Patents

Literature

2953 results about "One stage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

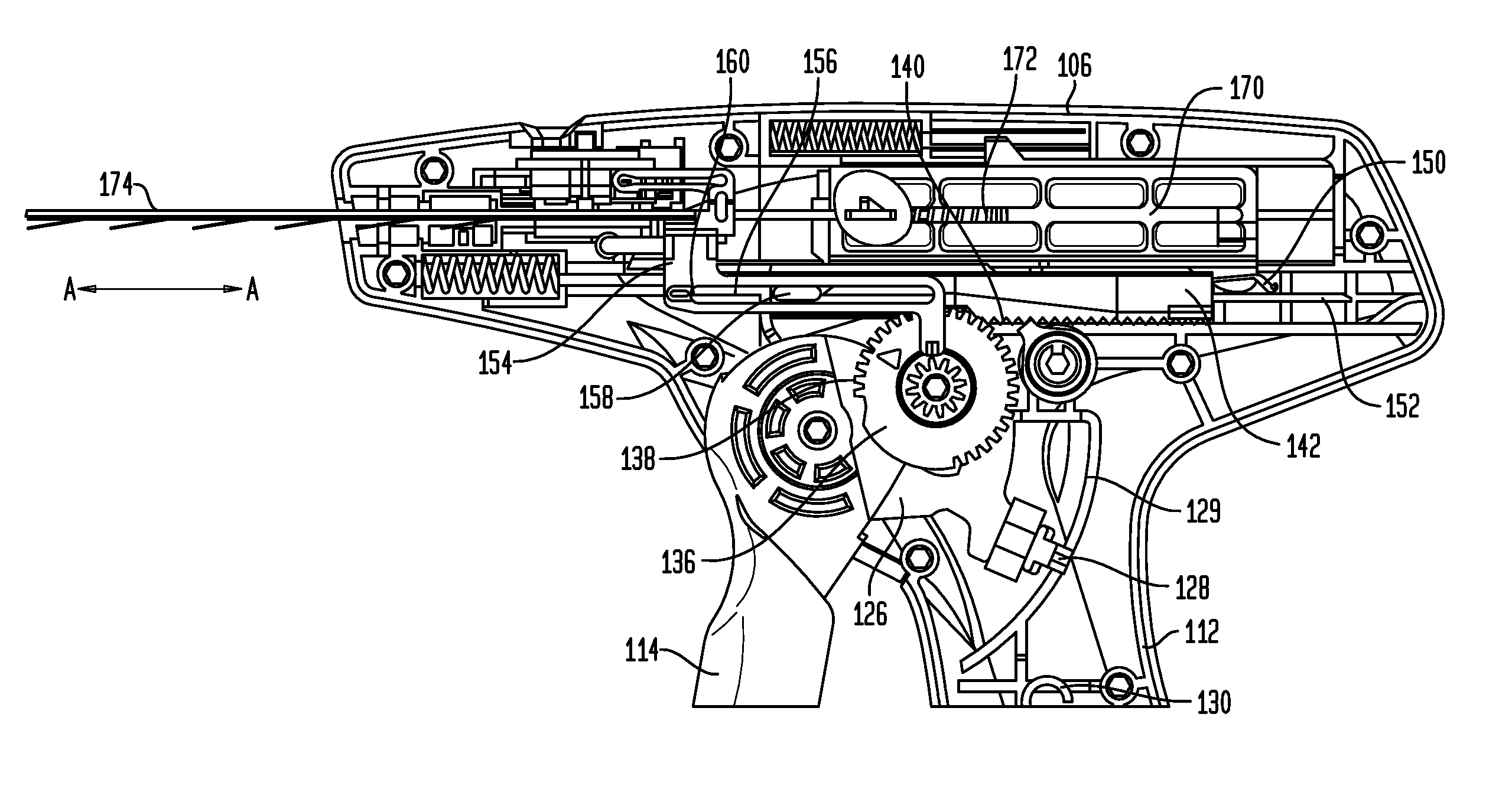

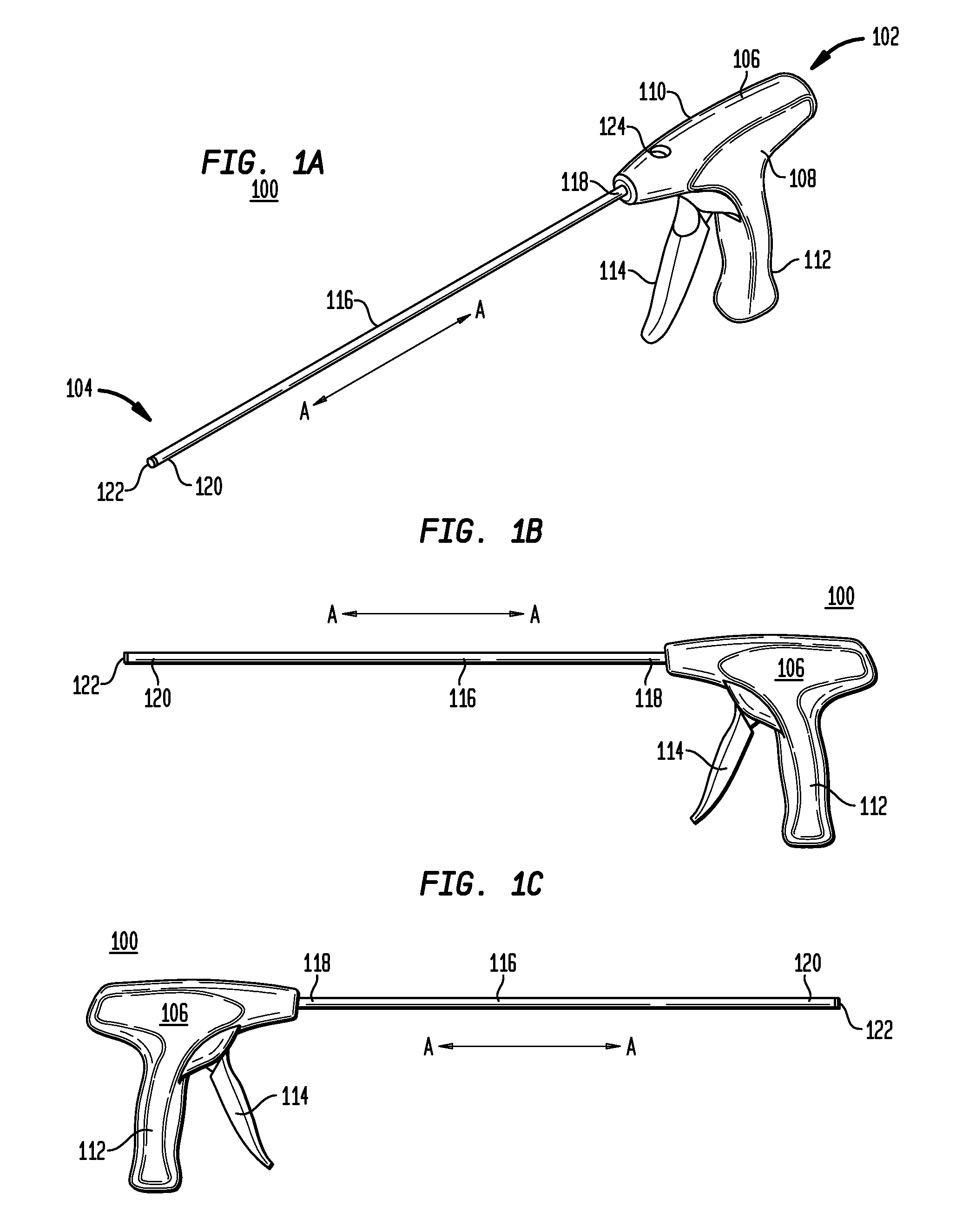

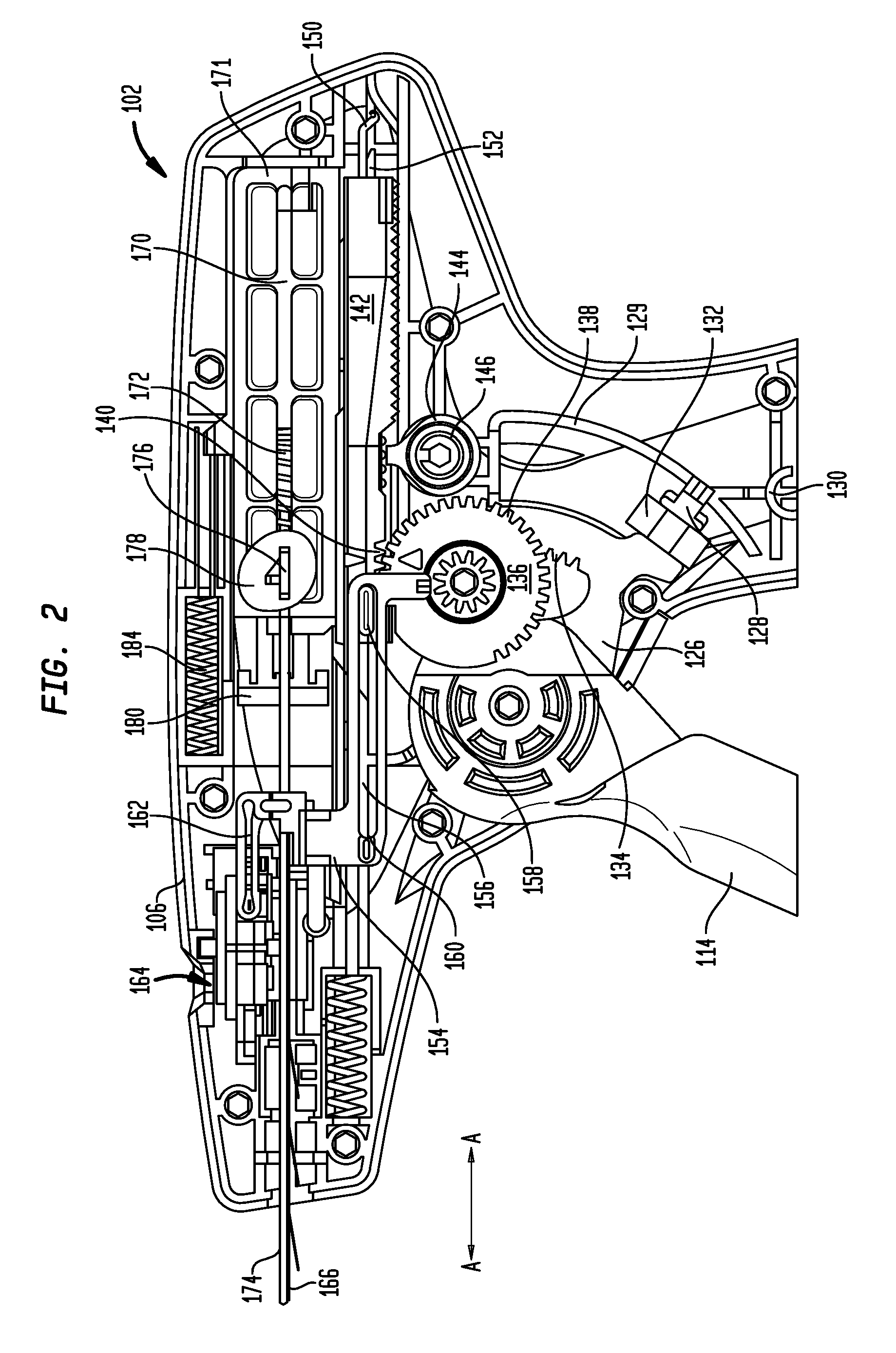

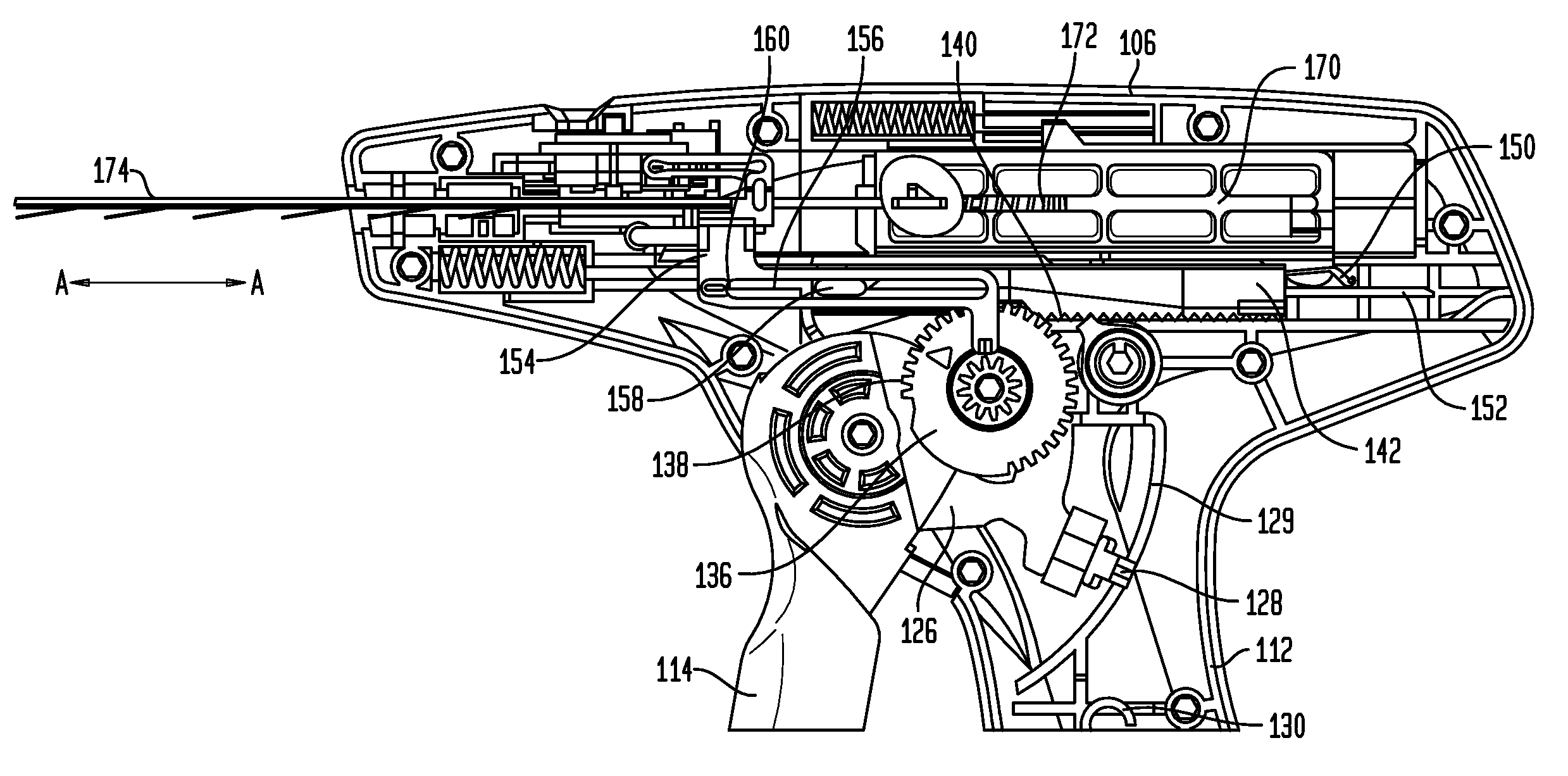

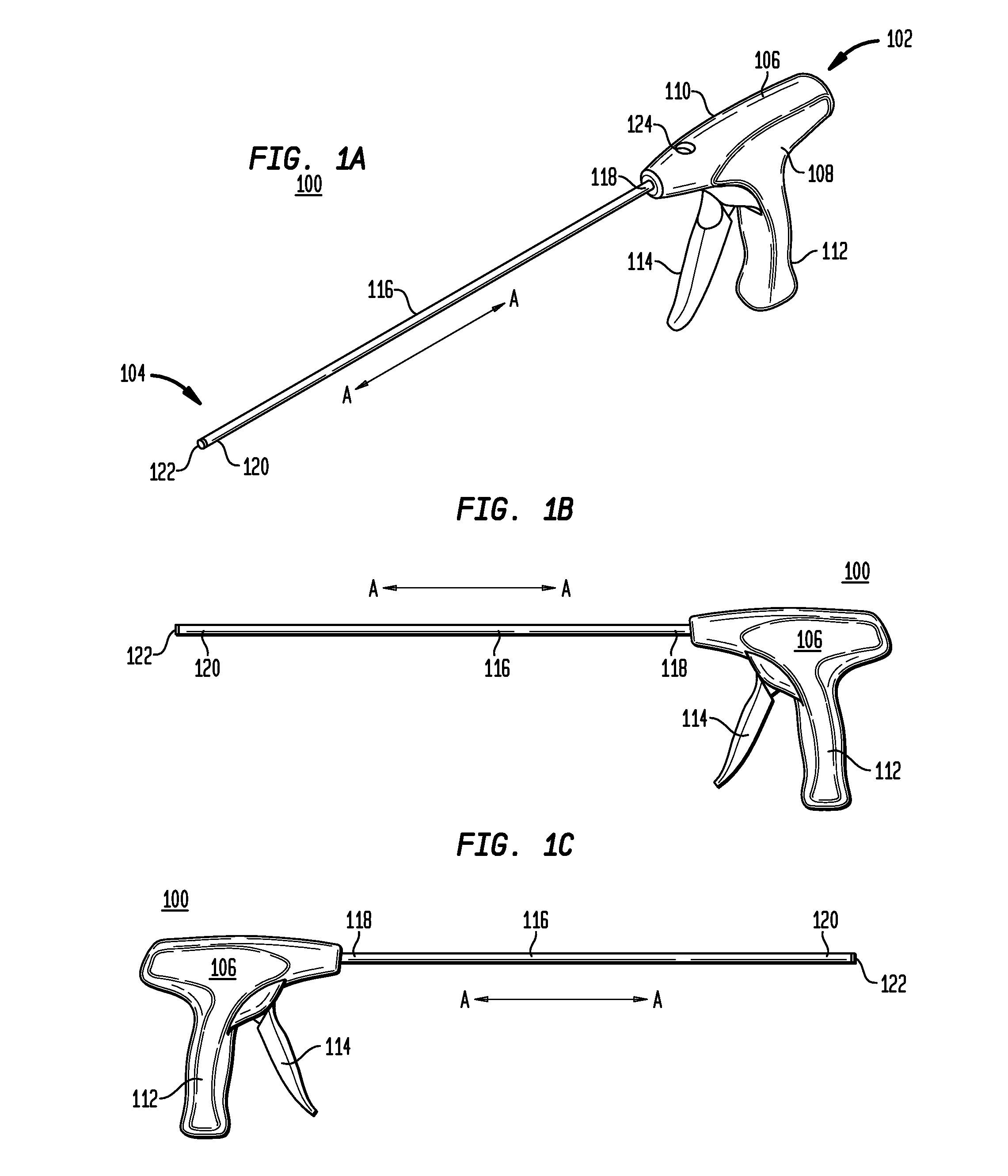

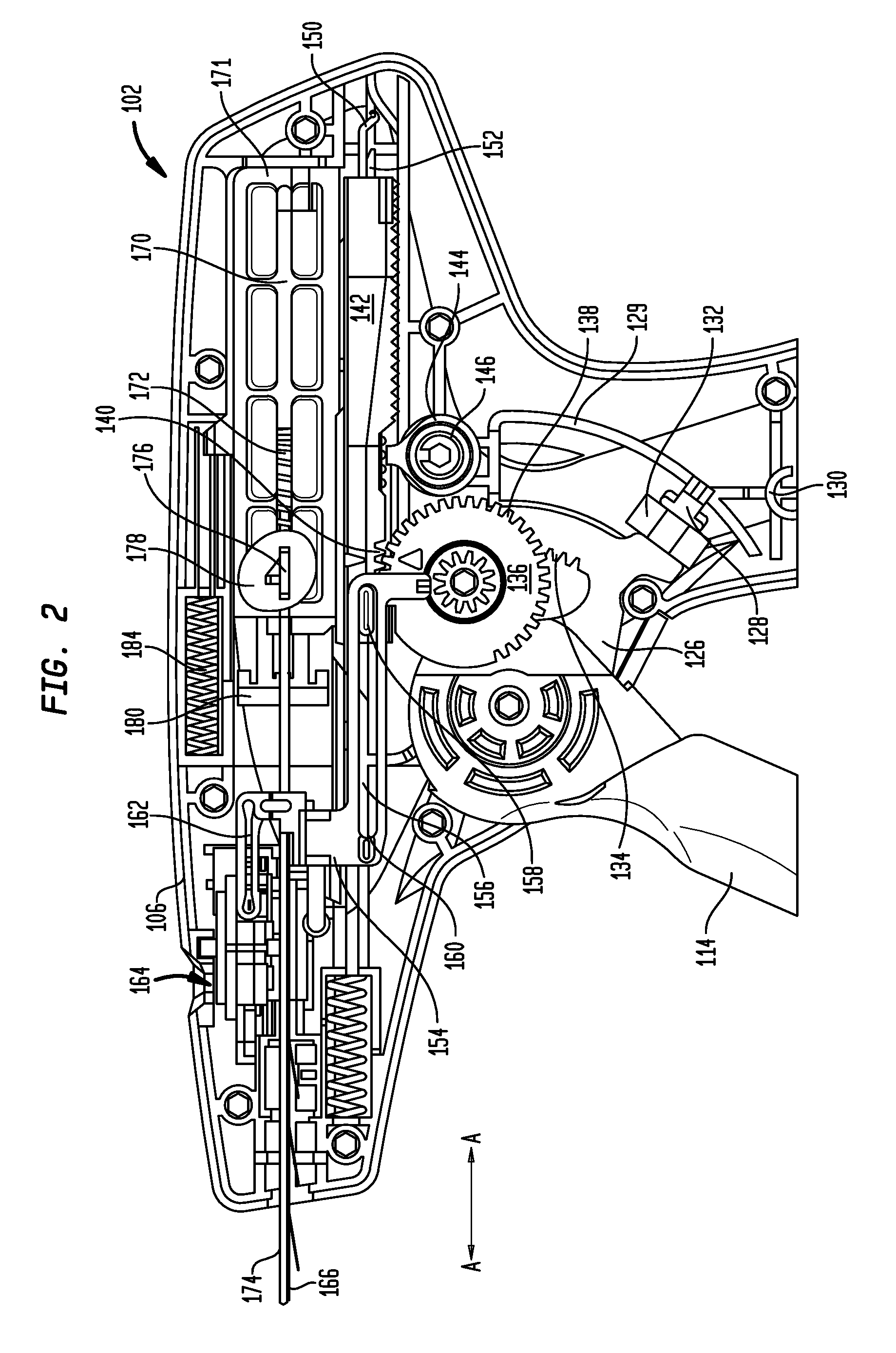

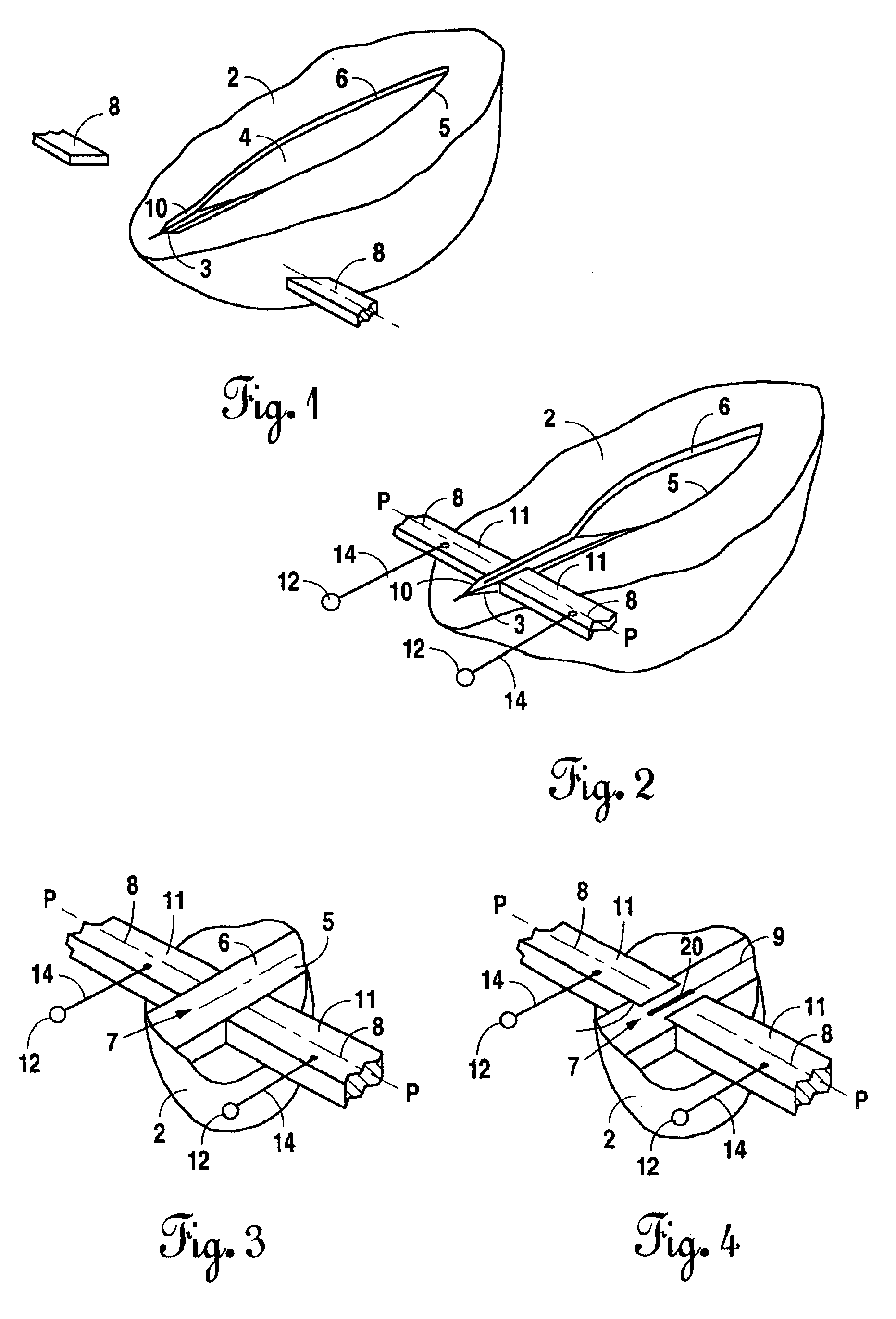

Surgical fasteners, applicator instruments, and methods for deploying surgical fasteners

ActiveUS8728099B2Accurate insertionGuarantees proper engagementSuture equipmentsStapling toolsEngineeringSurgical Fasteners

A firing system for an applicator instrument adapted to dispense surgical fasteners includes a housing, an elongated shaft extending from the housing, a firing rod disposed within the elongated shaft, a firing rod release engageable with the firing rod for preventing distal movement of the firing rod during at least one stage of a firing cycle, a trigger mounted to the housing, and a firing spring having a first end connected with the firing rod and a second end adapted for being sequentially coupled and decoupled from the trigger during the firing cycle. The firing cycle includes an initial stage in which the trigger is open and decoupled from the energy storing element, and the firing spring is at least partially compressed, and a piloting stage during which the firing rod release is disengaged from the firing rod for enabling distal movement of the firing rod.

Owner:ETHICON INC

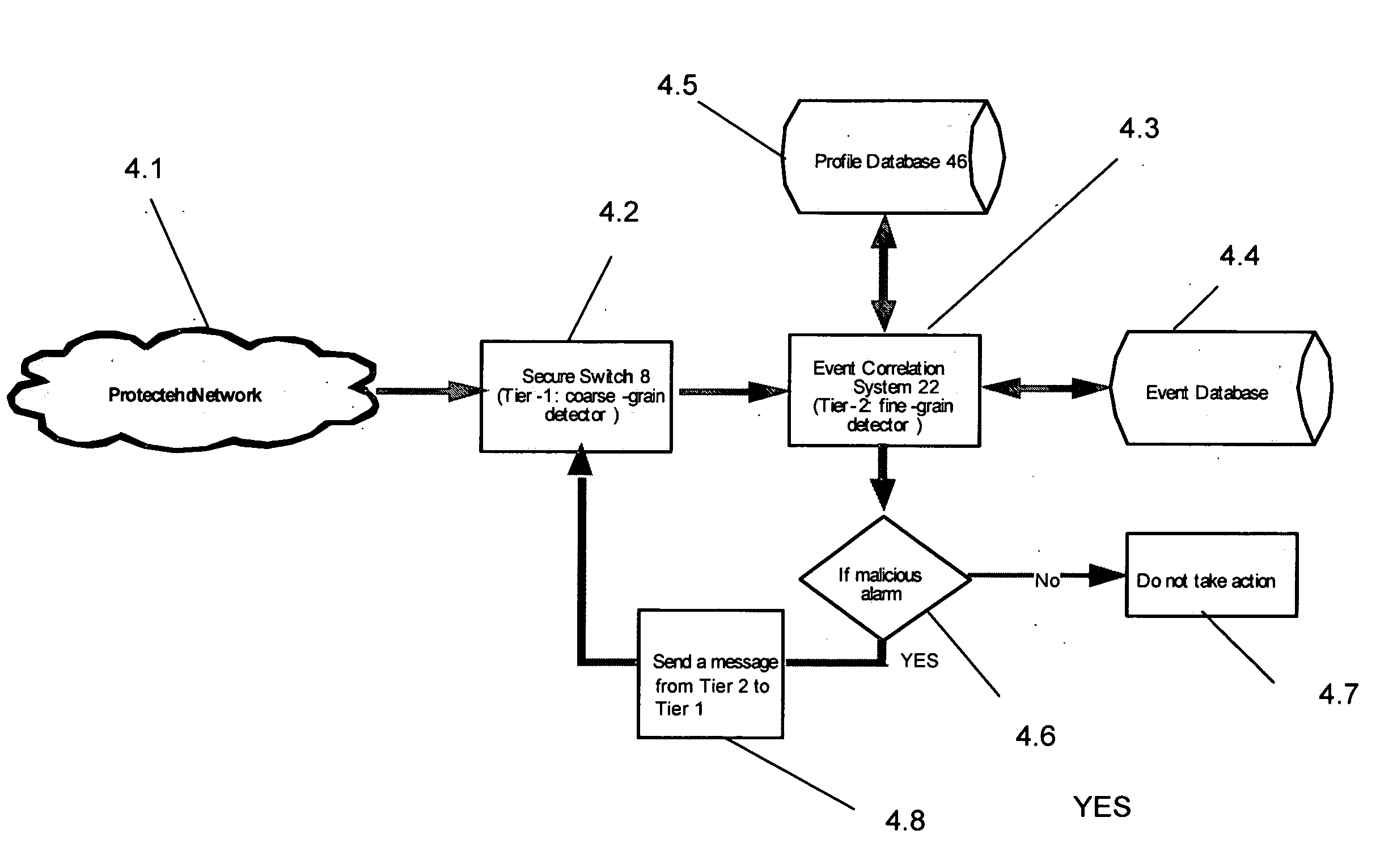

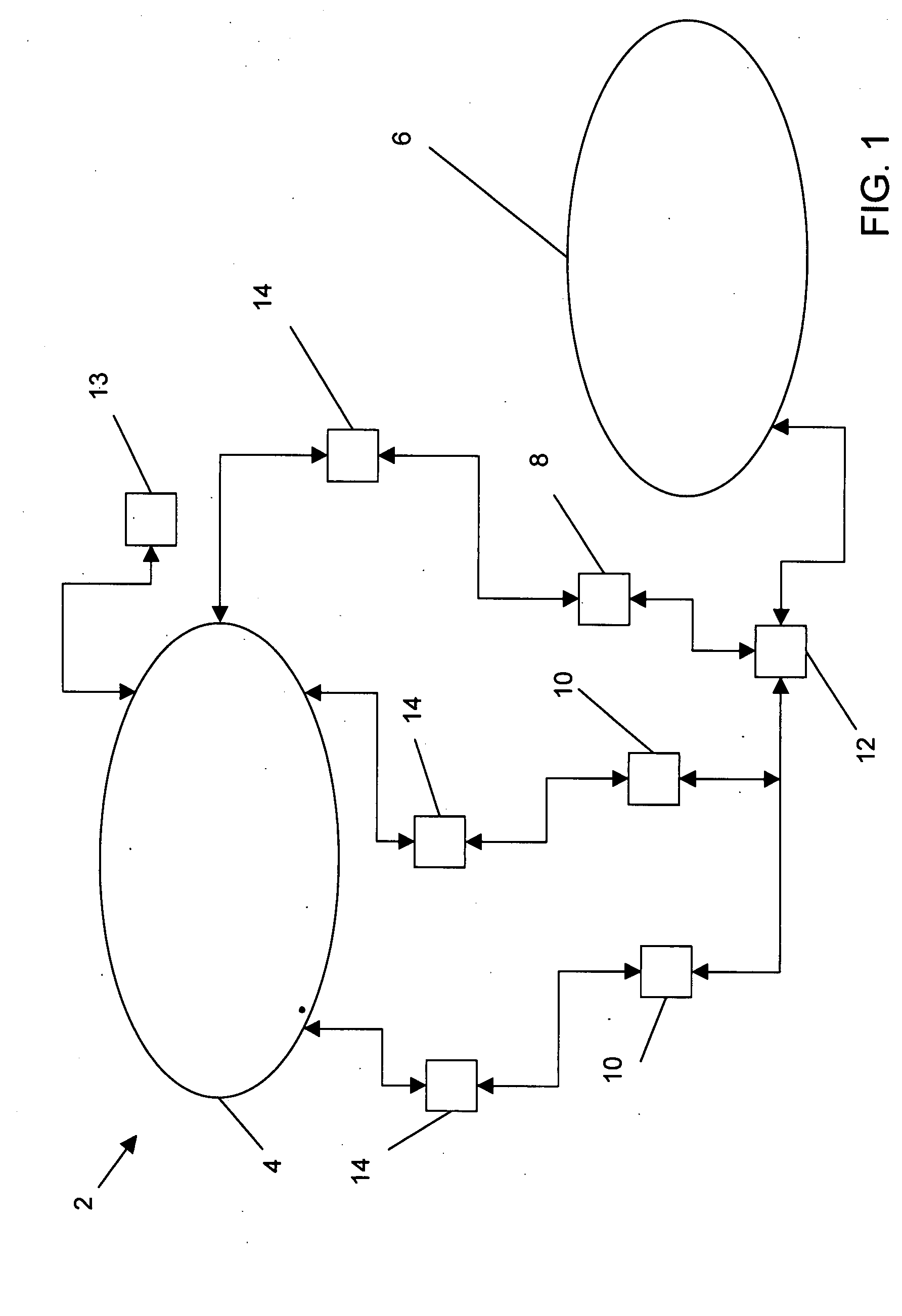

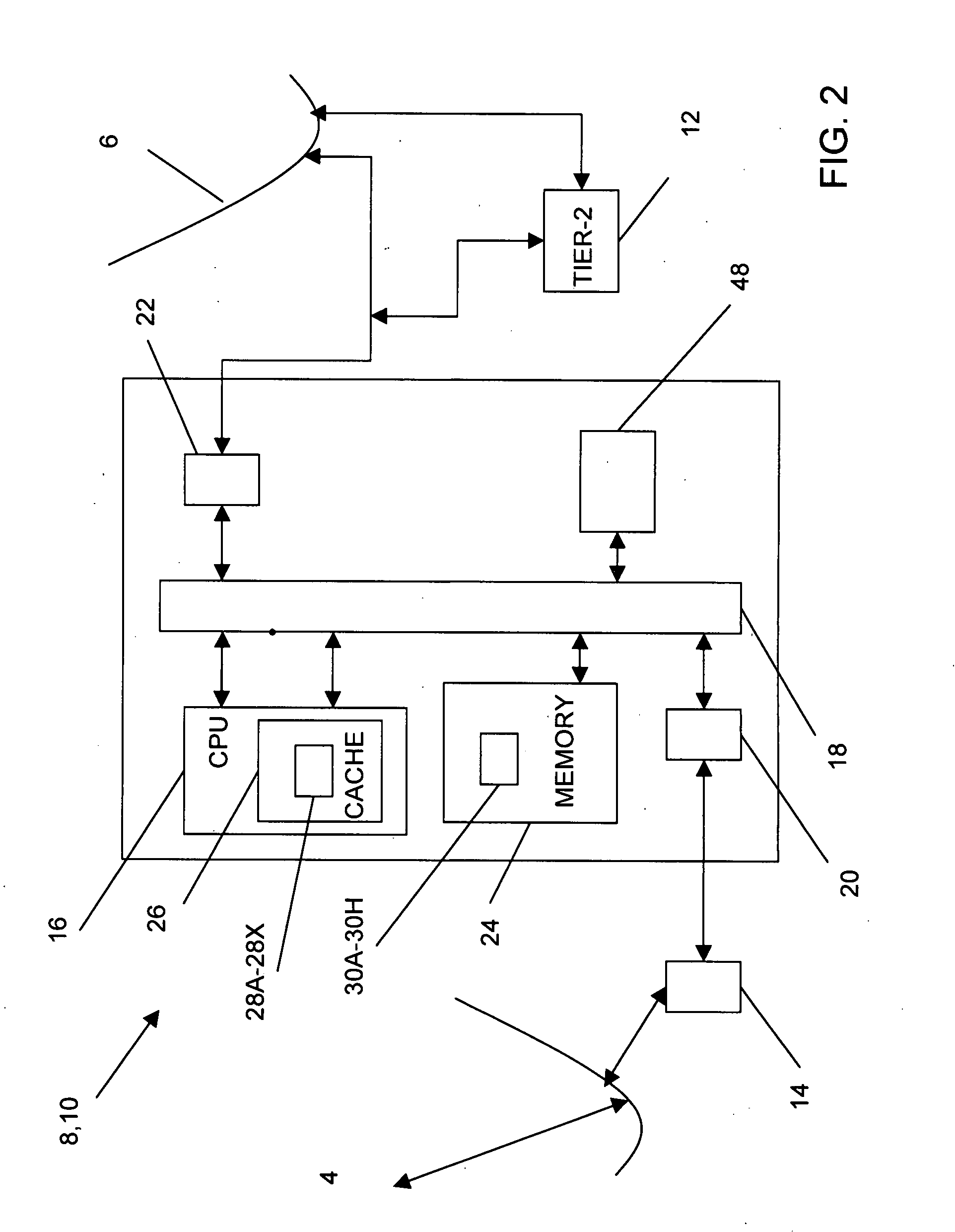

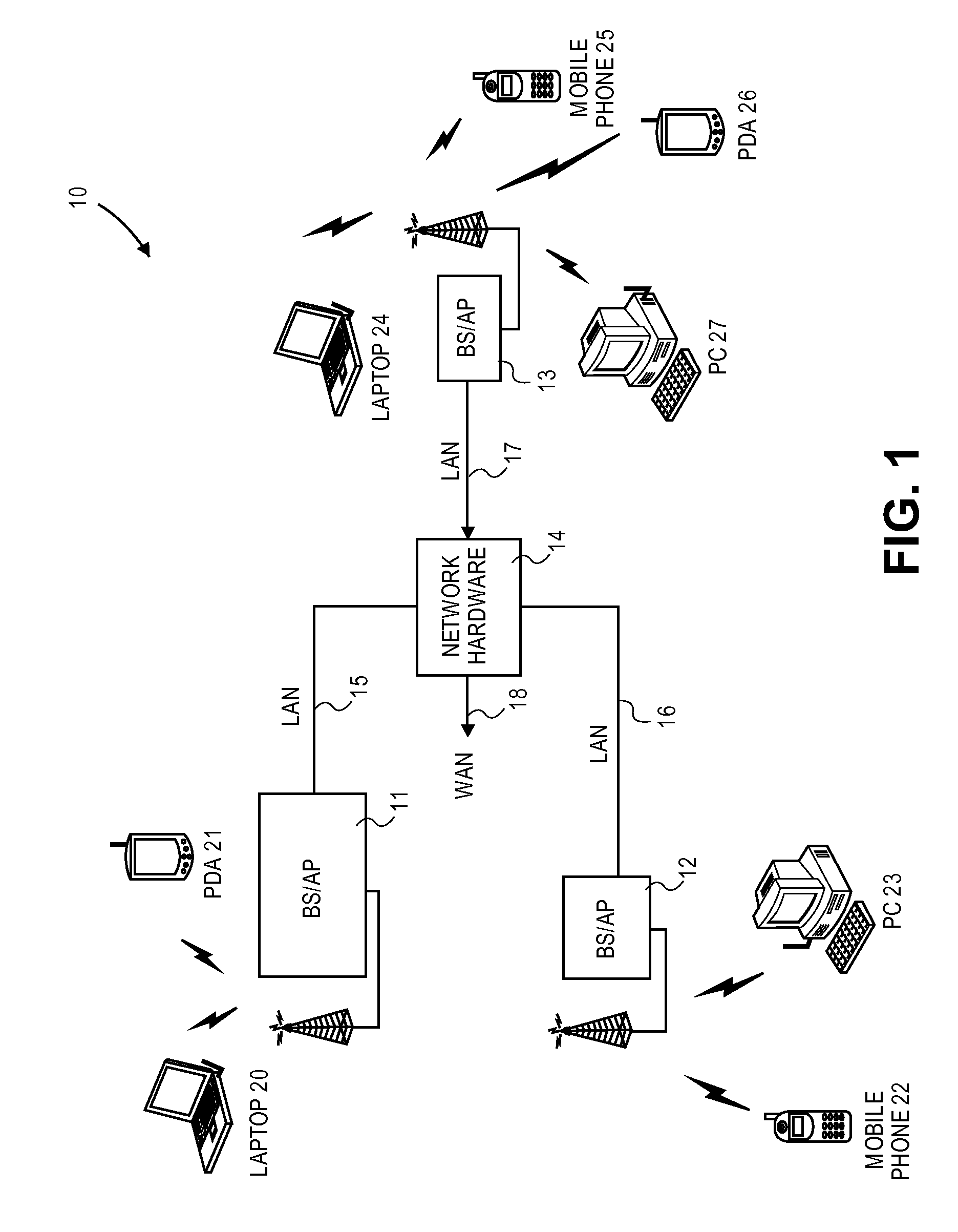

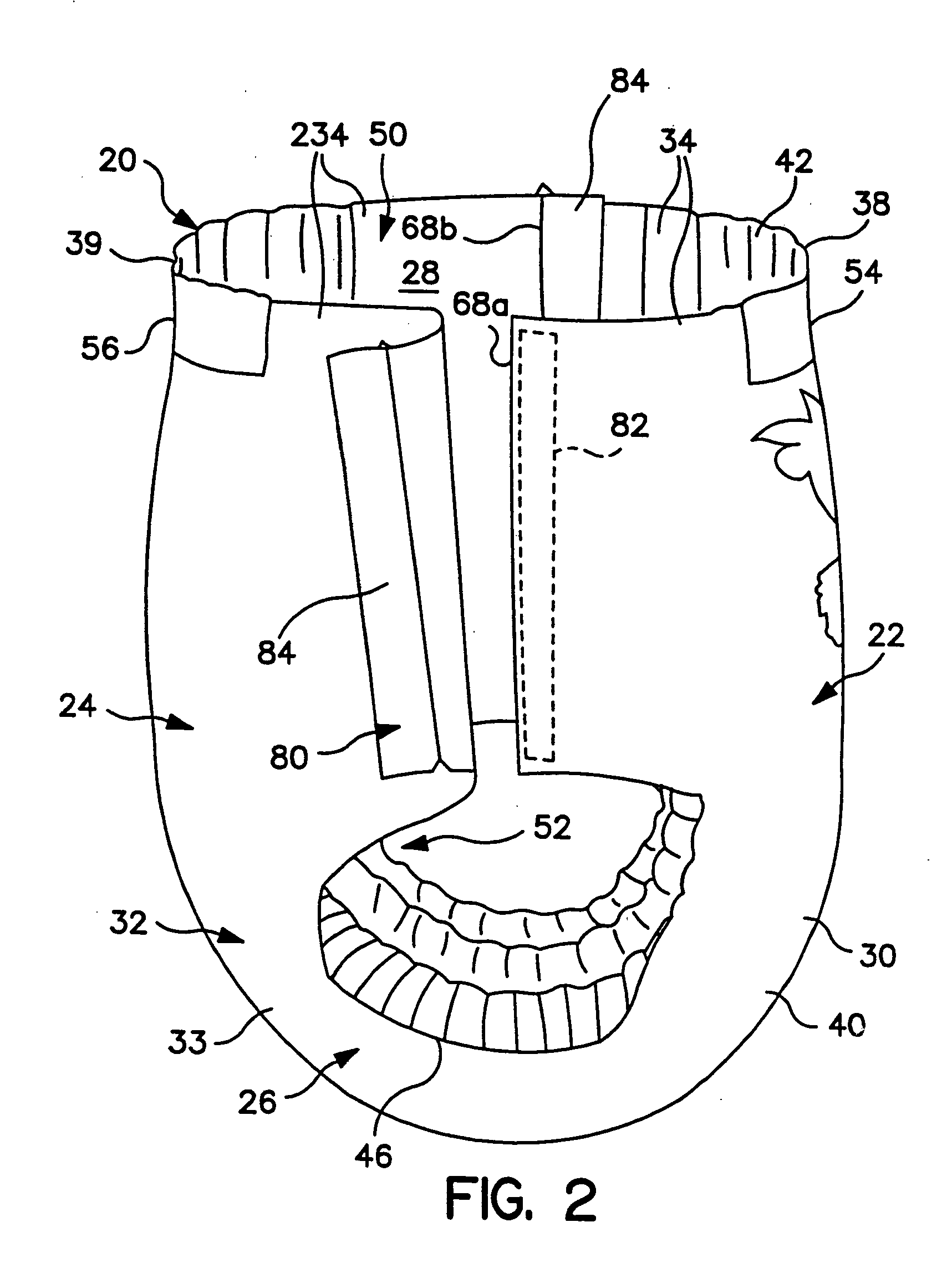

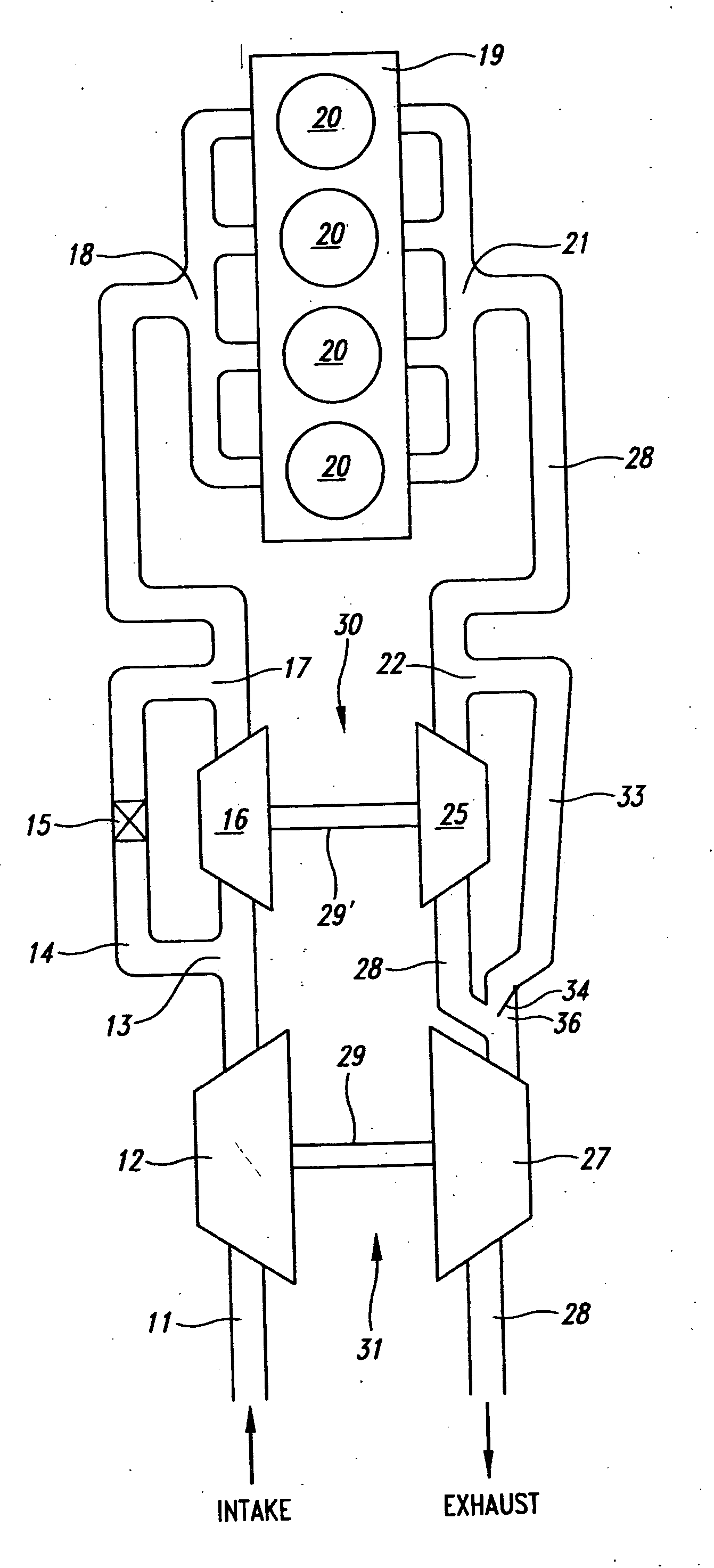

Method, system and computer-readable media for reducing undesired intrusion alarms in electronic communications systems and networks

InactiveUS20080295172A1Reduce probabilityHigh speed detectionMemory loss protectionError detection/correctionCommunications systemElectronic communication

A method, system and computer-readable media that enable the employment of an intrusion detection process are provided. This present invention is able to differentiate between certain malicious and benign incidents by means of a two-stage anomaly-based intrusion detection and prevention system. The invented system works at high-speed and with low-memory resources requirements. In particular, the invented method is implemented in a two-stage detector that performs coarse grain detection using sub-profiles 30A-30H (key features extracted from a profile) at one stage and fine grain (detailed behavioral profile) detection at another stage to eliminate unwanted attacks and false positives. Furthermore, in order to suppress specific alarms, the invented system allows the administrator to specify detailed profiles 32A-32H. By using a sub-profile extractor, a sub-profile is extracted, which is then downloaded into the coarse grain detector.

Owner:NEVIS NETWORLS INC

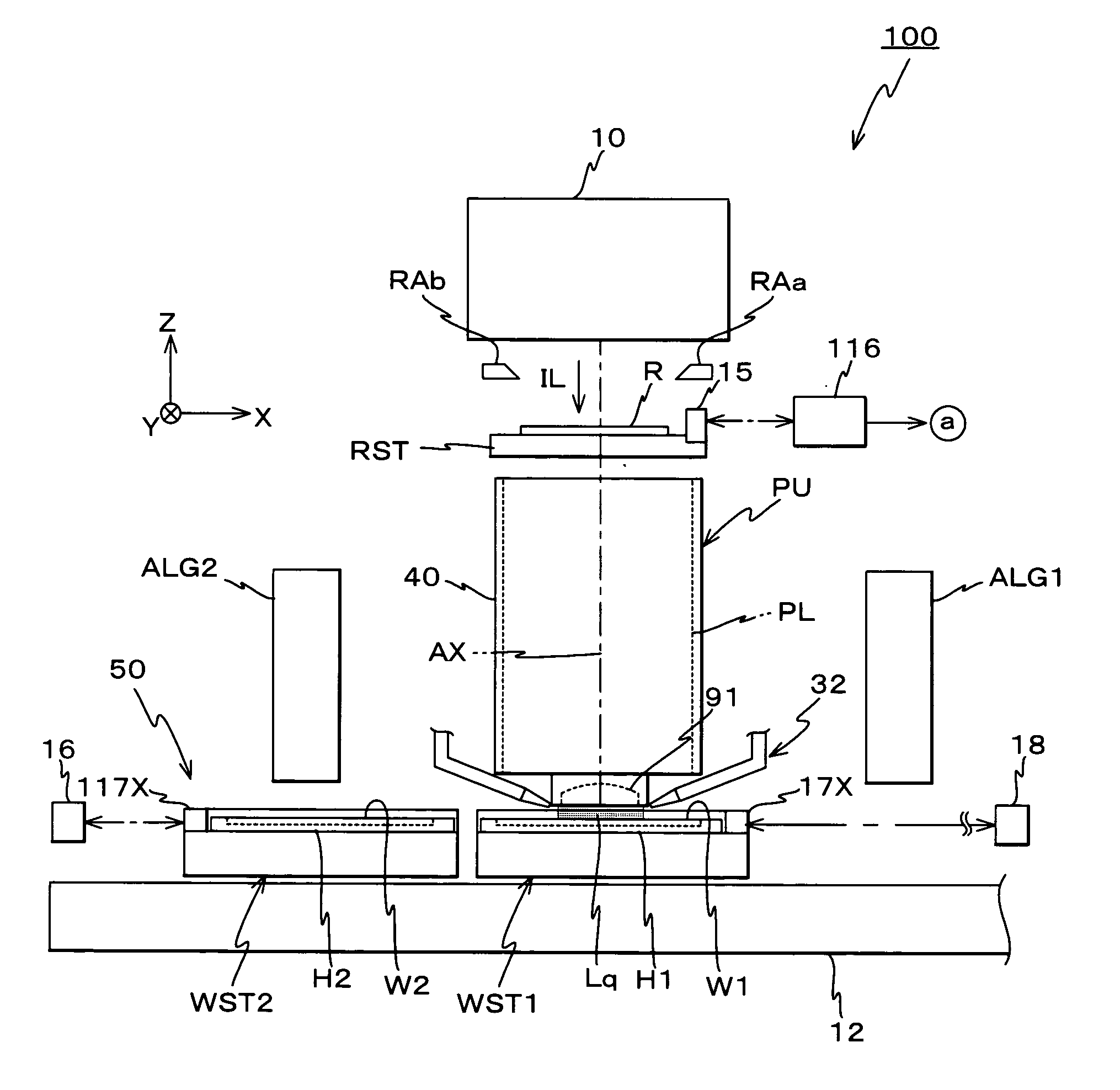

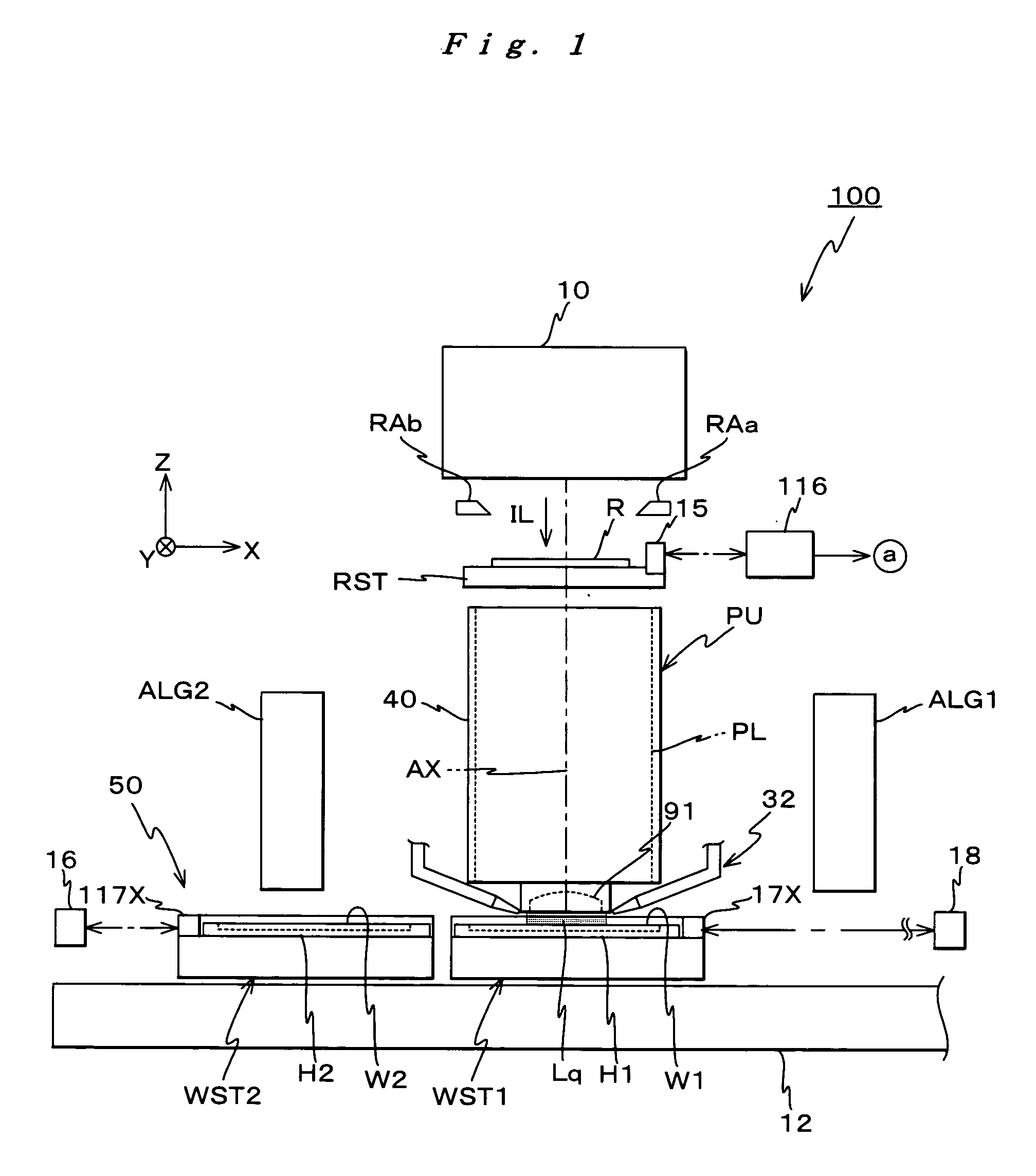

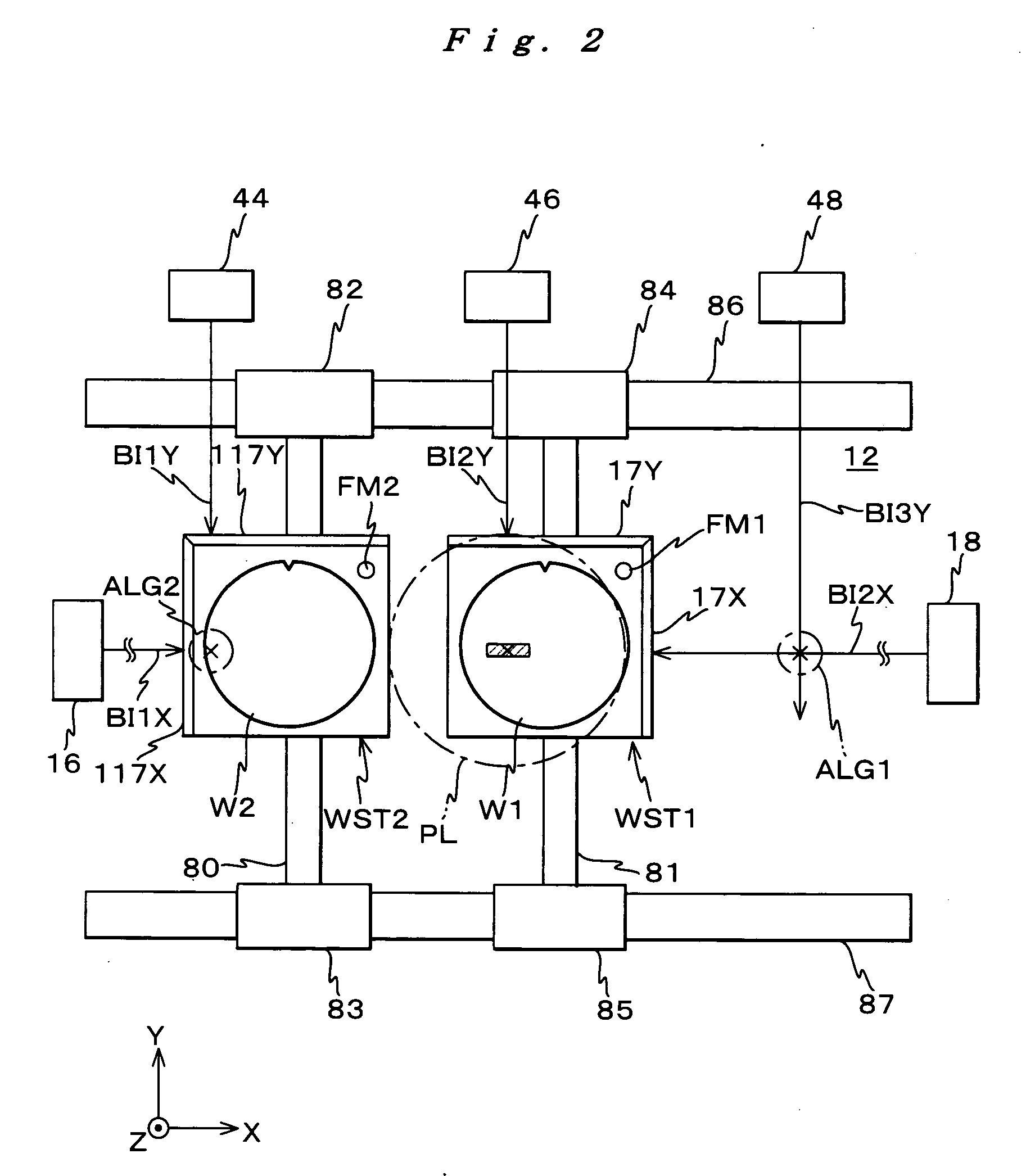

Stage drive method and stage unit, exposure apparatus, and device manufacturing method

InactiveUS20070127006A1Preventing and suppressing leakage of liquidImprove throughputSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringImage plane

When a transition from a first state where one stage is positioned at a first area directly below projection optical system to which liquid is supplied to a state where the other stage is positioned at the first area, both stages are simultaneously driven while a state where both stages are close together in the X-axis direction is maintained. Therefore, it becomes possible to make a transition from the first state to the second state in a state where liquid is supplied in the space between the projection optical system and the specific stage directly under the projection optical system. Accordingly, the time from the completion of exposure operation on one stage side until the exposure operation begins on the other stage side can be reduced, which allows processing with high throughput. Further, because the liquid can constantly exist on the image plane side of the projection optical system, generation of water marks on optical members of the projection optical system on the image plane side is prevented.

Owner:NIKON CORP

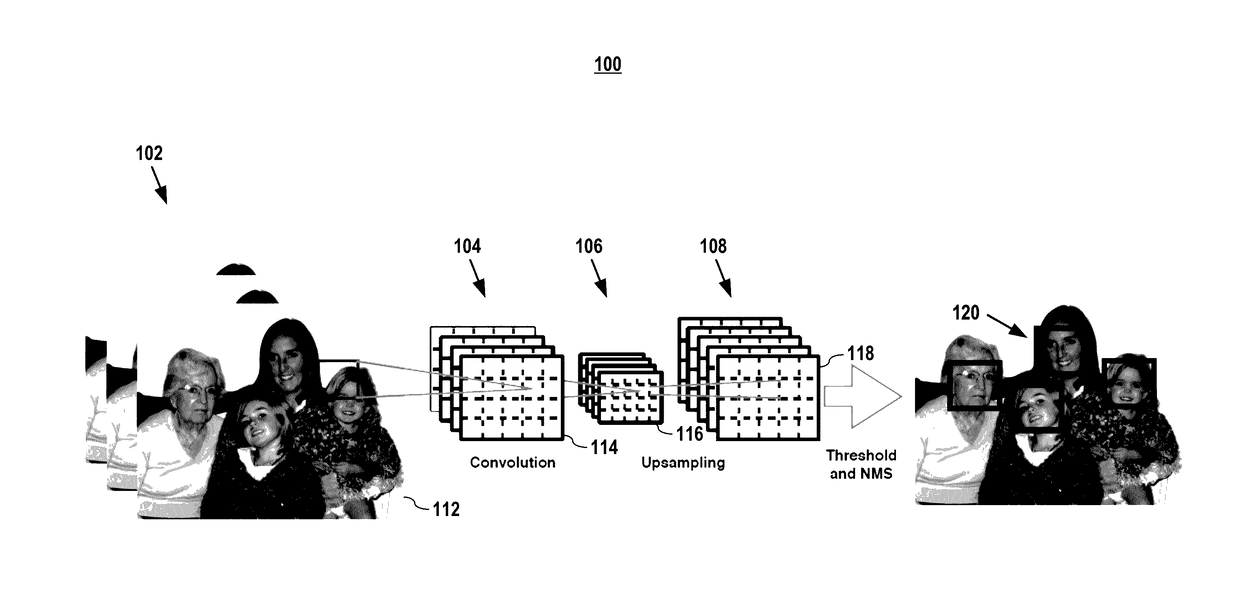

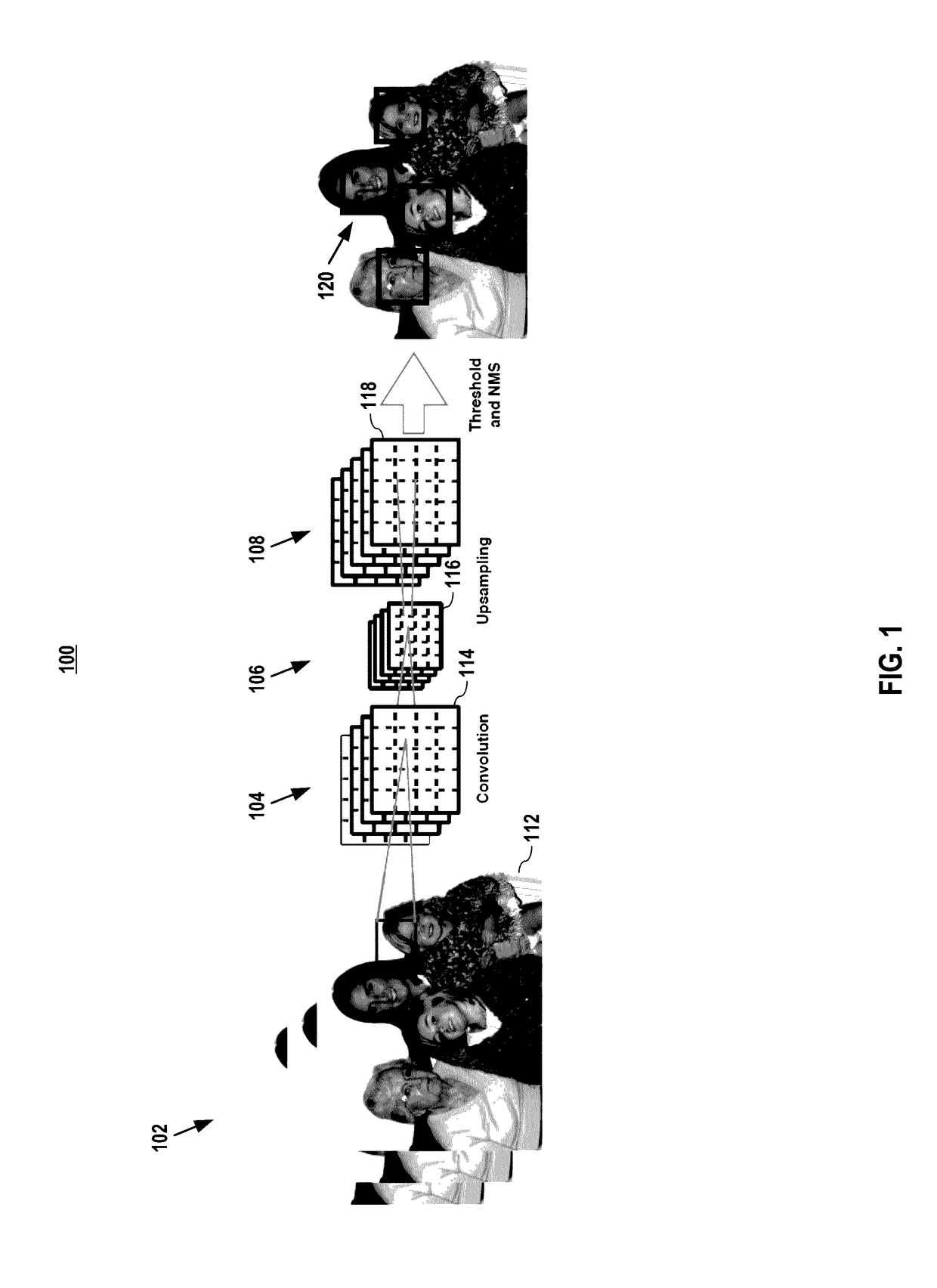

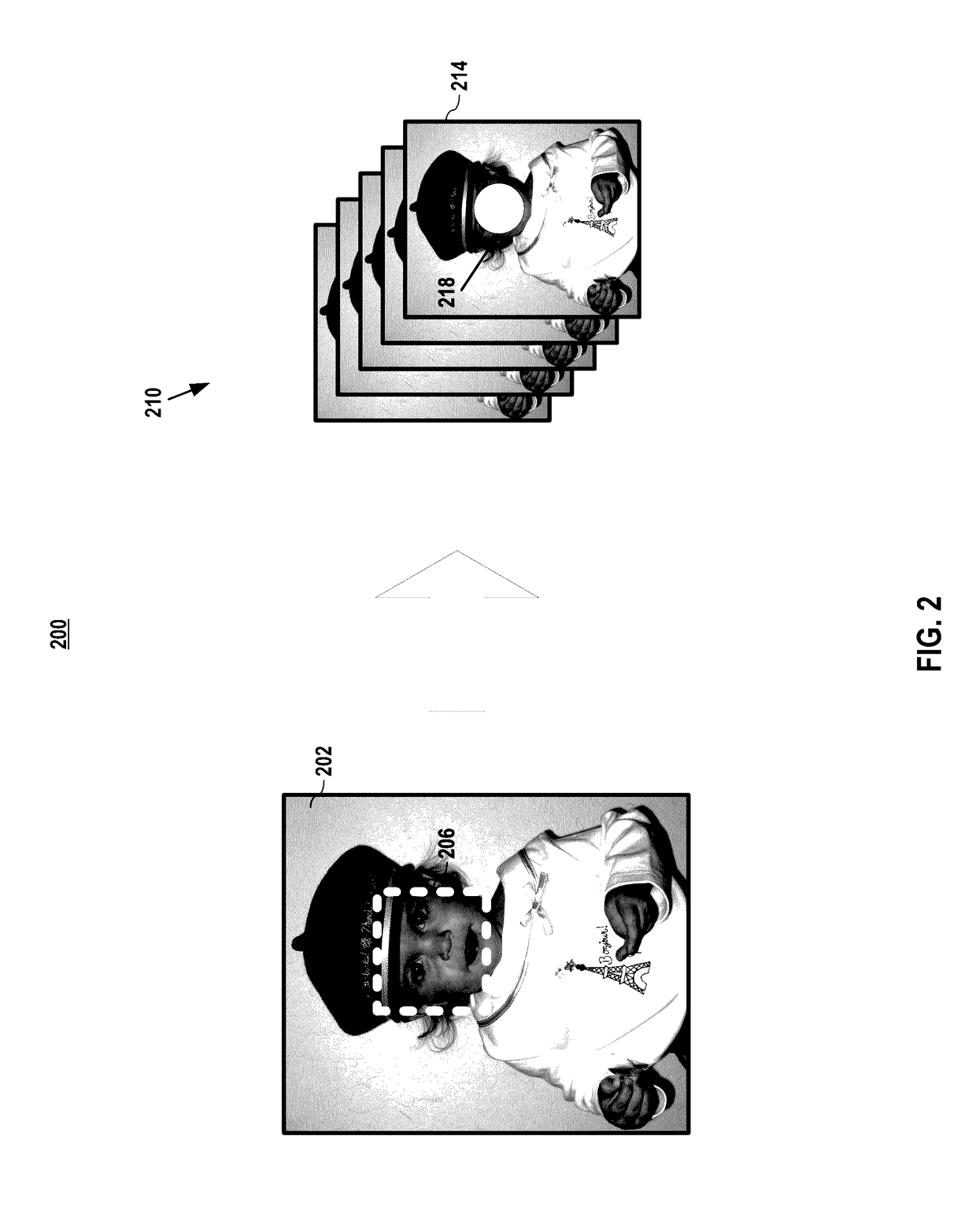

Systems and methods for end-to-end object detection

Presented are systems and methods that provide a unified end-to-end detection pipeline for object detection that achieves impressive performance in detecting very small and highly overlapped objects in face and car images. Various embodiments of the present disclosure provide for an accurate and efficient one-stage FCN-based object detector that may be optimized end-to-end during training. Certain embodiments train the object detector on a single scale using jitter-augmentation integrated landmark localization information through joint multi-task learning to improve the performance and accuracy of end-to-end object detection. Various embodiments apply hard negative mining techniques during training to bootstrap detection performance. The presented are systems and methods are highly suitable for situations where region proposal generation methods may fail, and they outperform many existing sliding window fashion FCN detection frameworks when detecting objects at small scales and under heavy occlusion conditions.

Owner:BAIDU USA LLC

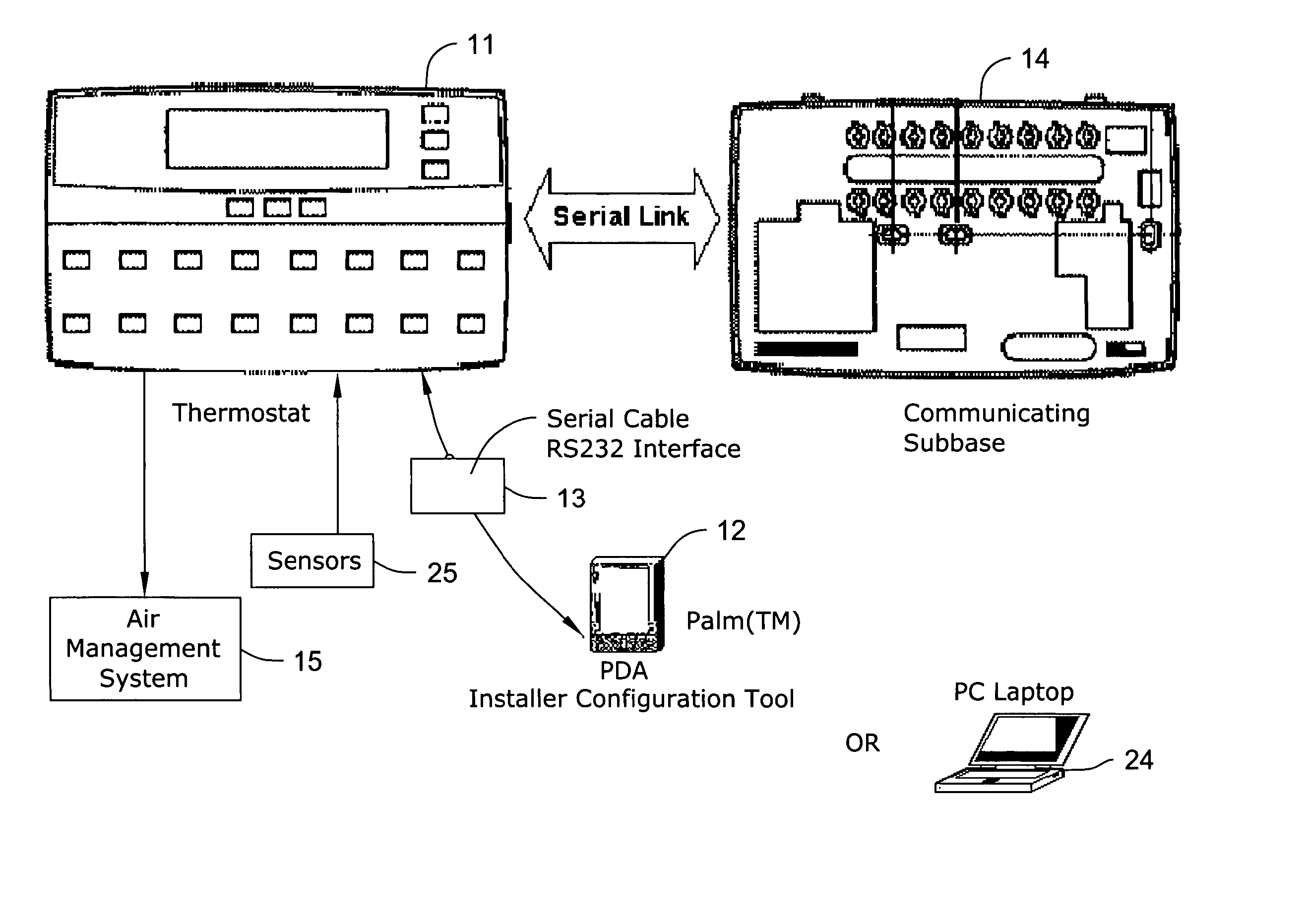

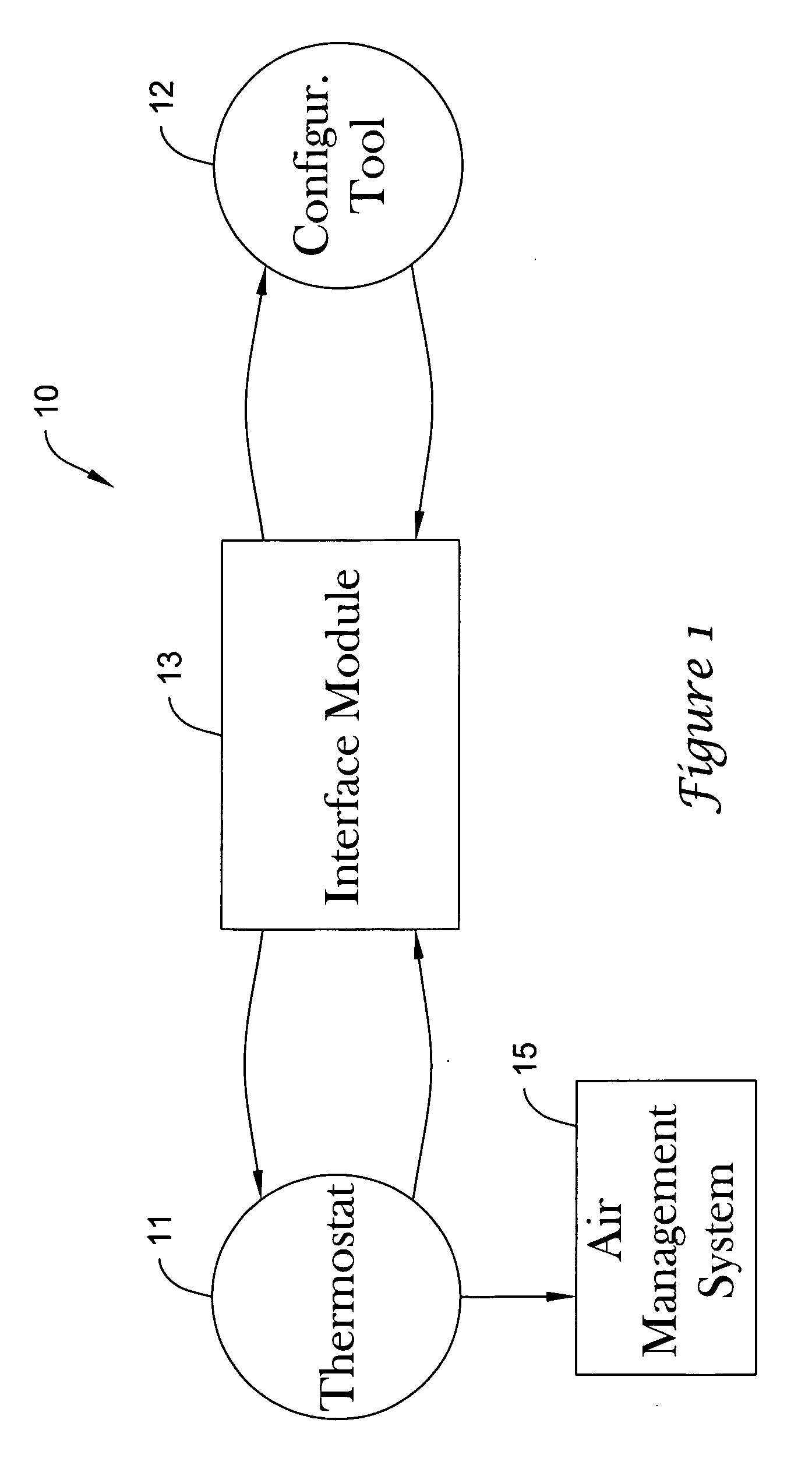

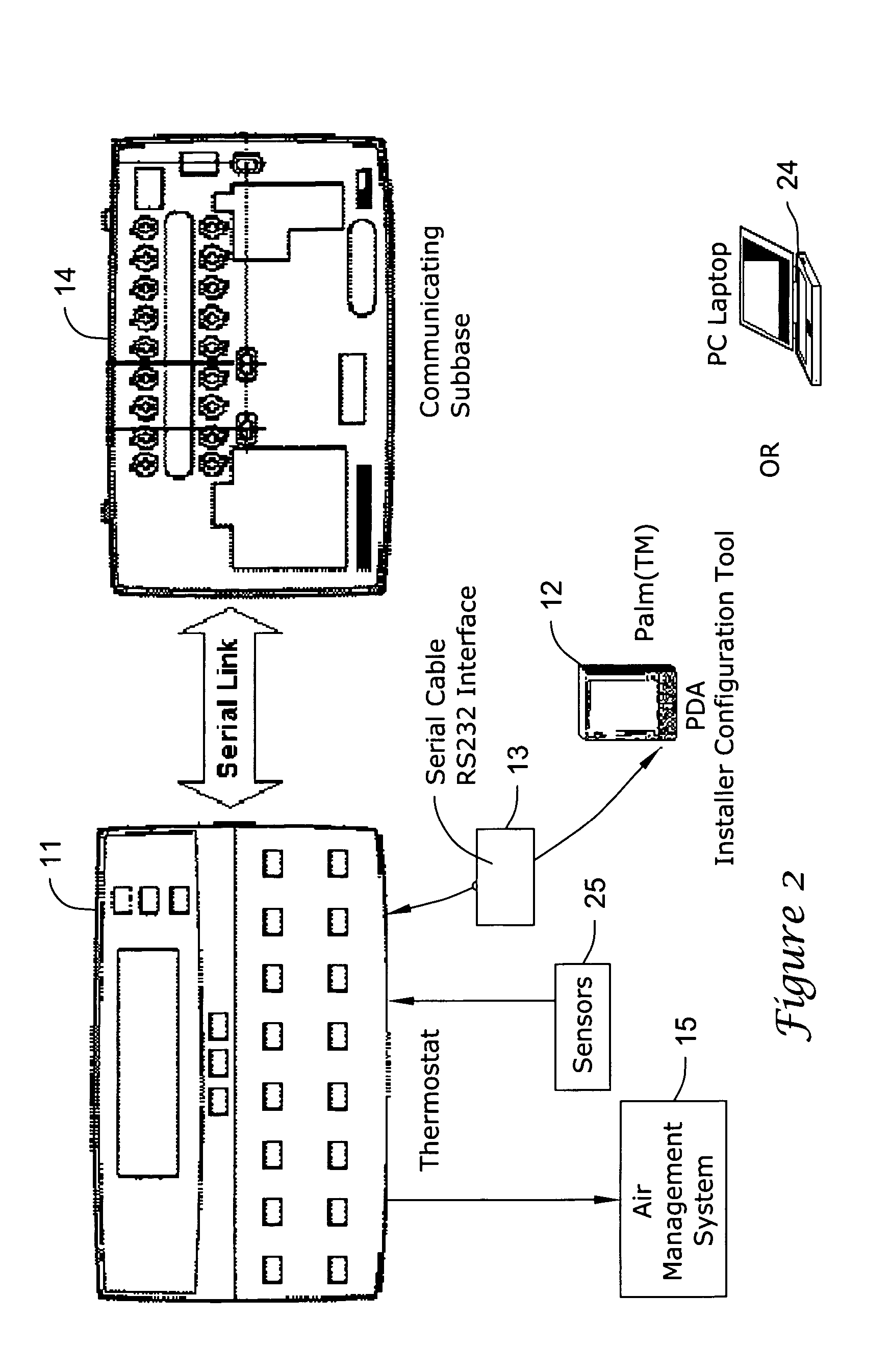

Thermostat having modulated and non-modulated provisions

ActiveUS20050040247A1Quick and efficientEasy to adaptMechanical apparatusSpace heating and ventilation safety systemsAir managementEngineering

A thermostat providing modulated or analog control of valves or dampers of an air management system. This permits operating a single cooling or heating stage with partially open valves or dampers as needed, since one full stage that is either fully on or off may not be easy to manage for effective air management of a particular type of building, zone or facility. The thermostat may also provide non-modulated control of multi-stage cooling and heating systems. The thermostat may even be used to control a modulated system having more than one stage of cooling or heating.

Owner:HONEYWELL INT INC

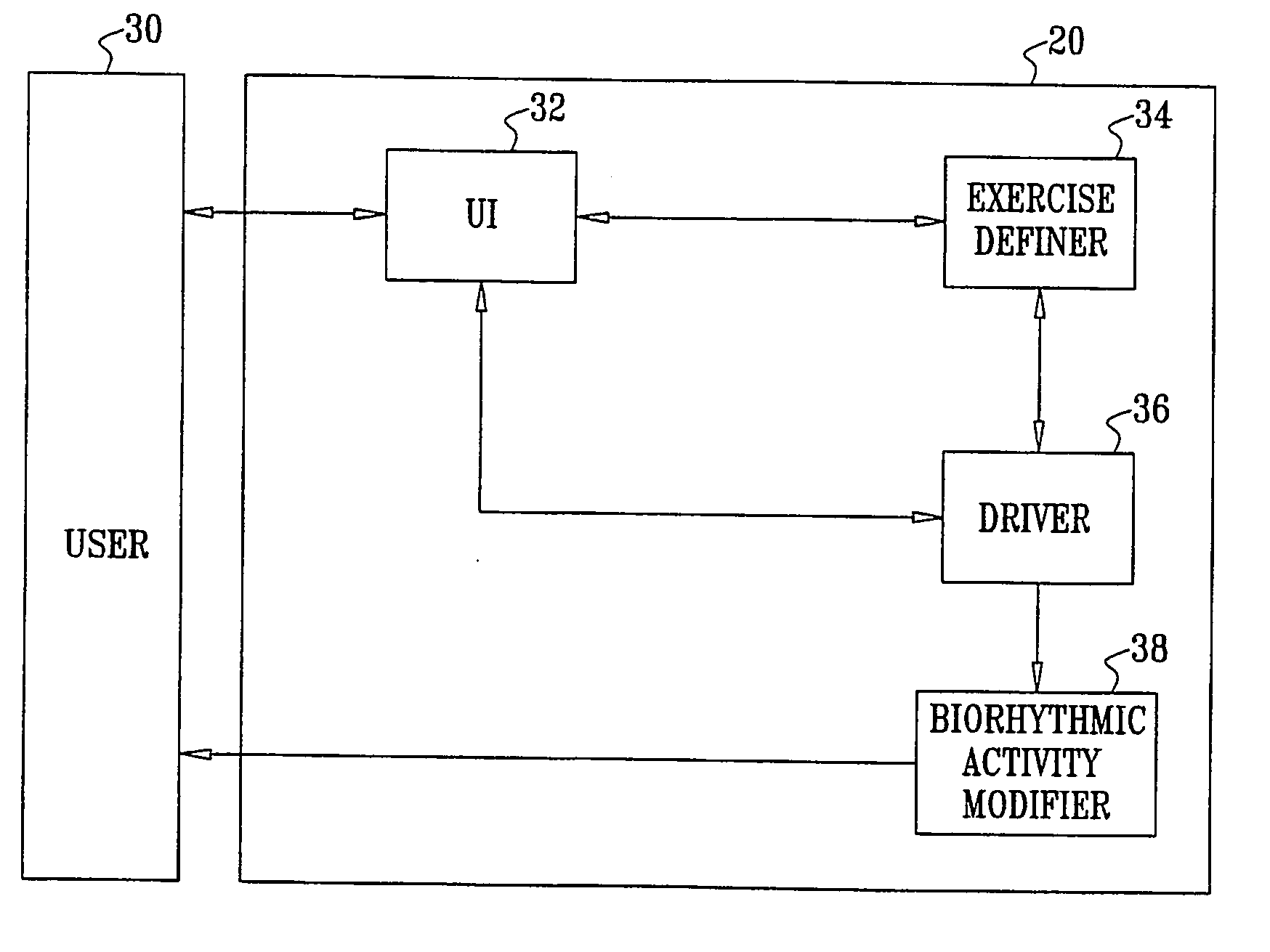

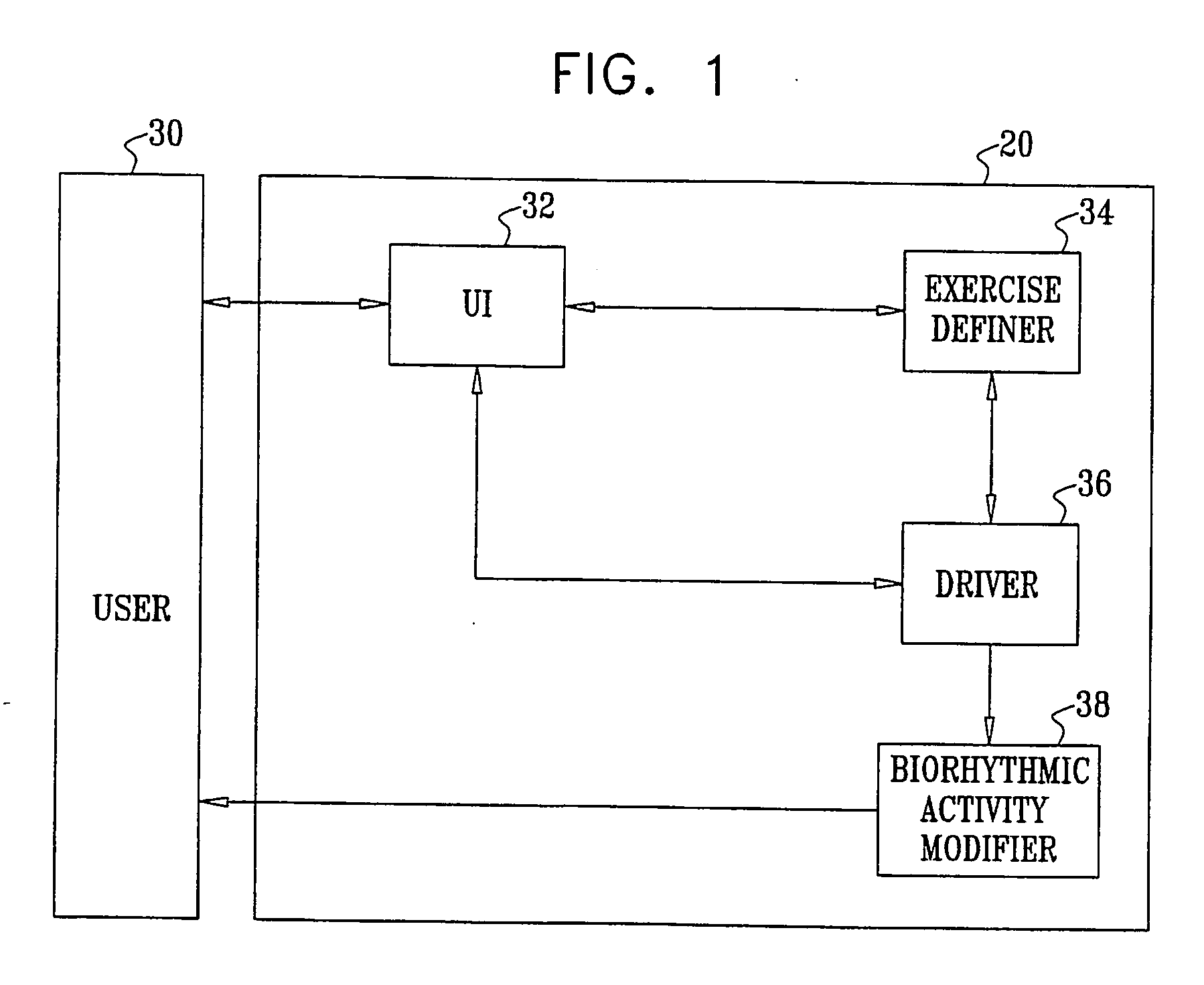

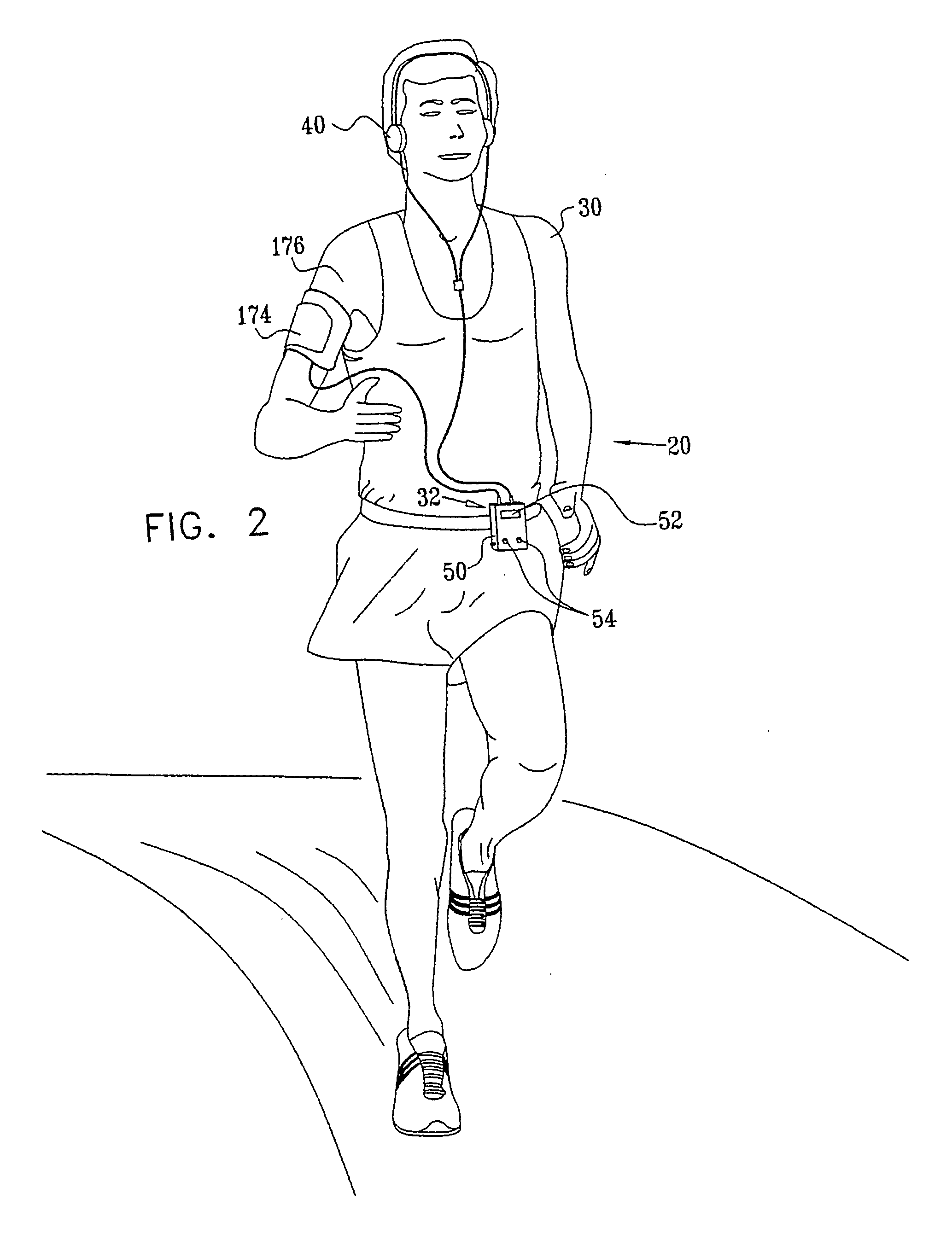

Generalized metronome for modification of biorhythmic activity

ActiveUS20060102171A1Increasing tissue oxygenationReduce peripheral impedanceGymnastic exercisingVibration massageMedicineMetronome

Owner:2BREATHE TECHOGIES LTD

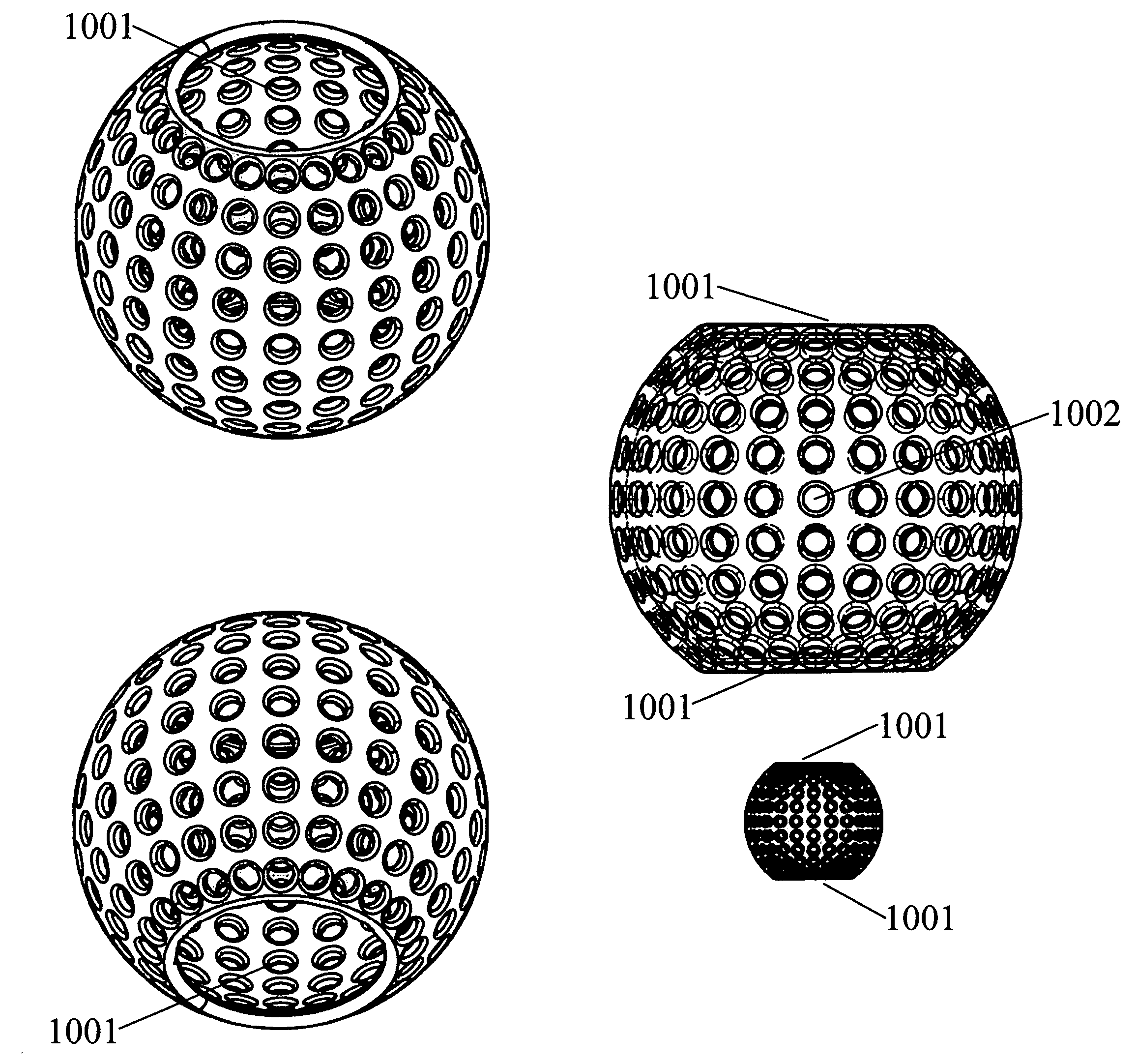

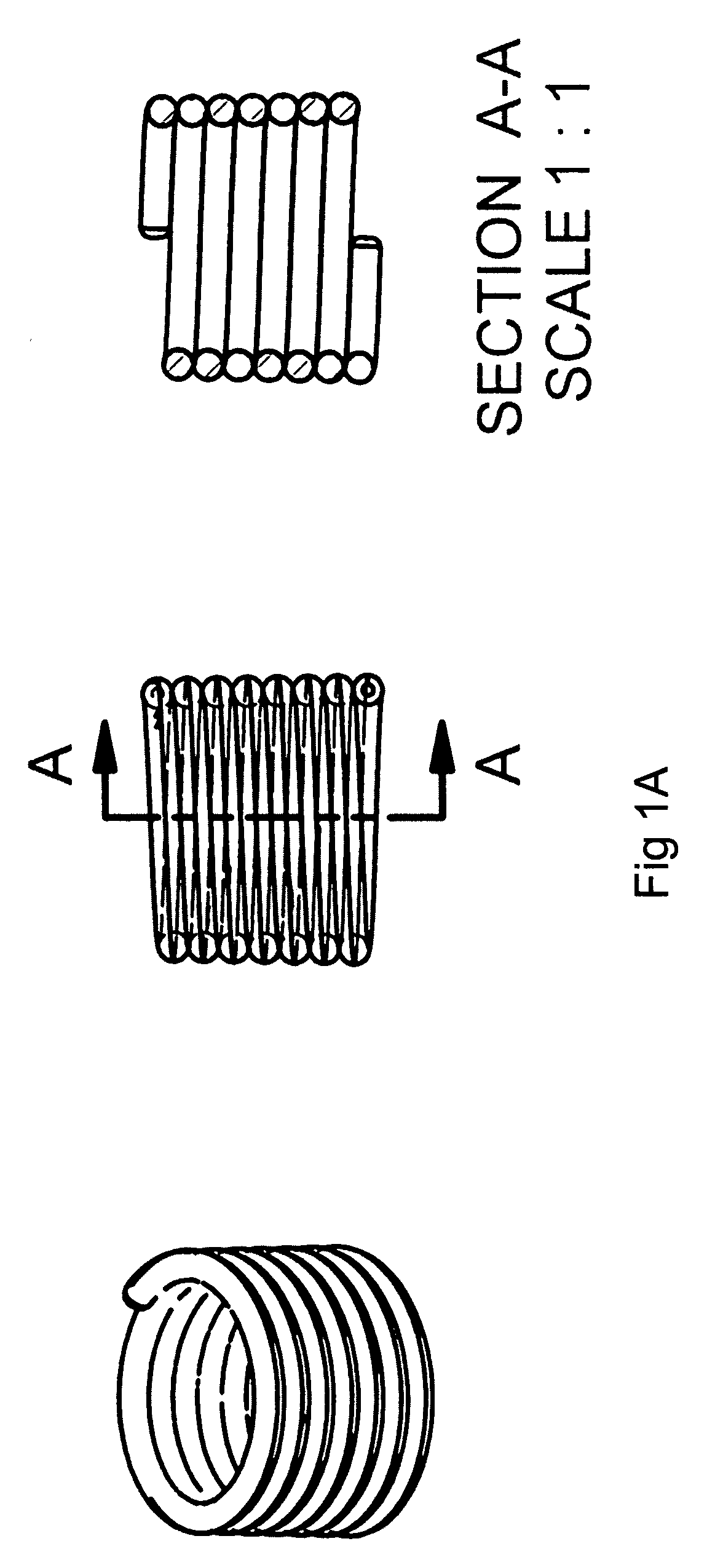

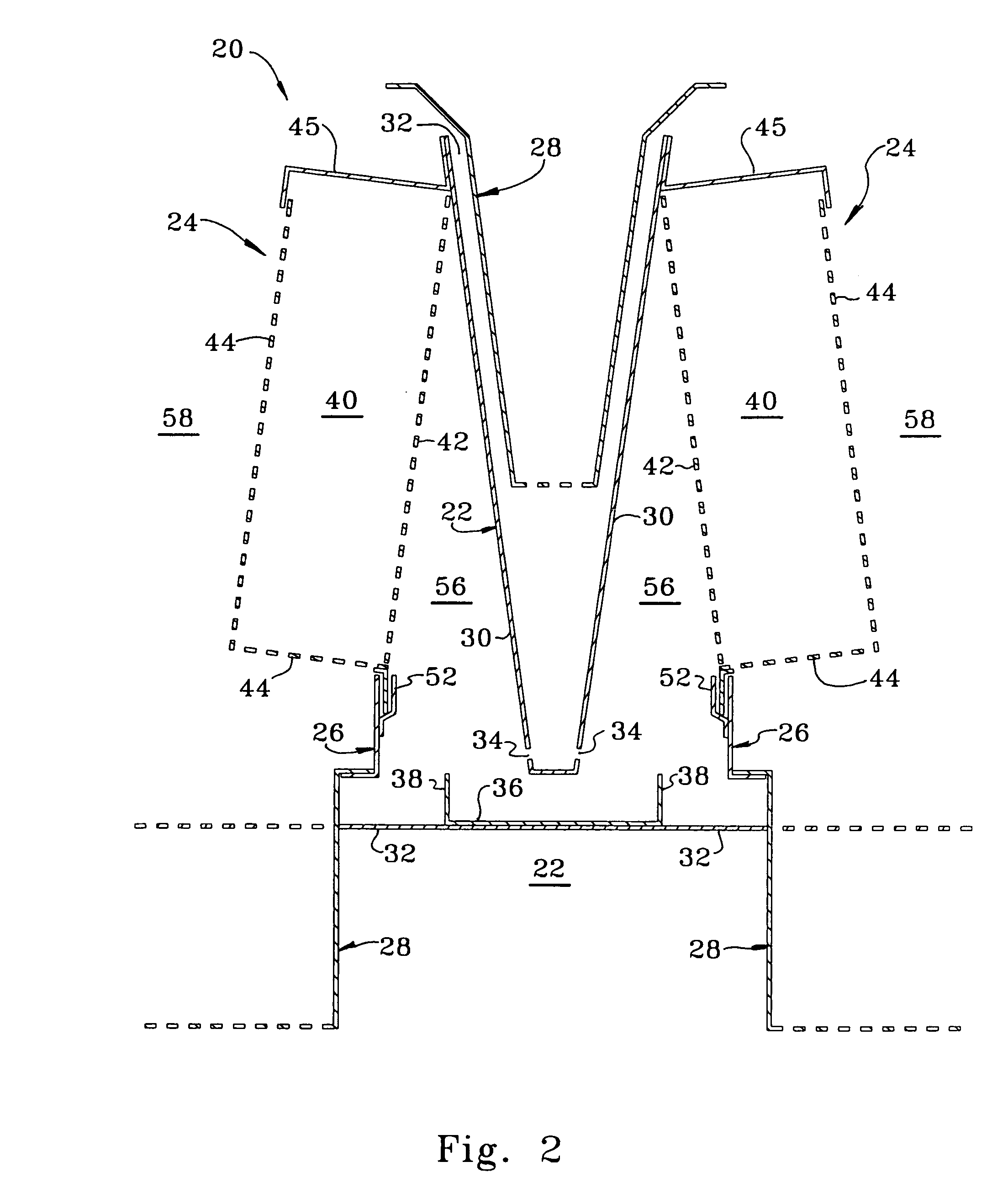

Annulus fibrosus stent

The Annulus Fibrosus Stent (AFS) is a platform of barriers used in the intervertebral disc. The barrier can be inserted into an intervertebral disc to act to reinforce and / or supplement the disc. The AFS can be inserted at any of the many different stages of disc pathology. The AFS can be inserted to prevent pressure and dissection of disc material which in and of itself can decrease and / or eliminate pain from damaged AF fibers. The AFS can be inserted before disc pathology progresses to a substantial event such as a disc herniation. It can be inserted at any time in the progression of the natural history of disc disease. It can even be inserted when substantially the entire intervertebral disc has been removed. It can be inserted in conjunction with another procedure such as a Nucleus Pulposus Replacement (NPR) or Total Disc Replacement (TDR), etc. The various shapes and material of the AFS in this patent are designed to address particular clinical situations, particular anatomy and particular stages of disc degeneration. The AFS can be inserted directly through the AF, or by a technique of detaching part of the AF with bone without actually cutting a substantial part of AF fibers or layers of fibers or by the Transosseous approach.

Owner:HYDE EDWARD ROBERT JR

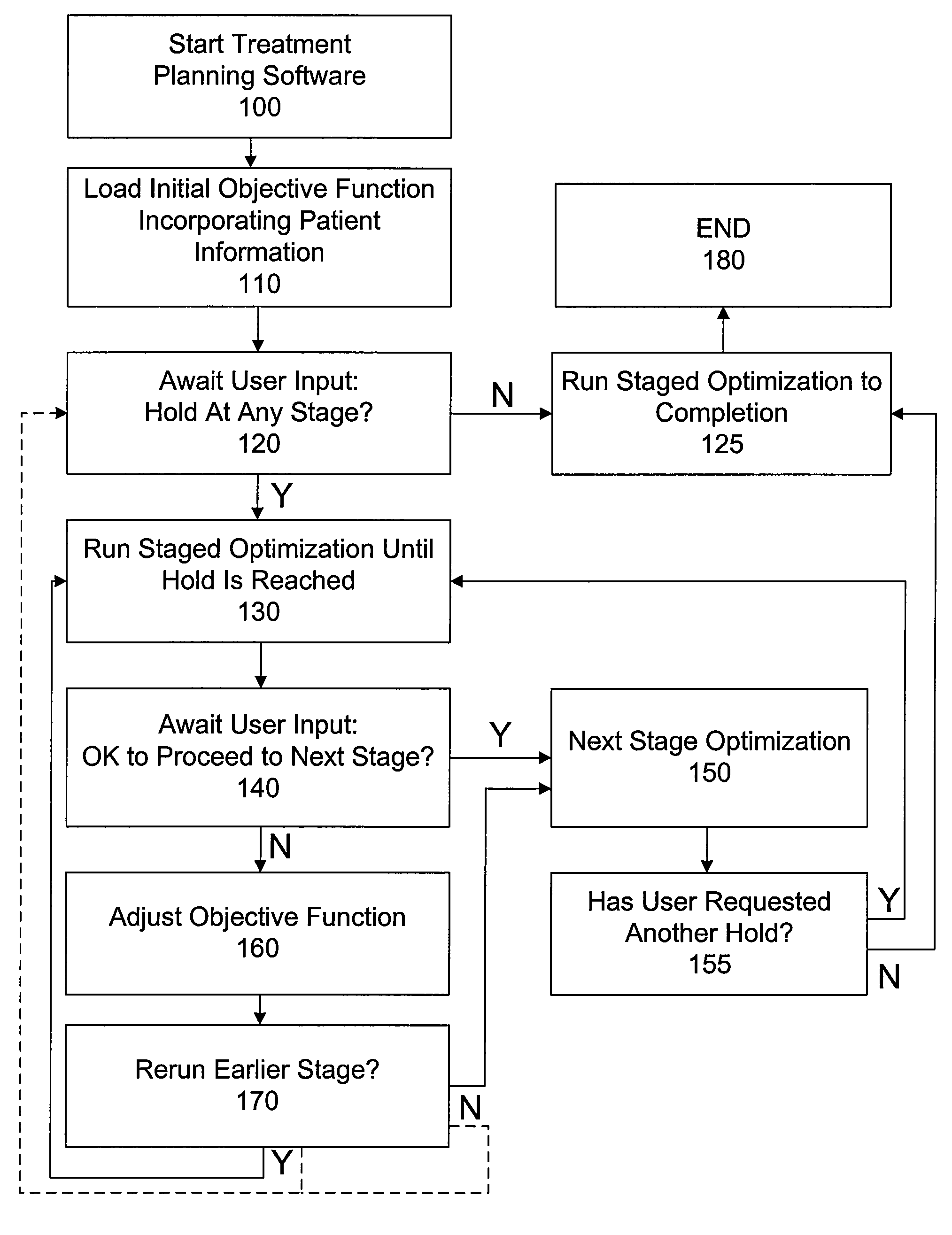

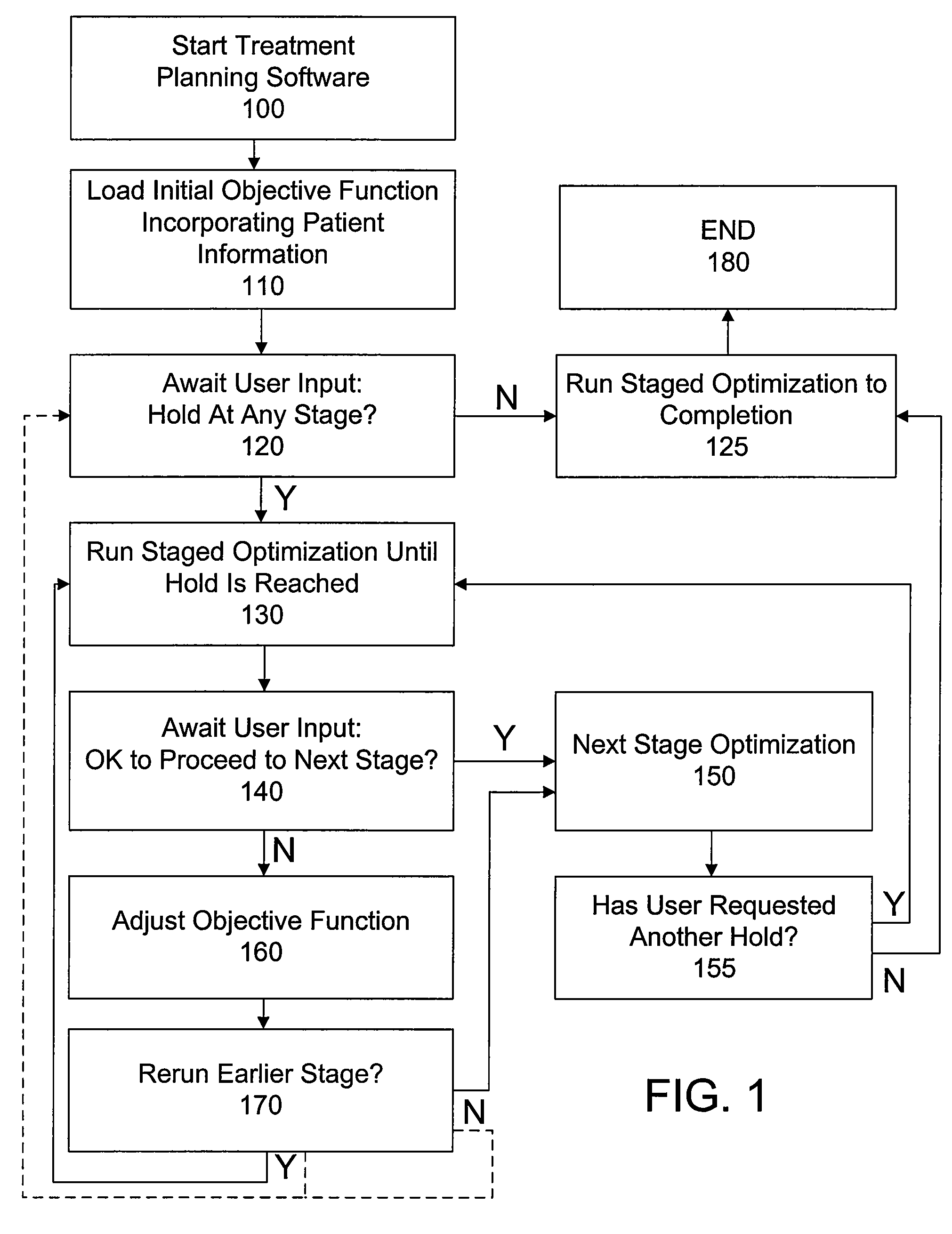

Interactive treatment plan optimization for radiation therapy

ActiveUS7817778B2Increase speed and efficiencyPromote resultsX-ray/gamma-ray/particle-irradiation therapyTherapy planningArc therapy

An interactive method for radiation treatment planning is disclosed. The method applies to staged treatment planning algorithms, as used, for example, with arc therapy. It allows the user to hold the optimization algorithm at a stage in order to make adjustments to the objective function before advancing to the next stage. If adjustments are made, the user can revert to an earlier stage and re-run the optimization process using the adjusted objective function. While a hold is imposed, the treatment planning software may continue optimization at the current stage.

Owner:VARIAN MEDICAL SYST INT AG

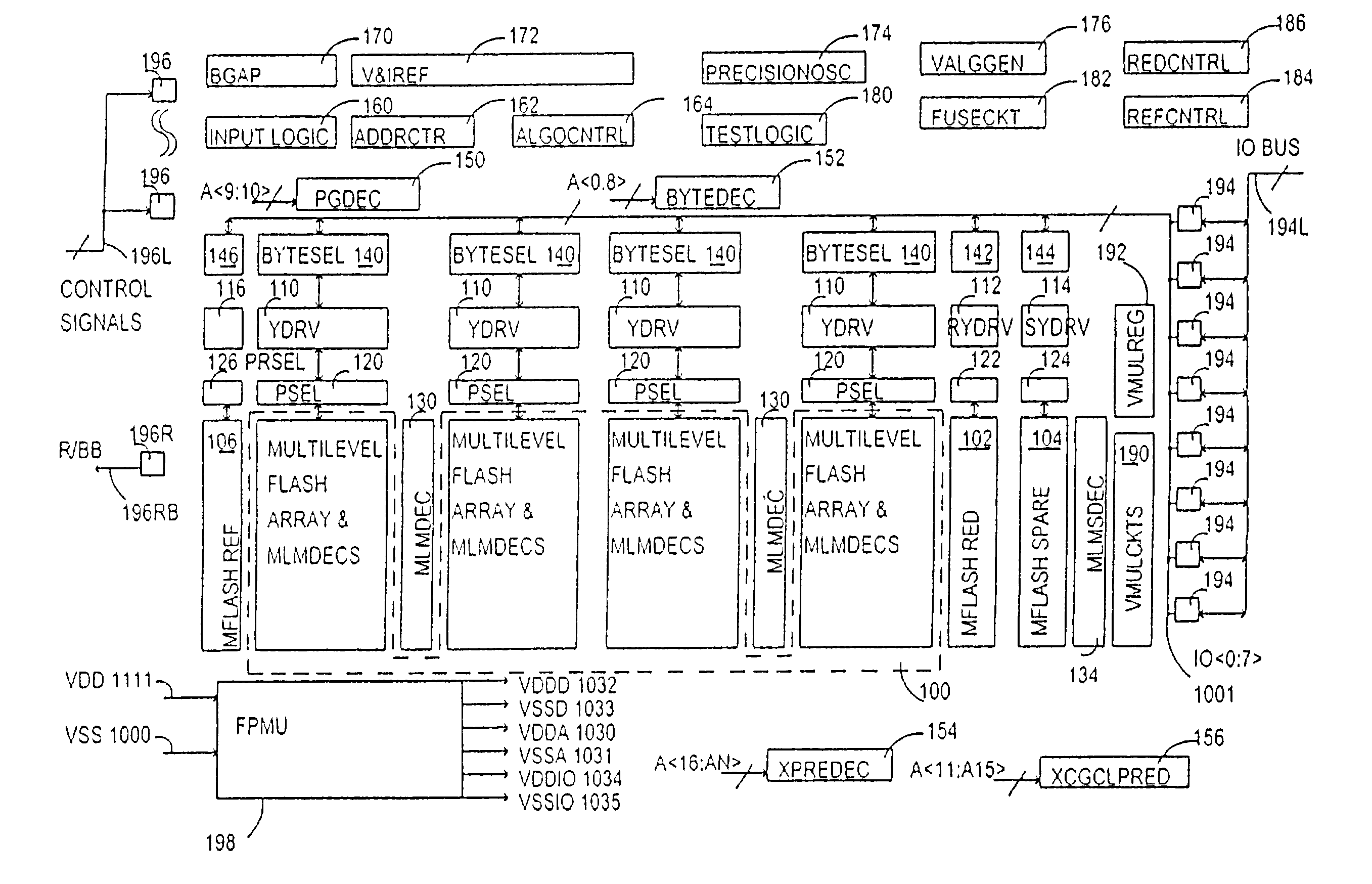

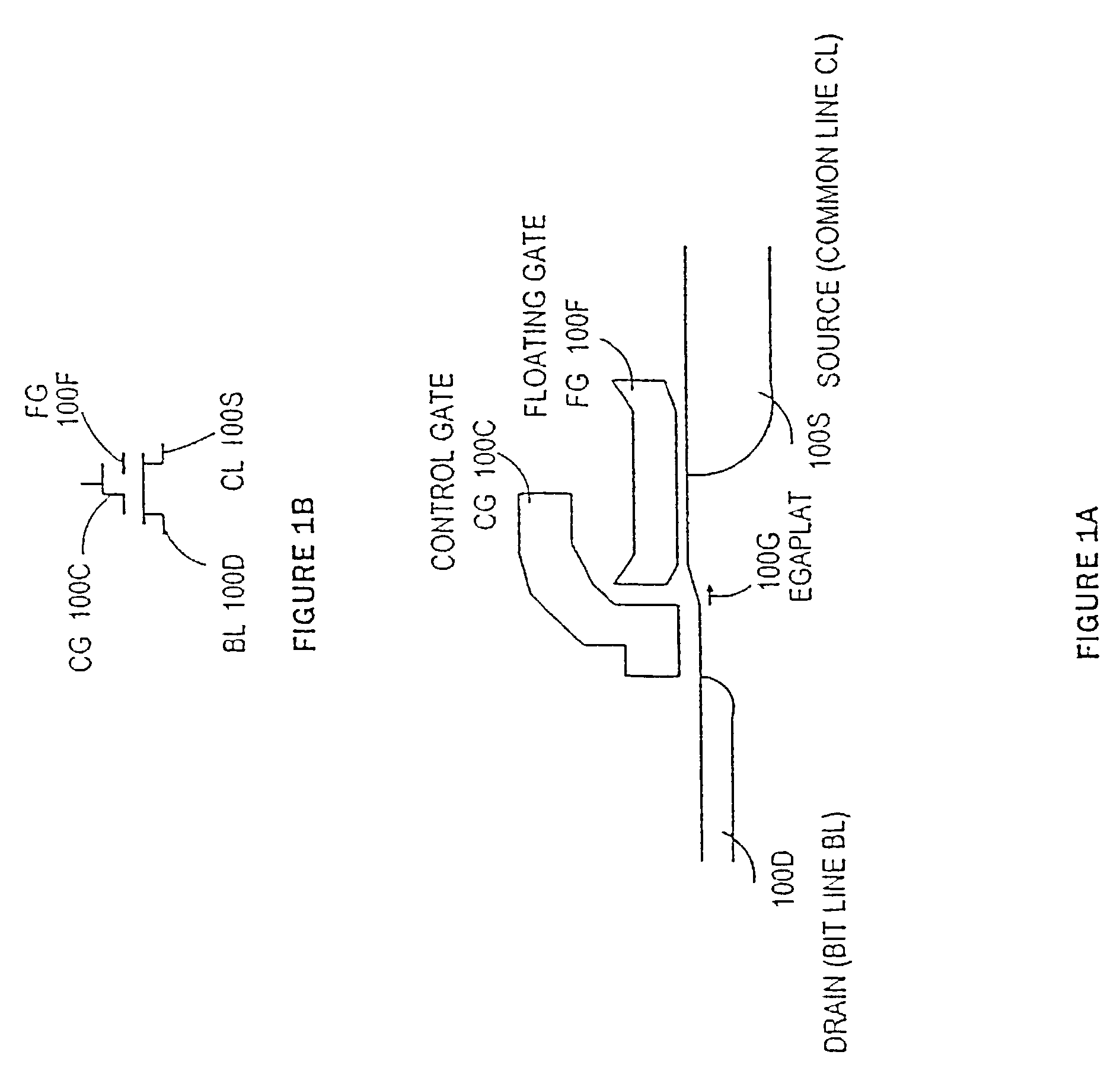

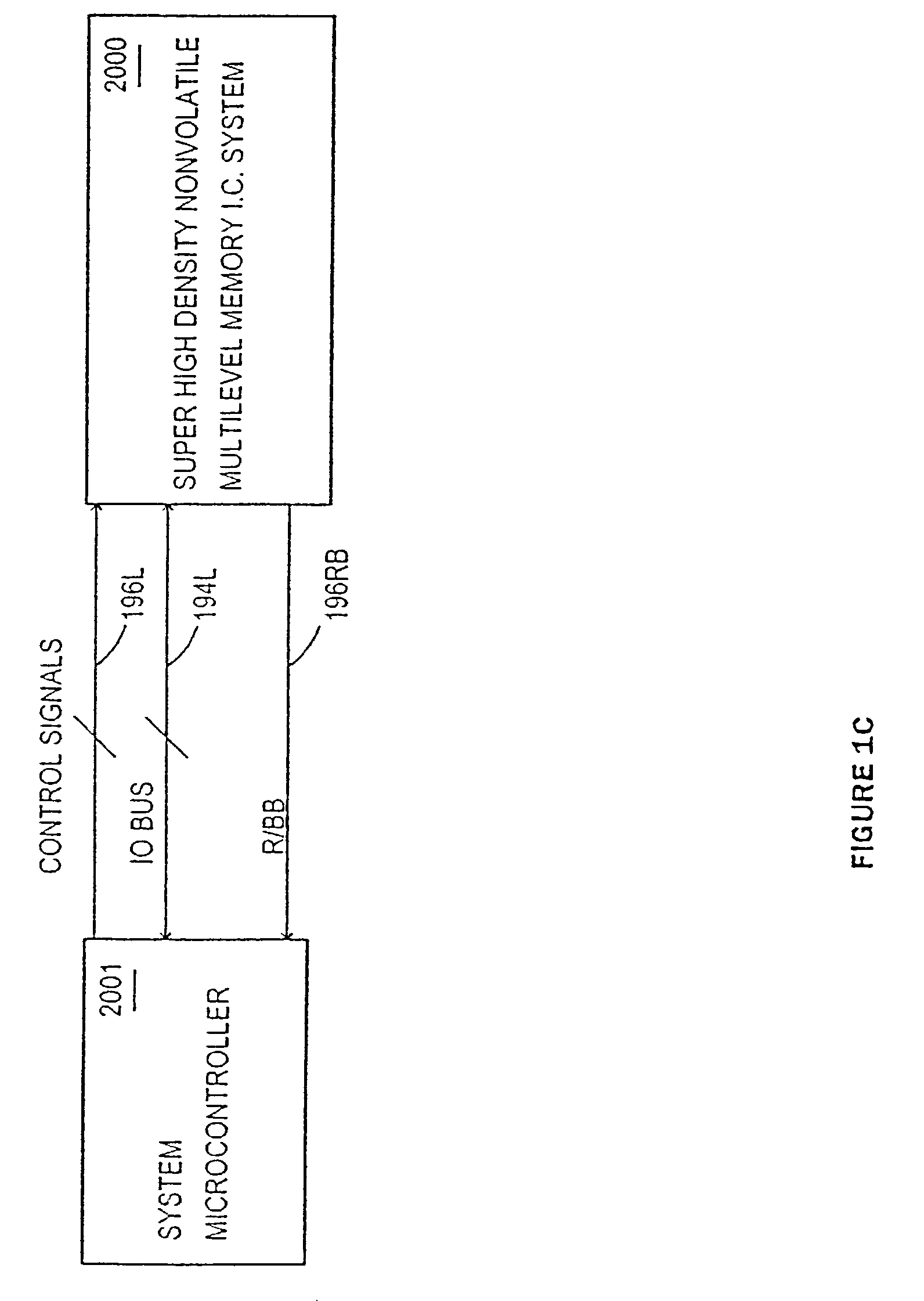

Digital multilevel memory system having multistage autozero sensing

A digital multibit non-volatile memory integrated system includes autozero multistage sensing. One stage may provide local sensing with autozero. Another stage may provide global sensing with autozero. A twisted bitline may be used for array arrangement. Segment reference may be used for each segment. The system may read data cells using a current sensing one or two step binary search. The system may use inverse voltage mode or inverse current mode sensing. The system may use no current multilevel sensing. The system may use memory cell replica sensing. The system may use dynamic sensing. The system may use built-in byte redundancy. Sense amplifiers capable of sub-volt (<<1V) sensing are described.

Owner:SILICON STORAGE TECHNOLOGY

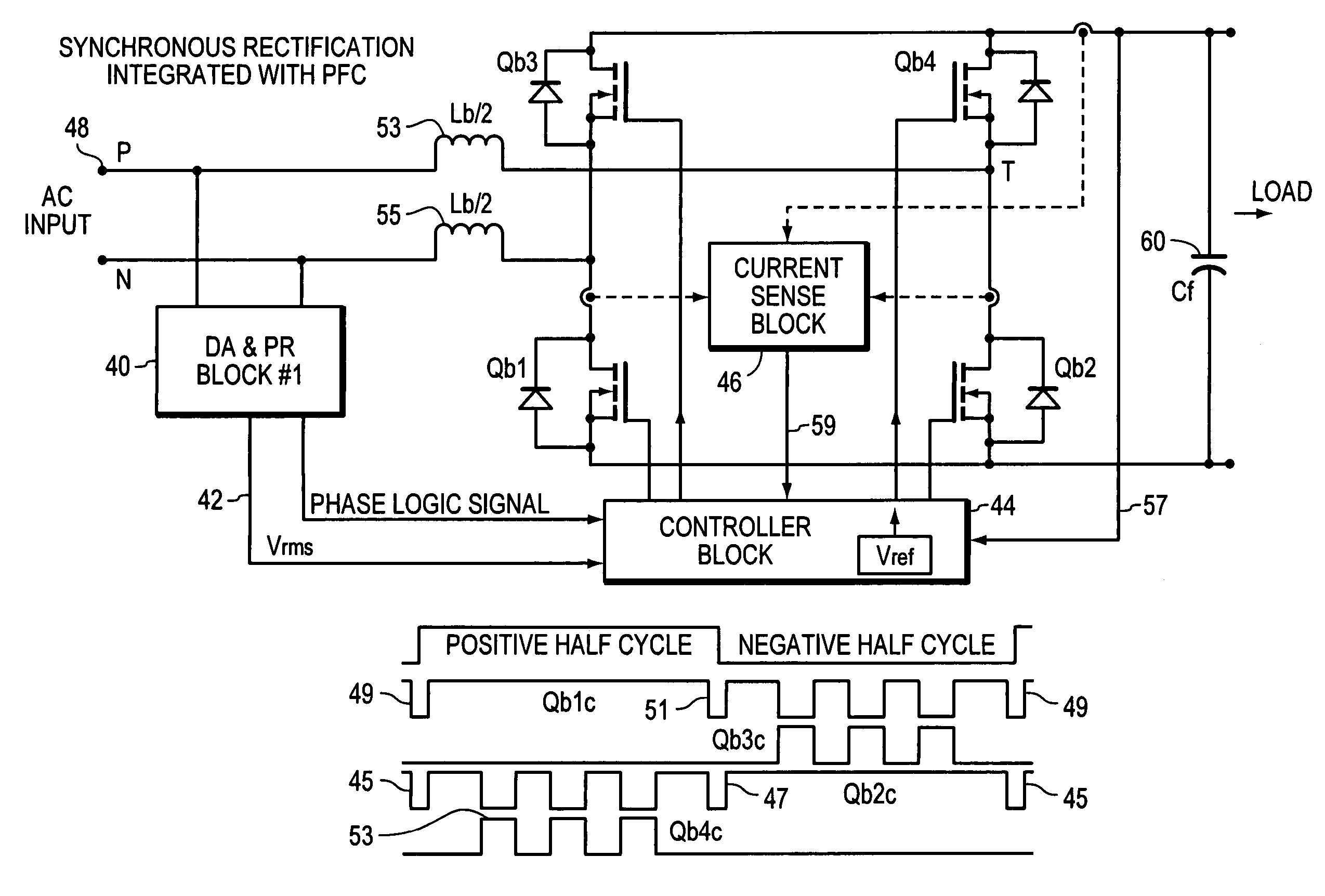

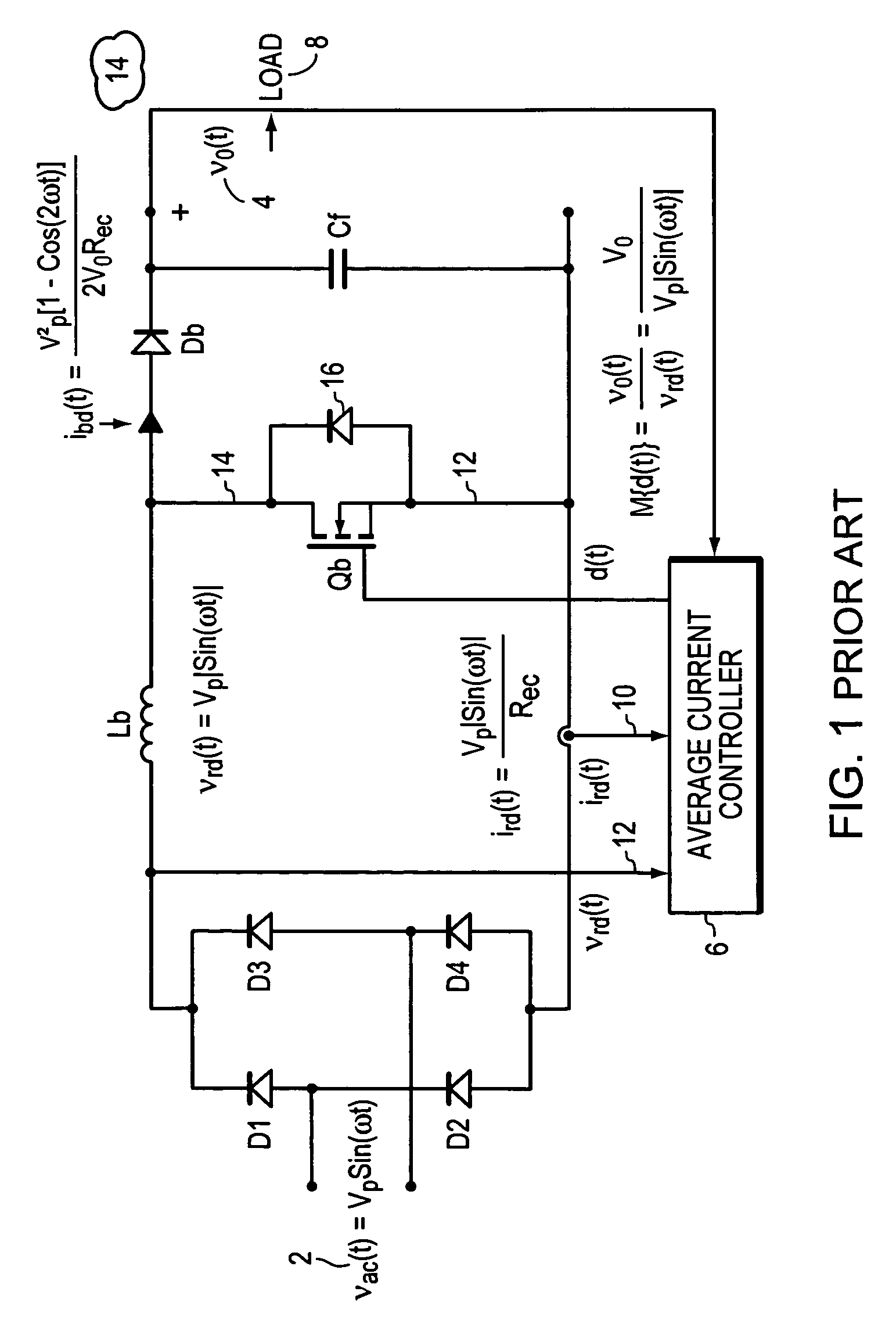

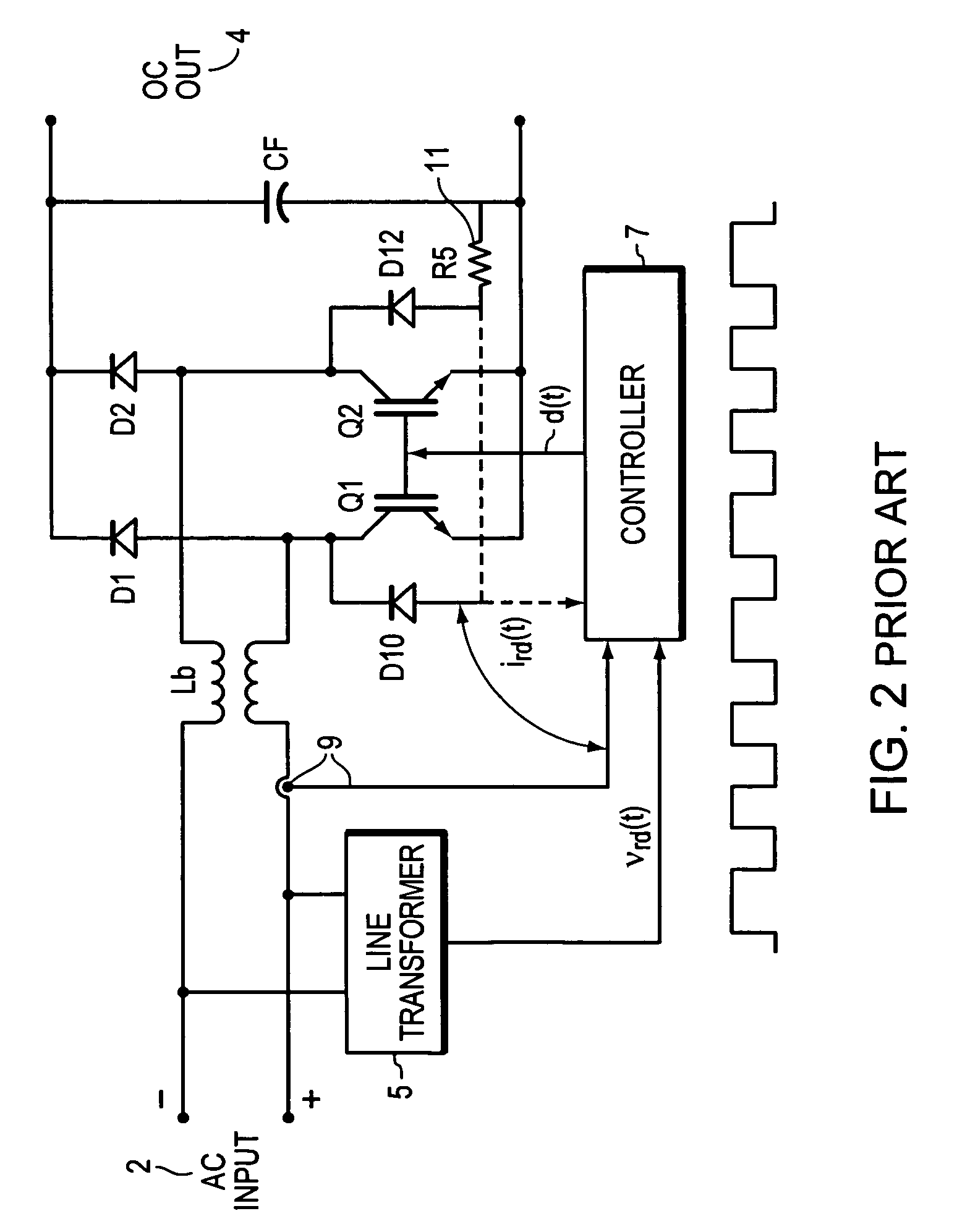

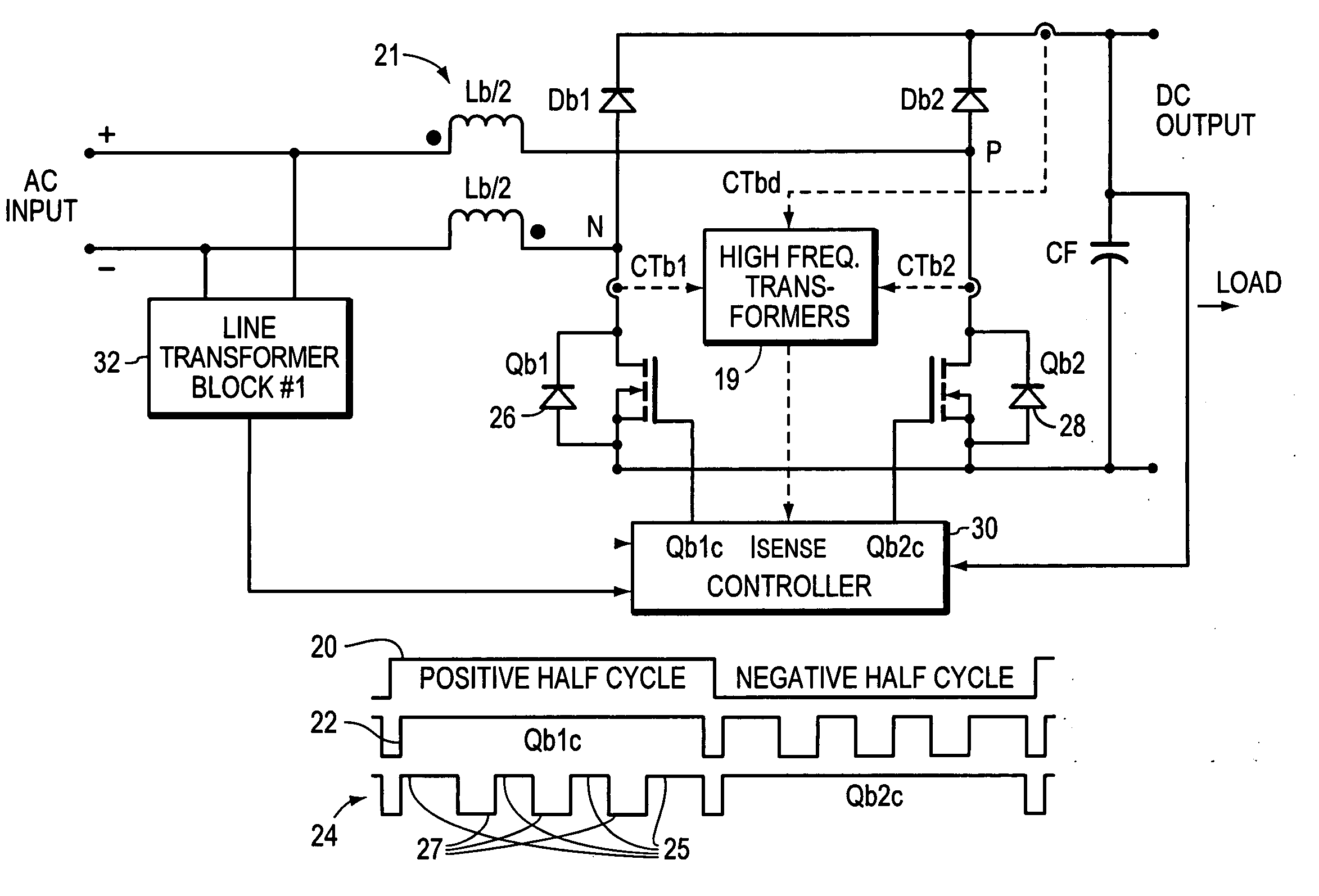

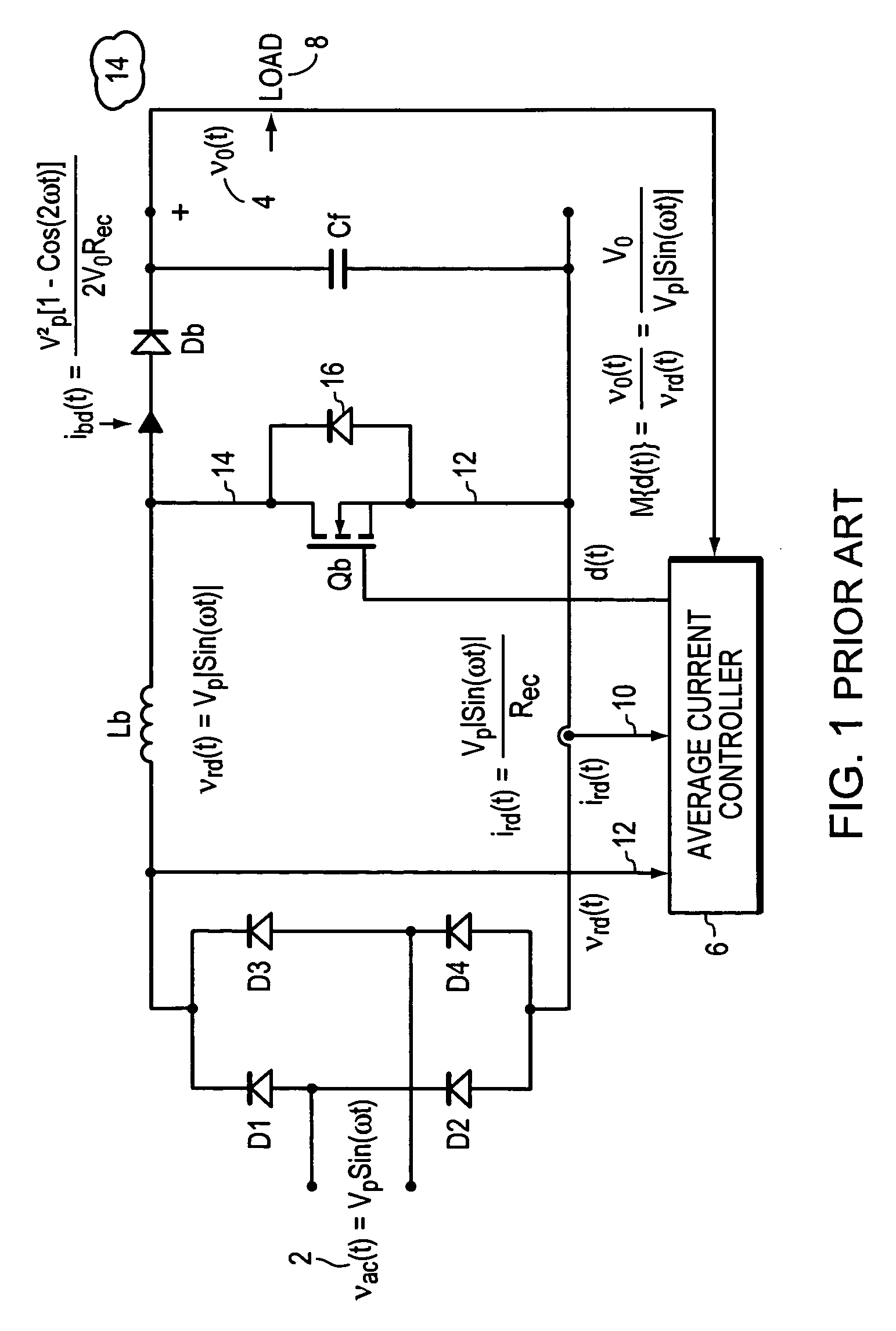

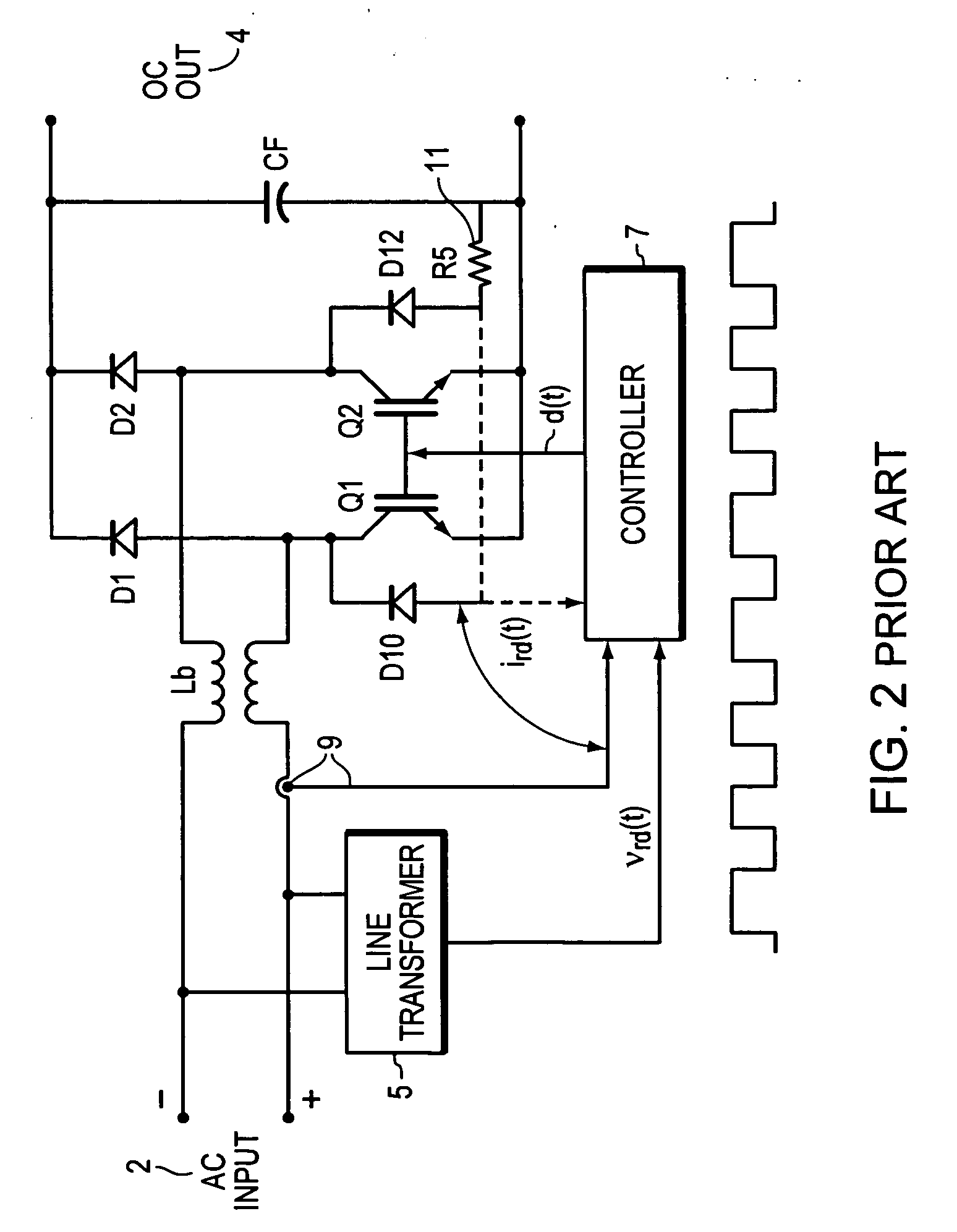

Vrms and rectified current sense full-bridge synchronous-rectification integrated with PFC

ActiveUS7269038B2Ac-dc conversion without reversalEfficient power electronics conversionMOSFETFull bridge

A synchronous full bridge rectifier is controlled to provide a power factor near unity. The full bridge rectifiers are transistors each with a controlling input. The AC input signal and currents within the circuit are sensed and sent to a controller. In response, the controller output control signals to turn on / off the rectifying MOSFETS on a timely basis to form a power factor of near one with respect to the AC input signal. The full wave rectifier is made of N-channel MOSFET's, some with fast body diodes. The MOSFET's are rectifiers and PFC control elements. The result is a one stage synchronous rectifier with PFC. A solid state precision analog differential amplifier senses the AC line waveform and high frequency current transformers sense the currents. The controller accepts the inputs of the amplifier and the sensed currents and outputs control signals that turn on and off the four MOSFET's. The timing of turning on / off is arranged so that the current drawn from the AC source is sinusoidal and matches the phase of the sinusoidal AC source.

Owner:SEMICON COMPONENTS IND LLC

Vrms and rectified current sense full-bridge synchronous-rectification integrated with PFC

ActiveUS20070058402A1Ac-dc conversion without reversalEfficient power electronics conversionMOSFETPower factor

A synchronous full bridge rectifier is controlled to provide a power factor near unity. The full bridge rectifiers are transistors each with a controlling input. The AC input signal and currents within the circuit are sensed and sent to a controller. In response, the controller output control signals to turn on / off the rectifying MOSFETS on a timely basis to form a power factor of near one with respect to the AC input signal. The full wave rectifier is made of N-channel MOSFET's, some with fast body diodes. The MOSFET's are rectifiers and PFC control elements. The result is a one stage synchronous rectifier with PFC. A solid state precision analog differential amplifier senses the AC line waveform and high frequency current transformers sense the currents. The controller accepts the inputs of the amplifier and the sensed currents and outputs control signals that turn on and off the four MOSFET's. The timing of turning on / off is arranged so that the current drawn from the AC source is sinusoidal and matches the phase of the sinusoidal AC source.

Owner:SEMICON COMPONENTS IND LLC

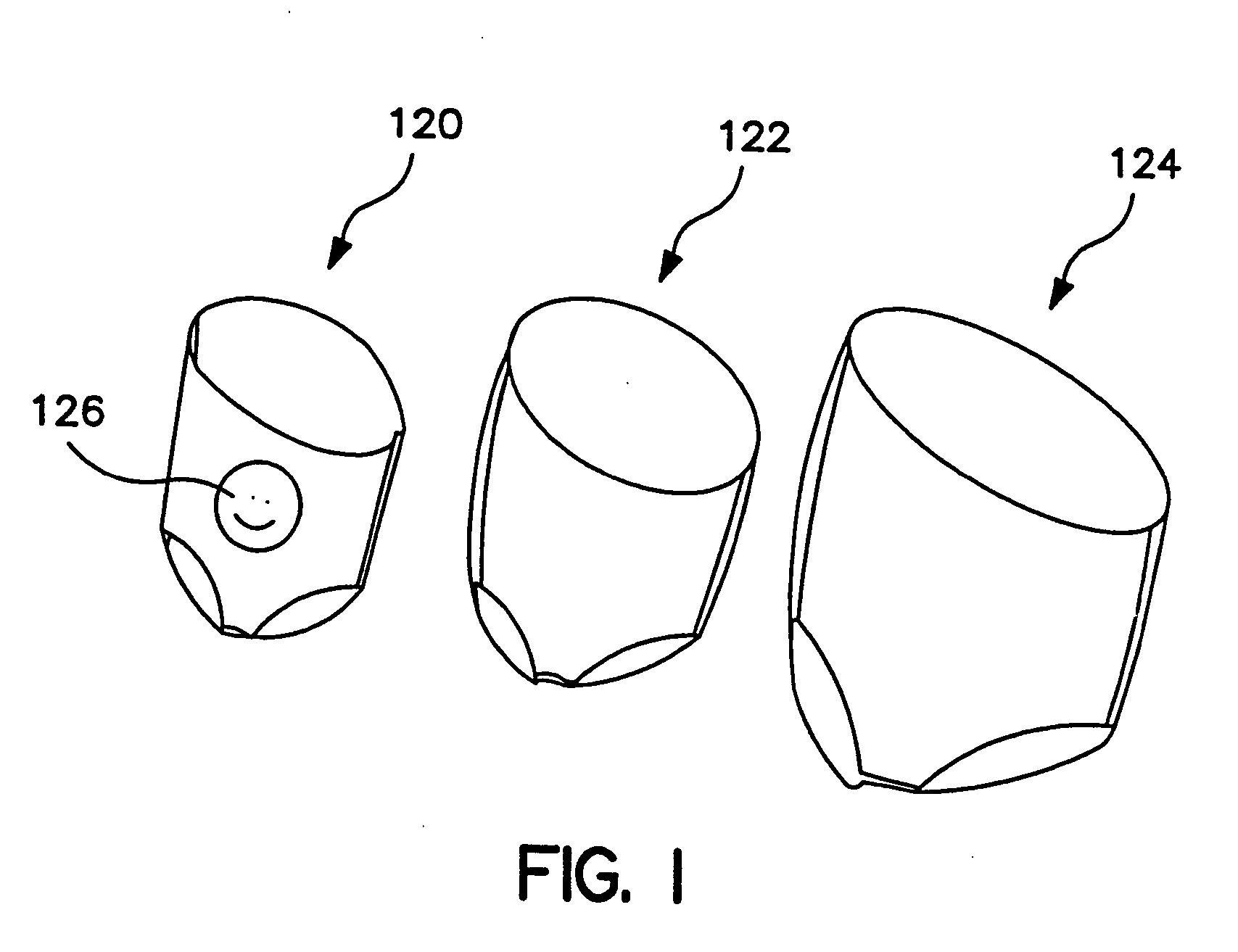

Surgical fasteners, applicator instruments, and methods for deploying surgical fasteners

ActiveUS20100292713A1Easy to collapseImprove abilitiesSuture equipmentsStapling toolsEngineeringSurgical Fasteners

A firing system for an applicator instrument adapted to dispense surgical fasteners includes a housing, an elongated shaft extending from the housing, a firing rod disposed within the elongated shaft, a firing rod release engageable with the firing rod for preventing distal movement of the firing rod during at least one stage of a firing cycle, a trigger mounted to the housing, and a firing spring having a first end connected with the firing rod and a second end adapted for being sequentially coupled and decoupled from the trigger during the firing cycle. The firing cycle includes an initial stage in which the trigger is open and decoupled from the energy storing element, and the firing spring is at least partially compressed, and a piloting stage during which the firing rod release is disengaged from the firing rod for enabling distal movement of the firing rod.

Owner:ETHICON INC

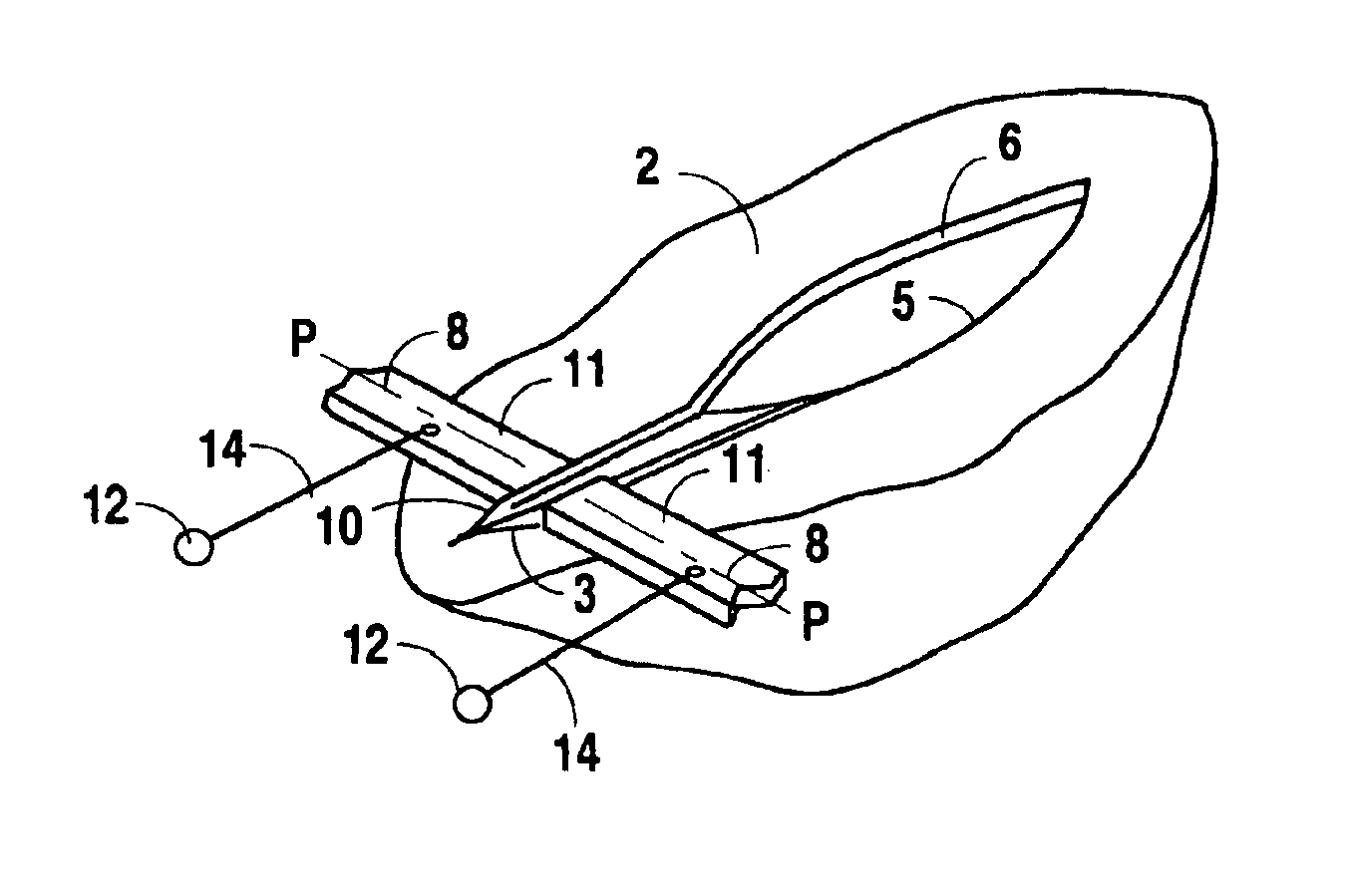

Bonding of soft biological tissues by passing high frequency electric current therethrough

InactiveUS7025764B2Avoid stickingAvoid burnsDiagnosticsSurgical instruments for heatingForcepsEngineering

Technique for bonding soft biological tissue having an incision therein with forceps adapted to grip a portion of tissue on both sides of incision. Electrodes are secured to forceps for contracting the tissue portion. An electrical power source provides a high frequency electrical signal to electrodes to be passed through the tissue portion. The electrical power source is controlled to provide electrodes with one voltage signal during a first of two stages, wherein the voltage rises linearly, and another voltage signal during a second of the two stages, wherein the voltage is stabilized and modulated with a low frequency rectangular signal. A clamping means applies force with the forceps to compress the tissue at one or different levels during two time periods while the high frequency voltage is passed through the electrodes. The tissue impedance is measured as a function of time, with its minimal value being determined and stored.

Owner:BIOFUSE MEDICAL TECH +1

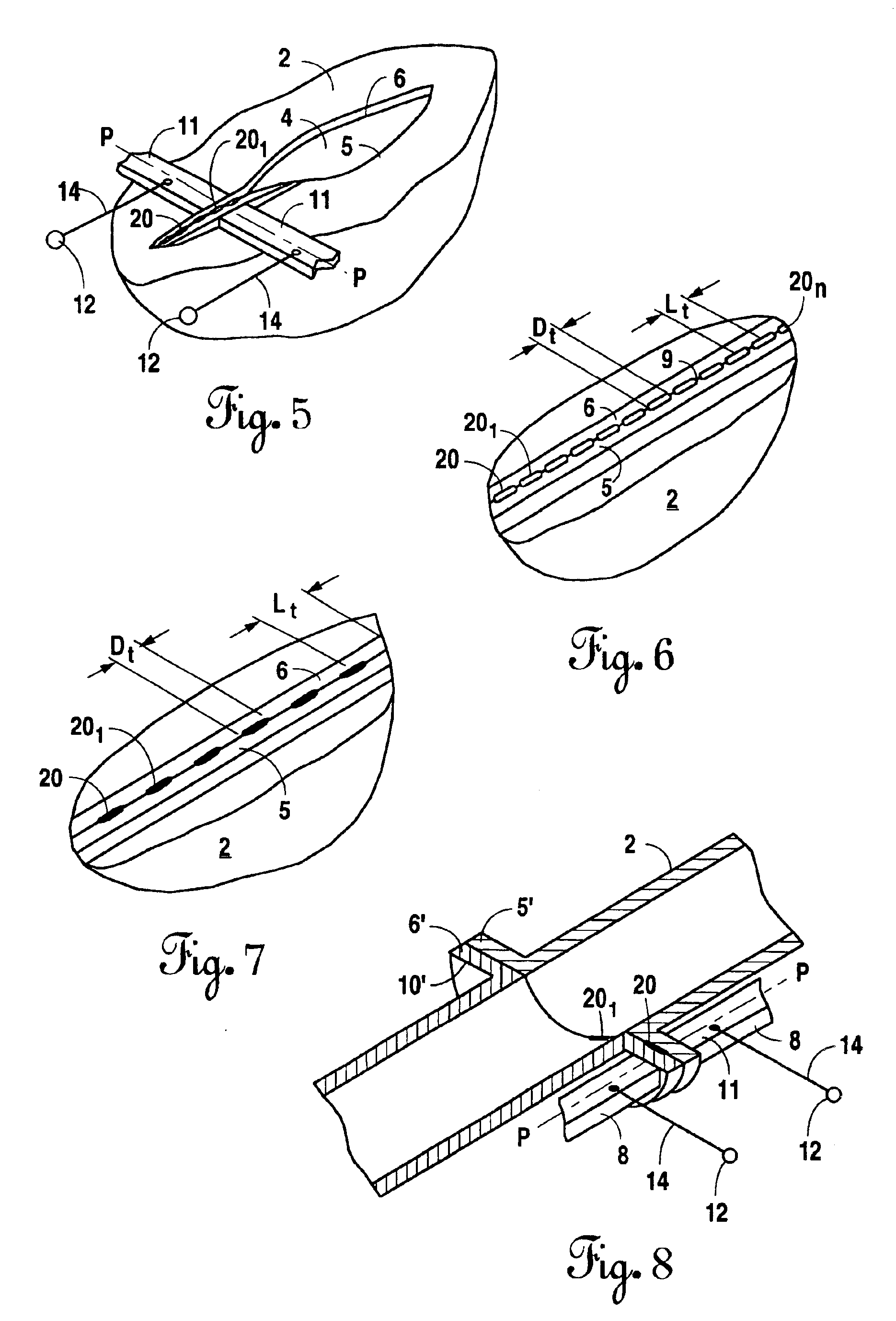

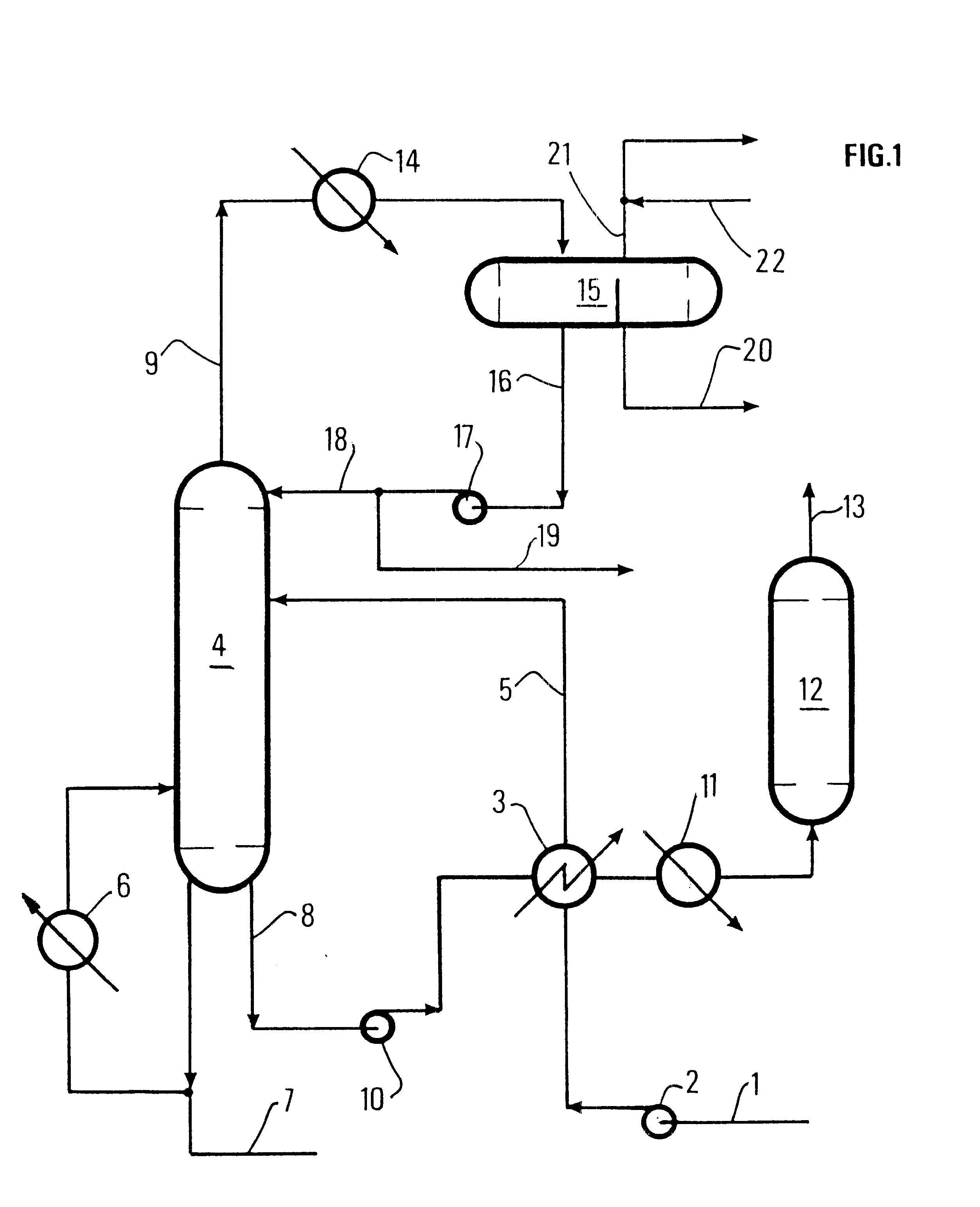

Process for the production of synthesis gas with conversion of CO2 into hydrogen

ActiveUS7846979B2Useful thermal recovery on the gasification effluentCombustible gas chemical modificationProductsSteam reformingPartial oxidation

Process for the production of liquid hydrocarbons from a feedstock that comprises at least one elementary feedstock from the group of biomass, coal, lignite, petroleum residues, methane, and natural gas, comprising: at least one stage a) for gasification of the feedstock by partial oxidation and / or steam reforming to produce a synthesis gas SG; a stage b) for separating CO2 from SG and a portion of the effluent of the subsequent stage c); the mixing of a portion of the CO2 that is separated with a gas of an H2 / CO ratio of more than 3; a stage c) for partial conversion with hydrogen, thermal or thermocatalytic, of the CO2 that is present in said first mixture according to the reaction: CO2+H2→CO+H2O in a specific reaction zone that is separated from said gasification zone or zones; a stage d) for Fisher-Tropsch synthesis on a synthesis gas that comprises at least a portion of SG and at least a portion of the CO that is produced by the conversion of CO2 into hydrogen.

Owner:INST FR DU PETROLE

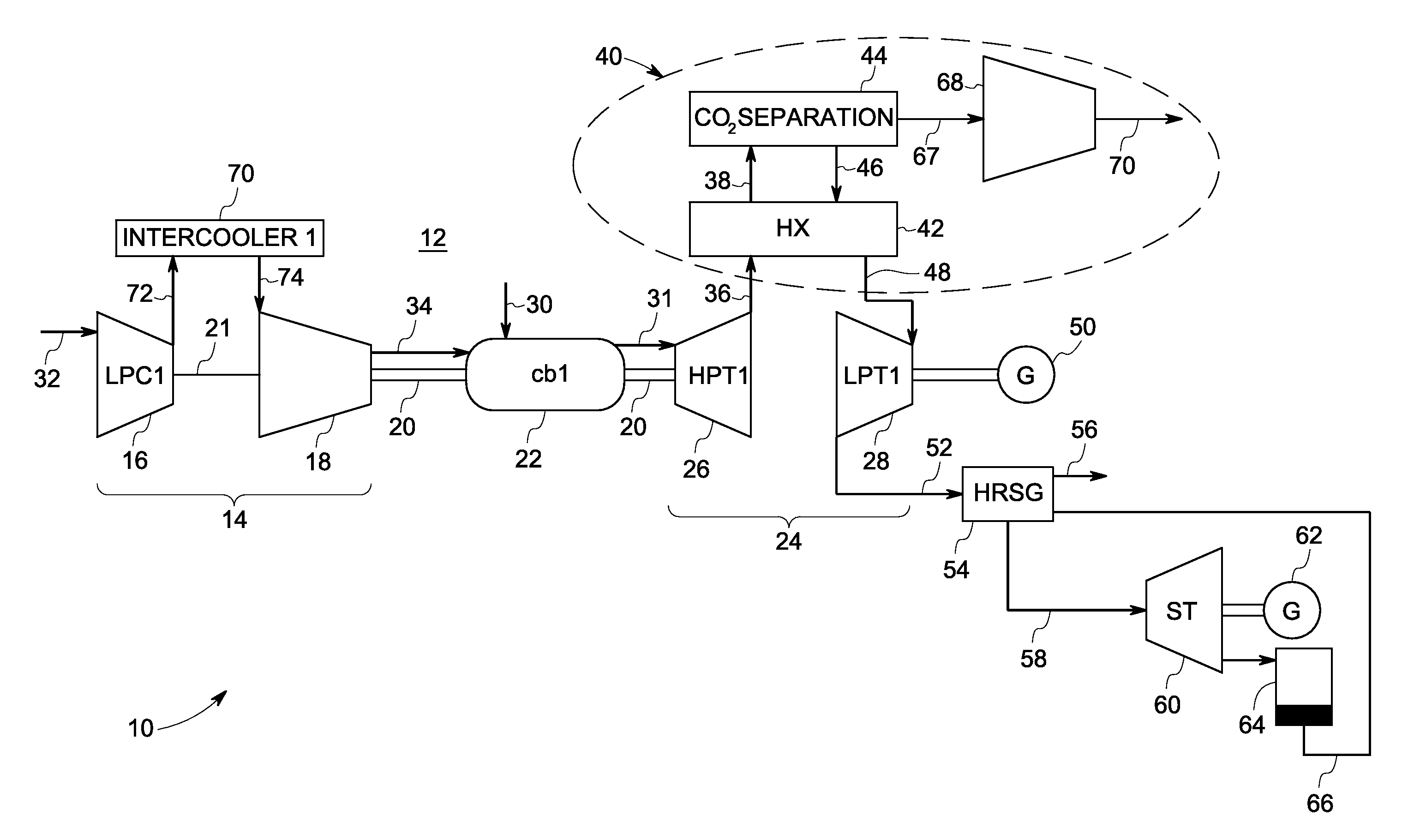

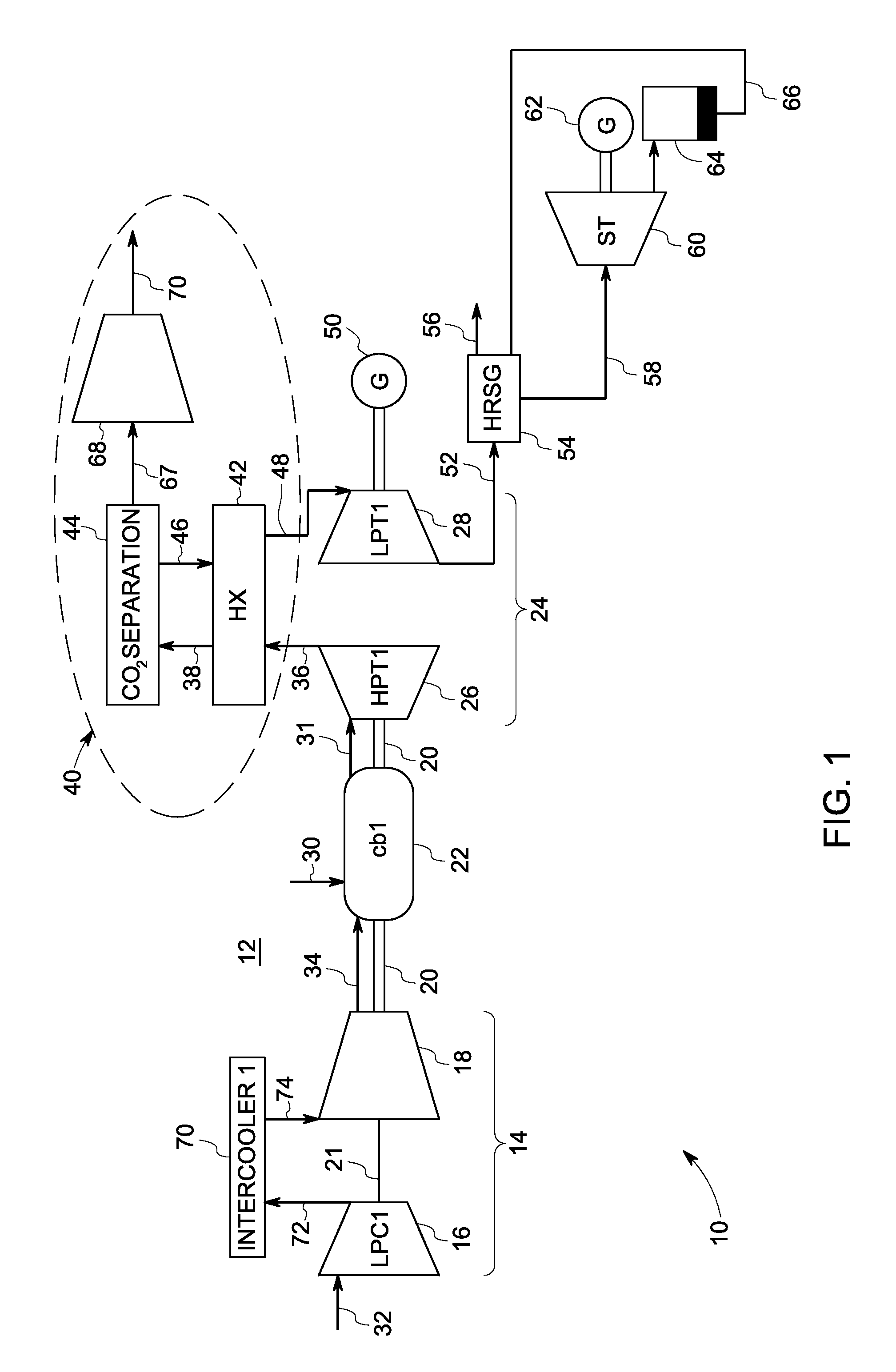

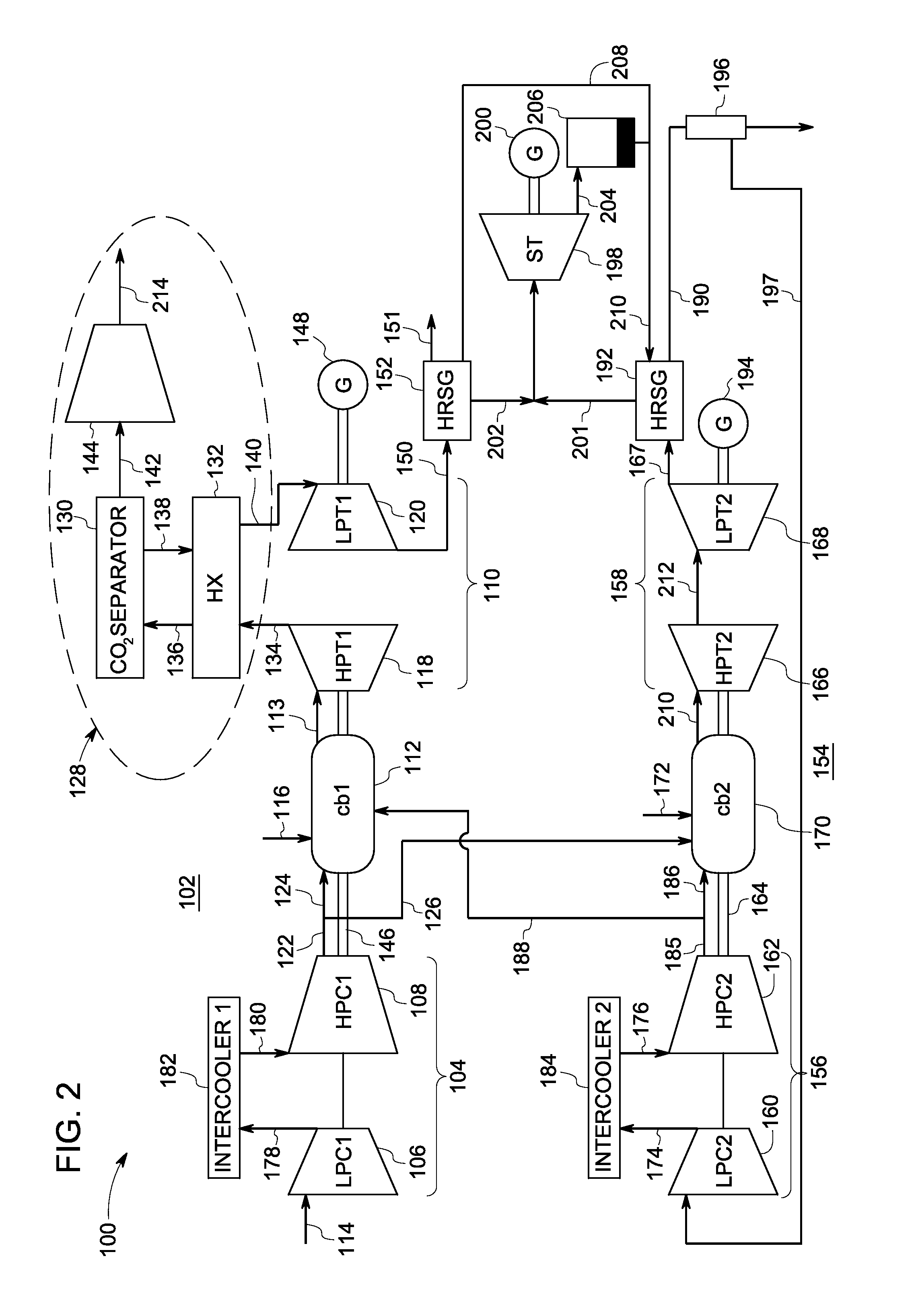

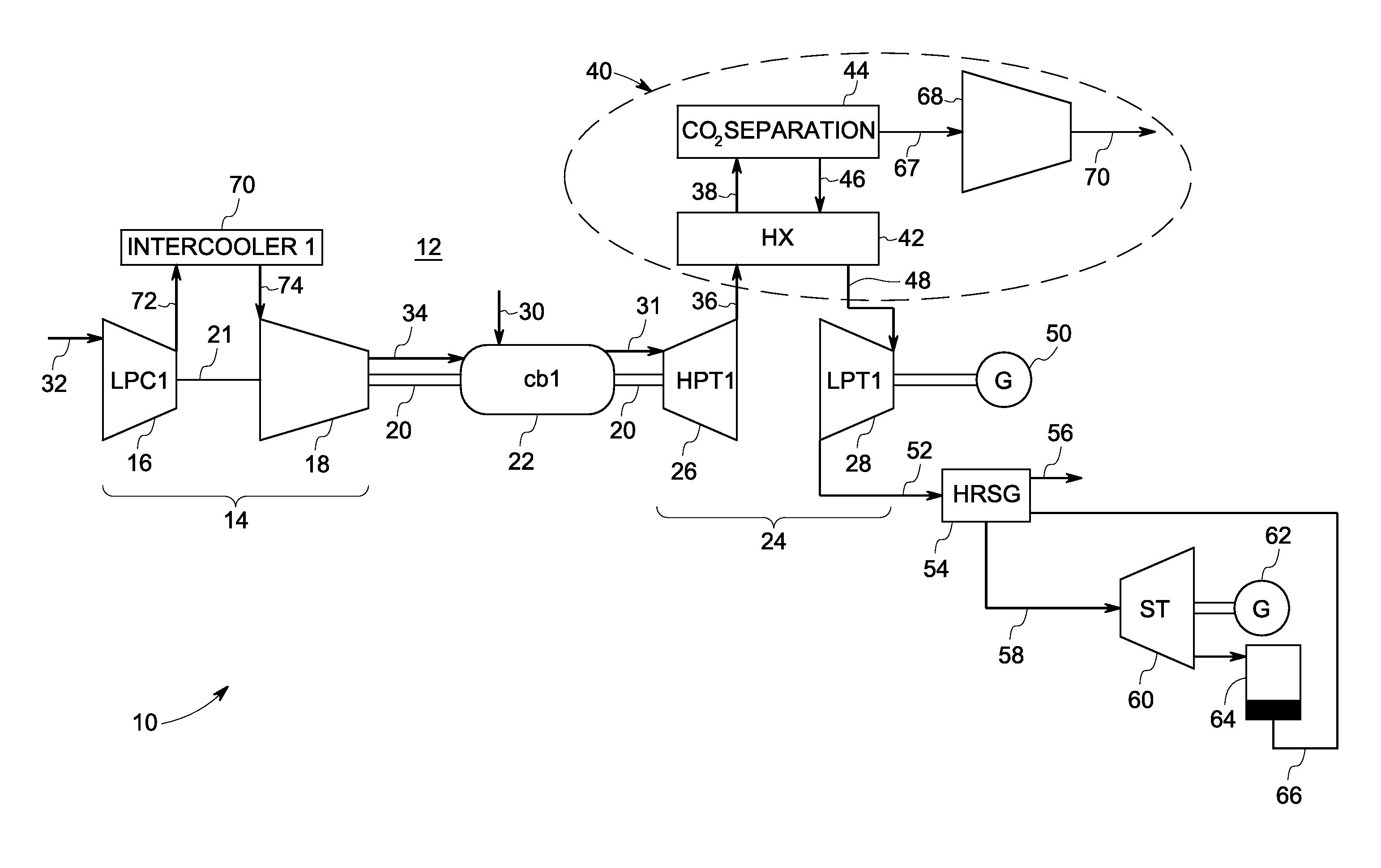

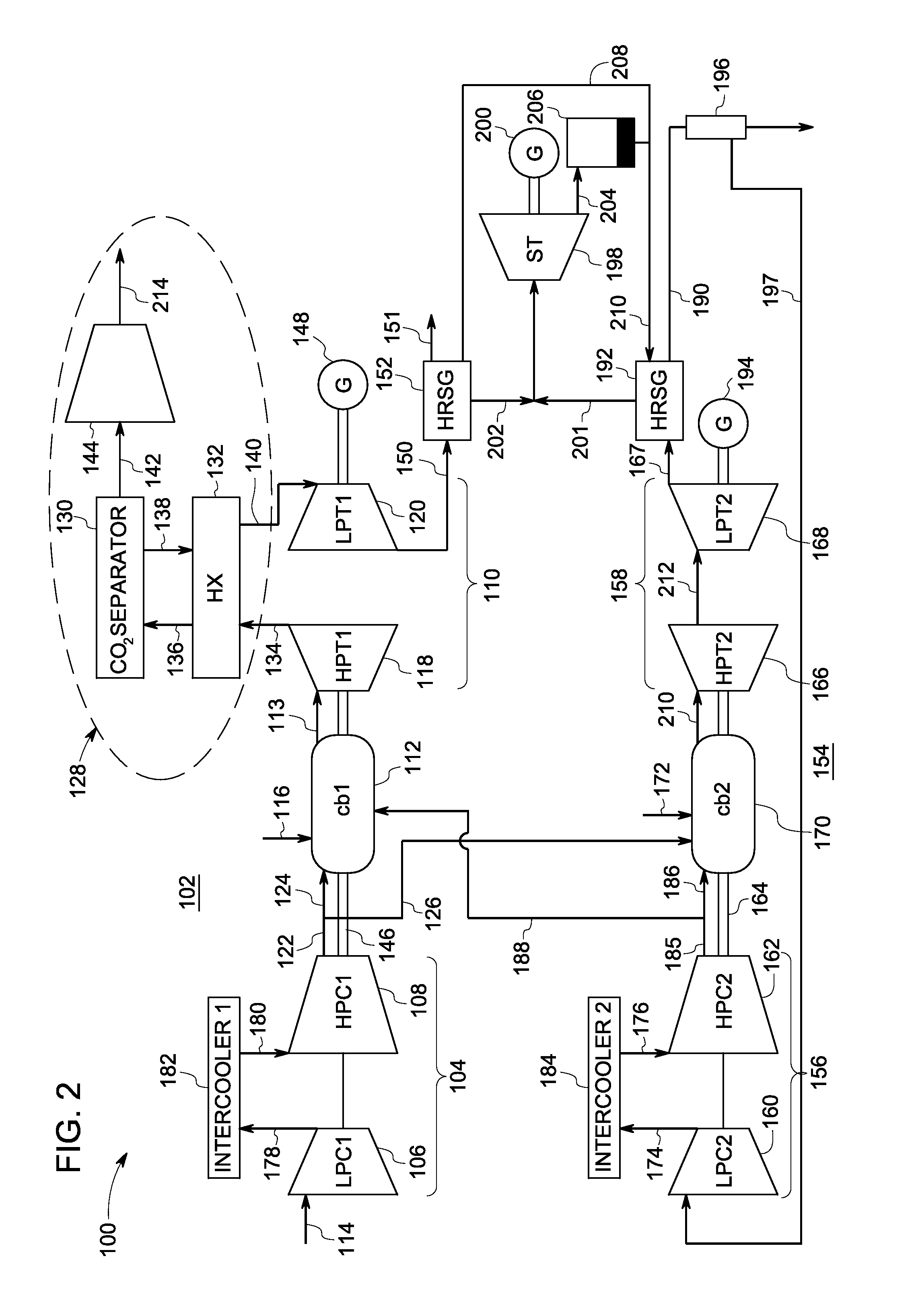

Systems and methods for power generation with carbon dioxide isolation

InactiveUS20080104939A1Dispersed particle separationGas turbine plantsCombustion chamberHigh pressure

A power generation system includes at least one turbine system. The turbine system includes a compressor section comprising at least one stage, configured to supply a compressed oxidant and a combustion chamber configured to combust the compressed oxidant and a fuel stream comprising carbon-based fuels and to generate a hot flue gas. The turbine system further includes an expander section having an inlet for receiving the hot flue gas comprising at least two stages. The two stages include a high-pressure expander configured to generate an expanded exhaust gas rich in CO2. The high-pressure expander fluidly coupled to a low-pressure expander configured to generate a final exhaust and electrical energy. A CO2 separation system is fluidly coupled to the high-pressure expander for receiving the expanded exhaust gas from the high-pressure expander and providing a CO2 lean gas that is then fed to the low-pressure expander.

Owner:GENERAL ELECTRIC CO

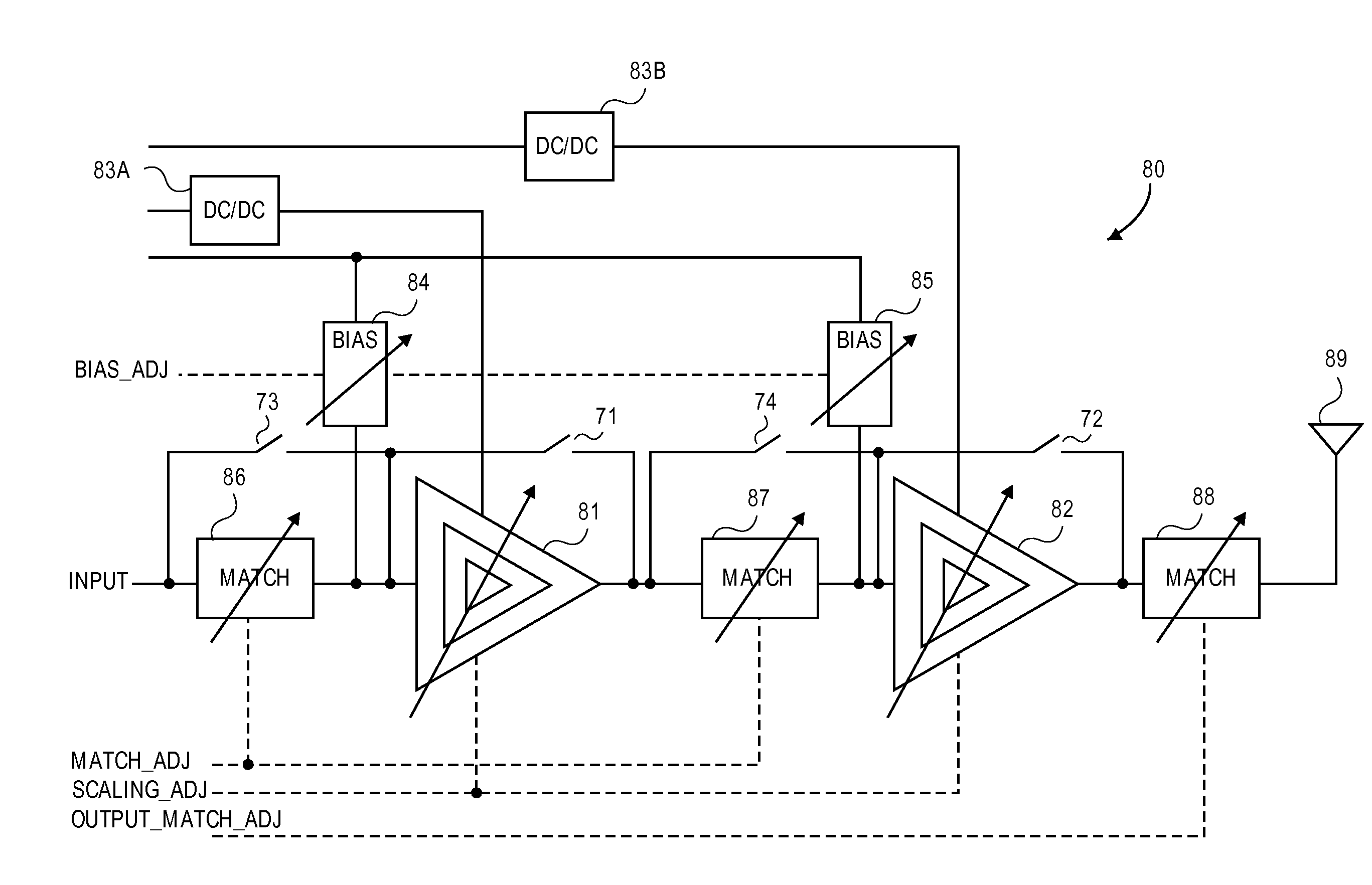

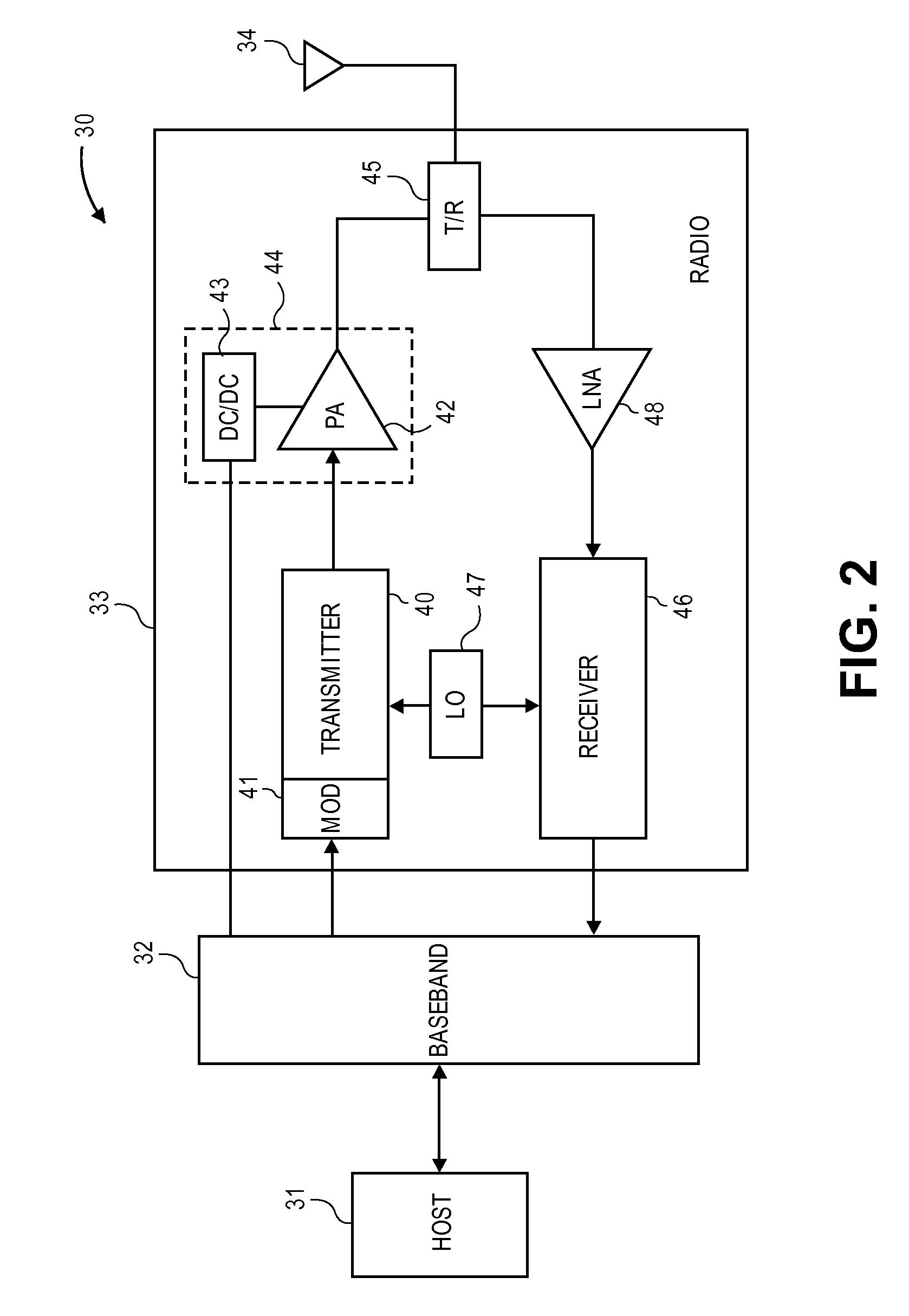

Dynamic stability, gain, efficiency and impedance control in a linear/non-linear CMOS power amplifier

A power amplifier (PA) provides dynamic stability and gain control for linear and non-linear operation. The PA operates with a baseband processor and a transmitter, in which the PA receives a signal from the transmitter for power amplification prior to transmission of the signal. The PA is configured to select between the linear mode of operation and the non-linear mode of operation, in which device scaling within the PA is achieved by changing a device sizing of at least one stage of the PA. Further to changing the device size, the PA changes biasing resistance and impedance of a matching network in response to the changing of the device size to control power output and stability for the PA.

Owner:AVAGO TECH INT SALES PTE LTD

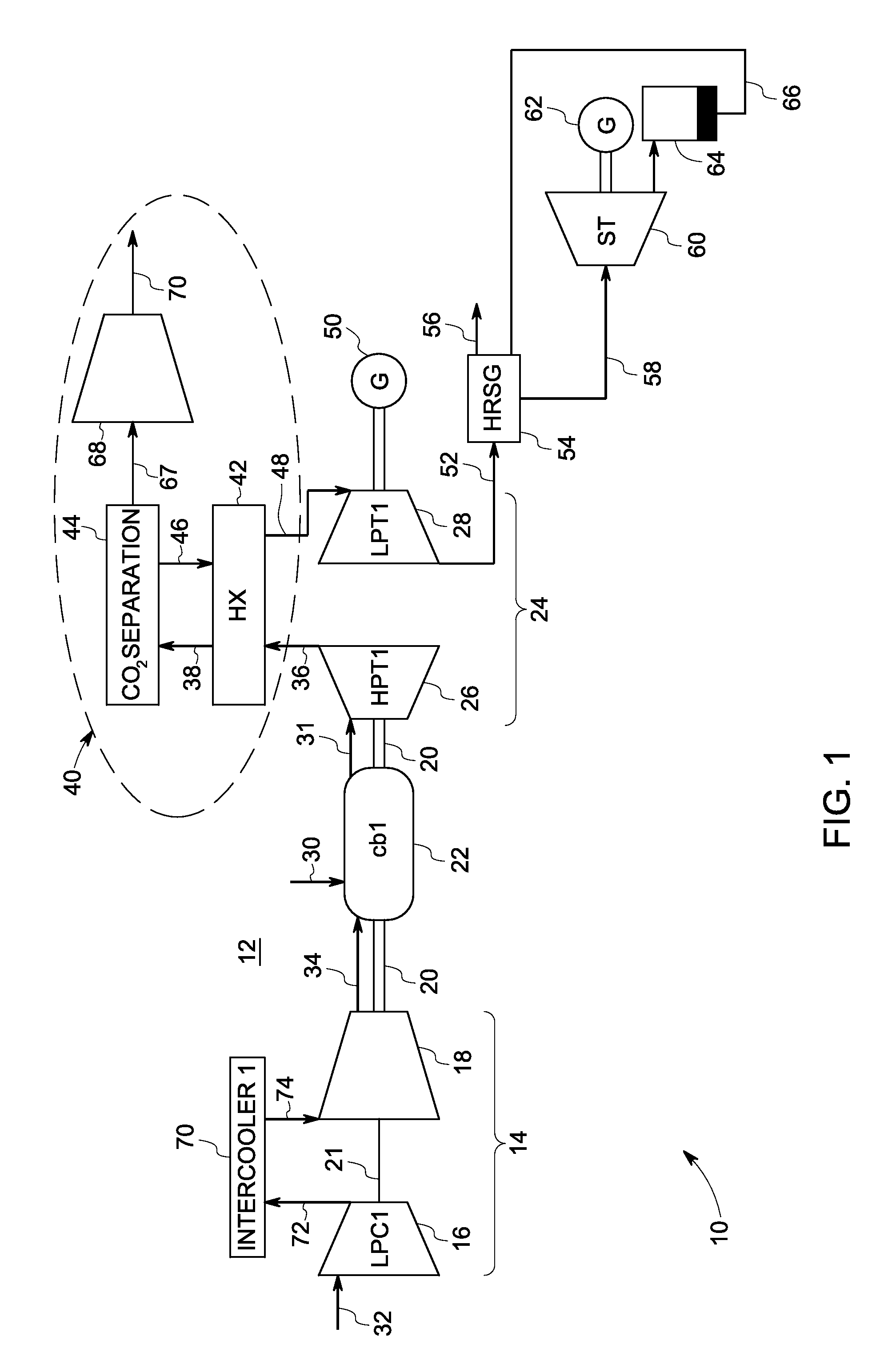

Systems and methods for power generation with carbon dioxide isolation

A power generation system includes at least one turbine system. The turbine system includes a compressor section comprising at least one stage, configured to supply a compressed oxidant and a combustion chamber configured to combust the compressed oxidant and a fuel stream comprising carbon-based fuels and to generate a hot flue gas. The turbine system further includes an expander section having an inlet for receiving the hot flue gas comprising at least two stages. The two stages include a high-pressure expander configured to generate an expanded exhaust gas rich in CO2. The high-pressure expander fluidly coupled to a low-pressure expander configured to generate a final exhaust and electrical energy. A CO2 separation system is fluidly coupled to the high-pressure expander for receiving the expanded exhaust gas from the high-pressure expander and providing a CO2 lean gas that is then fed to the low-pressure expander.

Owner:GENERAL ELECTRIC CO

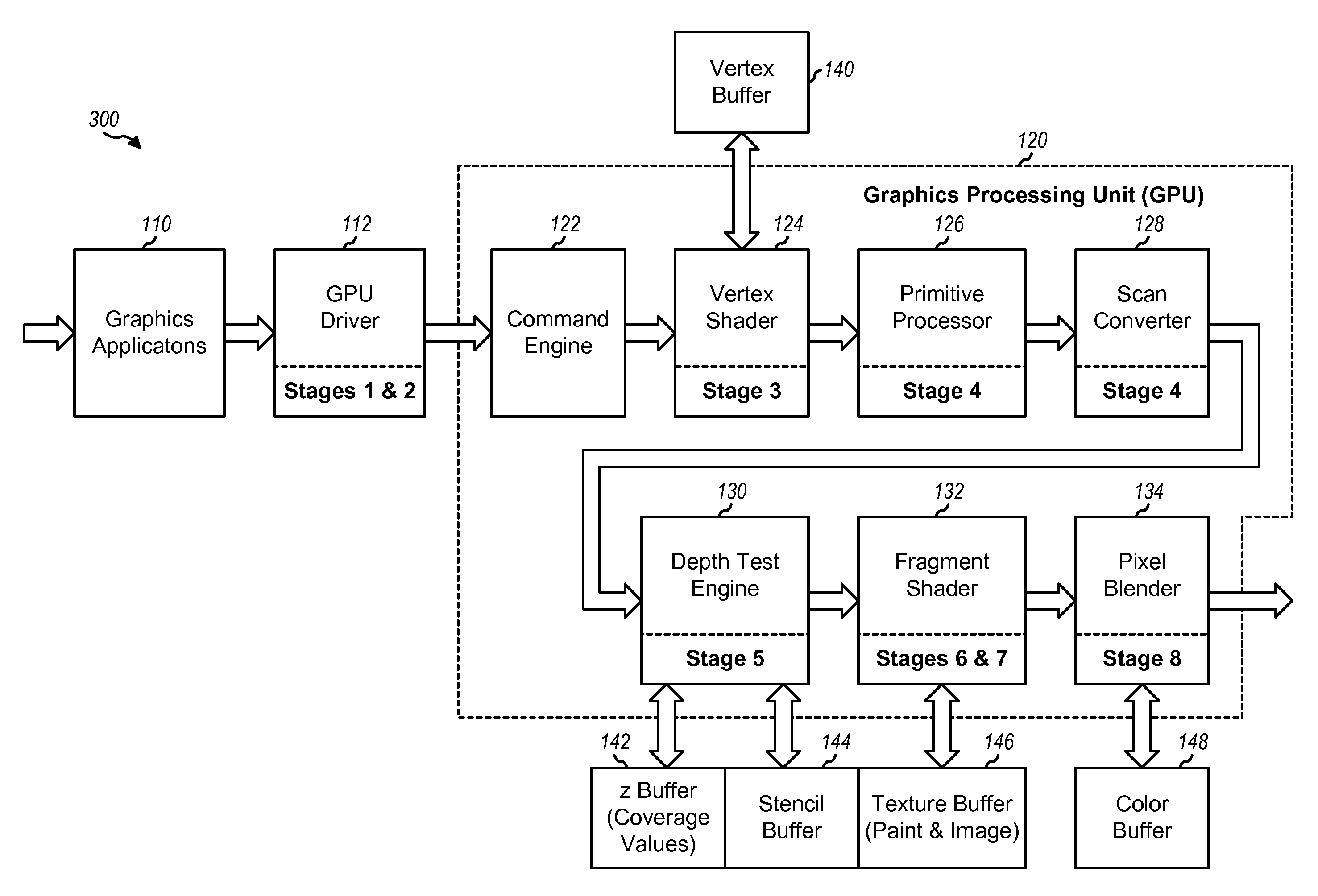

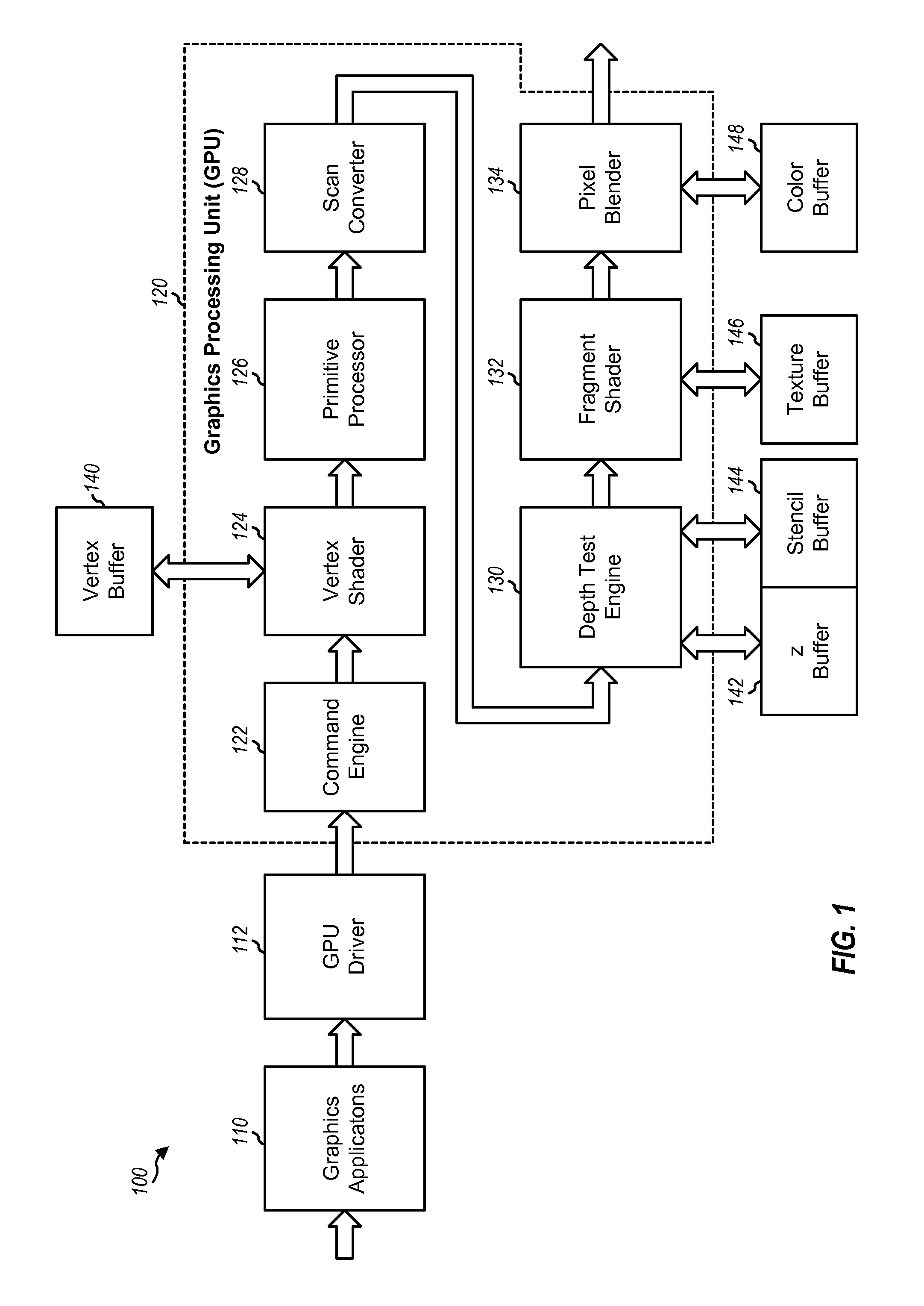

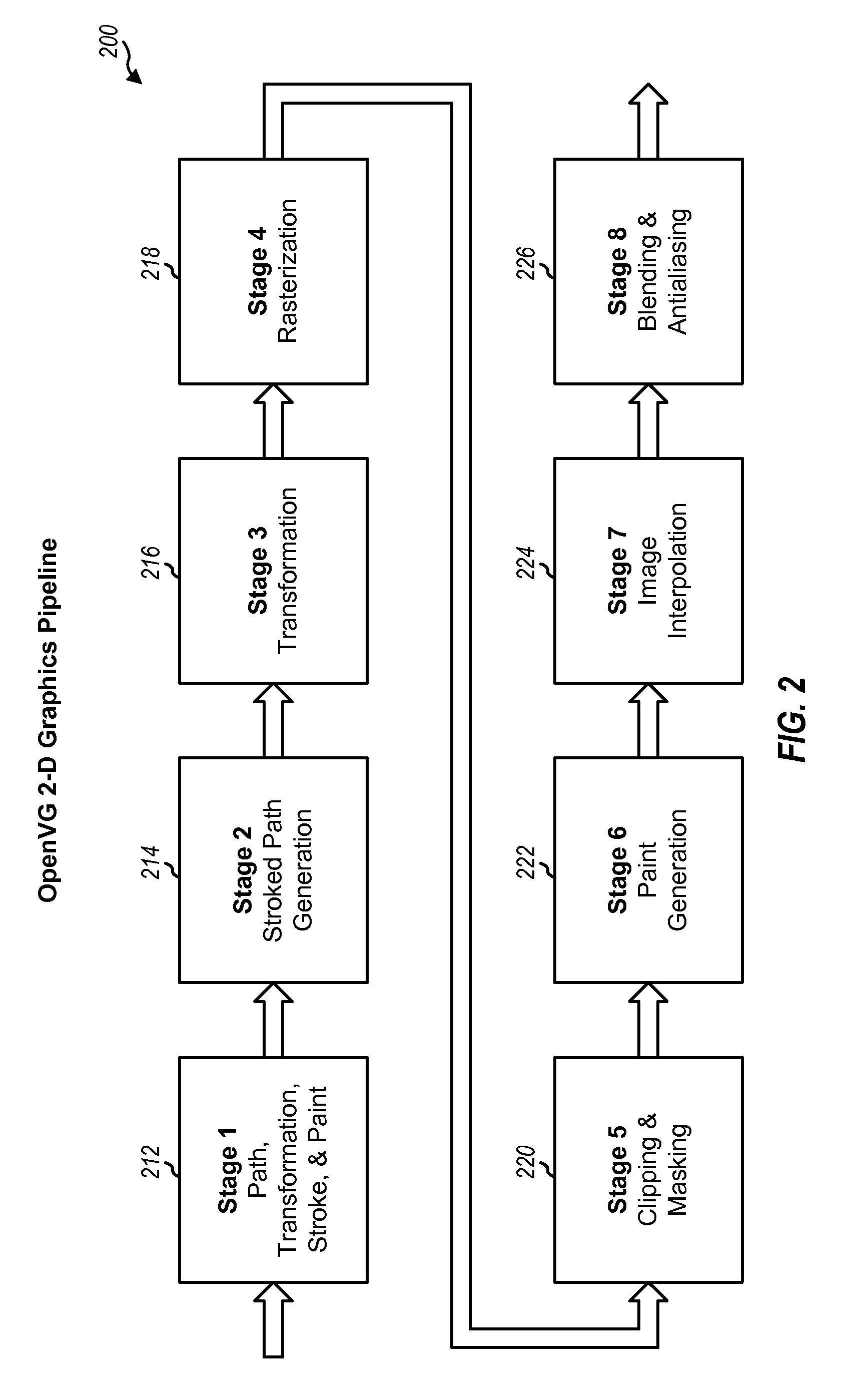

Efficient 2-d and 3-d graphics processing

ActiveUS20080198168A1Easy to useEffective supportDigital computer detailsCathode-ray tube indicatorsComputational scienceGraphics processing unit

Techniques for supporting both 2-D and 3-D graphics are described. A graphics processing unit (GPU) may perform 3-D graphics processing in accordance with a 3-D graphics pipeline to render 3-D images and may also perform 2-D graphics processing in accordance with a 2-D graphics pipeline to render 2-D images. Each stage of the 2-D graphics pipeline may be mapped to at least one stage of the 3-D graphics pipeline. For example, a clipping, masking and scissoring stage in 2-D graphics may be mapped to a depth test stage in 3-D graphics. Coverage values for pixels within paths in 2-D graphics may be determined using rasterization and depth test stages in 3-D graphics. A paint generation stage and an image interpolation stage in 2-D graphics may be mapped to a fragment shader stage in 3-D graphics. A blending stage in 2-D graphics may be mapped to a blending stage in 3-D graphics.

Owner:QUALCOMM INC

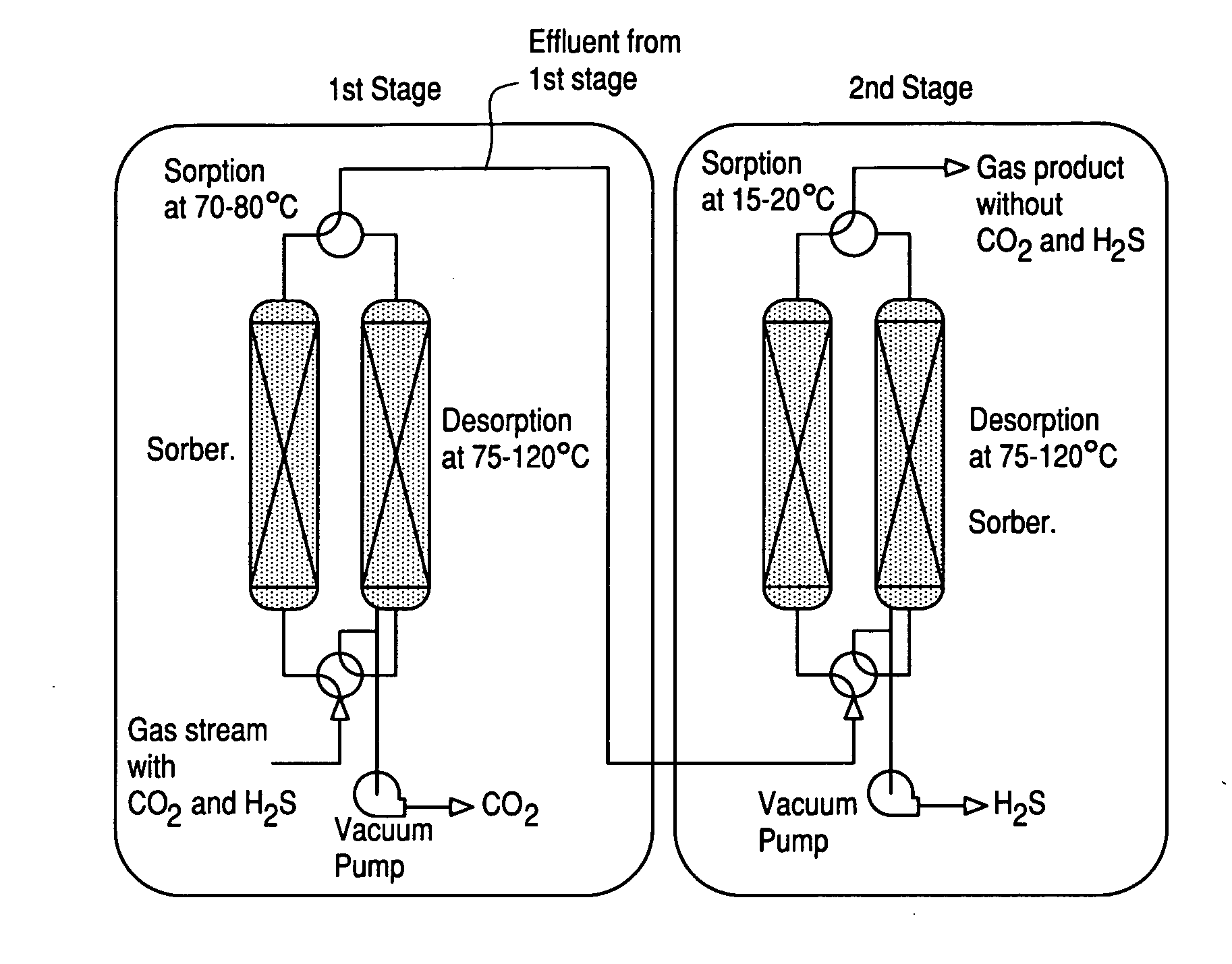

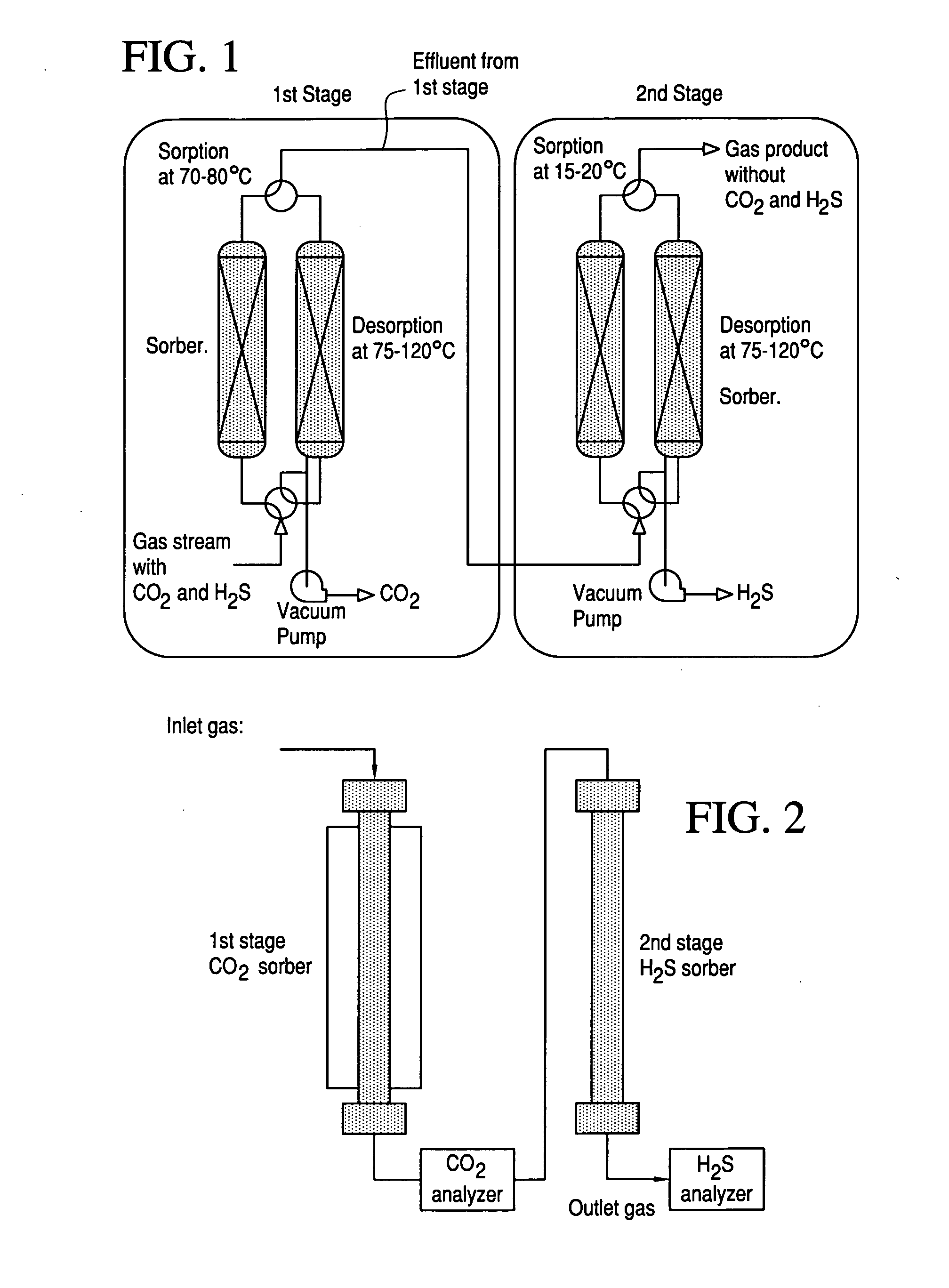

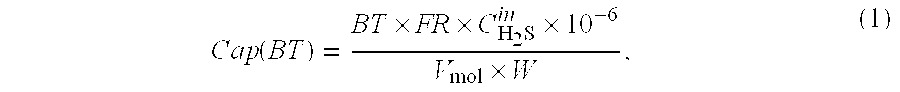

Novel sorbents and purification and bulk separation of gas streams

InactiveUS20080264254A1Large capacityLittle and no corrosive effectNitrous oxide captureGas treatmentSorbentDesorption

Porous-material-supported polymer sorbents and process for removal of undesirable gases such as H2S, COS, CO2, N2O, NO, NO2, SO2, SO3, HCl, HF, HCN, NH3, H2O, C2H5OH, CH3OH, HCHO, CHCl3, CH2Cl2, CH3Cl, CS2, C4H4S, CH3SH, and CH3—S—CH3 from various gas streams such as natural gas, coal / biomass gasification gas, biogas, landfill gas, coal mine gas, ammonia syngas, H2 and oxo-syngas, Fe ore reduction gas, reformate gas, refinery process gases, indoor air, fuel cell anode fuel gas and cathode air are disclosed. The sorbents have numerous advantages such as high breakthrough capacity, high sorption / desorption rates, little or no corrosive effect and are easily regenerated. The sorbents may be prepared by loading H2S—, COS—, CO2—, N2O, NO—, NO2—, SO2—, SO3—, HCl—, HF—, HCN—, NH3—, H2O—, C2H5OH—, CH3OH—, HCHO—, CHCl3—, CH2Cl2—, CH3Cl—, CS2—, C4H4S—, CH3SH—, CH3—S—CH3-philic polymer(s) or mixtures thereof, as well as any one or more of H2S—, COS—, CO2—, N2O, NO—, NO2—, SO2—, SO3—, HCl—, HF—, HCN—, NH3—, H2O—, C2H5OH—, CH3OH—, HCHO—, CHCl3—, CH2Cl2—, CH3Cl—, CS2—, C4H4S—, CH3SH—, CH3—S—CH3-philic compound(s) or mixtures thereof on to porous materials such as mesoporous, microporous or macroporous materials. The sorbents may be employed in processes such as one-stage and multi-stage processes to remove and recover H2S, COS, CO2, N2O, NO, NO2, SO2, SO3, HCl, HF, HCN, NH3, H2O, C2H5OH, CH3OH, HCHO, CHCl3, CH2Cl2, CH3Cl, CS2, C4H4S, CH3SH and CH3—S—CH3 from gas streams by use of, such as, fixed-bed sorbers, fluidized-bed sorbers, moving-bed sorbers, and rotating-bed sorbers.

Owner:PENN STATE RES FOUND +1

Process for the production of purified water and hydrocarbons from fossil resources

InactiveUS6462097B1Reduce adsorbate contentTreatment using aerobic processesIon-exchanger regenerationSorbentPurified water

A process for the production of purified water and hydrocarbons comprising at least one stage of separation of the water and hydrocarbons formed during a Fischer-Tropsch synthesis, at least one stage of purification of the separated water by bringing it into contact with at least one adsorbent selected from the group consisting of: the active carbons, clays which are hydrophobic or rendered hydrophobic, and zeolites which are hydrophobic or rendered hydrophobic. This process may optionally include a stripping stage before the adsorption step.

Owner:INST FR DU PETROLE +2

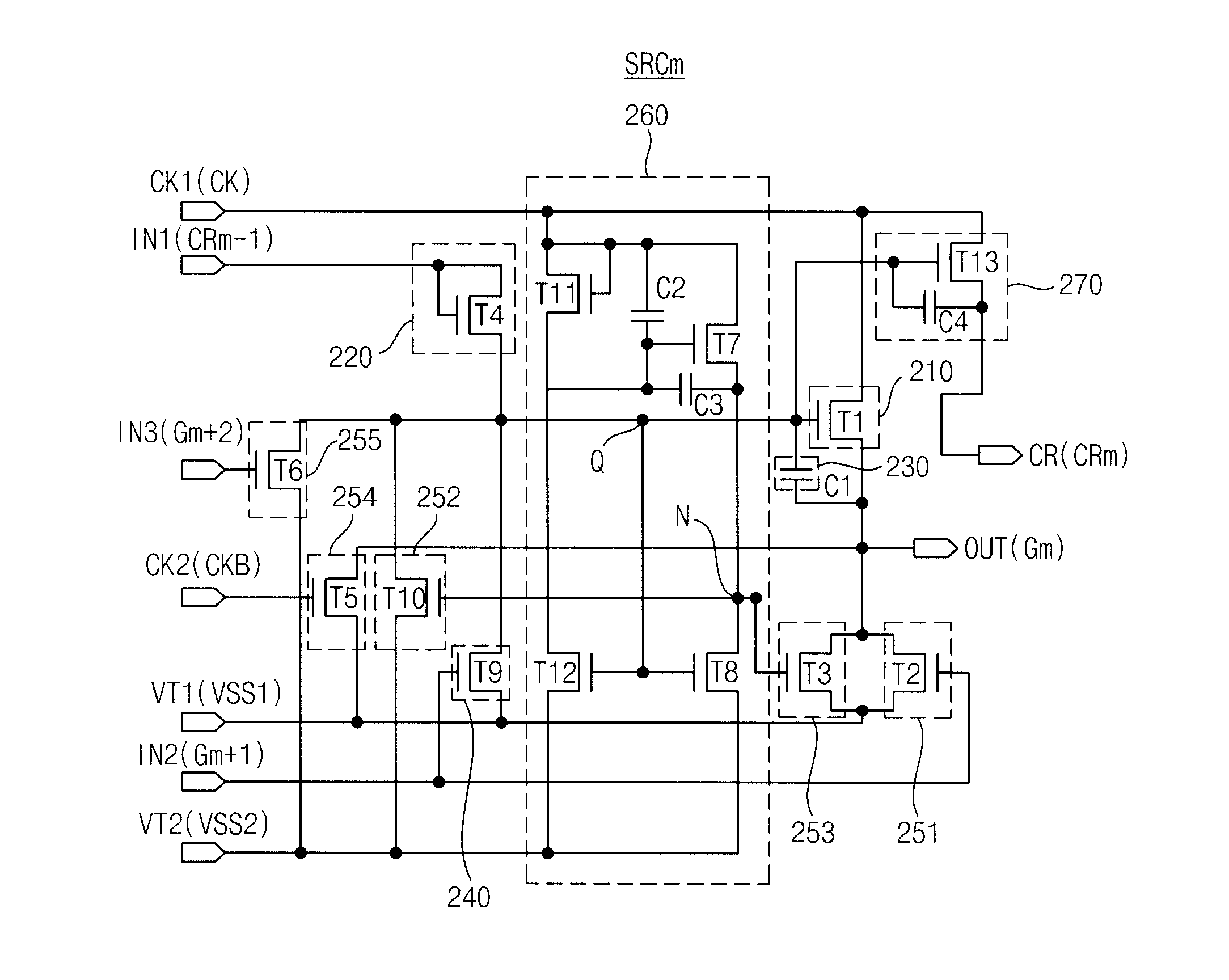

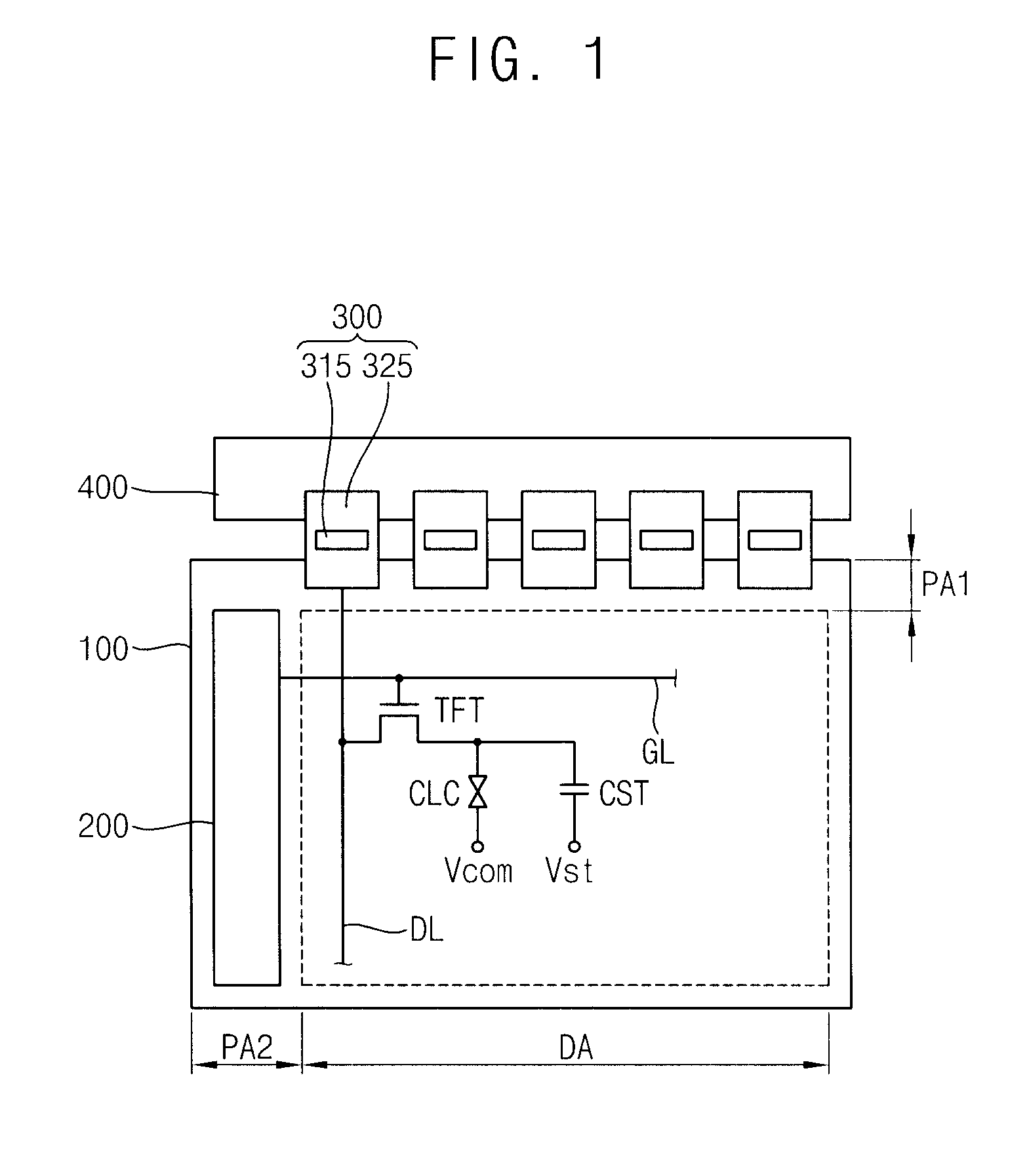

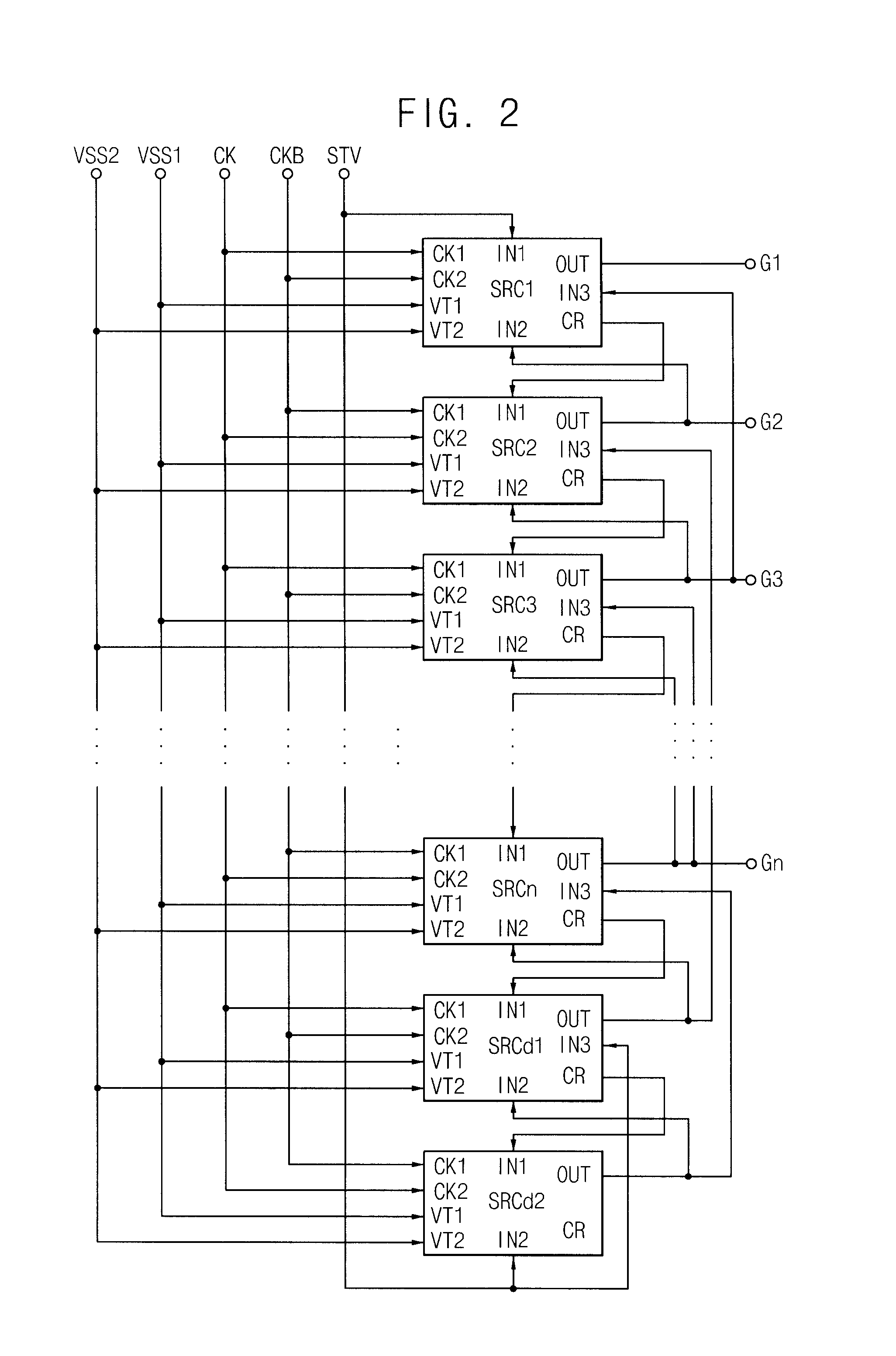

Gate drive circuit and method of driving the same

ActiveUS20100277206A1Improve driving reliabilityReduce noiseStatic indicating devicesDigital storageDriver circuitLow voltage

In a gate drive circuit including stages which are cascaded and which output gate signals each of the stages includes a first node, an output part, a first holding part and a second holding part. A voltage of the first node is converted to a high voltage in response to one of a vertical start signal and a carry signal of one of previous stages. The output part outputs a first clock signal as a gate signal through an output terminal in response to the high voltage of the first node. The first holding part applies a first low voltage to the output terminal, in response to a gate signal output from at least one of following stages. The second holding part applies a second low voltage, which is less than the first low voltage, to the first node in response to a gate signal output from at least one stage among following stages.

Owner:SAMSUNG DISPLAY CO LTD

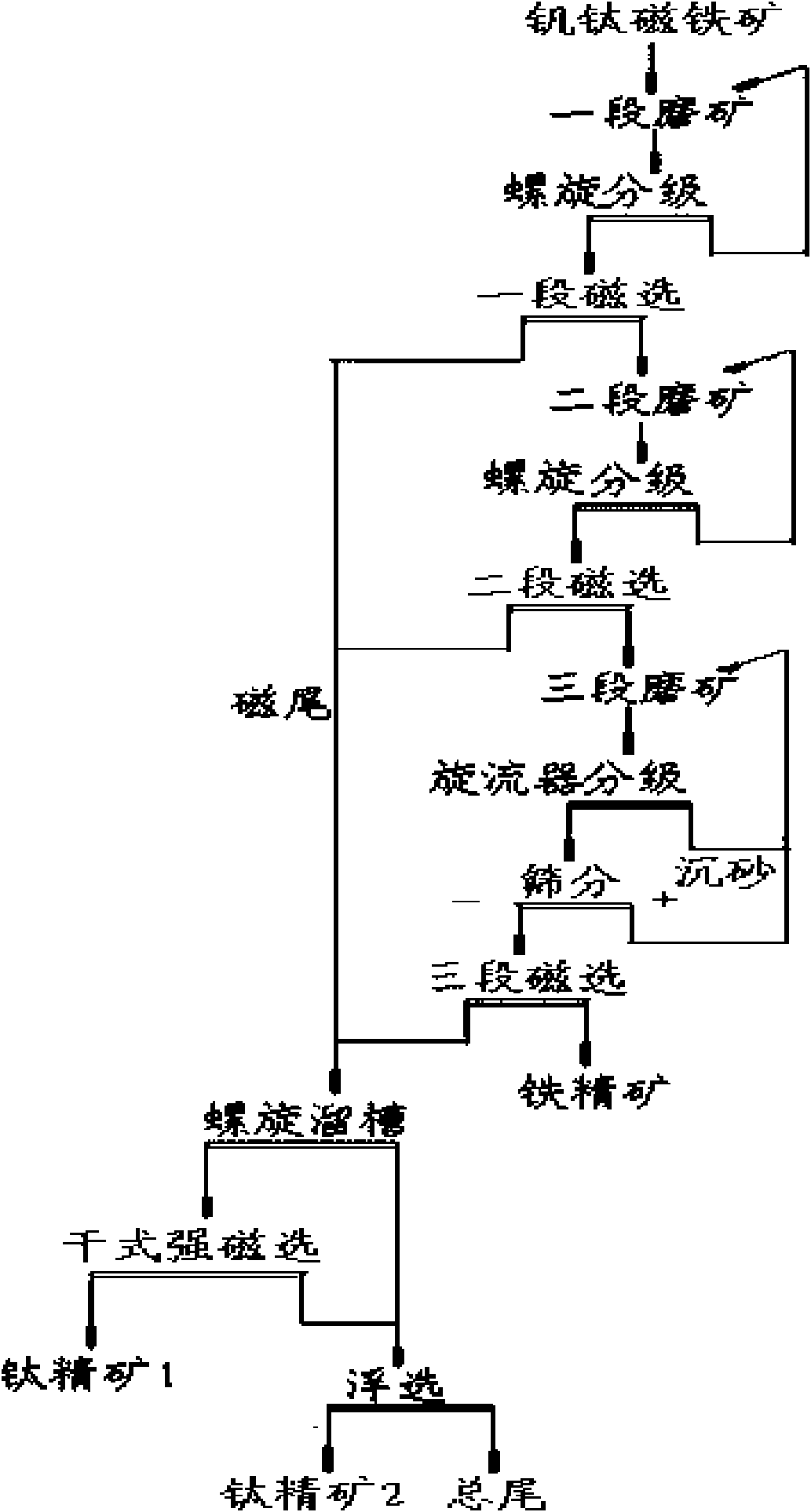

Vanadium titano-magnetite screen method

ActiveCN101564707AQuality improvementHigh recovery rateFlotationMagnetic separationMagnetiteMaterials science

The invention relates to a screen method for vanadium titano-magnetite with high quality, belonging to the ore screen field. The method adopts three stage-grinding and stage-concentration process for magnetic separation, wherein the field intensity of one-stage magnetic separation is 3000-4000 Gs; the field intensity of two-stage magnetic separation is 1800-2200 Gs; and the field intensity of three-stage magnetic separation is 1300-1700 Gs. The recovery rate of the screened iron ore concentrate and the titanium ore concentrate is high and the screened cost of the screened iron ore concentrate and the titanium ore concentrate is low, thus providing a new selection for the low grade vanadium titano-magnetite resource and having a broad application prospect.

Owner:四川安宁铁钛股份有限公司

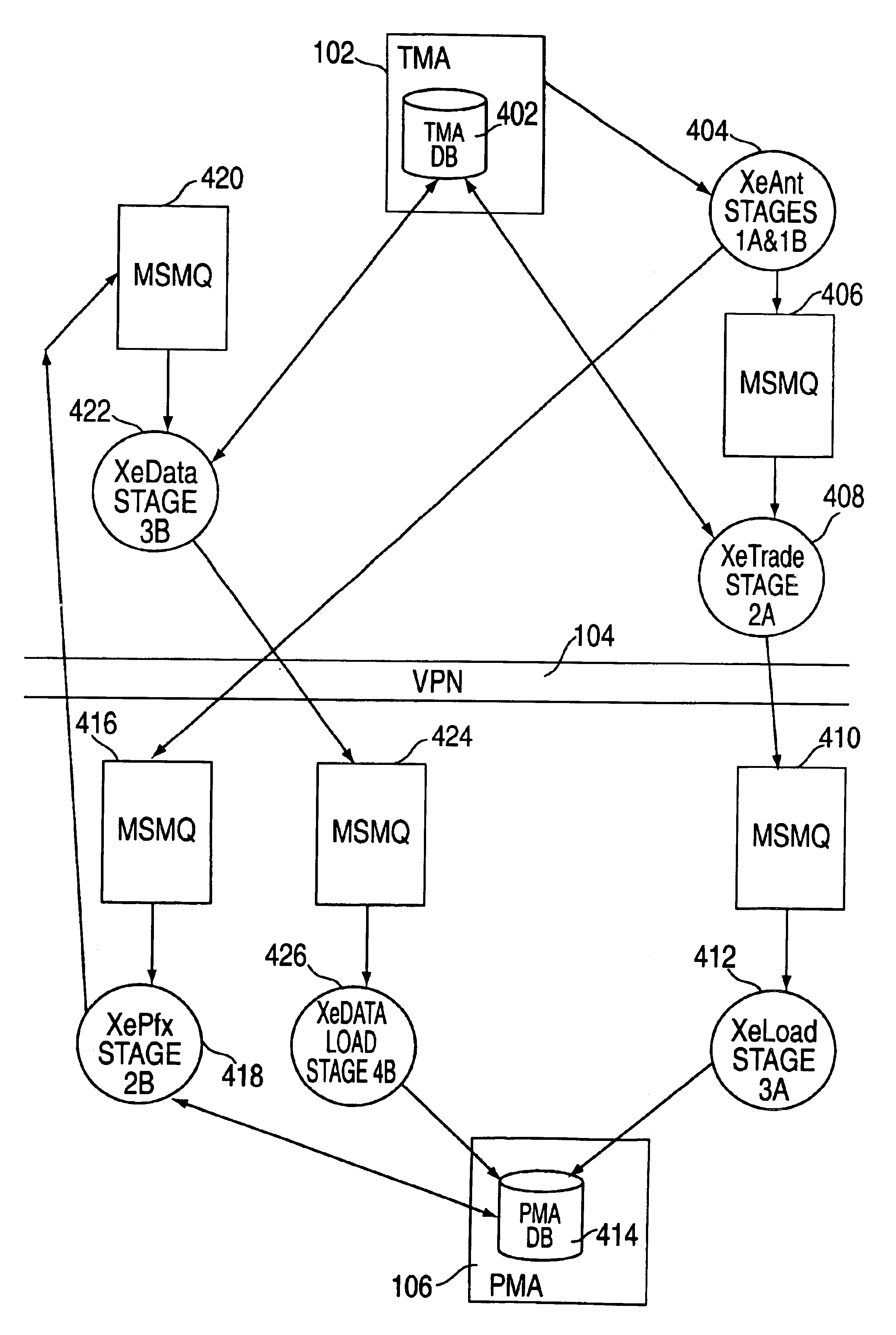

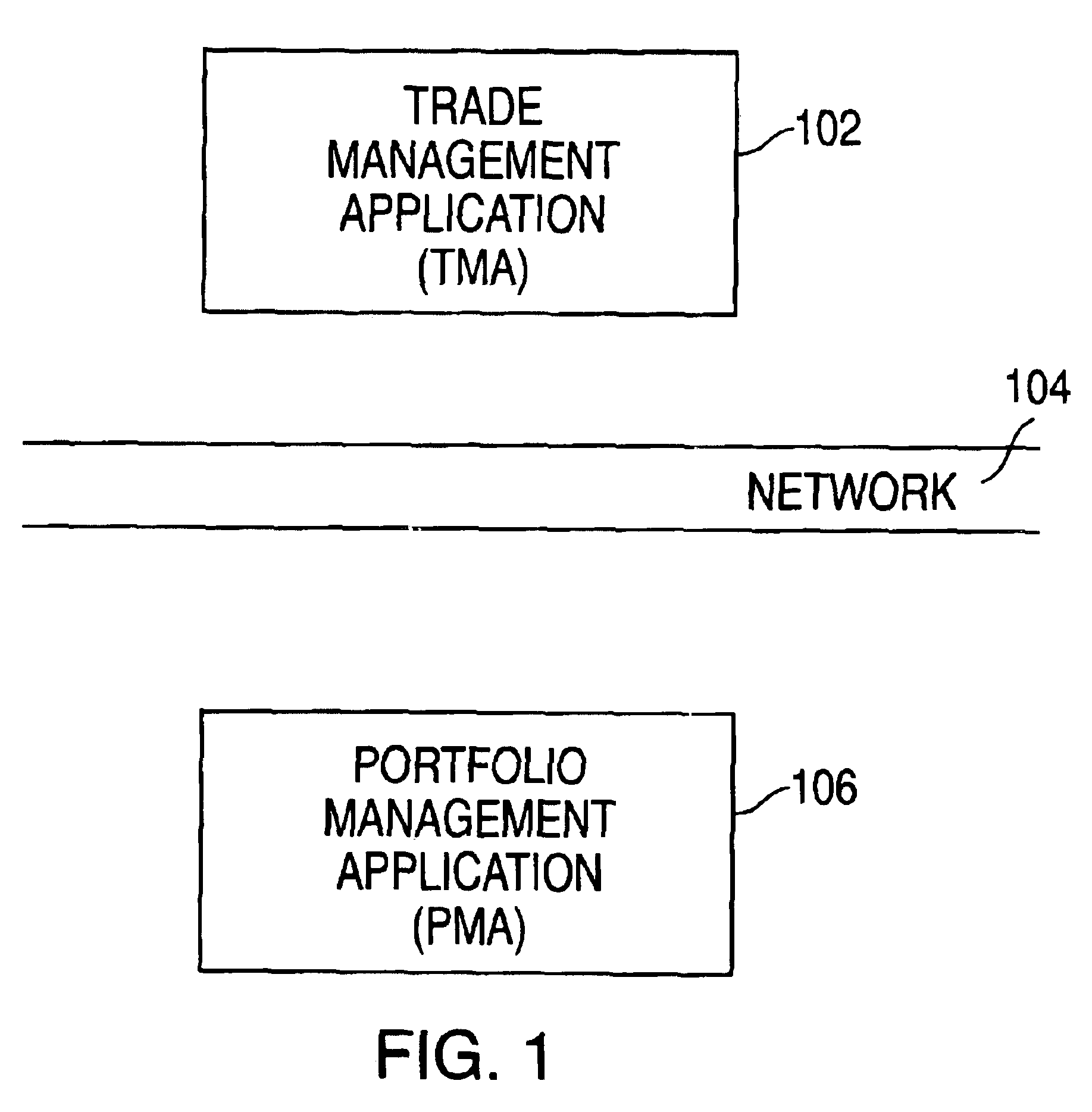

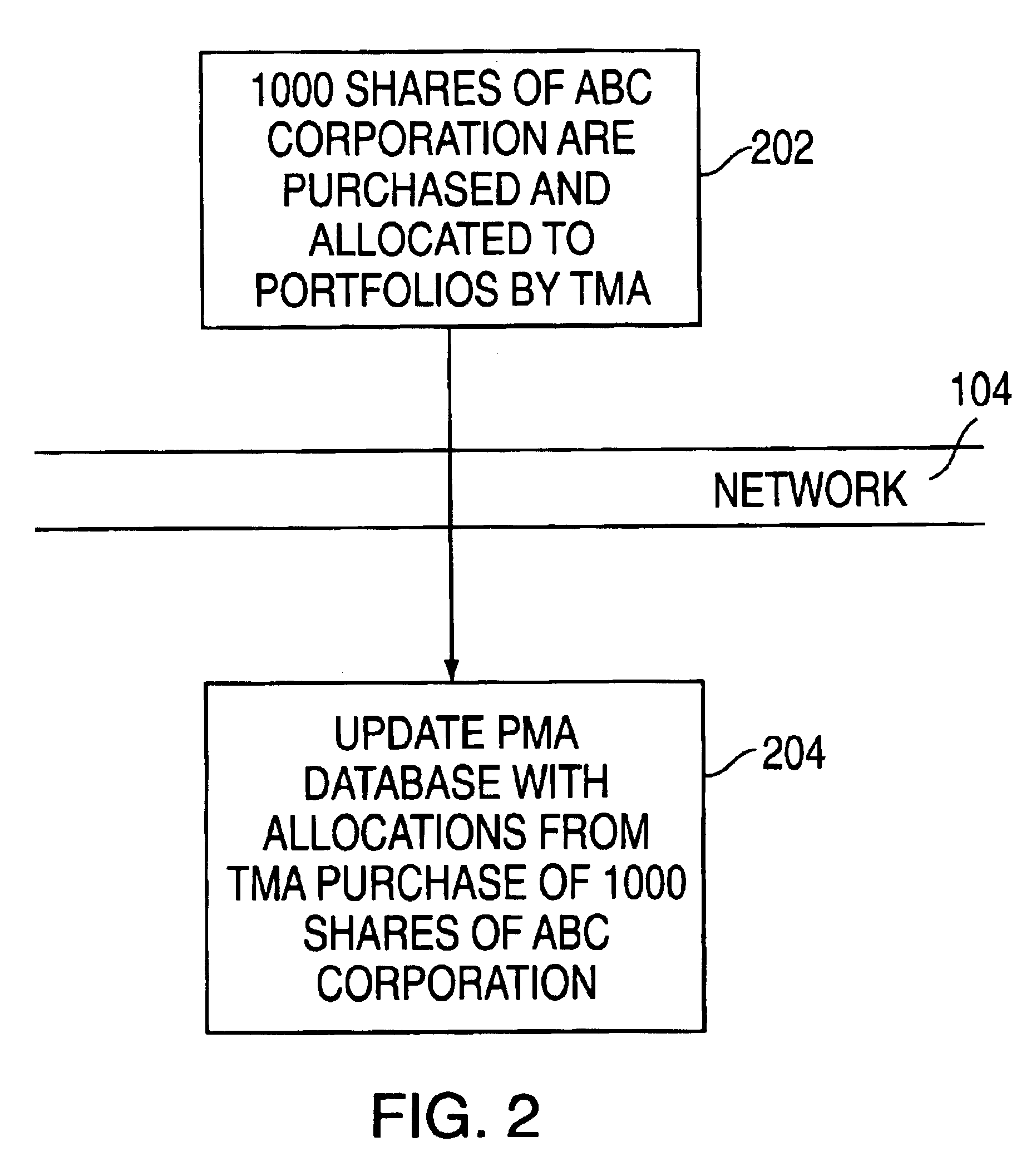

Method and system for straight through processing

InactiveUS6845507B2Simple developmentSimplify deploymentFinanceInterprogram communicationMessage passingStraight-through processing

A method and system for performing straight through processing is presented. The method includes monitoring a queue in order to detect a specific message. This message is parsed to take it from an external format into an internal format. The contents of the message include stages, with one stage being marked as active, and each stage having at least one step and a queue identifier. The processing specified in the steps contained in the active stage is performed, the active stage is marked inactive, and a new stage is marked active. The message is parsed back into the external format and directed to the queue specified by the queue identifier. Additional embodiments include a storage medium and a signal propagated over a propagation medium for performing computer messaging.

Owner:SS&C TECHNOLOGIES

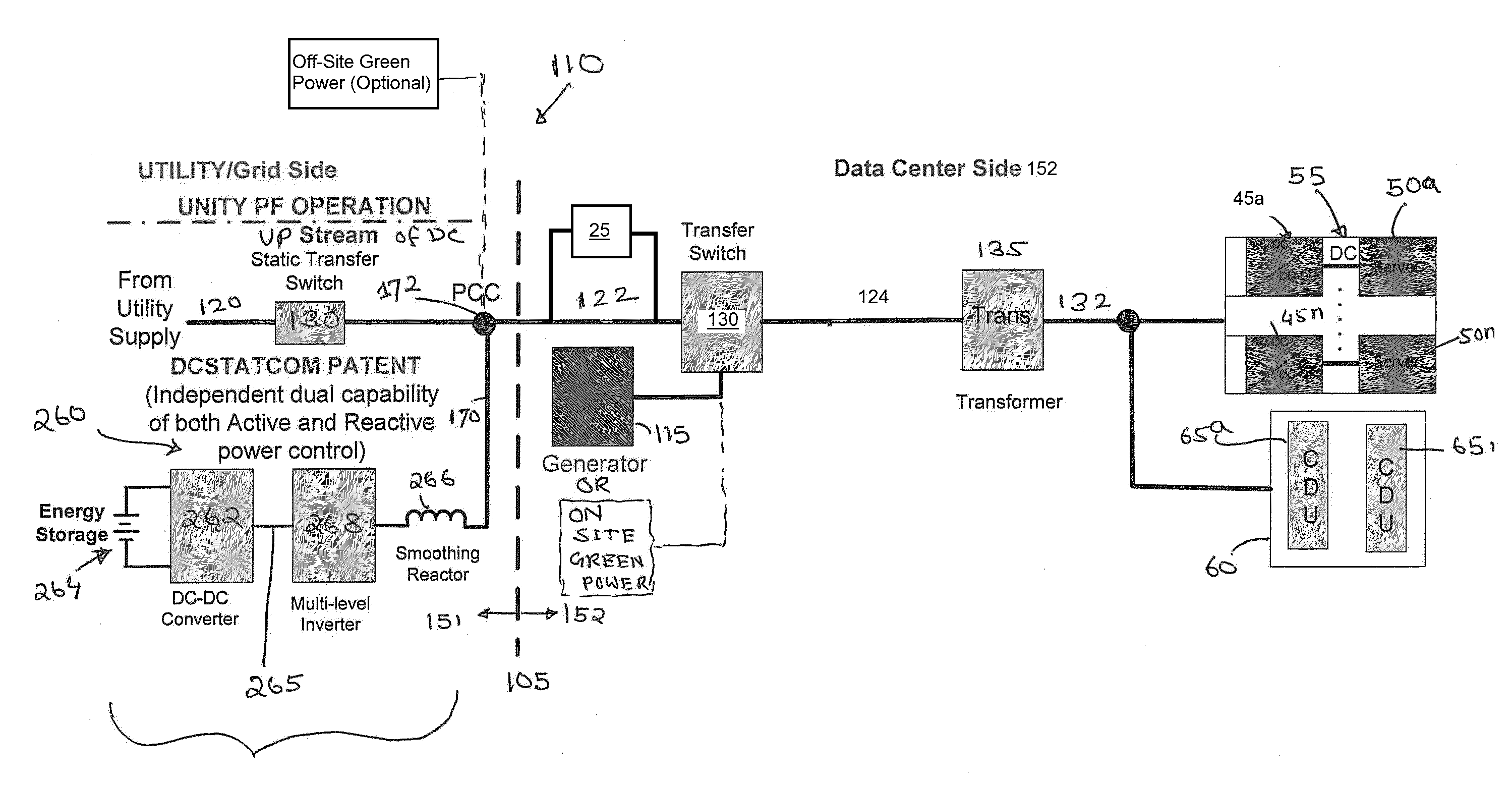

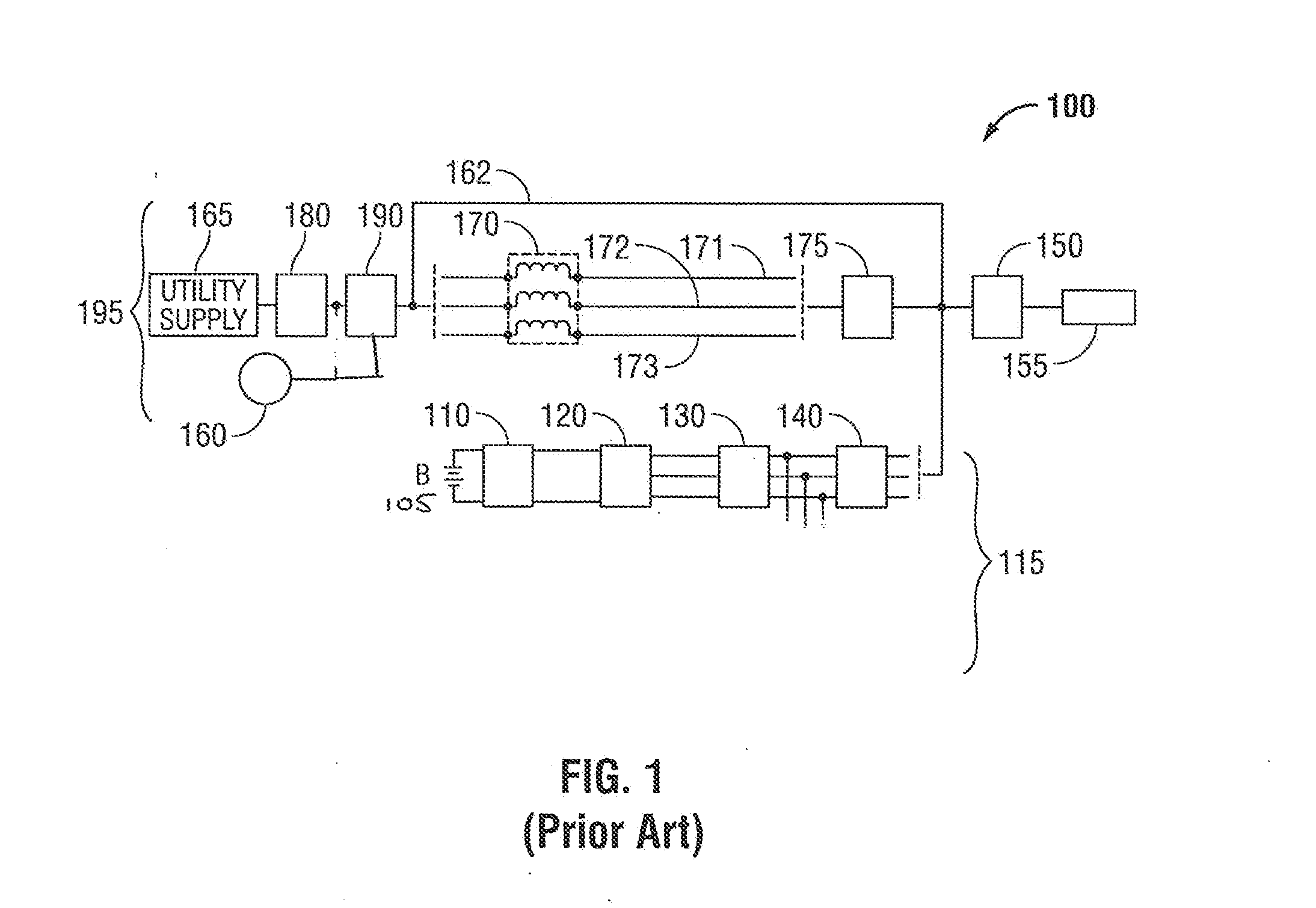

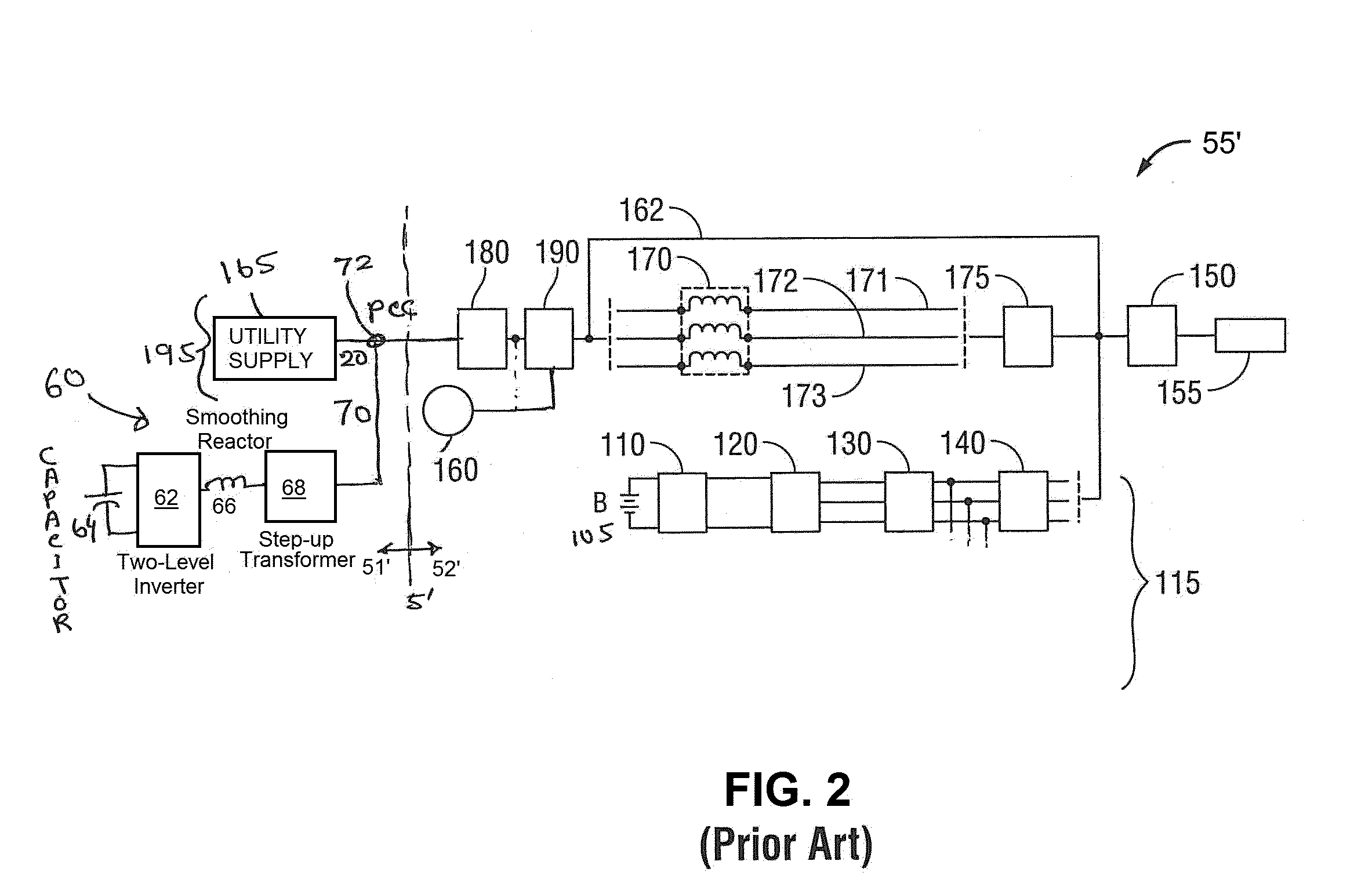

Multi-level medium voltage data center static synchronous compensator (dcstatcom) for active and reactive power control of data centers connected with grid energy storage and smart green distributed energy sources

Systems and methods for supplying power (both active and reactive) at a medium voltage from a DCSTATCOM to an IT load without using a transformer are disclosed. The DCSTATCOM includes an energy storage device, a two-stage DC-DC converter, and a multi-level inverter, each of which are electrically coupled to a common negative bus. The DC-DC converter may include two stages in a bidirectional configuration. One stage of the DC-DC converter uses a flying capacitor topology. The voltages across the capacitors of the flying capacitor topology are balanced and switching losses are minimized by fixed duty cycle operation. The DC-DC converter generates a high DC voltage from a low or high voltage energy storage device such as batteries and / or ultra-capacitors. The multi-level, neutral point, diode-clamped inverter converts the high DC voltage into a medium AC voltage using a space vector pulse width modulation (SVPWM) technique.

Owner:INERTECH IP

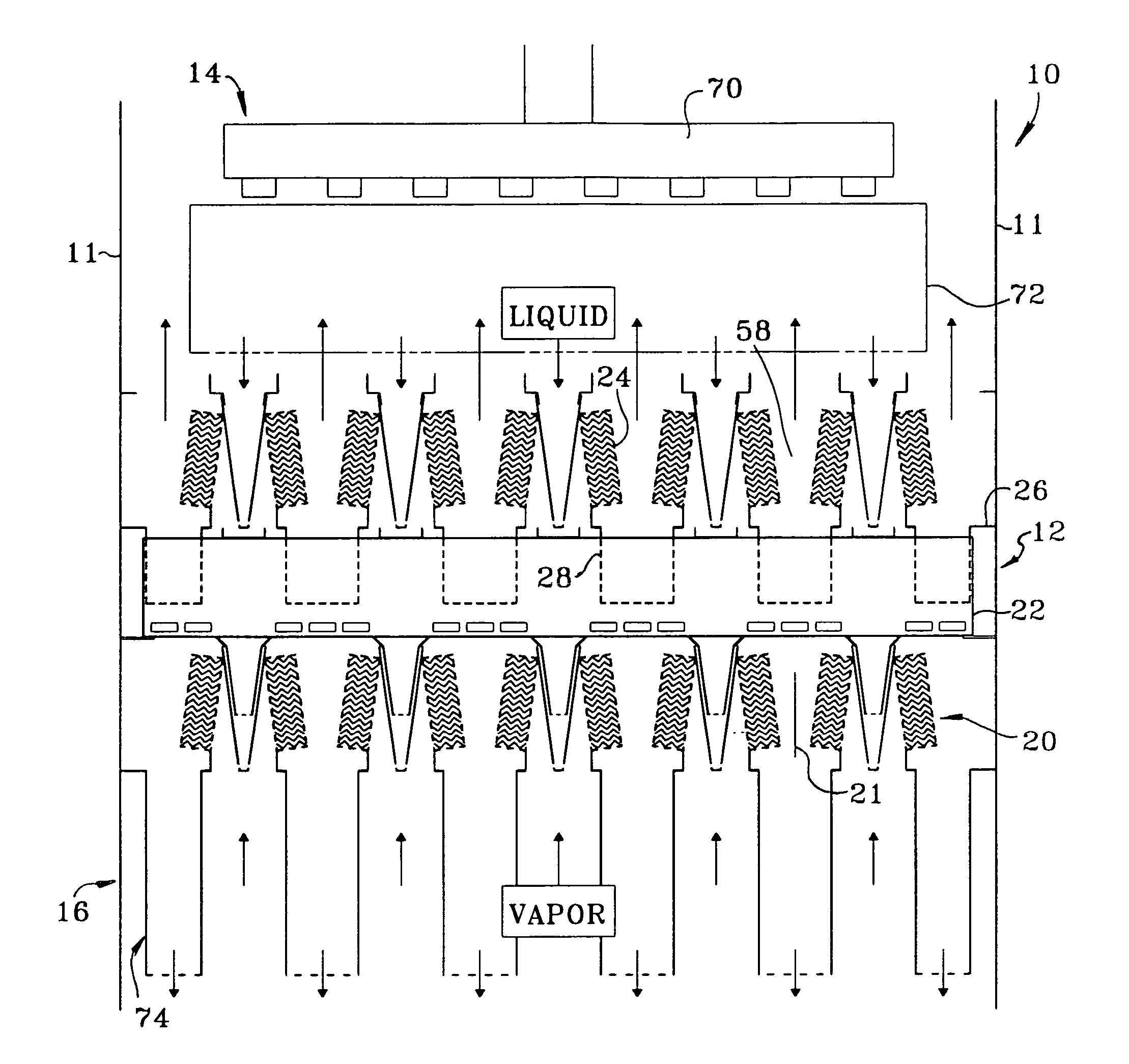

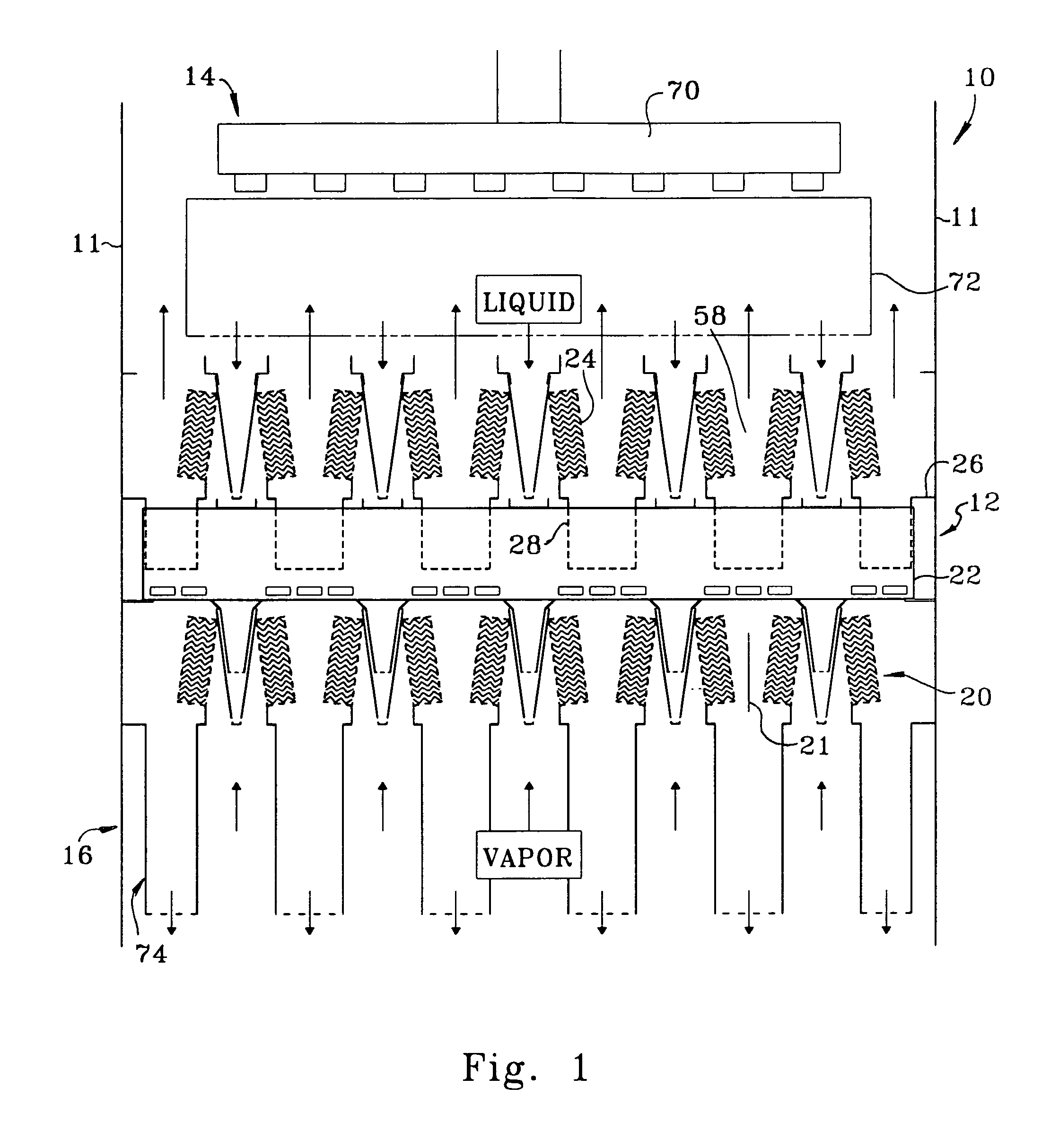

Co-current vapor-liquid contacting apparatus

ActiveUS7424999B2Easily redistributedIncrease capacityCombination devicesLiquid degasificationVapor liquidFractionating column

Owner:UOP LLC

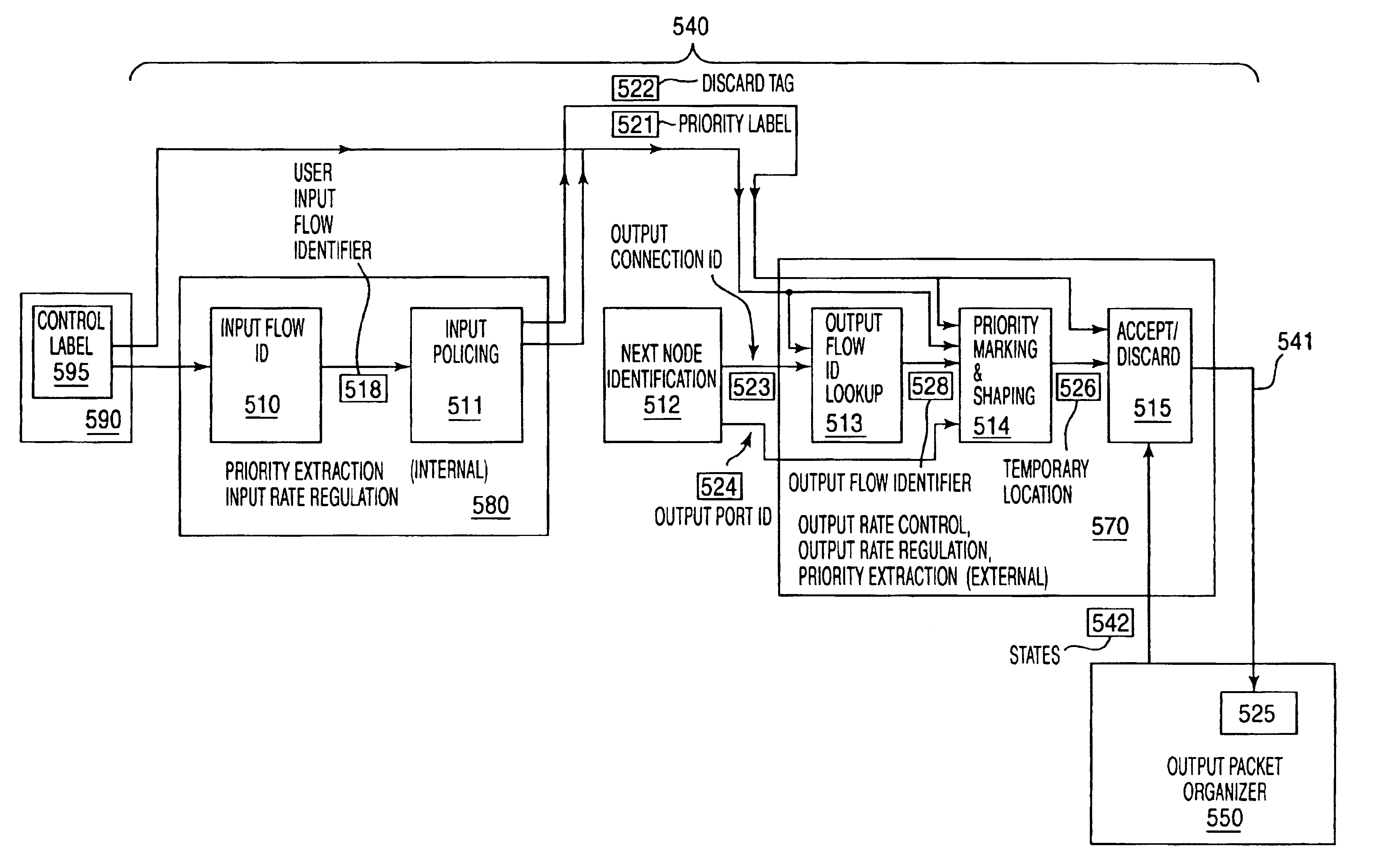

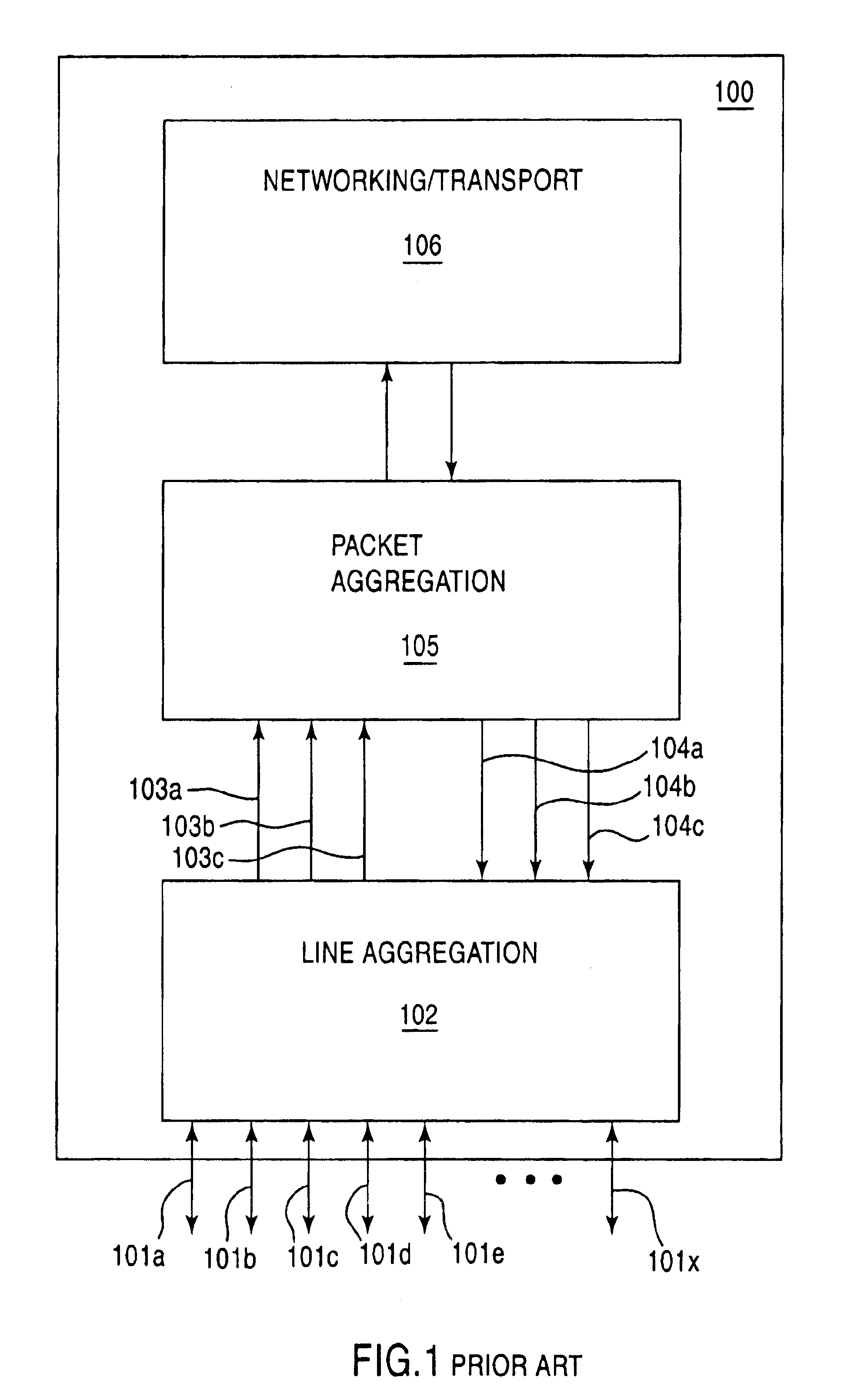

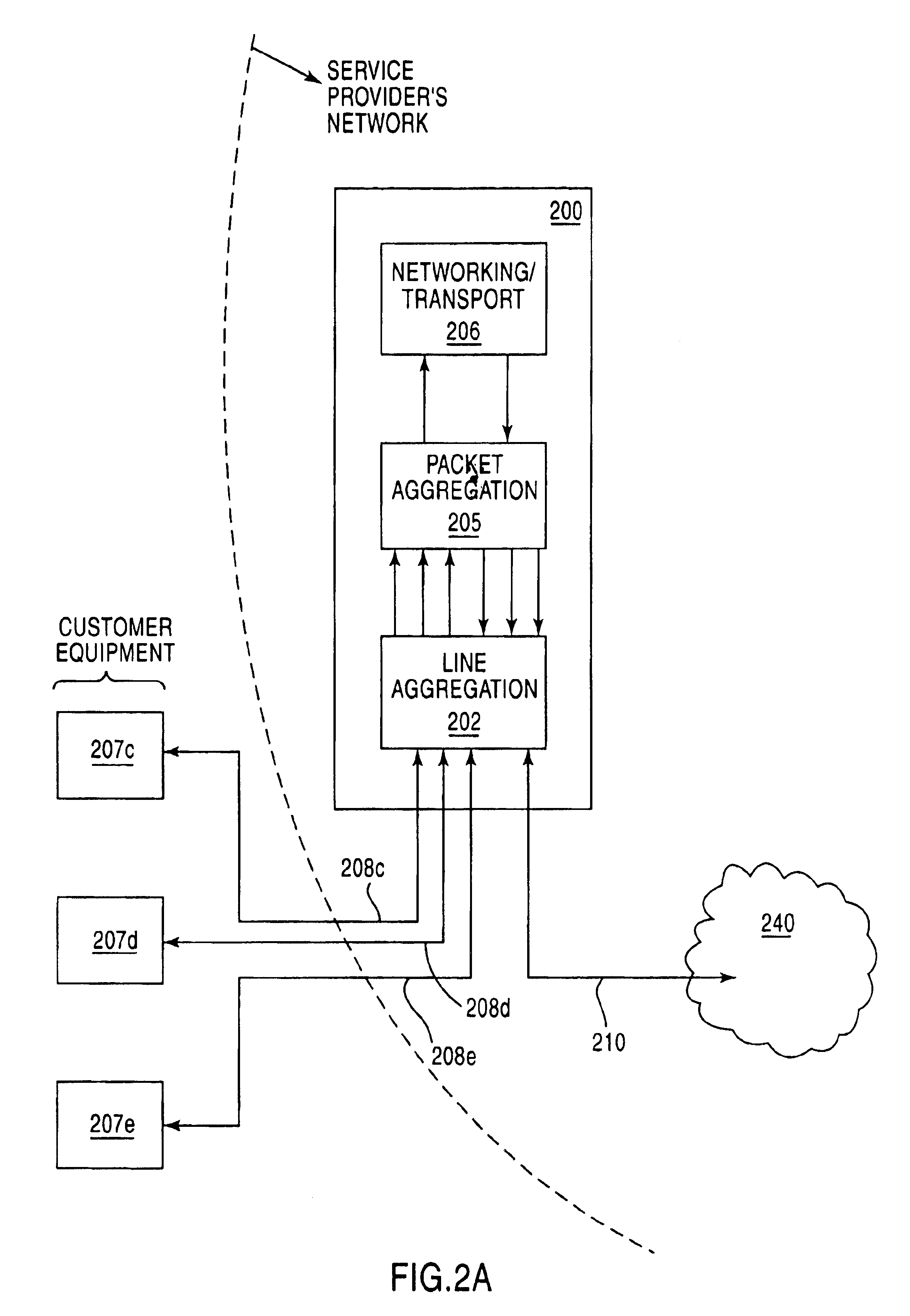

Method and apparatus for input rate regulation associated with a packet processing pipeline

InactiveUS6882642B1Multiplex system selection arrangementsCircuit switching systemsComputer sciencePacket processing

A method is described that involves presenting packet header information from a packet and packet size information for the packet to a pipeline that comprises multiple stages. One of the stages identifies, with the packet header information, where input flow information for the packet is located. The input flow information is then fetched. The input flow information identifies where input capacity information for the packet is located and the input capacity information is then fetched. Another of the stages compares an input capacity for the packet with the packet's size and indicates whether the packet is conforming or non-conforming based upon the comparison. The input capacity is calculated from the input capacity information.

Owner:NOKIA SOLUTIONS & NETWORKS OY

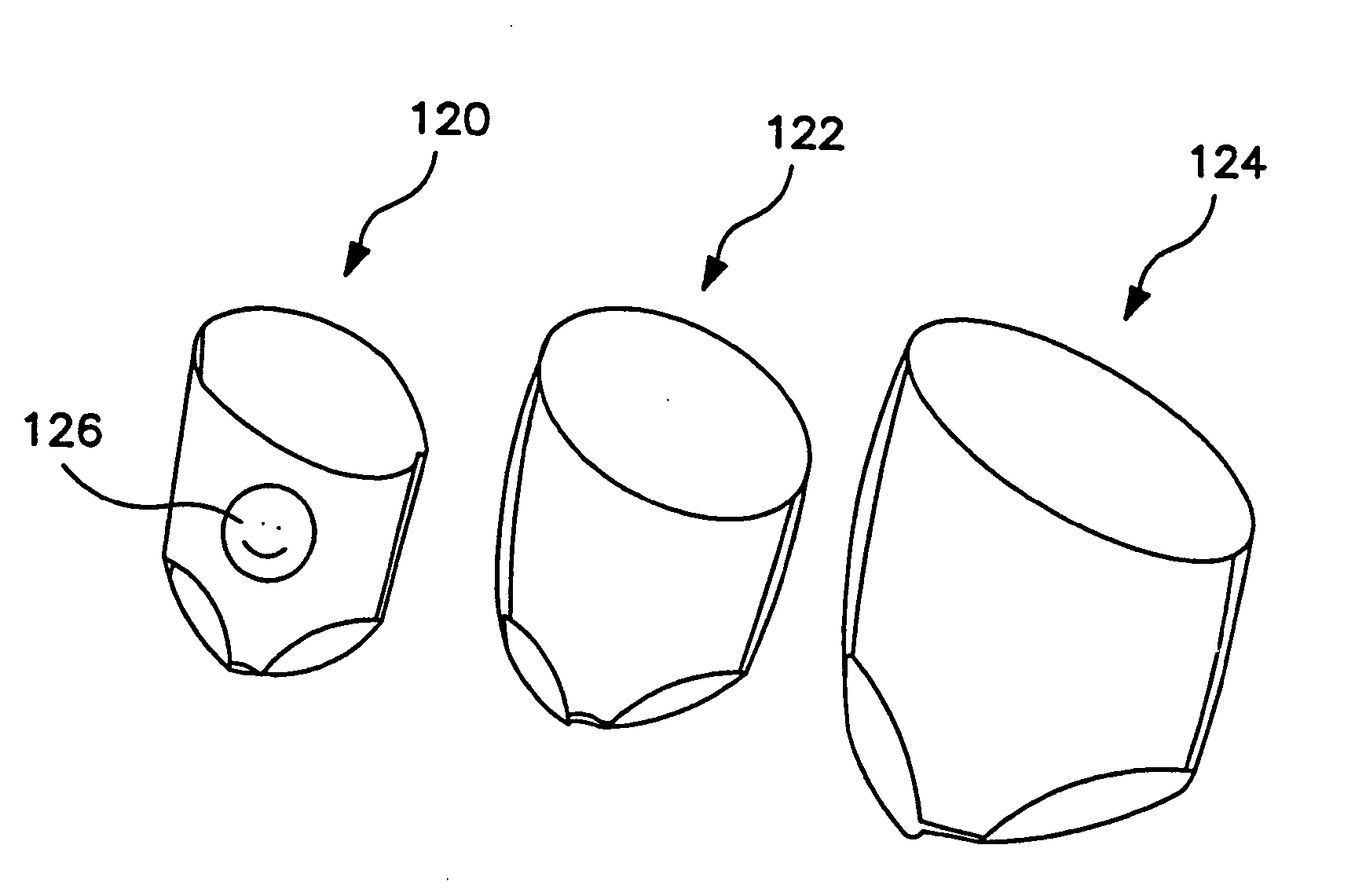

Method of providing a series of disposable absorbent articles to consumers

InactiveUS20050137543A1Improve the level ofPoor water absorptionBaby linensTamponsPotty trainingEngineering

A method of providing a series of types of pant-like garments and corresponding information to consumers. The series includes two or more pant-like garments, each of the garments corresponding to a stage of toilet training. Each of the garments in the series may differ from one another in terms of absorbent capacity, size, and / or features. The information provided to the consumer helps the consumer discern which garment from the series is most appropriate for a child in a specific stage of the toilet training process.

Owner:KIMBERLY-CLARK WORLDWIDE INC

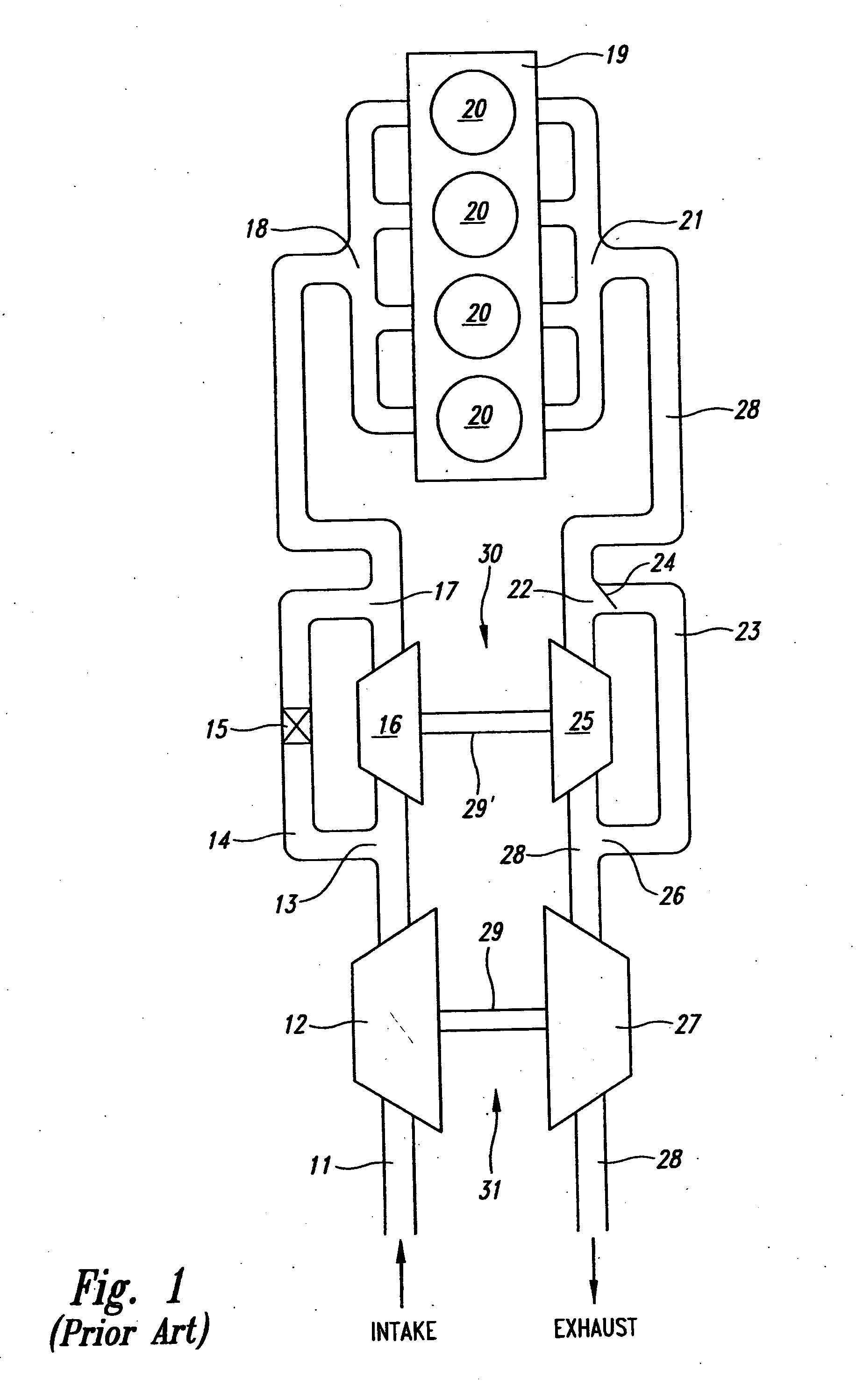

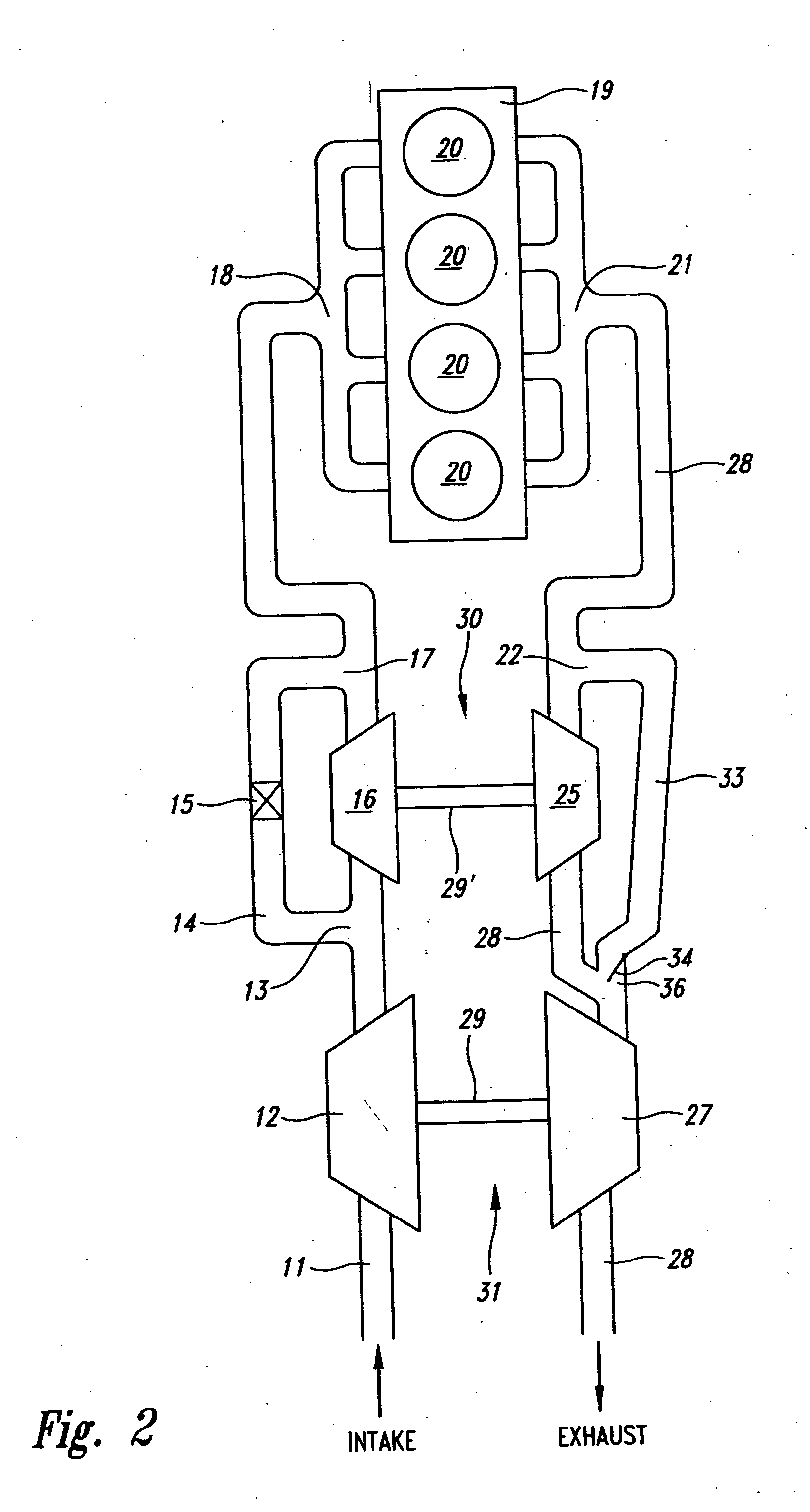

Multi-stage turbocharging system with efficient bypass

InactiveUS20060042247A1Improve efficiencyLoss of useful energyNon-fuel substance addition to fuelInternal combustion piston enginesImpellerTurbine wheel

A more efficient multi-stage turbocharging system and method for internal combustion engine systems is set forth. The present invention recovers the loss of a portion of exhaust energy that conventionally occurs in bypassing exhaust flow from one stage to another in a multi-stage turbocharging system. The preferred method of preserving such exhaust energy is through converting a portion of the exhaust energy of the bypassed flow from pressure to kinetic energy (velocity) by passing the bypassed flow through a VGT vane outlet or other variable geometry valve / nozzle, and then not allowing the accelerated flow to dissipate energy before reaching the subsequent stage's turbine wheel, where the accelerated flow may then be converted to a mechanical rotational force by the lower pressure turbine's wheel. Preferred hardware for achieving the object of the invention is also set forth, including a preferred two-volute low pressure turbocharging system with a VGT mechanism in one turbine volute only, or an alternative low pressure turbocharger with two low pressure turbines on a common shaft (again, preferably, with a VGT mechanism in one turbine only).

Owner:ENVIRONMENTAL PROTECTION AGENCY US

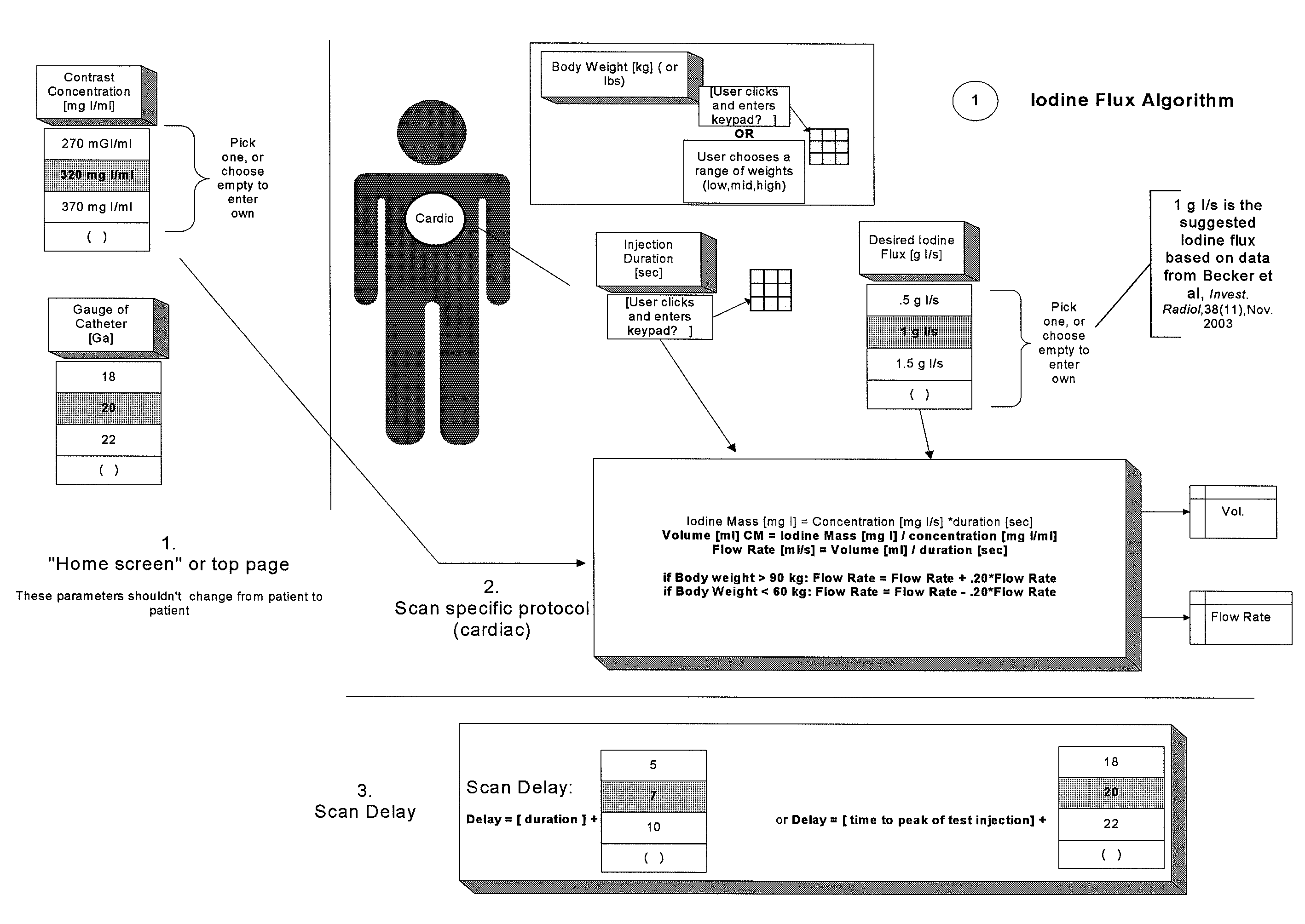

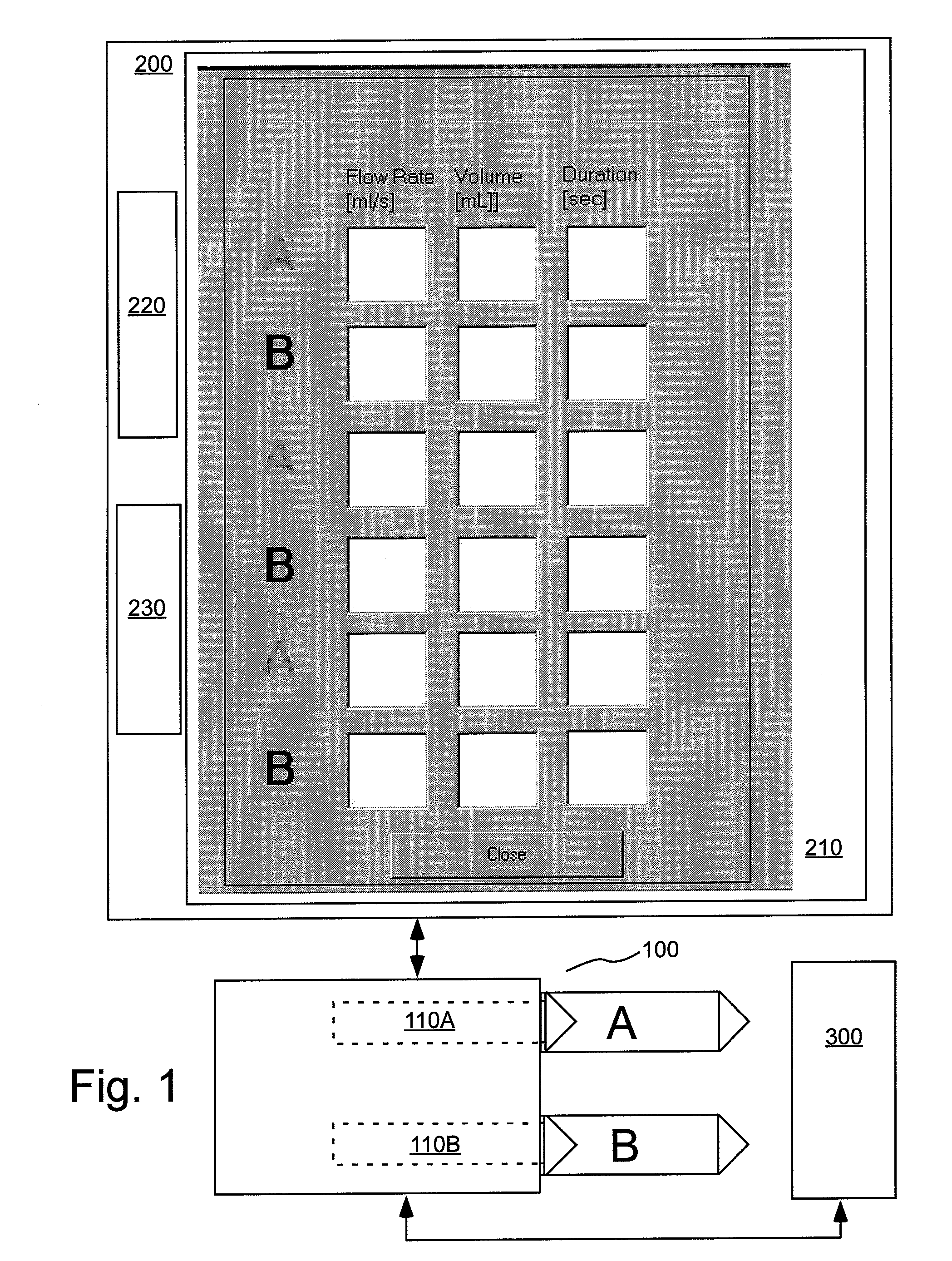

Patient-based parameter generation systems for medical injection procedures

ActiveUS20100113887A1Lower the volumeUltrasonic/sonic/infrasonic diagnosticsDrug and medicationsBody mass indexBiomedical engineering

A system includes a parameter generation system to determine parameters of at least one phase of an injection procedure based at least in part upon a type of the injection procedure. The parameter generator system determines the amount of a pharmaceutical that is to be delivered to a patient at least in part on the basis of the concentration of an agent in the pharmaceutical and at least on part on the basis of a function that depends upon and varies with a patient parameter. The patient parameter can, for example, be weight, body mass index, body surface area or cardiac output. The pharmaceutical can, for example, include a contrast enhancing agent for use in an imaging procedure.

Owner:BAYER HEALTHCARE LLC

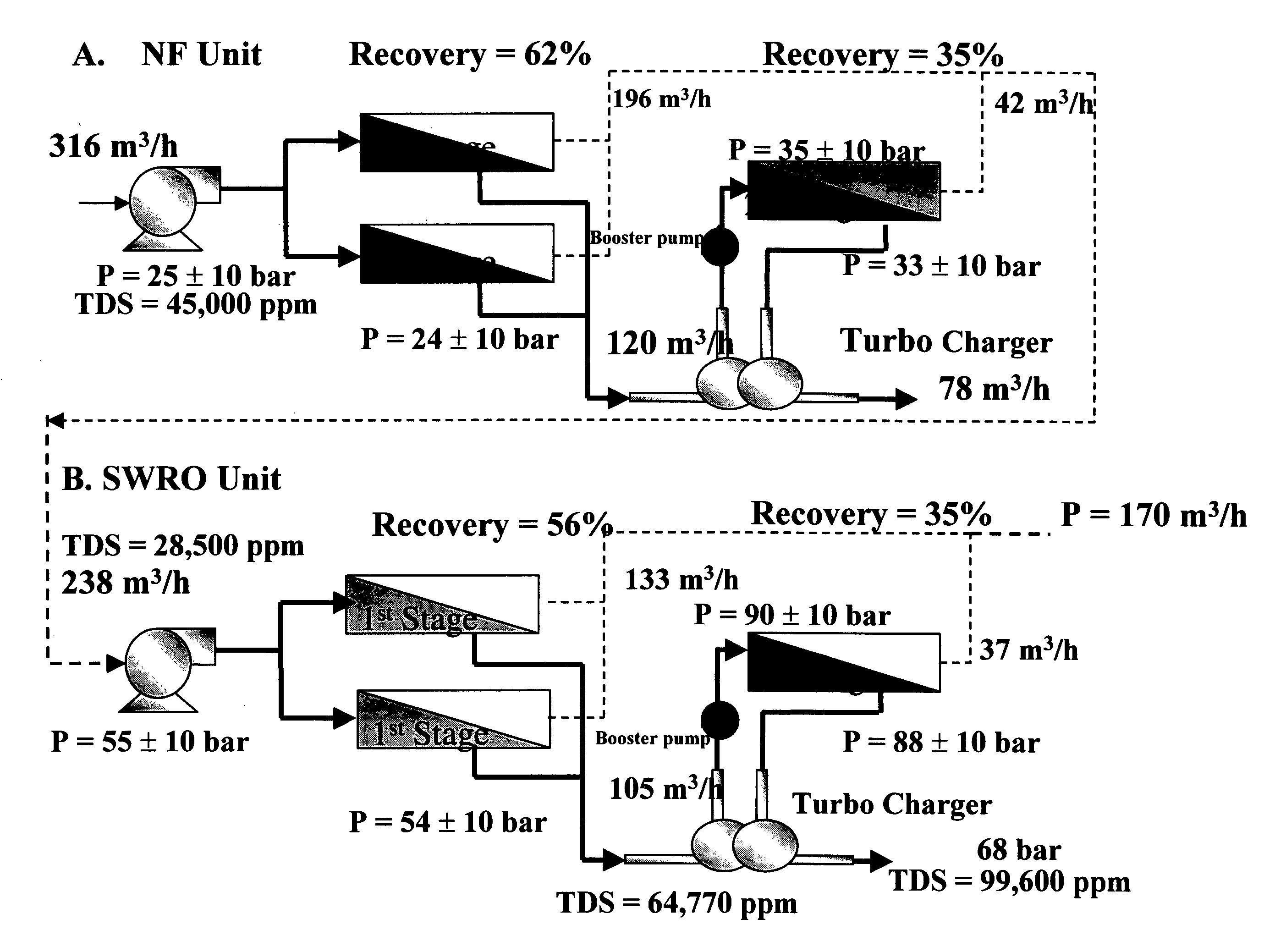

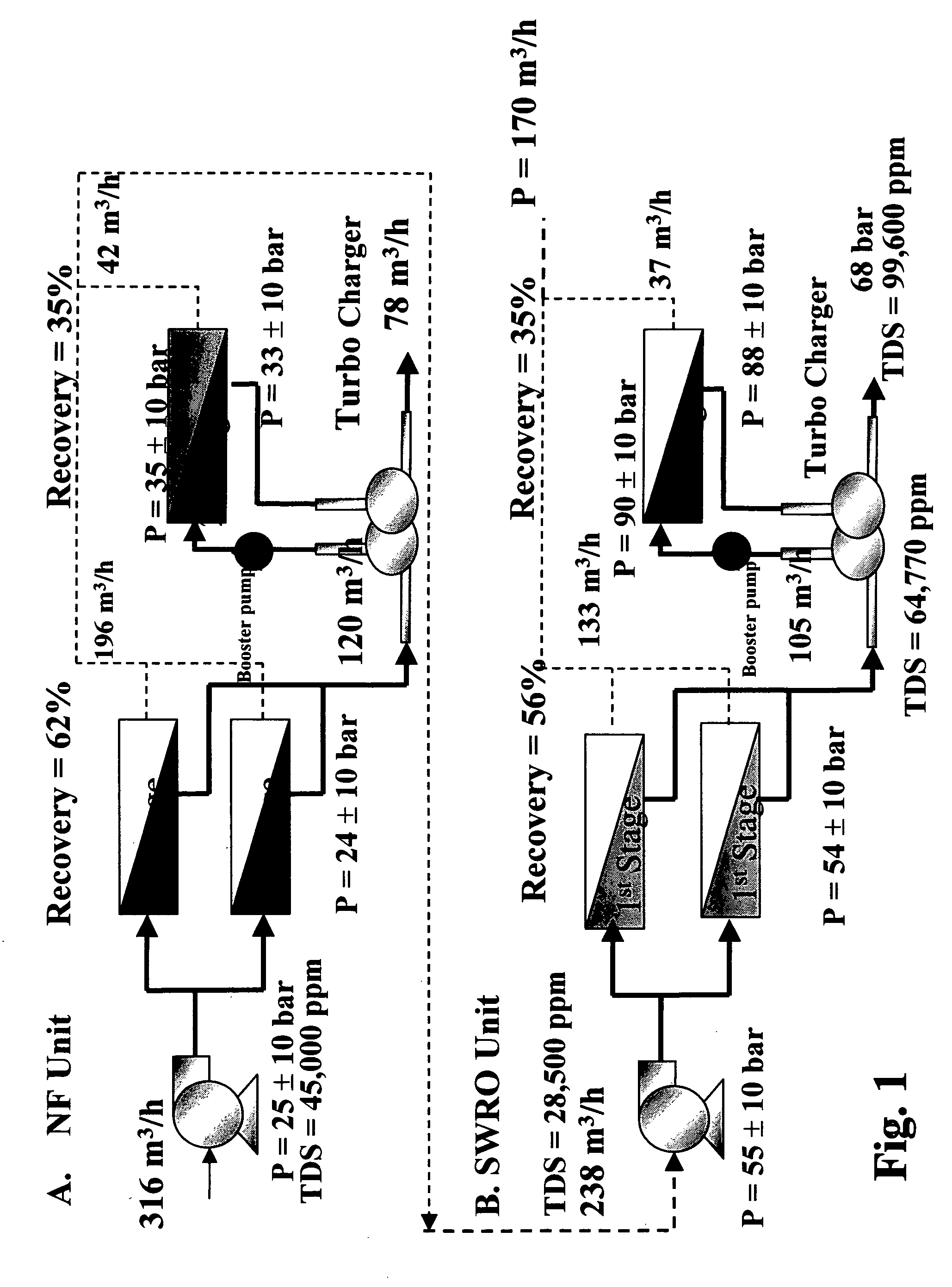

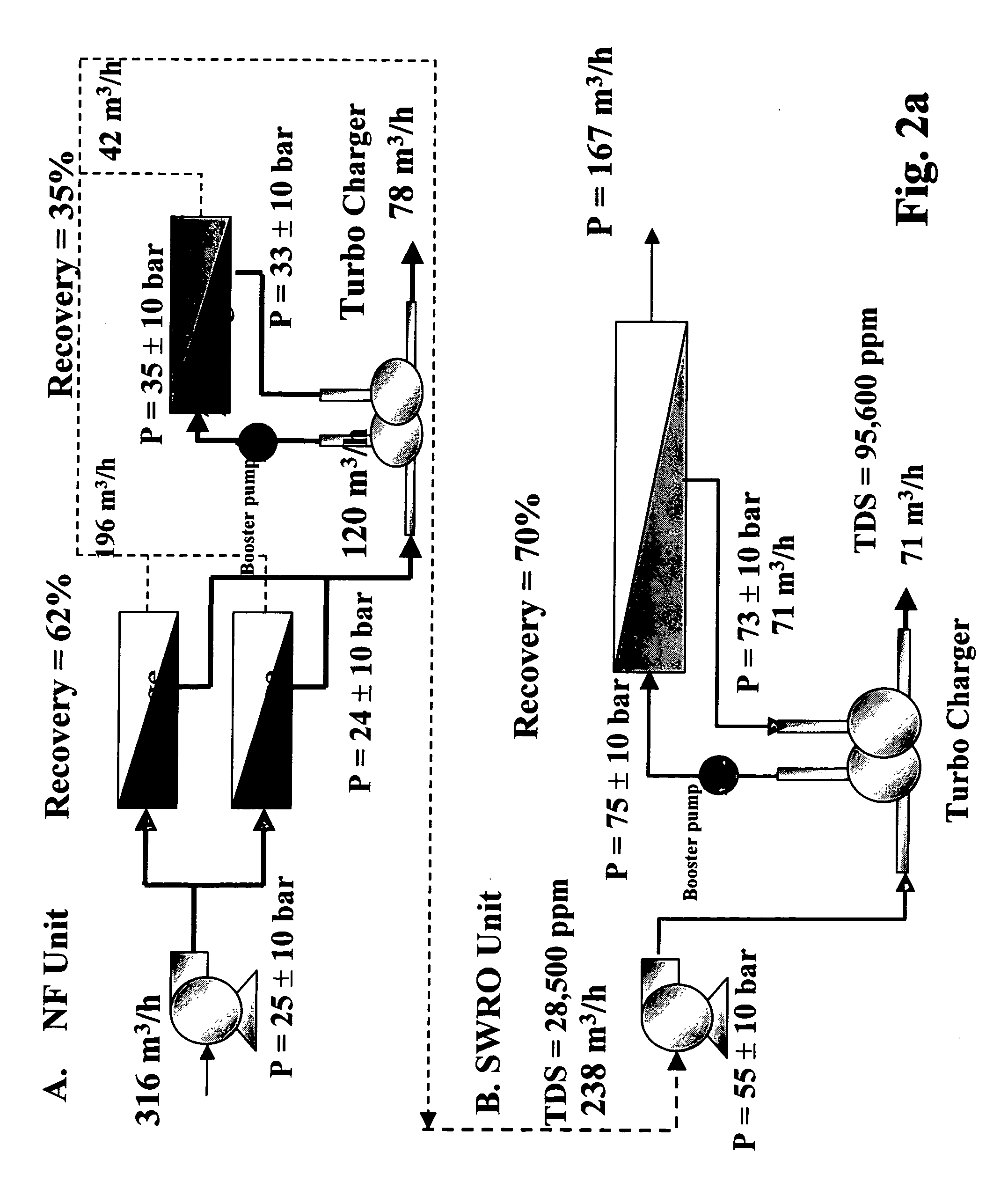

Fully integrated NF-thermal seawater desalination process and equipment

InactiveUS20060157410A1High yieldEffectively and efficiently dealGeneral water supply conservationReverse osmosisDistillationEngineering

An optimal thermal seawater desalination process is disclosed, which combines two or more substantially different water pretreatment processes in a unique manner and in a special configuration, hereto unknown to prior desalination arts, to produce a high yield of high quality fresh water, including potable water. In this process a two stage NF membrane pretreatment unit (NF2) with an energy recovery turbo charger (TC) device in between the stages or equipped with an energy recovery pressure exchanger (PX) is synergistically combined with at least one thermal desalination unit to form a dual hybrid of NF2-Thermal (FIG. 4 ), or alternatively the two stage NF2 unit is synergistically combined with a two stage SWRO unit (SWRO2) with an energy recovery TC in between the stages or combined with one stage SWRO (SWRO1) equipped with an energy recovery TC or PX system and the reject from the SWRO2 or SWRO1 unit is made make-up to a thermal unit to form a tri-hybrid of NF2-SWRO2 reject-Thermal (FIG. 5 ). In both the cases of di- or trihybrids the thermal unit is equivalent to a multistage flash distillation (MSFD) or multieffect distillation (MED) or vapor compression distillation (VCD) or thermal reheat (RH) evaporator. Typically a process of this invention using the two stage NF2 initial pretreatment step will perform a semi-desalination step by reducing feed TDS by about 35 to 50%, but most important, especially to the thermal seawater desalination process, it removes the water recovery limiting, scale forming hardness ions of Ca++ and Mg++ by better than 80% and their covalent anions of sulfate to better than 95% and bicarbonate to about 65%. The removal of scale forming hardness ions, especially SO4=, and bicarbonates allowed for the operation of thermal unit in the above hybrids at top brine temperature (TBT) much greater than its present TBT limit by the singular conventional process of 120° C. for MSFD and operation of MED or VCD or RH unit at TBT much higher than their present TBT limit of 65-70° C., with many advantages gained by this process over prior art sweater desalination processes. The process of this invention exceeds all prior thermal seawater desalination arts in efficiency, including water yield, product water recovery ratio and unit water cost as well as in energy consumption per unit product which is equivalent or less than other efficient prior art seawater thermal desalination processes. By this process, an NF product recovery ratio of 75 and 80% or better is achieved from the high salinity Gulf sea (TDS≈45,000 ppm) and about an equal product recovery ratio is also obtained from the SWRO or thermal unit when it is operated on NF product for a total water recovery ratio in excess of 52% for seawater

Owner:SALINE WATER CONVERSION CORP SWCC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com