Patents

Literature

8546 results about "Inspection method" patented technology

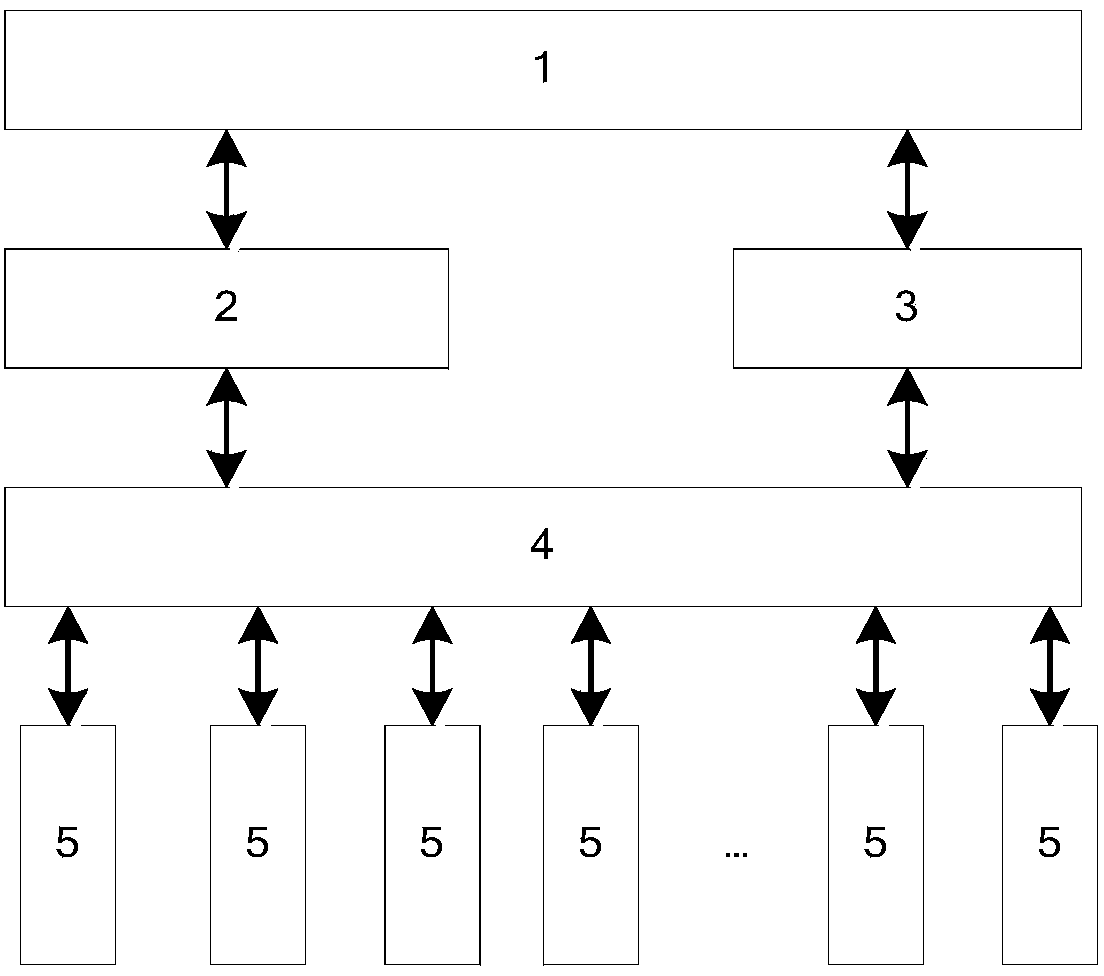

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An inspection method can be assigned to master inspection characteristics or directly to an inspection characteristics in an inspection plan. An Inspection method can be created in one plant and the same method can be used in other plants.

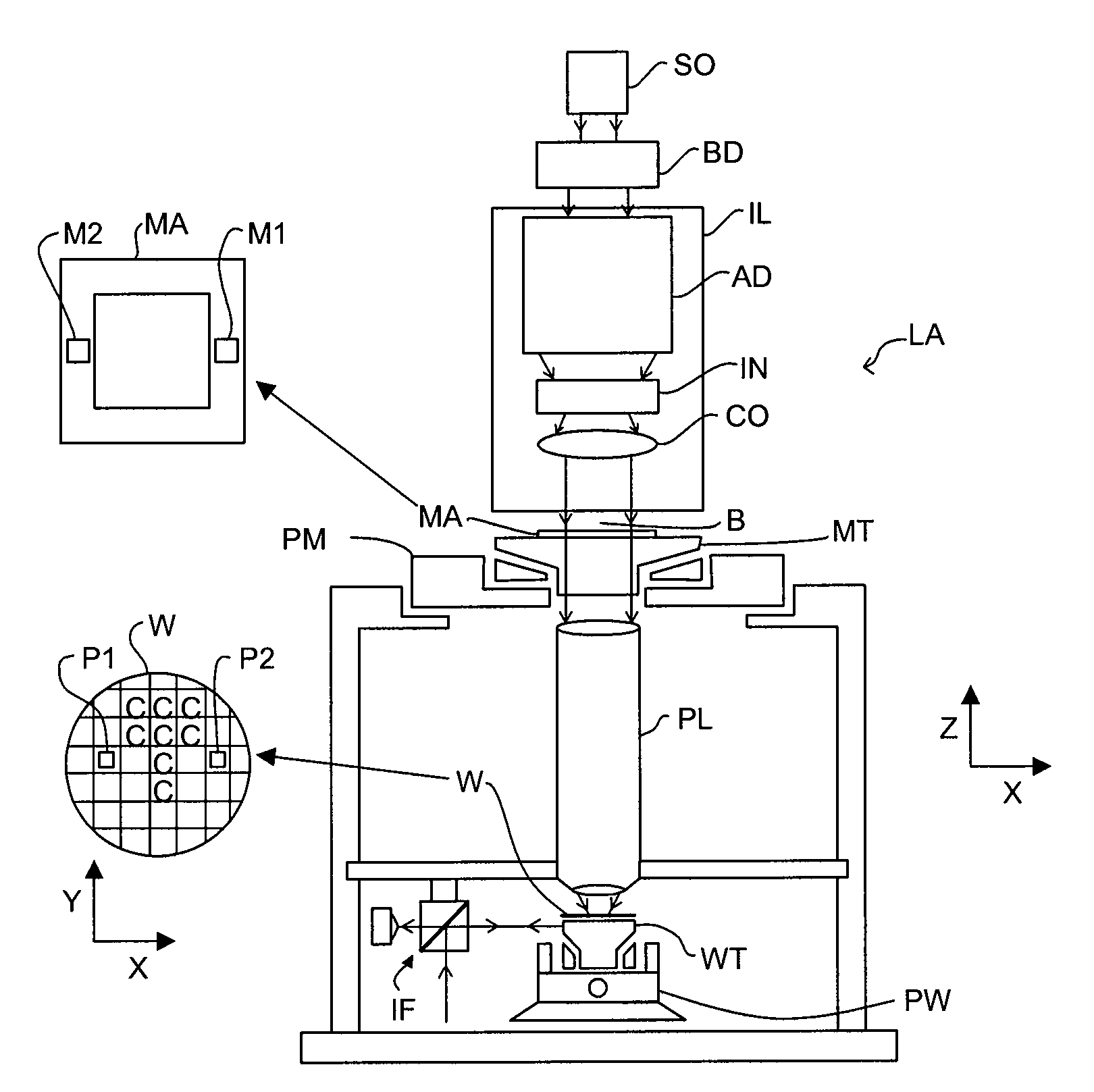

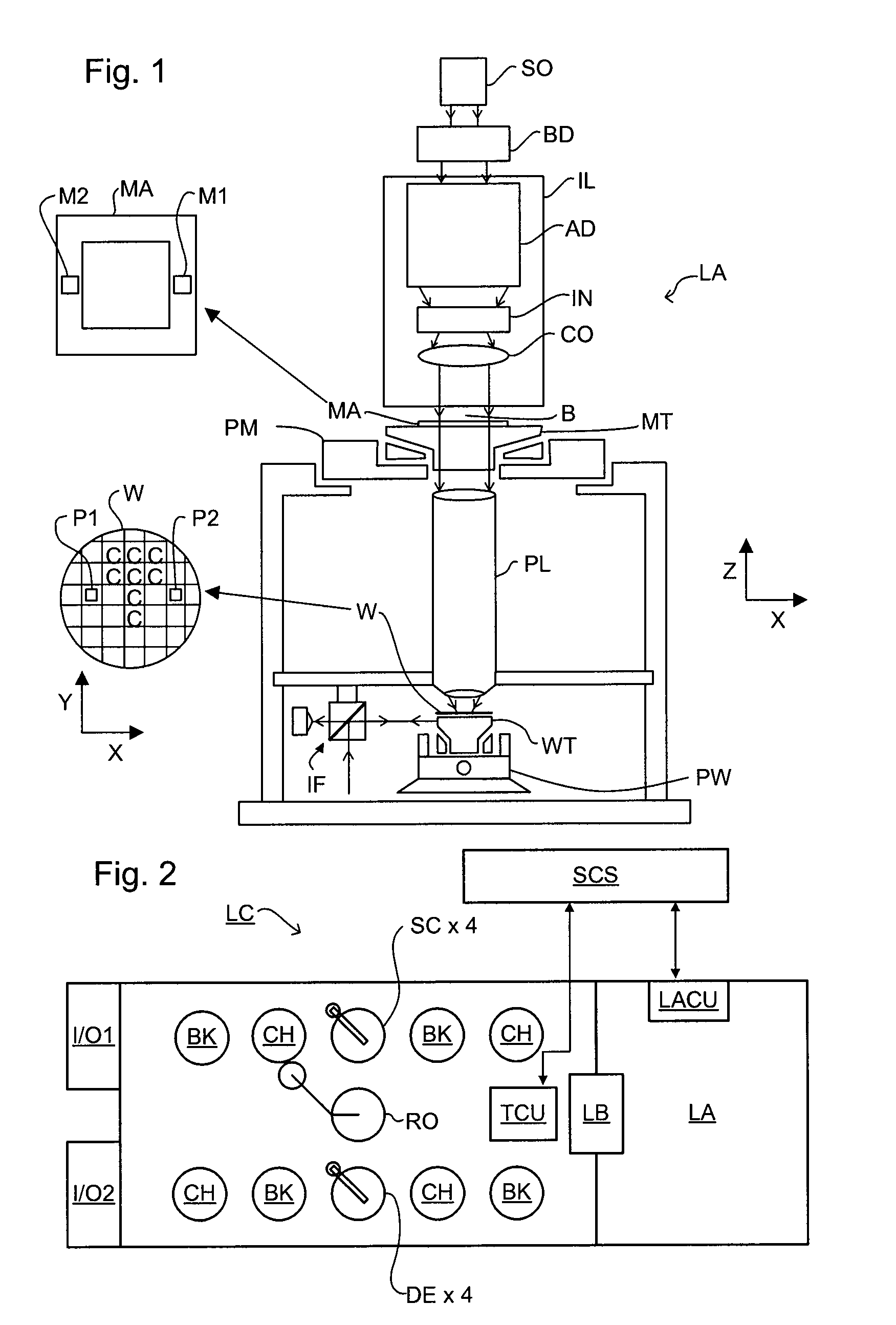

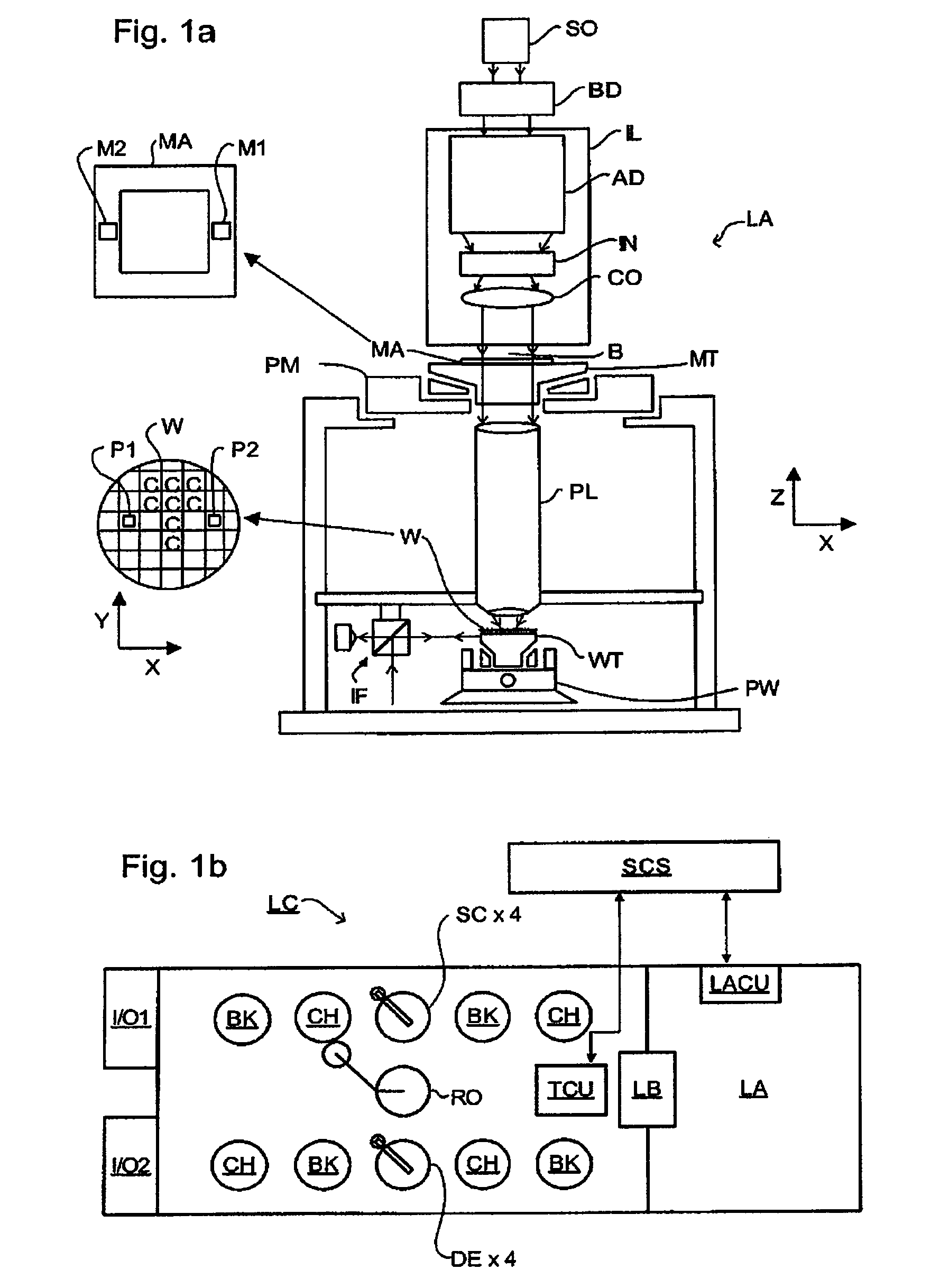

Inspection Apparatus, Lithographic Apparatus, Lithographic Processing Cell and Inspection Method

ActiveUS20100201963A1Increase the number ofPossible to separateRaman/scattering spectroscopySpectrum generation using diffraction elementsFour quadrantsZeroth order

For angular resolved spectrometry a radiation beam is used having an illumination profile having four quadrants is used. The first and third quadrants are illuminated whereas the second and fourth quadrants aren't illuminated. The resulting pupil plane is thus also divided into four quadrants with only the zeroth order diffraction pattern appearing in the first and third quadrants and only the first order diffraction pattern appearing in the second and third quadrants.

Owner:ASML NETHERLANDS BV

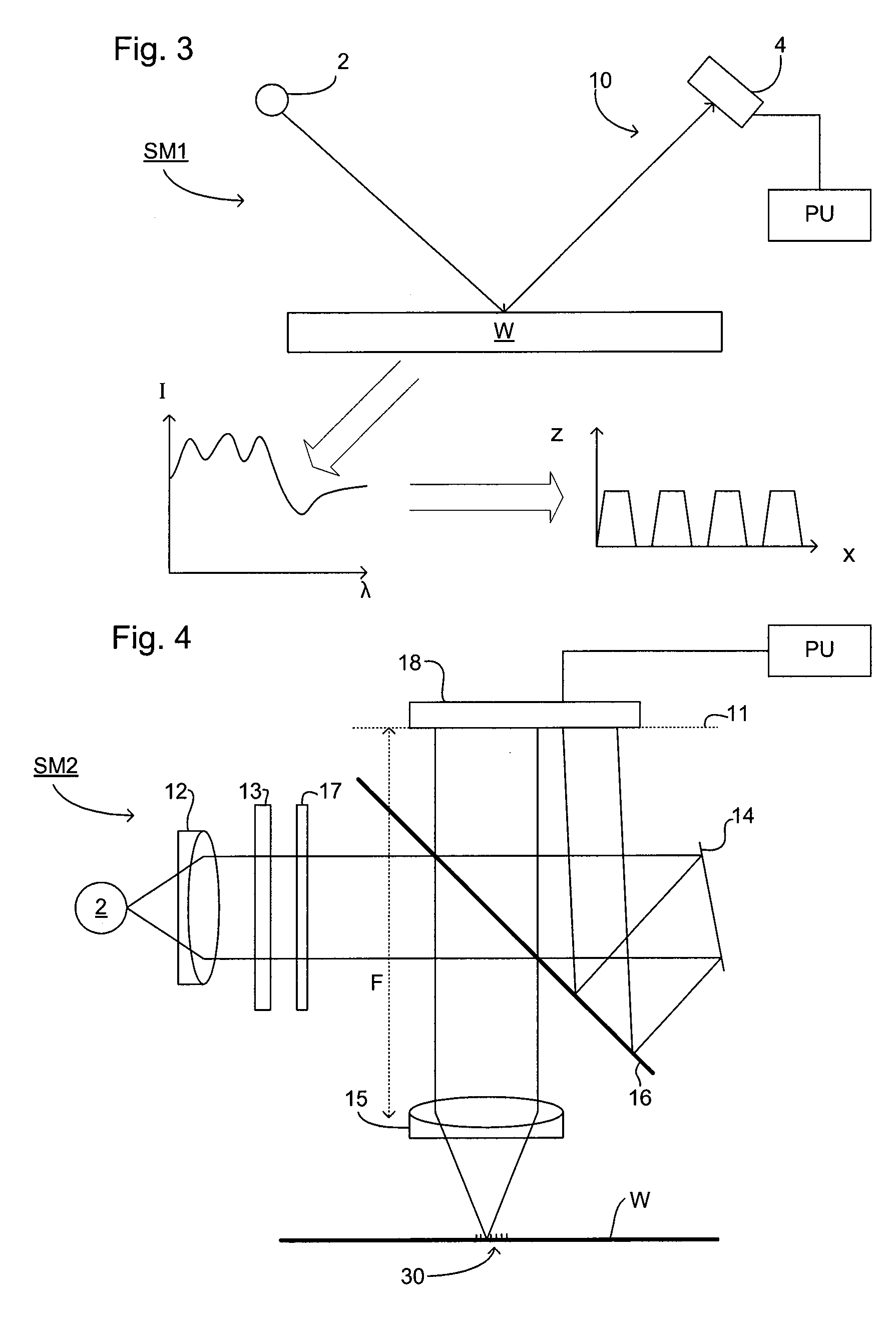

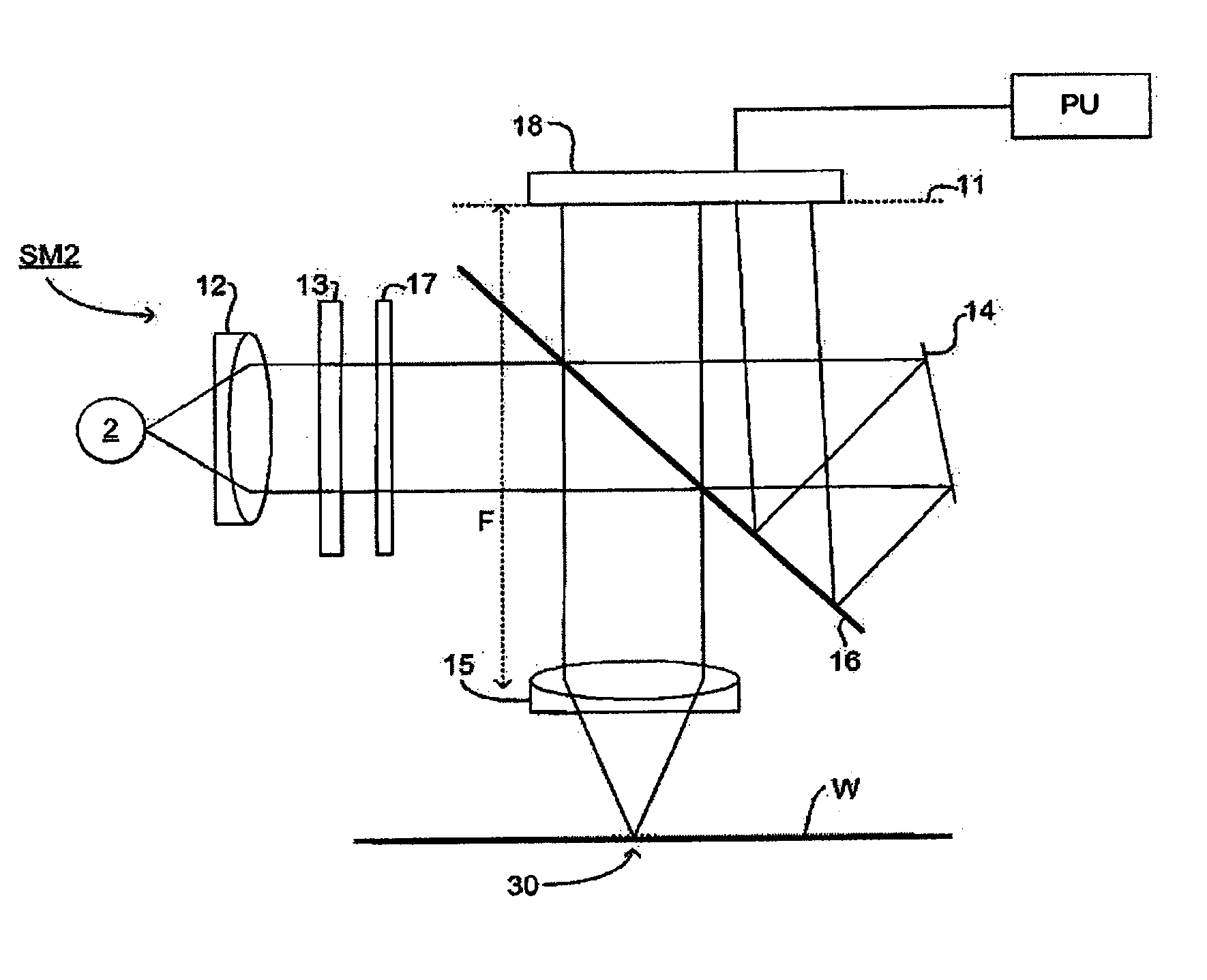

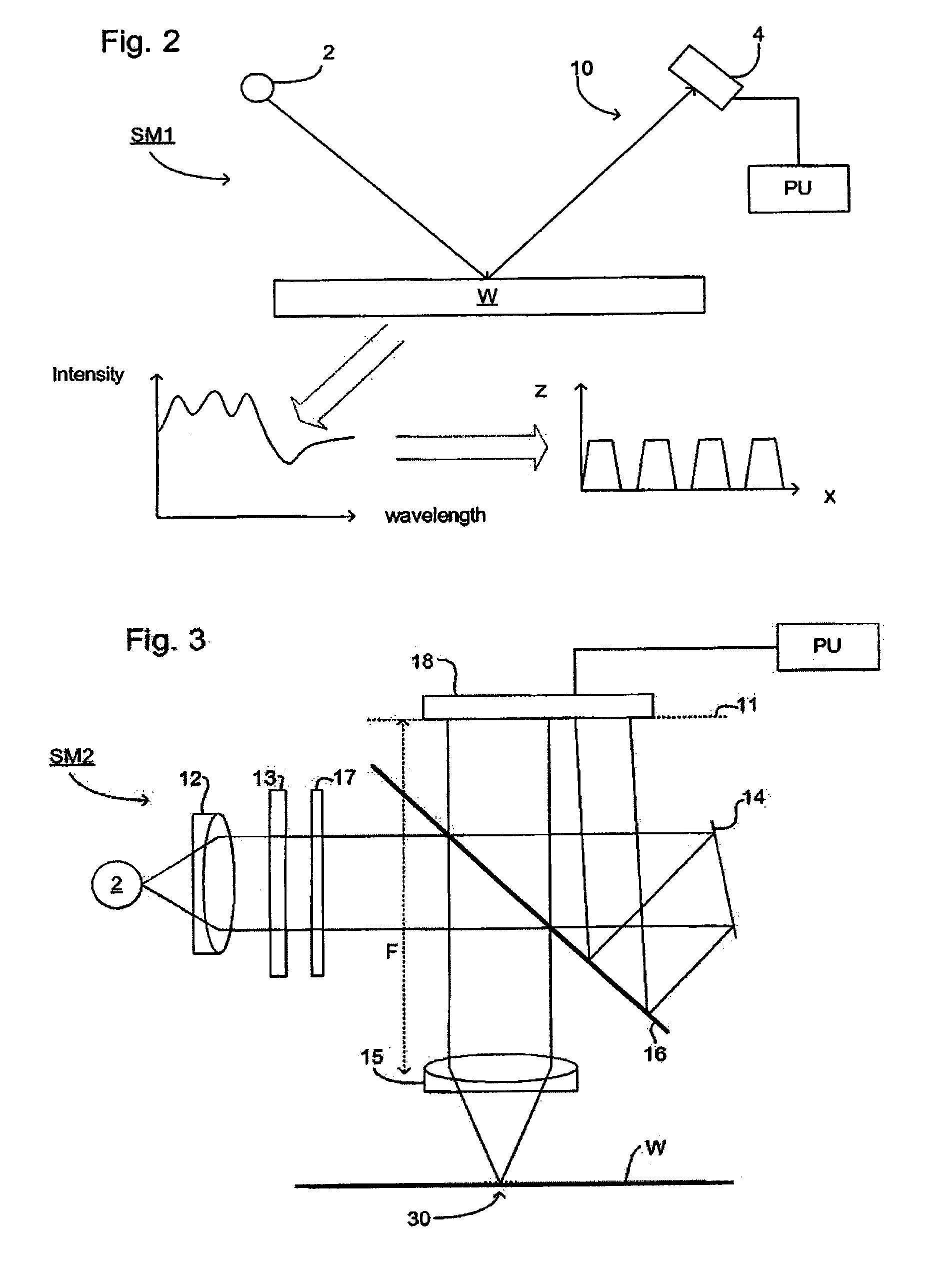

Inspection Method and Apparatus, Lithographic Apparatus, Lithographic Processing Cell and Device Manufacturing Method

ActiveUS20100007863A1Small targetRadiation pyrometrySpectrum investigationHigh numerical aperturePupil

An apparatus and method to determine a property of a substrate by measuring, in the pupil plane of a high numerical aperture lens, an angle-resolved spectrum as a result of radiation being reflected off the substrate. The property may be angle and wavelength dependent. The radiation that is reflected off the substrate is radially polarized.

Owner:ASML NETHERLANDS BV

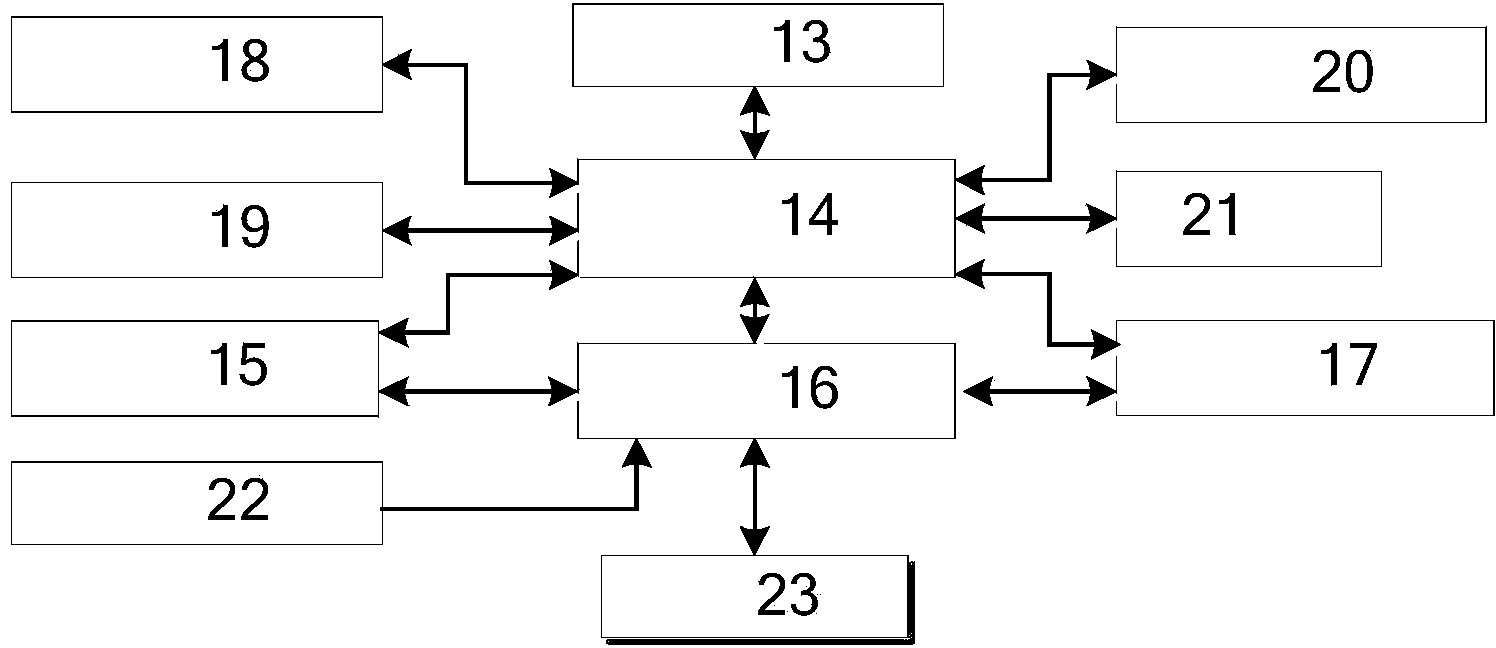

Substation intelligent robot inspection system and inspection method

ActiveCN102280826AInspection path optimizationIn place detection time is fastCircuit arrangementsSustainable buildingsSmart substationTransformer

The invention discloses an intelligent robot inspection system and an intelligent robot inspection method for transformer station. The intelligent robot inspection system comprises a monitoring centre, which is connected to at least one station robot intelligent inspection system of a transformer station, and each station robot intelligent inspection system comprises at least one base station. At the same time, the transformer station is also provided with an environment acquisition subsystem inside and fixed point monitoring subsystems disposed at devices needed to be monitored in the transformer station. The intelligent inspection robot is provided with an intelligent inspection robot lower computer connected to a detection unit, the detection unit includes an infrared detection unit and an ultraviolet detection unit, and the ultraviolet detection unit includes an ultraviolet video server and an ultraviolet detection device. The intelligent robot inspection system and the intelligent robot inspection method have the advantages of optimized inspection path, excellent safety protection, high intelligent degree, all-time fault detection and seamless video monitor, thus providing brand new technology detection means and all-round safety guarantee for an intelligent transformer station.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

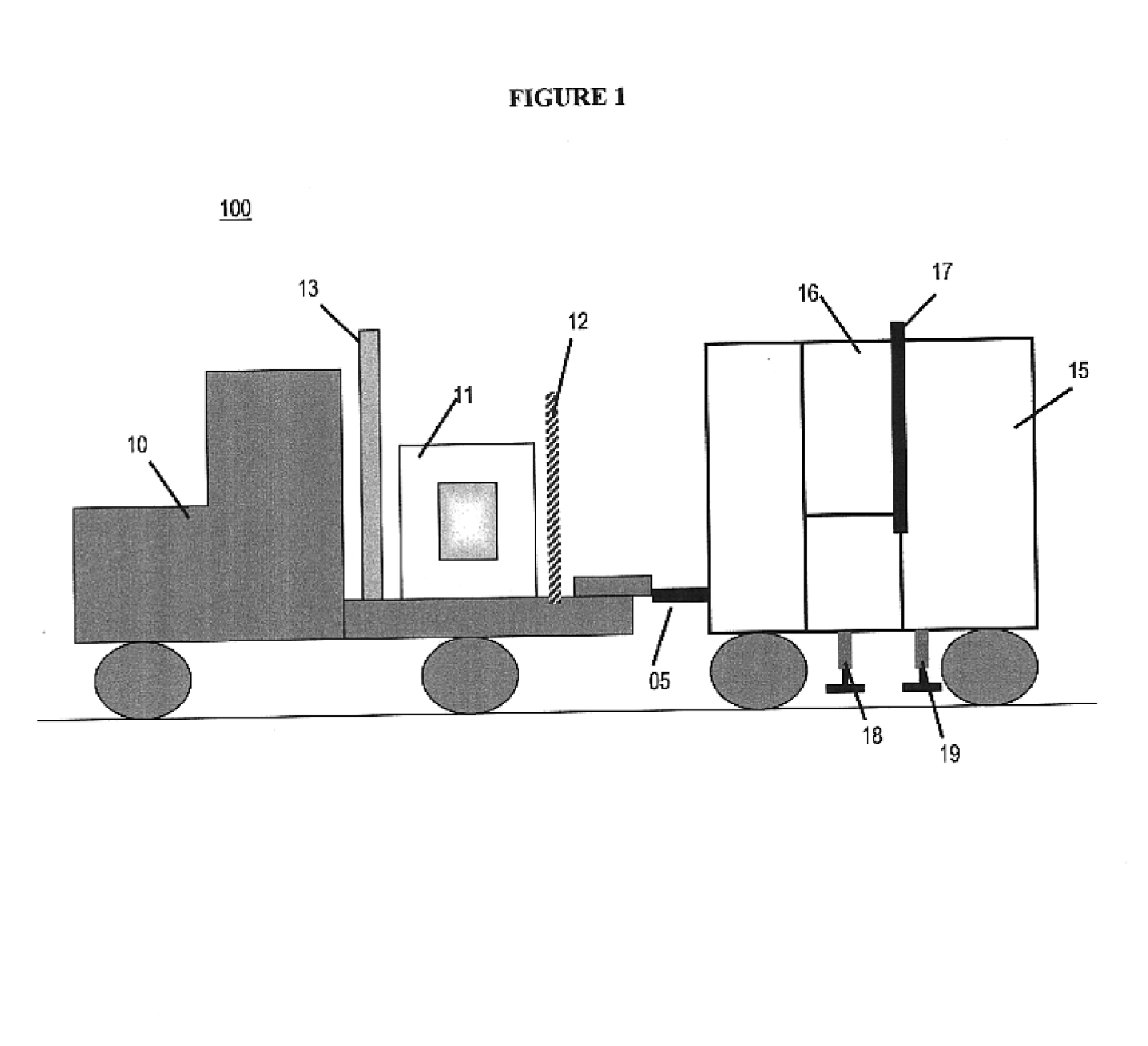

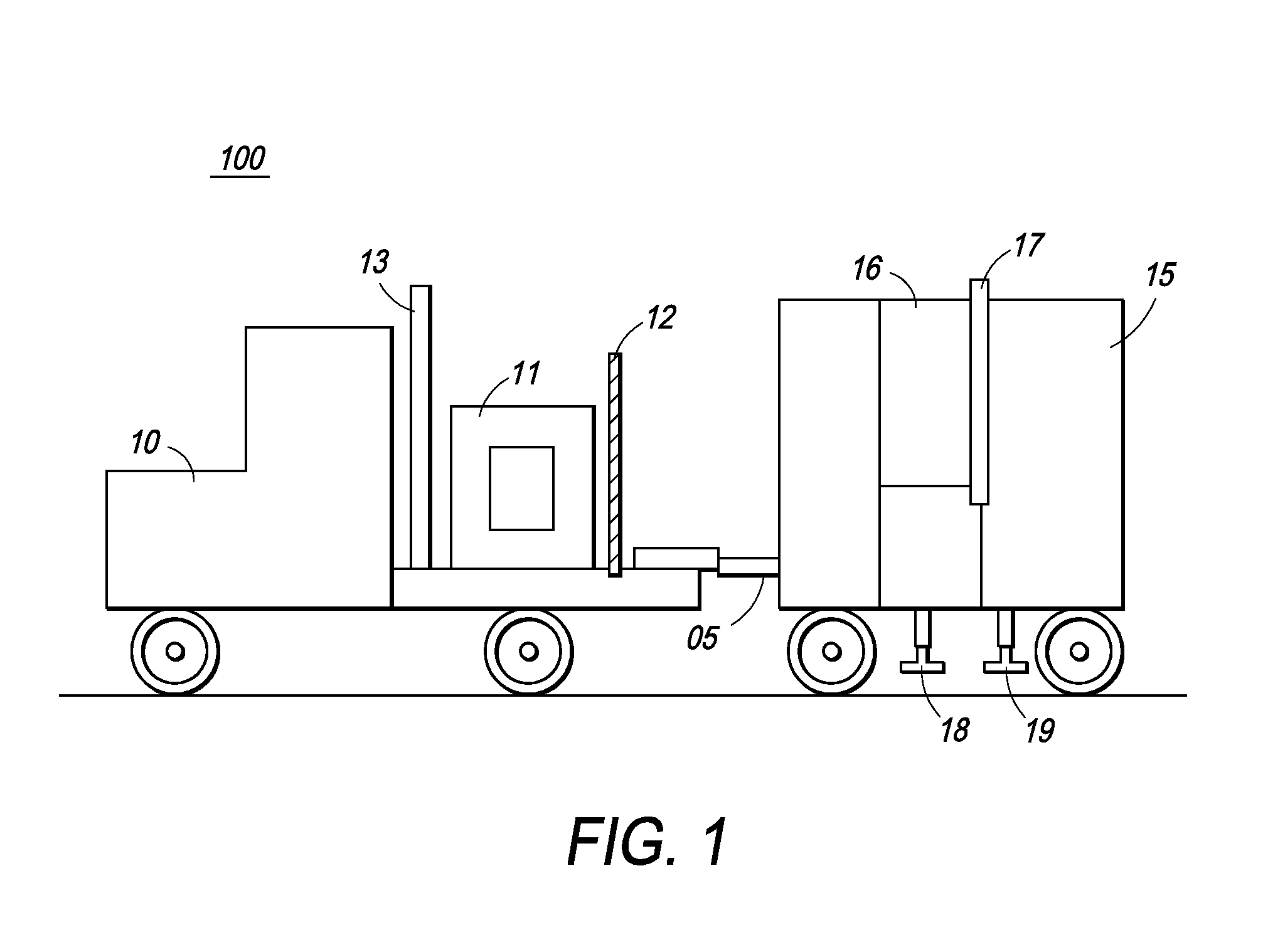

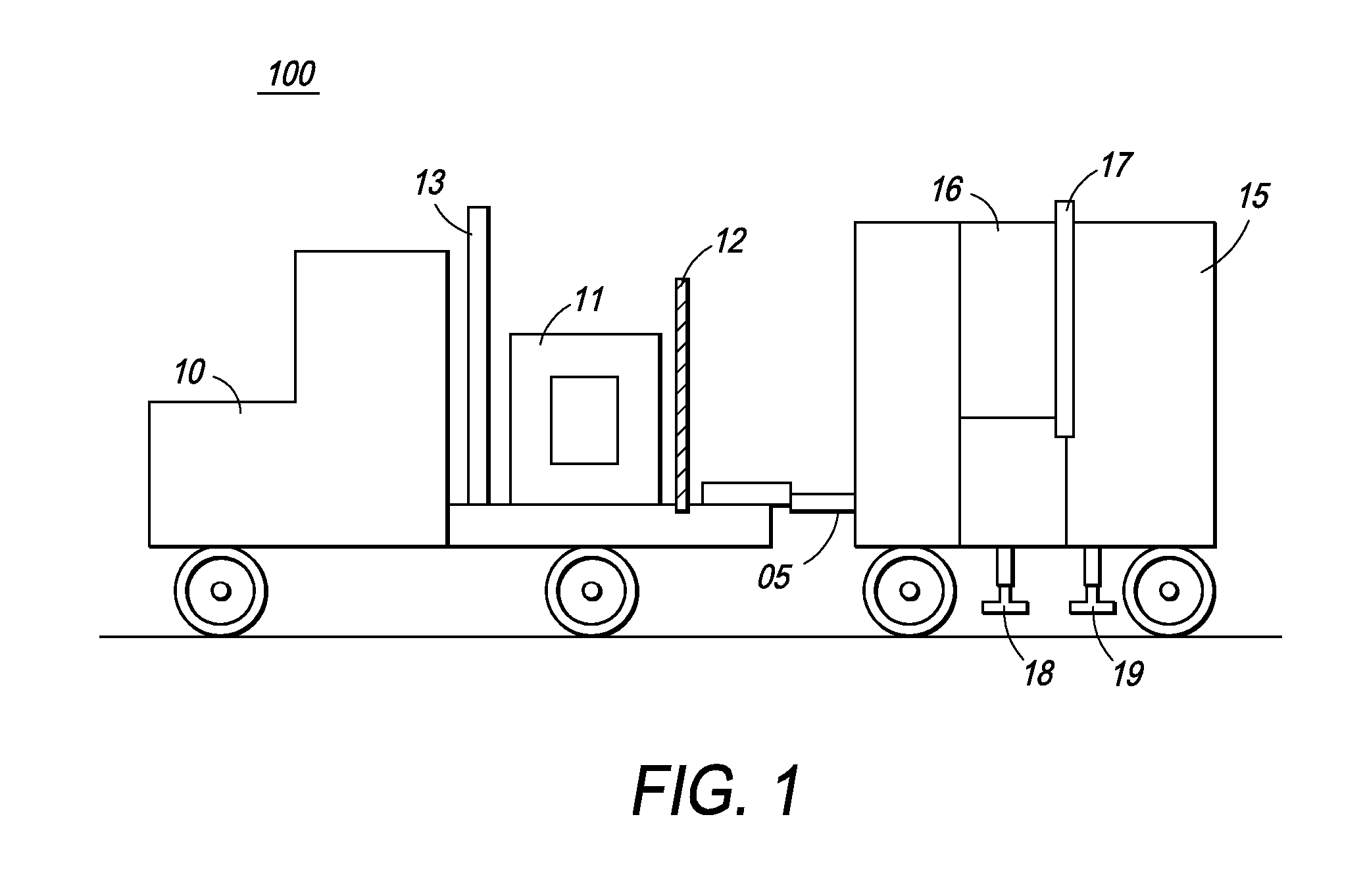

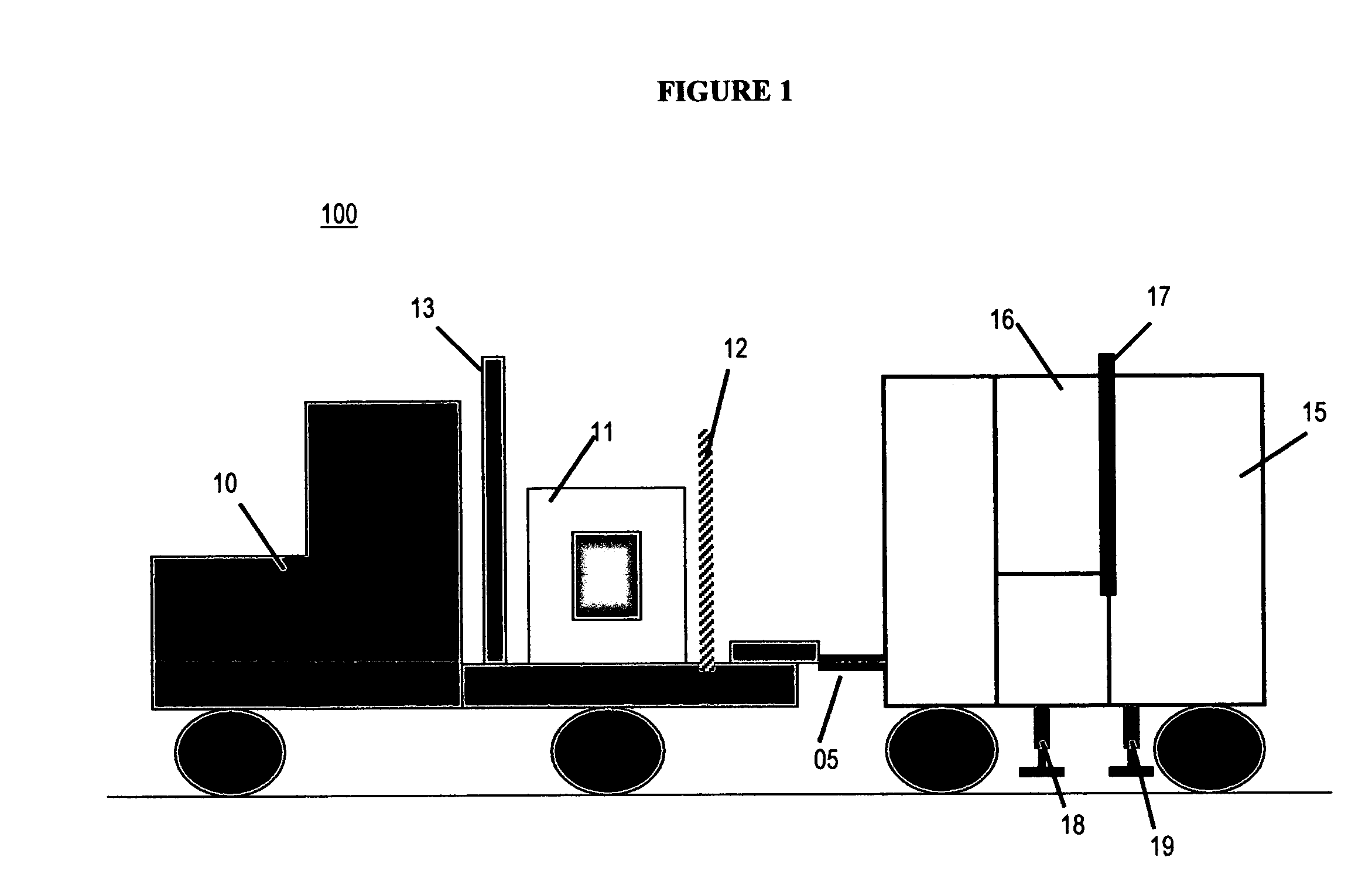

Self-contained, portable inspection system and method

InactiveUS6843599B2Rapidly deployableCost-effectively and accurately on uneven surfaceX-ray apparatusMaterial analysis by transmitting radiationComputer moduleEngineering

The inspection methods and systems of the present invention are mobile, deployable, and capable of scanning a wide variety of receptacles cost-effectively and accurately on uneven surfaces. The inspection system comprises an inspection module that, in a preferred embodiment, is in the form of a mobile trailer capable of being towed and transported to its intended operating site with the help of a tug-vehicle. The tug-vehicle preferably includes at least one source of electromagnetic radiation, a hydraulic lift system to load and unload the radiation source, and at least one radiation shield plate positioned on the back of the driver cabin of the tug-vehicle.

Owner:RAPISCAN SYST INC (US)

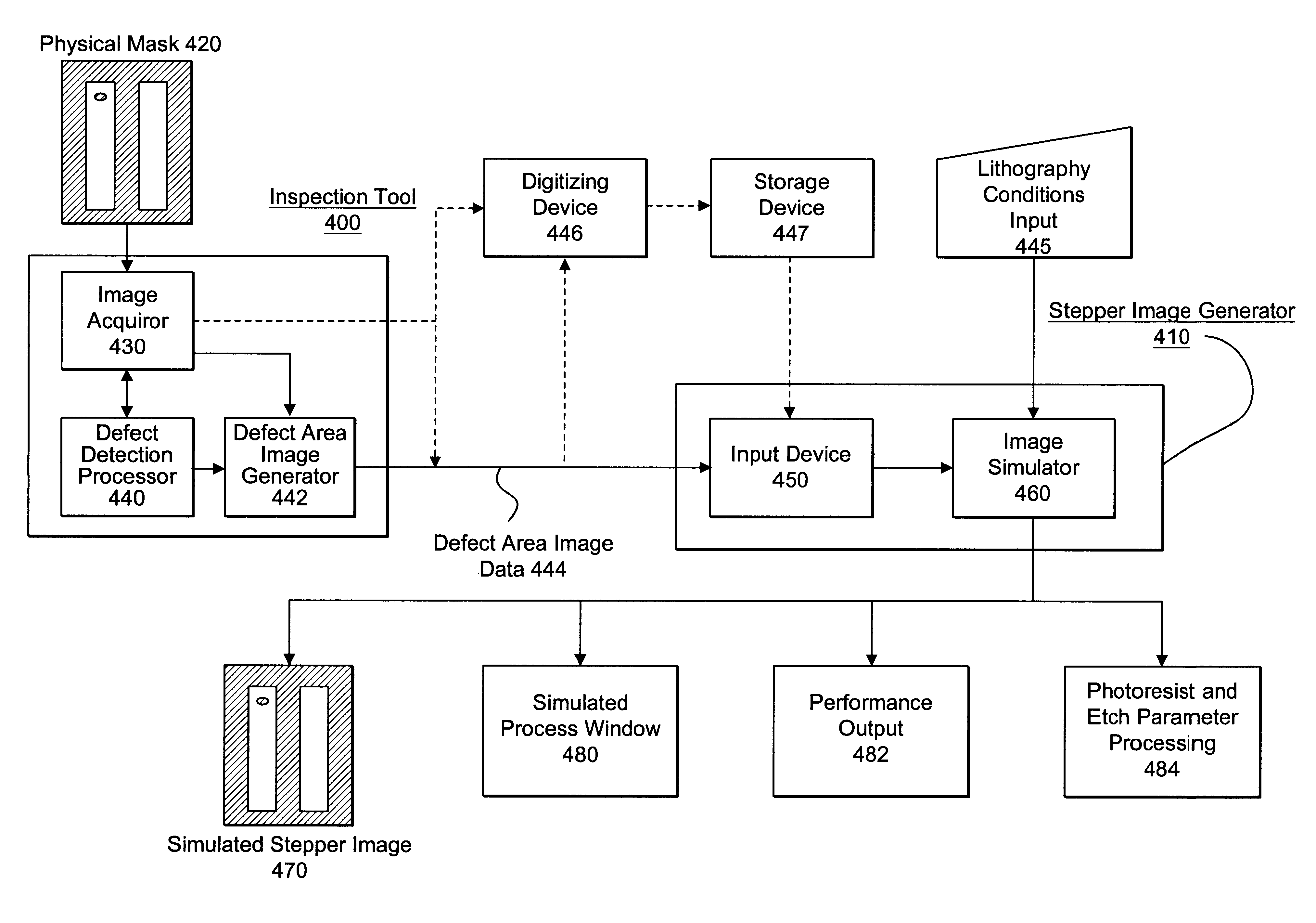

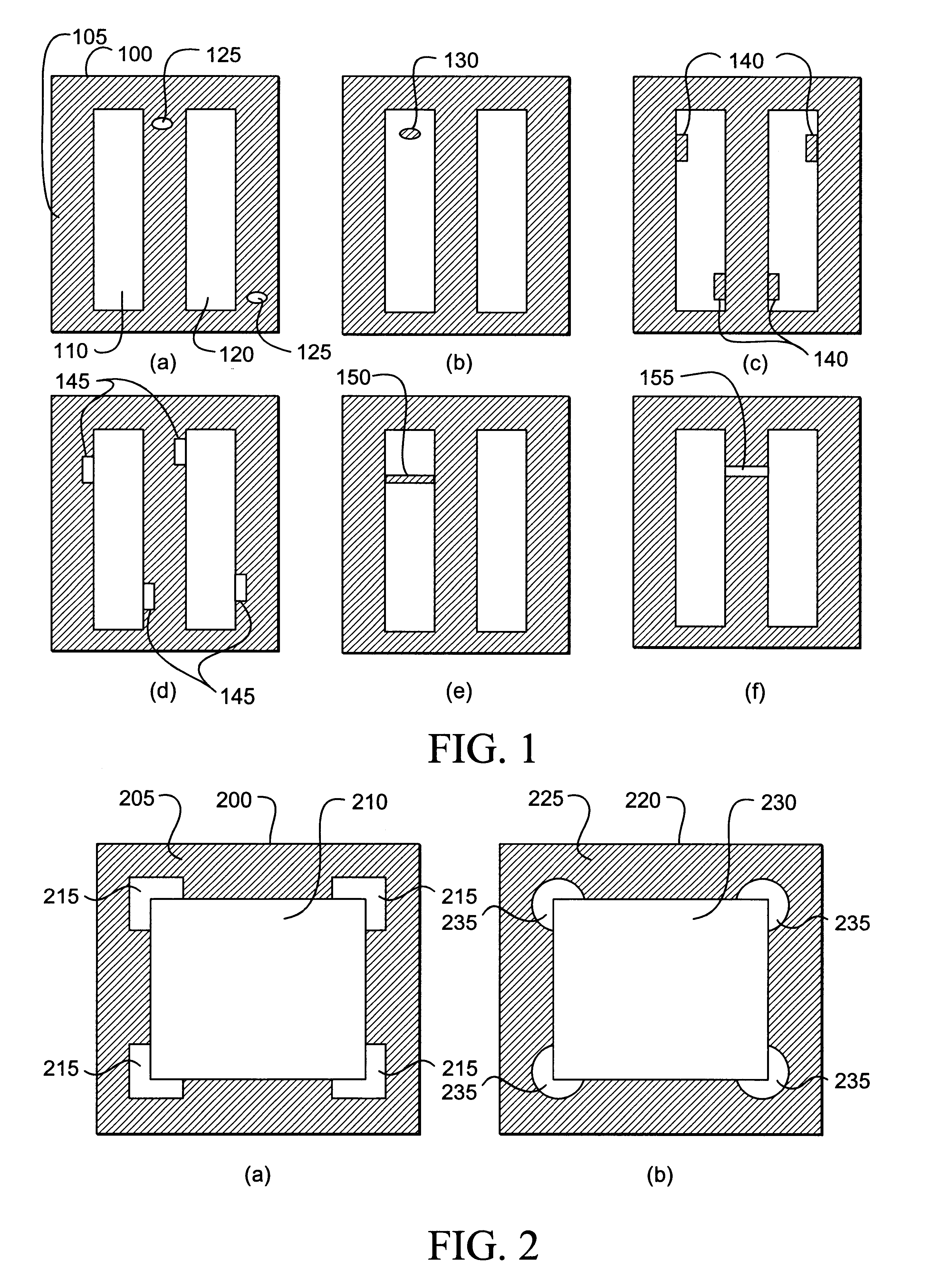

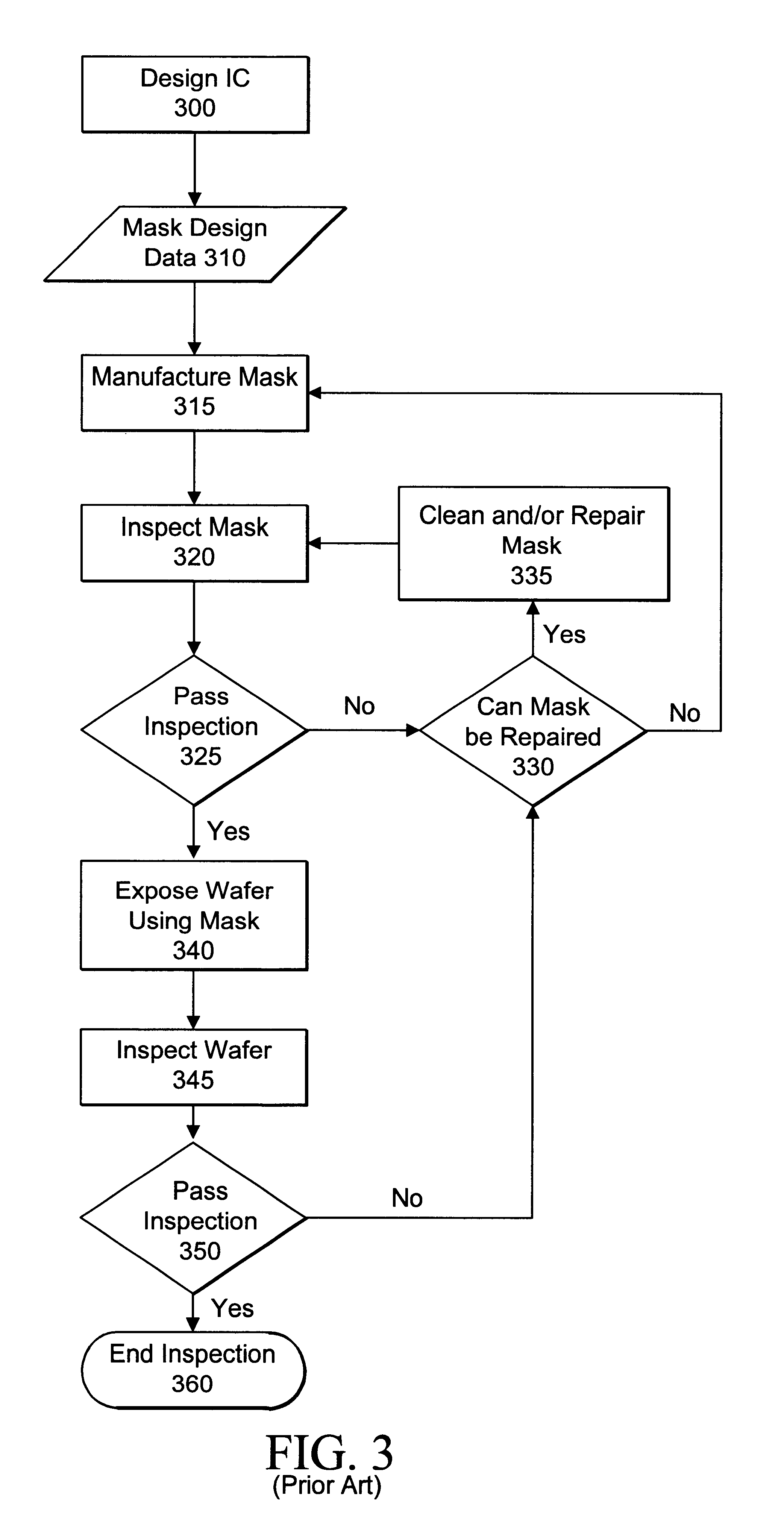

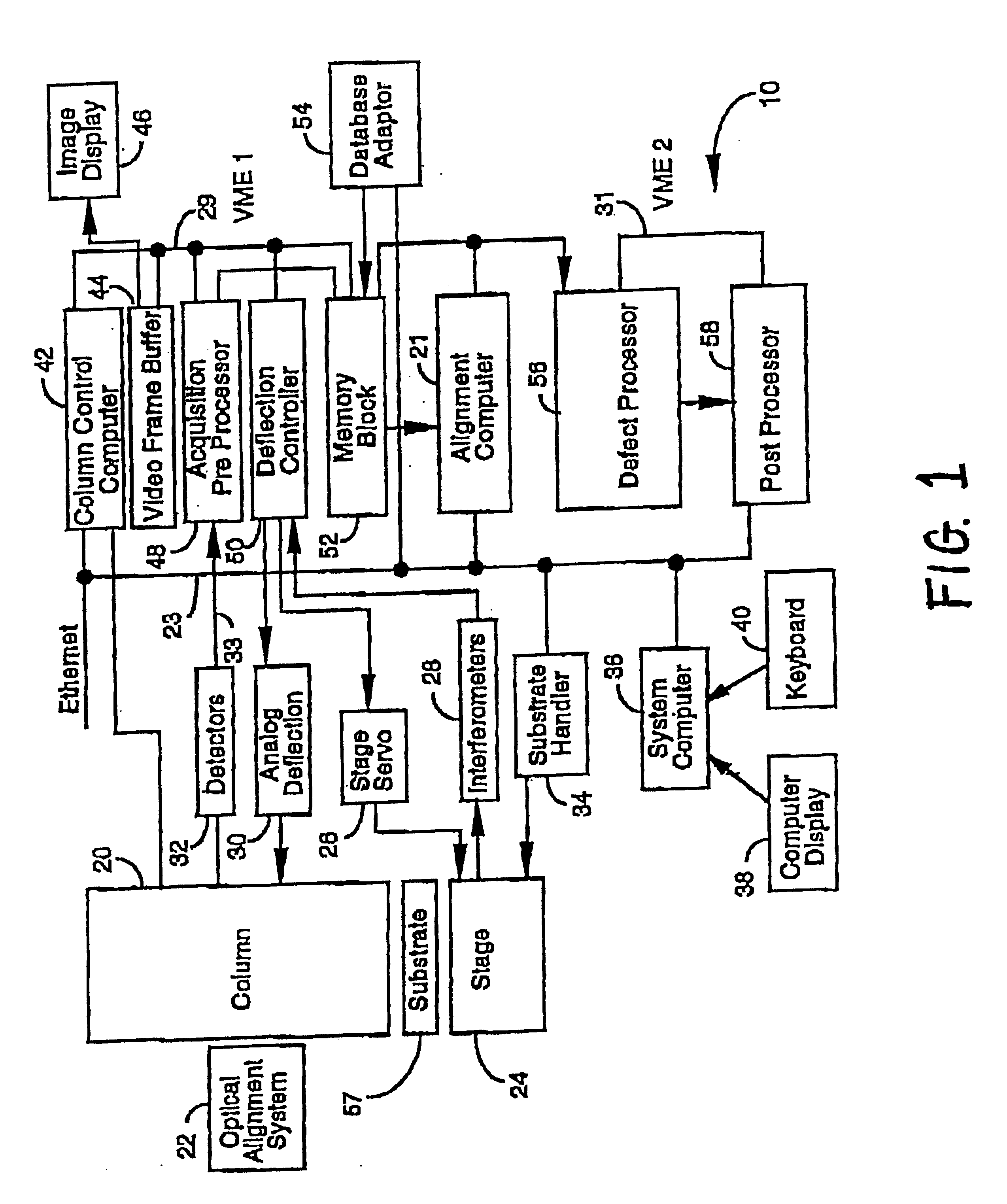

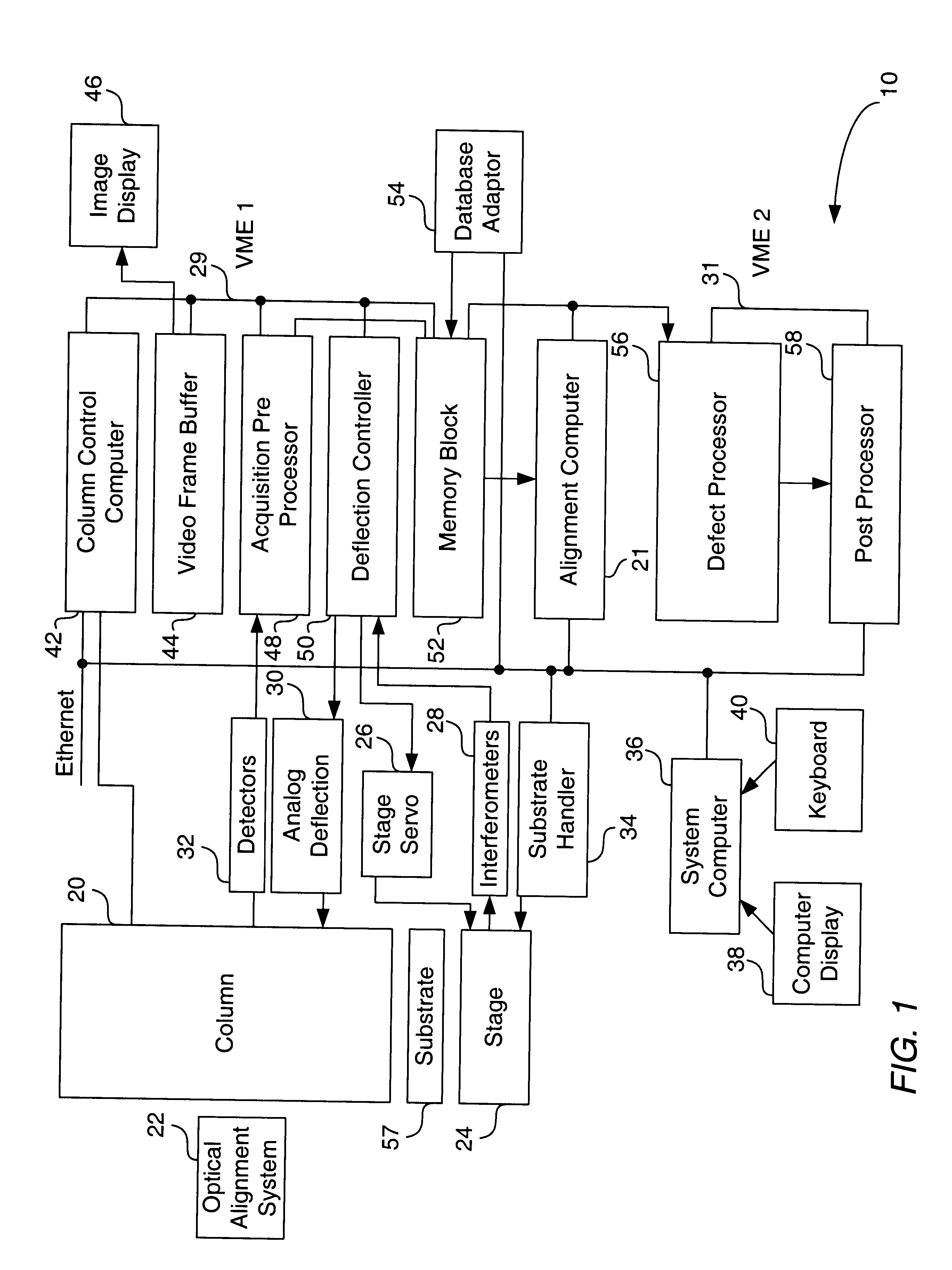

Visual inspection and verification system

A method and apparatus for inspecting a photolithography mask for defects is provided. The inspection method comprises providing a defect area image to an image simulator wherein the defect area image is an image of a portion of a photolithography mask, and providing a set of lithography parameters as a second input to the image simulator. The defect area image may be provided by an inspection tool which scans the photolithography mask for defects using a high resolution microscope and captures images of areas of the mask around identified potential defects. The image simulator generates a first simulated image in response to the defect area image and the set of lithography parameters. The first simulated image is a simulation of an image which would be printed on a wafer if the wafer were to be exposed to an illumination source directed through the portion of the mask. The method may also include providing a second simulated image which is a simulation of the wafer print of the portion of the design mask which corresponds to the portion represented by the defect area image. The method also provides for the comparison of the first and second simulated images in order to determine the printability of any identified potential defects on the photolithography mask. A method of determining the process window effect of any identified potential defects is also provided for.

Owner:SYNOPSYS INC

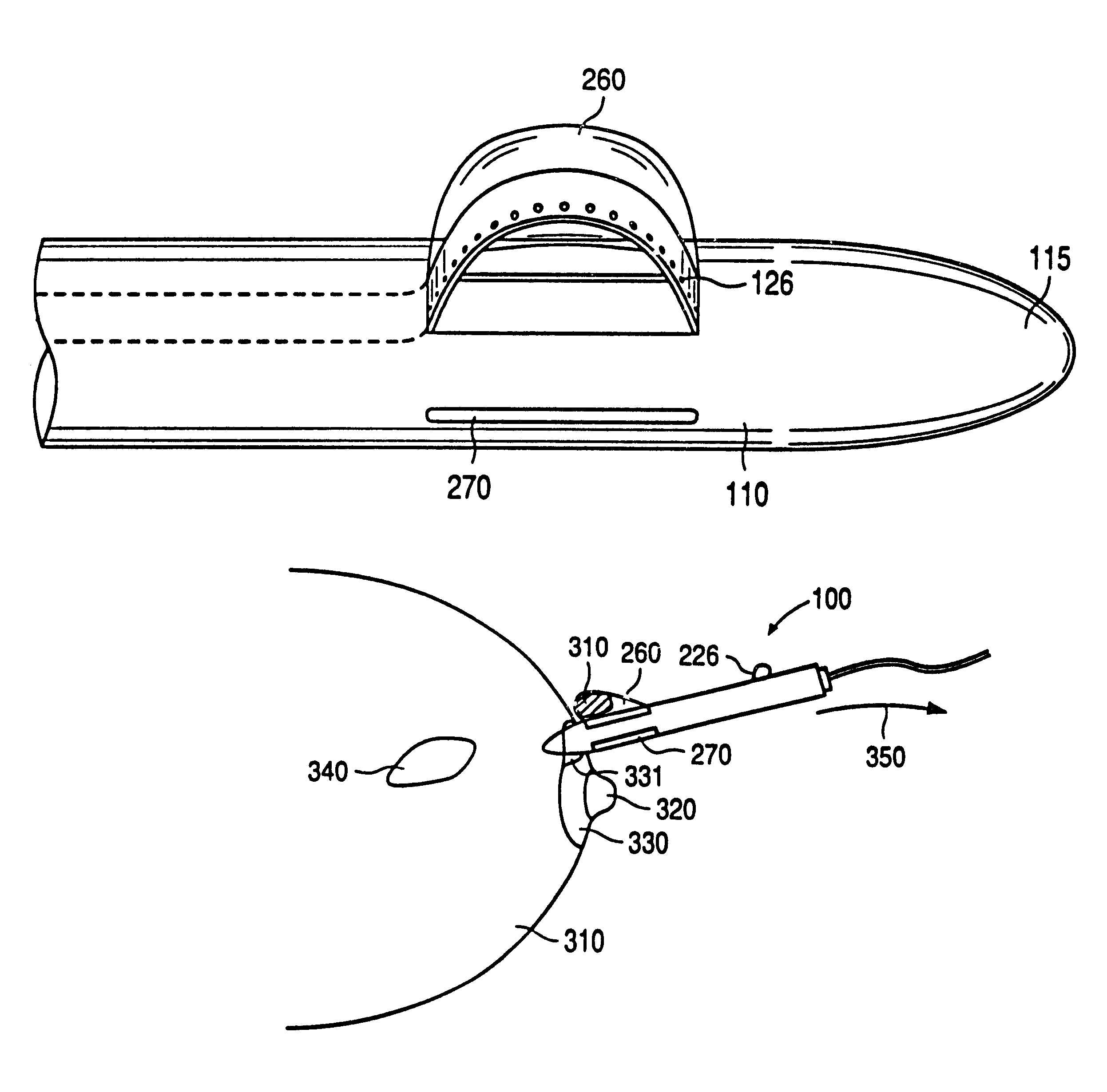

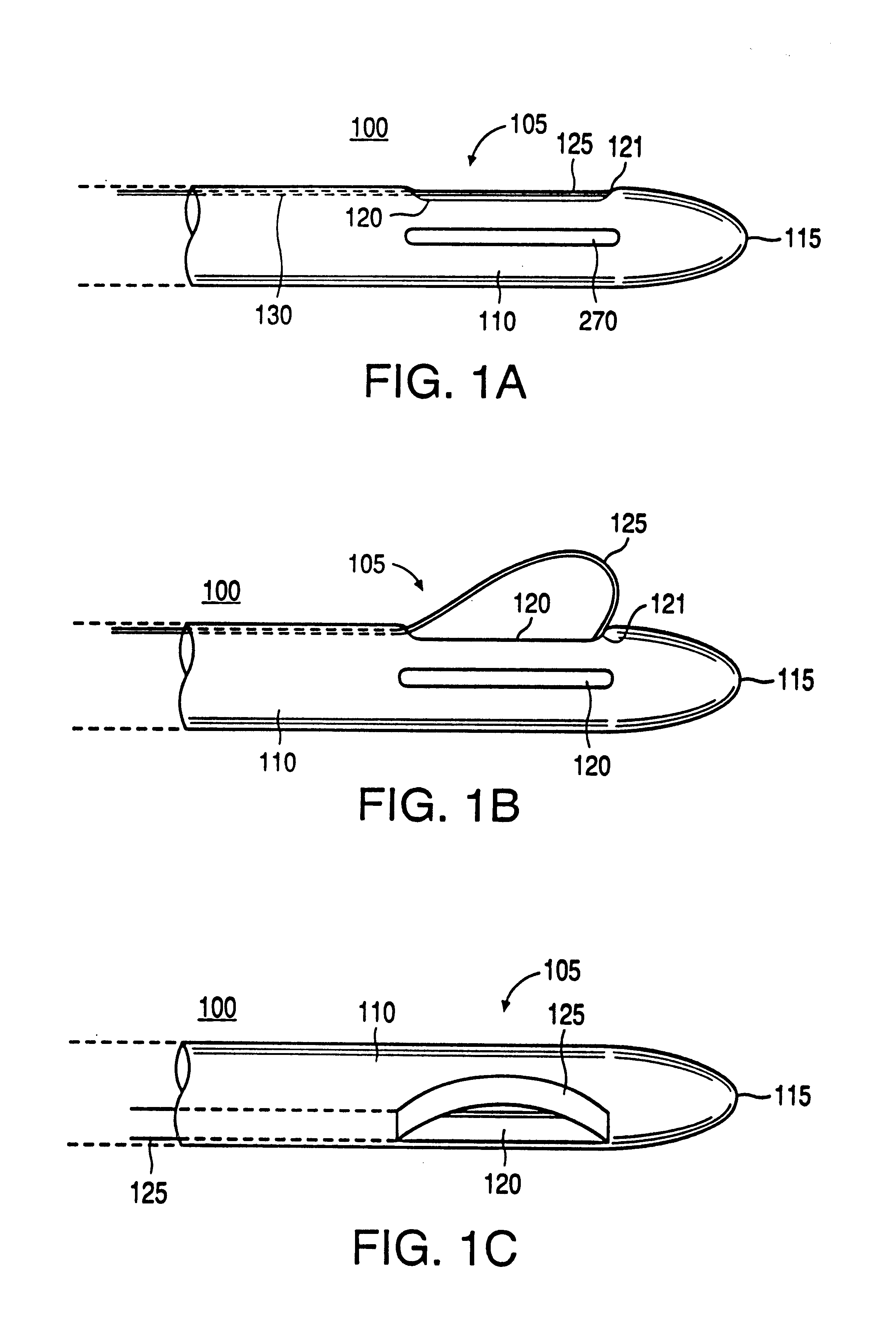

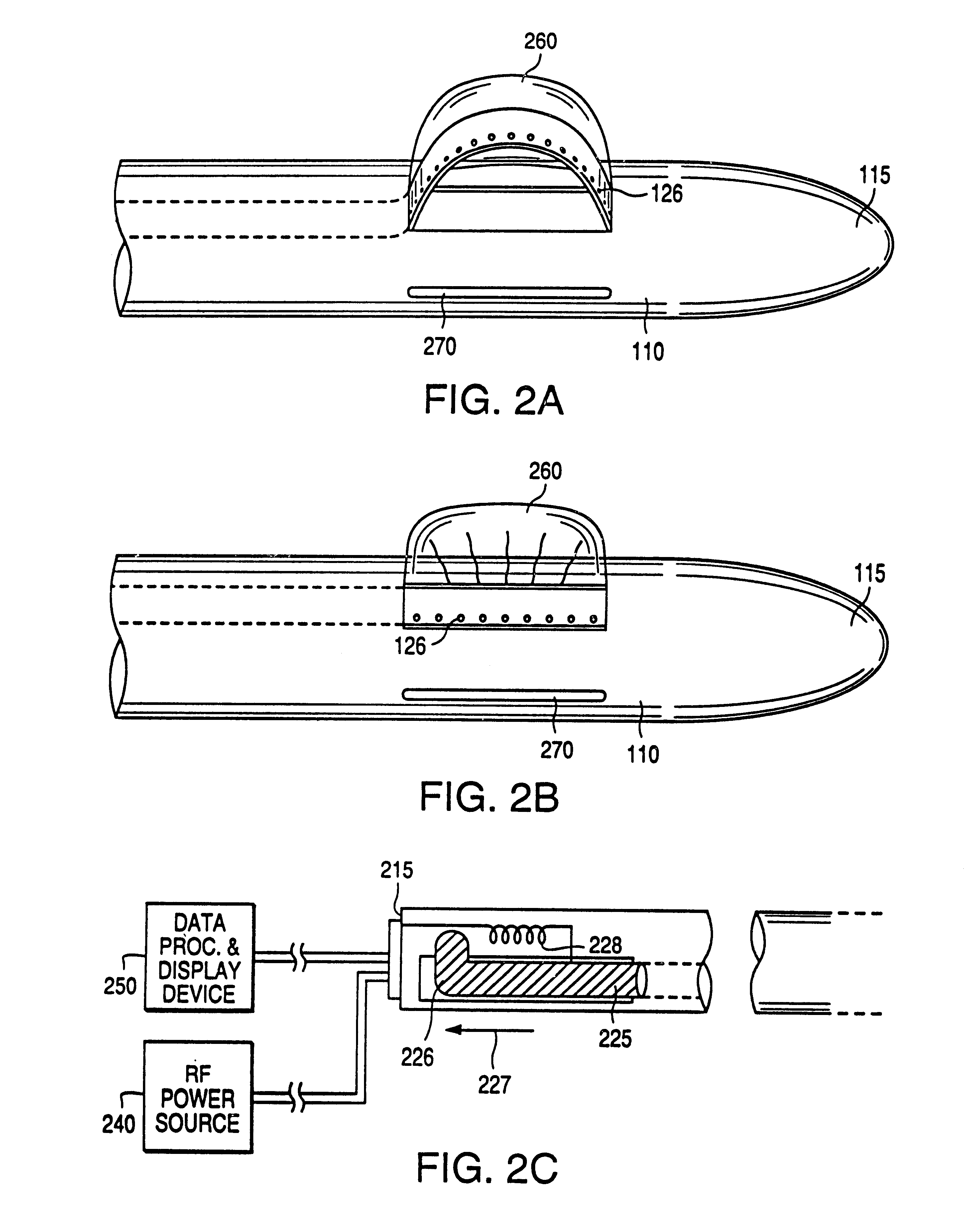

Excisional biopsy device and methods

InactiveUS6849080B2Efficiently and safely exciseMinimize complicationUltrasonic/sonic/infrasonic diagnosticsCannulasBiopsy methodsDistal portion

An excisional biopsy device includes a tubular member having a window near a distal tip thereof; a cutting tool, a distal end of the cutting tool being attached near the distal tip of the tubular member, at least a distal portion of the cutting tool being configured to selectively bow out of the window and to retract within the window; and a tissue collection device externally attached at least to the tubular member, the tissue collection device collecting tissue excised by the cutting tool as the biopsy device is rotated and the cutting tool is bowed. An excisional biopsy method for soft tissue includes the steps of inserting a generally tubular member into the tissue, the tubular member including a cutting tool adapted to selectively bow away from the tubular member and an external tissue collection device near a distal tip of the tubular member; rotating the tubular member; selectively varying a degree of bowing of the cutting tool; collecting tissue severed by the cutting tool in the tissue collection device; and retracting the tubular member from the soft tissue. The tubular member may include an imaging transducer and the method may include the step of displaying information received from the transducer on a display device and the step of varying the degree of bowing of the cutting tool based upon the displayed information from the imaging transducer. Alternatively, the imaging transducer may be disposed within a removable transducer core adapted to fit within the tubular member.

Owner:ENCAPSULE MEDICAL

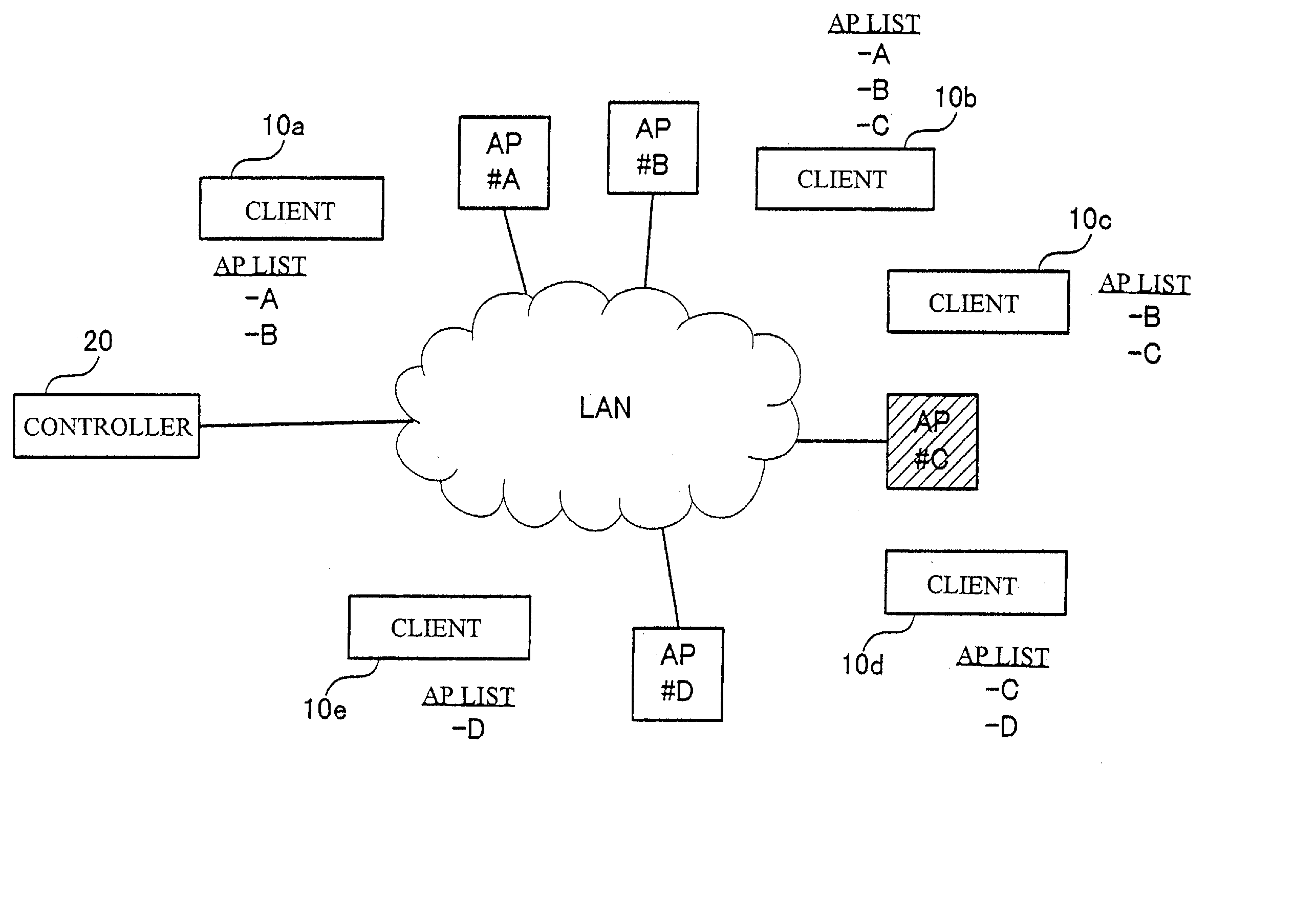

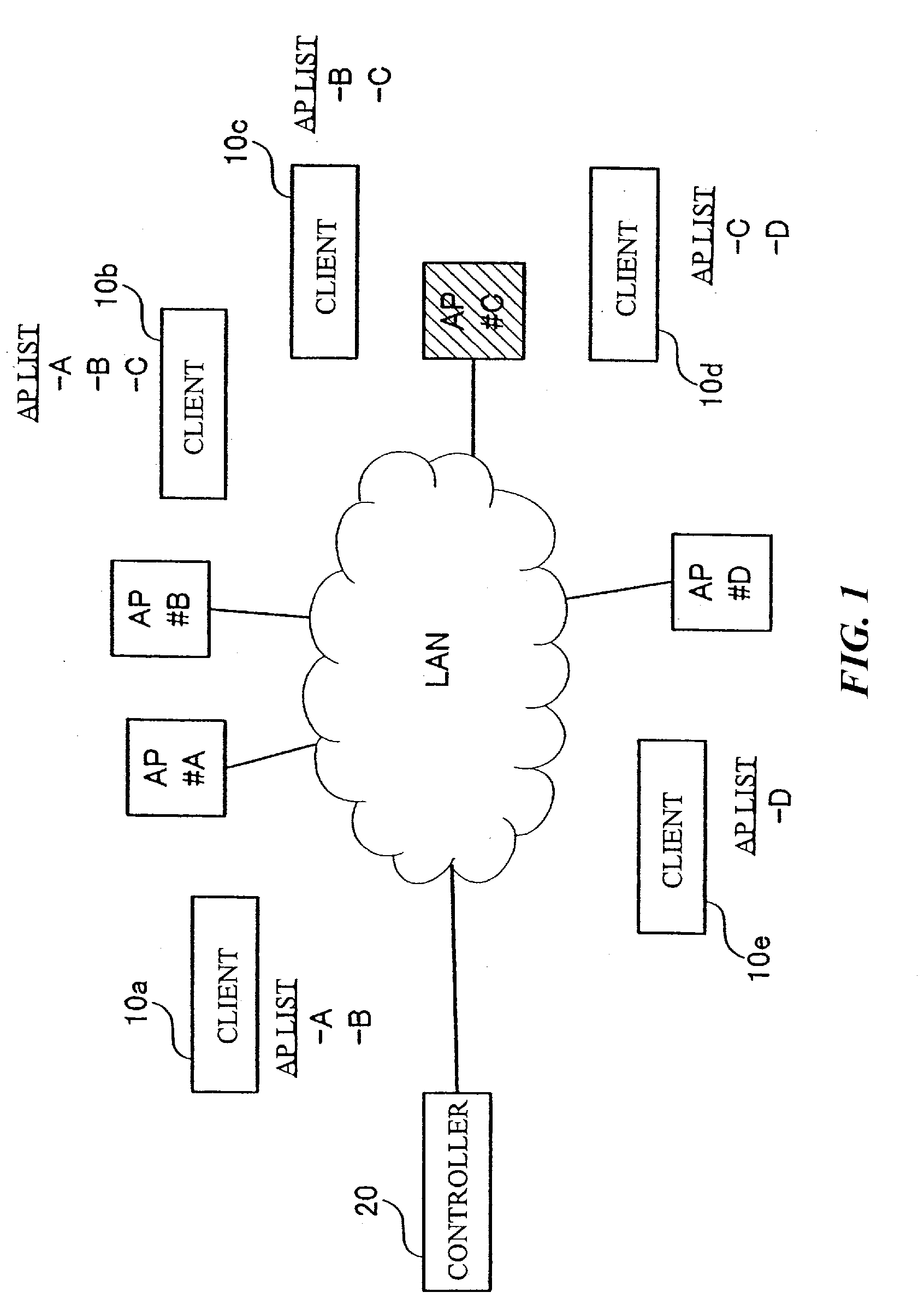

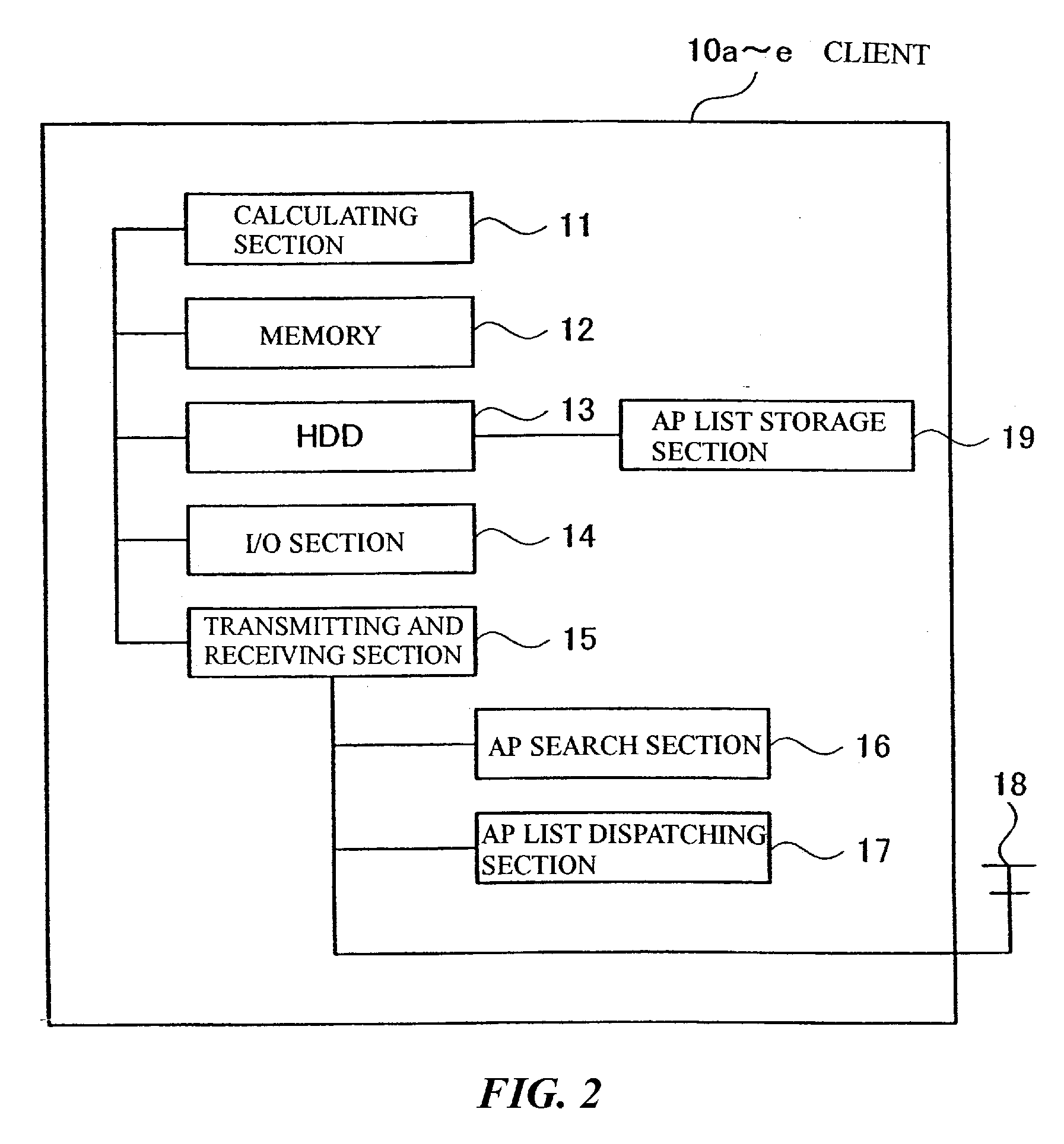

Network security system, computer, access point recognizing method, access point checking method, program, storage medium, and wireless LAN device

Abstract of the Disclosure In a network security system, clients search for neighbor access points (APs) in order to establish wireless connections to a LAN. As a result of the search, each of the clients dispatches a list of access points obtained to a controller. The controller detects non-registered access points by comparing a list of previously registered access points with the lists dispatched by the clients.

Owner:LENOVO PC INT

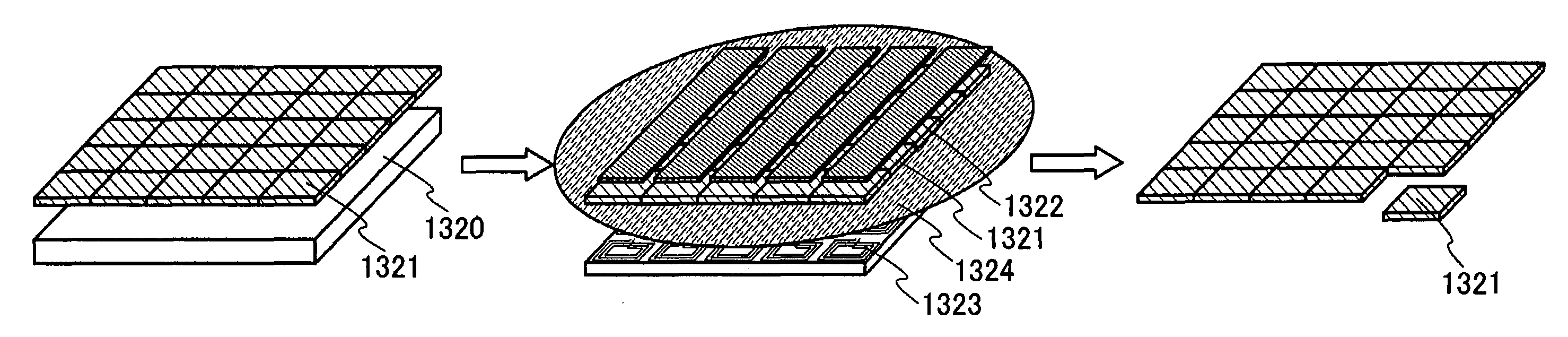

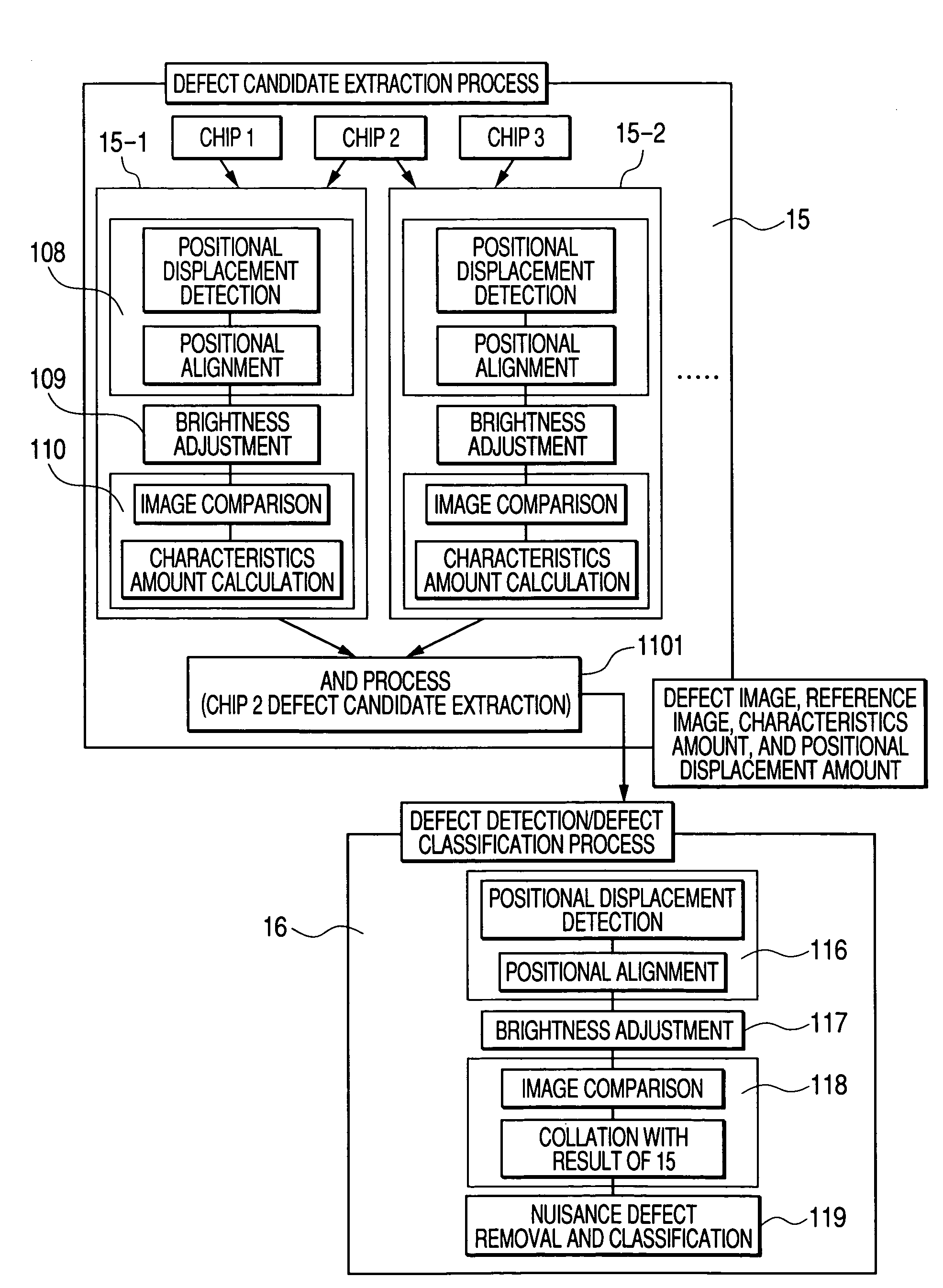

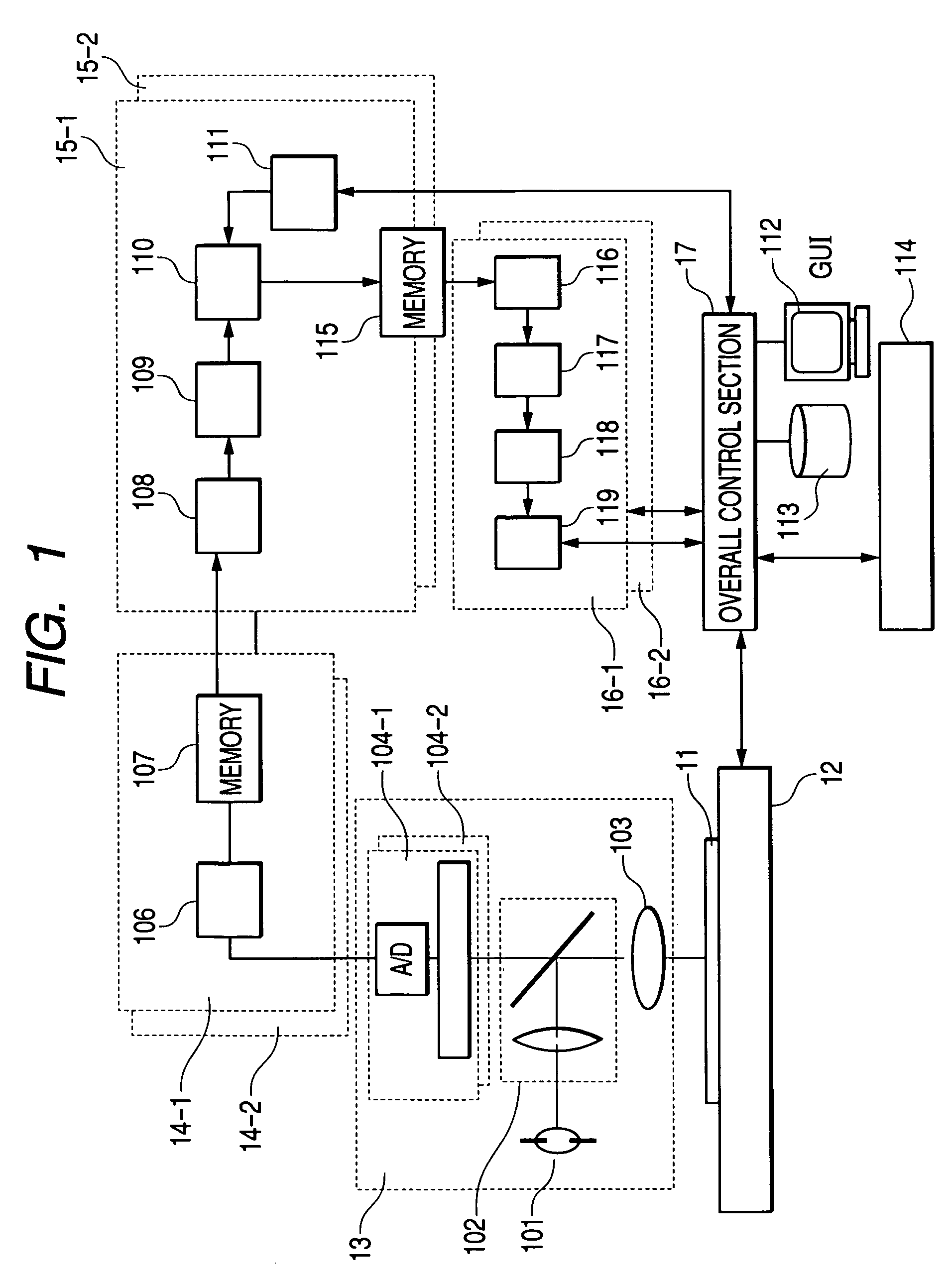

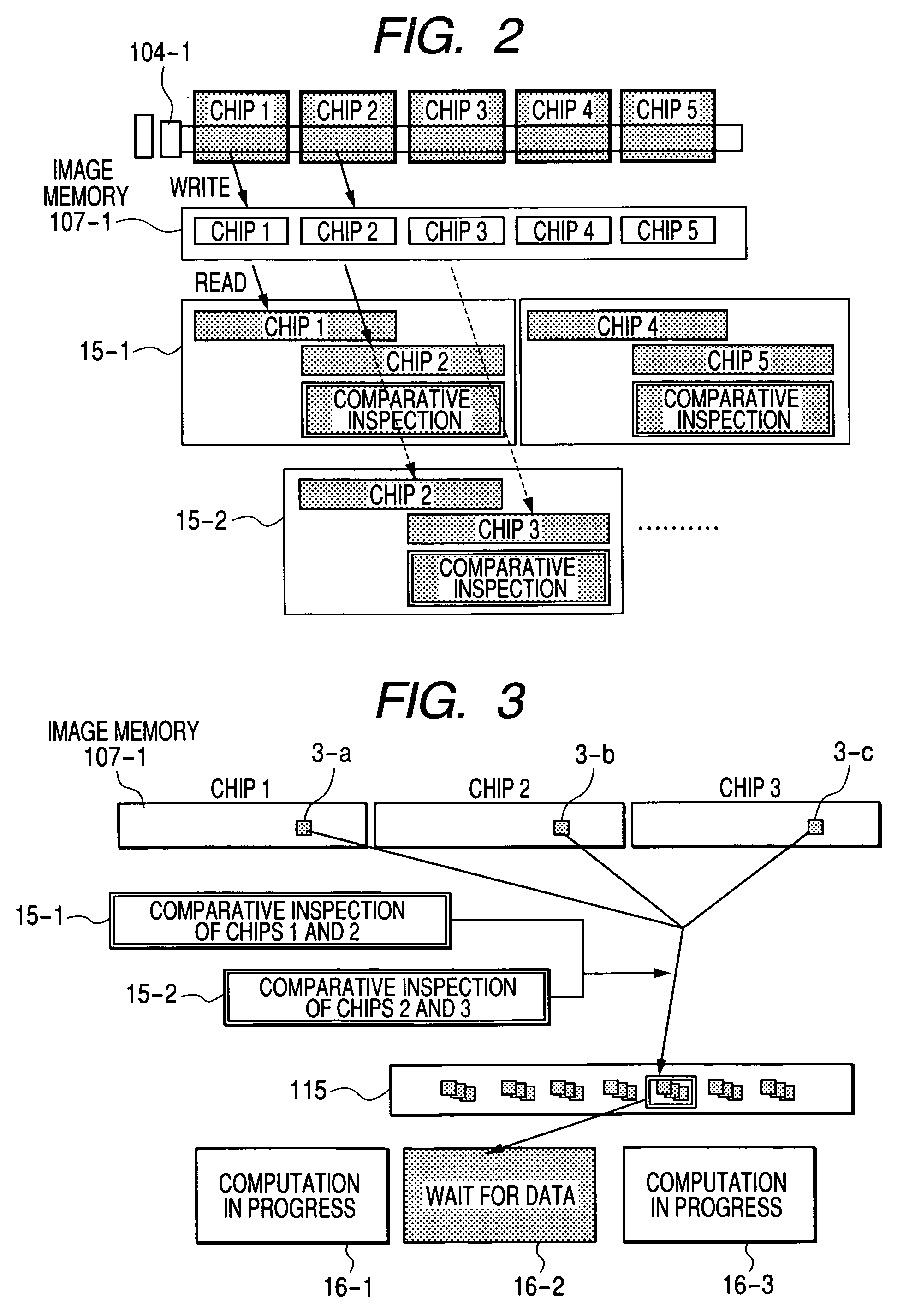

Inspection system, inspection method, and method for manufacturing semiconductor device

InactiveUS7112952B2Reduce in quantityImprove throughputTesting sensing arrangementsSemiconductor/solid-state device testing/measurementPosition controlSemiconductor

Owner:SEMICON ENERGY LAB CO LTD

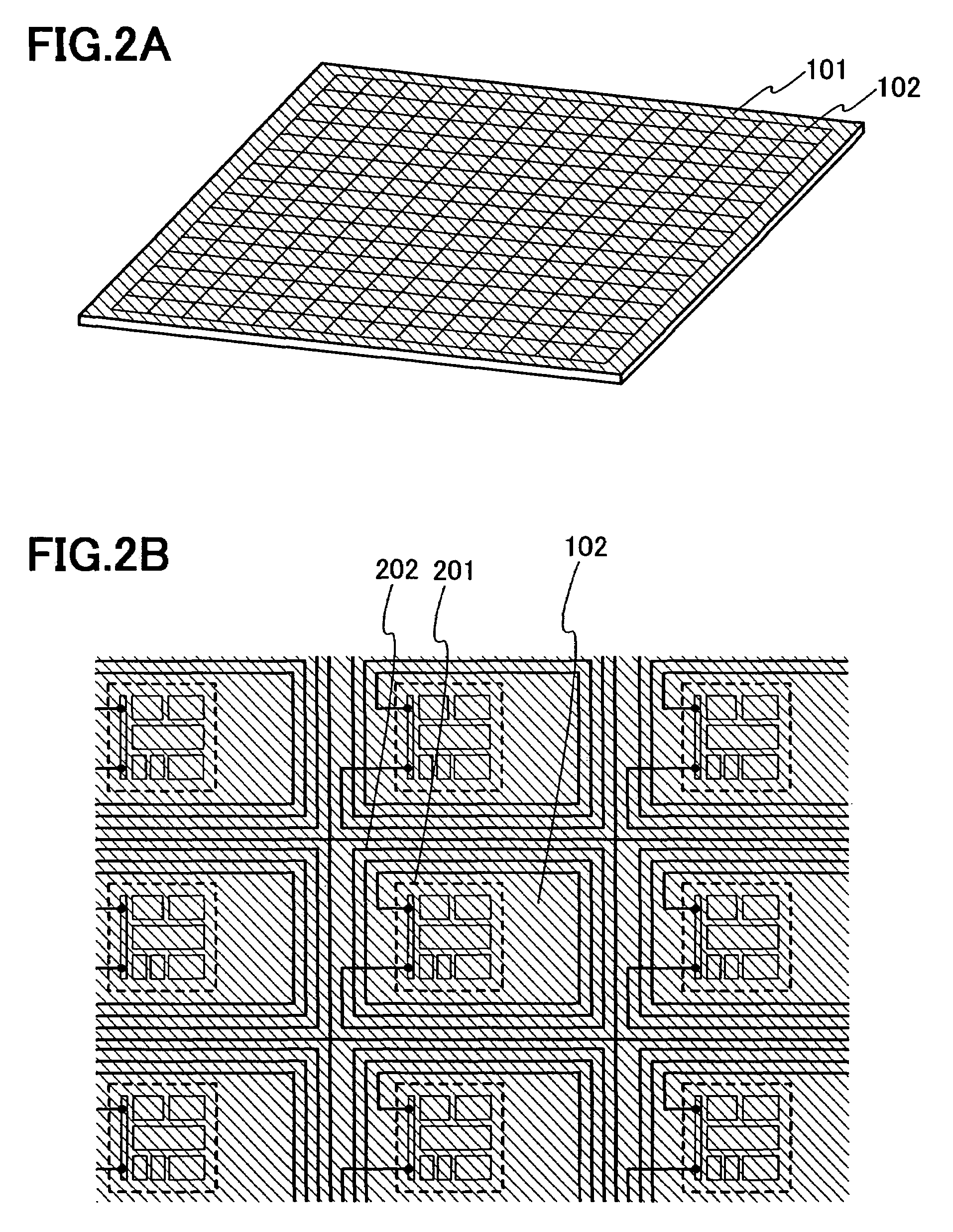

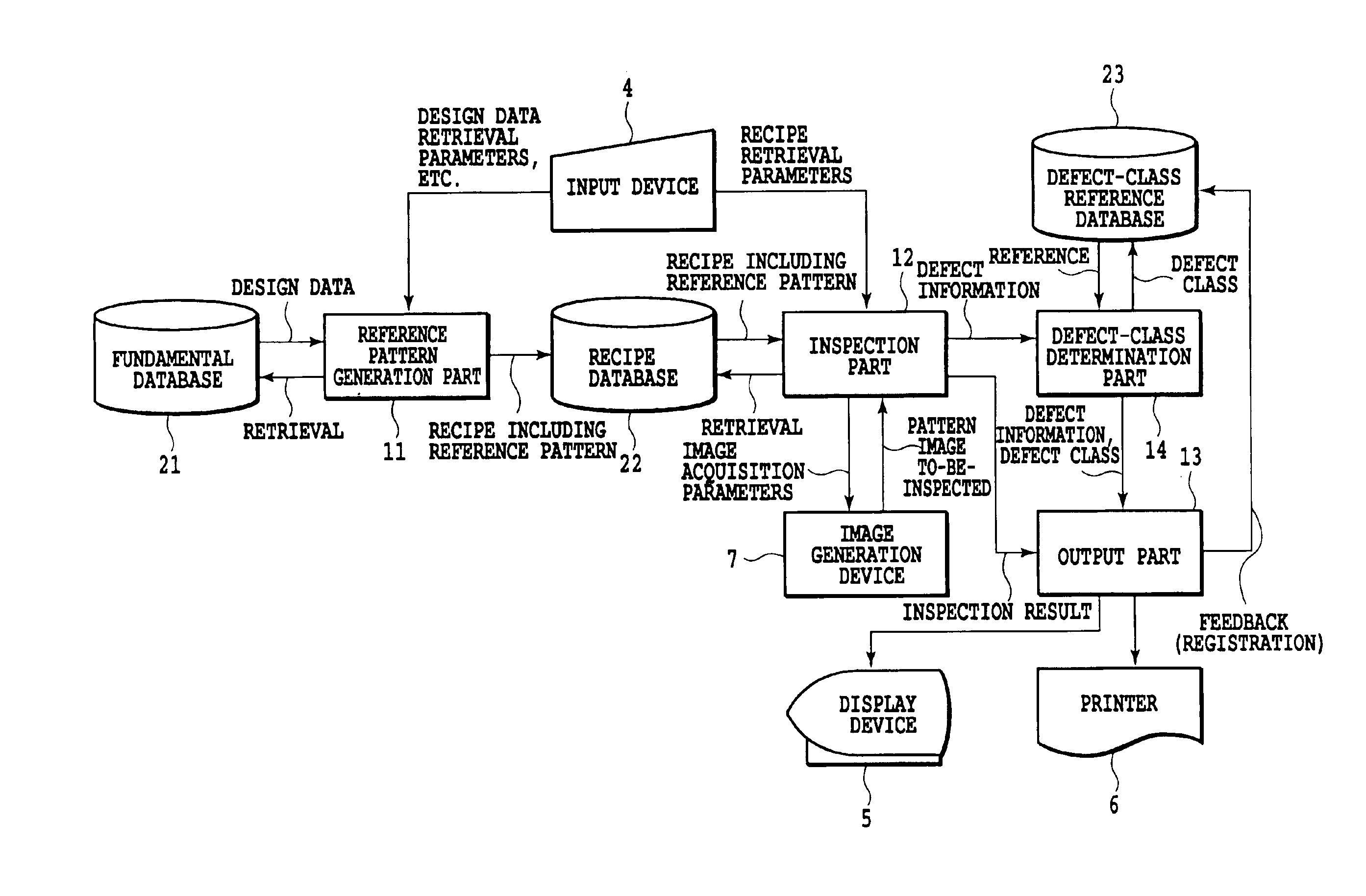

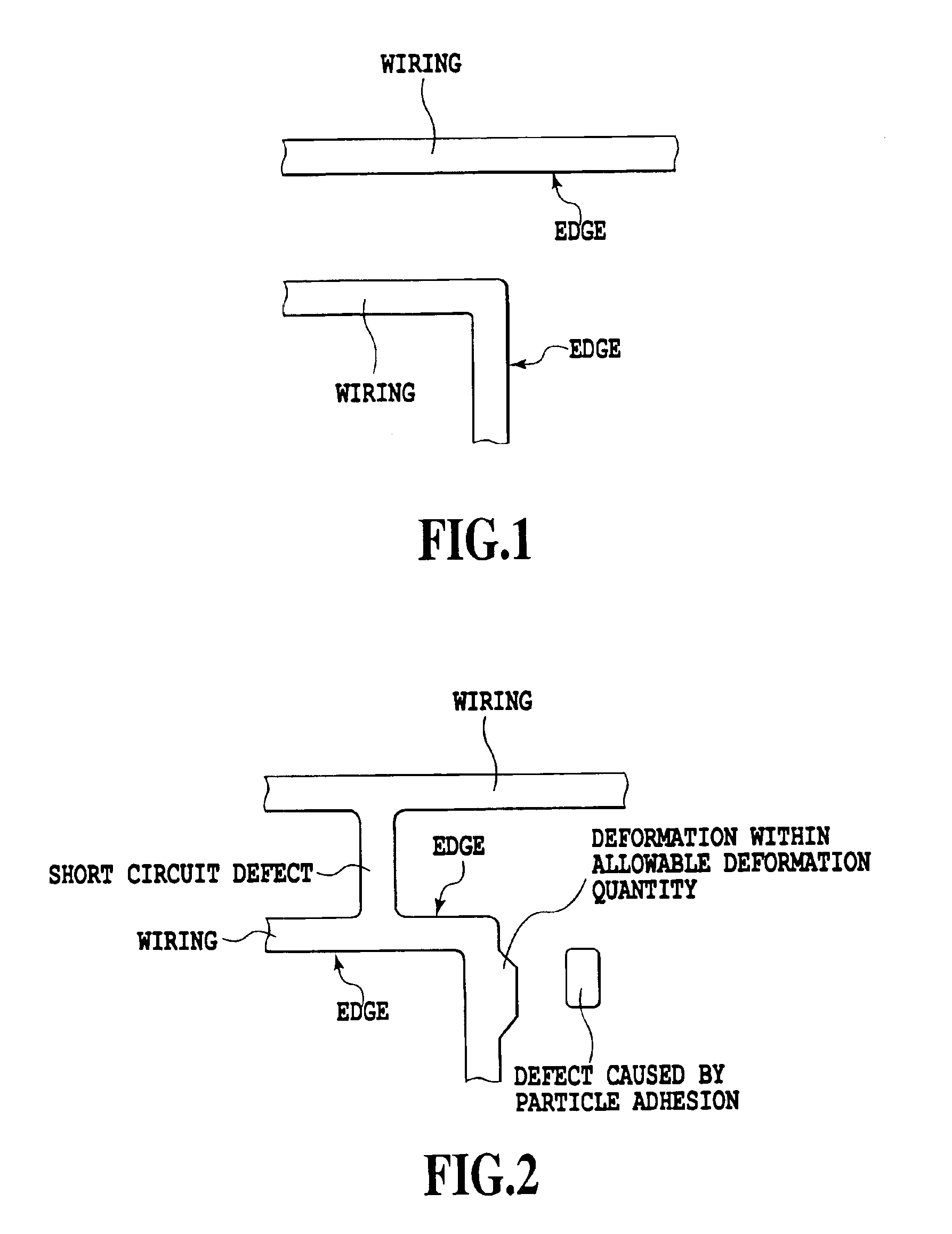

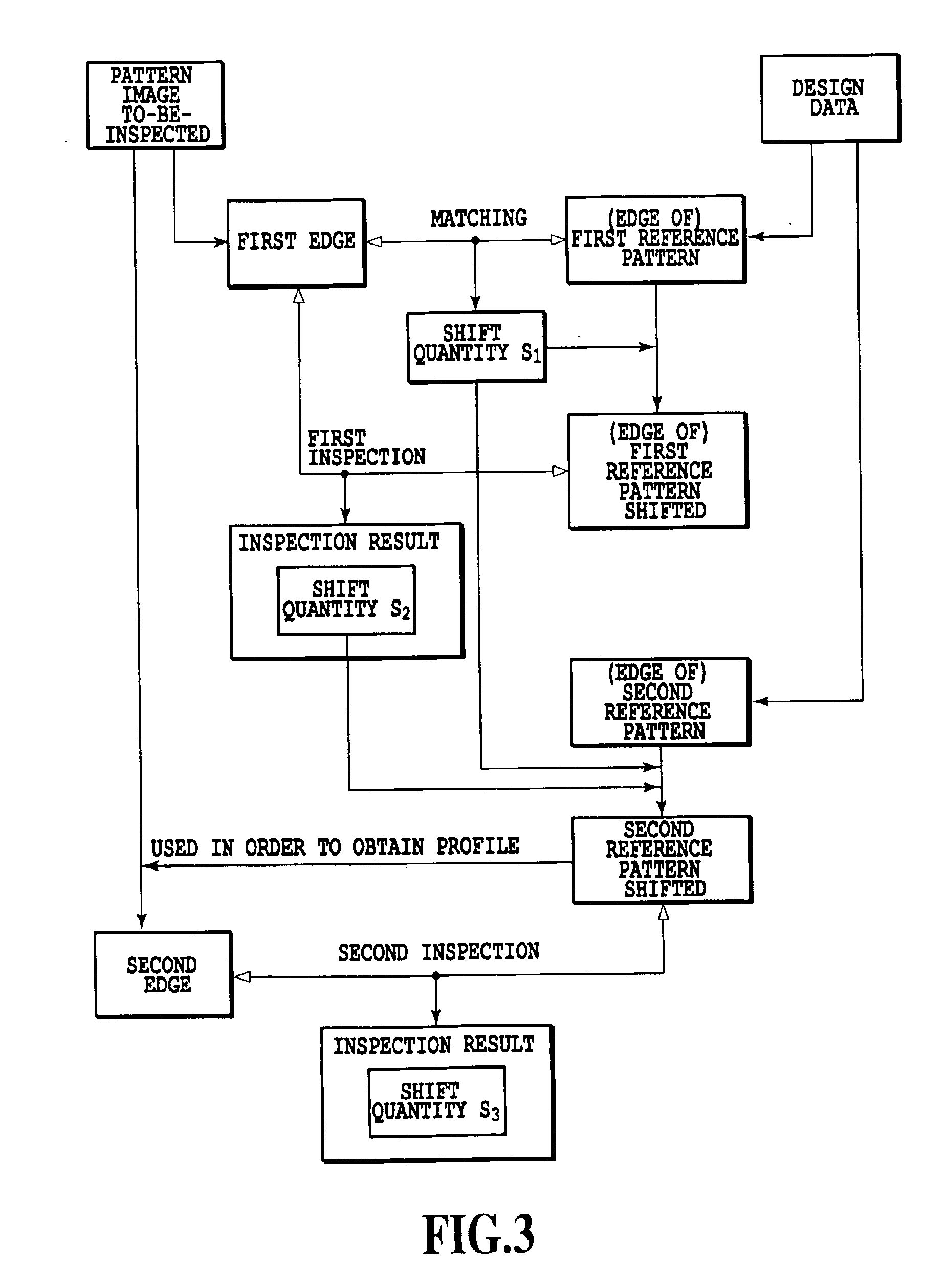

Pattern inspection apparatus, pattern inspection method, and recording medium

InactiveUS6868175B1Stable defect detectionImage enhancementMaterial analysis using wave/particle radiationPattern recognitionReference patterns

Owner:TASMIT INC

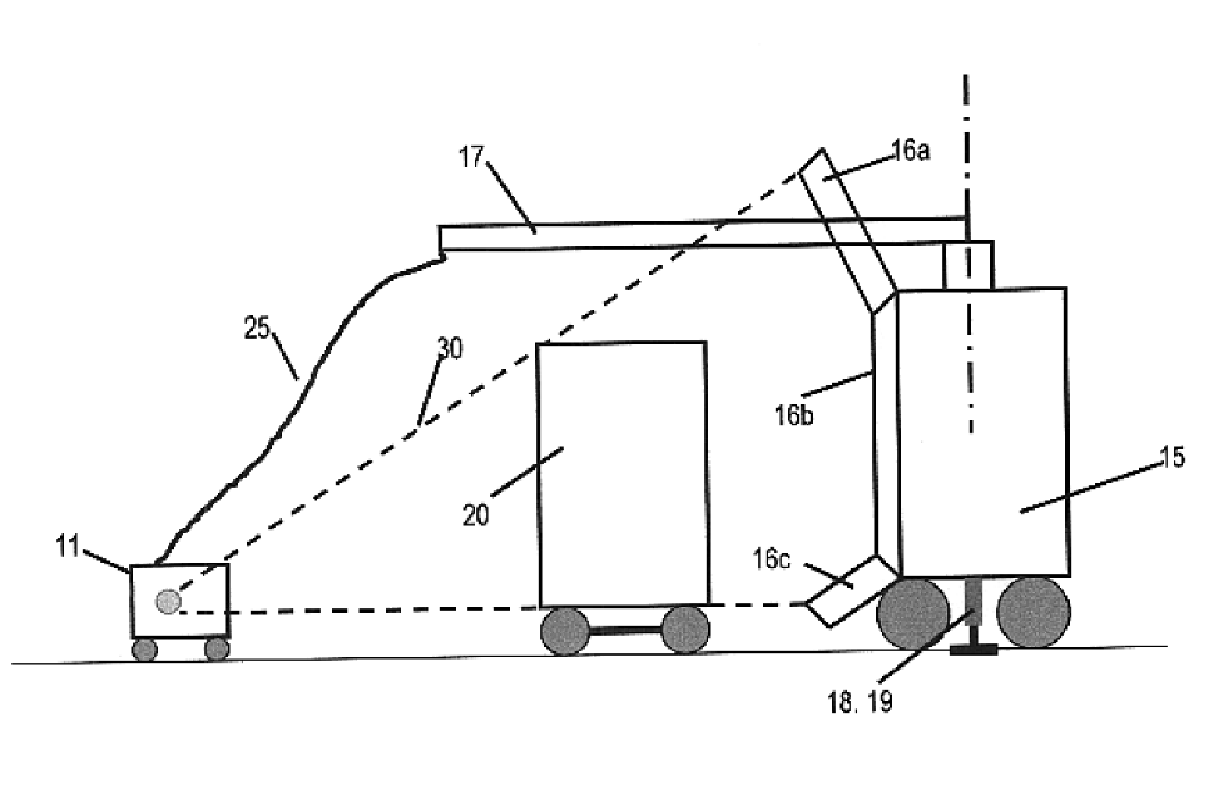

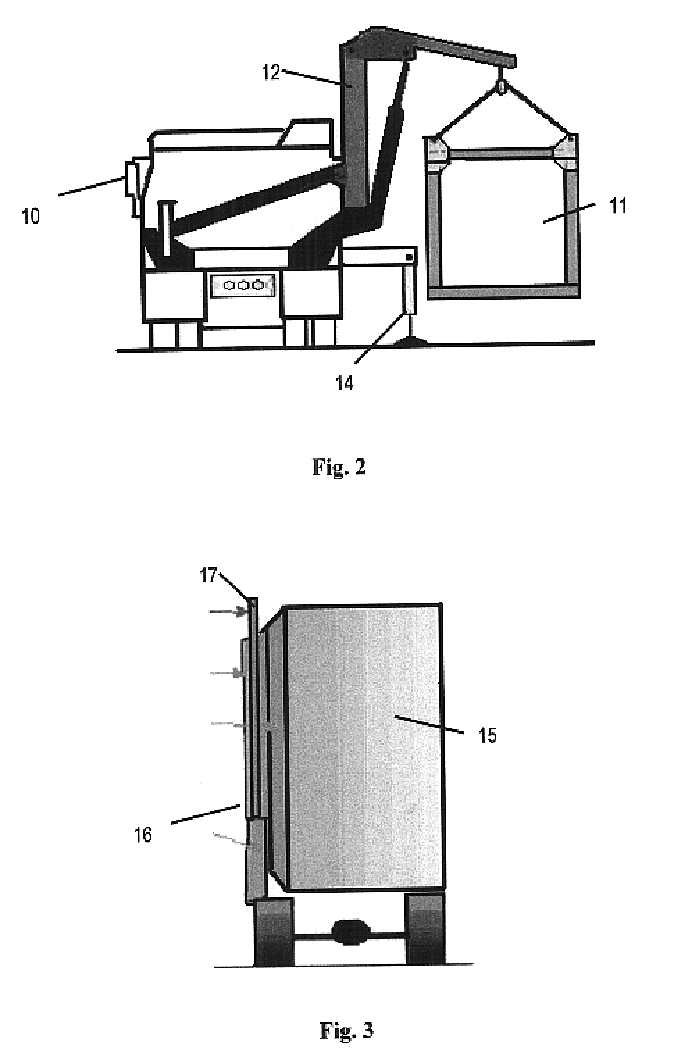

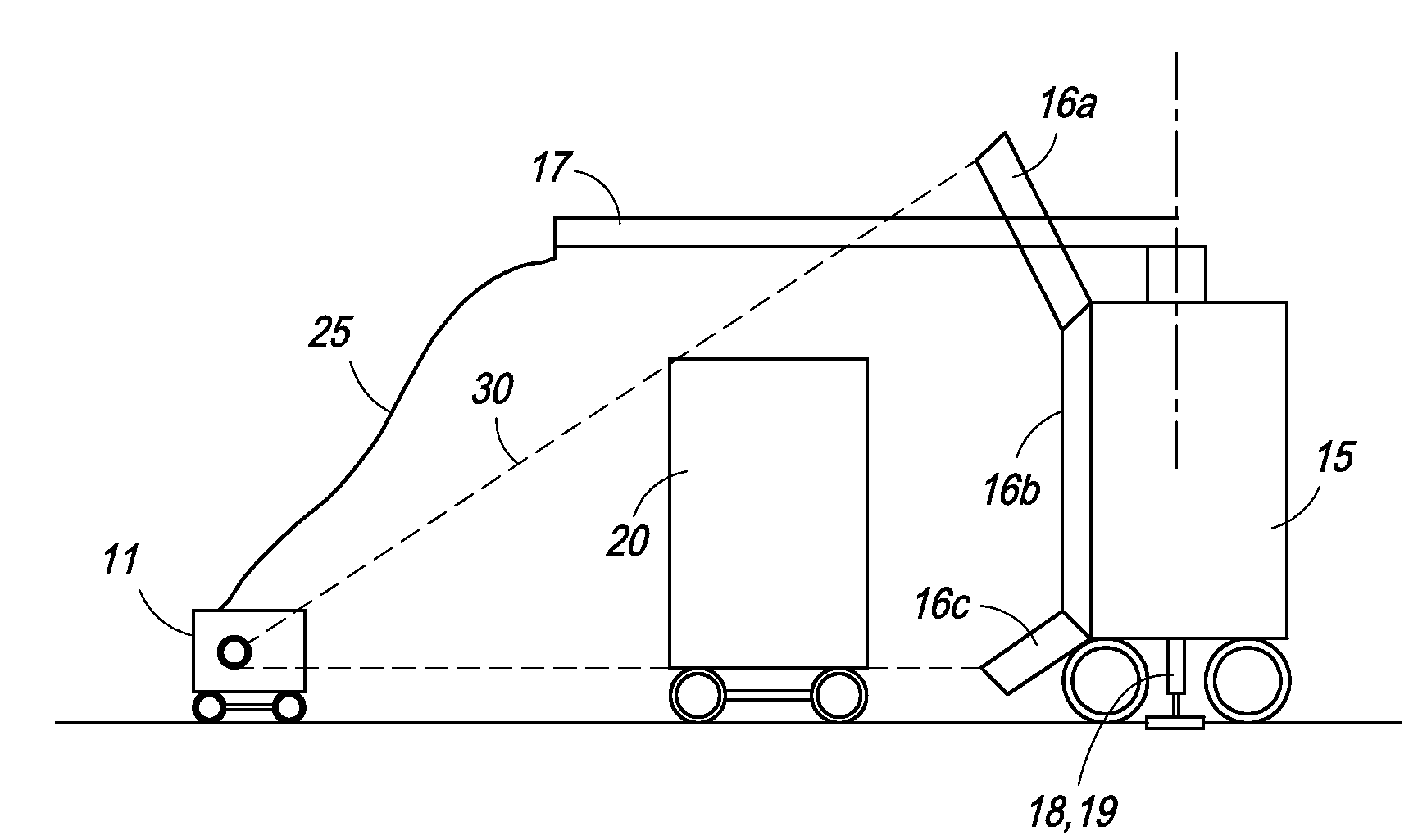

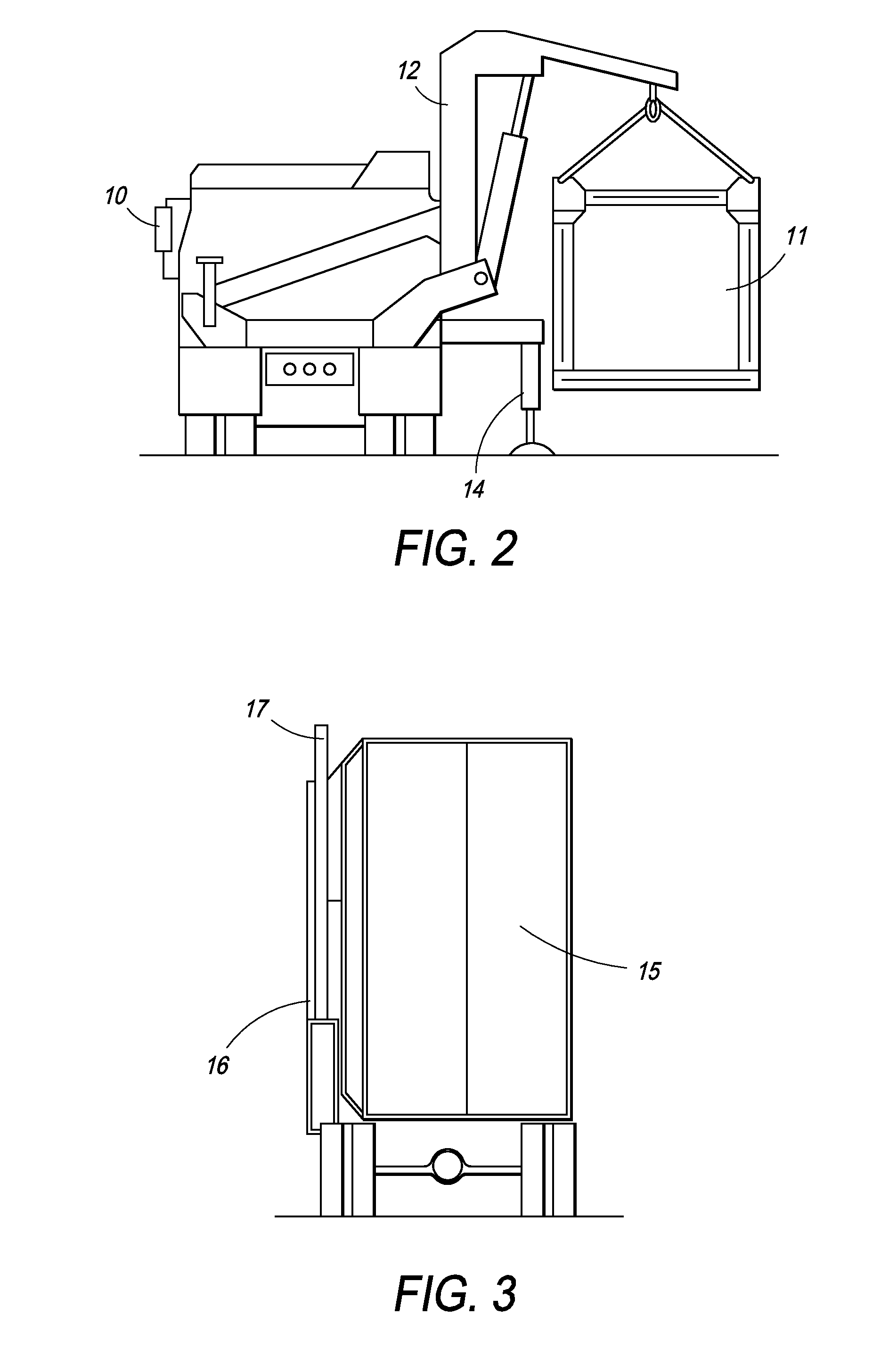

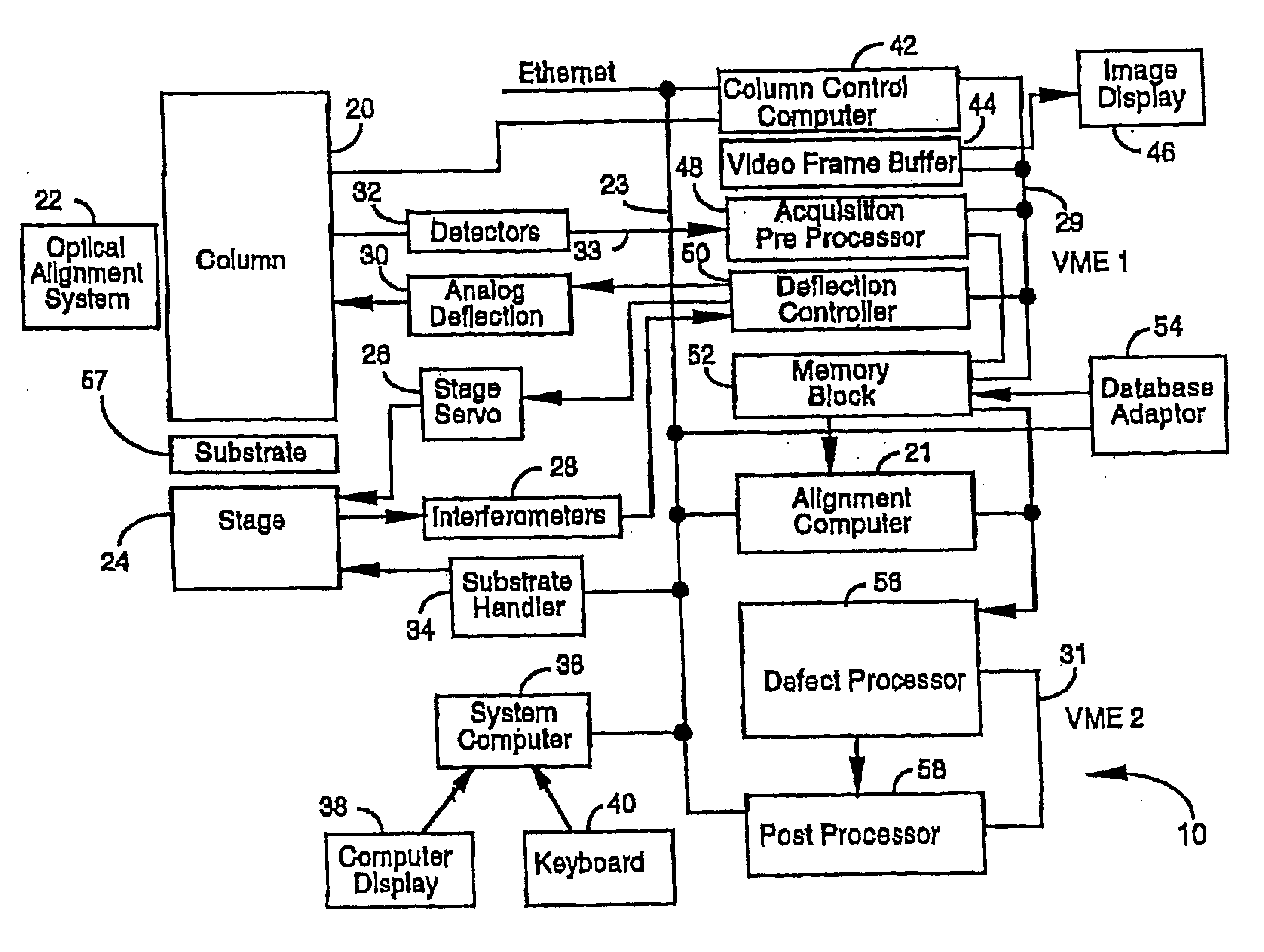

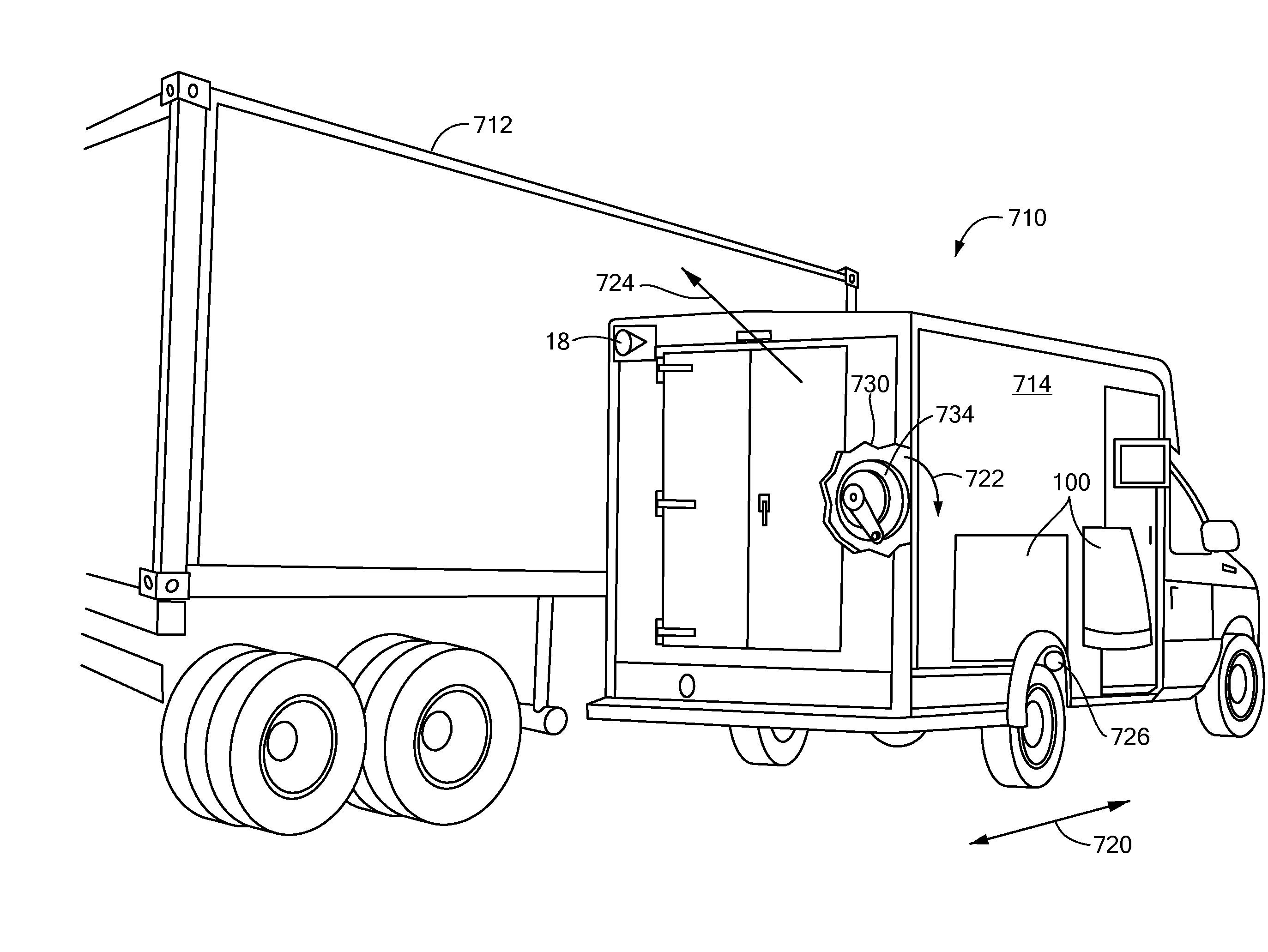

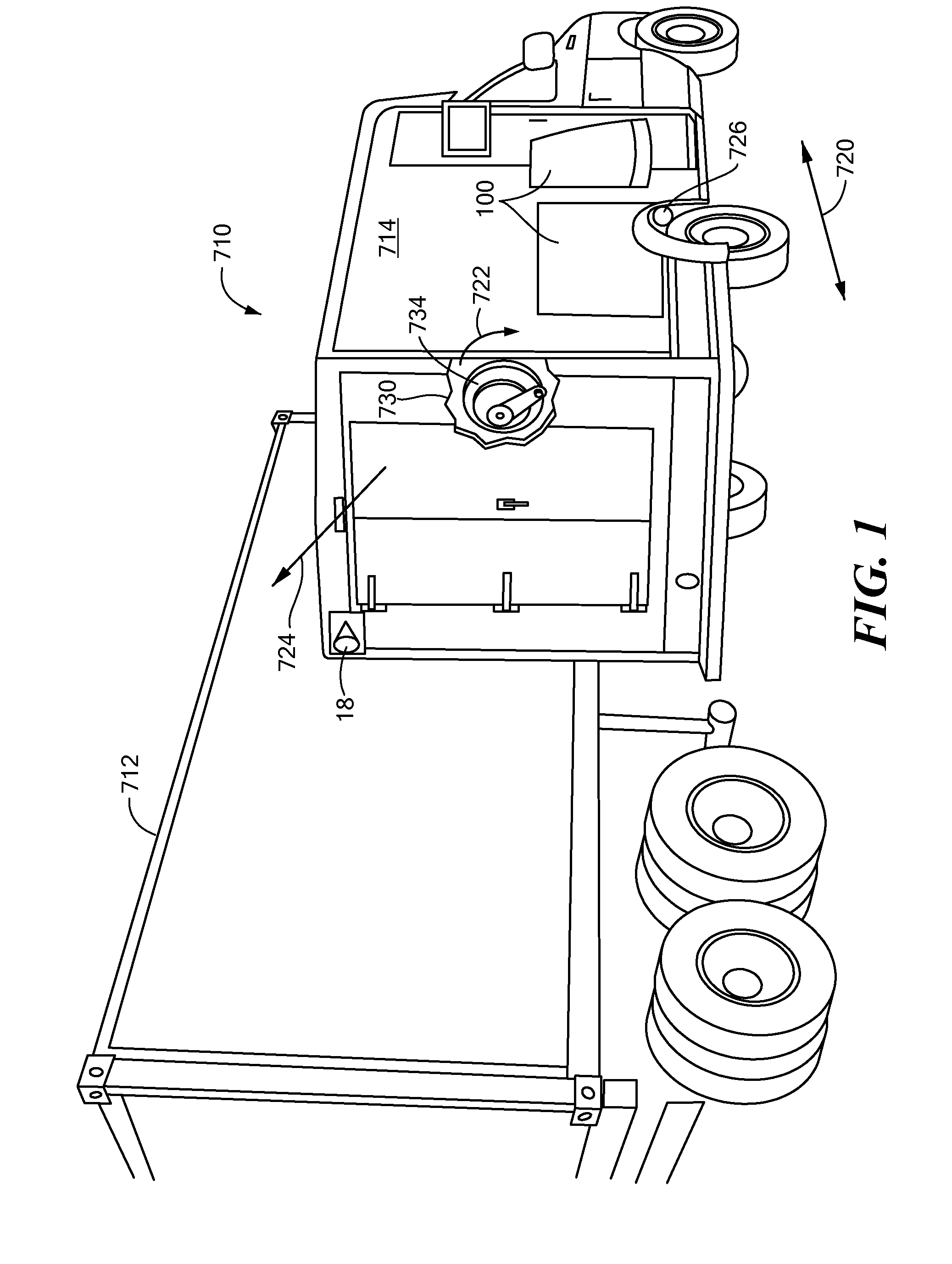

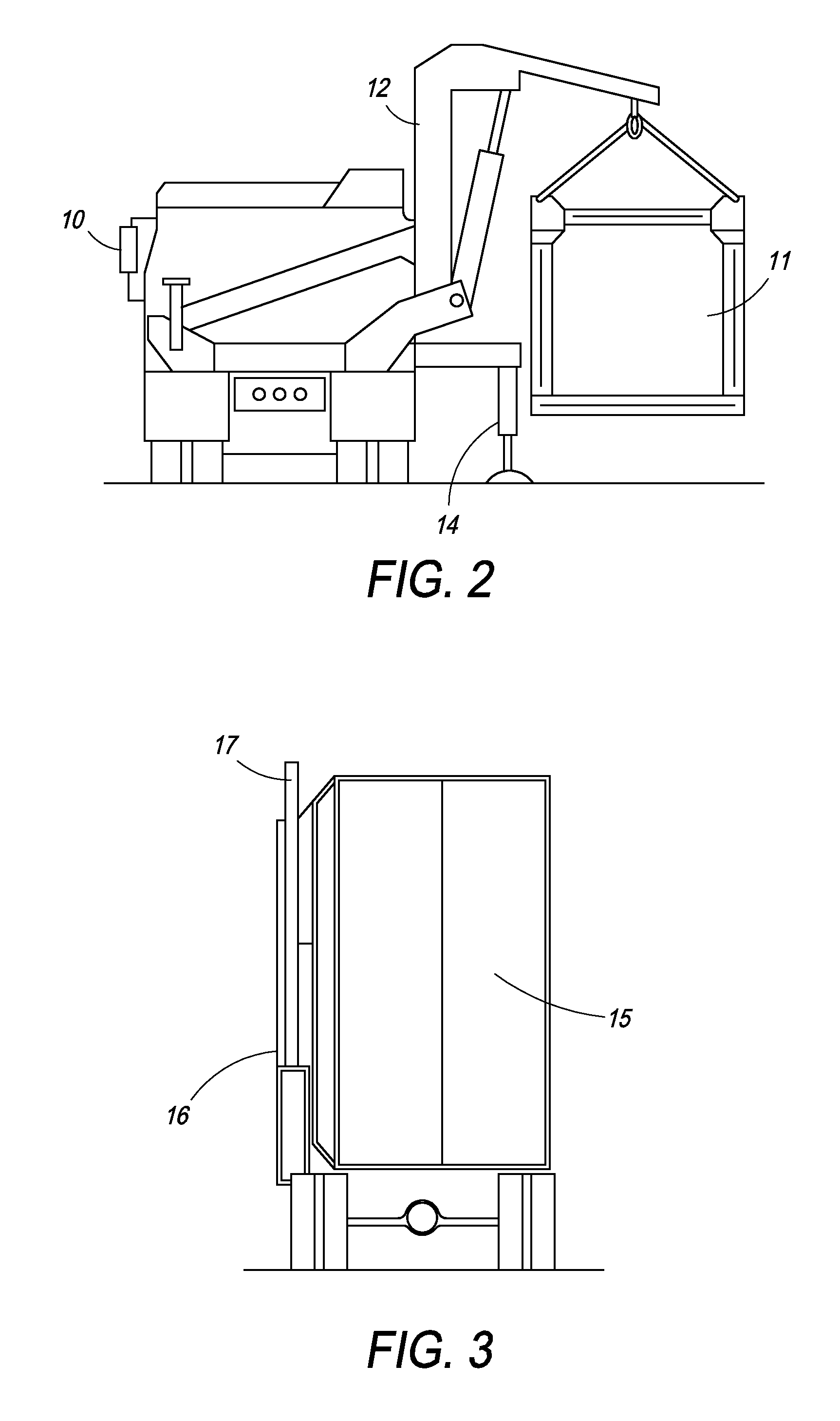

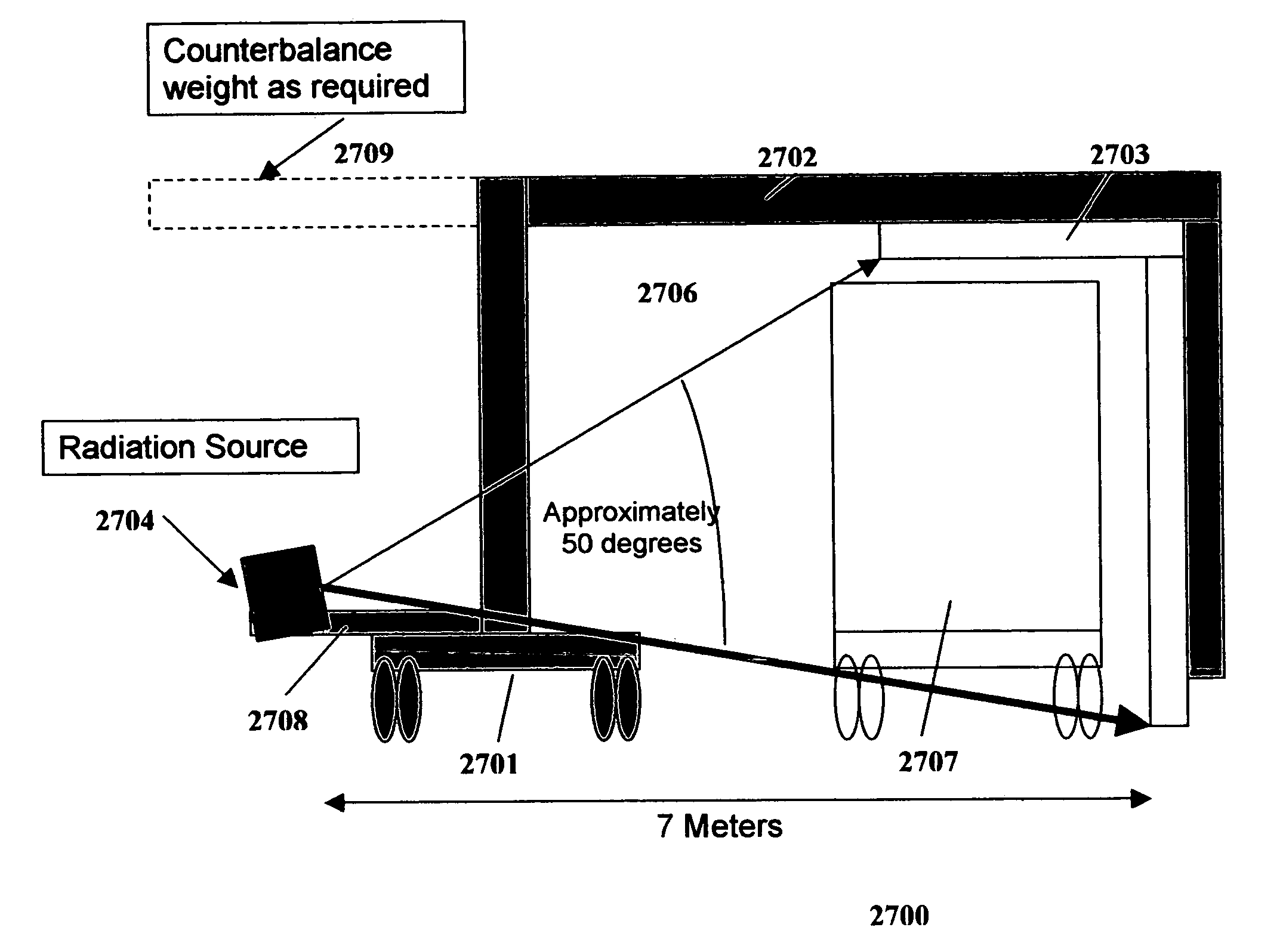

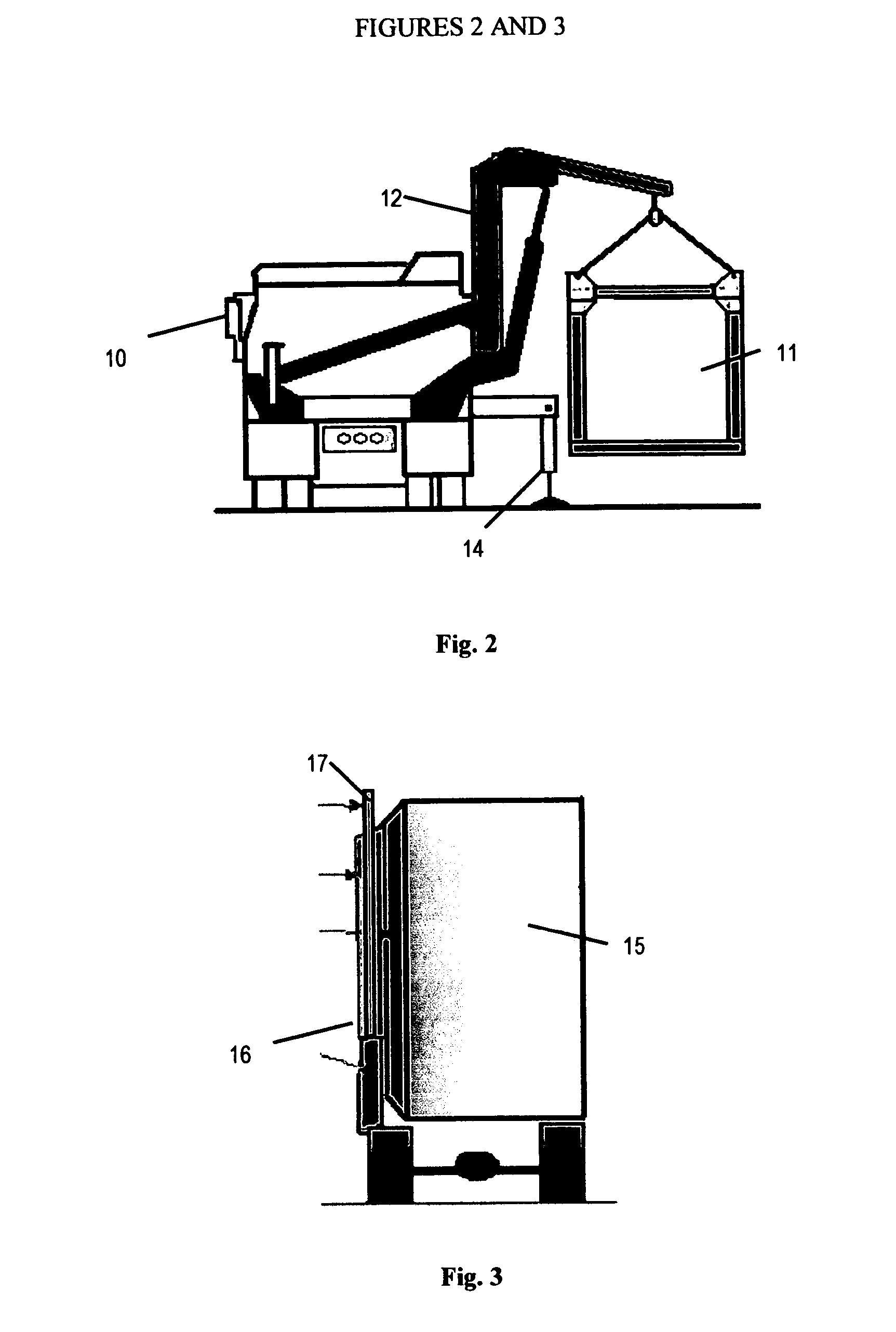

Single boom cargo scanning system

InactiveUS7322745B2Rapidly deployableCost-effectively and accurately on uneven surfaceRadiation/particle handlingParticle suspension analysisMobile vehicleDetector array

The inspection methods and systems of the present invention are mobile, rapidly deployable, and capable of scanning a wide variety of receptacles cost-effectively and accurately on uneven surfaces. The present invention is directed toward a portable inspection system for generating an image representation of target objects using a radiation source, comprising a mobile vehicle, a detector array physically attached to a movable boom having a proximal end and a distal end. The proximal end is physically attached to the vehicle. The invention also comprises at least one source of radiation. The radiation source is fixedly attached to the distal end of the boom, wherein the image is generated by introducing the target objects in between the radiation source and the detector array, exposing the objects to radiation, and detecting radiation.

Owner:RAPISCAN SYST INC (US)

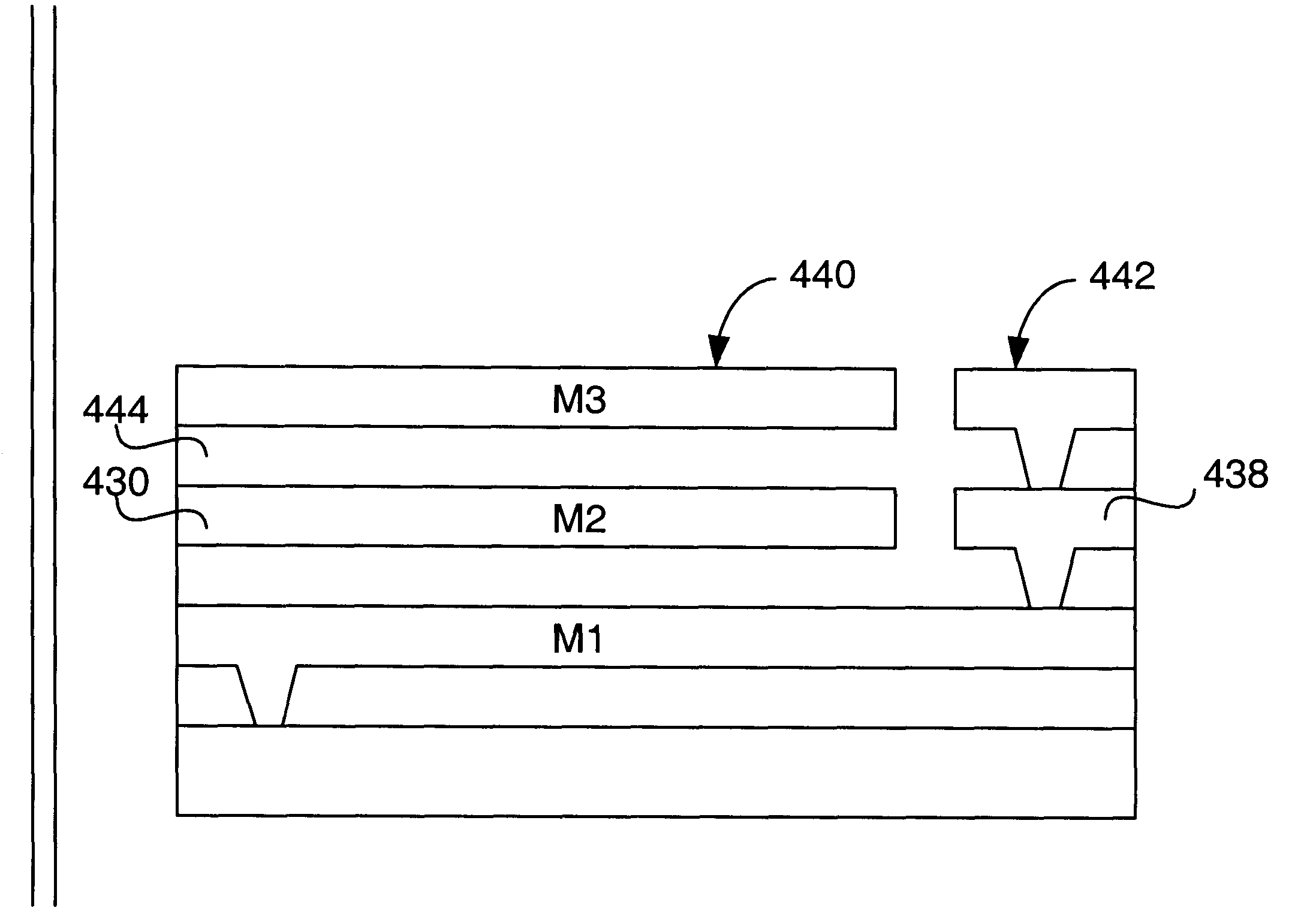

Inspectable buried test structures and methods for inspecting the same

InactiveUS6509197B1Easily dry-etchedEasy to processSemiconductor/solid-state device testing/measurementElectric discharge tubesVoltage contrastSemiconductor

Disclosed is a semiconductor die having a lower test structure formed in a lower metal layer of the semiconductor die. The lower conductive test structure has a first end and a second end. The first end is coupled to a predetermined voltage level. The semiconductor die also includes an insulating layer formed over the lower metal layer. The die further includes an upper test structure formed in an upper metal layer of the semiconductor die. The upper conductive test structure is coupled with the second end of the lower conductive test structure. The upper metal layer is formed over the insulating layer. In a specific implementation, the first end of the lower test structure is coupled to ground. In another embodiment, the semiconductor die also includes a substrate and a first via coupled between the first end of the lower test structure and the substrate. In yet another aspect, the lower test structure is an extended metal line, and the upper test structure is a voltage contrast element. Methods for inspecting and fabricating such semiconductor die are also disclosed.

Owner:KLA TENCOR CORP

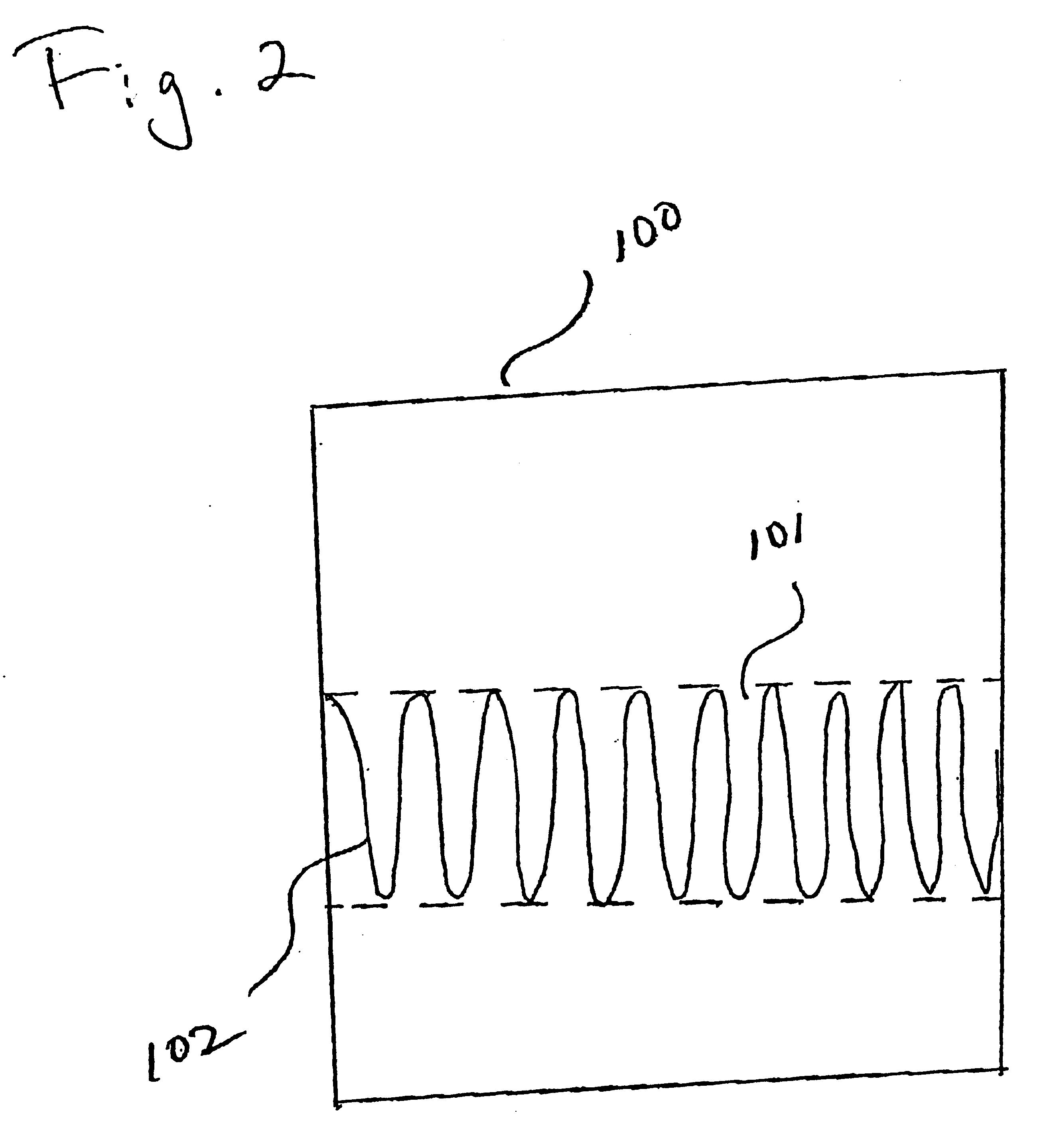

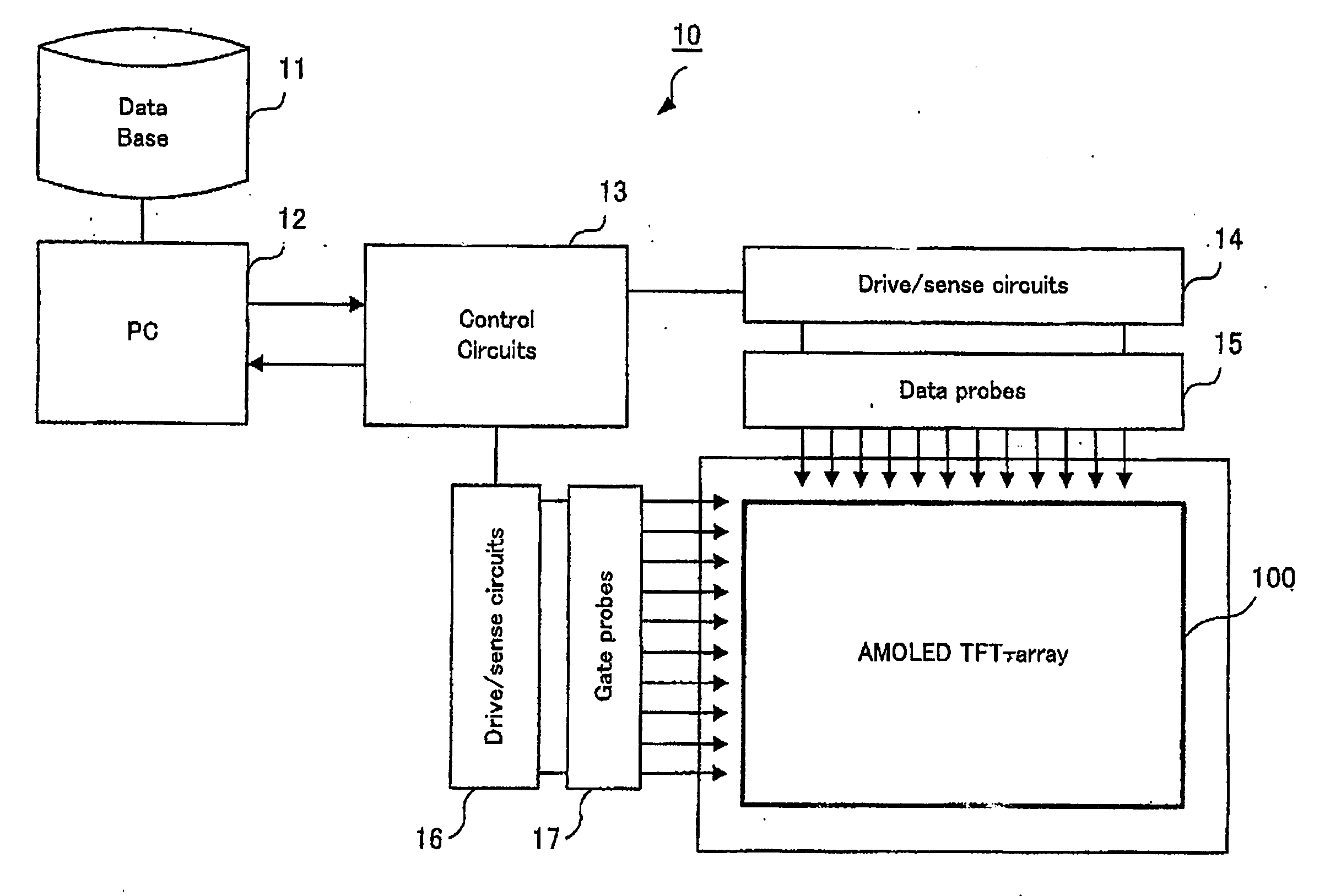

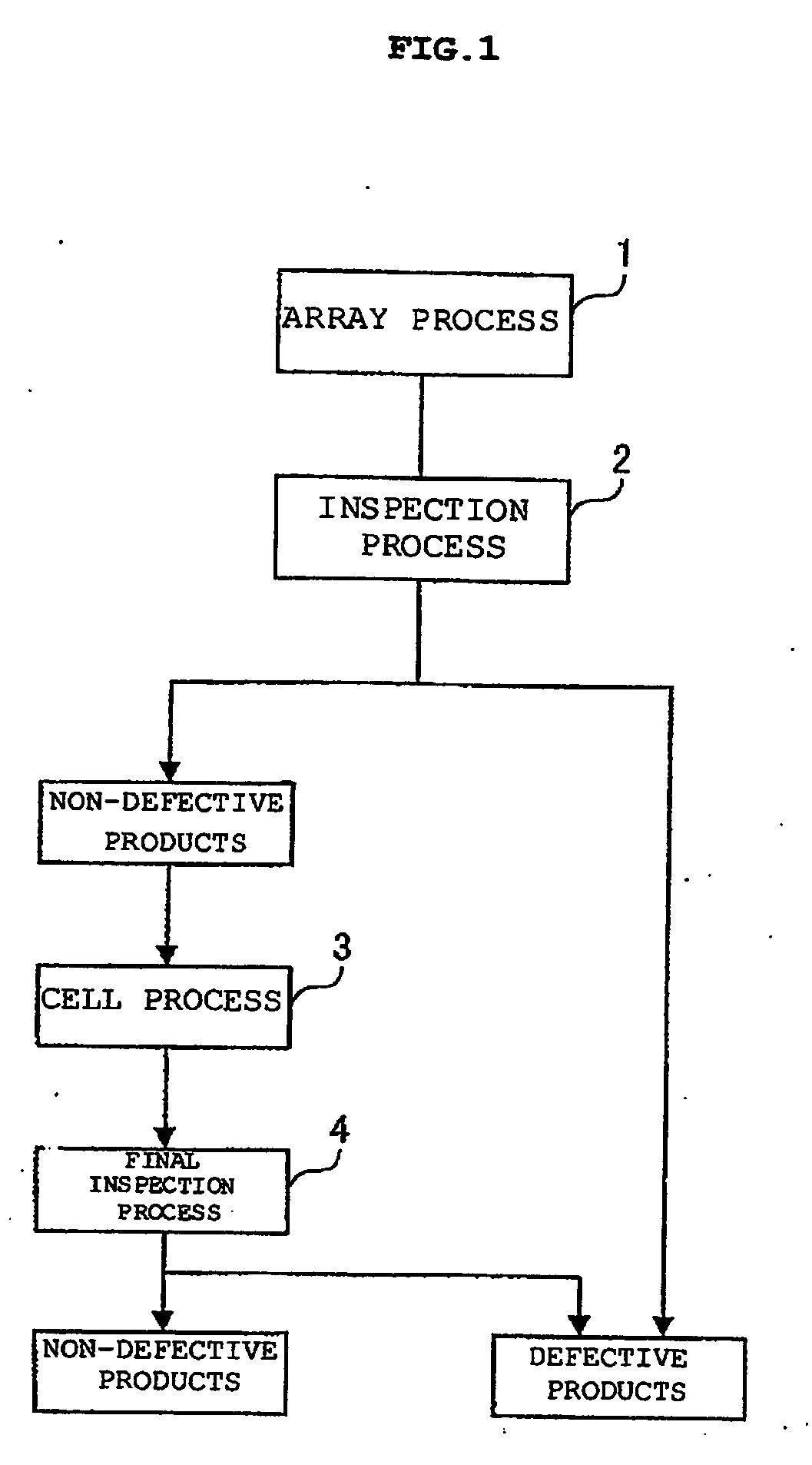

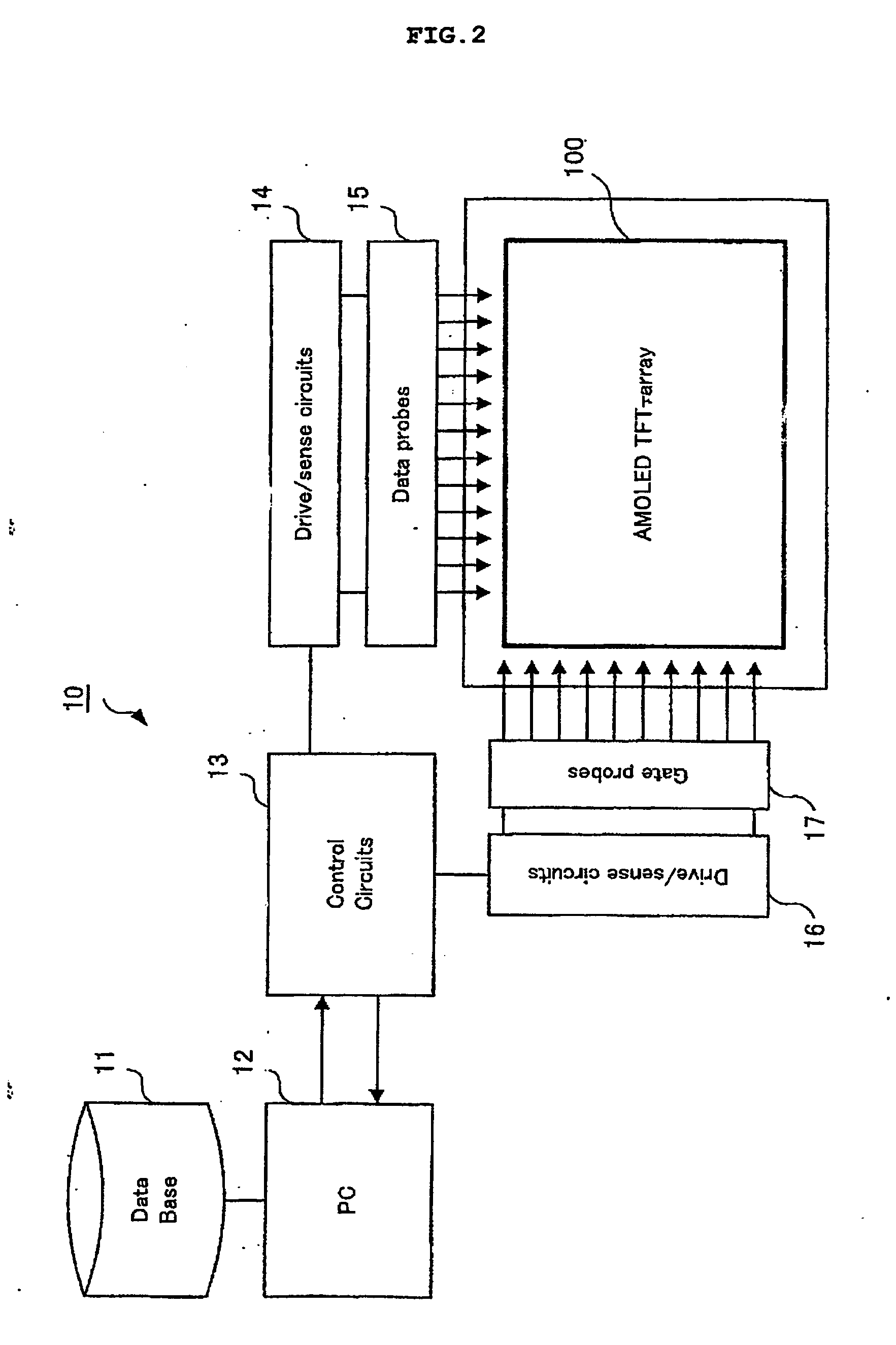

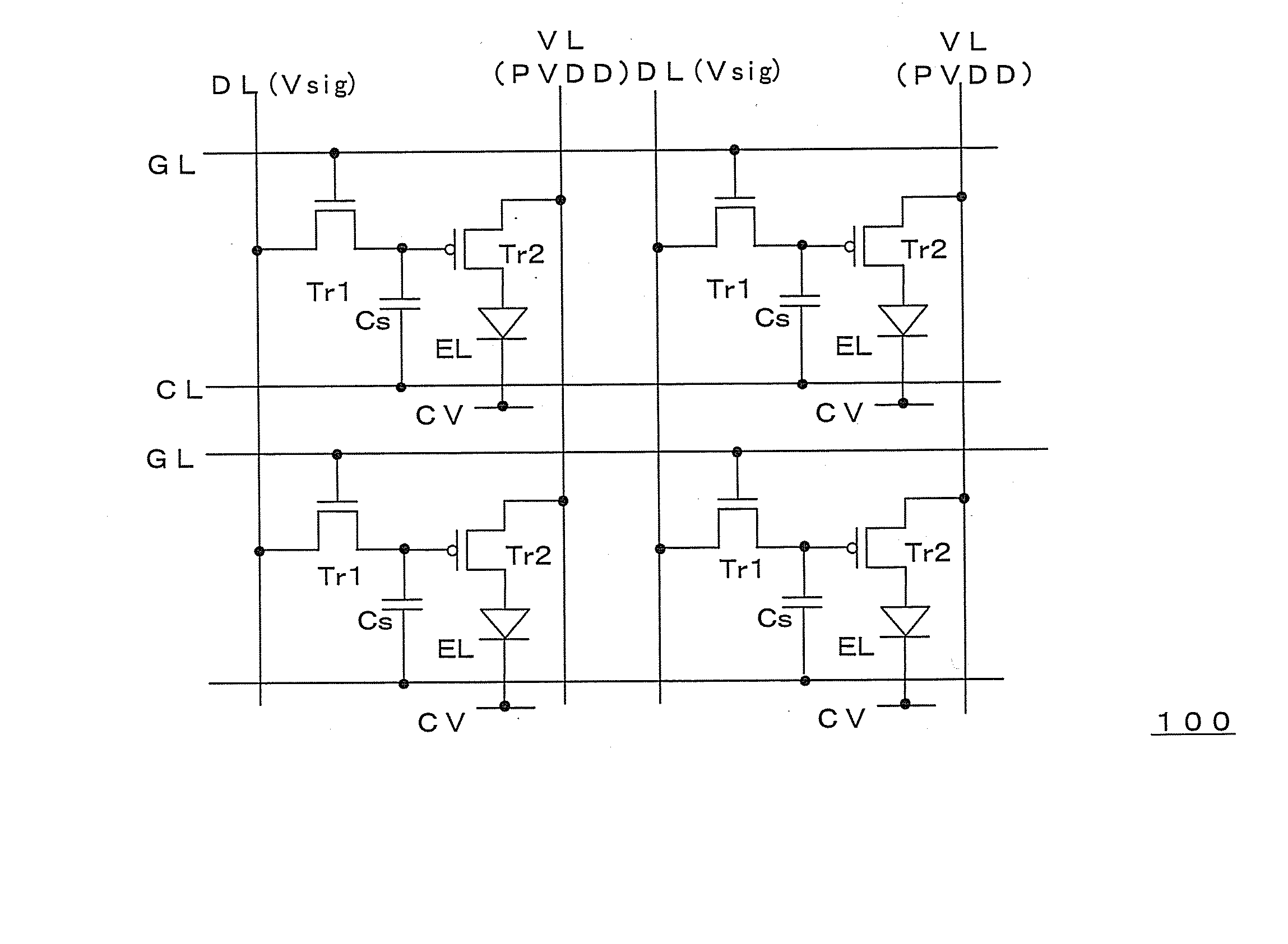

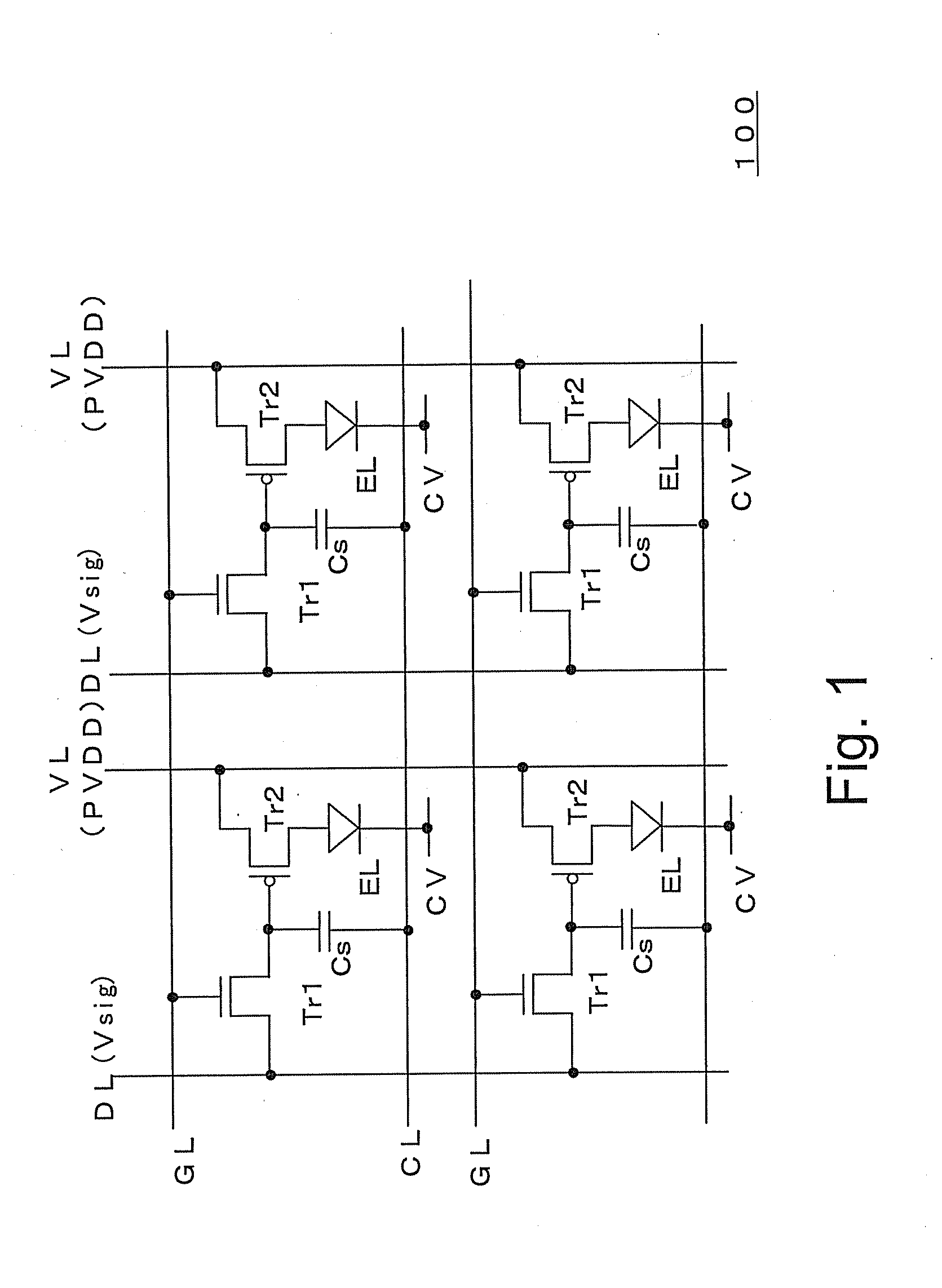

Inspection device and inspection method for active matrix panel, and manufacturing method for active matrix organic light emitting diode panel

InactiveUS20070075727A1Accuracy of estimationTransistorSemiconductor/solid-state device testing/measurementActive matrixParasitic capacitance

An inspection method includes an array process of forming a TFT array on a substrate to fabricate an active matrix panel, an inspection process of carrying out a performance test on the fabricated active matrix panel, and a cell process of mounting an OLED on the active matrix panel after the inspection process. In the inspection process, variation in parasitic capacitance through a pixel electrode is measured when driving TFTs constituting the active matrix fabricated in the array process are turned on and when the driving TFTs are turned off, and open / short defects in the driving TFTs are thereby inspected.

Owner:INT BUSINESS MASCH CORP

Method and apparatus for inspecting pattern defects

InactiveUS7388979B2High sensitivityIncrease speedImage enhancementImage analysisPattern recognitionComputer graphics (images)

The present invention relates to a pattern defect inspection method and apparatus that reveal ultramicroscopic defects on an inspection target in which ultramicroscopic circuit patterns are formed, and inspect the defects with high sensitivity and at a high speed. The present invention provides a pattern inspection apparatus for comparing the images of corresponding areas of two formed patterns that should be identical with each other, and judging any mismatched image area as a defect. The pattern inspection apparatus includes means for performing an image comparison process on a plurality of areas in a parallel manner. Further, the pattern inspection apparatus also includes means for converting the gradation of the image signals of compared images in each of a plurality of different processes. Therefore, the present invention can properly detect defects even if the same patterns of compared images differ in brightness.

Owner:HITACHI HIGH-TECH CORP

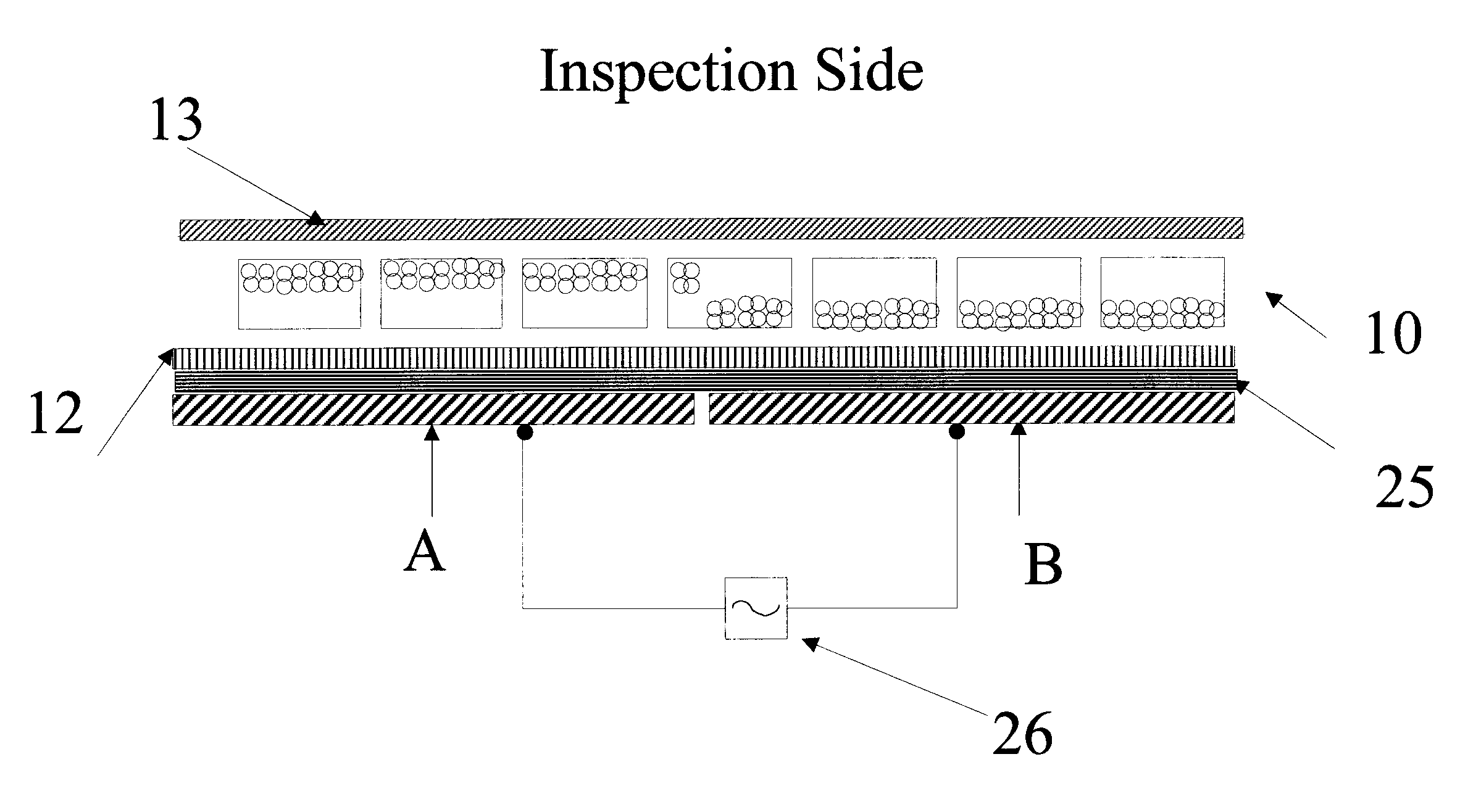

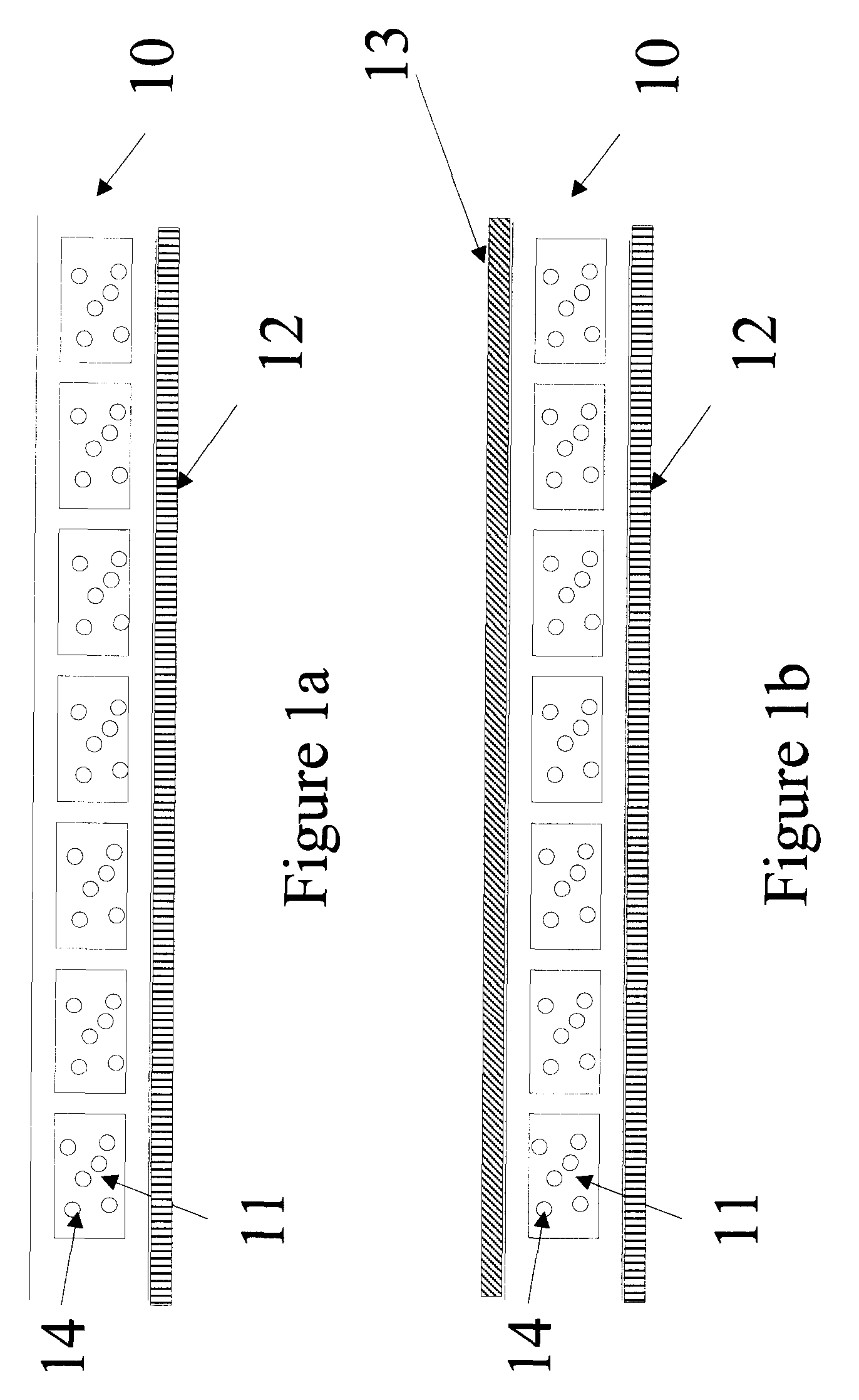

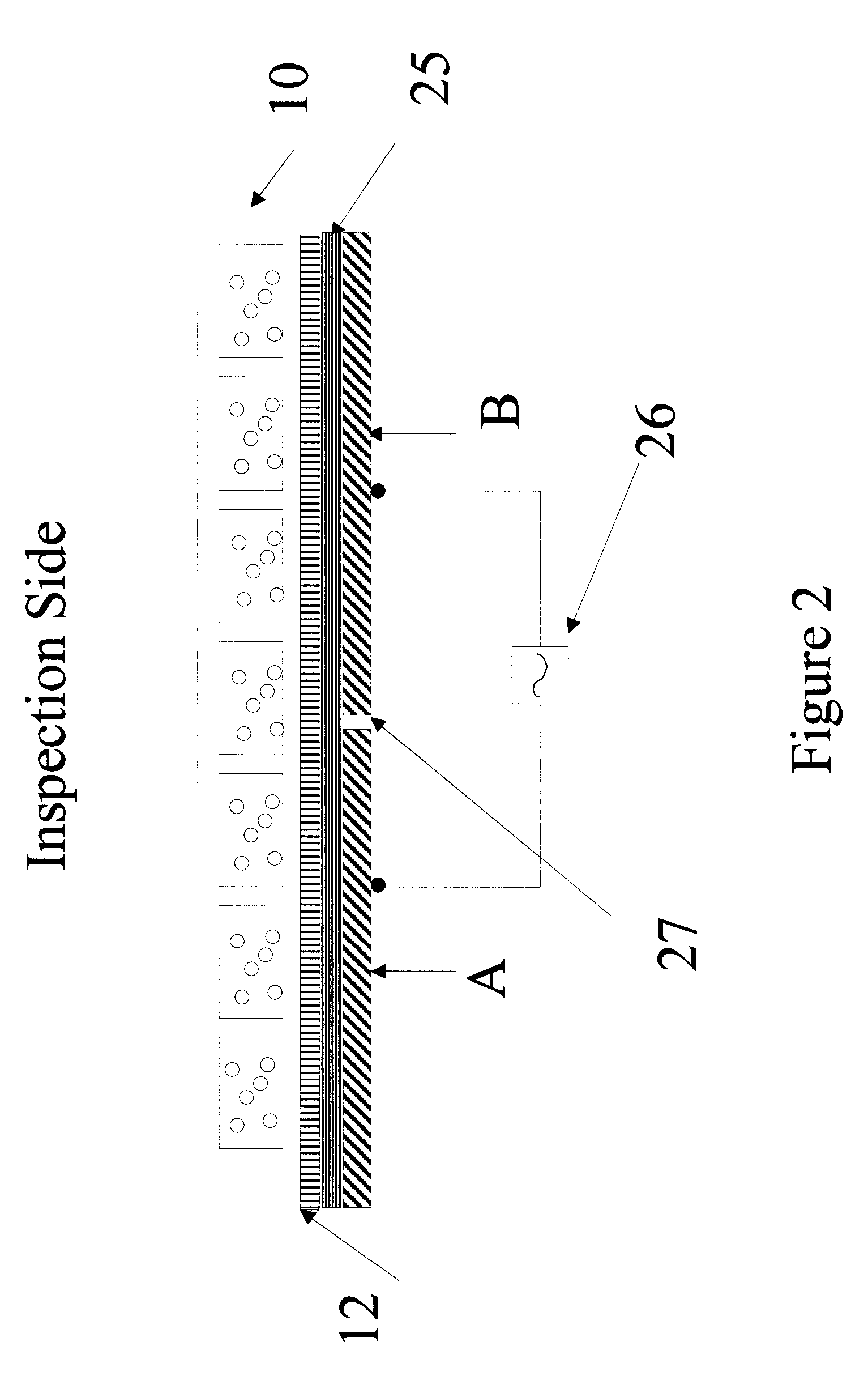

Inspection methods for defects in electrophoretic display and related devices

InactiveUS7982479B2Cathode-ray tube indicatorsInput/output processes for data processingElectrophoresisDisplay device

The present invention relates to methods for inspection of defects in an electrophoretic display and related devices. The method may be carried out with one or more testing electrodes. The method comprises applying a voltage difference to two testing electrodes which are in contact with the display panel, or applying a voltage difference to a testing electrode and a electrode layer. The methods may be applied in in-line or off-line inspection of a display panel.

Owner:E INK CALIFORNIA

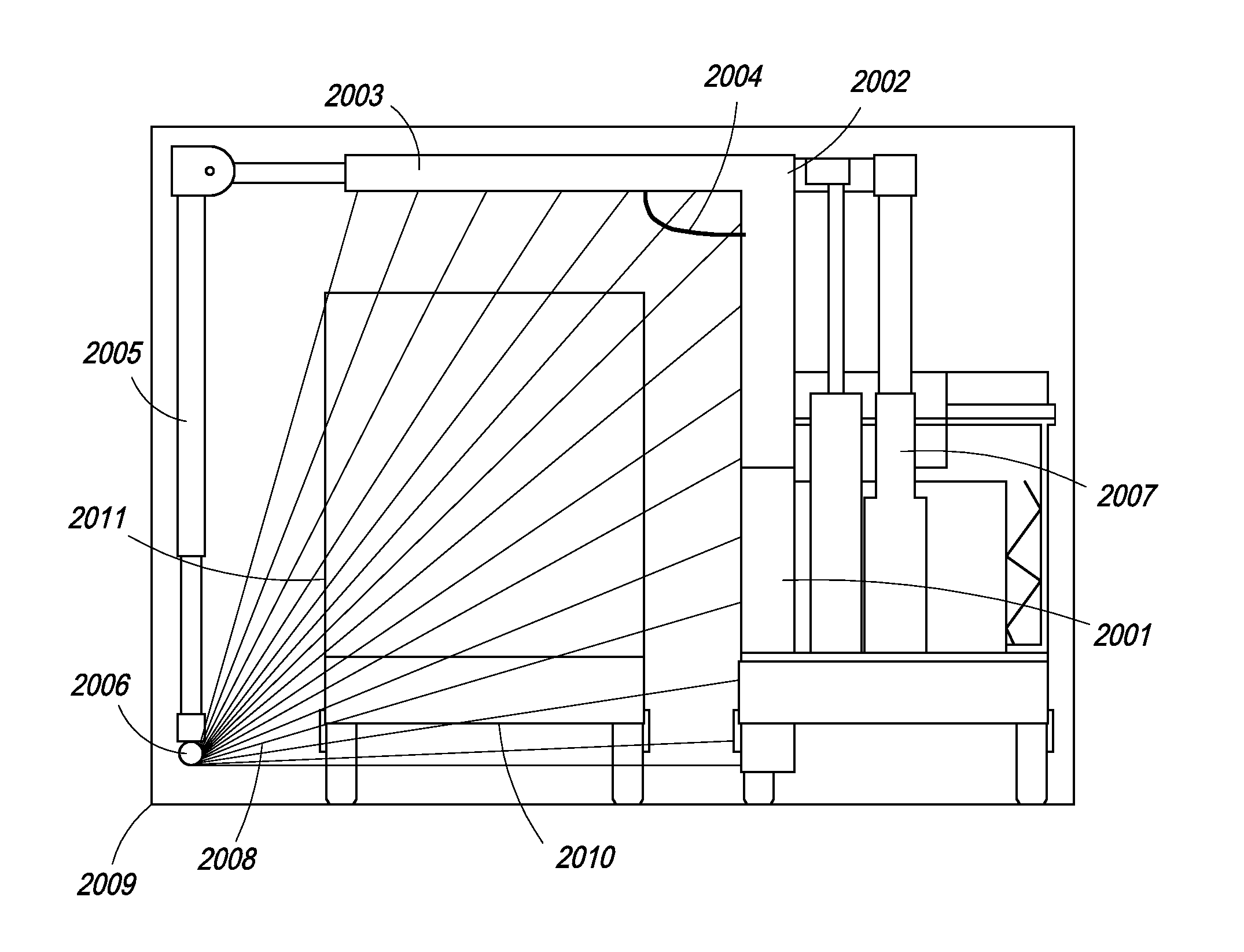

X-Ray Inspection Trailer

InactiveUS20090257555A1Material analysis by transmitting radiationMaterial analysis using radiation diffractionForward scatterX-ray

An inspection system, and inspection methods, based upon an imaging enclosure characterized by an enclosing body. A source of penetrating radiation and a detector module are concealed entirely within the body of a conveyance such as a trailer. A characterizing value or an image is formed with respect to an inspected object that is disposed entirely outside the conveyance and the characterizing value or image is made available to a remotely disposed operator. Additional detectors may be disposed distally to the inspected object and may detect transmitted, or forward-scattered, penetrating radiation.

Owner:AMERICAN SCI & ENG INC

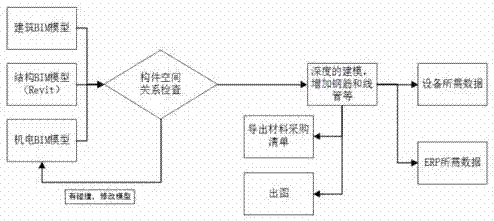

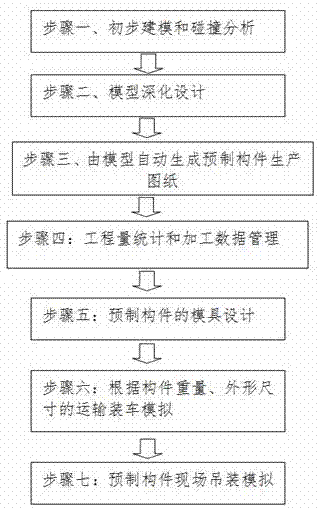

Assembled building deepening design method based on BII software

ActiveCN107967399AImprove accuracyImprove efficiencyGeometric CADSpecial data processing applicationsProduction drawingCollision analysis

The invention provides an assembled building deepening design method based on BII software. The assembled building deepening design method comprises the following steps of 1, conducting preliminary modeling and collision analysis; 2, conducting model deepening design; 3, automatically generating member production drawing through a model; 4, conducting engineering amount statistics and processing data management; 5, designing a mold of a prefabricated member; 6, conducting transportation vehicle-loading simulating and optimizing according to the member weight and the profile size; 7, conductingfield hoisting and simulating of the prefabricated member, and optimizing the hoisting sequence. Aiming at defects of an existing prefabricated member deepening design method, it is adopted that firstly, a three-dimensional model is modeled before deepening design drawing is drawn, a three-dimensional examination method is adopted, after the space conflict relation between the prefabricated member is excluded, the drawing is generated, a large amount of modification of the drawing is avoided, parts in the model all have the accurate three-dimensional size, material information and member subordination relationship, a member material list can be generated simply by conveying the information, and thus an accurate and efficient effect is achieved.

Owner:GUANGDONG JIAN YUAN CONSTR ASSEMBLY IND CO LTD

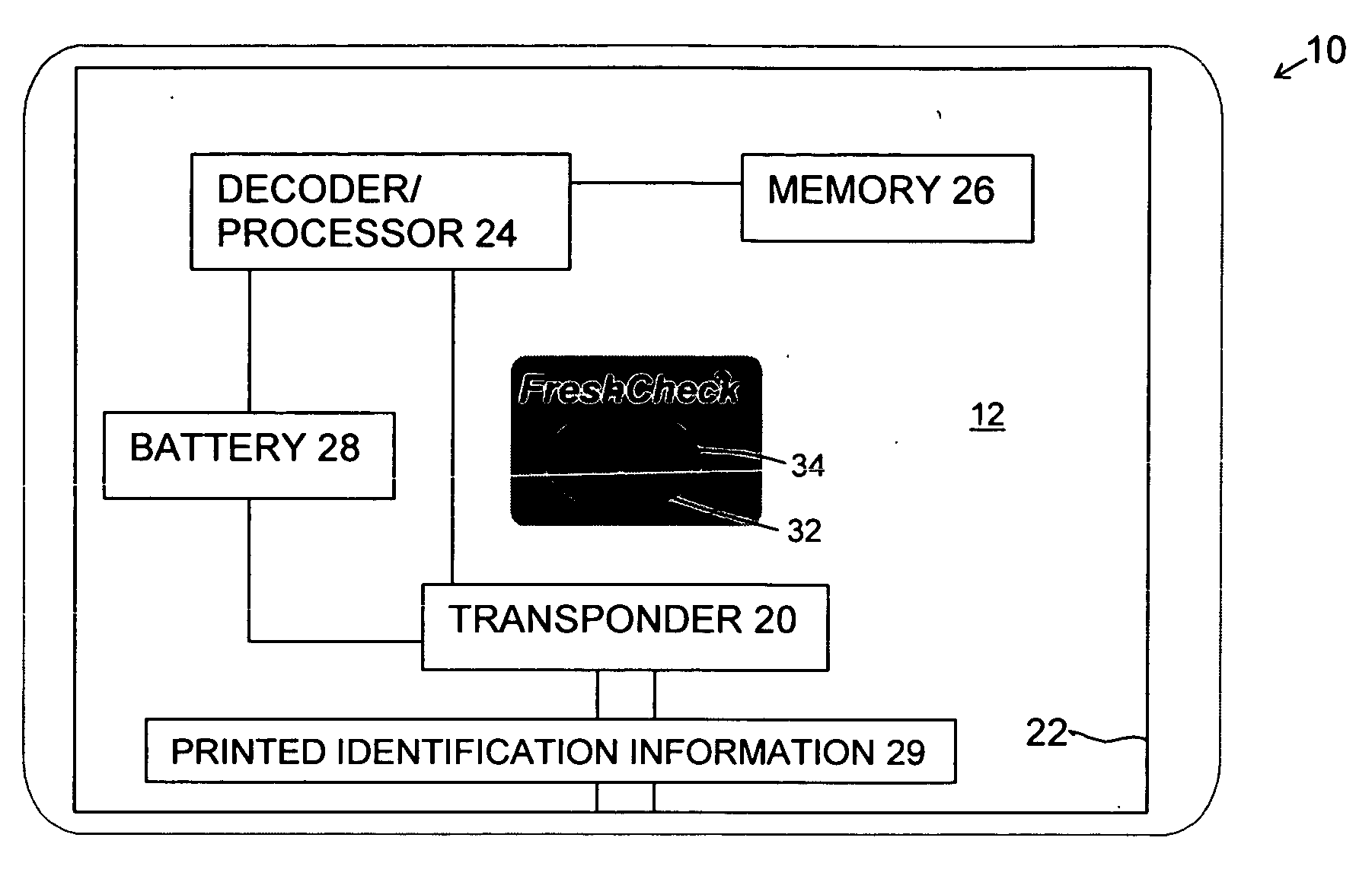

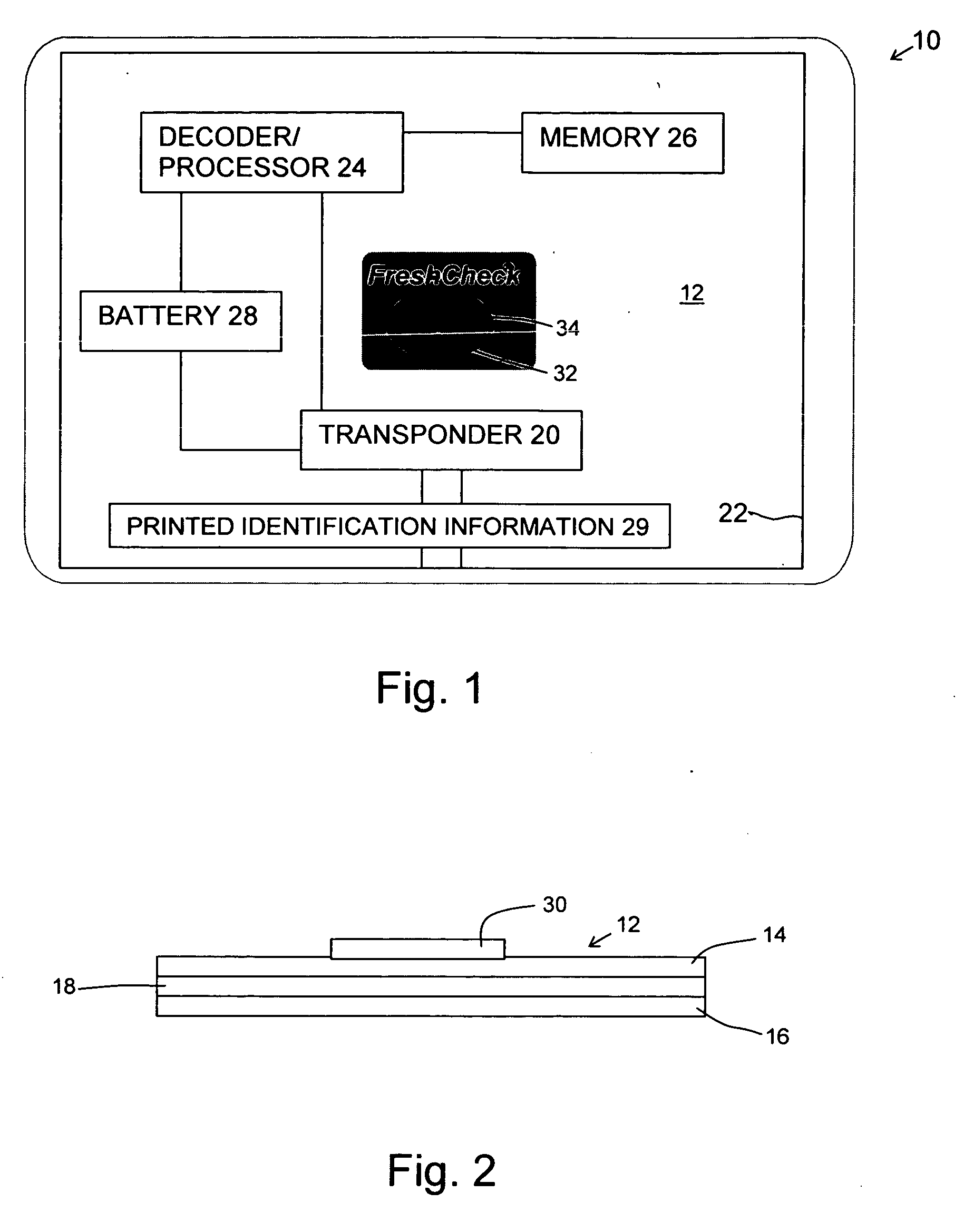

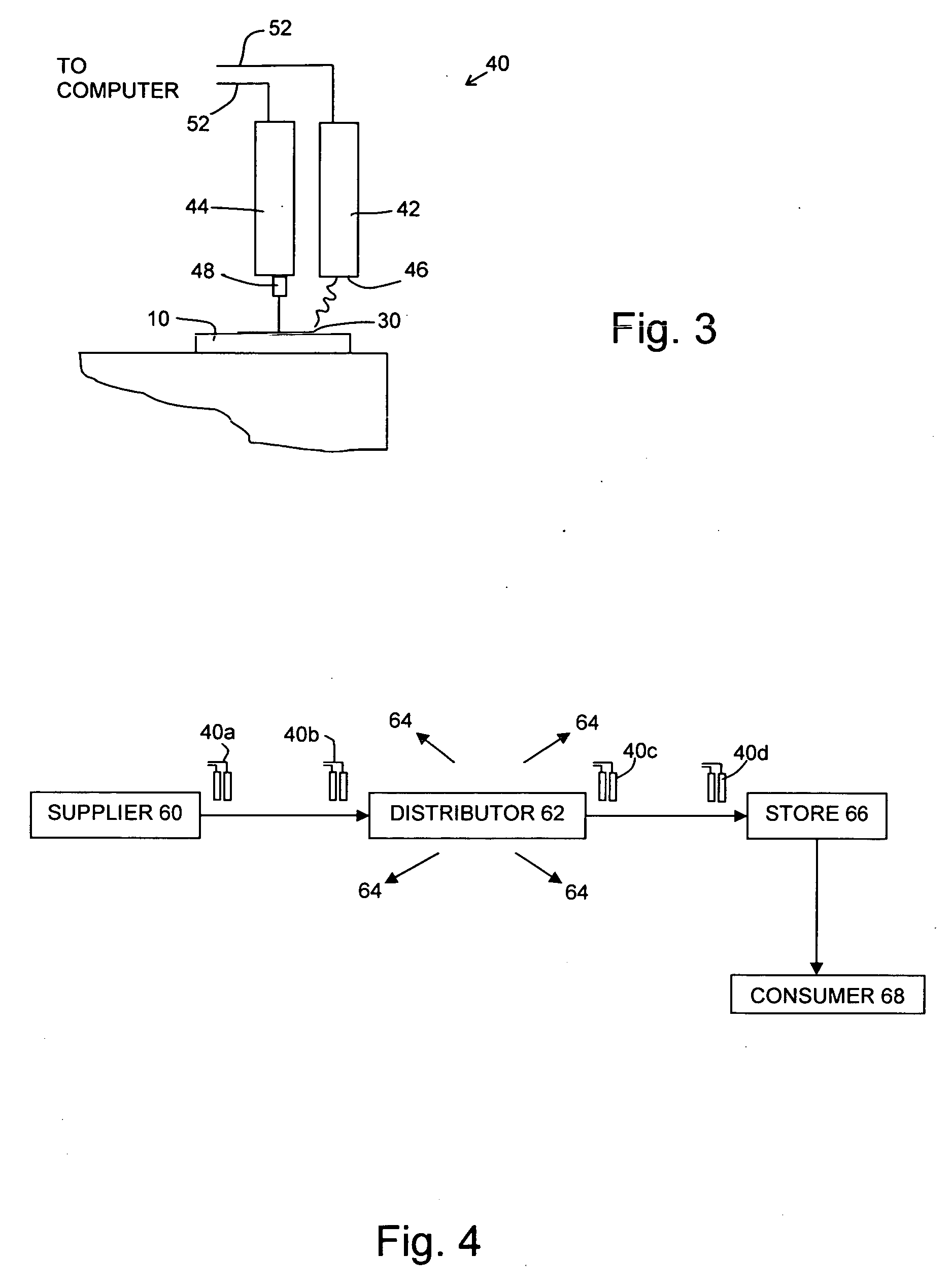

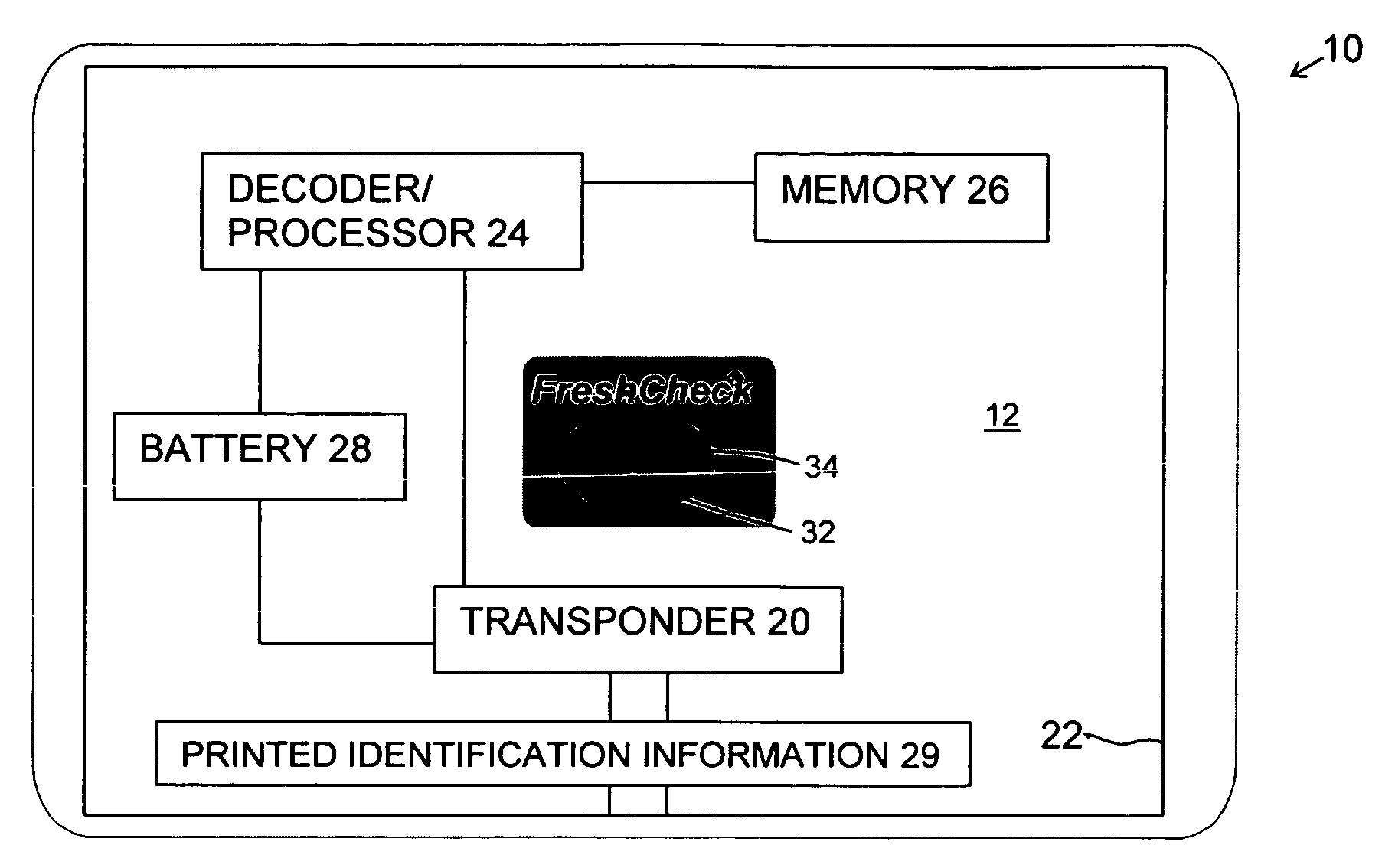

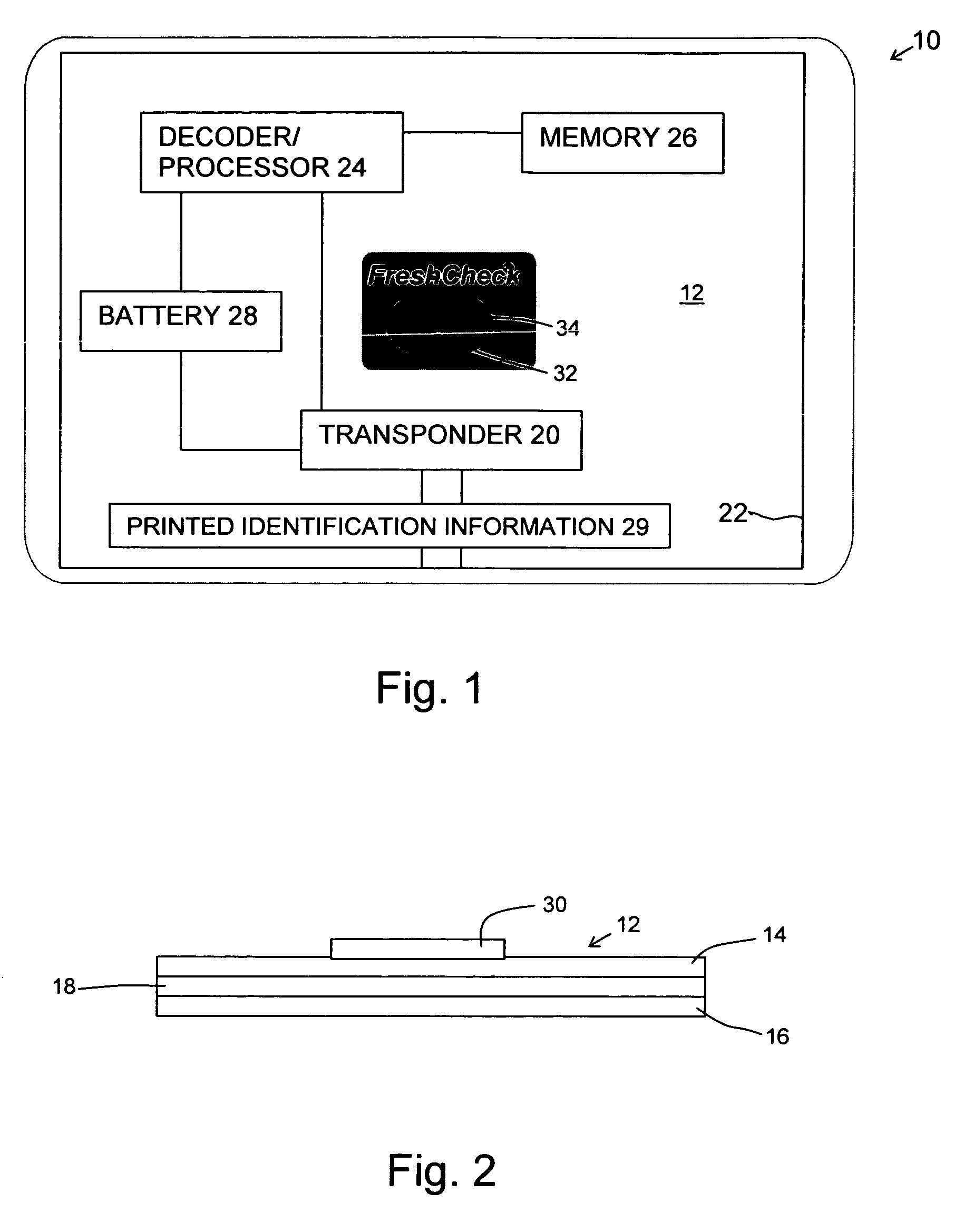

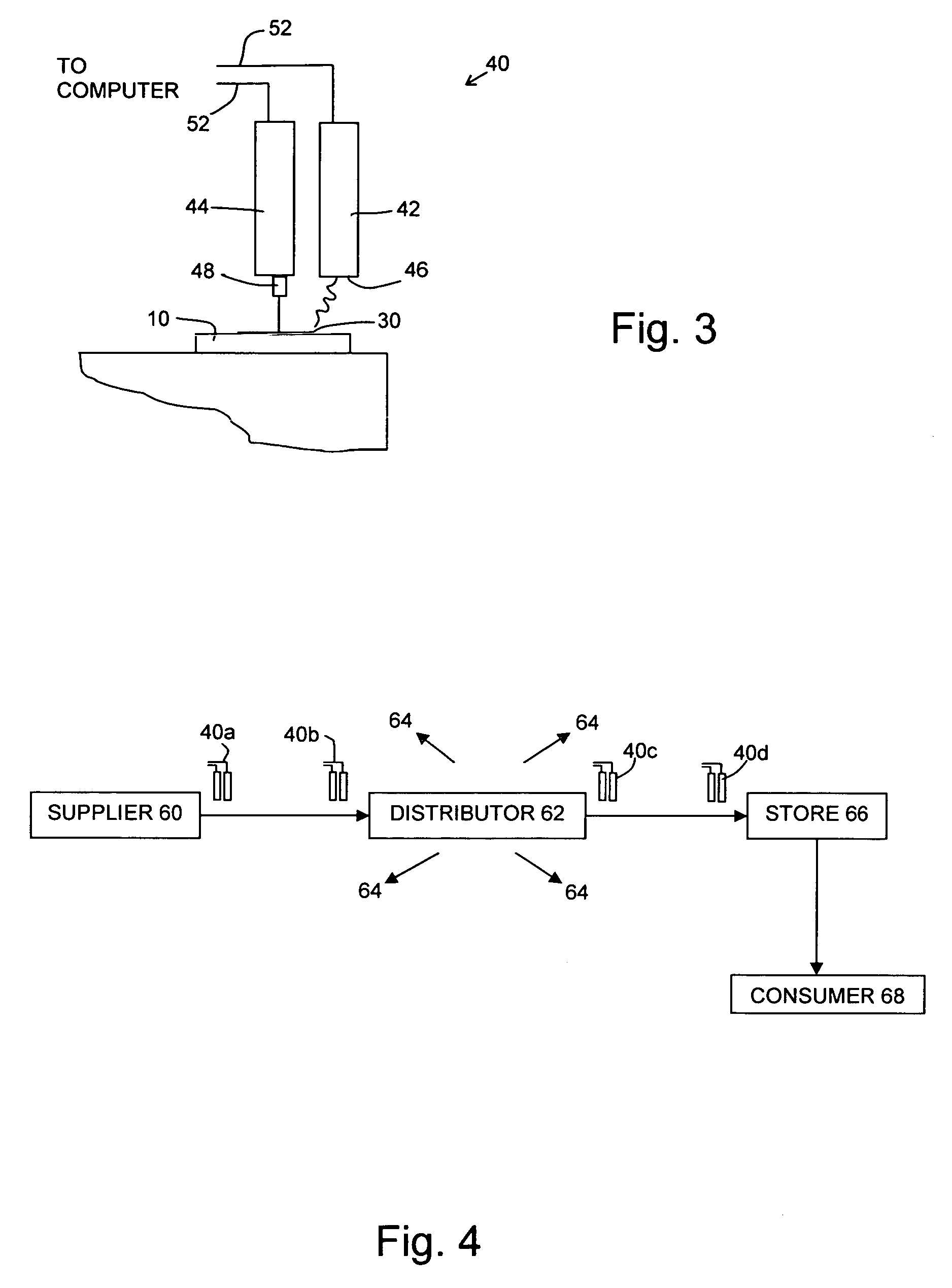

RFID tag with visual environmental condition monitor

ActiveUS20060145863A1Easy to processEasy to readContainer decorationsLevel indicationsStatistical analysisColor changes

A combination RFID tag intended to be associated with a host product, for example by being secured to the outside of a package containing a perishable product, e.g. foodstuffs or vaccines, which RFID tag is provided with a visually readable environmental condition exposure indicator. The visual indicator can sense the exposure of the RFID tag to an environmental condition e.g. temperature, experienced by the host product providing a visual indication, e.g. a color change, readable externally of the RFID tag of the sensed environmental condition. The visual indicator can be chemically active, for example an acetylenic agent, and may be responsive to cumulative temperature excursions over time. The novel RFID tag 11 and tag inspection methods of the invention permit an efficacious harnessing of information about the condition exposure history of a specific inventory item including product identification and related data. The information from multiple items can be compiled into a database that may be audited or statistically analyzed to reveal useful information regarding the handling of the items.

Owner:TEMPTIME CORP

Inspectable buried test structures and methods for inspecting the same

InactiveUS6576923B2Reduce pressureNanotechSemiconductor/solid-state device testing/measurementEngineeringVoltage contrast

Disclosed is a semiconductor die having a lower test structure formed in a lower metal layer of the semiconductor die. The lower conductive test structure has a first end and a second end. The first end is coupled to a predetermined voltage level. The semiconductor die also includes an insulating layer formed over the lower metal layer. The die further includes an upper test structure formed in an upper metal layer of the semiconductor die. The upper conductive test structure is coupled with the second end of the lower conductive test structure. The upper metal layer is formed over the insulating layer. In a specific implementation, the first end of the lower test structure is coupled to ground. In another embodiment, the semiconductor die also includes a substrate and a first via coupled between the first end of the lower test structure and the substrate. In yet another aspect, the lower test structure is an extended metal line, and the upper test structure is a voltage contrast element. Methods for inspecting and fabricating such semiconductor die are also disclosed.

Owner:KLA CORP

Single boom cargo scanning system

InactiveUS7369643B2Rapidly deployableCost-effectively and accurately on uneven surfaceX-ray apparatusMaterial analysis by transmitting radiationMobile vehicleDetector array

The inspection methods and systems of the present invention are mobile, rapidly deployable, and capable of scanning a wide variety of receptacles cost-effectively and accurately on uneven surfaces. The present invention is directed toward a portable inspection system for generating an image representation of target objects using a radiation source, comprising a mobile vehicle, a detector array physically attached to a movable boom having a proximal end and a distal end. The proximal end is physically attached to the vehicle. The invention also comprises at least one source of radiation. The radiation source is fixedly attached to the distal end of the boom, wherein the image is generated by introducing the target objects in between the radiation source and the detector array, exposing the objects to radiation, and detecting radiation.

Owner:RAPISCAN SYST INC (US)

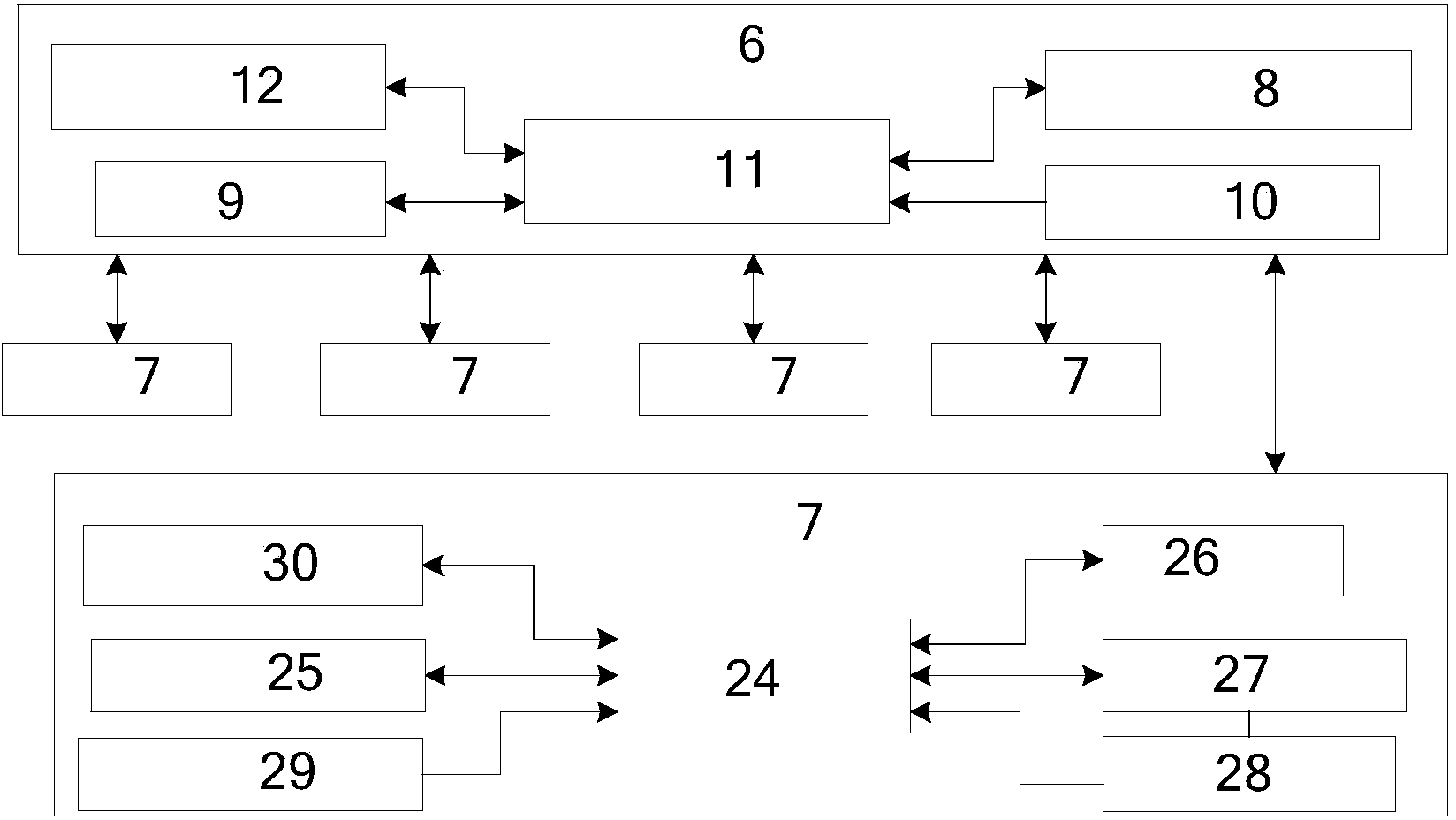

Intelligent inspection system and inspection method for electric transmission line by unmanned aerial vehicle

ActiveCN103824340AReduce idle rateImplement configurationRegistering/indicating working of machinesMonitoring systemUncrewed vehicle

The invention discloses an intelligent inspection system and an inspection method for an electric transmission line by an unmanned aerial vehicle. The intelligent inspection system comprises an inspection mission planning system, a dispatching system, a monitoring system, an inspection result processing platform and mobile branch stations, wherein the inspection mission planning system communicates with the inspection result processing platform and the dispatching system respectively; the inspection result processing platform and the dispatching system communicates with the monitoring system respectively; the monitoring system is connected and communicate with the mobile branch stations. The inspection method has the benefits that factors of the inspection unmanned aerial vehicle, inspection equipment, an inspector, and the like accessing the dispatching platform through a dispatching terminal can be dispatched effectively to realize equipped configuration of unmanned aerial vehicle inspection resource; the usage rates of personnel and equipment can be improved; the no-load rate and vacancy rate of the inspection equipment are reduced; through centralized monitoring of condition information inspected by the unmanned aerial vehicle, unmanned aerial vehicle inspection dispatching personnel can master unmanned aerial vehicle inspection in the large effectively; the service life of the unmanned aerial vehicle is prolonged.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

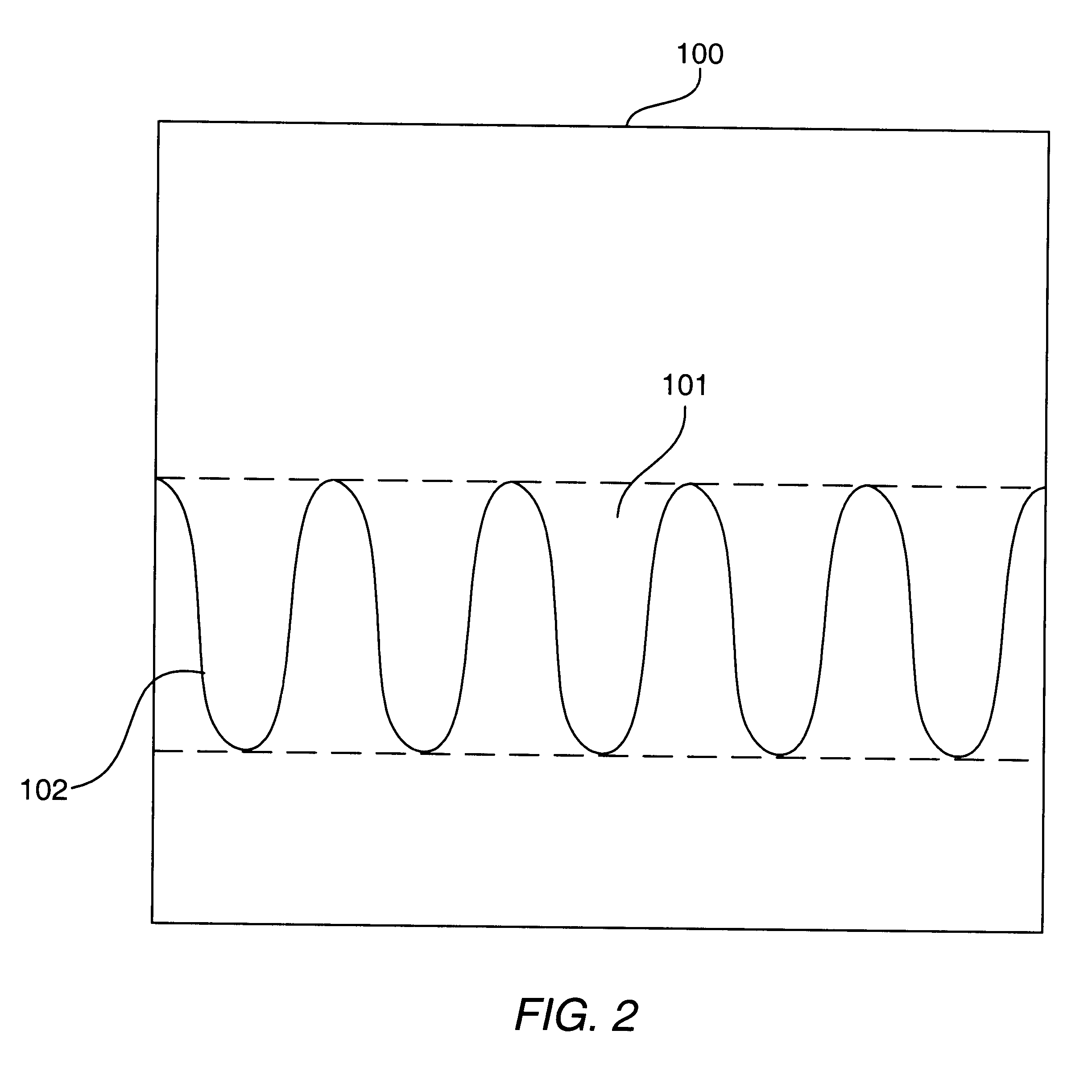

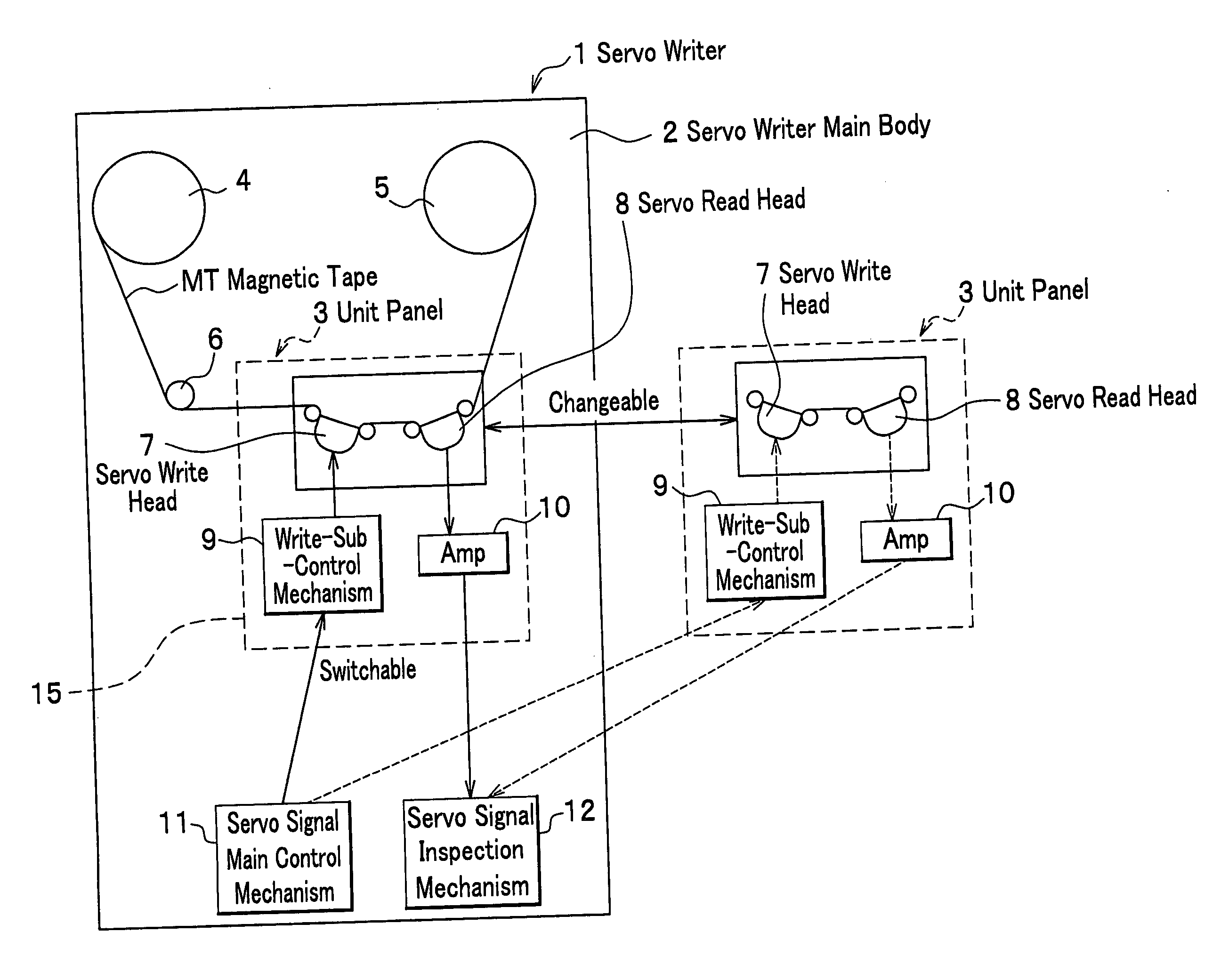

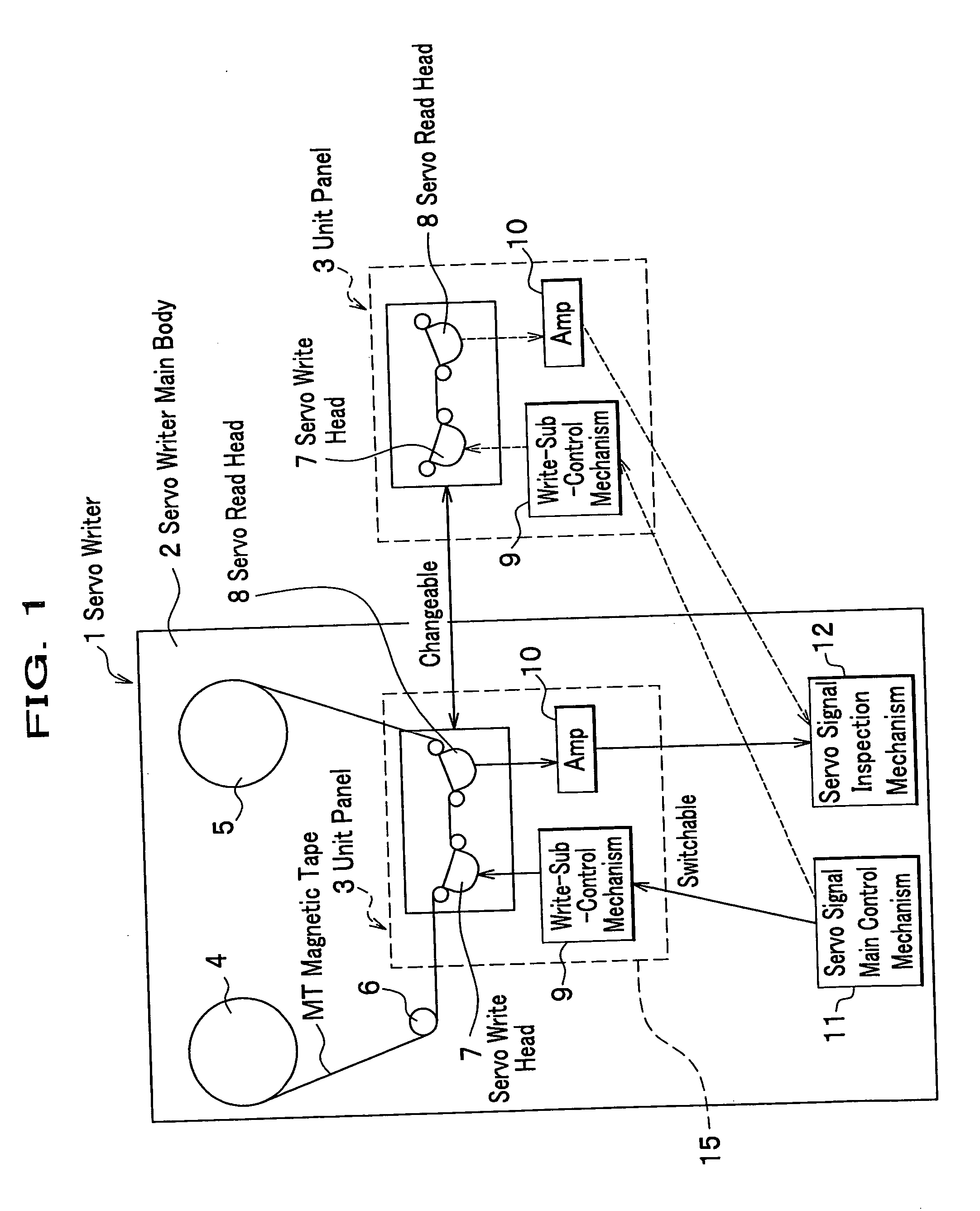

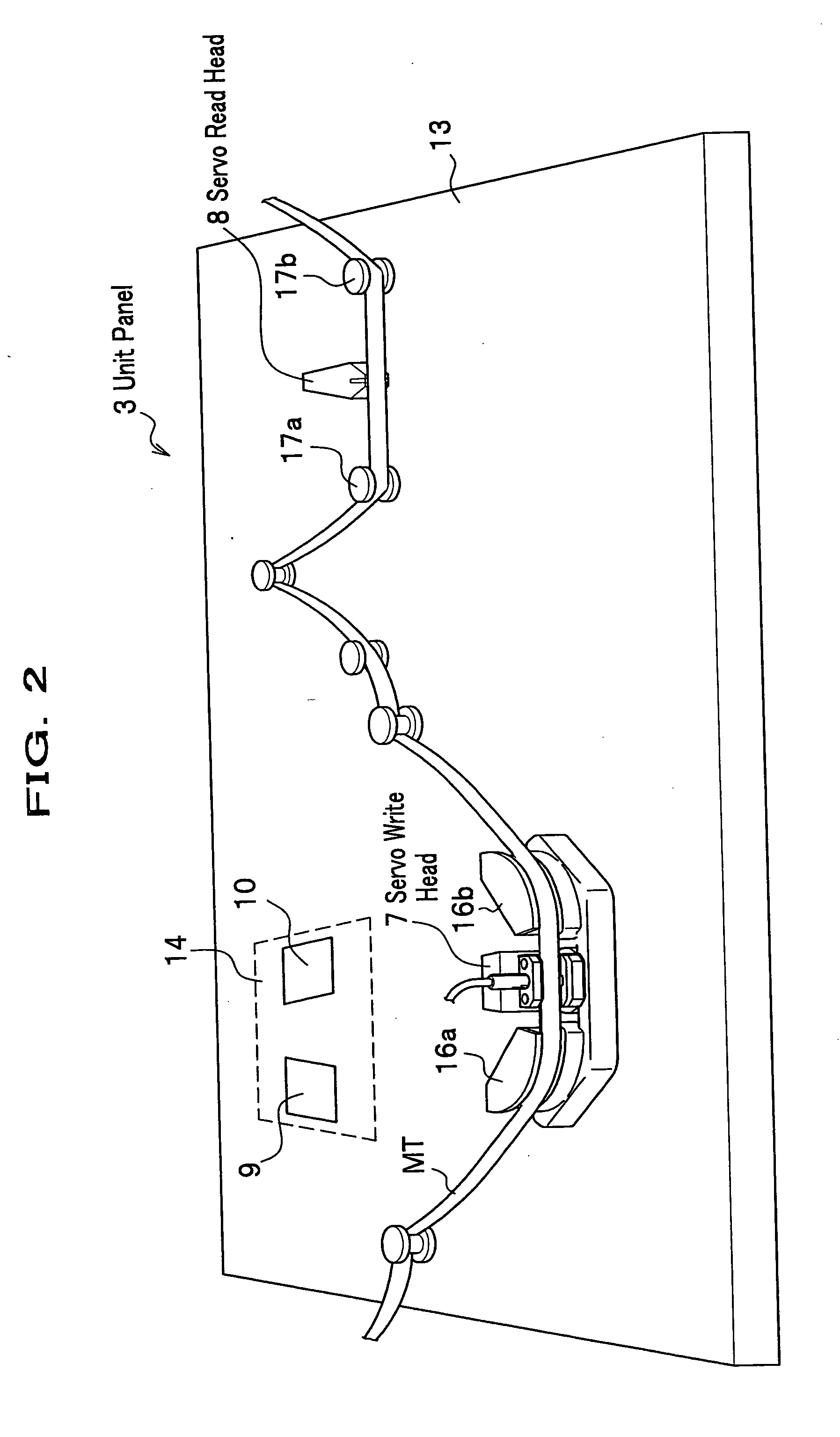

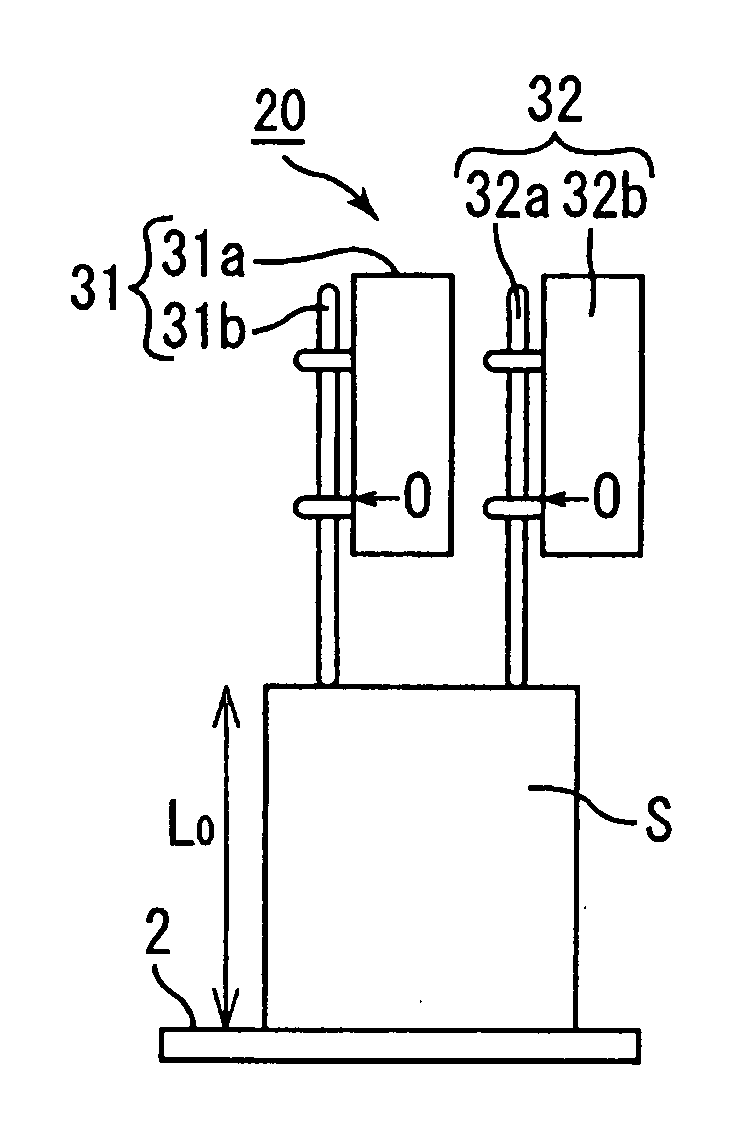

Servo writer, and write and inspection method of servo signal

InactiveUS20060056095A1Short timeDriving/moving recording headsFilamentary/web record carriersMagnetic tapeEngineering

A servo writer of the invention writes a servo signal in a magnetic tape, reads and inspects the signal, and has a servo writer main body and a plurality of unit panels changeably loaded to a panel change unit provided at the main body according to a product class of the tape, wherein any of the unit panels has a servo write head for writing the signal in the tape and a write-sub-control mechanism for controlling a writing of the signal by the write head, wherein the write head and the sub-control mechanism write a predetermined signal in the tape, and wherein the main body has a signal main control mechanism for mainly controlling a writing of the signal in the tape by the write head, a servo read head for reading the signal written in the tape, and a signal inspection mechanism for processing and inspecting the signal.

Owner:FUJIFILM CORP +1

RFID tag with visual environmental condition monitor

ActiveUS7209042B2Easy to processEasy to readContainer decorationsLevel indicationsTime responseStatistical analysis

A combination RFID tag intended to be associated with a host product, for example by being secured to the outside of a package containing a perishable product, e.g. foodstuffs or vaccines, which RFID tag is provided with a visually readable environmental condition exposure indicator. The visual indicator can sense the exposure of the RFID tag to an environmental condition e.g. temperature, experienced by the host product providing a visual indication, e.g. a color change, readable externally of the RFID tag of the sensed environmental condition. The visual indicator can be chemically active, for example an acetylenic agent, and may be responsive to cumulative temperature excursions over time. The novel RFID tag 11 and tag inspection methods of the invention permit an efficacious harnessing of information about the condition exposure history of a specific inventory item including product identification and related data. The information from multiple items can be compiled into a database that may be audited or statistically analyzed to reveal useful information regarding the handling of the items.

Owner:TEMPTIME CORP

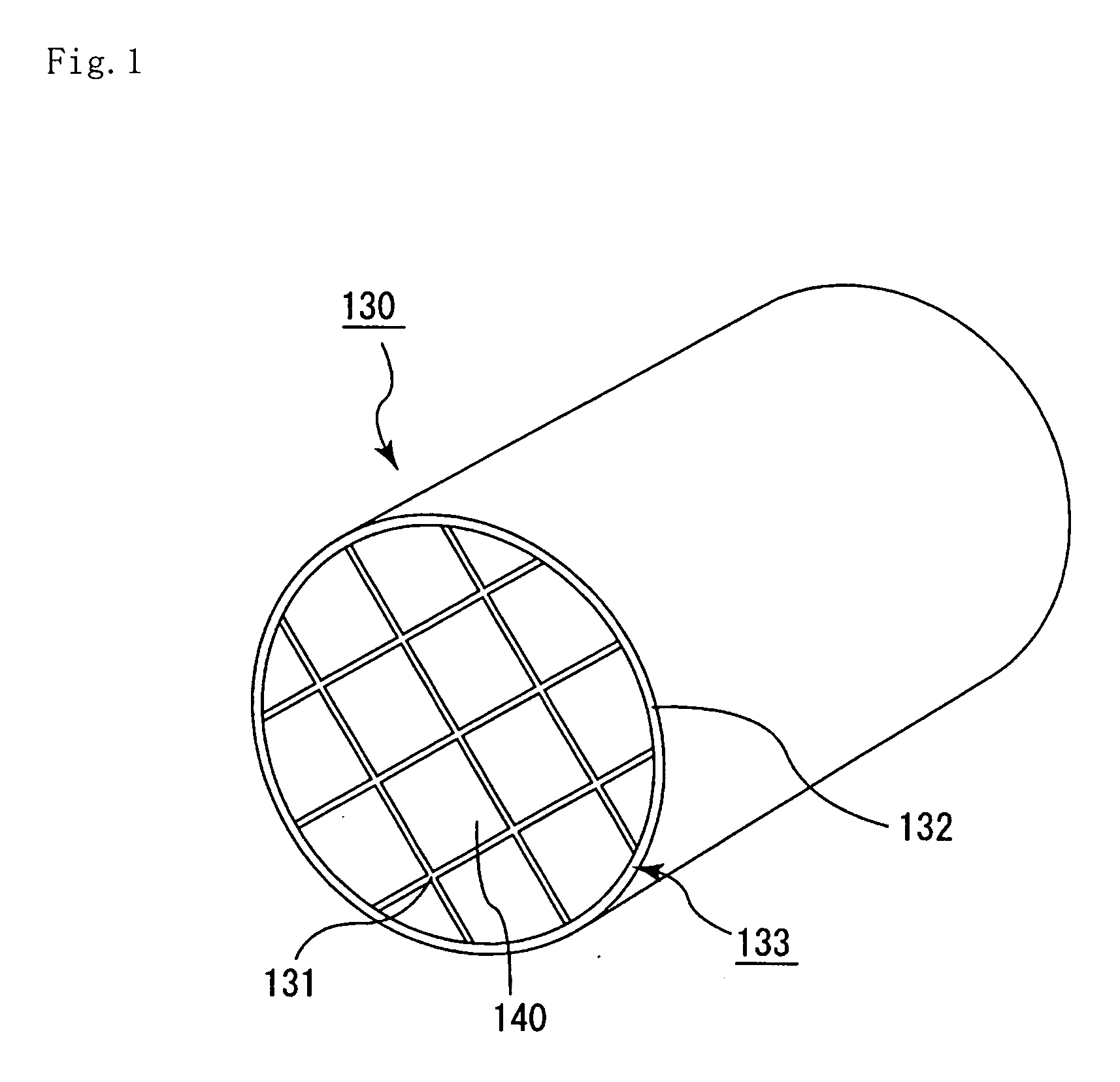

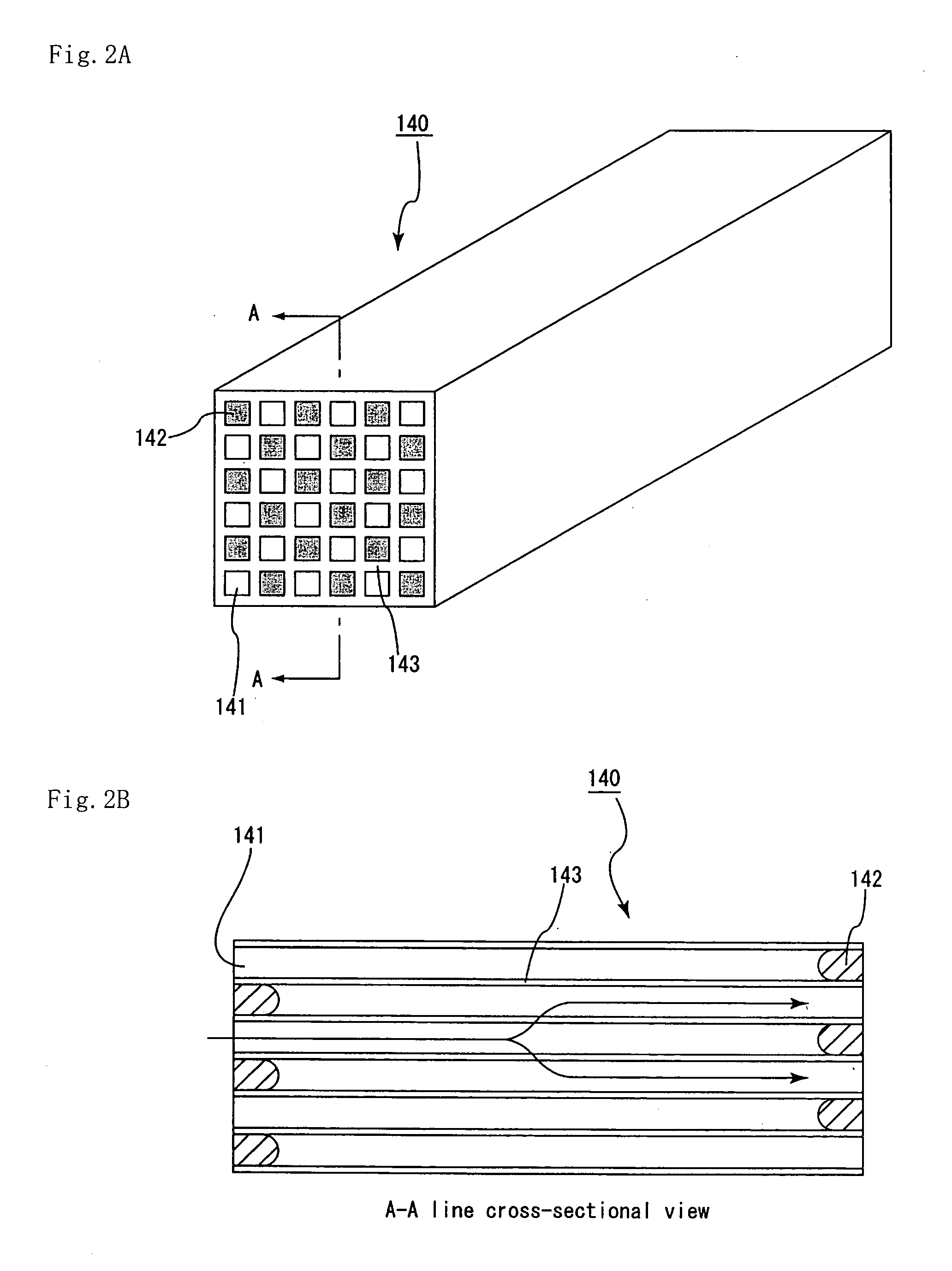

Method for inspecting honeycomb structured body and method for manufacturing honeycomb structured body

InactiveUS20070175060A1Good informationShort timeWalking sticksInternal combustion piston enginesEngineeringCell wall

Owner:IBIDEN CO LTD

Self-contained mobile inspection system and method

InactiveUS7486768B2Rapidly deployableCost-effectively and accurately on uneven surfaceHandling using diaphragms/collimetersRadiation beam directing meansMobile vehicleDetector array

The inspection methods and systems of the present invention are mobile, rapidly deployable, and capable of scanning a wide variety of receptacles cost-effectively and accurately on uneven surfaces. The present invention is directed toward a portable inspection system for generating an image representation of target objects using a radiation source, comprising a mobile vehicle, a detector array physically attached to a movable boom having a proximal end and a distal end. The proximal end is physically attached to the vehicle. The invention also comprises at least one source of radiation. The radiation source is fixedly attached to the distal end of the boom, wherein the image is generated by introducing the target objects in between the radiation source and the detector array, exposing the objects to radiation, and detecting radiation.

Owner:RAPISCAN SYST INC (US)

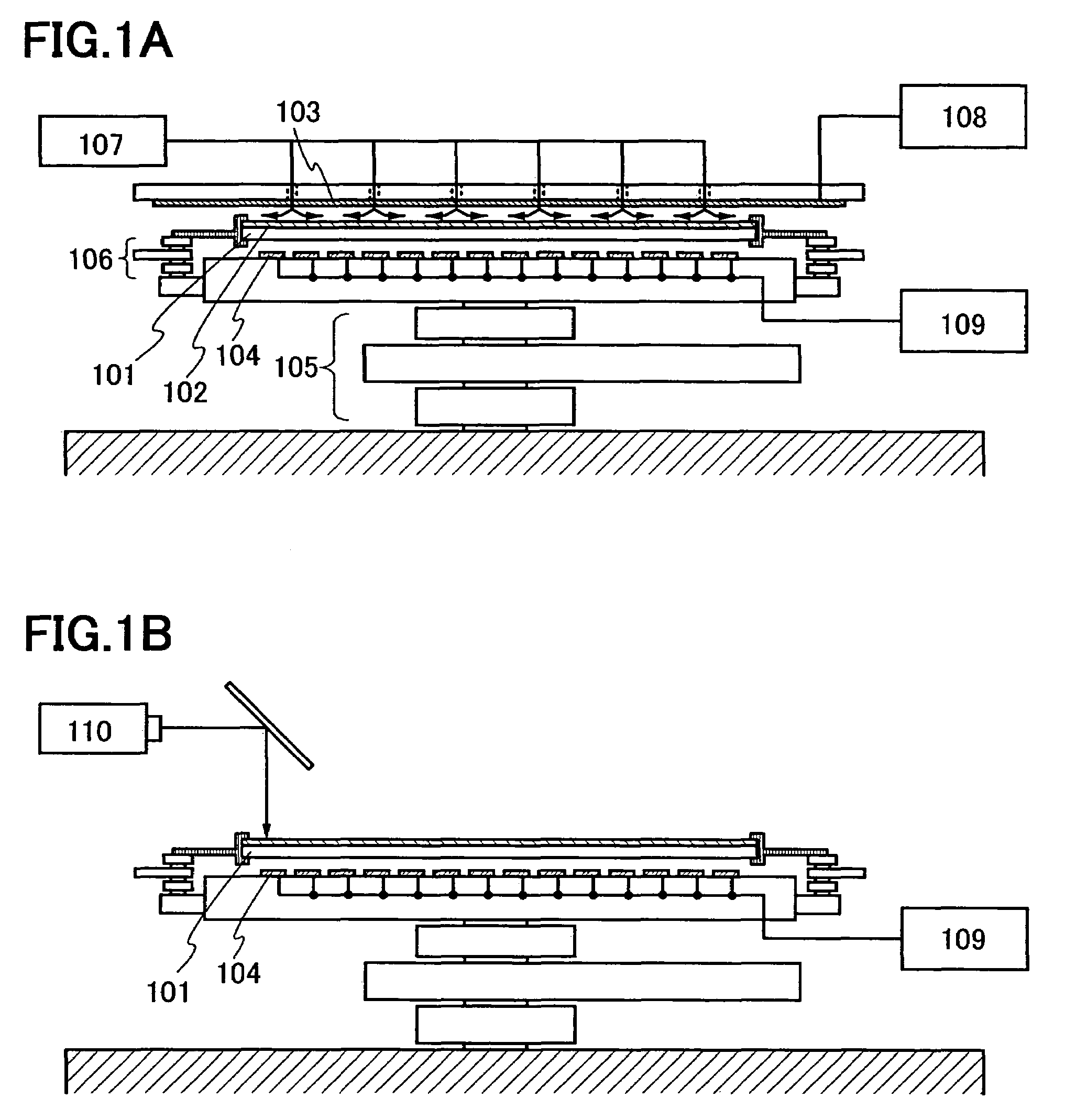

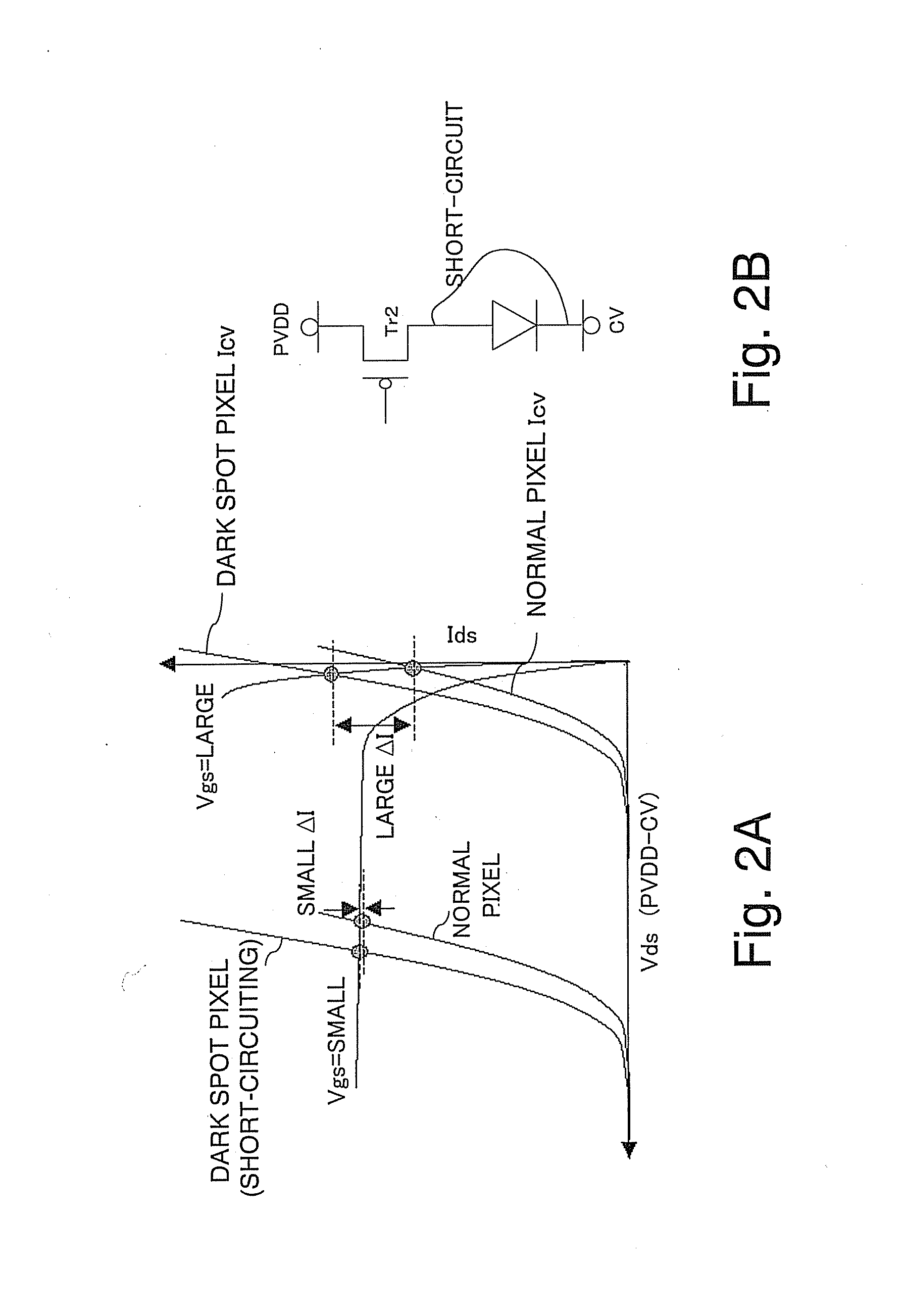

Method of inspecting defect for electroluminescence display apparatus, defect inspection apparatus, and method of manufacturing electroluminescence display apparatus using defect inspection method and apparatus

A dark spot defect caused by short-circuiting of an EL element is detected based on an emission brightness or a current flowing through the EL element when an element driving transistor which controls a drive current to be supplied to the EL element is operated in its linear operating region and the EL element is set to an emission level. A dim spot defect caused by a characteristic variation of the element driving transistor can be detected based on a current flowing through the EL element when the element driving transistor is operated in its saturation operating region and the EL element is set to the emission level. When an abnormal display pixel is detected based on an emission brightness, a pixel which is determined as an abnormal display pixel and which is not determined as a dark spot defect during a dark spot inspection is determined, and the pixel is detected as a dim spot defect caused by the characteristic variation of the element driving transistor.

Owner:SEMICON COMPONENTS IND LLC

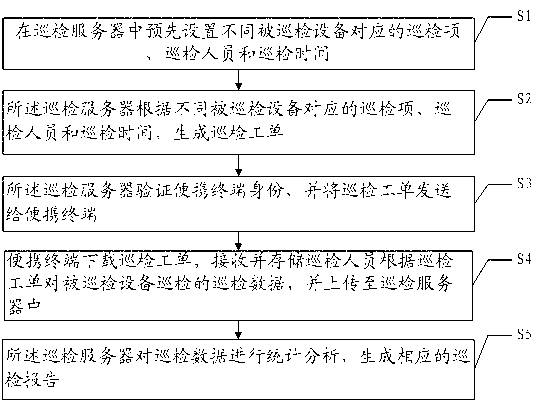

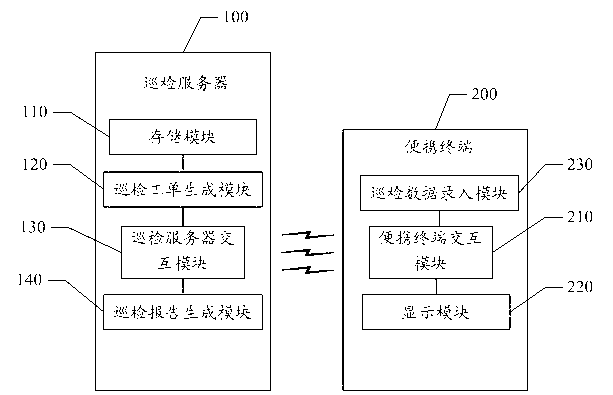

Inspection method and inspection system

ActiveCN103325153AAchieving summaryRealize analysisChecking time patrolsStatistical analysisHand held

The invention discloses an inspection method and an inspection system. The inspection method comprises the steps that: inspection items, inspectors and inspection time corresponding to different inspection devices are set in an inspection server in advance; the inspection server generates inspection work orders according to the inspection items, the inspectors and the inspection time corresponding to the different inspection devices; the inspection server verifies the identity of a portable terminal and sends the inspection work orders to the portable terminal; the portable terminal downloads the inspection work orders, receives and stores inspection data of an inspected device inspected according to the inspection work orders by the inspector, and uploads the inspection data to the inspection server; the inspection server performs statistic analysis on the inspected data to generate a corresponding inspection report, and the inspection data of devices are reported through the hand-held portable terminal, so that the workload of inspection is greatly reduced and the inspection efficiency is significantly improved. Therefore, the collection and the analysis of the inspection data are realized, thereby providing the great convenience for users to know the condition of an inspected device in real time and perform the corresponding maintenance.

Owner:SHENZHEN XBROTHER TECH

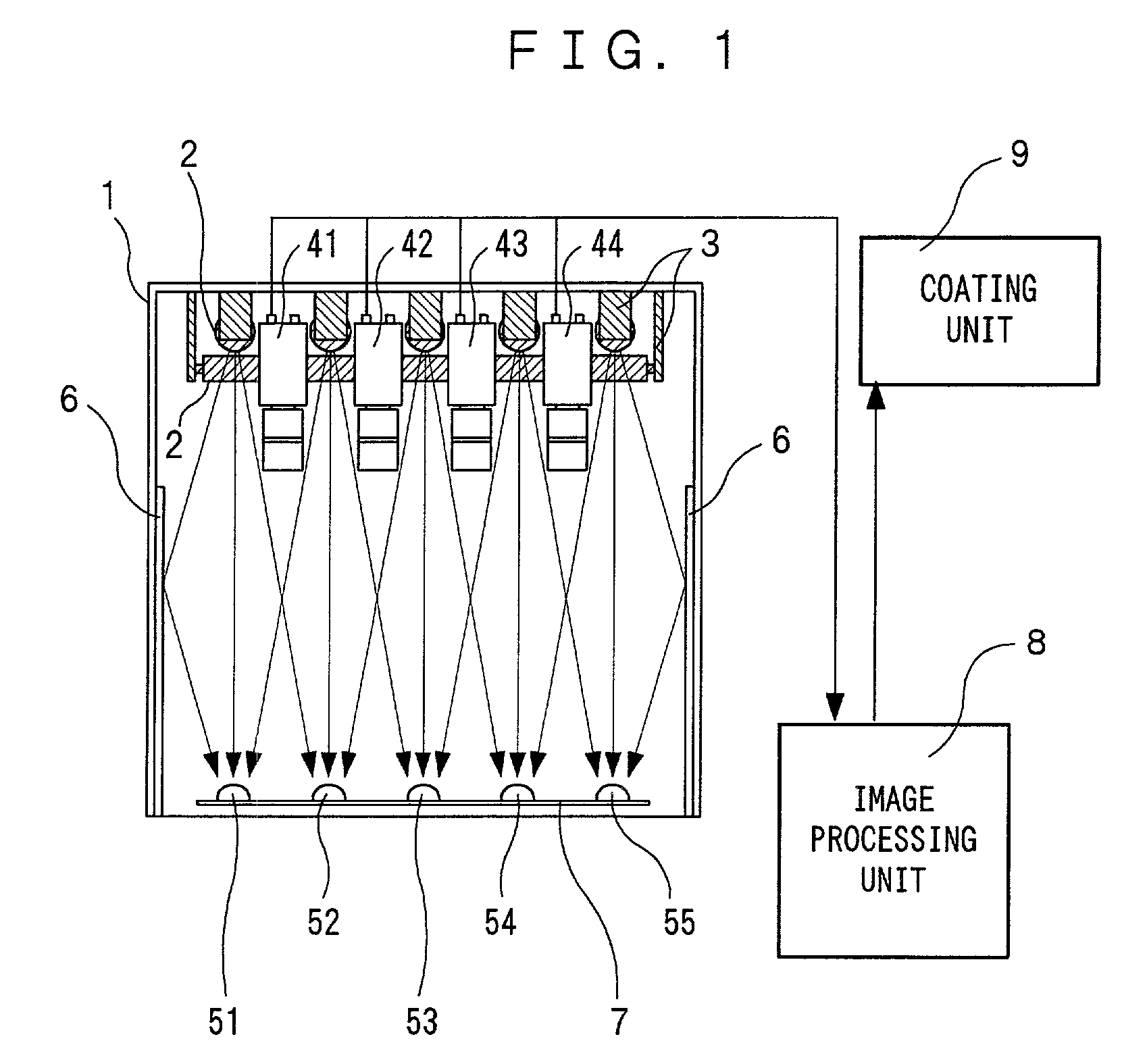

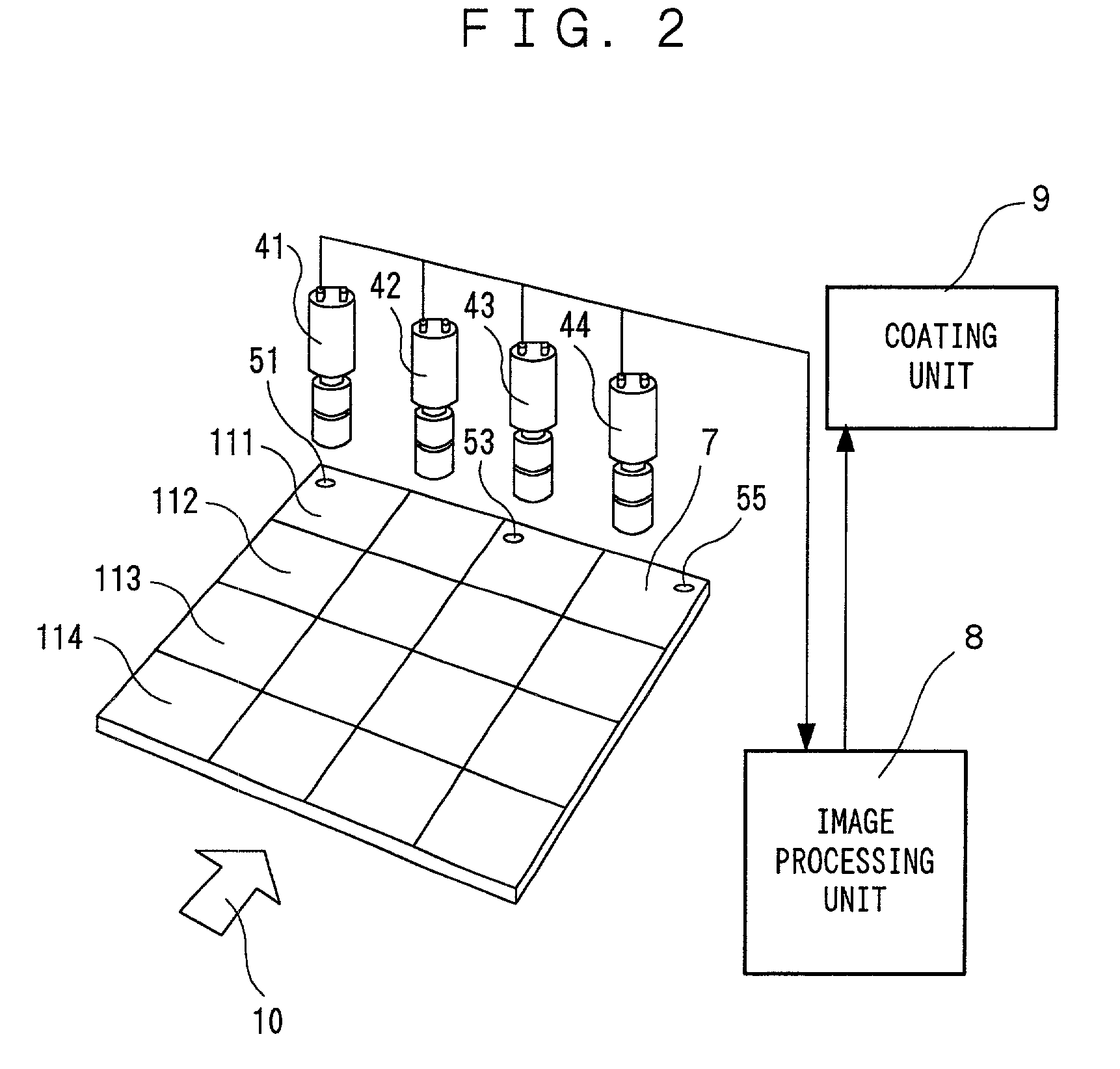

Transparent liquid inspection apparatus, transparent liquid inspection method, and transparent liquid application method

InactiveUS7276380B2Increase speedImprove accuracyBioreactor/fermenter combinationsBiological substance pretreatmentsImaging processingComputer science

The present invention provides a transparent liquid inspection apparatus capable of identifying a boundary between a transparent liquid applied on a base material which provides a multi-piece product and the base material, and automatically inspecting an applied condition of the transparent liquid without influence of a background of the base material. A projected image of an illumination source (2) is reflected on a surface of the transparent liquid as a mirror, the projected image is picked up by cameras (41 to 44), and the image is analyzed by an image processing unit (8), thereby inspecting an amount of displacement of the transparent liquid from a predetermined application position and expansion of the surface of the transparent liquid.

Owner:PHC HLDG CORP

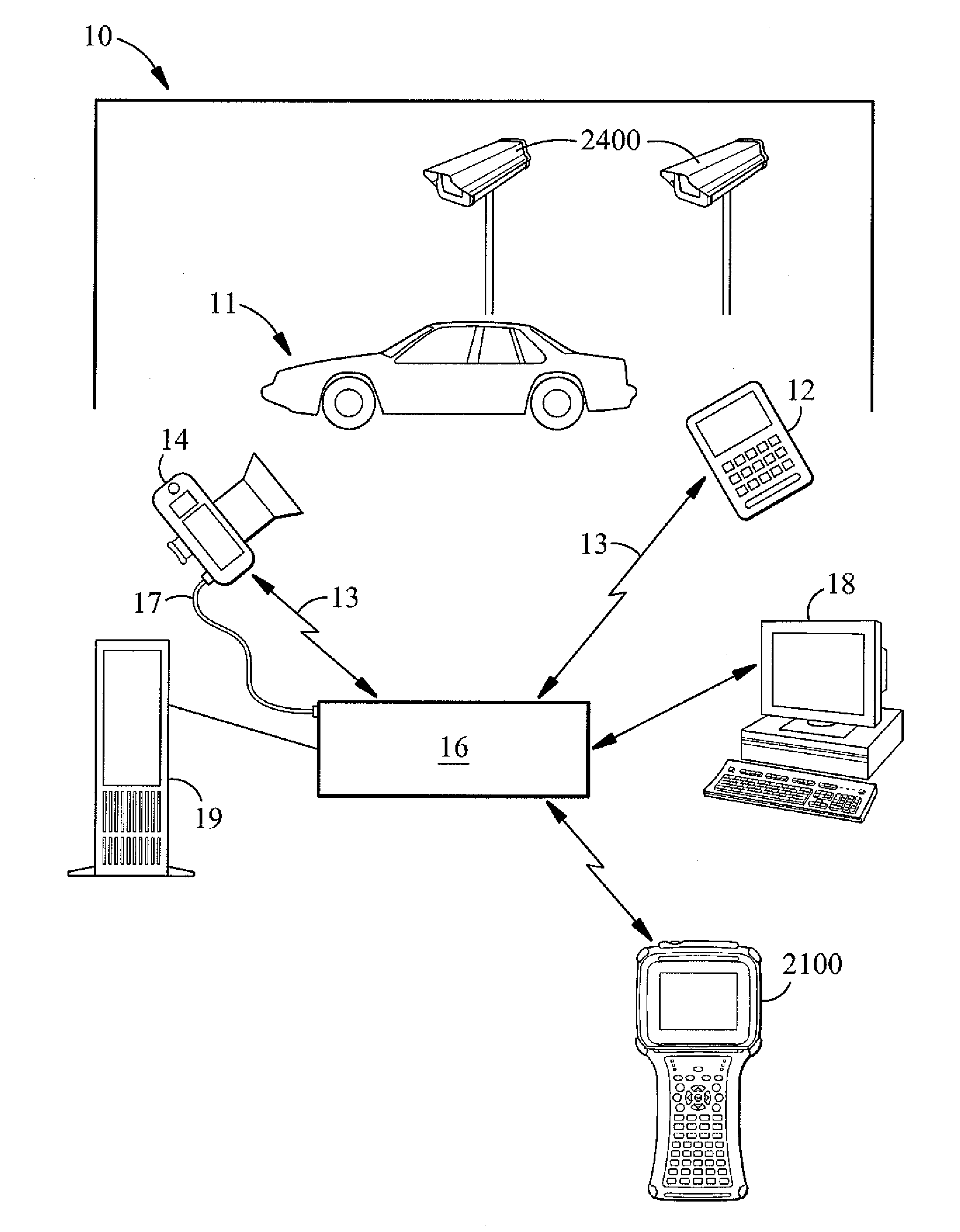

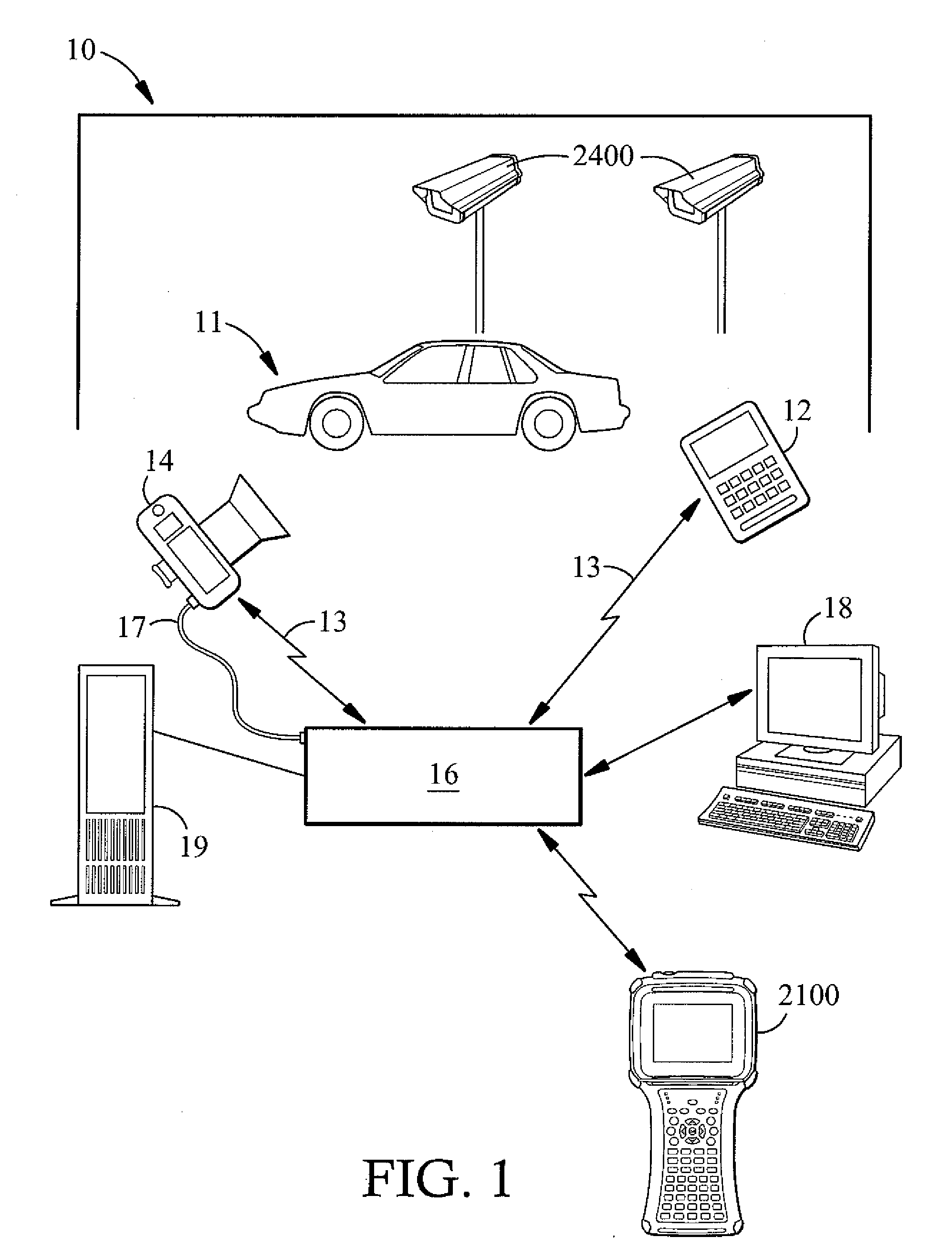

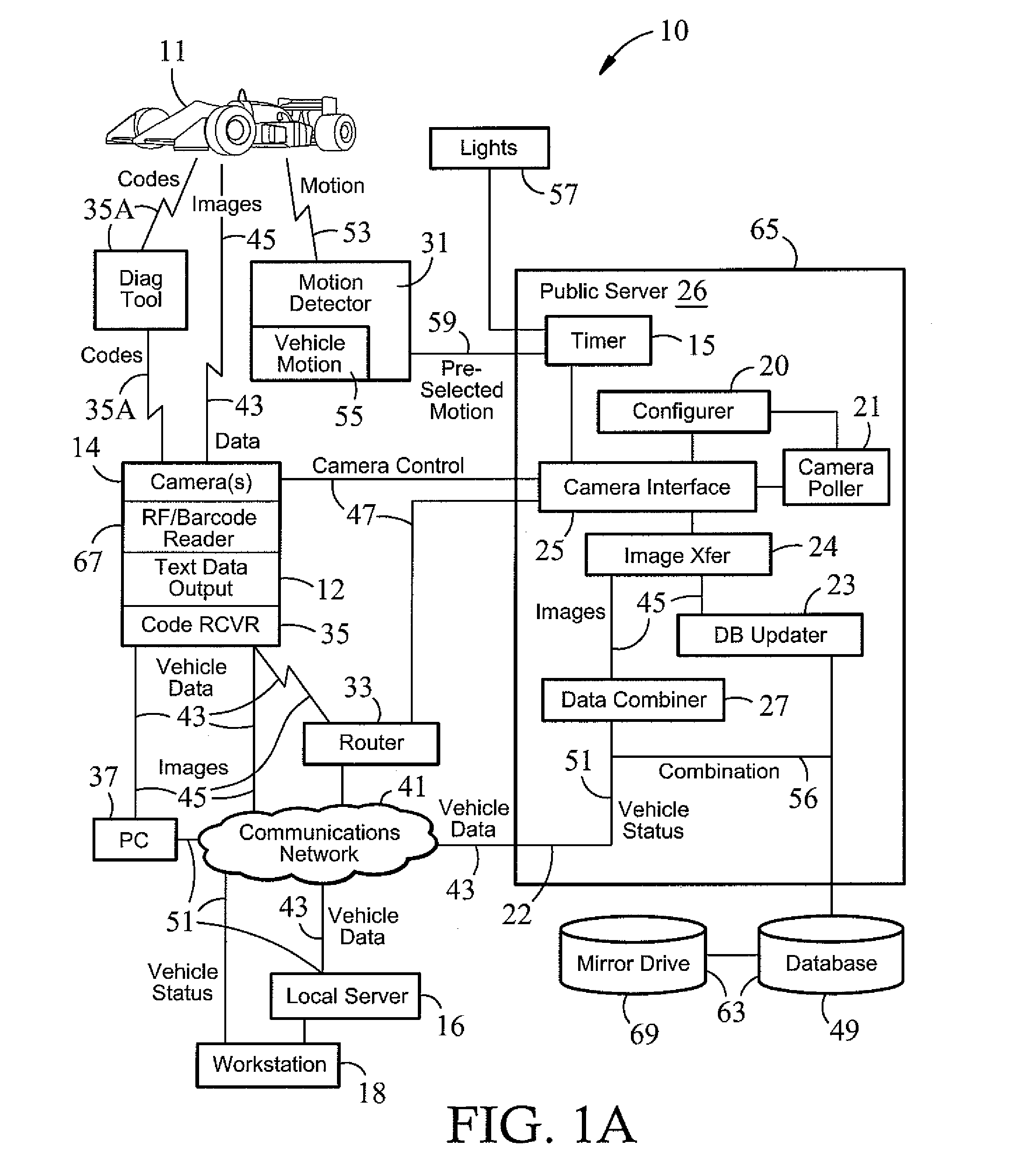

Automated Vehicle Check-In Inspection Method and System With Digital Image Archiving

InactiveUS20070250232A1Quick searchSure easyVehicle testingData processing applicationsIn vehicleDigital image

A collection of software scripts, programs and web pages that capture, organize, and store wireless and digital device data and images of customer / lot vehicles for use in vehicle dealerships, service, and repair locations. Reports and views of the collected, organized data in real-time are provide.

Owner:AUTOCHECKMATE

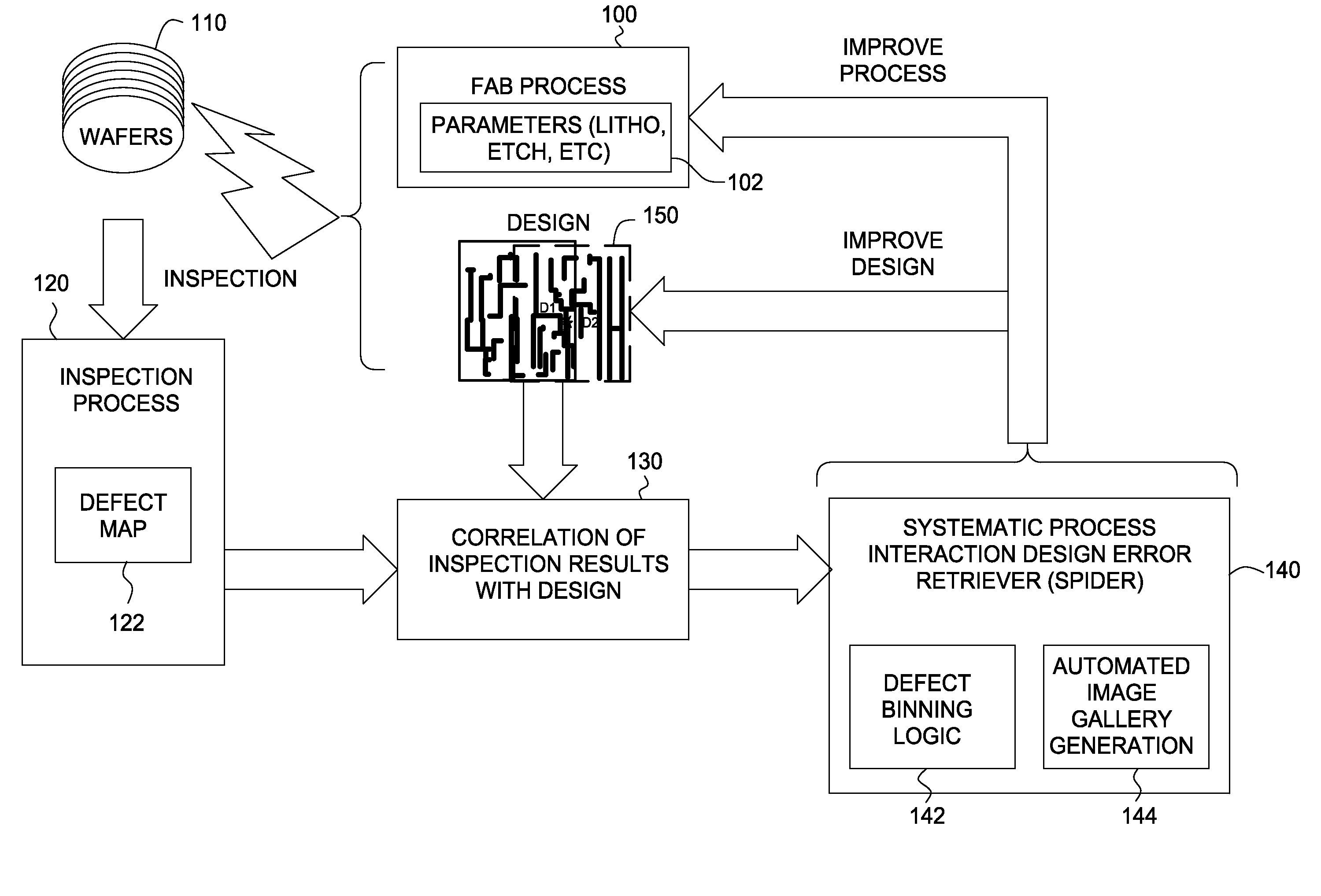

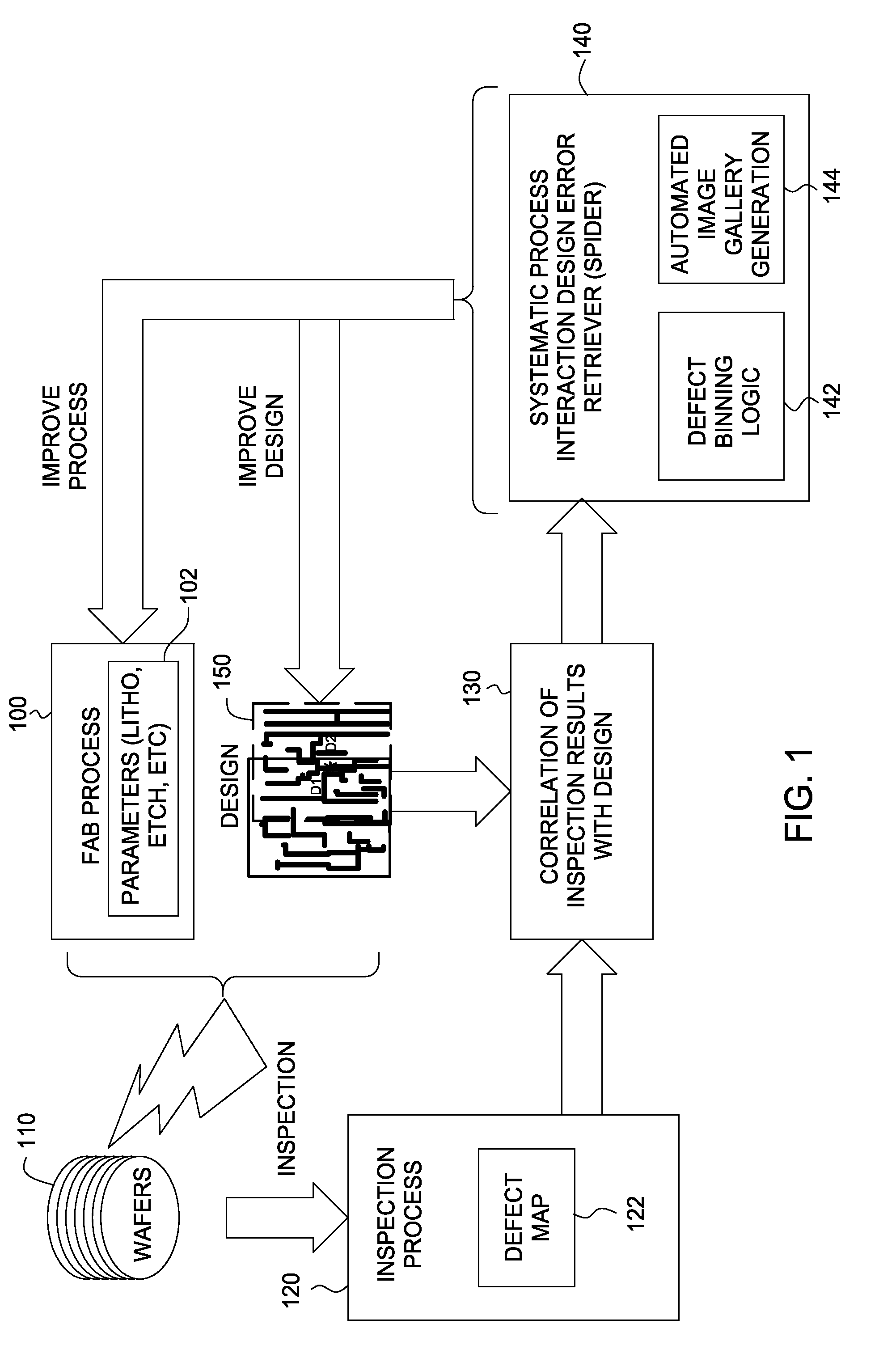

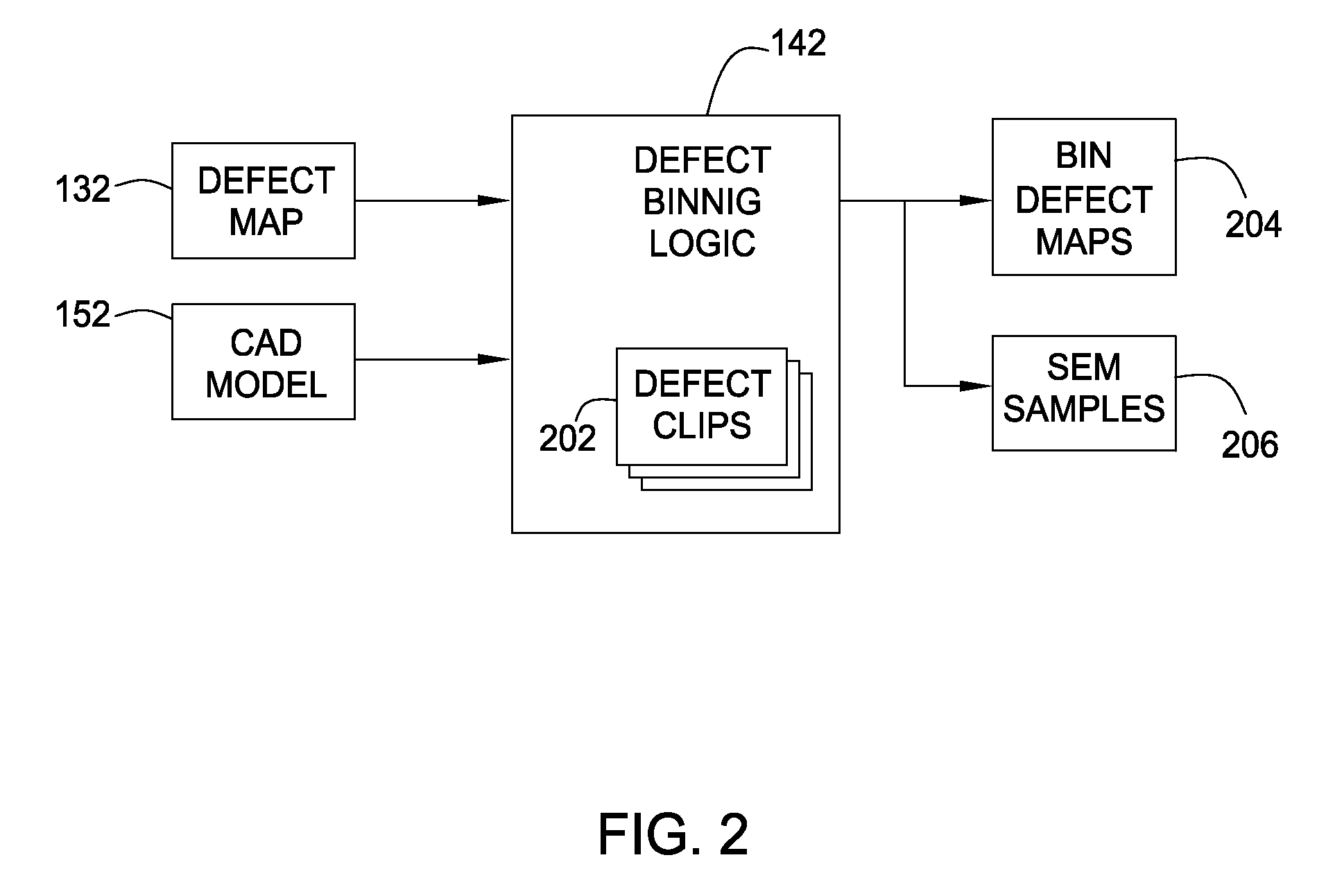

Grouping systematic defects with feedback from electrical inspection

ActiveUS20070052963A1Photomechanical apparatusMaterial analysis by optical meansEngineeringSemiconductor

Methods and apparatus for categorizing defects on workpieces, such as semiconductor wafers and masks used in lithographically writing patterns into such wafers are provided. For some embodiments, by analyzing the layout in the neighborhood of the defect, and matching it to similar defected neighborhoods in different locations across the die, defects may be categorized by common structures in which they occur.

Owner:APPLIED MATERIALS INC

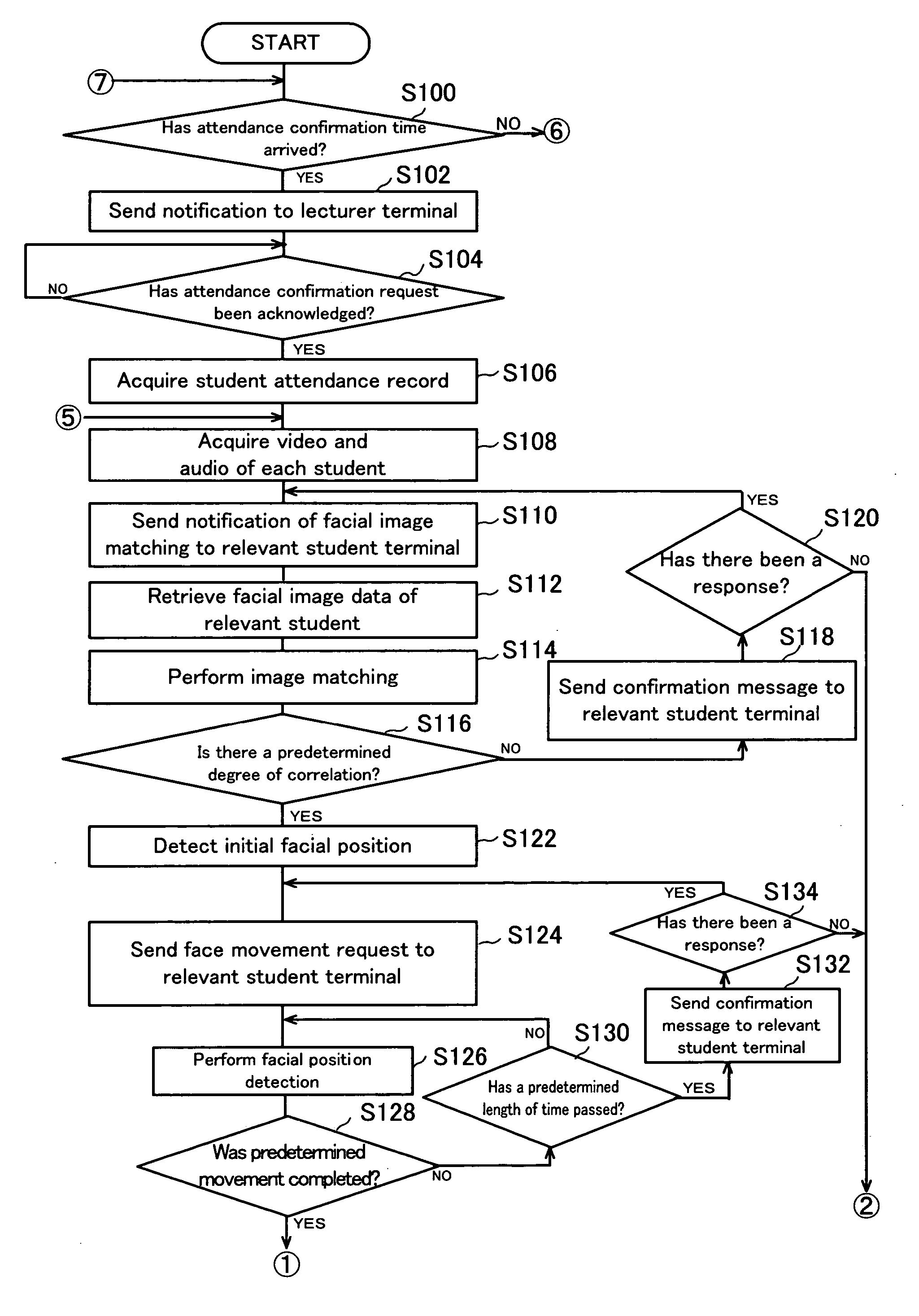

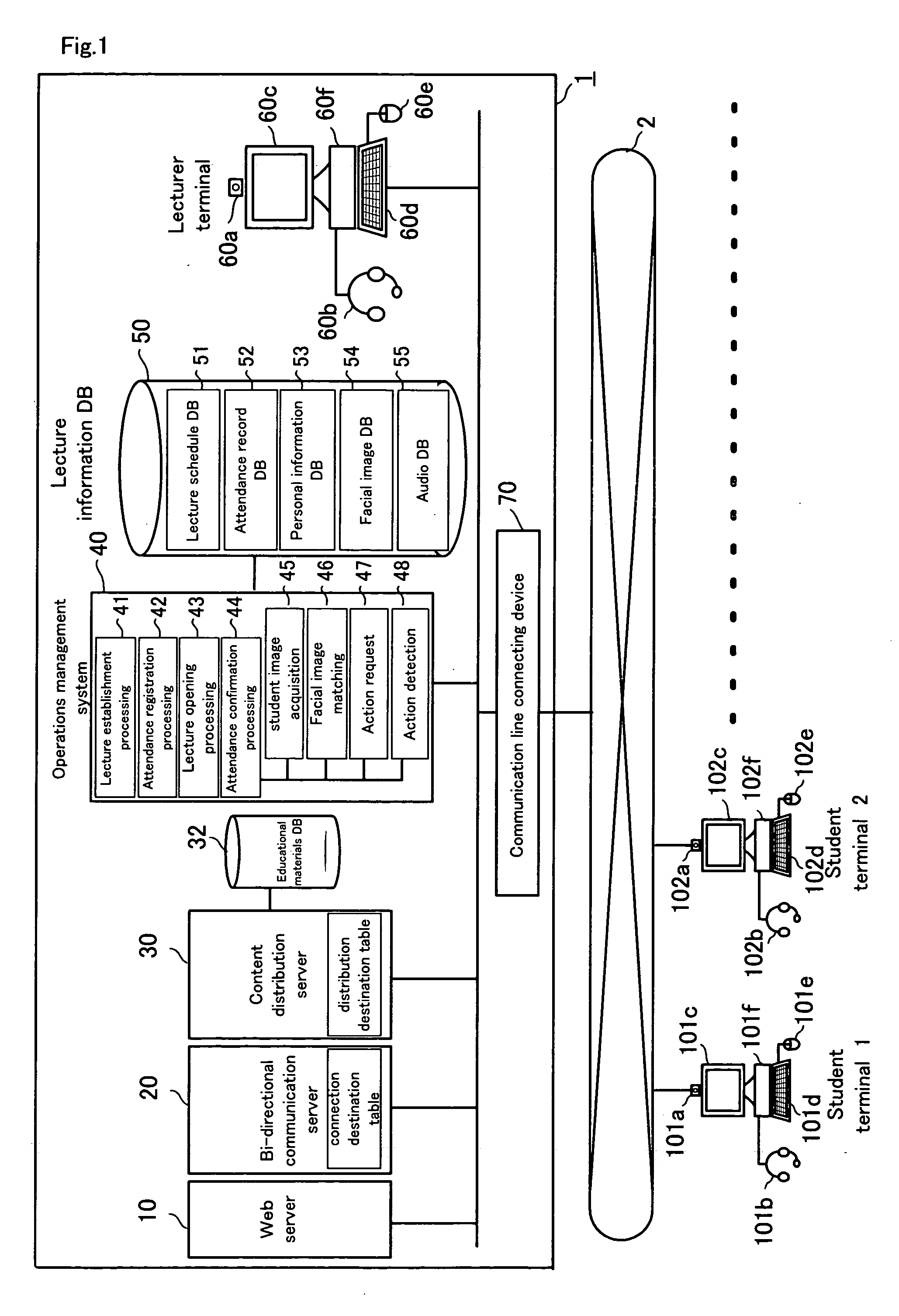

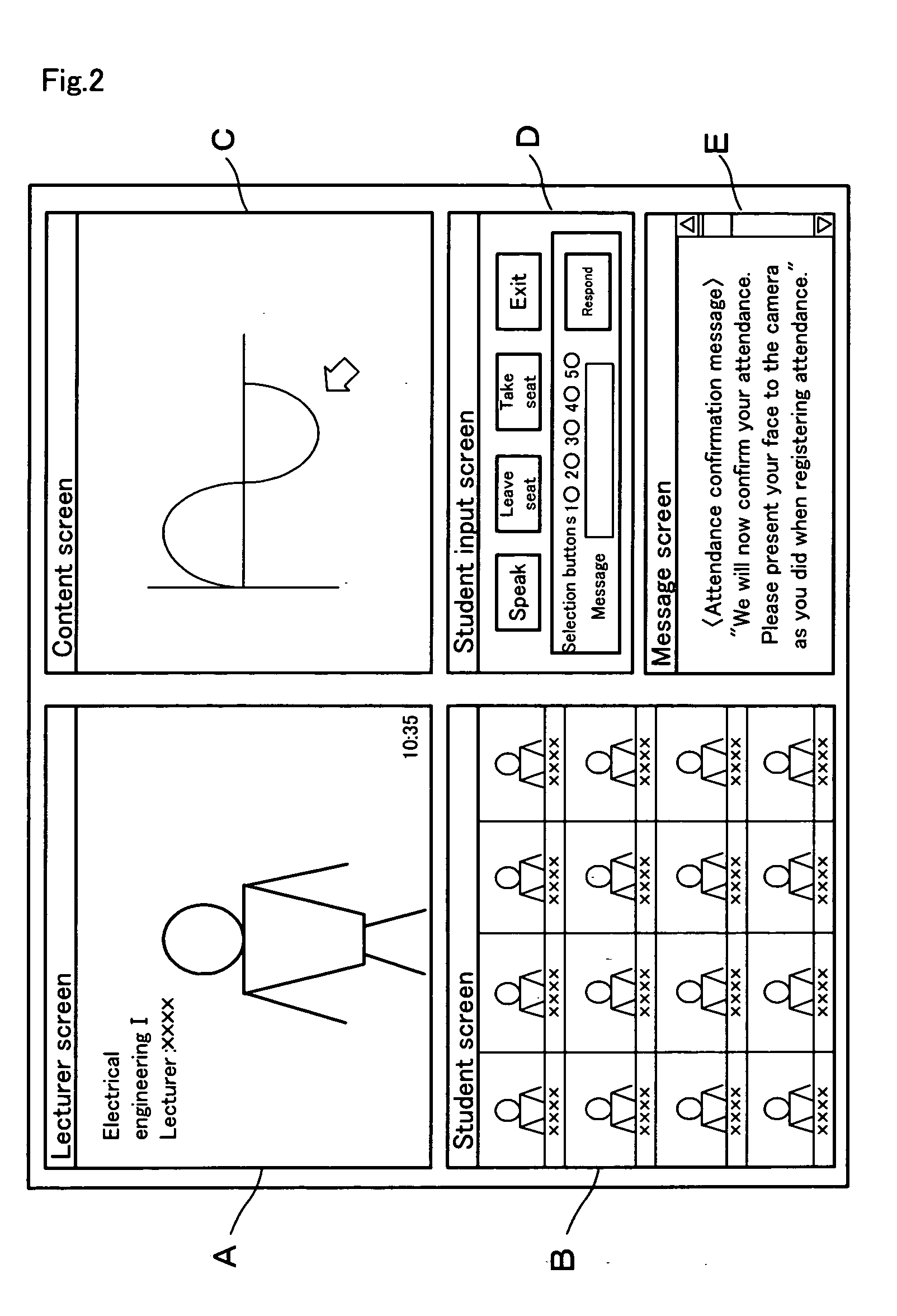

Remote education system, course attendance check method, and course attendance check program

InactiveUS20060057550A1Data processing applicationsTelevision conference systemsRequest - actionContent distribution

A remote education system includes a Web server, a bidirectional communication server, a content distribution server, an operations management system, a lecturer terminal, and a communication line connection device, and provides remote education to student terminals via the Internet. The operations management system includes a lecture information database for storing lecture schedules, attendance records, and personal information, facial images, and audio, of the students, and performs a lecture establishment processing, an attendance registration processing, a lecture opening processing, an attendance confirmation processing, and the like. The attendance confirmation processing includes a student image acquisition processing, a facial image matching processing, an action request processing, and an action detection processing, which match facial images of students, and detect image changes that occur in response to requested actions.

Owner:GINGANET CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com