Patents

Literature

46946results about How to "Avoid deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apparatus for applying surgical fastners to body tissue

InactiveUS7624903B2Increase awarenessAvoid deformationSuture equipmentsStapling toolsSurgical stapleSupporting system

Owner:COVIDIEN LP

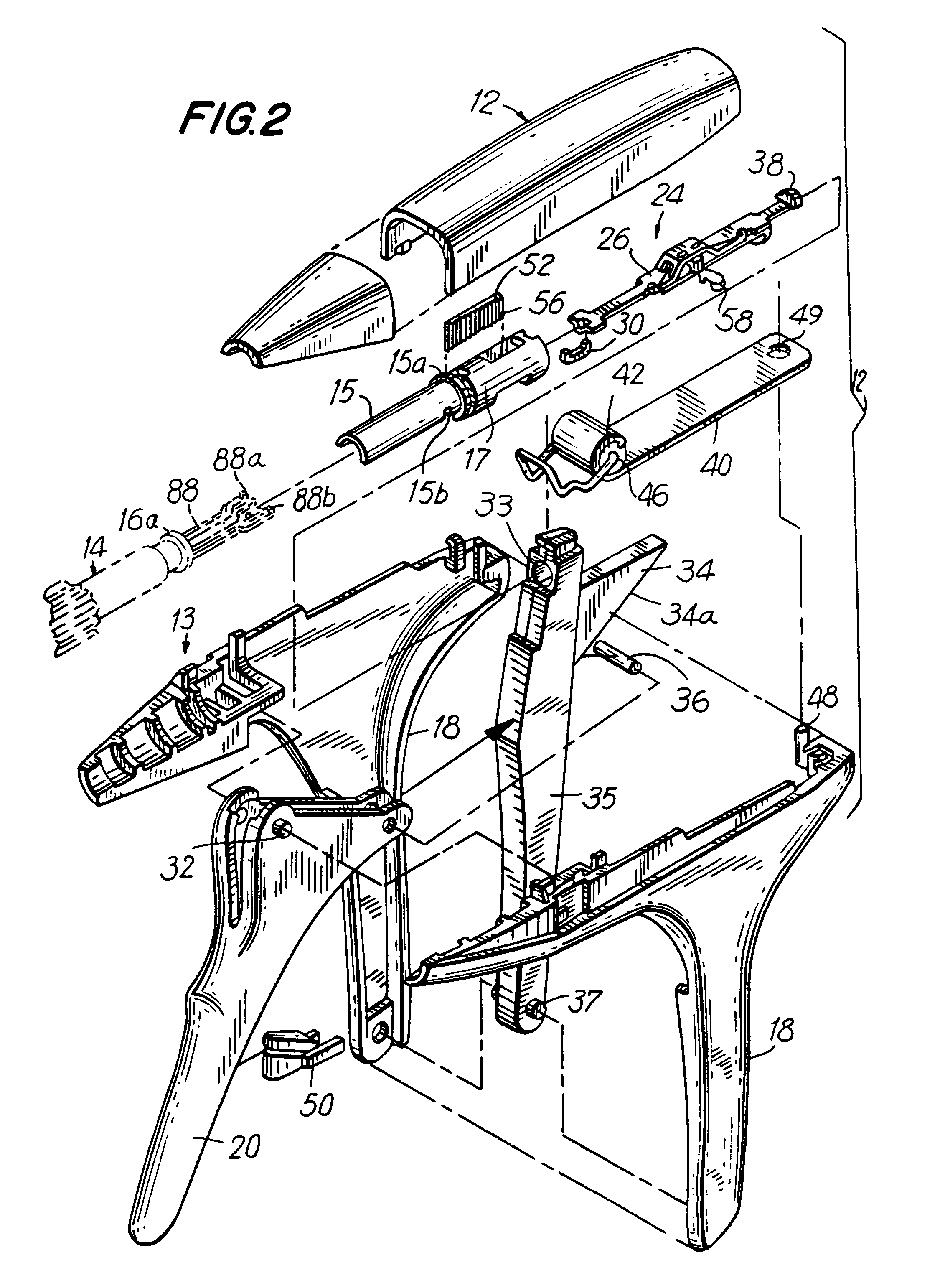

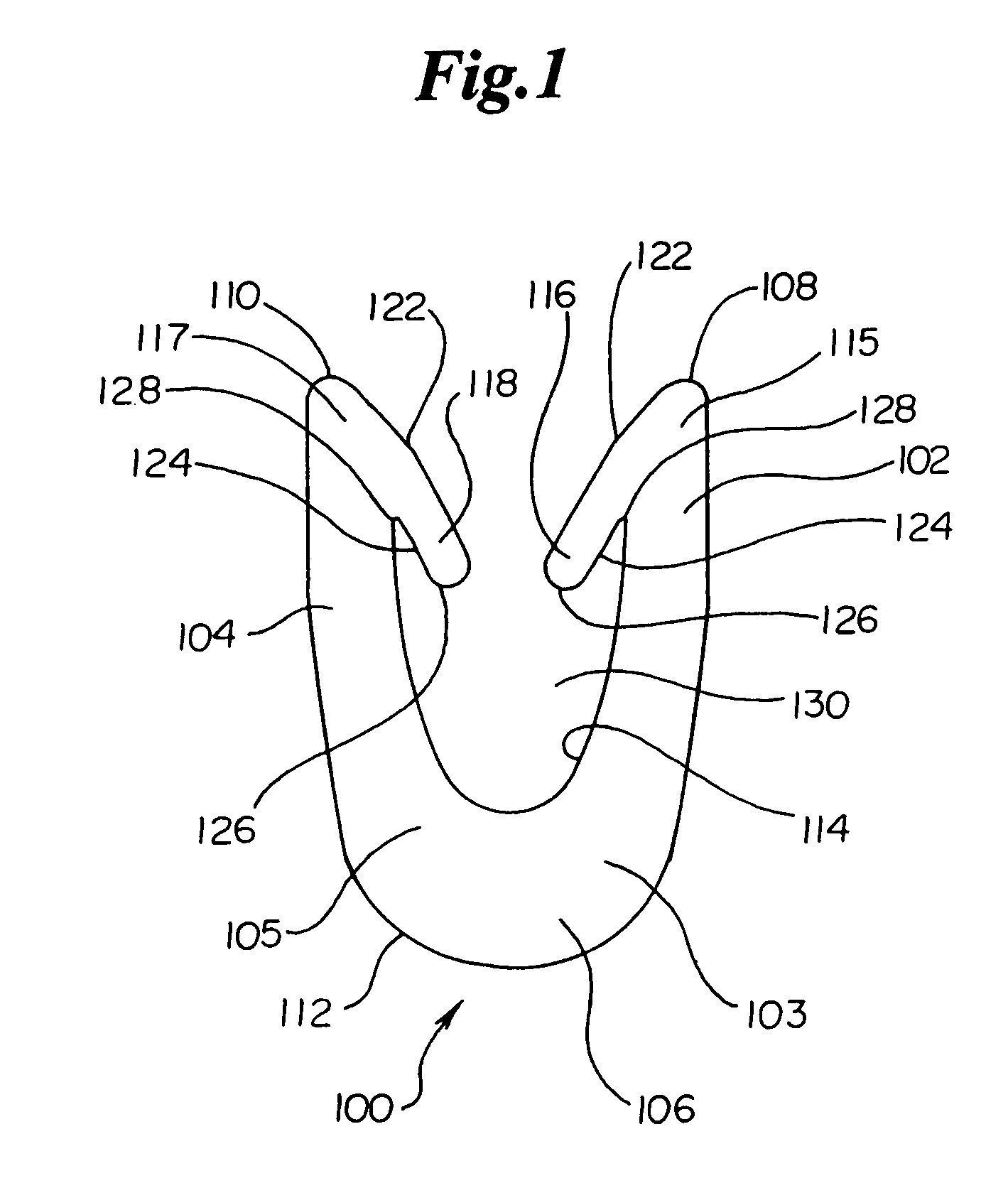

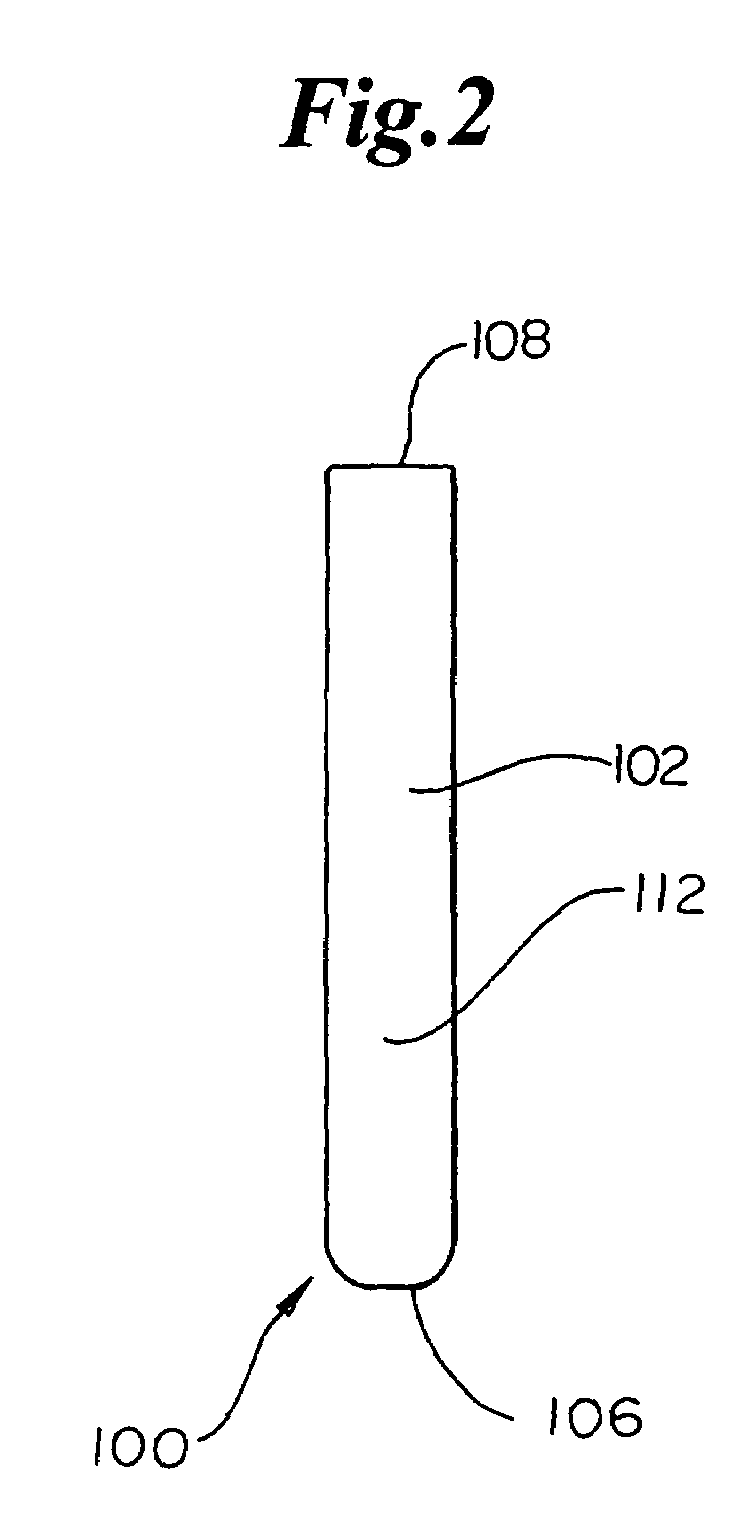

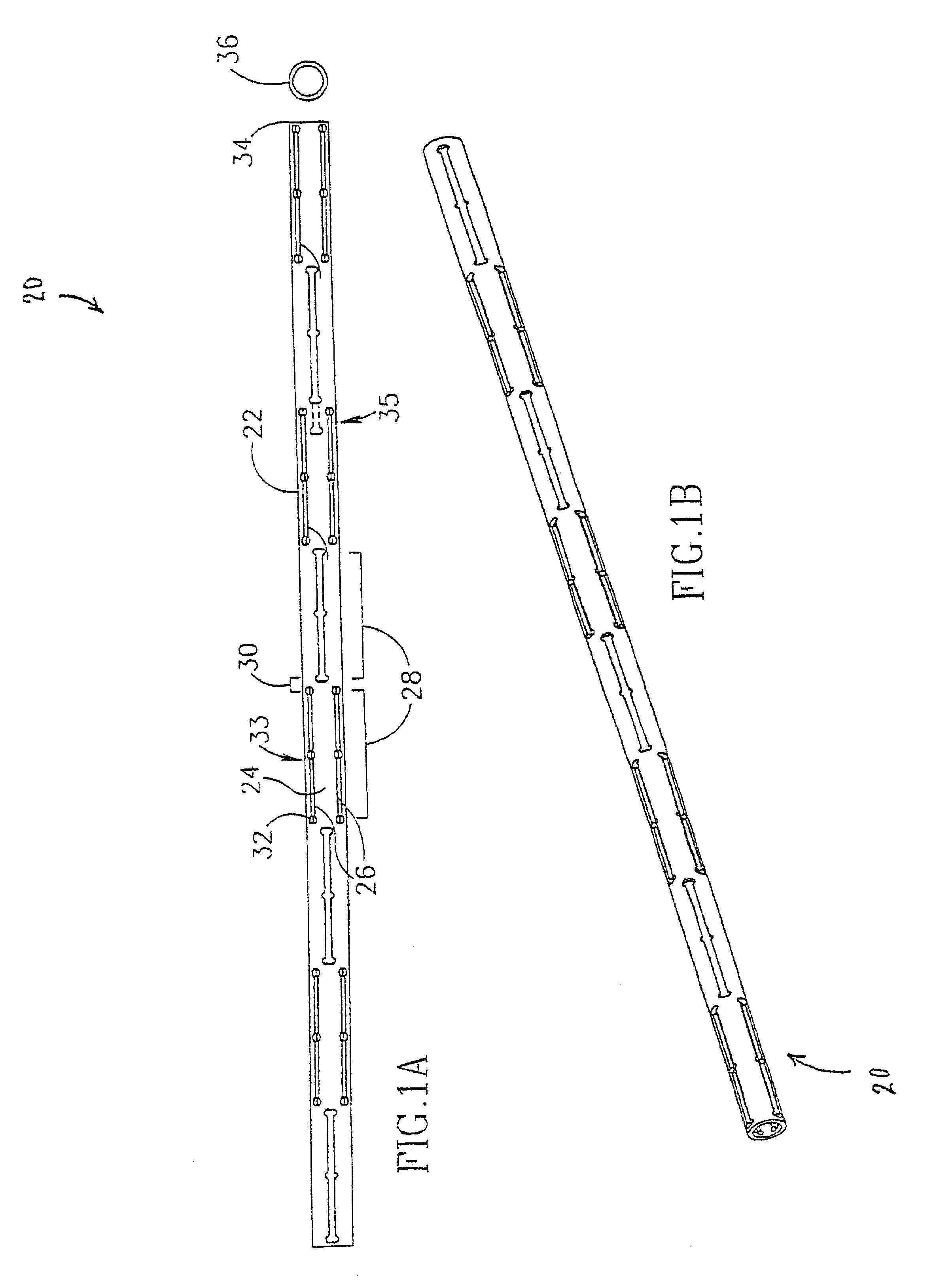

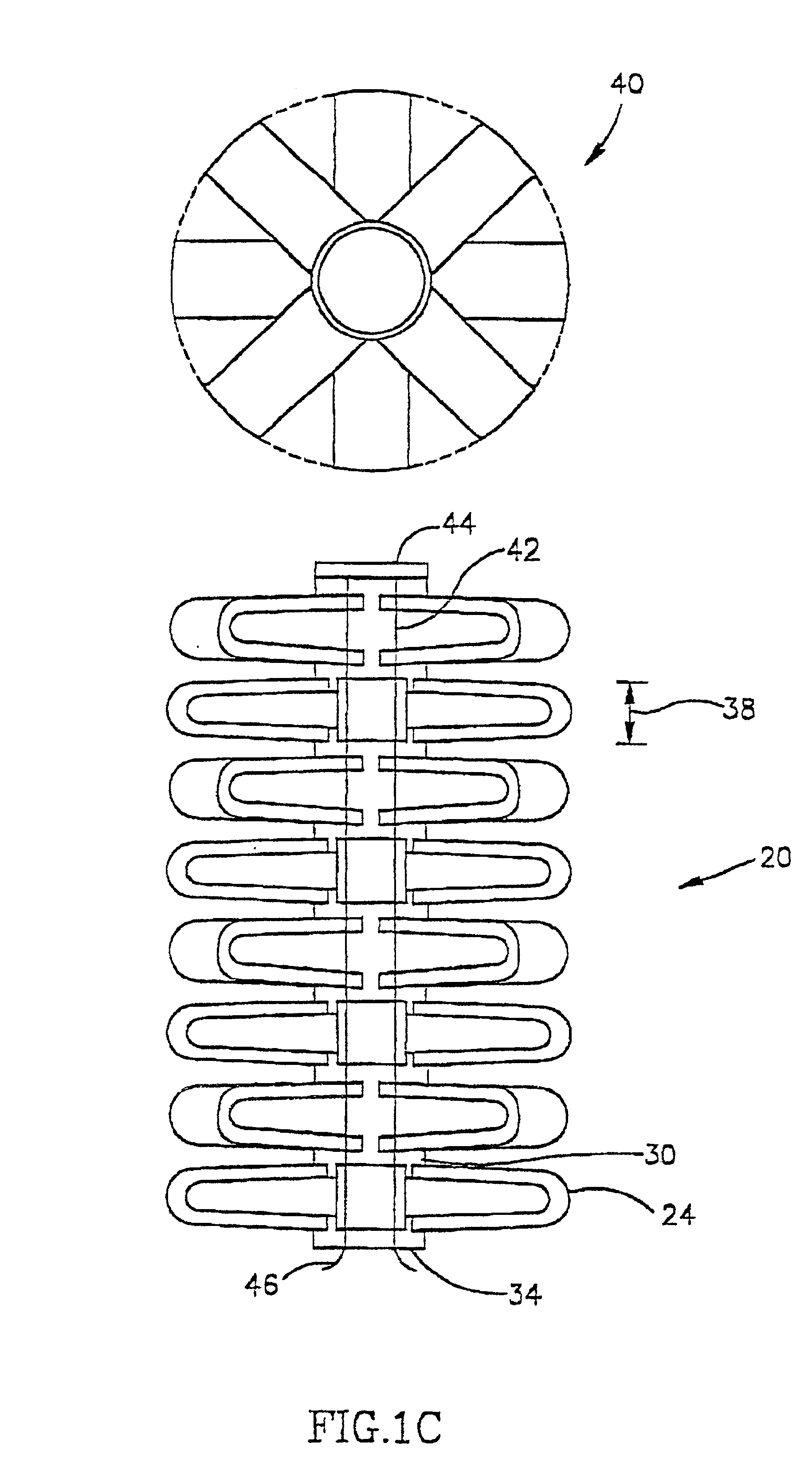

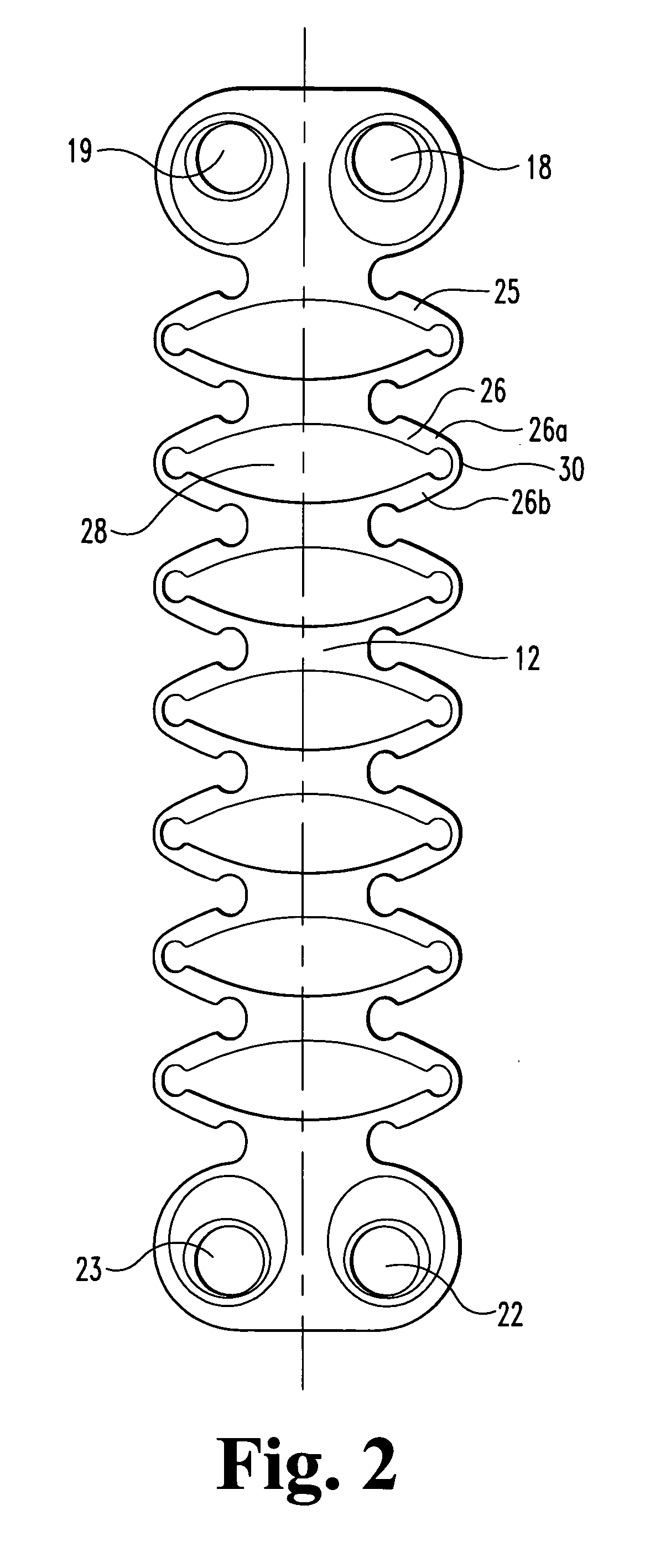

Dynamic bioabsorbable fastener for use in wound closure

InactiveUS7112214B2Prevent and reduce deformationAvoid deformationJoint implantsStaplesBiomedical engineeringBioabsorbable polymer

A fastener for insertion into pierced openings of a tissue wound has a body formed of a generally bioabsorbable polymer defining an initial capture area internal to the body. The body includes a pair of arms, each with an inwardly projecting cleat operably joined at an elbow portion defining an internal elbow angle. The arms are operably joined to a backspan at a shoulder portion defining an internal shoulder angle. A durable tissue retention zone is defined between the cleat and the arm. The elbow portion and the internal elbow angle define an insertion width greater than a width of the pierced openings resulting in the pierced openings stretching over the cleat and being elastically retained within the durable tissue retention zone. The fastener initially captures wound tissue in the initial capture area and then dynamically reforms in response to lateral stresses applied by the wound tissue without a fracture failure of the fastener until a minimum degradation period.

Owner:INCISIVE SURGICAL

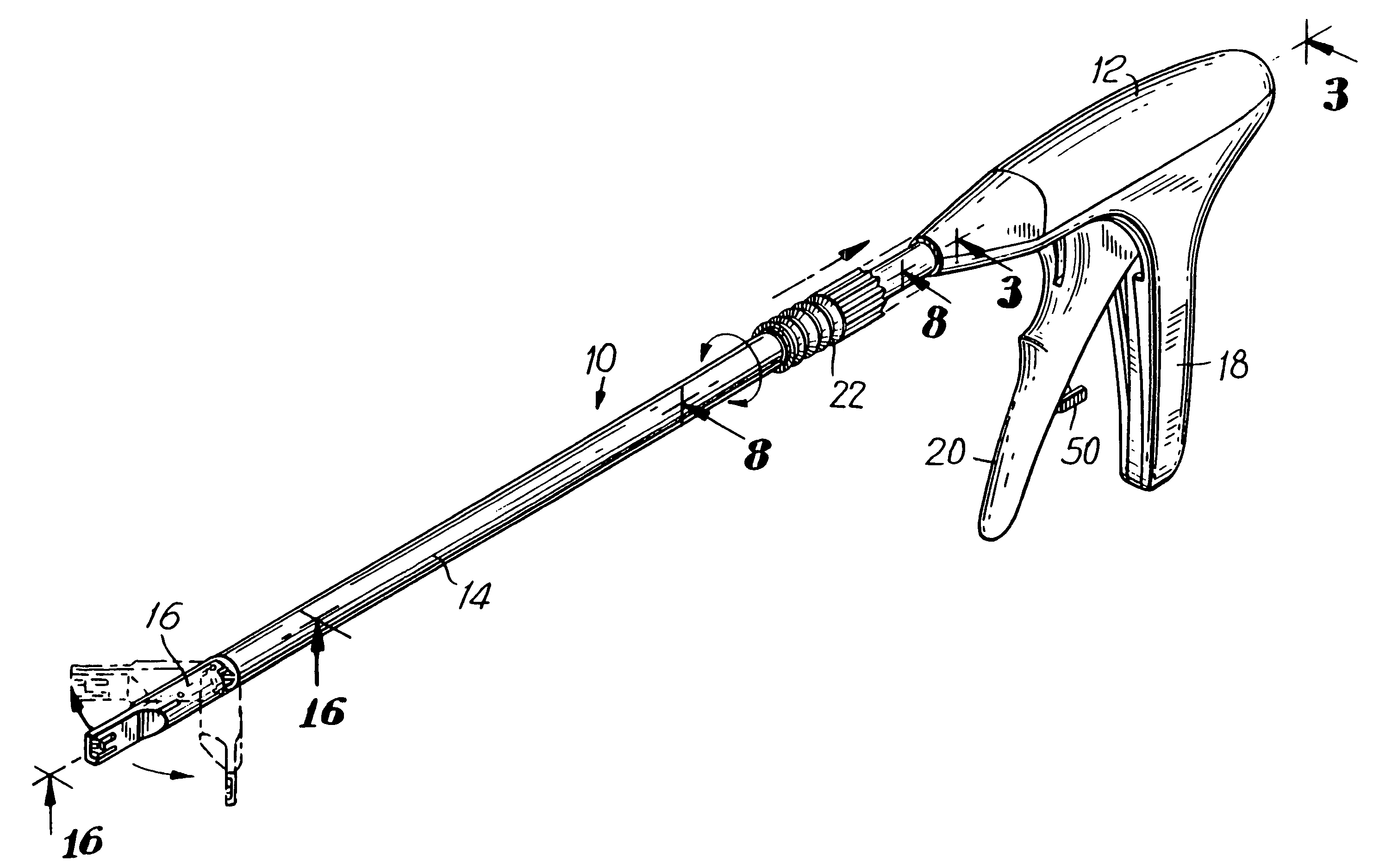

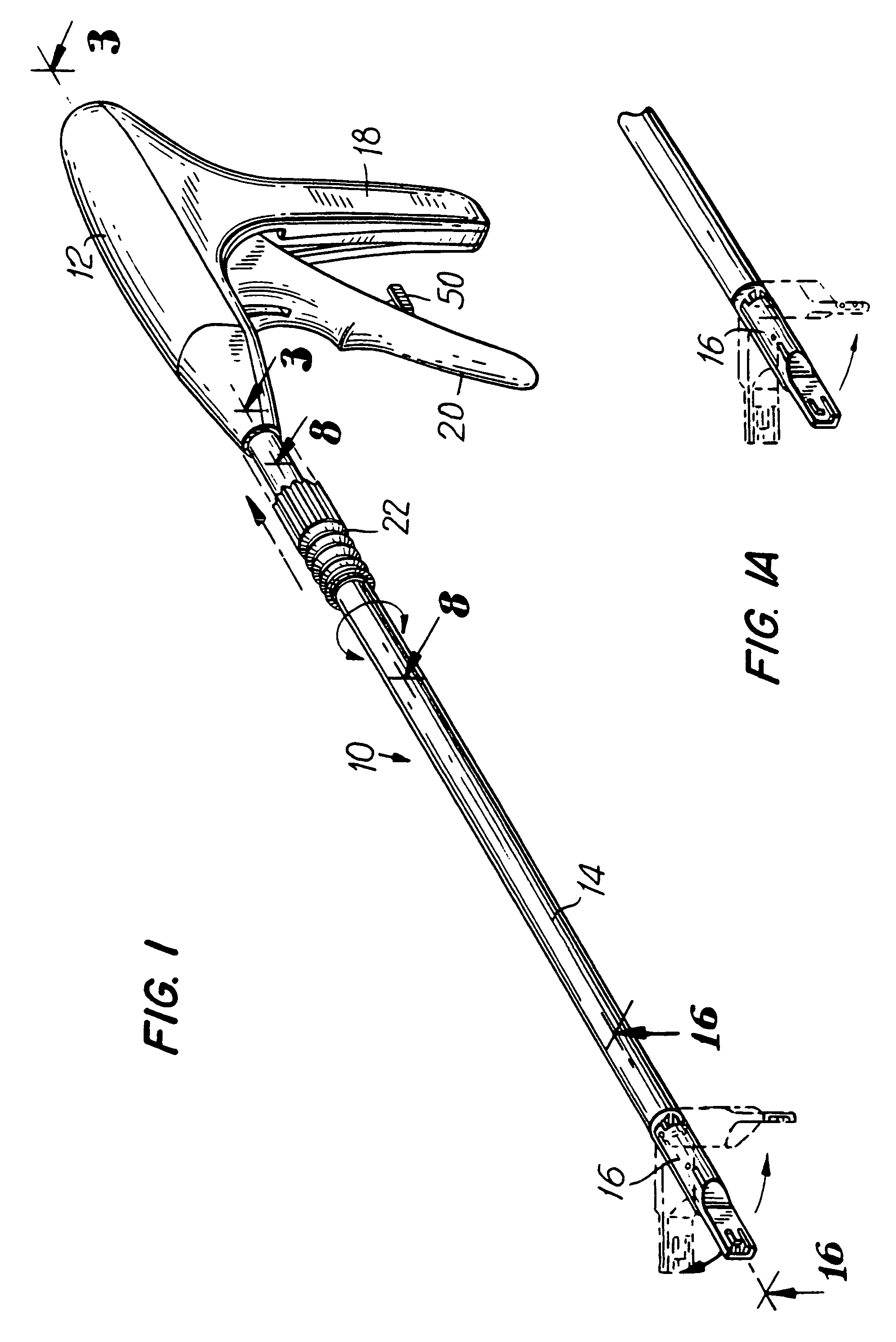

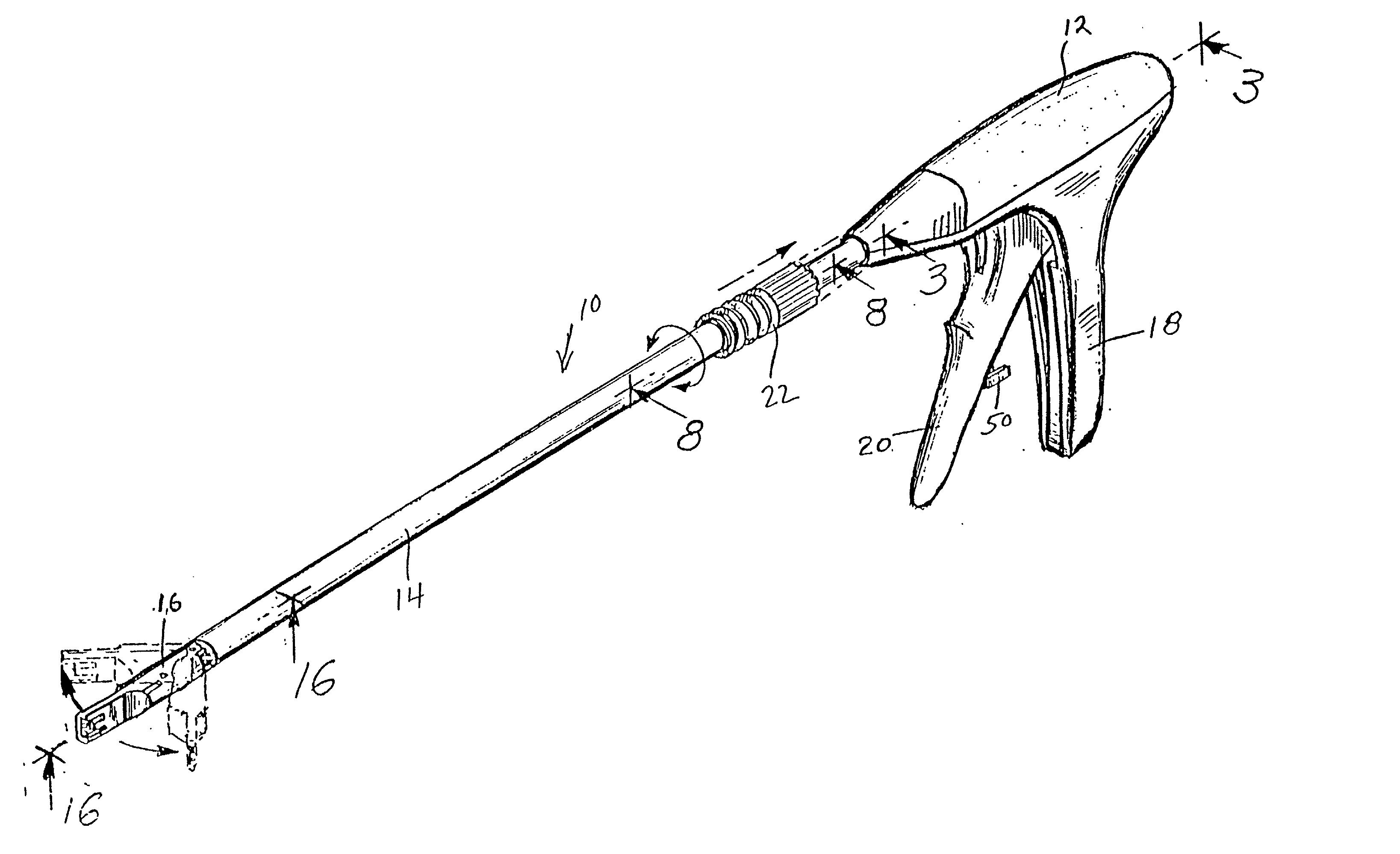

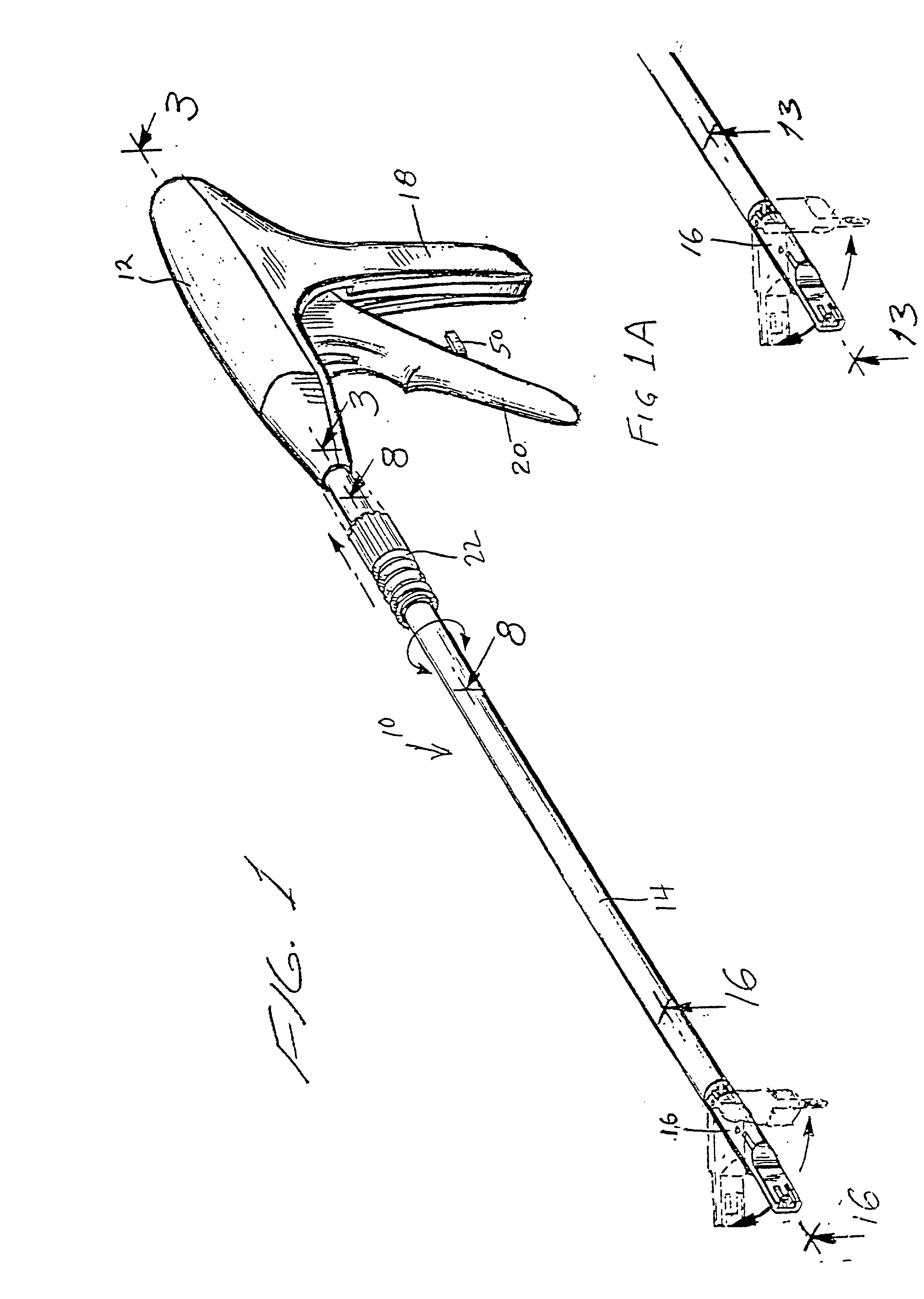

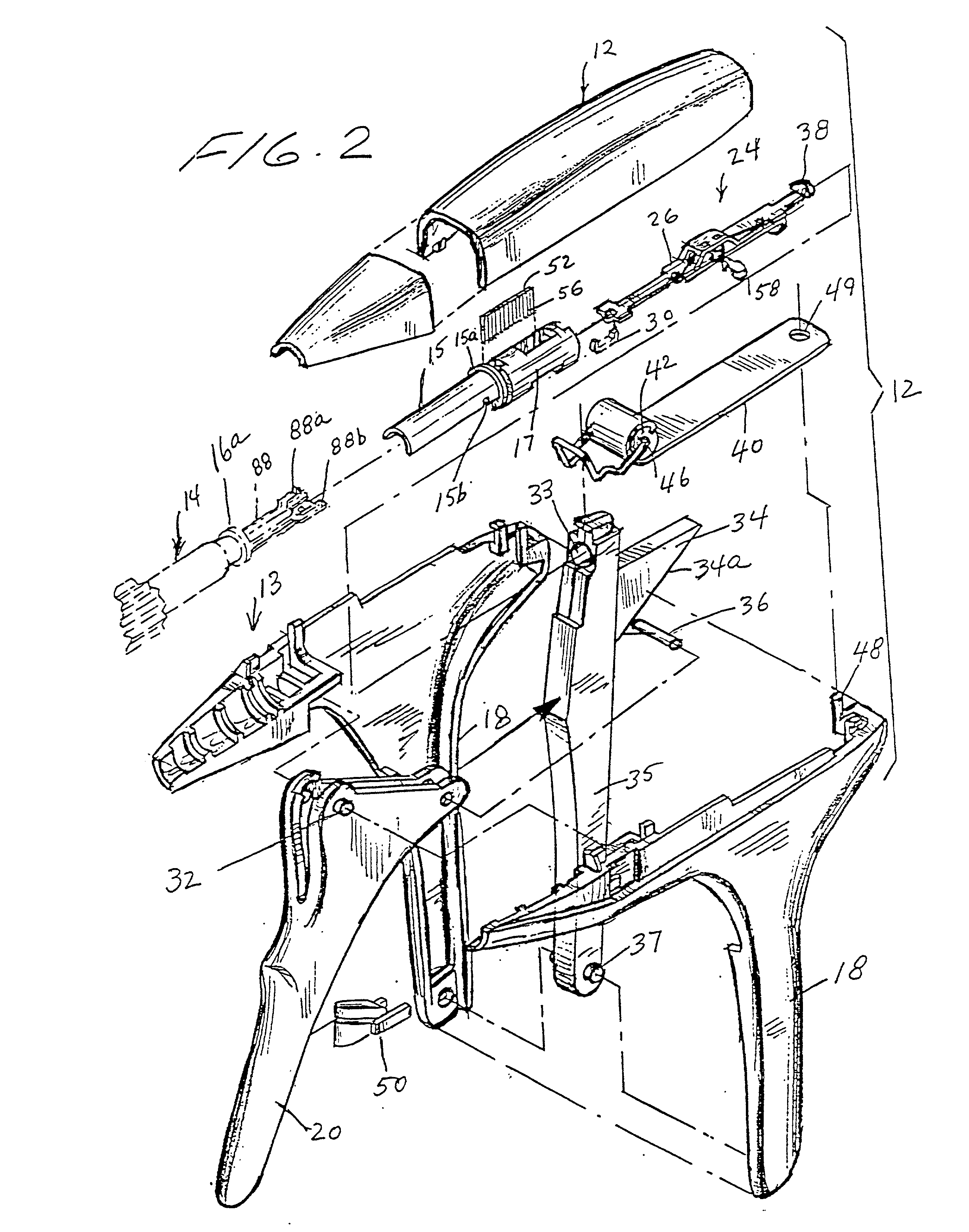

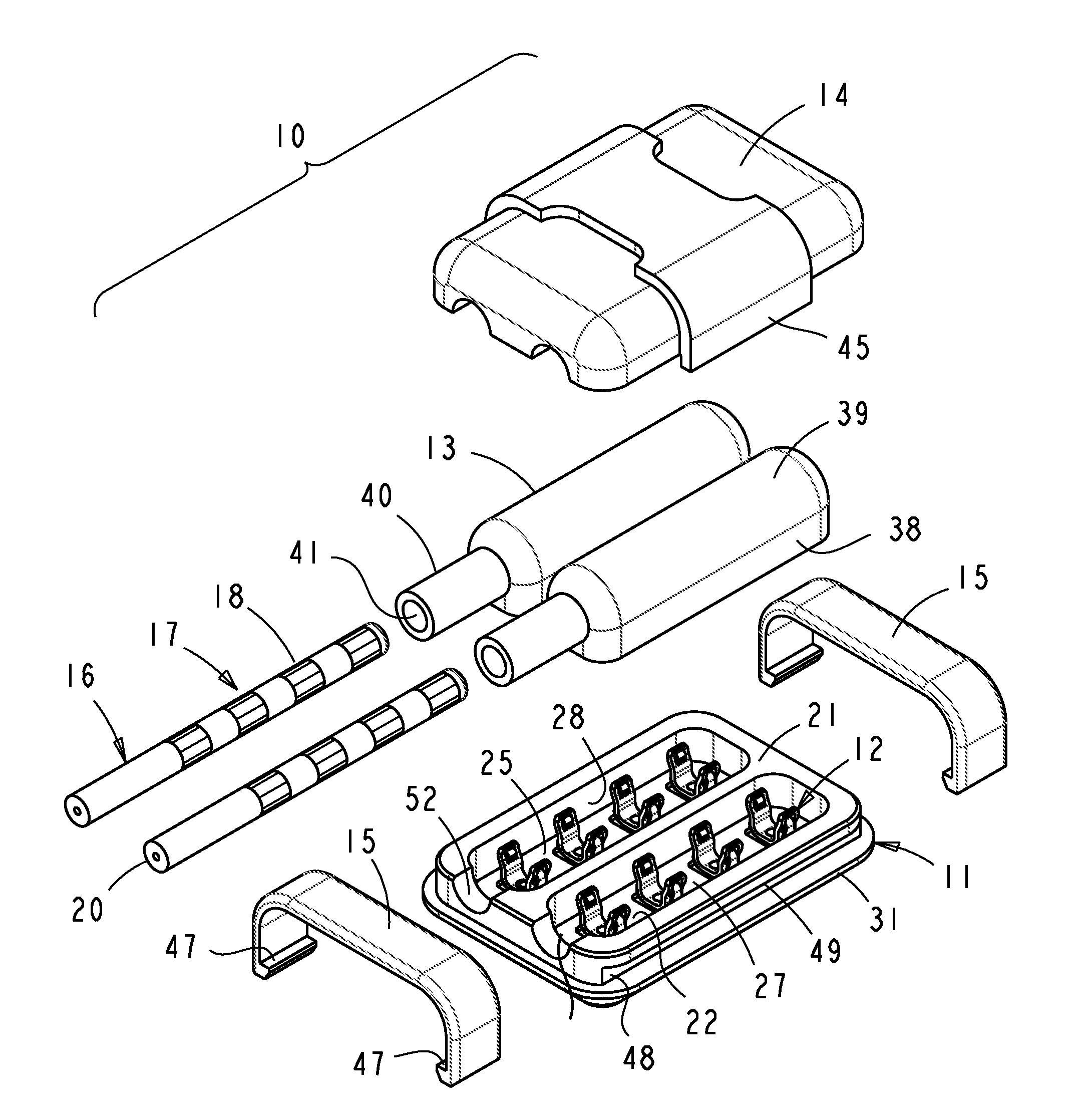

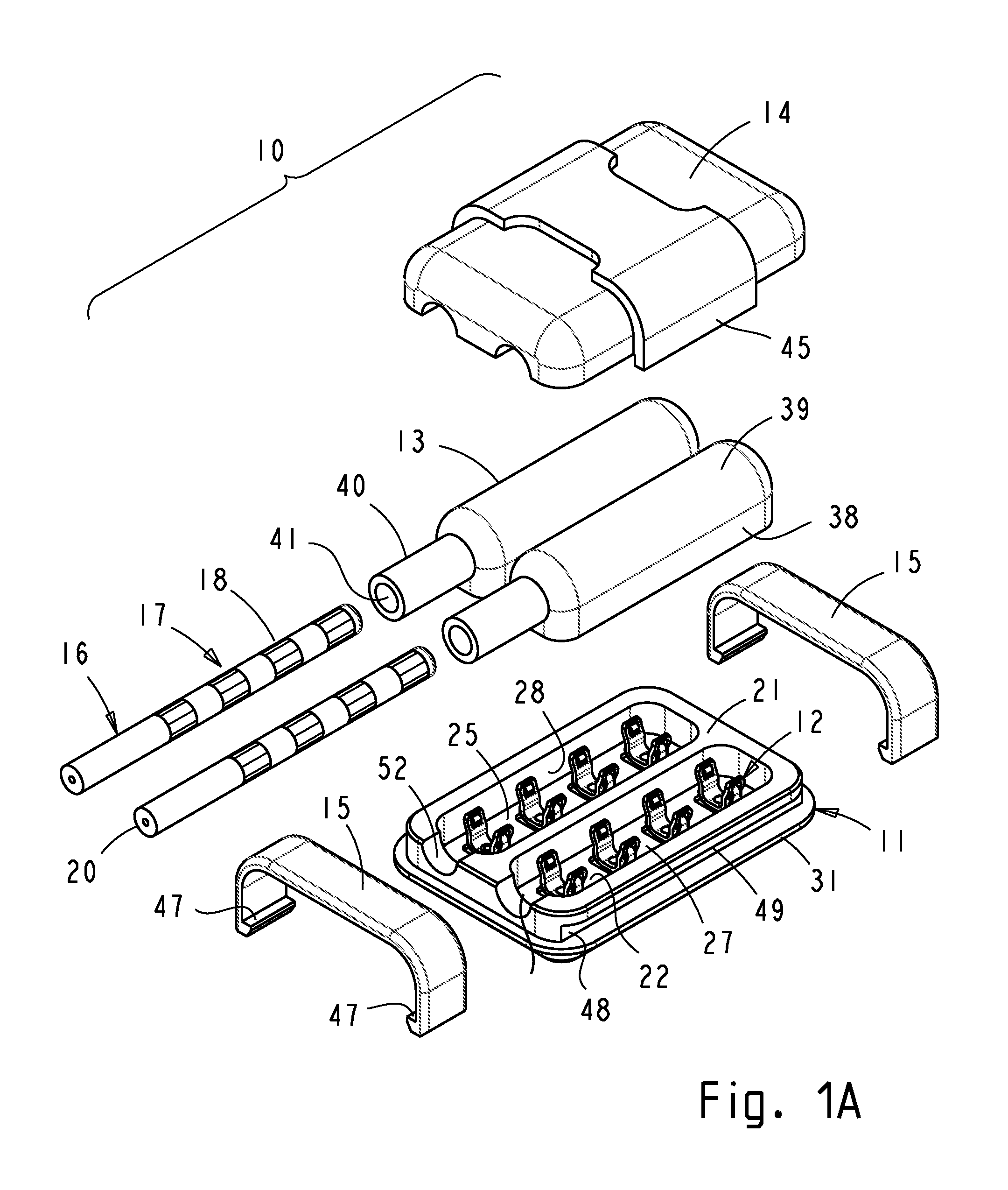

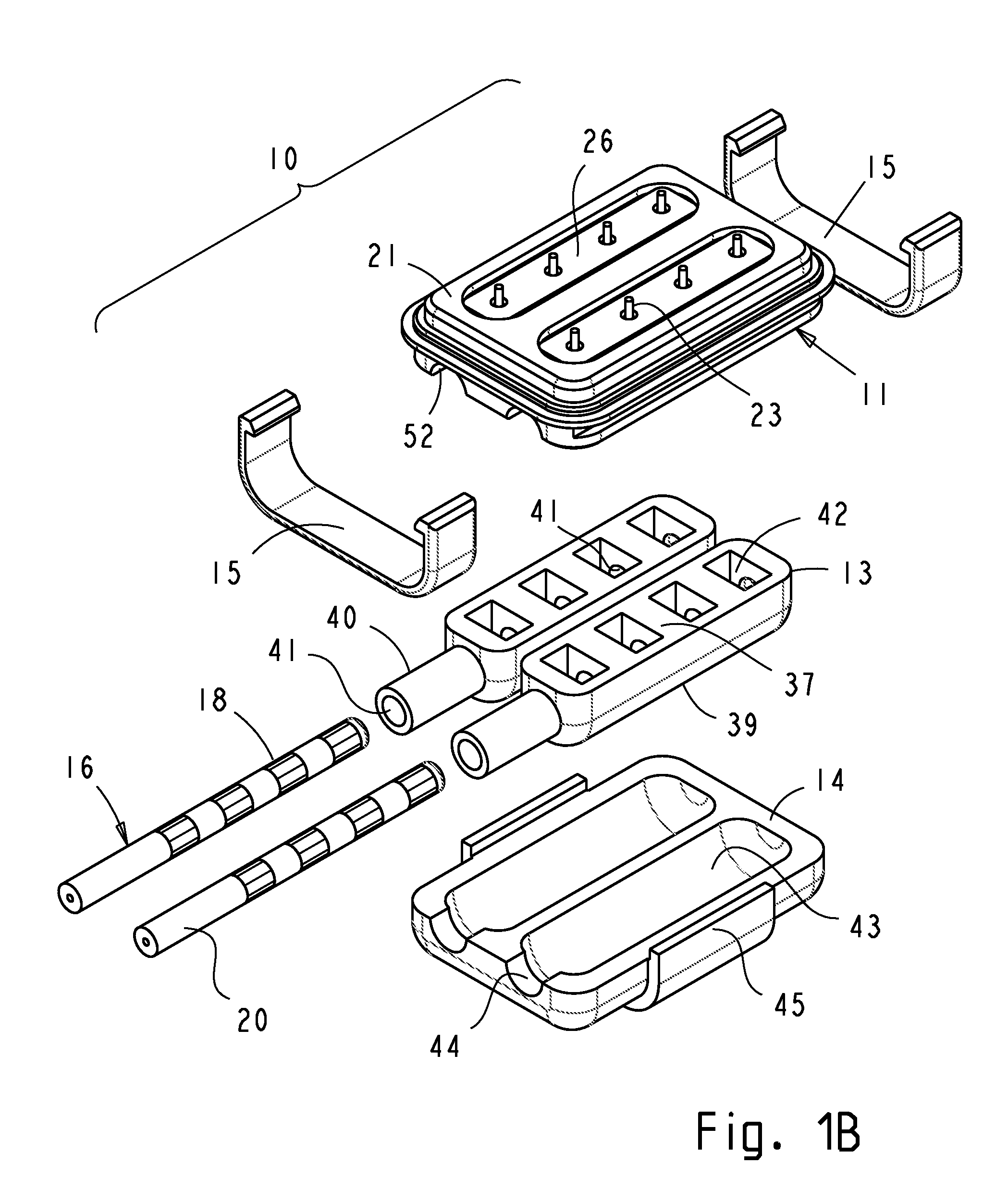

Apparatus and method for applying surgical staples to attach an object to body tissue

InactiveUS20020117534A1Avoid deformationSuture equipmentsStapling toolsSupporting systemSurgical staple

An apparatus is disclosed for endoscopic application of surgical staples adapted to attach surgical mesh to body tissue in laparoscopic hernia surgery. The apparatus includes a frame, and a generally elongated endoscopic section connected to the frame and extending distally therefrom. A staple storage cartridge is removably supported on a pivotal support system at the distal end portion of the endoscopic section with each staple being configured and adapted to attach the mesh to the body tissue. An elongated pusher system formed of several assembled components and extending from the frame to the endoscopic section is provided for individually advancing at least one staple at a time distally for positioning adjacent the surgical mesh and the body tissue. The pusher system also includes a trigger system to actuate the pusher. The trigger system is provided with perceptible tactile sensing means to indicate when the legs of the staple being advanced are exposed so as to be visible to the user for positioning and orientation purposes. Anvil means provides for individually closing each staple to encompass at least a portion of the surgical mesh and to penetrate the body tissue in a manner to attach the portion of the mesh to the body tissue. Projecting distally of the cartridge support system is a pair of legs which are dimensioned and configured to engage the staple during closure to prevent unwanted roll or deformation outside of the plane of the staple.

Owner:TYCO HEALTHCARE GRP LP

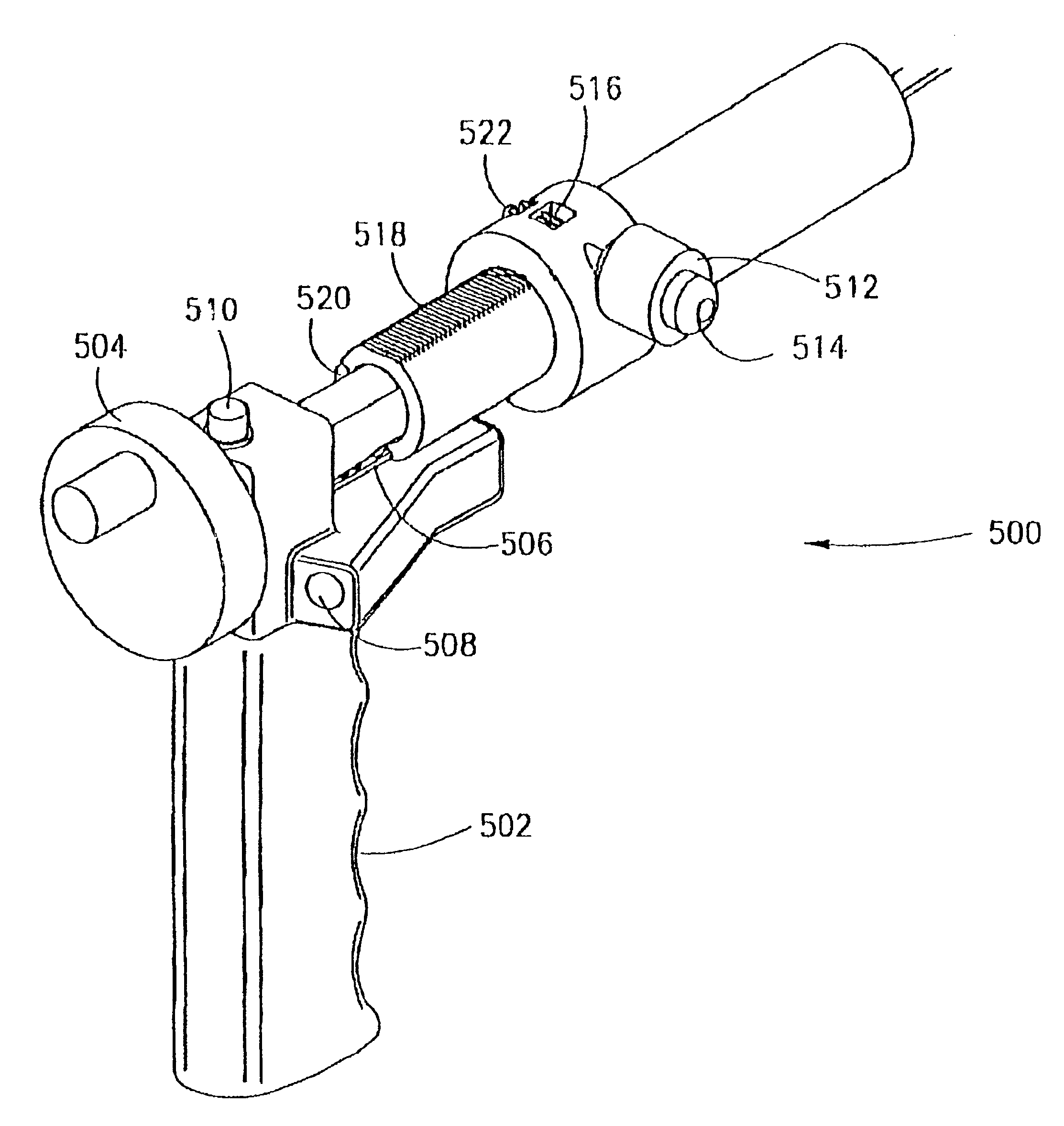

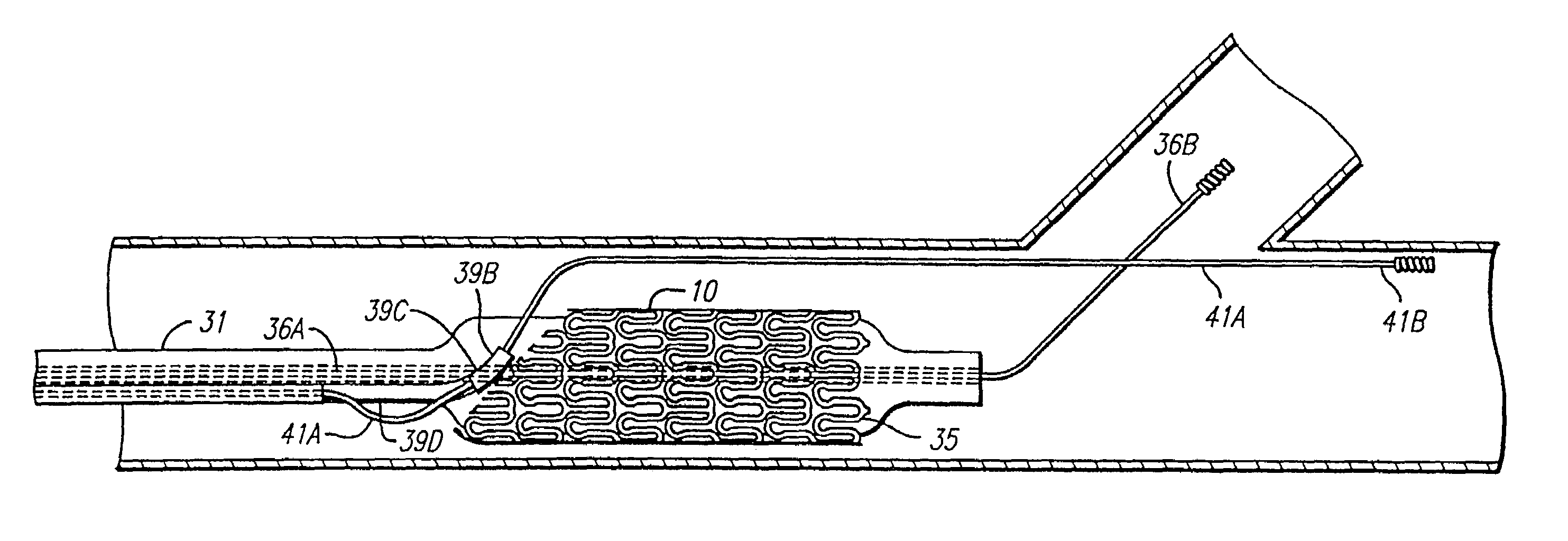

Expandable element delivery system

InactiveUS7097648B1Restraint torsionReduce torqueDental implantsInternal osteosythesisEngineeringDelivery system

Apparatus for controlling the deformation of an implant during deployment thereof, comprising: a force application mechanism for applying deformation force to the implant, by motion of a force applicator against the implant; and a restraint element positioning mechanism that positions a restraining element such that the deformation of the implant is controlled by restraint of the restraining element on allowable deformation; and a synchronizer that synchronizes the motion of the restraining element and the force applicator, to achieve a desired deformation of the implanted.

Owner:KYPHON

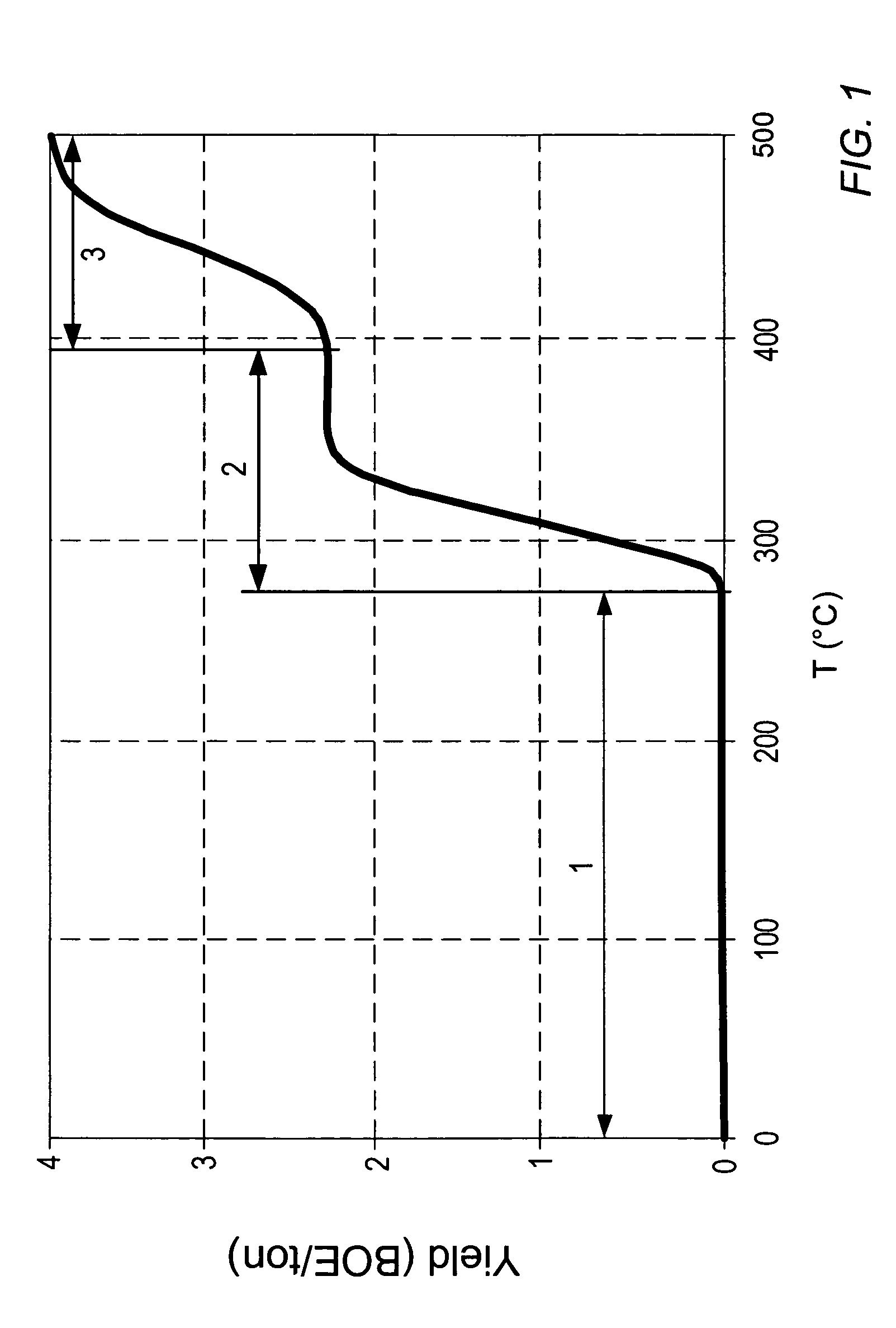

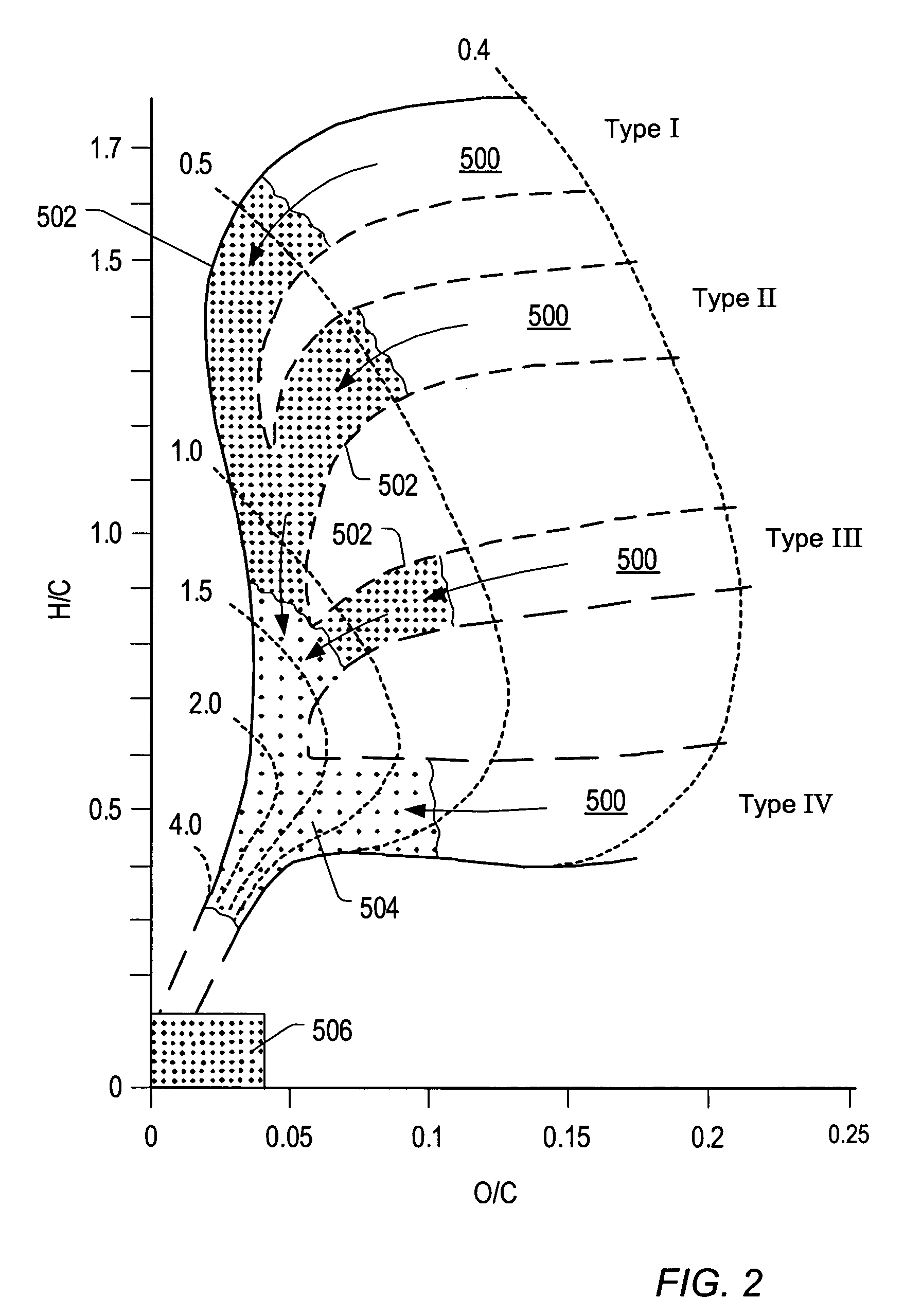

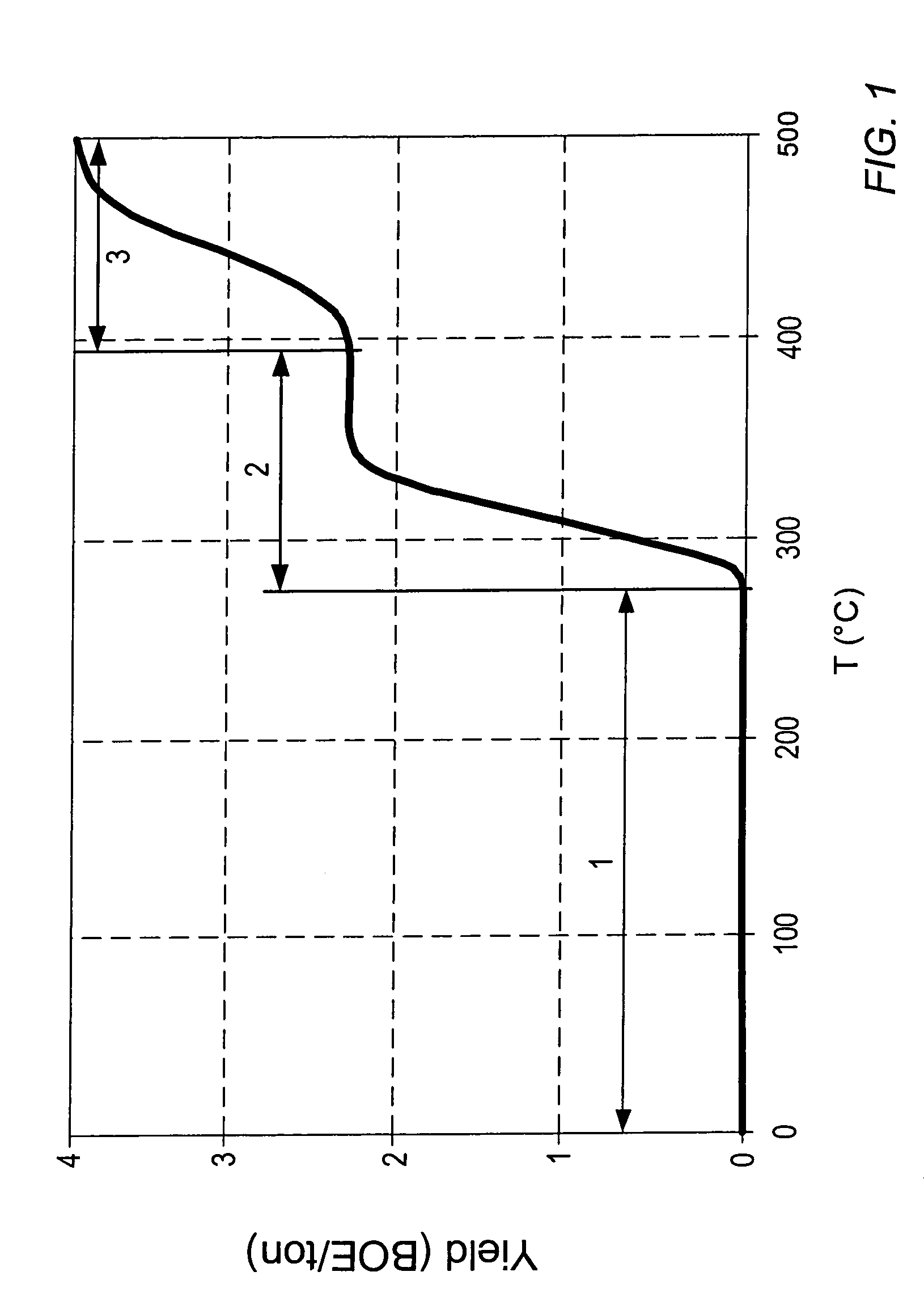

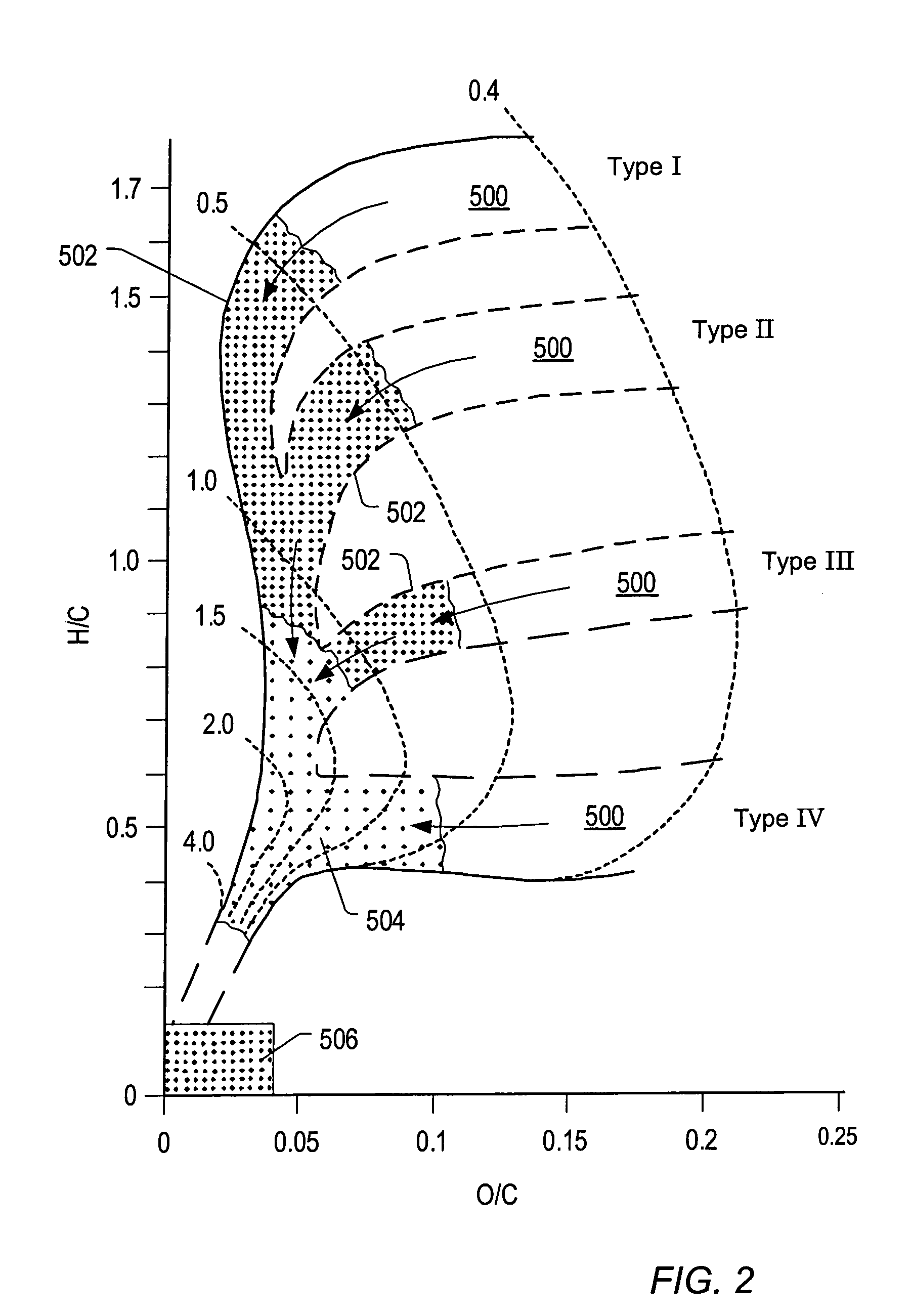

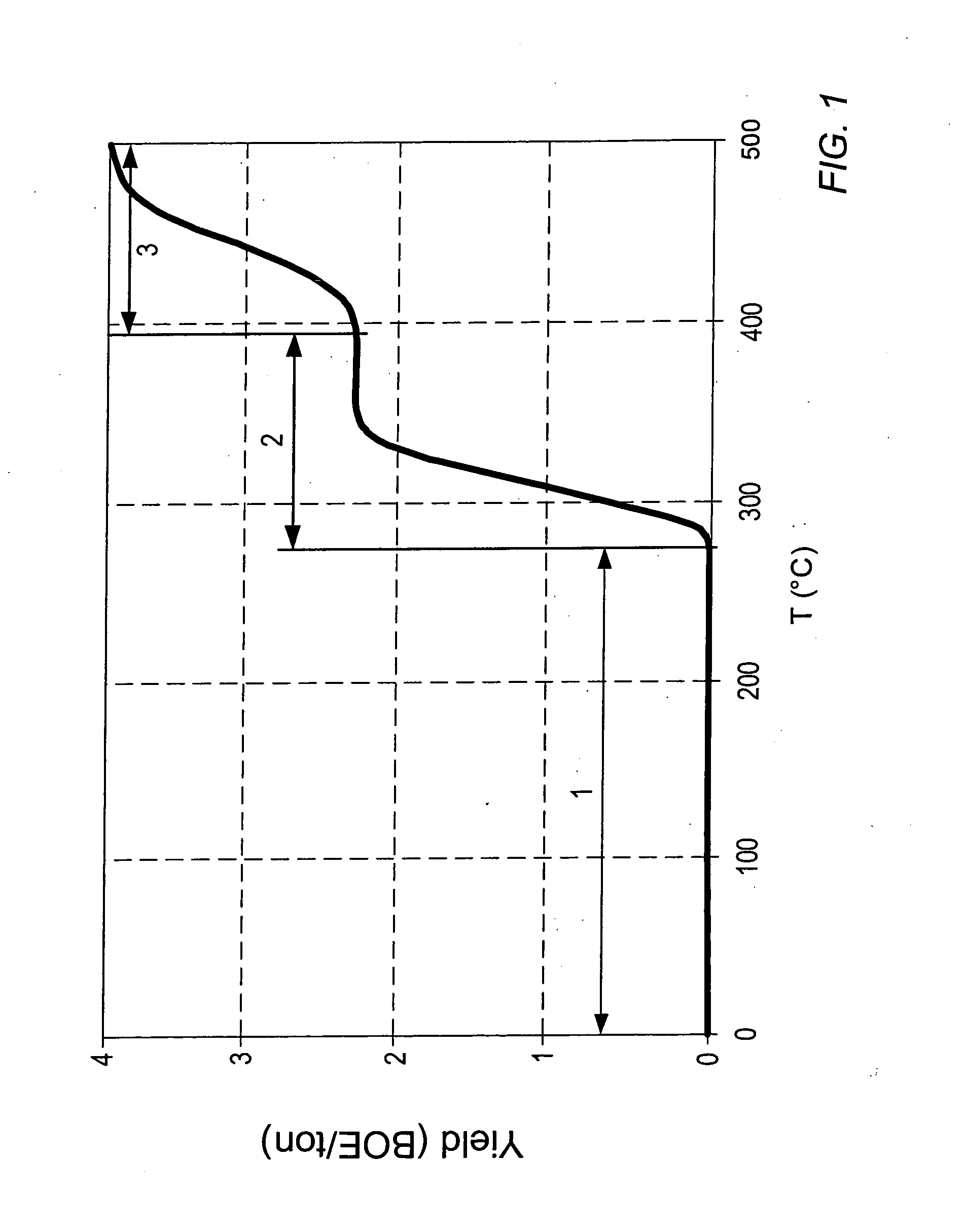

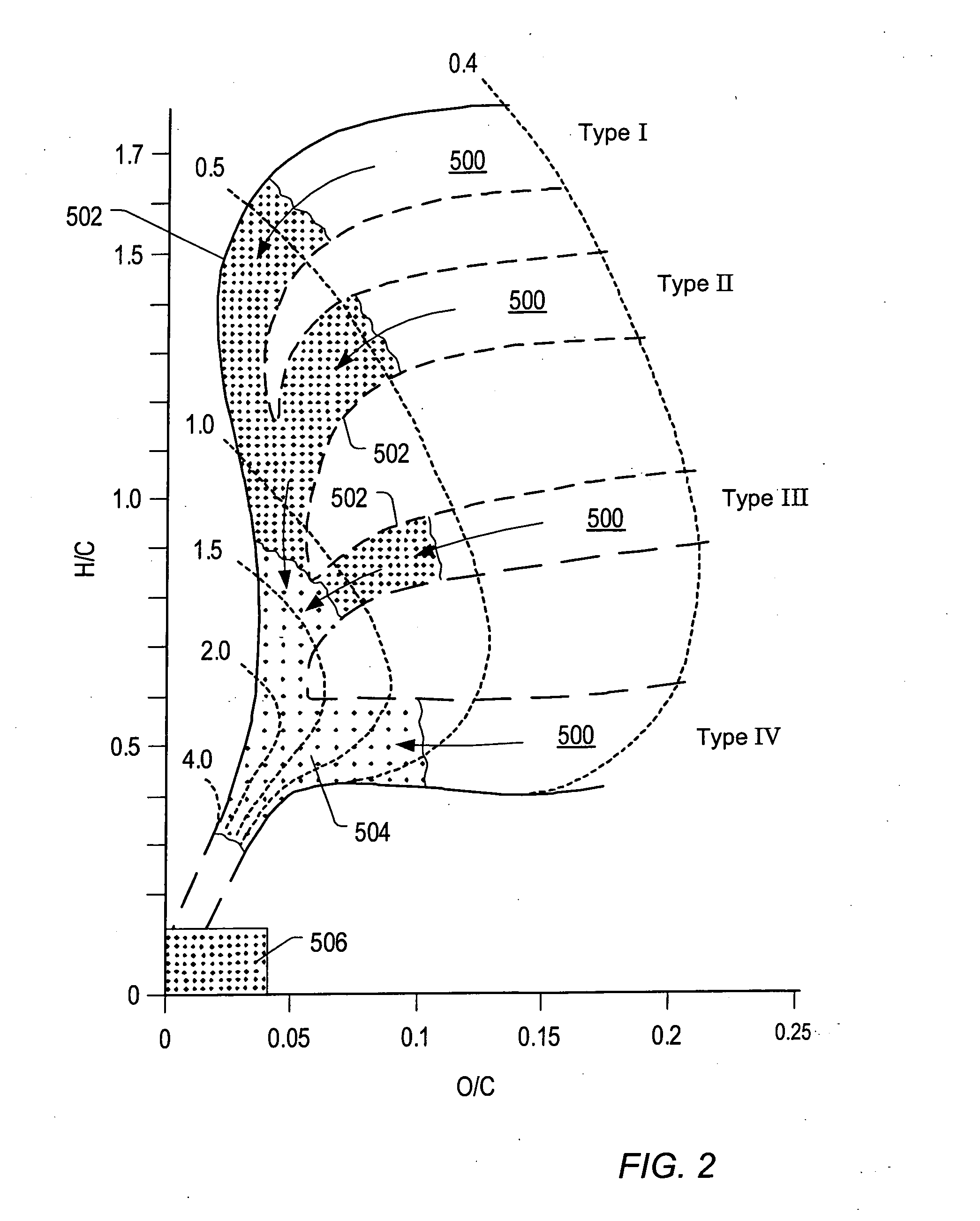

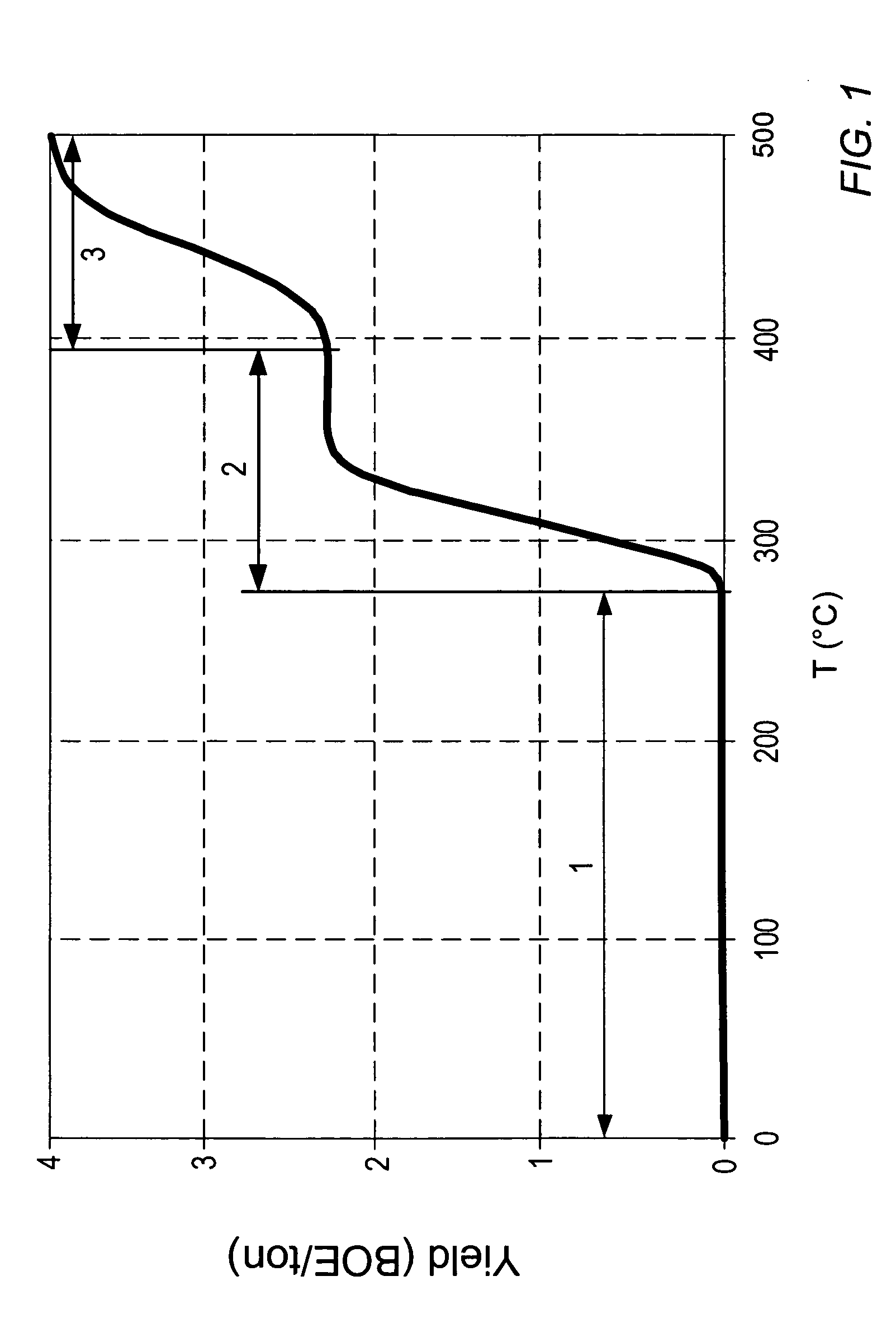

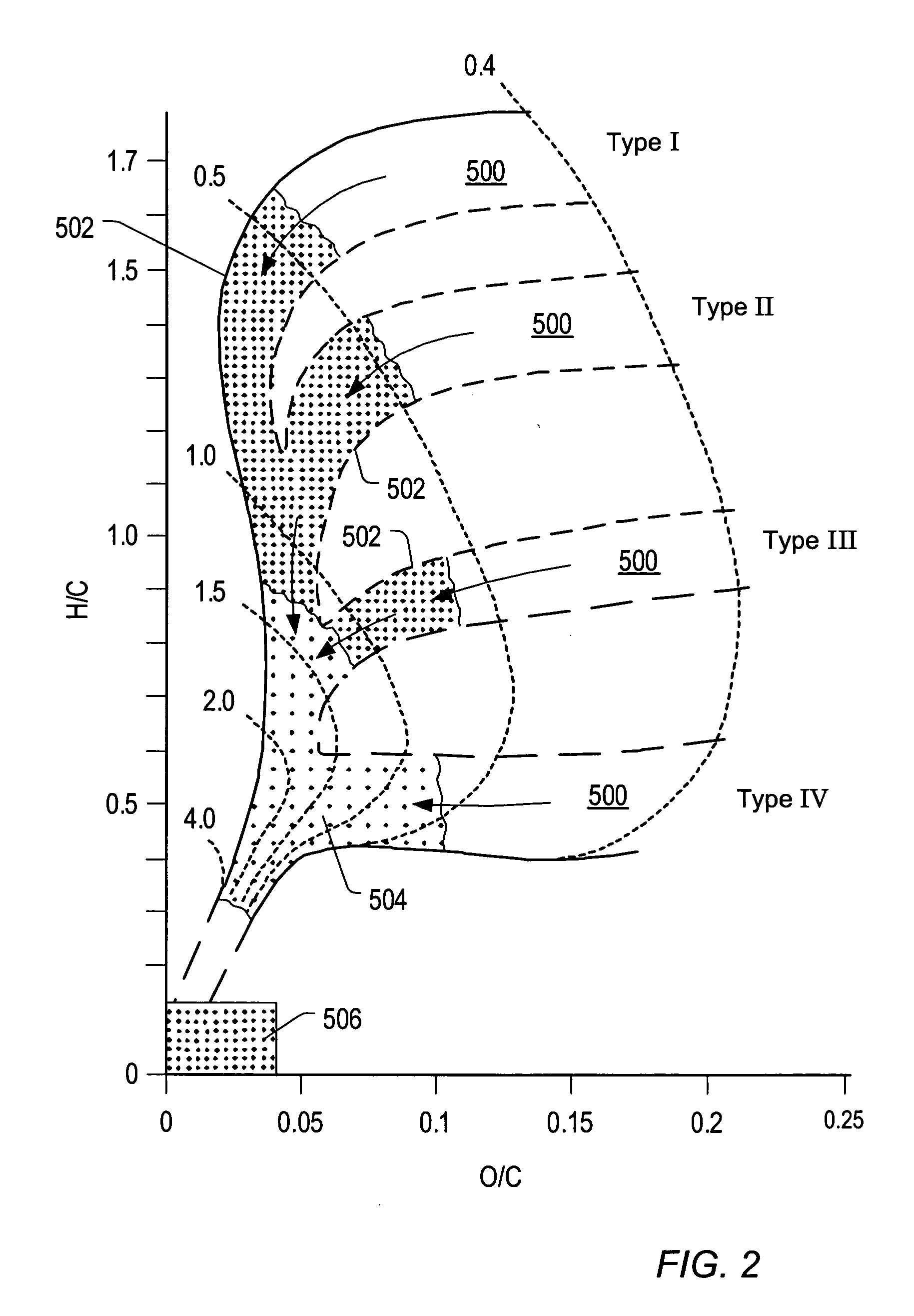

Thermal processes for subsurface formations

A process may include providing heat from one or more heaters to at least a portion of a subsurface formation. Heat may transfer from one or more heaters to a part of a formation. In some embodiments, heat from the one or more heat sources may pyrolyze at least some hydrocarbons in a part of a subsurface formation. Hydrocarbons and / or other products may be produced from a subsurface formation. Certain embodiments describe apparatus, methods, and / or processes used in treating a subsurface or hydrocarbon containing formation.

Owner:SHELL OIL CO

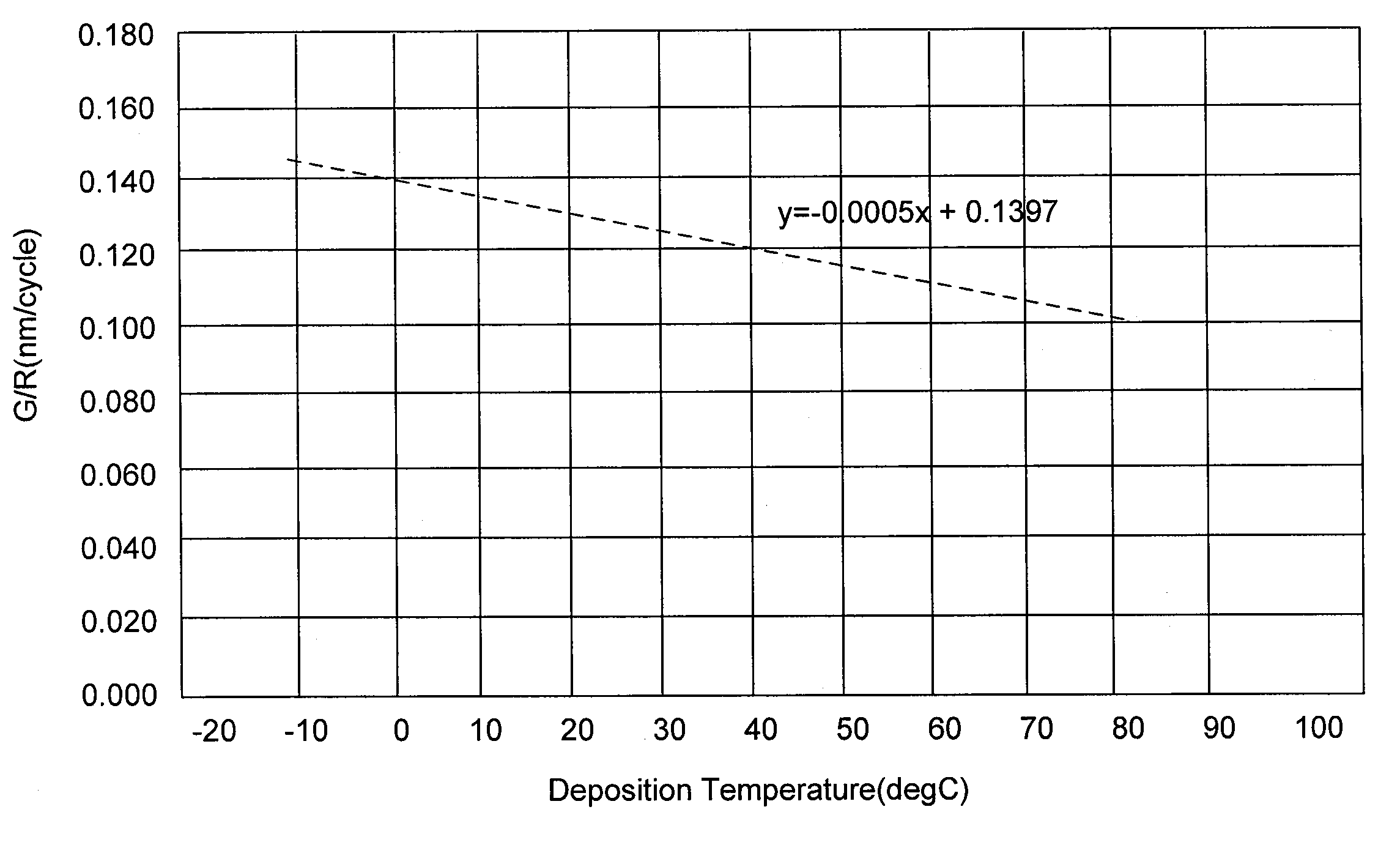

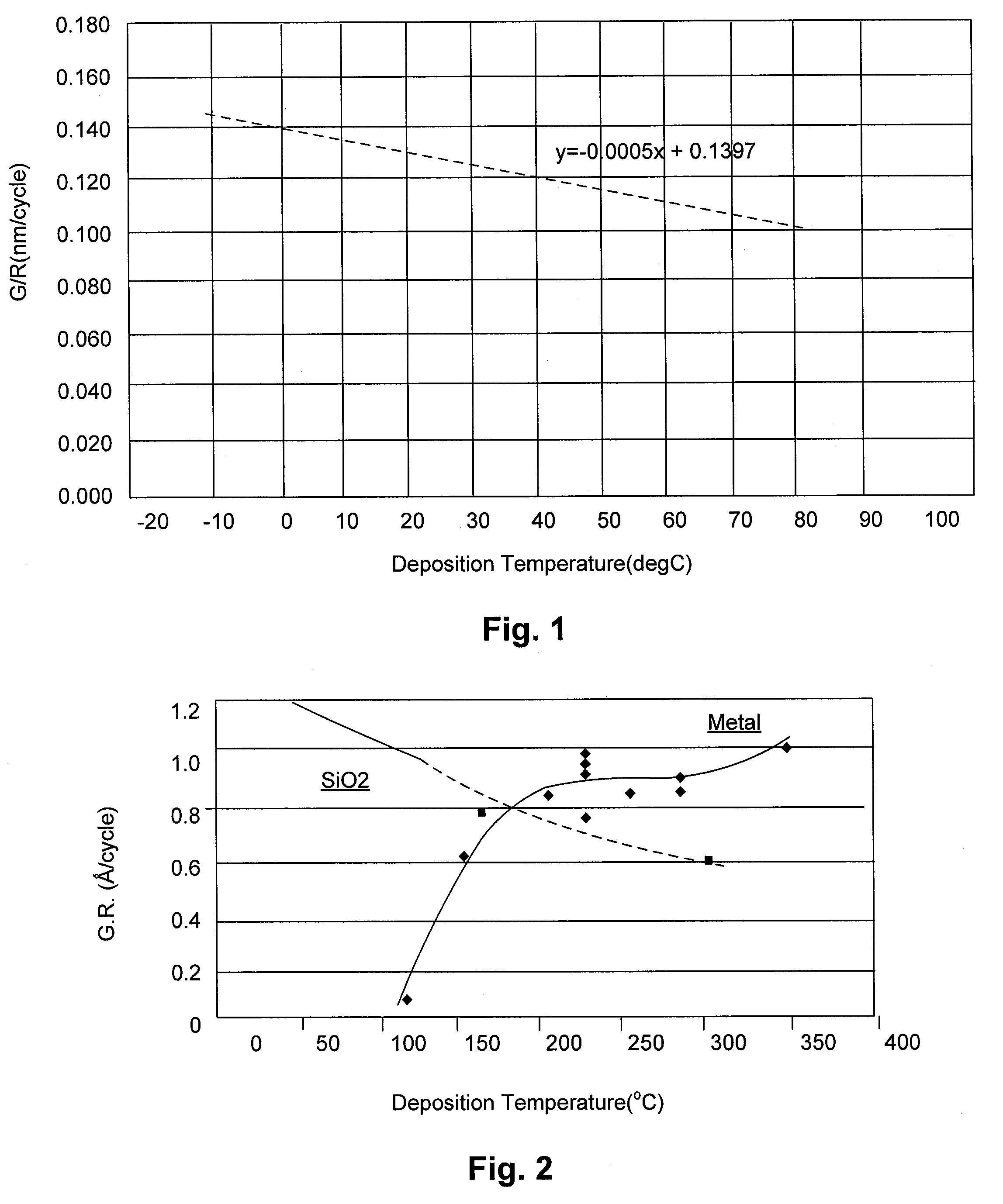

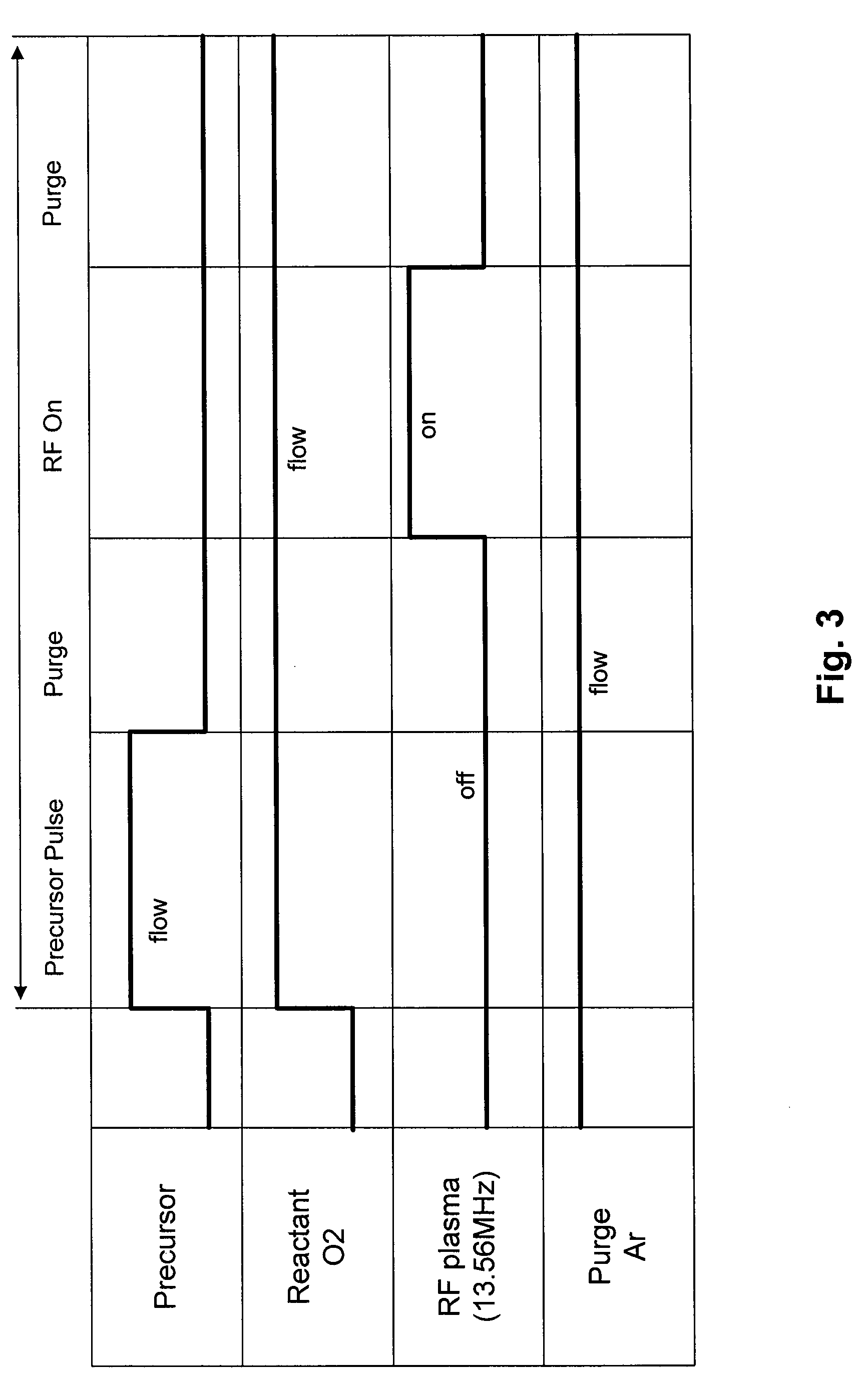

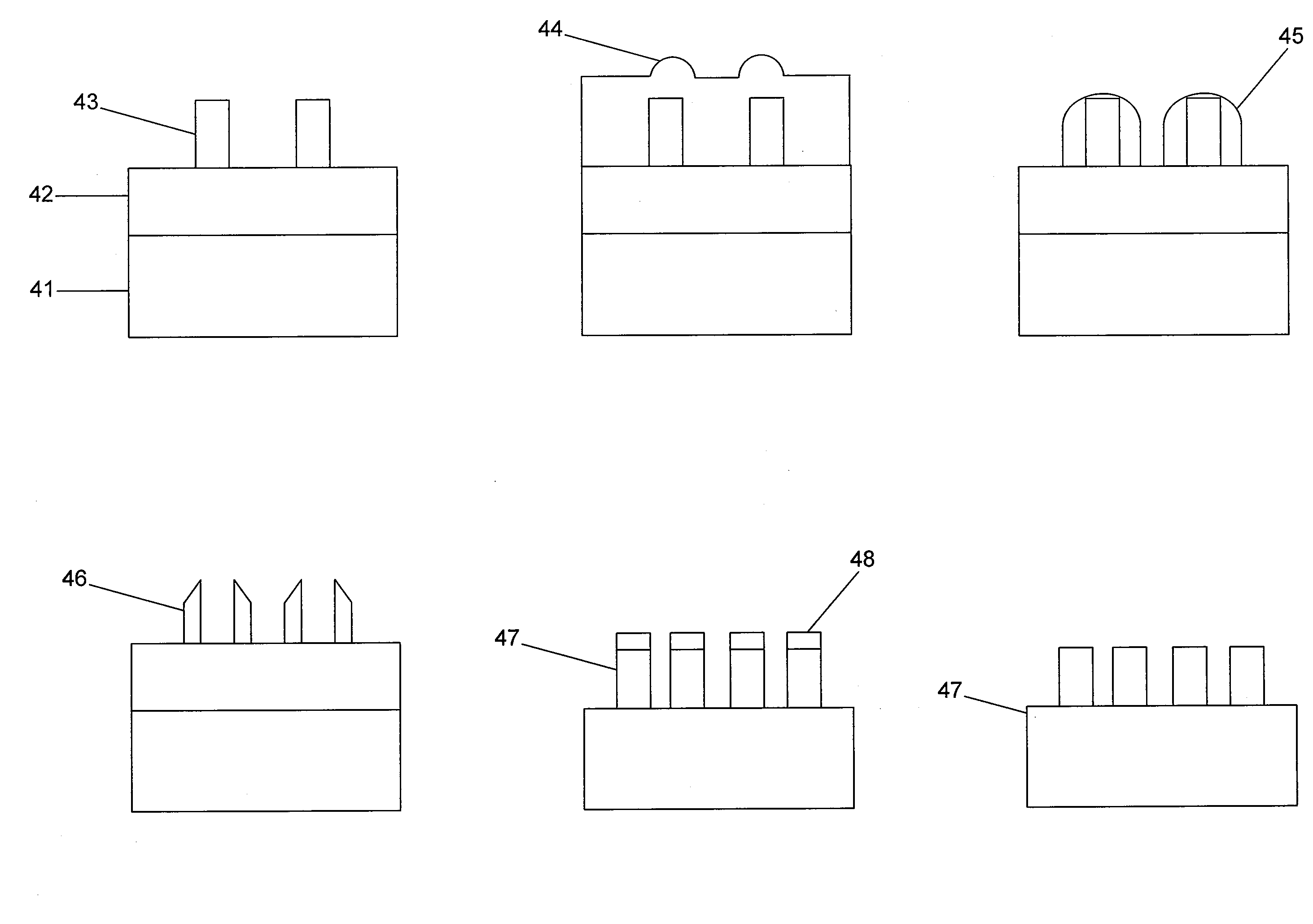

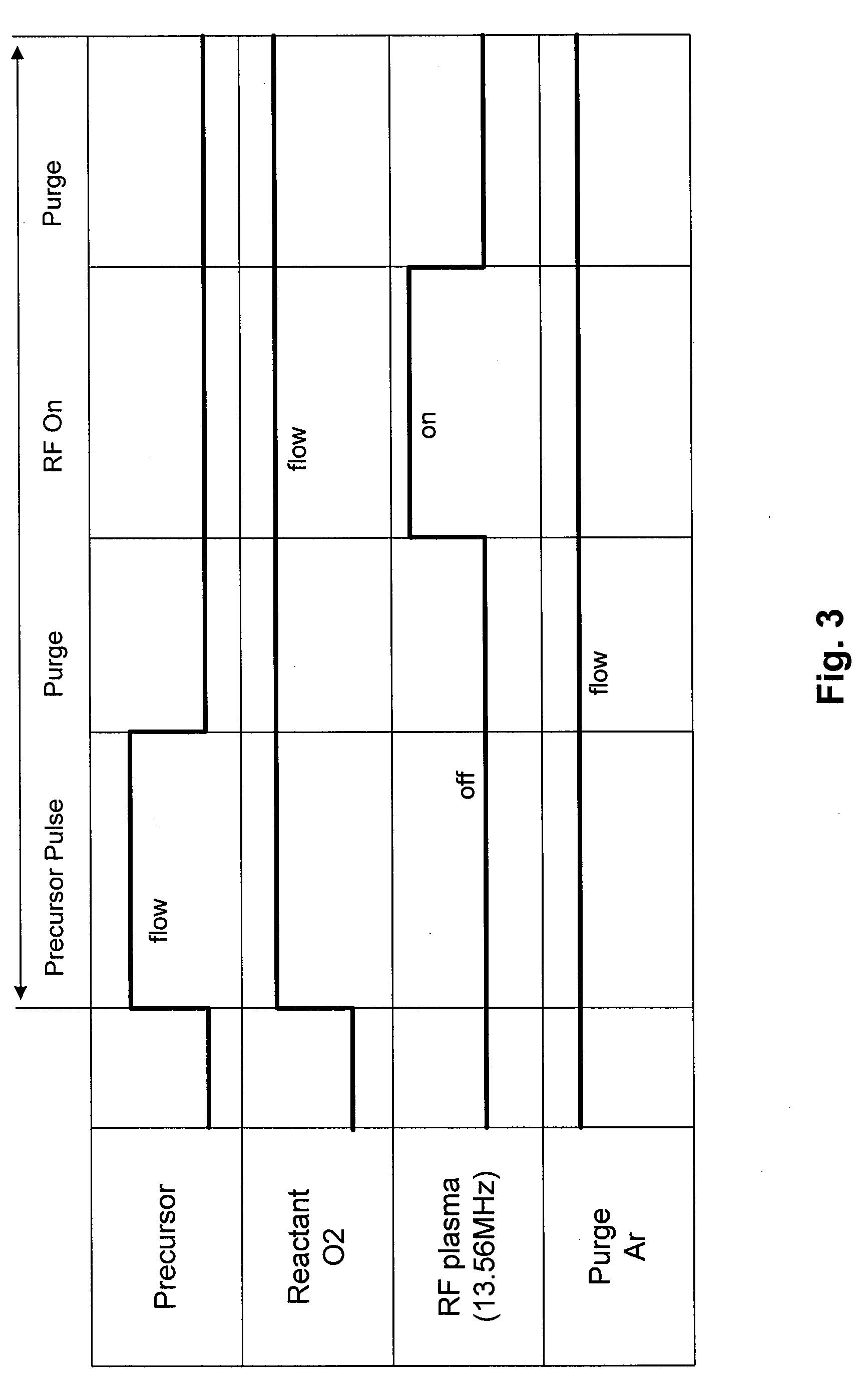

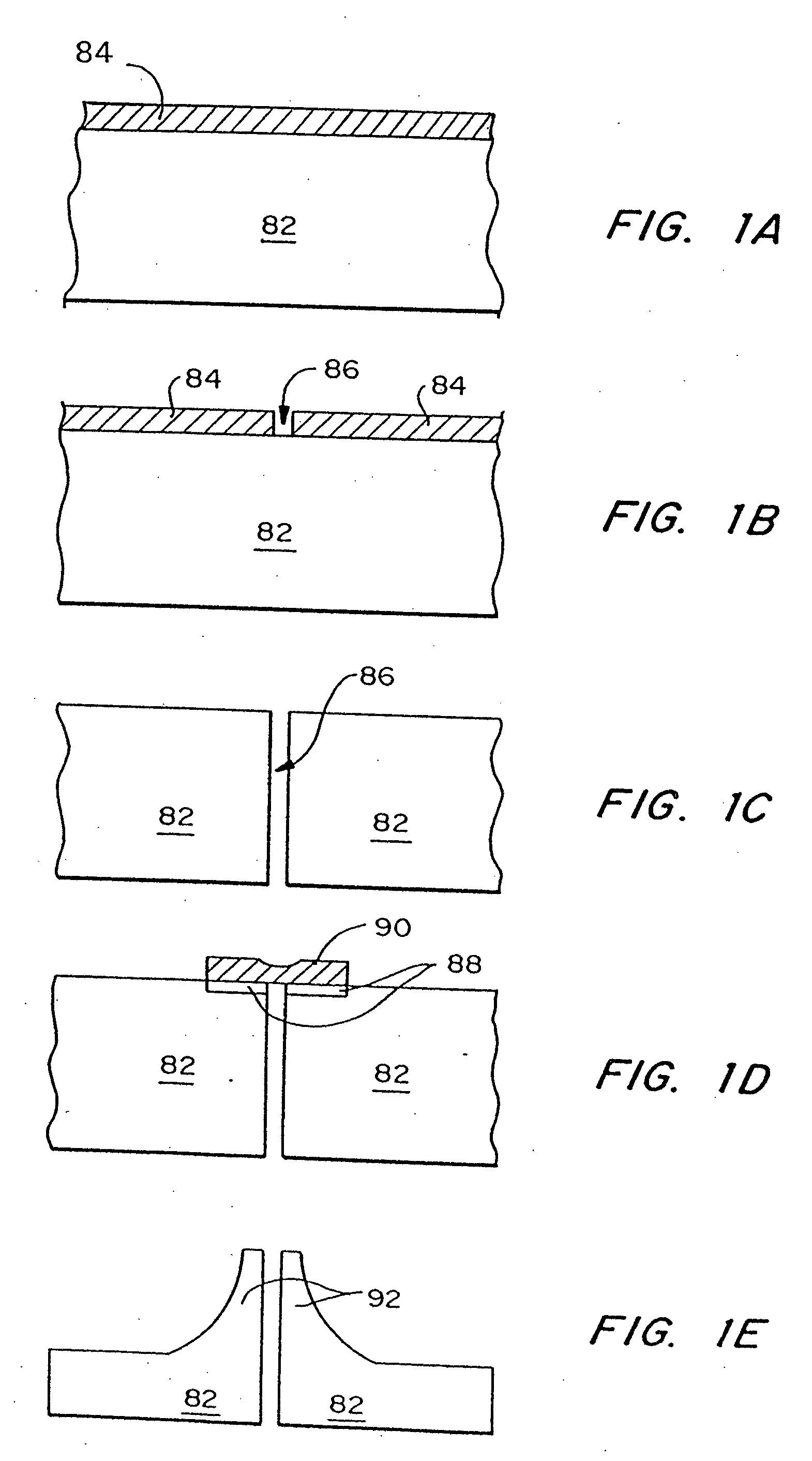

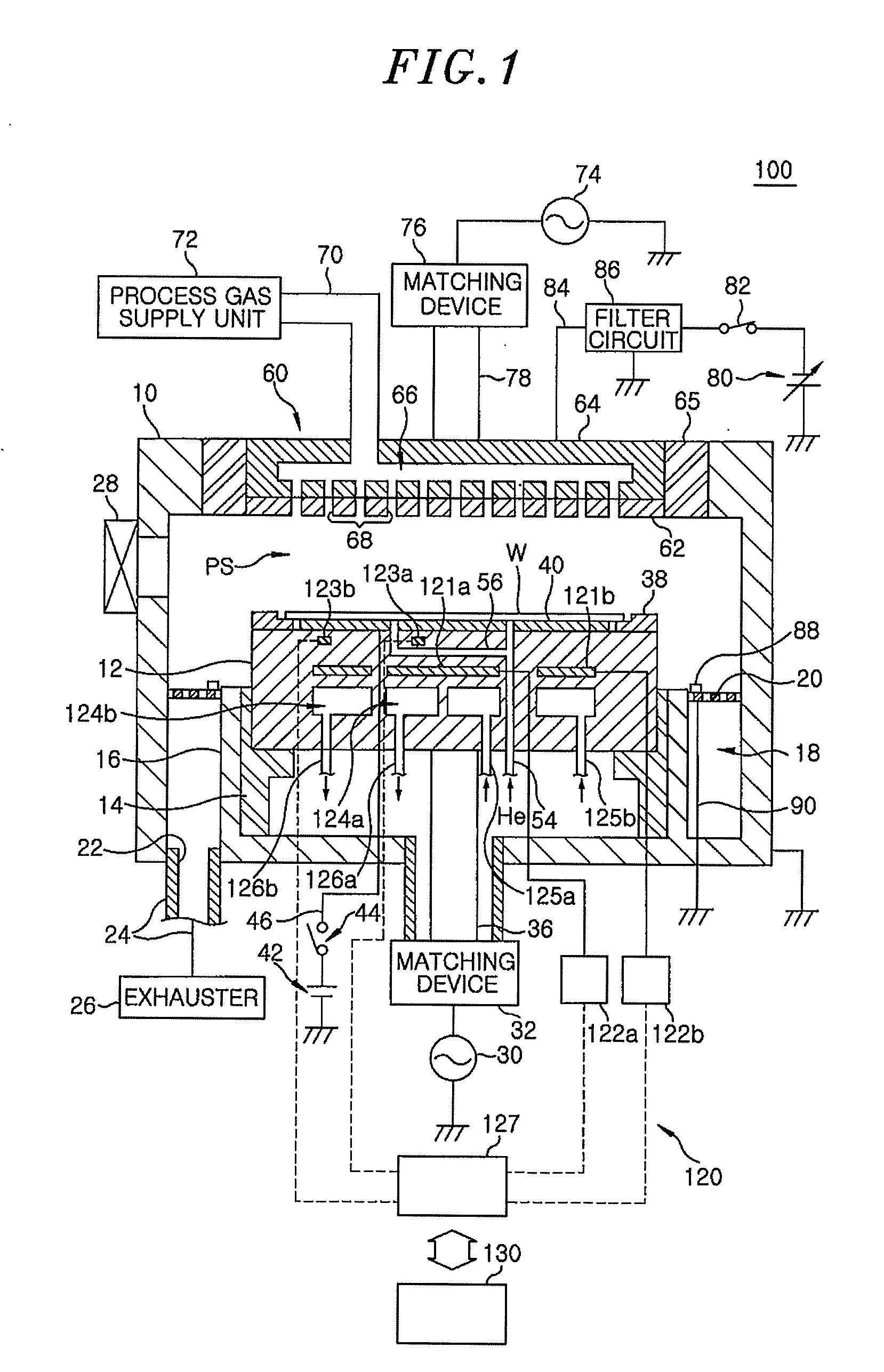

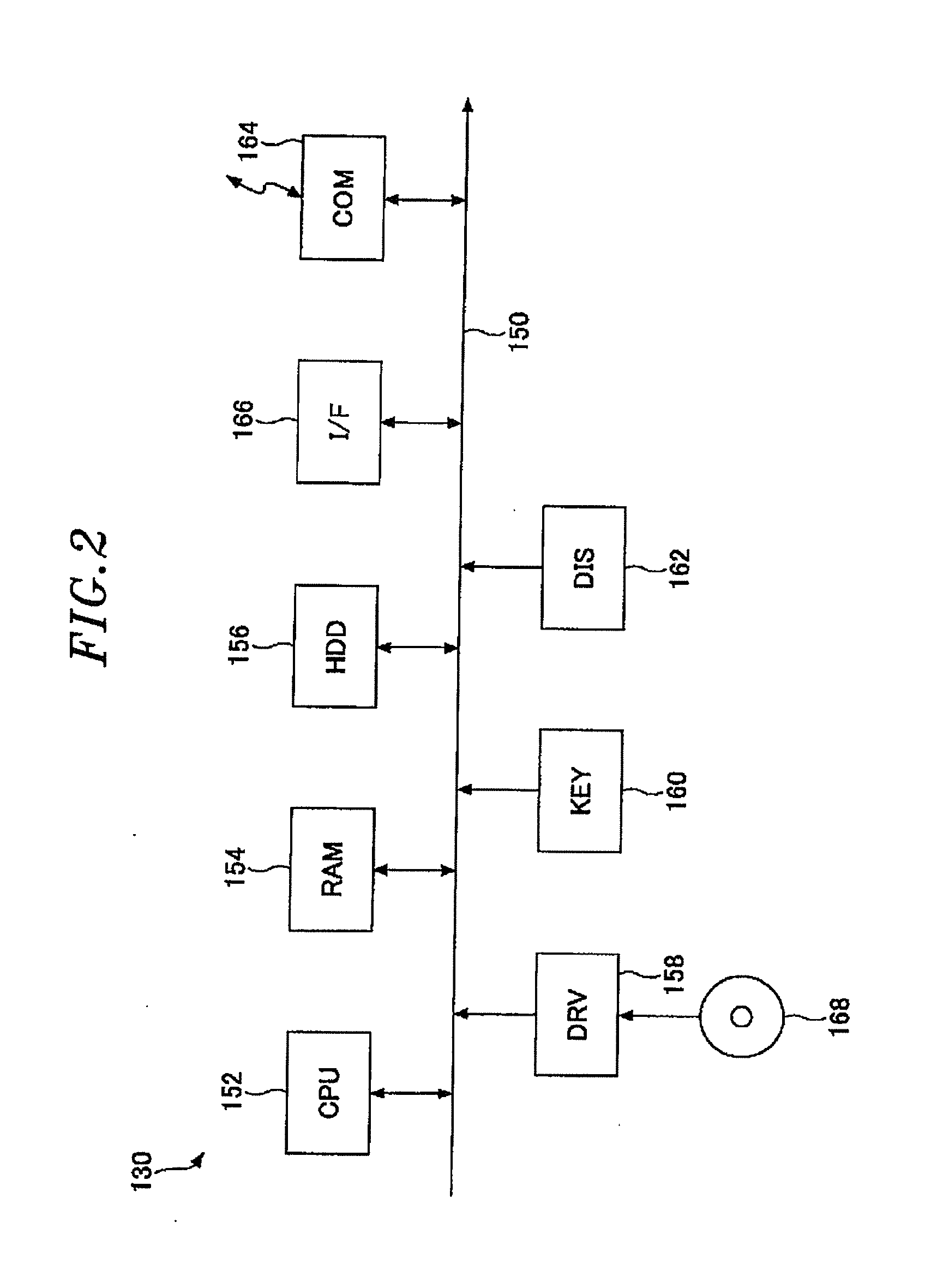

Method of depositing silicon oxide film by plasma enhanced atomic layer deposition at low temperature

ActiveUS8197915B2Increase deposition rateInhibition is effectiveSemiconductor/solid-state device manufacturingPhotosensitive material processingResistDeposition temperature

Owner:ASM JAPAN

Method of Depositing Silicon Oxide Film by Plasma Enhanced Atomic Layer Deposition at Low Temperature

ActiveUS20100255218A1Increase deposition rateInhibition is effectiveLiquid surface applicatorsSemiconductor/solid-state device manufacturingResistDeposition temperature

A method of depositing a silicon oxide film on a resist pattern or etched lines formed on a substrate by plasma enhanced atomic layer deposition (PEALD) includes: providing a substrate on which a resist pattern or etched lines are formed in a PEALD reactor; controlling a temperature of a susceptor on which the substrate is placed at less than 50° C. as a deposition temperature; introducing a silicon-containing precursor and an oxygen-supplying reactant to the PEALD reactor and applying RF power therein in a cycle, while the deposition temperature is controlled substantially or nearly at a constant temperature of less than 50° C., thereby depositing a silicon oxide atomic layer on the resist pattern or etched lines; and repeating the cycle multiple times substantially or nearly at the constant temperature to deposit a silicon oxide atomic film on the resist pattern or etched lines.

Owner:ASM JAPAN

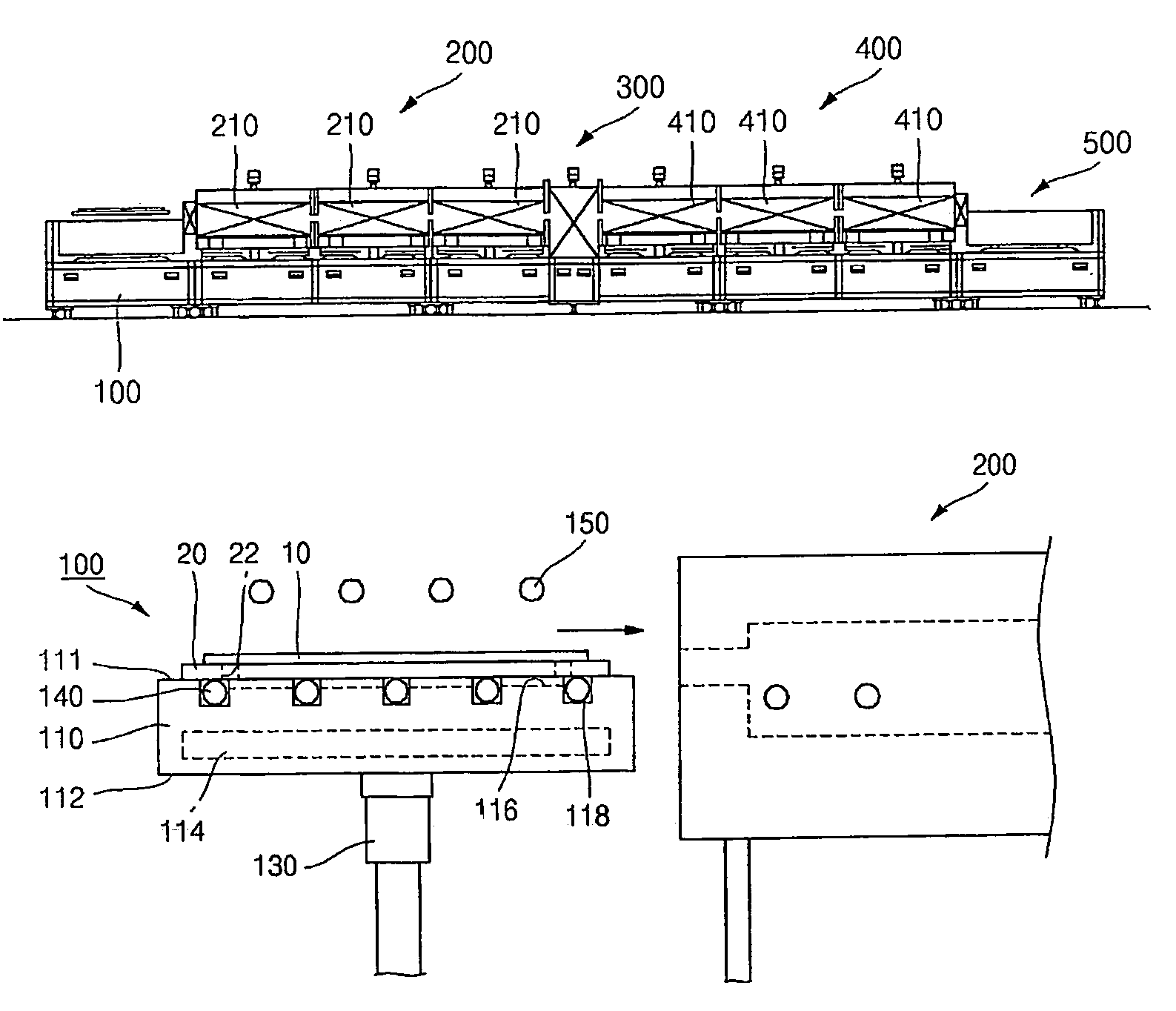

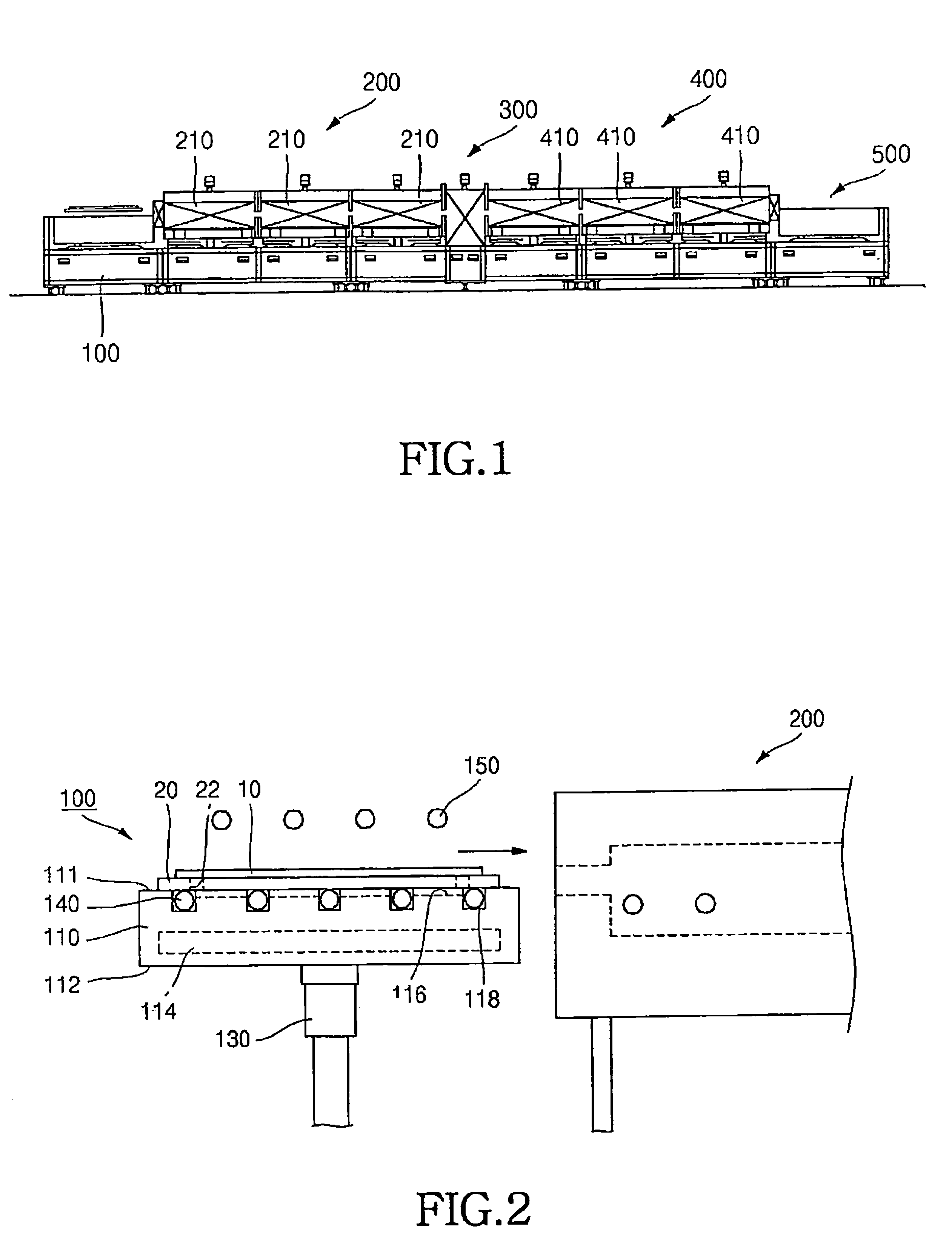

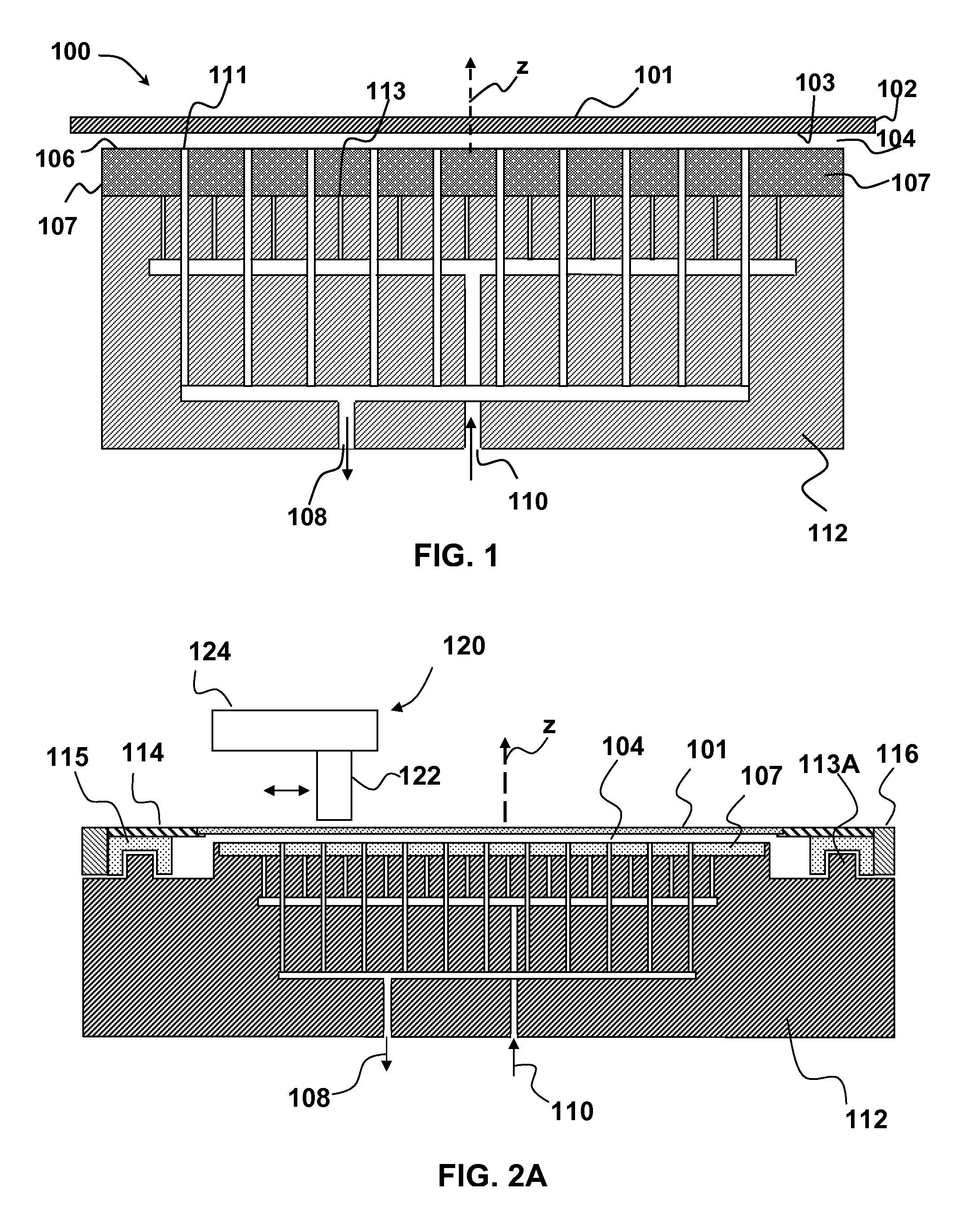

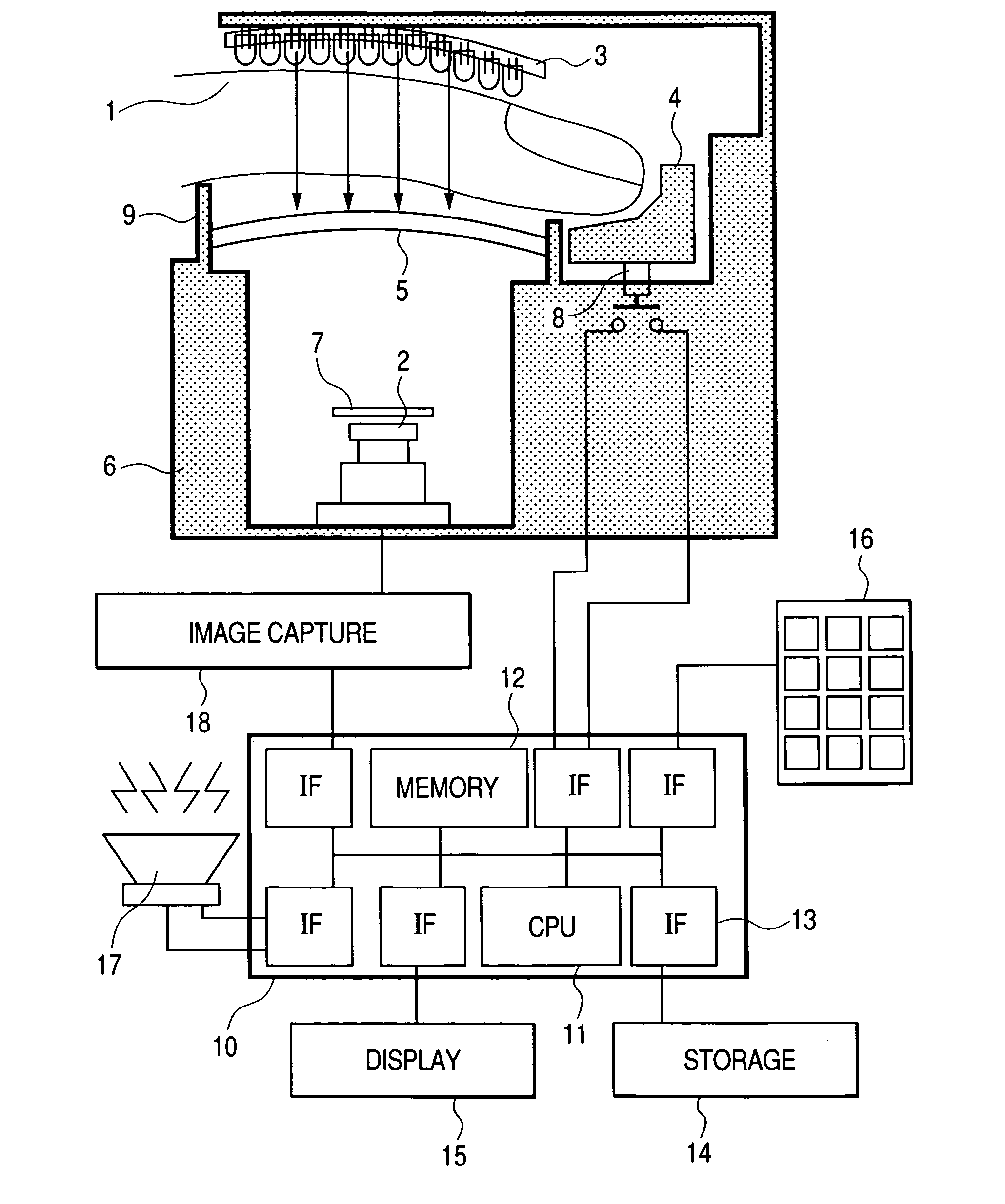

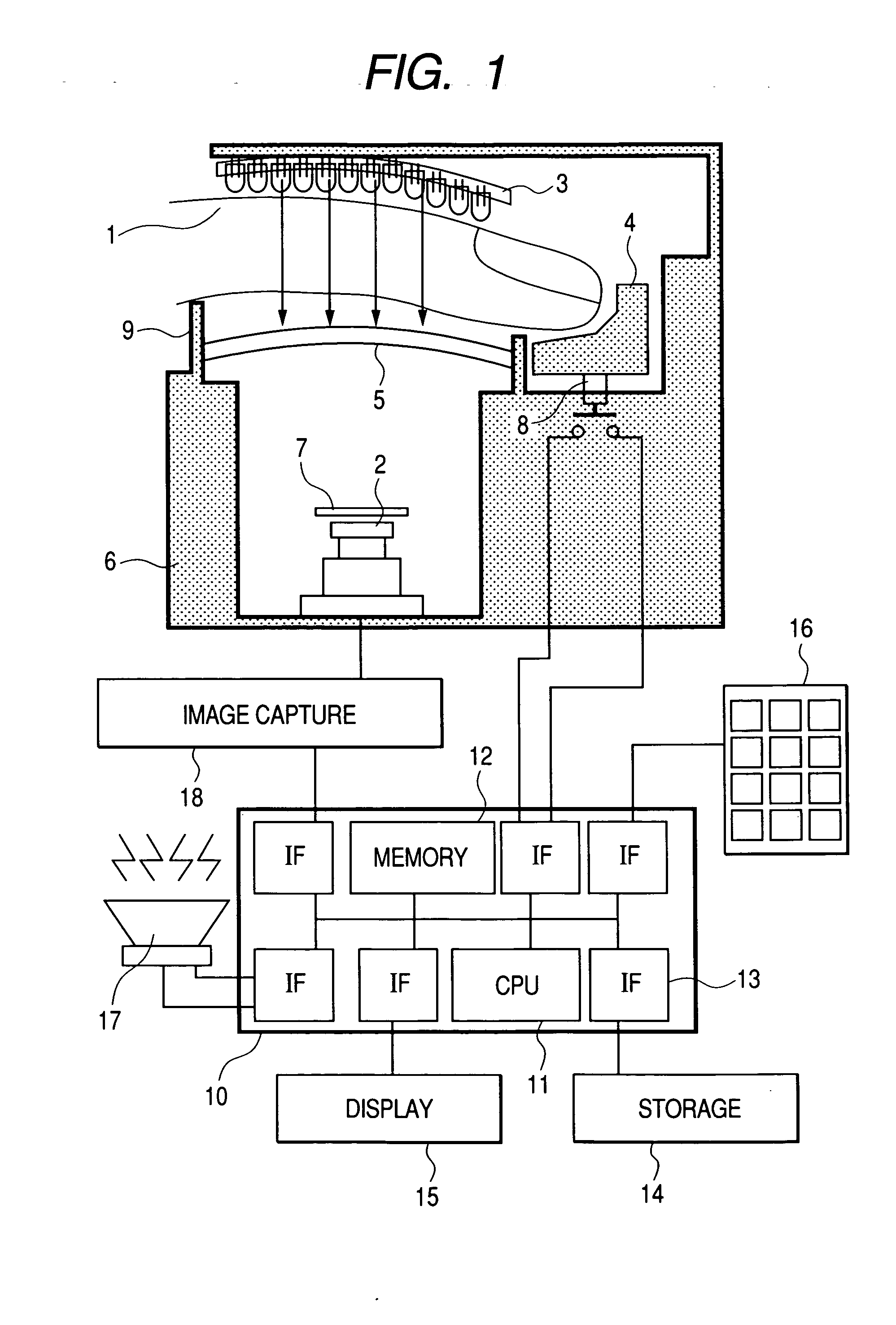

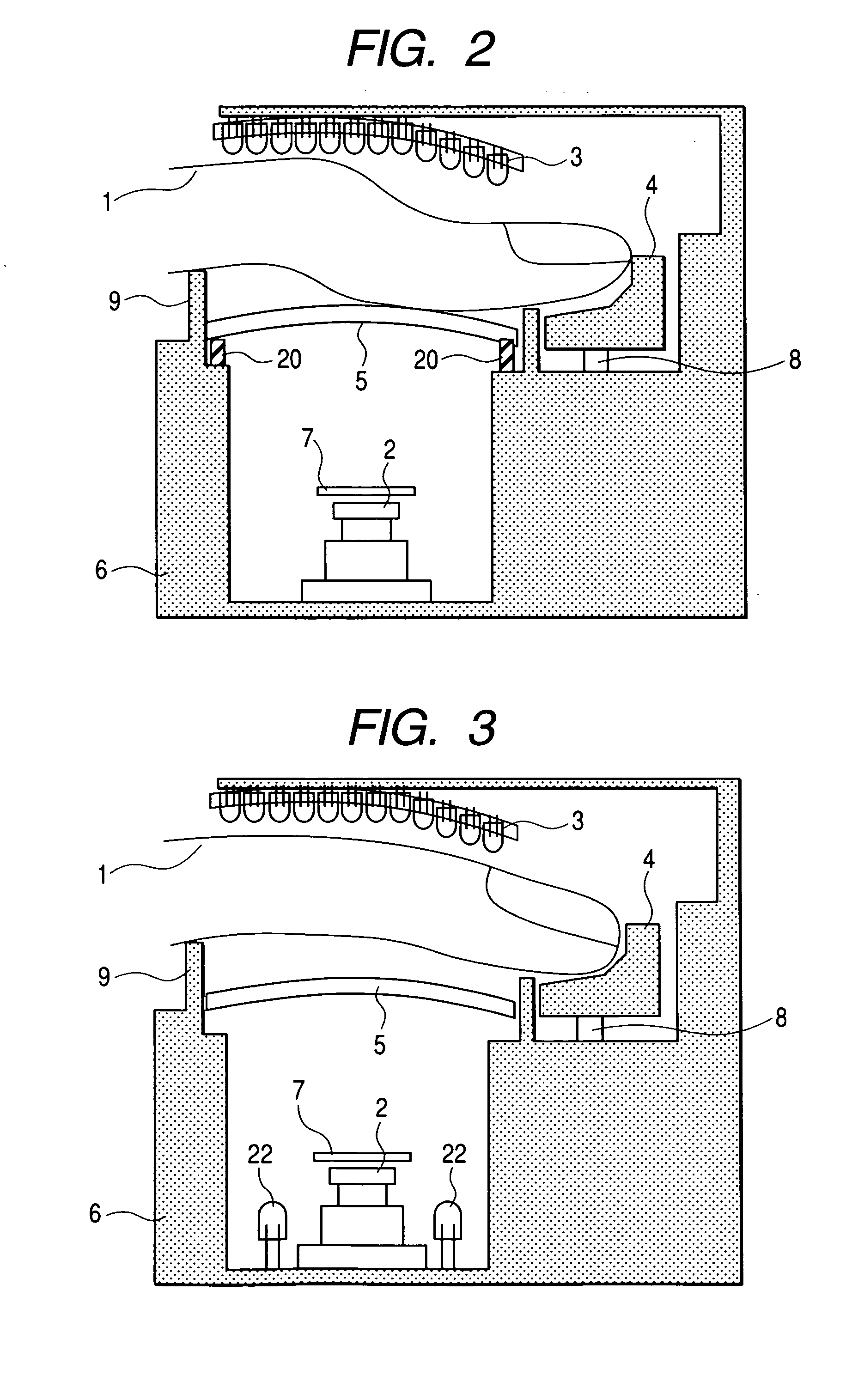

System for heat treatment of semiconductor device

InactiveUS7989736B2Avoid damageIncrease temperatureFurnaces without endless coreSemiconductor/solid-state device manufacturingElectromotive forceSilicon thin film

Disclosed is a heat treatment system for semiconductor devices. The heat treatment system is used in a heat treatment process for semiconductor devices, such as a crystallization process for an amorphous silicon thin film or a dopant activation process for a poly-crystalline silicon thin film formed on a surface of a glass substrate of a flat display panel including a liquid crystal display (LCD) or an organic light emitting device (OLED). The heat treatment system transfers a semiconductor device after uniformly preheating the semiconductor device in order to prevent deformation of the semiconductor device during the heat treatment process, rapidly performs the heat treatment process under the high temperature condition by heating the semiconductor device using a lamp heater and induction heat derived from induced electromotive force, and unloads the semiconductor device after uniformly cooling the semiconductor device such that the semiconductor device is prevented from being deformed when the heat treatment process has been finished. The heat treatment system rapidly performs the heat treatment process while preventing deformation of the semiconductor device by gradually heating or cooling the semiconductor device.

Owner:VIATRON TECH INC

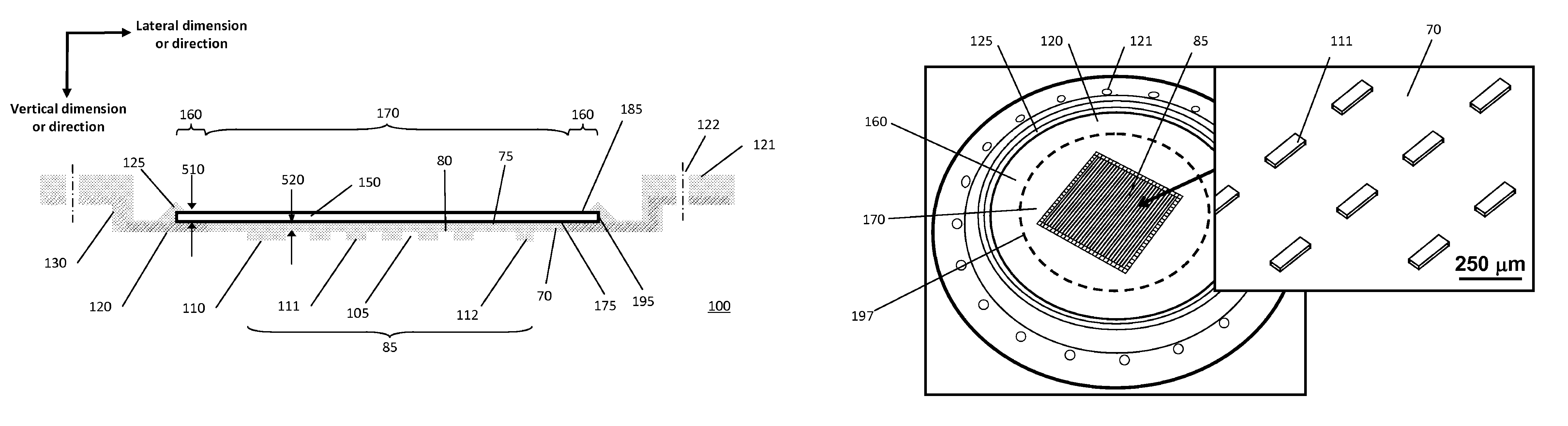

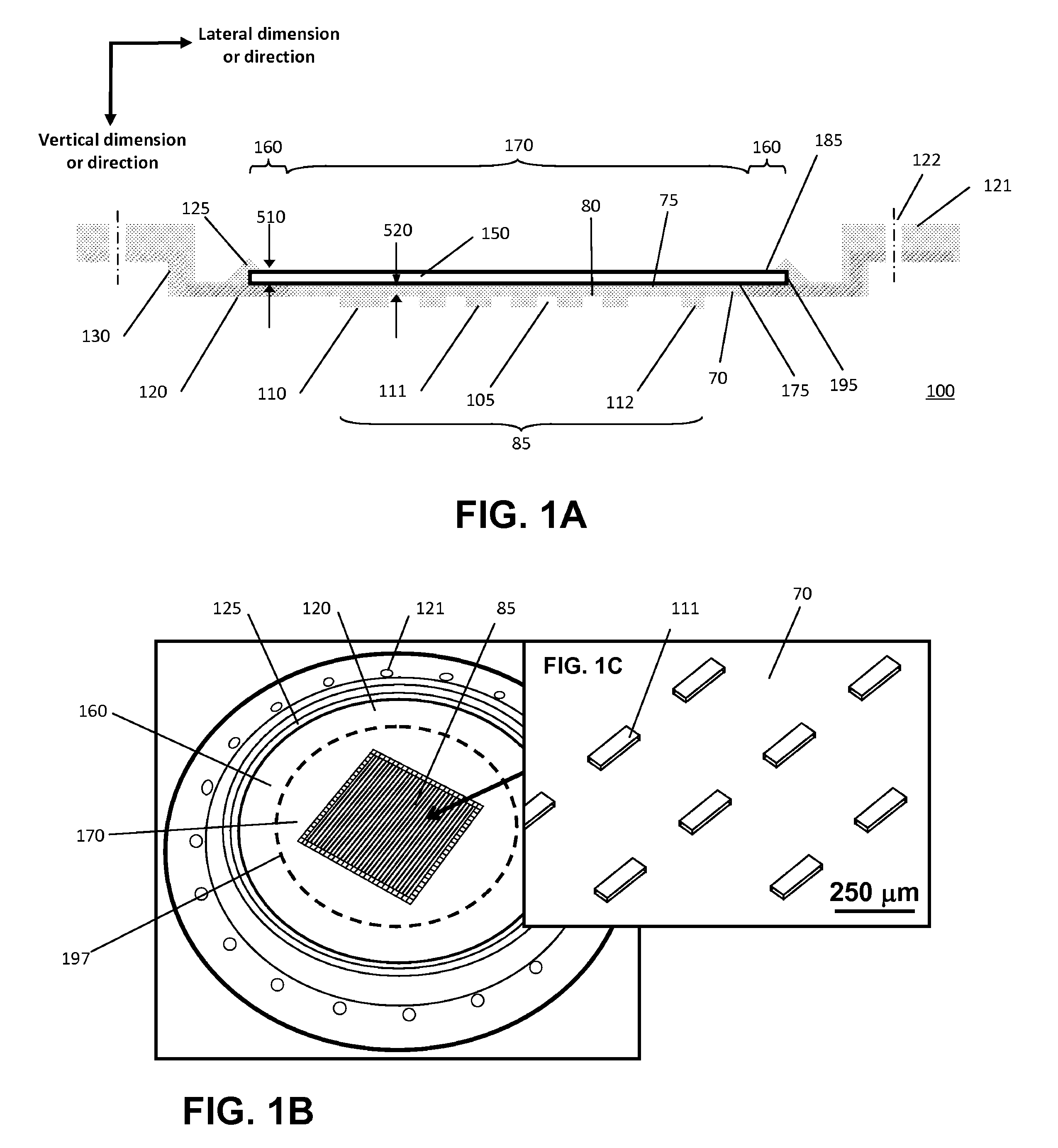

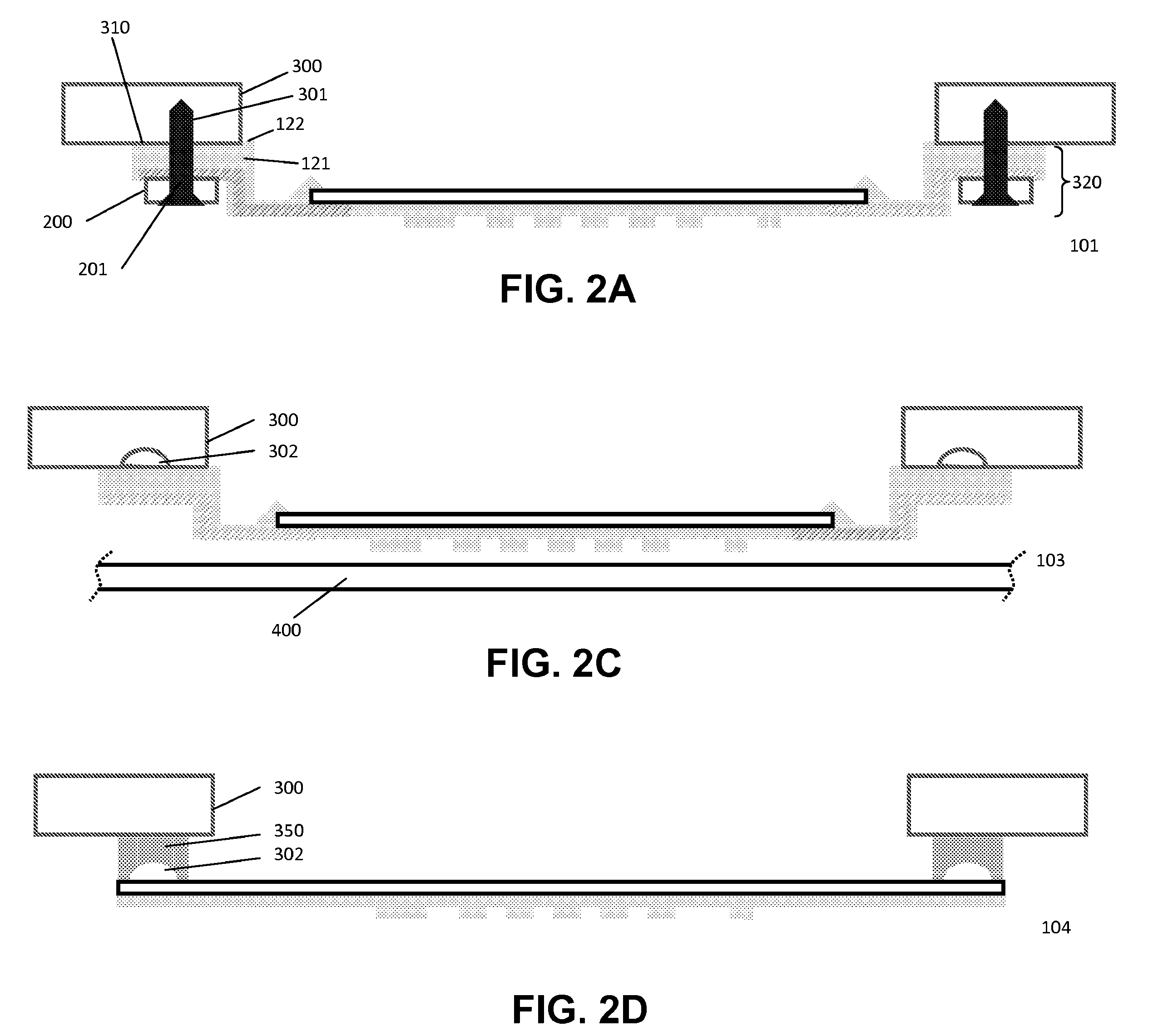

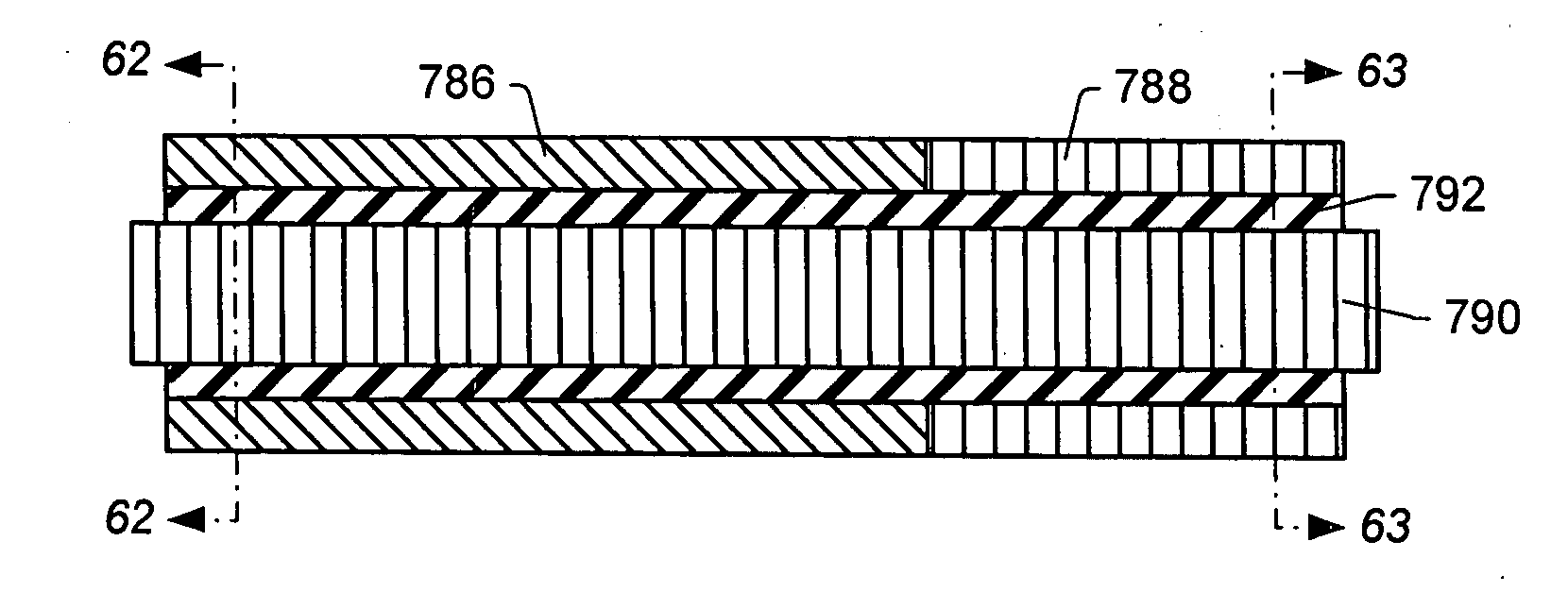

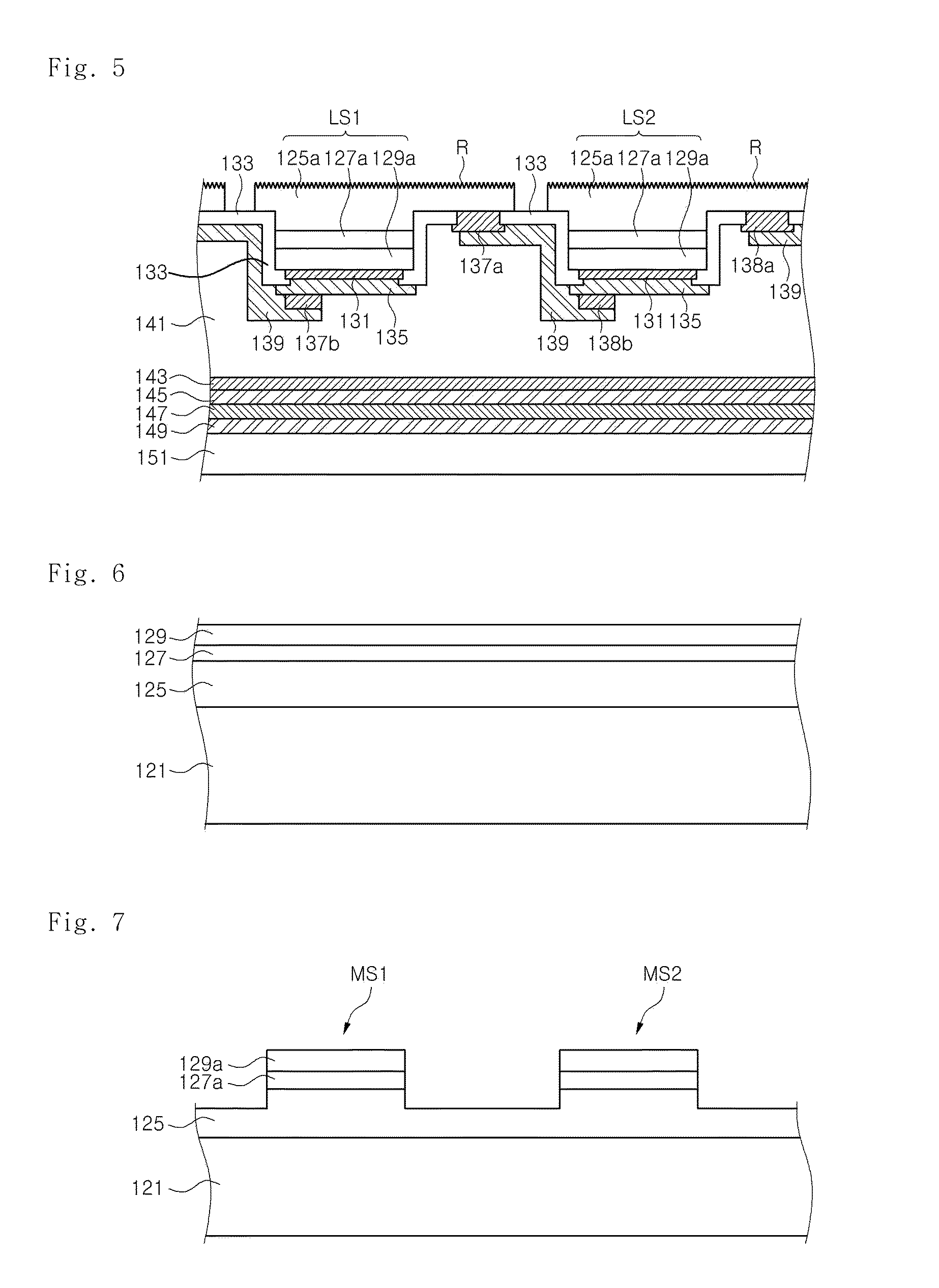

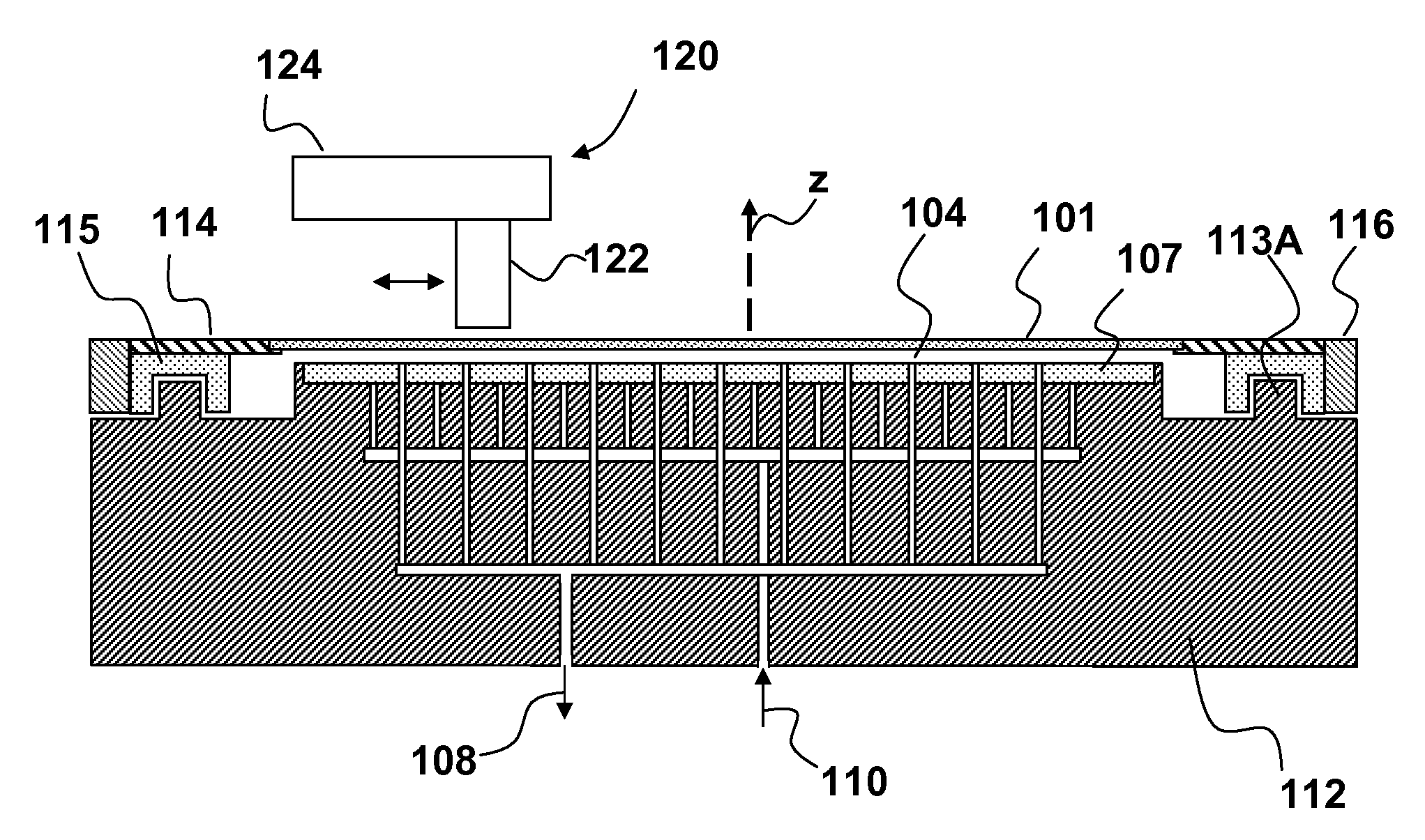

Reinforced composite stamp for dry transfer printing of semiconductor elements

ActiveUS7927976B2Easy to controlPrecise and repeatable vertical motionTurning machine accessoriesMouldsSemiconductor structureContact force

Provided are reinforced composite stamps, devices and methods of making the reinforced composite stamps disclosed herein. Reinforced composite stamps of certain aspects of the present invention have a composition and architecture optimized for use in printing systems for dry transfer printing of semiconductor structures, and impart excellent control over relative spatial placement accuracy of the semiconductor structures being transferred. In some embodiments, for example, reinforced composite stamps of the present invention allow for precise and repeatable vertical motion of the patterned surface of the printing apparatus with self-leveling of the stamp to the surface of a contacted substrate. Reinforced composite stamps of certain aspect of the present invention achieve a uniform distribution of contact forces between the printing apparatus patterned surface and the top surface of a substrate being contacted by the reinforced composite stamp of the printing apparatus.

Owner:X DISPLAY CO TECH LTD

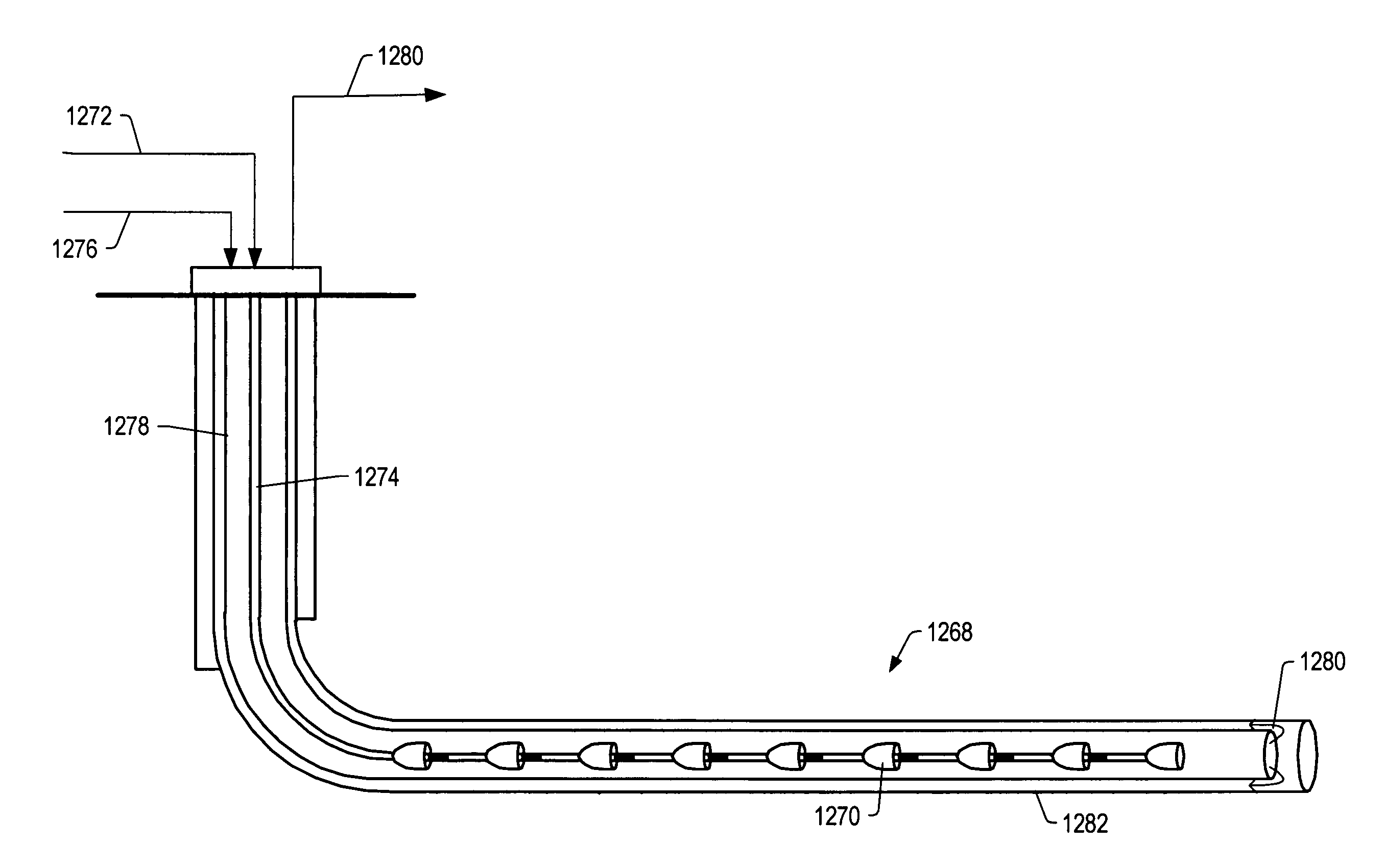

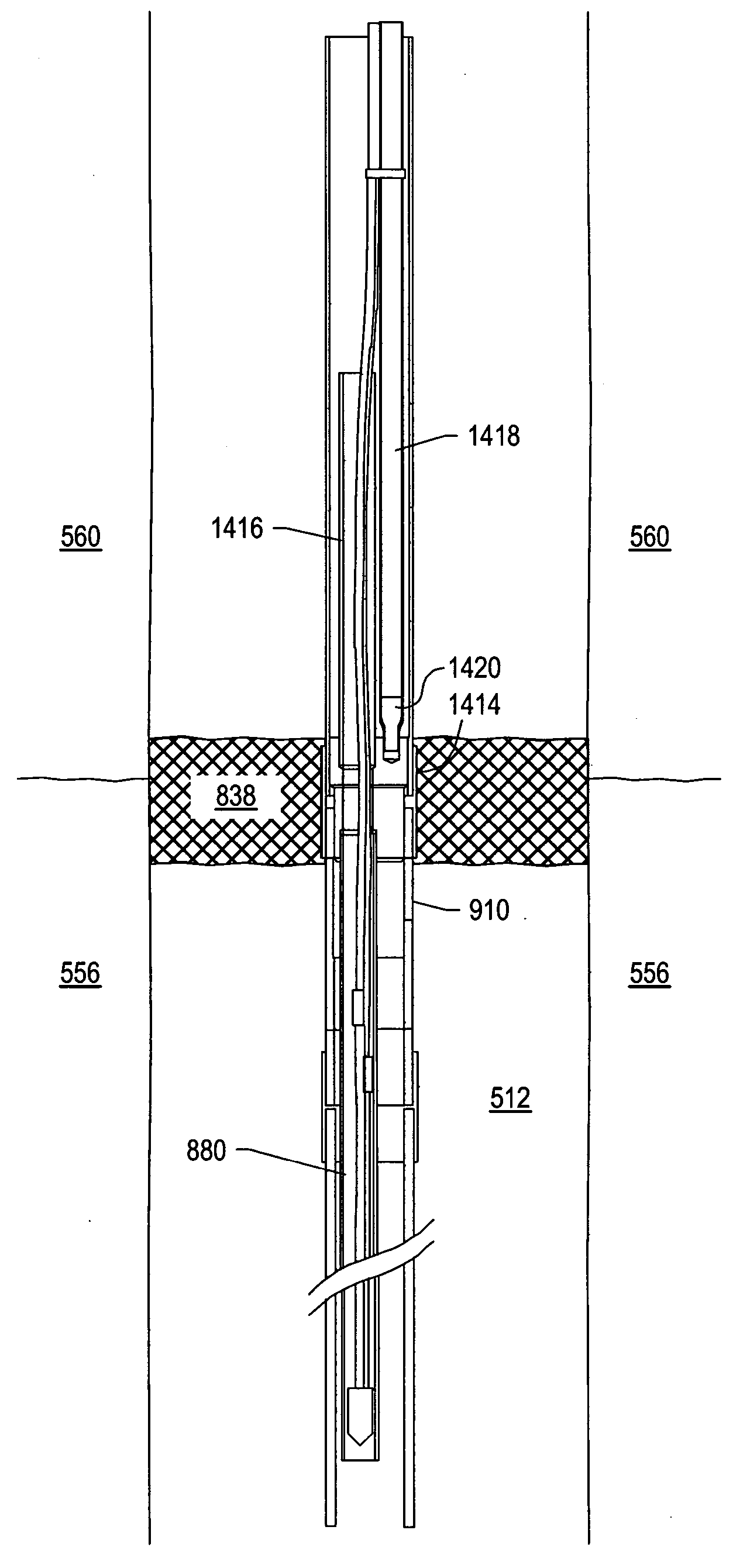

Staged and/or patterned heating during in situ thermal processing of a hydrocarbon containing formation

A method for treating a hydrocarbon containing formation is described. The method for treating a hydrocarbon containing formation may include heating a first volume of the formation using a first set of heaters. A second volume of the formation may be heated using a second set of heaters. The first volume may be spaced apart from the second volume by a third volume of the formation. The first volume, second volume, and / or third volume may be sized, shaped, and / or located to inhibit deformation of subsurface equipment caused by geomechanical motion of the formation during heating.

Owner:SHELL OIL CO

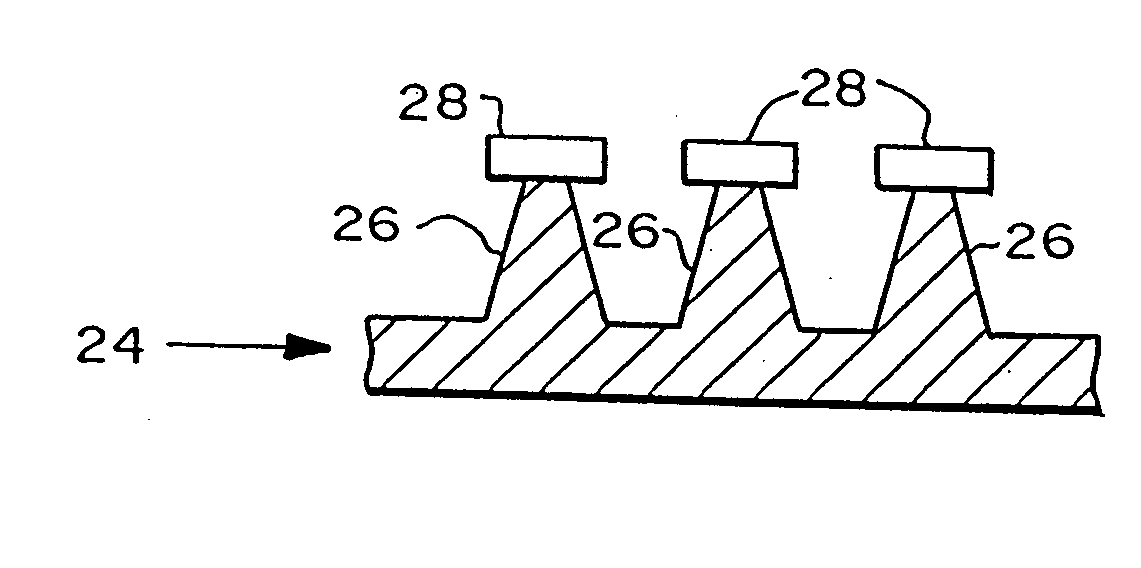

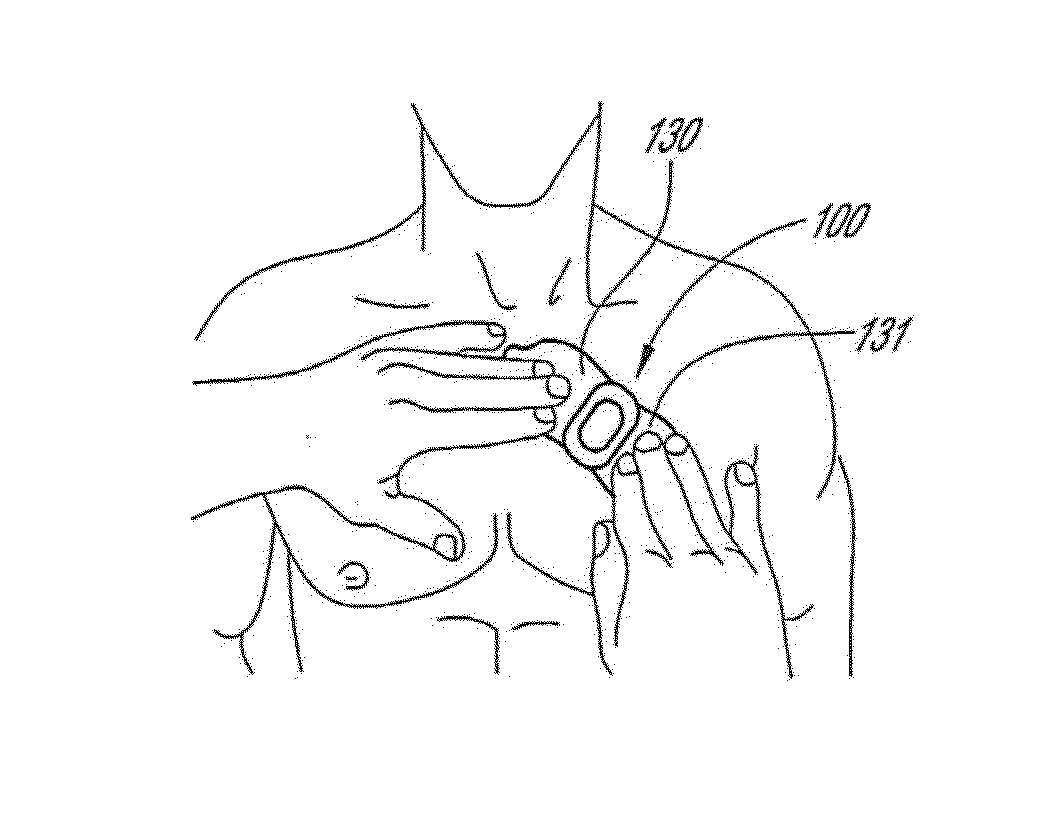

Devices and methods for enhanced microneedle penetration of biological barriers

InactiveUS20050137531A1Easy to transportEnhanced interactionAdditive manufacturing apparatusSurgerySkin surfacesTissue skin

Microneedle devices and methods of use thereof are provided for the enhanced transport of molecules, including drugs and biological molecules, across tissue by improving the interaction of microneedles and a deformable, elastic biological barrier, such as human skin. The devices and methods act to (1) limit the elasticity, (2) adapt to the elasticity, (3) utilize alternate ways of creating the holes for the microneedles to penetrate the biological barrier, other than the simply direct pressure of the microneedle substrate to the barrier surface, or (4) any combination of these methods. In preferred embodiments for limiting the elasticity of skin, the microneedle device includes features suitable for stretching, pulling, or pinching the skin to present a more rigid, less deformable, surface in the area to which the microneedles are applied (i.e. penetrate). In a preferred embodiments for adapting the device to the elasticity of skin, the device comprising one or more extensions interposed between the substrate and the base end of at least a portion of the microneedles.

Owner:VALERITAS LLC (US) +1

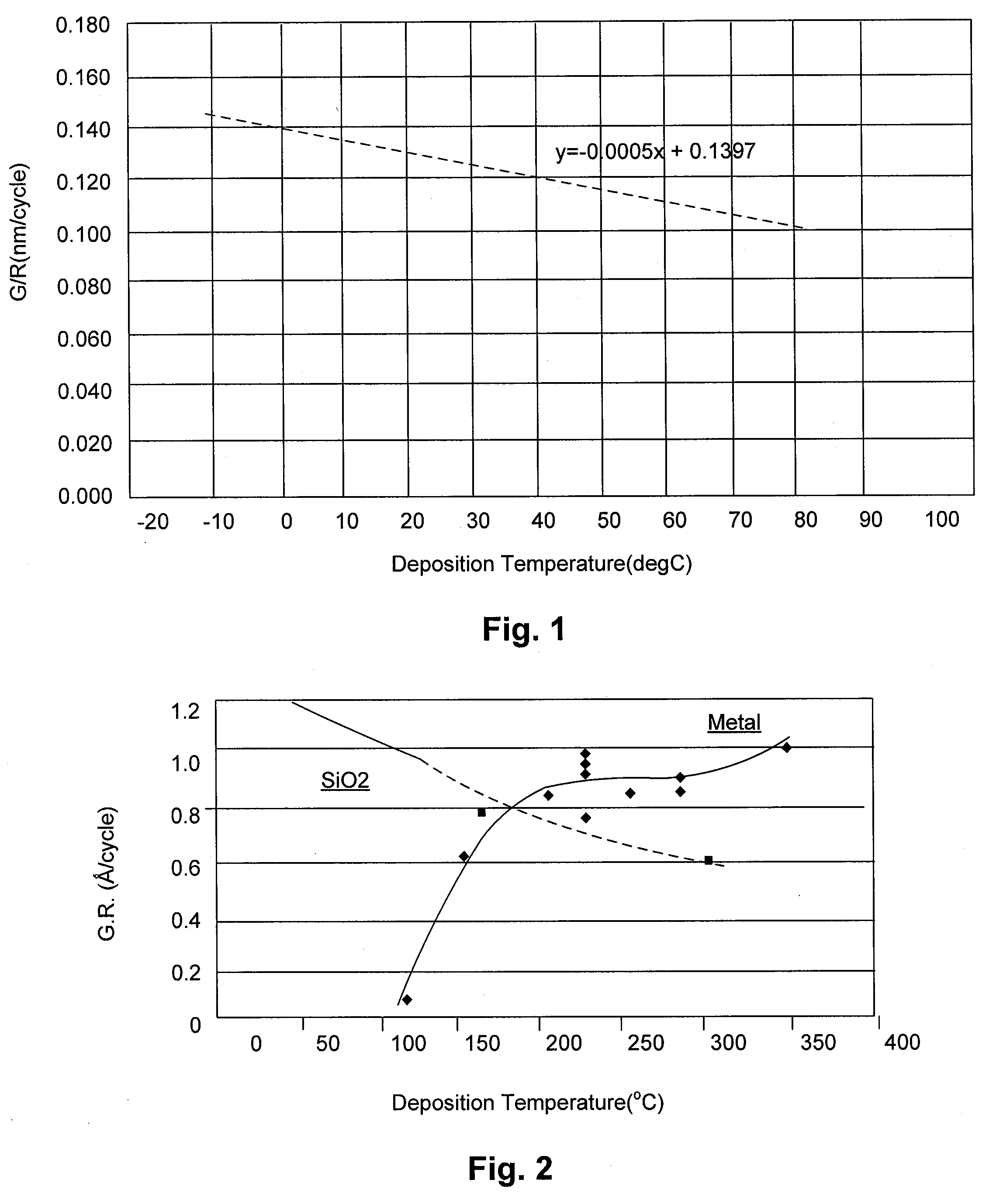

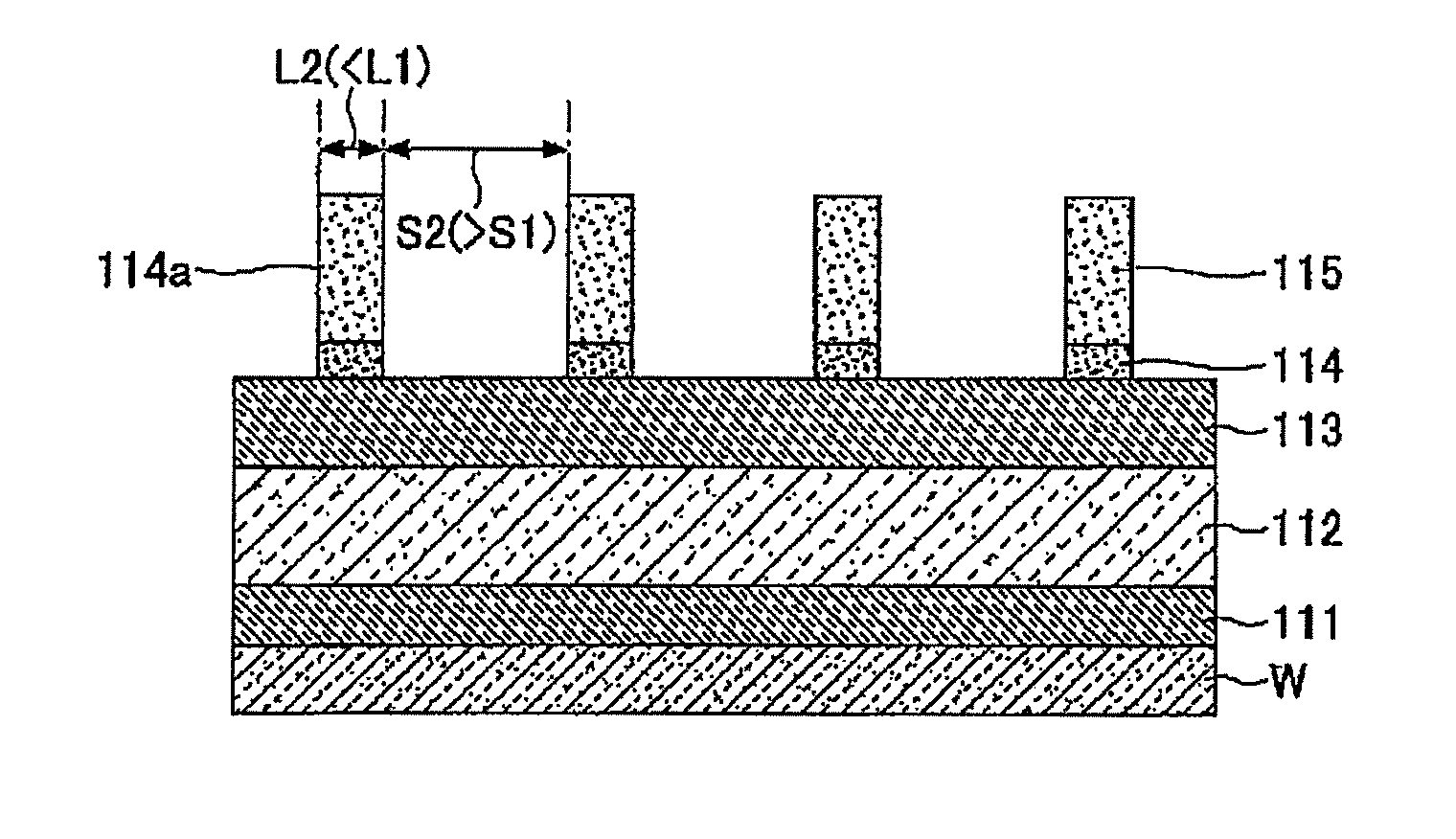

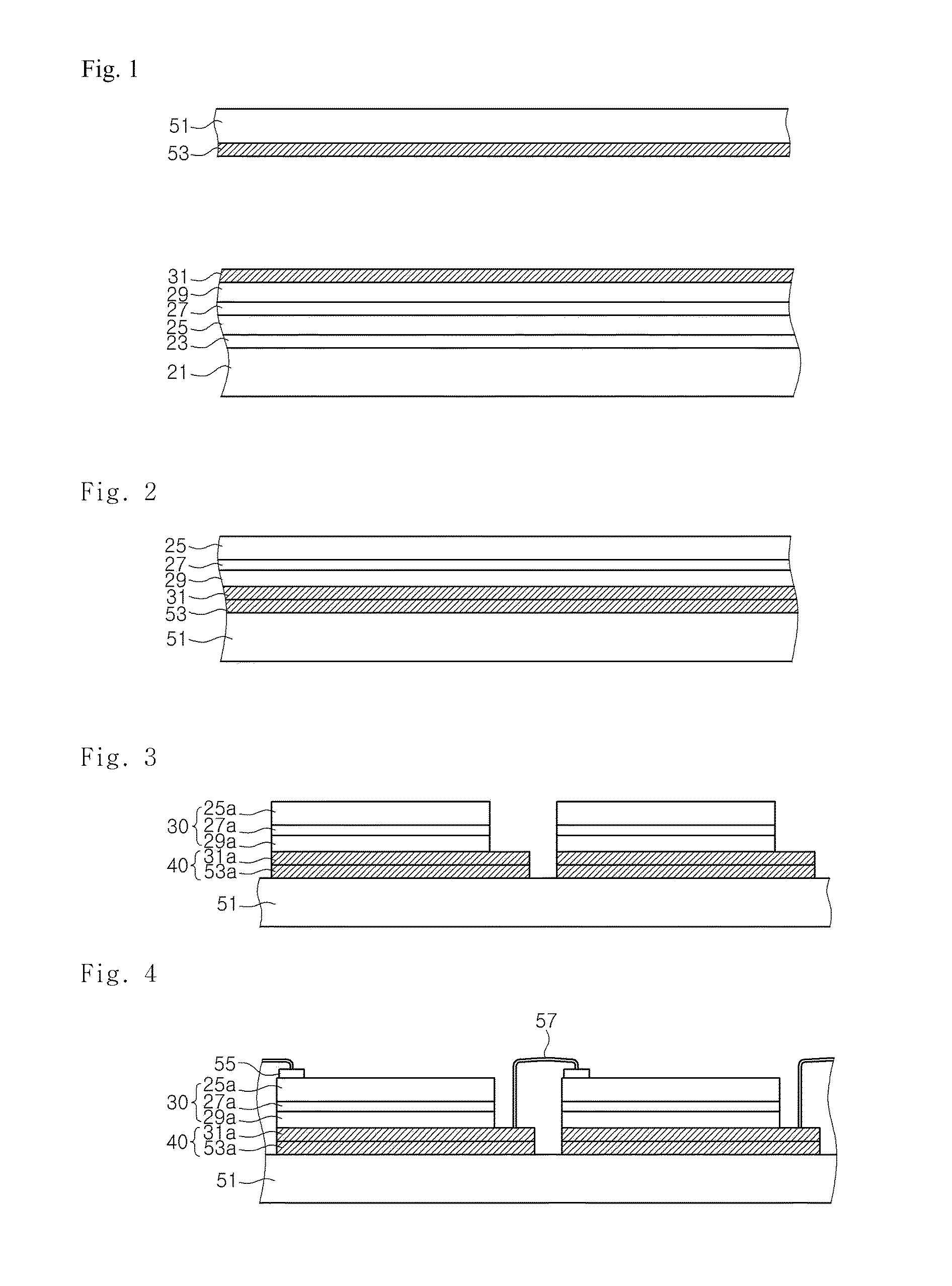

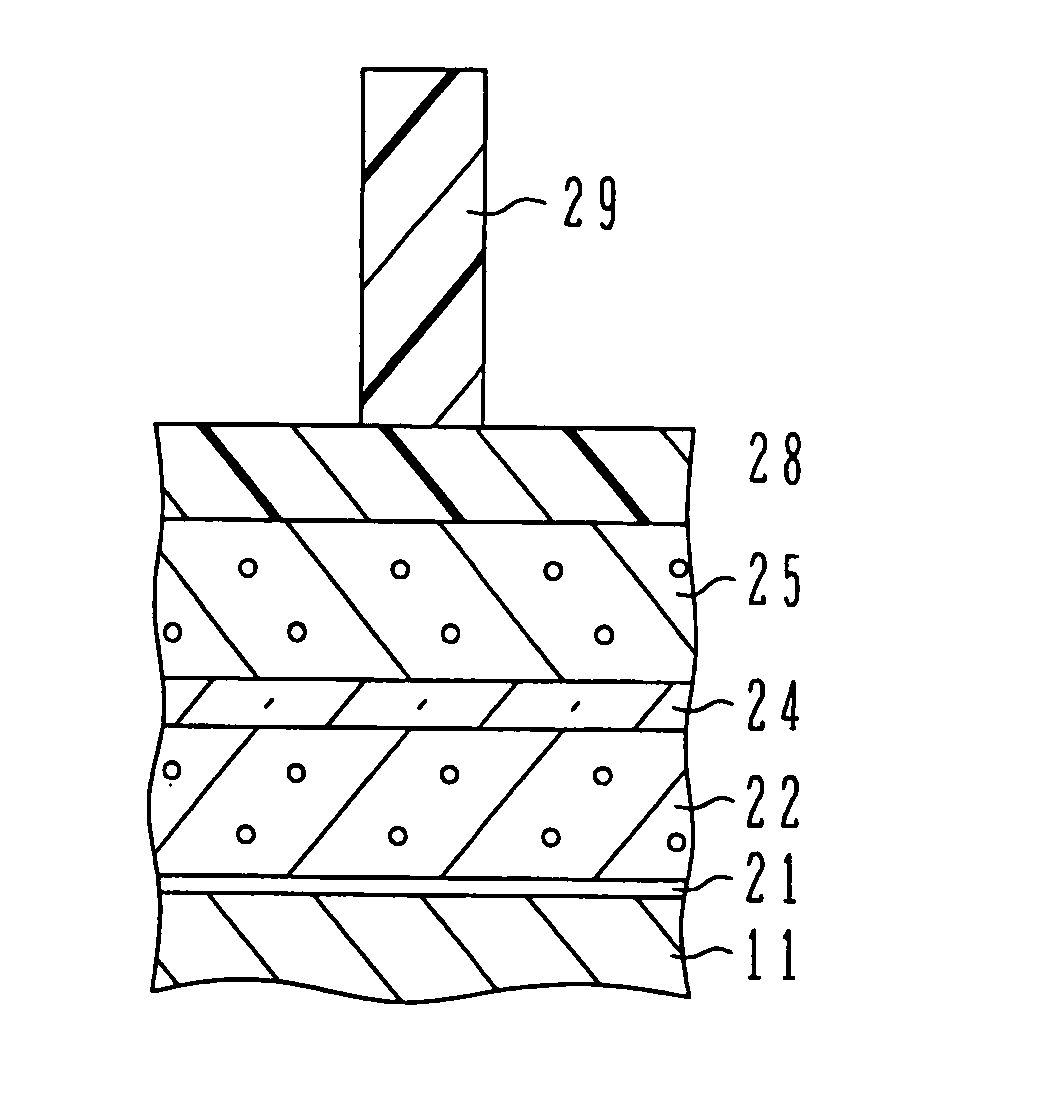

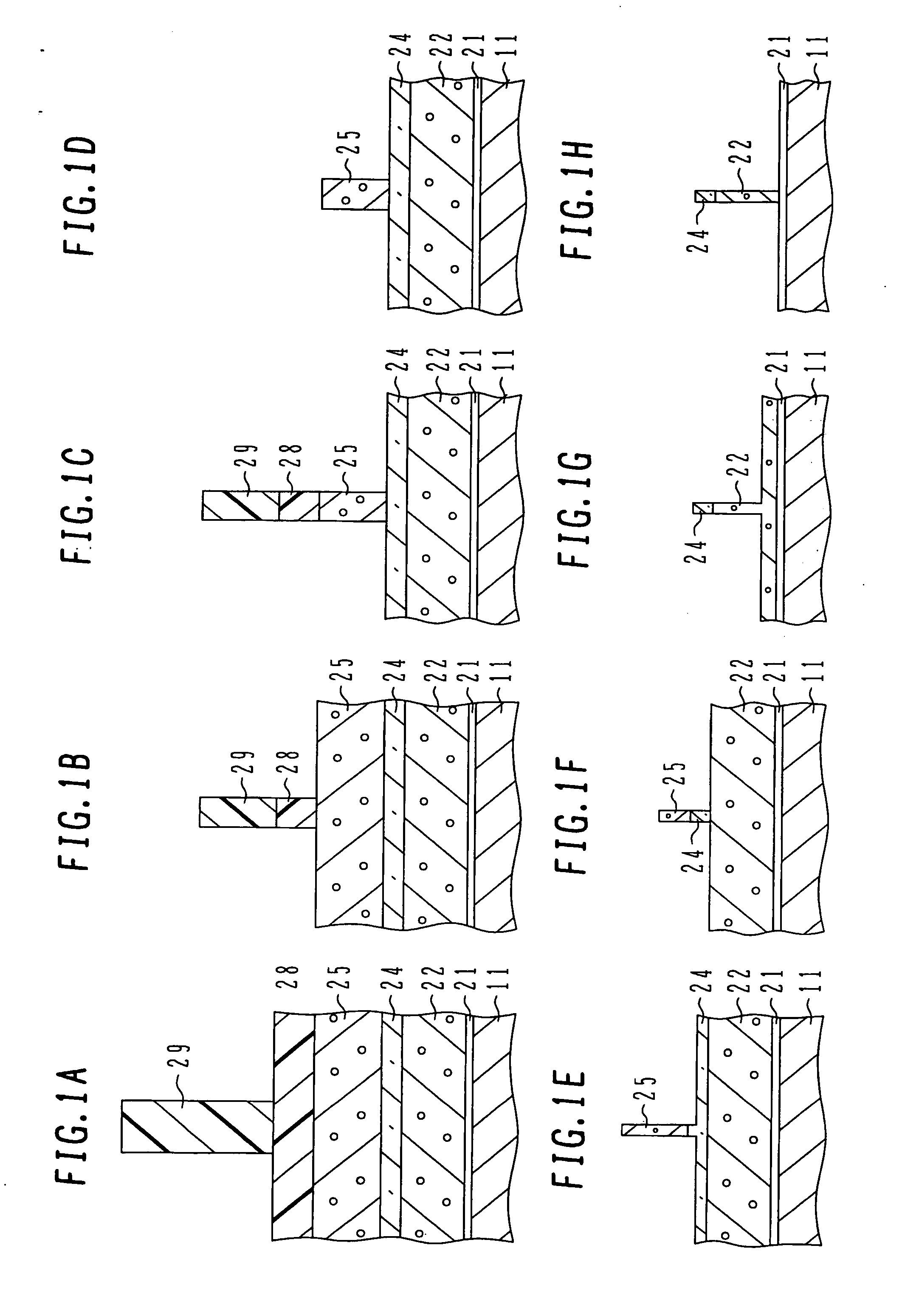

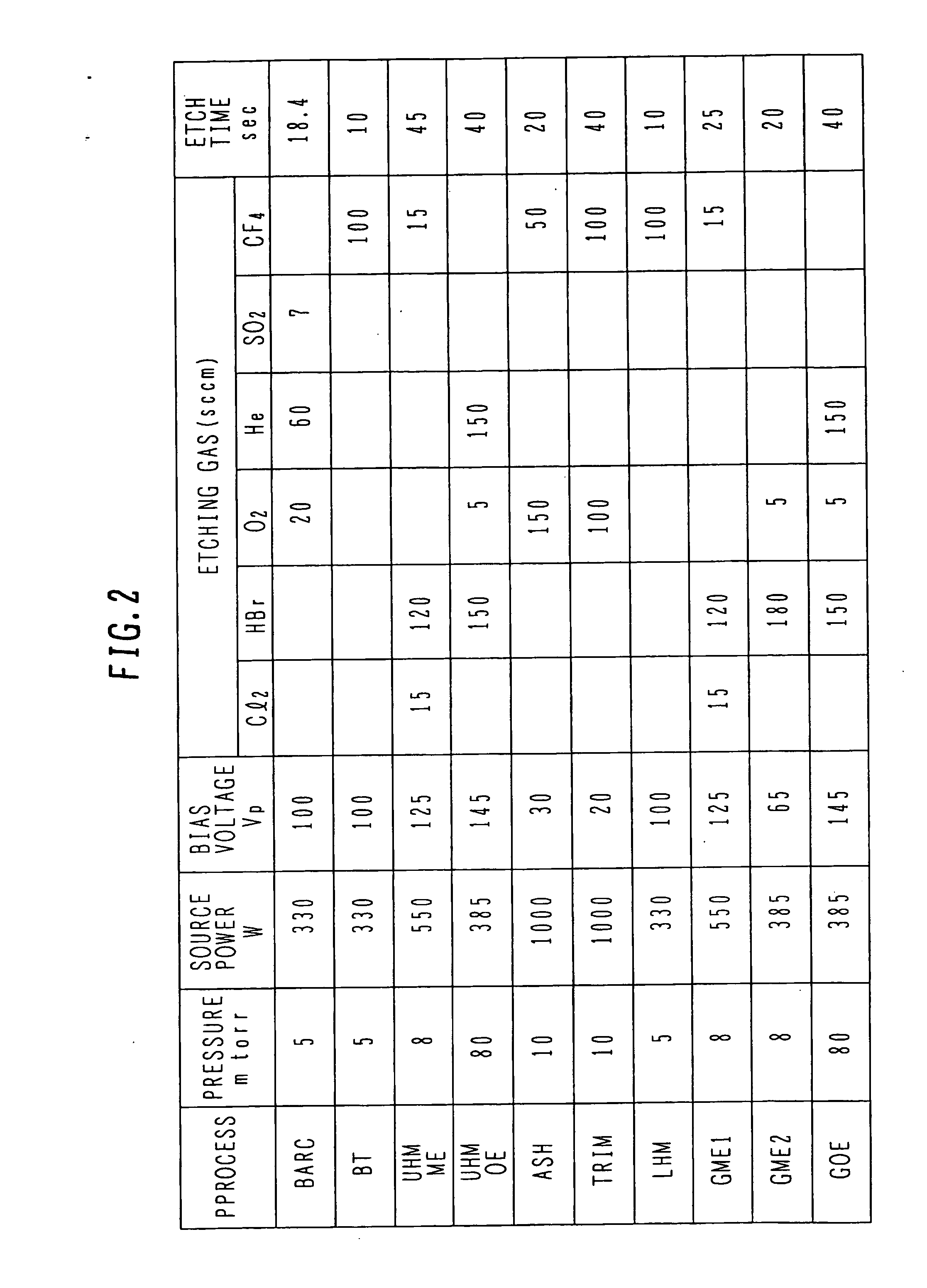

Method of forming mask pattern and method of manufacturing semiconductor device

InactiveUS20130023120A1Avoid deformationElectric discharge tubesSemiconductor/solid-state device manufacturingResistSilicon oxide

A method of forming a mask pattern includes a first pattern forming step of etching an anti-reflection coating film by using as a mask a first line portion made up of a photo resist film formed on the anti-reflection film to form a pattern including a second line portion made up of the photo resist film and the anti-reflection film; an irradiation step of irradiating the photo resist film with electrons; a silicon oxide film forming step to cover the second line portion isotropically; and an etch back step of etching back the silicon oxide film such that the silicon oxide film is removed from the top of the second line portion as sidewalls of the second line portion. The method further includes a second pattern forming step of ashing the second line portion to form a mask pattern including a third line portion made up of the silicon oxide film and remains.

Owner:TOKYO ELECTRON LTD

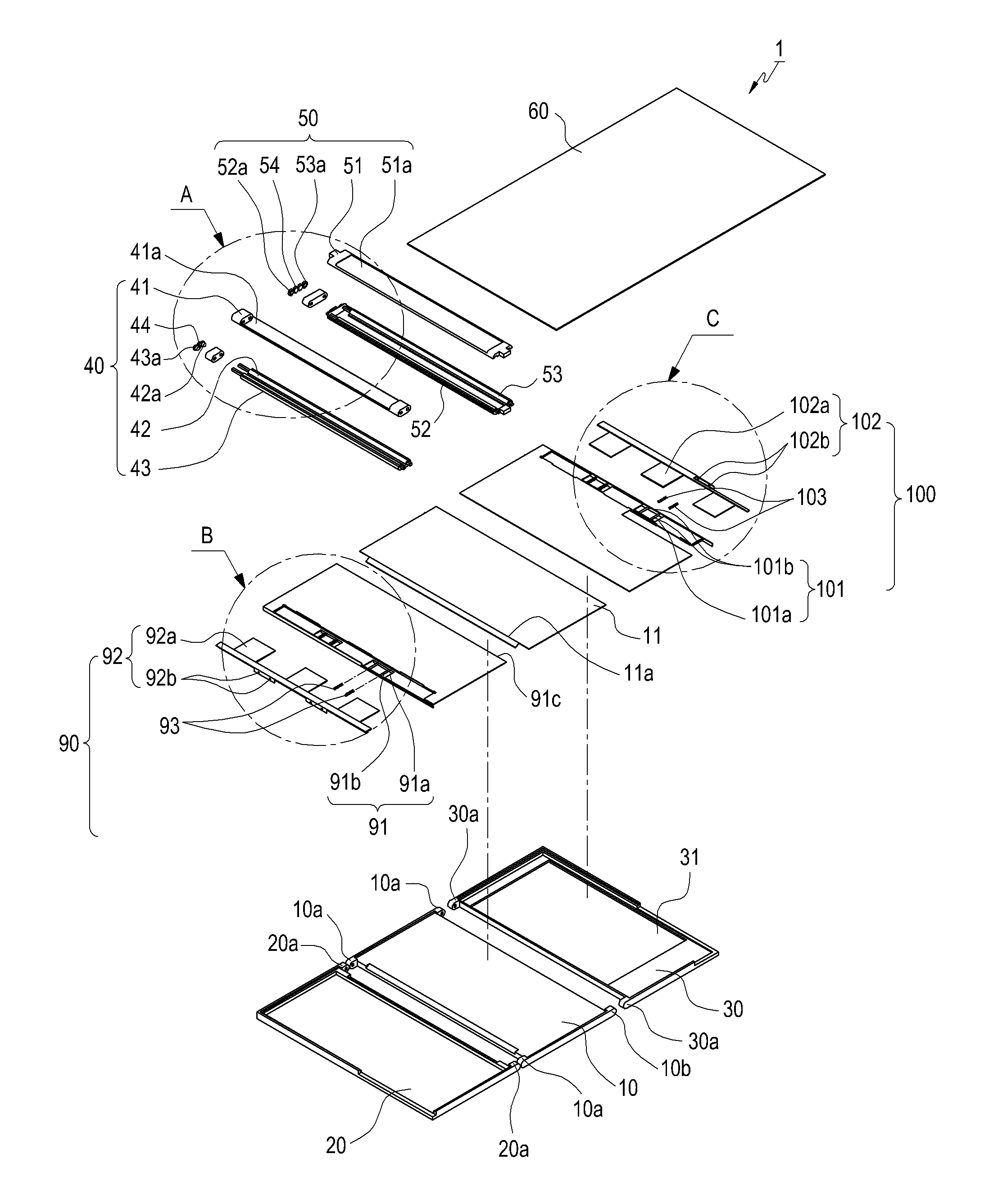

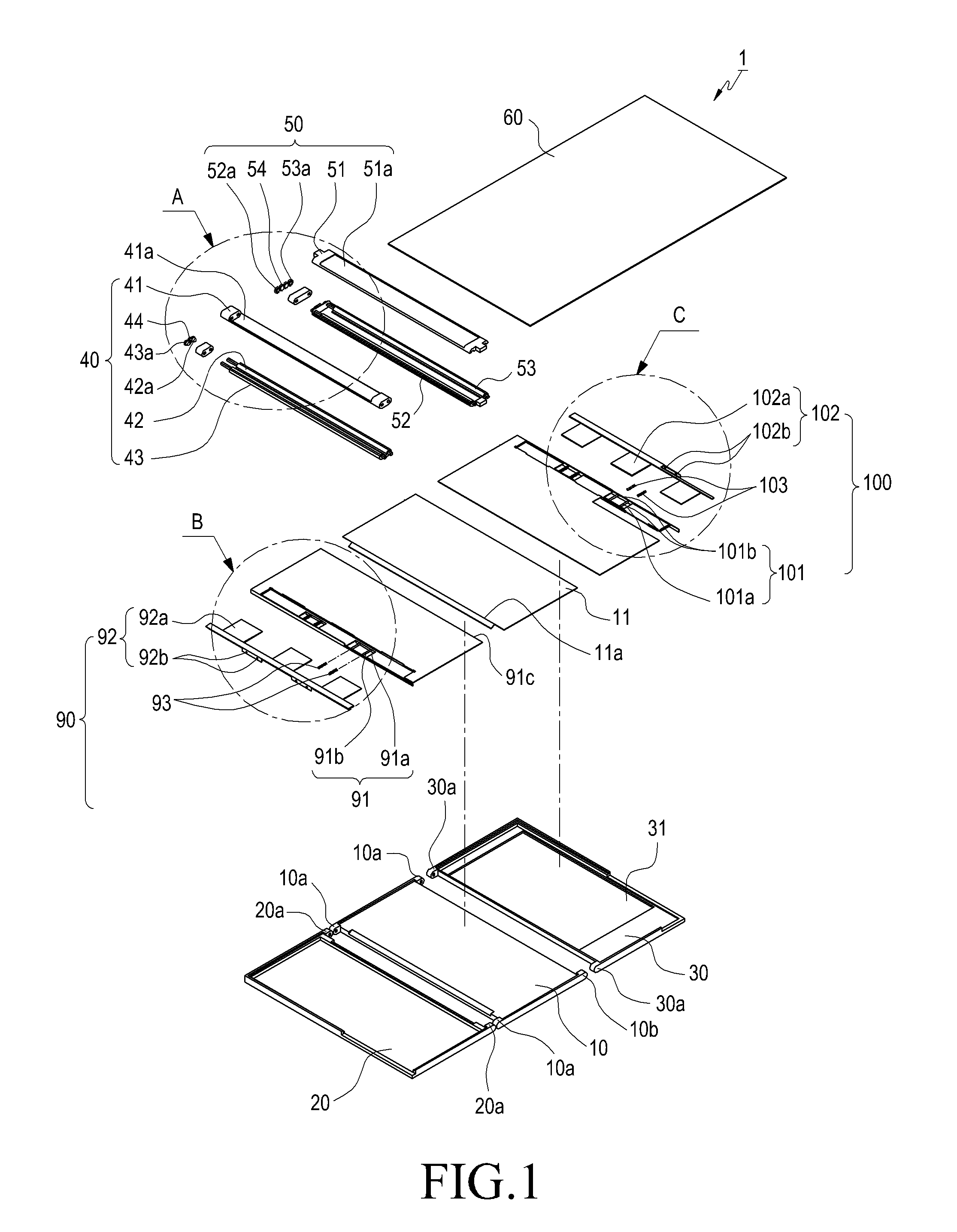

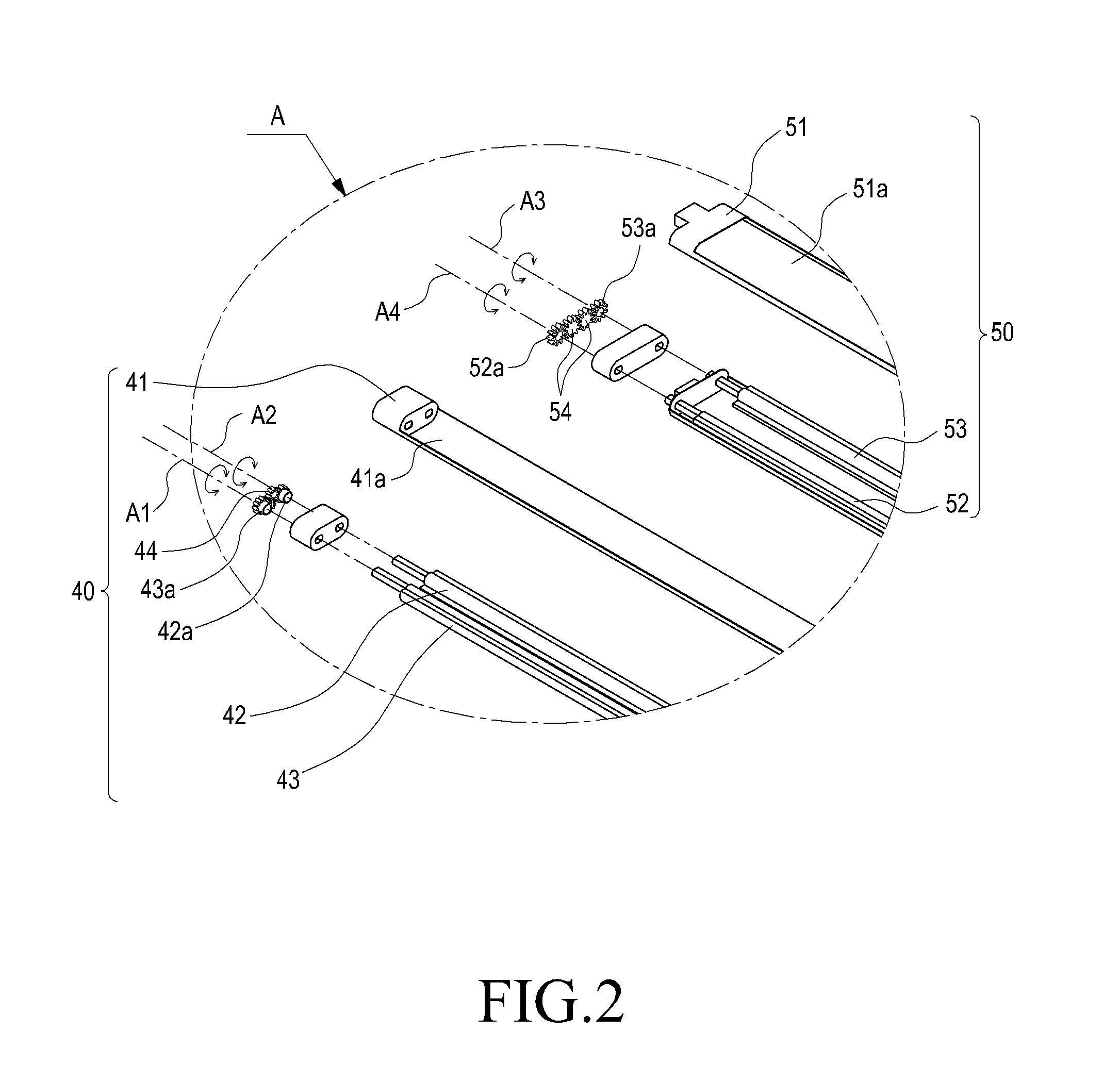

Portable communication device having flexible display unit

InactiveUS20120264489A1Avoid problemsFunction increaseDigital data processing detailsTransmissionEngineeringFlexible display

A portable communication device having a flexible display unit to form a predetermined curvature or be unfolded includes a first housing, second and third housings rotatably coupled to both ends of the first housing, first and second hinge modules provided between the first, second, and third housings to enable the second and third housings to rotate. The flexible display unit is provided on the first, second, and third housings to form a curvature or be unfolded on the first, second, and third housings through rotation together with the second and third housings, first and second curvature space portions formed between the first, second, and third housings allow formation of the curvature of the flexible display unit.

Owner:SAMSUNG ELECTRONICS CO LTD

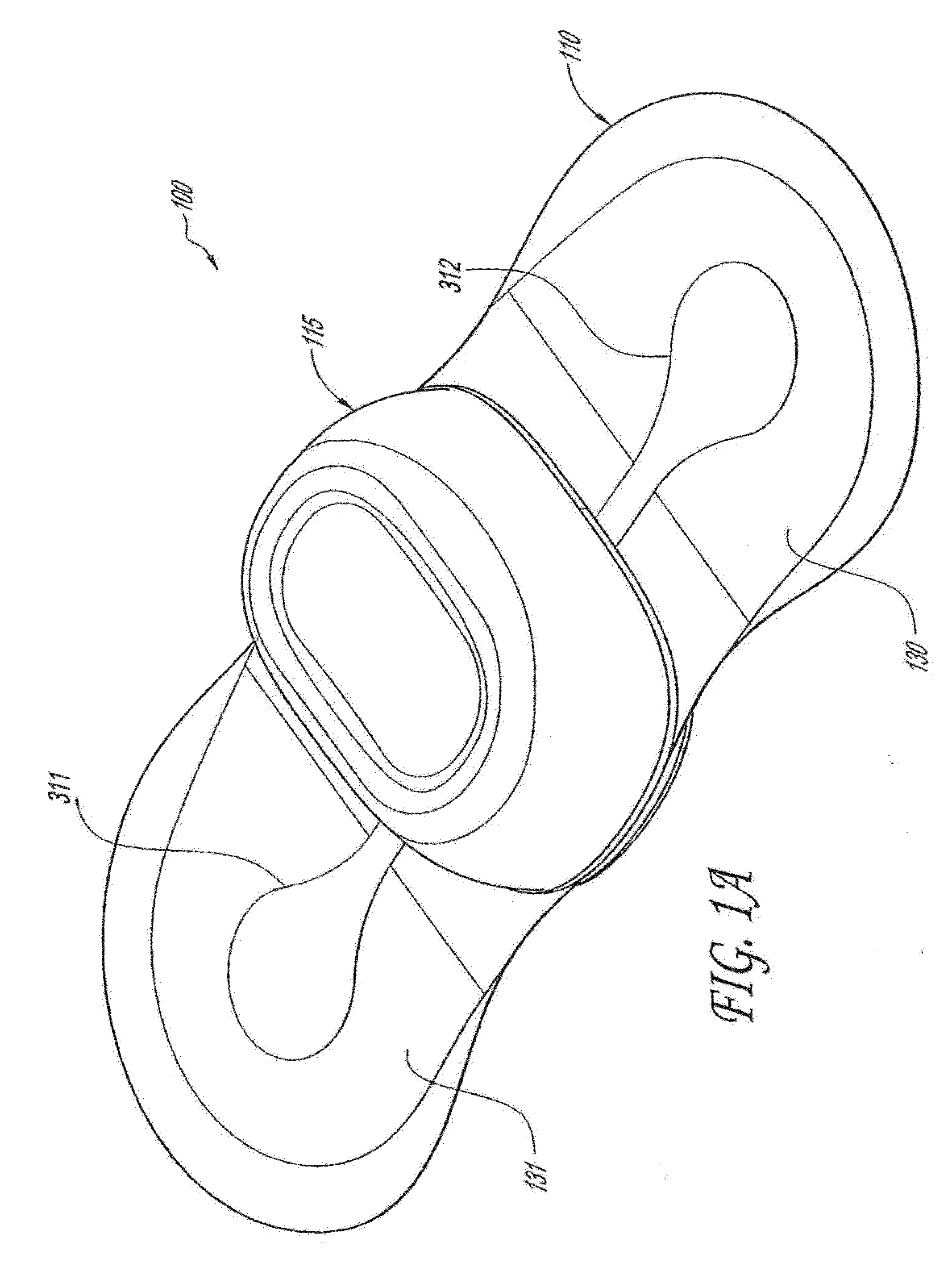

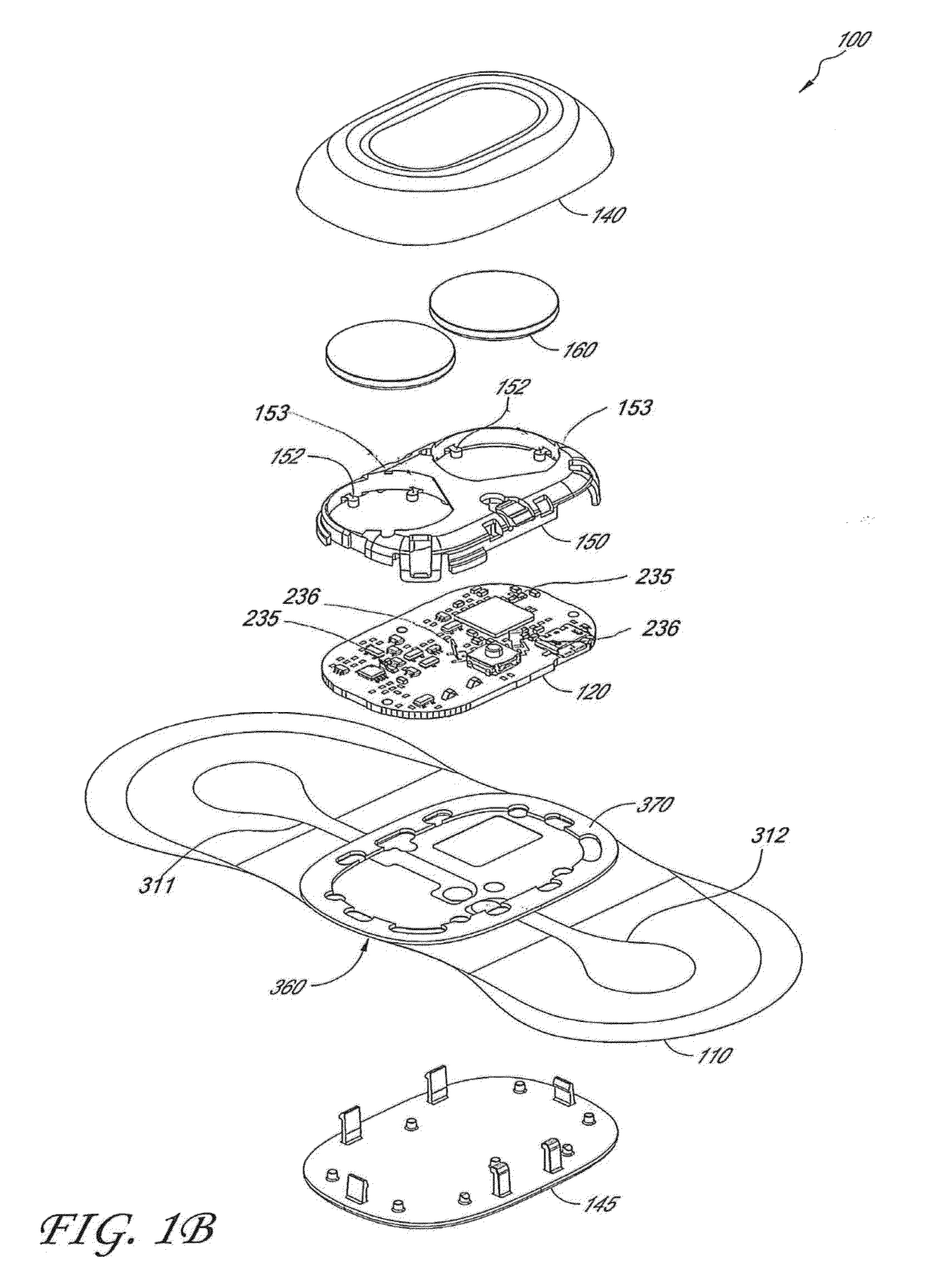

Physiological monitoring device

InactiveUS20140206977A1Avoid mechanical stressPrecise positioningElectrocardiographyInertial sensorsPhysiological monitoringLong term monitoring

The present invention relates to a physiological monitoring device. Some embodiments of the invention allow for long-term monitoring of physiological signals. Further embodiments may also allow for the monitoring of secondary signals such as motion.

Owner:IRHYTHM TECH

Variable frequency temperature limited heaters

InactiveUS20050006097A1Avoid deformationReduce heatThermal drillingInsulationElectrical resistance and conductancePower flow

A heater system may include an alternating current supply and an electrical conductor. Alternating current may be applied to one or more electrical conductors at a frequency between about 100 Hz and about 1000 Hz. The electrical conductors may be located in a formation. The electrical conductors may resistively heat upon application of the alternating electrical current. At least one of the electrical conductors may include an electrically resistive ferromagnetic material. The electrical conductor may provide a reduced amount of heat above or near a selected temperature. Heat may transfer from the electrical conductor to a part of formation.

Owner:SHELL OIL CO

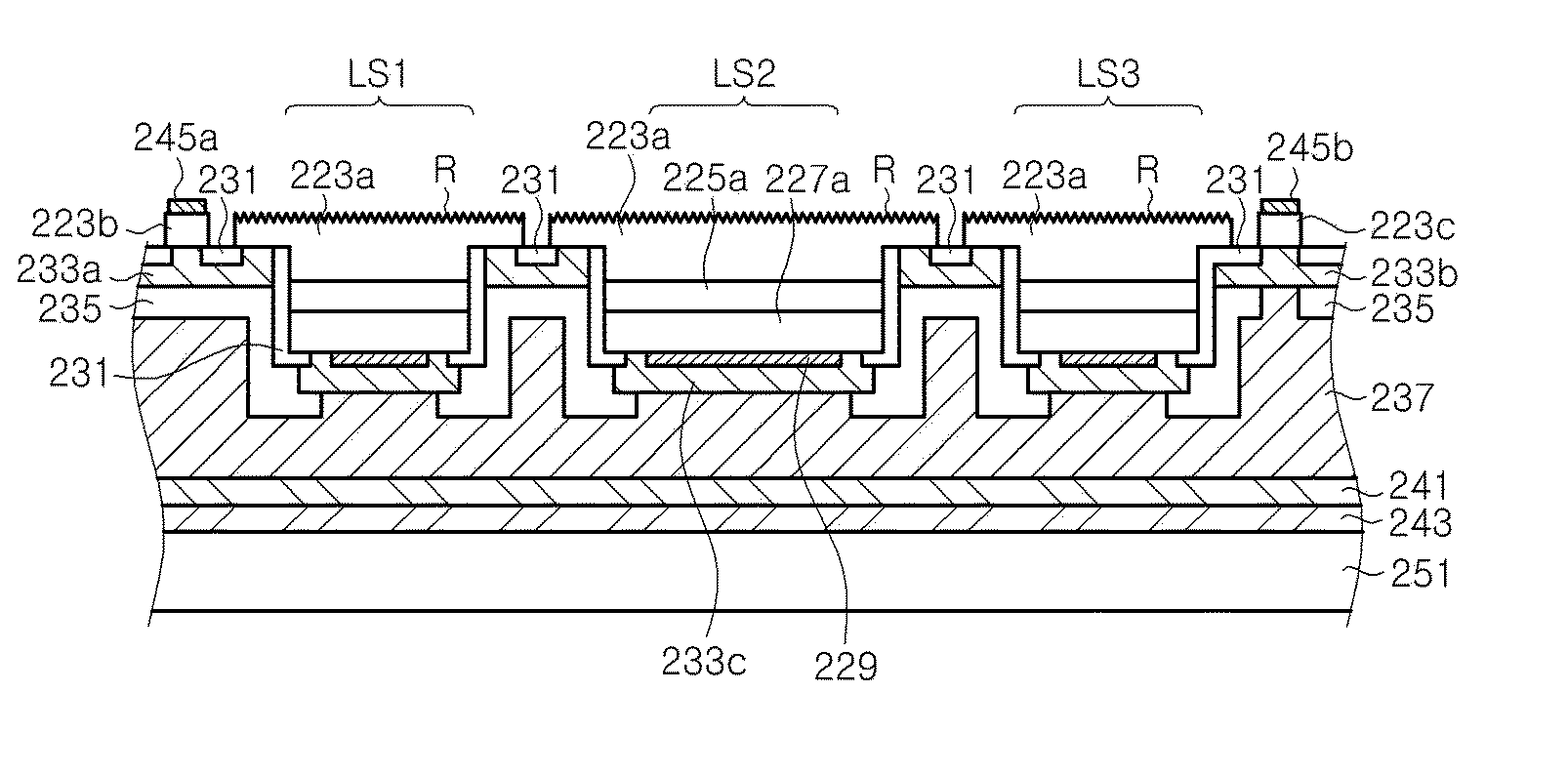

Light emitting device and method of fabricating the same

ActiveUS20100078656A1Reduce lossesAvoid deformationSolid-state devicesSemiconductor/solid-state device manufacturingActive layerLight emitting device

Disclosed are a light emitting device and a method of fabricating the same. The light emitting device comprises a substrate. A plurality of light emitting cells are disposed on top of the substrate to be spaced apart from one another. Each of the light emitting cells comprises a first upper semiconductor layer, an active layer, and a second lower semiconductor layer. Reflective metal layers are positioned between the substrate and the light emitting cells. The reflective metal layers are prevented from being exposed to the outside.

Owner:SEOUL VIOSYS CO LTD

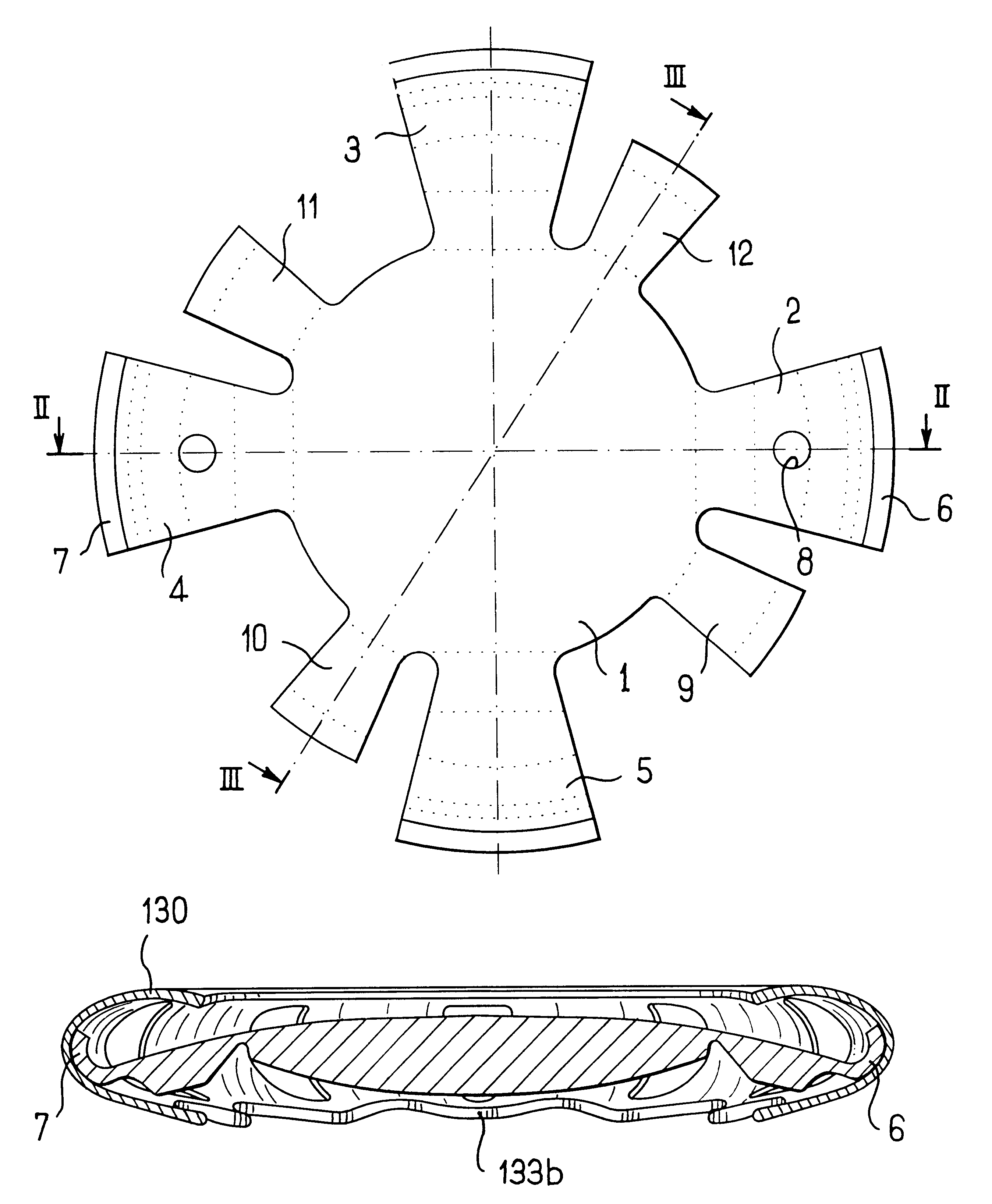

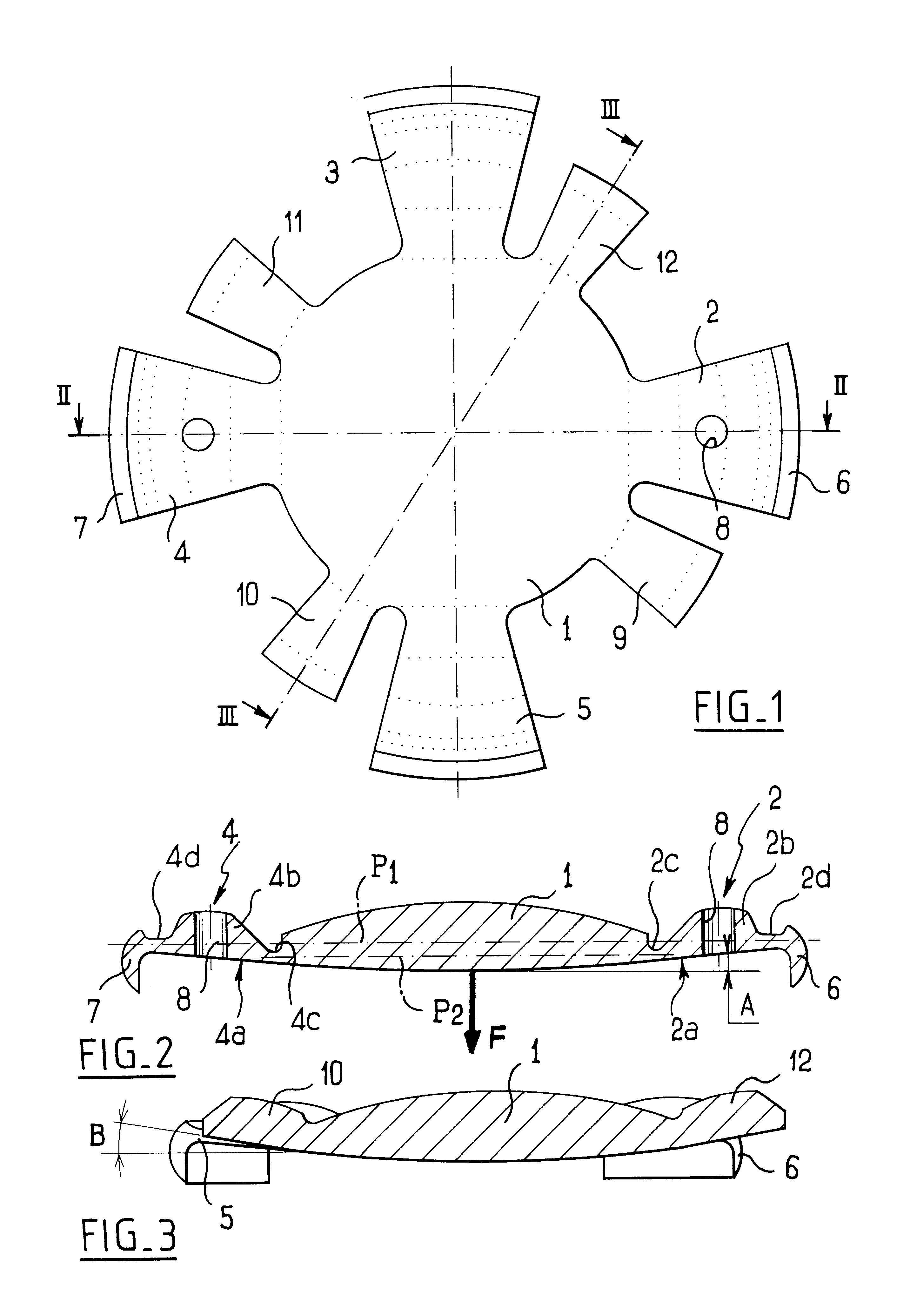

Intraocular implant and an artificial lens device

An accommodating intraocular implant for locating in the capsular bag, the implant comprising a single piece of elastically deformable material constituting a central lens (1) and at least two haptic portions (2, 4) in the form of radial arms for bearing via their free ends against the equatorial zone of the capsular bag, the free end of each radial arm (2, 4) being fitted with a shoe (6, 7) of substantially toroidal outside surface enabling the implant to bear against the equatorial zone of the bag, the connection between each shoe (6, 7) and the corresponding arm (2, 4) being of the hinge type situated in the vicinity of the posterior edge of the shoe (6, 7) and being formed by a first thin portion (2d, 4d) of the arm, while the connection between each arm and the lens is of the hinge type implemented at the anterior surface of the lens by a second likewise thin portion (2c, 4c) of the arm, the plane (P1) containing the first thin portions being situated behind the plane (P2) containing the second thin portions.

Owner:HANNA KHALIL PROF DR

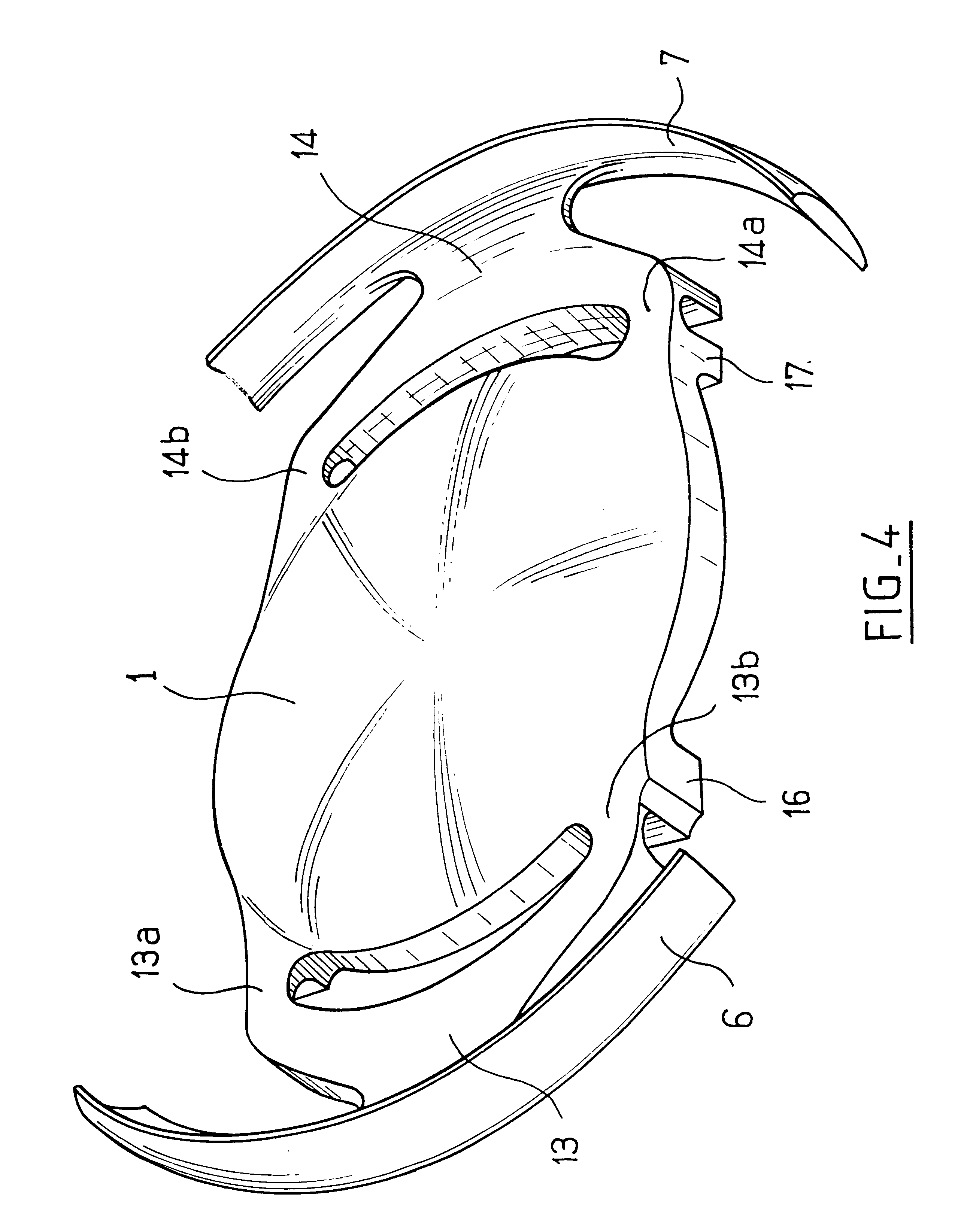

Stabilizing a substrate using a vacuum preload air bearing chuck

ActiveUS20080229811A1Improve rigidityAvoid deformationLinear bearingsGas cushion bearingsAir bearingEngineering

Substrate processing method and apparatus are disclosed. The substrate processing apparatus includes a non-contact air bearing chuck with a vacuum preload.

Owner:KLA TENCOR TECH CORP

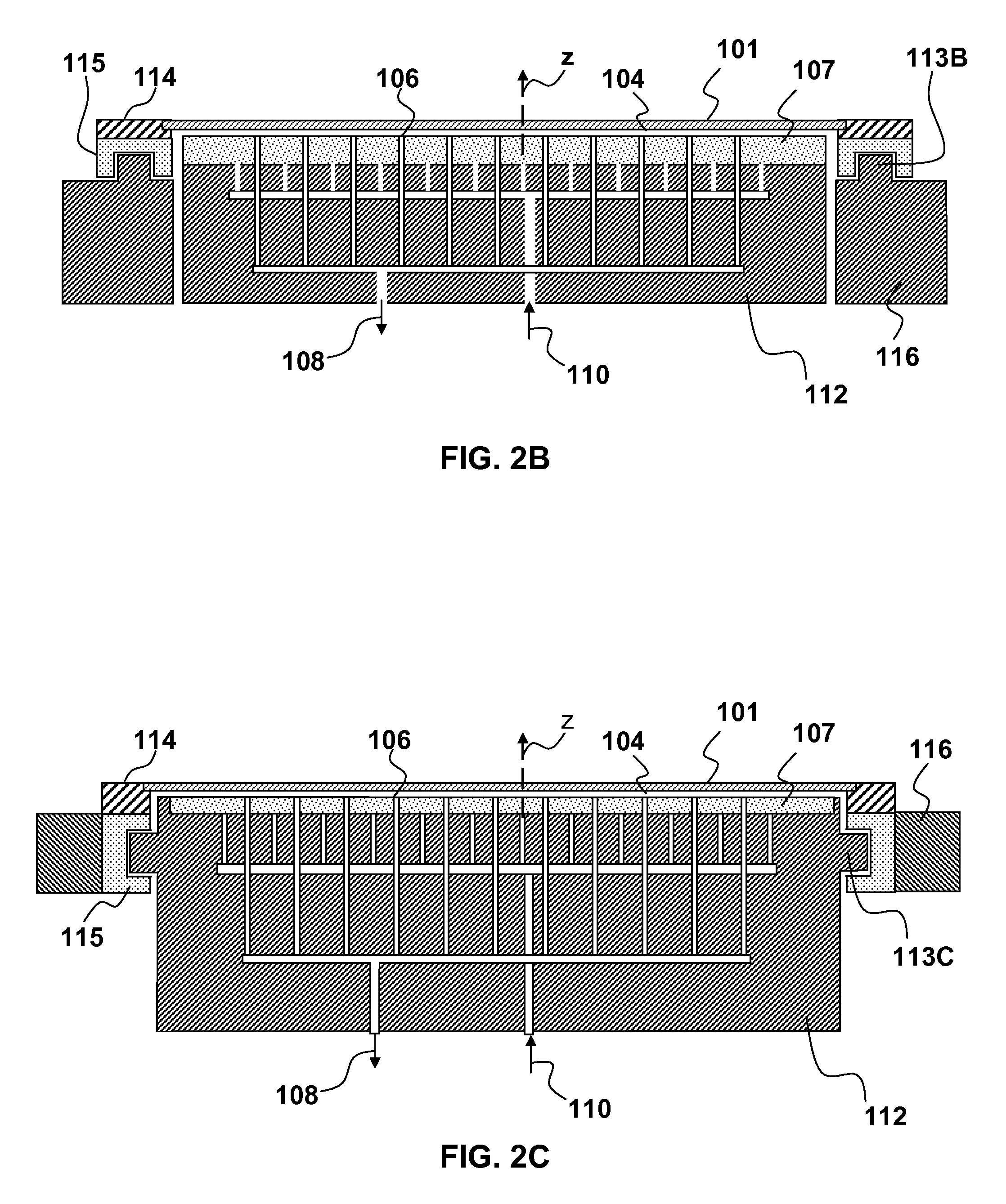

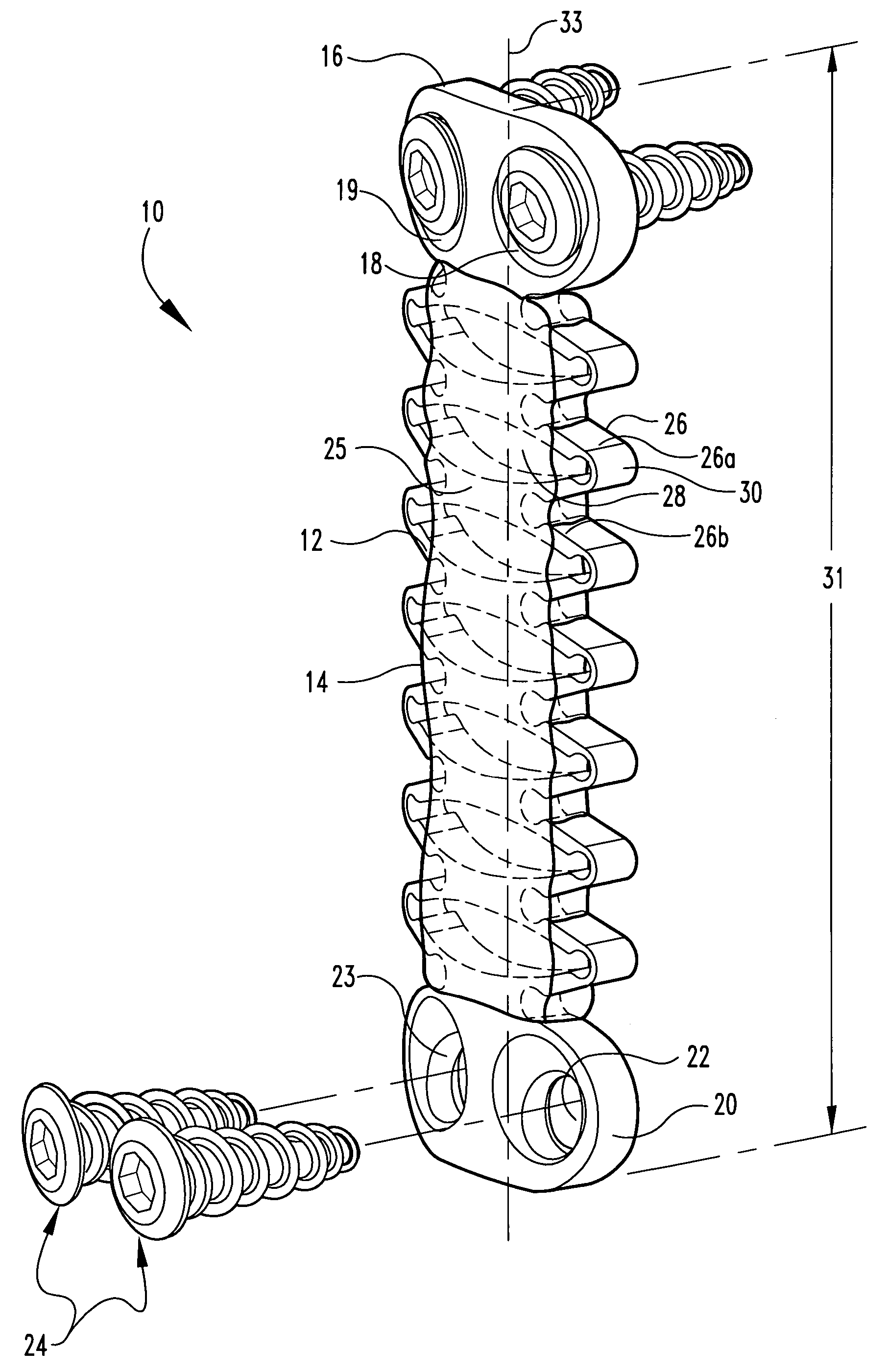

Dynamizable orthopedic implants and their use in treating bone defects

InactiveUS20050085814A1Effectively immobilizedAvoid deformationSuture equipmentsInternal osteosythesisBone ingrowthBone structure

The present invention generally relates to bone fixation devices and methods for promoting arthrodesis of bone defects. The bone fixation devices can provide sufficient support to the bone defect while allowing bone ingrowth and minimizing the risk to stress shield and / or pseudo-arthrodesis. The bone fixation devices include a degradable component that allows the device to gradually transfer the load from the supporting member to the growing bone structure in vivo.

Owner:SDGI HLDG

Golf club head and method of making the same

InactiveUS6852038B2Hitting sound is improvedImprove accuracyGolf clubsGolfing accessoriesEngineeringCasting mold

Owner:DUNLOP SPORTS CO LTD

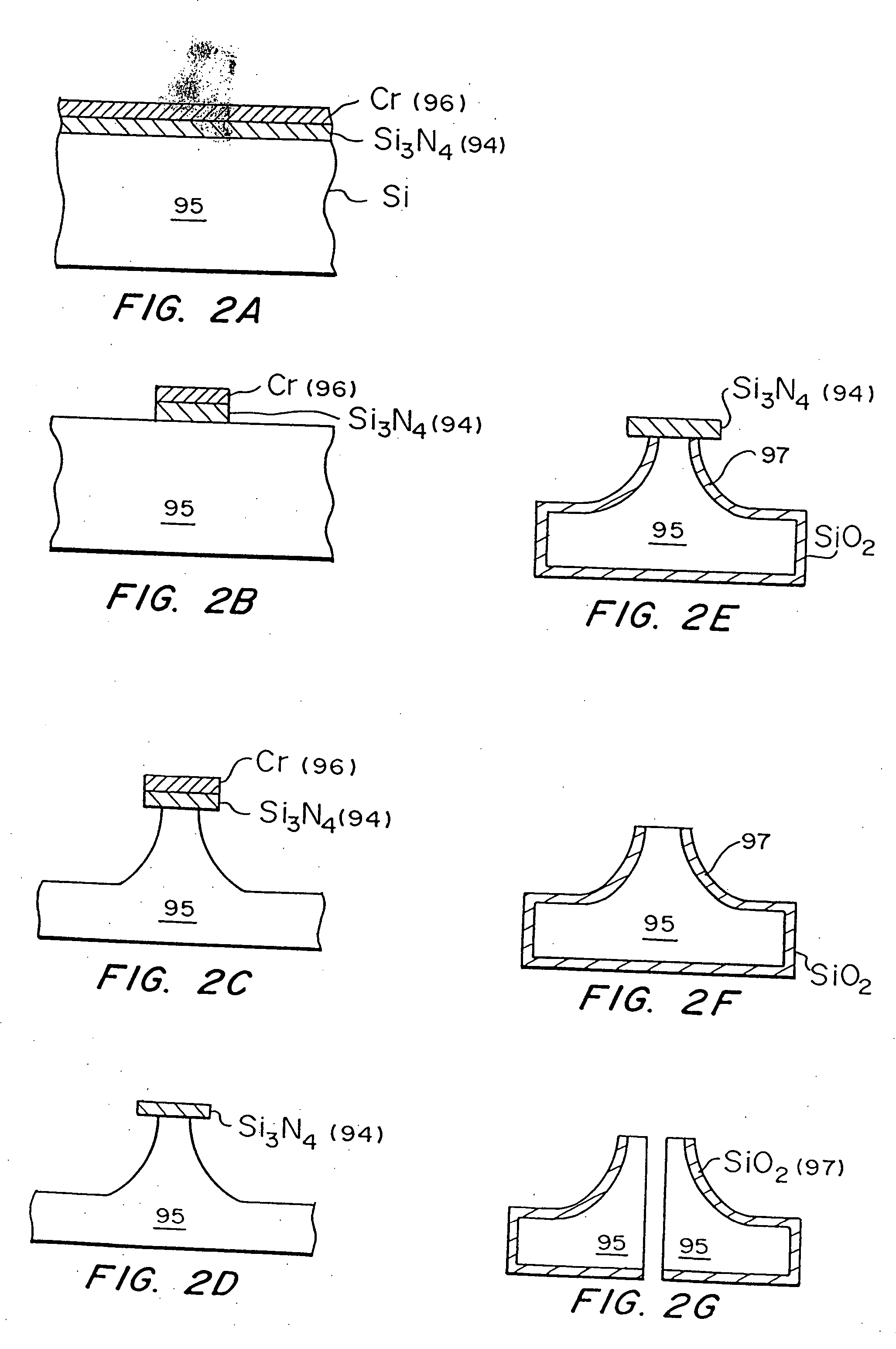

Manufacture method for micro structure

InactiveUS20070037101A1Easy to etchImprove controllabilitySemiconductor/solid-state device manufacturingPhotosensitive material processingResistMicro structure

A micro structure manufacture method includes the steps of: (a) preparing an etching object having an etching target film, provided with a lower hard mask layer and an upper hard mask layer stacked on the etching target film; (b) forming a resist pattern above the etching object; (c) etching the upper hard mask film by using the resist pattern as an etching mask to form an upper hard mask; (d) after the step (c), removing the resist pattern; (e) after the step (d), thinning the upper hard mask by etching; (f) etching the lower hard mask film by using the thinned upper hard mask as an etching mask to form a lower hard mask; and (g) etching the etching target film by using the upper hard mask and the lower hard mask as an etching mask, wherein the upper hard mask film is capable of being more easily etched, using the resist pattern as a mask, than the lower hard mask film. The micro structure manufacture method can etch a fine pattern with good yield.

Owner:FUJITSU LTD

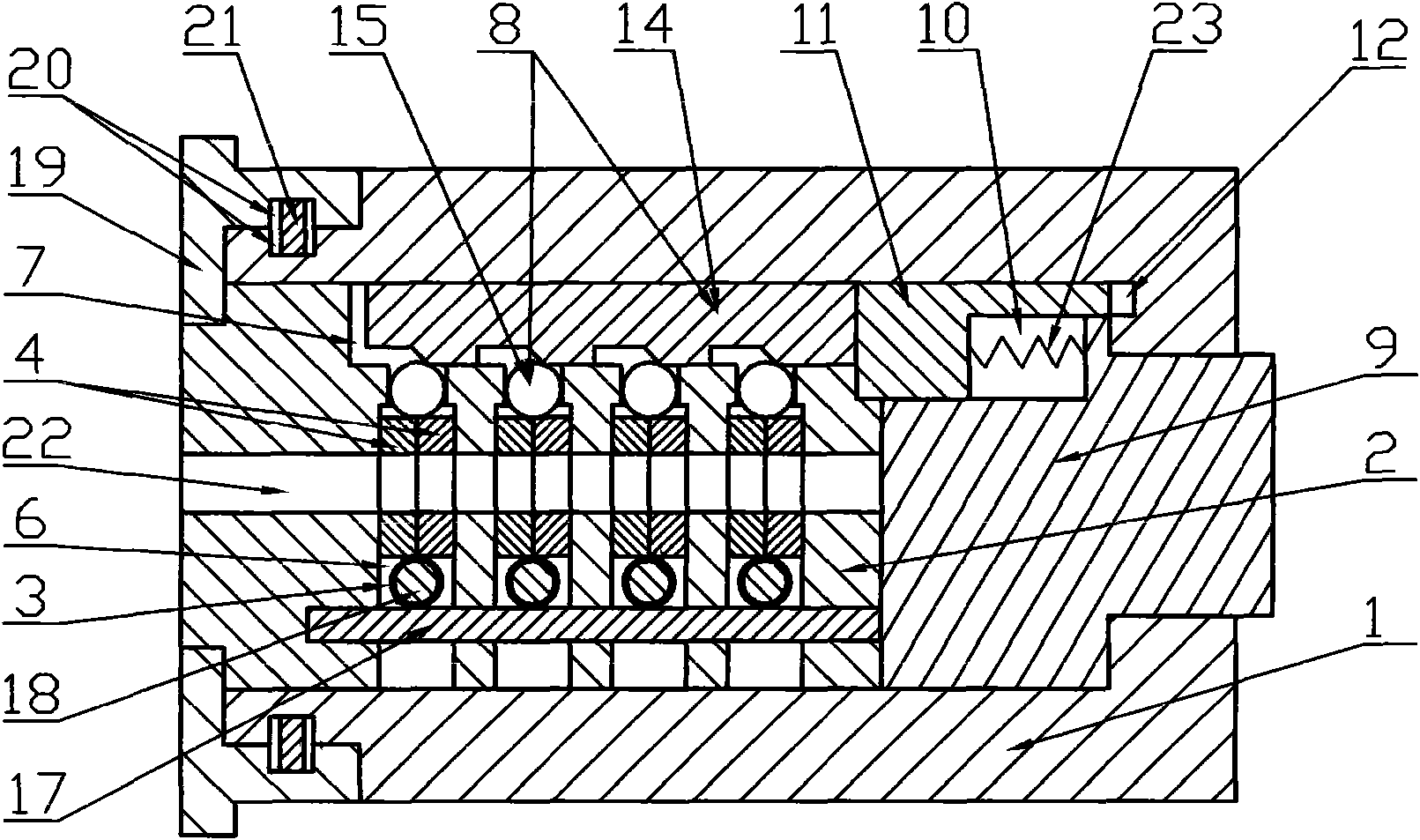

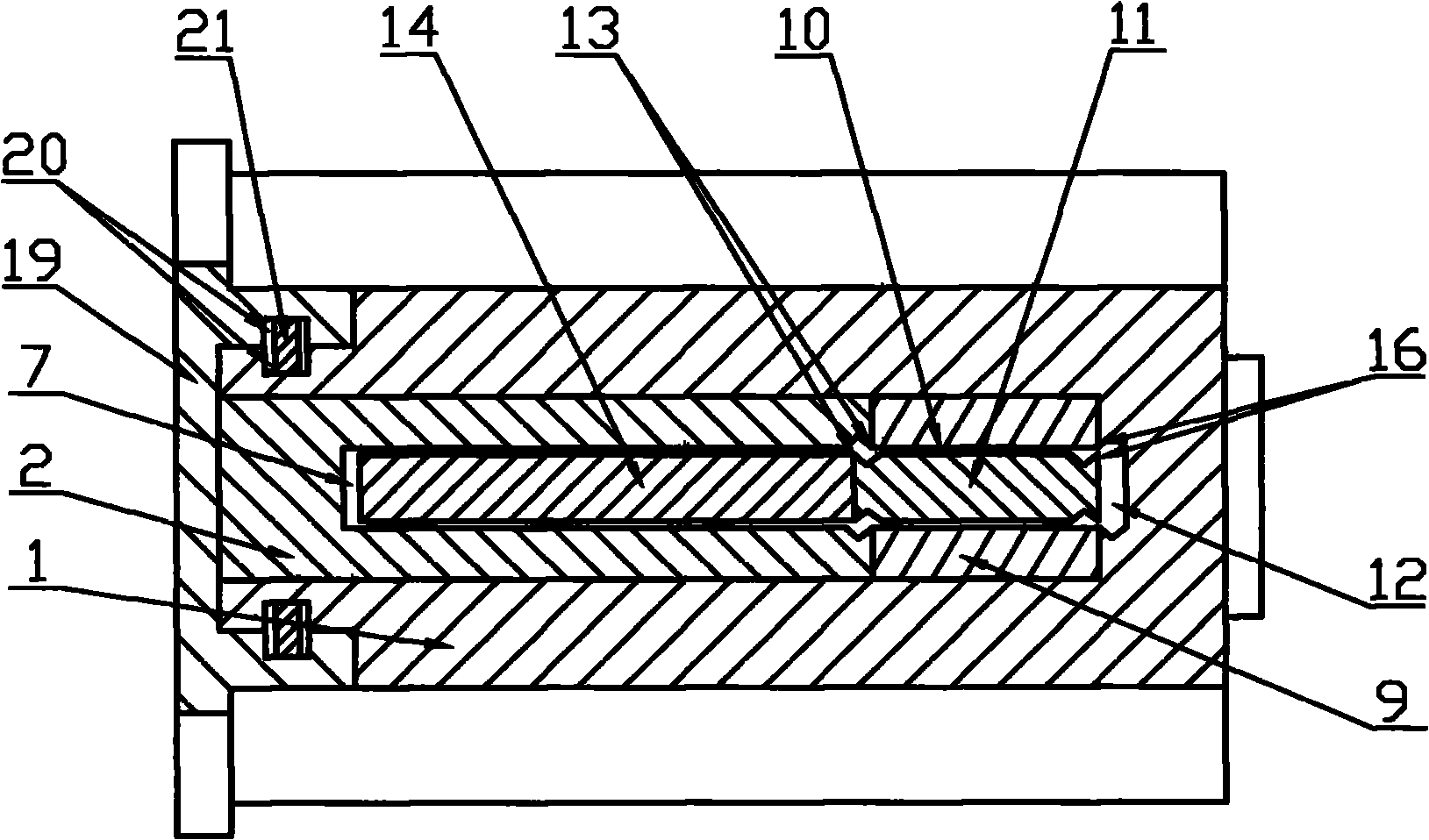

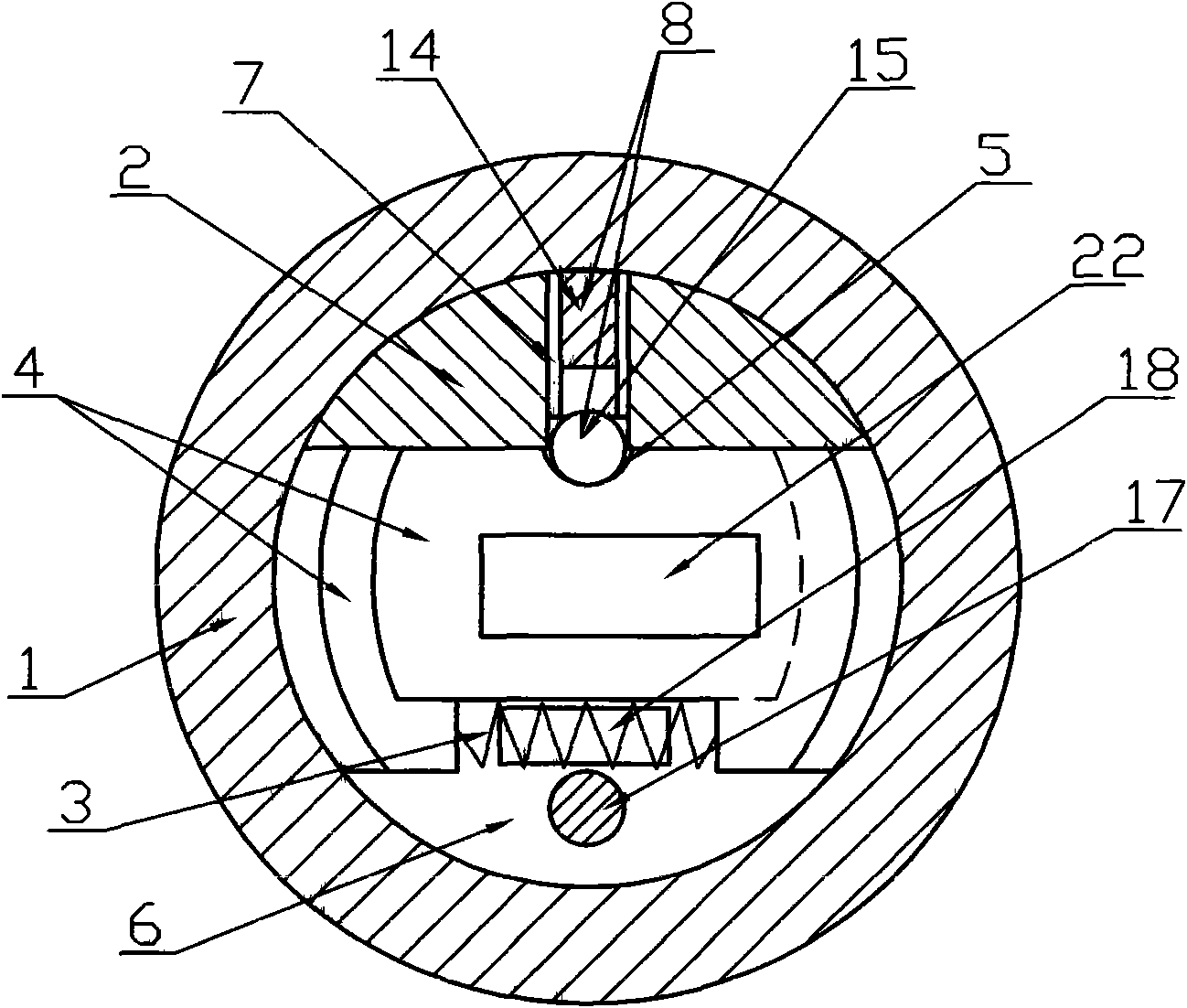

Front and back lock

InactiveCN102080470ASolve slipping and idlingAvoid deformationCylinder locksEngineeringMechanical engineering

The invention discloses a front and back lock comprising a lock body (1), a front lock cylinder (2), a spring (3) and a keyhole (22); the front lock cylinder (2) is internally provided with an atypical spring (4) with a side wall notch (5); the front lock cylinder (2) is internally provided with a side spring hole (7) communicated with a spring hole (6); the side spring hole (7) is internally provided with a side spring (8); a rear lock cylinder (9) is arranged in the rear of the front lock cylinder (2) and is provided with a rear spring hole (10) corresponding to the rear end of the side spring hole (7); the rear spring hole (10) is internally provided with a lock spring (11); and the lock body (1) is internally provided with a lock body spring hole (12) corresponding to the lock spring (11). The front and back lock is characterized in that a sharp corner (13) is arranged at the front end of the lock spring (11), or the sharp corners (13) are simultaneously arranged at the front end of the lock spring (11) and the rear end of the side spring hole (7). The lock ensures the stable leakage of the front lock cylinder (2) and the rear lock cylinder (9) by utilizing the mutual occlusion of the sharp corner (13) at the front end of the lock spring (11) and the sharp corner (13) at the rear end of the side spring hole (7). When the lock is unlocked by using an unlocking tool, the front lock cylinder (2) is idle, thereby effectively preventing from being twisted and pulled by the unlocking tool and rotated by external force to open and increasing the safety of the lock.

Owner:谢煜光

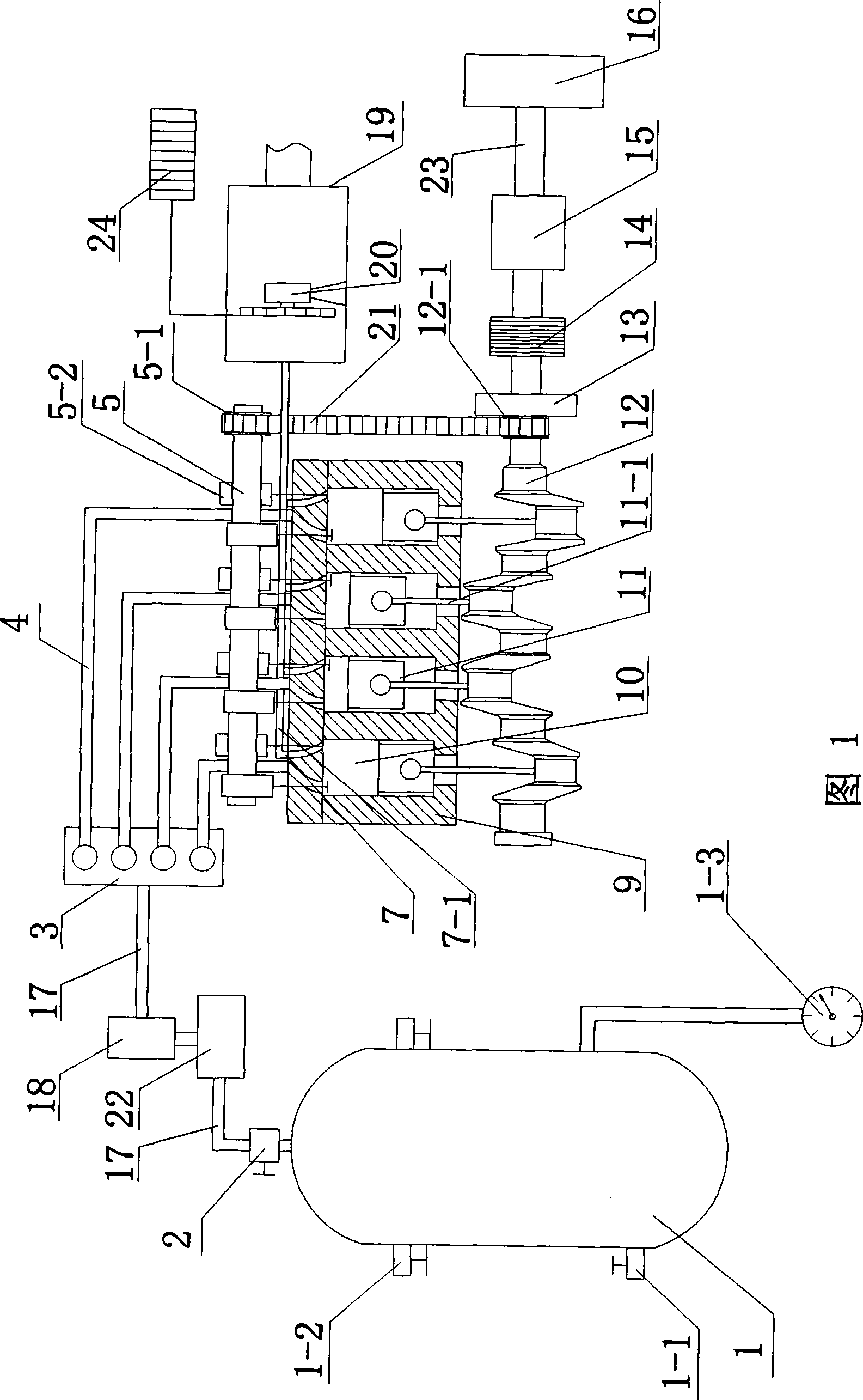

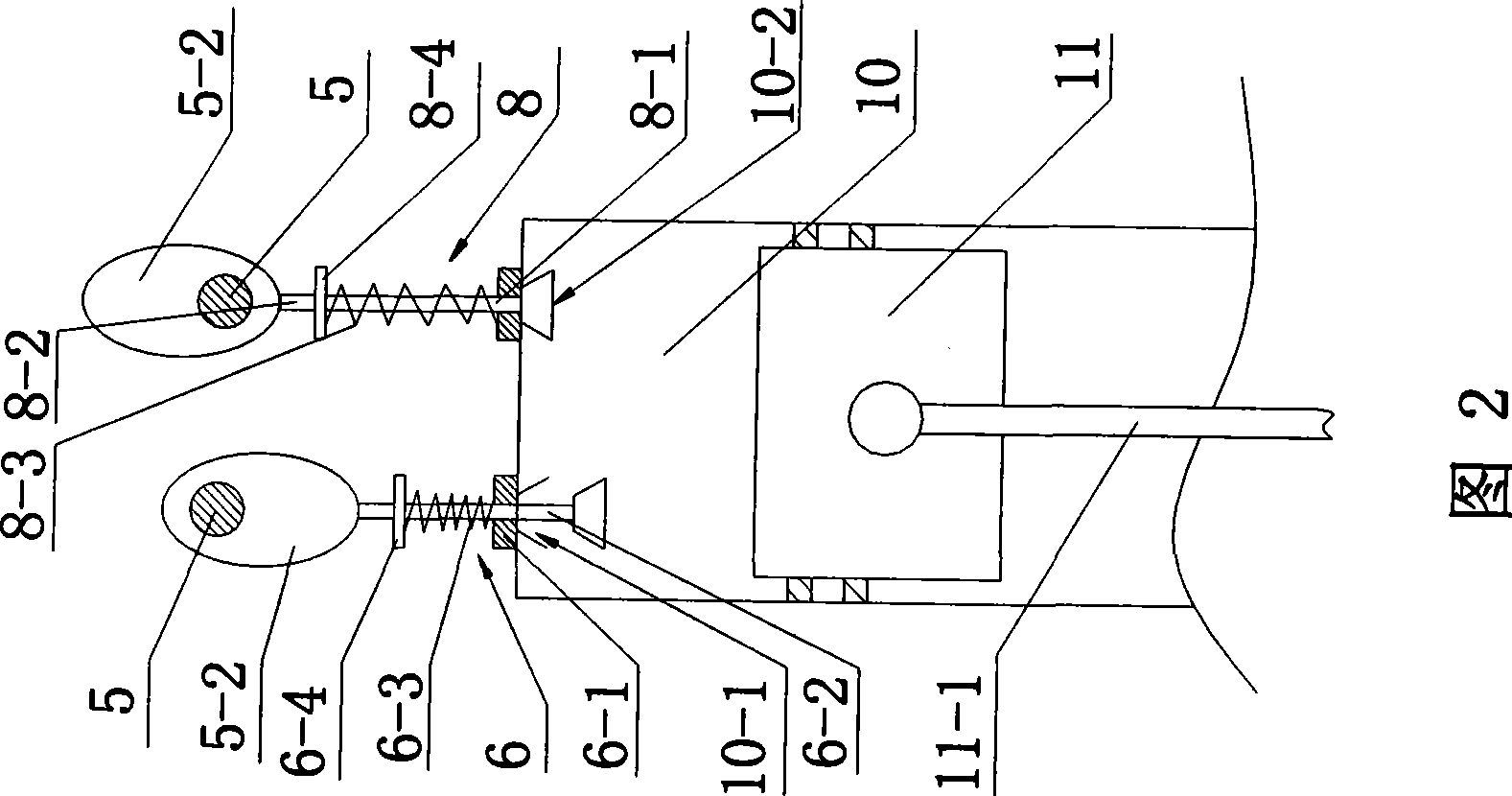

Air power engine assembly

InactiveCN101413403ALow costNo pollutionMechanical power devicesEngines characterised by uniflow principleDistributorPiston

The invention relates to an air-powered engine assembly, which comprises an air tank, an air valve, an air distributor, an intake pipe, camshafts, an intake duct, an exhaust control device, air cylinders, pistons, crankshafts, couplers, clutches, automatic gearboxes and differentials connected with the outside. The assembly is characterized in that the air valve, a constant pressure chamber and a pressure controller are arranged between the air tank and the air distributor; the air distributor is connected with a plurality of air cylinders on an air cylinder gasket; each air cylinder is connected with an exhaust chamber through an exhaust manifold; the exhaust chamber is provided with a turbine generator which is connected with a storage batter; the air cylinders are provided with the camshafts for controlling the air intake and exhaust of the air cylinders; the air cylinders are provided inside with the pistons for driving the crankshafts to rotate; the camshafts and the crankshafts are connected by chains; and the crankshafts are connected with the differentials through the couplers, the clutches and the gearboxes in turn. Therefore, doing work through air compression rather than fuel, the air-powered engine assembly has the advantages of avoiding waste gas discharge and air pollution, along with reliable operation, convenient operation, economical efficiency, practicality and so on. In addition, due to recycle of the waste gas for power generation, the air-powered engine assembly saves energy and reduces costs.

Owner:周登荣 +1

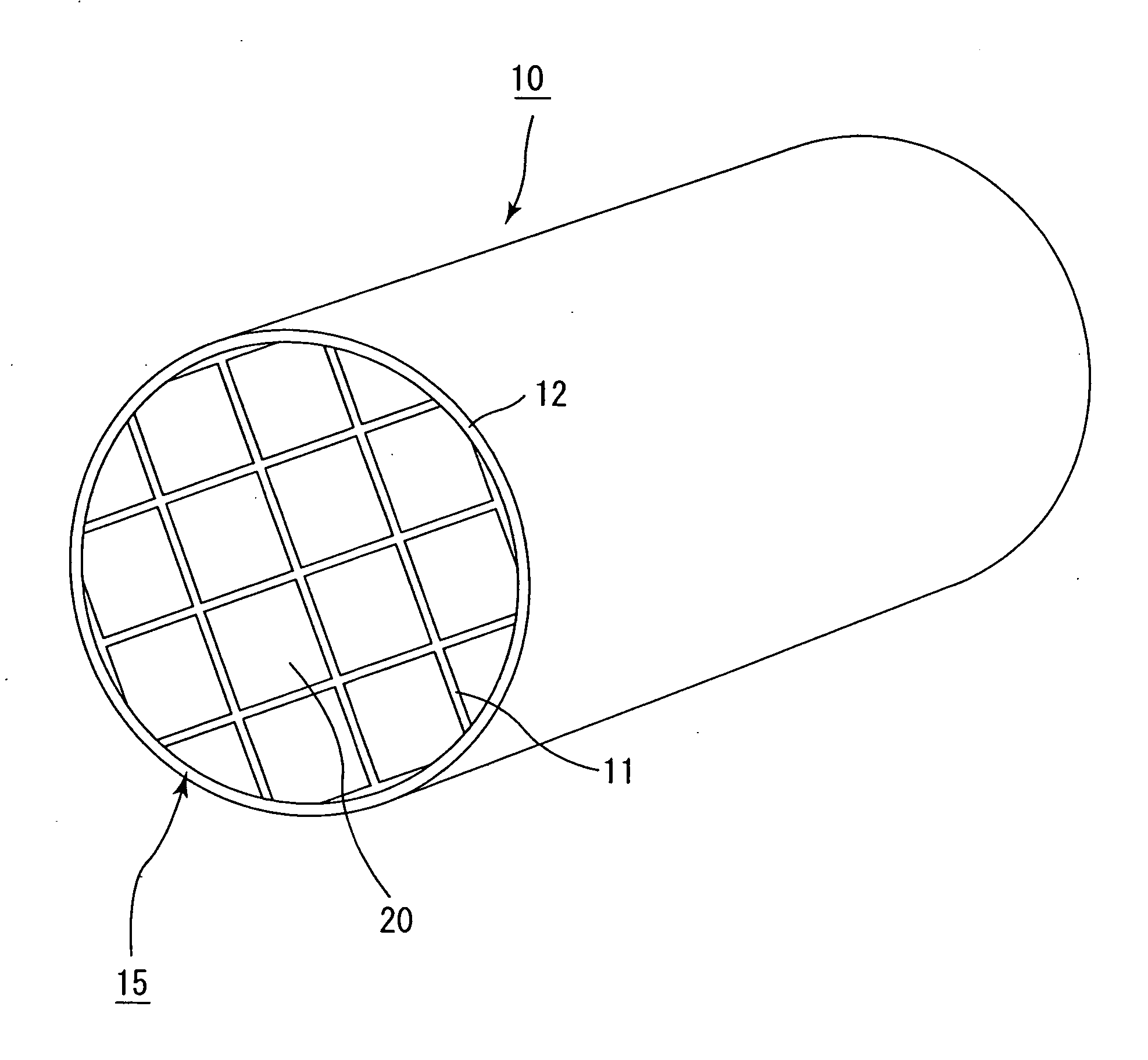

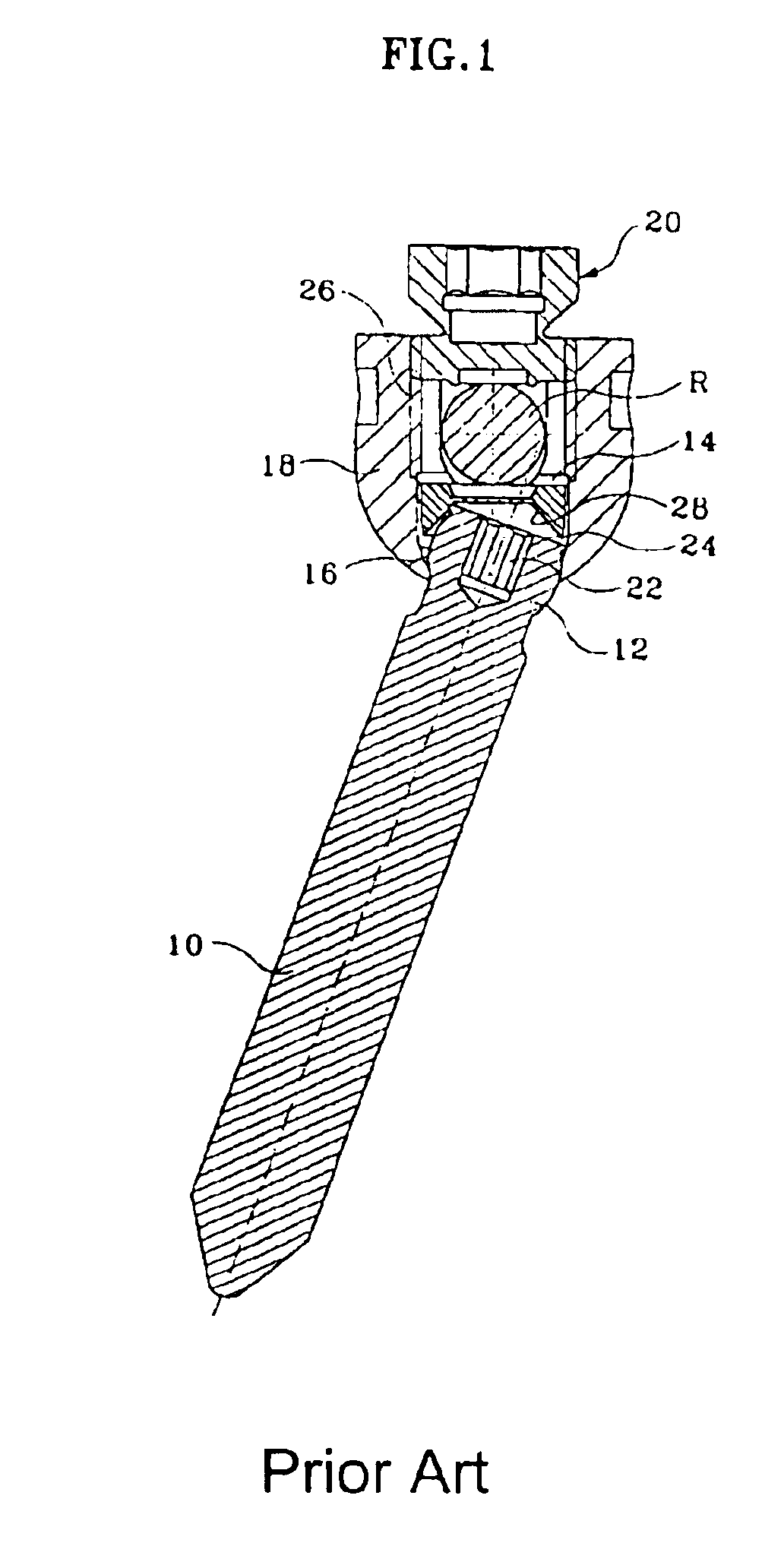

Implantable connector with protected contacts

InactiveUS7736191B1Avoid deformationAvoid accidental damageElectrotherapyCoupling device detailsElectrical conductorMedical device

An implantable connector electrically connects multi-conductor leads to an implantable medical device such as a neurostimulator. The connector is assembled directly into a hermetic feedthrough of the implantable device and utilizes the feedthrough housing as a sustaining structure for connector clamping. The receptacle contacts detachably connect proximal lead contacts to corresponding feedthrough pins, which provide pass-through connections to electronic circuitry contained in a hermetically sealed case. The receptacle contact has resilient contact tines designed to engage a corresponding lead contact in a sliding manner. The receptacle contact is integrated with a contact guard which protects the receptacle contact from inadvertent handling damage. The contact guard is substantially more rigid than the resilient contact to resist deformation. The contact guard protectively shields the receptacle contact tines and prevents unintended contact tine excursion. In one embodiment, the contact guard is pre-attached to the receptacle contact prior to joining to the feedthrough pin. In another embodiment, the contact guard is an integral part of the feedthrough pin. Numerous embodiments with contact preload are provided.

Owner:SOCHOR JERZY ROMAN

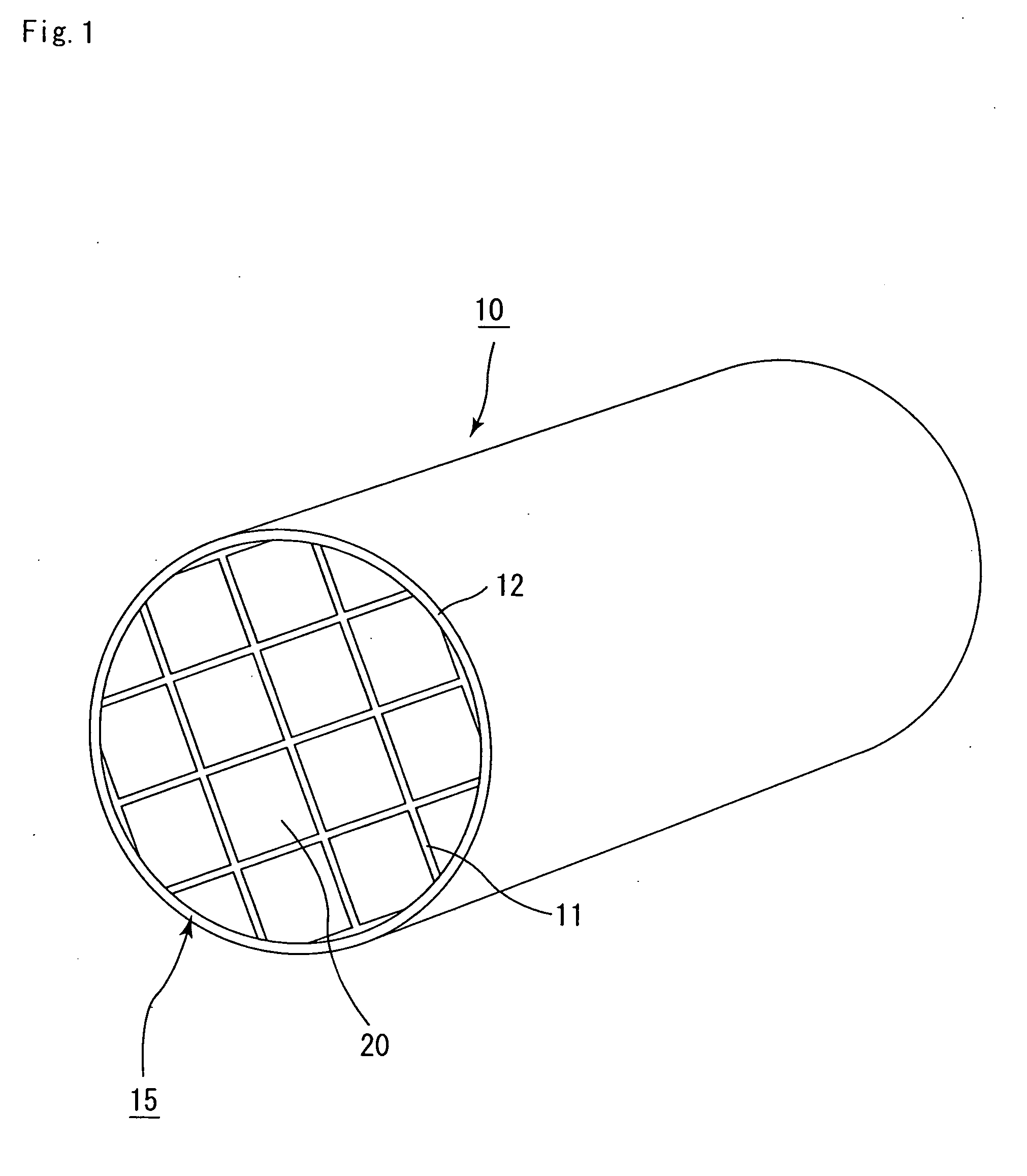

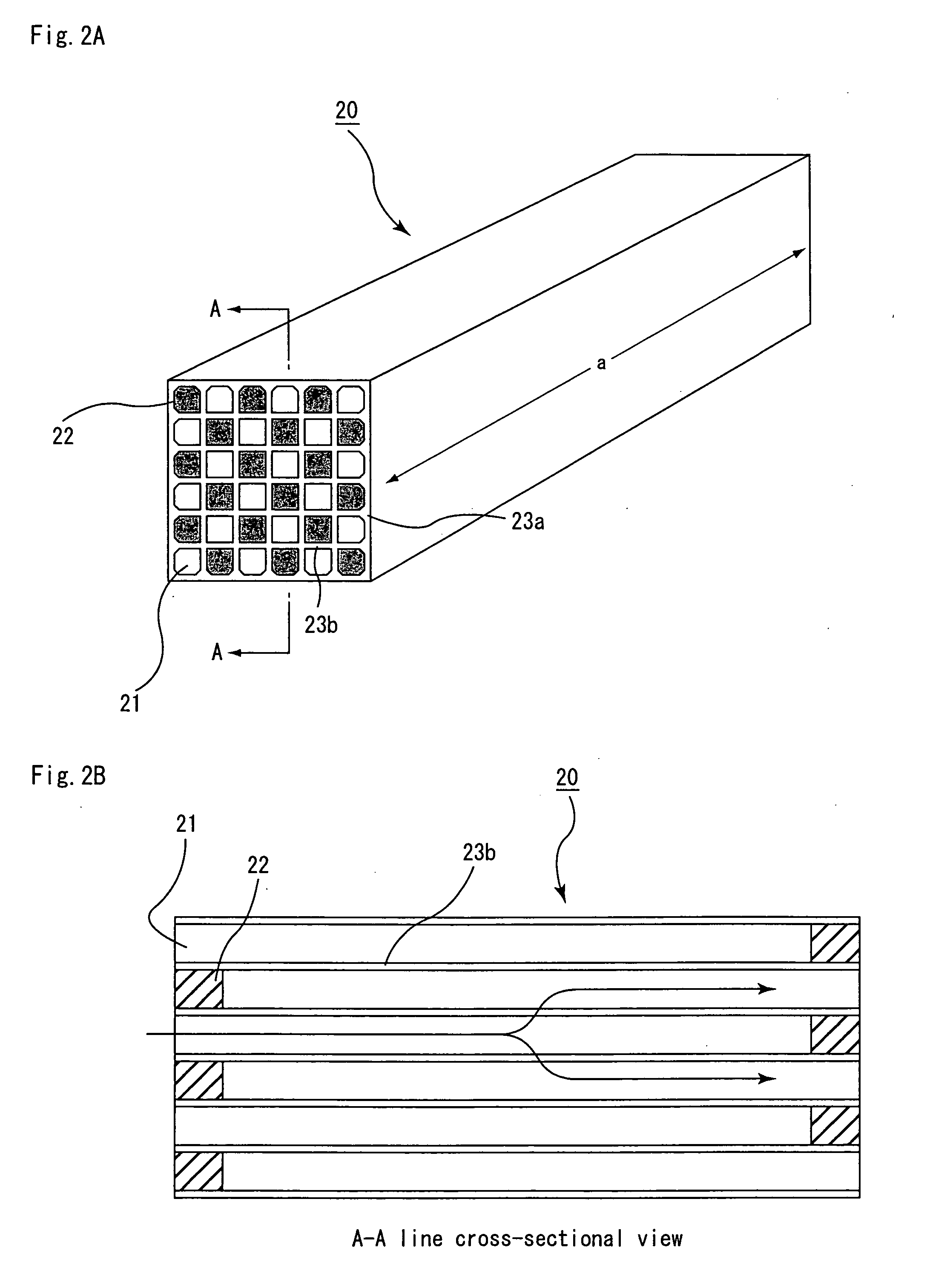

Honeycomb structured body, method for manufacturing honeycomb structured body, and exhaust gas purifying device

InactiveUS20070130897A1Avoid deformationReduce generationPhysical/chemical process catalystsInternal combustion piston enginesEdge surfaceCell wall

A honeycomb structured body in which a plurality of porous ceramic members are combined with one another by interposing an adhesive layer, each of the porous ceramic members having a plurality of cells placed in parallel with one another in a longitudinal direction with a cell wall therebetween and an outer edgewall on the outer edge surface thereof, wherein the thickness of the outer edge wall of the porous ceramic member is greater than the thickness of the cell wall, and each of the porous ceramic members has a filling body which is provided so as to fill in at least one corner portion of at least one outermost cell of the porous ceramic members.

Owner:IBIDEN CO LTD

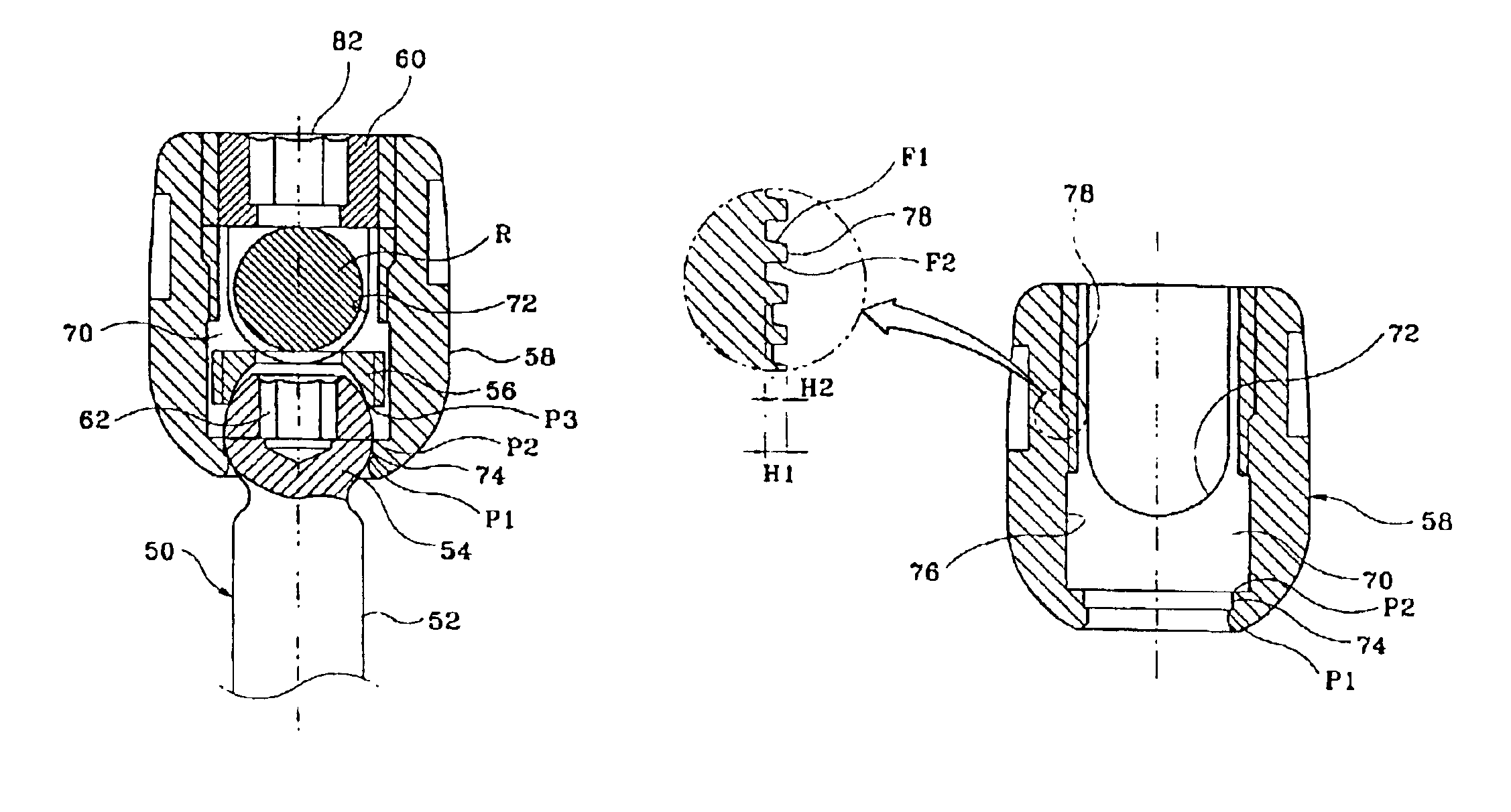

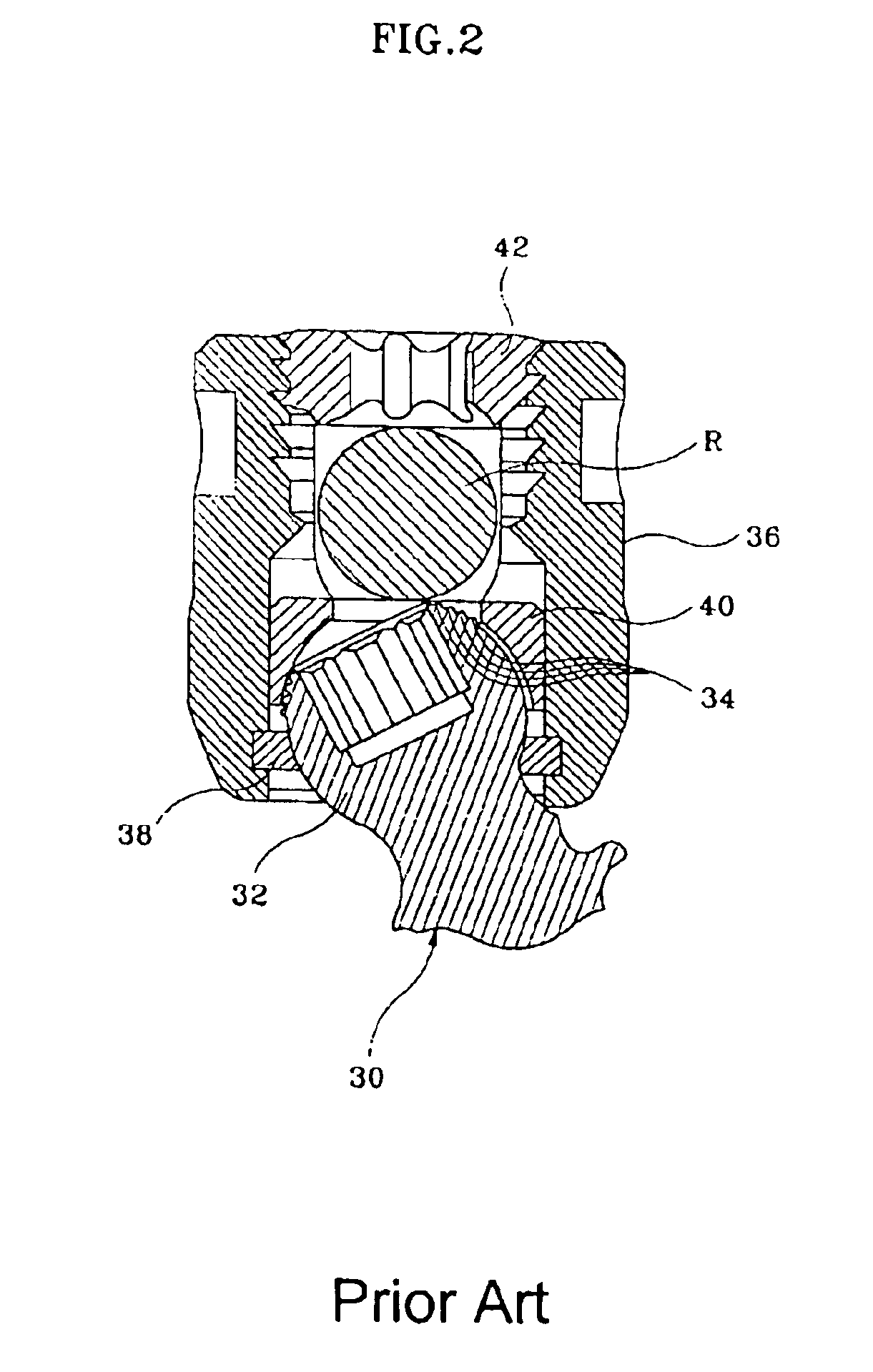

Bone fixation apparatus

InactiveUS6905500B2Prevent movementImprove supportInternal osteosythesisJoint implantsBiomedical engineeringBones fixation

Disclosed is a bone fixation apparatus. This device comprises a bone screw having a head; a cap member placed on an upper part of the head of the bone screw; a receiver member having a bore in which the cap member and the head of the bone screw are respectively accommodated and held, and a U-shaped channel through which a support bar extends; and a compression member threadedly coupled into the receiver member to downwardly bias the support bar. A multitude of stepped portions are formed at a lower end and inner surface of the receiver member to be brought into linear contact with an outer surface of a lower part of the head so that the supporting force for the head of the bone screw is increased.

Owner:U & I INC

Thermal processes for subsurface formations

InactiveUS20050051327A1Reduce heatMaintaining separation distanceSurveyConstructionsGeophysicsHydrocarbon

A process may include providing heat from one or more heaters to at least a portion of a subsurface formation. Heat may transfer from one or more heaters to a part of a formation. In some embodiments, heat from the one or more heat sources may pyrolyze at least some hydrocarbons in a part of a subsurface formation. Hydrocarbons and / or other products may be produced from a subsurface formation. Certain embodiments describe apparatus, methods, and / or processes used in treating a subsurface or hydrocarbon containing formation.

Owner:SHELL OIL CO

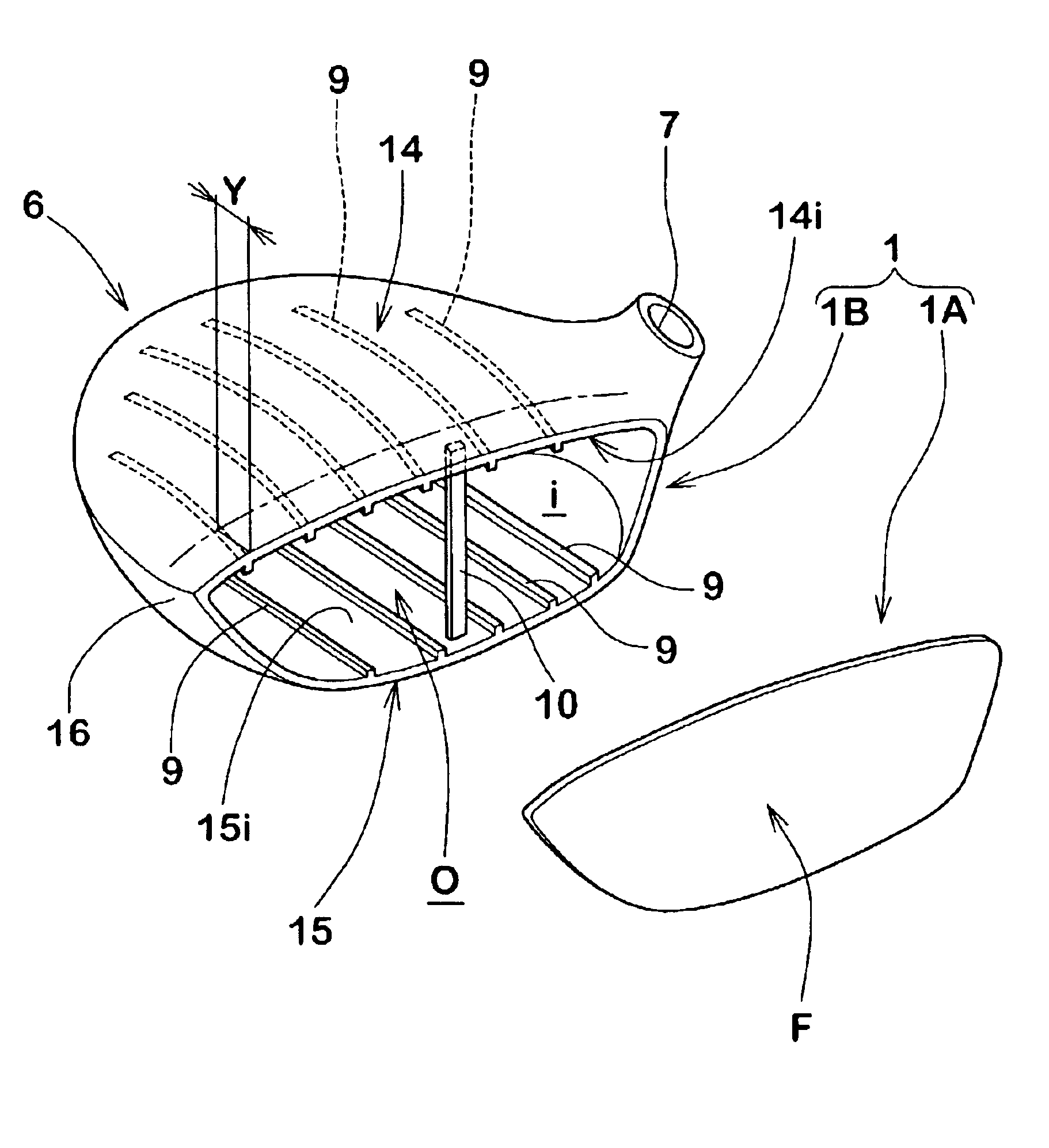

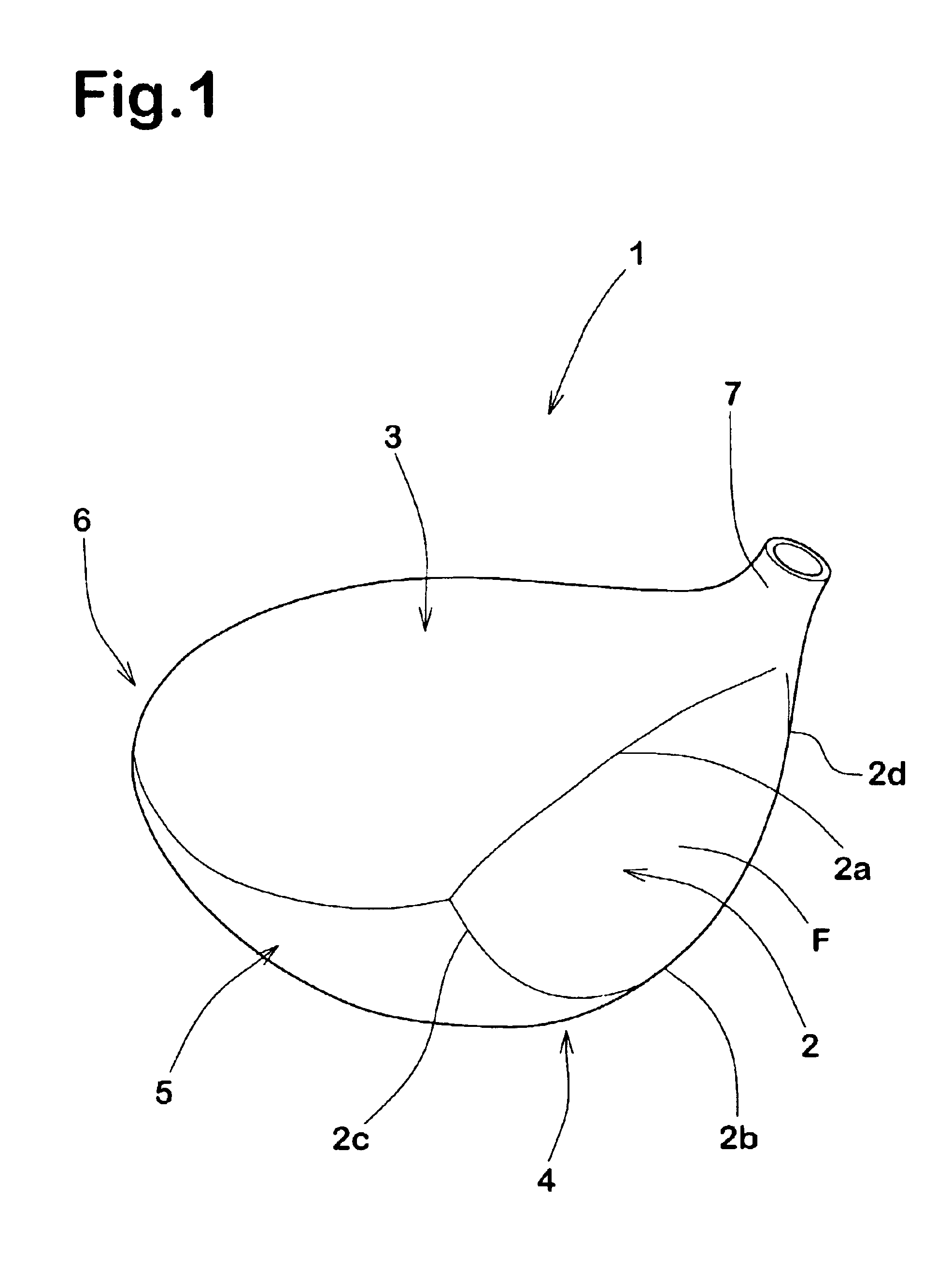

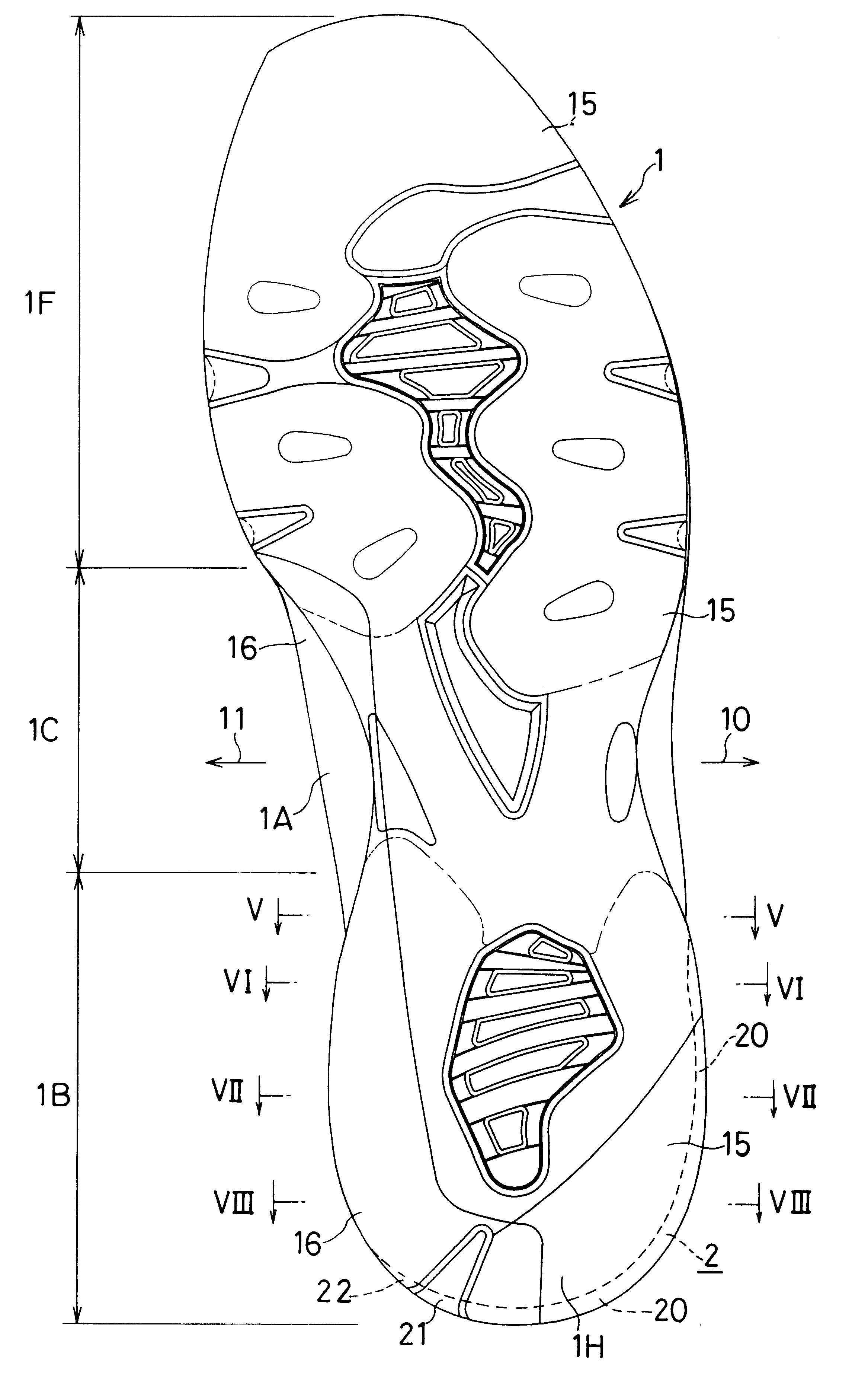

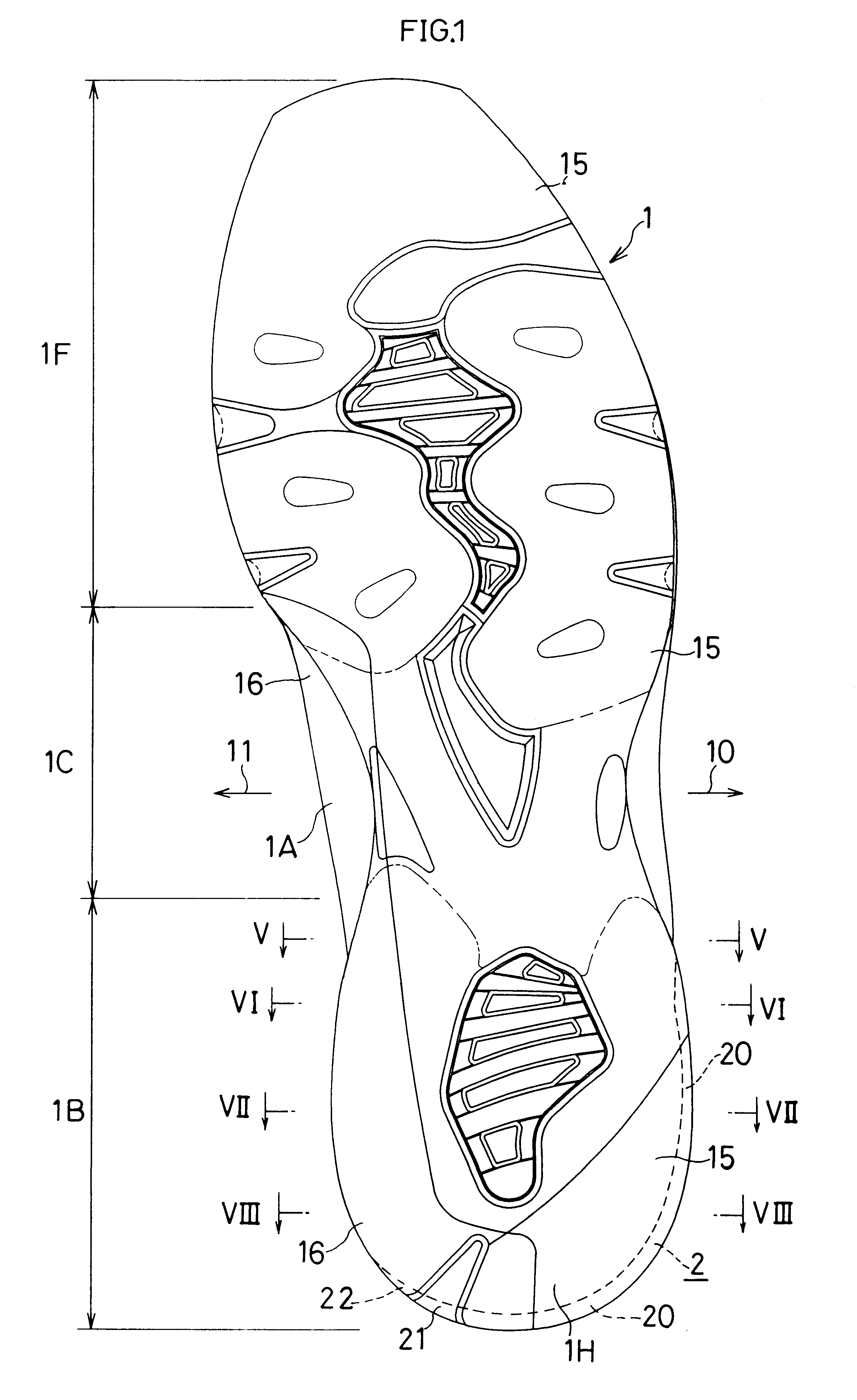

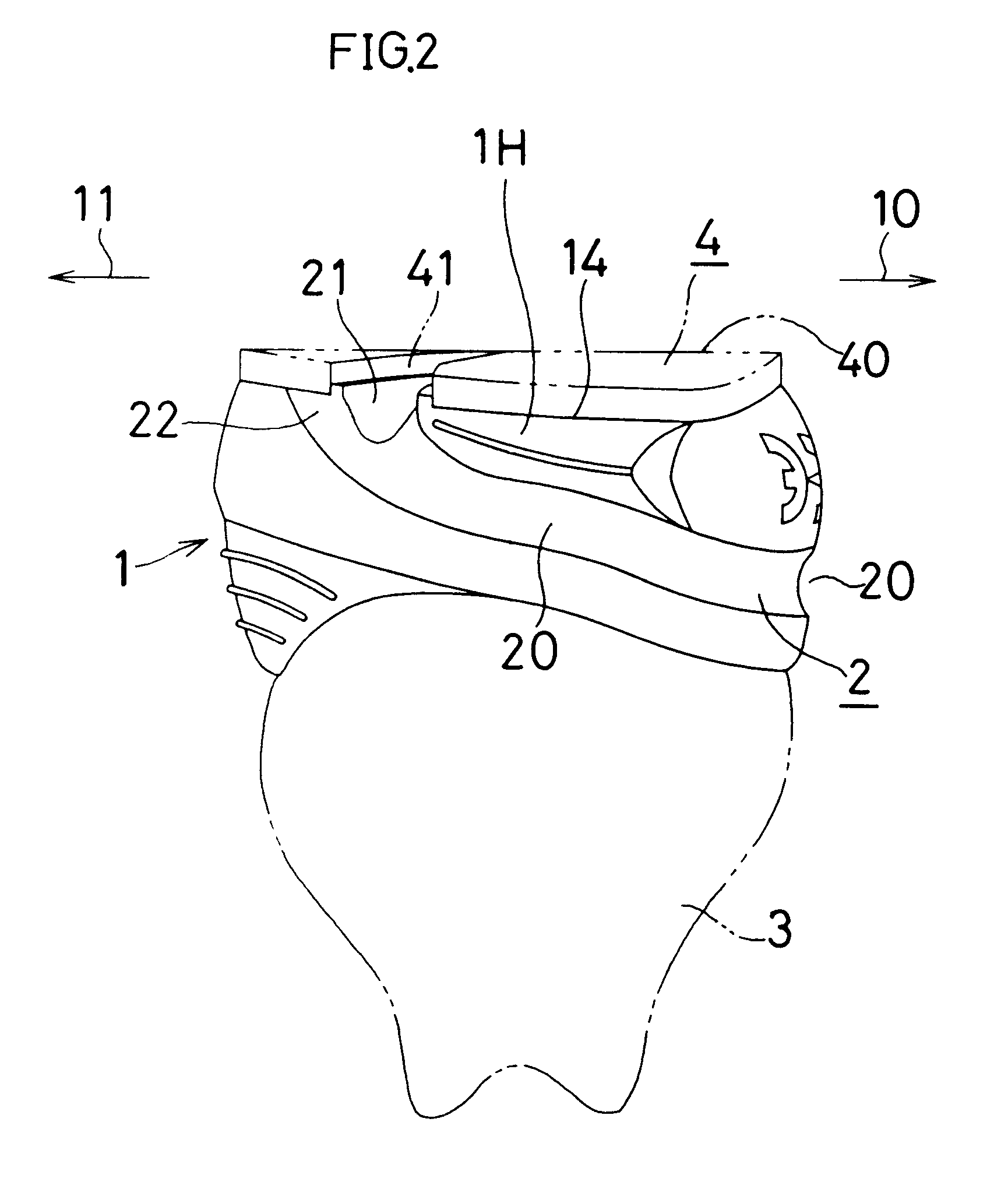

Athletic shoe

An athletic shoe comprises an upper (3) for accommodating an instep of a foot, and outer sole (4) having a tread on bottom surface, and a midsole (1) interposed between the upper (3) and the outer sole (4). A shock absorbing groove (2) is formed in the midsole (1). The shock absorbing groove (2) is formed of a long transverse groove (20) and a short longitudinal groove (21) in a continuous manner. The transverse groove (20) is formed on the midsole (1) extending from a side face of a rear foot part (1B) of the midsole (1) on lateral side (10) of the foot to a back face of a heel part (1H) of the midsole (1) and has an end (22) on the heel part (1H). The longitudinal groove (21) is formed in such a manner as to cut out the heel part (1H) of the midsole (1) from a lower end face of the midsole (1) toward the end of the transverse groove (20).

Owner:ASICS CORP

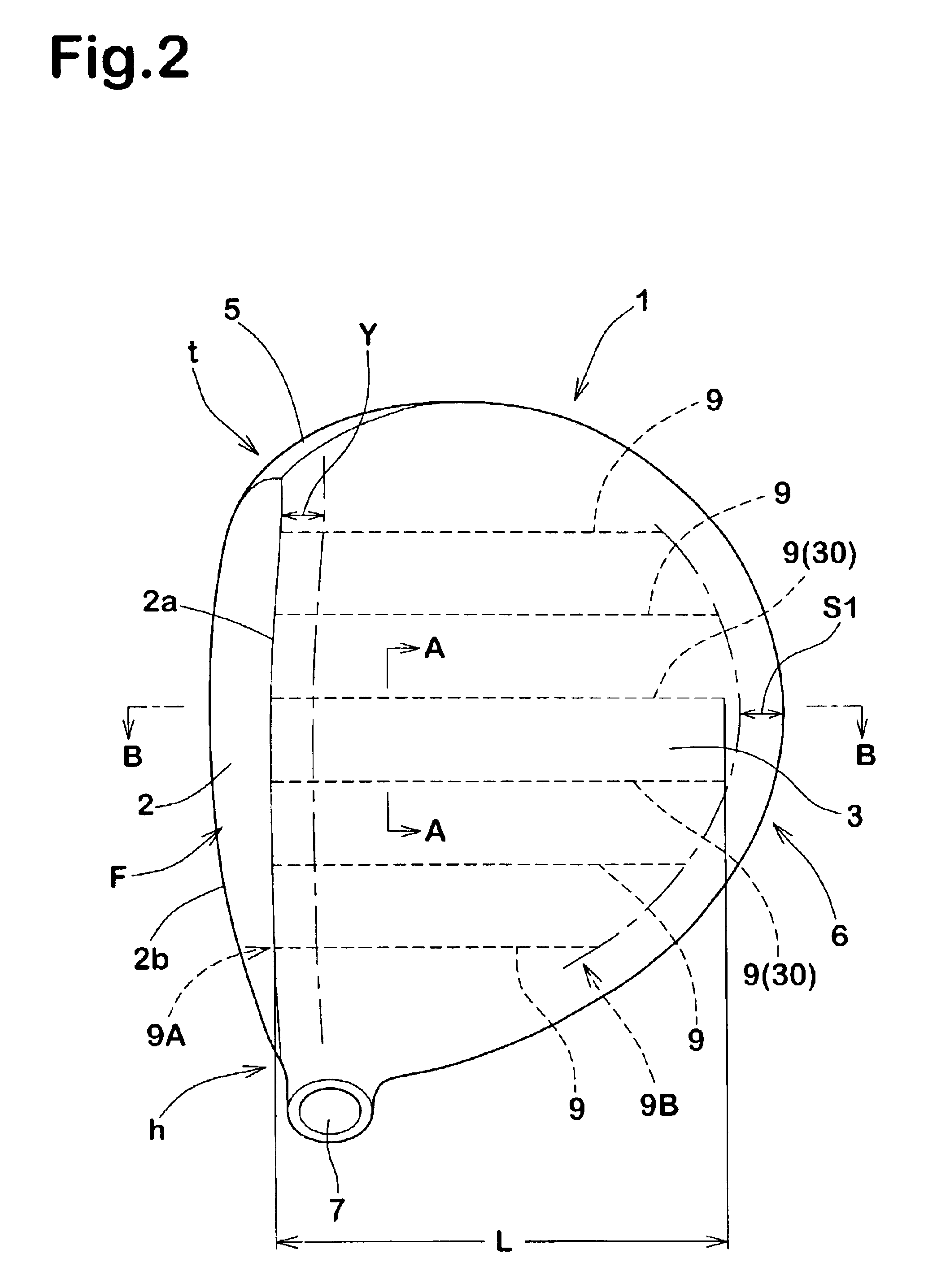

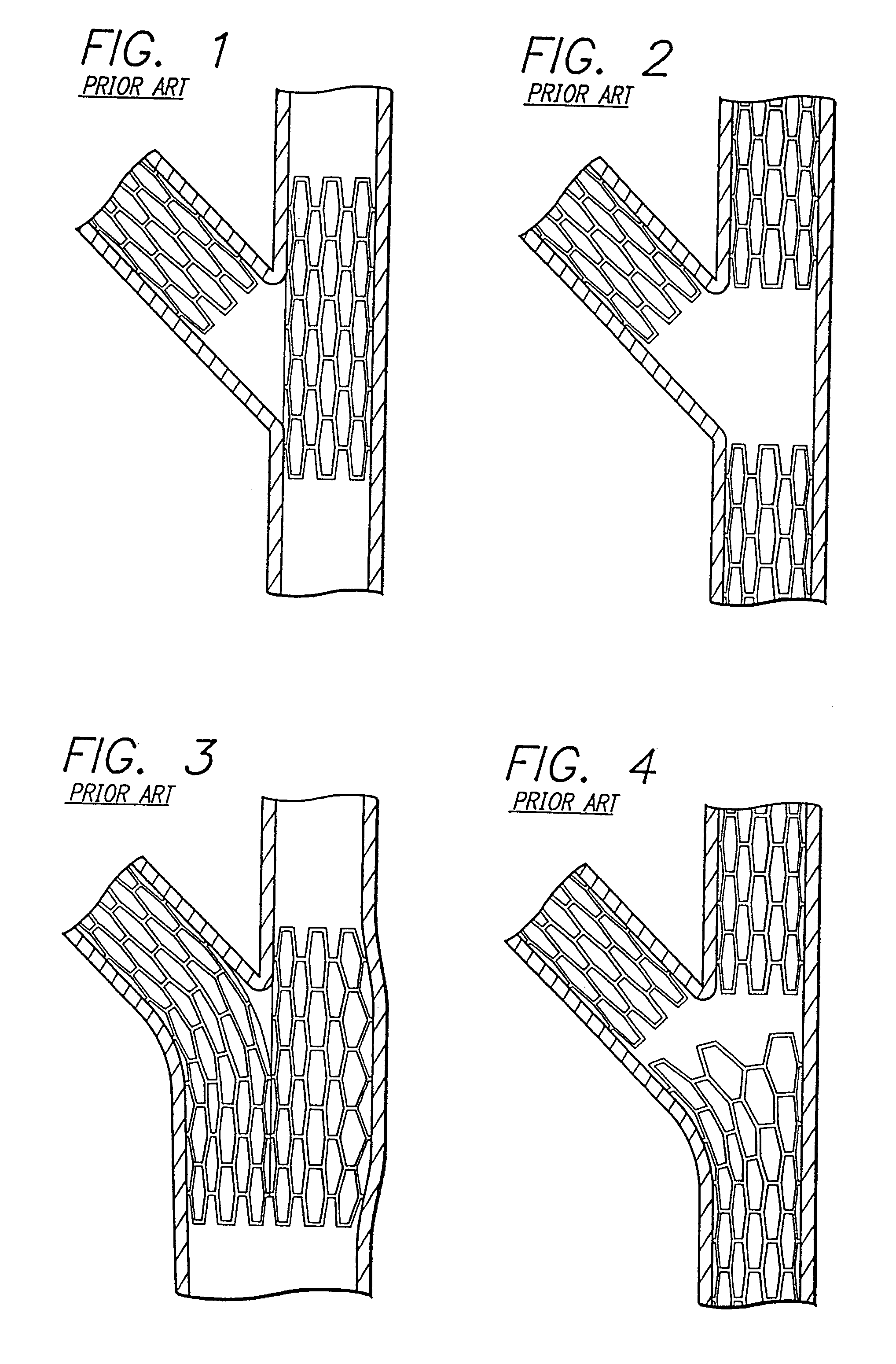

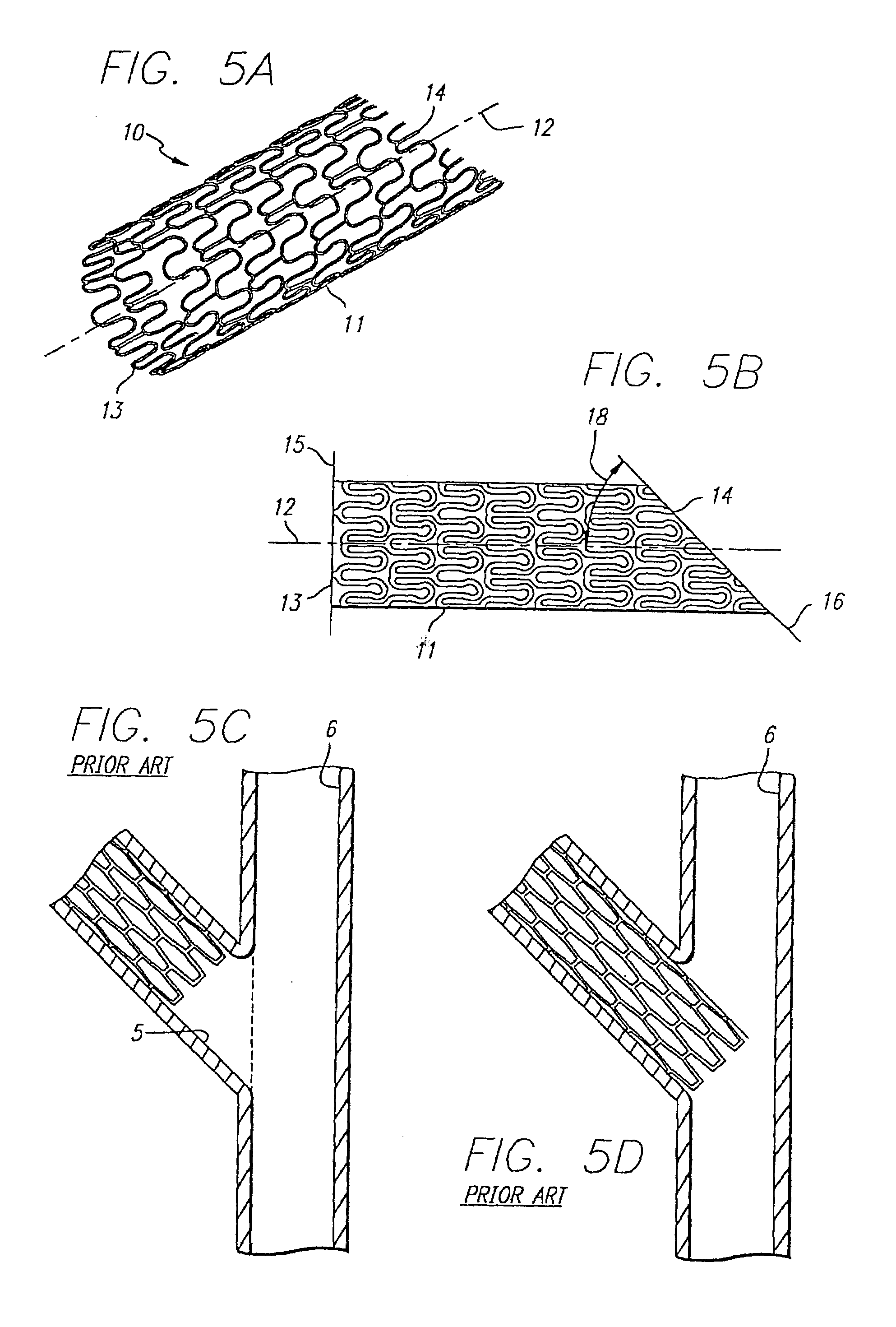

Stent and catheter assembly and method for treating bifurcations

An apparatus and method is provided for stenting bifurcated vessels. A proximal angled stent is configured for implanting in a side-branch vessel wherein the proximal angled stent has an angulated portion that corresponds to the angle formed by the intersection of the side-branch vessel and the main vessel so that all portions of the side-branch vessel at the bifurcation are covered by the proximal angled stent. A main-vessel stent is provided for implanting in the main vessel, wherein the main-vessel stent has an aperture or stent cell that aligns with the opening to the side-branch vessel to permit unobstructed blood flow between the main vessel and the side-branch vessel. Side-branch and main-vessel catheter assemblies are advanced over a pair of guide wires for delivering, appropriately orienting, and implanting the proximal angled stent and the apertured stent.

Owner:ABBOTT CARDIOVASCULAR

Personal identification device and method

ActiveUS20050047632A1Recognition capability decreaseLow costImage analysisPerson identificationFinger vein recognitionLight-adapted

A personal identification device and method prevent the reduction in the finger vein recognition rate which otherwise occur due to erroneous insertion of a finger by a user not accustomed to operation or insertion of a false finger at low cost. The device includes an imager picking up an image of a finger vein pattern, a light source emitting light adapted to be transmitted through the finger, an image operating unit matches the image, guides indicating the position of picking up the finger image, a detector detecting the contact between the finger and the guides, another light source radiating light reflected from the thick of the finger, a switch which is depressed by the forward end of the finger, a further light source emitting light transmitted through the forward end of the finger, and a light-sensor receiving the light from the further light source through the finger.

Owner:HITACHI LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com