Patents

Literature

26068 results about "Food processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Food processing is the transformation of agricultural products into food, or of one form of food into other forms. Food processing includes many forms of processing foods, from grinding grain to make raw flour to home cooking to complex industrial methods used to make convenience foods.

Preparation method of plant enzyme food

The invention discloses a preparation method of plant enzyme food, belonging to the field of food processing technology. The method comprises the following steps of: performing twice fermentation and compounding on the natural plant raw materials of fresh fruits, vegetables, mushrooms, medicines, grains and flowers to obtain the secondary-fermentation stock solution or raw sauce, and storing; filling and sealing the secondary-fermentation stock solution or raw sauce to obtain liquid or sauce-type plant enzyme food or compound plant enzyme food; or performing low-temperature concentration and freeze drying to obtain solid plant enzyme food or compound plant enzyme food. Due the adoption of the preparation method, the obtained natural plant enzyme food has the functions of improving the immunity of human body, activating cells, promoting metabolism and the like.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Compound flocculant taking natural minerals as main components

InactiveCN104229957AEfficient removalApplicable to a wide range of PHWater resource protectionWater/sewage treatment by flocculation/precipitationDry weightNatural mineral

The invention discloses a compound flocculant taking natural minerals as main components. The compound flocculant is mainly prepared from the following components by weight percent: 60%-85% of natural minerals, 8%-38% traditional inorganic flocculant and 3%-10% of organic polymer flocculant. According to the invention, key points are as follows: in the compound flocculant taking natural minerals as main components, the weight of the natural minerals, the inorganic flocculant and the organic polymer flocculant is dry weight; and the compound flocculant is implemented to purification of civil engineering wastewater, natural water, industrial wastewater, oily wastewater, fluoride wastewater, food processing wastewater, auto parts processing wastewater, colored wastewater, clean wastewater, semiconductor processing wastewater, restaurant waste water, mine water, slaughter wastewater, grinding wastewater, sewage effluent and the like.

Owner:张家领

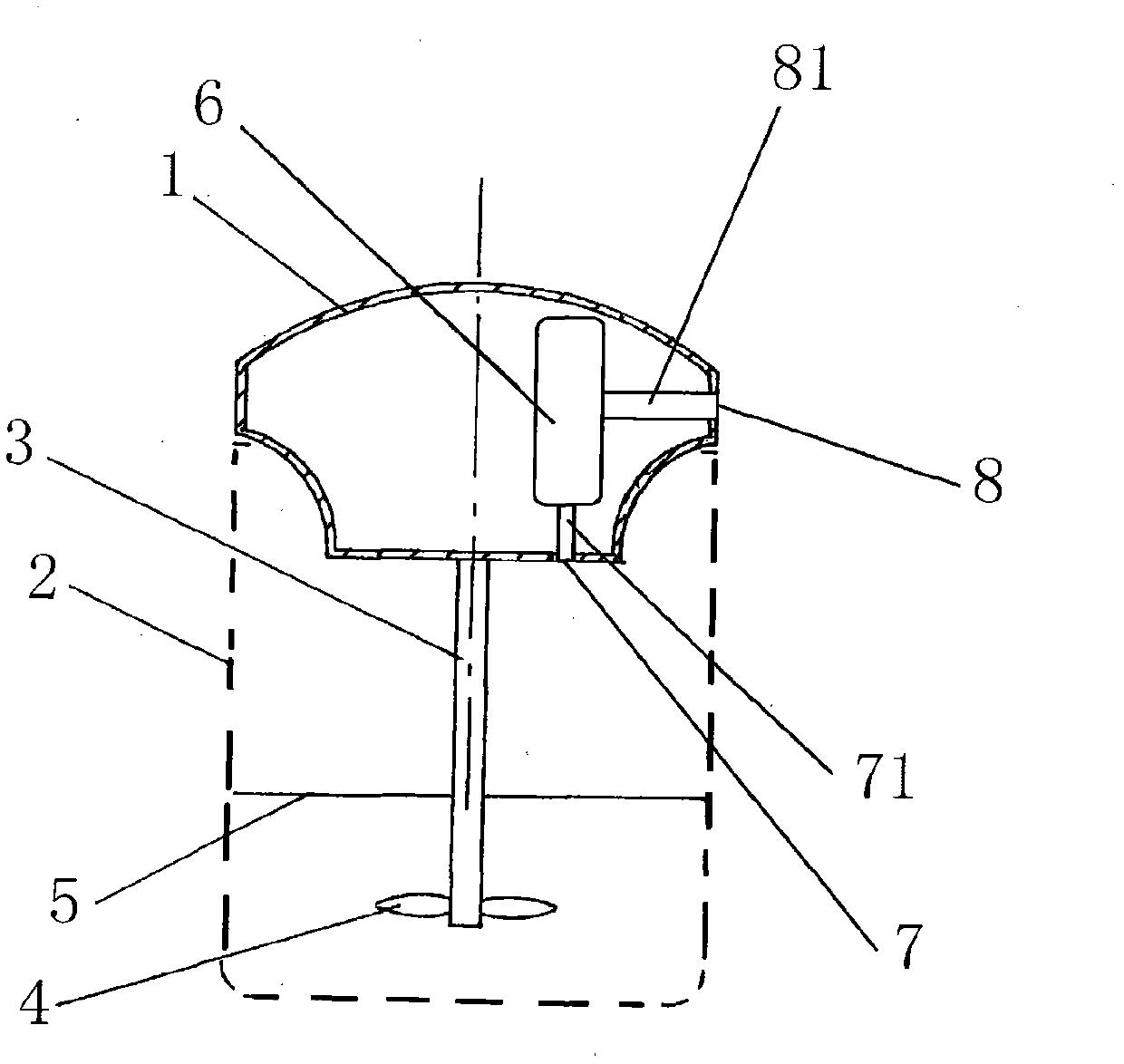

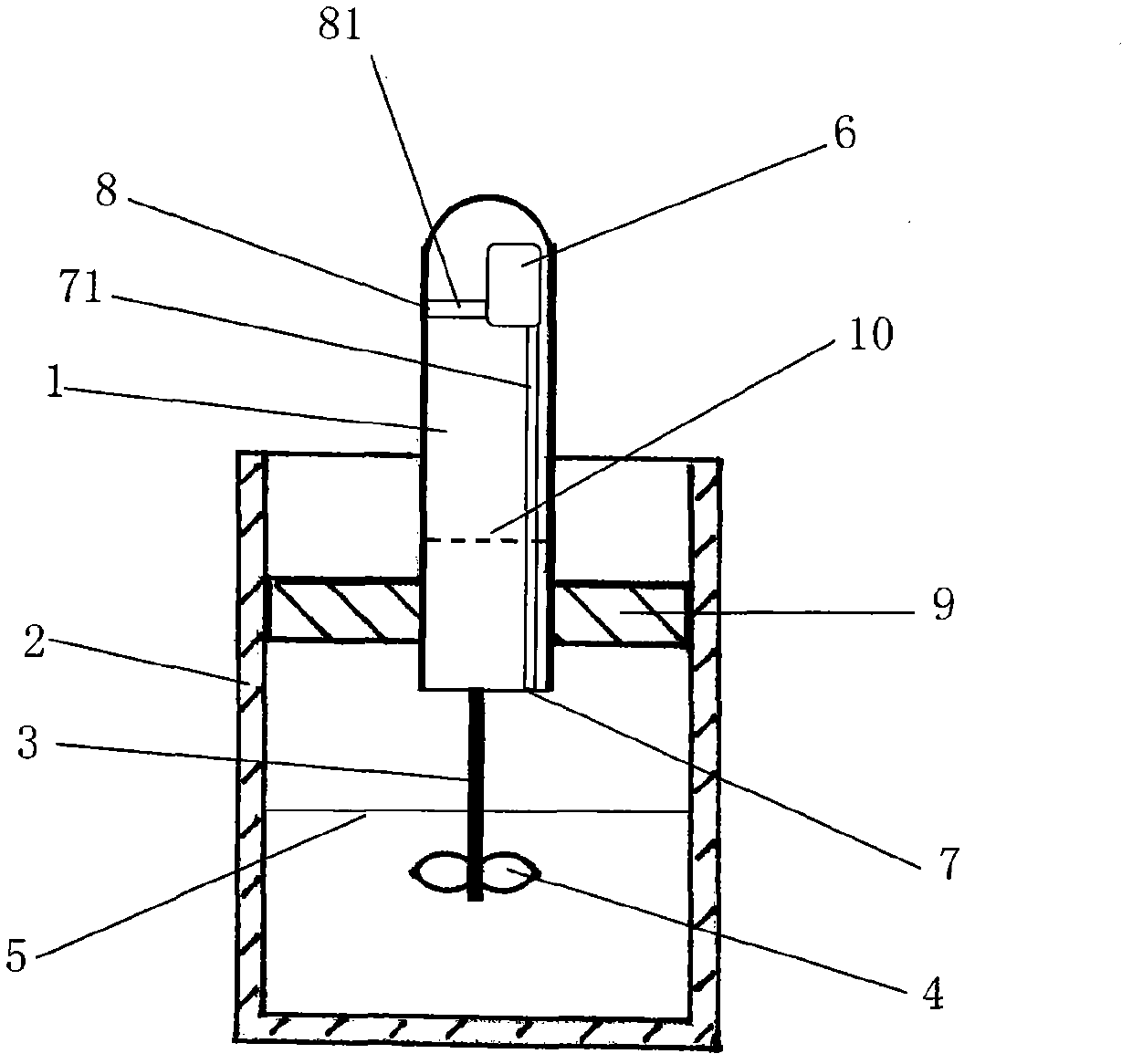

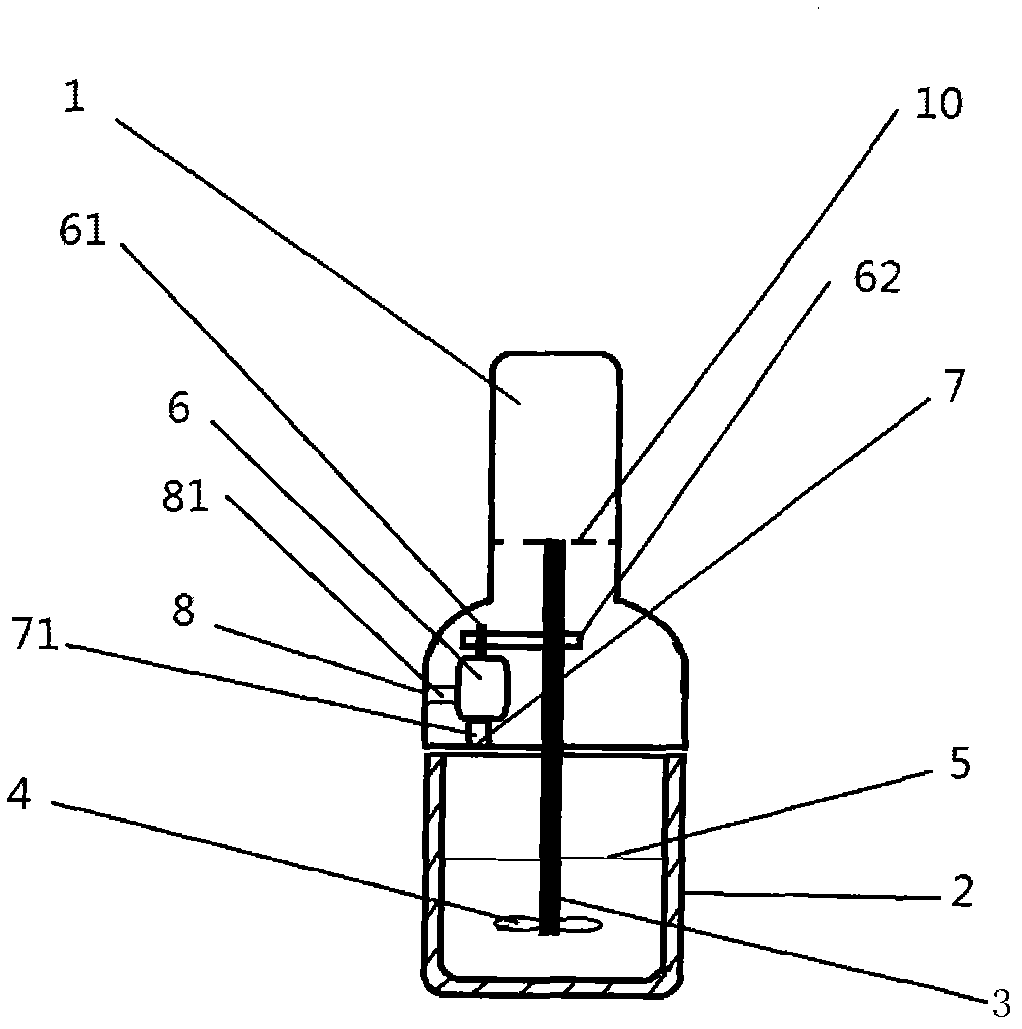

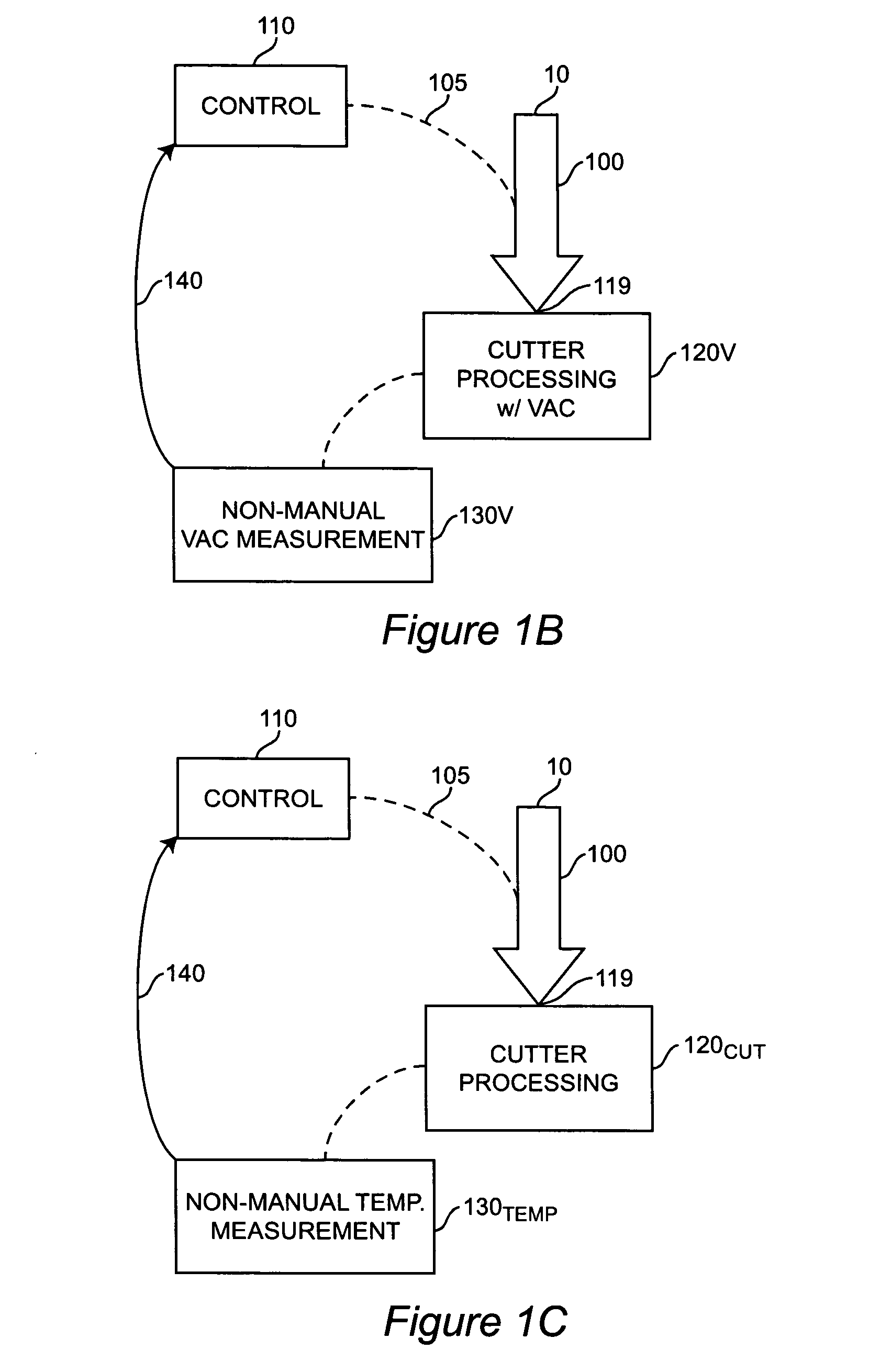

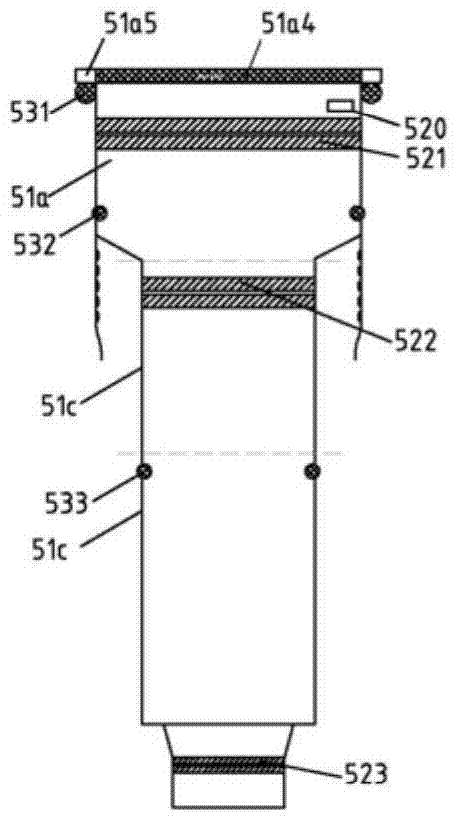

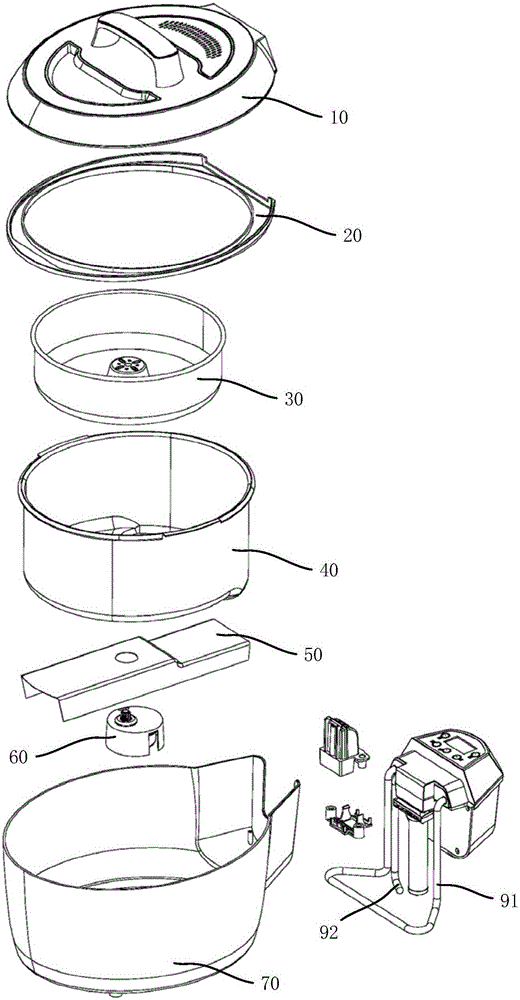

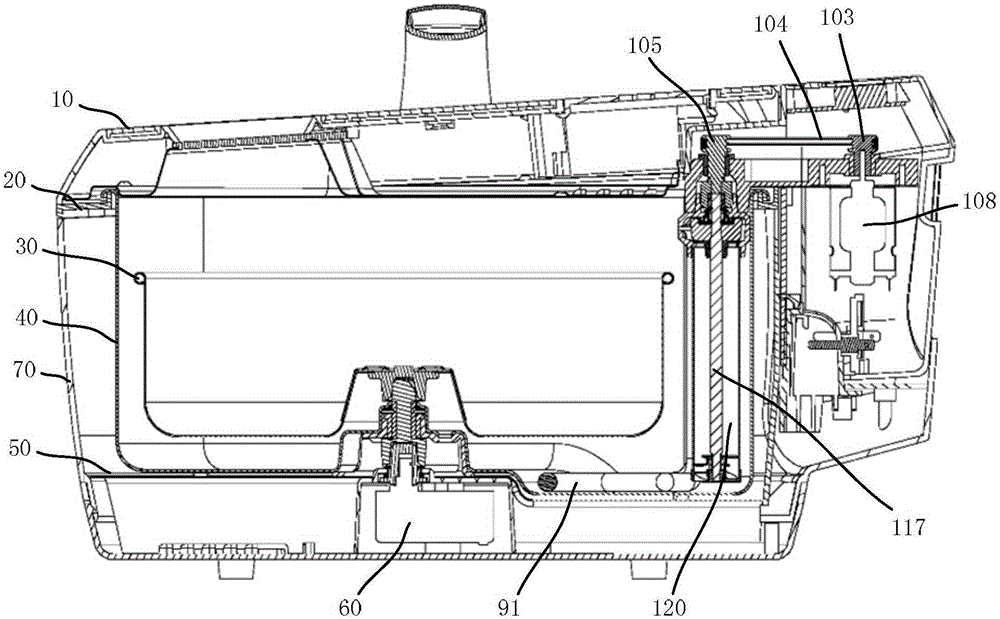

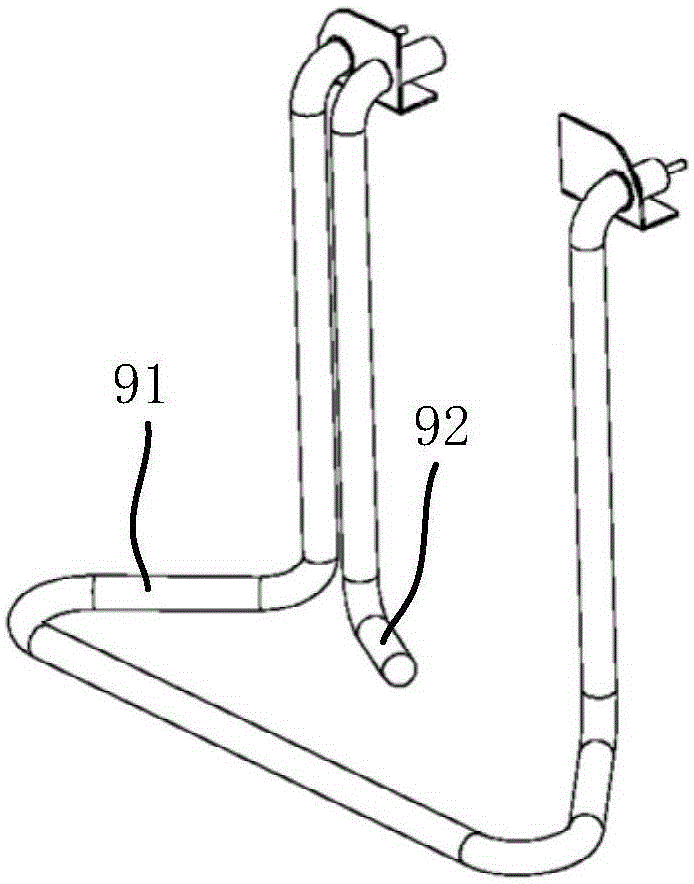

Food processing machine with electric sucking pump and method for vacuumizing to produce foodstuff liquid

The invention relates to a food processing machine with an electric sucking pump and a method for vacuumizing to produce foodstuff liquid. The food processing machine comprises a crushing cutter device, a machine head or a machine base, a motor, a barrel and a control circuit board, wherein the barrel is provided with a sealing device, has or does not have a heating device. An electric sucking pump is arranged on the machine head, the machine base, the sealing device, the barrel or a barrel handle of the food processing machine, the sucking port of the electric sucking pump is positioned in the barrel and above the foodstuff liquid level, the exhaust port of the electric sucking pump is communicated with the outer part of the barrel; and the electric power source of the electric sucking pump is an independent motor, an electromagnetic vibration device, a piezoelectric ceramic vibration device or the crushing cutter device of the food processing machine. A sealing mode is adopted to seal the barrel of the food processing machine, the electric sucking pump is used to pump air out of the barrel, then crushing and heating are carried out to crush and heat the foodstuff in the barrel of the food processing machine under the vacuum condition, the oxidation of the foodstuff liquid is greatly reduced and avoided for the crushing and heating processes, so the nutritive loss is reduced, and the good taste and appearance color are kept.

Owner:王晓东

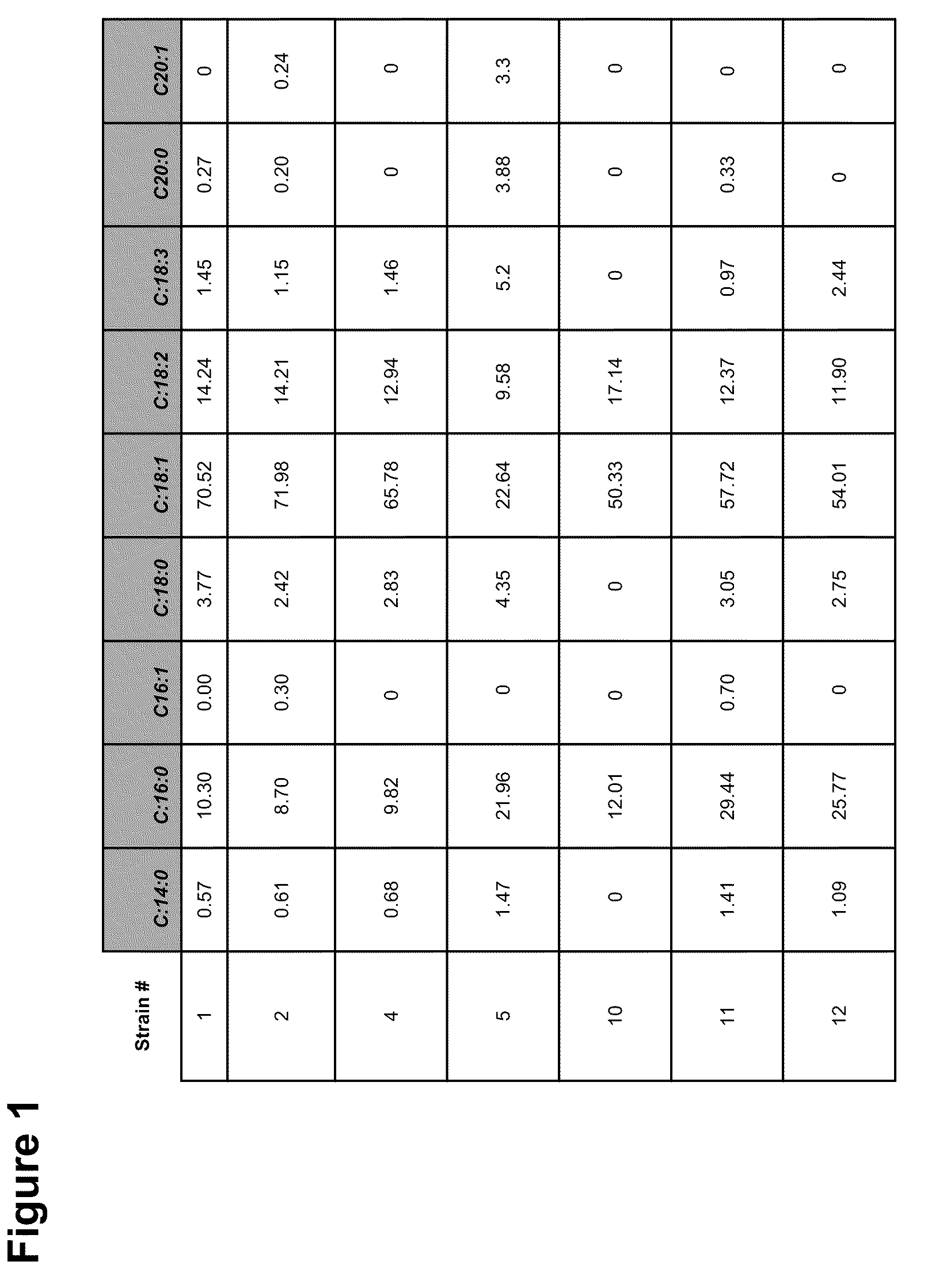

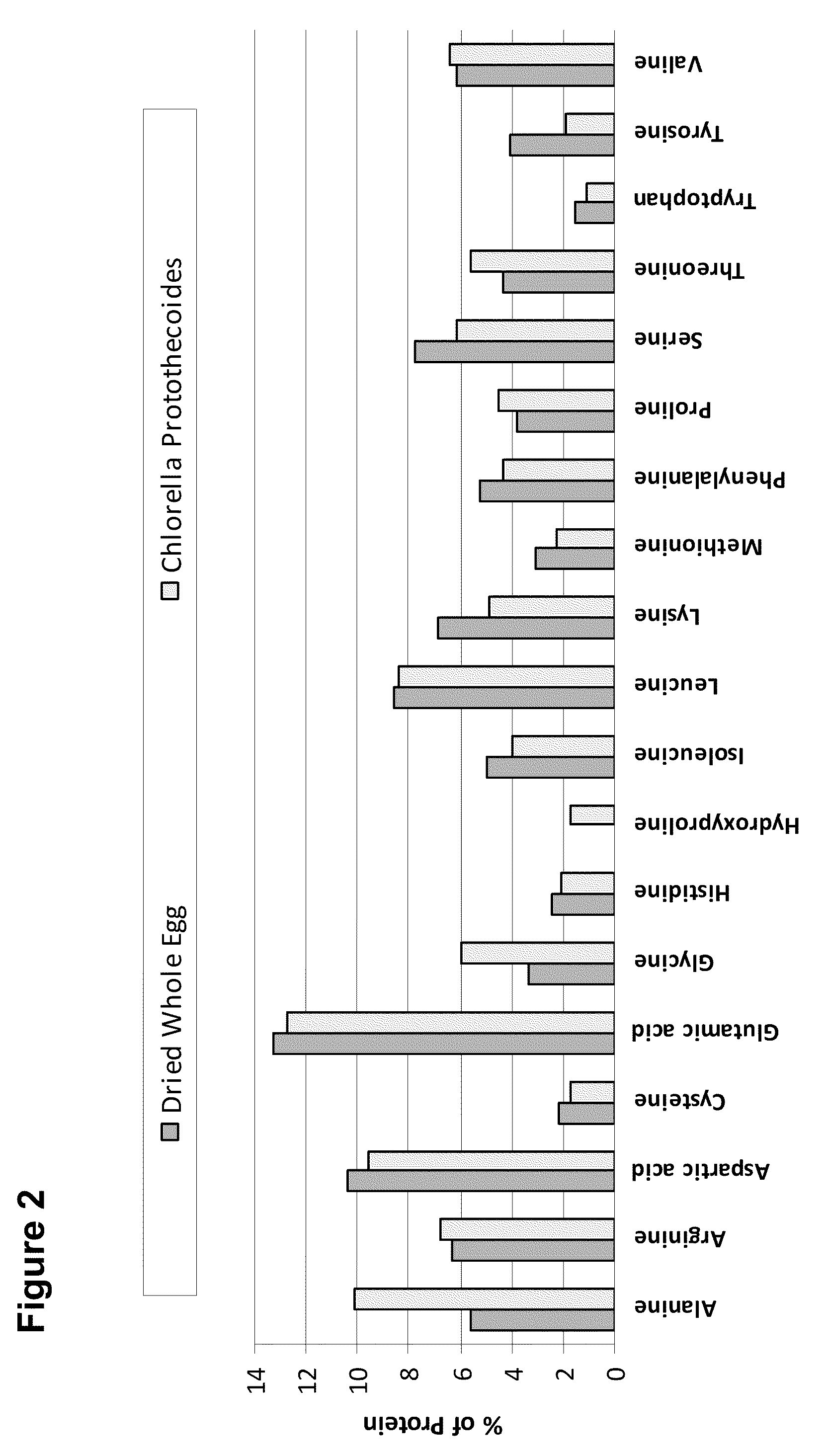

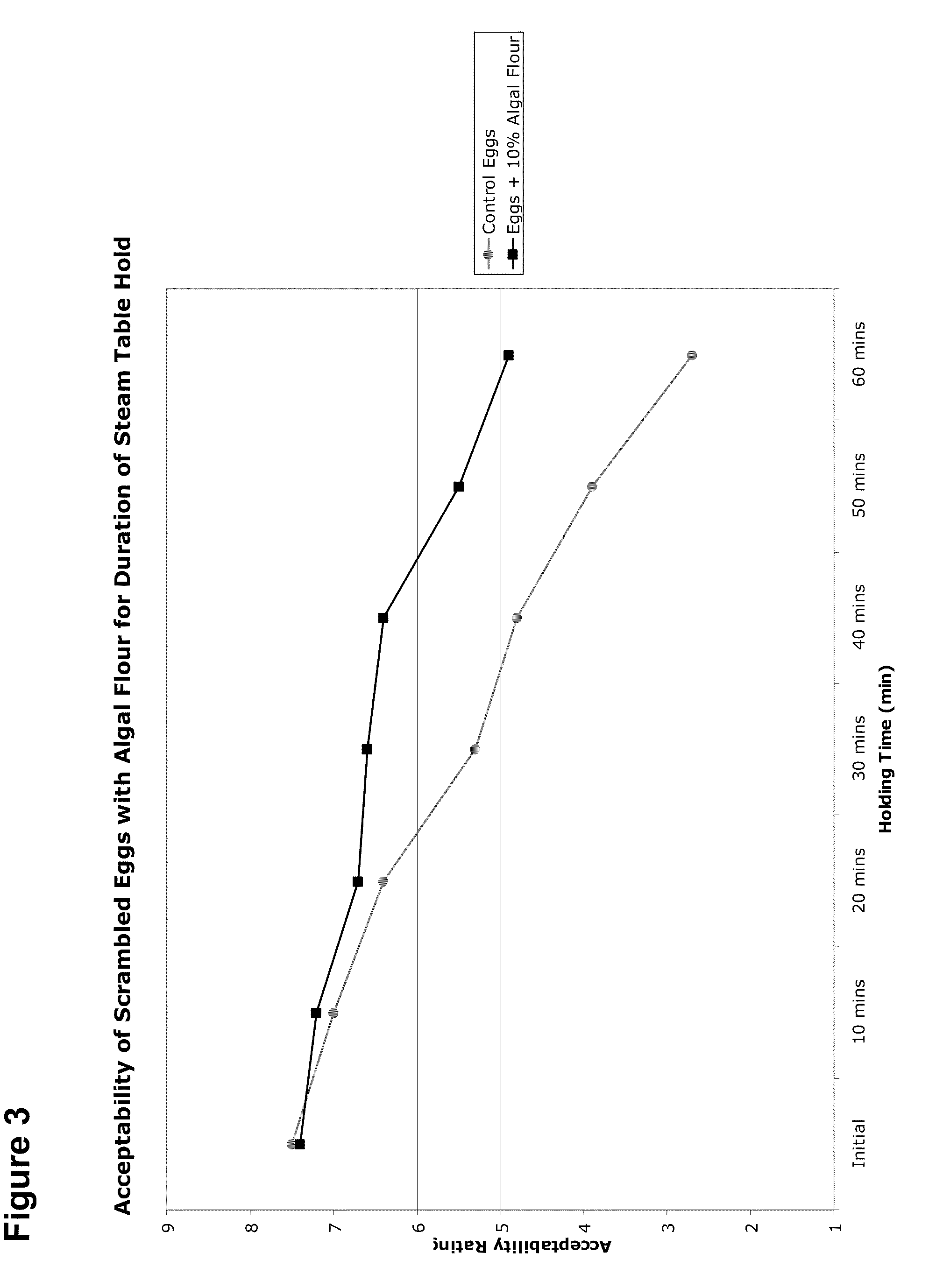

Reduced Fat Foods Containing High-Lipid Microalgae with Improved Sensory Properties

InactiveUS20100297331A1Reduce heat loadSimilar and identical organoleptic propertySpread compositionsDough treatmentLipid formationAlgae

Foods containing microalgae biomass with high levels of lipid are disclosed. Examples of foods include sauces, dressings, spreads, mayonnaise, and other edible materials that contain microalgae, where the edible materials are traditionally associated with delivery of saturated fats and oils. Further provided by the invention are such microalgae-containing foods with reduced caloric load compared to traditional foods of the same type, and in various embodiments the novel foods have similar or identical organoleptic properties as full-fat versions of the foods. Also provided are methods of formulating and manufacturing the novel foods and for manufacturing microalgae-based intermediates for manufacturing the same. The novel foods and intermediates can be manufactured using existing fermentation and food processing equipment, and can replace existing food products with healthier microalgae-derived food that have desirable structural and organoleptic properties.

Owner:TERRAVIA HLDG INC

Food product surface sterilization apparatus and method

InactiveUS20040052702A1Increase temperatureReduce food product temperature changeFood preservationIndirect heat exchangersUnsafe conditionUltraviolet

An apparatus is disclosed for the micro-organism surface sterilization of foods using, a "germicidal" such as light waves (e.g., ultraviolet), and in some cases in combination with (or replaced by) one or more of sound waves and ozone. The surface sterilizer apparatus may include a plurality of germicidal (e.g., ultraviolet) emitters for surface sterilization of foods that are, e.g., rotated in a drum or rotated via a screw auger. Assemblies of emitters for the germicidal may be constructed to be watertight (i.e., withstand a high pressure, heated water spray), and movable relative to the drum or screw conveyor for easy cleaning and maintenance. The apparatus may also include a controller (e.g., programmable logic controller) for controlling the sterilization process so that the apparatus does not endanger personnel nearby, and so that the food is properly sterilized. The controller may vary the amount of germicidal used, the rate that food traverses the apparatus, the inclination of the apparatus, and terminate sterilization processing when an unsafe condition is detected. The apparatus may be used in-line with other food processing equipment for the real-time sterilization of food. The controller may also communicate with food processing components upstream of the apparatus for controlling the flow of food to the surface sterilizer

Owner:C & S EQUIP COMPANY

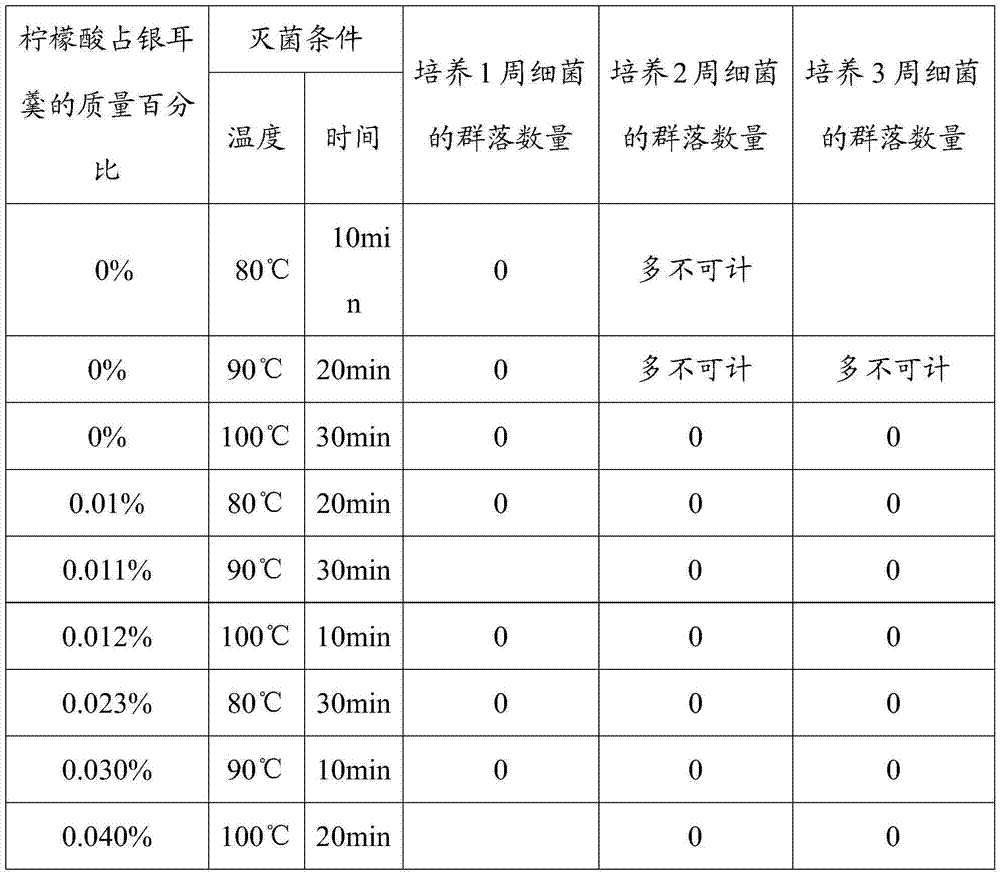

Ready-to-eat white fungus soup and preparation method thereof

The invention belongs to the technical field of food processing, and particularly relates to ready-to-eat white fungus soup and a preparation method thereof. The ready-to-eat white fungus soup is prepared from the following components in percentage by weight: 12.1-20.0% of fresh white funguses, 3.0-10.0% of crystal sugar, 0.011-0.040% of citric acid, 3.0-10.0% of red jujubes, 3.0-10.0% of lily bulbs, and the balance being water. The method for preparing the ready-to-eat white fungus soup comprises the following steps of preparing white fungus pulp, preparing mixed liquor and preparing finished products. The white fungus soup in which the fresh white funguses are used as main raw materials is rich in nutrition, has the efficacies of nourishing yin, nourishing the lung, nourishing the stomach, nourishing the heart and soothing the nerves, is fragrant and sweet in taste, and refreshing and smooth in mouth feel. The defects that in the prior art, white fungus soup products are single in nutrient components, and the taste of the conventional white fungus soup products cannot meet the requirements of different crowds for taste are overcome.

Owner:谢勇 +1

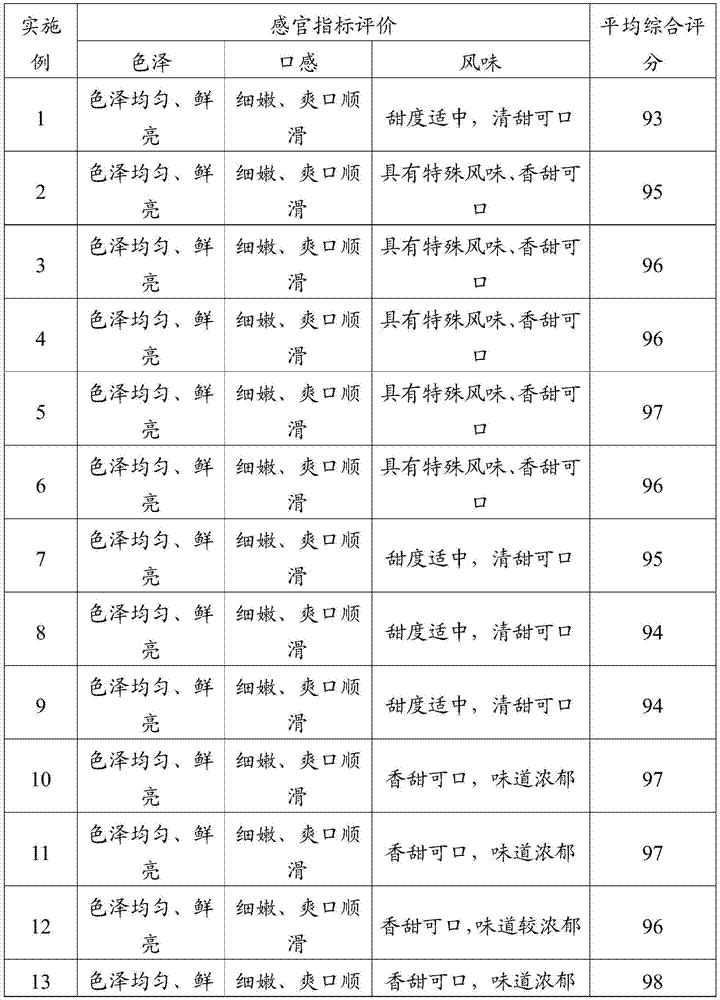

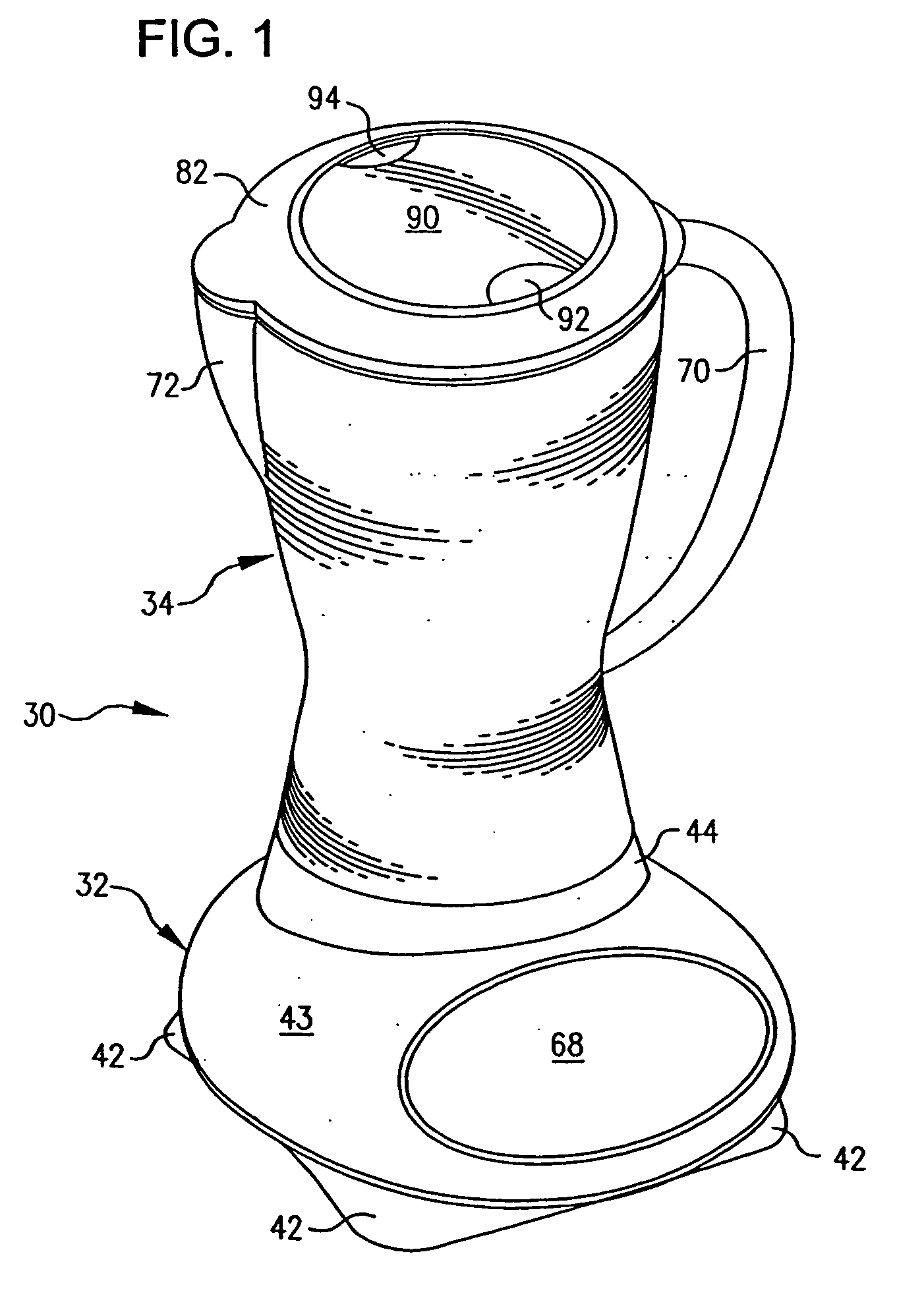

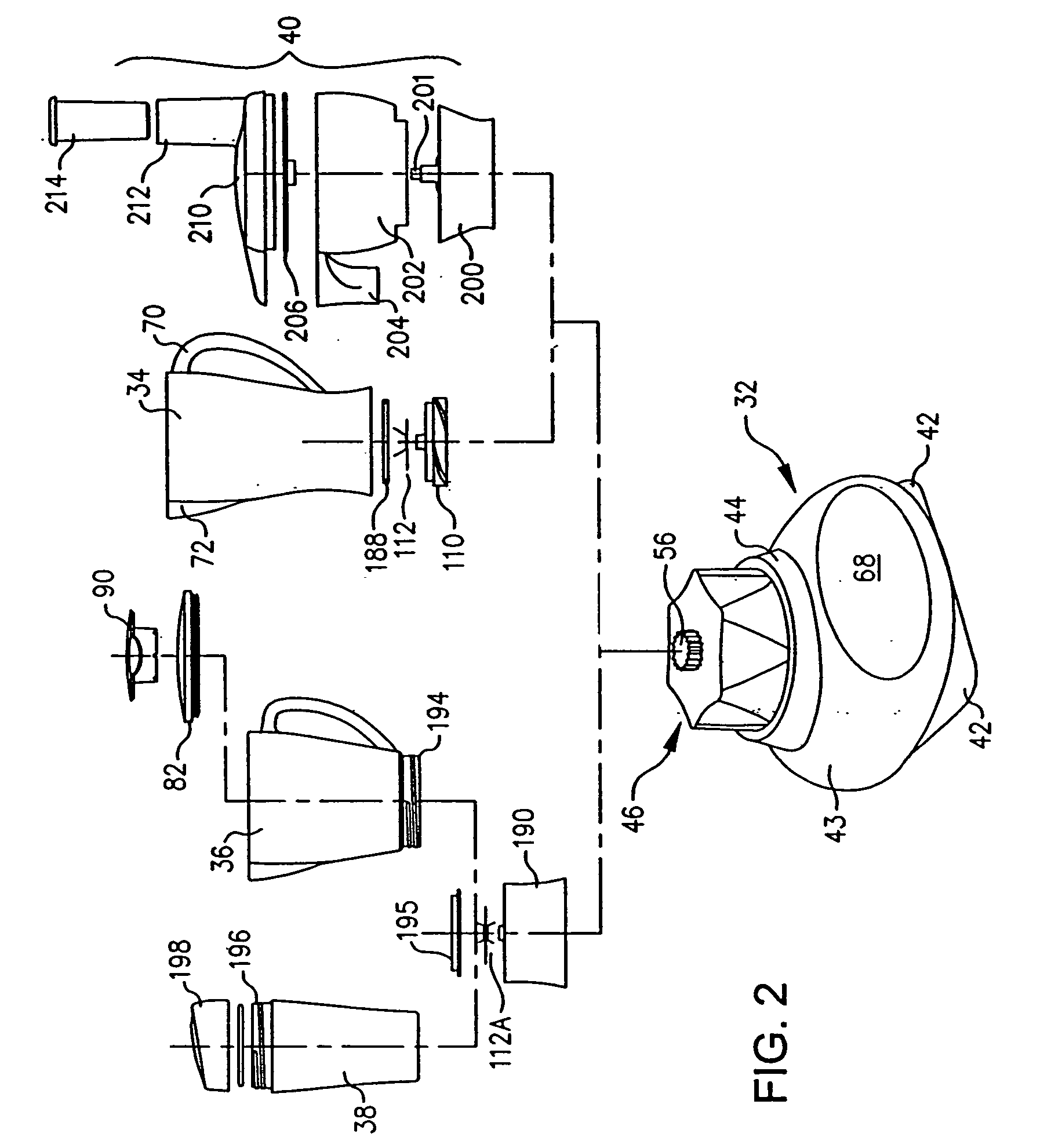

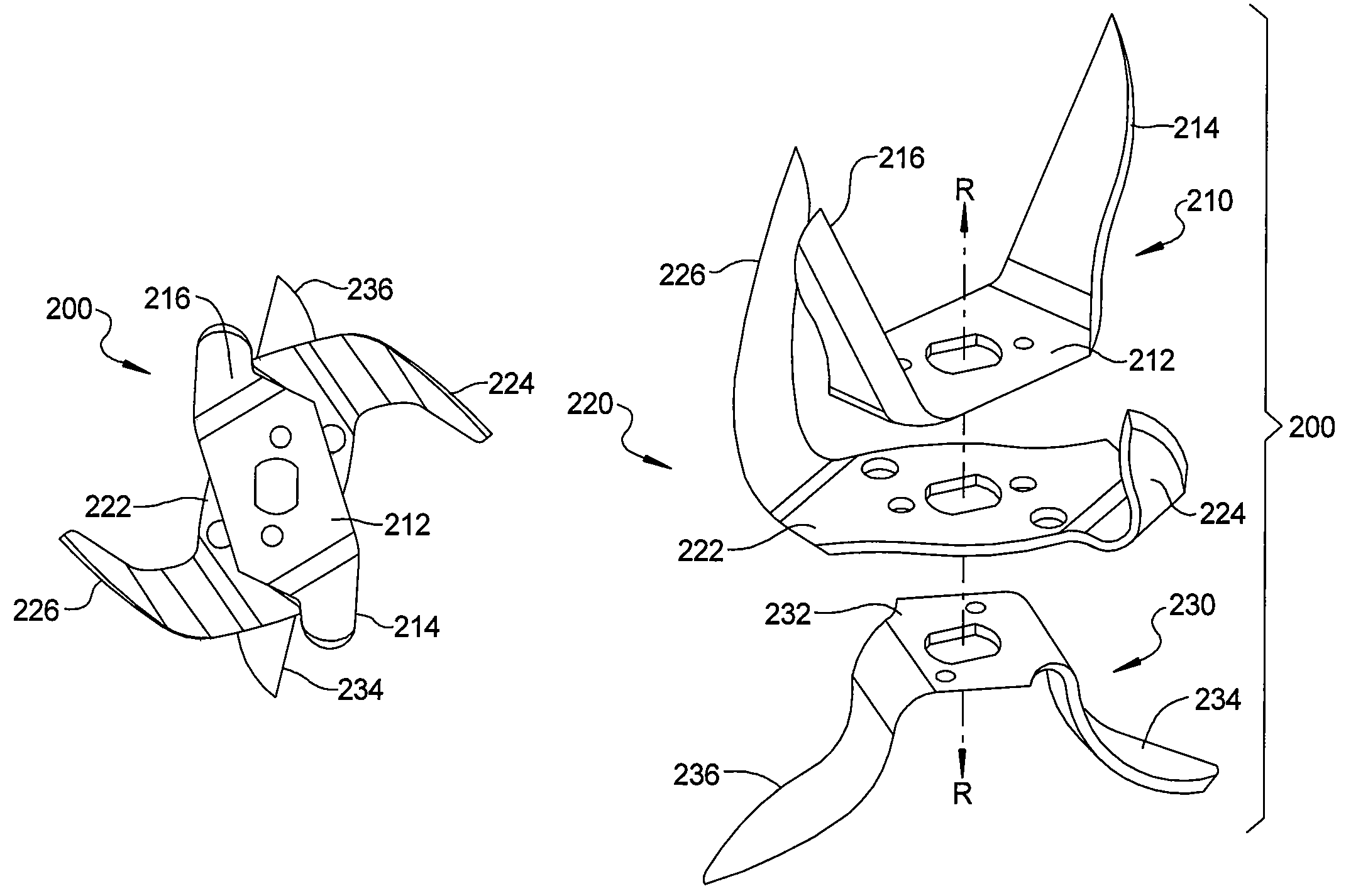

Blender base with food processor capabilities

InactiveUS20050068846A1Avoid vibrationImprove stabilityGas current separationTransportation and packagingMicrocontrollerLiquid-crystal display

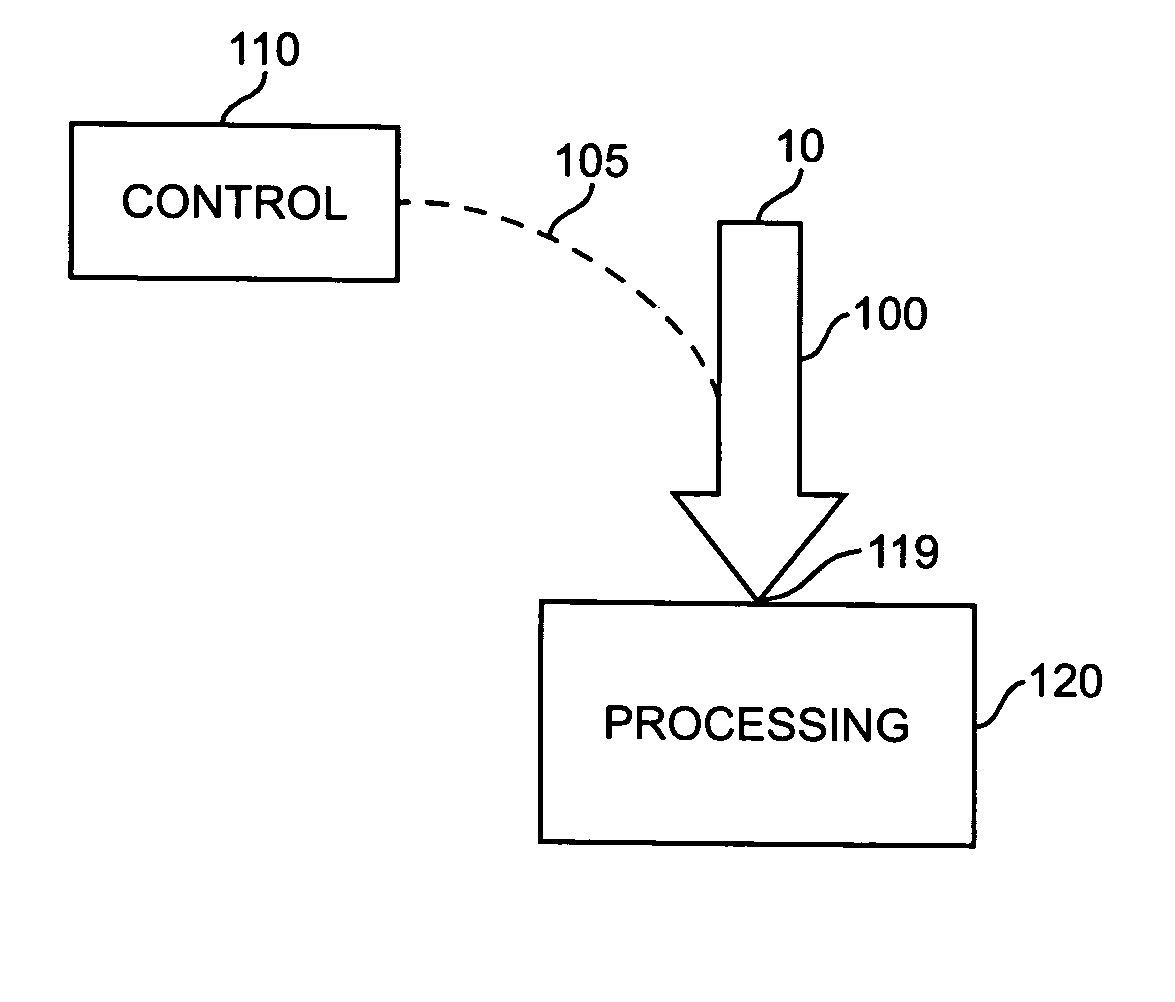

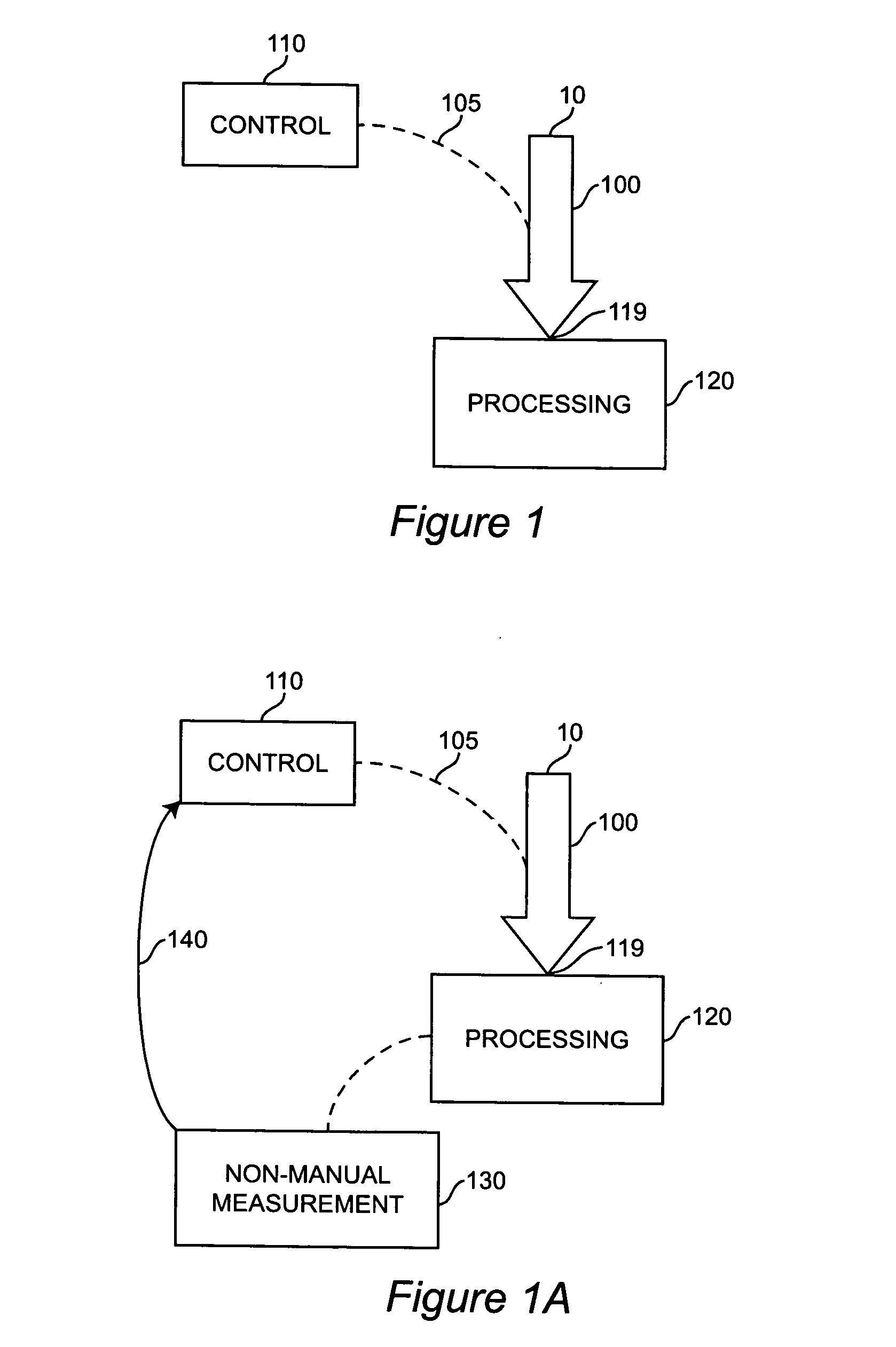

A blender base that may be used with a food processor container, a blender container, and a single use beverage container. The blender container includes a novel blade unit having a food processor-style blade and blender type blades. Programs with preprogrammed motor commands for desired operations are stored in memory and may be selected by a user on a user interface. The user interface may include a liquid crystal display, or function switches and light emitting diodes. Upon selection of a particular pre-defined function, the microcontroller retrieves the appropriate program from the read only memory and specifies the preprogrammed motor commands to accomplish the selected function.

Owner:WULF JOHN DOUGLAS +5

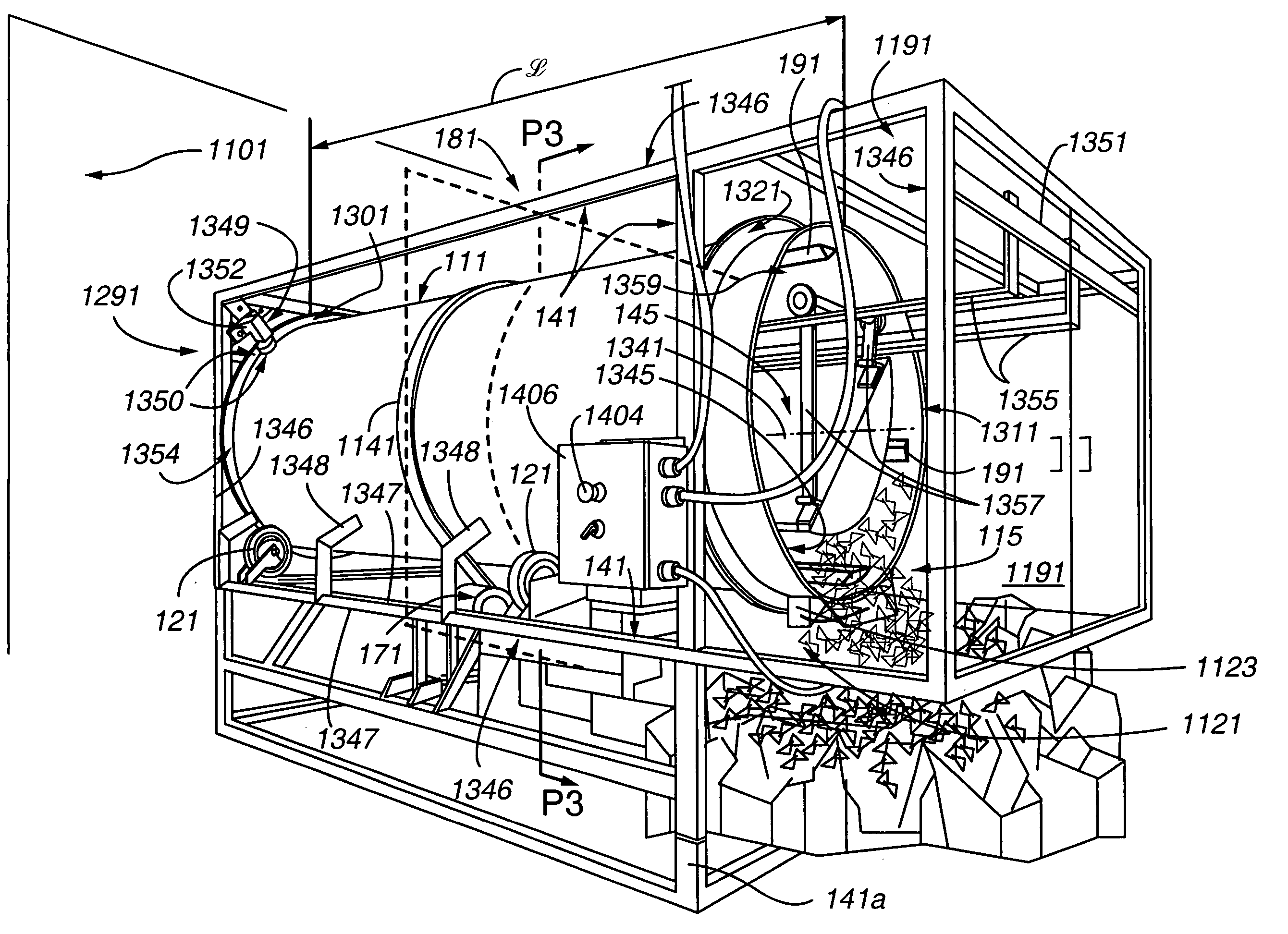

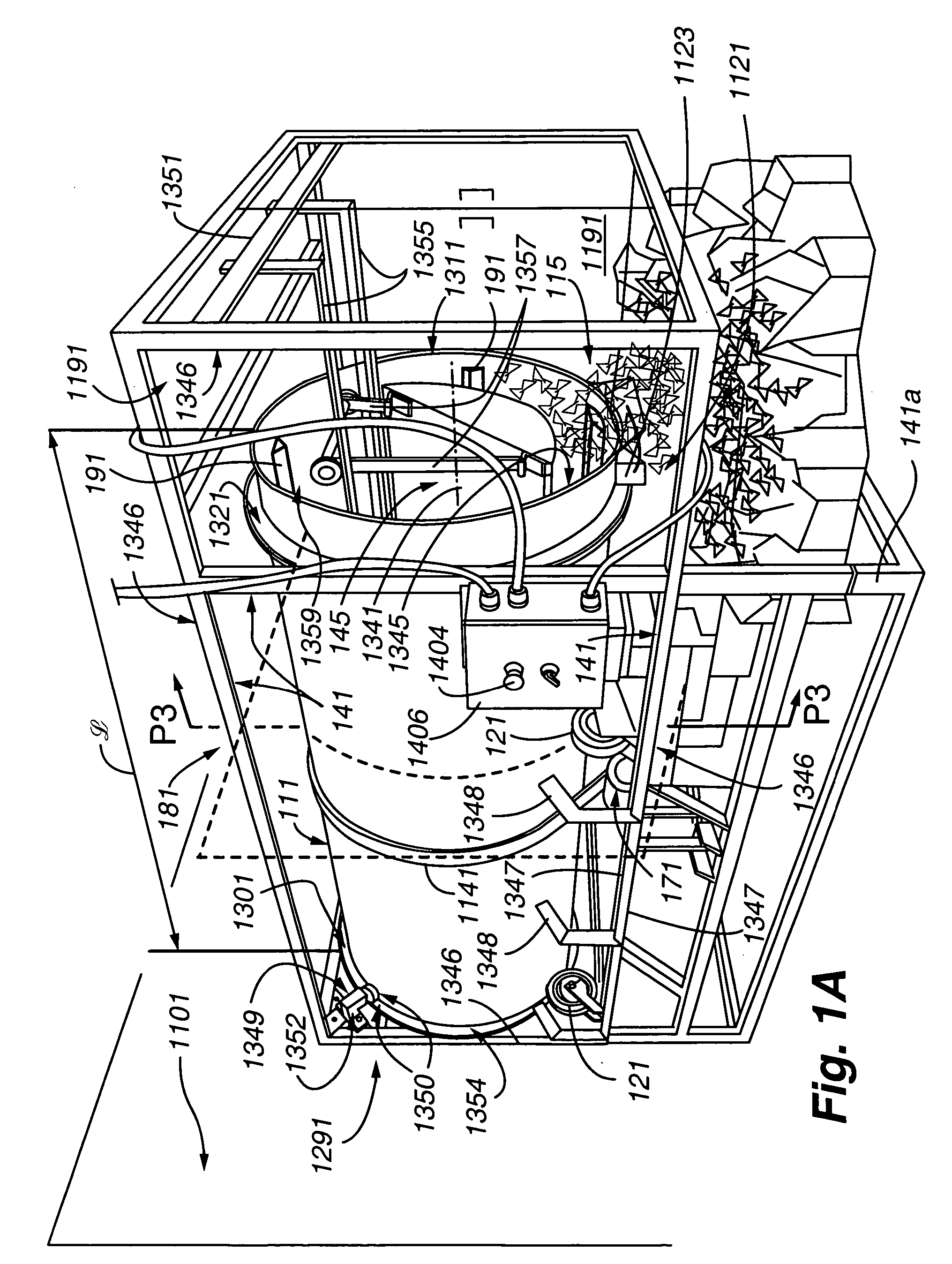

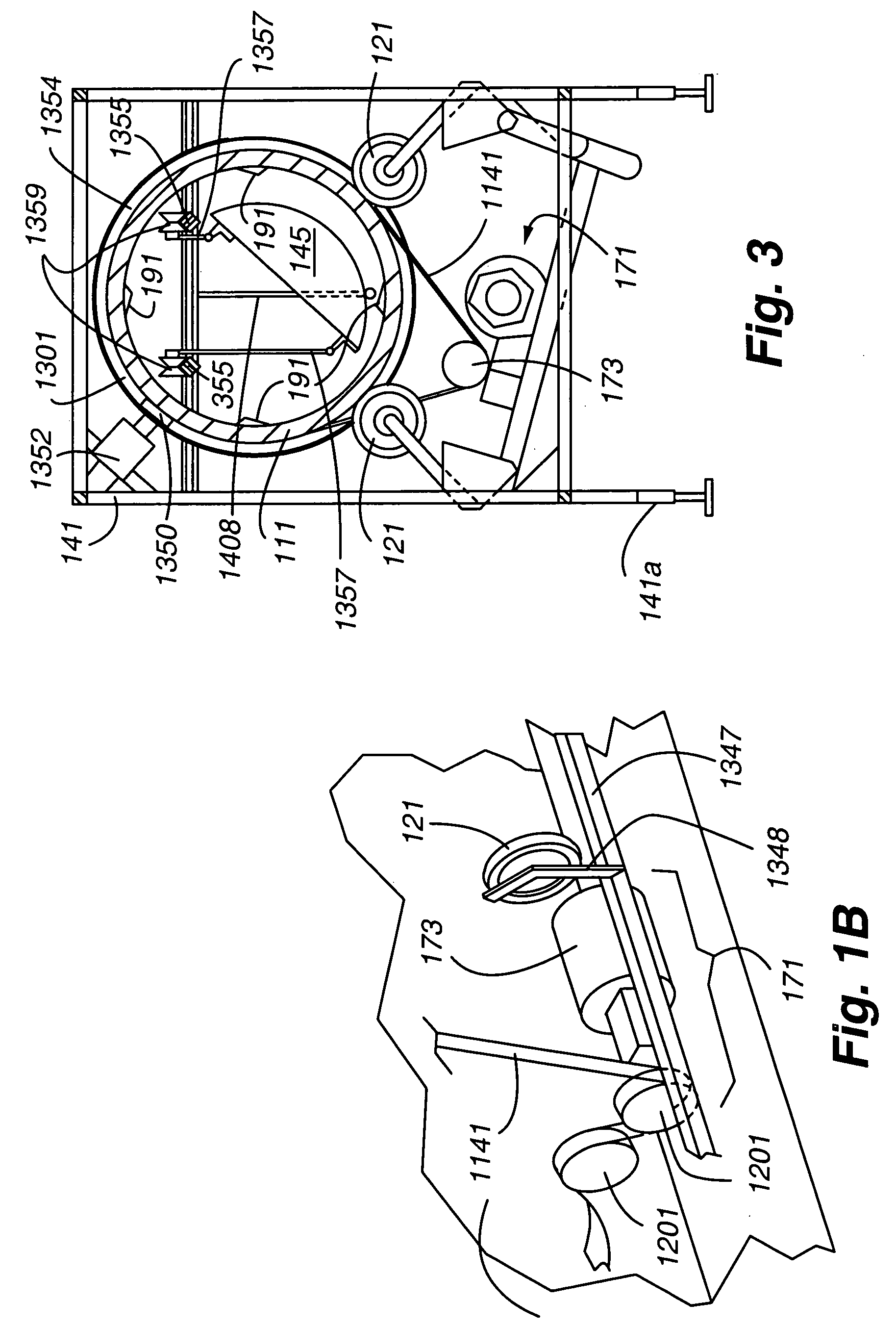

Feeding mechanism auto-adjusting to load for use in automatic high-security destruction of a mixed load, and other feeding systems

A inventive feeding mechanism continuously feeds and continuously subjects to shredding, cutting, recycling, sorting, or other processing, a load consisting of a mixture of different-thickness materials, such as a mixture of paper, compact disks (CDs), cassette tapes, videotapes, etc. The auto-adjusting feeding mechanism is useable in high-security destruction, food processing, recycling, sorting, processing, and other applications.

Owner:CASTRONOVO CHARLES A

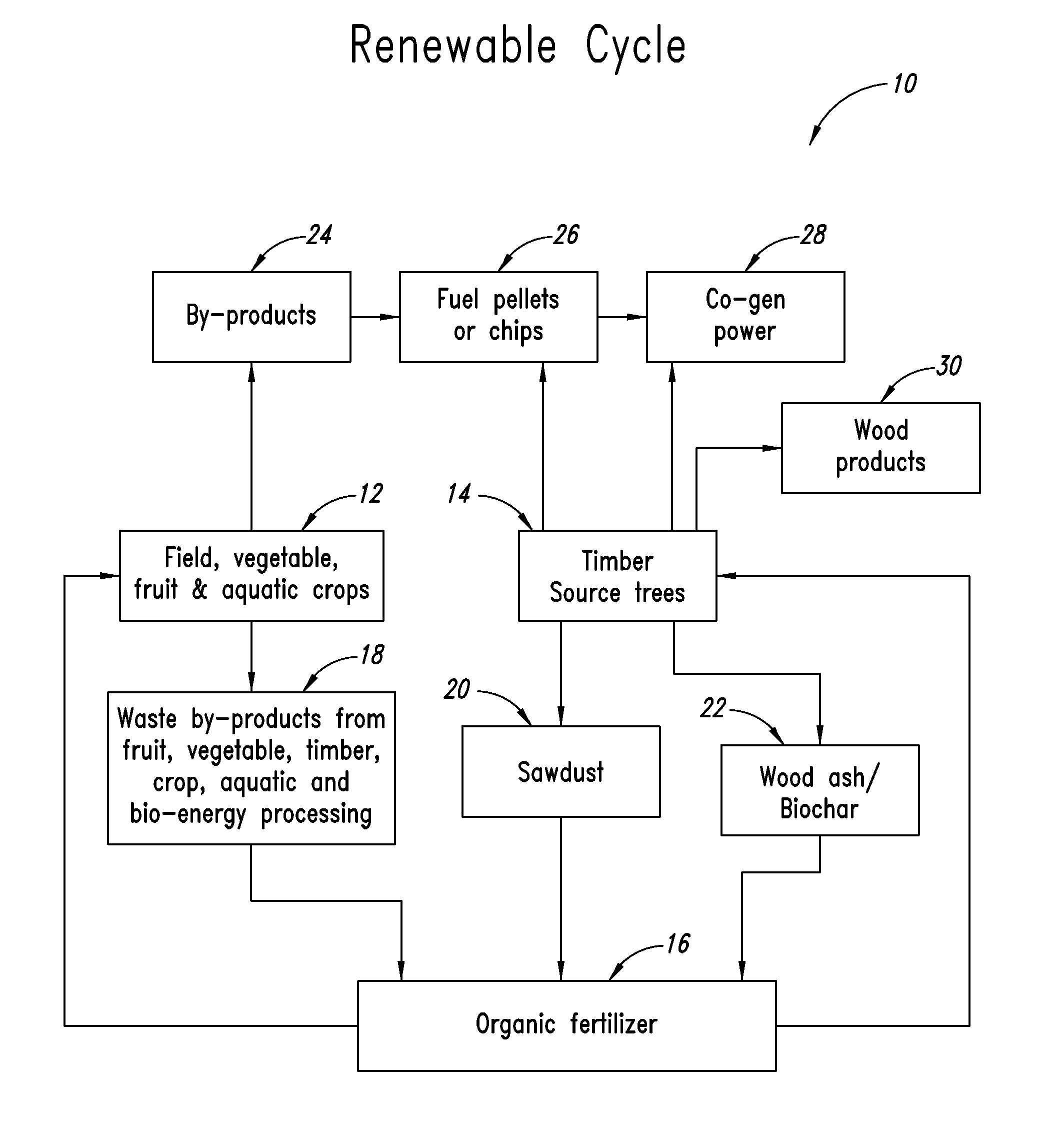

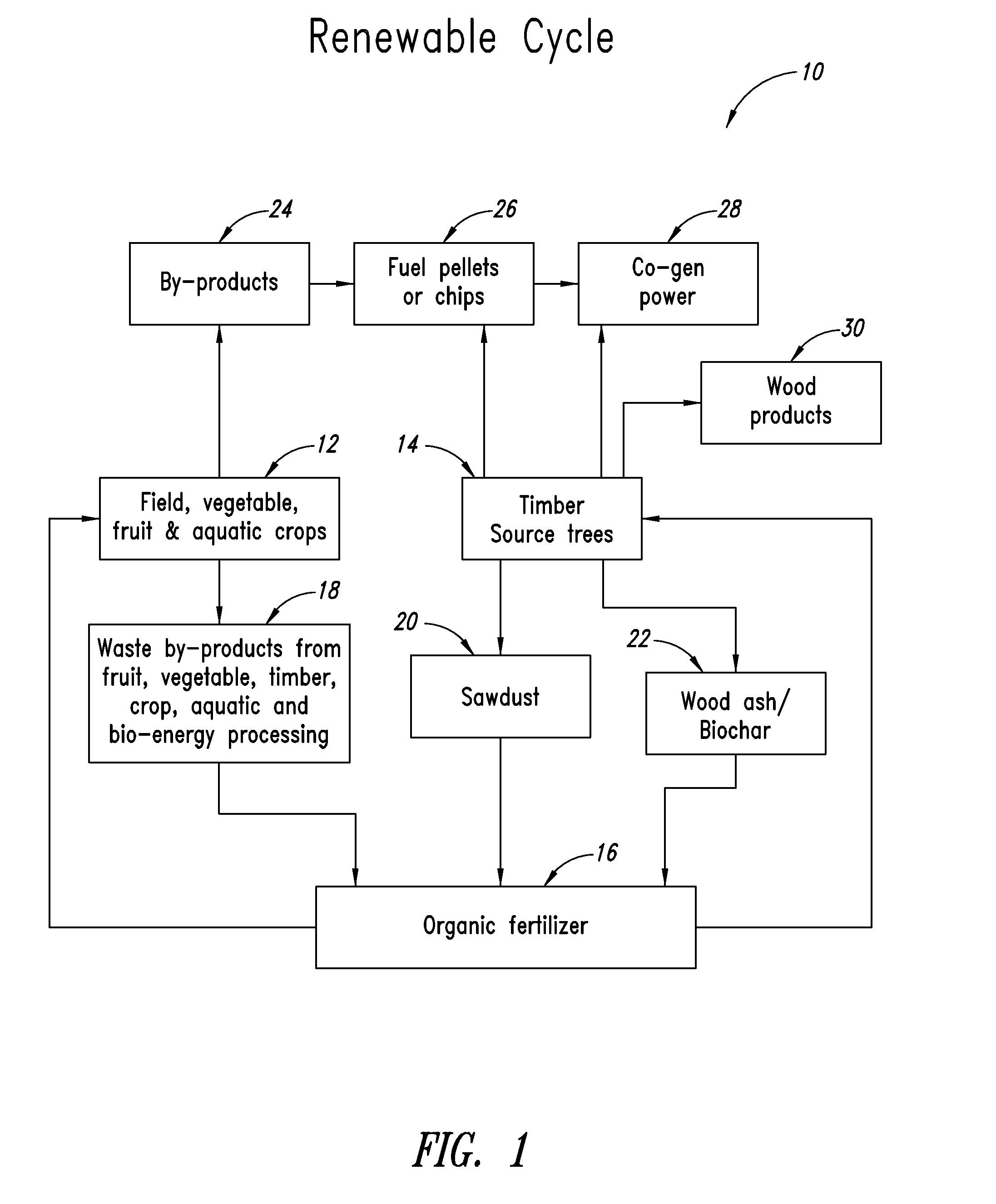

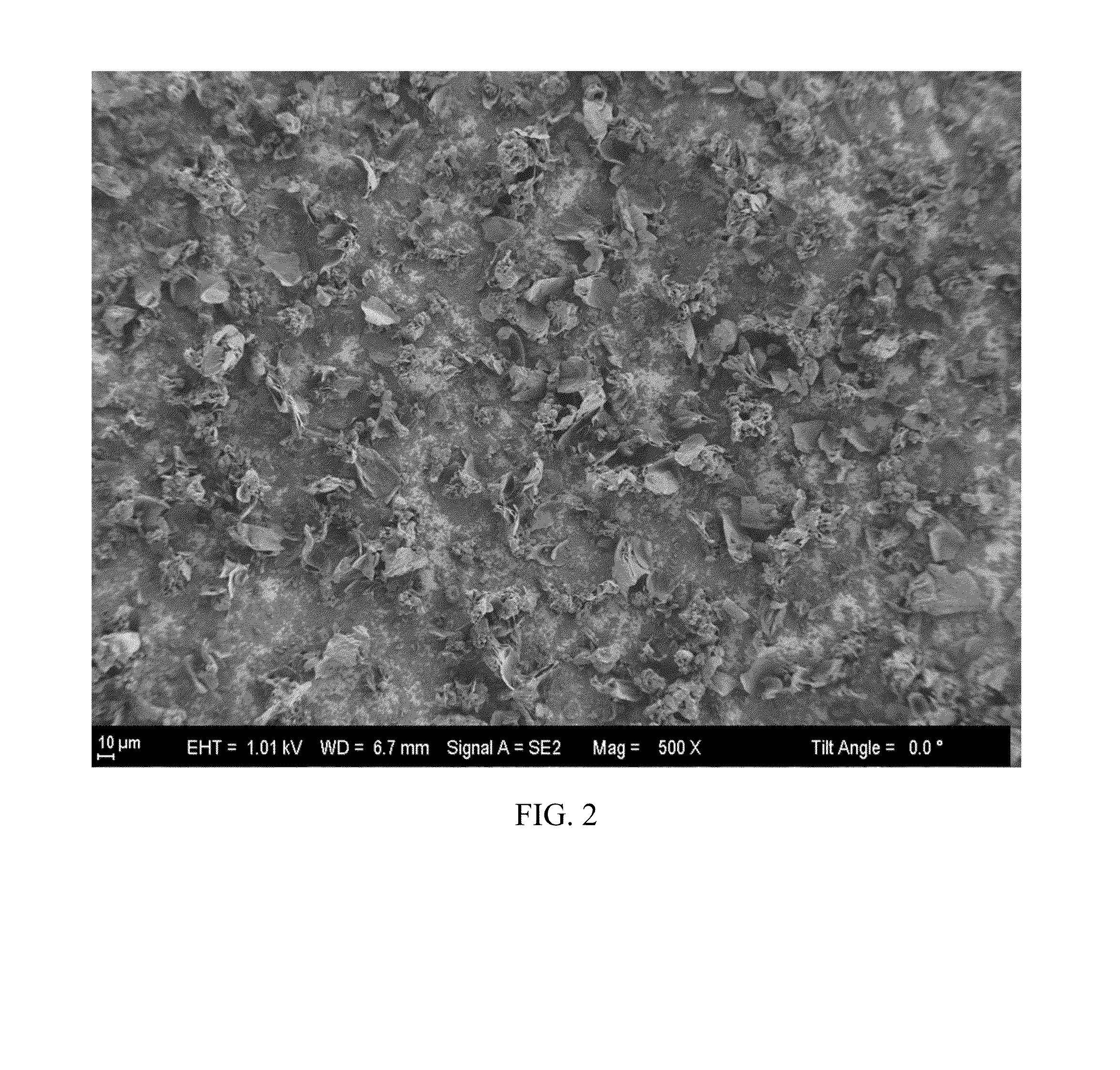

Organic soil treatment compound and method of making and using

InactiveUS20110023566A1Promote plant growthImprove scalabilityClimate change adaptationBioloigcal waste fertilisersParticulatesSoil treatment

A composition is provided that includes particulates from wood, chaff, hulls, crop compost, biochar, or waste residue, wood or crop ash and biochar, and a nitrogen source from waste residue from gasification processes, food processing waste water or other residual by-products of forest, aquatic, food or feed processing. Ideally, all of the components are environmentally friendly, from natural products, and free of manufactured chemicals.

Owner:ECOTRAC ORGANICS

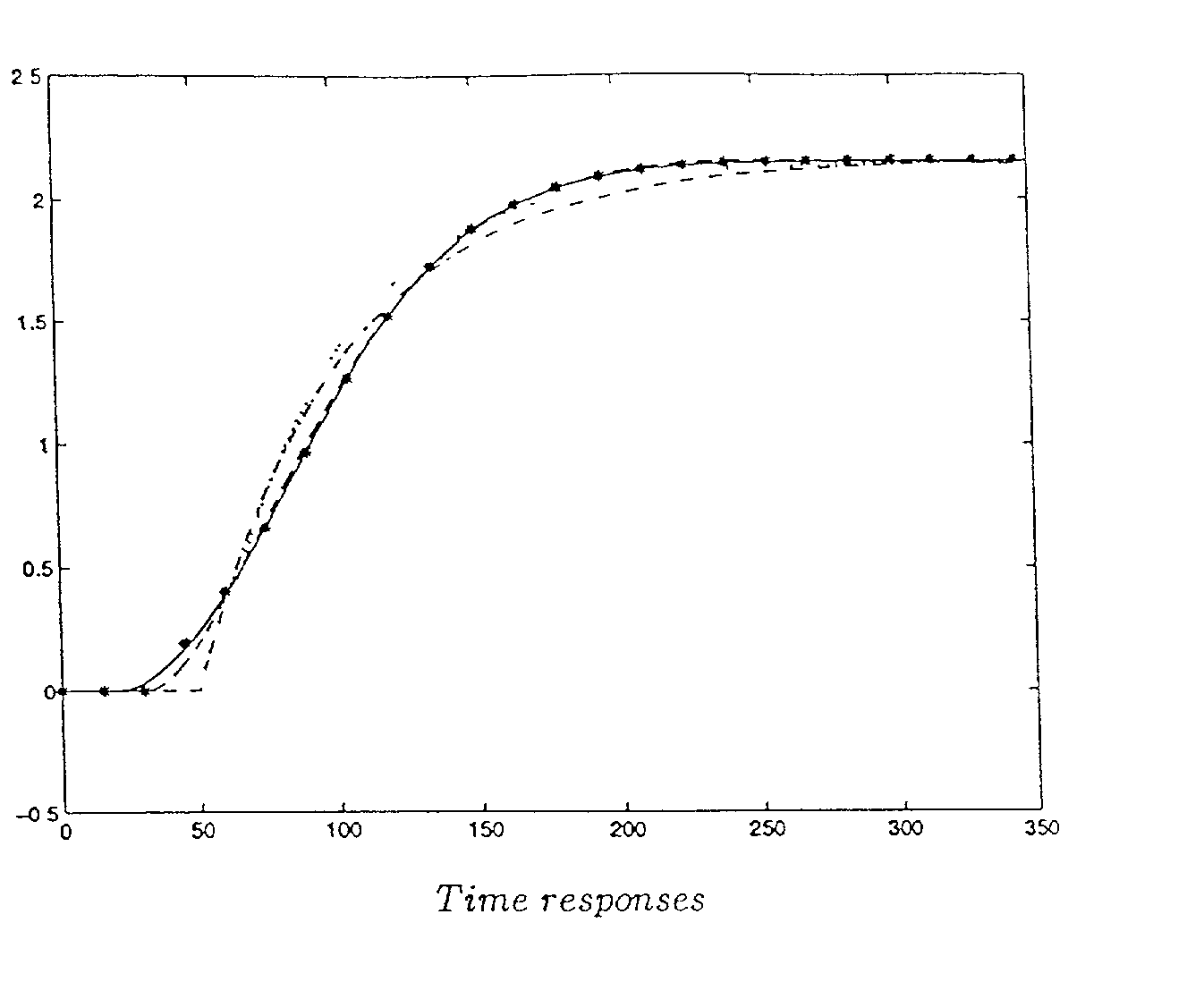

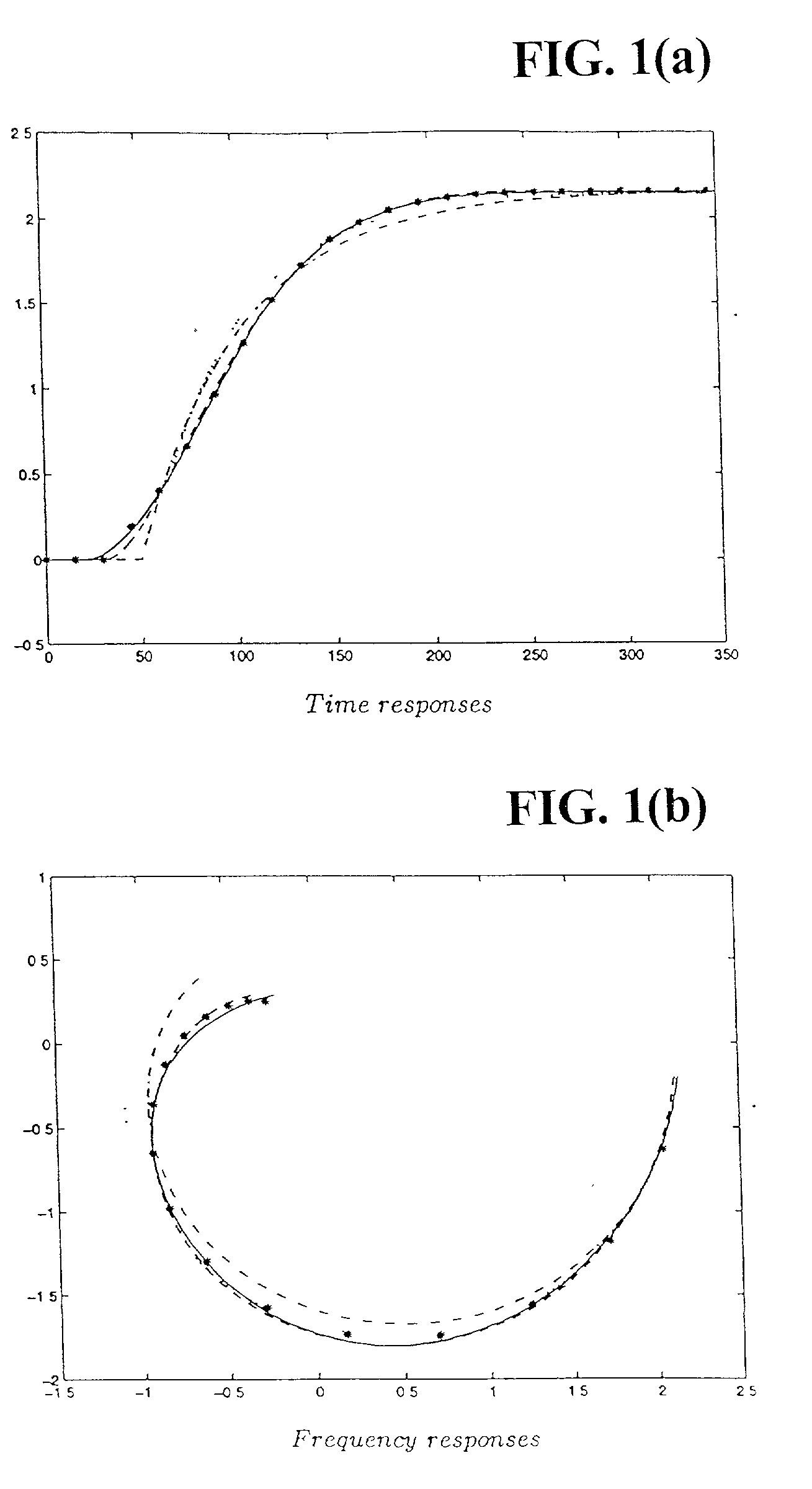

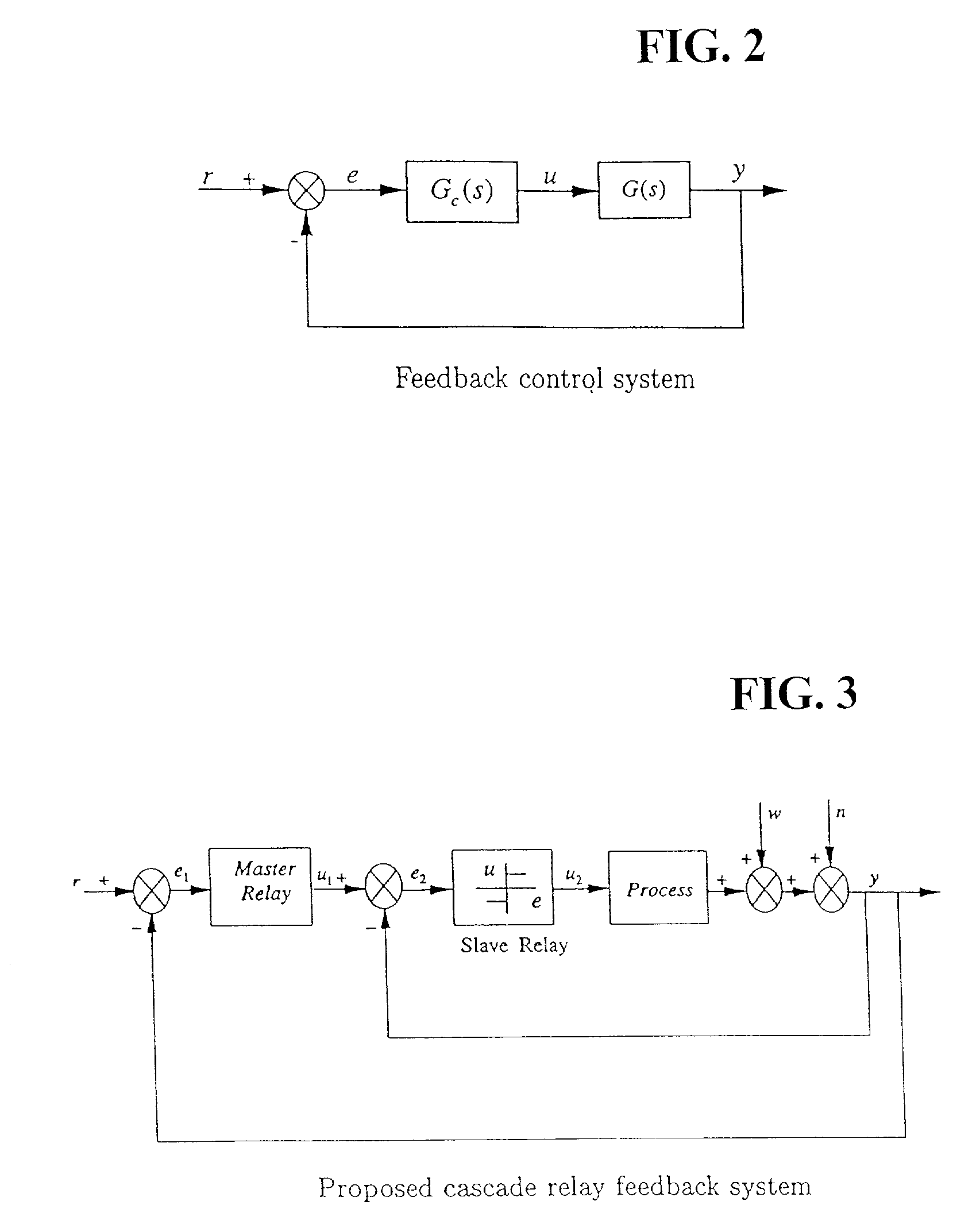

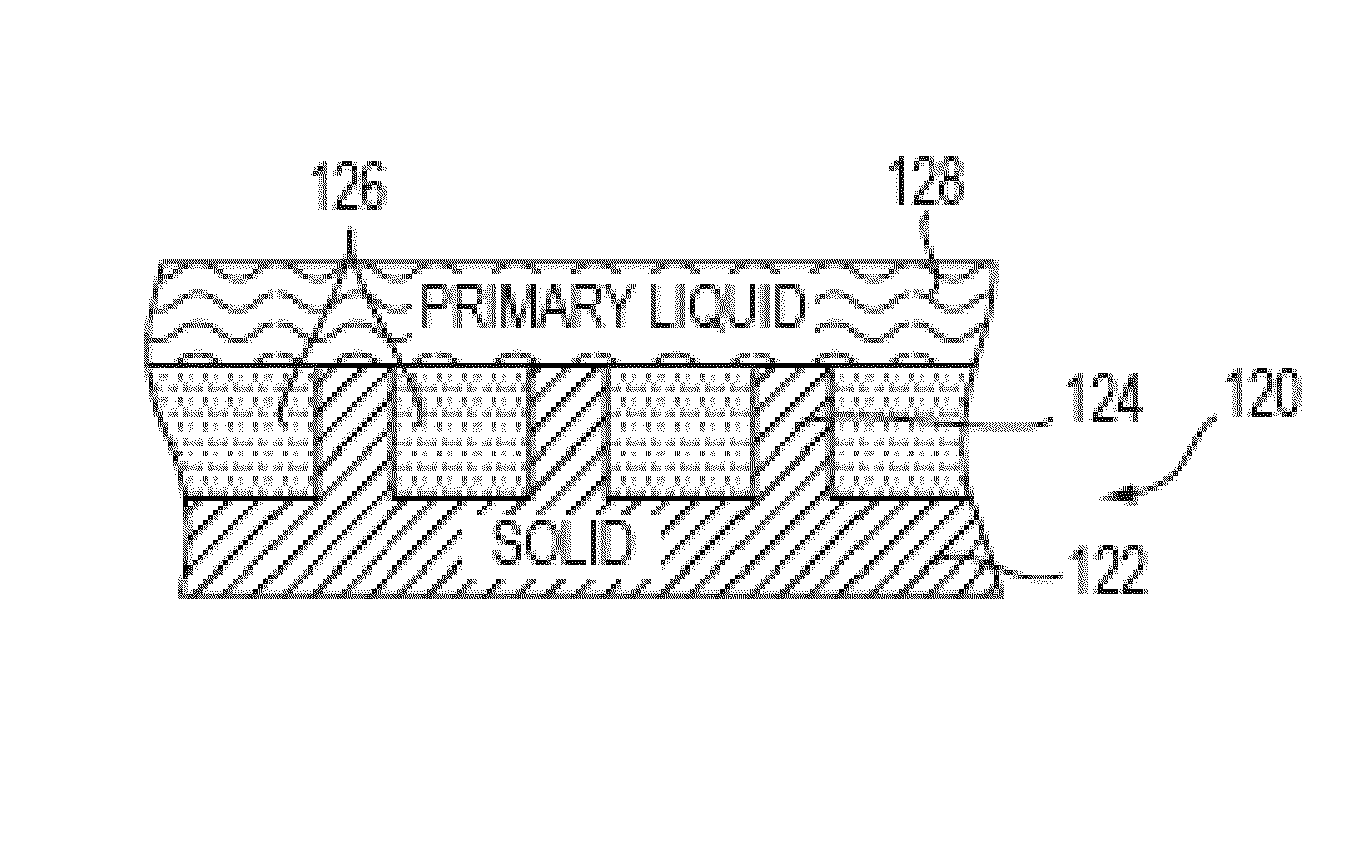

Robust process identification and auto-tuning control

InactiveUS20020111758A1Accurate estimateImprove performanceAmplifier modifications to reduce noise influenceVoltage-current phase angleGuidelineTime delays

A simple yet effective and robust identification method is presented using process step responses for process identification that can provide a continuous transfer function with time-delay without iteration. A cascade relay provides accurate and reliable more points on the process frequency response. The internal model principle is employed to design single-loop controller of PID or high-order types with best achievable control performance for controller tuning, e.g. both single and multivariable cases are covered. The process identification and control design portions can be easily integrated into a control system auto-tuning package. Further, a general control scheme for disturbance rejection is given which can significantly improve disturbance rejection performance over conventional feedback systems with time delays. Practical issues such as noises, real-time implementation and tuning guidelines are also provided. The present invention provide general, systematic, effective, and applicable methods for process identification and control for a wide range of industries such as process and chemical plants, food processing, waste water treatment and environmental systems, oil refinery, servo and mechatronic systems, where a system model is needed for analysis, prediction, filtering, optimization and management, and / or where control or better control is required for their systems.

Owner:NAT UNIV OF SINGAPORE

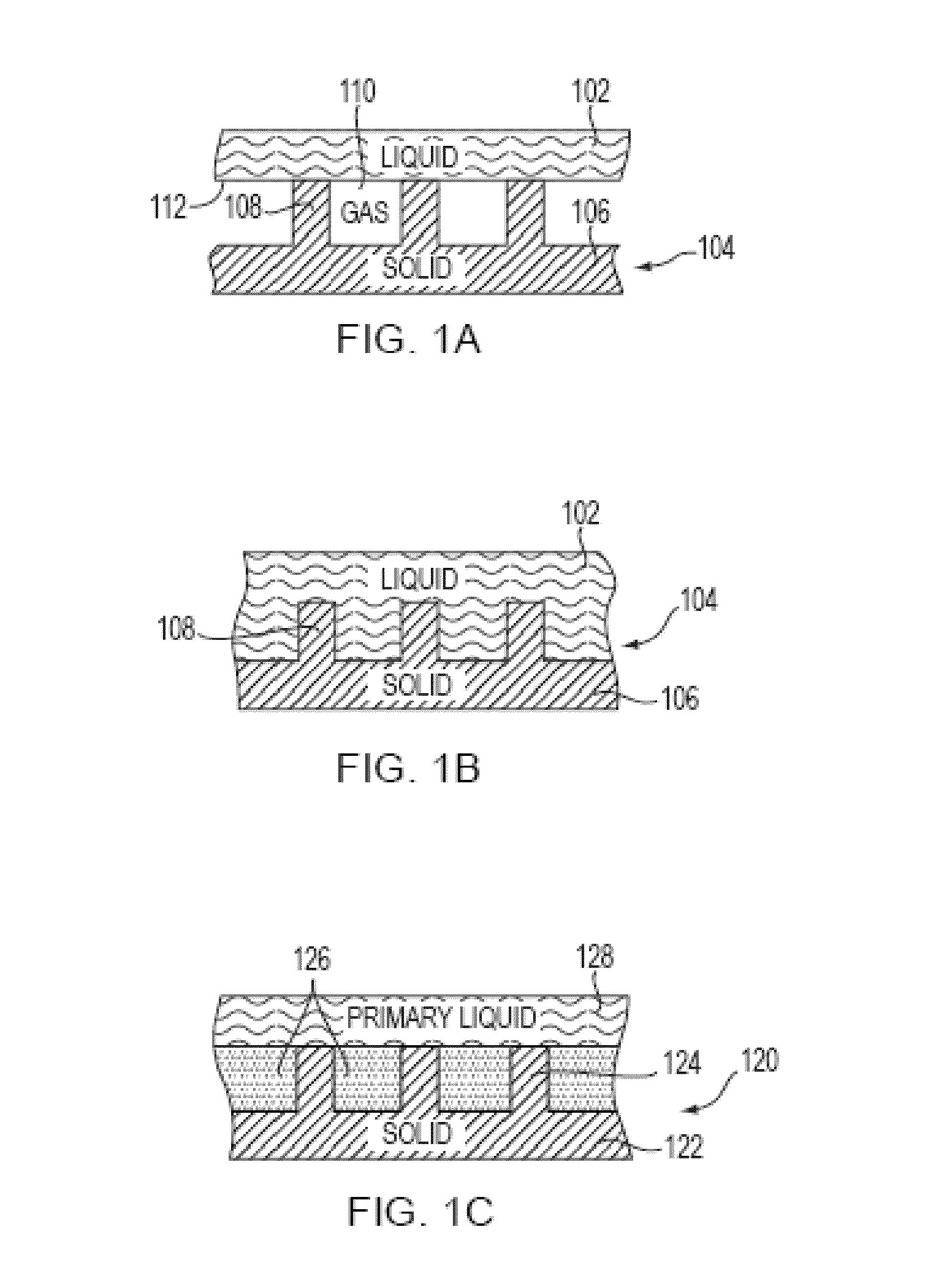

Self-lubricating surfaces for food packaging and food processing equipment

ActiveUS8535779B1Improve health and safetyAvoid leachingRecord information storageMagnetic recordingFood packagingTomato ketchup

In certain embodiments, the invention relates to an article having a liquid-impregnated surface. The surface includes a matrix of solid features (e.g., non-toxic and / or edible features) spaced sufficiently close to stably contain a liquid therebetween or therewithin, wherein the liquid is non-toxic and / or edible. The article may contain, for example, a food or other consumer product, such as ketchup, mustard, or mayonnaise.

Owner:MASSACHUSETTS INST OF TECH

Antimicrobial salt solutions for food safety applications

ActiveUS7090882B2Reduce in quantityInhibit microorganismsMilk preservationDough treatmentBiologyFood processing

Owner:CARGILL INC

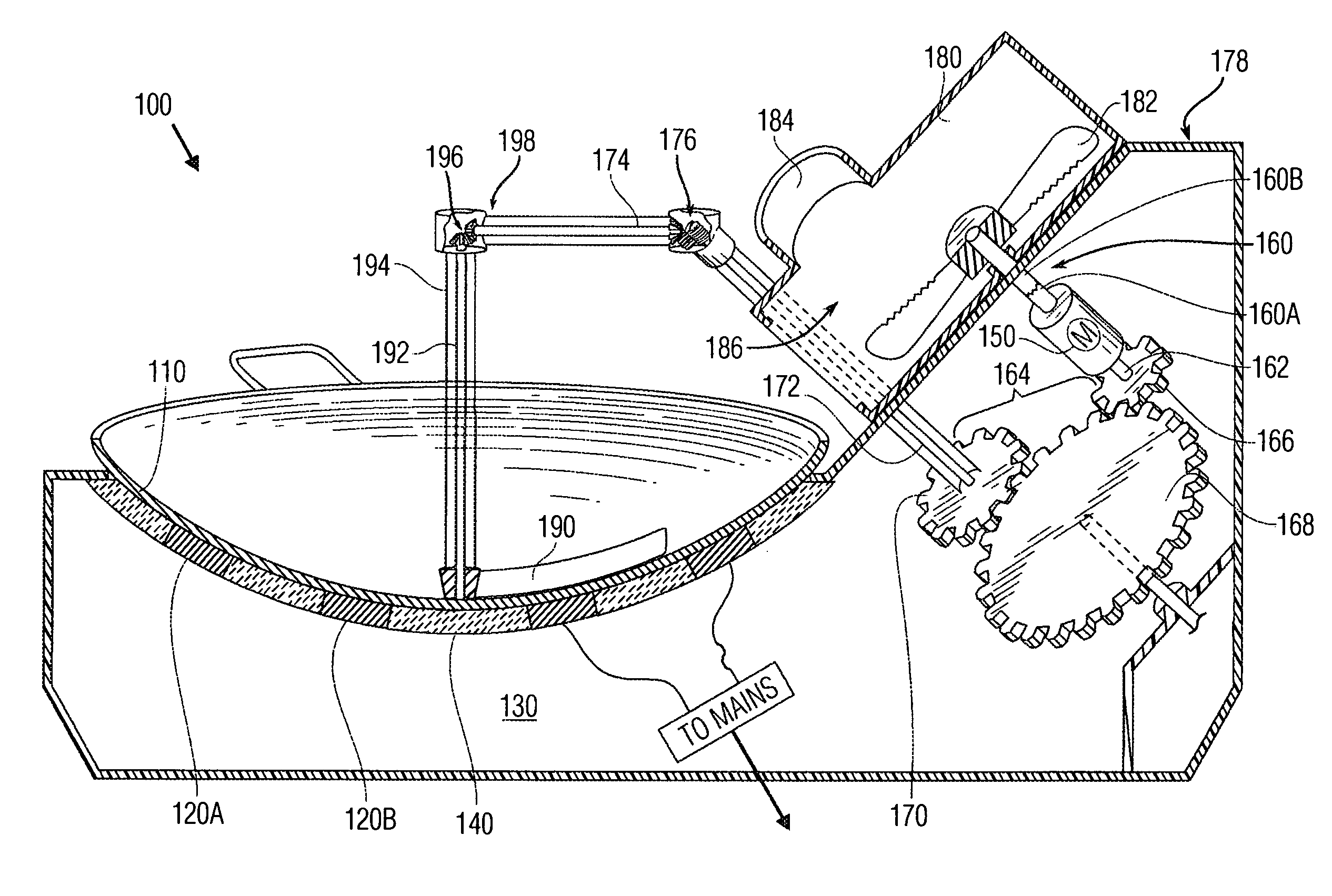

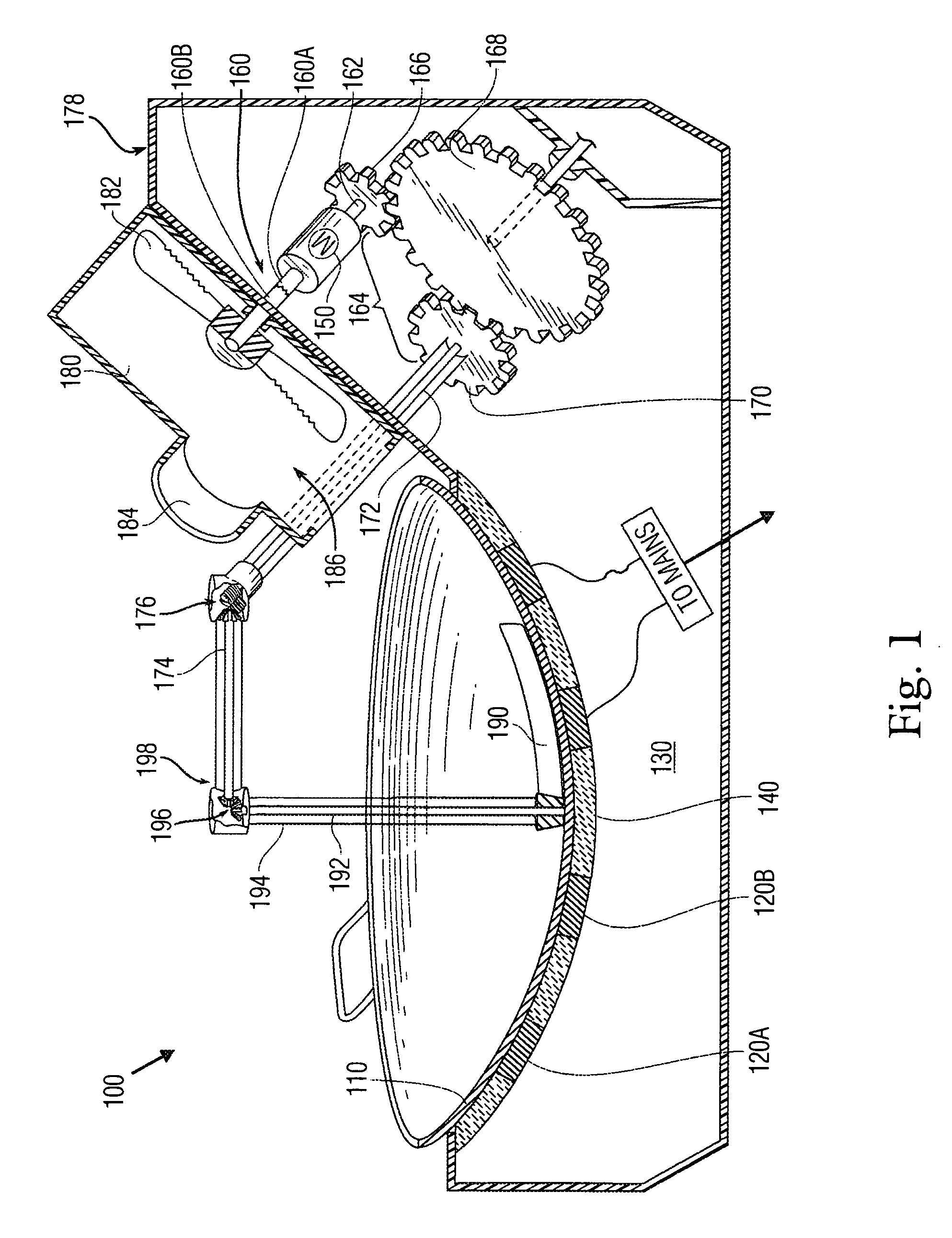

Electric wok having food processor with automatic feed

A device for processing and cooking food comprises a base housing a heating element for a food cooking function and a controllable motor for a food processing function. A container seatable on the base has an inlet for introducing food and an outlet for processed food. A blade is rotatably mounted within the container and driven by the controllable motor to process any food that is introduced into the container. A removable pan is seatable on the base proximate to the heating element to define a cooking surface. The outlet is positioned relative to the removable pan so that any food introduced into the container exits the outlet directly onto the cooking surface. A spatula can be coupled to the base and positioned within the removable pan for movement across the cooking surface to stir the processed food as it is cooked. A method is also disclosed.

Owner:LEASON HLDG

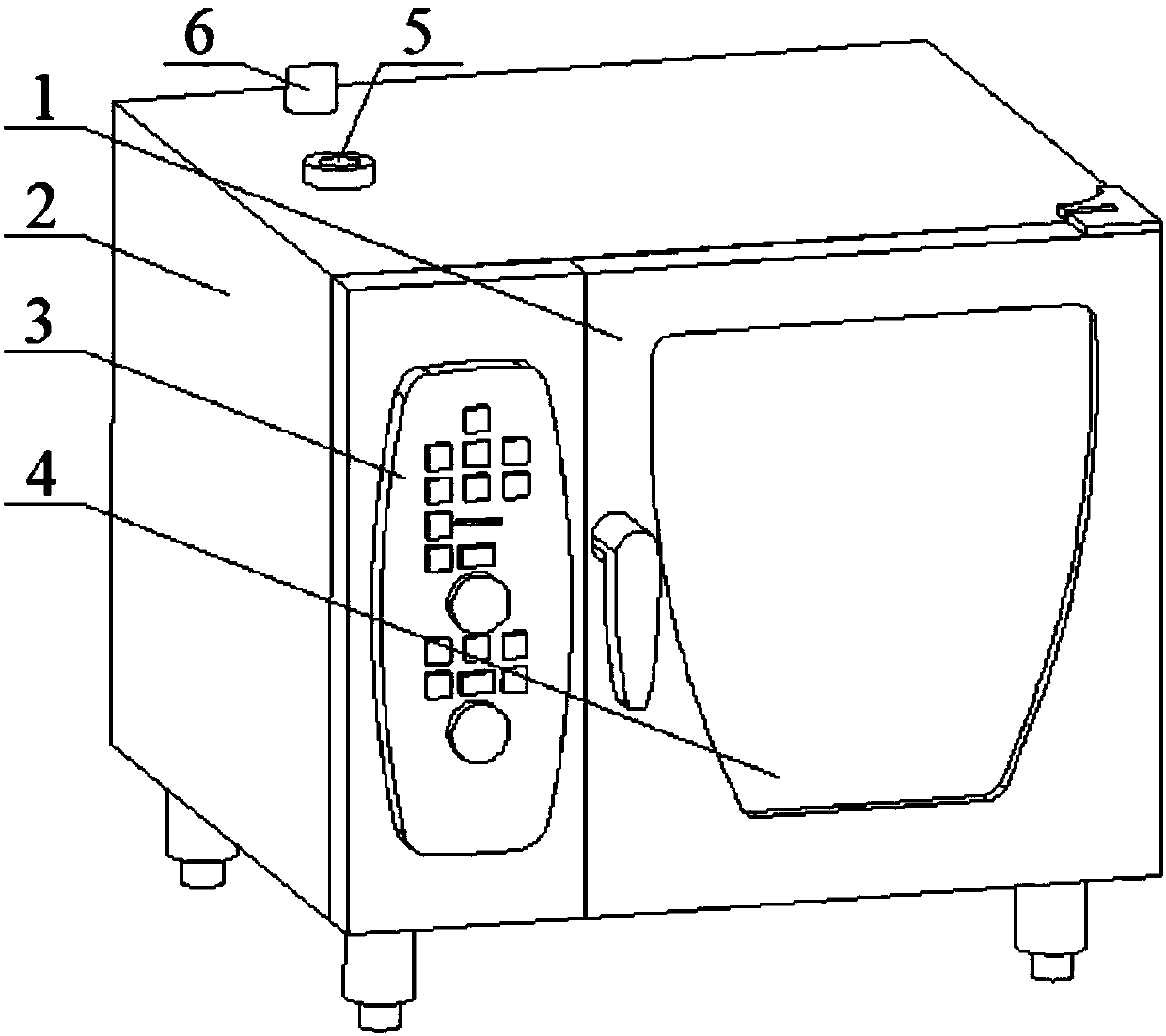

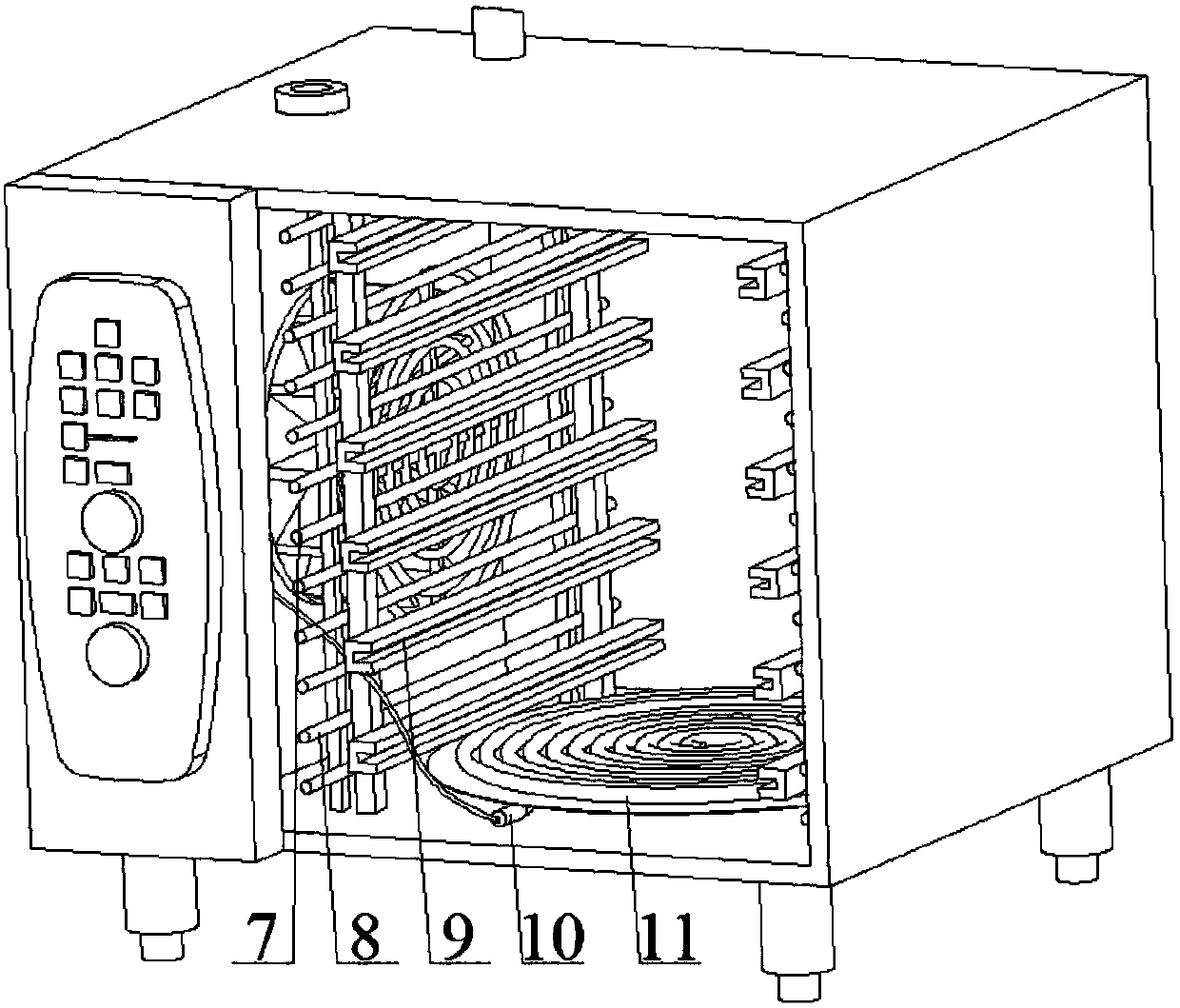

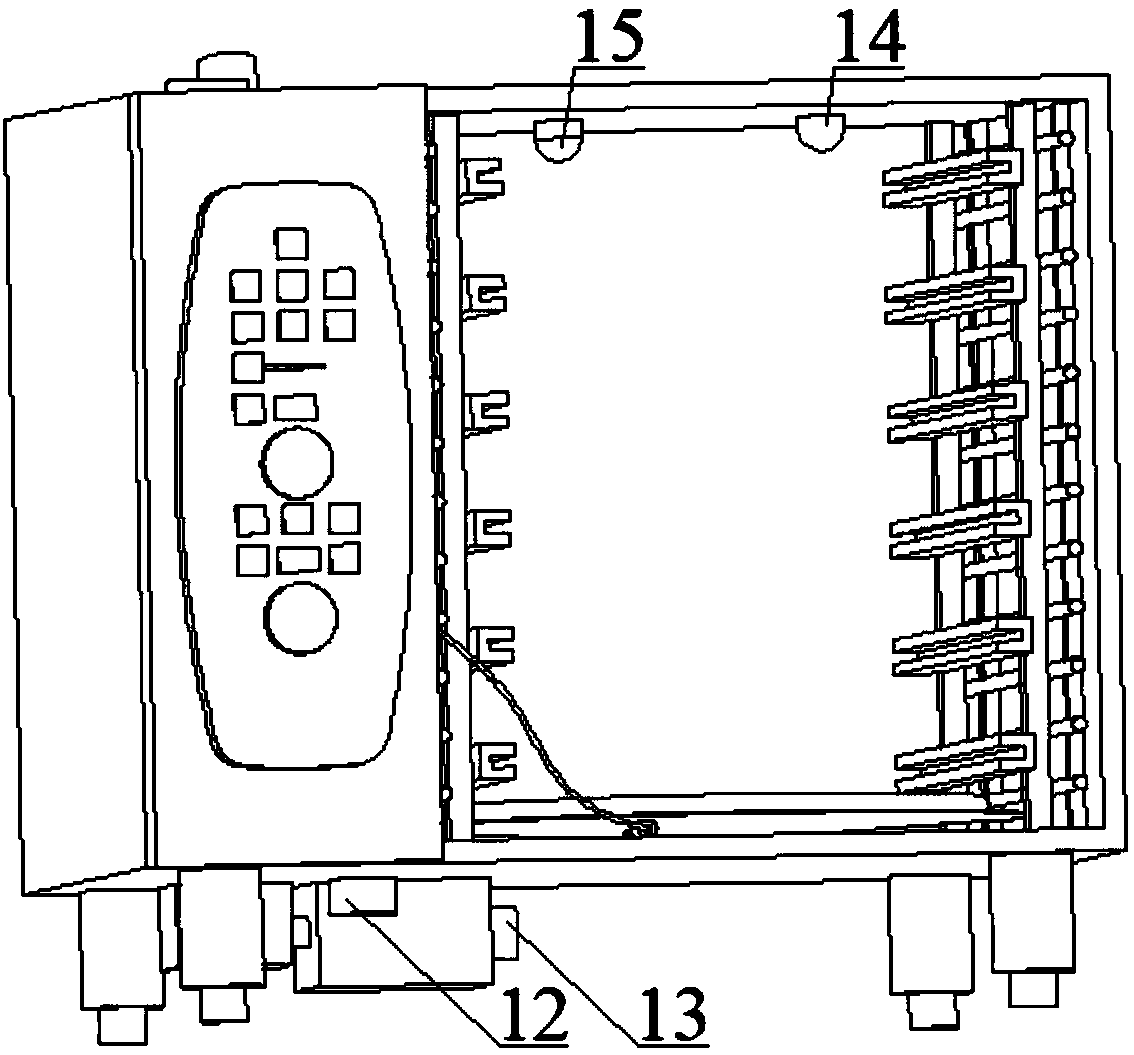

Steaming oven having multiple operating modes

PendingCN107898351AMeet the diverse needs of processingRapid coolingRoasters/grillsWarming devicesComputer moduleEngineering

The invention provides a steaming oven having multiple operating modes. The steaming oven is characterized by comprising an oven body, a steaming-baking module, a humidity regulating and detecting module, a menu editing and storing module, a central temperature detecting module and a control module, wherein the oven body comprises a steaming-baking chamber and a control chamber, the steaming-baking module comprises heating tubes, a steam generator, a turbo fan and an infrared thermodetector, the humidity regulating and detecting module comprises a dryer, a humidifier and a humidity detecting gauge, the menu editing and storing module comprises a menu memorizer and a USB flash disk reading port, the central temperature detecting module is used for food internal-temperature detection, and the control module comprises a photographing camera, a timer, an alarm apparatus, a controller and a central processing unit and is used for providing operation control. The steaming oven has multiple operation modes by arranging the modules, can meet the diversified food processing demands and is high in processing efficiency.

Owner:珠海家宝德科技有限公司

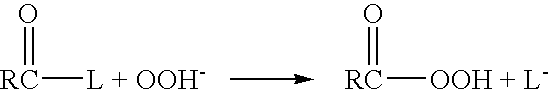

Decontamination formulations for disinfection and sterilization

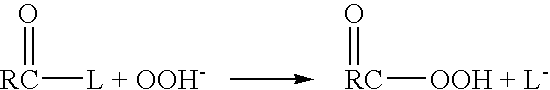

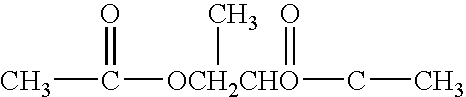

Aqueous decontamination formulations that neutralize biological pathogens for disinfection and sterilization applications. Examples of suitable applications include disinfection of food processing equipment, disinfection of areas containing livestock, mold remediation, sterilization of medical instruments and direct disinfection of food surfaces, such as beef carcasses. The formulations include at least one reactive compound, bleaching activator, inorganic base, and water. The formulations can be packaged as a two-part kit system, and can have a pH value in the range of 7-8.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Non-thermal sterilization method for apple cloudy juice

InactiveCN101214081AEffective sterilizationExtended processing timeFood scienceEscherichia coliEngineering

The invention discloses a liquid food novel non-thermal sterilization method, in particular a non-thermal sterilization method of cloudy apple juice which belongs to the food processing technology field. The technical scheme includes adopting the aseptic operation to send the cloudy apple juice into a reaction vessel and adopting pulse type carbon dioxide with high density for the sterilization. The concrete operation step is: firstly, pumping carbon dioxide with high density into the reaction vessel; secondly, treating for a certain period at the set temperature and pressure condition; thirdly, releasing the carbon dioxide after the treatment to lower the pressure in the reaction vessel to the normal pressure; fourthly, operating the steps from the first to the third repeatedly for more than two times for the pulse type carbon dioxide with high density treatment. The killing effect of Escherichia coli in the cloudy apple juice which is processed in the invention can achieve the result of lowering at least five logarithms to satisfy the commercial aseptic requirement. Compared with the present non-thermal sterilization method, the invention has more obvious sterilization effect and can shorten the treatment time and save energy. The invention has the advantages of low processing temperature, energy saving and environmental protection and can maintain the good flavor of the cloudy apple juice.

Owner:CHINA AGRI UNIV

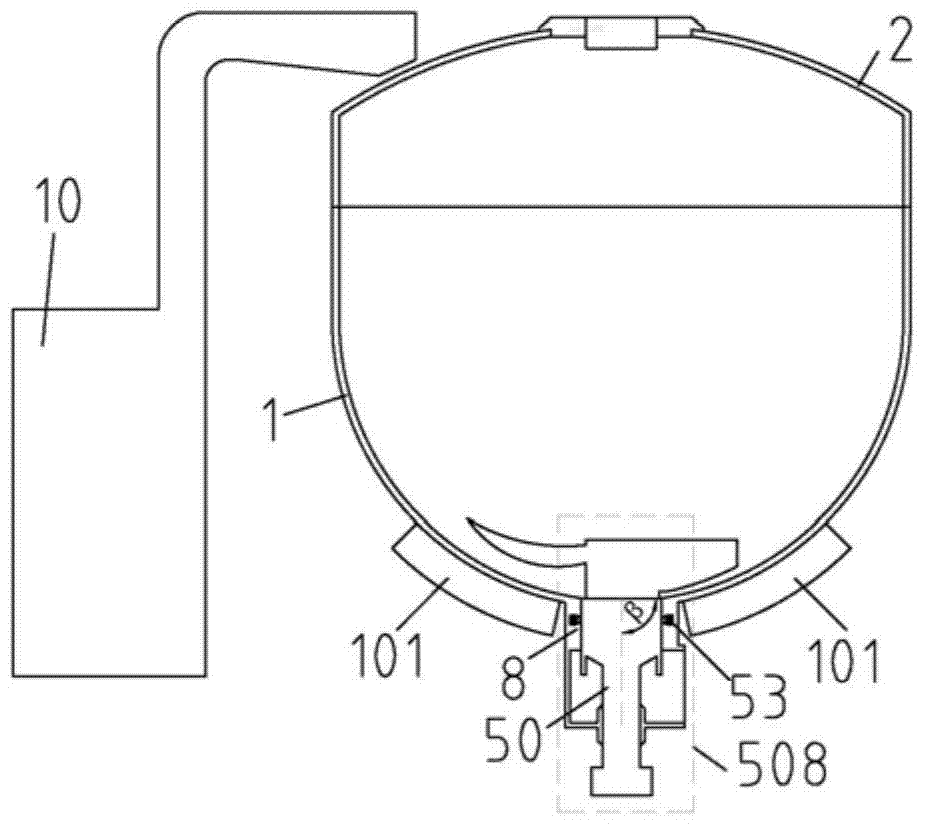

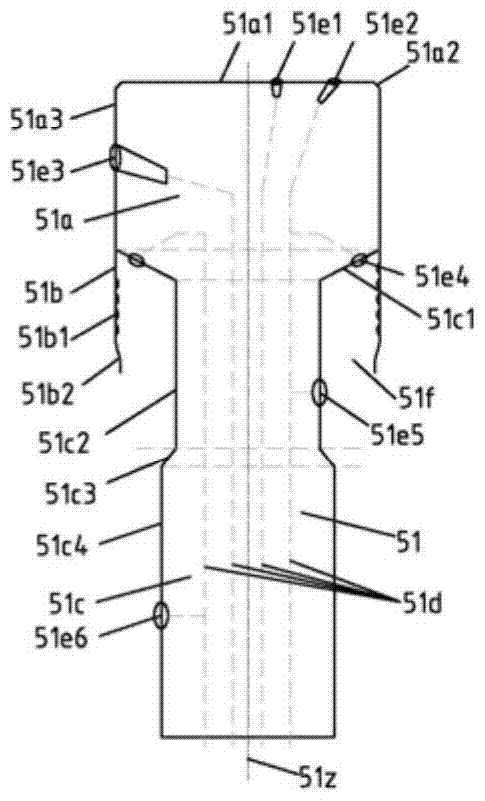

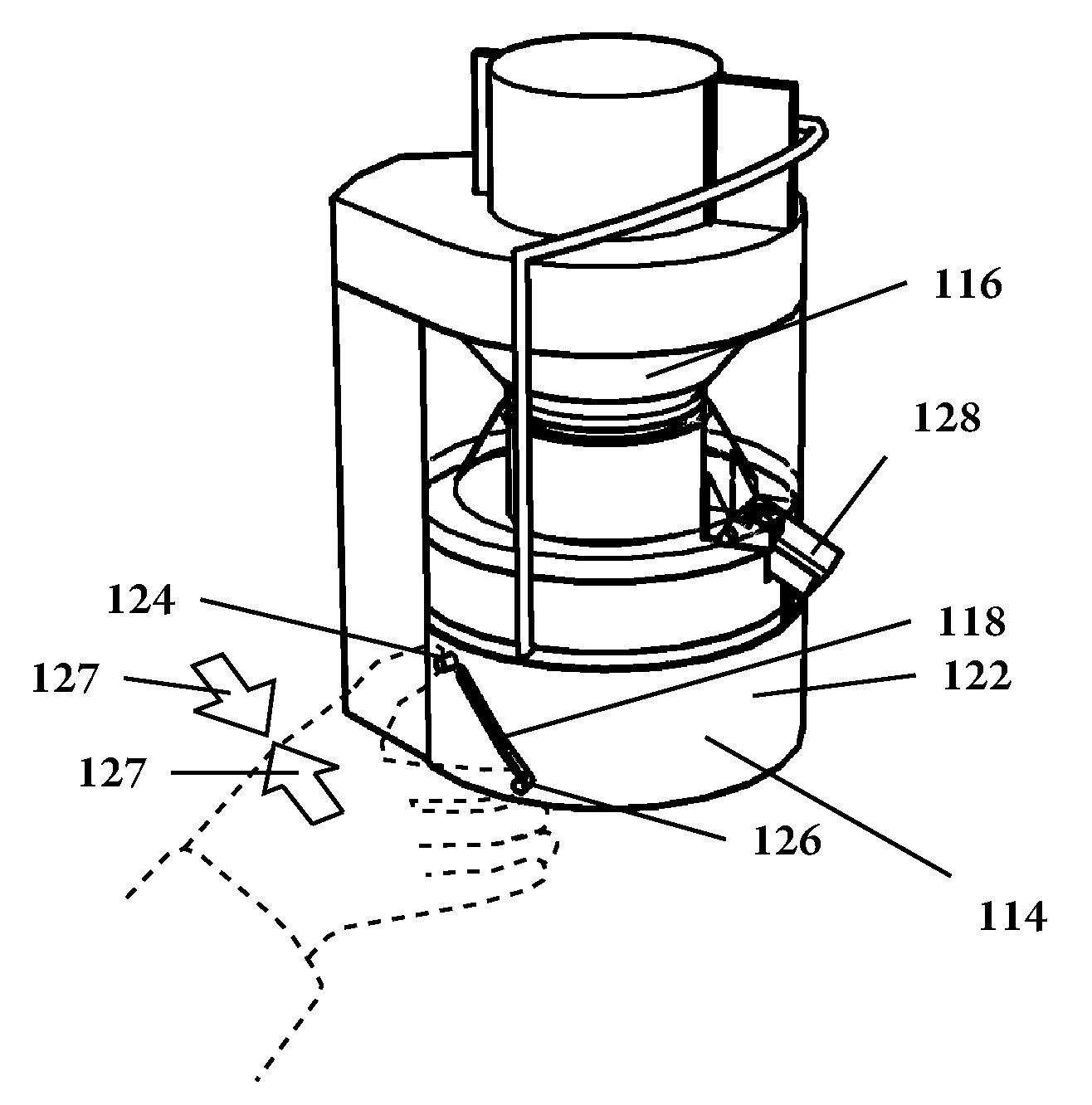

Bottom leaking-spraying device for cooking equipment and cooking equipment of bottom leaking-spraying device

According to the embodiment, the invention discloses a bottom leaking-spraying device for cooking equipment and the cooking equipment, wherein the bottom leaking-spraying device comprises a bottom rotary-spraying system and a bottom leaking pipe system; the bottom rotary-spraying system is used for cleaning food and washing a pot; and by virtue of the bottom leaking pipe system, wastewater from cleaning the food and wastewater residues obtained from washing the pot can be discharged, usable fluid can be filtered out, water can be injected into the pot and the food in the pot can be cleaned. The cooking equipment provided by the invention can achieve automation of food processing (such as stirring, grinding, dough kneading and the like), heating cooking, food cleaning and pot cleaning, and in addition, the cooking equipment can be used for automatically grinding and cleaning food residues in a sink. With the application of the scheme, the cooking equipment can reduce workload of a user; therefore, a cooking equipment solution and equipment, which are broad in application and are safe and sanitary, are offered to smart home; and various cooking equipment can be achieved.

Owner:李亚锐

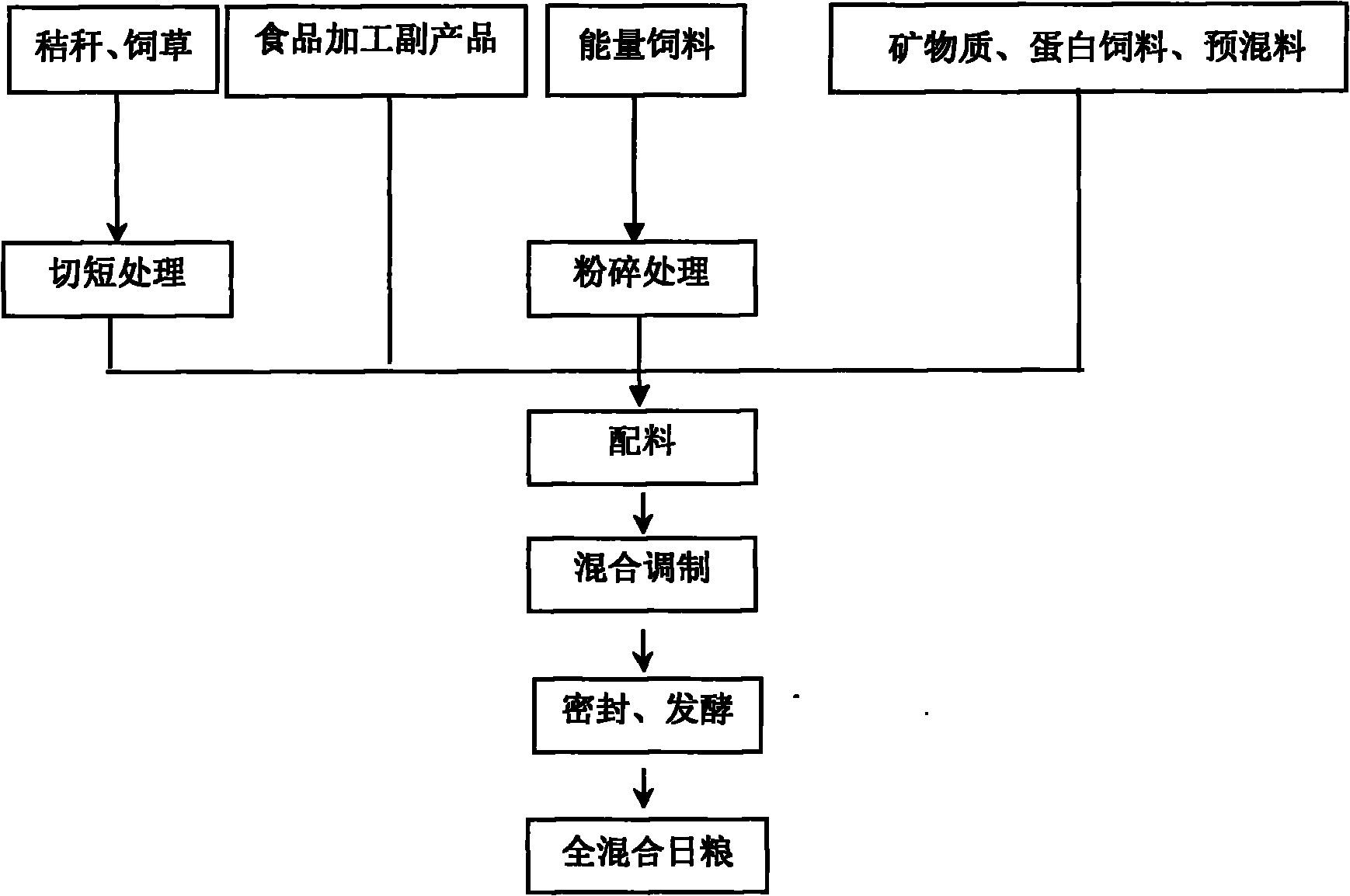

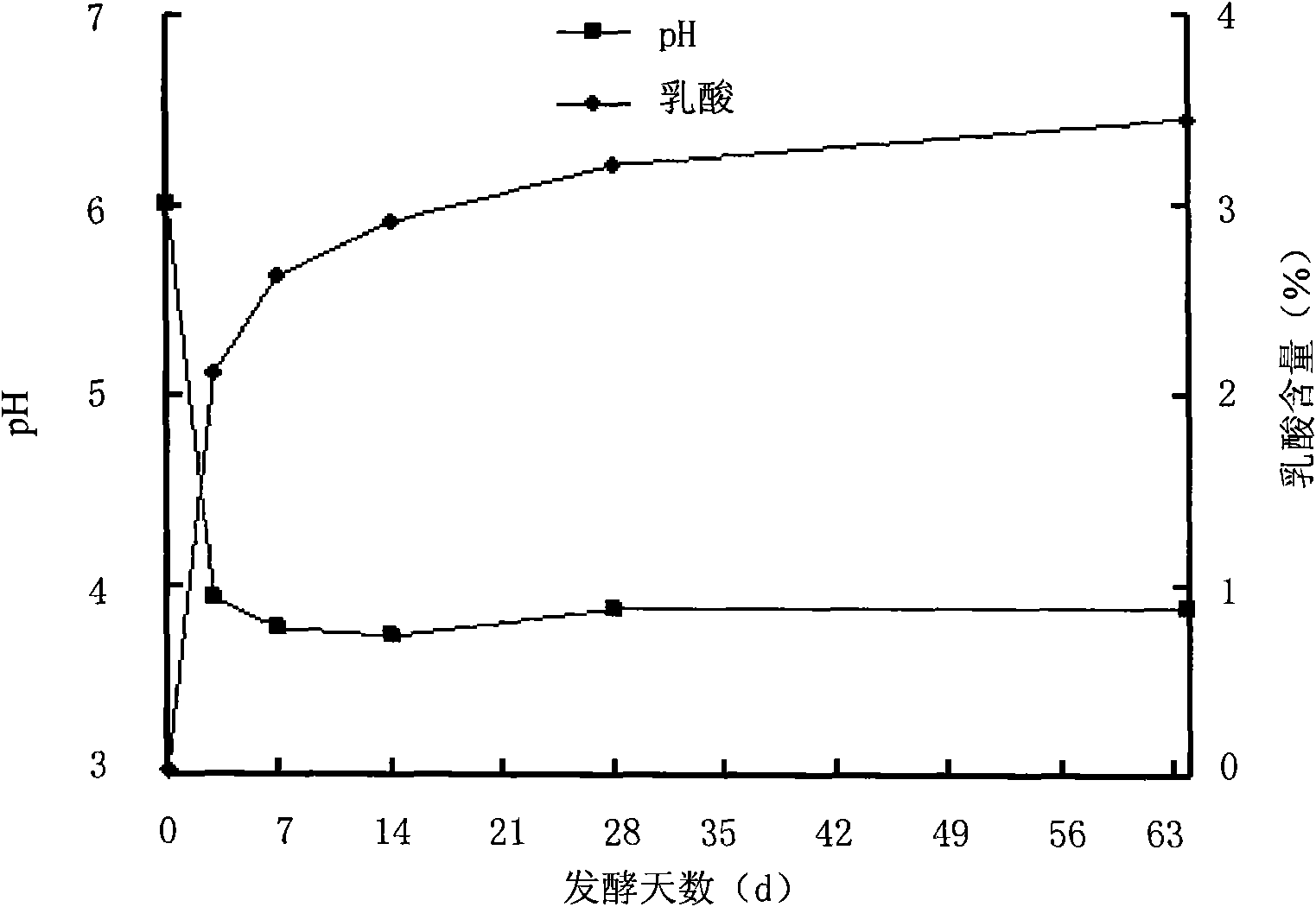

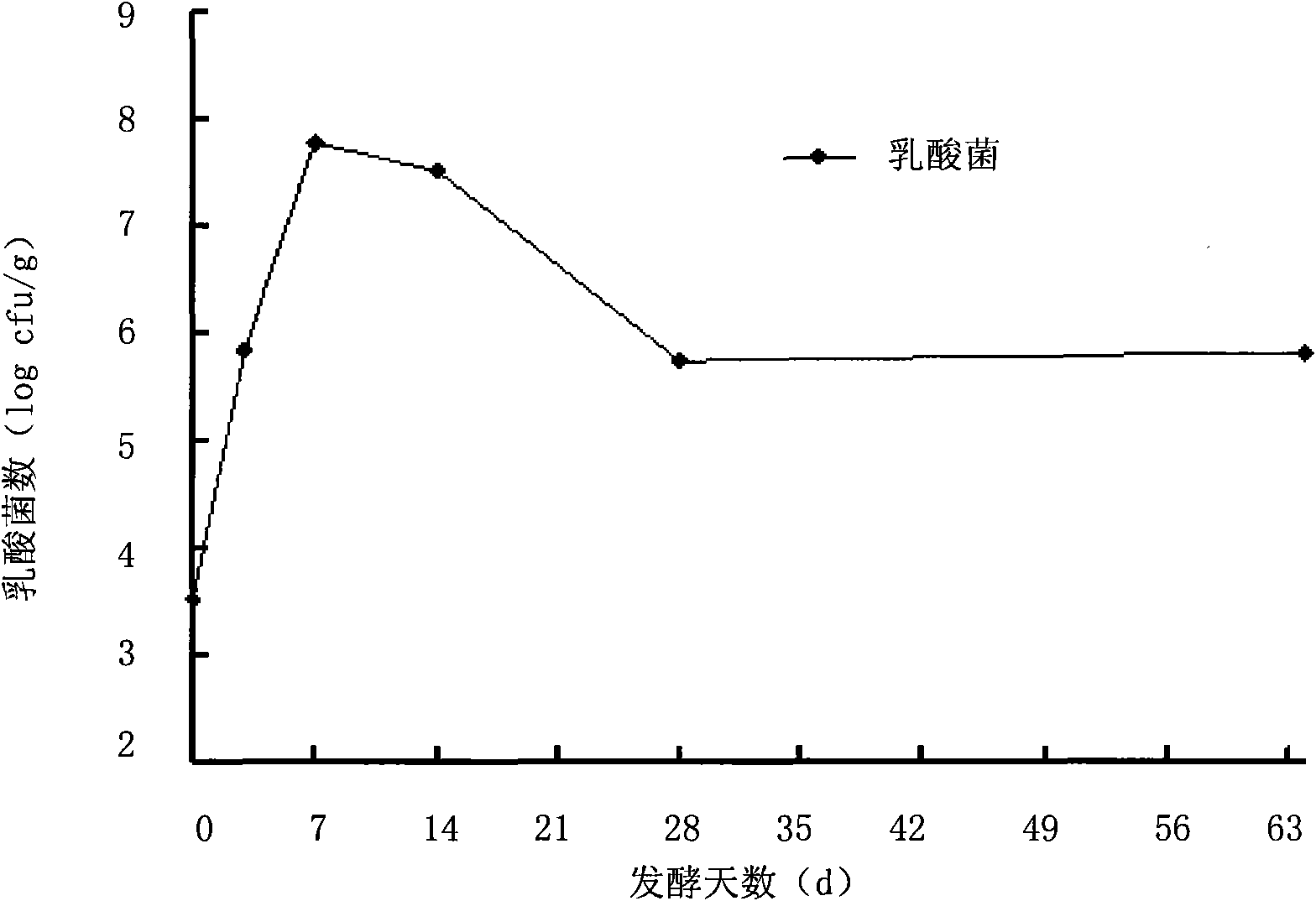

Low-concentrate type fermented total mixed ration for dairy cows and preparation method thereof

InactiveCN101828635ALow costIncrease contentFood processingAnimal feeding stuffAdditive ingredientTrace element

The invention discloses a low-concentrate type fermented total mixed ration (TMR) for dairy cows and a preparation method thereof. The TMR is prepared by the following steps of: (1) mixing the following materials in part by mass to obtain a mixture: 15 to 20 parts of straw, 4 to 8 parts of fodder grass, 6 to 12 parts of protein feed, 25 to 30 parts of energy feed, 3 to 6 parts of minerals and molasses, 40 to 45 parts of food processing by-products and 0.5 to 1 part of premix compound of trace elements and vitamins; (2) adjusting the moisture content of the mixture of the step (1) to be between 40 and 50 percent; and (3) sealing and fermenting the mixture of the step (2) for more than 14 days to obtain the ration for the dairy cows. The TMR of the invention has the following advantages of: low cost; complete nutrition and homogeneous components to avoid animal picky eaters and significantly improve the production performance of animals; and high aerobic stability. The low-concentrate type fermented total mixed ration for the dairy cows opens up a new technique and an effective way for efficient utilization of the resources of the straw and the food processing by-products, and has important practicability and application promotion values.

Owner:CHINA AGRI UNIV

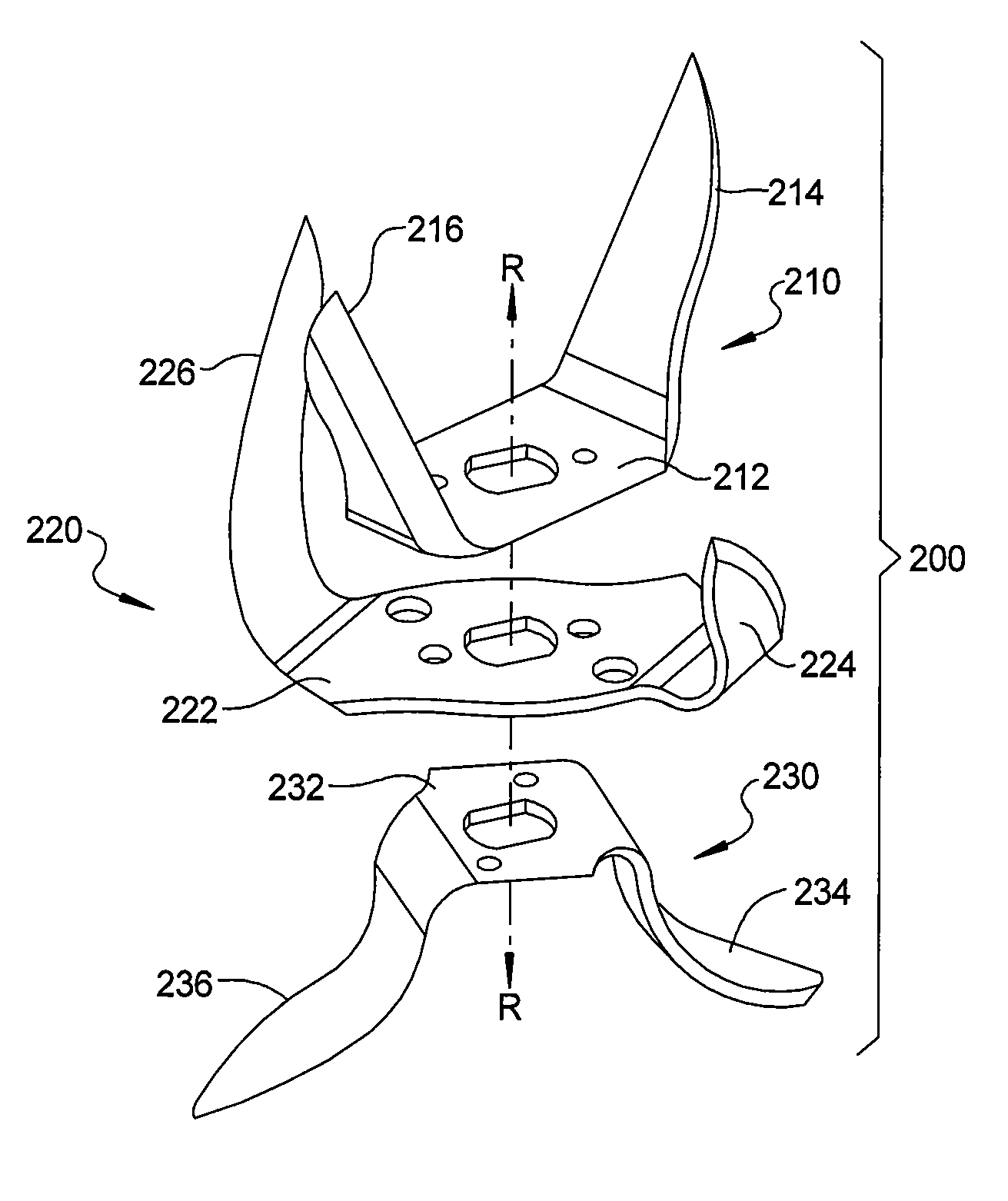

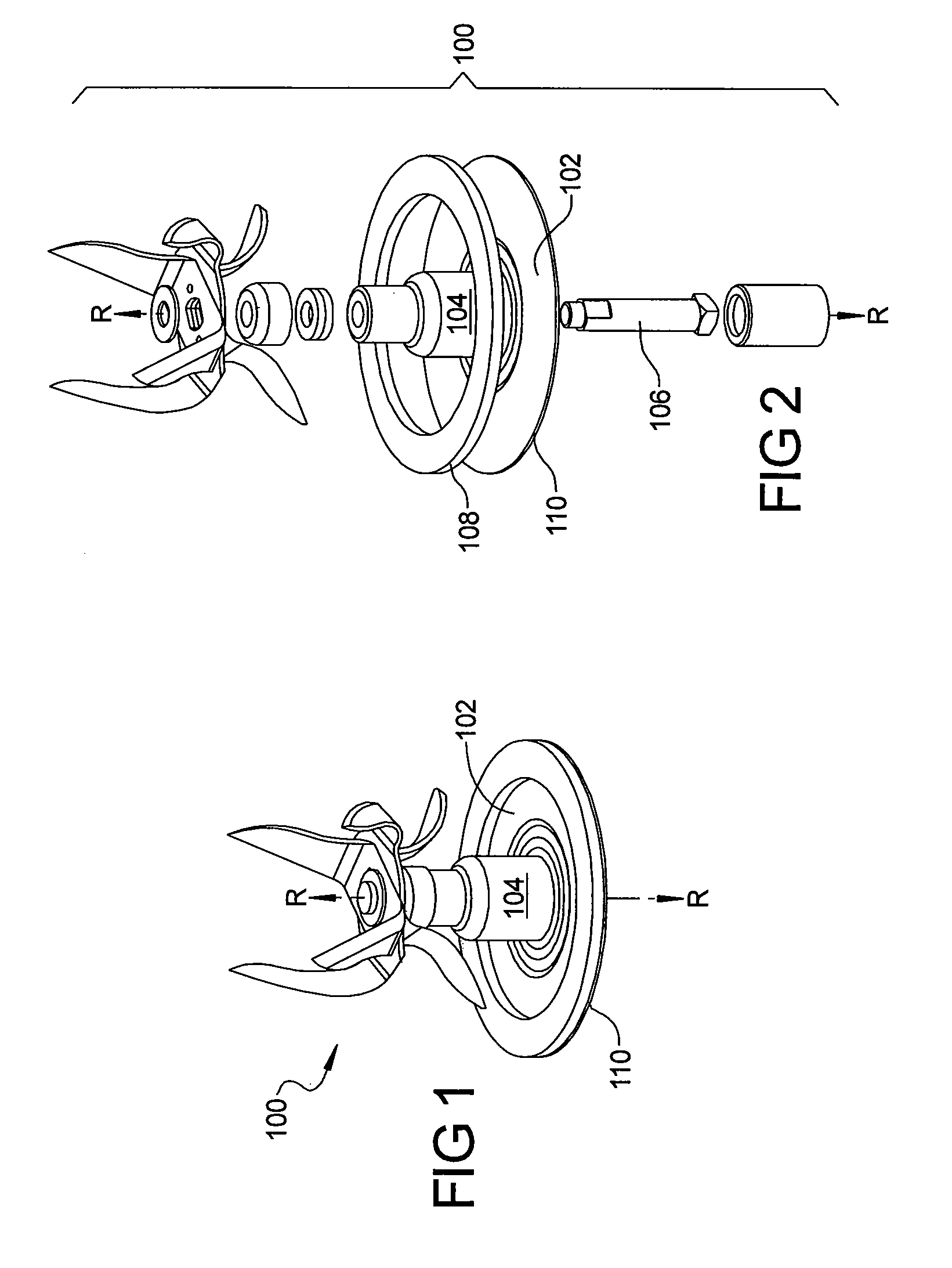

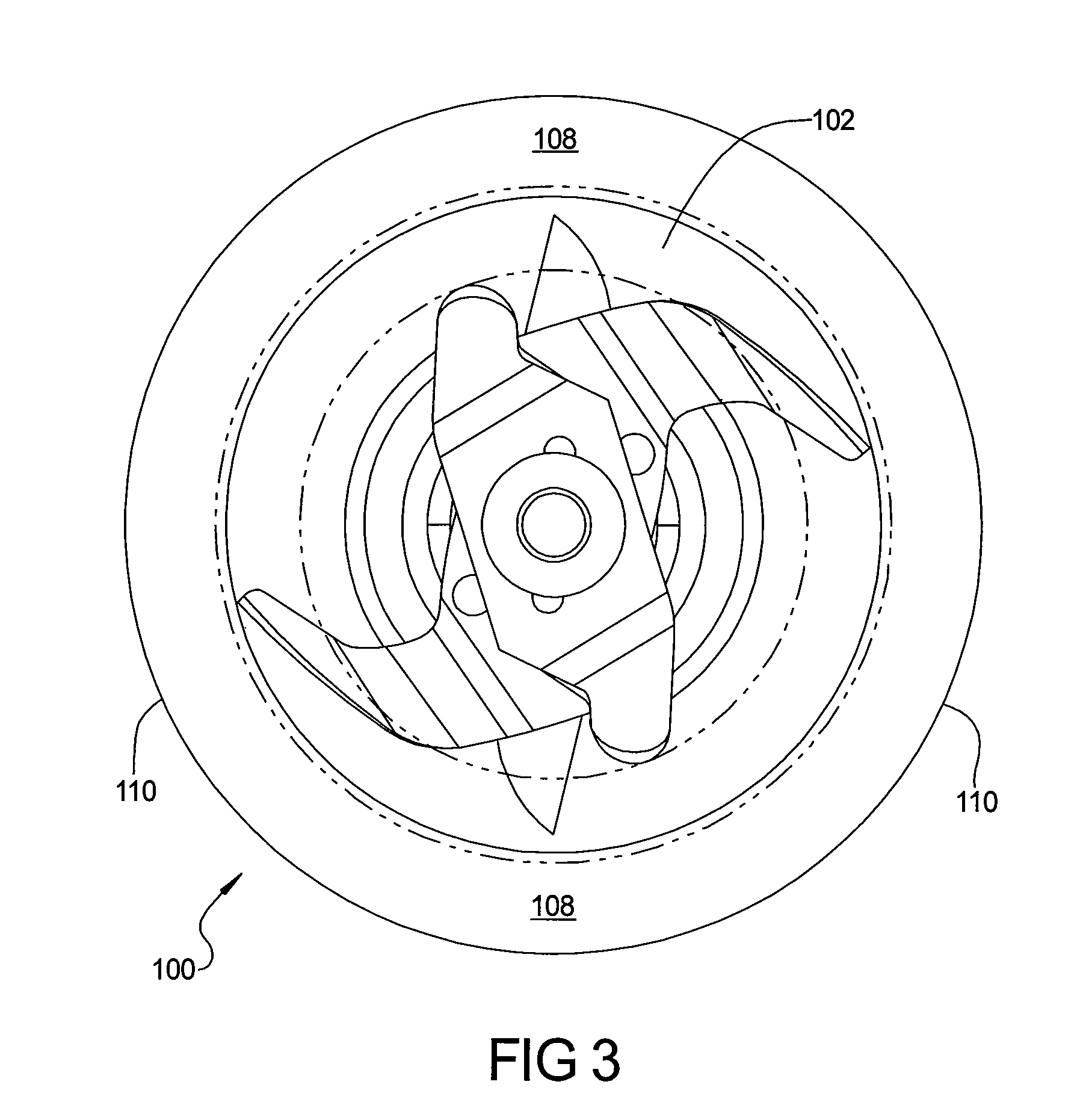

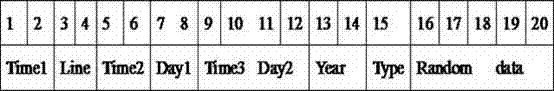

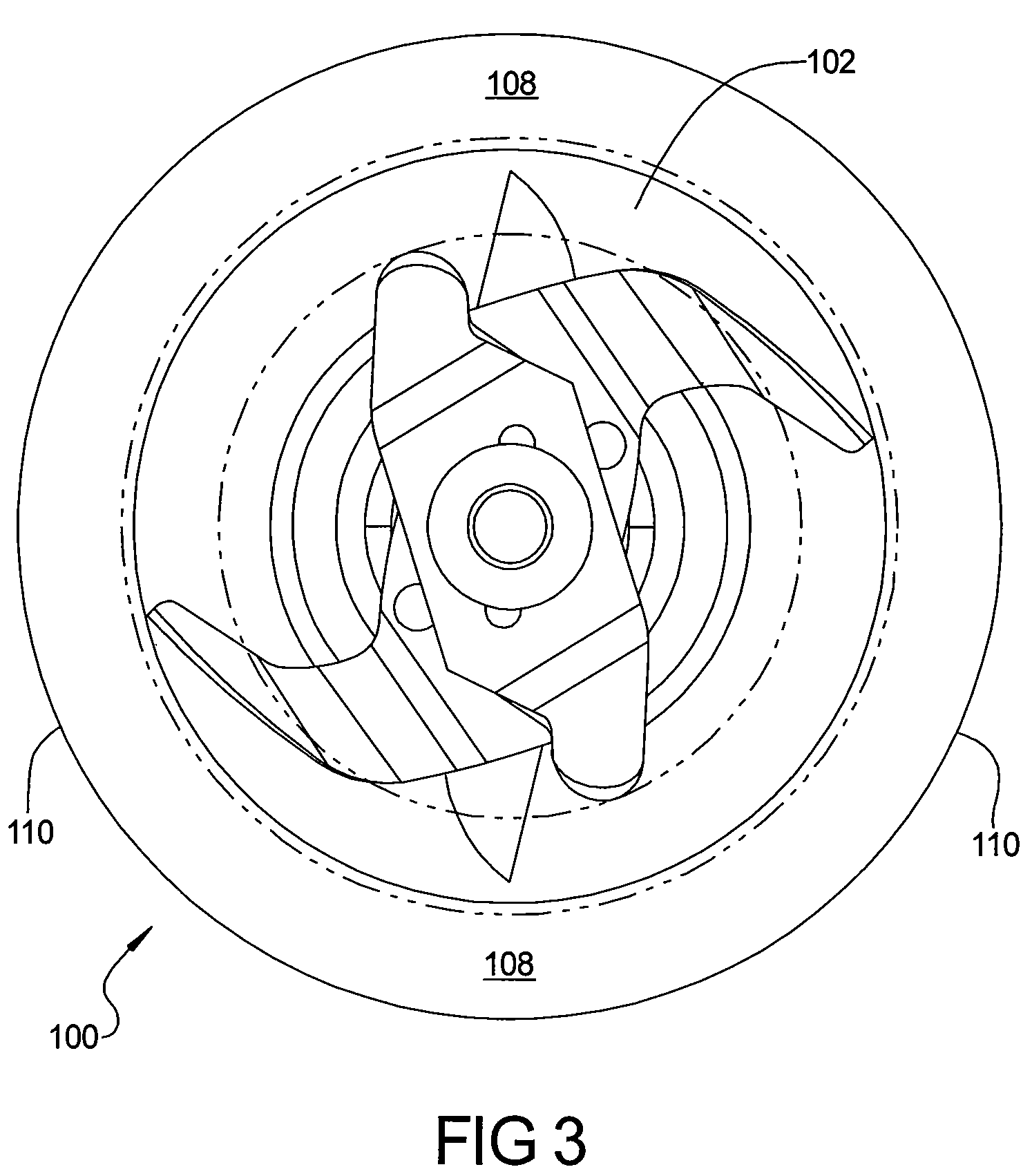

Blender/food processor blade arrangement for small throated blender jars

ActiveUS20080198691A1Improve abilitiesEasy to operateRotary stirring mixersKitchen equipmentSide effectSemi solid

A blade assembly suited for both blending and food processing in small throat blender jars is provided. The blade assembly comprises a plurality of blade forms each designed to perform a specific blending or processing task while simultaneously working together and with the geometric restrictions of the jar to optimize the assembly's capability to crush ice, blend or mix liquids and / or semi-solid materials, and to chop, cut, or slice solid food items without the need for user interaction to clear compacted items from the blades and / or the walls or bottom of the jar during its operation. The improved performance also serves the beneficial side effect of improved bearing and motor life in the blender / food processor.

Owner:SUNBEAN PROD INC

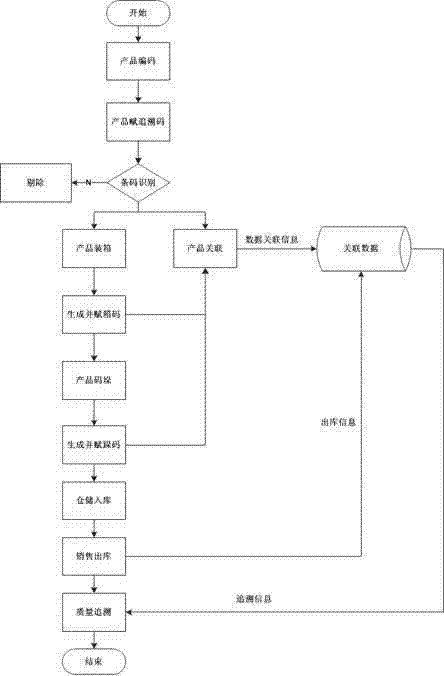

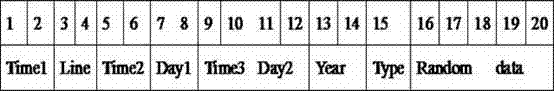

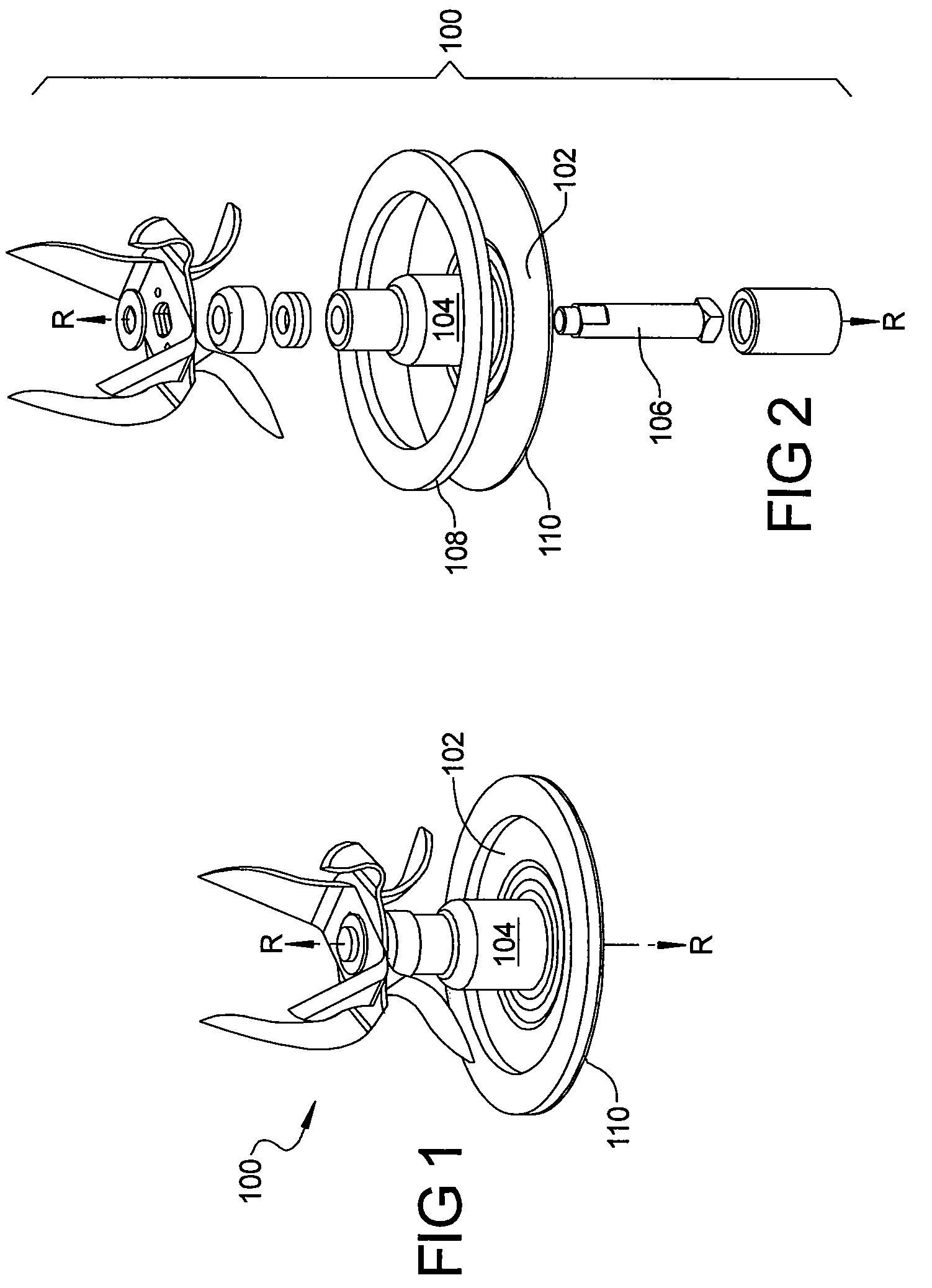

Quality safety tracing method for food processing enterprises

InactiveCN103761546ANo repeated codes appearMeet randomnessCo-operative working arrangementsDebit schemesProduction lineRelational database

The invention discloses a quality safety tracing method for food processing enterprises. The quality safety tracing method includes the steps that a laser coder generates random tracing codes according to a coding rule when a laser marking machine in a production line device is dynamically read in an on-line tagging mode; the laser marking machine carries out tracing mode marking on products on a production line, and two-dimension codes and plain codes are all marked on packages; a fixed reader is used for scanning and reading designated tagged code portions of the products; the two-dimension codes are successfully scanned and read, the tracing codes are recorded, and relevance between the tracing codes and commodity attribute information is completed; if the two-dimension codes fail to be scanned, the two-dimension codes will be removed through a removing device; the commodity tracing code information and the commodity attribute information are recorded into a relational database; after the products are packaged, package code data and product tracing code data are related; the products are stacked, stacking codes and tagged stacking codes are generated, and the stacking codes and the product package code data are related; the stacking codes are scanned, storage of the products is completed, delivery orders and the stacking codes are scanned to complete delivery, and the database records delivery information.

Owner:武汉华工赛百数据系统有限公司

Blender/food processor blade arrangement for small throated blender jars

ActiveUS7641380B2Improve abilitiesEasy to operateRotary stirring mixersKitchen equipmentSide effectSemi solid

A blade assembly suited for both blending and food processing in small throat blender jars is provided. The blade assembly comprises a plurality of blade forms each designed to perform a specific blending or processing task while simultaneously working together and with the geometric restrictions of the jar to optimize the assembly's capability to crush ice, blend or mix liquids and / or semi-solid materials, and to chop, cut, or slice solid food items without the need for user interaction to clear compacted items from the blades and / or the walls or bottom of the jar during its operation. The improved performance also serves the beneficial side effect of improved bearing and motor life in the blender / food processor.

Owner:SUNBEAN PROD INC

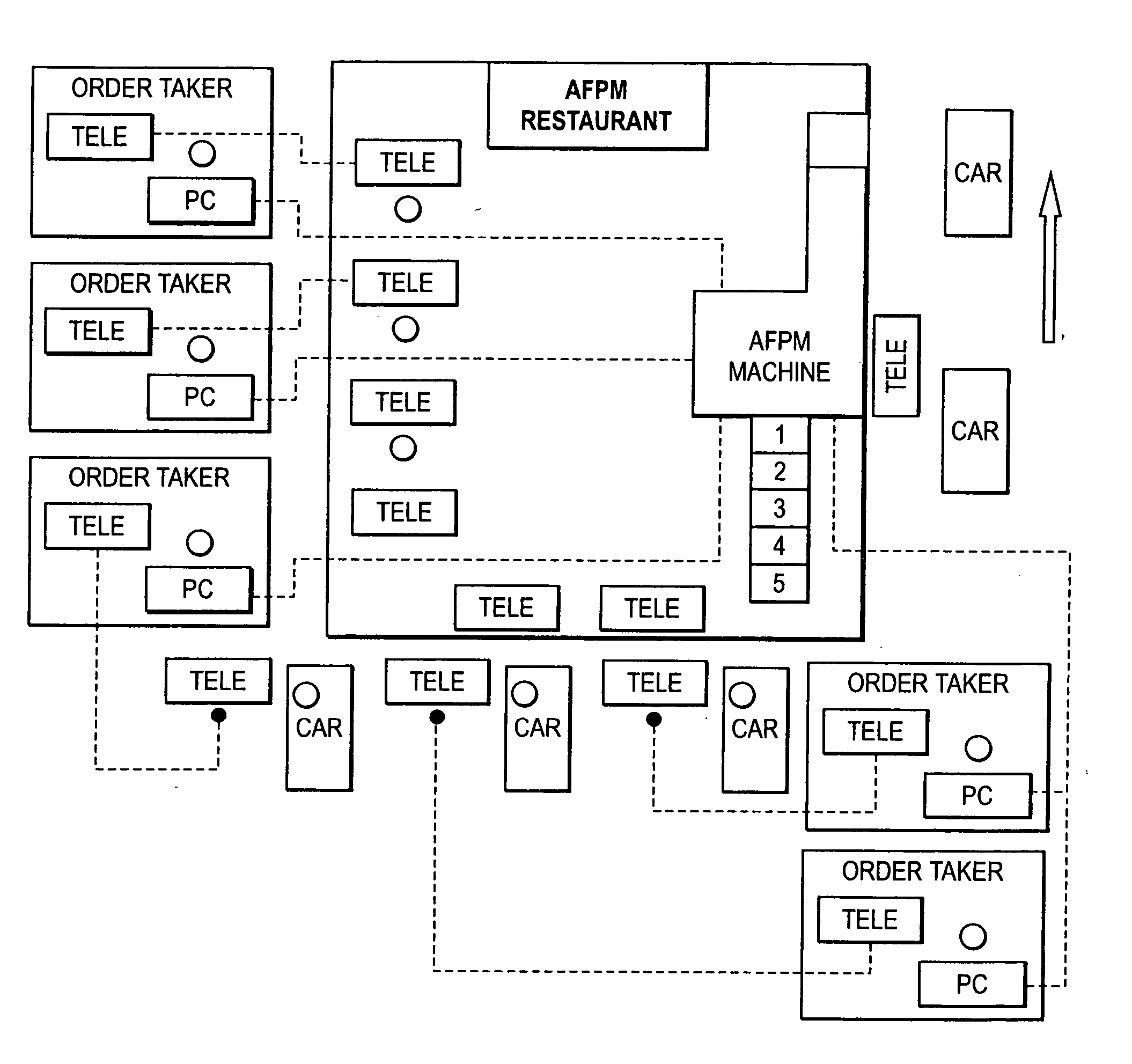

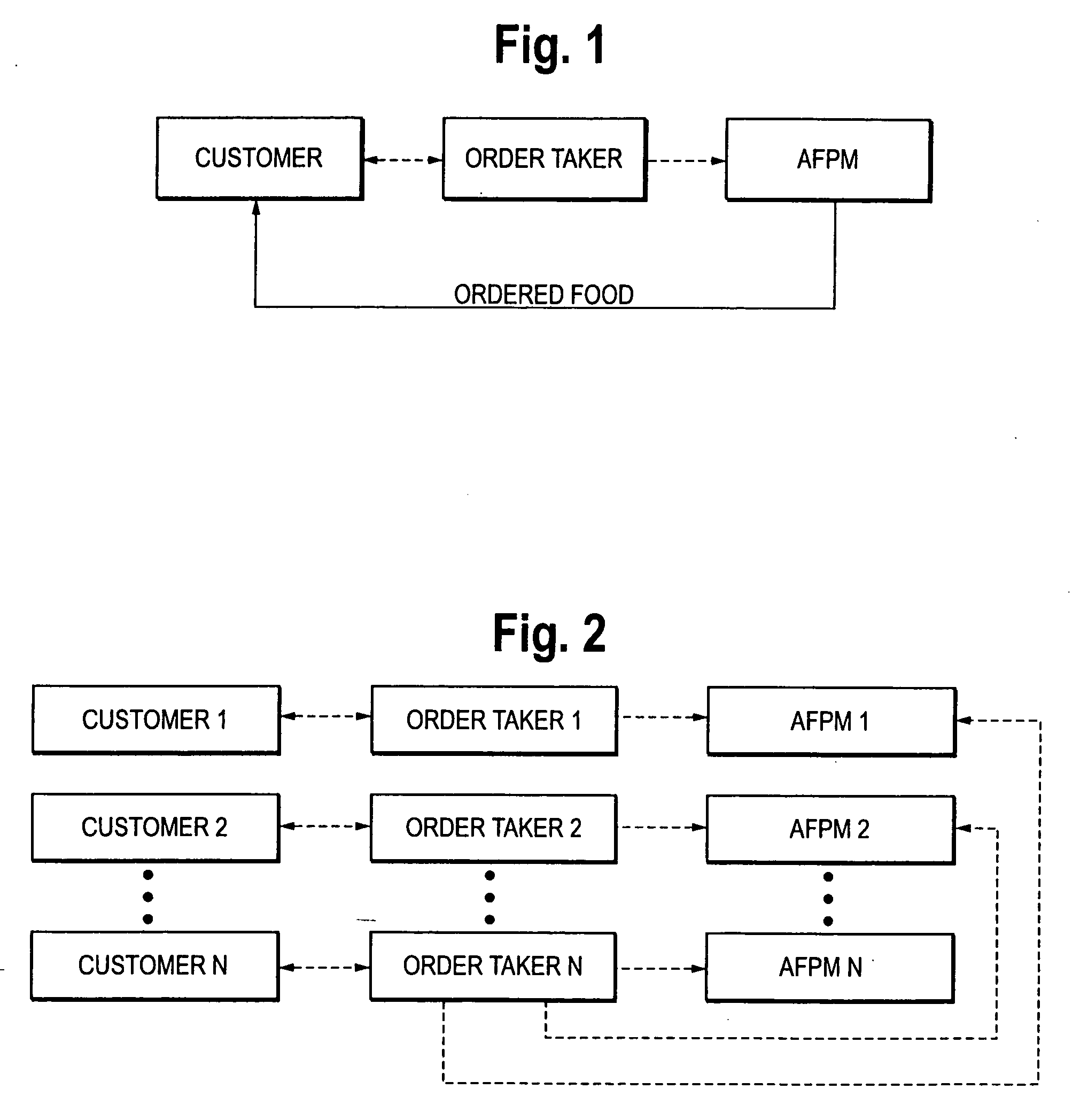

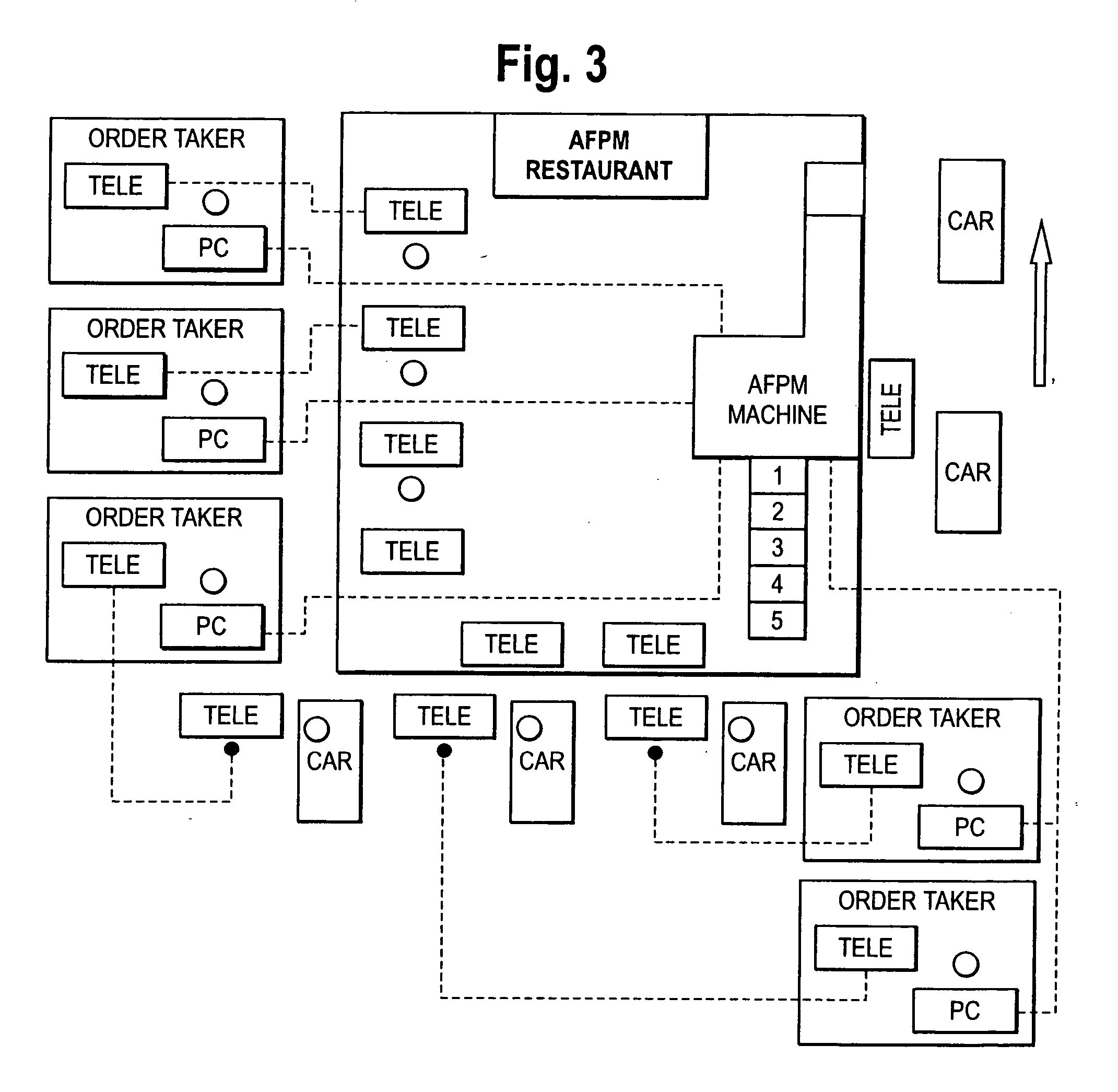

Systems and methods of ordering at an automated food processing machine

InactiveUS20050267811A1Easy to useAcutation objectsApparatus for meter-controlled dispensingThe InternetEngineering

A customer of an Automated Food Preparation Machine communicates via telephone to a remotely located human order taker who negotiates a food order from a menu that is accessible to the customer and then via the Internet, the order taker obtains control of the remotely located Automated Food Preparation Machine and activates it to produce an ordered menu item.

Owner:ALMBLAD ROBERT E

Fried food processing device

The invention discloses a fried food processing device which overcomes the defects that a frying pot in the prior art is unreasonable in design and some parts are difficult to clean. The device comprises an outer shell, a pump pipe, a motor and an upper cover matched with the outer shell. The outer shell is provided with a bottom and a wall. A driver is arranged at the bottom of the outer shell. A supporting plate is connected to the driver. A pot body is supported on the supporting plate. A frying basket is arranged in the pot body. A first opening of the pump pipe is located above the frying basket. A second opening is located at the bottom of the pot body. The first opening is provided with supercharging blades driven by the motor to rotate. A heating element is arranged at the bottom of the pot body and / or around the pump pipe. The fried food processing device automatically operates during operation and is an oil-saving efficiency full-automatic device.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

Method for improving solidifying point of Fischer-Tropsch wax

InactiveCN103980940AImprove stabilityHigh melting pointPetroleum wax recoveryChemical industryTwo step

The invention relates to a method for preparing high-melting-point refined wax capable of being applied to plastics, rubber processing, wood processing, food processing and other industries and particularly relates to a method for improving the solidifying point of Fischer-Tropsch wax. According to the method for preparing high-melting-point refined wax with excellent performances, distillation refining is carried out on light-weight oil serving as a raw material by means of continuous high-vacuum distillation, wherein the light-weight oil is produced by indirect coal liquefaction; According to the technical scheme, the method comprises two steps, namely, firstly, feeding the raw material in an evaporator by a feed pump so as to heat and evaporate the oil components and other low-boiling-point substances under the conditions of high temperature and high vacuum degree; secondly, feeding the coal-based synthetic oil without oil components and other low-boiling-point substances into a distiller, heating and evaporating the coal-based synthetic oil products by using heat-conduction oil under extremely high vacuum condition, condensing and capturing in a condenser to obtain the target product. The method disclosed by the invention can be widely used in the field of chemical industry.

Owner:SHANXI LUAN MINING GRP

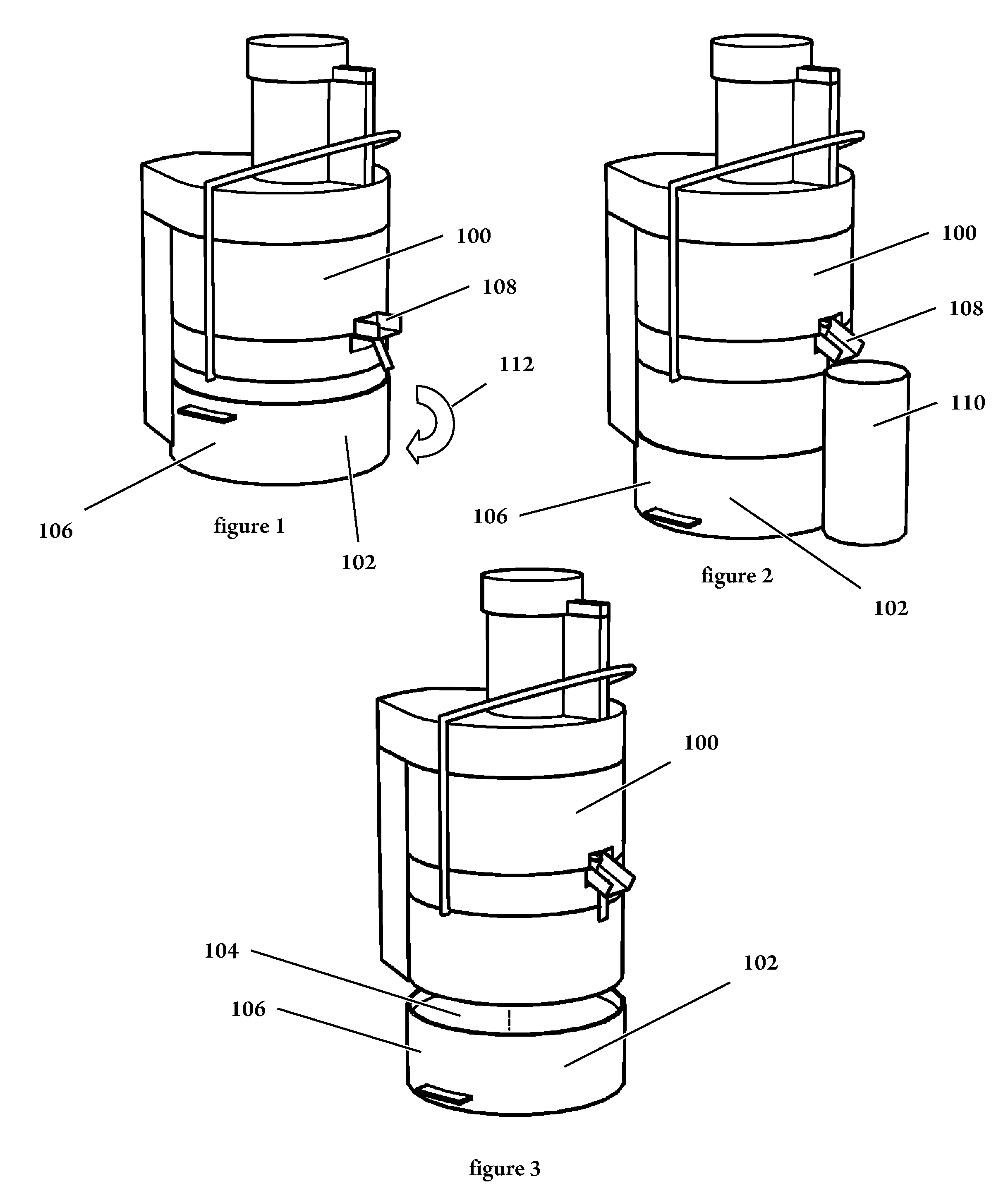

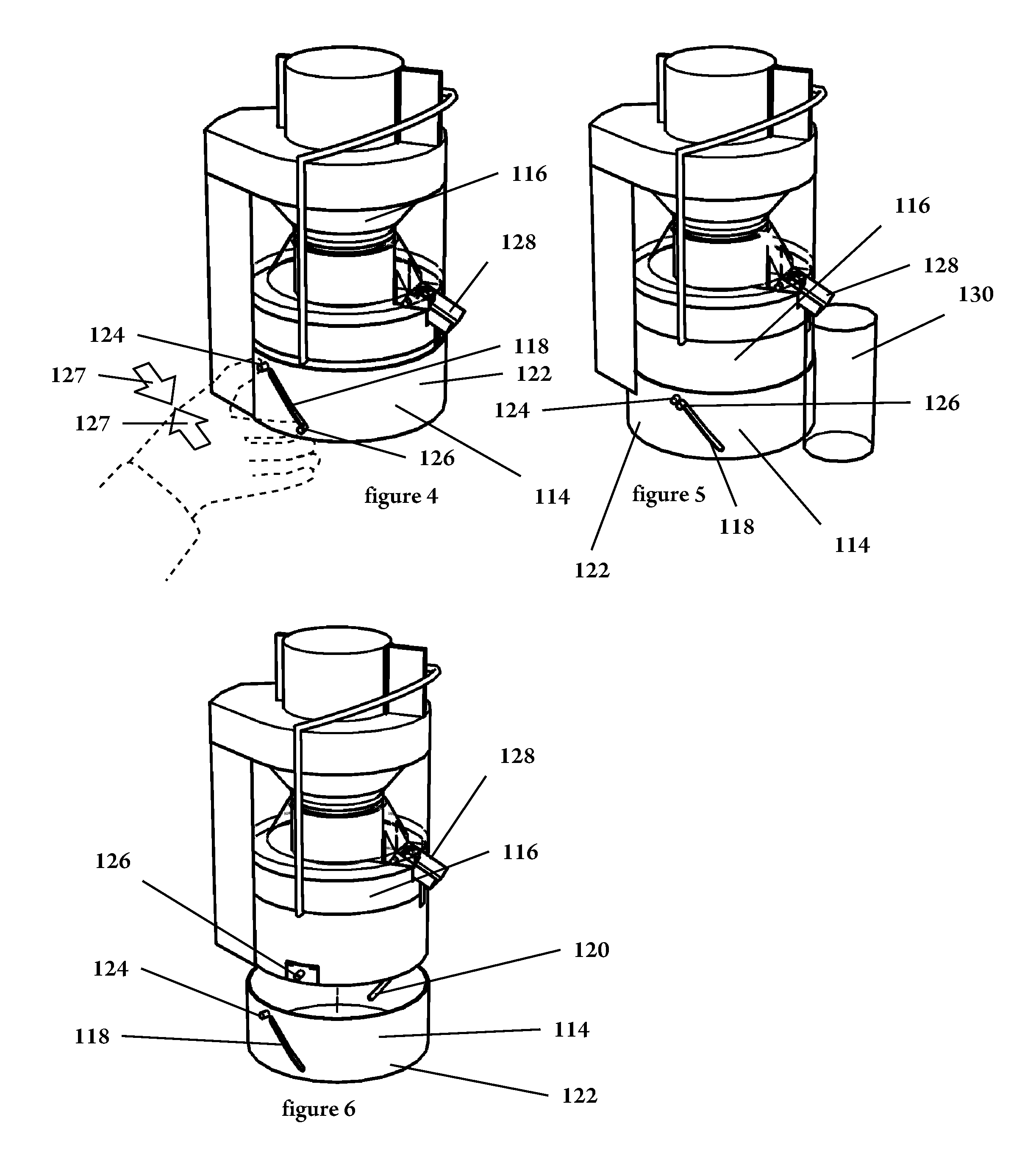

Devices and methods to disintegrate foods

The subject application is directed to a food processing device to extract juice. The device includes an inlet coupled to a disintegrator. The inlet is configured to accept food items and the disintegrator configured to disintegrate food items passed through the inlet. The device further includes a separator that accepts the disintegrated food items and separates out the liquid components from the food item. The device further includes a reservoir that is coupled to the separator for accepting and holding the liquid components. The reservoir includes a translucent member for viewing of liquid levels within the reservoir, and a valved outlet. The valved outlet is configured to allow or prevent the flow of liquid from the reservoir through the valved outlet.

Owner:BACKUS ALAN

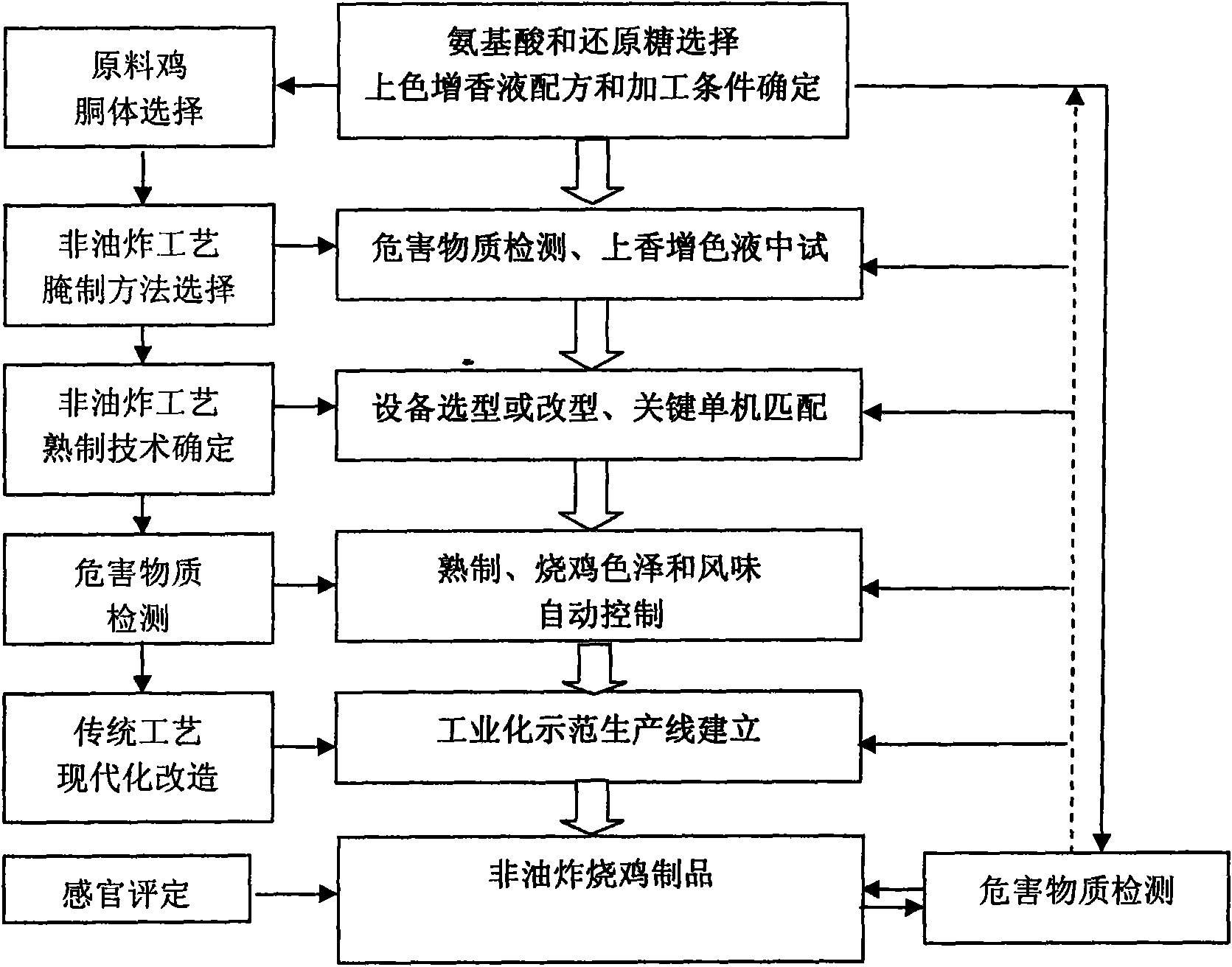

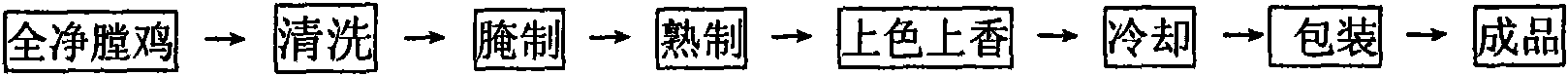

Non-fried production method for grilled chicken

InactiveCN101940273ALow content of hazardous substancesGreat tasteFood preparationFlavorMaillard reaction

The invention relates to a food processing method, in particular to a non-fried production method for grilled chicken. Different heating modes are adopted in the non-fried new process, then fragrant color increasing liquid is applied to the surface of a poultry carcass by selecting a proper method, Maillard reaction is further performed under certain condition, the poultry carcass generates the color similar to that of the traditional grilled chicken, meanwhile, multiple natural flavor substances can be produced, and the fragrance of the product is increased. By adopting the technology, the method realizes modernized technical reformation of the traditional special grilled chicken product processing technique, furthest reduces carcinogenic benzopyrene and heterocyclic amine in the traditional special fried grilled chicken products, avoids illegal colorants, and develops a novel grilled chicken product with good taste, good flavor, good color and high safety.

Owner:赵保雷

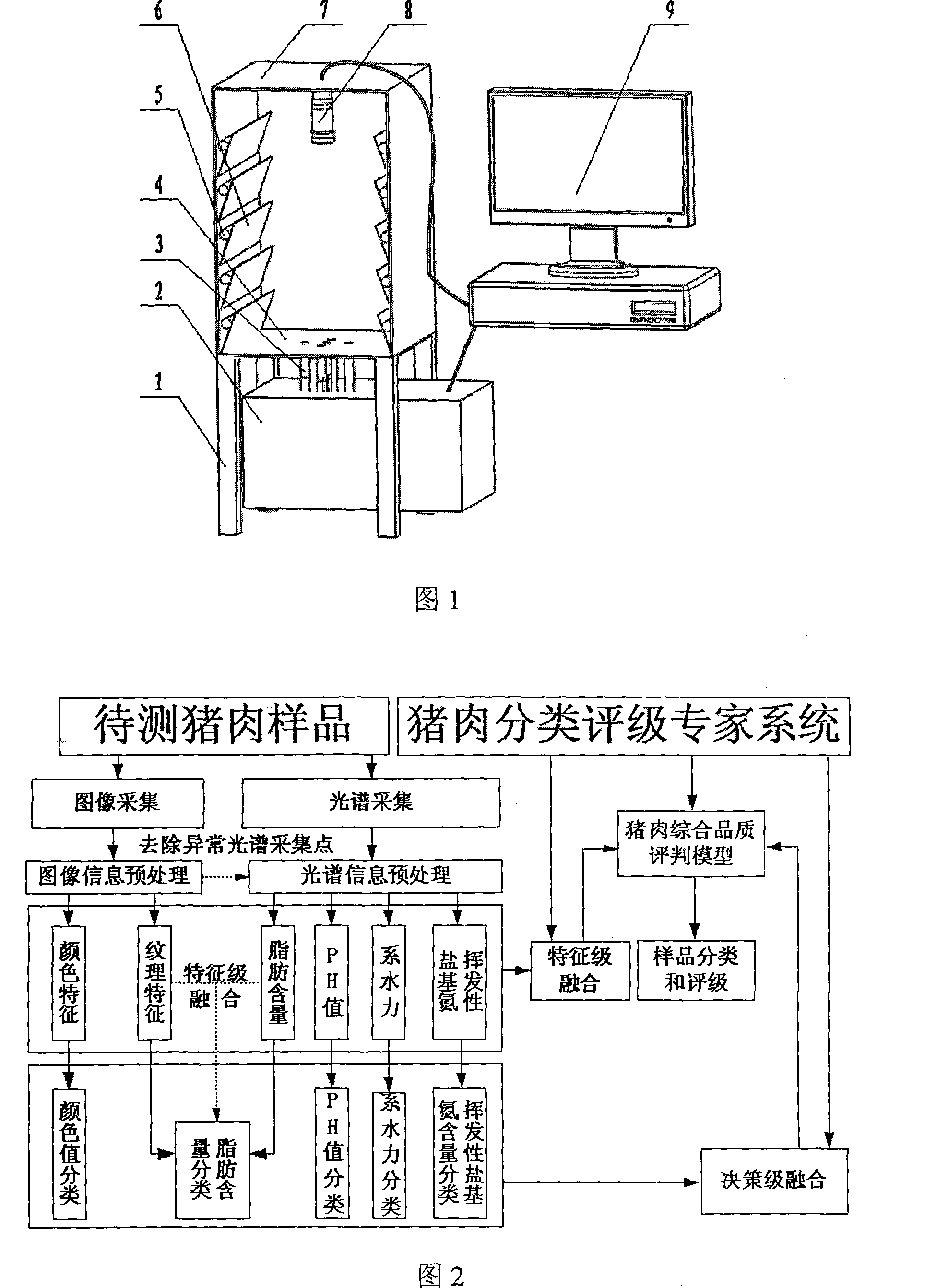

Method and apparatus for nondestructively testing food synthetic quality

ActiveCN101251526AFast NDTThe detection process is fastMaterial analysis by optical meansTesting foodFood materialFood classification

The invention discloses a non-destructive inspection method for the comprehensive quality of food and a device thereof, wherein image information reflecting characteristics of an inspected object, such as color, texture, size and shape, etc. is acquired by a machine vision system, and spectral information reflecting physical and chemical indexes of the sample such as moisture, sugar, protein, lipid and PH value, etc. is obtained by a spectrographic detection system, and the acquired image information and the spectral information undergo the preprocessing on the data layer and the information integration on the characteristic layer or the decision layer; together with a built food classification grading expert system, the quality of the inspection object is comprehensively graded. The invention comprehensively utilizes the light image information and the spectral information to inspect the appearance and inner quality of food, thereby the invention can make a quick, convenient, non-destructive and objective inspection on the comprehensive quality of food; the method and the device are widely used to classify food materials, monitor the food processing and grade the food, etc., which ensures the quality of food and contributes to the good quality and low price of food.

Owner:ZHEJIANG UNIV

Detergent tablet

InactiveUS7153817B2Improve production stabilityDifficult to bindInorganic/elemental detergent compounding agentsTableware washing/rinsing machine detailsDistilled waterNon ionic

A machine cleaner tablet comprising from about 10 to about 75% of a limescale remover acid, from about 1 to about 20% of low foaming non-ionic surfactant, from about 0.5 to about 5% of a detergency enzyme and wherein the tablet has a pH measured as a 1% solution in distilled water at 20° C. in the range from about 1 to about 5. The tablet is used for cleaning the interior of automatic dishwashers, food processing machines and the like.

Owner:THE PROCTER & GAMBLE COMPANY

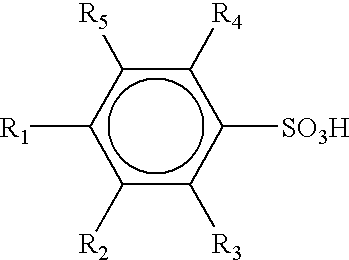

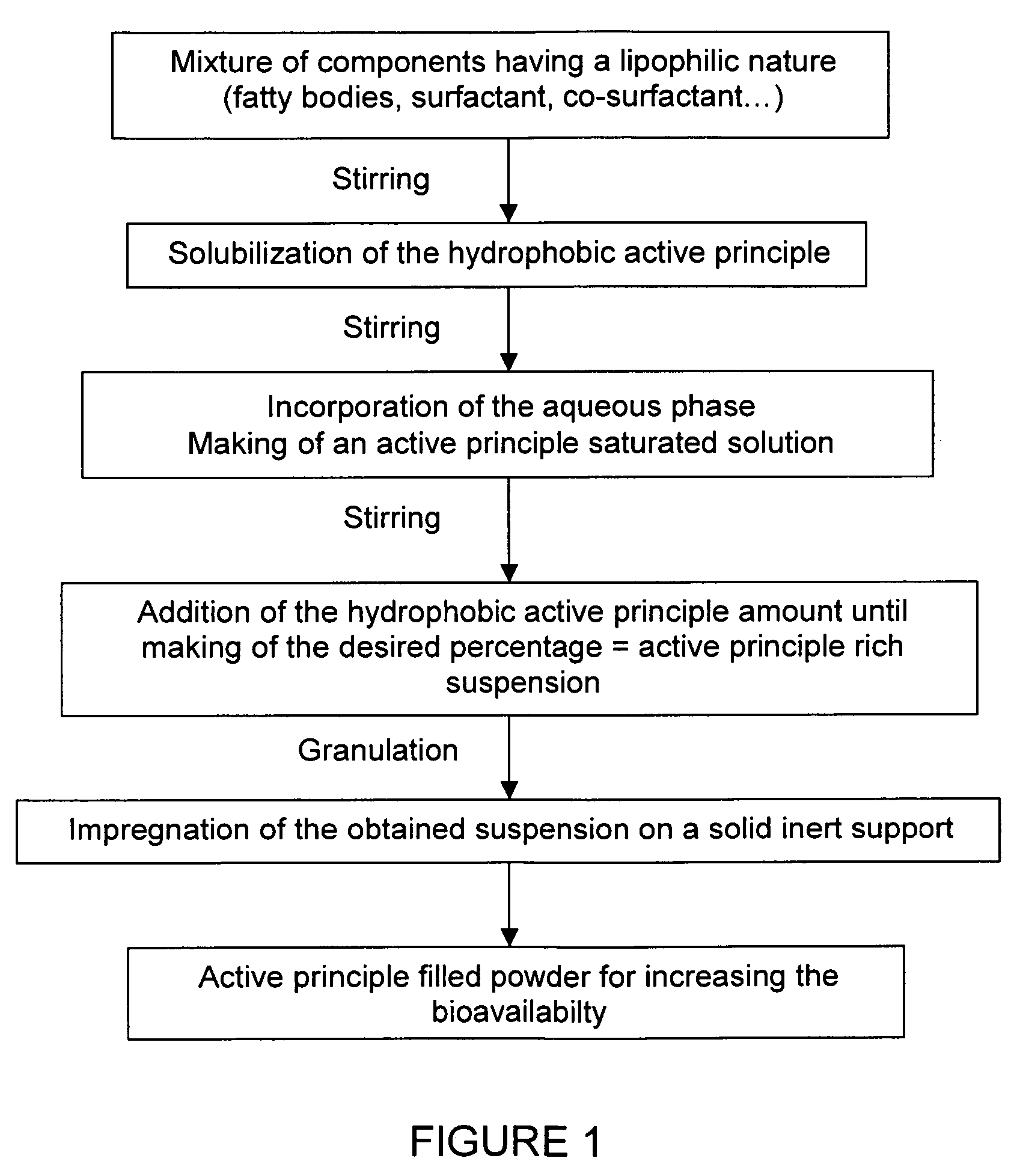

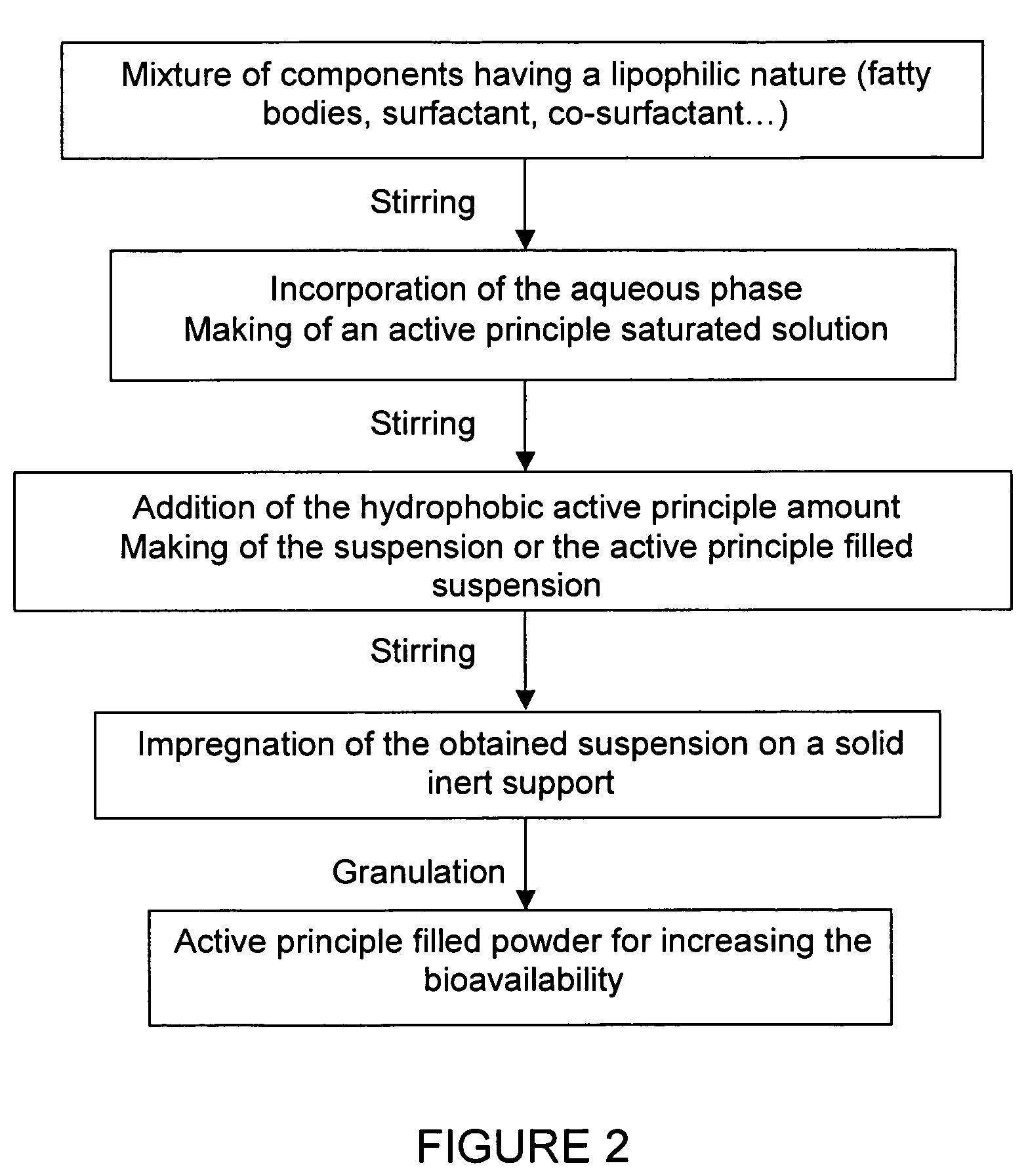

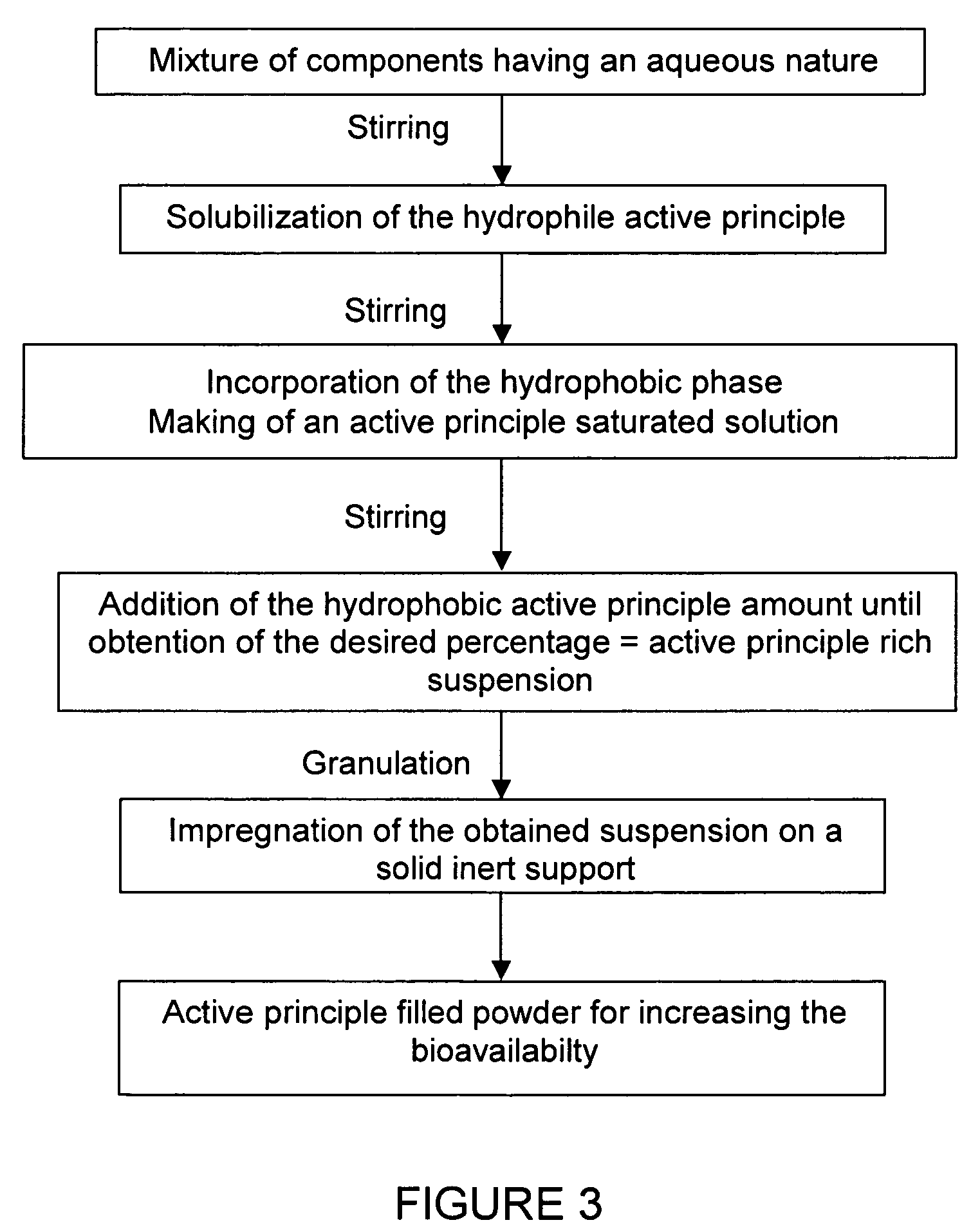

Impregnated powder improving bioavailability and/or solubility and method of production

This invention relates to an impregnated powder for increasing the bioavailabilty and / or the solubility of at least one active principle comprising a solid, inert support in a particle form impregnated by a liquid medium comprising a hydrophobic phase and optionally a hydrophilic phase, at least one surfactant and at least one active principle dissolved in at least one of said phases, wherein said active principle(s) is(are) also present in at least one of said phases in the form of a suspension.Such an impregnated powder is used as a base for various preparations in the pharmaceutical, parapharmaceutical and cosmetic field, in the food complement field and in the food processing industry.

Owner:GALENIX INNOVATIONS

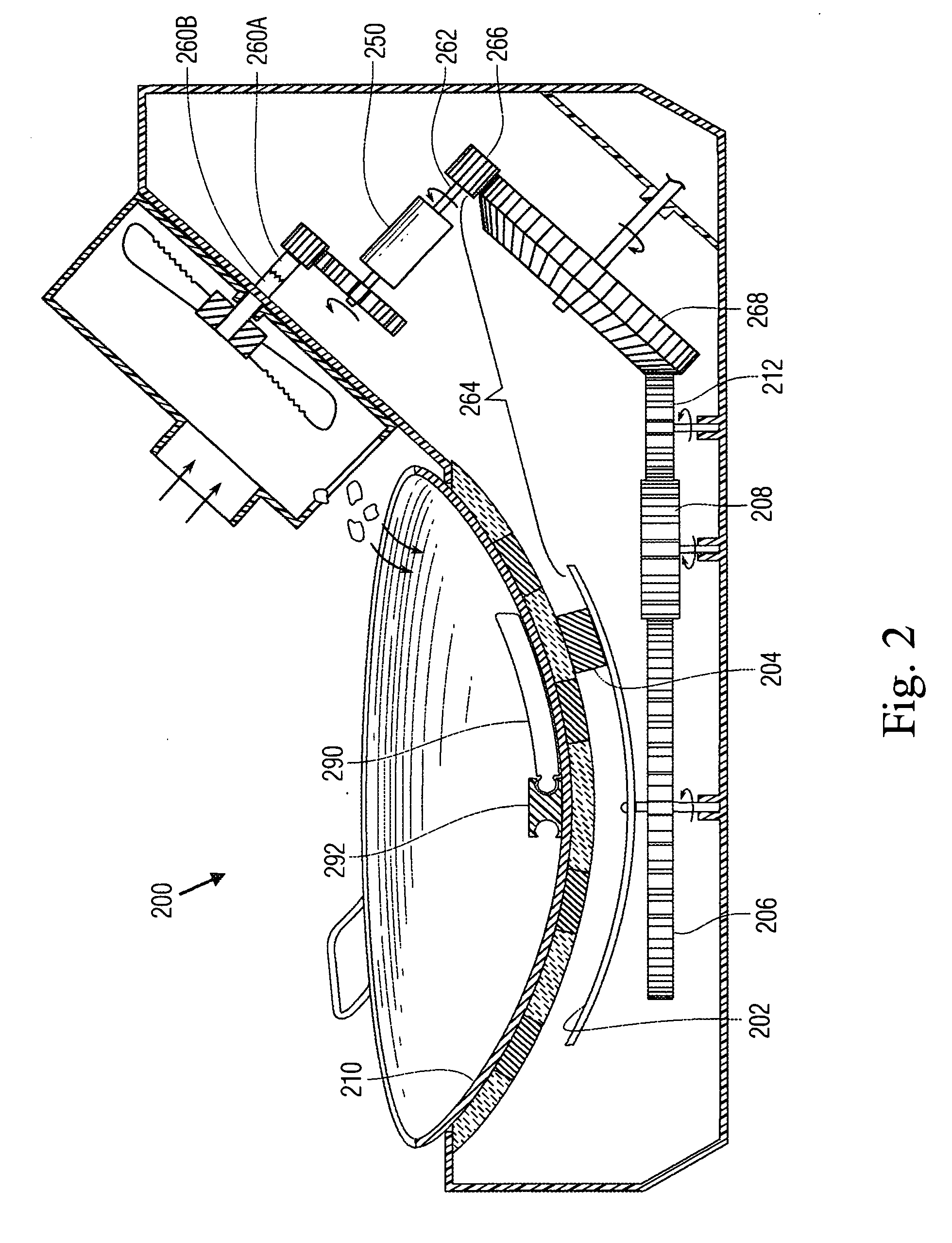

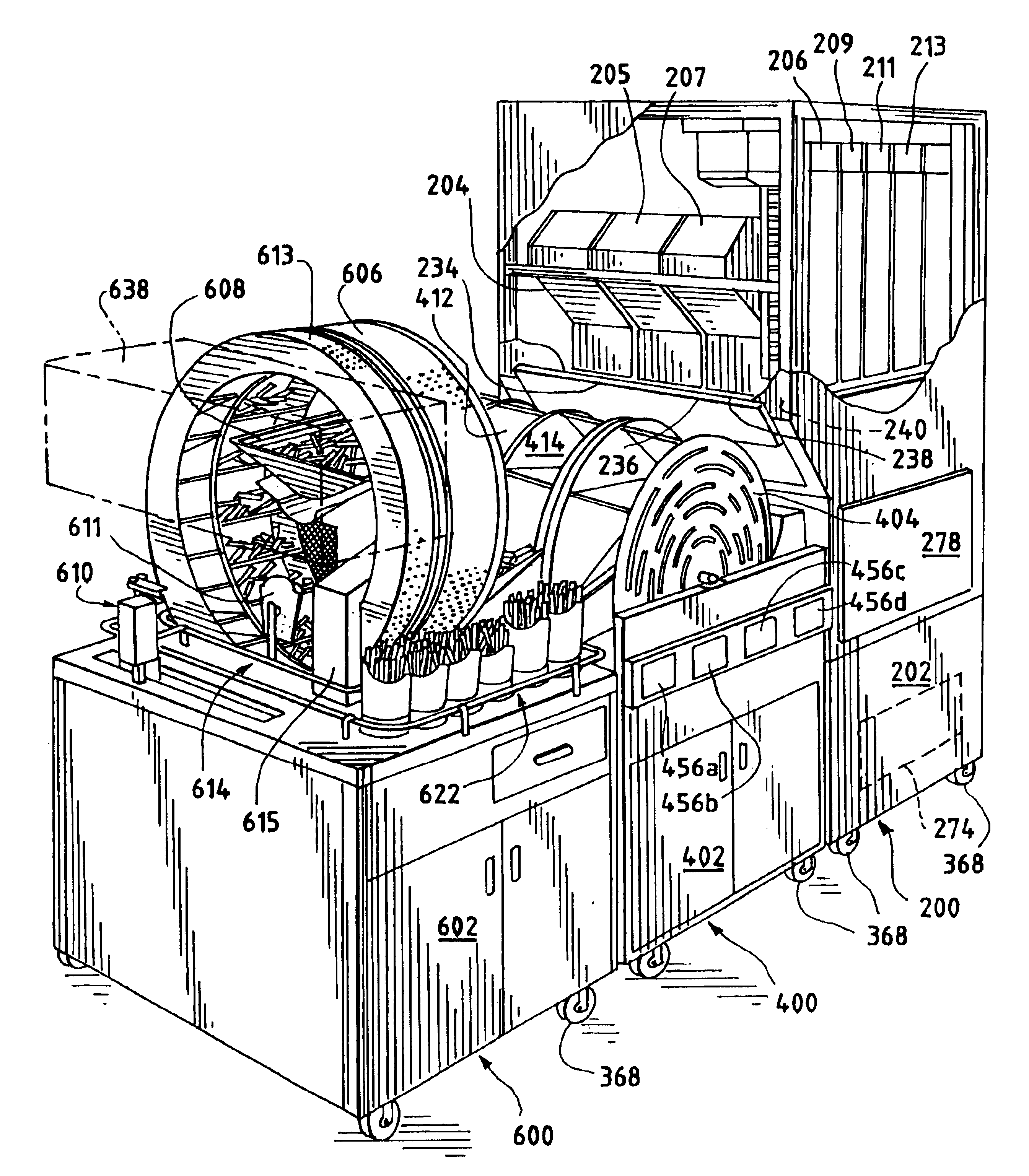

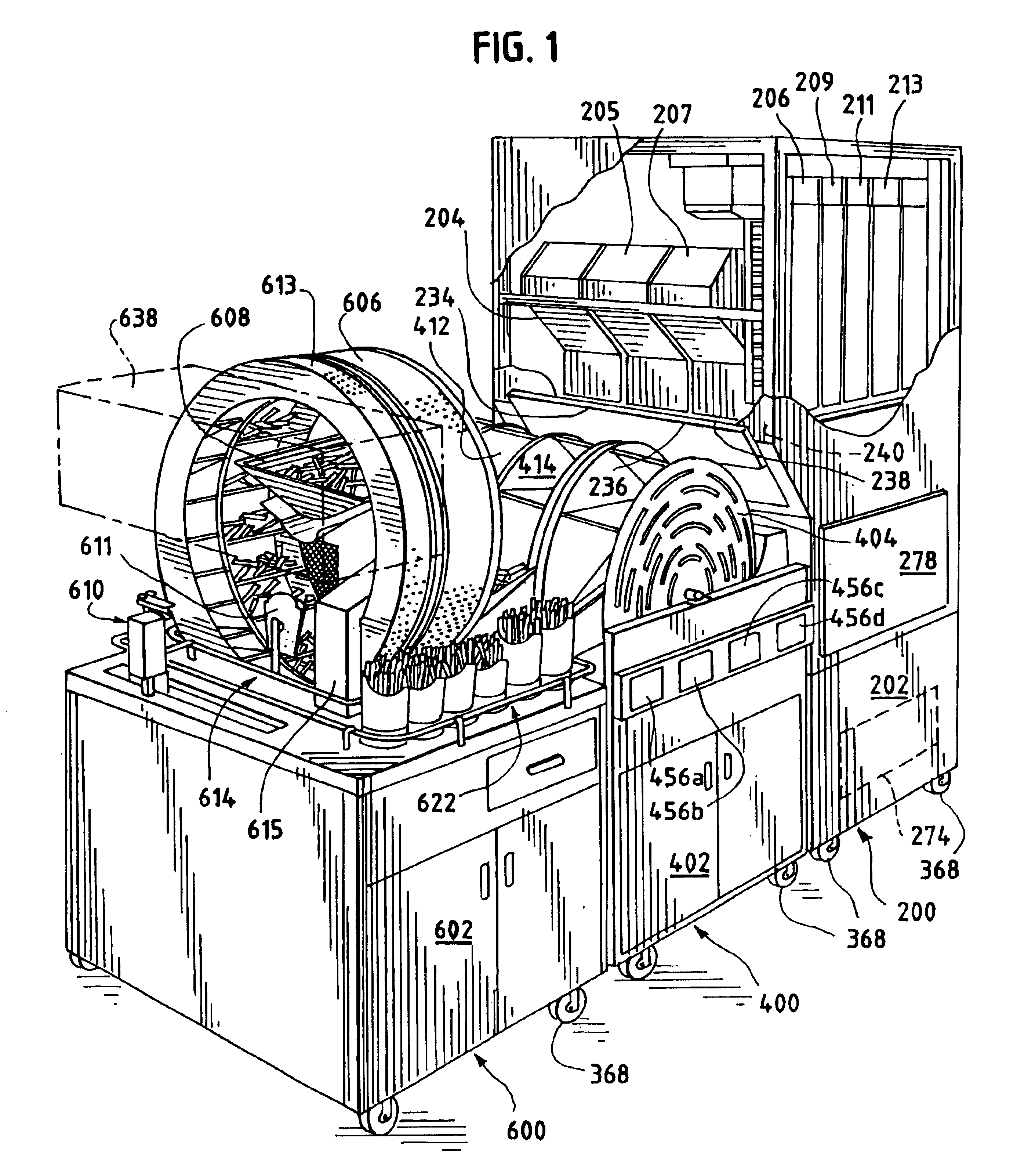

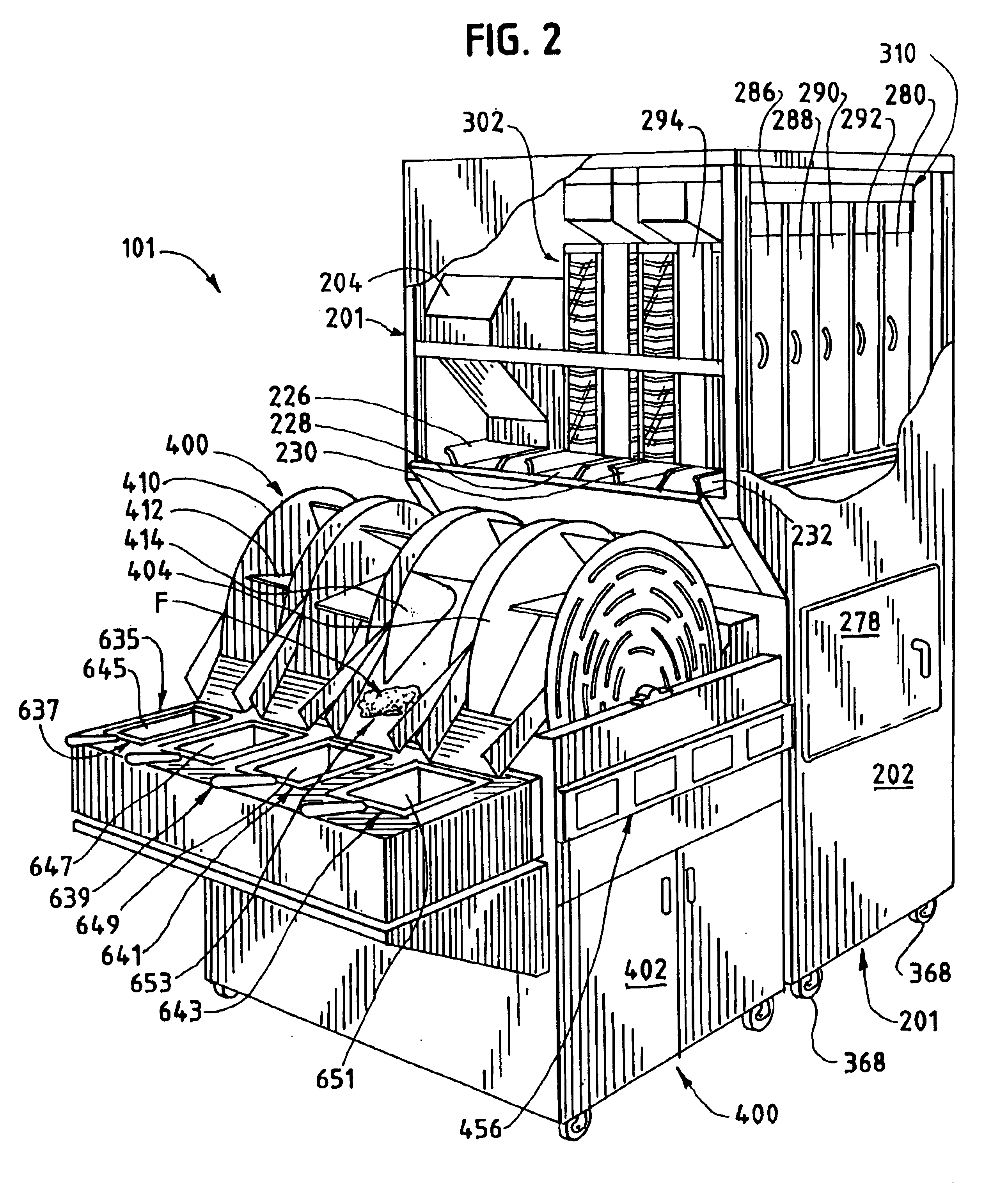

Automated food frying device and method

An automated food processing system and method is provided that allows food to be dispensed, fried and packaged in a suitable container, which may be an individual portion-sized container. In one embodiment, the system includes separate automated modules for dispensing, frying and packaging the food.In one embodiment, an automated dispensing device dispenses a predetermined portion of food from a bulk storage container or food dispensing magazine. Food is dispensed from the automated dispensing device to an automated fry device that can include at least one circular fry wheel having a plurality of food containing compartments. After the food is fried it is dispensed from the fry device to an automated packaging device. The automated packaging device dispenses food to a container that may be an individual portion-sized container that is retrieved, erected and held into position for filling by an automated container handling system. After a food container is filled, a conveyor system transports the filled container to a suitable pick-up location.

Owner:RESTAURANT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com