Patents

Literature

39002 results about "Water treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water treatment is any process that improves the quality of water to make it more acceptable for a specific end-use. The end use may be drinking, industrial water supply, irrigation, river flow maintenance, water recreation or many other uses, including being safely returned to the environment. Water treatment removes contaminants and undesirable components, or reduces their concentration so that the water becomes fit for its desired end-use. This treatment is crucial to human health and allows humans to benefit from both drinking and irrigation use.

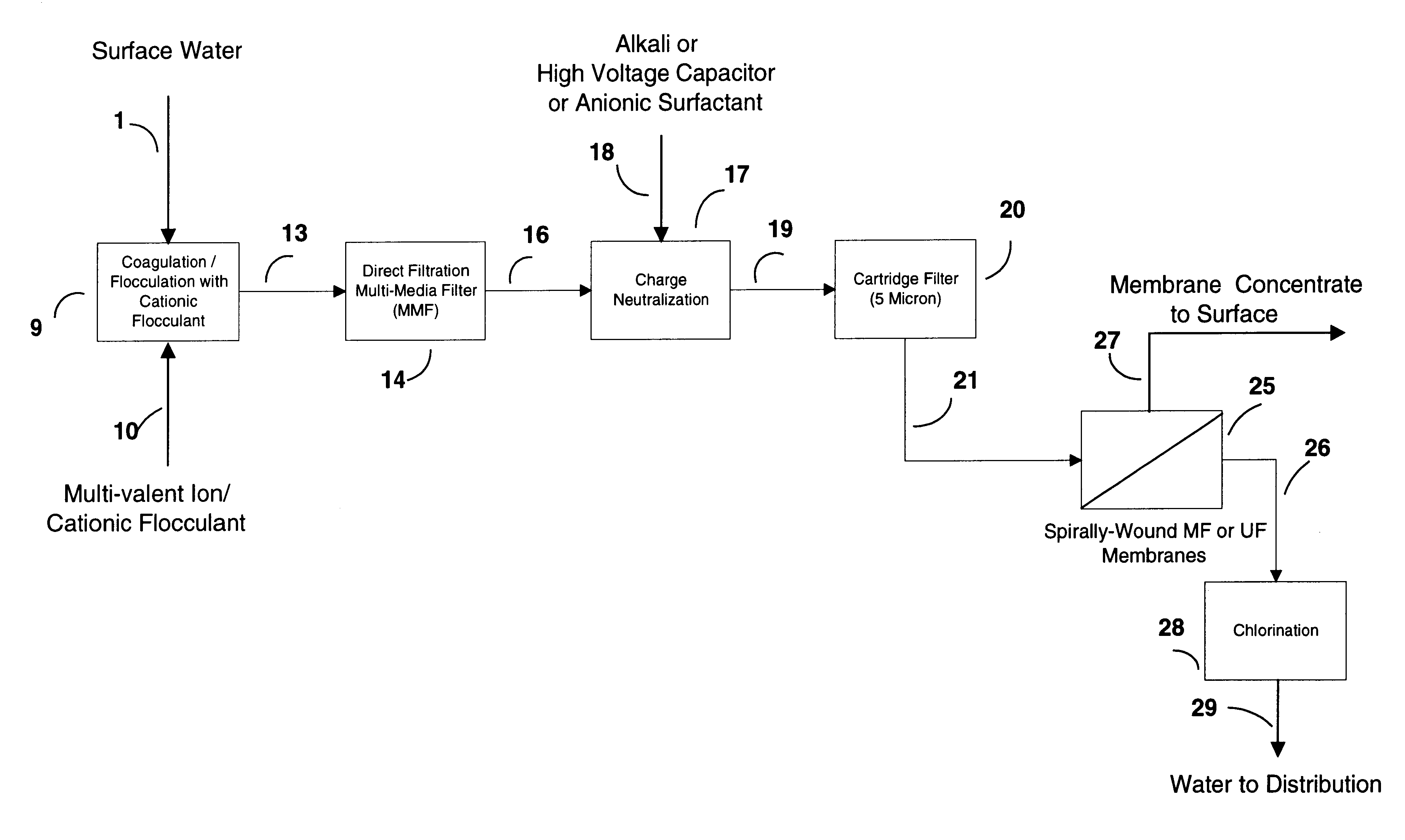

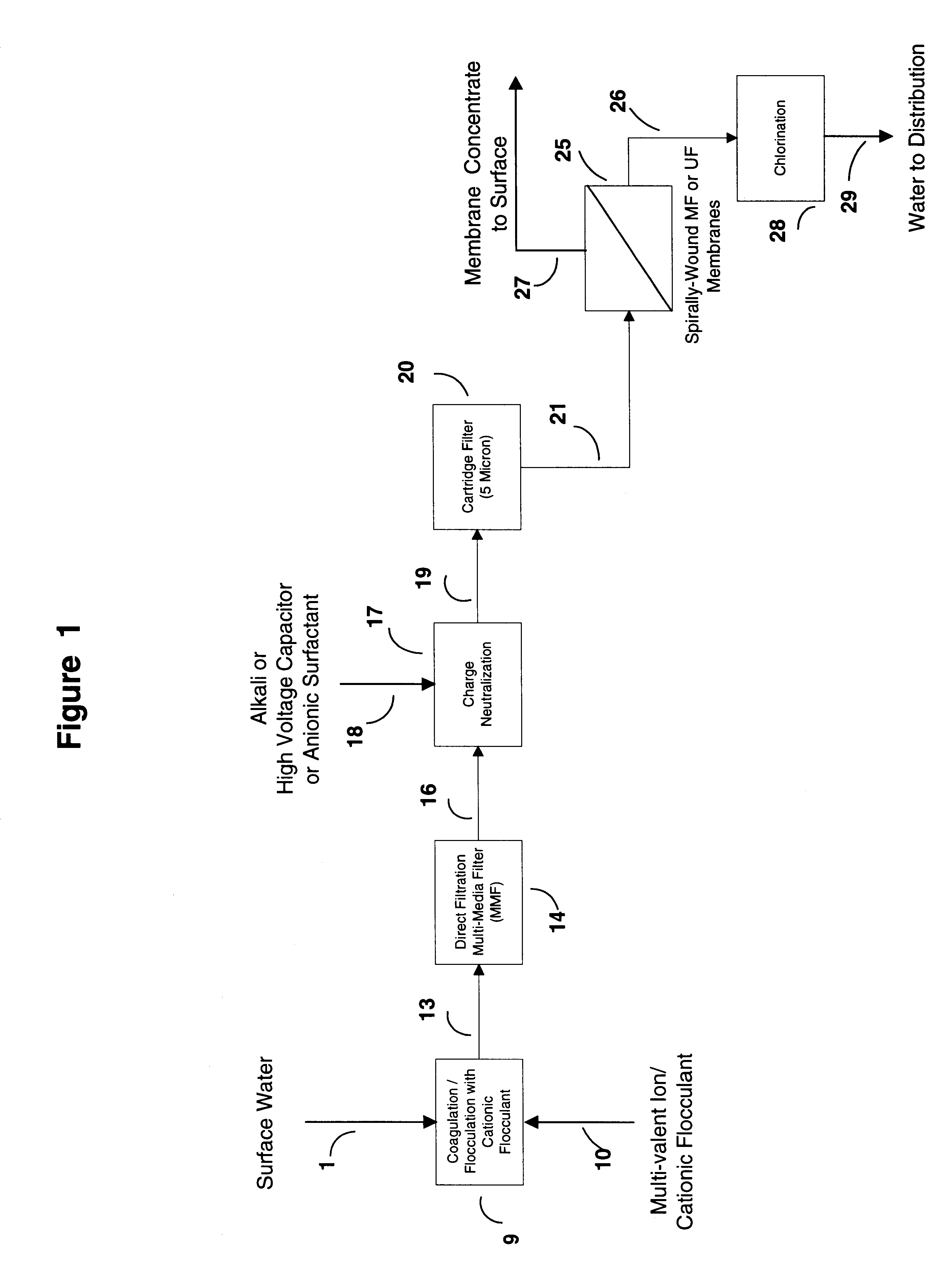

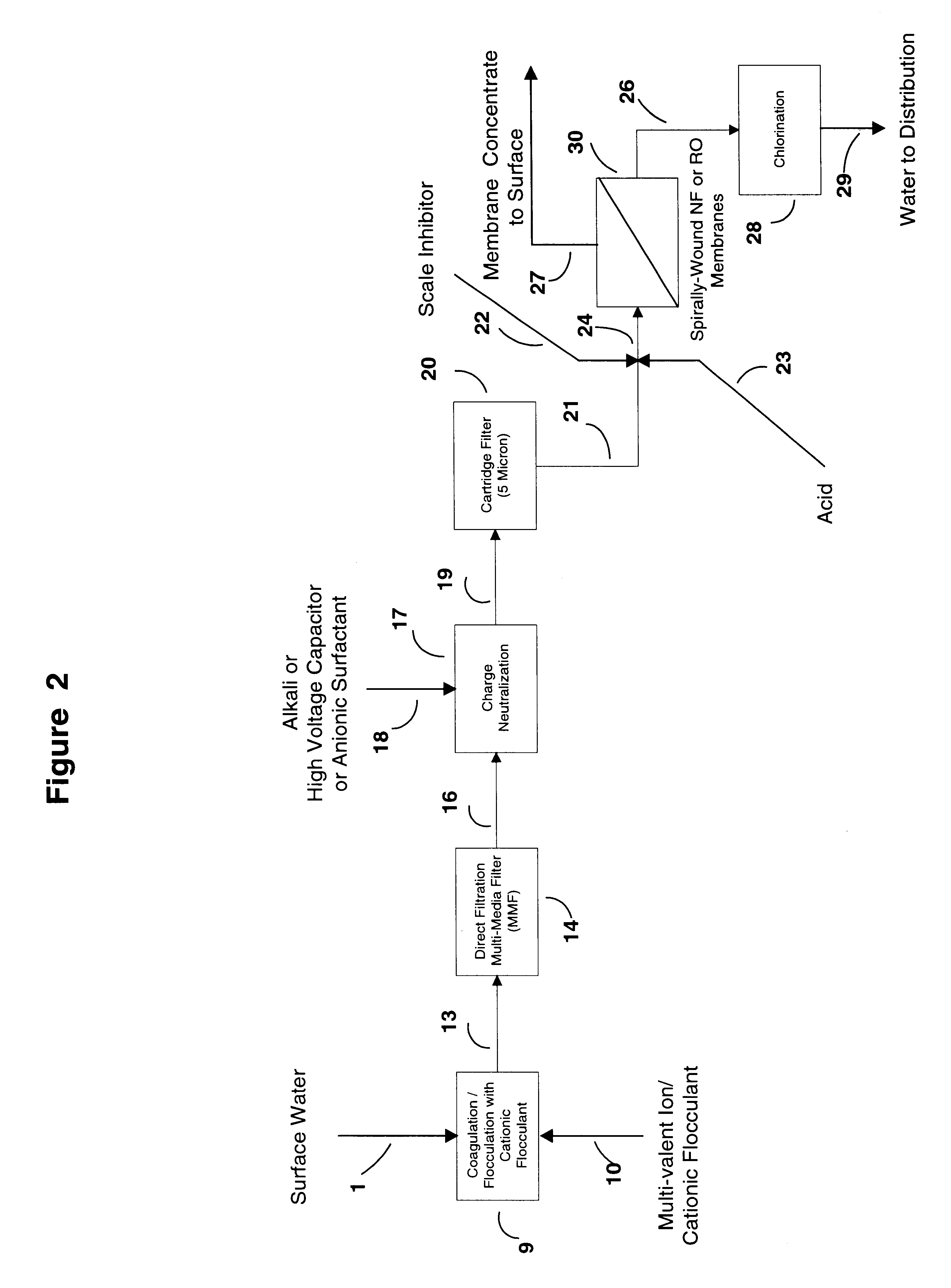

Water treatment process for membranes

InactiveUS6416668B1Effective and safe and reliable to produceCapital and operating costMembranesUltrafiltrationZeta potentialFiltration

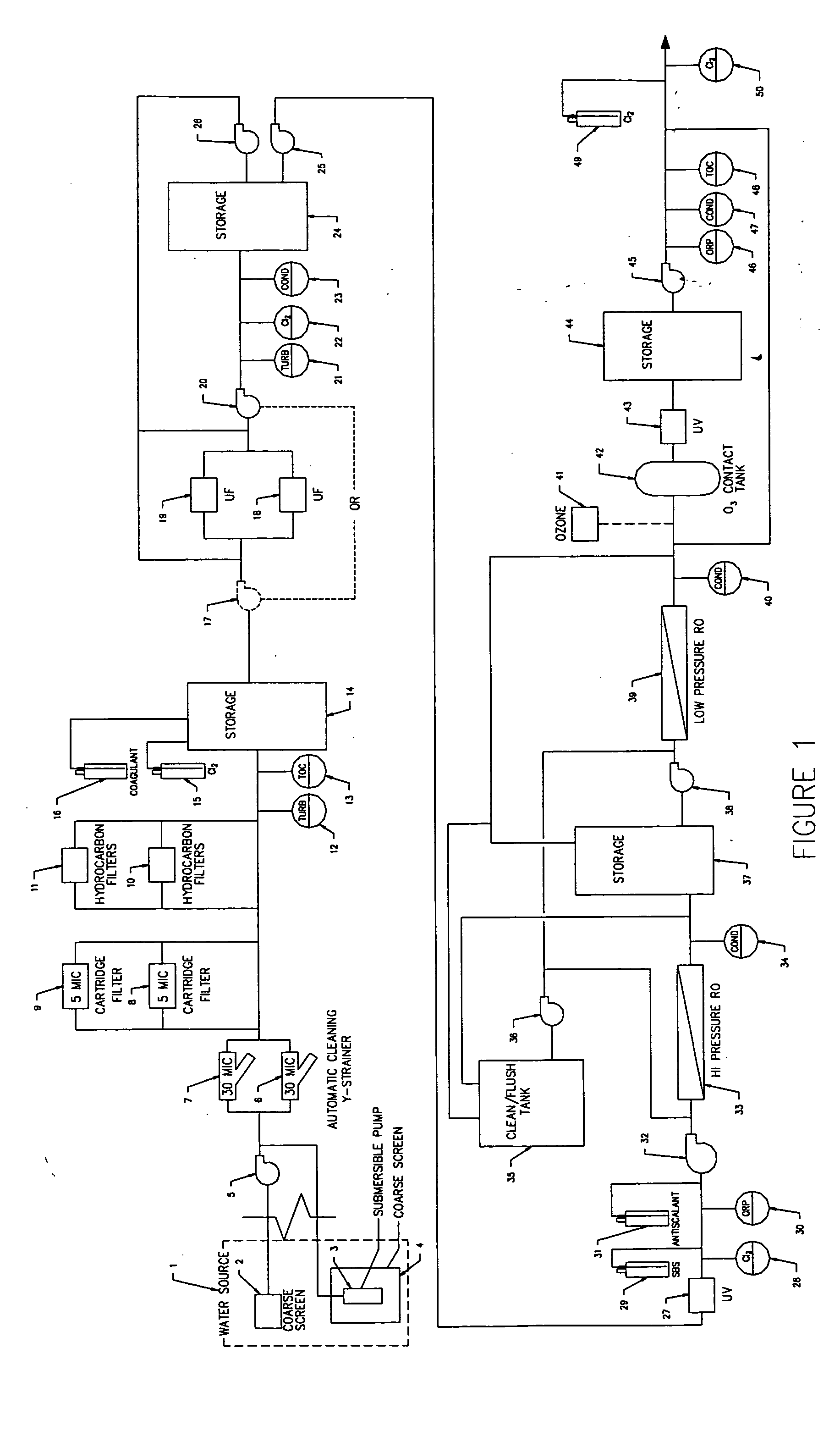

This invention discloses a cost-effective process for separating contaminants and a wide-range of fouling material from surface water, ground water and from industrial effluents. Having undergone effective pre-treatment, the water can be purified further by using high-surface area spirally wound micro-filtration (MF), ultra-filtration (UF), nano-filtration (NF) or reverse osmosis (RO) membranes. High-quality potable water free from pathogen and other contaminants is thus produced at low-cost from the pre-treated surface water and ground-water. Conversely, pre-treated industrial effluents are further purified at a relatively low-cost using NF or RO membranes, thus producing water suitable for recycle or surface discharge. The process of this invention uses cationic inorganic and / or polymeric flocculants to coagulate and flocculate the water-borne colloidal matter (e.g. clays, iron hydroxides, naturally occurring matter (NOM's), etc.), followed by filtration using a multi-media filter, charge neutralization and reversal and final filtration using a 5-micron cartridge filter. These pre-treatment steps provides a good quality water having a low Silt Density Index and a significant negative zeta potential, thereby ensuring against irreversible chemical fouling of the spirally-wound membranes.

Owner:AL SAMADI RIAD A

Efficient water treatment flocculant

InactiveCN101327976AEfficient purificationPromote generationWater/sewage treatment by flocculation/precipitationWater qualityHigh intensity

The invention relates to a high efficiency water treatment flocculant for drinking water and water treatment comprising a metal cation flocculant which is characterized in that the high efficiency water treatment flocculant also comprises a high efficiency adsorption component and an assistant medicament to be remixed, inwhich the weight ratio is: the high efficiency adsorption component 5-15%, the metal cation flocculant 50-85%, the assistant medicament 5-15%. The obvious characteristics of the invention are that each component can play the advantages of high intensity of the flocs of the inorganic flocculant and large flocs of the polymeric flocculant, overcomes the drawback of small flocs of the inorganic flocculant and low intensity of the flocs of the organic flocculant. The existence of the high adsorption component plays the action of adsorption of the organic compounds and heavy metal ion which are difficult to flocculat and precipitate, also plays the role of aid-coagulation, decoloration and deflavour. Thus the flocculant of the invention has advantages of good coagulation effect, large alum blossom, rapid settling velocity, good effluent quality and few dosage or the like.

Owner:郭振岳 +1

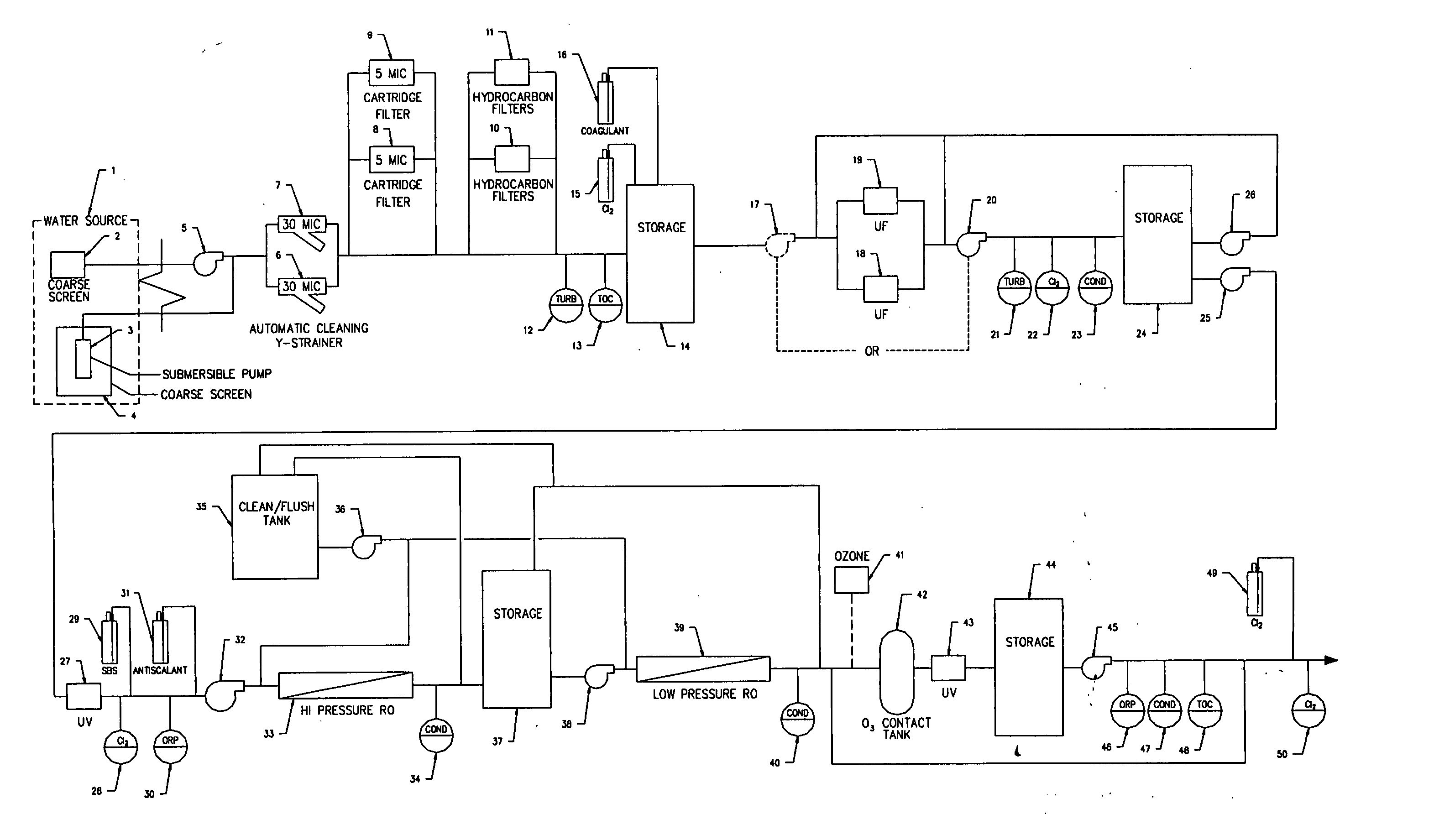

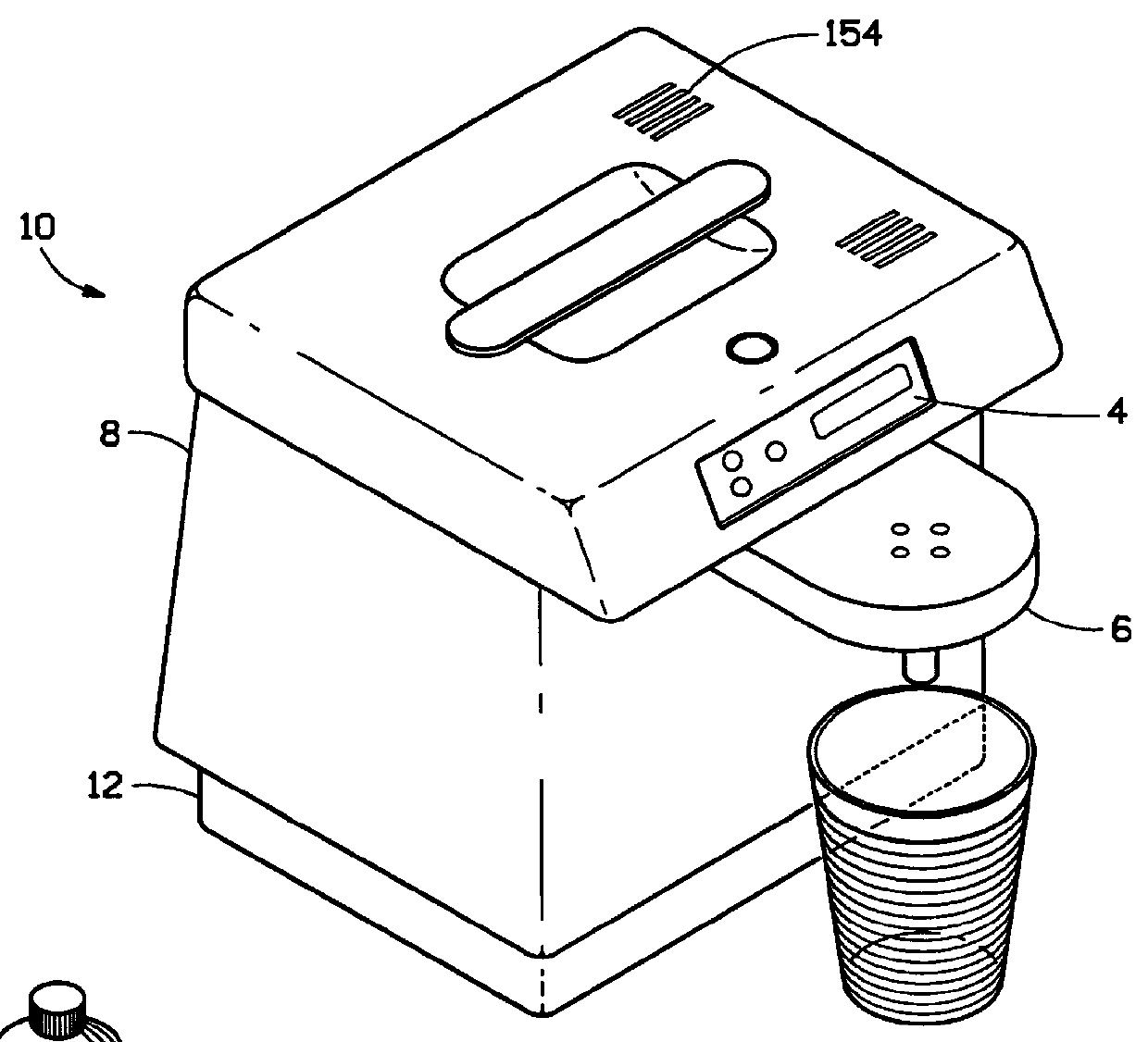

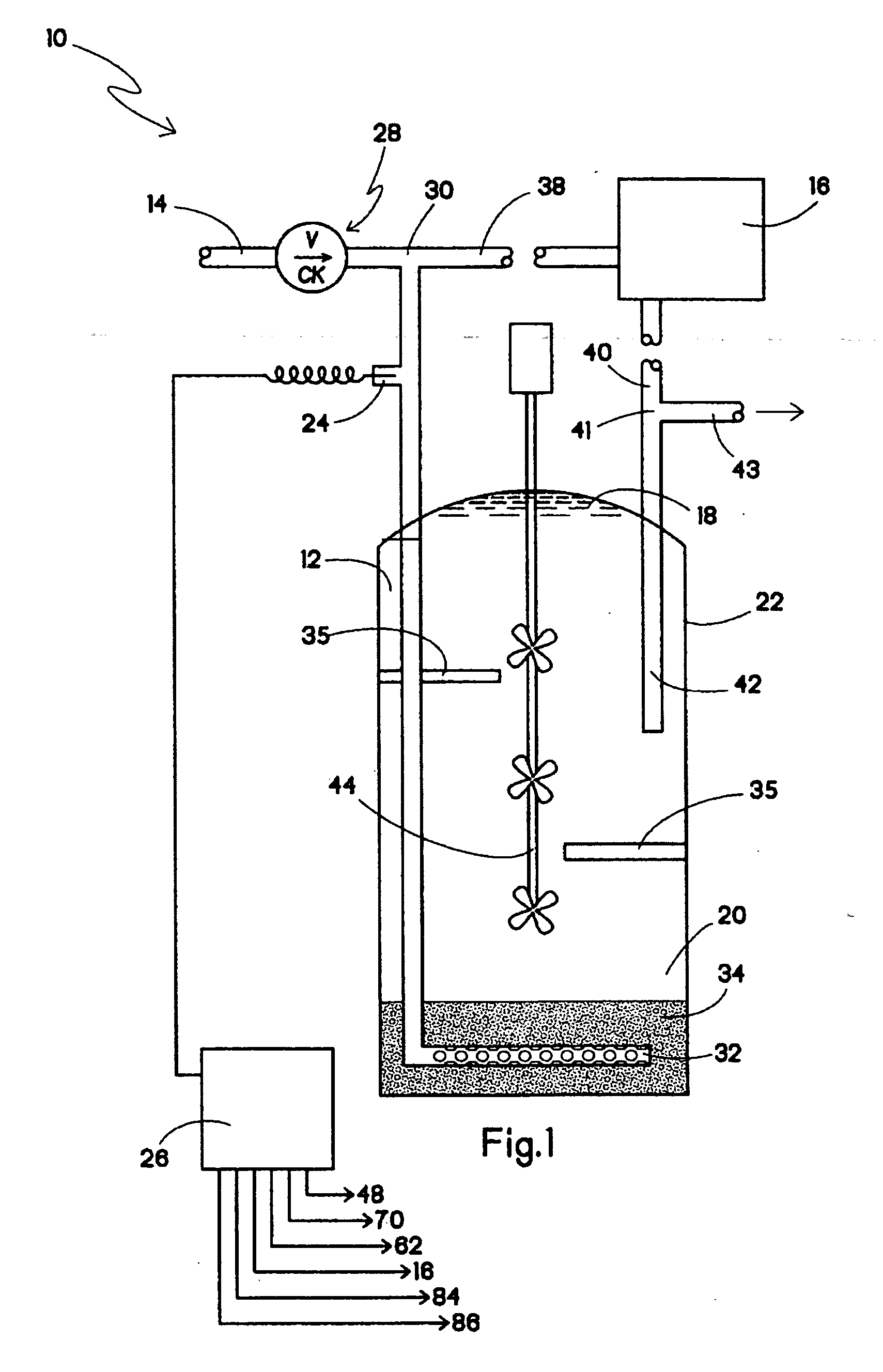

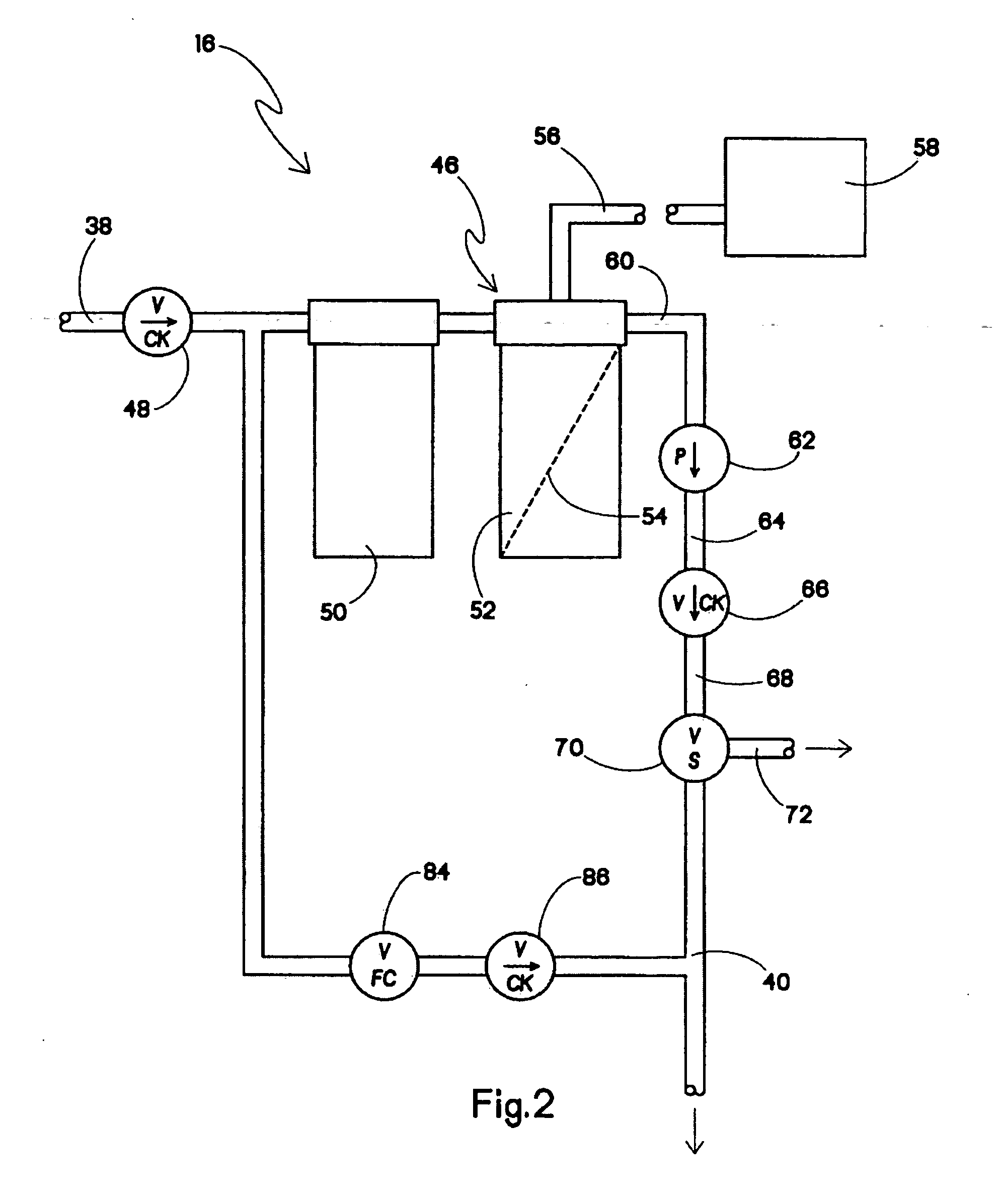

Water purifier and method of making and using the same

ActiveUS20050139530A1Fully removedGeneral water supply conservationTreatment involving filtrationHigh concentrationPurification methods

A method of producing safe drinking water from virtually any water source utilizing a water purification system is disclosed. The method includes a combination of water purification methods with a control system that evaluates water quality and functional processing parameters, such as pressure and flow. The control system determines what water processing methods to utilize and how most efficiently to operate them. The system is capable of treating highly contaminated water to the necessary degree to produce safe drinking water. Furthermore, the system regulates and cleans itself to maintain functionality despite receiving high concentrations of various contaminants from the feed water source.

Owner:HEISS CHRISTOPHER

Method for preparing loading functional oxide porous carbon

InactiveCN101780952AThe shape is fine and differentFine and varied structureOther chemical processesBy adsorptionPorous carbonMaterials science

The invention relates to a method for preparing a loading functional oxide porous carbon, which belongs to the technical field of carbon material. The method comprises the following steps of: selecting biomass material, and carbonizing at the temperature of 400-1000 DEG C in vacuum or on inert condition; preparing porous carbon by a physical activating or chemical activating process according to the requirement on the pore structure by the carbonized porous carbon; immersing the porous carbon into a precursor solution of an element M, cleaning many times with distilled water, and drying; roasting on the porous carbon at the temperature of 300-1000 DEG C in vacuum or on inert atmosphere, and then the active carbon of the loading functional oxide MxOy is prepared. The active carbon of the loading functional oxide MxOy prepared by the invention has the special pore structure of the biomass, also has the functions performed by the oxides, and has important application value in water treatment, hydrogen storage, photocatalysis, fuel cells and relevant fields.

Owner:SHANGHAI JIAO TONG UNIV

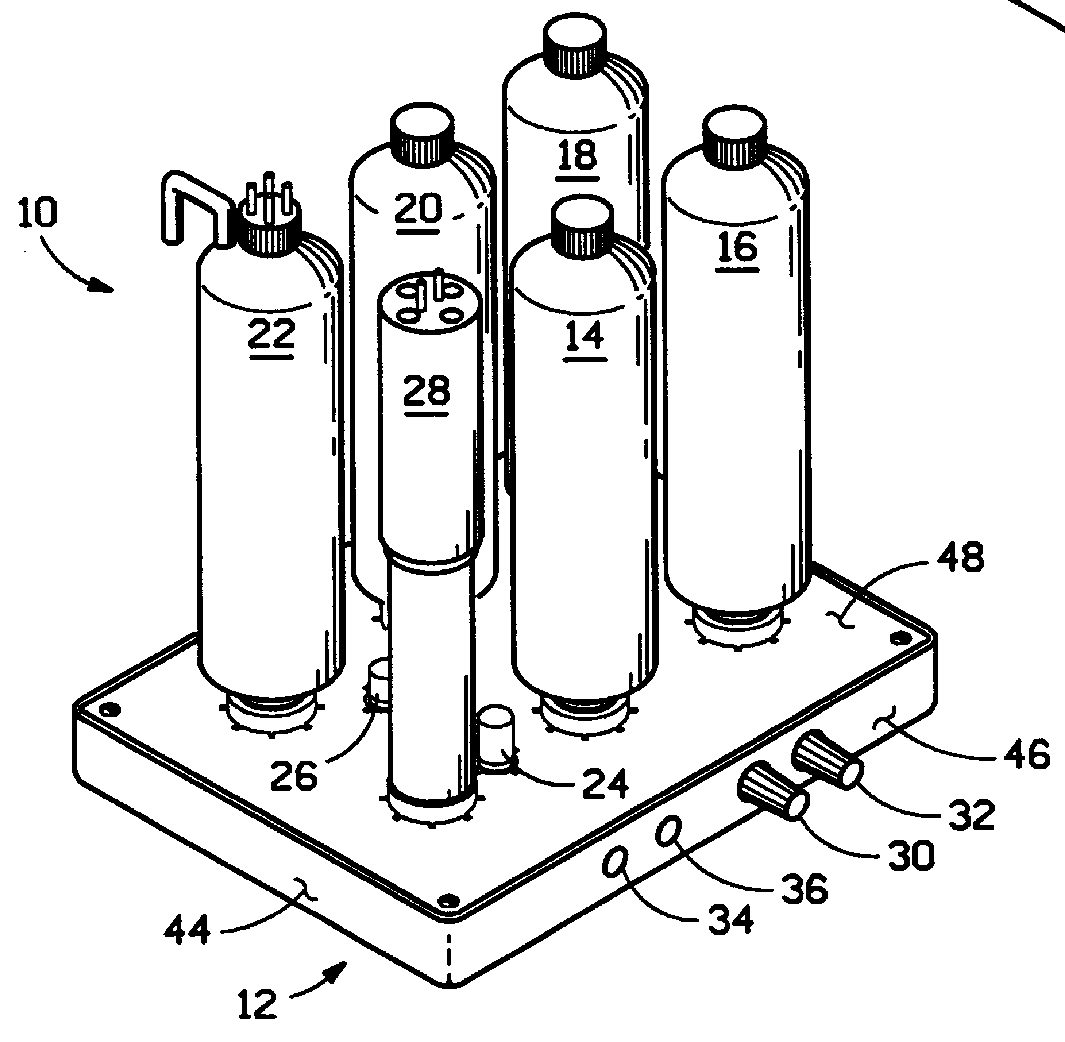

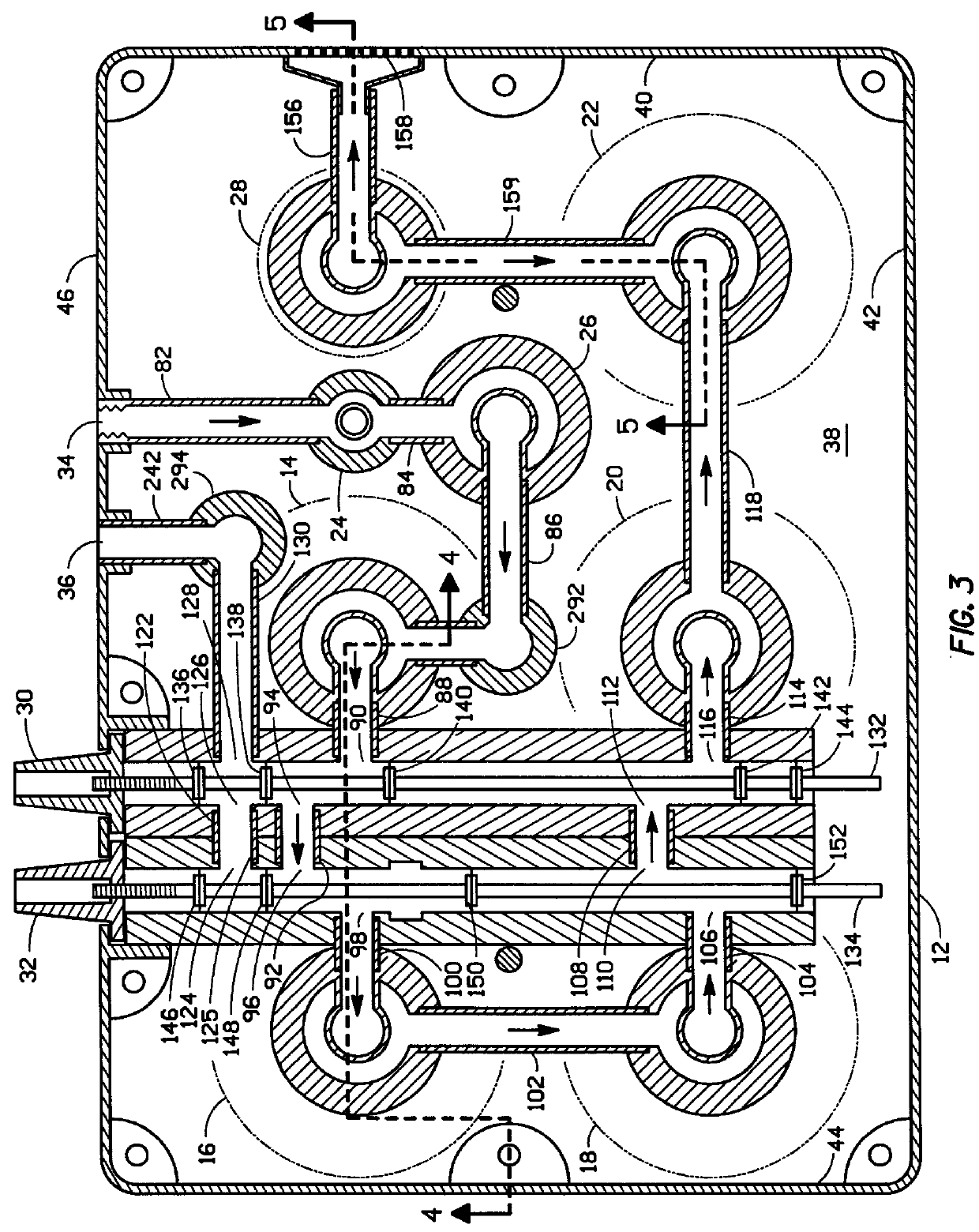

Point-of-use water purification system with a cascade ion exchange option

InactiveUS6080313AHigh purityEasy to install and replaceSolid sorbent liquid separationLoose filtering material filtersFiltrationIon exchange

A modular water treatment and purification system, suitable for home use, is connected to a water supply and contains a closed fluid treatment circuit extending to a water outlet. The closed fluid circuit flows through a plurality of replaceable water treatment modules each having a specific water treatment function, such as the removal of a particular material from the water by the use of filtration, carbon adsorption, ion exchange or the addition of a chemical to balance the desired water conditions. Preferably the circuit also includes traversing a radiation device, for example an ultra violet light, for the purpose of sanitizing the water.

Owner:KELADA MAHER I

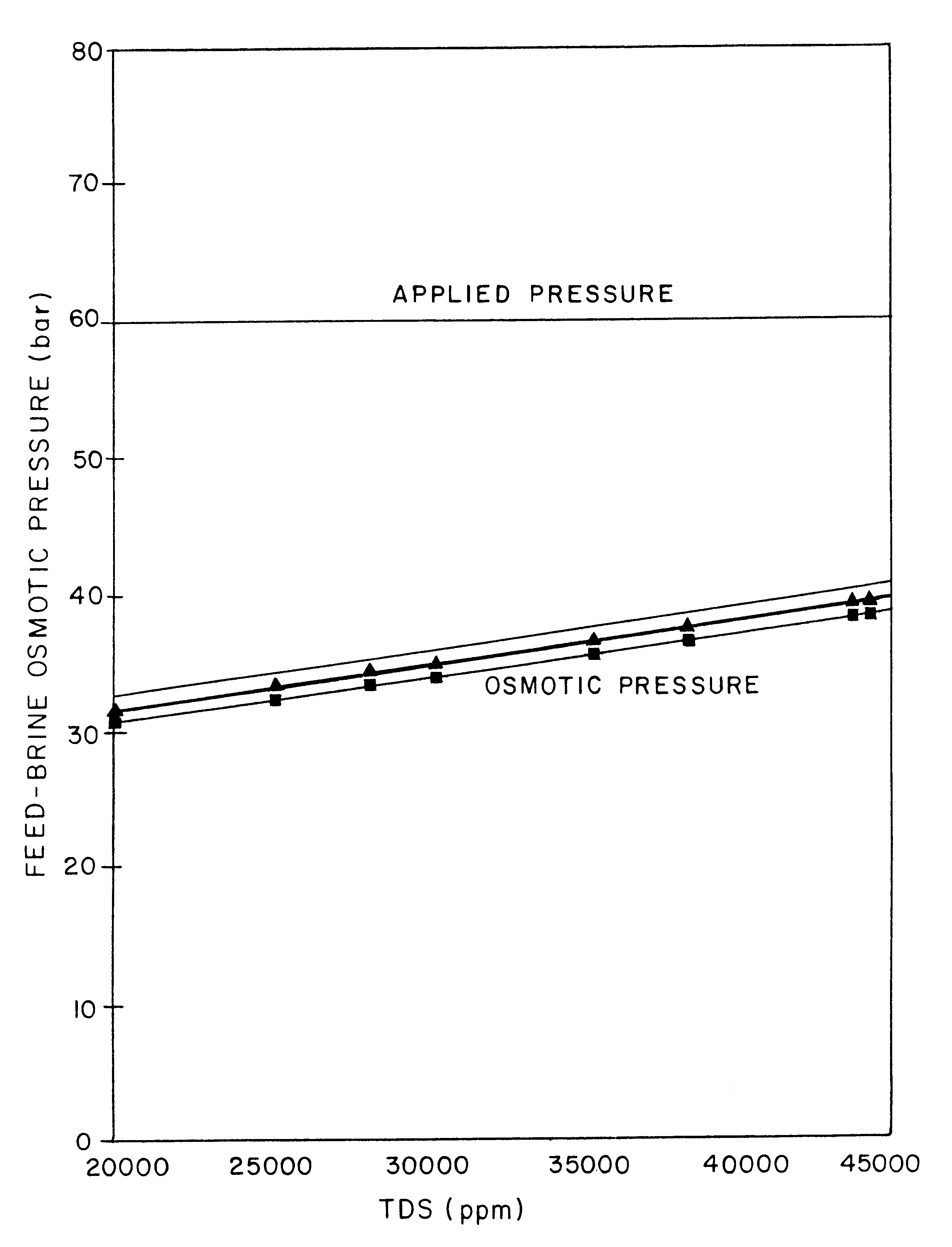

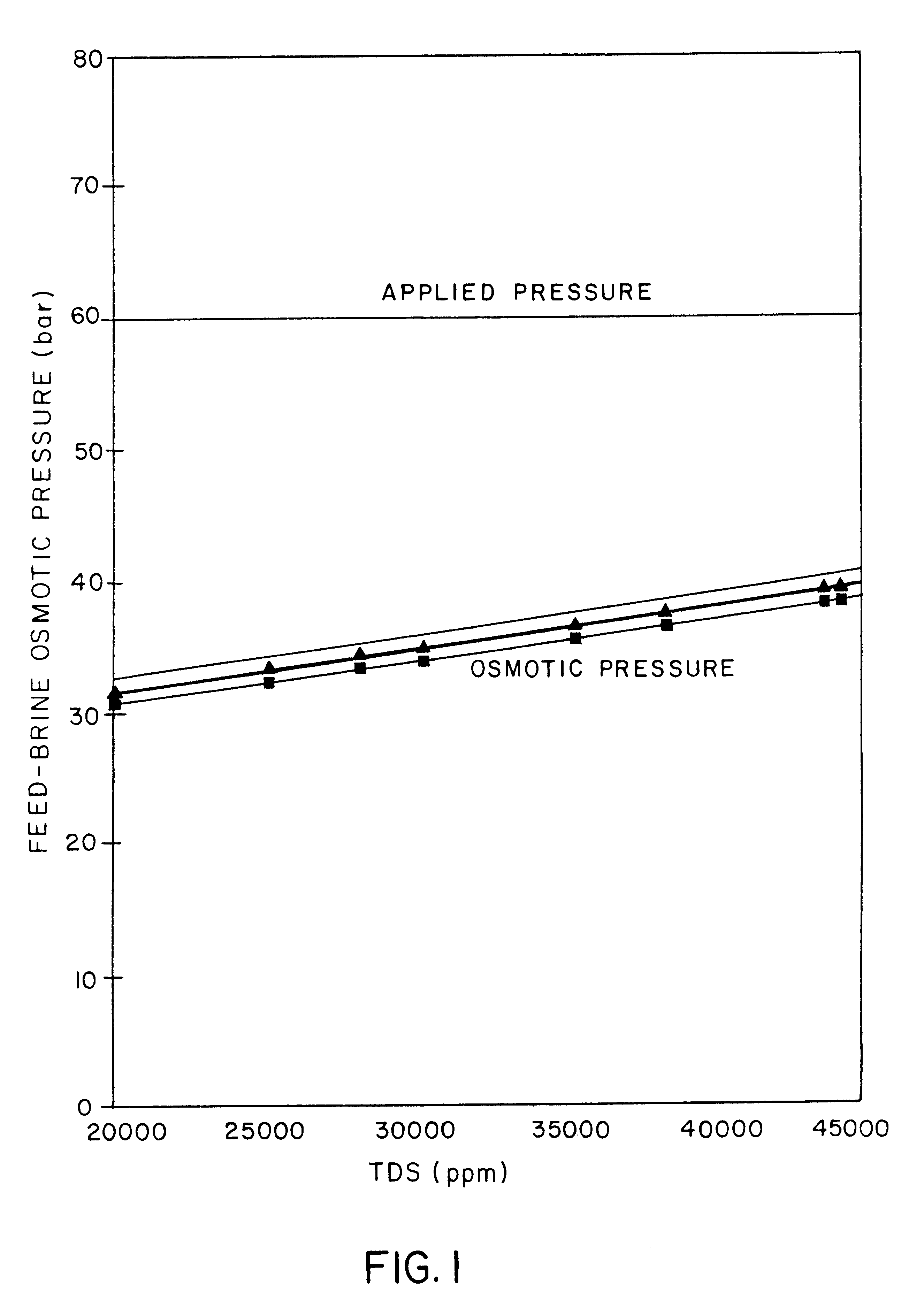

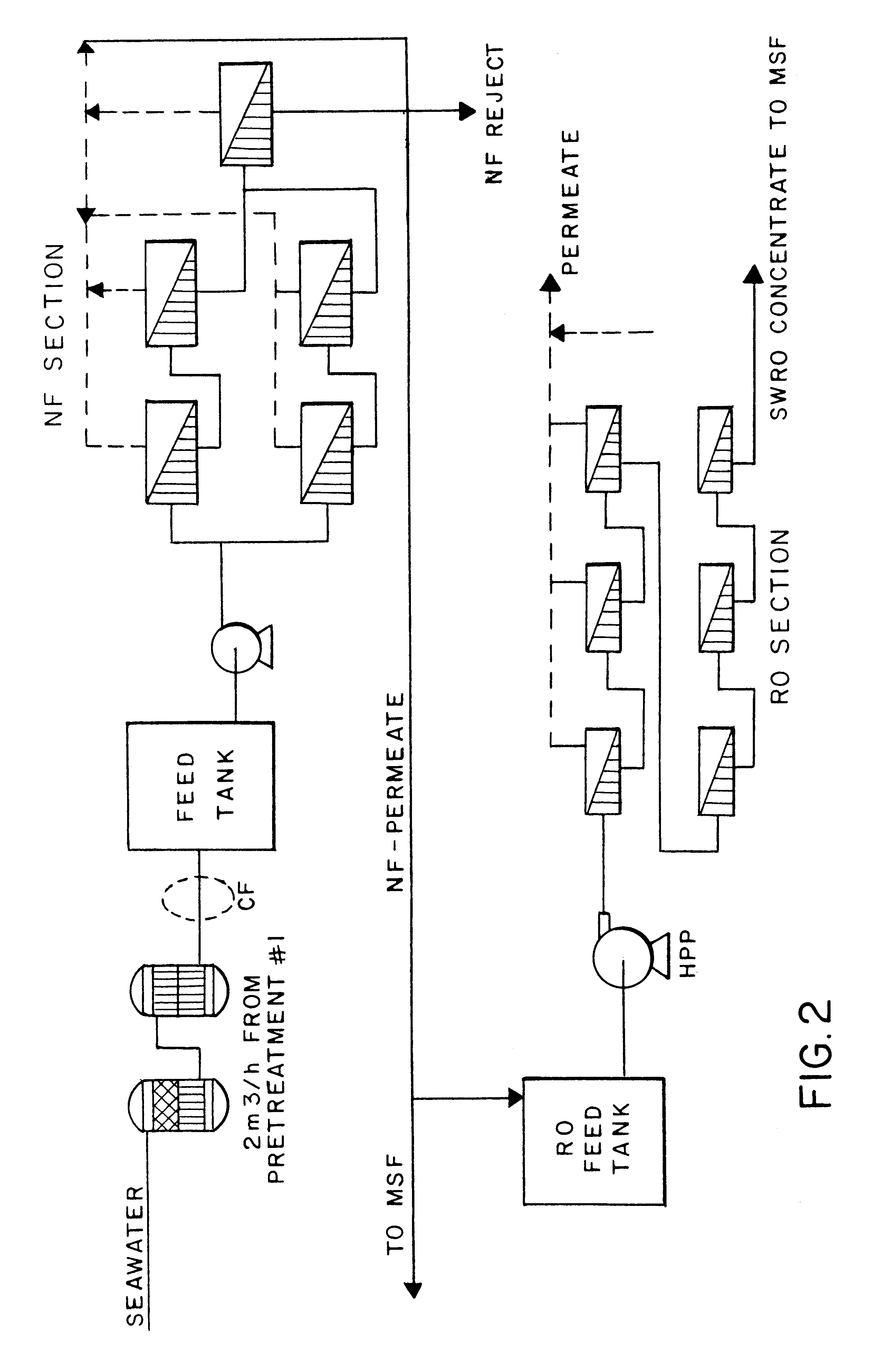

Process for desalination of saline water, especially water, having increased product yield and quality

InactiveUS6508936B1General water supply conservationSeawater treatmentTotal dissolved solidsDistillation

A desalination process is disclosed which combining two or more substantially different water treatment processes in a unique manner to desalinate saline water, especially sea water, to produce a high yield of high quality fresh water, including potable water, at an energy consumption equivalent to or less than much less efficient prior art desalination processes. In this process a nanofiltration step is synergistically combined with at least one of sea water reverse osmosis, multistage flash distillation. multieffect distillation of vapor compression distillation to provide an integrated desalination system by which sea water can be efficiently and economically converted to high quality potable water in yields which are at least 70%-80% greater than the yields available from the prior art processes. Typically a process of this invention using the nanofiltration initial step will produce, with respect to sea water feed properties, calcium, magnesium, sulfate and bicarbonate ion content reductions of 63%-94%, pH decreases of about 0.4-0.5 units and total dissolved solids content reductions of 35%-50%.

Owner:SALINE WATER CONVERSION CORP

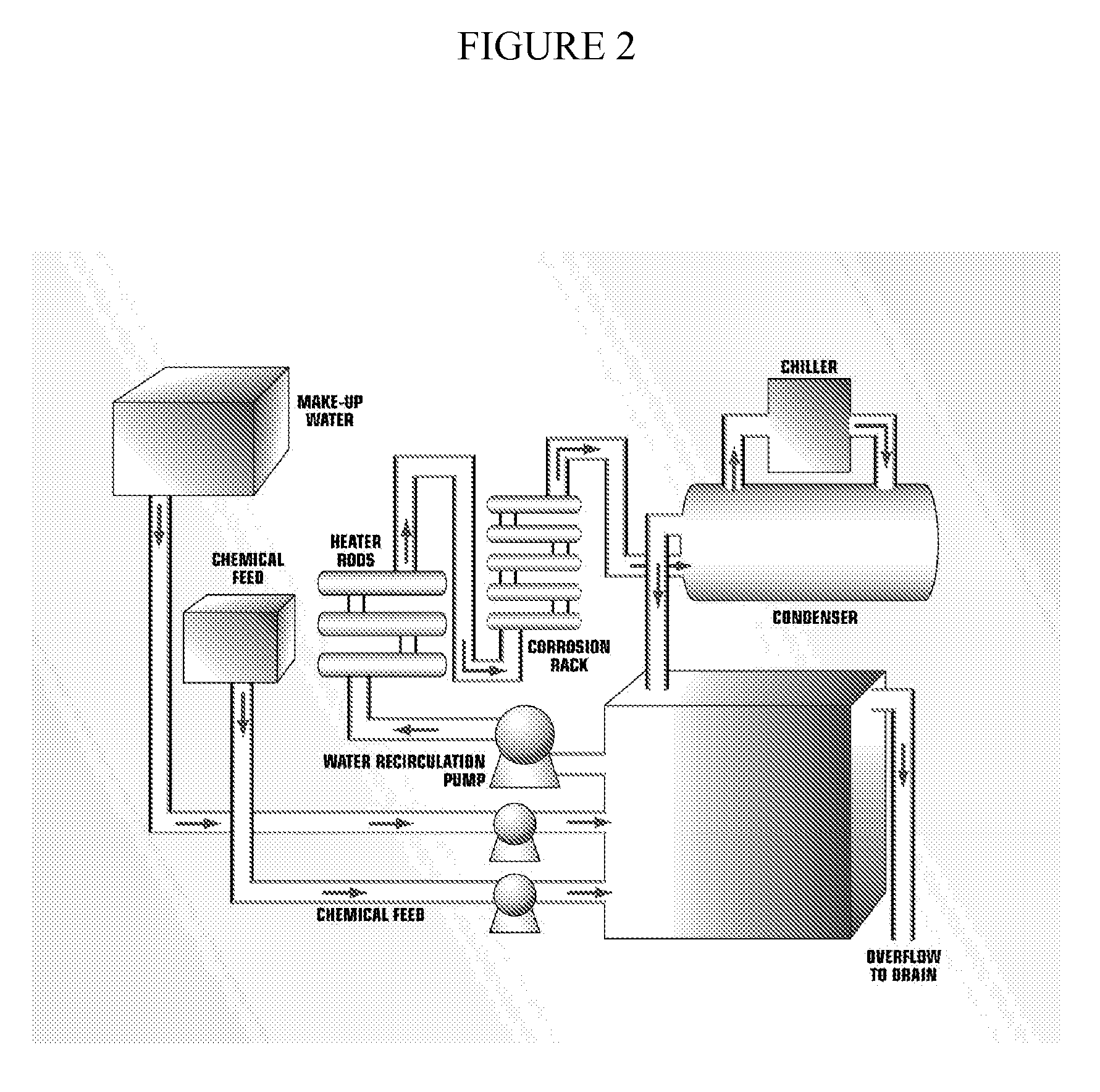

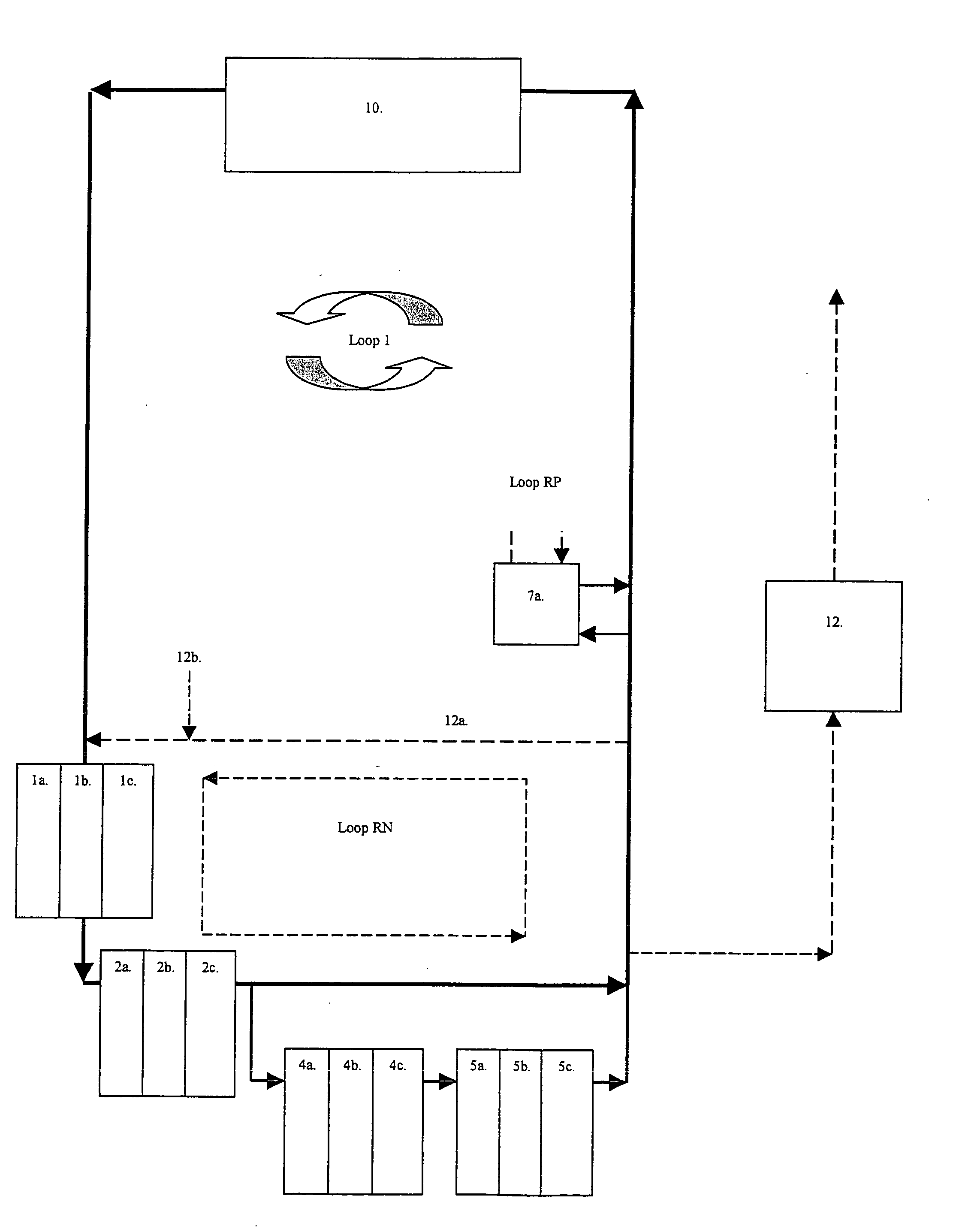

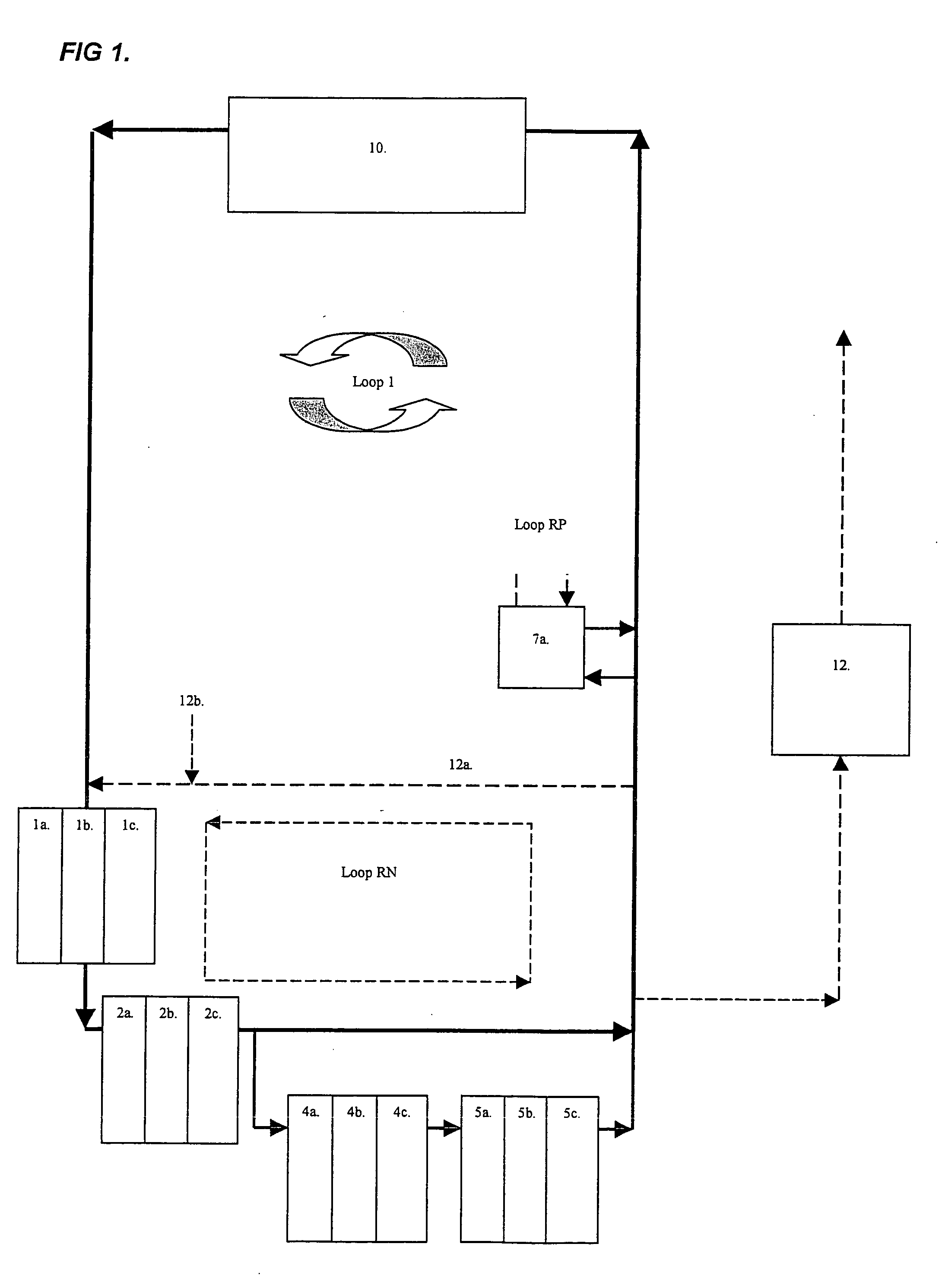

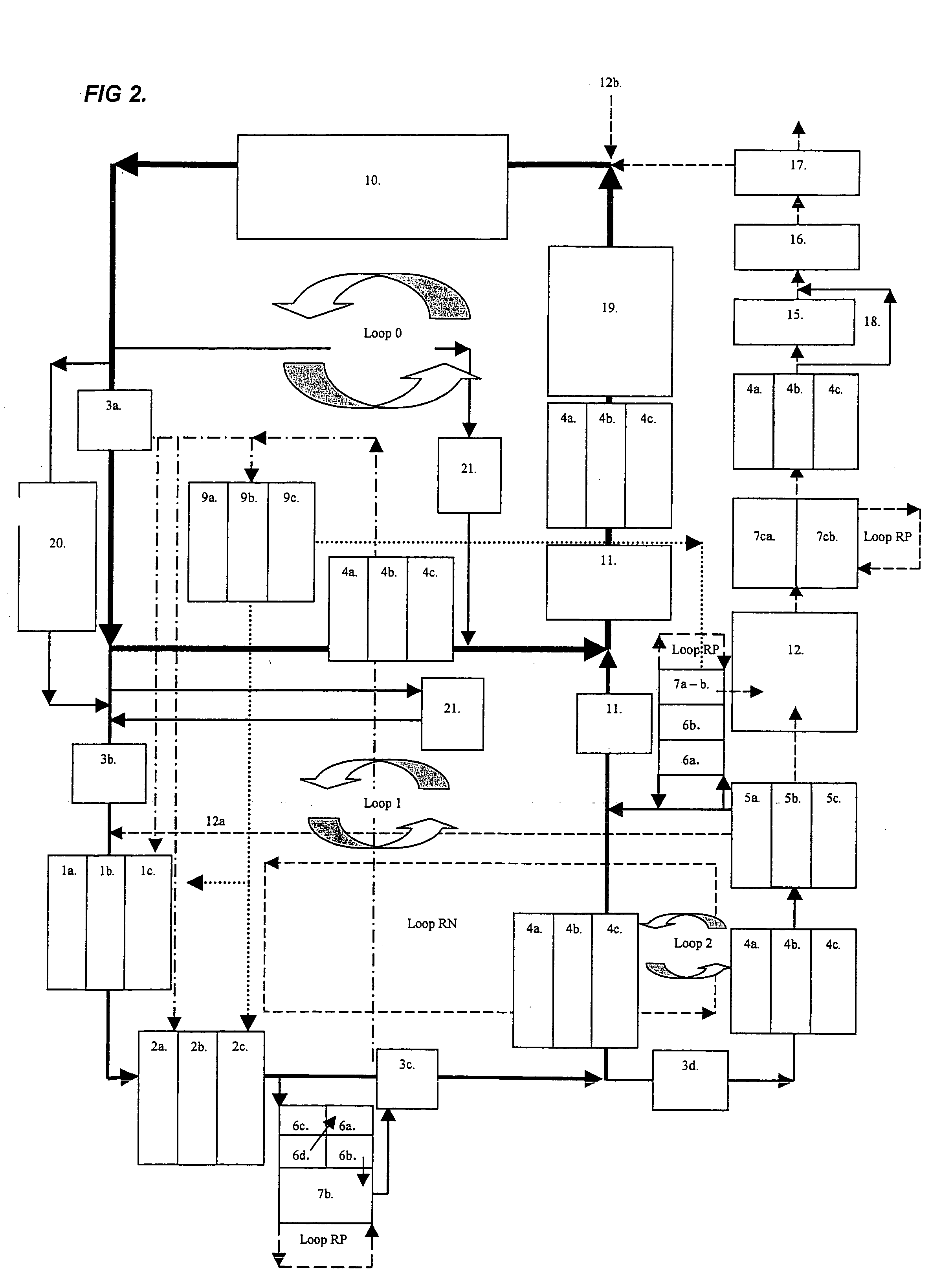

Integrated closed loop system for industrial water purification

InactiveUS7001519B2Improve purification efficiencyTreatment using aerobic processesWater/sewage treatment by irradiationOrganic matterIndustrial water

The present invention relates to an integrated closed loop system for aquaculture in at least one culturing tank and using continuous bioreactor technology for the biological treatment and removal of organic material, nitrogen and phosphorous, comprising: an integrated, partially or wholly closed loop system for waste water treatment, where the water contains nitrogen containing compounds and / or substances, comprising at least one production unit of such nitrogen containing compounds and / or substances and using continuous bioreactor technology for the biological treatment and removal of organic matter, nitrogen and phosphorous from the said water at continuous flow, comprising: a) at least one suspended carrier bioreactor for bacterial growth under anoxic conditions to cause anaerobic denitrification, with one or several compartments, preceding b) at least one suspended-carrier bioreactor for bacterial growth under oxic conditions to cause aerobic nitrification, c) the denitrification taking place after the production unit, and d) the nitrification taking place prior to the production unit in a by-pass mode as part of the continuous flow.

Owner:GREENFISH

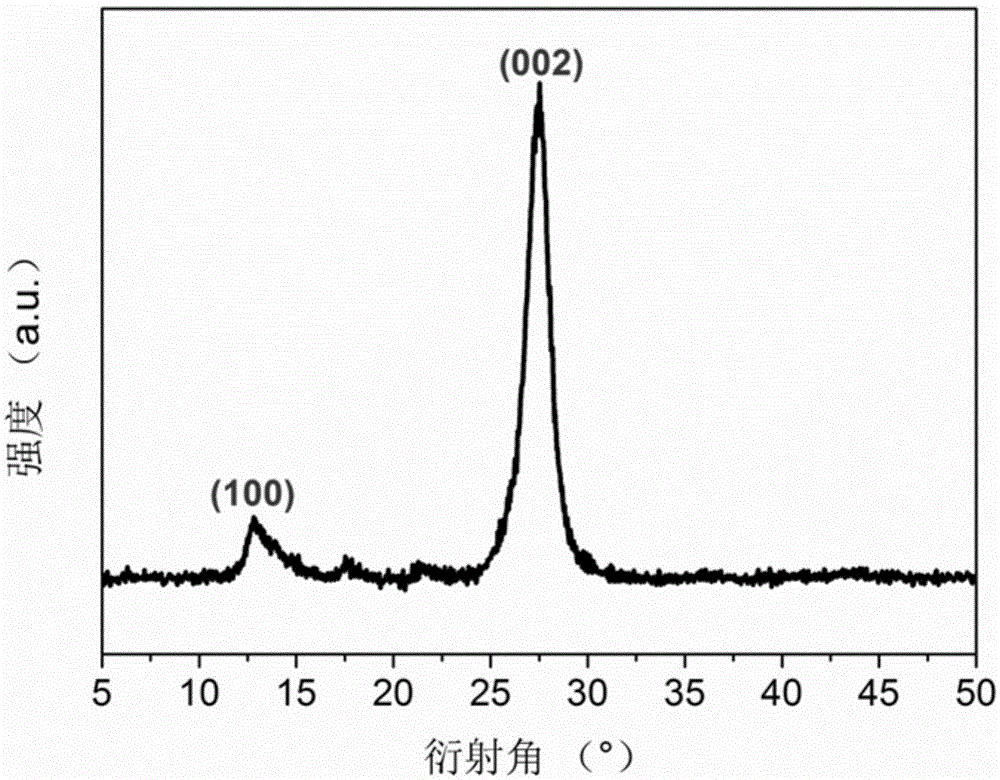

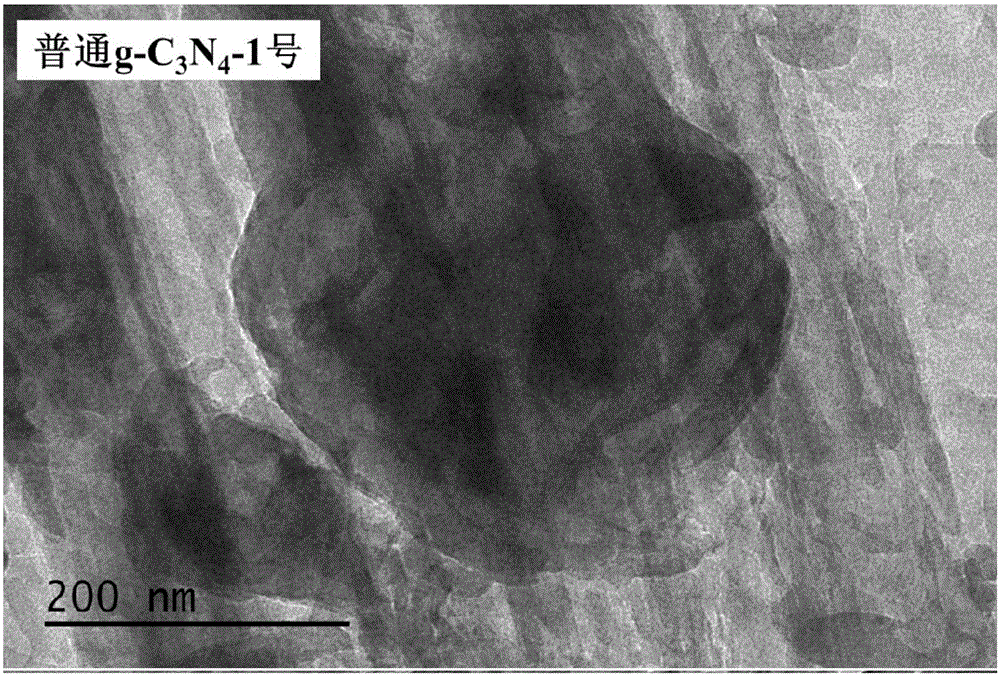

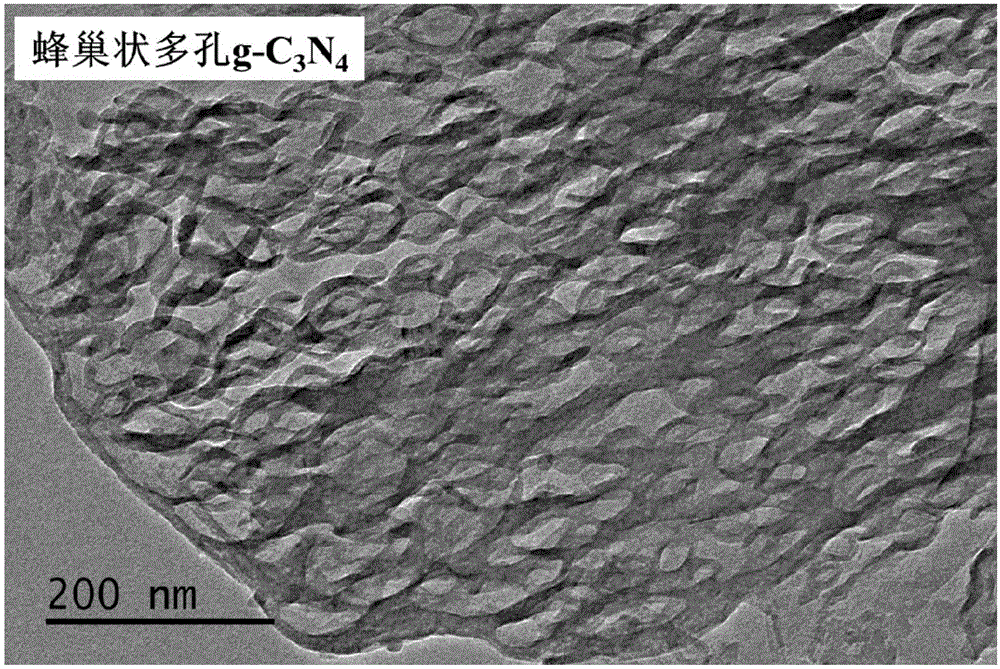

Graphite-phase carbon nitride (g-C3N4) material and preparation method and application thereof

ActiveCN105126893APlay a pore-forming roleAppropriate speedPhysical/chemical process catalystsWater/sewage treatment by irradiationCalcinationMaterials science

The invention relates to a method for preparing a graphite-phase carbon nitride (g-C3N4) material. The method includes the steps that a carbon nitride precursor and ammonium salt are evenly mixed, and then calcination is conducted so that the porous g-C3N4 material can be obtained. The ammonium salt is any one of ammonium base salts capable of generating ammonia gas through thermal decomposition or is the combination of at least two of the ammonium base salts. In the preparation process of the g-C3N4 material, the ammonium salt is added into the carbon nitride precursor to be mixed. In the high-temperature calcining process, the ammonium salt is subjected to pyrogenic decomposition to generate gas, a pore-forming effect on the g-C3N4 material is achieved, and the cellular porous g-C3N4 material is obtained. In the preparation process of the g-C3N4 material, template agents are not used, and thus the method is simple, efficient and environmentally friendly; the prepared g-C3N4 material is high in photocatalytic activity and can be used in the pollution control processes such as exhaust gas and wastewater treatment.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

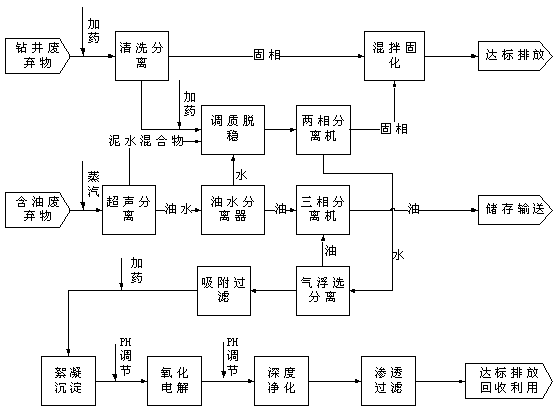

Method for comprehensive treatment of oilfield waste

ActiveCN102849880BSolve the use problemMeet the actual needs of protectionWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesElectrolysisSludge

The invention discloses a method for comprehensive treatment of oilfield waste, which is characterized by comprising the process steps of cleaning and separation, ultrasonic separation, tempering and destabilization, oil-water separation, centrifugal separation, mixed curing, air floatation separation, adsorption filtration, flocculating settling, oxidization electrolysis, deep purification and permeable filtration. Thus, the oilfield waste is treated and utilized in a classified manner, so that sump oil is recovered, the solid phase achieves the discharge standard of oilfield sludge treatment design specifications (SY / T6851-2012) or is reutilized for construction material manufacturing, and the liquid phase achieves the sewage comprehensive discharge standard (GB8978-1996) after being subjected to water treatment.

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

Composite semipermeable membrane, processfor producing the same, and method of purifying water with the same

InactiveUS6406626B1Semi-permeable membranesWater/sewage treatment bu osmosis/dialysisPurification methodsHigh rate

The present invention relates to a composite semipermeable membrane which is characterized in that it is a composite semipermeable membrane in which there is formed by polycondensation on top of a microporous support membrane a crosslinked polyamide ultra-thin membrane layer from polyfunctional amine, polyfunctional acid halide and polyfunctional acid anhydride halide, and the flow of water permeate at an operating pressure of 0.3 MPa, a temperature of 25° C. and a pH of 6.5 lies in the range from 0.8 to 4.0 m3 / m2.day and, furthermore, the percentage humic acid removal is at least 98%; a method for the production thereof; and a water purification method employing same. With the composite semipermeable membrane obtained by means of the present invention it is possible, in particular, to recover drinking water at a high rate by permitting passage of silica and preventing deposition thereof at the membrane surface while selectively separating / removing the pollutants and trace quantities of harmful materials and their precursors, etc, contained in the raw water in water treatment plants.

Owner:TORAY IND INC

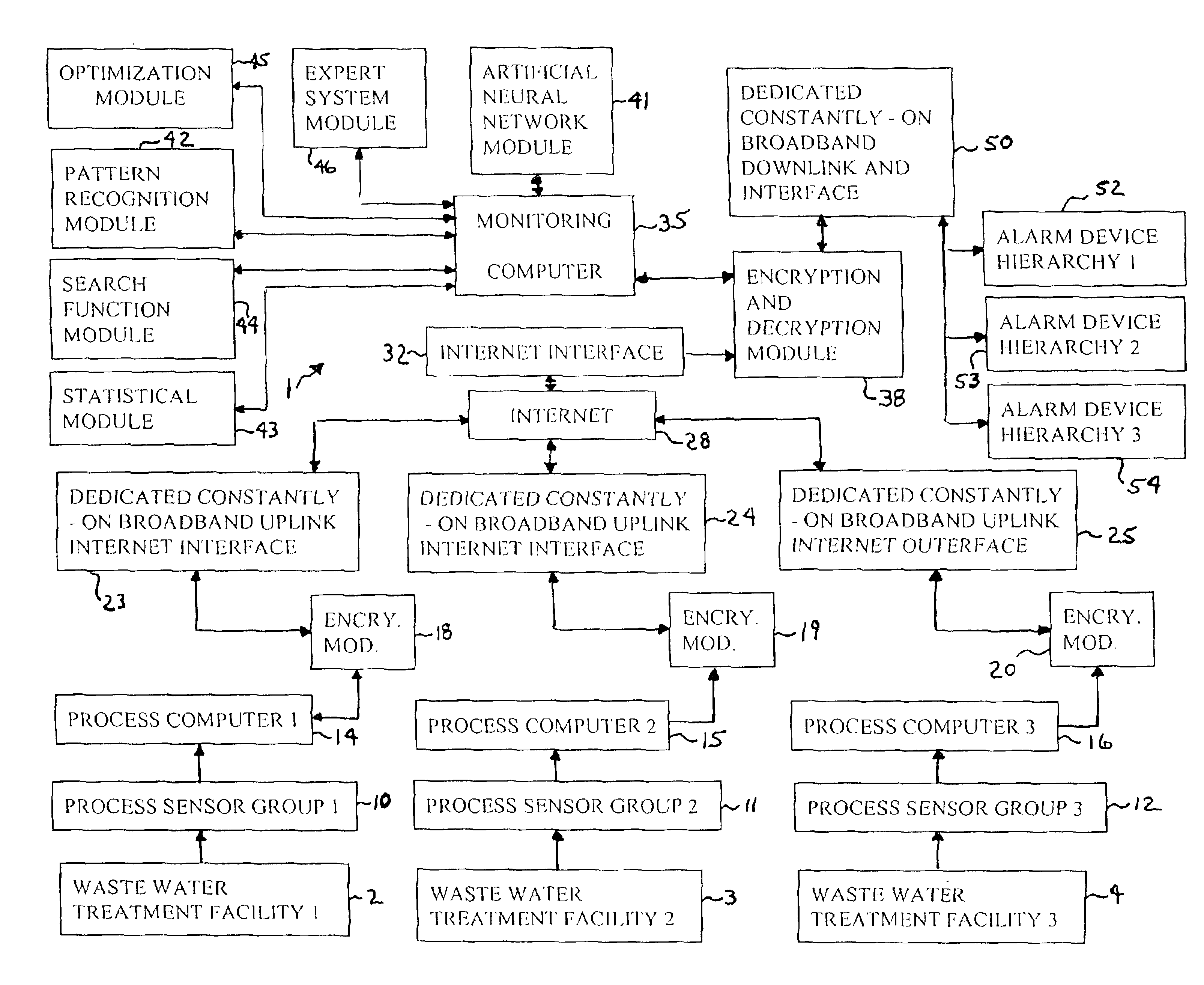

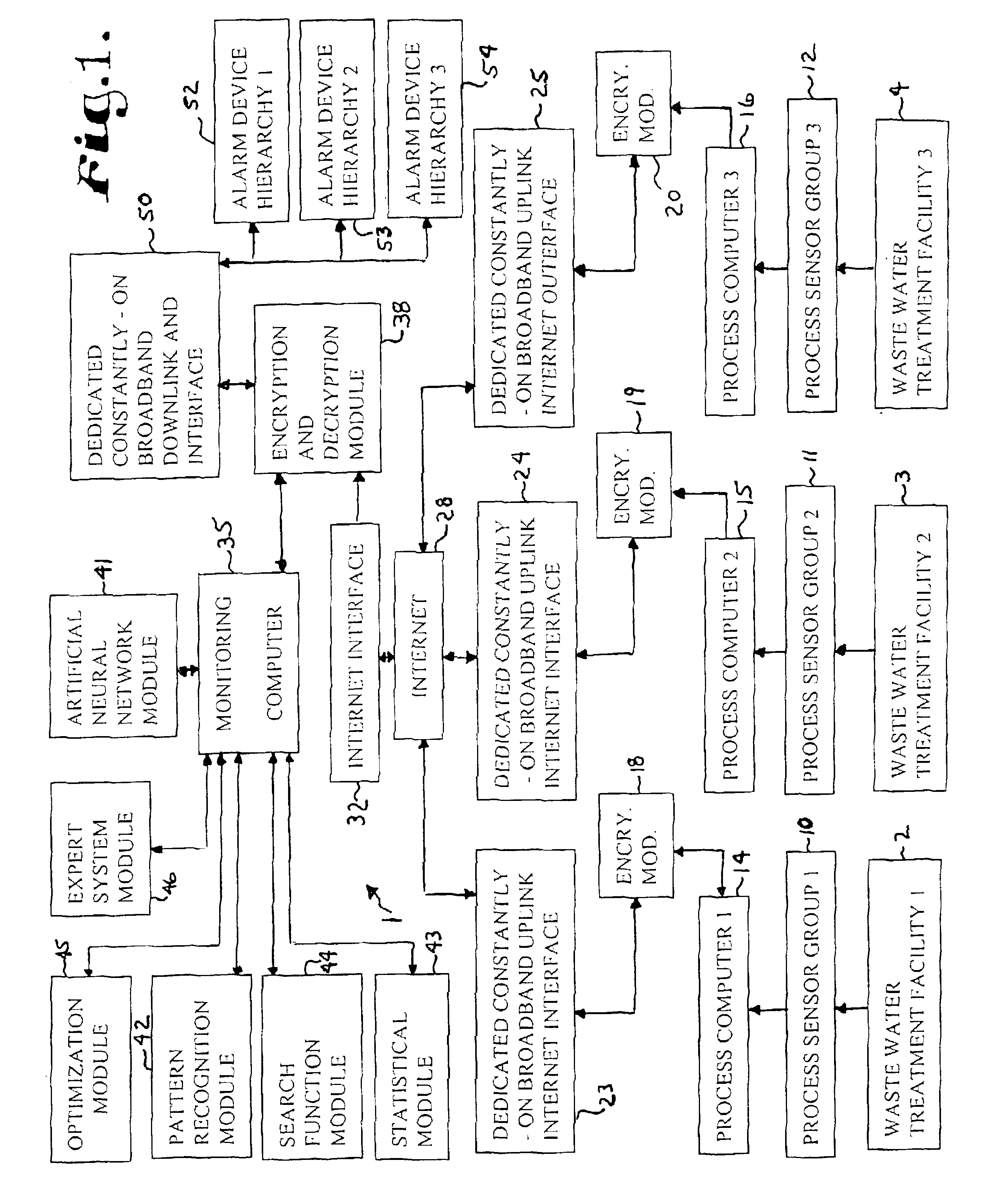

Water treatment monitoring system

InactiveUS6845336B2Reduce severityBackingTesting/calibration apparatusElectrical testingReal-time dataAnalysis data

A computer system linked by the internet to various remote waste water treatment facilities. The system receives real-time data from the facilities and analyzing the data to determine likely operational upsets and future effluent water quality. The computer system sends signals to a hierarchy of parties depending on the severity of predicted upsets problems and events. The computer also provides a probability distribution of such upsets and water quality and recommendations as how to adjust facility operating parameters to avoid or reduce the upsets to acceptable parameters and maintain effluent water quality parameters within preselected limits.

Owner:NEOCHLORIS

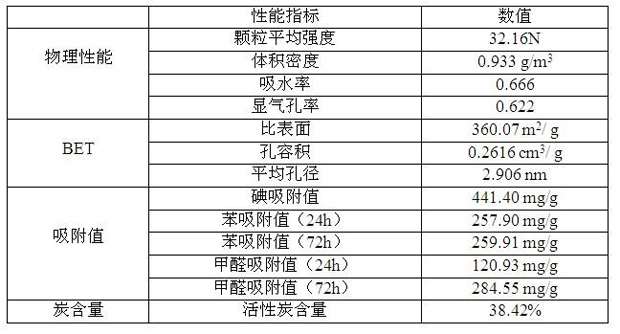

Activated alumina and activated carbon compounded material and preparation method thereof

InactiveCN101890336AAchieve the perfect combinationEasy to useCatalyst carriersOther chemical processesActivated carbonAir purification

The invention provides an activated alumina and activated carbon compounded material and a preparation method thereof. According to a formula, the material comprises the following raw materials in percentage by mass: 40 to 99 percent of aluminum hydroxide, 1 to 60 percent of activated carbon, and 15 to 35 percent of binder. The material is prepared by uniformly mixing, pelleting, ageing, molding, airing, sintering, rinsing, drying and the like. The invention aims to compound the activated carbon with the activated alumina; on the one hand, the material with a certain shape can be processed, the defects of loose shape, low strength, difficult recovery and the like of the activated carbon are overcome, and the material is easy to recycle; and on the other hand, the adsorption property of the activated alumina material is greatly improved. The method has the advantages of simpleness, practicality, readily available raw materials, low cost and suitability for industrial mass production, and can be widely applied to various fields such as industry, agriculture, environmental protection, air purification, water treatment and the like.

Owner:FUZHOU UNIV

Magnetic biological carrier and preparation method thereof

InactiveCN102225806APromote recoveryRealize dynamic regenerationSustainable biological treatmentBiological water/sewage treatmentResource utilizationEngineering

The invention discloses a magnetic biological carrier and a preparation method thereof. The raw materials of the magnetic biological carrier comprise aggregate, iron oxide, a binder and a reducing agent. The preparation method of the magnetic biological carrier comprises the following steps of: mixing the aggregate, iron oxide and the reducing agent, crushing, screening with a 60-mesh sieve to obtain a mixed material, adding water which is 30-60% of the mixed material by weight to the binder, stirring for dissolving the binder to obtain a binder solution, then mixing the binder solution with the mixed material, uniformly stirring, granulating and shaping to obtain 2-10 mm granules, drying the granules till the water content of the granules is less than 10%, and calcining at the temperature of 350-1100 DEG C for 0.2-10 hours to obtain the magnetic biological carrier. The magnetic biological carrier provided by the invention can be applied to the deep treatment of secondary treatment water of domestic sewage, meets the requirements of landscape water replenishing and circulating cooling water treatment, and can be used for realizing the deep treatment and resource utilization of industrial wastewater.

Owner:HEFEI UNIV OF TECH

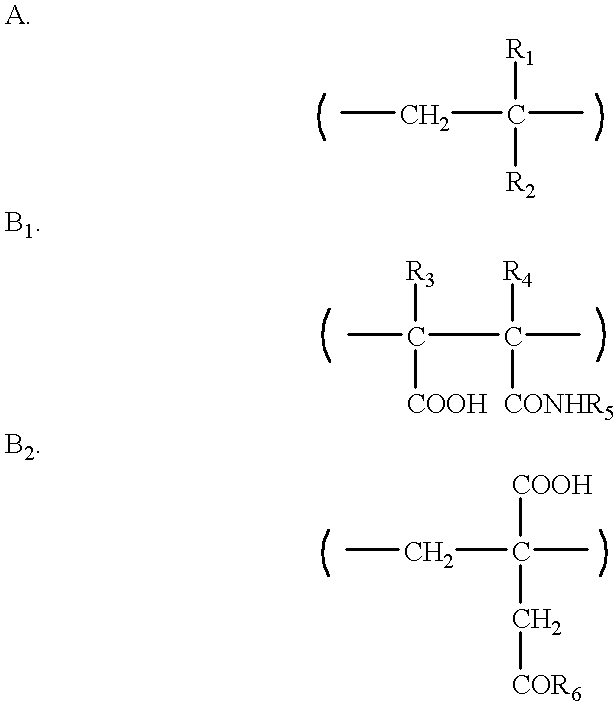

Modified Polysaccharides

InactiveUS20070015678A1Little and no calcium bindingLittle and no and co-building propertyTransportation and packagingWater softeningPolysaccharide VaccinePolysaccharide

Modified polysaccharide polymers for use as anti-scalant and dispersant. The polymers are useful in compositions used in aqueous systems. The modified polysaccharides are also useful in detergent formulations, water treatment, dispersants and oilfield applications and as fiberglass binders. Such applications include a modified polysaccharide having up to about 70 mole % carboxyl groups per mole of polysaccharide ASU and up to about 20 mole % aldehyde groups per mole of polysaccharide ASU. The applications can also include a blend of modified polysaccharides and other synthetic polymers.

Owner:AKZO NOBEL NV

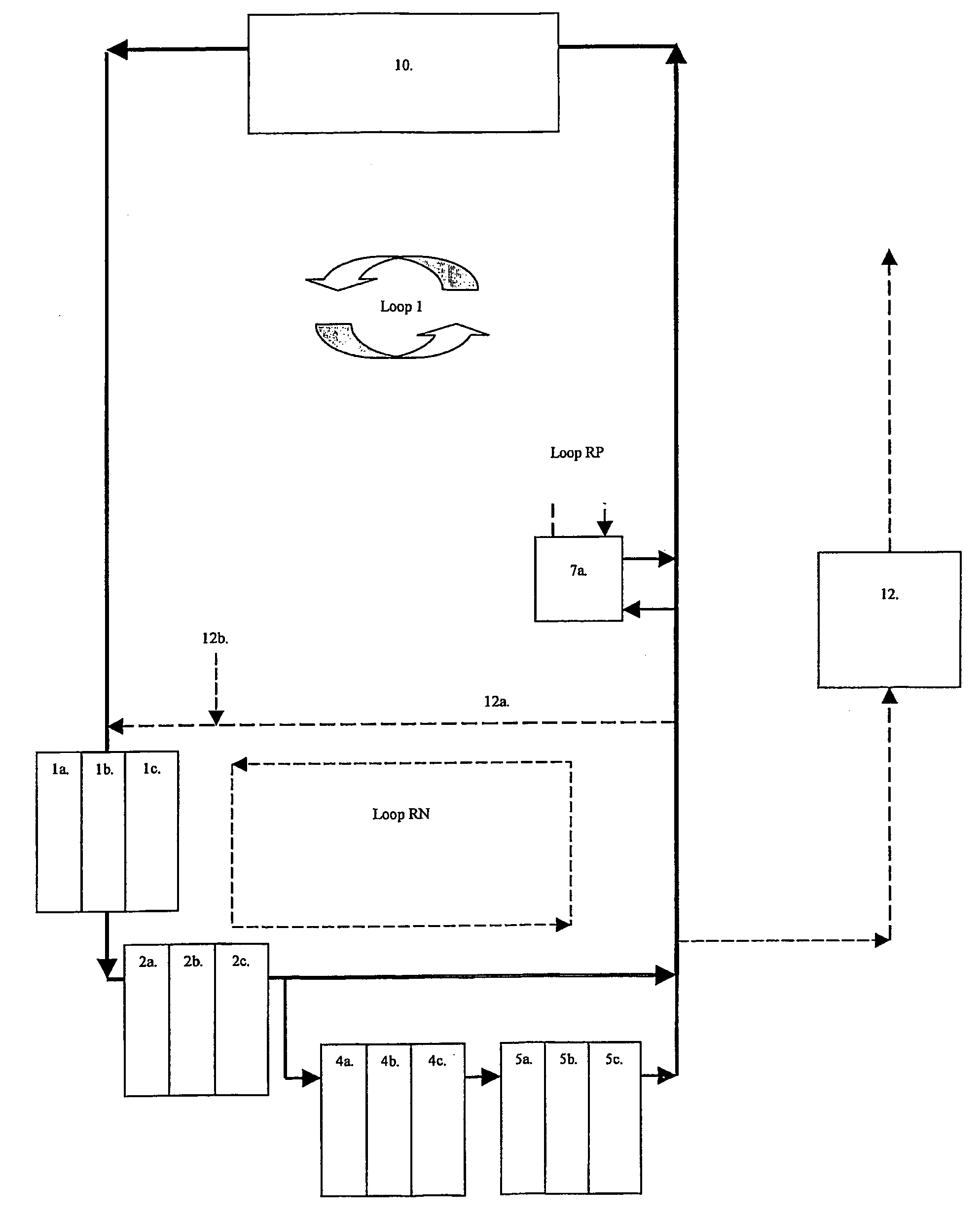

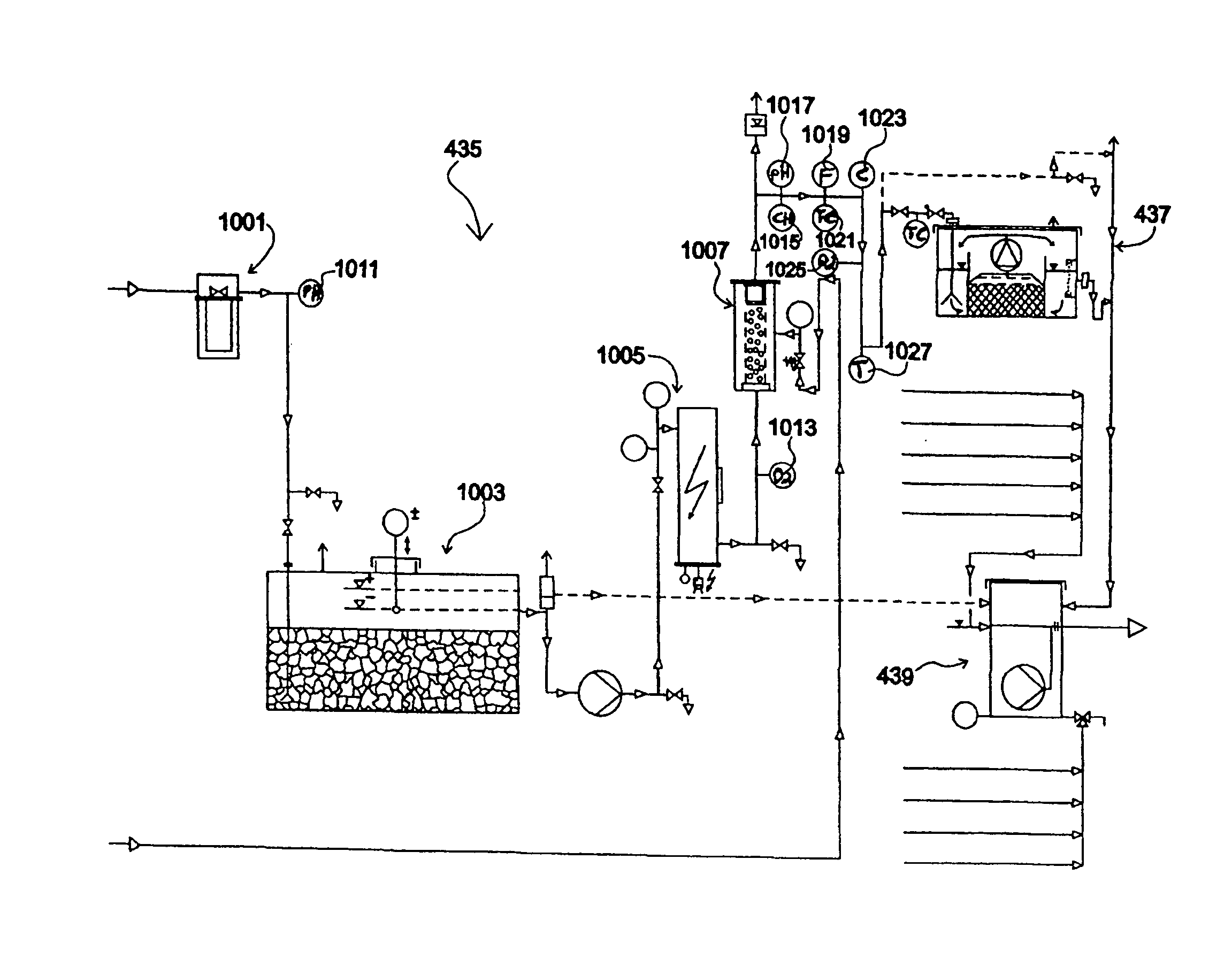

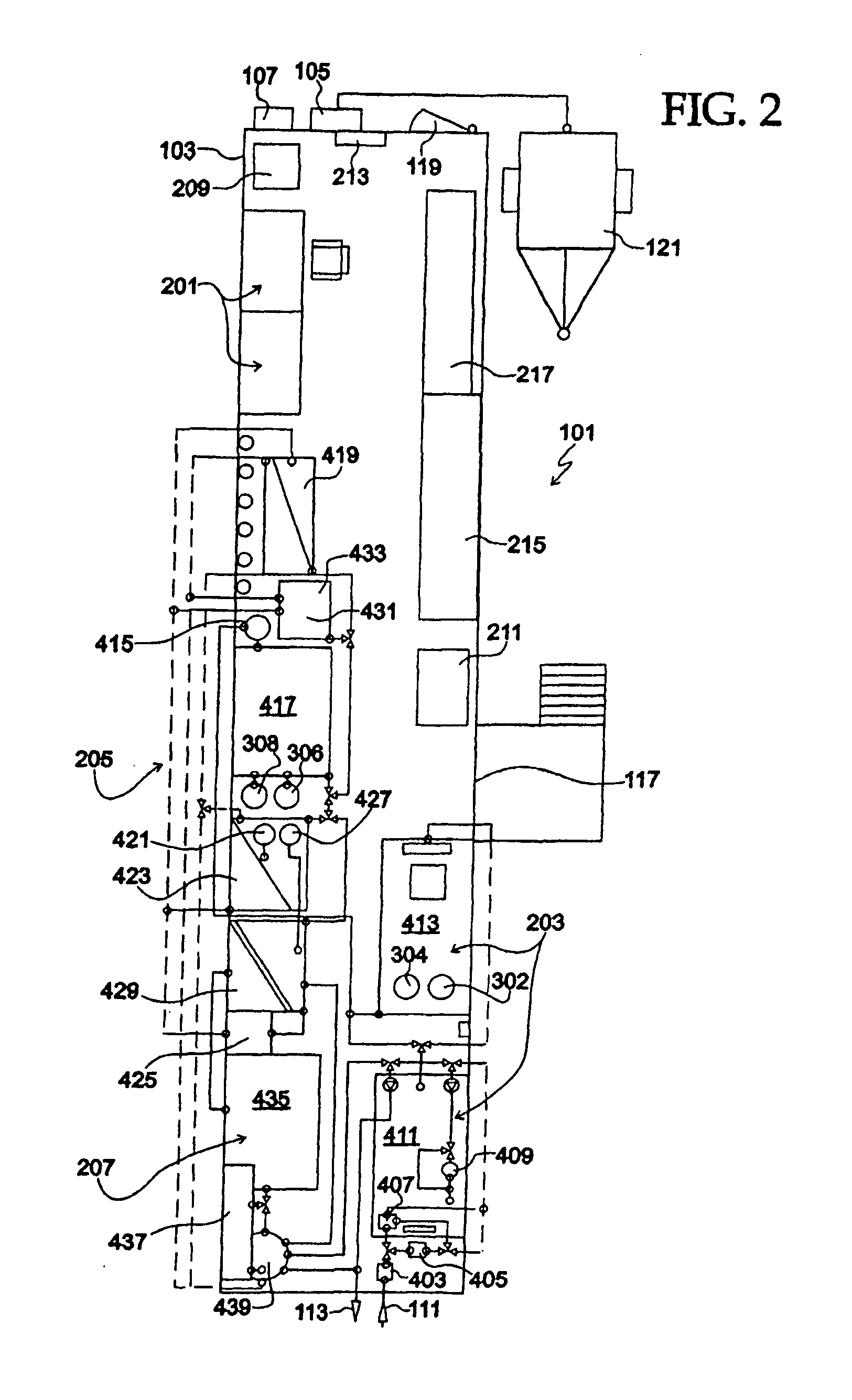

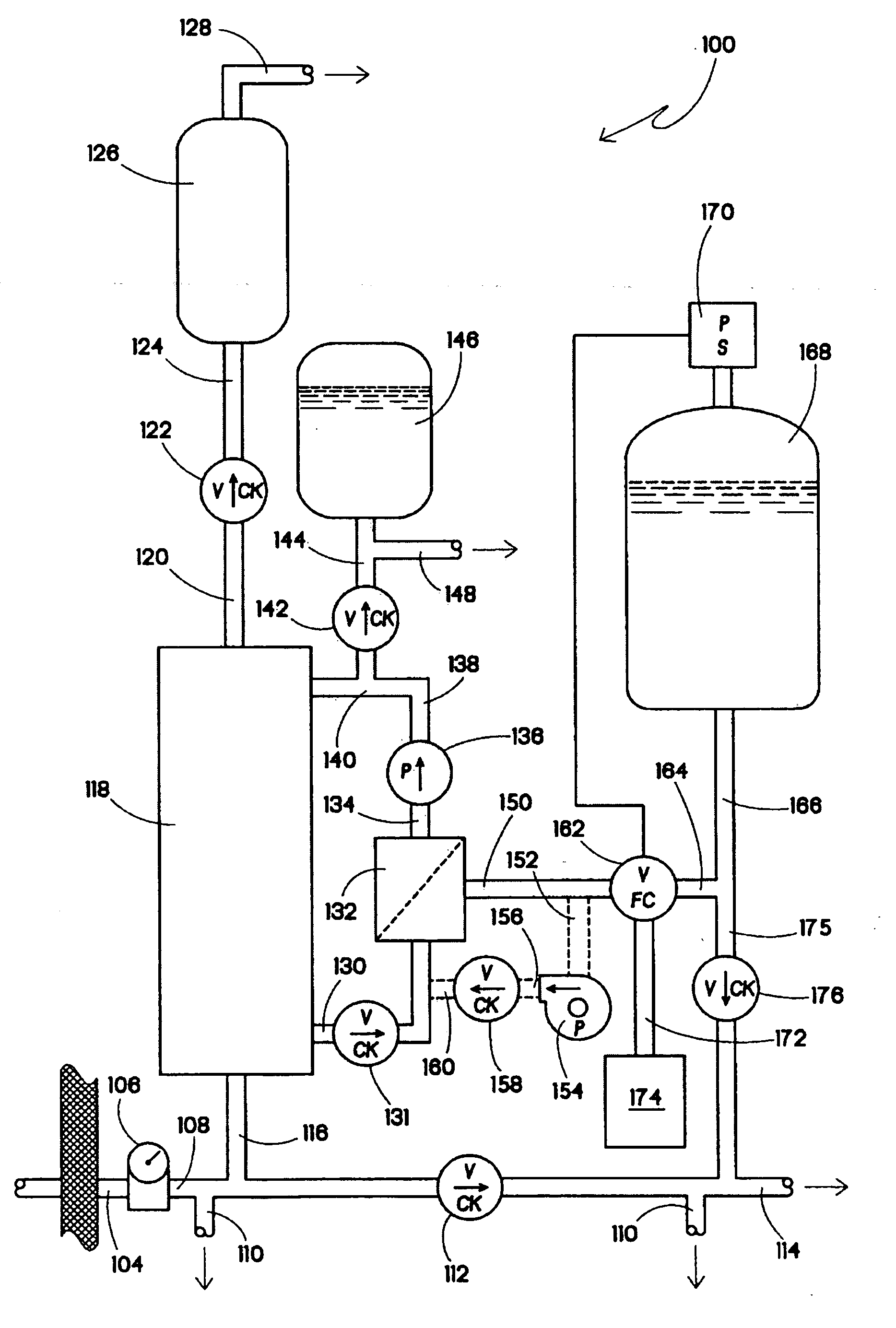

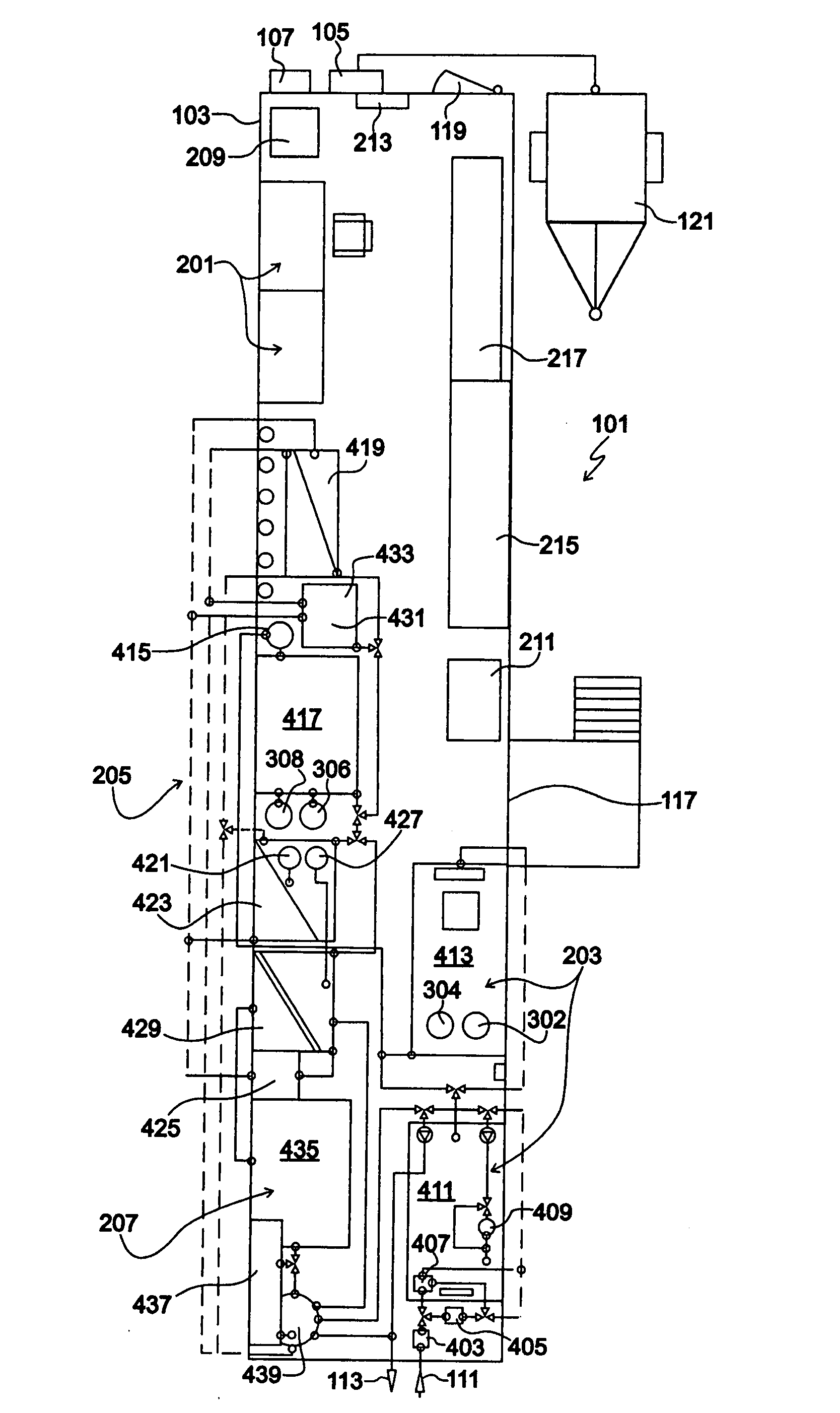

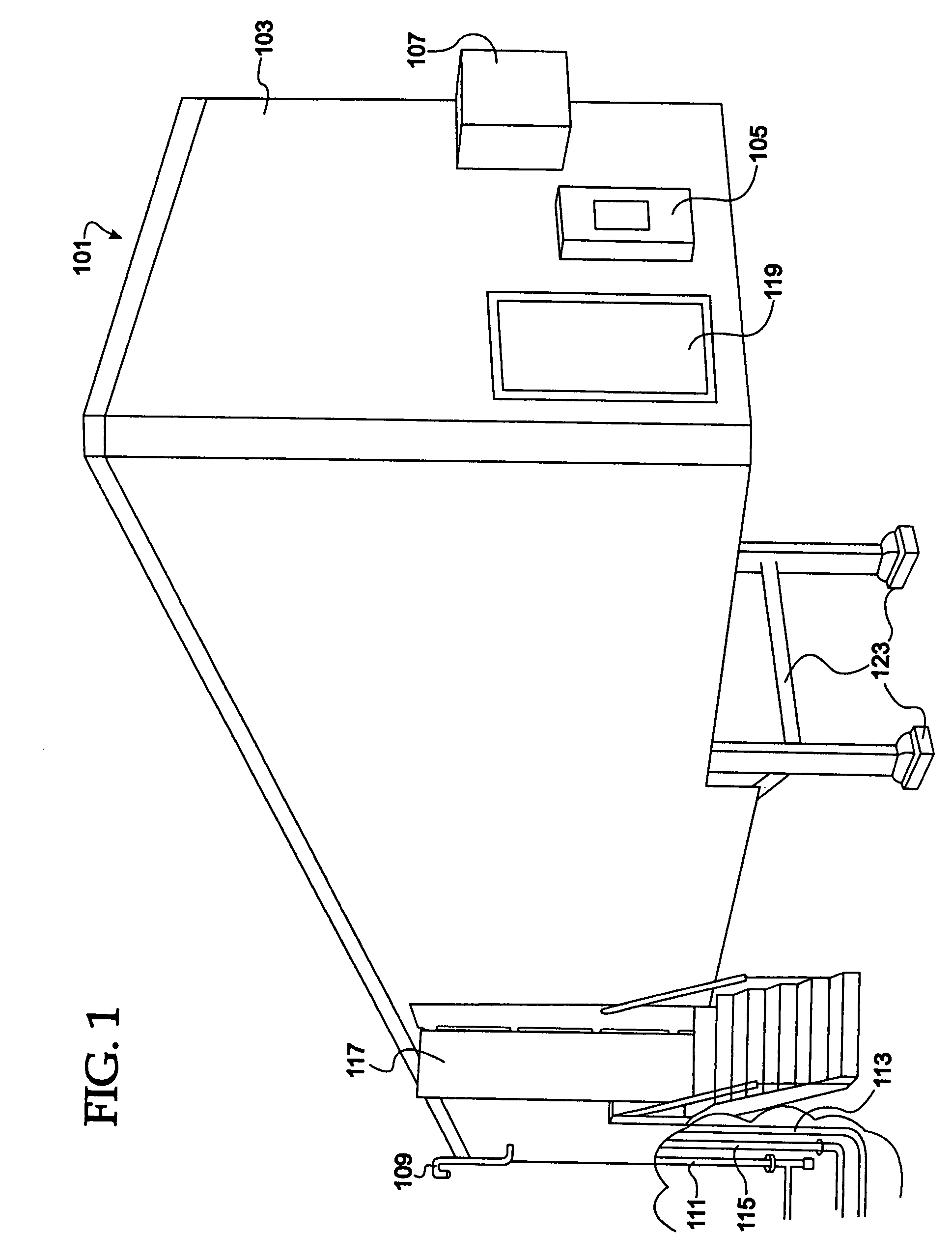

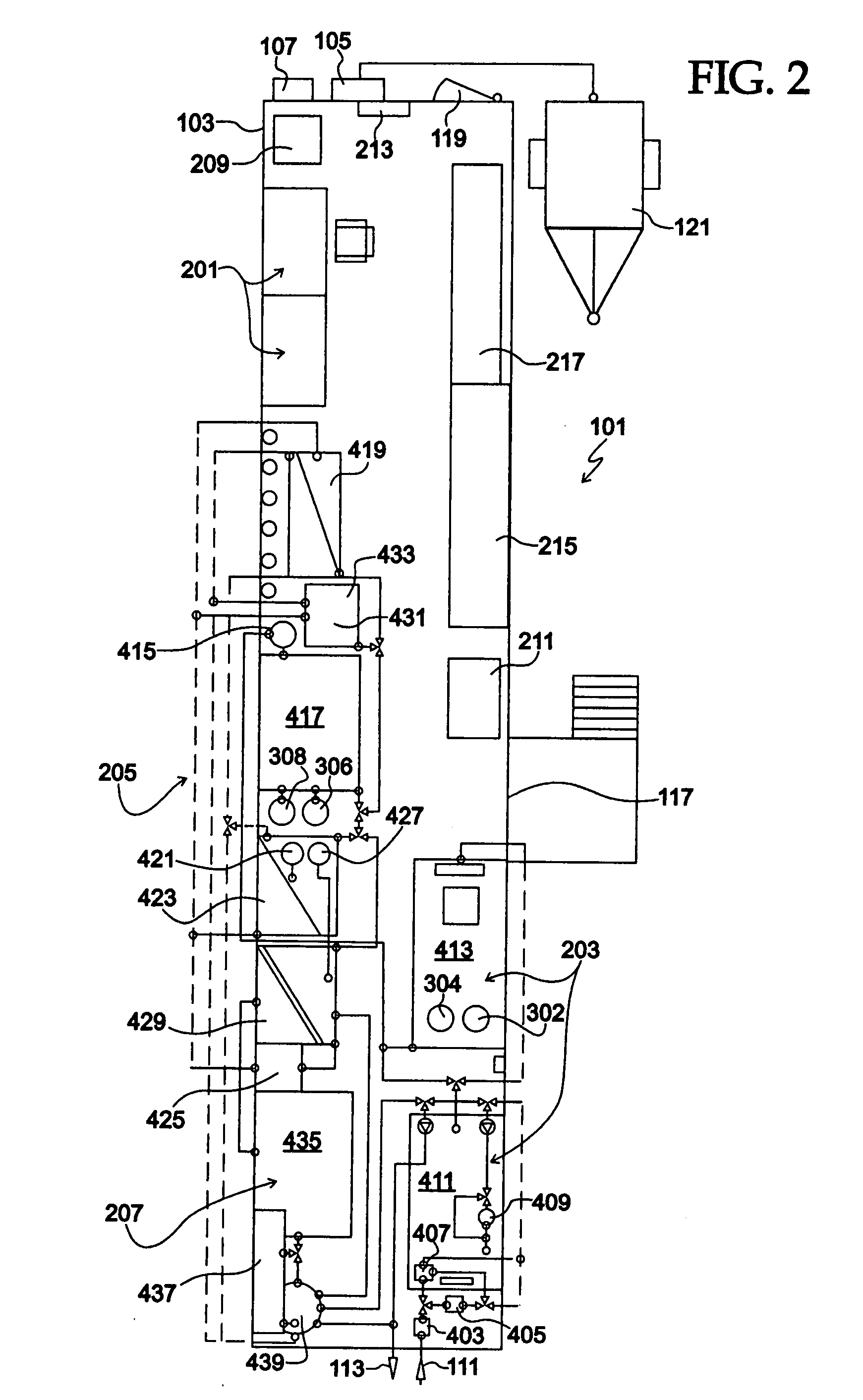

Mobile station and methods for diagnosing and modeling site specific full-scale effluent treatment facility requirements

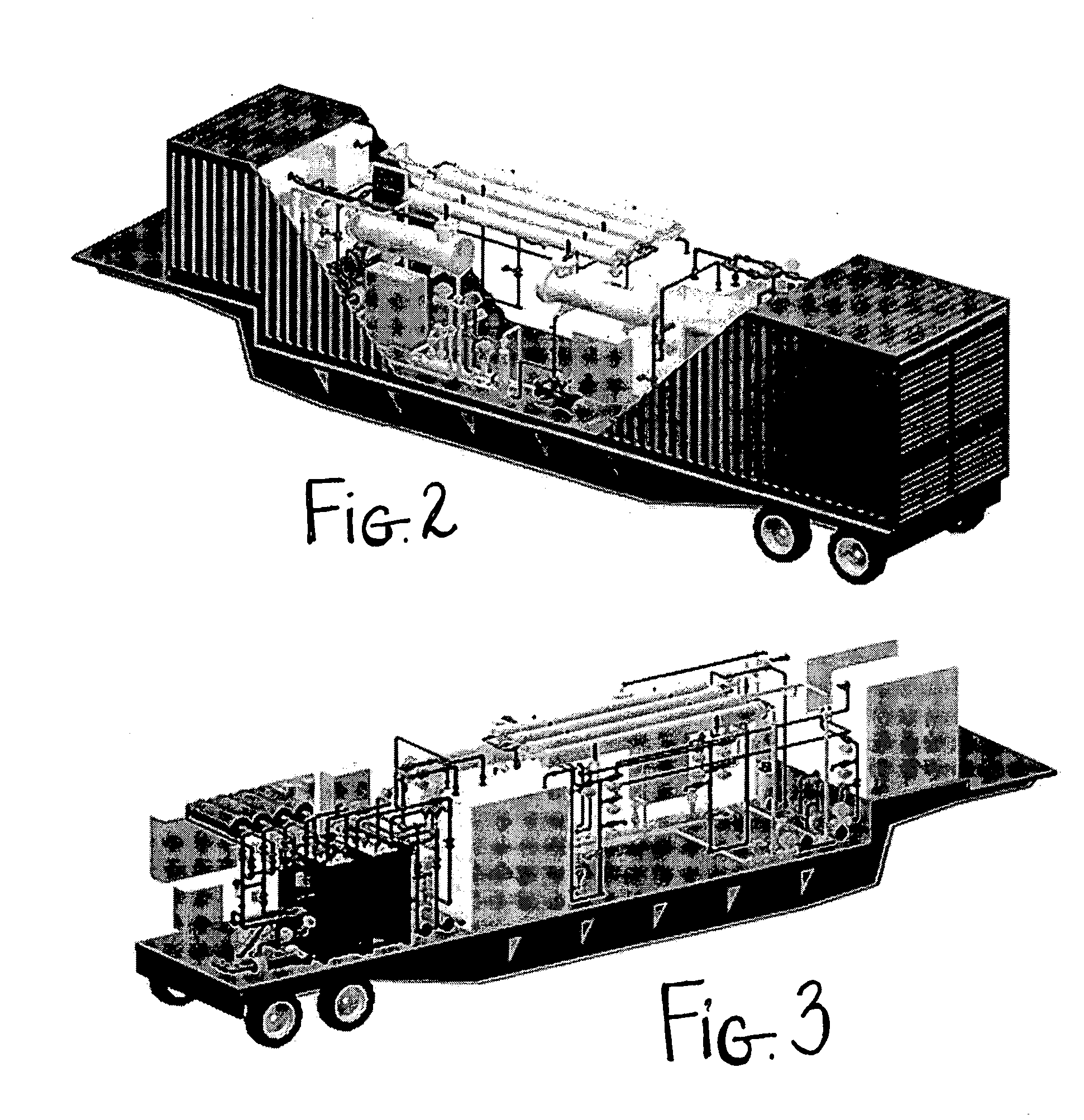

InactiveUS20110257788A1Reduce financial riskHigh continuity of operationWater/sewage treatment by neutralisationSustainable biological treatmentInitial treatmentIon exchange

A mobile station and methods are disclosed for diagnosing and modeling site specific effluent treatment facility requirements to arrive at a treatment regimen and / or proposed commercial plant model idealized for the particular water / site requirements. The station includes a mobile platform having power intake, effluent intake and fluid outflow facilities and first and second suites of selectably actuatable effluent pre-treatment apparatus. An effluent polishing treatment array is housed at the station and includes at least one of nanofiltration, reverse osmosis and ion-exchange stages. A suite of selectively actuatable post-treatment apparatus is housed at the station. Controls are connected at the station for process control, monitoring and data accumulation. A plurality of improved water treatment technologies is also disclosed. The modeling methods include steps for analyzing raw effluent to be treated, providing a field of raw effluent condition entry values and a field of treated effluent condition goals entry values, and utilizing said fields to determine an initial treatment model including a selection of, and use parameters for, treatment technologies from the plurality of down-scaled treatment technologies at the facility, the model dynamically and continuously modifiable during treatment modeling.

Owner:ROCKWATER RESOURCE

Integrated closed loop system for industrial water purification

InactiveUS20050061737A1Small surface areaIncreasing biofilm thicknessTreatment using aerobic processesWater/sewage treatment by irradiationOrganic matterIndustrial water

The present invention relates to an integrated closed loop system for aquaculture in at least one culturing tank and using continuous bioreactor technology for the biological treatment and removal of organic material, nitrogen and phosphorous, comprising: an integrated, partially or wholly closed loop system for waste water treatment, where the water contains nitrogen containing compounds and / or substances, comprising at least one production unit of such nitrogen containing compounds and / or substances and using continuous bioreactor technology for the biological treatment and removal of organic matter, nitrogen and phosphorous from the said water at continuous flow, comprising: a) at least one suspended carrier bioreactor for bacterial growth under anoxic conditions to cause anaerobic denitrification, with one or several compartments, preceding b) at least one suspended-carrier bioreactor for bacterial growth under oxic conditions to cause aerobic nitrification, c) the denitrification taking place after the production unit, and d) the nitrification taking place prior to the production unit in a by-pass mode as part of the continuous flow.

Owner:GREENFISH

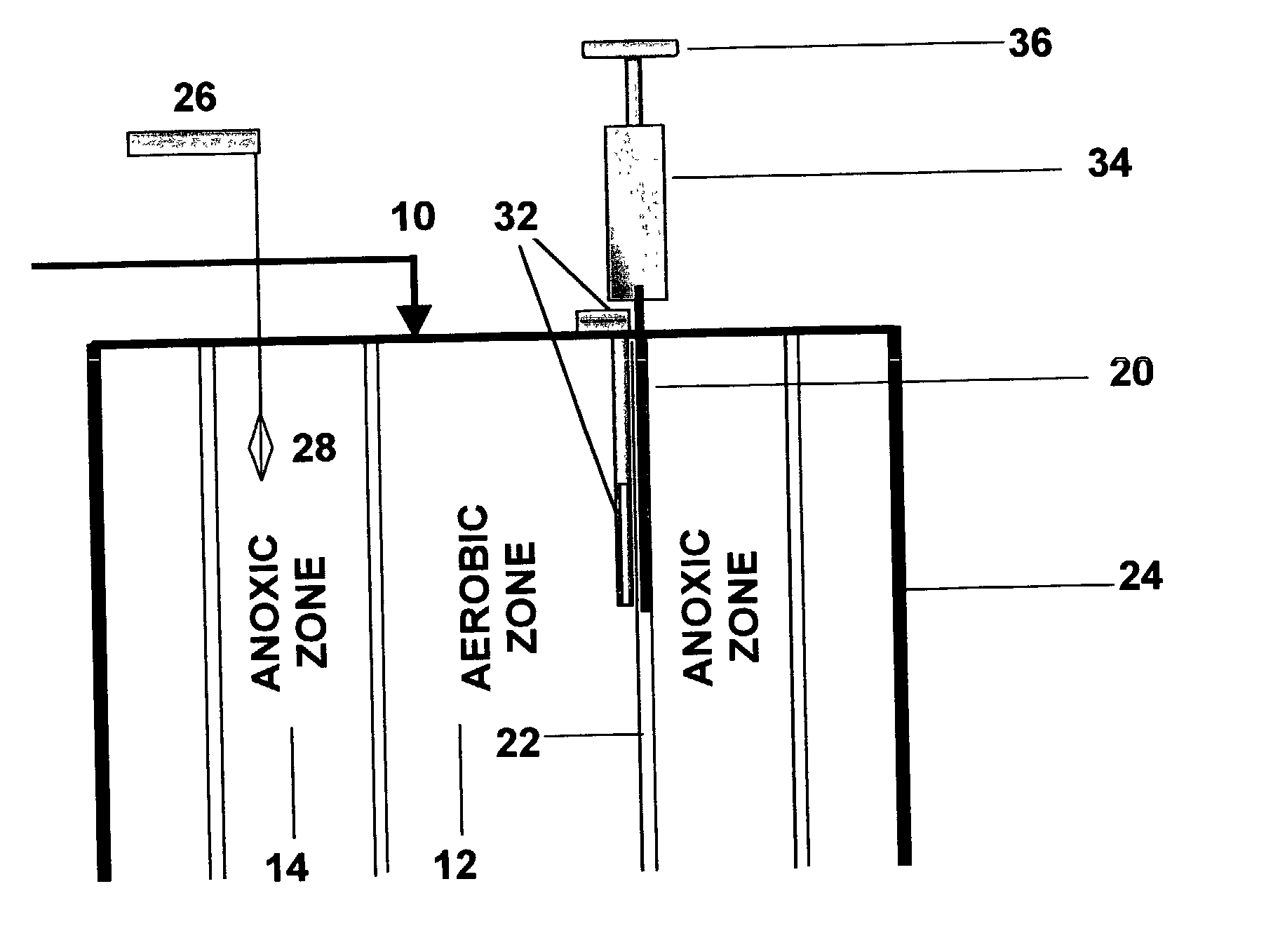

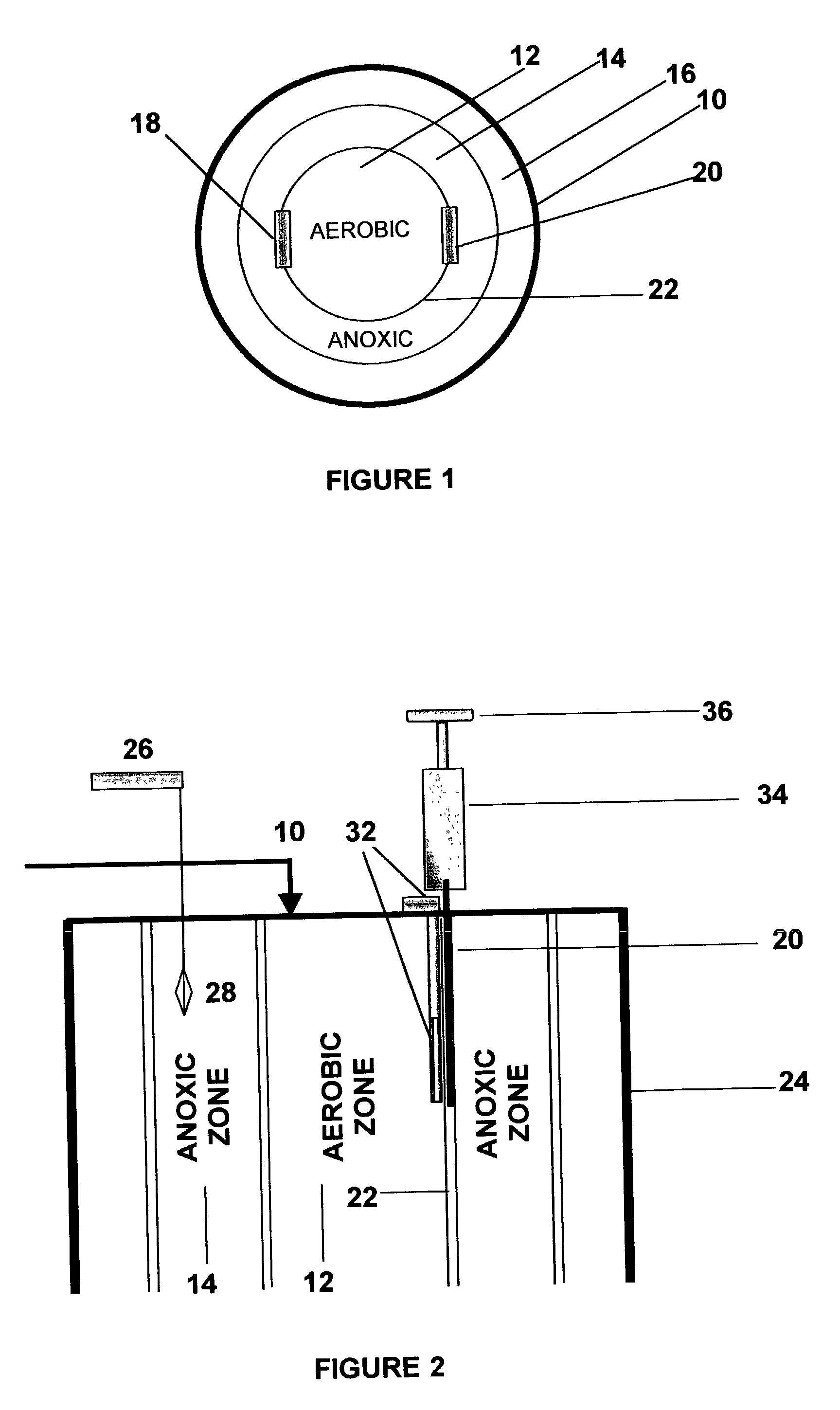

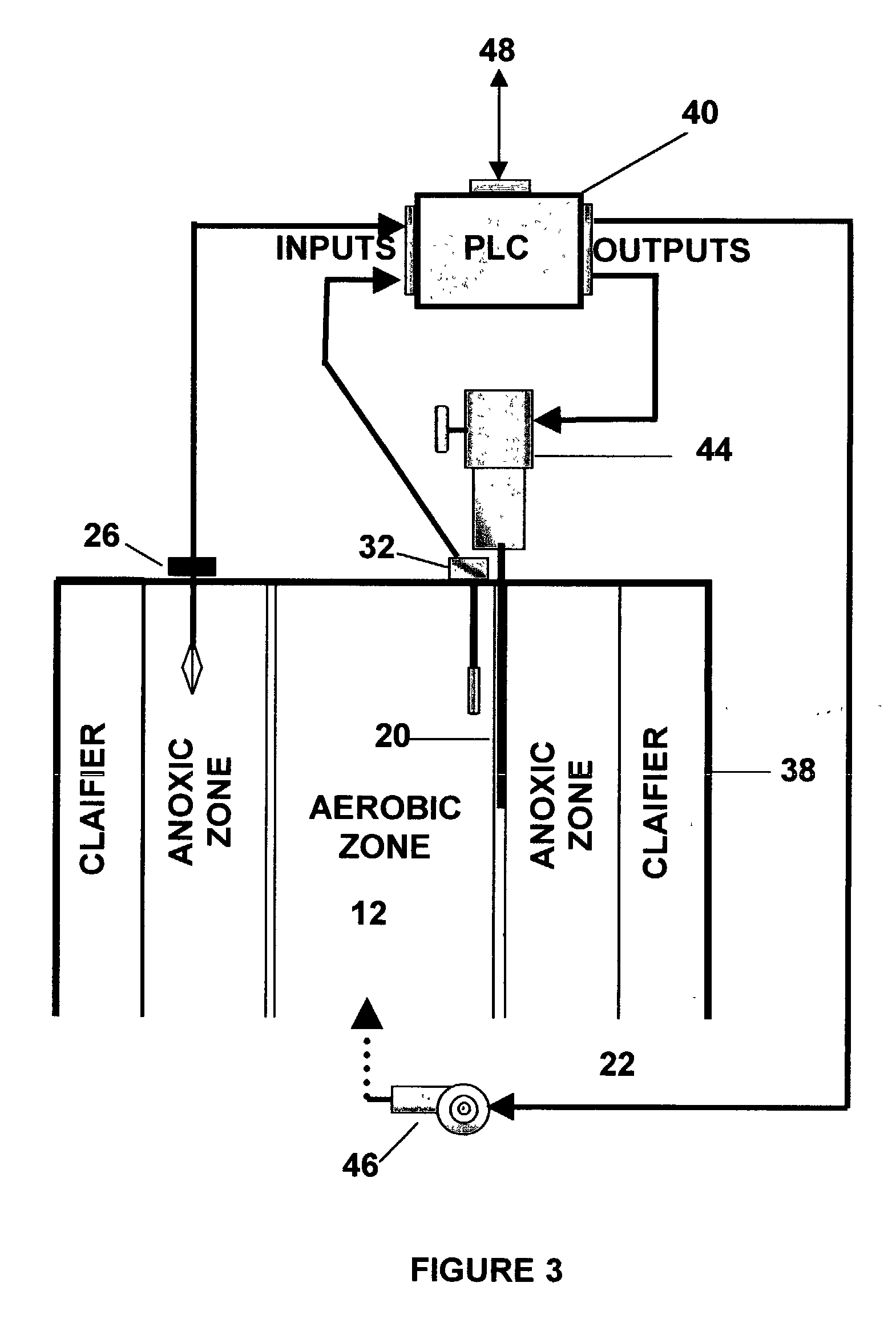

Dynamically responsive aerobic to anoxic inter-zone flow control system for single vessel multi-zone bioreactor wastewater treatment plants

InactiveUS20040035770A1Improve adaptabilityStable and fastLiquid separation auxillary apparatusWater treatment parameter controlProgram instructionProgrammable logic controller

An inter-zone aerobic to anoxic zone flow rate control system for single vessel multi-zone bioreactor plants for wastewater treatment is described herein. The system of the invention provides control of the relative treatment times of the mixed liquor in the horizontally disposed and adjacent aerobic and anoxic treatment zones of the bioreactor by providing one or more flow rate adjusting gates located between the aerobic and anoxic zones of the bioreactor. The opening of the gates is adjustable in accordance with sensed conditions in the treatment zones. An automated embodiment of the invention includes a programmable logic controller that provides control scripts for adjusting the opening of one or more flow control gates according to inputs from sensors and per programmed instructions. An automated and supervised embodiment of the invention includes a computer interfaced with a programmable automating controller. The computer provides status reports, commands to the programmable automating controller, storage and analysis of data, as well as a means of communicating to remote monitoring centers and networks.

Owner:ATARA ENVIRONMENTAL

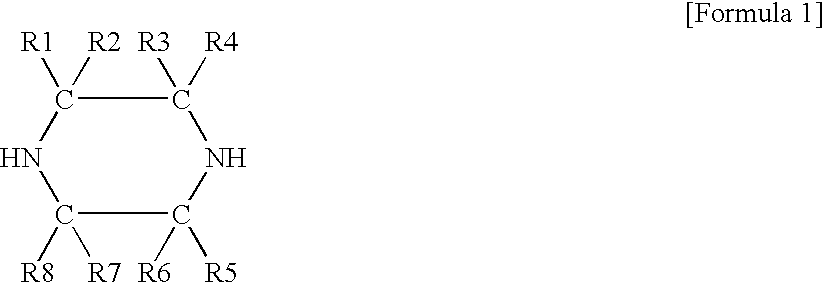

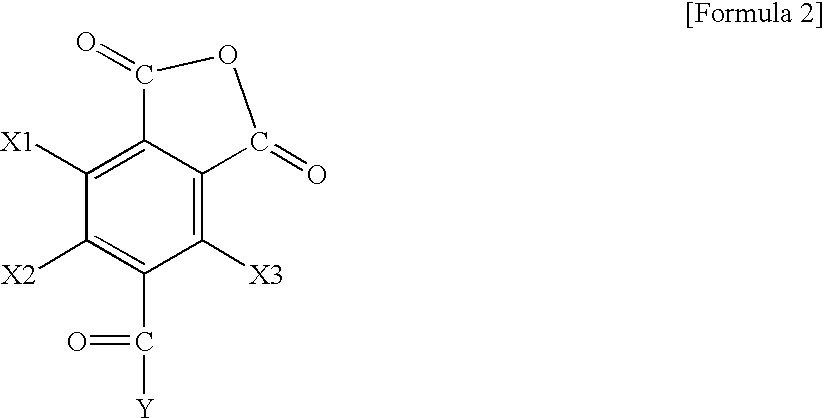

Flexible, flame-retardant, aqueous-processable photoimageable composition for coating flexible printed circuits

A flexible, flame-retardant, aqueous processable, photoimageable resin composition for forming a permanent, protective coating film for printed circuitry and a multilayer photoimageable element containing a layer of the photoimageable resin composition in combination with a low tack photoimageable resin sublayer and a temporary support film are disclosed. The photoimageable resin composition has excellent aqueous developability and provides a cured coating film having good flexibility, adhesion, solvent resistance, surface hardness, thermal resistance, electrical insulating properties and flame retardancy.

Owner:EI DU PONT DE NEMOURS & CO

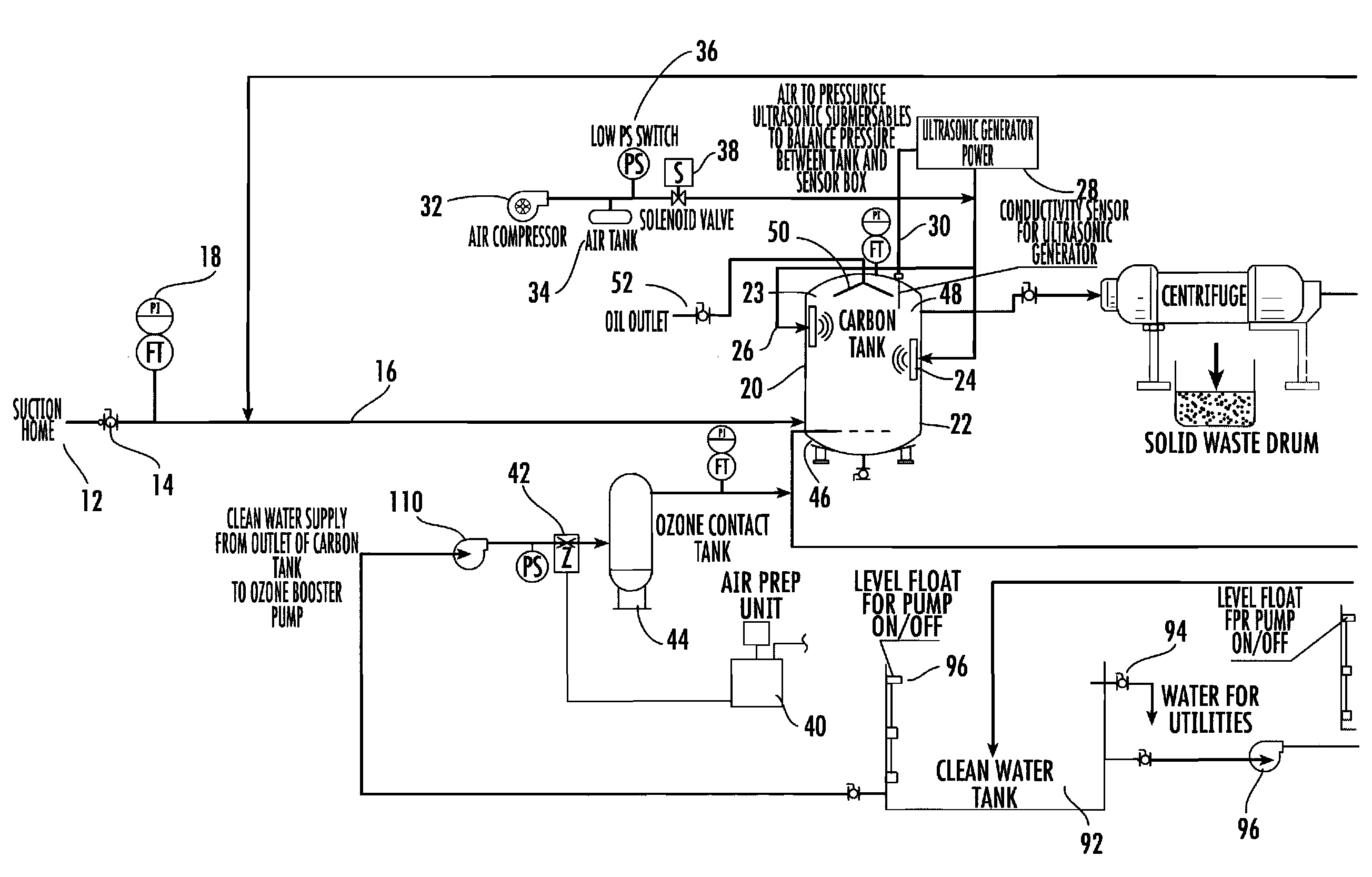

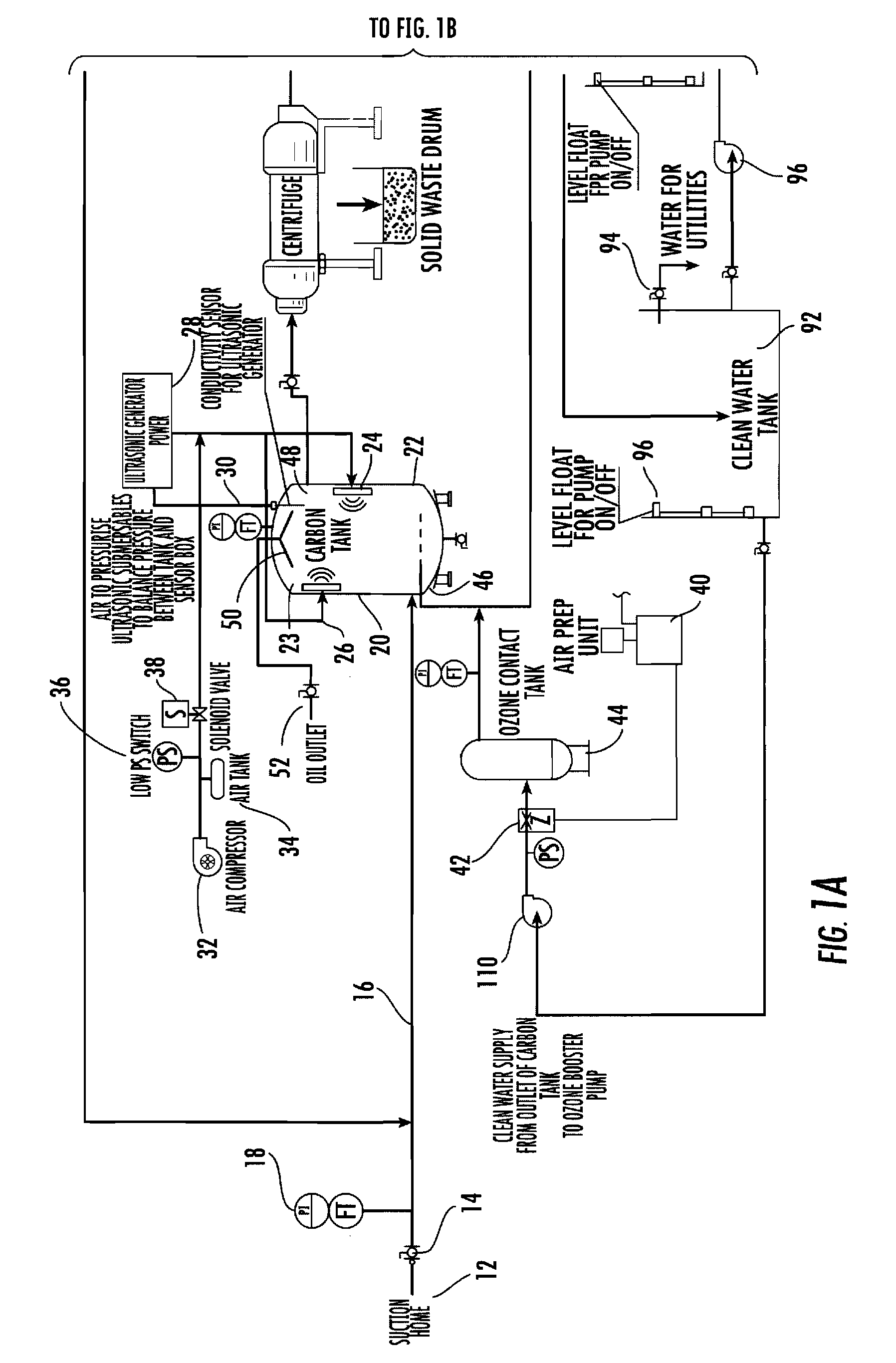

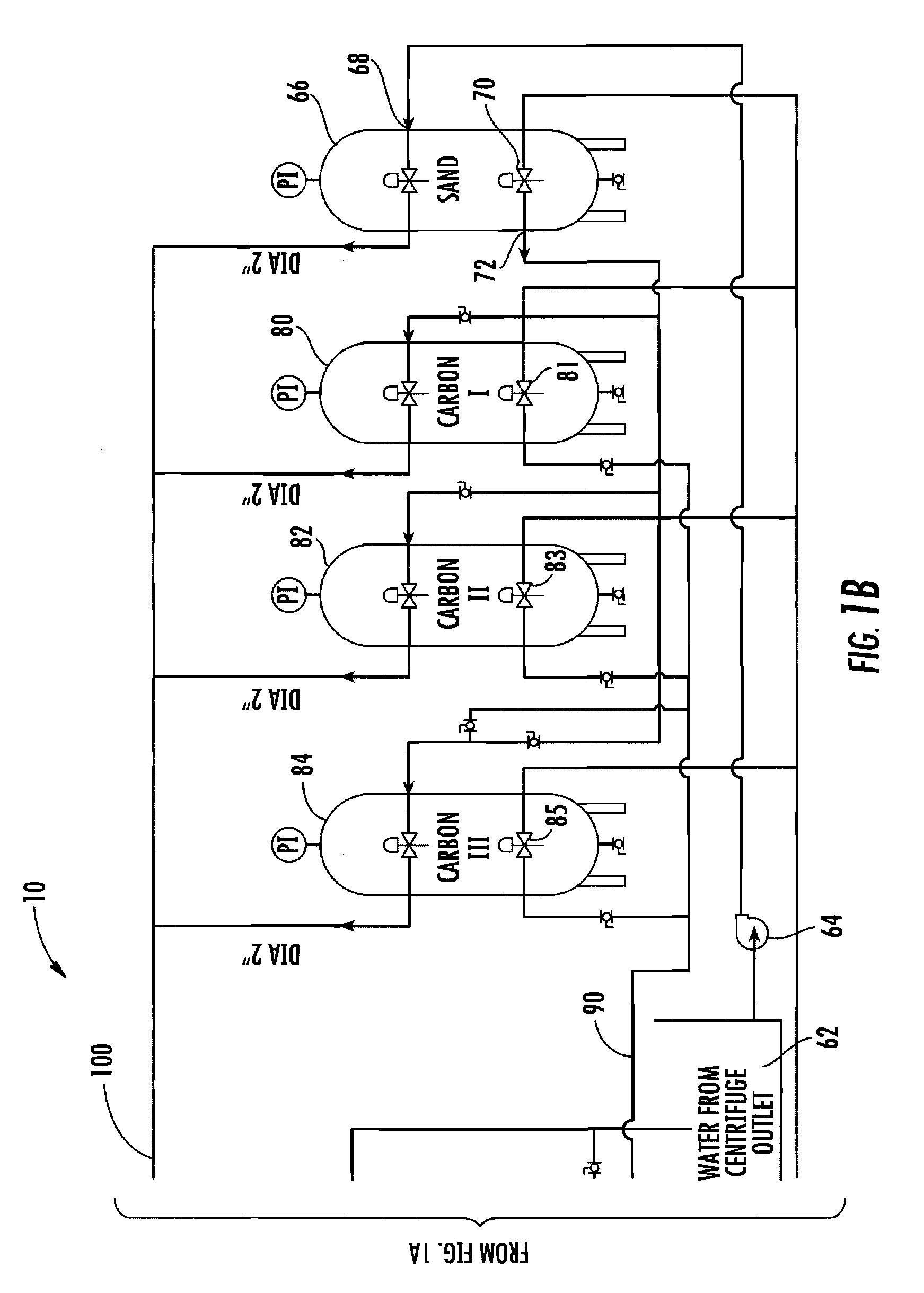

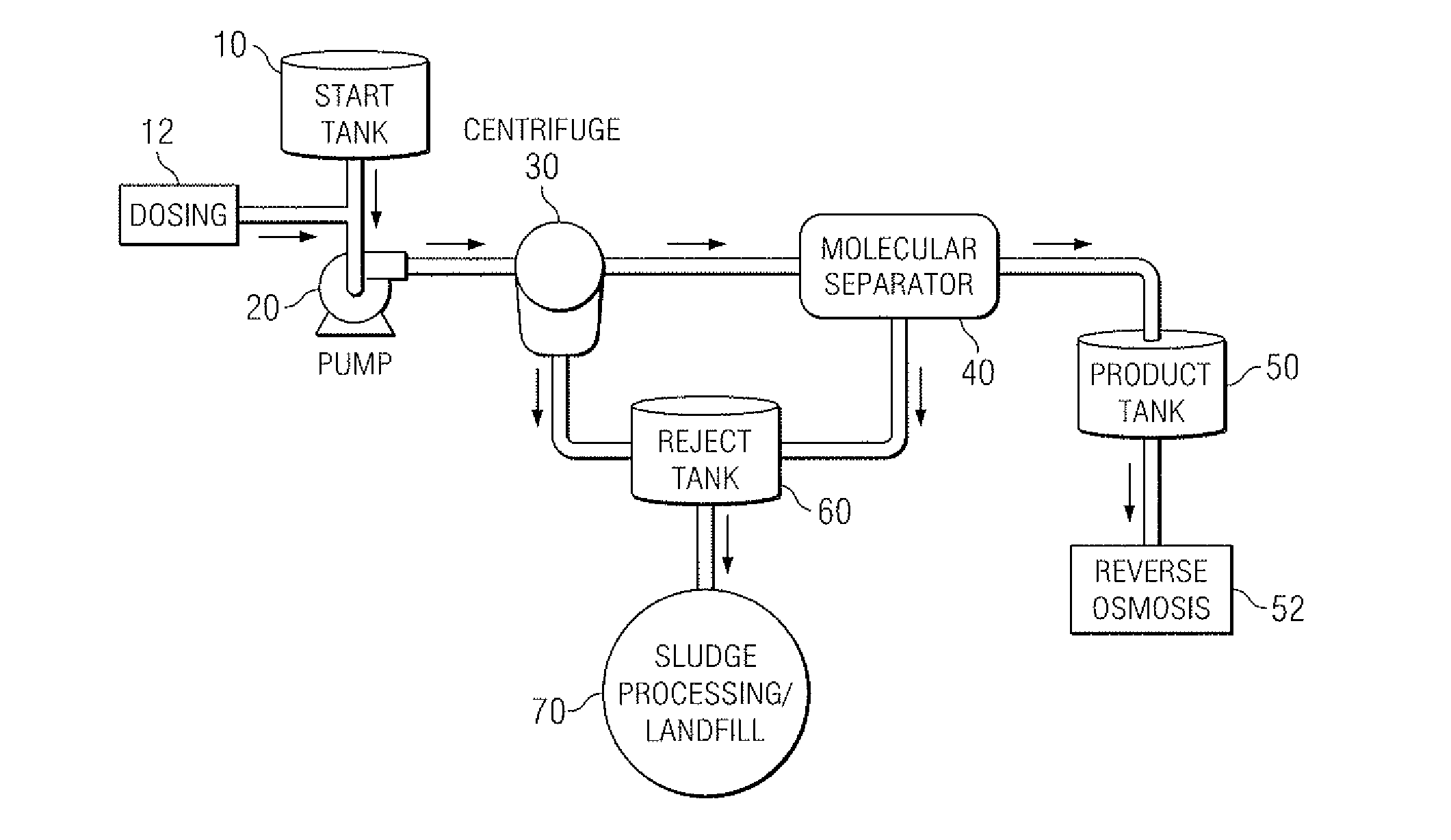

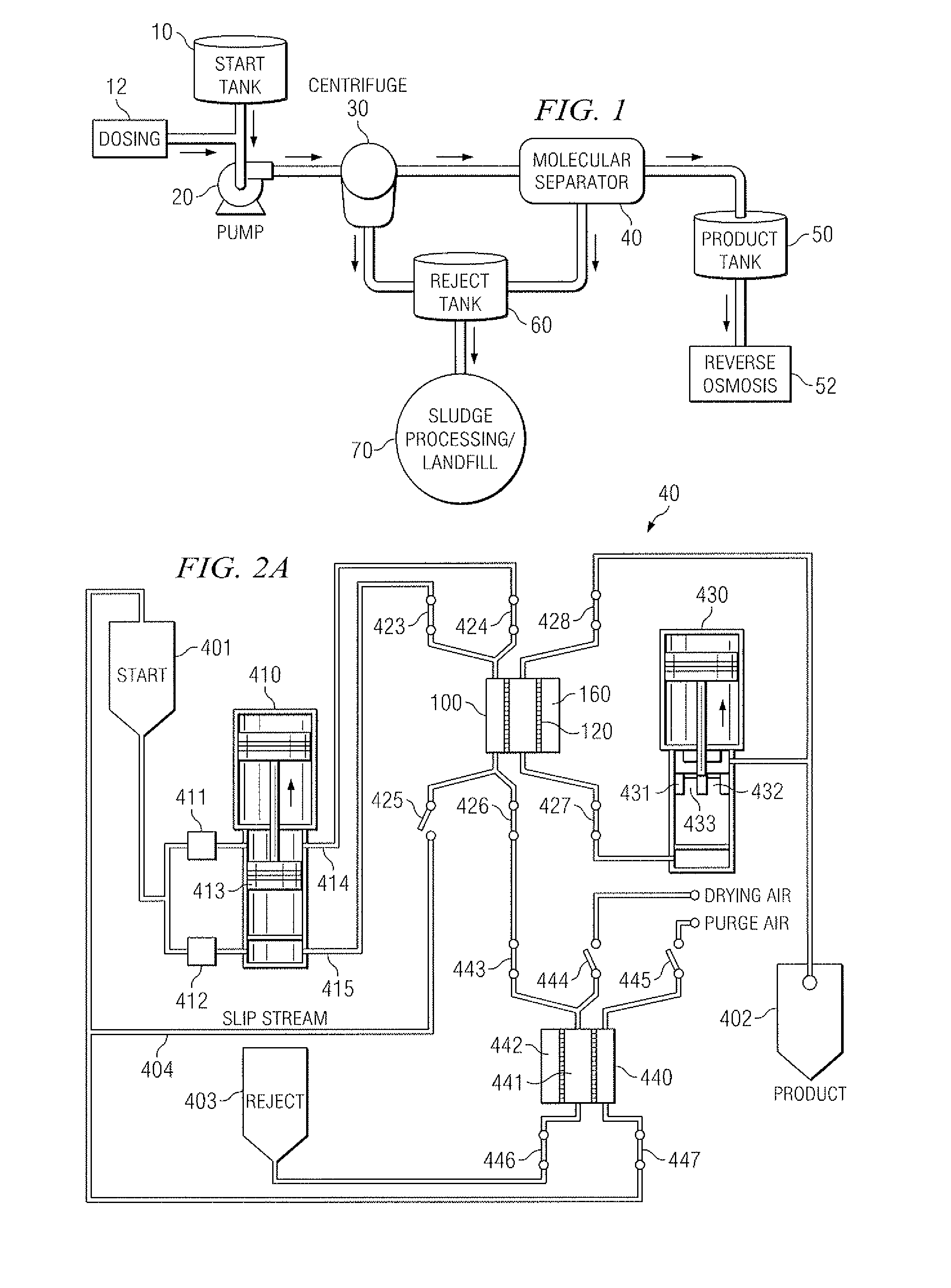

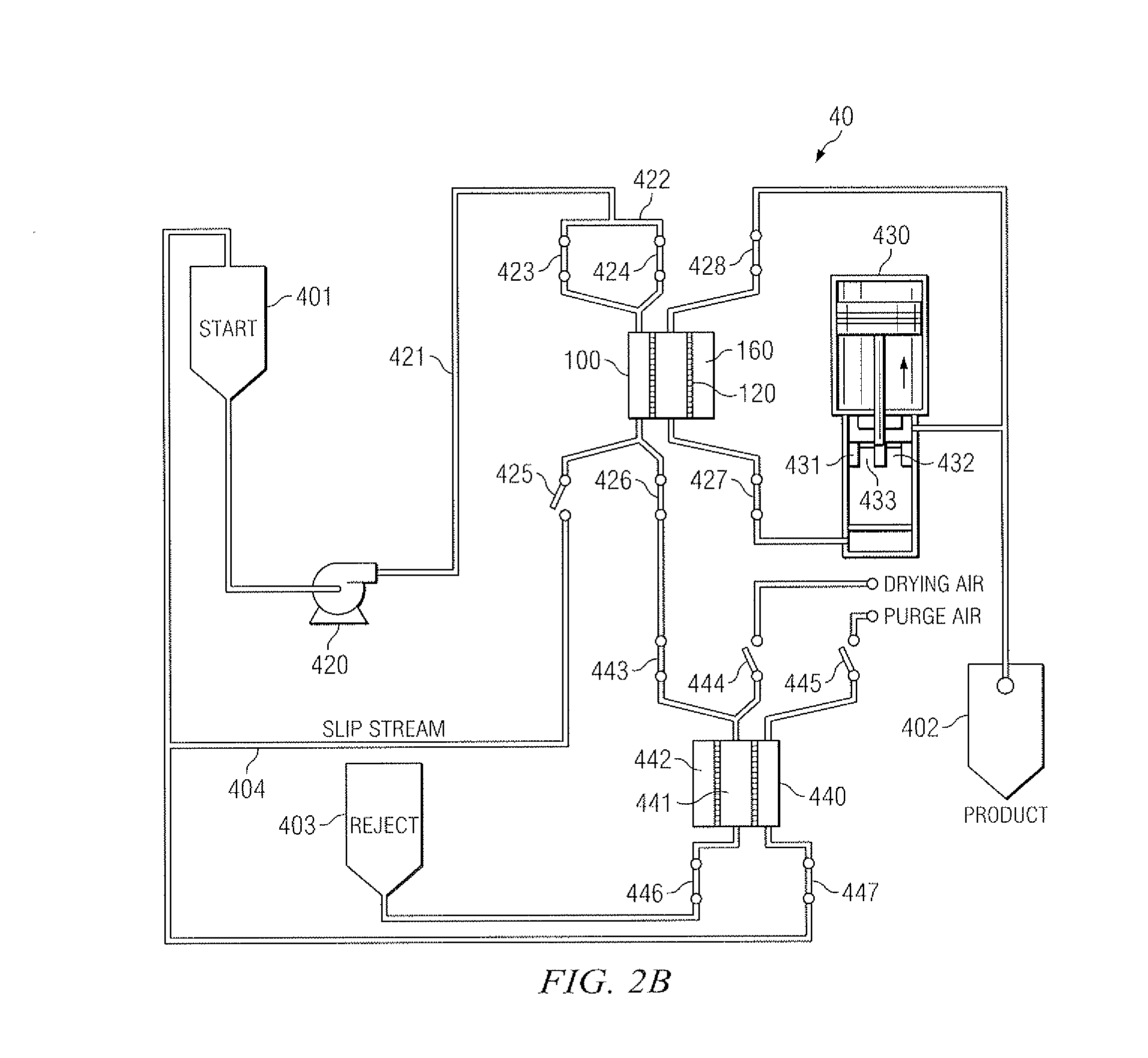

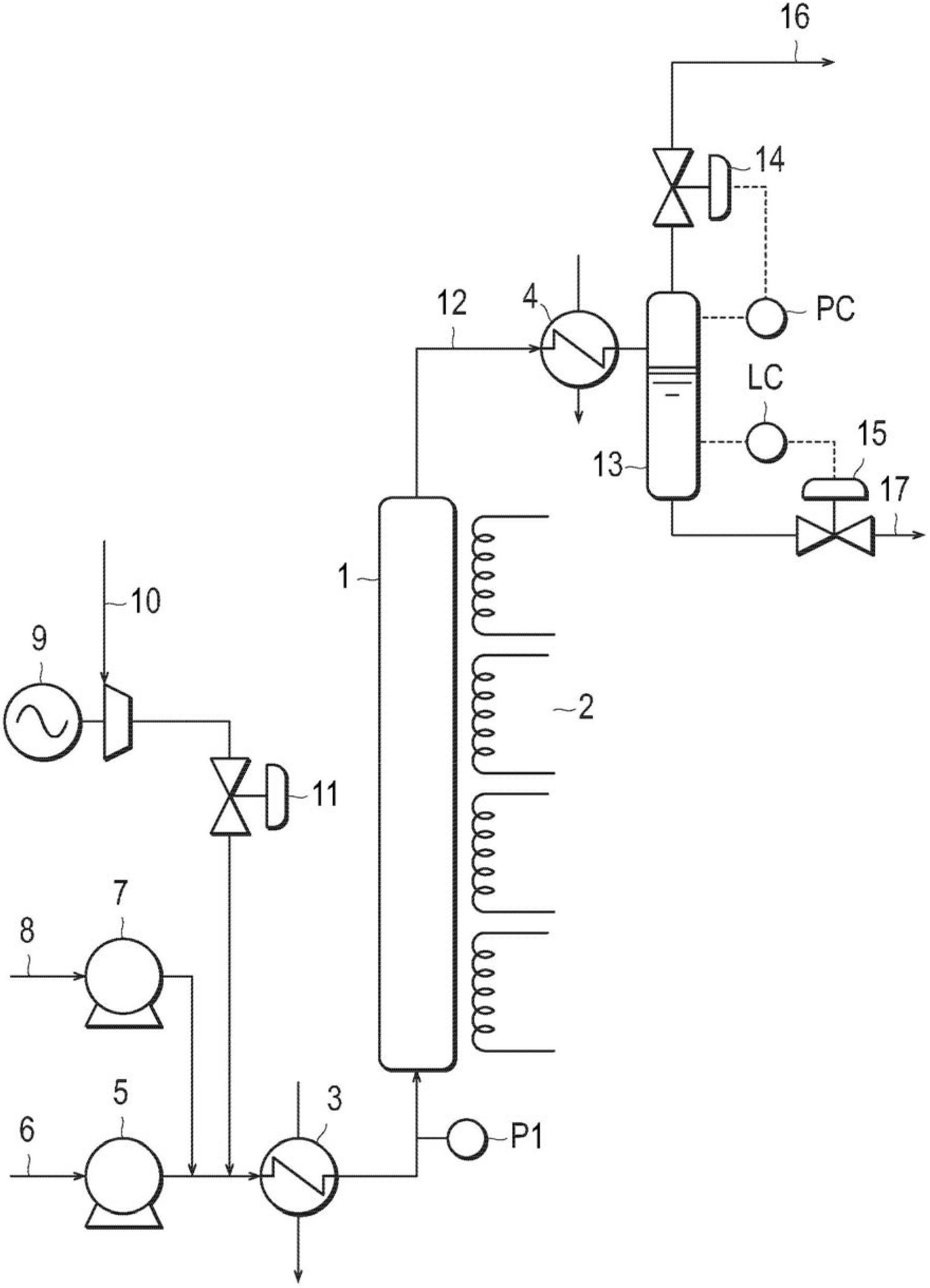

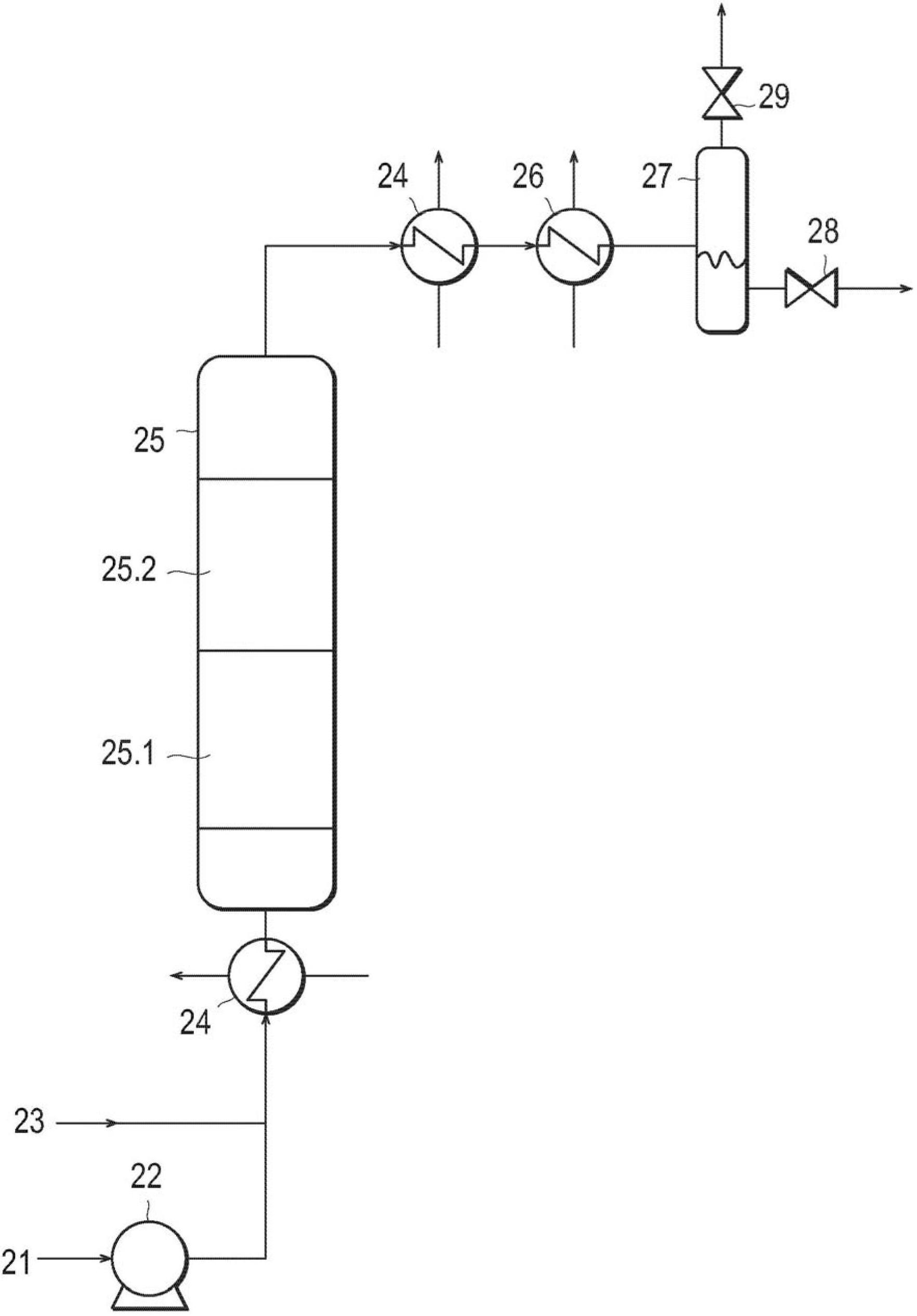

Enhanced water treatment for reclamation of waste fluids and increased efficiency treatment of potable waters

ActiveUS20090050572A1Low costCurrent expensiveWaste water treatment from quariesTreatment involving filtrationLiquid wastePotable water

Disclosed is a process for reclamation of waste fluids. A conditioning container is employed for receipt of waste material on a continuous flow for treatment within the container by immersible transducers producing ultrasonic acoustic waves in combination with a high level of injected ozone. The treated material exhibits superior separation properties for delivery into a centrifuge for enhanced solid waste removal. The invention discloses a cost efficient and environmentally friendly process and apparatus for cleaning and recycling of flowback, or frac water, which has been used to stimulate gas production from shale formations. The apparatus is mobile and containerized and suitable for installation at the well site.

Owner:BRISBEN WATER SOLUTIONS

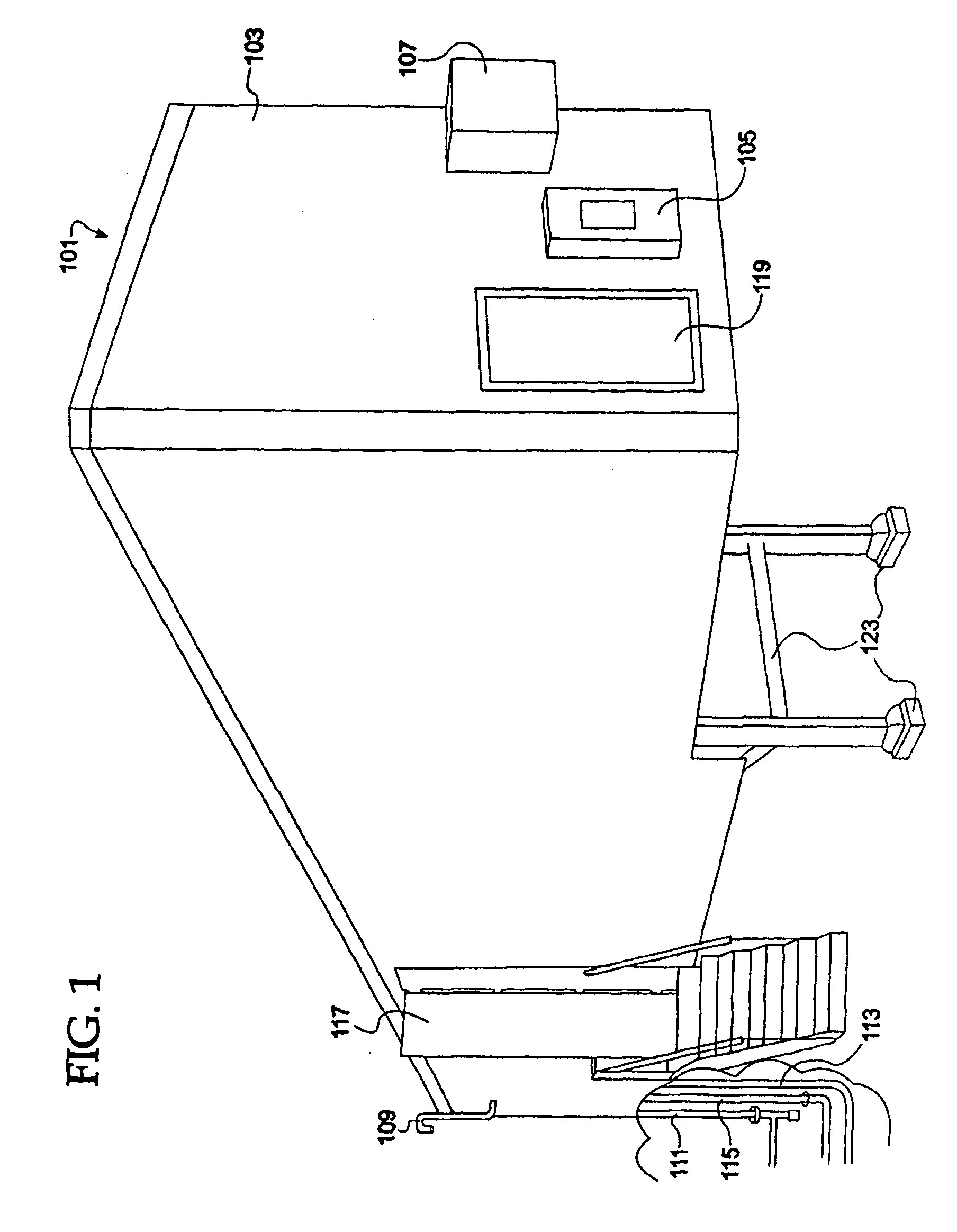

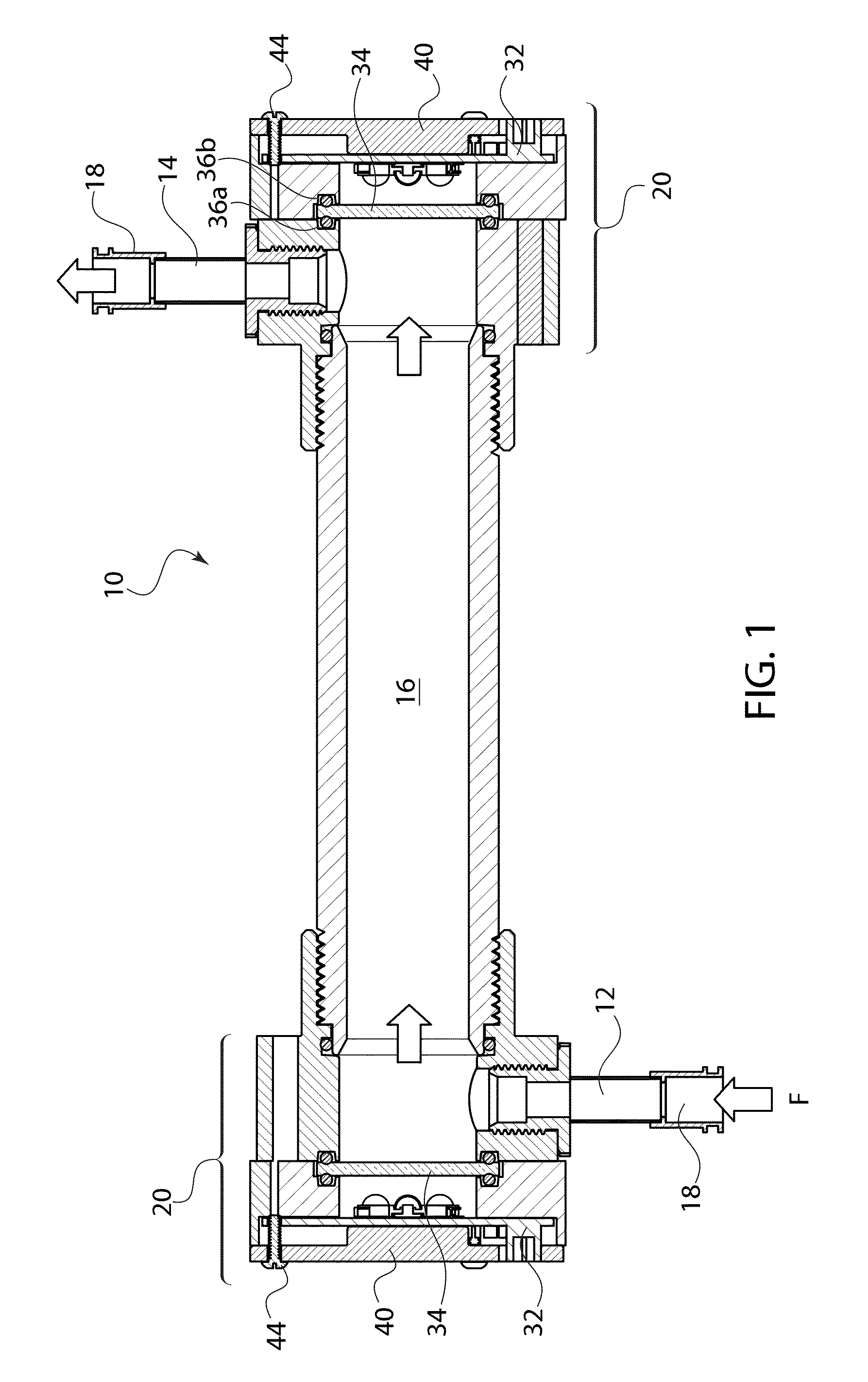

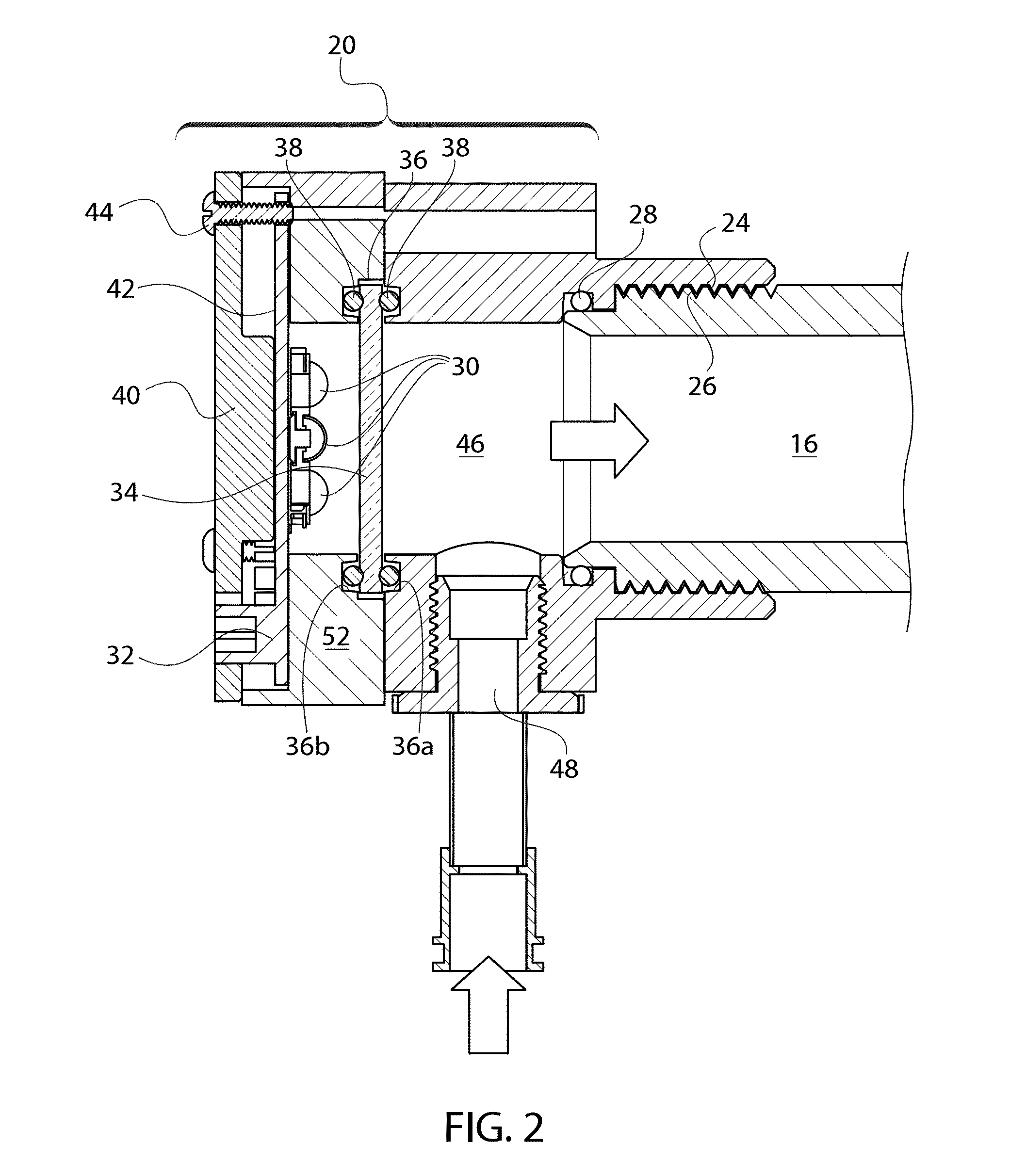

Flow-through tank for water treatment

ActiveUS20050109703A1Economically manufacturedSimple control systemWater distributersWater softeningTreatment systemWater treatment

A fluid treatment system includes at least one flow-through tank, a treatment device configured for treating at least one of an untreated fluid and a treated fluid and providing the treated fluid to the at least one flow-through tank and at least one sensing device configured for sensing the quality of fluid in the at least one flow-through tank. The sensing device is connected to the treatment device for providing the treated fluid to the at least one flow-through tank upon a determination of a quality of fluids in the at least one flow-through tank being less than or equal to a predetermined fluid quality threshold.

Owner:CULLIGAN INTERNATINOAL COMPANY

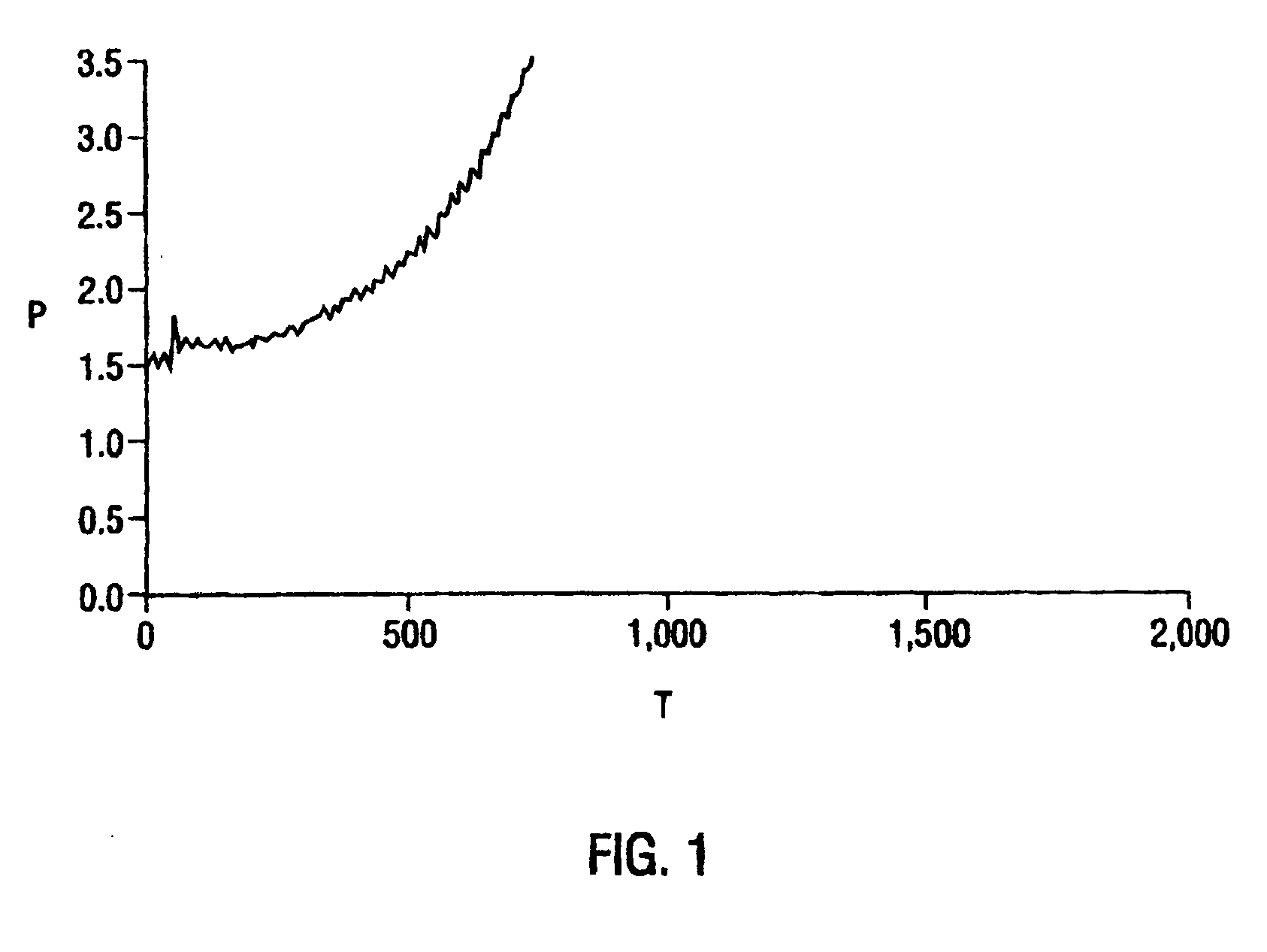

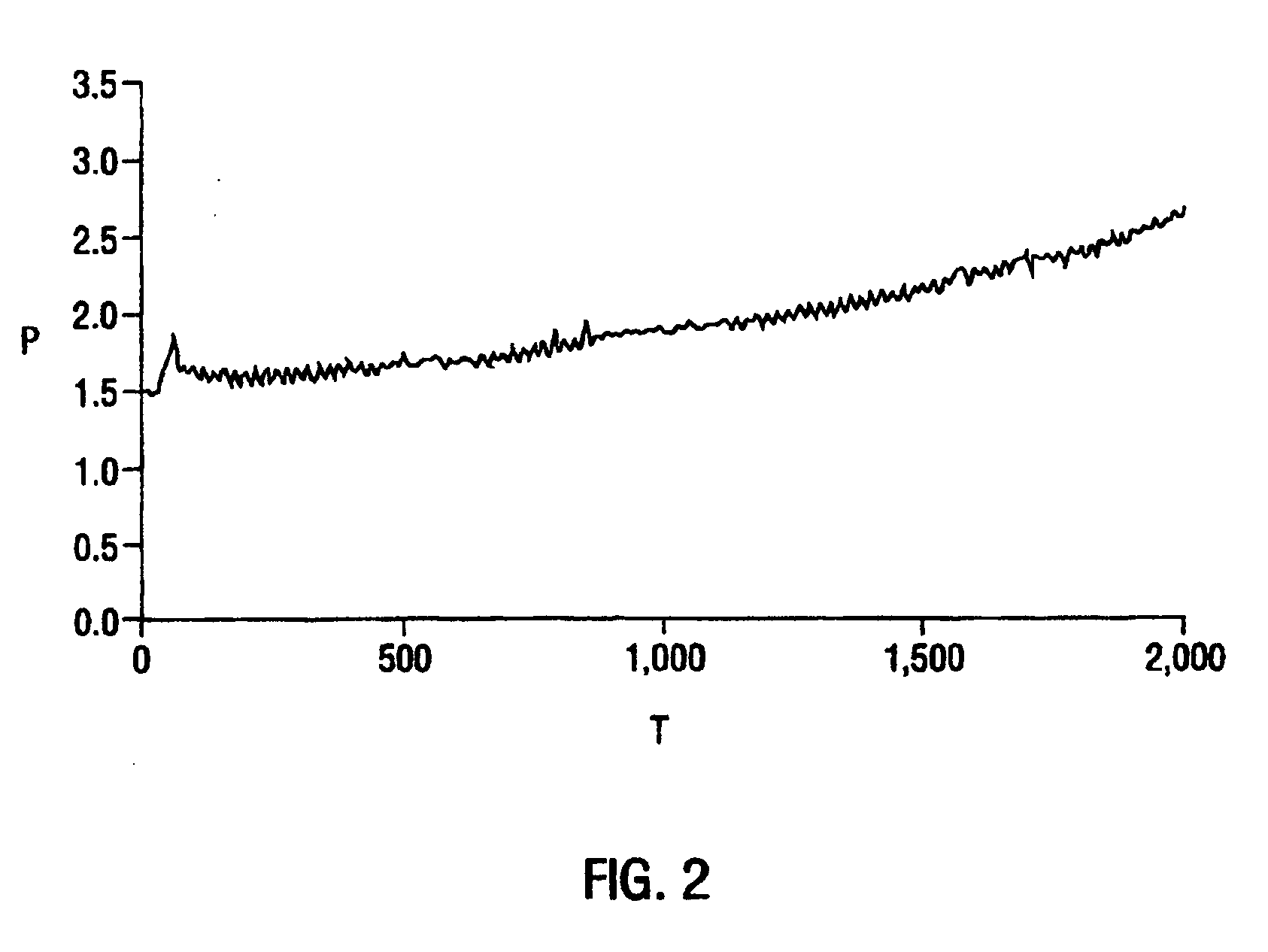

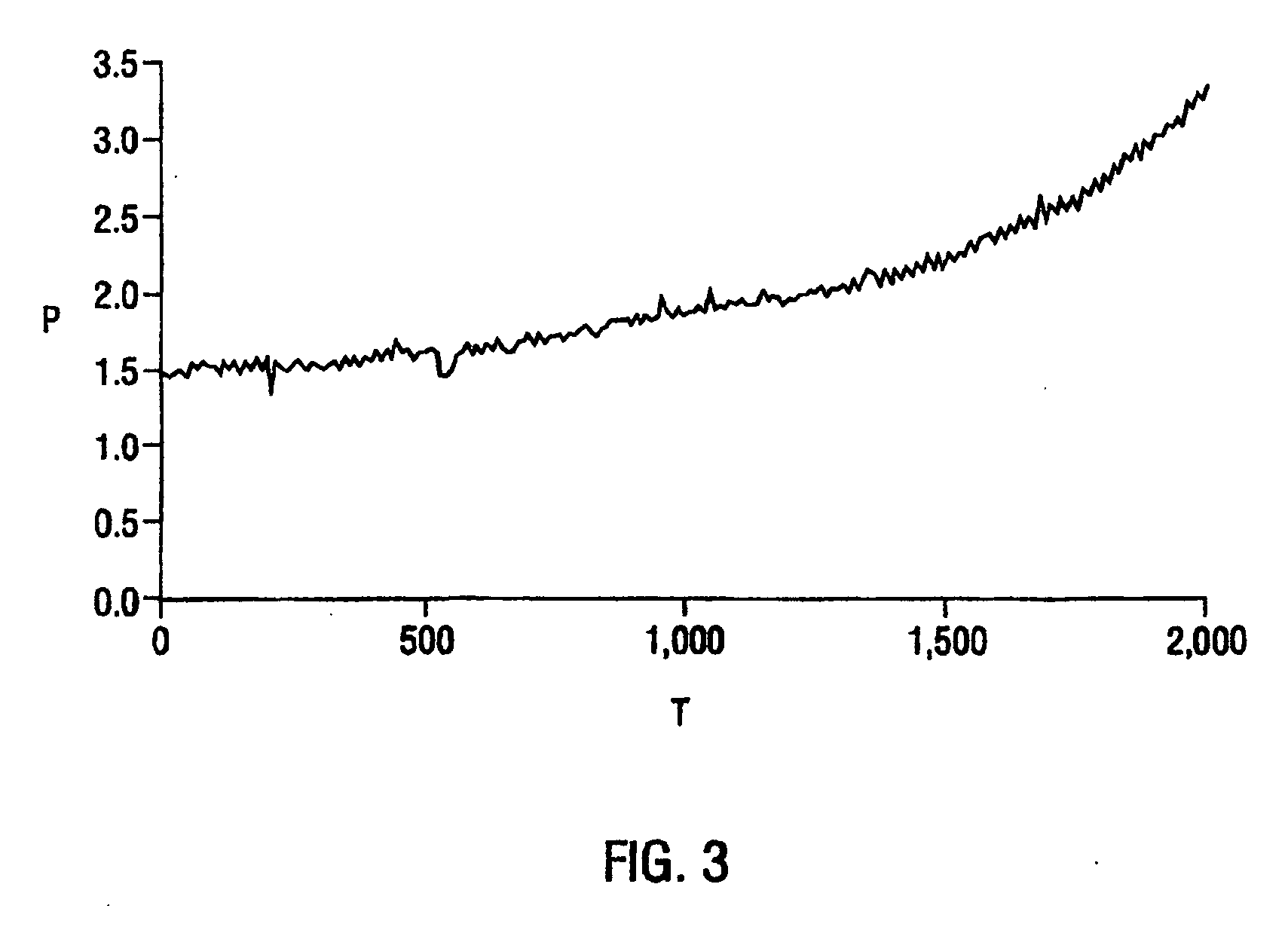

Robust process identification and auto-tuning control

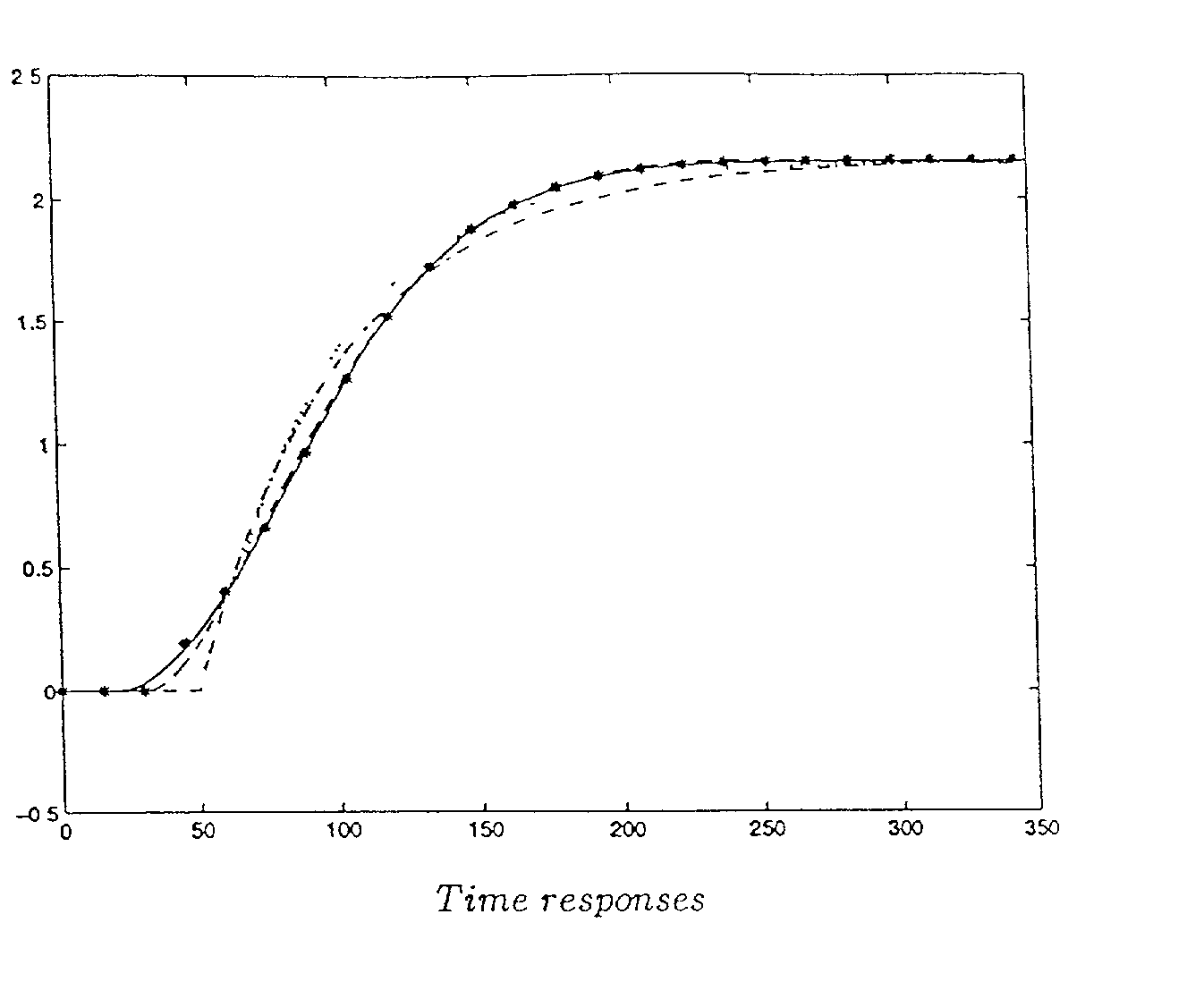

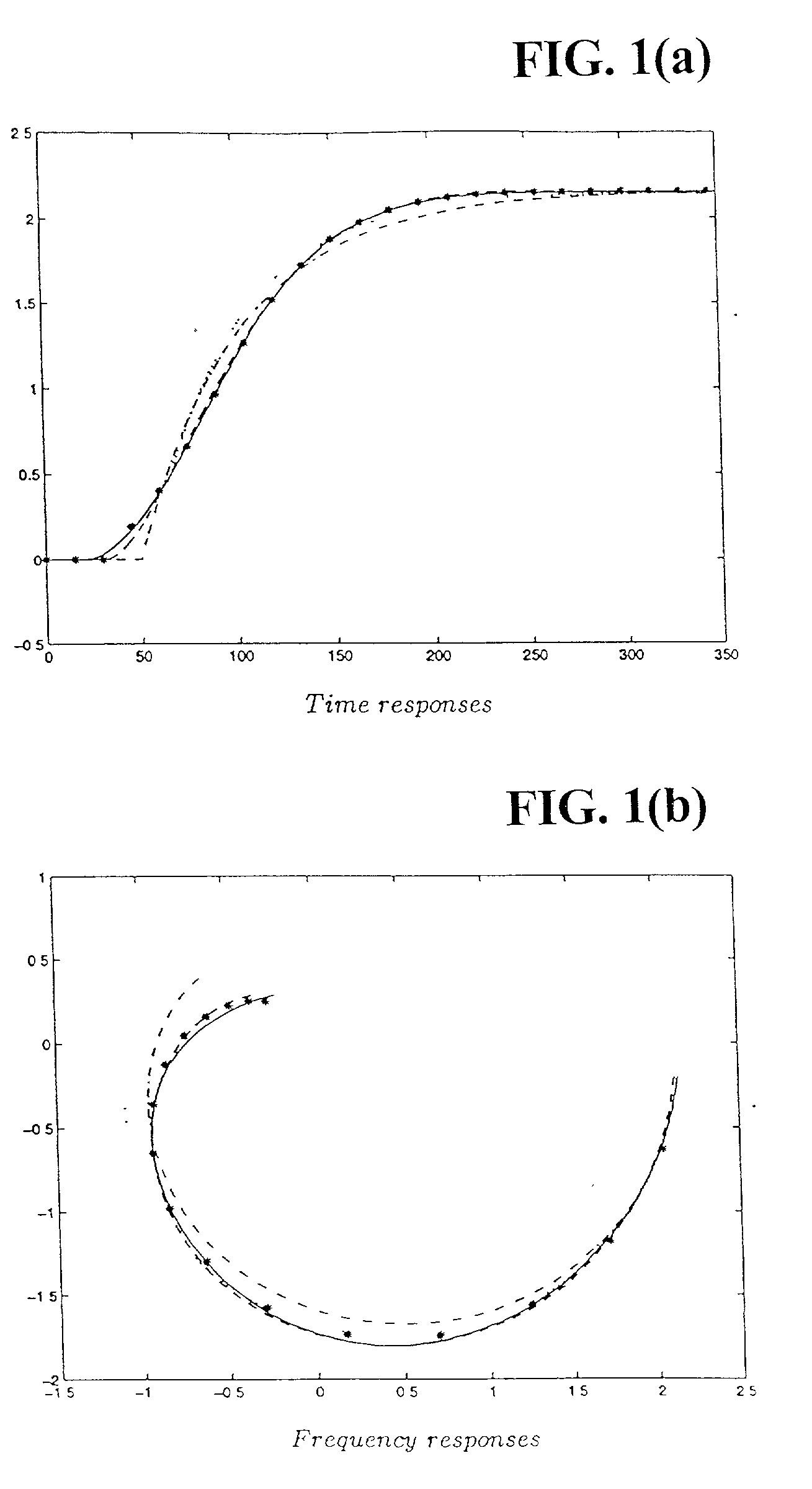

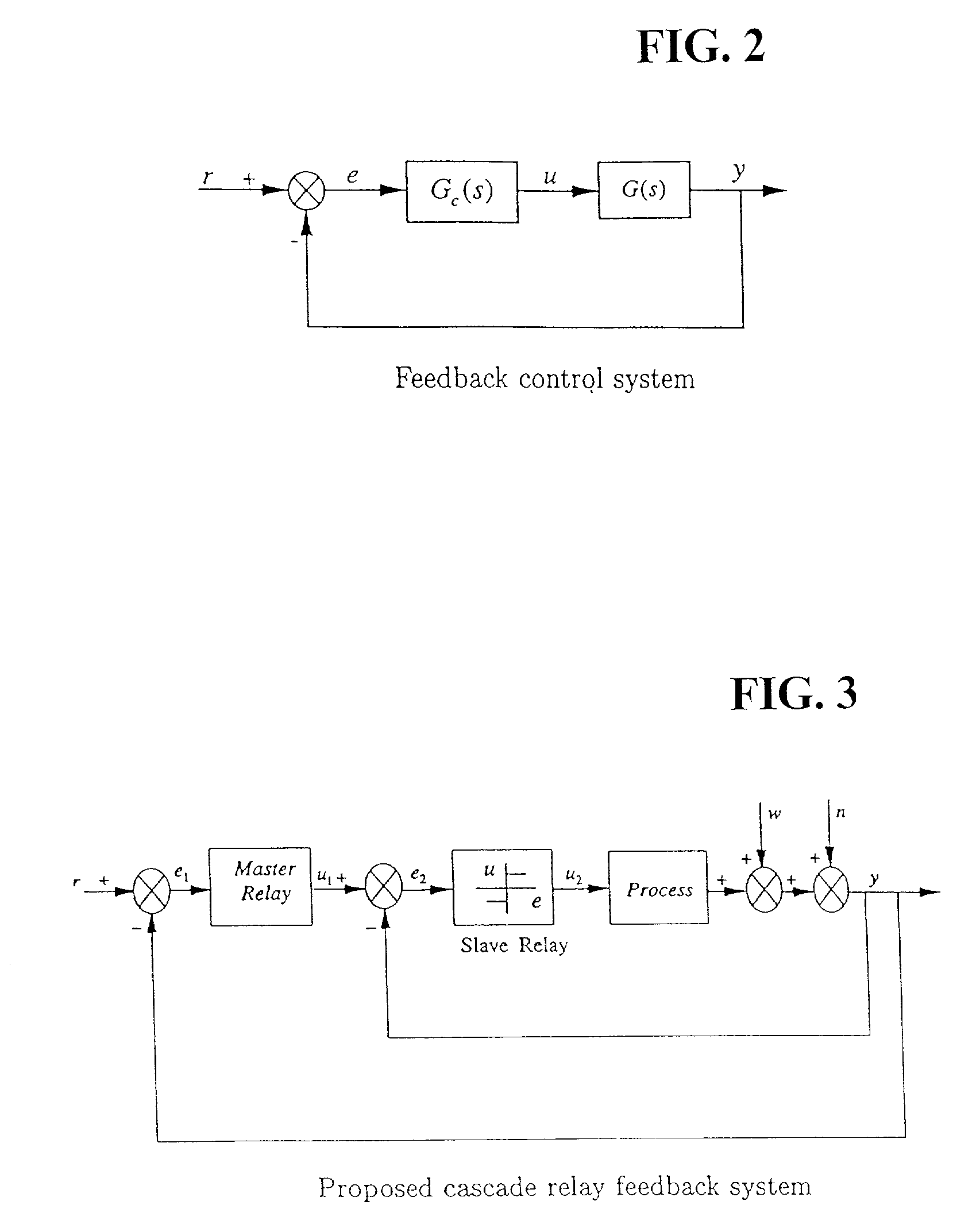

InactiveUS20020111758A1Accurate estimateImprove performanceAmplifier modifications to reduce noise influenceVoltage-current phase angleGuidelineTime delays

A simple yet effective and robust identification method is presented using process step responses for process identification that can provide a continuous transfer function with time-delay without iteration. A cascade relay provides accurate and reliable more points on the process frequency response. The internal model principle is employed to design single-loop controller of PID or high-order types with best achievable control performance for controller tuning, e.g. both single and multivariable cases are covered. The process identification and control design portions can be easily integrated into a control system auto-tuning package. Further, a general control scheme for disturbance rejection is given which can significantly improve disturbance rejection performance over conventional feedback systems with time delays. Practical issues such as noises, real-time implementation and tuning guidelines are also provided. The present invention provide general, systematic, effective, and applicable methods for process identification and control for a wide range of industries such as process and chemical plants, food processing, waste water treatment and environmental systems, oil refinery, servo and mechatronic systems, where a system model is needed for analysis, prediction, filtering, optimization and management, and / or where control or better control is required for their systems.

Owner:NAT UNIV OF SINGAPORE

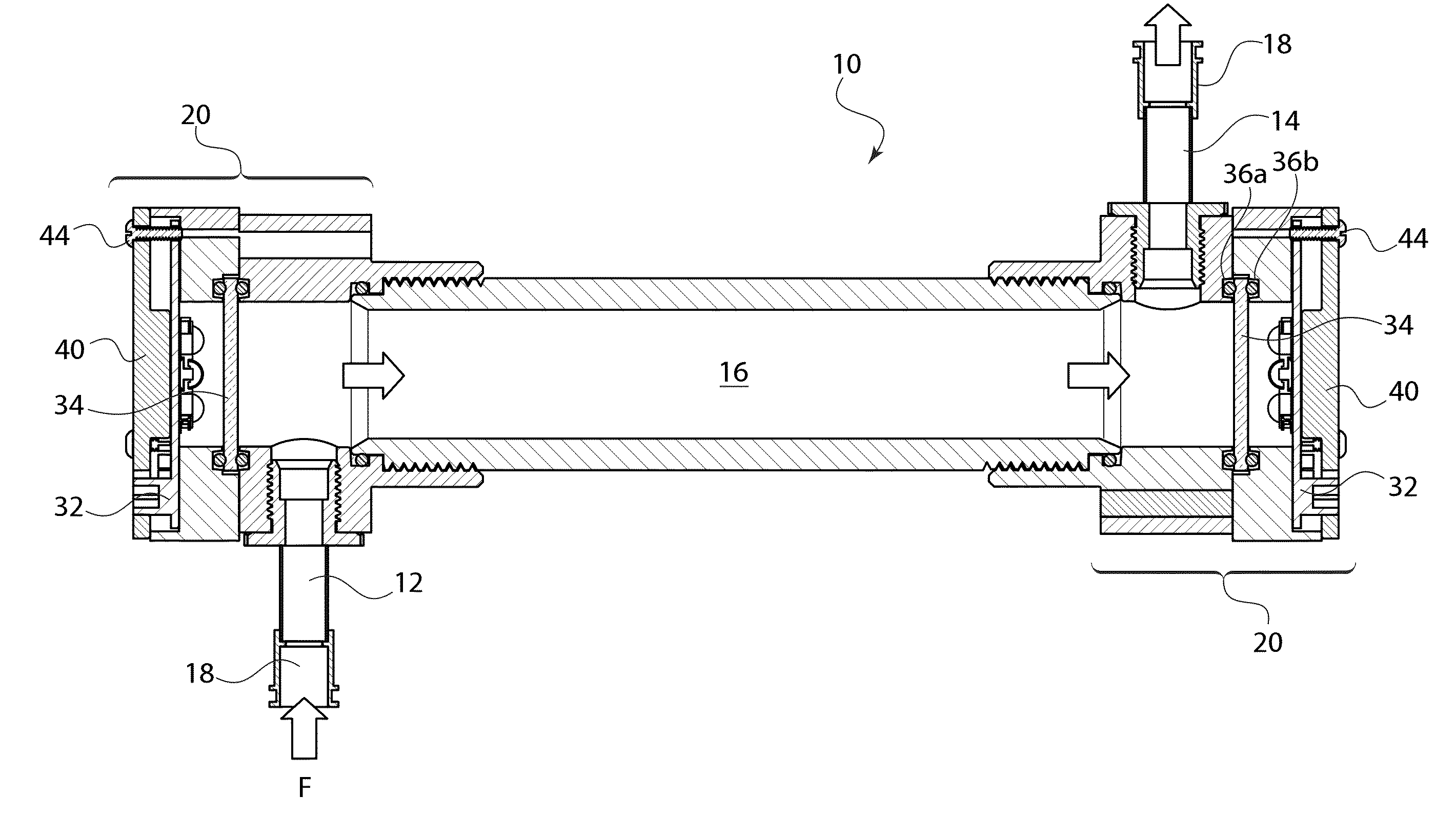

Produced water treatment method and apparatus

InactiveUS20080156709A1Improve filtration efficiencyEnhanced cavitationUltrafiltrationLoose filtering material filtersCavitationWaste collection

The present invention discloses a method and apparatus for separating particles and dissolved matter from a produced water fluid stream. Specifically, the present invention includes a first pressure source which transports untreated produced water or contaminated aqueous fluid into a separator annulus with a filter element disposed therein. The untreated fluid is placed under appropriate pressure sufficient to produce turbulent flow, increased particle kinetics and / or cavitation allowing the desired fluid to penetrate and pass into and through the filter media. The treated fluid is then transported to a collection tank. The contaminant matter retained by the filter media may be removed by the nearly instantaneous reverse pressurization of the separator annulus by a second pressure source thereby removing the contaminant particles away from contact with the filter media, and which may then be transported to a waste collection tank or a separator for further treatment.

Owner:TERVITA +1

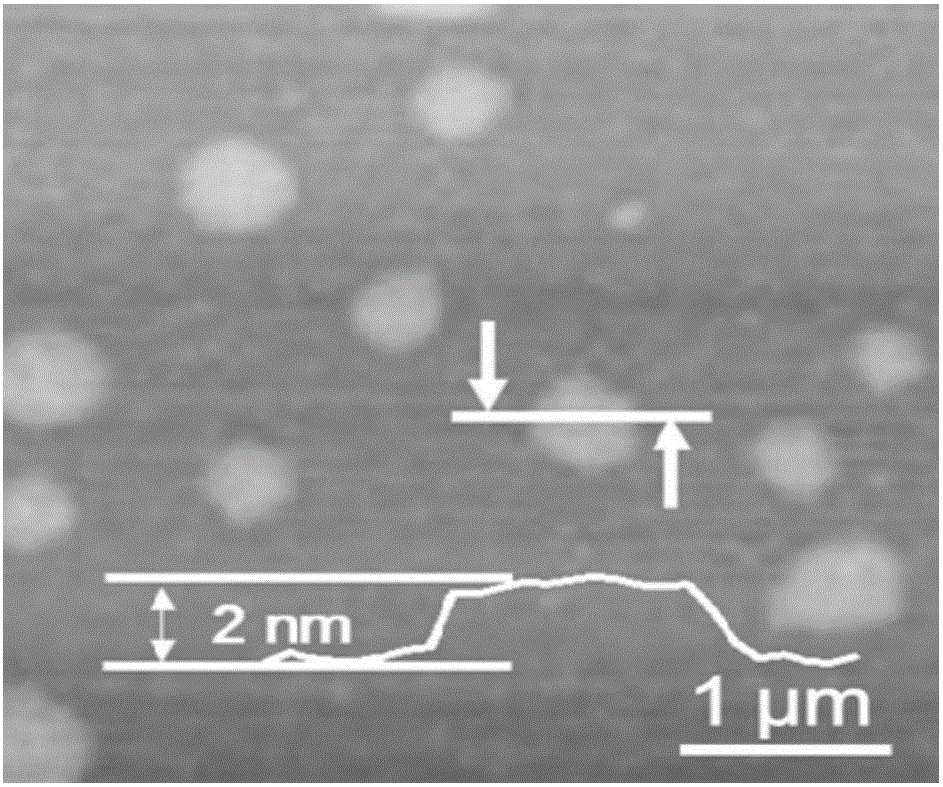

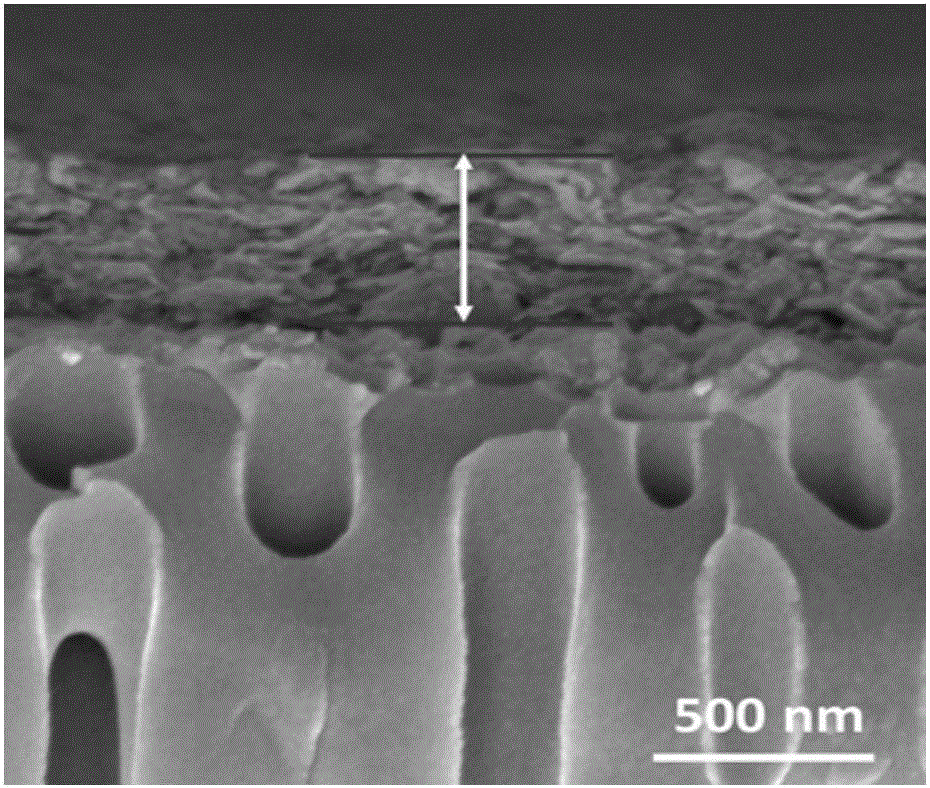

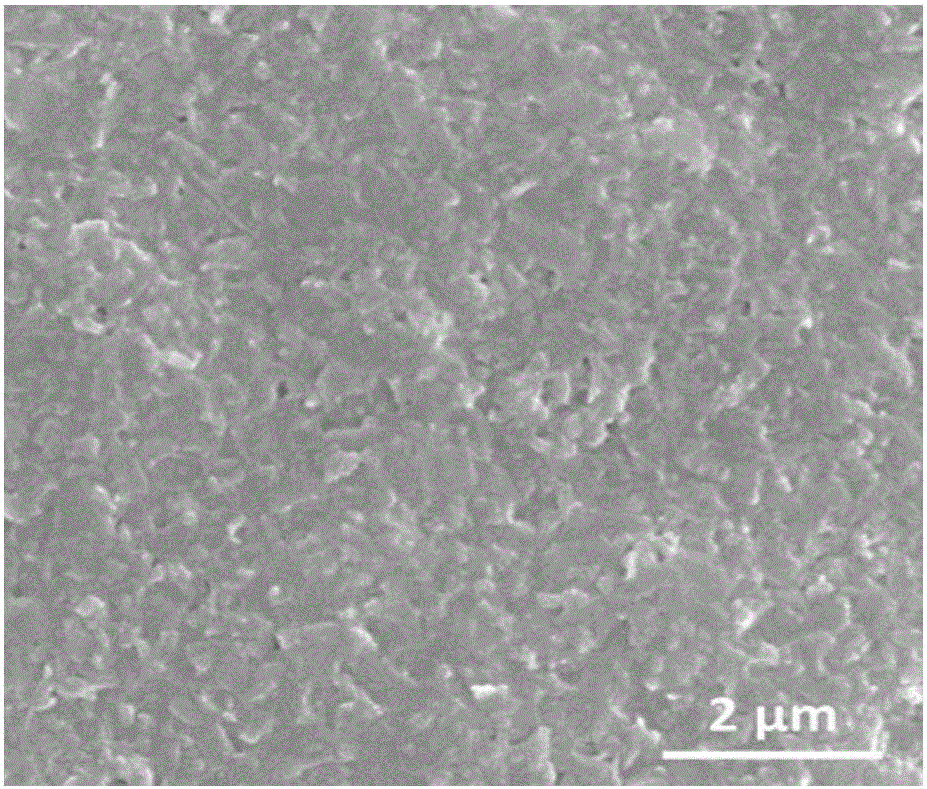

High-performance two-dimensional layered Ti3C2-MXene membrane, preparation method thereof and application of membrane in water treatment

ActiveCN106178979AIncrease water fluxHigh selectivitySemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPorous substrateCentrifugation

The invention belongs to the technical field of membrane preparation and water purification and discloses a high-performance two-dimensional layered Ti3C2-MXene membrane, a preparation method thereof and an application of the Ti3C2-MXene membrane in water treatment. The method comprises steps as follows: (1), Ti3AlC2 powder and an HF solution are mixed, stirred for a reaction, centrifugally washed and dried, and Ti3C2 powder is obtained; (2), the Ti3C2 powder and a solvent are mixed, stirred for the reaction, washed and dried, and treated powder is obtained; (3), the treated powder is dissolved in the solvent and subjected to ultrasonic treatment and centrifugation, a liquid supernatant is taken and dried, and a two-dimensional nanosheet is obtained; (4), a solution is prepared from the two-dimensional nanosheet and deposited on a porous substrate with a nano self-assembly technology, and the high-performance two-dimensional layered Ti3C2-MXene membrane is obtained. The membrane has ultrahigh water flux, higher selectivity and good mechanical property and stability; the method is simple, low in energy consumption and cost, good in repeatability and wide in applicability.

Owner:SOUTH CHINA UNIV OF TECH

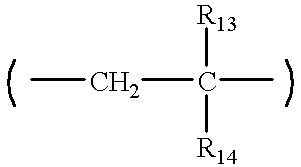

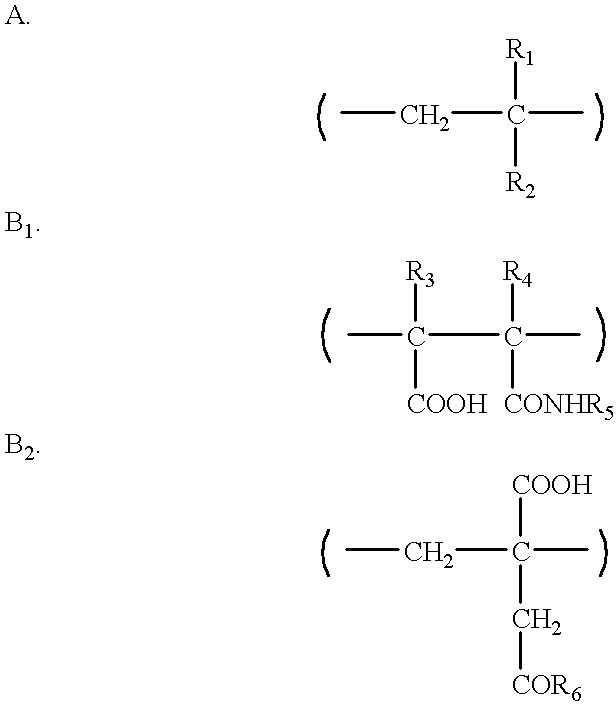

Compositions containing water control treatments and formation damage control additives, and methods for their use

InactiveUS20060065396A1Minimizes stepComparable and improved treatment resultConstructionsFluid removalControl treatmentRelative permeability

The present invention relates to compositions of aqueous compositions comprising relative permeability modifier (RPM) macromolecules and one or more formation damage control additives, for use in treating hydrocarbon-producing wells, formations, and equipment, as well as methods for the use of such compositions. Such compositions, comprising the RPM macromolecule and the one or more formation damage control additive, such as a scale control agent, can result in the formation of a composition wherein the components exhibit a “synergistic” effect, whereby the ability of the formation damage control additive to prevent formation damage is enhanced relative to the use of the same additive separately.

Owner:BAKER HUGHES INC

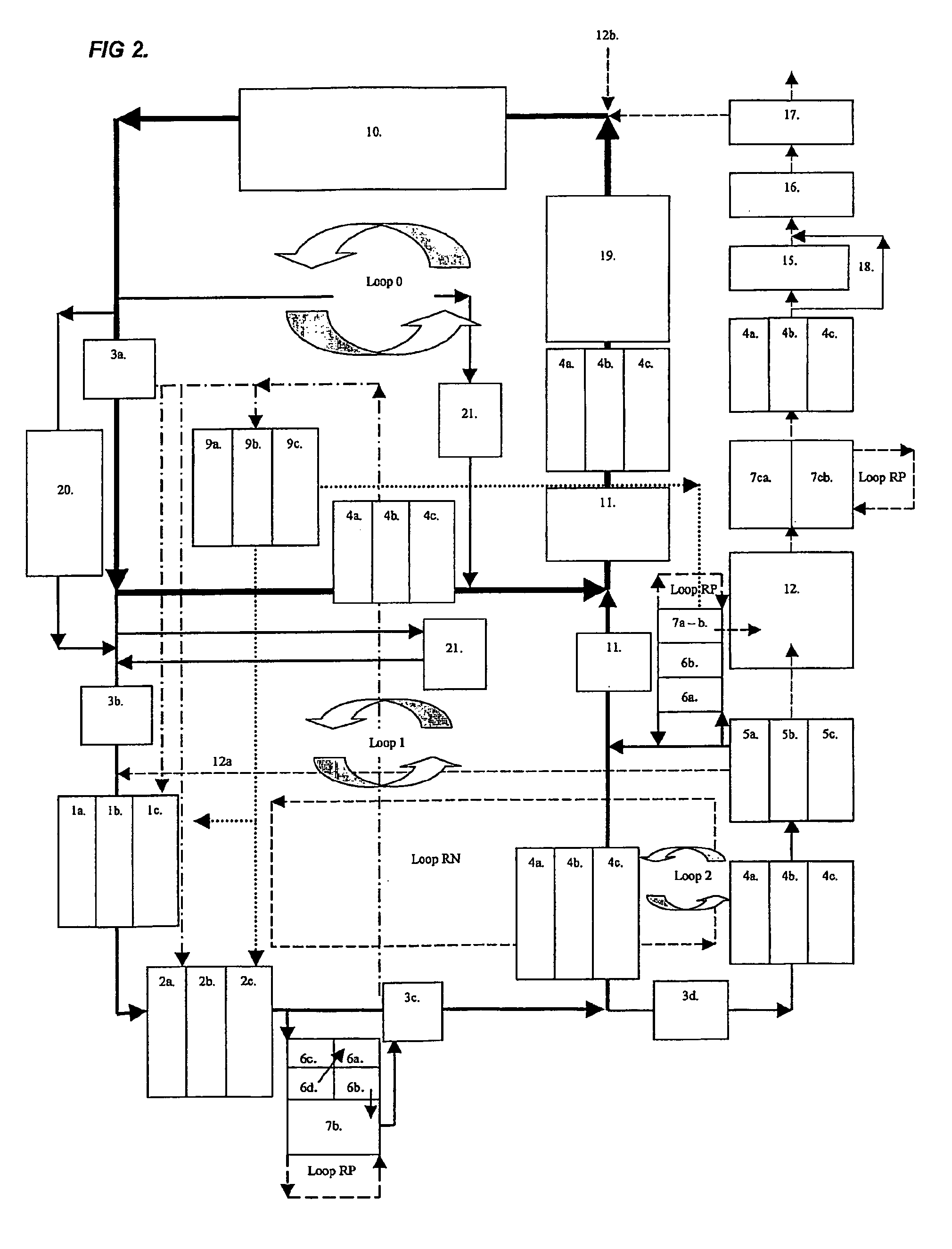

Mobile station and methods for diagnosing and modeling site specific effluent treatment facility requirements

InactiveUS20090032446A1Reduce financial riskHigh continuity of operationReverse osmosisFlash degasificationIon exchangeReverse osmosis

A mobile station and methods are disclosed for diagnosing and modeling site specific effluent treatment facility requirements to arrive at a treatment regimen and / or proposed commercial plant model idealized for the particular water / site requirements. The station includes a mobile platform having power intake, effluent intake and fluid outflow facilities and first and second suites of selectably actuatable effluent pre-treatment apparatus. An effluent polishing treatment array is housed at the station and includes at least one of nanofiltration, reverse osmosis and ion-exchange stages. A suite of selectively actuatable post-treatment apparatus are housed at the station. Controls are connected at the station for process control, monitoring and data accumulation. A plurality of improved water treatment technologies are also disclosed.

Owner:ROCKWATER RESOURCE

Point of use water treatment device

ActiveUS20150129776A1Water/sewage treatment by irradiationSpecific water treatment objectivesHeat spreaderWater treatment

Embodiments of the present invention provide a water treatment device that can treat water at its point of use. For example, the water treatment device may be positioned at or near a faucet outlet, so that water can be treated immediately before it leaves the faucet. The water treatment device may be a water treatment reactor with a plurality of UV LEDs positioned between a shield and a heat sink component.

Owner:MAG AEROSPACE IND INC

Non-phosphorus compound scale and corrosion inhibitor for treatment of circulating cooling water

ActiveCN1621362AEasy to useIncrease the concentration factorScale removal and water softeningPhosphateTungstate

The composite phosphate-free scale inhibiting corrosion inhibitor for treating circular cooling water consists of scale inhibitor and corrosion inhibitor. The scale inhibitor consists of one or several of PASP, PVA, oxidized starch, polyacrylic acid, acrylic acid / acrylate copolymer and acrylic acid / acrylate copolymer with sulfo radical. The corrosion inhibitor consists of one or several of sodium salt / potassium salt / ammonium salt of organic salt, sodium / potassium / ammonium borate, nitrous organic matter, soluble molybdenate, soluble tungstate, soluble nitrate, soluble nitrite and soluble zinc salt. The composite scale inhibiting corrosion inhibitor has excellent scale inhibiting and corrosion inhibiting performance, is environment friendly, and is especially the treatment of hard circulation water with high calcium and high alkali content.

Owner:BEIJING YANHUA XINGYE TECH DEV +1

Active alumina/active carbon composite material and preparation method thereof

InactiveCN102319557ASolve the strength problemSolve the problem of longevityCatalyst carriersOther chemical processesActivated carbonSludge

The invention discloses an active alumina / active carbon composite material and a preparation method thereof. The composite material comprises the following ingredients: 70-90 weight portions of sludge, 10-30 weight portions of active carbon, and 15-35 weight portions of binder, and is prepared by uniformly mixing, pelleting, aging, molding, drying in the air, sintering, rinsing and drying. Using sludge as raw material has an important meaning to environmental protection and recycling of waste. The invention has the advantages of simple preparation method, easy obtainment of raw material, and low cost, and can be widely applied in the fields of industry, agriculture, environmental protection, air cleaning, water treatment and the like.

Owner:FUZHOU UNIV

Catalyst for treatment of waste water, and method for treatment of waste water using the catalyst

InactiveCN102686521AStabilizationImprove purification effectWater contaminantsCatalyst activation/preparationIridiumWater use

Disclosed are: a catalyst which can exhibit an excellent catalytic activity and excellent durability for a long period in the wet oxidation treatment of waste water; a wet oxidation treatment method for waste water using the catalyst; and a novel method for treating waste water containing a nitrogenated compound, in which a catalyst to be used has a lower catalytic cost, the waste water containing the nitrogenated compound can be treated at high purification performance, and the high purification performance can be maintained. The catalyst for use in the treatment of waste water comprises an oxide of at least one element selected from the group consisting of iron, titanium, silicon, aluminum, zirconium and cerium as a component (A) and at least one element selected from the group consisting of silver, gold, platinum, palladium, rhodium, ruthenium and iridium as a component (B), wherein at least 70 mass% of the component (B) is present in a region positioned within 1000 [mu]m from the outer surface of the component (A) (i.e., the oxide), the component (B) has an average particle diameter of 0.5 to 20 nm, and the solid acid content in the component (A) (i.e., the oxide) is 0.20 mmol / g or more. The waste water treatment method uses a catalyst (a pre-catalyst) which is placed on an upstream side of the direction of the flow of the waste water and can convert the nitrogenated compound contained in the waste water into ammoniacal nitrogen in the presence of an oxidizing agent at a temperature of not lower than 100 DEG C and lower than 370 DEG C under a pressure at which the waste water can remain in a liquid state and a downstream-side catalyst (a post-catalyst) which is placed downstream of the direction of the flow of the waste water and can treat the waste water containing ammoniacal nitrogen.

Owner:NIPPON SHOKUBAI CO LTD

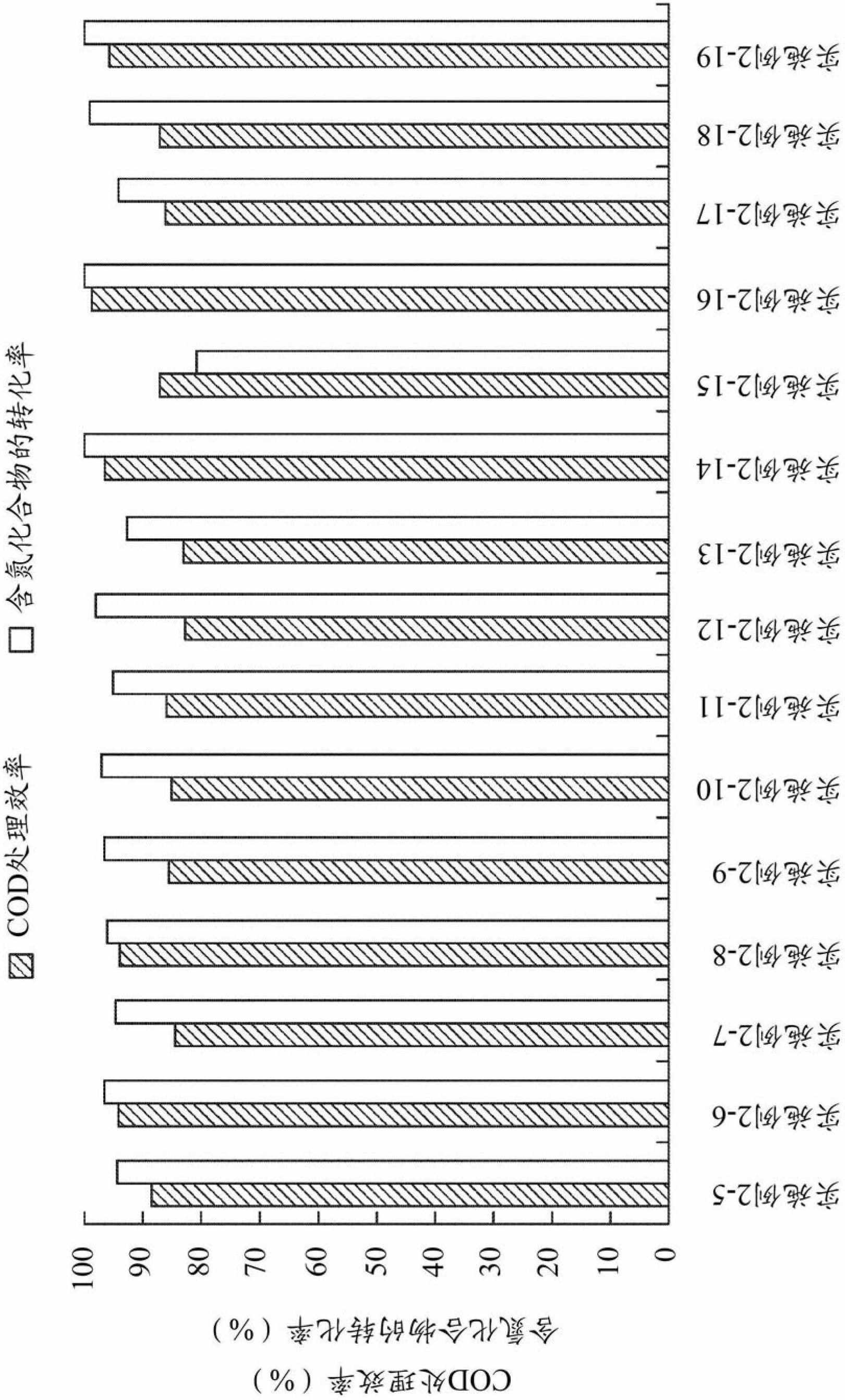

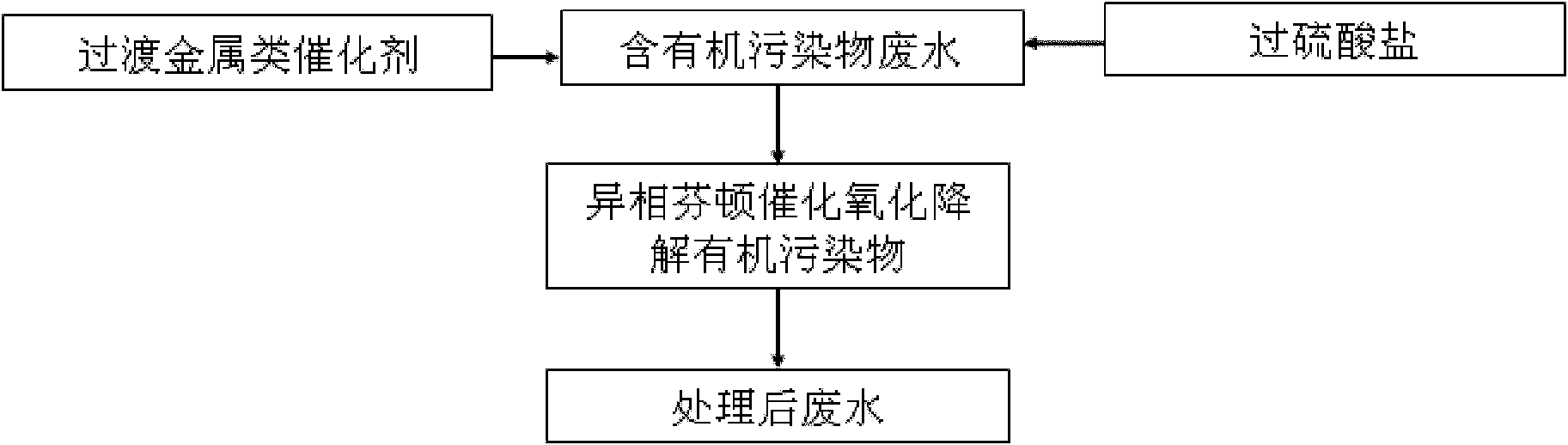

Processing method of heterocatalysis persulfate Fenton oxidation water

InactiveCN102020350ALong-lasting and efficient purificationImprove durabilityWater/sewage treatment by oxidationPersulfateFenton reagent

The invention proposes a processing technology of heterocatalysis persulfate Fenton oxidation water. In the method, transitional metal, transitional metallic oxide and a transitional metal / transitional metallic oxide composite material are used as out-phase Fenton reagents; and persulfate is catalyzed and decomposed to generate hydroxyl radical free radical, thus oxidizing to remove the organic matters in the waste water. Compared with the water treatment technique of homogeneous phase persulfate, the out-phase transitional metal and the transition metal oxide catalyst can slowly release transitional metal icons, thus ensuring that the organic matters in the water are purified lastingly and efficiently by the processing method of the heterocatalysis persulfate Fenton oxidation water. The processing technology of heterocatalysis persulfate Fenton catalyzed oxidation water built by the invention is suitable for processing various organic wastewater, has the advantages of good durability, high efficiency, environmentally friendliness, and no secondary pollution, is easy to operate, conforms to the requirements of actual water treatment units, and has great application potential in the field of environmental pollution regulation.

Owner:HUAZHONG NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com