Patents

Literature

11598 results about "Brush" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A brush or carbon brush is an electrical contact which conducts current between stationary wires and moving parts, most commonly in a rotating shaft. Typical applications include electric motors, alternators and electric generators.

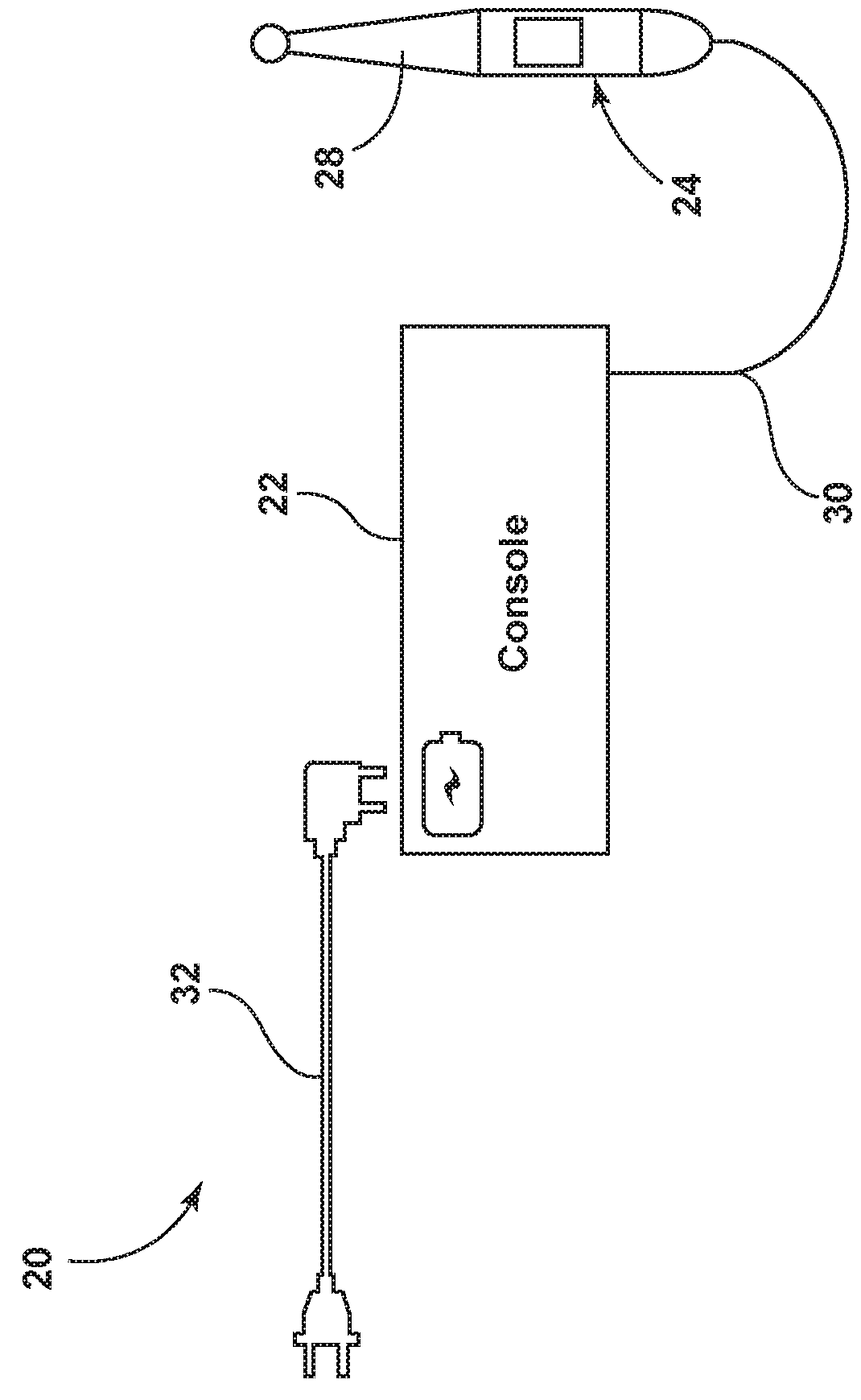

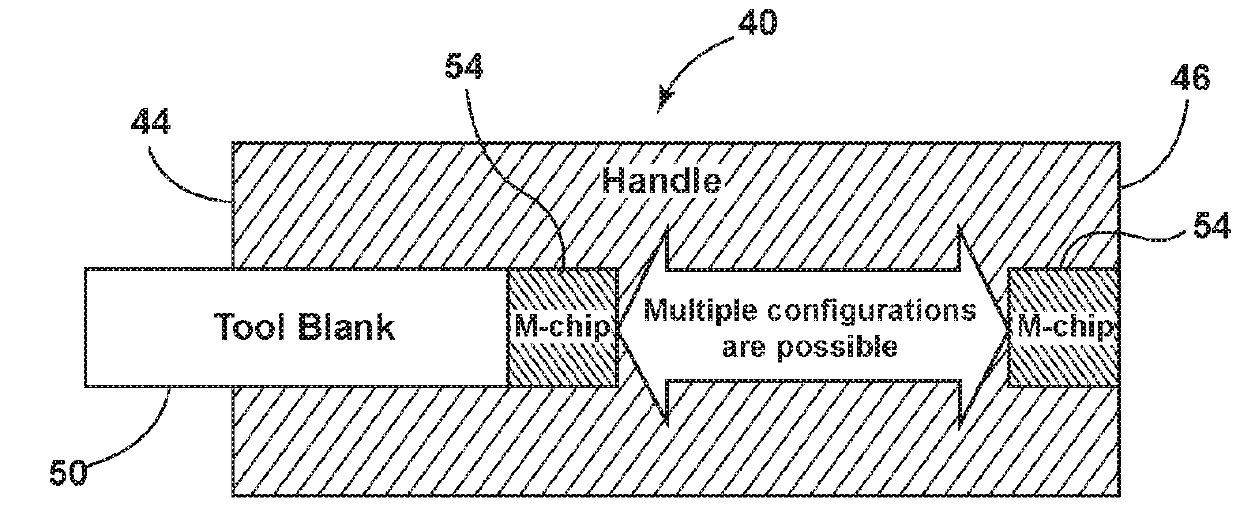

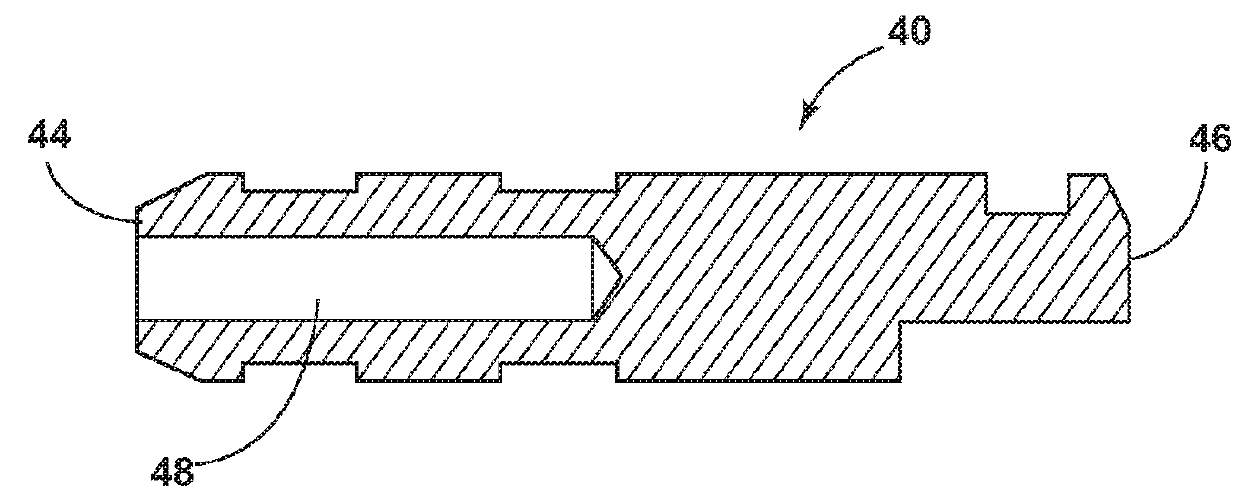

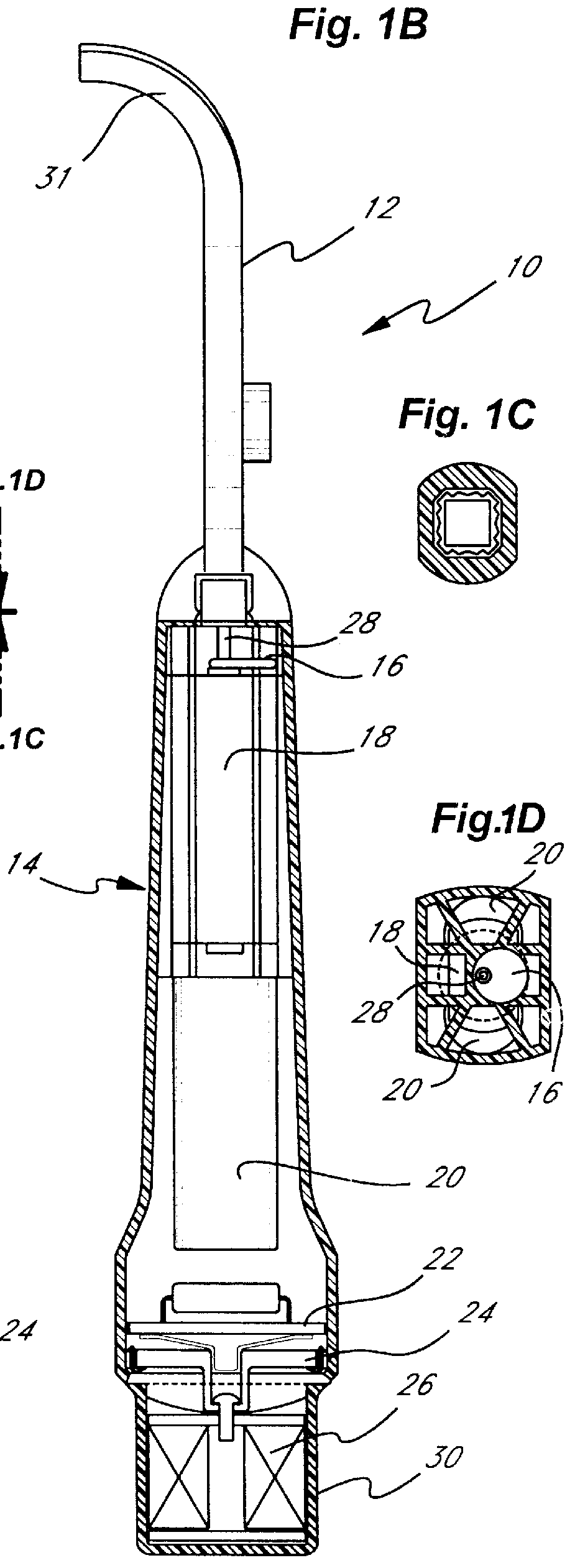

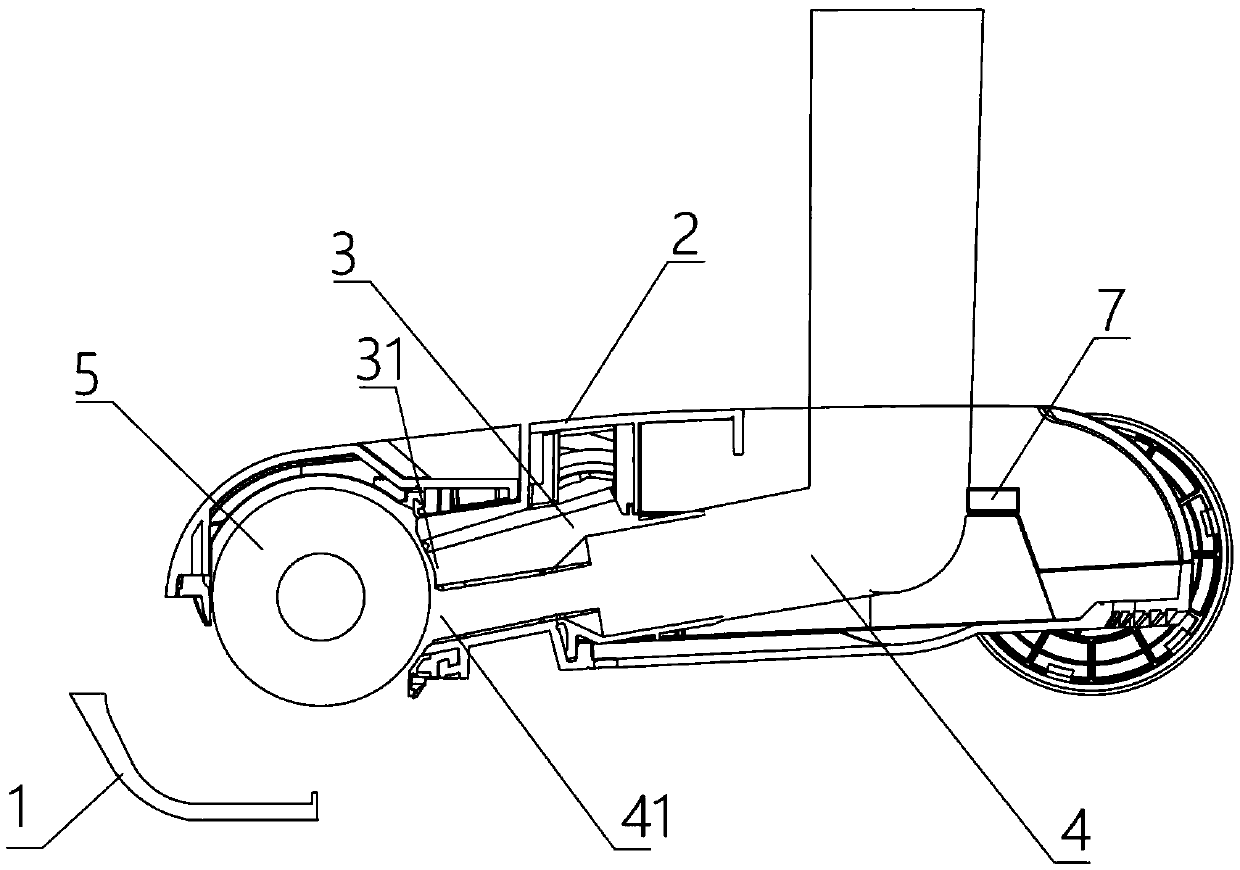

Electronic tool recognition system for dental devices

A tool for use with an electronic tool recognition system includes a tool blank with a distal tip configured for performing a procedure and a proximal handle encasing, fixedly, a proximal end of the tool blank. A tool-identifying apparatus including a mechanical resonator is embedded in a proximal end of the tool blank to provide a tool identifier. A conductive wire in electrical contact with the resonator provides the identifier to a processor. In another arrangement, conductive brushes in contact with slip rings provide the identifier to a processor. In another arrangement, a dental tool handle includes an insulating portion defining a recess in a proximal end of the handle configured to receive either a sensor or an information-managing chip.

Owner:THE KERR

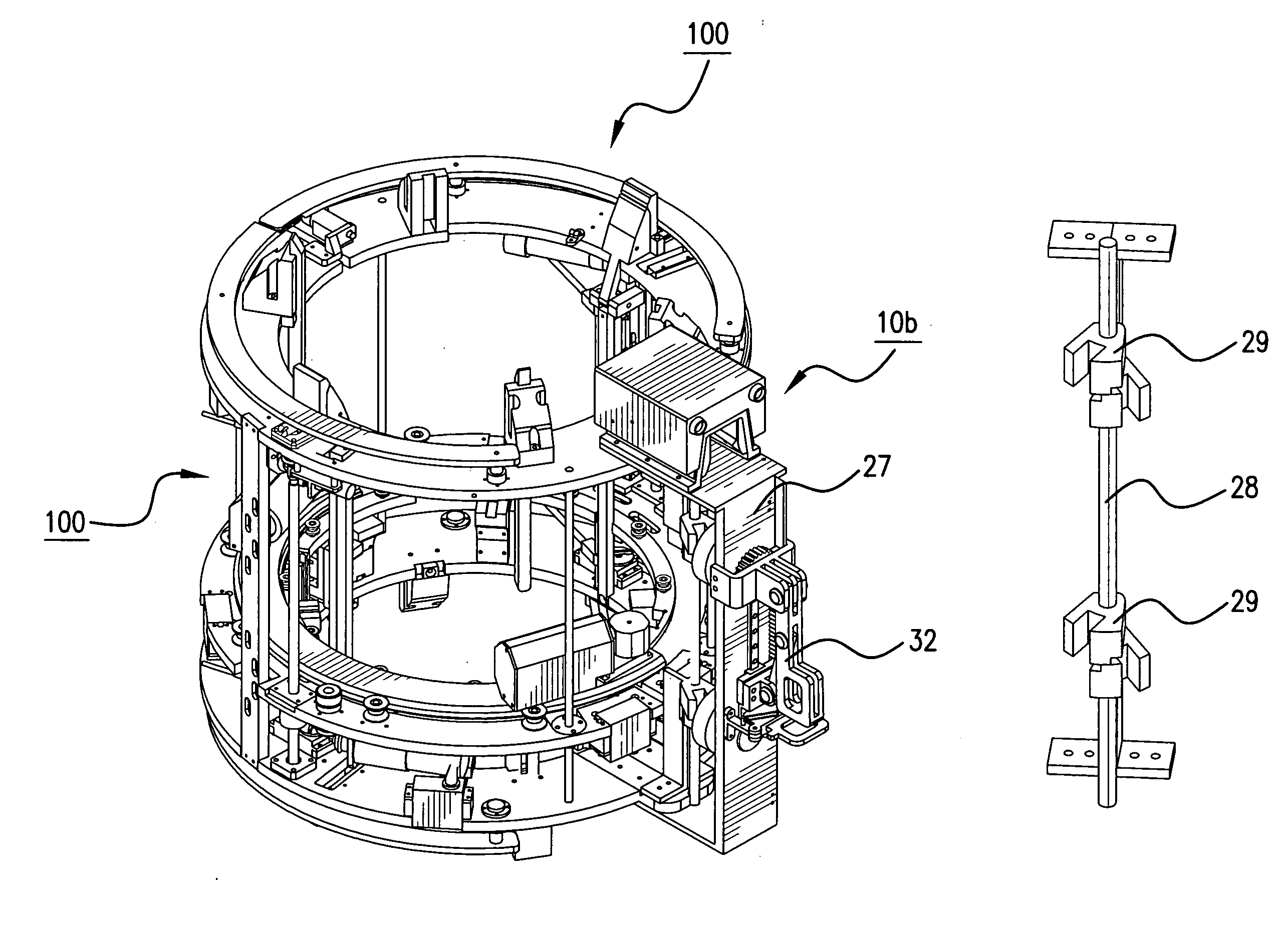

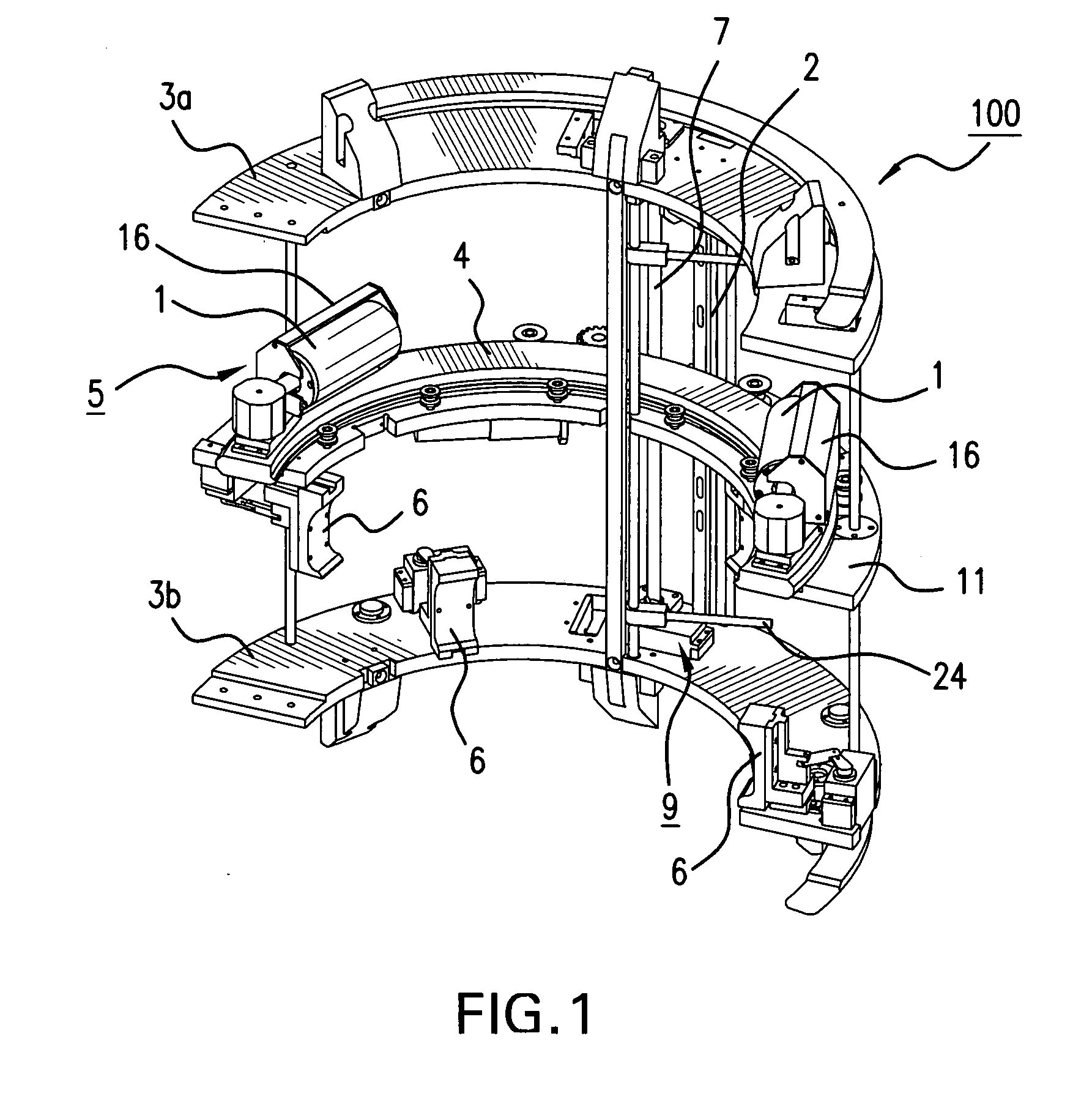

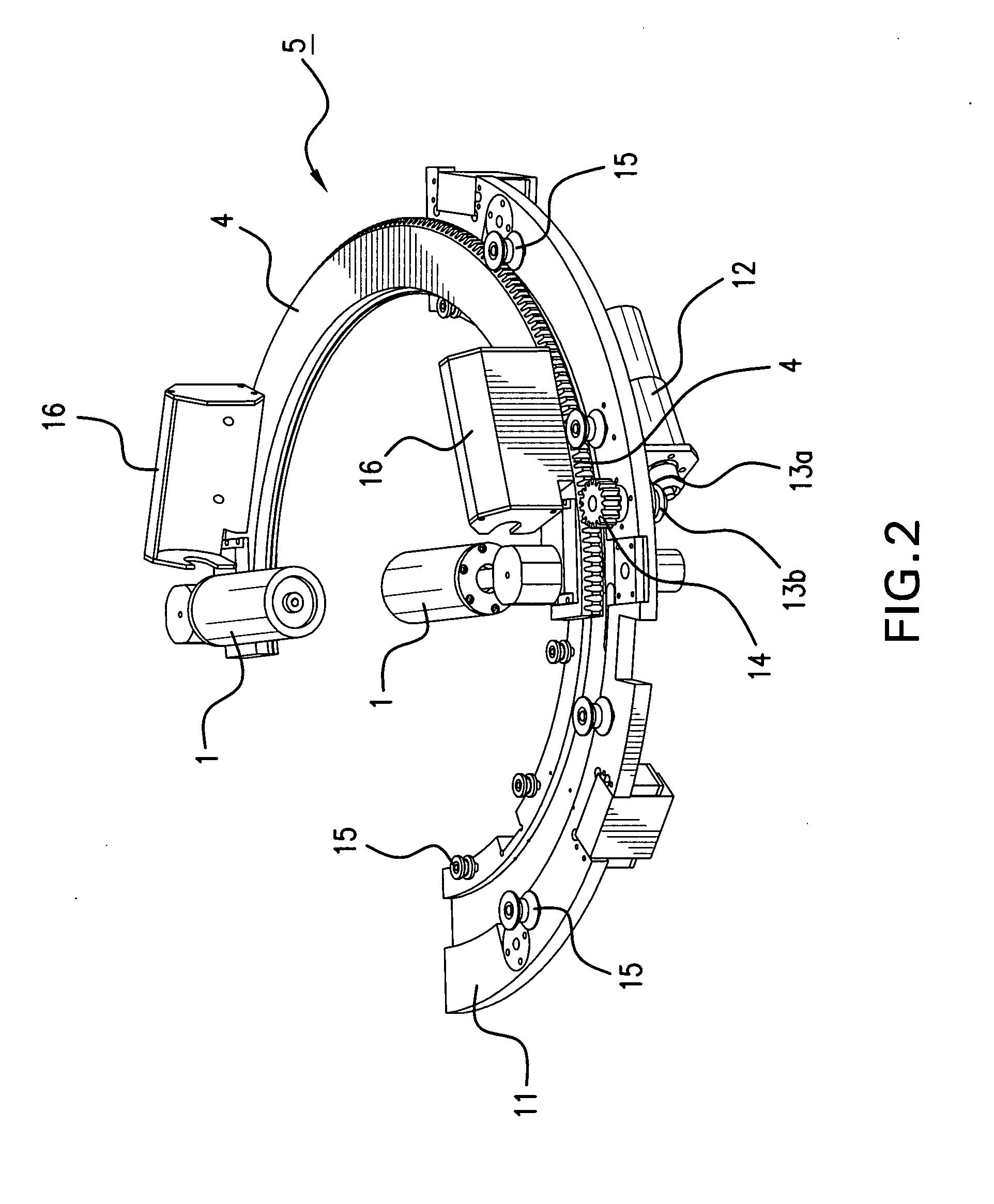

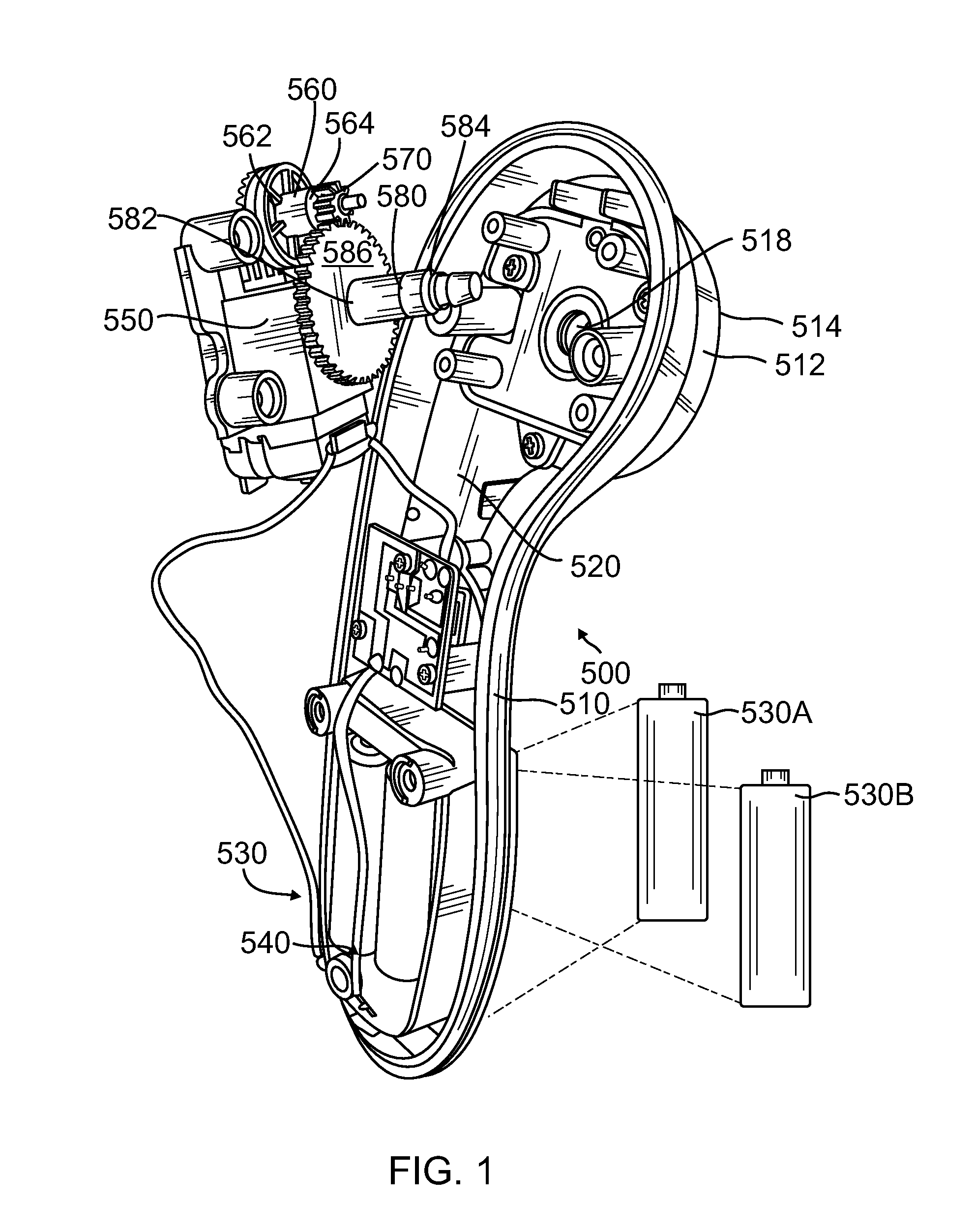

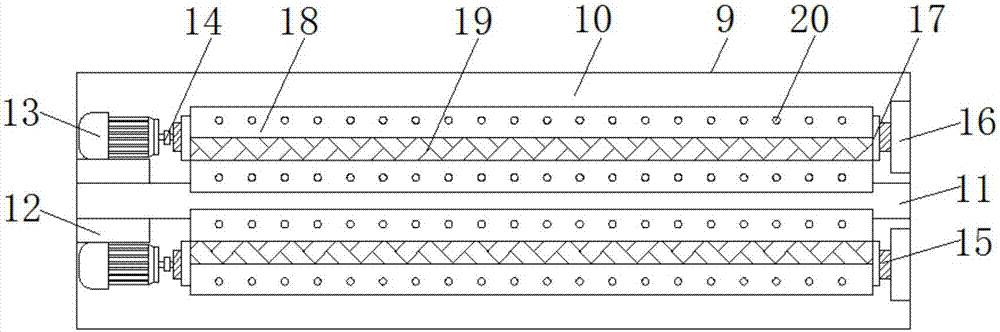

Robot mechanism for cleaning and inspection of live-line insulators

ActiveUS20080301891A1Improve efficiencyImprove securityBowling gamesCarpet cleanersBall bearingMechanical engineering

A robot mechanism adopts a dry cleaning method to clean the surface of live-line insulators without: using water and can perform cleaning and inspection of the surface of the live-line insulators while automatically moving along an insulator string. The robot mechanism includes a main unit having upper and lower wing frames connected with each other by a connecting bracket to surround the insulator string, a cleaning unit disposed between the upper and lower wing frames and including a base frame to perform dry cleaning with a rotational brush and a CM guide, a lift unit including a clamp and a ball-bearing screw to move the main unit up or down, and an inspection unit to electrically inspect the insulators; and a coupling unit to couple a pair of the main units to allow the pair of main units to move along a tension insulator string or a suspension insulator string.

Owner:KOREA ELECTRIC POWER CORP

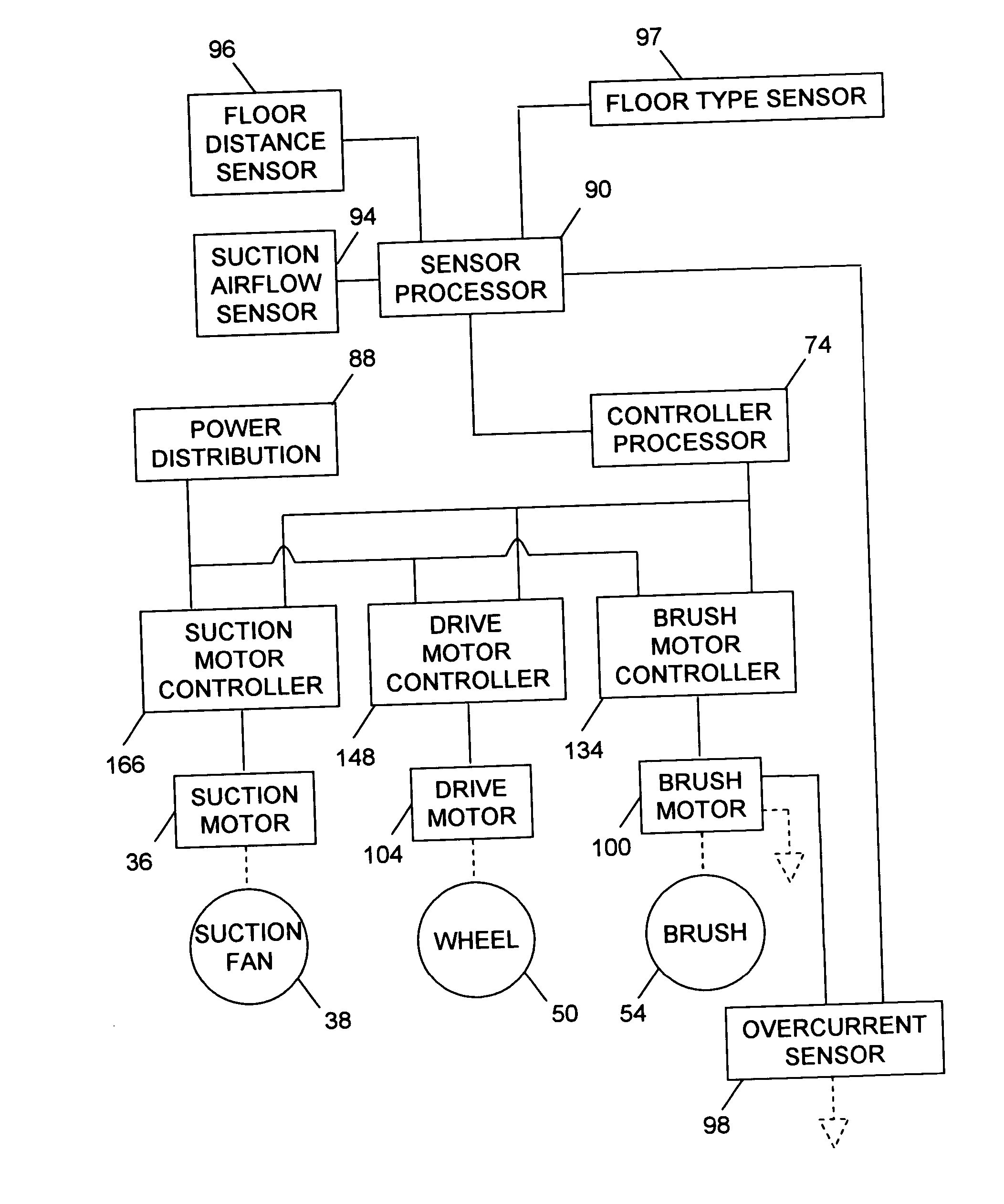

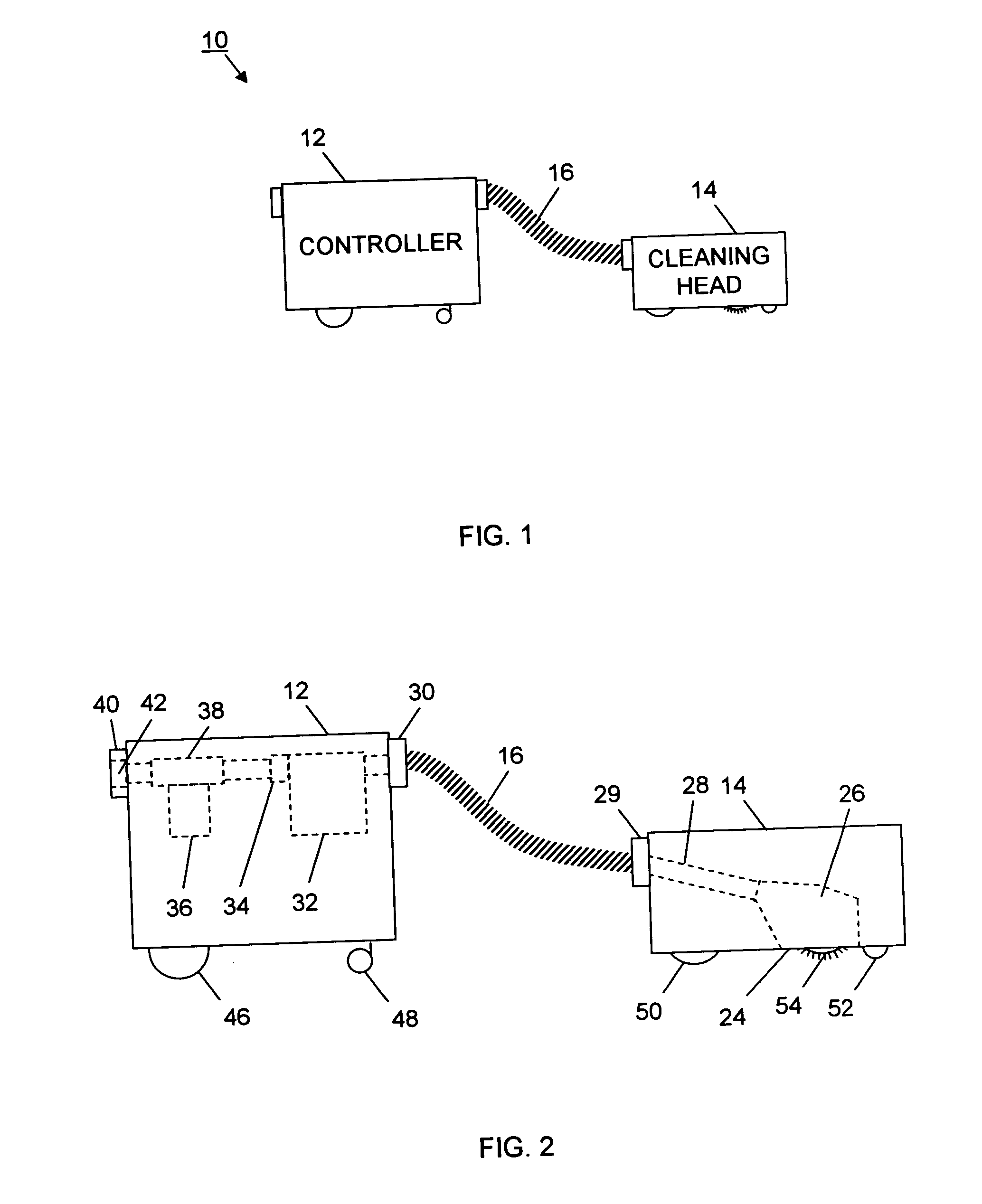

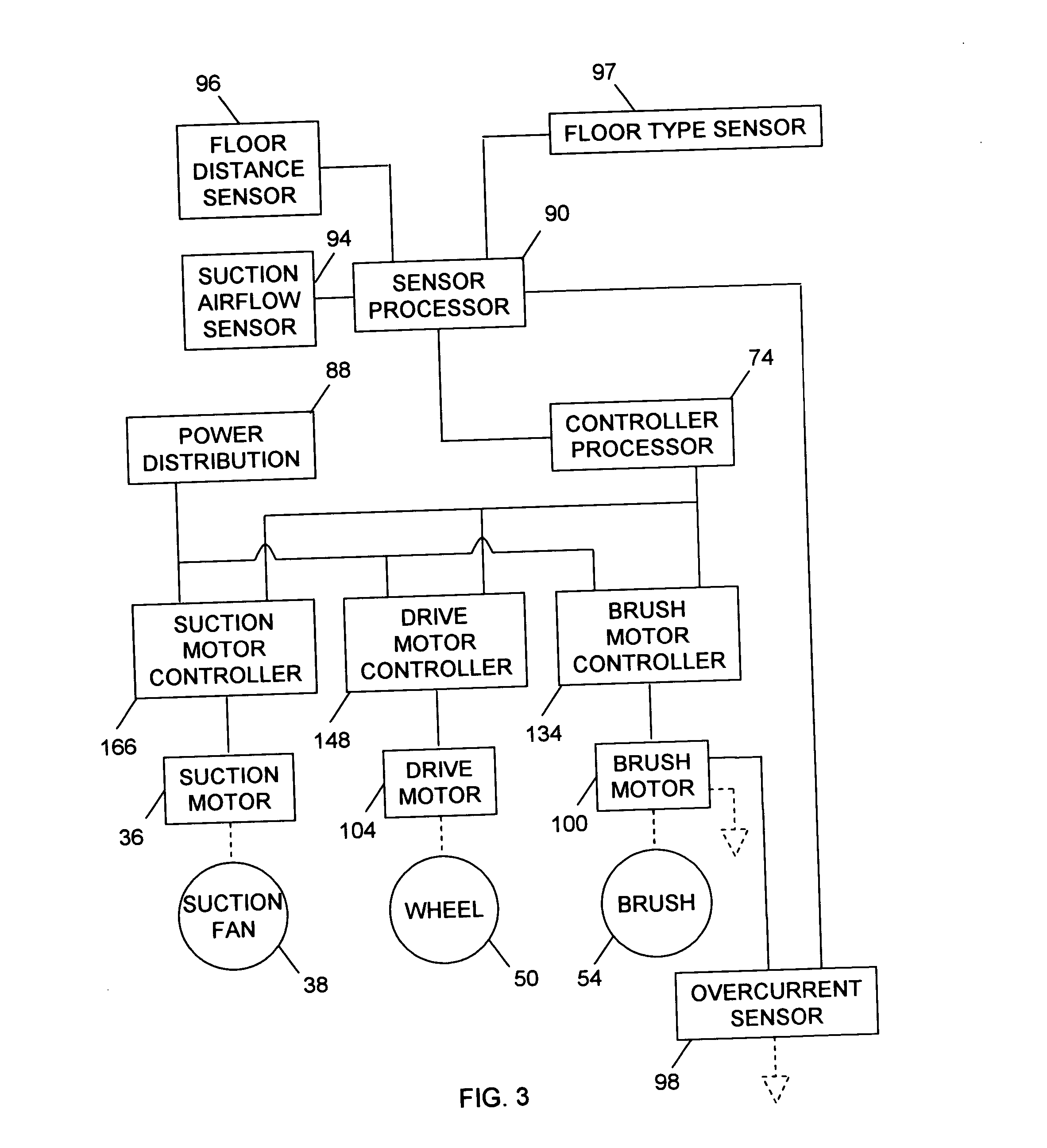

Sensors and associated methods for controlling a vacuum cleaner

Several methods of controlling a vacuum cleaner (10) using various types of sensors (94, 96, 97, 98) are provided. One method is based on a differential pressure between a suction airflow path and ambient air and includes: detecting the differential pressure, comparing the detected differential pressure to a predetermined threshold, and, when the detected differential pressure is less than the predetermined threshold, initiating a predetermined control procedure. A status indicator (164) is updated based on the detected differential pressure. Another method is based on a level of electrical current flowing through a brush motor (100). Still another method is based on a type or condition of the floor being traversed. Yet another method is based on a distance to a surface of a floor over which the vacuum cleaner is advancing. In another aspect of the invention, a vacuum cleaner is provided. In various combinations, the vacuum cleaner includes a vacuum source (36, 38), a brush motor (100), a drive motor (104), a controller processor (74), a sensor processor (90), an overcurrent sensor (98), a suction airflow sensor (94), a floor type sensor (97), and a floor distance sensor (96).

Owner:ROYAL APPLIANCE MFG

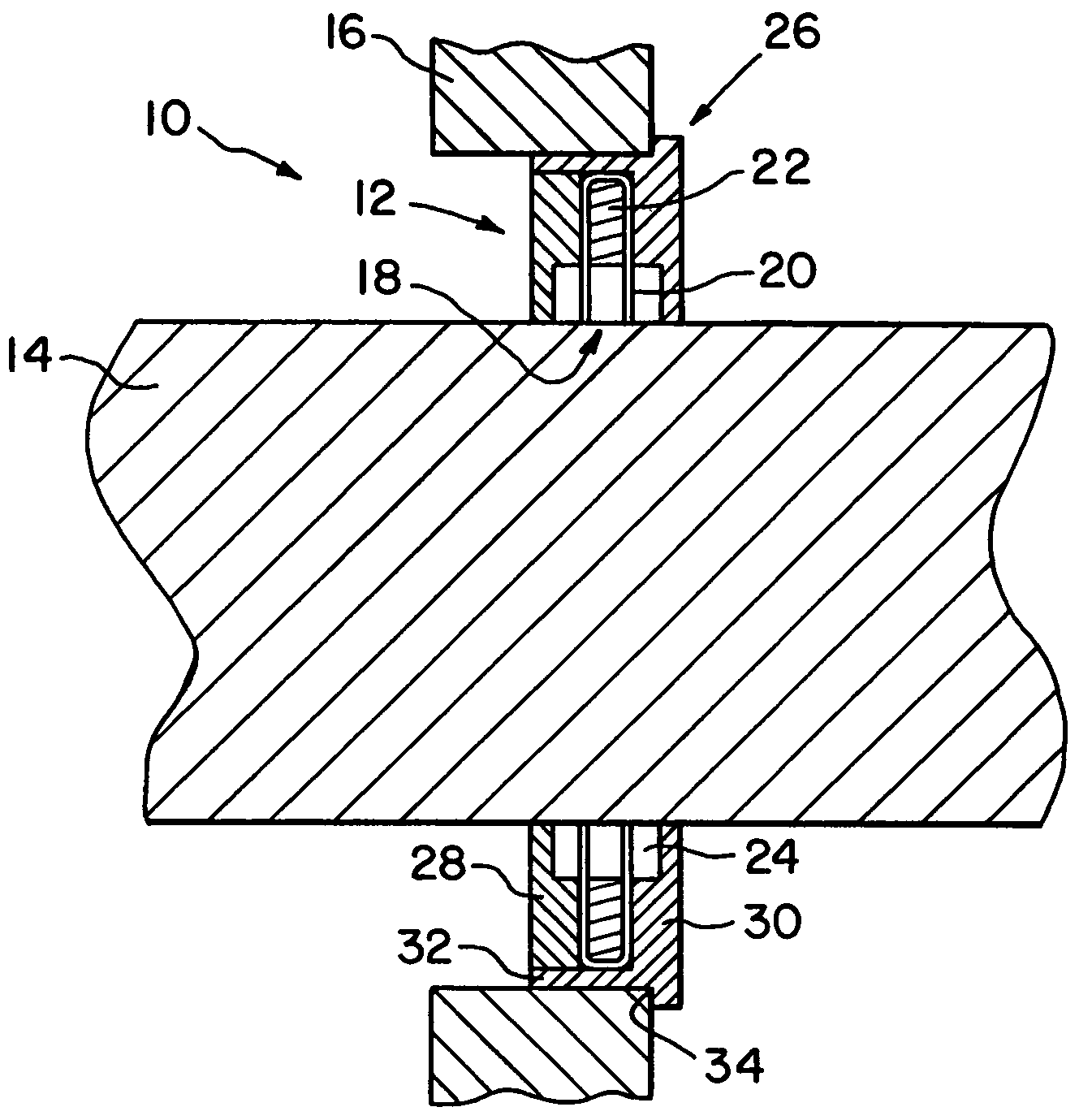

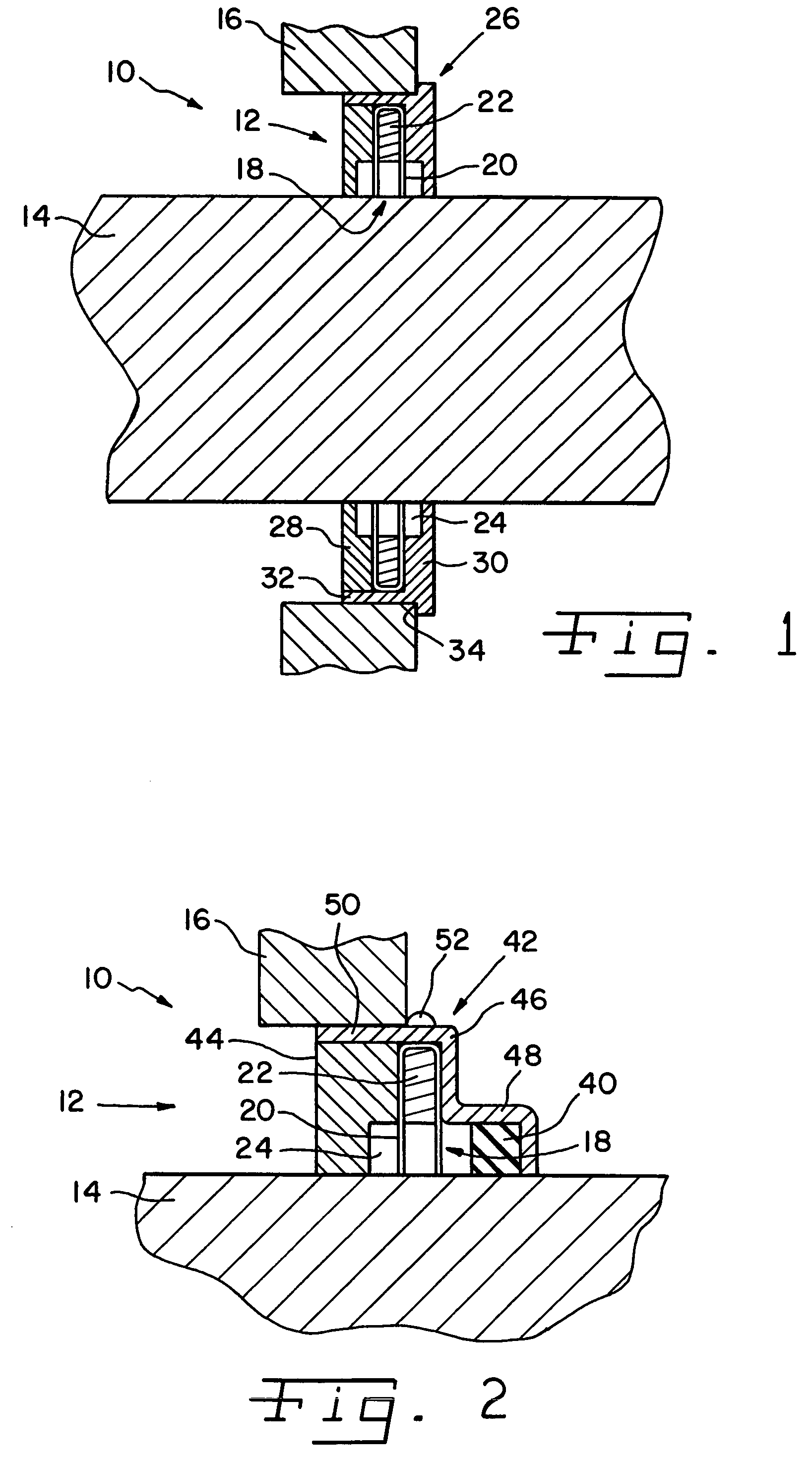

Grounding brush for mitigating electrical current on motor shafts

ActiveUS7193836B2Reduce shaft currentEfficient assemblyAssociation with grounding devicesEmergency protective arrangement detailsElectric machineClassical mechanics

A grounding brush for mitigating static electric charge on a motor shaft includes a plurality of filaments secured to an annular frame around the shaft, with tips of the filaments disposed in a channel defined by the frame. Conductive powder can be provided in the channel to improve current flow from the shaft to the filaments.

Owner:ILLINOIS TOOL WORKS INC

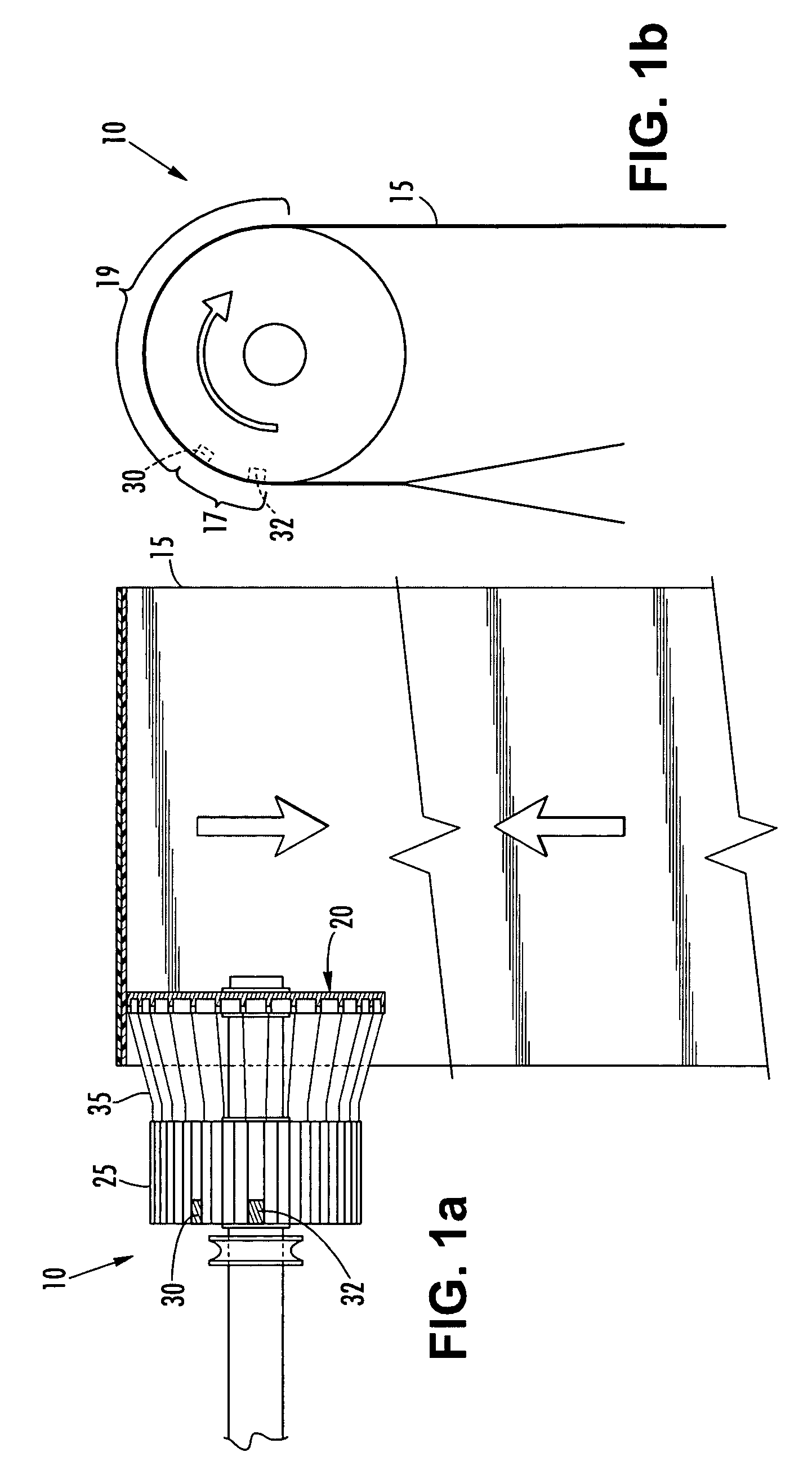

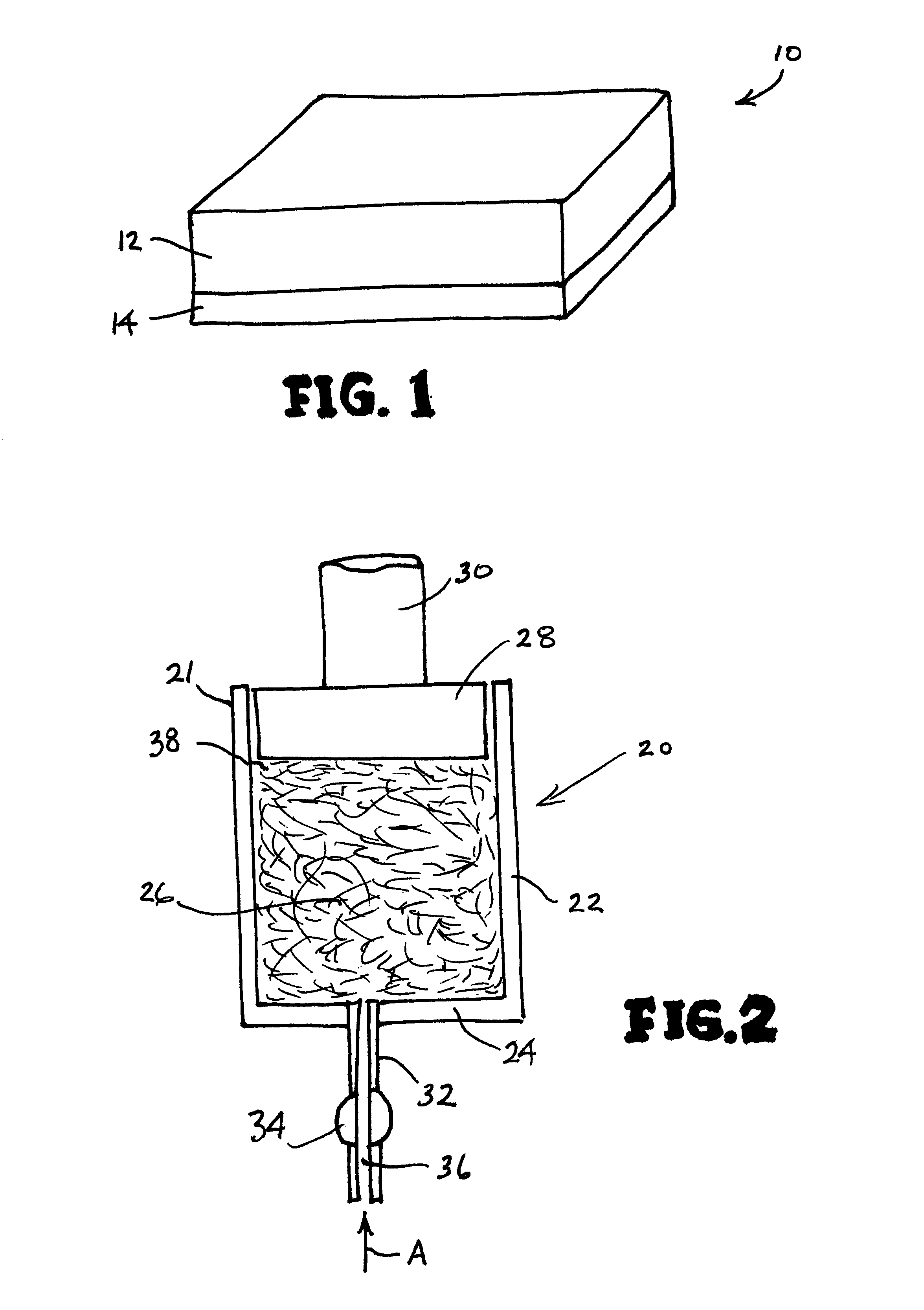

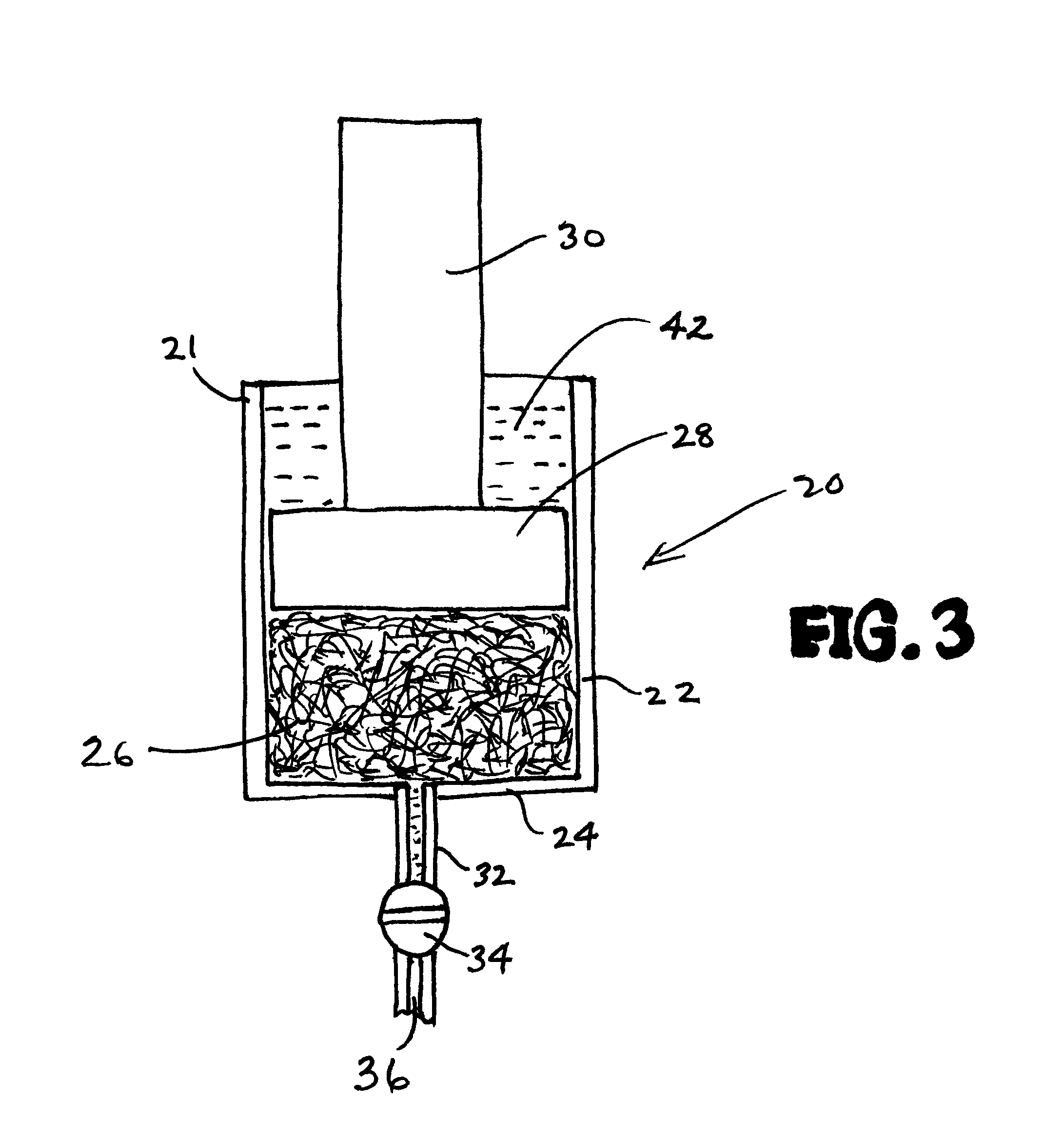

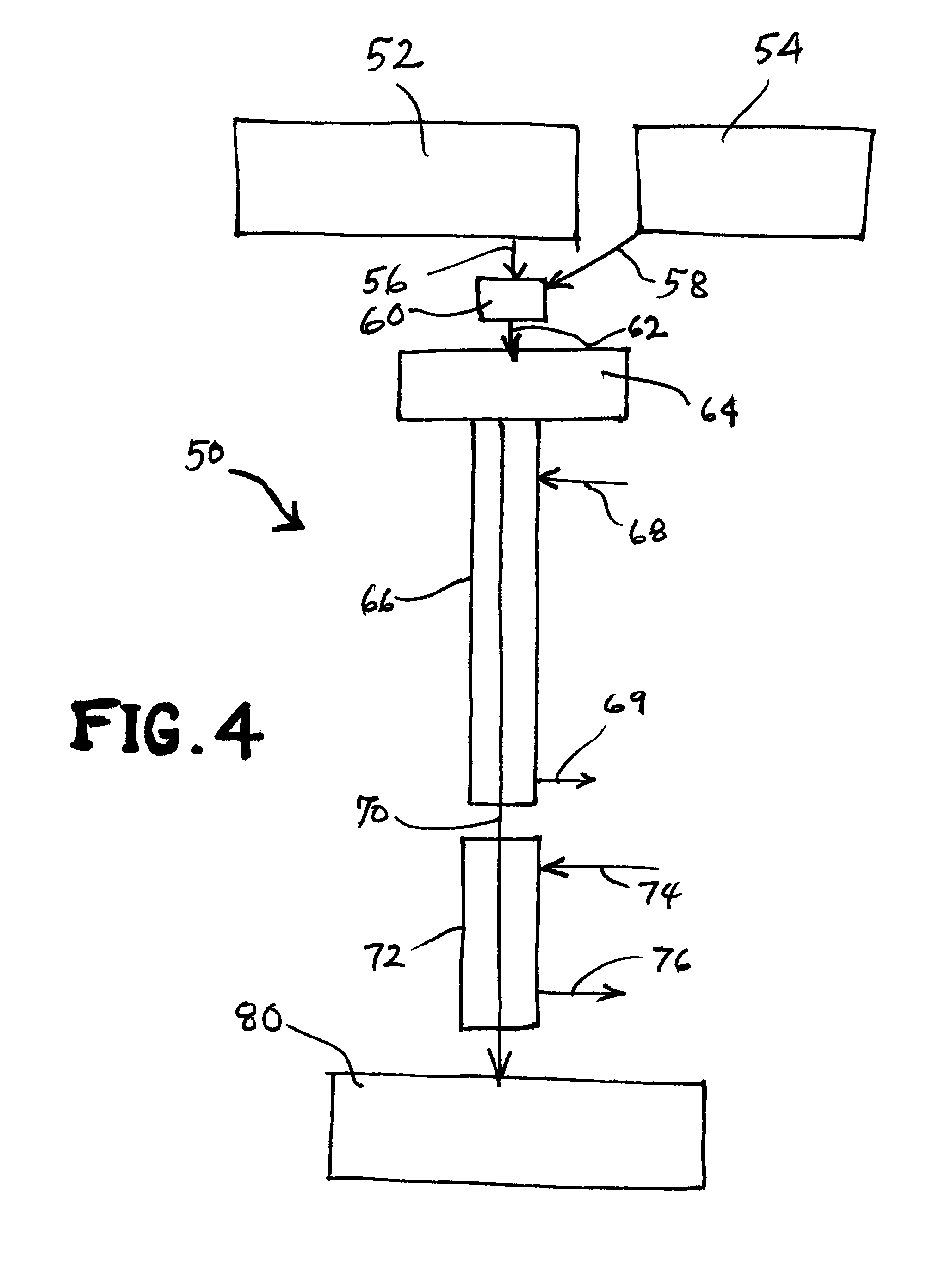

Rotary impulse sealer

ActiveUS7247219B2Increase or decrease sizeMechanical working/deformationLaminationElectrical resistance and conductanceEngineering

Owner:SEALED AIR U S

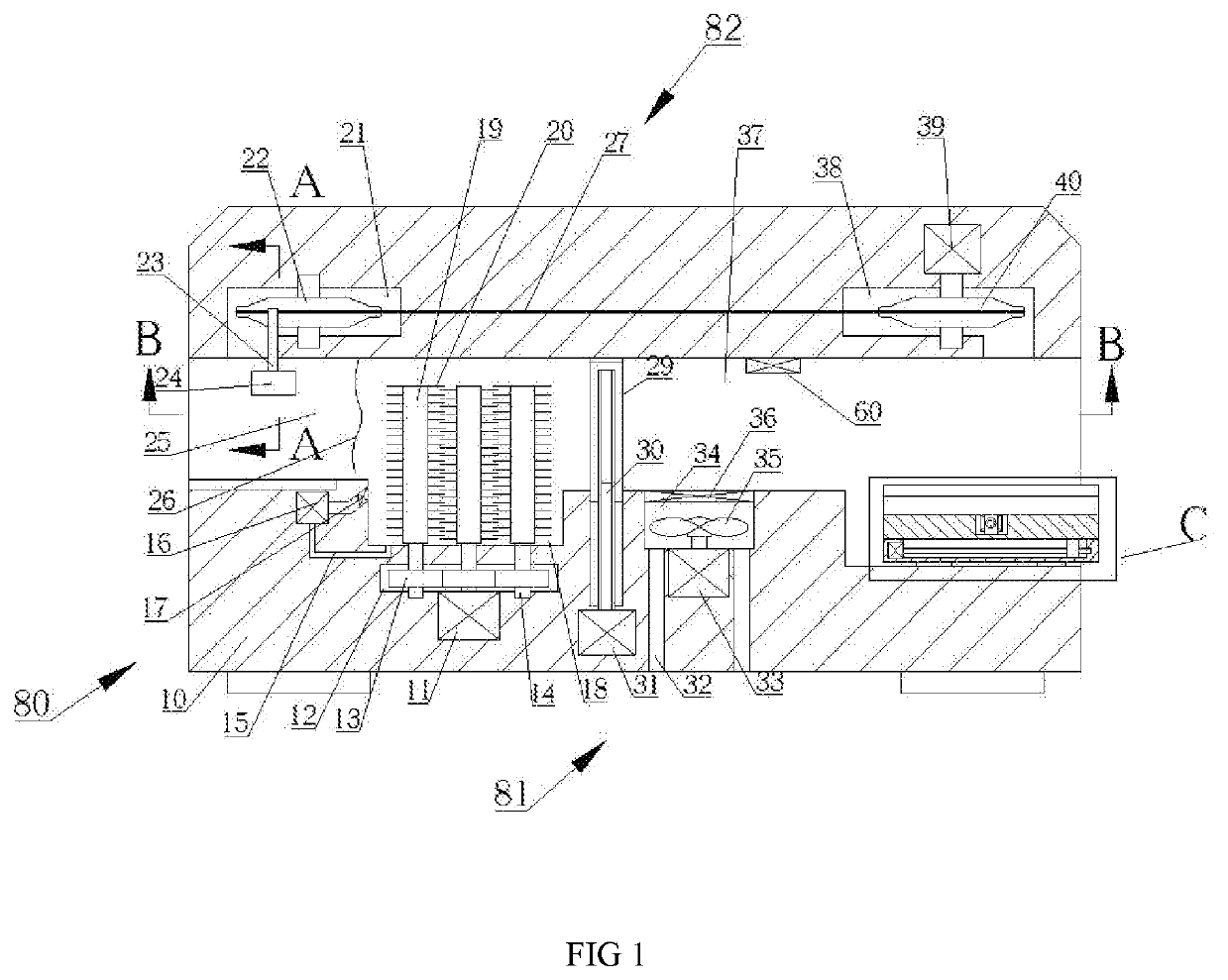

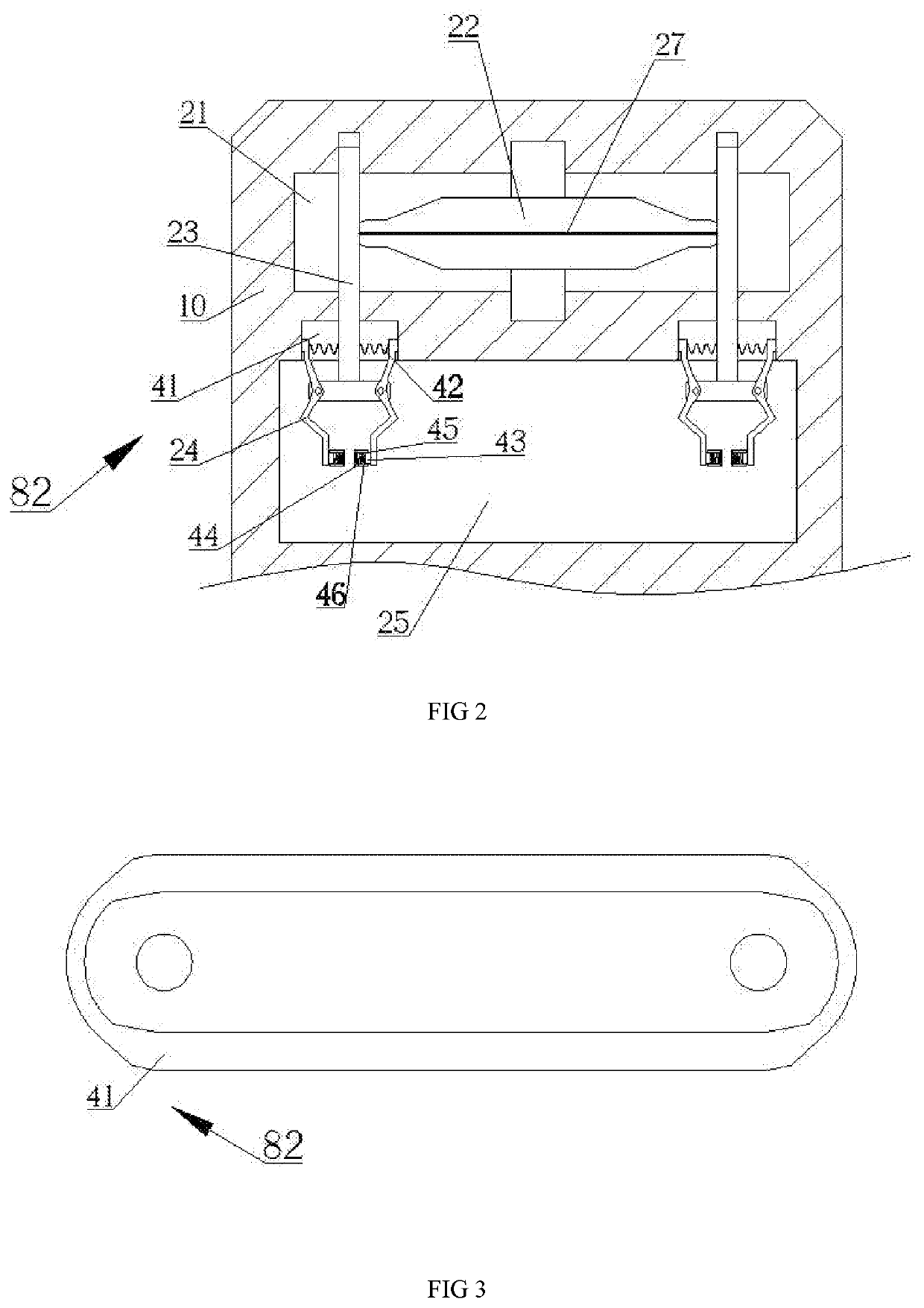

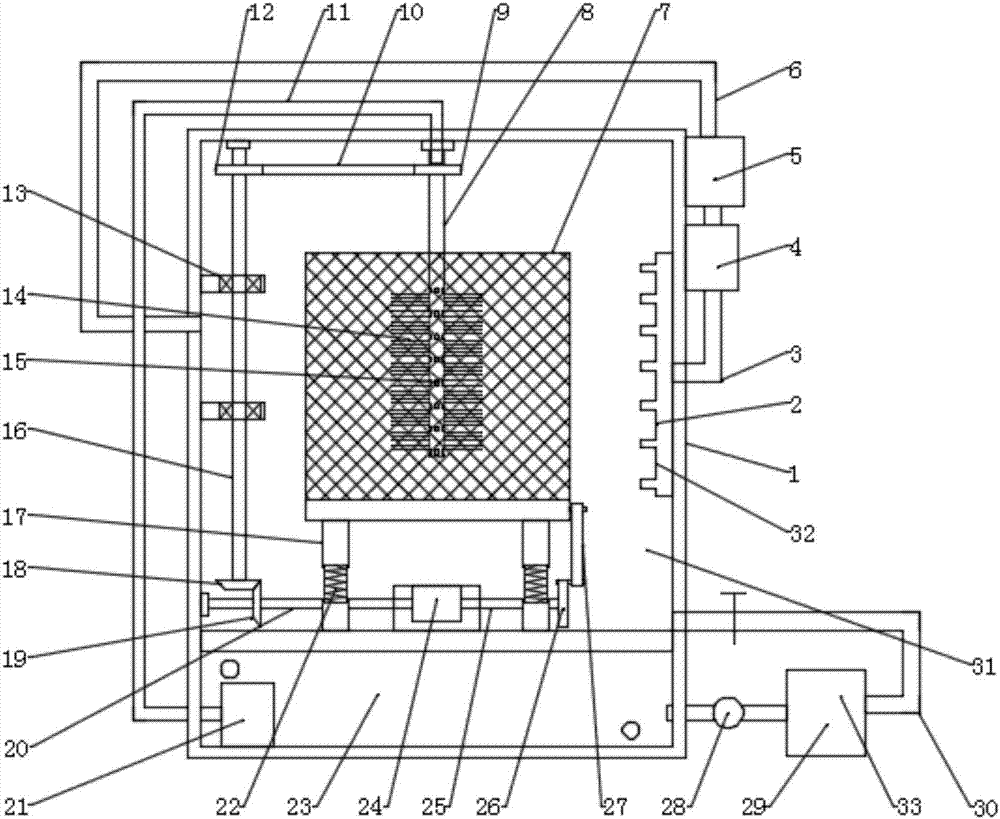

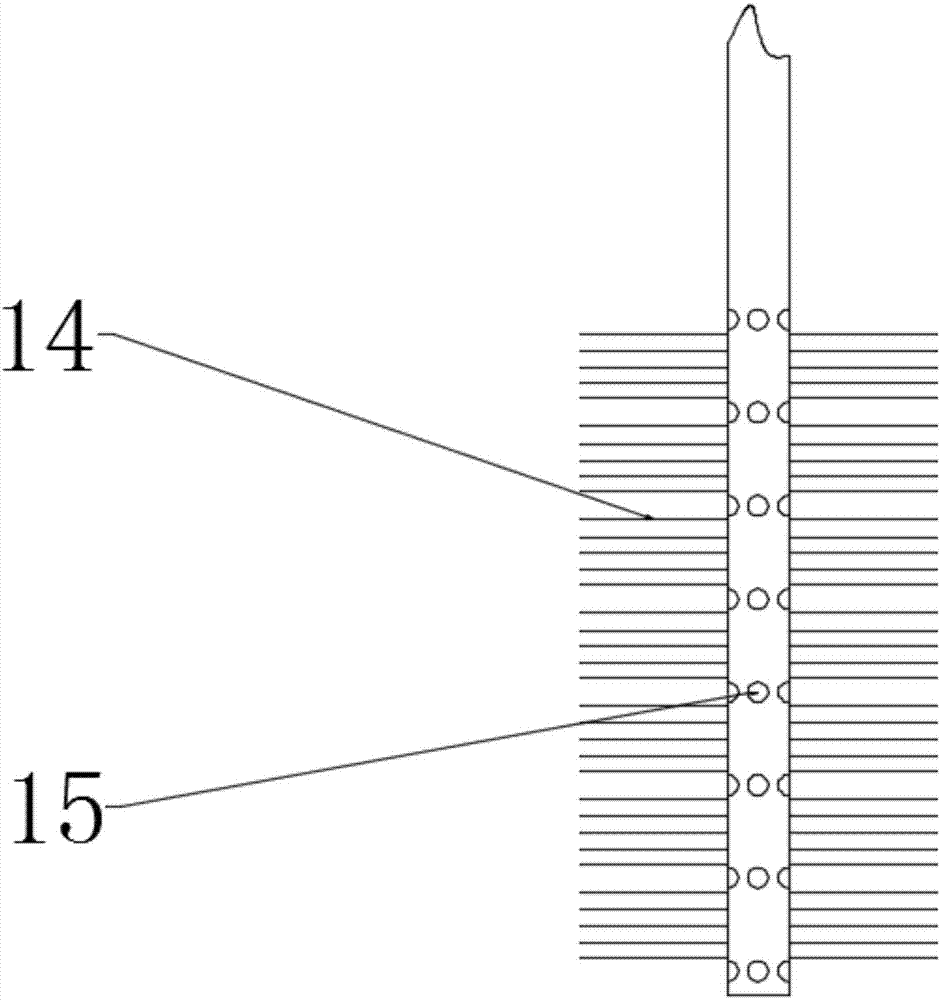

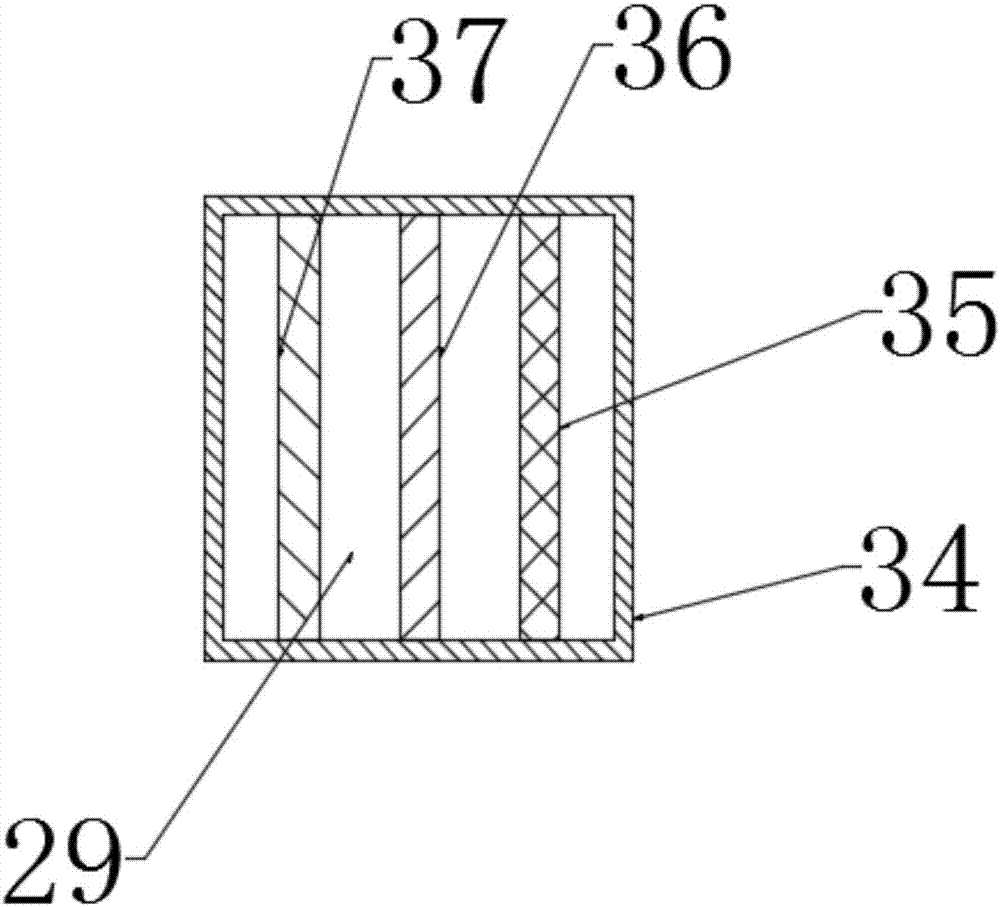

Glassware cleaning and drying equipment for medical experiments

InactiveUS20200108426A1Continuous cleaningIncrease flexibilityHollow article cleaningDrying gas arrangementsGlass vesselElectric machinery

The invention discloses a glassware cleaning and drying equipment for medical experiments, which includes a device cabinet, wherein a cleaning space is provided in the device cabinet, a brushing space communicating with the cleaning space is provided on a bottom wall of the cleaning space, and a water pump is fixedly installed in the left inner wall of the brushing space. The nozzle is fixedly installed on the output pipe. The brushing motor is started. The brushing motor drives the gear shaft to rotate. The brush cylinder and the washing brush that the gear shaft rotates rotate. The medical glassware is cleaned and disinfected. The effect of individual treatment is better and the disinfection is more thorough. The chuck can be changed according to the size of the clamped utensils. There is no need to change the mold for clamping the utensils.

Owner:WU MEIJUN

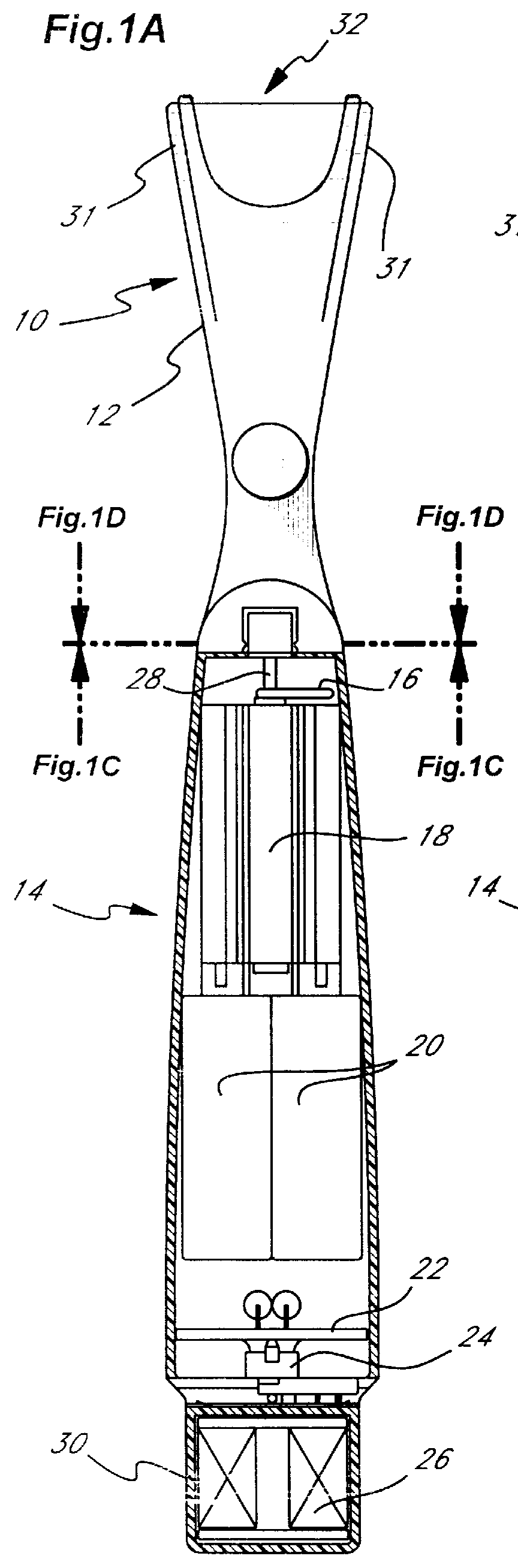

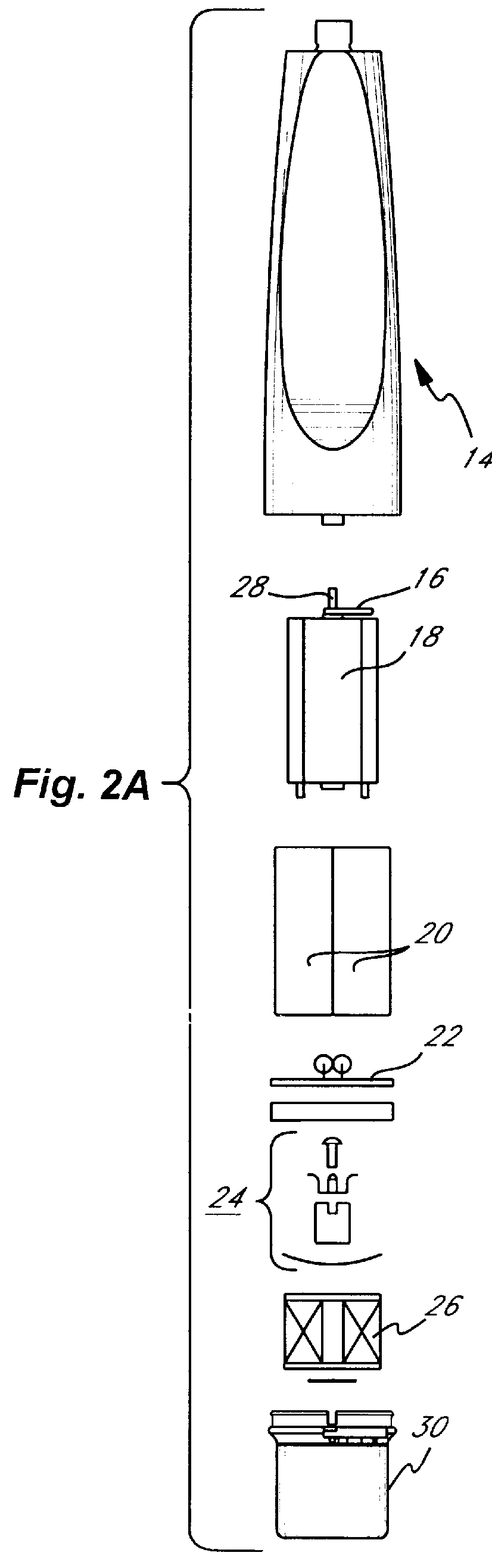

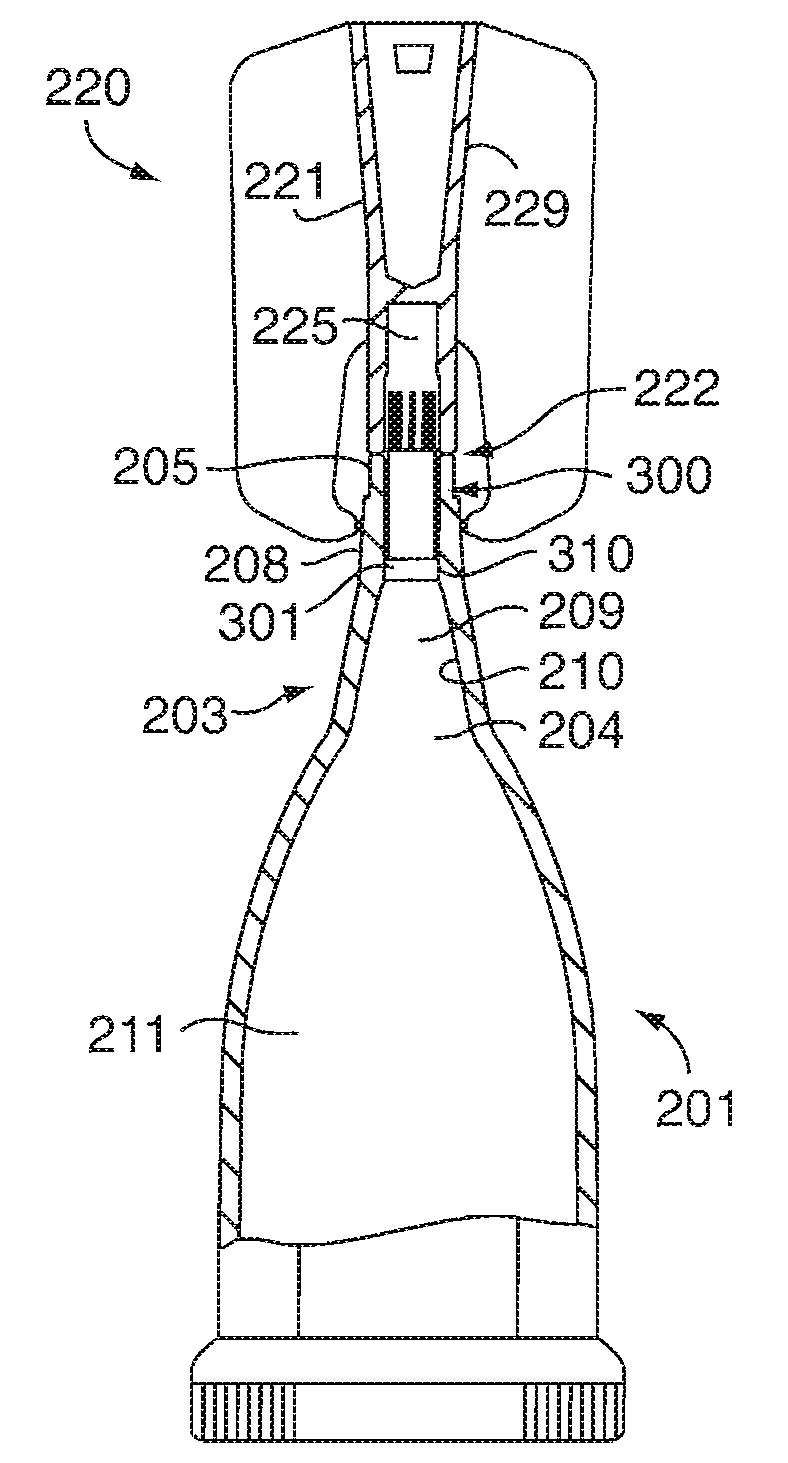

Sonic dental device

InactiveUSRE36699E1Improve easeImprove effectivenessGum massageTooth pluggers/hammersNatural resonanceDental floss

An electric device which removes supragingival and sub-gingival plaque and undesirable debris from the interproximal surfaces between teeth is described. This device utilizes a combination of sonic energy and dental floss which is secured between two tines, the tines being part of a flexible fork which is removable from a powered handle which contains batteries and an electric motor. The electric motor, which is coupled to an eccentrically mounted disc on an output shaft, revolves at sonic frequencies which in turn generates sonic energy that is transmitted to the flexible fork which holds the floss. The sonic energy is synchronized and in tune with the natural resonance frequencies of the fork thereby stimulating the resonance action of oscillating vertical and / or elliptical movement of the fork which in turn imparts cleaning energy to and enhances the cleaning properties of the floss. The flexible fork may be removed from the handle and replaced with other dental cleaning tools such as a brush, a pick, and / or a tray attachment.

Owner:AMDEN

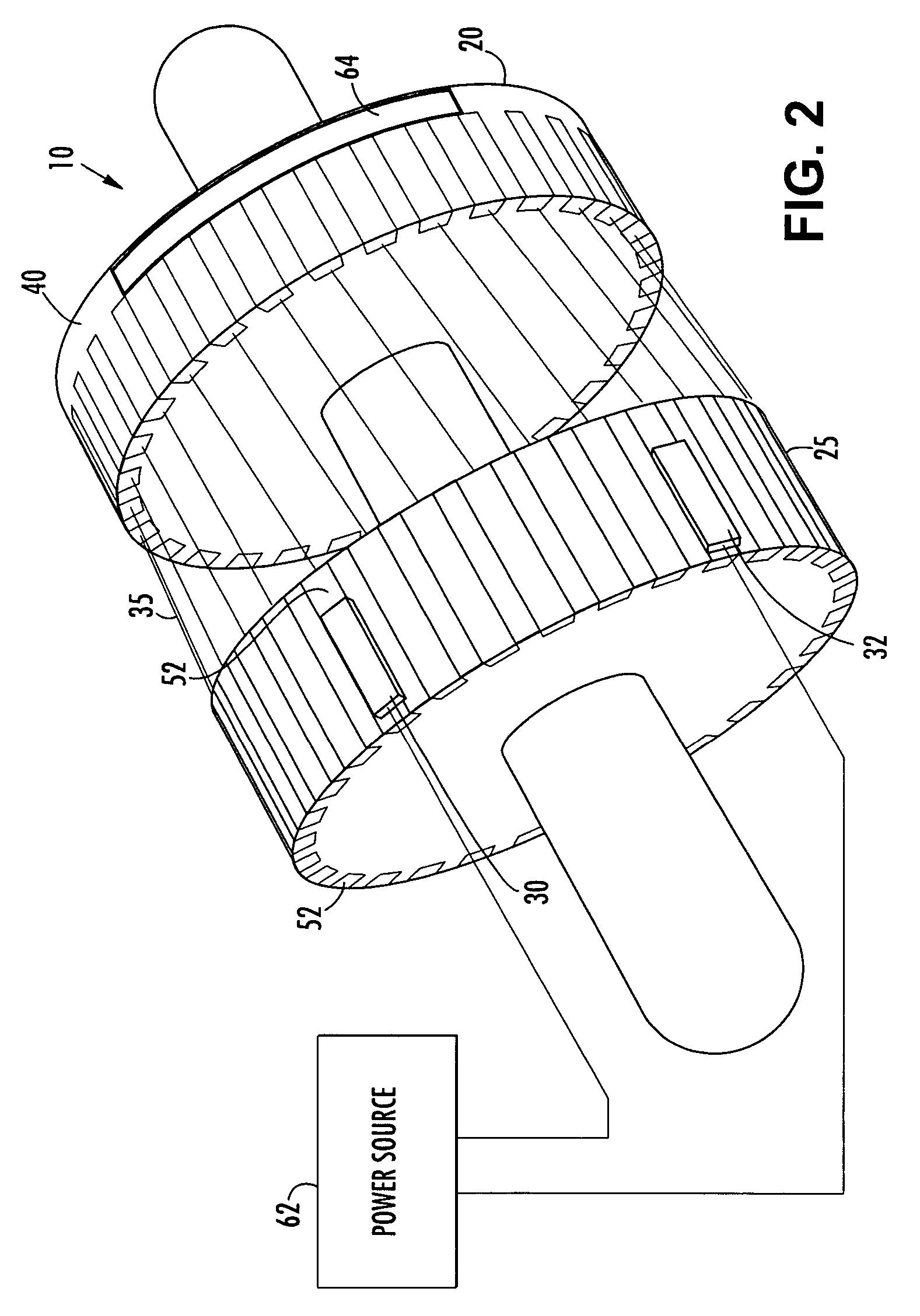

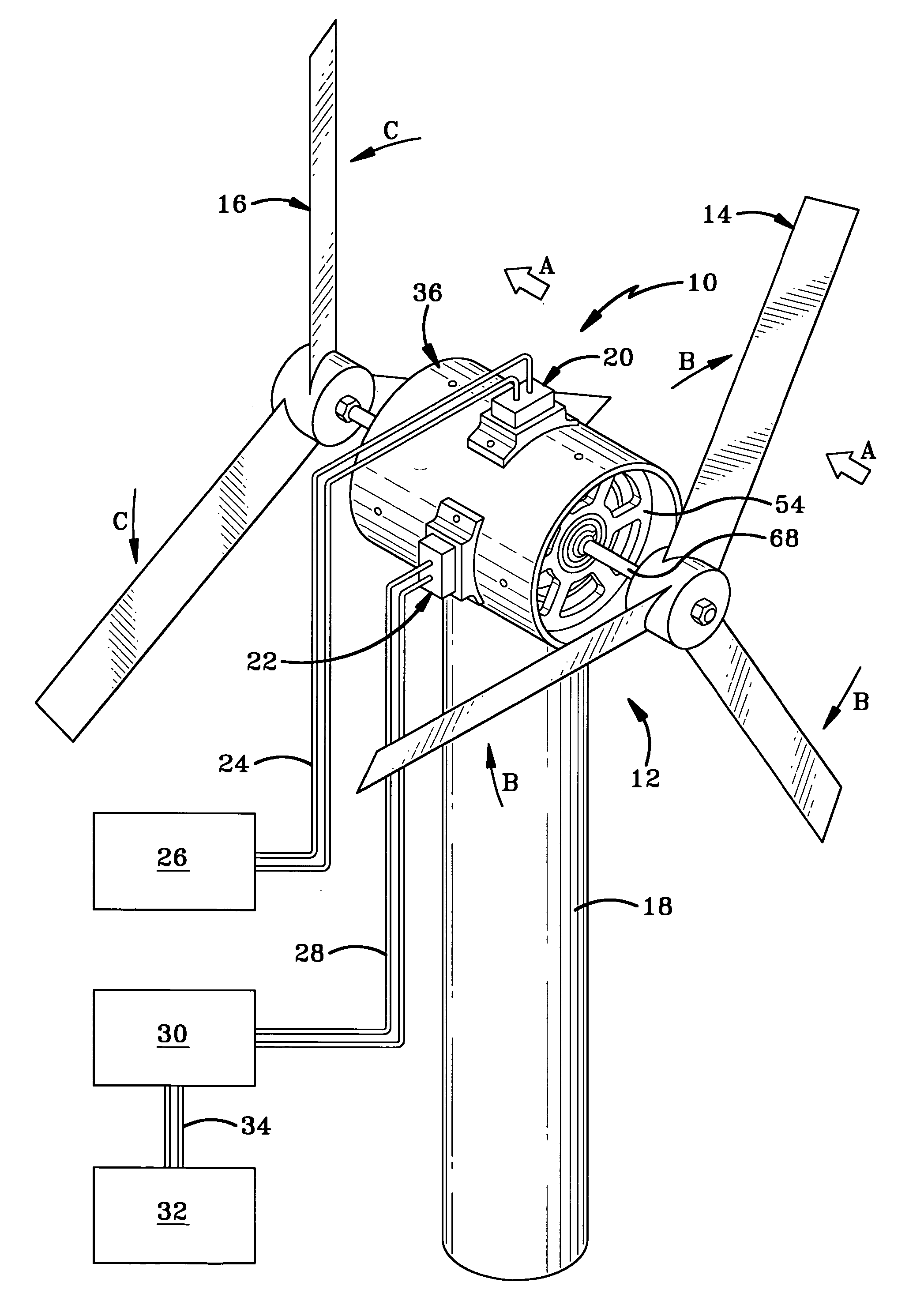

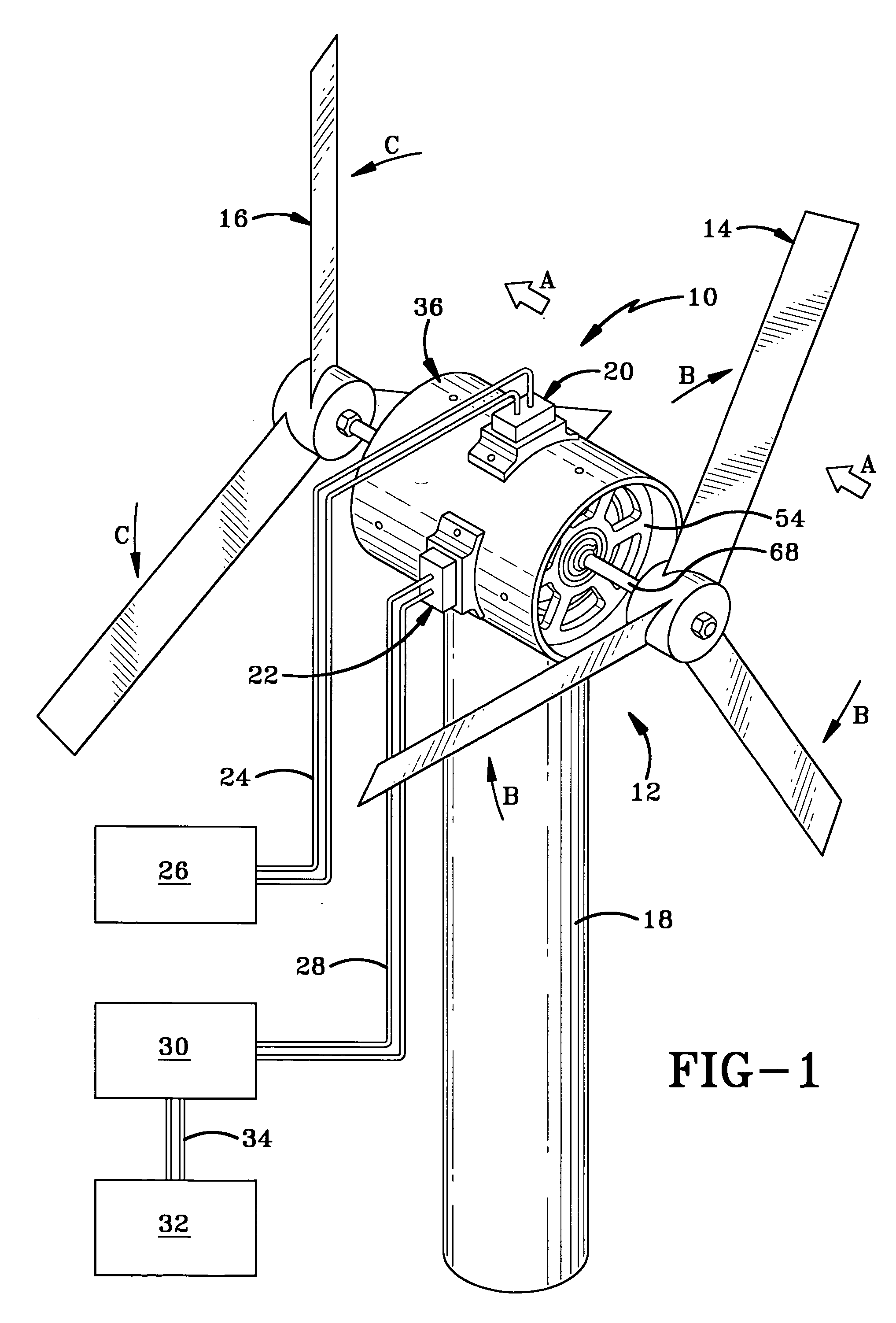

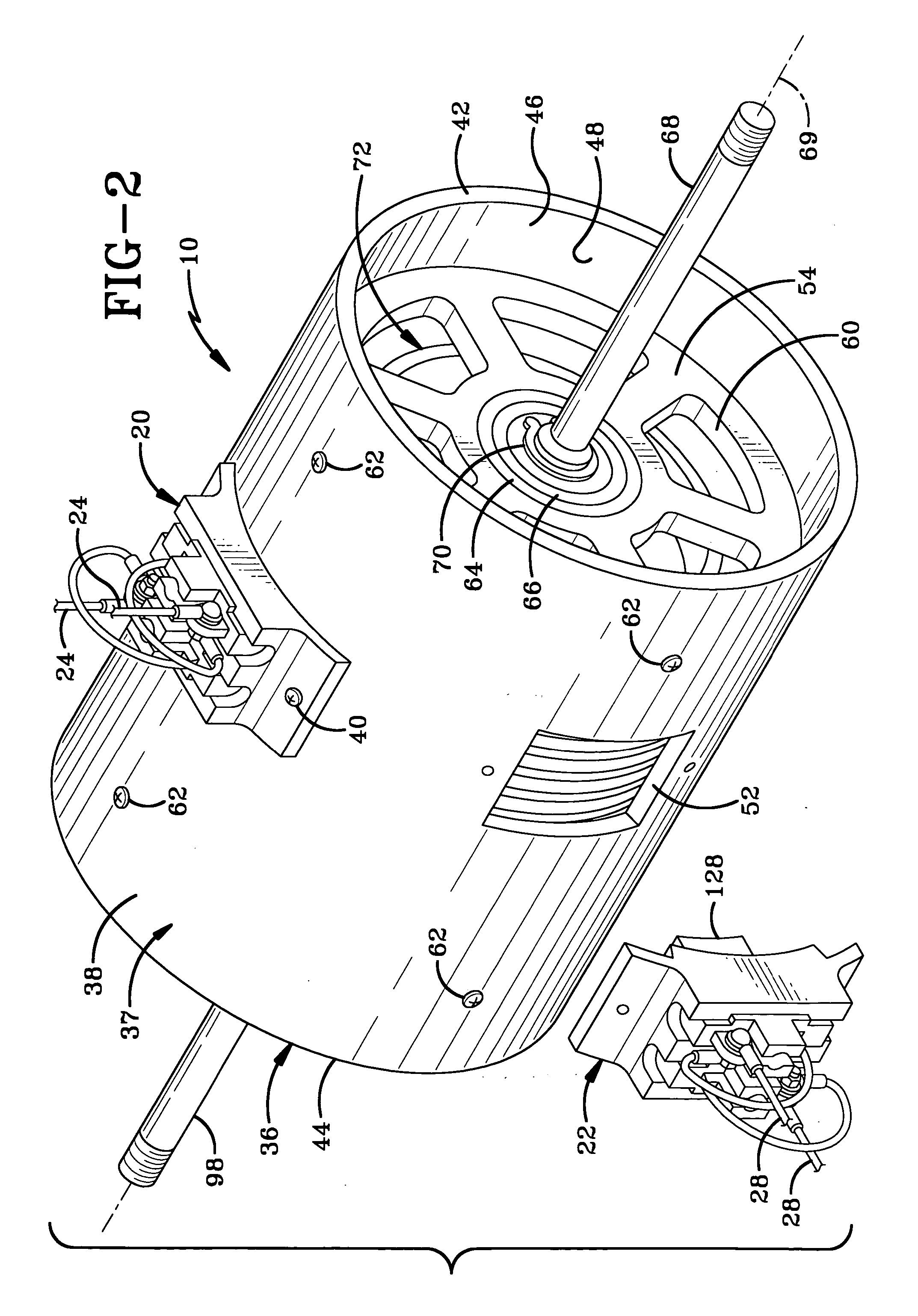

Counter rotating generator

A counter rotating generator has an outer housing including a cylindrical sidewall defining a pair of openings and a pair of circular mounting plates connected to the outer housing adjacent respective opposed ends thereof. A first shaft and an armature mounted thereon are rotatably mounted on one mounting plate. A second shaft and a field magnet mounted thereon via an inner housing is rotatably mounted on the other mounting plate in a direction opposite the armature. Slip rings are mounted on and encircle the inner housing. A pair of brush assemblies are mounted on the outer housing and extend respectively through the openings in sidewall thereof with brushes contacting the slip rings between and adjacent the inner housing and the outer housing sidewall. The large-diameter slip rings more quickly dissipate heat caused by frictional engagement of the brushes and slip rings, thus allowing the generator to operate at higher rates of revolution and higher temperatures.

Owner:FLORES PAUL JR

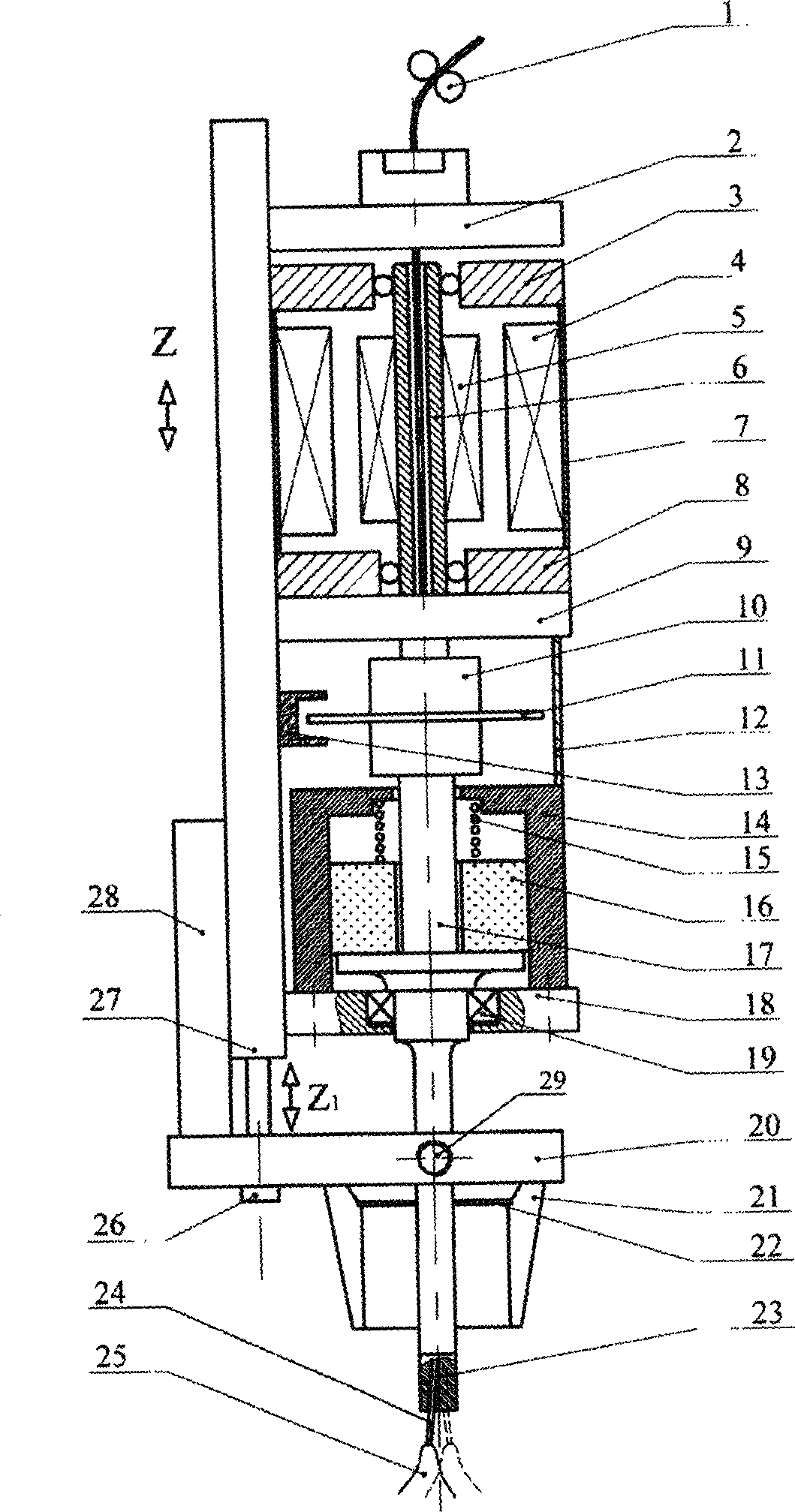

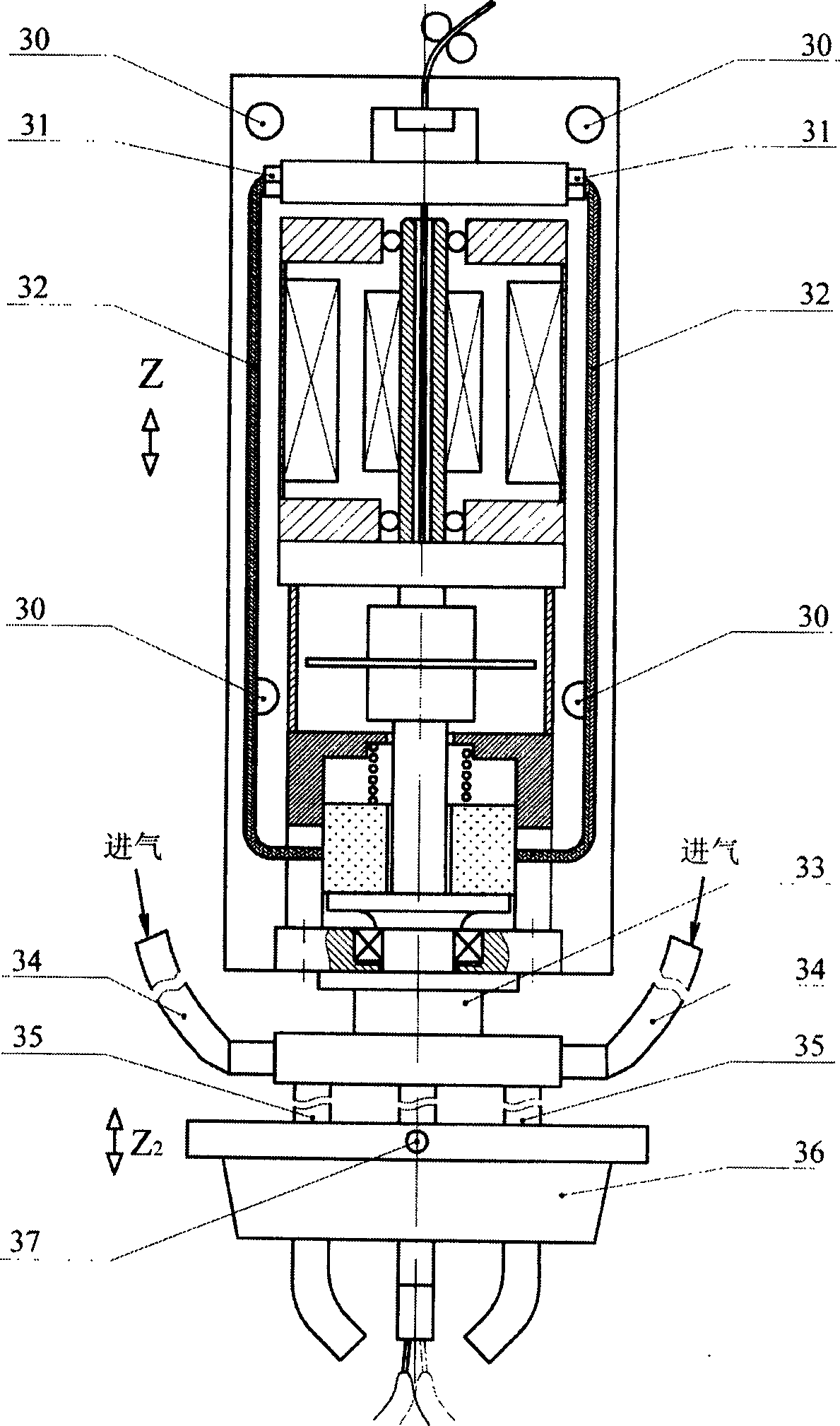

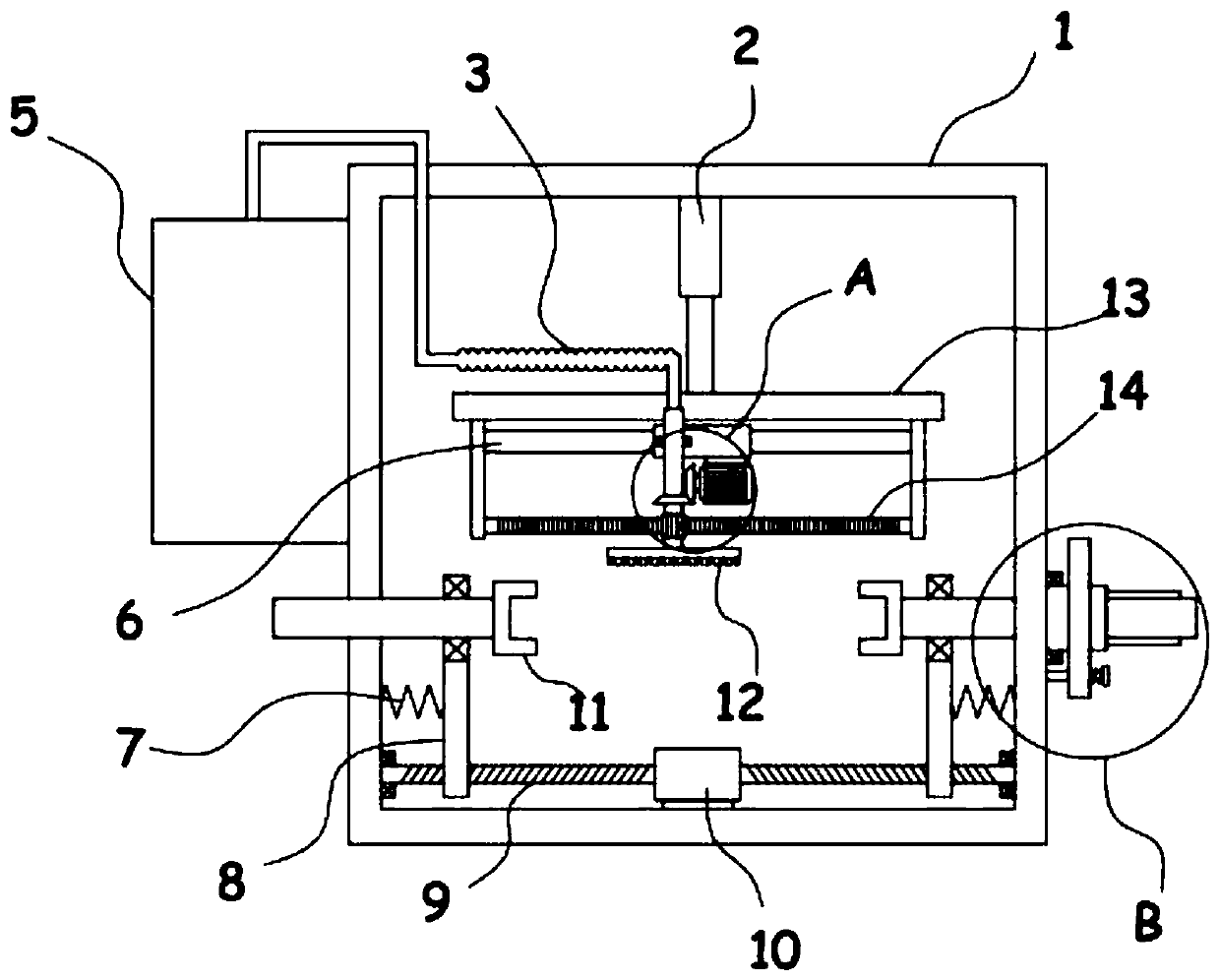

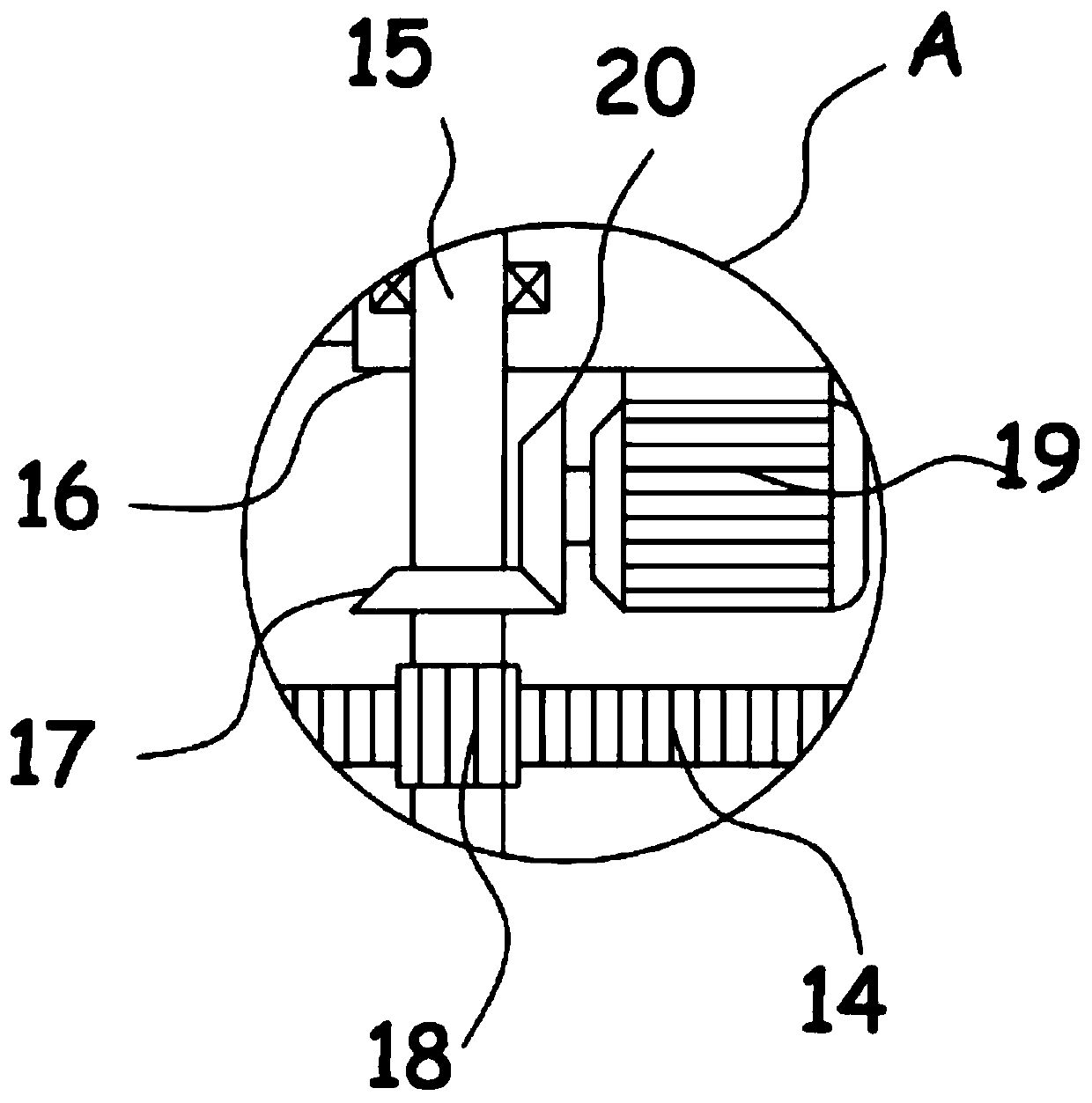

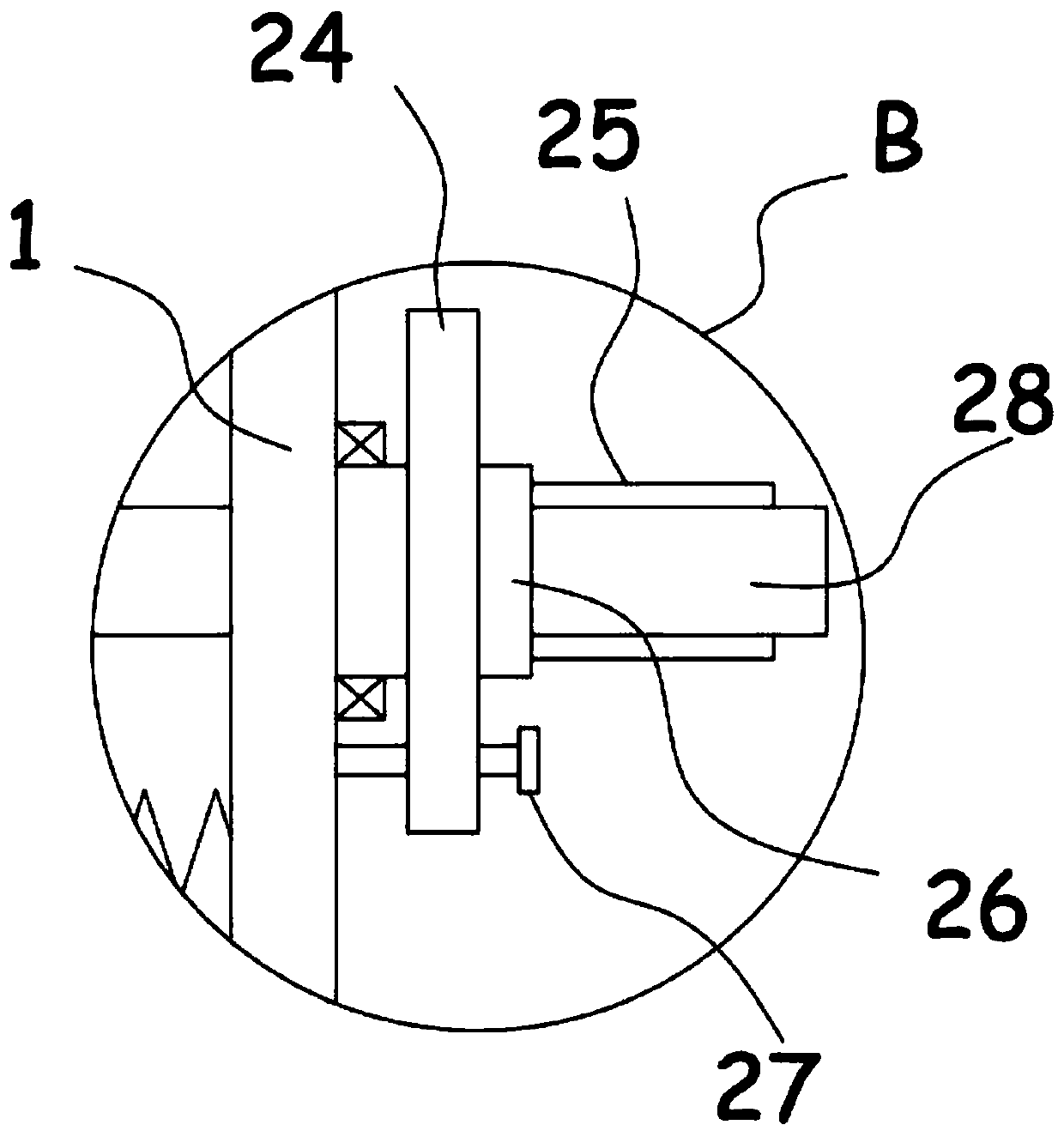

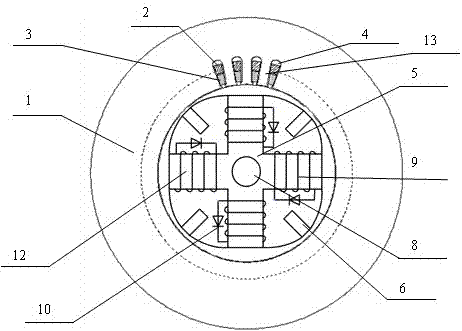

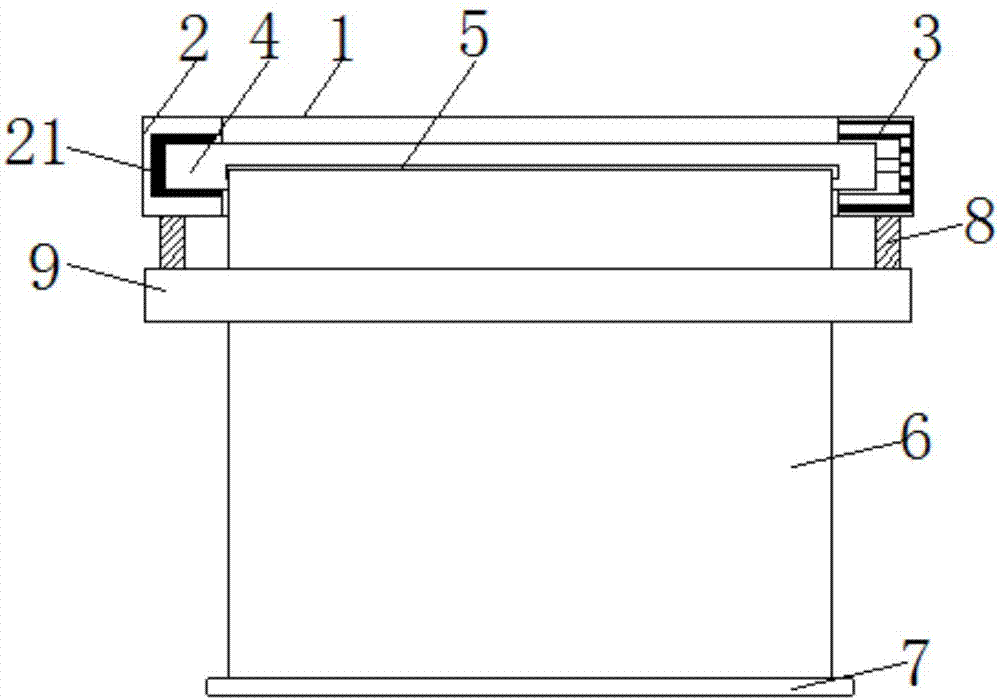

Rotary electric arc narrow gap welding method and device driven by hollow shaft motor

ActiveCN1657211AImprove welding qualityHigh working reliabilityArc welding apparatusGratingEngineering

A welding machine for welding in narrow gap by rotary arc is composed of a connector of welding electric cable, an electric motor unit with hollow shaft for feeding welding wire through it, an electric feeding unit of brush with close slide matching with the flange of electric conducting rod, a spray unit with eccentrical hole for generating the rotary arc at the front end of welding wire, and speed measuring unit consisting of raster and light coupler. Its straight nozzle can be inserted in the narrow gap to be welded.

Owner:JIANGSU UNIV OF SCI & TECH

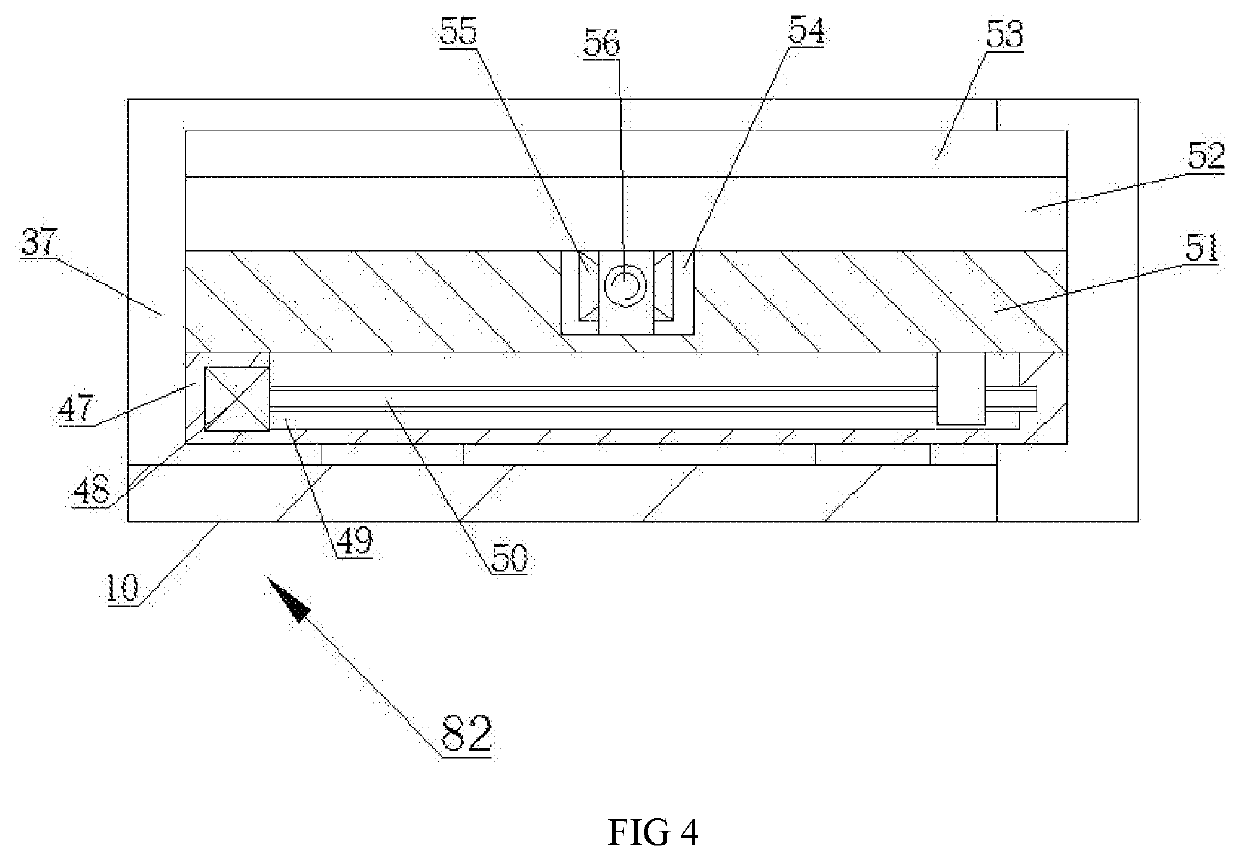

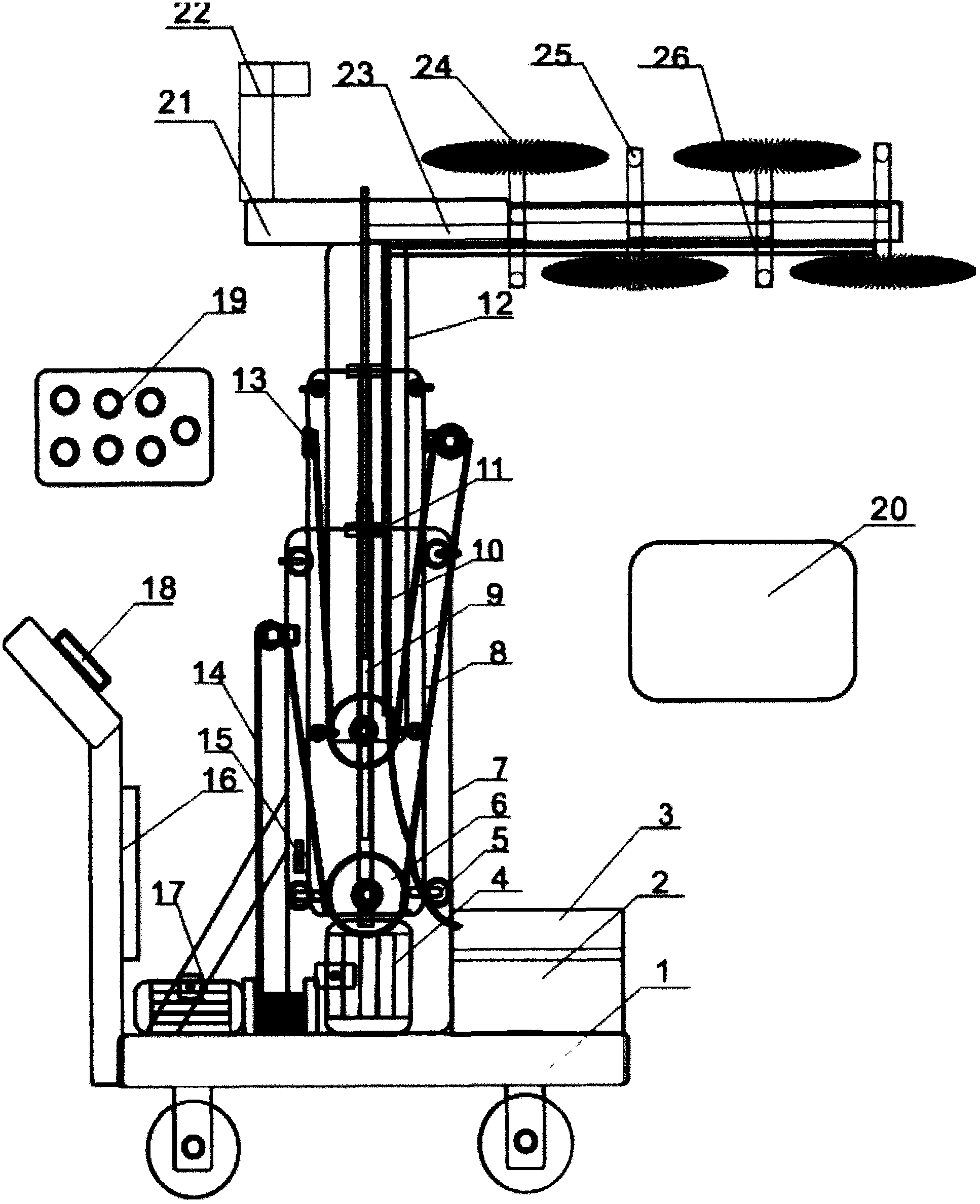

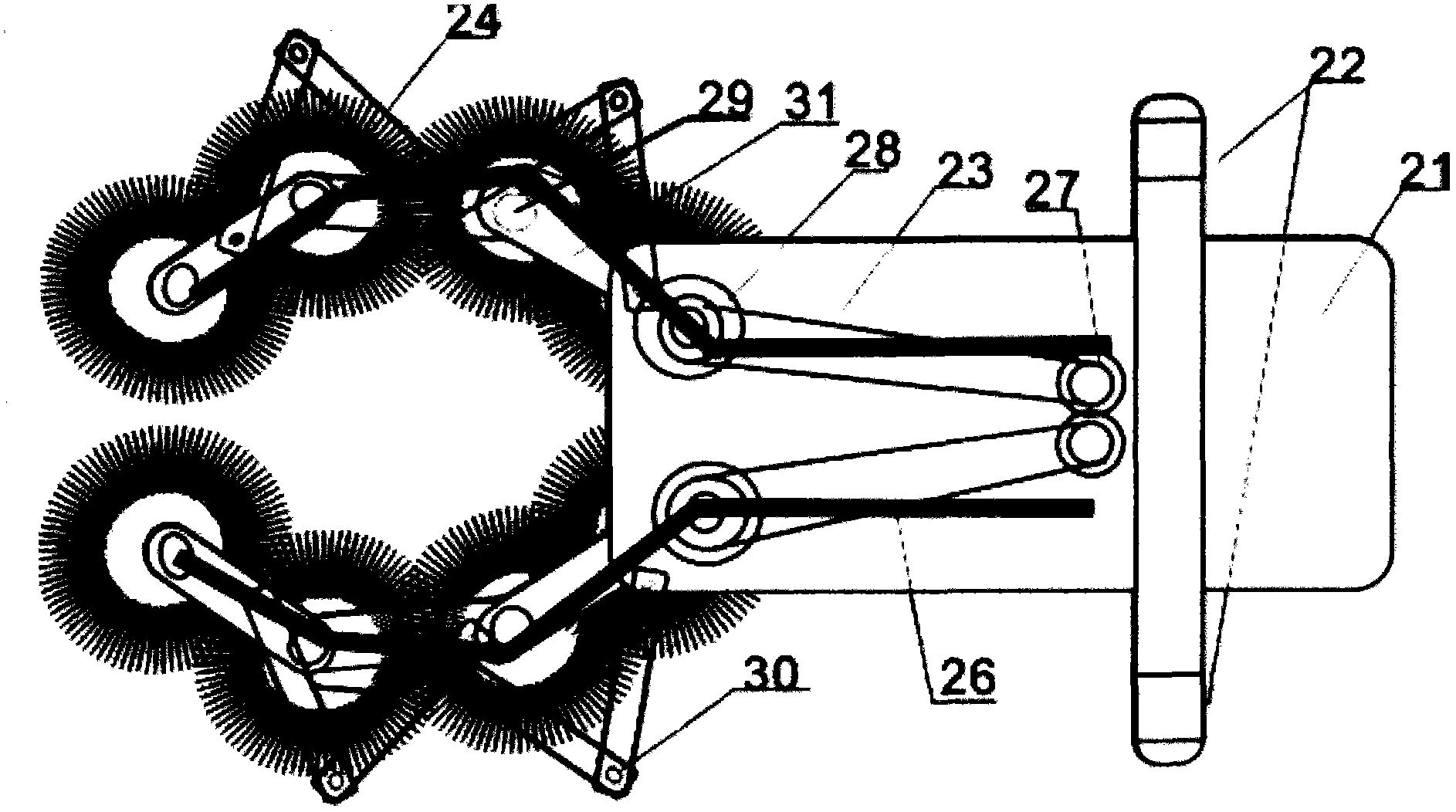

5000kv multifunctional full-automatic high-pressure electrified cleaning robot

InactiveCN103658113AEasy to cleanImprove efficiencyCleaning using toolsCleaning using liquidsRemote controlDisplay device

The invention relates to a 5000kV multifunctional full-automatic high-pressure electrified cleaning robot which is composed of a monitoring system, a cleaning system, a sweeping system and an operation system. The monitoring system transmits an operation image to a monitoring display through a wireless camera. The cleaning system is characterized in that a liquid box is connected with a high-pressure cleaning machine and a connection hose is connected with a cleaning nozzle. Cleaning liquid is sprayed onto an insulator. The sweeping system is characterized in that a power motor is connected with a three-grade square insulating telescopic shaft connected with a tong-shaped cleaning head. A brush is installed on the tong-shaped cleaning head. An insulating rope on a lifter is used for ascending and descending all grades of insulating frames on a three-grade insulating frame through a lifting pulley. The operation system is composed of a remote control operation plate, a manual operation plate and a remote control box. According to the 5000kV multifunctional full-automatic high-pressure electrified cleaning robot, three grades of ascending and descending are adopted, sweeping, cleaning and monitoring are integrated, the cleaning effect can be clearly seen and the cleaning effect can be recorded.

Owner:张刚平

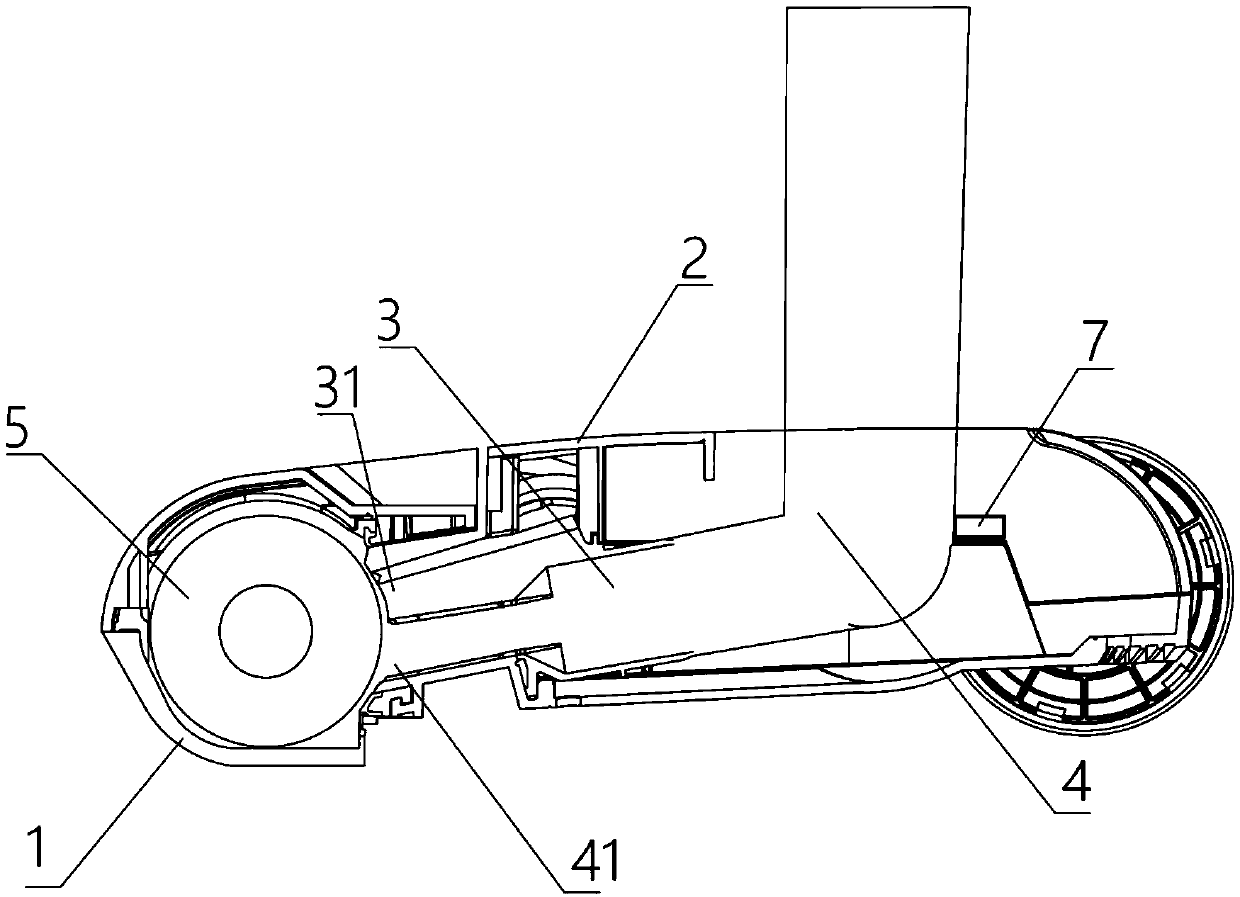

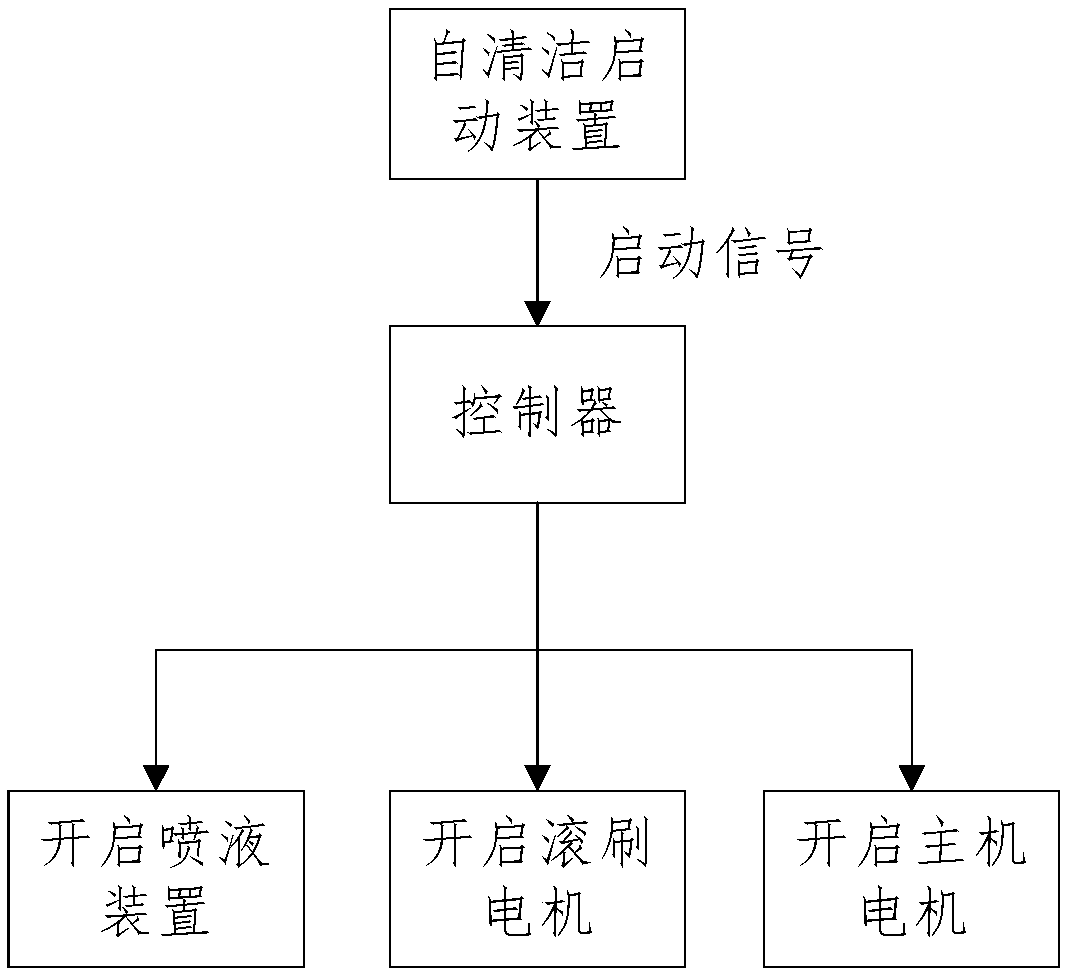

Surface cleaning machine and surface cleaning machine self-cleaning method

ActiveCN110946524AImprove experienceImprove operational convenienceCarpet cleanersFloor cleanersSurface cleaningControl engineering

The invention provides a surface cleaning machine and a self-cleaning method thereof. The surface cleaning machine comprises a controller, a liquid spraying device, a rolling brush, a rolling brush motor used for controlling the rolling brush, a suction device and a main machine motor used for controlling the suction device. The liquid spraying device, the rolling brush motor and the host motor are respectively connected with the controller; the controller starts a first cleaning mode according to a received starting signal, and in the first cleaning mode, the liquid spraying device is in a starting state and sprays liquid to the rolling brush, the rolling brush motor is in a starting state, the rolling brush rotates, the main machine motor is in the starting state, and liquid flowing through the rolling brush is sucked into the liquid suction pipeline. According to the surface cleaning machine, the convenience can be significantly improved, the cleaning effect is improved, and the user experience is improved.

Owner:TIANKE INTELLIGENT TECH CO LTD

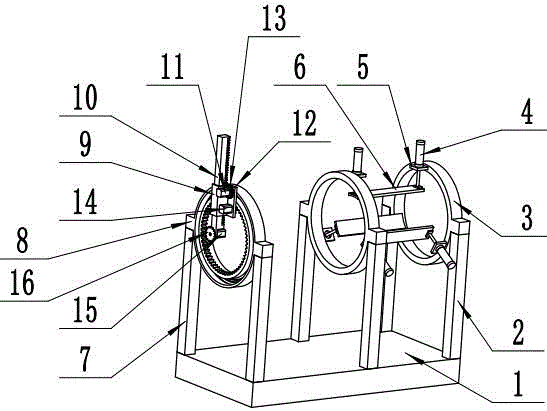

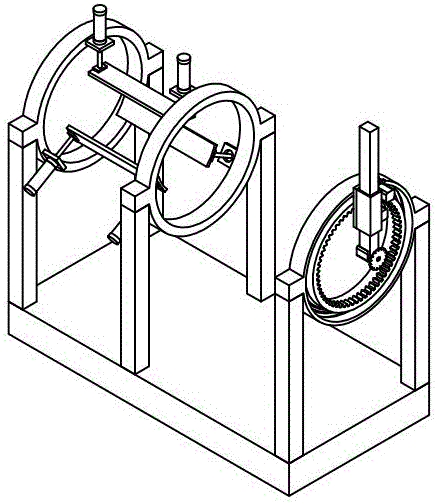

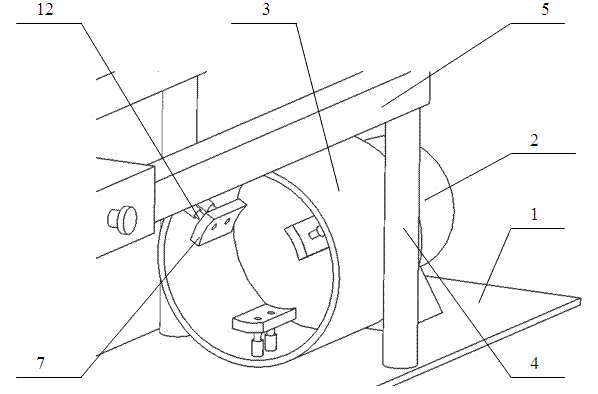

Outer-pipe circular cutting robot for steel pipe

ActiveCN106001735AImprove cutting efficiencyFast cutting speedTube shearing machinesShearing machine accessoriesGear wheelElectric machinery

The invention relates to an outer-pipe circular cutting robot for a steel pipe. The robot comprises a base, a steel pipe pressing plate, a circular cutting frame, an expansion link sleeve, an expansion link, an expansion link motor, a cutting mechanism fixing plate, a rotary motor, a cutting blade, an electric brush, an expansion link rack and an expansion link cutting motor fixing frame, wherein steel pipe frame stand columns of the expansion link motor fixing plate is fixedly arranged on the base, a steel pipe fixing sleeve is fixedly arranged on the steel pipe frame stand columns, the circular cutting frame is fixedly arranged on circular cutting frame stand columns, and the circular cutting frame stand columns are fixedly arranged on the base; the expansion link is arranged on the expansion link sleeve in a sliding way, the expansion link motor is fixedly arranged on the expansion link motor fixing plate, a stretching motor gear is fixedly arranged on an expansion link motor shaft, and the stretching motor gear is meshed with the expansion link rack; and the cutting motor is fixedly arranged on the expansion link cutting motor fixing frame, and the cutting blade is fixedly arranged on the cutting motor shaft. The robot can improve the steel pipe cutting efficiency, and is high in cutting speed, trim in notches and good in effect.

Owner:青岛昊坤机械制造有限公司

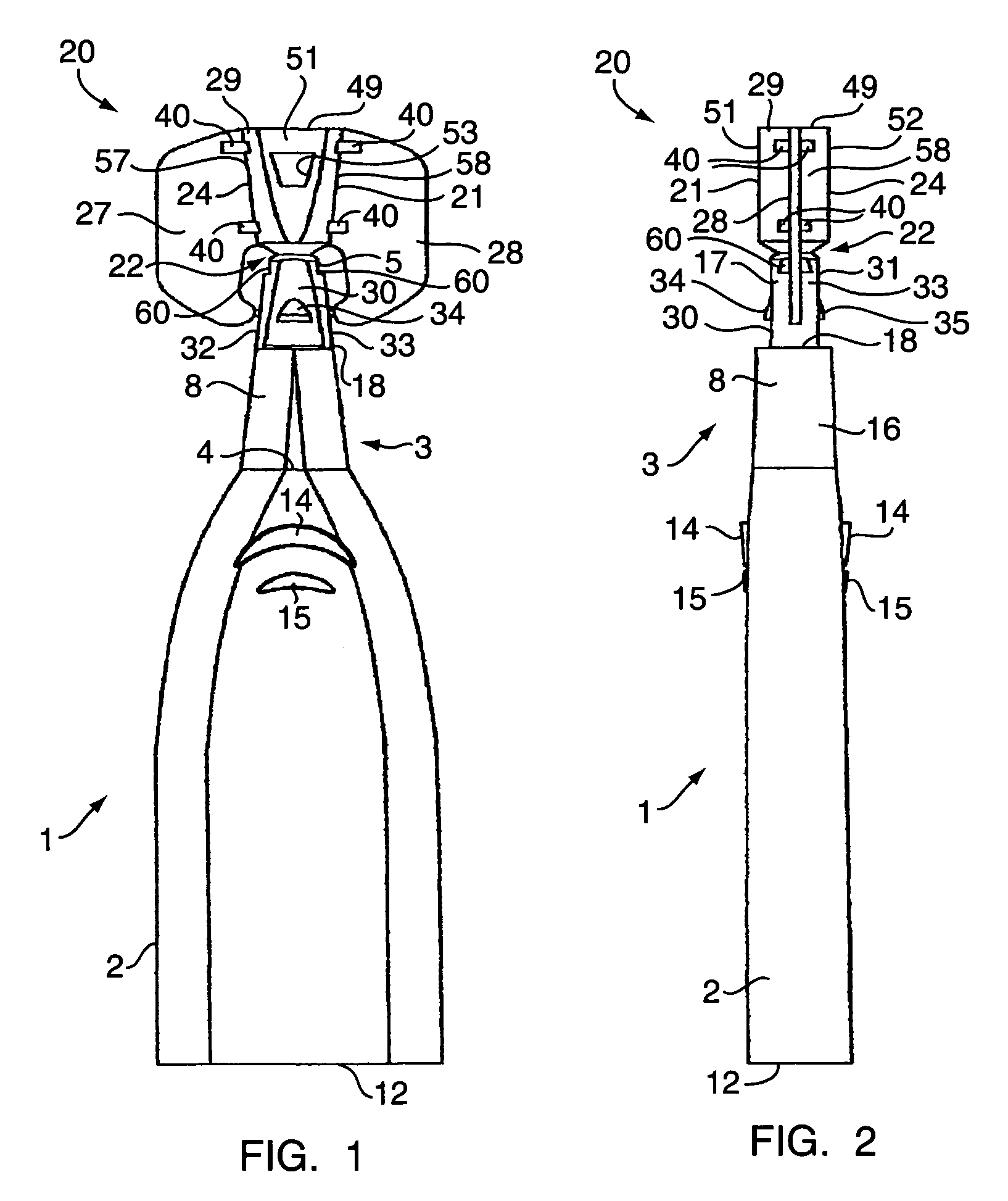

Nozzle assembly incorporating a molded flow through brush applicator and a reusable break-off cap, a container having a nozzle assembly and packaging therefor

A nozzle assembly (3, 20) with a reusable break-off cap (20) for dispensing a product from a container (1). On a dispensing end (5) of the nozzle (3) a break-off cap (20) is integrally formed thereon and closes off the dispensing end (5) of the nozzle (3). The break-off cap (20) is removable by breaking a frangible connection (22) between the nozzle (3) and the break-off cap (20). Removing the break-off cap opens the dispensing end (5) of the nozzle (3) thereby allowing product to be dispensed through the nozzle (3). The break-off cap (20) removed from the nozzle (3) can then be re-engaged with the nozzle (3) to close off the dispensing end (5) thereby preventing further product from being dispensed. The cap can be attached to or removed from the nozzle (3) as often as a user requires.

Owner:HENKEL IP & HOLDING GMBH

Vitreous carbon composite and method of making and using same

A reinforced vitreous carbon composite suitable for use in the formation of wear-resistant assemblies, such as joint prosthetic devices, bearings, current collectors, sealing components, brake linings, electrical motor brushes, and other tribological products. The reinforced composite is formed by impregnating a metal reinforcement structure with a furfuryl alcohol resin, and polymerizing the resin while thermally managing the polymerization process, to produce a poly(furfuryl) alcohol continuous phase that is isotropic, homogeneous and essentially completely void-free, e.g., in a bulk composite form having dimensions greater than 25 millimeters in each of the x, y and z directions thereof.

Owner:CARBON CERAMICS CO LLC

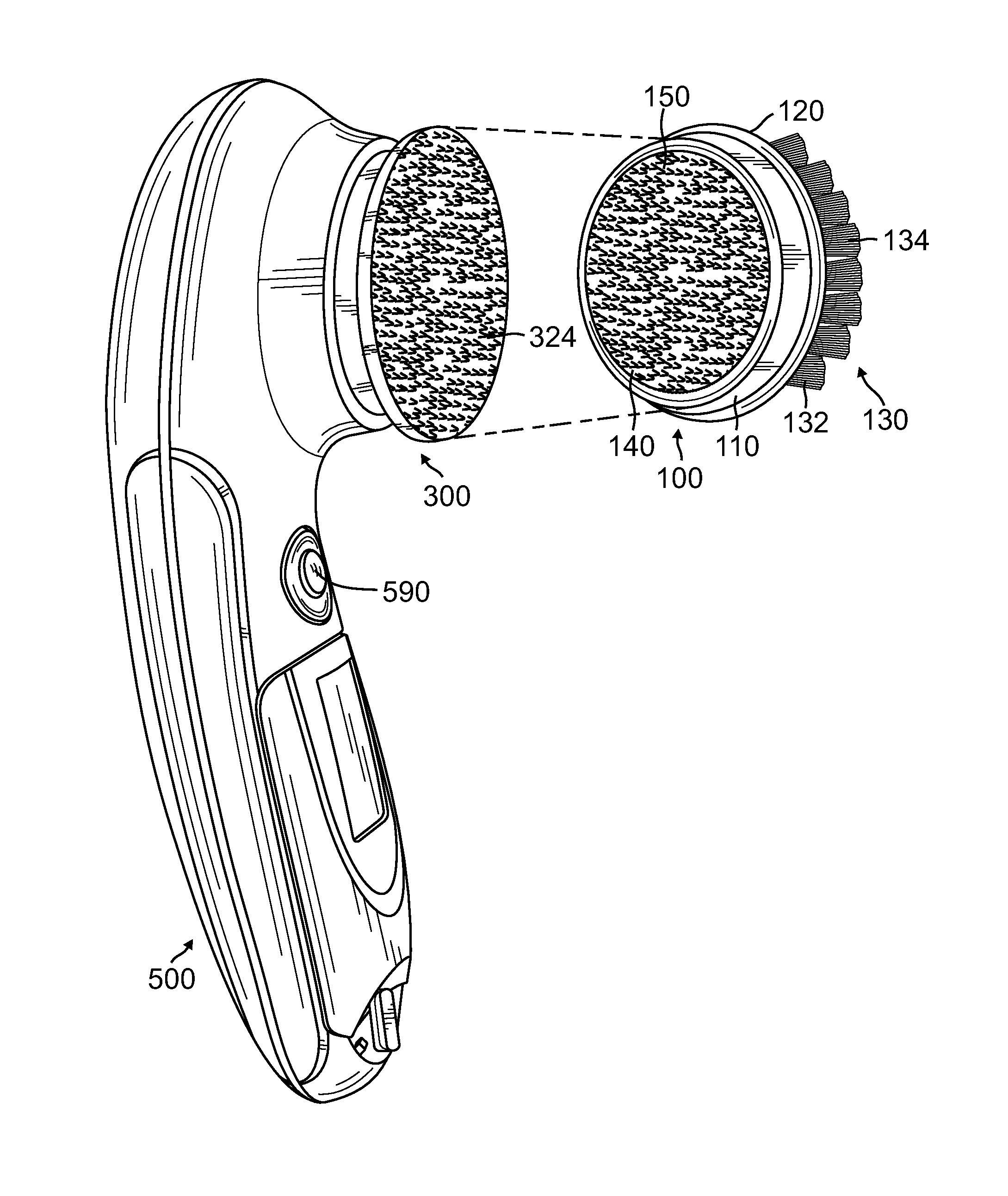

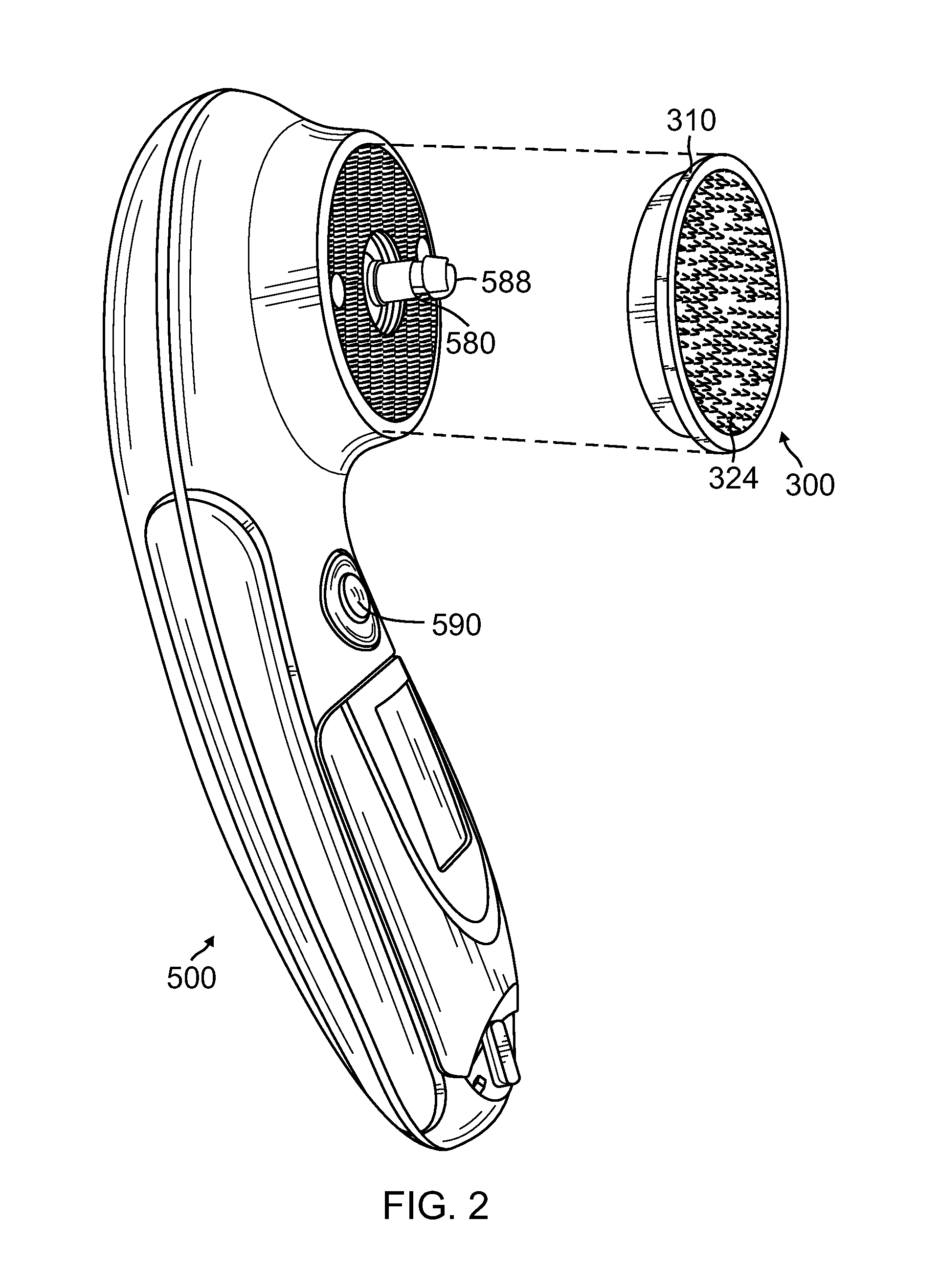

Rotating handheld motorized hand-piece including combination interchangeable microdermabrasion brush head, interchangeable heads having a latex sponge, and hook and loop fasteners to removably retain cleaning pads

A handheld apparatus including (a) a motorized hand-piece including a mechanical rotatable coupling shaft which is caused to rotate so that it imparts a rotating motion to the coupling shaft; (b) an interface cup member which includes a body with an exterior surface having hook and loop fasteners thereon and a lower surface with an interface opening which is affixed to the coupling member of the mechanical rotatable shaft; and (c) the hand-piece individually retaining a multiplicity of different interchangeable components which are used for different purposes, each different component affixed on one surface to the hook and loop fasteners of the interface cup and which rotate when the motorized hand piece is energized and causes the interface cup to rotate.

Owner:DE SOLEIL

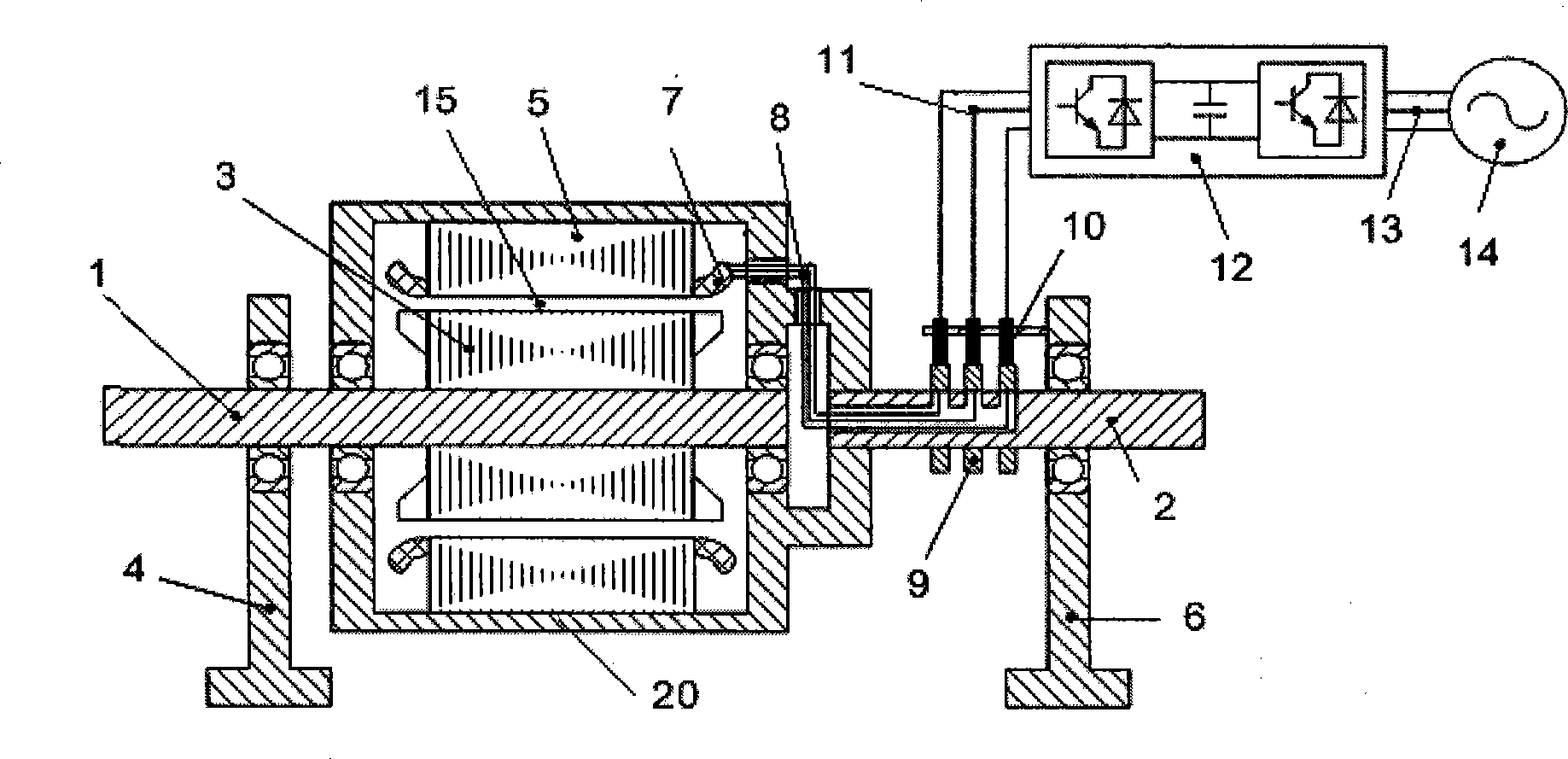

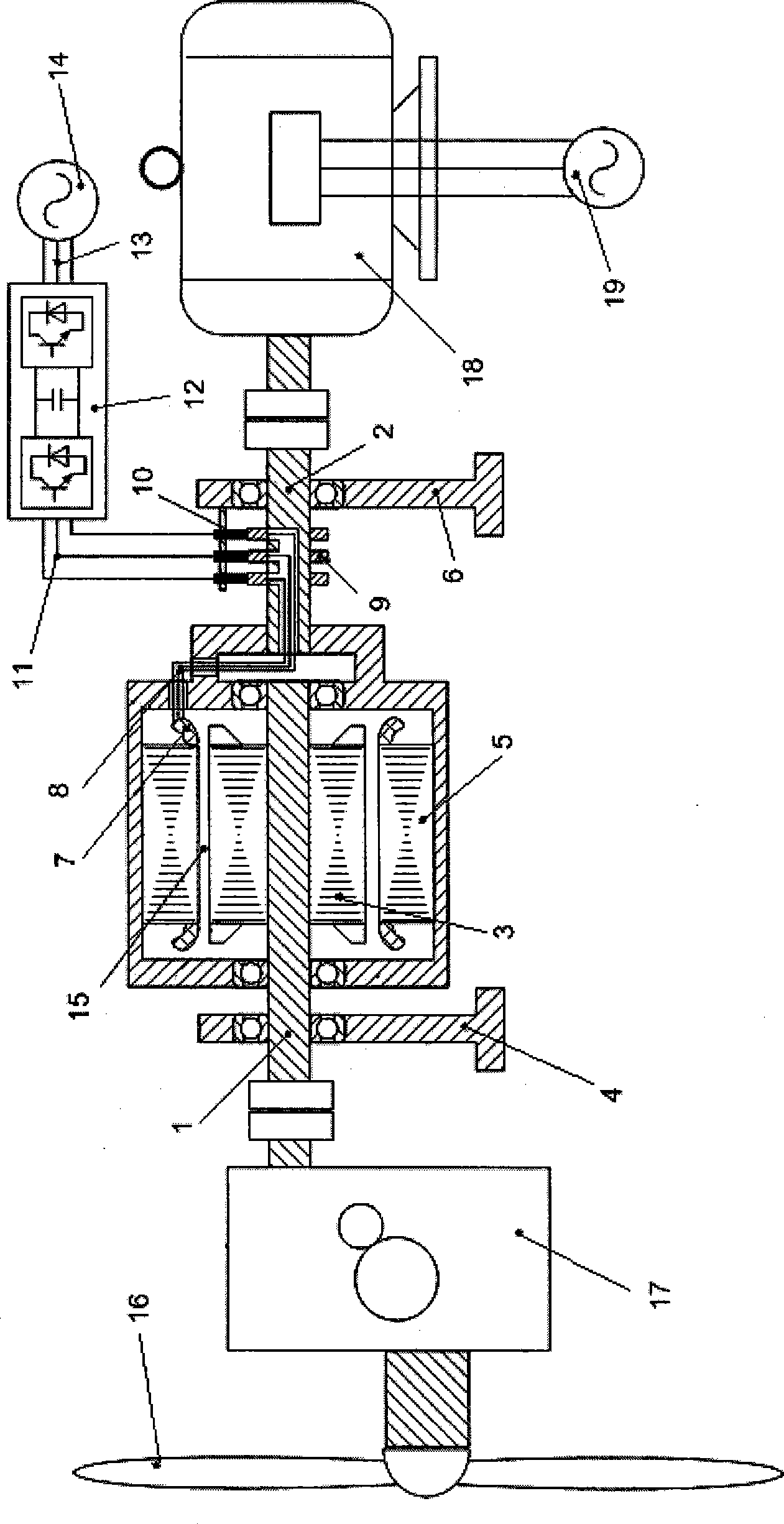

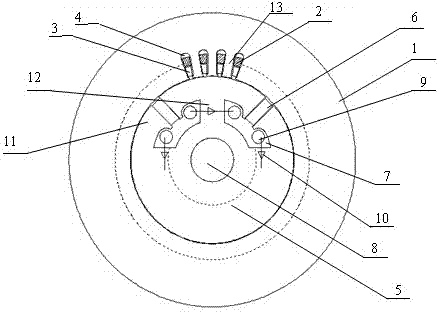

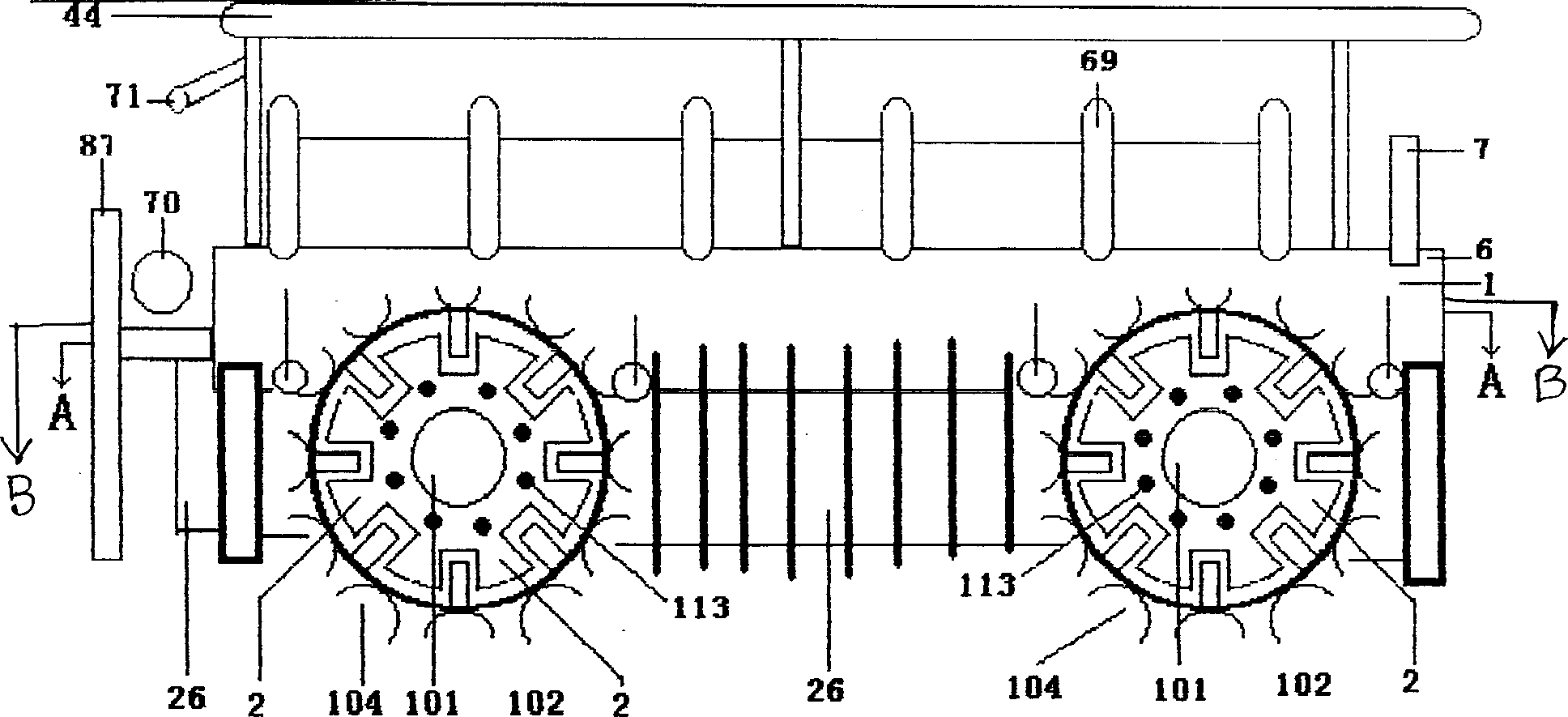

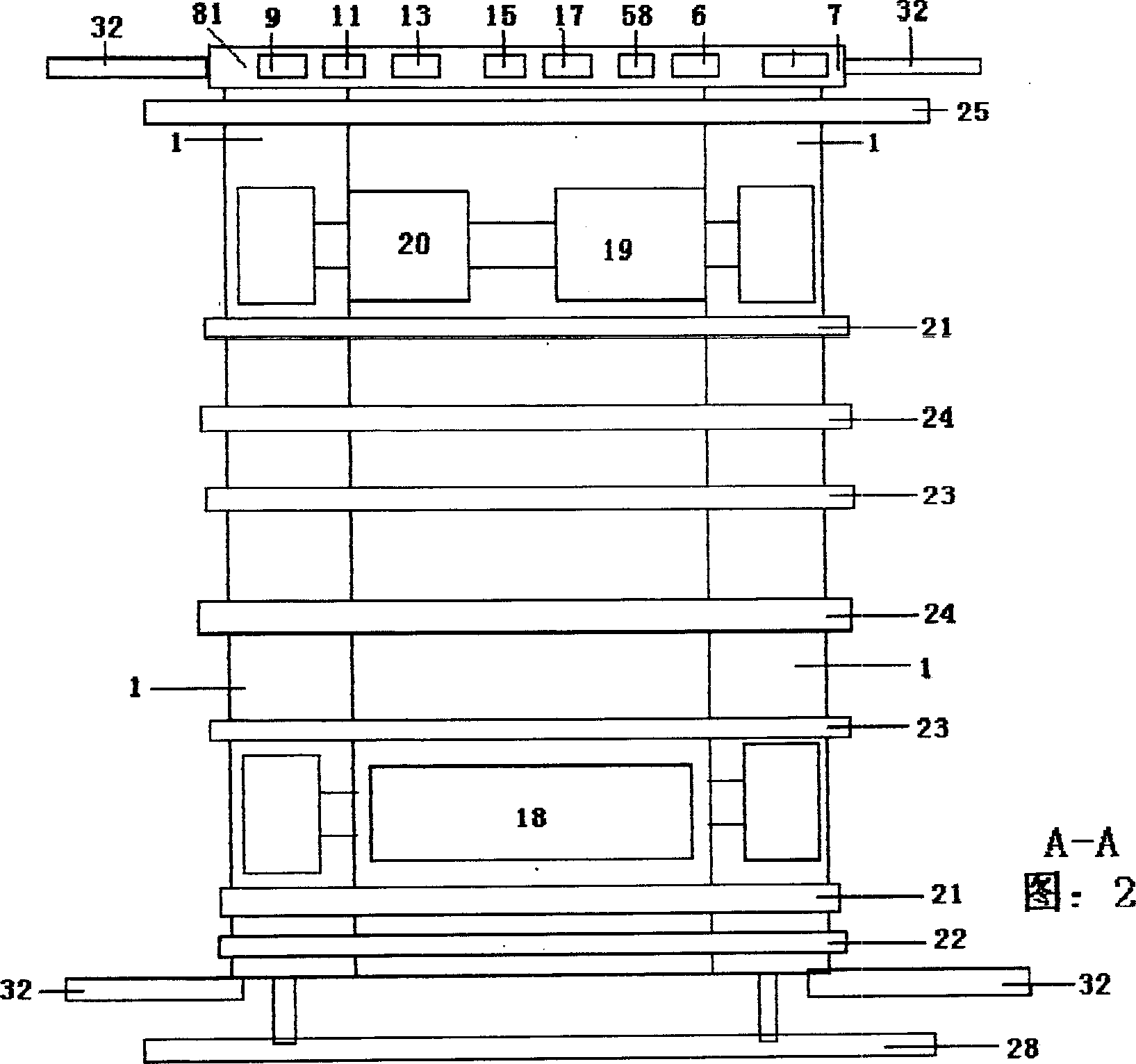

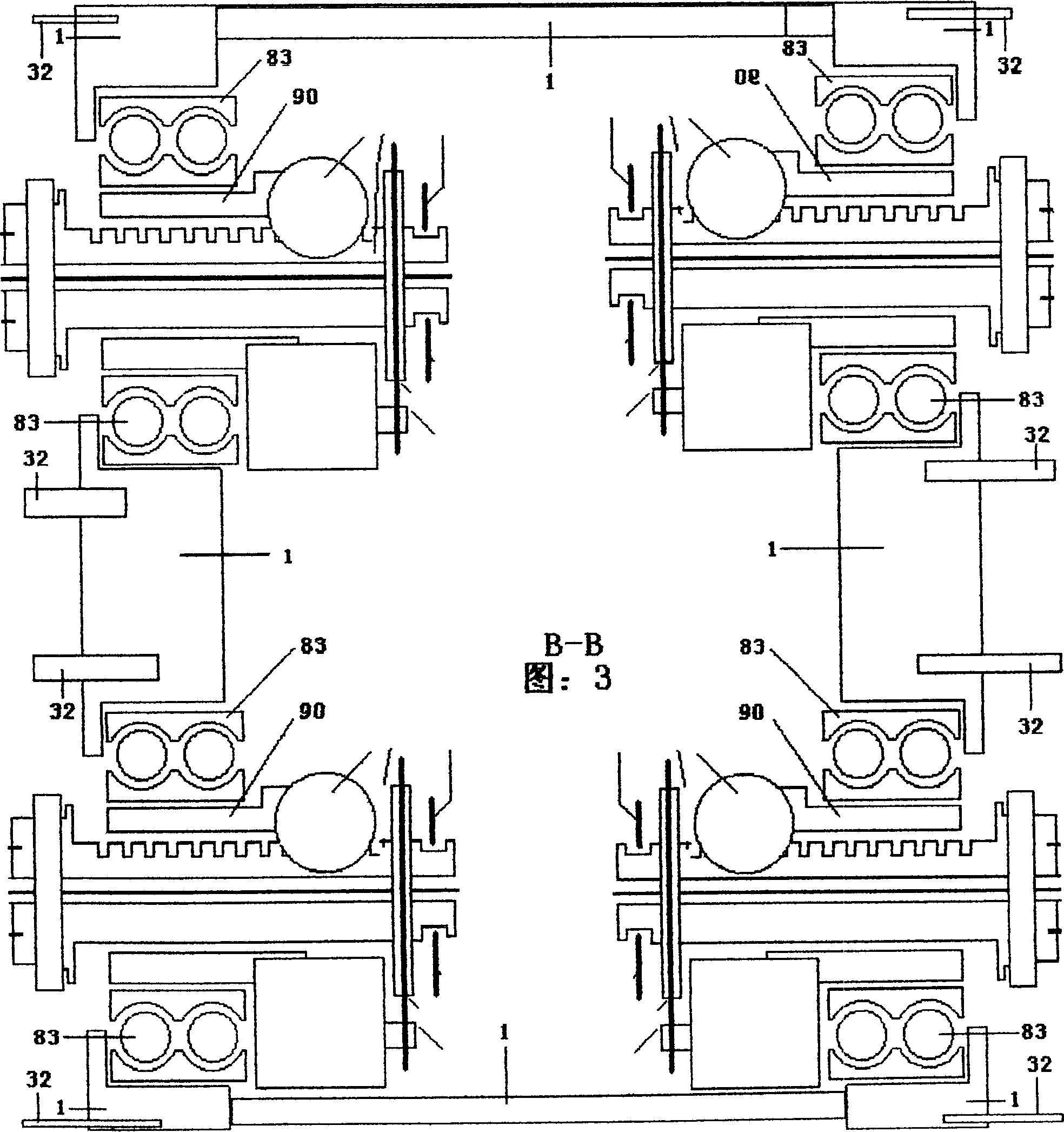

Variable-frequency control electromagnetic torsion coupler and use thereof

InactiveCN101465592AHard mechanical propertiesRealize stepless speed regulationDynamo-electric gearsDynamo-electric gear controlFrequency changerAlternating current

The invention relates to a variable-frequency speed-regulating magnetic torque coupler which is characterized in that: the coupler comprises a shell, and an inner rotor mechanical axis and an outer rotor mechanical axis are arranged in the shell; the inner rotor mechanical axis is connected with an inner rotor which is supported on a static bearing frame of the inner rotor, and the outer rotor mechanical axis is connected with an outer rotor which is supported on the static bearing frame of the outer rotor; an electromagnetic coupling working air gap is formed between the inner rotor and the outer rotor; the outer rotor is internally provided with an armature winding which is connected with a group of three-phase static electric brushes by three drainage slipping rings; the three-phase static electric brush is connected with the output end of a frequency converter, and the input end of the frequency converter is connected with a three-phase alternating-current electric fence. As a variable-frequency speed-regulating technology is introduced in a simple electric transmission system, non-contact torque transmission and stepless speed regulation between two rotary mechanical shafts can be realized by utilizing the principle of variable-frequency motors. The variable-frequency speed-regulating magnetic torque coupler can be widely applied to transmission systems.

Owner:TSINGHUA UNIV

Coating spraying mechanical device for building

ActiveCN110653125ARealize double-sided brushingImprove paint brushing efficiencyLiquid surface applicatorsLiquid spraying apparatusGear wheelArchitectural engineering

The invention discloses a coating spraying mechanical device for a building, and relates to the technical field of coating spraying The coating spraying mechanical device comprises a fixing frame anda coating box, wherein a clamping mechanism used for fixing a decorative plate is connected to the fixing frame through a driving mechanism, a hanging bracket is hung on the fixing frame through an electric push rod, a brush coating mechanism communicating with the coating box is arranged at the bottom of the hanging bracket, and a turnover mechanism used for driving the decorative plate to rotateis arranged on the fixing frame. The building decoration plate is clamped and fixed through the arranged clamping mechanism, the decorative plate is sprayed and rotated through the arranged brush coating mechanism, a rack and a gear are arranged in a threaded mode, the transverse position of the brush coating mechanism is moved, different positions on the decorative plate can be fully and comprehensively brushed and coated, the arranged turnover mechanism can turn over the decorative plate, double-sided brush coating of the decorative plate is achieved, and the paint brushing efficiency of the decorative plate is greatly improved.

Owner:江西高雅科技新材料有限公司

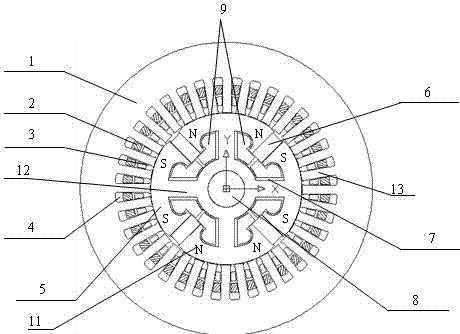

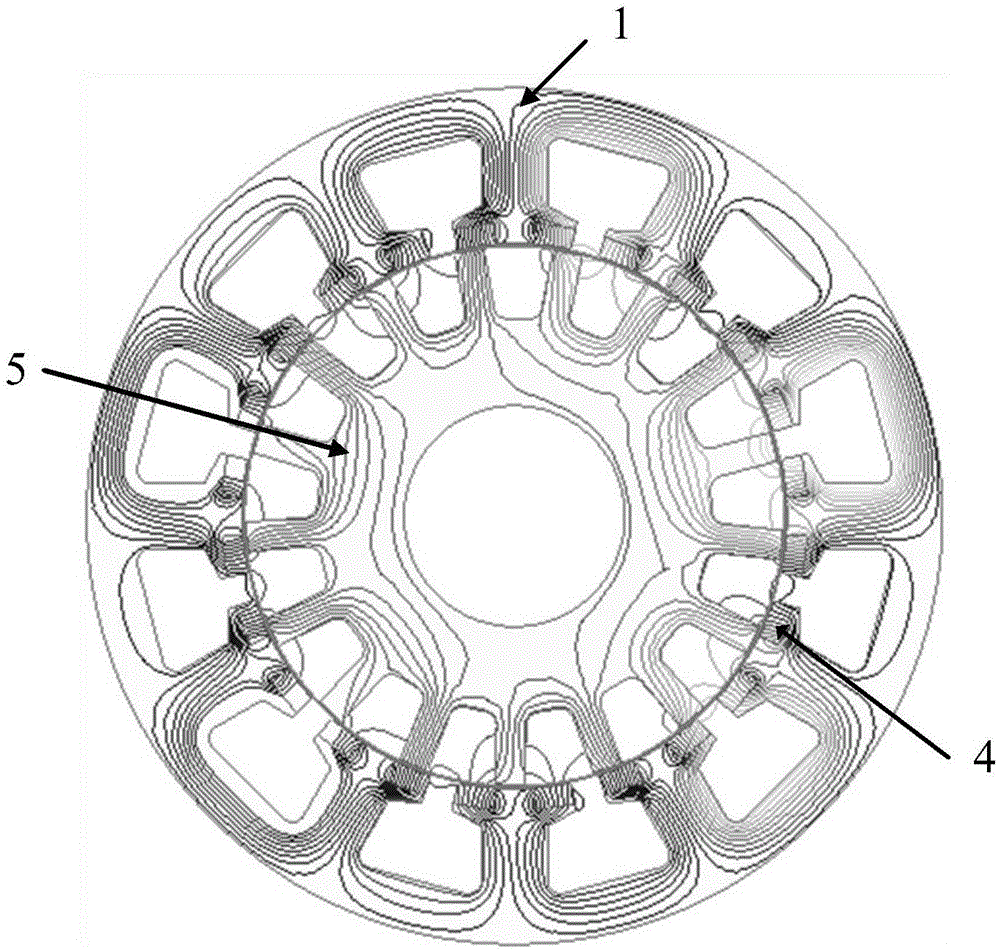

Induction excitation type mixed excitation brushless synchronous motor

InactiveCN103208893ARealize brushless excitationImprove power densityMagnetic circuit rotating partsMagnetic circuit stationary partsSynchronous motorEngineering

The invention relates to an induction excitation type mixed excitation brushless synchronous motor which structurally comprises a stator and a rotor. The stator comprises a stator core, an armature stator winding and a stator excitation winding, wherein the armature stator winding and the stator excitation winding are arranged in a stator groove. The rotor comprises a rotor core, permanent magnets, a plurality of rotor excitation windings, rectifier diodes and a rotary shaft, wherein the plurality of rotor excitation windings are independent from one another and short-circuited through the diodes respectively. The permanent magnets are arranged on the rotor, and the number of the permanent magnets can be determined as various forms according to an excitation requirement. When direct current is led into the stator excitation winding, constant magnetic fields are built in air gaps. When the rotary shaft rotates at the synchronous speed, excitation current of pulse vibration is inducted on the rotor windings, the size of air gap magnetic fields is changed, and output voltage of the motor is controlled by changing current intensity in the stator excitation winding. The induction excitation type mixed excitation brushless synchronous motor has the advantage of being free of brush slip ring, requiring no exciters, being simple in structure and achieving brushless excitation of the rotor excitation mixed excitation motor.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

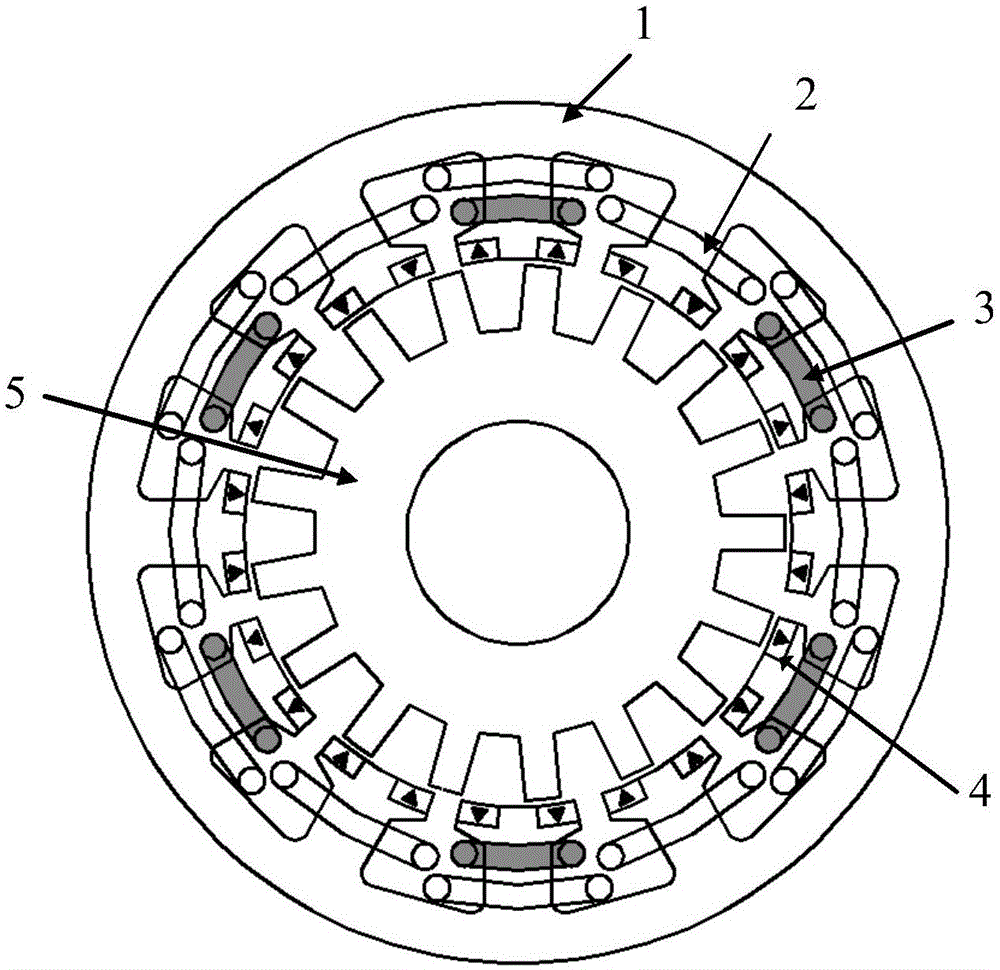

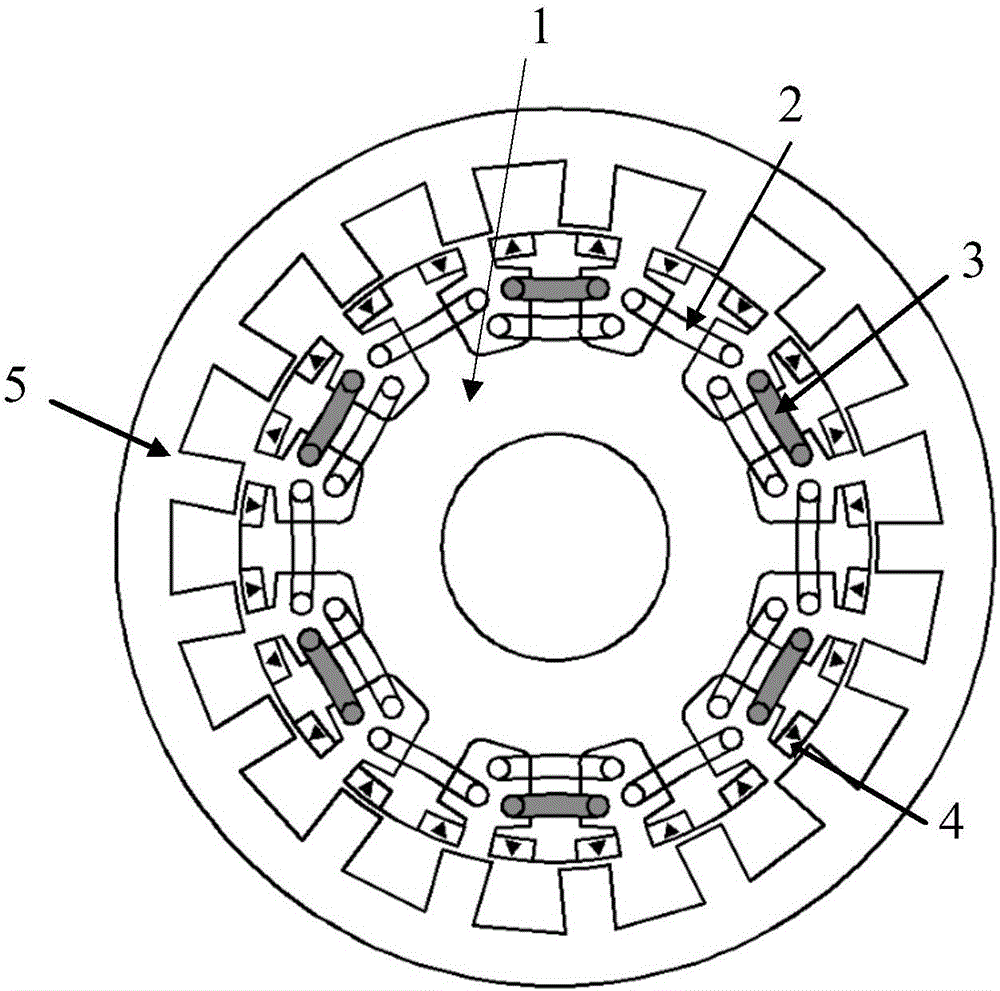

Hybrid excitation Motor

ActiveCN106385153AImprove reliabilityStrong magnetic adjustment abilitySynchronous machine detailsElectric machinesLow speedElectric machine

The present invention discloses a hybrid excitation motor. The comprises a stator and a rotor which are coaxially sleeved with each other; grooves are formed in the inner wall of the stator which sleeves the rotor or the rotor which sleeves the stator along the circumferential direction of the inner wall; grooves are formed in the outer surface of the rotor which is sleeved with the stator or the stator which is sleeved with the rotor; a direct-current excitation winding and an alternating-current armature winding are arranged in the stator grooves; each stator tooth is provided with protrusions which protrude out from the corresponding groove and are located at side surfaces of two sides of the groove; each protrusion is provided with a permanent magnet; the polarities of the two permanent magnets arranged at the two side surfaces of each stator tooth are the same; and the polarities of the permanent magnets of two adjacent teeth are opposite. When the motor of the invention operates at a low speed, current in the direct-current winding is positive, a total excitation magnetic field can be enhanced, and the overload capacity of the motor can be improved; and when the motor operates at a high speed, the current in the direct-current winding is negative, the total magnetic field can be weakened, and the flux weakening ability of the motor can be improved. The excitation motor of the invention has the advantages of low risk of irreversible demagnetization of the permanent magnets, small magnetic resistance of excitation magnetic fields, strong flux adjustment ability of the excitation windings and reliable and stable operation. According to the motor of the invention, slip rings and electric brushes are not needed, and therefore, problems such as the problem of sparks can be avoided.

Owner:HUAZHONG UNIV OF SCI & TECH

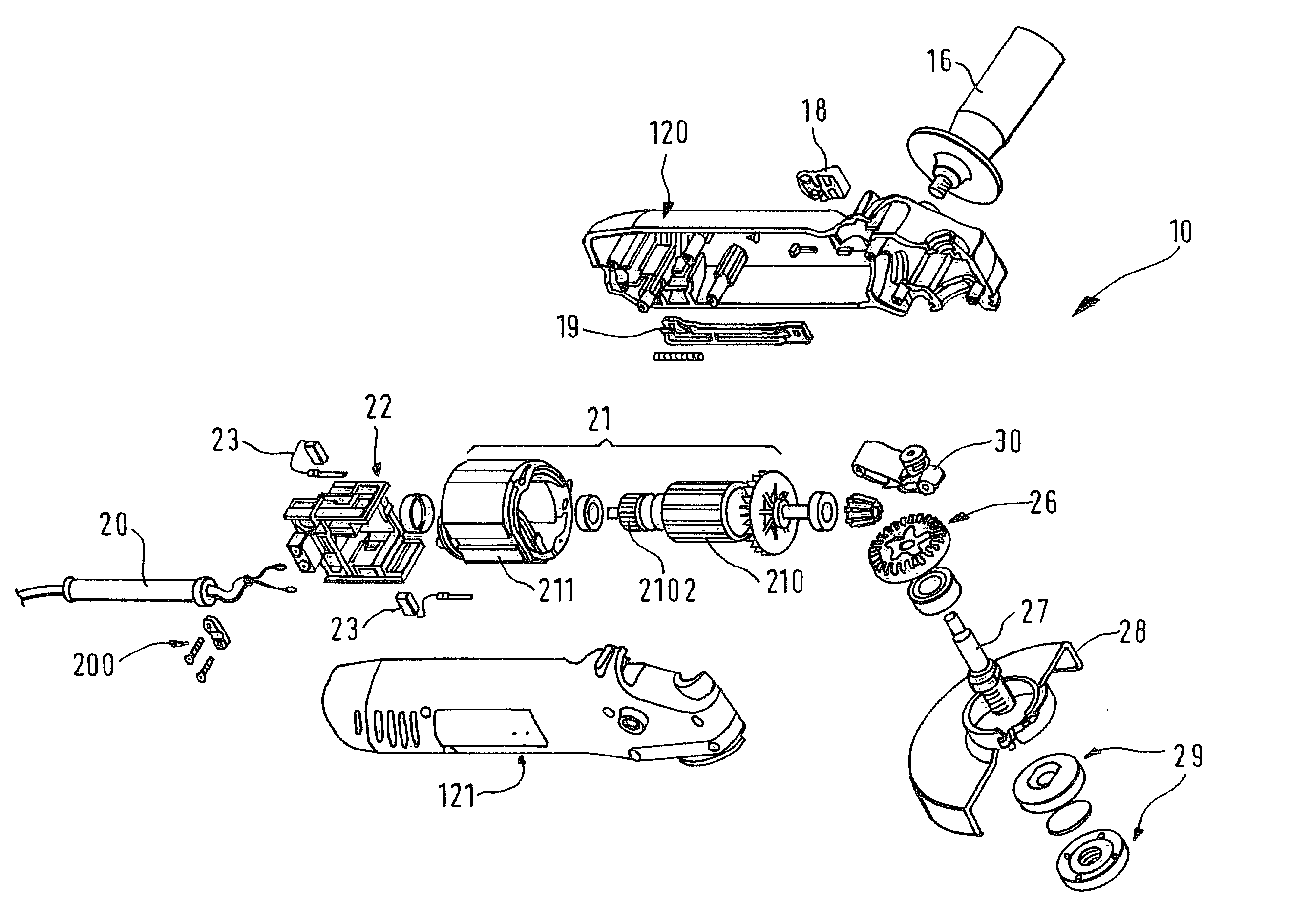

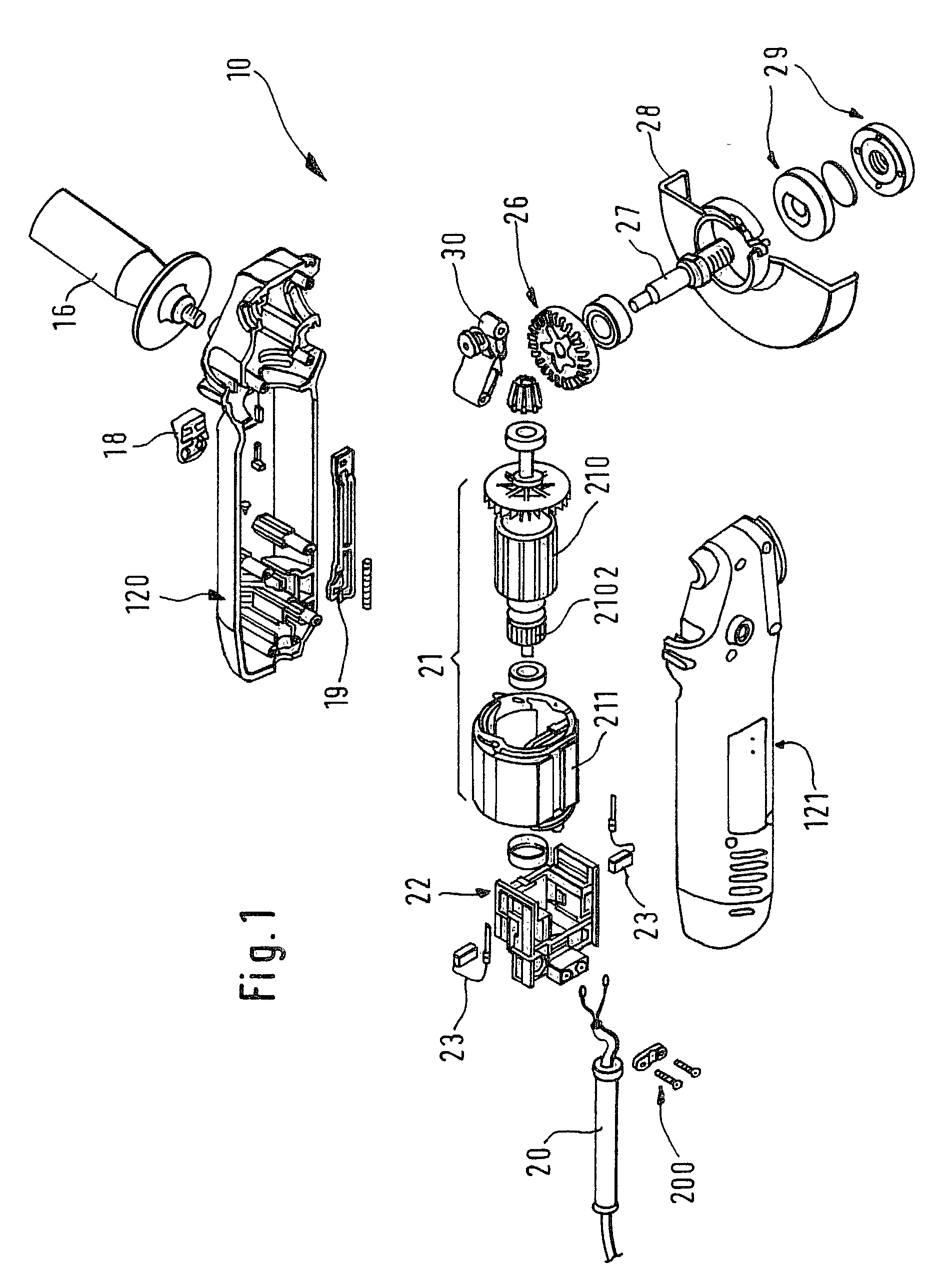

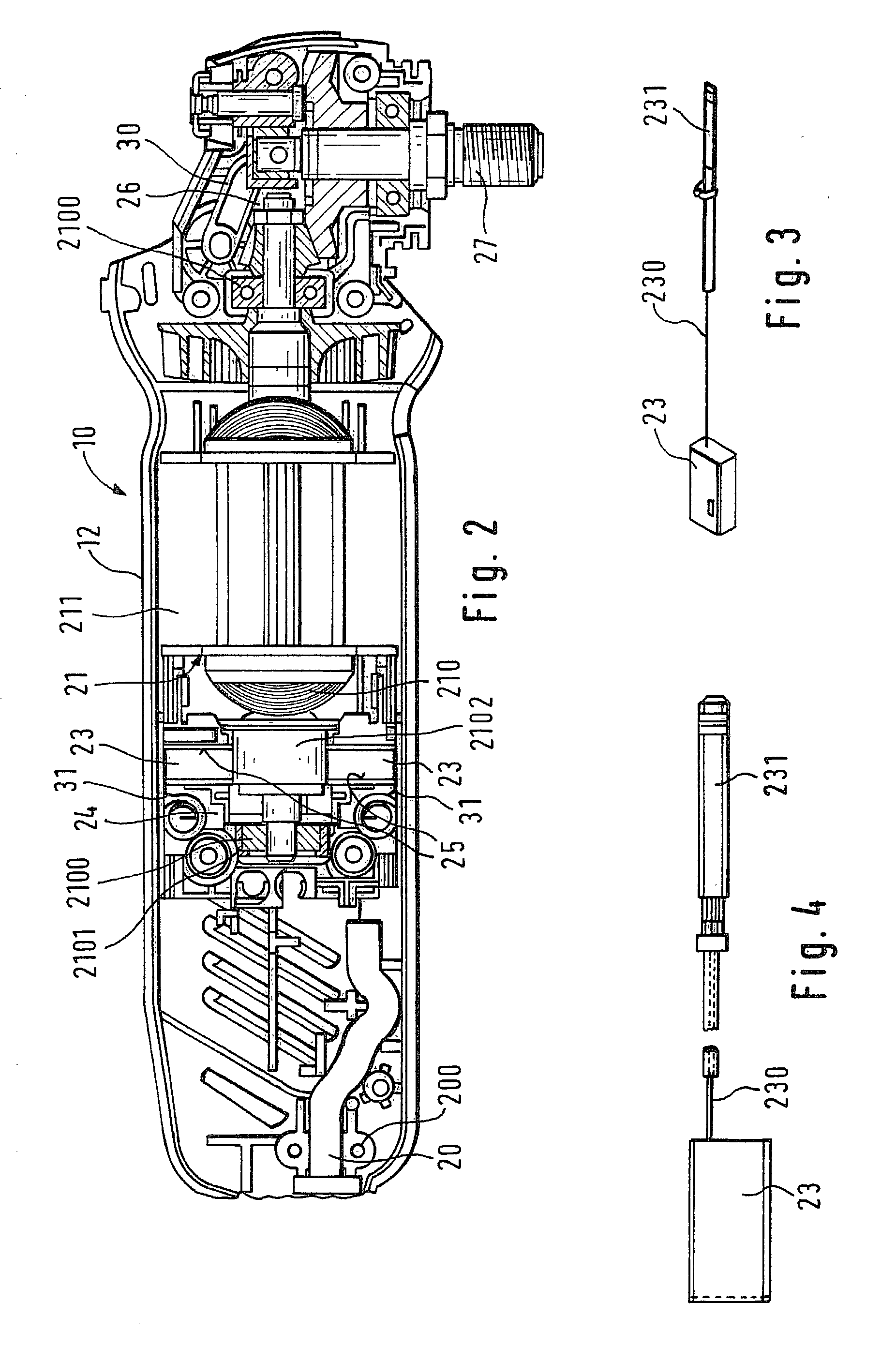

Angle grinder with electric drive

InactiveUS20020151262A1Low production costEasy to replaceWindingsRotary current collectorAngle grinderGear wheel

A power tool (10), in particular an angle grinder, having a housing (12) that receives an electric motor (21) and a gear (26), the motor (21) having a rotor (210) which is guided in rotor bearings (2100) and on one hand carries a collector (2102), which collector can be put into contact with a voltage source via carbon brushes (23) supported in brush plates, is made sturdier and easier to install in that the housing (12) comprises two longitudinally split housing shells (120, 121), and that the brush plates are part of a bearing bridge (24) that carries both the rotor bearing (2100) and the carbon brushes (23), and the bearing bridge (24), in the guide region of the carbon brushes (23), comprises plastic.

Owner:ROBERT BOSCH GMBH

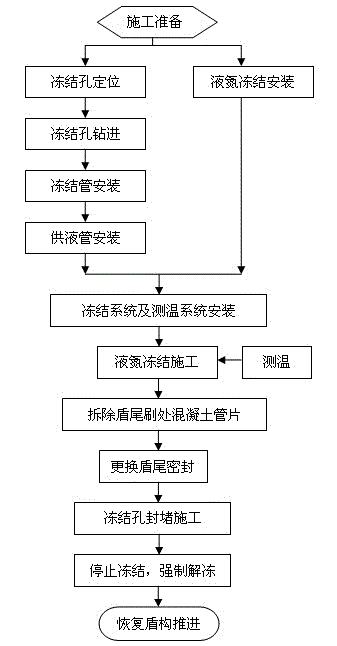

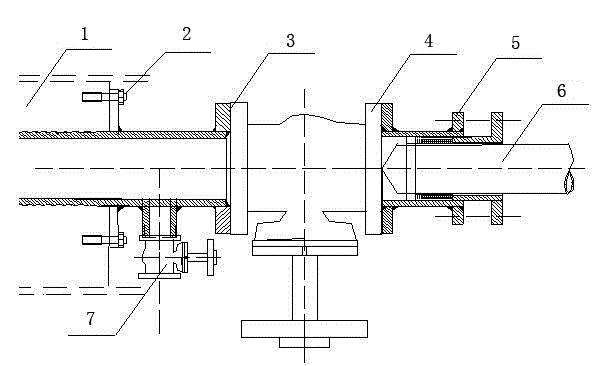

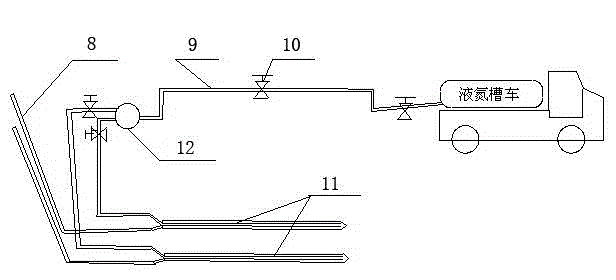

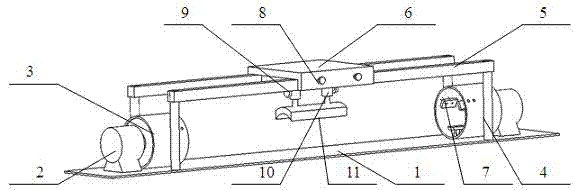

Method for replacing tail brush in shield tunnel through liquid nitrogen freezing

The invention relates to a maintenance method for shield equipment and discloses a method for replacing a tail brush in a shield tunnel through liquid nitrogen freezing. The method comprises the following processing steps: 1, preparation of construction; 2, construction of freezing holes; 3, installation of a freezing system and a temperature measuring system; 4, construction of liquid nitrogen freezing; 5, construction of sealing maintenance of a shield tail; 6, construction of formation sealing of the freezing holes; 7, construction of forced thawing; and 8, construction of propulsion of shield recovery. According to the invention, stratum is frozen through a liquid nitrogen freezing method to form a frozen curtain, so that the defect of indeterminacy of a traditional grouting method for carrying out the treatment of stratum consolidation and water sealing to bearing pressure permeable stratum can be avoided; and the method has the advantages of high strength, good uniformity, good water-resisting property and the like.

Owner:CHINA RAILWAY TUNNEL

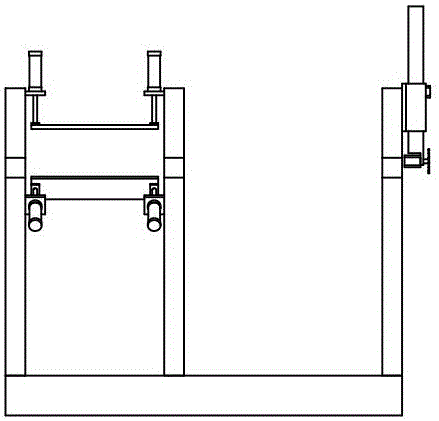

Semi-automatic efficient steel pipe outer wall cleaning device

The invention relates to a semi-automatic efficient steel pipe outer wall cleaning device which comprises a support plate, motors, pipe fitting fixing covers, support pillars, guide rail brackets, a movable bracket, bending plate locating plates, a hair brush fixing rack and clamp cylinders, wherein the support plate is provided with the pair of pipe fitting fixing covers; one side of each pipe fitting fixing cover is connected with a rotating shaft of the corresponding motor; the motors are arranged on the support plate; the clamp cylinders are fixed on the inner walls of the pipe fitting fixing covers; the bending plate locating plates are respectively arranged on telescopic rods of the clamp cylinders; the support pillars are respectively arranged at the two sides of the pipe fitting fixing covers; the two ends of the guide rail brackets are respectively connected with the upper ends of the support pillars arranged at one side of one pipe fitting fixing cover and one side of the other pipe fitting fixing cover; the bottom of the movable bracket is provided with the hair brush fixing rack; a hair brush is arranged under the hair brush fixing rack; the movable bracket is blocked on the two guide rail brackets by hook racks. According to the semi-automatic efficient steel pipe outer wall cleaning device, a steel pipe only needs to be fixed, the movable bracket is adjusted to different positions, and the two ends of the steel pipe are slightly cleaned, so that the whole cleaning is completed.

Owner:ZHANGJIAGANG CITY SHENGDINGYUAN PIPE MAKING

Efficient medial instrument cleaning device

InactiveCN107243480AAvoid wastingAvoid frequent replacementDrying gas arrangementsCleaning using toolsEngineeringScrub brushes

The invention discloses an efficient medial instrument cleaning device. The efficient medial instrument cleaning device comprises a box body, a cleaning cavity, a cleaning liquid cavity, a cleaning frame, a dual-shaft motor, a first belt wheel, a belt, a second belt wheel, a hollow pipe, spraying holes, a brush, a first water pipe, a water pump, a circulating device and a drying device; the device is provided with the dual-shaft motor, a disc and a connecting rod, through cooperation of above components, the cleaning frame is driven to shake continuously, medical instruments in the cleaning frame are continuously turned over, and are more sufficiently in contact with cleaning liquid, cleaning efficiency is improved, a first bevel wheel, a second bevel wheel, a rotating shaft, the first belt wheel, the belt, the second belt wheel and the hollow pipe are arranged, the brush continuously brushes medical instruments, stubborn stains on the surfaces of the medical instruments are removed, cleaning efficiency is improved, meanwhile, the spraying holes spray cleaning liquid from inside to outside, the cleaning liquid can sufficiently clean the all medical instruments, the blots are flushed out of the cleaning frame, and thorough cleaning can be further ensured.

Owner:童贤波

Multifunctional cleaning device for building surface

InactiveCN1511650AEffective guarantee of supplyEffective controlCleaning using liquidsBuilding support scaffoldsDrive wheelVehicle frame

The multifunctional cleaning apparatus for building surface consists of carriage, cleaning mechanism on leveling platform and driving wheel mechanism. The carriage is provided with solar cell plate, platform with guard rail, video camera, lamp, waterproof hood, clear water tank, waste water tank, electric interface, track, etc. The cleaning mechanism is provided with ice thawing unit, two rolling brushes, two pollutant sucking units, two scrapers, stoving unit and blower. The carriage is provided also wheels or circular caterpillar bands with sucking disc or combined forcepated wheels on special tracks. The present invention can operate on the surface of different buildings day and night.

Owner:李京岐

Method for controlling and treating bottom roller dross of carbon sleeve furnace

ActiveCN101906529AReduce running speed varianceReduce nodulationFurnace typesHeat treatment process controlDrossDew point

The invention discloses a method for controlling and treating bottom roller dross of a carbon sleeve furnace. The possibility of dross occurrence is reduced by effective preventive measures for controlling the brushing current of a brush roller, reducing the use of a severely-oxidized transition strip, controlling appropriate furnace pressure, dew point and hydrogen content according to the difference of process speeds and process temperatures, periodically adjusting the rotating speed of a furnace roller, reducing running speed difference between the furnace roller and band steel, controlling the temperature raising and lowering rates of process temperature transformation during steel transformation and the like. Simultaneously, different treatment methods are used according to different dross states, so that treatment time is shortened greatly. The problems of long treatment time, single treatment method, no distinguished treatment according to different dross states, grinding of all furnace bottom rollers during treatment, damage to the furnace bottom rollers without dross, effect on service life and the like are solved, the plate surface quality of a cold-rolled and annealed product is enhanced and product percent of pass is increased.

Owner:ANGANG STEEL CO LTD

Automatic dedusting type teaching projection curtain

InactiveCN106940512AGood projection effectImplement automatic cleanupProjectorsCleaning using toolsEngineeringMechanical engineering

Owner:杜美玲

Process for producing low-noise and high-performance electric brushes by using copper-coated graphite powder

InactiveCN102694329AReduce energy consumptionImprove efficiencyRotary current collectorBrushes manufacturePhysical chemistryGraphite

The invention discloses a process for producing low-noise and high-performance electric brushes by using substitutional copper-coated graphite powder, and the process comprises the following steps: 1) kneading graphite powder and a bonding agent together so as to obtain colloidal graphite powder; 2) mixing the colloidal graphite powder, additives and a release agent so as to obtain mixed powder; 3) adding methanol or a gasoline low-carbon-residue binder dilute-solution in the mixed powder, mixing and then adding copper coated graphite powder into the obtained mixture; and 4) airing the material powder mixed in the step 3), pressing the material powder, and finally, sintering the material powder, thereby obtaining a low-noise and high-performance electric brush. According to the process disclosed by the invention, through adopting chemical substitutional copper coated graphite powder which can be industrialized as raw materials, and overcoming the defects that a chemical substitutional copper coated graphite powder coating is loose, porous and poor in binding force, and in the process of application, a copper plating layer is easy to fall off, a low-noise and high-performance electric brush is prepared. According to the process, a product can be obtained just through one-step molding and low-temperature heat treatment, therefore, the process is simple in working procedure, low in energy consumption, high in efficiency and short in production cycle, and the cost of the process is lower than that of a process implemented by using electrographite.

Owner:自贡恒基电碳厂

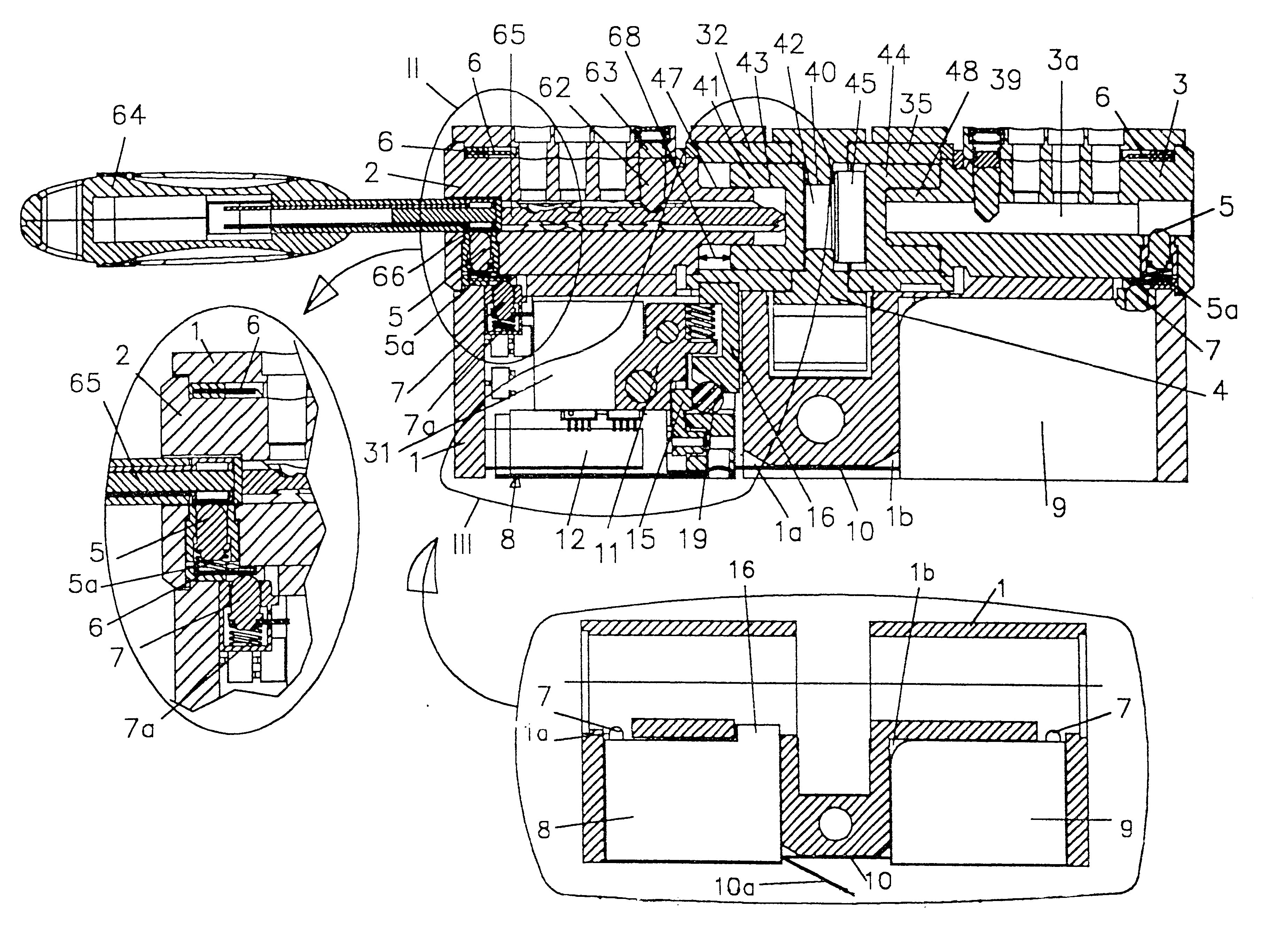

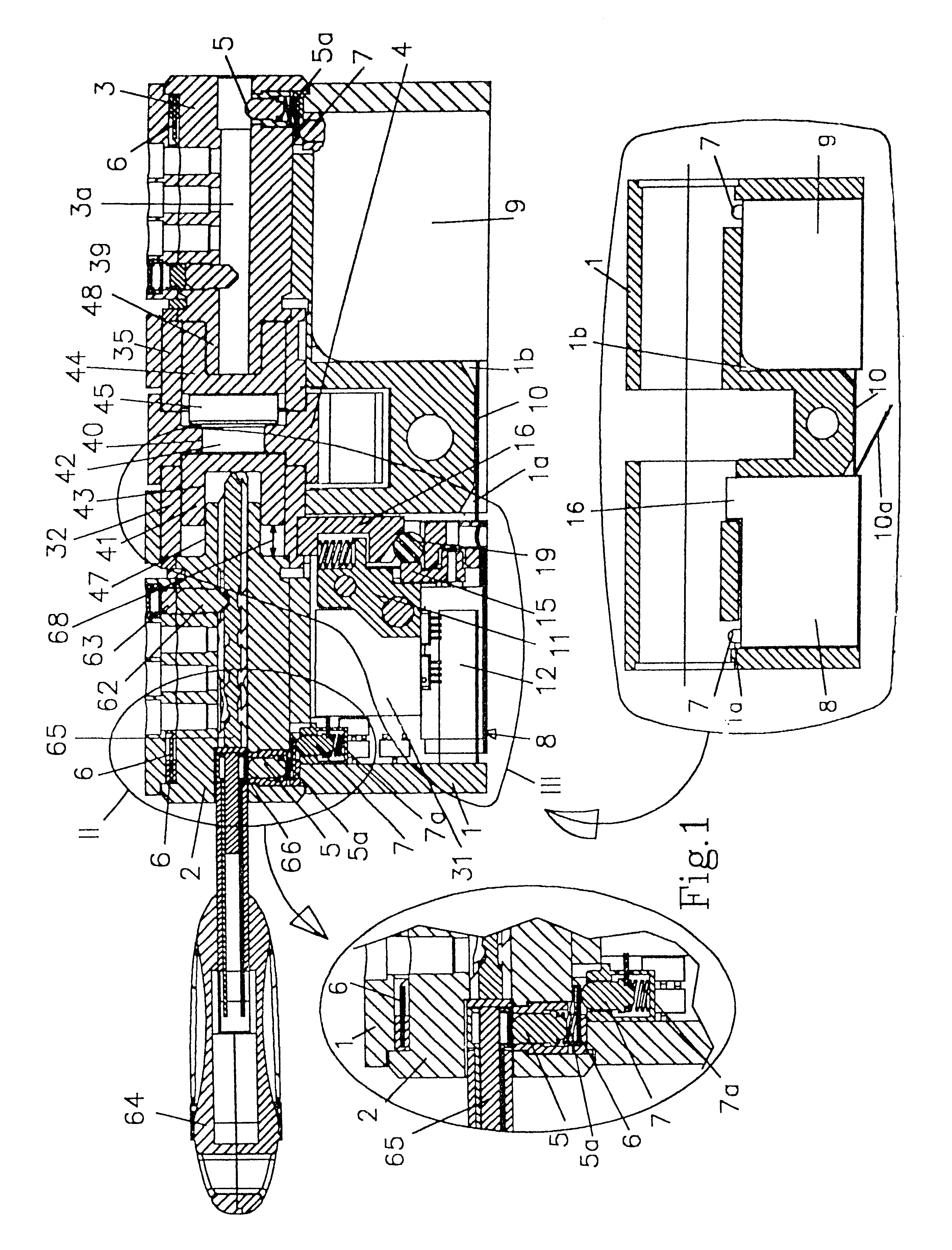

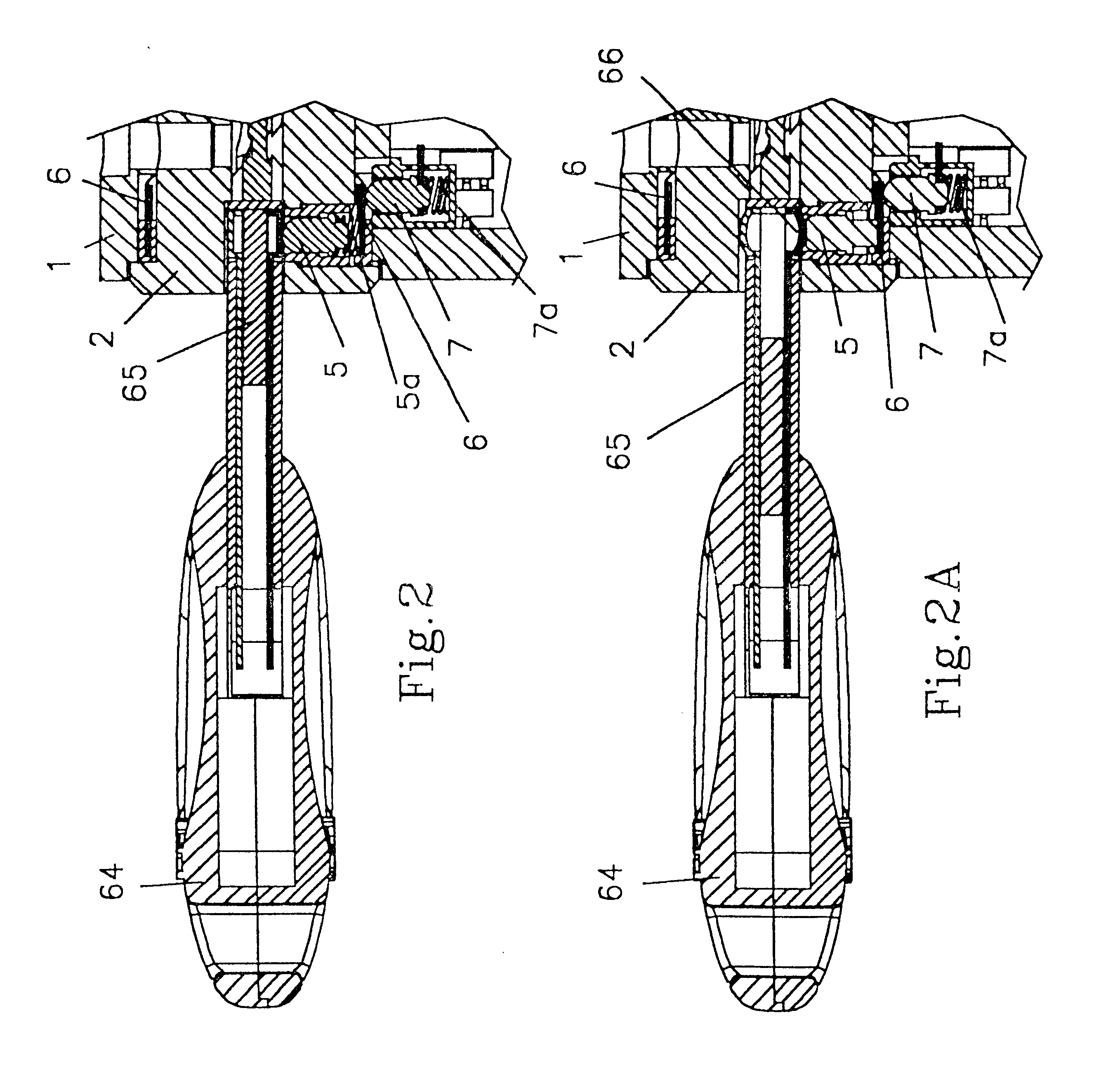

Locking cylinder

Locking cylinder, particularly an electronic locking cylinder and with electromechanical rotational blocking in which the electronic key (64) has facing electrical terminals (66) on blade (65), and the rotating core (2 or 3) of the cylinder has an external annular track (6) that is electrically conducting and with its internal face communicates with an electrical contact (5) supported on terminal (66); whereas the external annular track (6) is supported in the electrical brushes (7) of external (2) and internal (3) rotors; there is a first modular box (8) on the inside of a cast hollow part (1a) of external rotor (2) which box contains electrical brush (7), processing unit (31) and an electromechanical locking device, which incorporates a ball (19) and a vertical tumbler (16); as well as a second modular box (9) containing electrical brush (7) and the autonomous electrical source; the two modules are connected by the electrical conductor (10).

Owner:TALLERES DE ESCORIAZA SA

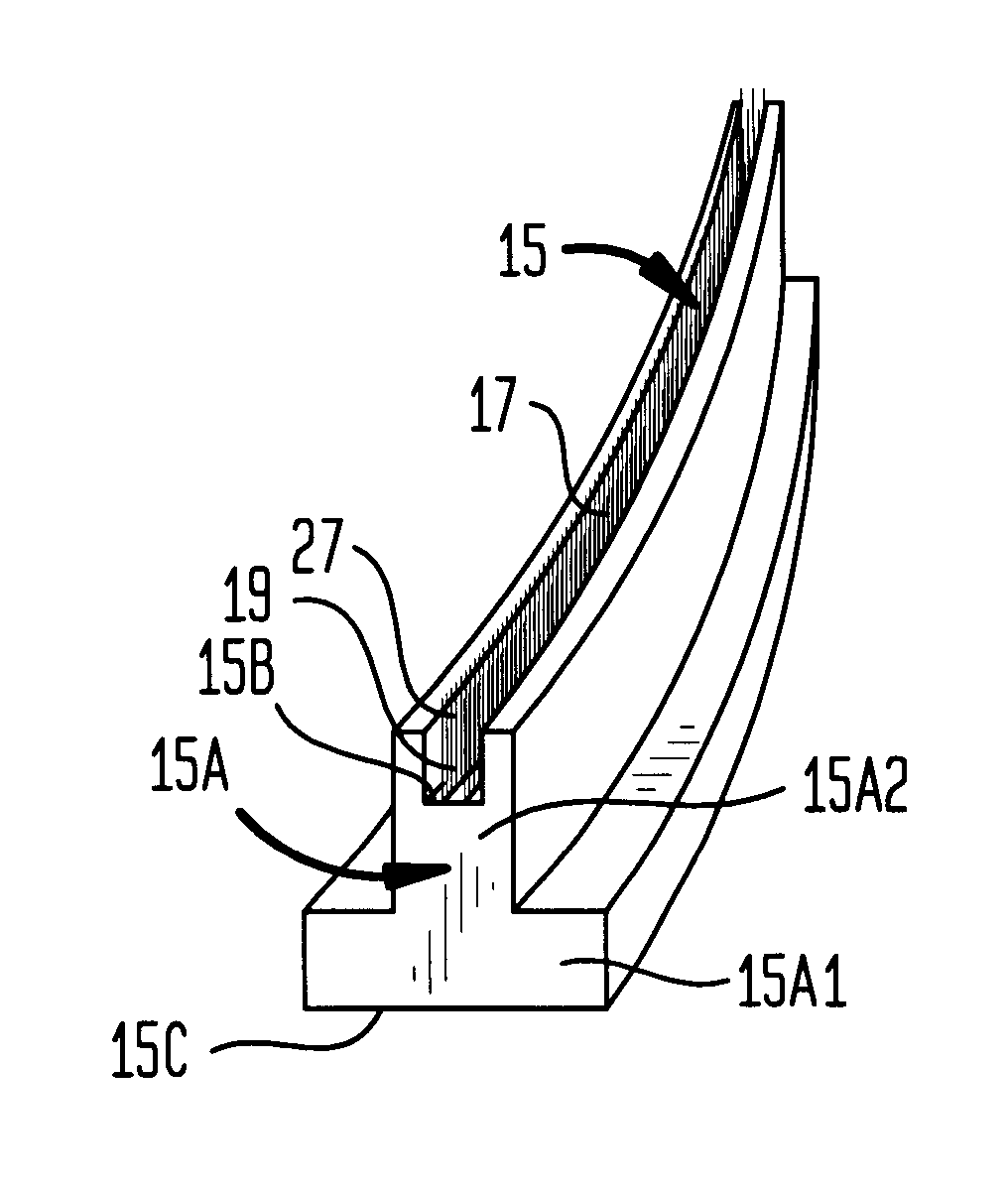

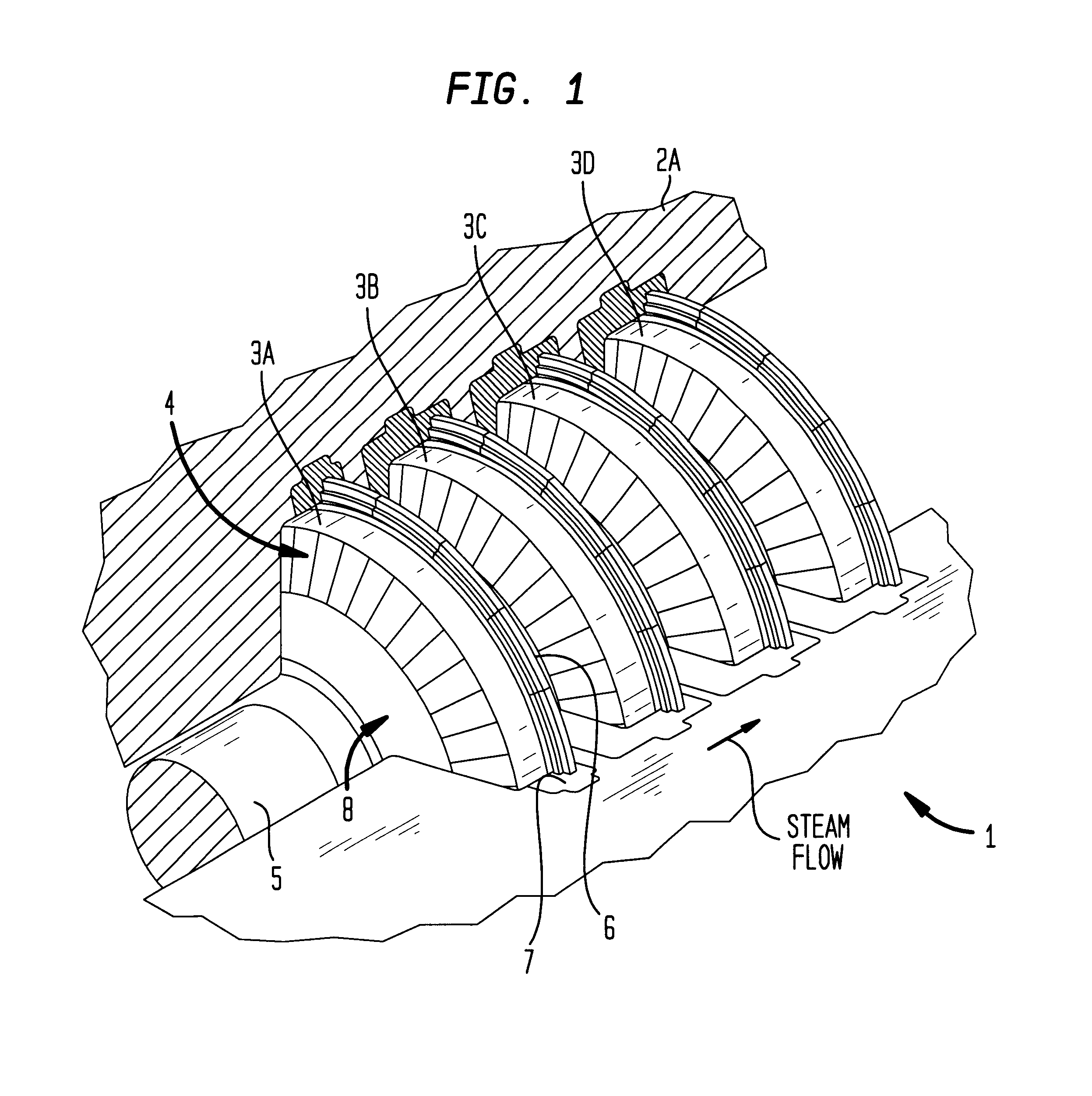

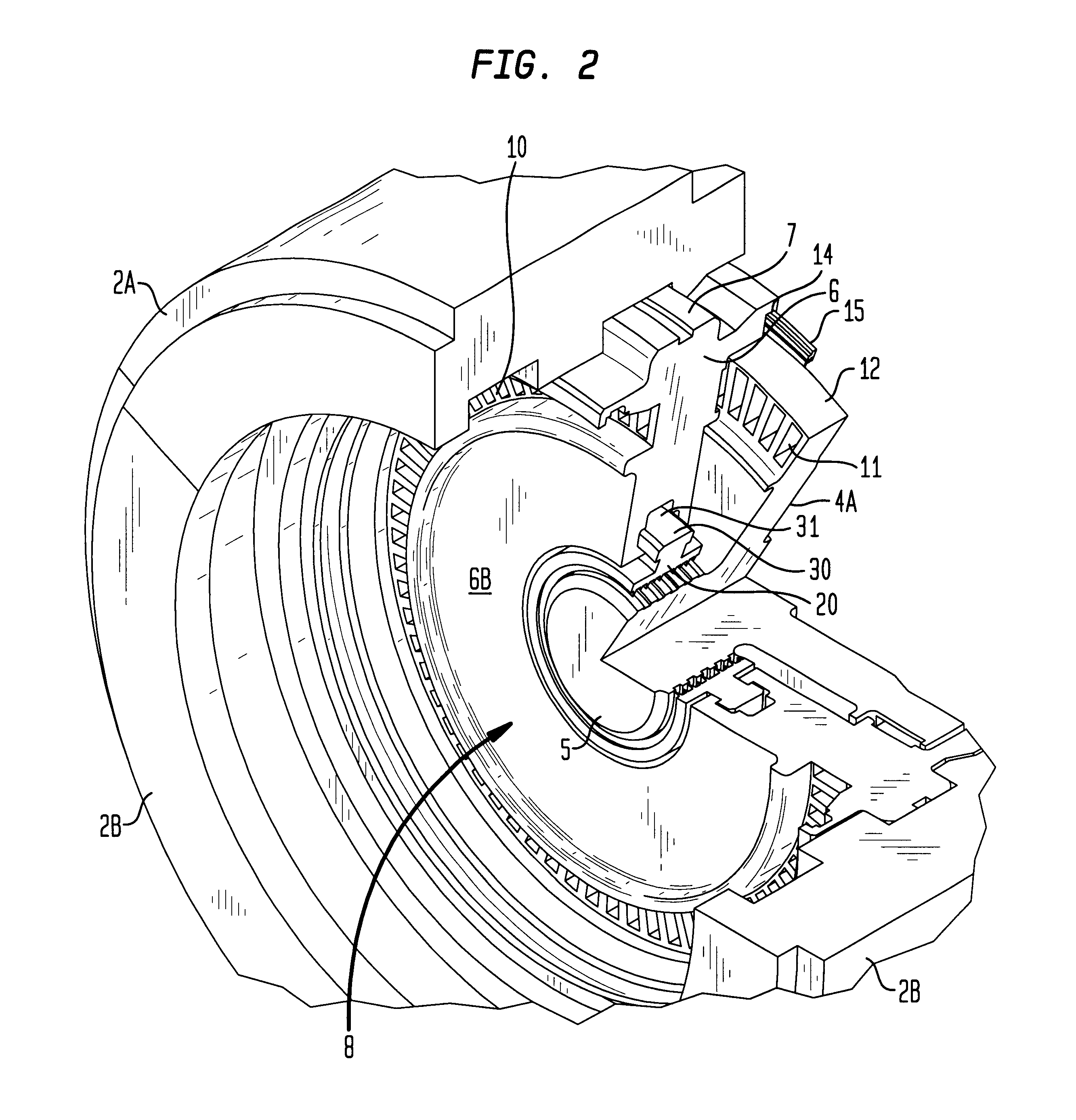

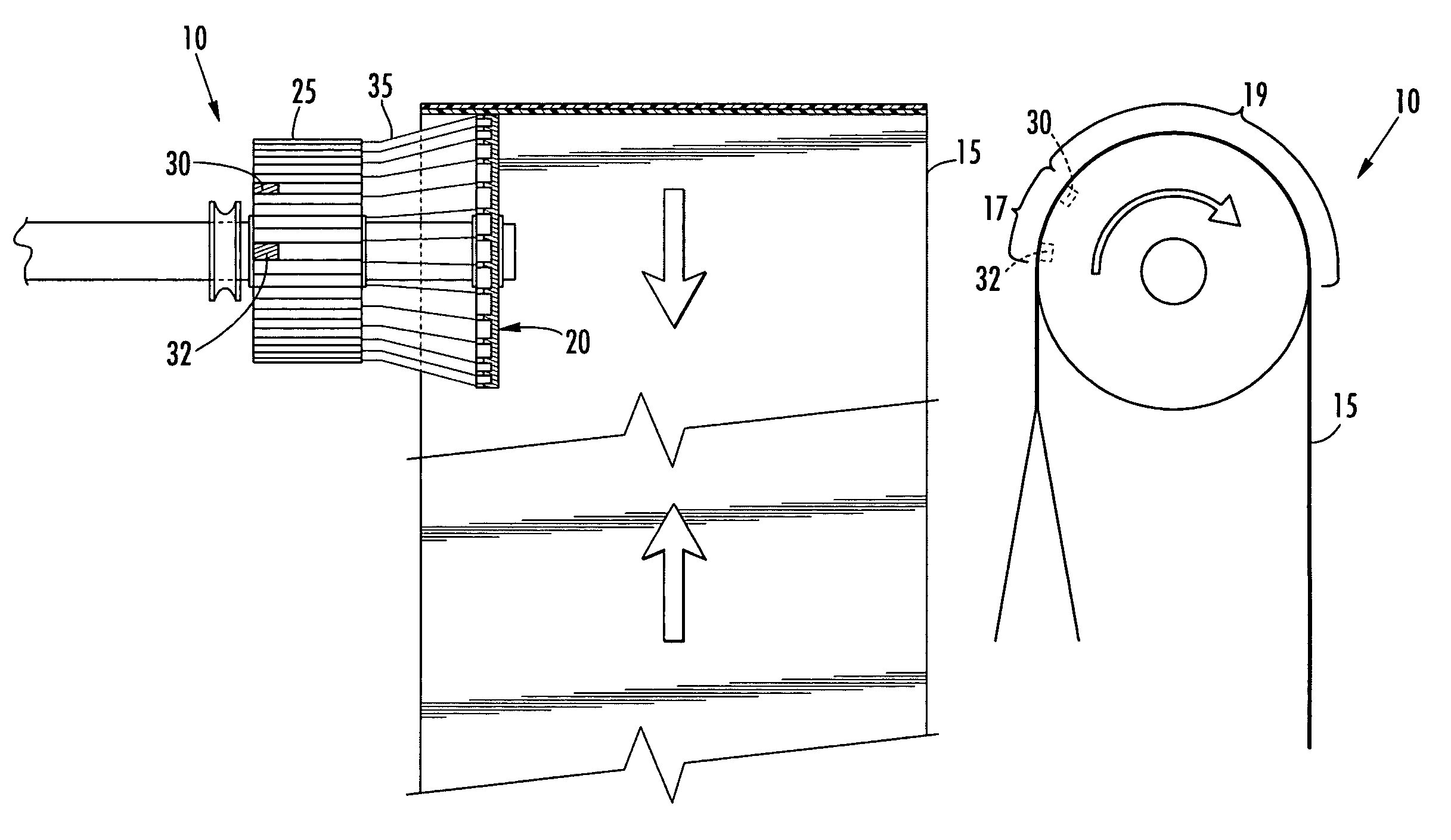

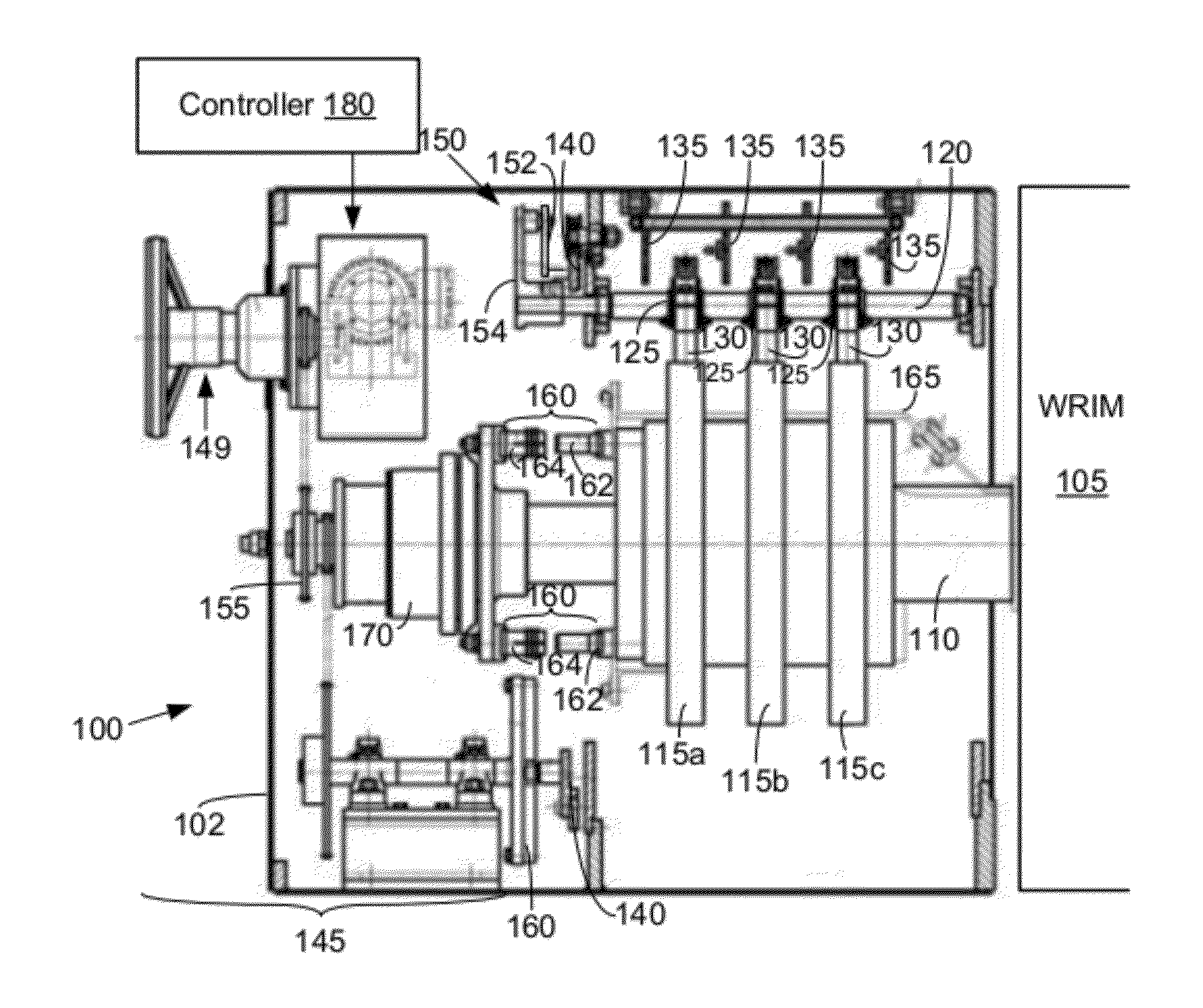

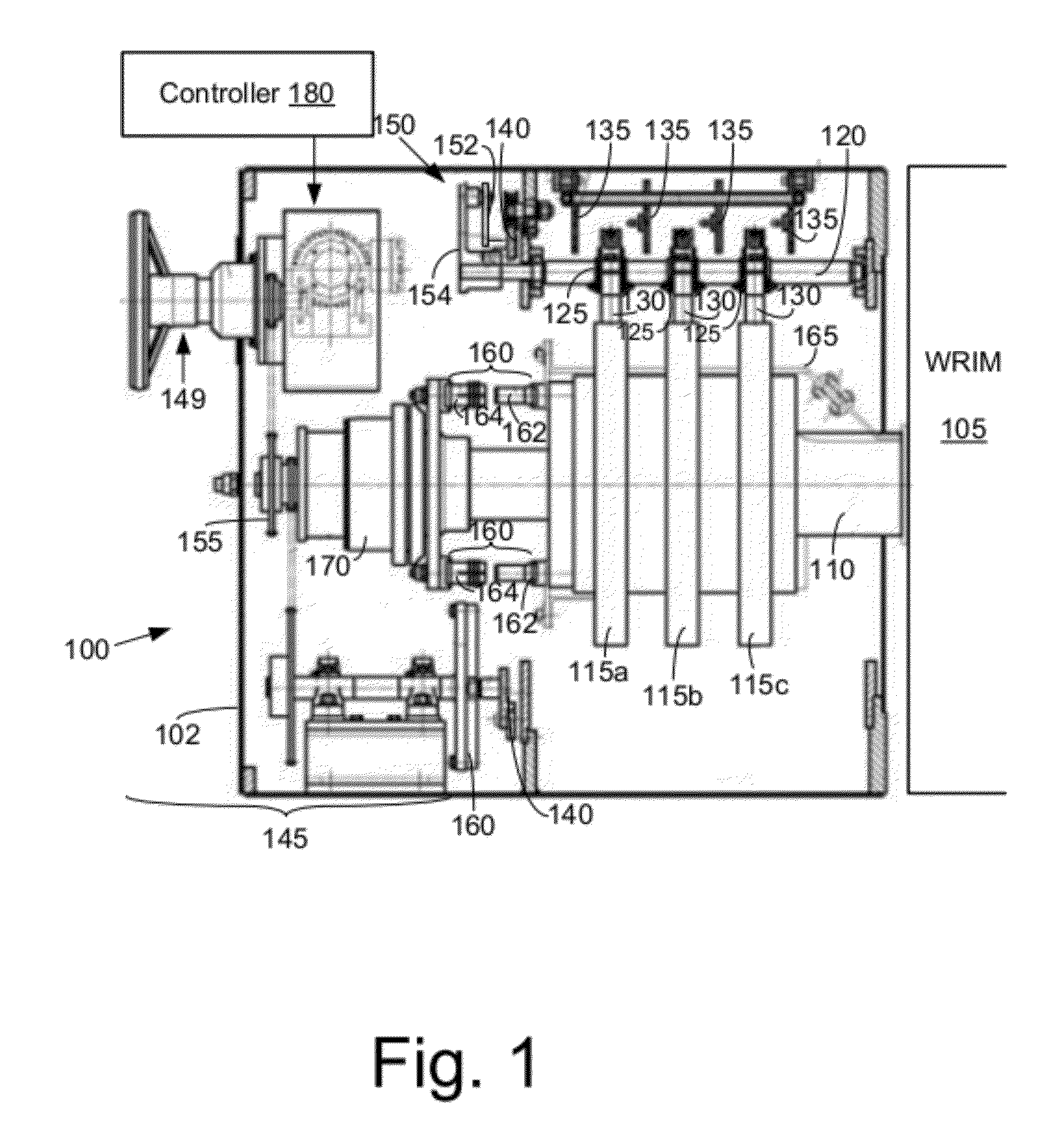

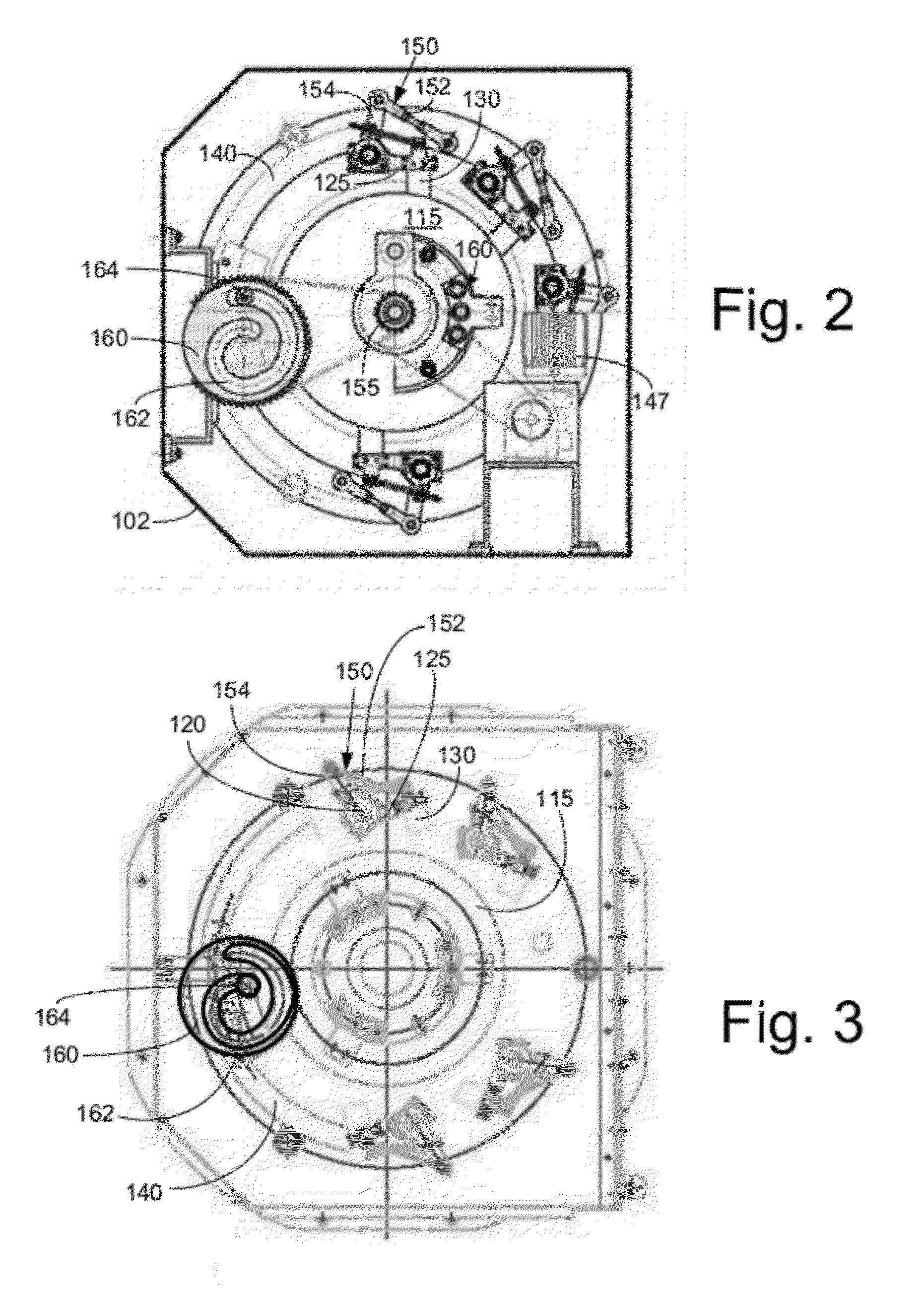

Systems, Methods, and Apparatus for Lifting Brushes of an Induction Motor

Systems, methods, and apparatus associated for lifting brushes and shorting slip rings are provided. One embodiment may include an actuating mechanism in operable communication with multiple brushes and a plurality of electrical contacts. Each of the brushes may be adapted for selective contact with a respective slip ring of an induction motor. The electrical contacts may be in electrical communication with respective terminals of rotor windings of the induction motor. When the actuating mechanism is actuated, at least a portion of the electrical contacts create electrical shorts between at least a portion of the slip rings and the rotor windings of the induction motor. When the actuating mechanism is actuated, at least a portion of the brushes are lifted from contacting the plurality of slip rings.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com