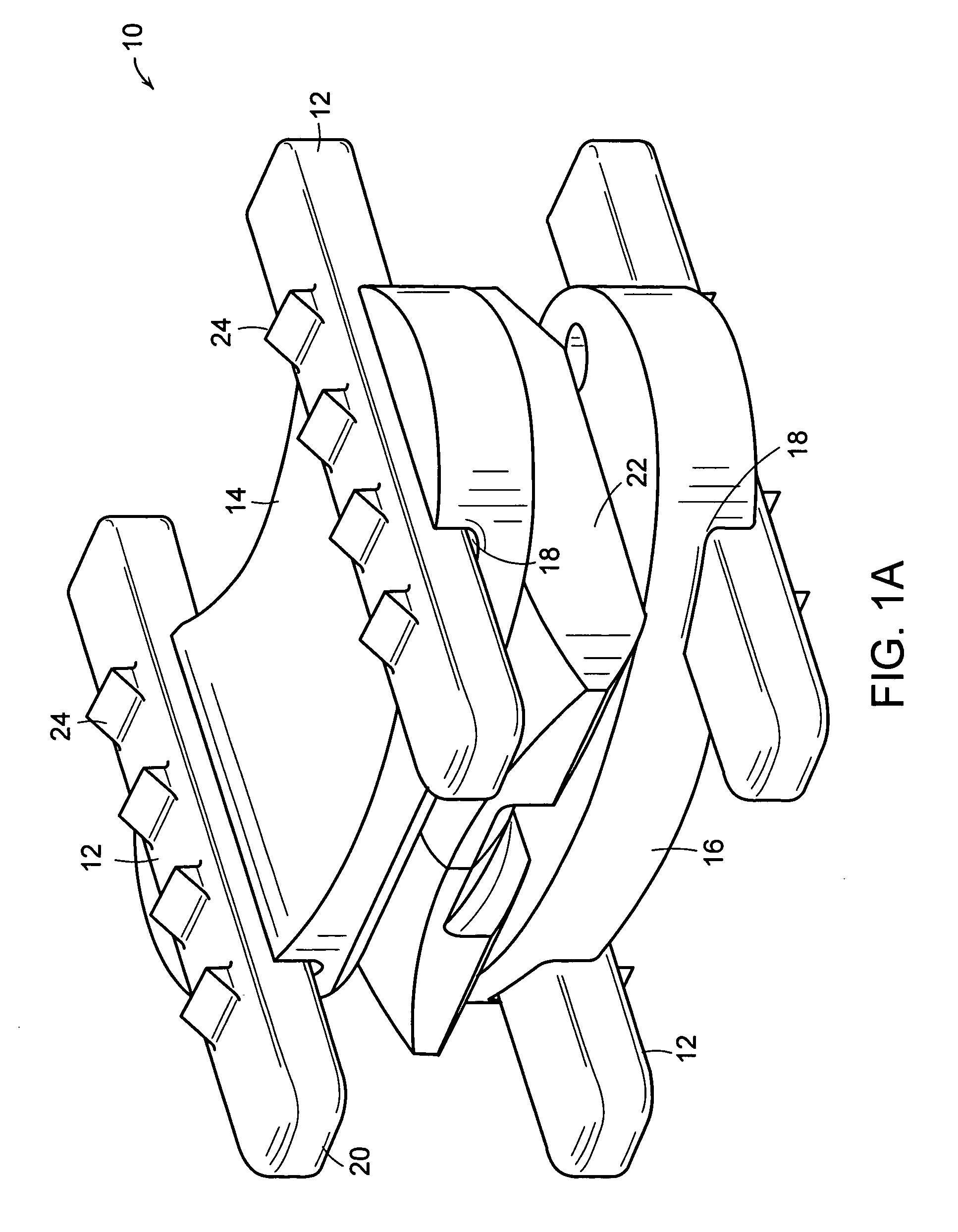

Patents

Literature

6048results about How to "Accurate location" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

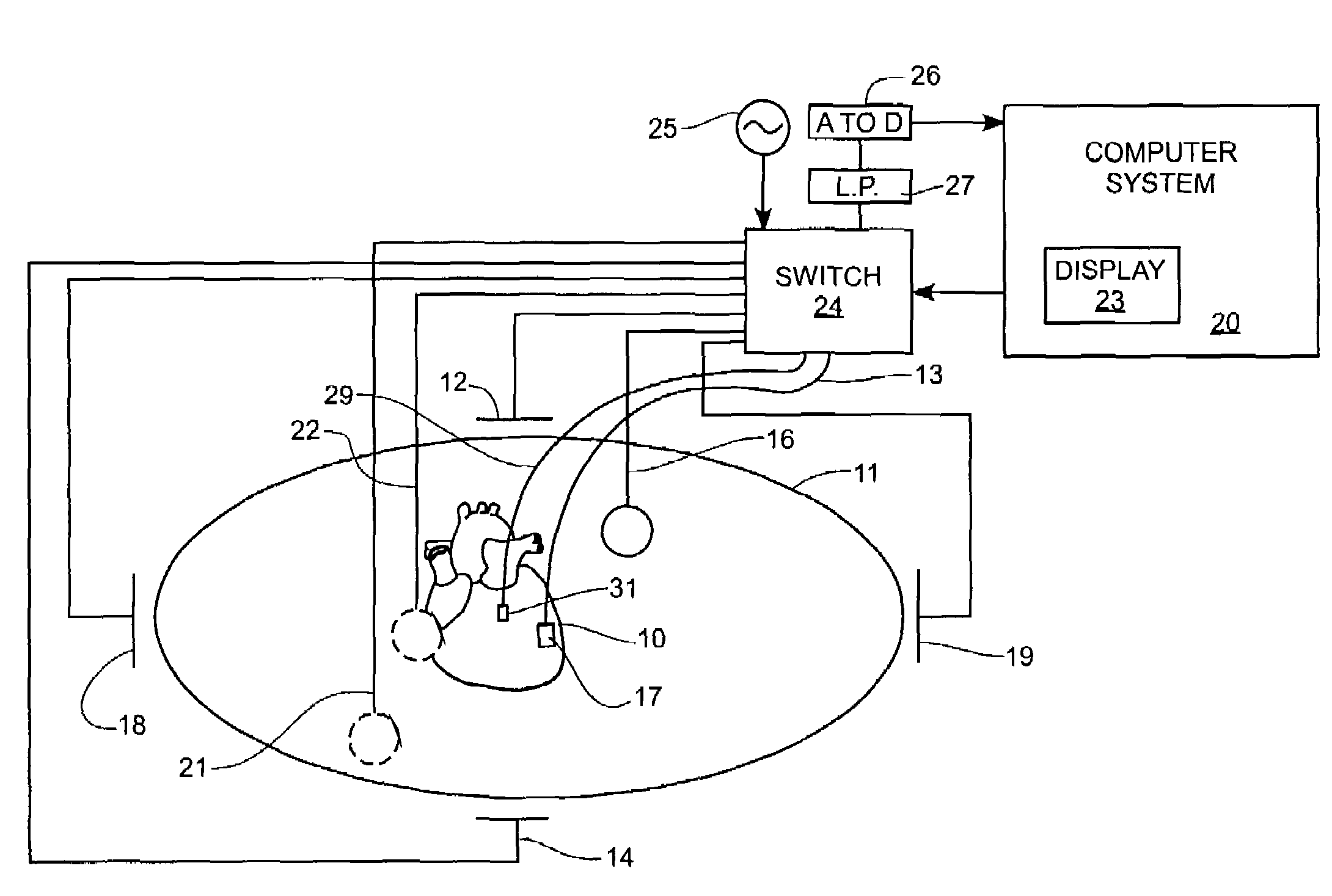

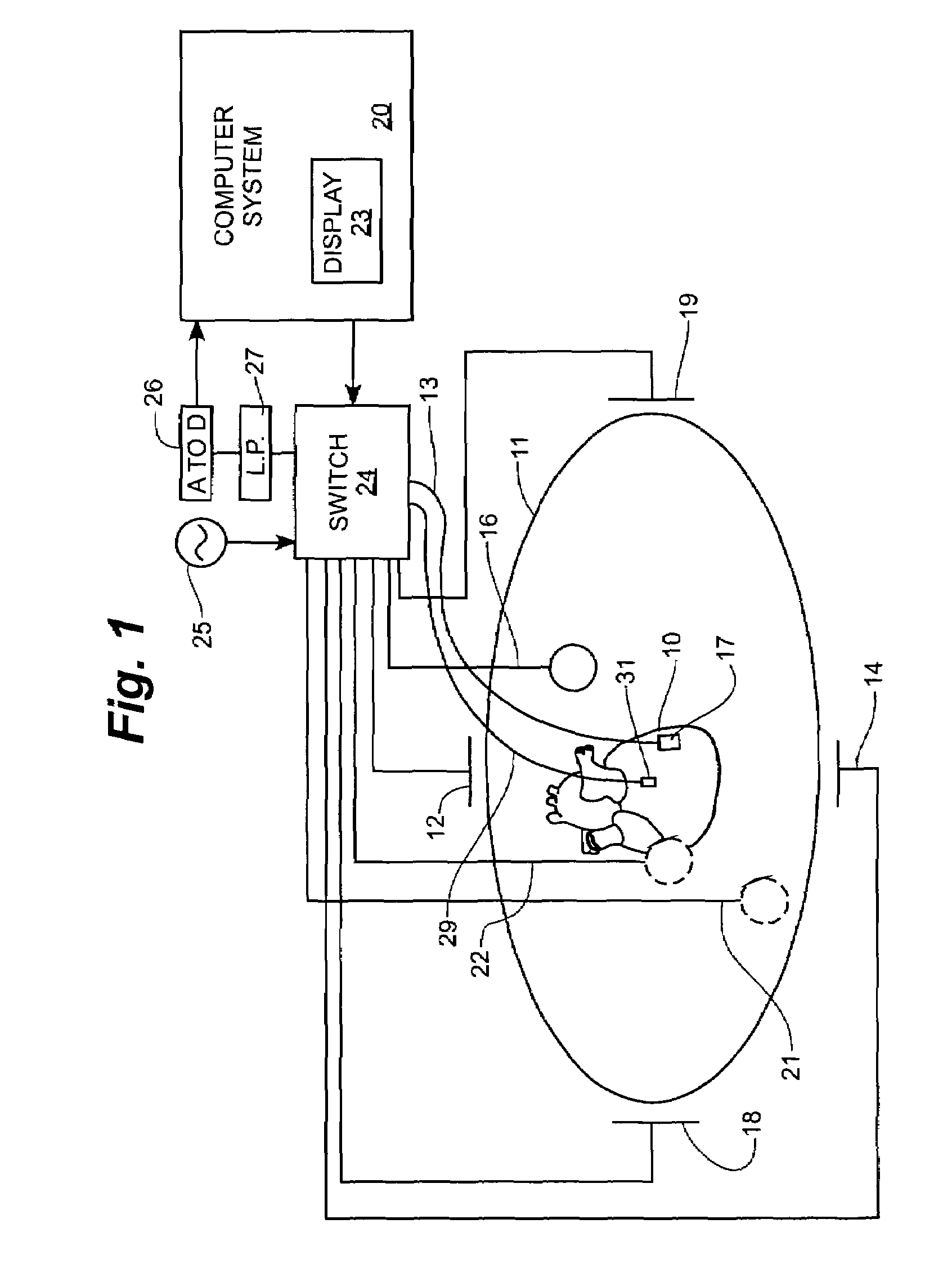

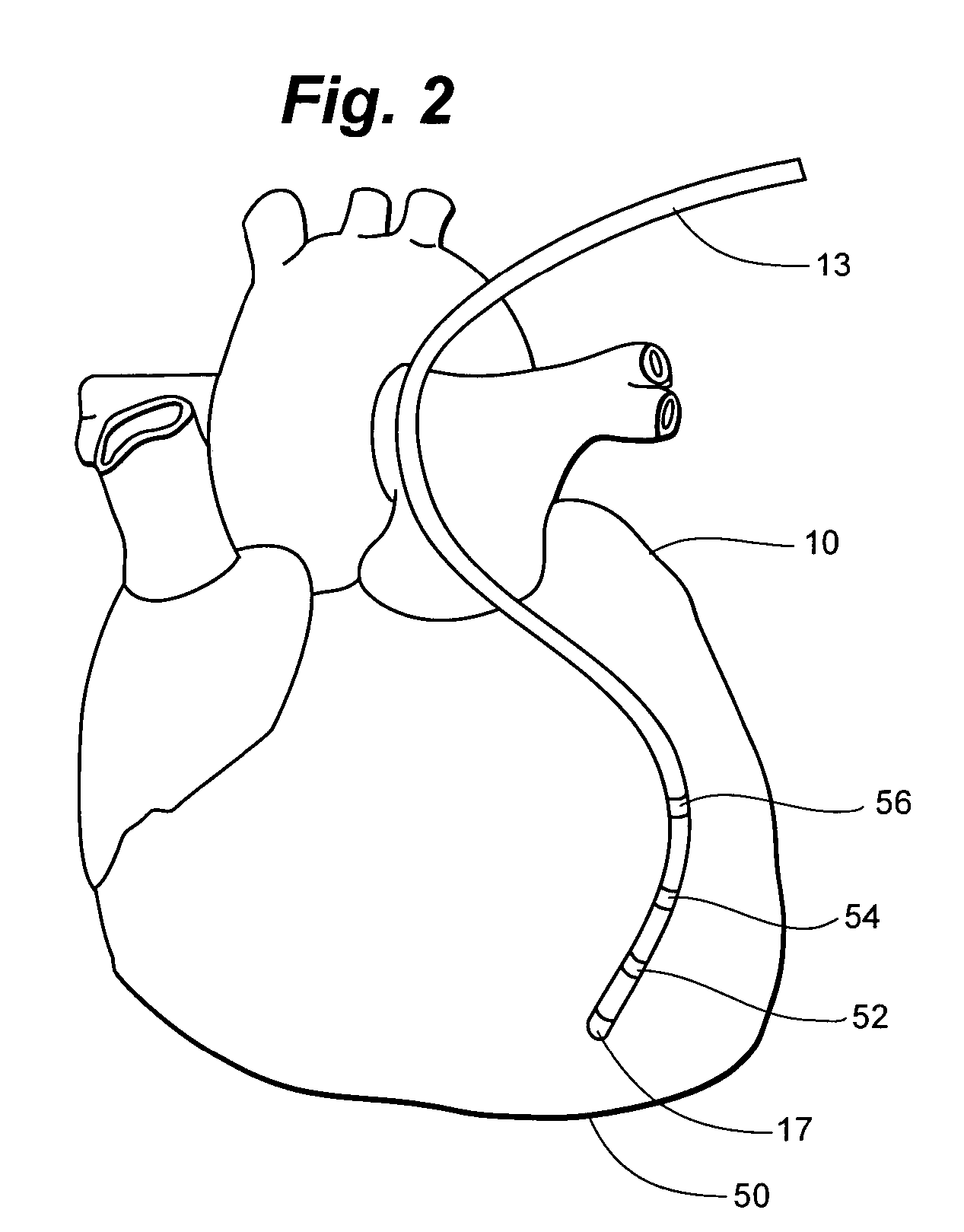

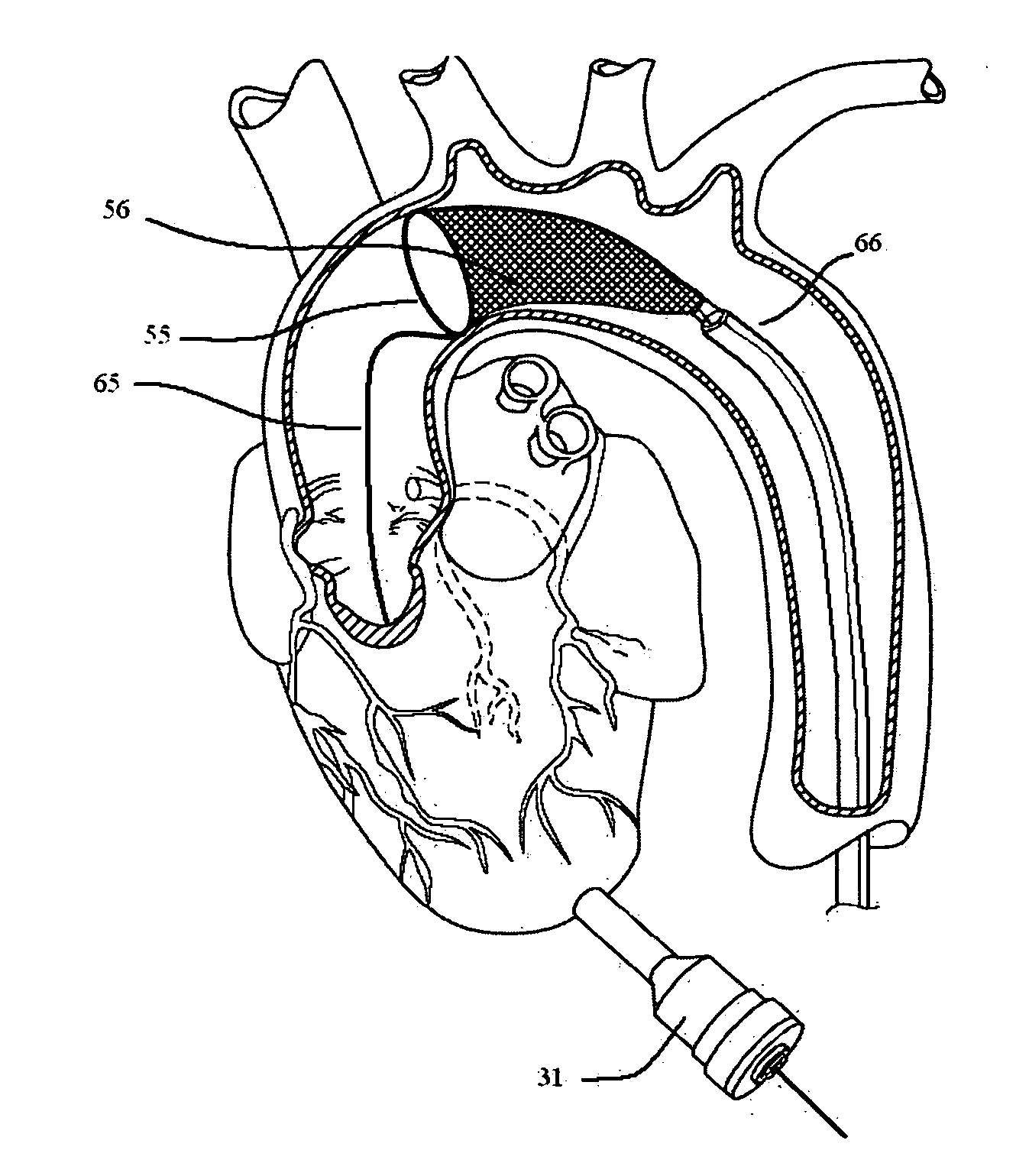

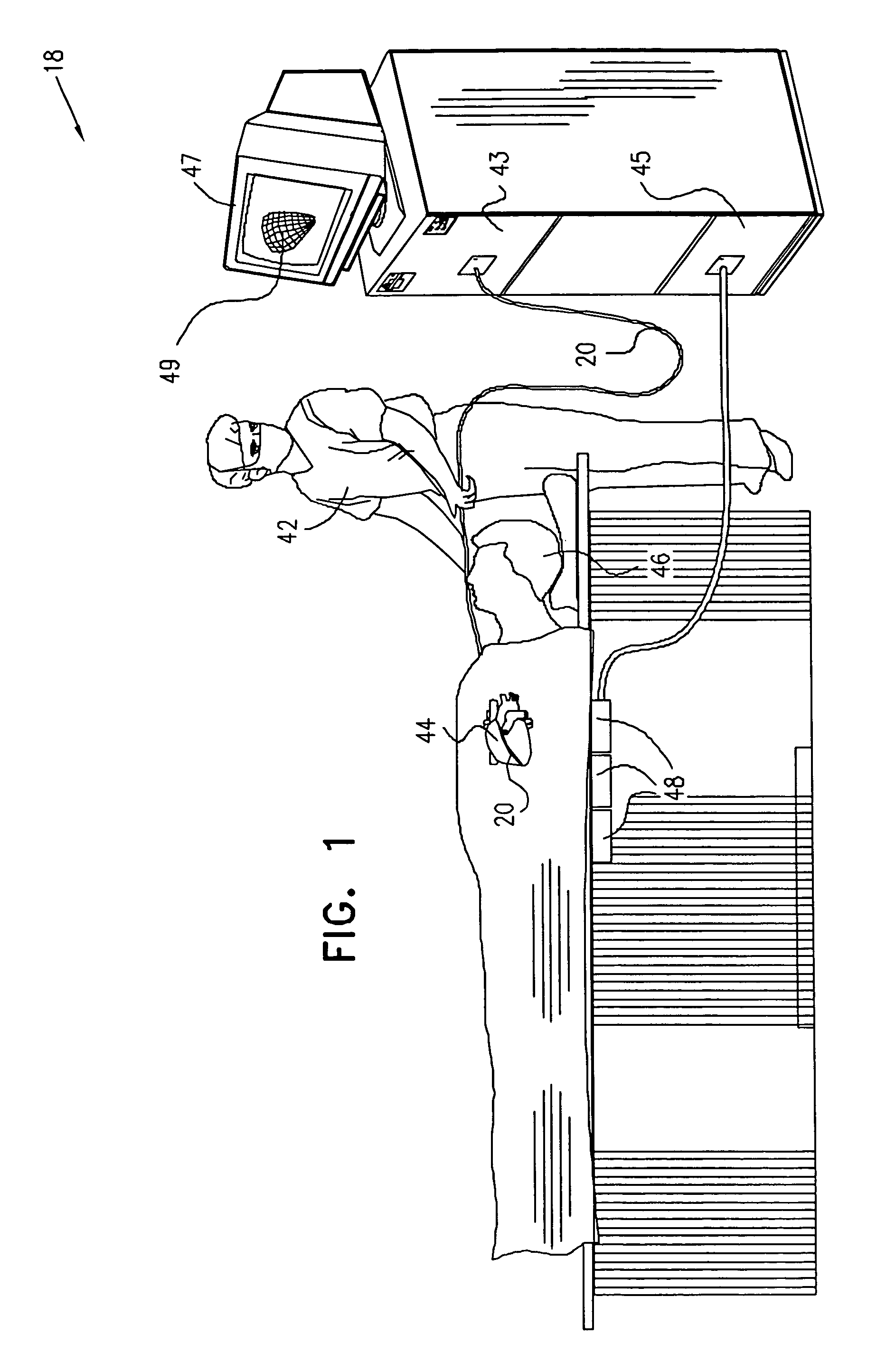

Method and apparatus for catheter navigation and location and mapping in the heart

InactiveUS7263397B2Enhance system functionsAccurate locationElectrocardiographyCatheterHeart chamberBiological activation

A medical system for finding and displaying the location of electrodes within the body. The electrodes may be used to measure the voltage on the heart wall and display this as an activation map on a geometry representing the heart chamber.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

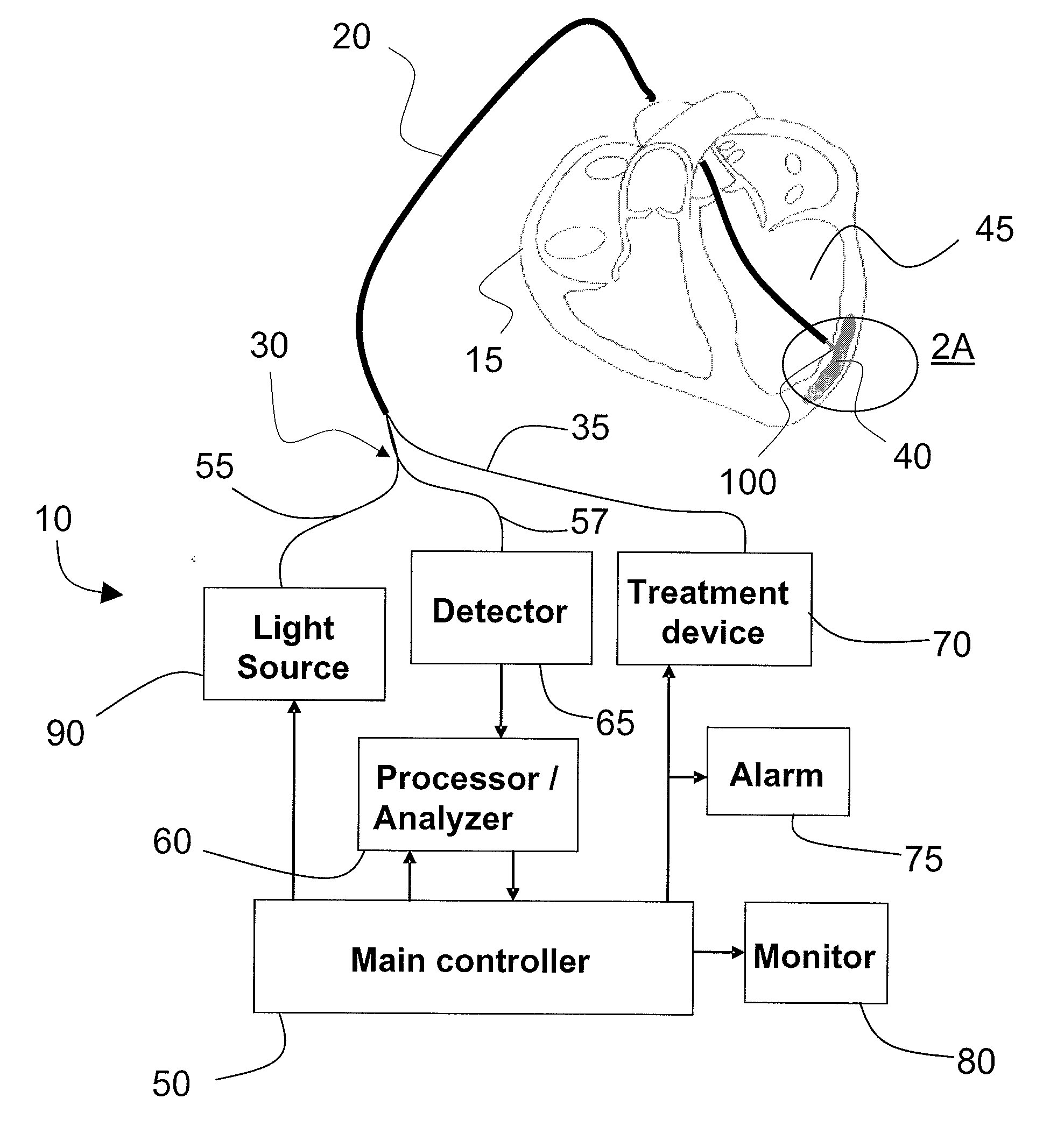

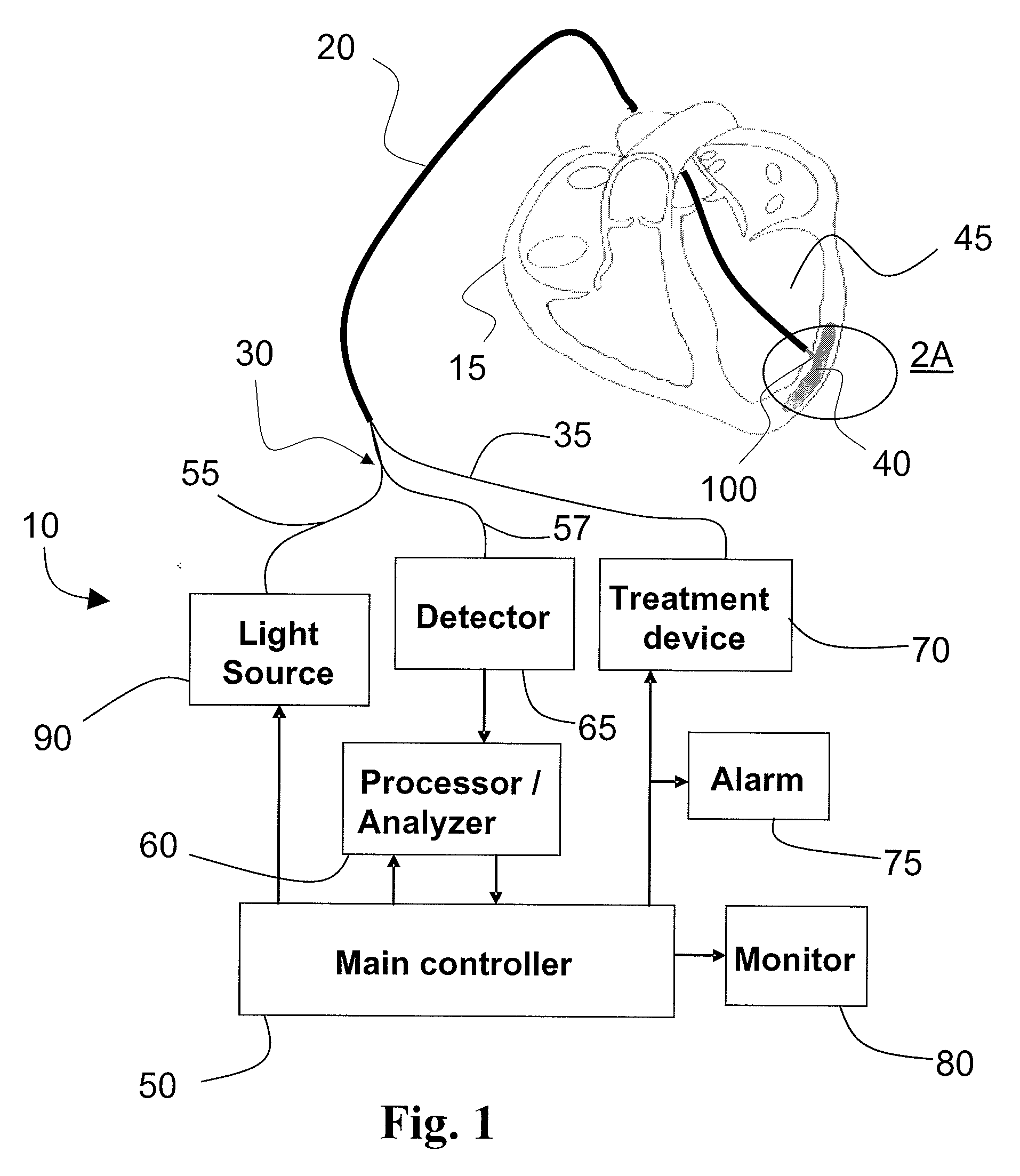

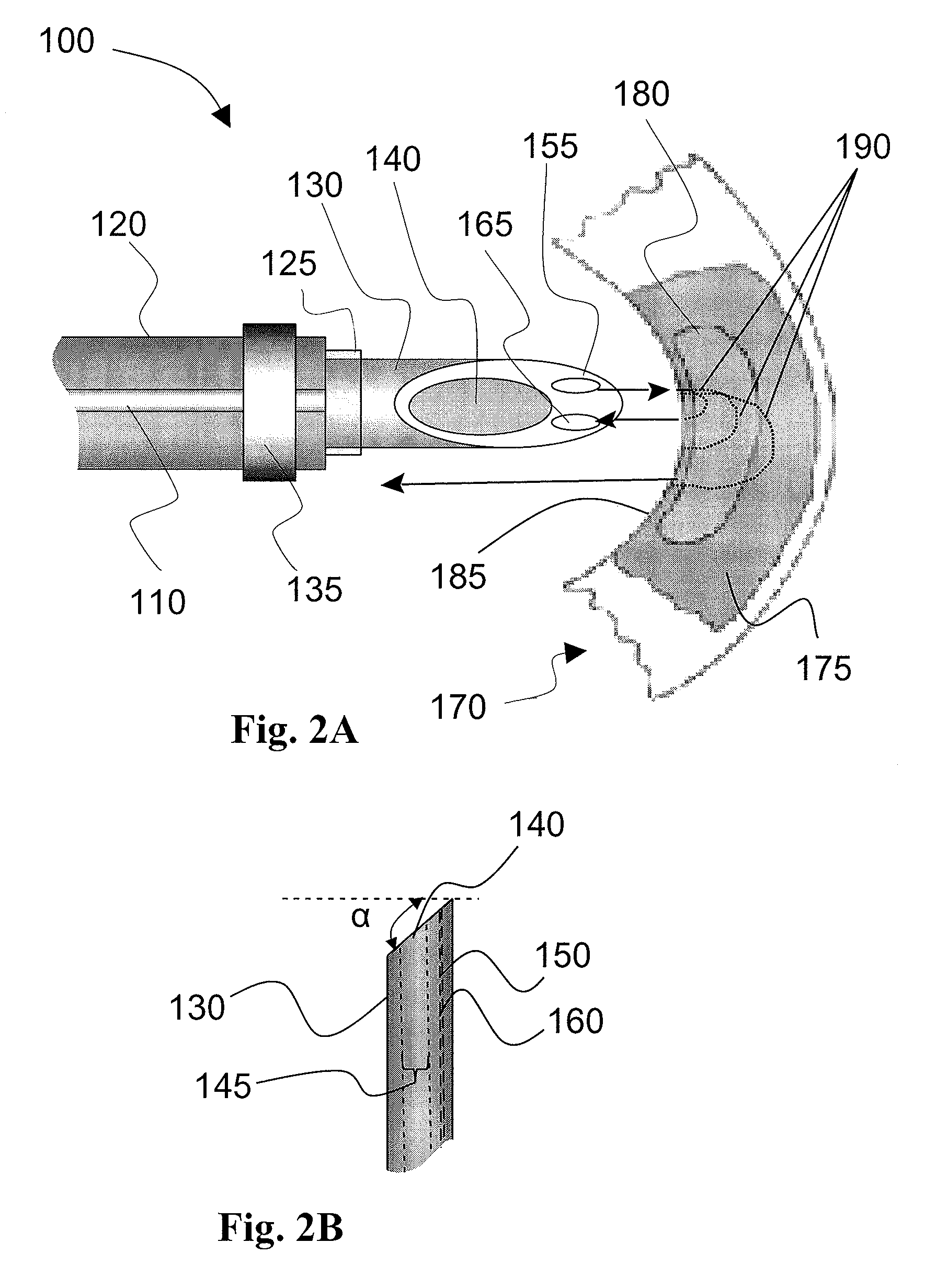

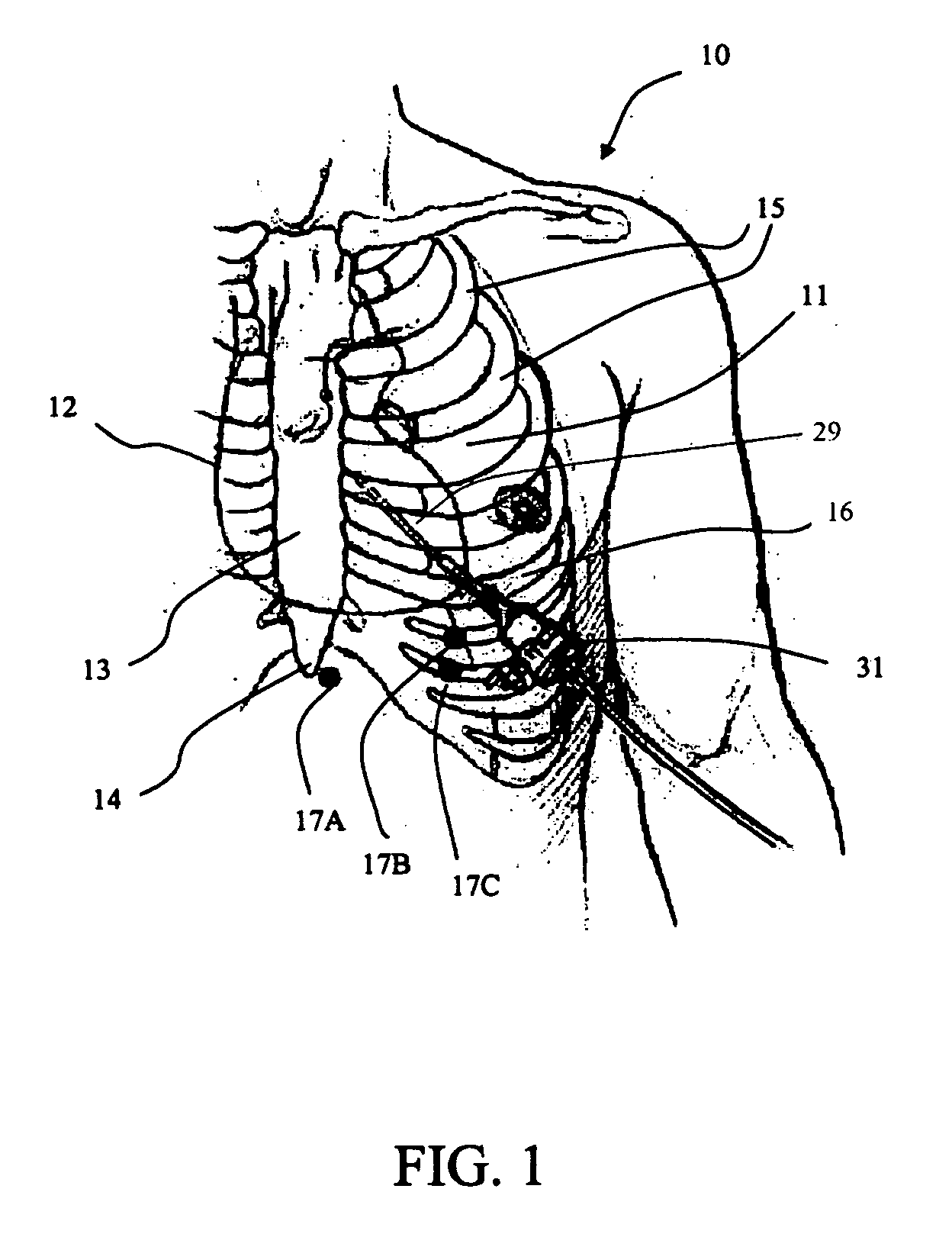

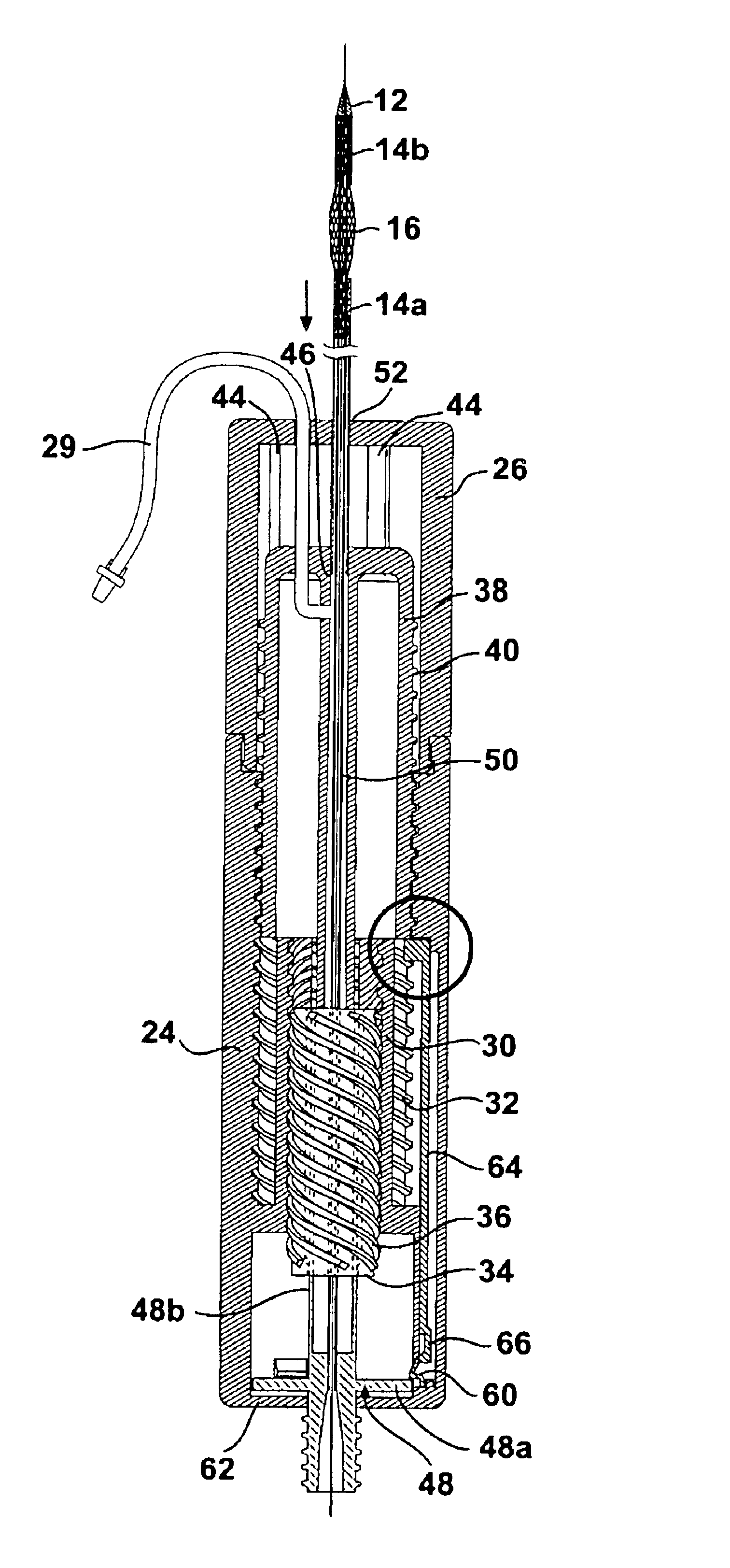

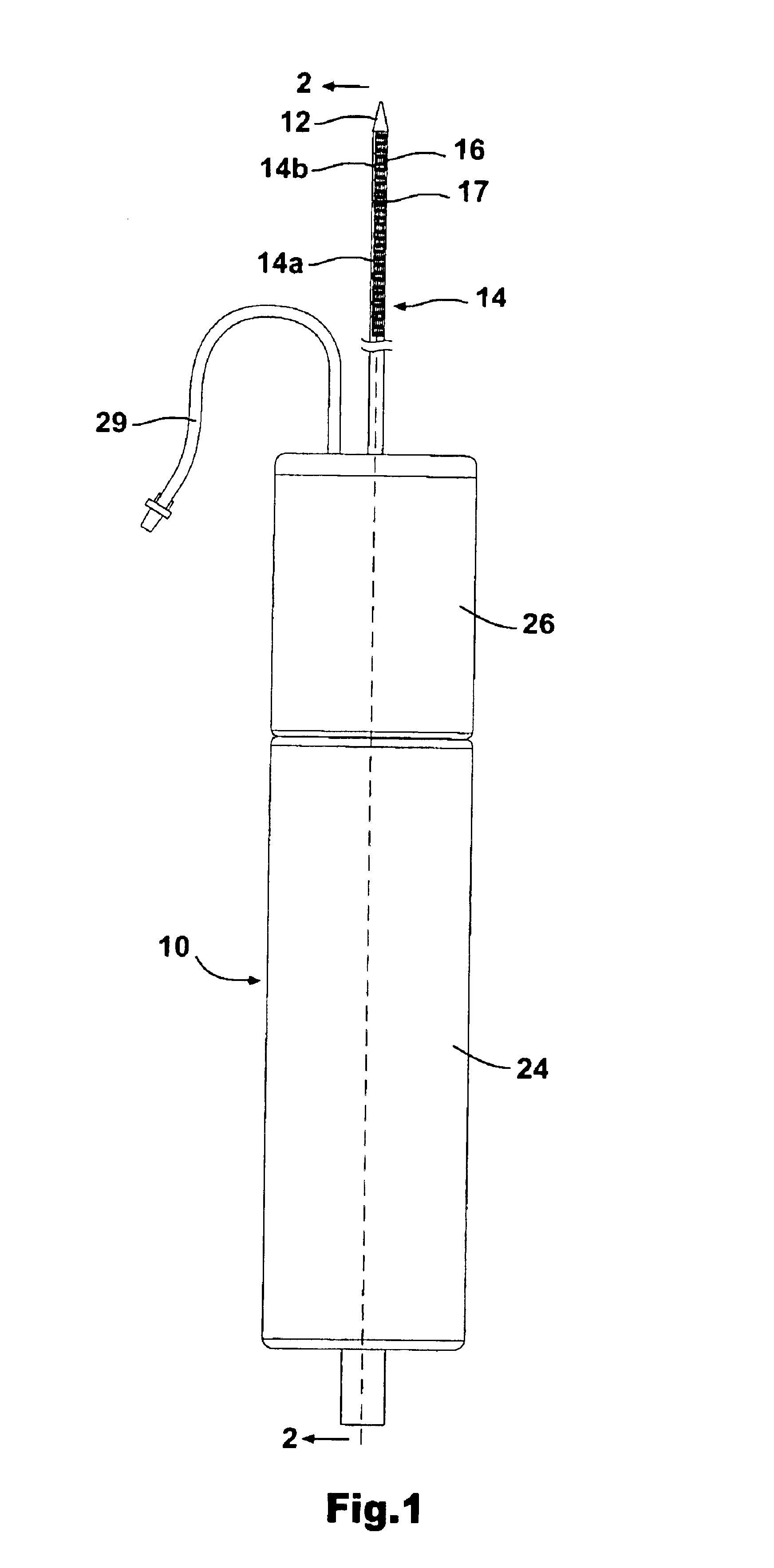

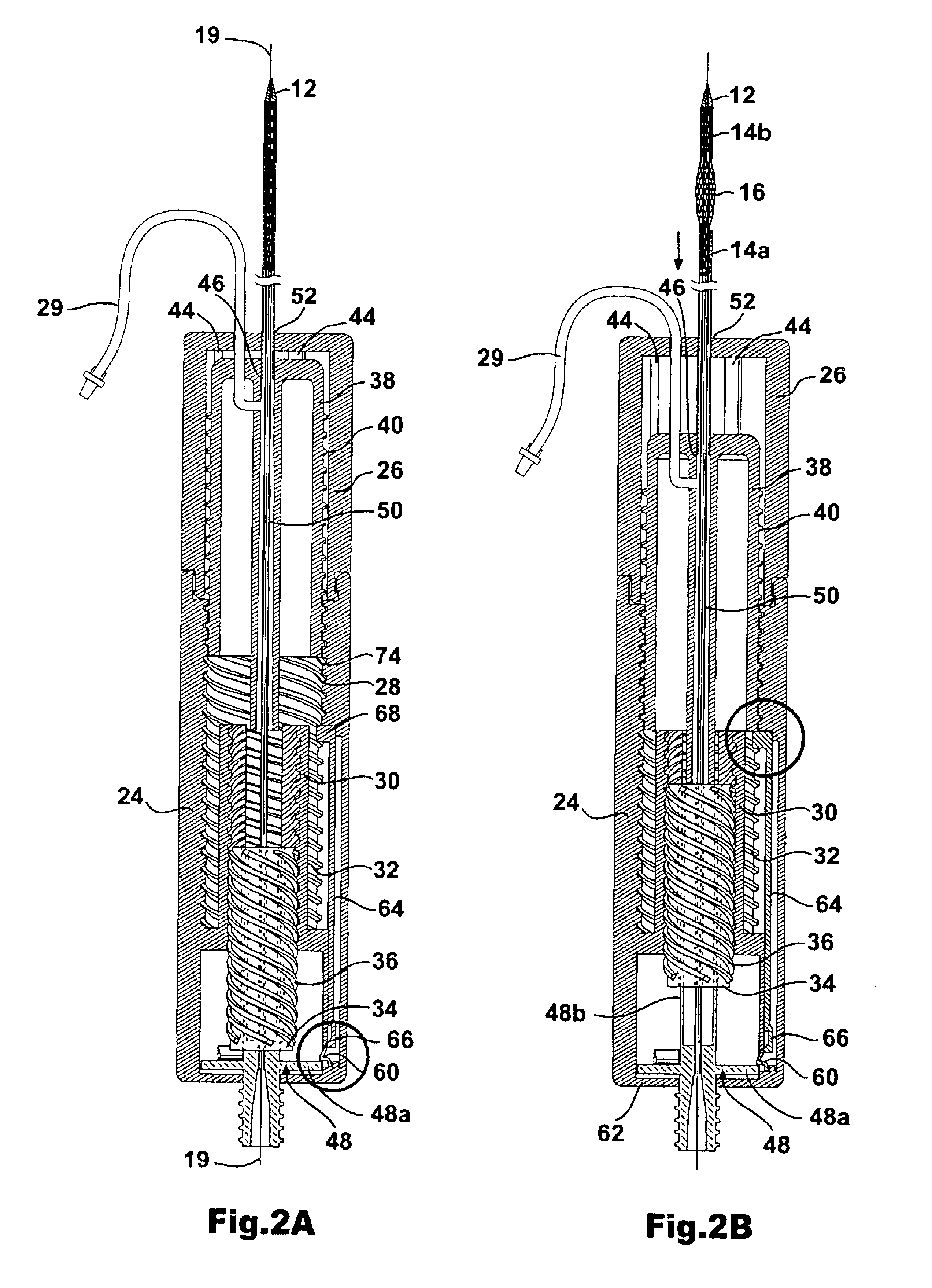

Method and apparatus for identifying and treating myocardial infarction

InactiveUS20080125634A1Safe and effectiveAccurate locationGuide needlesSurgical needlesVisual perceptionVisual feedback

A method and apparatus for analyzing and treating internal tissues and, in particular, tissues affected by myocardial infarct. The apparatus includes a catheterized device integrating an optical probe and treatment delivery system. The probe component includes fiber optic lines that can be used in conjunction with infrared spectroscopy to analyze various characteristics of tissues, including chemical, blood, and oxygen content, in order to locate those tissues associated with myocardial infarct, to determine the best location for applying treatment, and to monitor treatment and its effects. Physically integrated with the probe component is a treatment component for delivering treatments including stem cell and gene therapy, known for having beneficial effects on tissues associated with myocardial infarct. A control system coordinates operation of the catheter, including performing chemometric analysis with the use of model data, and for providing control and visual feedback to an operator.

Owner:CORNOVA

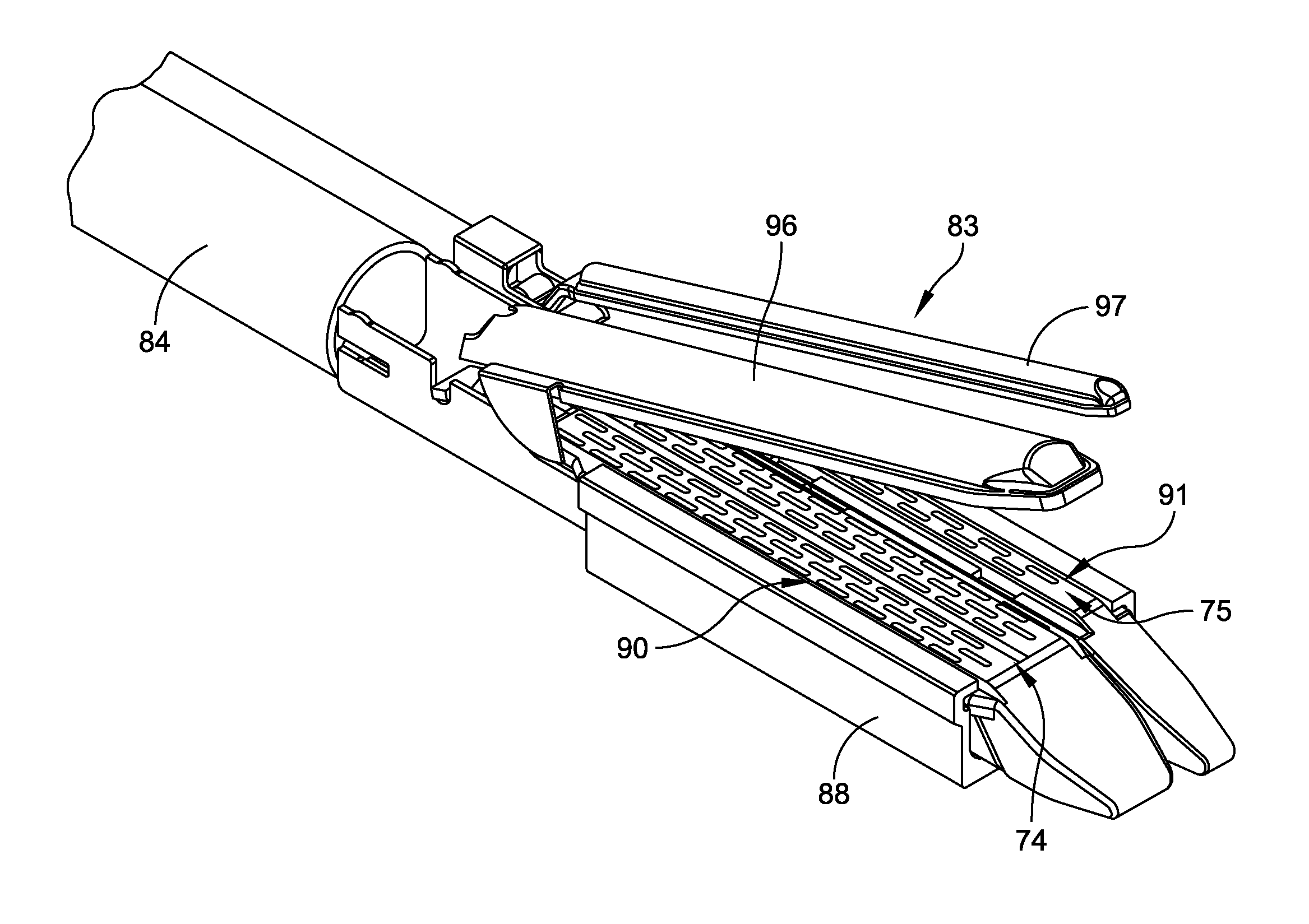

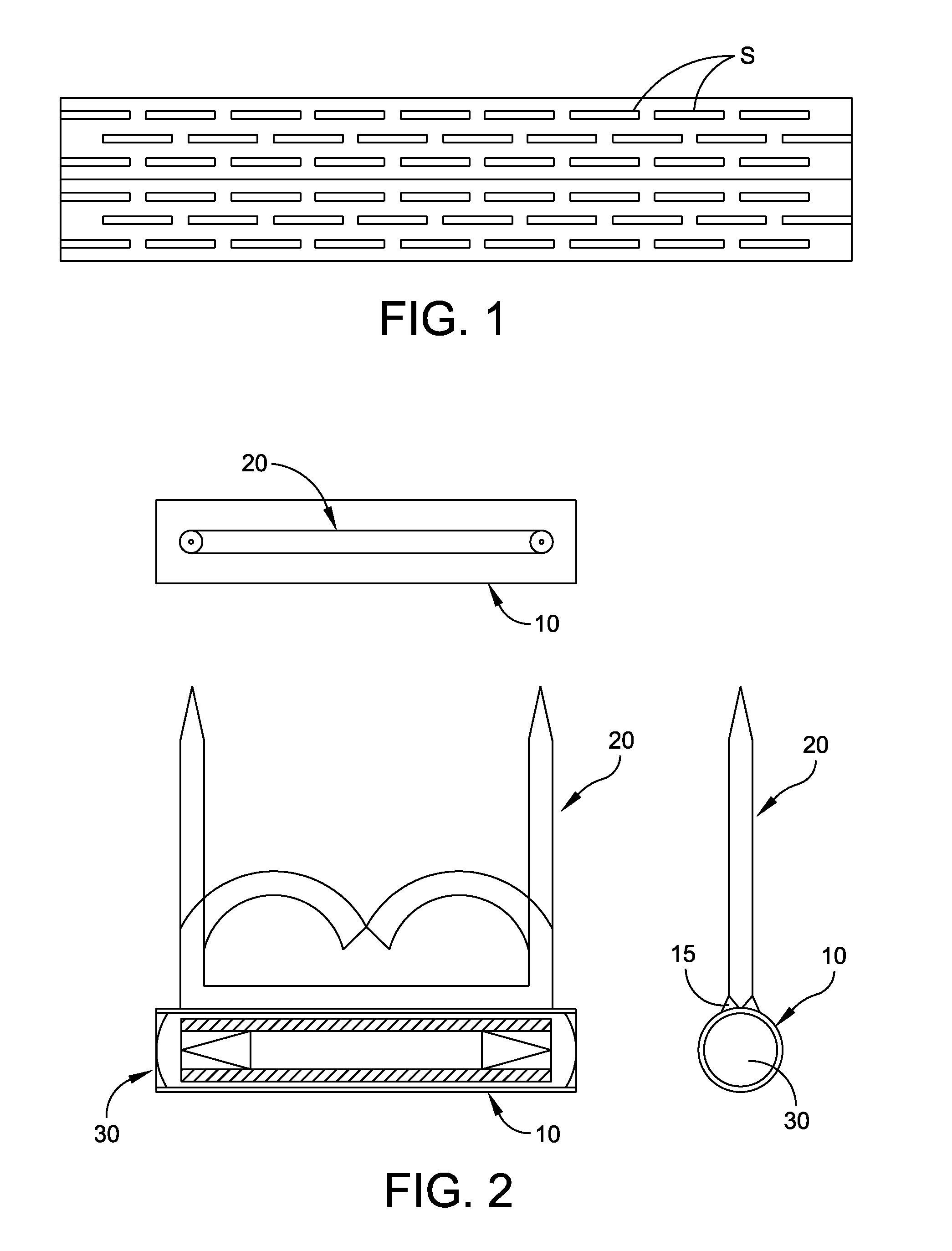

Radioactive therapeutic fastening instrument

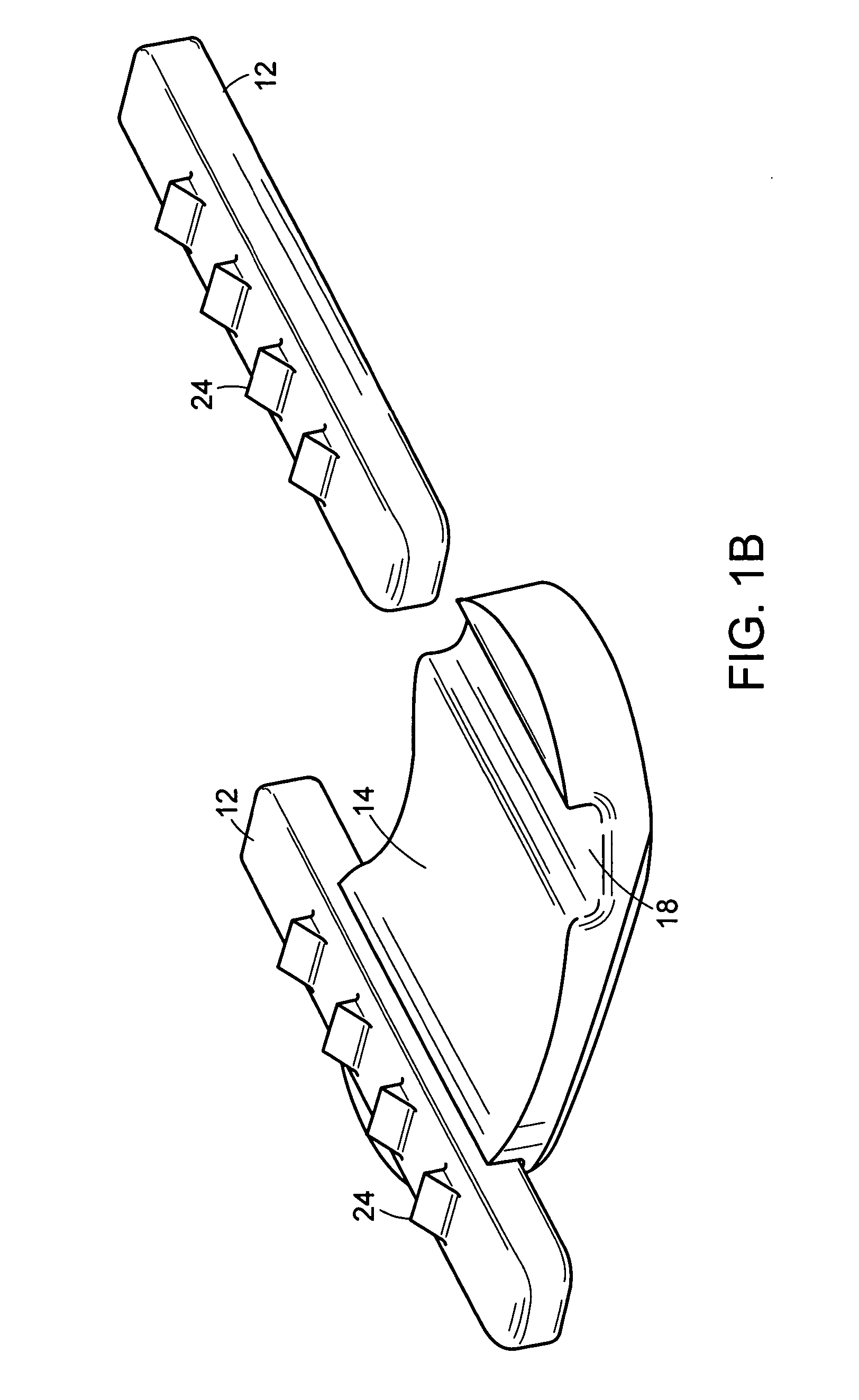

ActiveUS8267849B2For accurate placementReduce doseSuture equipmentsStapling toolsBrachytherapyEngineering

An instrument used for brachytherapy delivery in the treatment of cancer by radiation therapy including a handle having first and second handle actuators; an end effector; and an instrument shaft that connects the handle with the end effector. The end effector has first and second adjacent disposed staple mechanisms that each retain a set of staples. The first mechanism is for holding standard staples in a first array, and dispensing the standard staples under control of the corresponding first handle actuator. The second mechanism is for holding radioactive source staples in a second array, and dispensing said radioactive source staples under control of the corresponding second handle actuator. A holder is for receiving the first and second mechanisms in a substantially parallel array so that the standard staples close the incision at a surgical margin while the source staples are secured adjacent thereto.

Owner:POINT SOURCE TECH

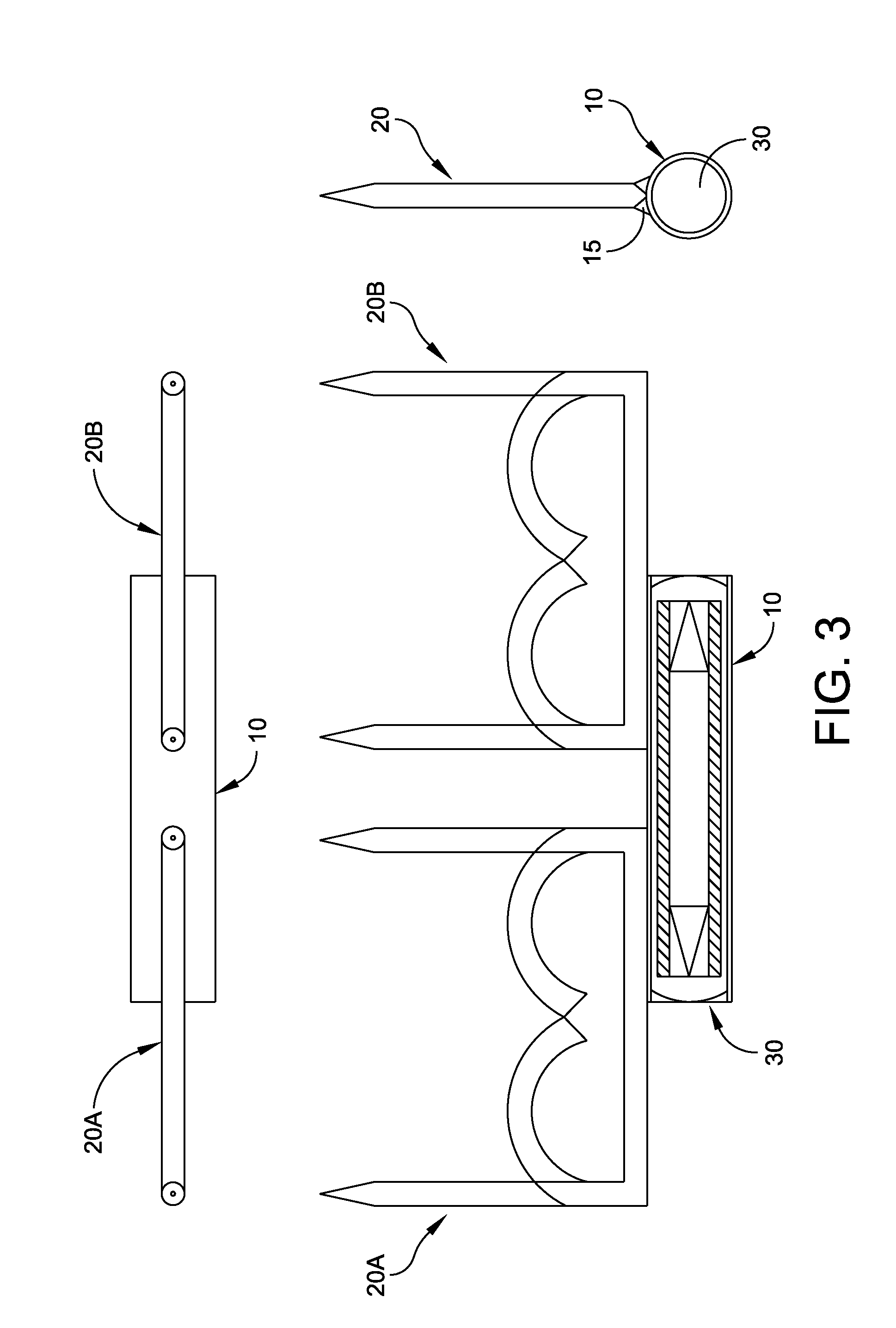

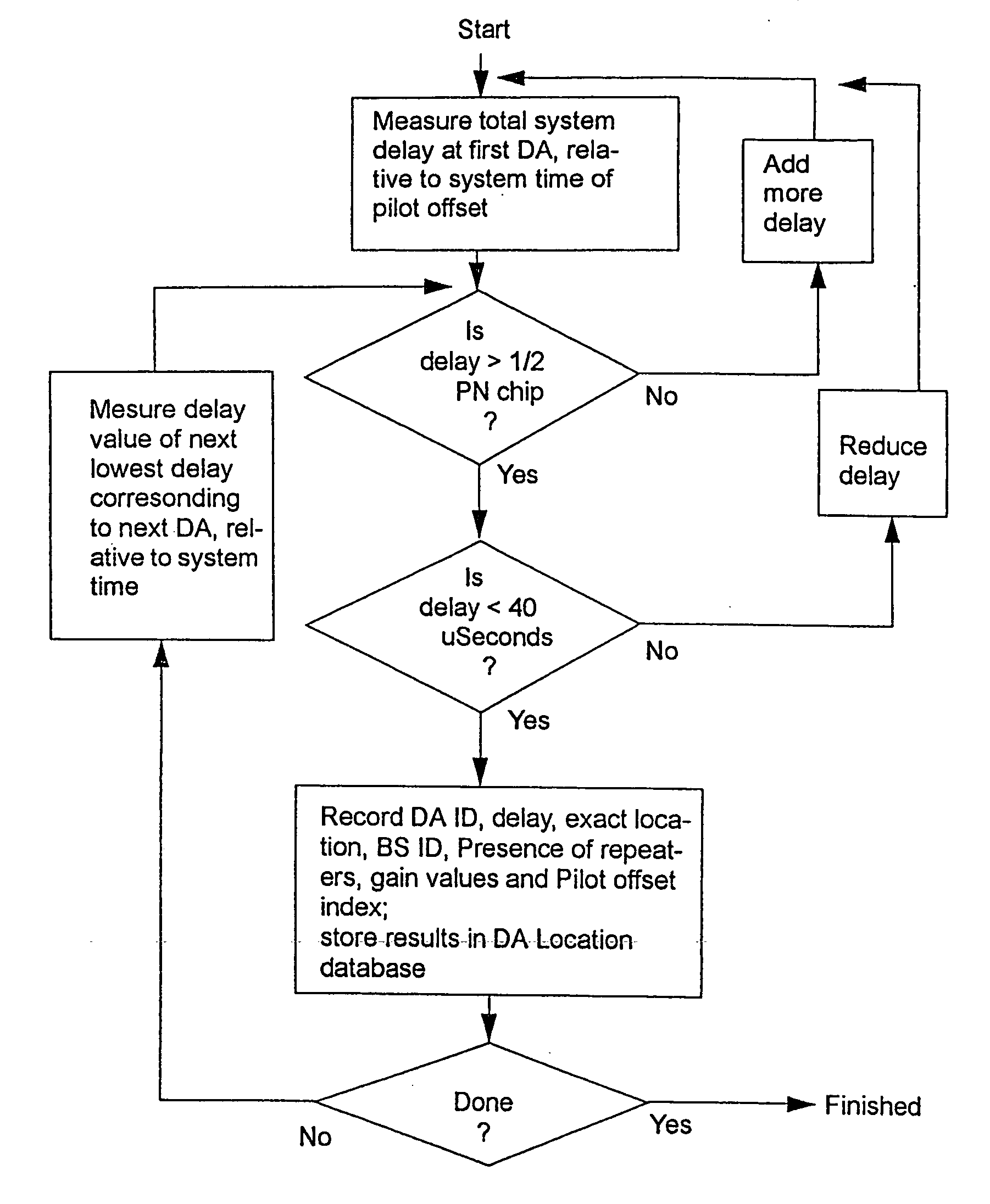

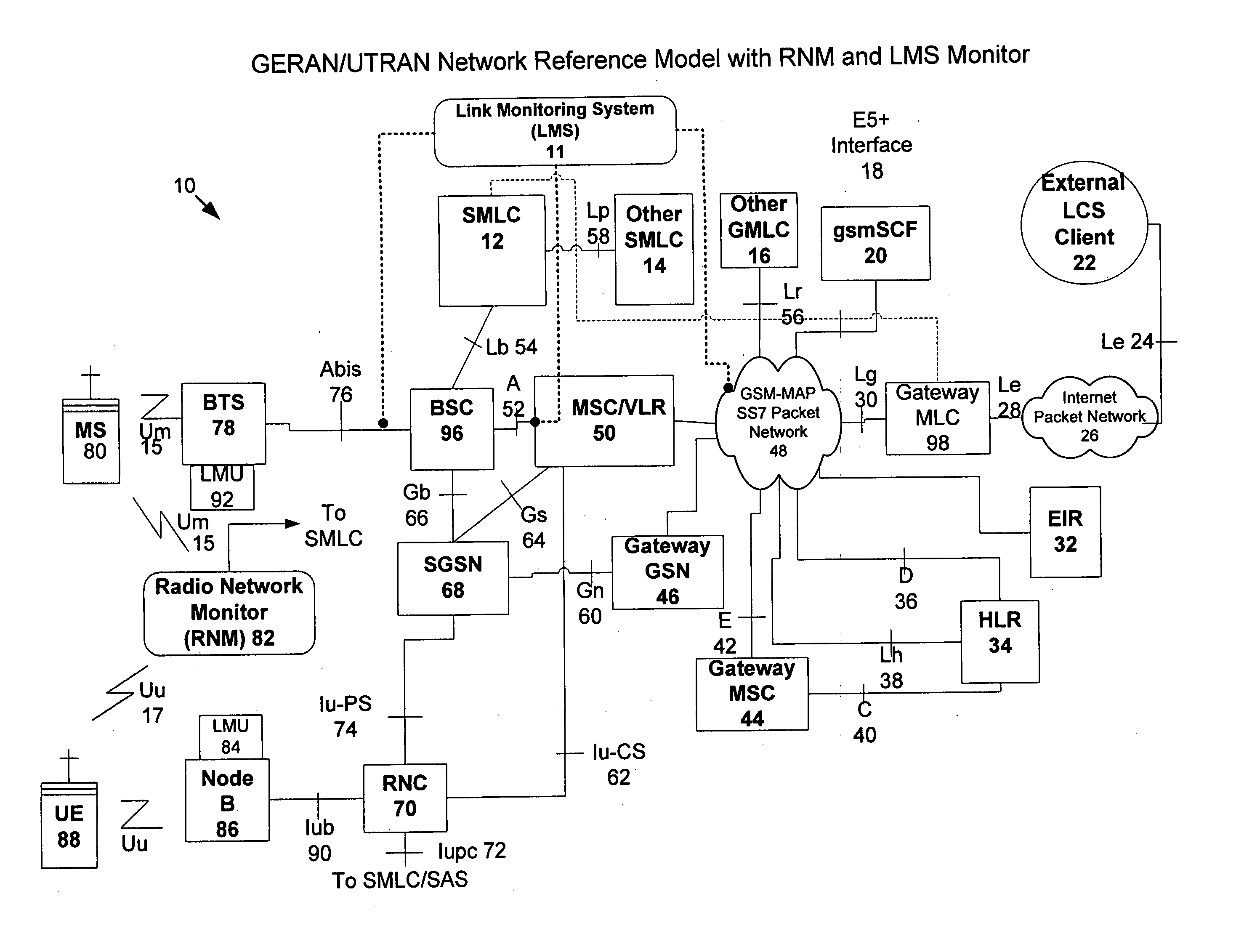

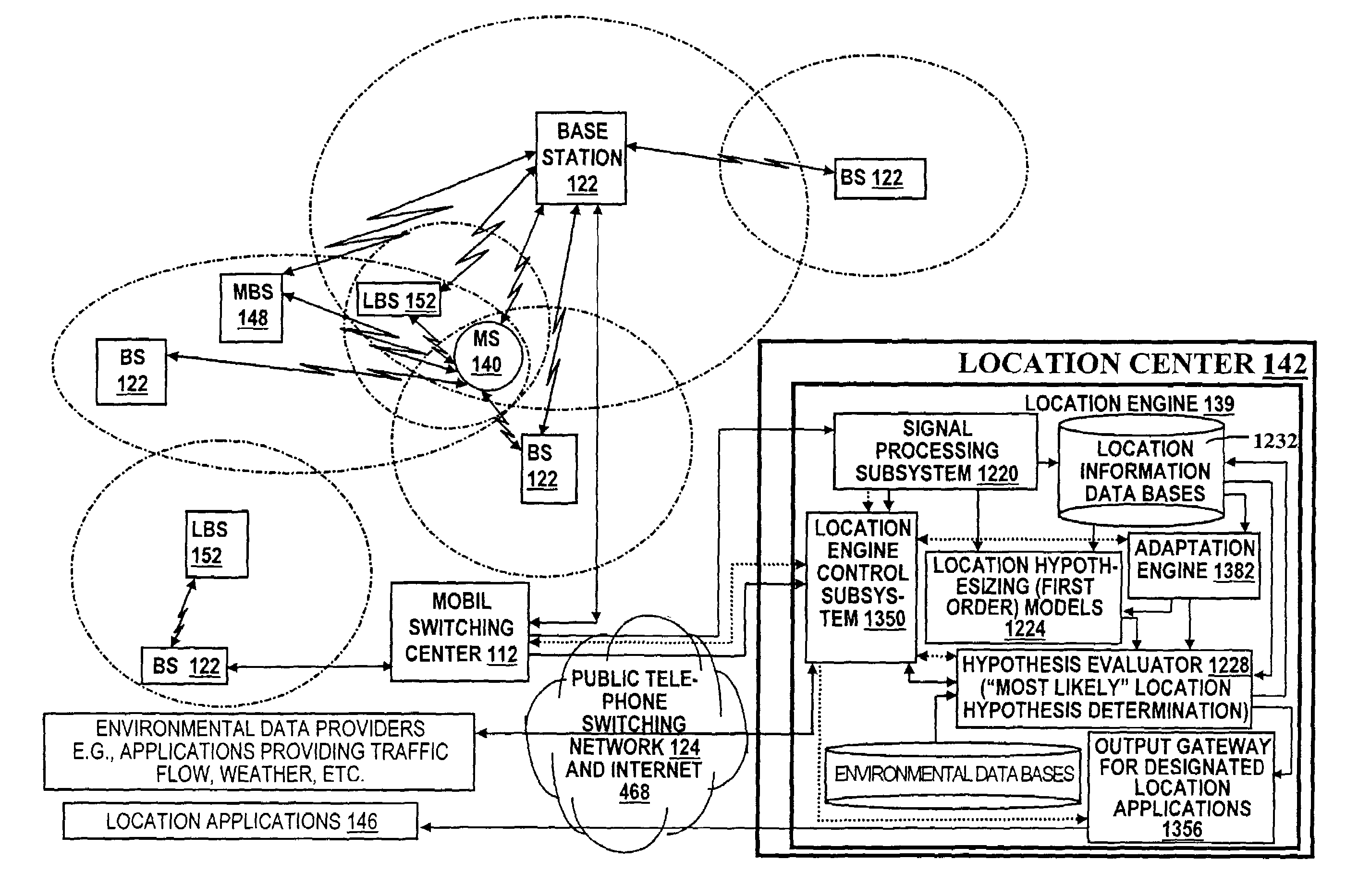

Locating a mobile station and applications therefor

InactiveUS20060025158A1Accurate locationEmergency connection handlingNetwork traffic/resource managementInternet communicationModularity

A location system is disclosed for wireless telecommunication infrastructures. The system is an end-to-end solution having one or more location systems for outputting requested locations of hand sets or mobile stations (MS) based on, e.g., AMPS, NAMPS, CDMA or TDMA communication standards, for processing both local mobile station location requests and more global mobile station location requests via, e.g., Internet communication between a distributed network of location systems. The system uses a plurality of mobile station locating technologies including those based on: (1) two-way TOA and TDOA; (2) home base stations and (3) distributed antenna provisioning. Further, the system can be modularly configured for use in location signaling environments ranging from urban, dense urban, suburban, rural, mountain to low traffic or isolated roadways. The system is useful for 911 emergency calls, tracking, routing, people and animal location including applications for confinement to and exclusion from certain areas.

Owner:FINETRAK LLC

Methods and systems for cardiac valve delivery

The present invention provides systems and methods for the repair, removal, and / or replacement of heart valves. The methods comprise introducing a delivery system into the heart, wherein a prosthesis is disposed on the delivery member attached to the delivery system, advancing the prosthesis to the target site, and disengaging the prosthesis from the delivery member at the target site for implantation. The present invention also provides implant systems for delivering a prosthesis to a target site in or near the heart. In one embodiment of the present invention, the implant system comprises a delivery system, an access system, and a prosthesis.

Owner:MEDTRONIC 3F THERAPEUTICS

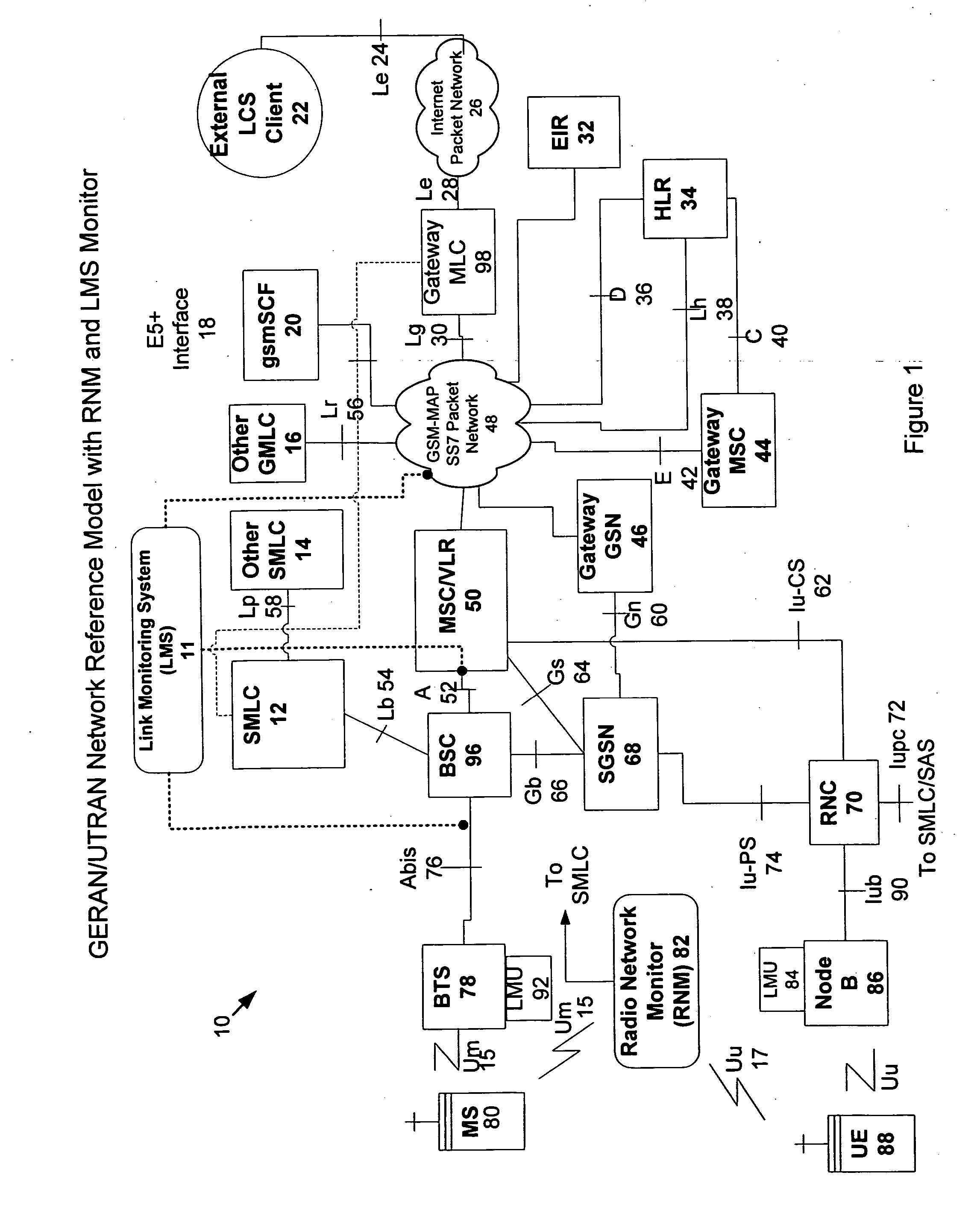

Advanced triggers for location-based service applications in a wireless location system

InactiveUS20060003775A1Accurate locationEmergency connection handlingPosition fixationCommunications systemWireless positioning

Method and systems are employed by a wireless location system (WLS) for locating a wireless device operating in a geographic area served by a wireless communications system. An exemplary method includes monitoring a set of signaling links of the wireless communications system, and detecting at least one predefined signaling transaction occurring on at least one of the predefined signaling links. Then, in response to the detection of the at least one predefined network transaction, at least one predefined location service is triggered.

Owner:TRUE POSITION INC

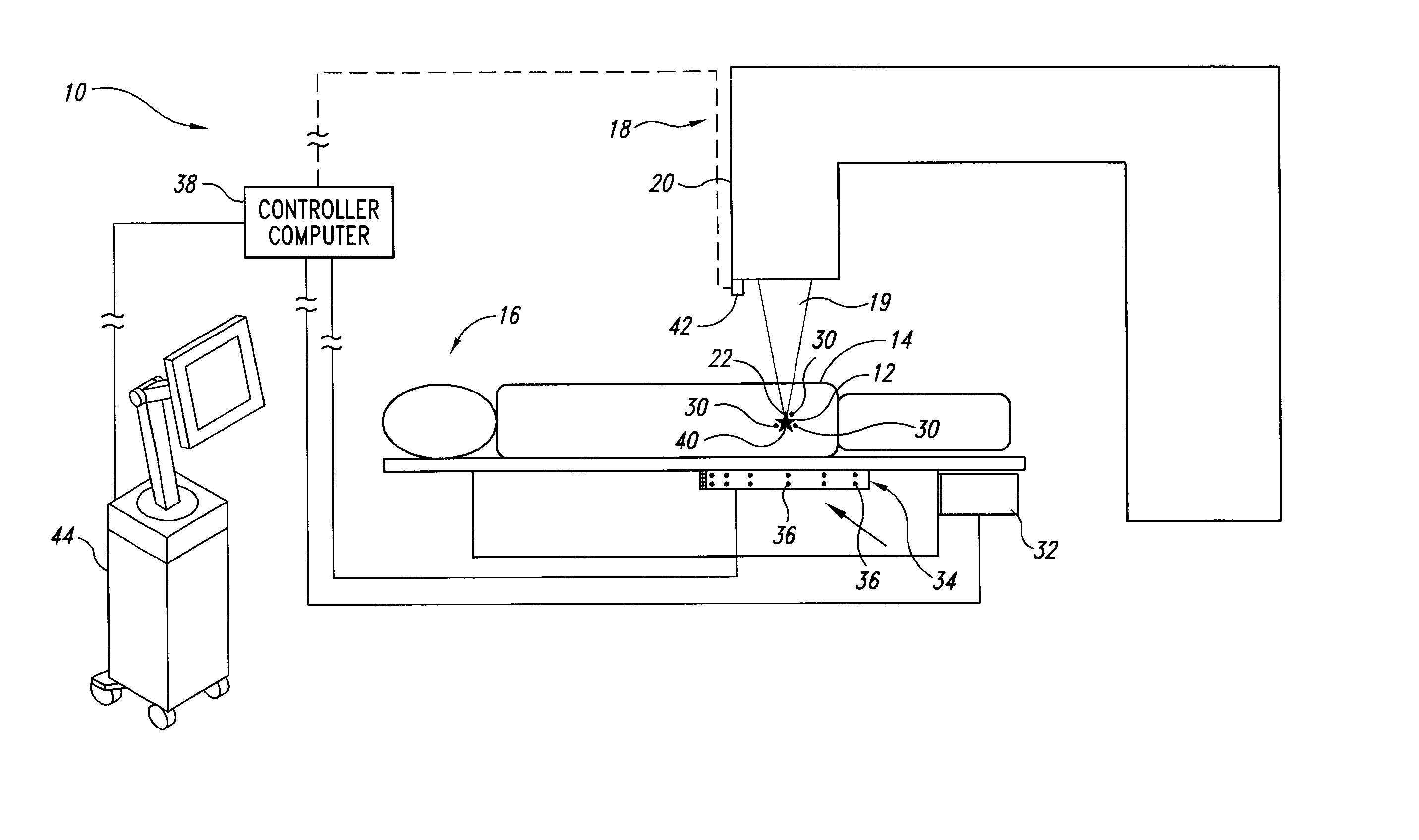

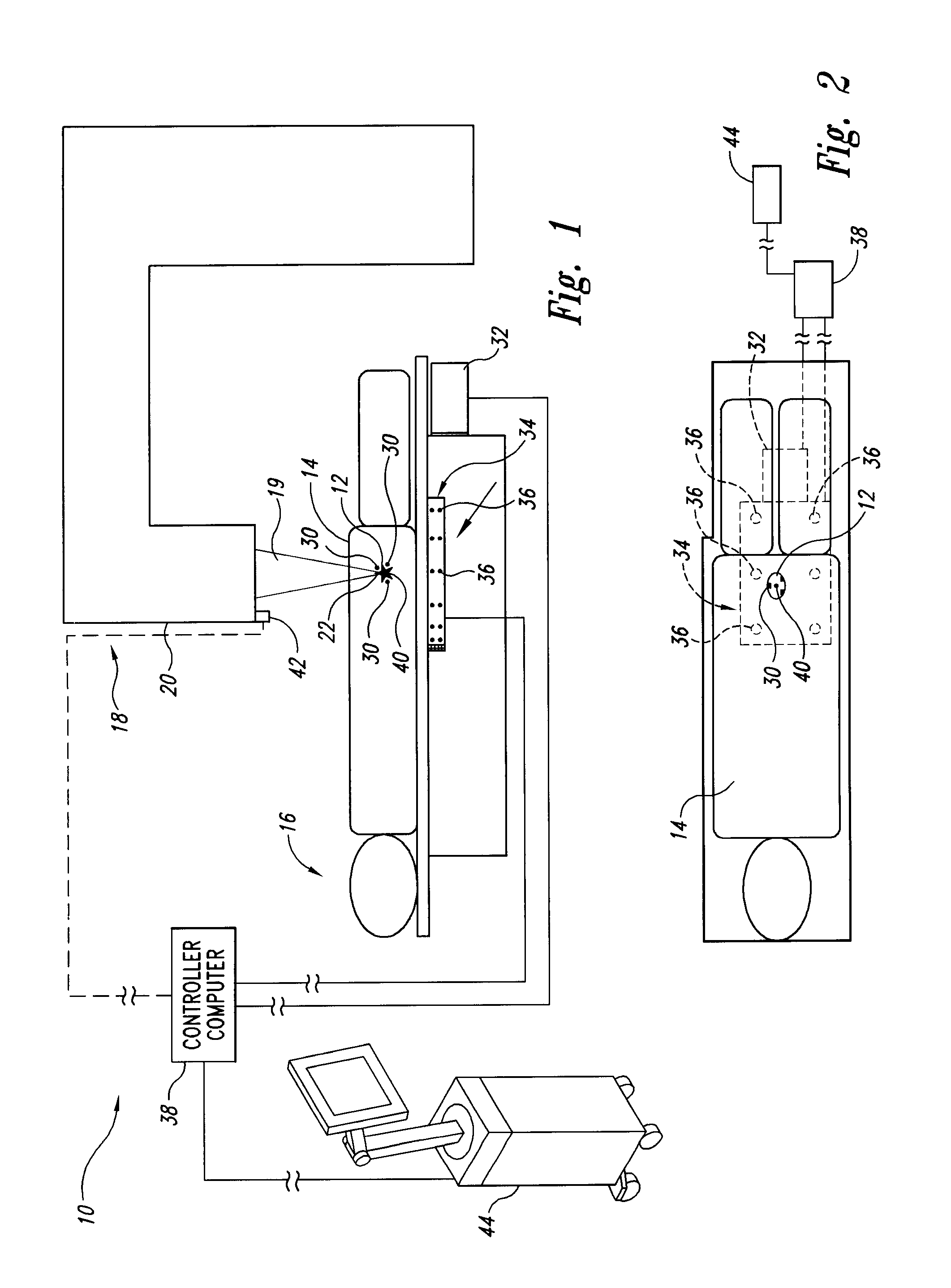

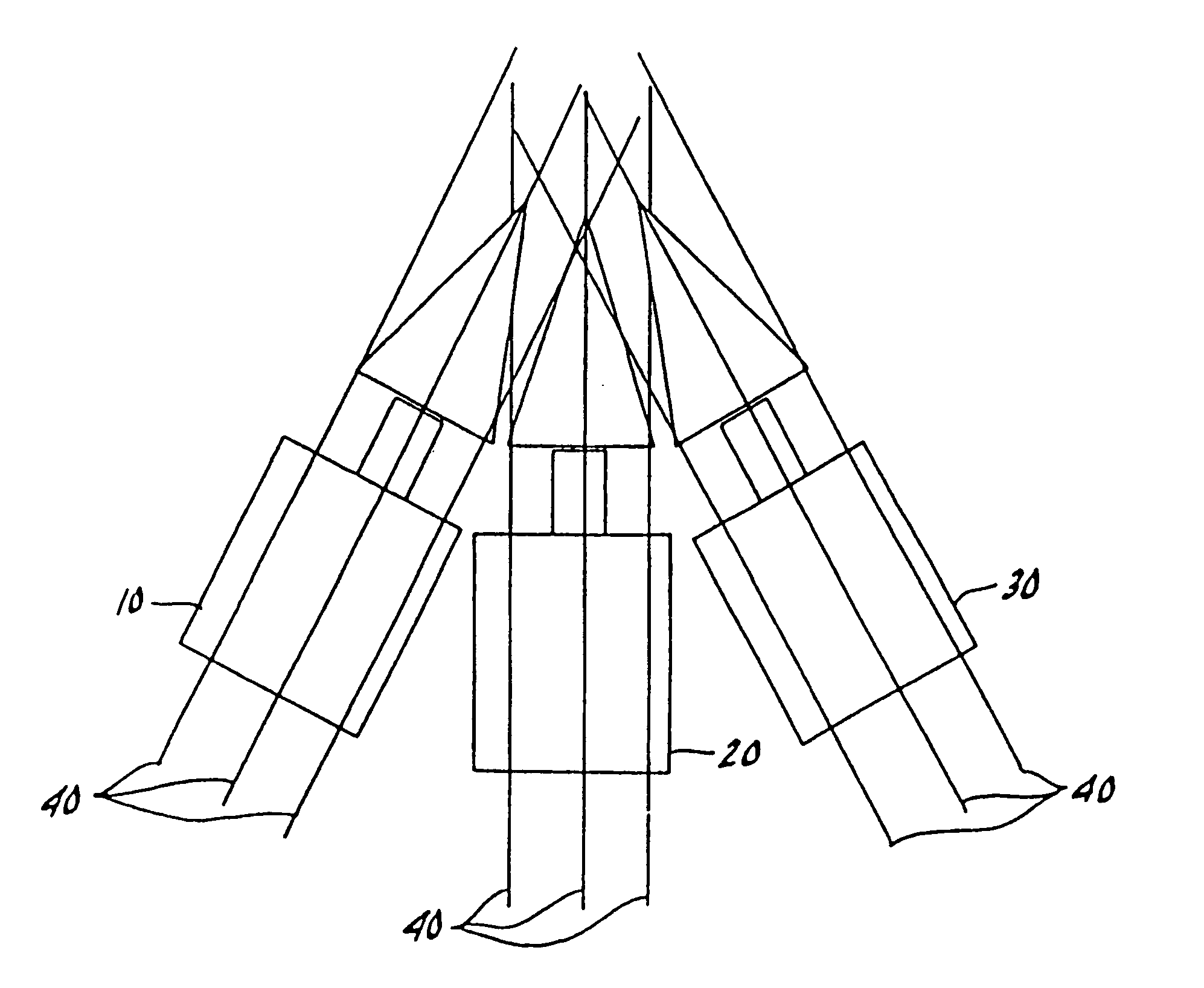

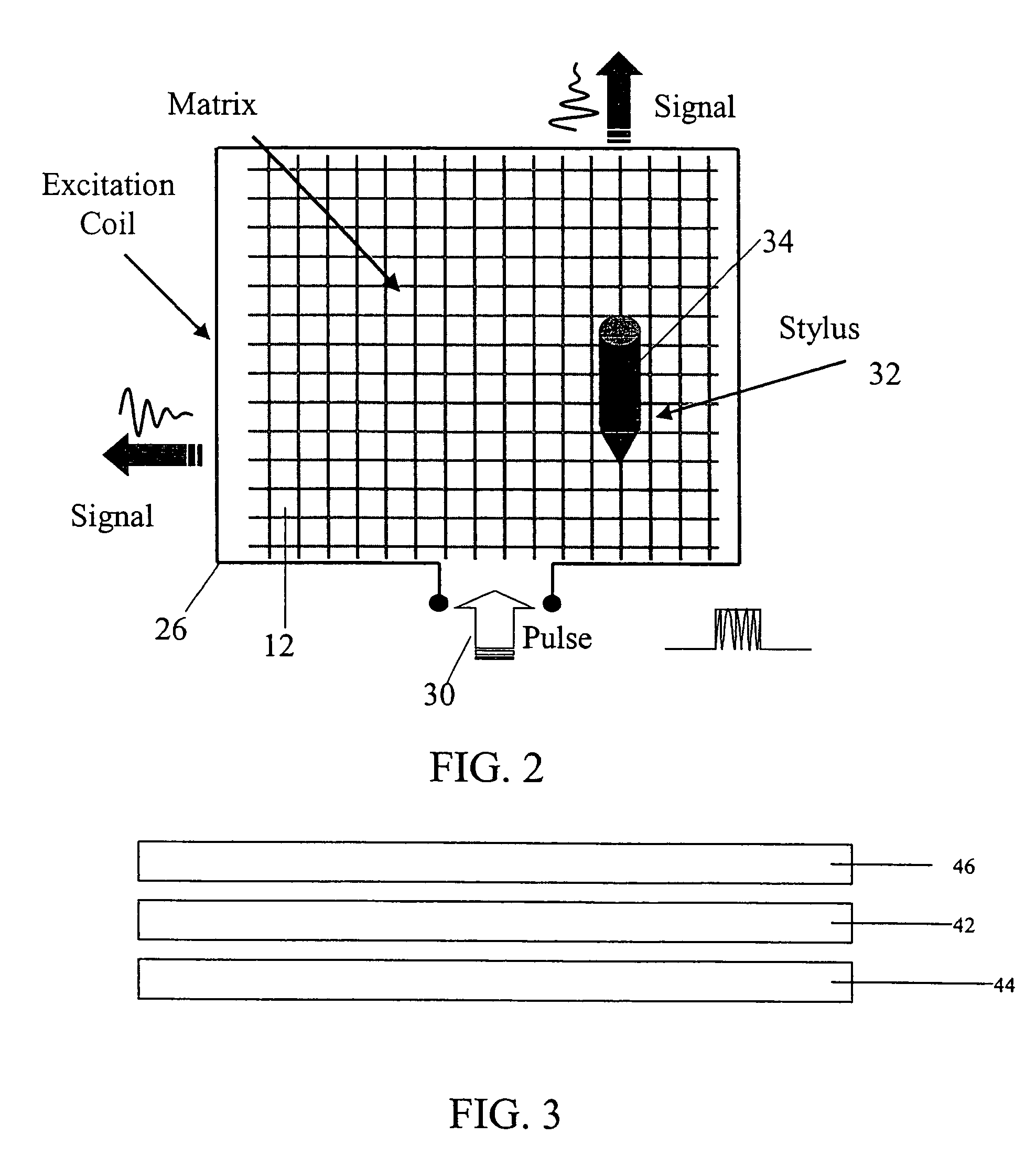

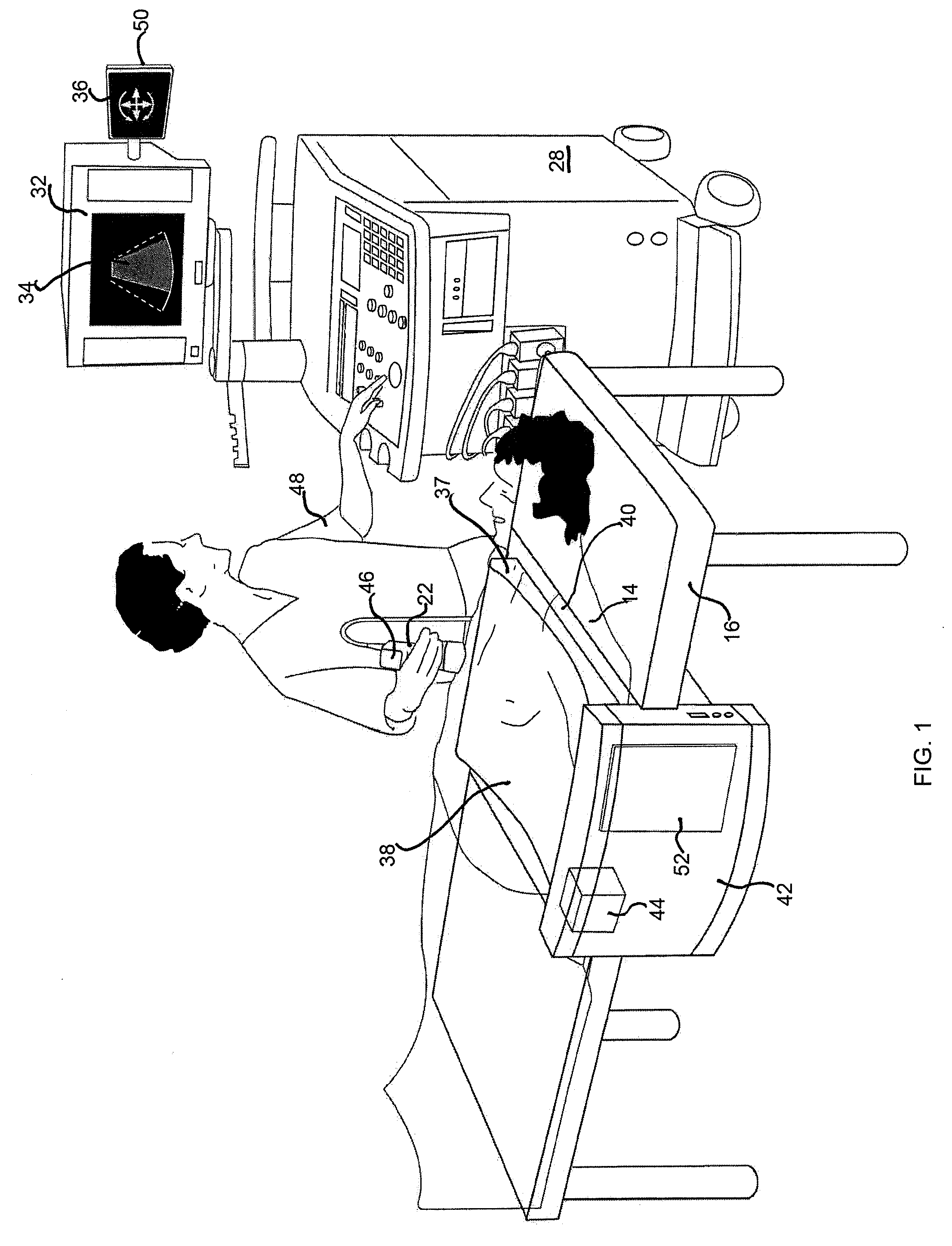

Guided Radiation Therapy System

InactiveUS20020193685A1Accurate locationAccurate trackingSurgical navigation systemsPosition fixationMonitoring systemIsocenter

<heading lvl="0">Abstract of Disclosure< / heading> A system and method for accurately locating and tracking the position of a target, such as a tumor or the like, within a body. In one embodiment, the system is a target locating and monitoring system usable with a radiation delivery source that delivers selected doses of radiation to a target in a body. The system includes one or more excitable markers positionable in or near the target, an external excitation source that remotely excites the markers to produce an identifiable signal, and a plurality of sensors spaced apart in a known geometry relative to each other. A computer is coupled to the sensors and configured to use the marker measurements to identify a target isocenter within the target. The computer compares the position of the target isocenter with the location of the machine isocenter. The computer also controls movement of the patient and a patient support device so the target isocenter is co-incident with the machine isocenter before and during radiation therapy.

Owner:CALYPSO MEDICAL +1

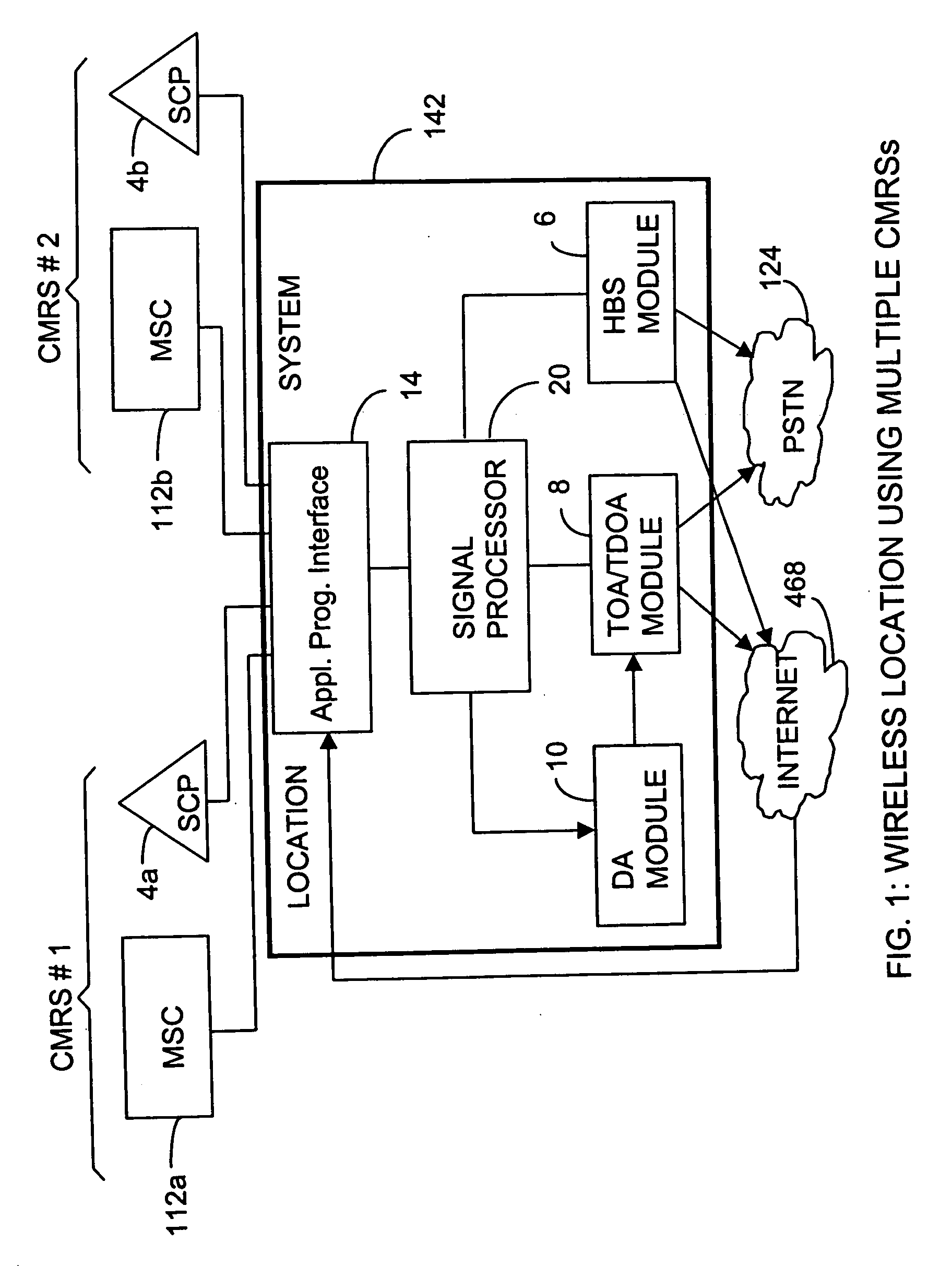

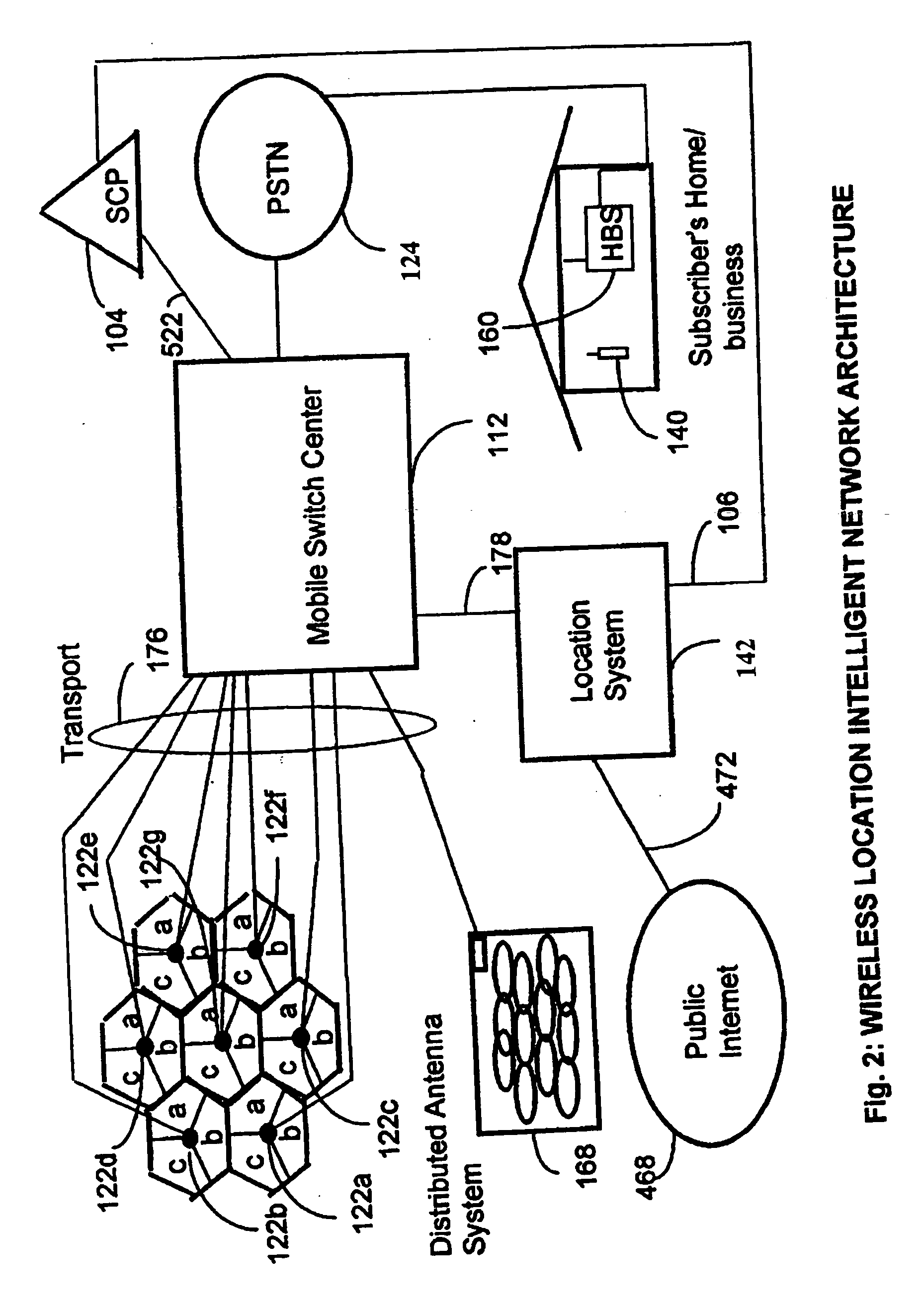

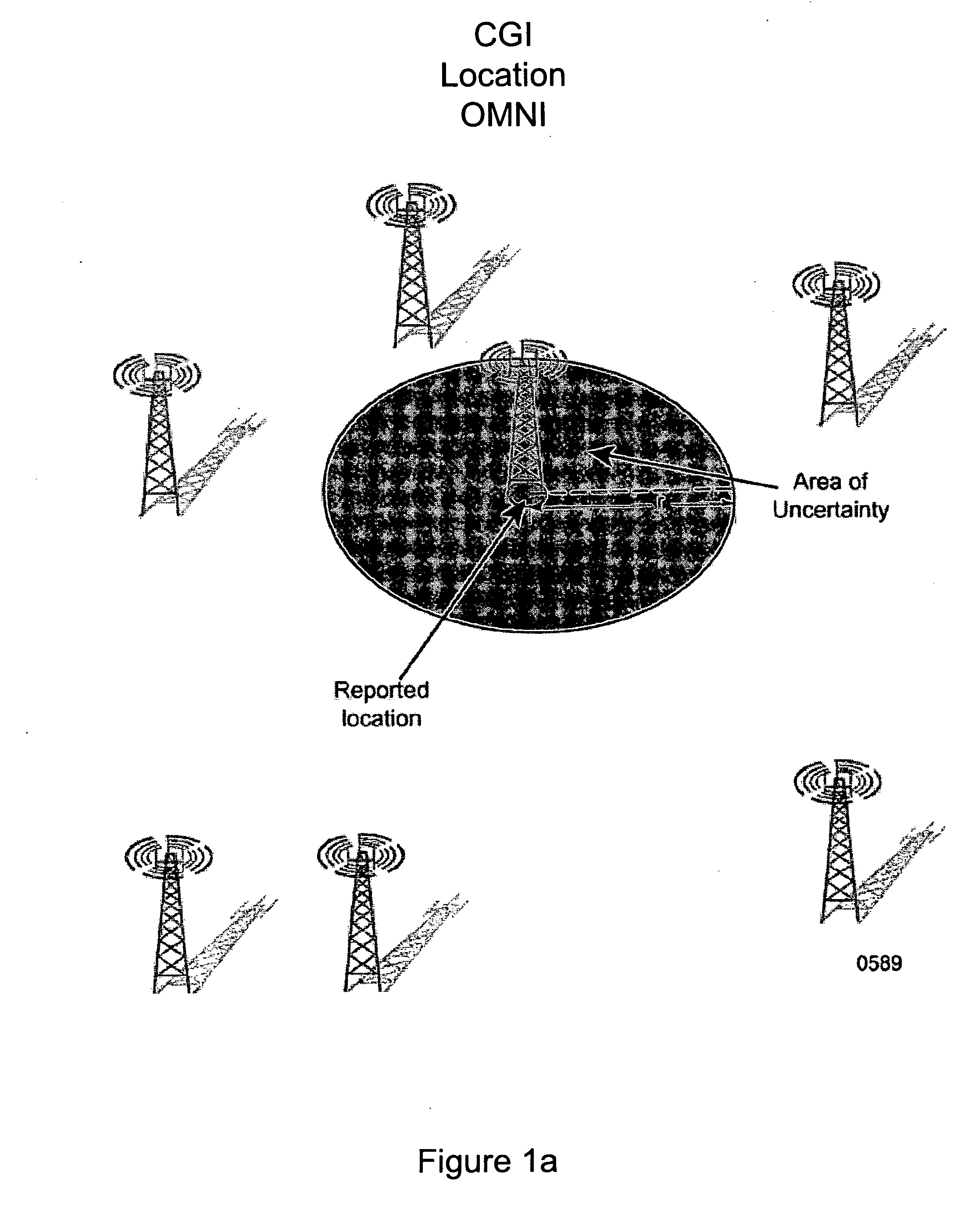

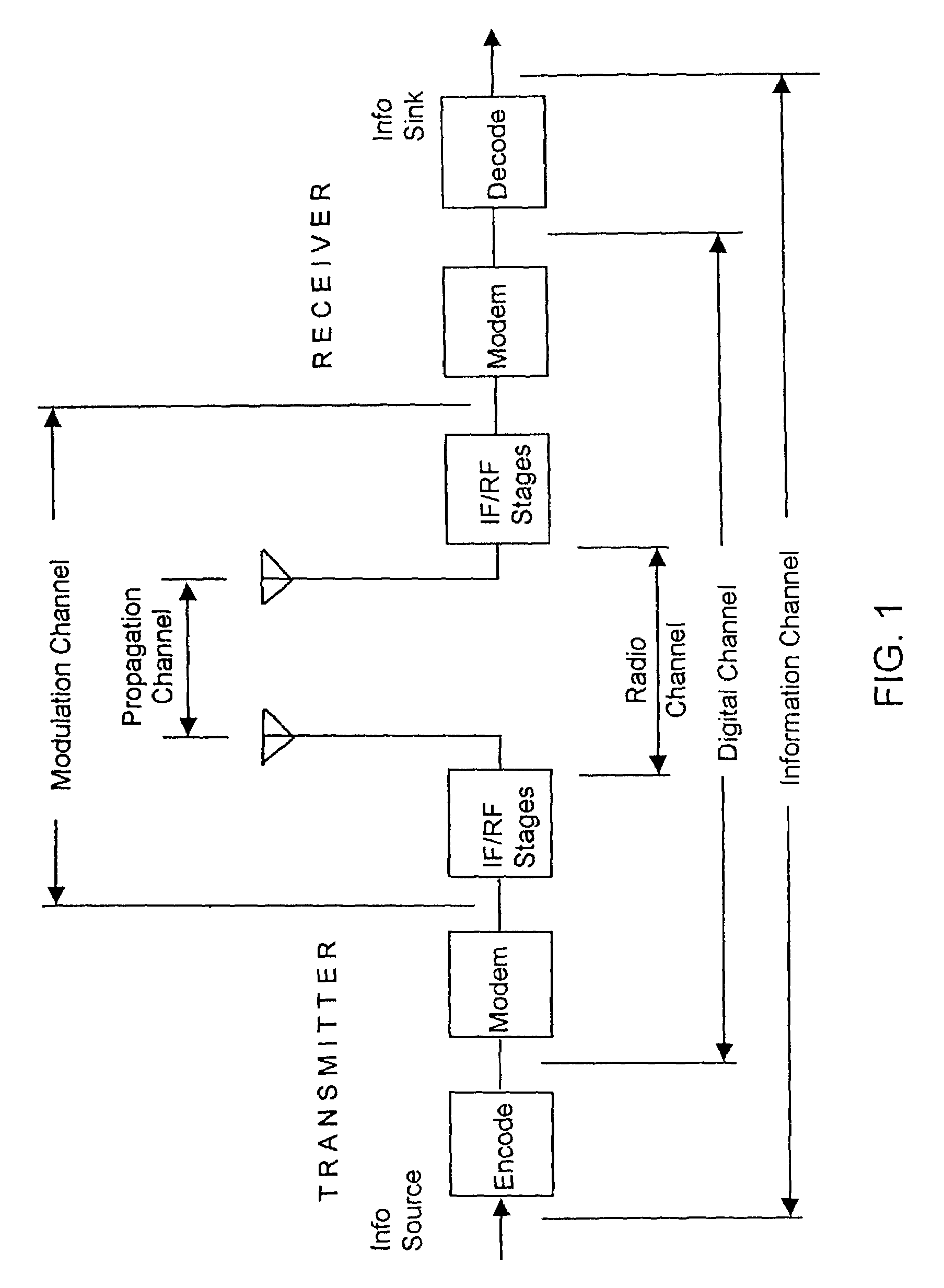

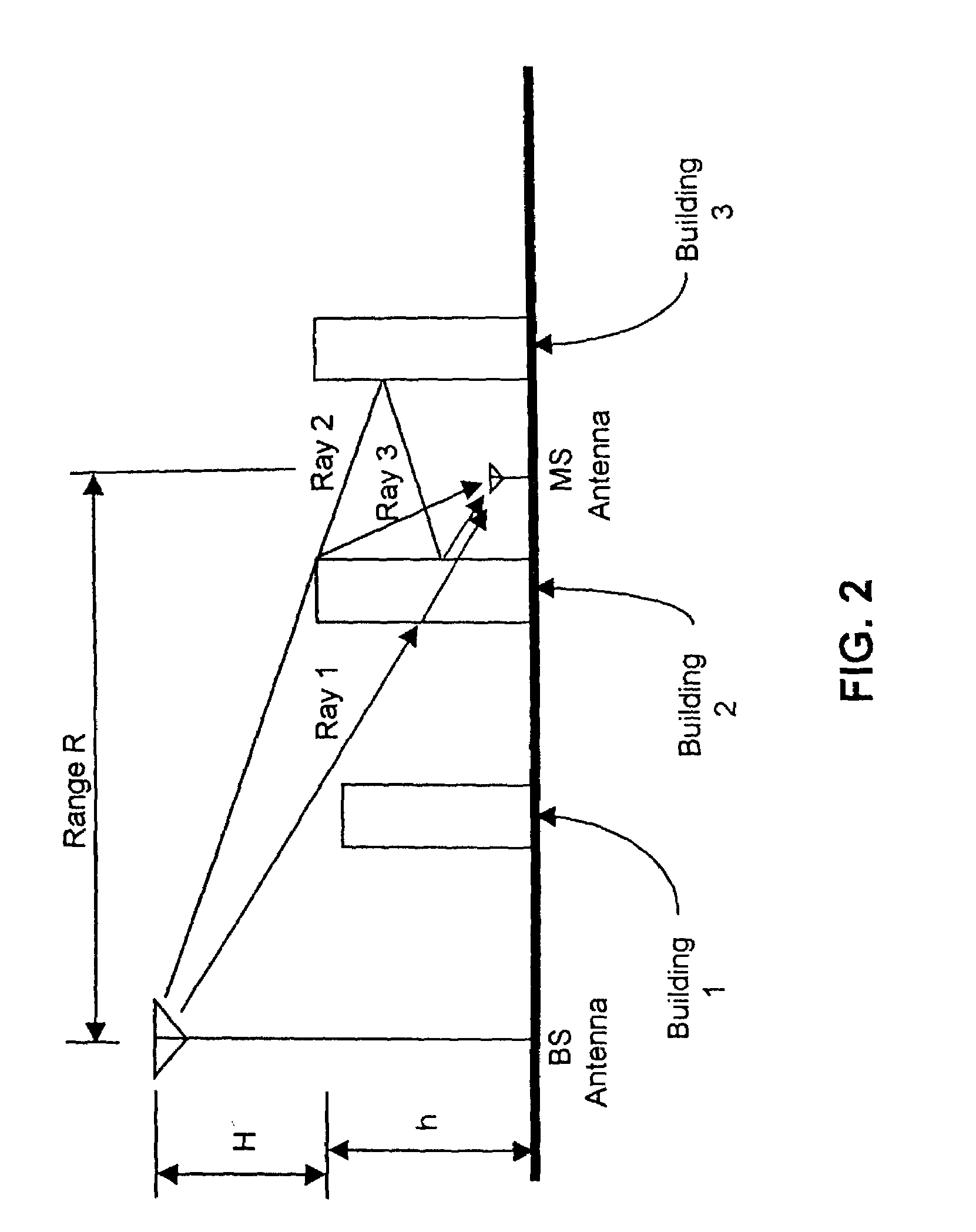

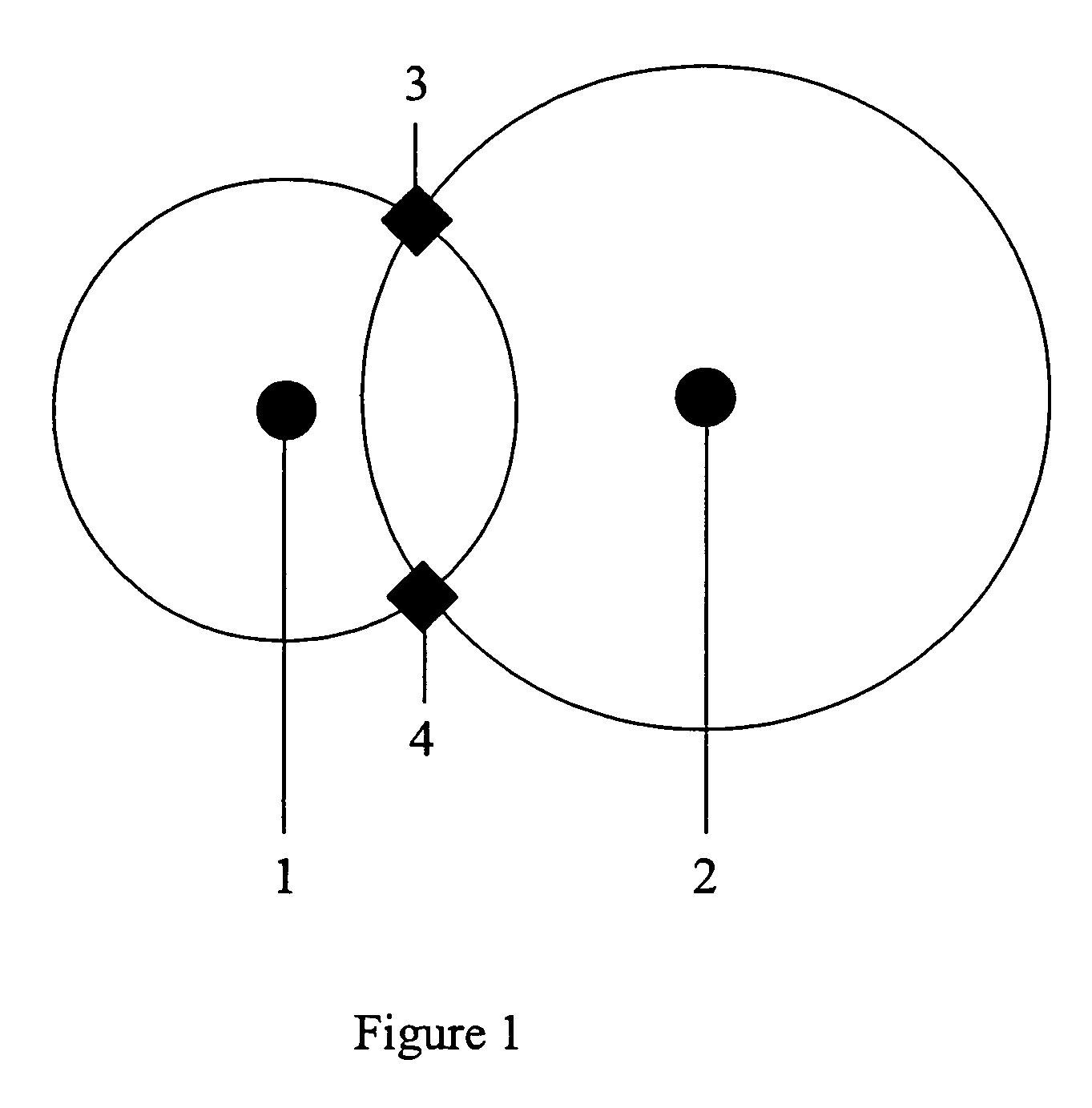

Geographic location using multiple location estimators

InactiveUS7298327B2Overcome inaccurate recognitionThe result is accurate and reliableDirection finders using radio wavesBeacon systems using radio wavesTerrainHeuristic

A location system is disclosed for commercial wireless telecommunication infrastructures. The system is an end-to-end solution having one or more location centers for outputting requested locations of commercially available handsets or mobile stations (MS) based on, e.g., CDMA, AMPS, NAMPS or TDMA communication standards, for processing both local MS location requests and more global MS location requests via, e.g., Internet communication between a distributed network of location centers. The system uses a plurality of MS locating technologies including those based on: (1) two-way TOA and TDOA; (2) pattern recognition; (3) distributed antenna provisioning; and (4) supplemental information from various types of very low cost non-infrastructure base stations for communicating via a typical commercial wireless base station infrastructure or a public telephone switching network. Accordingly, the traditional MS location difficulties, such as multipath, poor location accuracy and poor coverage are alleviated via such technologies in combination with strategies for: (a) automatically adapting and calibrating system performance according to environmental and geographical changes; (b) automatically capturing location signal data for continual enhancement of a self-maintaining historical data base retaining predictive location signal data; (c) evaluating MS locations according to both heuristics and constraints related to, e.g., terrain, MS velocity and MS path extrapolation from tracking and (d) adjusting likely MS locations adaptively and statistically so that the system becomes progressively more comprehensive and accurate. Further, the system can be modularly configured for use in location signaling environments ranging from urban, dense urban, suburban, rural, mountain to low traffic or isolated roadways. Accordingly, the system is useful for 911 emergency calls, tracking, routing, people and animal location including applications for confinement to and exclusion from certain areas.

Owner:TRACBEAM

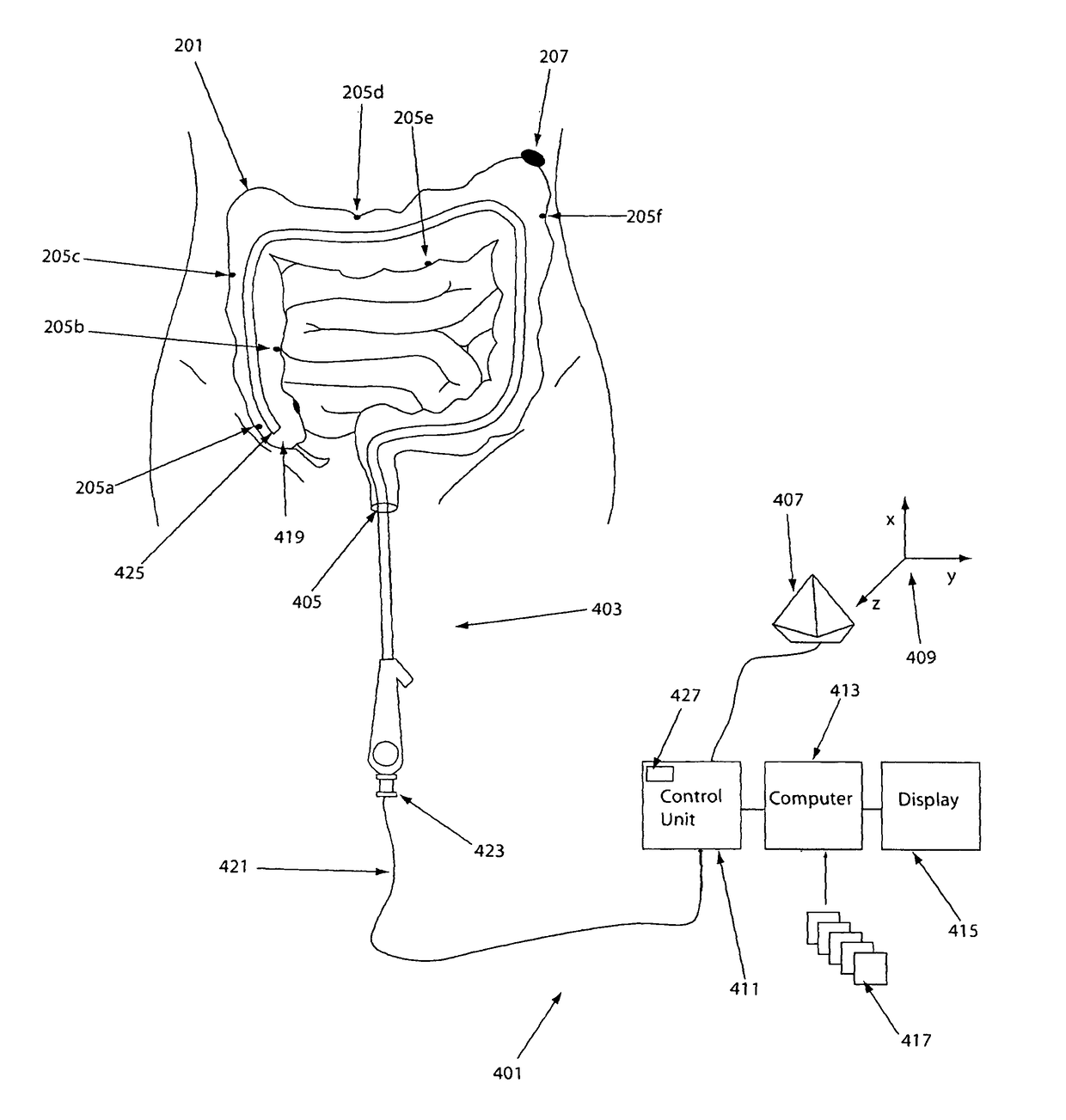

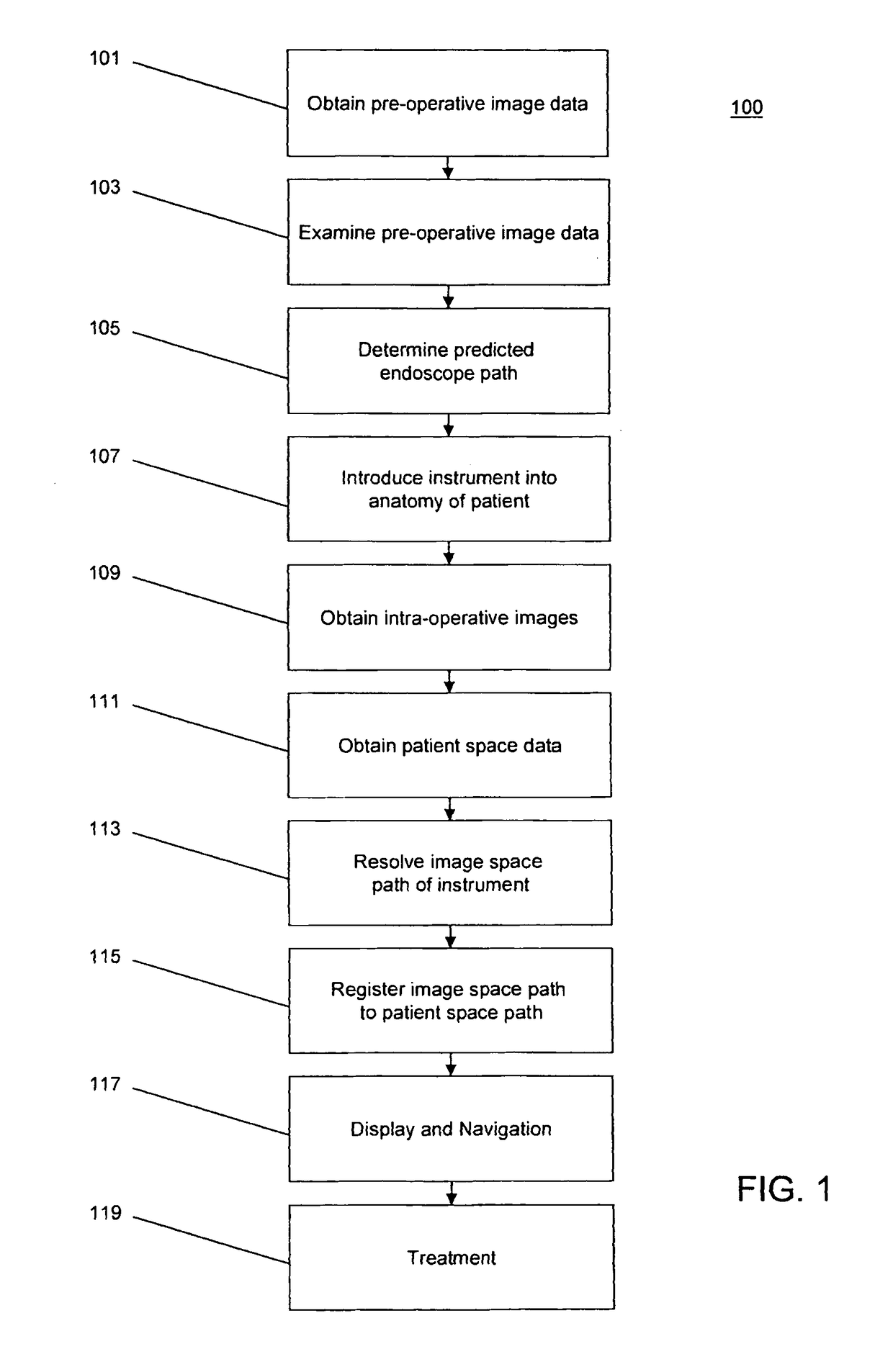

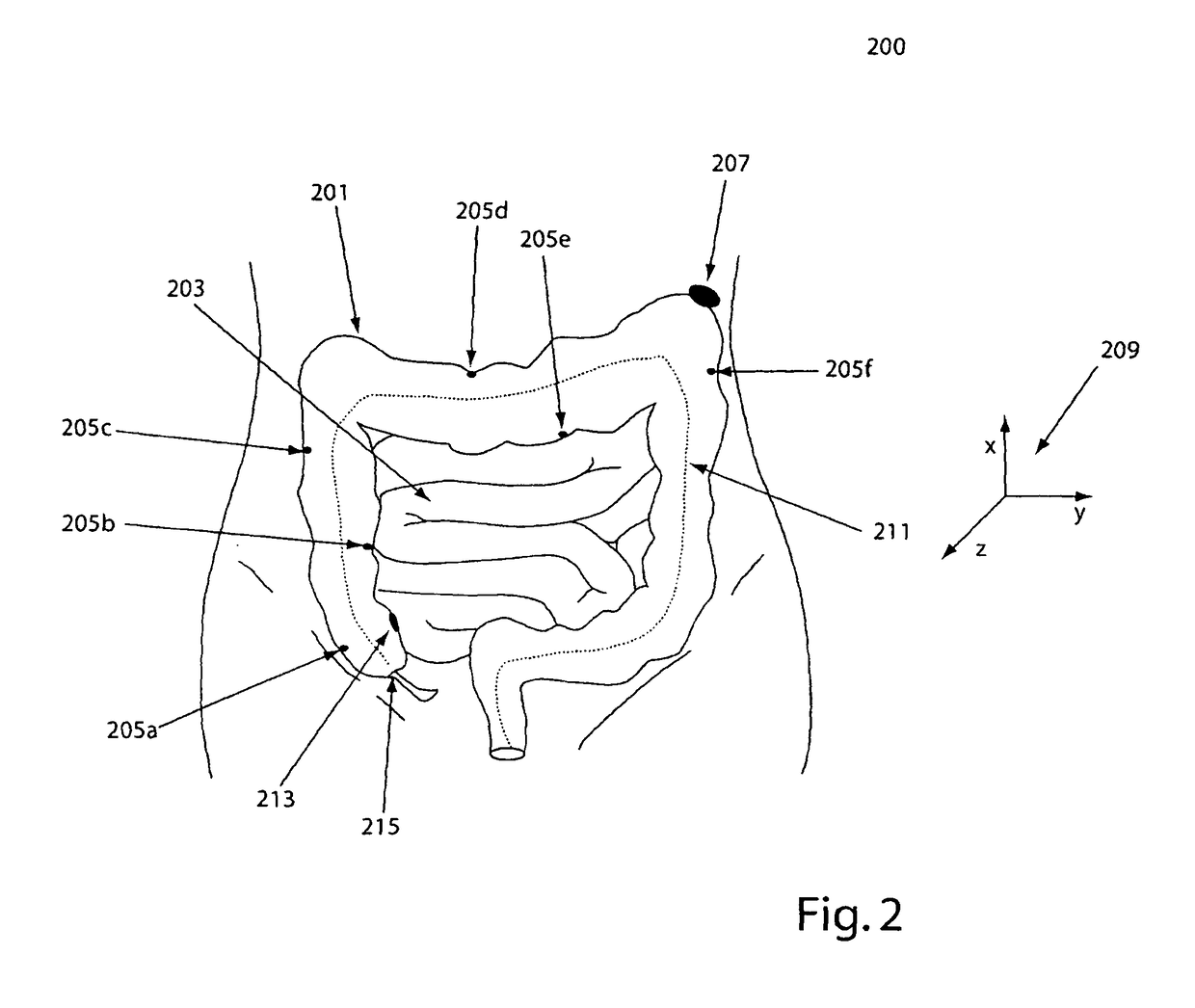

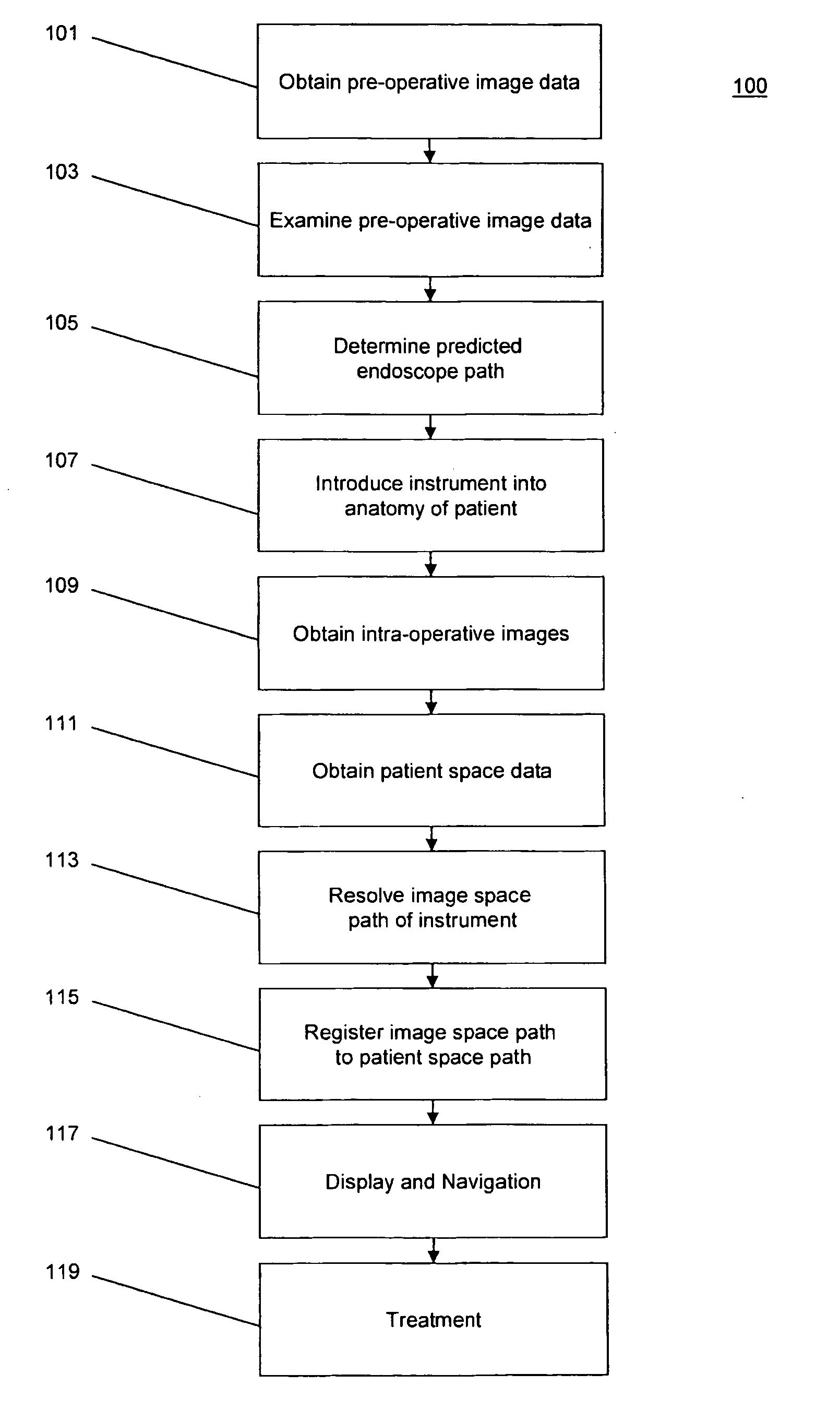

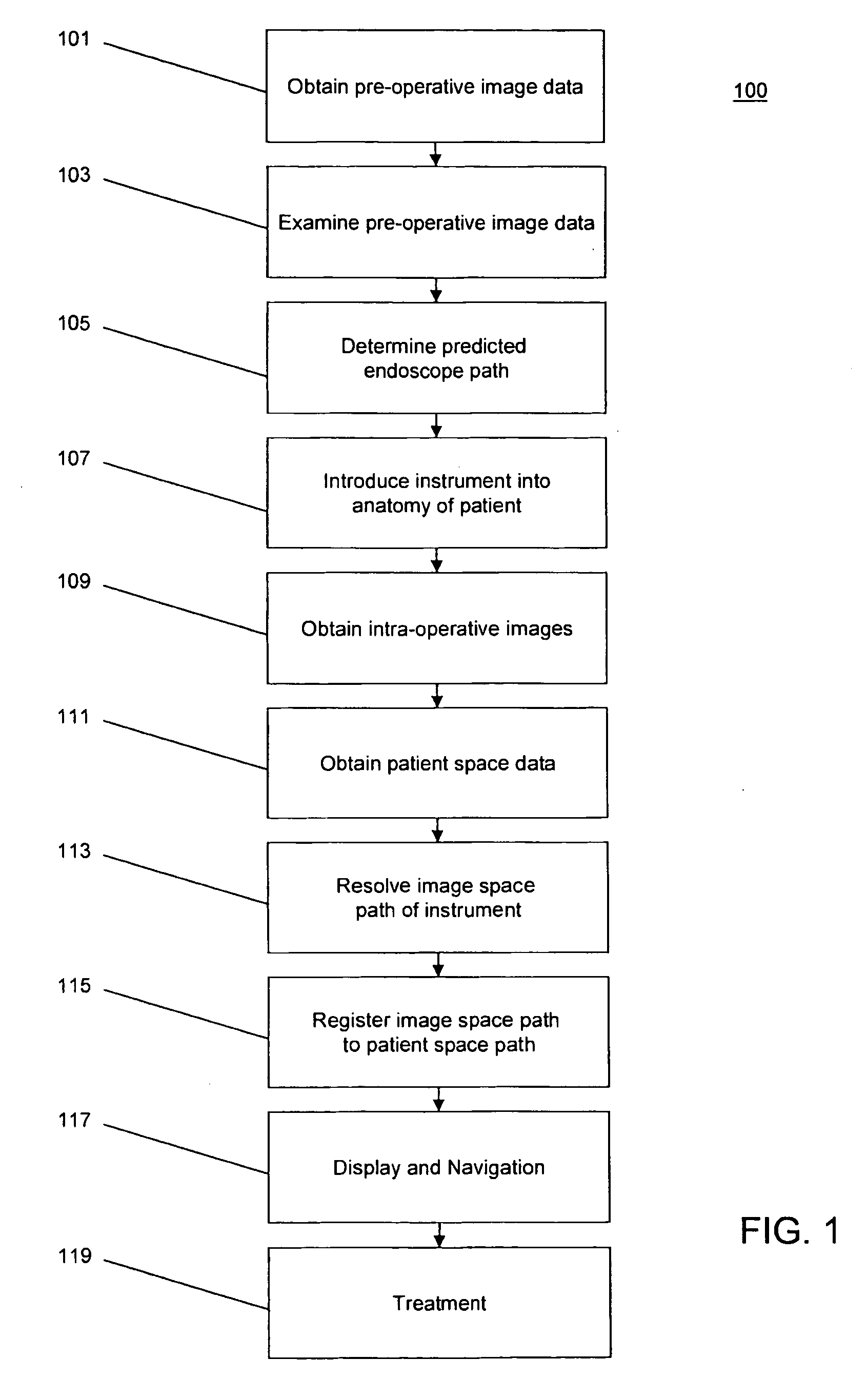

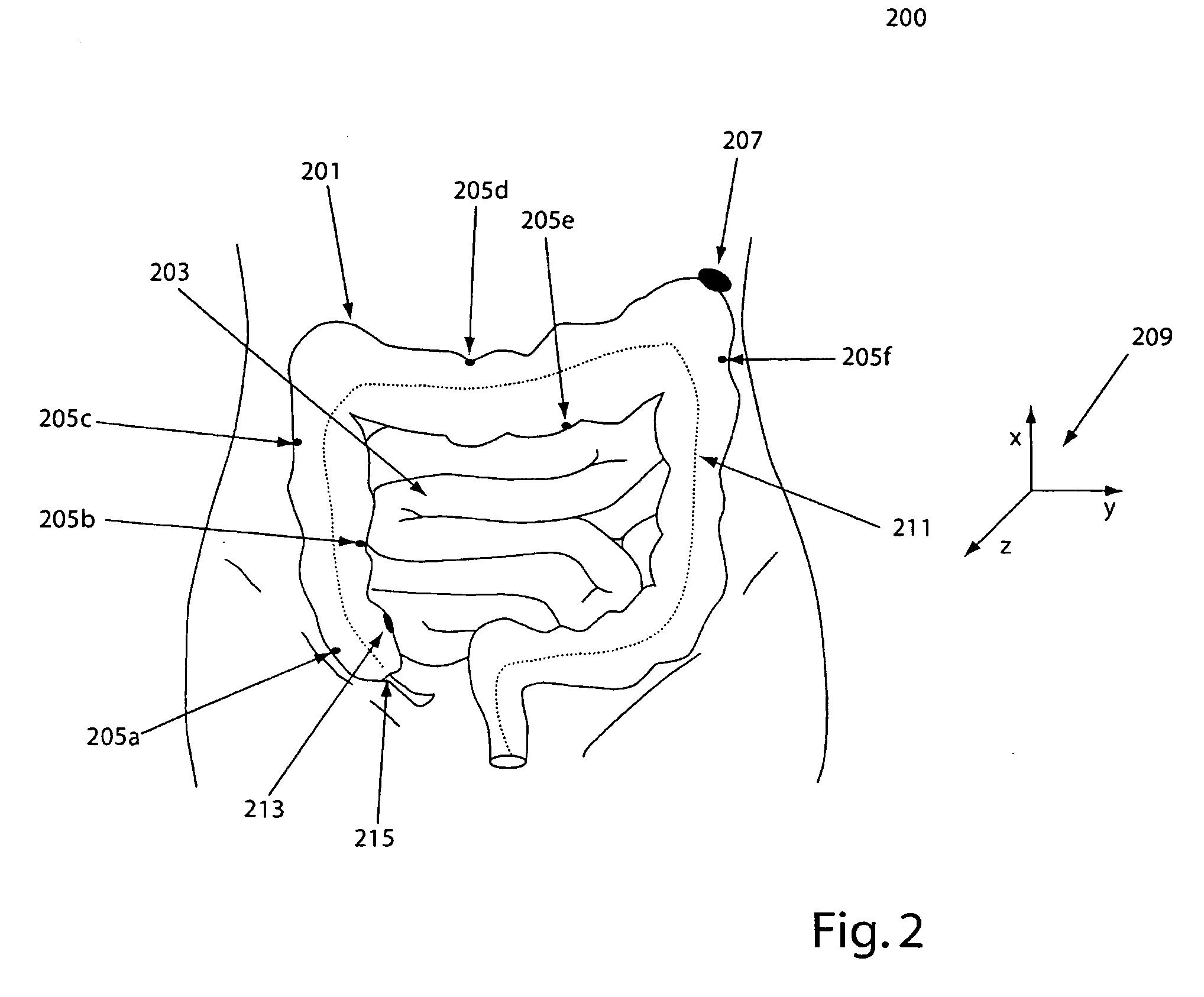

System, method and devices for navigated flexible endoscopy

The invention provides a method and system for performing an image-guided endoscopic medical procedure. The invention may include registering image-space coordinates of a path of a medical instrument within the anatomy of a patient to patient-space coordinates of the path of the medical instrument within the anatomy of the patient. In some embodiments, the image space coordinates of the path of the medical instrument may be predicted coordinates such as, for example, a calculated centerline through a conduit-like organ, or a calculated “most likely path” of the medical instrument within the anatomy of the patient. In other embodiments, the path of the medical instrument may be an actual path determined using intra-operative images of the patient's anatomy with the medical instrument inserted therein. The registered instrument may then be navigated to one or more items of interest for performance of the endoscopic medical procedure.

Owner:PHILIPS ELECTRONICS LTD

Stent delivery system

InactiveUS6849084B2Preventing undesired forward movement of tipMinimize movementStentsEar treatmentInsertion stentStent deployment

A first stent delivery system provided with a sheath for covering the stent, the sheath including proximal sheath portion adapted to be movable in a proximal direction and a distal sheath portion adapted to be moveable in a distal direction. A second stent delivery system including an outer and intermediate tubular members covering a chamber with a preloaded stent, the outer tubular member being retractable prior to the retraction of the intermediate sheath and release of the stent. A third stent delivery system including with an inflatable balloon at a distal end of the system for fixing the system in place within the vessel prior to the release of the stent thereby insure accurate stent deployment.

Owner:INTEK TECH

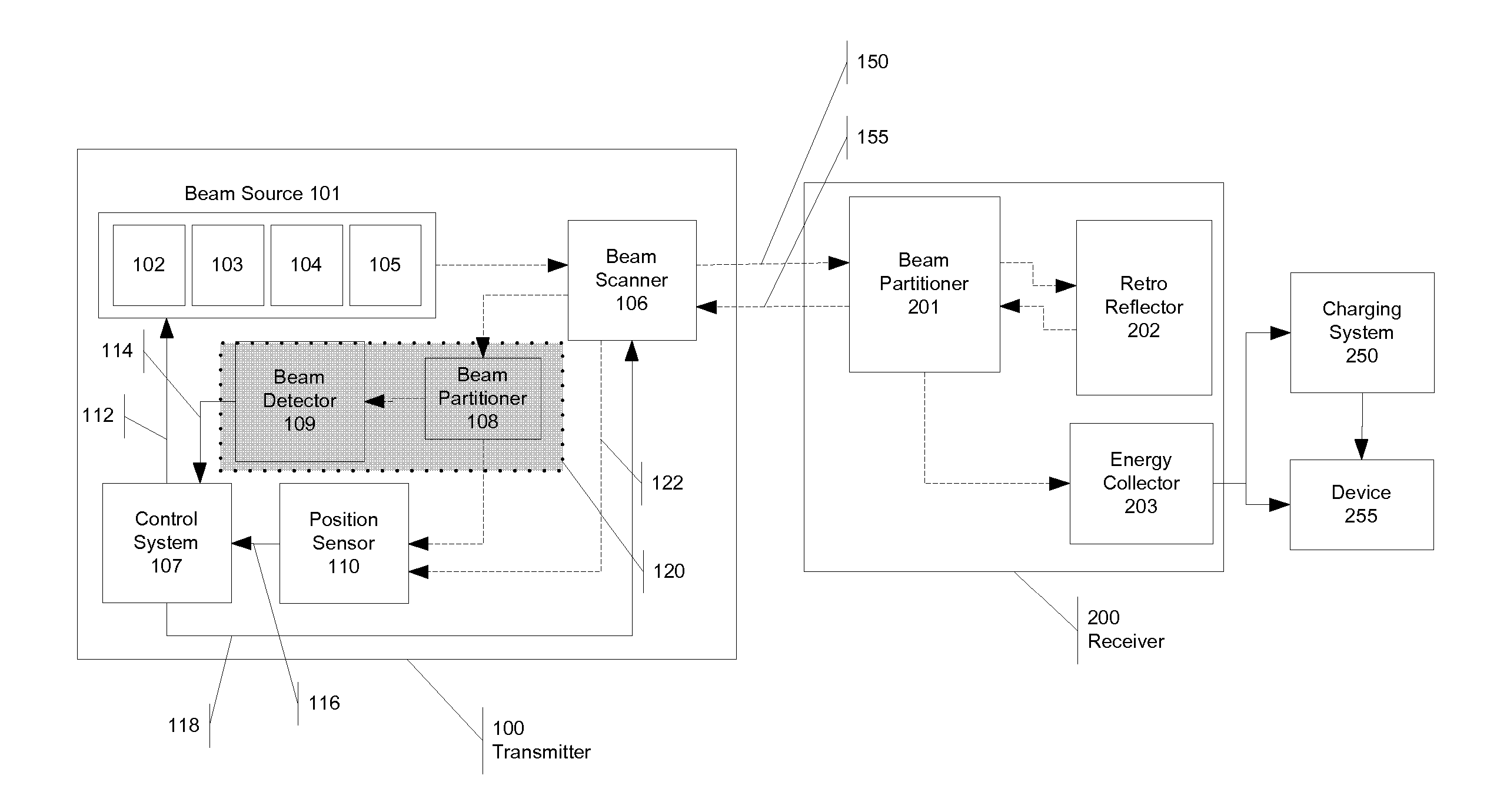

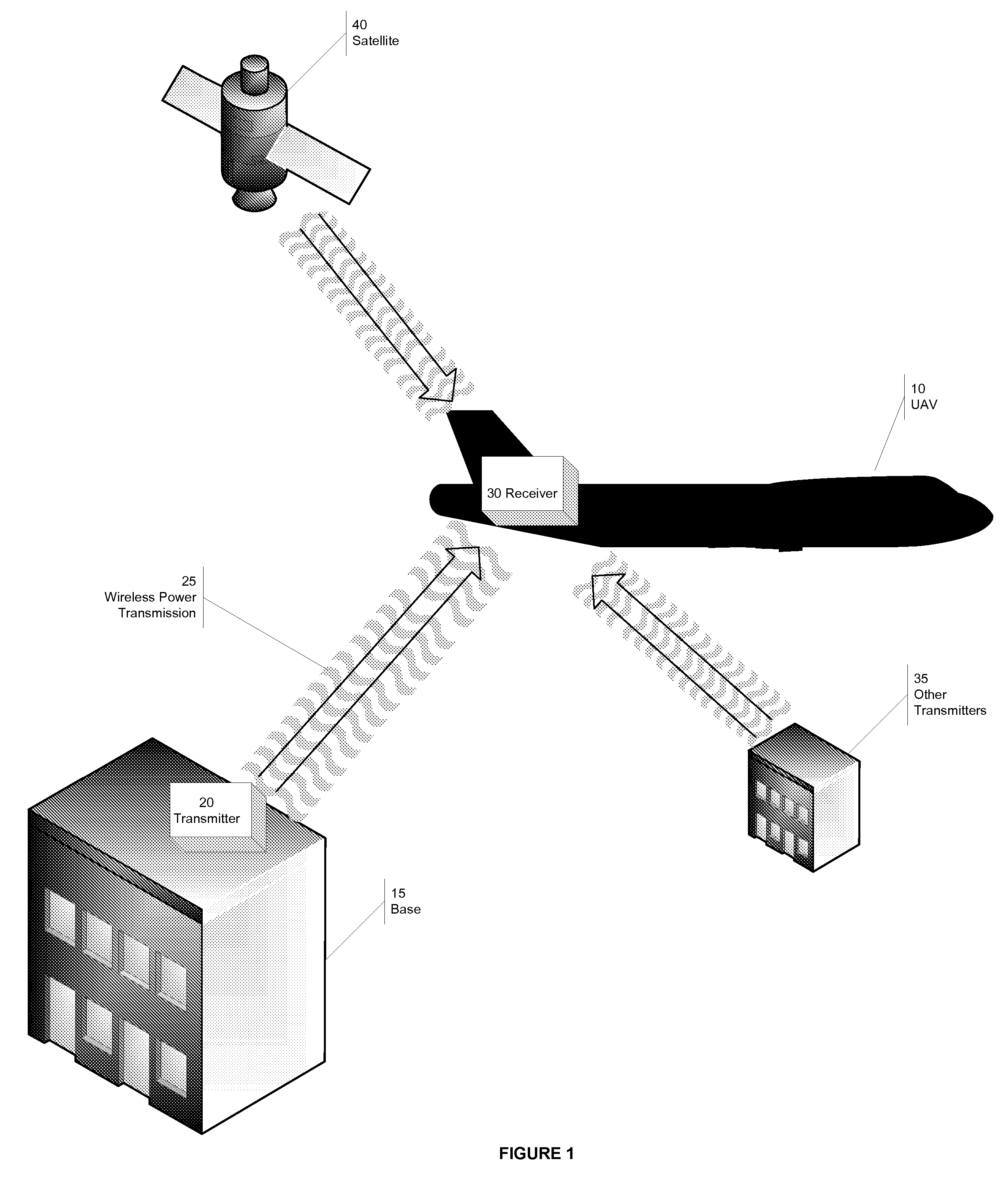

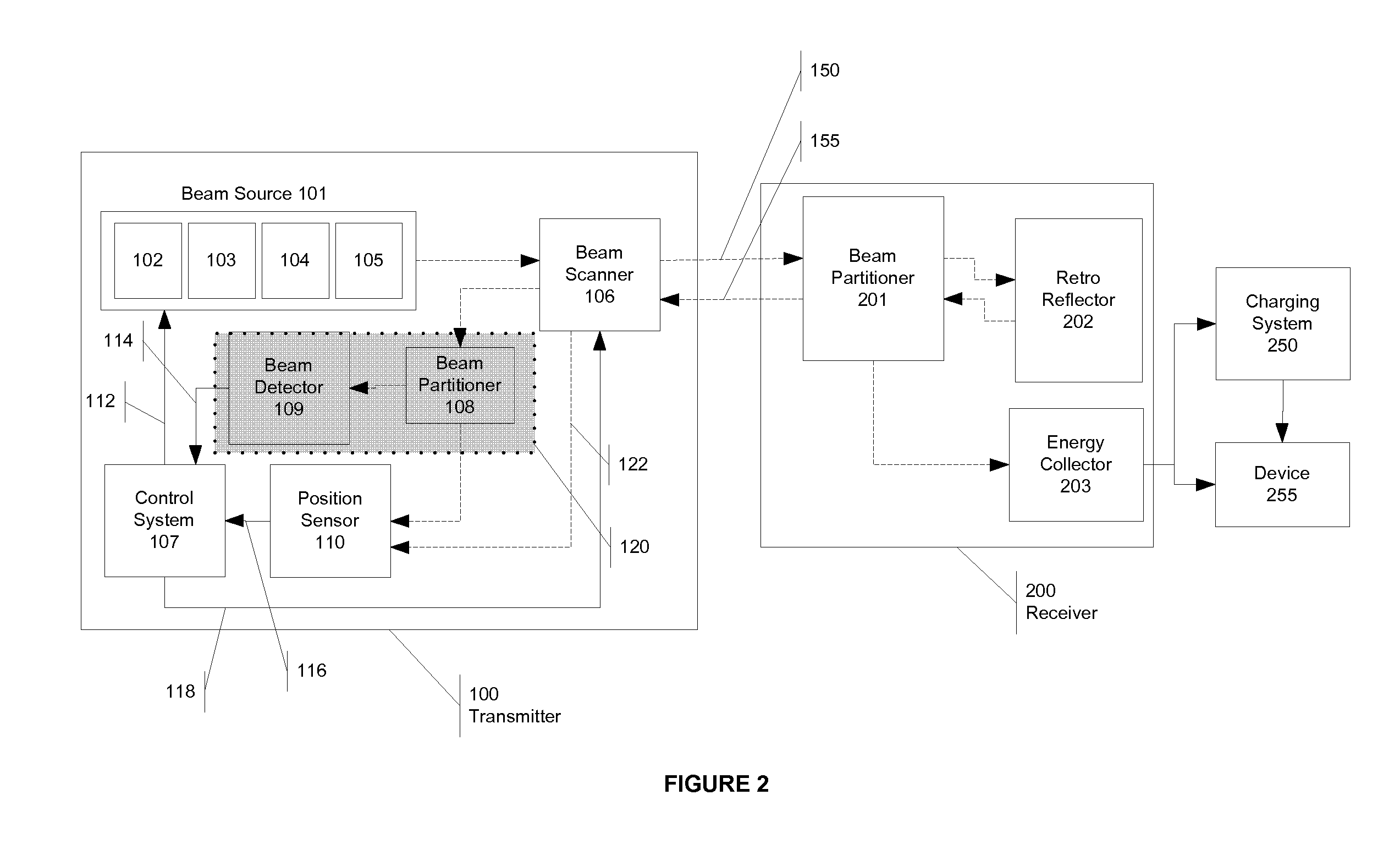

Wireless Power Transmission System

InactiveUS20060266917A1Quick scanImprove accuracyMicrobiological testing/measurementMaterial analysis by optical meansData transmissionElectric power

A novel method for wireless power transmission that comprises a transmitter and a receiver is disclosed. The receiver does not require an independent power source and is comprised of an optical feedback to the transmitter, and therefore does not require a separate communication channel to the transmitter. The transmitter uses the optical feedback to locate and track the receiver. The transmitter can optionally employ a macro adjusters and micro adjusters that direct the beam onto the receiver for optimal power transmission. The system also optionally has a tight loop beam detector to enhance safety of the system. Either the receiver and / or the transmitter may also encode data on the energy transmission, resulting in one-way or two-way data transmission.

Owner:BALDIS SISINIO F +2

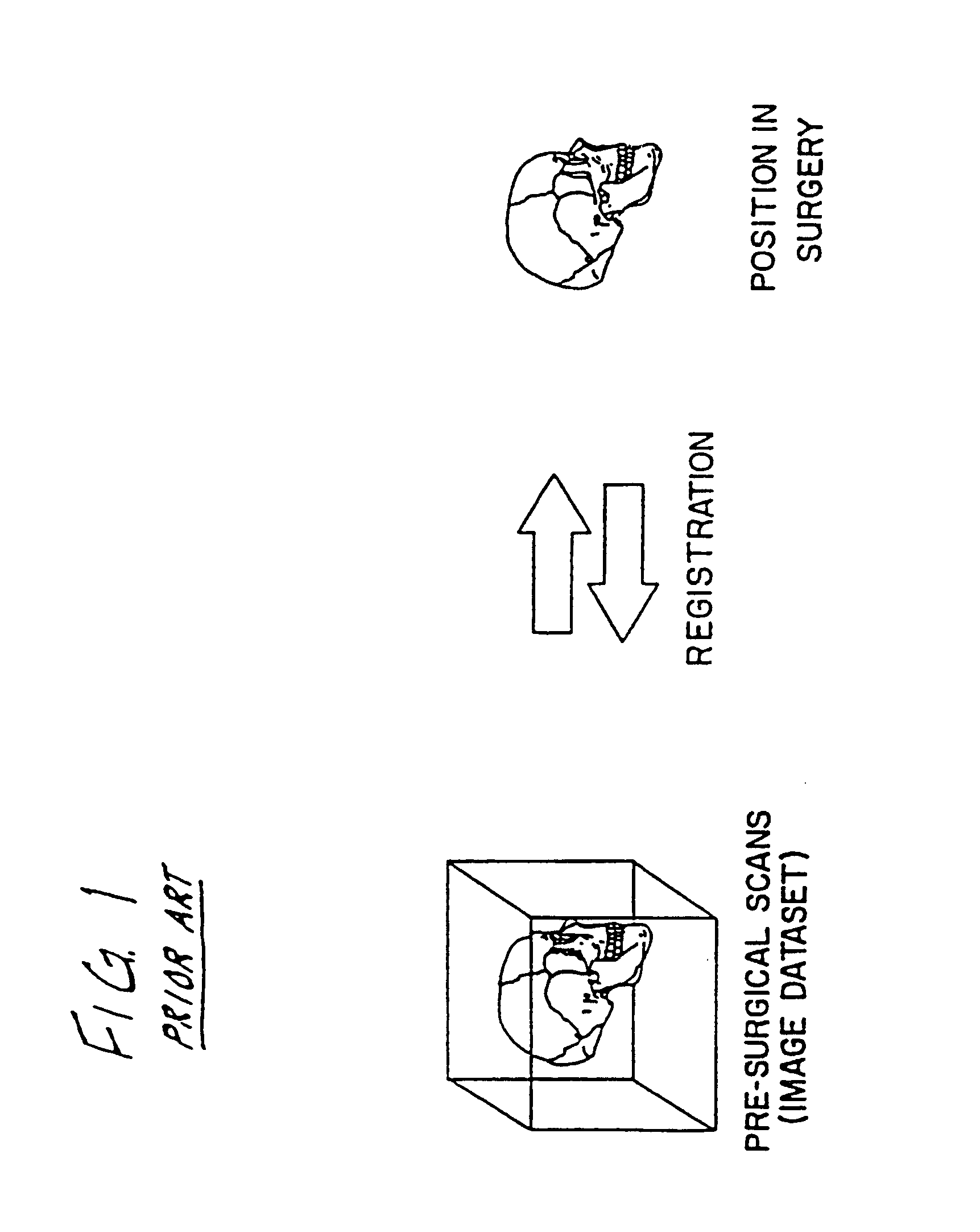

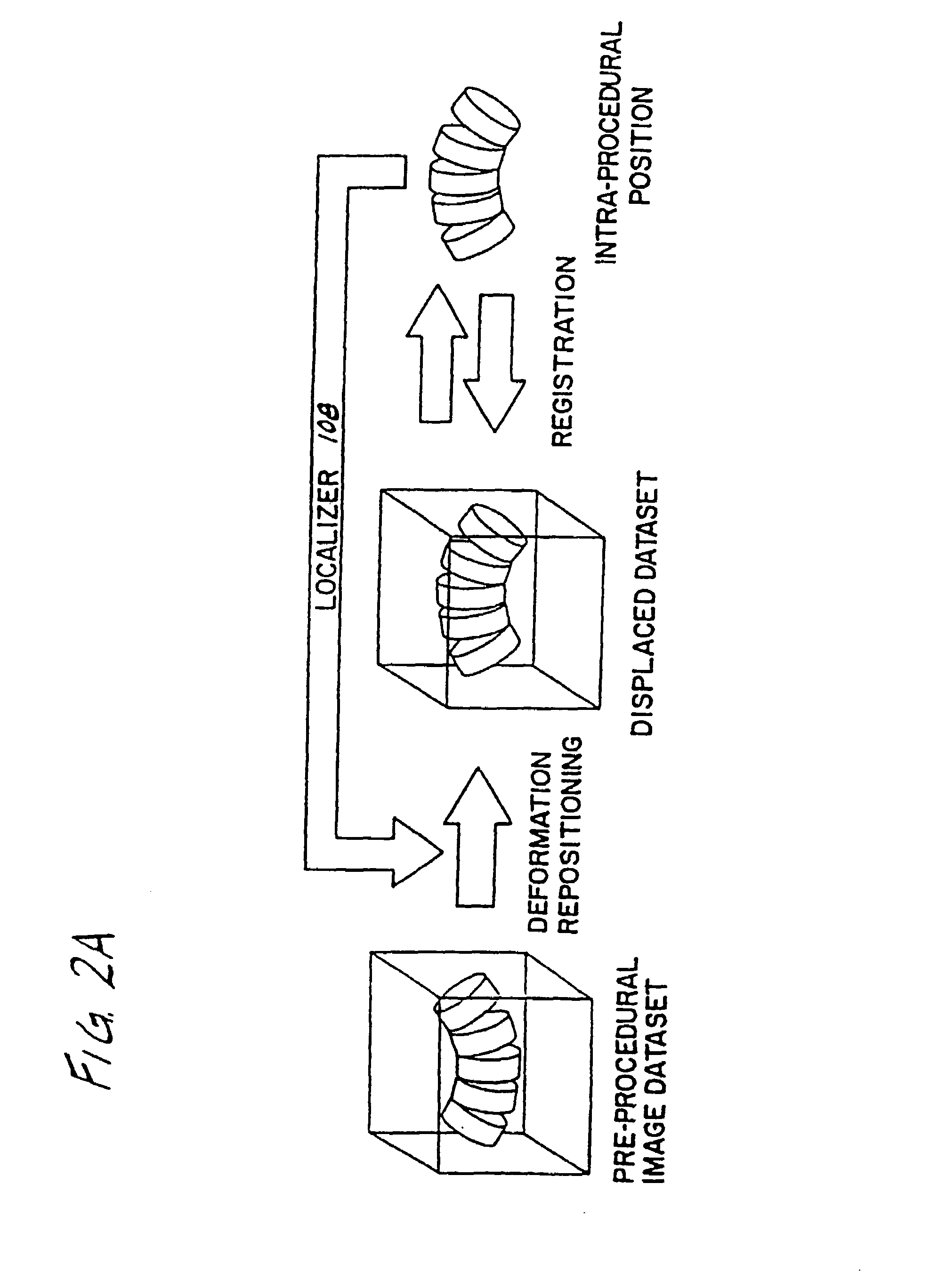

Surgical navigation systems including reference and localization frames

A system for use during a medical or surgical procedure on a body. The system generates an image representing the position of one or more body elements during the procedure using scans generated by a scanner prior or during the procedure. The image data set has reference points for each of the body elements, the reference points of a particular body element having a fixed spatial relation to the particular body element. The system includes an apparatus for identifying, during the procedure, the relative position of each of the reference points of each of the body elements to be displayed. The system also includes a processor for modifying the image data set according to the identified relative position of each of the reference points during the procedure, as identified by the identifying apparatus, said processor generating a displaced image data set representing the position of the body elements during the procedure. The system also includes a display utilizing the displaced image data set generated by the processor, illustrating the relative position of the body elements during the procedure. Methods relating to the system are also disclosed. Also disclosed are devices for use with a surgical navigation system having a sensor array which is in communication with the device to identify its position. The device may be a reference frame for attachment of a body part of the patient, such as a cranial reference arc frame for attachment to the head or a spine reference arc frame for attachment to the spine. The device may also be a localization frame for positioning an instrument relative to a body part, such as a localization biopsy guide frame for positioning a biopsy needle, a localization drill guide assembly for positioning a drill bit, a localization drill yoke assembly for positioning a drill, or a ventriculostomy probe for positioning a catheter.

Owner:SURGICAL NAVIGATION TECH +1

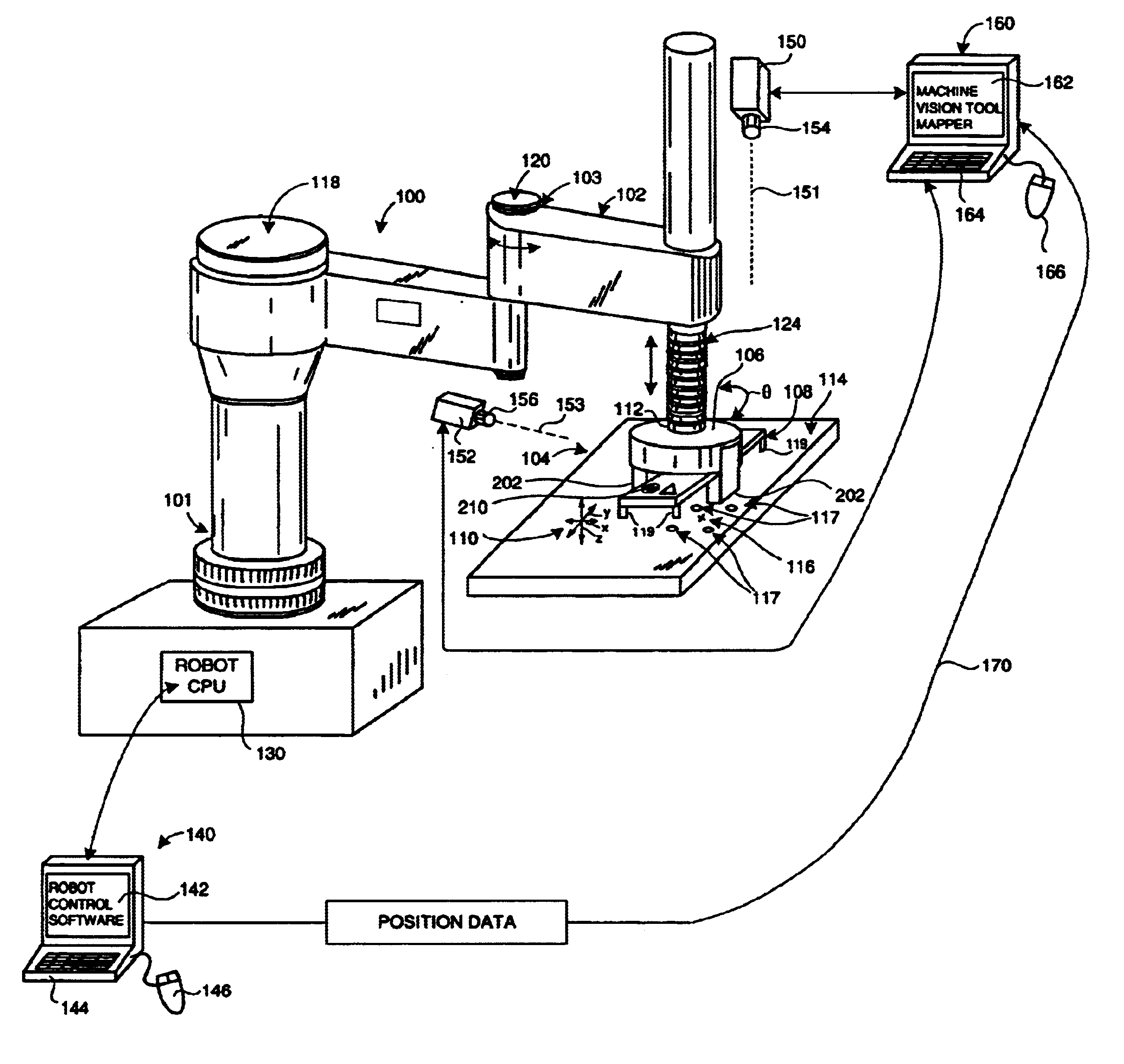

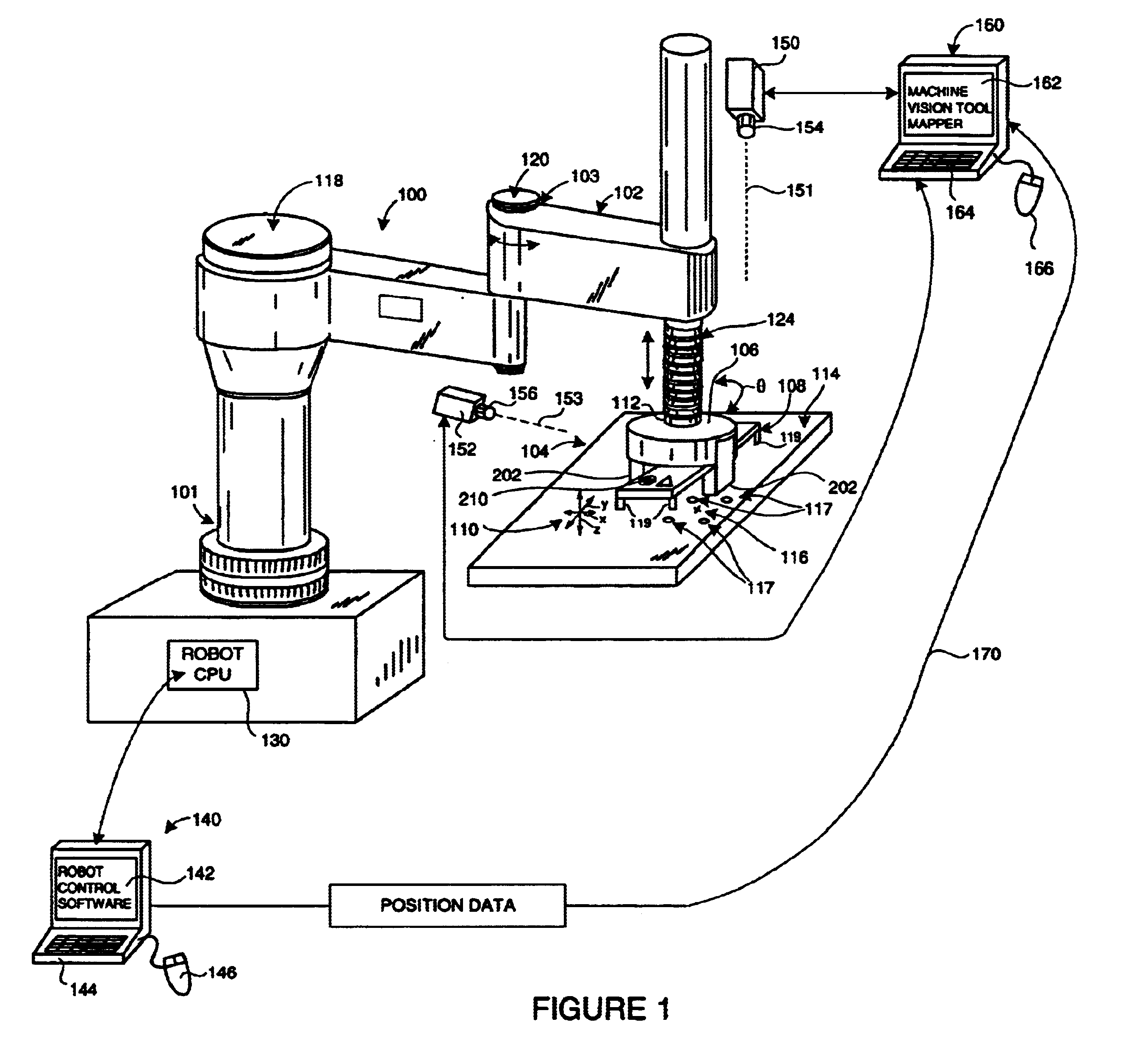

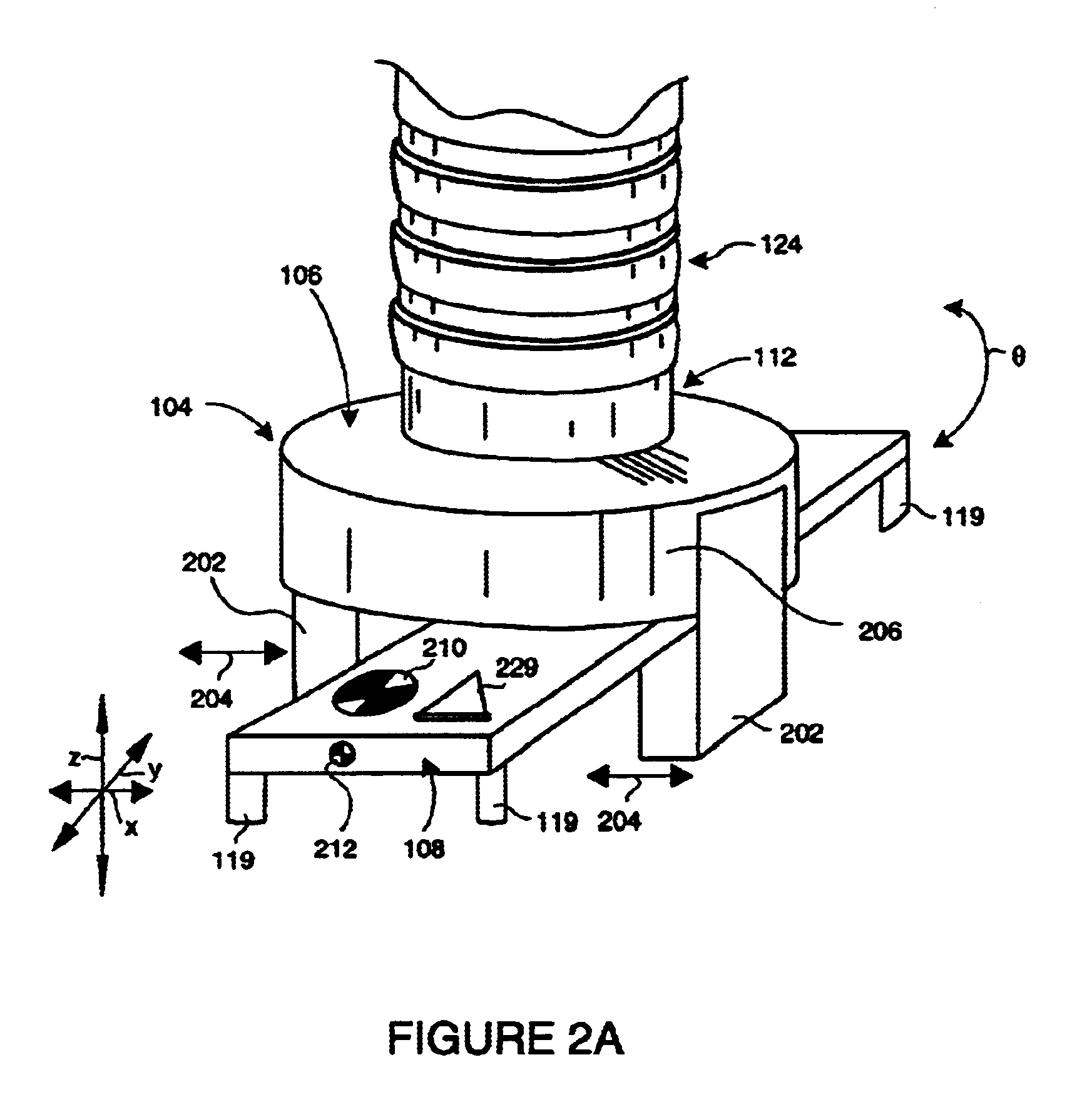

System and method for servoing robots based upon workpieces with fiducial marks using machine vision

InactiveUS6681151B1Sure easyLocated reliablyProgramme-controlled manipulatorPhotometry using reference valueEngineeringDegrees of freedom

A system and method for servoing robot marks using fiducial marks and machine vision provides a machine vision system having a machine vision search tool that is adapted to register a pattern, namely a trained fiducial mark, that is transformed by at least two translational degrees and at least one mon-translational degree of freedom. The fiducial is provided to workpiece carried by an end effector of a robot operating within a work area. When the workpiece enters an area of interest within a field of view of a camera of the machine vision system, the fiducial is recognized by the tool based upon a previously trained and calibrated stored image within the tool. The location of the work-piece is derived by the machine vision system based upon the viewed location of the fiducial. The location of the found fiducial is compared with that of a desired location for the fiducial. The desired location can be based upon a standard or desired position of the workpiece. If a difference between location of the found fiducial and the desired location exists, the difference is calculated with respect to each of the translational axes and the rotation. The difference can then be further transformed into robot-based coordinates to the robot controller, and workpiece movement is adjusted based upon the difference. Fiducial location and adjustment continues until the workpiece is located the desired position with minimum error.

Owner:COGNEX TECH & INVESTMENT

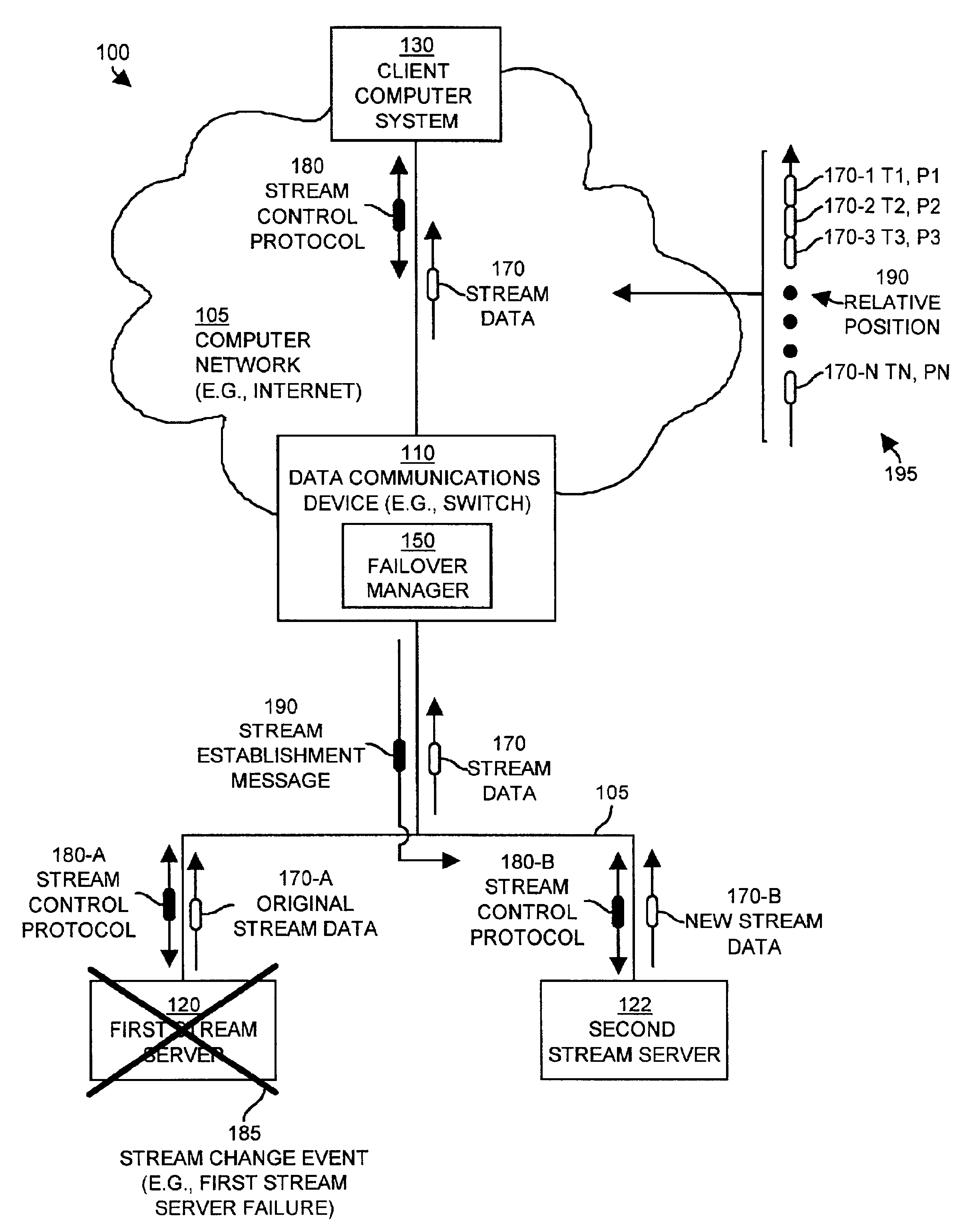

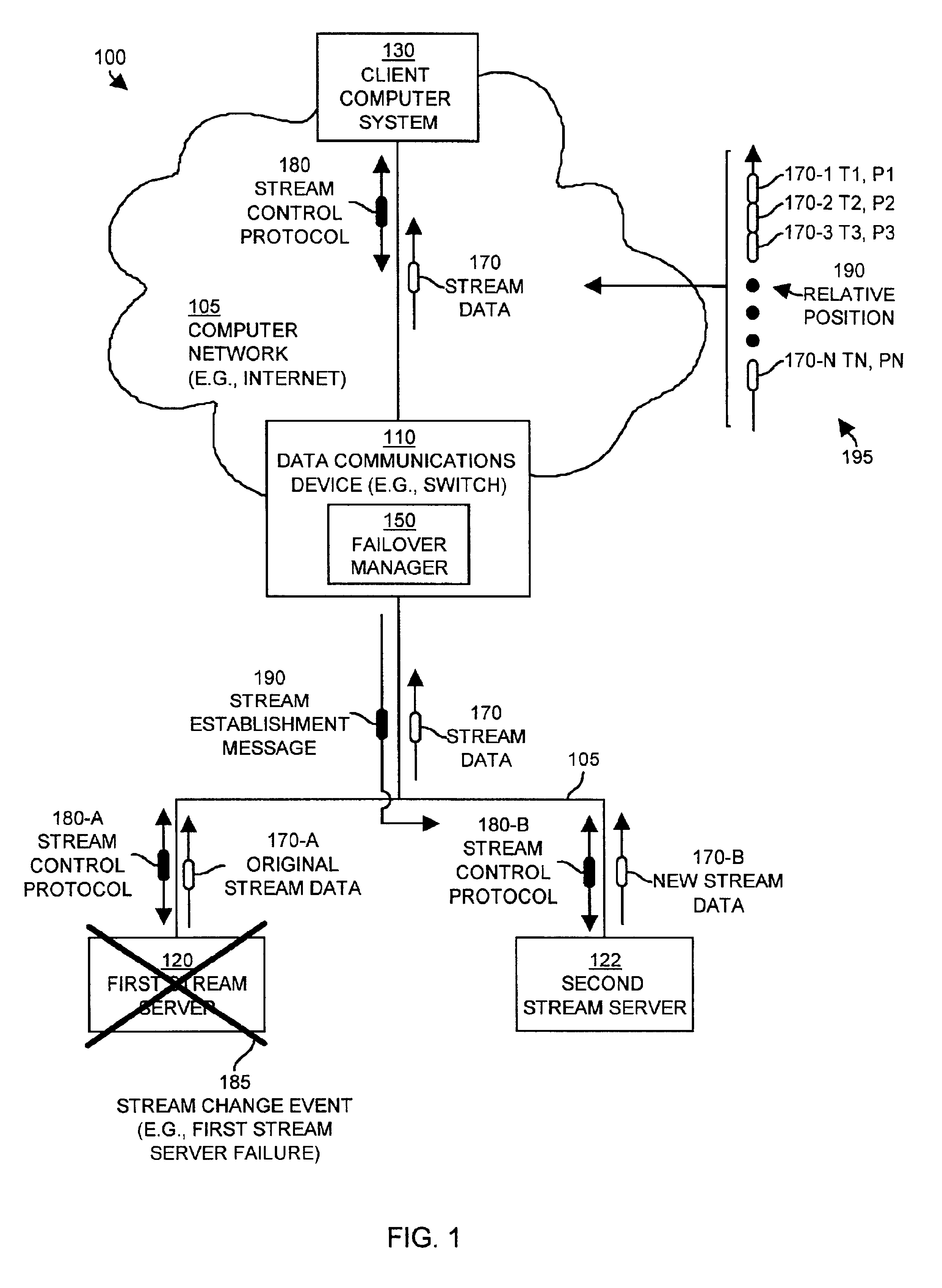

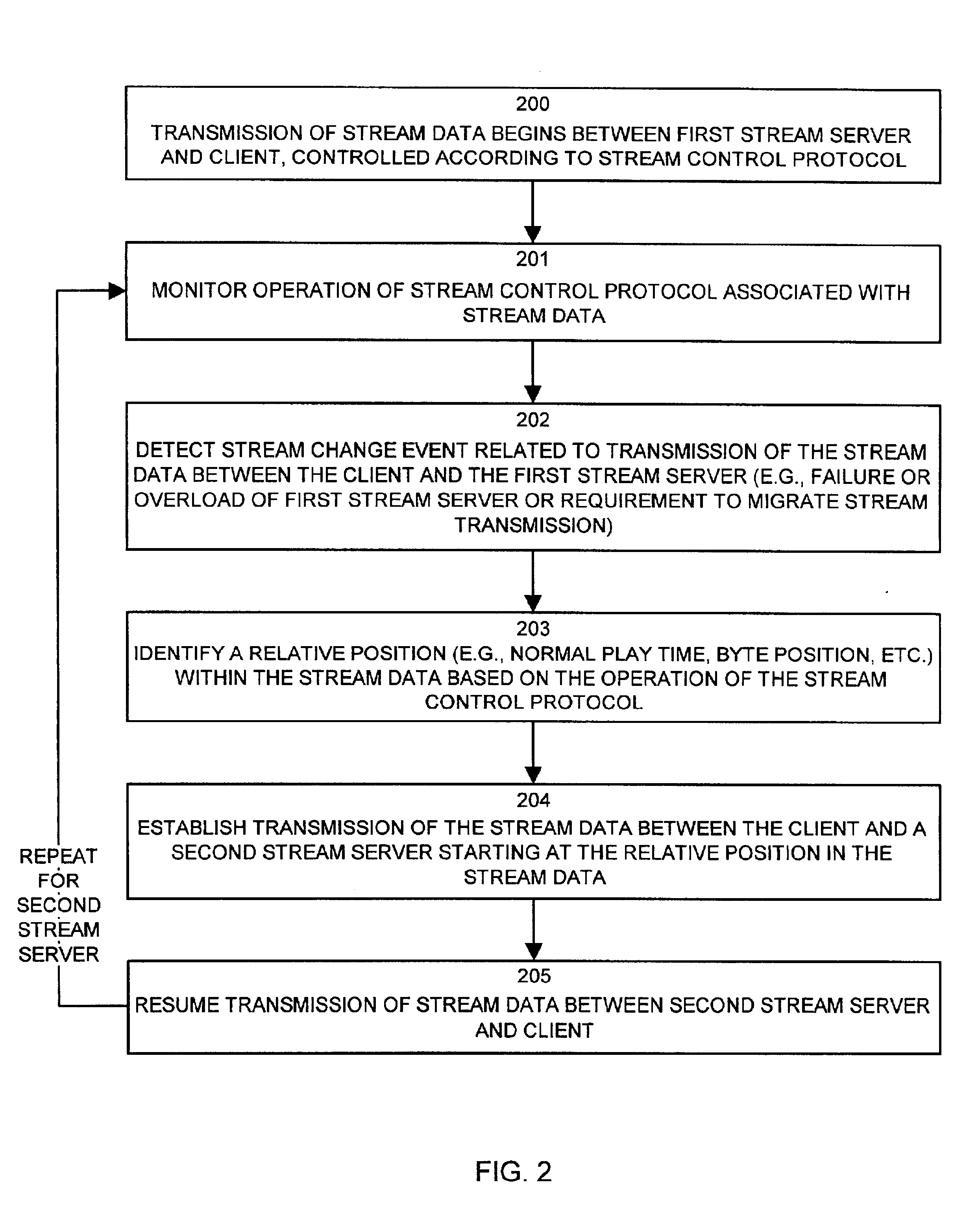

Methods and apparatus for controlling the transmission of stream data

ActiveUS6910078B1Accurate locationEffective serviceMultiple digital computer combinationsTransmissionFailoverStreaming data

Mechanisms and techniques provide a system that provides stream data to a client by monitoring operation of a stream control protocol such as RTSP associated with stream data transmitted between a client and a first stream server. The system detects a stream change event related to transmission of the stream data between the client and the first stream server and identifies a relative position within the stream data based on the operation of the stream control protocol. The system then establishes transmission of the stream data between the client and a second stream server starting at the relative position in the stream data. The system provides for mid-stream failover for the transmission of stream data such as real-time data with minimal perceptible loss of stream data by the client.

Owner:CISCO TECH INC

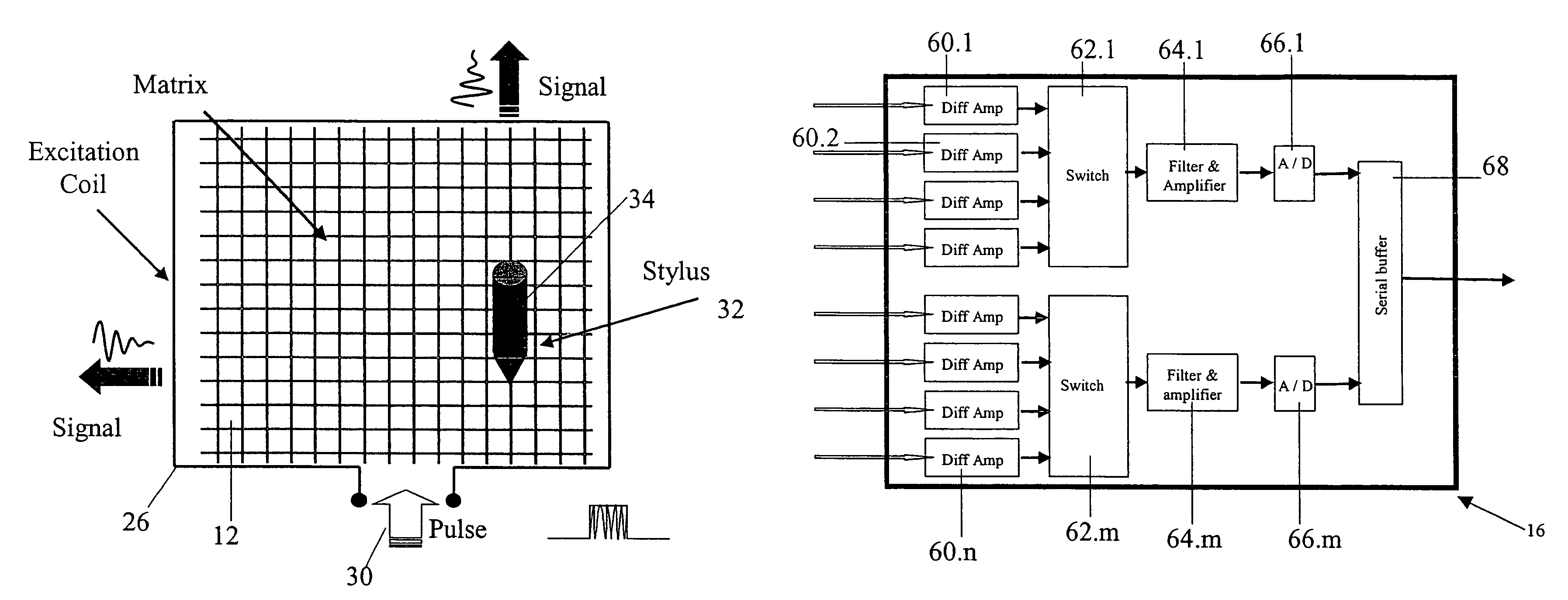

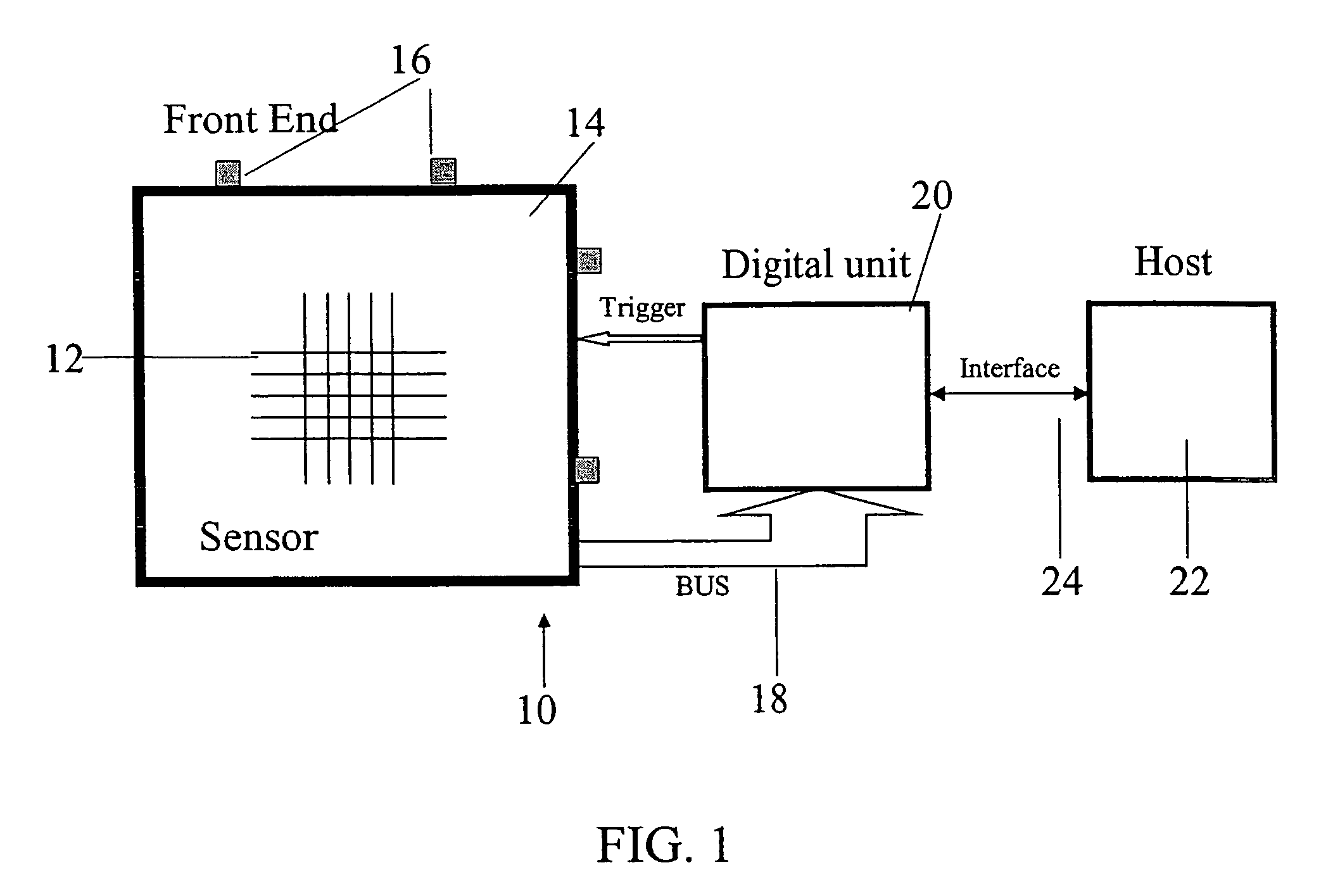

Transparent digitiser

ActiveUS7292229B2Overcome disadvantagesOvercome problemsTransmission systemsCathode-ray tube indicatorsDigital converterDifferential amplifier

A digitizer for user interaction via an object with an electronically refreshable display screen, the digitizer comprising: a transparent sensing arrangement of detectors located at said electronically refreshable display screen for detecting an electric field of said object, said detectors having outputs, and an arrangement of differential amplifiers associated with said outputs, thereby to apply differential detection between said outputs.

Owner:MICROSOFT TECH LICENSING LLC

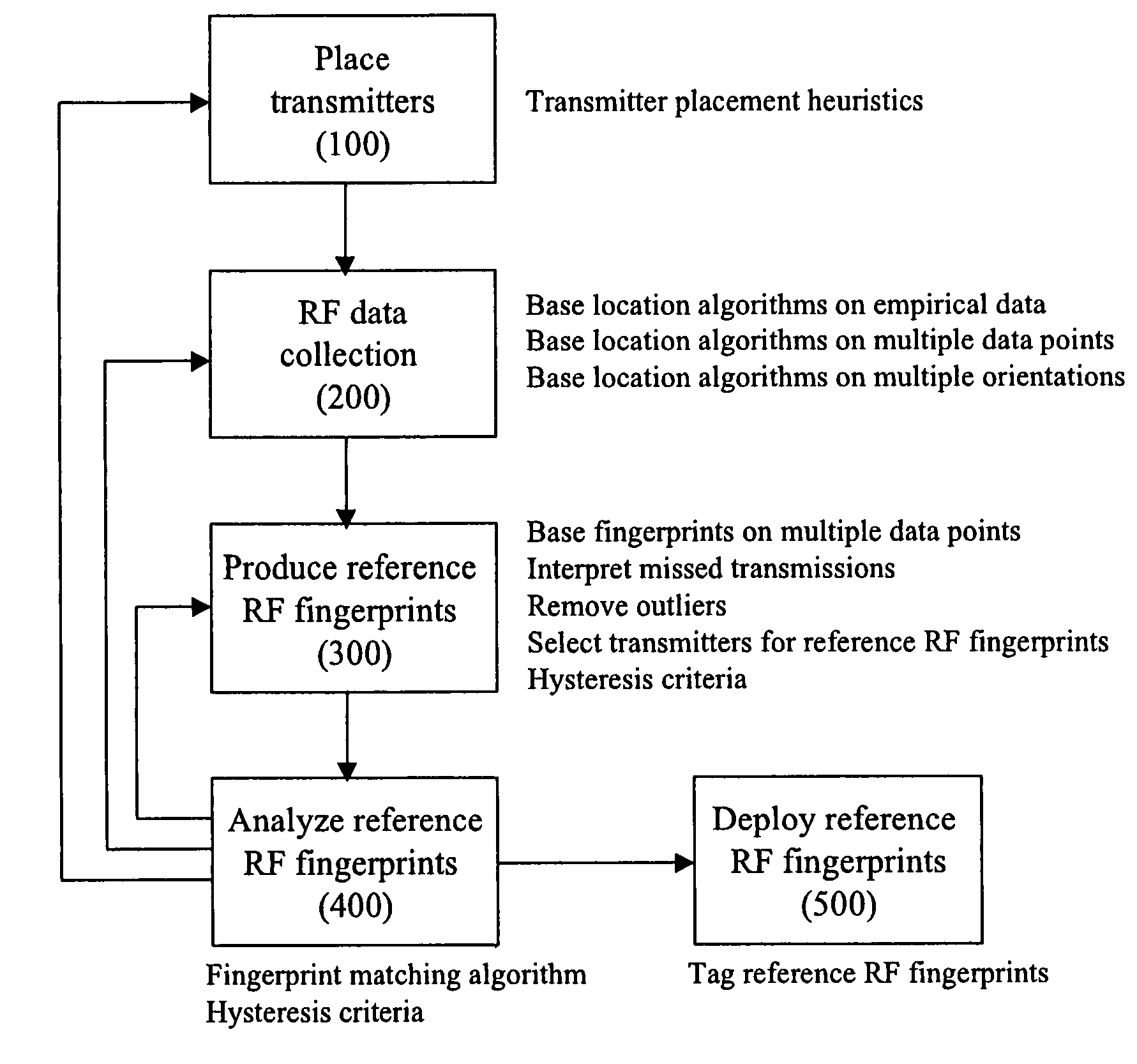

Method for RF fingerprinting

InactiveUS7346359B2Improve accuracyAccurate locationElectric signal transmission systemsImage analysisEngineeringLocation determination

The invention provides a novel method for preparing a wireless environment for location determination of a wireless mobile unit, and for location determination of a wireless mobile unit. In preparing the physical environment, the invention utilizes novel techniques, including novel techniques to place transmitters, the removal of outlying data in the creation of reference RF fingerprints, and algorithms to obtain accurate reference RF fingerprints. In determining the location of a wireless mobile unit, the invention utilizes novel techniques, including novel techniques to select transmitters, the removal of outlying data in the creation of reference RF fingerprints, and algorithms to obtain accurate reference RF fingerprints.

Owner:INNERWIRELESS

Location tracking of a metallic object in a living body

ActiveUS20090299175A1Readily targetFacilitates direct vascular flow measurementDiagnostic probe attachmentBlood flow measurement devicesIn stent restenosisLocation tracking

Owner:ZOLL MEDICAL ISRAEL LTD

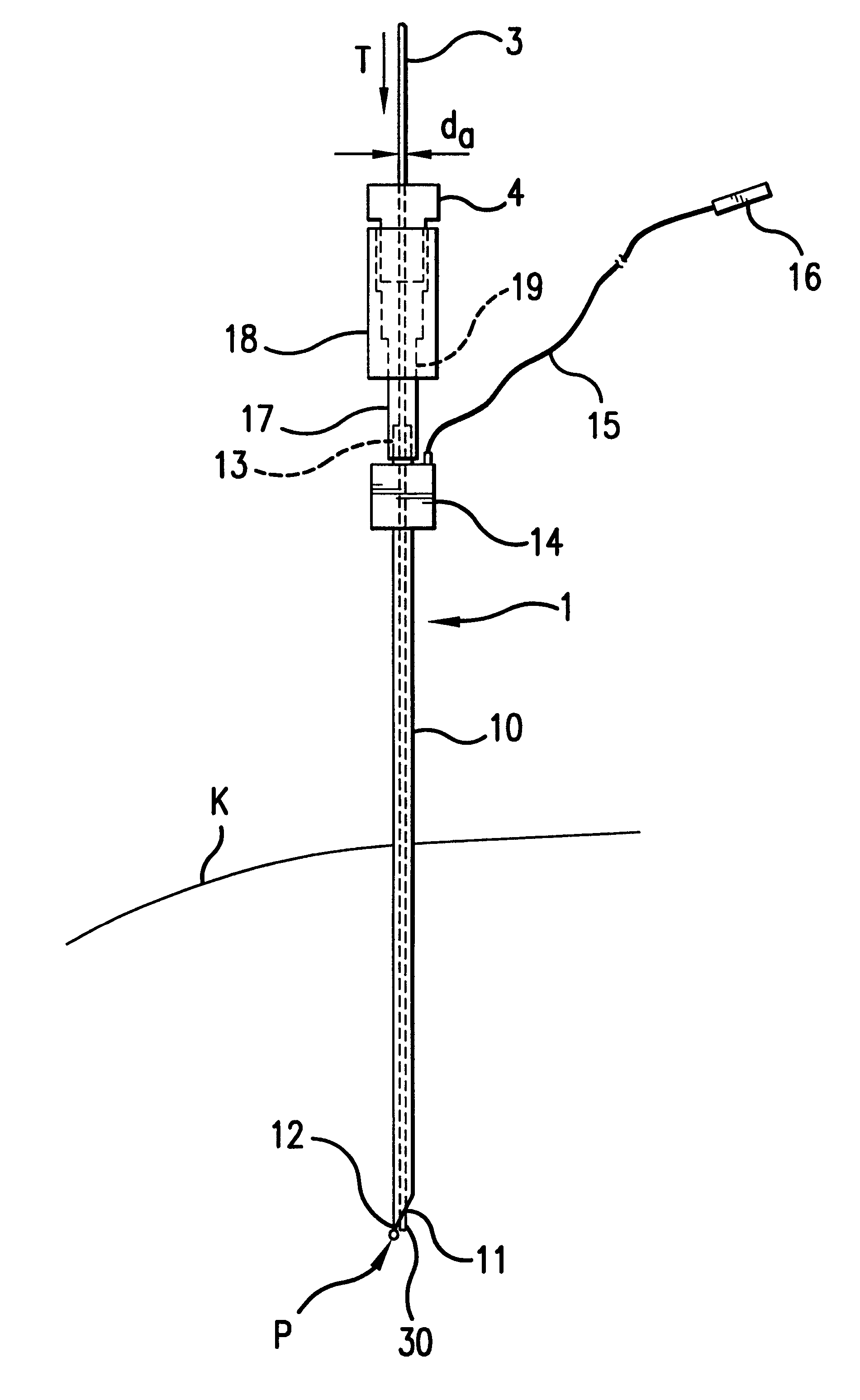

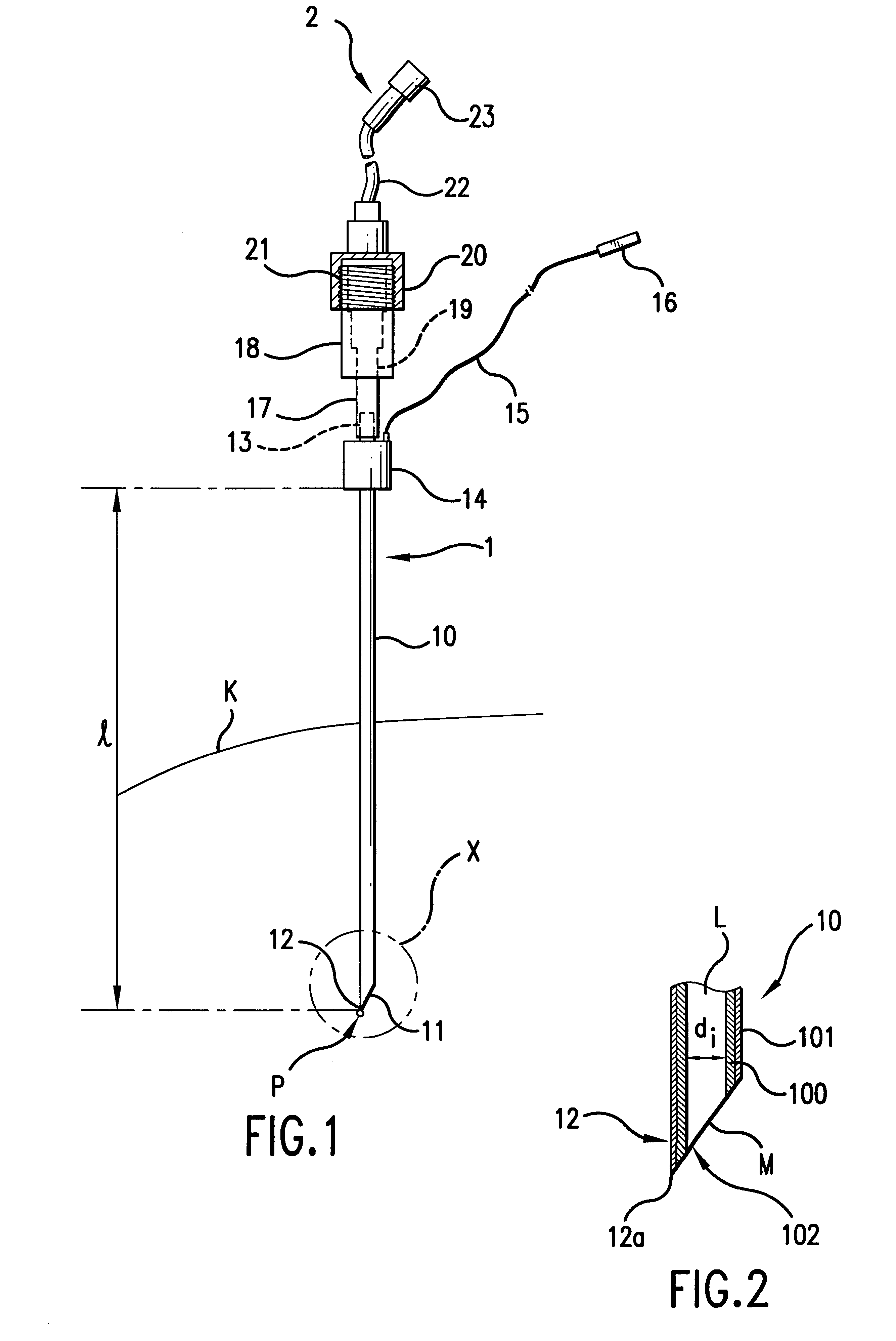

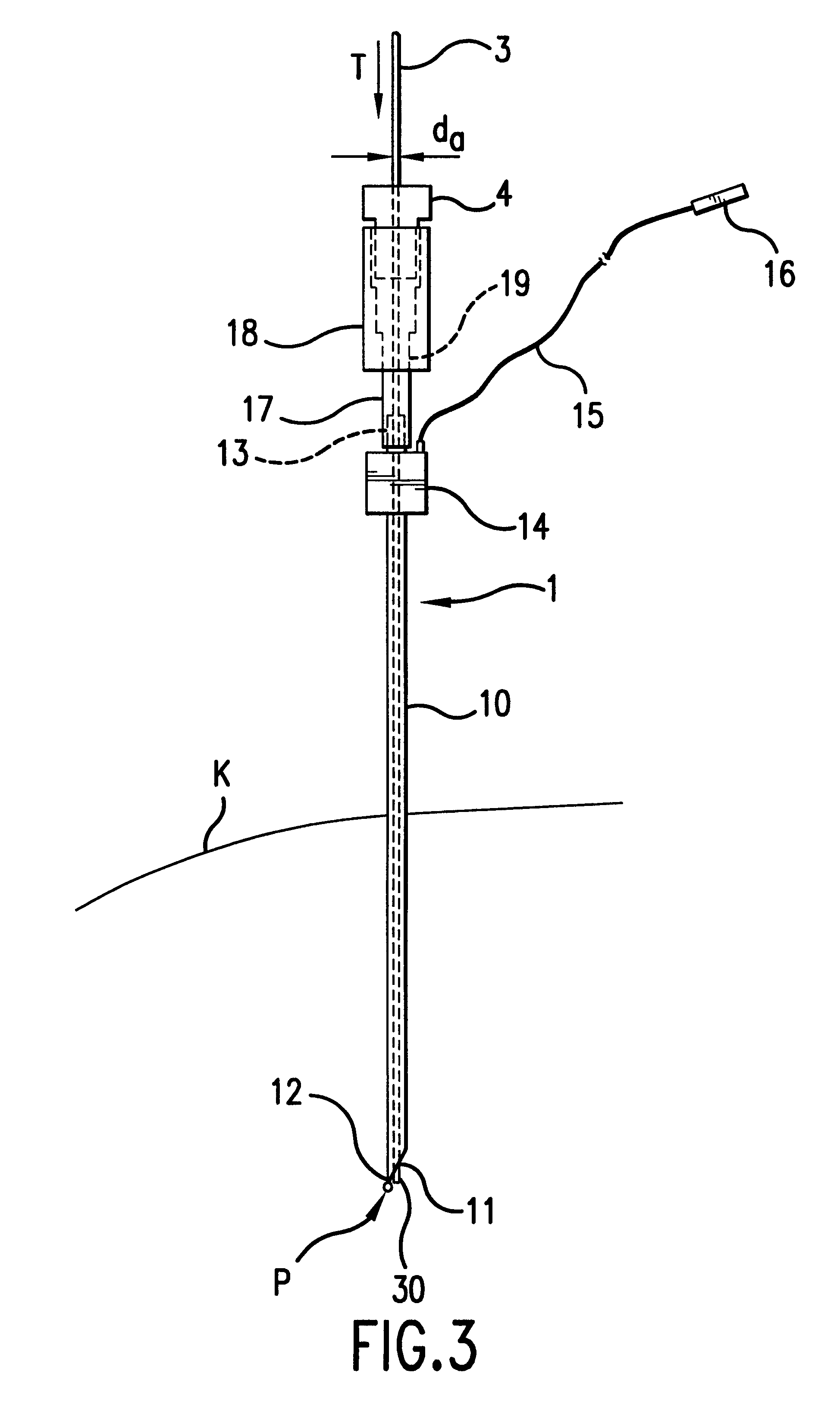

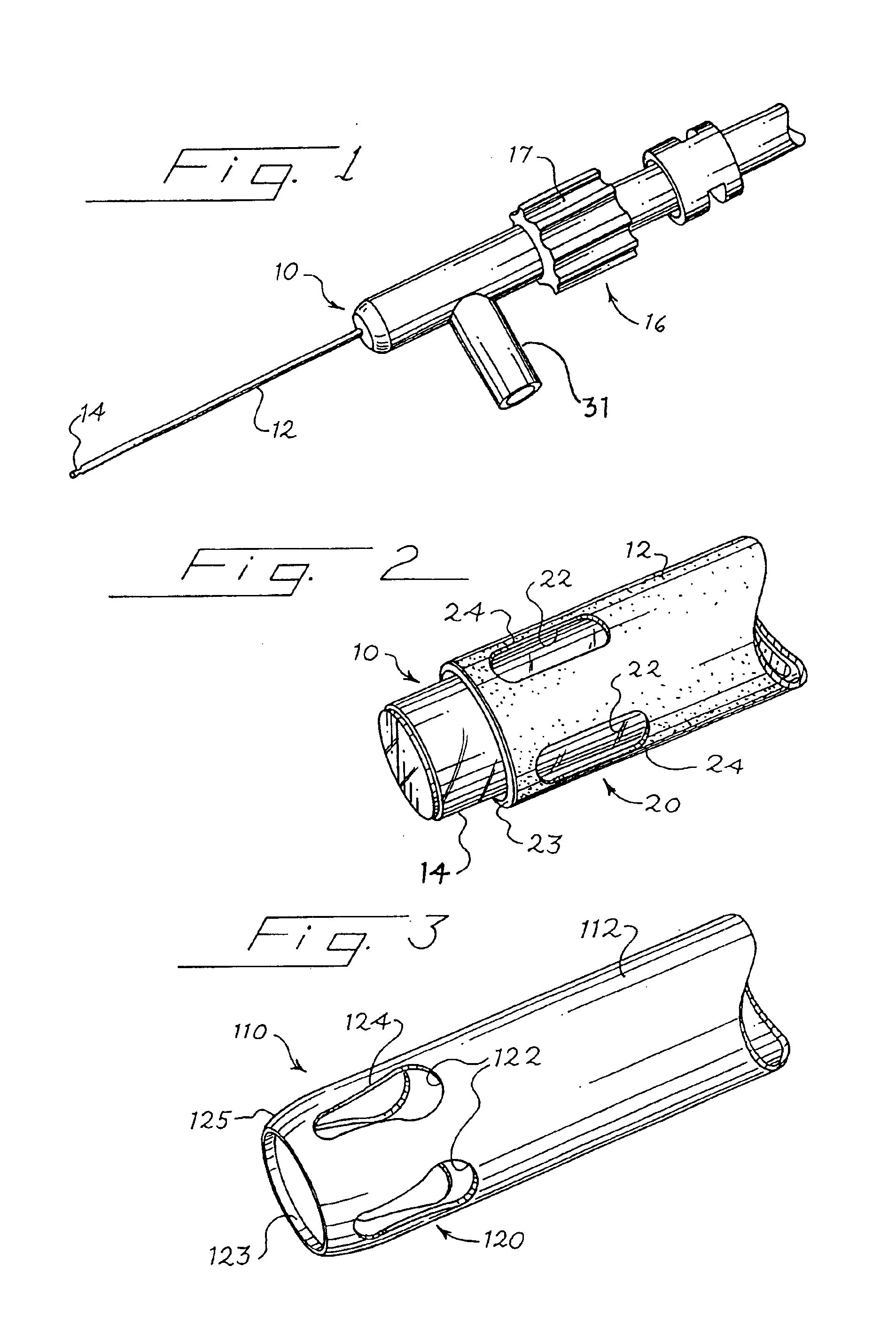

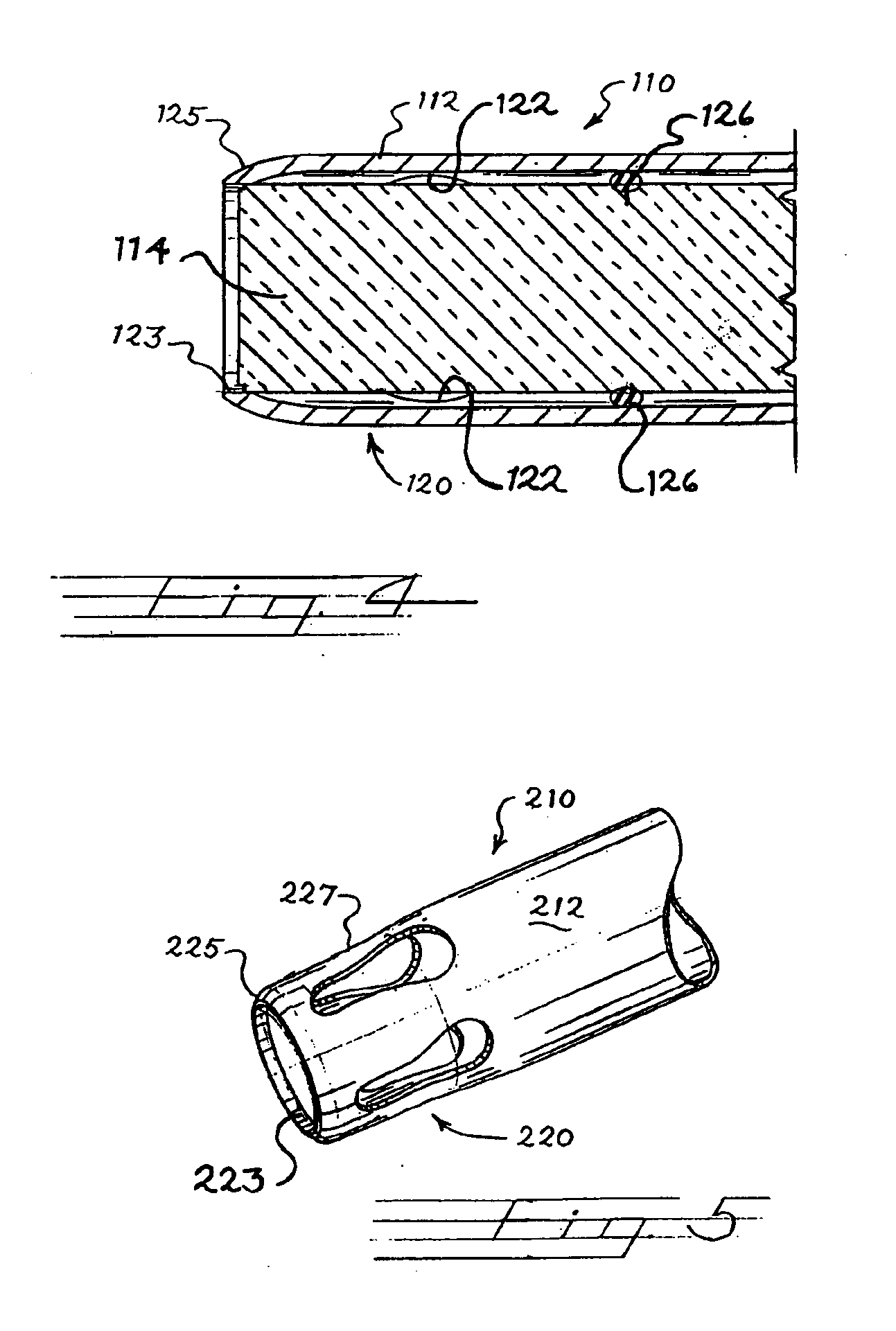

Device and method for the location and catheterization of the surroundings of a nerve

InactiveUS6298256B1Accurate locationEasy to useElectrotherapySurgical needlesHuman bodyVoltage source

A device for the location and catheterization of the surrounding area of a nerve of a human or animal body, including a catheter and an electrically conducting puncture needle with proximal and distal ends, which puncture needle forms a continuous lumen with its proximal and distal end open and having an inside diameter which at least corresponds to the outside diameter of the catheter and which, in the region of its proximal end, is equipped with an electrical connecting part for the connection of the puncture needle to an electrical voltage source. At the proximal end, a connecting element with a through-hole communicating with the lumen is provided, onto which an injection tube for the introduction of a liquid through the through-hole into the lumen of the puncture needle is connected, and through the through-hole of which the catheter can be pushed forward into the lumen of the puncture needle all the way to the distal end thereof. Also disclosed is a method for the location and catheterization of the surrounding area of a nerve using such a device.

Owner:MEYER FRANK EGBERT

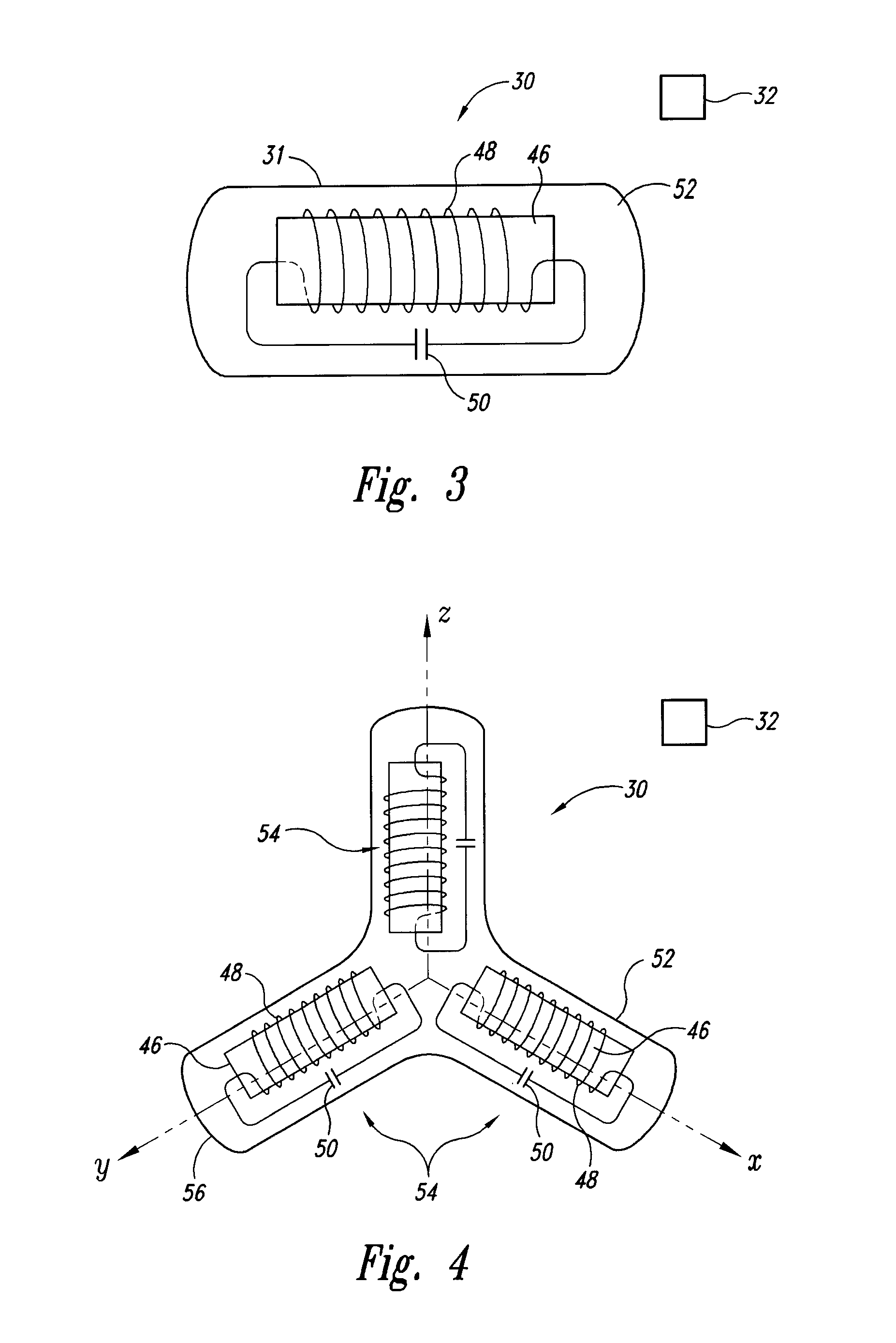

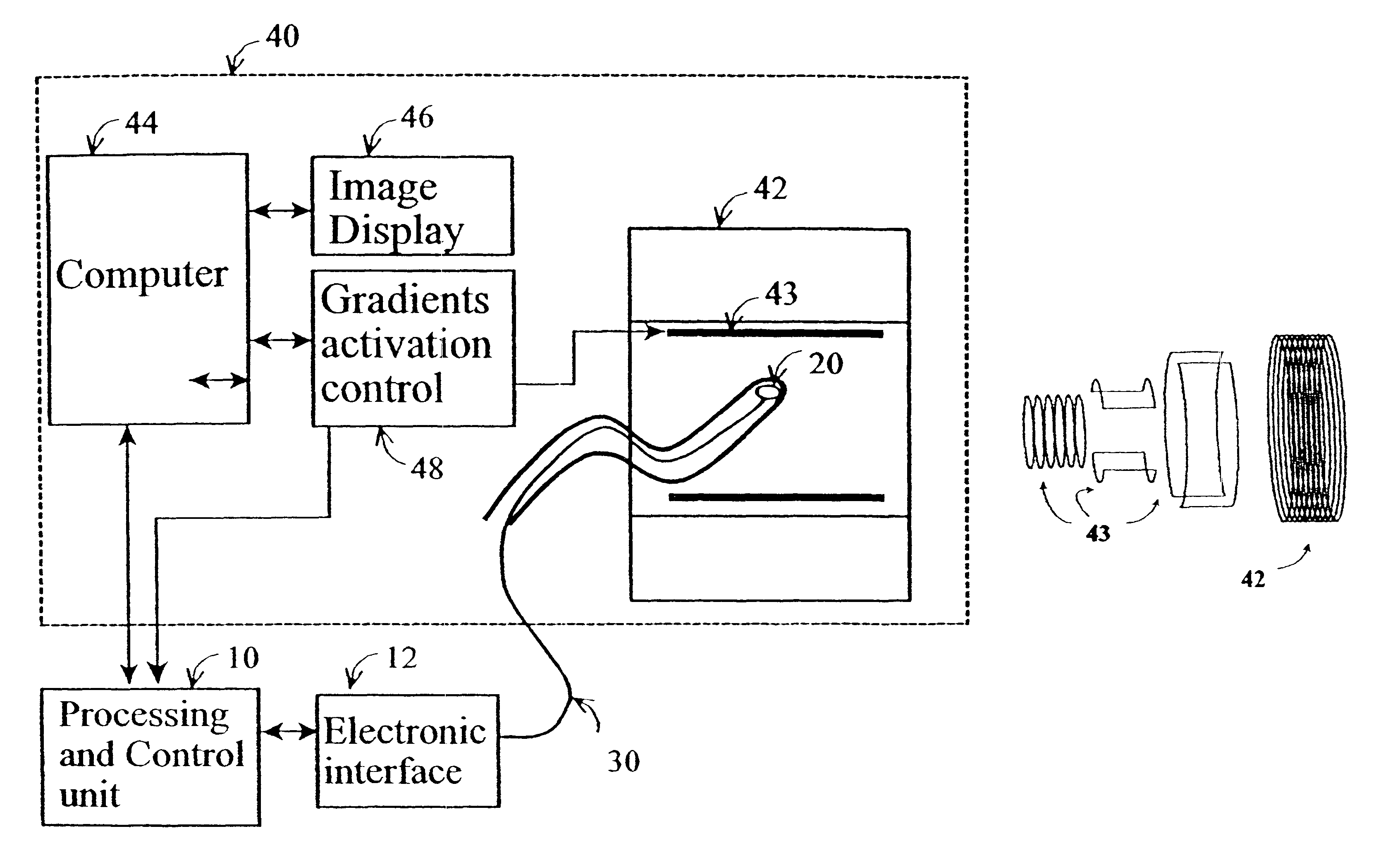

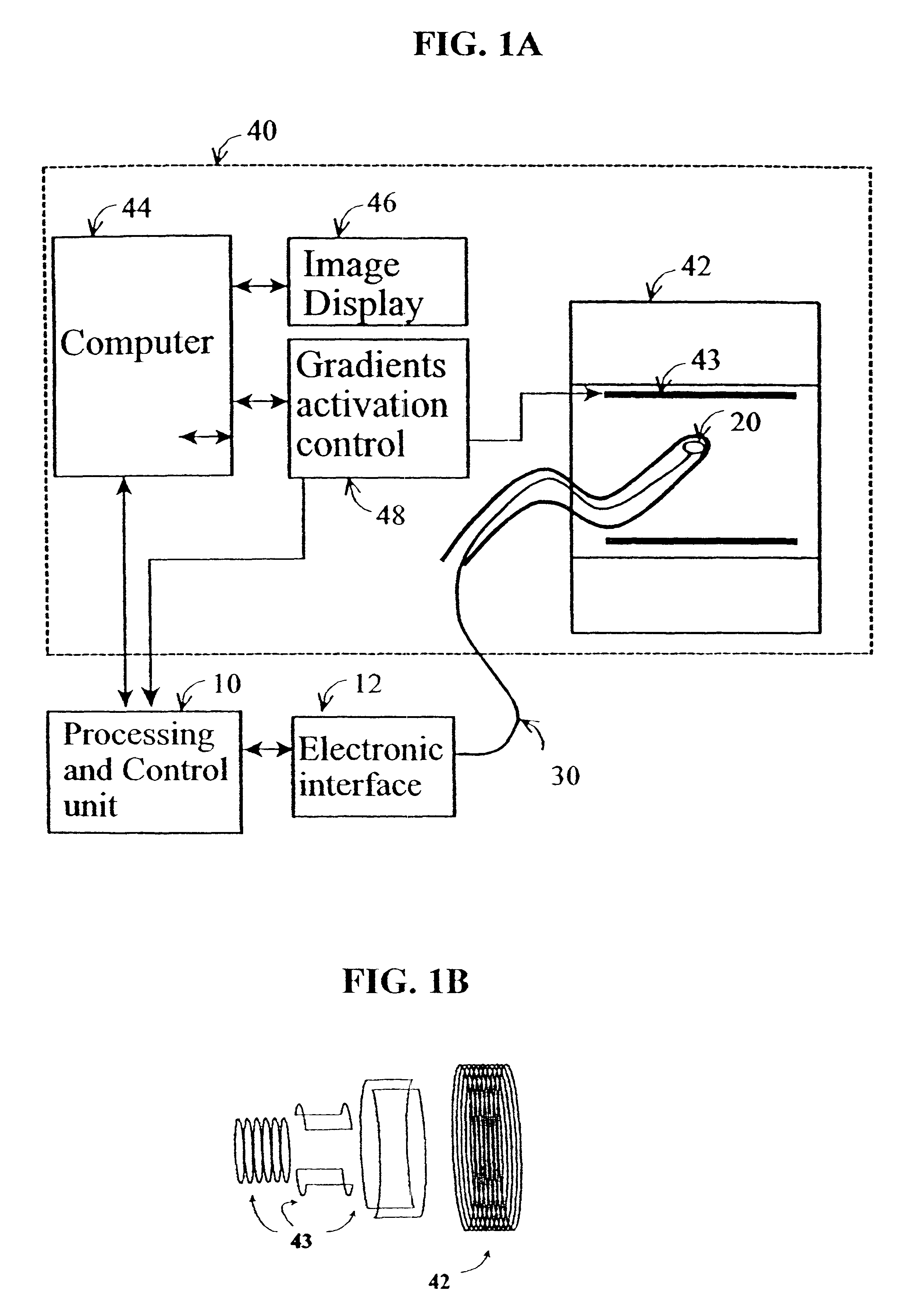

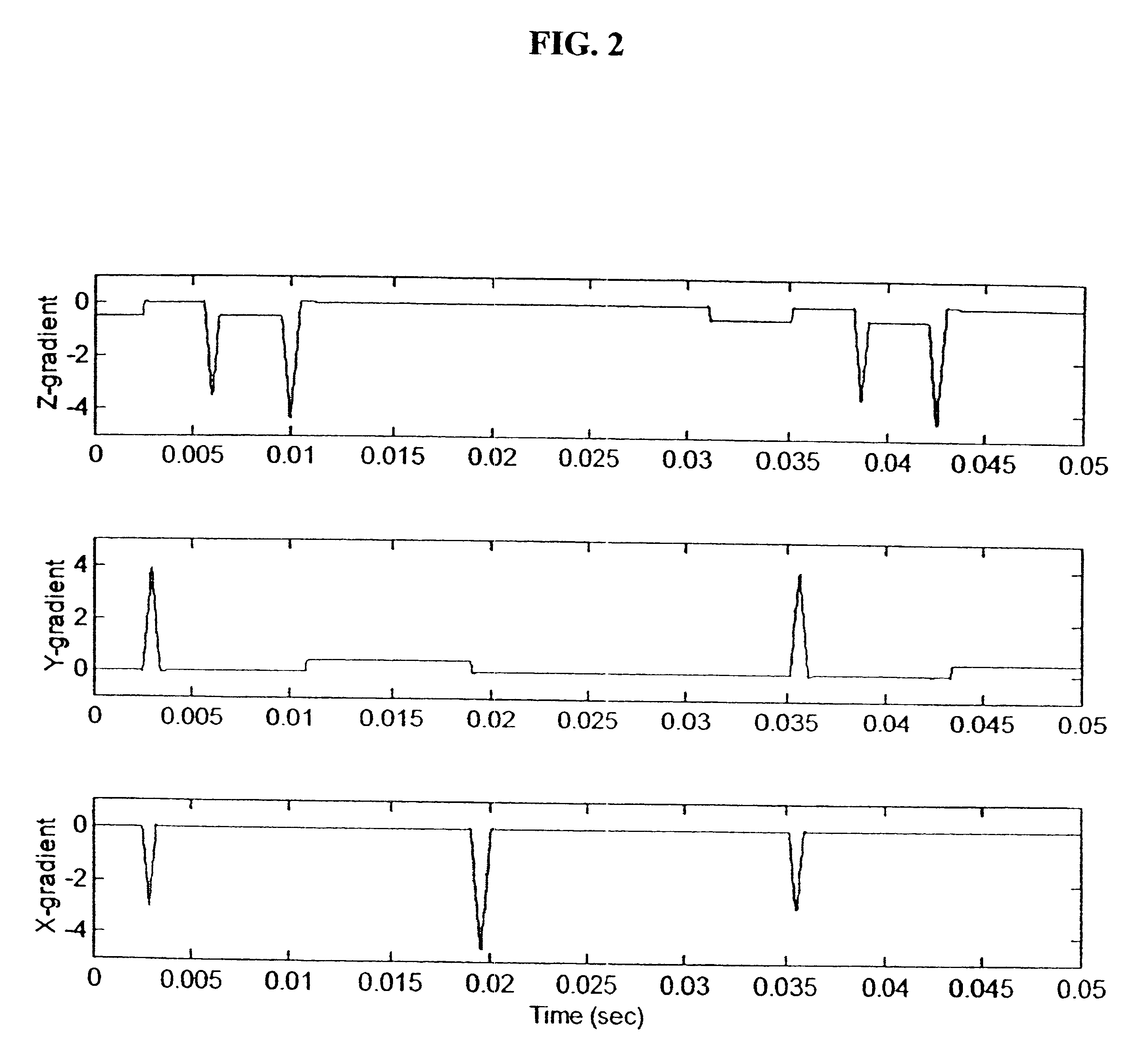

Method and apparatus to estimate location and orientation of objects during magnetic resonance imaging

InactiveUS6516213B1Limited accuracy of orientationSatisfies requirementDiagnostic recording/measuringSensorsMagnetic field gradientThree-dimensional space

Method and apparatus for determining the instantaneous location, the orientation of an object moving through a three-dimensional space by applying to the object a coil assembly including a plurality of sensor coils (20) having axes of known orientation with respect to each other including components in the three orthogonal planes; generating a time-varying, three-dimensional magnetic field gradient having known instantaneous values of magnitude and direction; applying the magnetic field gradient to the space, and object moving therethrough to induce electrical potentials in the sensor coils; measuring the instantaneous values of the induced electrical potentials generated in the sensor coils; processing the measured instantaneous values generated in the sensor coils together with the known magnitude, direction of the generated magnetic field gradient, the known relative orientation of the sensor coils in the coil assembly to compute the instantaneous location, orientation of the object within the space.

Owner:ROBIN MEDICAL

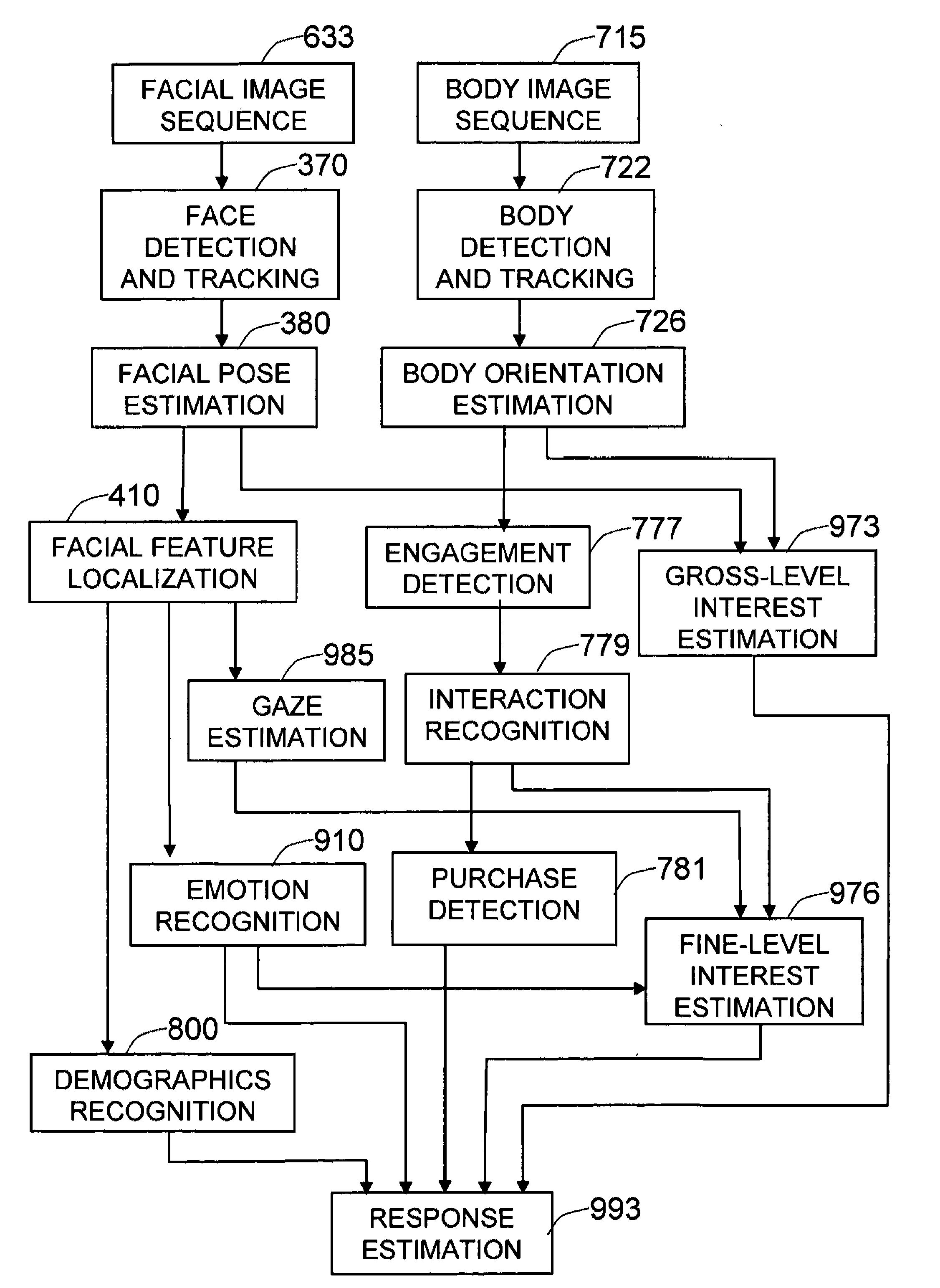

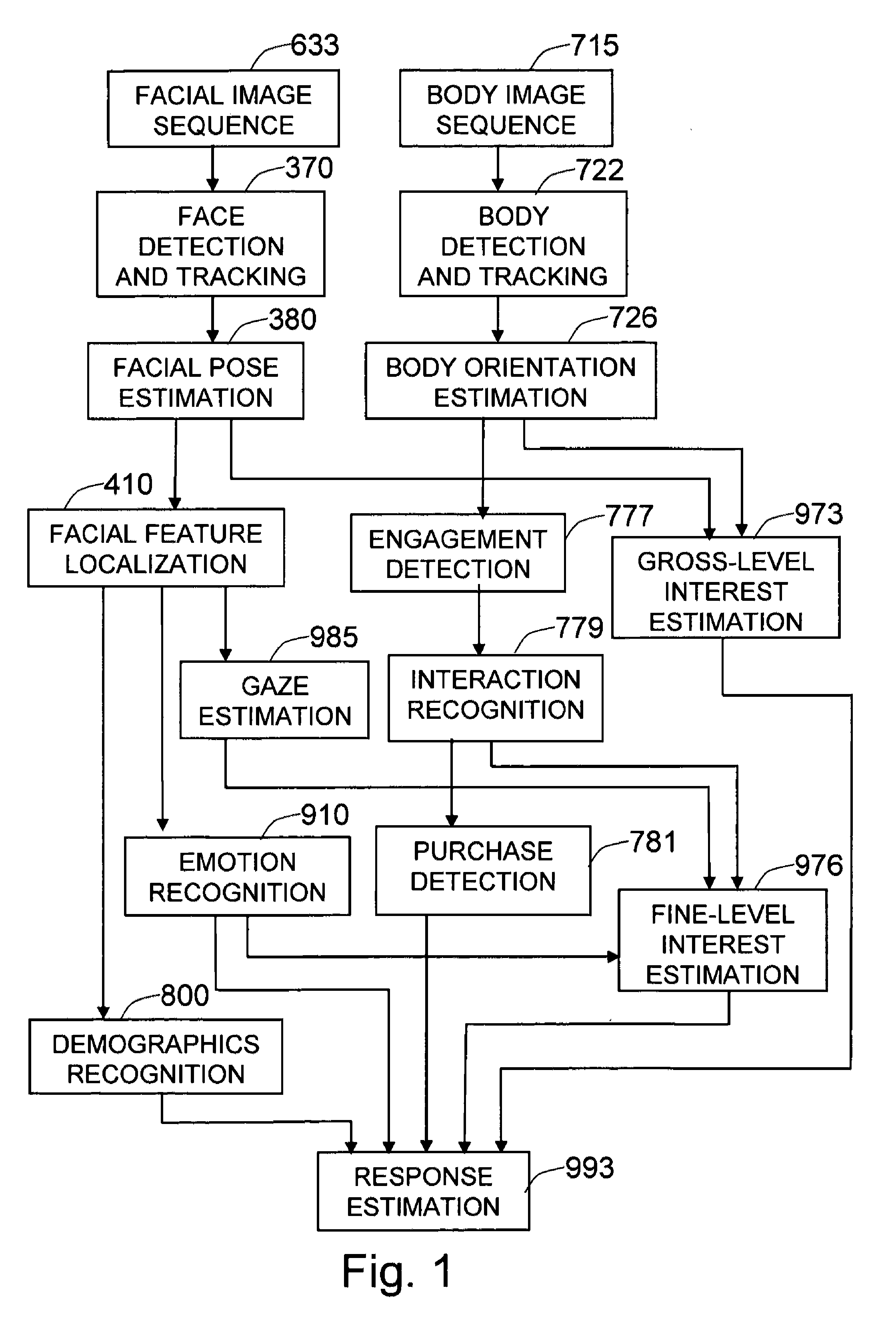

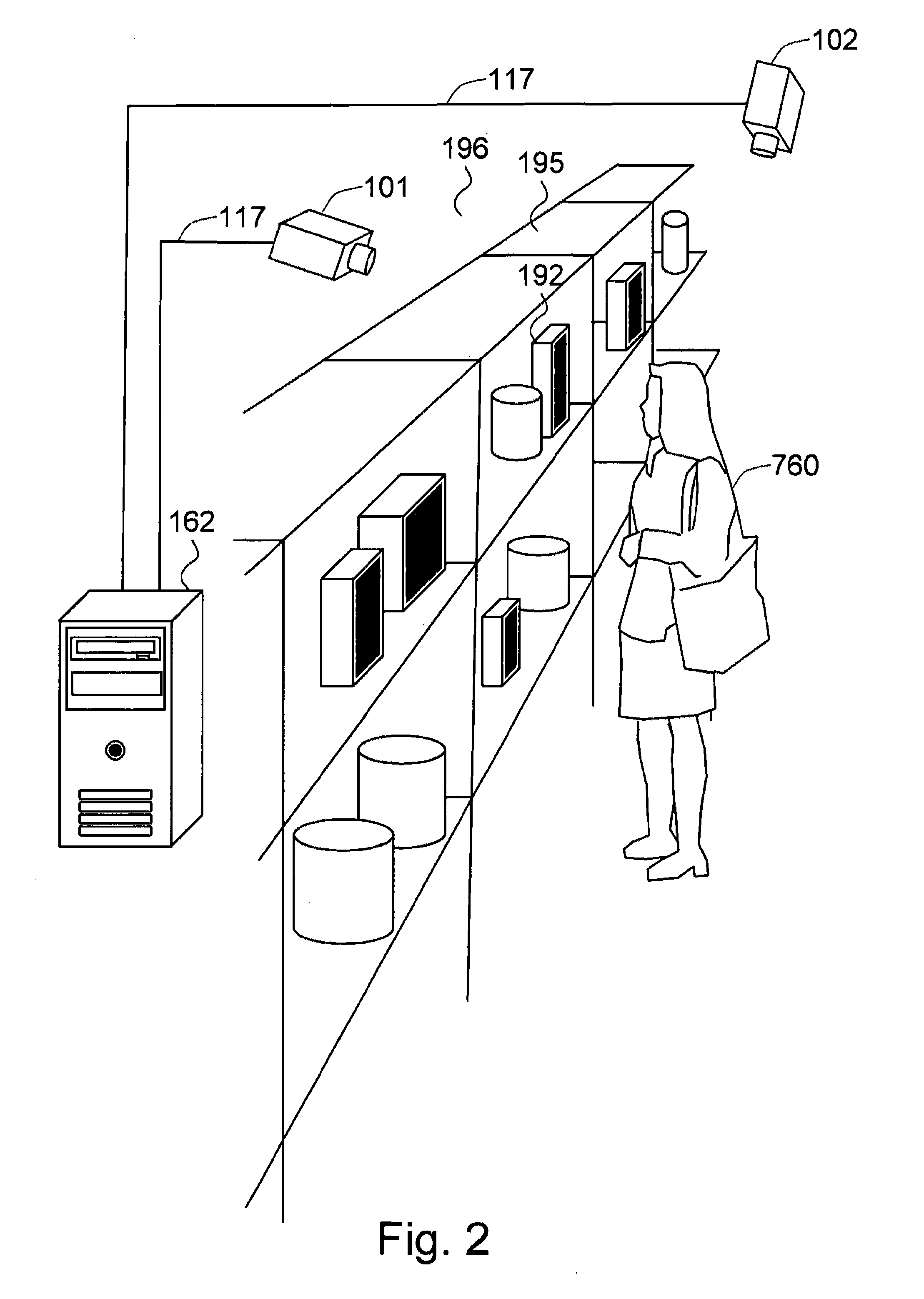

Method and system for measuring shopper response to products based on behavior and facial expression

ActiveUS8219438B1Reliable informationAccurate locationMarket predictionsAcquiring/recognising eyesPattern recognitionProduct base

The present invention is a method and system for measuring human response to retail elements, based on the shopper's facial expressions and behaviors. From a facial image sequence, the facial geometry—facial pose and facial feature positions—is estimated to facilitate the recognition of facial expressions, gaze, and demographic categories. The recognized facial expression is translated into an affective state of the shopper and the gaze is translated into the target and the level of interest of the shopper. The body image sequence is processed to identify the shopper's interaction with a given retail element—such as a product, a brand, or a category. The dynamic changes of the affective state and the interest toward the retail element measured from facial image sequence is analyzed in the context of the recognized shopper's interaction with the retail element and the demographic categories, to estimate both the shopper's changes in attitude toward the retail element and the end response—such as a purchase decision or a product rating.

Owner:PARMER GEORGE A

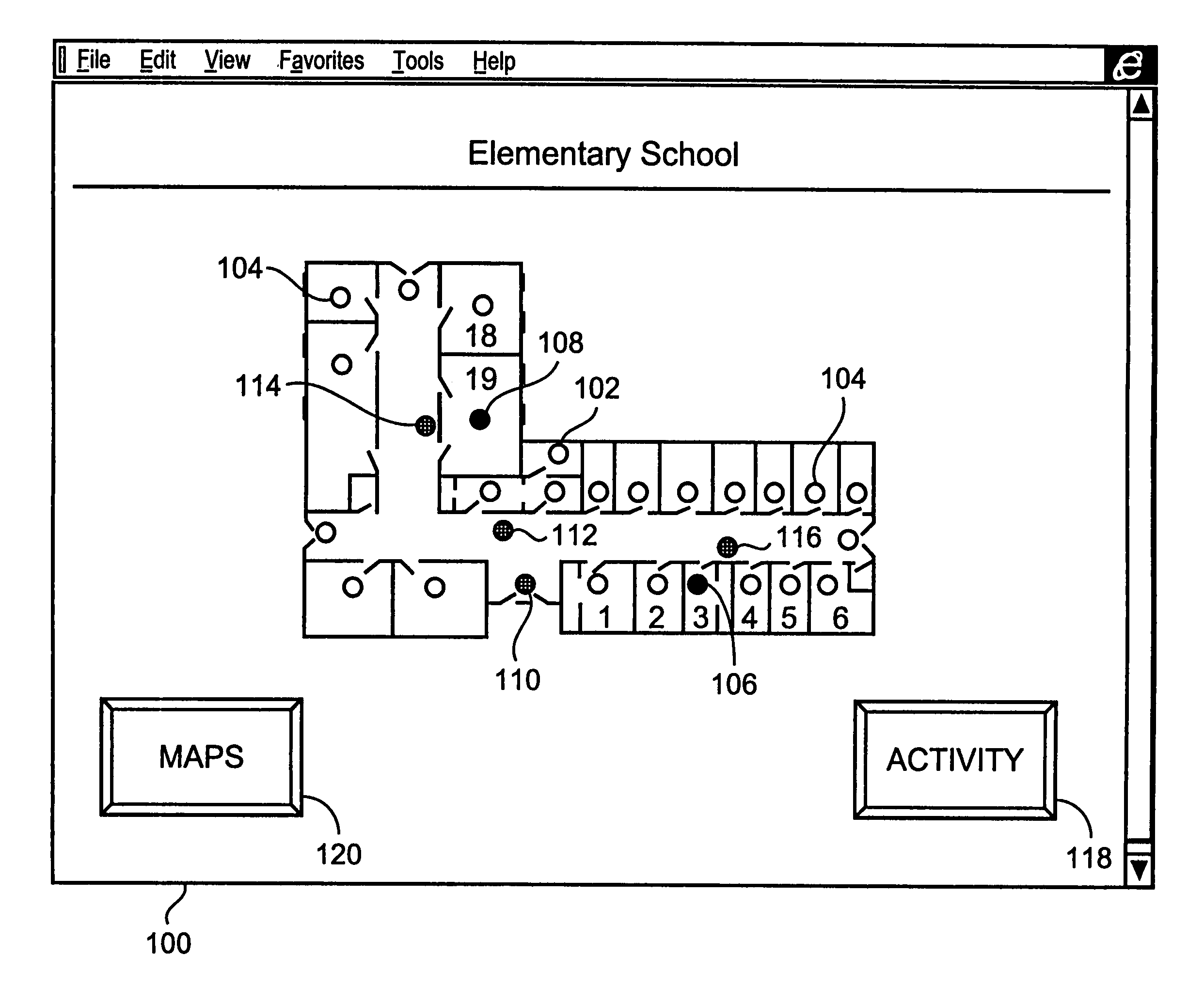

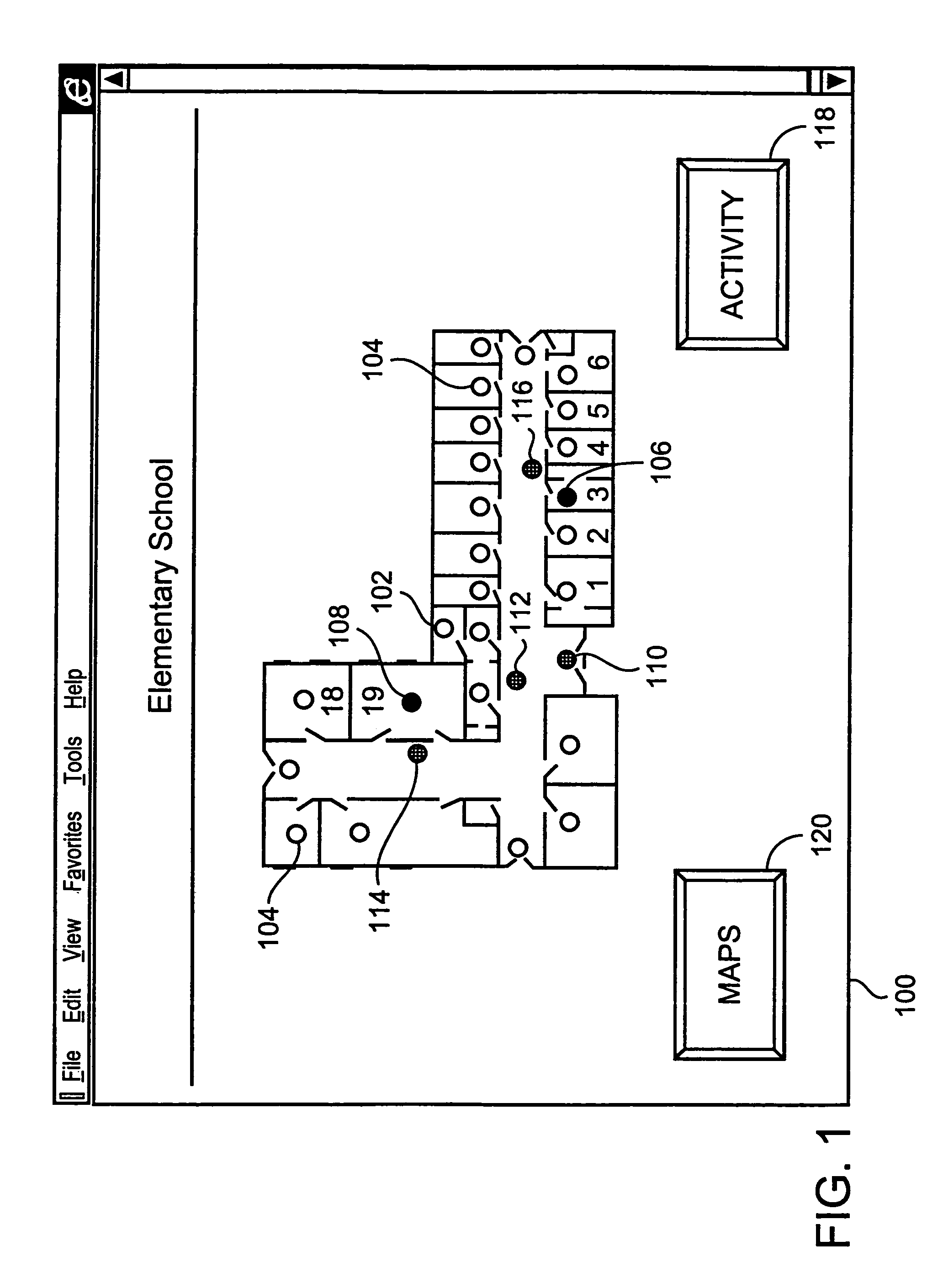

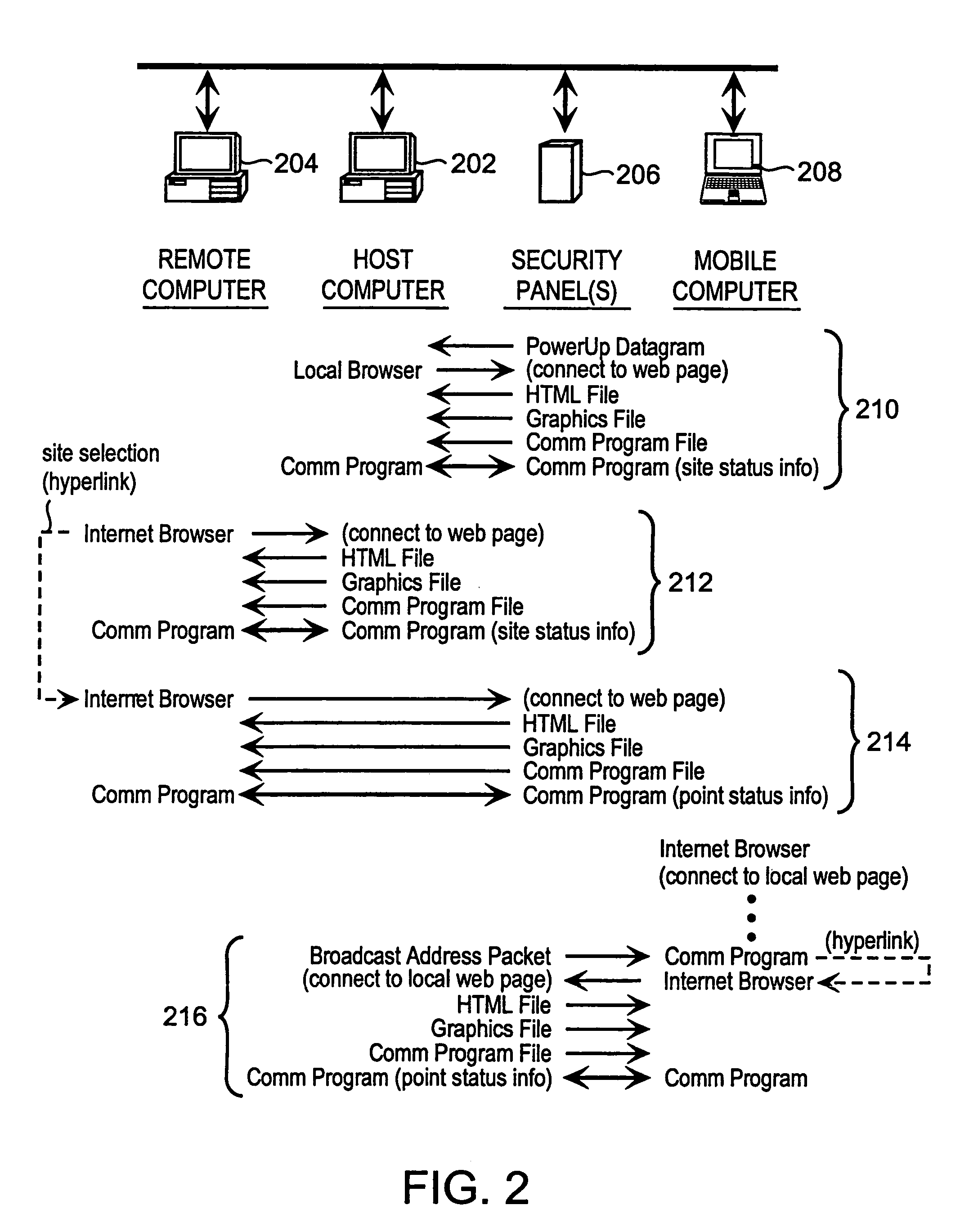

Method and apparatus for remotely monitoring a site

InactiveUS6972676B1Easy to distinguishAccurate locationElectric testing/monitoringElectric/electromagnetic visible signallingTime informationOperating energy

The present invention is directed to providing systems and methods for remotely monitoring sites to provide real time information which can readily permit false alarms to be distinguished, and which can identify and track the precise location of an alarm. In exemplary embodiments, monitoring capabilities such as intrusion / fire detection and tracking capabilities, can be implemented through the use of multistate indicators in a novel interface which permits information to be transmitted using standard network protocols from a remote site to a monitoring station in real-time over preexisting communication networks, such as the Internet. A wireless network can also be established using browser encapsulated communication programs (for example, active X control, Java applets, and so forth) to transmit data packets which comply with any standard wireless local area network protocol. Communications can thereby be established between a web server embedded in a centrally located host monitoring station and a separate security panel deployed in each of the buildings to be remotely monitored. In exemplary embodiments, communications can be handed off from the centrally located host monitoring station to a mobile monitoring station (for example, to a laptop computer in a responding vehicle, such as a police or fire vehicle). The handoff can be such that direct communications are established between a security panel site being monitored and the laptop, or over, for example, a cellular network or indirect communications can be established via the host monitoring station.

Owner:NETTALON SECURITY SYST

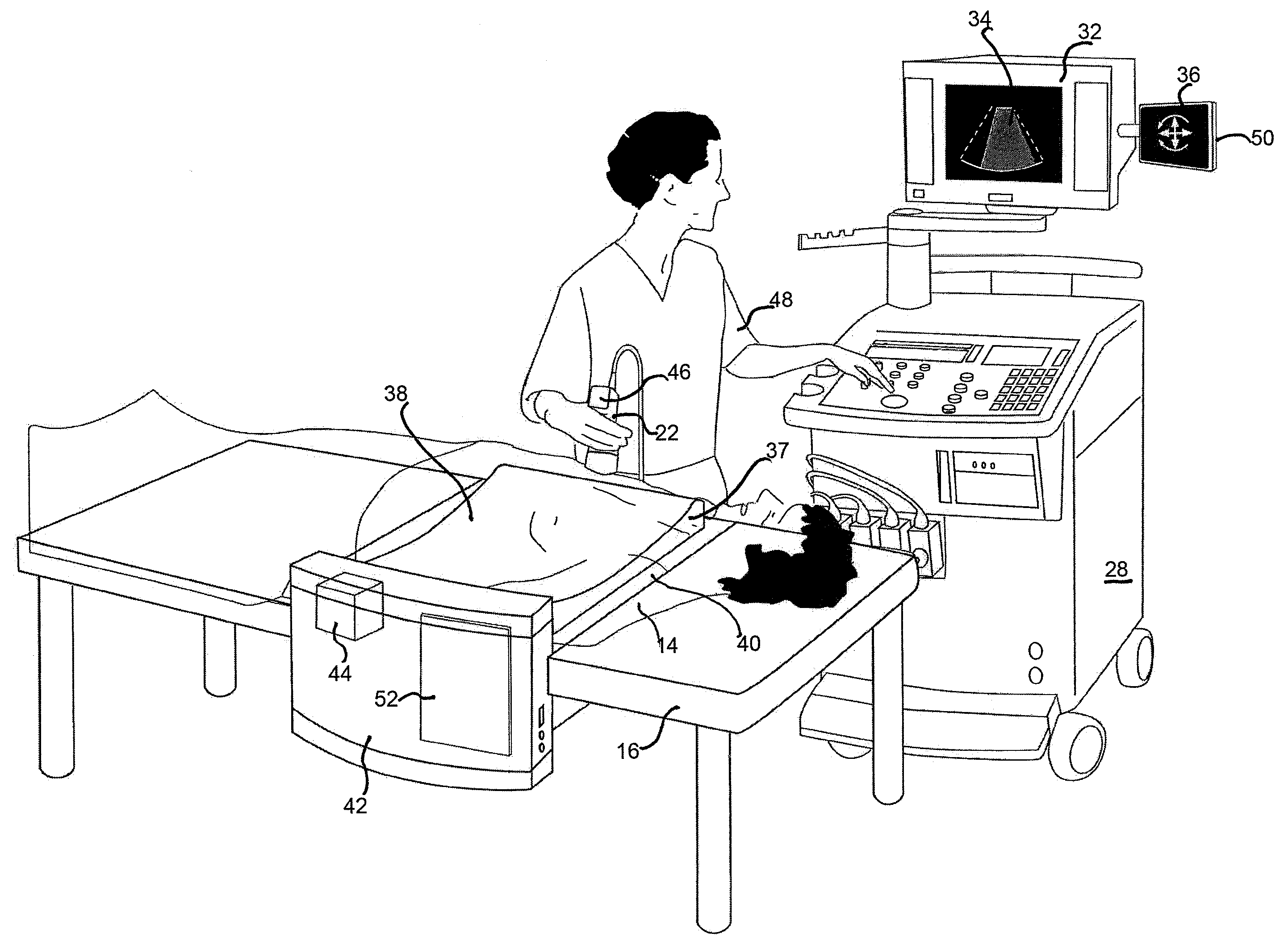

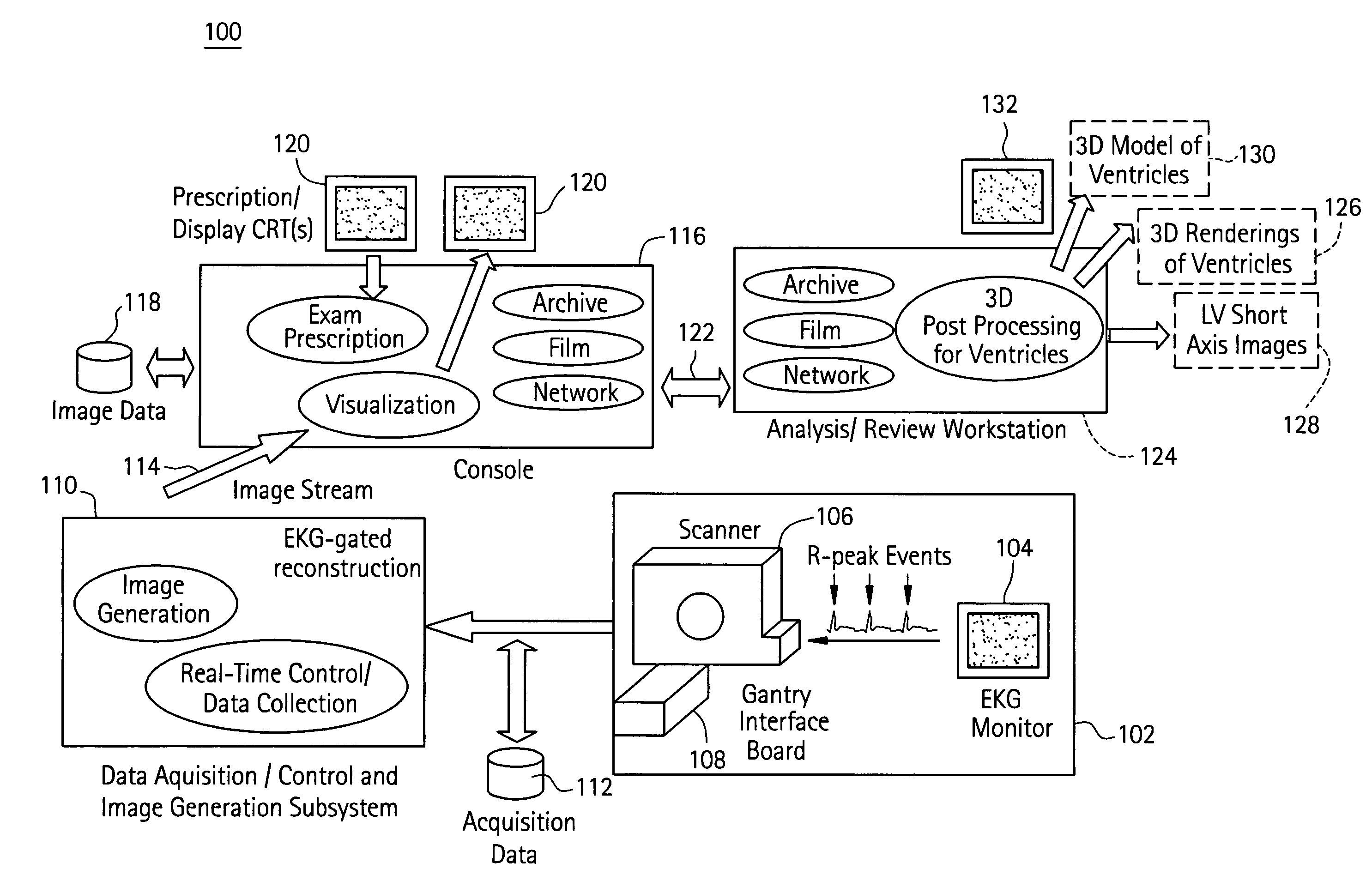

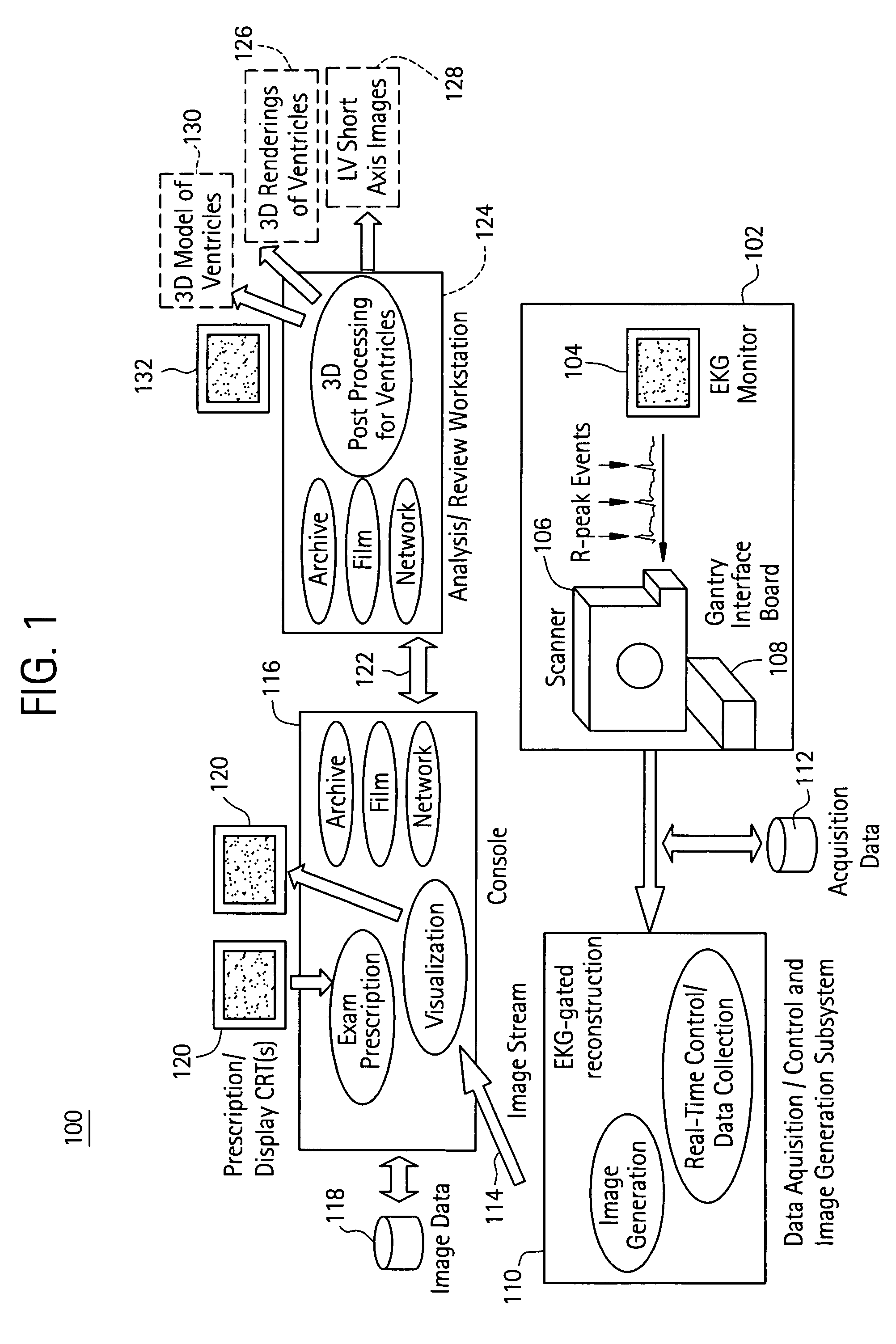

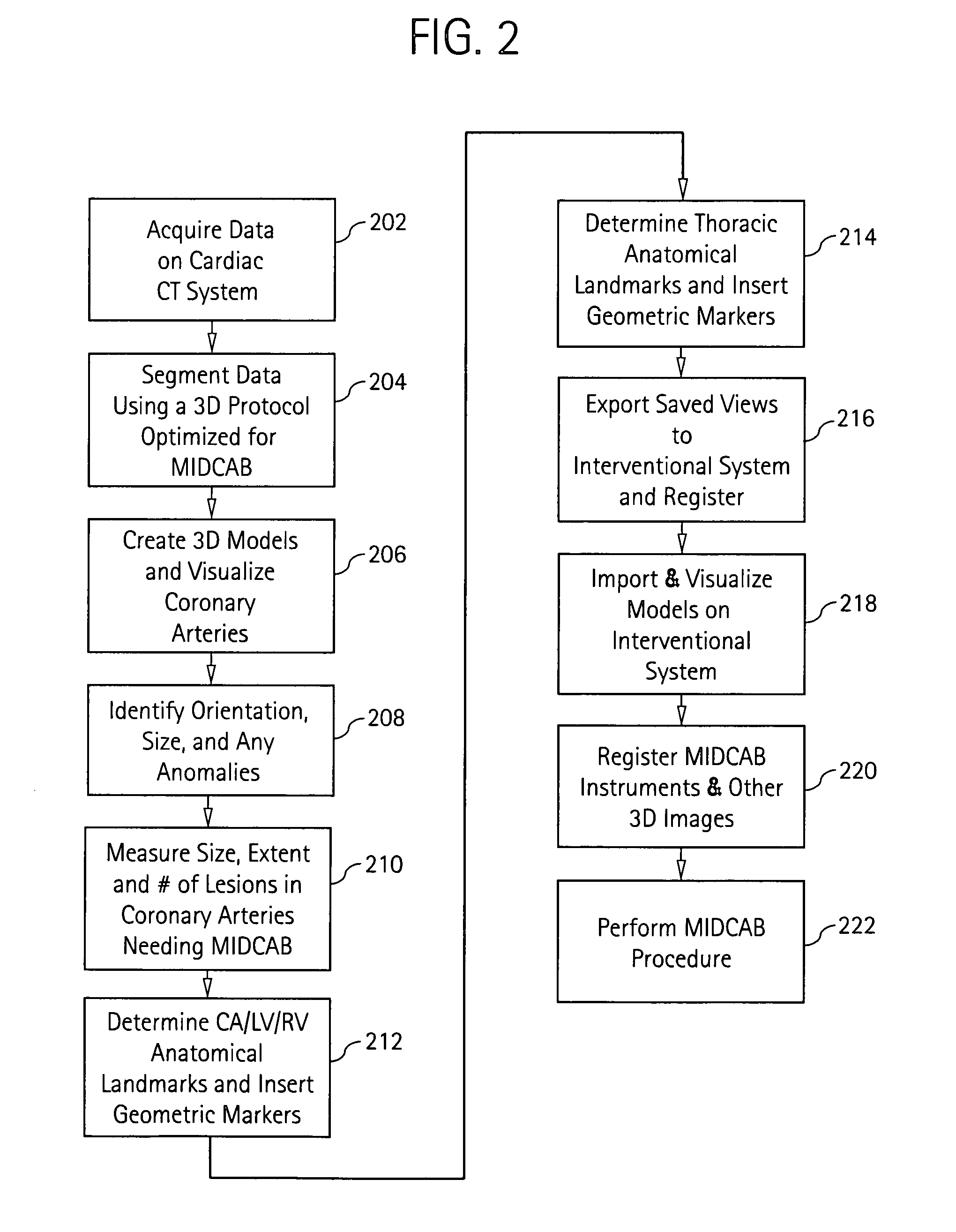

Cardiac imaging system and method for planning minimally invasive direct coronary artery bypass surgery

ActiveUS7813785B2High precisionShorten the construction periodUltrasonic/sonic/infrasonic diagnosticsMedical simulationAnatomical landmarkCoronary arteries

A method for planning minimally invasive direct coronary artery bypass (MIDCAB) for a patient includes obtaining acquisition data from a medical imaging system, and generating a 3D model of the coronary arteries and one or more cardiac chambers of interest. One or more anatomical landmarks are identified on the 3D model, and saved views of the 3D model are registered on an interventional system. One or more of the registered saved views are visualized with the interventional system.

Owner:APN HEALTH +1

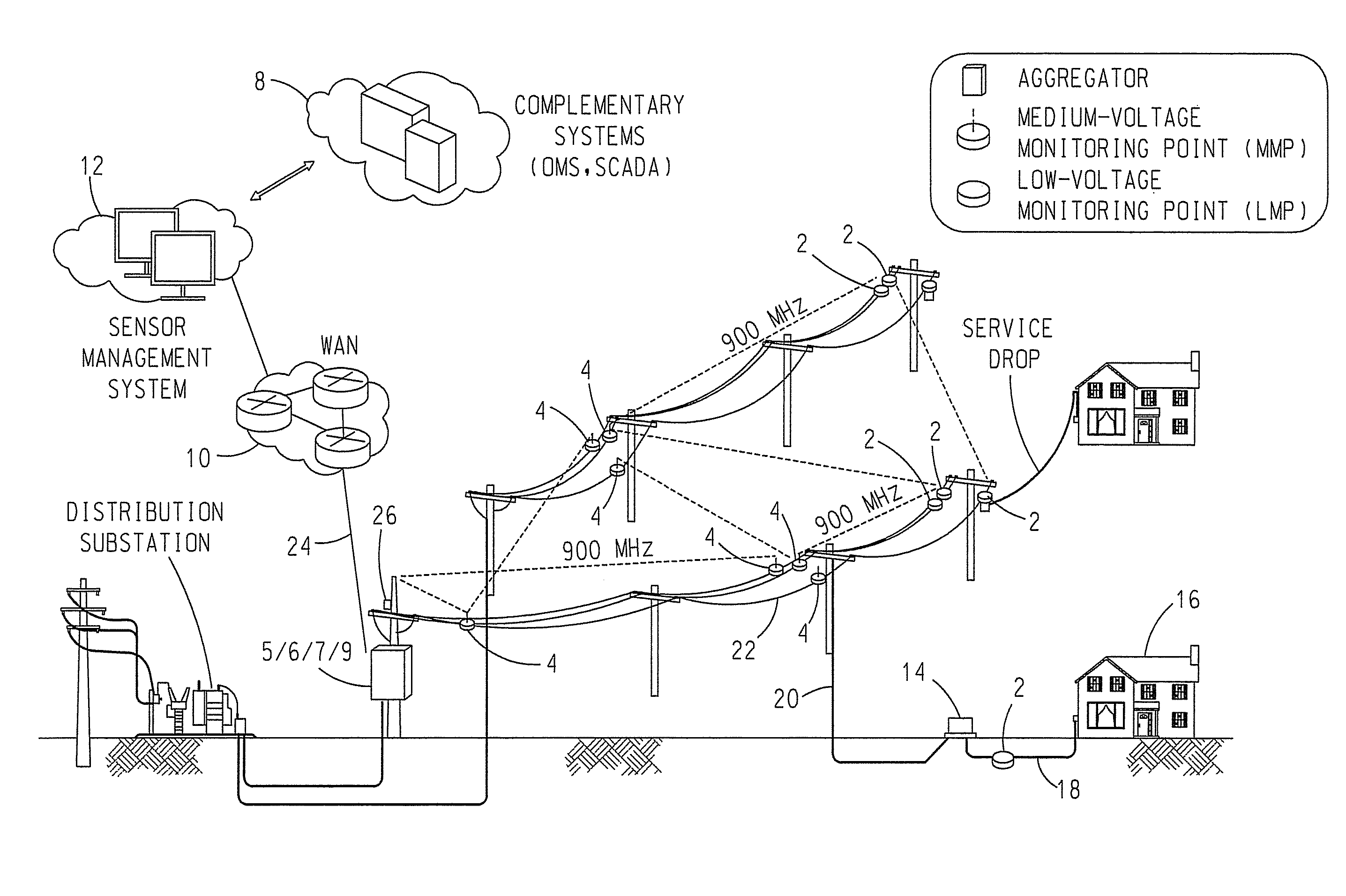

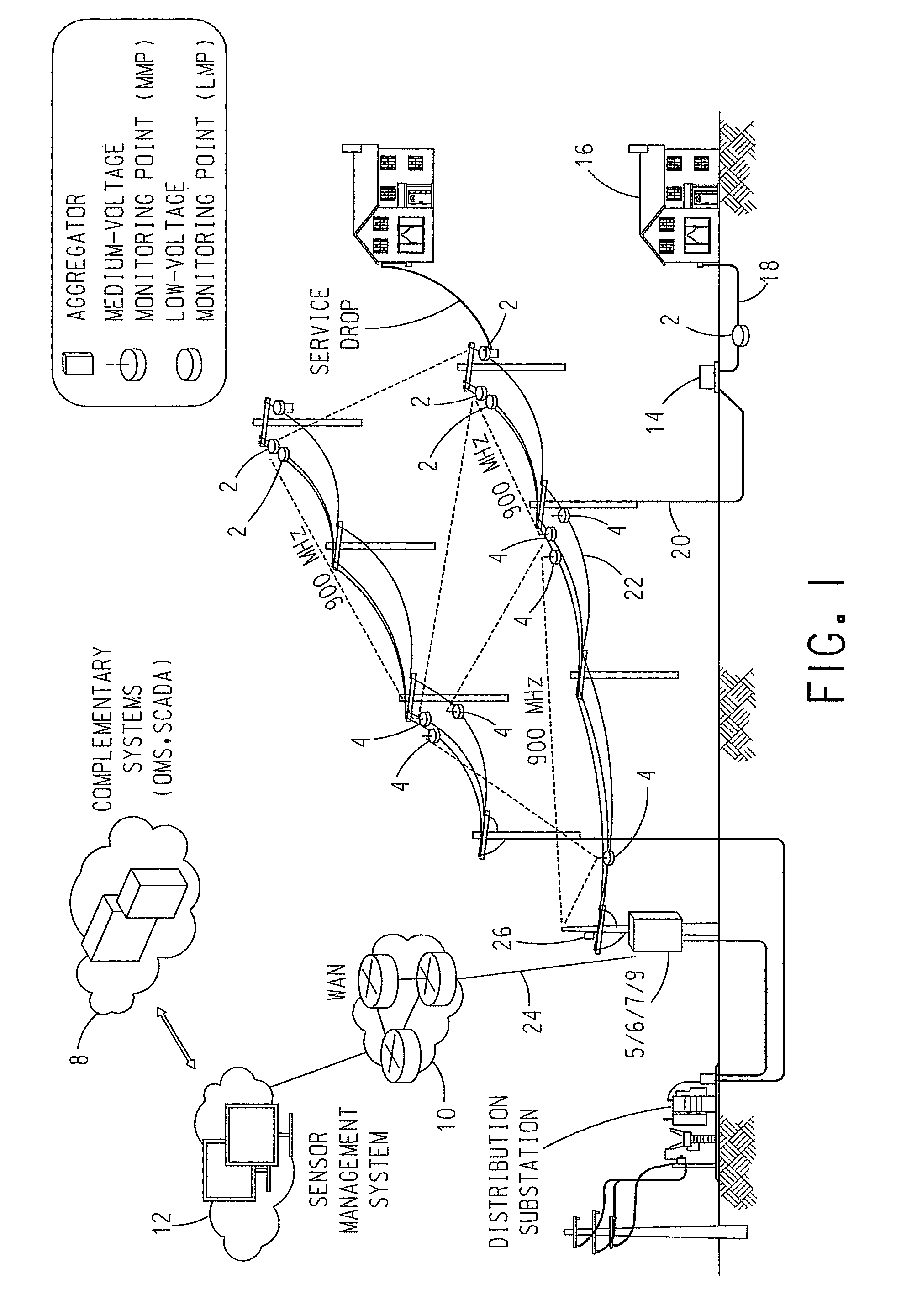

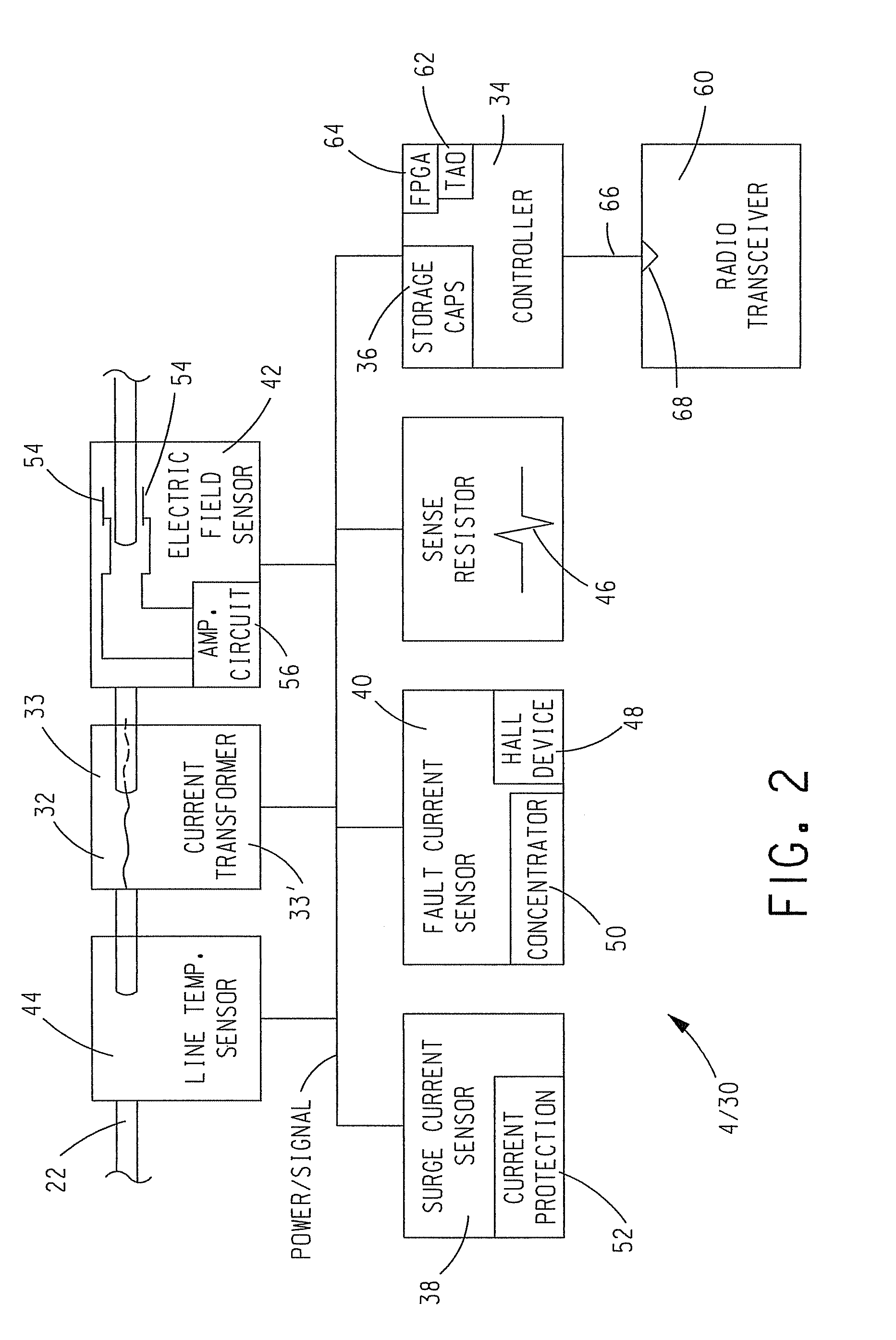

Power distribution monitoring system and method

ActiveUS8065099B2Low costMinimizes total cost of ownership and make-ready costElectric signal transmission systemsDigital data processing detailsMonitoring systemElectric power

A power distribution monitoring system includes a number of power line mounted monitors. Each monitor can acquire data regarding the delivery of electrical power in the power line, wirelessly transmit and receive messages, and electromagnetically acquire and store operating electrical power from electrical current flowing in the power line. The system also includes an aggregator that can wirelessly transmit and receive messages and wirelessly output beacon messages. In response to beacon signals wirelessly output by the aggregator, each monitor co-acts with the aggregator to dynamically build a wireless communication network for the wireless communication of the data acquired by the monitor regarding the delivery of electrical power in the power line to the aggregator.

Owner:ACLARA TECH LLC

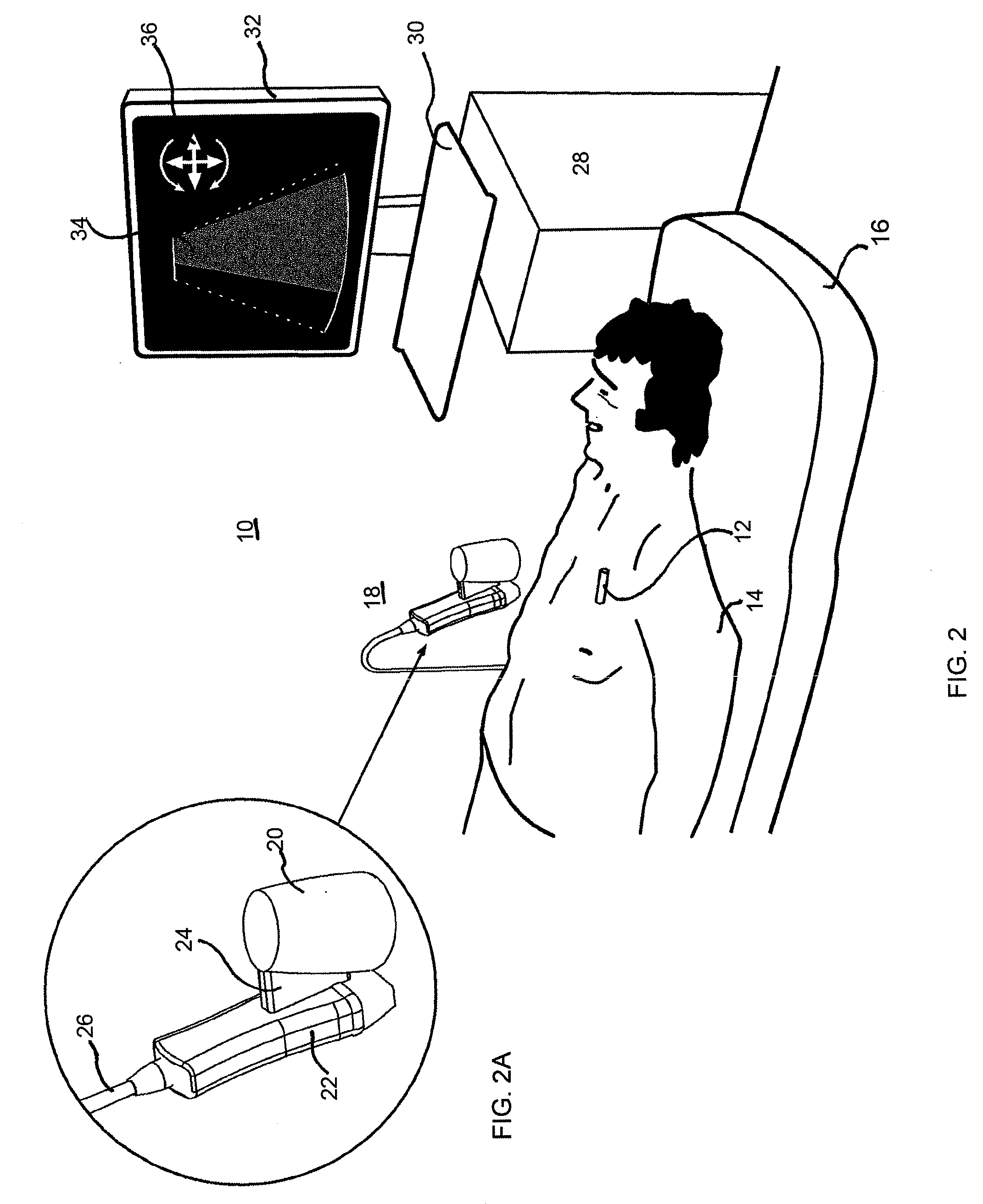

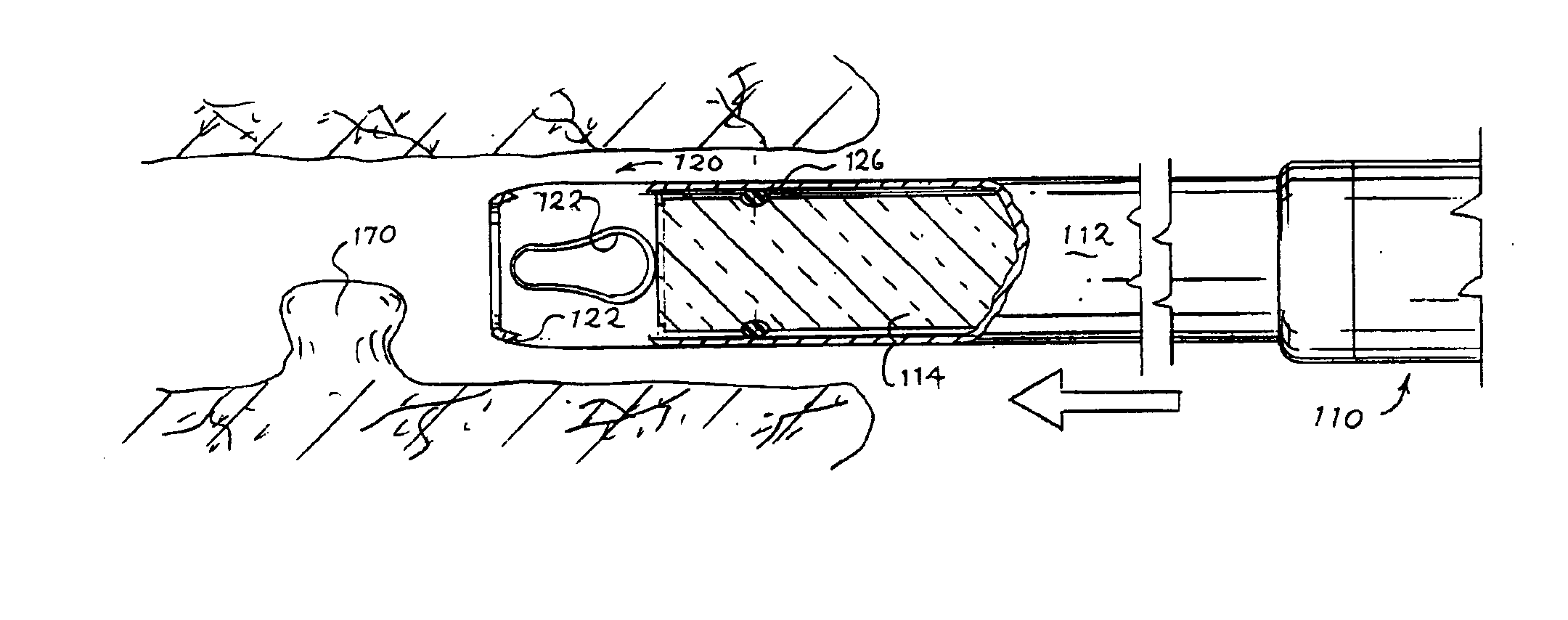

Biopsy device

InactiveUS6899685B2Precise positioningReduce the possibilityElectrotherapySurgical needlesMammary ductExcision procedures

A biopsy device suitable for collecting cells from a mammary duct is provided. The device is suitable for conducting brushing biopsy and tissue excision procedures. The device comprises a sheath that is rotatable about a longitudinal axis. The device further comprises an endoscope disposed within and extending through the sheath. An adjustment mechanism is also operatively connected to the endoscope to longitudinally extend and retract the endoscope within the sheath.

Owner:LACHOWICZ THEODORE COLLATERAL AGENT

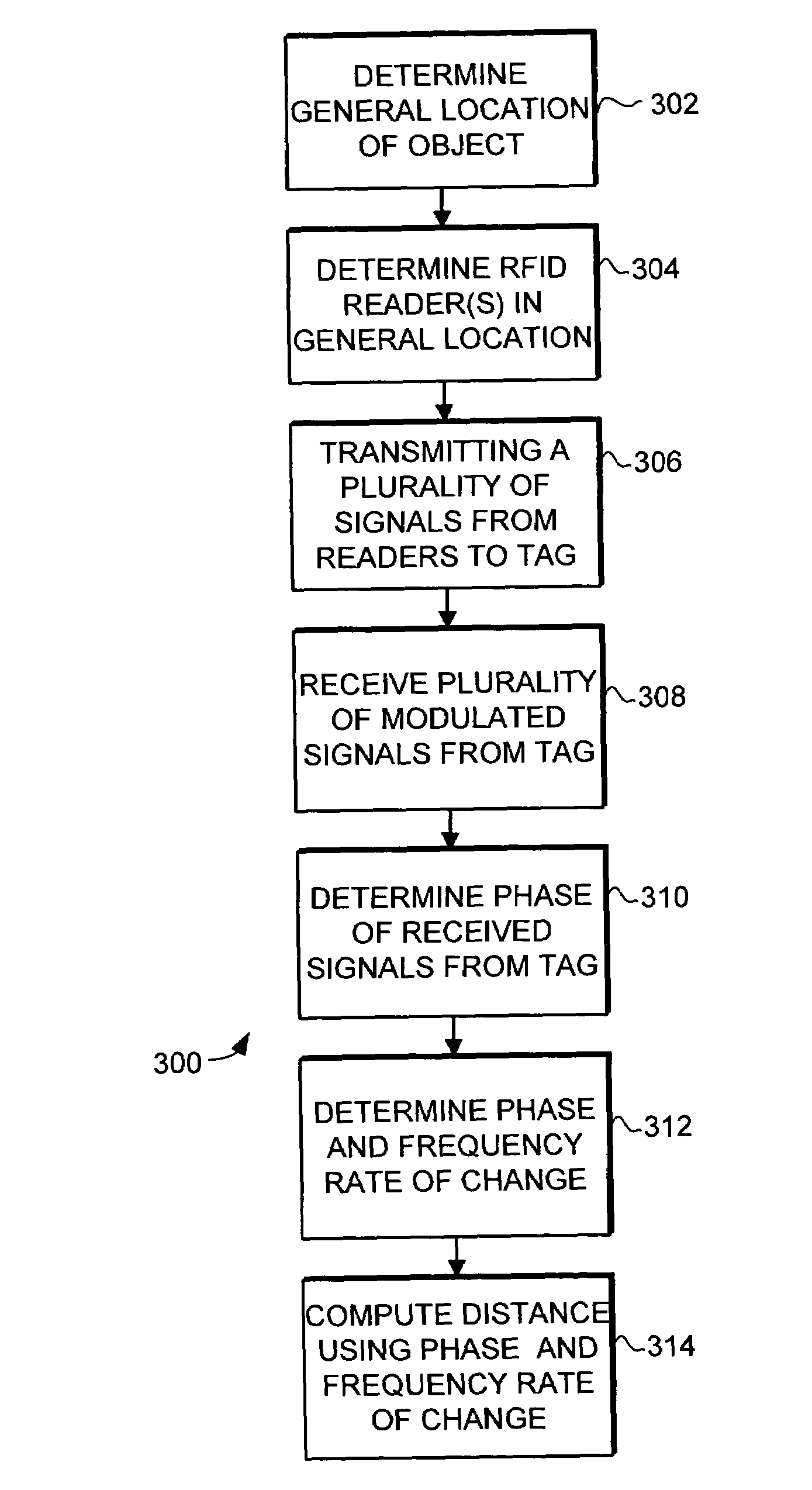

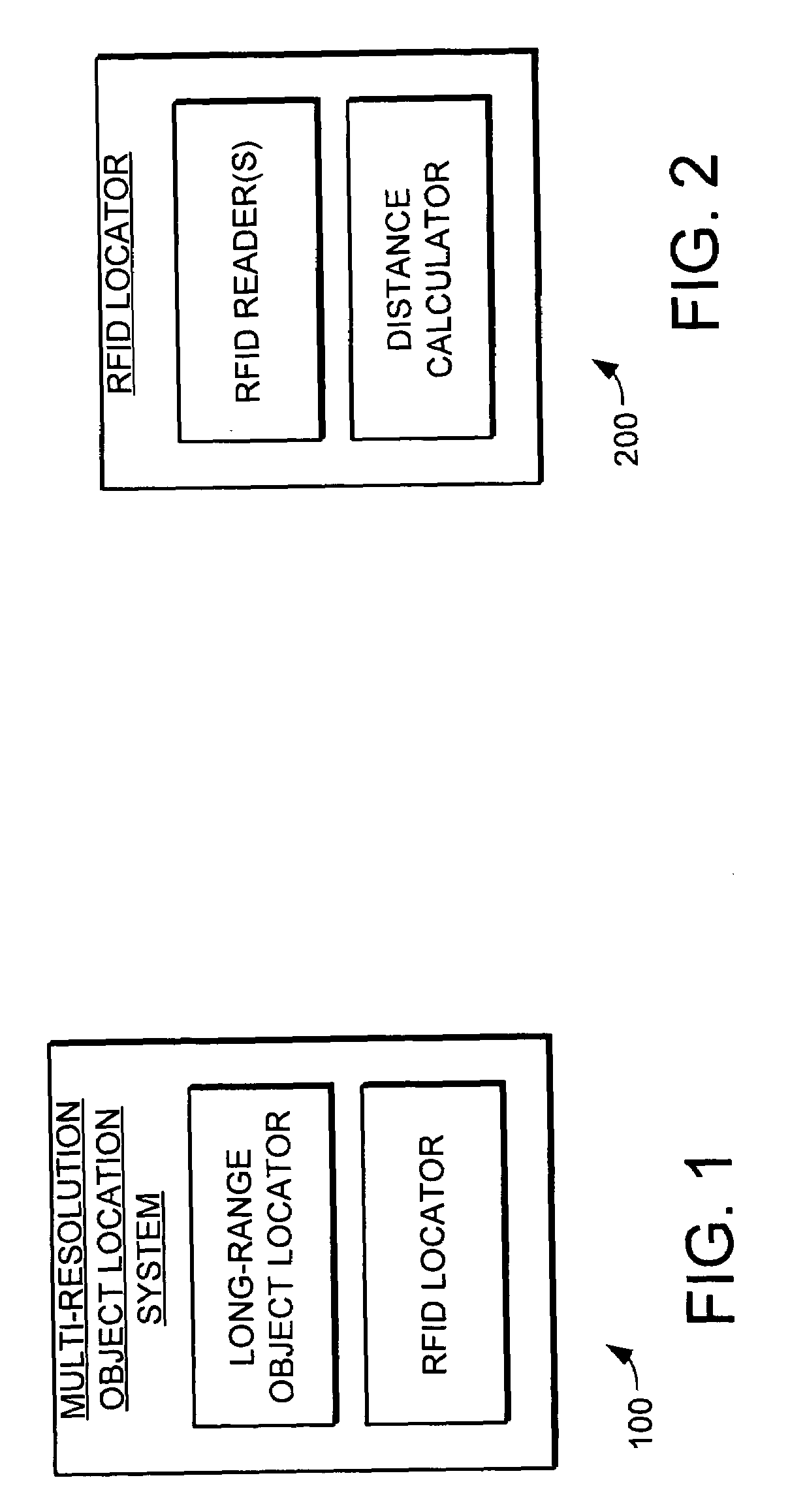

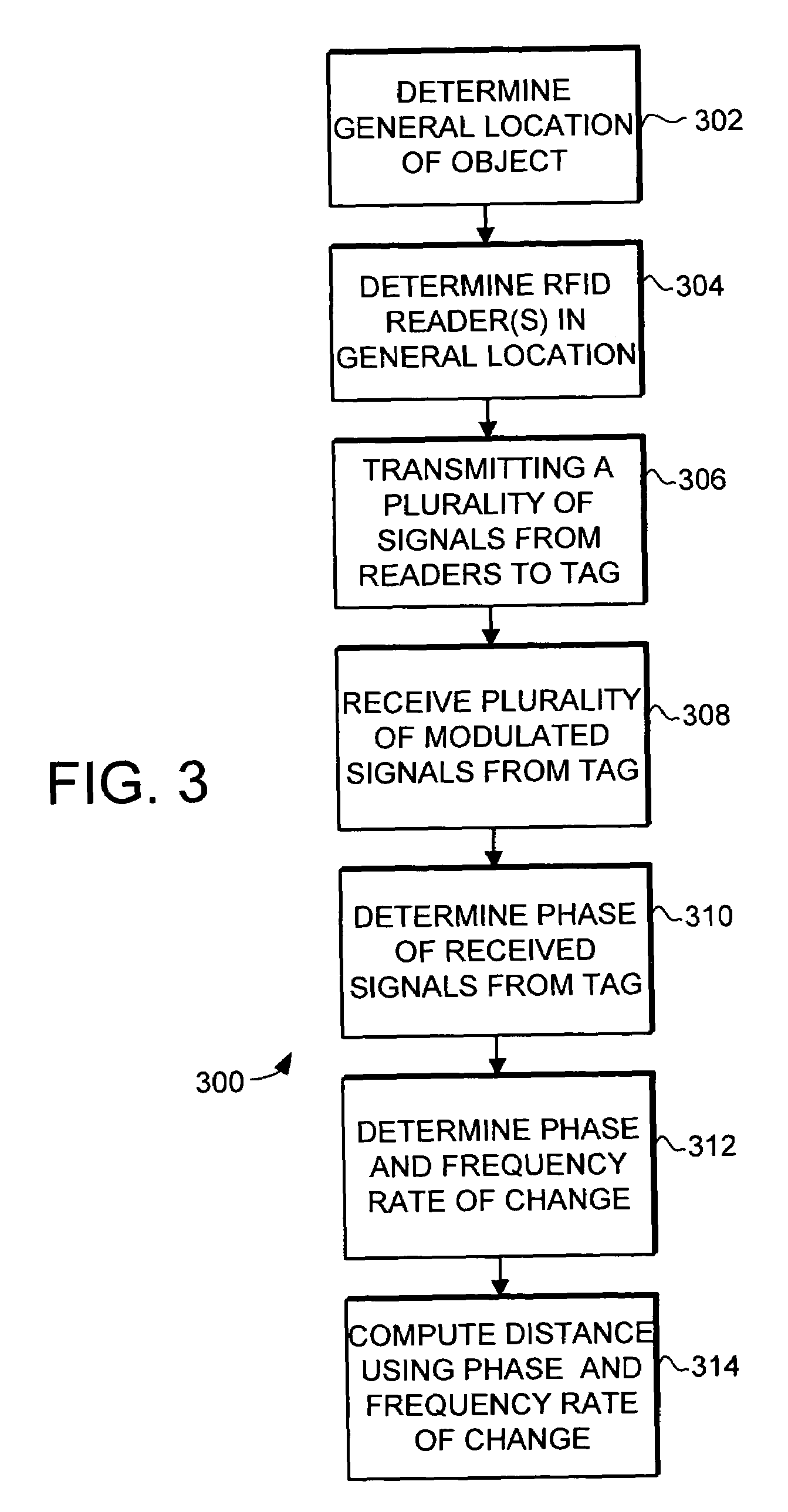

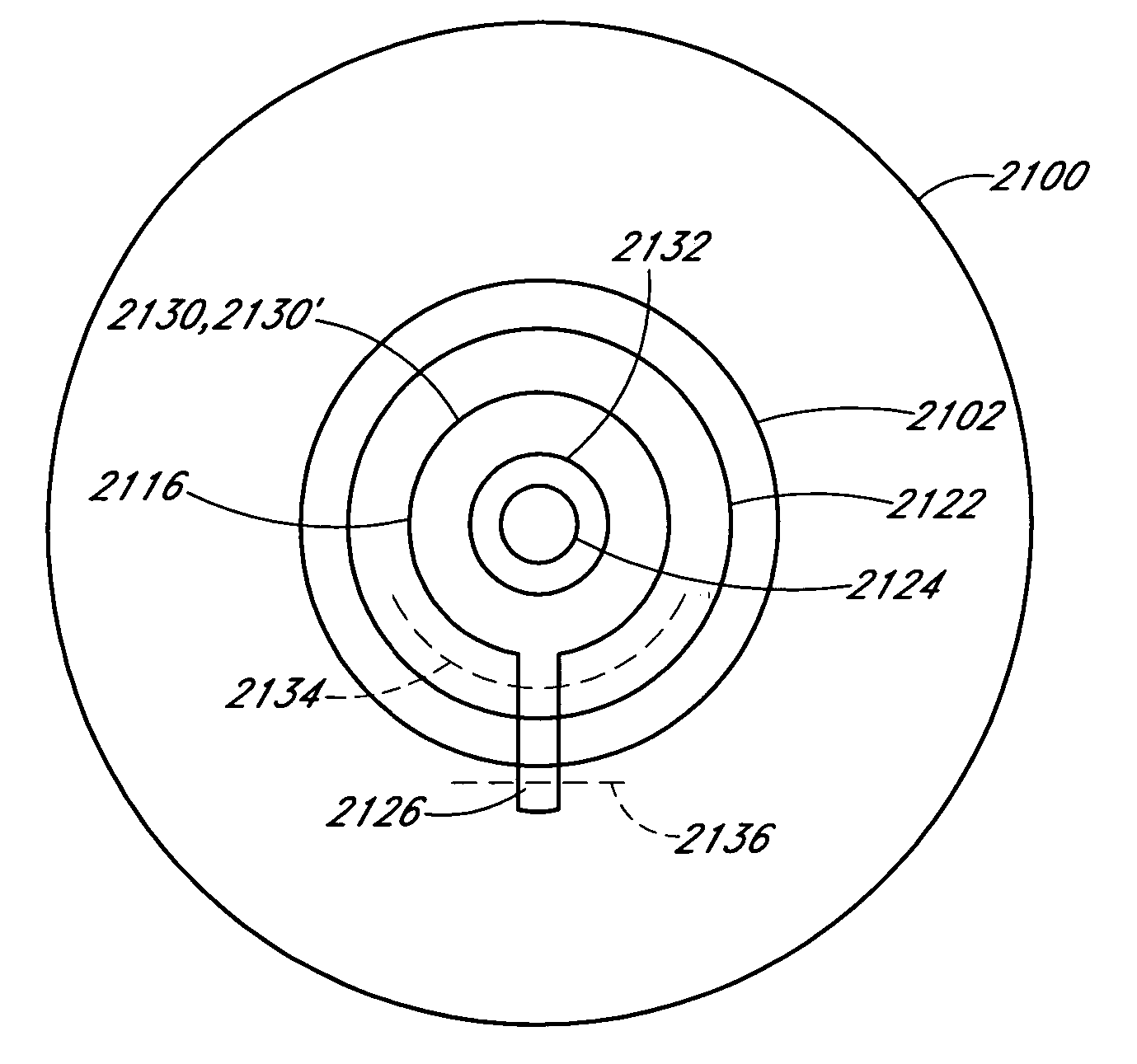

Multi-resolution object location system and method

ActiveUS7030761B2Efficiently and accurately determineLong rangeFrequency-division multiplex detailsTelephonic communicationImage resolutionMulti resolution

A multi-resolution object location system and method for locating objects is provided. The multi-resolution system and method uses a long-range object locator together with a more precise RFID locator to efficiently and accurately determine the location of objects that include an RFID tag. The long-range object locator has a relatively longer range and can cover a relatively large area to determine the general location of the object within the large area. The RFID locator has a relatively shorter range, but is able to locate the object more precisely. The object location system uses the long-range locator to first determine the general location of the object, and then the RFID locator is used to determine a more accurate location of the object. Thus, the multi-resolution object location system is able to provide both a long range location of objects over a large area and a precise location of objects.

Owner:SYMBOL TECH LLC

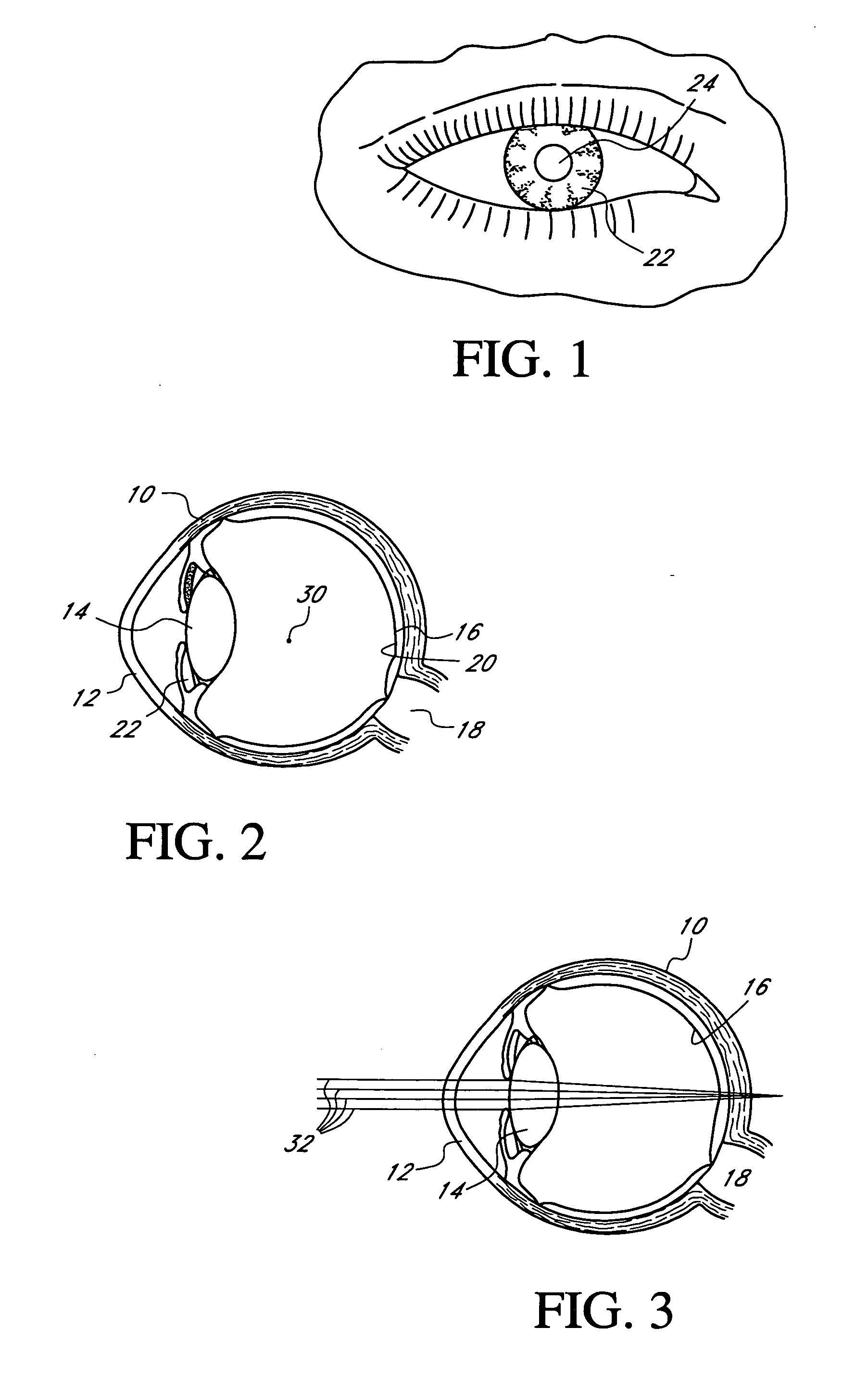

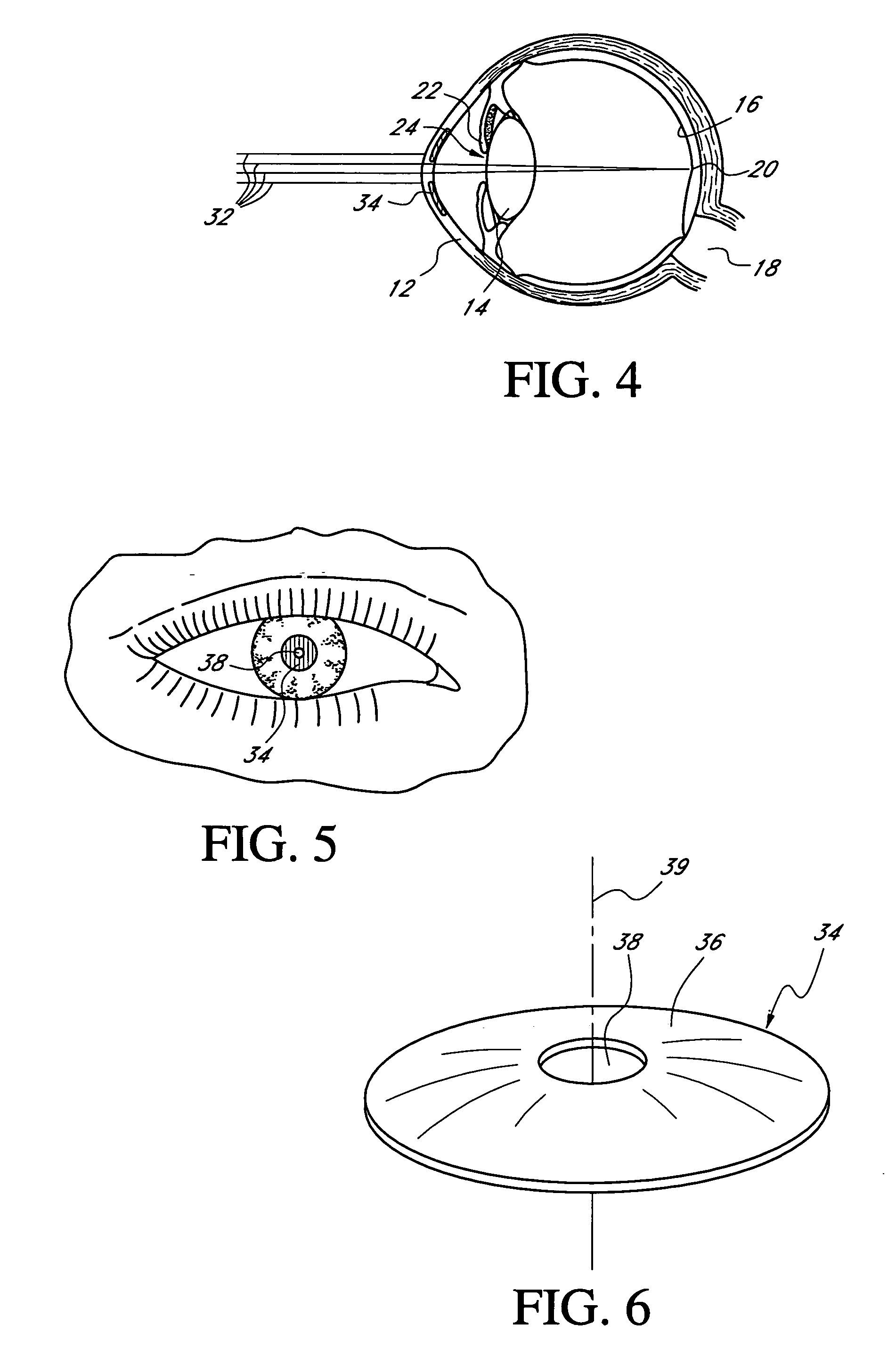

Ocular inlay with locator

InactiveUS20060235428A1Facilitate removalEasy to disassembleLaser surgeryIntraocular lensClinical settingsOptical contrast

A therapeutic ocular inlay for treatment of one or more vision defects including a locator structure or depth marker to facilitate location of the inlay post-implant. The locator structure or marker extends at least partially outside a pupil region. The depth or layer at which the inlay is implanted can be determined by locating the depth marker without requiring incisions with the pupil region. The locator structure can be substantially invisible under casual observation, however can be provided with enhanced optical contrast characteristics under selected viewing conditions. The locator is thus unobtrusive, however can be readily located in a clinical setting, for example with artificial UV illumination. The locator can be connected to, e.g., integrally formed with, the inlay or may be a separate component provided in combination with the inlay.

Owner:ACUFOCUS

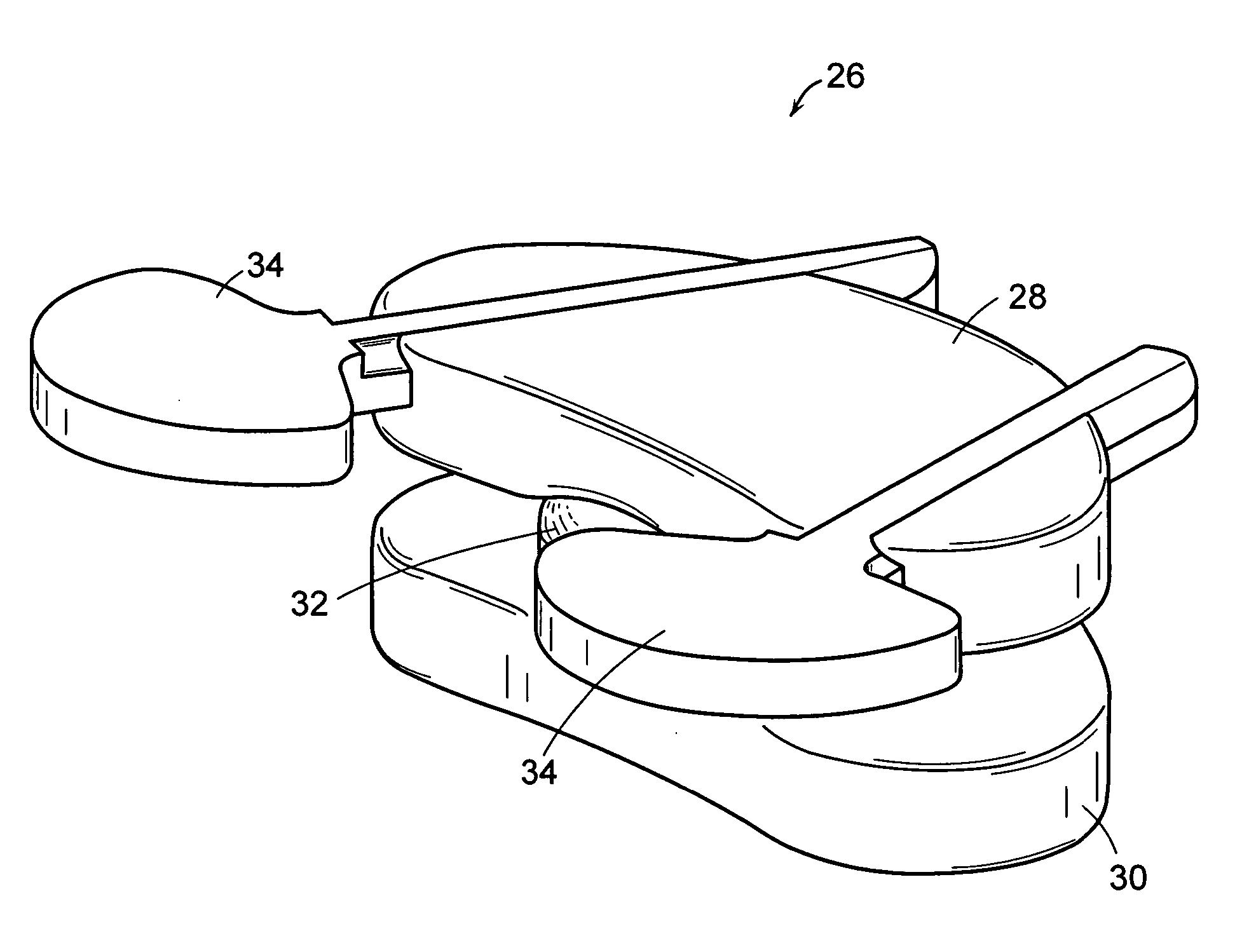

Intervertebral prosthetic disc

ActiveUS20060178745A1Increase surface areaAdd supportBone implantSpinal implantsLamina terminalisIntervertebral space

The present invention includes intervertebral prosthetic devices and methods for installing intervertebral prosthetic devices into an intervertebral space. In one embodiment, an intervertebral prosthetic disc includes a superior endplate; an inferior endplate; and at least one protrusion element, wherein at least one of the superior endplate and the inferior endplate is adapted to receive the protrusion element. In another embodiment, the invention includes an intervertebral prosthetic disc having a superior endplate including a core retaining member; an inferior endplate including a core retaining member; and an asymmetric core positioned between the superior endplate and the inferior endplate, wherein the superior endplate and the inferior endplate are adapted to accommodate the core. The present invention also includes an intervertebral prosthetic disc system that includes an intervertebral prosthetic disc and at least one spring element.

Owner:DEPUY SYNTHES PROD INC

System, method and devices for navigated flexible endoscopy

The invention provides a method and system for performing an image-guided endoscopic medical procedure. The invention may include registering image-space coordinates of a path of a medical instrument within the anatomy of a patient to patient-space coordinates of the path of the medical instrument within the anatomy of the patient. In some embodiments, the image space coordinates of the path of the medical instrument may be predicted coordinates such as, for example, a calculated centerline through a conduit-like organ, or a calculated “most likely path” of the medical instrument within the anatomy of the patient. In other embodiments, the path of the medical instrument may be an actual path determined using intra-operative images of the patient's anatomy with the medical instrument inserted therein. The registered instrument may then be navigated to one or more items of interest for performance of the endoscopic medical procedure.

Owner:PHILIPS ELECTRONICS LTD

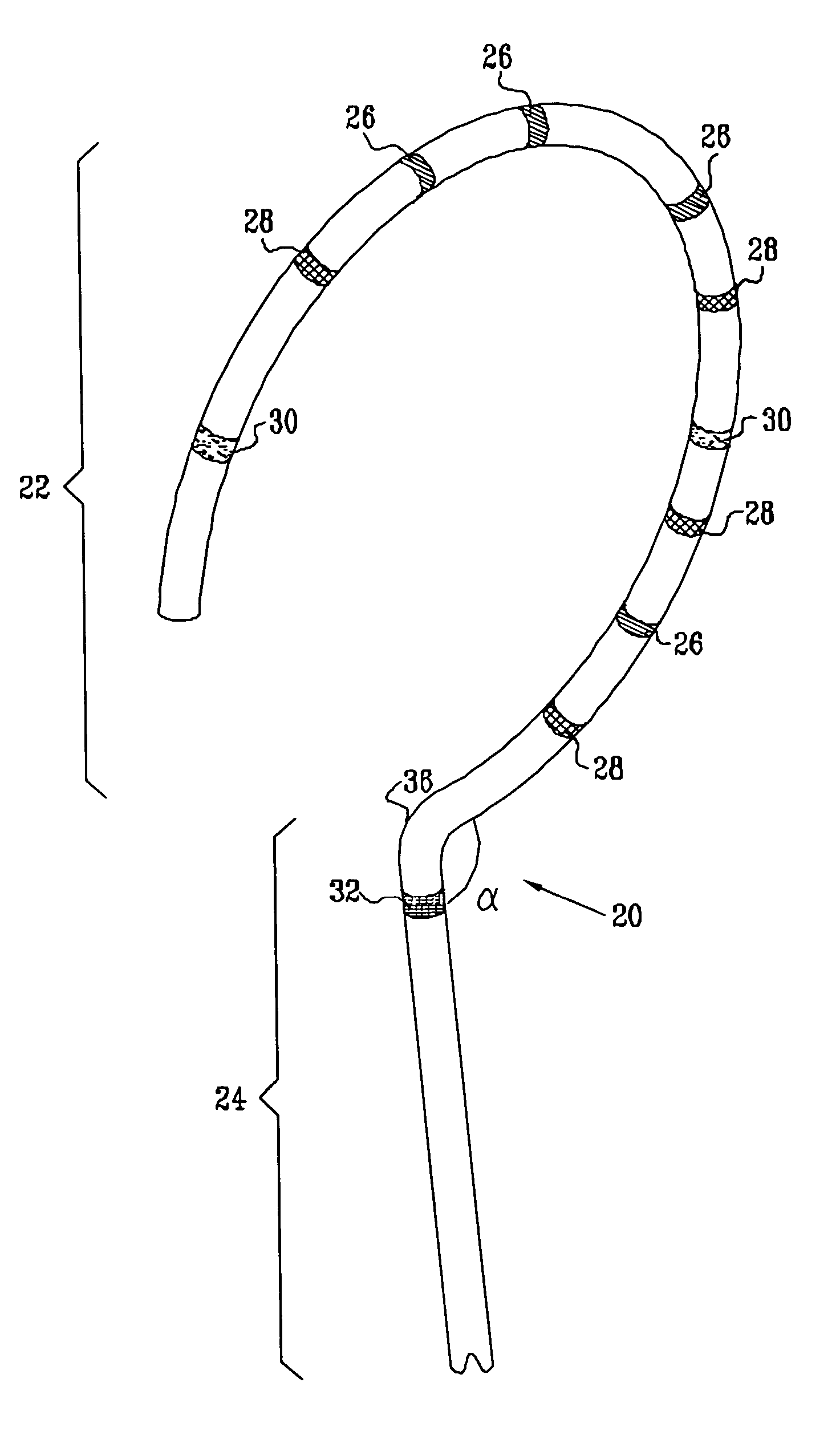

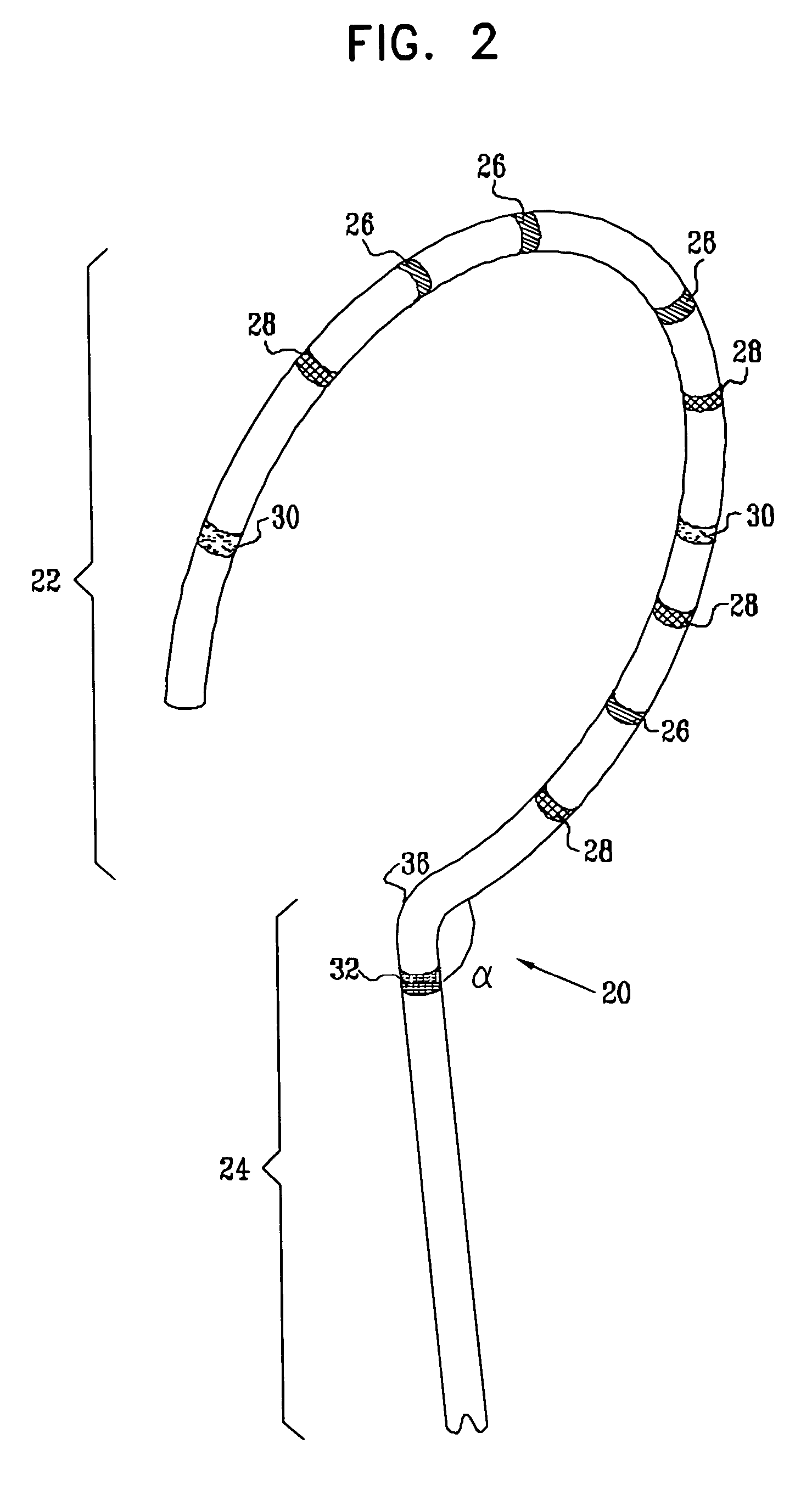

Lasso for pulmonary vein mapping and ablation

InactiveUS6973339B2Improve accuracyShorten the timeInternal electrodesDiagnostic recording/measuringVeinMedicine

Owner:BIOSENSE WEBSTER INC

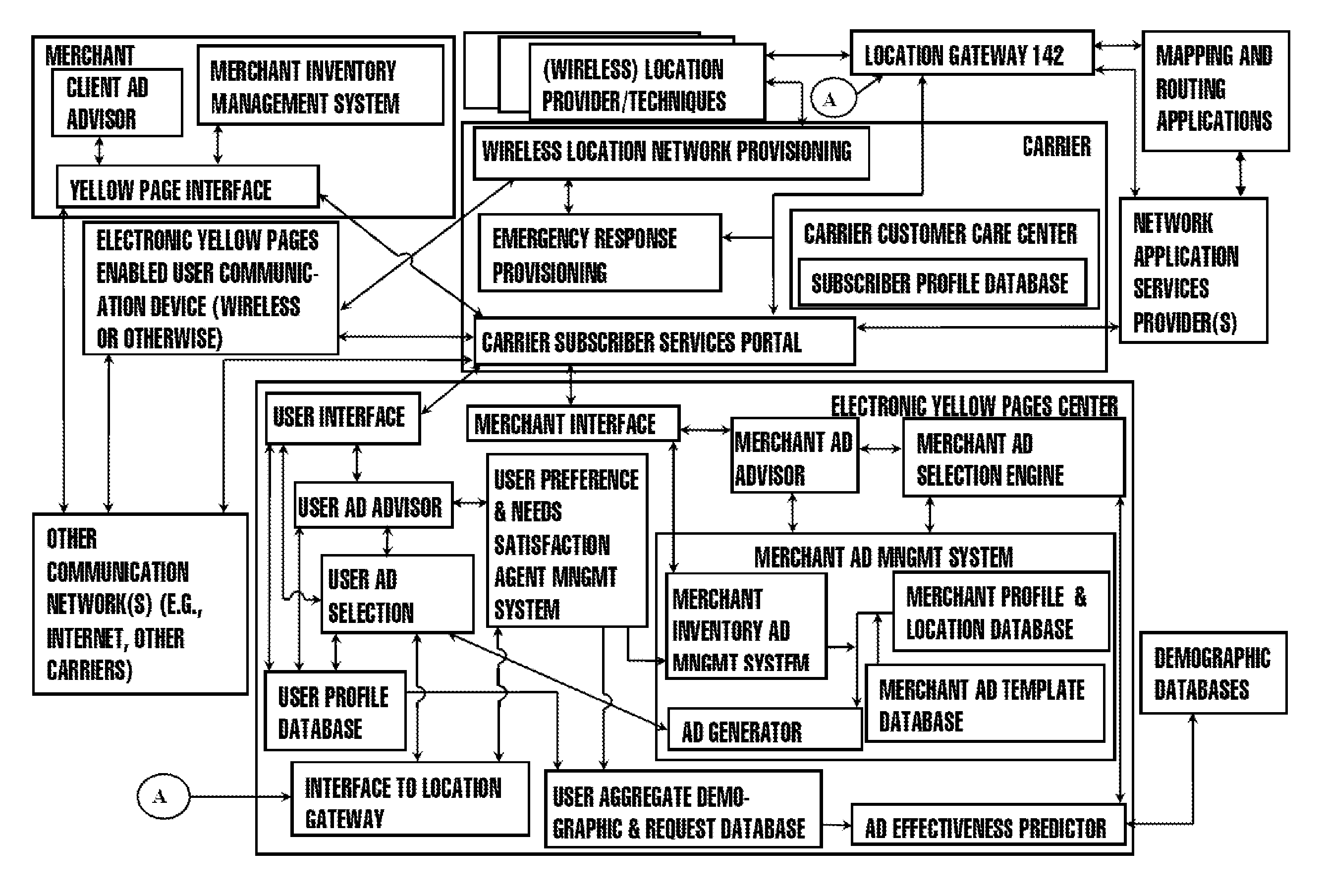

Wireless location routing applications and archectiture therefor

InactiveUS20060276201A1Accurate locationPosition fixationRadio/inductive link selection arrangementsInternet communicationCall tracing

A system for wirelessly locating mobile station / units (MS) and using resulting location determinations for providing a product or service is disclosed. The system is useful for routing an MS user to a plurality of desired locations, alerting an MS user to a nearby desired product or service based on satisfaction of user criteria, and providing enhanced security and 911 response. In one embodiment, the system responds to MS location requests via, e.g., Internet communication between a distributed network of location processing sites. A plurality of locating technologies including those based on: (1) TDOA; (2) pattern recognition; (3) timing advance; (5) GPS and network assisted GPS, (6) angle of arrival, (7) super resolution enhancements, and (8) supplemental information from low cost base stations can be activated, in various combinations, by system embodiments. MS location difficulties resulting from poor location accuracy / reliability and / or poor coverage are alleviated via such technologies in combination with automatically adapting and calibrating system performance according to environmental and geographical changes so that the system becomes progressively more comprehensive and accurate. Further, the system can be modularly configured for use in location signaling environments ranging from urban, dense urban, suburban, rural, mountain to low traffic or isolated roadways. Accordingly, the system is useful for 911 emergency calls, tracking, routing, people and animal location including applications for confinement to and exclusion from certain areas.

Owner:MOBILE MAVEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com