Patents

Literature

90 results about "Tine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tines (also tynes), prongs or teeth are parallel or branching spikes forming parts of a tool or natural object. They are used to spear, hook, move or otherwise act on other objects. They may be made of metal, wood, bone or other hard, strong materials.

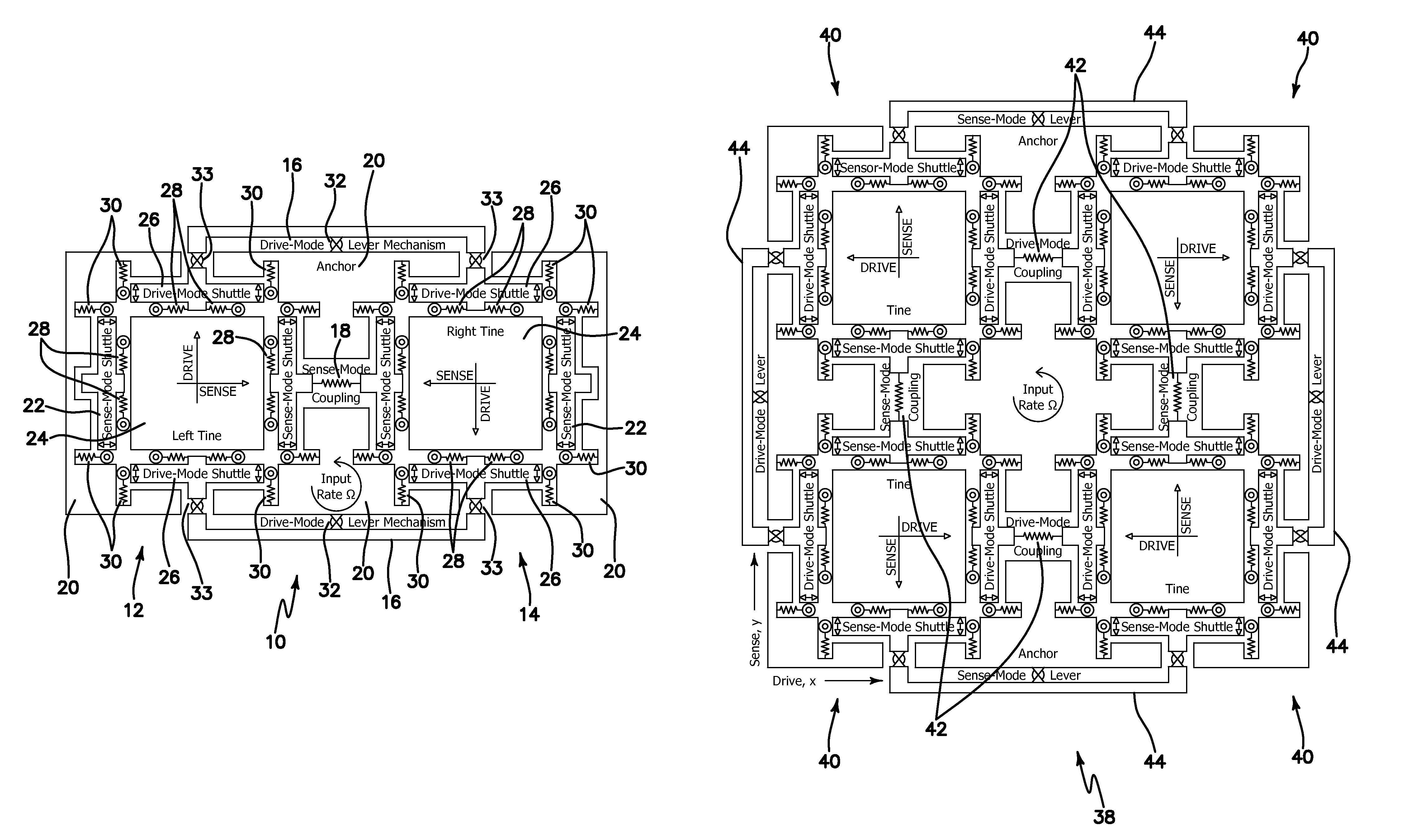

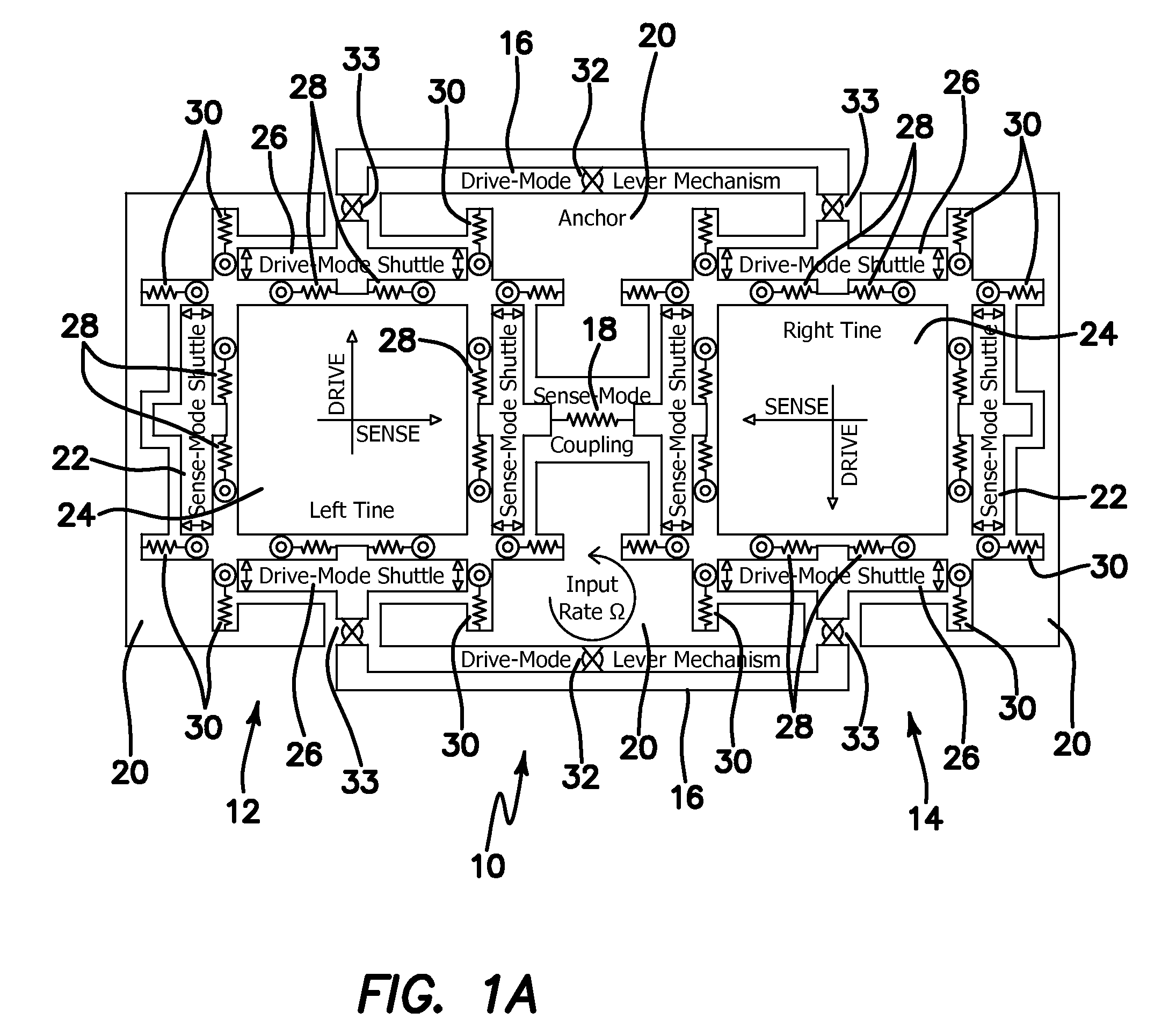

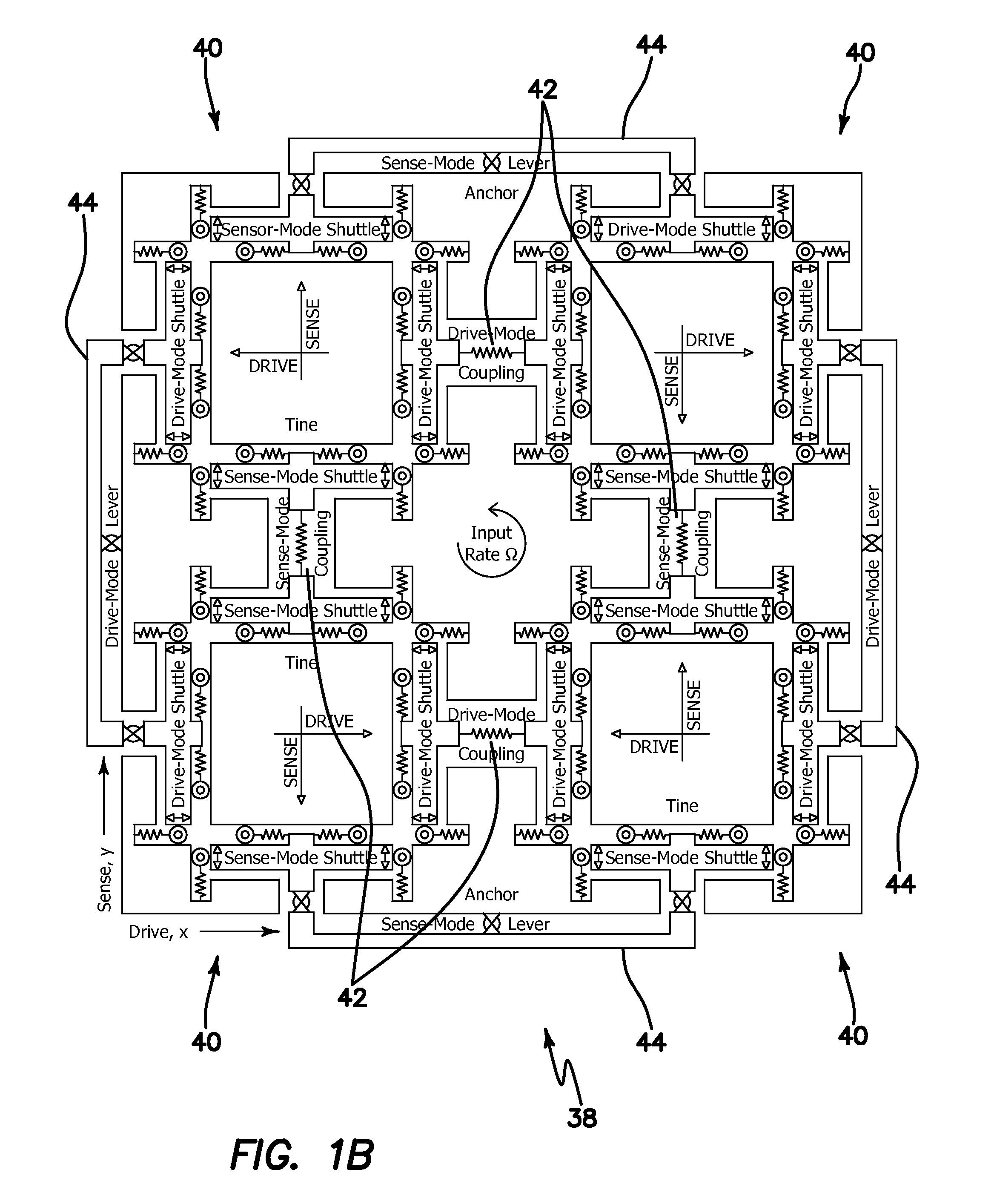

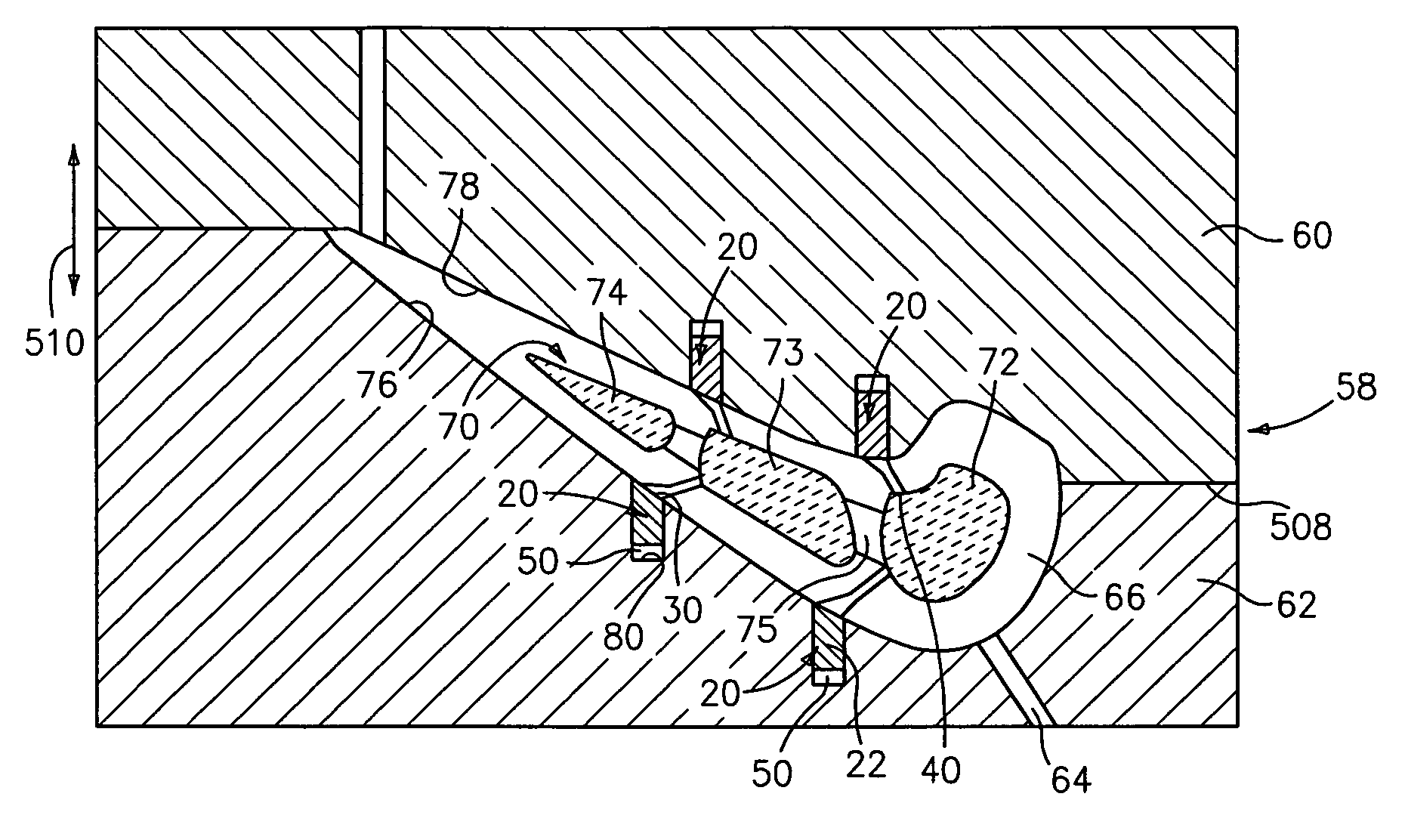

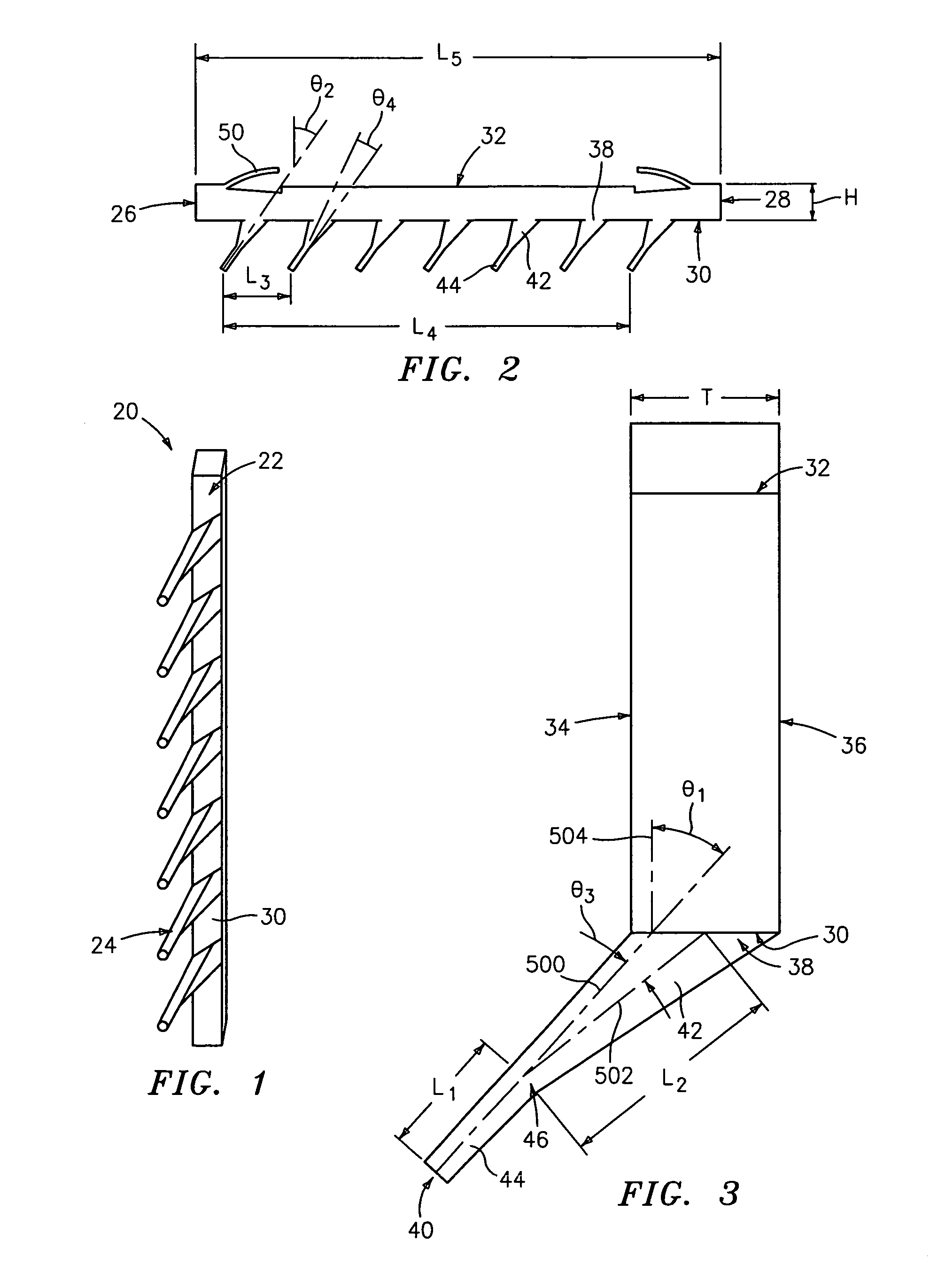

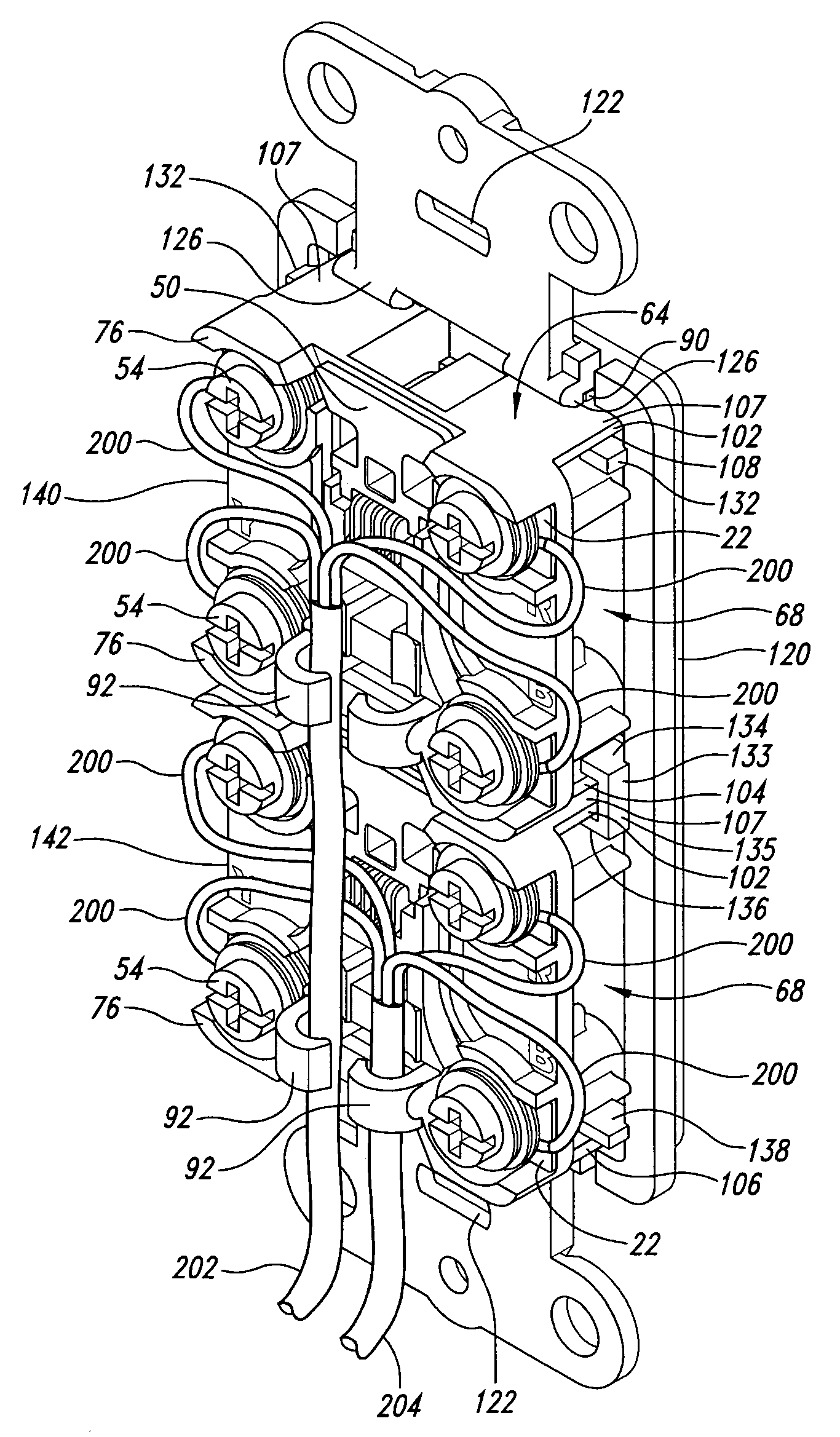

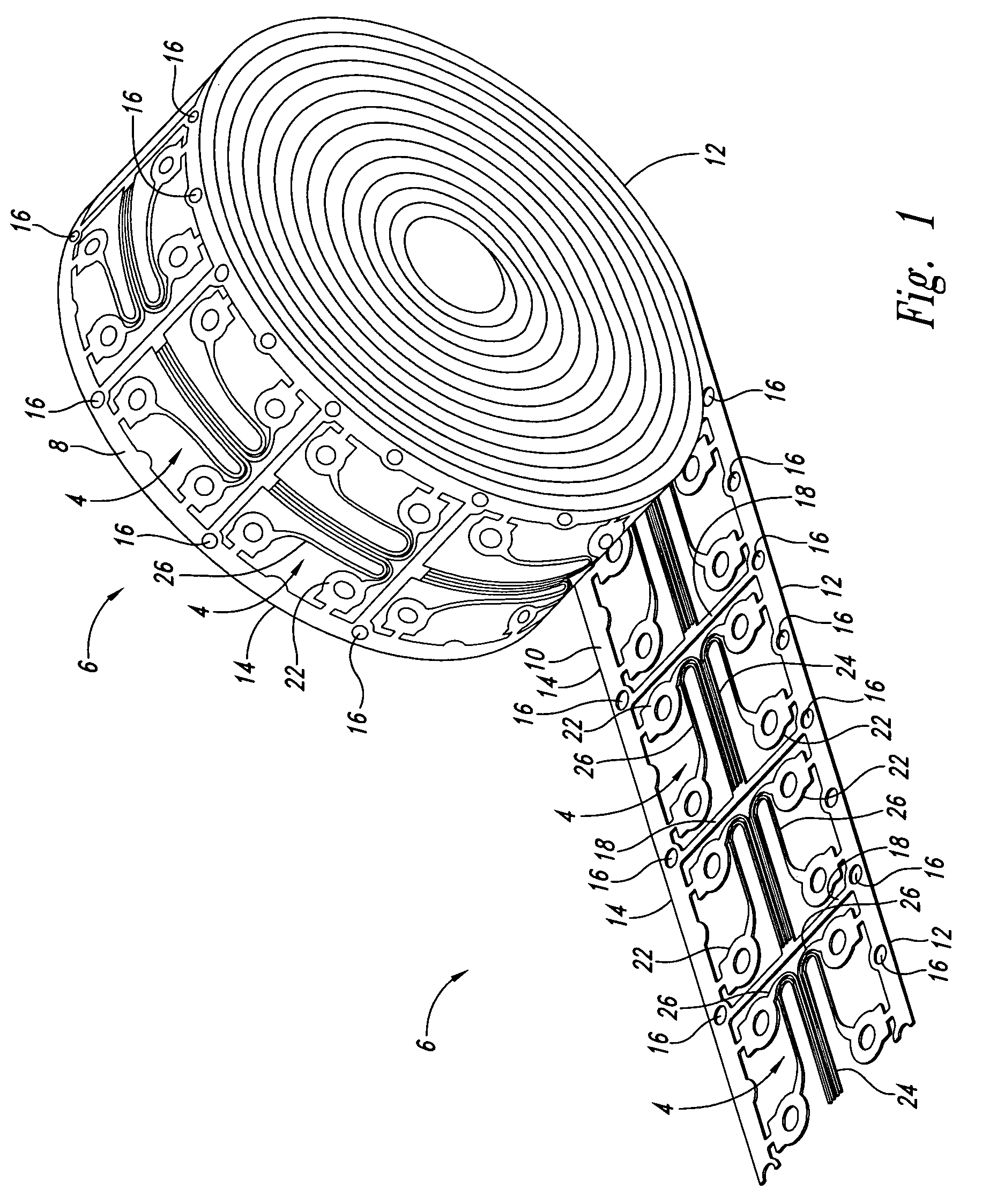

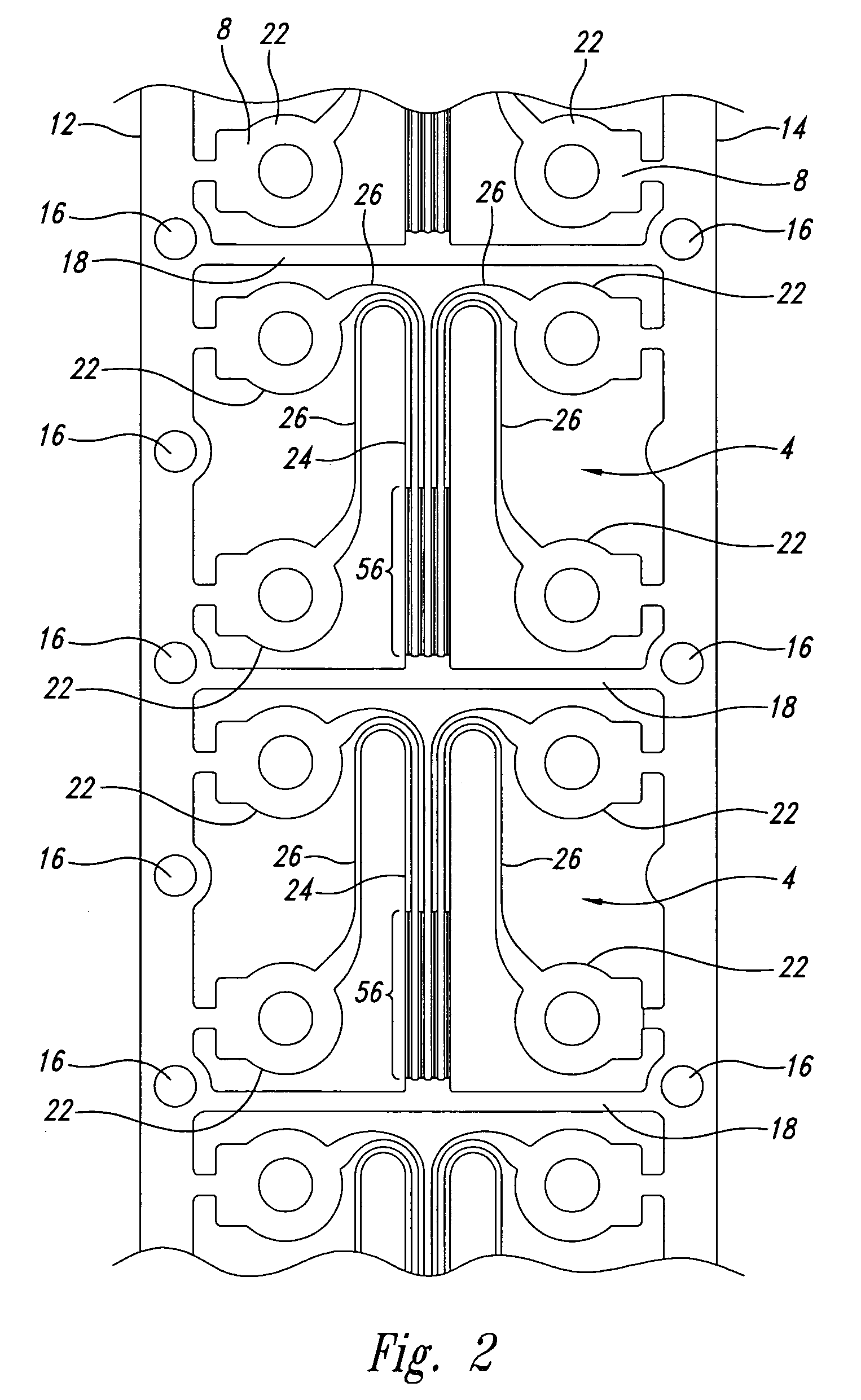

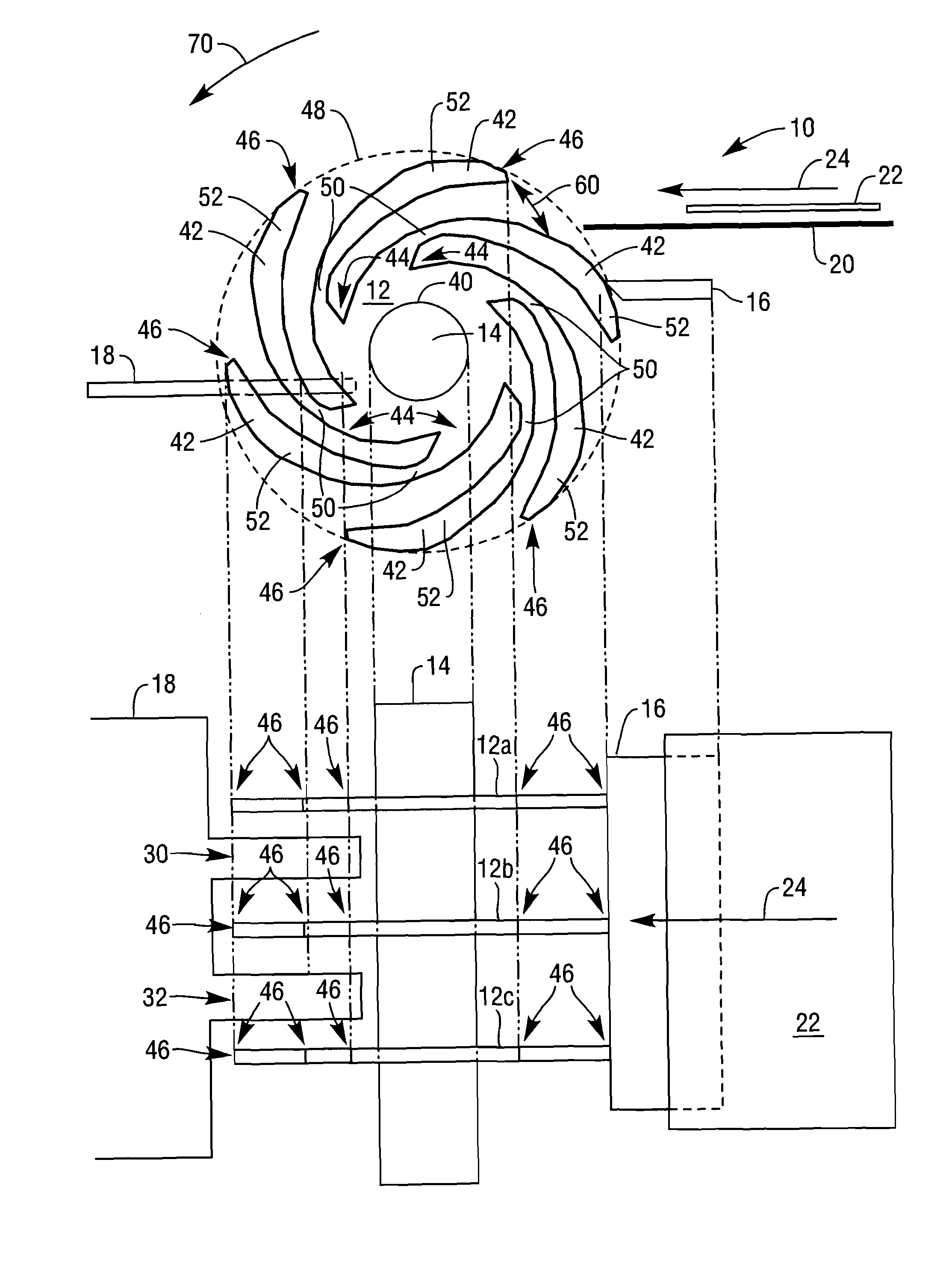

Micromachined tuning fork gyroscopes with ultra-high sensitivity and shock rejection

ActiveUS8322213B2Energy consumption is minimizedQuality improvementAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsTuning forkDynamic balance

A vibratory rate z-axis gyroscope is characterized by drive-mode and sense-mode quality factors and rate sensitivity and is fabricated with at least two decoupled vibratory tines, a levered drive-mode mechanism coupled between the tines to structurally force anti-phase drive-mode motion of the tines at a predetermined drive frequency, to eliminate spurious frequency modes of the anti-phase drive-mode motion of the tines lower than the predetermined drive frequency and to provide synchronization of drive- and sense-mode motion of the tines, and a sense-mode mechanism coupled between the tines arranged and configured to provide a linearly coupled, dynamically balanced anti-phase sense-mode motion of the tines to minimize substrate energy dissipation and to enhance the sense-mode quality factor and rate sensitivity.

Owner:RGT UNIV OF CALIFORNIA

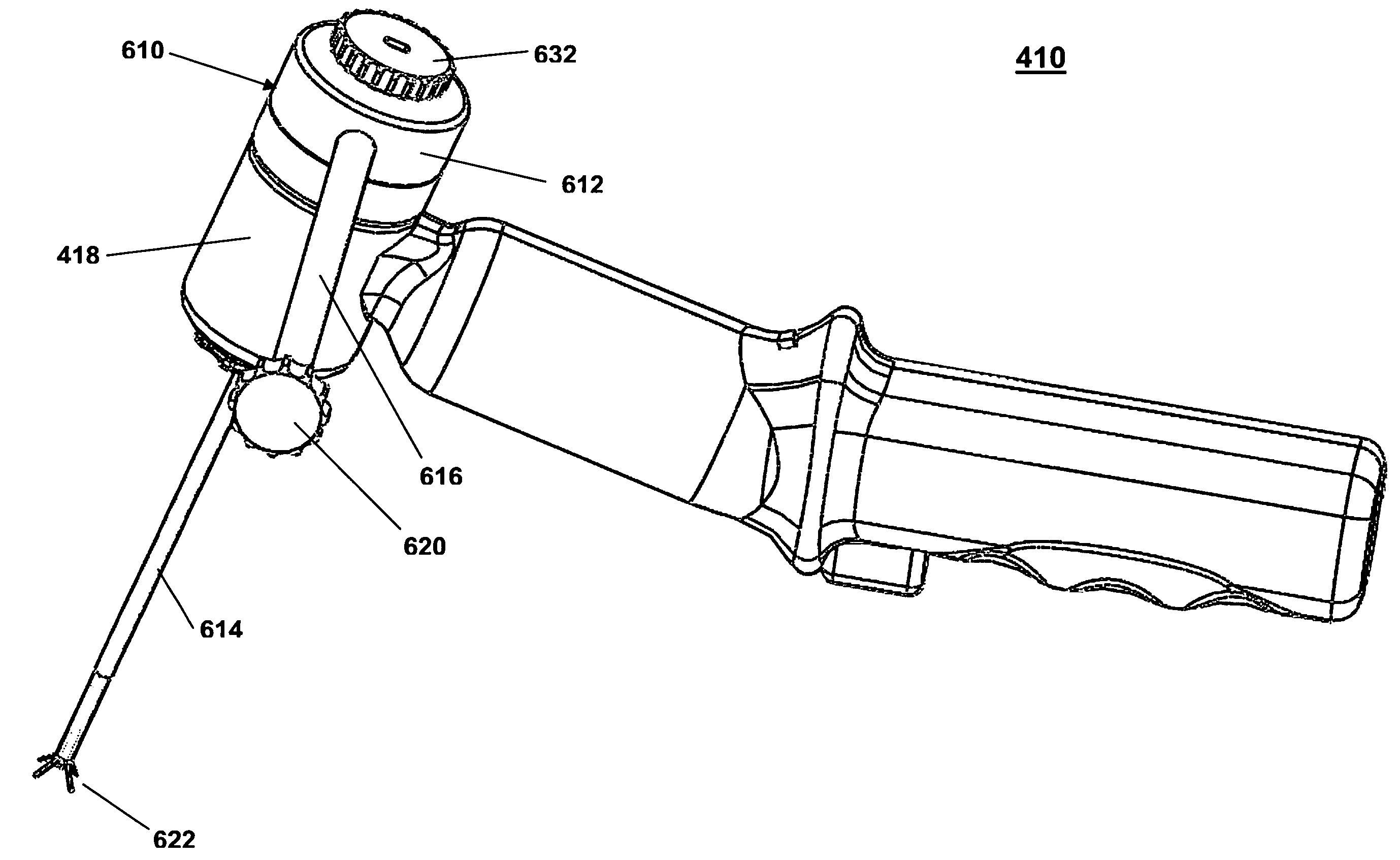

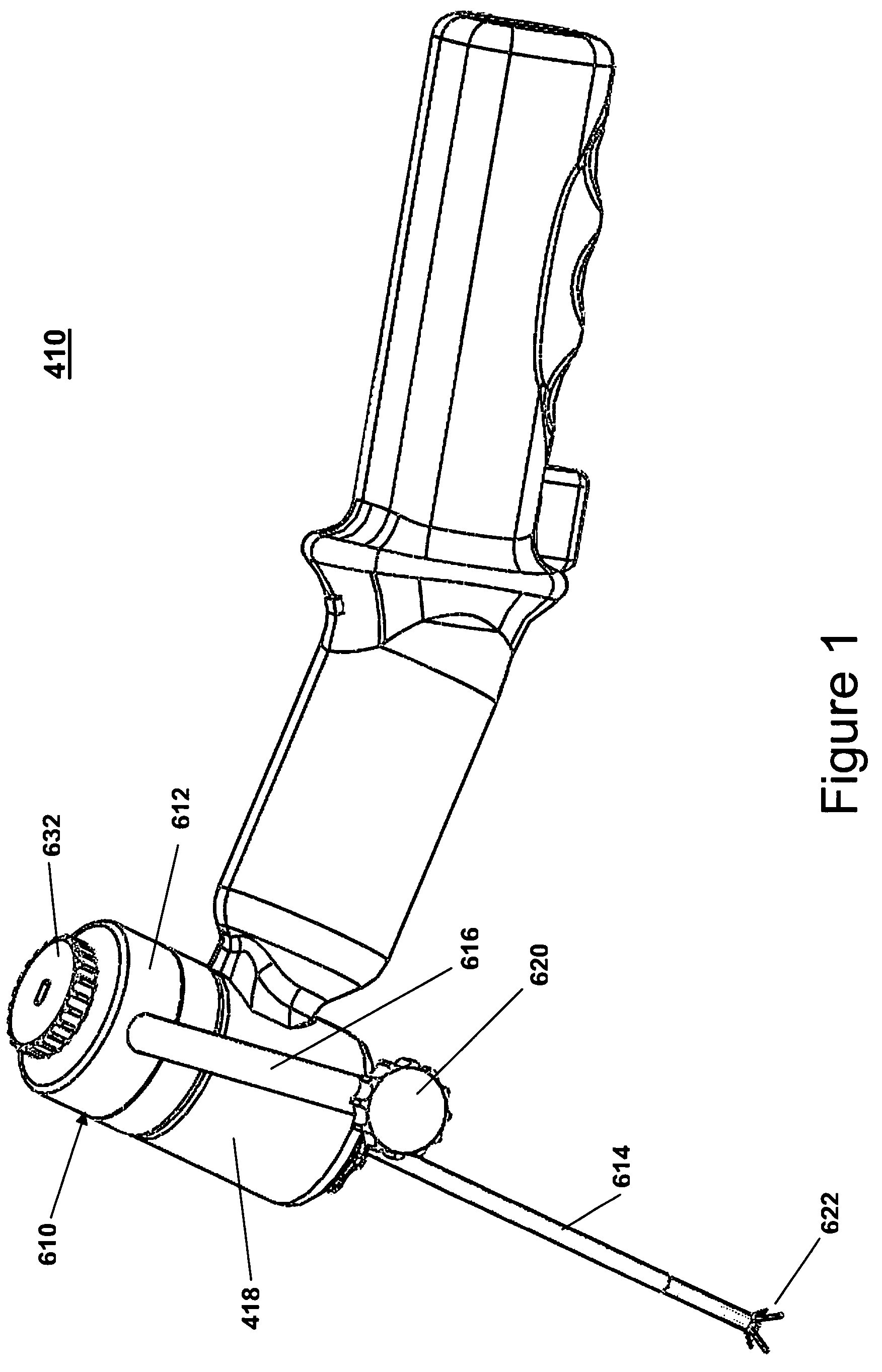

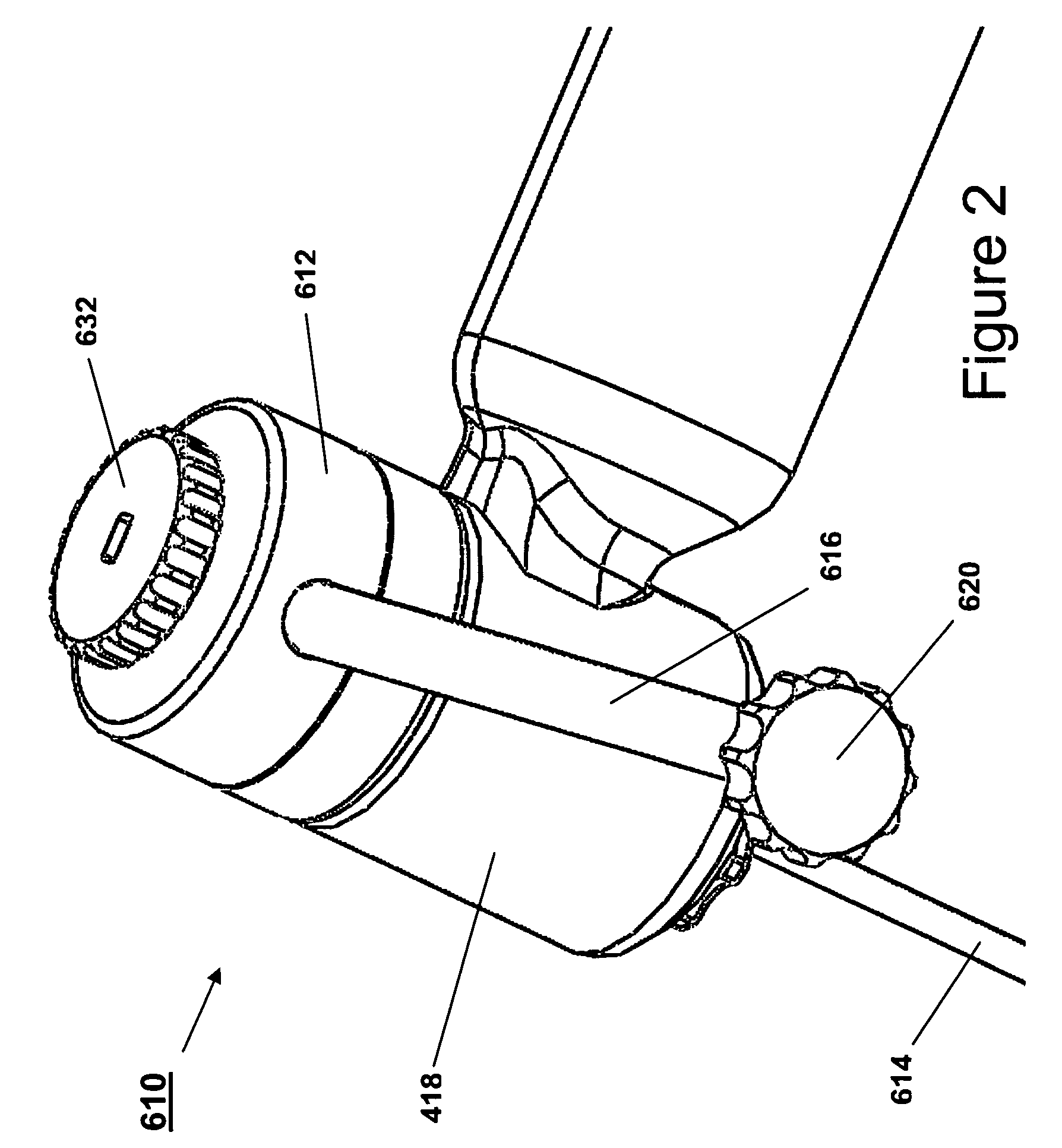

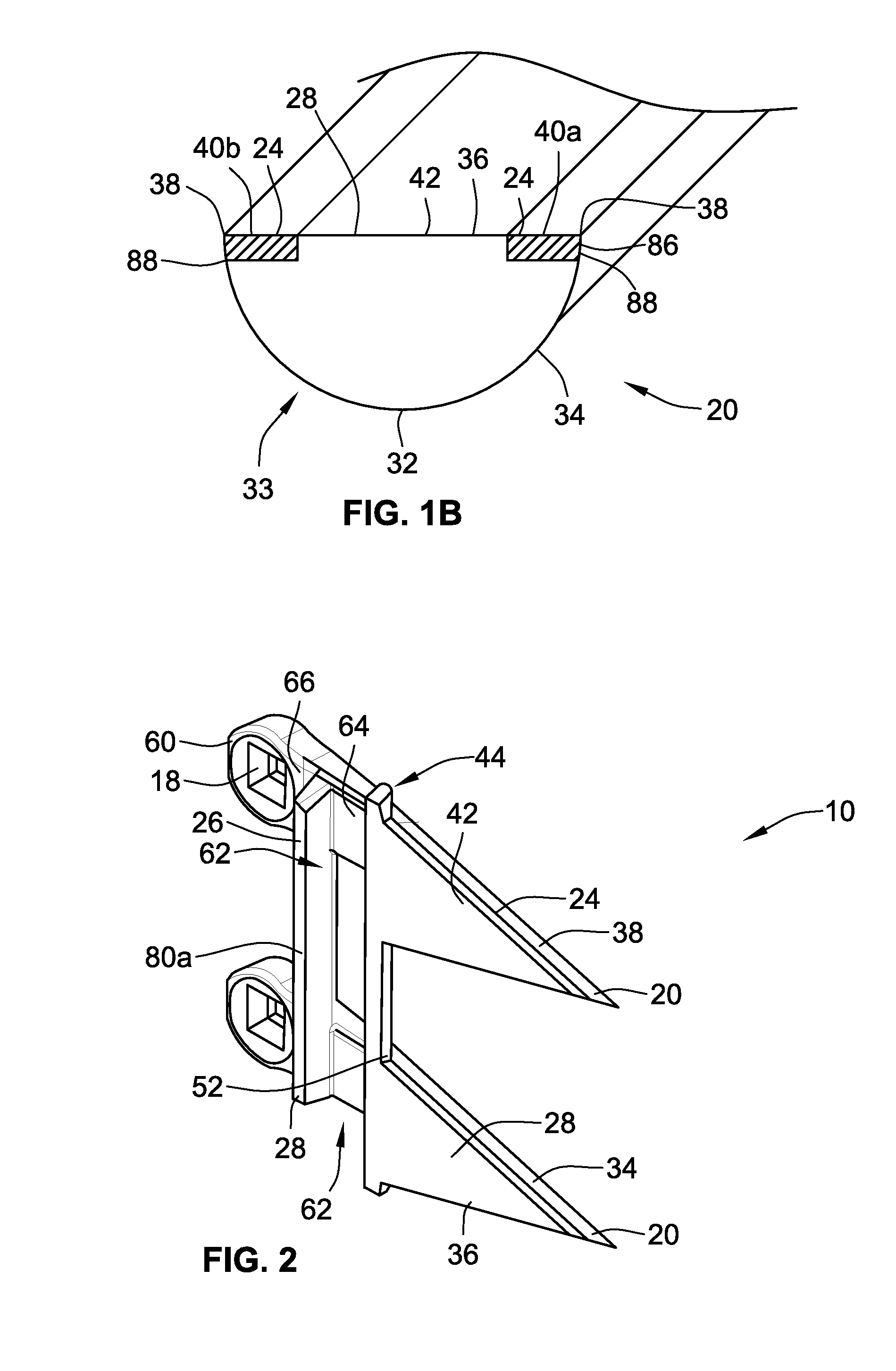

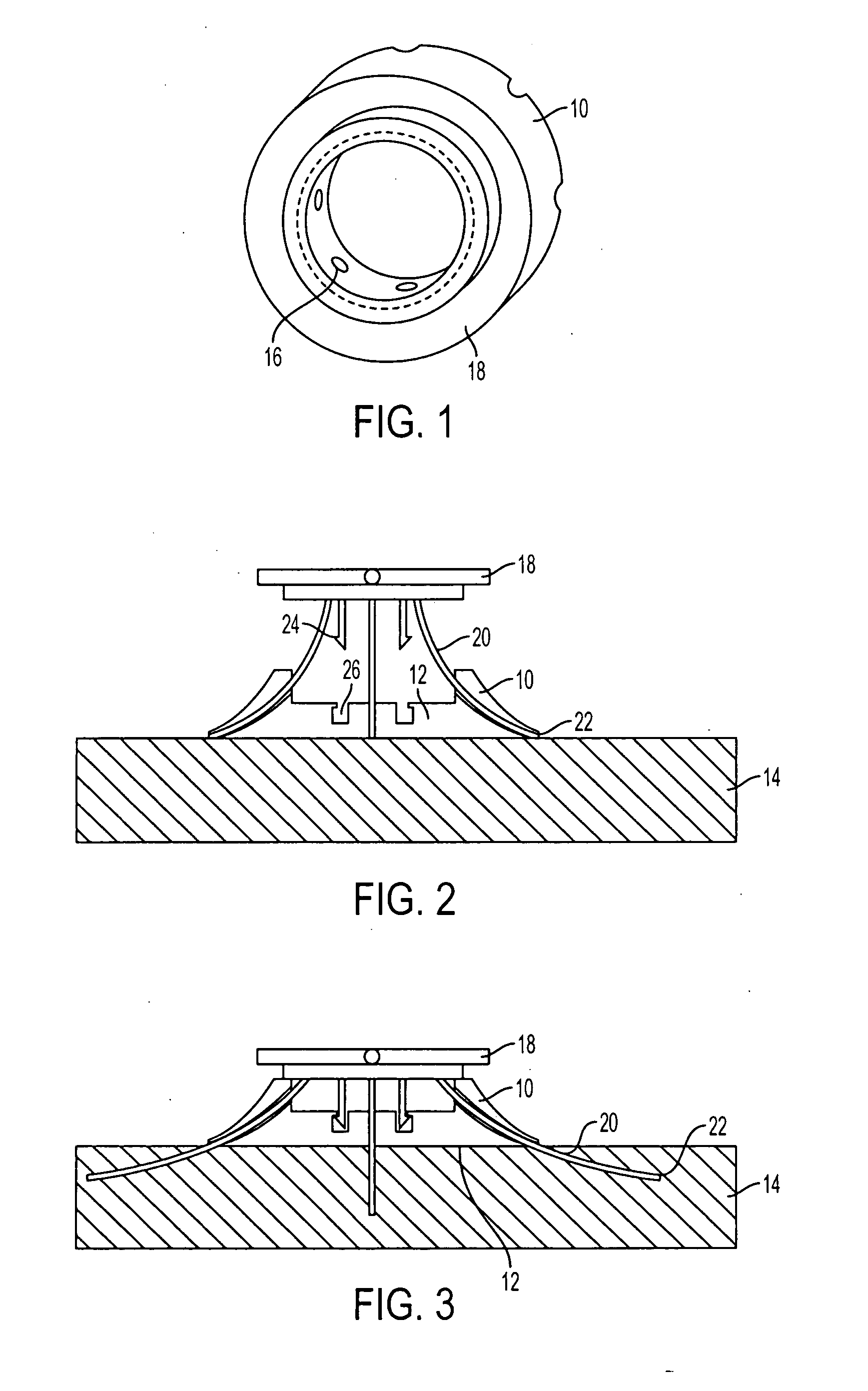

Cavity creation device and methods of use

InactiveUS20070282345A1Precise alignmentAccurate and rapid and safe placementSurgeryDiagnostic markersLow speedCurette

A cavity drill is provided, which is configured for use with a bone drill. The cavity drill includes a body. The bone drill has a first portion movably connected to a second portion. A third portion is movably connected to the second portion. The body is mounted with the third portion of the bone drill. A sheath extends from the third portion to a distal end. A curette is connected with the distal end of the bone drill. The curette is composed of retractable cutting tines / blades which are turned / powered by the bone drill motor. The curette tines can be used in a partially or fully deployed state and at low or high speed. The curette is designed to create cavities of varying size in a bone. The cavity drill and the bone drill may include a radiation protection guard and radiolucent portions. Methods of use are also provided.

Owner:OSTEO INNOVATIONS

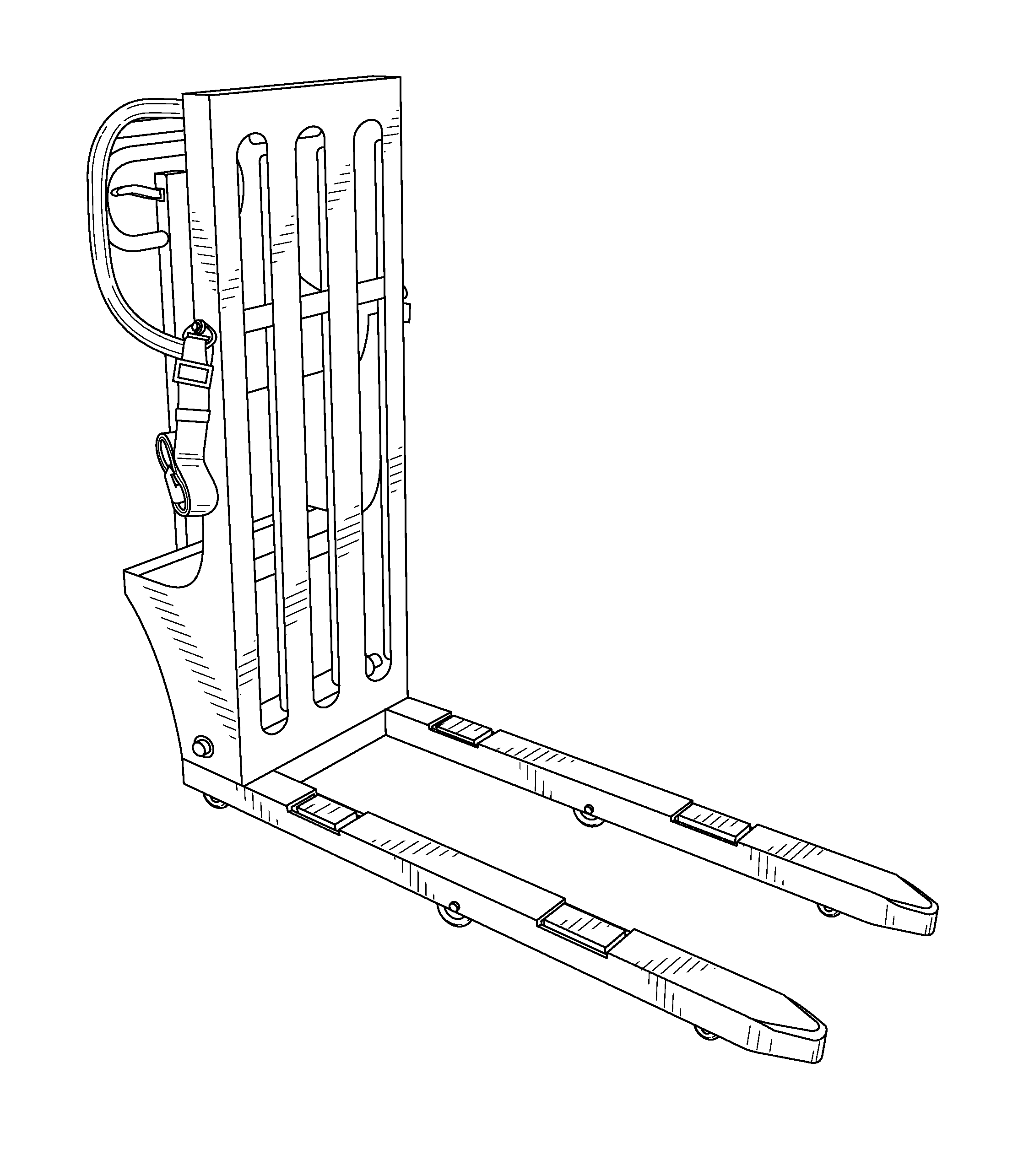

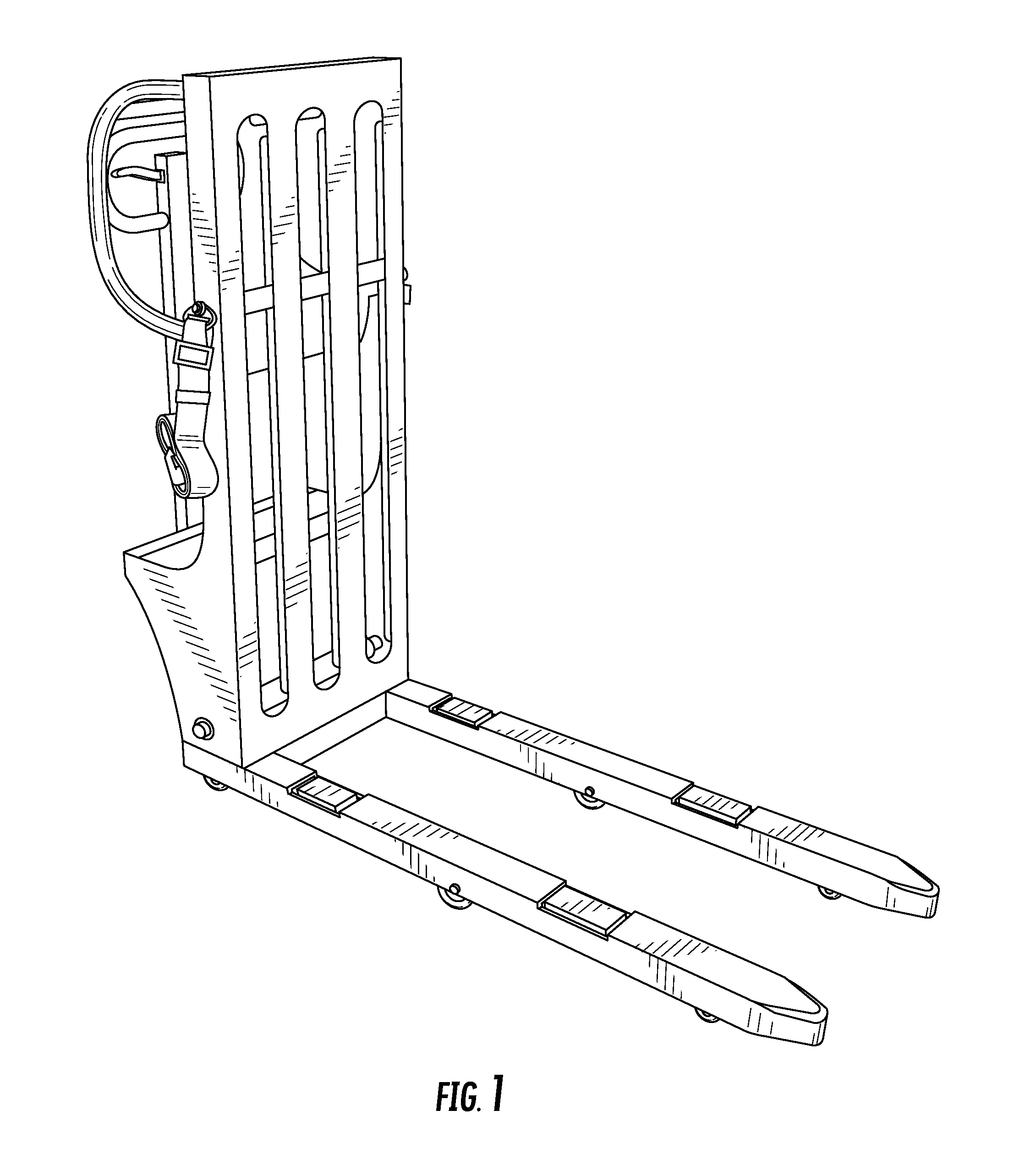

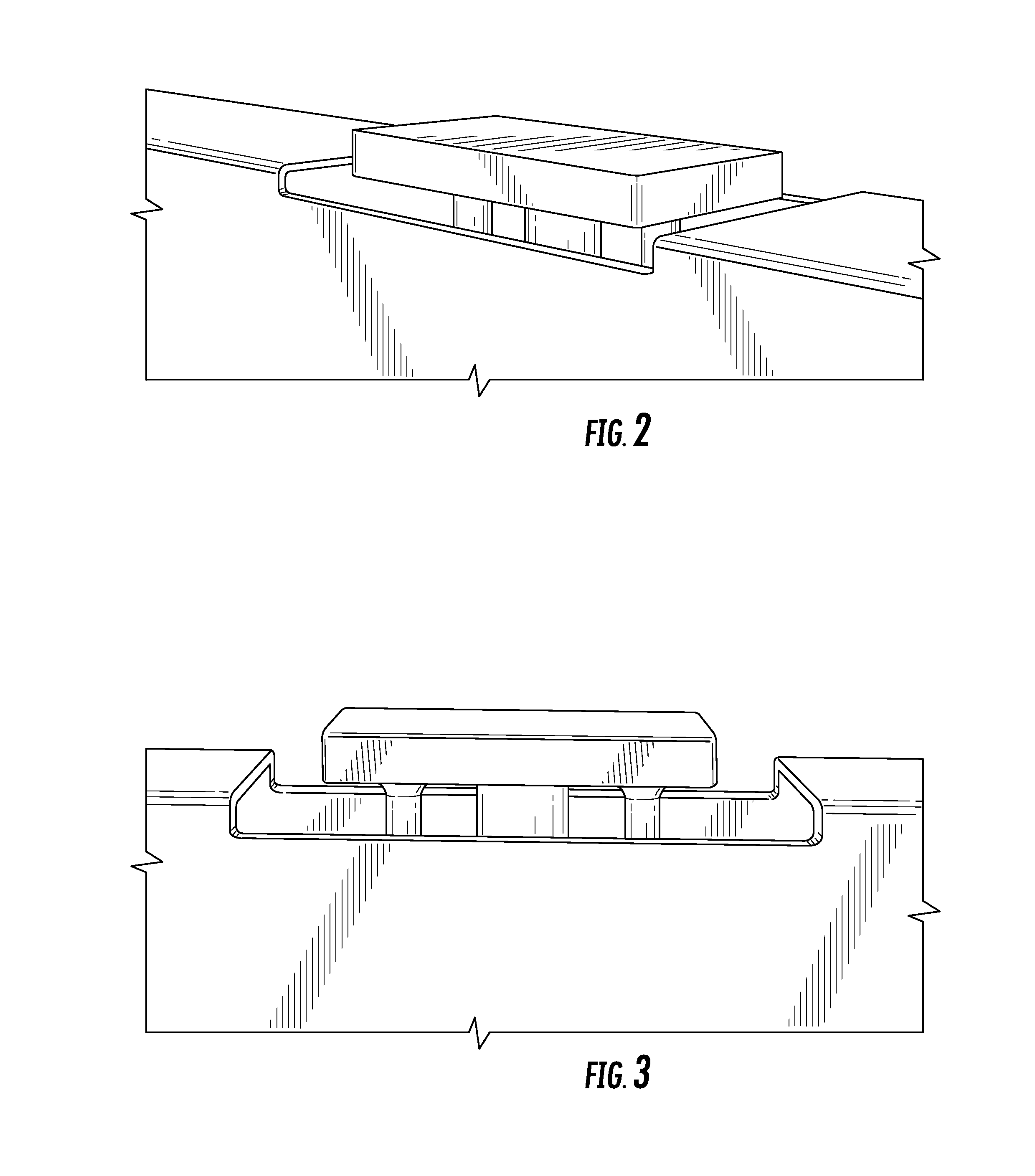

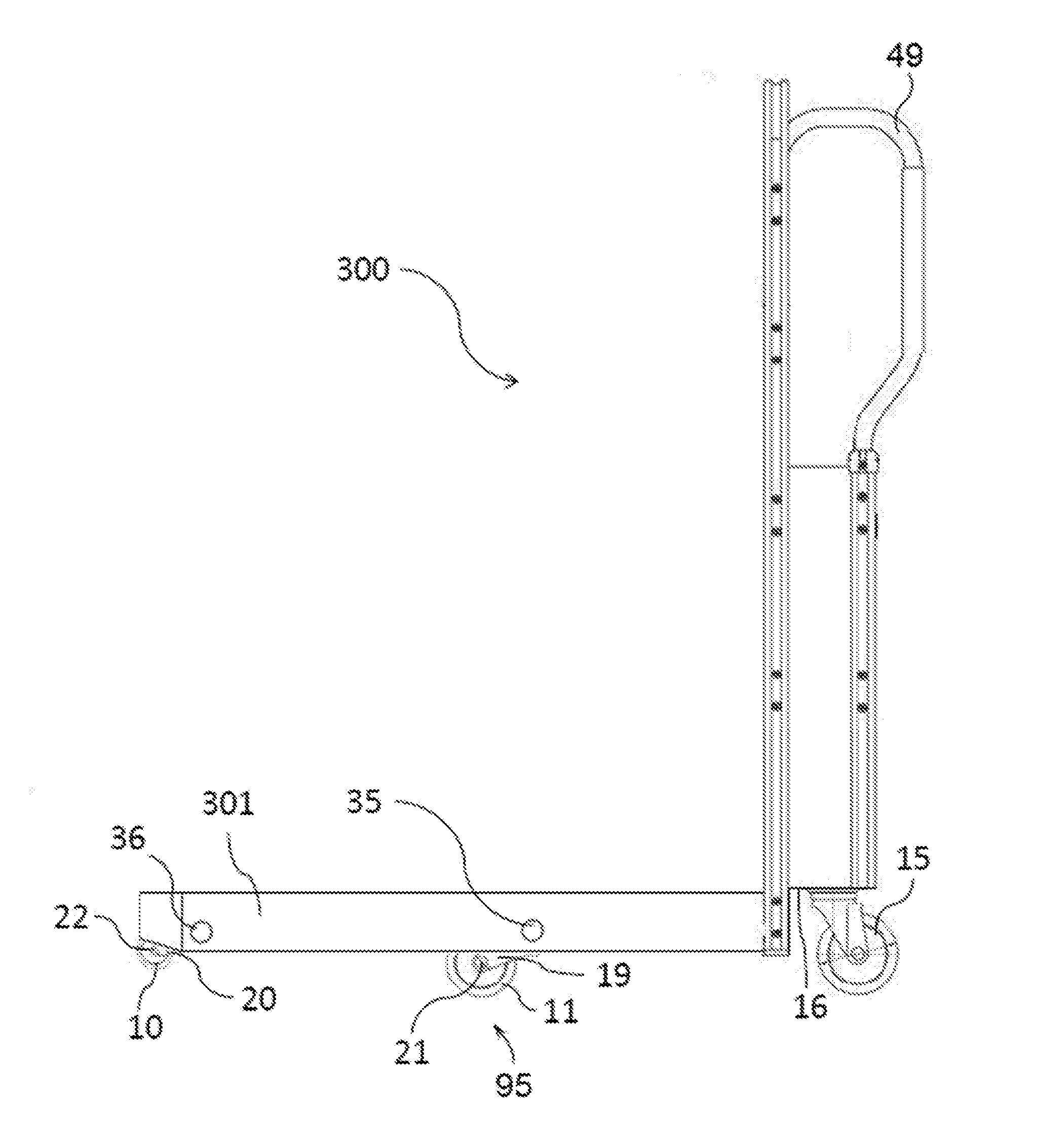

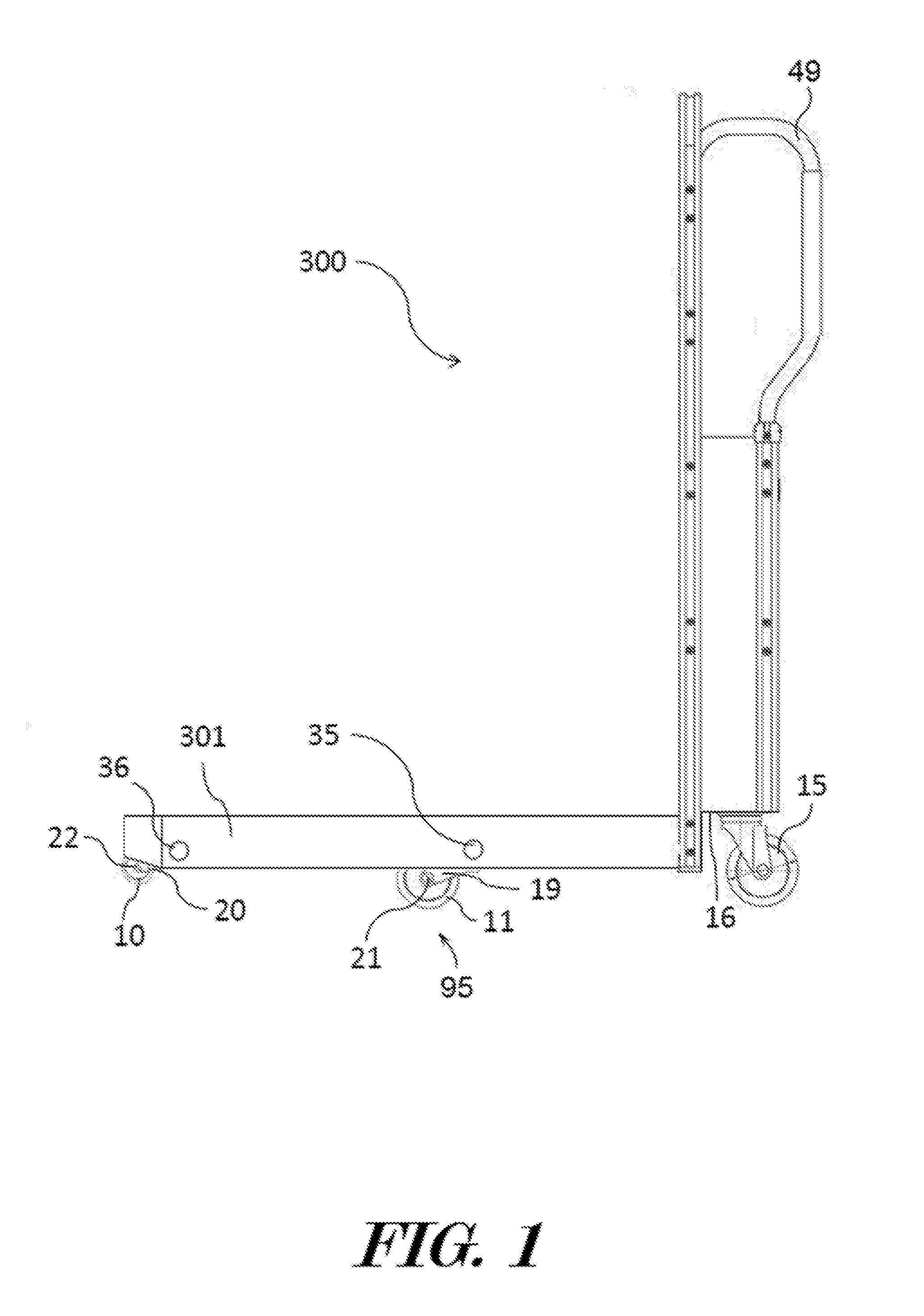

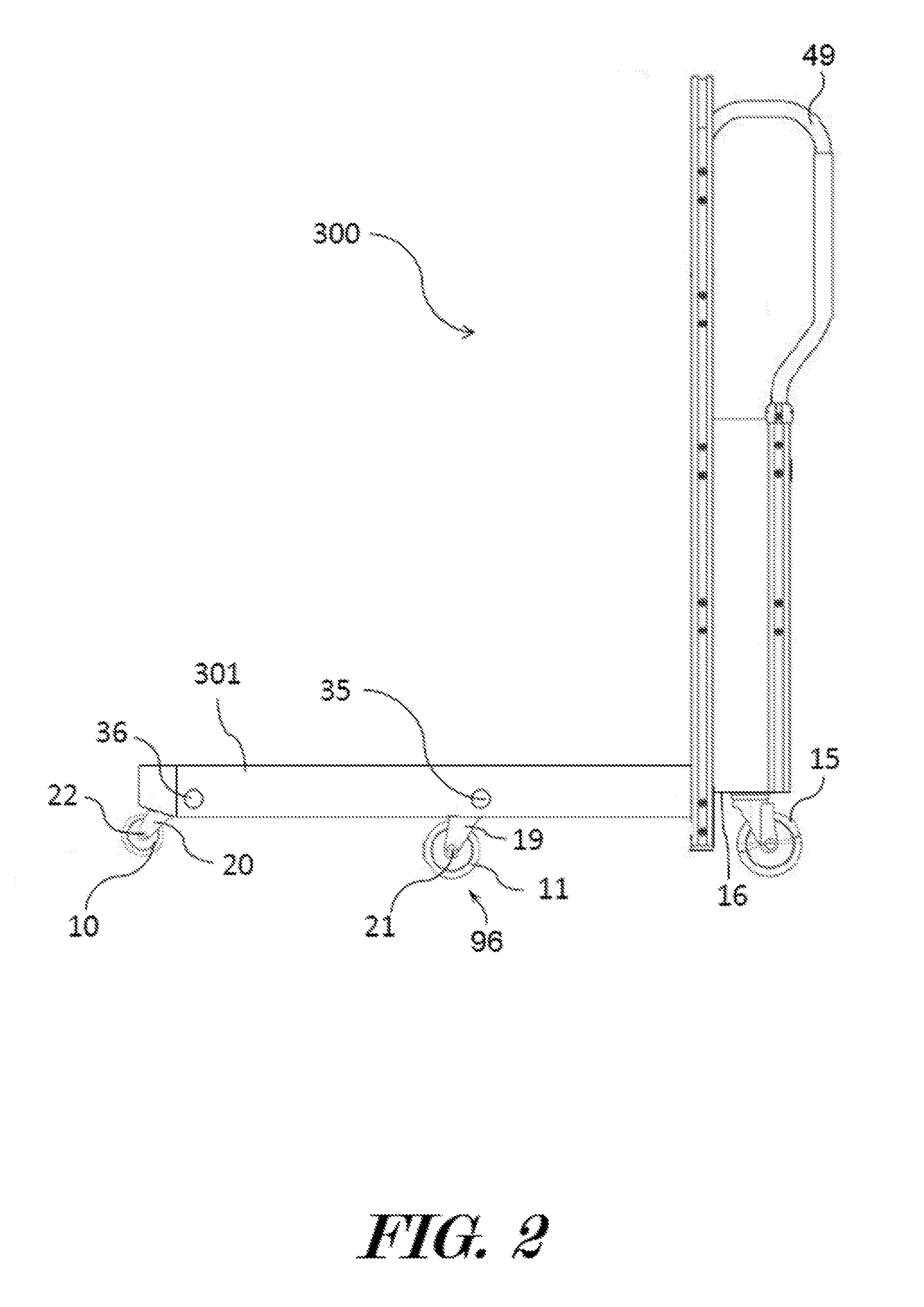

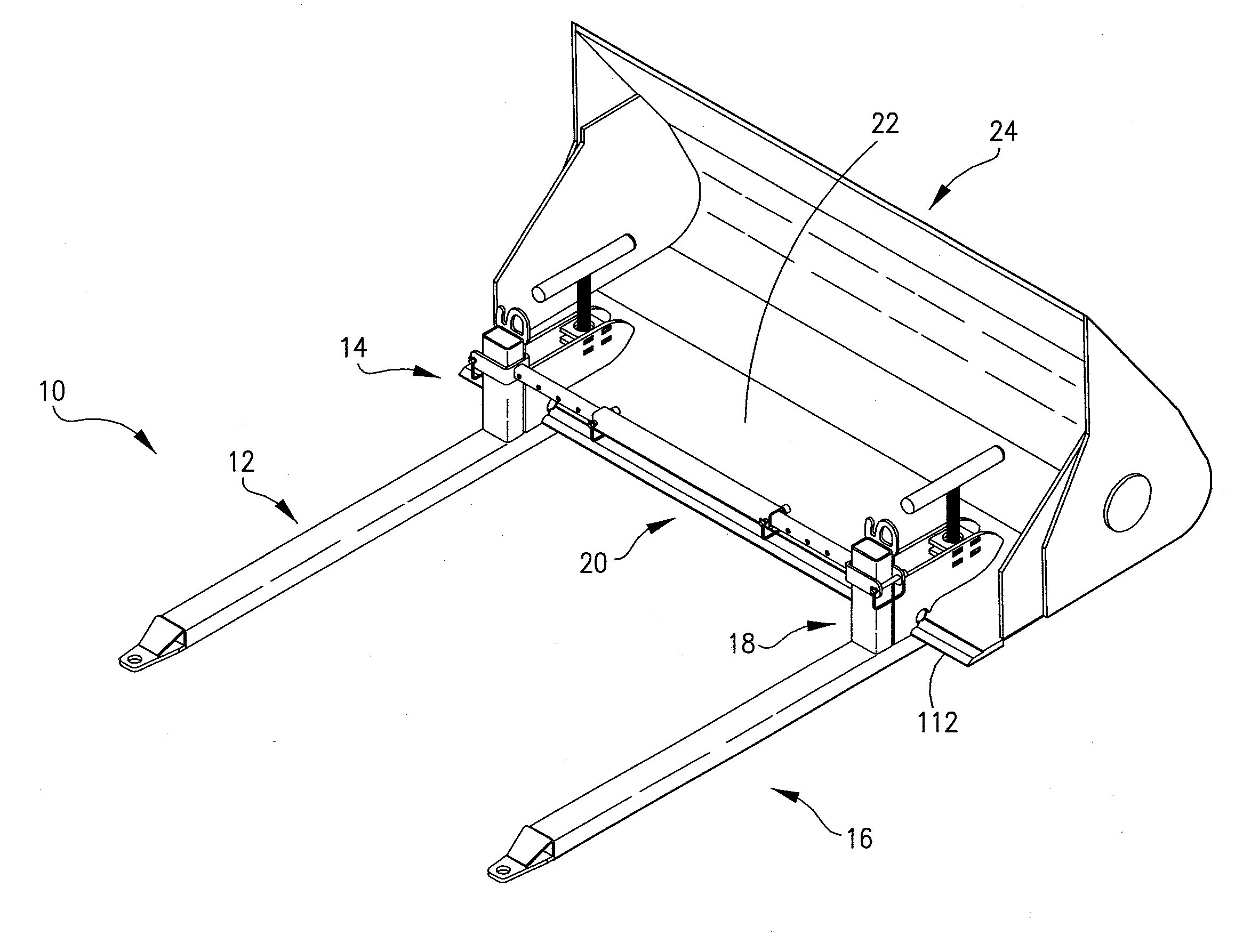

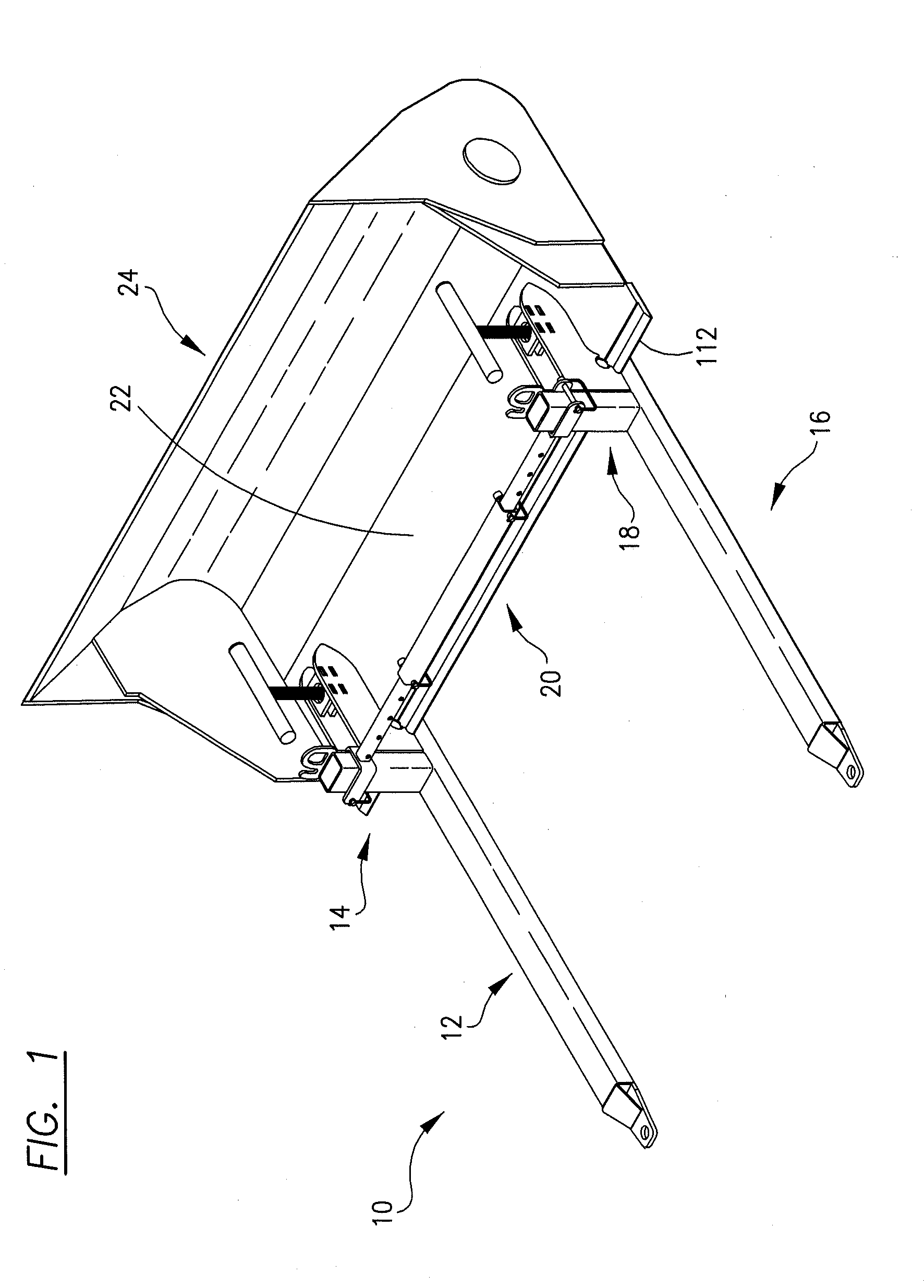

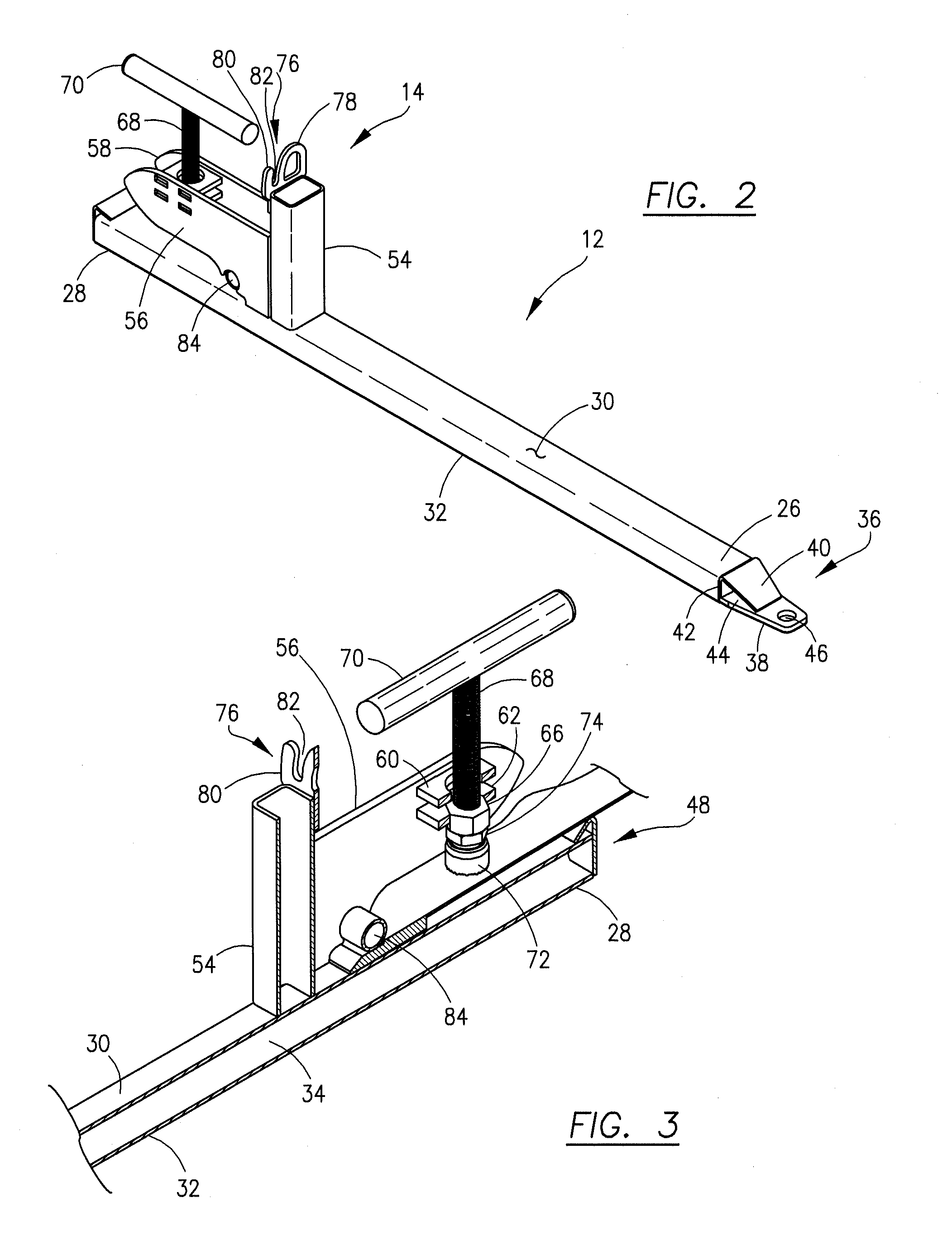

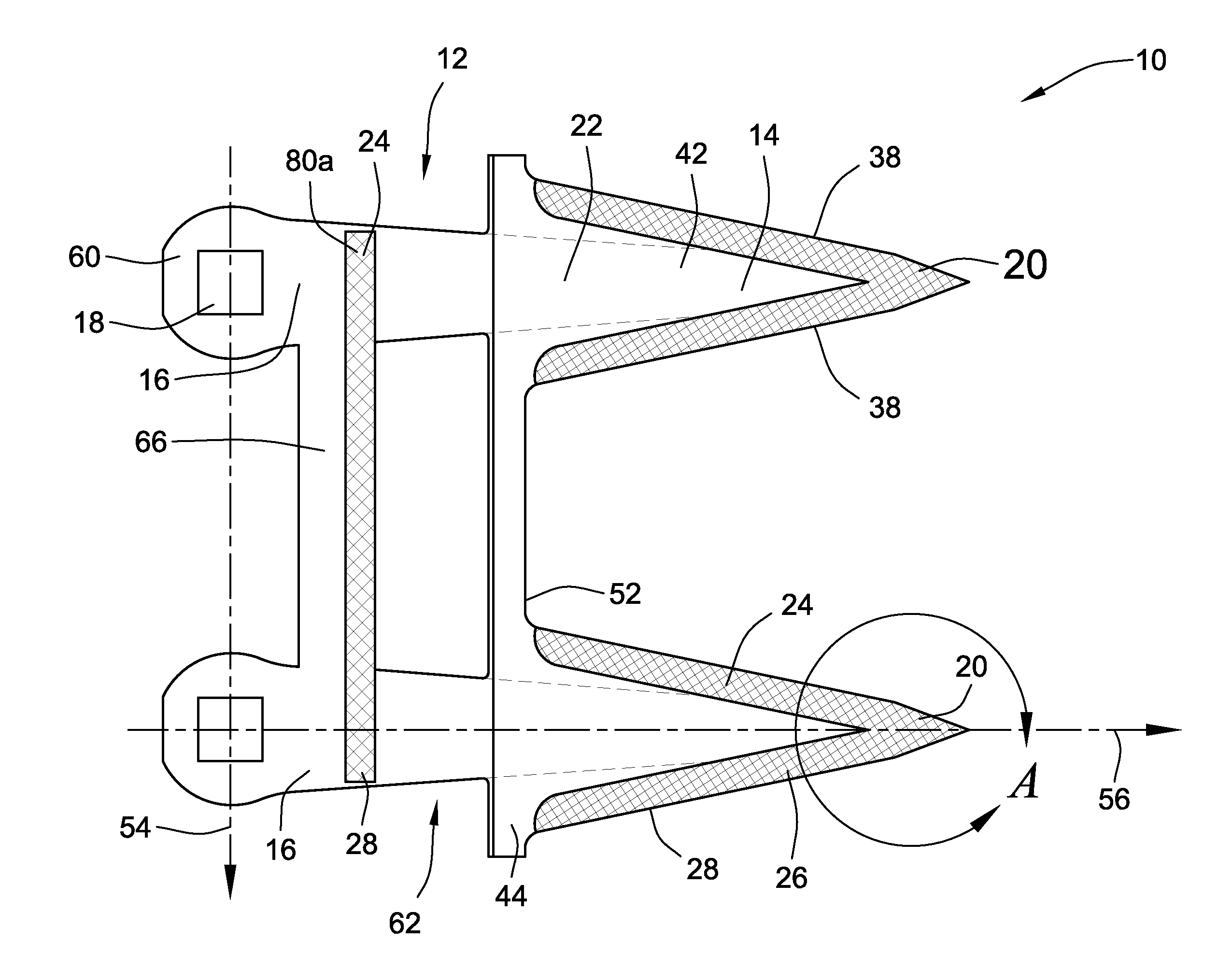

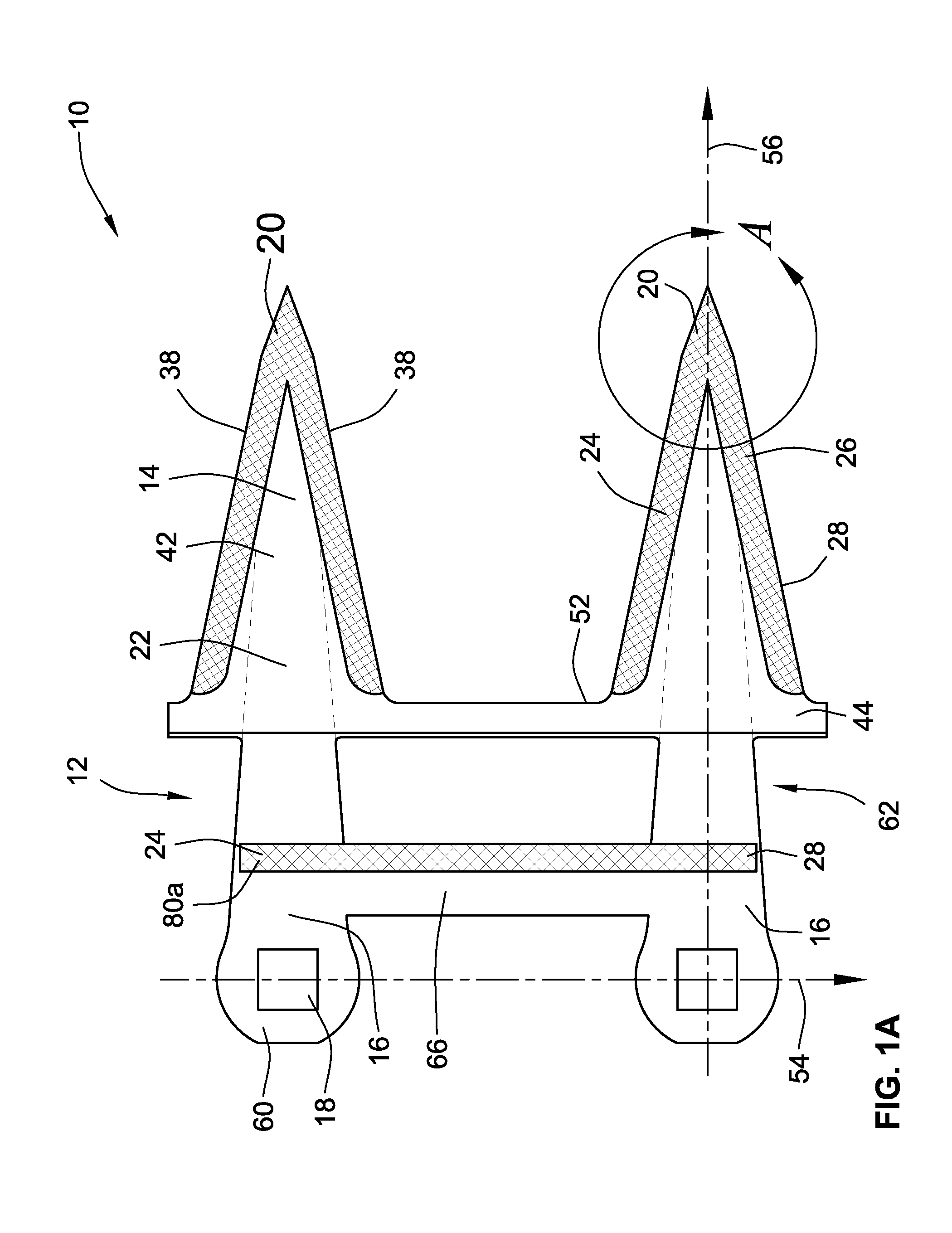

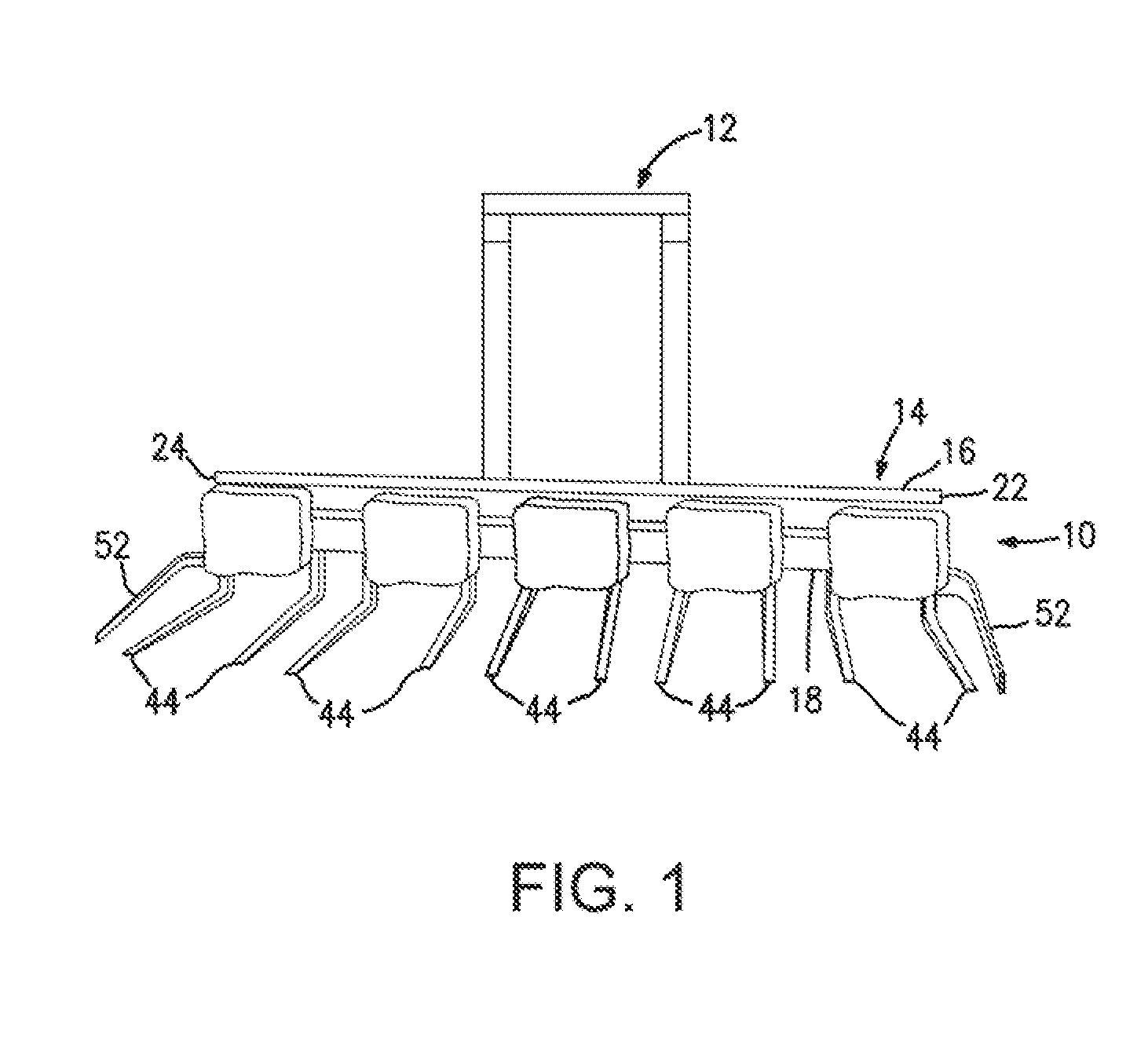

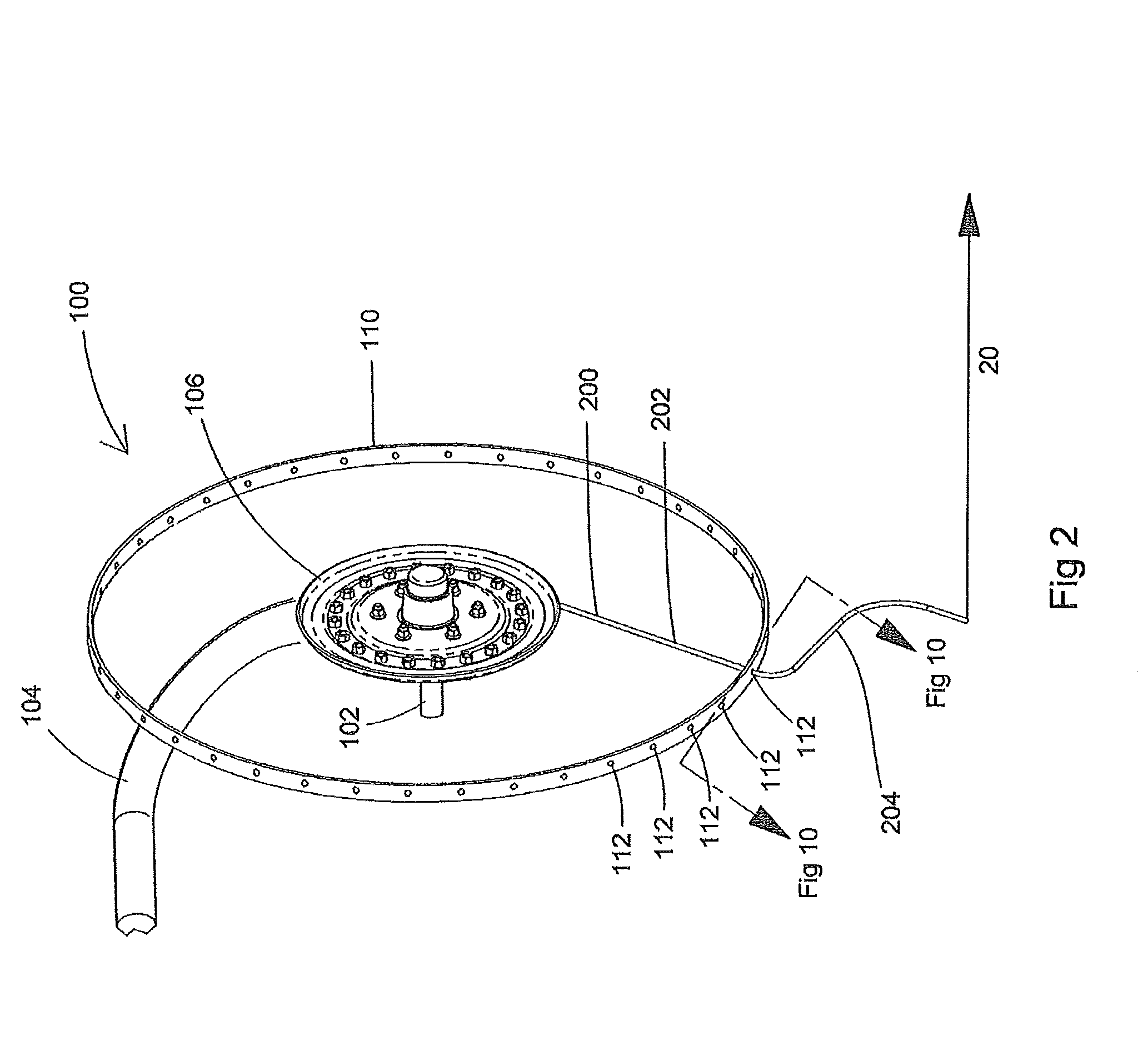

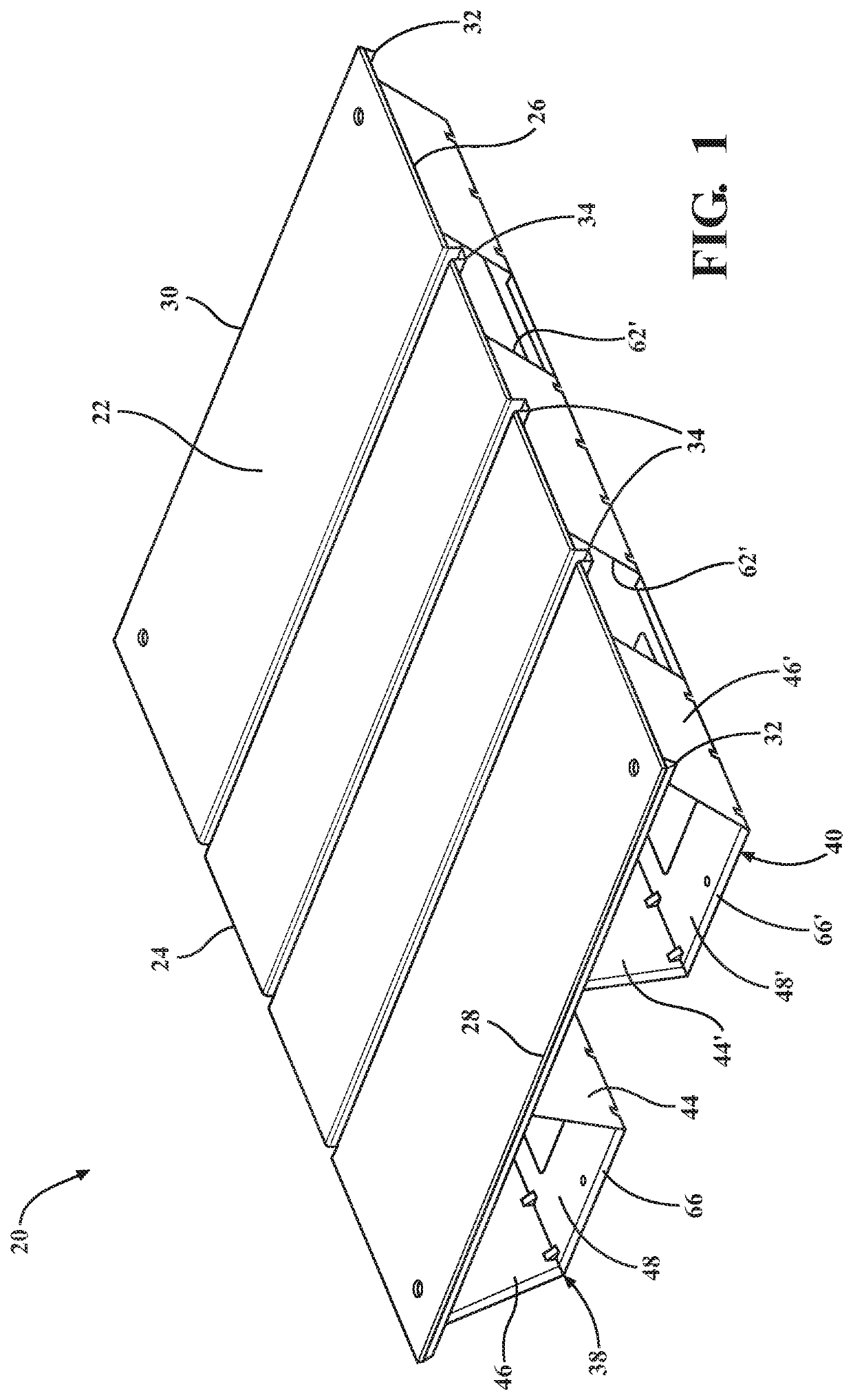

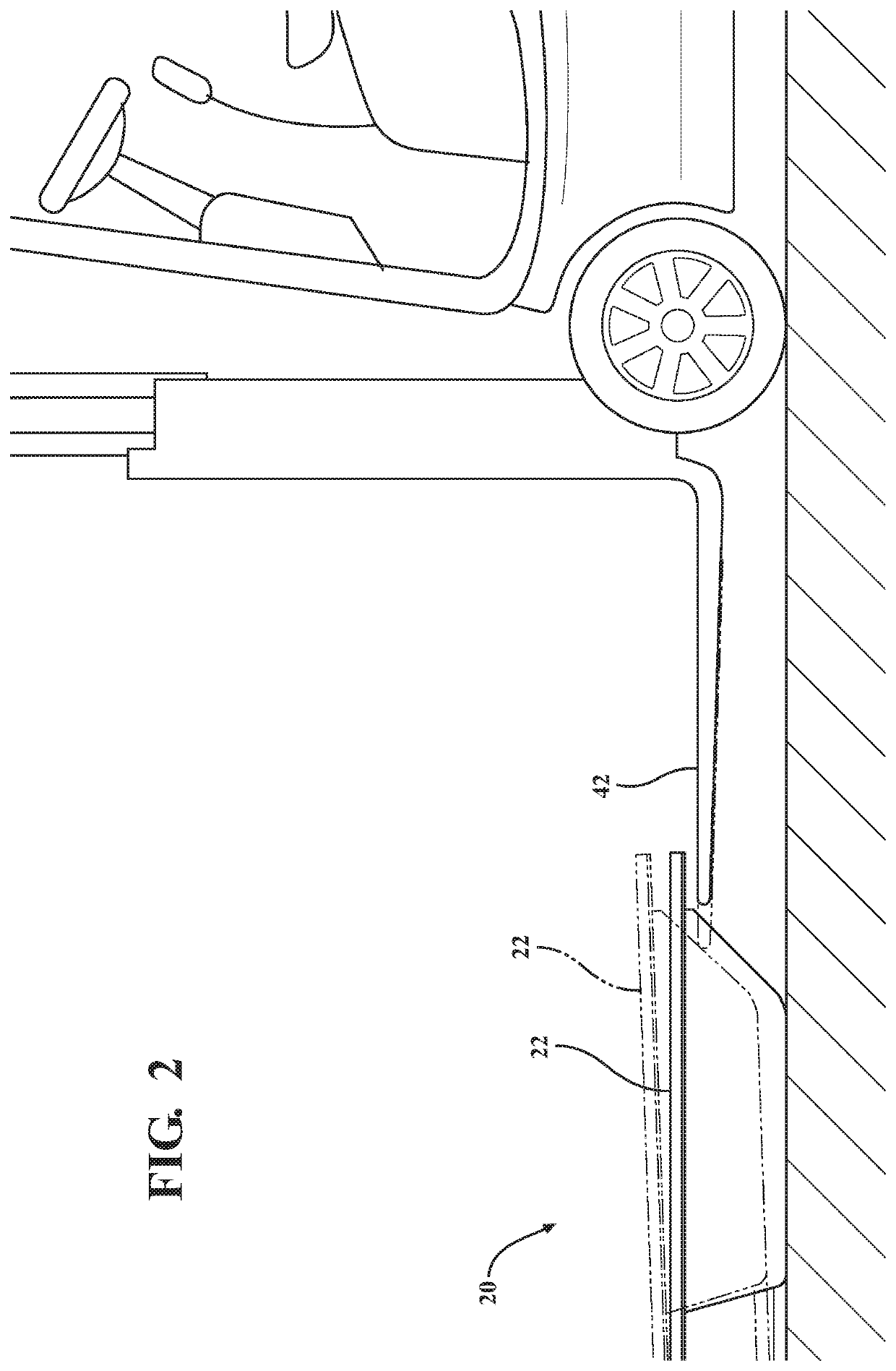

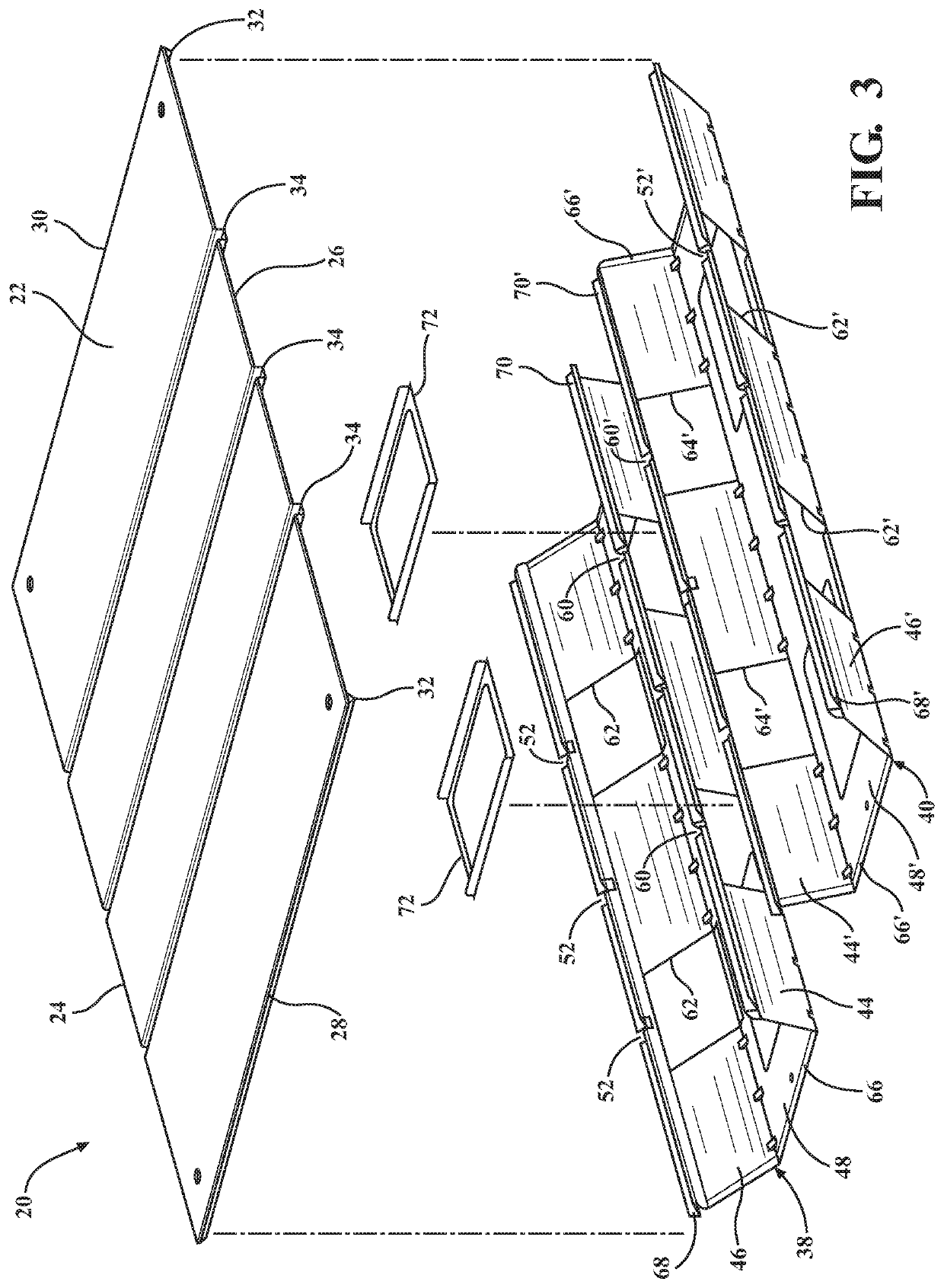

Pallet transportation assembly and processes of transporting pallets using the same

The present invention relates to a pallet transportation assembly comprising a first and second tine, each having a top, a bottom, a front wheel, a middle wheel, a rear wheel, and a riser; and a body coupled to the first and second tines comprising a tine adjustment system and a vertical backing portion.

Owner:COCA-COLA BOTTLING CO UNITED INC

Investment casting

Owner:RTX CORP

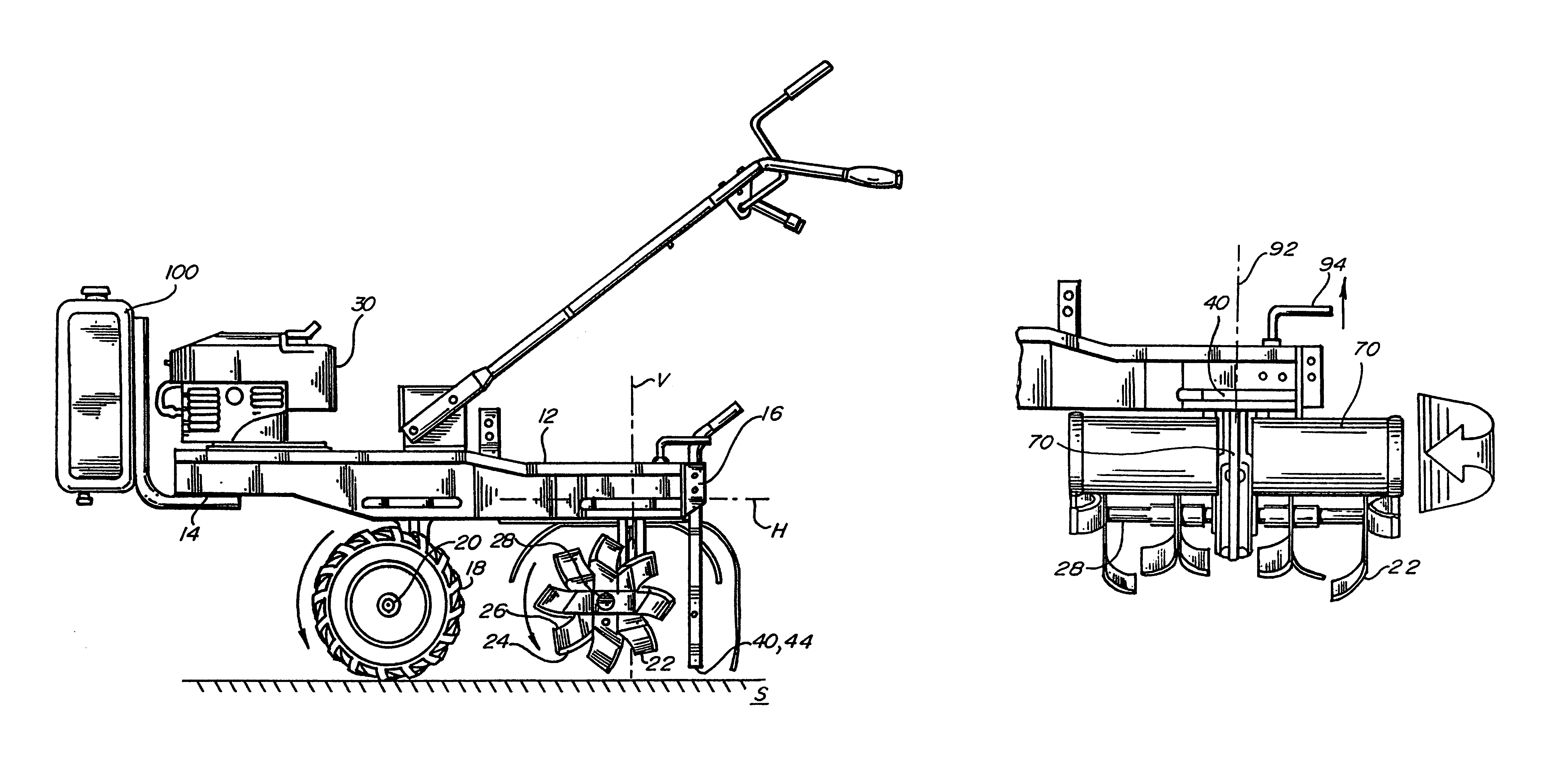

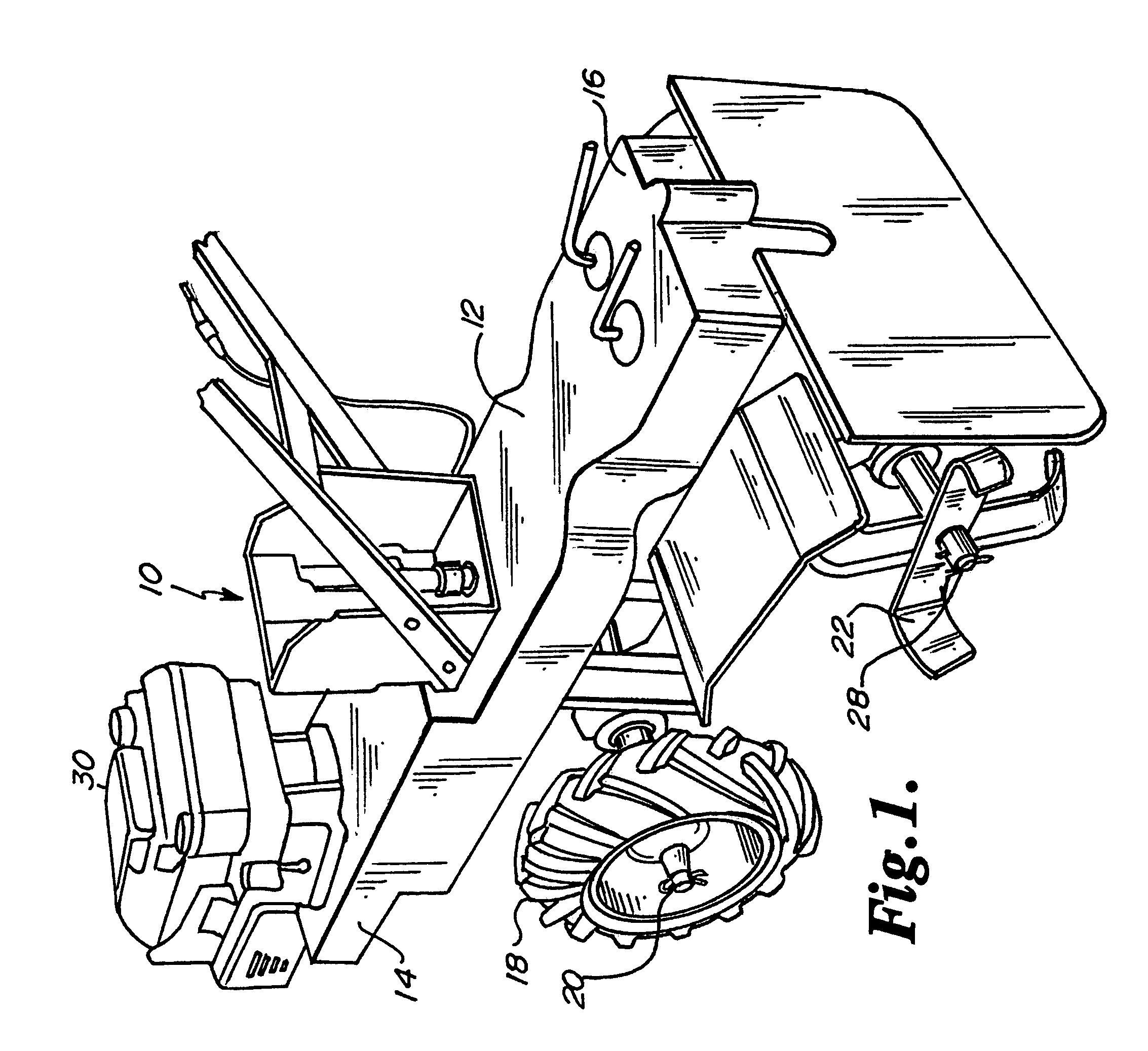

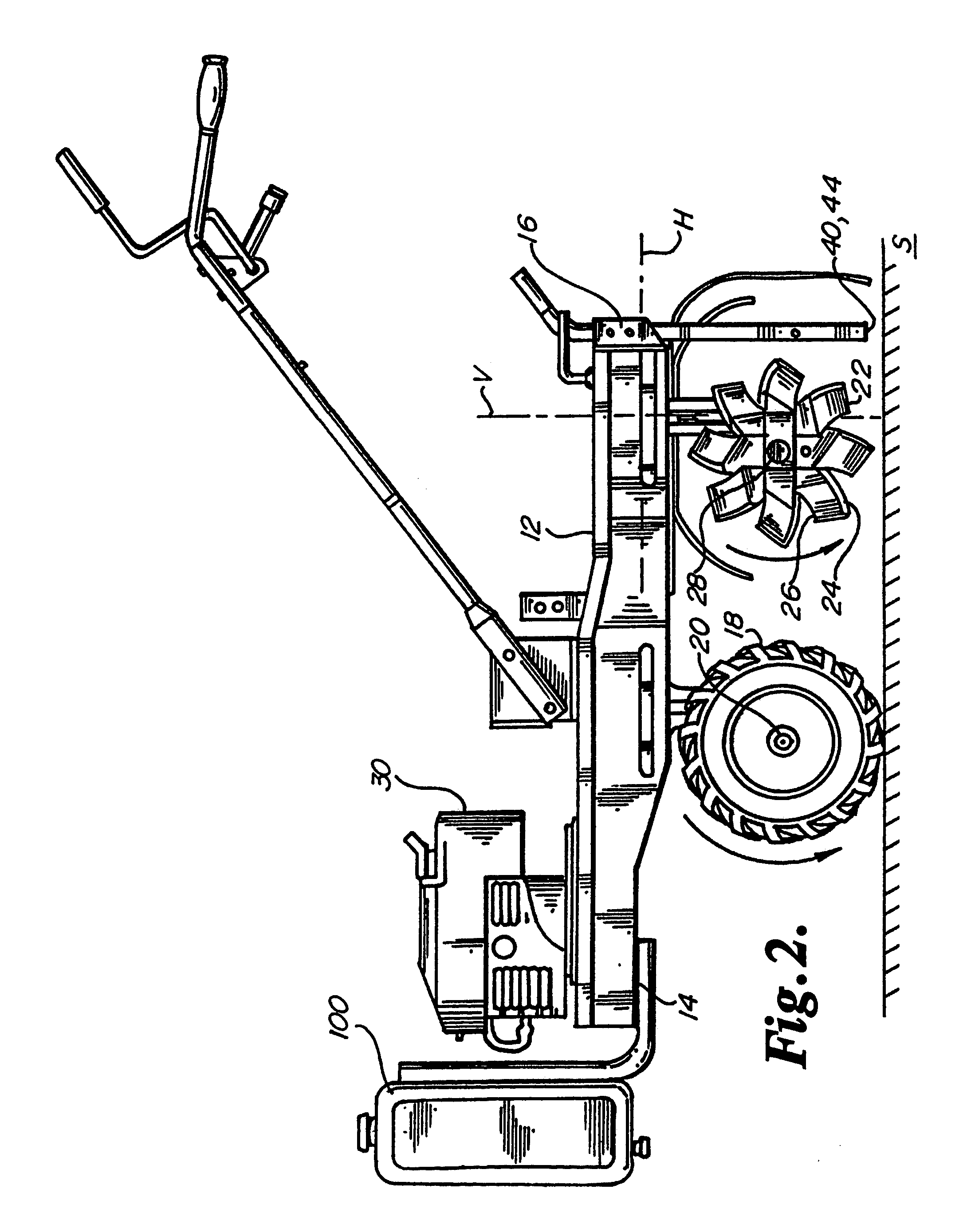

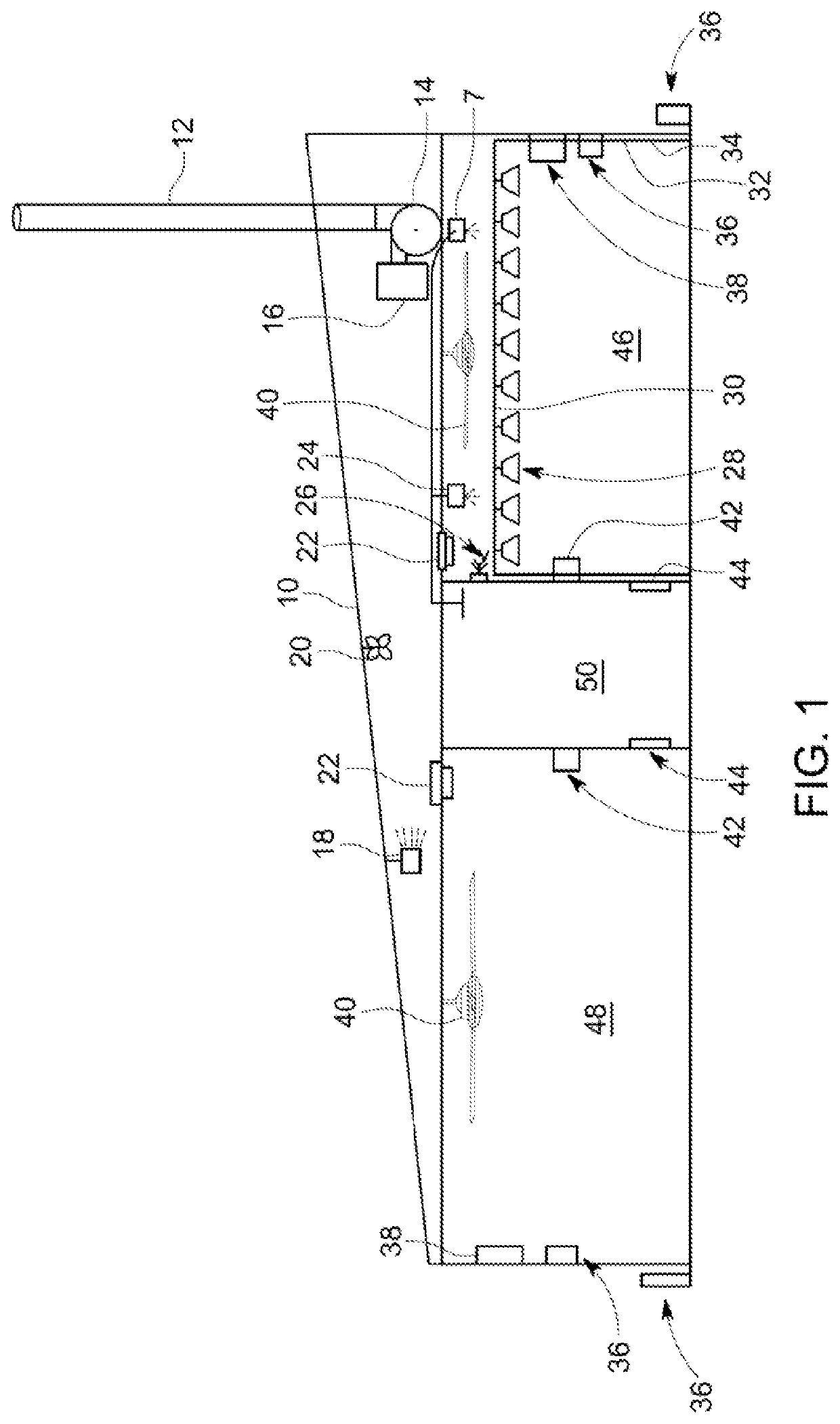

Convertible rear-tine tiller

A rear-tine roto-tiller with a chassis having a forward end and a rearward end; a set of rotating tines at the rearward end; a set of ground-engaging wheels between the forward end and the tines; and a tine transmission mounted on a substantially vertical shaft at the rearward end with a substantially horizontal shaft holding the tines. The tine transmission is rotatable about the vertical shaft between a first position in which the tines rotate in the same direction as the wheels and a second position in which the tines rotate in a direction opposite the direction of rotation of the wheels, thus allowing easy conversion between SRT mode and CRT mode.

Owner:ARDISAM

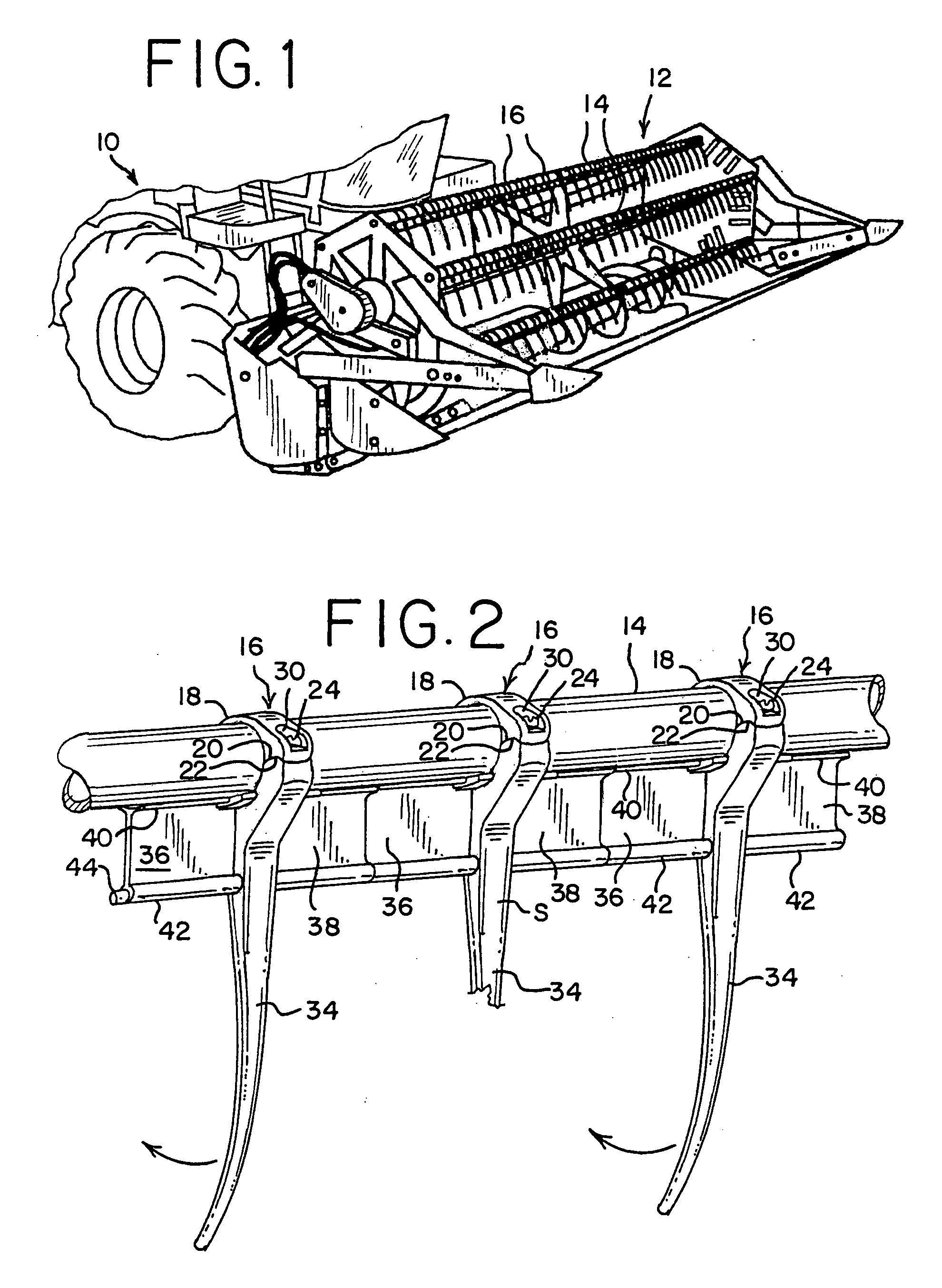

Harvester reel tine repair

ActiveUS20050091955A1Impair efficient operationWasteful of effortHaymakersHarvestersEngineeringMechanical engineering

Repair of a broken finger of a harvester reel pickup tine is accomplished by positioning a repair finger having a cavity over the broken finger stub so that the broken finger stub of the harvester reel pickup tine is received in the cavity of the repair finger, and the repair finger is then fastened adjacent one end to the pickup tine when the broken finger stub is in the cavity.

Owner:PLASTIC DESIGNS

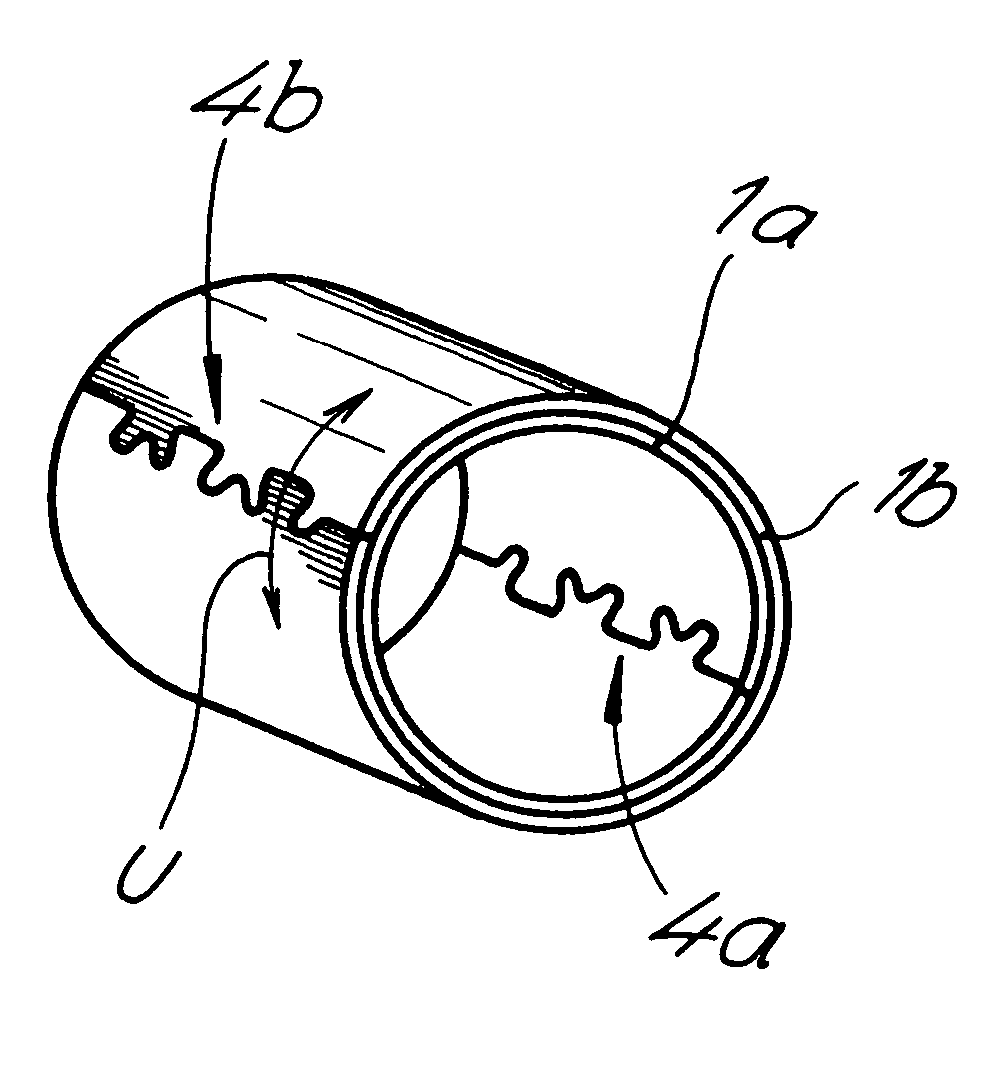

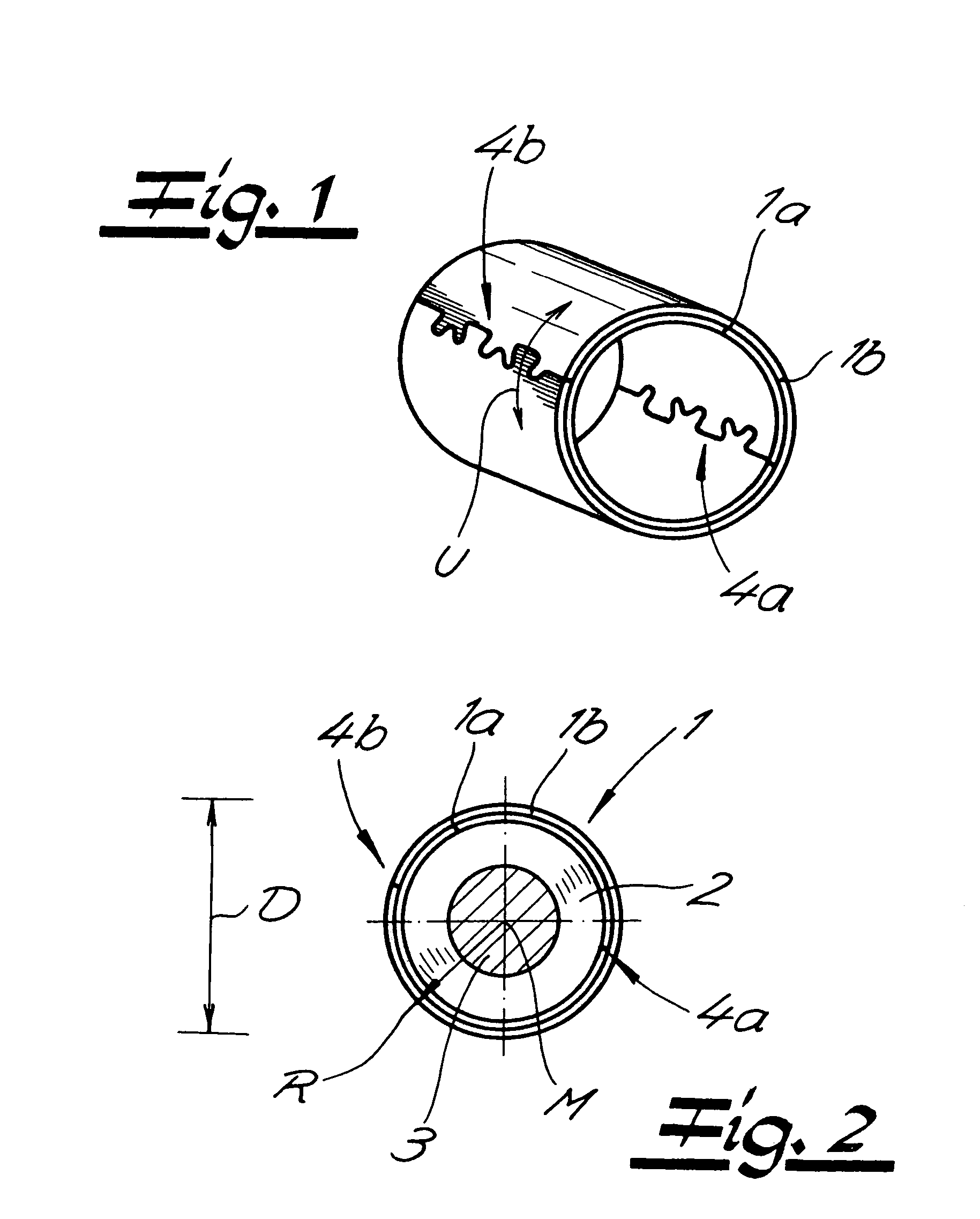

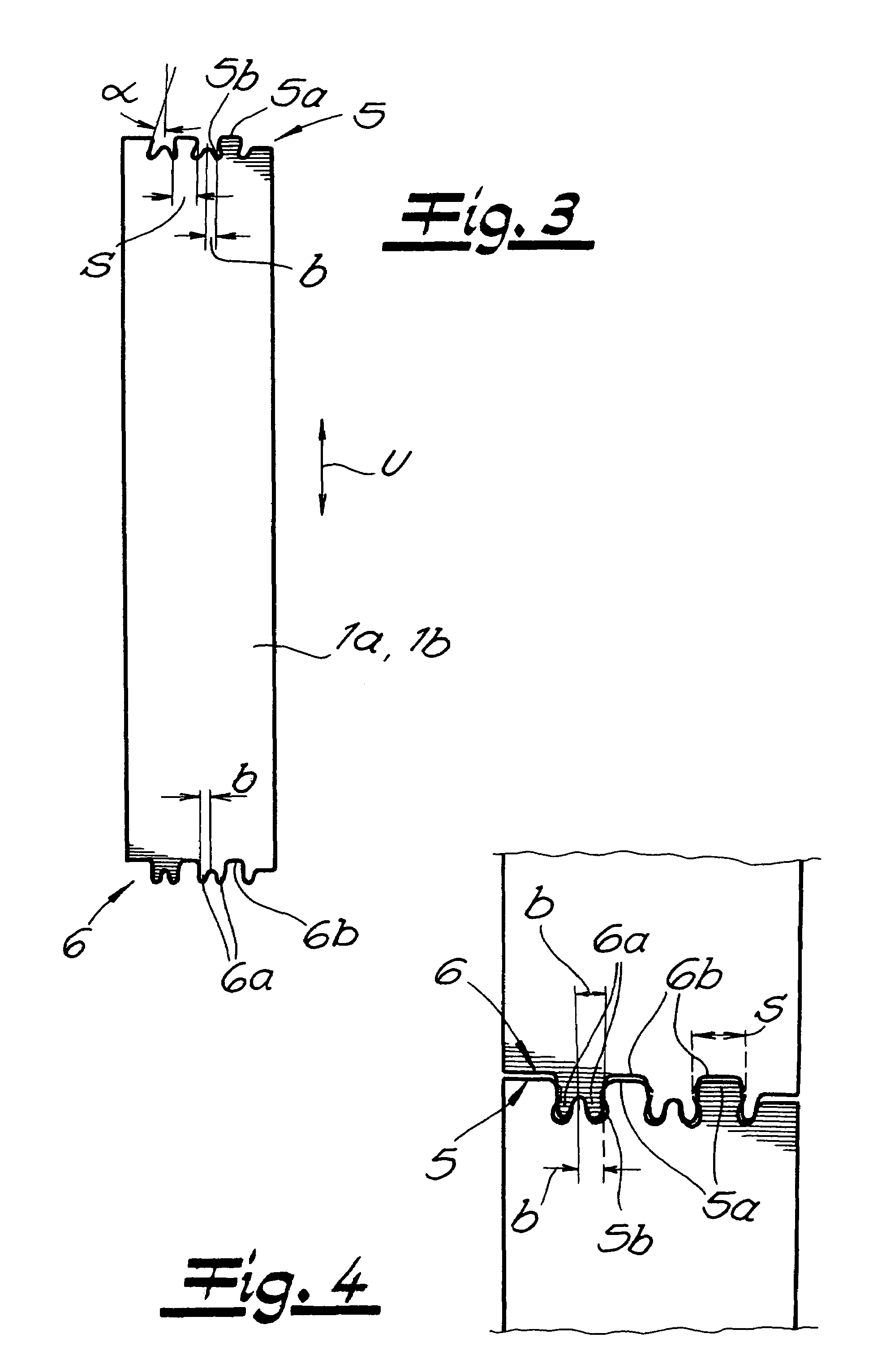

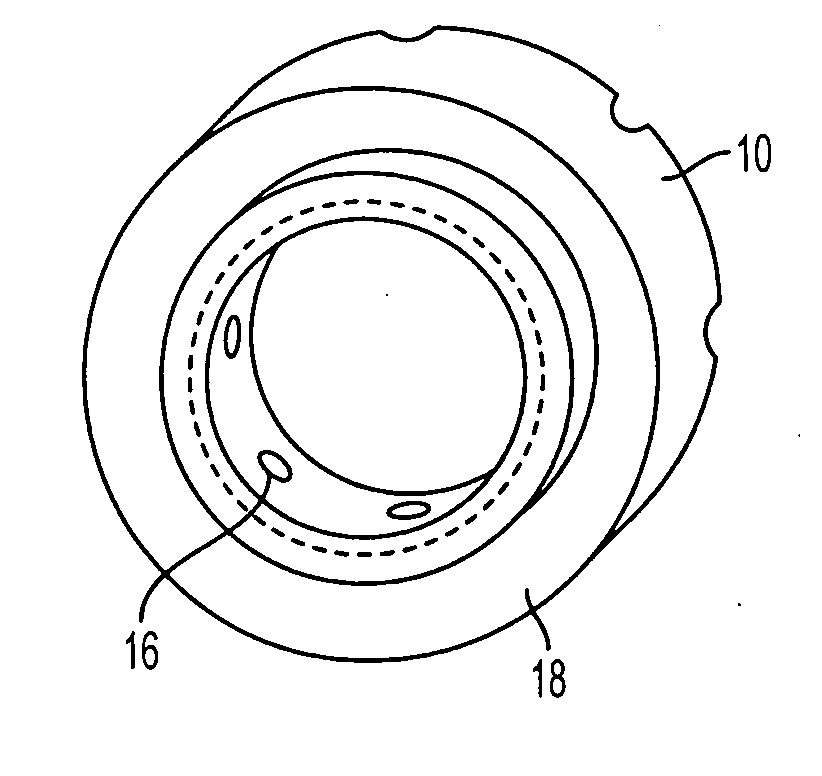

Bearing, particularly rubber bearing

A bearing, particularly a rubber bearing, has in its fundamental structure at least one bearing bushing and one rubber body surrounded by the bearing bushing. The bearing bushing has at least one longitudinal parting line having edge profiles that are complementary to one another, provided at adjacent longitudinal edges. The tines and tine recesses, respectively, engage into one another at the edge profiles which are complementary to one another. The tine along the one longitudinal edge, in each instance, dips into a related tine recess on the other longitudinal edge, essentially in the circumference direction of the bearing bushing in the course of production. During this process, the tine is plastically deformed by a predetermined measure, so that the tine and the related tine recess wedge into one another.

Owner:STABITEC STANZ BIEGETECHN

Pallet transporting device

In some embodiments, the device may comprise a rocker arm, fist tine, and second tine which may be coupled to a chassis. A first proximal wheel yoke having a first retractable load bearing wheel may be pivotally coupled to the first tine. A first distal wheel yoke having a first retractable counter balance wheel may also be pivotally coupled to the first tine. A first tappet may be coupled to the first proximal wheel yoke, to the first distal wheel yoke, and to the rocker arm. A second proximal wheel yoke having a second retractable load bearing wheel may be pivotally coupled to the second tine. A second distal wheel yoke having a second retractable counter balance wheel may also be pivotally coupled to the second tine. A second tappet may be coupled to the second proximal wheel yoke, to the second distal wheel yoke, and to the rocker arm.

Owner:OCONNELL BRIAN

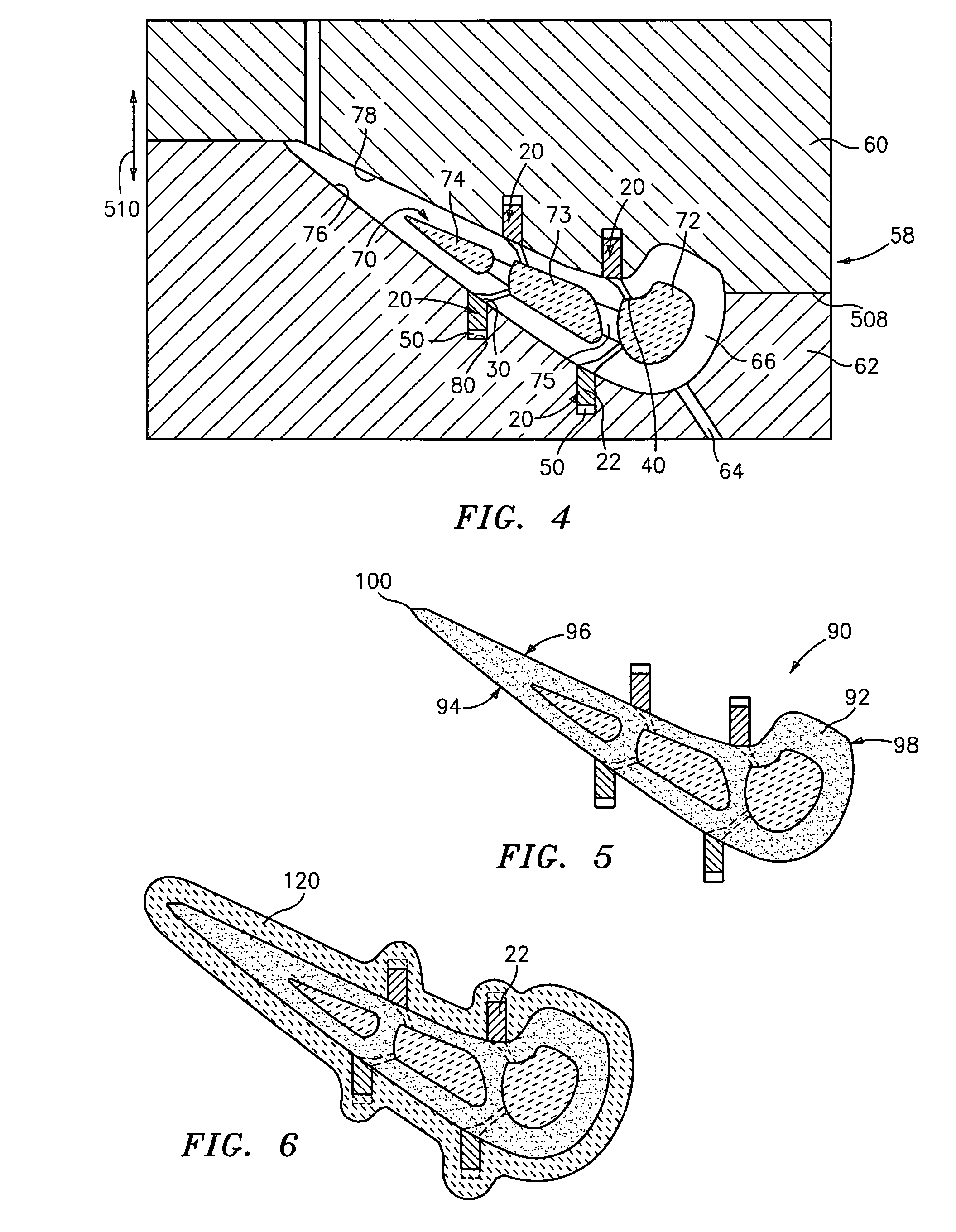

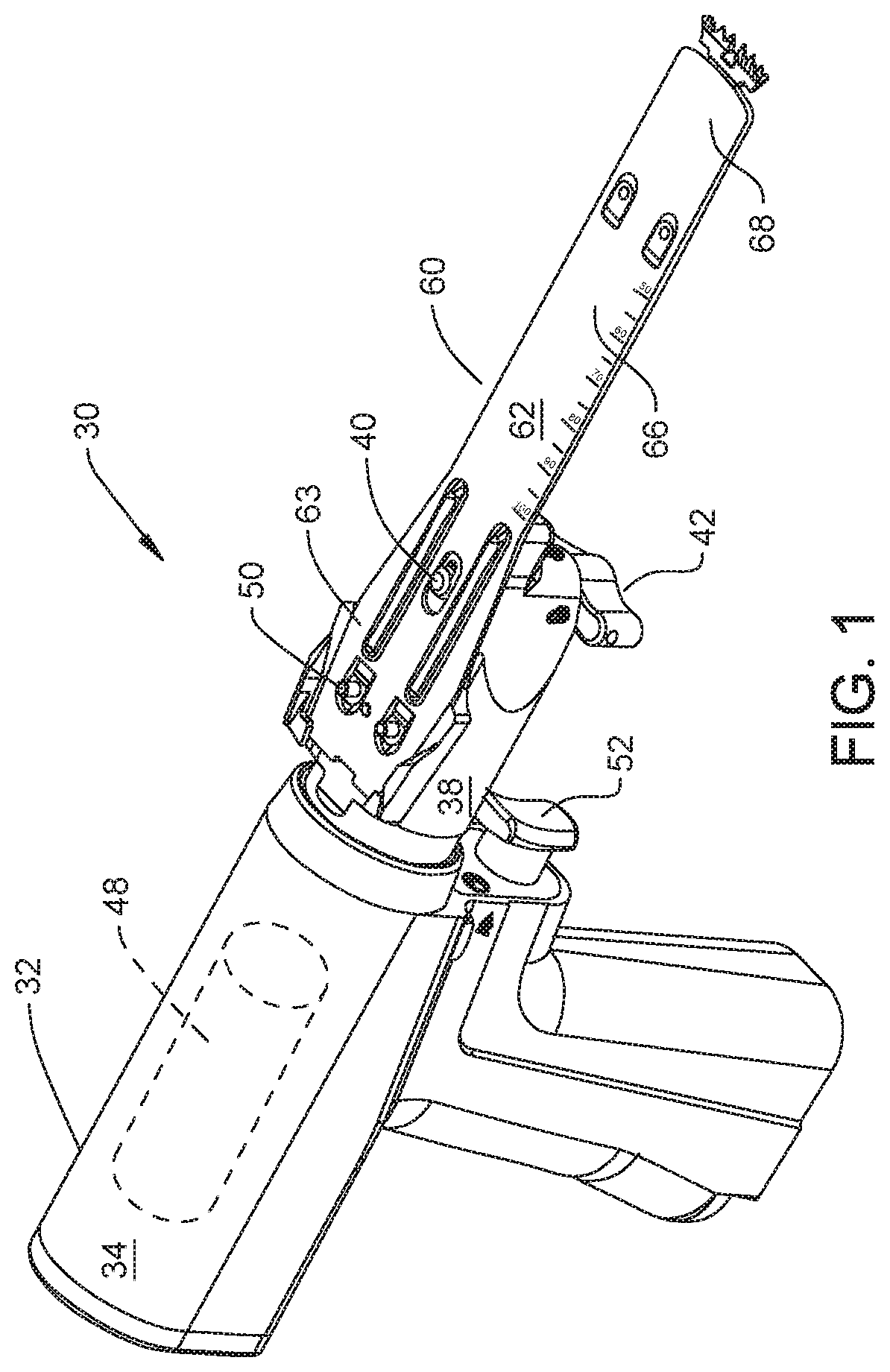

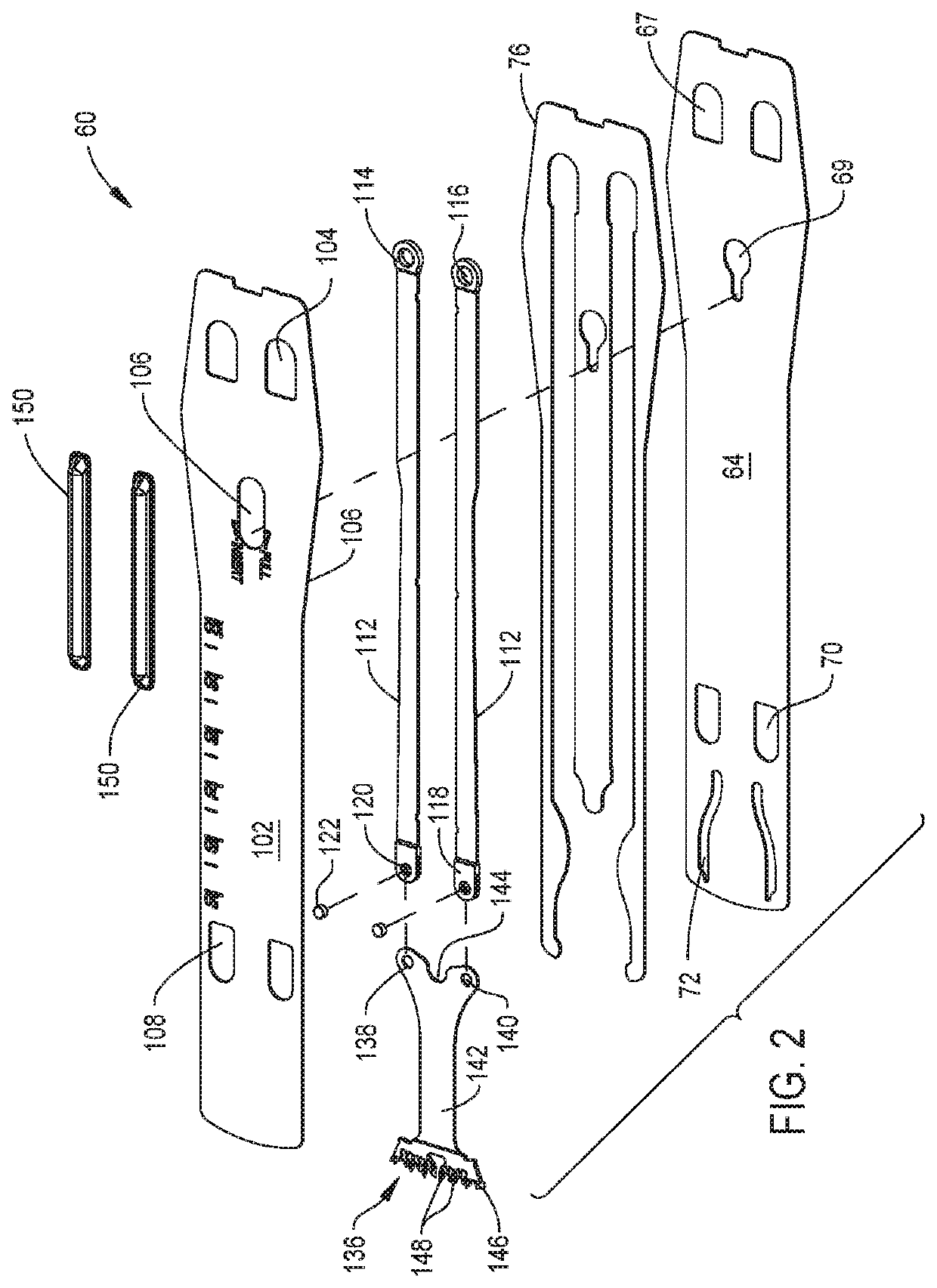

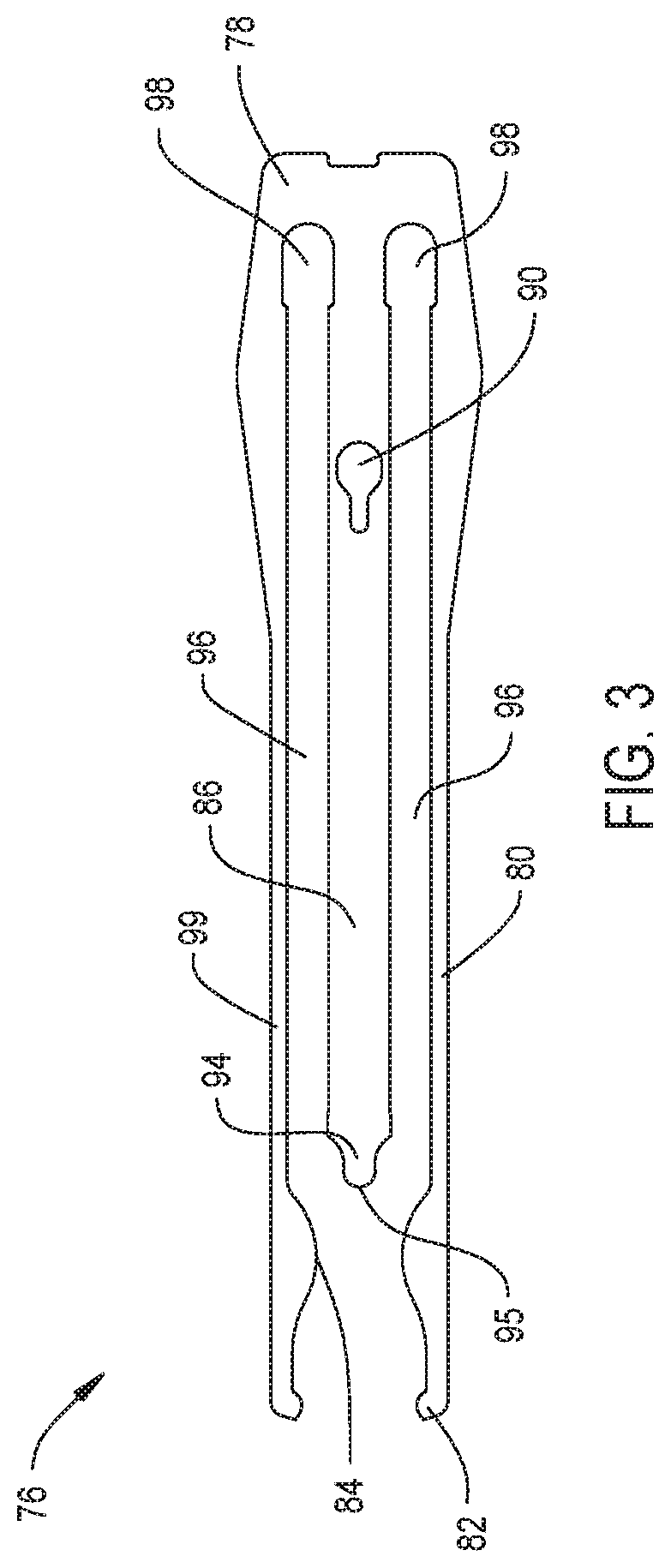

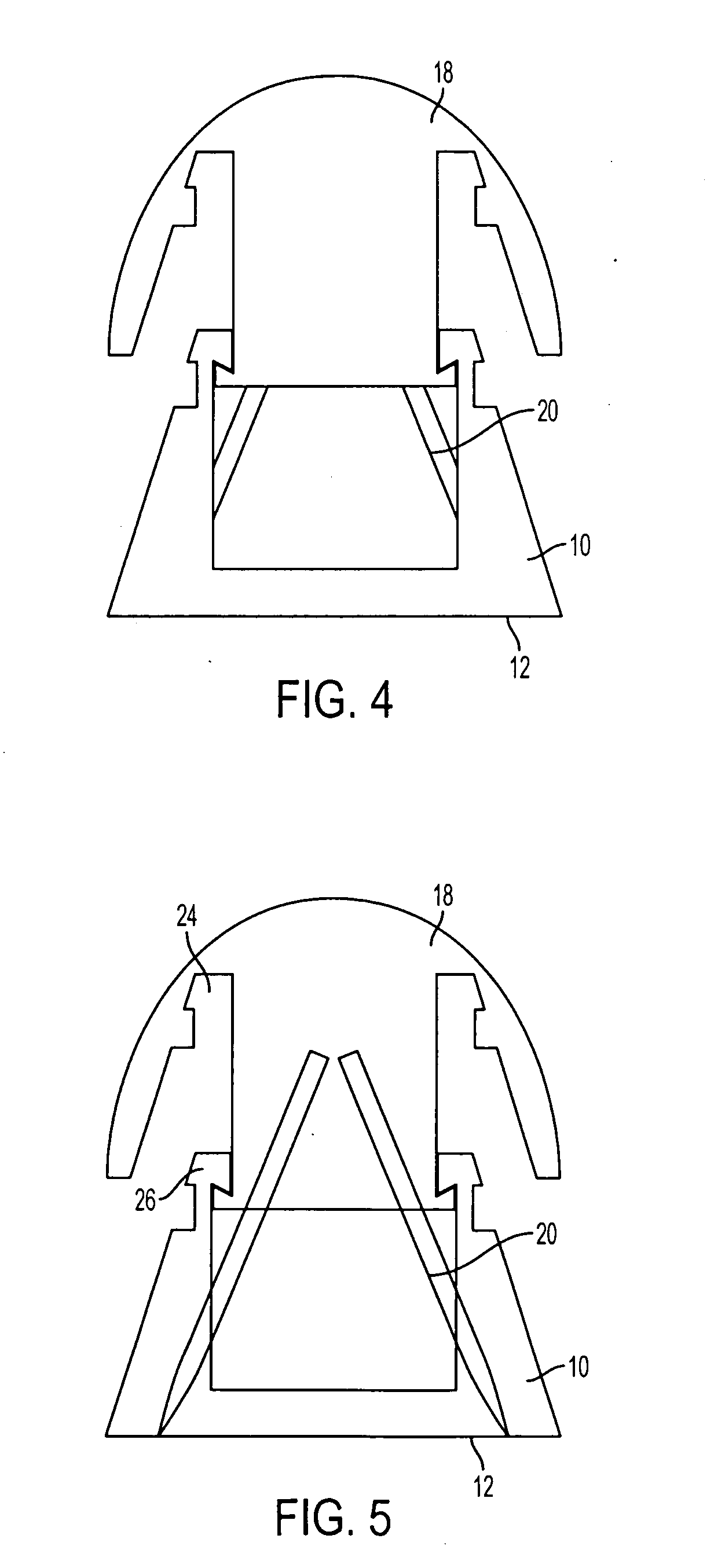

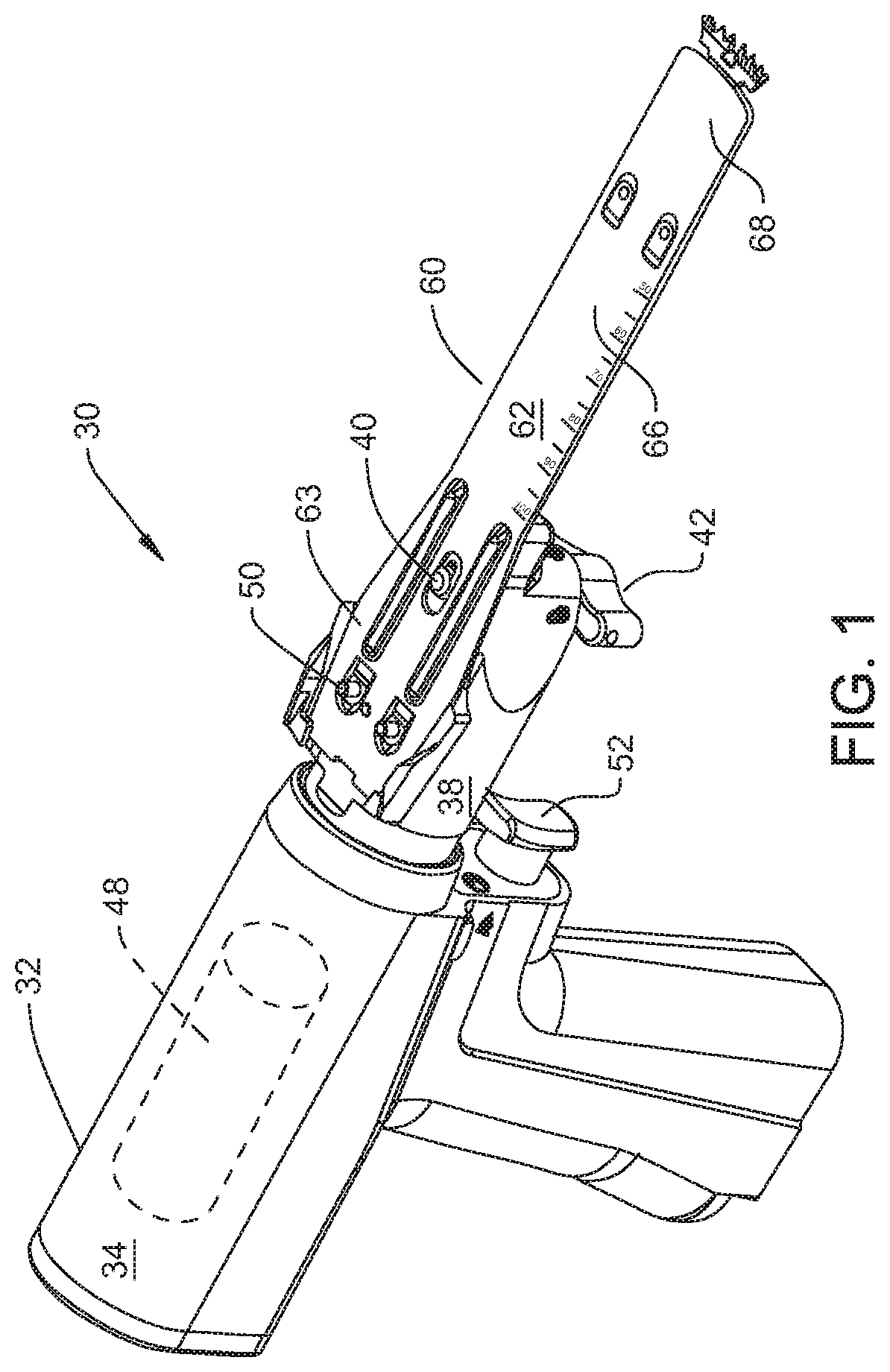

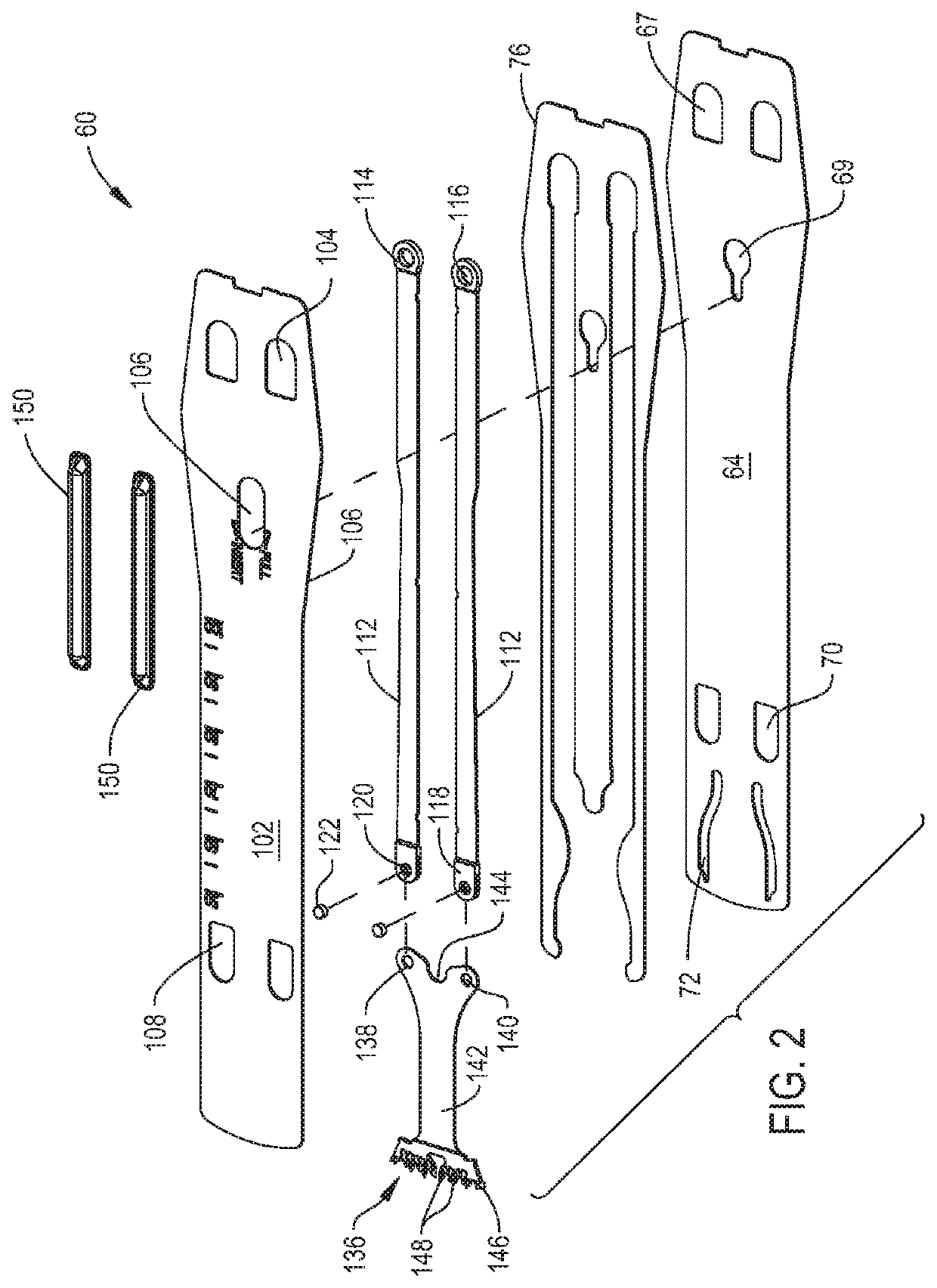

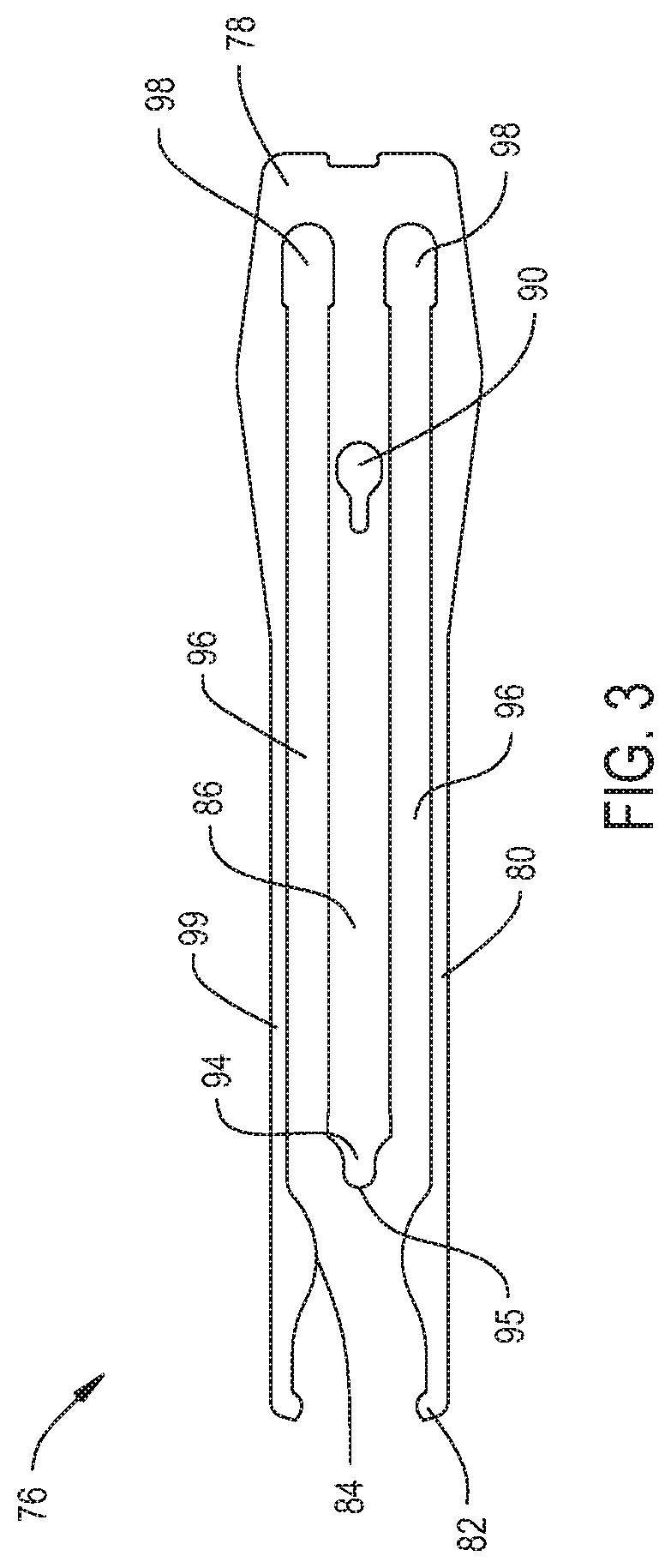

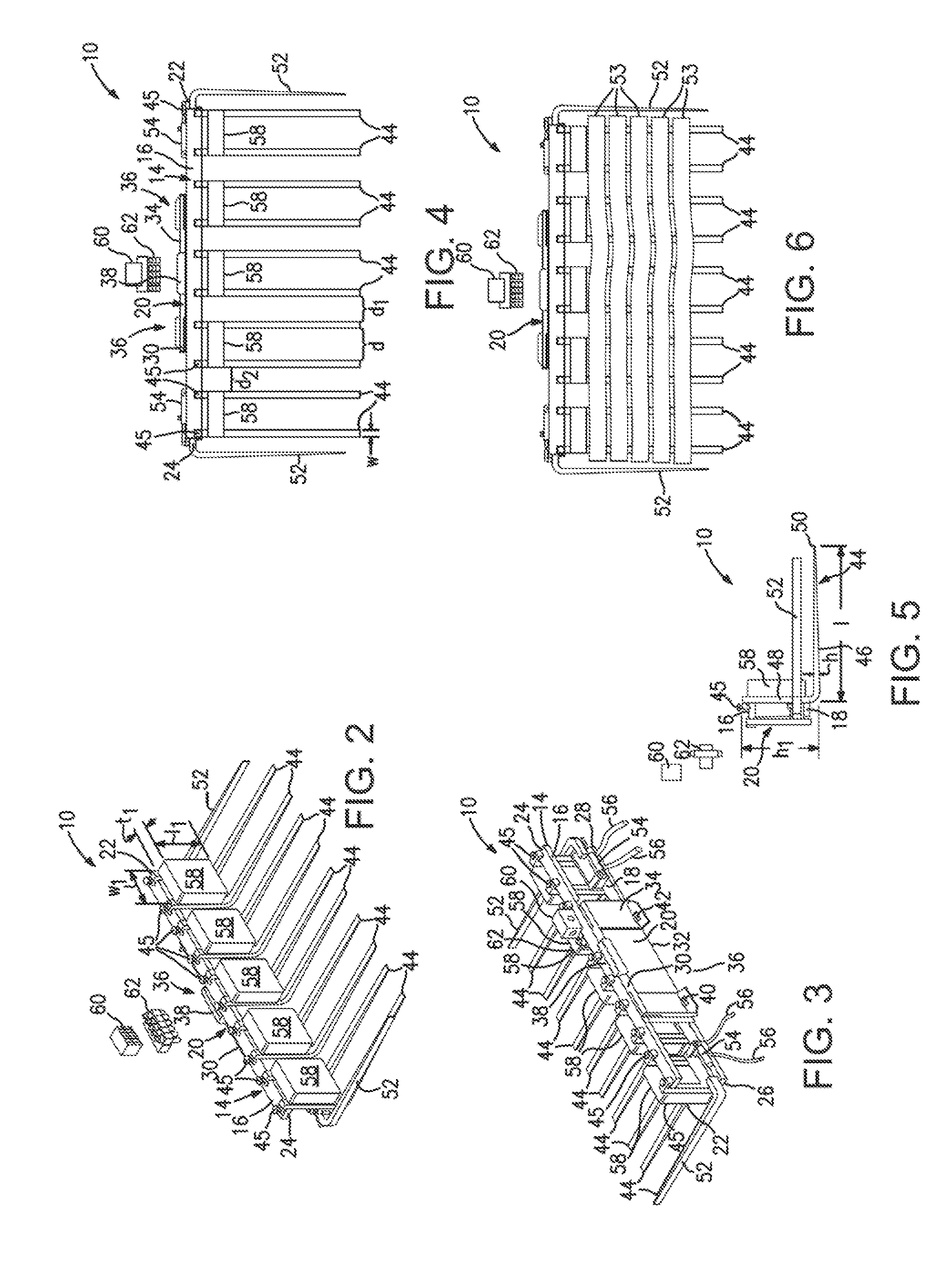

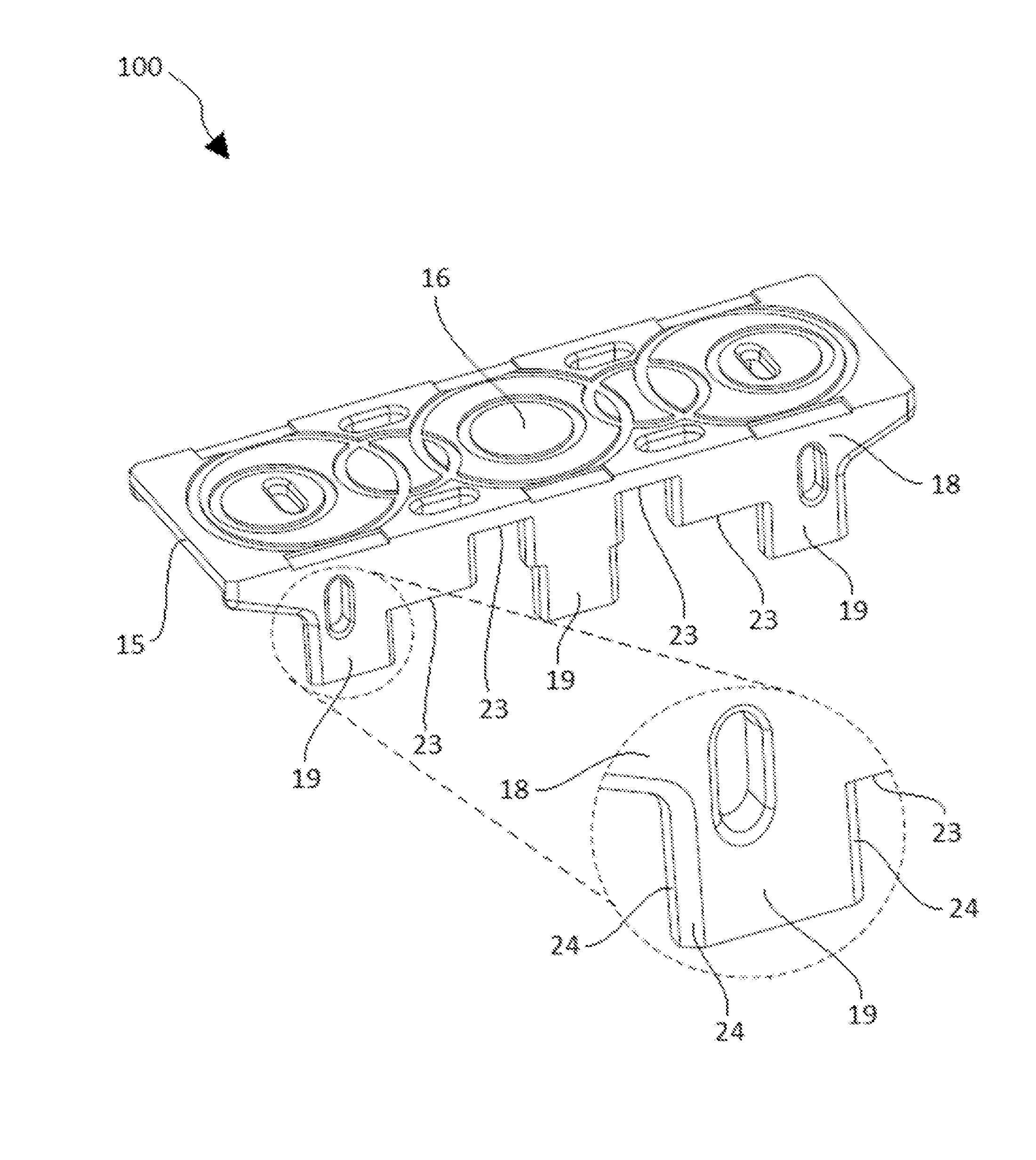

Surgical sagittal blade cartridge with a reinforced guide bar

ActiveUS10687823B2Less chance of bendingMetal sawing devicesMetal sawing toolsPhysical medicine and rehabilitationTine

A surgical sagittal saw cartridge that includes a guide bar formed form an inner plate and opposed outer plates, the inner plate having a head. The cartridge has a blade that is disposed against the head of the inner plate. The inner plate is formed to have an inner tine and two opposed outer tines. The inner tine is formed to define the head against which the blade is disposed. The outer tines extend forward of the inner tine so as to define a space between the outer tines in which the blade is seated.

Owner:STRYKER EURO OPERATIONS HLDG LLC

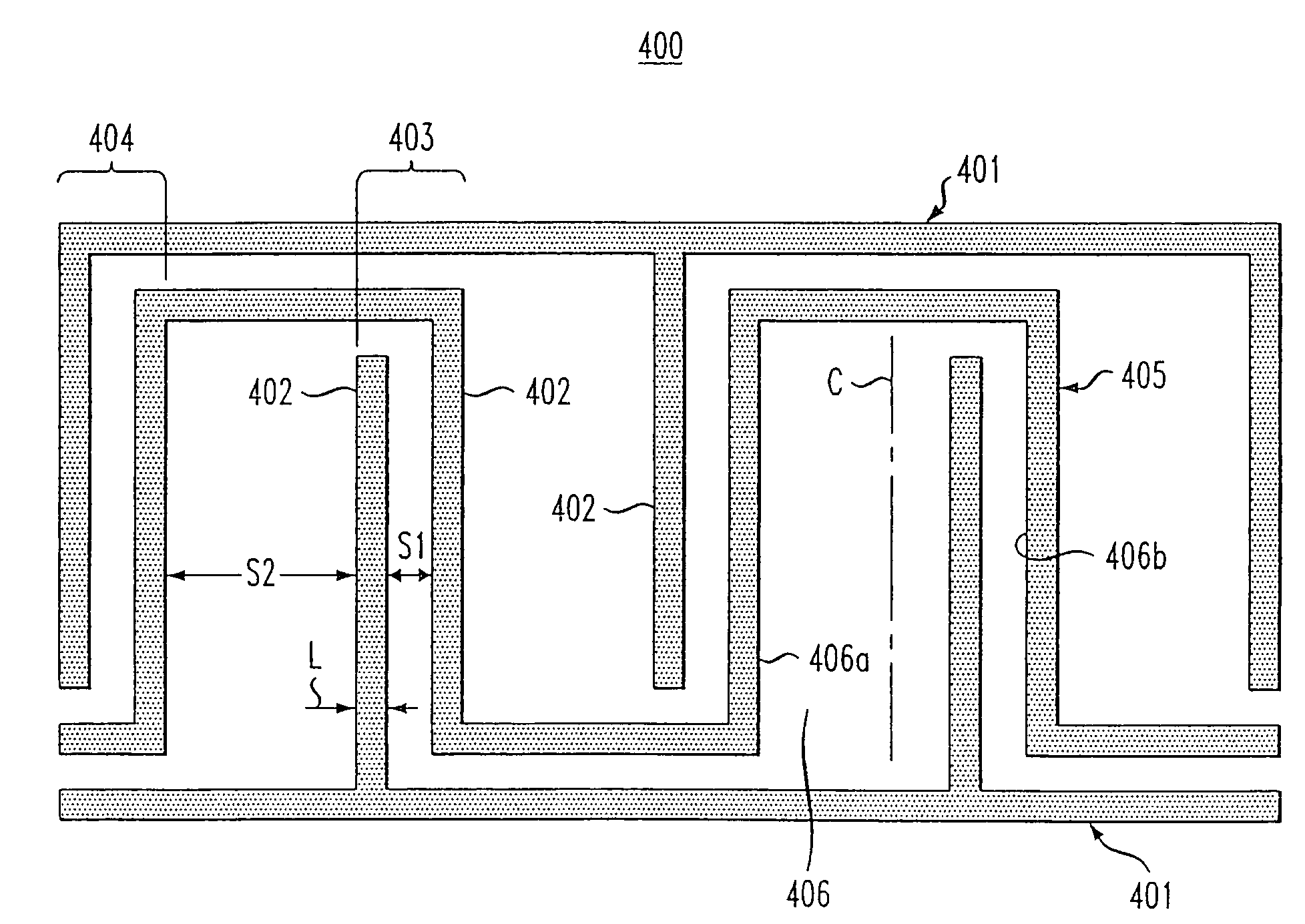

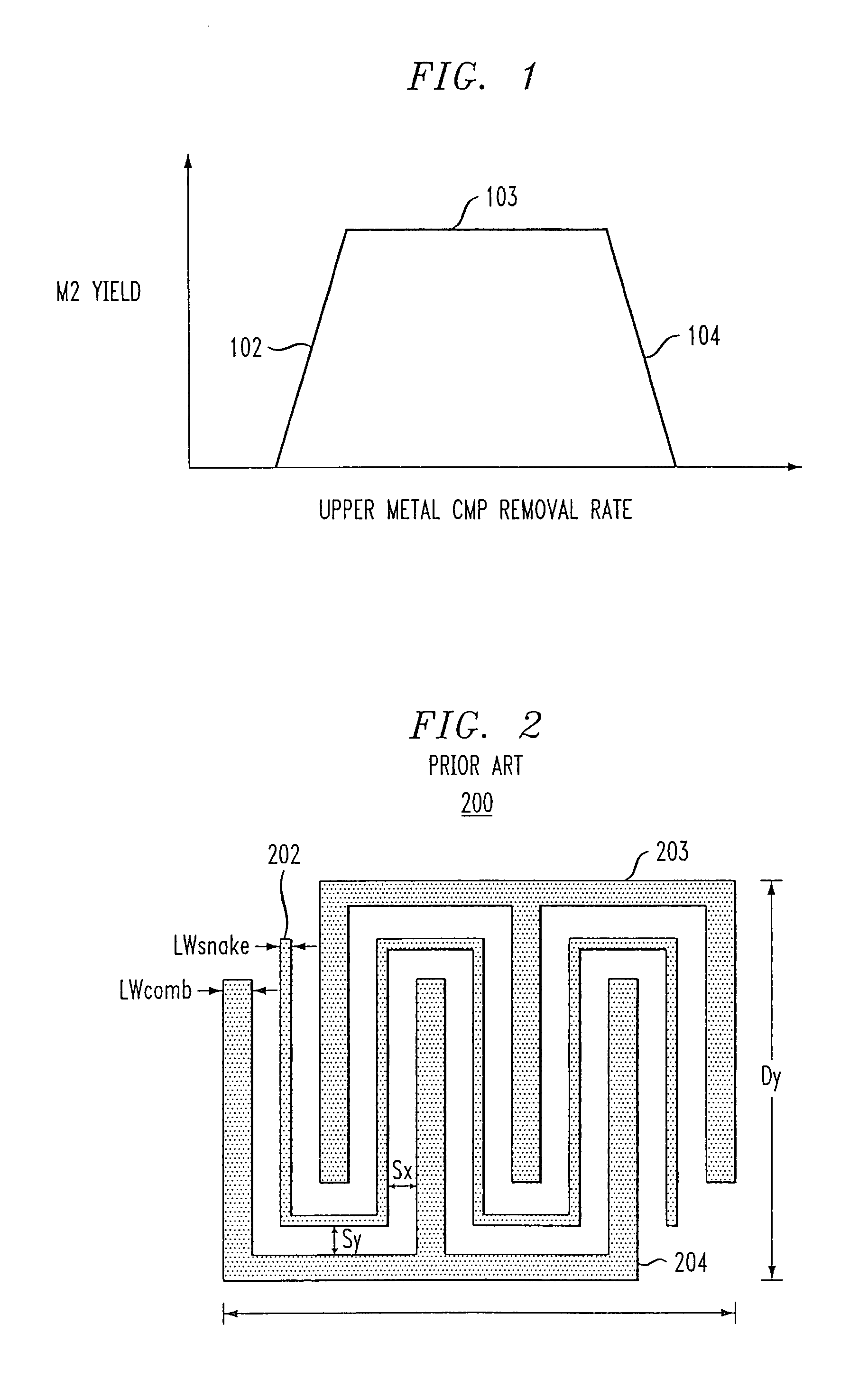

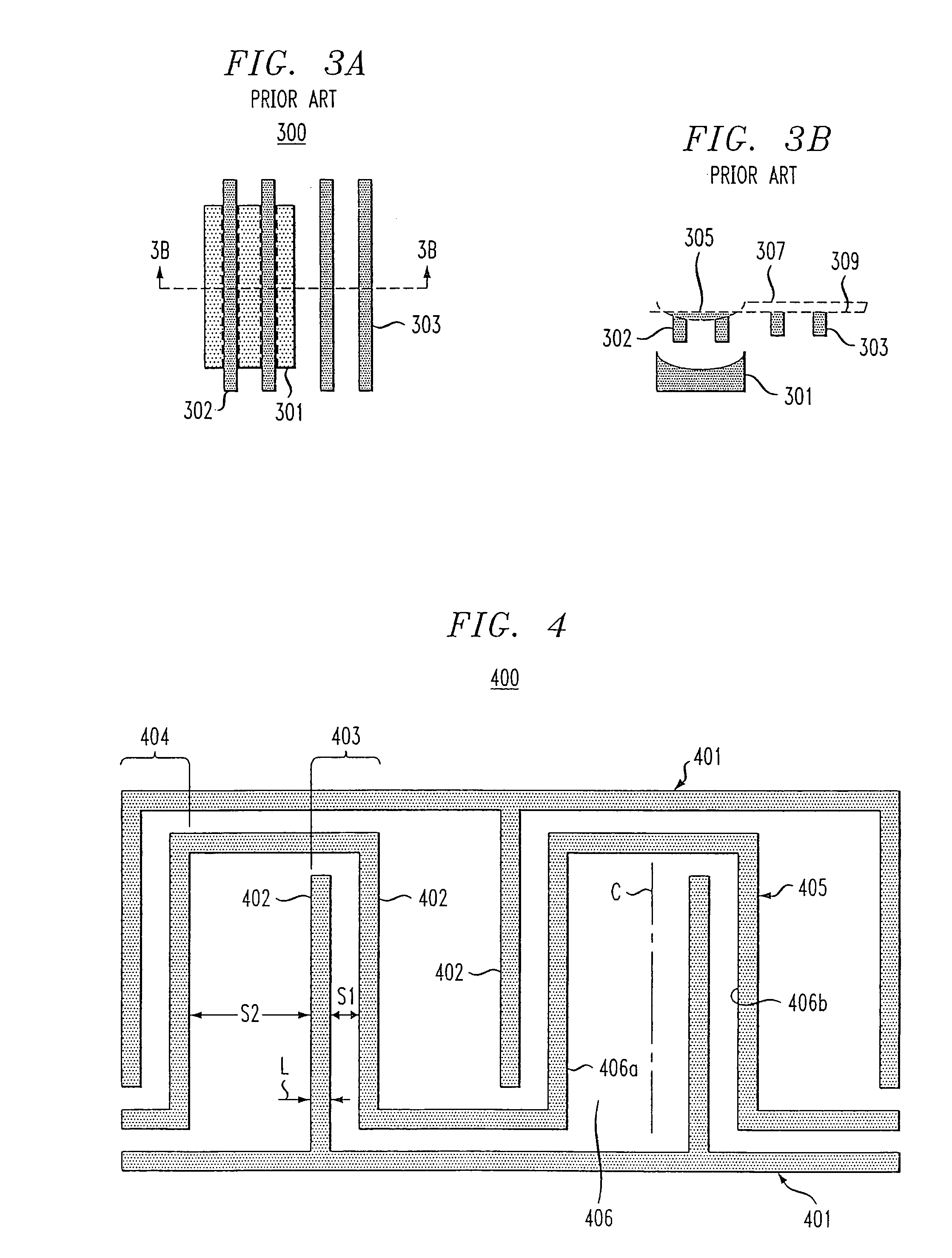

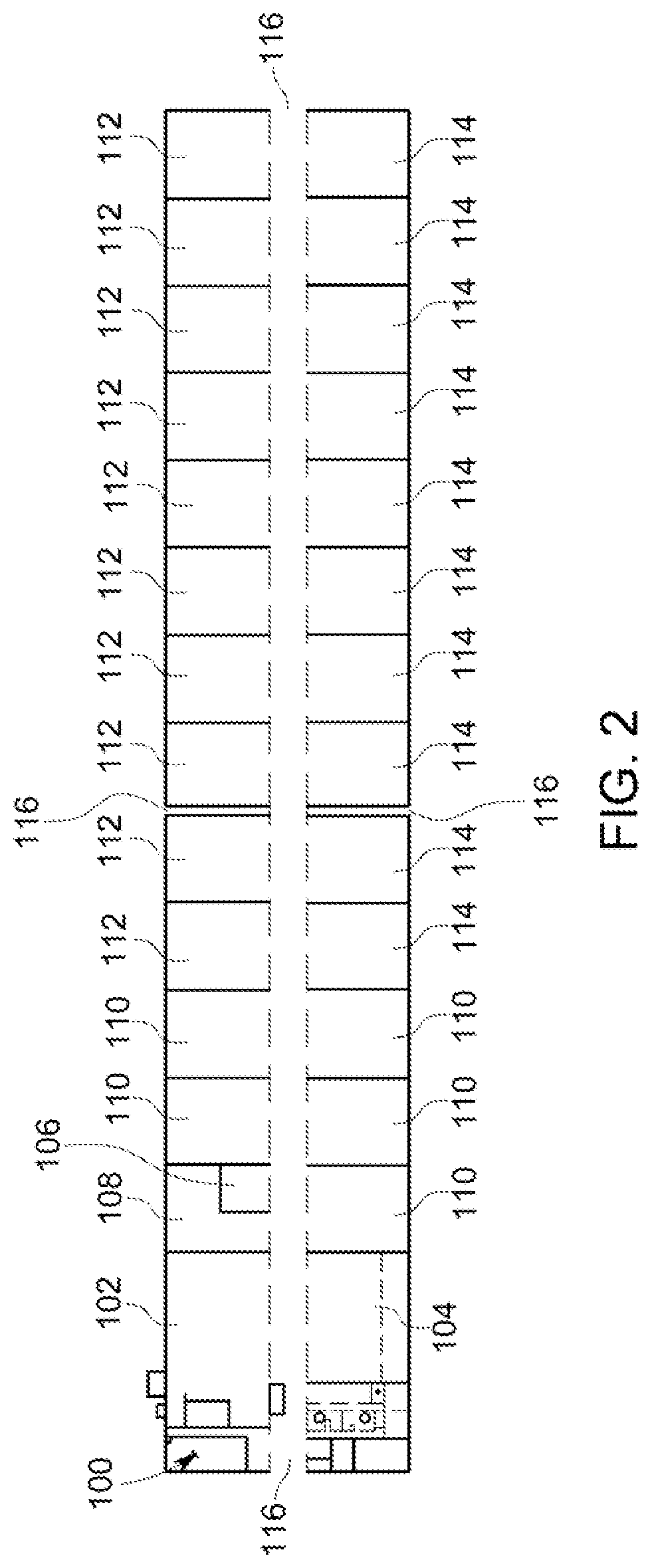

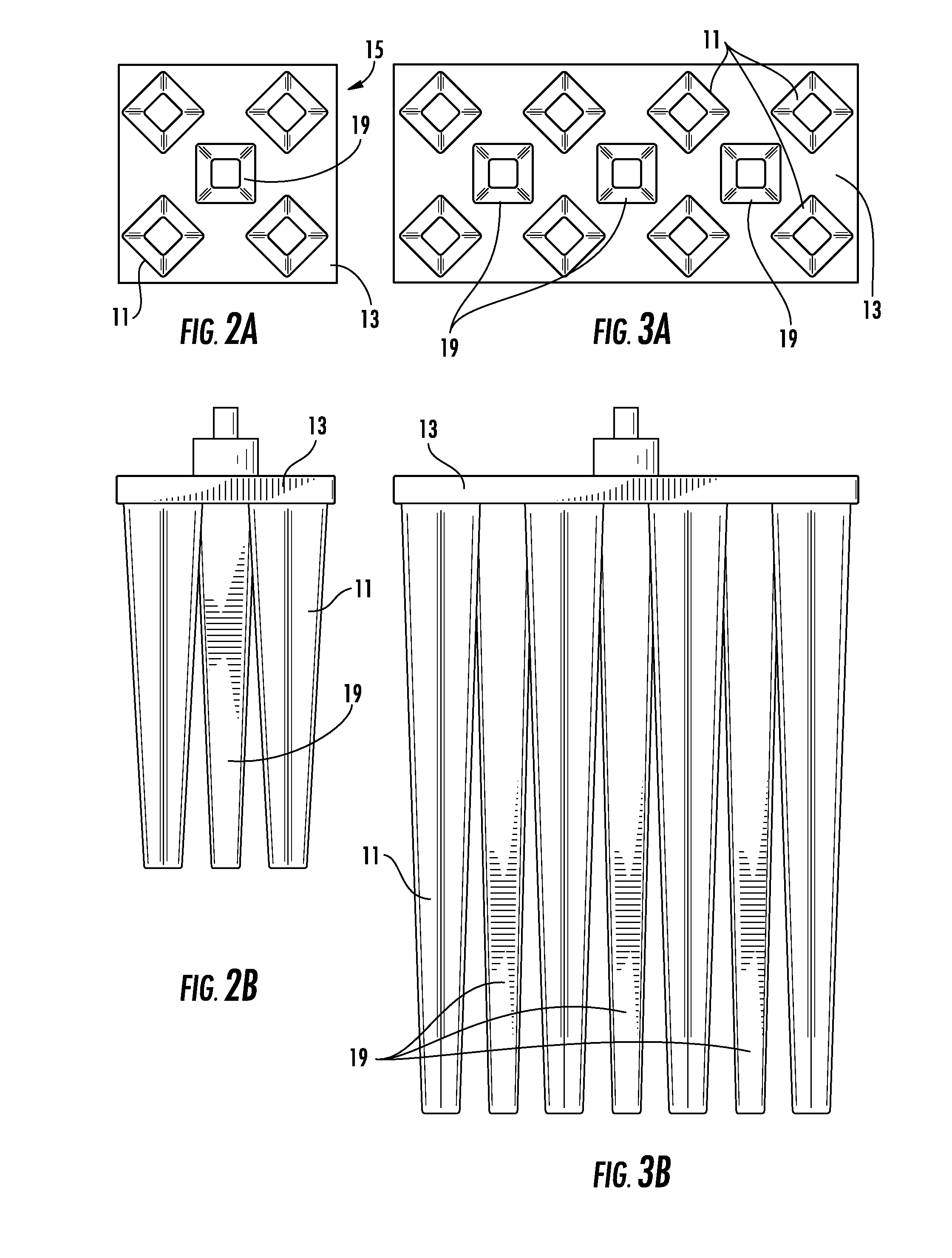

Test structures and models for estimating the yield impact of dishing and/or voids

InactiveUS7348594B2Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEngineeringTest structure

A test structure comprising a test pattern is formed on a substrate. The test pattern includes a first comb structure having a plurality of tines, and a second structure. The second structure may be a snake structure having a plurality of side walls or a second comb structure having a plurality of side walls. The tines of the first comb structure are positioned within side walls of the snake structure or second comb structure. The tines of the first comb structure are offset from a center of the side walls. Test data collected from the test structure are analyzed, to estimate product yield. The test structure may have a lower layer pattern, such that topographical variations of the lower layer pattern propagate to an upper layer pattern of the test structure.

Owner:PDF SOLUTIONS INC

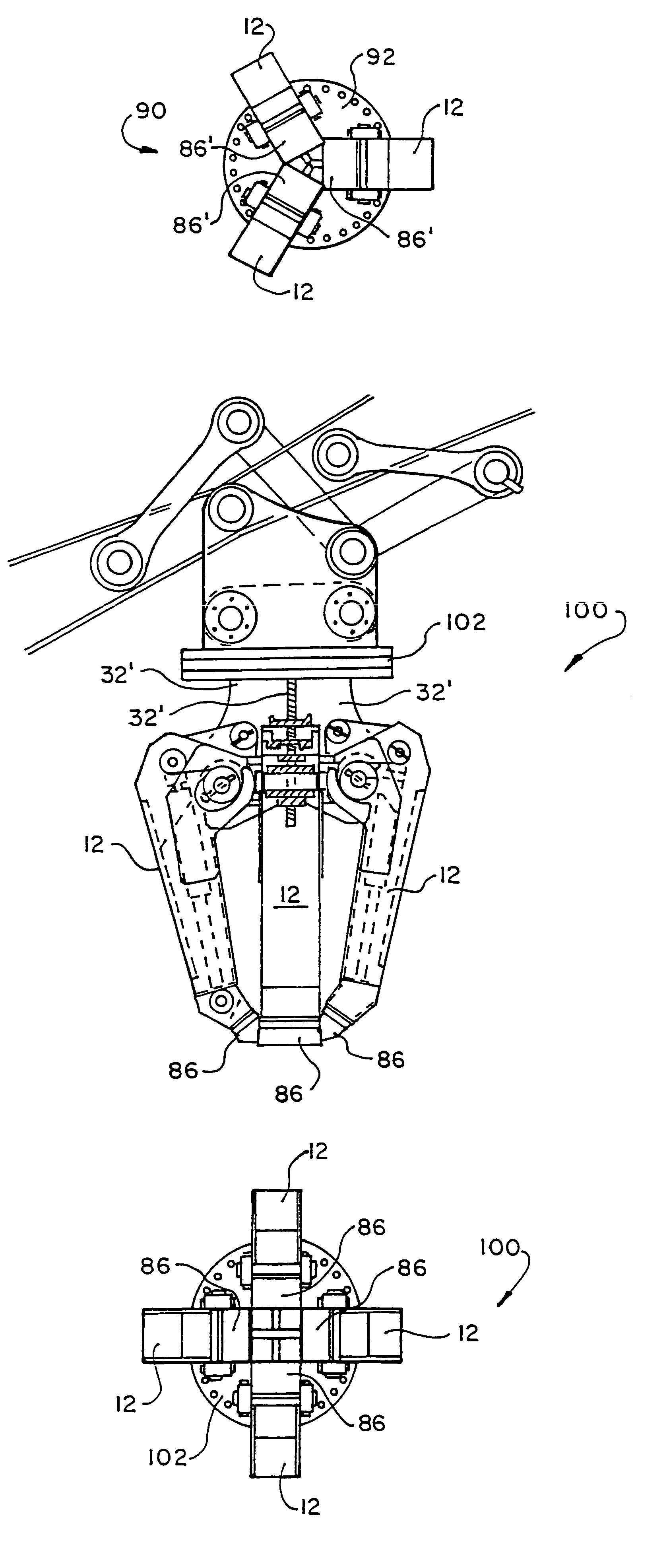

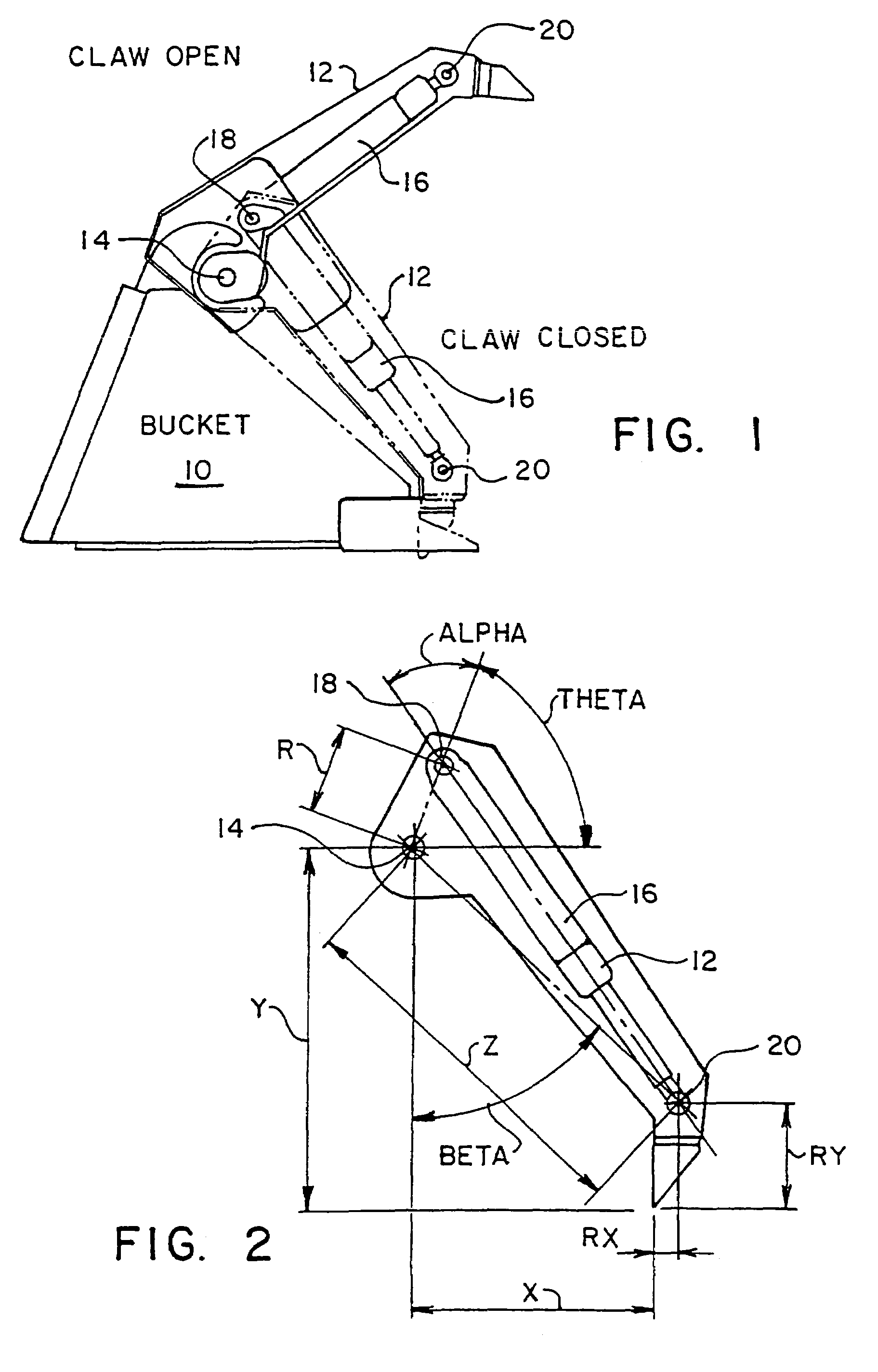

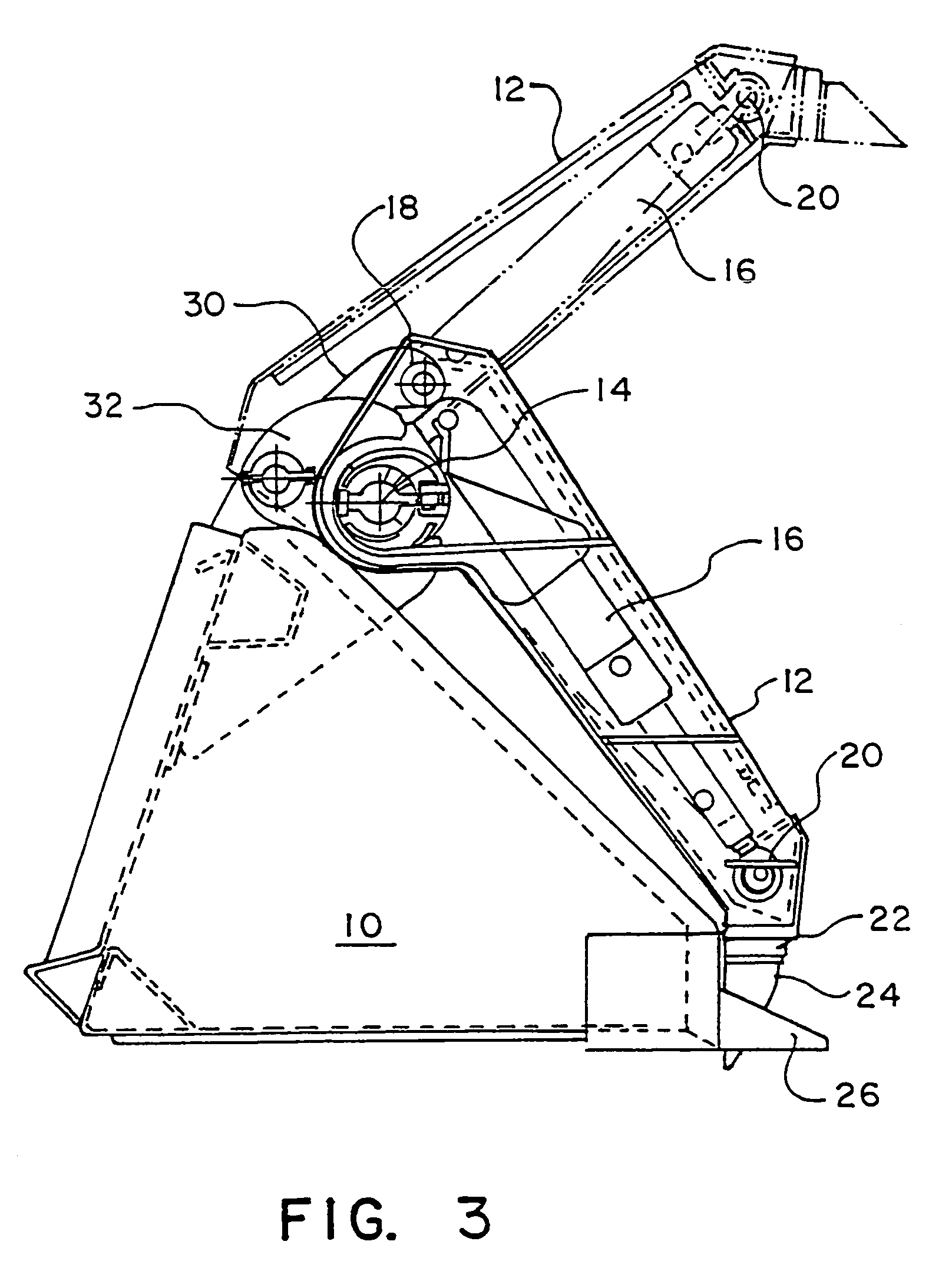

Demolition equipment having universal tines and a method for designing a universal tine

A claw tine for demolition equipment includes an elongated claw tine pivotally movable about a pivot point between an open and closed position by a hydraulic cyliner. The total angular rotation of the claw tine is at least 75 degrees, generally between 75 and 100 degrees. The maximum holding force is positioned 25 to 40 degrees from the closed position. The claw tine is adapted to be incorporated into a wide varity of demolition equipment including a bucket and claw structure attachment and a variety of grapples.

Owner:RAMUN JOHN R

Fork lift attachment for multi-purpose bucket

InactiveUS6988866B2Reduce movementSimple designMechanical machines/dredgersLifting devicesEngineeringMechanical engineering

A fork lift attachment for multi-purpose buckets that is easily installed and secured. The mechanism fits under the bucket and is supported by a slot on the top side of the tine and a latch at the heel of the tine. The latch is tightened causing the fork lift attachment to be cinched onto the bucket. A security chain readily and visibly secures the latch so as to prevent the fork lift attachments from being dislodged even if the hydraulics open the bucket.

Owner:ARROW ACQUISITION

Clamp-on fork lift attachment

ActiveUS20140248111A1Improve rigidityMechanical machines/dredgersLifting devicesEngineeringBackhoe loader

A clamp-on fork lift attachment having spaced tines which may be temporarily secured to the blade portion of a loader bucket used on equipment such as backhoe loaders and front end loaders includes a lifting plate, a leveling indicator, tie-down elements and a stabilizer bar connected between the spaced tines.

Owner:WERNER CO

Laser hardened knife guard

A laser hardened knife guard is provided. In one aspect, the invention provides for a knife guard that comprises a guard body that further comprises a base material. The base material includes a mounting bar that defines at least one bolt hole and at least one tine projecting forward from the mounting bar. The base material has a first hardness. A laser treated material is formed into or in the base material. The laser treated material comprises a second hardness greater than the first hardness.

Owner:KONDEX CORP

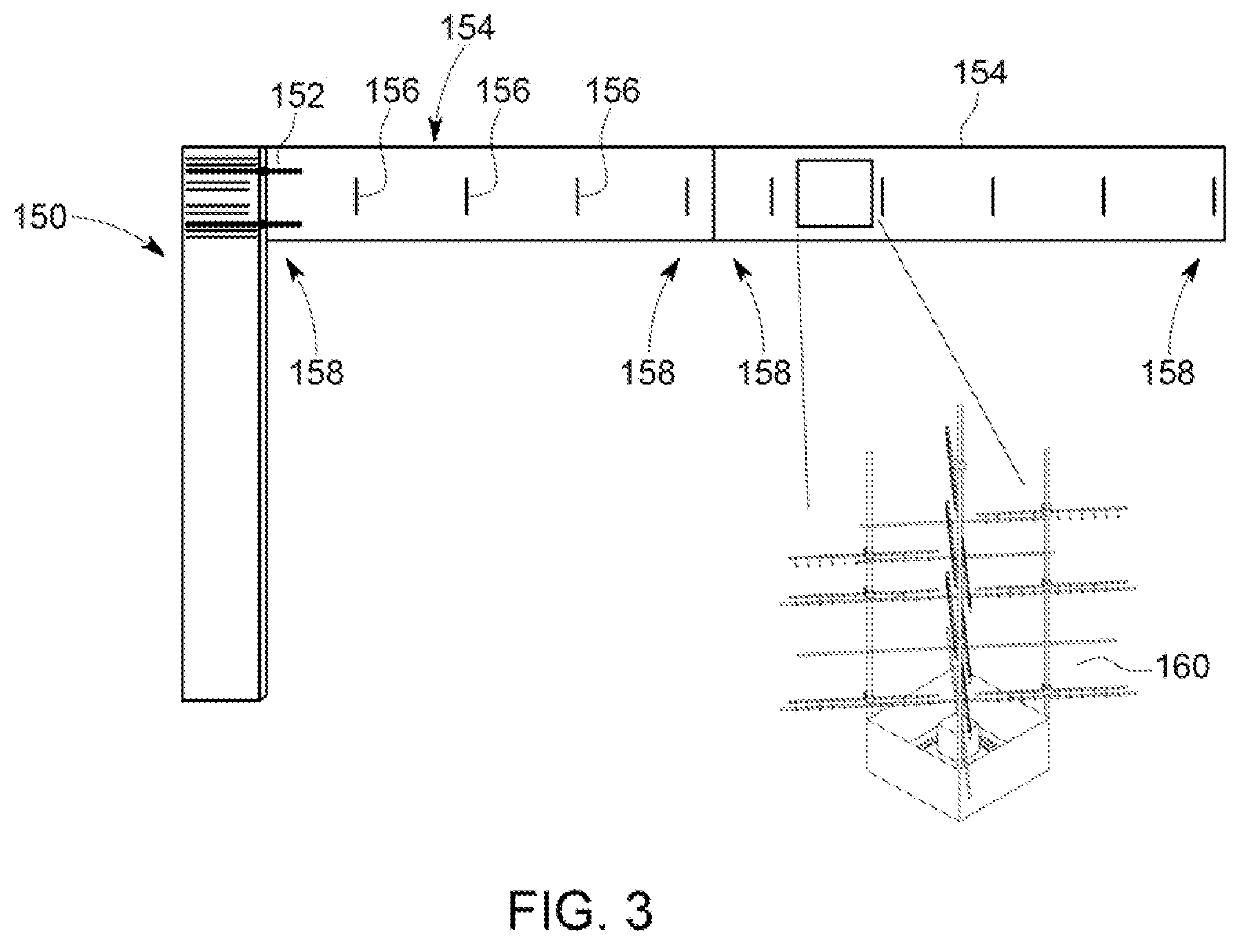

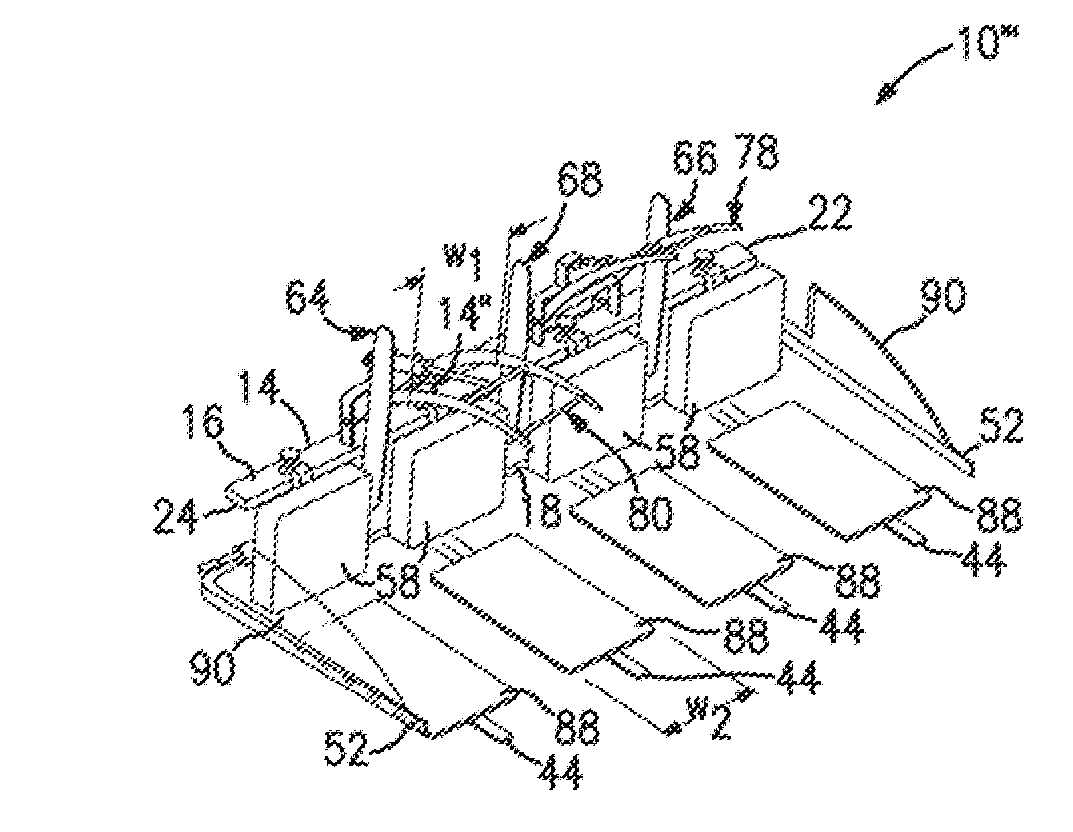

Tray and Trellis System for an Automated Farm with Robots Working on Plants

PendingUS20210243967A1Easy to manufactureLess timeProgramme-controlled manipulatorGraftingTineGrommet

A Tray and Trellis System includes vertical posts or legs, longitudinal members, and cross members. Combs include tines fixed at one end to longitudinal members on one side, and releasably engaged at their other end to other longitudinal members on the other side. Further combs include tines fixed to a cross member at one end, and releasably engaged to another cross member at the other end. There may be intermediate cross members having tines fixed to them and other tines releasably engaged to them. Fixation of the tines may be by clips, rings, welding, bonding, fastening, or by molding as a single piece. The releasably engaged ends of the tines may be engaged with snap-fit slot features in the longitudinal members, the cross members, or the clips or rings, or may be engaged with open grommets inserted into openings in the longitudinal members or cross members.

Owner:BARTROM MICHAEL +2

Device that attaches to a surface

Owner:ALVA IP I +2

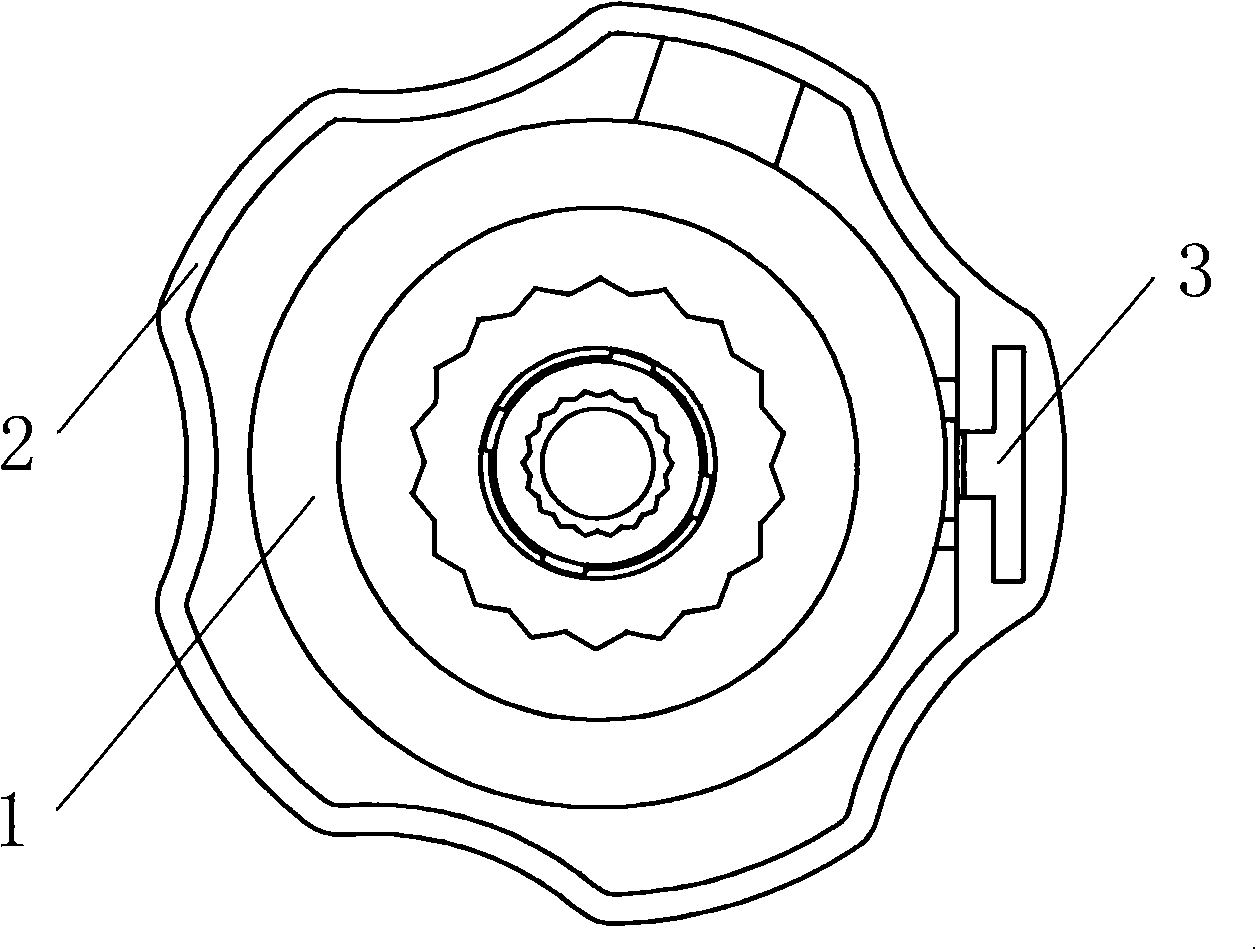

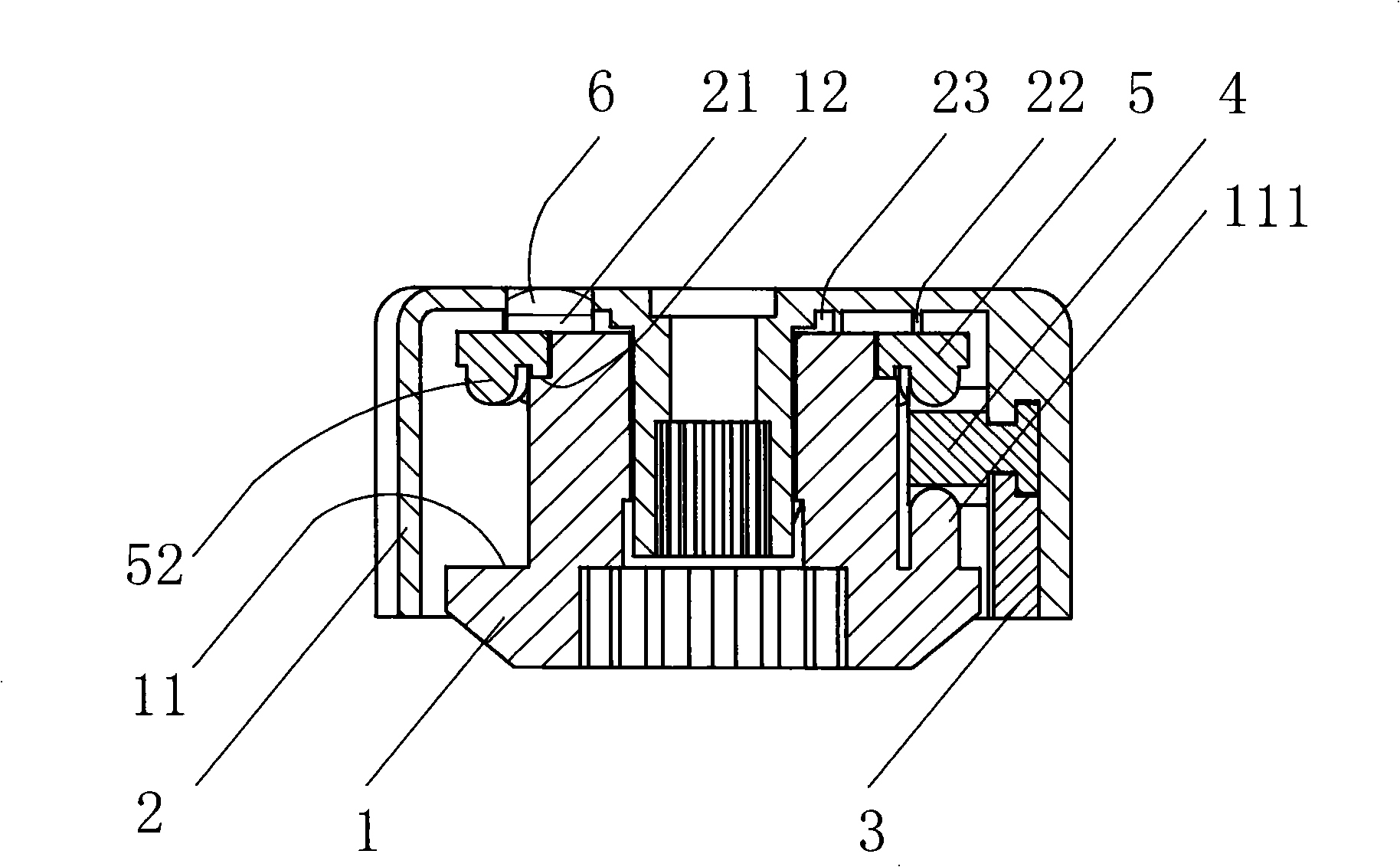

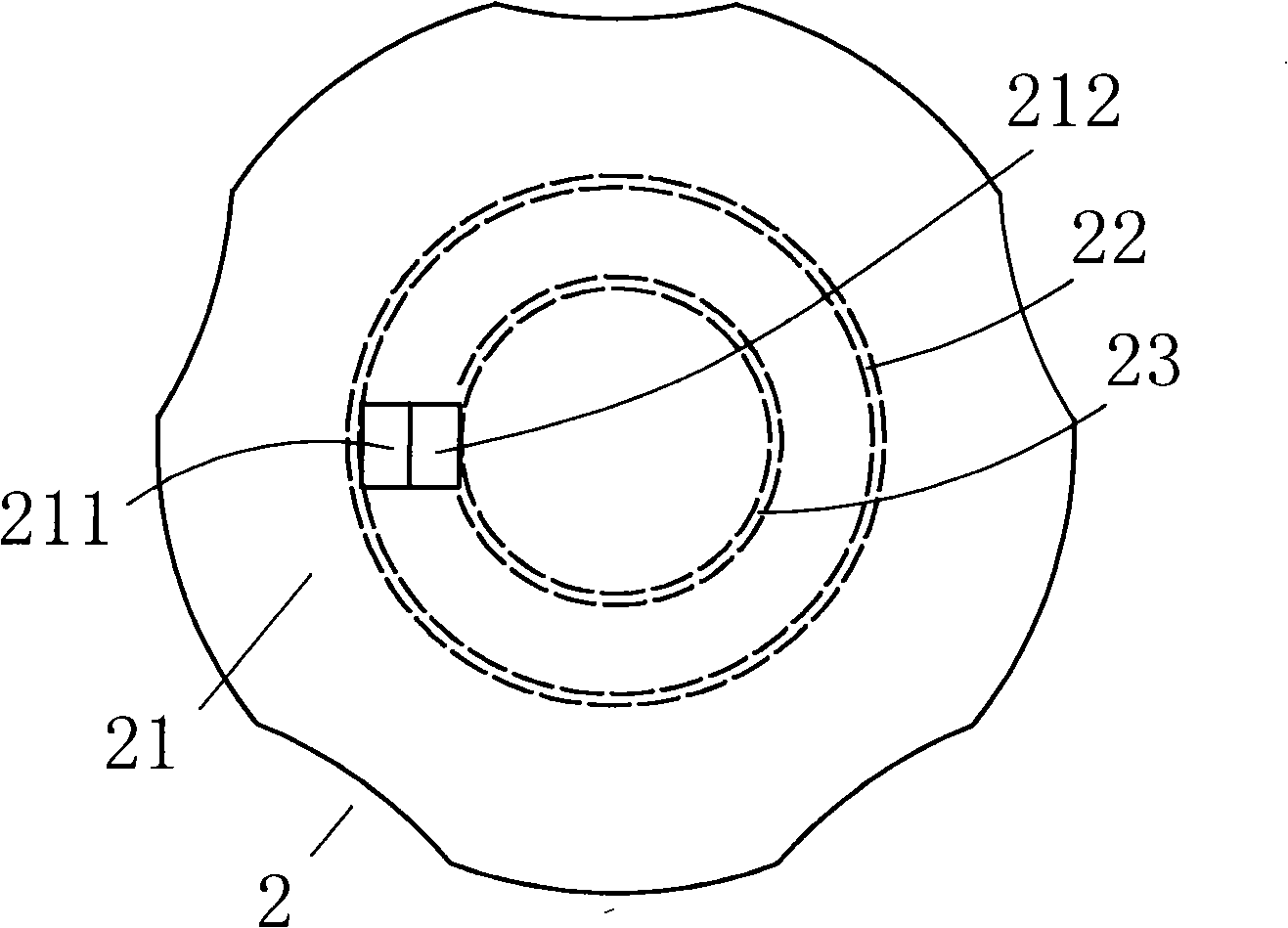

Digital display unit of valve

InactiveCN101298892AEasy to controlAccurate calculation of liquid flowOperating means/releasing devices for valvesGear wheelGear tooth

The invention relates to the valve technical field, namely a valve digital display unit, including a base, wherein a tine meshing with the gear is arranged at the lower part of the outer surface of the base, and a ring of scale and / or scale valve for indication is arranged on the upper surface of the base, an upper annular boss is formed to contract inwards arranged on the upper part of the outer surface of the base; a large dial, which is a tourus, wherein a scale and / or a scale valve is arranged on the upper surface of the tourus, and a ring of tines meshing with the gear is arranged at the lower part of the tourus; a gear, which is arranged with gear teeth meshing with the tines on the base and the large dial, and the gear is arranged on the side wall of the handle case through the gear shaft; a handle case, the superior wall of which is arranged with a small window for observing the scale and / or the scale valve on the base and the large dial. The invention has the advantages of compact structure, beautiful appearance, accurate figure-reading, convenience, which is suitable for a plurality of valves.

Owner:ZHEJIANG WORLD BRASS

Termination block

InactiveUS7039183B2Avoid damageInterconnection arrangementsRelieving strain on wire connectionTineLead frame

A termination block having spaced apart rear and front faces with rear and front apertures, respectively, and a plurality of mounting surfaces on the rear face. A screw receiving portion receiving a screw is positioned at each mounting surface. An interior recess is between the rear and front faces, accessible from the rear and front faces through the rear and front apertures. A terminal connection pad is positioned at the rear face at each mounting surface, and a plurality of tines extend through the rear aperture and are positioned within the interior recess for access through the front aperture. Each tine has a flat contact end portion. A plurality of trace members positioned at the rear face, each electrically coupling together one of the terminal connection pads and one of the tines. The terminal connection pads, tines and trace members are formed as part of a stamped, thin, flat lead frame.

Owner:LEVITON MFG

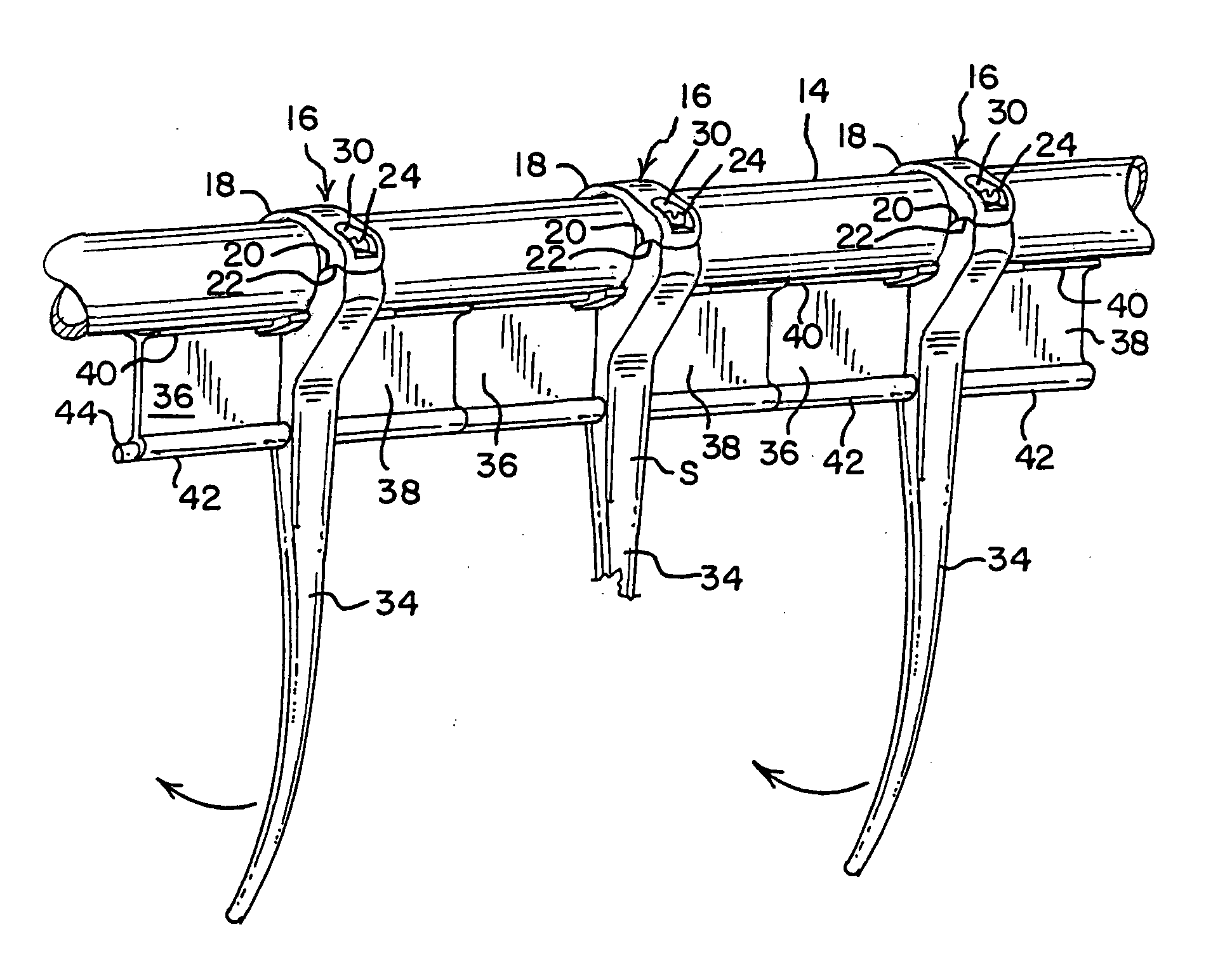

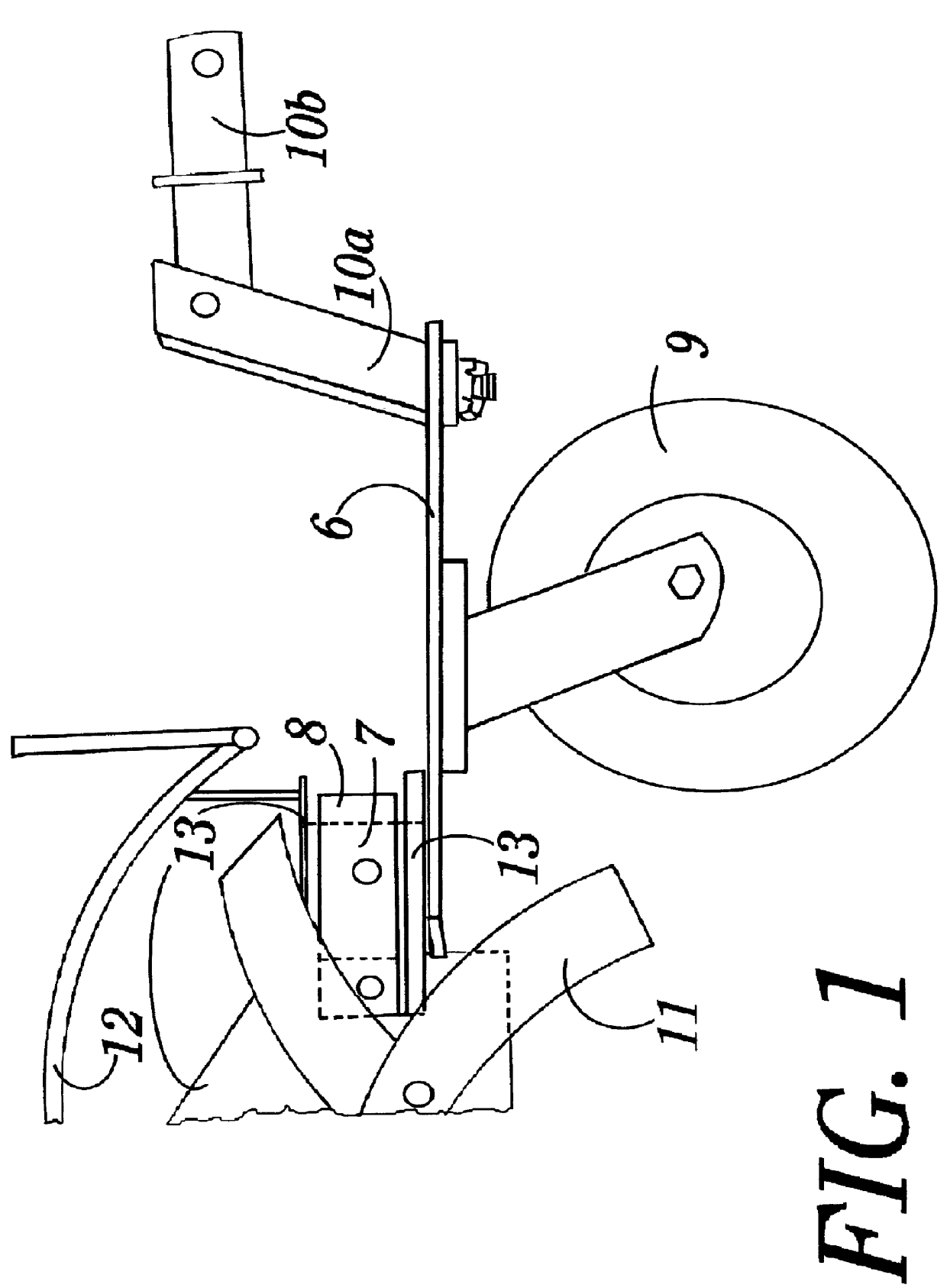

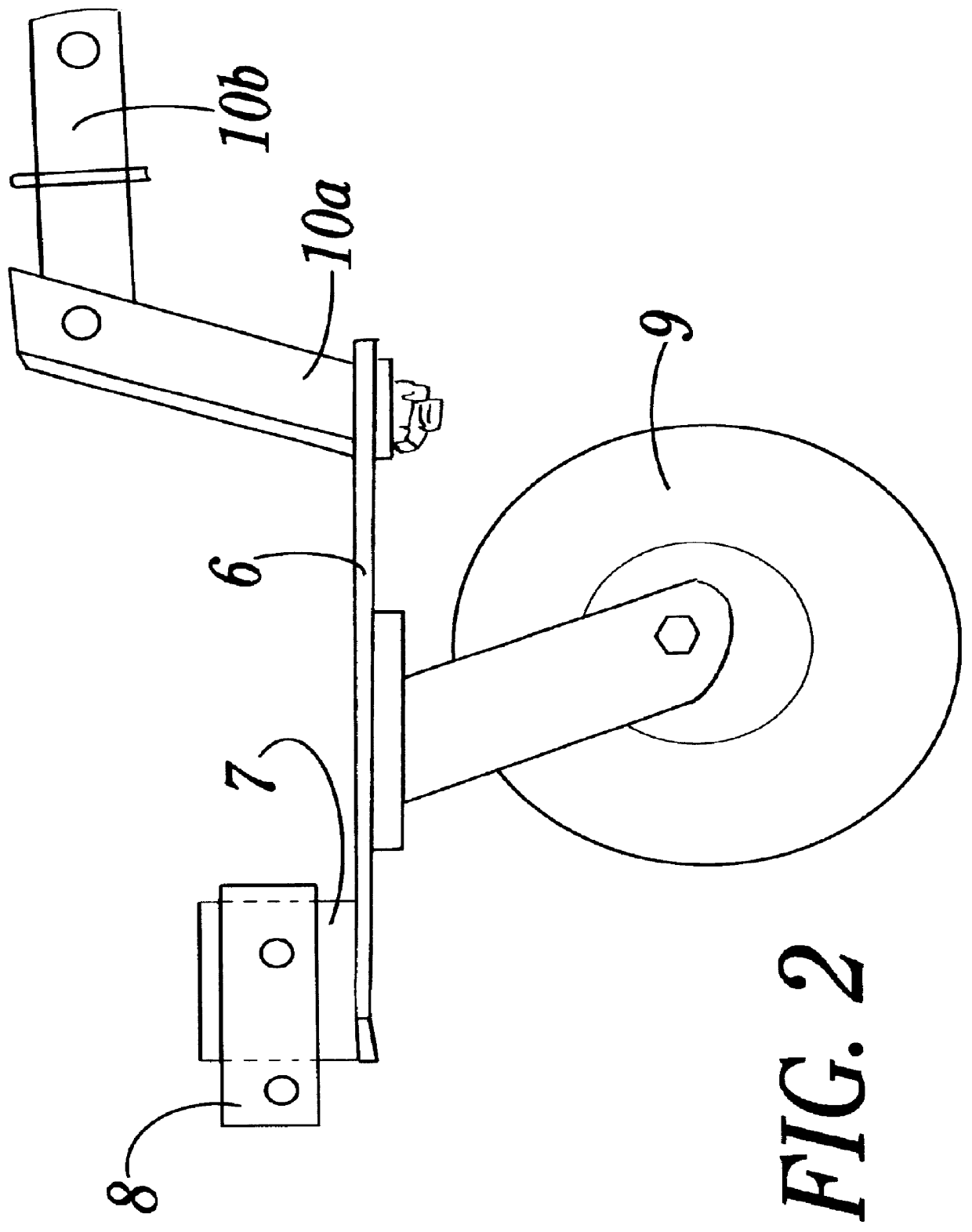

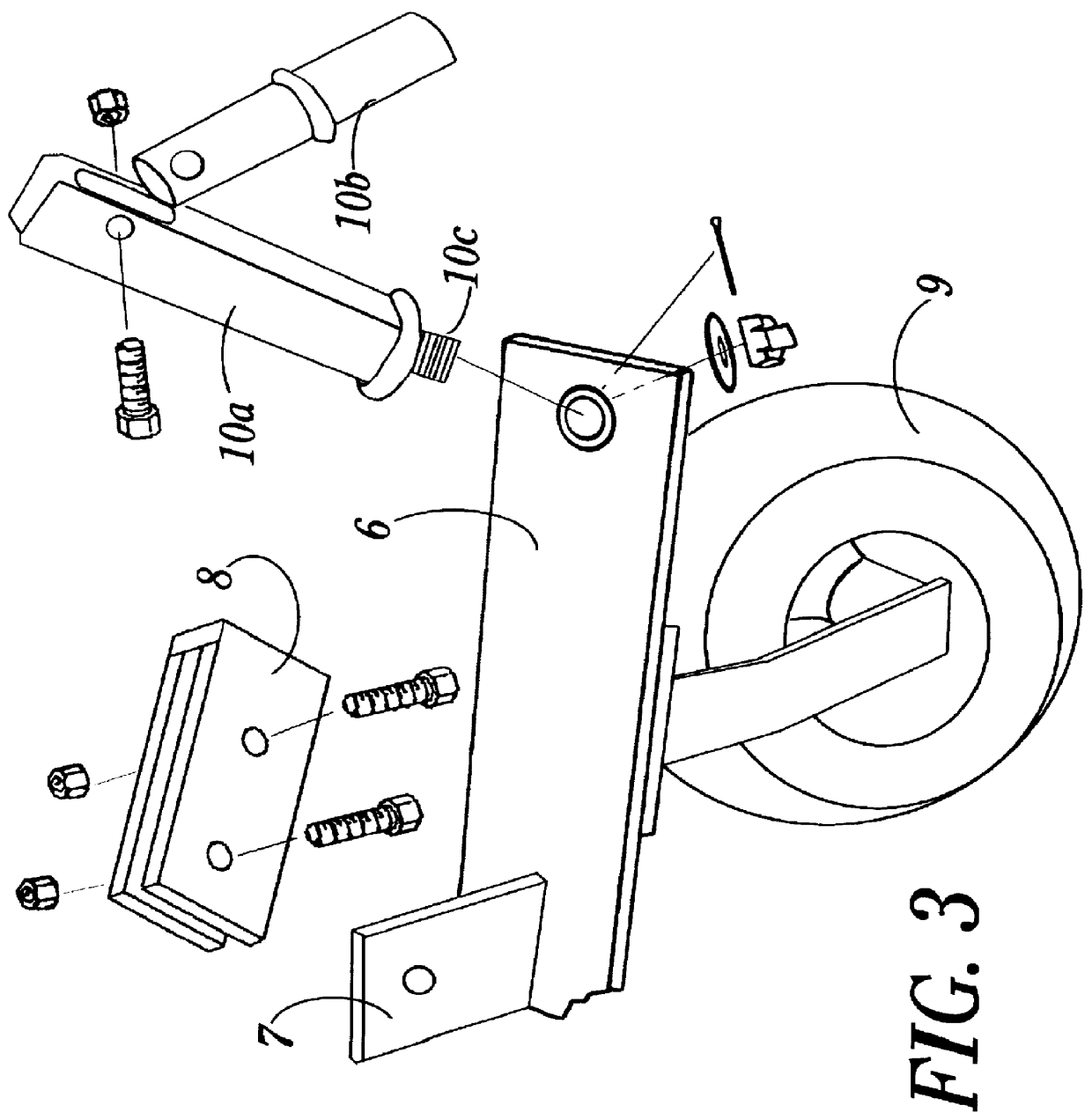

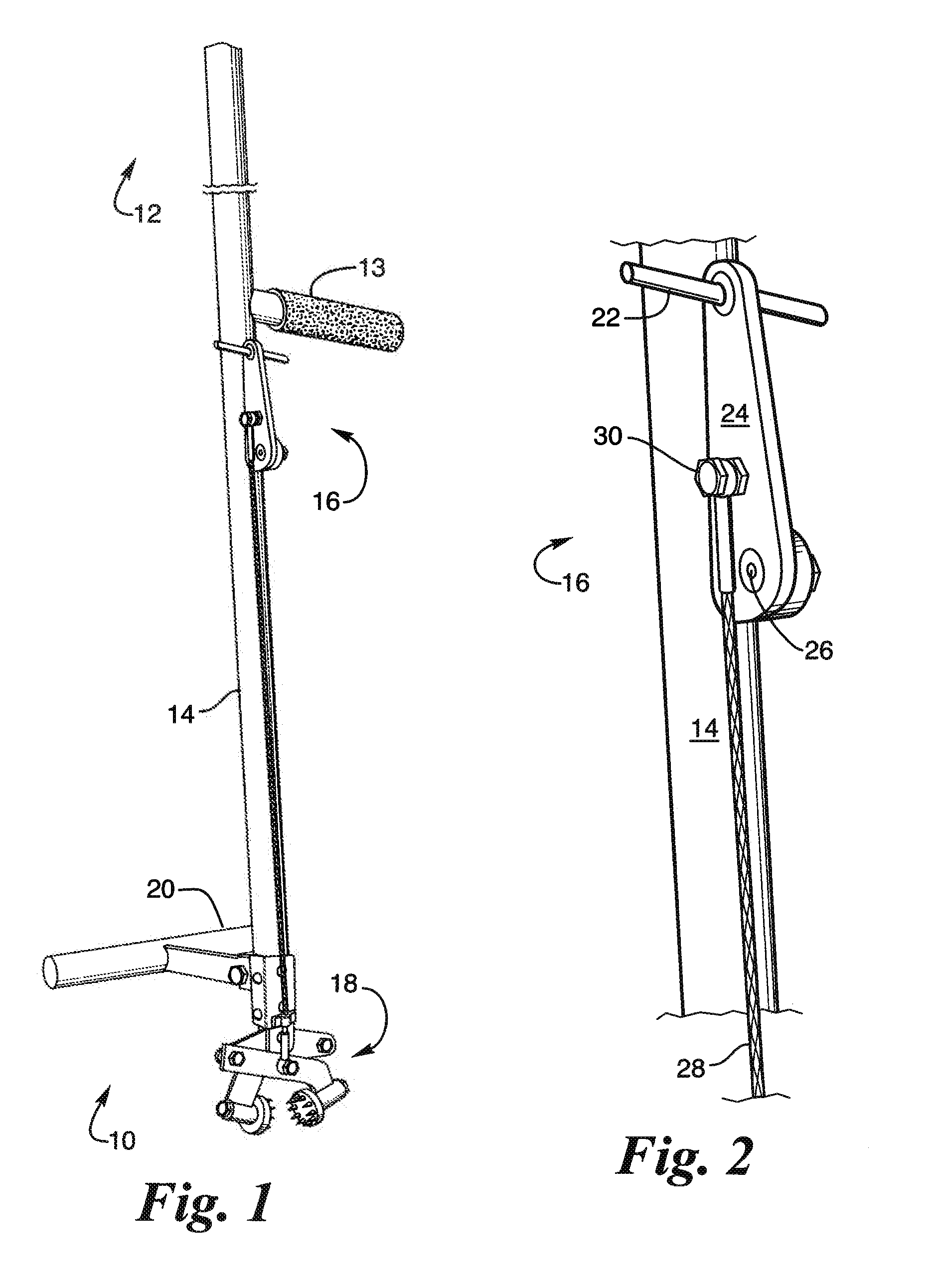

Rotary tiller attachment to facilitate towing

InactiveUS6131670ASimple and effective and economicalEffective and practicalAgricultural machinesSoil-working equipmentsMotor driveDrive wheel

An attachment kit with swiveling wheel for converting a self-propelled rotary tiller with rear tines and motor driven wheels into a towing machine. The attachment kit is secured to the tiller in place of the drag stake. A mounting bracket (8) allows for the assembly to be easily mounted to the rotary tiller without removing either tines (11) or the tine guard (12). The attachment kit with swiveling wheel (9) adds versatility and stability to the rotary tiller by converting it into a towing machine which can be used to tow many different types of trailers, nut harvesters, garden carts, etc. A towing tower (10a) and (10b) to facilitate towing a nut harvester easily connects to the attachment kit. The attachment kit also accepts ball-type hitches and drop-pin hitches.

Owner:JOHNSON JOHN TRAVIS

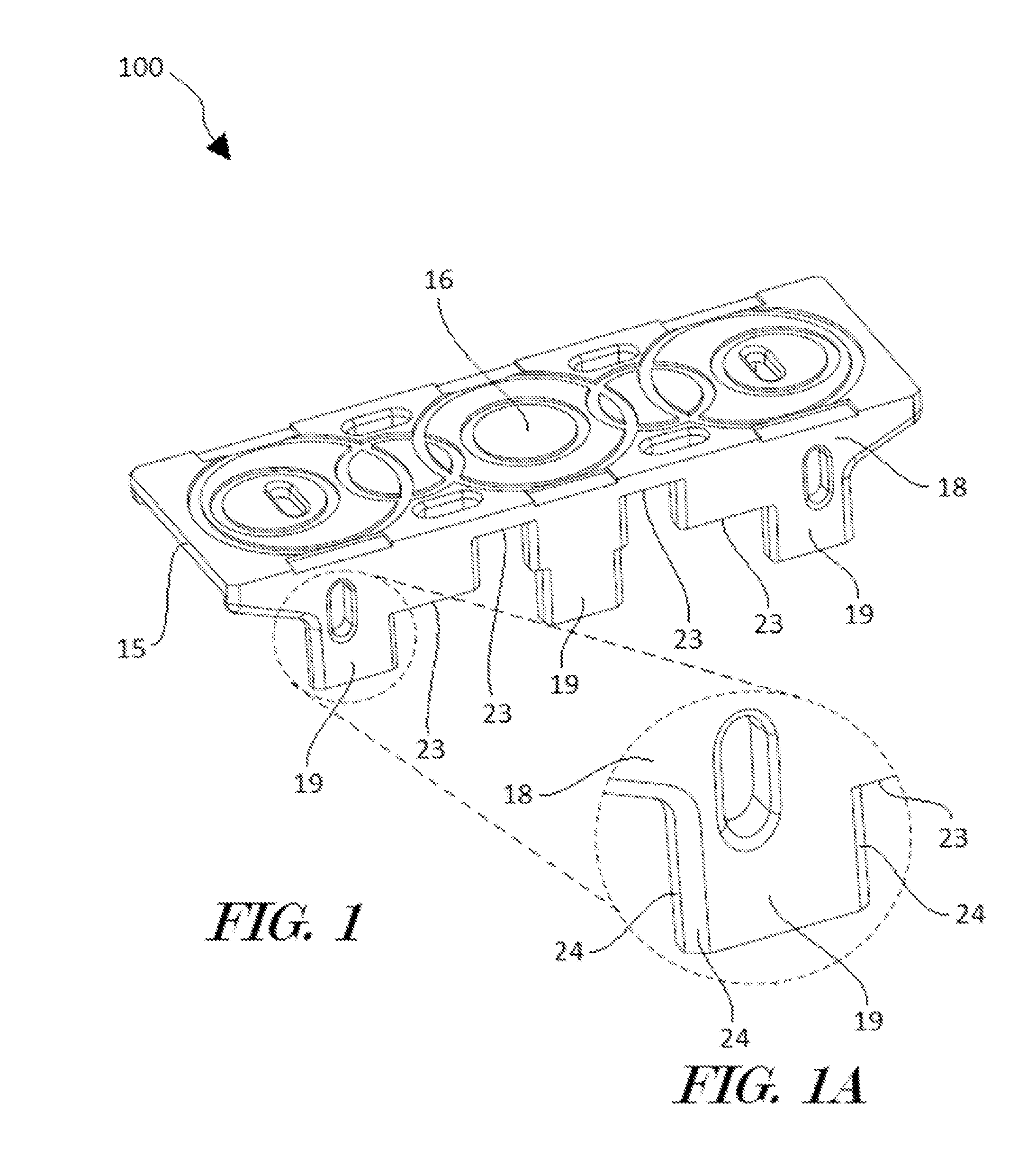

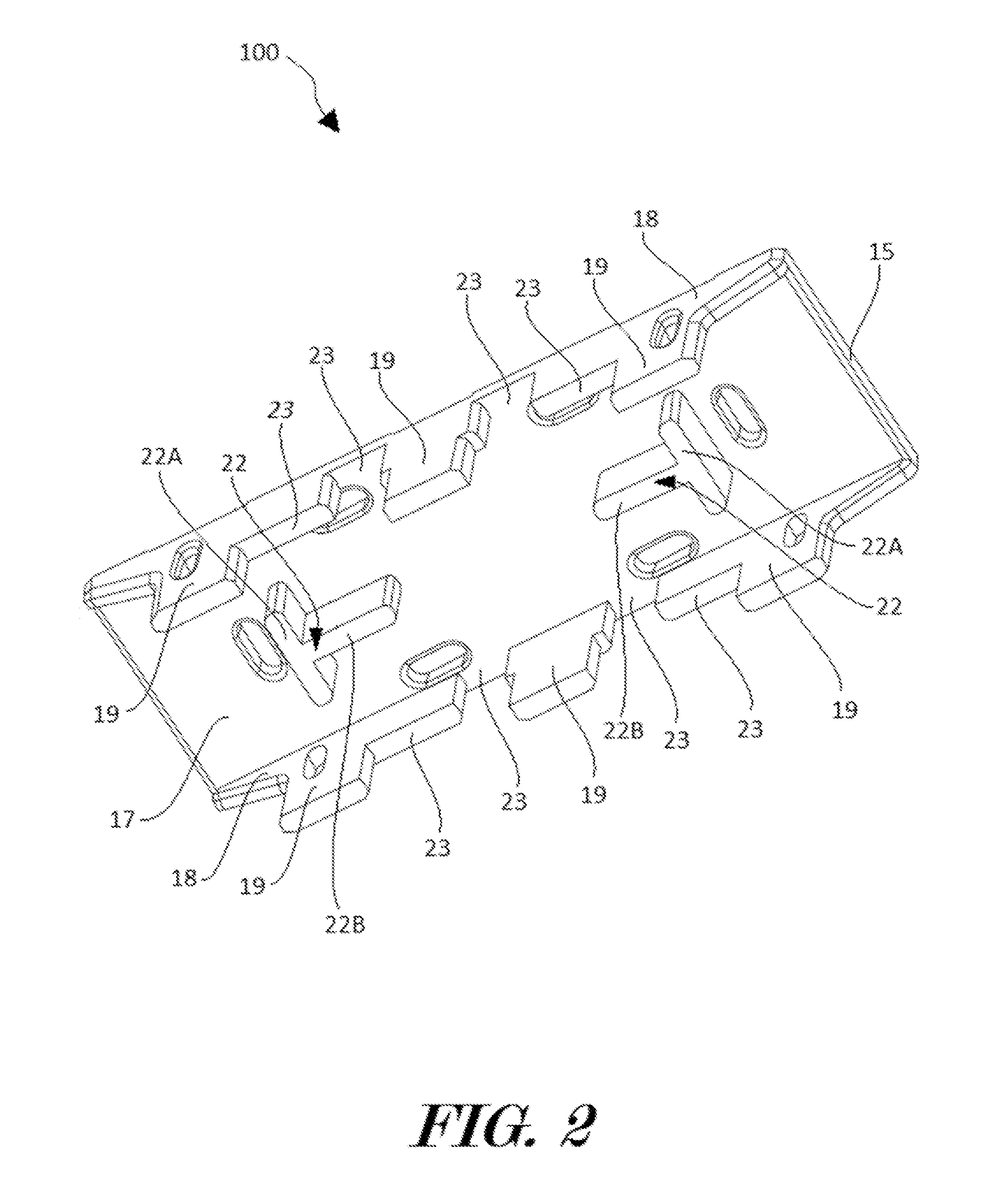

Surgical Sagittal Blade Cartridge With A Reinforced Guide Bar

ActiveUS20200315632A1Less chance of bendingMetal sawing devicesMetal sawing toolsPhysical medicine and rehabilitationTine

A surgical sagittal saw cartridge that includes a guide bar formed from an inner plate and opposed outer plates, the inner plate defining a head. The cartridge has a blade that is disposed against the head of the inner plate. The inner plate may comprise an inner tine and / or two opposed outer tines. The inner tine may be formed to define the head against which the blade is disposed. The outer tines extend distally so as to define a space between the outer tines in which the blade is seated.

Owner:STRYKER EURO OPERATIONS HLDG LLC

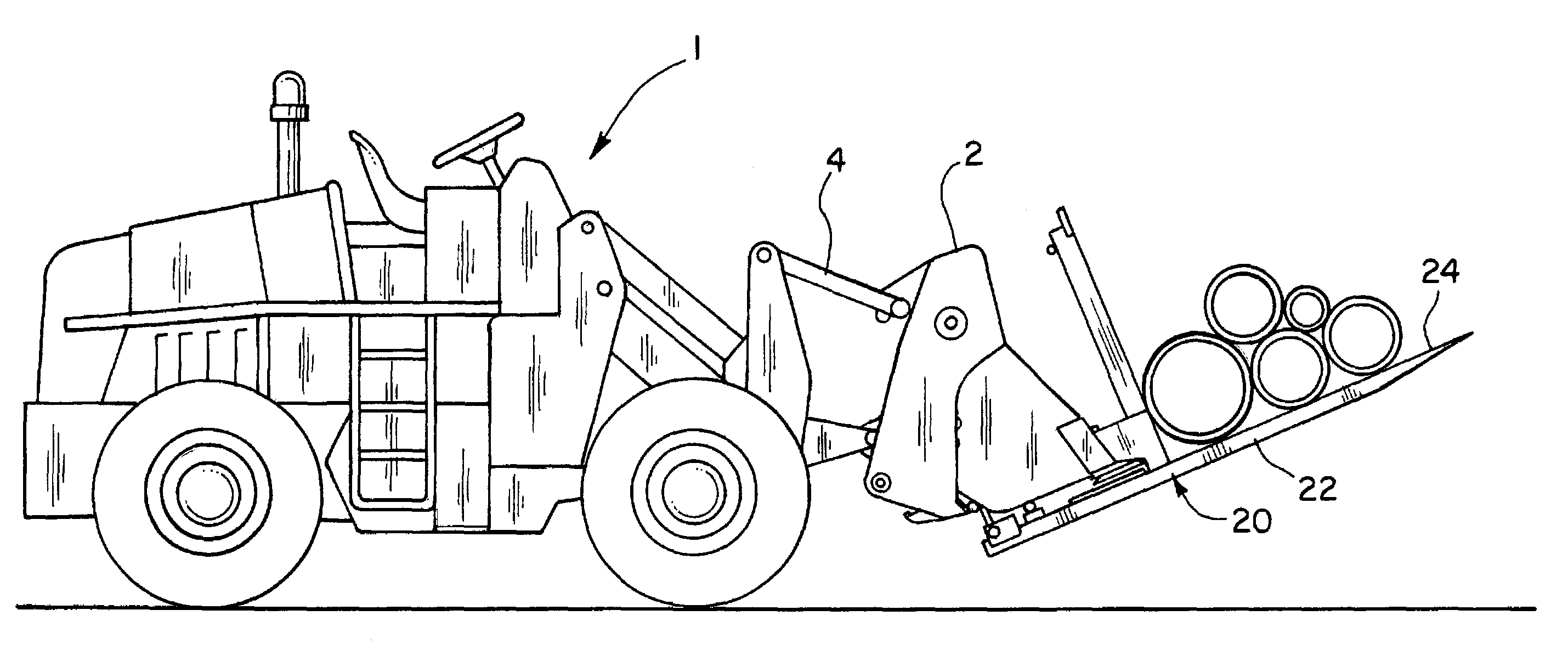

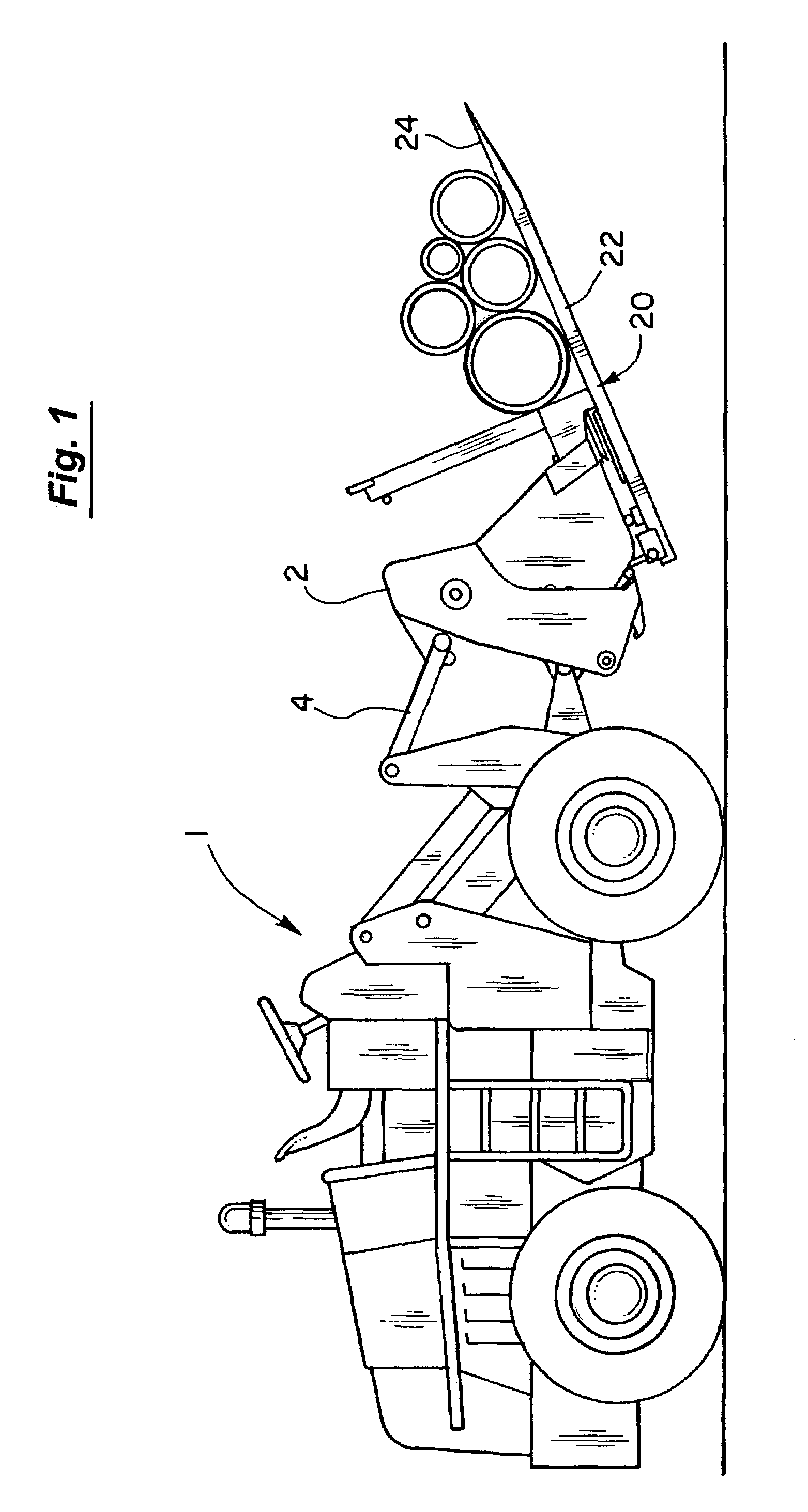

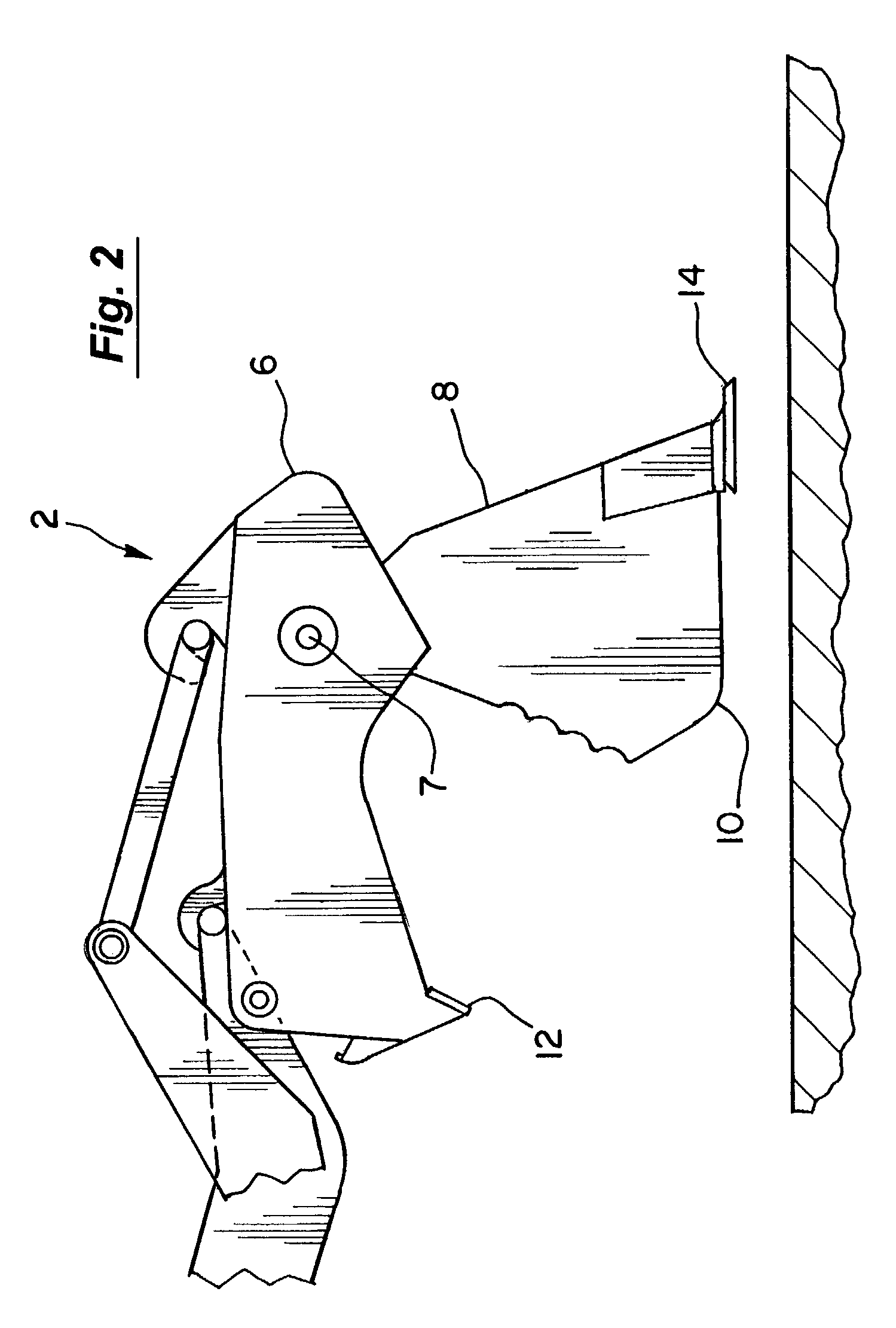

Pickup and alignment mechanism for logs and a method of use

ActiveUS20150343661A1Easy to operateSave timeMetal sawing devicesFeeding devicesKnife bladesEngineering

A pickup and alignment mechanism for logs is disclosed along with a method of using the mechanism. The pickup and alignment mechanism includes a frame, a connector and a plurality of L-shaped tines secured to the frame. The plurality of L-shaped tines is grouped into pairs. The pickup and alignment mechanism also includes a pair of side tine. The pickup and alignment mechanism is designed to be removably mounted to a motorized vehicle. All of the L-shaped tines can be hydraulically or pneumatically actuated to remove from between one to six logs from a stacked pile of logs. The one to six logs are then raised above ground level and are aligned relative to one another so that they can be easily cut into smaller piece of firewood by a person with a chain saw. The person with the chain saw will approach the front of the pickup and alignment mechanism and face the motorized vehicle. The pickup and alignment mechanism further includes a plurality of bumpers secured to each pair of L-shaped tines. The bumpers provide a clearance such that the blade of the chain saw can be kept a safe distance away from the frame to prevent damage to the blade.

Owner:ZORN GARY LEE

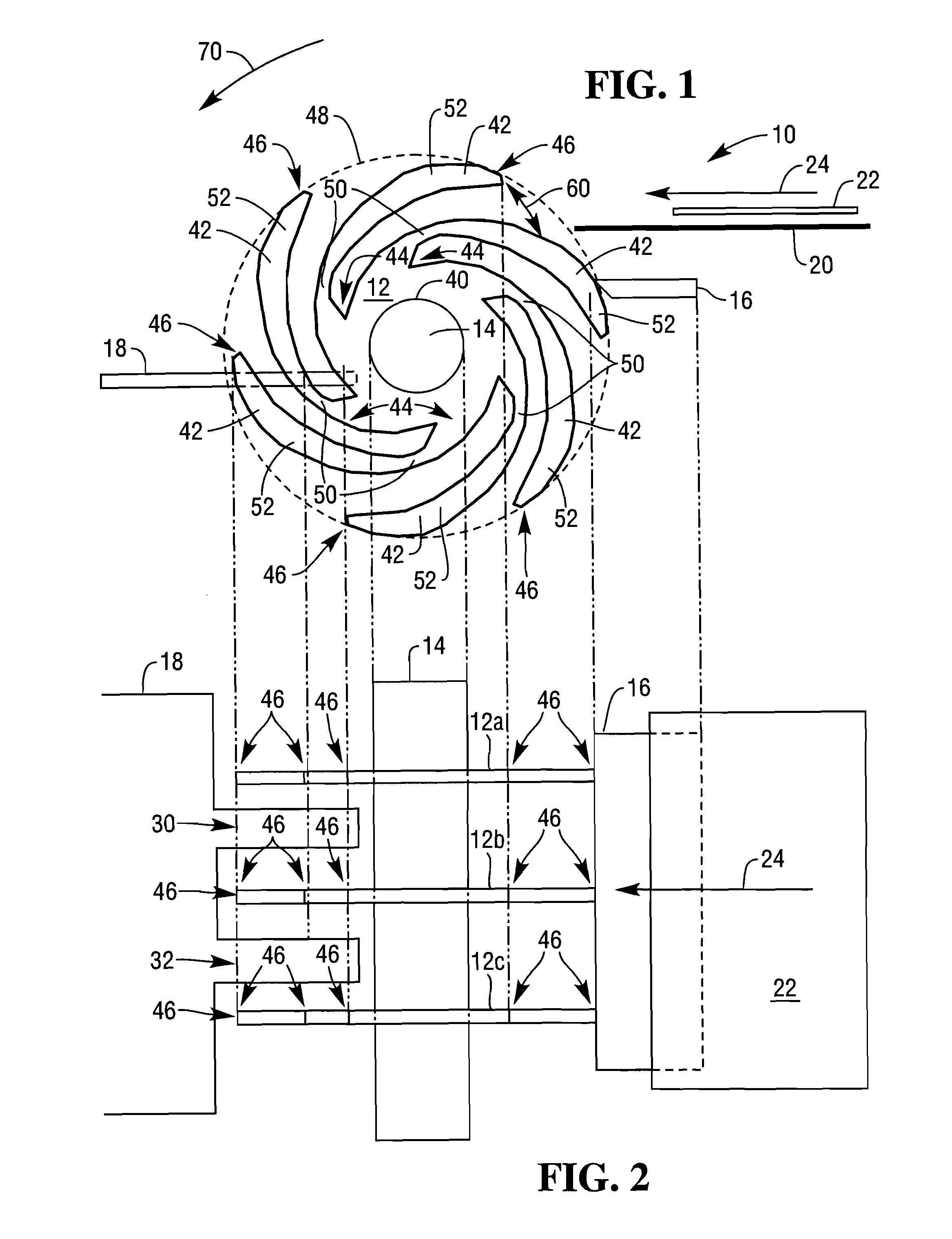

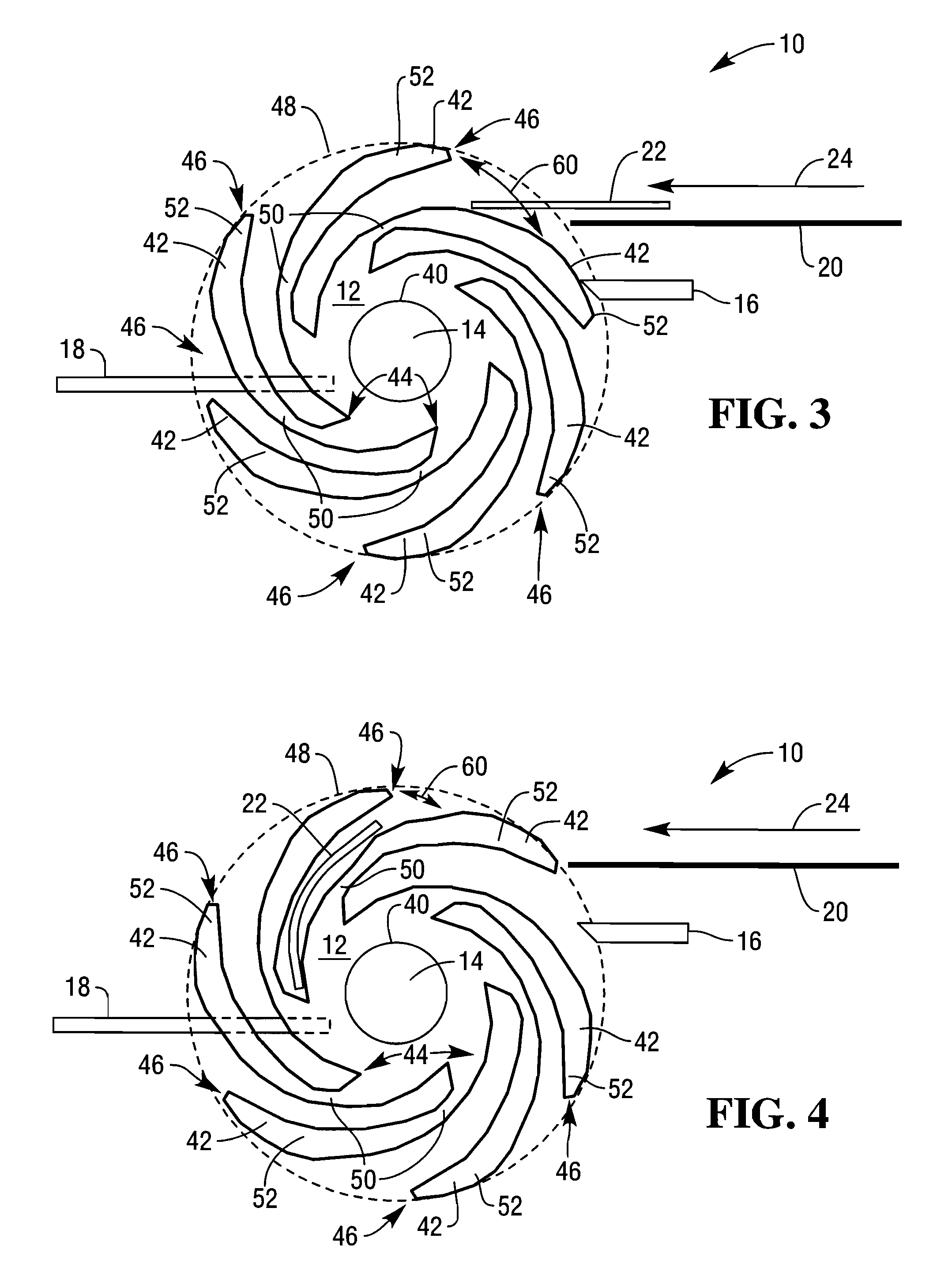

Media stacker

A media stacker unit comprises: (i) at least one stacker wheel and (ii) a detent. The stacker wheel includes: a hub for mounting on an axle, and a plurality of arcuate tines, each tine being coupled to the hub at a hub end and extending transverse to the axle to a point radially spaced from the axle at a capture end. When the stacker wheel is rotated about the axle, the capture ends traverse a capture circumference. Each tine further comprises a resilient tine portion. The detent partially extends within the capture circumference for engaging with and temporarily retarding a capture end as the stacker wheel is rotated. This reduces the time during which that capture end blocks a media transport path, thereby reducing the possibility of a media item colliding with a capture end and jamming the media stacker unit.

Owner:NCR CORP

Rake wheel with plastic support band for tines

Owner:VERMEER MFG CO

Pallet with tine support elements

An improved pallet comprising: a support deck with an upper load contacting surface and a lower ground facing surface; a first and second sidewall, each with ground contacting legs and each connected to two elongate sides of the support deck; a pallet cavity formed below said lower ground facing surface of the support deck and between said first and second sidewalls; and a support element with a tine contacting surface protruding vertically down from the lower ground facing surface of the support deck partially into the pallet cavity but not below the ground contacting legs of the first and second sidewalls.

Owner:INTREK LOGISTICS

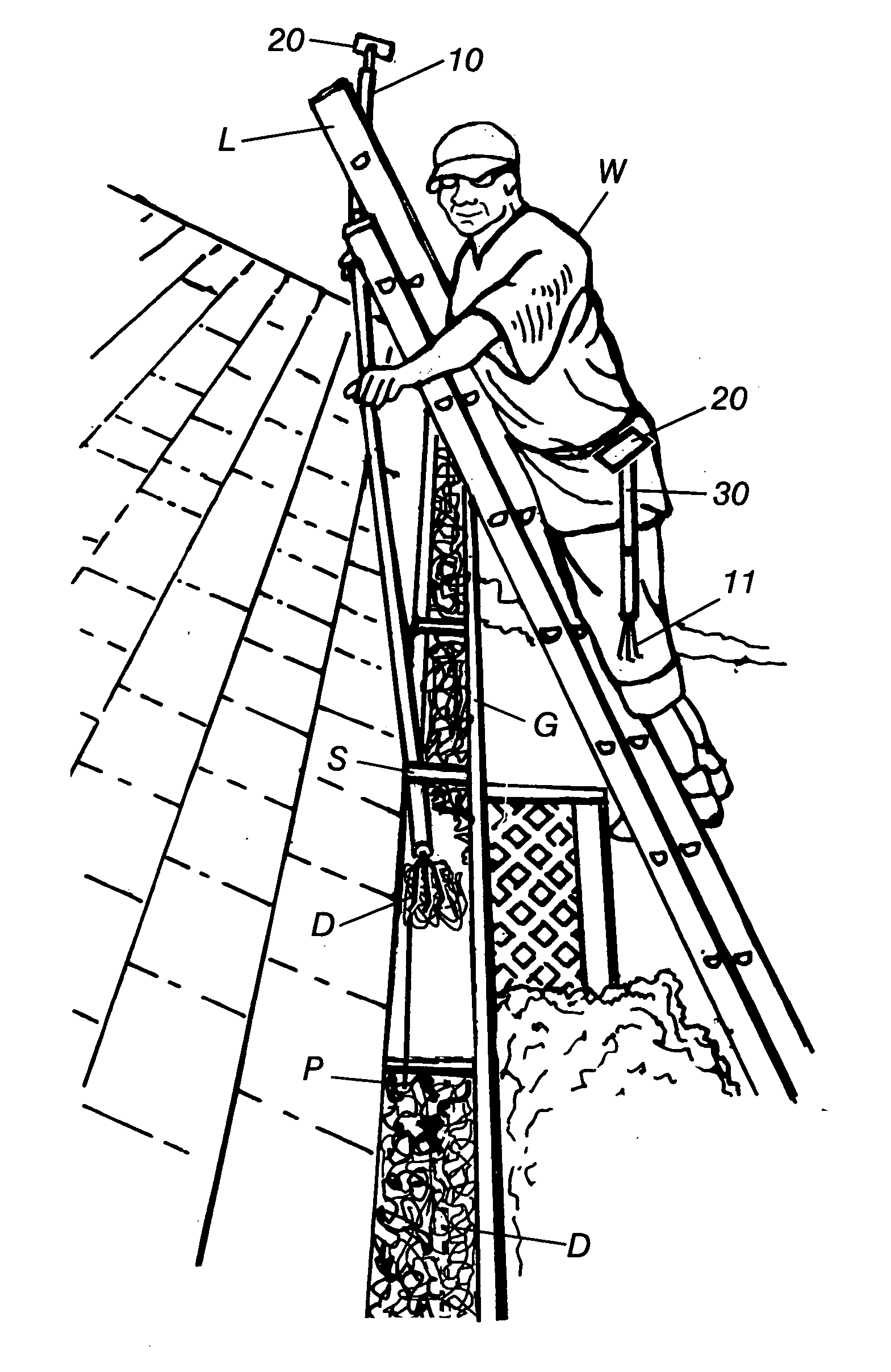

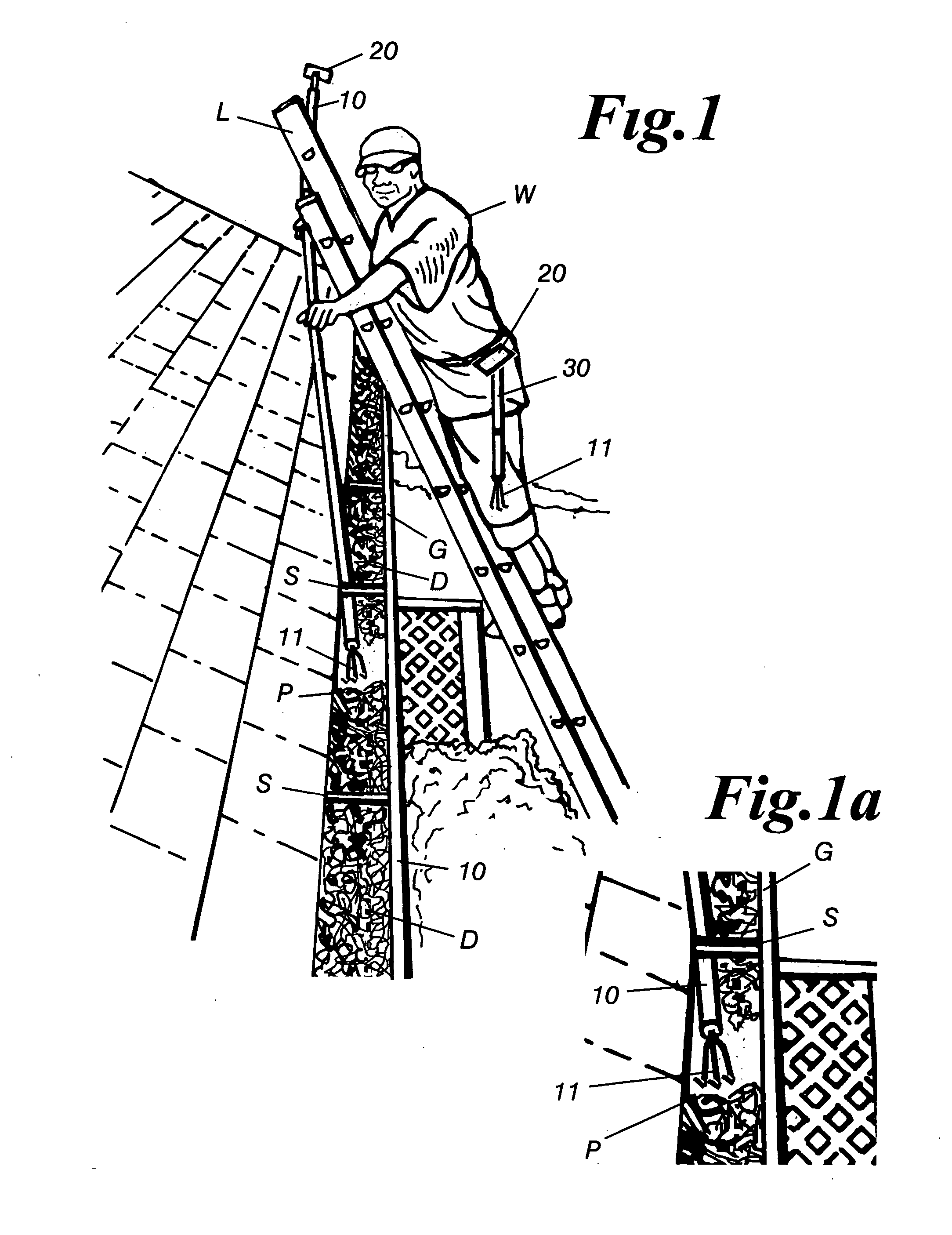

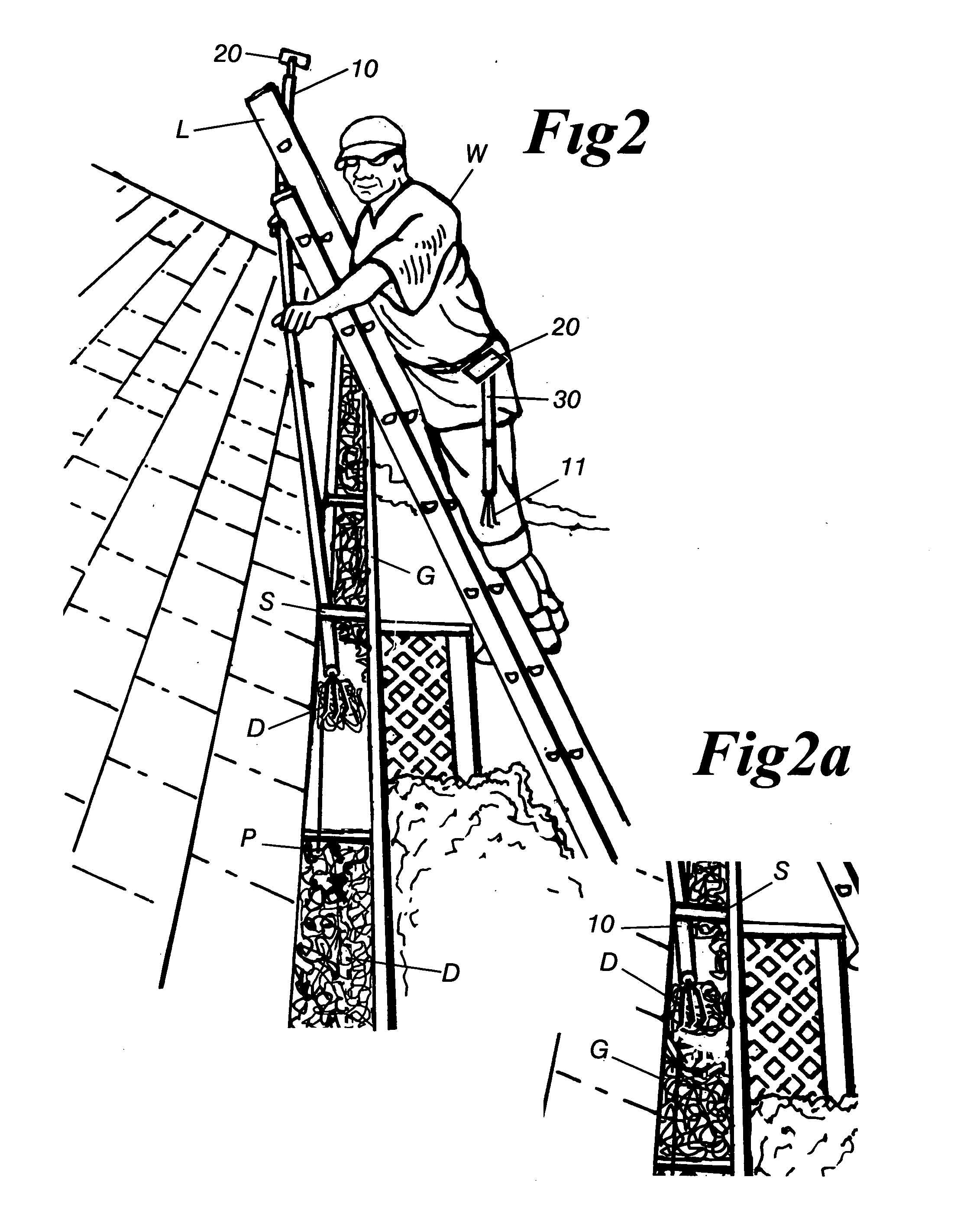

Apparatus and method for cleaning gutters

InactiveUS20050093315A1Readily availableRoof coveringForksMechanical engineeringBuilding construction

Owner:MITCHENER CALVIN LEE

Brush remover

In some embodiments, a brush remover may include one or more of the following features: (a) an elongated frame, (b) an operator's station located at an end of the elongated frame, (c) scissor gear located at an opposite end of the elongated frame, (d) an actuation lever coupled to the frame, (e) a cable operably coupled to the actuation lever and to the scissor gear, (f) a support leg coupled to the opposite end of the elongated frame adjacent to the scissor gear, (g) a pincher operably coupled to the scissor gear, (h) a tine located on a pinching surface of the pincher, and (i) a spring operably coupled to the scissor gear.

Owner:B A C INDS

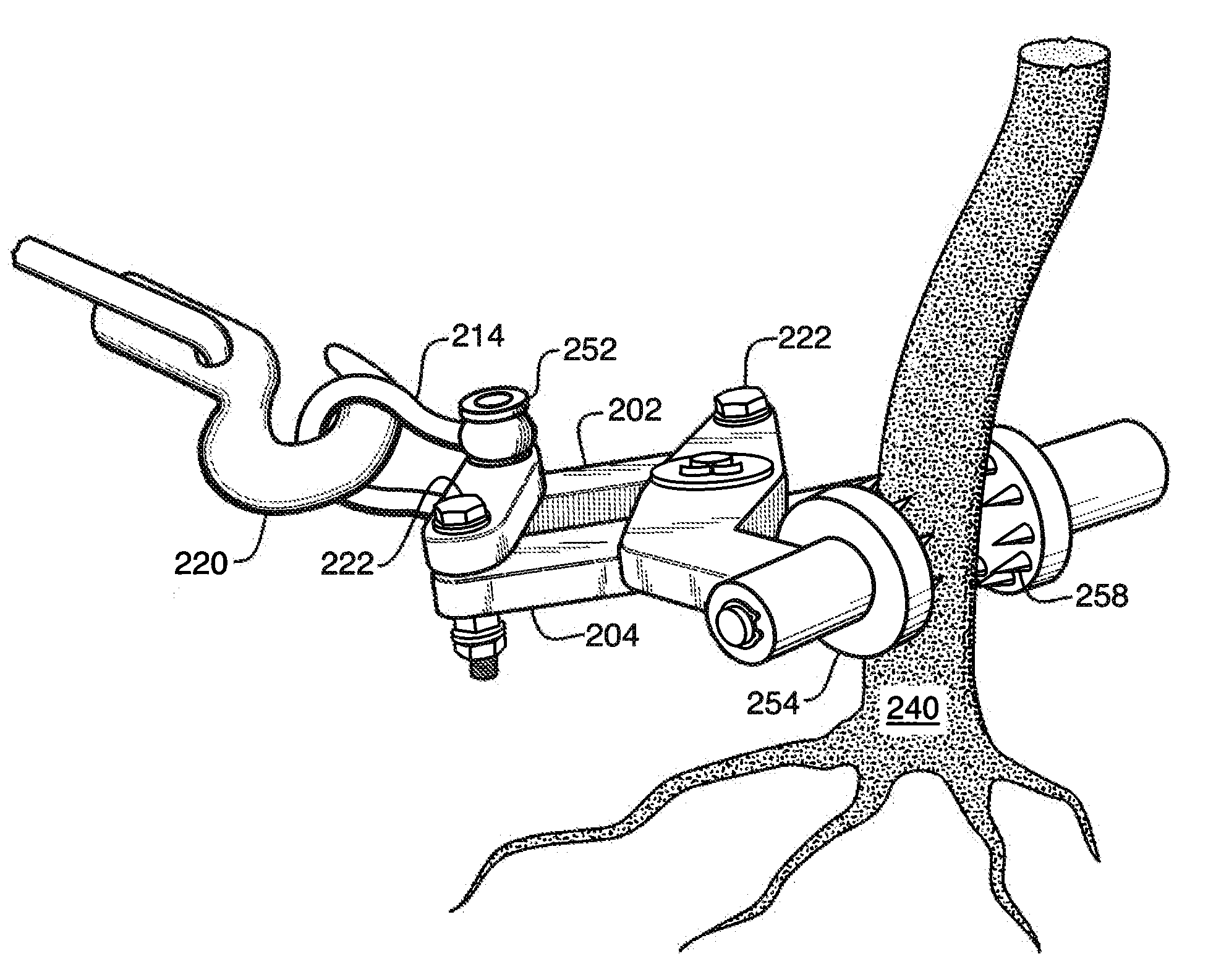

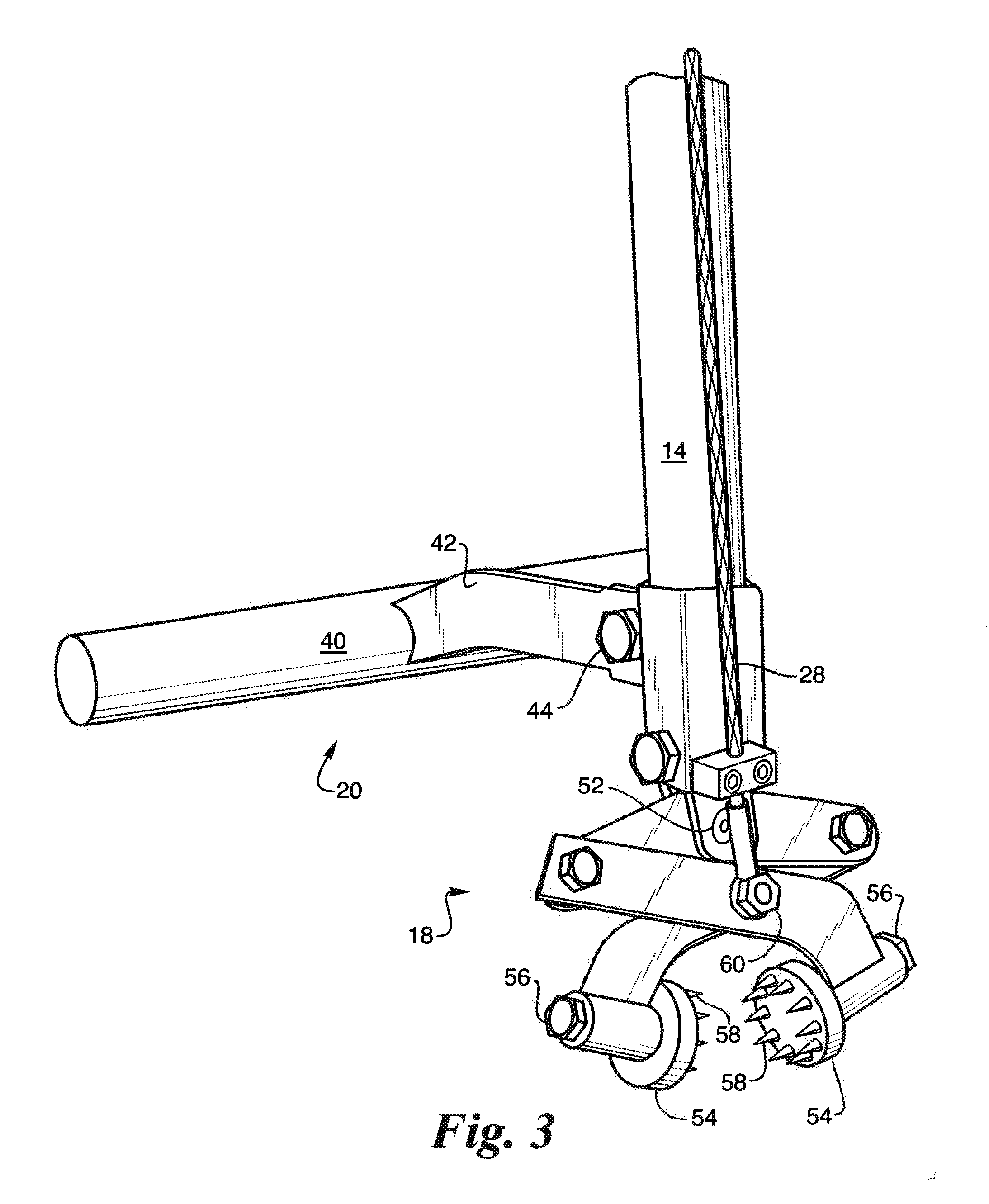

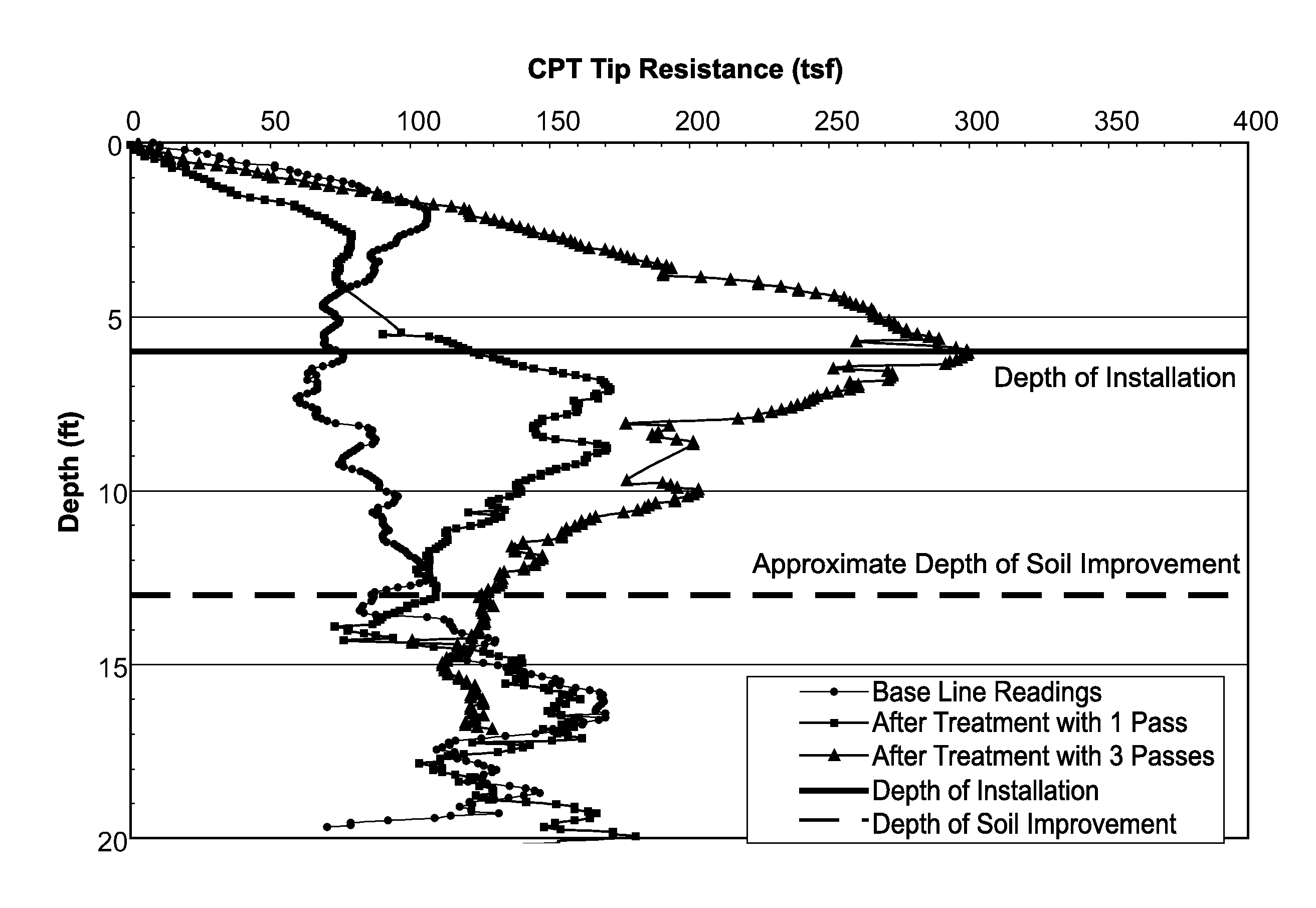

Method for Ground Improvement With Hardened Inclusions

Owner:GEOPIER FOUND CO INC

Metal pallet

ActiveUS11242173B2Improve the immunityDeflection resistance can be improvedRigid containersTineEngineering

A sheet metal pallet assembly includes a deck and an undercarriage. The deck is reinforced about its outer edges by longitudinal and transverse perimeter girding. The deck is further reinforced by one or more transverse reinforcement ribs and interior longitudinal girding. The undercarriage is composed of left and right fork tube risers joined together by bridges. The fork tube risers are configured to receive the tines of a forklift. Each fork tube riser has inner and a outer legs, each splayed at an a respective angle. Preferably, the splay angle of the outer leg is greater than the splay angle of the inner leg. The ends of each fork tube riser are folded over with a hem to improve strength and present a blunt edge. The undercarriage may, optionally, be fabricated from a single monolithic piece of sheet metal.

Owner:RICKABAUGH MICHAEL G

Shellfish cracking utensil

A shellfish cracking utensil has a handle portion and a head portion, with the head portion comprising (a) a base region having a lower part and an upper part, with the lower part being connected to one end of the handle portion, and (b) first and second tines connected to, and extending outwardly from, the upper part of the base region. The tines are preferably of substantially equal length, extending in substantially parallel relationship and defining a gap between them for inserting a shell portion of a shellfish. The two tines are substantially prong-shaped with the second tine wider than the first tine. The second tine has a bump portion on an edge thereof facing the first tine, preferably near the end of the second tine.

Owner:RIZZO MICHAEL F

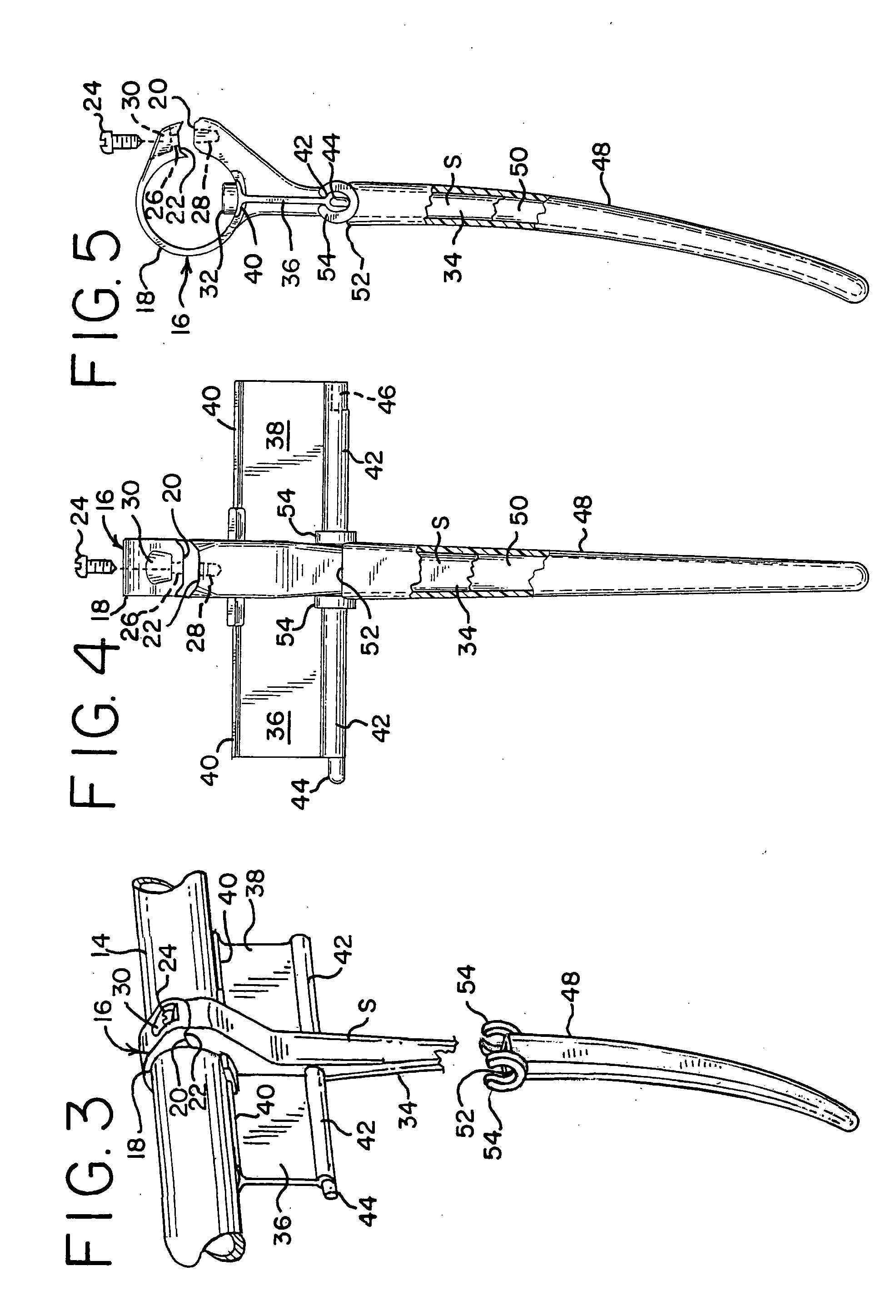

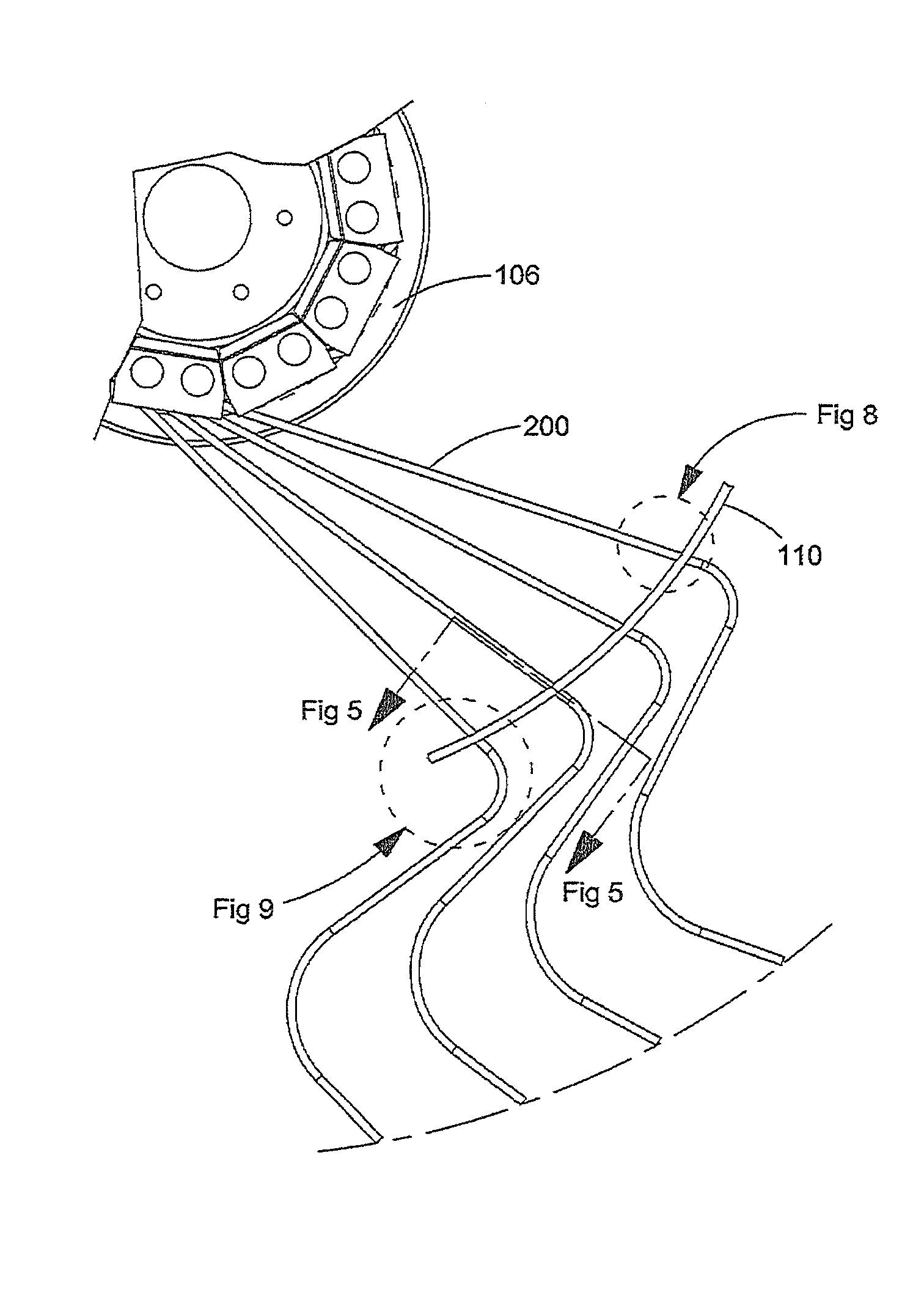

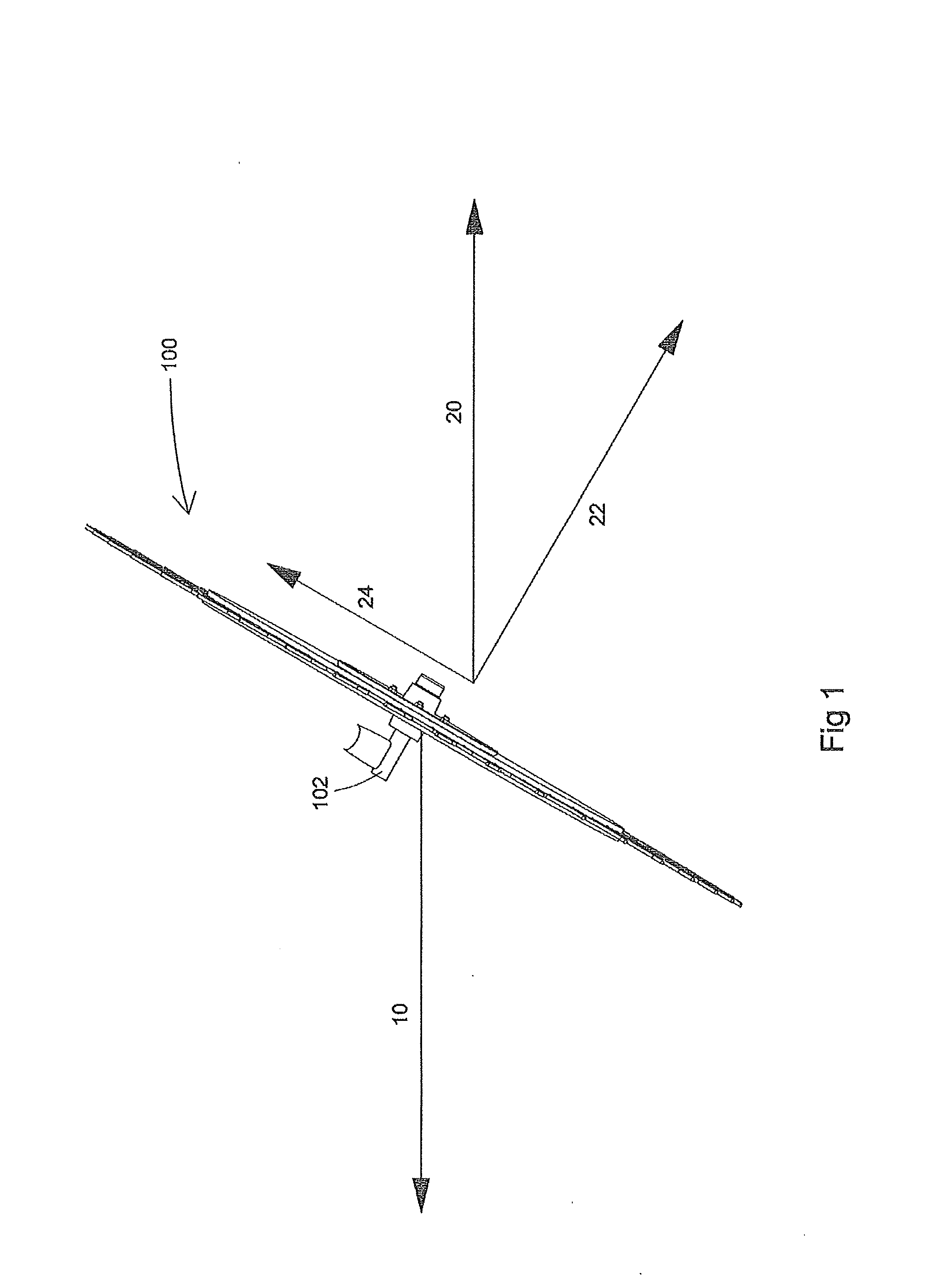

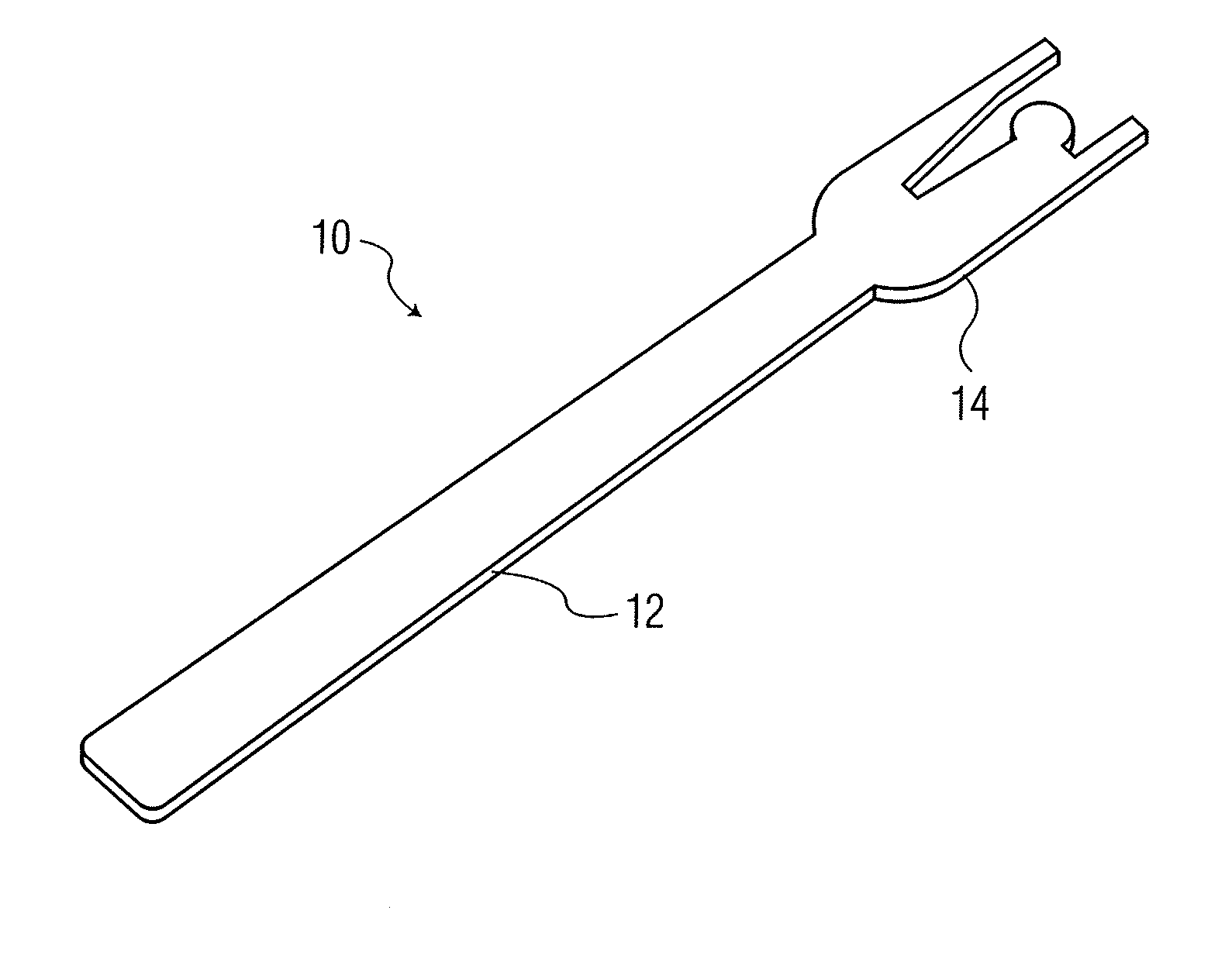

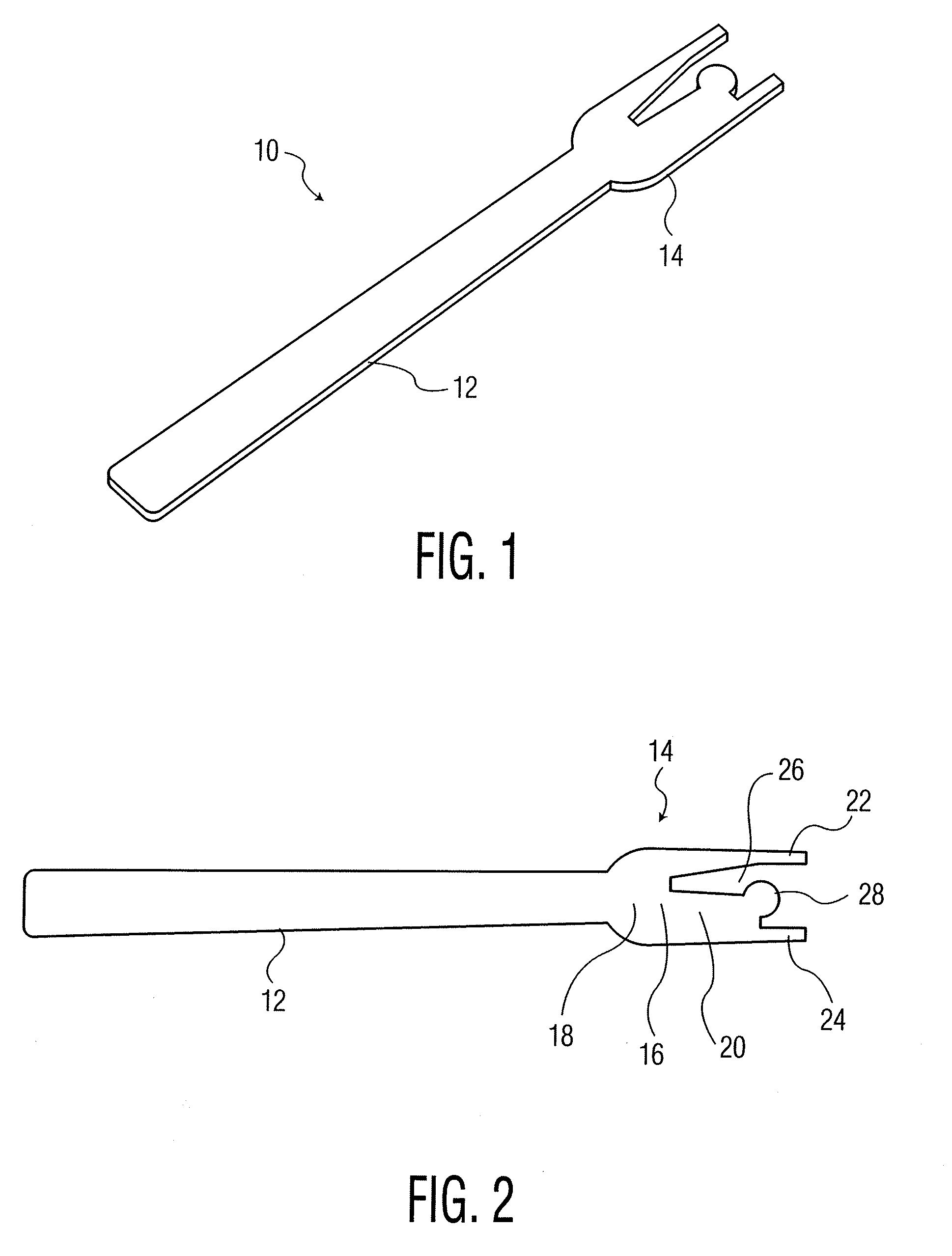

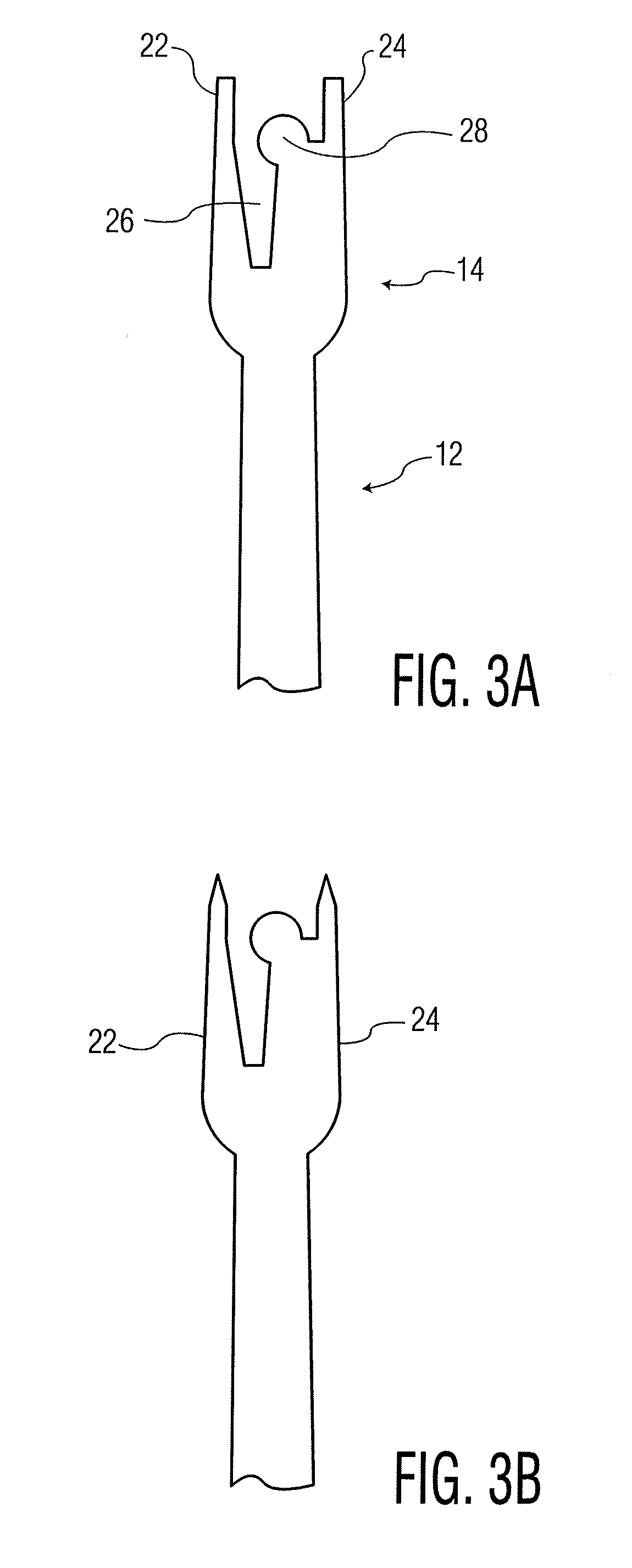

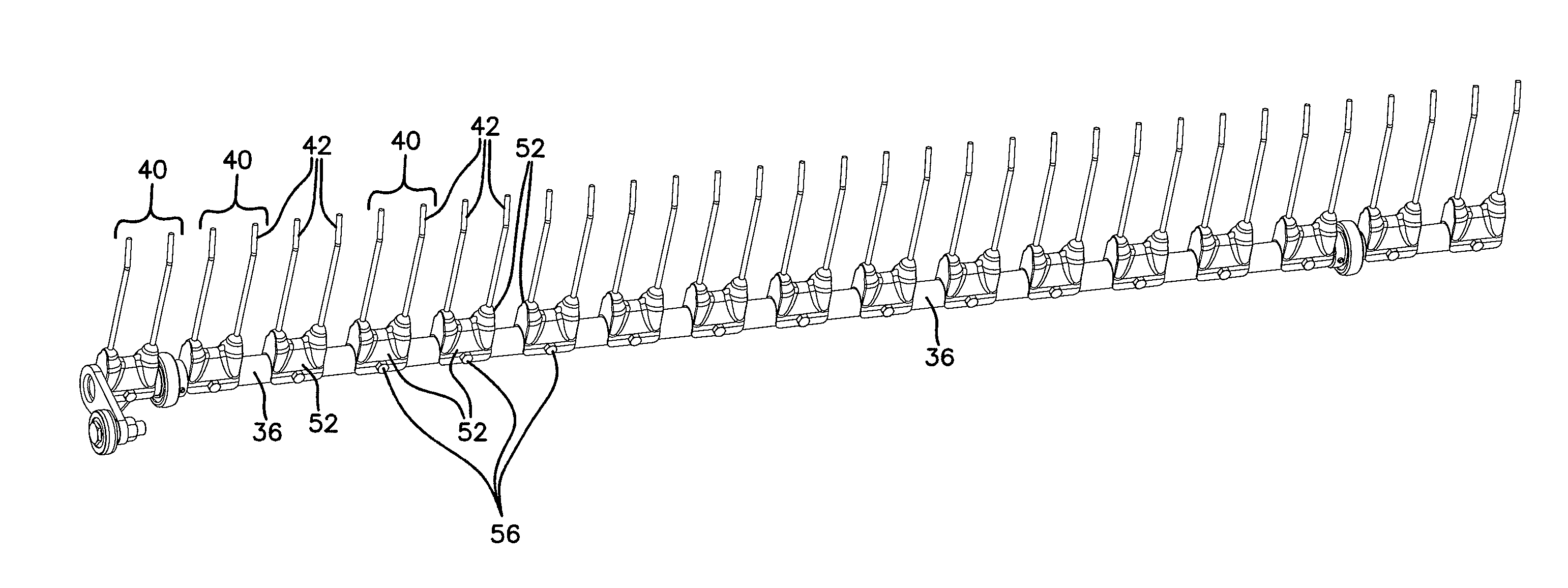

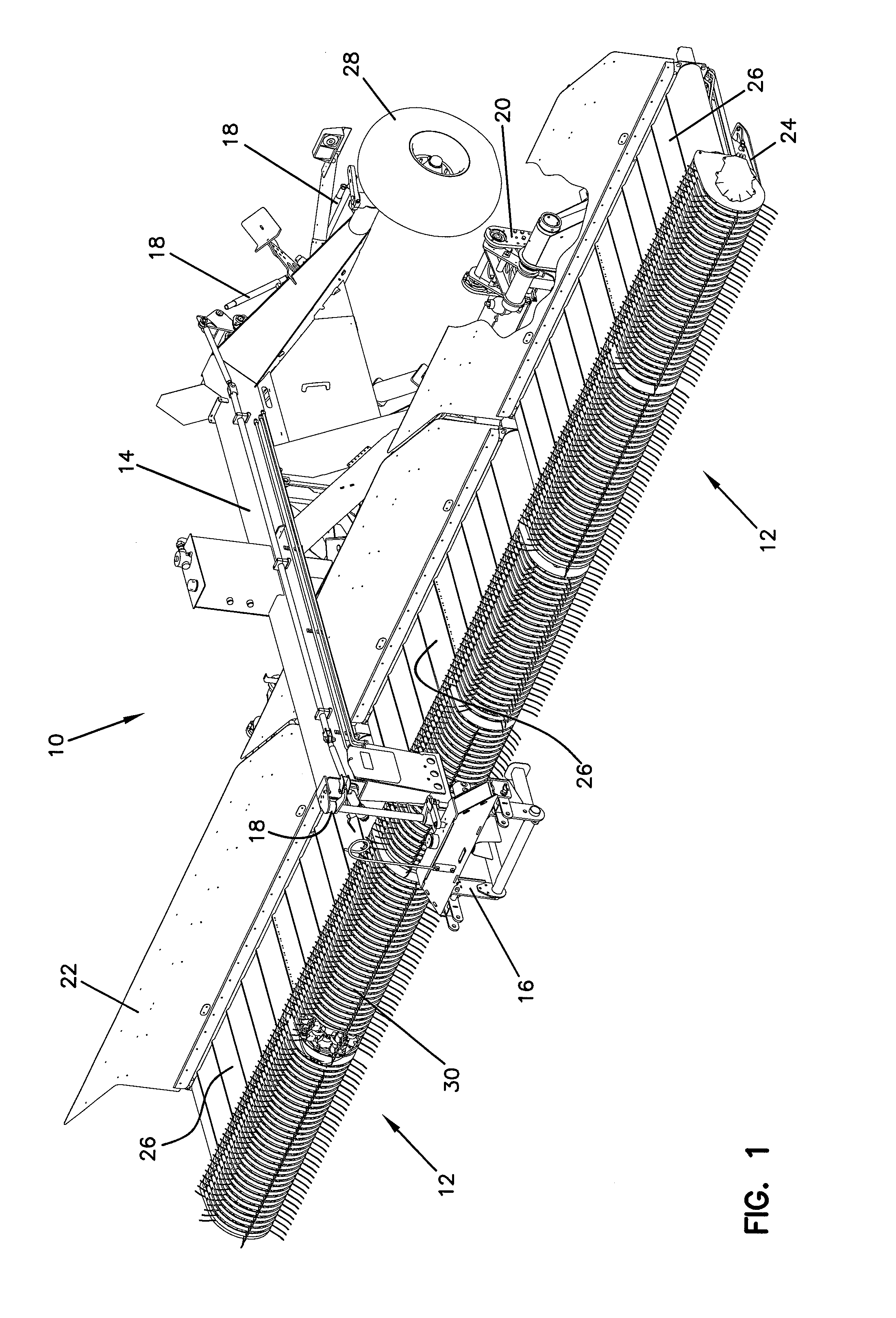

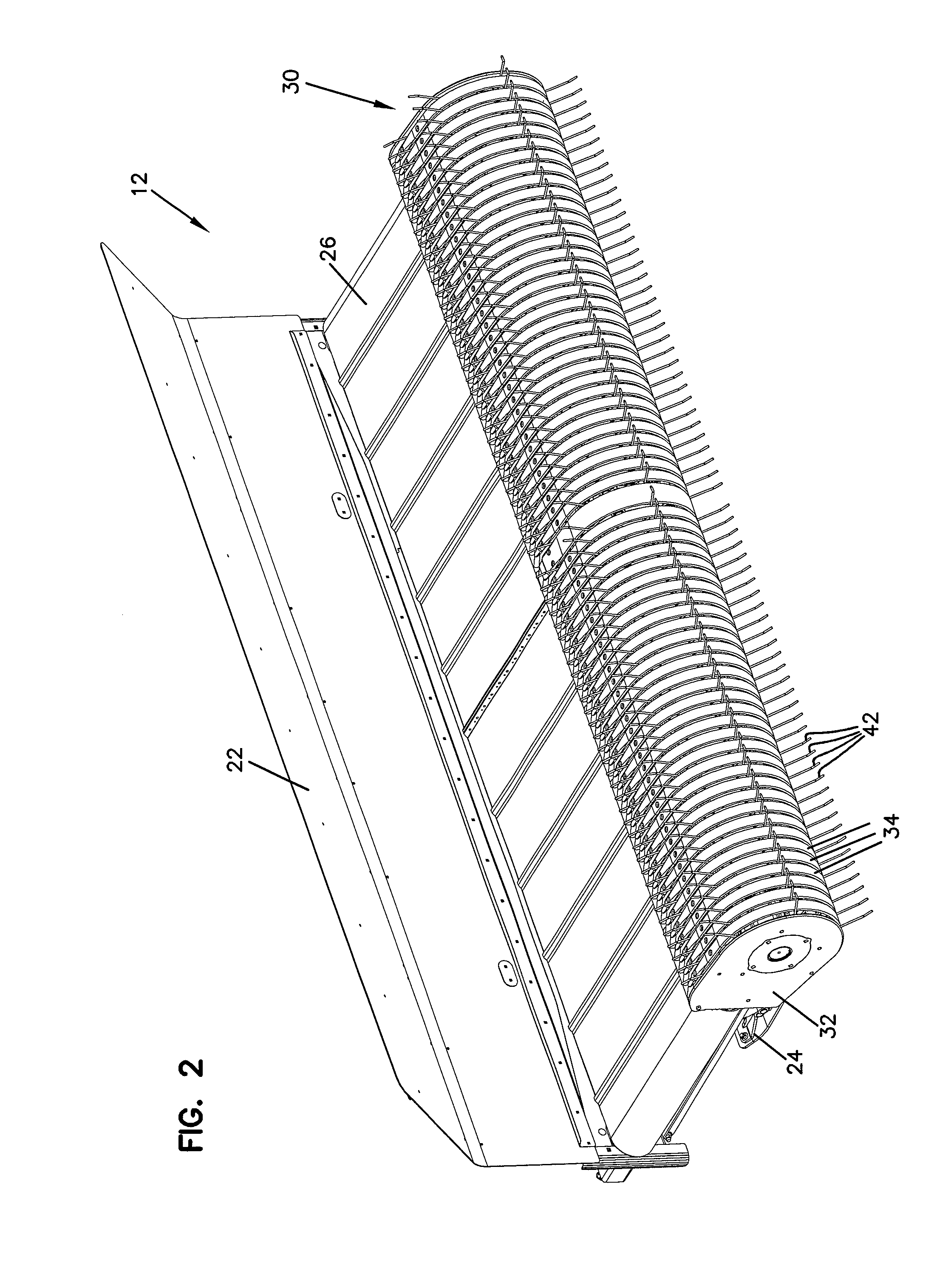

Tine assembly

ActiveUS20110239606A1Rigid enoughReduces lateral flexureLoadersMowersMechanical engineeringEngineering

A tine assembly is used with an agricultural machine such as a harvester or hay merger. The tine assemblies mount on a reel that rotates about an axis extending transverse to the direction of travel. The tine assembly includes a first tine and a second tine, each having a main extended portion and a lateral portion extending transverse to the main portion at a mounting end of the tines. The lateral portions mount into tabs or opposite ends of a sleeve. The sleeve or tabs and mounting end of the tines are enclosed by a molded mounting portion that also includes a reinforcing arcing element configured for mounting to the reel bar. The arcing element includes orifices that allow for easily bolting and unbolting the tine assemblies for easy attachment and removal.

Owner:OXBO INT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com