Patents

Literature

6812 results about "Exposure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In photography, exposure is the amount of light per unit area (the image plane illuminance times the exposure time) reaching a photographic film or electronic image sensor, as determined by shutter speed, lens aperture and scene luminance. Exposure is measured in lux seconds, and can be computed from exposure value (EV) and scene luminance in a specified region.

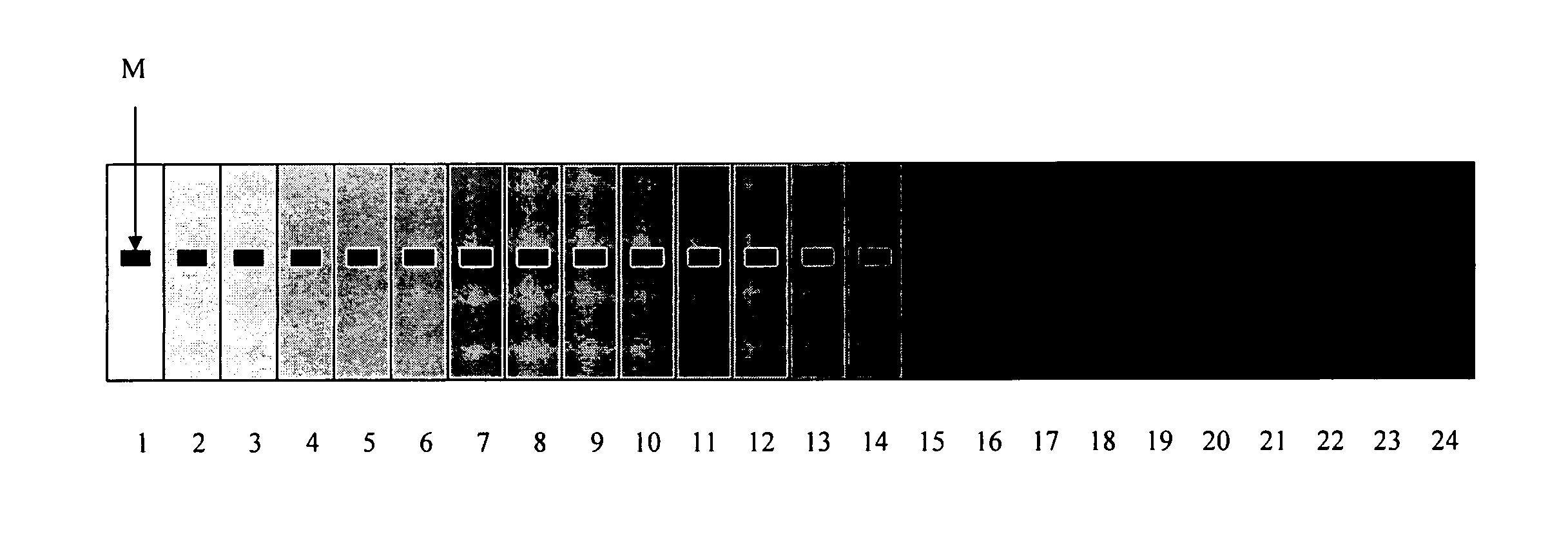

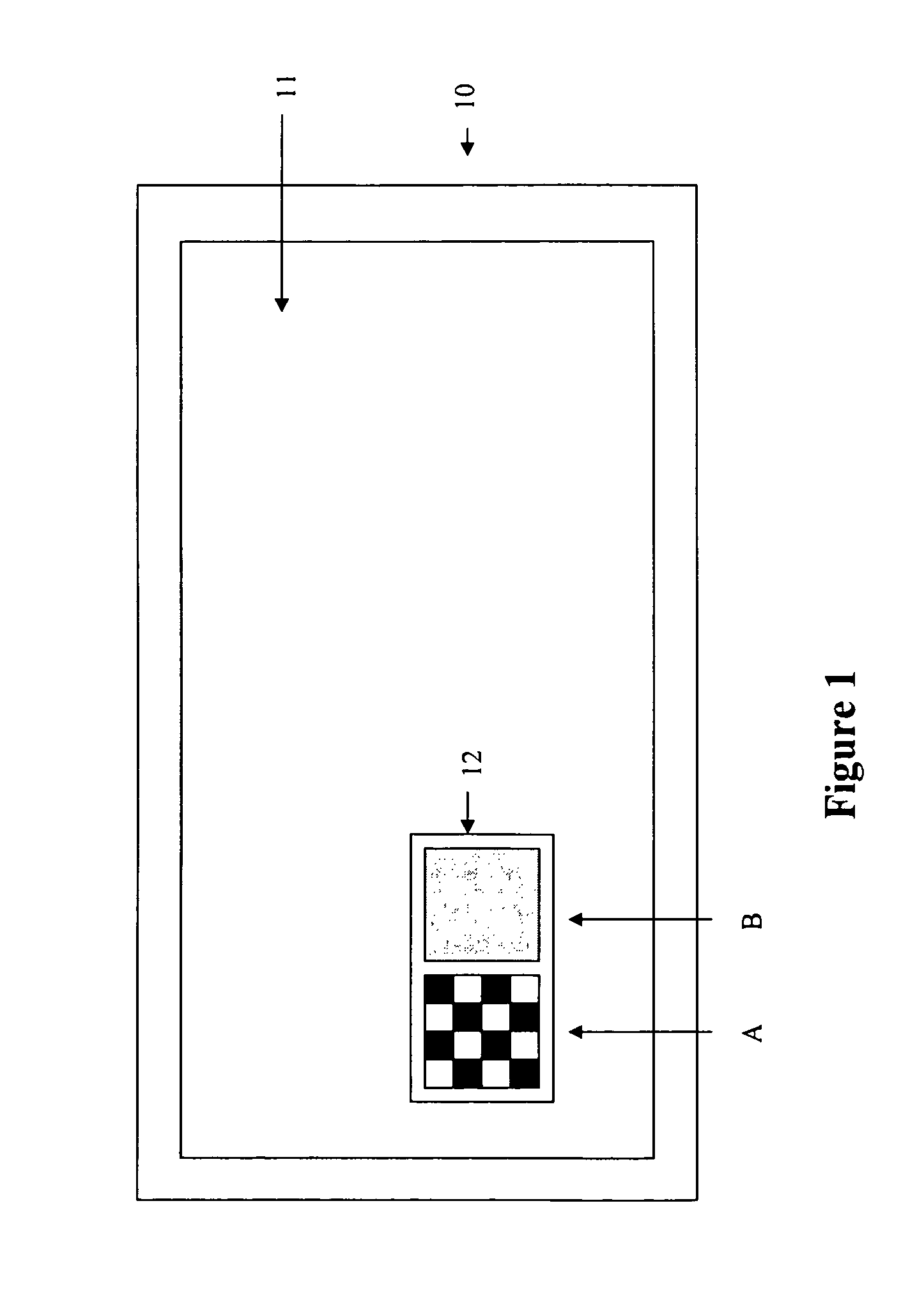

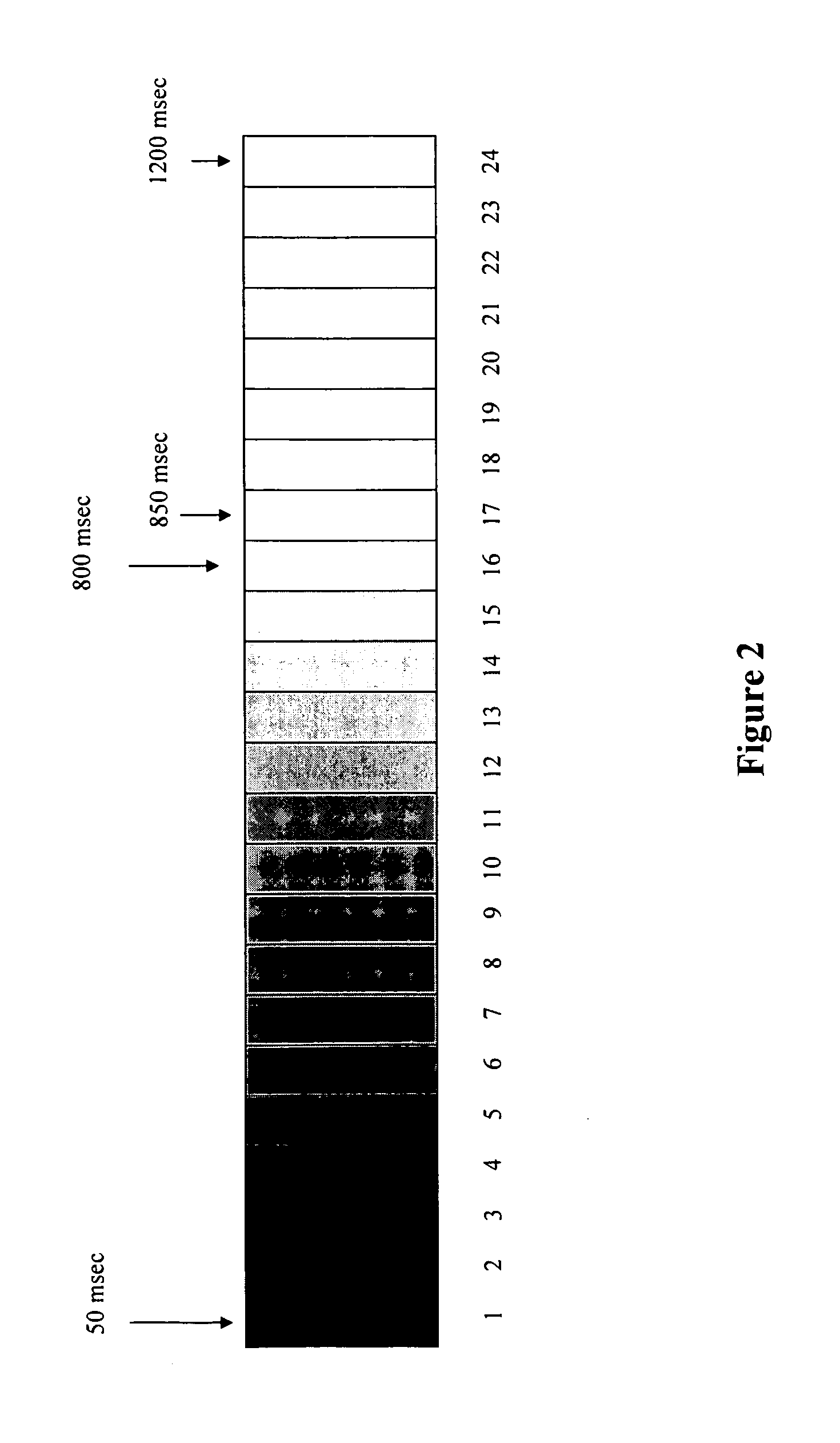

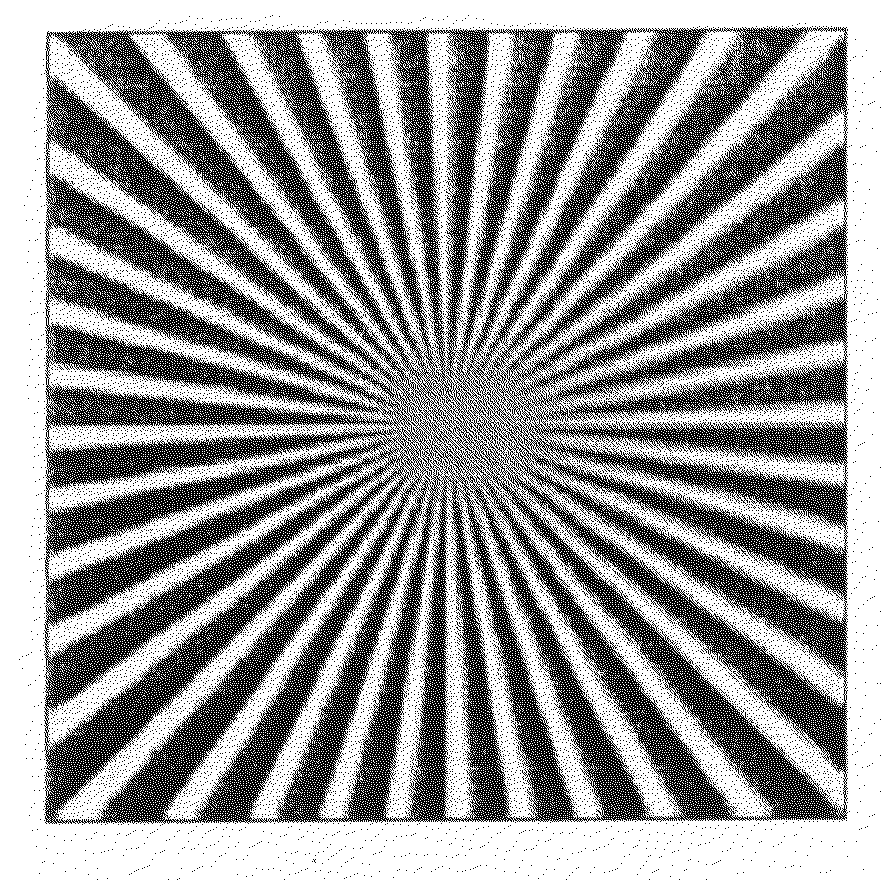

Lithographic Focus and Dose Measurement Using A 2-D Target

ActiveUS20110249244A1Minimize overall surface areaArea minimizationPhotomechanical apparatusSemiconductor/solid-state device manufacturingRadiologyScatterometer

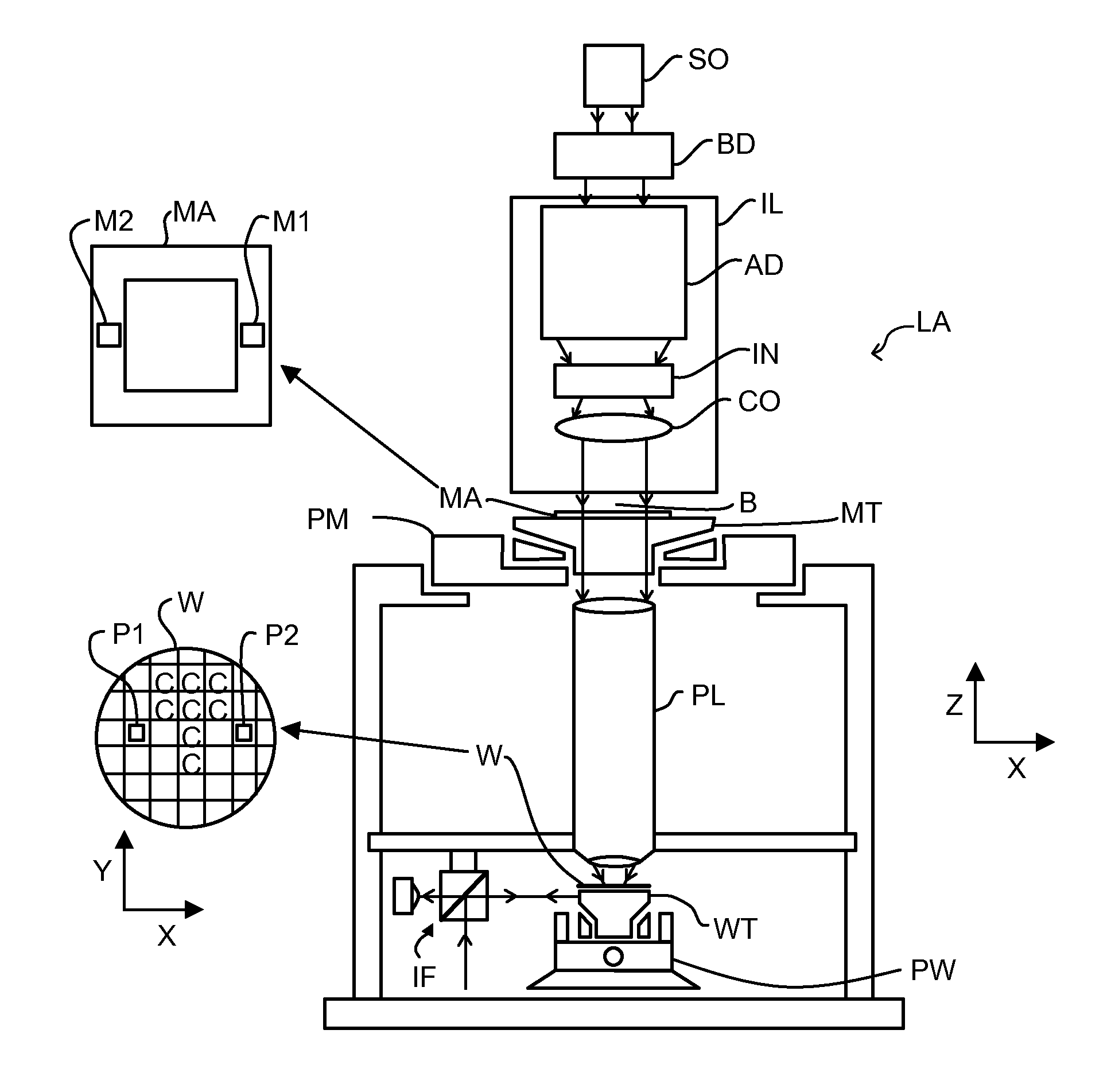

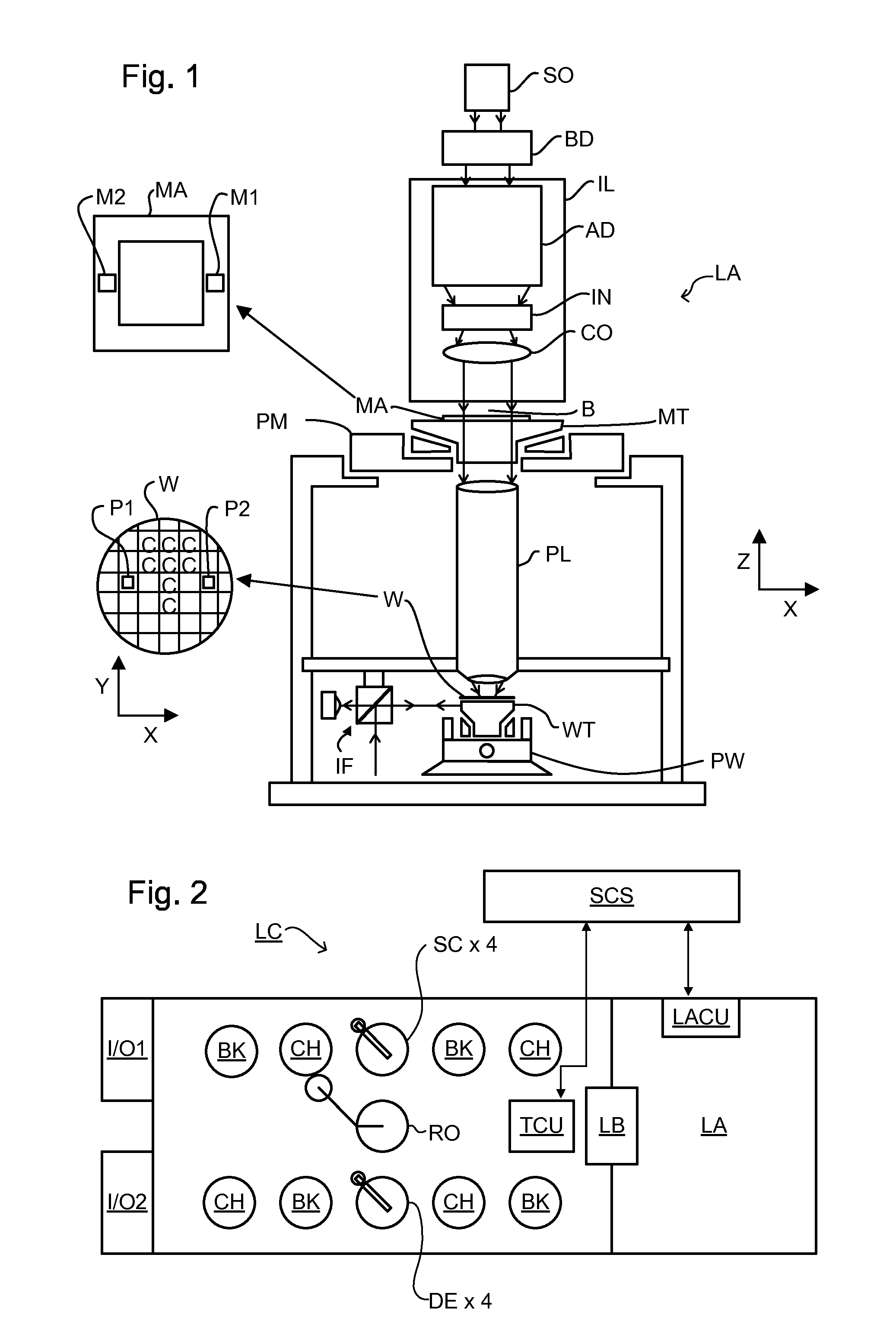

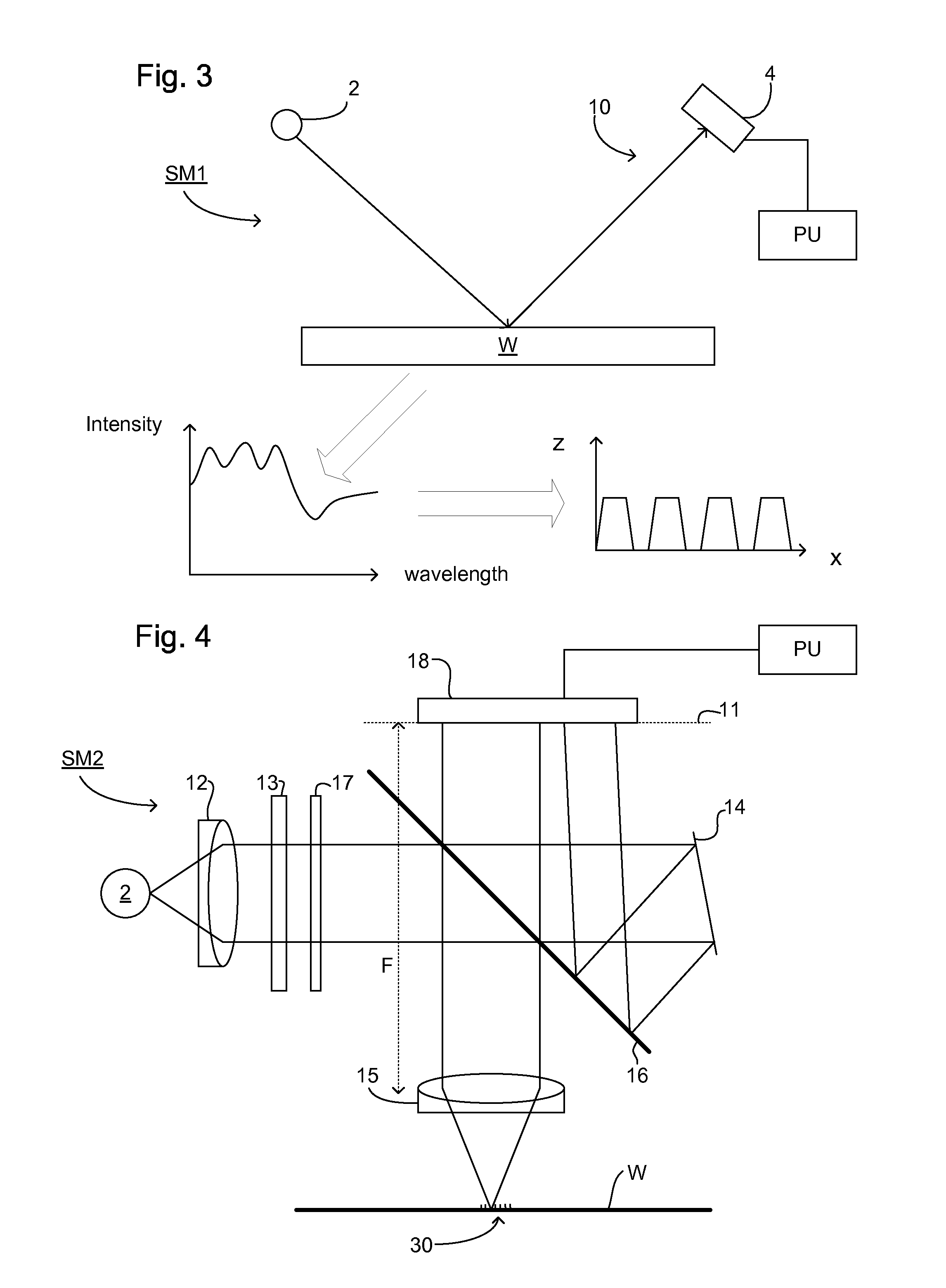

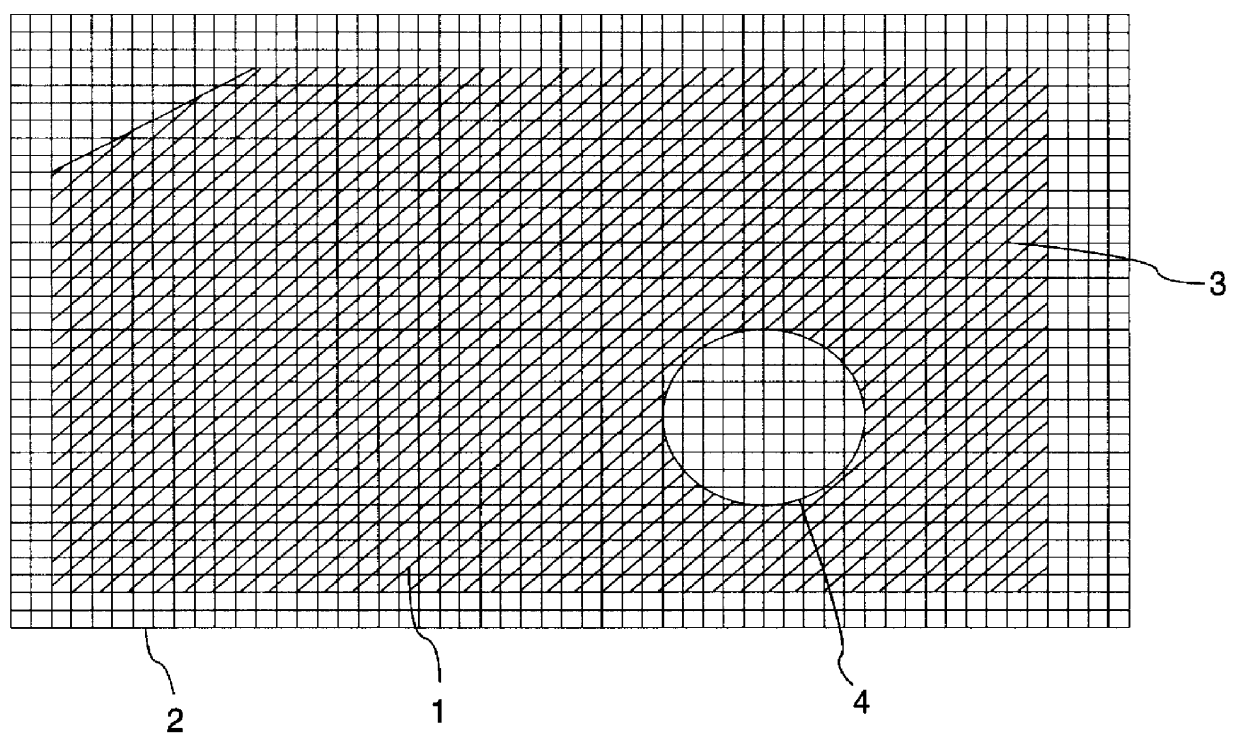

In order to determine whether an exposure apparatus is outputting the correct dose of radiation and its projection system is focusing the radiation correctly, a test pattern is used on a mask for printing a specific marker onto a substrate. This marker is then measured by an inspection apparatus, such as a scatterometer, to determine whether there are errors in focus and dose and other related properties. The test pattern is configured such that changes in focus and dose may be easily determined by measuring the properties of a pattern that is exposed using the mask. The test pattern may be a 2D pattern where physical or geometric properties, e.g., pitch, are different in each of the two dimensions. The test pattern may also be a one-dimensional pattern made up of an array of structures in one dimension, the structures being made up of at least one substructure, the substructures reacting differently to focus and dose and giving rise to an exposed pattern from which focus and dose may be determined.

Owner:ASML NETHERLANDS BV

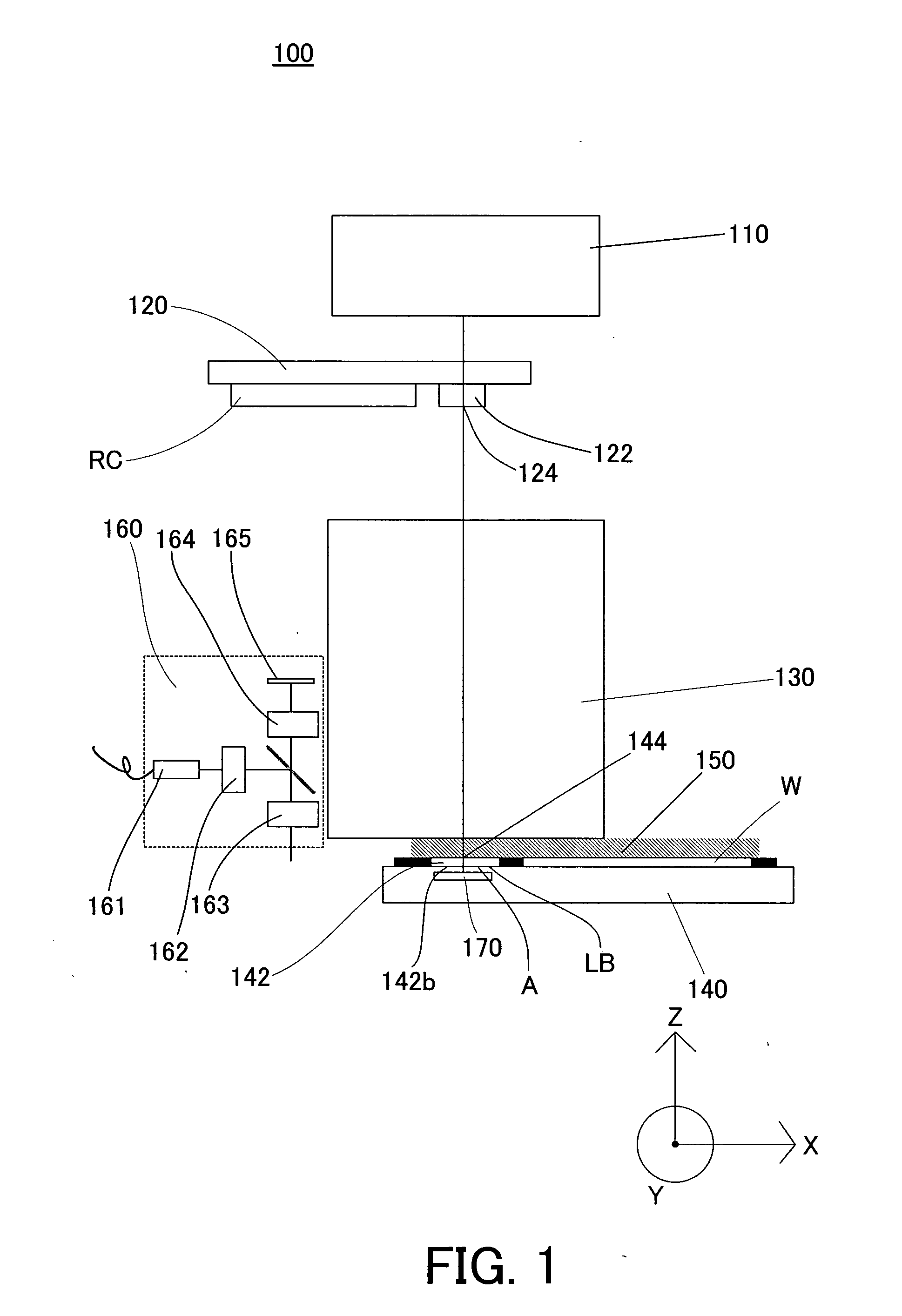

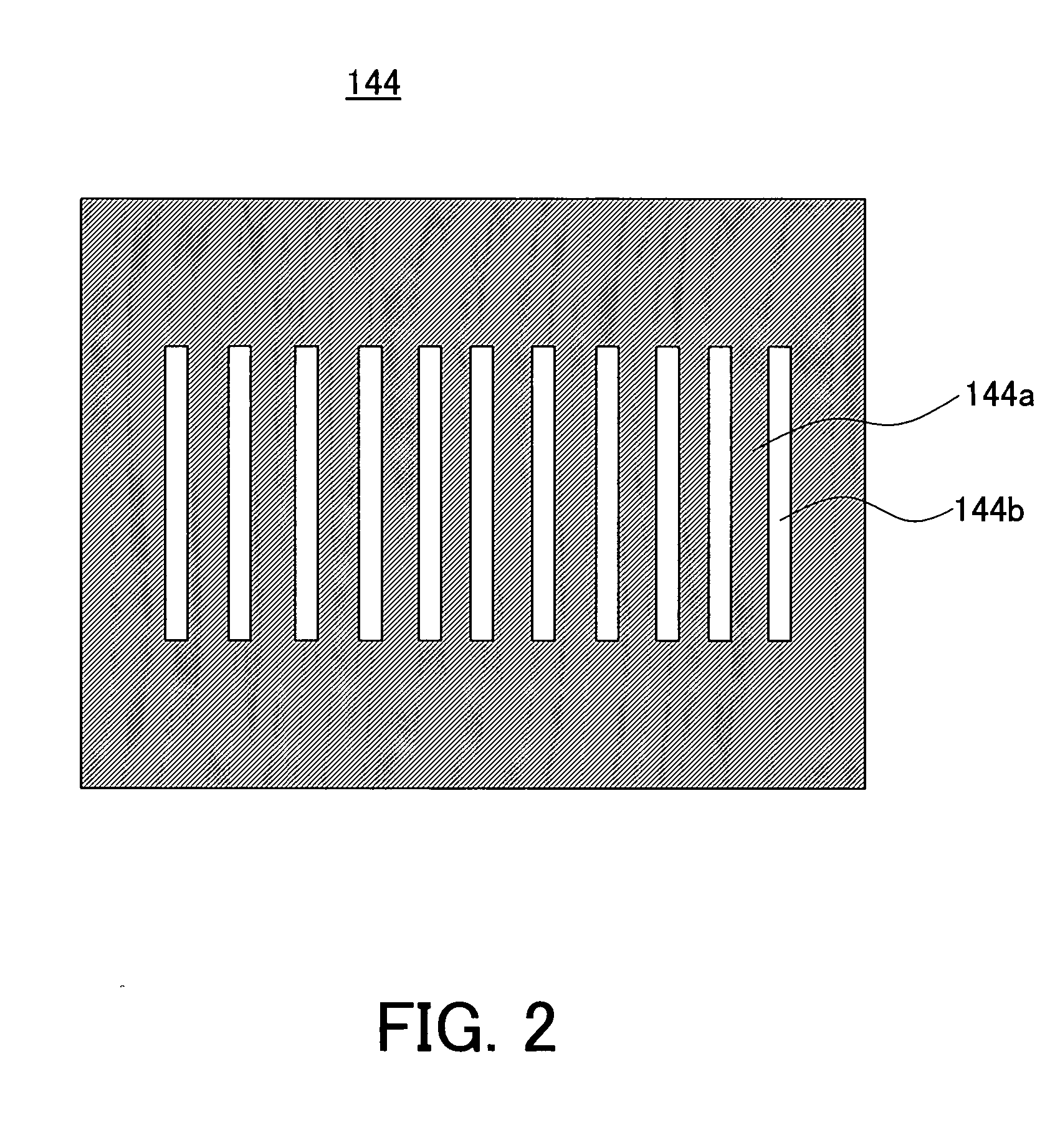

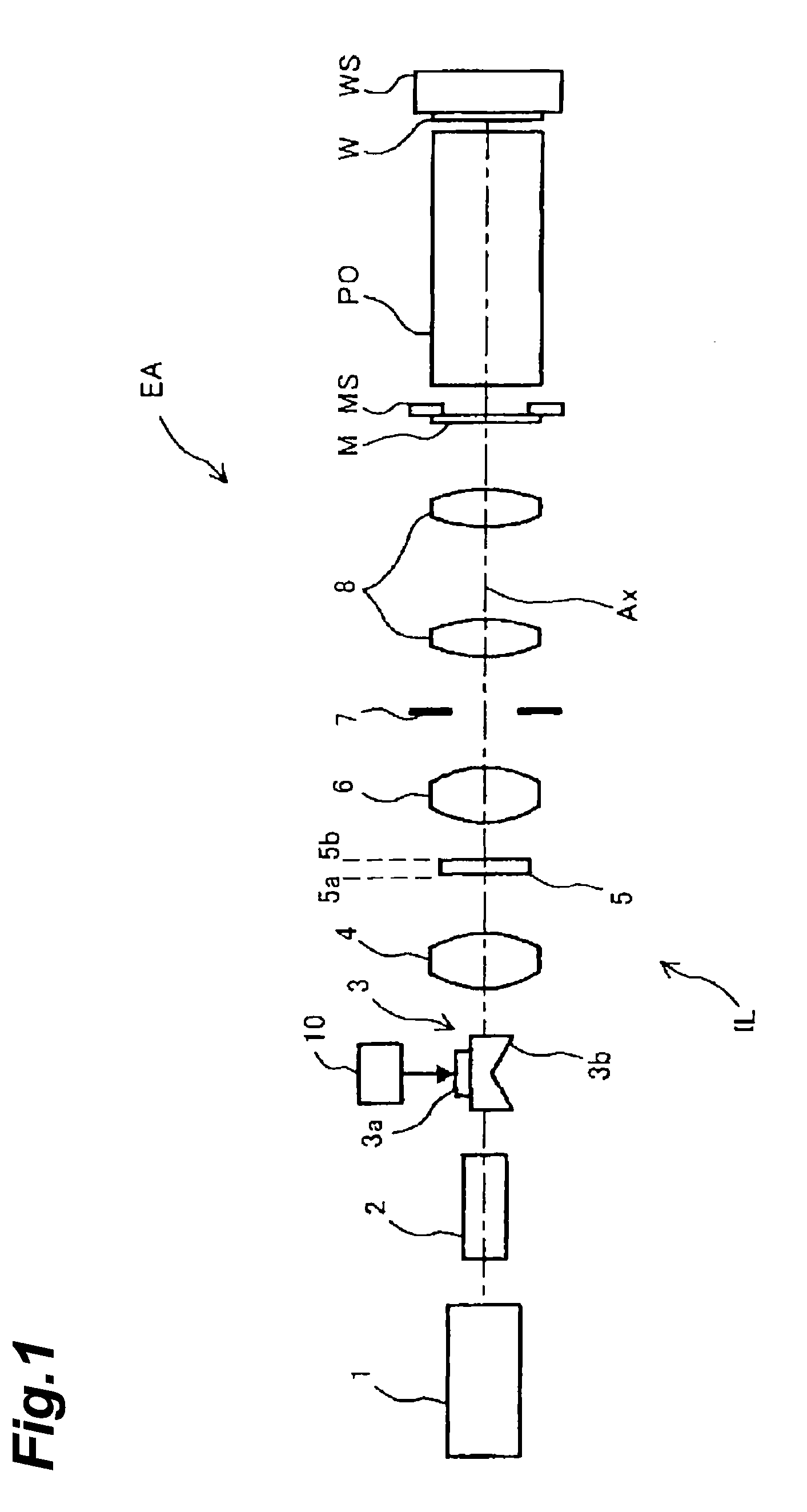

Exposure apparatus

InactiveUS20050146693A1Accurate exposureLarge numerical apertureSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusRefractive indexReticle

An exposure apparatus includes a projection optical system for projecting a pattern on a reticle onto an object to be exposed, a reference mark that serves as a reference for an alignment between the reticle and the object, a first fluid that has a refractive index of 1 or greater, and fills a space between at least part of the projection optical system and the object and a space between at least part of the projection optical system and the reference mark, and an alignment mechanism for aligning the object by using the projection optical system and the first fluid.

Owner:CANON KK

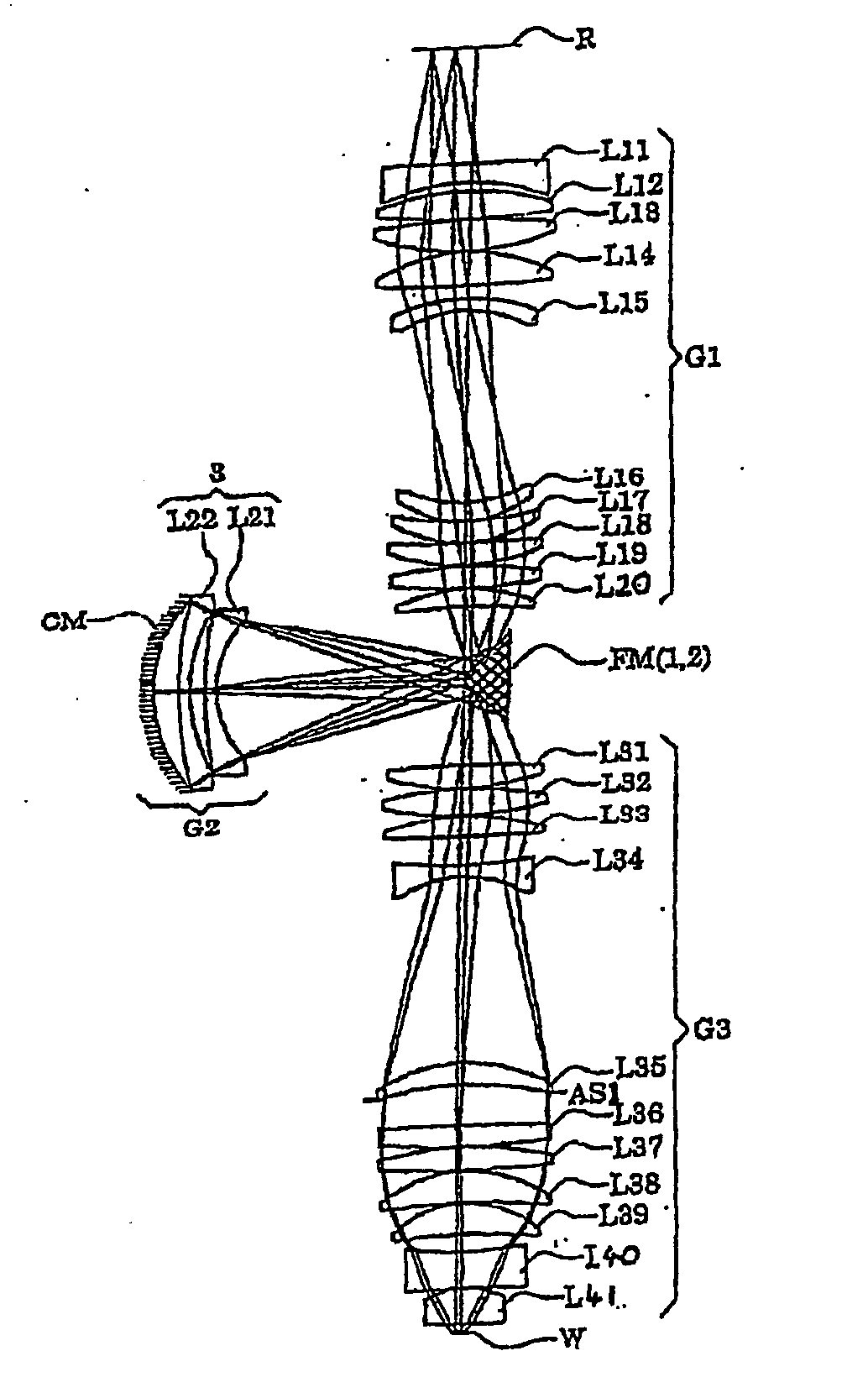

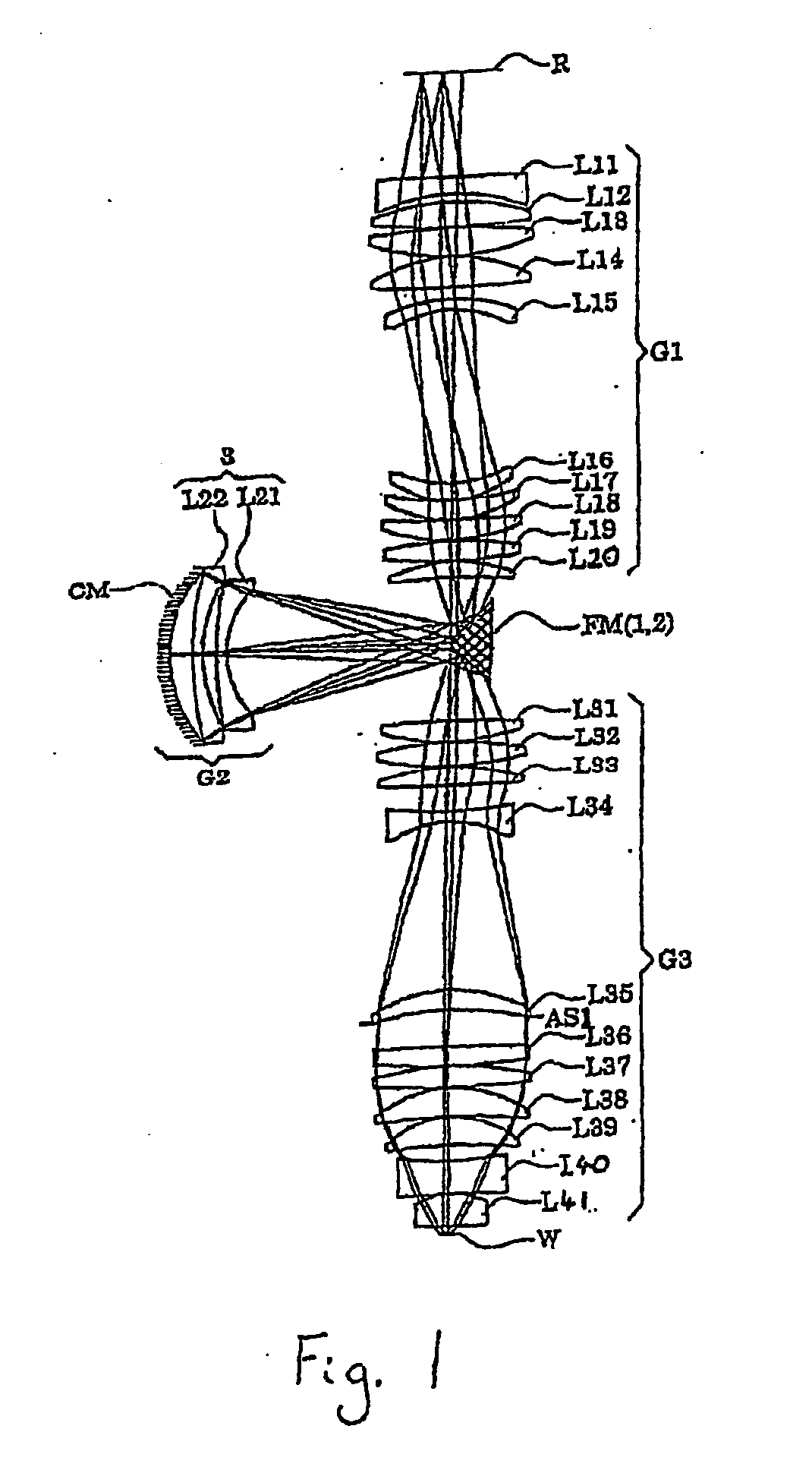

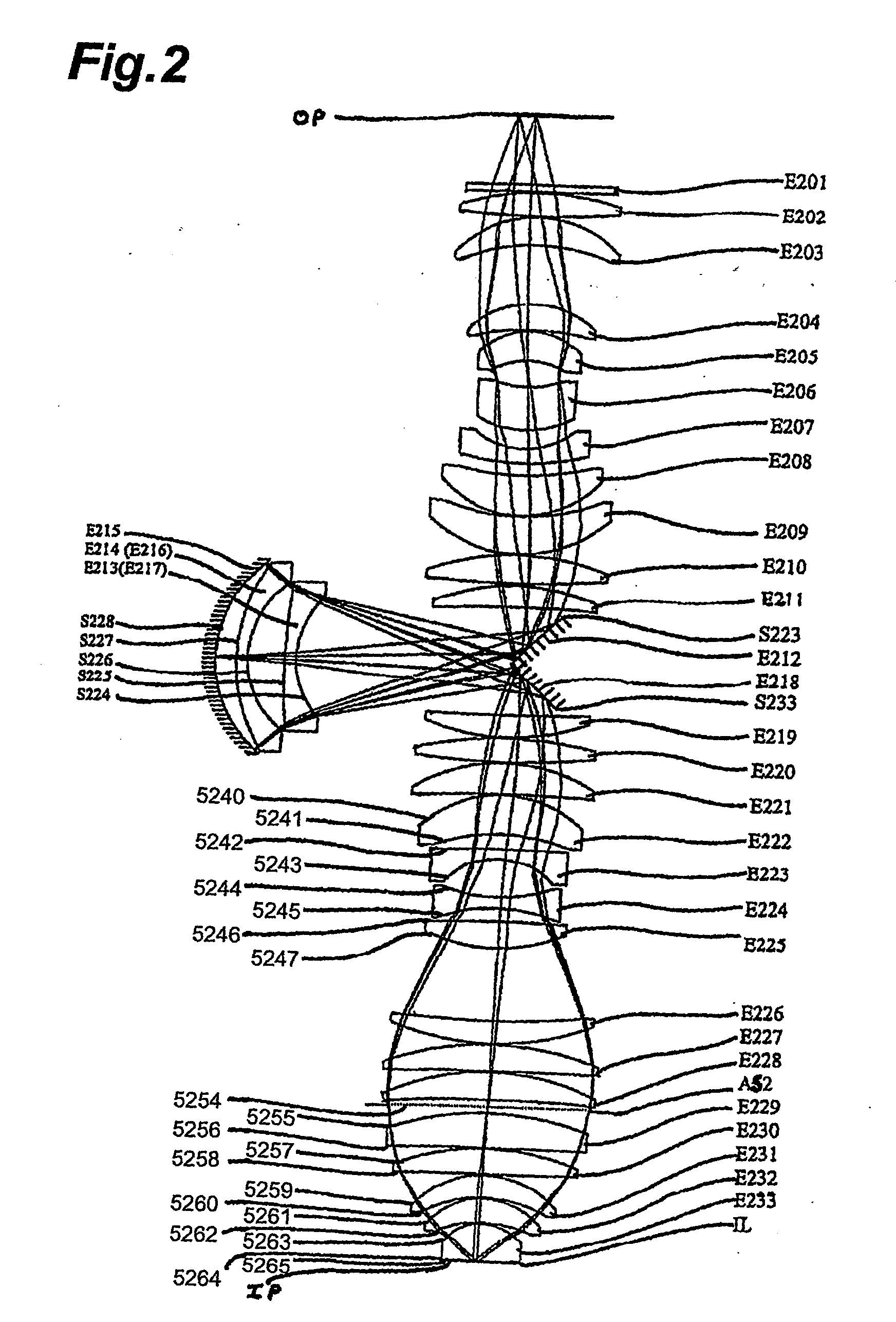

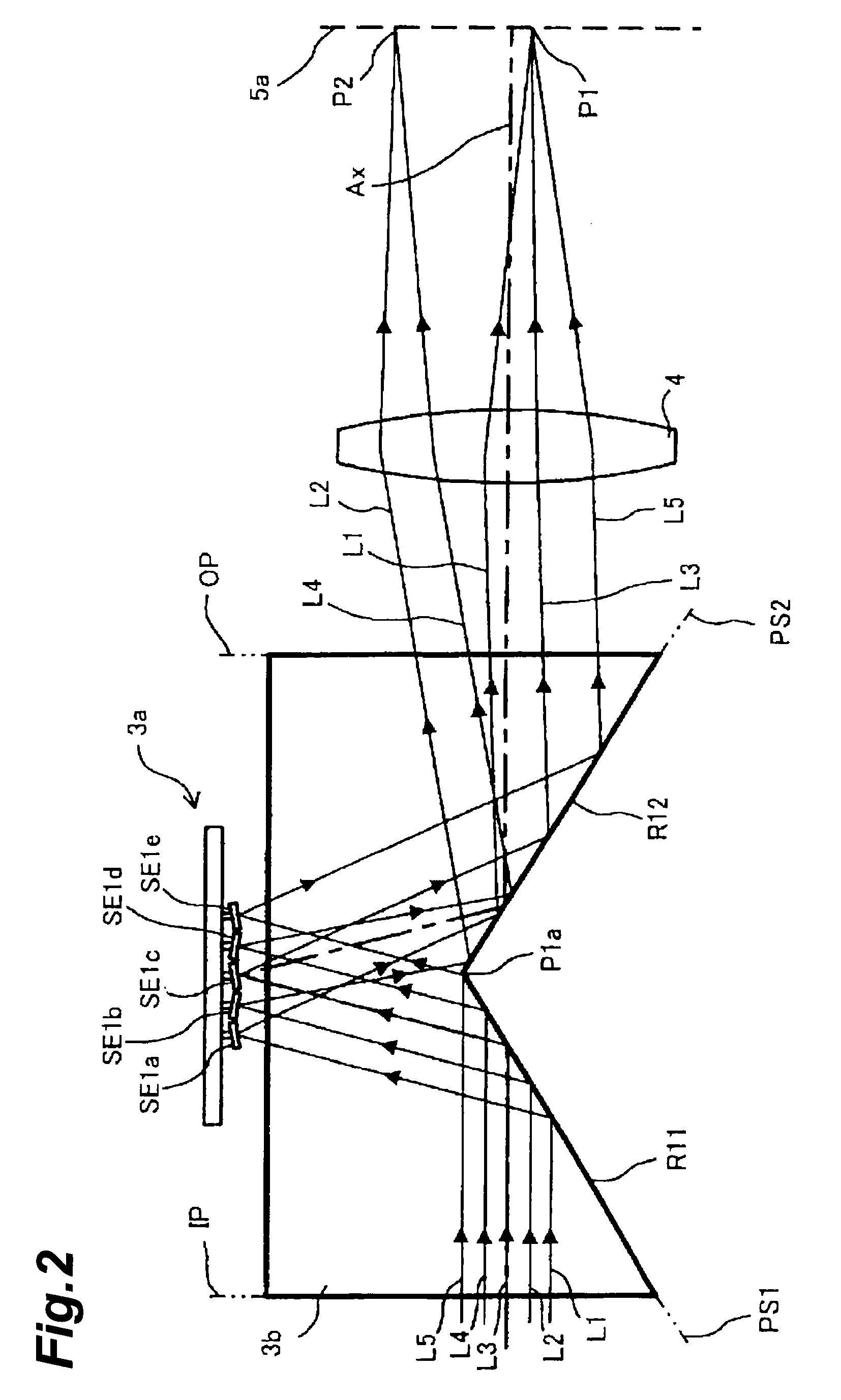

Projection optical system and method for photolithography and exposure apparatus and method using same

InactiveUS20050248856A1Large image-sideWide effective image forming areaSemiconductor/solid-state device manufacturingMicroscopesWide fieldProjection system

Optical Projection System and Method for Photolithography. A lithographic immersion projection system and method for projecting an image at high resolution over a wide field of view. The projection system and method include a final lens which decreases the marginal ray angle of the optical path before light passes into the immersion liquid to impinge on the image plane.

Owner:NIKON CORP

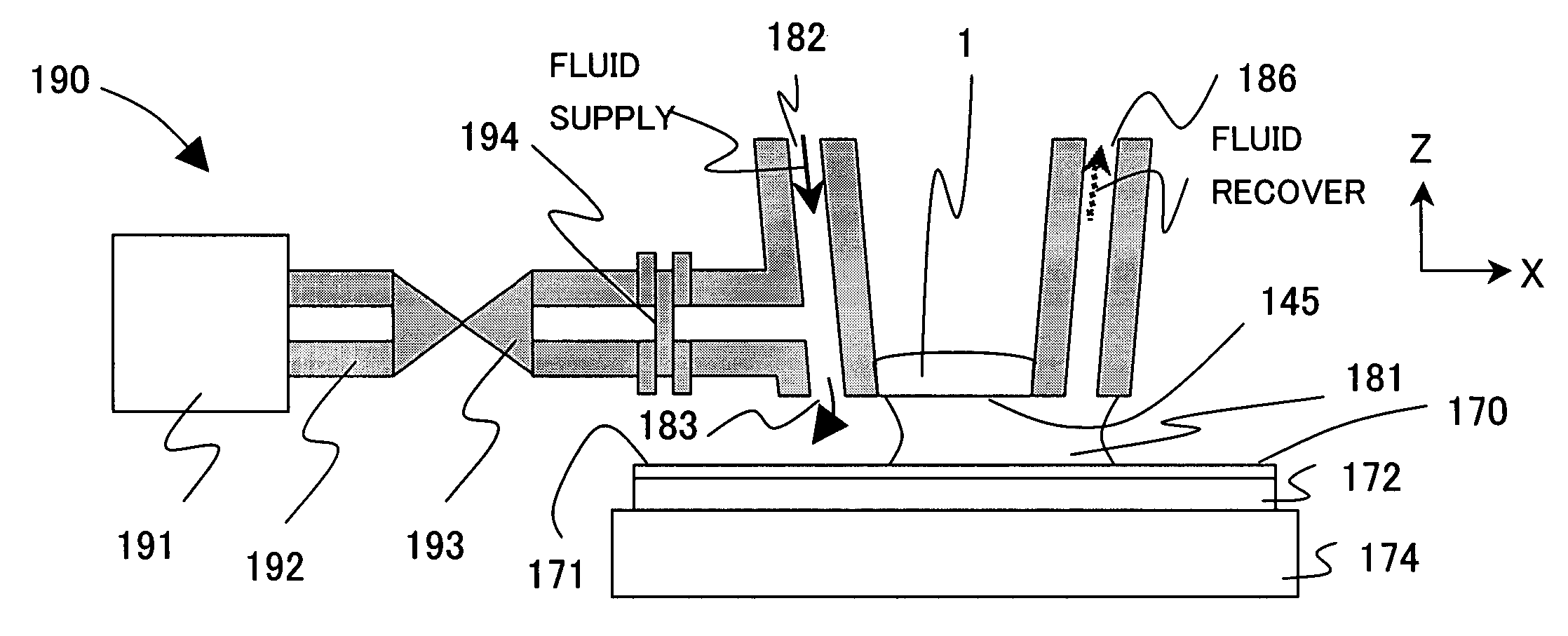

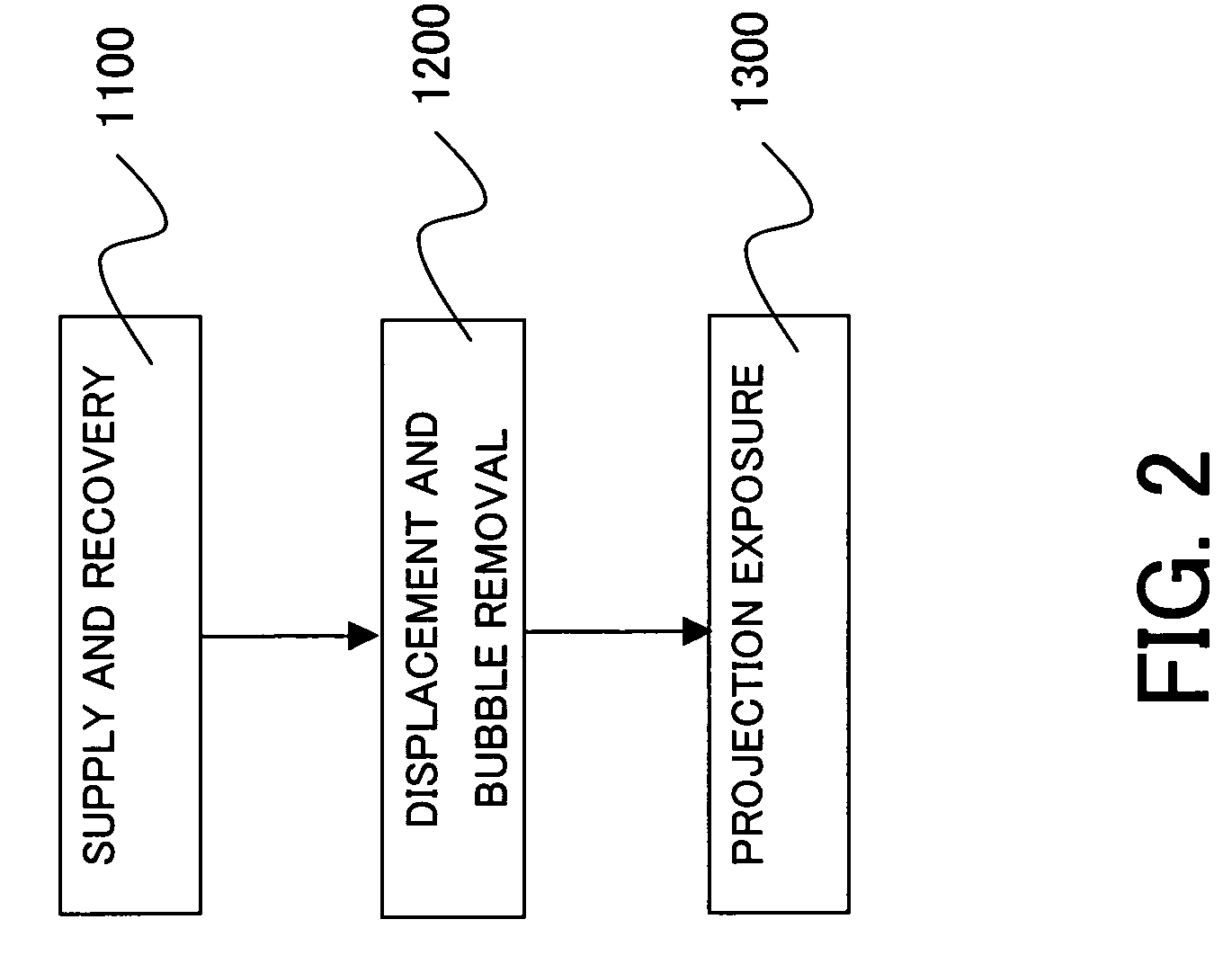

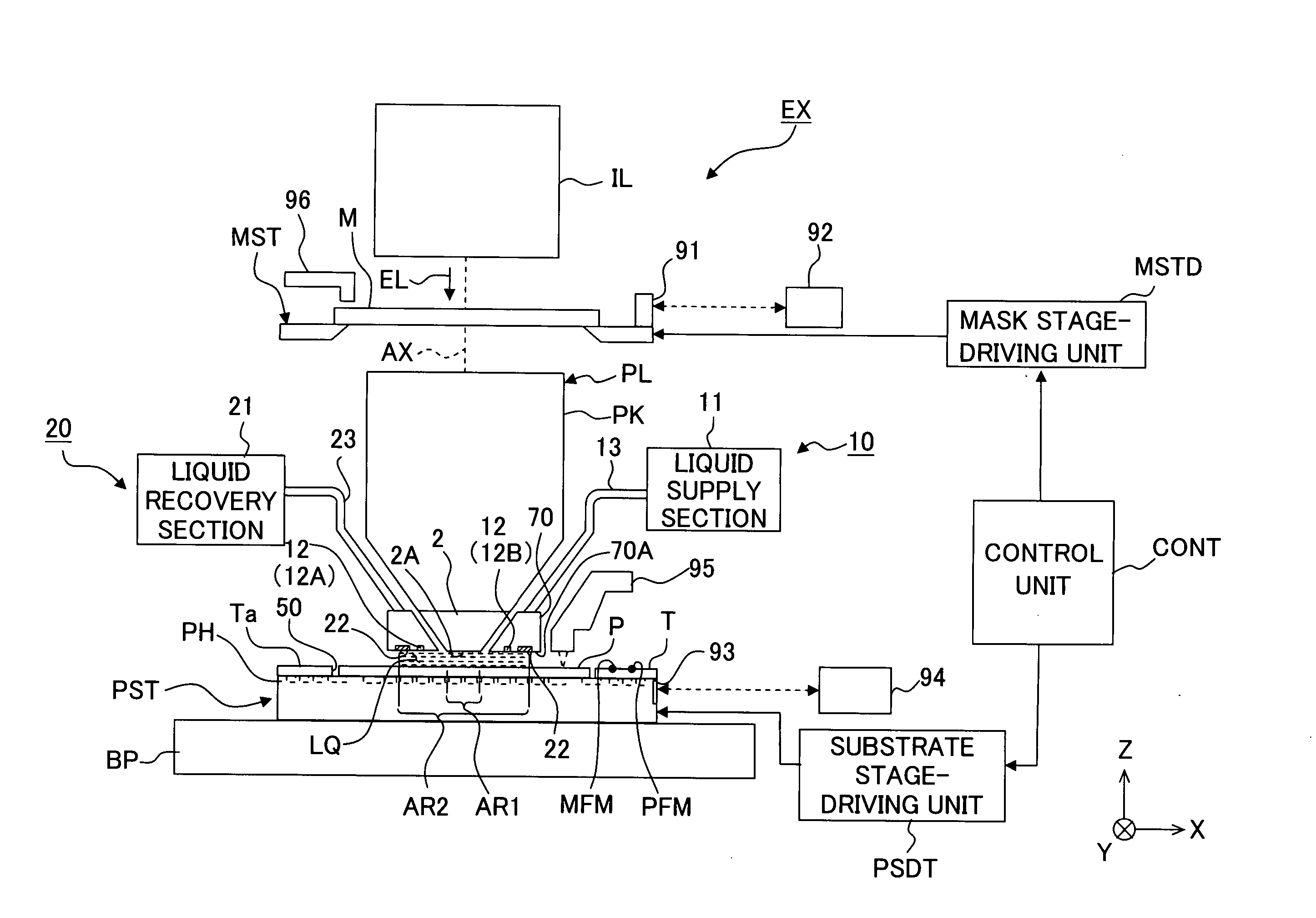

Exposure apparatus and method

InactiveUS20050140948A1High-quality exposureSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusPhysicsOptics

An exposure method includes the steps of introducing fluid between a surface of an object to be exposed, and a final surface of a projection optical system, displacing an interface of the fluid arranged between the surface of the object and the final surface of the projection optical system, and projecting a pattern on a mask onto the object via the projection optical system and the fluid.

Owner:CANON KK

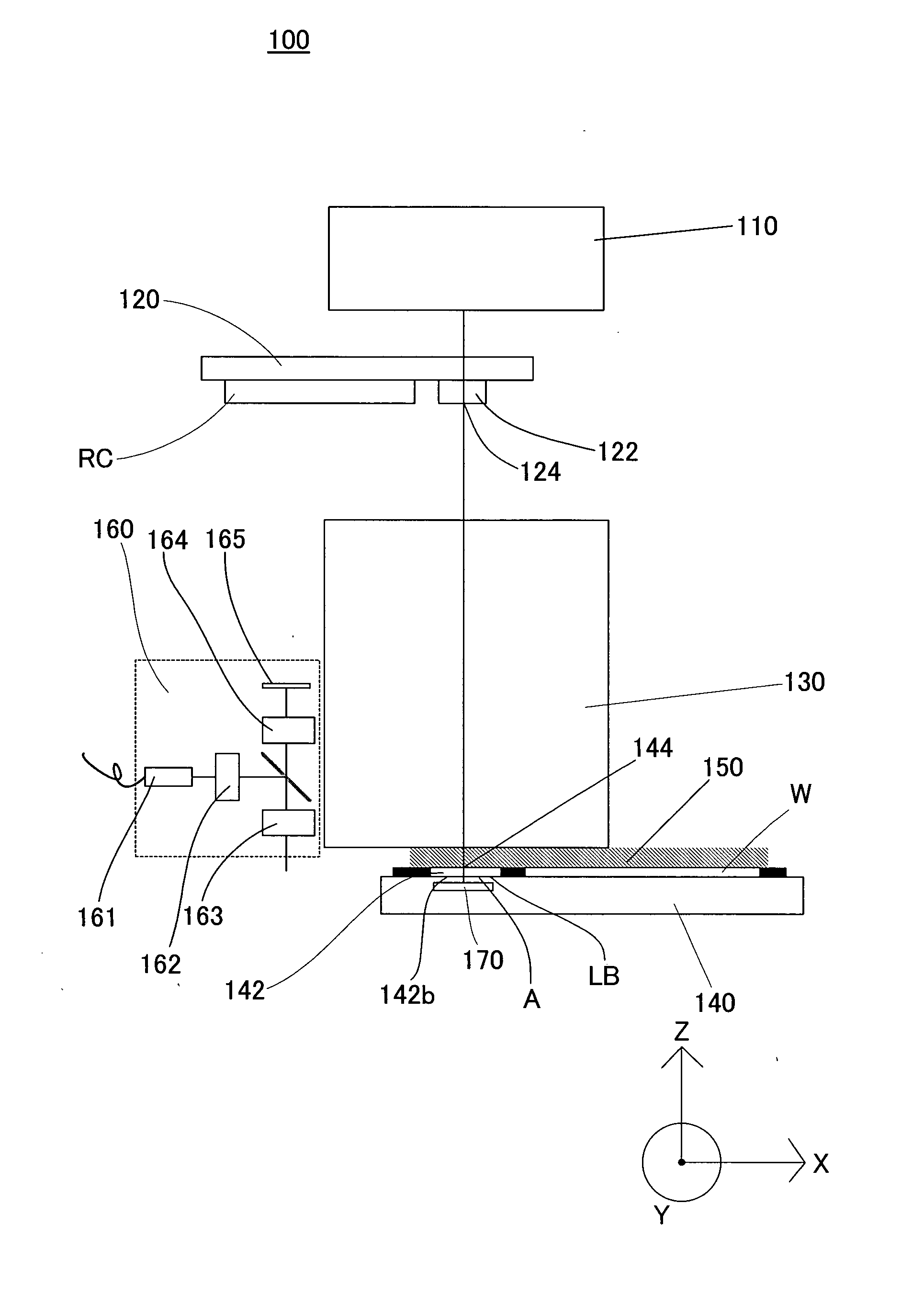

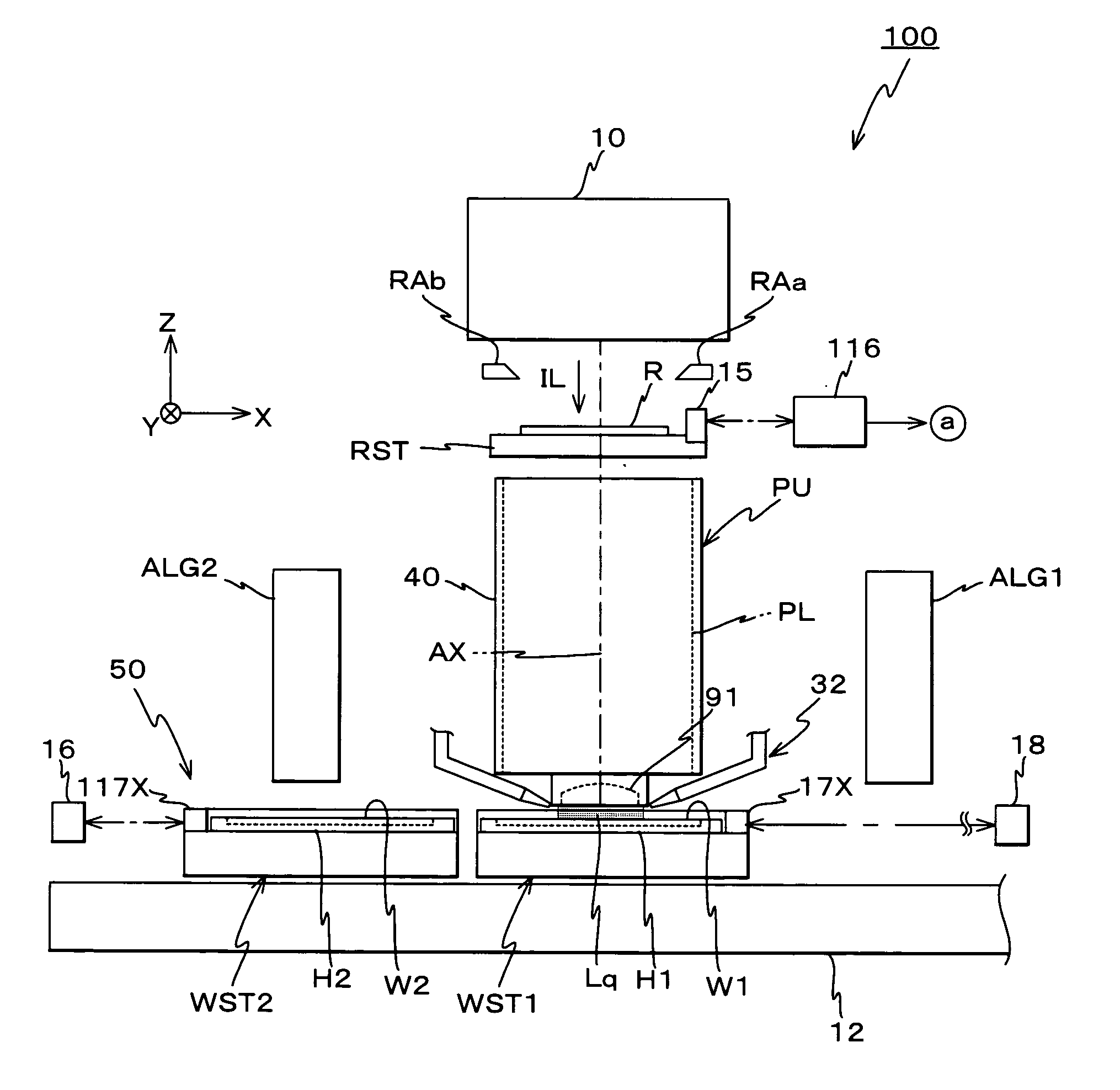

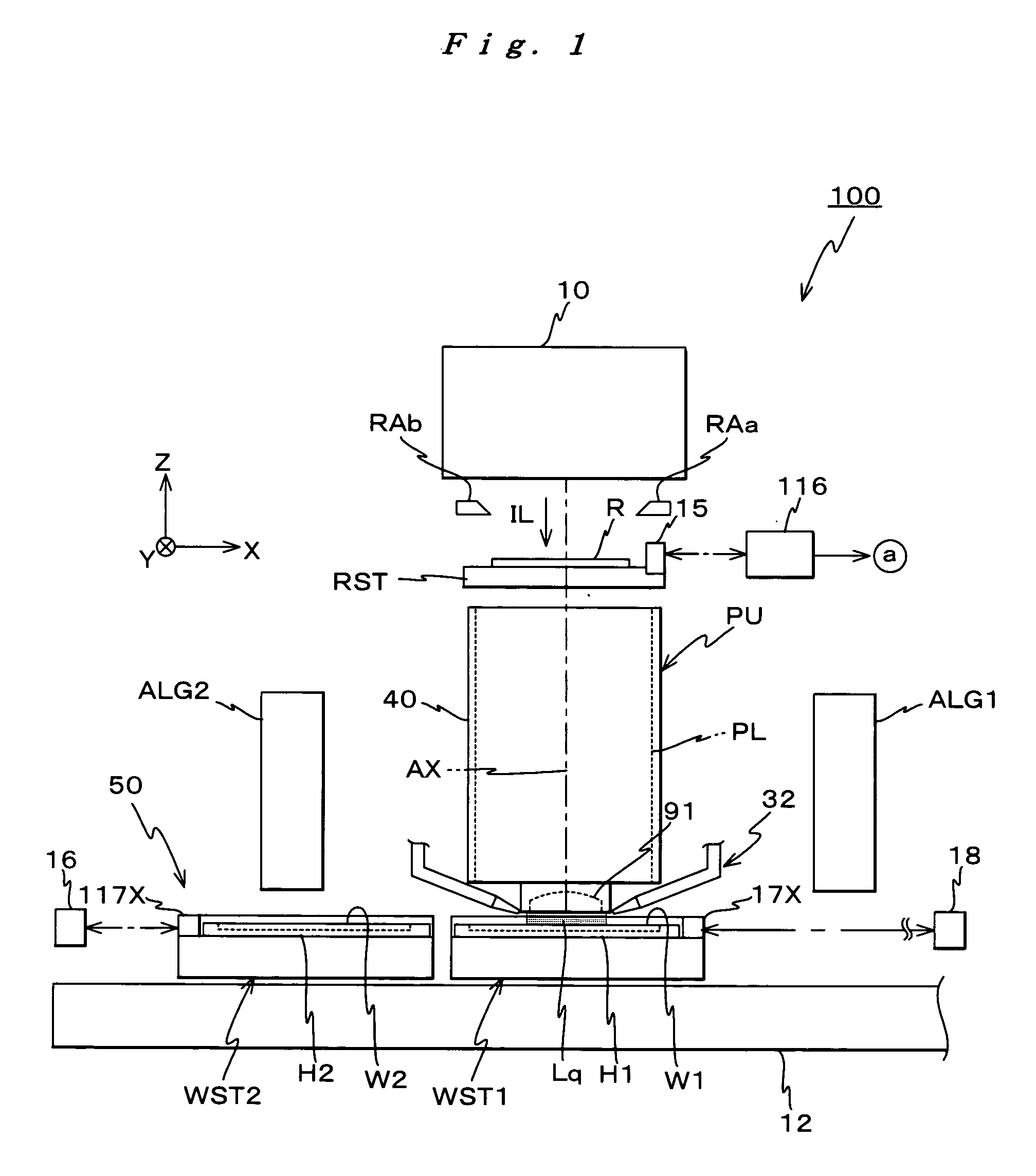

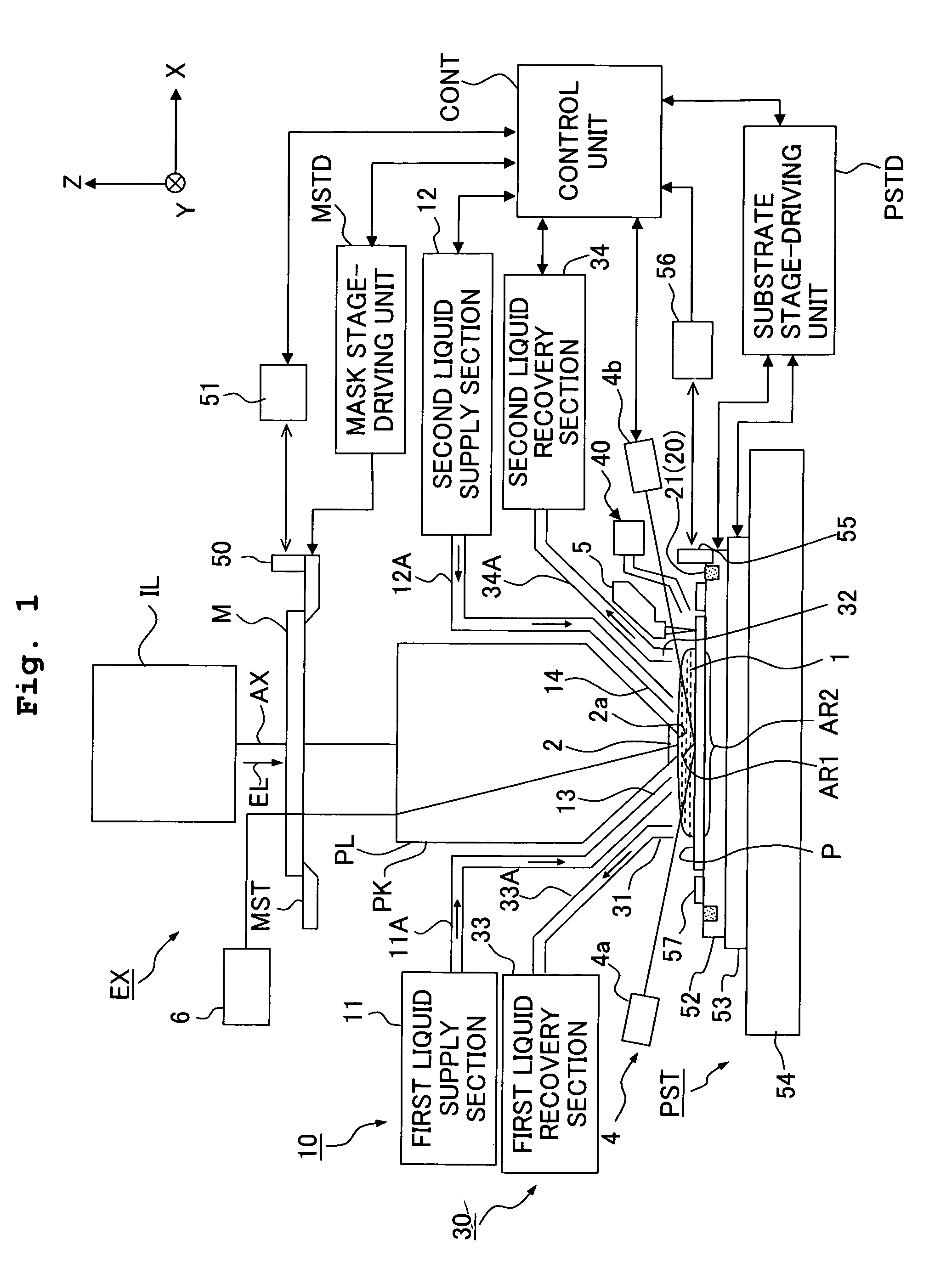

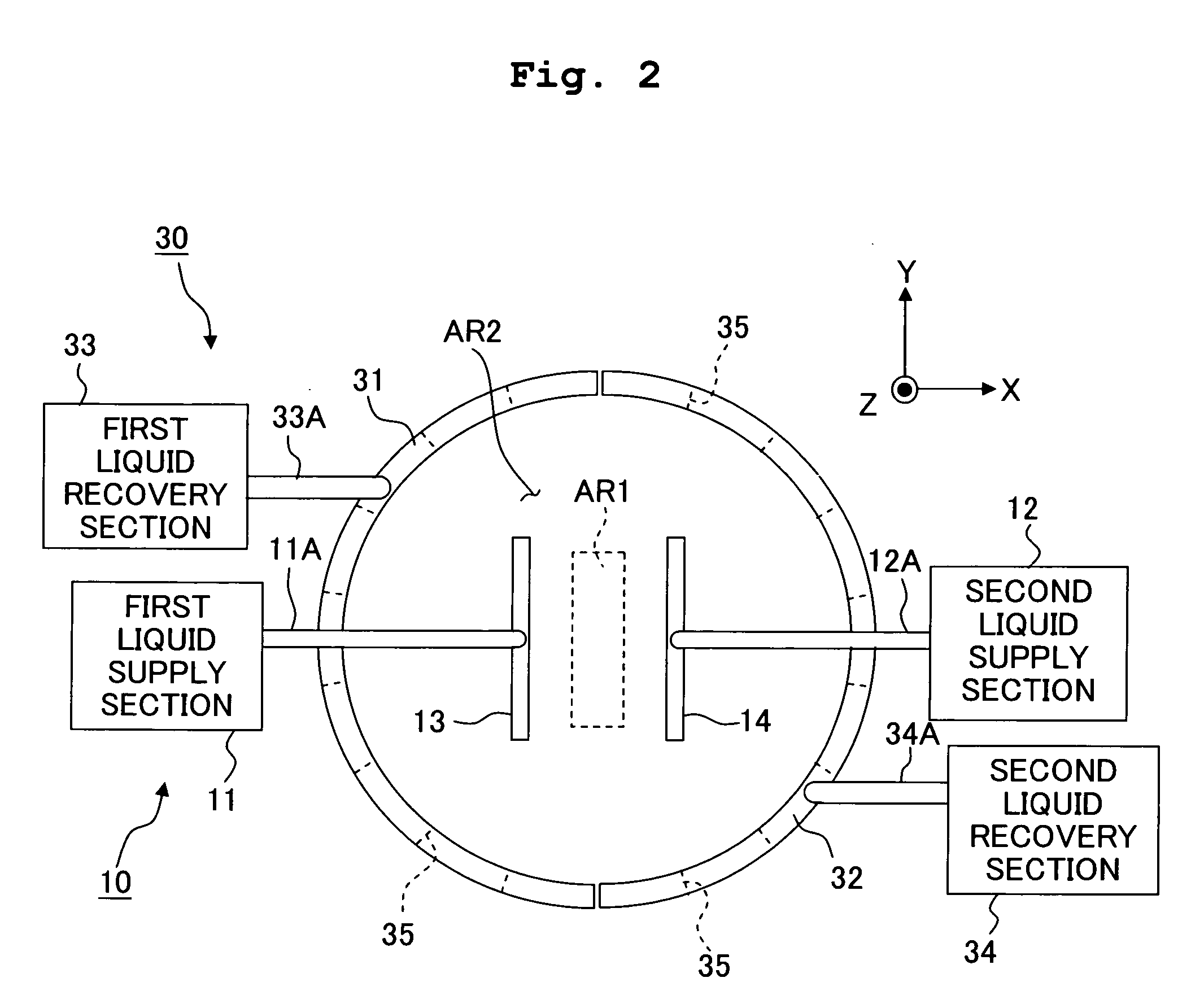

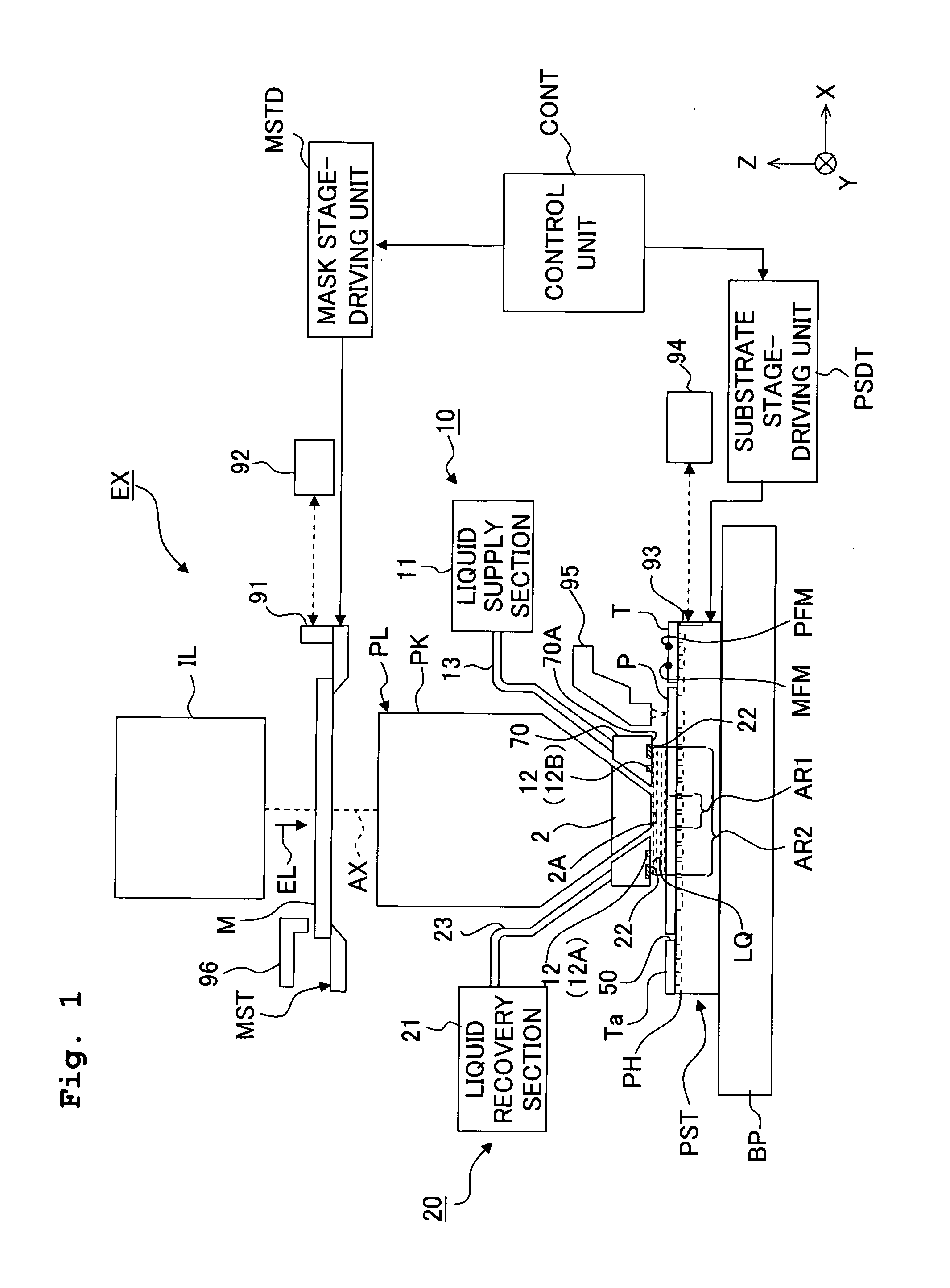

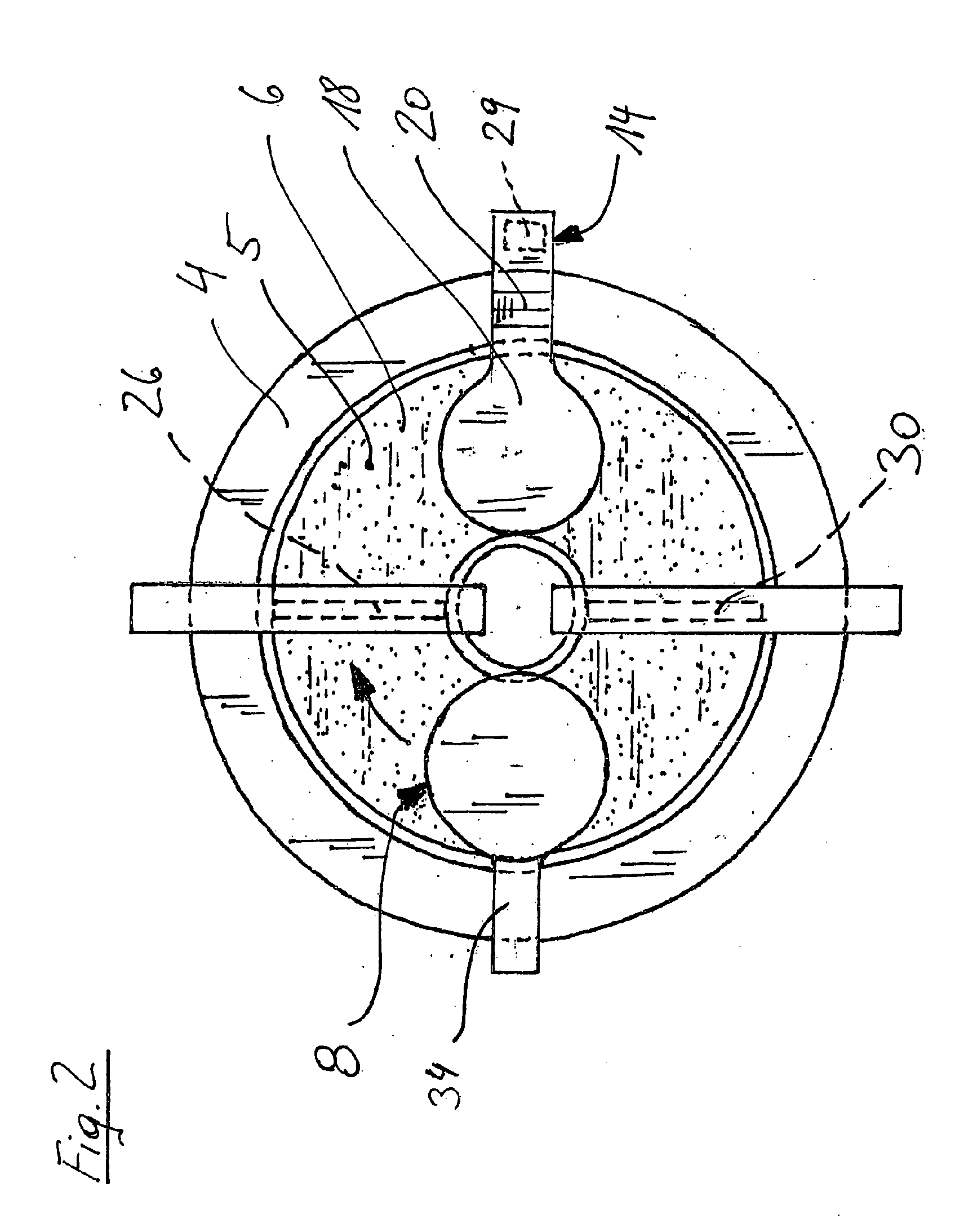

Stage drive method and stage unit, exposure apparatus, and device manufacturing method

InactiveUS20070127006A1Preventing and suppressing leakage of liquidImprove throughputSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringImage plane

When a transition from a first state where one stage is positioned at a first area directly below projection optical system to which liquid is supplied to a state where the other stage is positioned at the first area, both stages are simultaneously driven while a state where both stages are close together in the X-axis direction is maintained. Therefore, it becomes possible to make a transition from the first state to the second state in a state where liquid is supplied in the space between the projection optical system and the specific stage directly under the projection optical system. Accordingly, the time from the completion of exposure operation on one stage side until the exposure operation begins on the other stage side can be reduced, which allows processing with high throughput. Further, because the liquid can constantly exist on the image plane side of the projection optical system, generation of water marks on optical members of the projection optical system on the image plane side is prevented.

Owner:NIKON CORP

Exposure apparatus and method for producing device

InactiveUS20060077367A1Forming accuratelySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringImage plane

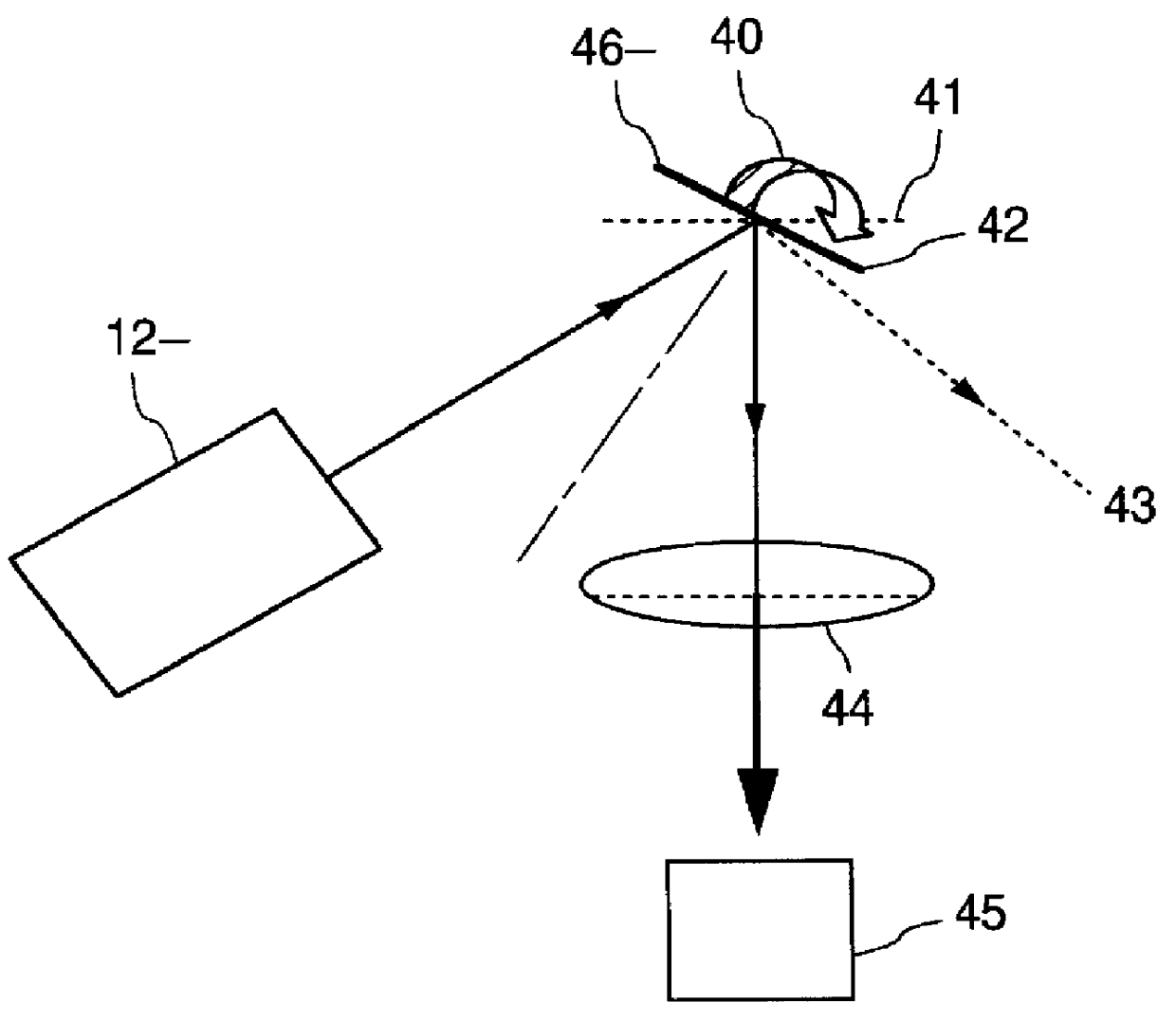

There is provided an exposure apparatus capable of forming a desirable device pattern by removing unnecessary liquid when performing exposure by projecting a pattern onto the substrate via a projection optical system and the liquid. The exposure device projects an image of the pattern onto the substrate P via the projection optical system and the liquid so as to expose the substrate P. The exposure device includes a liquid removing mechanism 40 which removes the liquid remaining on a part 7 arranged in the vicinity of the image plane of the projection optical system.

Owner:NIKON CORP

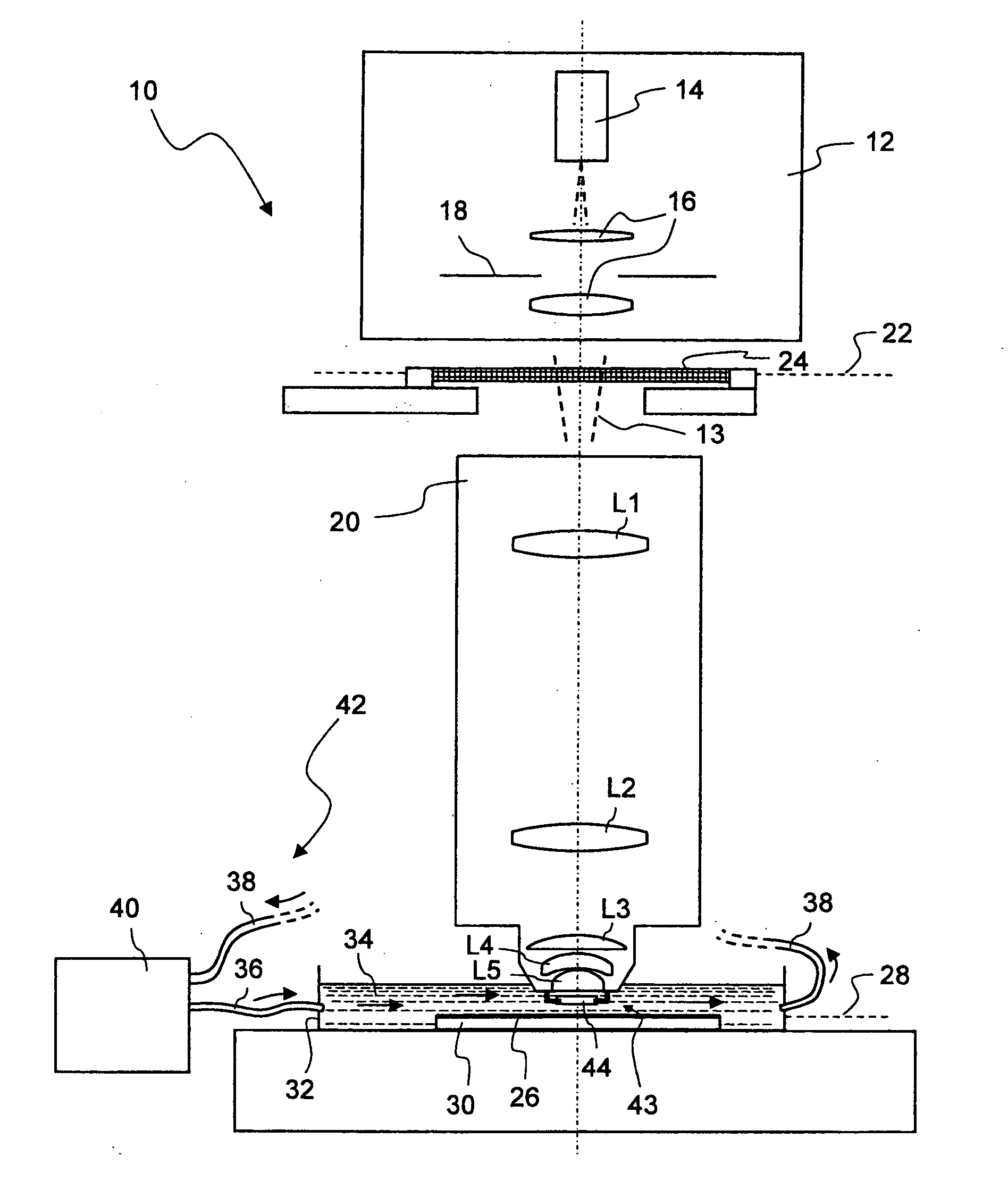

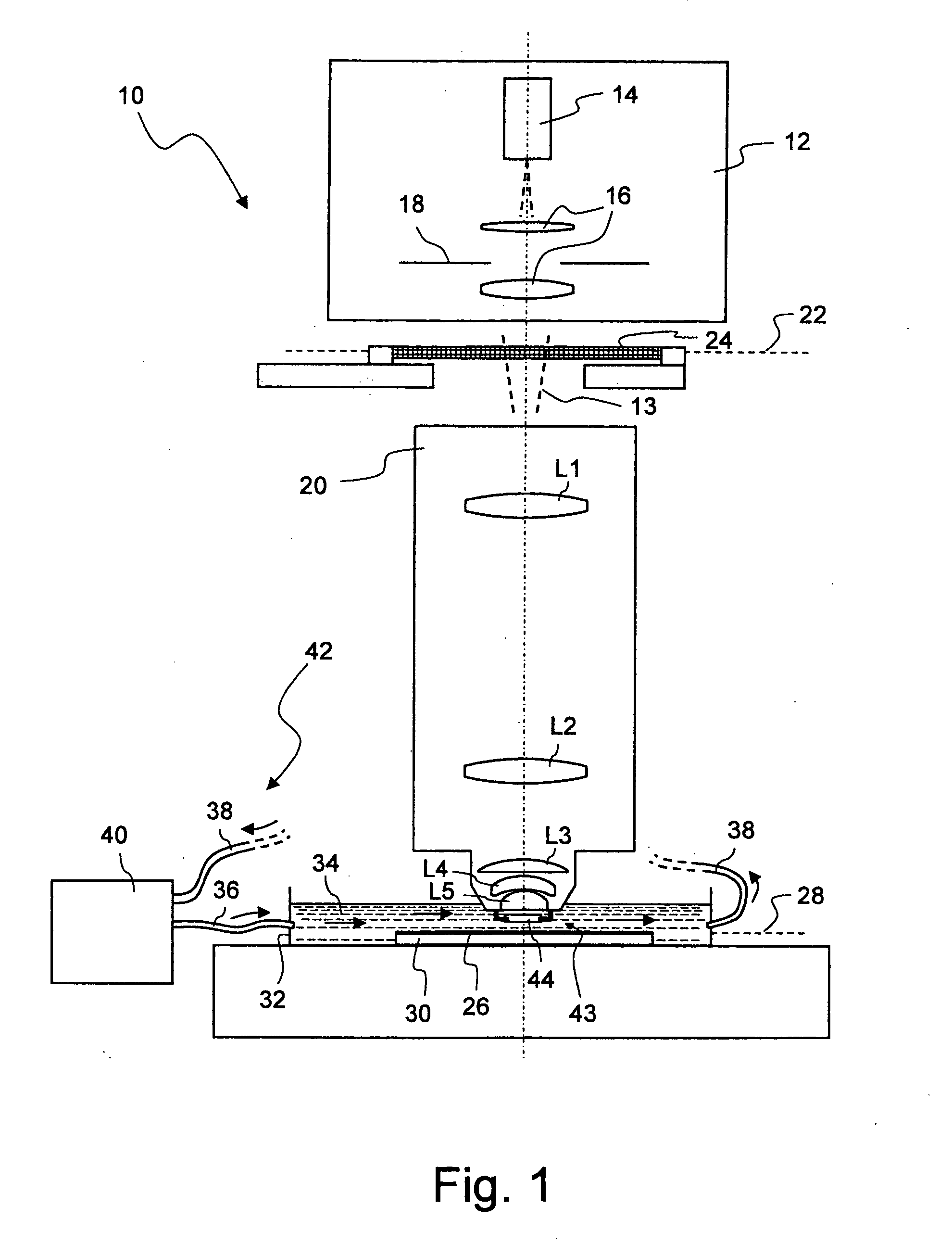

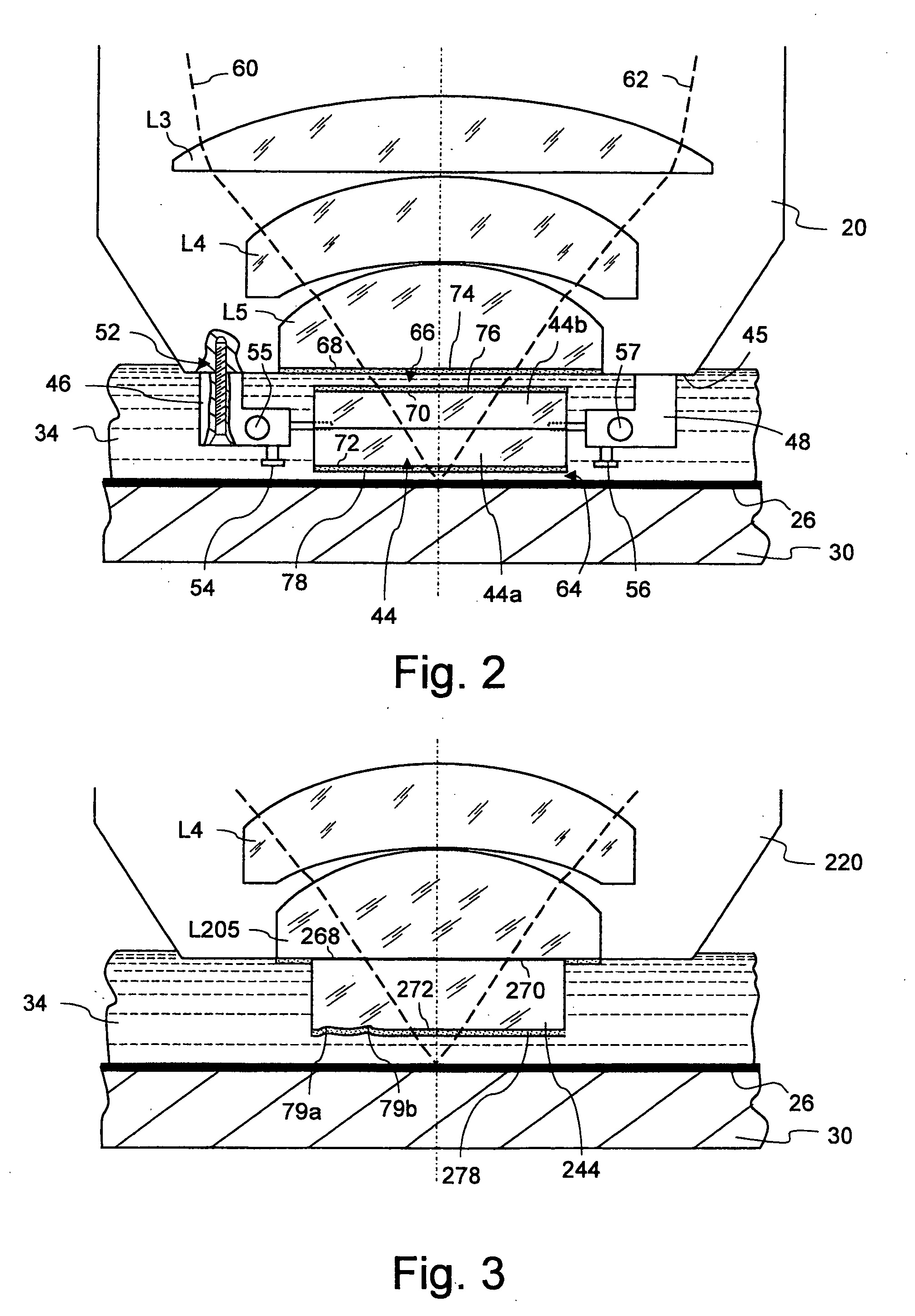

Microlithographic projection exposure apparatus

InactiveUS20050068499A1Simple structureReliable and low-maintenance operationProjectorsPhotomechanical exposure apparatusCamera lensPhysics

A microlithographic projection exposure apparatus contains an illumination system (12) for generating projection light (13) and a projection lens (20; 220; 320; 420; 520; 620; 720; 820; 920; 1020; 1120) with which a reticle (24) that is capable of being arranged in an object plane (22) of the projection lens can be imaged onto a light-sensitive layer (26) that is capable of being arranged in an image plane (28) of the projection lens. The projection lens is designed for immersion mode, in which a final lens element (L5; L205; L605; L705; L805; L905; L1005; L1105) of the projection lens on the image side is immersed in an immersion liquid (34; 334a; 434a; 534a). A terminating element (44; 244; 444; 544; 644; 744; 844; 944; 1044; 1144) that is transparent in respect of the projection light (13) is fastened between the final lens element on the image side and the light-sensitive layer.

Owner:CARL ZEISS SMT GMBH

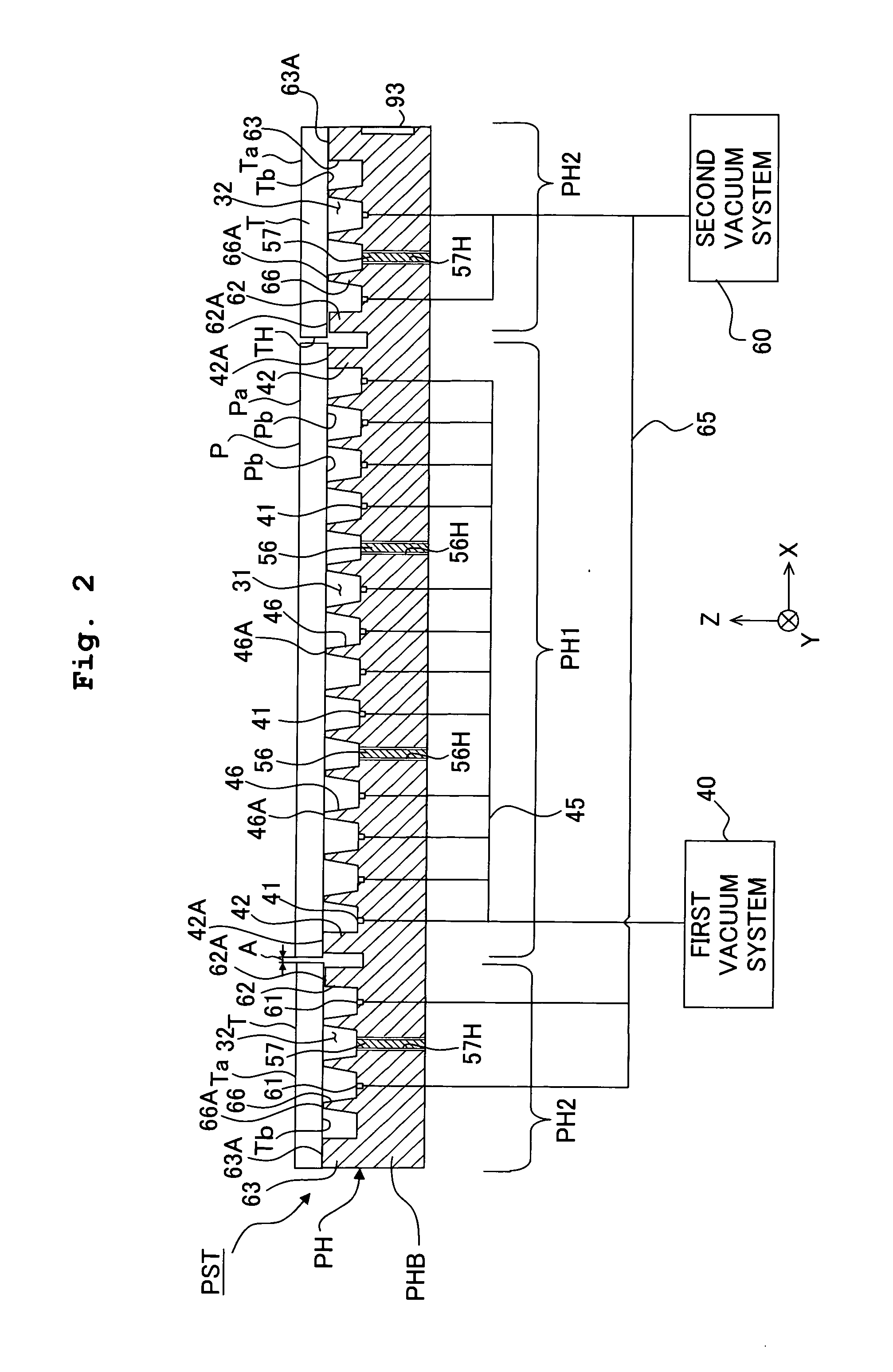

Substrate holding unit, exposure apparatus having same, exposure method, method for producing device, and liquid repellent plate

InactiveUS20070177125A1Good adhesionEasy detachmentSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringExposure

A substrate holder includes a base; a first holding portion which is formed on the base and which attracts and holds a substrate; and a second holding portion which is formed on the base and which attracts and holds a plate member in the vicinity of the substrate attracted and held by the first holding portion. In an exposure apparatus including such a substrate holder, the plate can be exchanged easily, thereby making the maintenance of the apparatus easy. Consequently, such an exposure apparatus is suitable for immersion exposure.

Owner:NIKON CORP

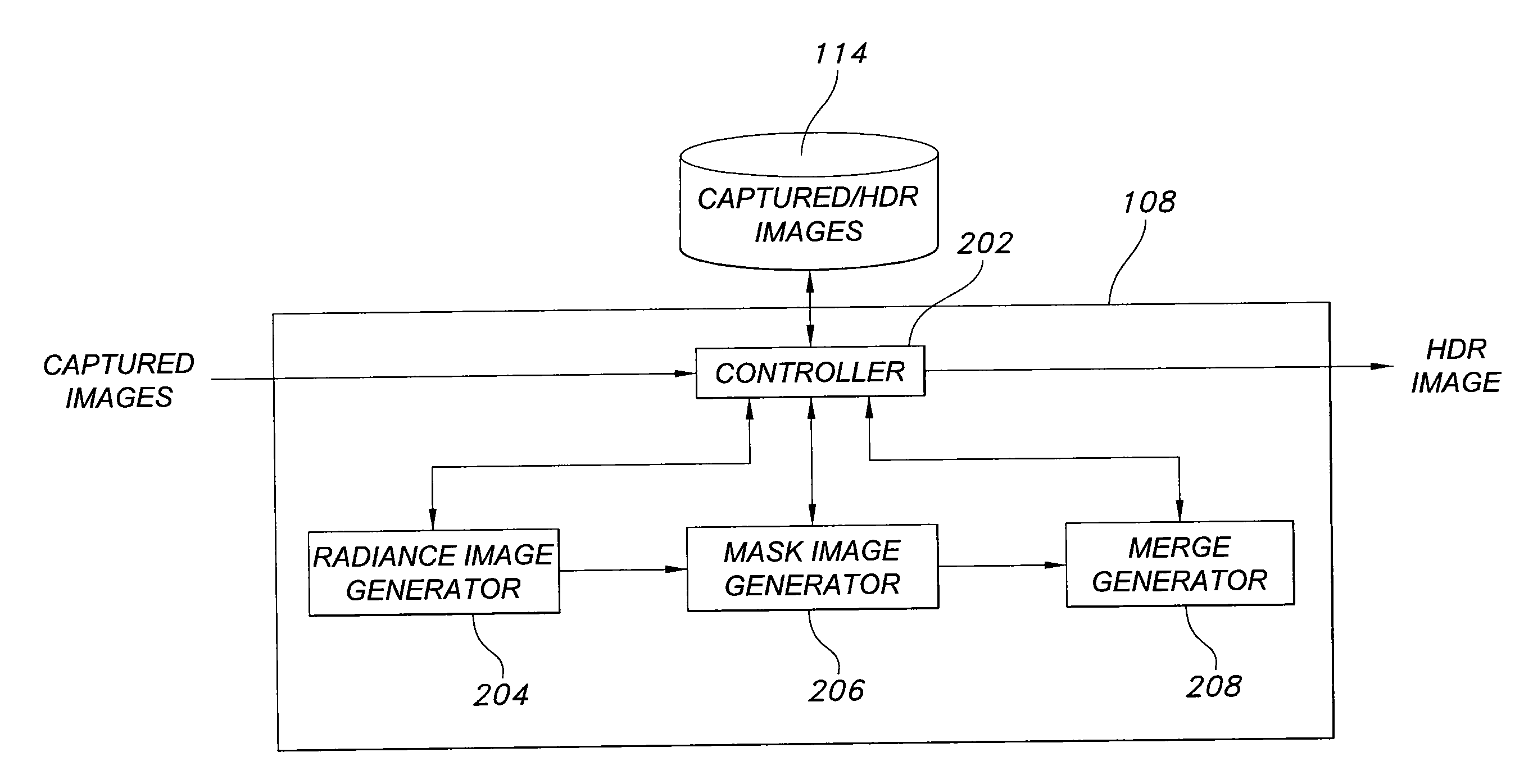

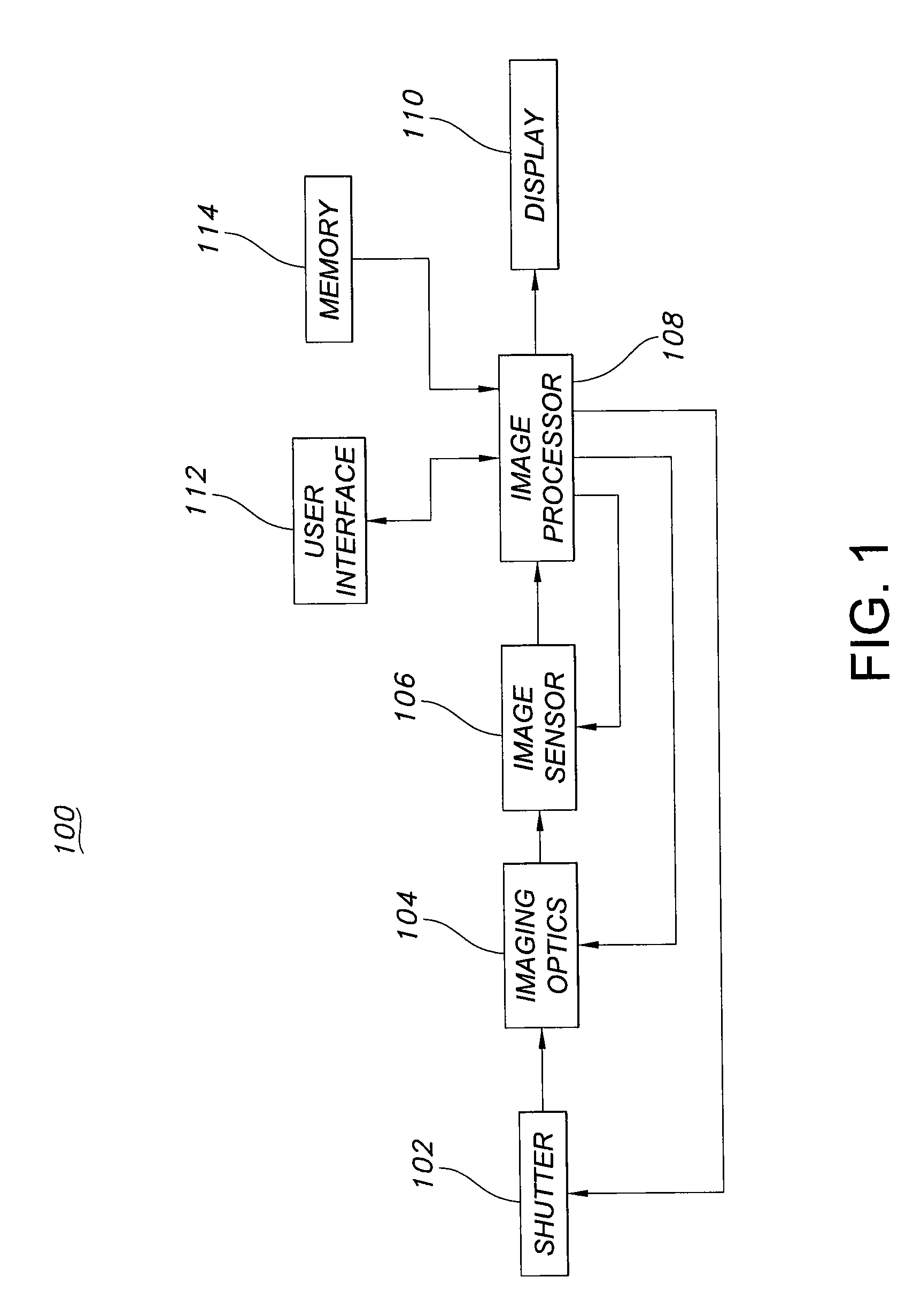

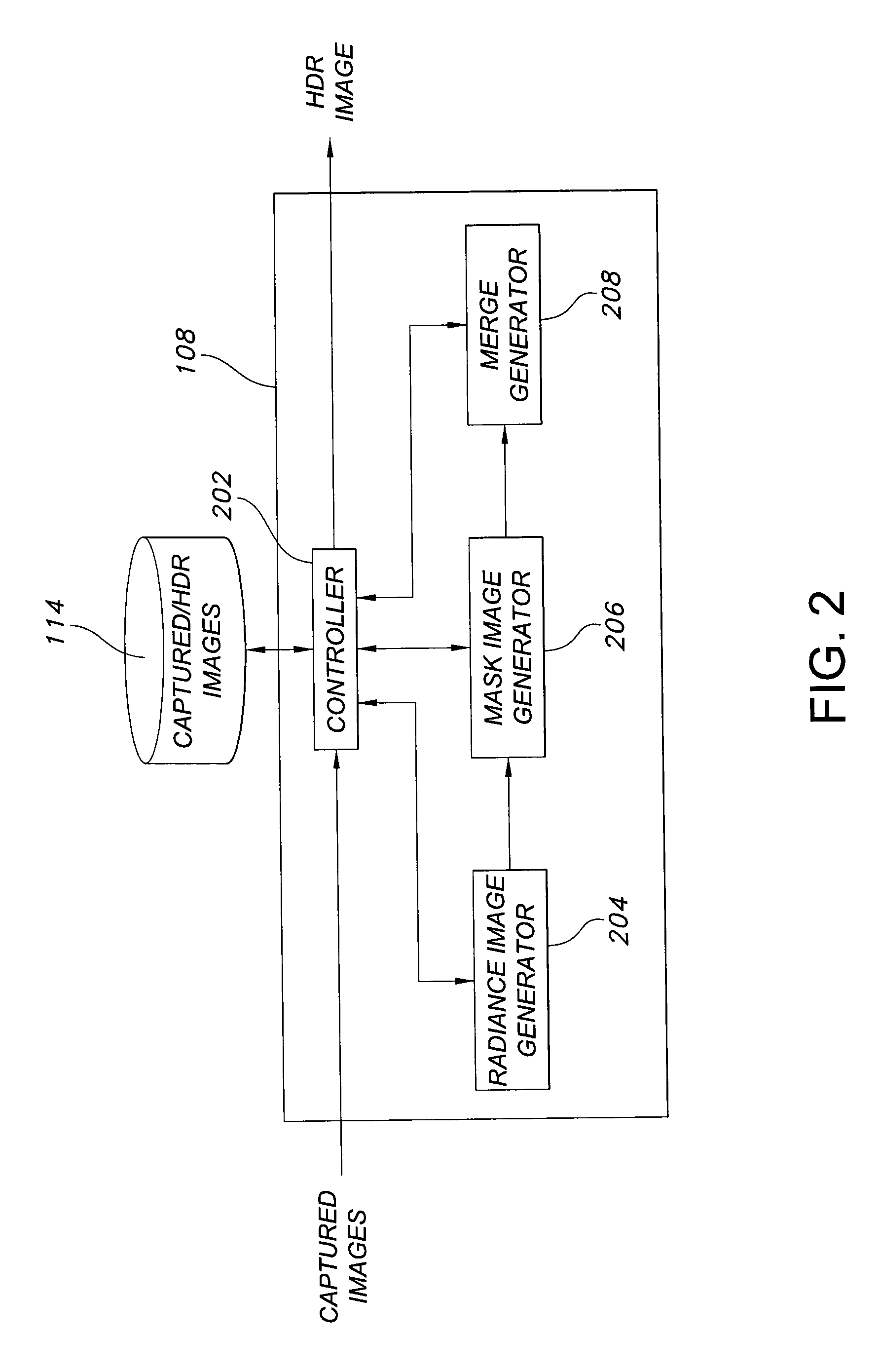

Method of capturing high dynamic range images with objects in the scene

Methods, image processors and imaging devices for capturing a high dynamic range (HDR) image. Multiple images of a scene are captured at respectively different exposure settings. A further image of an object placed in the scene is captured at one exposure setting. A first radiance image is formed from the multiple images. A second radiance image is formed from the further image. The first radiance image and the second radiance image are merged to form the HDR image.

Owner:APTINA IMAGING CORP

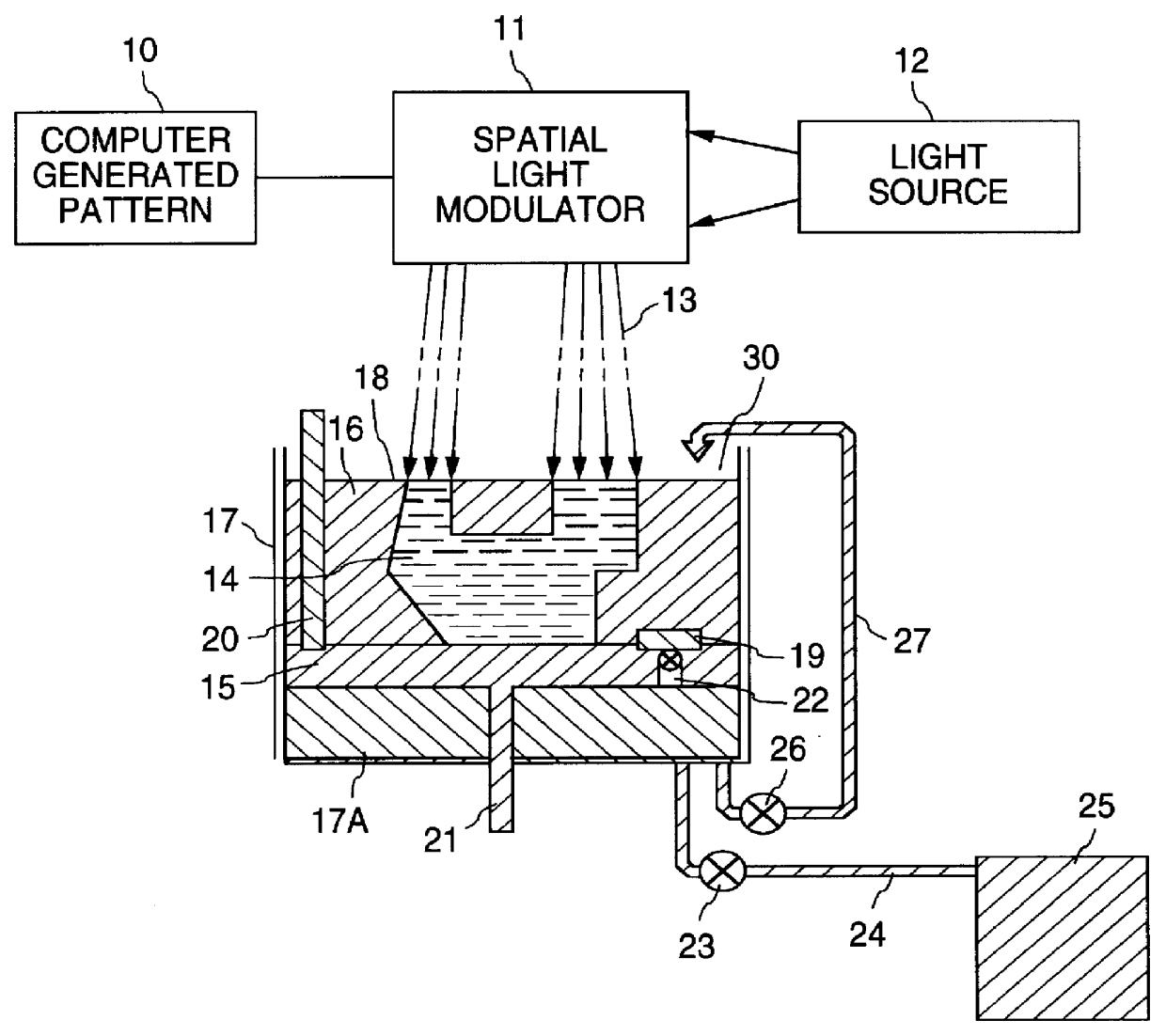

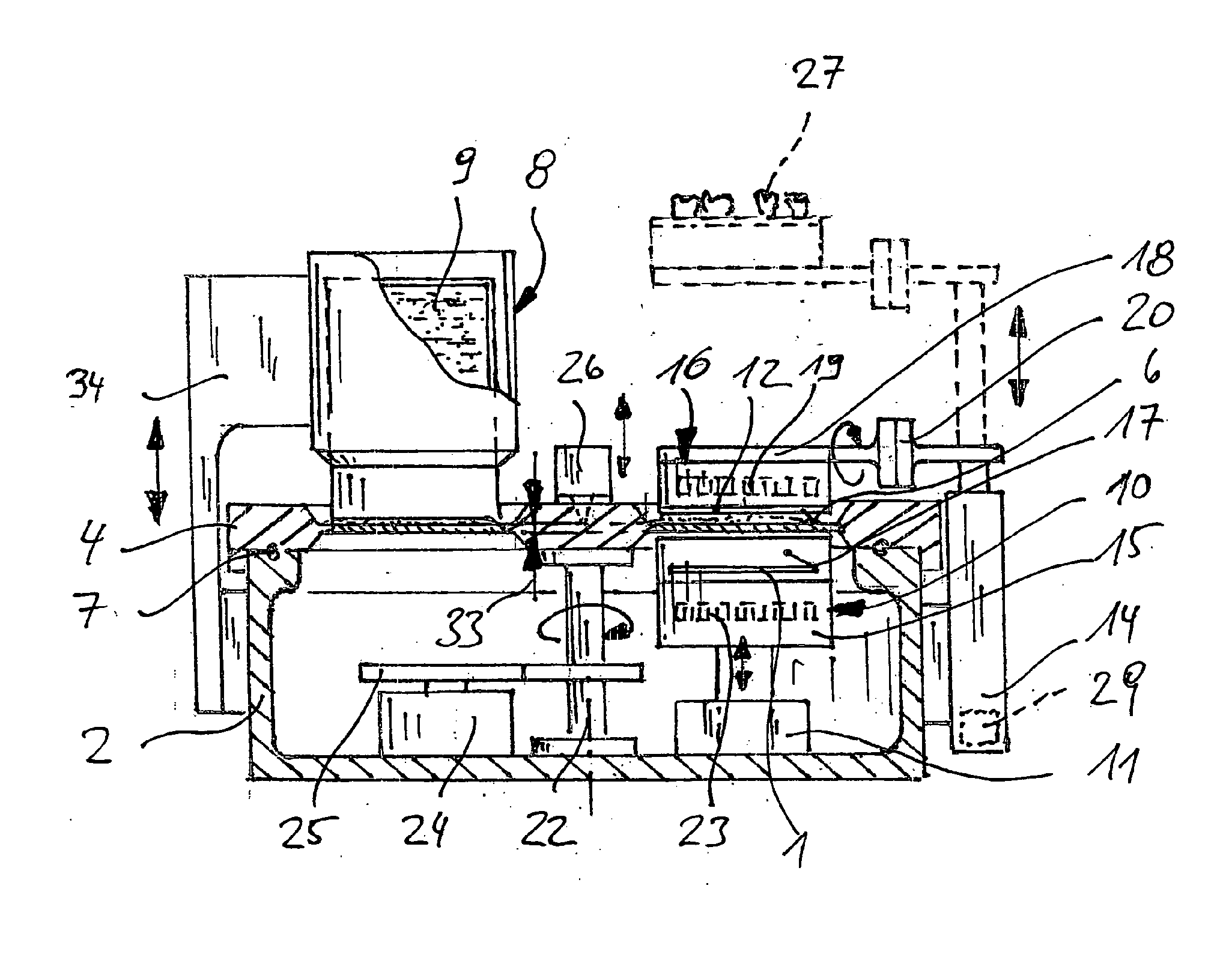

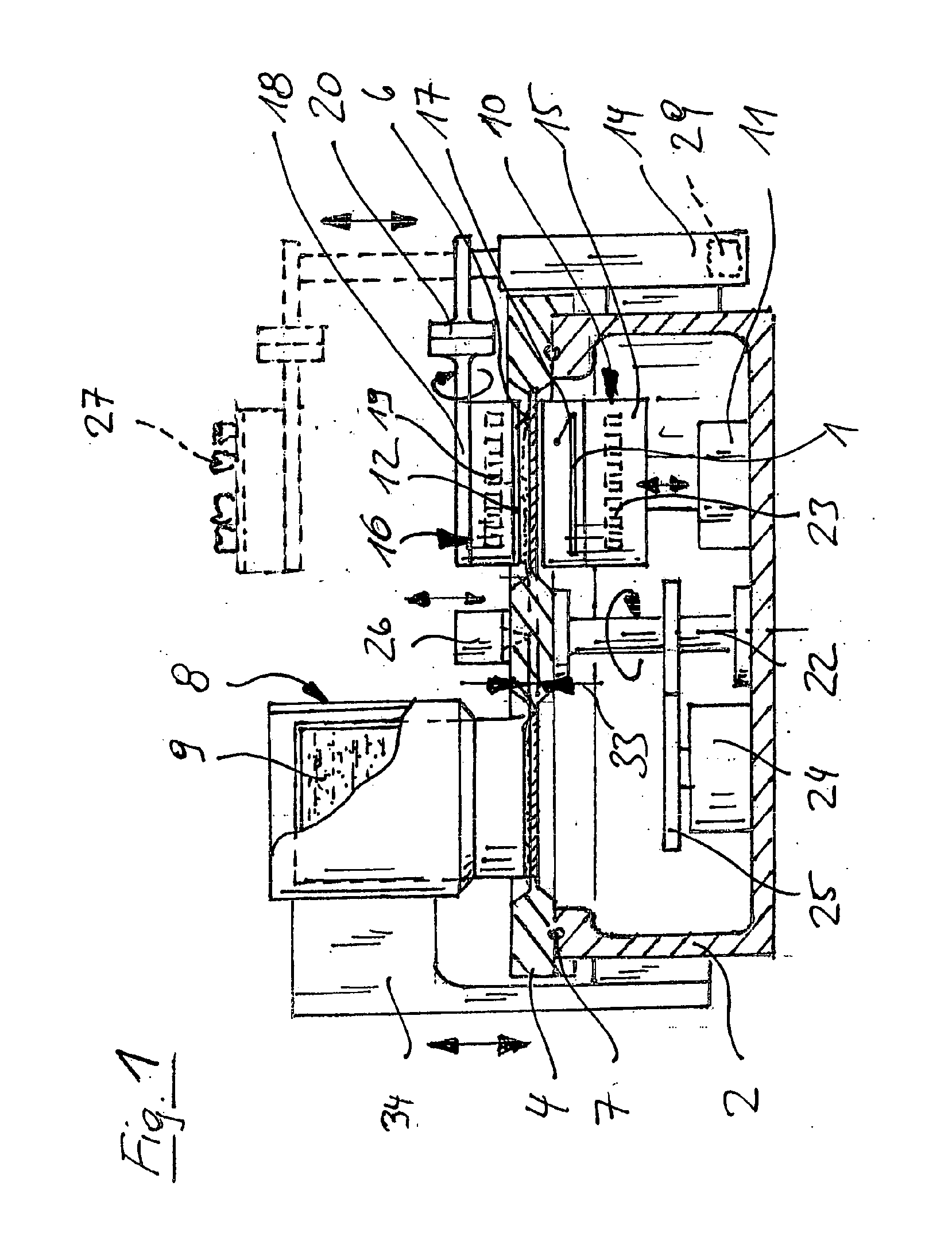

Apparatus and method for production of three-dimensional models by spatial light modulator

InactiveUS6051179AFacilitate cross-linkingHigh mechanical strengthAdditive manufacturing apparatusAnalogue computers for control systemsSpatial light modulatorWide beam

An apparatus and the method of its operation for rapid prototyping of a three-dimensional object which includes a radiant energy source of a wide beam of radiant energy of suitable intensity and wavelength for curing a layer of photo-curable resin contained in an open vat, a spatial light modulator (SLM) having an array of pixel elements which are individually digitally controllable by a computer, for modulating the radiant energy beam projected from the radiant energy source on a pixel by pixel basis, to form a series of time sequential images of the cross-sectional laminae of the object, an optical system for focusing each image formed by the SLM, one at a time, onto successive layers of photo-curable resin for predetermined exposure times to thereby form stacked laminae of cured resin, each lamina of cured resin being in the shape of a different one of the cross-sectional laminae, and a piston support for lowering each lamina of cured resin after it is formed by the SLM and for depositing a layer of resin corresponding to the thickness of one cross sectional lamina of the three-dimensional object before the step of projecting a new image by the SLM. The SLM, the piston support for lowering, and the optical system operate repeatedly and sequentially until a complete copy of the object is thereby produced.

Owner:GLOBAL FILTRATION SYST

Method and system for combining multiple exposure images having scene and camera motion

ActiveUS20060177150A1Quality improvementImprove signal-to-noise ratioImage enhancementTelevision system detailsSignal-to-noise ratio (imaging)Radiance

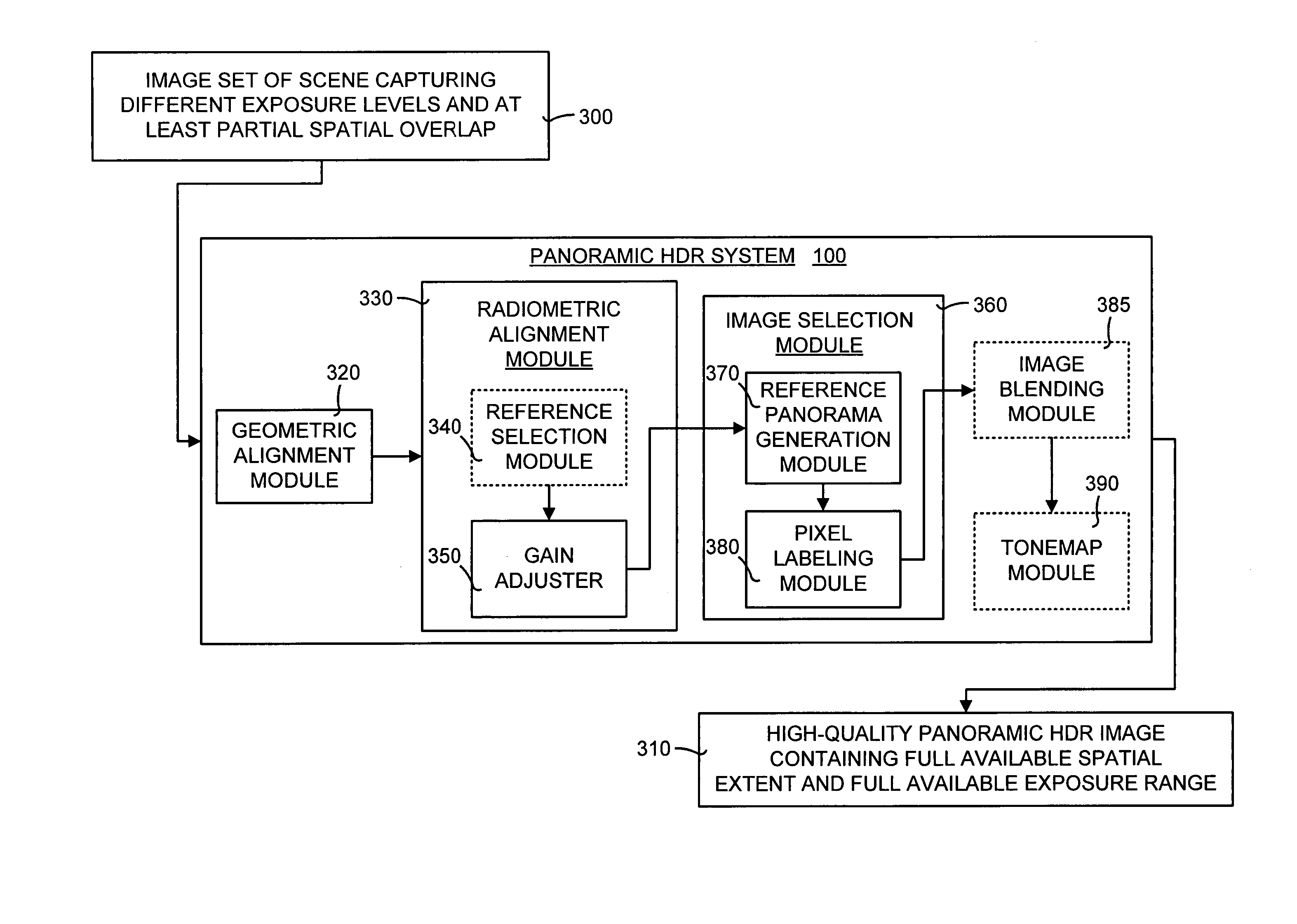

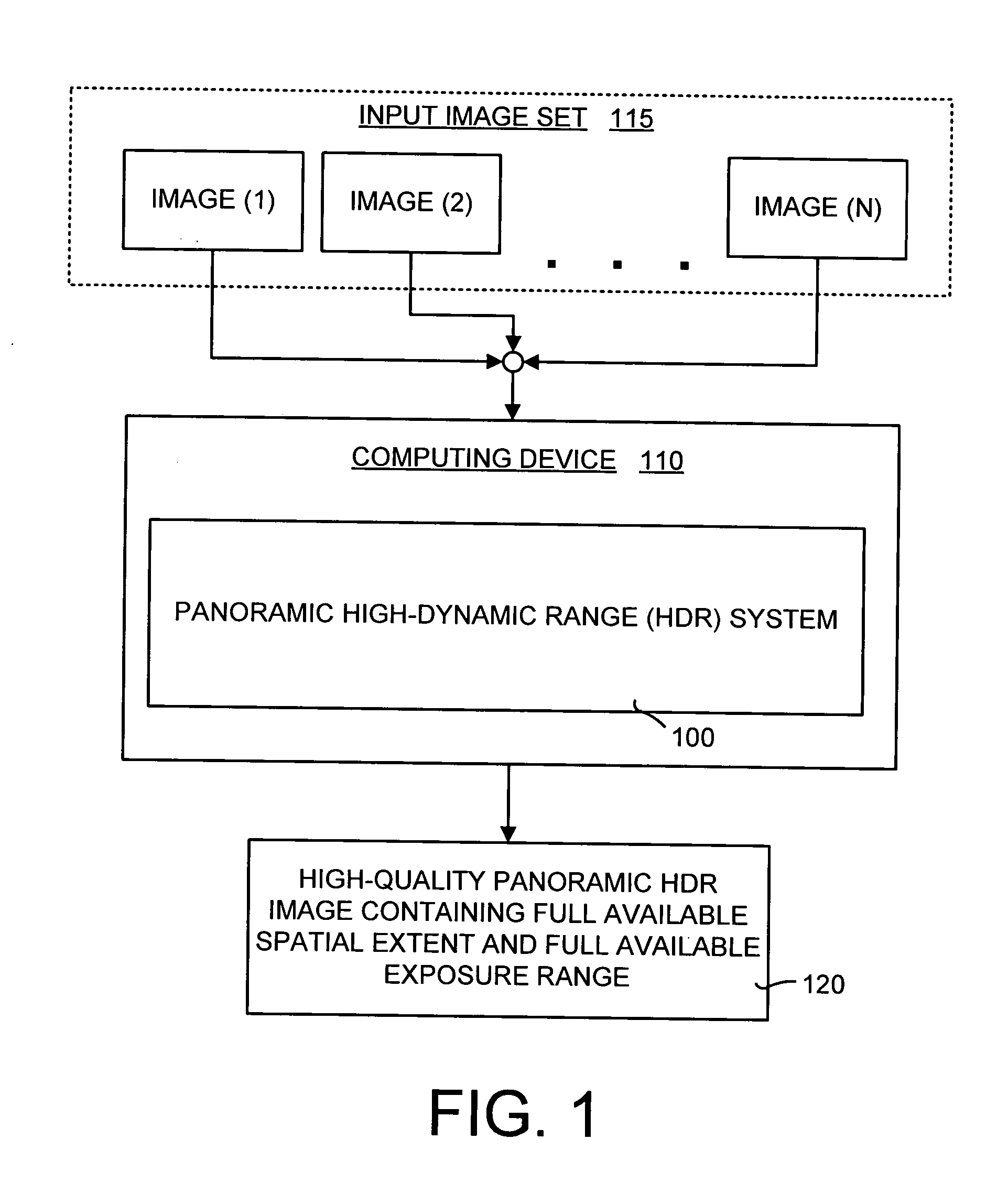

A panoramic high-dynamic range (HDR) image method and system of combining multiple images having different exposures and at least partial spatial overlap wherein each of the images may have scene motion, camera motion, or both. The major part of the panoramic HDR image method and system is a two-pass optimization-based approach that first defines the position of the objects in a scene and then fills in the dynamic range when possible and consistent. Data costs are created to encourage radiance values that are both consistent with object placement (defined by the first pass) and of a higher signal-to-noise ratio. Seam costs are used to ensure that transitions occur in regions of consistent radiances. The result is a high-quality panoramic HDR image having the full available spatial extent of the scene along with the full available exposure range.

Owner:MICROSOFT TECH LICENSING LLC

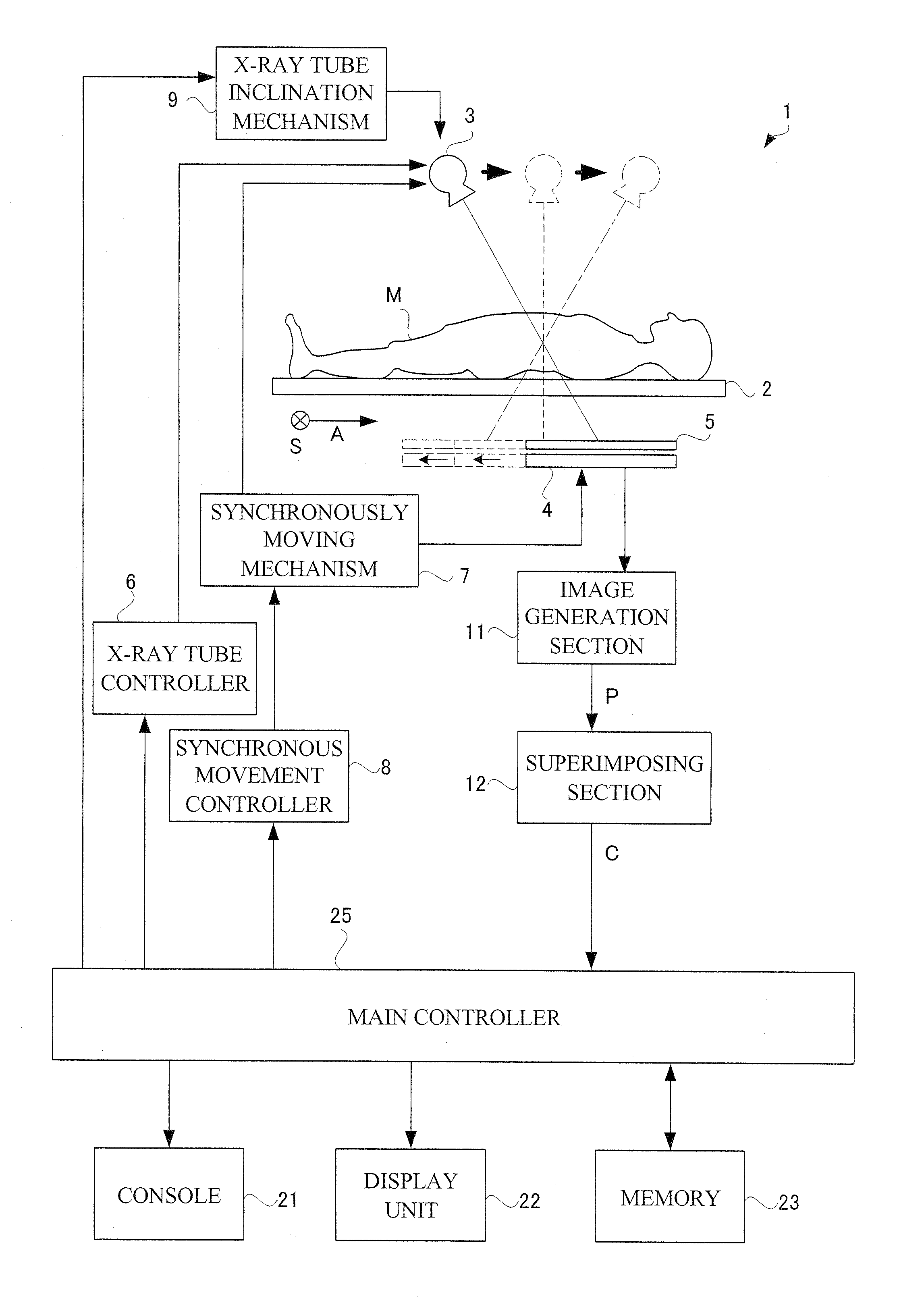

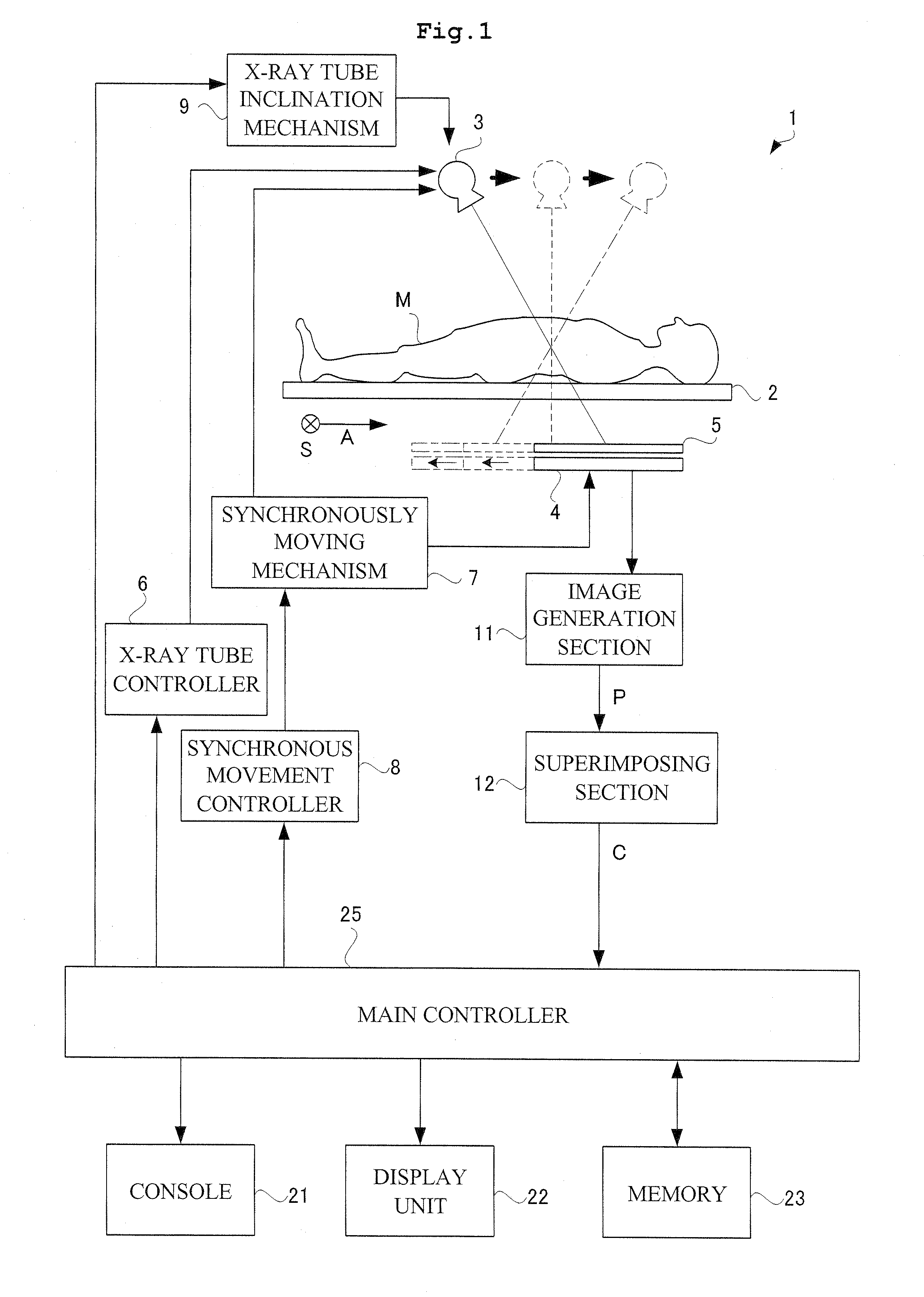

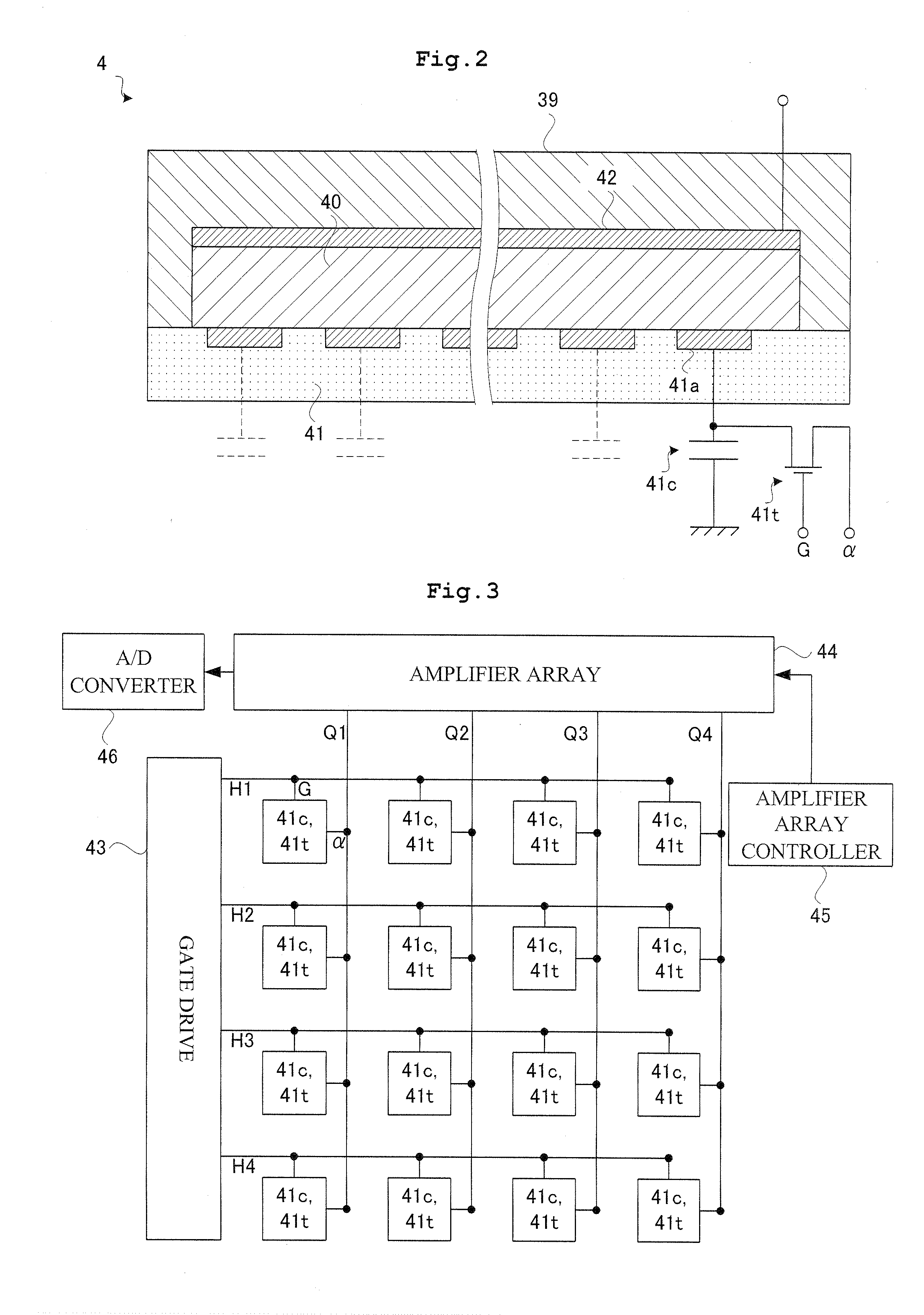

Radiographic apparatus

ActiveUS8798231B2Material analysis using wave/particle radiationRadiation/particle handlingFluoroscopic imageFluorescence

One object of this invention is to provide radiography apparatus with suppressed exposure to a subject in tomography mode. An FPD provided in X-ray apparatus according to this invention converts X-rays into electric signals, and thereafter amplifies the signals to output them to an image generation section. According to this invention, an amplification factor is higher in a tomography mode than in a spot radiography mode. A tomographic image is obtained through superimposing two or more fluoroscopic image. In comparison of the fluoroscopic images, they differ from one another in appearance of the false image. Accordingly, superimposing the images may achieve cancel of the false images. In this way, the tomographic image finally obtained has no false image.

Owner:SHIMADZU CORP

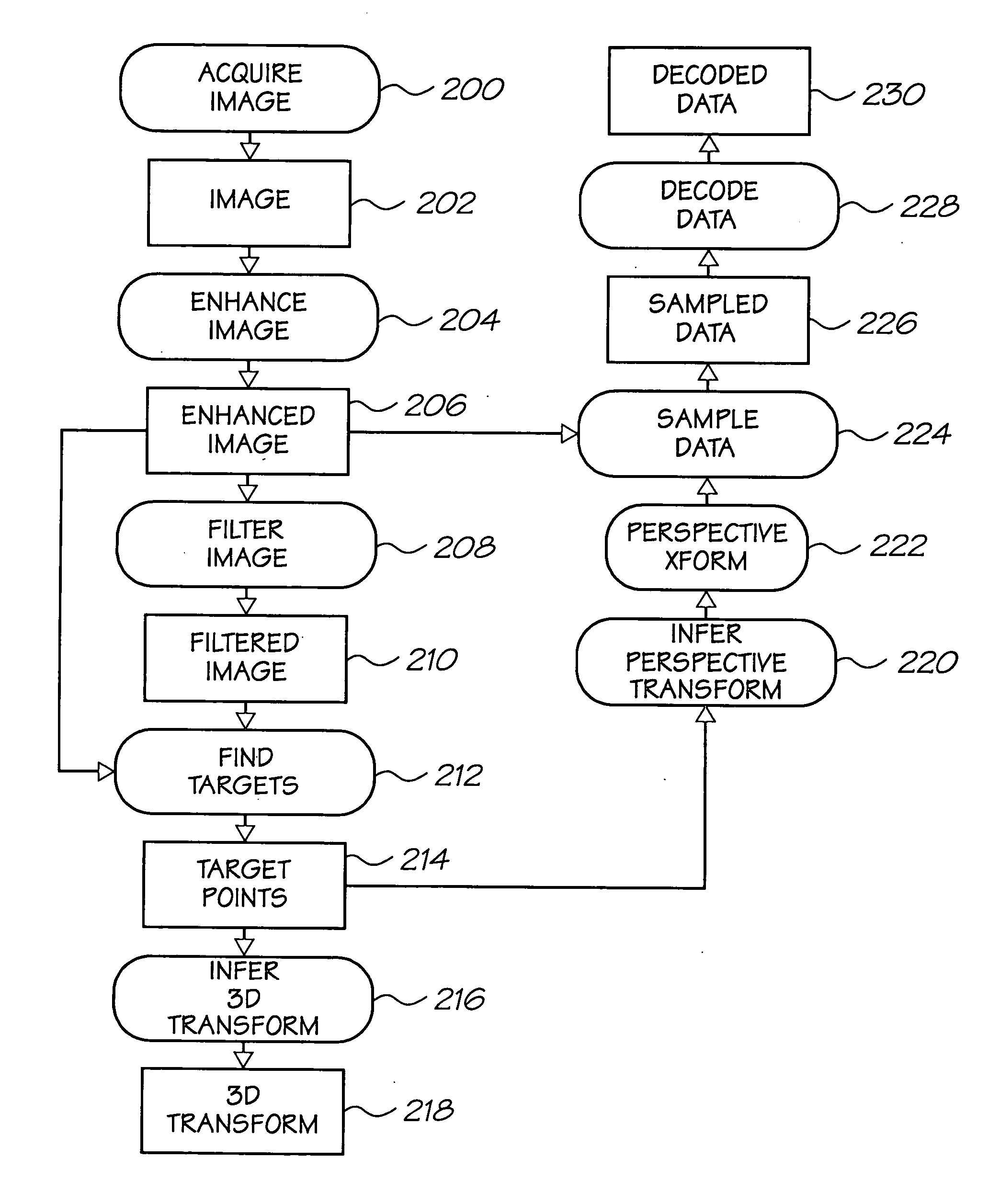

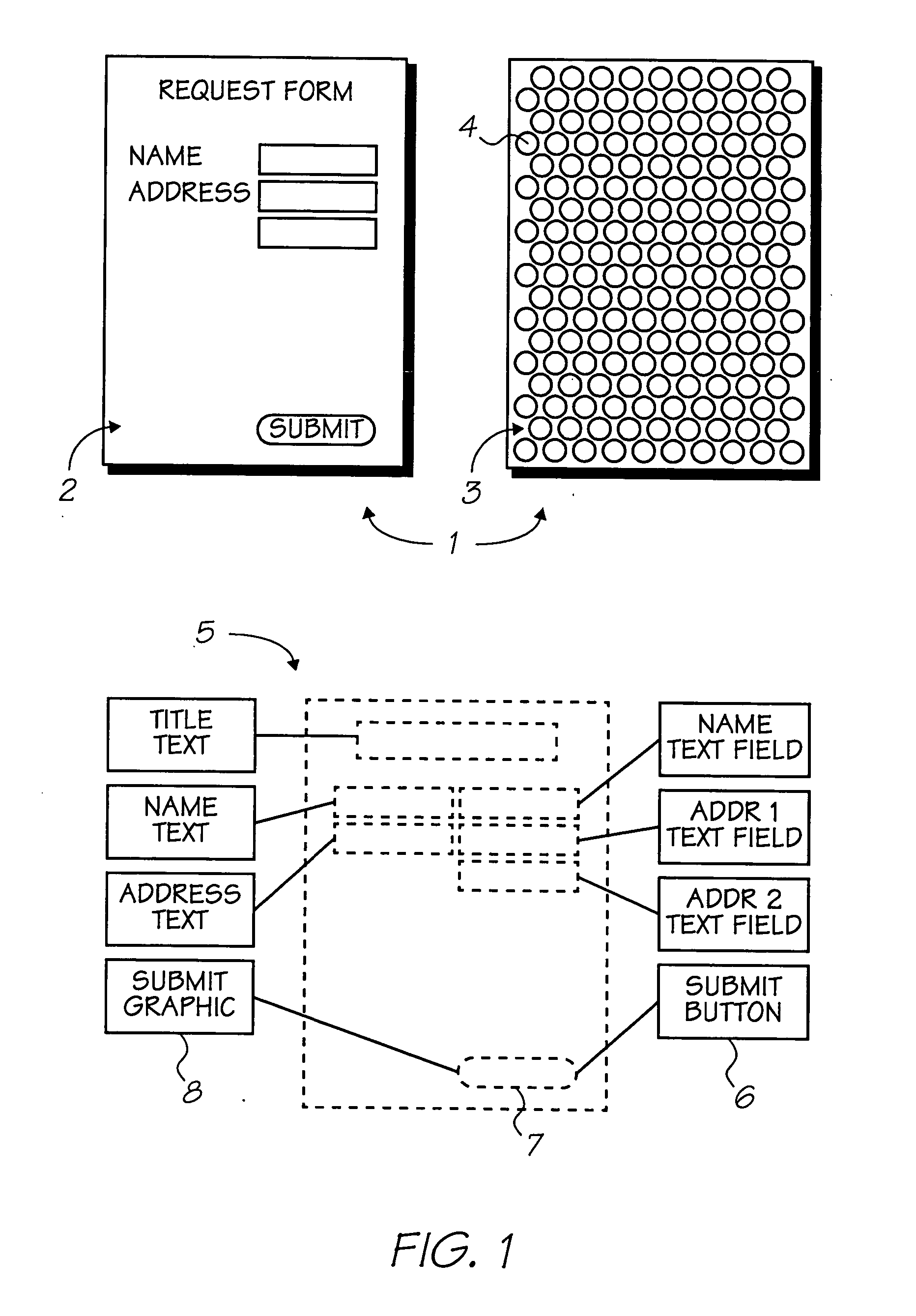

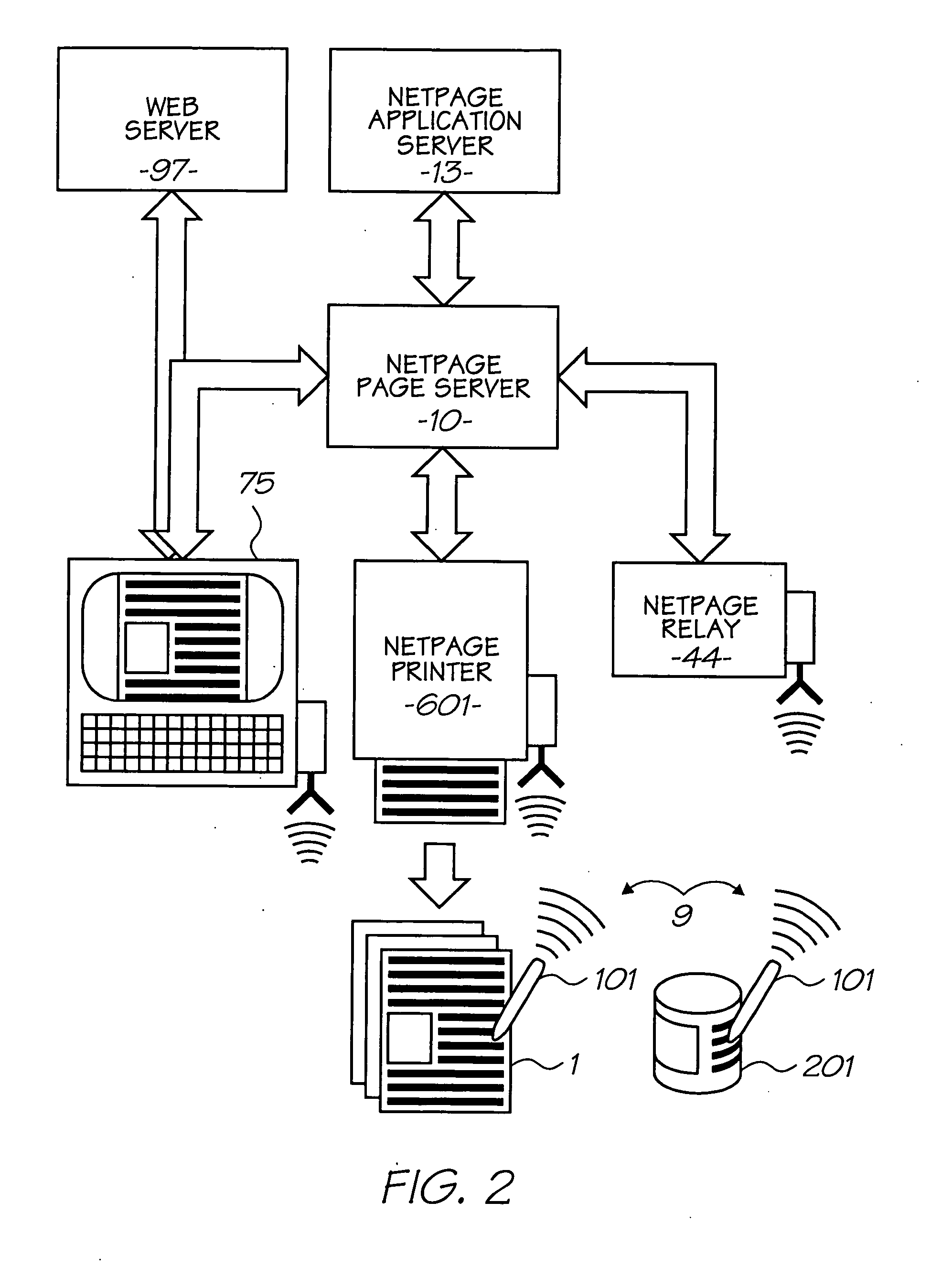

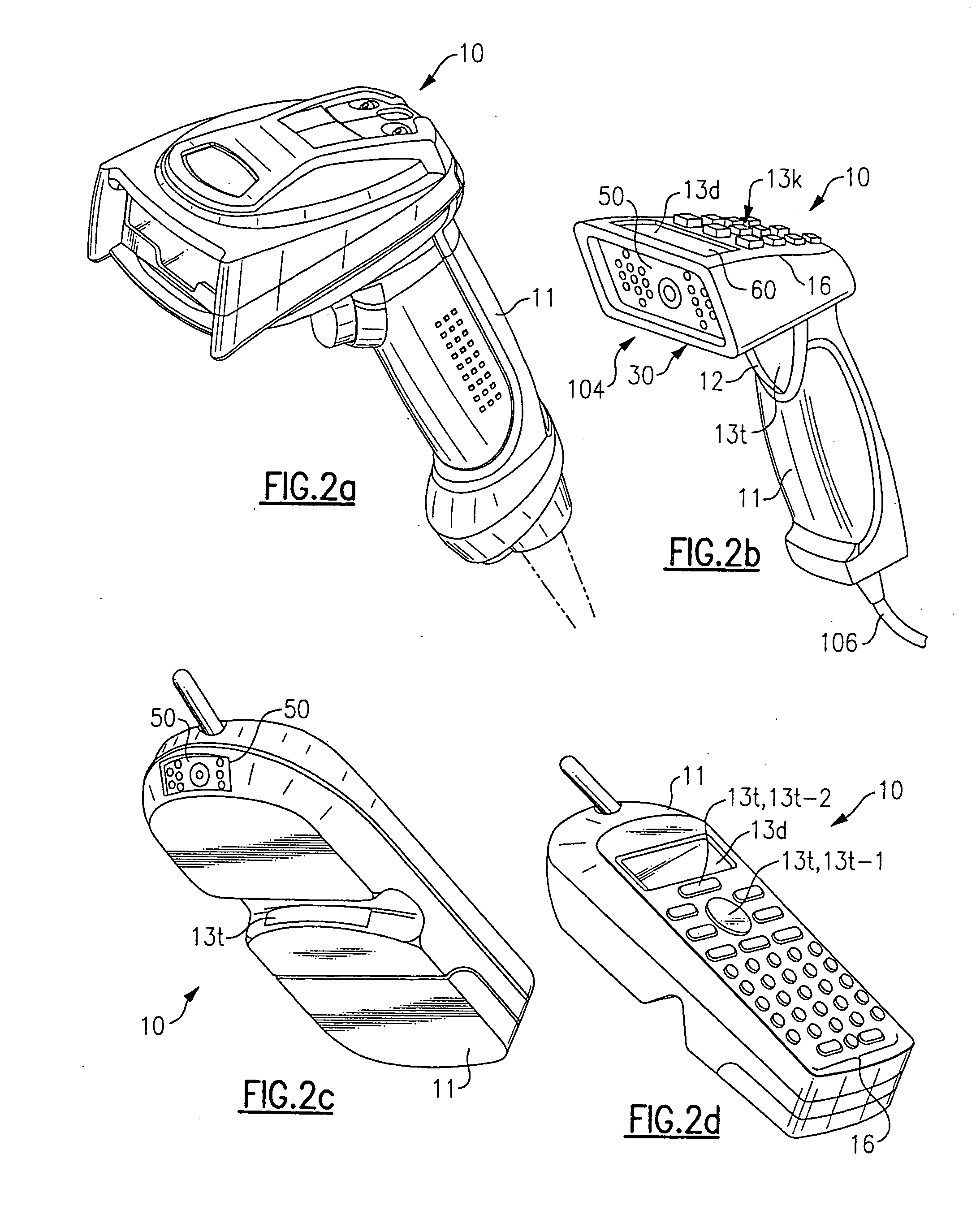

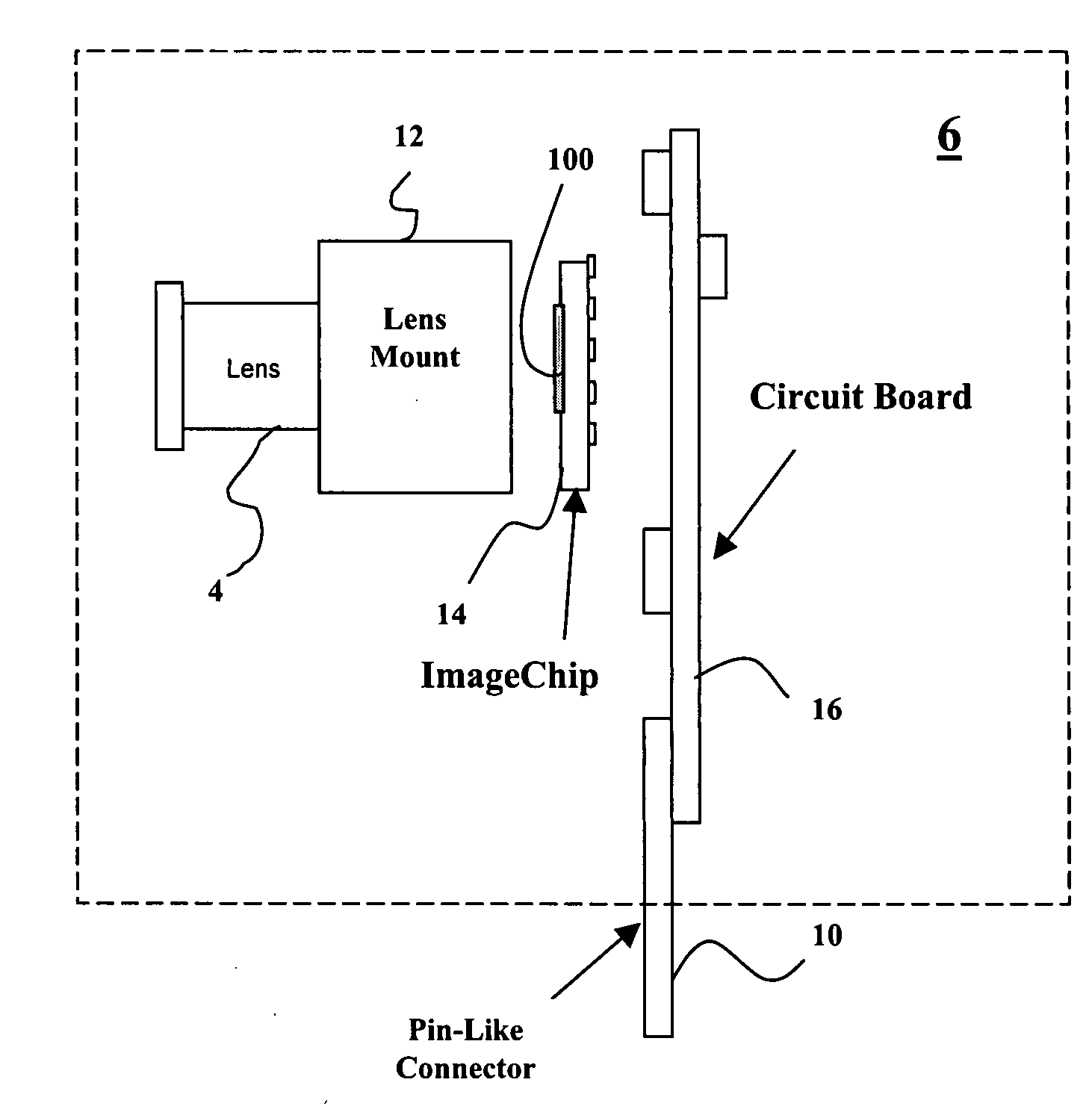

Scanning device for coded data

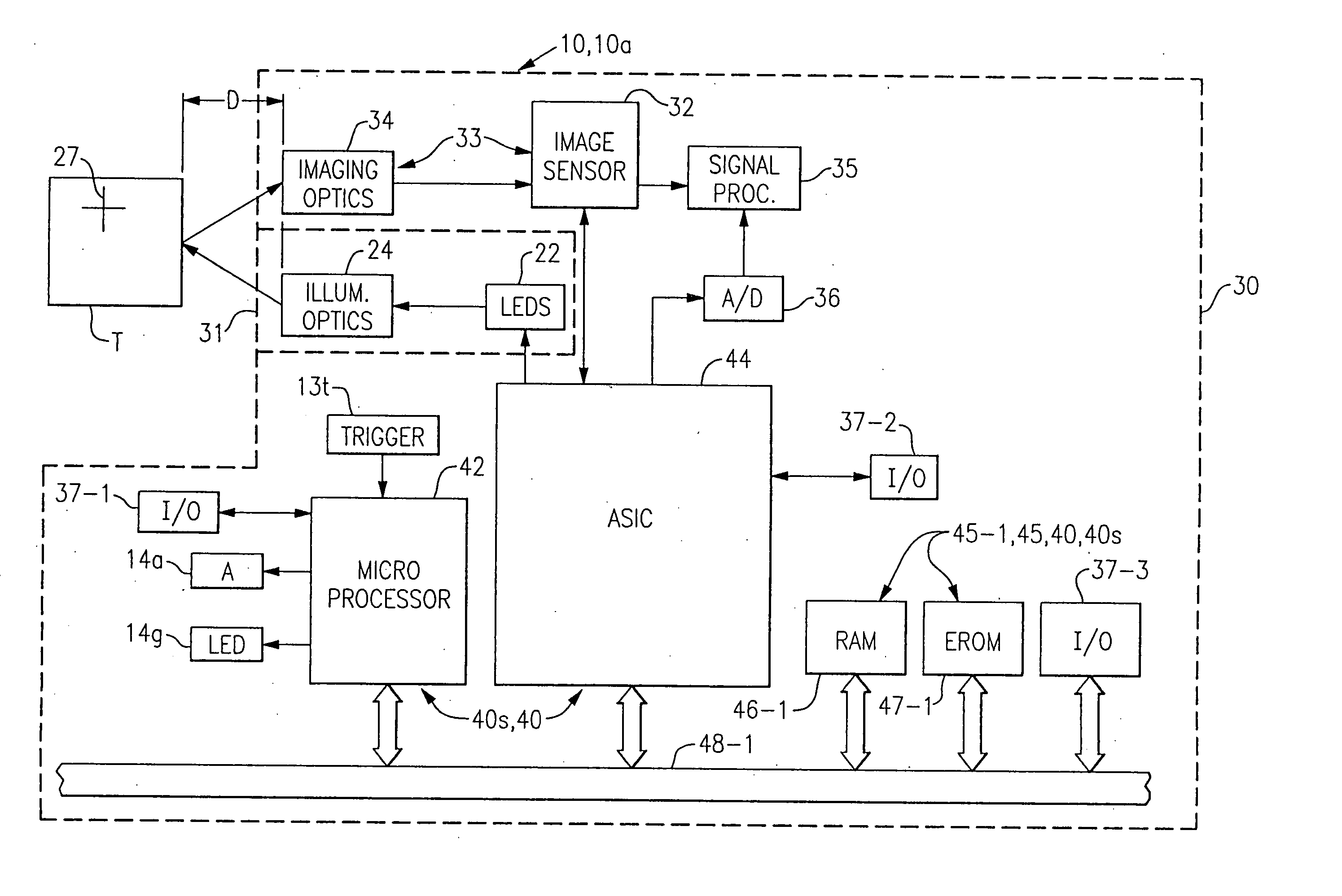

InactiveUS20050254106A9Input/output for user-computer interactionDigital data processing detailsGratingPhotodetector

A scanning device for: scanning coded data disposed on a surface; and generating interaction data based on the sensed coded data, the interaction data being indicative of interaction of the scanning device with the surface; the coded data including, at a plurality of locations on the interface surface, a corresponding plurality of coded data portions, the scanning device comprising: (a) a laser source and scan optics configured to emit a scanning beam through an aperture in a housing of the scanning device, the scanning beam being directed in first and second orthogonal directions to thereby generate a raster scan pattern over a scanning patch, the scanning patch being positioned to cause the exposure of the at least one coded data portion when the surface and the sensing device are positioned operatively with respect to each other; (b) a photodetector for detecting reflection of the scanning beam from the surface, thereby to capture sample information; (c) at least one analog to digital converter for converting the captured sample information into sample data; (d) a first framestore for storing successive sample data as image data; (e) an image processor for processing the image data to generate processed image data; (e) a host processor for generating the interaction data based at least partially on the processed image data.

Owner:SILVERBROOK RES PTY LTD

Illumination apparatus, illumination method, exposure apparatus, and device manufacturing method

ActiveUS20090116093A1Photomechanical apparatusNon-linear opticsTarget surfaceSpatial light modulator

To optionally forming a multilevel light intensity distribution on an illumination pupil plane, the illumination apparatus implements Köhler illumination on an illumination target surface, using as a light source the light intensity distribution formed on the illumination pupil plane on the basis of light from a light source. The illumination apparatus has a spatial light modulator, a condensing optical system, and a control unit. The spatial light modulator has a plurality of reflecting surfaces which are two-dimensionally arranged and postures of which can be controlled independently of each other. The condensing optical system condenses light from the reflecting surfaces to form a predetermined light intensity distribution on the illumination pupil plane. The control unit controls the number of reflecting surfaces contributing to arriving light, for each of points on the illumination pupil plane forming the light intensity distribution, according to a light intensity distribution to be formed on the illumination pupil plane.

Owner:NIKON CORP

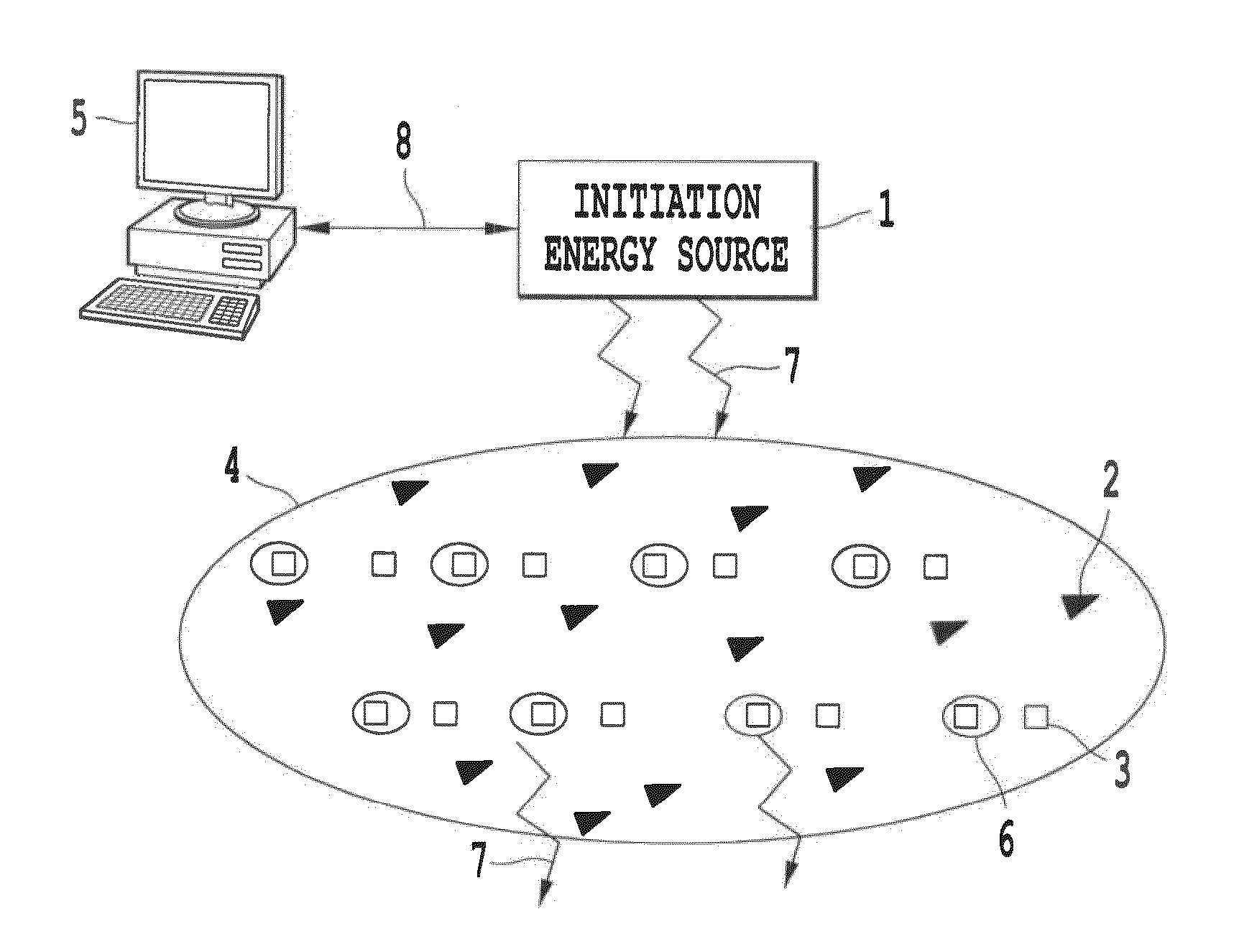

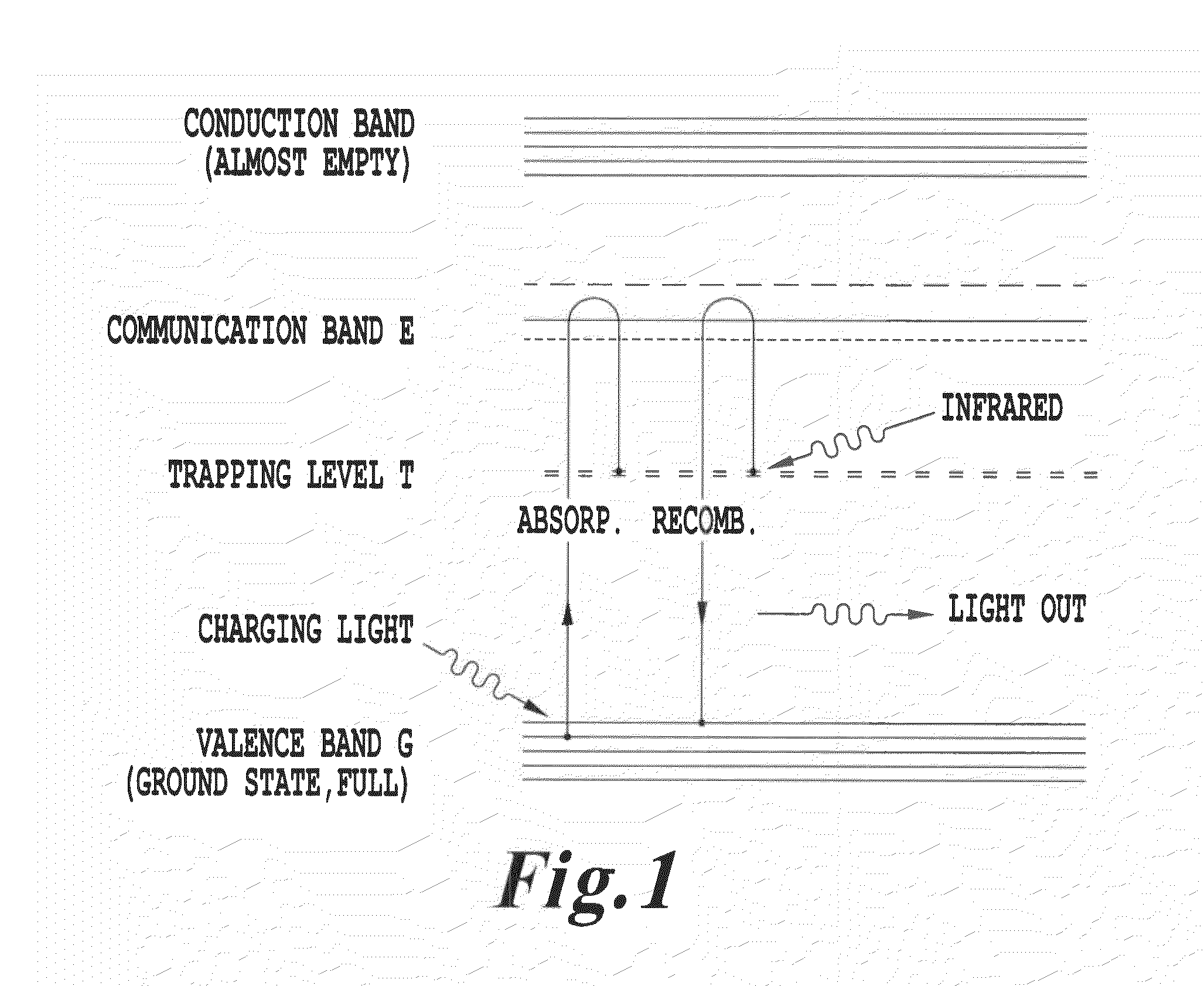

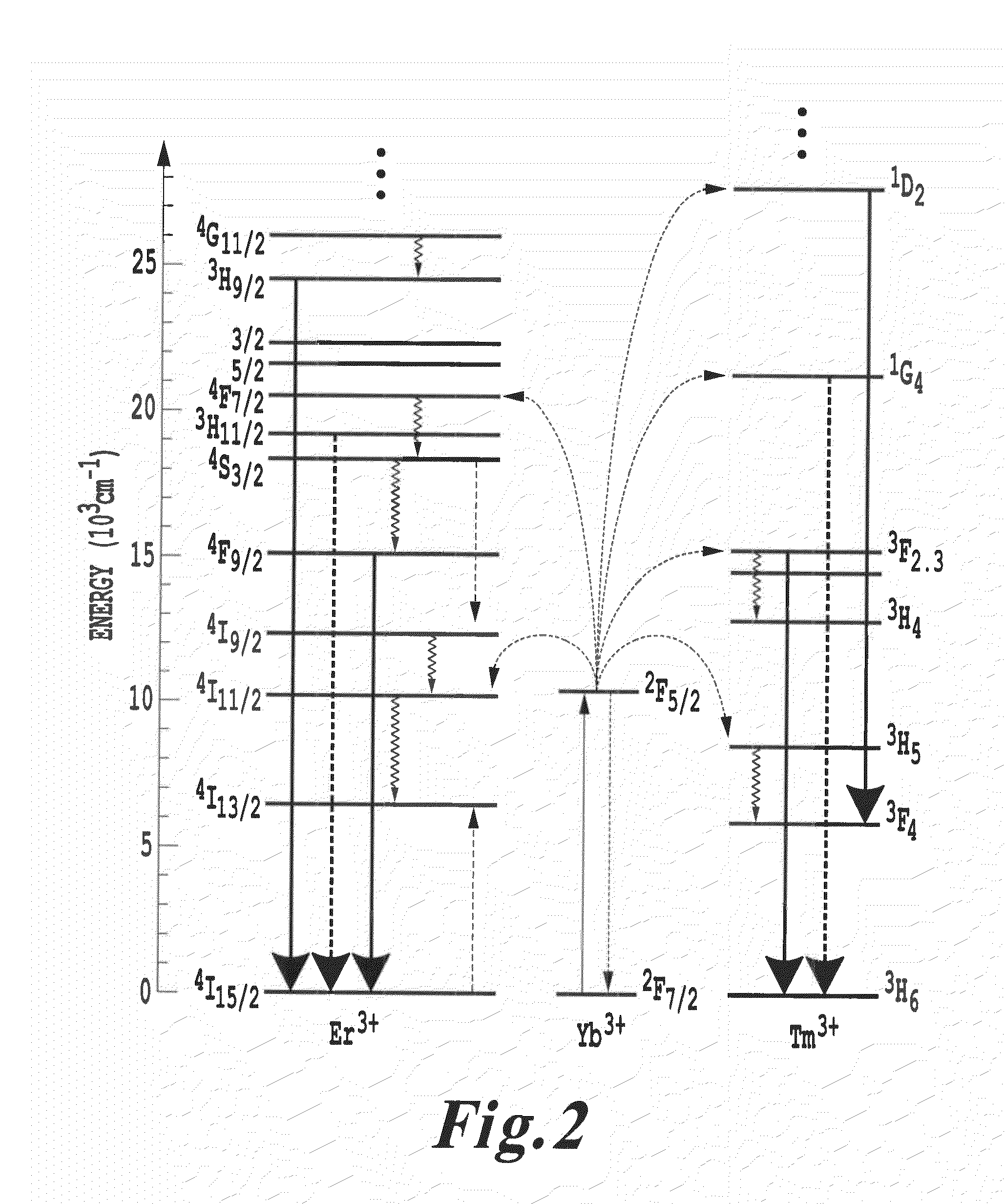

Up and down conversion systems for production of emitted light from various energy sources

ActiveUS20100261263A1Enhance upconversionOptical radiation measurementMaterial nanotechnologyHigh energyRadiation

A system for energy upconversion and / or down conversion and a system for producing a photostimulated reaction in a medium. These systems include 1) a nanoparticle configured, upon exposure to a first wavelength λ1 of radiation, to generate a second wavelength λ2 of radiation having a higher energy than the first wavelength λ1 and 2) a metallic structure disposed in relation to the nanoparticle. A physical characteristic of the metallic structure is set to a value where a surface plasmon resonance in the metallic structure resonates at a frequency which provides a spectral overlap with either the first wavelength λ1 or the second wavelength λ2, or with both λ1 and λ2. The system for producing a photostimulated reaction in a medium includes a receptor disposed in the medium in proximity to the nanoparticle which, upon activation by the second wavelength λ2, generates the photostimulated reaction.

Owner:DUKE UNIV +1

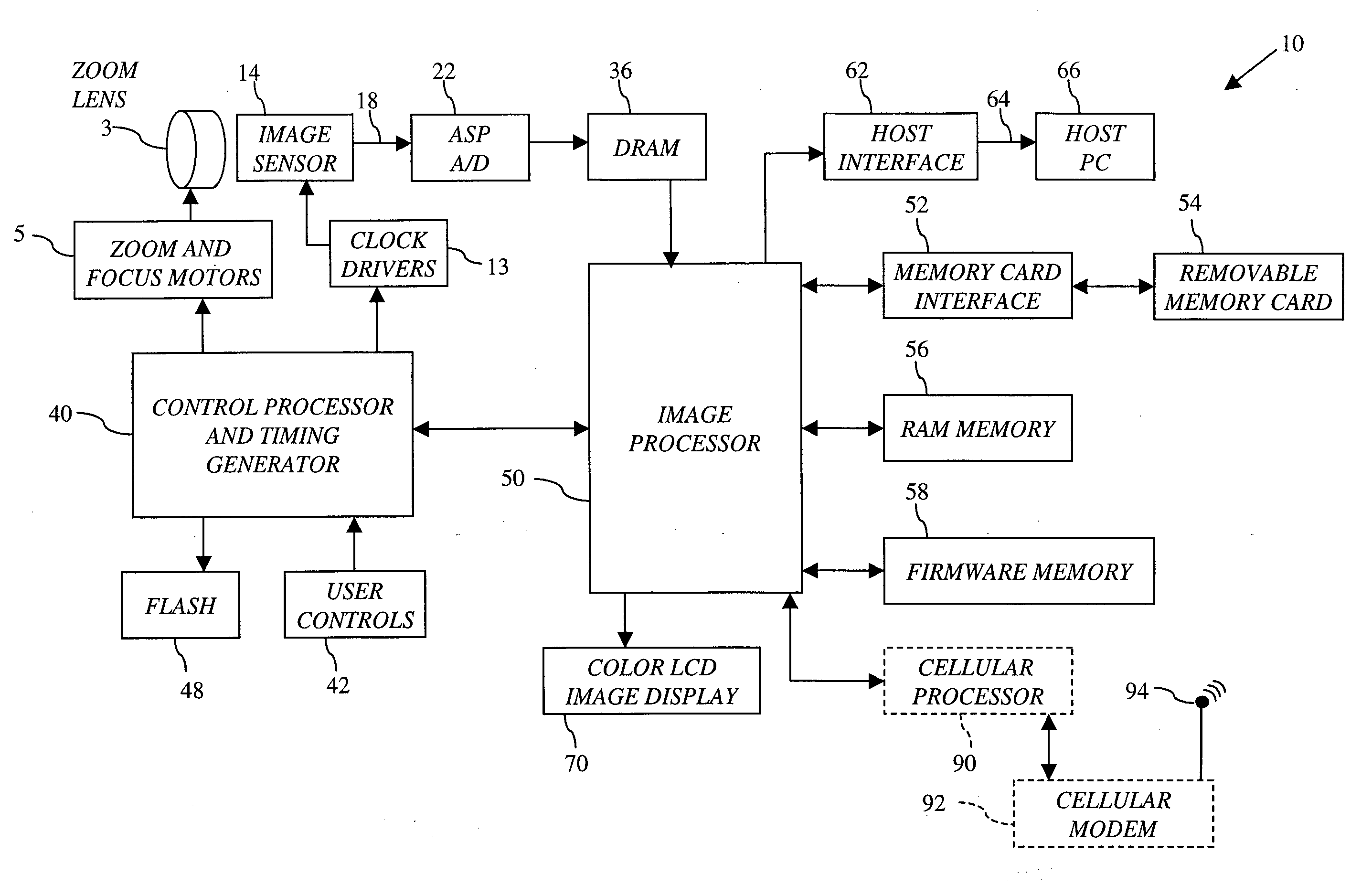

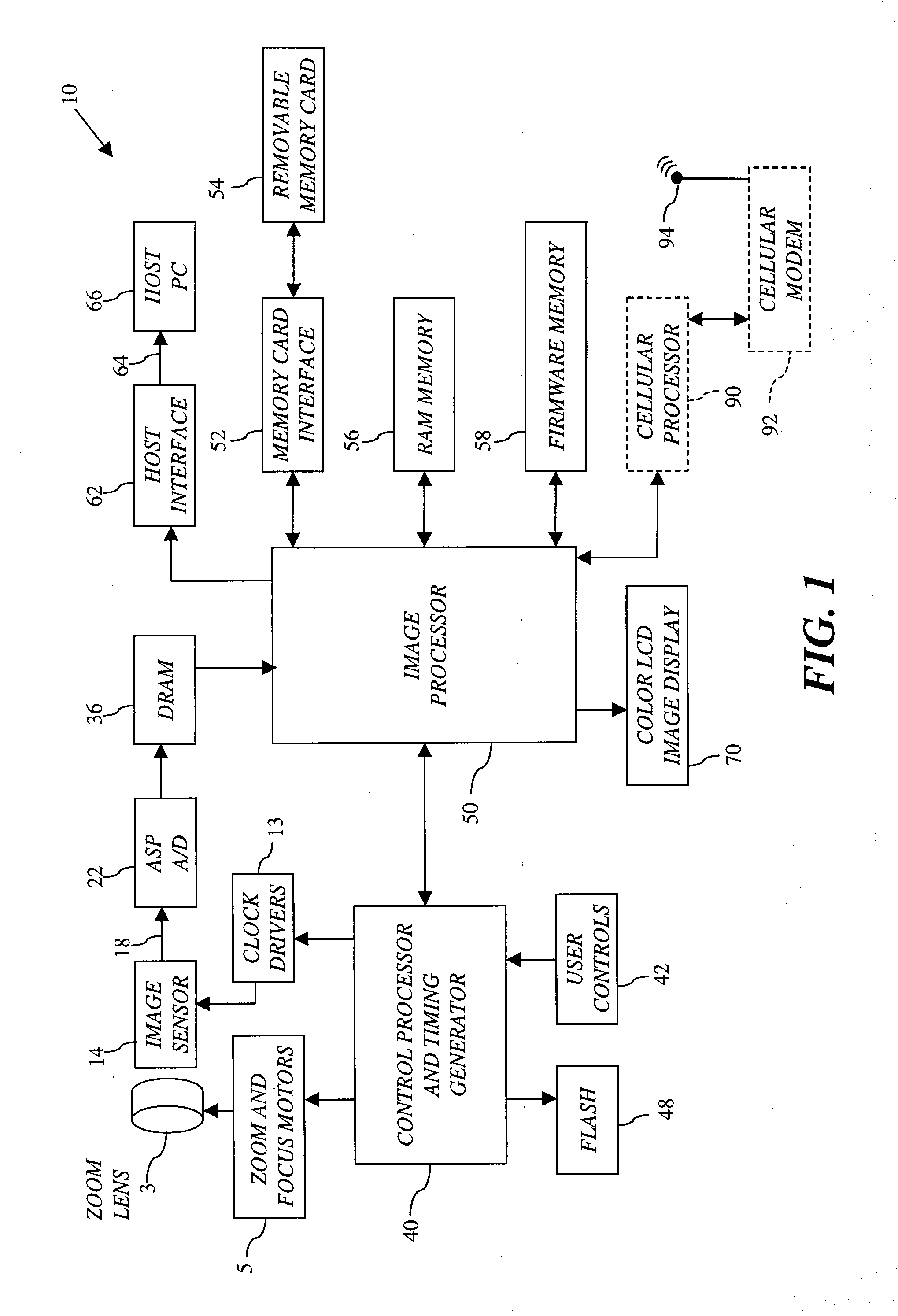

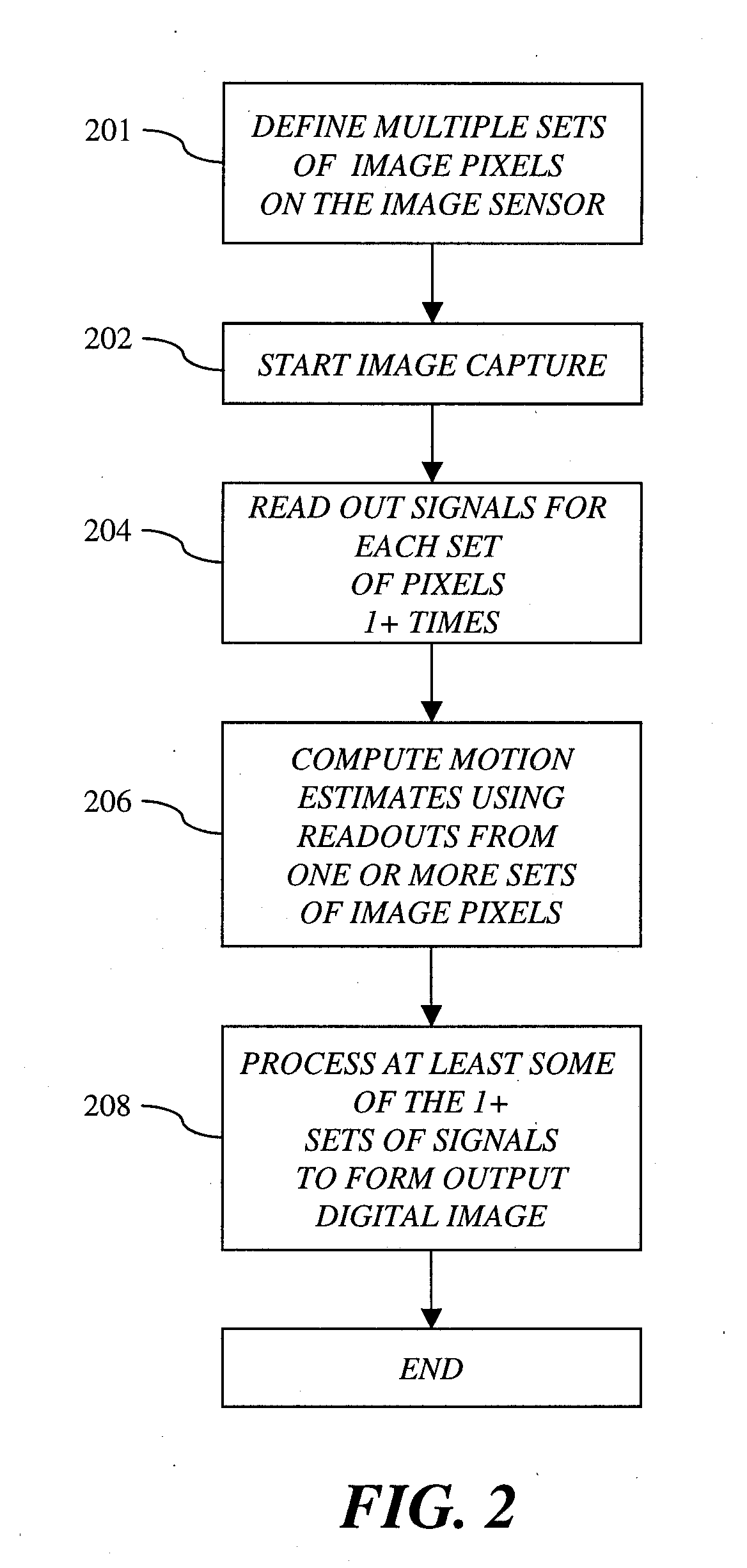

Determining and correcting for imaging device motion during an exposure

A system and method for determining and correcting for imaging device motion during an exposure is provided. According to various embodiments of the present invention, multiple sets of image pixels are defined on an image sensor, where each set of pixels is at least partially contained in the output image area of the image sensor. Signals from each set of image pixels are read out once or more during an exposure, motion estimates are computed using signal readouts from one or more sets of image pixels, and signal readouts from one or more sets of the image pixels are processed to form the final output image.

Owner:OMNIVISION TECH INC

Capturing and Rendering High Dynamic Range Images

ActiveUS20120002082A1Speed up speed upQuick snapImage enhancementTelevision system detailsImaging processingComputer graphics (images)

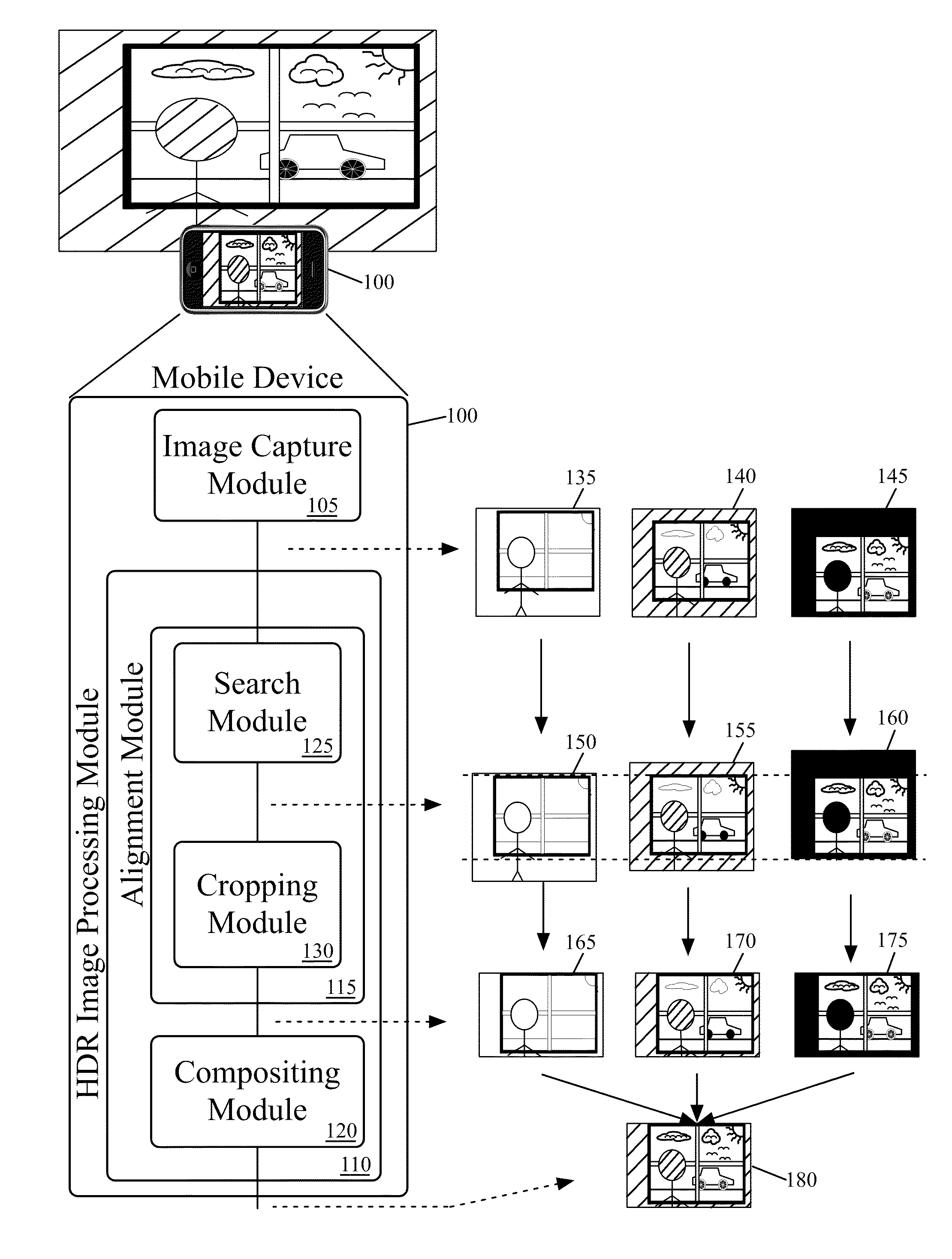

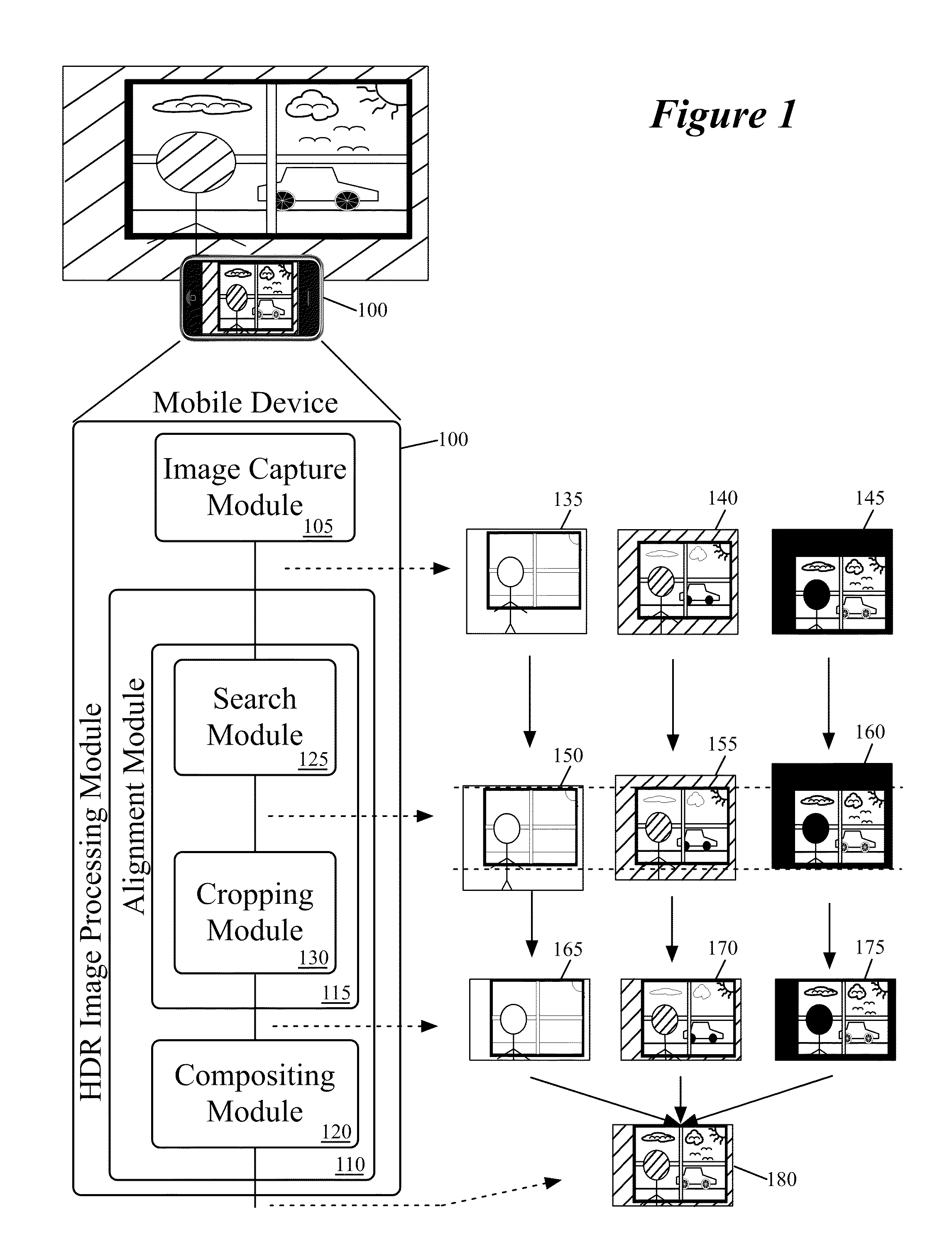

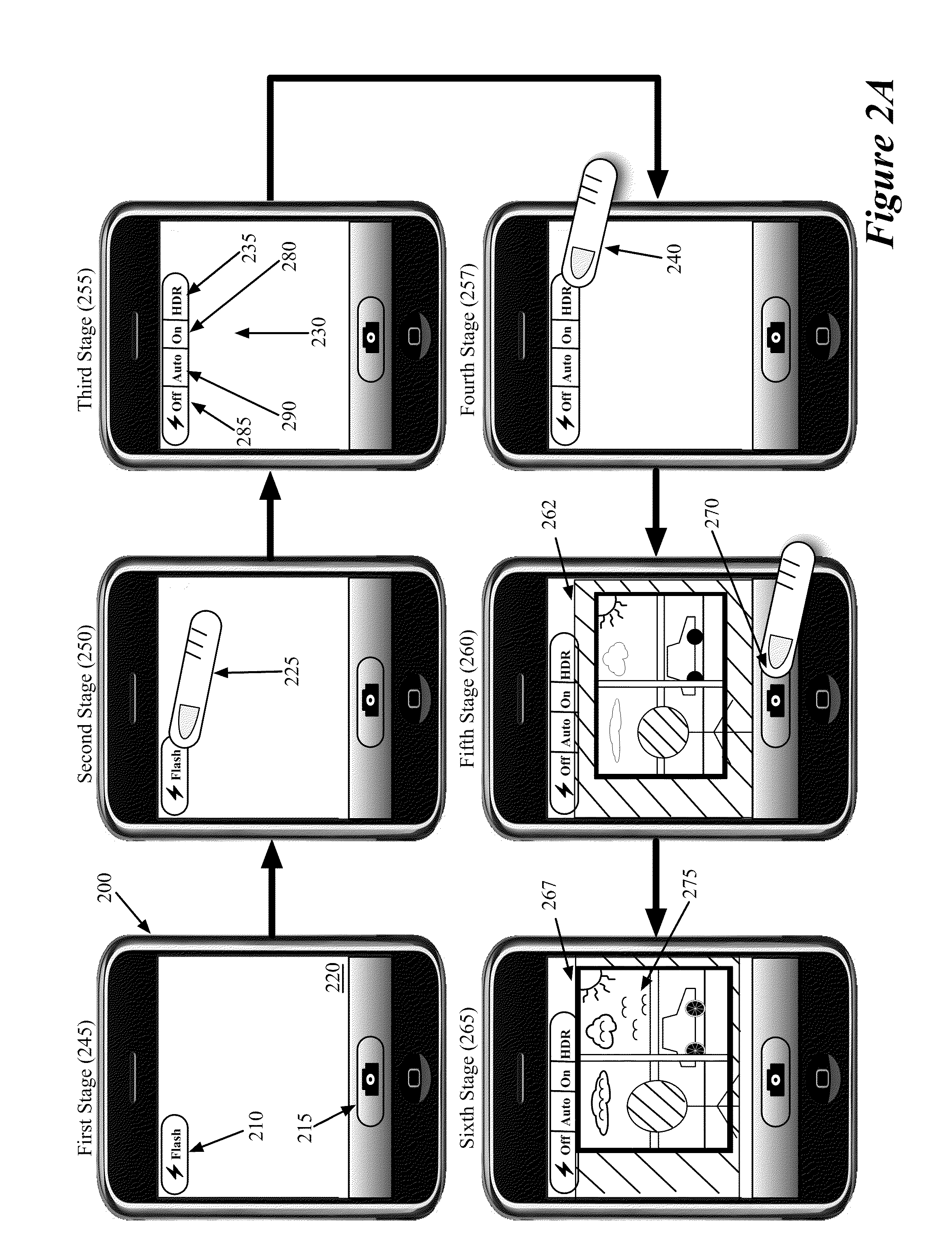

Some embodiments of the invention provide a mobile device that captures and produces images with high dynamic ranges. To capture and produce a high dynamic range image, the mobile device of some embodiments includes novel image capture and processing modules. In some embodiments, the mobile device produces a high dynamic range (HDR) image by (1) having its image capture module rapidly capture a succession of images at different image exposure durations, and (2) having its image processing module composite these images to produce the HDR image.

Owner:APPLE INC

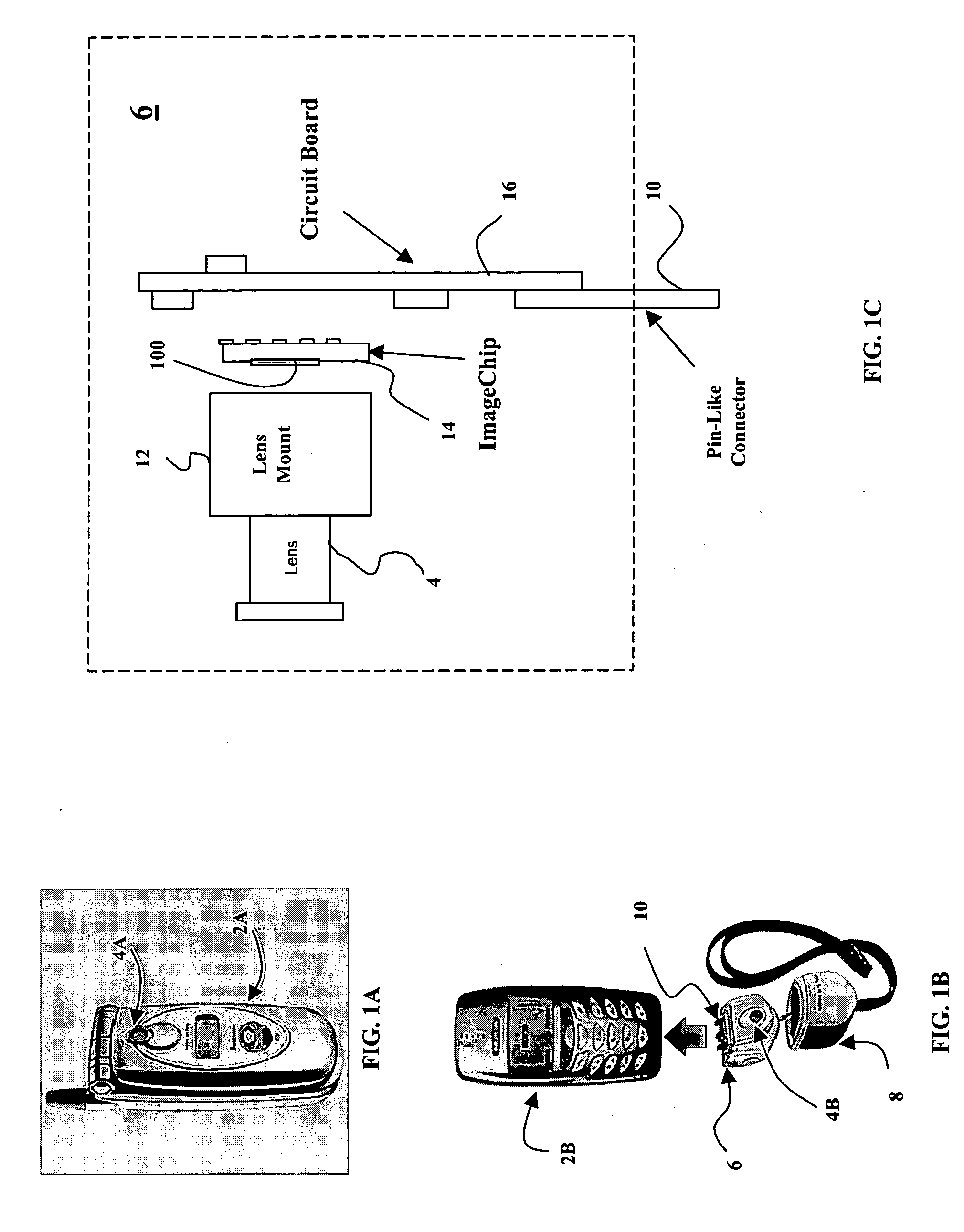

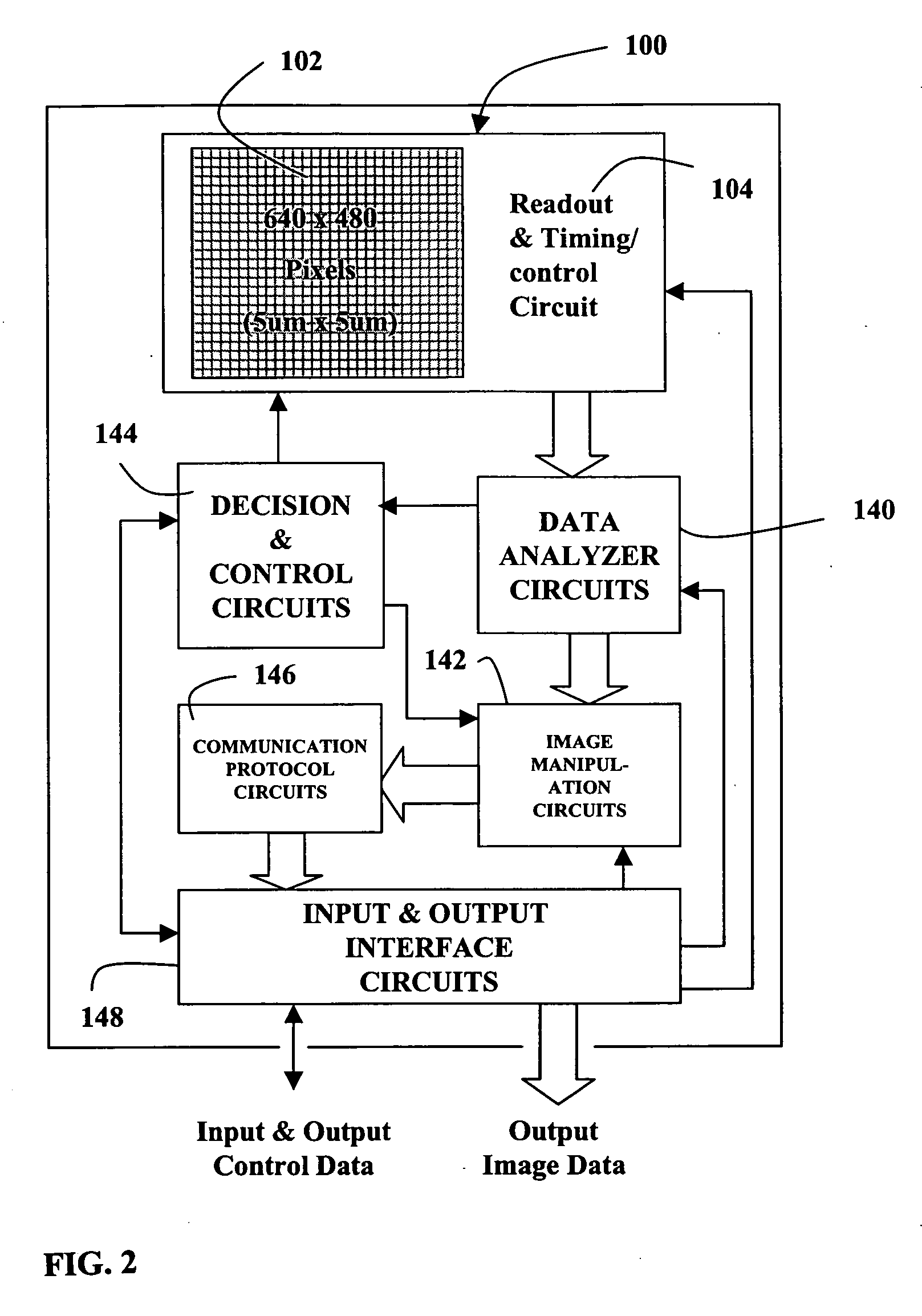

Adaptive optical image reader

InactiveUS20050056699A1Data augmentationExtension of timeCharacter and pattern recognitionExposure controlDigital imageDigital converter

A digital image reading system including an image sensor and a computer that is programmed to adjust the frame rate of the image sensor, and to obtain a maximum frame rate of the image sensor for obtaining an acceptable image. An algorithm for adjusting the frame rate evaluates image parameters and calculates new exposure times, gain values, and exposure settings to support a maximum frame rate of the image sensor. A process for obtaining an acceptable image with an image reader evaluates an image signal level and adjusts the frame rate if the signal level is outside of a predetermined range. The process adjusts the image sensor to run at a maximum operational frame rate. A digital image reading system including multiple separate digitizers for use in various read environments and under various read conditions.

Owner:HAND HELD PRODS

Approach to adjust driving waveforms for a display device

Owner:E INK CORPORATION

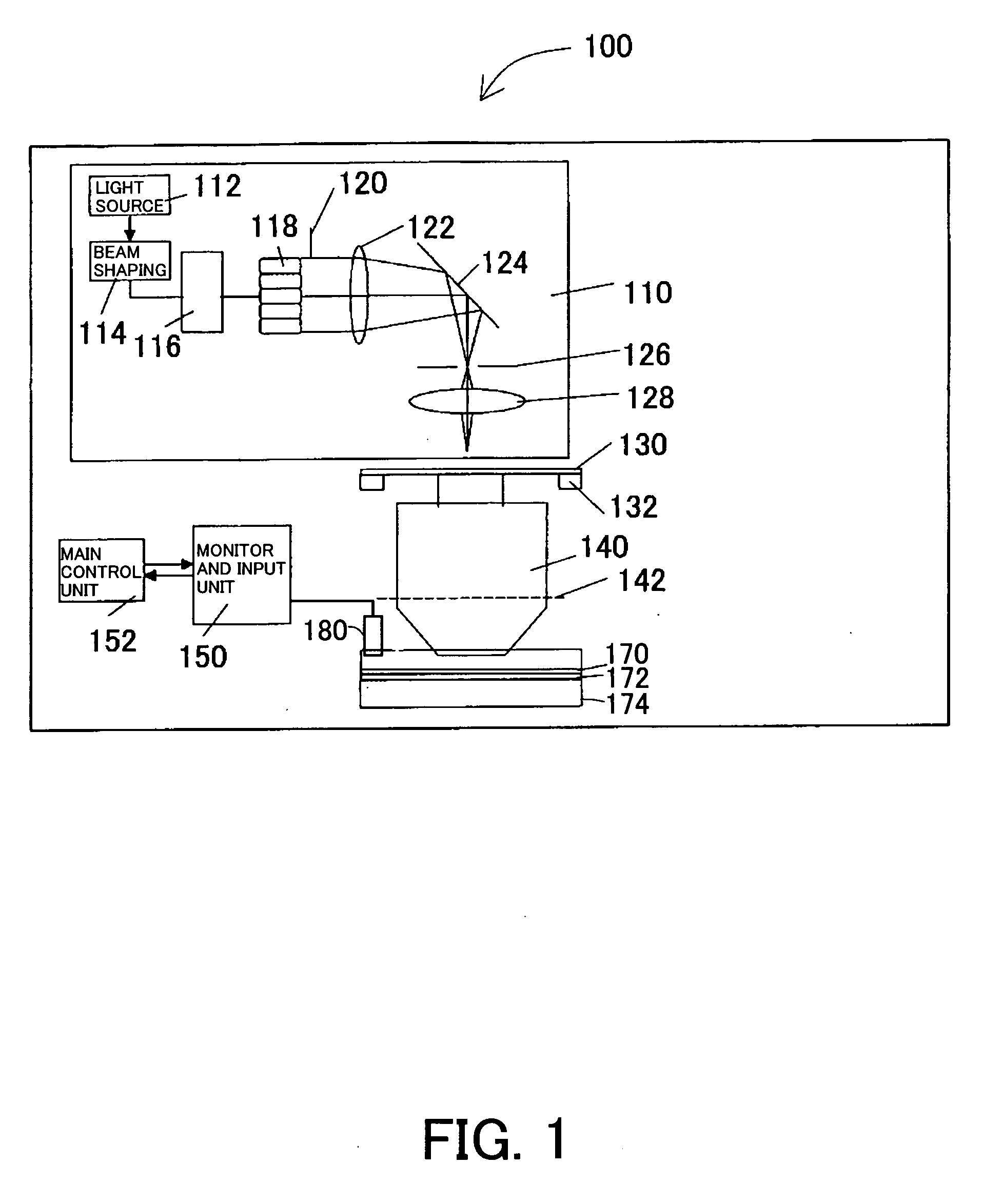

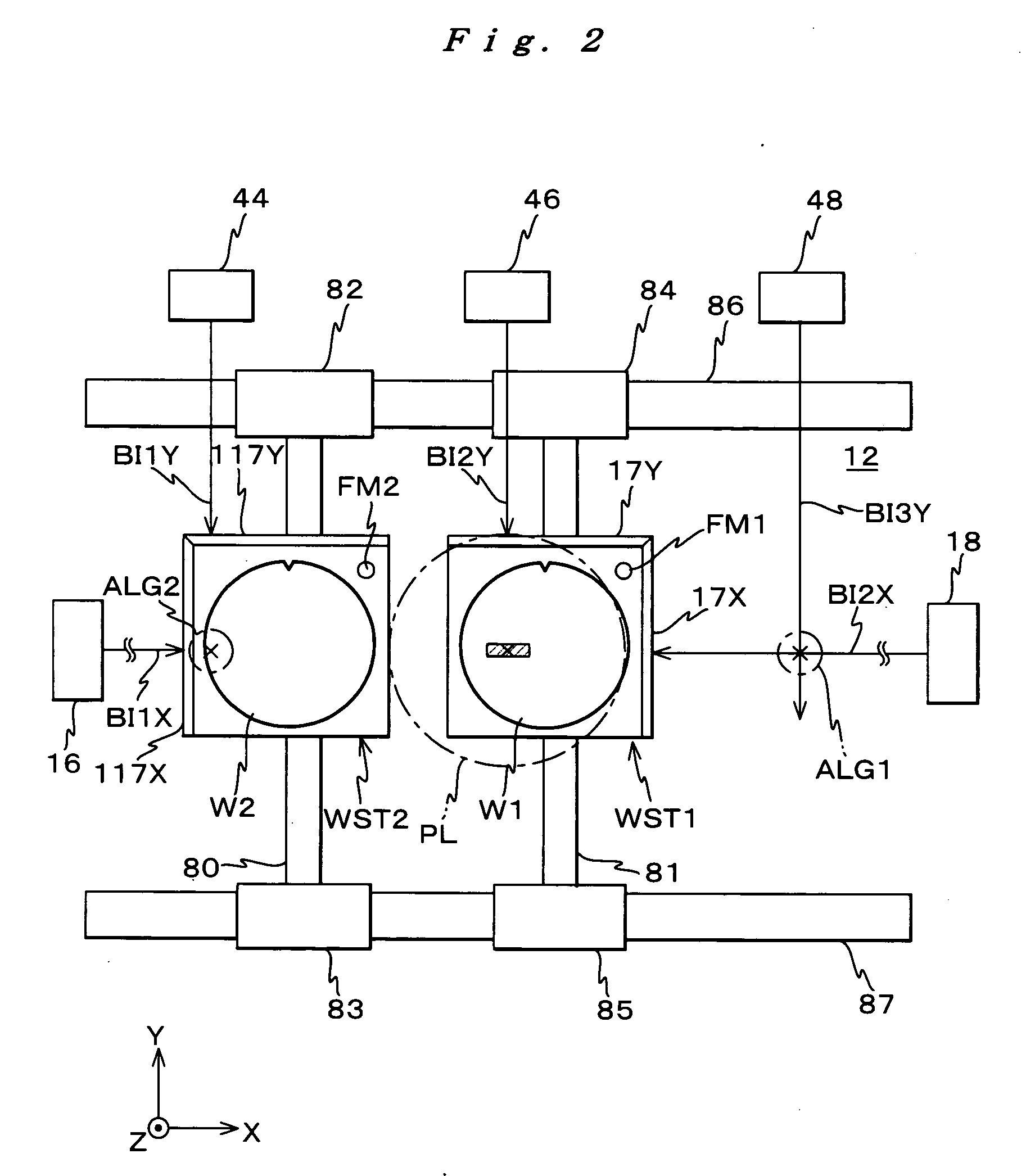

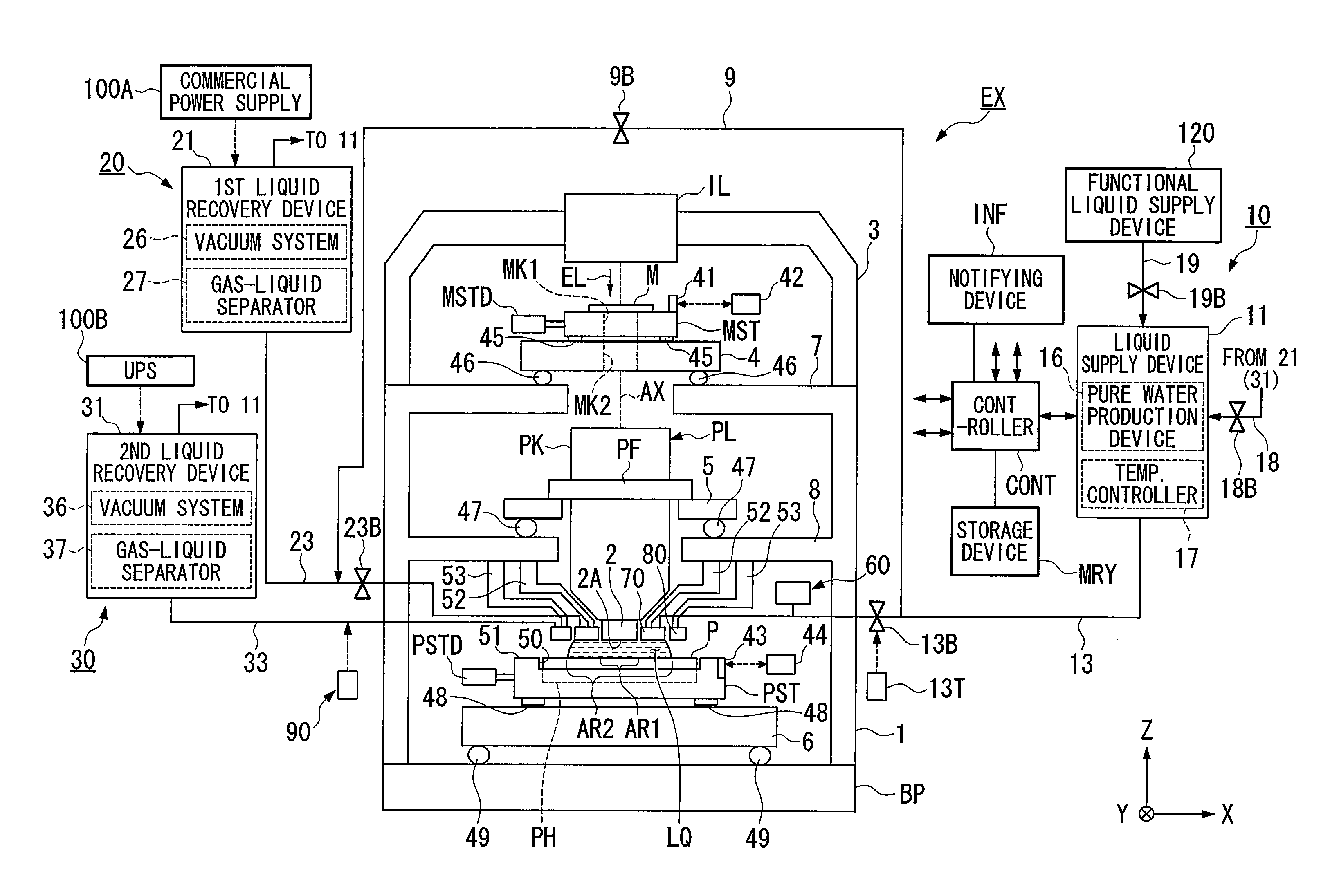

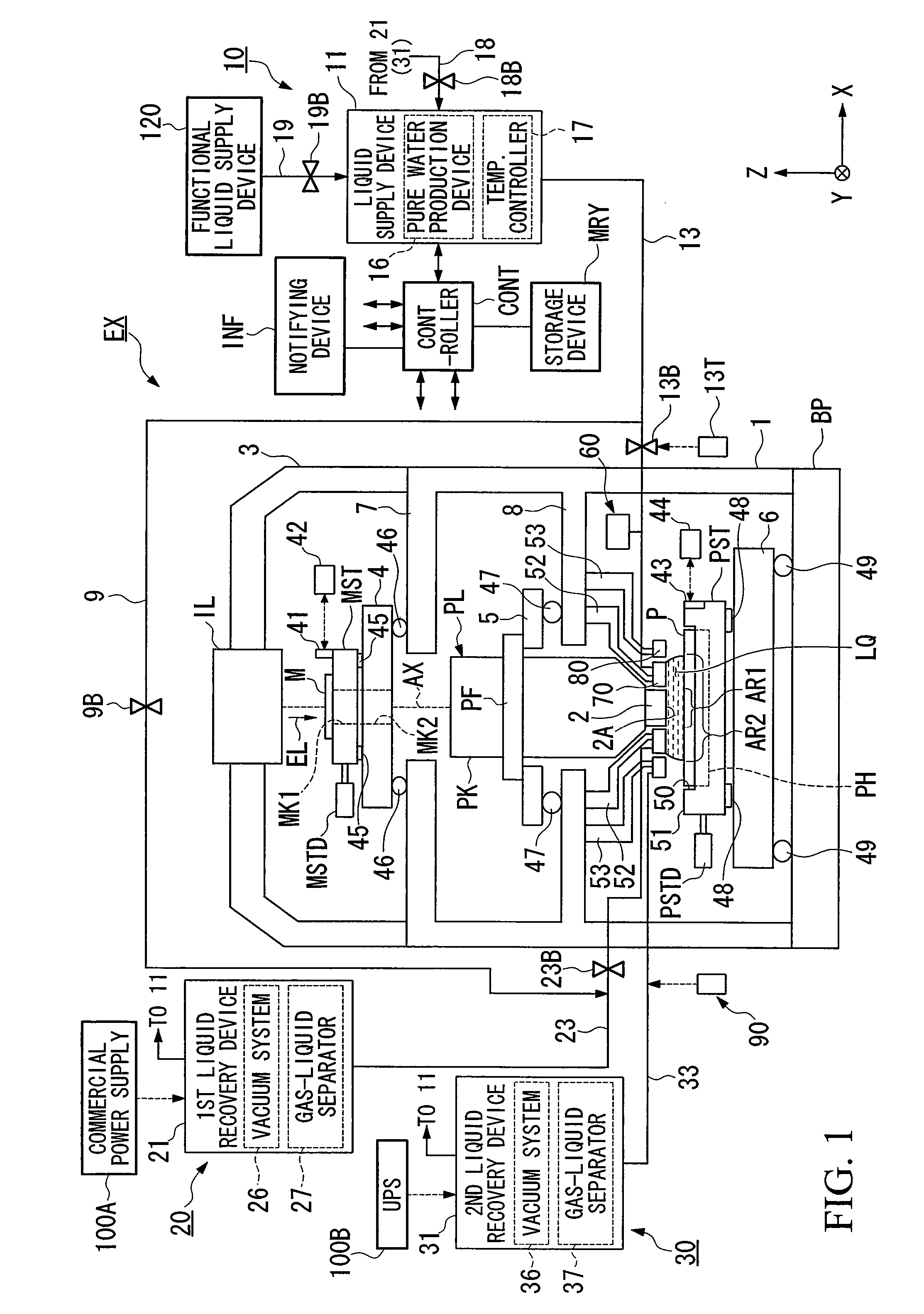

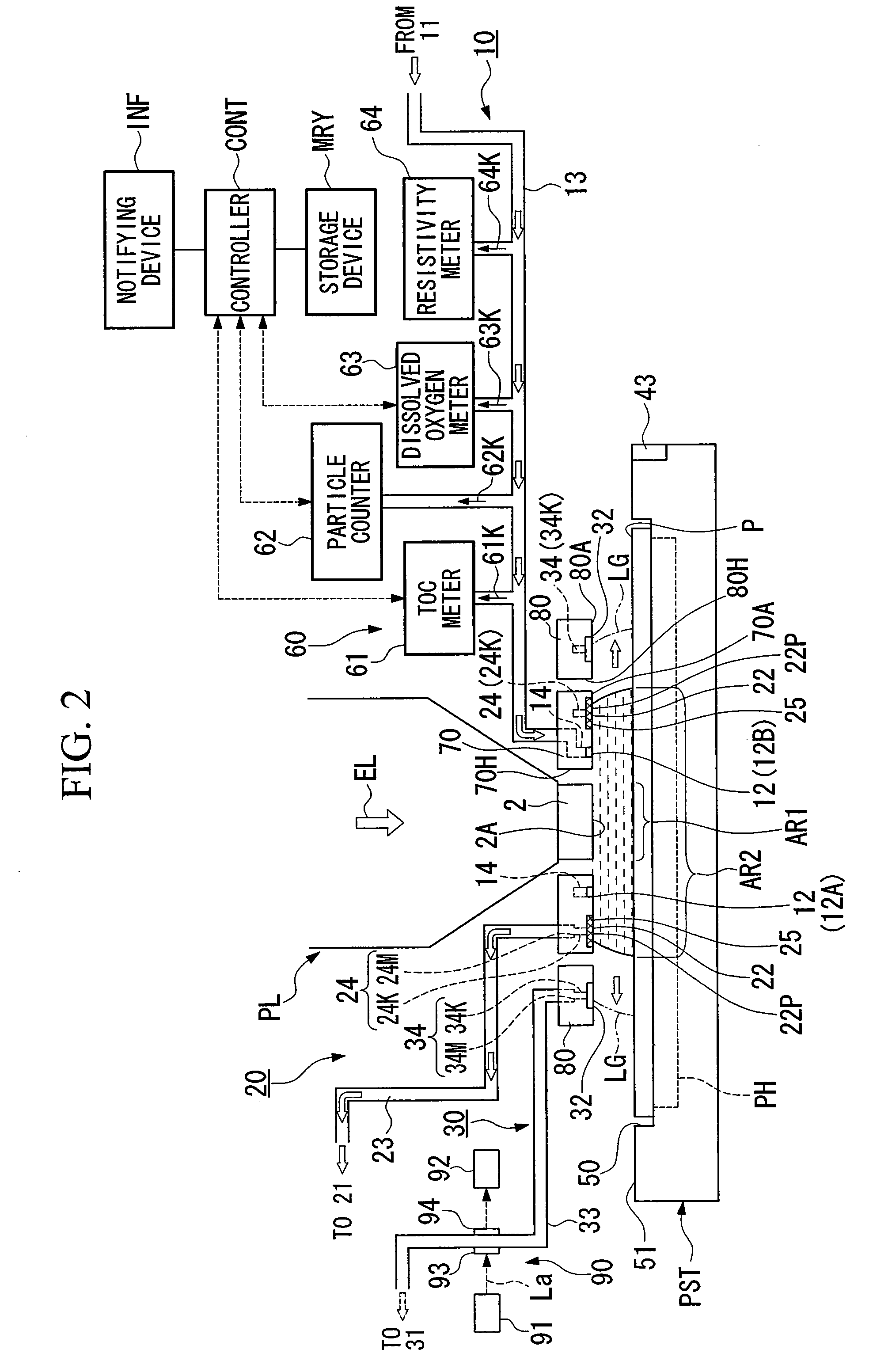

Exposure apparatus and device manufacturing method

InactiveUS20070242247A1Ensure correct executionSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusProjection opticsEngineering

There is provided an exposure apparatus capable of accurately performing an exposure process and a measurement process based on a liquid immersion method. The exposure apparatus (EX), which forms a liquid immersion area (AR2) of a liquid (LQ) on an image surface side of a projection optical system (PL), and exposes a substrate (P) via the projection optical system (PL) and the liquid (LQ) of the immersion area (AR2), is provided with a measuring device (60) which measures at least one of a property and composition of the liquid (LQ) for forming the liquid immersion area (AR2).

Owner:NIKON CORP

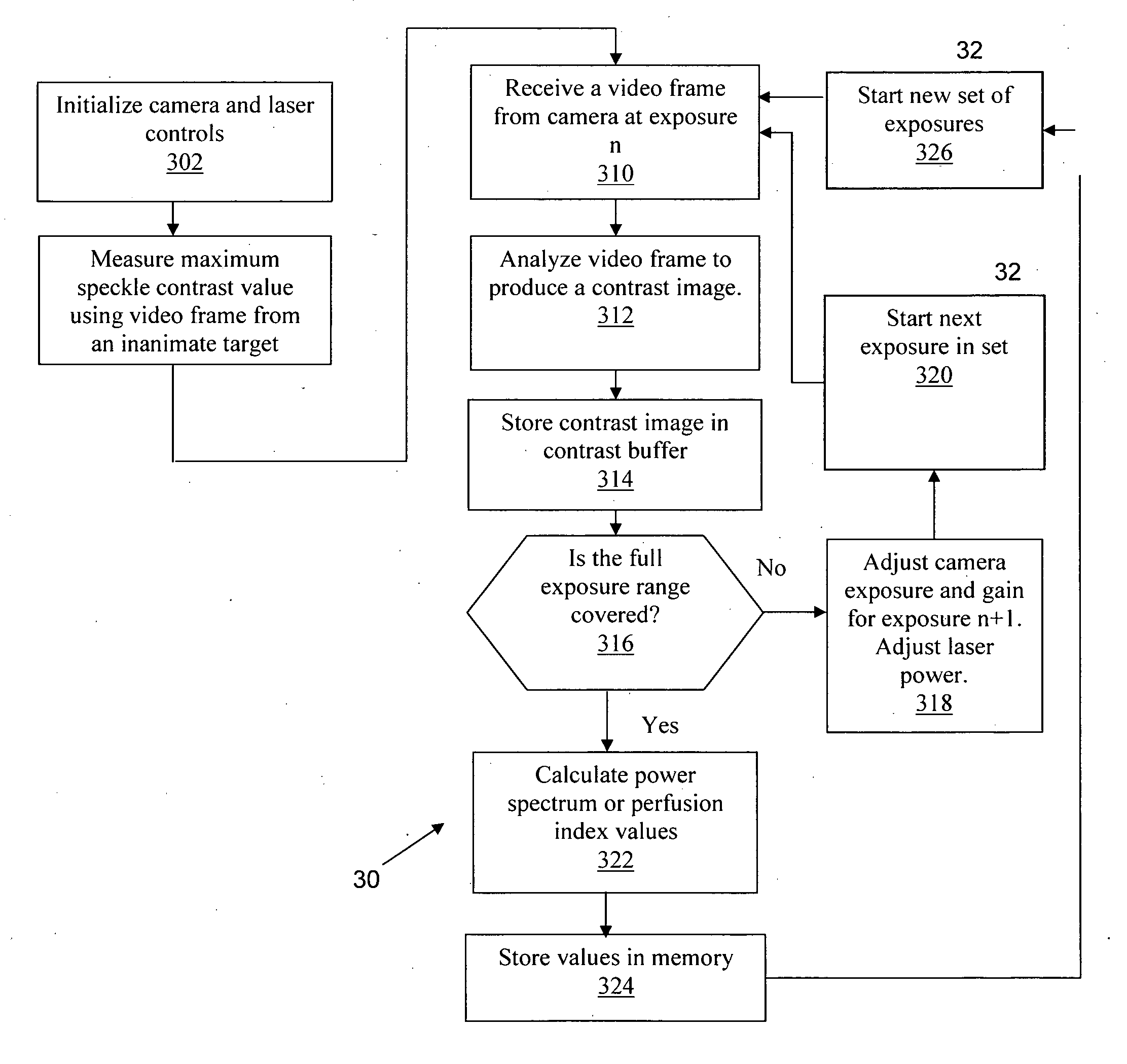

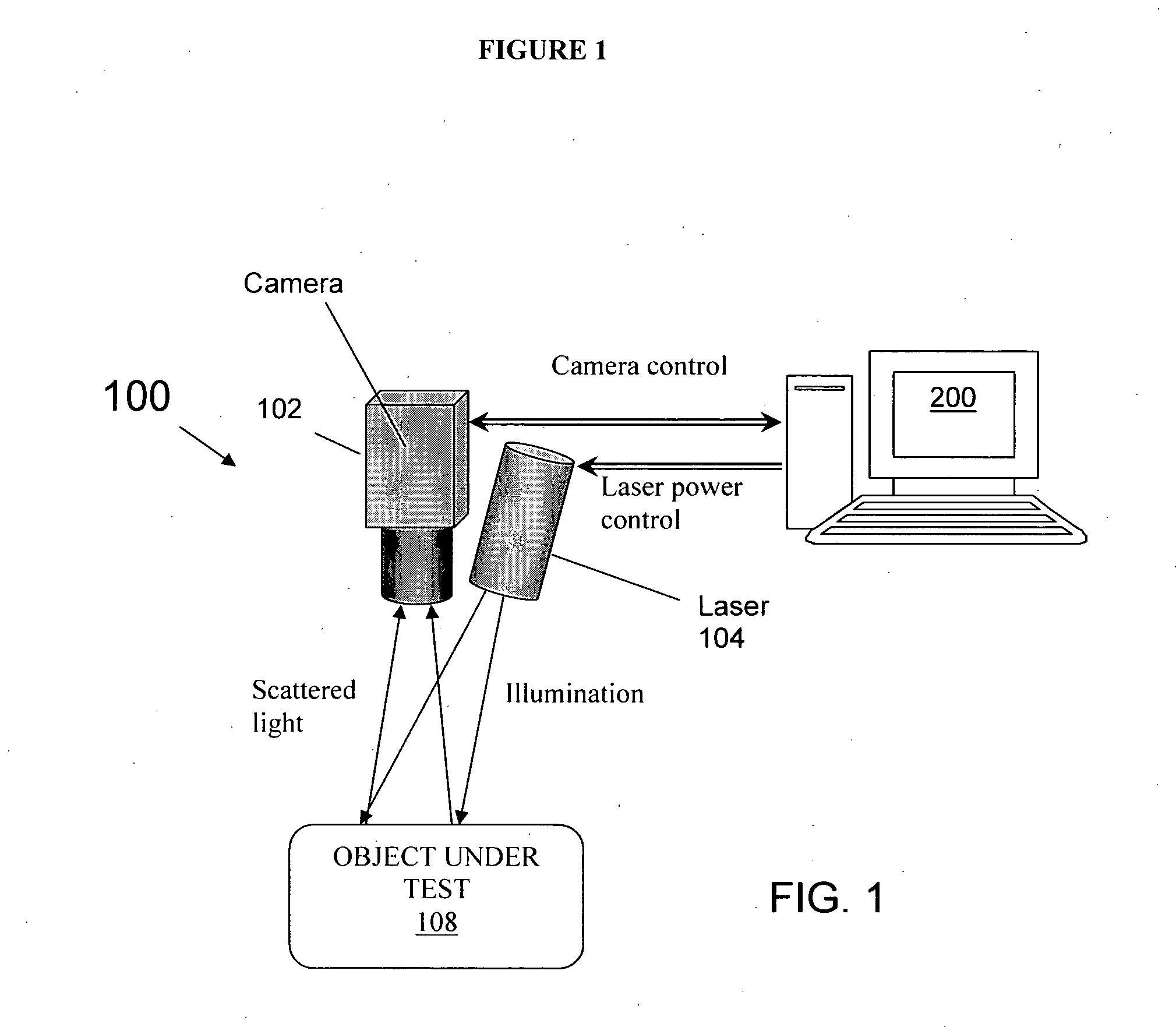

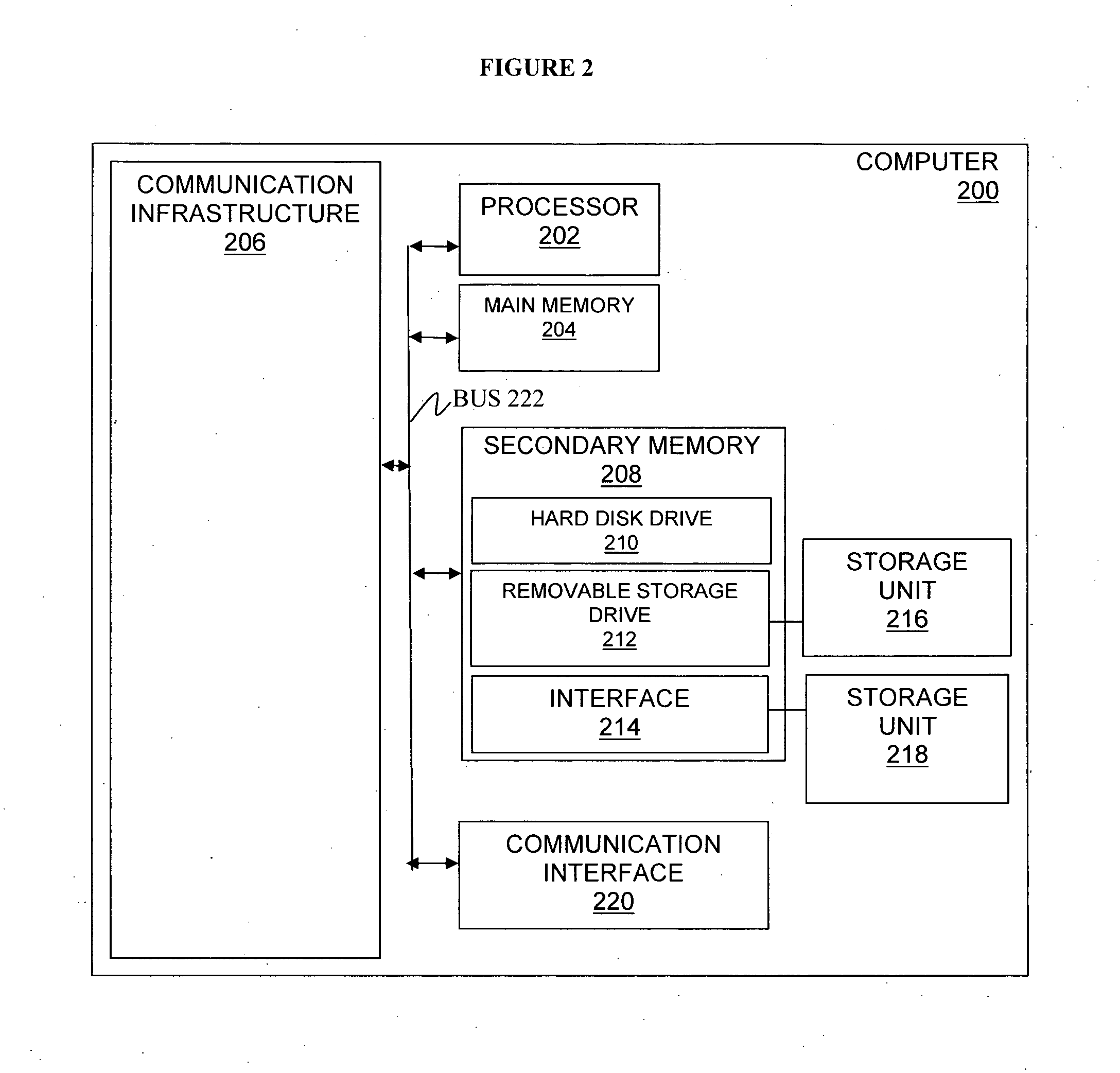

Laser Speckle Imaging Systems and Methods

ActiveUS20110013002A1Eliminate vibrational motionEliminate relative motionImage analysisDiagnostics using lightDigital videoLaser light

An apparatus and method for measuring perfusion in a tissue. The method comprising the steps of recording images of the tissue under laser light, calculating a plurality of contrast images from the plurality of images of the tissue, determining a power spectrum of scattered light from the plurality of contrast images, and determining perfusion from the power spectrum. The apparatus comprises a digital video camera, a laser light source, and a processor arranged to operate the camera to produce a plurality of images with different exposure times, receive the plurality of images from the camera and process the images to determine a power spectrum and determine perfusion from the power spectrum.

Owner:CALLAGHAN INNOVATION

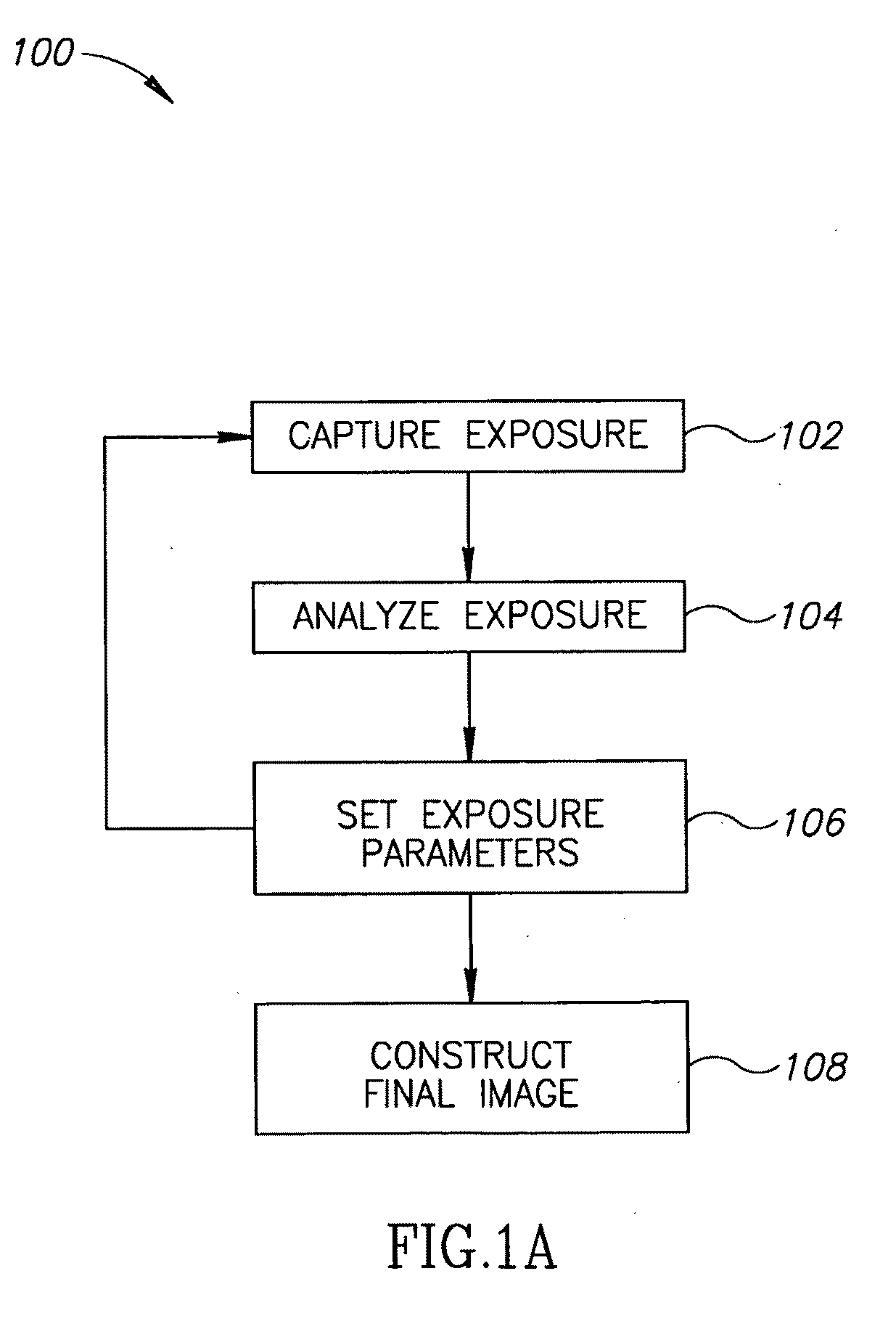

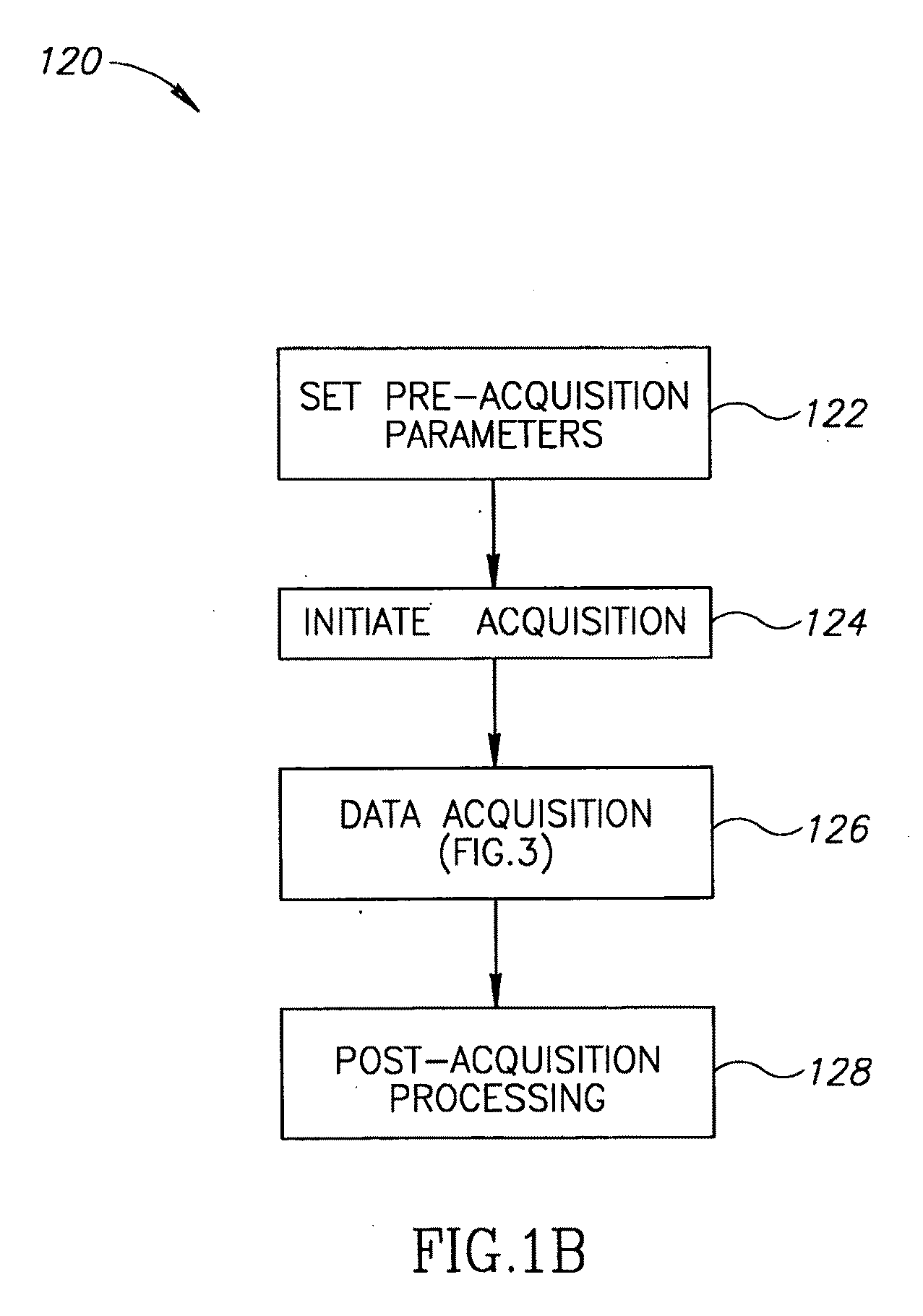

Adaptive Exposure Control

InactiveUS20090040364A1Increase depth of fieldSmall apertureTelevision system detailsGeometric image transformationSingle exposureExposure control

A method for constructing a final image using adaptive exposure control in multiple exposure photography, comprising: (a) capturing an exposure; (b) analyzing the exposure at least to determine deficiencies in the exposure; (c) setting exposure parameters for at least one next exposure adapted to construct the final image with ameliorated deficiencies; (d) capturing the at least one next exposure using the set exposure parameters; and, (e) constructing a final image utilizing portions of at least the two exposures.

Owner:MEP IMAGING TECH

Imageable element with solvent-resistant polymeric binder

InactiveUS7261998B2Enhances on-press solvent resistanceProlong lifeRadiation applicationsSemiconductor/solid-state device manufacturingPolymer scienceBackbone chain

The present invention provides an imageable element including a lithographic substrate and an imageable layer disposed on the substrate. The imageable layer includes a radically polymerizable component, an initiator system capable of generating radicals sufficient to initiate a polymerization reaction upon exposure to imaging radiation, and a polymeric binder having a hydrophobic backbone and including both constitutional units having a pendant cyano group attached directly to the hydrophobic backbone, and constitutional units having a pendant group including a hydrophilic poly(alkylene oxide) segment. When the imageable element is imaged and developed, the resulting printing plate may exhibit improved on-press solvent resistance and longer press life.

Owner:KODAK POLYCHROME GRAPHICS

Electronic image sensor

InactiveUS20060164533A1Avoid complicationsAccurate exposureTelevision system detailsTelevision system scanning detailsEngineeringFrame rate

An electronic imaging sensor. The sensor includes an array of photo-sensing pixel elements for producing image frames. Each pixel element defines a photo-sensing region and includes a charge collecting element for collecting electrical charges produced in the photo-sensing region, and a charge storage element for the storage of the collected charges. The sensor also includes charge sensing elements for sensing the collected charges, and charge-to-signal conversion elements. The sensor also includes timing elements for controlling the pixel circuits to produce image frames at a predetermined normal frame rate based on a master clock signal (such as 12 MHz or 10 MHz). This predetermined normal frame rate which may be a video rate (such as about 30 frames per second or 25 frames per second) establishes a normal maximum per frame exposure time. The sensor includes circuits (based on prior art techniques) for adjusting the per frame exposure time (normally based on ambient light levels) and novel frame rate adjusting features for reducing the frame rate below the predetermined normal frame rate, without changing the master clock signal, to permit per frame exposure times above the normal maximum exposure time. This permits good exposures even in very low light levels. (There is an obvious compromise of lowering of the frame rate in conditions of very low light levels, but in most cases this is preferable to inadequate exposure.) These adjustments can be automatic or manual.

Owner:E PHOCOS

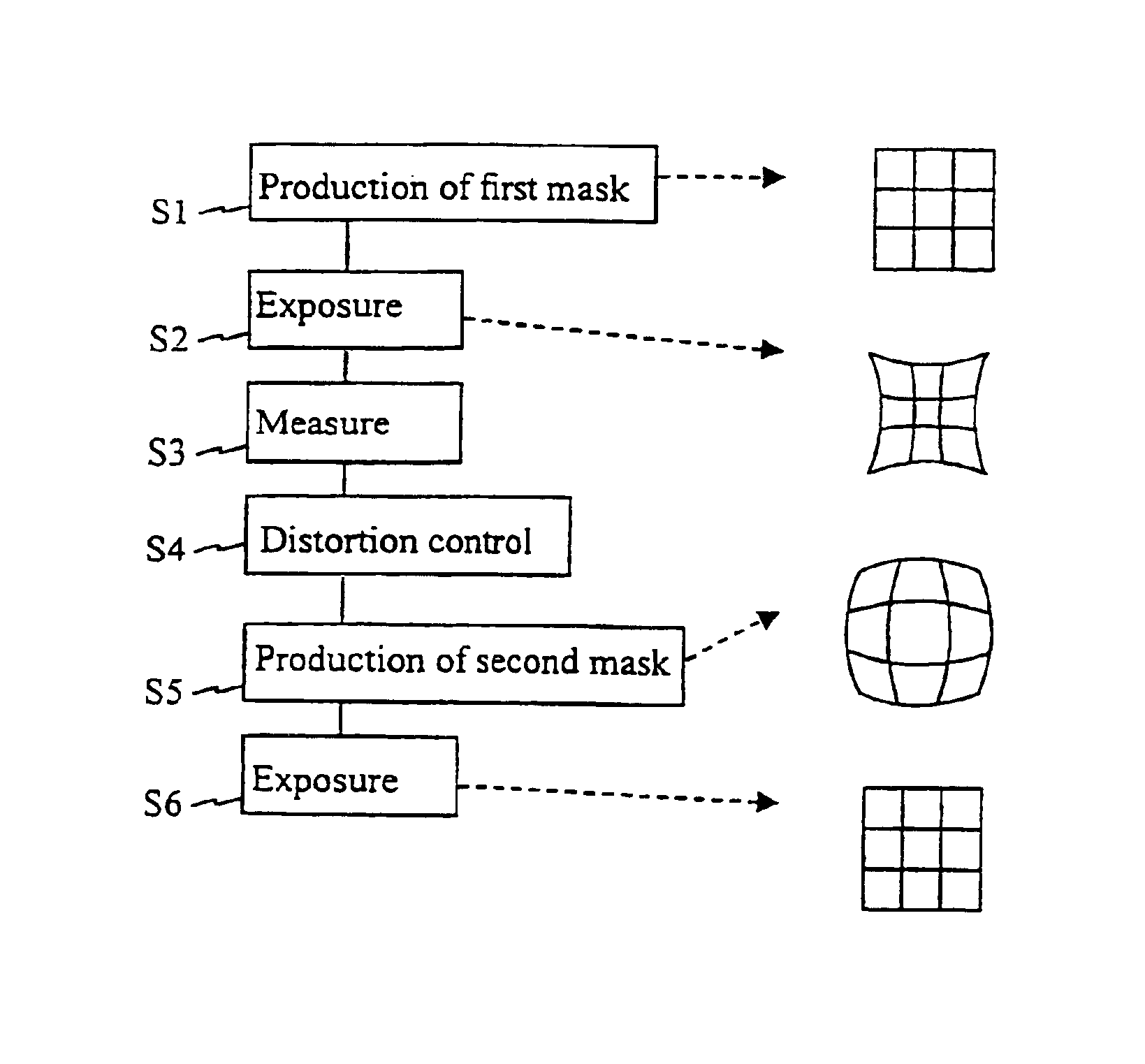

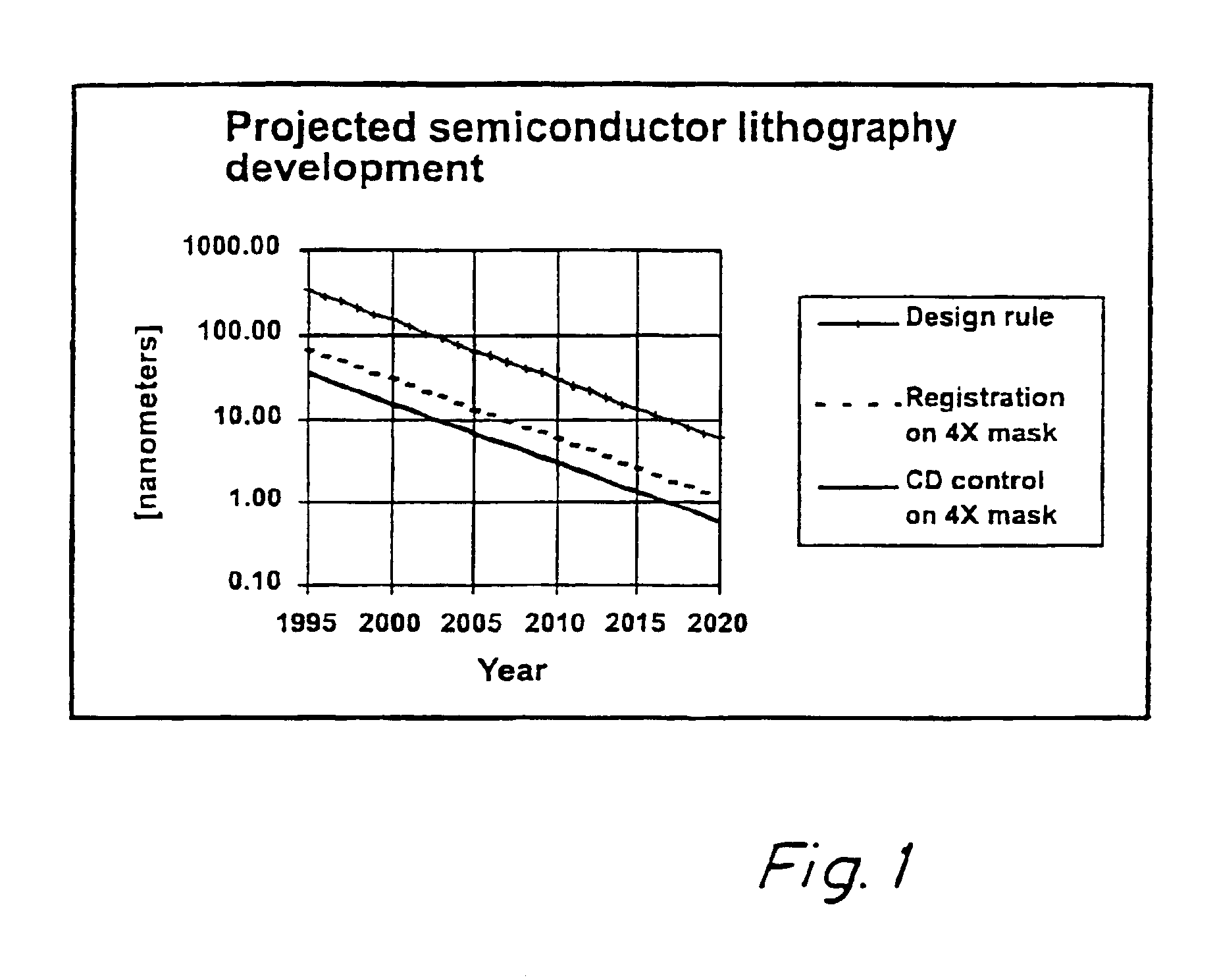

Method for error reduction in lithography

InactiveUS6883158B1High precisionSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusError reductionEngineering

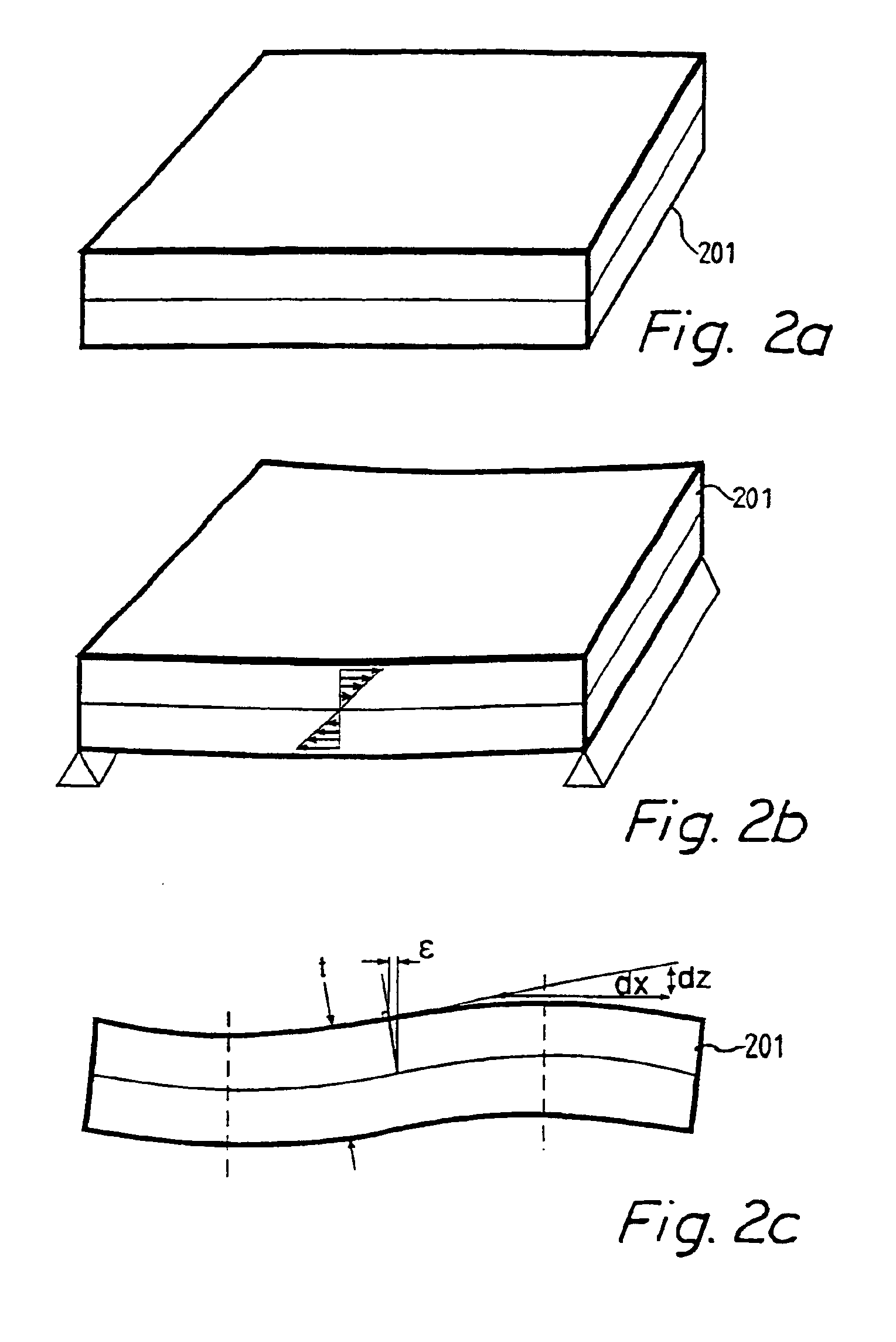

The present invention relates to a method and a system for predicting and correcting geometrical errors in lithography using masks, such as large-area photomasks or reticles, and exposure stations, such as wafer steppers or projection aligners, printing the pattern of said masks on a workpiece, such as a display panel or a semi-conductor wafer. The method according to the invention comprises the steps of collecting information about a mask substrate, a mask writer, an exposure stati n, and / or about behavior of a processing step that will occur after the writing of the mask. Further the method comprises predicting from the combined information distorsions occuring in the pattern, when it is subsequently printed on the workpiece; calculating from said prediction a correction to diminish said predicted distorsion, and exposing said pattern onto said mask substrate while applying said correction for said distorsions.

Owner:MICRONIC LASER SYST AB

Solid-state imaging device

InactiveUS6046466ASharp image can be stably obtainedRealize automatic adjustmentTransistorTelevision system detailsSensor arrayMOSFET

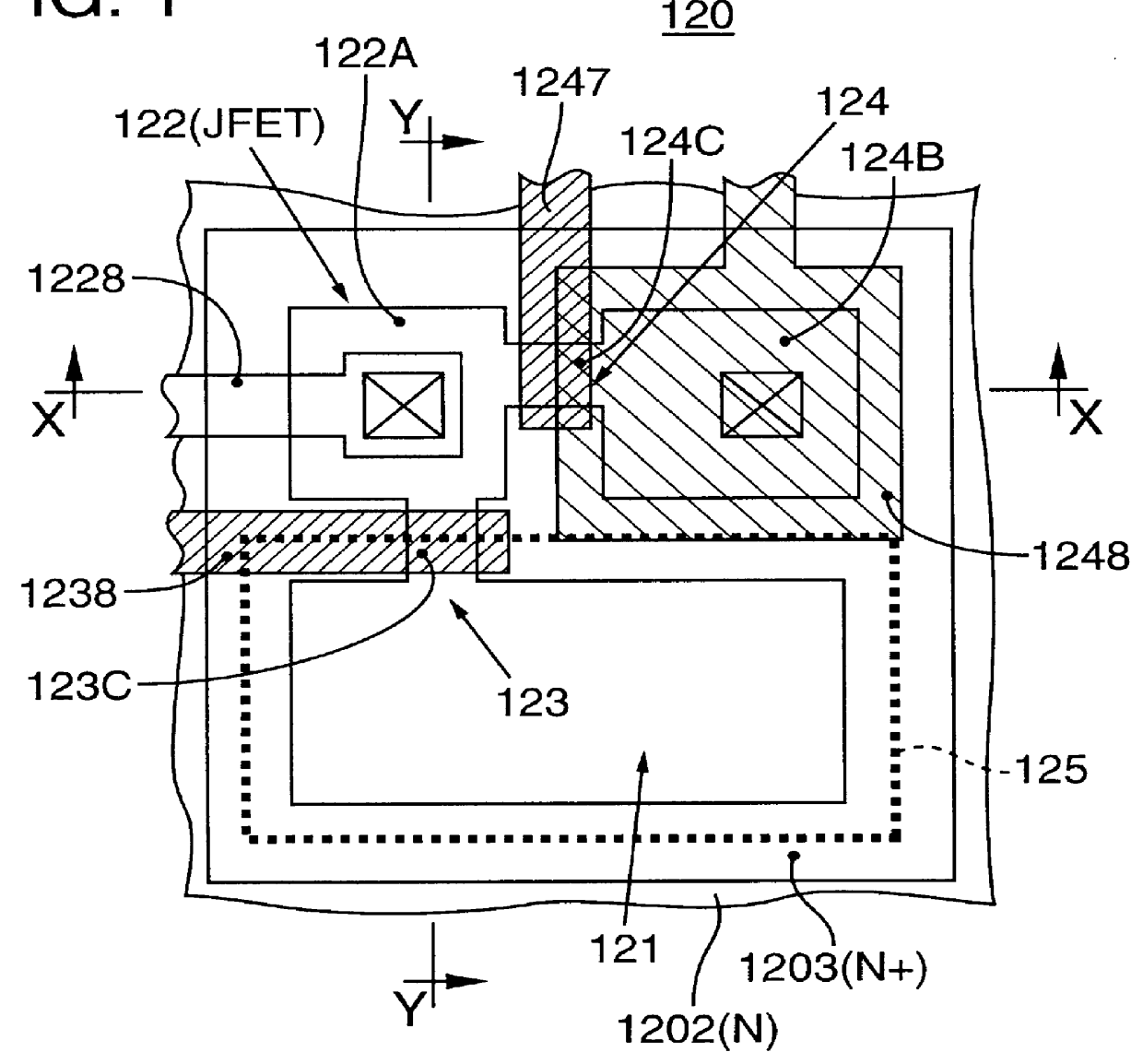

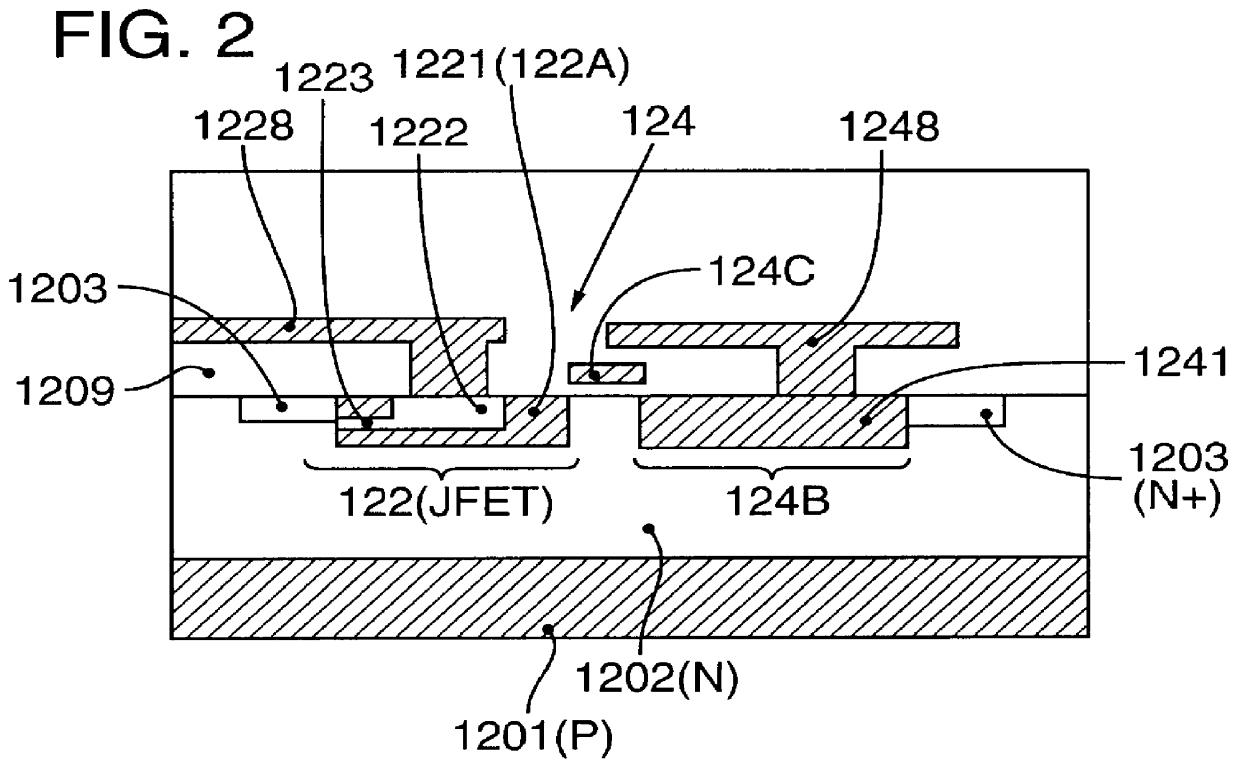

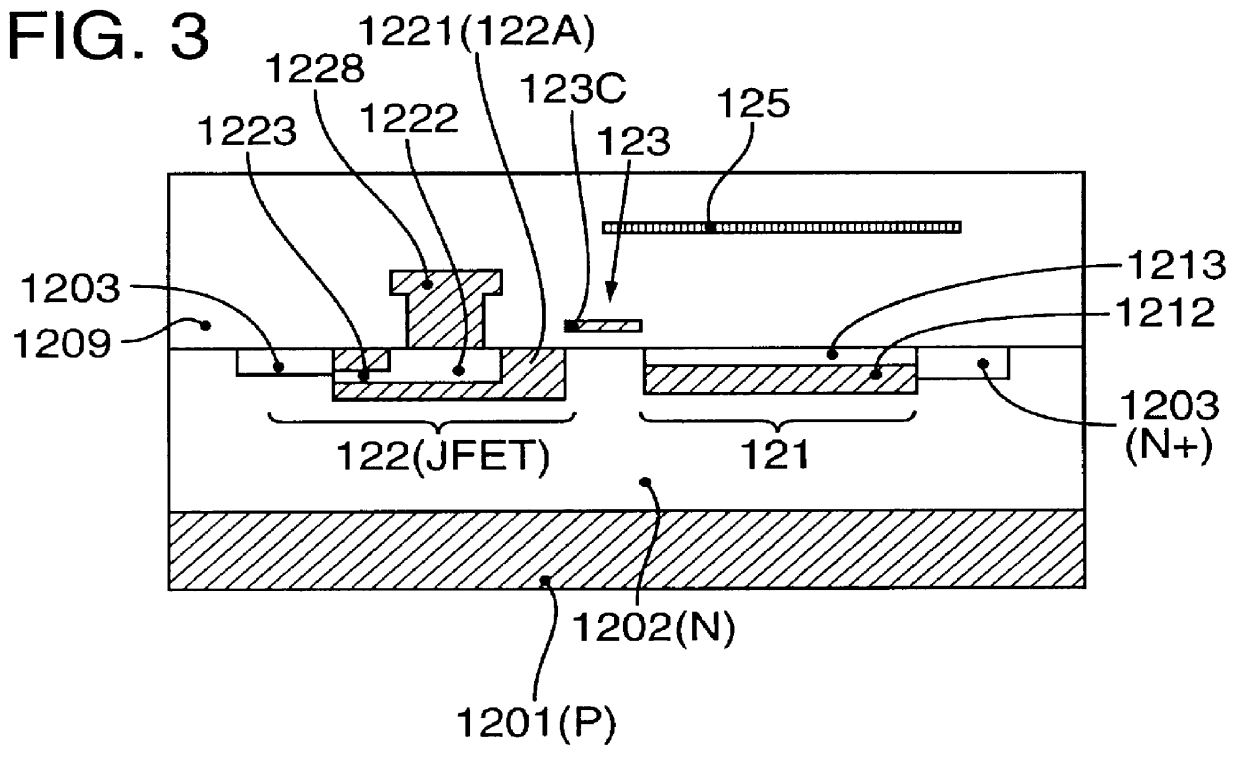

A photoelectric conversion device suitable for use as an element of a photodetector array includes a photodiode for generating a first signal charge in response to incident light, an output unit including a JFET, and at least one transistor having an electrode that generates a second signal charge in response to incident light. The first and second signal charges may be output separately or combined. The second signal charge, or the first and second signal charges combined, may be monitored during an exposure time to determine the desired end of the exposure. An image sensor array may have one or more pixels with such light monitoring capability. The output signal for monitoring the light may be output over a reset drain interconnection, directly from the monitoring pixel or through other pixels via inter-pixel MOSFETS. Exposure time may be controlled, by timing a shutter or a strobe or the like, based on the monitored accumulation of signal charge during exposure. Microlenses may be provided on-chip to increase the effective aperture ratio of the array. The microlenses are designed to avoid interfering with the incident light used for monitoring. Resulting pixel-to-pixel variations in effective aperture ratio, if any, may be electronically compensated.

Owner:NIKON CORP

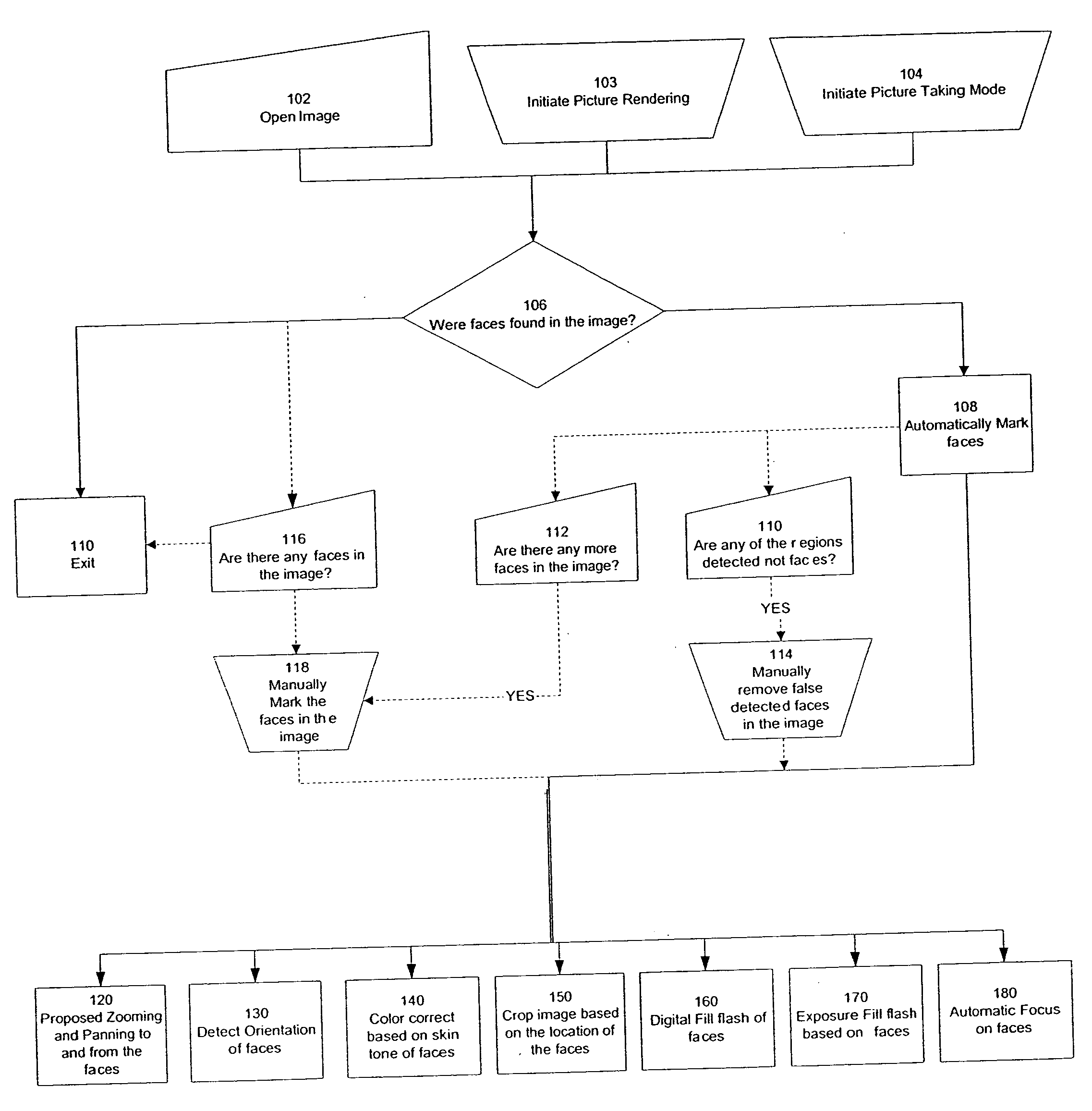

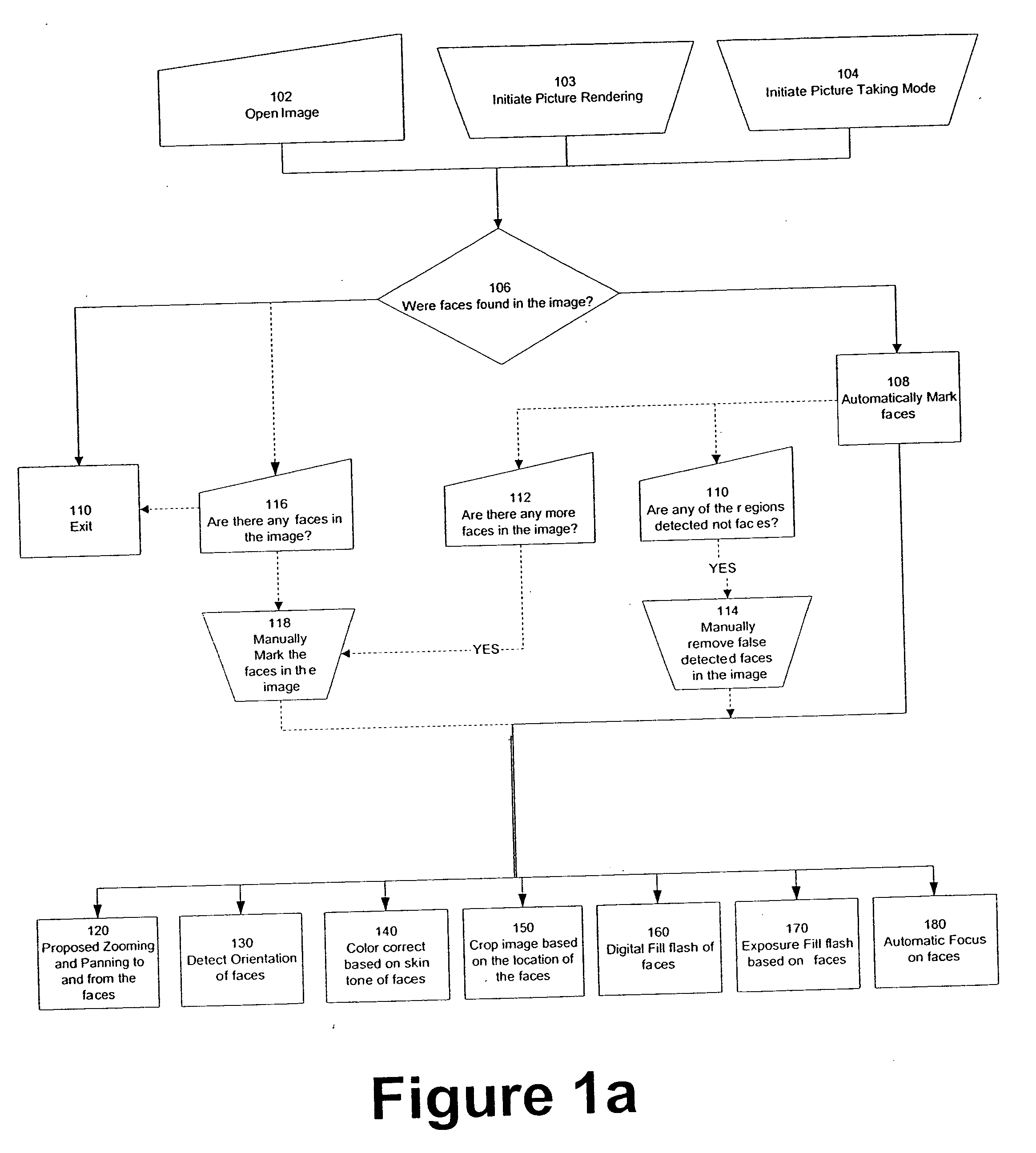

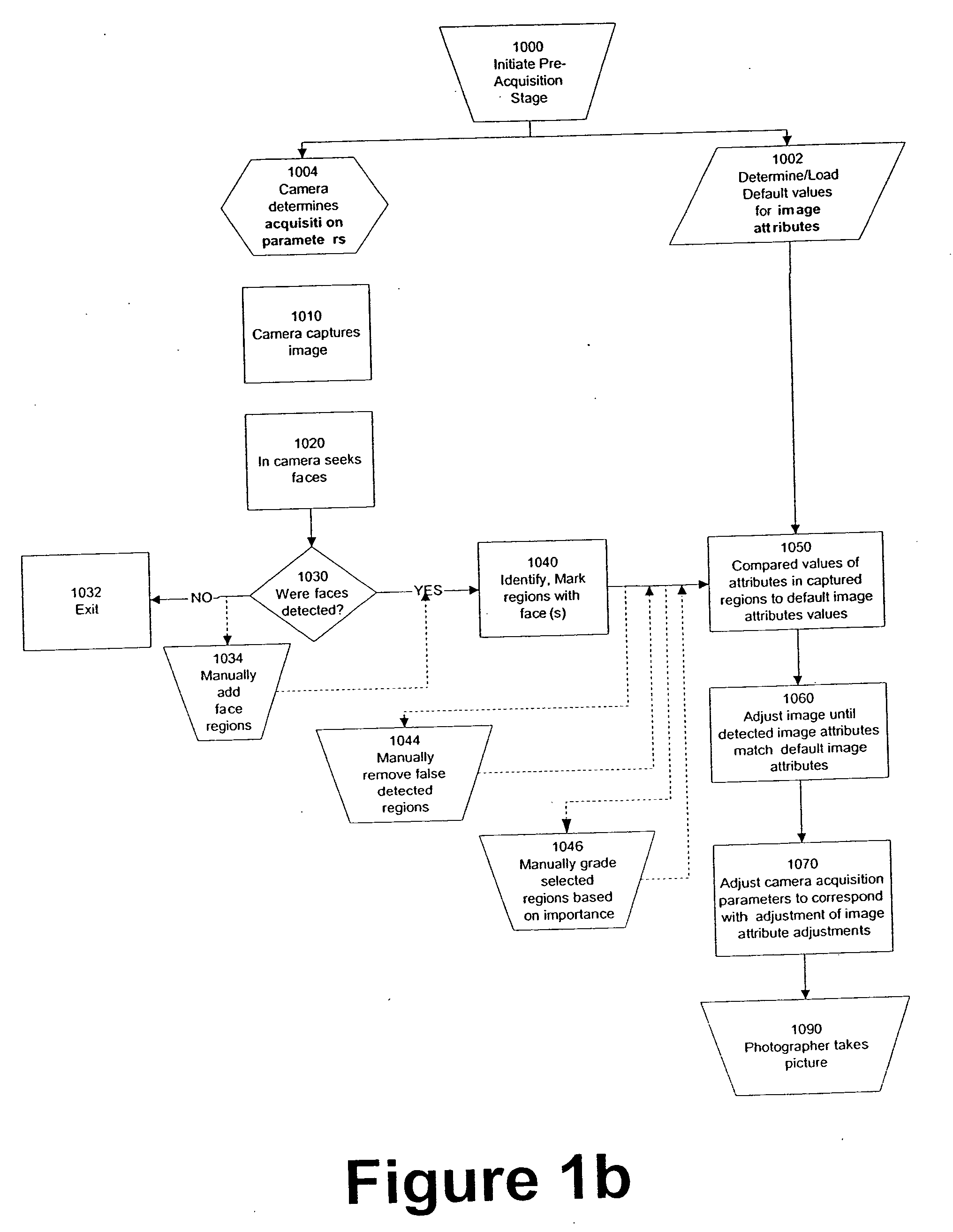

Perfecting the effect of flash within an image acquisition devices using face detection

Within a digital acquisition device with a built in flash unit, the exposure of an acquired digital image is perfected using face detection in the acquired image is provided. Groups of pixels that correspond to plural images of faces are identified within a digitally acquired image, and corresponding image attributes to the group of pixels are determined. An analysis is performed of the corresponding attributes of the groups of pixels. It is then determined to activate the built-in flash unit based on the analysis. An intensity of the built-in flash unit is determined based on the analysis. Alternatively based on similar analysis, a digital simulation of the fill flash is performed on the image.

Owner:FOTONATION LTD

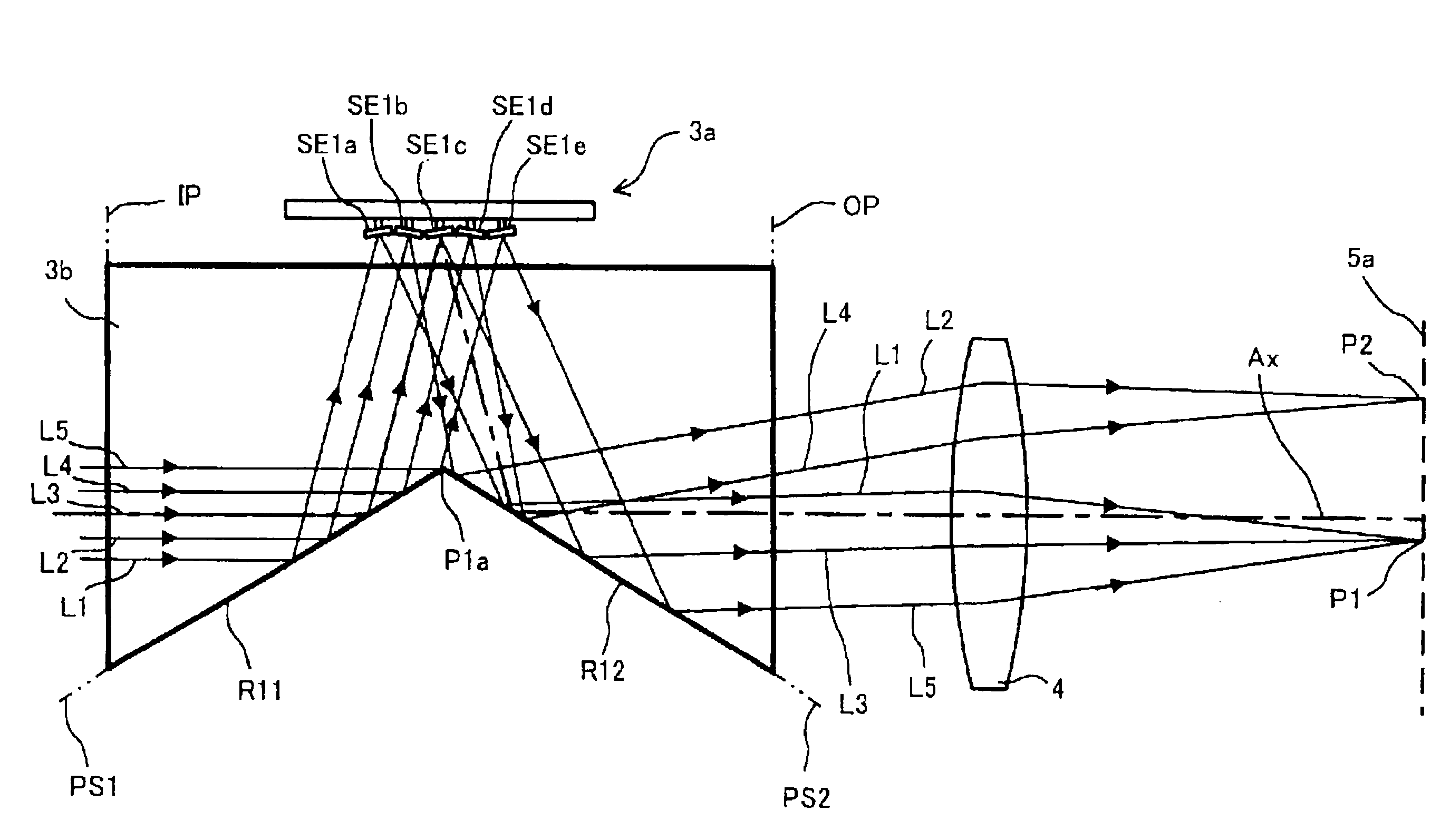

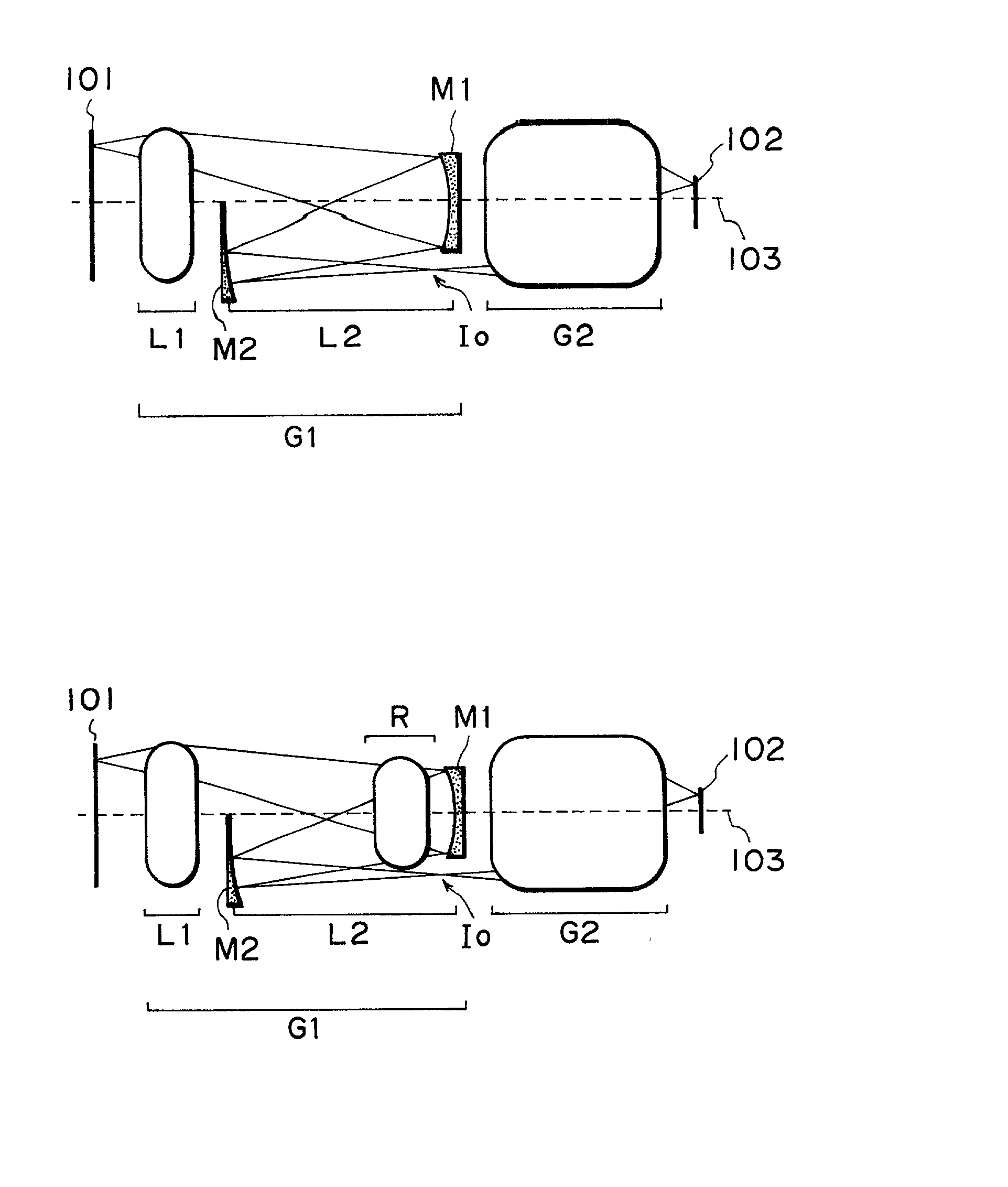

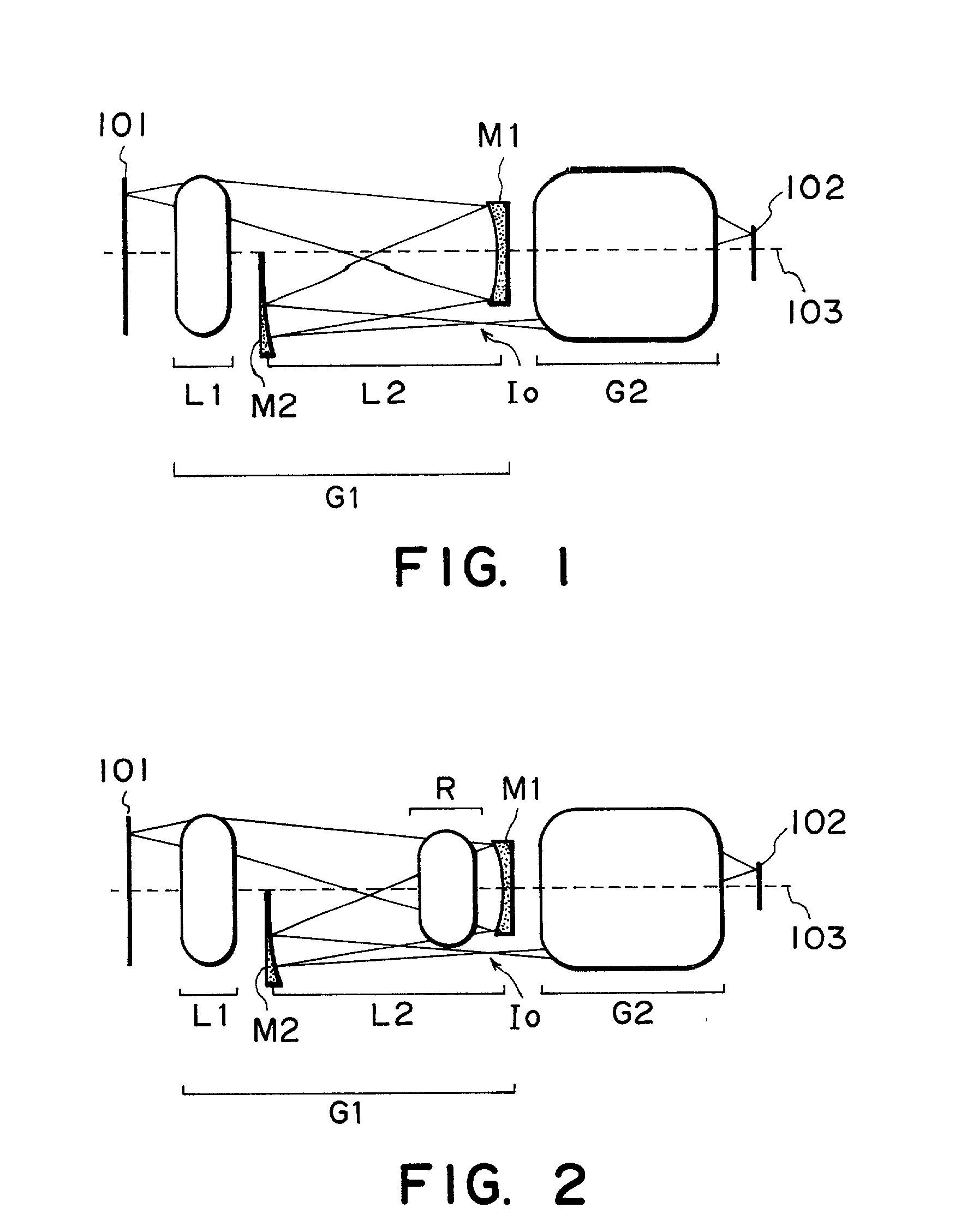

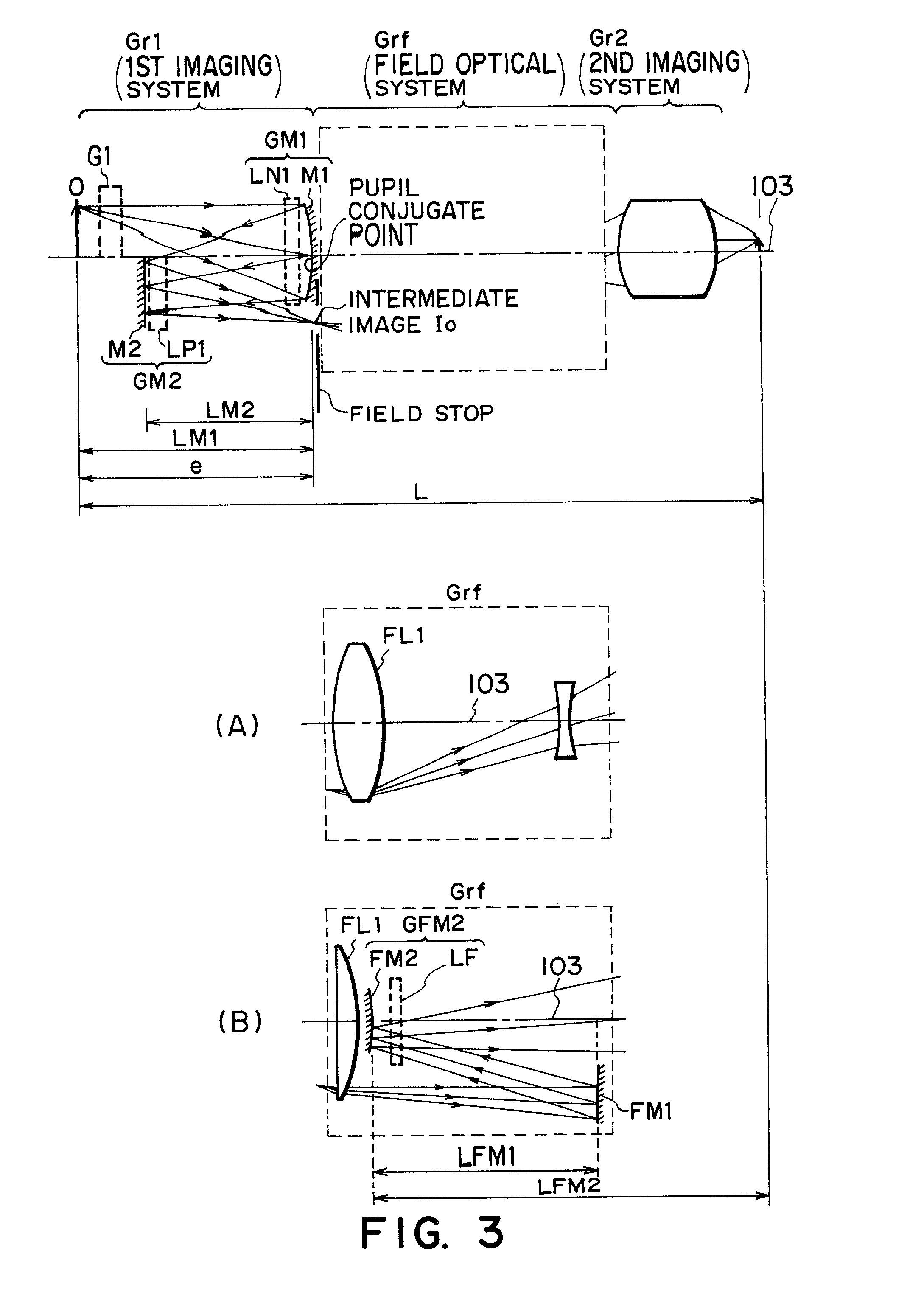

Projection optical system and projection exposure apparatus

InactiveUS20020024741A1Semiconductor/solid-state device manufacturingPhotomechanical exposure apparatusProjection opticsOptical axis

Disclosed is a projection optical system for projecting an image of an object onto an image plane, which includes a first imaging optical system for forming an image of the object, a second imaging optical system for re-imaging the image upon the image plane, wherein the first and second imaging optical systems are disposed in an order from the object side and are disposed along a common straight optical axis, wherein the first imaging optical system includes a first mirror for reflecting and collecting abaxial light from the object, wherein one of the first and second imaging optical systems includes a second mirror for reflecting light from the first mirror to the image plane side, and wherein, with the second mirror, the abaxial light is caused to pass an outside of an effective diameter of the first mirror.

Owner:CANON KK

Device And Method For Processing Light-Polymerizable Material For Building Up An Object In Layers

ActiveUS20110309554A1High viscositySimple methodAdditive manufacturing apparatusTailstocks/centresControl cellStructural engineering

A method and a device for processing a light-polymerizable material (5, 55) for building up an object (27) in layers, using a lithography based generative manufacture having a construction platform (12) for building up the object (27), a projecting exposure unit (10, 60) that can be controlled for locally selected exposing of a surface on the construction platform (12, 62) to an intensity pattern having a prescribed shape, and a control unit (11, 61) prepared for polymerizing overlapping layers (28) on the construction platform (12, 62) in successive exposure steps, each having a prescribed geometry, by controlling the projecting exposure unit (10, 60), in order to thus successively build up the object (27) in the desired shape, said shape resulting from the sequence of layer geometries. The invention is characterized in that a further exposure unit (16, 66) for exposing the surface of the construction platform (12, 62) is provided on the side opposite the projecting exposure unit (10, 60), and that the construction platform (12, 62) is designed to be at least partially transparent to light, and that the control unit (11, 61) is designed for controlling the further exposure unit (16, 66) at least while building up the first layer (28), said layer adhering to the construction platform (12, 62), for exposing in the prescribed geometry.

Owner:VIENNA UNIVERSITY OF TECHNOLOGY +1

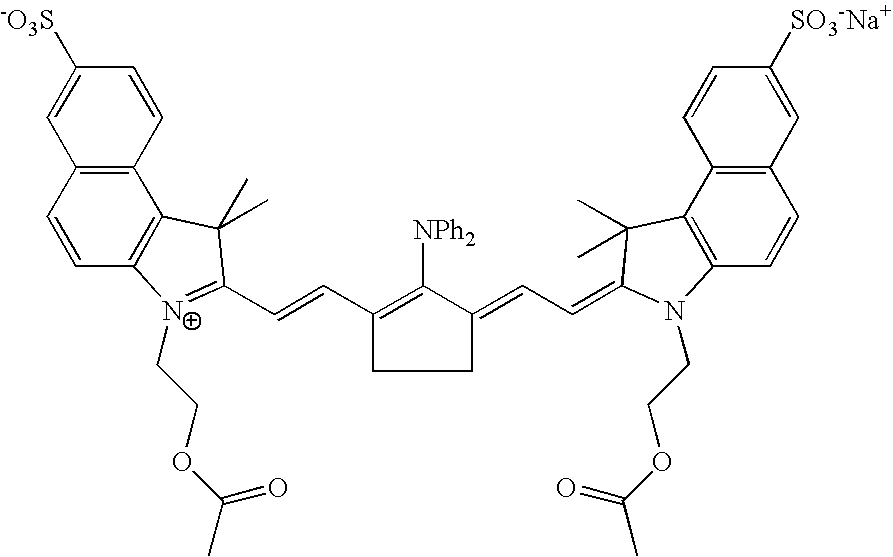

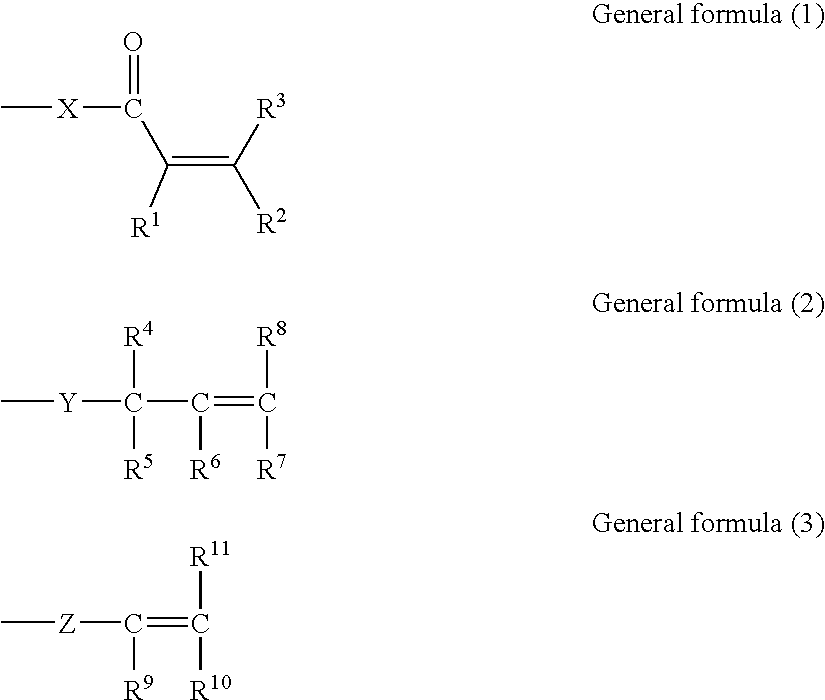

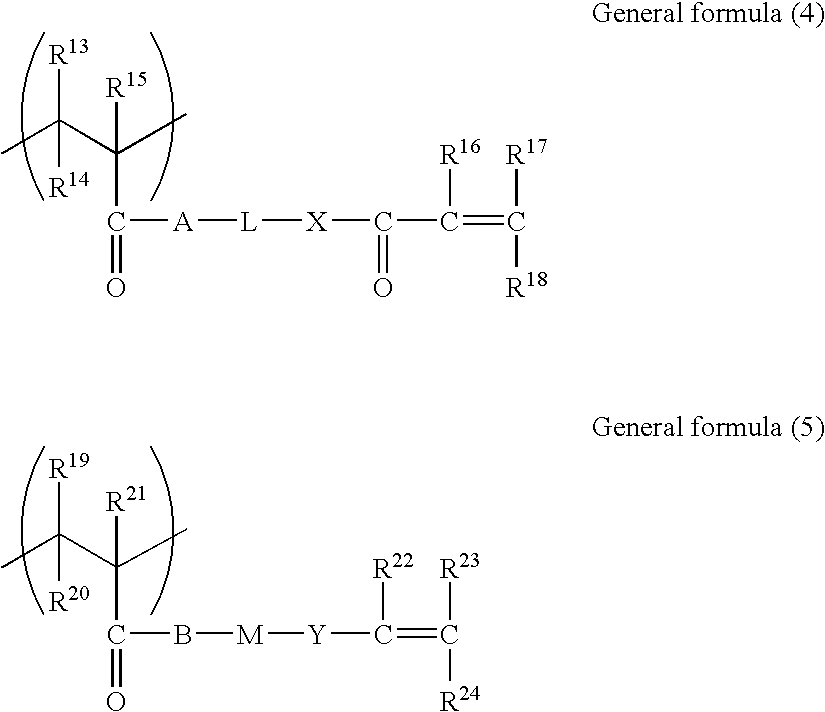

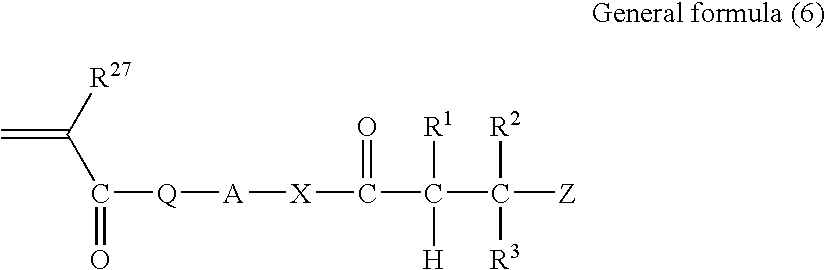

Image recording material

InactiveUS6916595B2Improve performanceX-ray/infra-red processesPhotosensitive materialsSide chainImage recording

A heat mode type negative image recording material is provided which comprises (A) a polymer compound that is insoluble in water but is soluble in an alkali aqueous solution and has at least one of groups represented by general formulae (1) to (3) on a side chain; (B) a photothermal conversion agent; and (C) an onium salt compound forming radicals by heat mode exposure with light that is capable of being absorbed by said photothermal conversion agent (B), said heat mode type negative image recording material being capable of recording an image by heat mode exposure. The general formulae are defined in the specification.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com