Patents

Literature

354results about "Haymakers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Suspension System for Wheel Rakes

A suspension system for rakes having at least one floating rake wheel has a hydraulic cylinder is used for both lift and suspension of the floating rake wheel. A hydraulic accumulator provides expansion room for hydraulic fluid to move in and out of the hydraulic cylinder during suspension.

Owner:VERMEER MFG CO

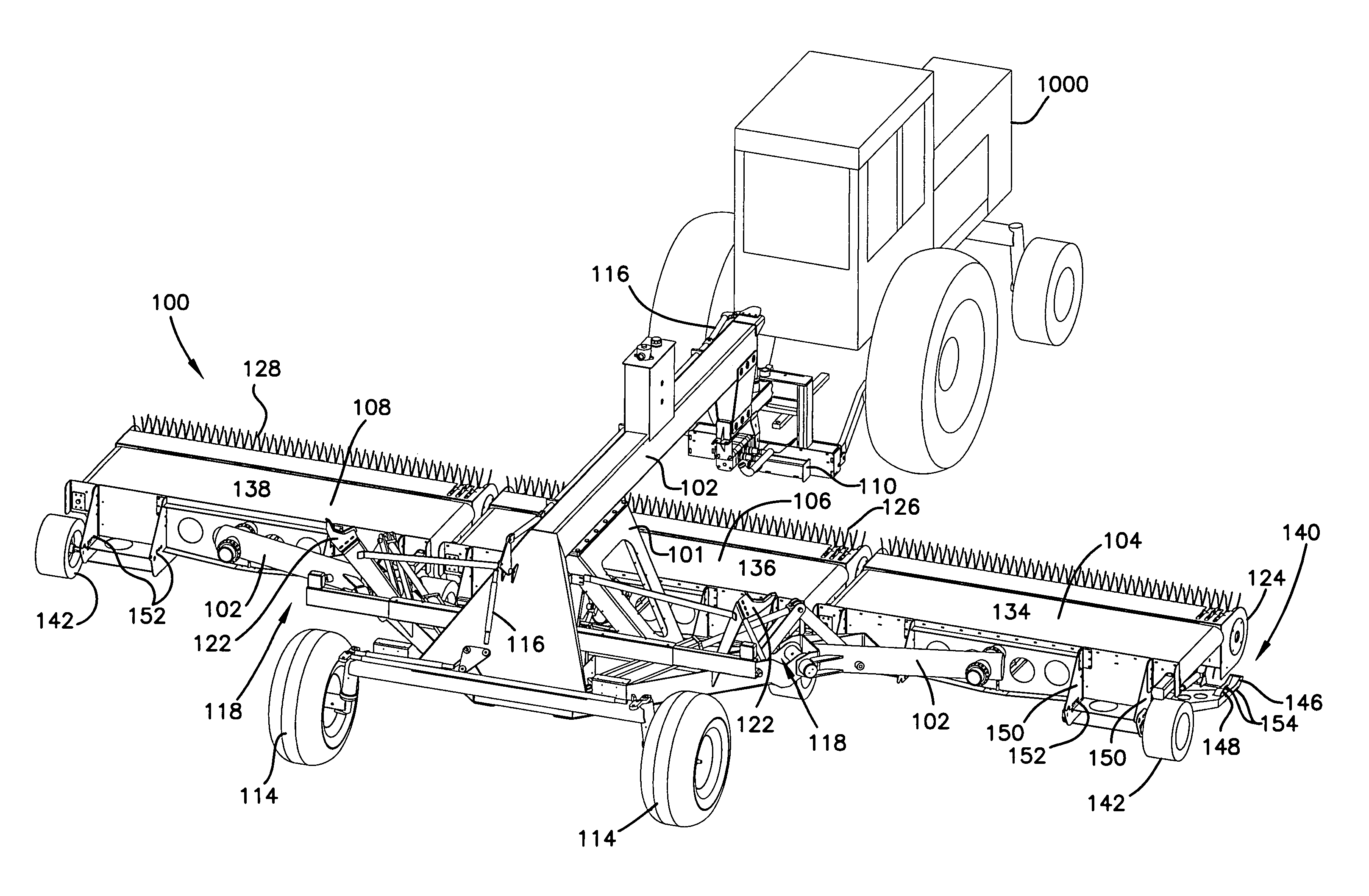

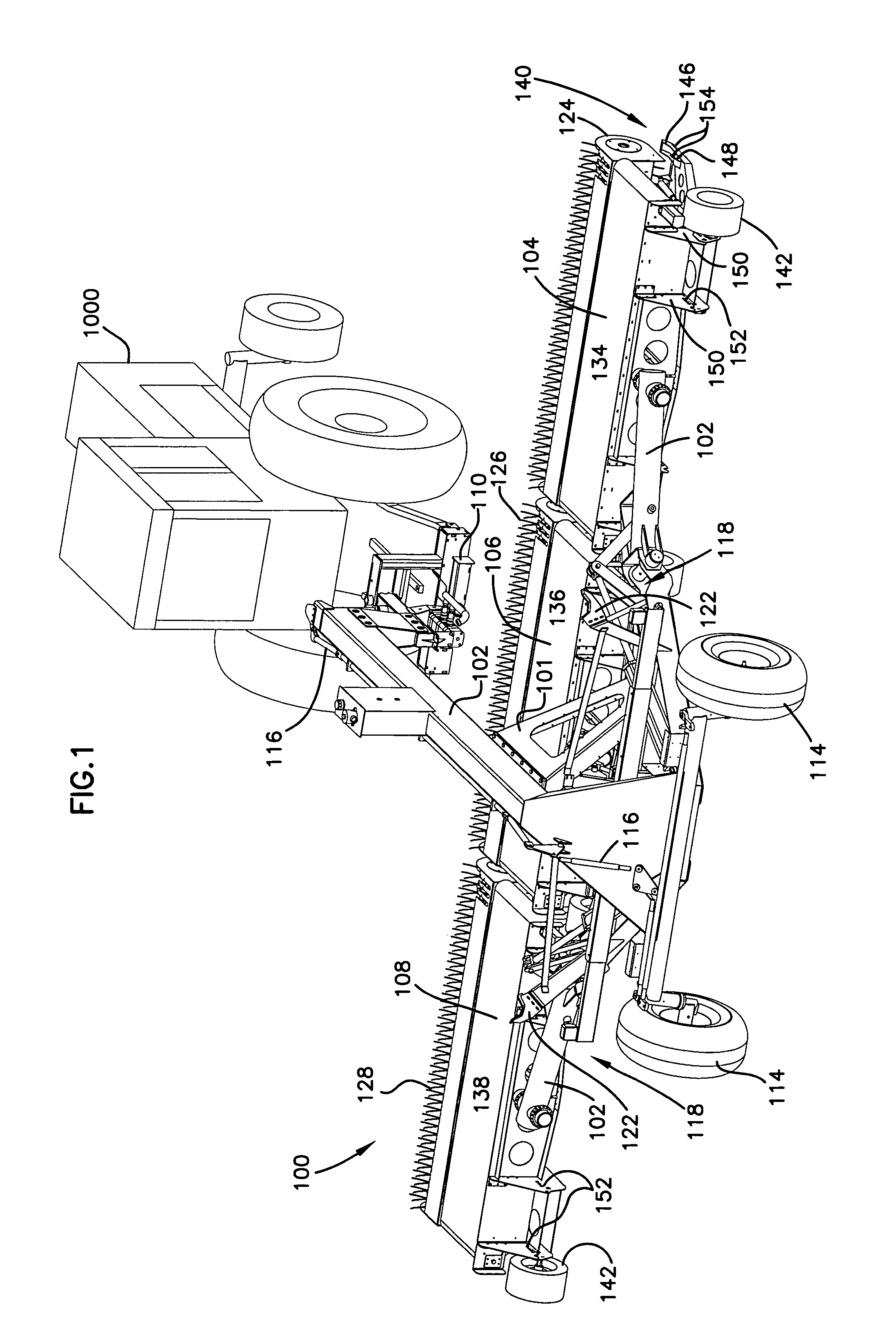

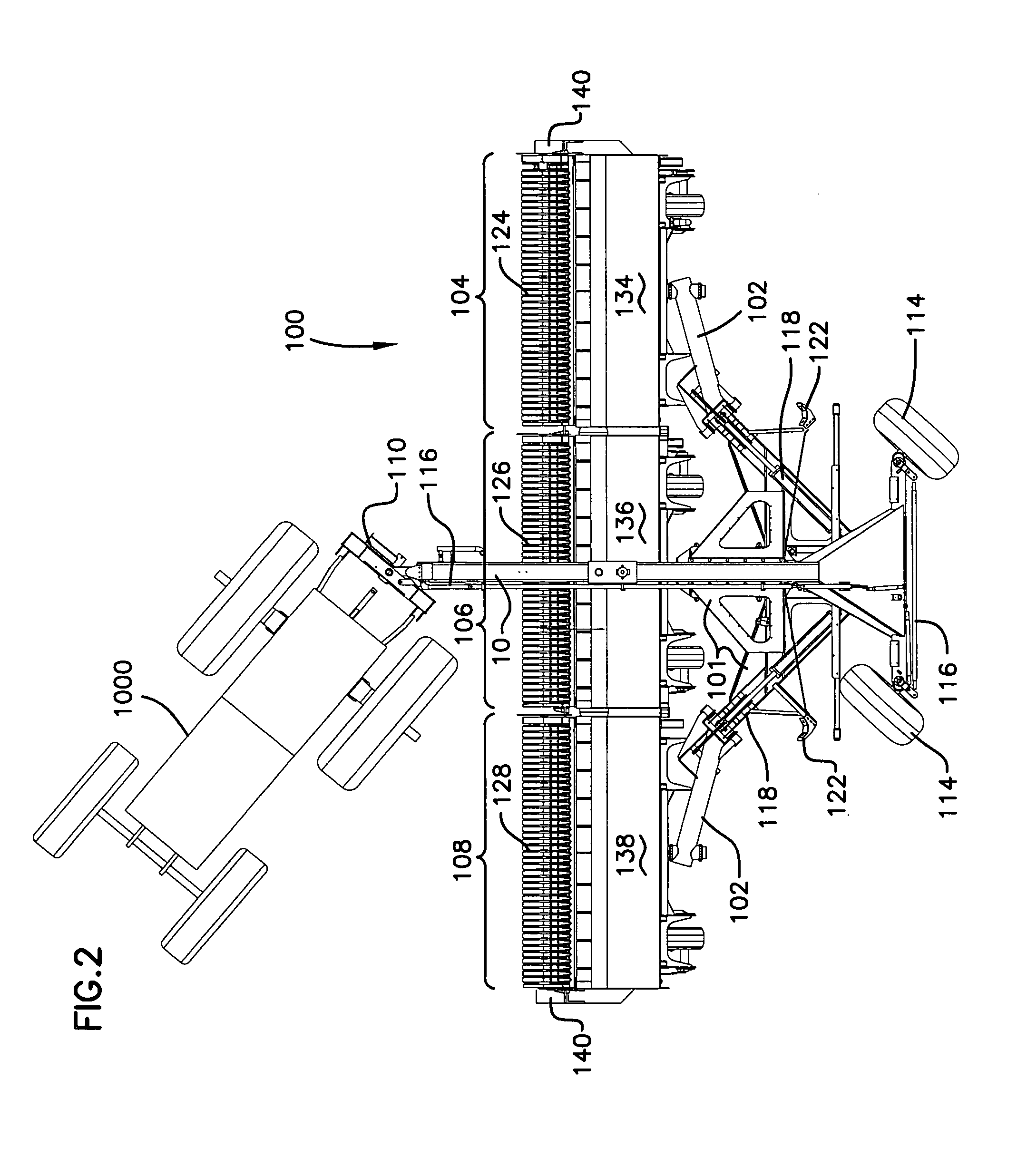

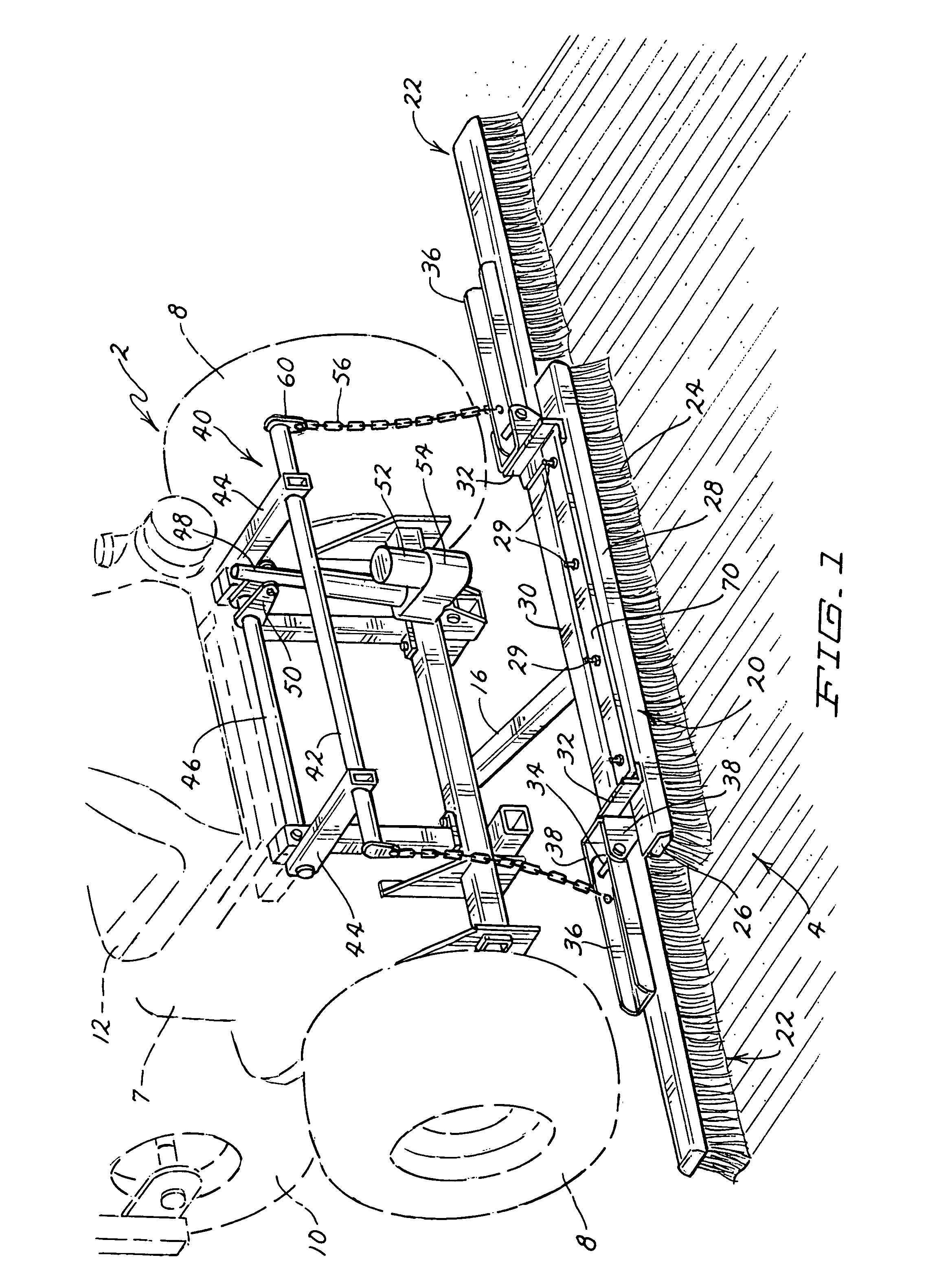

Windrow merging apparatus

InactiveUS7310929B2Reduce weightSpadesAgricultural machinesPickup Device ComponentMechanical engineering

A windrow merger has a frame supporting first, second and third pickup assemblies, with the two outside pickup assemblies foldable between an extended use position and a retracted travel position. Each of the pickup assemblies includes a reversible conveyor providing multiple windrow merging configurations. The pickup assemblies are interchangeable and aligned to define an unobstructed pickup face.

Owner:OXBO INT CORP

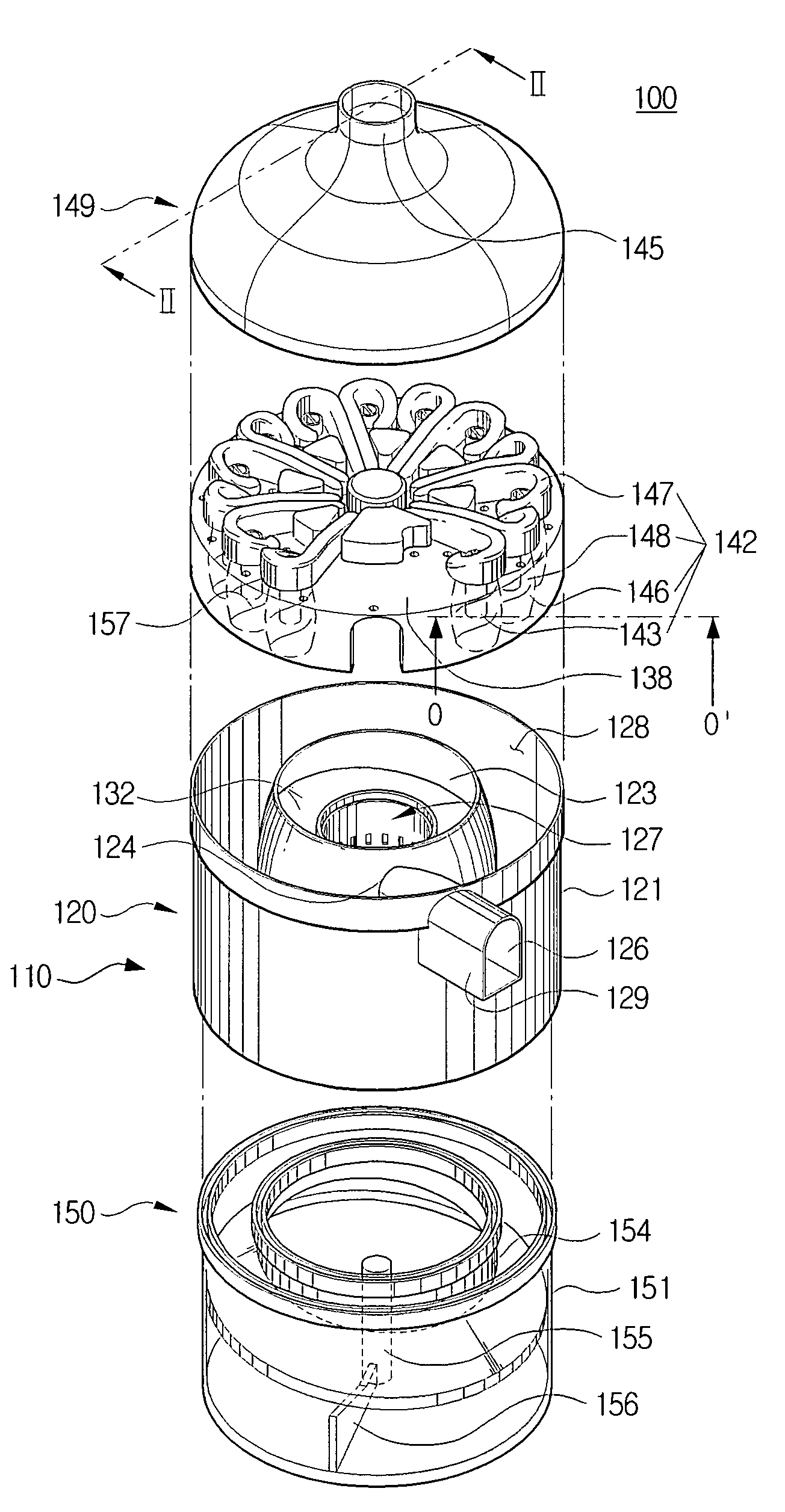

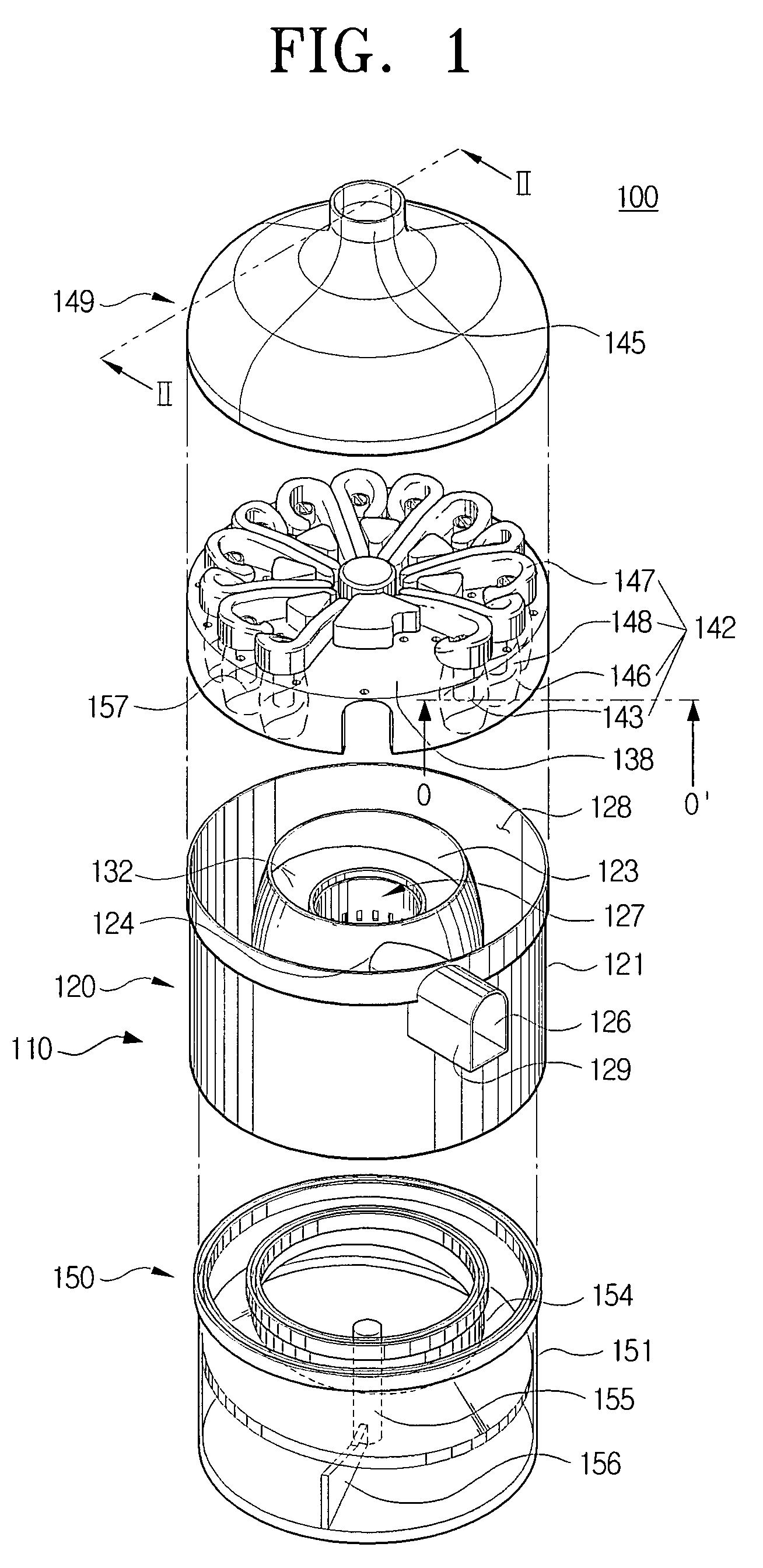

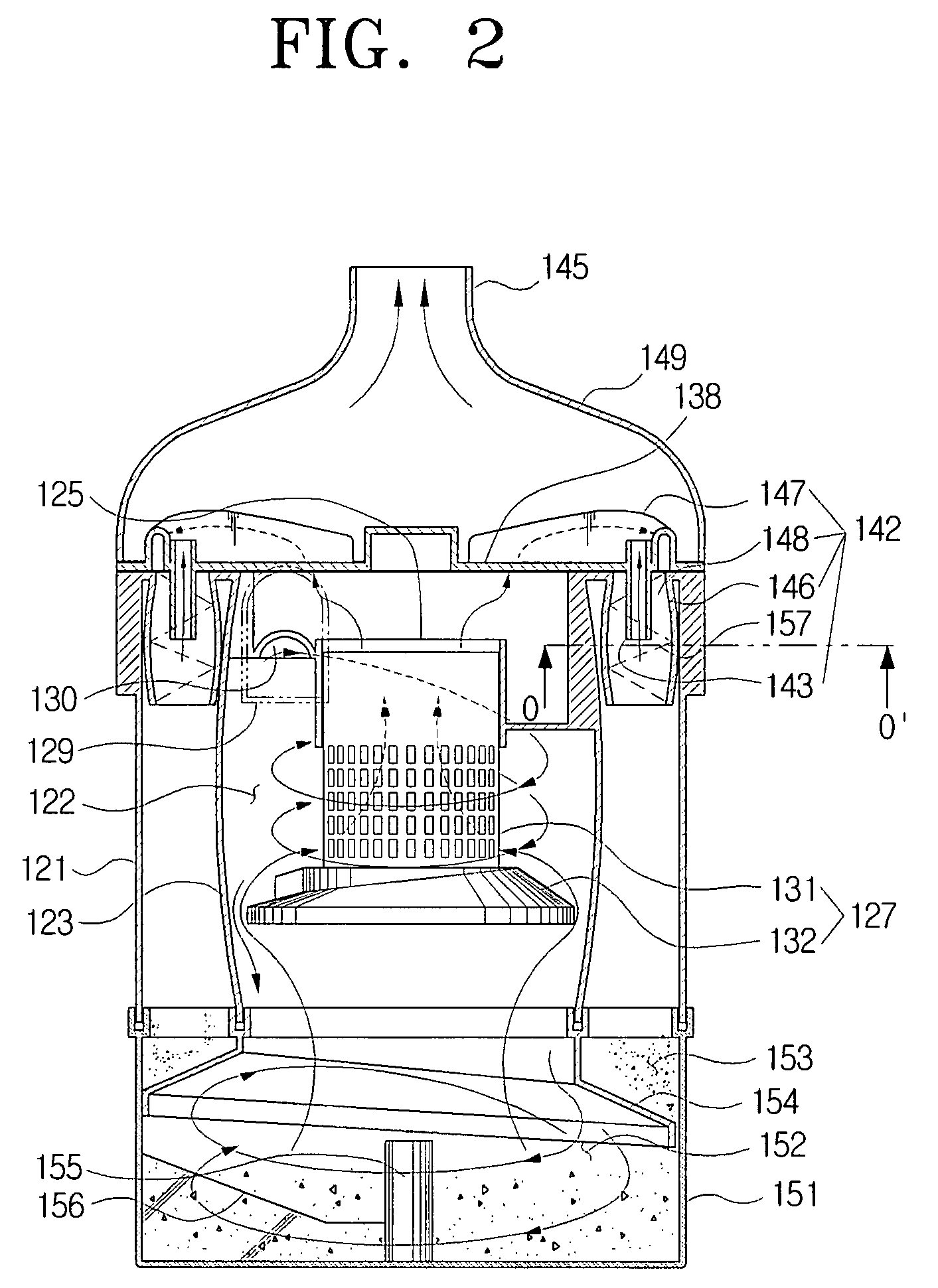

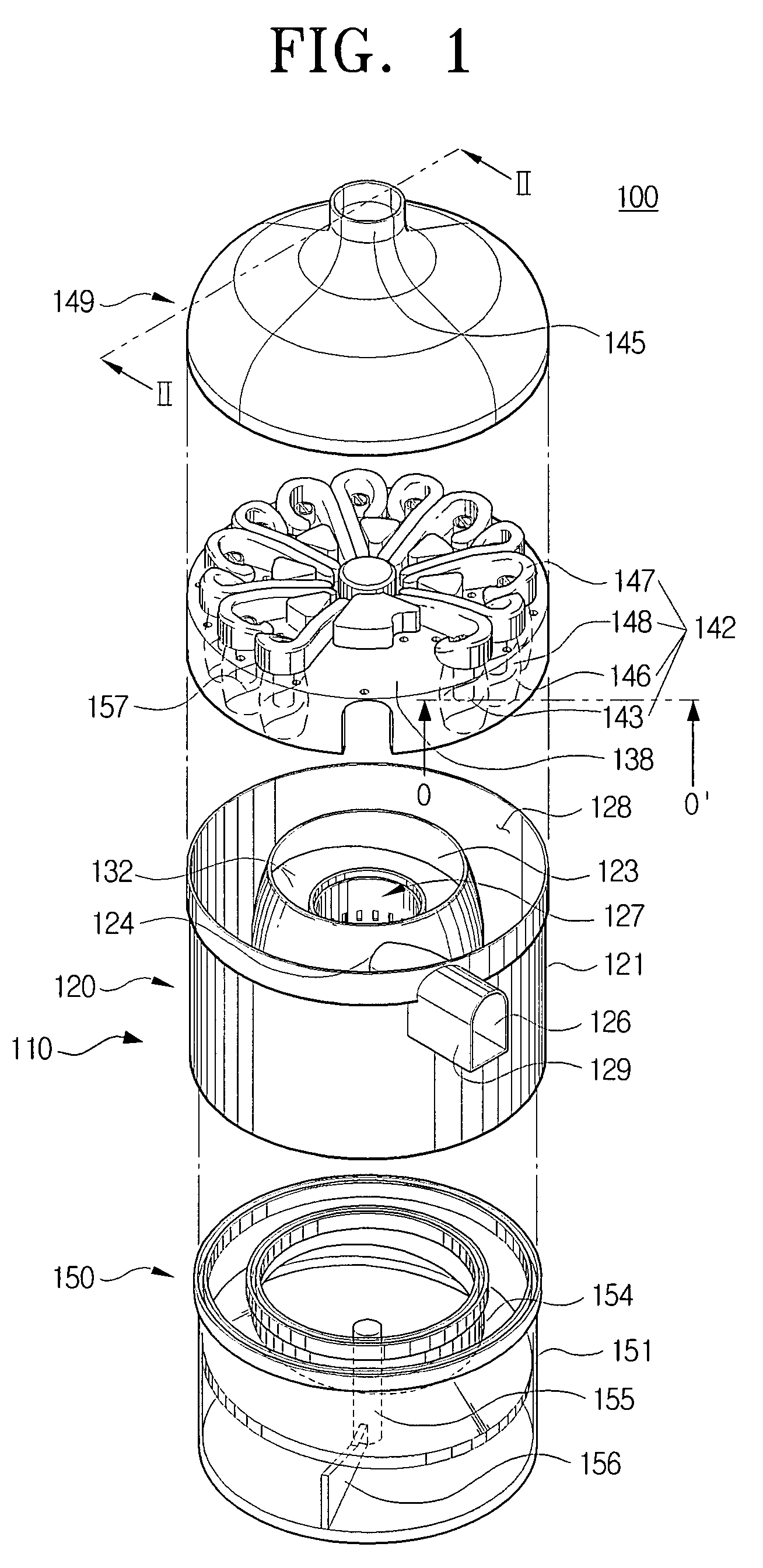

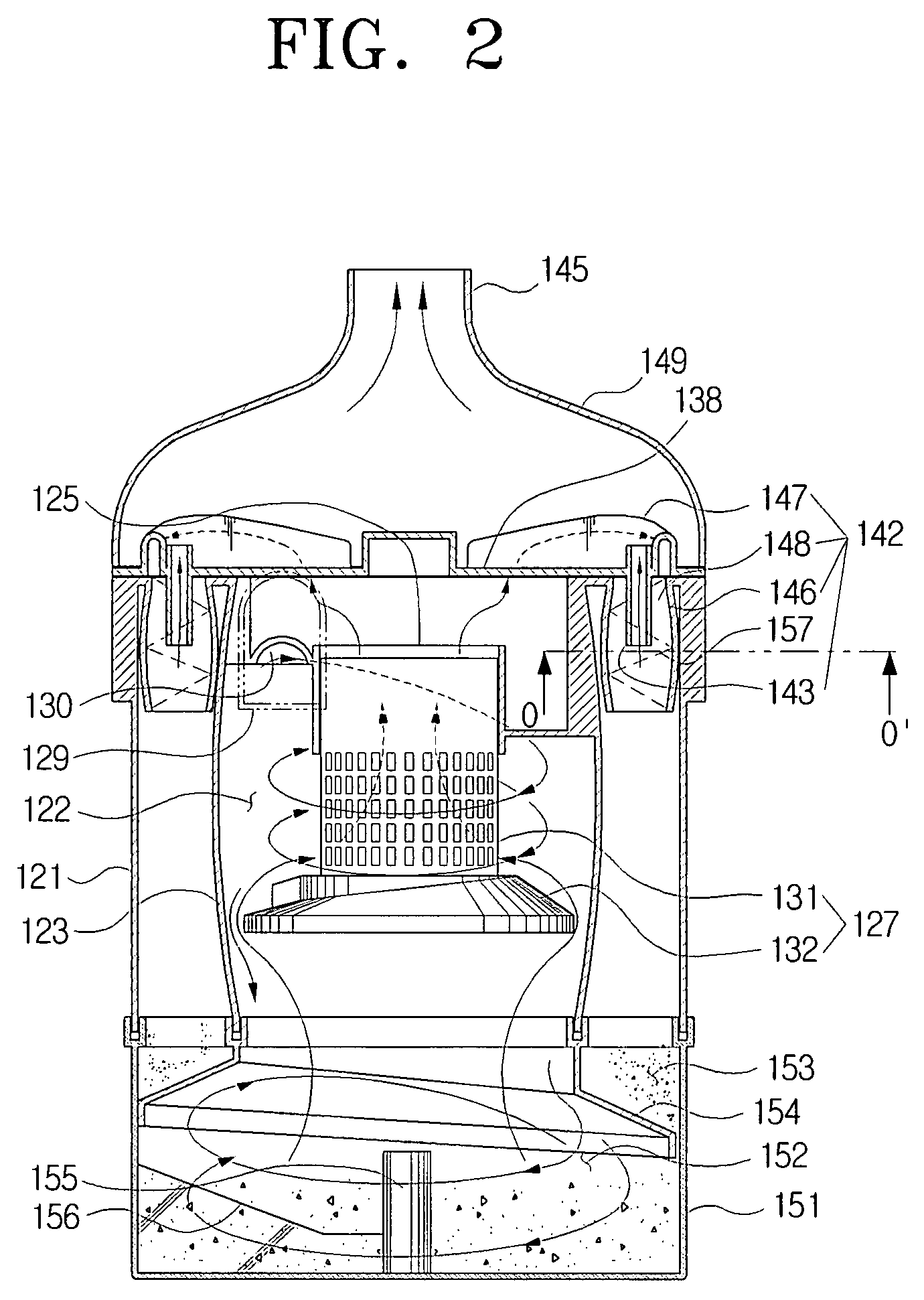

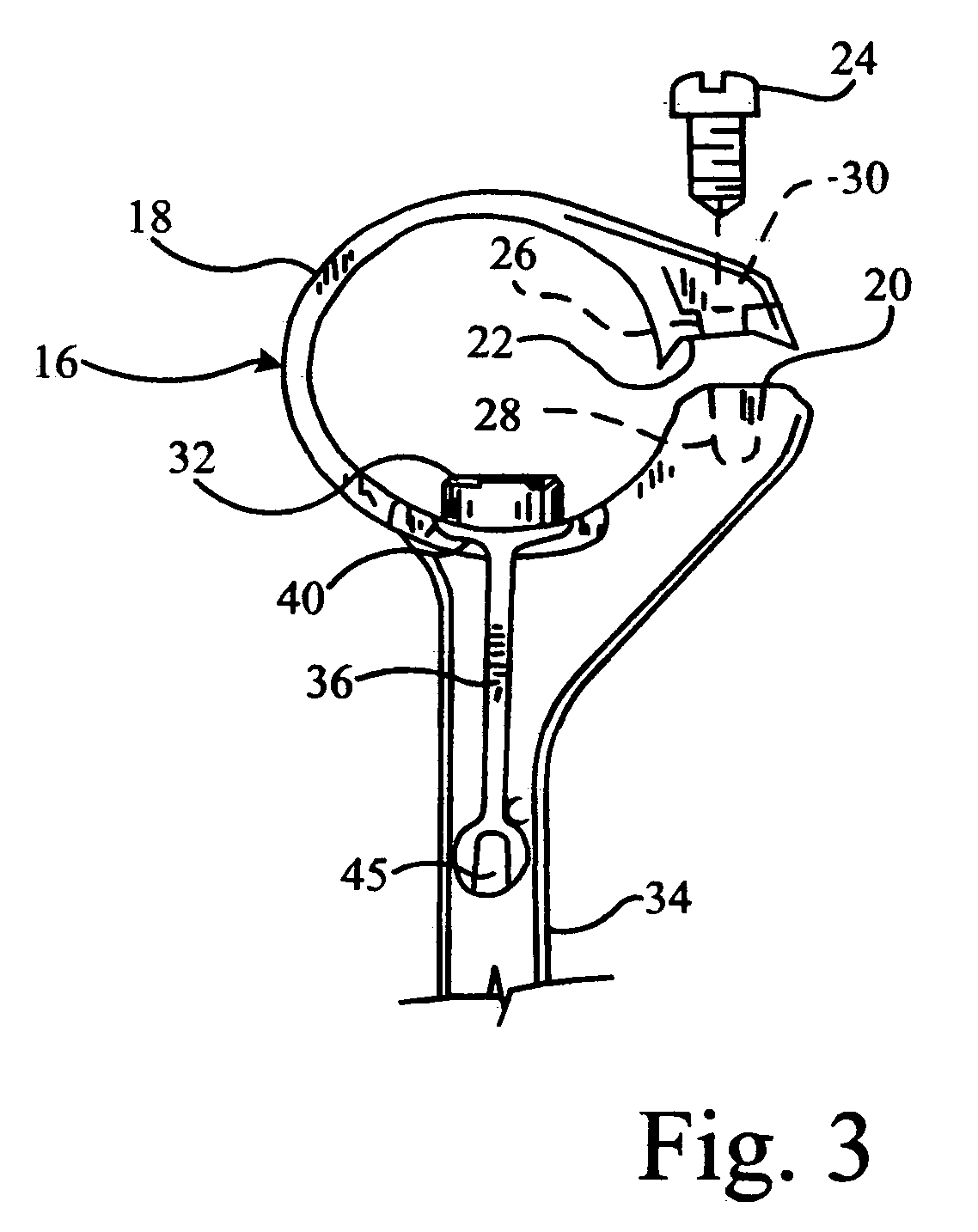

Multi cyclone dust-separating apparatus of vacuum cleaner

InactiveUS20080264017A1Reduce running noiseReduce total pressure lossSuction filtersReversed direction vortexCycloneVacuum cleaner

A multi cyclone dust-separating apparatus is disclosed that includes a cyclone unit having a first cyclone, a plurality of second cyclones, and a dust collecting unit. The first cyclone is disposed so that a longitudinal axis thereof is substantially vertically arranged. The first cyclone separates relatively large dust or dirt from air drawn in through a first air inflow part. Each of the second cyclones is disposed so that longitudinal axes thereof are substantially vertically arranged. Each of the second cyclones has a second air inflow part to communicate with the first cyclone and an air discharging part to discharge the air. The second cyclones separate relatively minute dust or dirt from the air drawn in through the second air inflow part. The dust collecting unit is disposed below the cyclone unit to collect and store the dust or dirt separated from the air by the cyclone unit.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

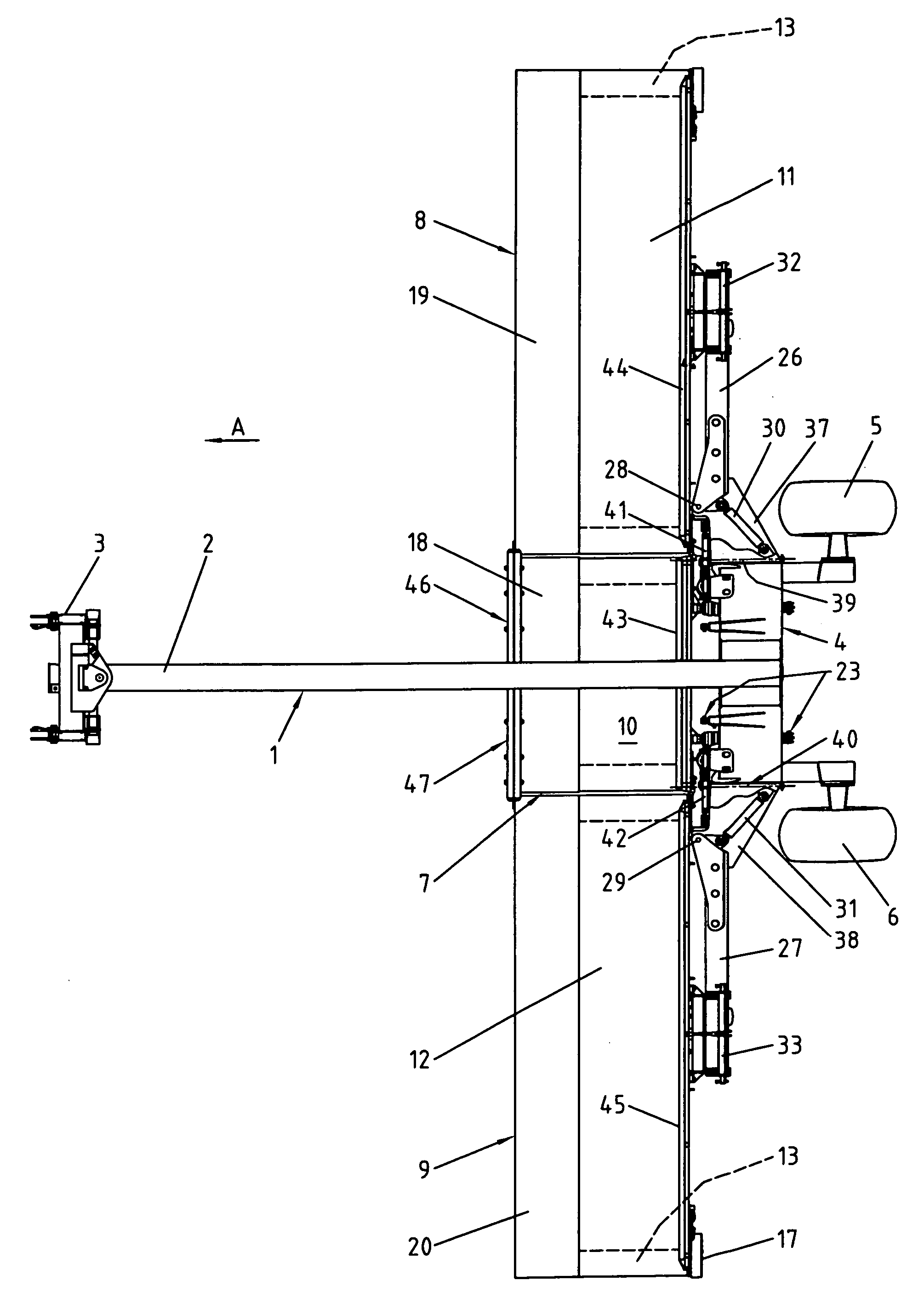

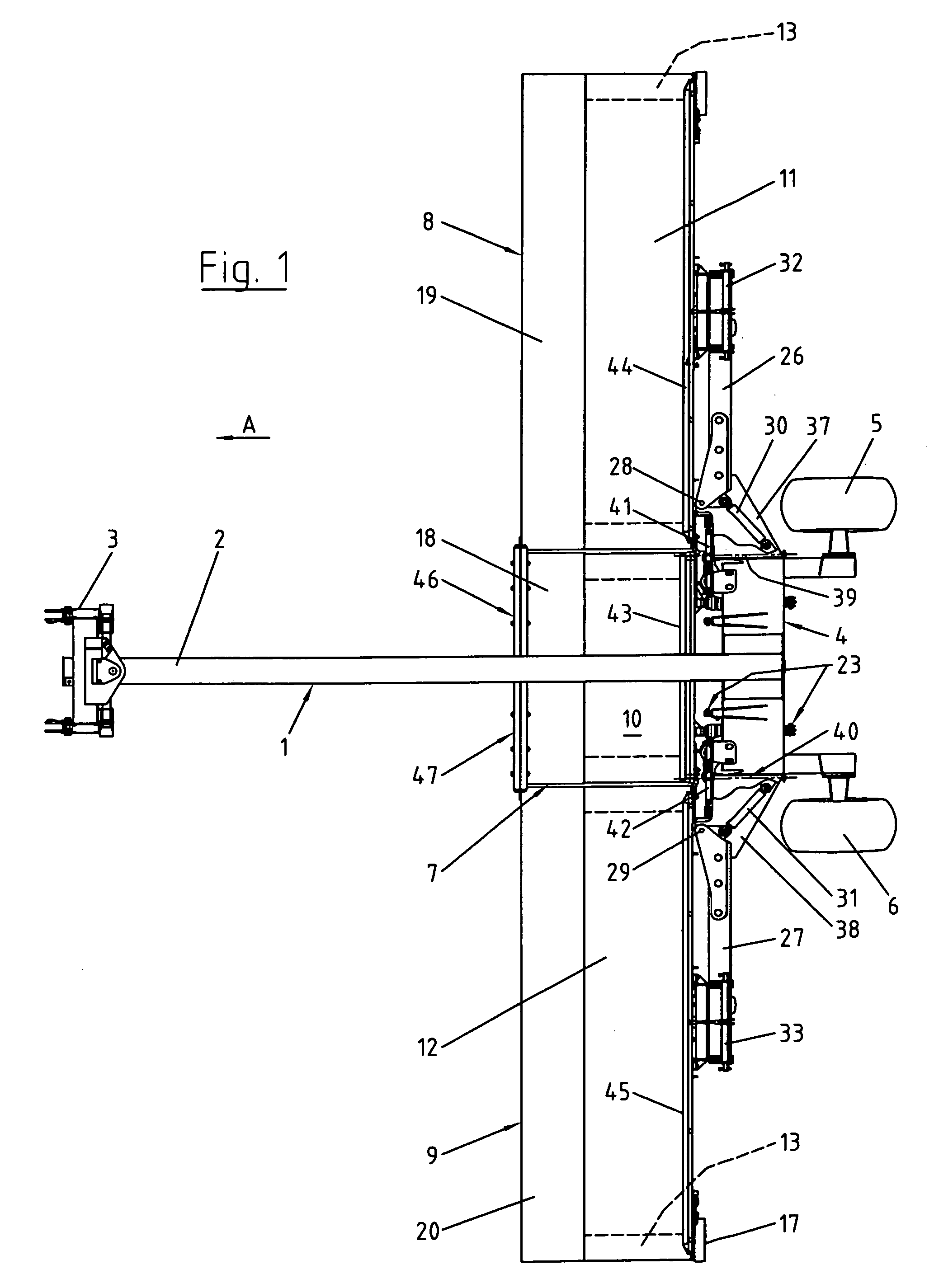

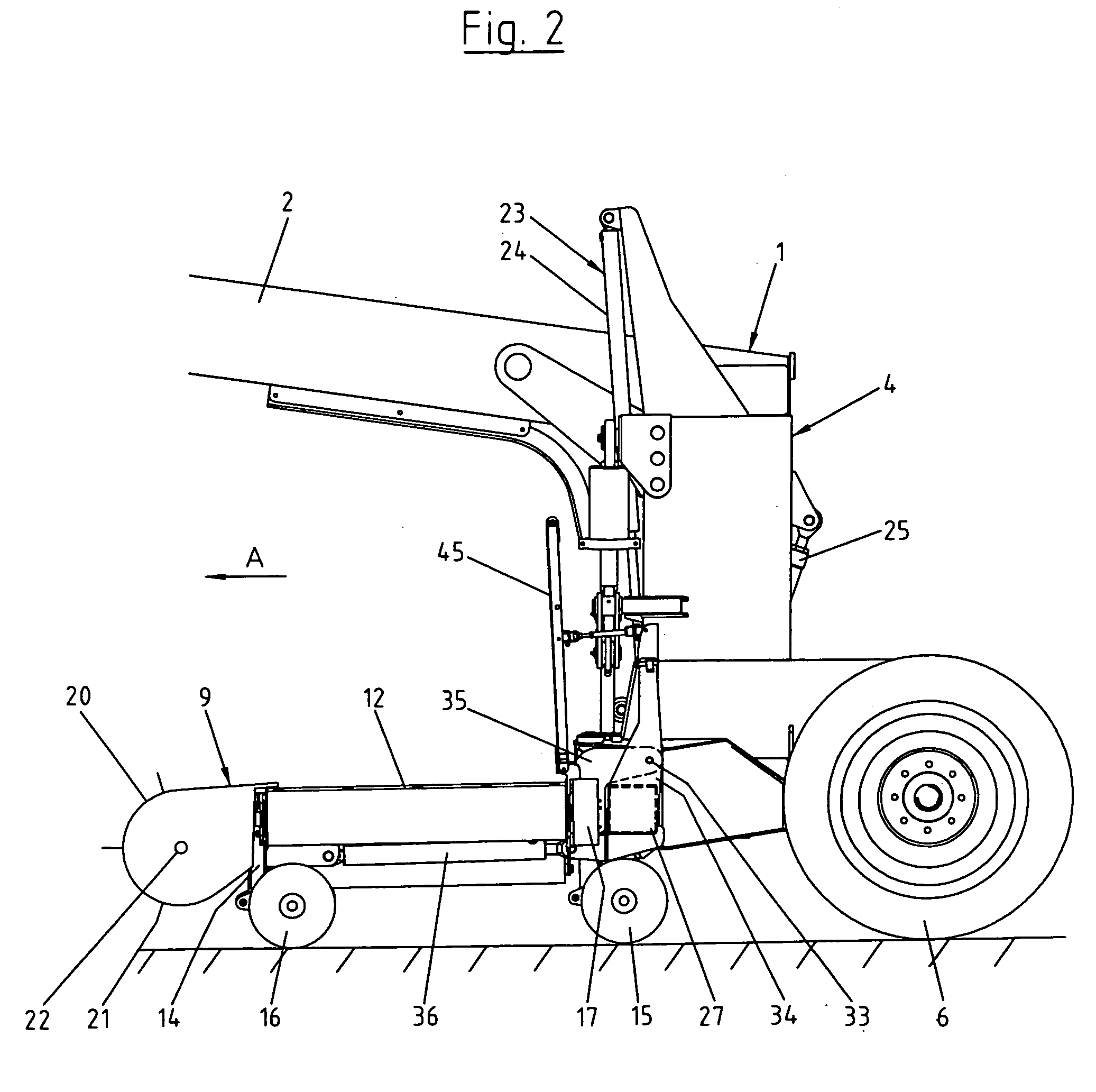

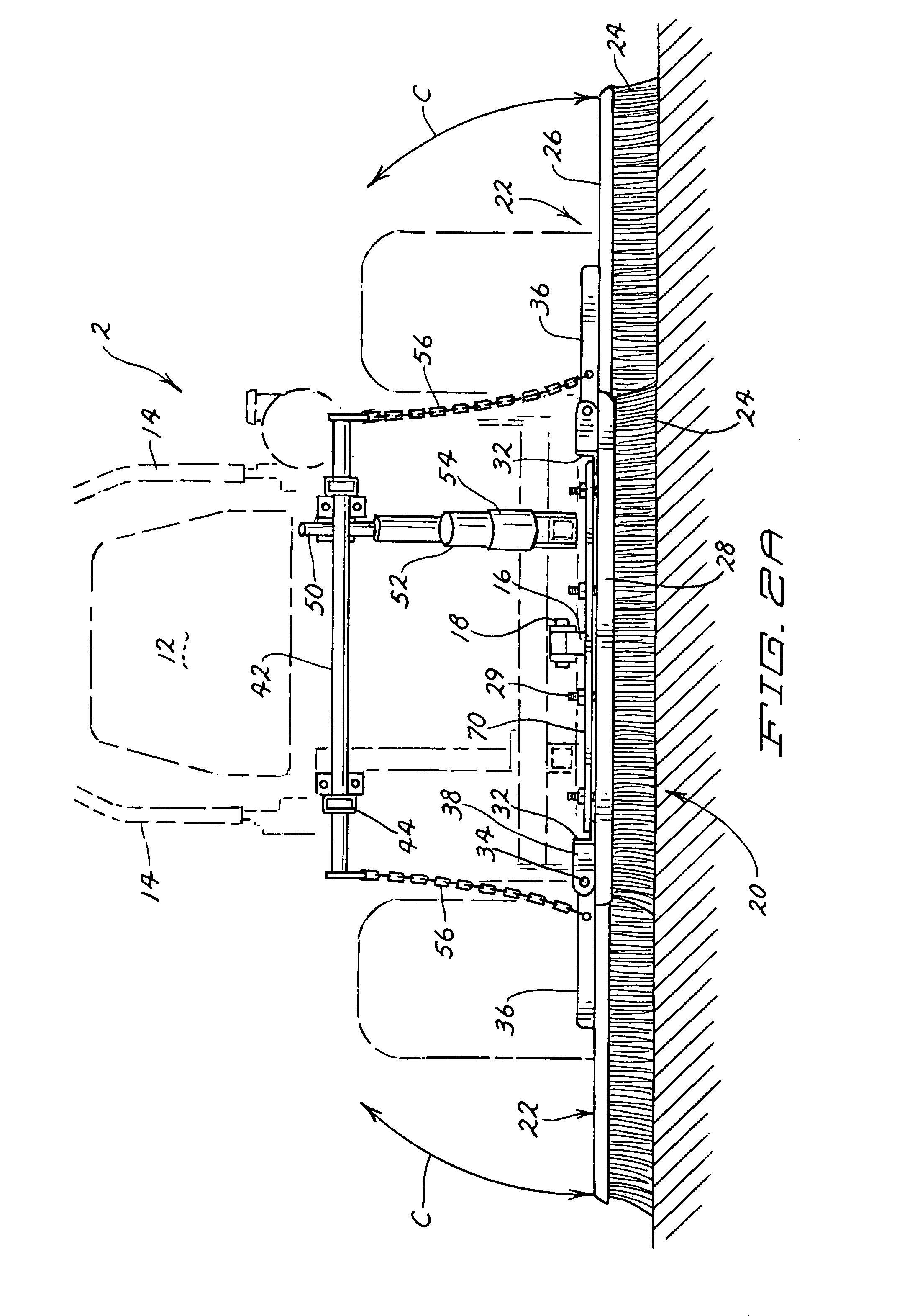

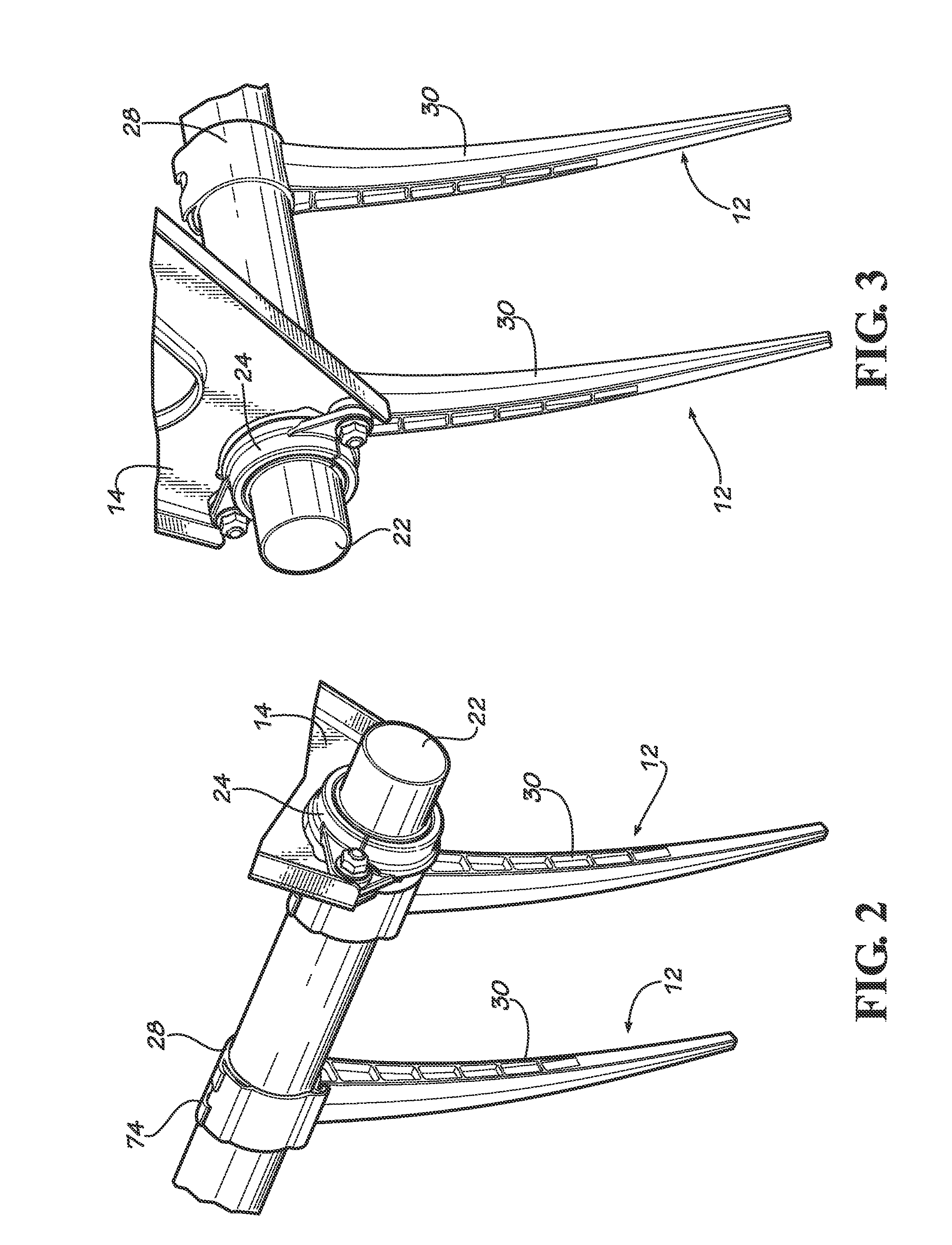

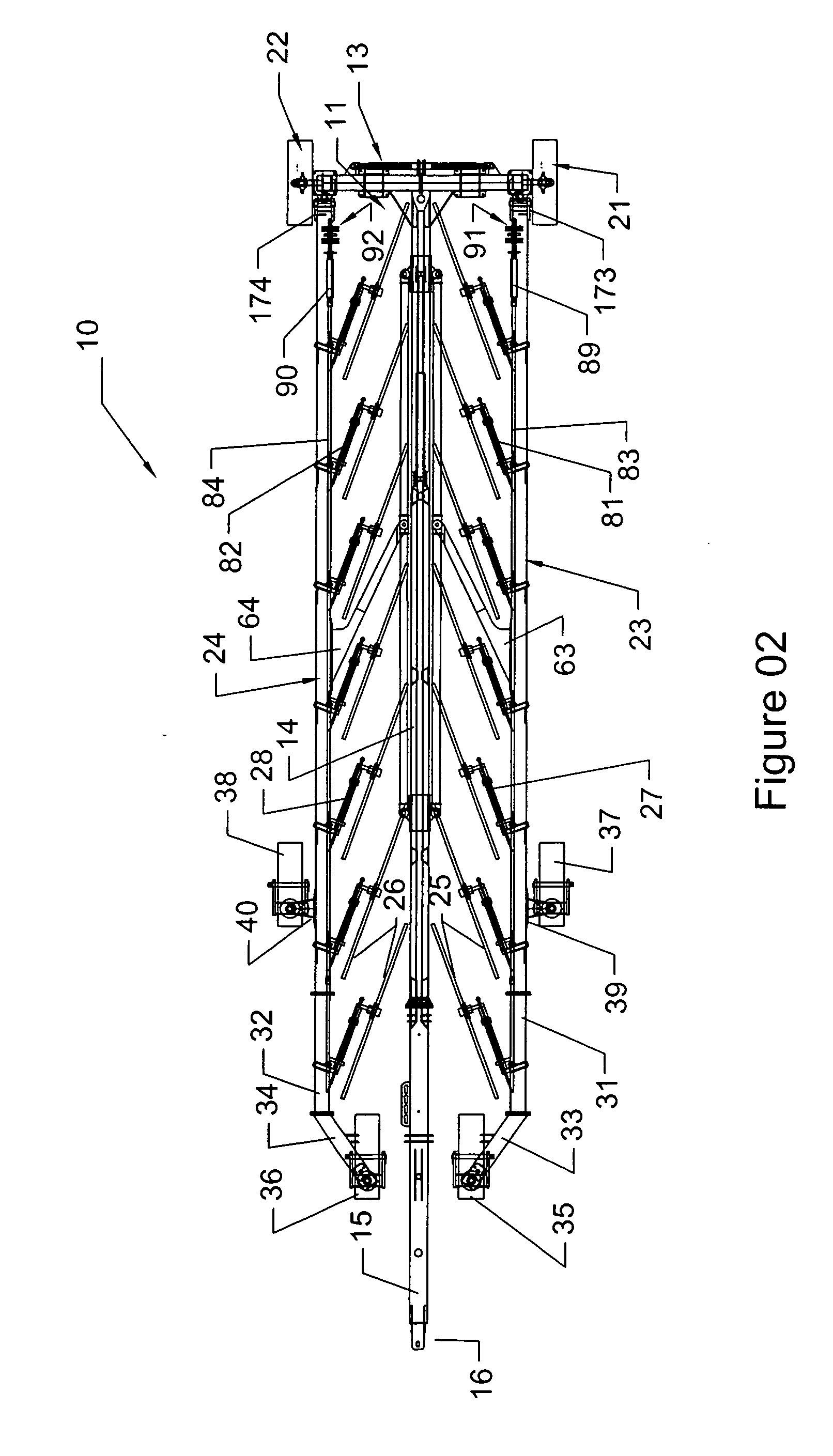

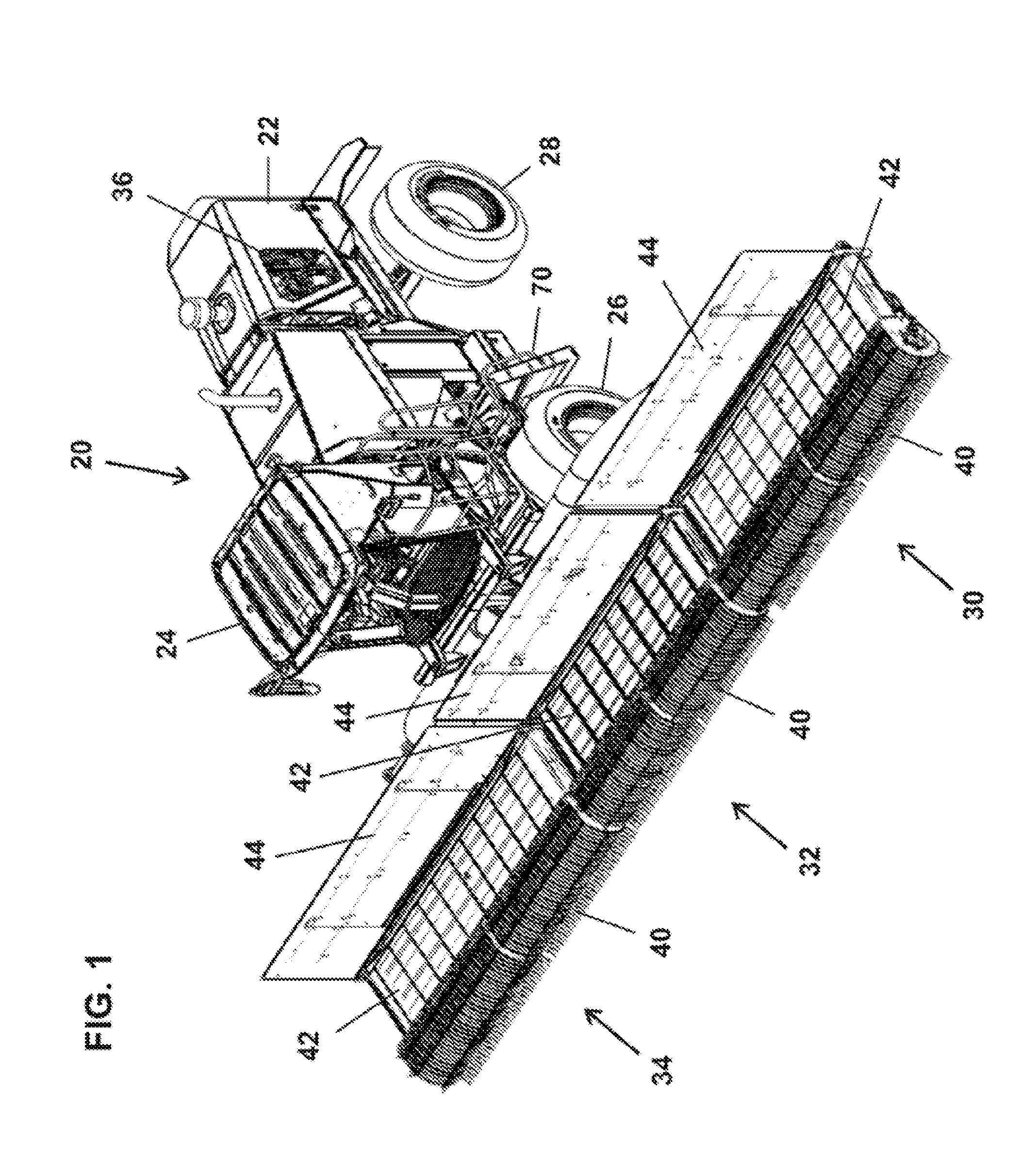

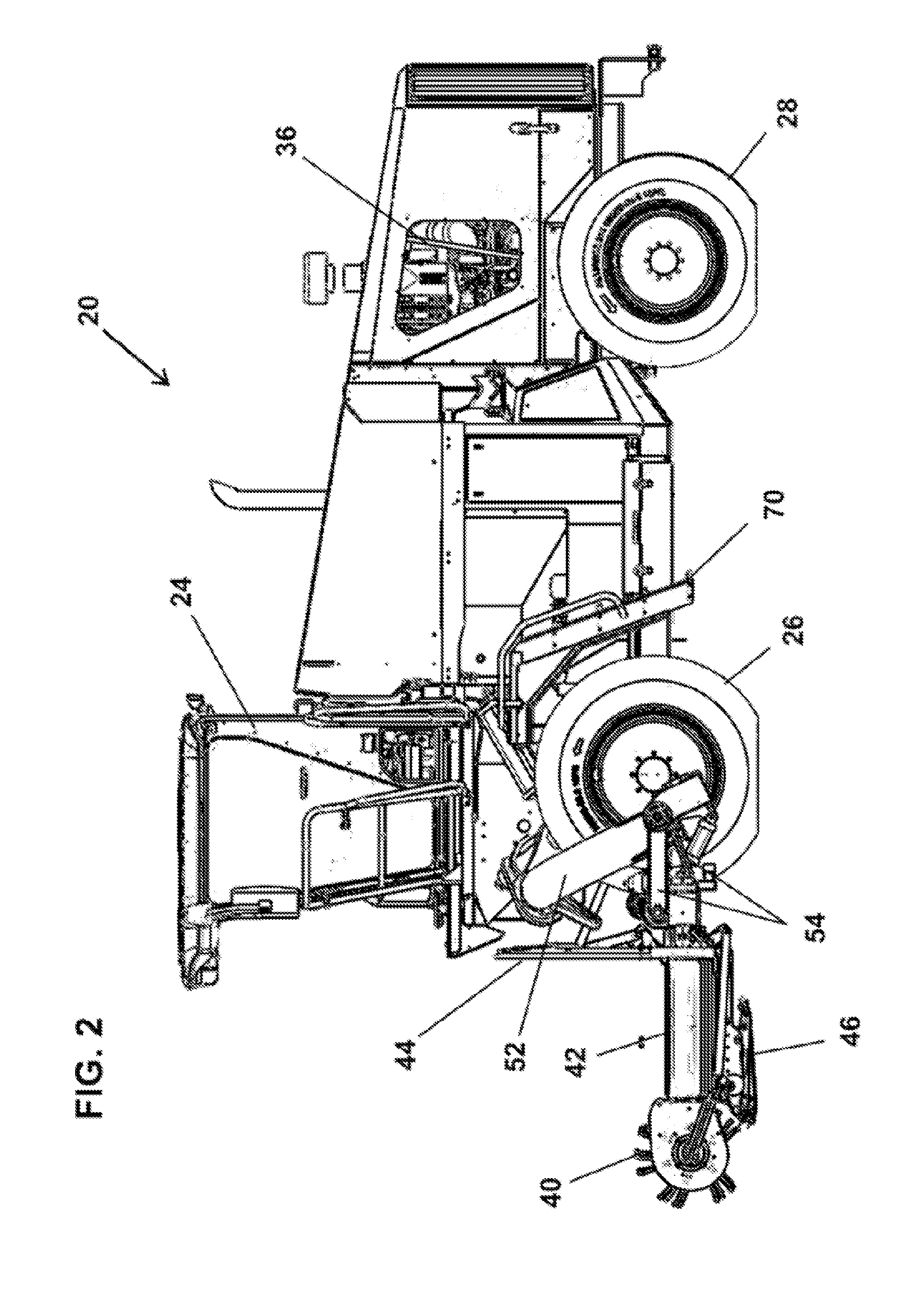

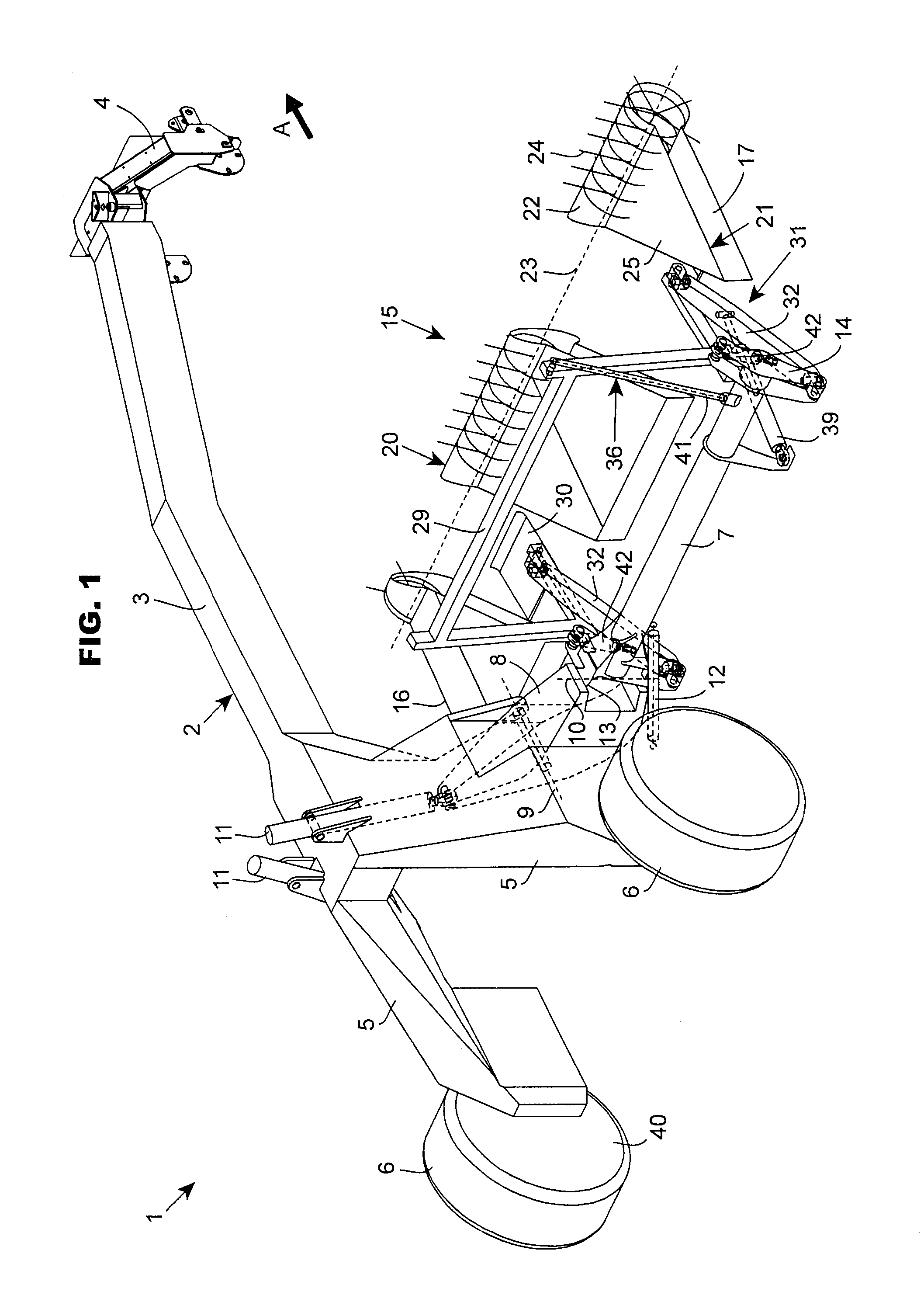

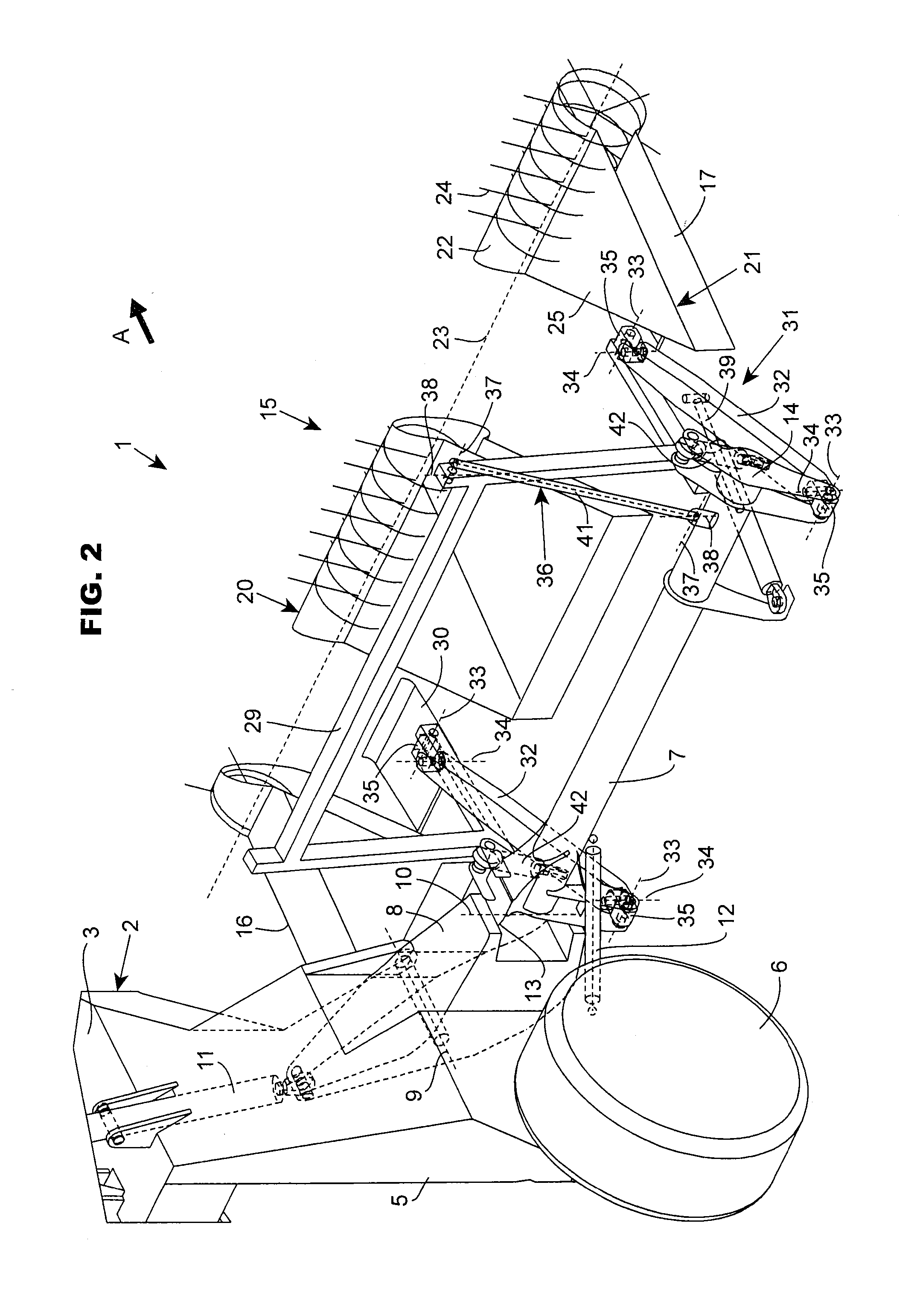

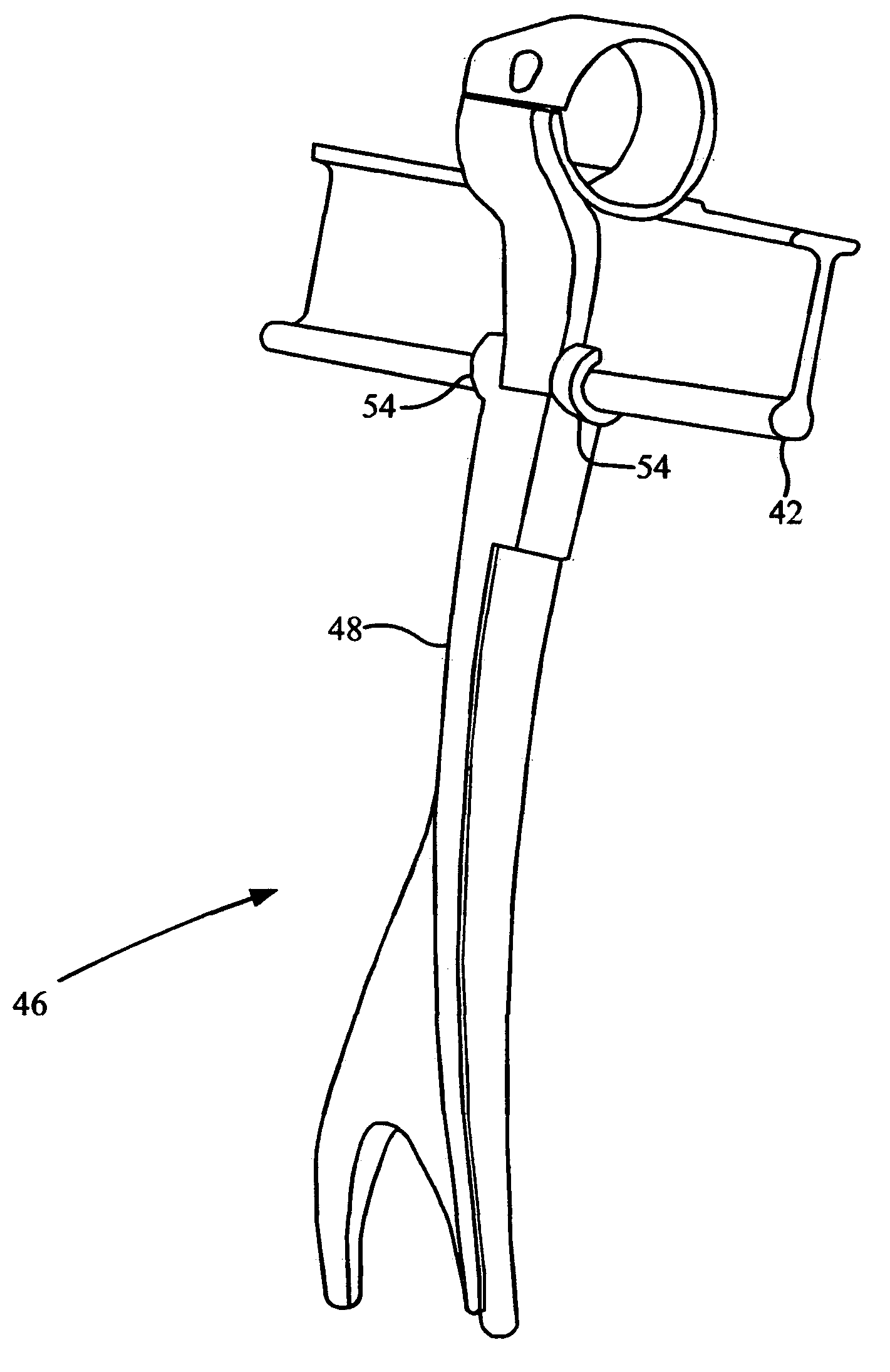

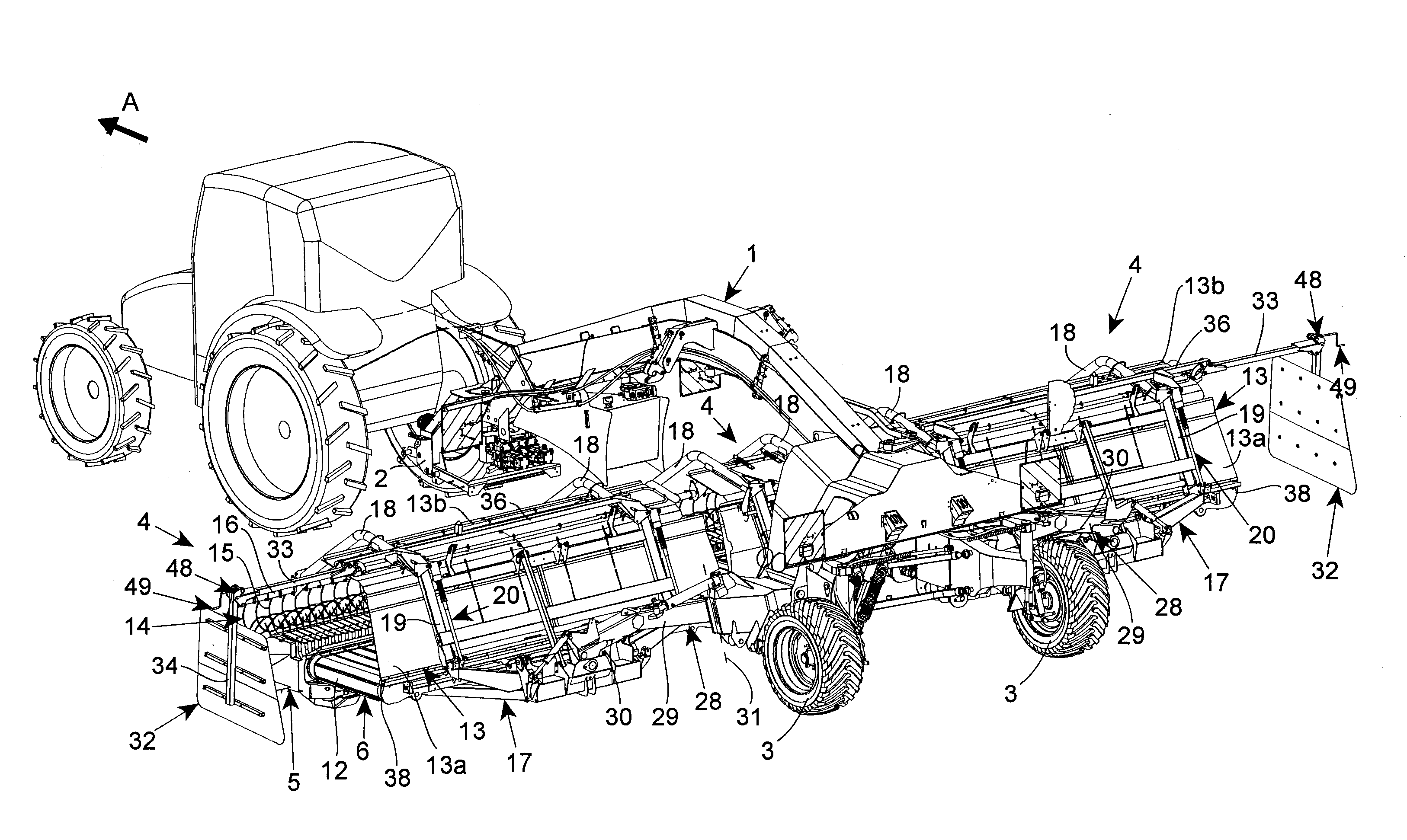

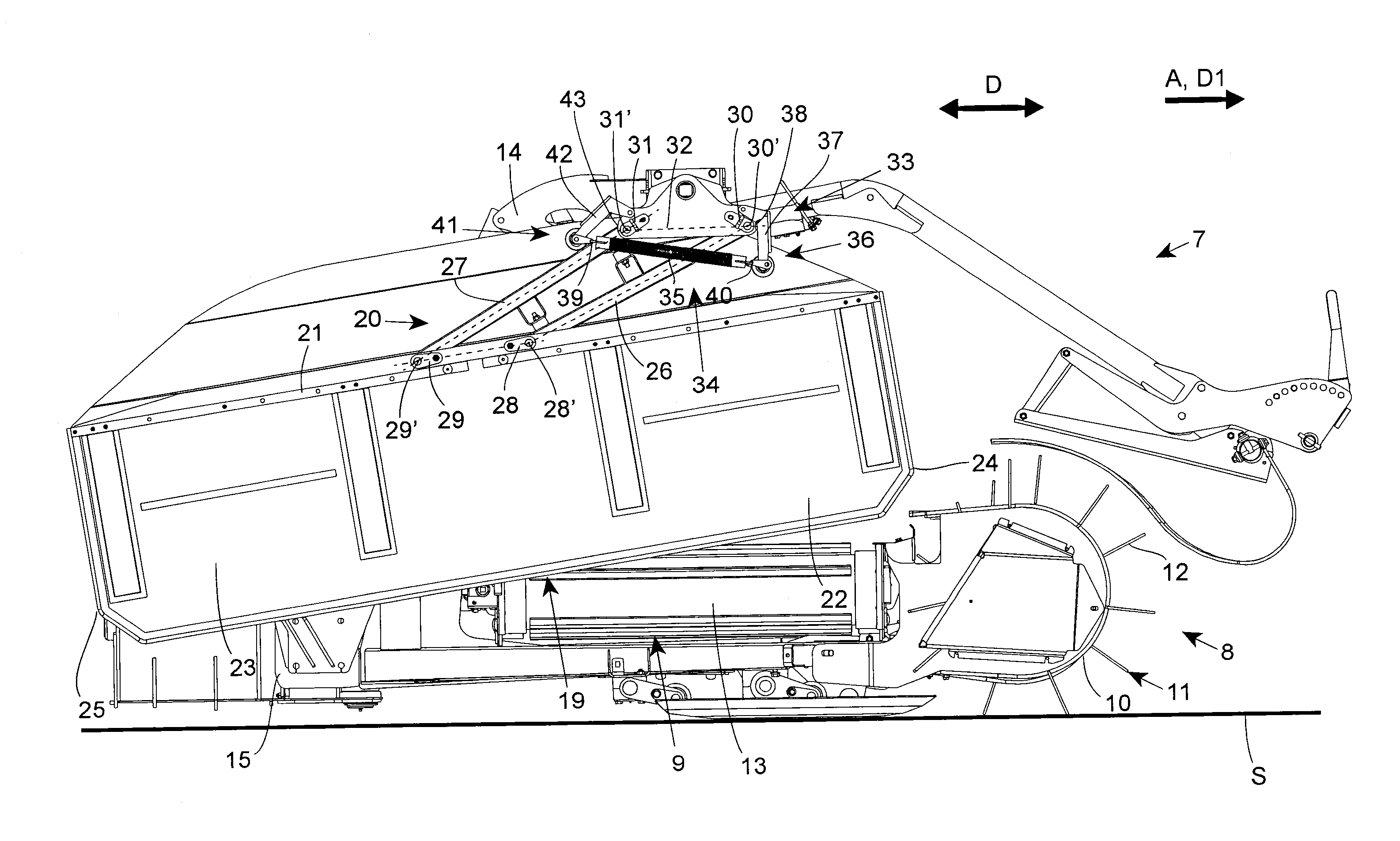

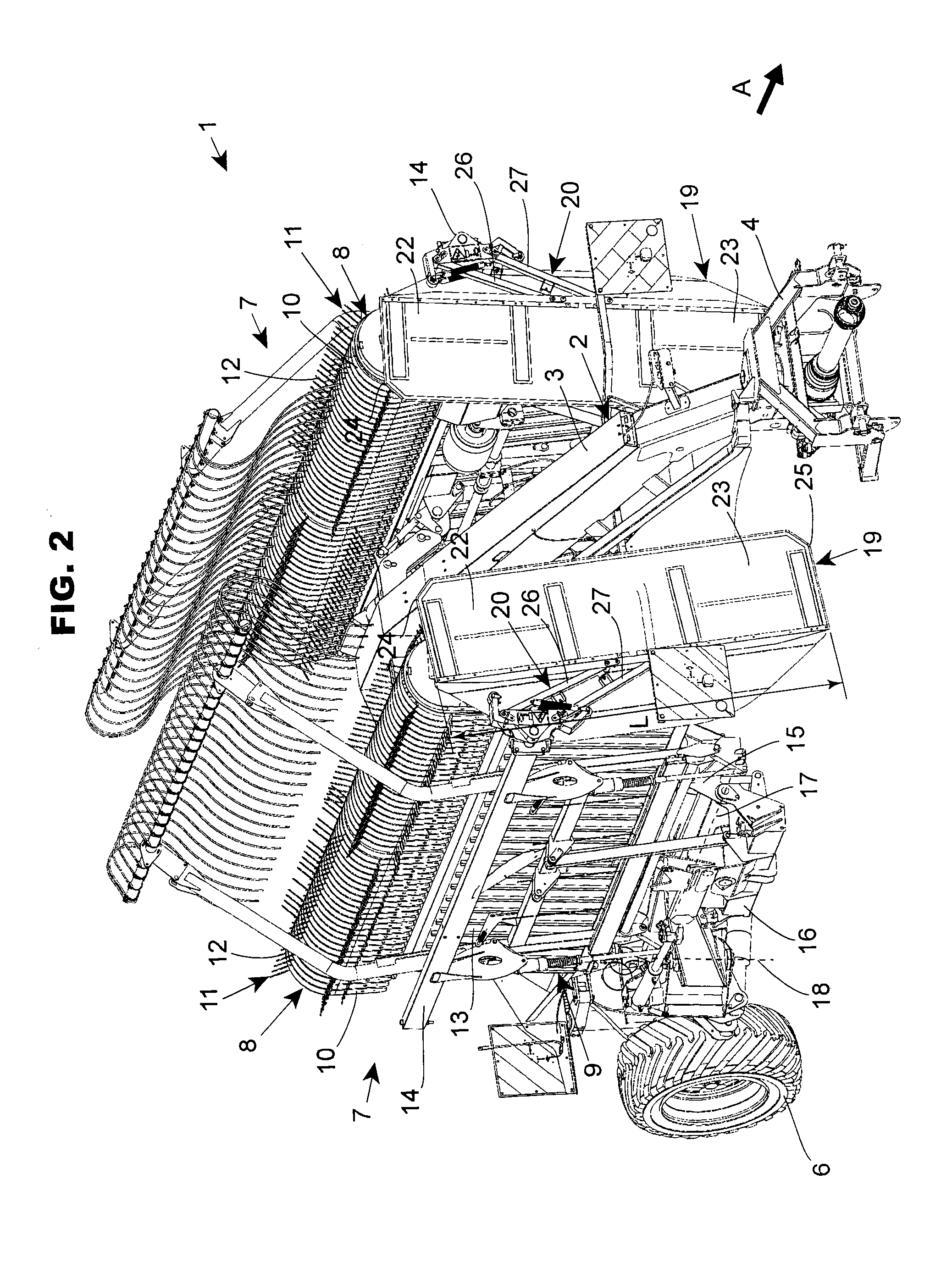

Multi-axis floating merger suspension

A crop merging machine includes a trailer frame, a drawbar assembly coupled to an axle, and a header assembly including a frame and a wheel. The merging machine further includes a pick-up assembly coupled to the header frame and a cross-conveyor assembly coupled to the header frame adjacent to the pick-up assembly. The pick-up and cross-conveyor assemblies are configured to cooperate to lift crop materials off the field surface and move the crop materials laterally to discharge onto the field surface to form a windrow. The merging machine includes a suspension assembly disposed between the trailer frame and header assembly, the suspension assembly being coupled to the header assembly and trailer frame and configured to allow the header assembly to pivot, relative to the trailer frame, about a first axis of rotation and to pivot about a second, distinct axis of rotation to follow a contour of the field surface.

Owner:KUHN NORTH AMERICA

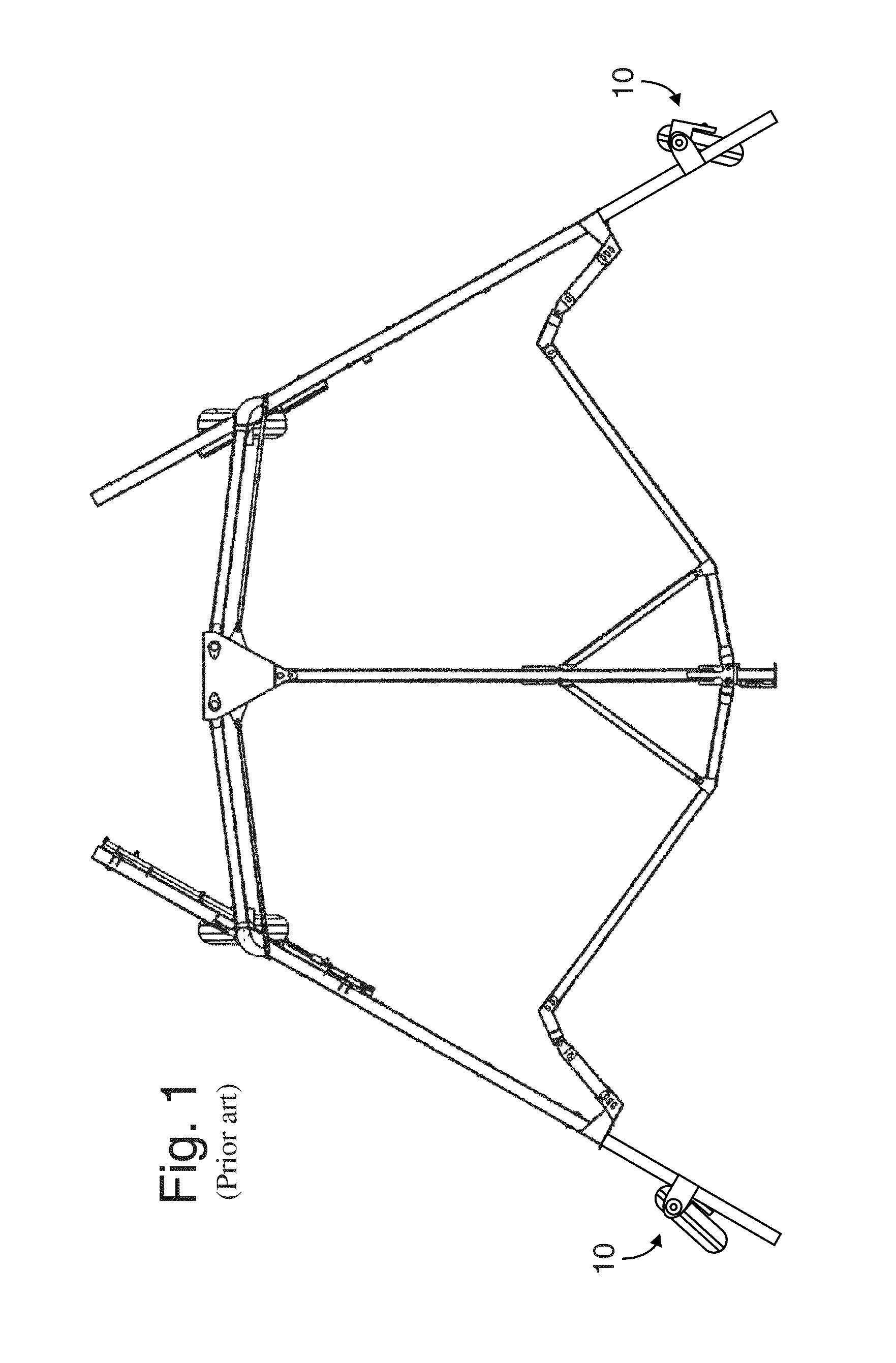

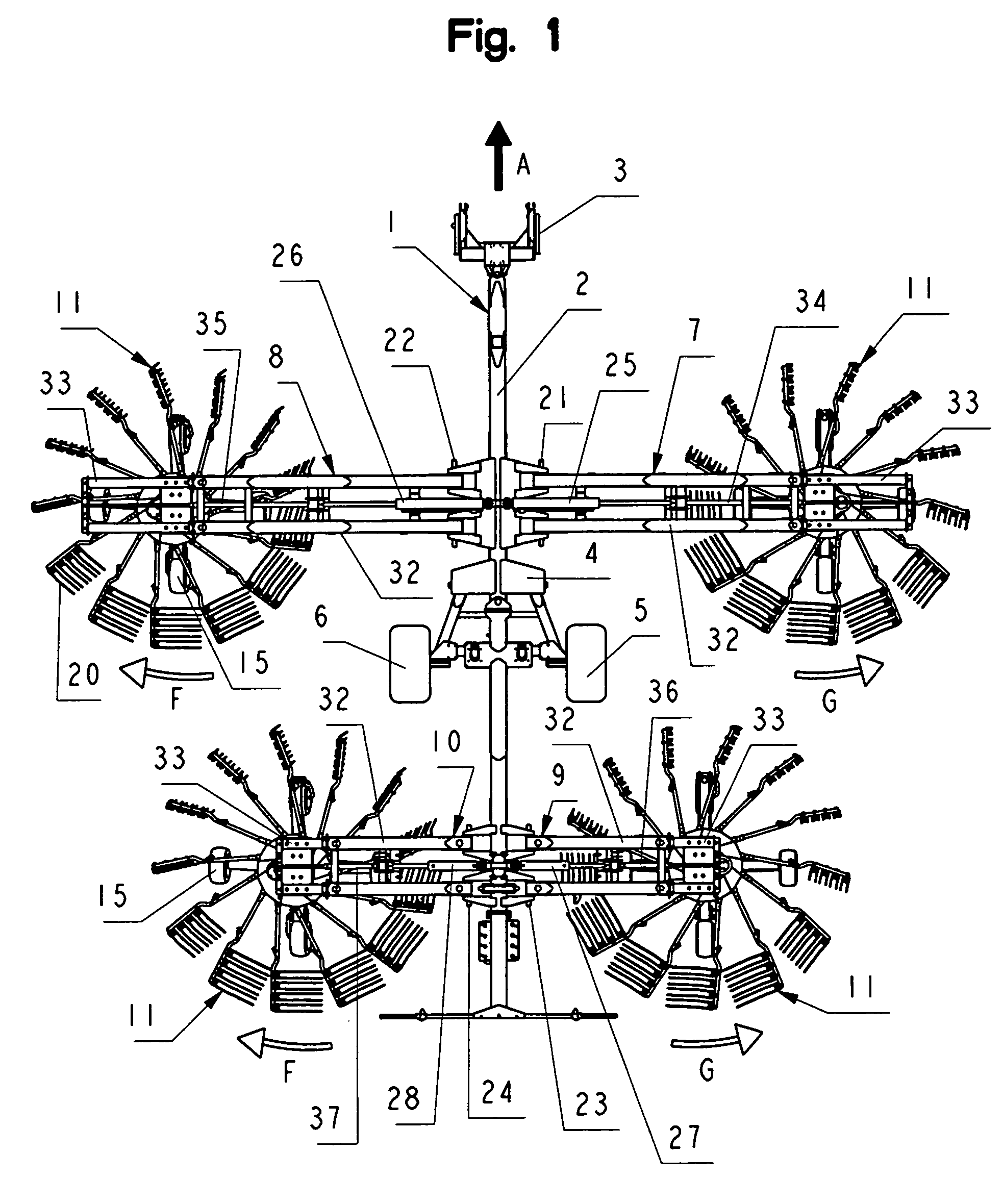

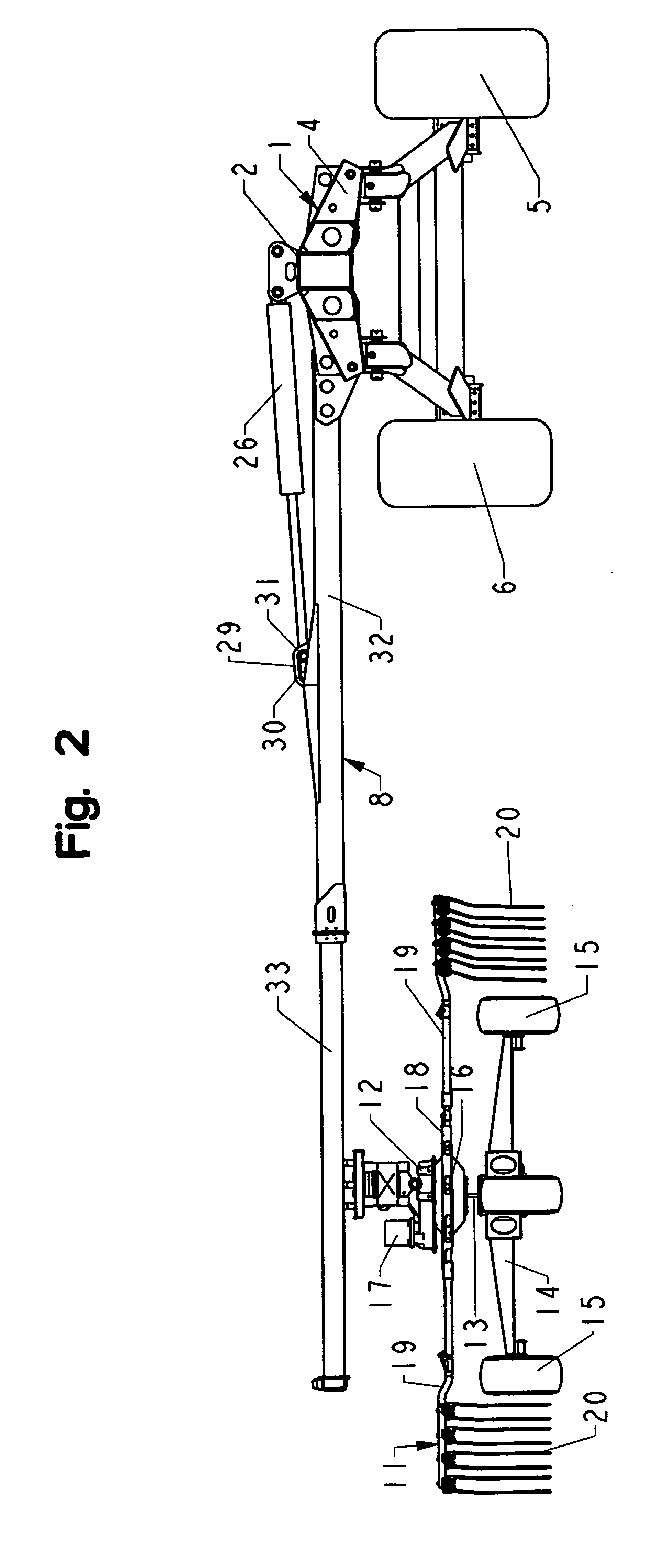

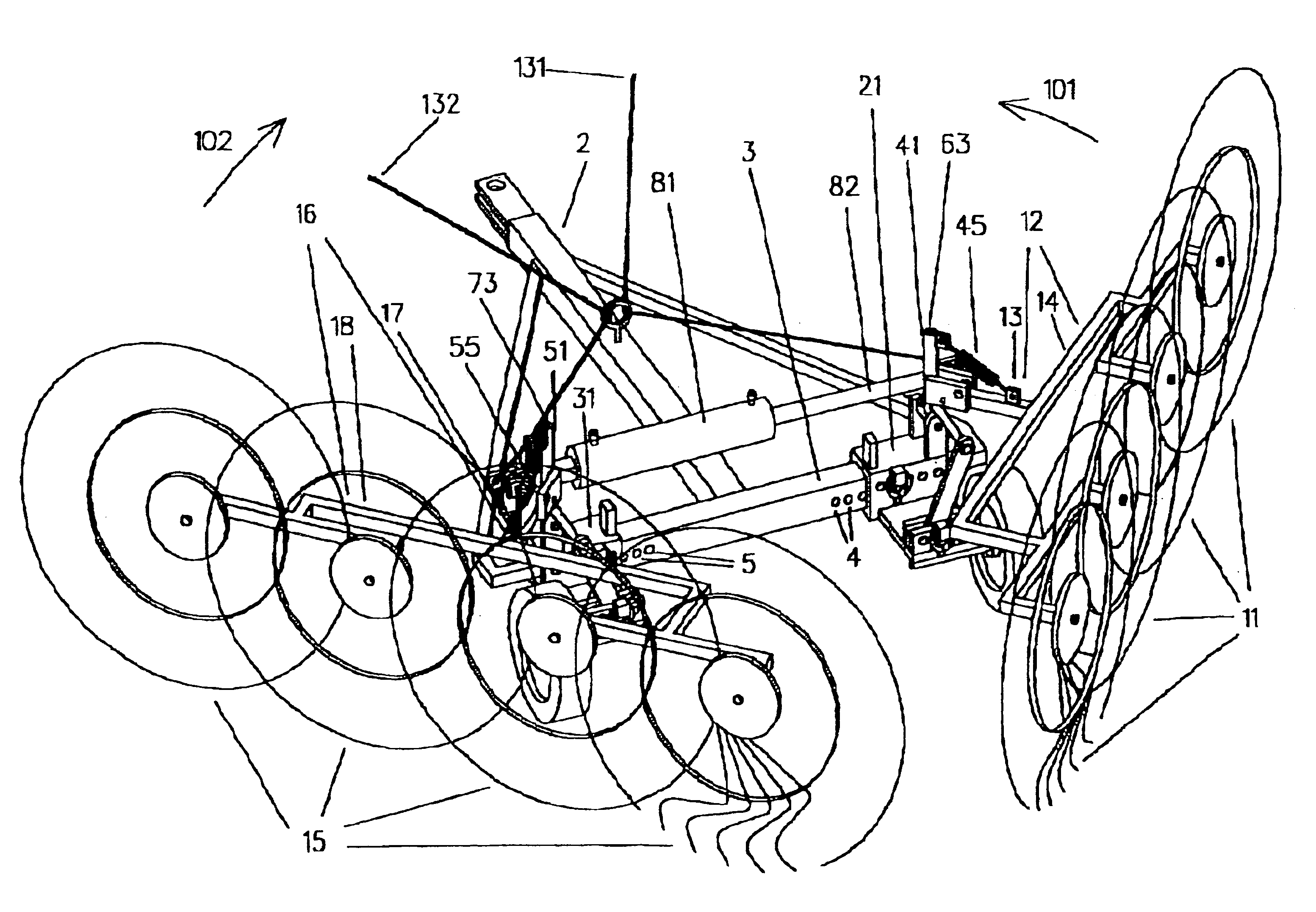

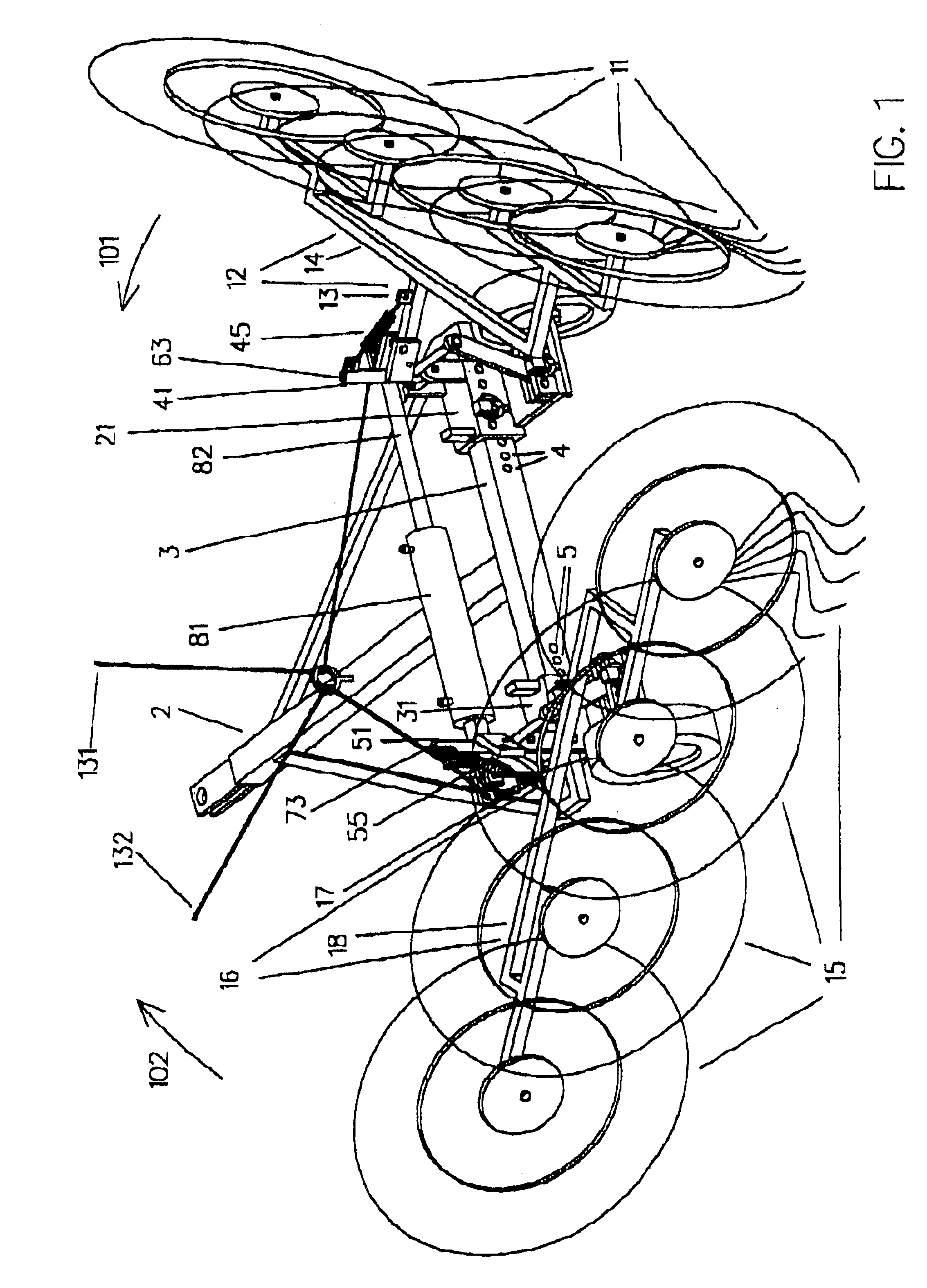

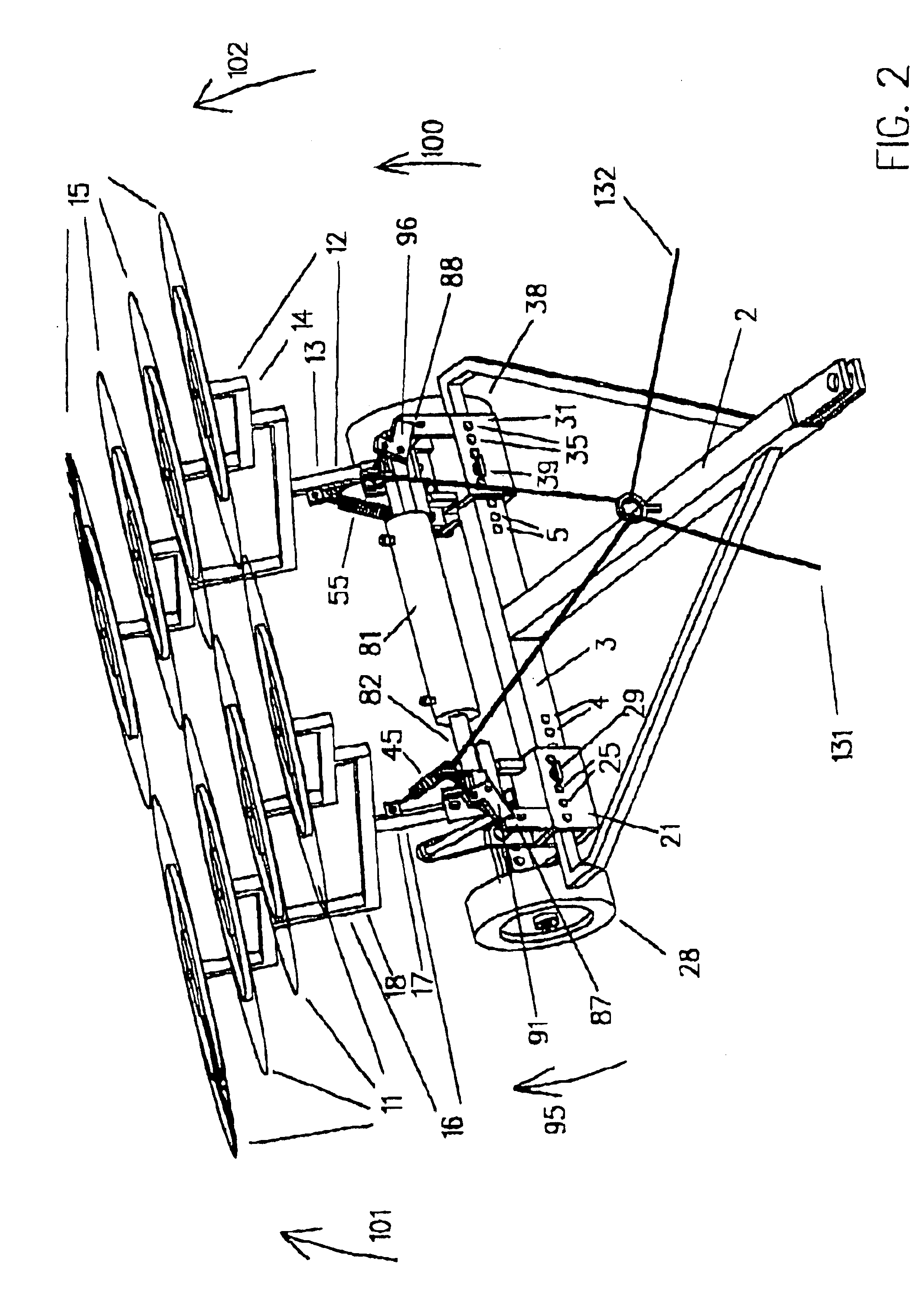

Agricultural machine for swathing products lying on the ground

ActiveUS20060254244A1Improve stabilityReduce widthAgricultural machinesMowersHorizontal axisEngineering

An agricultural machine for grouping windrows together or for windrowing products lying on the ground, comprising in particular a main frame supporting a central gathering and windrowing device and two side gathering and windrowing devices connected to support arms that extend laterally during work, each of said side support arms being articulated relative to the main frame on a substantially vertical axis about which it is foldable at an angle of approximately 90° for transport and each of said side gathering and windrowing device being articulated on its support arm by means of a substantially horizontal axis about which it is foldable upwards at an angle of approximately 90° to obtain a reduced machine width for transport.

Owner:KUHN SA

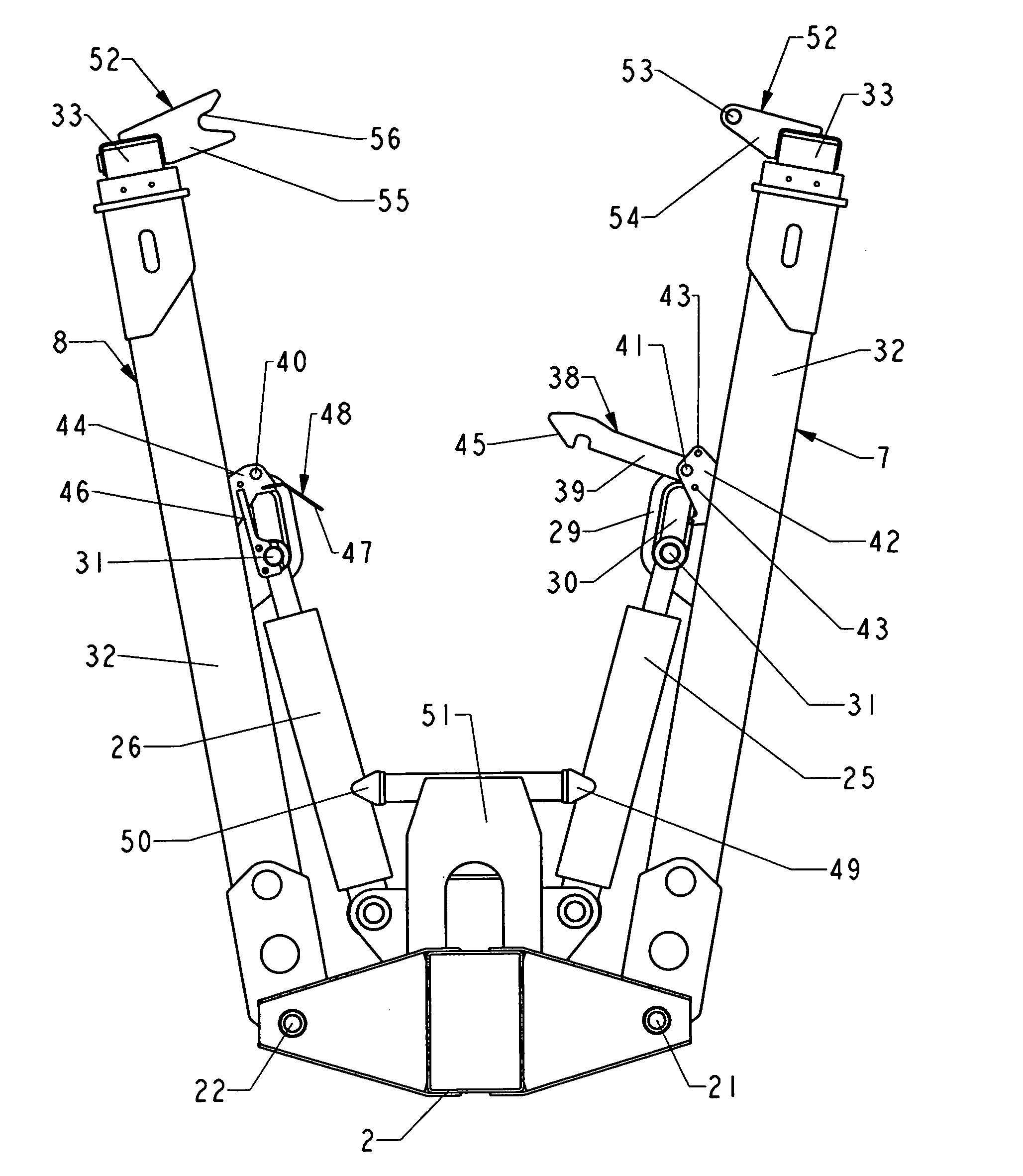

Bifold transport lock

ActiveUS7849933B2Reduce the possibility of damageReduce in quantitySpadesAgricultural machinesEngineeringMechanical engineering

An apparatus includes a tongue, a pivotable beam linked to the tongue, a cylinder configured to move the pivotable beam from an operating position to a transport position, which is narrower than the operating position, and a latchable member connected to the pivotable beam. A locking assembly includes first and second dogs which can receive the latchable member. The second dog can move relative to the first dog from an open position to a closed position in response to movement of the latchable member such that movement of the latchable member out of the second dog opening is blocked by the first dog while the second dog is in the closed position. The apparatus includes a locking member that moves in response to movement of the cylinder from an unlocked to a locked position to lock the dogs in the closed position.

Owner:KUHN NORTH AMERICA

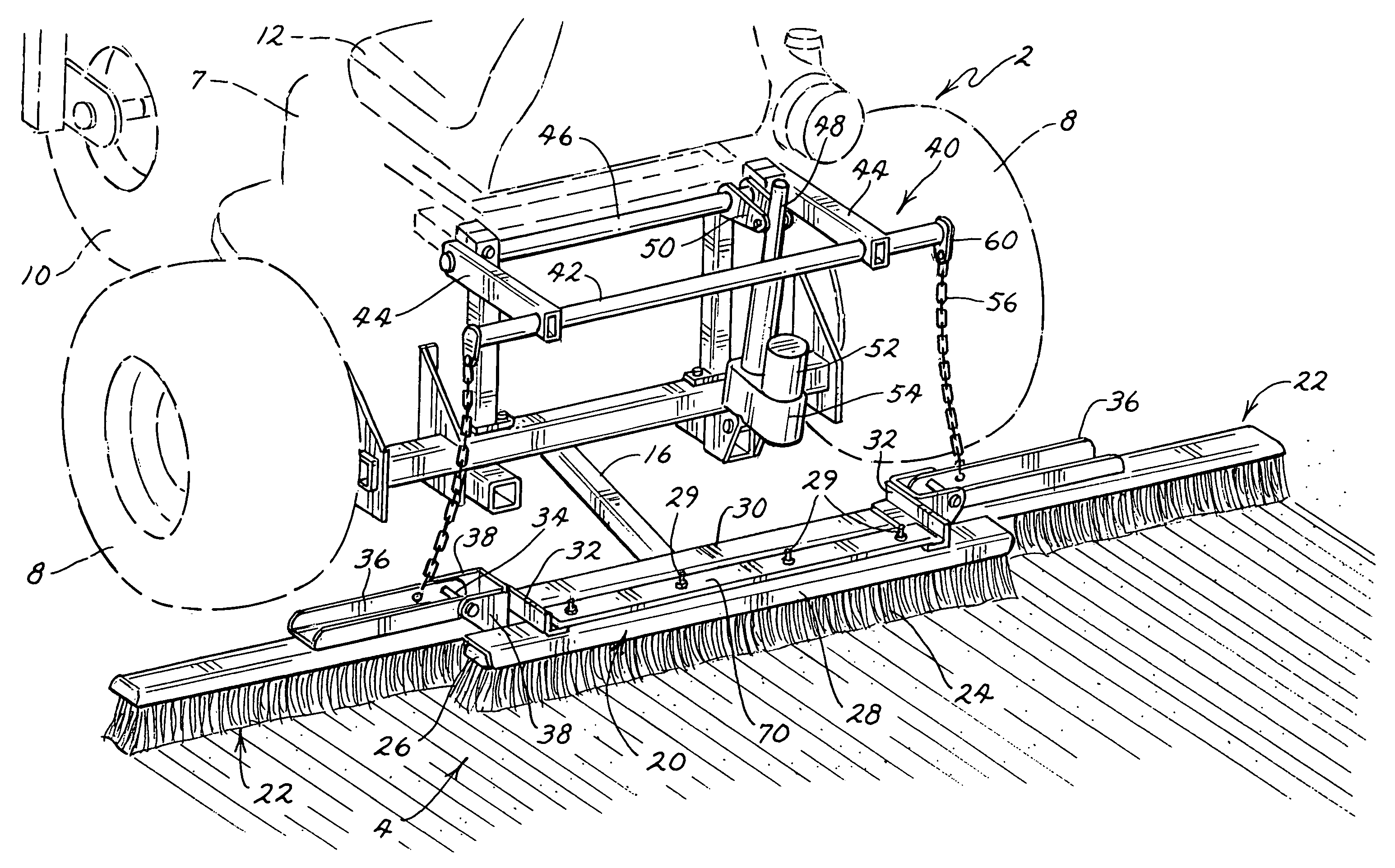

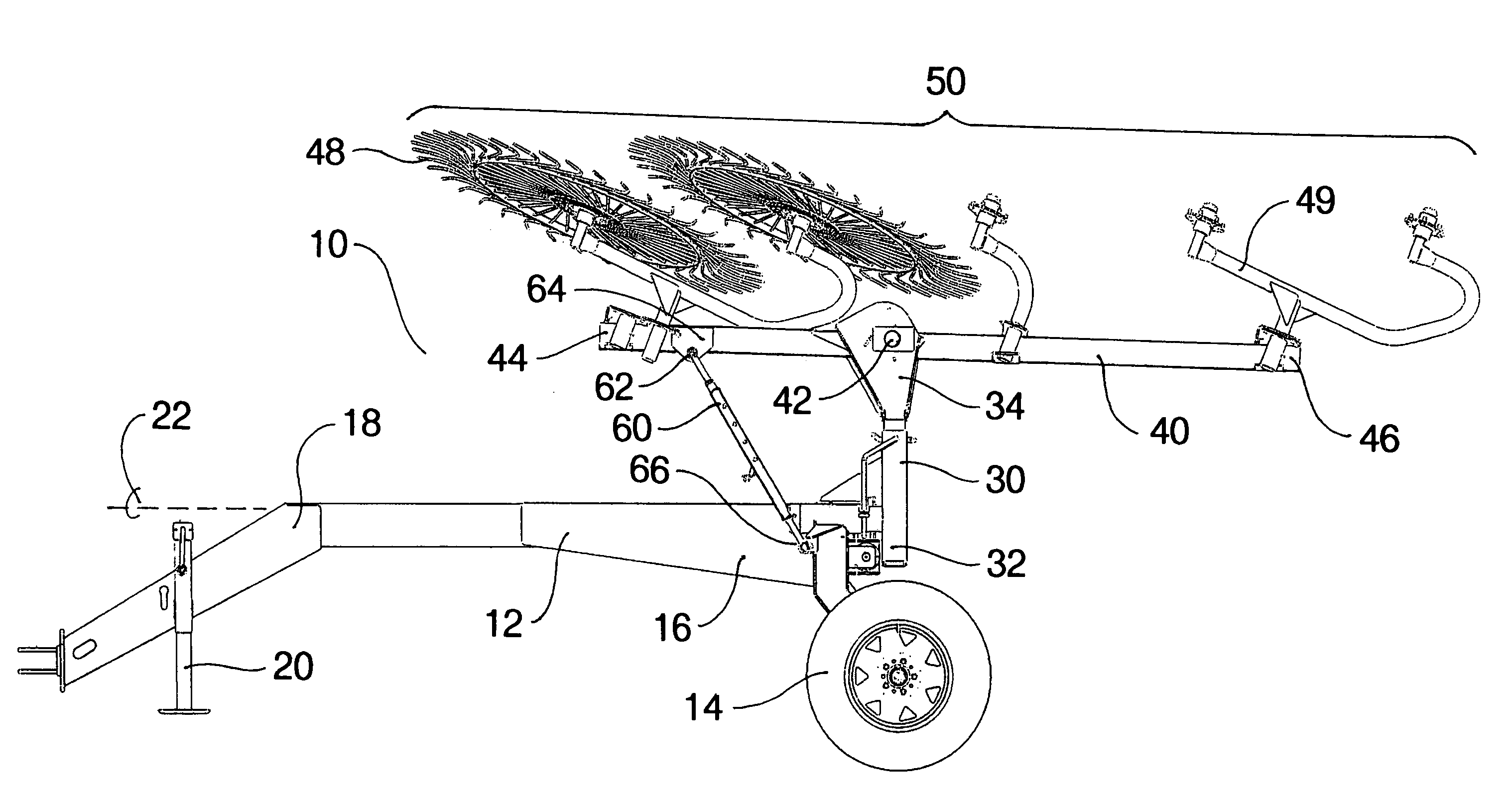

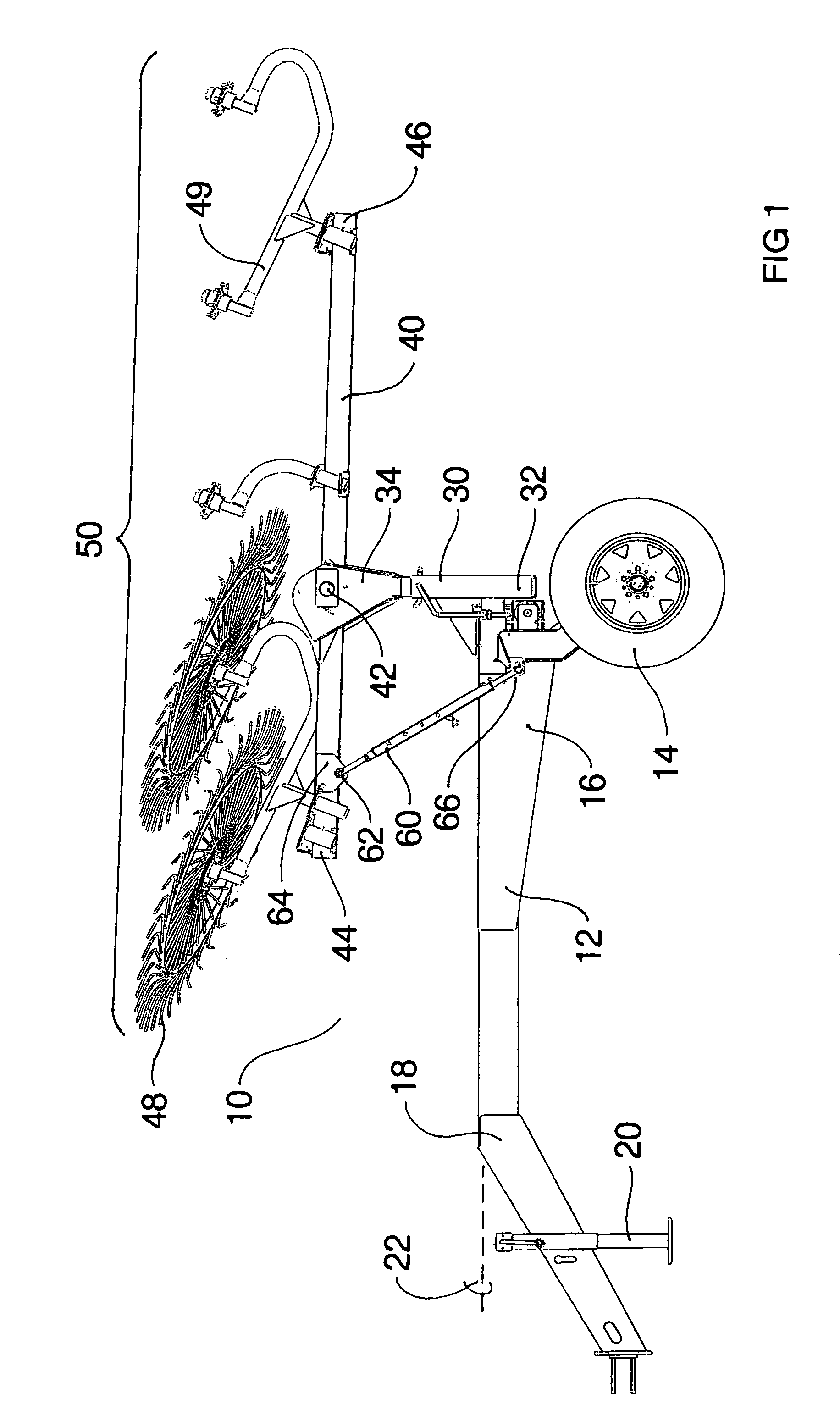

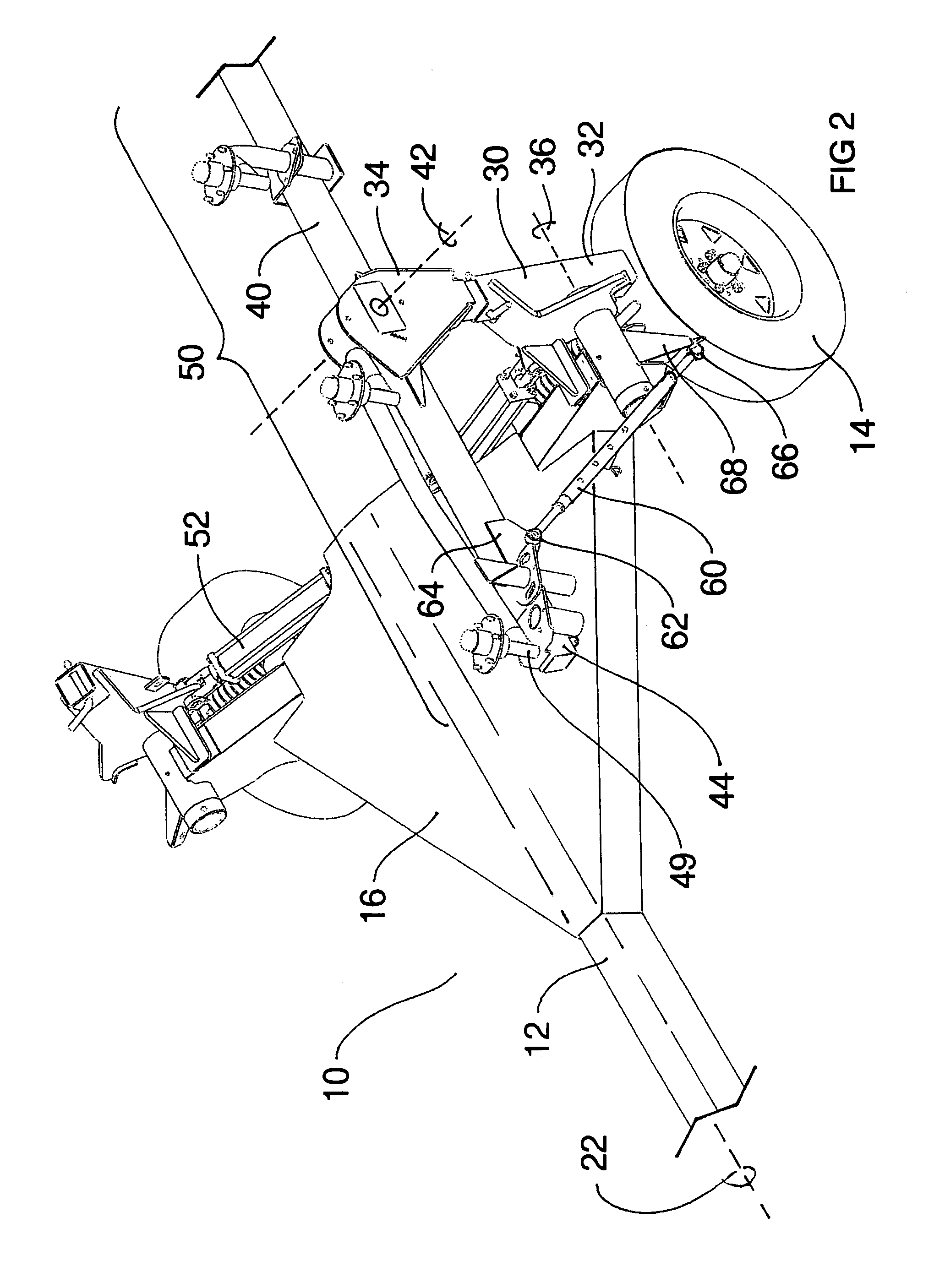

Powered ZRT sand grooming vehicle and grooming brush rake

A sand grooming vehicle comprises a vehicle having zero radius turn capability. The vehicle includes a front caster wheel, two independently driven rear wheels, and twin control sticks for allowing spin turning of the vehicle by driving the outboard drive wheel and stopping or reversing the inboard wheel. A trailing brush rake is towed behind the vehicle to groom the sand. The brush rake includes a center brush and two pivotal side brushes connected to opposite ends of the center brush. The pivots connecting the side brushes and the center brush are elevated above the plane of engagement of the bristles of the side brushes and the sand. Thus, during a spin turn of the vehicle, the side brush on the inside of the turn lifts to avoid pushing a ridge of sand behind that side brush. This permits the vehicle and the brush rake to groom the sand surface without leaving any ungroomed teardrops at the inside of turns and without leaving ridges of sand on the sand surface.

Owner:TORO CO THE

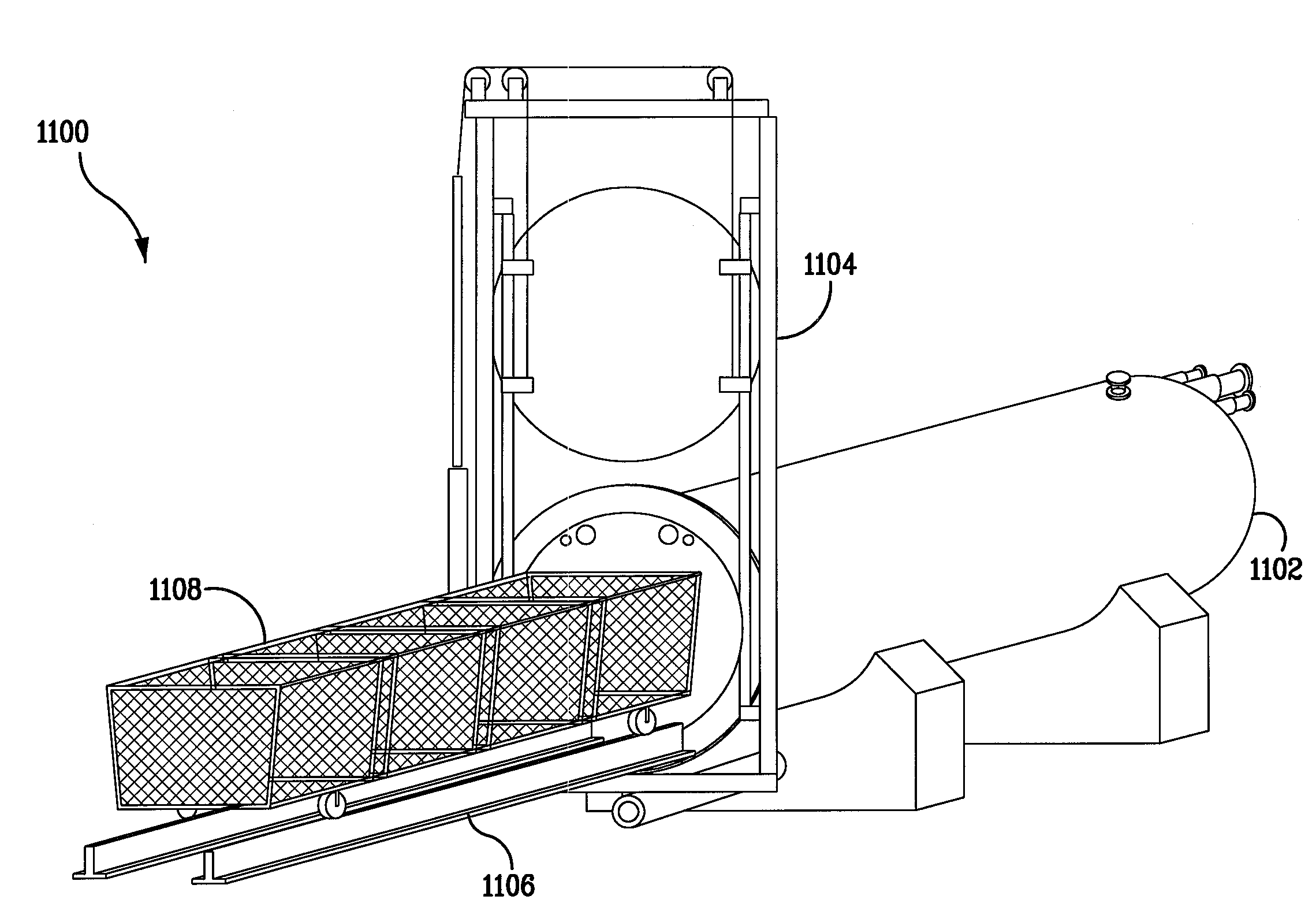

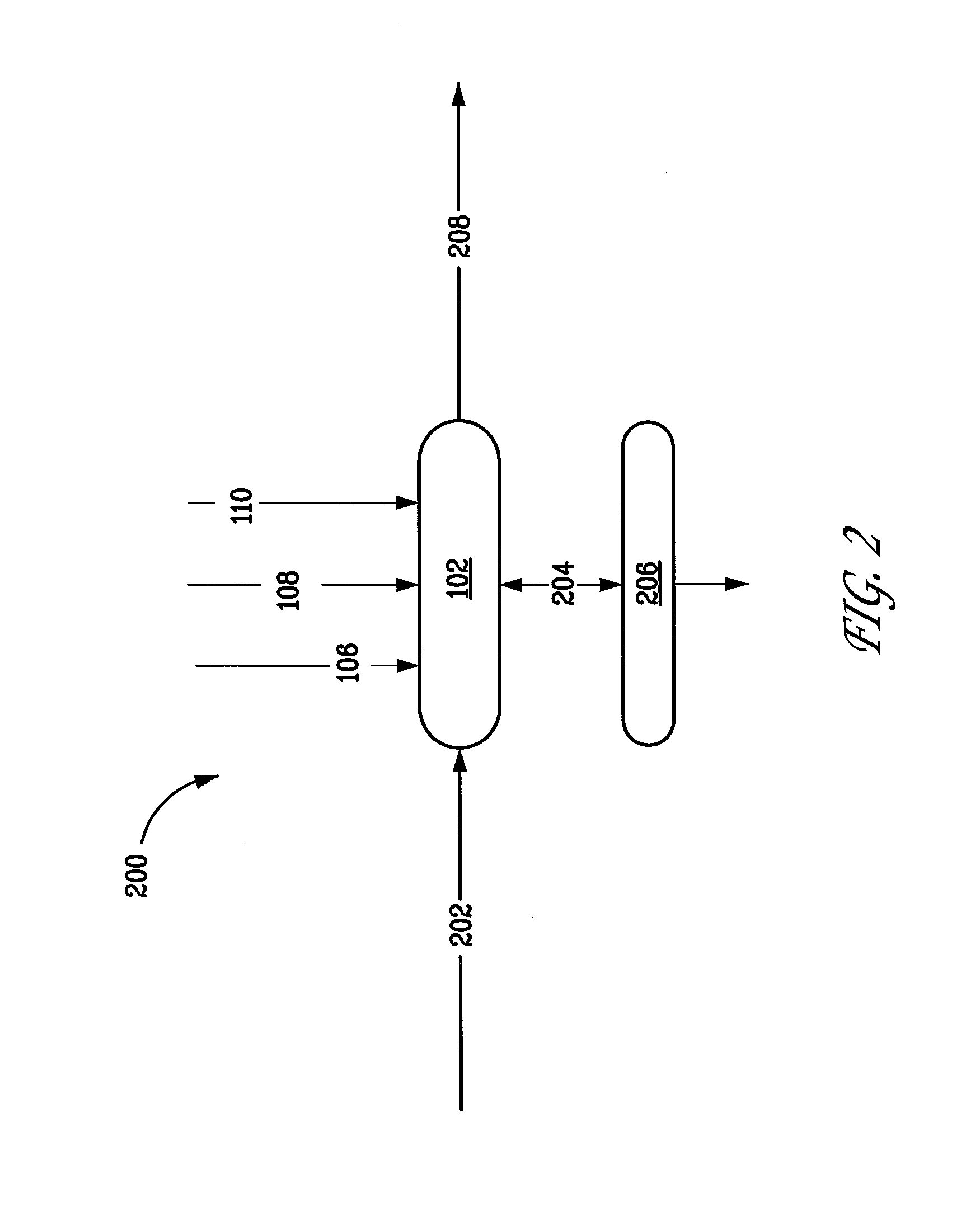

Upgrading Carbonaceous Materials

ActiveUS20100005710A1Reduce weight percentageReduce the temperatureHaymakersBiofuelsMaterials science

Owner:SKYE ENERGY HLDG

Animal bedding groomer

A grooming apparatus, for sloping, aerating and fluffing bedding material in livestock free stalls, is attached to a vehicle such as a skid steer. The grooming apparatus includes a rotary arm, having grooming members, and connected to the vehicle by a boom. The rotary arm, when viewed across the stalls, is angled at a slope. The grooming members contact the bedding material to fluff and aerate it, and arrange it according to the slope. The rotary arm, when viewed from the end of a stall, may be pitched forward or rearward. These pitches and angles permit the grooming members to more effectively move the bedding material within each stall to create the slope. Such a slope is beneficial for livestock that prefers a sloped bed. Using the boom, the rotary arm can be moved up and / or out of the way when the vehicle is moved through doorways and the like.

Owner:SUPERIOR ATTACHMENTS

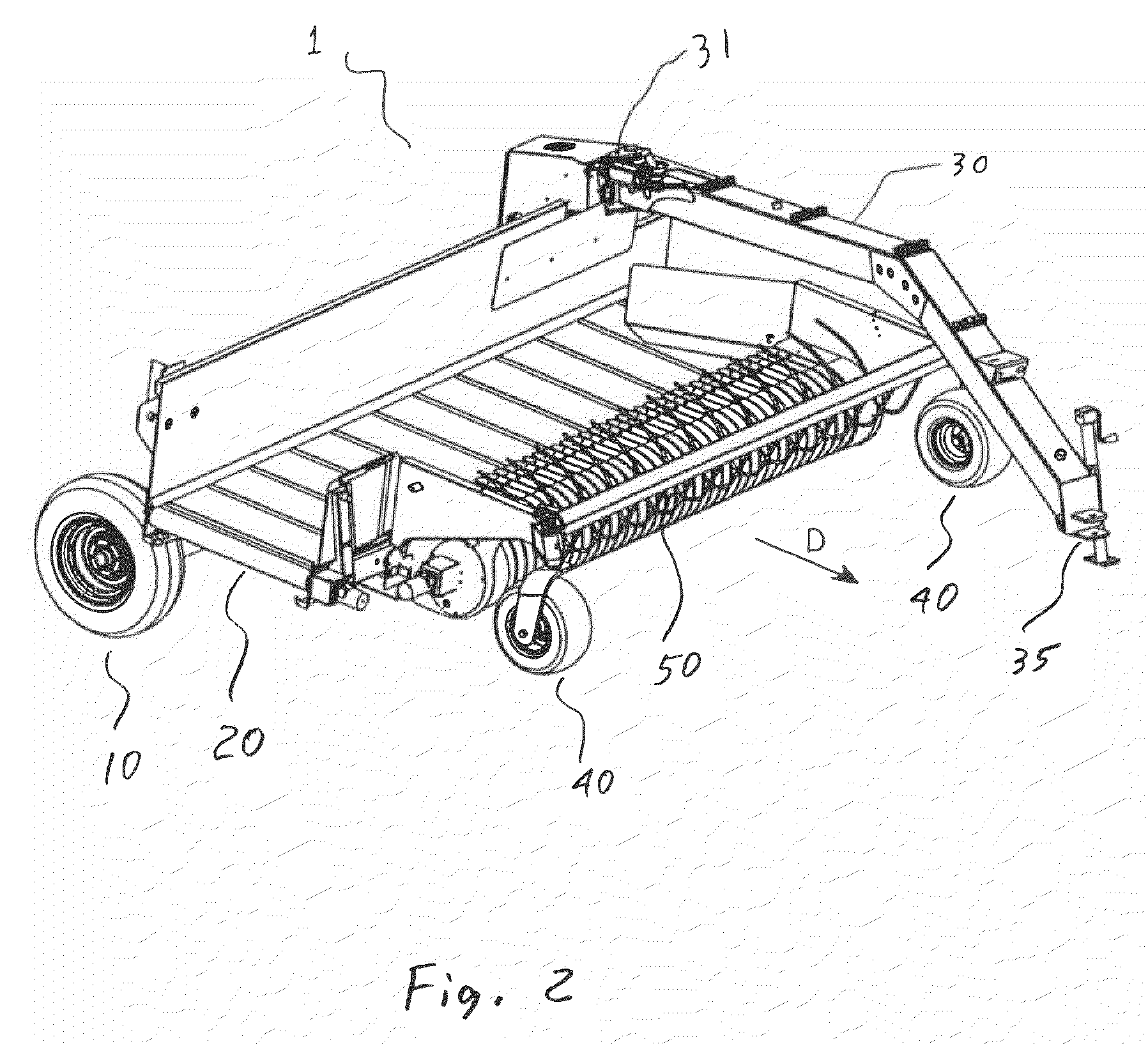

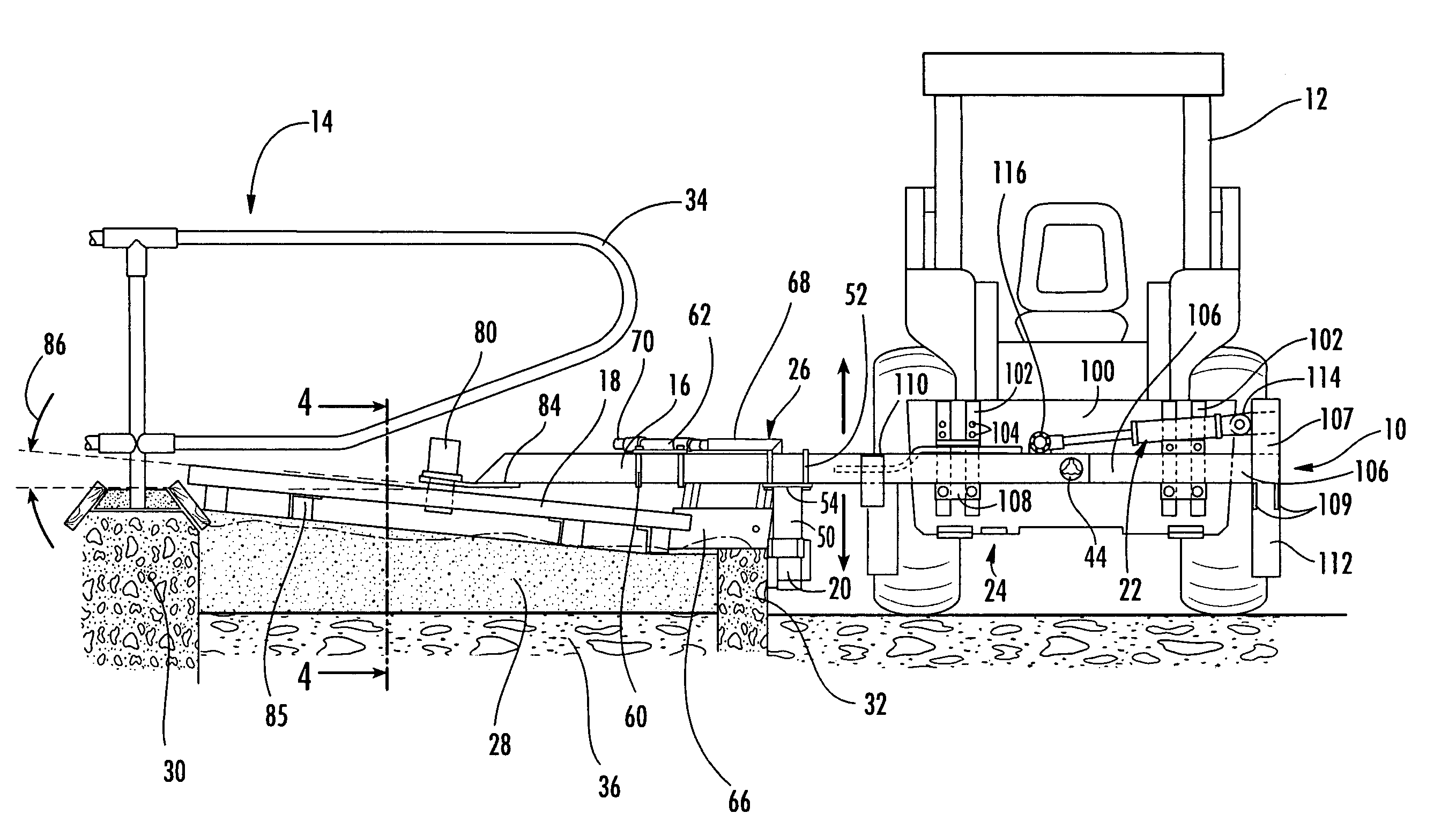

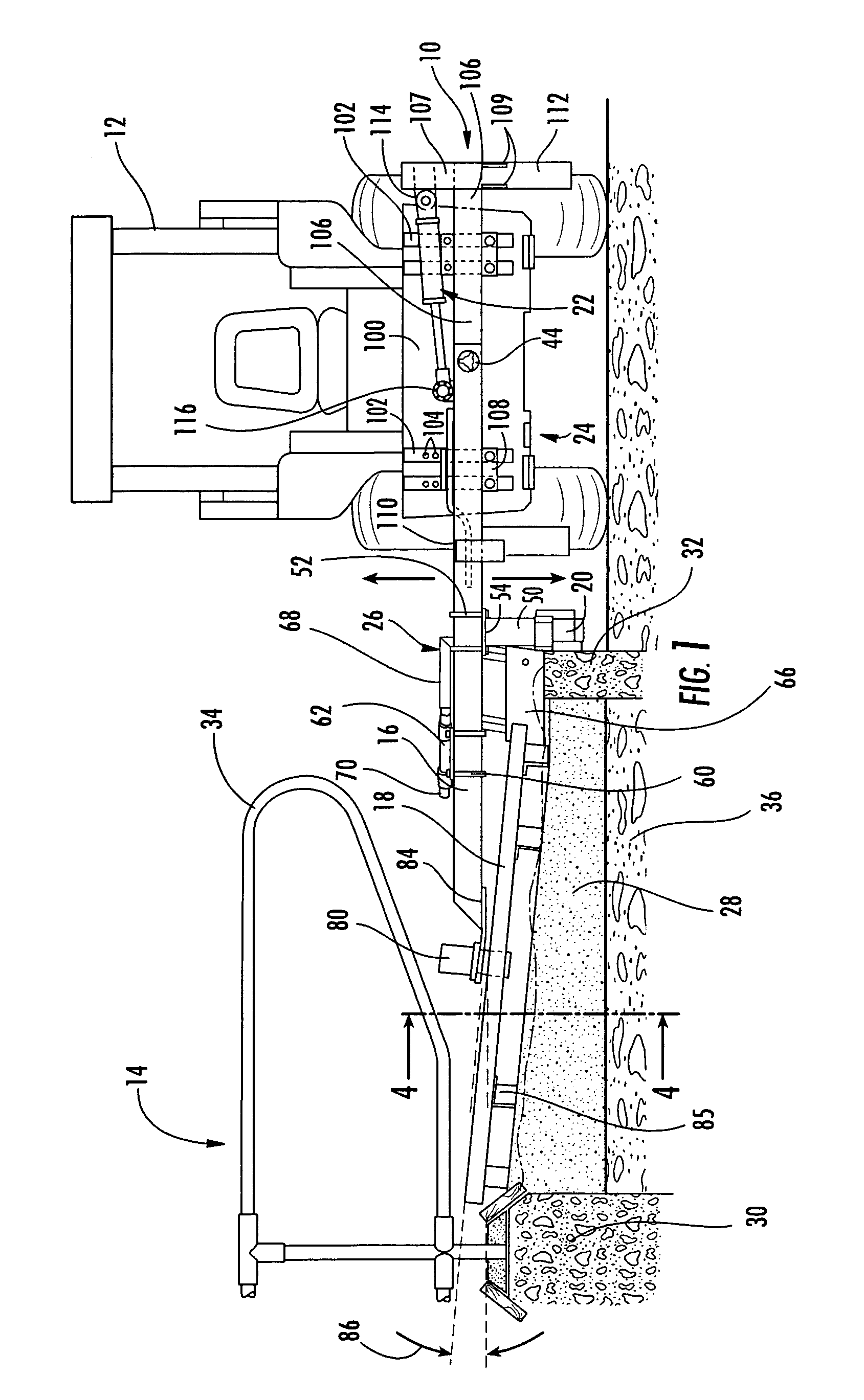

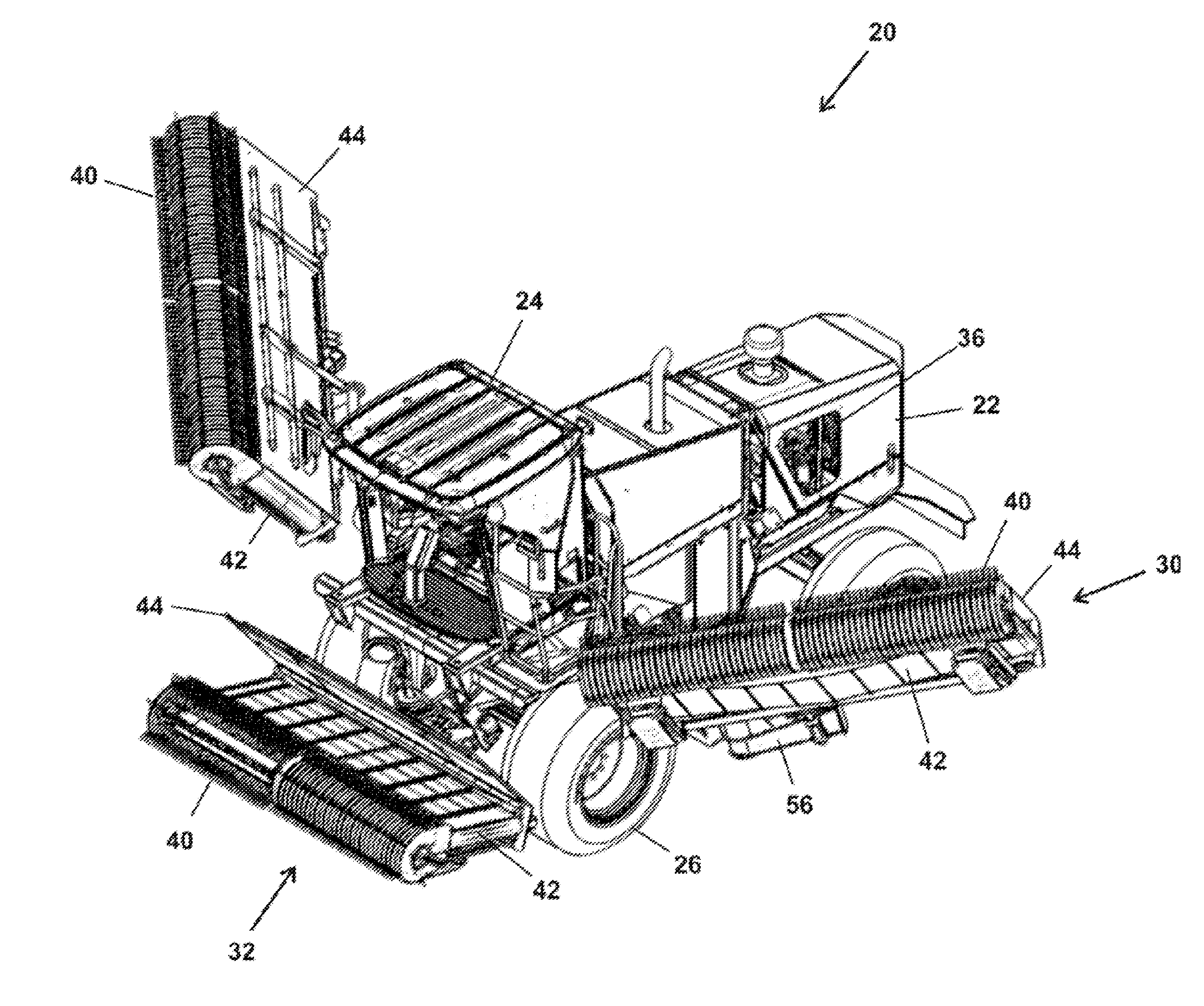

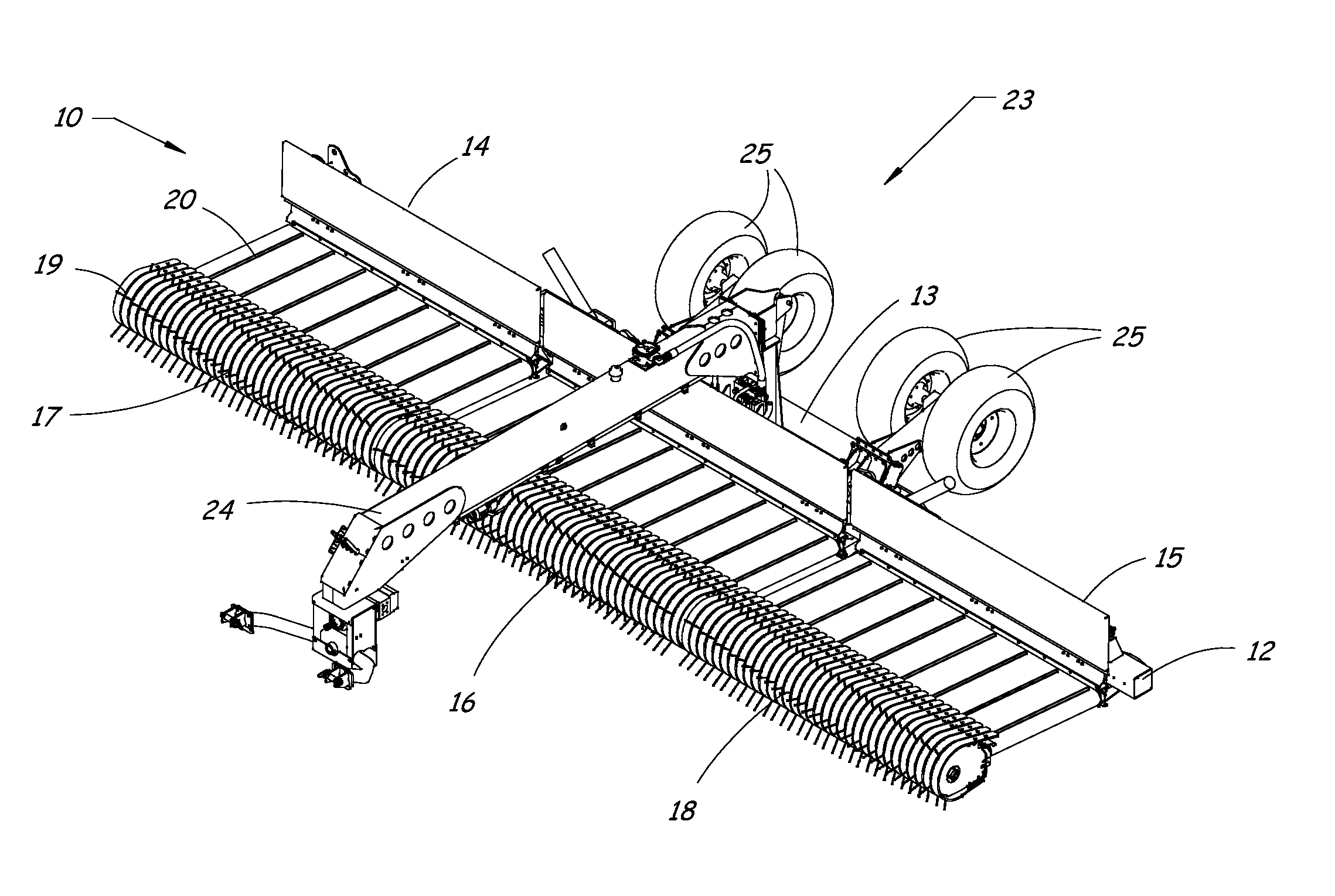

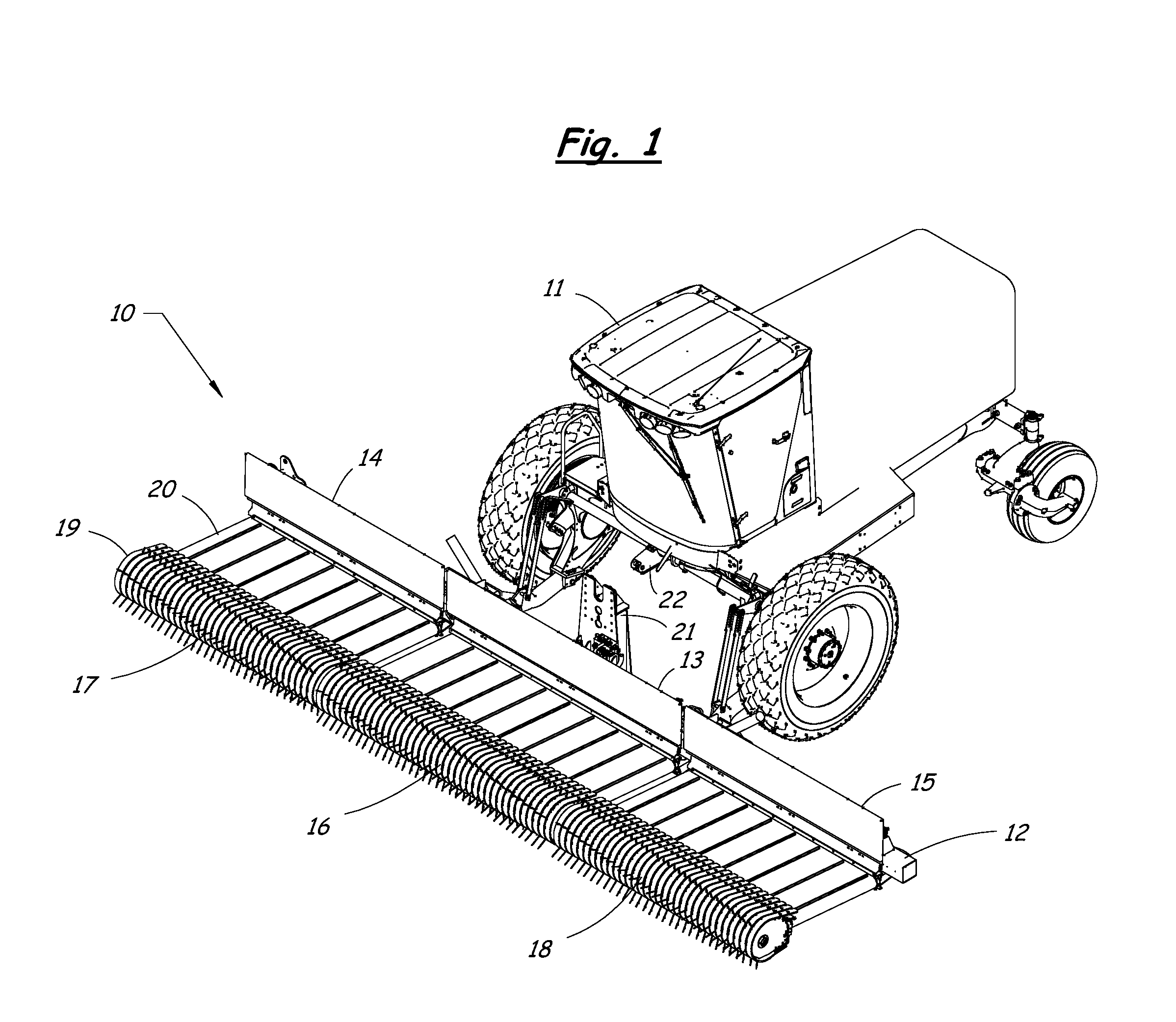

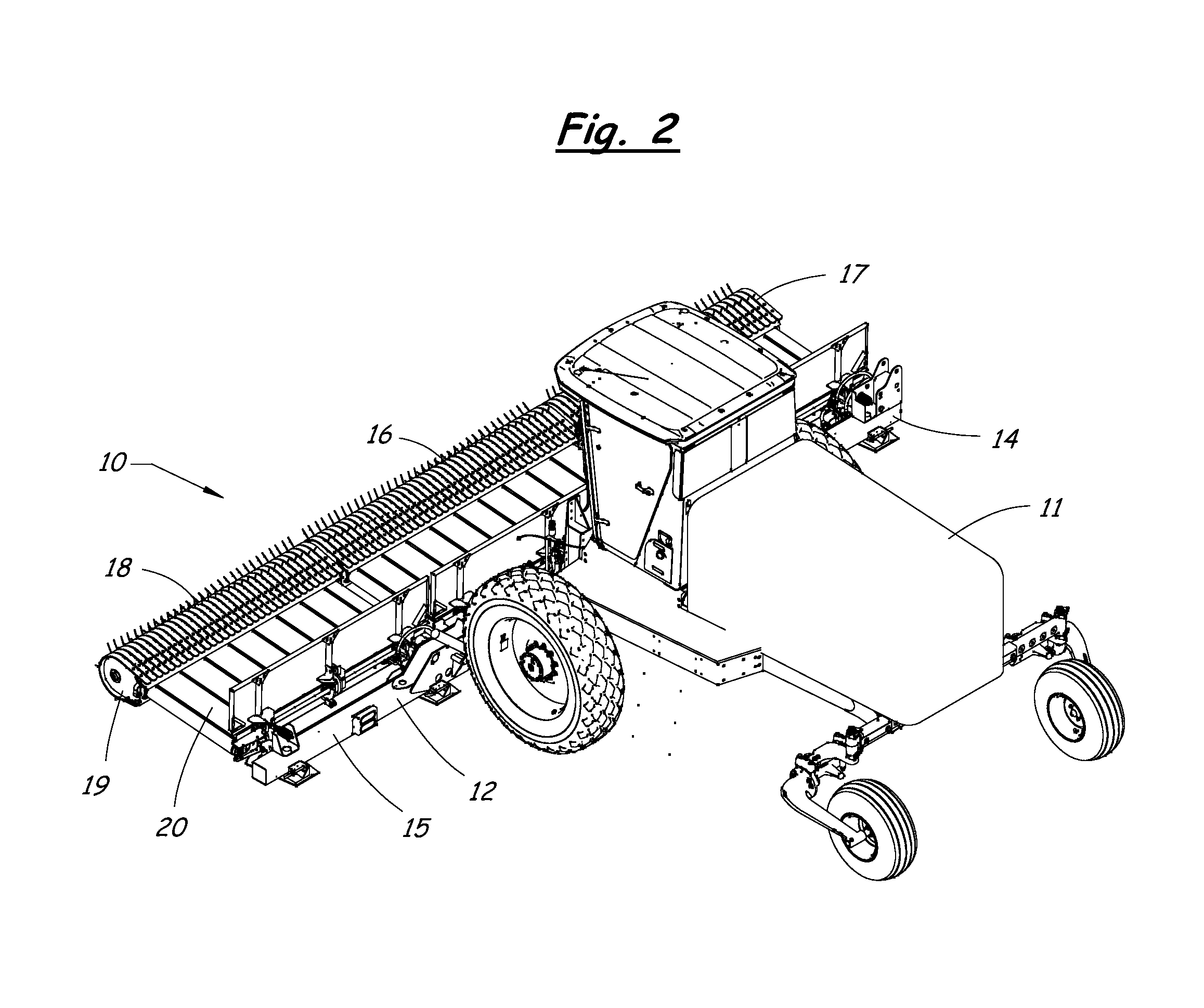

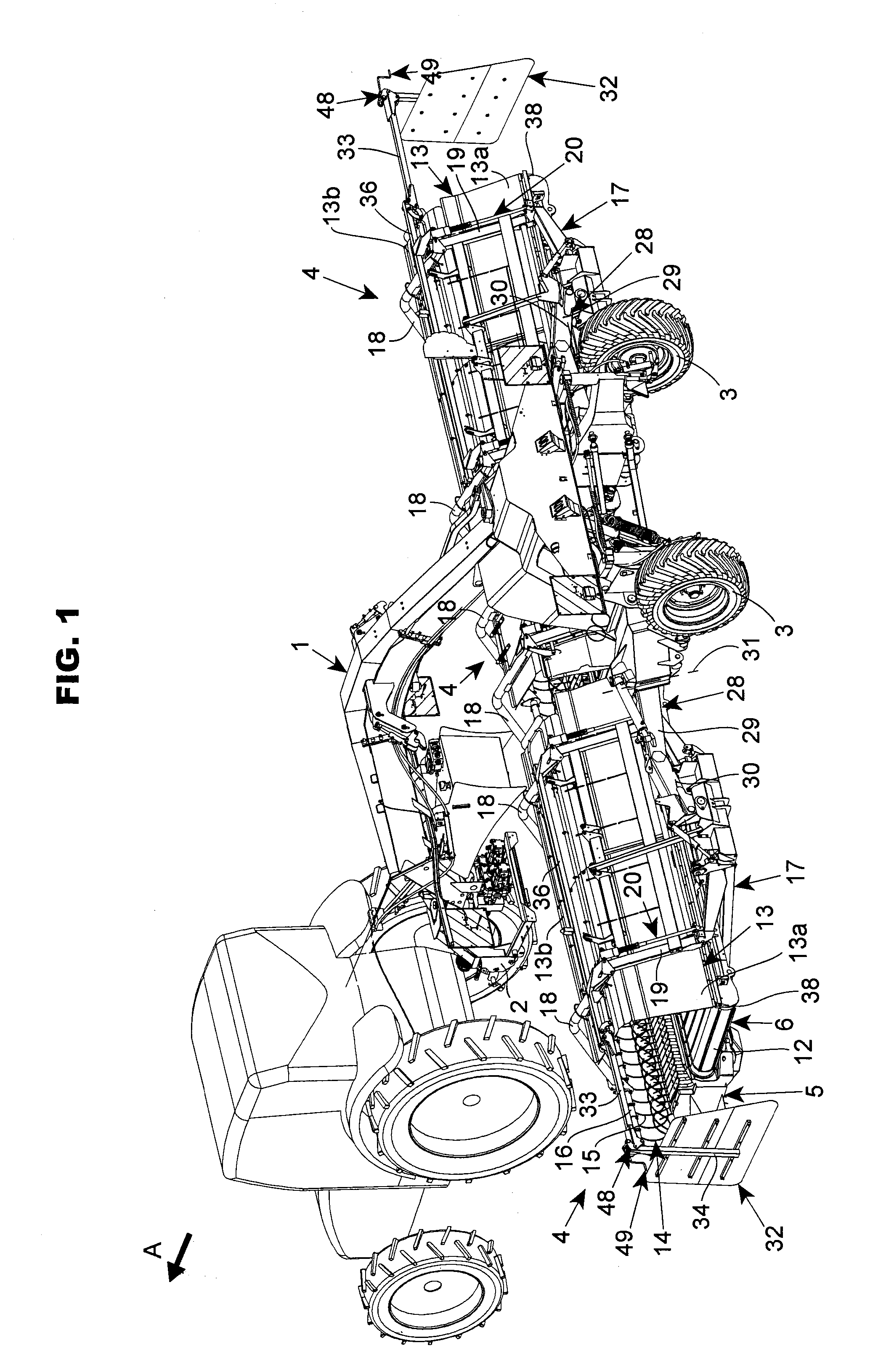

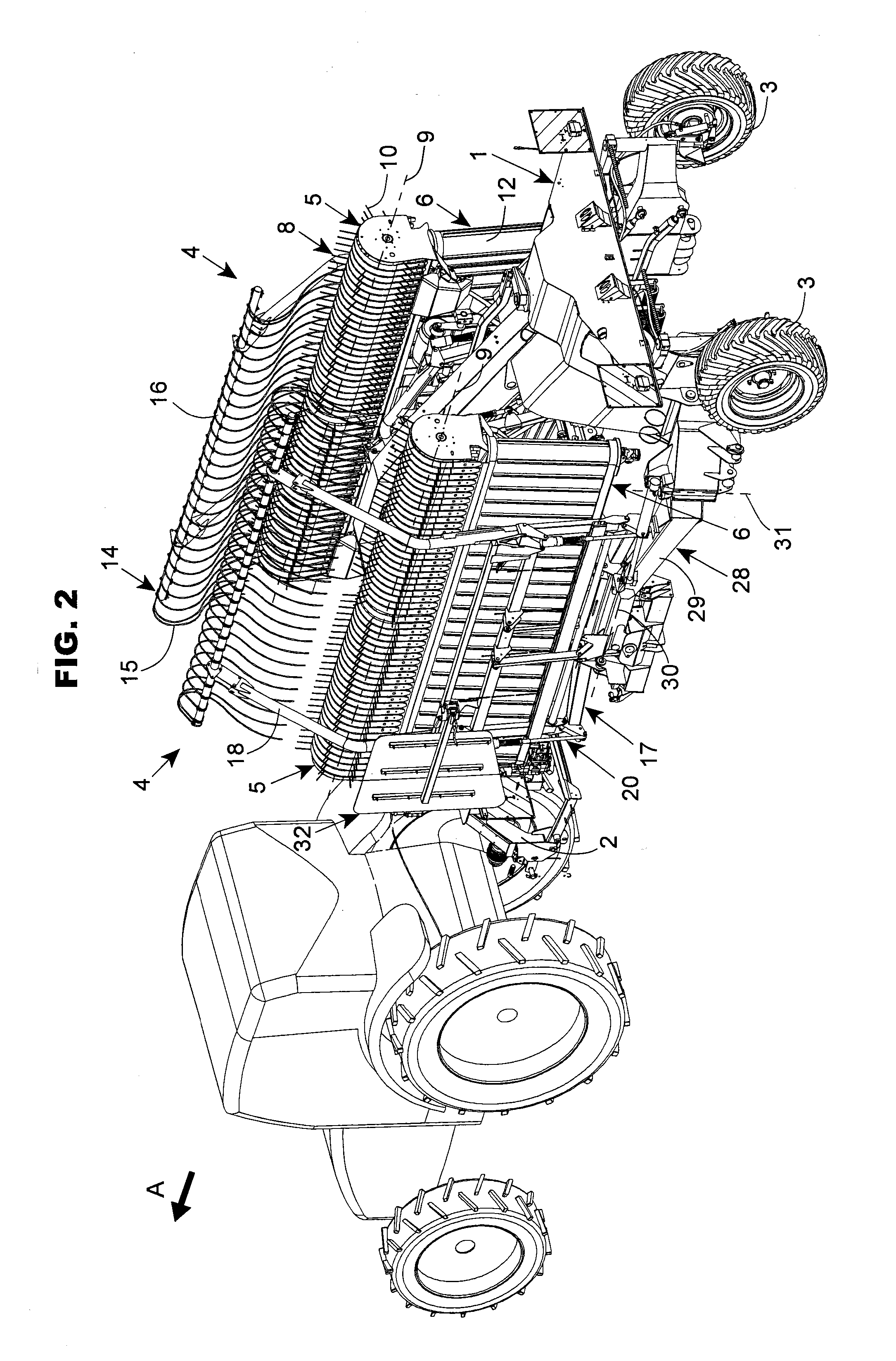

Self-propelled windrow merger

A self-propelled windrow merger includes a motor and a chassis. At the front of the merger are a first pickup and transfer assembly, a second pickup and transfer assembly and a third pickup and transfer assembly. A cab is above and behind the second pickup and transfer assembly. A folding mechanism for moves each of the pickup and transfer assemblies between a first position wherein the first, second and third pickup and transfer assemblies are laterally aligned and a second position wherein the first and third pickup and transfer assemblies are positioned rear of the cab.

Owner:OXBO INT CORP

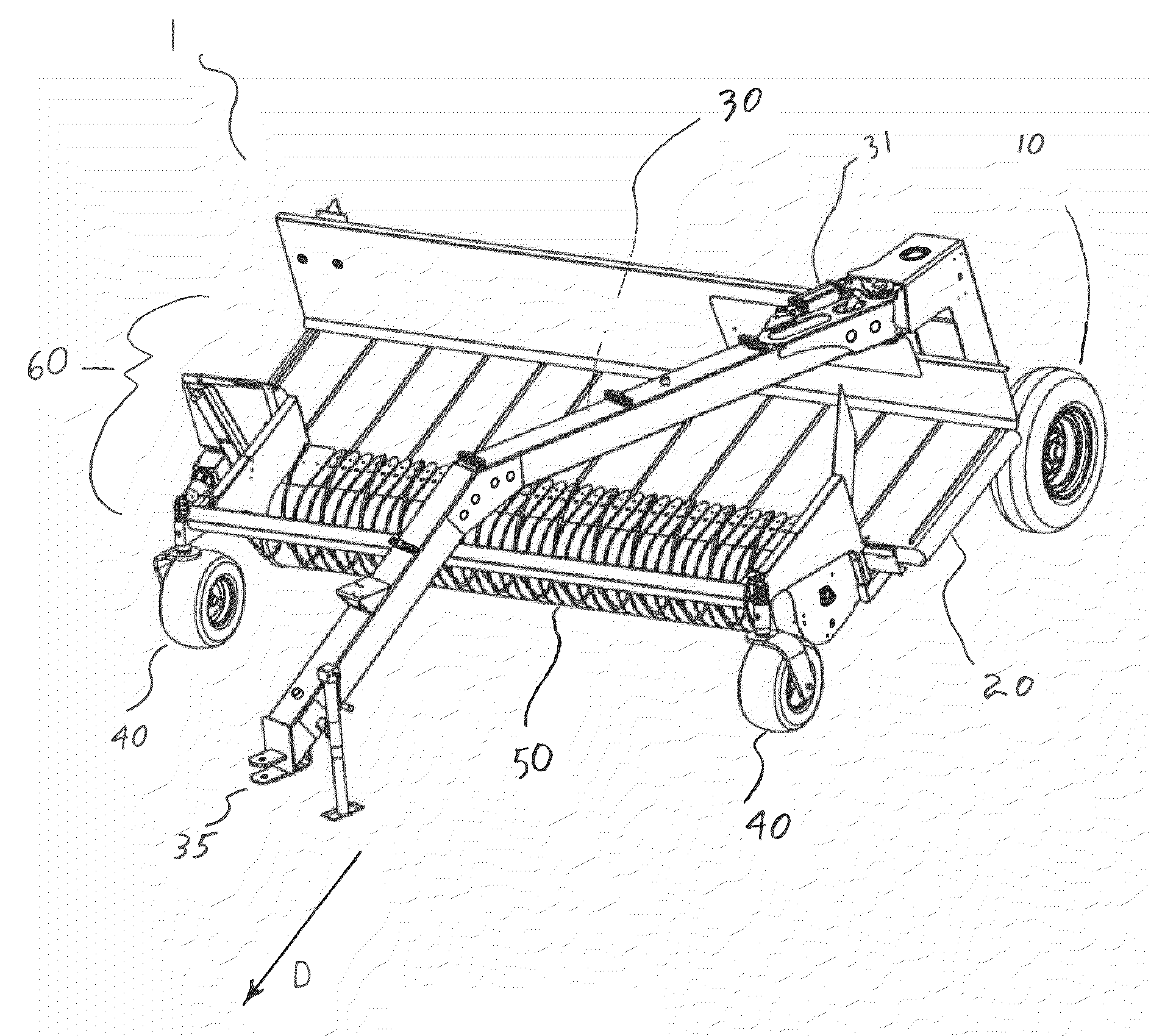

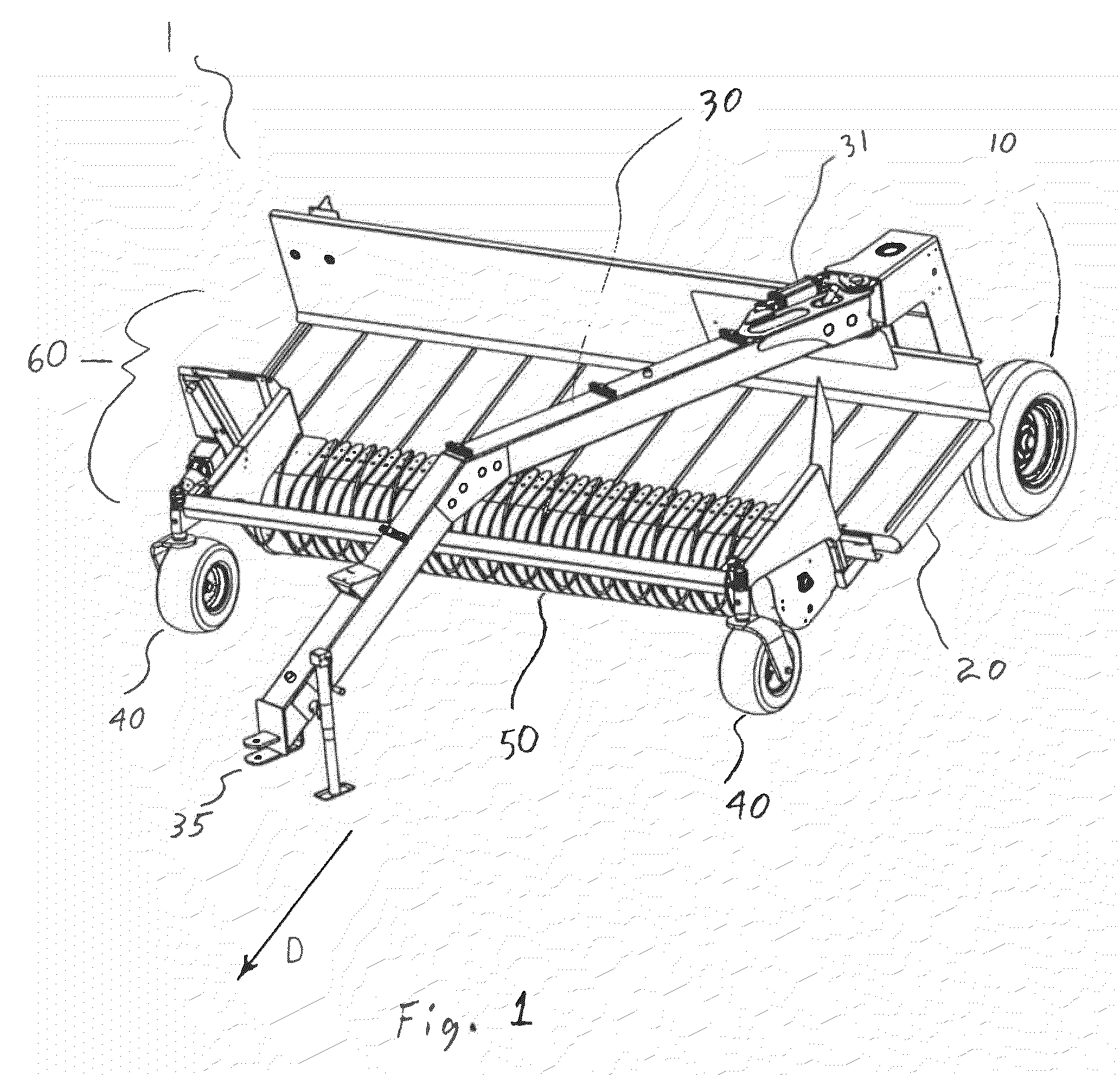

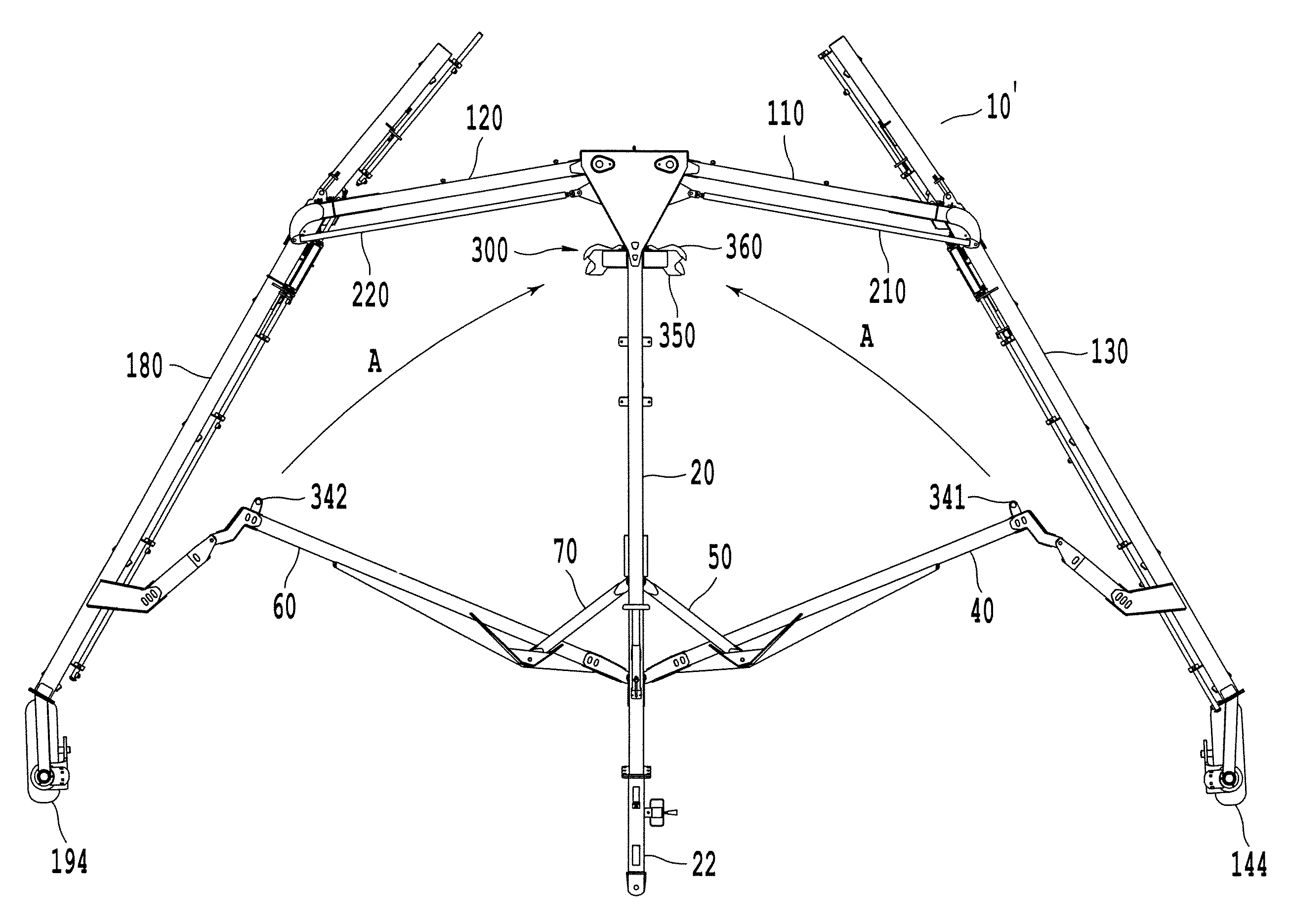

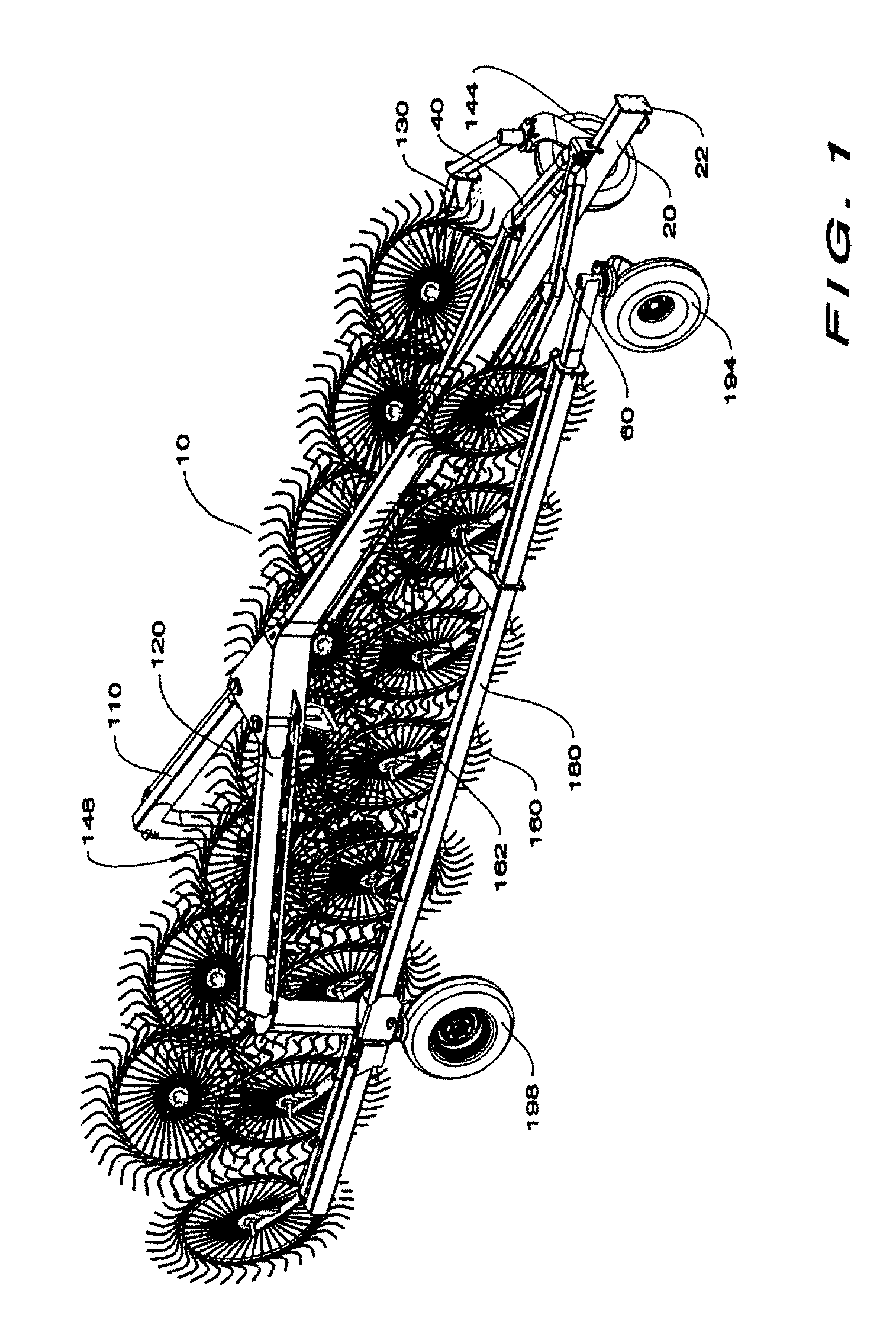

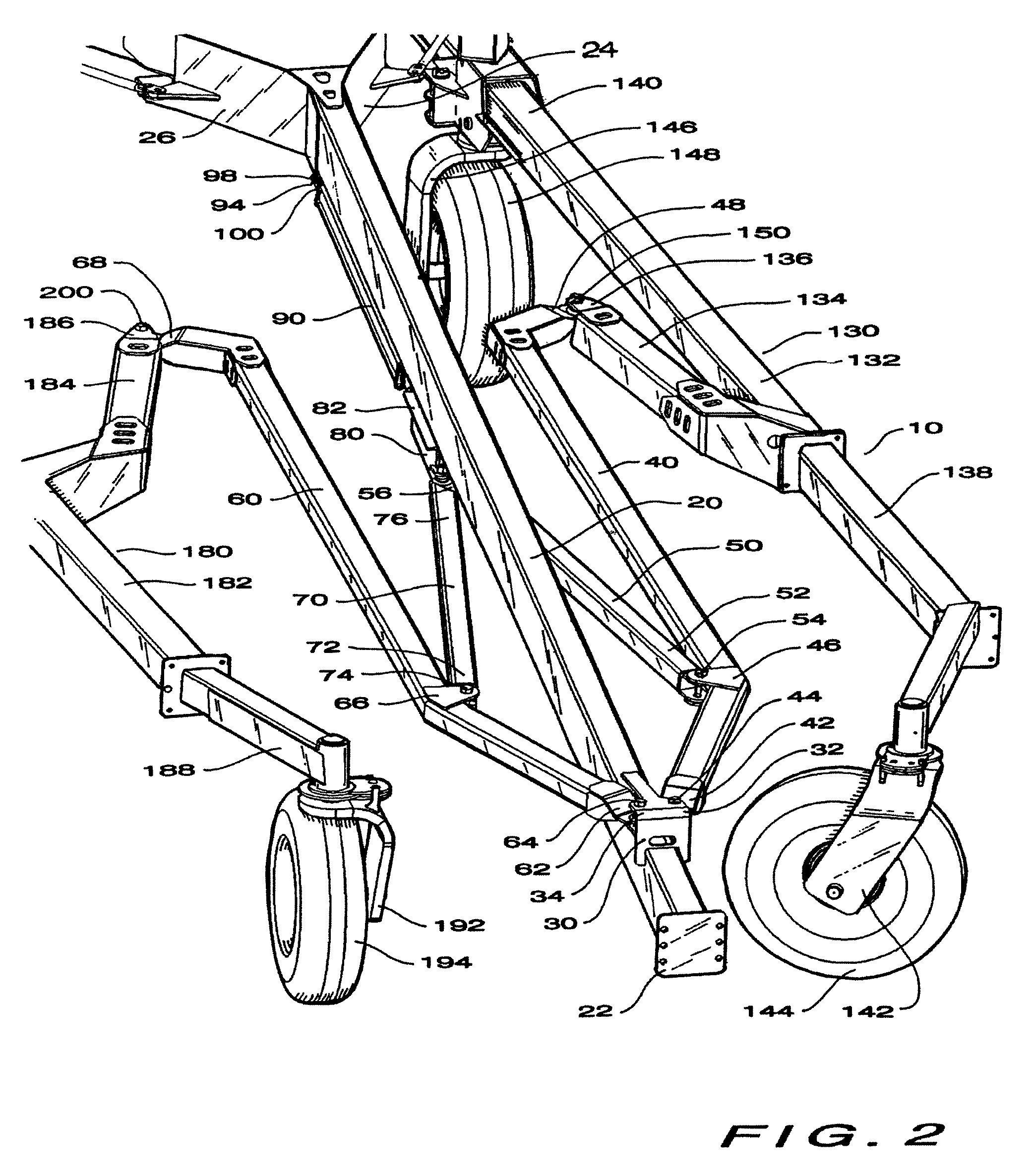

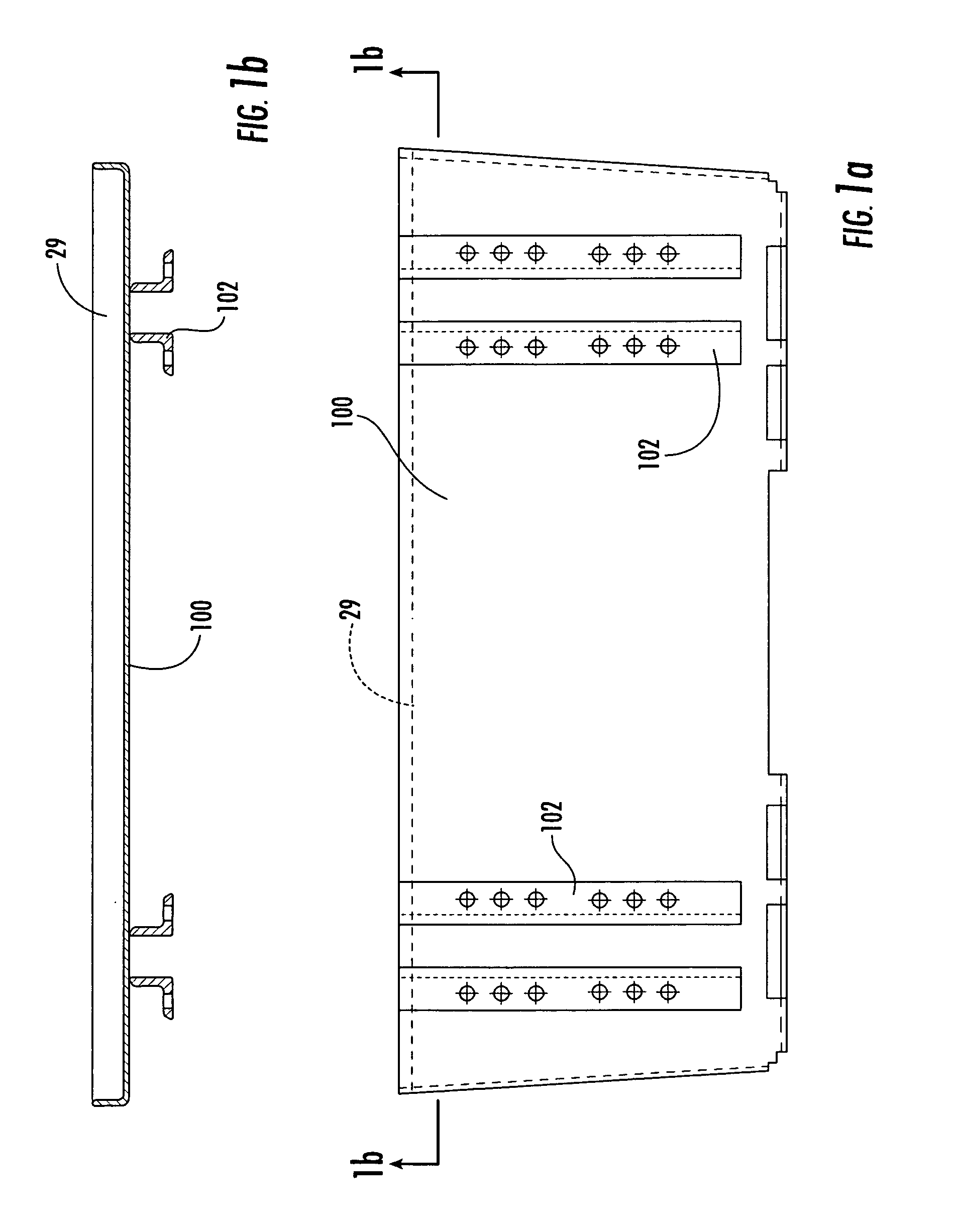

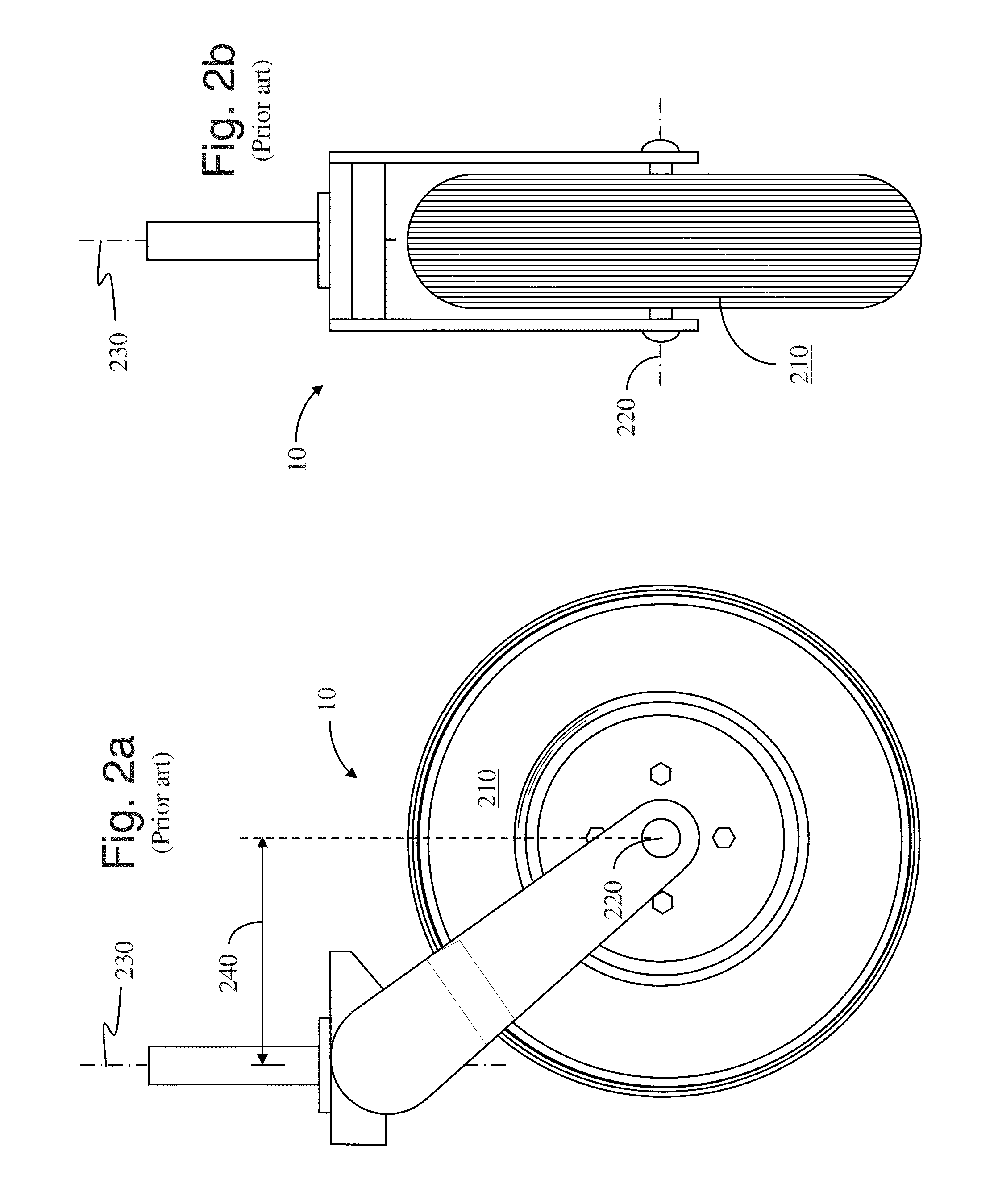

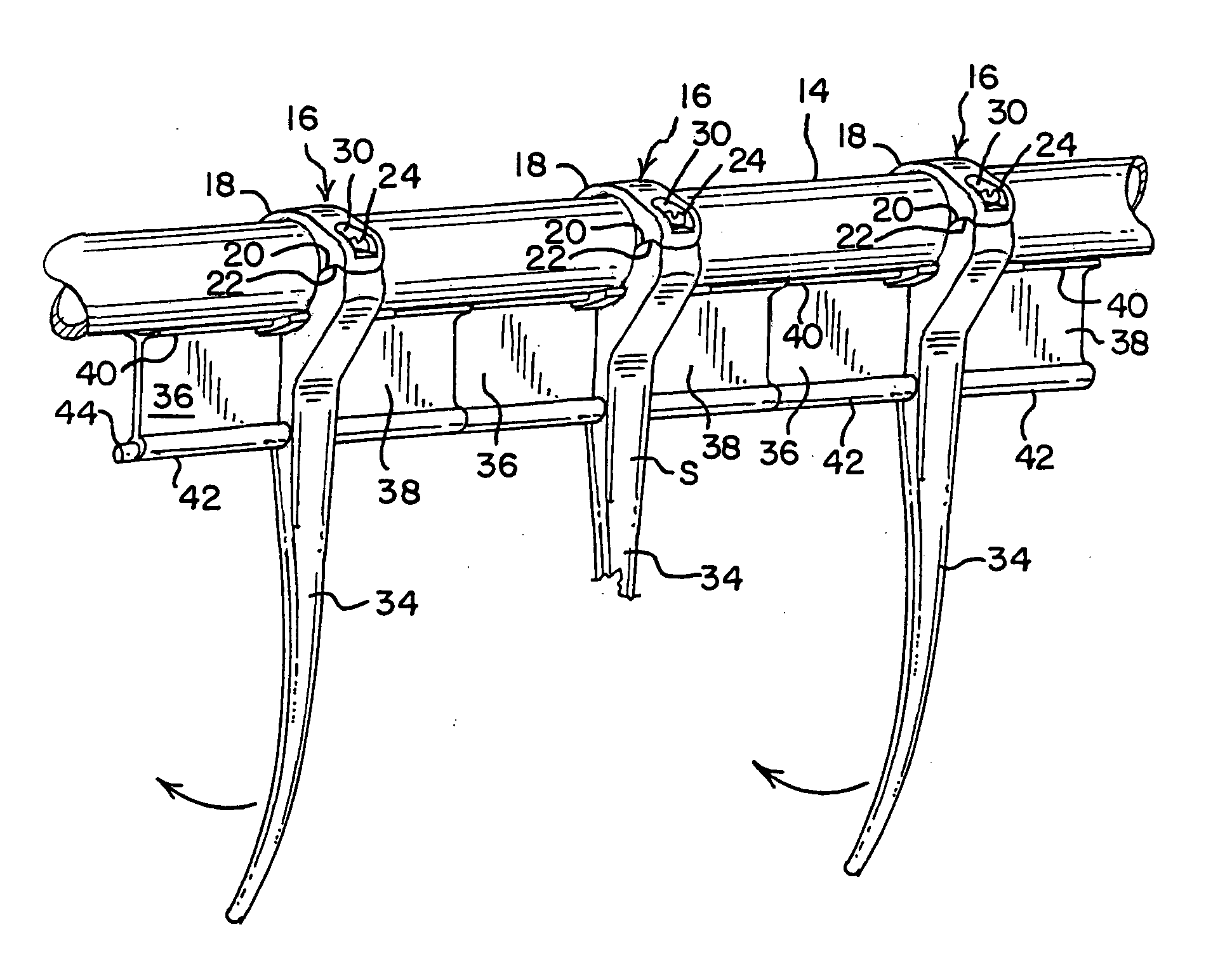

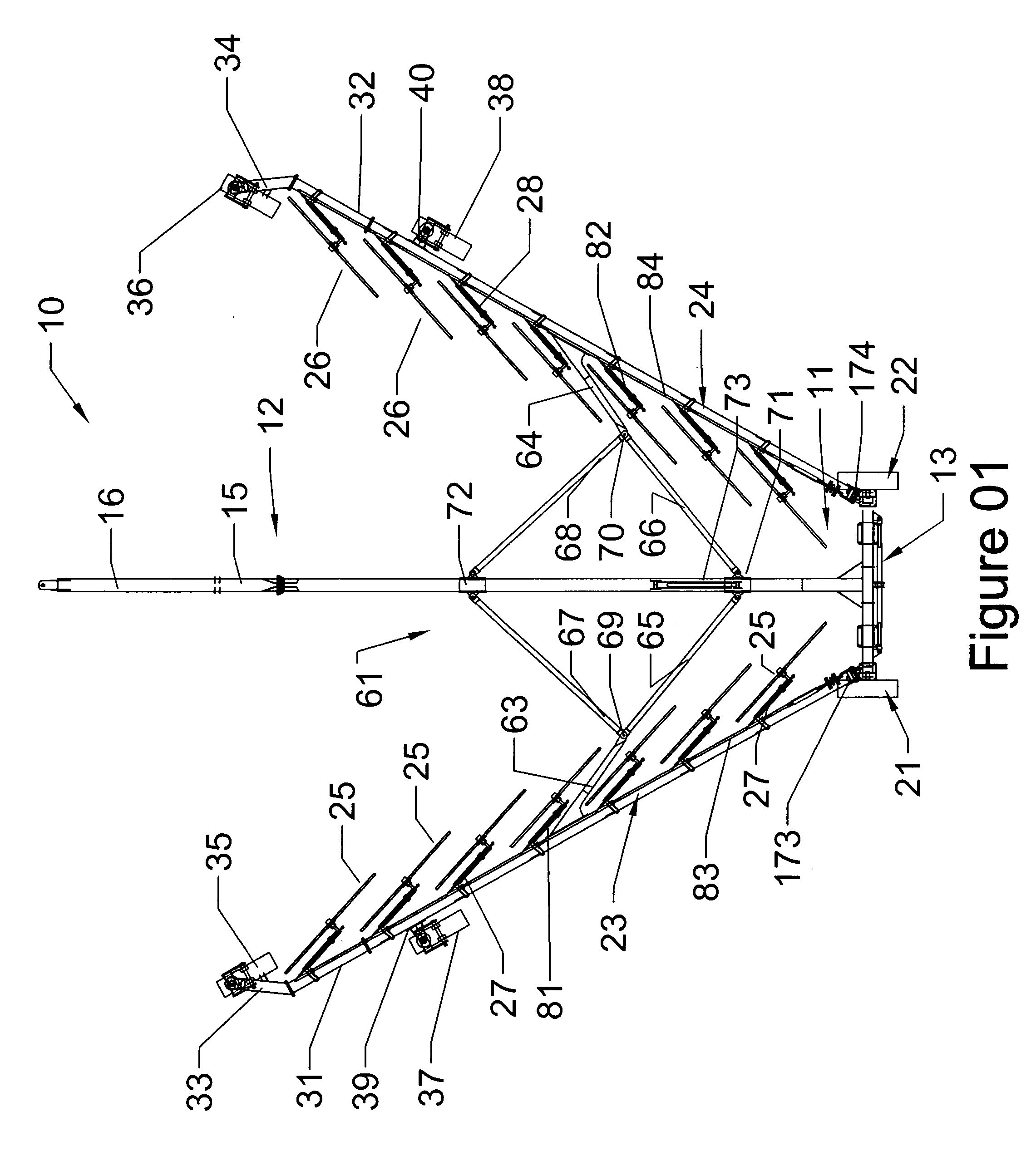

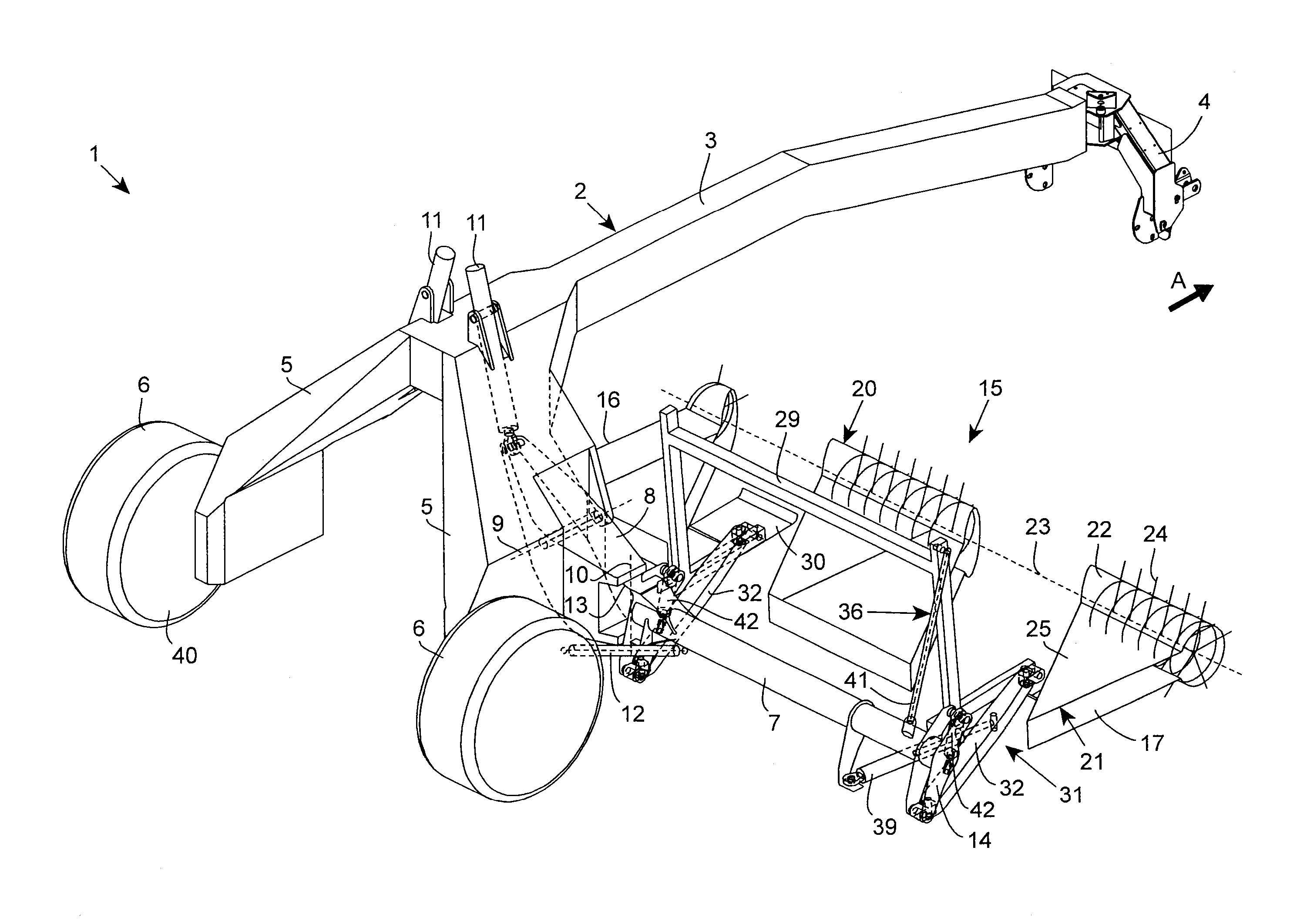

Folding frame for an agricultural implement

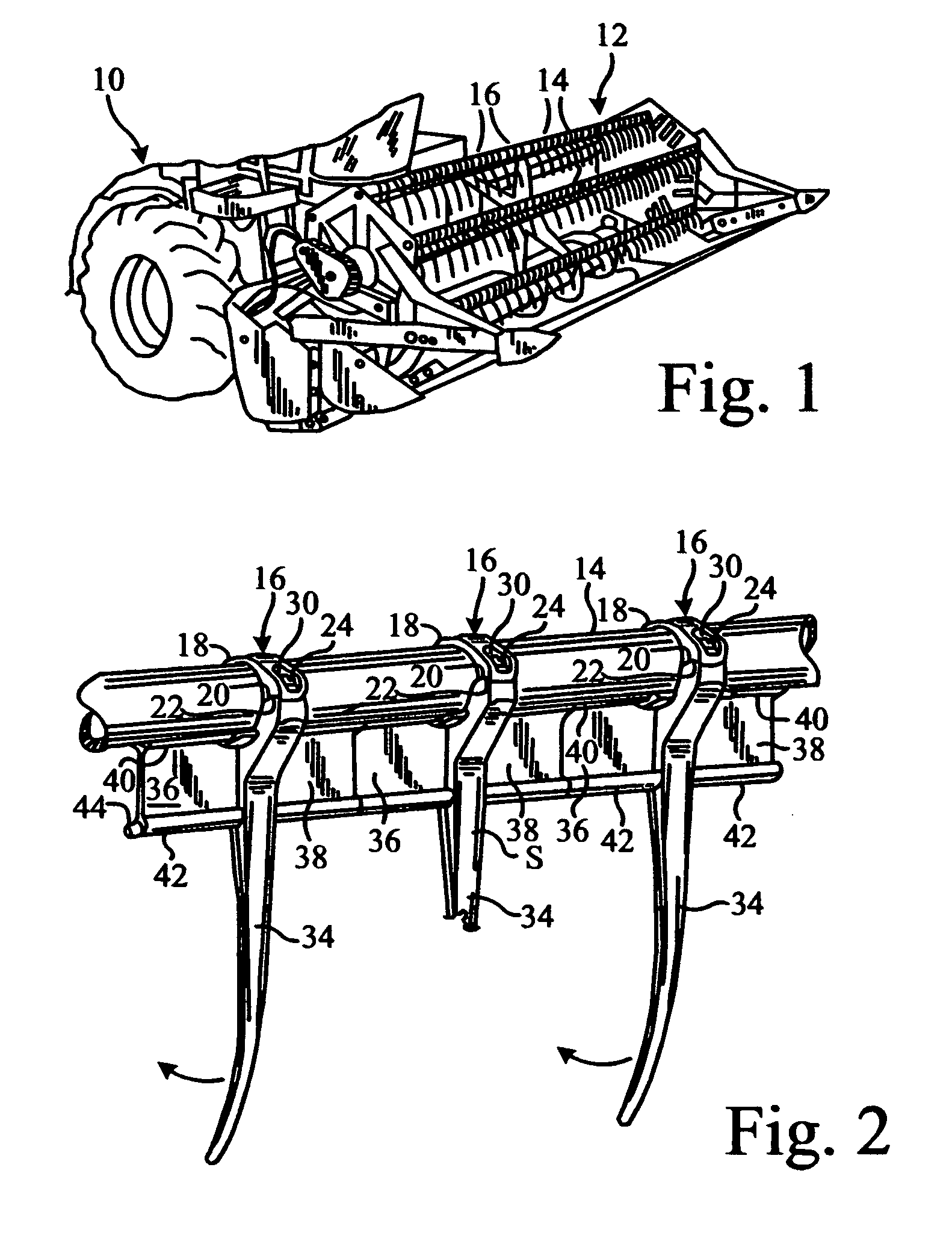

ActiveUS8657025B2Narrow widthHigh strengthSpadesAgricultural machinesAgricultural engineeringWindrow

A folding frame for an agricultural implement such as a wheel rake. The frame includes ground engaging wheels and two toolbars foldable for operation and for transport. The folding frame is provided flexibility to conform to uneven surfaces, yet stability against the torques and forces of operation. A slidable tongue provides folding action between the transport position and the operating position. A spacing between rear ends of the two toolbars may be altered hydraulically for wider or narrower windrows. A novel caster wheel provides support for the toolbars and is located so that the implement's transport position is narrower than the prior art's.

Owner:VERMEER MFG CO

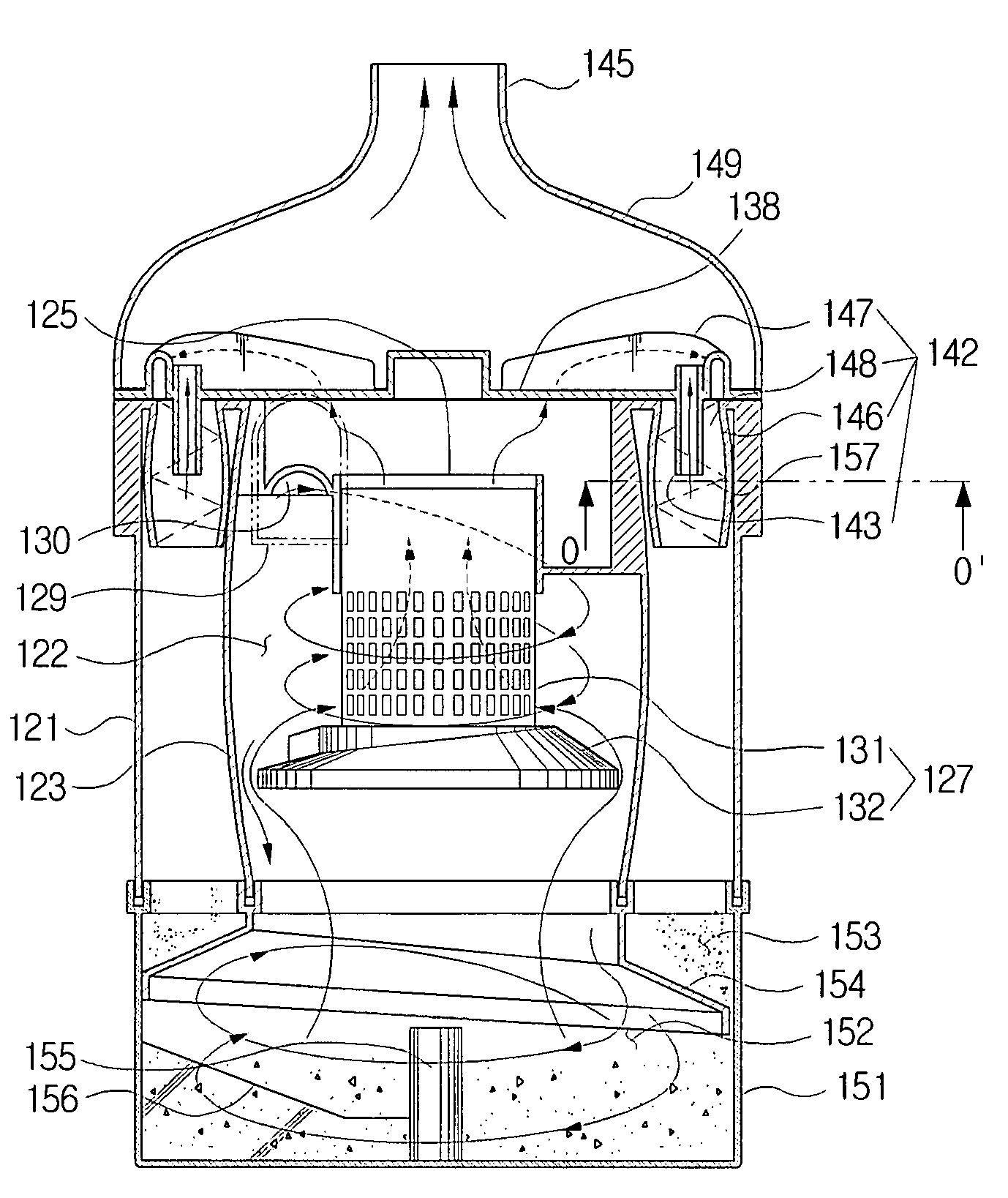

Multi cyclone dust-separating apparatus of vacuum cleaner

InactiveUS7776115B2Reduce running noiseReduce total pressure lossSuction filtersReversed direction vortexCycloneEngineering

A multi cyclone dust-separating apparatus is disclosed that includes a cyclone unit having a first cyclone, a plurality of second cyclones, and a dust collecting unit. The first cyclone is disposed so that a longitudinal axis thereof is substantially vertically arranged. The first cyclone separates relatively large dust or dirt from air drawn in through a first air inflow part. Each of the second cyclones is disposed so that longitudinal axes thereof are substantially vertically arranged. Each of the second cyclones has a second air inflow part to communicate with the first cyclone and an air discharging part to discharge the air. The second cyclones separate relatively minute dust or dirt from the air drawn in through the second air inflow part. The dust collecting unit is disposed below the cyclone unit to collect and store the dust or dirt separated from the air by the cyclone unit.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Harvester reel tine repair

InactiveUS7124564B2Impair efficient operationMaximizes timeHarvestersHaymakersEngineeringMechanical engineering

Owner:PLASTIC DESIGNS

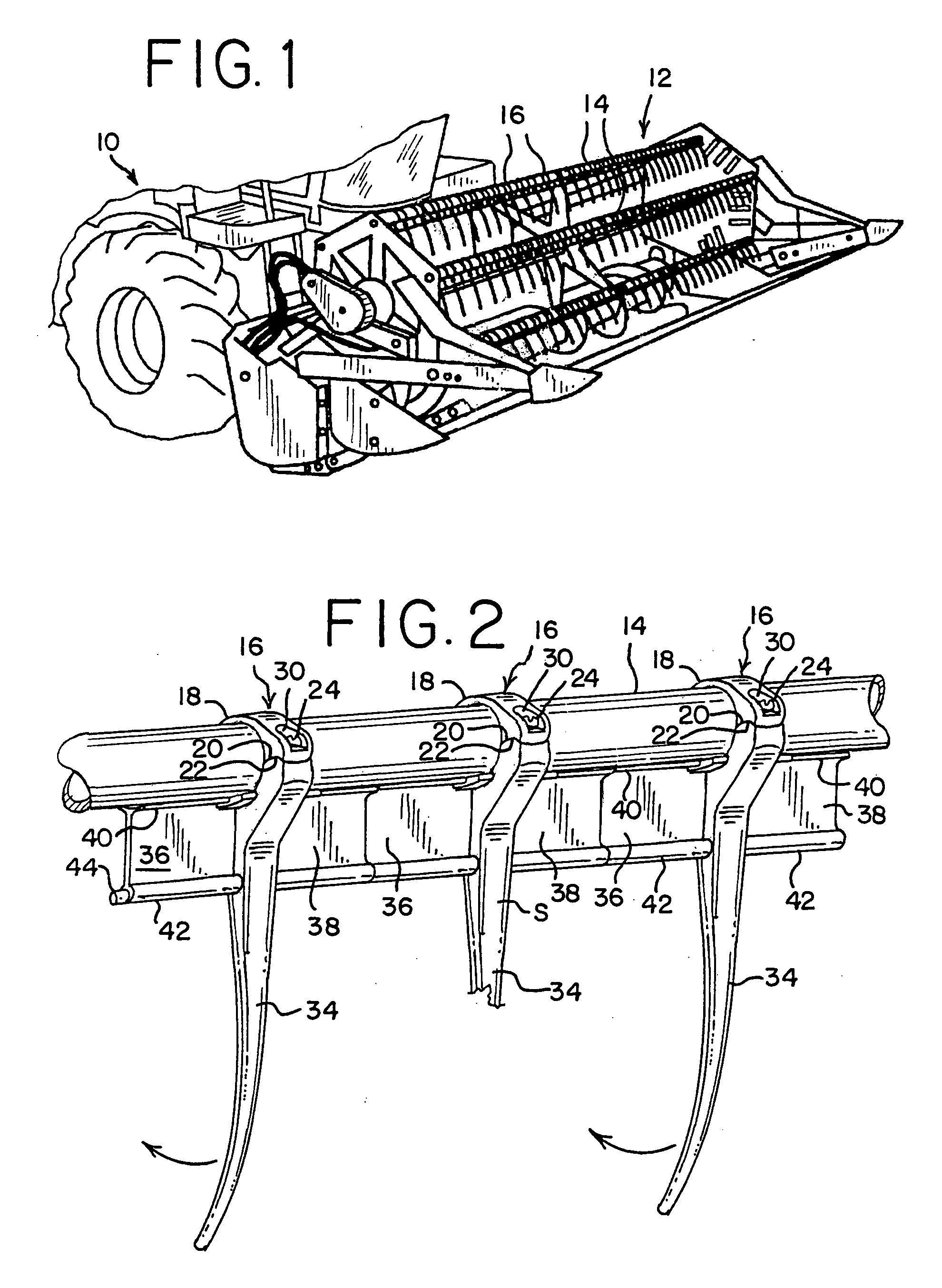

Foldable hay rake

Owner:ROWSE HYDRAULIC RAKES

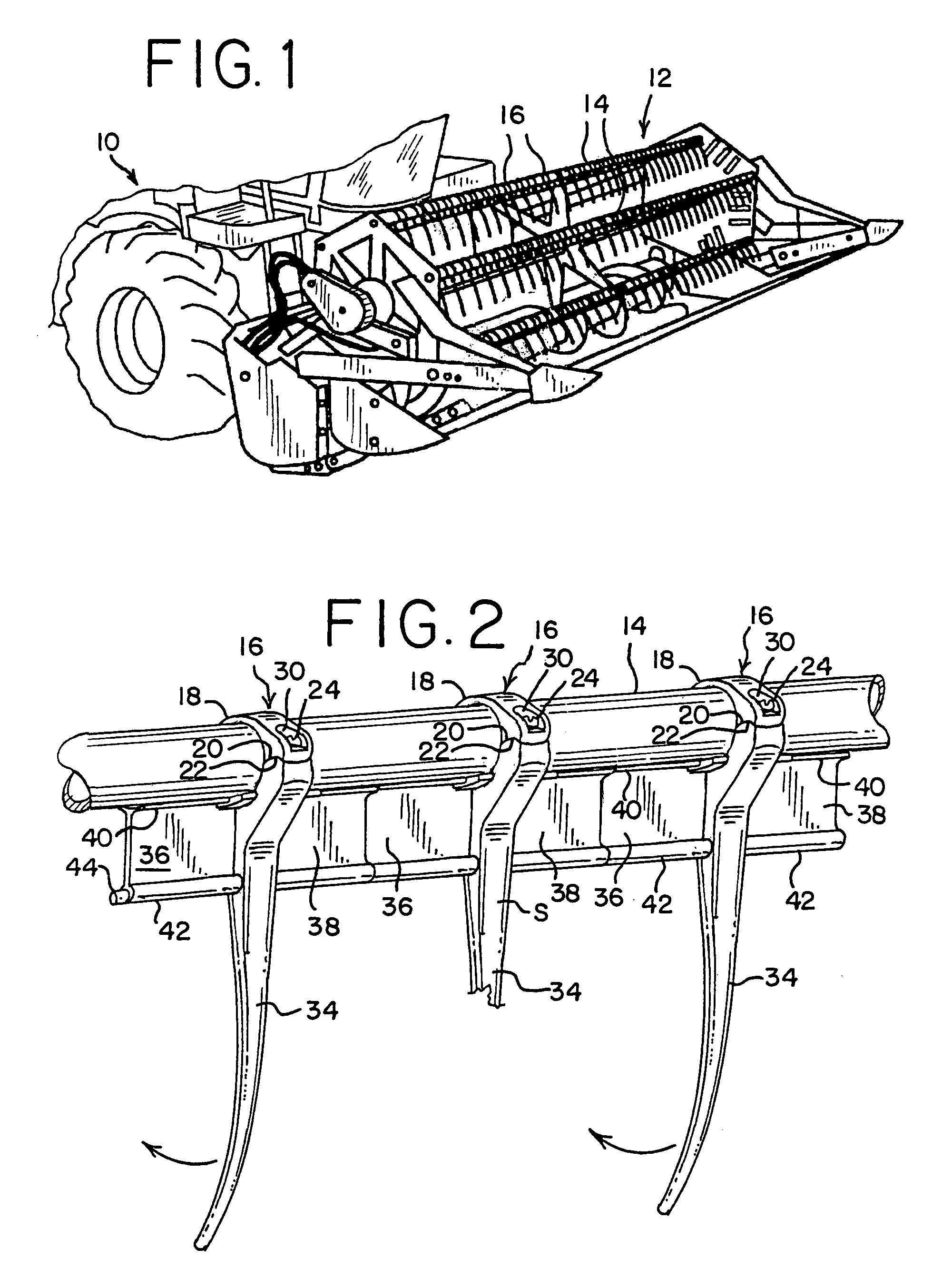

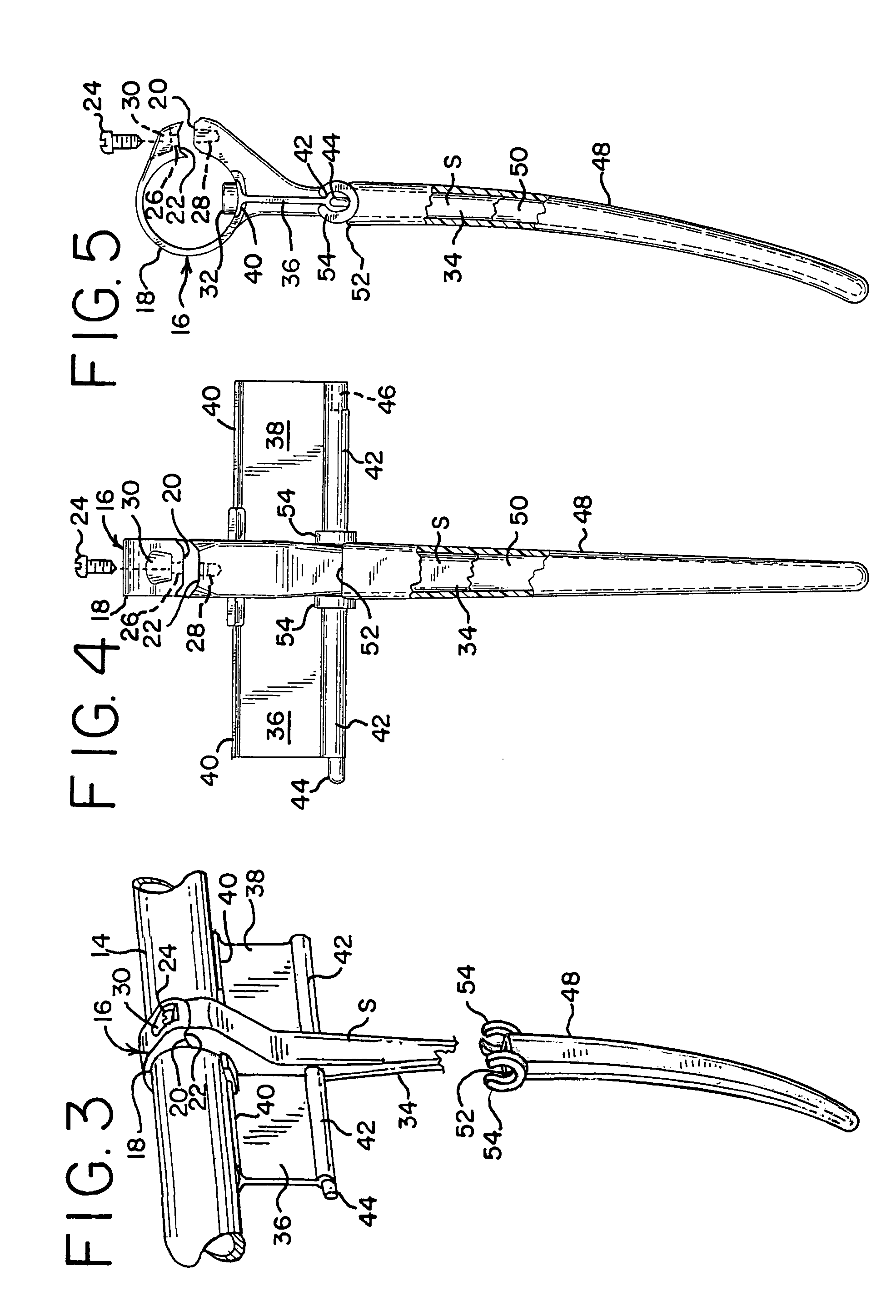

Harvester reel tine repair

ActiveUS20050091955A1Impair efficient operationWasteful of effortHaymakersHarvestersEngineeringMechanical engineering

Repair of a broken finger of a harvester reel pickup tine is accomplished by positioning a repair finger having a cavity over the broken finger stub so that the broken finger stub of the harvester reel pickup tine is received in the cavity of the repair finger, and the repair finger is then fastened adjacent one end to the pickup tine when the broken finger stub is in the cavity.

Owner:PLASTIC DESIGNS

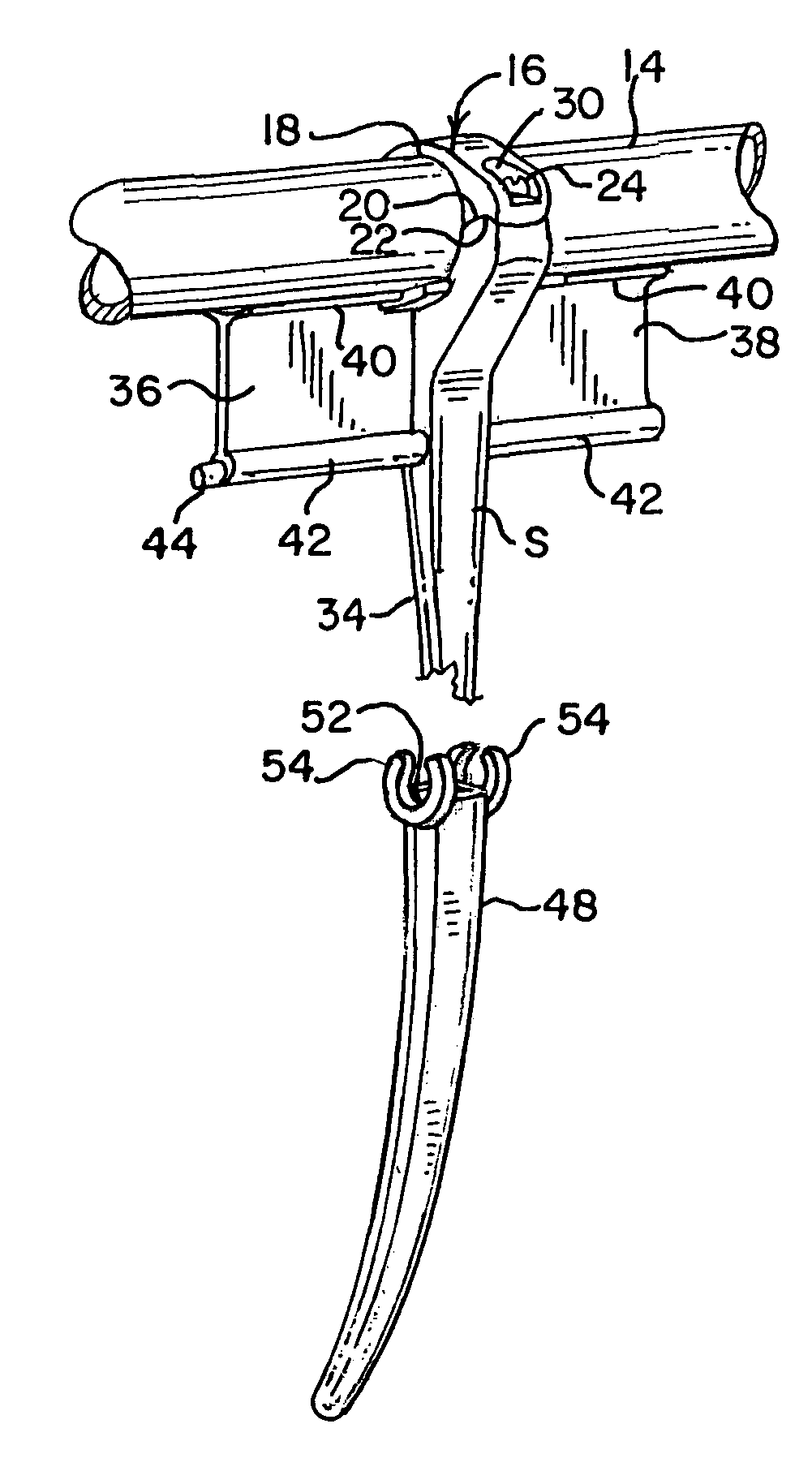

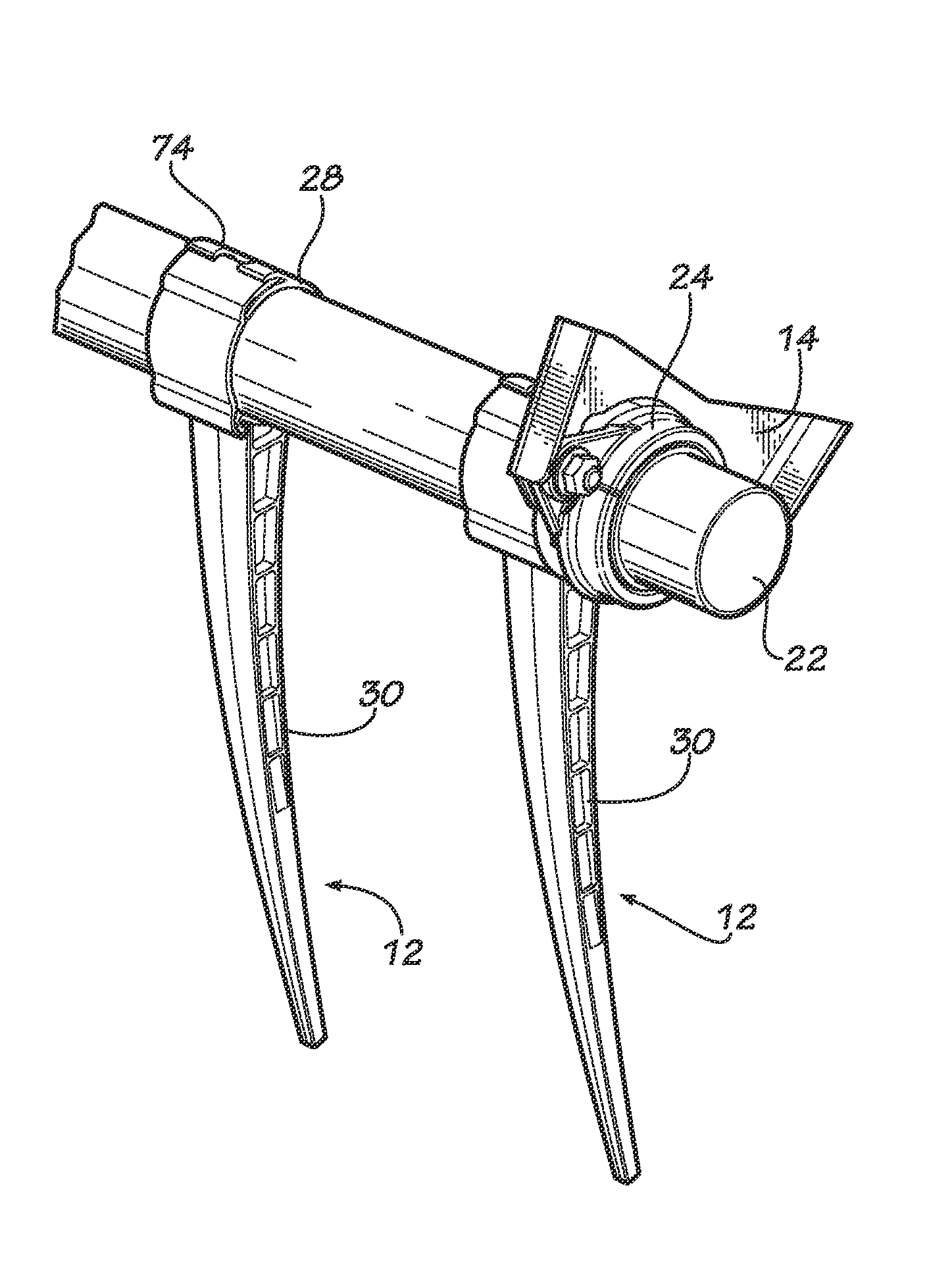

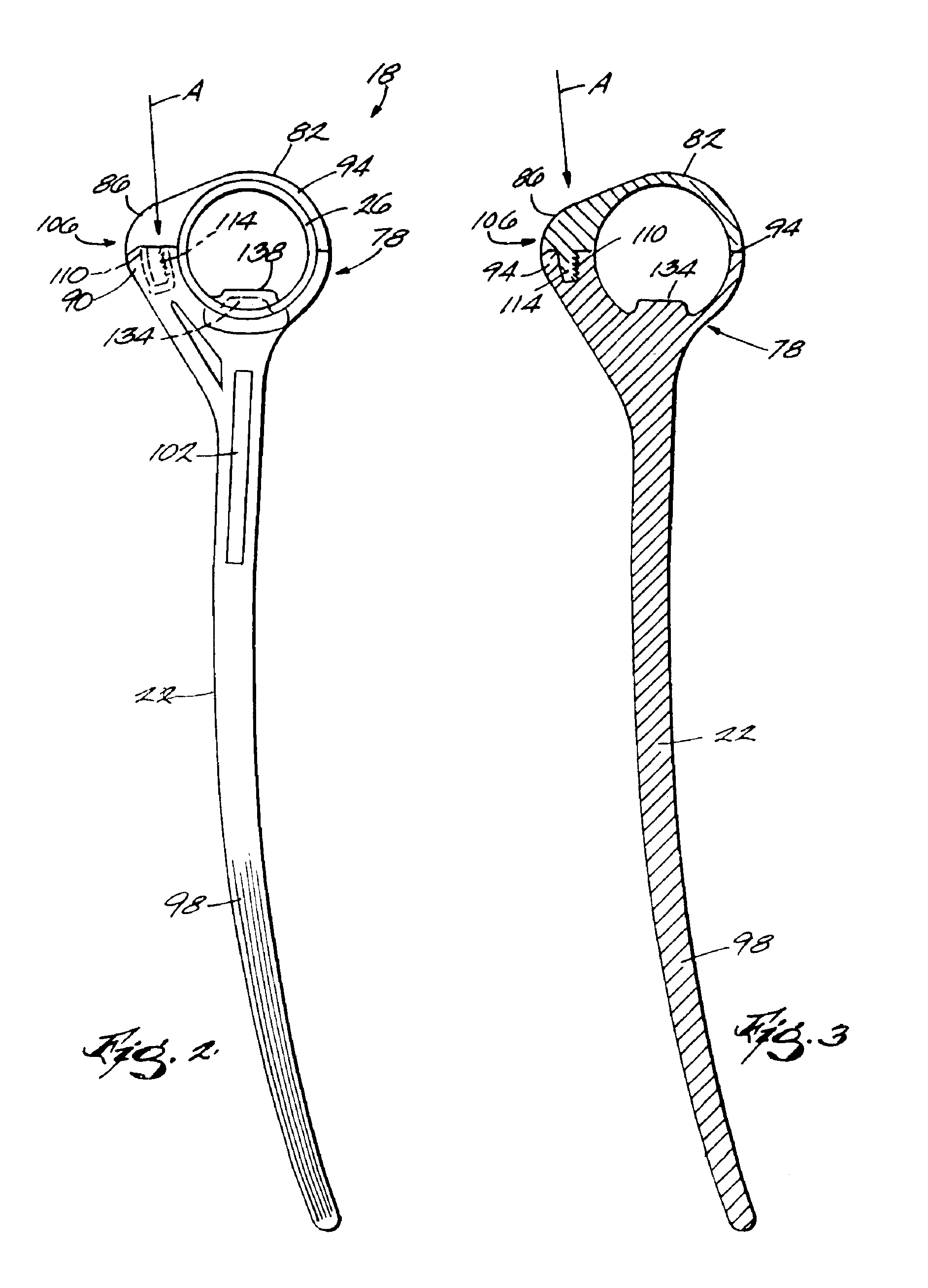

Clip on Reel Tine

InactiveUS20140260171A1Quickly and easily and removedPrevent accidental unlockingHaymakersEngineeringScrew thread

A plastic tine for mounting on a support tube of a harvester reel has a generally C-shaped mounting base that snaps onto the backside of the tube and an elongated finger that projects outwardly and normally downwardly from the mounting base. A generally C-shaped clip, oriented reversely to the mounting base, partially surrounds the front side of the support tube and is connected to one leg of the mounting base in such a manner that a free end of the clip can be swung toward and away from a corresponding opposite leg of the mounting base. Interlocking structure on the free end of the clip and corresponding distal end of the mounting base retains the clip in place against the front side of the support tube when the clip is fully installed. A special guard protectively overlies the free end of the mounting clip when it is locked to the mounting base so as to prevent accidental dislodgment by crop materials and residue during field operations. Provision is made for attachment of the tine to the tube by a threaded fastener in case the clip is dislodged or unavailable in the field. Alternative embodiments include an integral one-piece construction wherein the clip is integral with the rest of the tine and a separate two-part construction wherein the clip is a separate piece attachable to the rest of the tine.

Owner:AGCO CORP

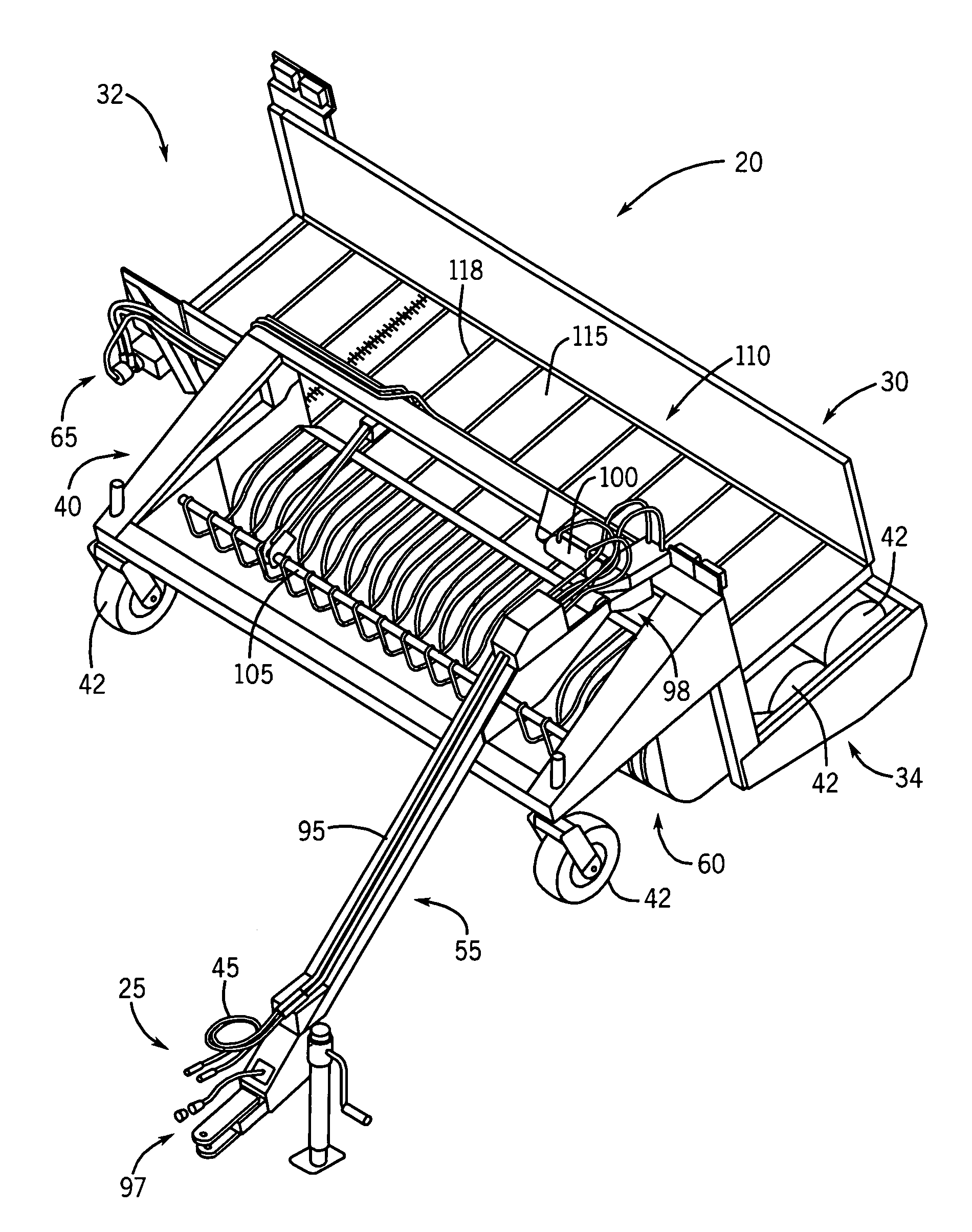

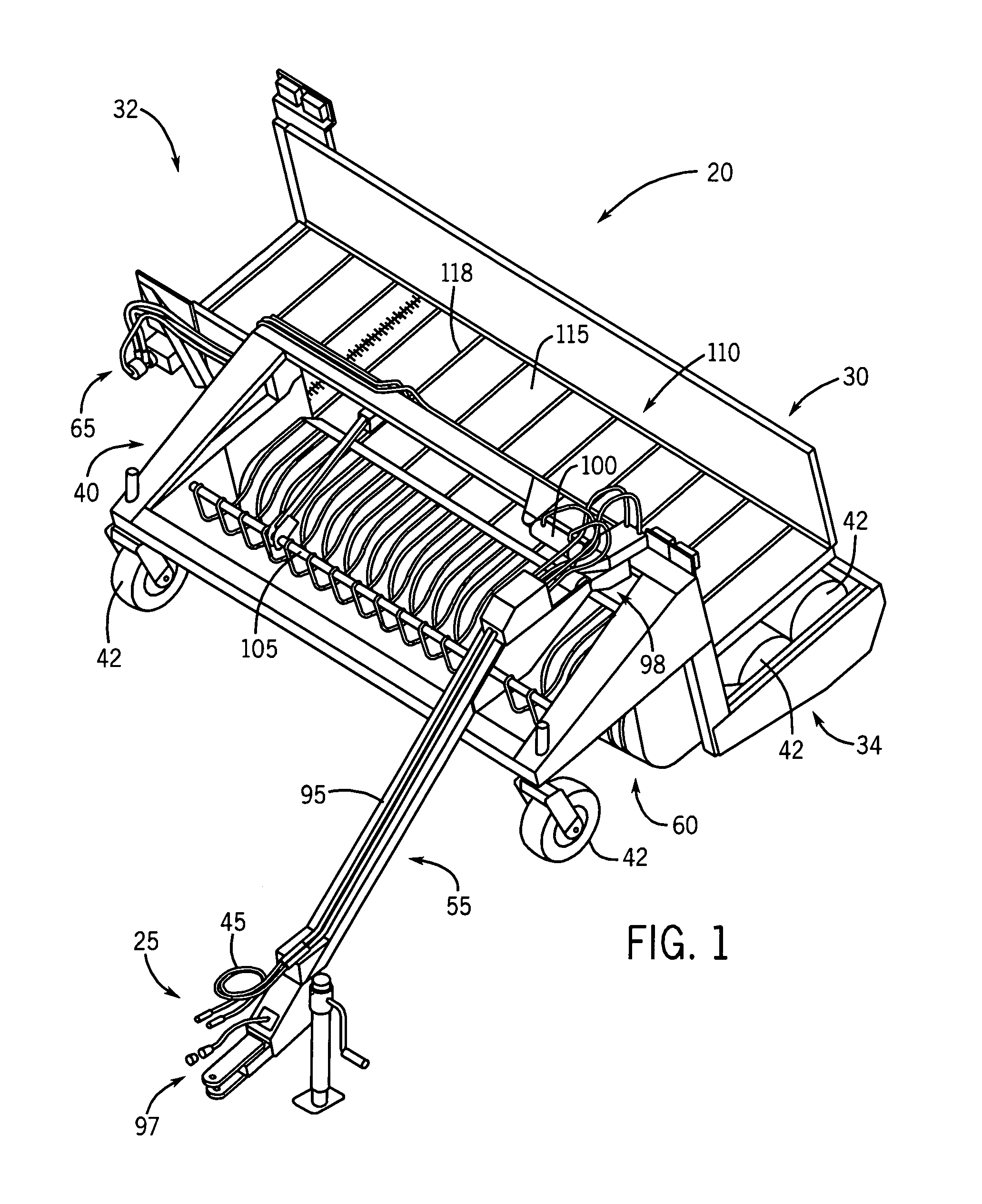

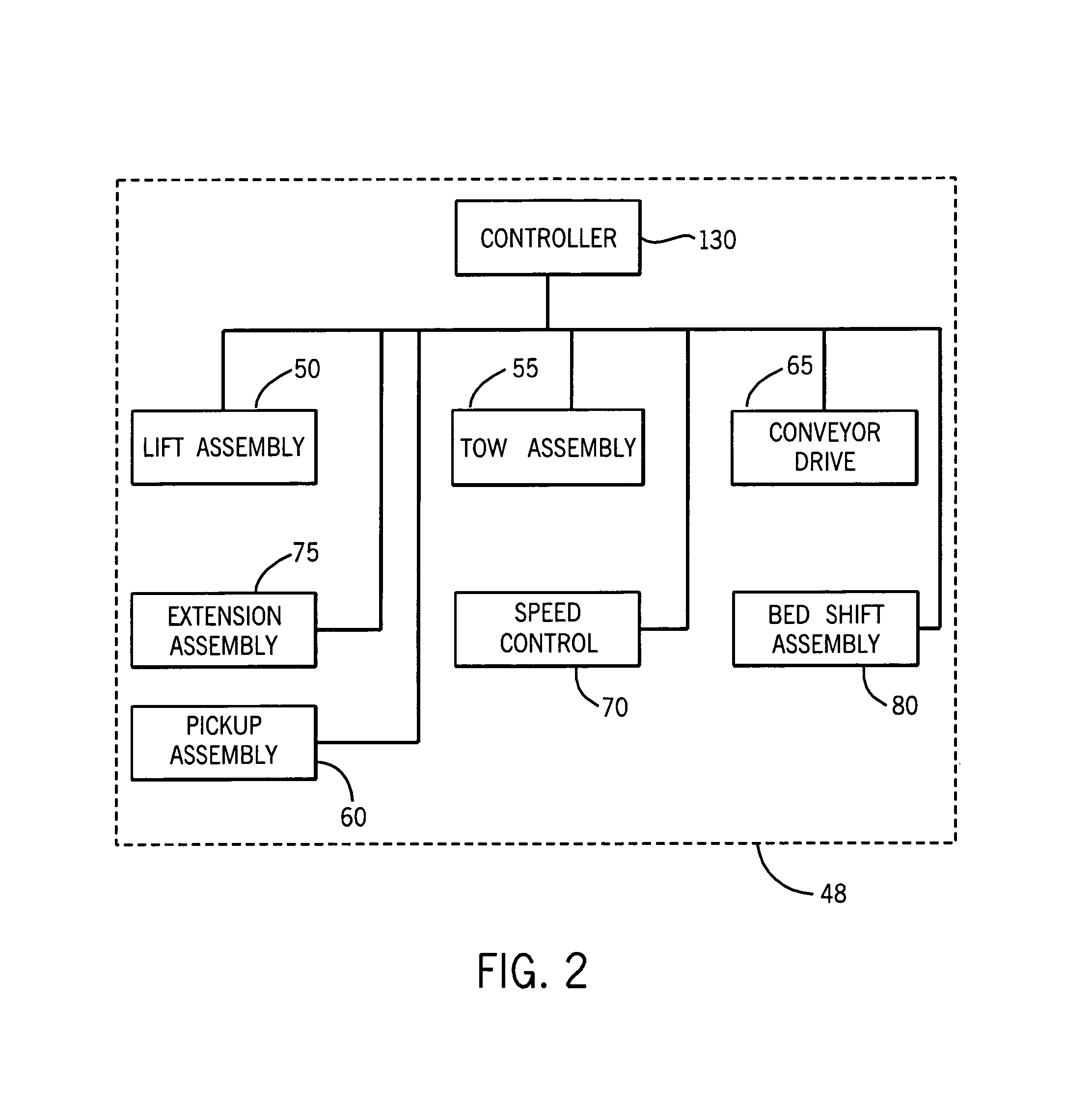

Control arrangement for a pull-type windrow merger

InactiveUS6971225B1Accelerated dryingGood conditionHaymakersHarvestersControl signalBiological activation

A control arrangement is configured to remotely control operation of a windrow merger pulled by a tow vehicle. The windrow merger includes a plurality of functional systems or assemblies configured to selectively collect and discharge crop material, and that can be adjusted to alter the operating characteristics or parameters of the windrow merger. The control arrangement includes a controller, a housing, and a harness configured to communicate control signals from the controller to the number of functional assemblies. The control arrangement further includes a manifold assembly configured to the control signals from the controller to respective control valves operable to control operation of the number of functional assemblies. Thereby, the controller allows the operator to regulate operation and activation of each of the number of functional assemblies from the operator's cab of the tow vehicle.

Owner:GHEL CO

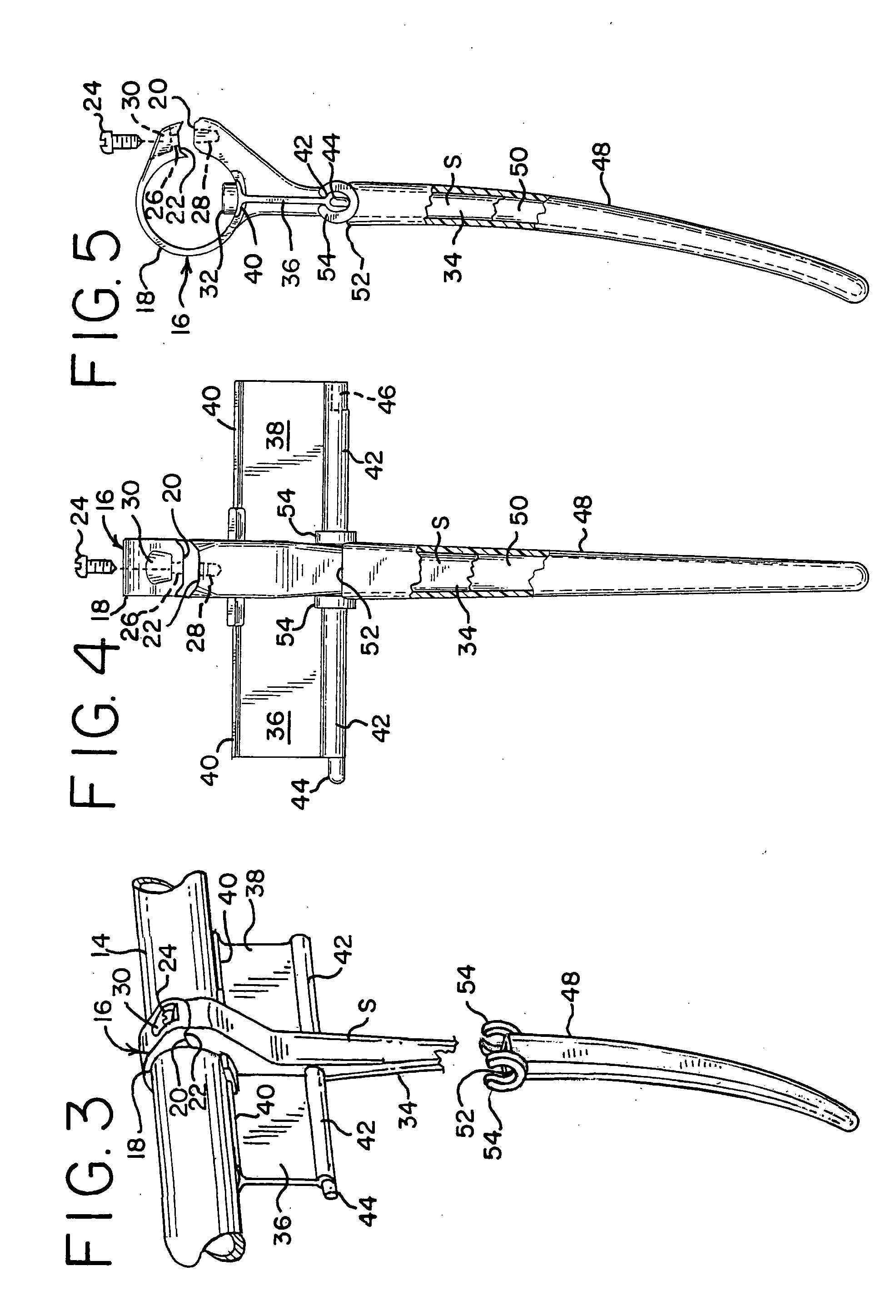

Adjustable hay rake

Owner:KUHN NORTH AMERICA

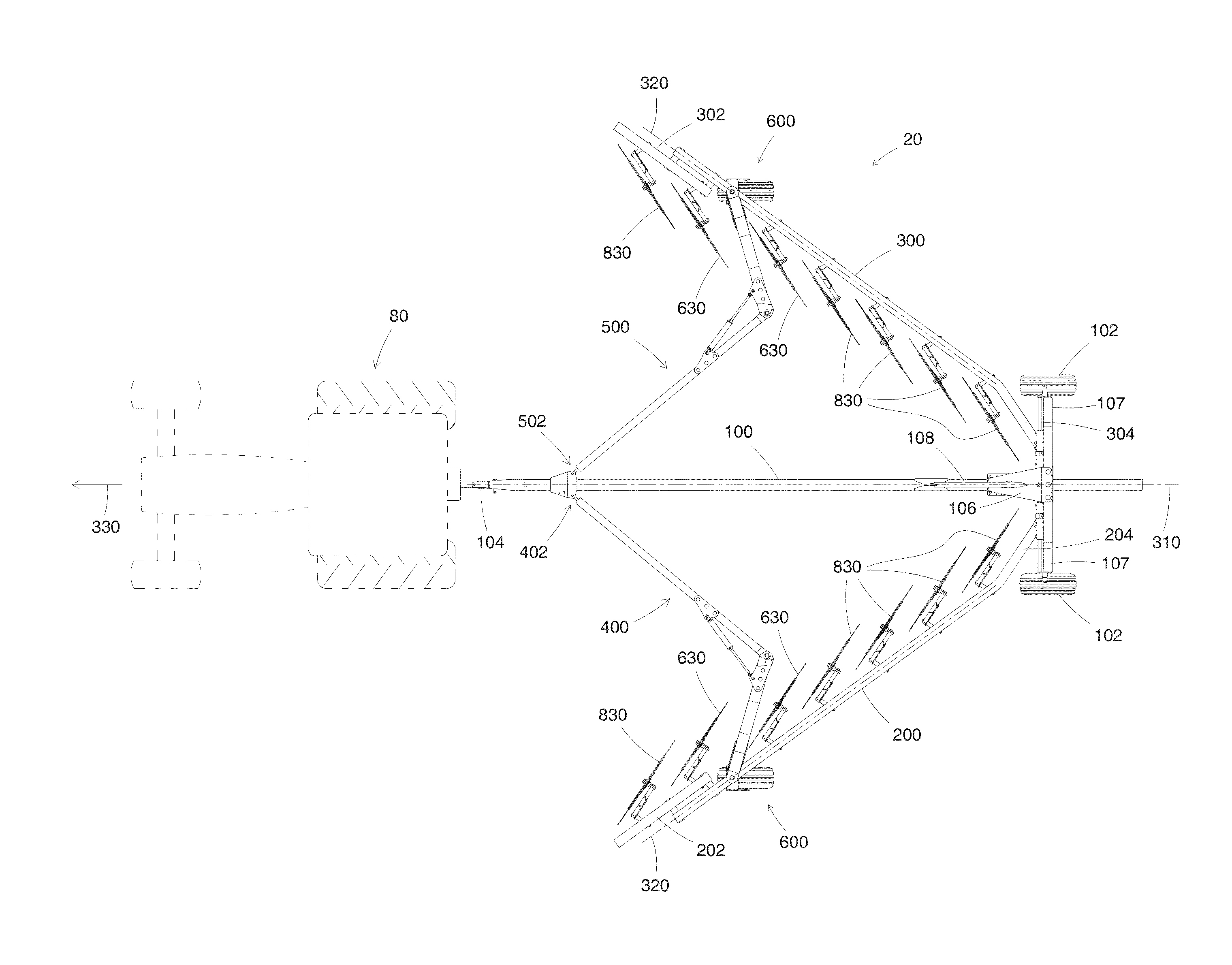

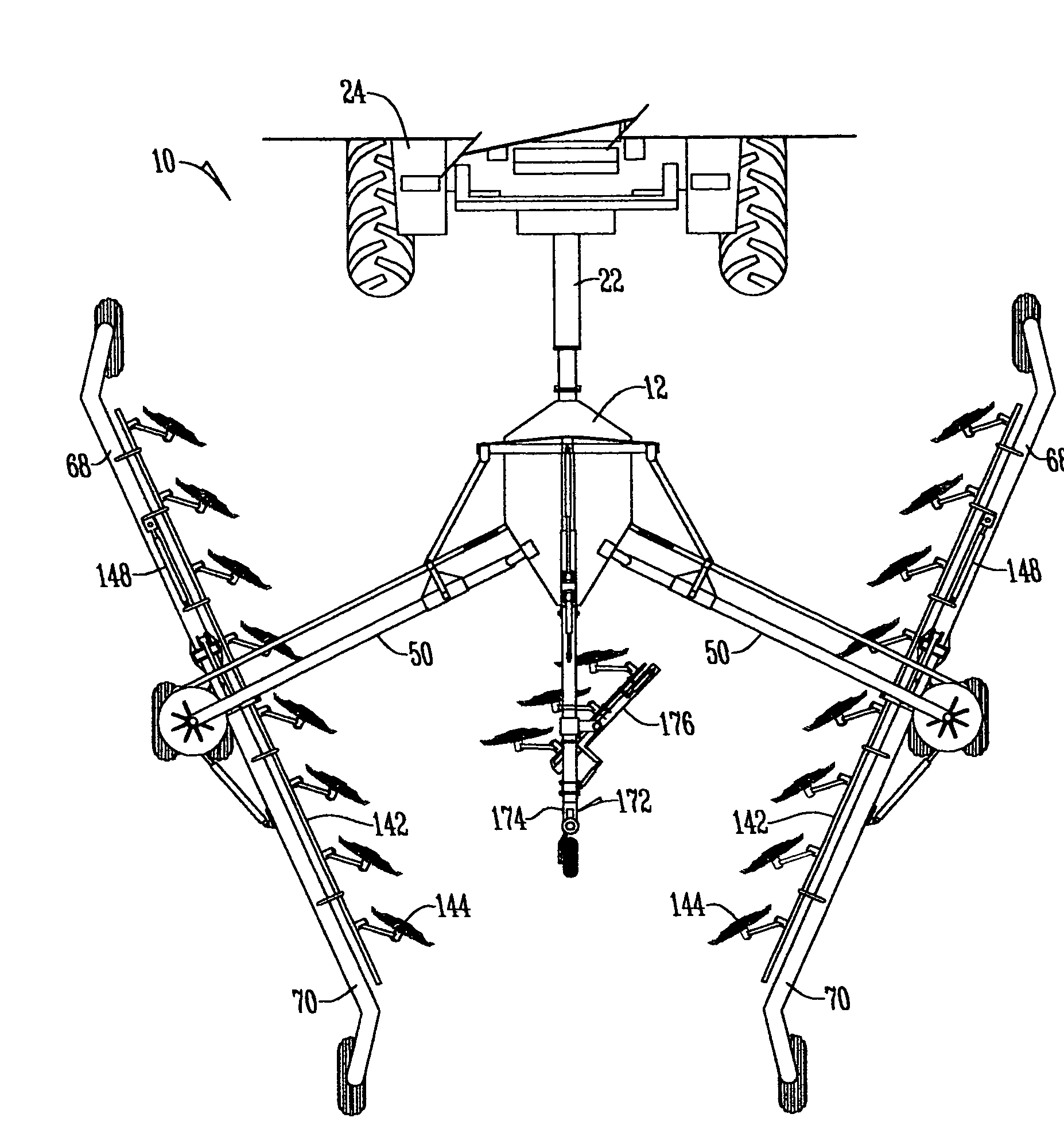

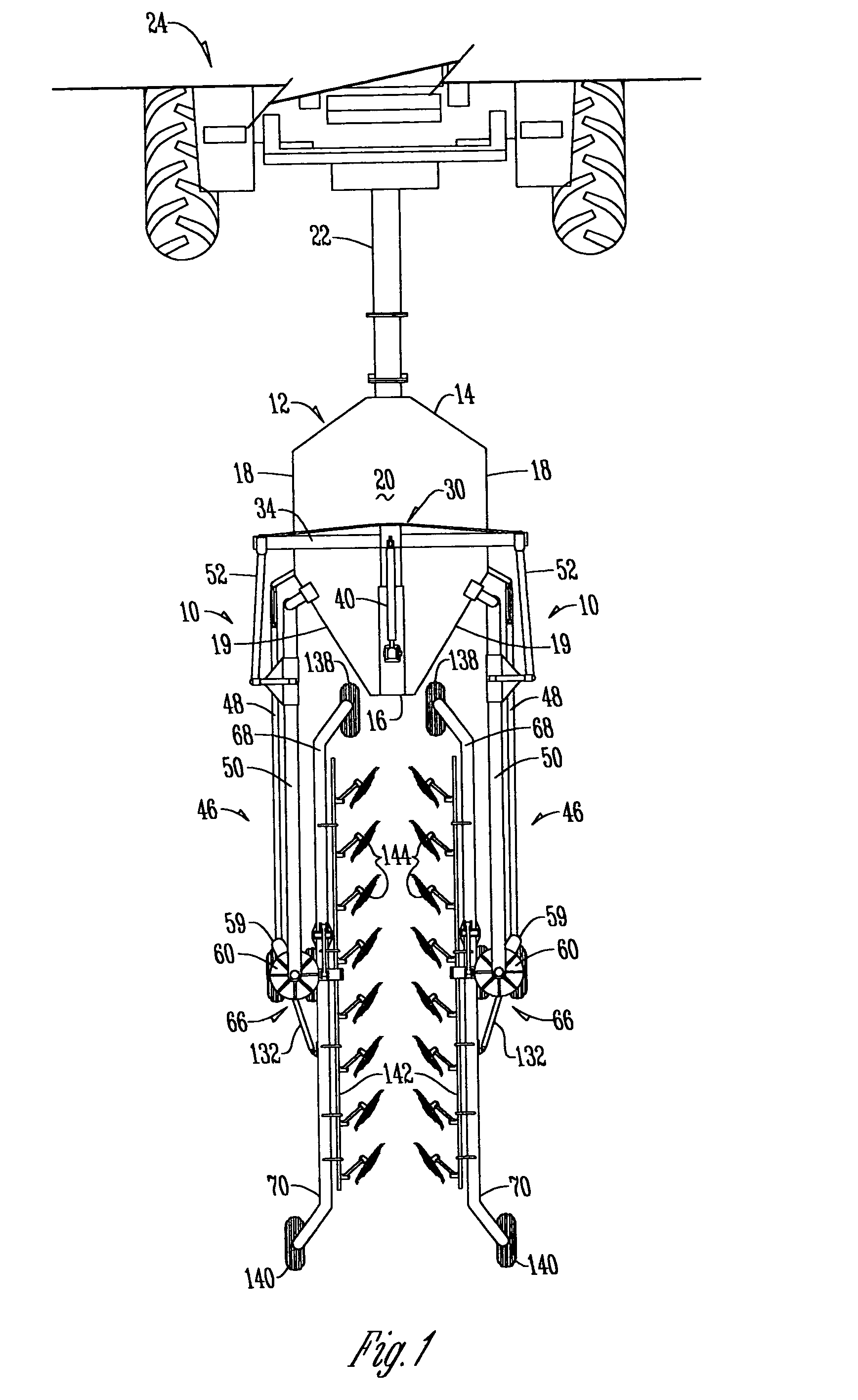

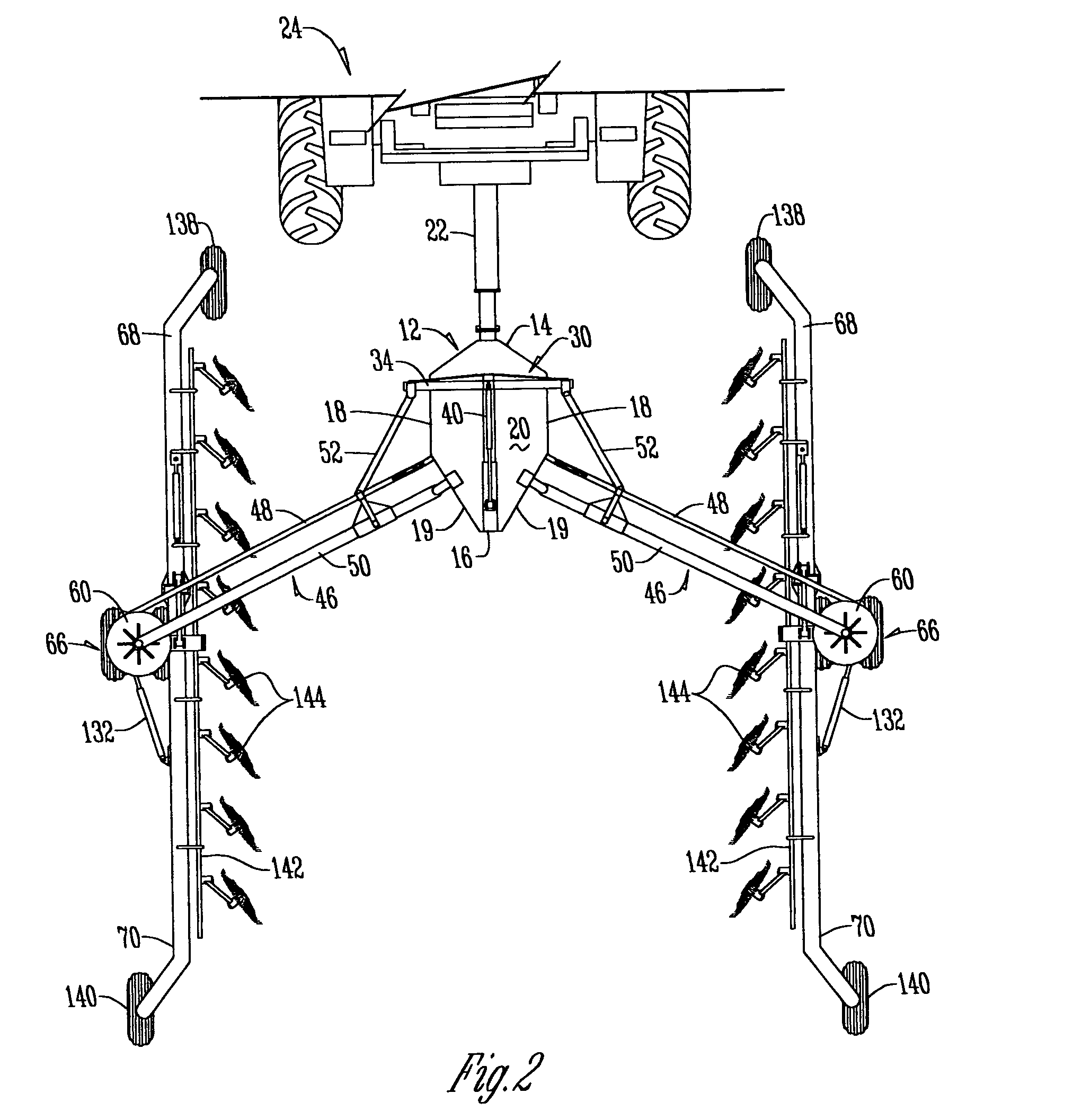

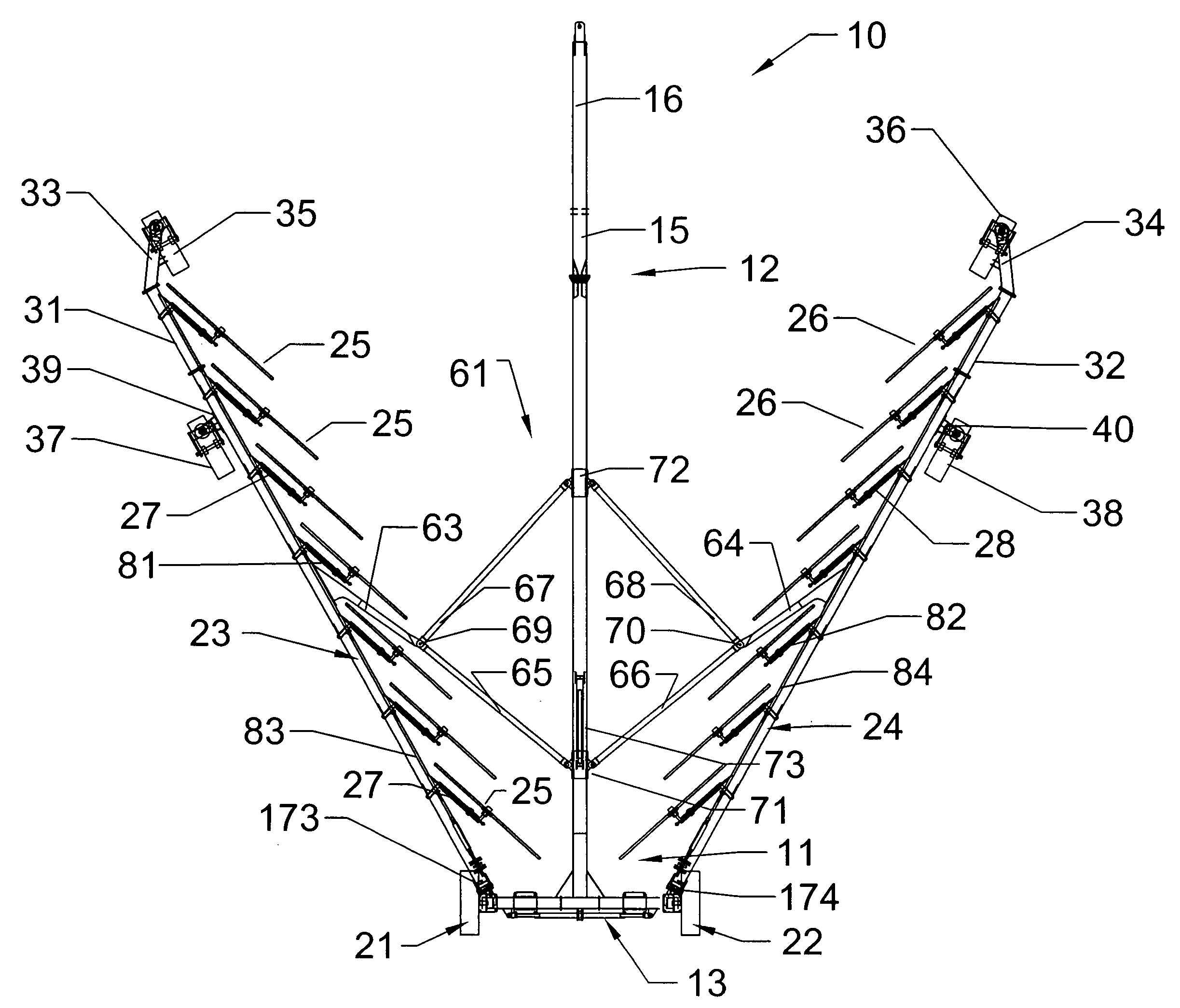

V-rake

The V-rake has an elongated tow beam with a front end adapted to be connected to a towing vehicle and a back end fixed to a back section, the back section is supported by a wheel assembly, which may be a set of tandem wheels. The V-rake further includes first and second rake booms each having a front end and a back end pivotally connected to the back section such that the front ends of the booms can be swung between a transport position and an operating position. The front end of each boom has at least one castor wheel for support. The back section is further adapted to controllably change the distance between the back ends of the booms to adjust the width of a resulting windrow. A number of rake wheels are mounted on each of the rake booms on the side of the boom nearest to the tow beam, wherein the rake wheels are adapted to move vertically with respect to the rake boom using a compression spring mechanism. The rake wheel includes a center disk, an outer ring and tines passing through the outer ring with the ends of the tines individually fixed to the center disk, and may further include a windguard.

Owner:BRIDGEVIEW MFG

Haying machine

InactiveUS7100350B2Relieve pressureImprove securityAgricultural machinesSoil-working equipmentsEngineeringMechanical engineering

A haymaking machine including a frame carrying at least one pair of rotors connected to carrying arms that may be moved from a working position, in which they are substantially horizontal, to a transport position, in which they are substantially vertical, and vice-versa. The carrying arms of at least one pair of rotors include a latching mechanism that connects them together and locks them with regard to one another in the transport position.

Owner:KUHN SA

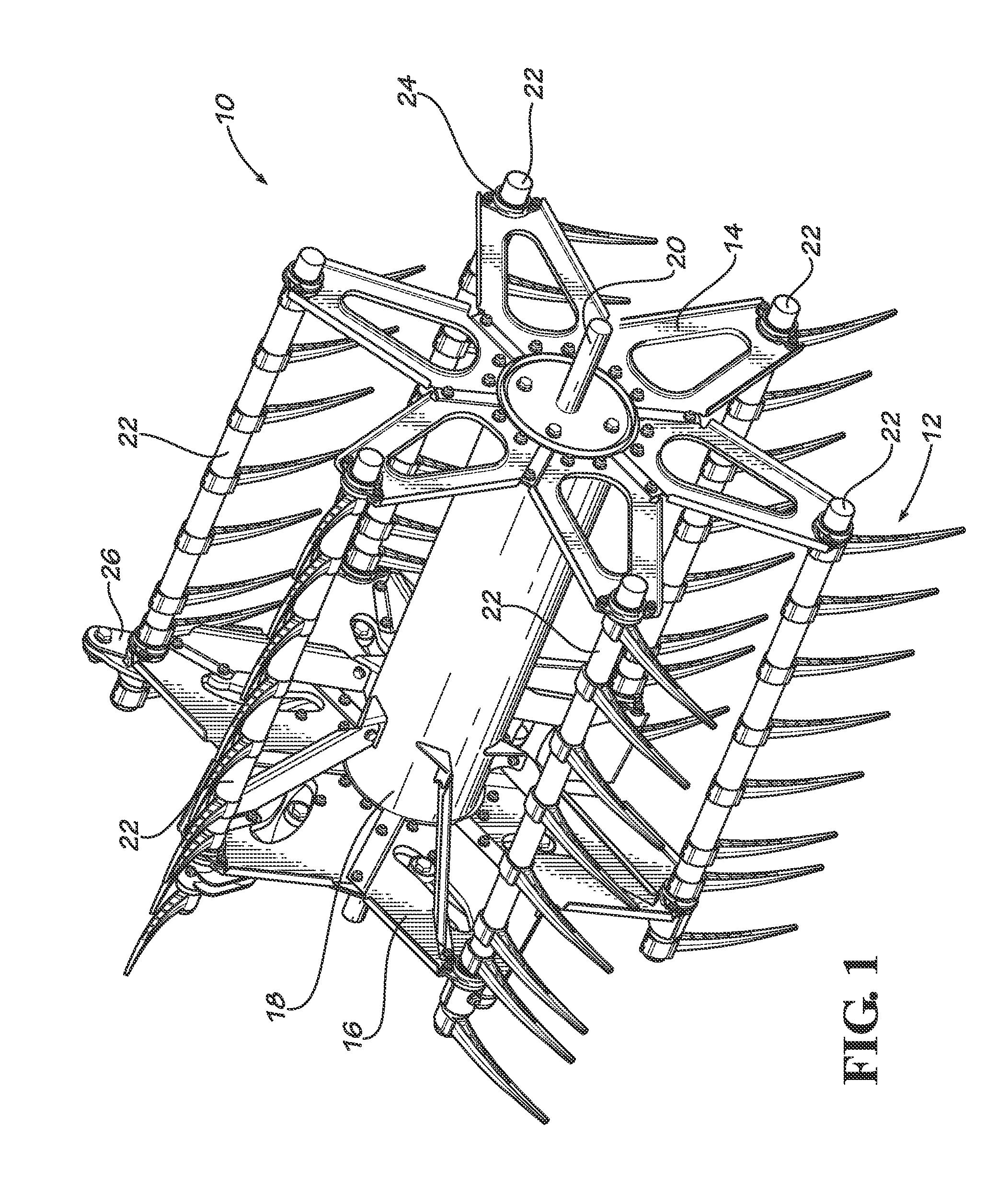

Harvester tine and bat assembly

InactiveUS6910323B2Rule out the possibilityGood removal effectHarvestersHaymakersMicrochiropteraEngineering

A combination for a harvester pickup reel, a harvester tine, and a method of assembling a pickup reel. In some aspects, the combination for a harvester pickup reel comprises a shaft, a tine supportable on the shaft for rotation with the shaft, and a fastener assembly integrally formed on one of the shaft and the tine. In other aspects, the combination for a harvester pickup reel comprises a shaft, a tine supportable on the shaft for rotation with the shaft and a fastener assembly. In such aspects, the fastener assembly comprises a first fastener member including a projection and a second fastener member defining a recess, the projection being insertable into the recess. In some aspects, the harvester tine comprises a support portion connectable with the second shaft to support the tine for rotation with the second shaft, the support portion being connectable to the second shaft without separate fasteners. In other aspects, the harvester tine comprises a support portion connectable with the second shaft to support said tine for rotation with the second shaft and a fastener assembly integrally formed with the support portion and engageable to connect the support portion to the second shaft.

Owner:HCC

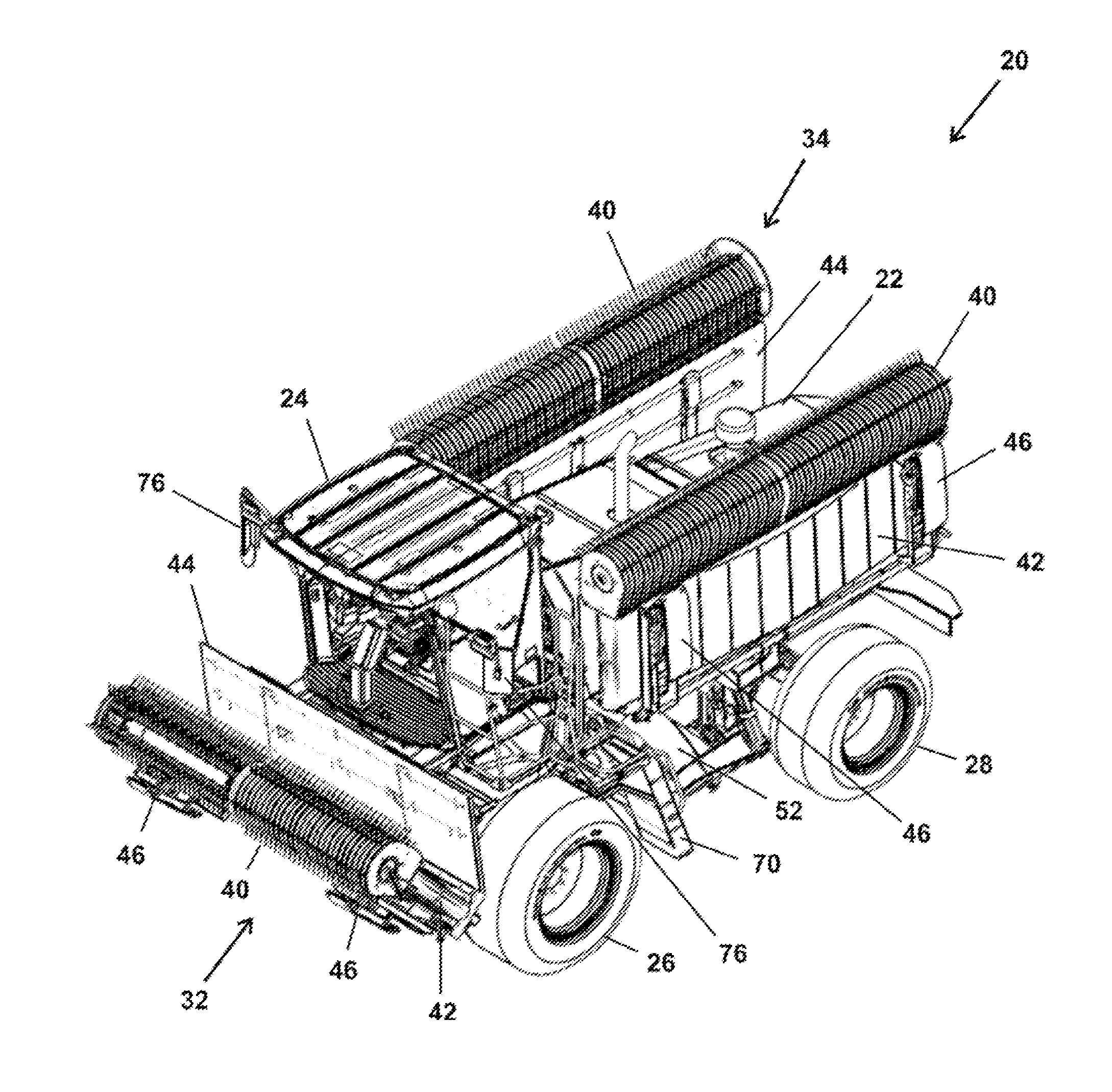

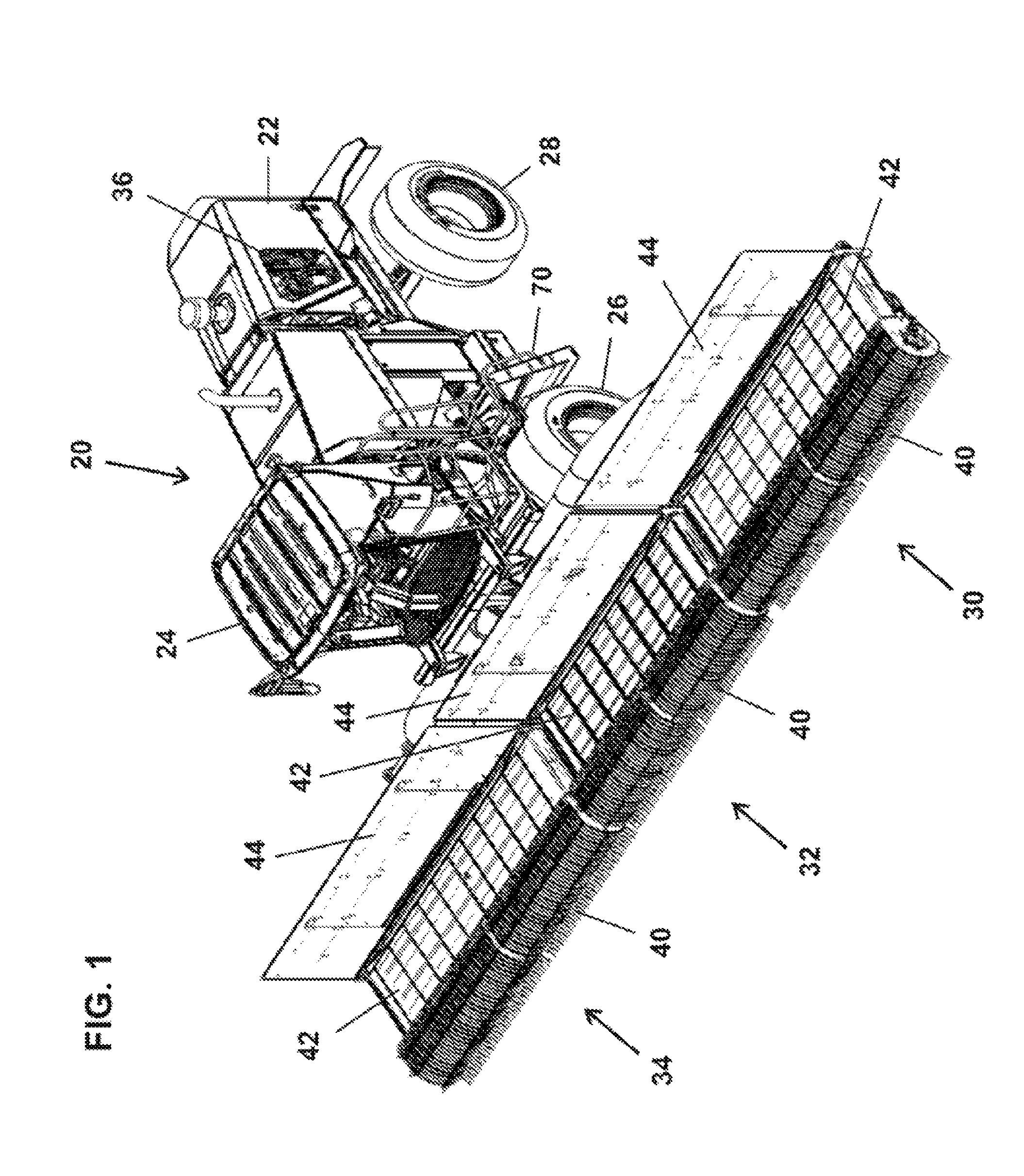

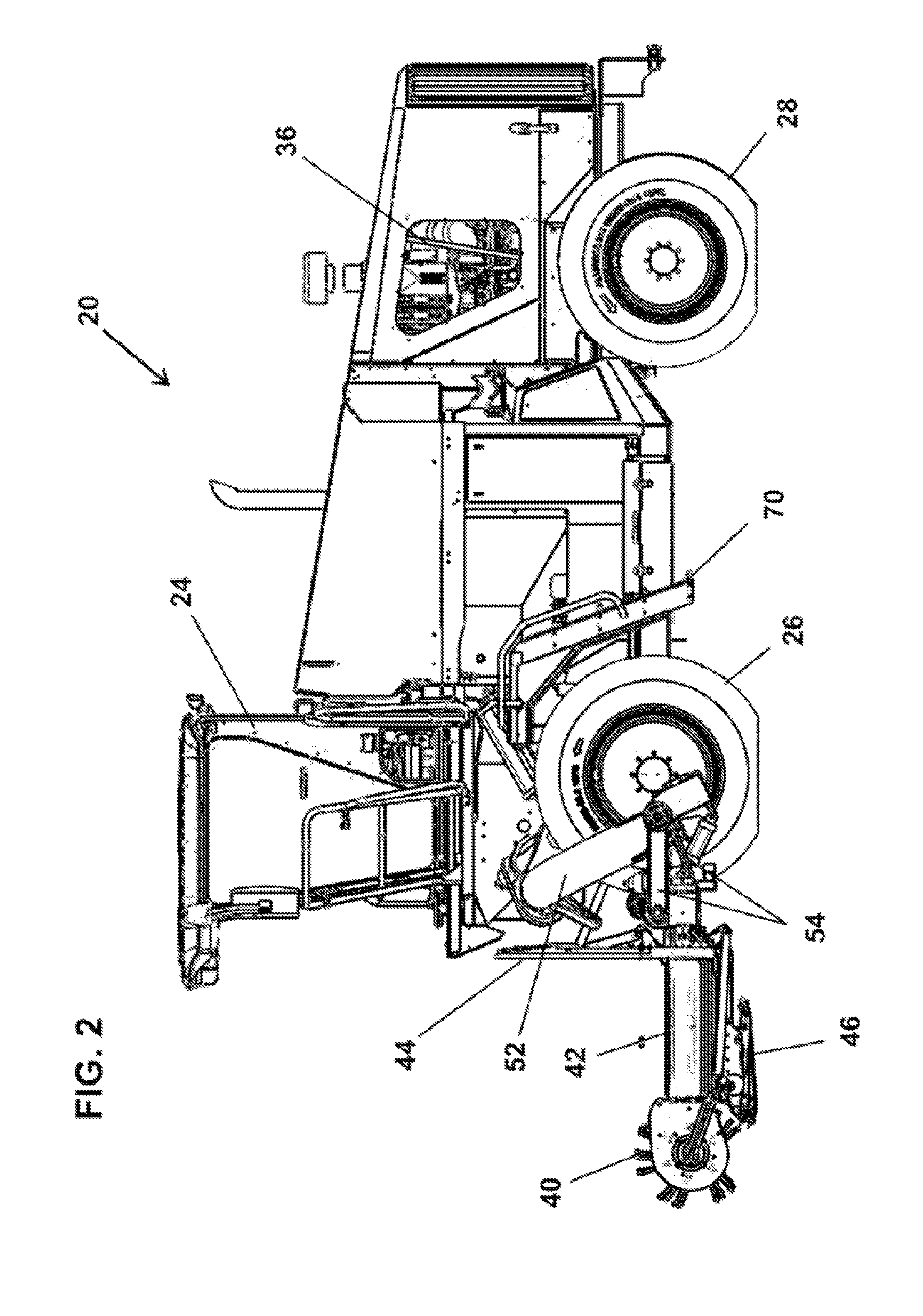

Self-propelled merger

A self-propelled windrow merger includes a motor and a chassis. At the front of the merger are a first pickup and transfer assembly, a second pickup and transfer assembly and a third pickup and transfer assembly. A cab is above and behind the second pickup and transfer assembly. A folding mechanism for moves each of the pickup and transfer assemblies between a first position wherein the first, second and third pickup and transfer assemblies are laterally aligned and a second position wherein the first and third pickup and transfer assemblies are positioned rear of the cab.

Owner:OXBO INT CORP

Machine for harvesting fodder

InactiveUS20150020492A1Easy to adjustIncrease in sizeAgricultural machinesLoadersHorizontal axisEngineering

A machine for the harvesting of plants, movable in a direction of advance, comprises an arm movable between work and transport configurations, a tool comprising lateral ends and being able to occupy a work position and another position, a connecting device via which the tool is connected to the arm and enabling a first movement of the tool relative to the arm, during which the lateral ends move vertically relative to the arm in the same vertical direction relative thereto, the connecting device comprising means making it possible to operate a second transverse and horizontal movement of the tool relative to the arm and making it possible to operate this second movement independently of the first movement. The connecting device comprises an arm oriented in the direction of advance when the support arm is in the work configuration, this arm is articulated on the support arm about a first transverse and horizontal axis when the support arm is in the work configuration, and this arm can, by pivoting about the first axis, move vertically relative to the support arm in the work configuration.

Owner:KUHN SA

Multi-prong conversion tine for a harvester reel and method

InactiveUS20090056295A1Easily and rapidly converted and repairedEasy to replaceLoadersMowersLateral extensionEngineering

An agricultural harvester includes a harvester reel with a plurality of pickup tines spaced along a length thereof, and at least one in situ conversion tine. Each conversion tine includes an elongate hollow body having a cavity with an open proximal end. The hollow body is positioned over the pickup tine such that the pickup tine extends through the proximal end and is received within the cavity. At least one fastener adjacent the proximal end fastens the hollow body over the pickup tine. At least one lateral extension extends from the hollow body in a lateral direction along the length of the harvester reel.

Owner:DEERE & CO

Adjustable tracked side-delivery hay rake

InactiveUS6959531B2Easy and comfortable to operateEasily realizedHaymakersUniversal jointEngineering

An adjustable tracked side-delivery hay rake for use in agriculture for collecting the hay in tidy haycoks, is provided with adjustable wheels movable between a raised and narrow position, suitable for transport and based on the presence—on the arms supporting the wheels—of universal joints that allow movements in all directions.

Owner:D &G INT

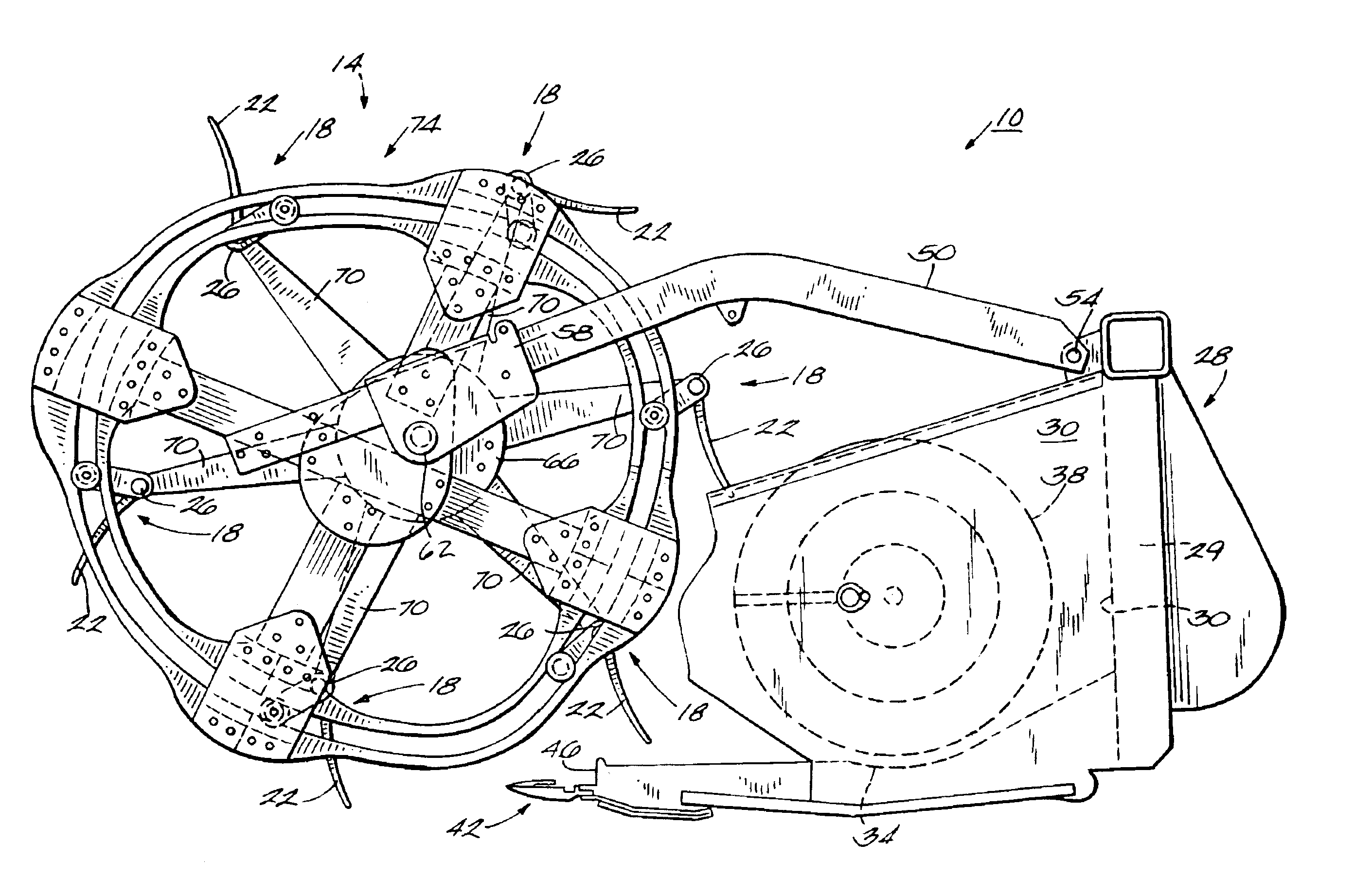

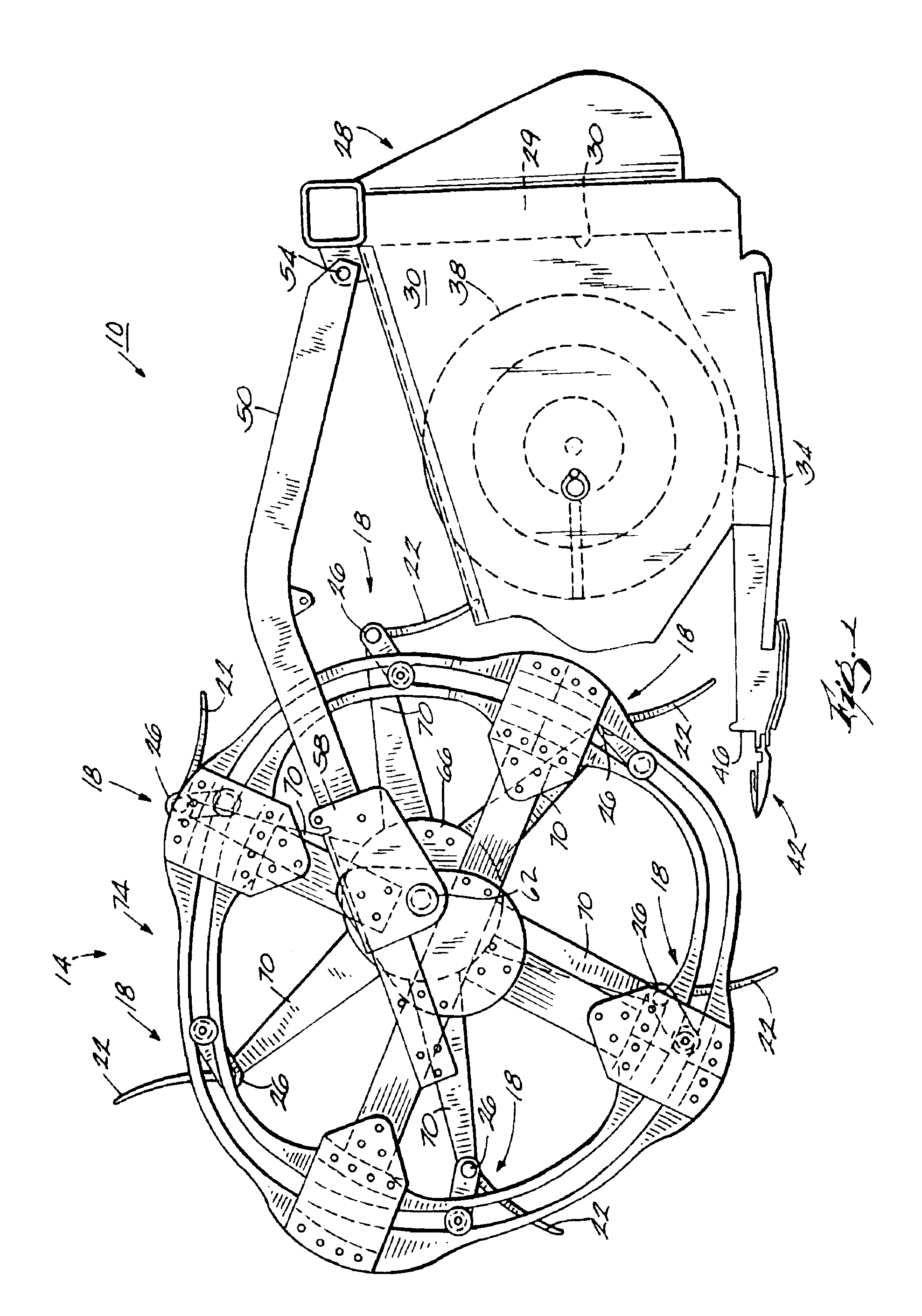

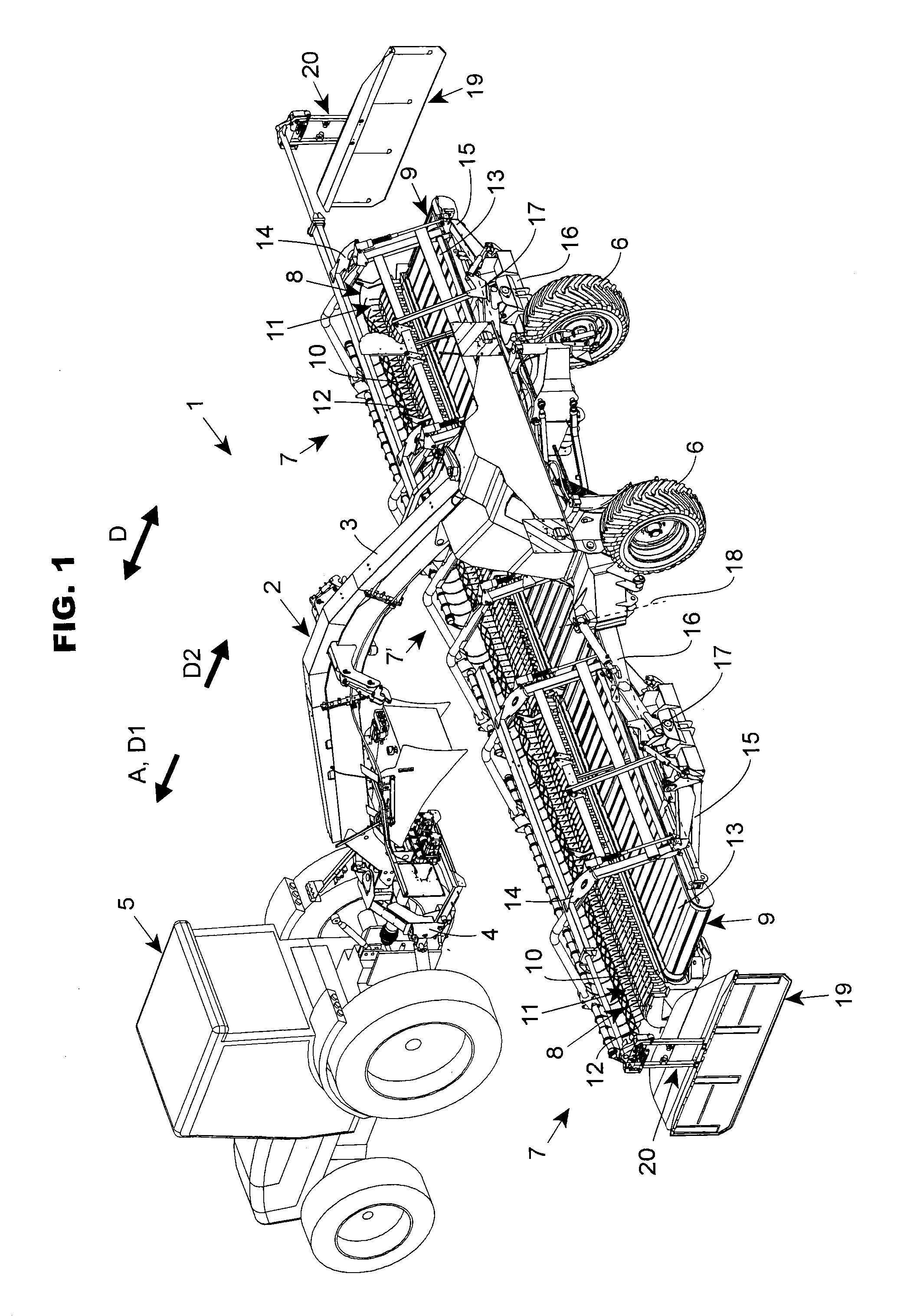

Continuous windrow merger

InactiveUS20140260168A1Improved crop flowEasy to assembleAgricultural machinesLoadersTraction unitWindrow

A continuous windrow merger has a frame that supports center, right and left pickup assemblies. The pickup assemblies each include a pickup head and a conveyor assembly. The pickup head has a cylindrical reel and a plurality of tines extending radially outwardly from the reel. The pickup head is arranged to pickup and deliver crop material rearward to the conveyor assembly. The conveyor assembly has a draper belt with an upper surface arranged to receive crop material from the pickup head and transfer the crop material in a lateral direction. The draper belt is mounted with the upper surface sloping downwardly and rearwardly from the pickup head. The merger has a folded configuration for transport in which the right and left wing frame sections extend generally vertically above the center frame section. The frame can be attached to the front of a self-propelled traction unit or towed behind a tractor.

Owner:RCI ENG

Haymaking machine comprising an improved deflector

InactiveUS20140196429A1Large working widthReduced dimensionAgricultural machinesHaymakersEngineeringLawn mower

A haymaking machine comprises a harvesting device comprising a rotor driven about an axis which is horizontal and perpendicular to a direction of advance during work, teeth, the points of which describe a curve envelope when the rotor turns about the axis, and a conveyor moving the plants transversely to the direction of advance, the machine comprising a deflector connected to an arm connected to the harvesting device by means of an articulation, about which the arm can pivot between a first position in which the deflector is arranged, during work, beside and at a distance from a lateral end of the harvesting device, and a second position. In the second position and considering the machine during work, the deflector and the arm extend flat and at least partially above the harvesting device.

Owner:KUHN SA

Forage harvesting machine with an improved deflector

InactiveUS20150282426A1Dissipating part of energyImprove protectionHarvestersHaymakersAnimal ForagingEngineering

An agricultural machine for forage harvesting, including a frame supporting a work unit able to occupy a work position in which it can pick up plants lying on the ground and shift them sideways, a side deflector being connected to the frame by a connecting device allowing the deflector to occupy an operation position relative to the work unit, in which the deflector can receive a flow of plants shifted sideways by the work unit. The connecting device is designed so that, while the machine moves in a direction and the work unit is in the work position, the deflector can perform a movement relative to the work unit from the operation position, longitudinally in a direction opposite the movement direction, when a resultant of a force exerted on the deflector exceeds a determined threshold.

Owner:KUHN SA

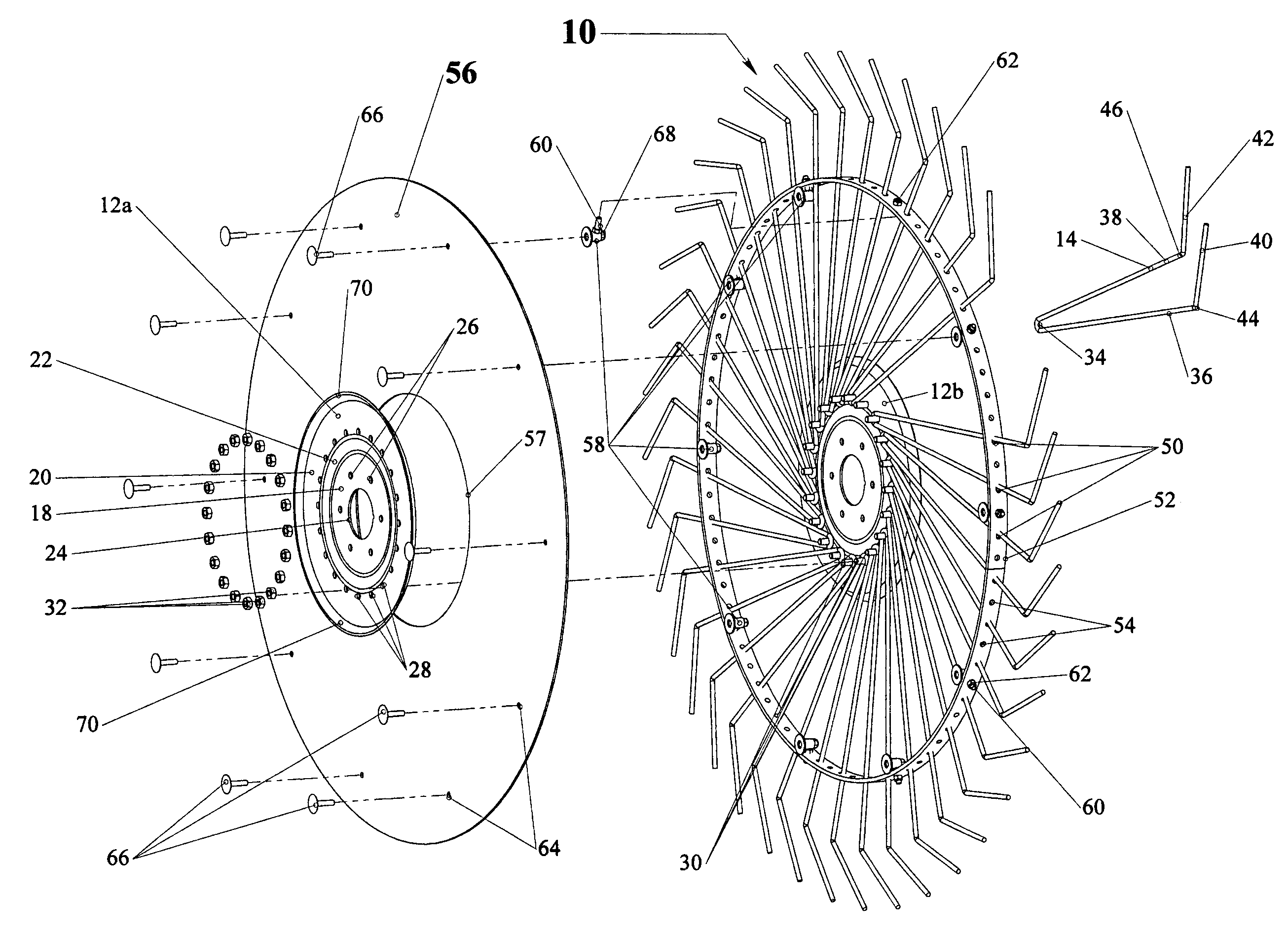

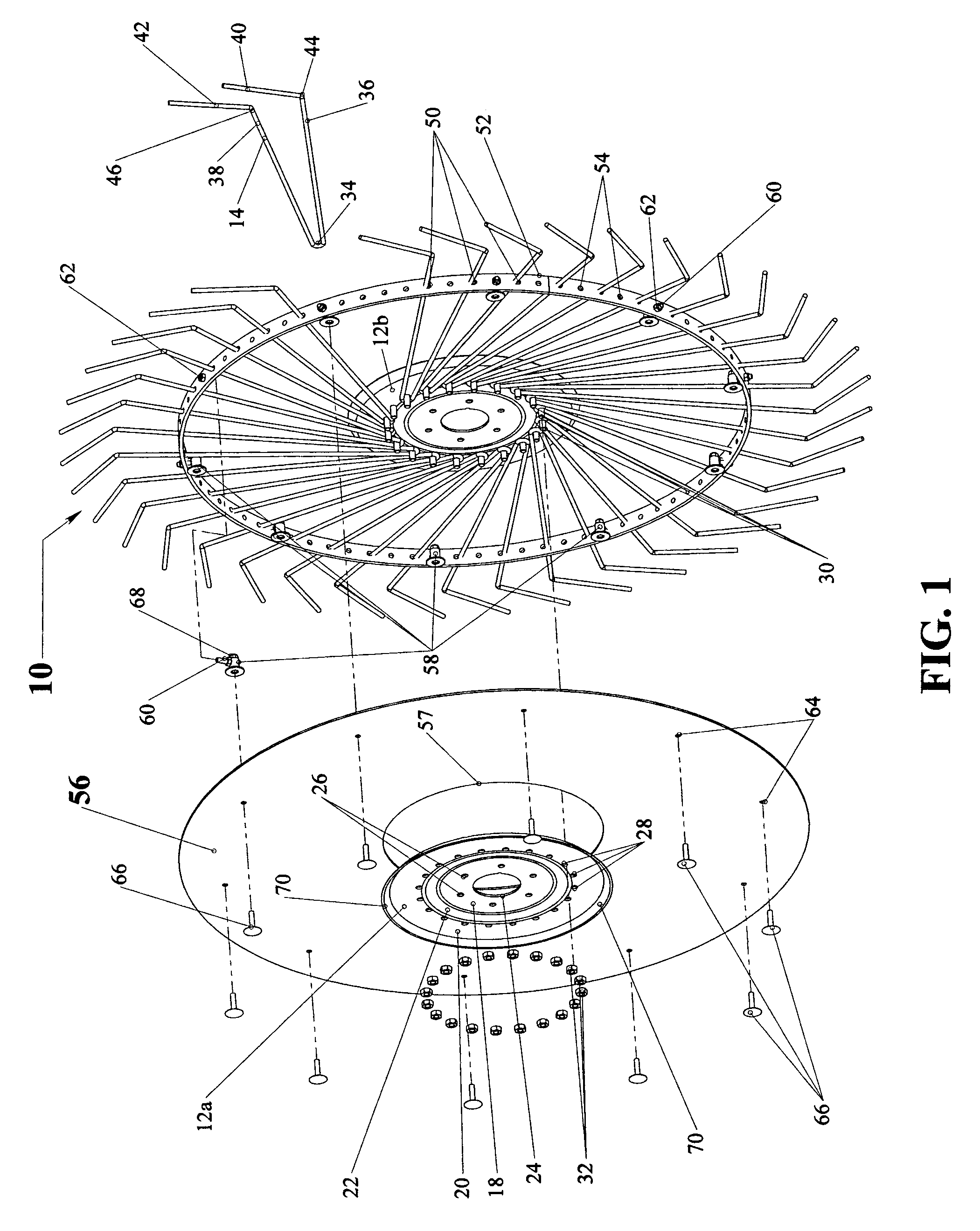

Rake wheel

A rake wheel includes a hub and a plurality of tines connected to the hub and extending outwardly therefrom to an annular rim concentric with the hub. Each tine is journaled through a first plurality of apertures formed in the rim and projects outwardly from the rim. A second plurality of apertures is formed in the rim, having a size and shape substantially the same as the first plurality of apertures, and will receive the tines when the first set of apertures becomes worn or otherwise ineffective.

Owner:MILLER FREDDIE

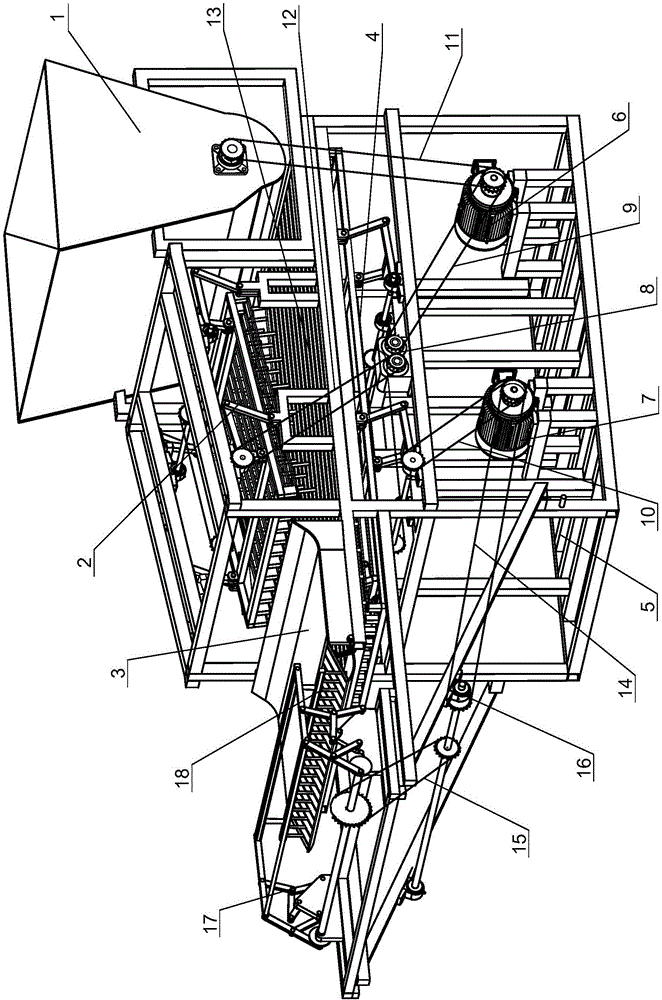

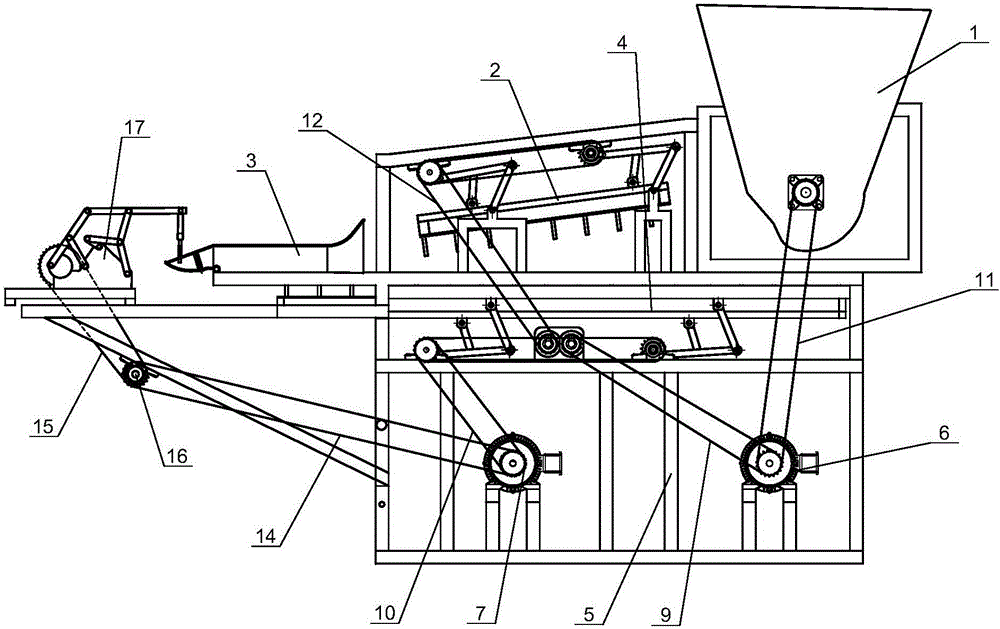

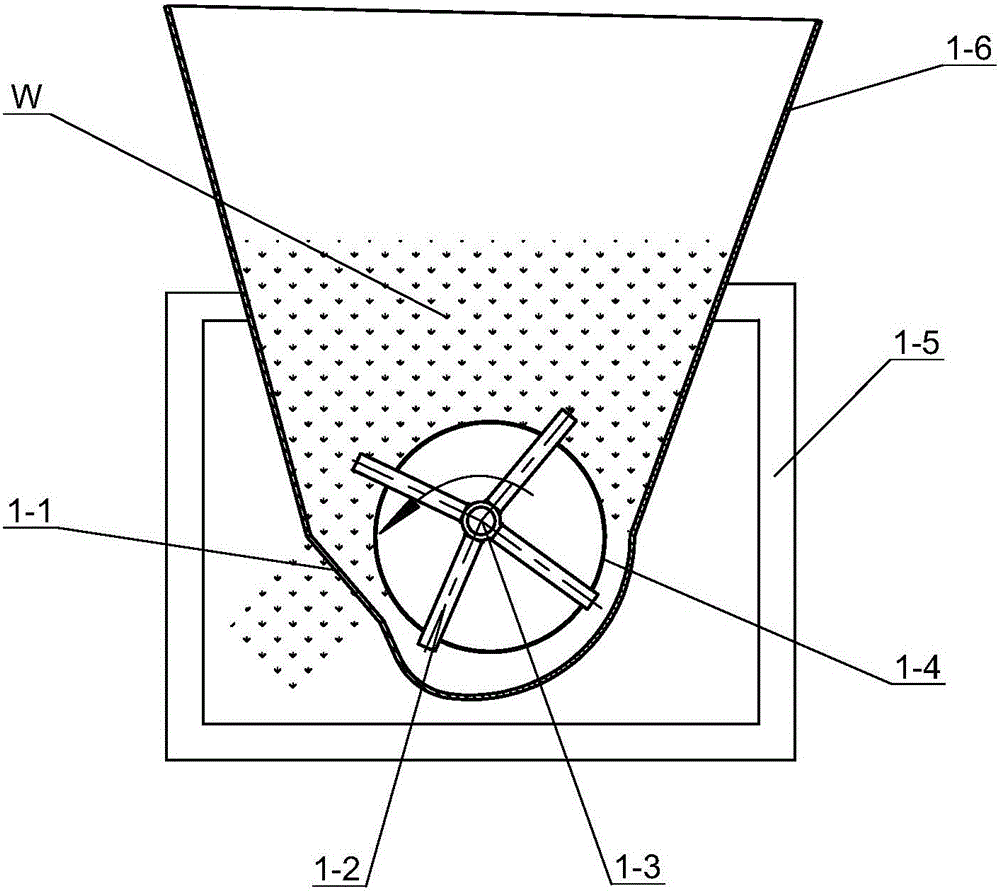

Automatic bundle distributing, paving, harrowing and cutting device

The invention relates to an automatic bundle distributing, paving, harrowing and cutting device. A material support is arranged at the top of a base of the device, a speed changing box is arranged at the middle part of the base of the device, and a first driving motor and a second driving motor are arranged at the lower part of the base of the device; a feeding part and an upper conveying part are respectively arranged on the material support, the upper conveying part is arranged at one side of the feeding part, a discharging part is arranged at one side of the upper conveying part and is connected with a harrowing and cutting execution part, the upper conveying part is connected with the first driving motor by virtue of the speed changing box, and the feeding part is connected with the first driving motor; one end of a harrowing and cutting part is connected with the harrowing and cutting execution part, the other end of the harrowing and cutting part is connected with an intermediate transmission part, the intermediate transmission part is connected with the second driving motor, and a lower conveying part is arranged below the material support and is connected with the second driving motor. By simulating automatic paving, harrowing and cutting operations carried out on straws by hands, the effects of paving, conveying and antientanglement in a weaving process utilizing smashed rice straws are effectively achieved.

Owner:HUNAN AGRICULTURAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com