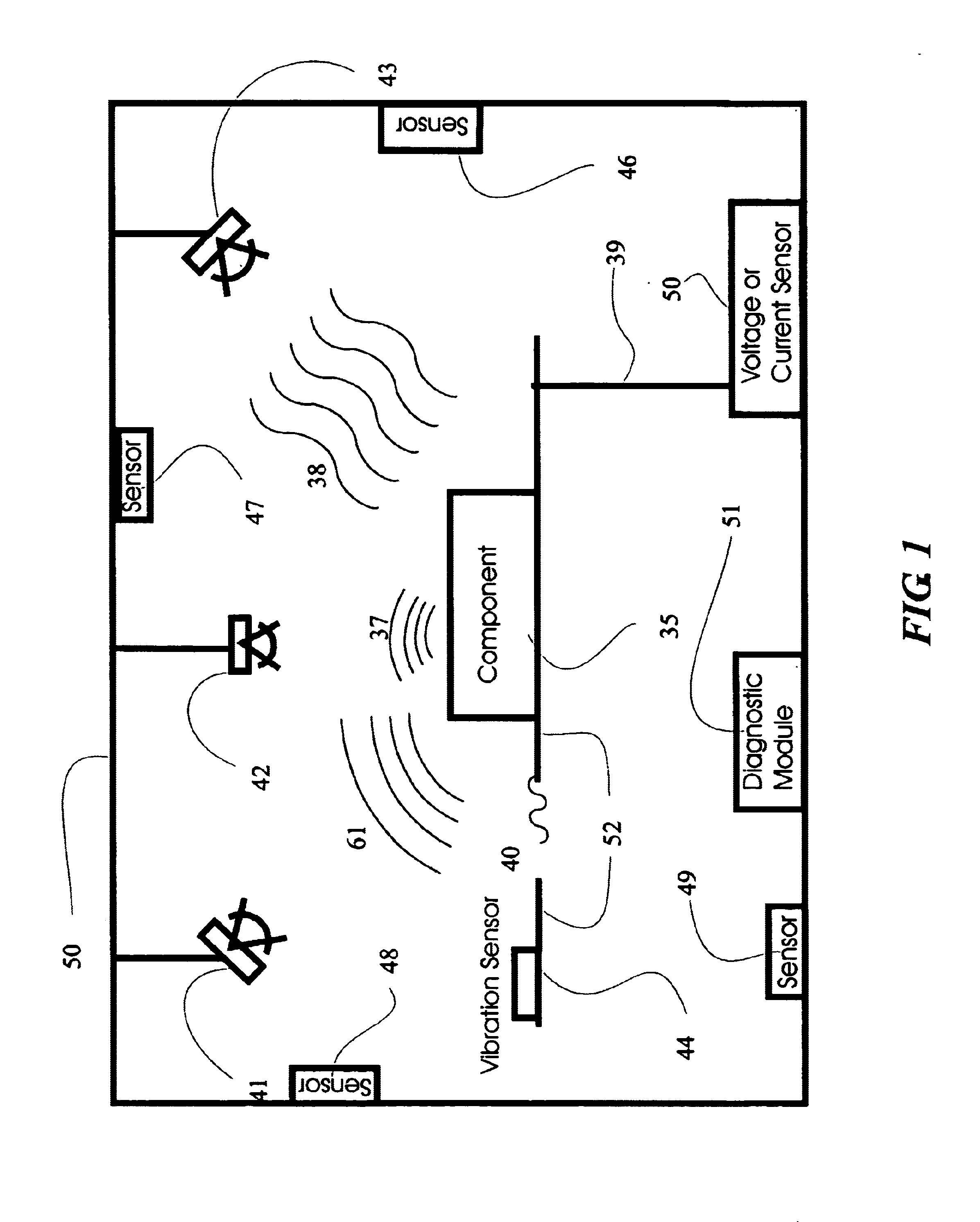

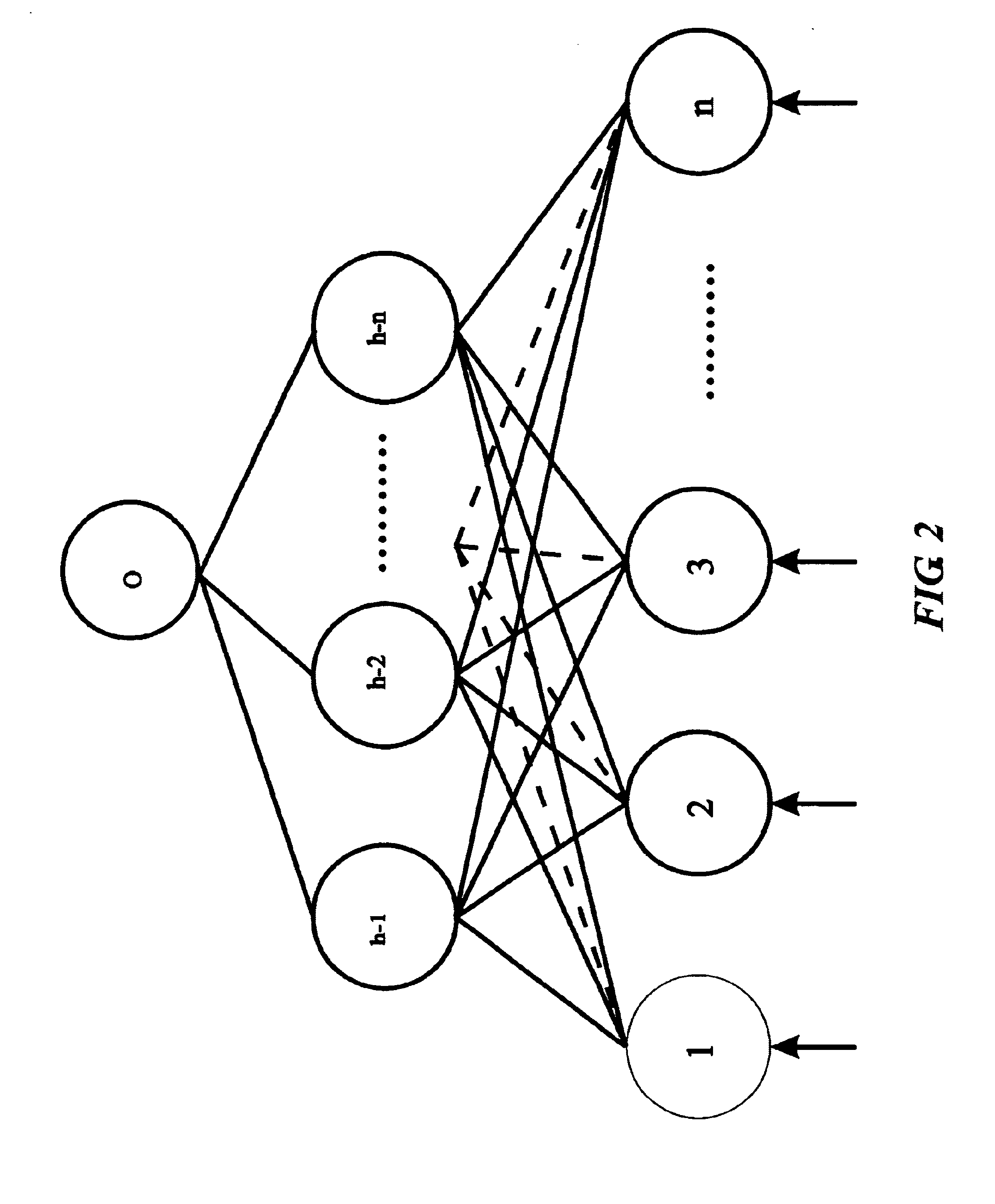

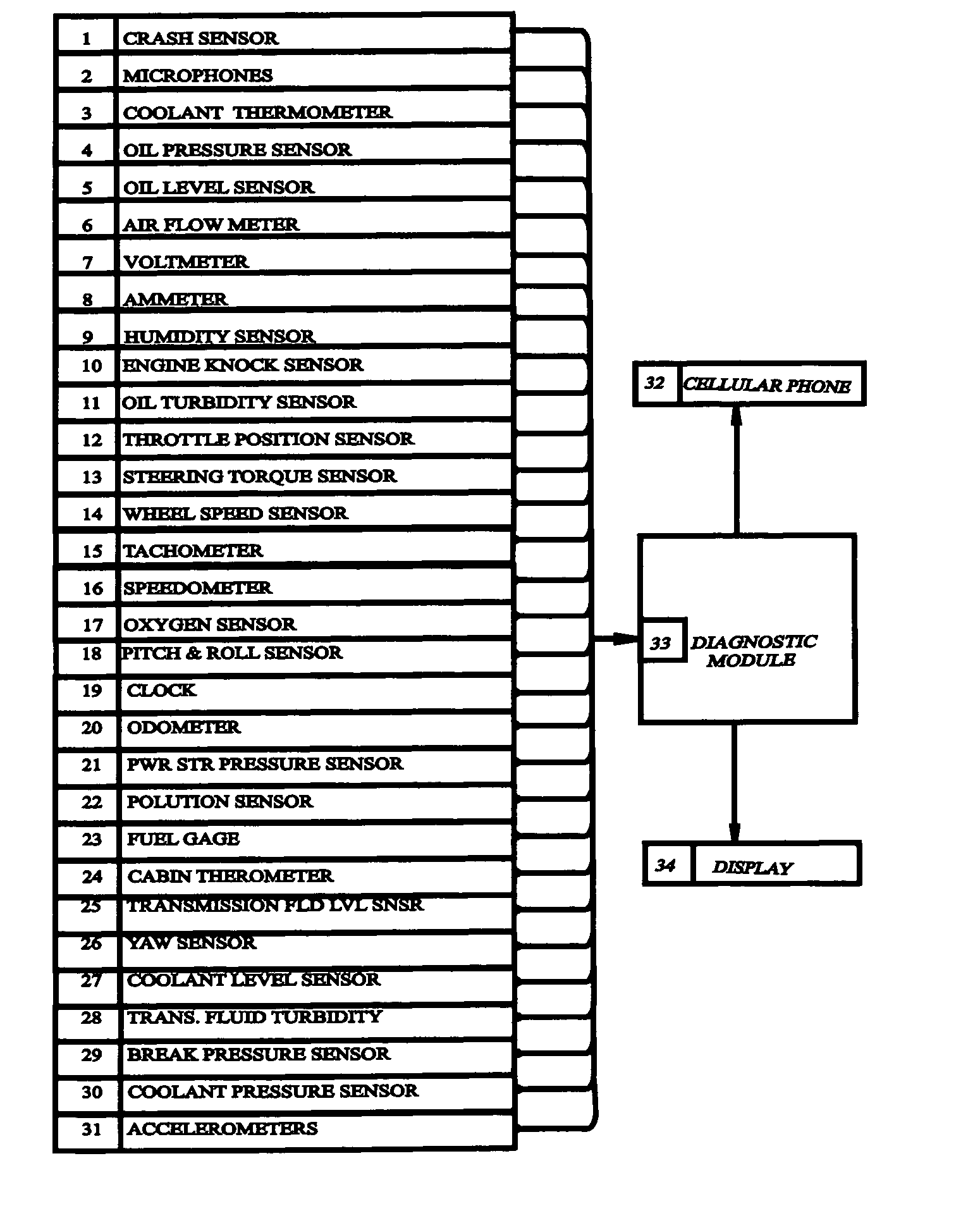

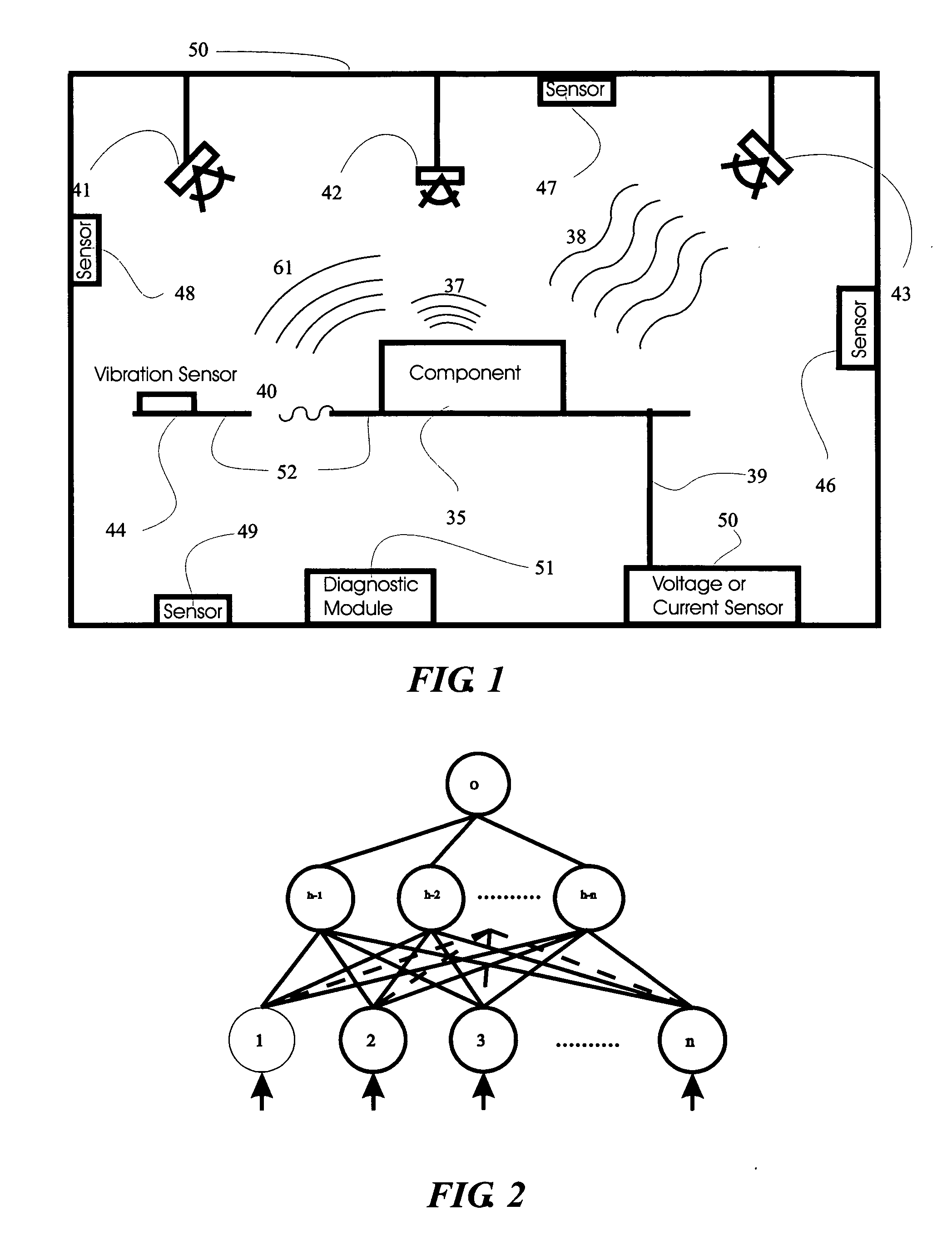

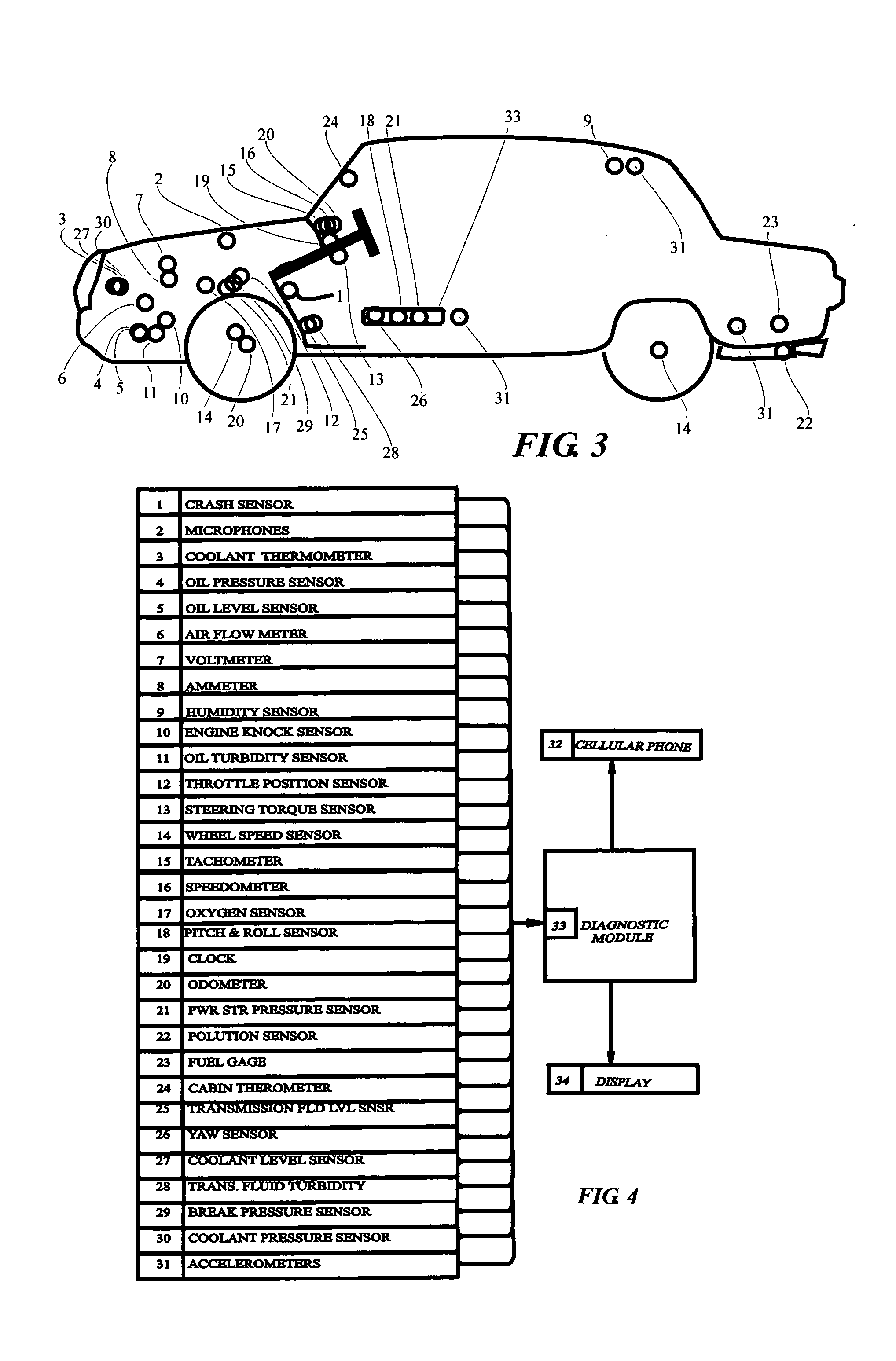

System and method for vehicle diagnostics

InactiveUS7103460B1Low costPrecise positioningVehicle testingRegistering/indicating working of vehiclesReliability engineeringDiagnostic methods

Method and system for diagnosing whether vehicular components are operating abnormally based on data obtained from sensors arranged on a vehicle. In a training stage, output from the sensors during normal operation of the components is obtained, each component is adjusted to induce abnormal operation thereof and output from the sensors is obtained during the induced abnormal operation. A determination is made as to which sensors provide data about abnormal operation of each component based on analysis of the output from the sensors during normal operation and during induced abnormal operation of the components. During operation of the vehicle, the output from the sensors is obtained and analyzed, e.g., by inputting it into a pattern recognition algorithm or neural network generated during the training stage, in order to output an indication of abnormal operation of any components being diagnosed.

Owner:AMERICAN VEHICULAR SCI

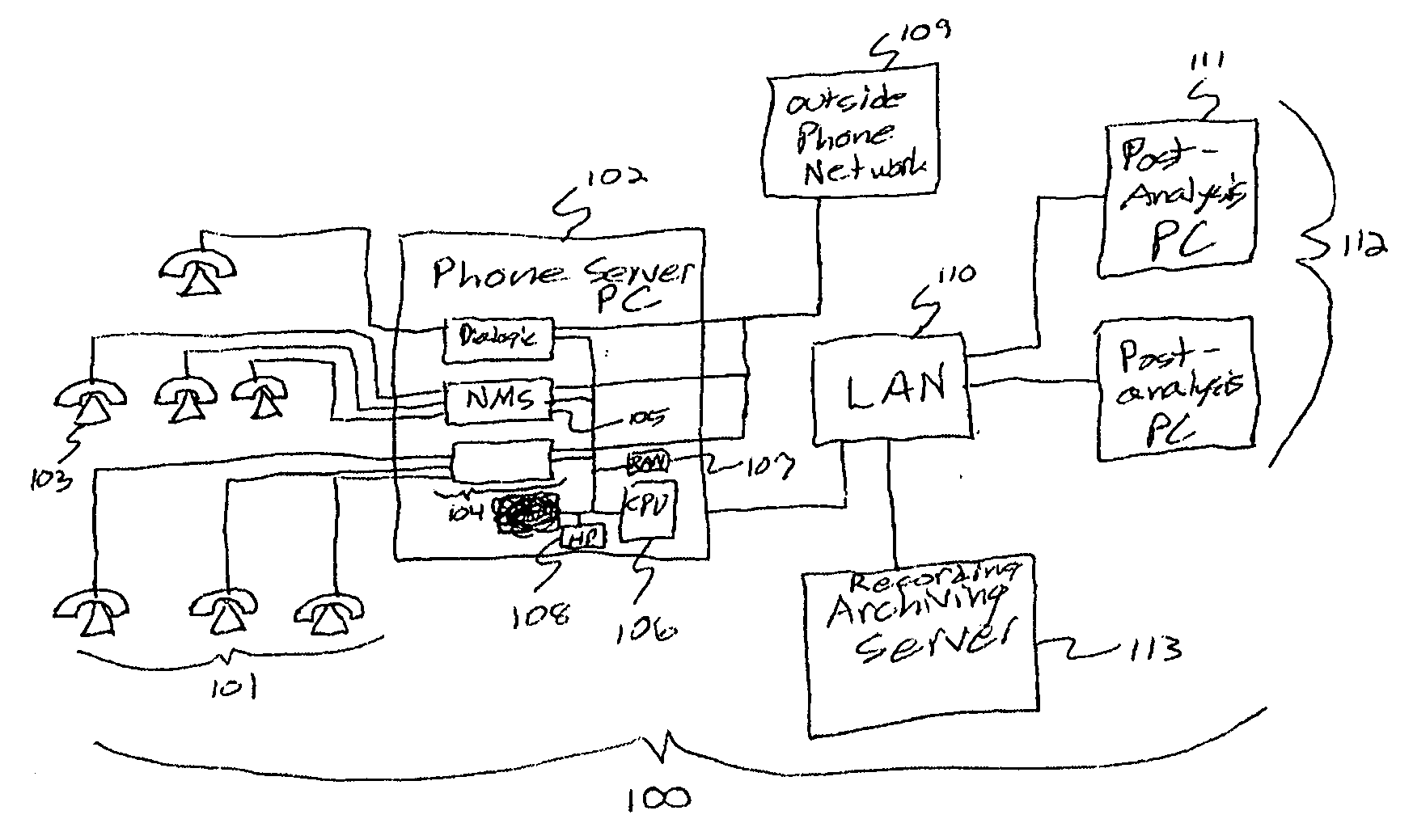

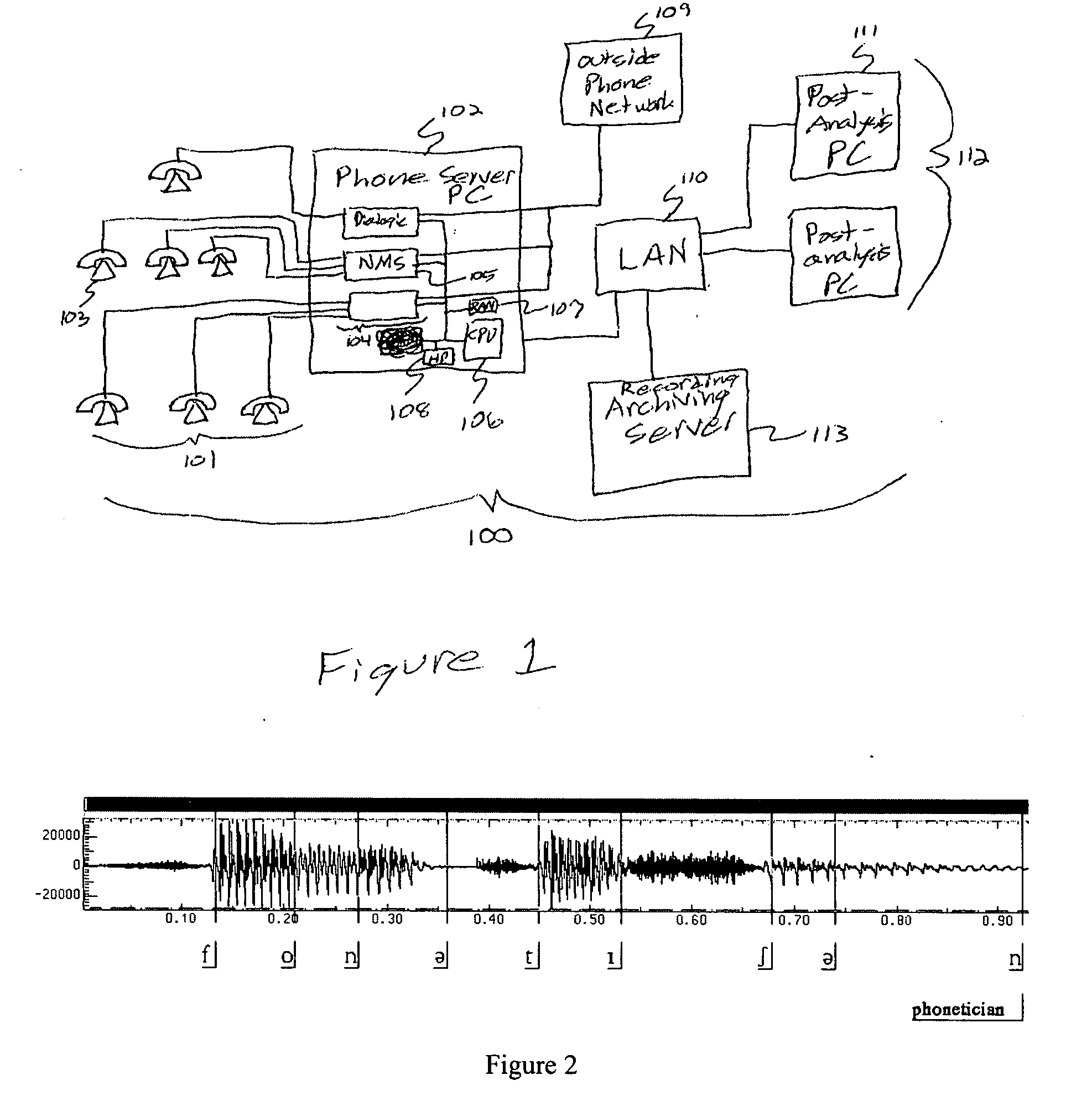

Multi-party conversation analyzer & logger

ActiveUS20070071206A1High precisionFacilitate interruptionInterconnection arrangementsSubstation speech amplifiersGraphicsSurvey instrument

A multi-party conversation analyzer and logger uses a variety of techniques including spectrographic voice analysis, absolute loudness measurements, directional microphones, and telephonic directional separation to determine the number of parties who take part in a conversation, and segment the conversation by speaking party. In one aspect, the invention monitors telephone conversations in real time to detect conditions of interest (for instance, calls to non-allowed parties or calls of a prohibited nature from prison inmates). In another aspect, automated prosody measurement algorithms are used in conjunction with speaker segmentation to extract emotional content of the speech of participants within a particular conversation, and speaker interactions and emotions are displayed in graphical form. A conversation database is generated which contains conversation recordings, and derived data such as transcription text, derived emotions, alert conditions, and correctness probabilities associated with derived data. Investigative tools allow flexible queries of the conversation database.

Owner:SECURUS TECH LLC

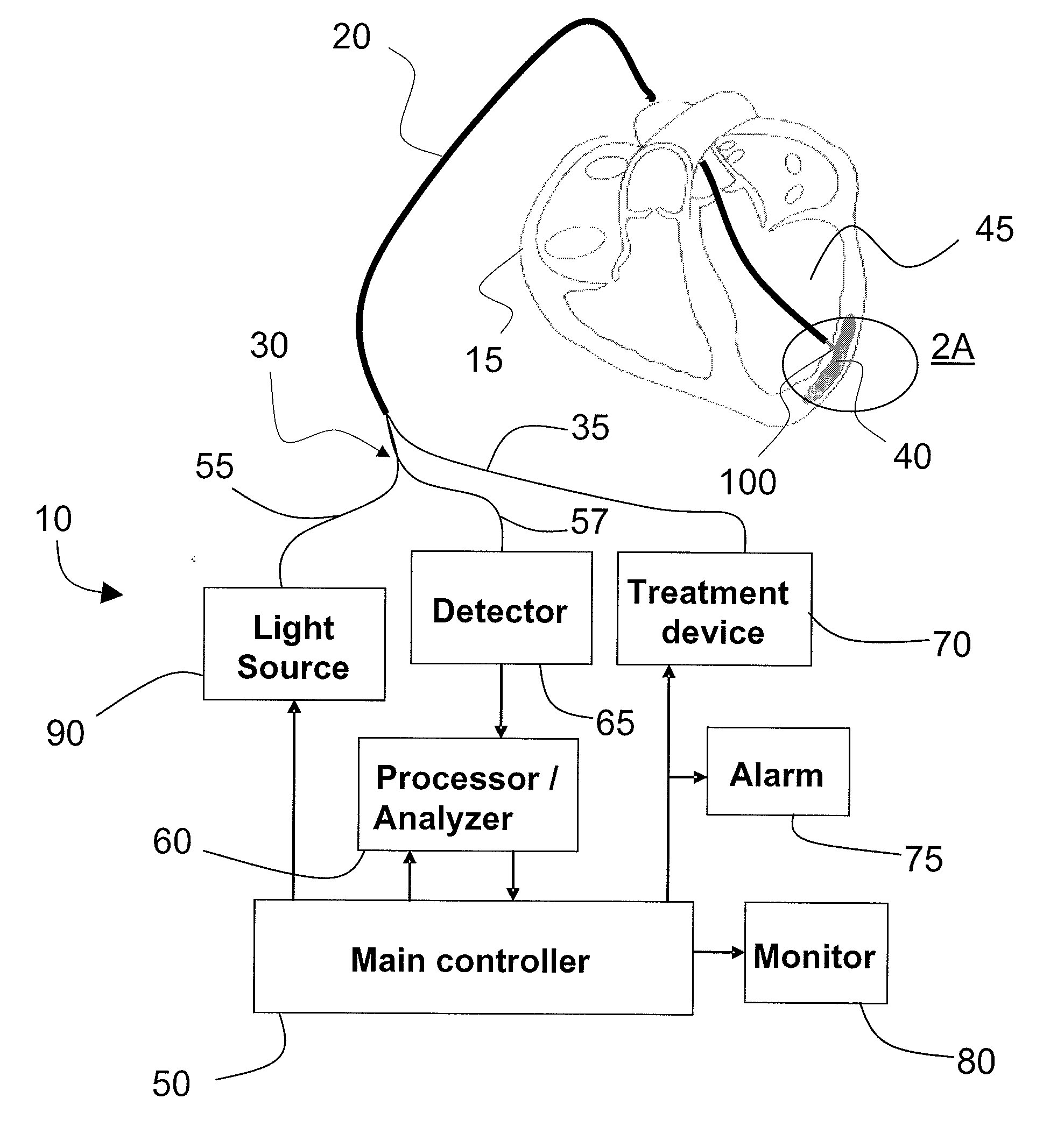

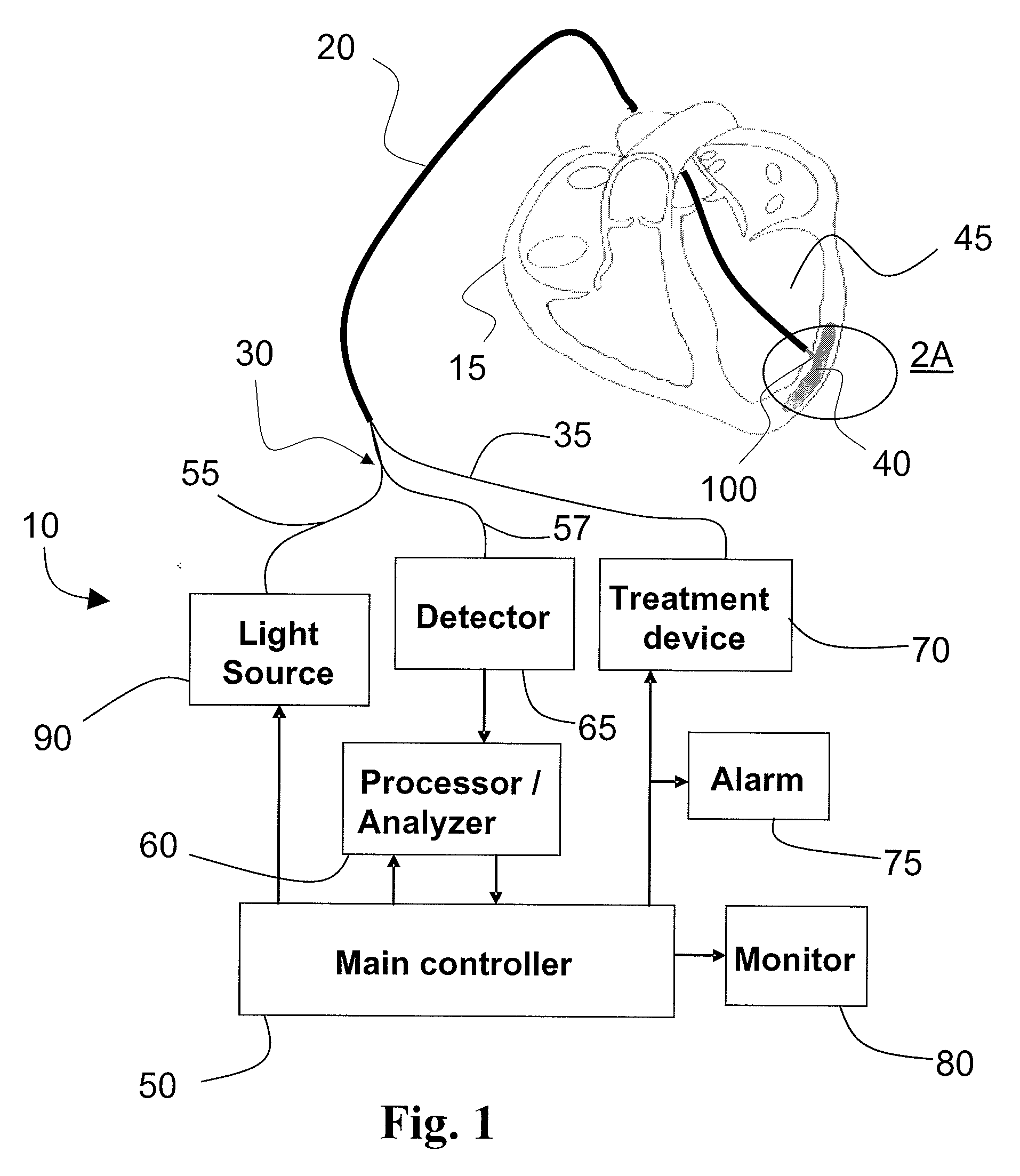

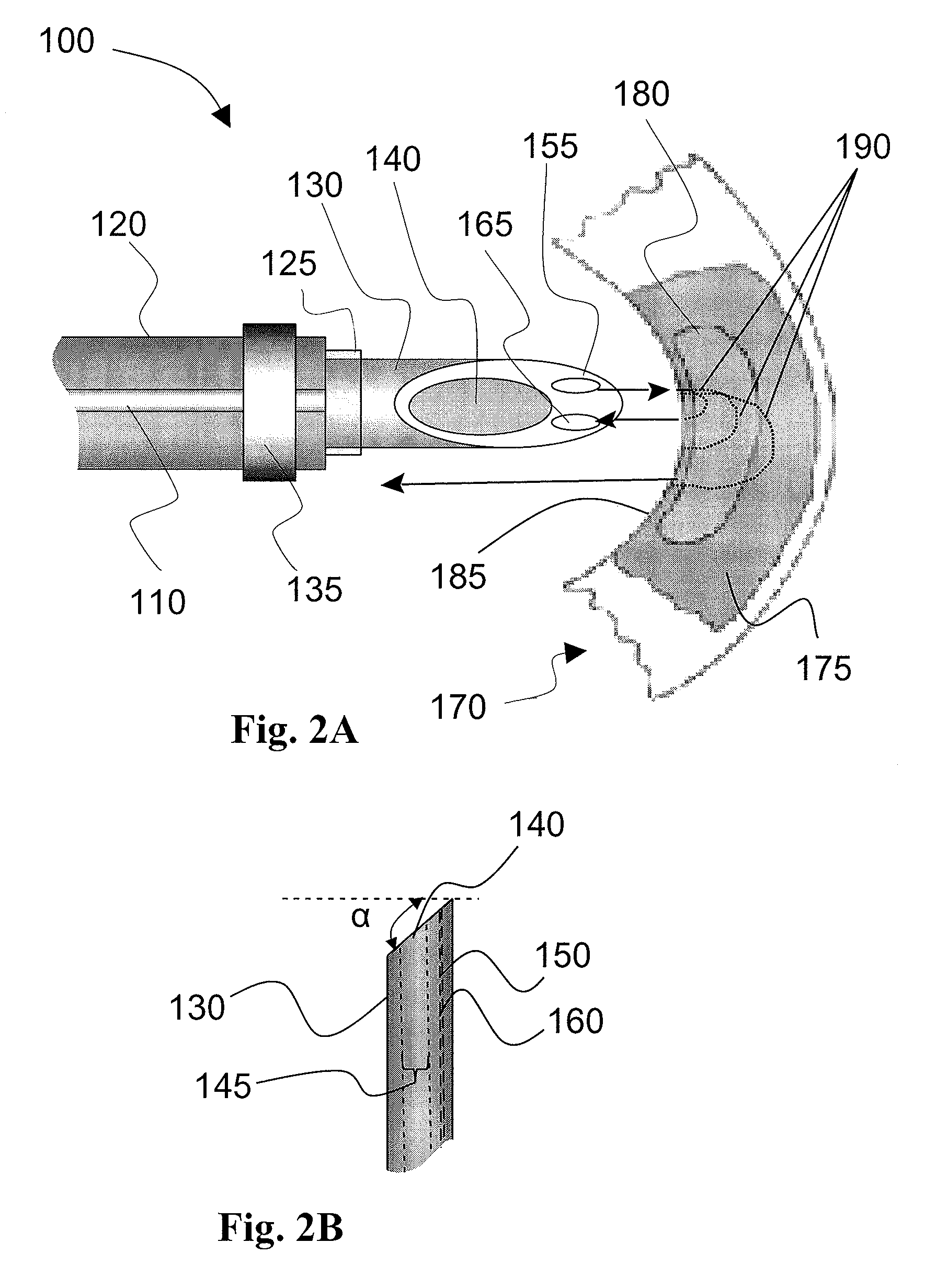

Method and apparatus for identifying and treating myocardial infarction

InactiveUS20080125634A1Safe and effectiveAccurate locationGuide needlesSurgical needlesVisual perceptionVisual feedback

A method and apparatus for analyzing and treating internal tissues and, in particular, tissues affected by myocardial infarct. The apparatus includes a catheterized device integrating an optical probe and treatment delivery system. The probe component includes fiber optic lines that can be used in conjunction with infrared spectroscopy to analyze various characteristics of tissues, including chemical, blood, and oxygen content, in order to locate those tissues associated with myocardial infarct, to determine the best location for applying treatment, and to monitor treatment and its effects. Physically integrated with the probe component is a treatment component for delivering treatments including stem cell and gene therapy, known for having beneficial effects on tissues associated with myocardial infarct. A control system coordinates operation of the catheter, including performing chemometric analysis with the use of model data, and for providing control and visual feedback to an operator.

Owner:CORNOVA

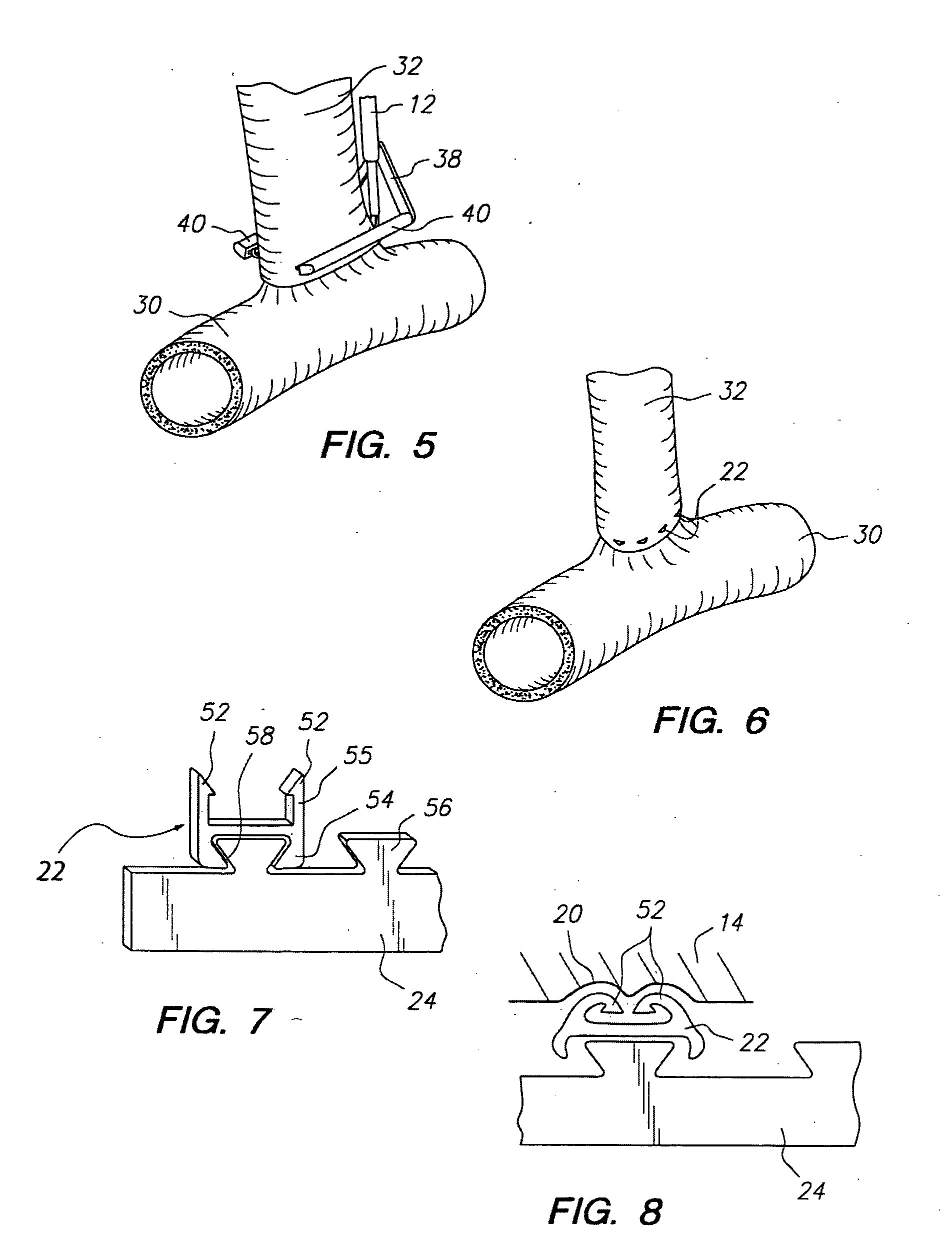

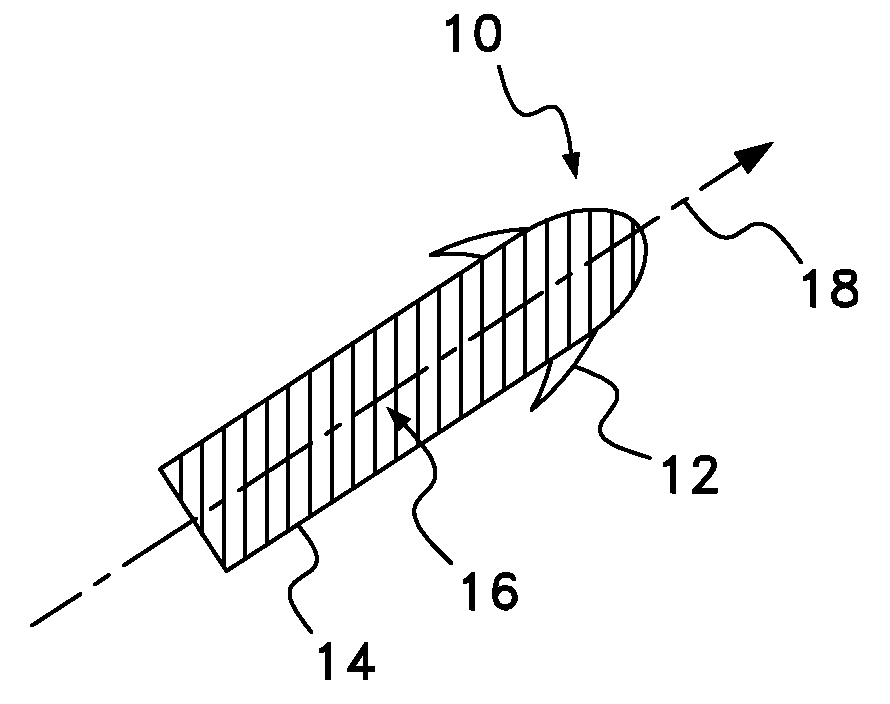

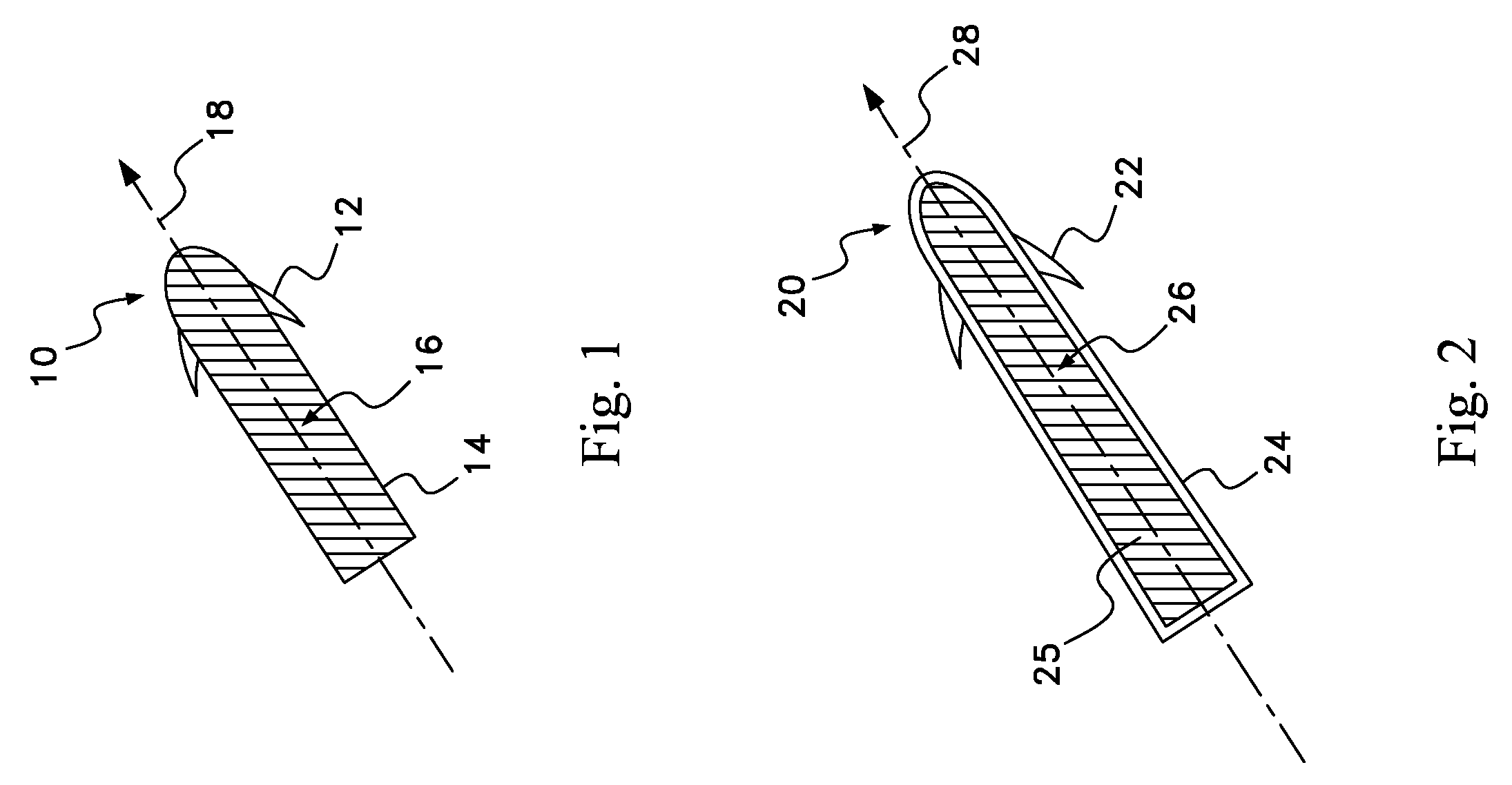

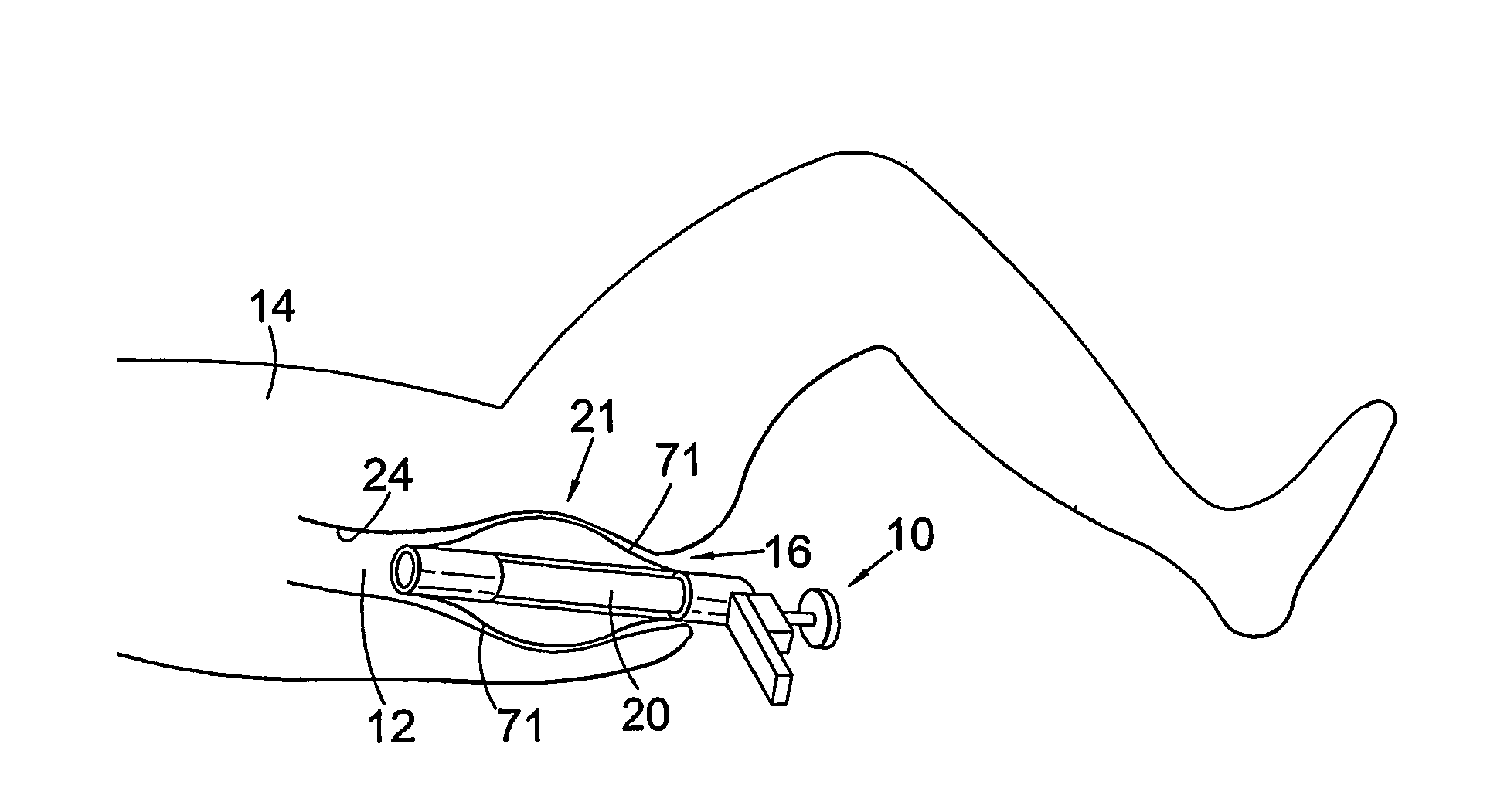

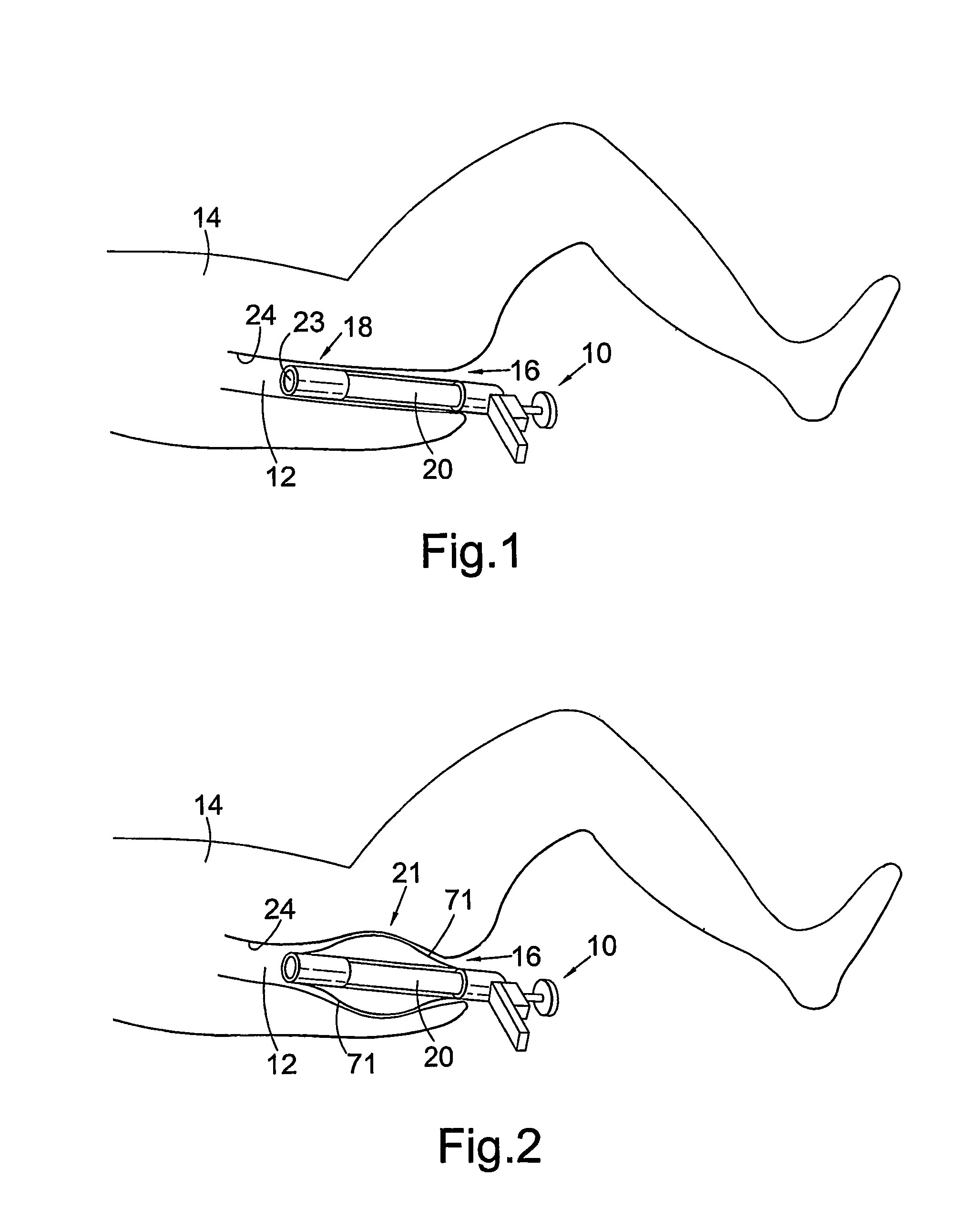

Rectal expander

There is disclosed medical apparatus of the type for use in surgery such as transanal endoscopic microsurgery, as well as methods of providing access to, inspecting and enabling surgery within a body passage. In one embodiment of the invention, medical apparatus in the form of a rectal expander (10) is disclosed, the expander (10) being adapted for location at least partly within a body passage such as the rectum (12) of a patient (14), the expander (10) having a leading end (18) and an access area in the form of an opening (20) for access from the expander (10) into the rectum (12), at least part of the opening (20) being spaced from the leading end (18), and the expander (10) being controllably movable between collapse and expansion positions, for expanding the rectum (12).

Owner:UNIVERSITY OF DUNDEE

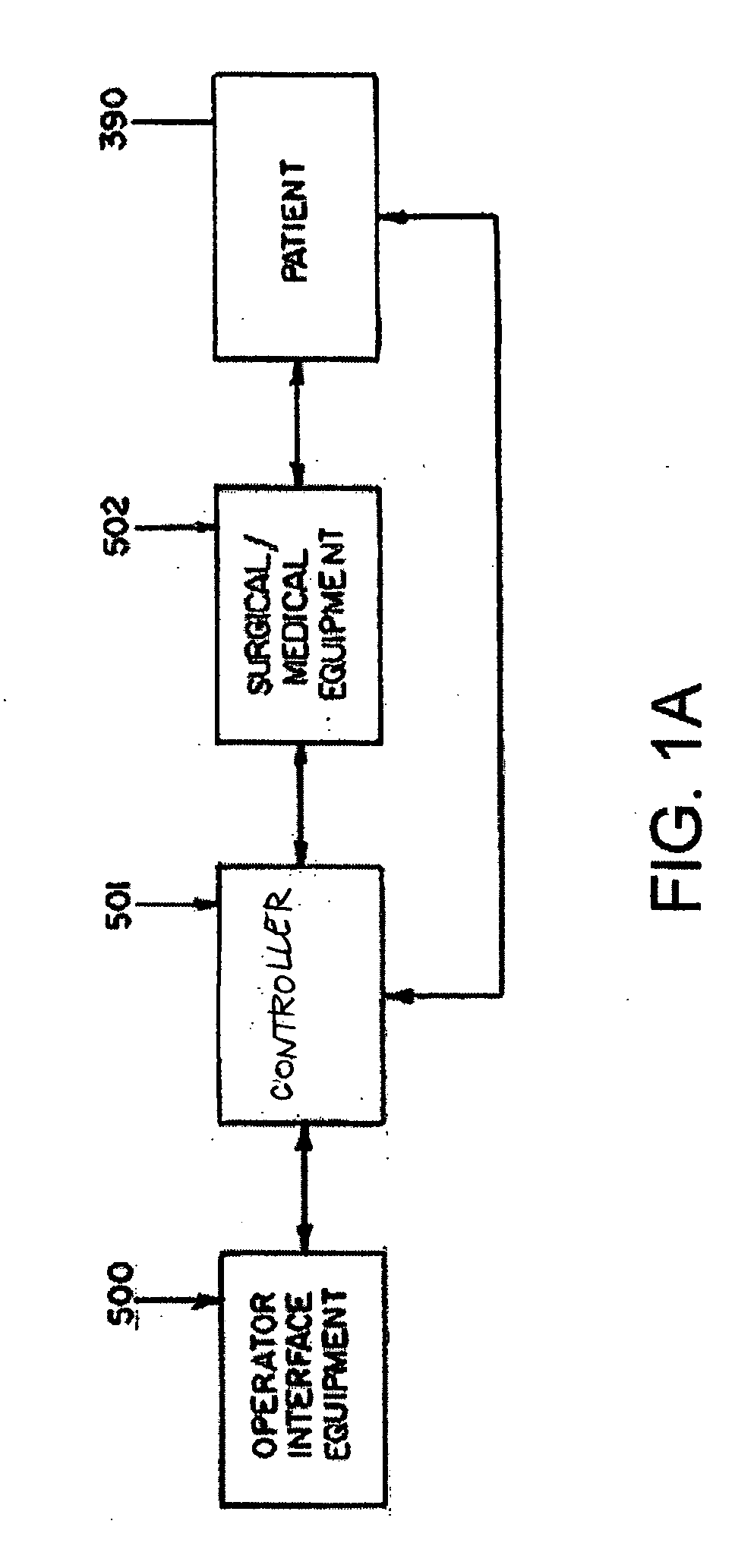

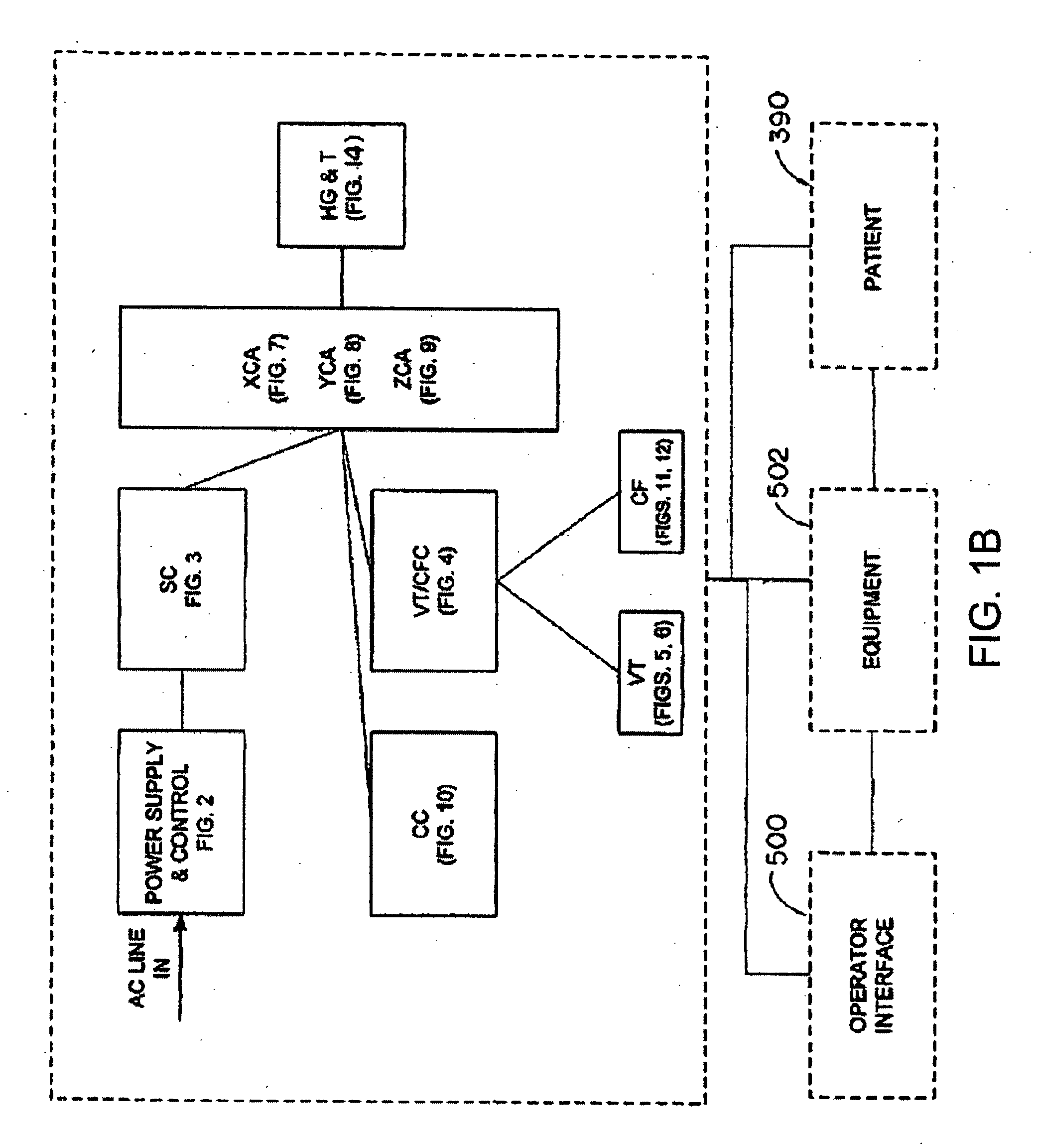

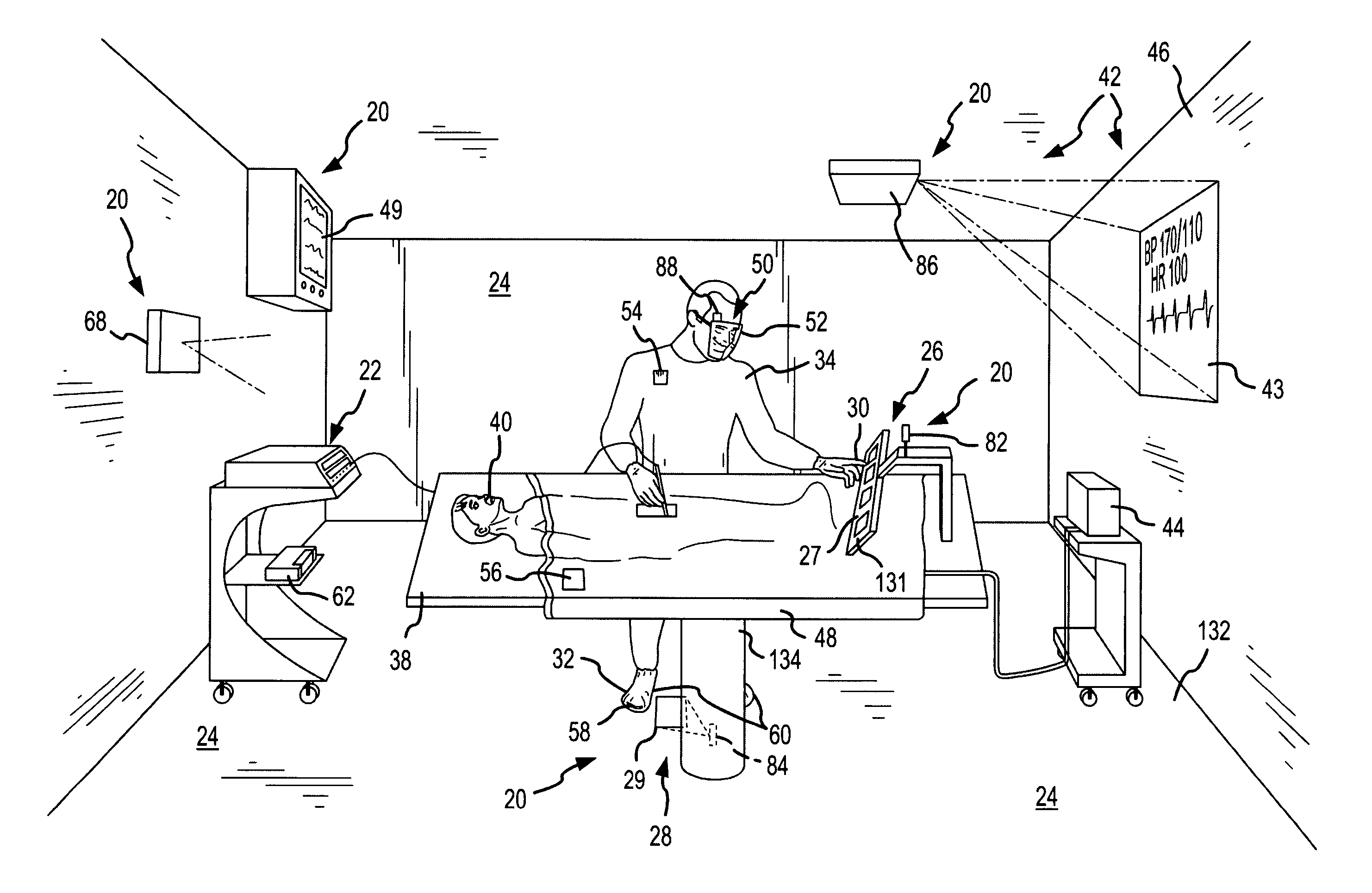

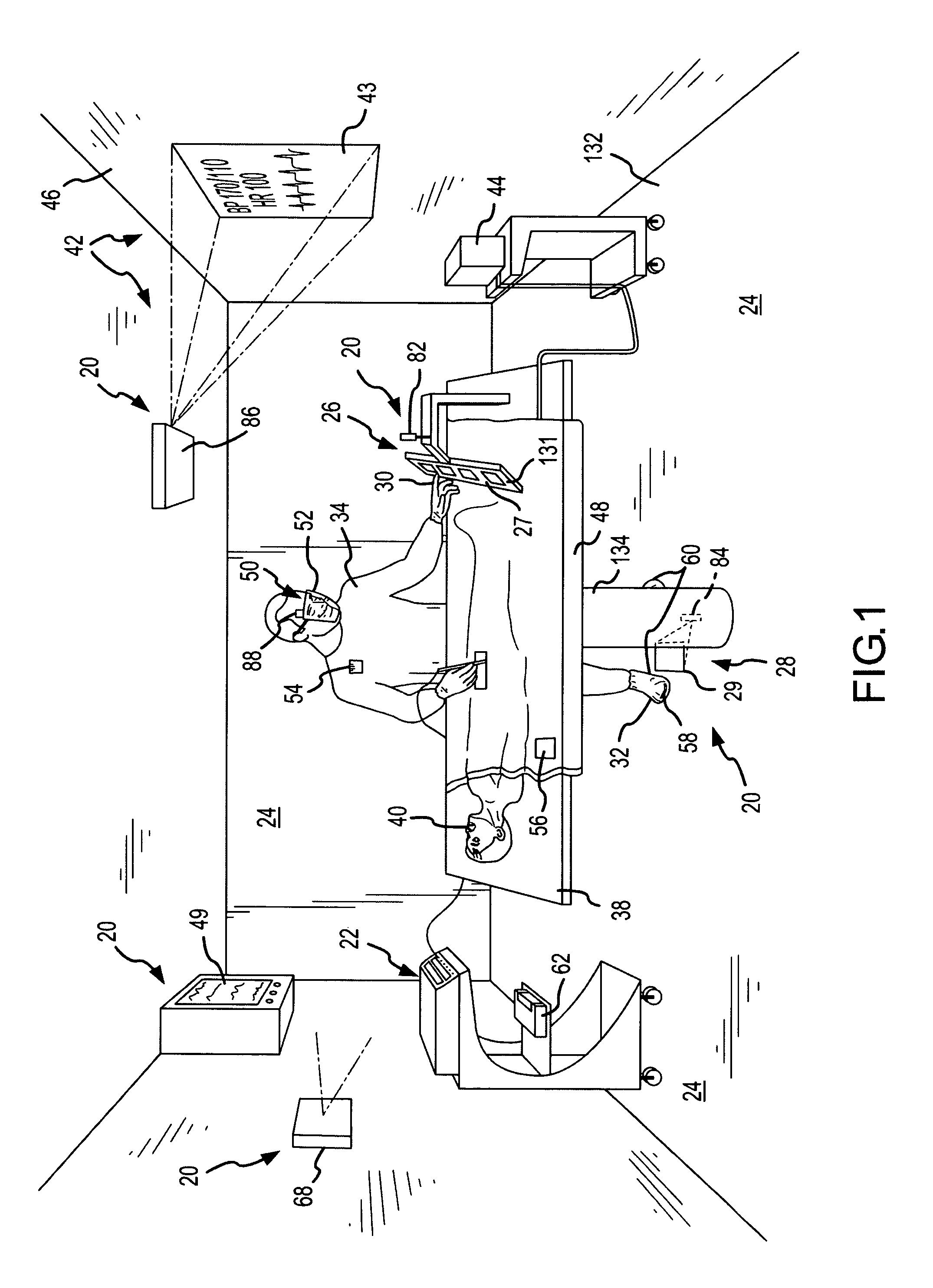

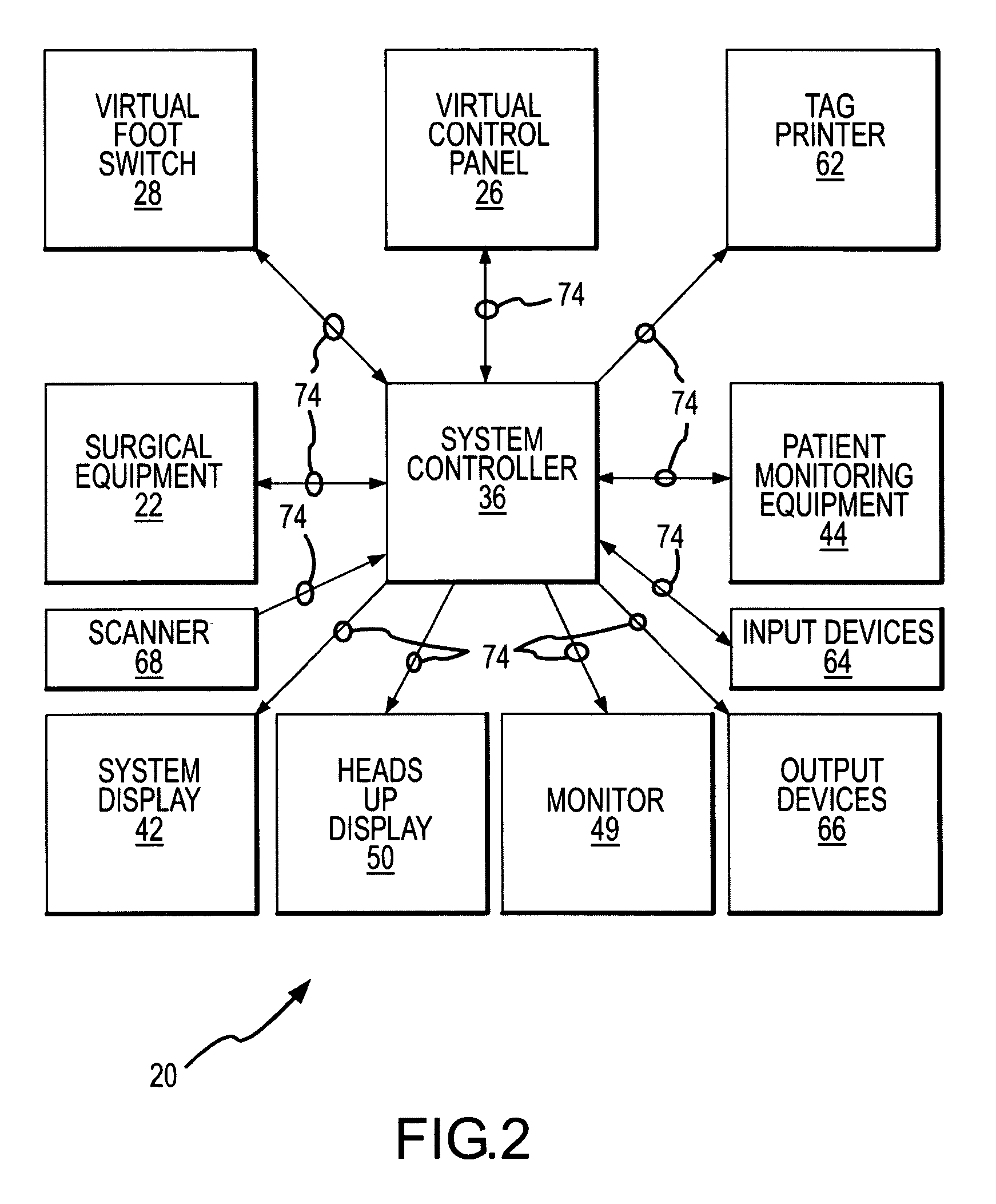

Virtual operating room integration

InactiveUS7317955B2Direct and accurate controlEliminating clutter and risk of trippingElectrotherapyMechanical/radiation/invasive therapiesSurgical operationSTERILE FIELD

A virtual control system for an operating room establishes virtual control devices to control surgical equipment and patient monitoring equipment and to display control, status and functionality information concerning the surgical equipment and condition information of the patient. The virtual control devices permit direct interaction by the surgeon while maintaining a sterile field, and avoid the use of actual physical devices and electrical cables connecting them to the surgical equipment.

Owner:CONMED CORP

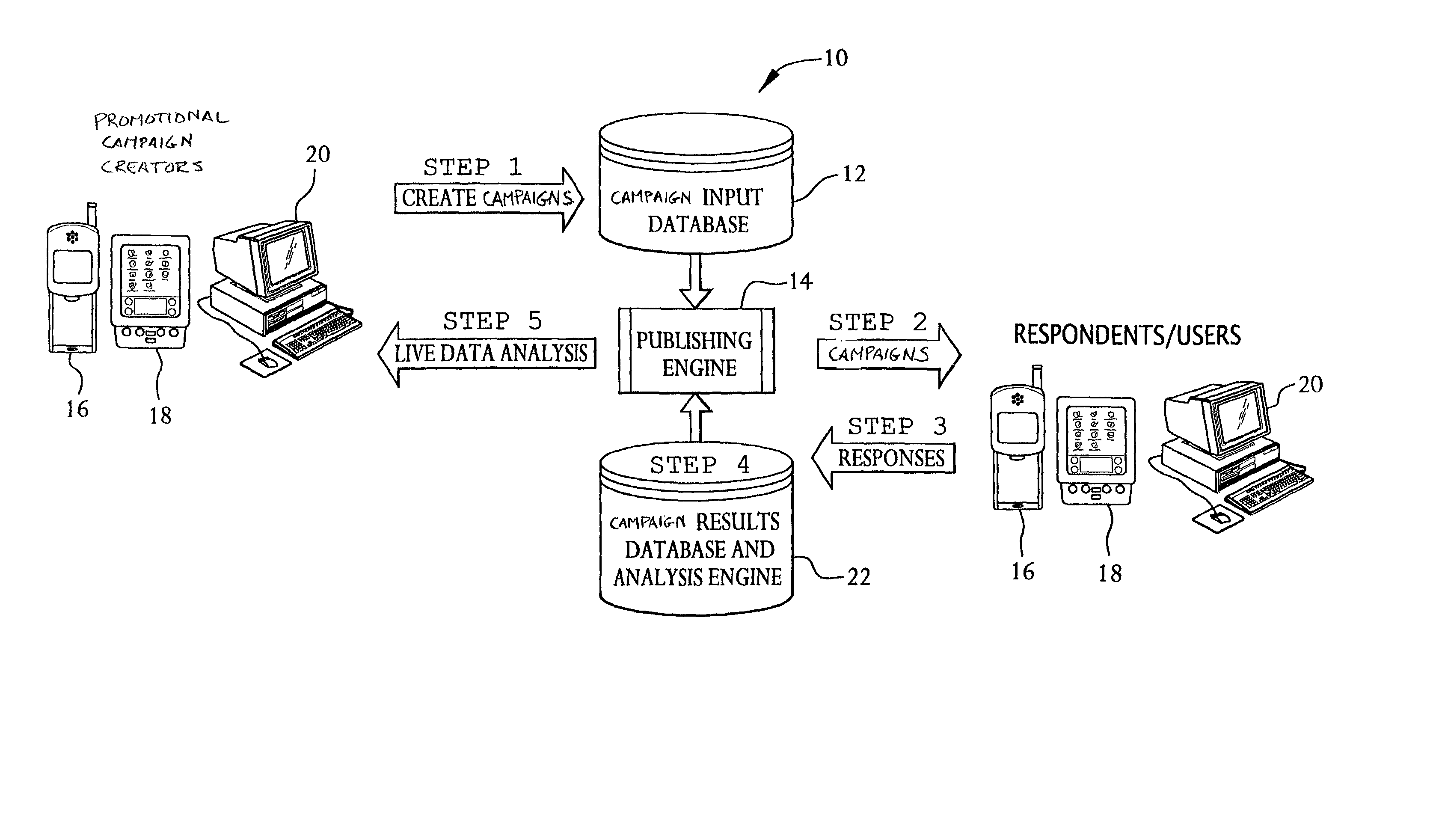

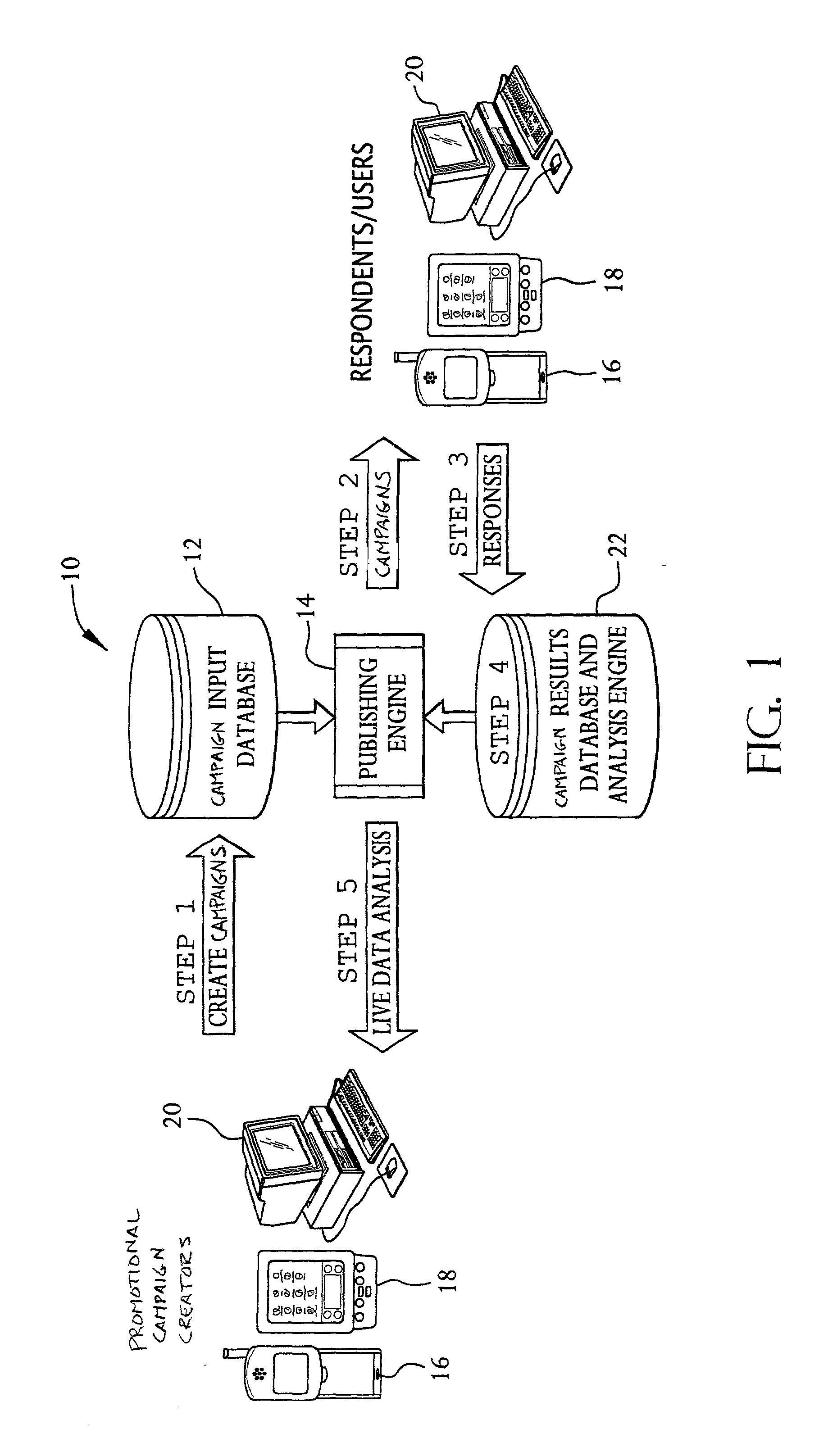

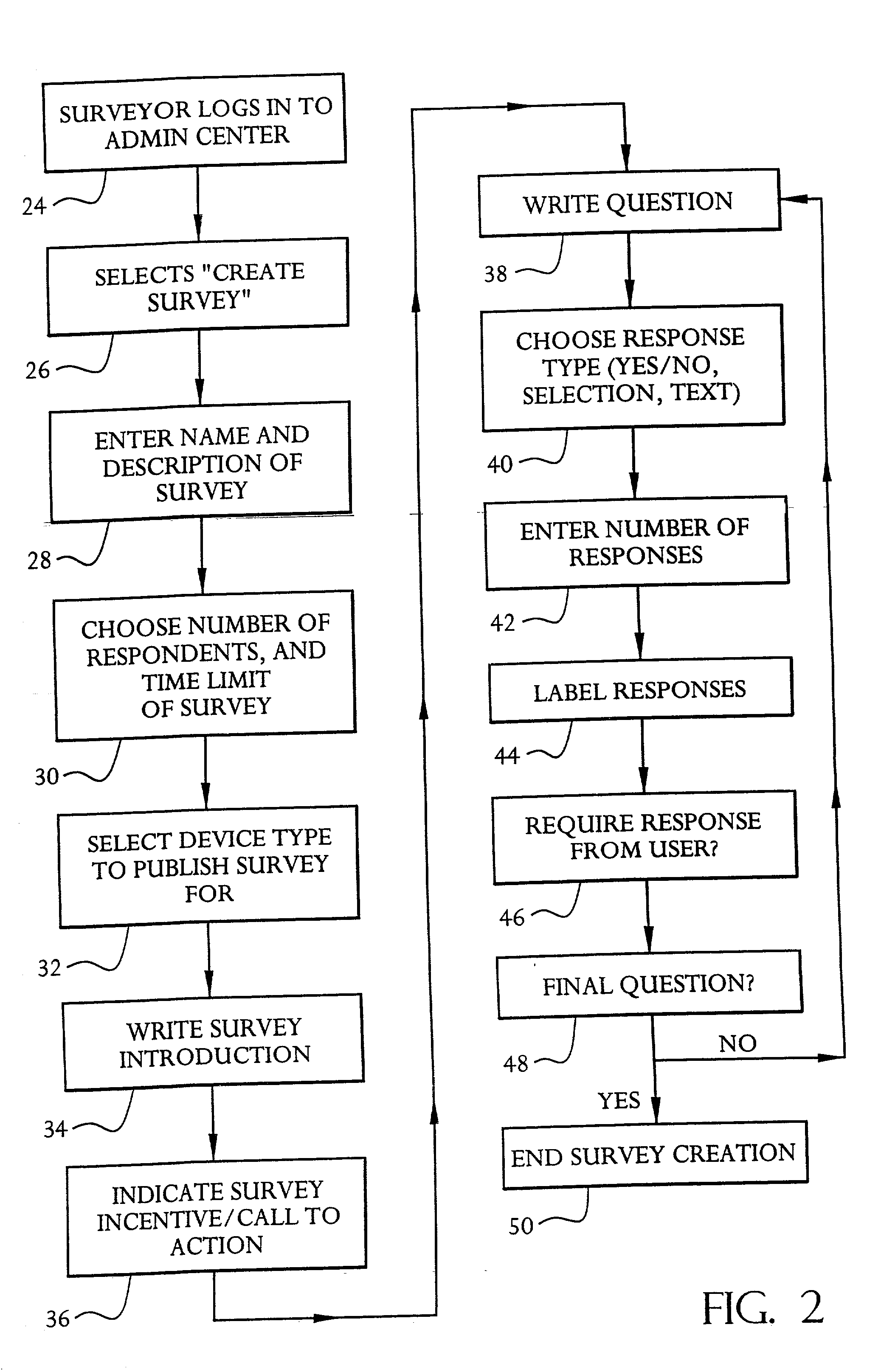

System for conducting user-specific promotional campaigns using multiple communications device platforms

InactiveUS20020128908A1None have been truly successfulPrecise positioningElectrical appliancesMarketingElectronic communicationEngineering

A system for conducting promotional campaigns for multiple types of electronic communications devices. The promotional campaigns may include advertising and marketing campaigns involving the use of one or more of surveys, interactive games, contests, sweepstakes, location-based promotions, and tie-ins with brick-and-mortar outlets. The invention provides a process for (1) creating a promotional campaign, (2) simultaneously publishing the promotional campaign to users via a plurality of types of electronic communications devices, and (3) making the results of the promotional campaign available to the creator of the promotional campaign via communications devices of the creator's choice. Users of the system select the types of advertising and marketing campaigns in which they would be interested in participating. User-provided demographic, location, user preferences, device permissions settings and other user profile information enables creators of promotional campaigns to precisely direct those campaigns to receptive audiences and precisely monitor the success of those campaigns.

Owner:LEVIN BRIAN E +2

Wireless and powerless sensor and interrogator

InactiveUS6988026B2Low costPrecise positioningVehicle testingRegistering/indicating working of vehiclesCapacitanceRadio frequency energy

Arrangement and method for monitoring a tire mounted to the vehicle in which a thermal radiation detecting device detects the temperature of the tire at different circumferential locations along the circumference of the tire. The detected temperatures of the tire are analyzed to determine, for example, whether a difference in thermal radiation is present between the circumferential locations of the tire, and if so, an action is effected in response to the analysis. The thermal radiation detecting devices are preferably supplied with power wirelessly, e.g., through an inductive system, a capacitive system or a radio frequency energy transfer system.

Owner:AMERICAN VEHICULAR SCI

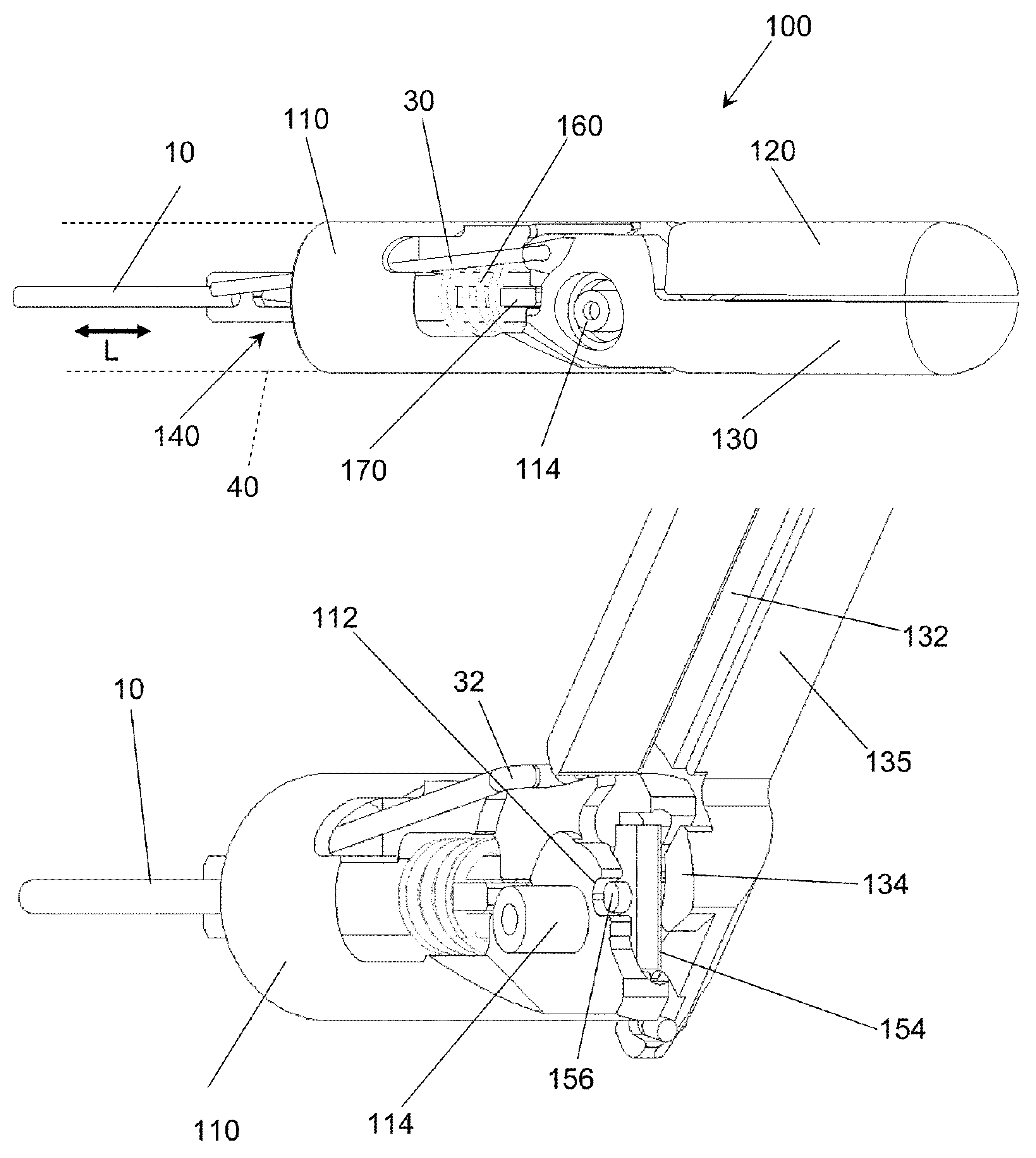

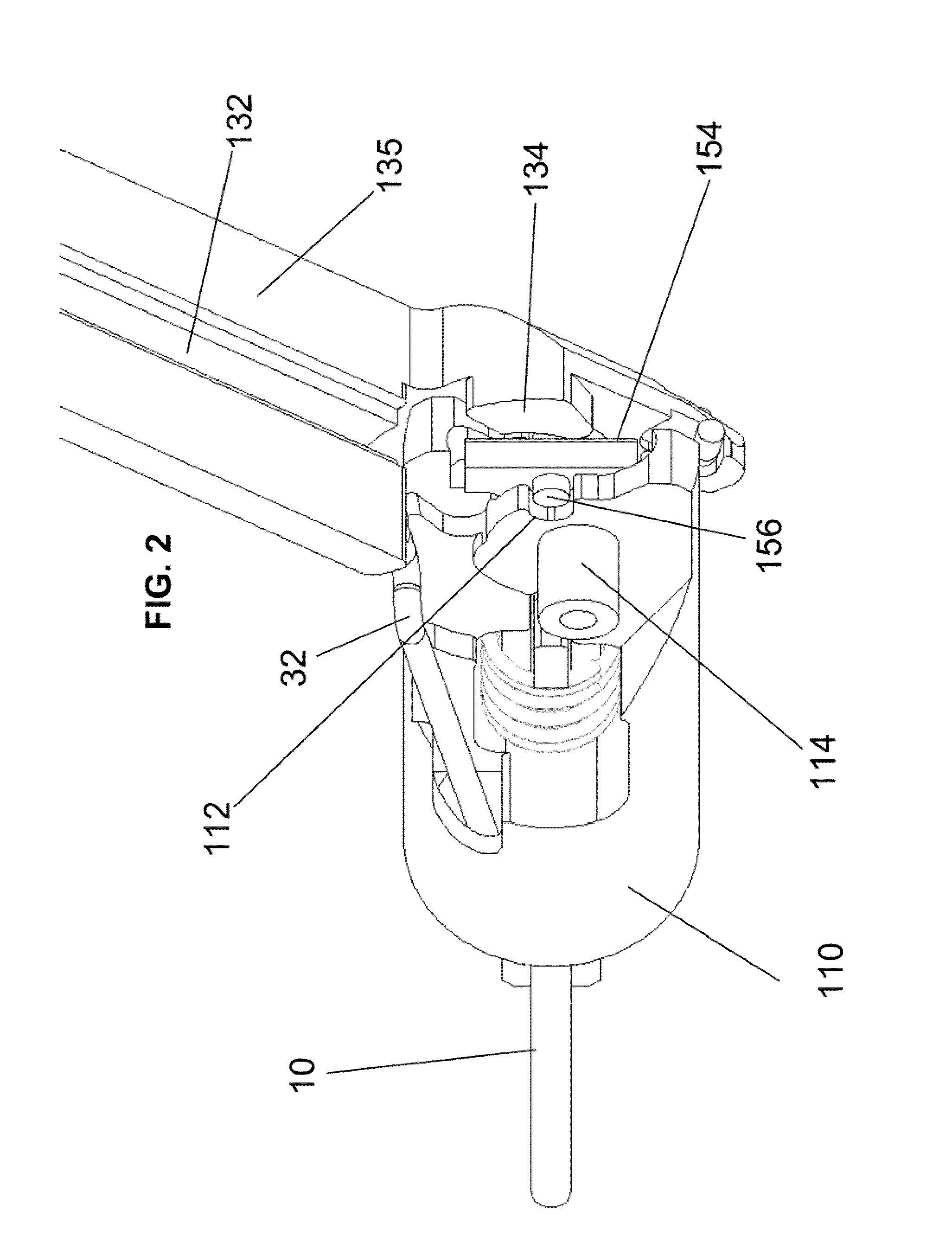

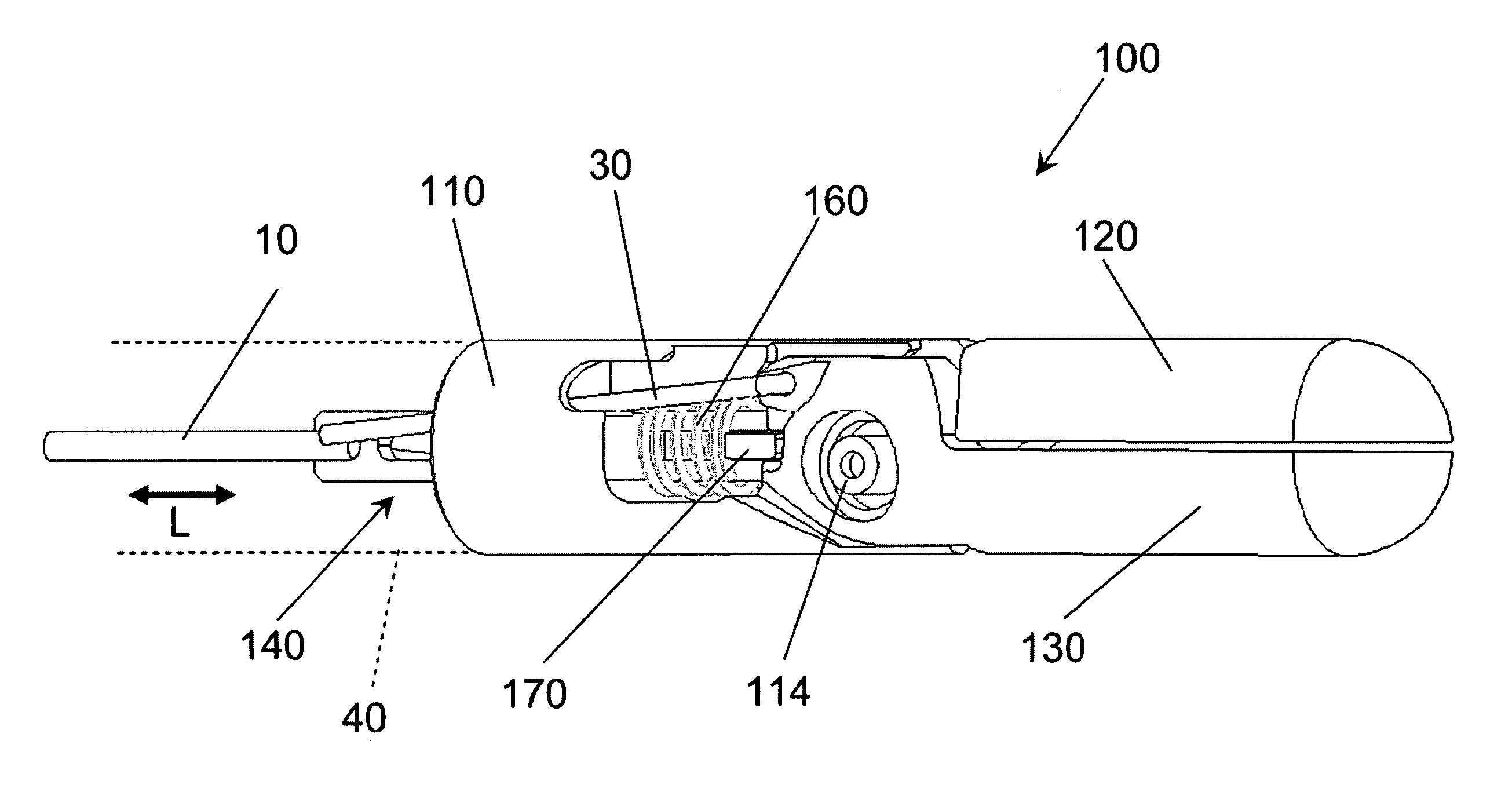

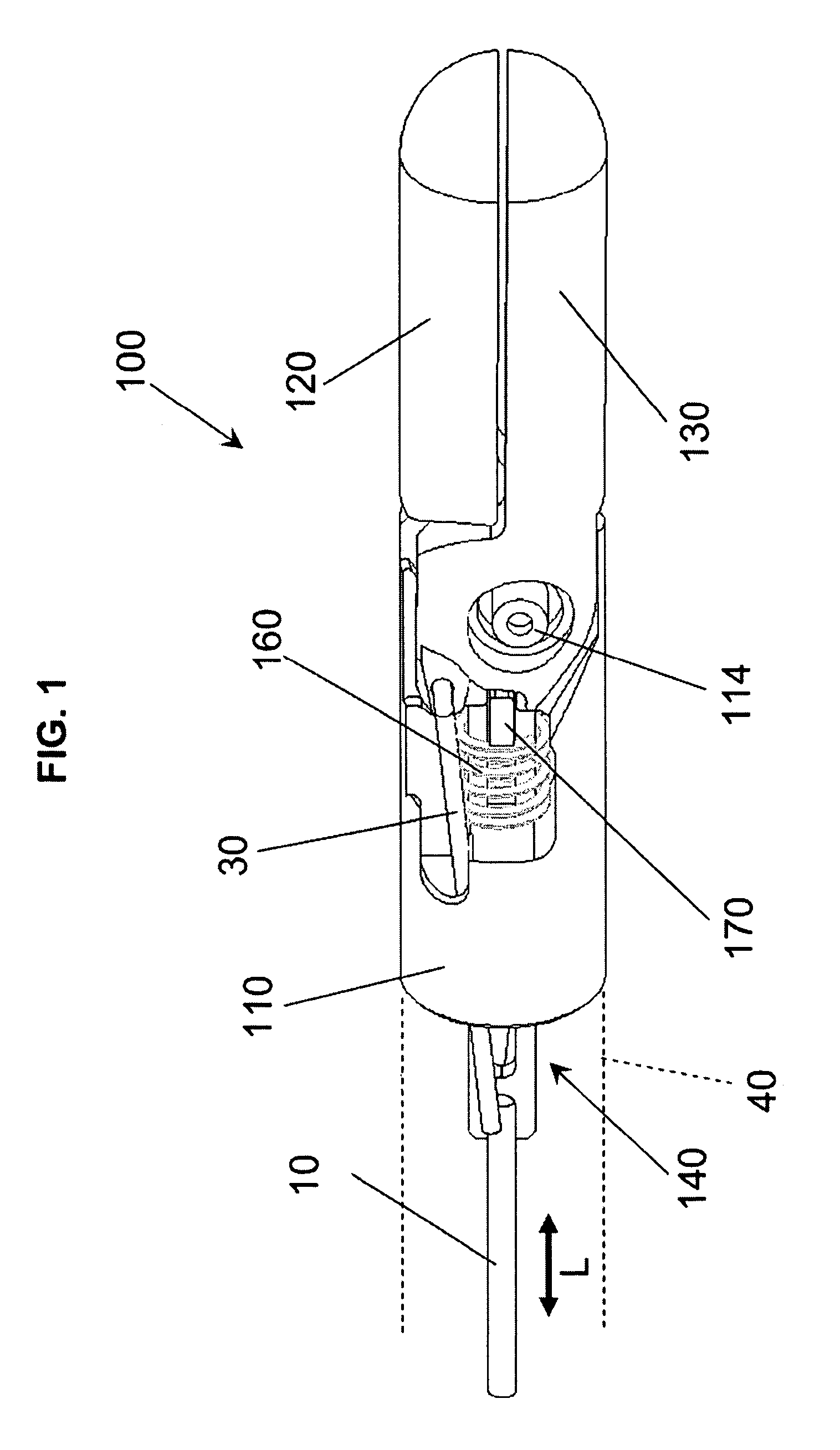

Cordless medical cauterization and cutting device

ActiveUS8377059B2Precise positioningSufficient forceCatheterSurgical instrument detailsRadio frequency signalActuator

A cordless surgical device includes a modular battery, a radio-frequency signal generating assembly, a surgical handle and an interchangeable circuit casing. The RF signal generating assembly includes RF-signal-generating circuitry, a voltage-control circuit and an external output. The voltage circuit is configured to control an output of the RF-signal-generating circuitry. The handle is configured to support a bipolar end effector having jaws with bipolar contacts and a cutting blade disposed between the jaws. The handle includes leads operable to receive RF signals from the external output and defines an aseptically sealable battery-holding compartment configured to hold the battery. The circuit casing is configured to house the RF signal generating assembly and includes a securing connection adapted to couple the external output of the RF signal generating assembly to the leads. The external output is operable to impart RF signals to the handle when the circuit casing connects to the handle.

Owner:COVIDIEN AG

Methods and apparatuses for image guided medical procedures

ActiveUS20070167801A1Reduction of image brightnessEliminate artifactsMedical simulationUltrasonic/sonic/infrasonic diagnosticsImage alignmentMedical procedure

Methods and apparatuses for the image guidance and documentation of medical procedures. One embodiment includes combining small field of view images into a recorded image of with a large field of view and aligning the small field of view real time image with the recorded image through correlation of imaging data. A location and orientation determination system may be used to track the imaging system and provide a starting set of image alignment parameters and / or provide change updates to a set of image alignment parameters, which is then further improved through correlating imaging data. The recorded image may be selected according to real time measurement of a cardiac parameter during an image guided cardiac procedure. Image manipulations planned based on the recorded image can be stored and applied to the real time information. The position of the medical device may be determined and recorded through manipulating a cursor in a 3-D image space shown in two non-parallel views.

Owner:ABBOTT CARDIOVASCULAR

Systems and methods for performing image guided procedures within the ear, nose, throat and paranasal sinuses

Devices, systems and methods for performing image guided interventional and surgical procedures, including various procedures to treat sinusitis and other disorders of the paranasal sinuses, ears, nose or throat.

Owner:ACCLARENT INC

System for obtaining vehicular information

InactiveUS20050273218A1Low costPrecise positioningVehicle testingVehicle seatsDirectional antennaRadio frequency

System for obtaining information about a vehicle or a component therein includes sensors arranged to generate and transmit a signal upon receipt and detection of a radio frequency (RF) signal and a multi-element, switchable directional antenna array. Each antenna element is directed toward a respective sensor and transmitter RF signals toward that sensor and receive return signals therefrom. A control mechanism controls transmission of the RF signals from the antenna elements, e.g., causes the antenna elements to be alternately switched on in order to sequentially transmit the RF signals and receive the return signals from the sensors or cause the antenna elements to transmit the RF signals simultaneously and space the return signals from the sensors via a delay line in circuitry from each antenna element such that each return signal is spaced in time in a known manner without requiring switching of the antenna elements.

Owner:AMERICAN VEHICULAR SCI

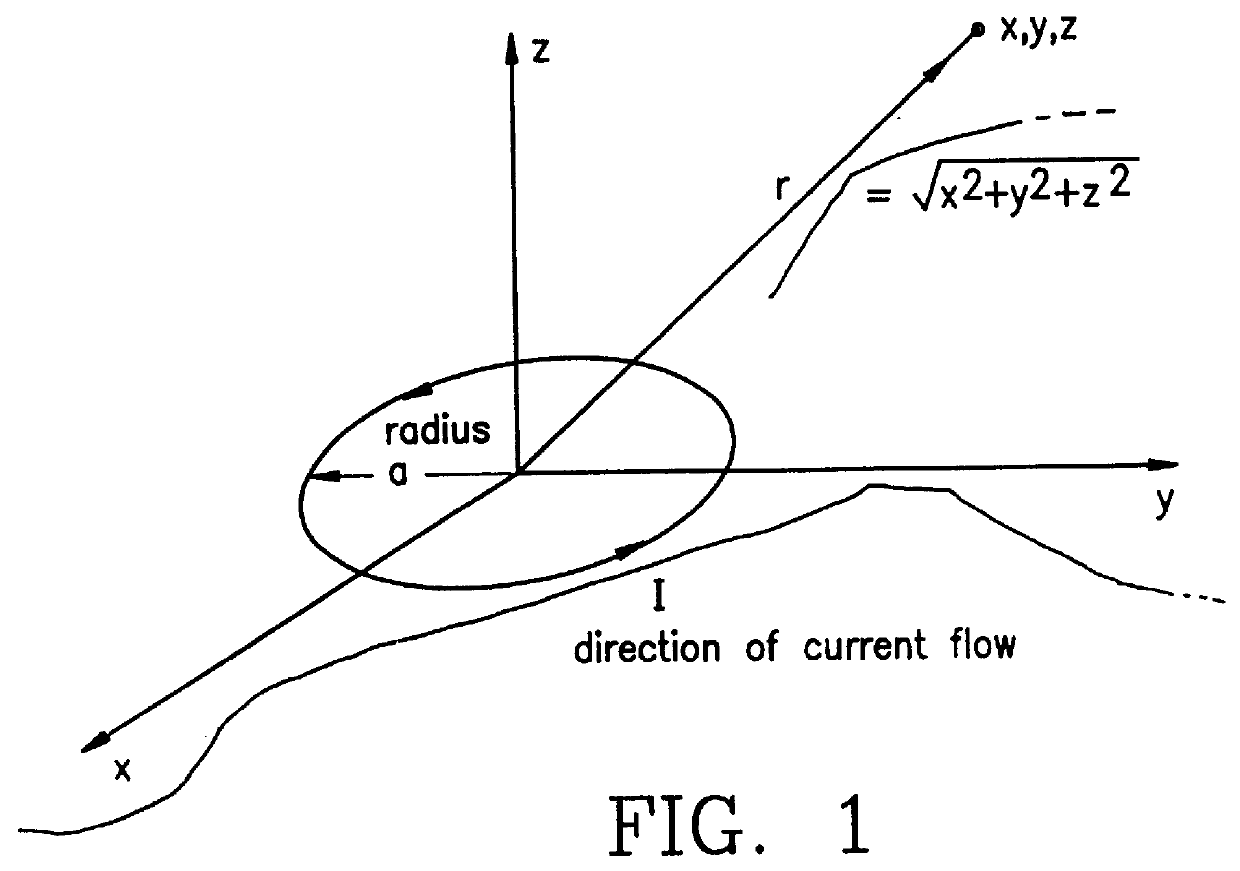

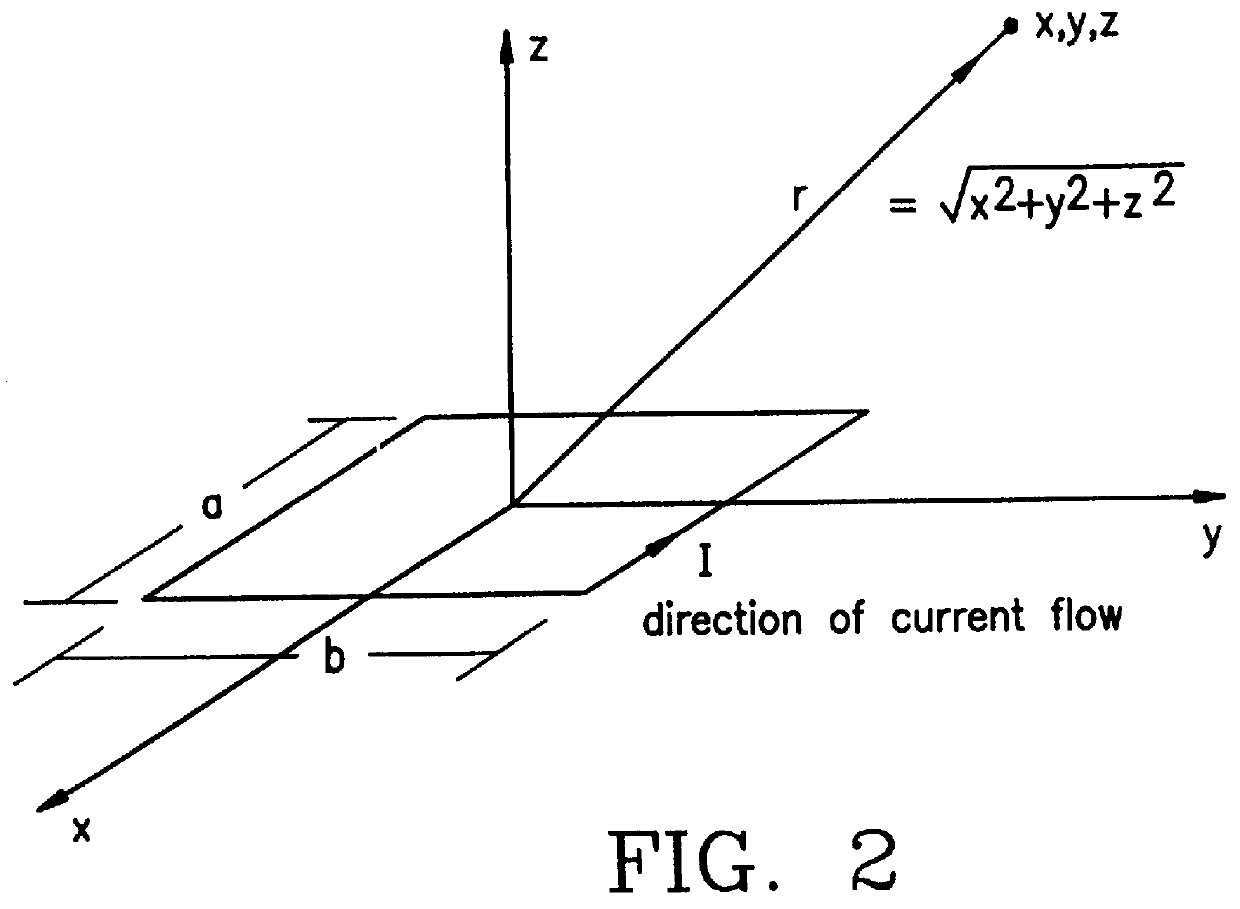

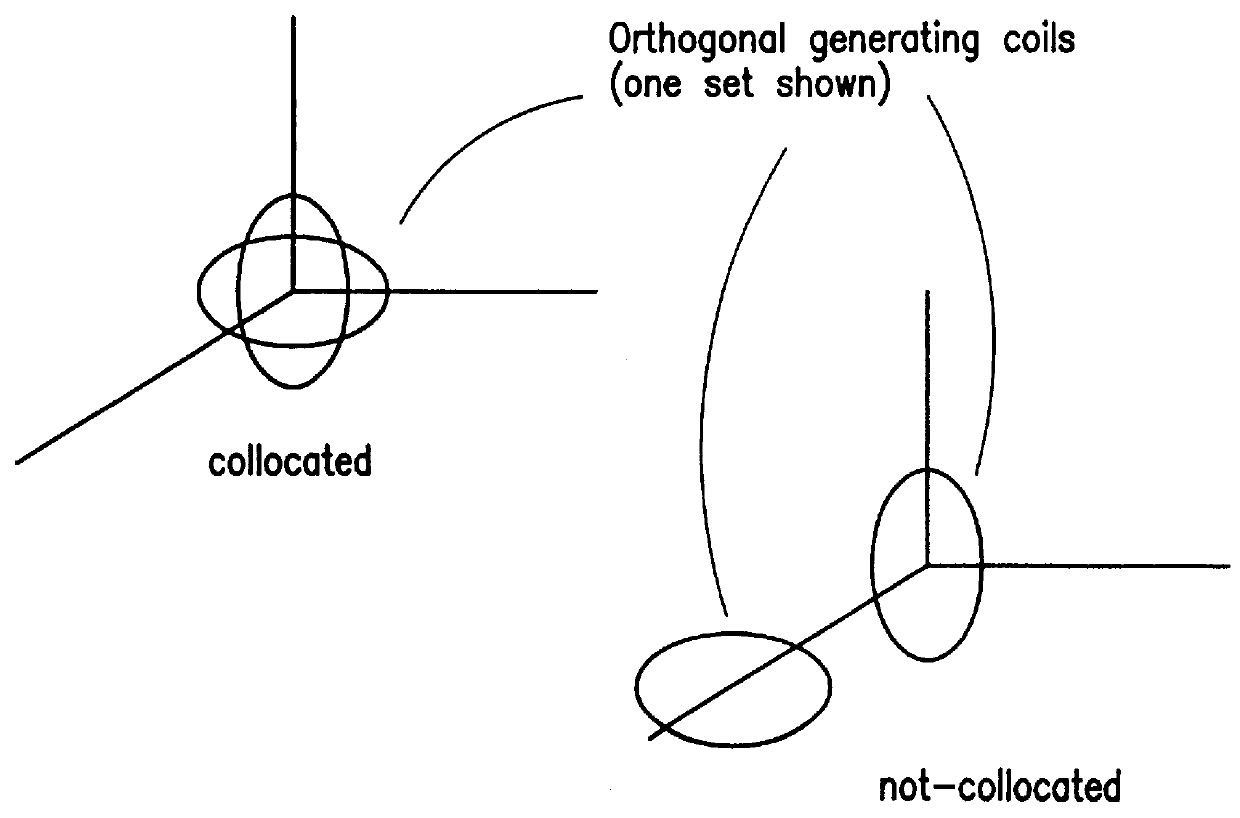

Measuring position and orientation using magnetic fields

InactiveUS6073043APrecise positioningMinimize timeMagnetic measurementsSurgeryMagnetic trackingMagnetic field coupling

A method and apparatus for determining the position and orientation of a remote object relative to a reference coordinate frame includes a plurality of field-generating elements for generating electromagnetic fields, a drive for applying, to the generating elements, signals that generate a plurality of electromagnetic fields that are distinguishable from one another, a remote sensor having one or more field-sensing elements for sensing the fields generated and a processor for processing the outputs of the sensing element(s) into remote object position and orientation relative to the generating element reference coordinate frame. The position and orientation solution is based on the exact formulation of the magnetic field coupling as opposed to approximations used elsewhere. The system can be used for locating the end of a catheter or endoscope, digitizing objects for computer databases, virtual reality and motion tracking. The methods presented here can also be applied to other magnetic tracking technologies as a final "polishing" stage to improve the accuracy of their P&O solution.

Owner:CORMEDICA

Methods and devices for performing procedures within the ear, nose, throat and paranasal sinuses

Devices, systems and methods for performing image guided interventional and surgical procedures, including various procedures to treat sinusitis and other disorders of the paranasal sinuses, ears, nose or throat.

Owner:ACCLARENT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com