Patents

Literature

38results about How to "For accurate placement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

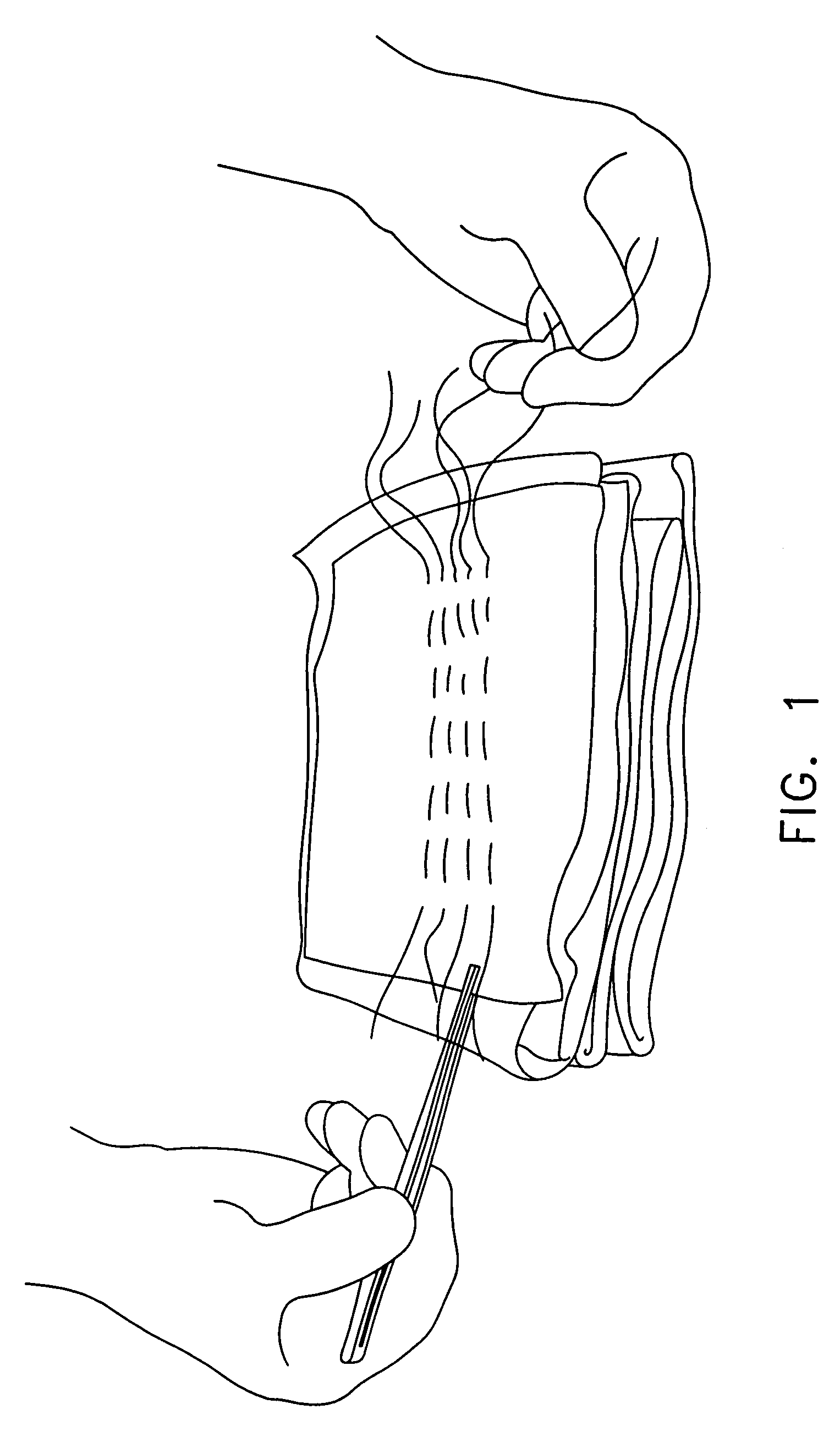

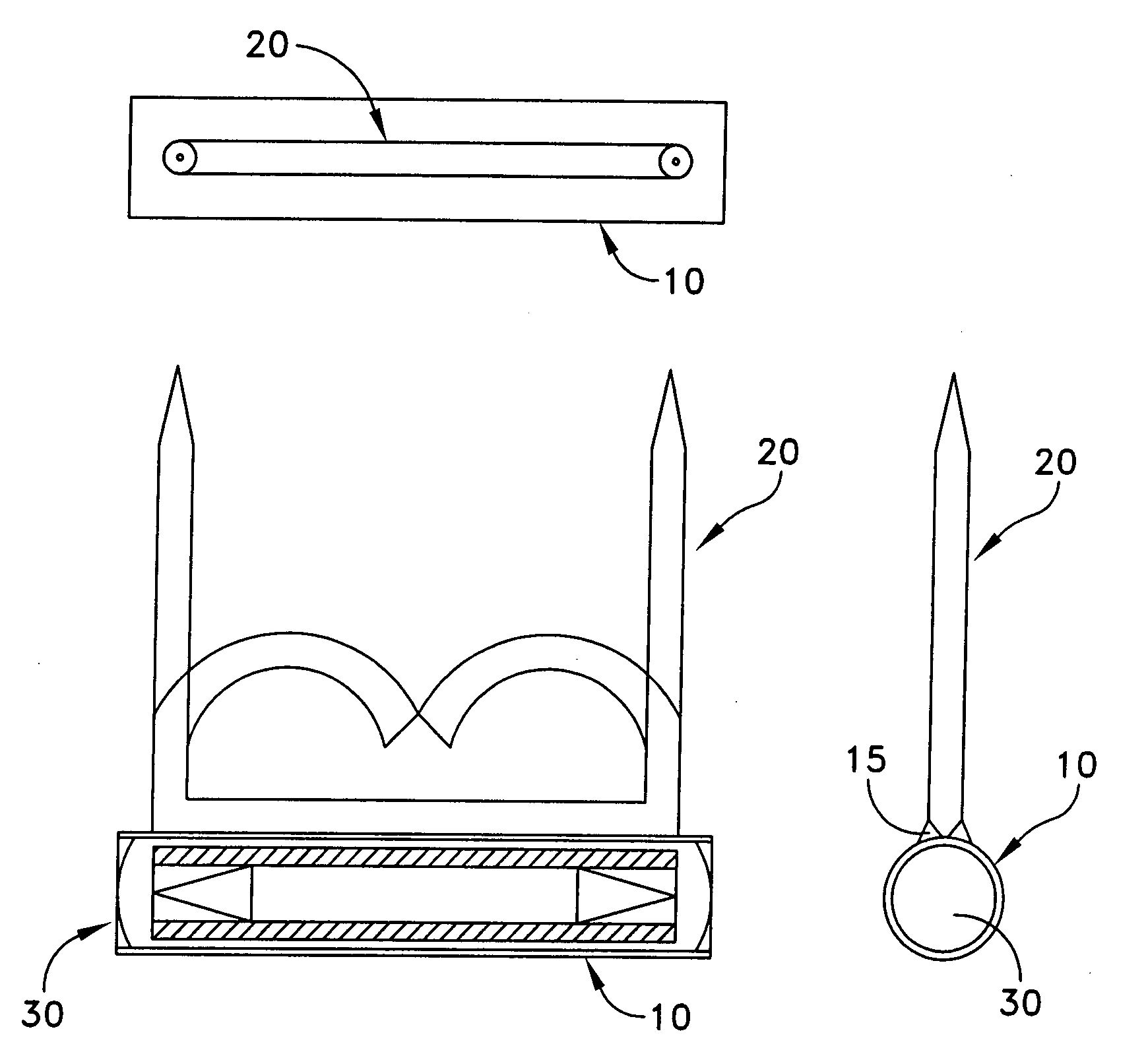

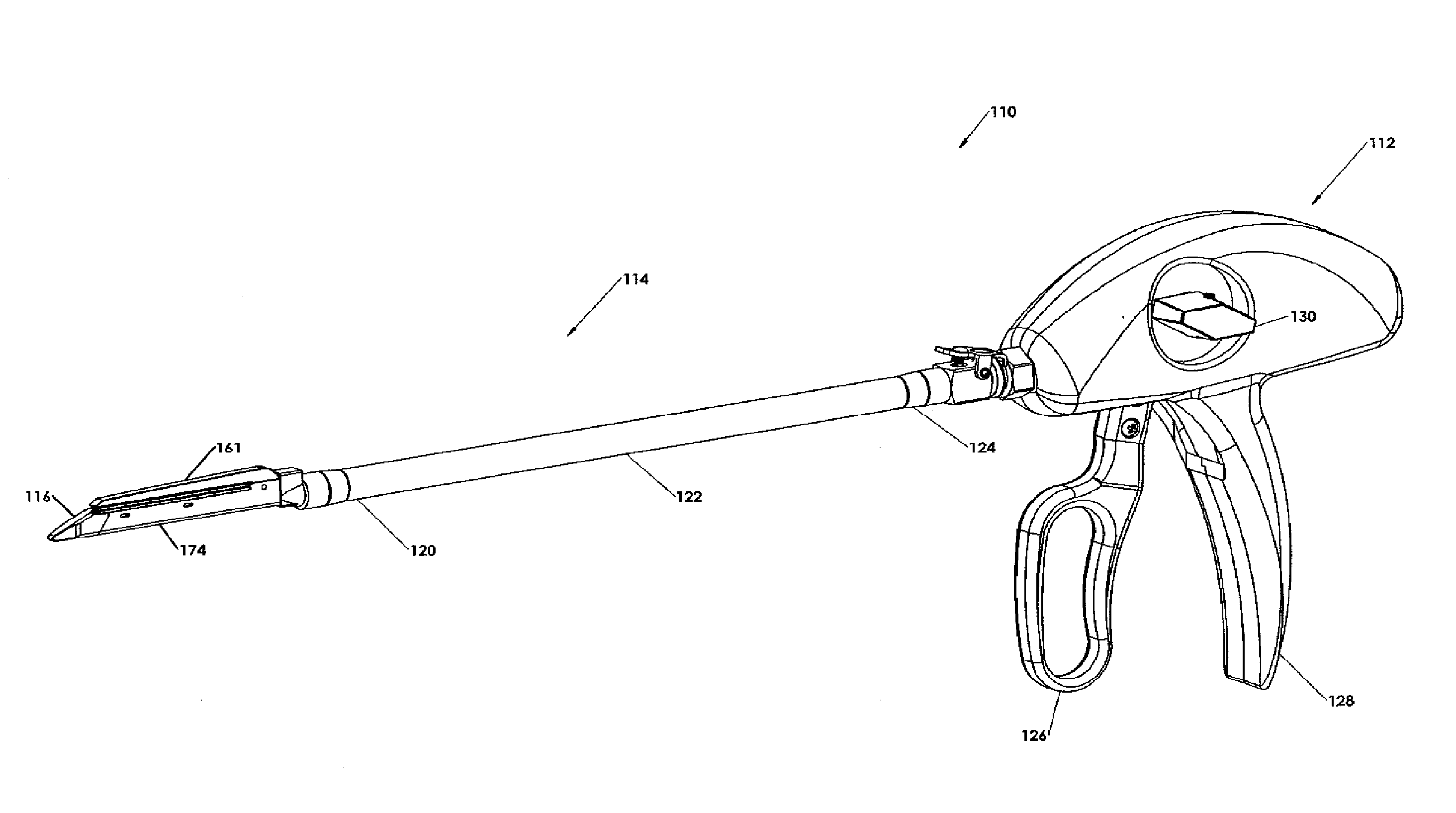

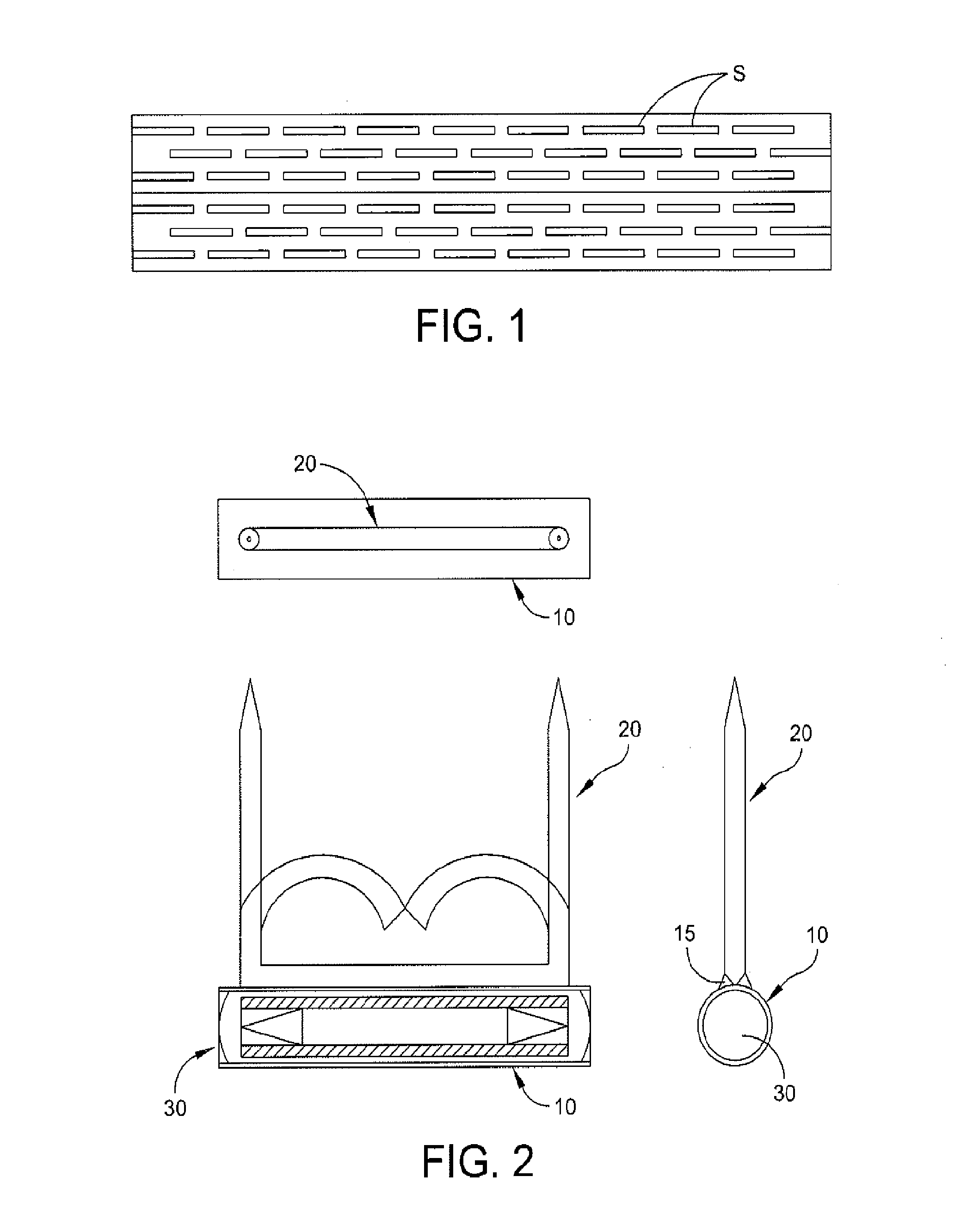

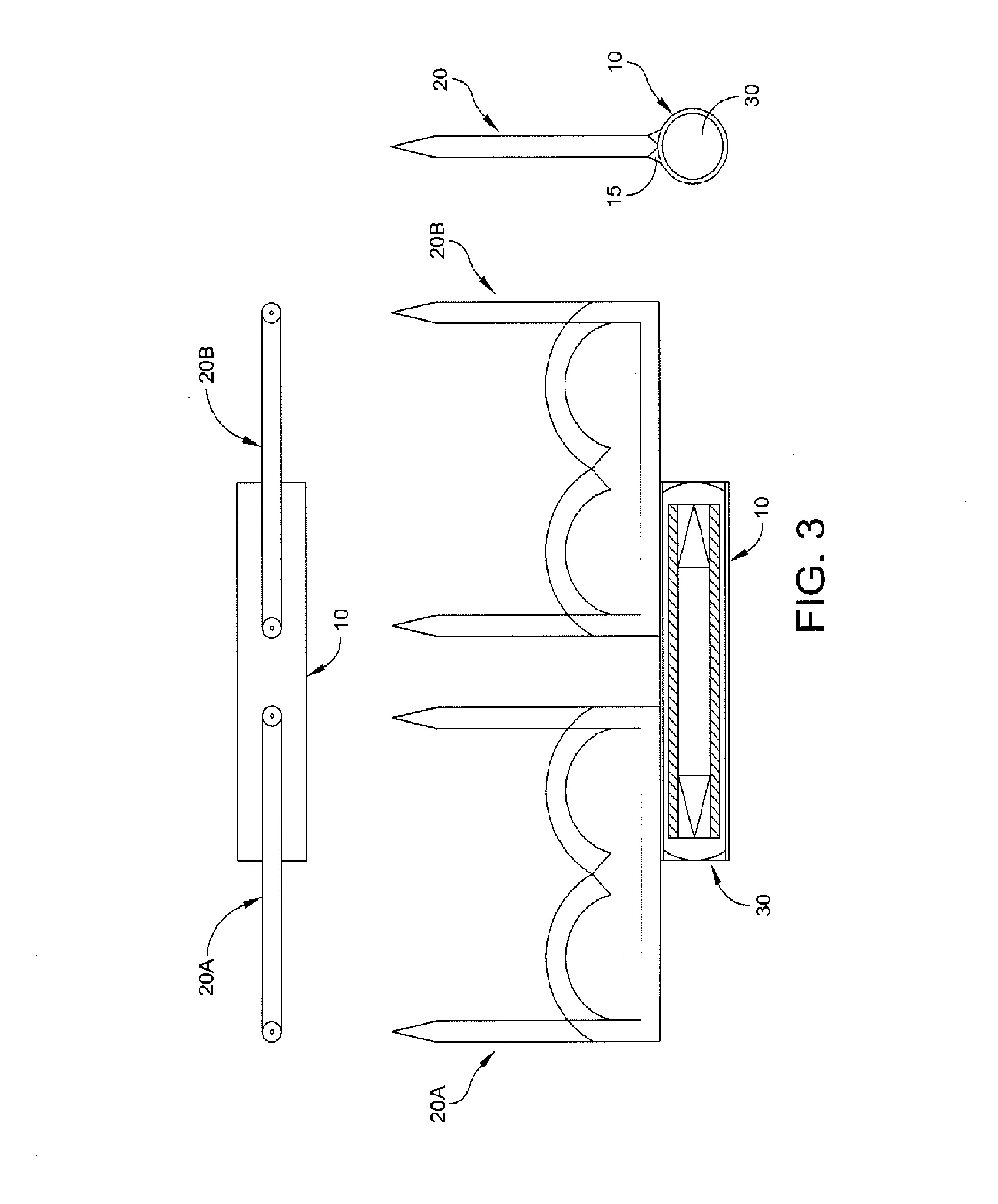

Radioactive therapeutic fastening instrument

ActiveUS8267849B2For accurate placementReduce doseSuture equipmentsStapling toolsBrachytherapyEngineering

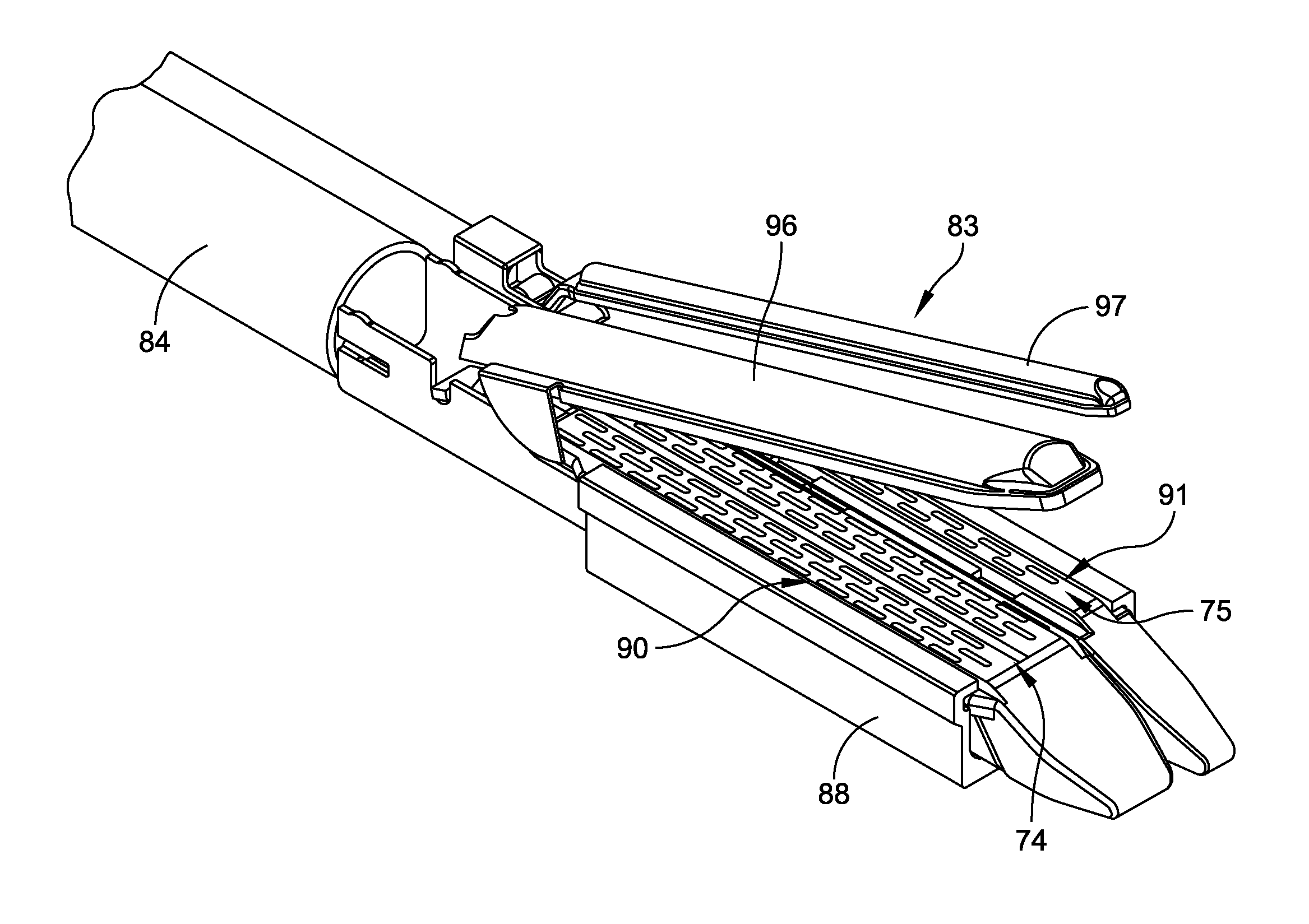

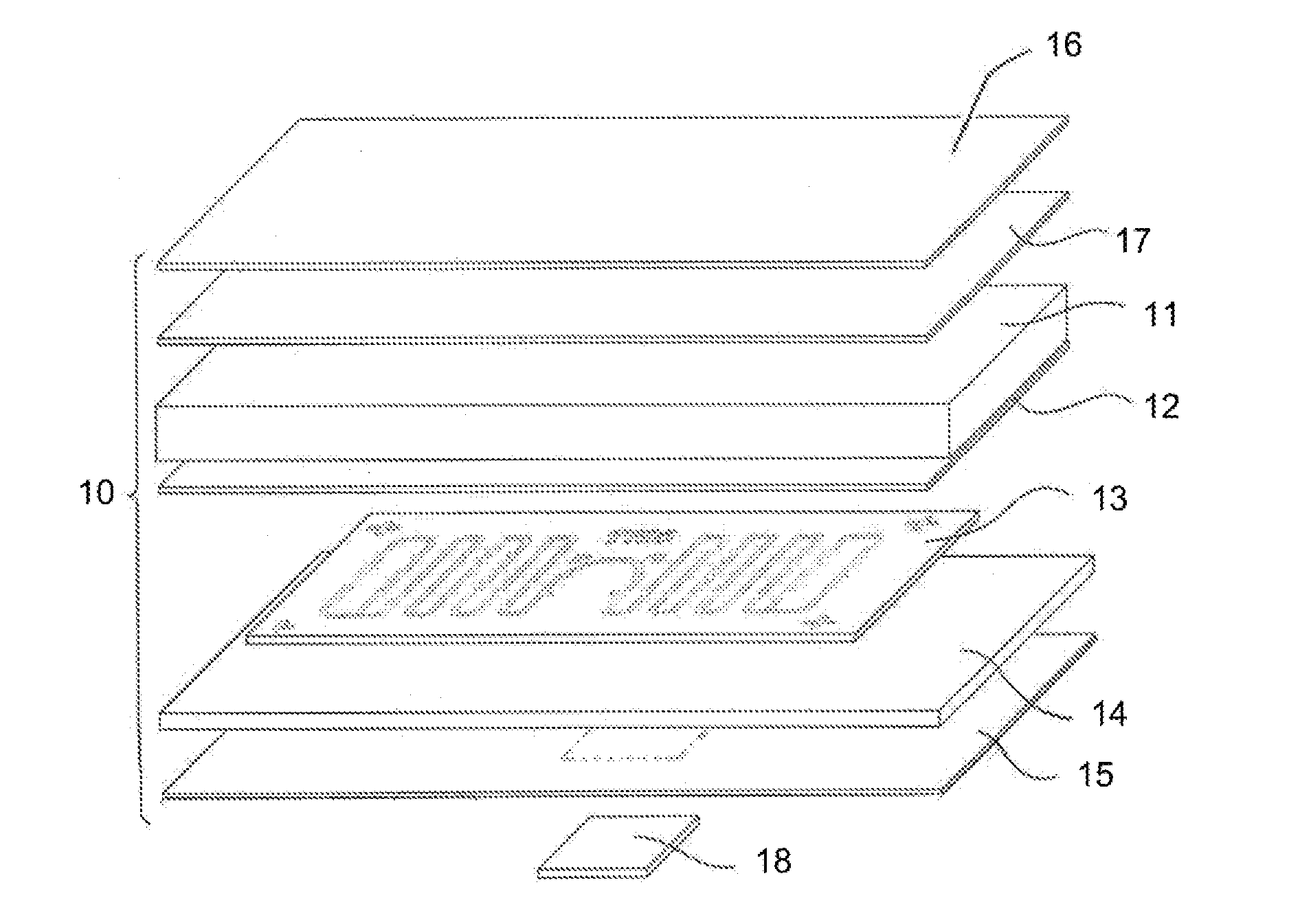

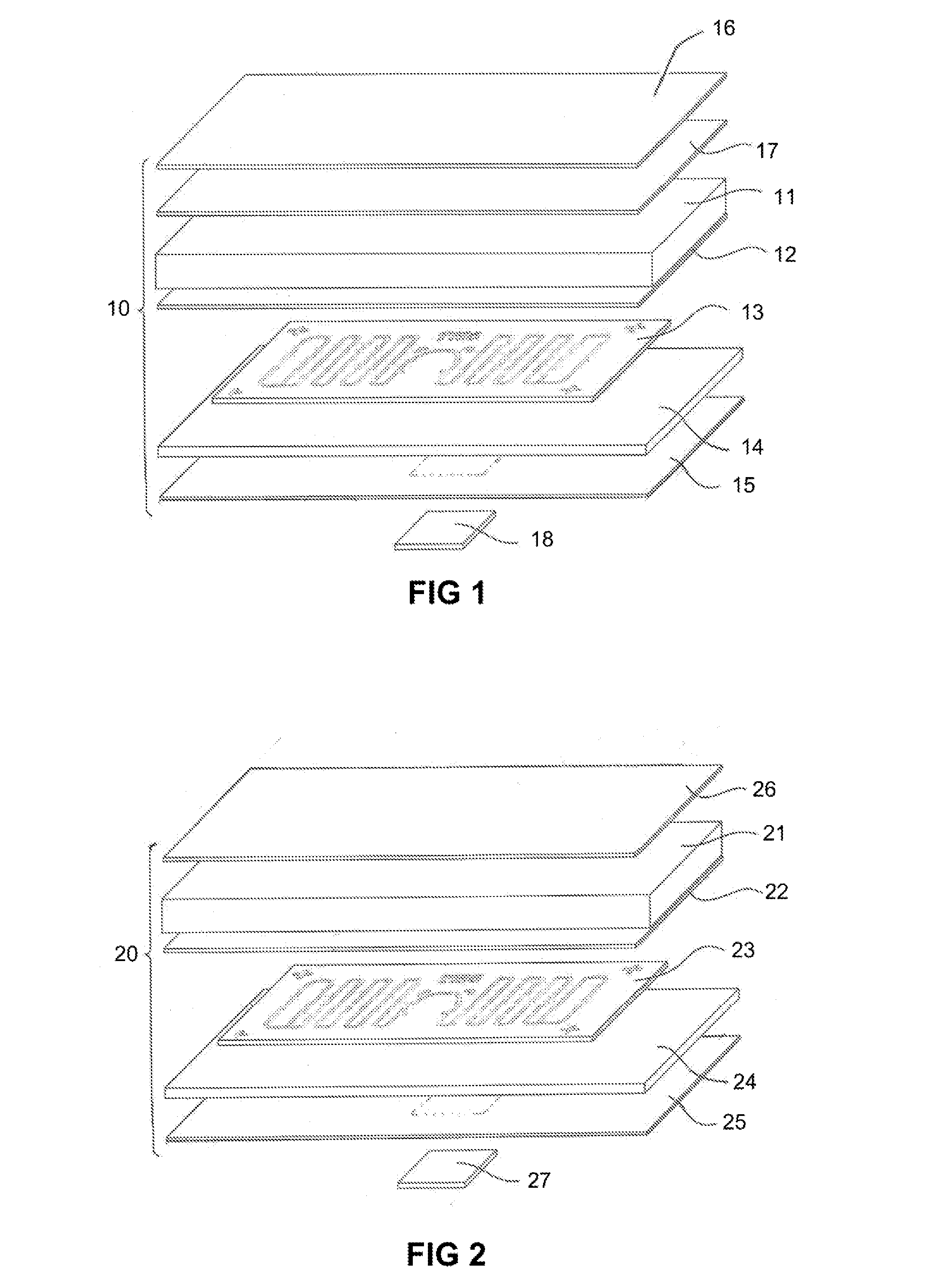

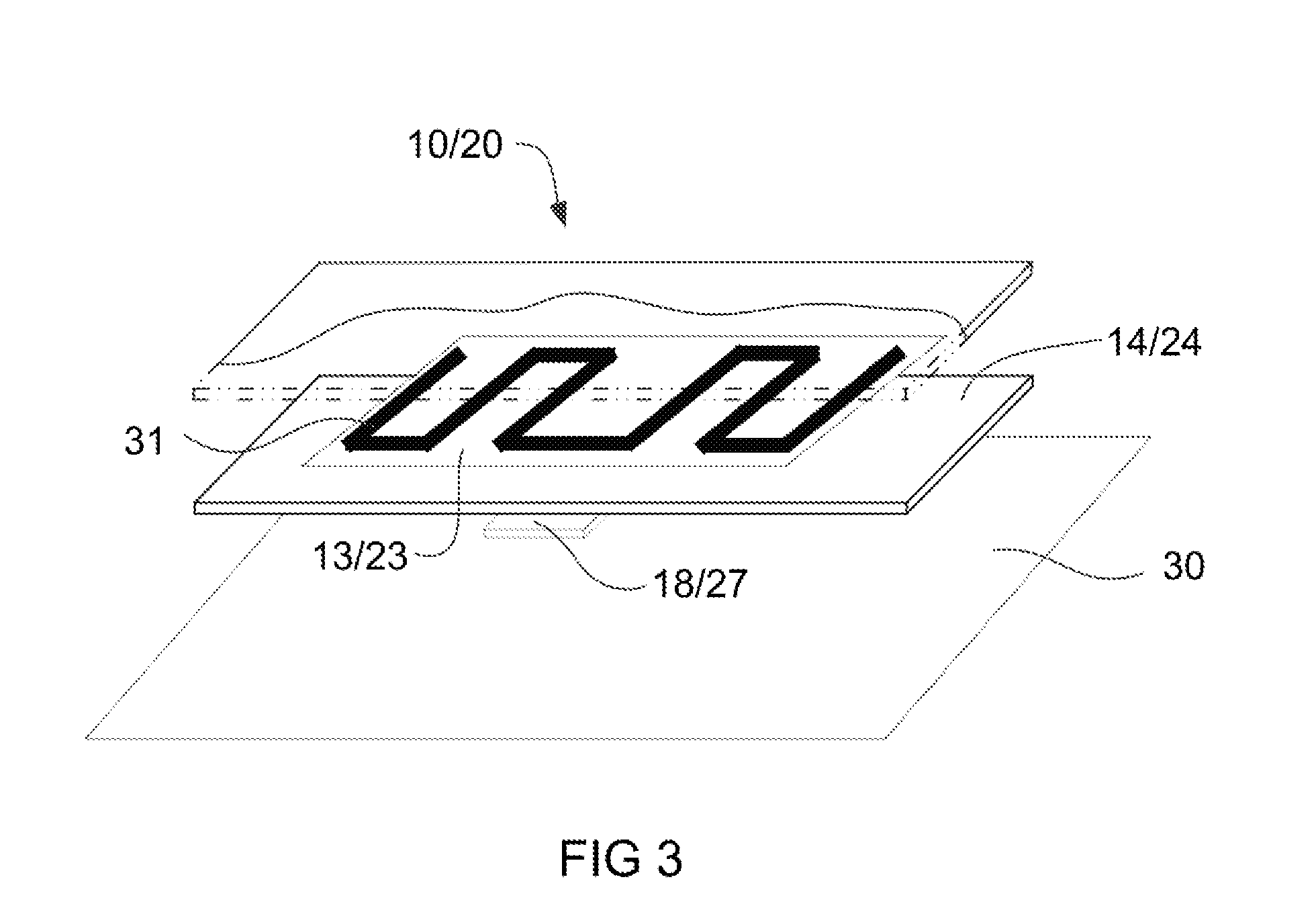

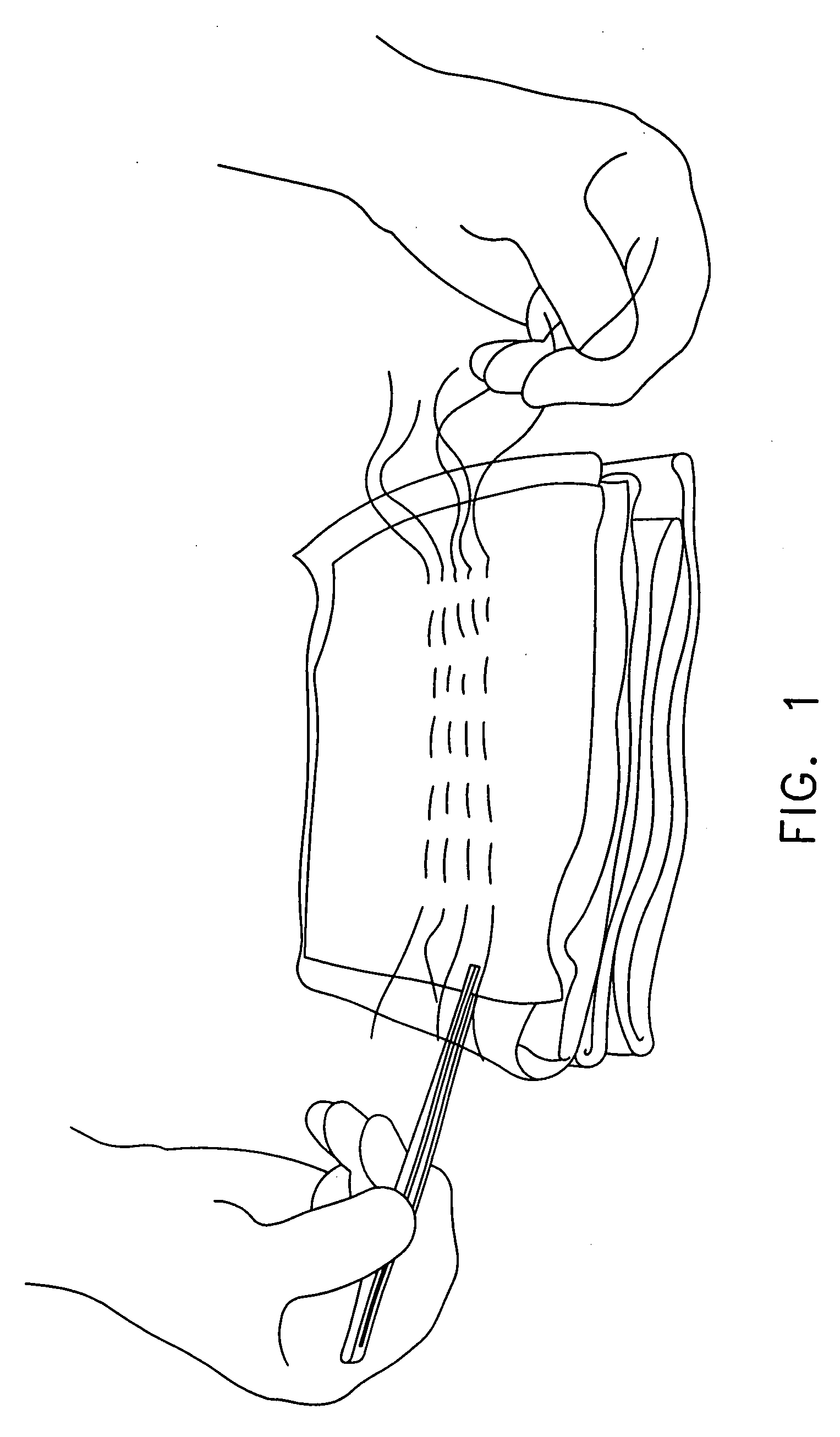

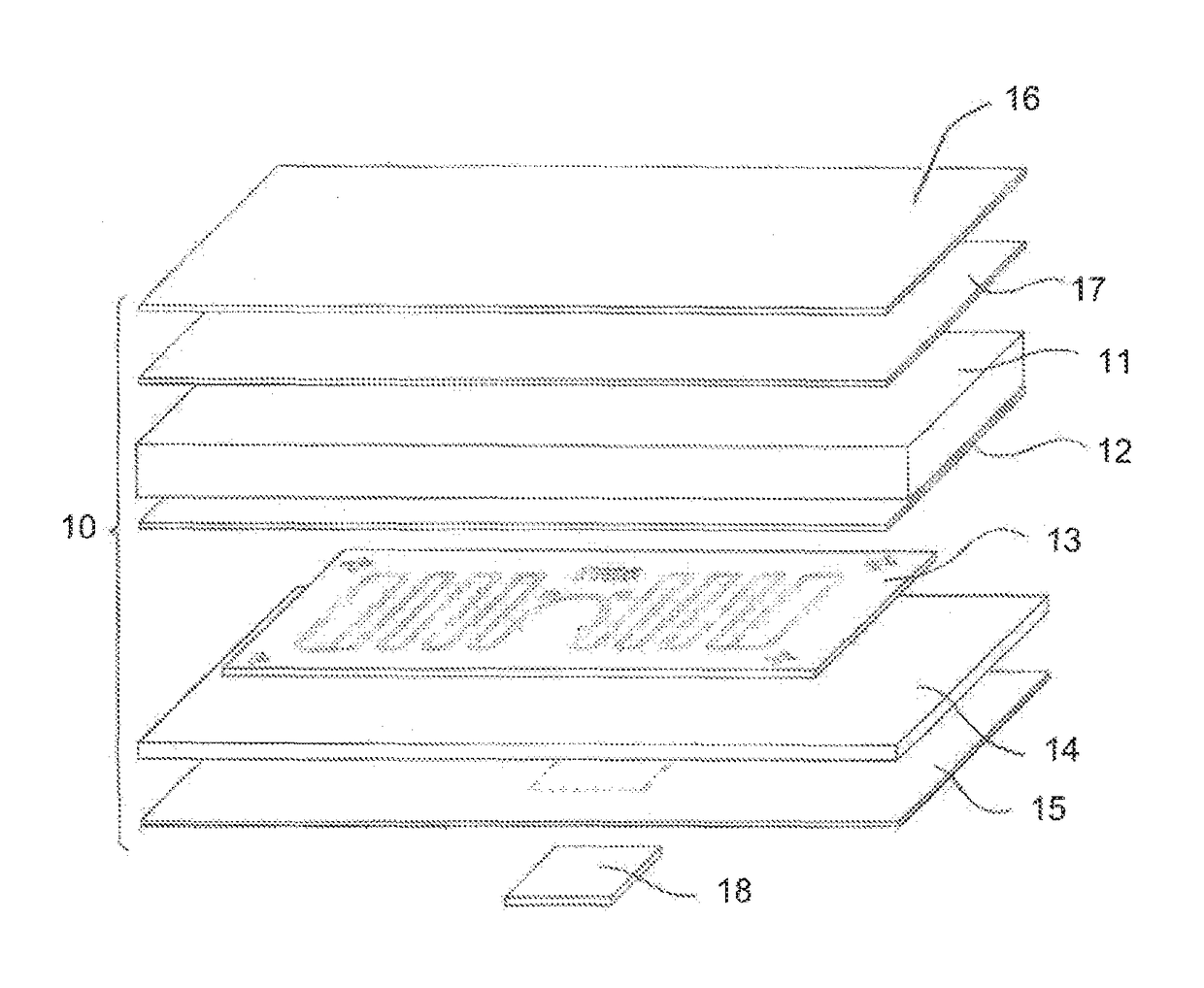

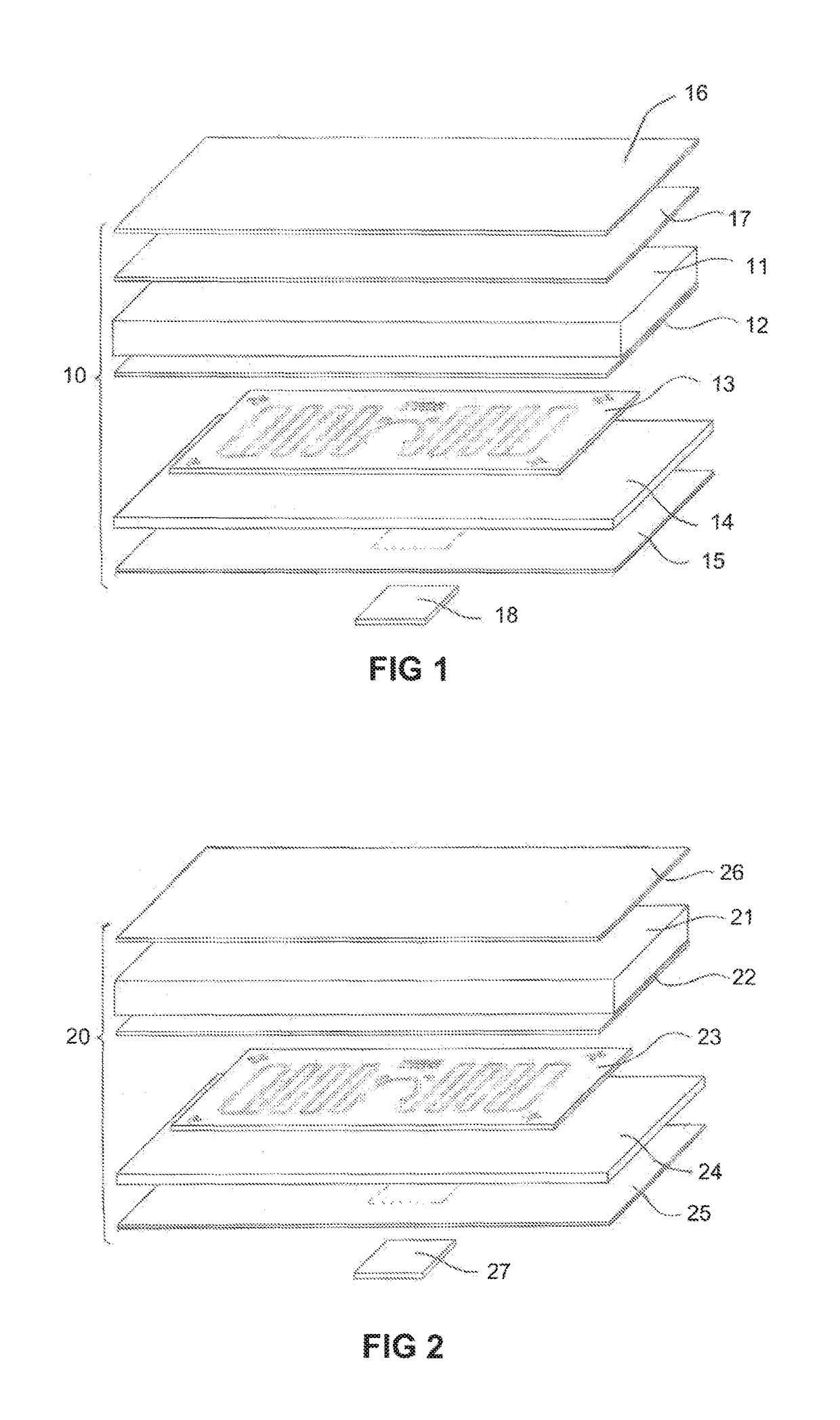

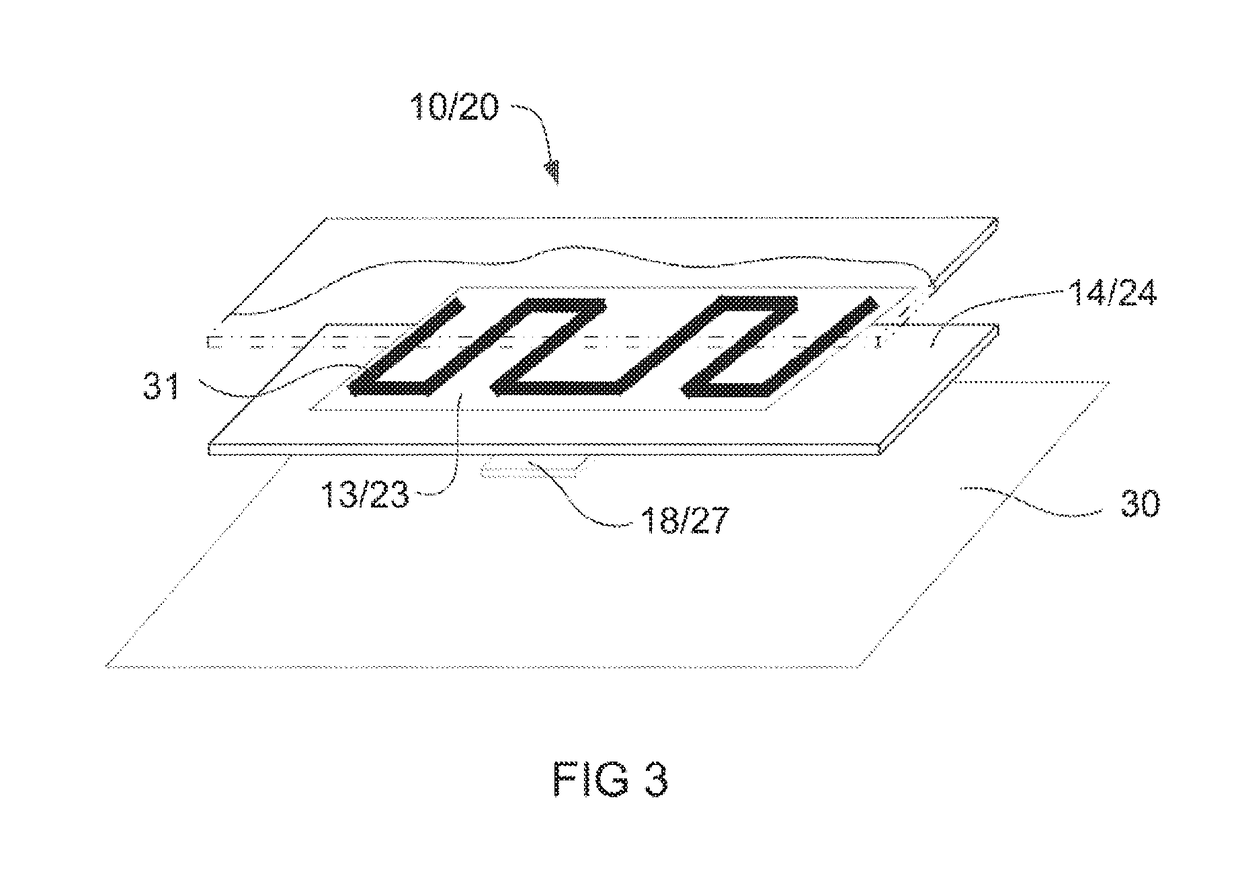

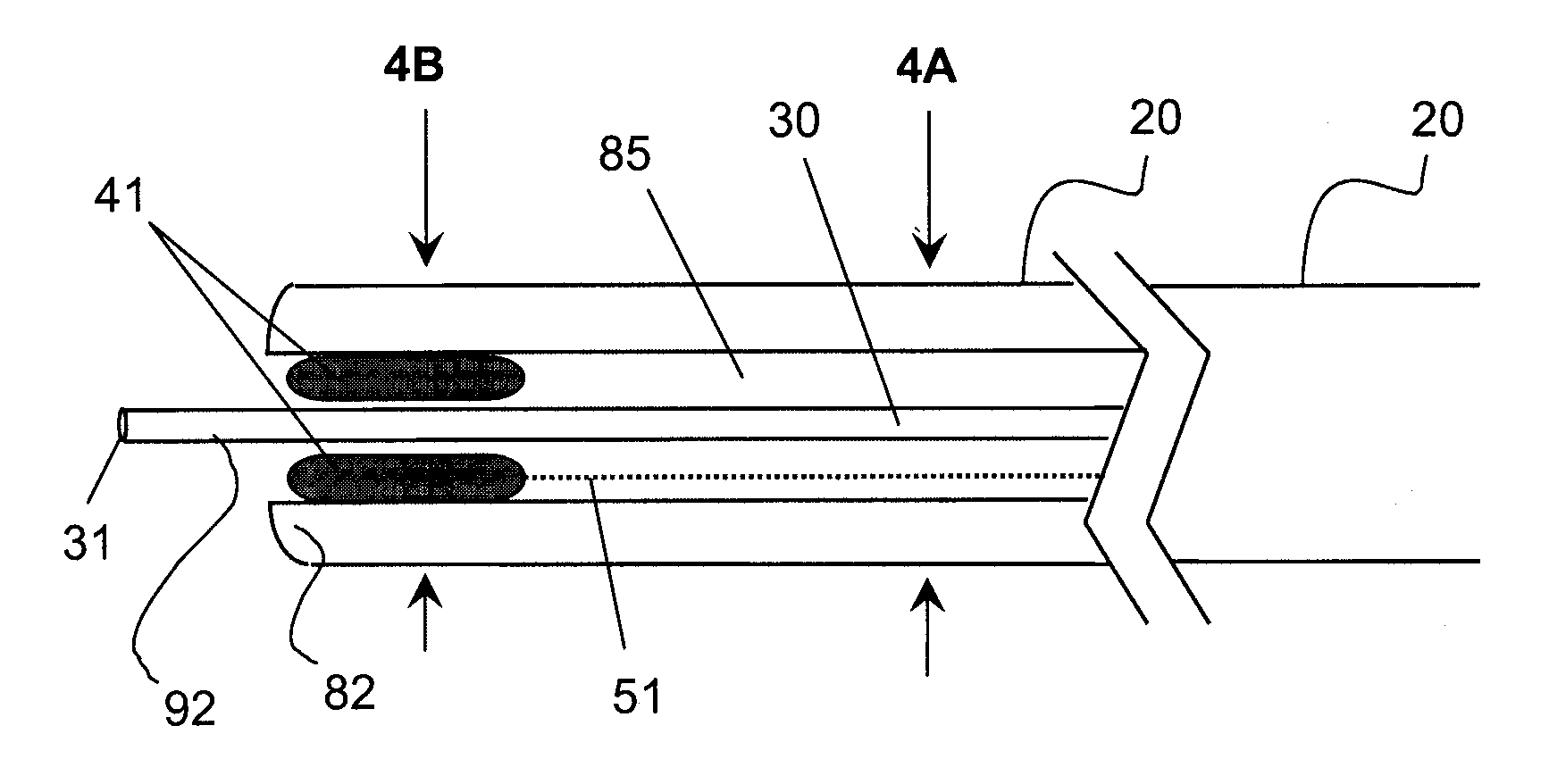

An instrument used for brachytherapy delivery in the treatment of cancer by radiation therapy including a handle having first and second handle actuators; an end effector; and an instrument shaft that connects the handle with the end effector. The end effector has first and second adjacent disposed staple mechanisms that each retain a set of staples. The first mechanism is for holding standard staples in a first array, and dispensing the standard staples under control of the corresponding first handle actuator. The second mechanism is for holding radioactive source staples in a second array, and dispensing said radioactive source staples under control of the corresponding second handle actuator. A holder is for receiving the first and second mechanisms in a substantially parallel array so that the standard staples close the incision at a surgical margin while the source staples are secured adjacent thereto.

Owner:POINT SOURCE TECH

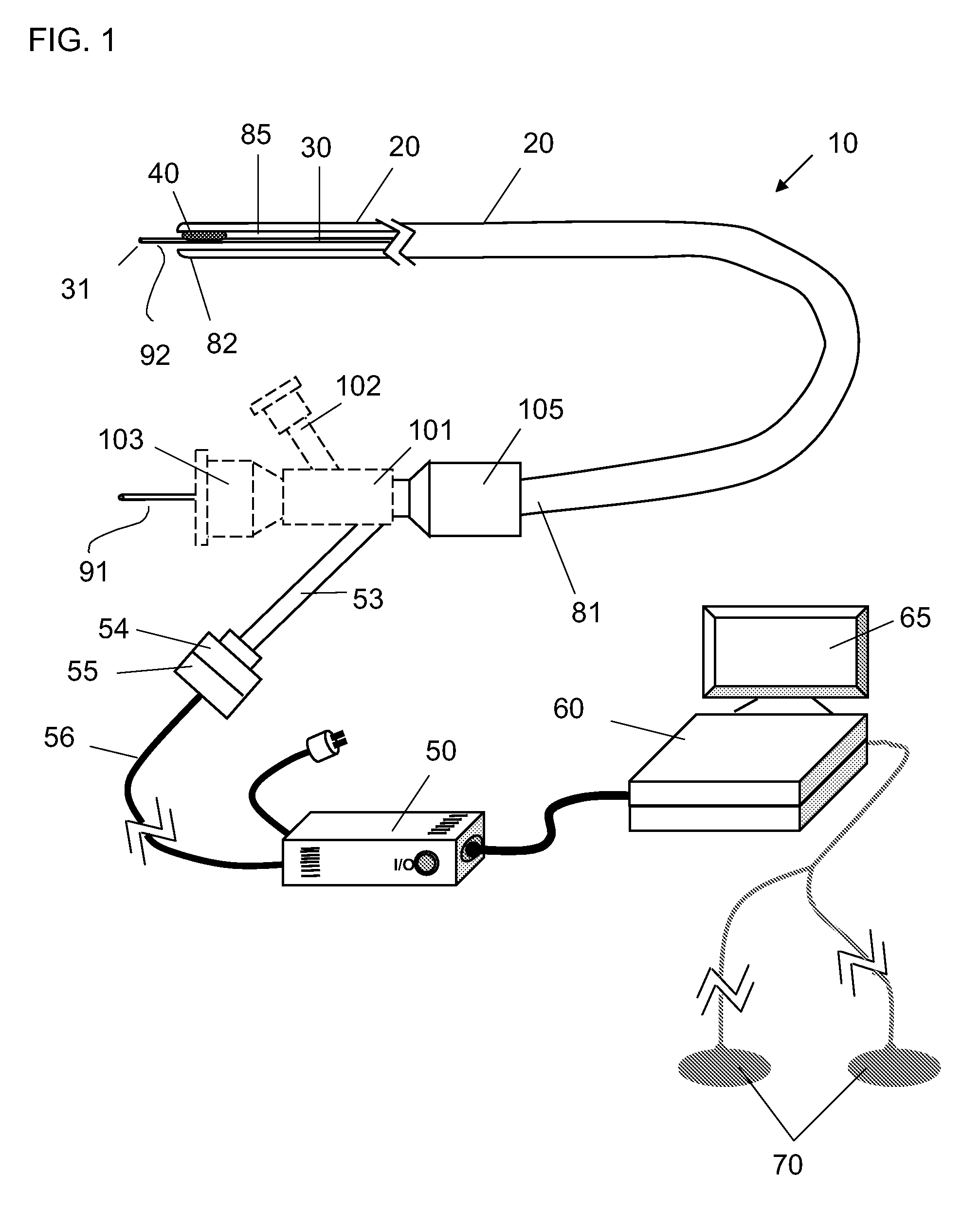

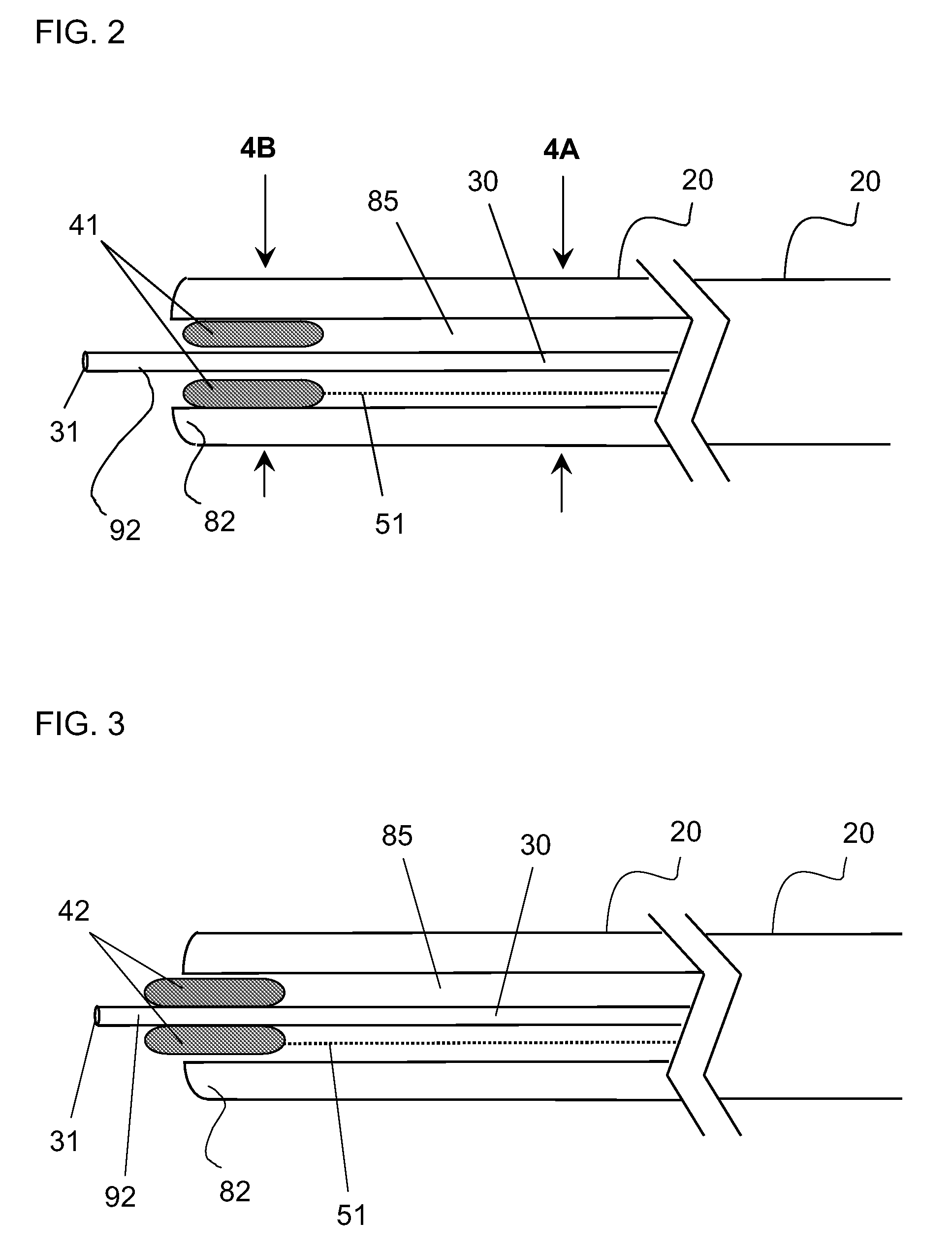

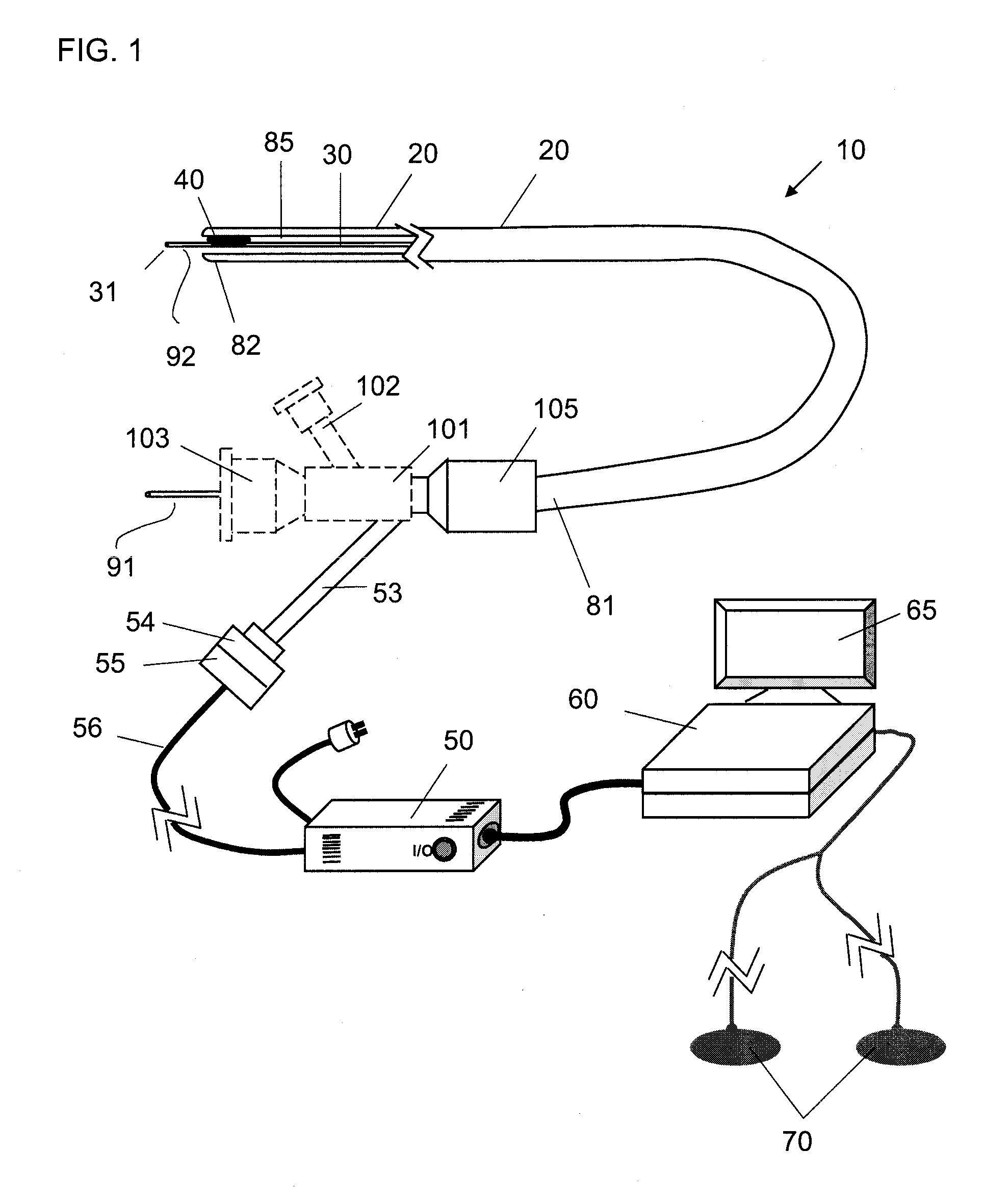

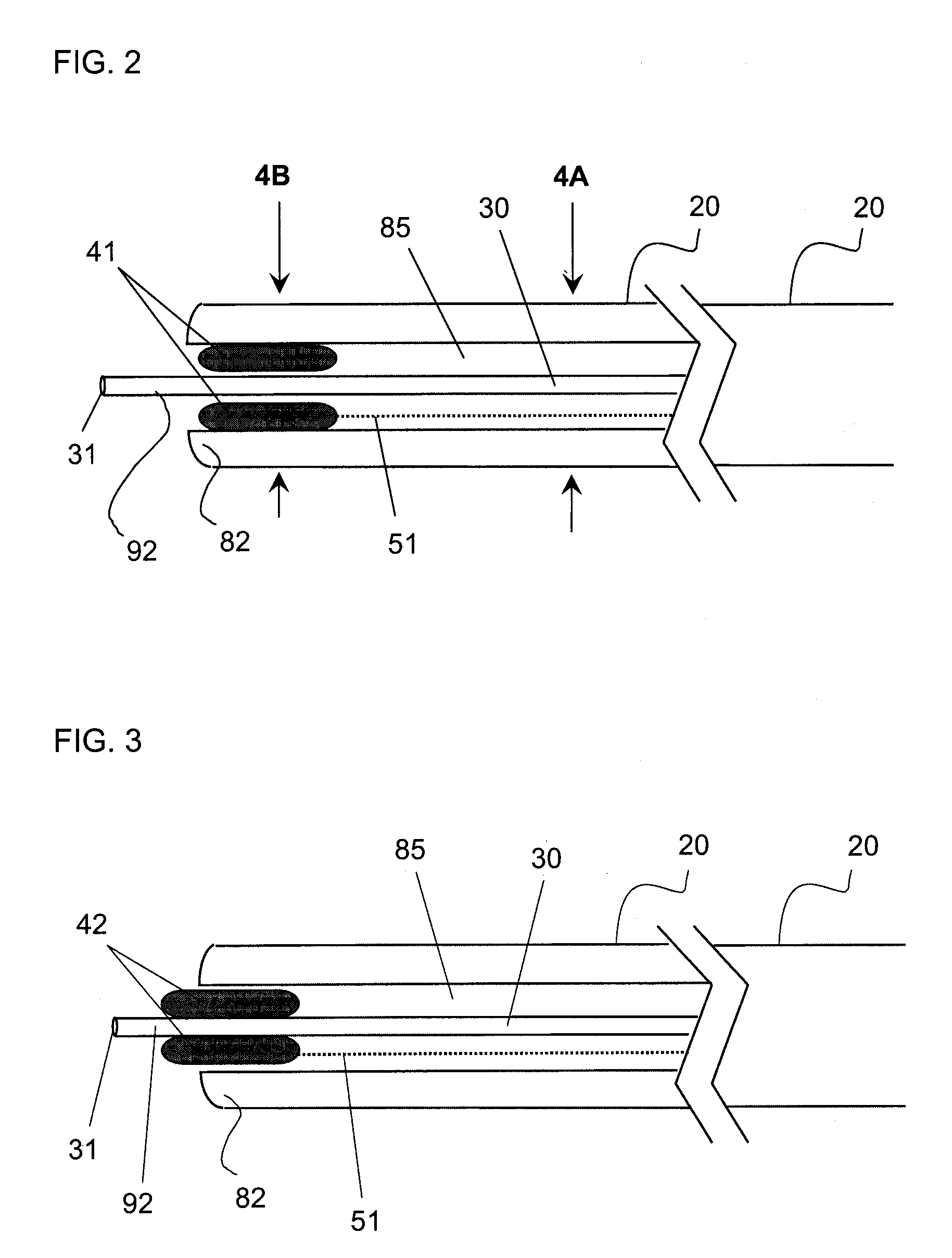

Apparatus and Method for Guided Chronic Total Occlusion Penetration

InactiveUS20080294037A1For accurate placementAvoids and reduces complicationUltrasonic/sonic/infrasonic diagnosticsSurgeryTotal occlusionIntravascular catheter

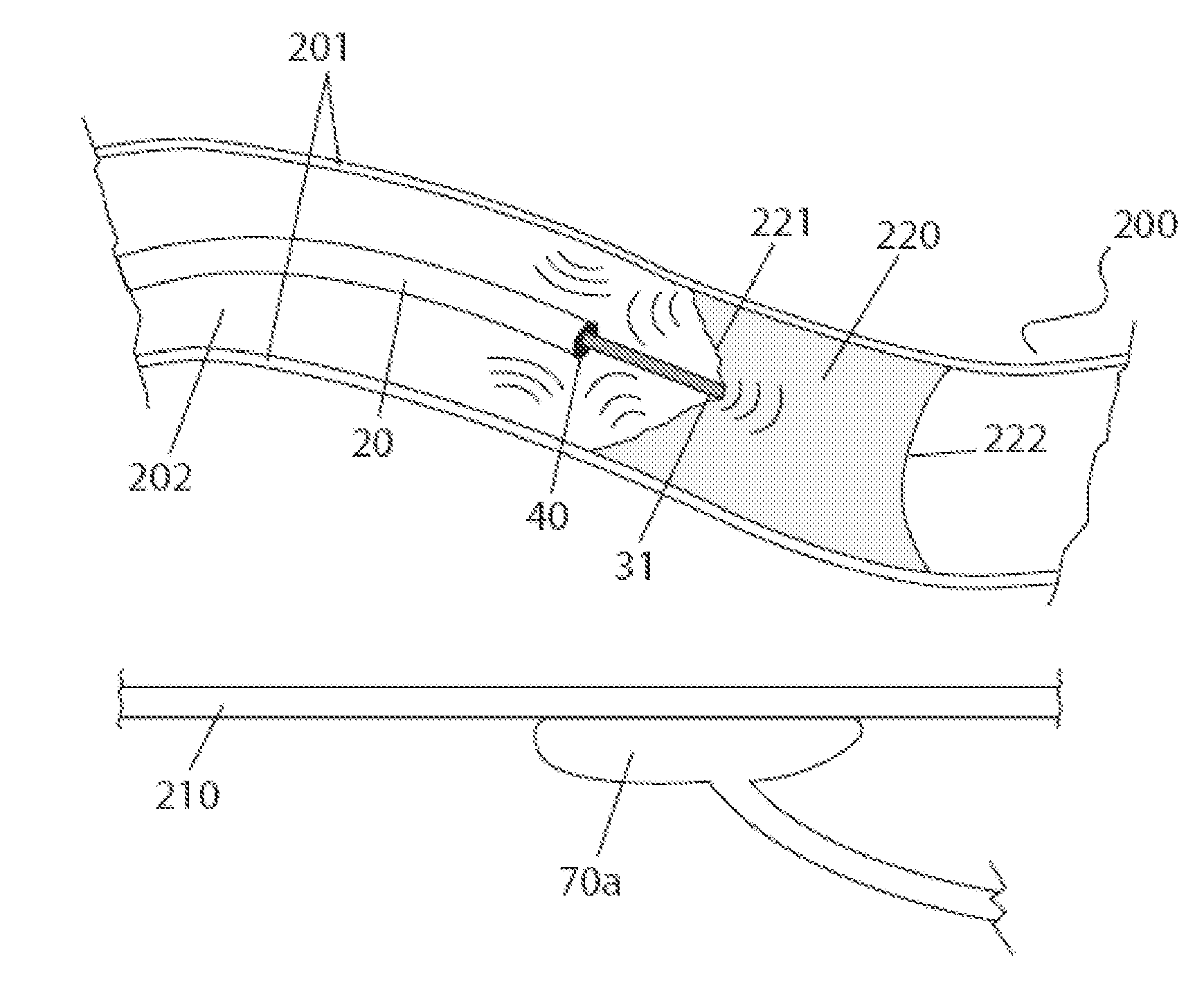

An apparatus and method for guided penetration of a chronic total occlusion in a blood vessel are disclosed. The invention is directed to an apparatus that facilitates accurate placement of a drilling tip within a body lumen using ultrasound-based detection to determine the position of the intravascular catheter relative to the vessel occlusion and vessel walls.

Owner:MEDINOL LTD

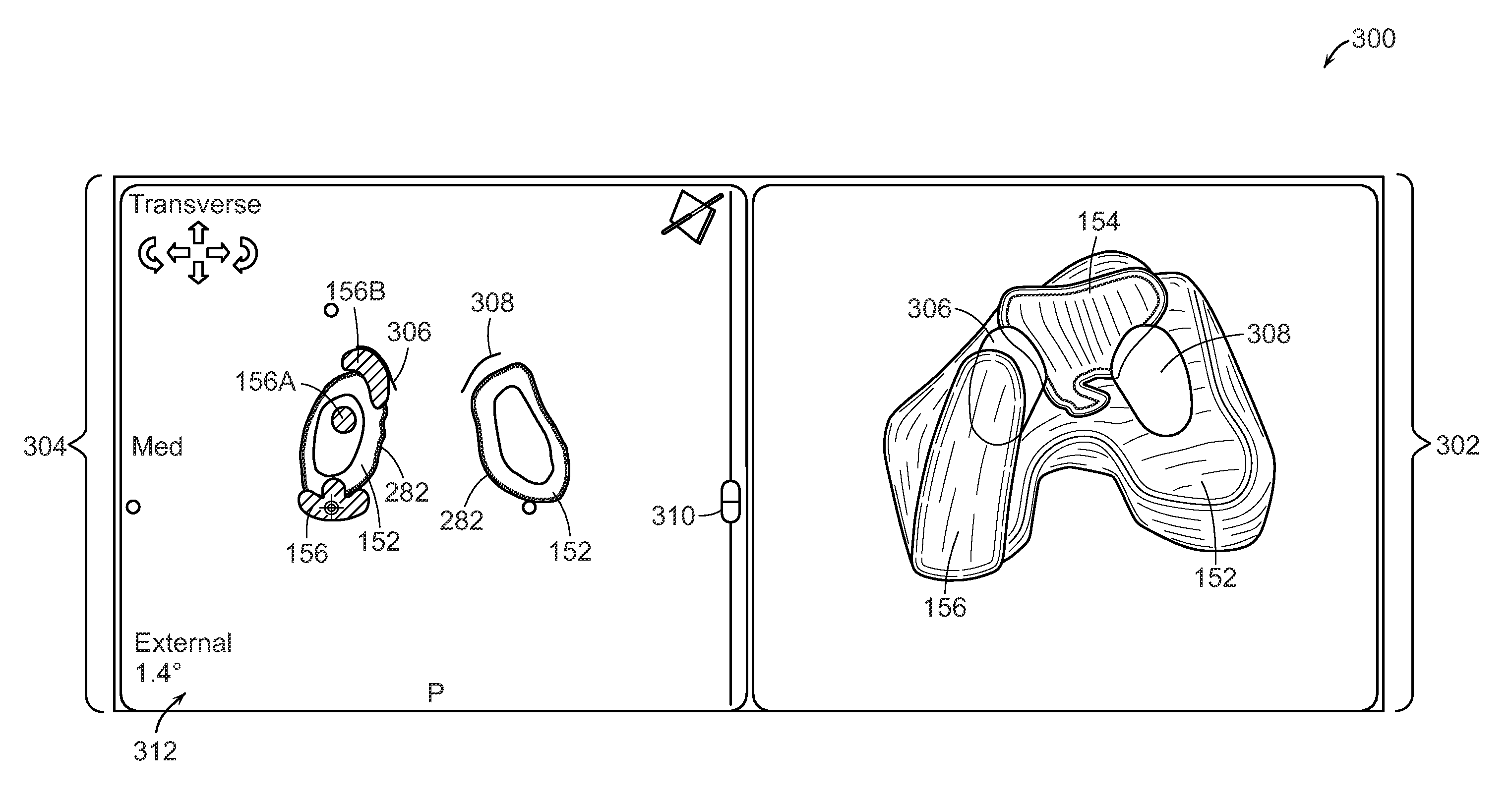

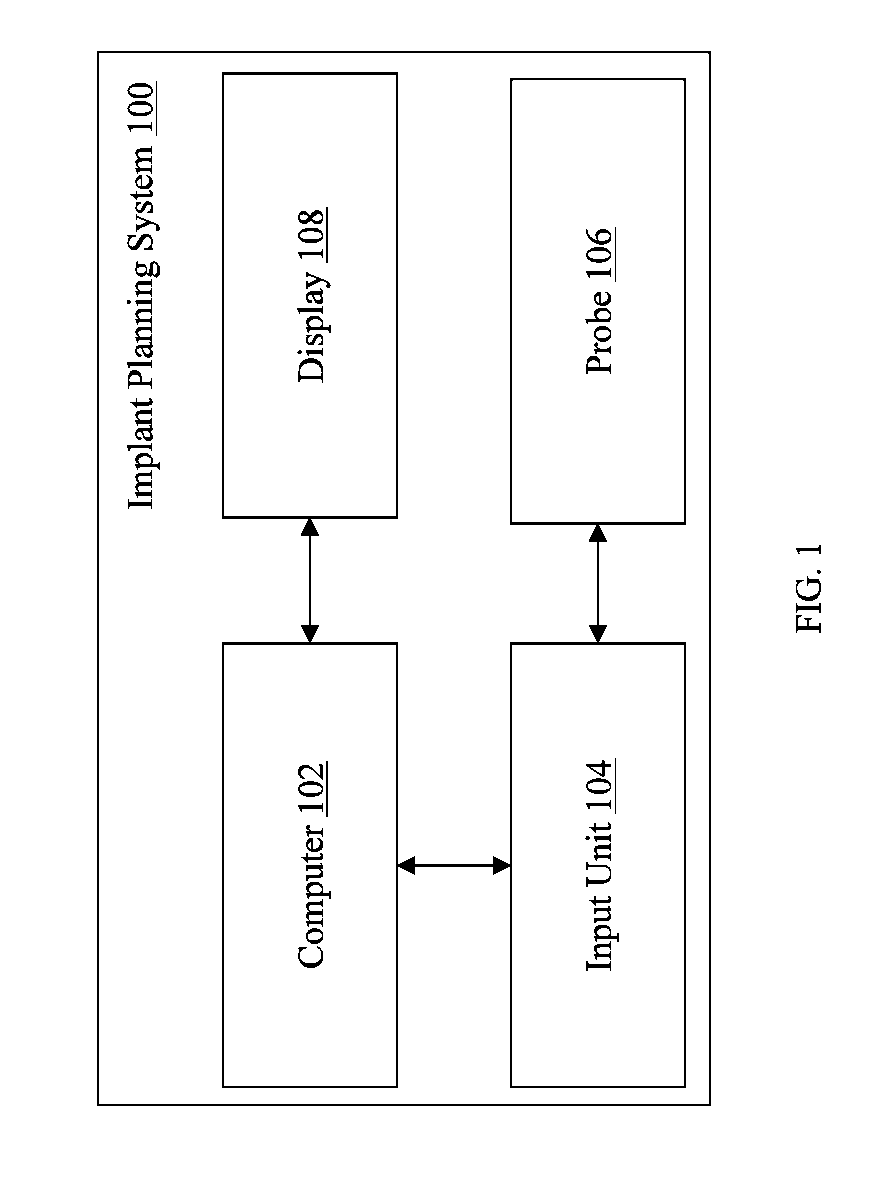

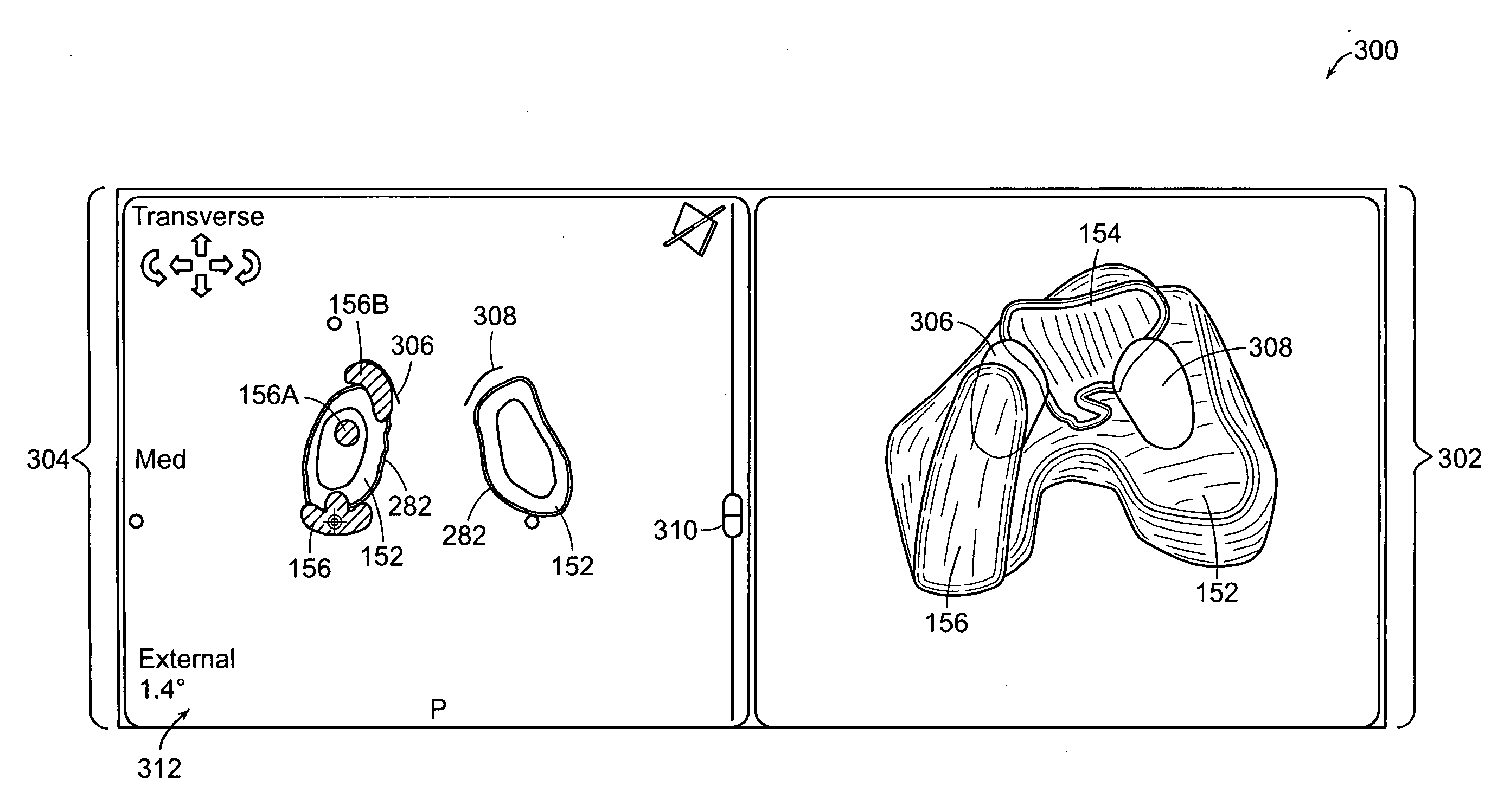

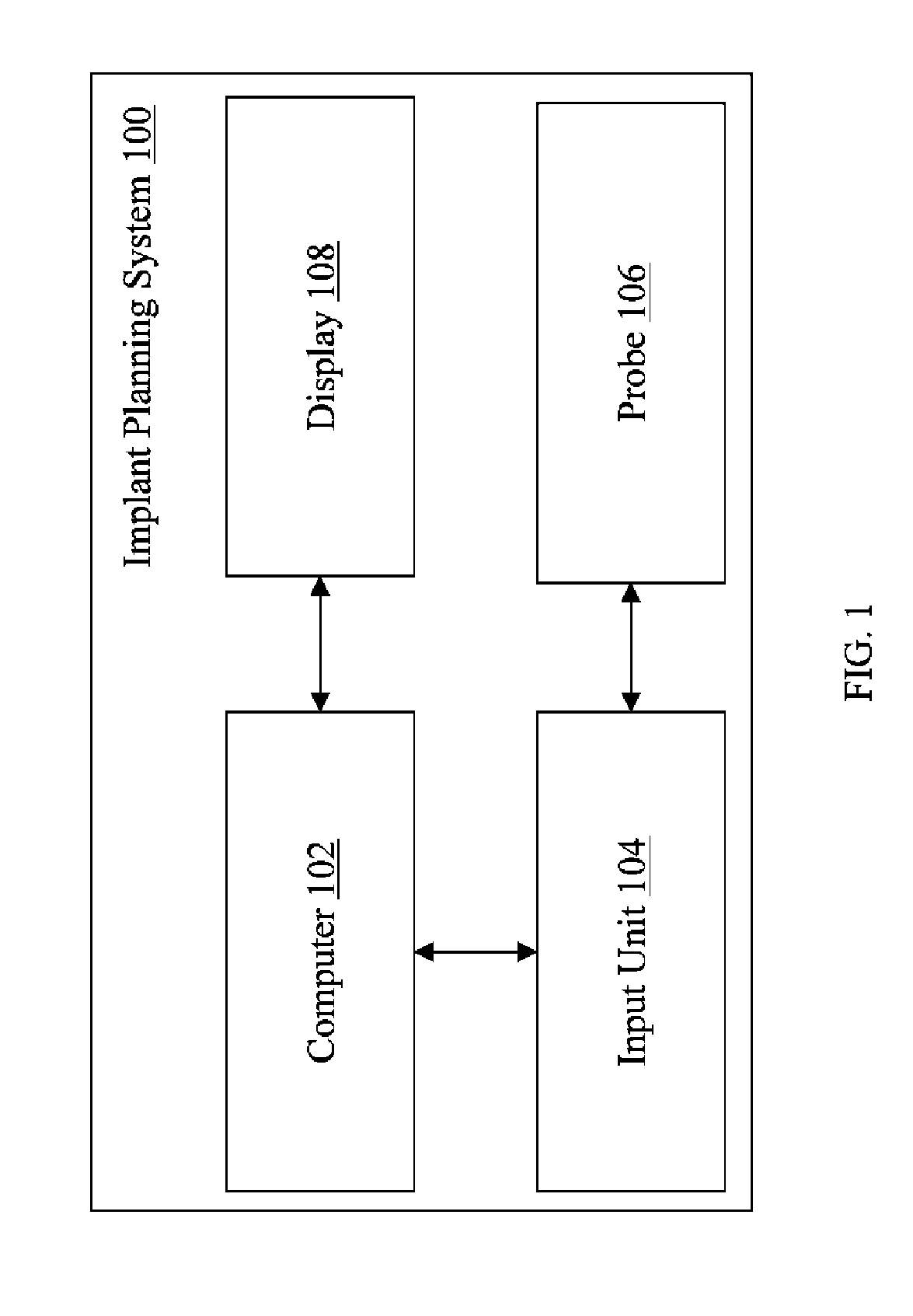

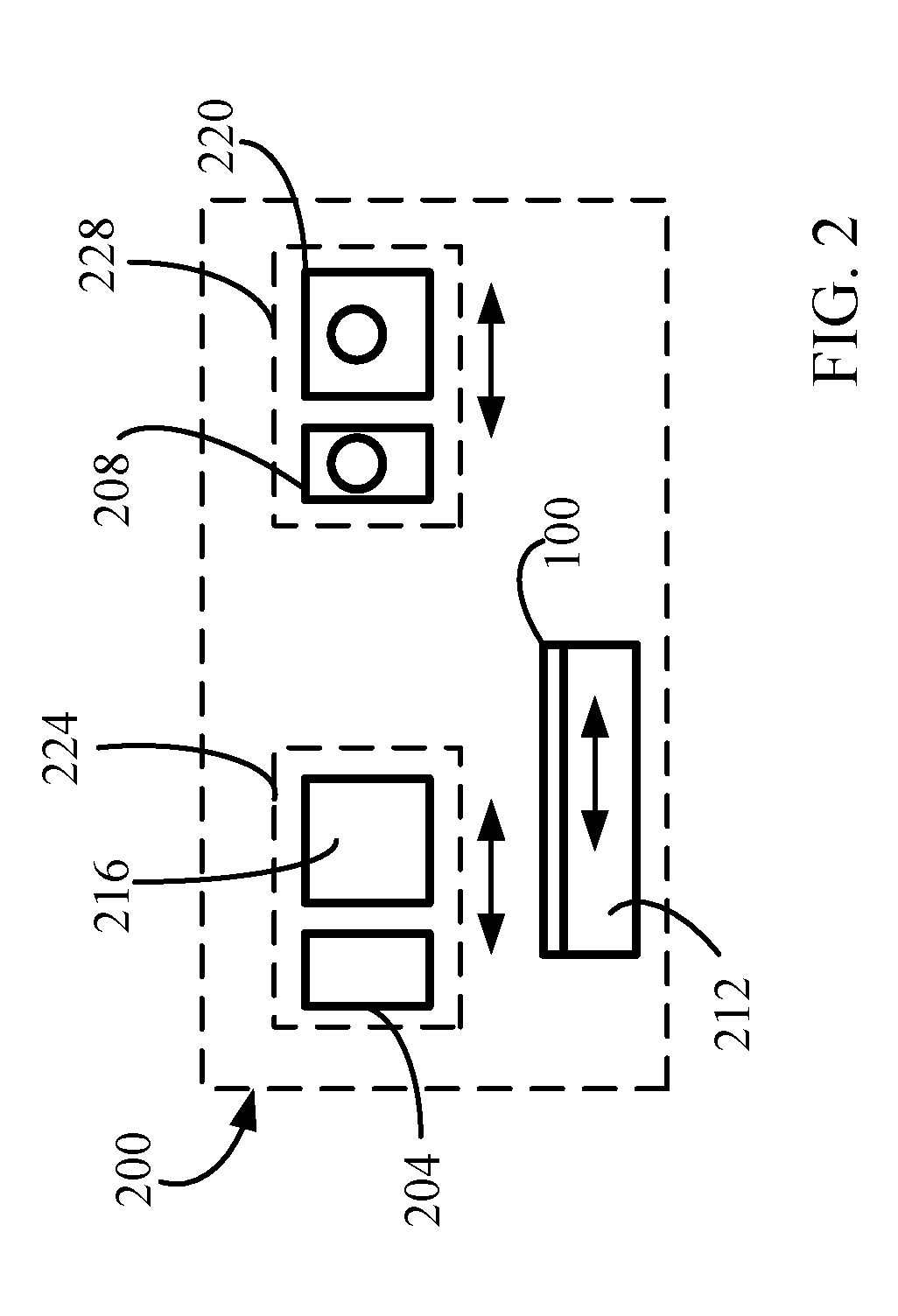

Implant planning for multiple implant components using constraints

InactiveUS20100153081A1For accurate placementAvoid positioningImage enhancementMechanical/radiation/invasive therapiesBiomedical engineeringComputer program

Described are computer-based methods and apparatuses, including computer program products, for implant planning for multiple implant components using constraints. A representation of a bone and a representation of a first implant component are displayed with respect to the representation of the bone. A representation of a second implant component is displayed, wherein the first implant component and the second implant component are physically separated and not connected to each other. A positioning of the representation of the second implant component that violates at least one positioning constraint is prevented, wherein the positioning constraint is based on the representation of the first implant component.

Owner:MAKO SURGICAL CORP

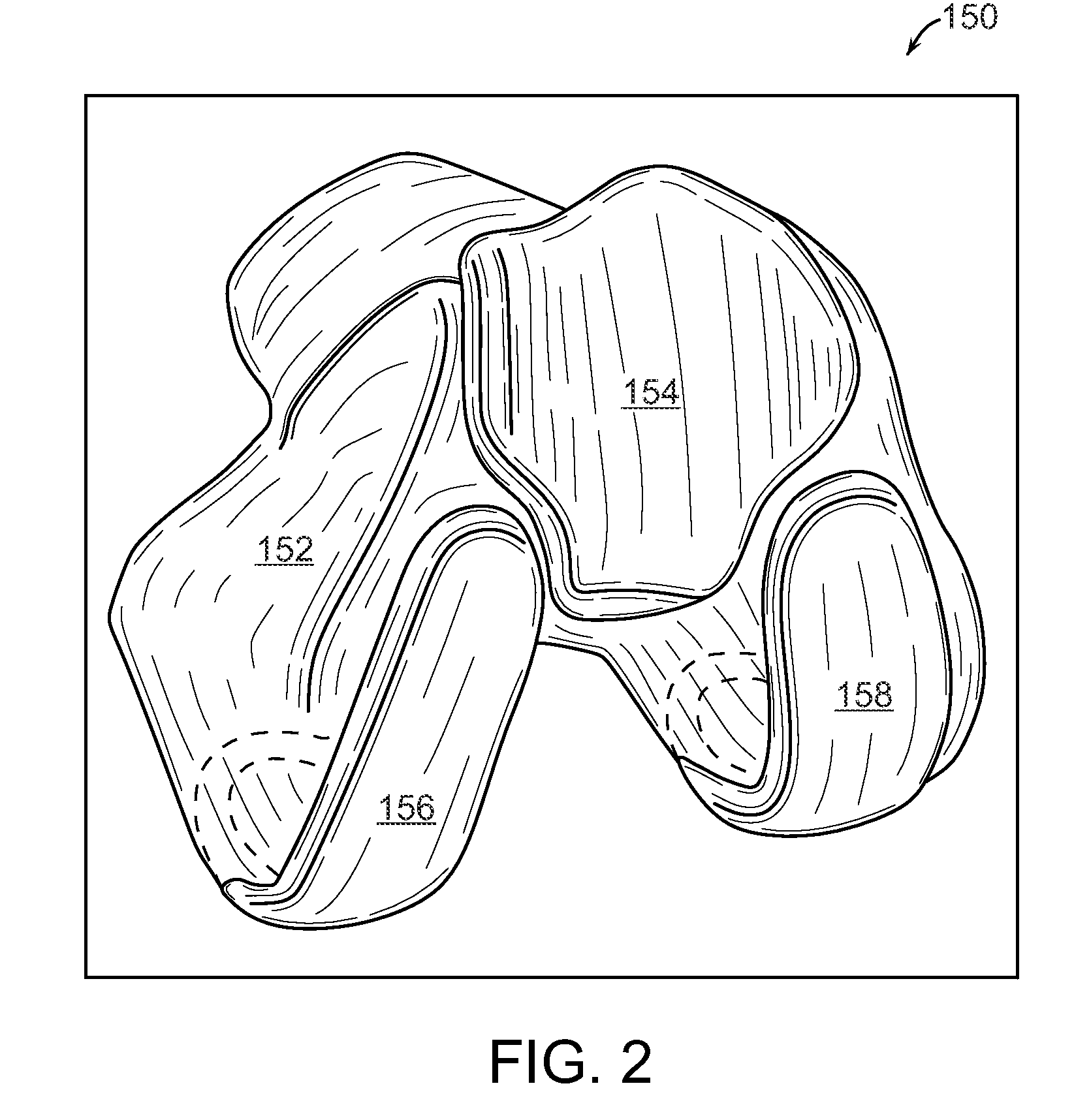

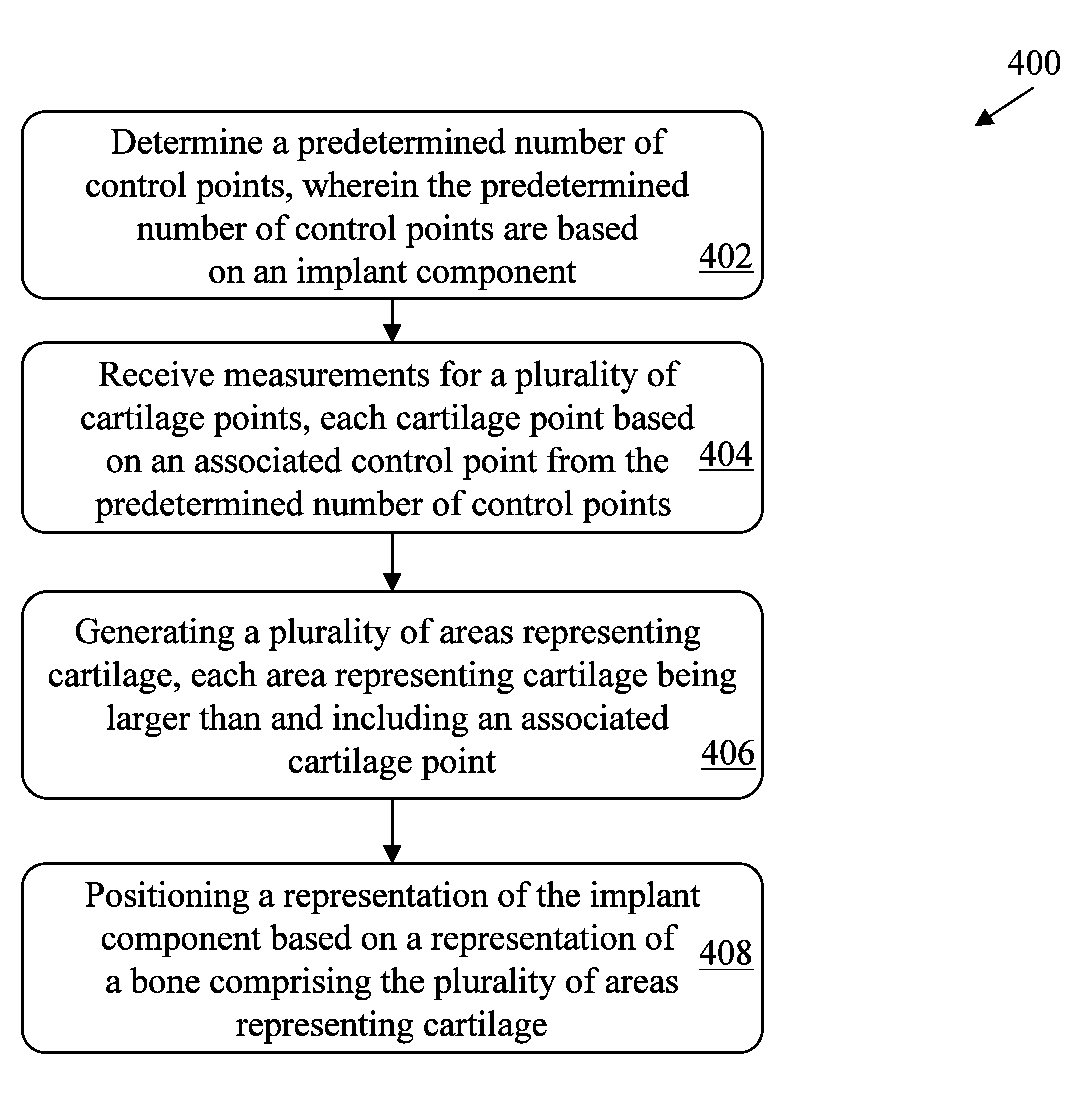

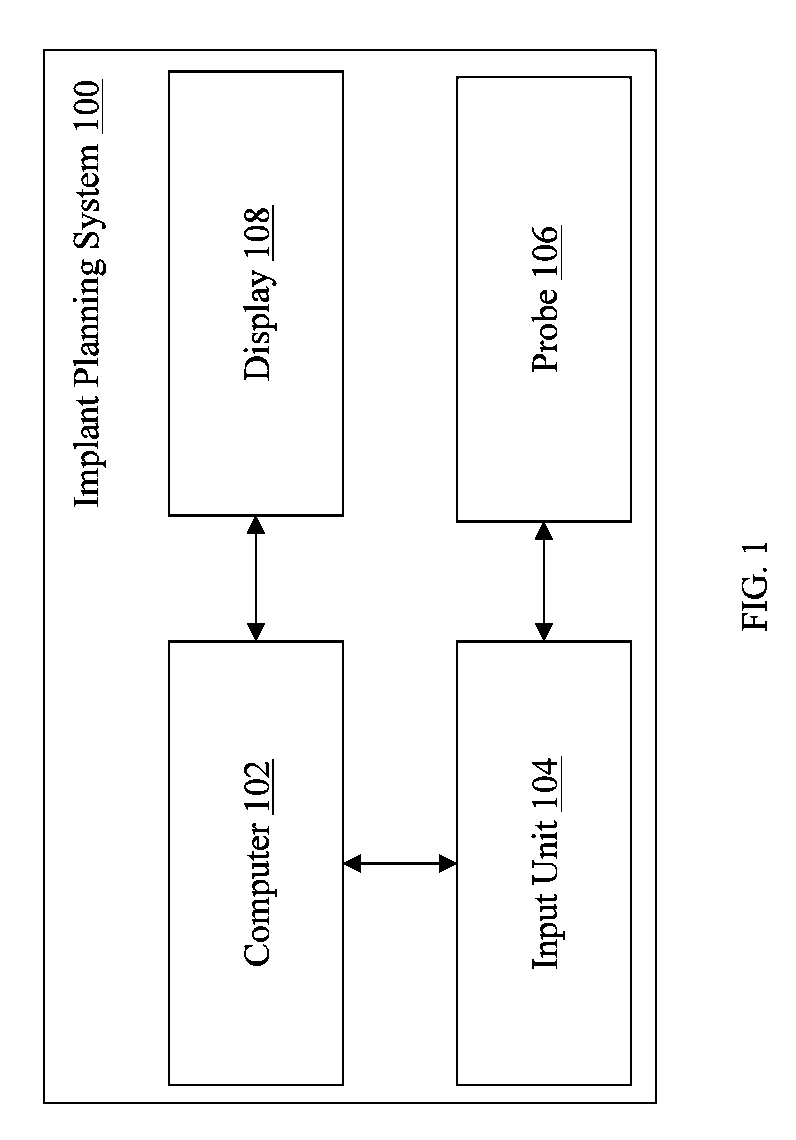

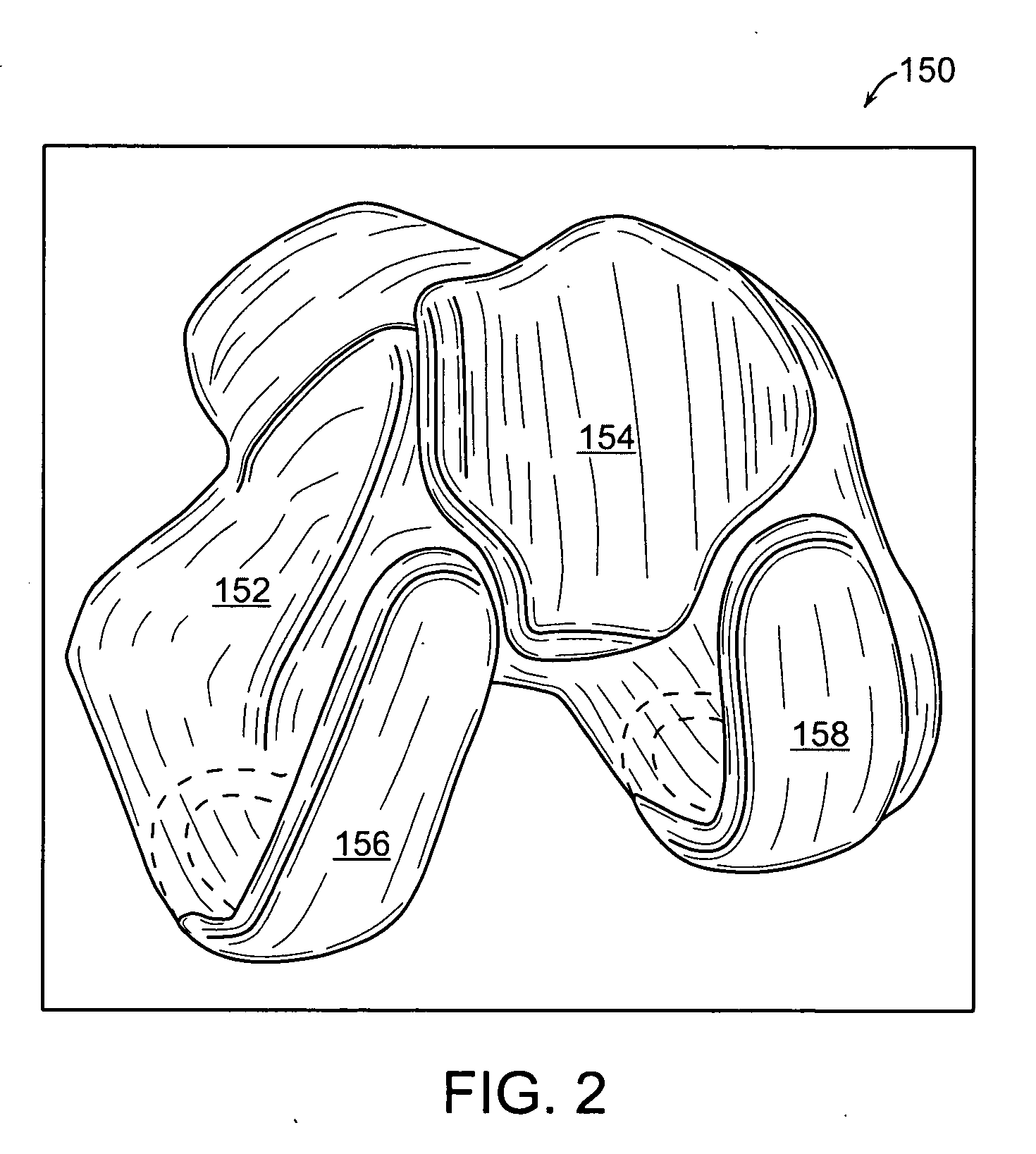

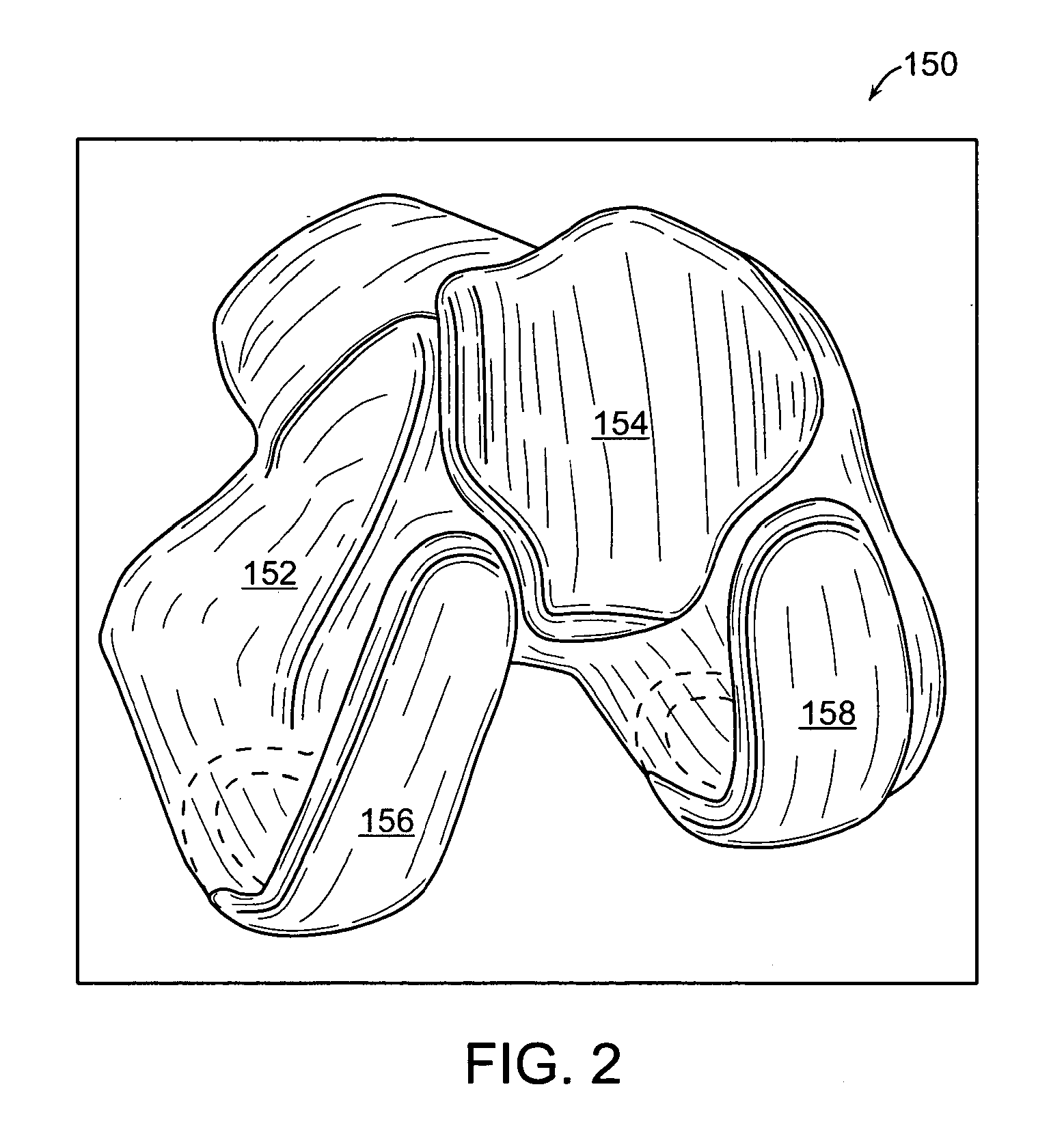

Implant planning using areas representing cartilage

ActiveUS20100153076A1For accurate placementAvoid positioningImage enhancementMechanical/radiation/invasive therapiesBiomedical engineeringComputer program

Described are computer-based methods and apparatuses, including computer program products, for implant planning using areas representing cartilage. A predetermined number of control points for generating a predetermined number of areas representing cartilage are determined, wherein the predetermined number of control points are based on an implant component. Measurements corresponding to a plurality of measured cartilage points are received, wherein each cartilage point is based on an associated control point from the predetermined number of control points. A plurality of areas representing cartilage are generated, wherein each area representing cartilage is larger than and projects to an associated control point from the plurality of control points. A representation of the implant component is positioned based on a representation of a bone, the representation of the bone comprising representations of the plurality of areas representing cartilage.

Owner:MAKO SURGICAL CORP

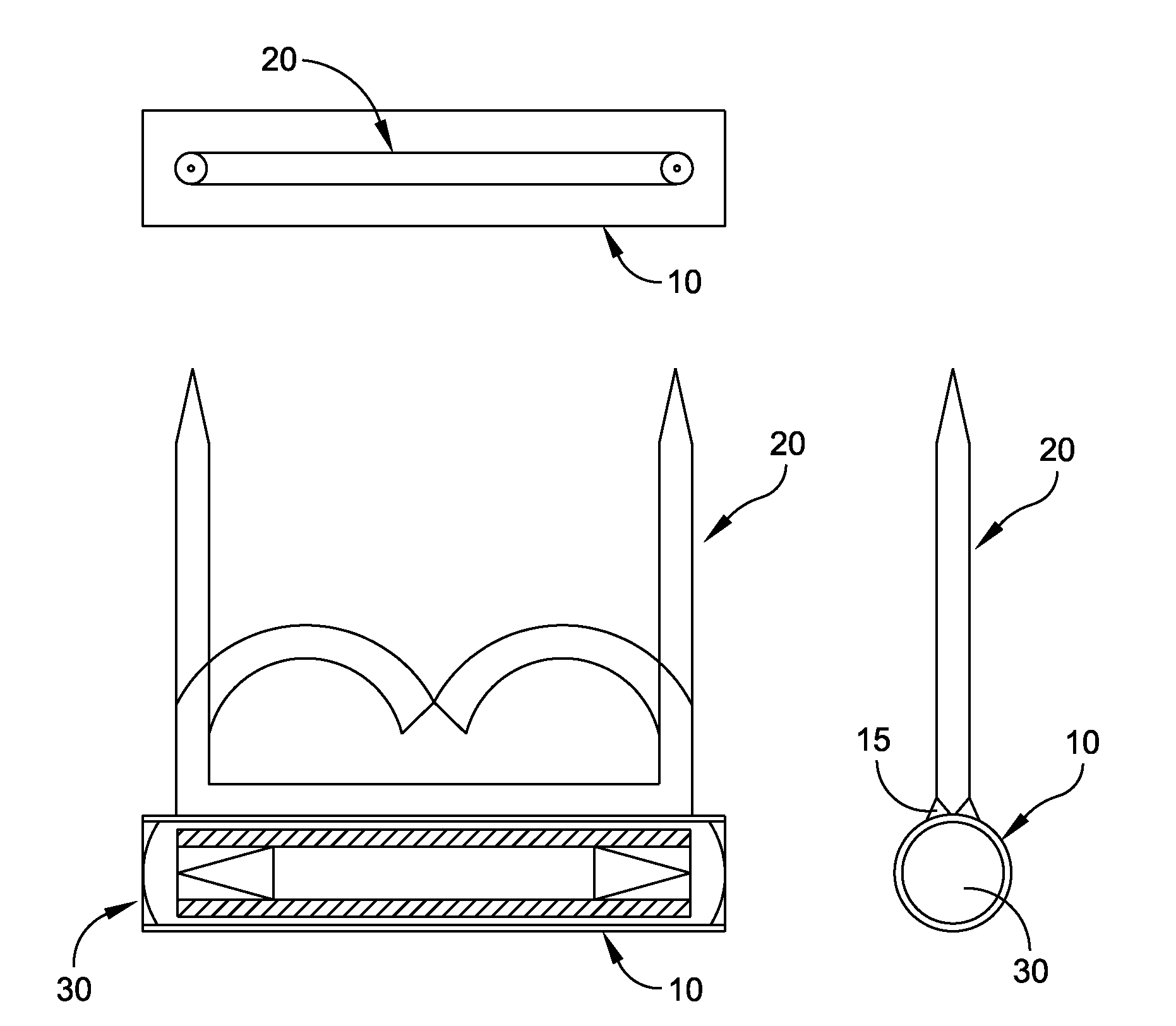

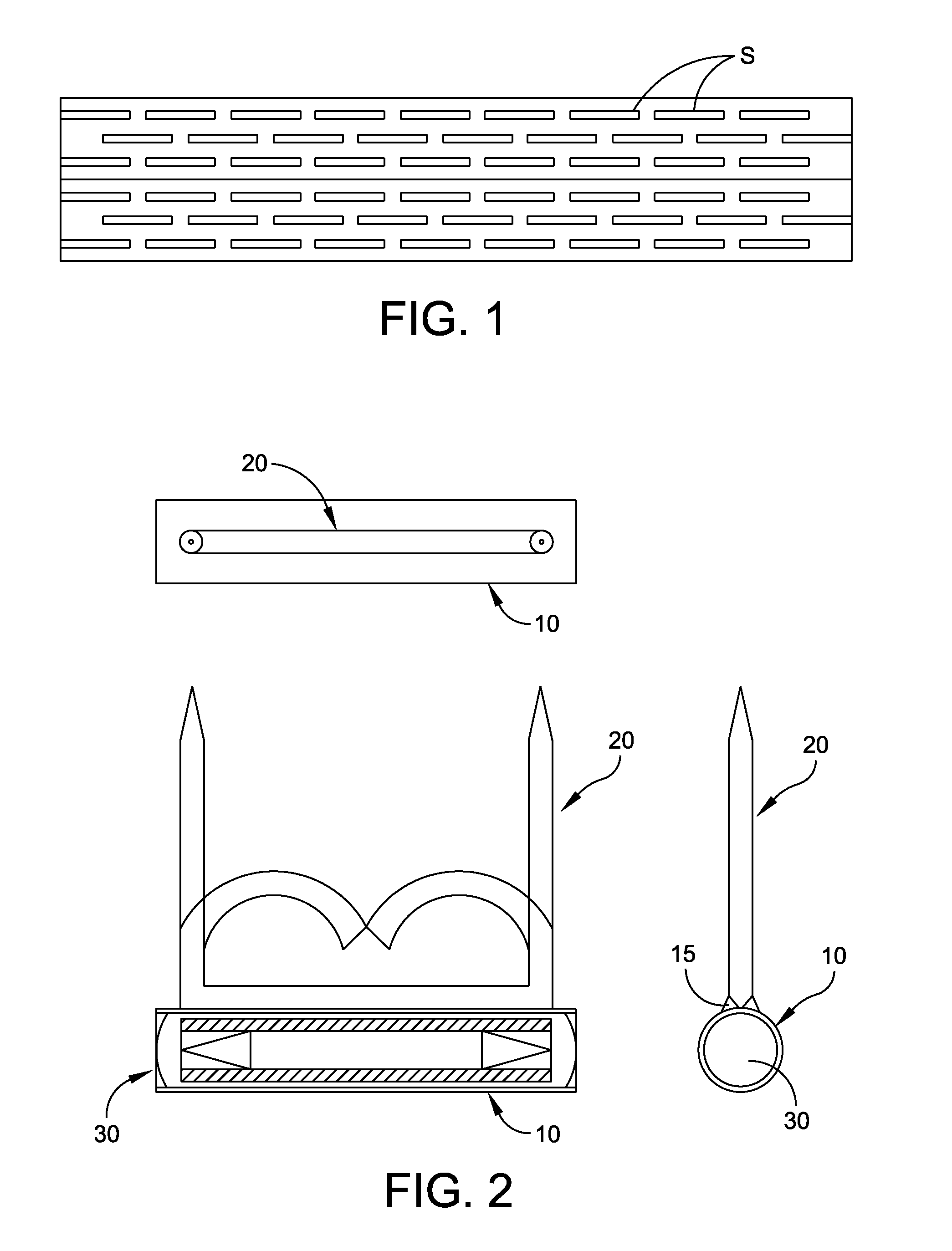

RFID tag assemblies and process

ActiveUS20150278671A1Reduce wearFor accurate placementLaminationLamination apparatusHot meltEngineering

A process is disclosed for attaching an RFID tag such as an AK module or QFP package to a flexible surface such as textile or fabric. The process comprises providing a heat fusible label including at least a first layer having a first adhesive layer, a substrate layer including a secondary antenna structure, a heat activated second adhesive layer and a pressure sensitive adhesive (PSA) layer for holding the RFID tag. The process further includes positioning the RFID tag on the PSA layer, pressing the tag against the PSA layer such that the PSA layer holds the tag against the heat fusible label at least temporarily, positioning the heat fusible label with the RFID tag on the flexible surface and applying heat and pressure to the heat fusible label to melt the heat activated layer and to fuse the label to the flexible surface.

Owner:HID TEXTILE SERVICES SARL

Radioactive therapeutic fastening instrument

ActiveUS20110245578A1For accurate placementReduce radiation doseSuture equipmentsStapling toolsBrachytherapyEngineering

An instrument used for brachytherapy delivery in the treatment of cancer by radiation therapy including a handle having first and second handle actuators; an end effector; and an instrument shaft that connects the handle with the end effector. The end effector has first and second adjacent disposed staple mechanisms that each retain a set of staples. The first mechanism is for holding standard staples in a first array, and dispensing the standard staples under control of the corresponding first handle actuator. The second mechanism is for holding radioactive source staples in a second array, and dispensing said radioactive source staples under control of the corresponding second handle actuator. A holder is for receiving the first and second mechanisms in a substantially parallel array so that the standard staples close the incision at a surgical margin while the source staples are secured adjacent thereto.

Owner:POINT SOURCE TECH

Precast panel mounting system

InactiveUS20070119109A1For accurate placementUniform spaceCovering/liningsCeramic shaping apparatusAbutmentAngular orientation

A rigid elongate mounting bracket has an embedment portion and an extension portion. The extension portion has a fastener opening and abutment means. When cast into a precast panel in an appropriate angular orientation adjacent to an edge of a cladding panel, the extension portion projects rearwardly and laterally away from the rear face of the panel end such that the end of the extension portion is disposed at a distance away from the panel's rear face corresponding to a desired air space, and the abutment means is substantially aligned with the panel's rear face. Each panel preferably has at least two brackets spaced along its upper edge and two more along its lower edge. A first panel may be mounted to a supporting structure using fasteners driven through the fastener openings of the upper brackets. A second panel may then be positioned with its lower brackets extending downward behind the first panel, with the abutment means of the second panel's lower brackets engaging the rear face of the first panel, such that the lower end of the second panel is laterally stabilized by the first panel, with a uniform air space being formed between the supporting structure and the panels' rear faces.

Owner:KUELKER PETER

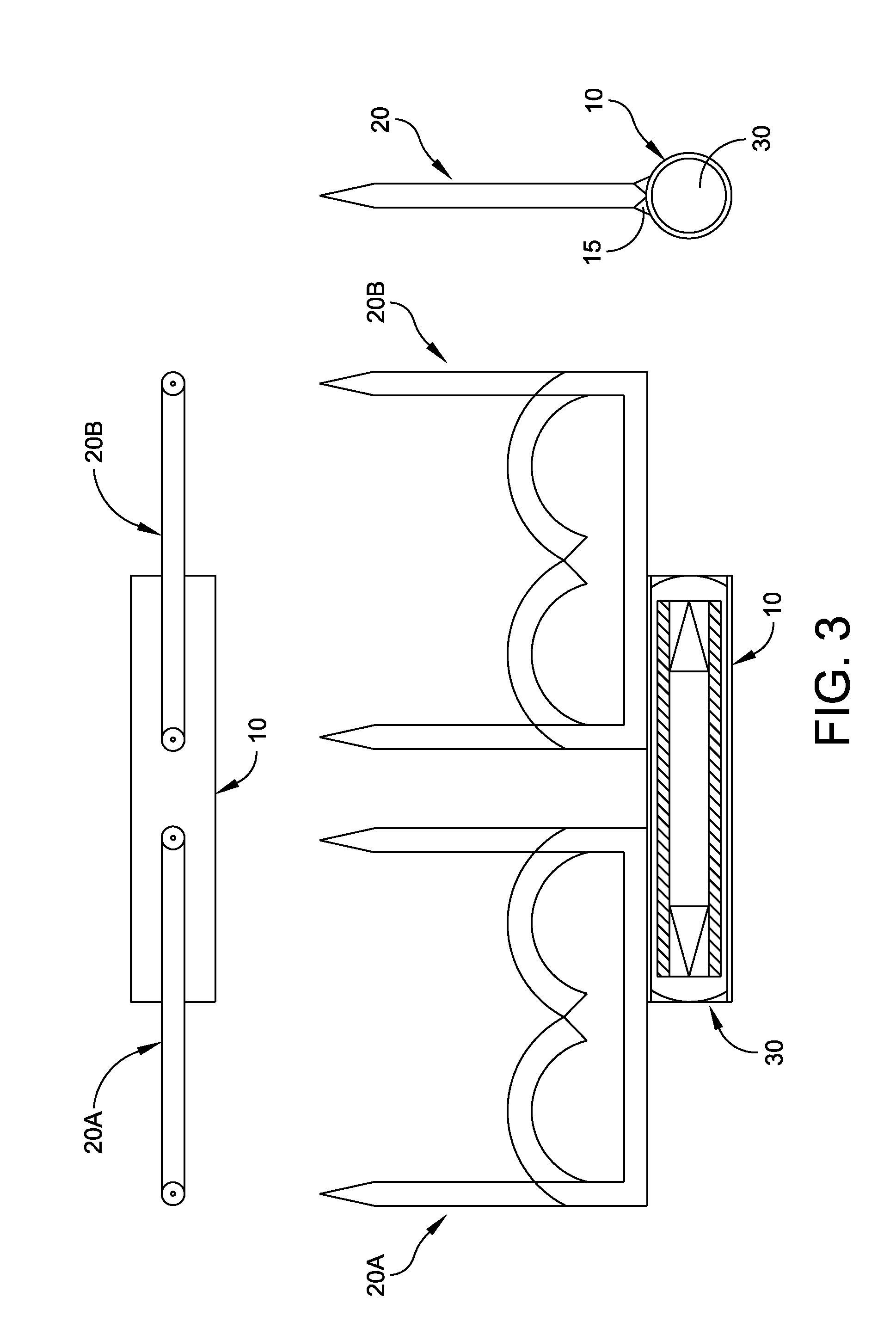

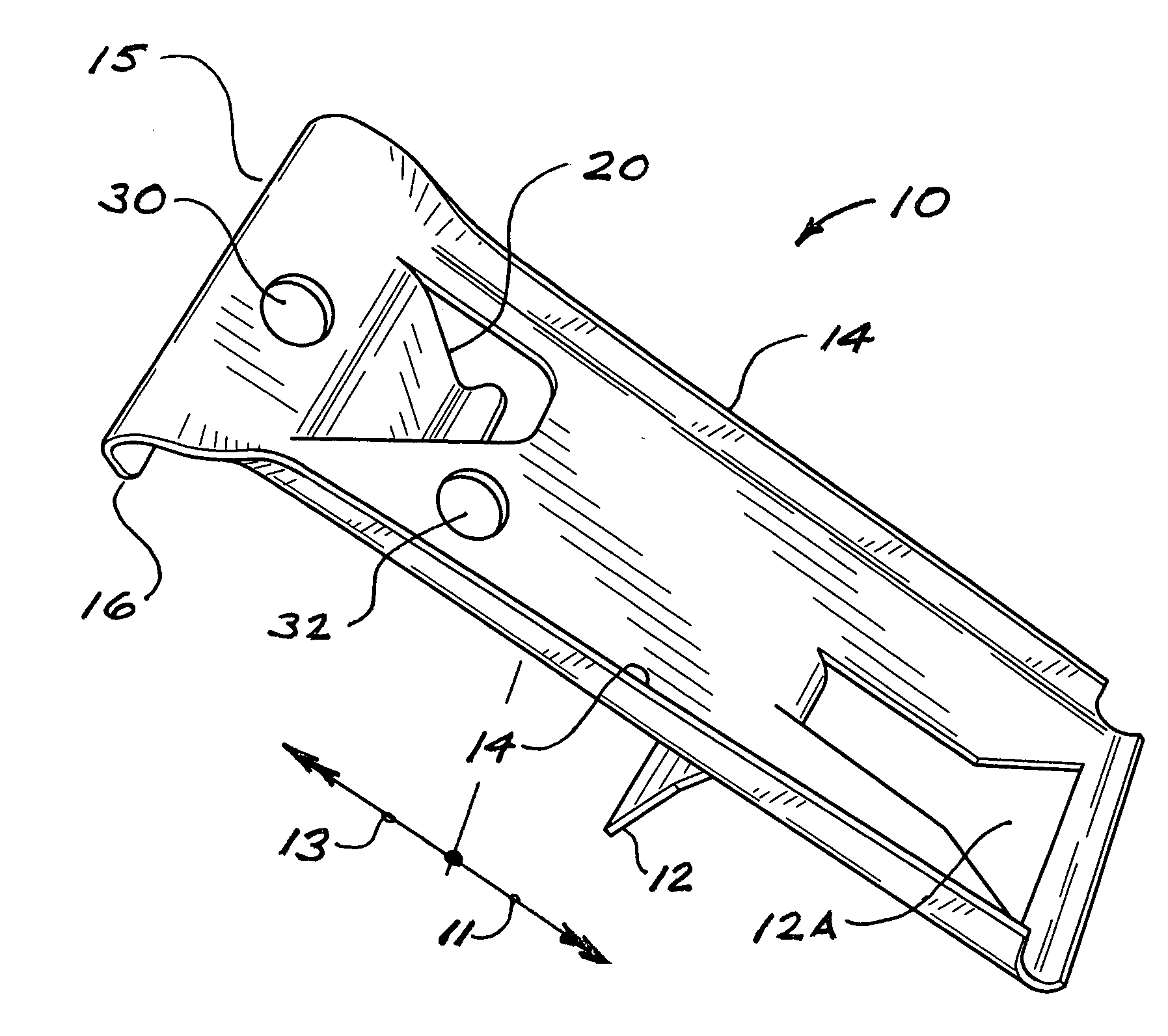

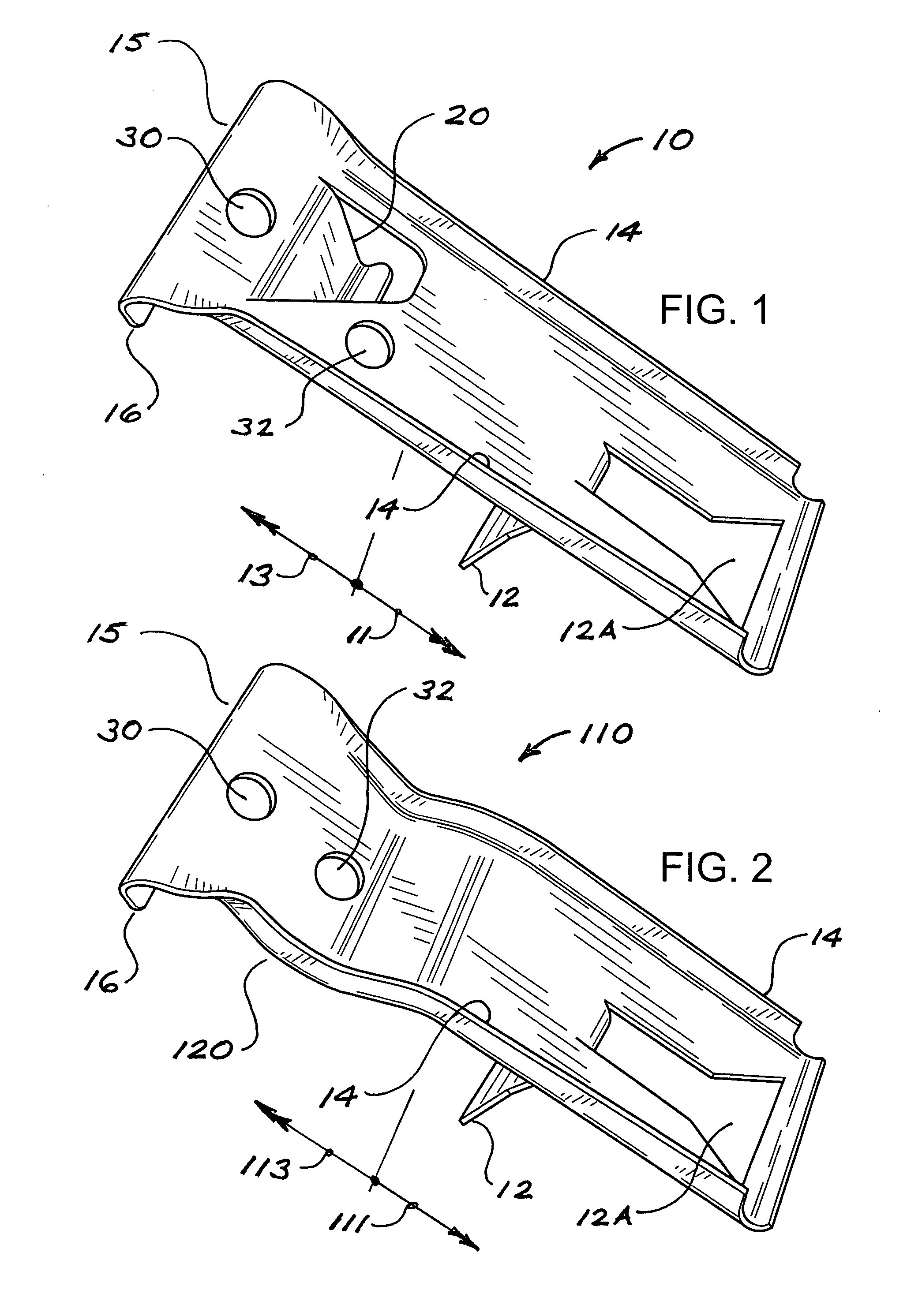

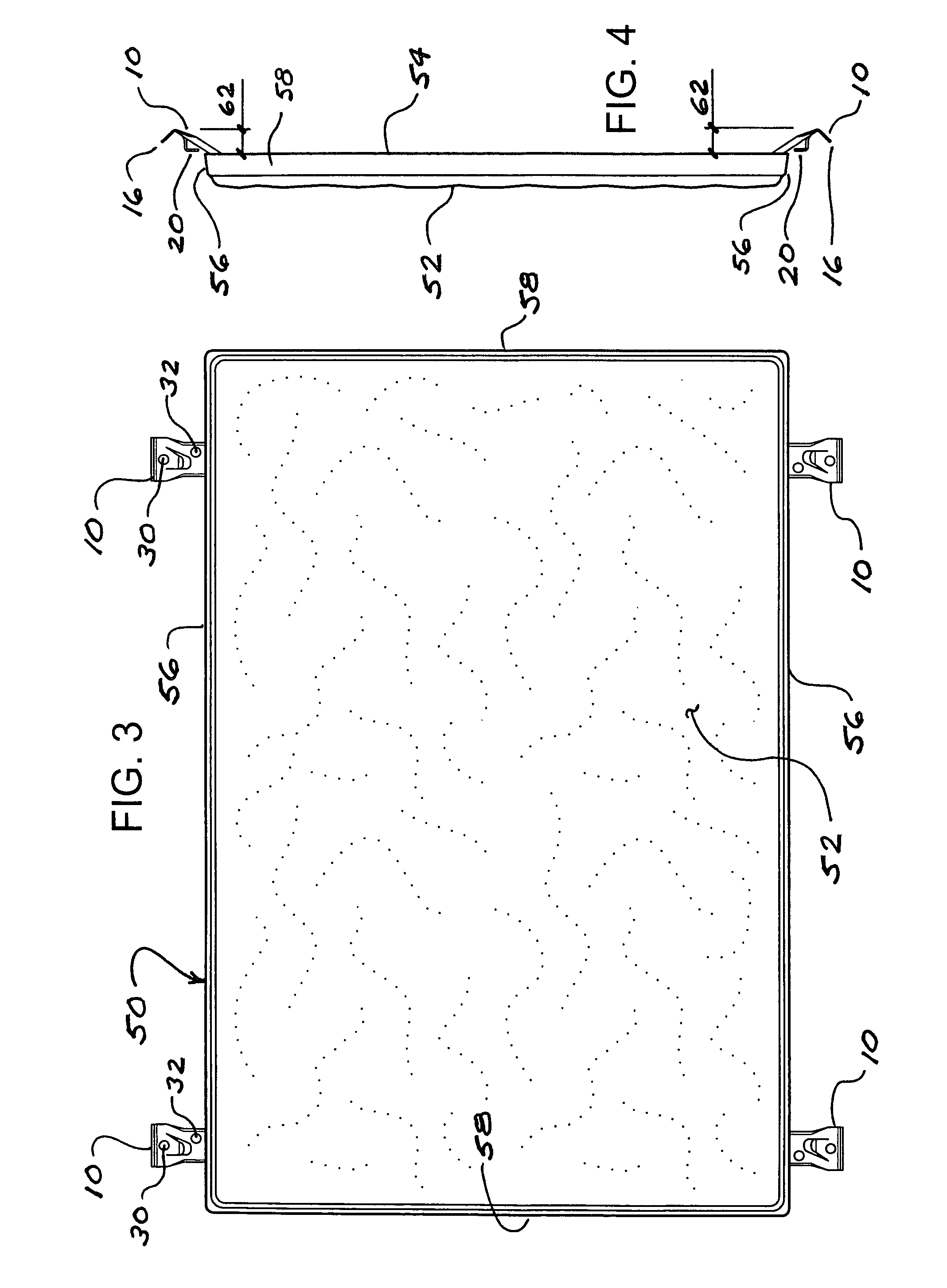

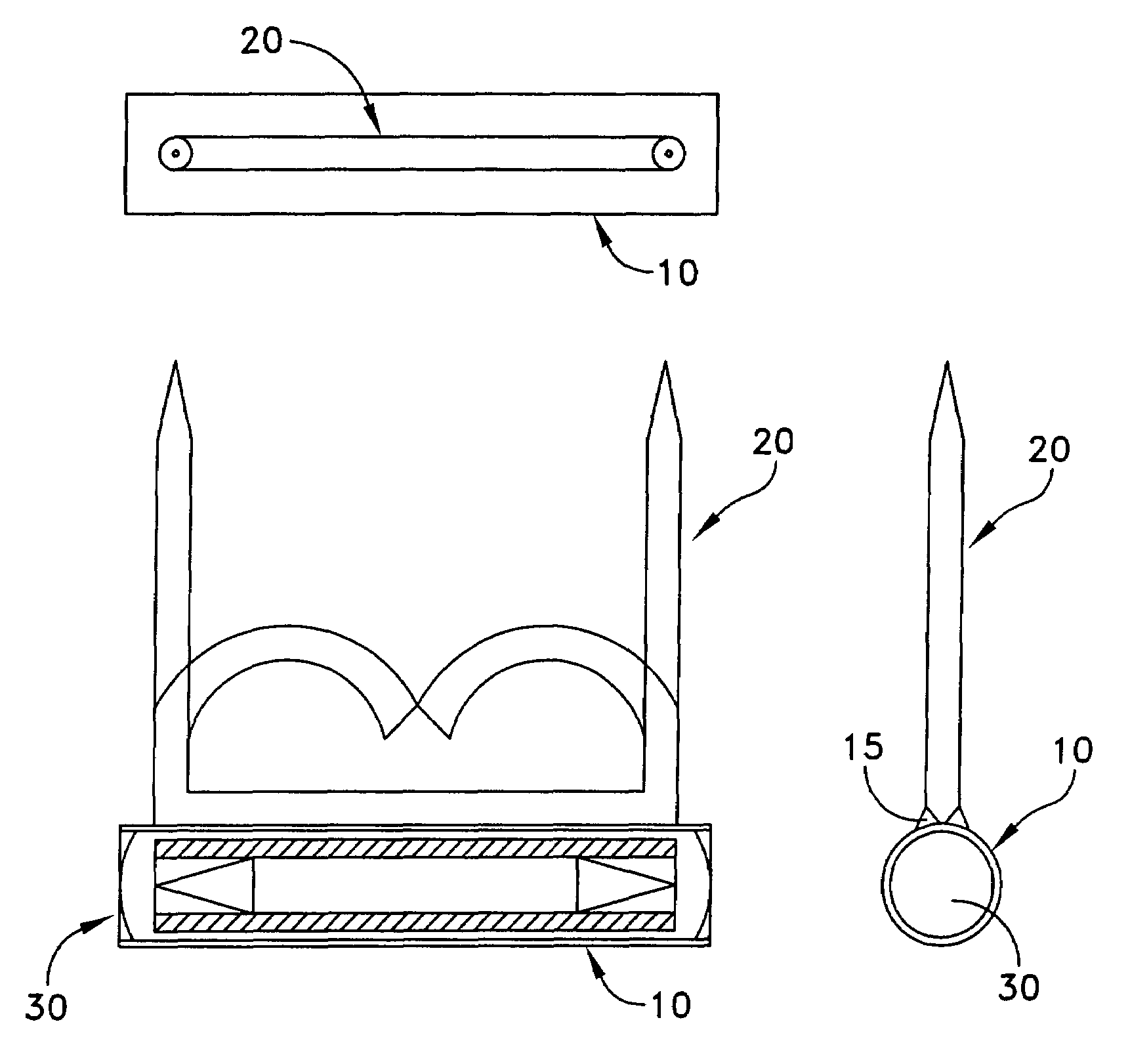

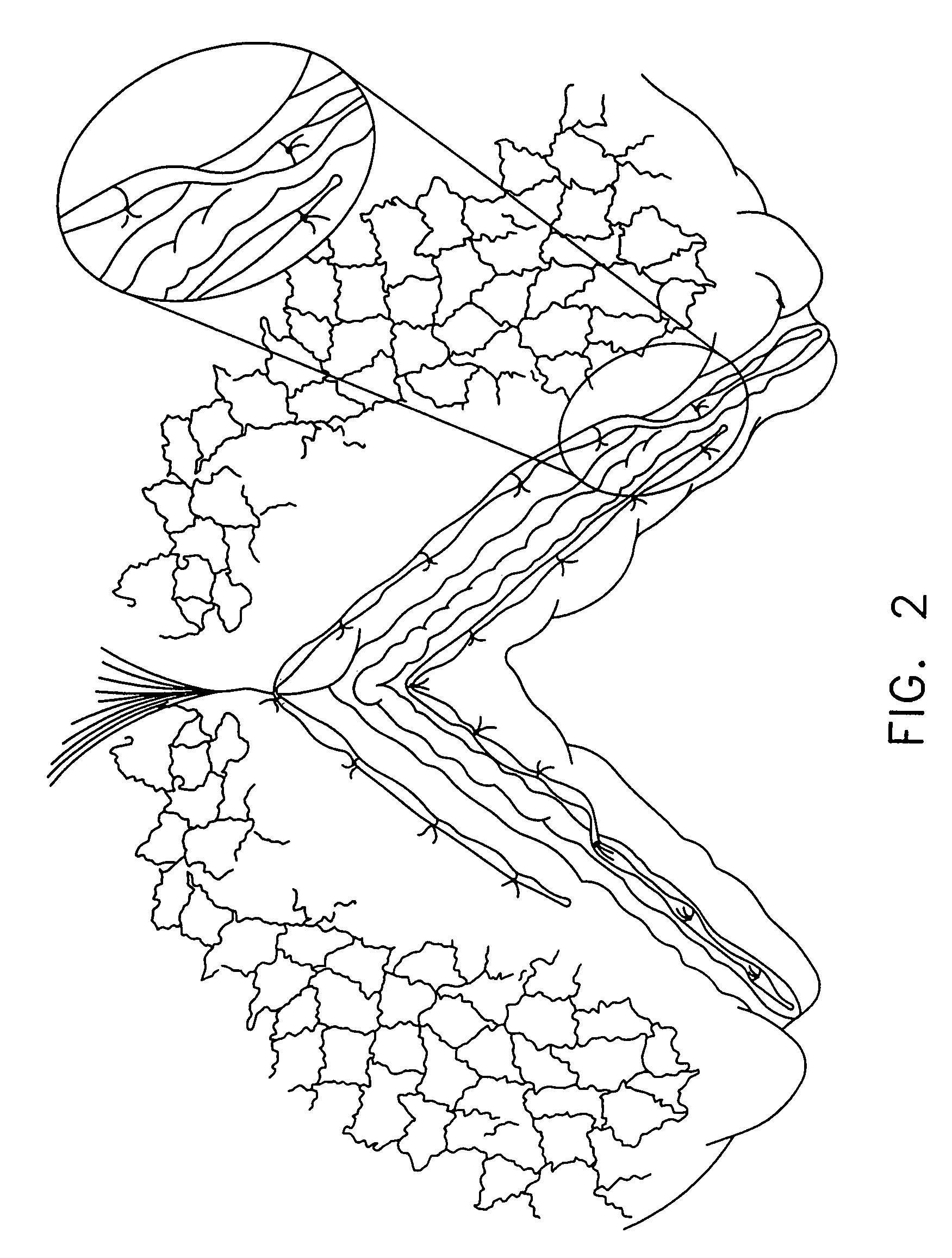

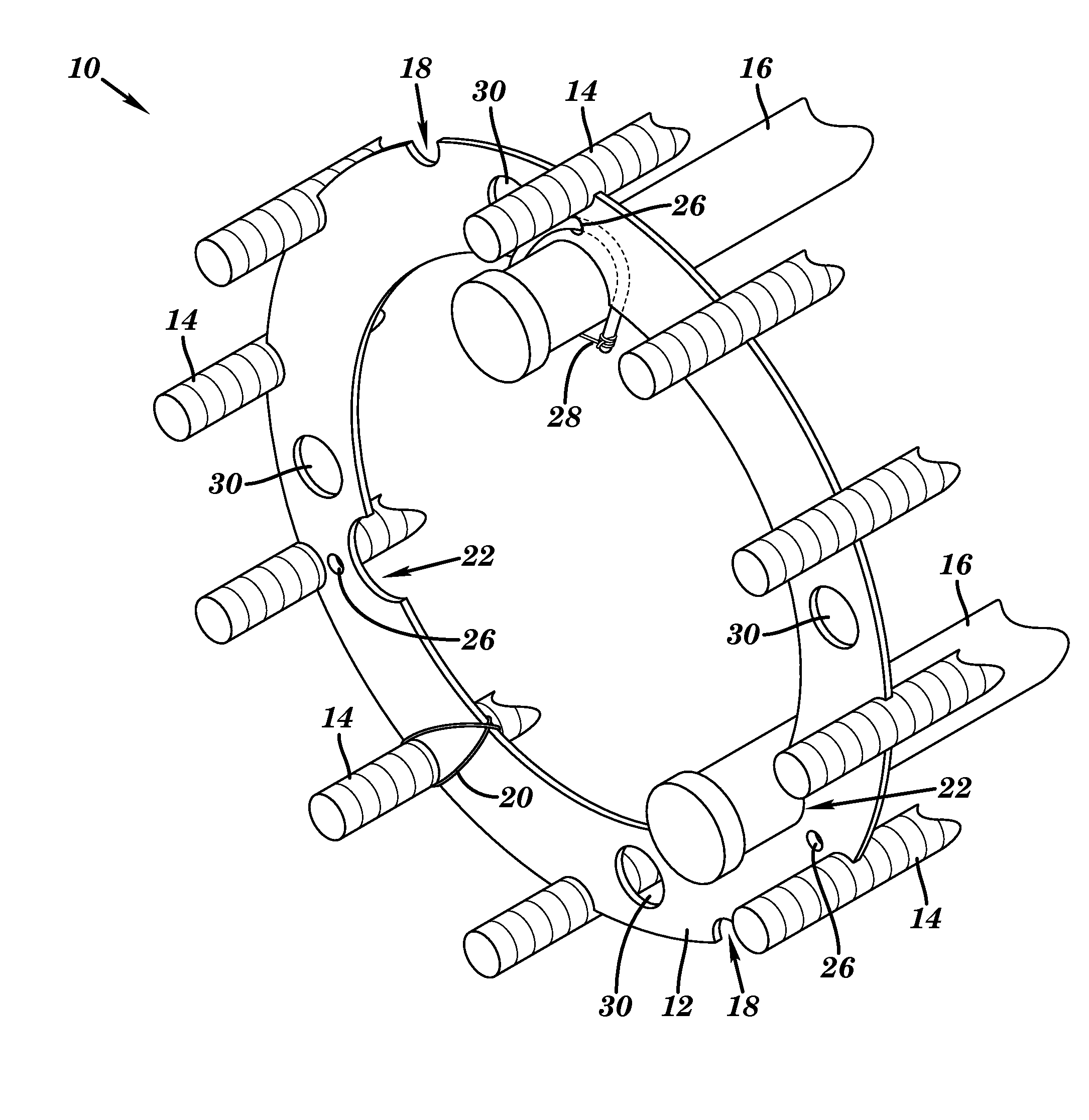

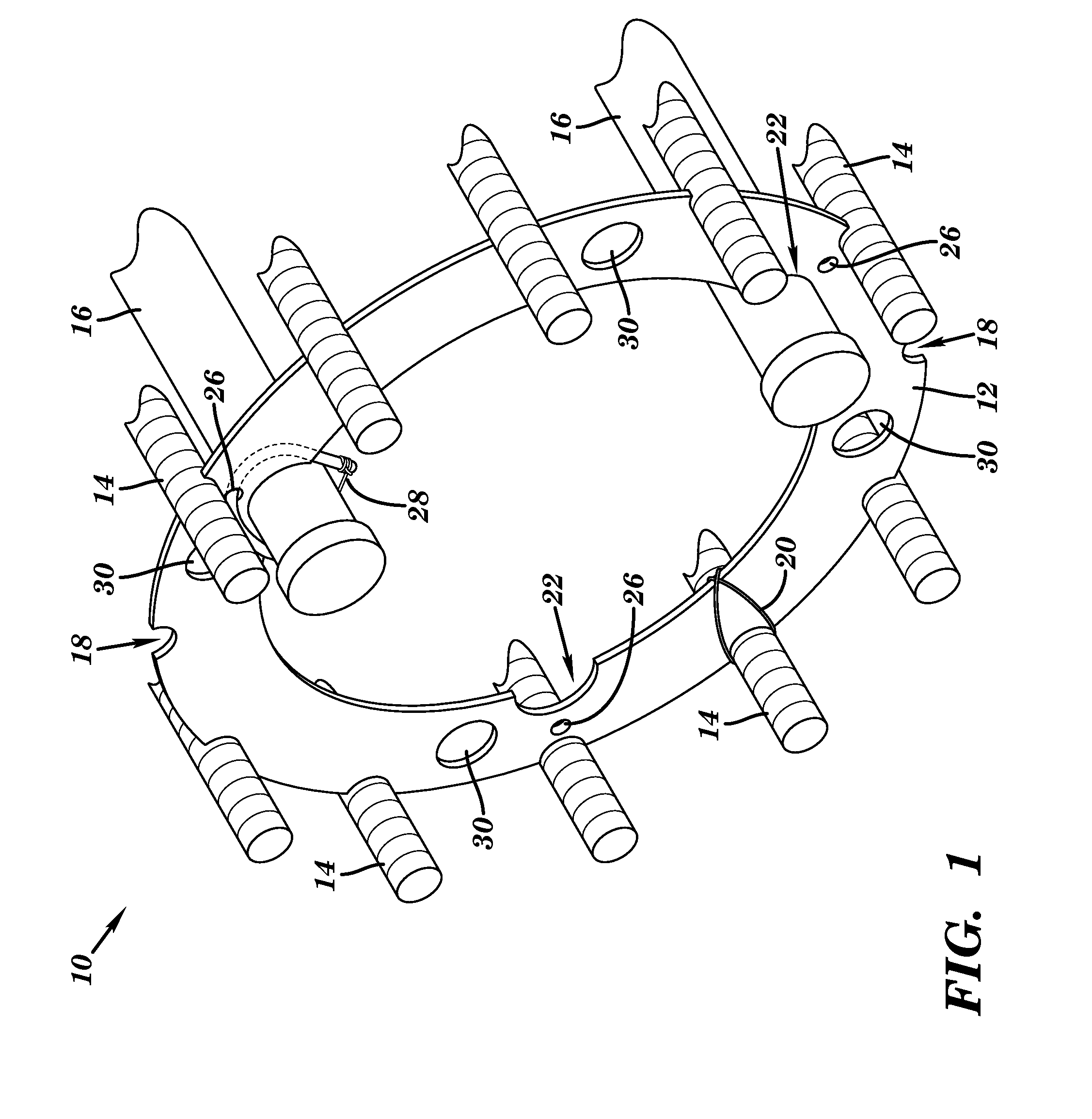

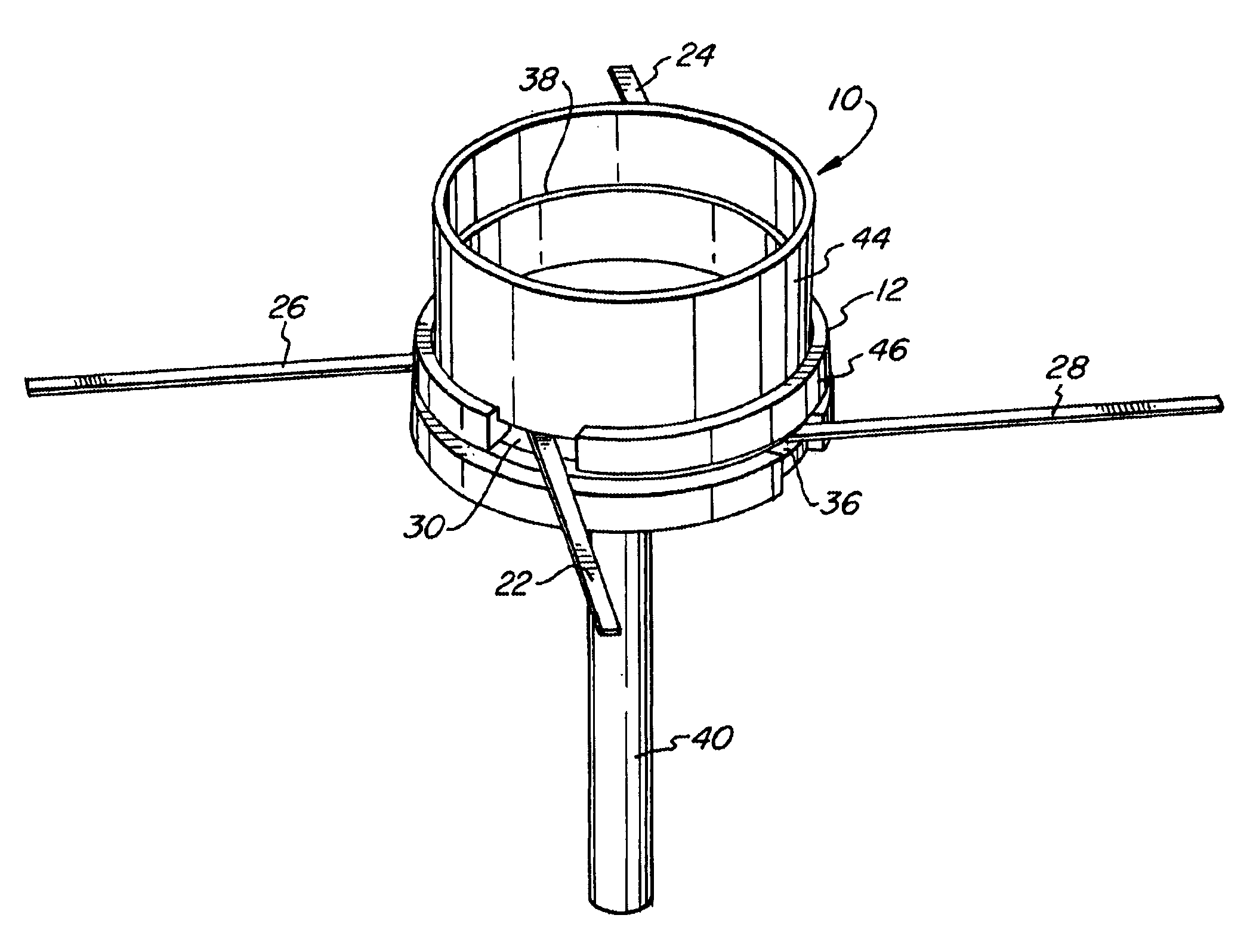

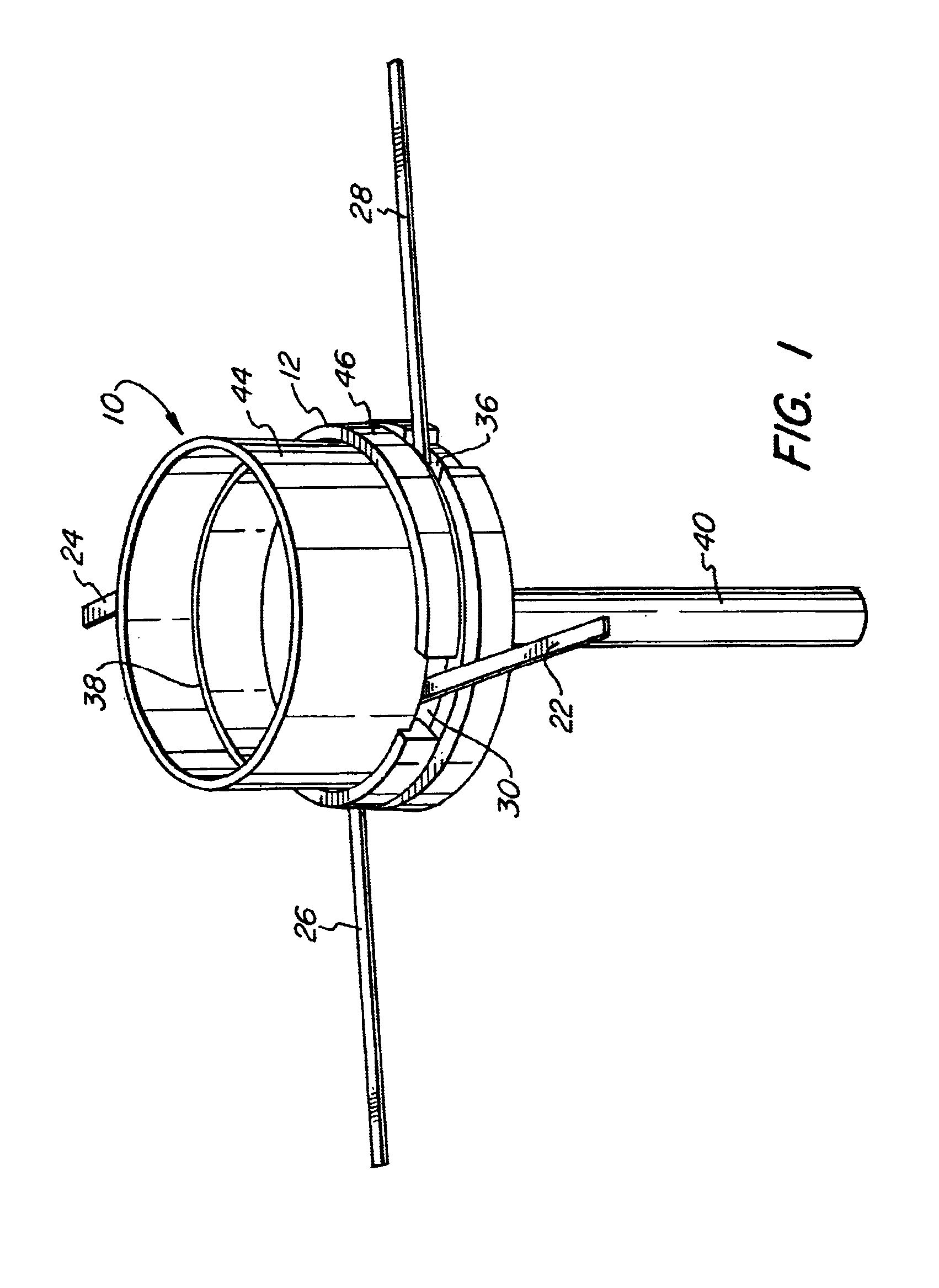

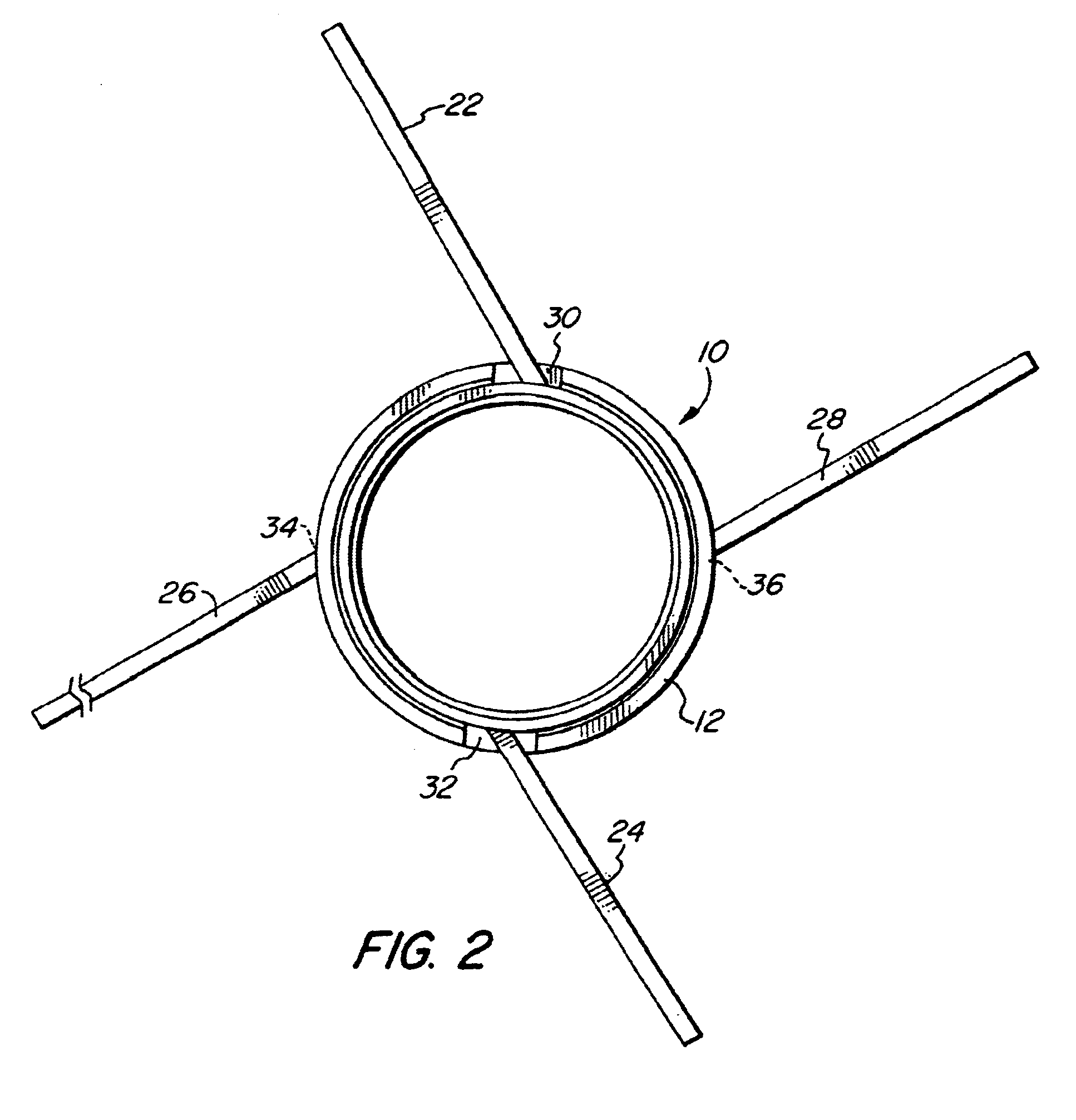

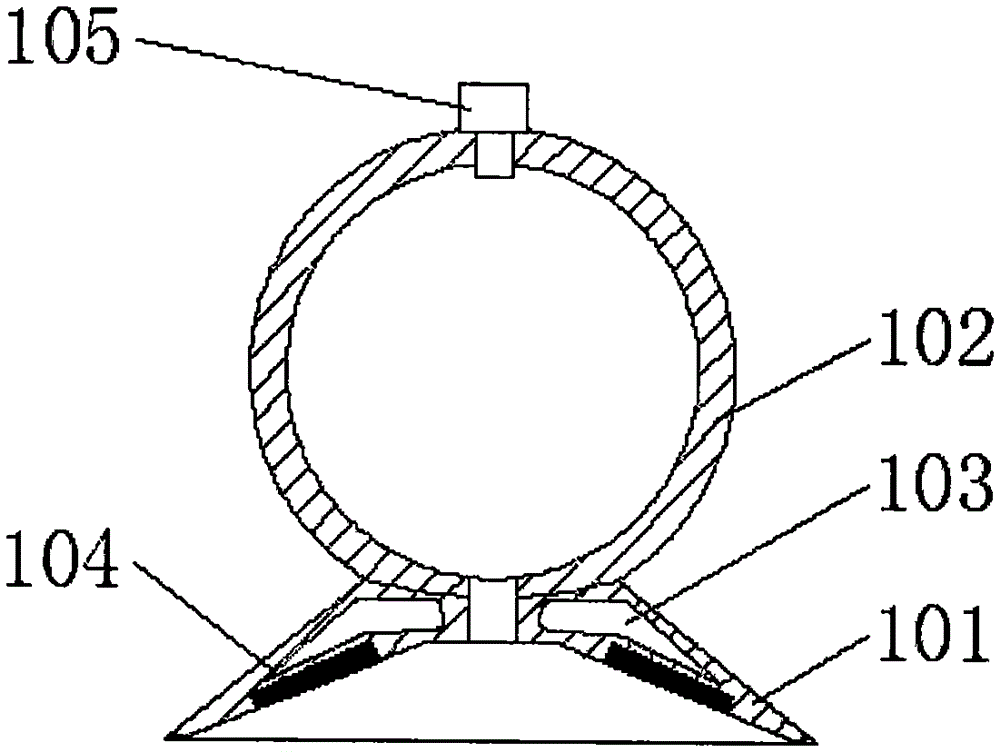

Radioactive therapeutic apparatus

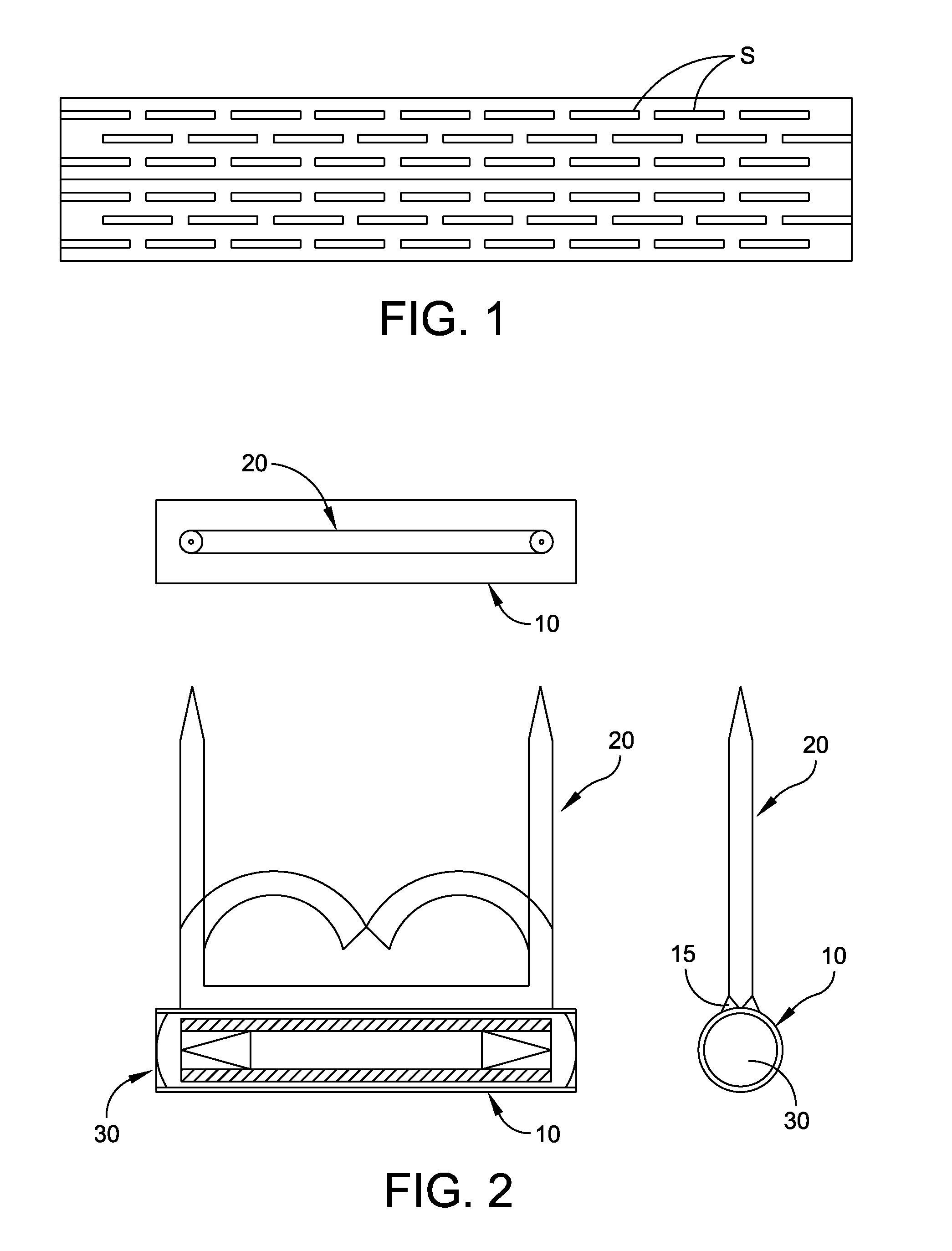

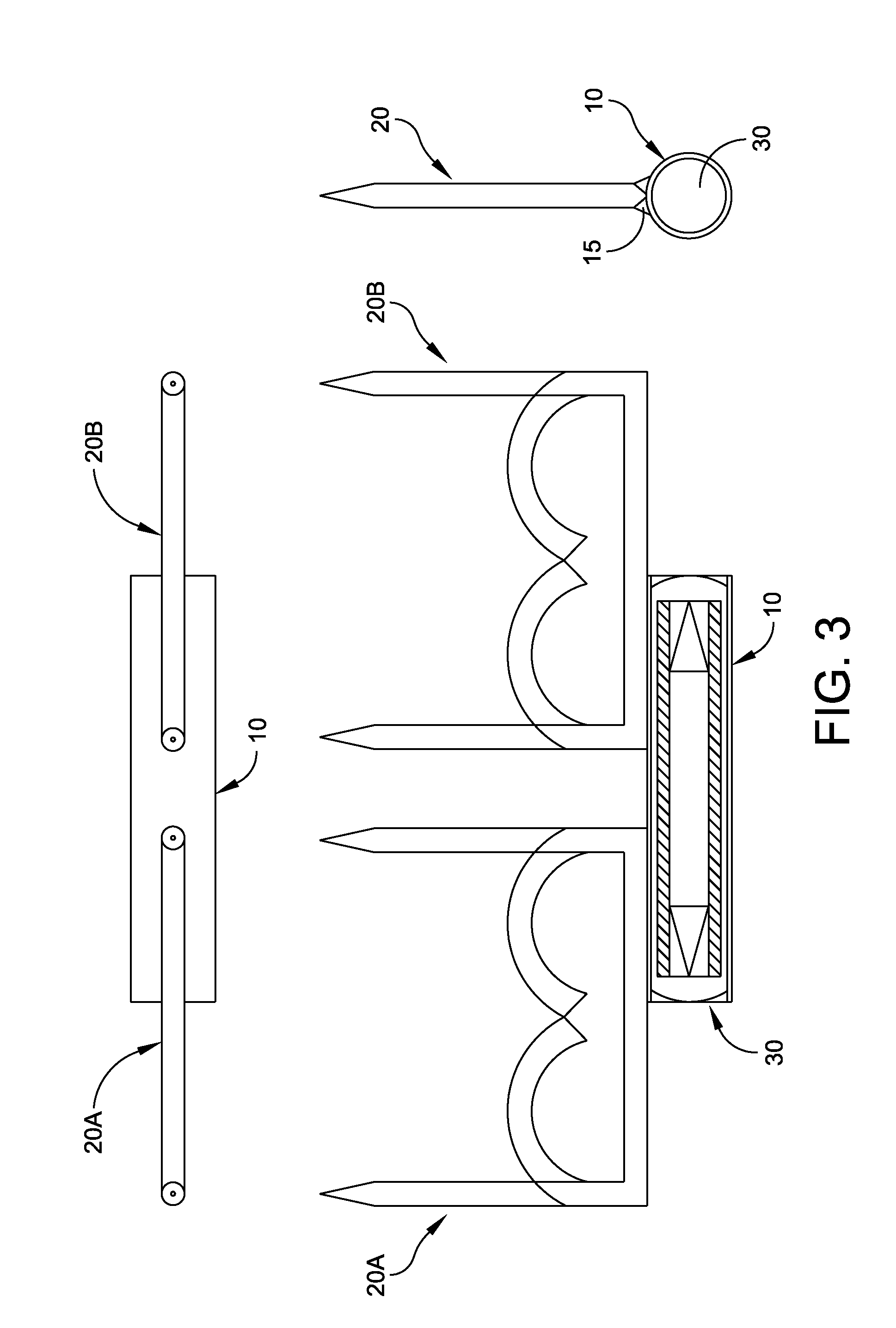

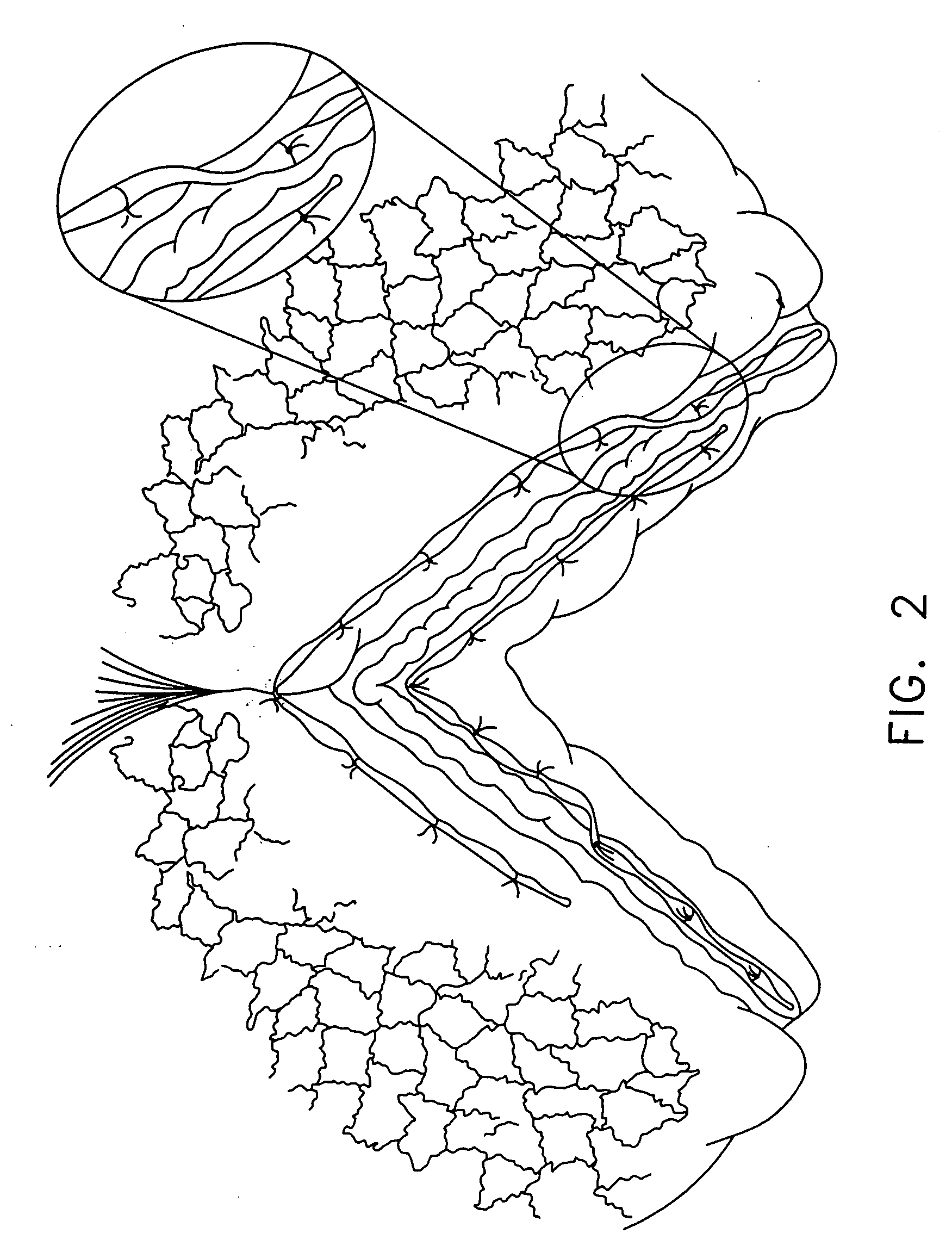

ActiveUS7604586B2For accurate placementReduce doseRadiation therapySurgical staplesSurgical stapleSurgical incision

A method and device for applying a radioactive source to a tissue site is disclosed. The device facilitates the precise placement of, for example, 125Iodine seeds relative to the surgical margin, assures the seeds remain fixed in their precise position for the duration of the treatment, overcomes the technical difficulties of manipulating the seeds through the narrow surgical incision, and reduces the radiation dose to the clinicians. The device incorporates the radioactive seeds into a fastening means, preferably surgical staples, used in the surgical procedure. In this way, the seeds are concurrently secured in position directly adjacent to the surgical resection and remain immobile.

Owner:POINT SOURCE TECH

Implant Planning for Multiple Implant Components Using Constraints

ActiveUS20120310617A1For accurate placementAvoid positioningImage enhancementMechanical/radiation/invasive therapiesBiomedical engineeringComputer program

Described are computer-based methods and apparatuses, including computer program products, for implant planning for multiple implant components using constraints. A representation of a bone and a representation of a first implant component are displayed with respect to the representation of the bone. A representation of a second implant component is displayed, wherein the first implant component and the second implant component are physically separated and not connected to each other. A positioning of the representation of the second implant component that violates at least one positioning constraint is prevented, wherein the positioning constraint is based on the representation of the first implant component.

Owner:MAKO SURGICAL CORP

Radioactive therapeutic apparatus

ActiveUS20070244351A1For accurate placementReduce doseRadiation therapySurgical staplesSurgical stapleSurgical incision

A method and device for applying a radioactive source to a tissue site is disclosed. The device facilitates the precise placement of, for example, 125Iodine seeds relative to the surgical margin, assures the seeds remain fixed in their precise position for the duration of the treatment, overcomes the technical difficulties of manipulating the seeds through the narrow surgical incision, and reduces the radiation dose to the clinicians. The device incorporates the radioactive seeds into a fastening means, preferably surgical staples, used in the surgical procedure. In this way, the seeds are concurrently secured in position directly adjacent to the surgical resection and remain immobile.

Owner:POINT SOURCE TECH

Anchoring System for Fixing Objects to Bones

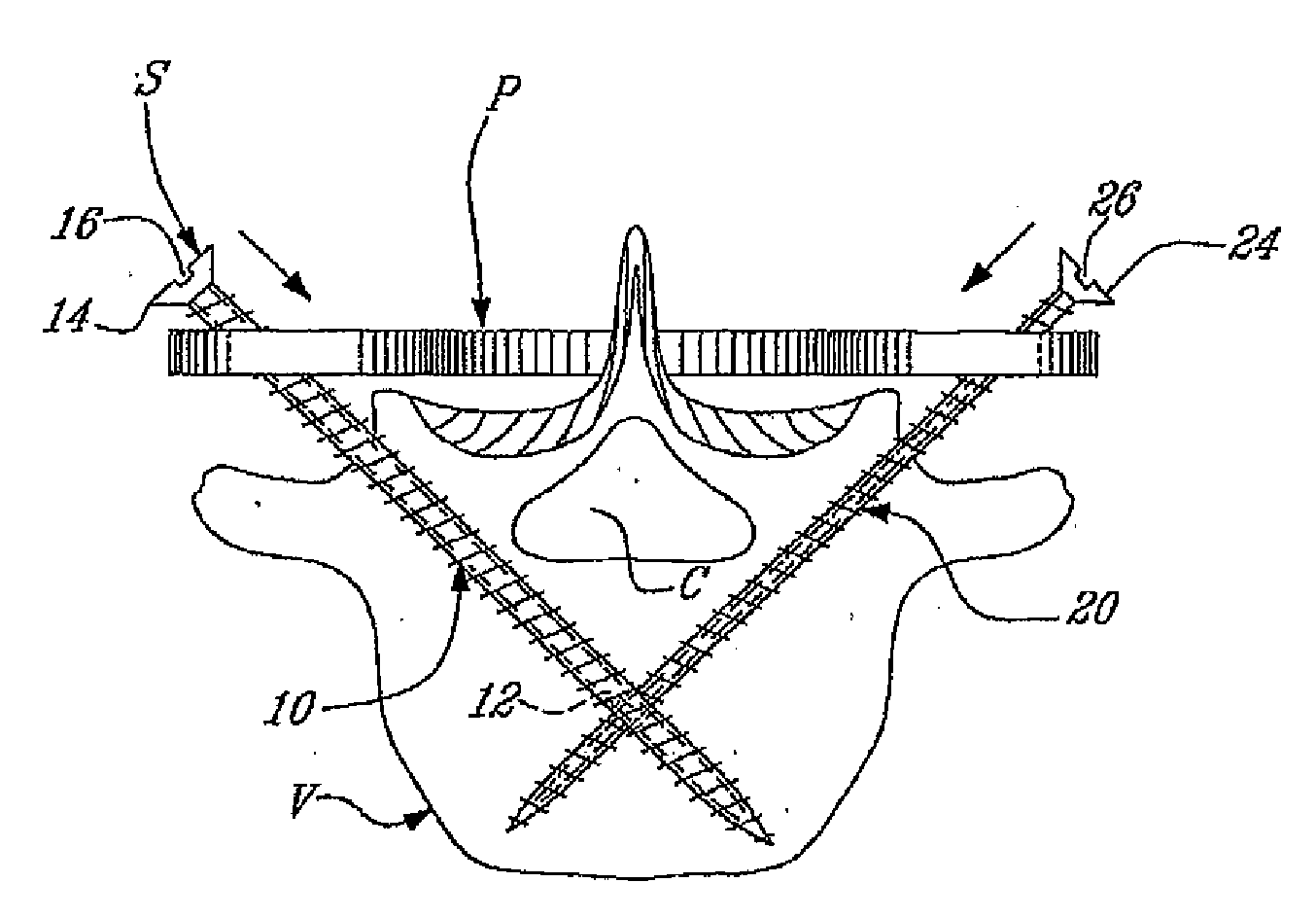

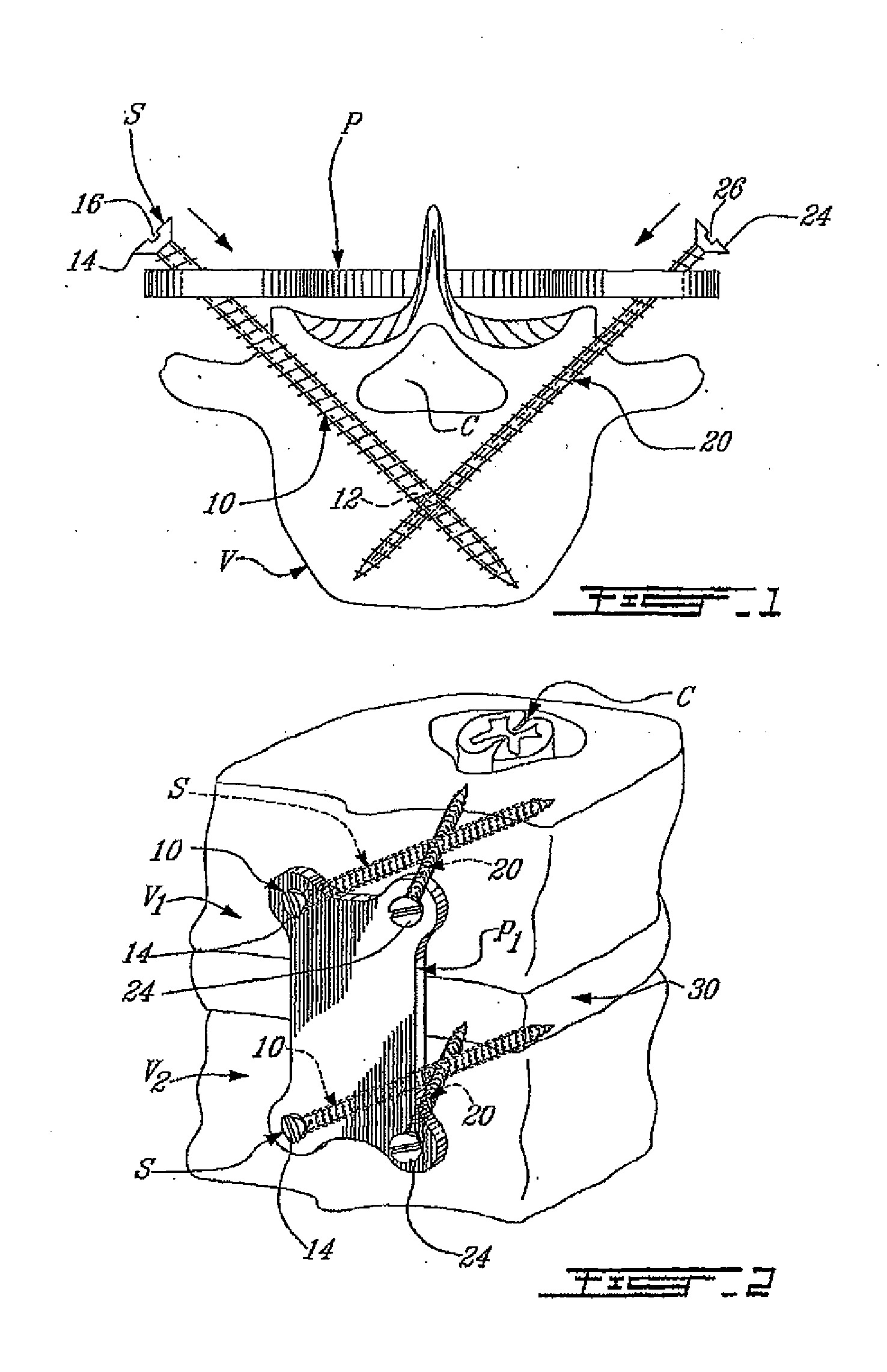

InactiveUS20080188896A1For accurate placementImprove stabilitySuture equipmentsInternal osteosythesisEngineeringFastener

A spinal plate system that allows for increased spinal stability is provided. In an embodiment, a spinal plate system is provided that includes first and second slidable plates coupled together. Each of the first and second slidable plates includes first and second fasteners that are obliquely oriented relative to the corresponding slidable plate. The first and second fasteners are fixed to each other at their distal ends thereby forming a triangular frame consisting of the corresponding slidable plate and the first and second fasteners. In addition, a fastener guide is provided that facilitates the accurate placement of the first and second fasteners for each of the first and second slidable plates.

Owner:ORTHOPLEX

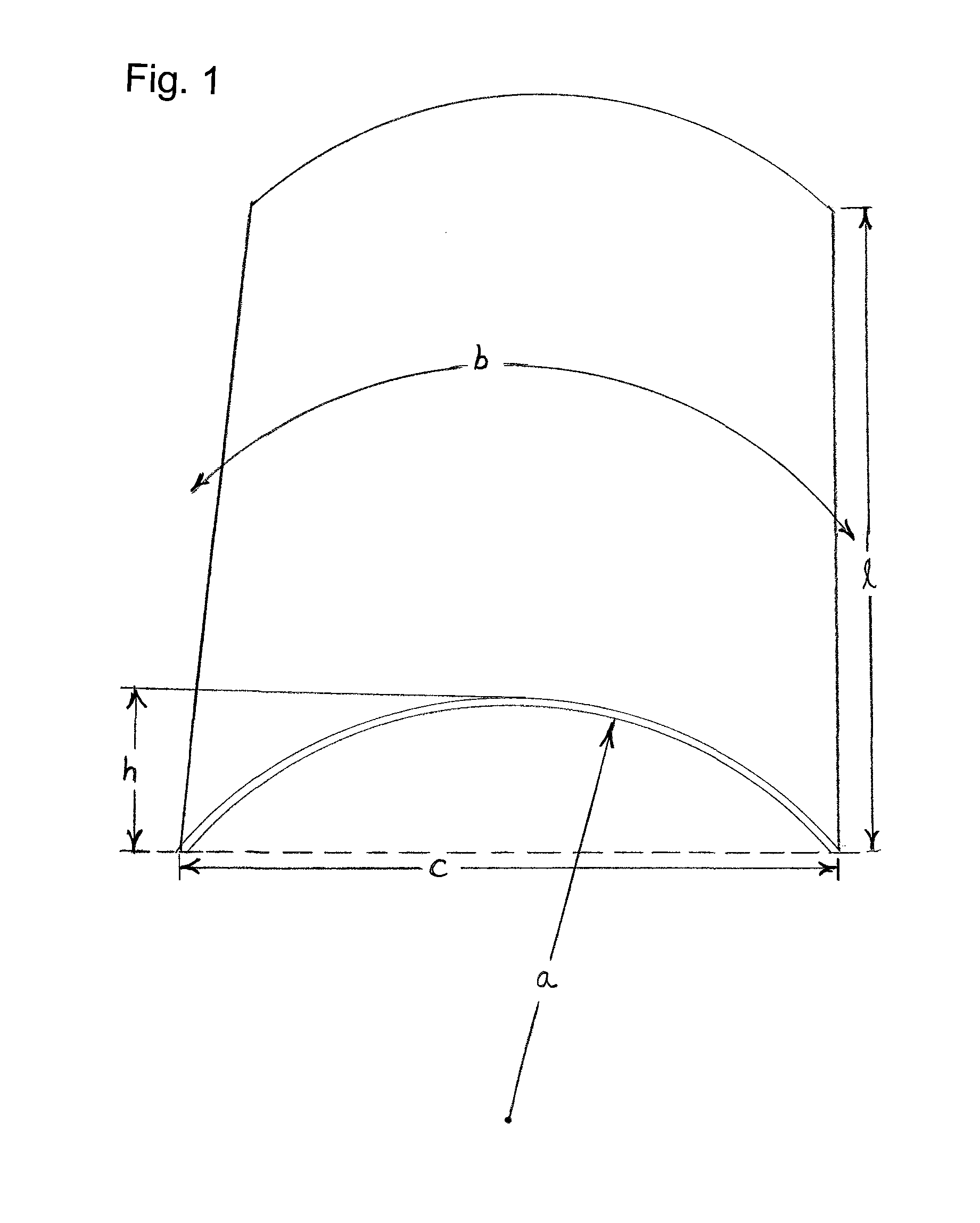

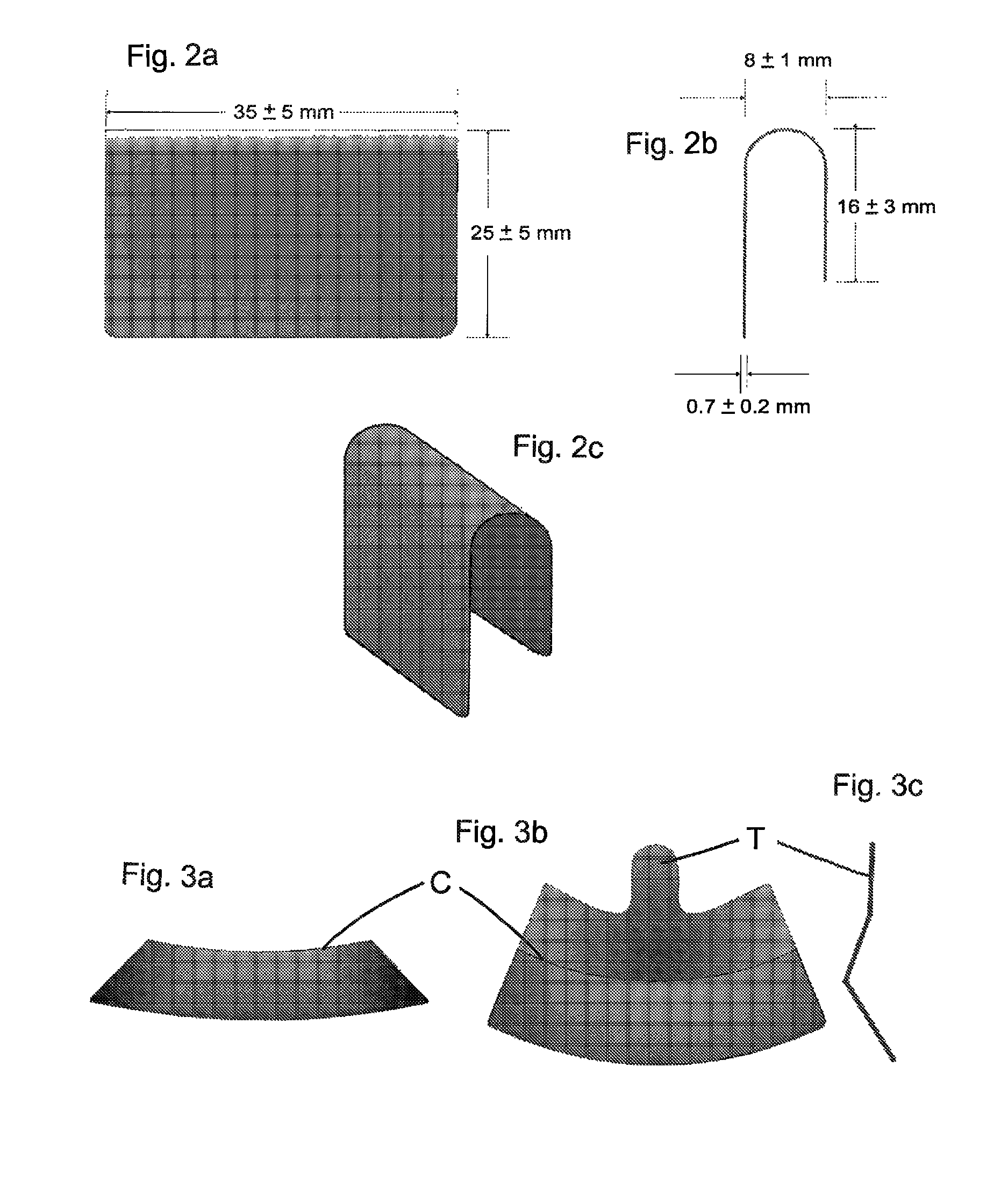

Self-supporting collagen tunnel for guided tissue regeneration and method of using same

InactiveUS8353967B2For accurate placementPrecise positioningBiocidePeptide/protein ingredientsIliac screwBiomedical engineering

A biocompatible, self-supporting, curved, collagen membrane adapted to be secured by bone tacks or bone screws over exposed bone at a desired bone graft site in the alveolar ridge of a patient such that the membrane defines a space having a predetermined height and width over the exposed bone, in which the membrane maintains its structural integrity for at least 4 months after implantation at the bone graft site and then naturally breaks down and is resorbed by the patient's body, a method of making such a membrane, and a method of using such a membrane for vertical augmentation of the alveolar ridge of the patient.

Owner:CARDOSO RONALD

RFID tag assemblies and process

Owner:HID TEXTILE SERVICES SARL

Apparatus and method for guided chronic total occlusion penetration

InactiveUS20120283565A1For accurate placementImprove permeabilityUltrasonic/sonic/infrasonic diagnosticsBalloon catheterTotal occlusionIntravascular catheter

An apparatus and method for guided penetration of a chronic total occlusion in a blood vessel are disclosed. The invention is directed to an apparatus that facilitates accurate placement of a drilling tip within a body lumen using ultrasound-based detection to determine the position of the intravascular catheter relative to the vessel occlusion and vessel walls.

Owner:MEDINOL LTD

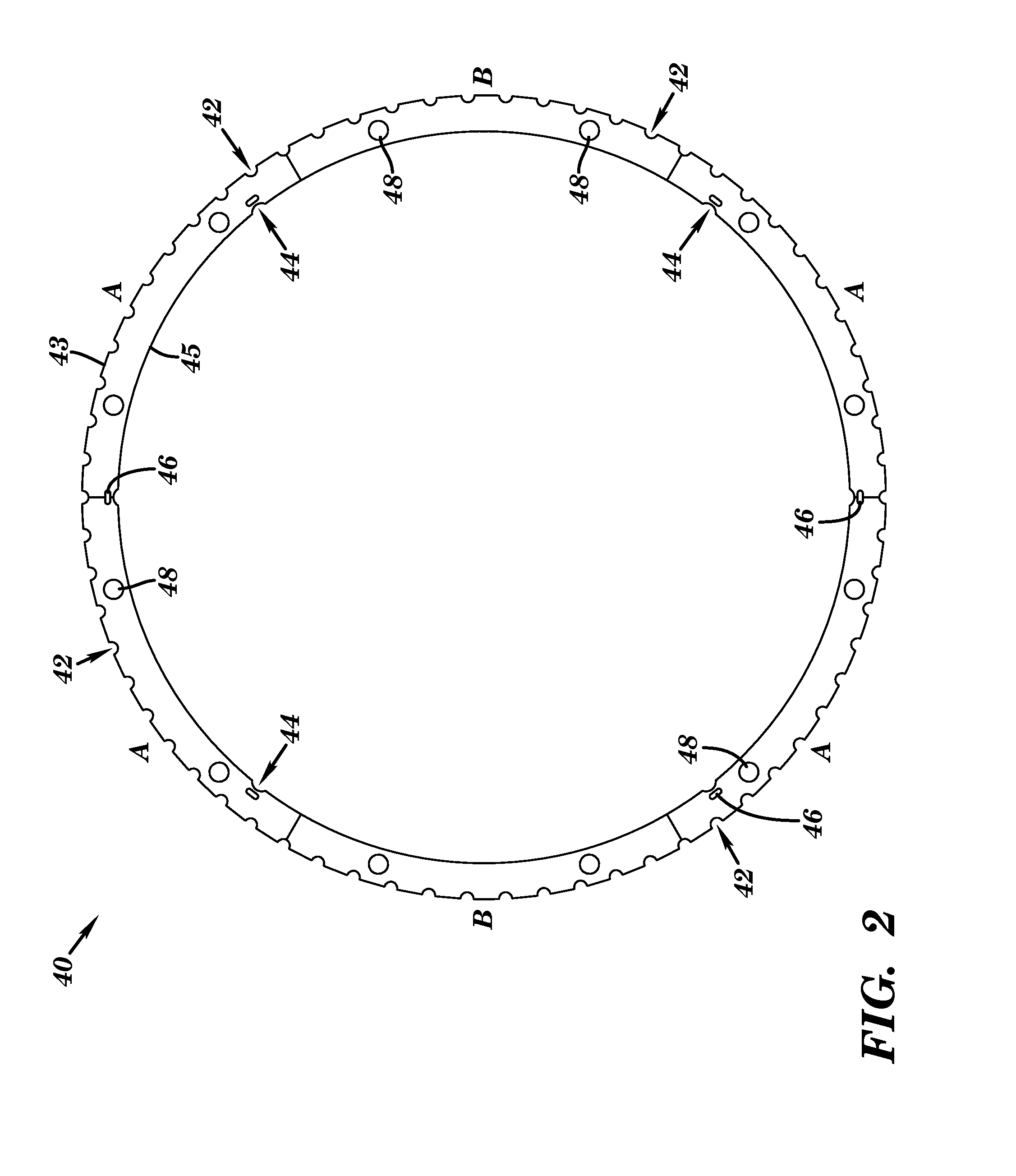

Rebar cage stiffener ring

ActiveUS8387329B2Added fabricationFor accurate placementTowersBuilding reinforcementsEngineeringRebar

Owner:DIMENSION FABTORS

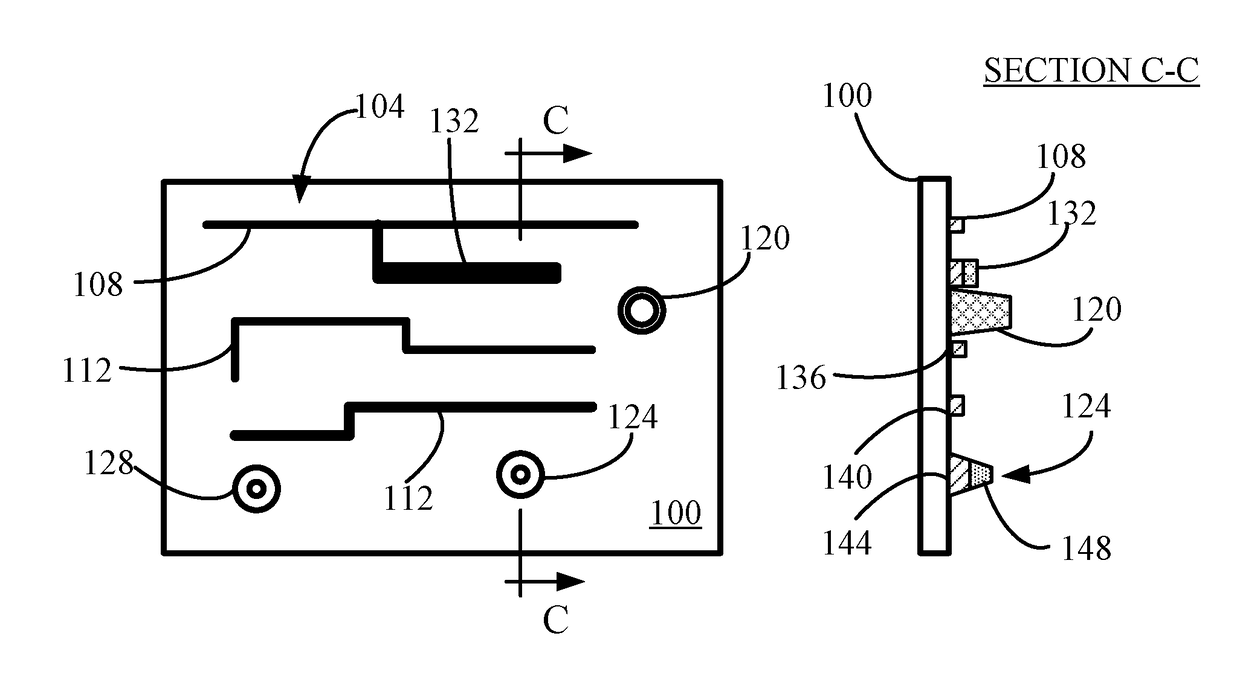

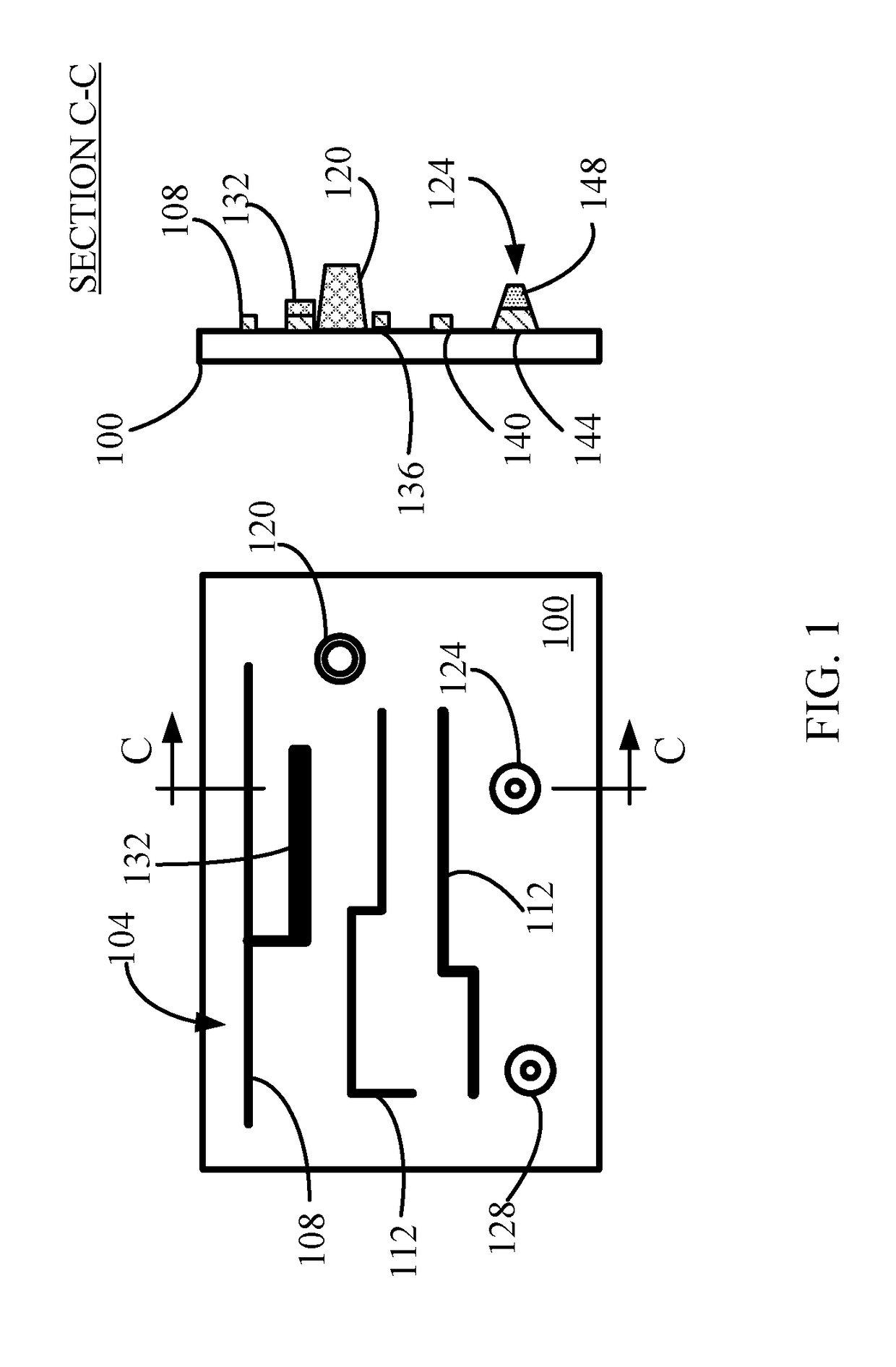

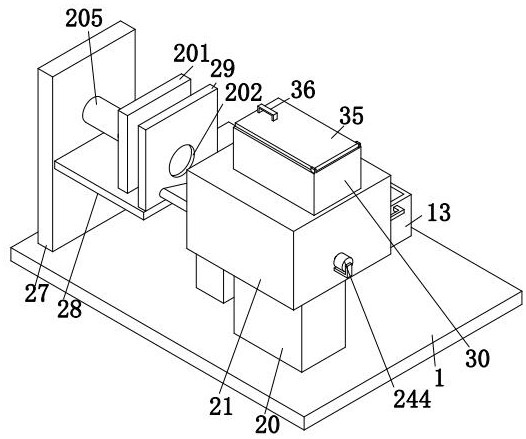

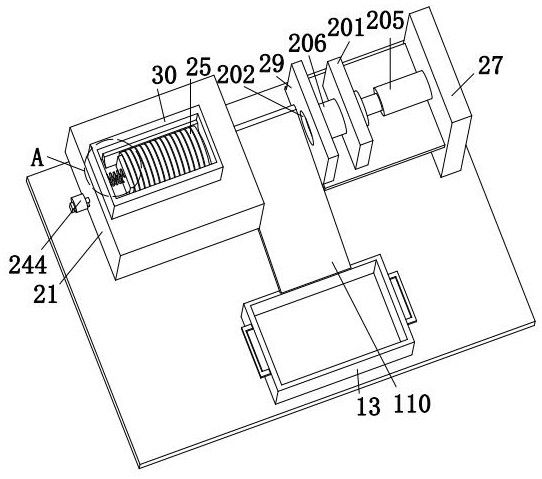

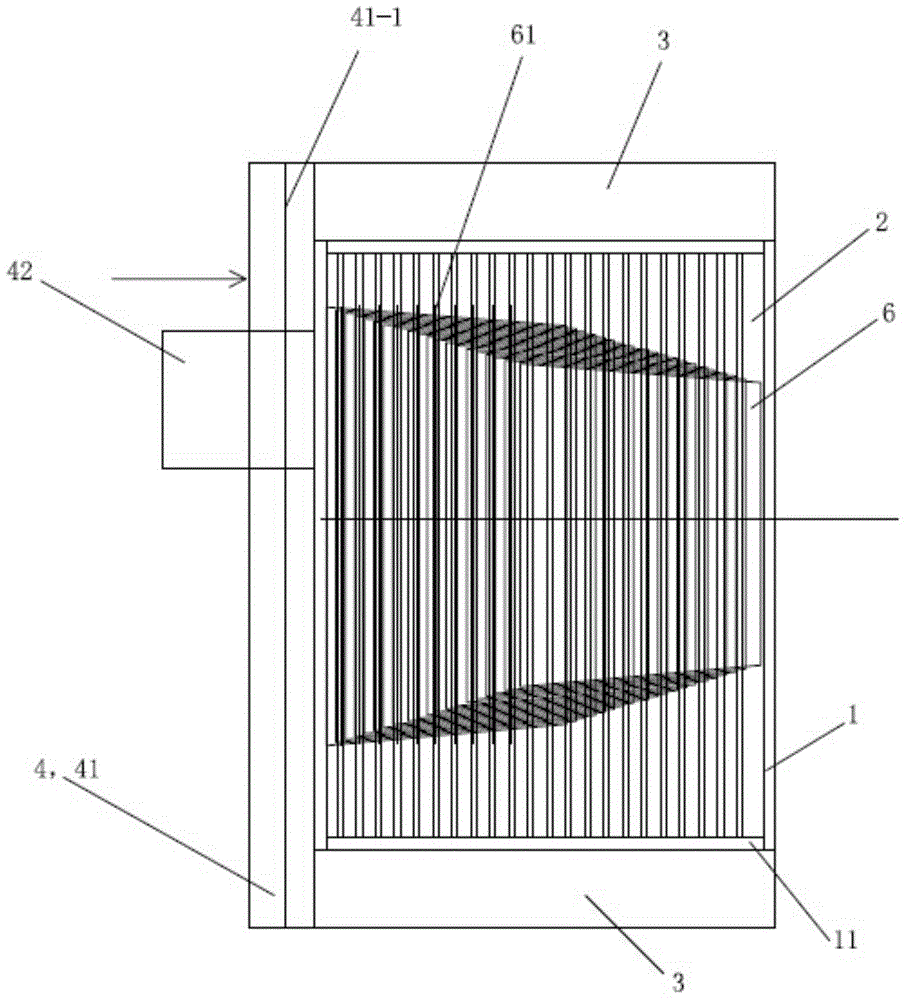

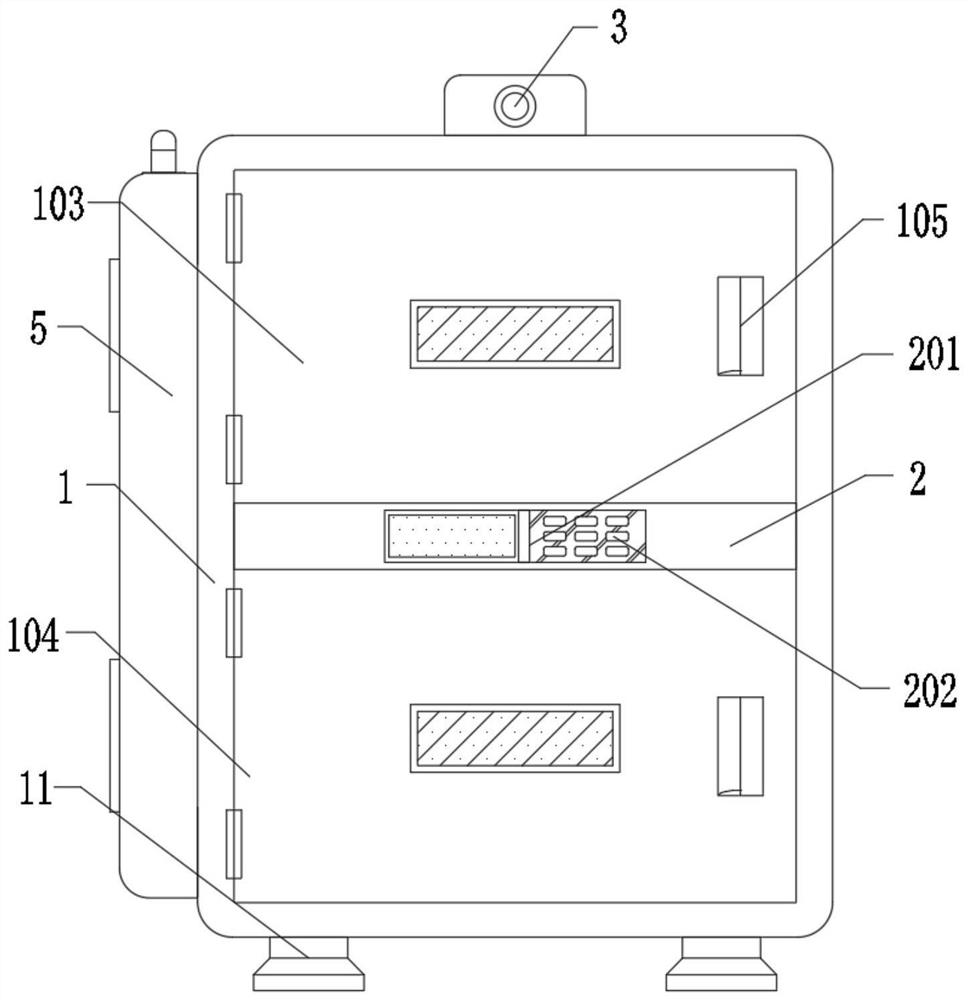

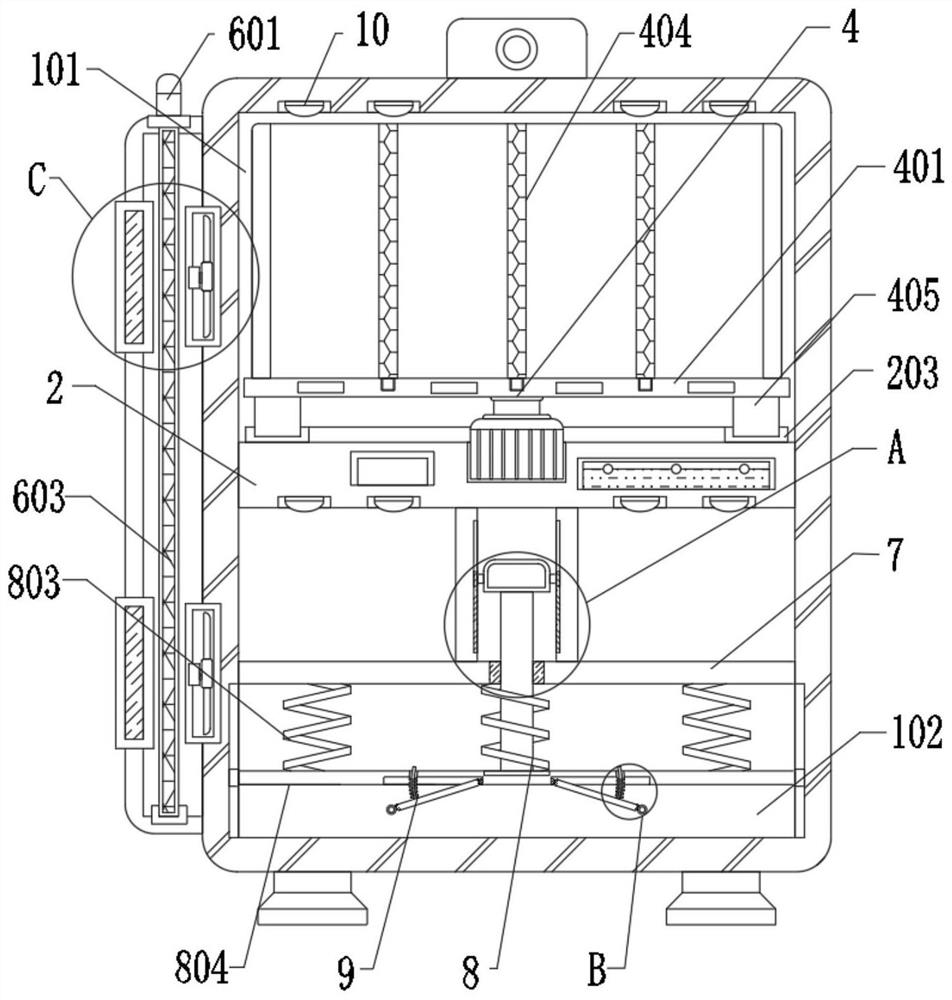

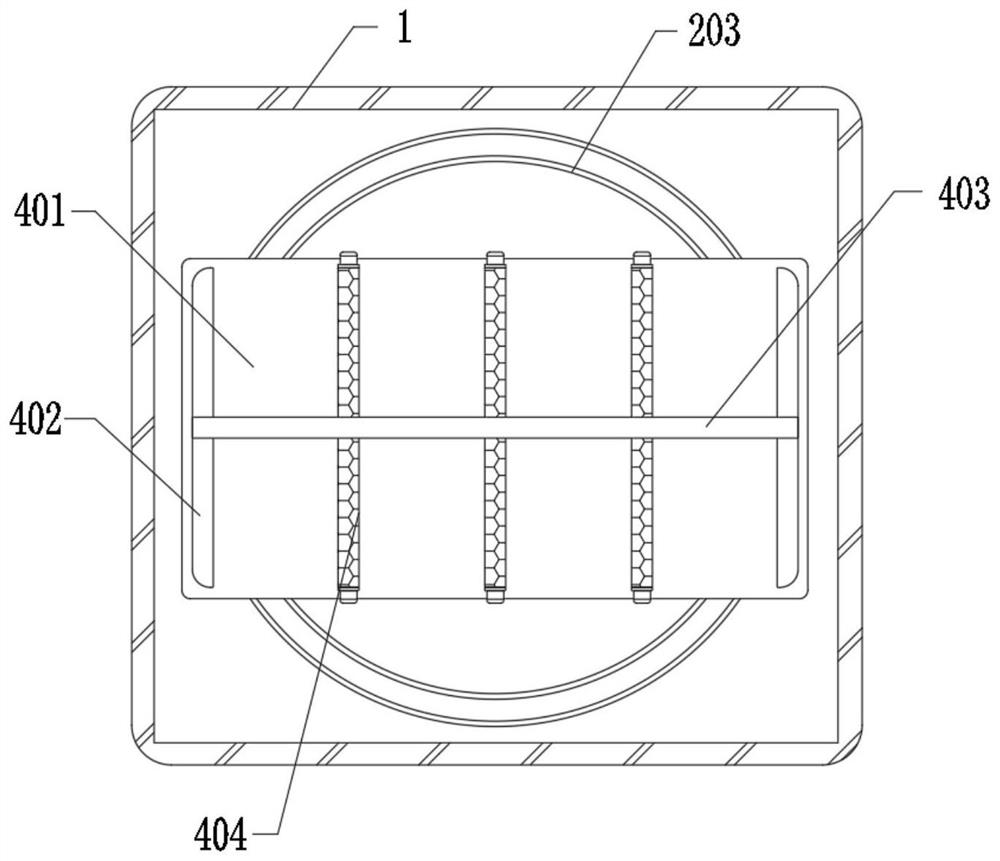

Instrument material holder and method of fabrication thereof

InactiveUS6860632B2Labor intensive processFor accurate placementThermometer detailsMaterial heat developmentConductor CoilHOLDING CHAMBER

A housing for a material holder includes an intermediate housing member having a generally horizontal member, an upper recess and a lower recess, an upper housing member having a generally horizontal member and a wall defining a material holding chamber, the upper housing member being seated within the upper recess of the intermediate housing member, and a lower housing member having a generally horizontal member, the lower housing member being seated within the lower recess of the intermediate housing member. The upper recess, the generally horizontal member of the intermediate housing member and the generally horizontal member of the upper housing member define a first cavity adapted to receive a first winding assembly, and the lower recess, the generally horizontal member of the intermediate housing member and the generally horizontal member of the lower housing member define a second cavity adapted to receive a second winding assembly.

Owner:PERKINELMER U S LLC

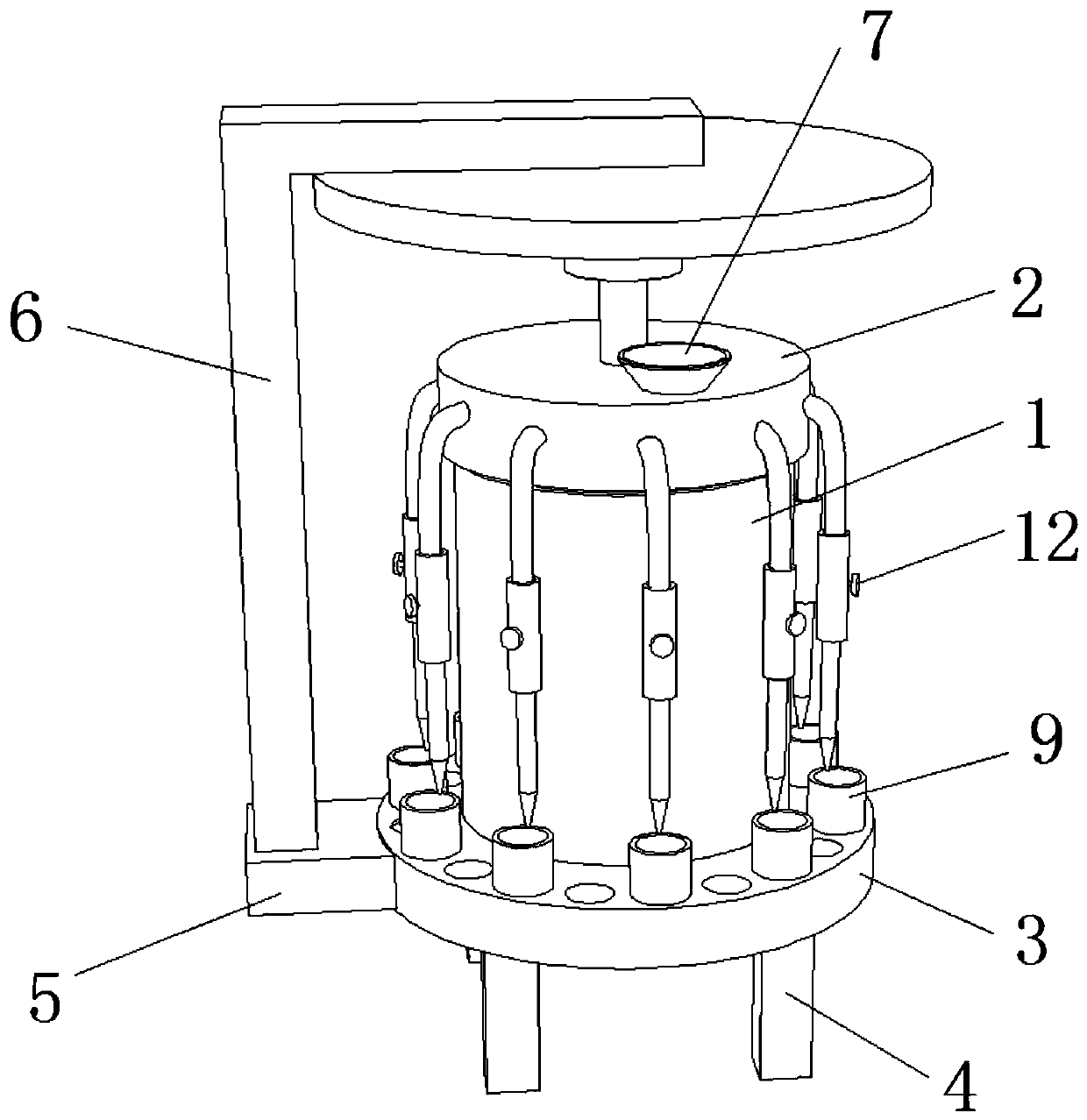

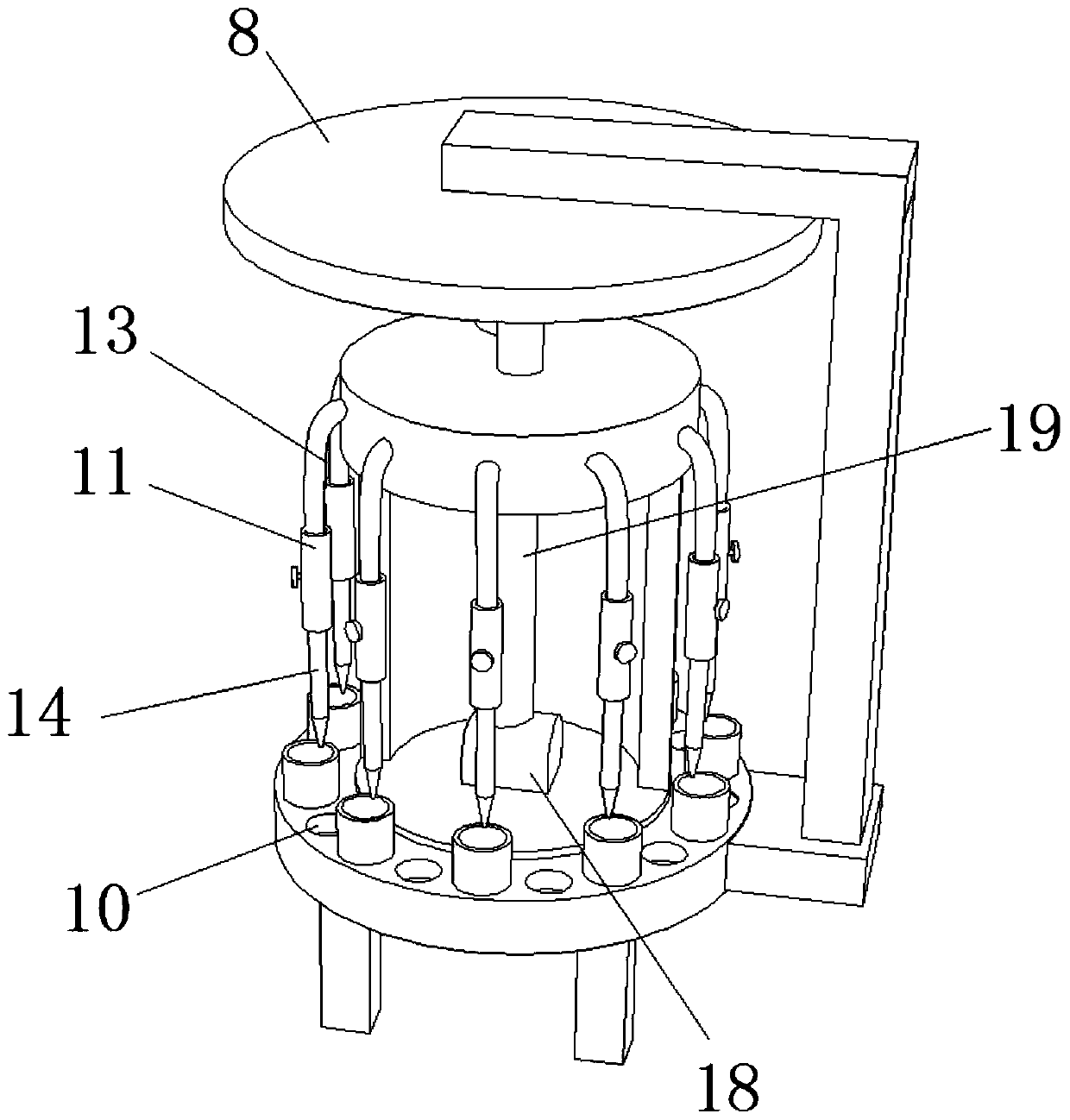

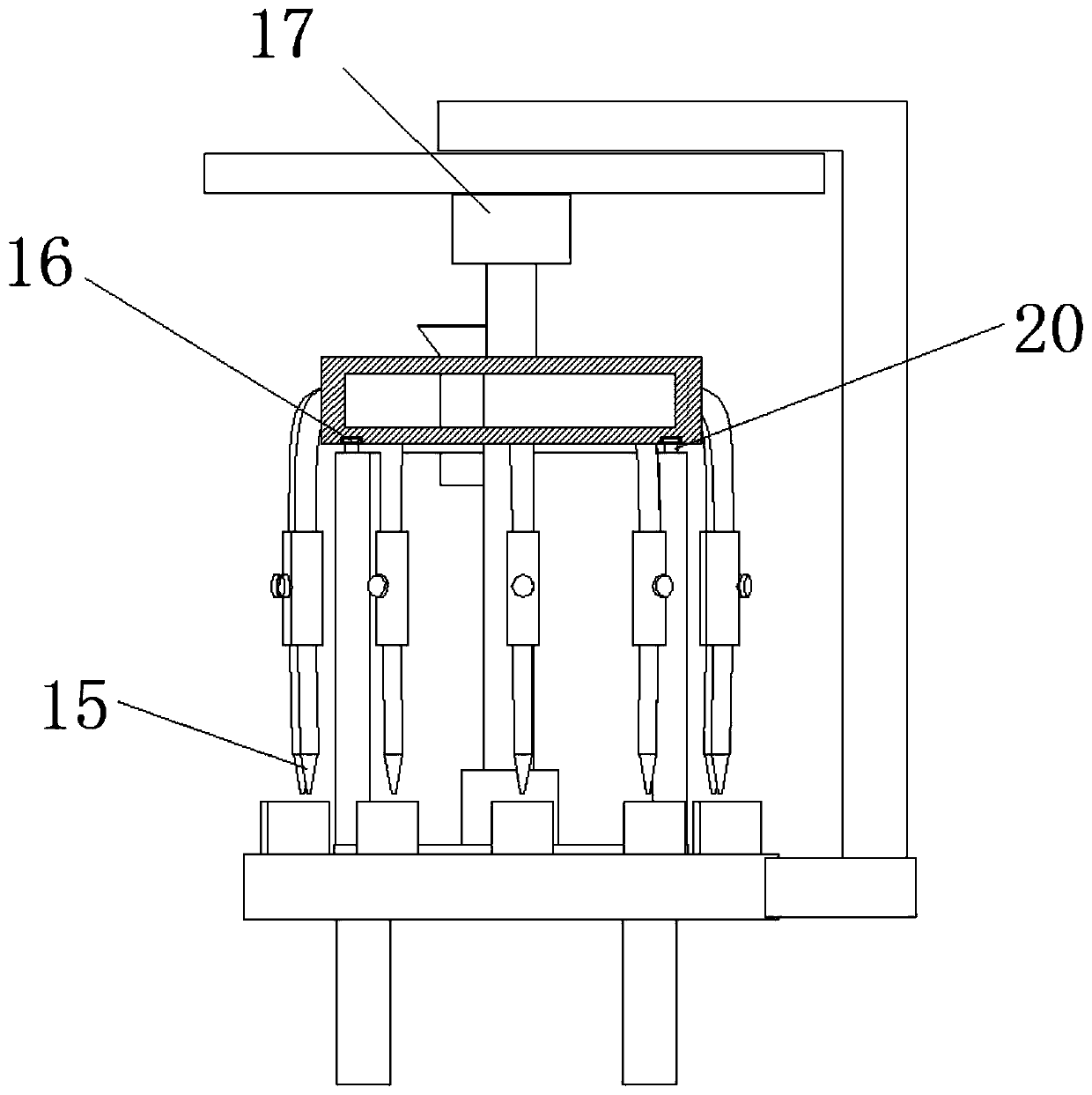

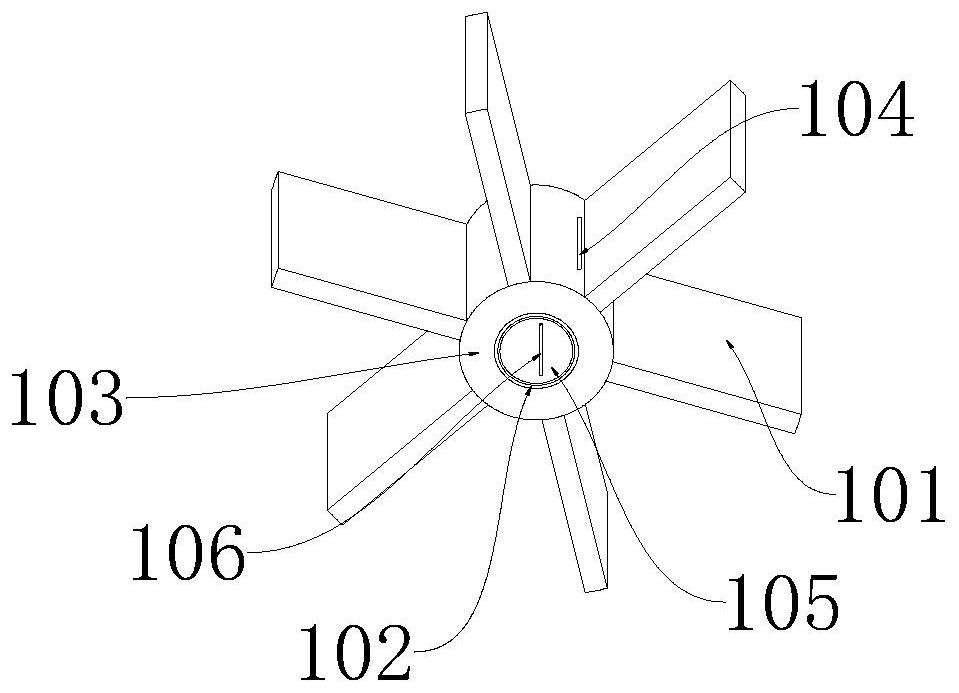

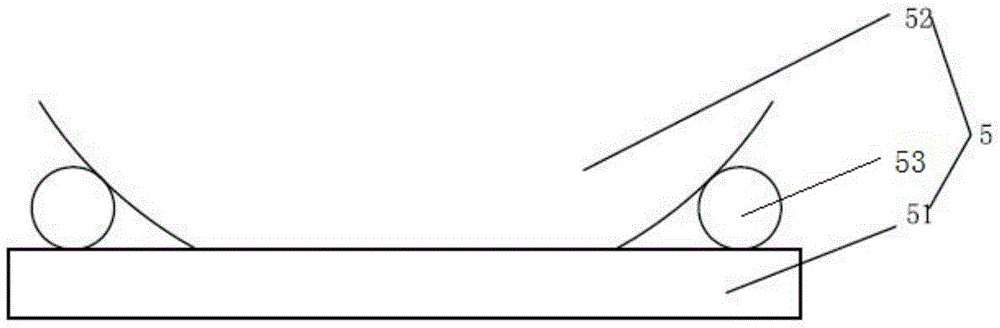

Metering and filling device used in camellia seed oil production process

InactiveCN110835081AConducive to manual operationOperation without backlashLiquid bottlingAgricultural scienceAgricultural engineering

The invention discloses a metering and filling device used in a camellia seed oil production process, and relates to the technical field of metering and filling devices. The metering and filling device used in the camellia seed oil production process aims to solve the problems in the prior art that the metering and filling device used in the camellia seed oil production process is inconvenient tooperate manually and the filling efficiency of the existing filling device which is convenient for manual operation is low. The metering and filling device used in the camellia seed oil production process comprises an oil barrel, wherein the lower end of the oil barrel is connected with a fixing seat, a plurality of filling bottles are placed at the upper end of the fixing seat, the upper end of the oil barrel is connected with a rotary cover, a cavity is arranged in the rotary cover, a plurality of filling guns are connected to the side end of the rotary cover, an extension plate is connectedto the side end of the fixing seat, an L-shaped support column is connected to the upper end of the extension plate, a bearing plate is connected to the lower end of the L-shaped support column, a motor is connected to the lower end of the bearing plate, and the power output end of the motor is fixedly connected to the center of the upper end of the bearing plate. The metering and filling deviceused in the camellia seed oil production process is convenient for manual operation, the rotary cover and the filling guns are driven by the motor to rotate for filling, thus gapless connection operation can be realized, operation time is saved, and filling efficiency is improved.

Owner:湖南神农国油生态农业发展有限公司

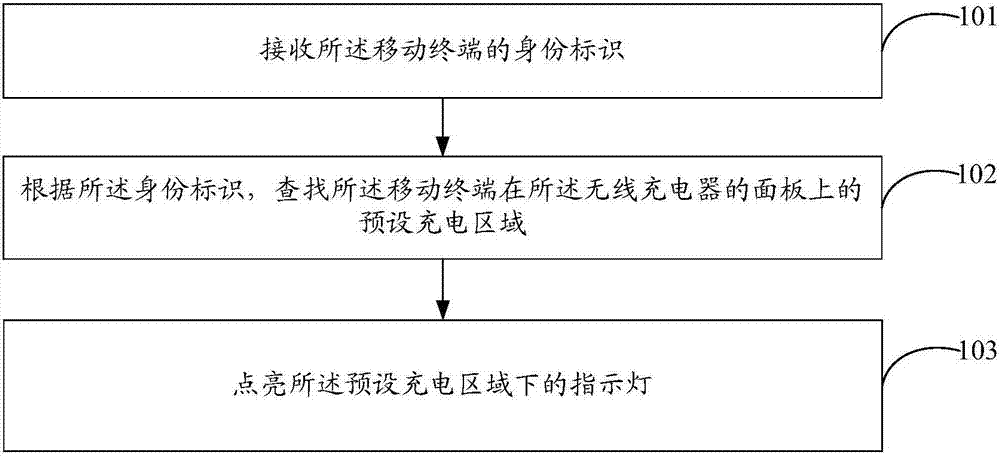

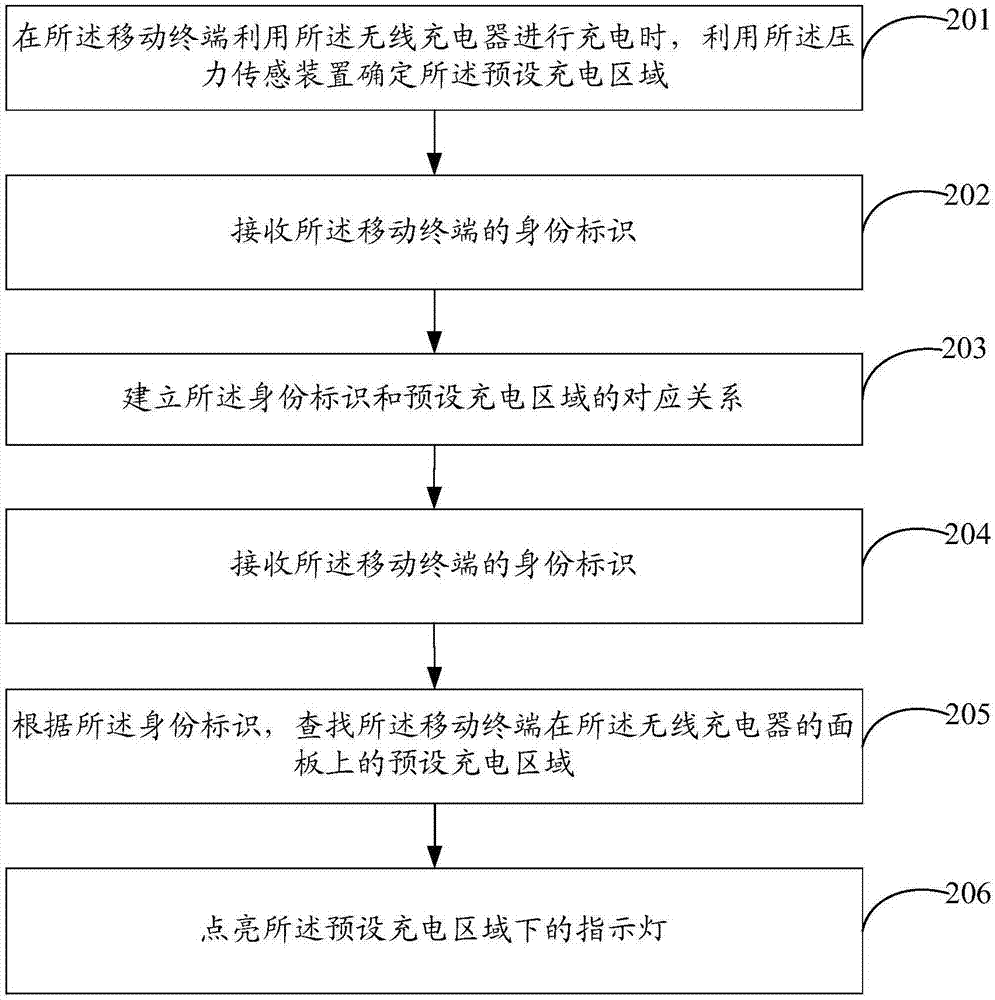

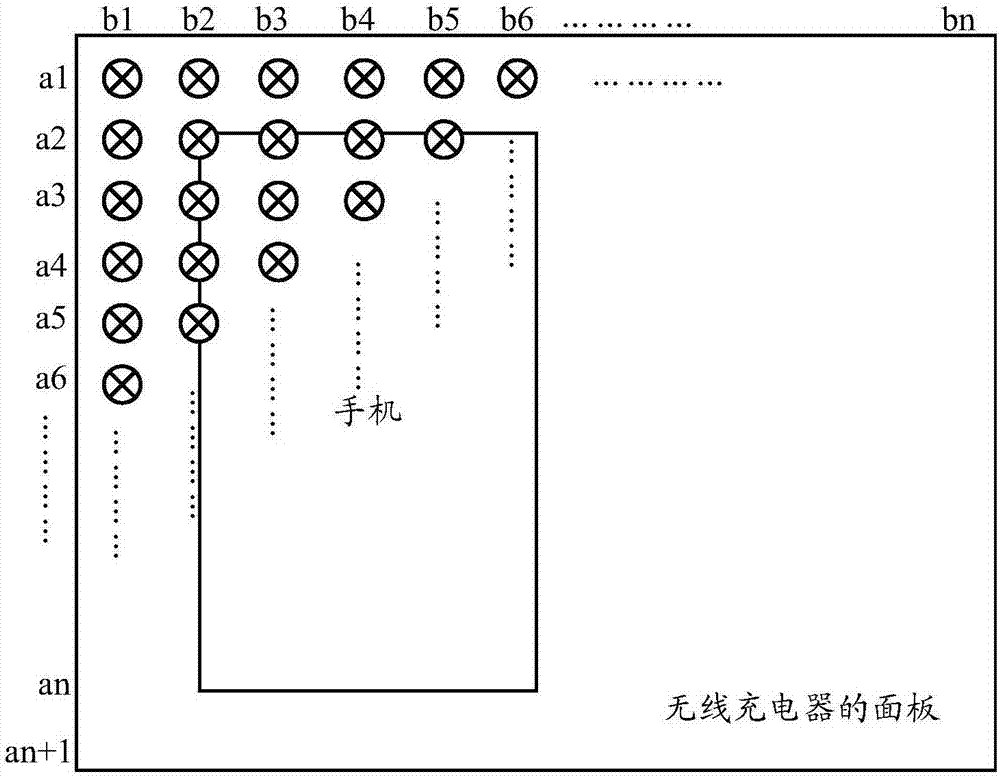

Charging area display method, and wireless charger

ActiveCN107317374AFor accurate placementDifferent batteries chargingForce measurementTelecommunicationsComputer terminal

The embodiment of the invention provides a charging area display method, and a charger. The method is applied to the wireless charger. A plurality of indication lamps used for indicating charging areas are arranged below a panel of the wireless charger. The method comprises the following steps: receiving an identifier of a mobile terminal; according to the identifier, searching for a preset charging area for the mobile terminal on the panel of the wireless charger; and lightening the indication lamp below the preset charging area. The preset charging area is pre-determined for the mobile terminal placed on the panel of the wireless charger, so that when the mobile terminal needs to be charged in a wireless manner, a placement location of the mobile terminal needs not be adjusted every time to search for the charging area; and the indication lamps are used to prompt the preset charging areas for different mobile terminals, so that the mobile terminals can be placed in positions where the charging efficiencies are higher than the charging efficiencies in random placement positions, and the problem that the placement positions of the mobile terminals need to be adjusted for multiple times every time before charging is avoided.

Owner:VIVO MOBILE COMM CO LTD

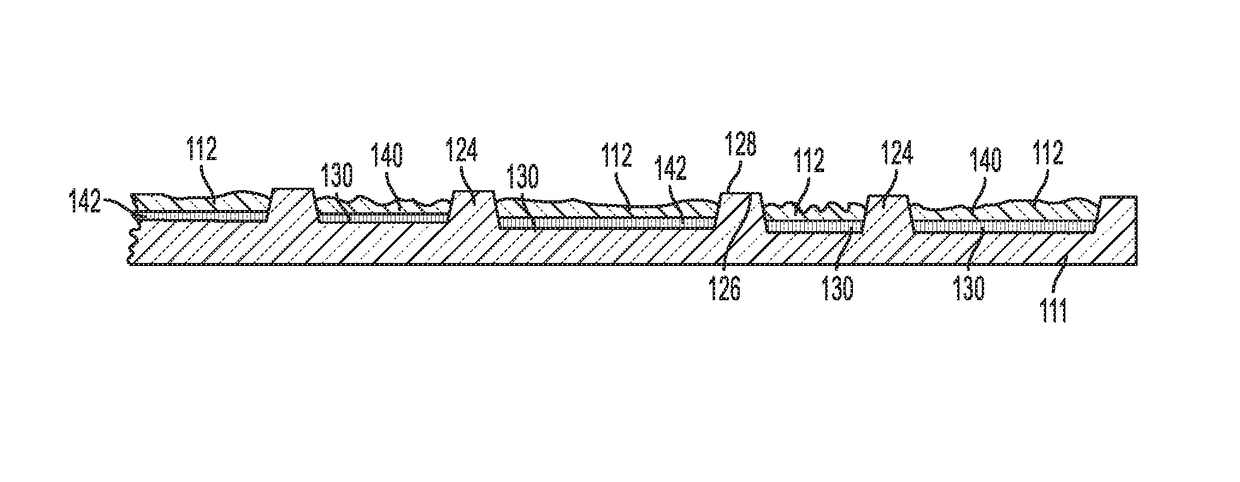

Printing high aspect ratio patterns

ActiveUS9750141B2For accurate placementComplicate the second printed layer registrationPrinted circuit aspectsPrinted circuits stress/warp reductionEngineeringViscosity

Described are an apparatus and a method for printing a high aspect ratio and / or specific vertical geometry pattern. The apparatus operates in a multi-pass printing mode and includes one or more paste dispensing mechanism configured to dispense a high viscosity paste to form a pattern on a substrate. At least one paste dispensing mechanism is configured to dispense the paste to a segment of the pattern printed at an earlier pass. The paste is dispensed to the relevant segment of the pattern earlier printed before the paste printed at the earlier made pass is dry or what is termed “wet-on-wet” printing.

Owner:WUHAN DR LASER TECH CORP LTD

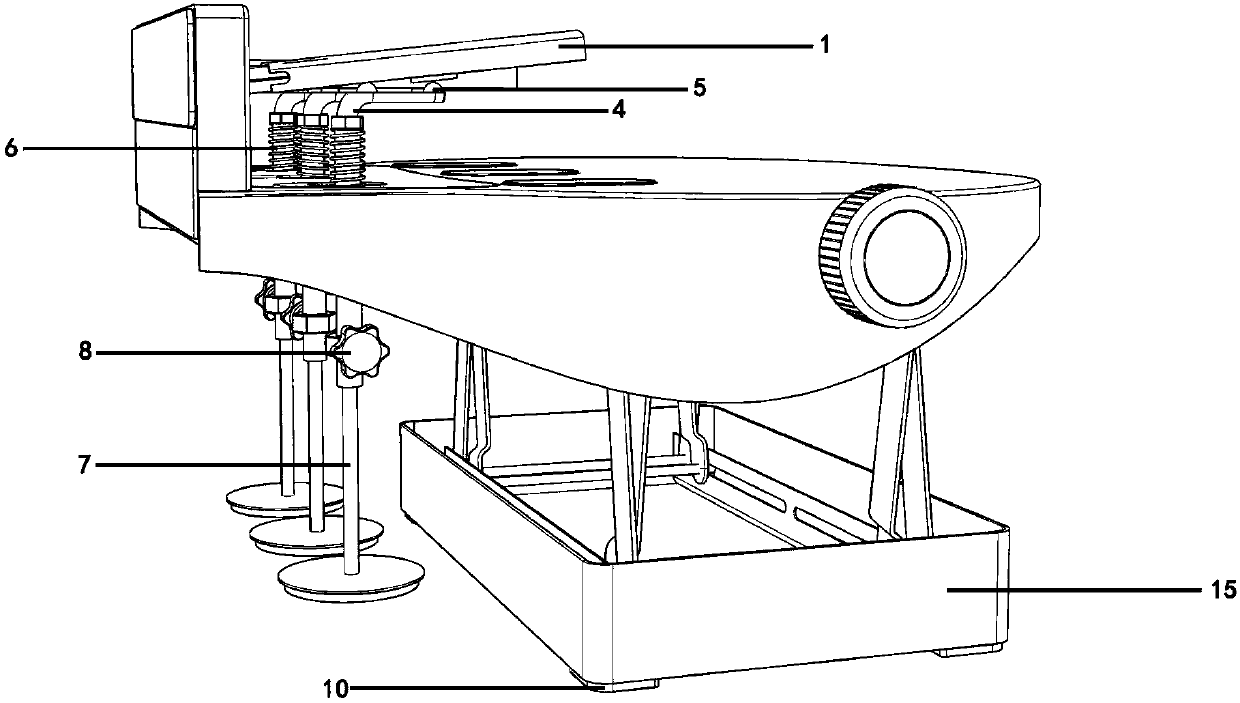

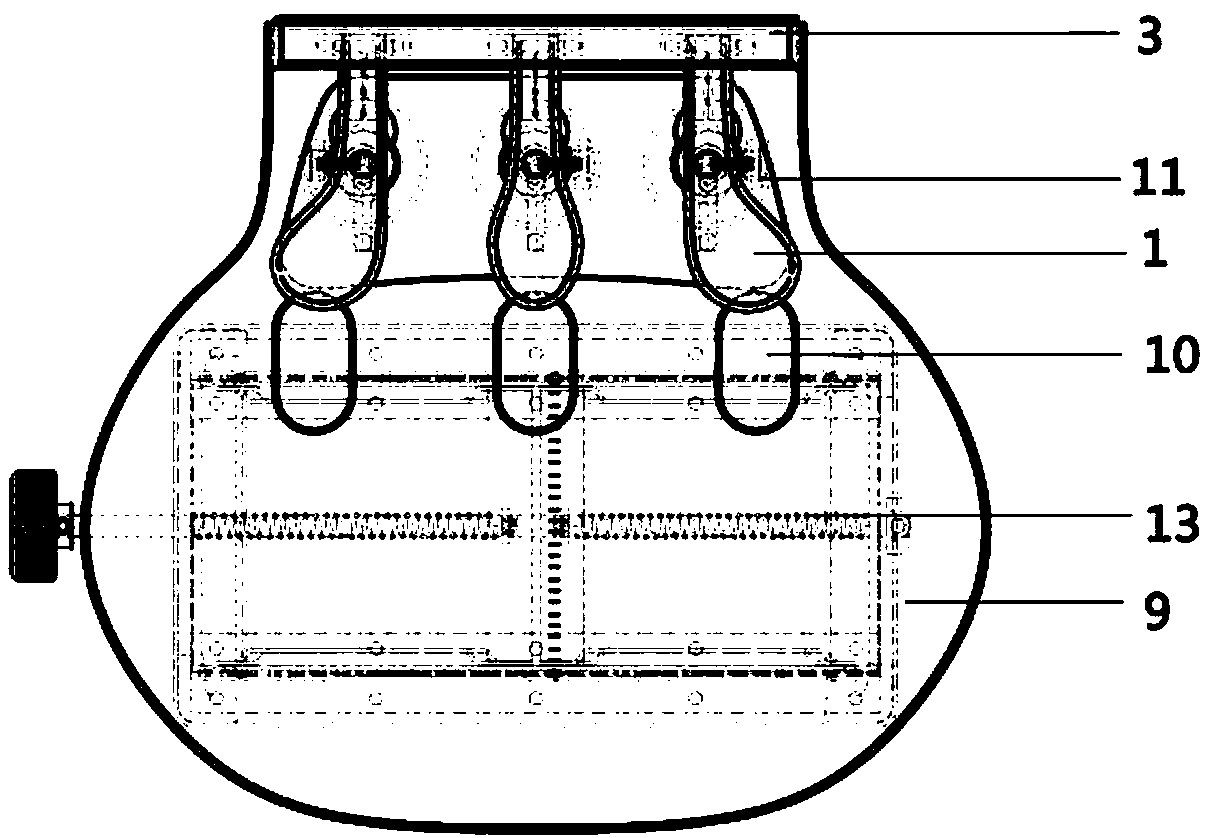

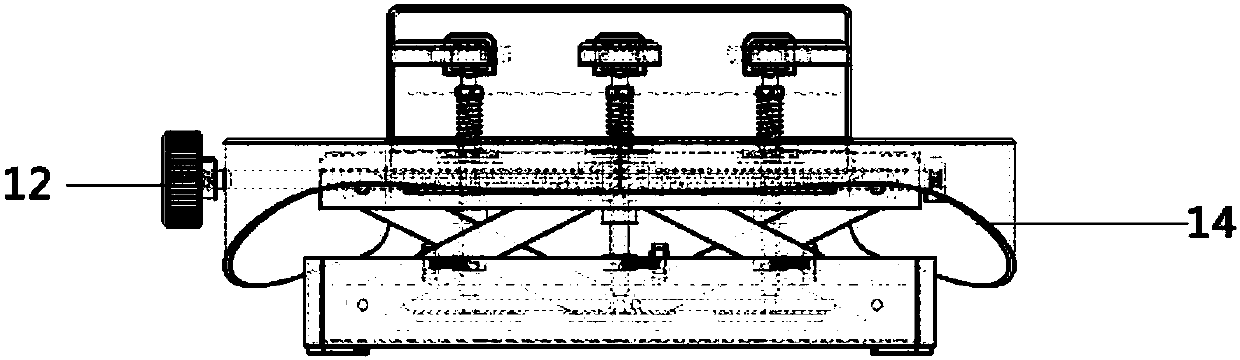

Auxiliary pedal of children's piano

PendingCN107731203AEasy to playRealize the pedal effectStringed musical instrumentsPianoRotational axis

The invention discloses an auxiliary pedal of a children's piano. The auxiliary pedal of the children's piano comprises an extending pedal, a pedal fixing plate, a foot placing face plate and an X adjusting device; the extending pedal performs sliding adjustment with a sliding groove through an internally provided telescopic rod and is connected with the pedal fixing plate through a rotating shaft, and the extending pedal is occluded with the convex scale on a bending pressing rod to adjust the telescopic length of the pedal. A height adjusting rotary knob is arranged on the left side of the foot placing face plate, the X adjusting device is arranged in a pedestal and is fixedly connected with the foot placing face plate through the rotating shaft, a rubber pad and a colorless transparentacrylic plate are embedded on the surface of the foot placing face plate, three through holes are formed in the acrylic plate, and the bending pressing rod acts on the piano pedal through the effect of the through holes in the acrylic plate. A rubber handle is arranged in the right side of the auxiliary pedal of the children's piano, so that the auxiliary pedal of the children's piano is convenient to carry.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

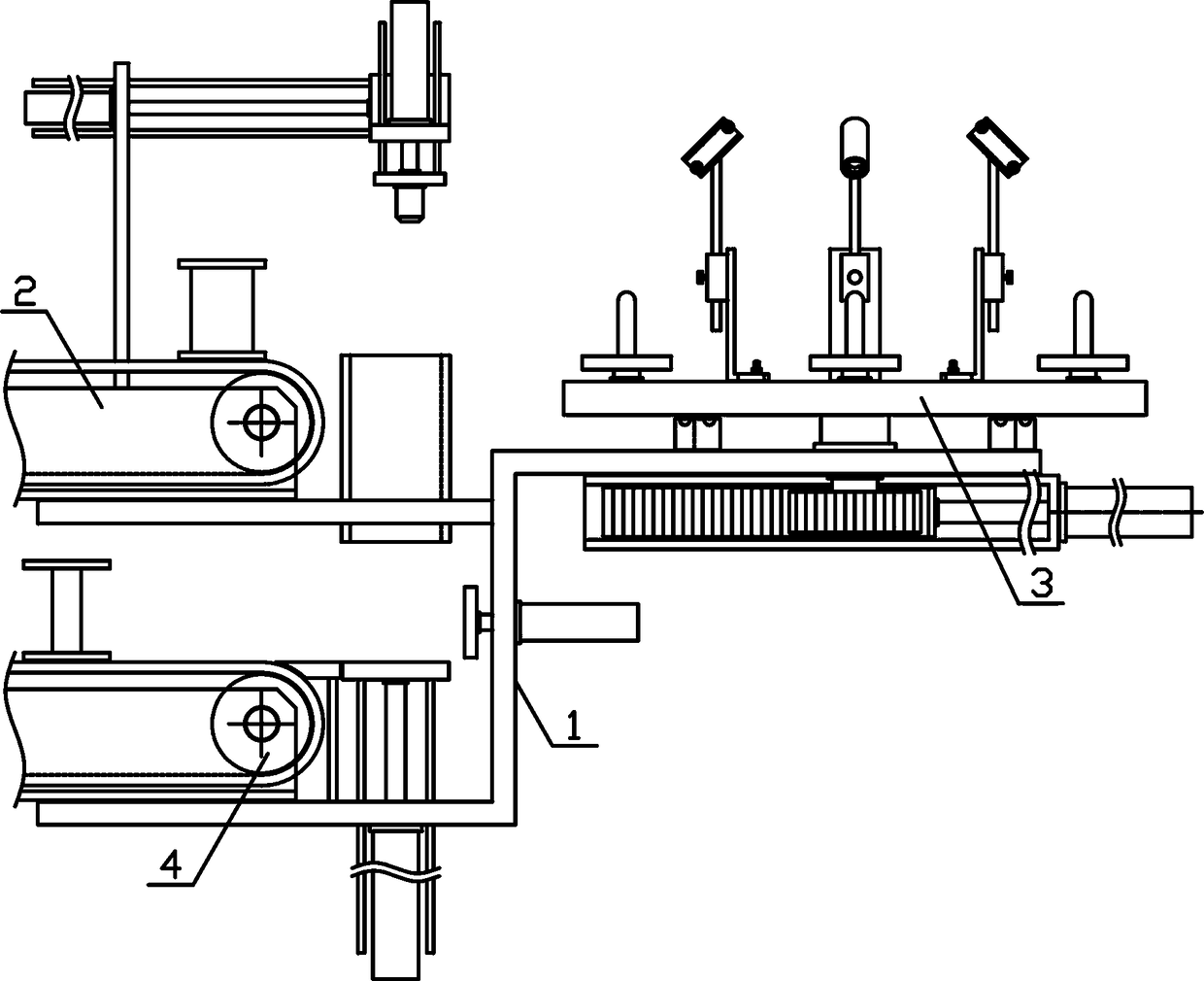

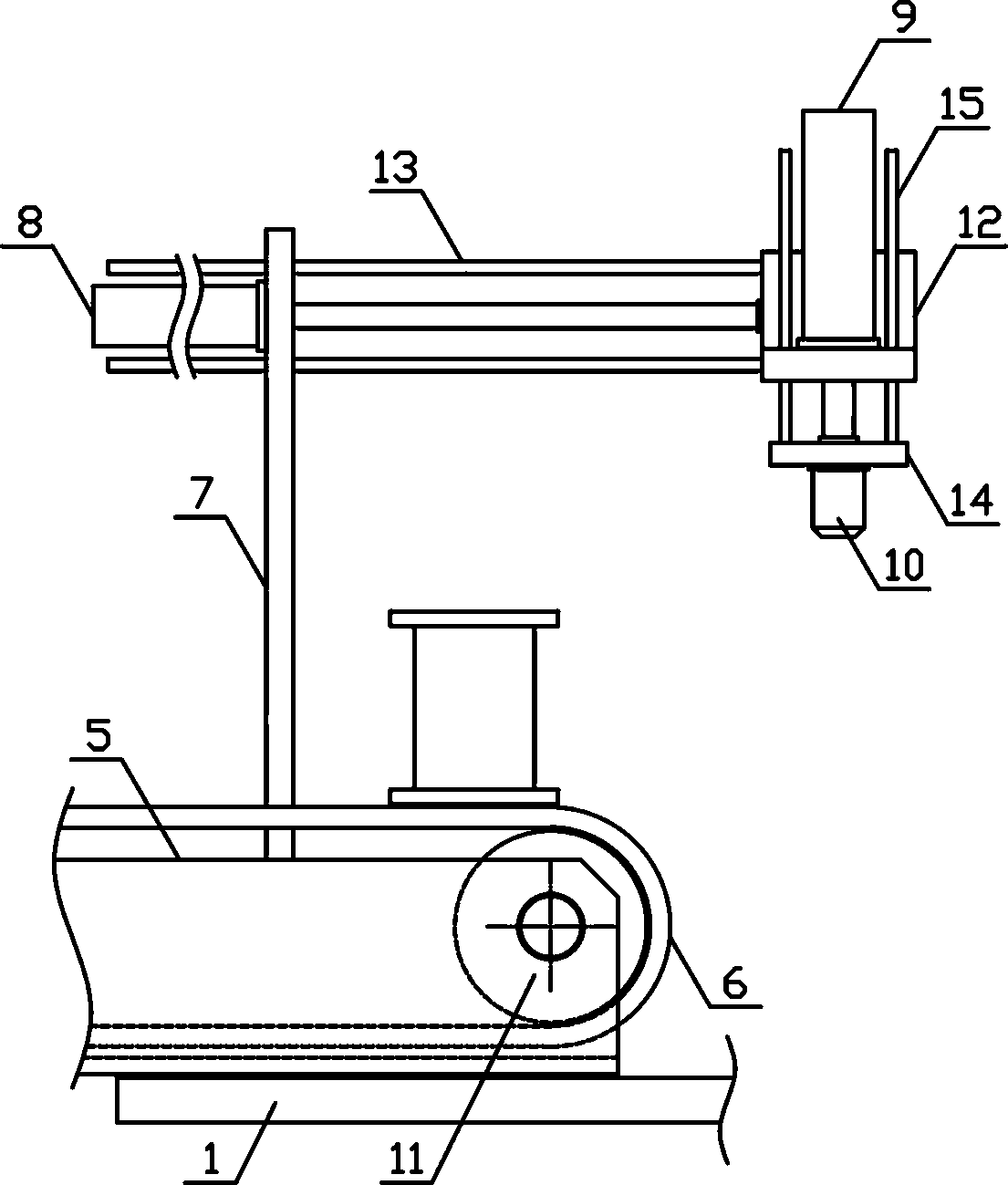

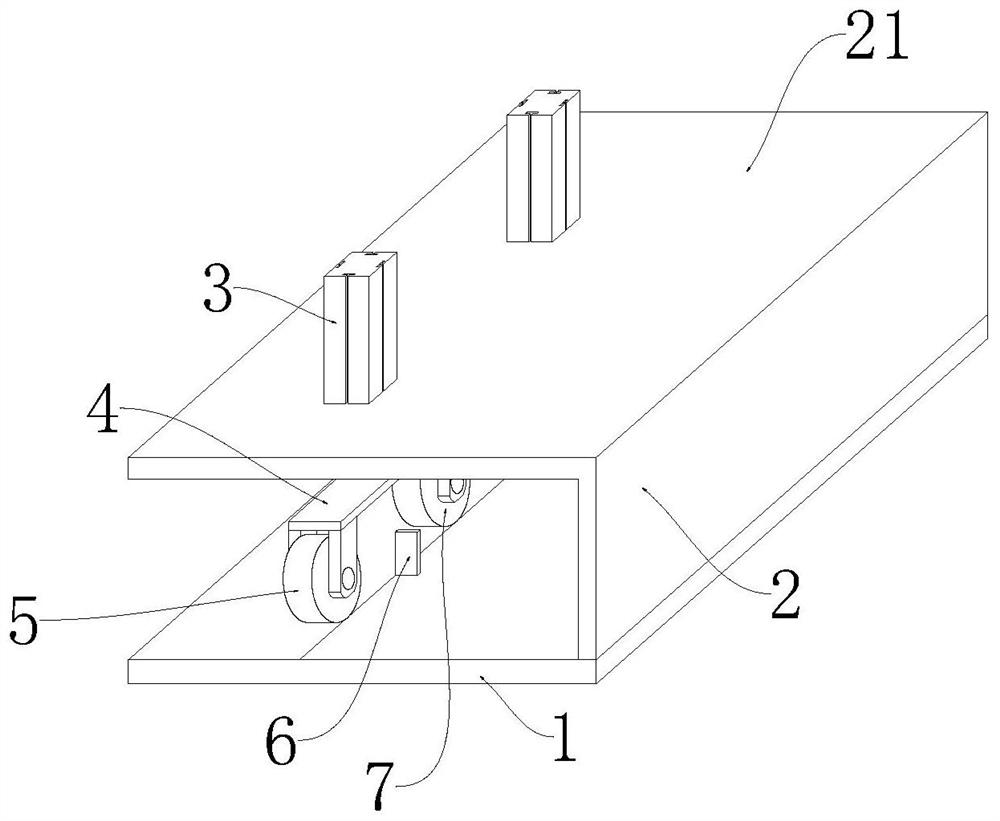

Automatic replacement mechanism for chemical fiber cone yarns

The invention discloses an automatic replacement mechanism for chemical fiber cone yarns, and belongs to the field of chemical fiber conveying processing mechanical equipment. A cone yarn feeding mechanism and a cone yarn retreating mechanism of the automatic replacement mechanism are arranged on a fixed bracket from top to bottom in sequence, a yarn unwinding mechanism is horizontally arranged atthe position, on one side of the cone yarn feeding mechanism, of the fixed bracket, a cone yarn feeding material belt is horizontally arranged on the upper side of a cone yarn feeding bracket, the output end of a cone yarn feeding air cylinder is fixedly provided with a cone yarn feeding connecting plate, and a cone yarn clamping gas expansion shaft is vertically and fixedly arranged at the portion, on the middle portion of the lower side of a cone yarn clamping connecting plate, of a cone yarn clamping air cylinder; and the middle portion of the lower side of a yarn guiding rotary disc is fixedly connected with the upper end of a reciprocating rotating shaft, a plurality of yarn guiding mechanisms on the upper side of the yarn guiding rotary disc and cone yarn containing circular platesare arranged correspondingly, the output end of a cone yarn bearing air cylinder is horizontally and fixedly provided with a cone yarn bearing connecting plate, and a cone yarn retreating material belt is horizontally arranged on the upper side of a cone yarn retreating bracket. The automatic replacement mechanism is reasonable in structure design, a plurality of chemical fiber cone yarns can be continuously and conveniently transferred and replaced one by one in a convenient and efficient manner, so that multi-strand chemical fiber silks can be stably, accurately and synchronously transmitted, and the needs of production and use are met.

Owner:桐乡市宏力纺织股份有限公司

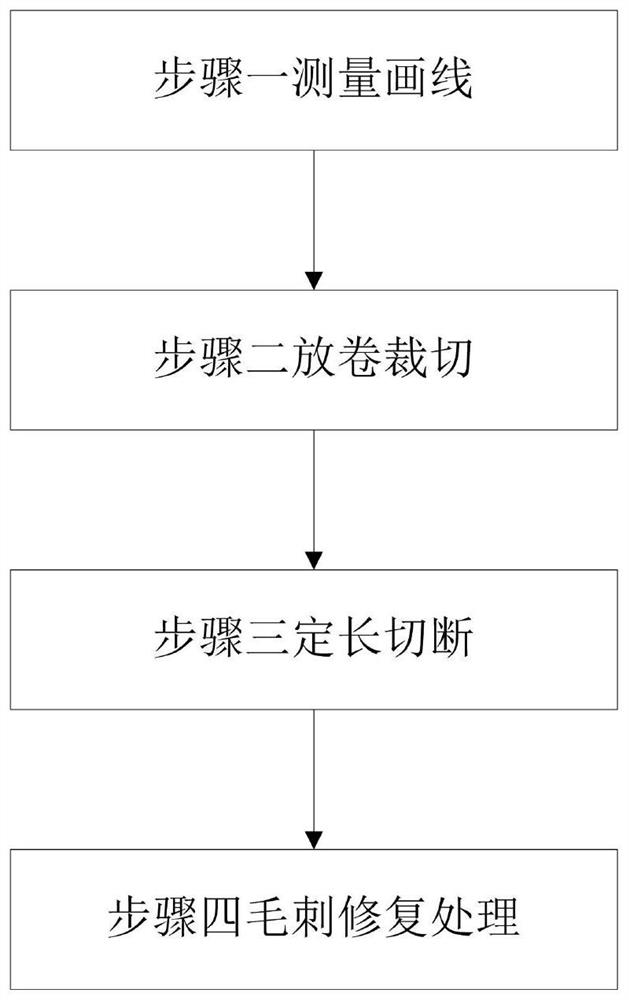

Non-woven geotextile shaping treatment method

InactiveCN111826935AEasy to burn offEasy to export collectionSingeingSevering textilesThermodynamicsNonwoven fabric

The invention relates to the technical field of non-woven fabric, in particular to a non-woven geotextile shaping treatment method. The method mainly comprises the multiple steps of measuring and linedrawing, unwinding and cutting, fixed-length cutting, burr repairing treatment and the like. An auxiliary treatment facility used in the steps of the method places the cut non-woven geotextile at theupper end of a bottom plate. The side, needing to be deburred, of the non-woven geotextile is attached to a burr scraping assembly. In the process of backwards moving the non-woven geotextile, the burr scraping assembly scrapes and unfolds burrs which are attached to the side edge of the non-woven geotextile. When the non-woven geotextile moves to the position below a flame spraying assembly, a flame which is sprayed out by the flame spraying assembly burns the burrs of the non-woven geotextile, and the burrs of the non-woven geotextile can be broken and separated from the non-woven geotextile. Meanwhile, a material falling guide assembly rotates to drive the burrs falling on the surface of the material falling guide assembly to rotate, and therefore the burrs are conveniently collected,combustion and falling operation of the burrs are facilitated, the manpower is replaced by machinery, and the working efficiency is improved.

Owner:朱姣

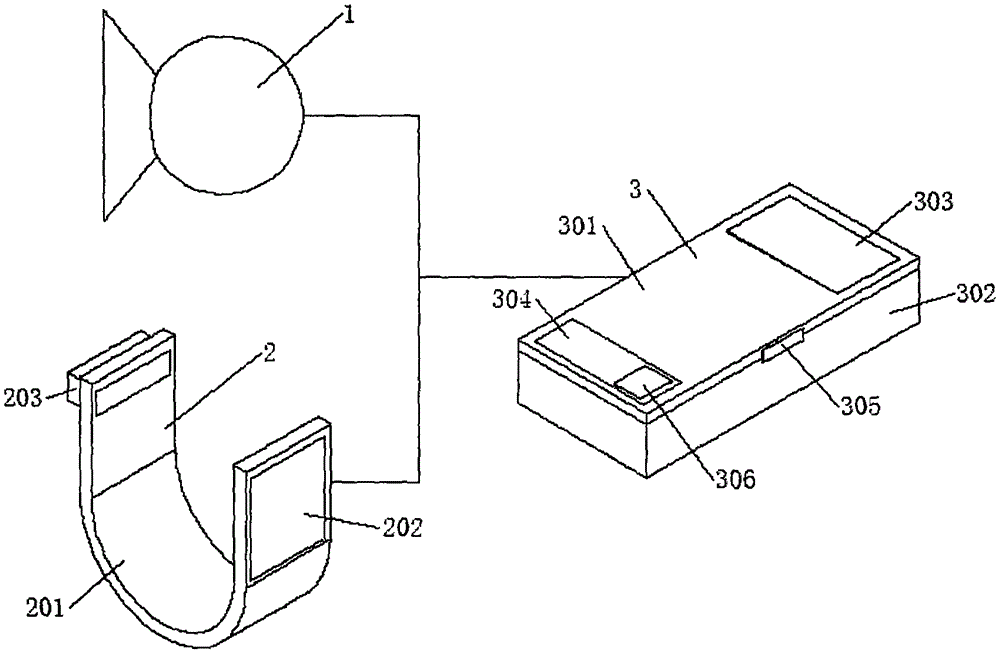

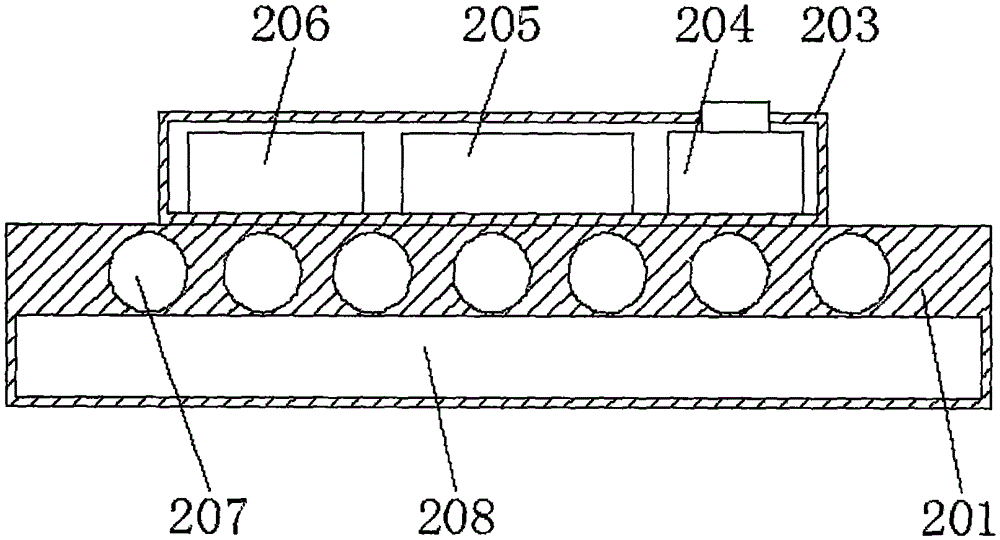

Detector for cardiovascular medicine

The invention discloses a detector for cardiovascular medicine. The detector comprises a heart sound collector, a pulse detection wristband and an integrating box, wherein the heart sound collector and the pulse detection wristband are connected to the integrating box by virtue of lead wires; the heart sound collector further comprises a sucker and a suction bag; the top end of the sucker is connected to the bottom end of the sucker, and the middles of the sucker and the suction bag communicate by virtue of a slim hole; annular heart sound collecting sheets are arranged on the inner walls of the sucker, and the top end of the suction bag is formed with an opening and is provided with an air intake plug; the pulse detection wristband comprises a wristband and an equipment box; the outer side of the left end of the wristband is connected to the equipment box by virtue of a rivet; an air pump, a data analyzer and a controller which is provided with a switch are sequentially arranged inside the equipment box from left to right; a pulse tester is arranged on the inner side of the wristband; and the pulse tester is connected to the data analyzer by virtue of a lead wire. The novel practical equipment is small in volume, convenient for carrying and is simple to operate, and the equipment is suitable for home users.

Owner:QINGDAO MUNICIPAL HOSPITAL

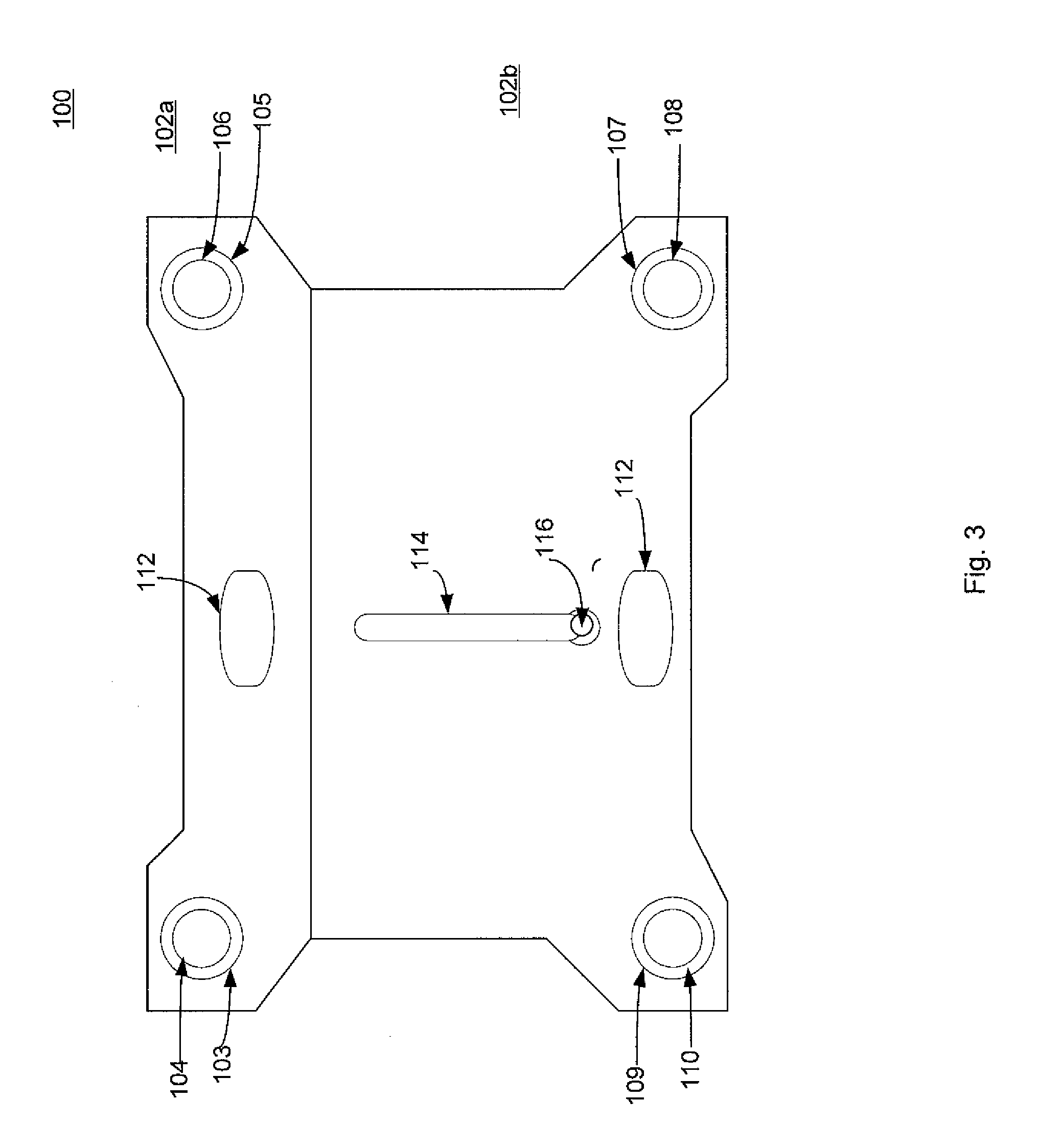

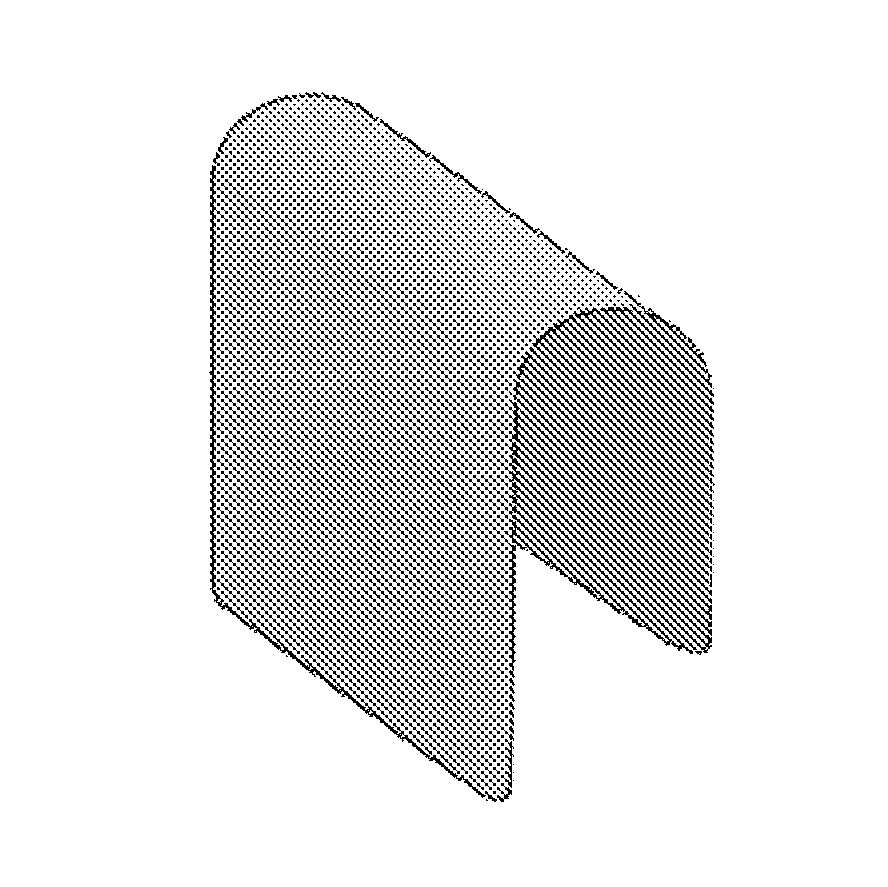

Delivery applicator for radioactive staples for brachytherapy medical treatment

An instrument used for brachytherapy delivery in the treatment of cancer by radiation therapy including a handle having first and second handle actuators; an end effector; and an instrument shaft that connects the handle with the end effector. The end effector has first and second adjacent disposed staple cartridges that each retain a set of staples. The first mechanism is for holding standard staples in a first array, and dispensing the standard staples under control of the corresponding first handle actuator. The second mechanism is for holding radioactive source staples in a second array, and dispensing said radioactive source staples under control of the corresponding second handle actuator. The actuating device is removably attachable to an actuator arm on a proximal end. A staple applicator cartridge holder is attached to the actuator arm on a distal end. The staple applicator cartridge is mountable in the holder and having a plurality of slots for mounting of radioactive source staples therein. An anvil therein crimps the staples.

Owner:POINT SOURCE TECH

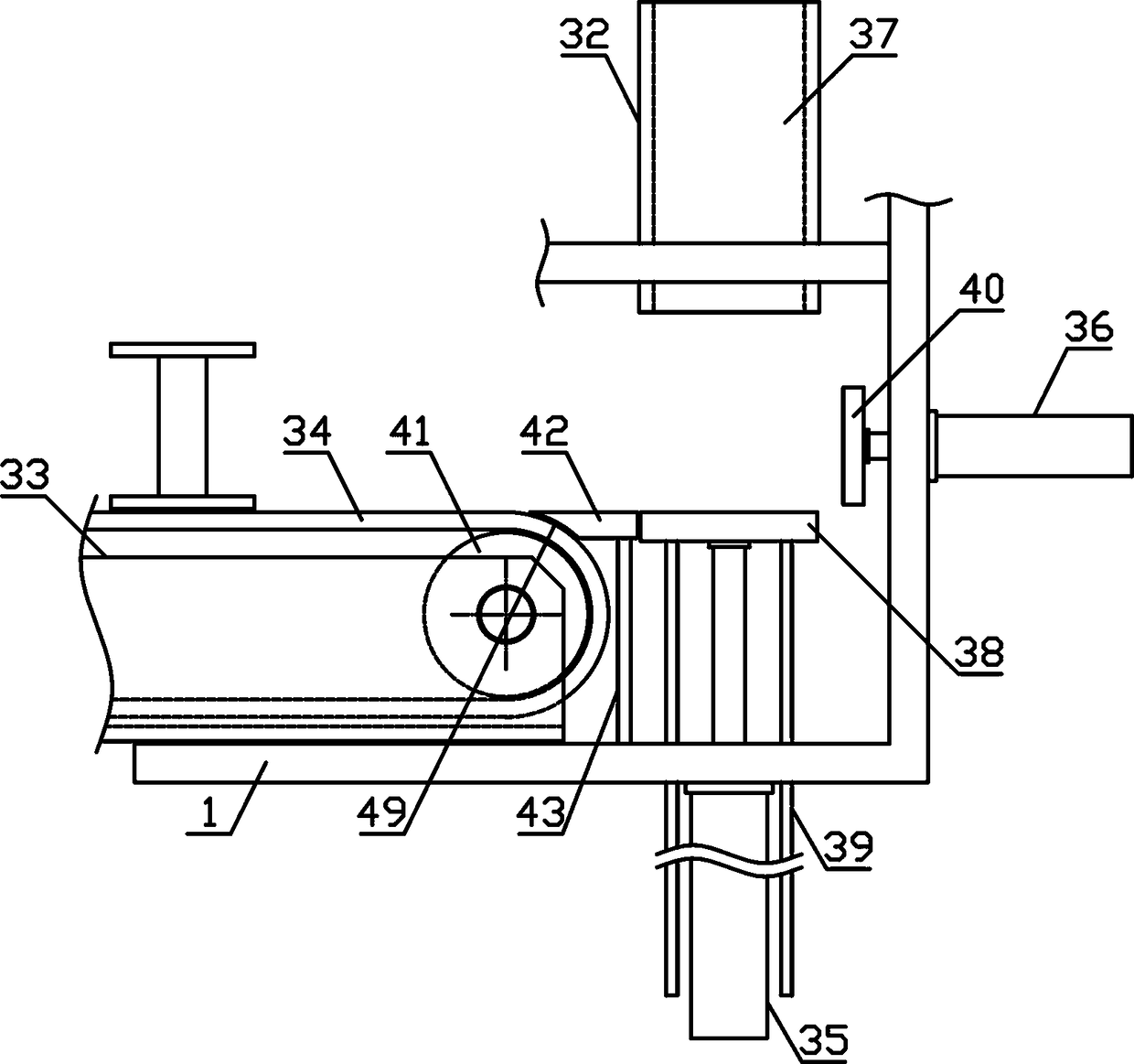

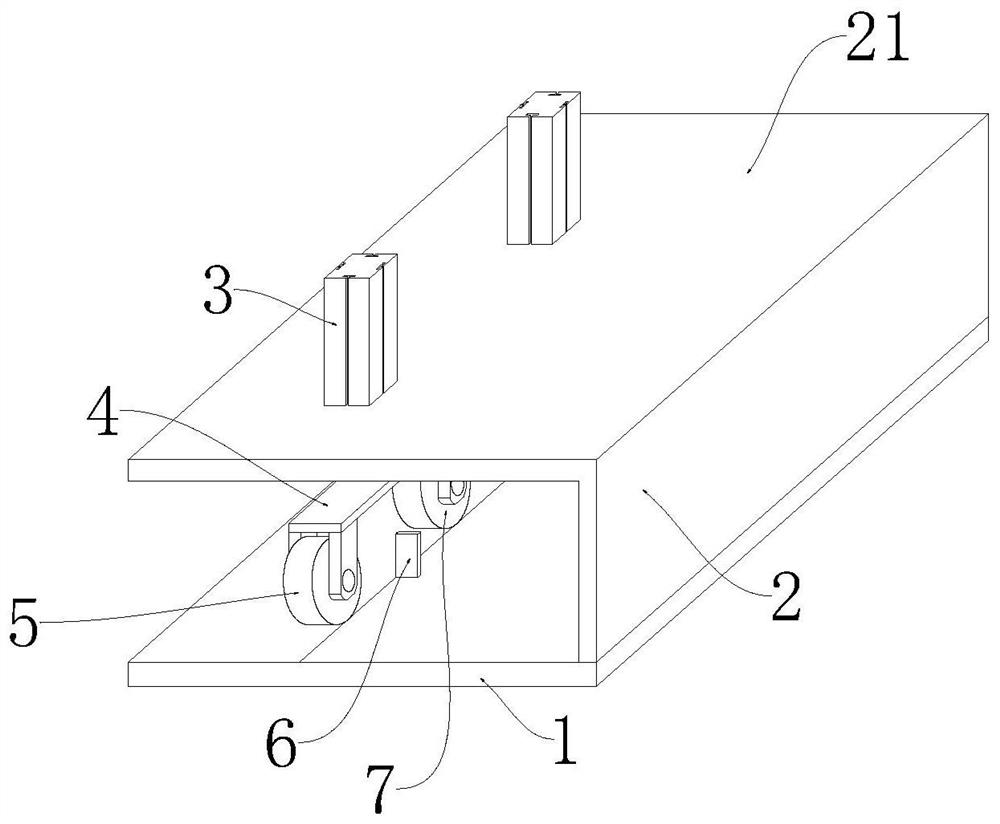

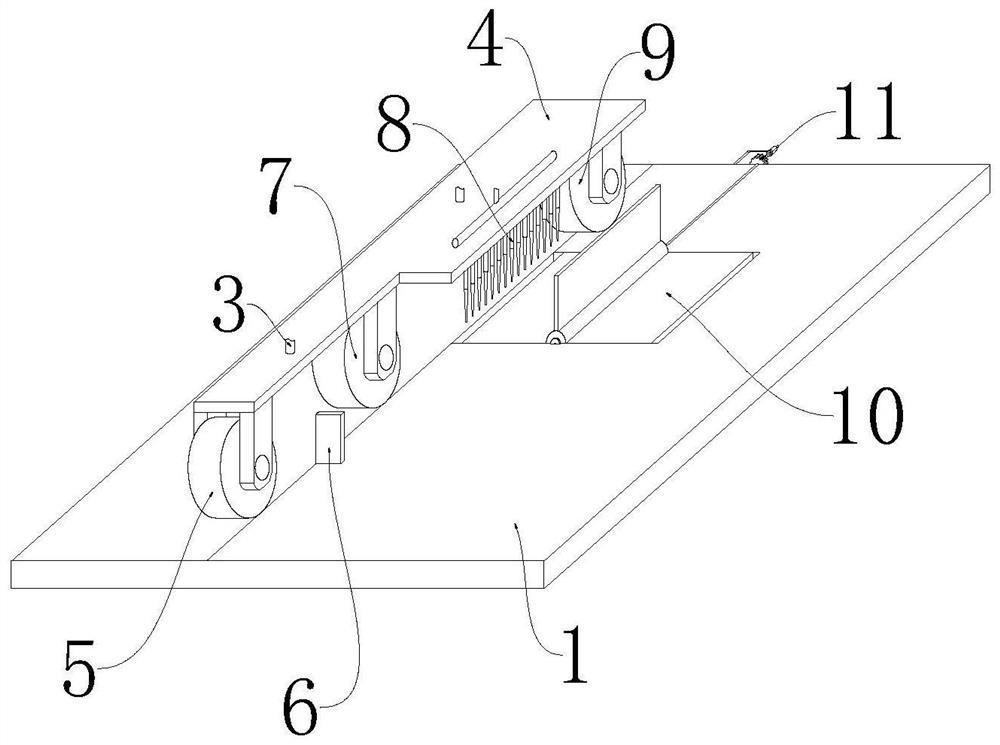

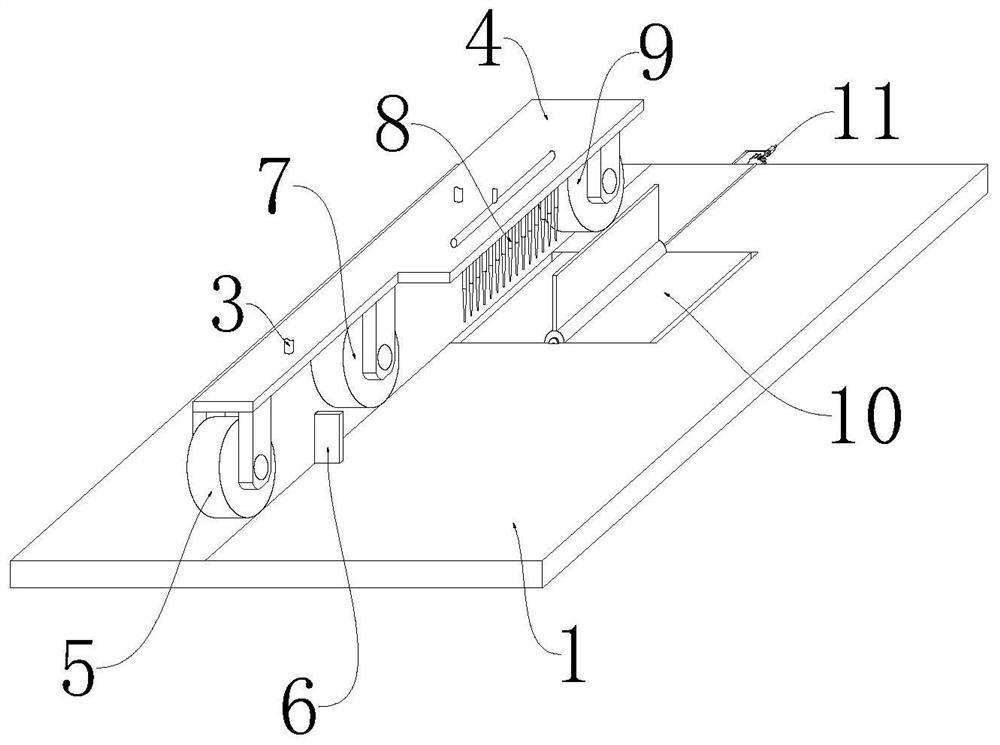

Non-woven geotextile cutting treatment and shaping integration device

InactiveCN111826867AEasy to burn offEasy to export collectionSingeingHeating/cooling textile fabricsMechanical engineeringGeotextile

The invention relates to the technical field of cloth processing, in particular to a non-woven geotextile cutting treatment and shaping integration device. The device comprises a bottom plate, a burrscraping assembly, a flame spraying assembly and a material falling guide assembly. A cut non-woven geotextile is placed at the upper end of the bottom plate, and the side, needing to be deburred, ofthe non-woven geotextile is attached to the burr scraping assembly. In the process that the non-woven geotextile is moved backwards, the burr scraping assembly scrapes and spreads burrs which are attached to the side edge of the non-woven geotextile. When the non-woven geotextile is moved to the position below the flame spraying assembly, a flame sprayed by the flame spraying assembly burns the burrs of the non-woven geotextile, and the burrs of the non-woven geotextile can be broken and separated from the non-woven geotextile. Meanwhile, a material falling guide assembly rotates to drive theburrs falling on the surface of the material falling guide assembly to rotate, and therefore the burrs are conveniently collected, the burrs are scraped and spread, the burrs are conveniently burnt and conveniently fall off, the manpower is replaced by machinery, and the working efficiency is improved.

Owner:朱姣

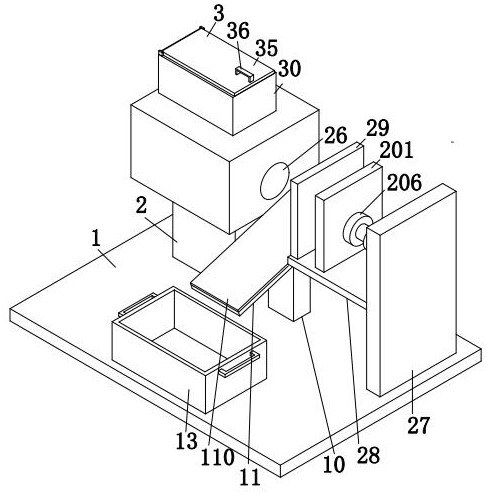

A kind of capacitor aluminum shell manufacturing and processing equipment

ActiveCN113441596BReduce impactAvoid deformationShaping toolsMetal-working feeding devicesStampingMolding machine

The invention relates to the technical field of stamping and processing of capacitor aluminum shells, in particular to a manufacturing and processing equipment for capacitor aluminum shells, which includes a bottom plate, a forming mechanism and a blanking mechanism. A forming mechanism is installed on the upper end of the bottom plate, and a lower material mechanism; the molding mechanism adopted in the present invention blows air to the cavity of the die through the air pump and the driving effect of the punch after the aluminum shell is formed, so that the aluminum shell after forming can be taken out from the cavity of the die, and then passed through the take-off plate The blocking effect makes the aluminum shell directly detach from the outer wall of the punch and fall downwards, avoiding the deformation of the aluminum shell due to the difficulty in grasping the demoulding force during manual demoulding, and at the same time, the raw material plate is driven downward automatically by the unloading mechanism Drop to the right side of the push plate, and suck air through the suction hole through the air pump to absorb the raw material plate, avoiding the problem of inaccurate placement of the raw material plate.

Owner:徐州苏惠智能电气有限公司

Reinforced fabric sewing device and sewing method

ActiveCN104947330AImprove bindingReduce deformationTextiles and paperEngineeringWind power generation

The invention discloses a reinforced fabric sewing device and a sewing method. The device includes a sewing platform, pressure plates, guide rails and a sewing machine, wherein the upper surface of the sewing platform is a hollow frame; the pressure plates include an upper pressure plate and a lower pressure plate, and a plurality of strips of sewing zones are uniformly arranged on the pressure plates; the guide rails are arranged at the two ends of the sewing platform in the lateral directions; the sewing machine includes a sewing machine stand and a sewing machine head; the sewing machine stand spans across the guide rails longitudinally and is connected with the guide rails in a sliding manner; the sewing machine head is arranged on the sewing machine stand, and can move along the sewing machine stand longitudinally. The frame type sewing platform is arranged and used for laying fabric, the fabric is placed between the upper pressure plate and the lower pressure plate, and the suture line is sutured in the sewing zones of the upper and lower pressure plates, so that the laid center line can be easily calibrated, and the production time of the whole process is reduced; in addition, all layers of reinforced fabric can be pressed tightly, the combination degree among all layers of reinforced fabric is high, and little deformation is caused, therefore, high-performance wind power generation used blade roots can be obtained.

Owner:NEWTRY COMPOSITE

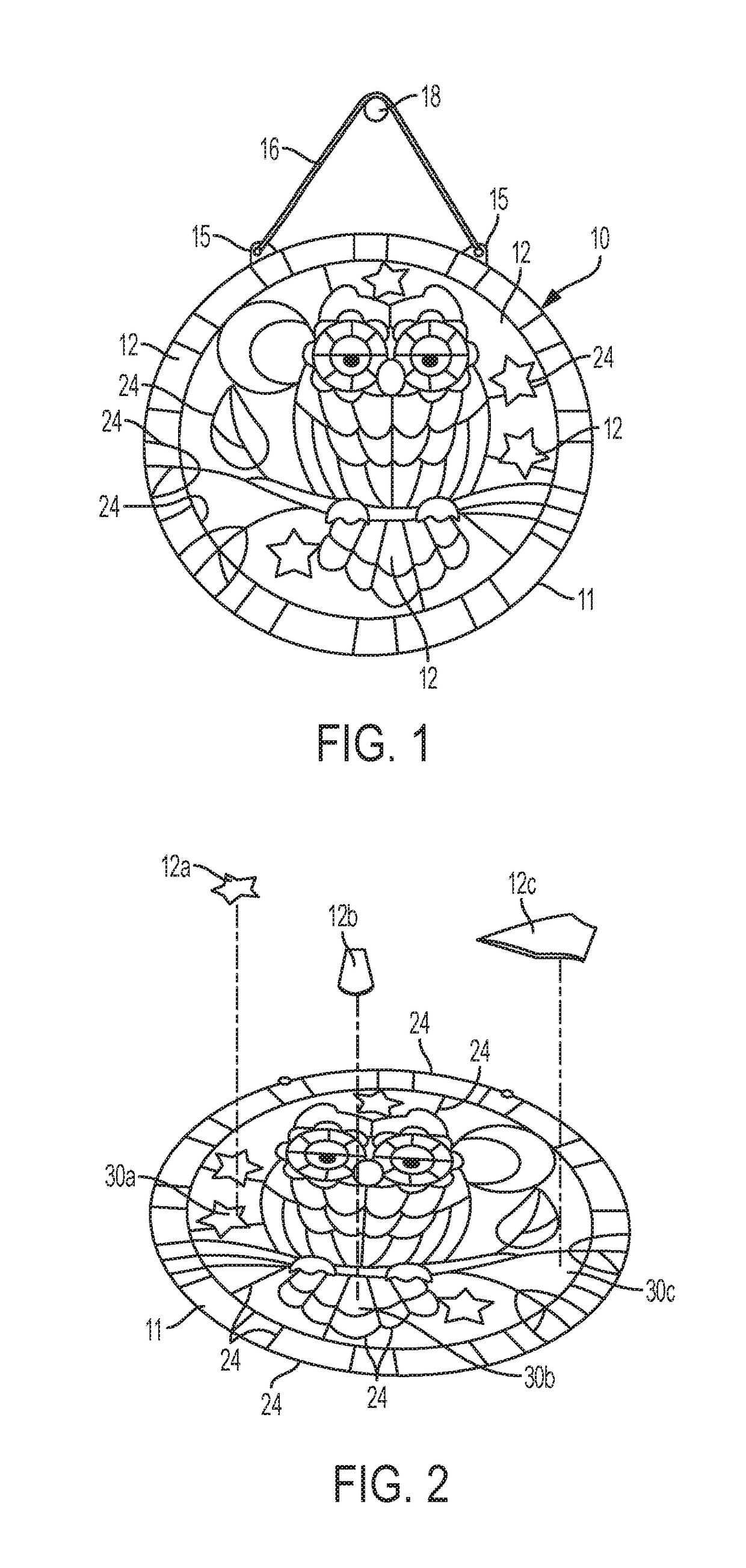

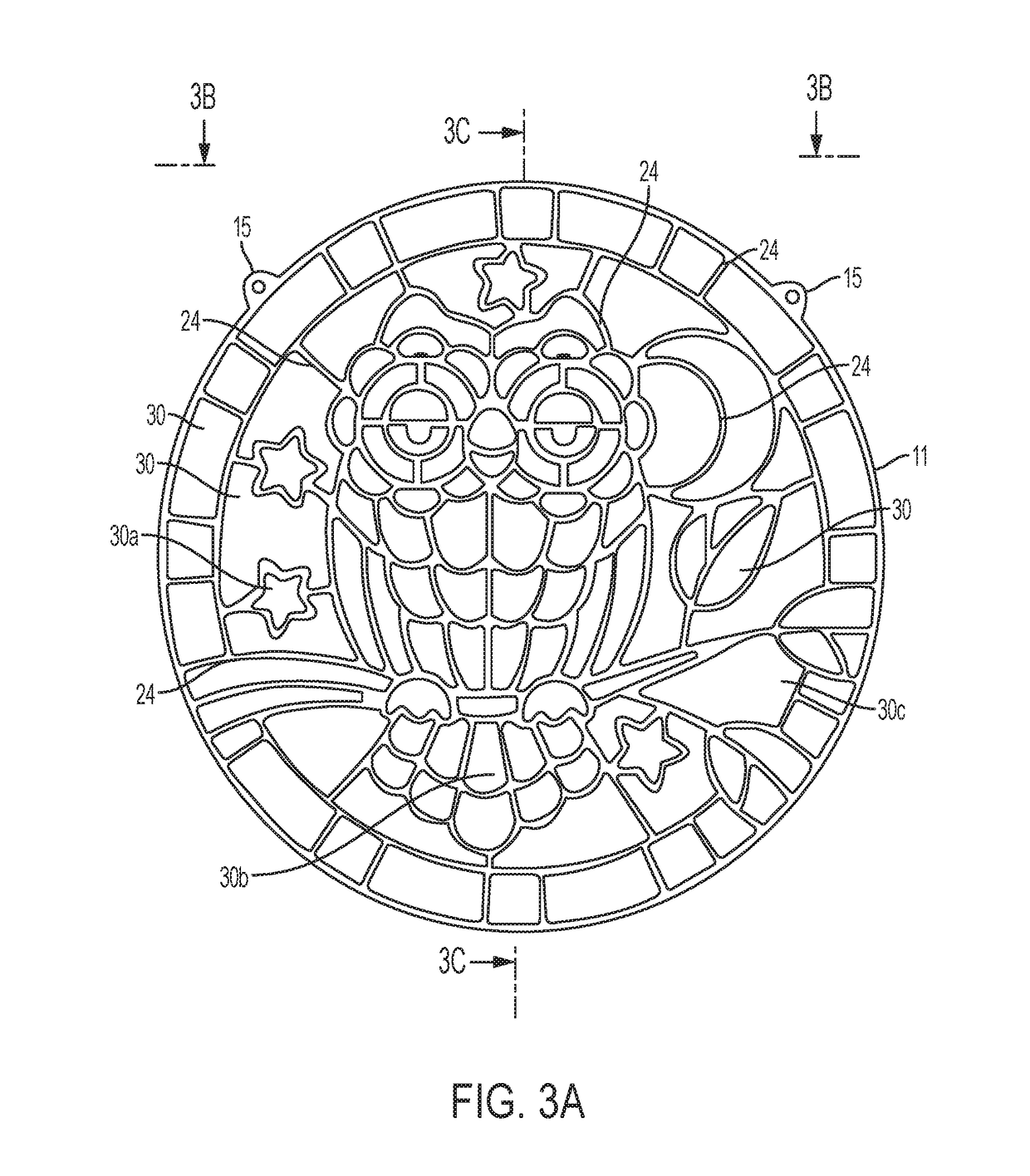

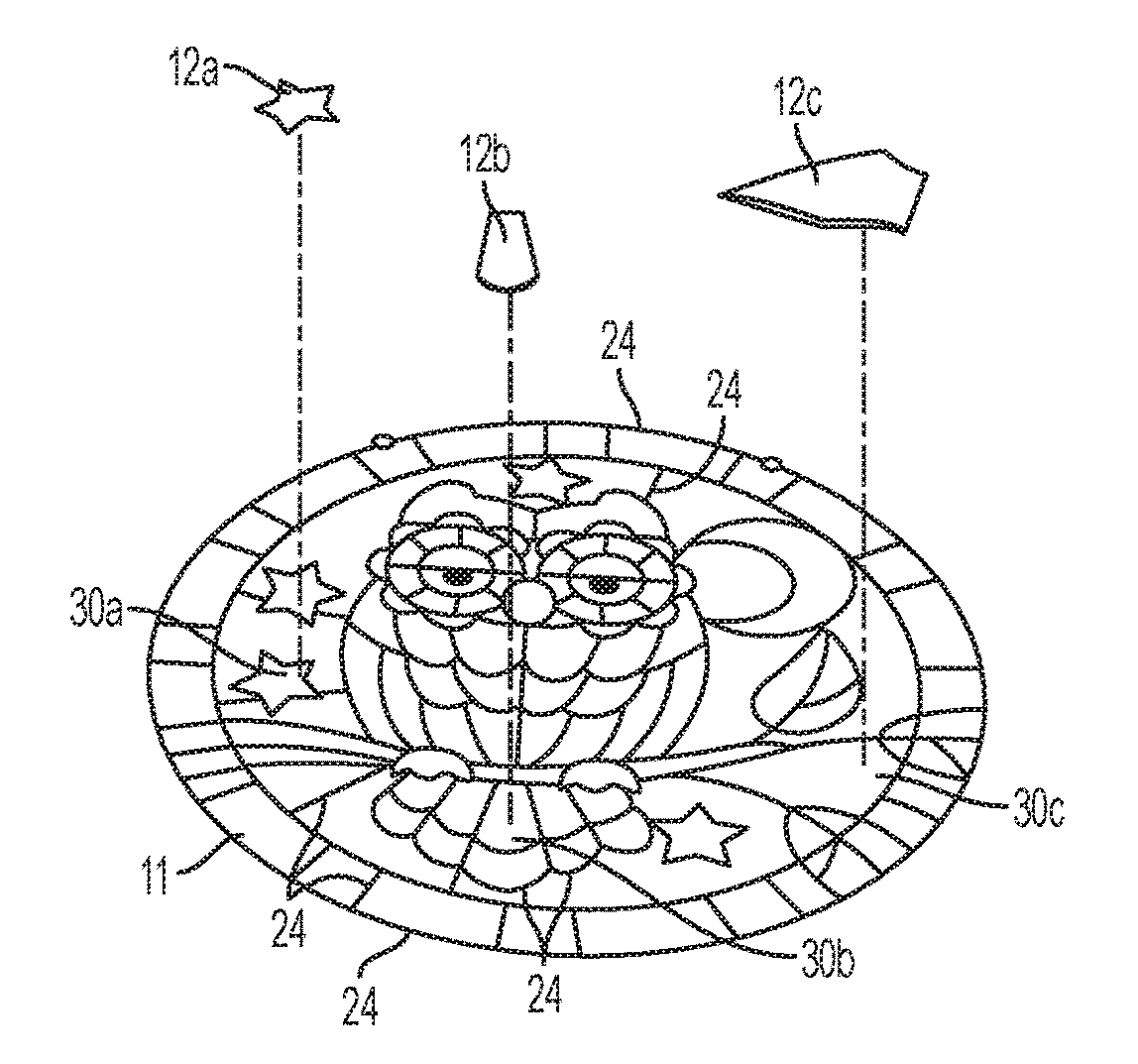

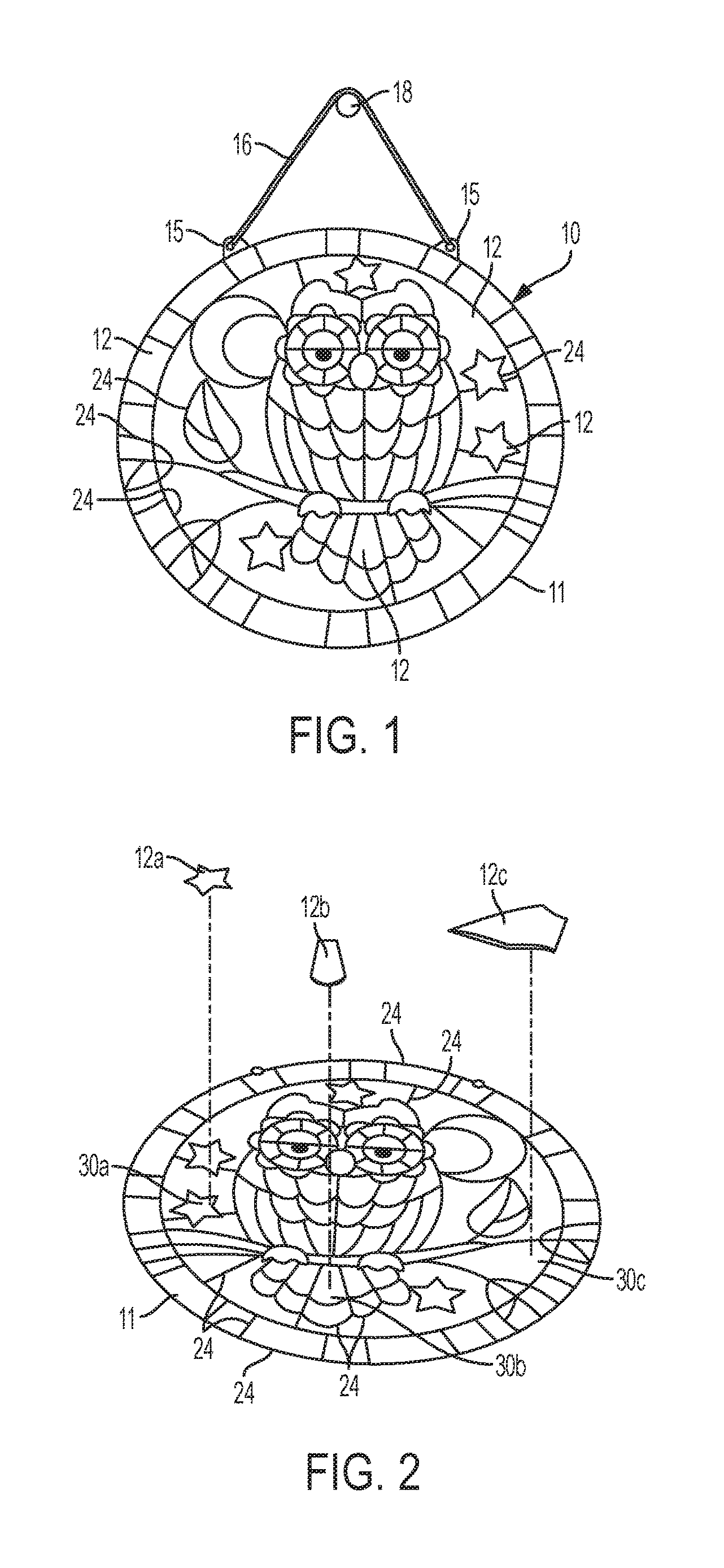

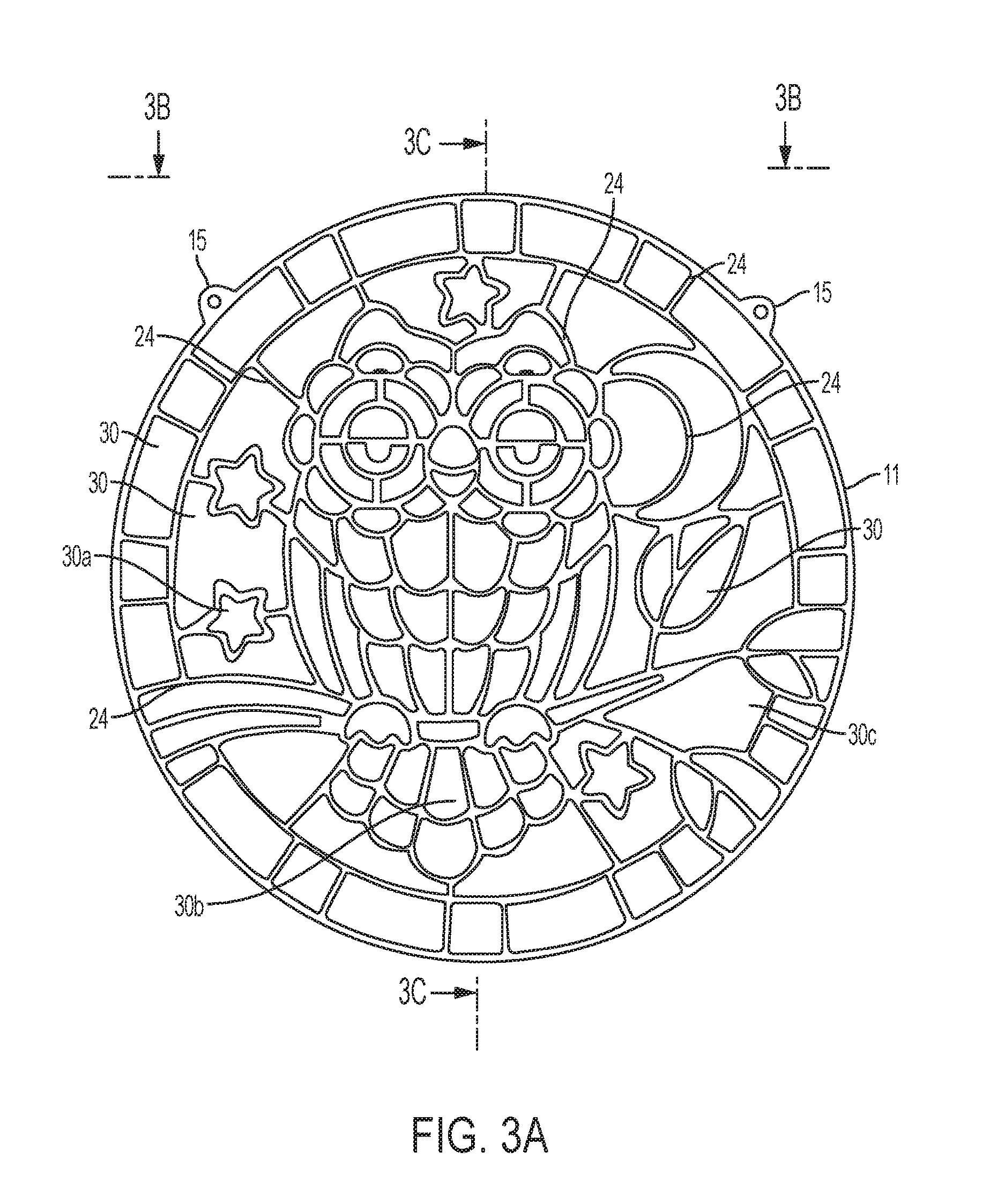

Kit for simulated stained glass article, article produced from the kit, and substrate for the article

Owner:MELISSA & DOUG LLC

Classifiable archive management device based on artificial intelligence

InactiveCN114515073AGuaranteed stabilityEasy to storeBook cabinetsBook-troughsMechanical engineeringIndustrial engineering

The invention discloses a classifiable archive management device based on artificial intelligence, and relates to the technical field of archive management.The classifiable archive management device based on artificial intelligence comprises a cabinet body and a second storage groove, a middle mounting plate is fixedly arranged at the middle end of the cabinet body, and a first storage groove is formed in the upper portion of the middle mounting plate in the cabinet body; a storage mechanism is arranged in the first storage groove, a second storage groove is formed below the middle mounting plate in the cabinet body, a partition plate is fixedly arranged in the second storage groove, a vertical plate is fixedly arranged on the surface of the upper end of the partition plate, and a pressing assembly is arranged in the second storage groove through the partition plate; according to the classifiable archive management device based on artificial intelligence, archives can be effectively classified, and paper archives can be leveled and fixed.

Owner:BINZHOU POLYTECHNIC

Kit for simulated stained glass article, article produced from the kit, and substrate for the article

A kit for making a simulated stained glass article, having a light-transmissive molded plastic substrate with an array of ridges on one major surface, laterally defining a pattern of upwardly open spaces, and a set of light-transmissive molded plastic colored stickers that are respectively peripherally shaped to fit conformingly into the spaces of the pattern. Side walls of the ridges are beveled at an angle sufficient to enable release of the substrate from a mold but are steep enough to facilitate precise placement of the stickers in the spaces and to minimize transmission of light around the edges of the stickers. In an article made from the kit, the stickers and ridges simulate the glass pieces and lead cames of a conventional stained glass window.

Owner:MELISSA & DOUG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com