Patents

Literature

5693results about "Liquid degasification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

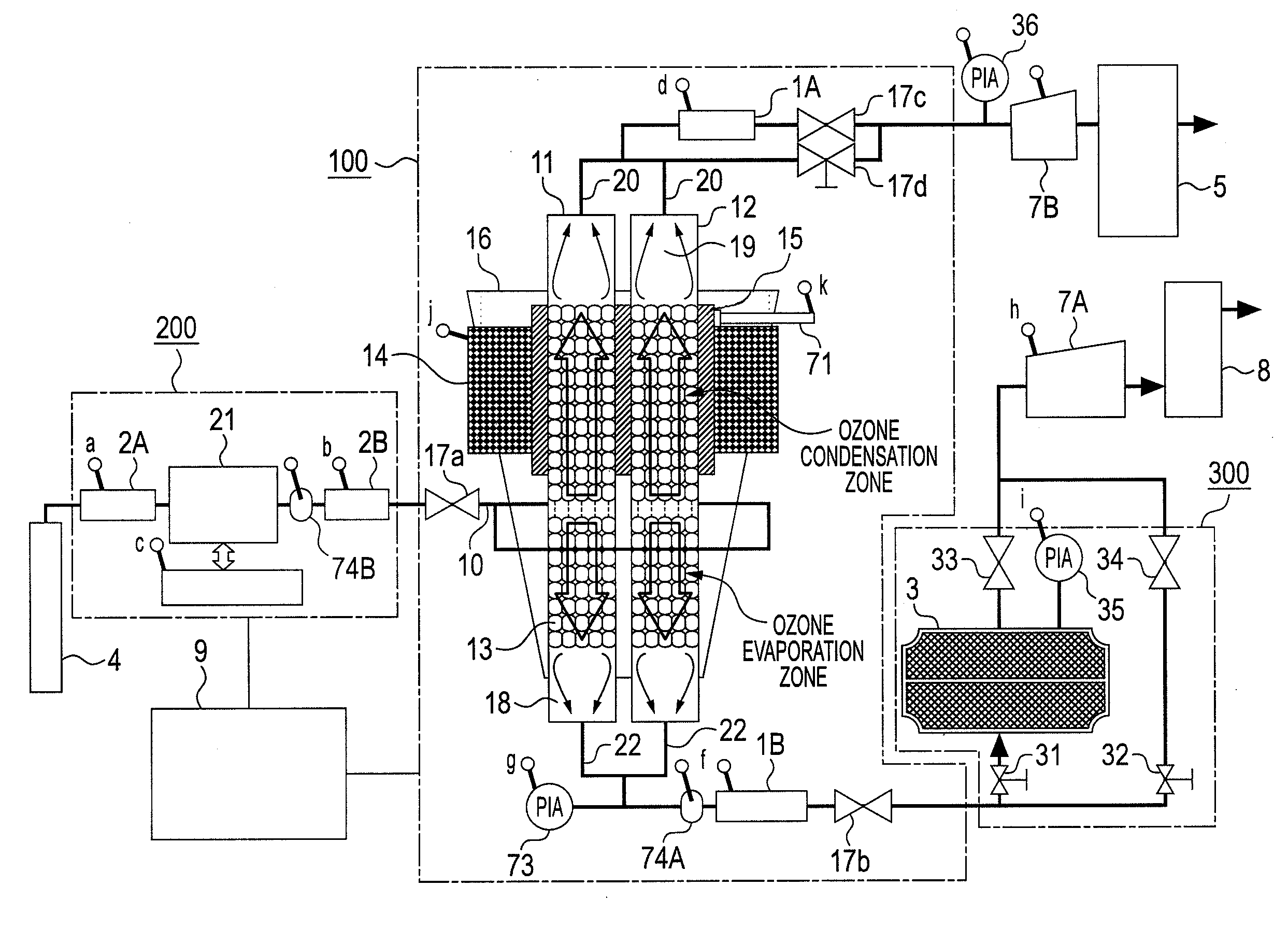

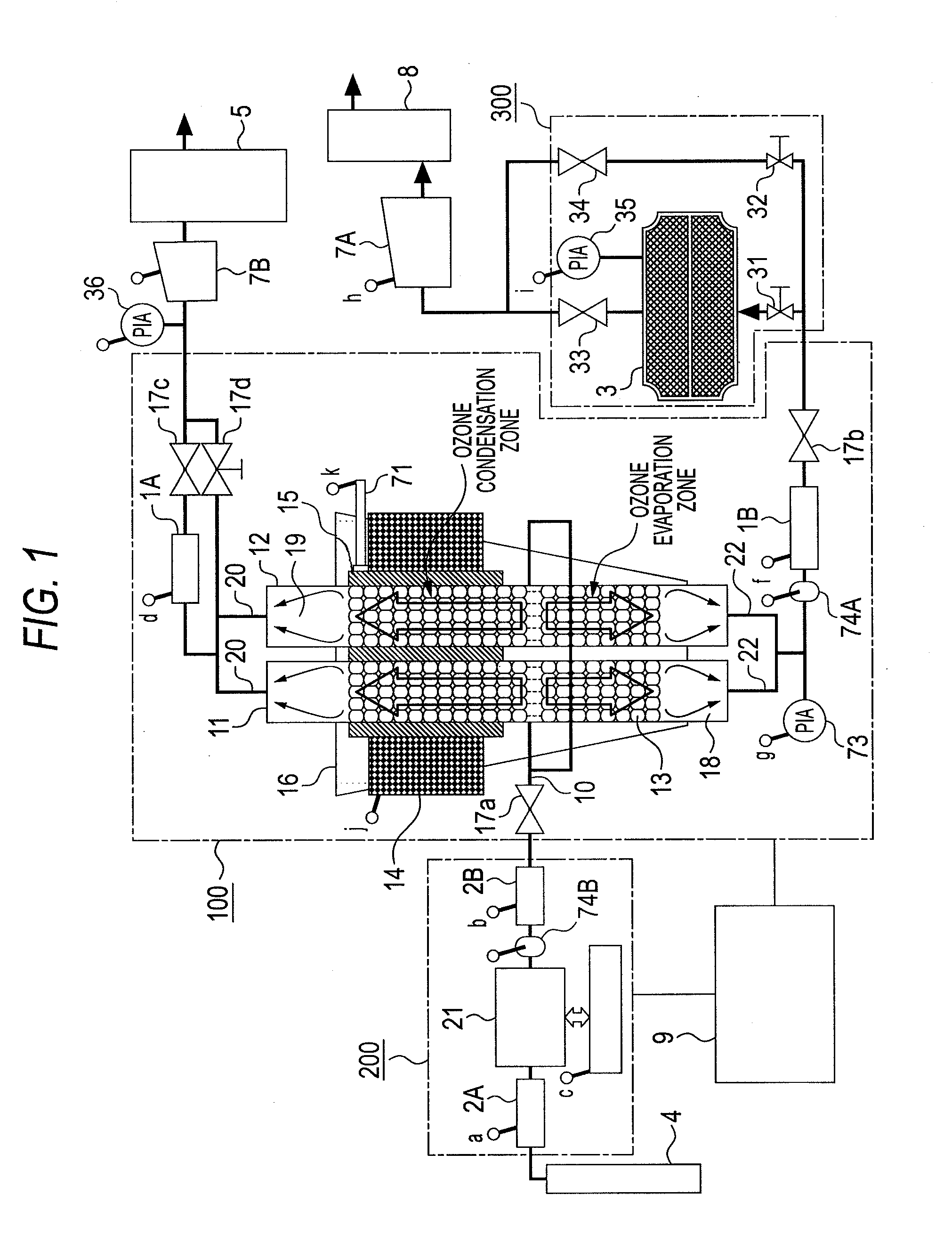

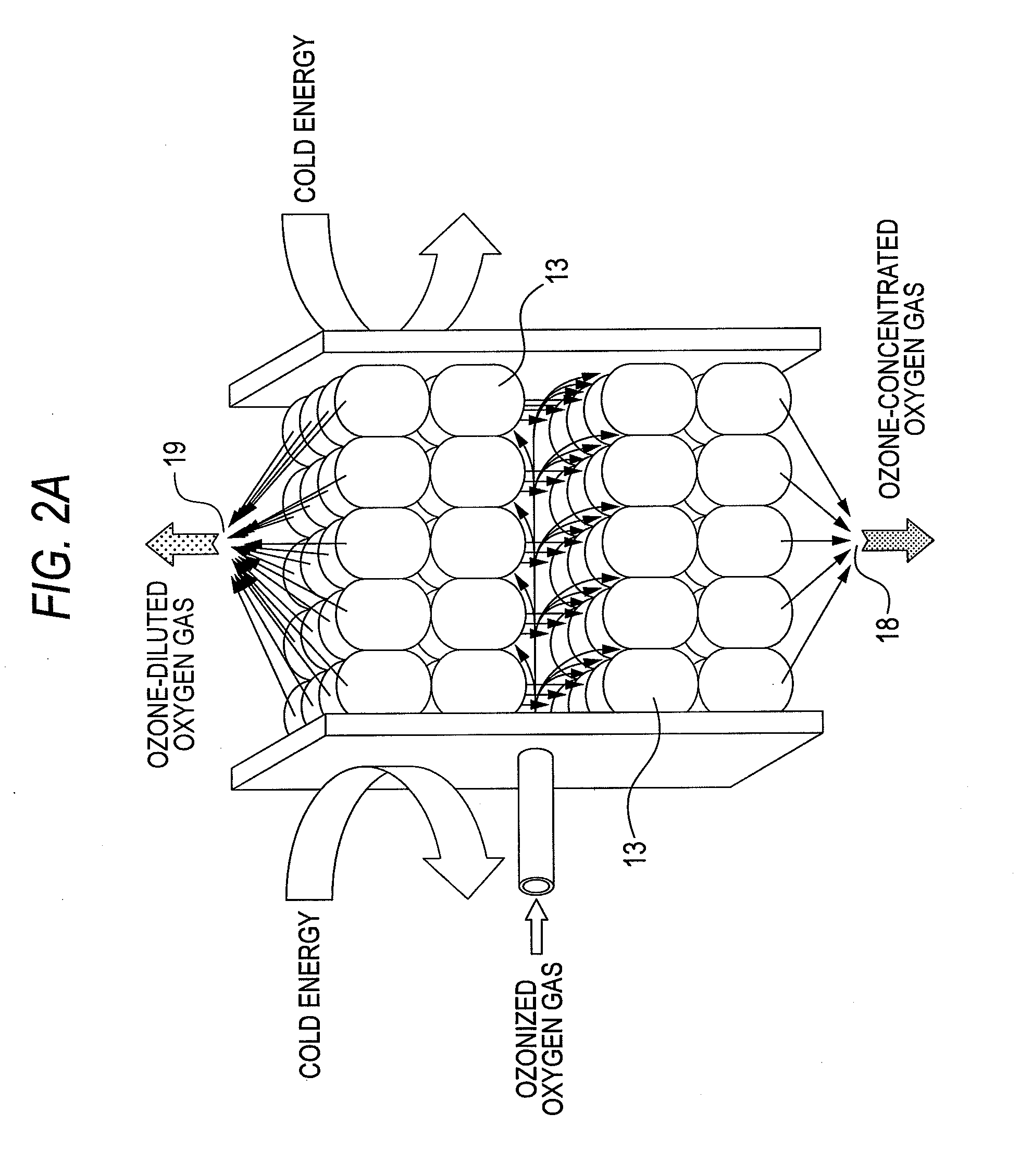

Apparatus for concentrating and diluting specific gas and method for concentrating and diluting specific gas

ActiveUS20100162752A1Improve processing efficiencySmall sizeSolidificationGas treatmentSpherical shapedVaporization

One ozone concentrating chamber is provided therein with a part of a cooling temperature range where ozone can be selectively condensed or an oxygen gas can be selectively removed by transmission from an ozonized oxygen gas, and a part of a temperature range where condensed ozone can be vaporized, and condensed ozone is vaporized by moving condensed ozone with flow of a fluid or by gravitation to the part where condensed ozone can be vaporized, whereby the ozonized oxygen gas can be increased in concentration. Such a constitution is provided that a particle material 13 for condensation and vaporization filled in the ozone concentrating chambers 11 and 12 has a spherical shape of a special shape with multifaceted planes on side surfaces, or an oxygen transmission membrane 130 capable of selectively transmitting an oxygen gas in an ozone gas is provided.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

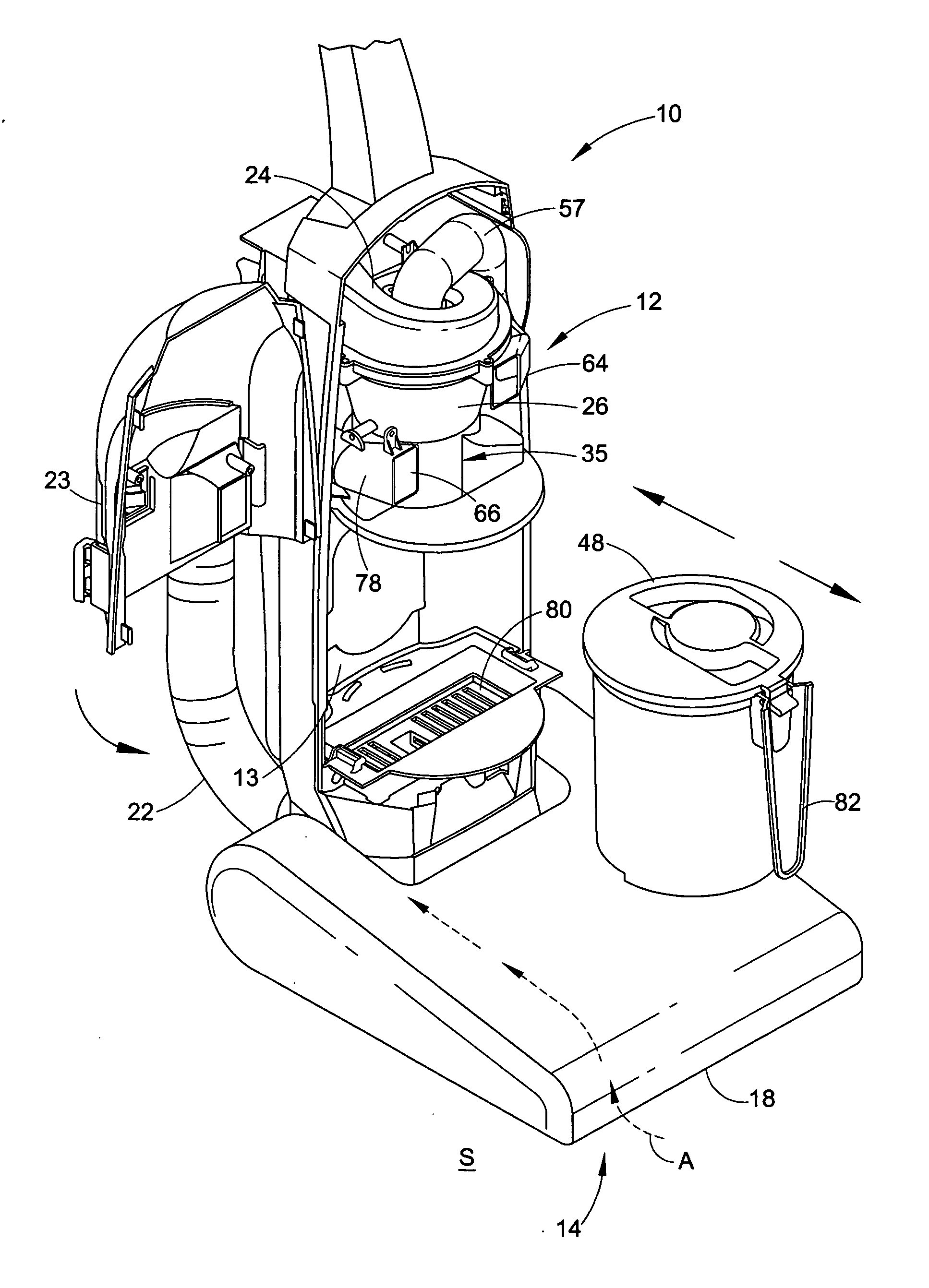

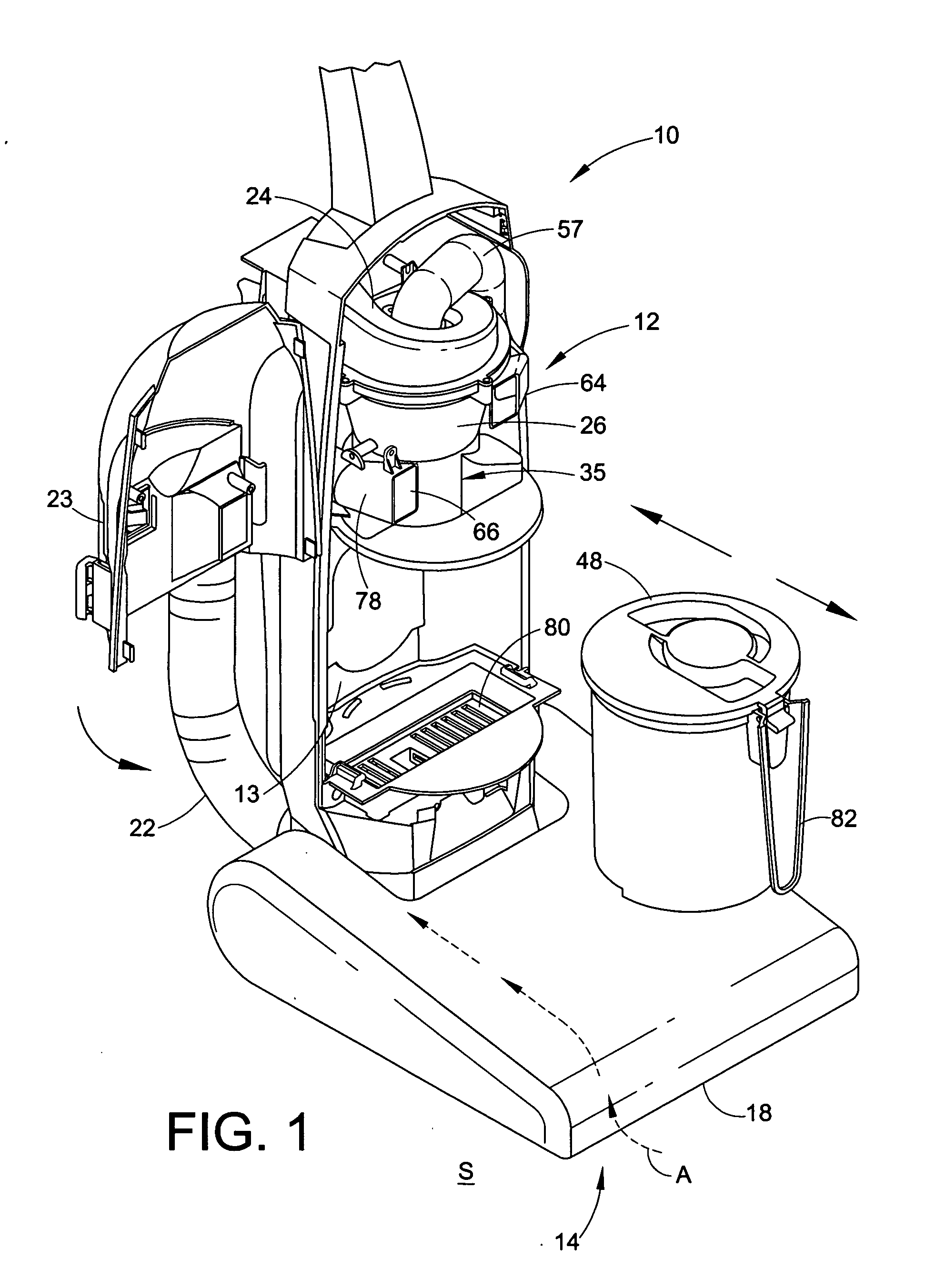

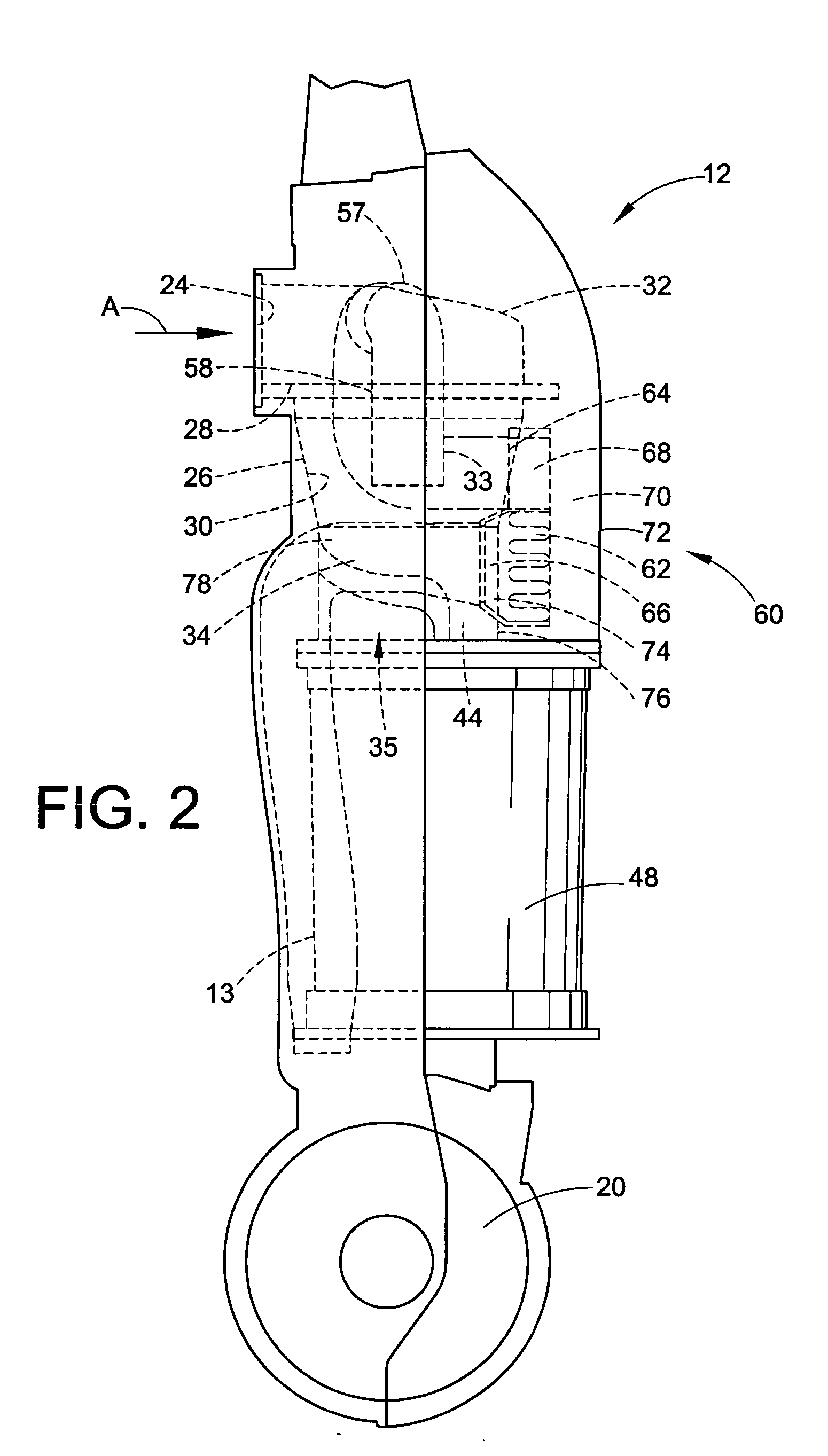

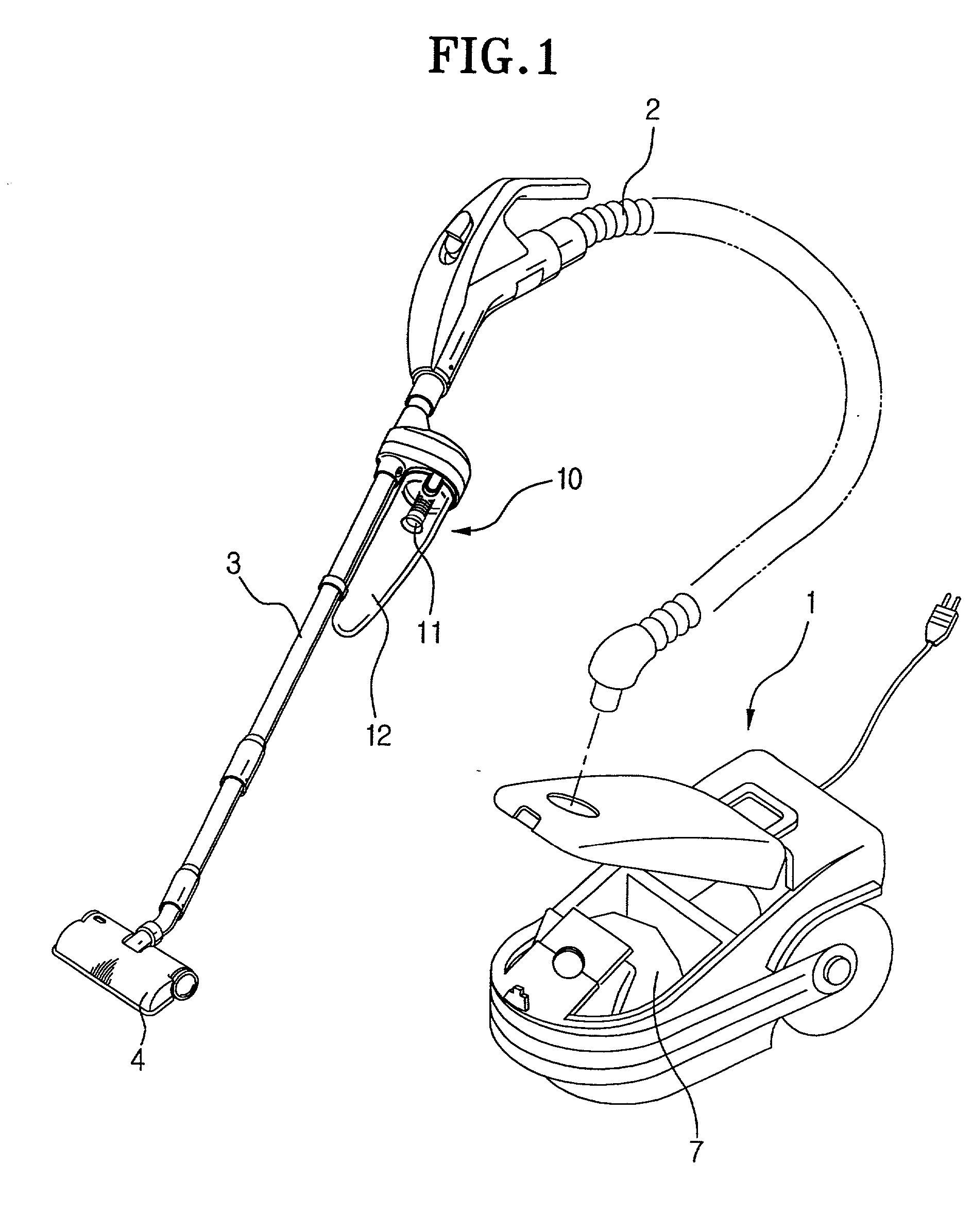

Cyclonic vacuum cleaner

InactiveUS20050138763A1Improve efficiencyEasy to emptyCleaning filter meansCombination devicesCycloneVacuum cleaner

A cyclonic vacuum cleaner includes a body portion, a nozzle portion and a dirt cup which is removable from the body portion. The dirt cup collects dirt and other debris separated by a cyclone and a cyclone slinger portion in the body portion. A main filter may be housed in a transparent filter door downstream of the cyclone. The dirt cup may be inserted into and sealingly held within the body portion by using a rotational camming structure.

Owner:MIDEA AMERICA CORP

Cryogenic process utilizing high pressure absorber column

Owner:ABB LUMMUS GLOBAL INC

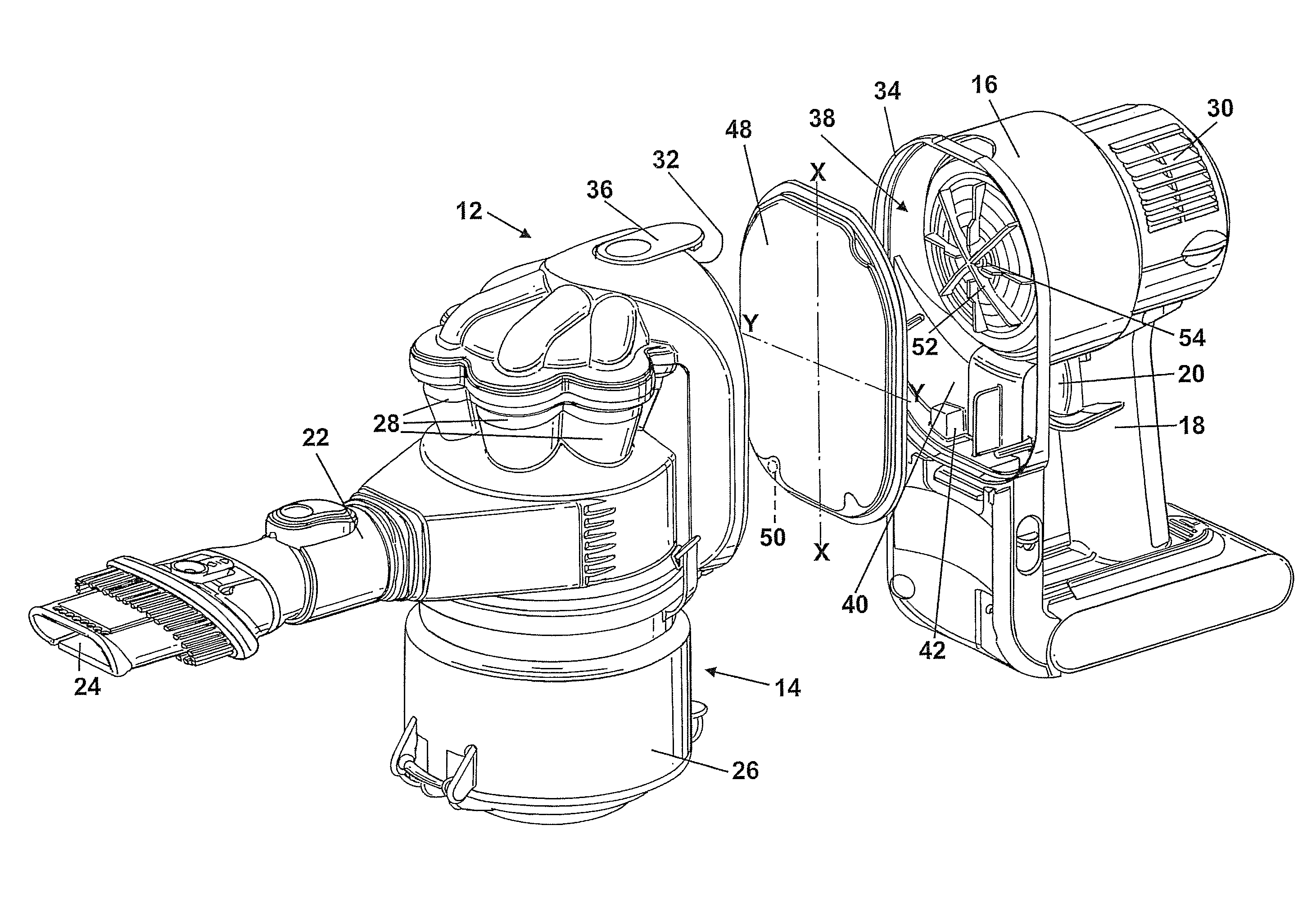

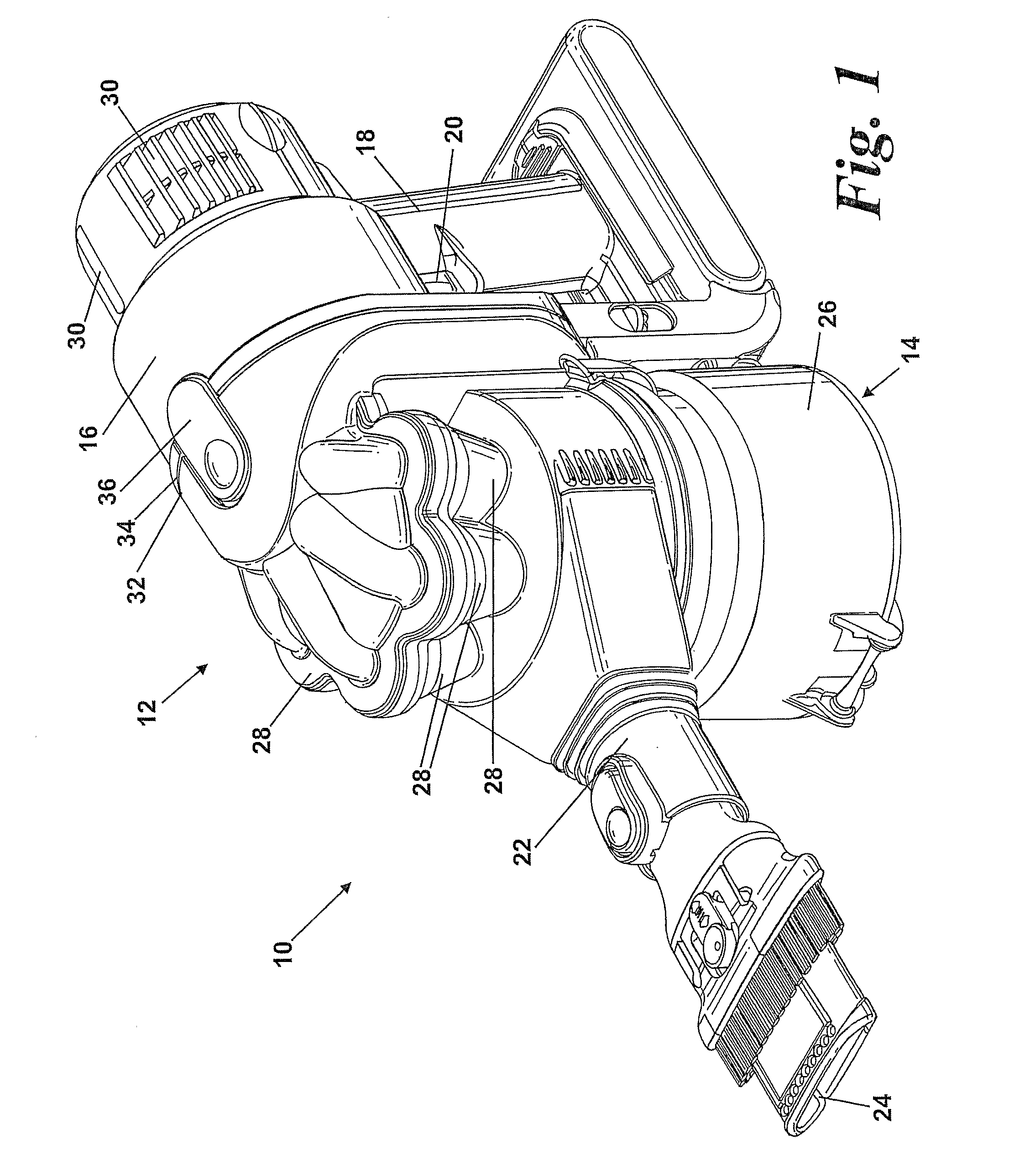

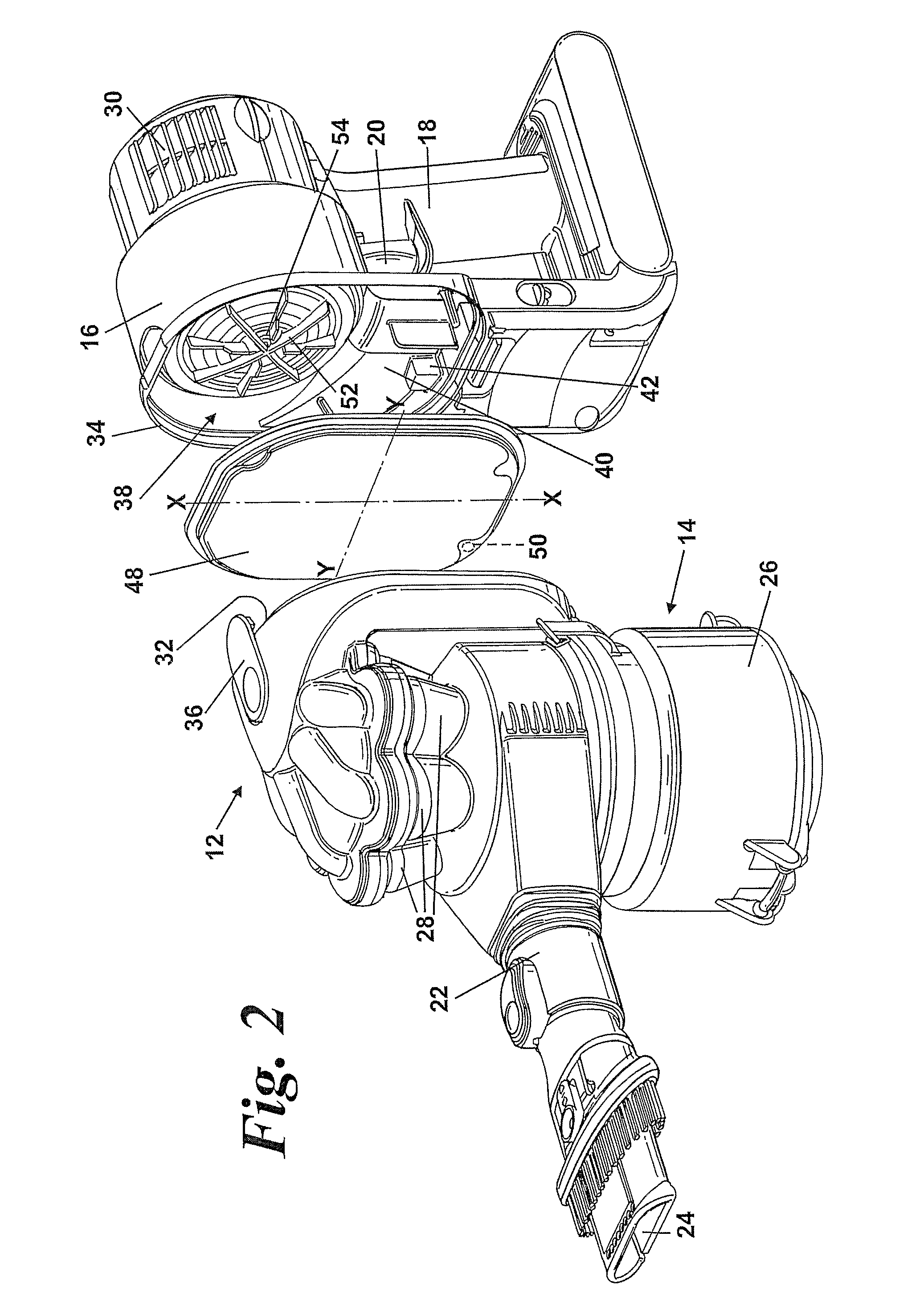

Handheld cleaning appliance

InactiveUS7931716B2Reduce cloggingLess prone to failureCombination devicesAuxillary pretreatmentHand heldWaste management

A cleaning appliance includes a main body, a filter and an interlock. The main body includes an airflow generator, a separating apparatus separating dirt and dust from an airflow, and a flowpath between the separating apparatus and the airflow generator delimited by a wall. The interlock has a first part located on the filter and a second part located on the main body outside the flowpath, arranged to communicate remotely when the filter is correctly located in the pre-determined position. The interlock is arranged selectively to allow or prevent operation of the airflow generator depending upon the relative separation between the first and second parts. By providing an interlock which has first and second parts which communicate remotely, the second part located on the main body can be isolated from the airflow path so that the second part is not subject to dirt and dust carried by the airflow.

Owner:DYSON TECH LTD

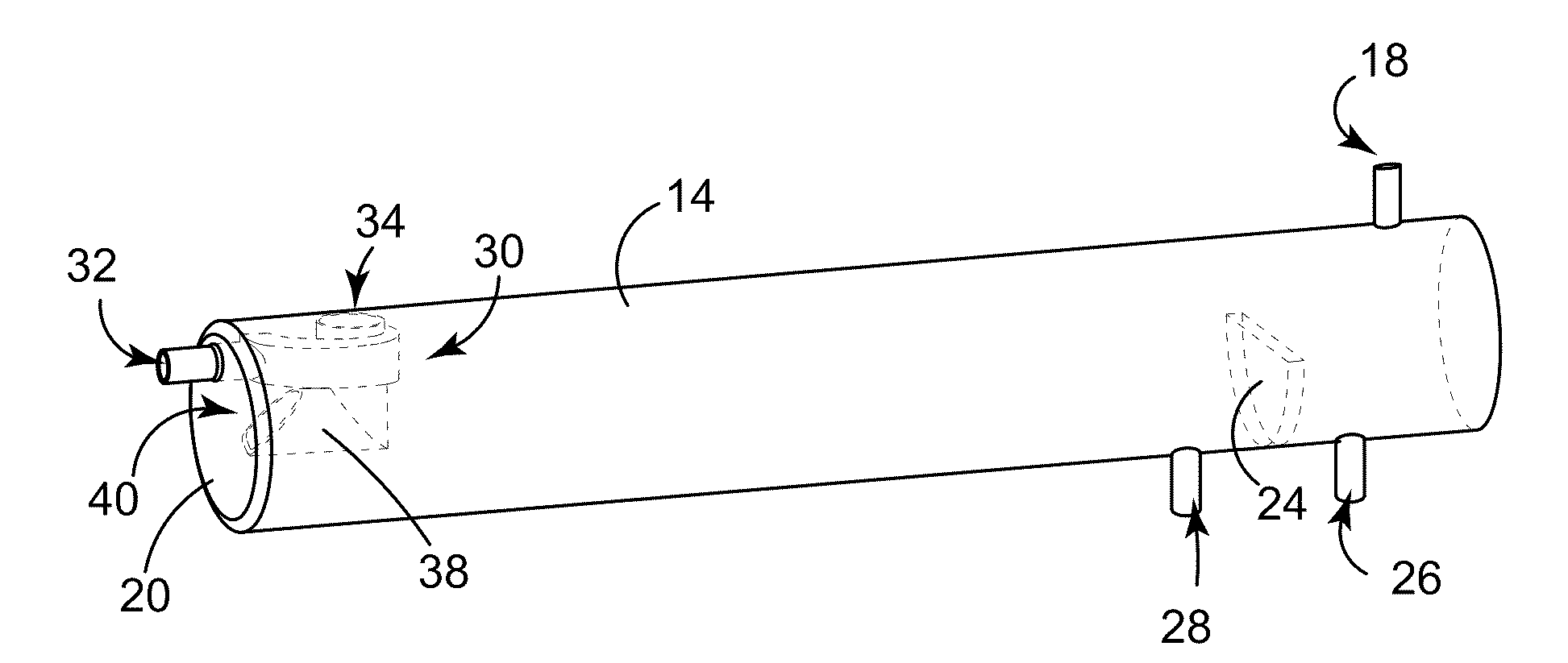

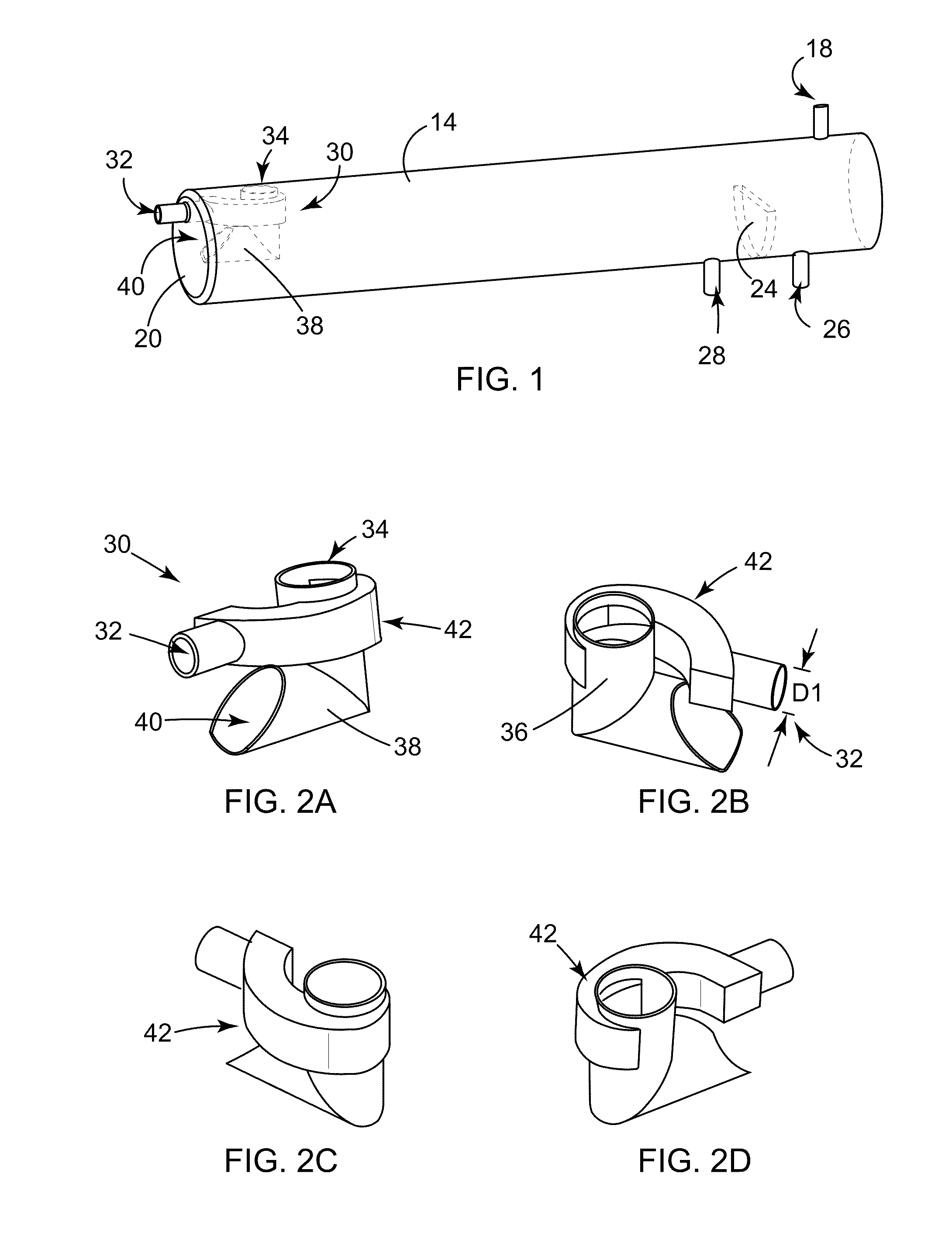

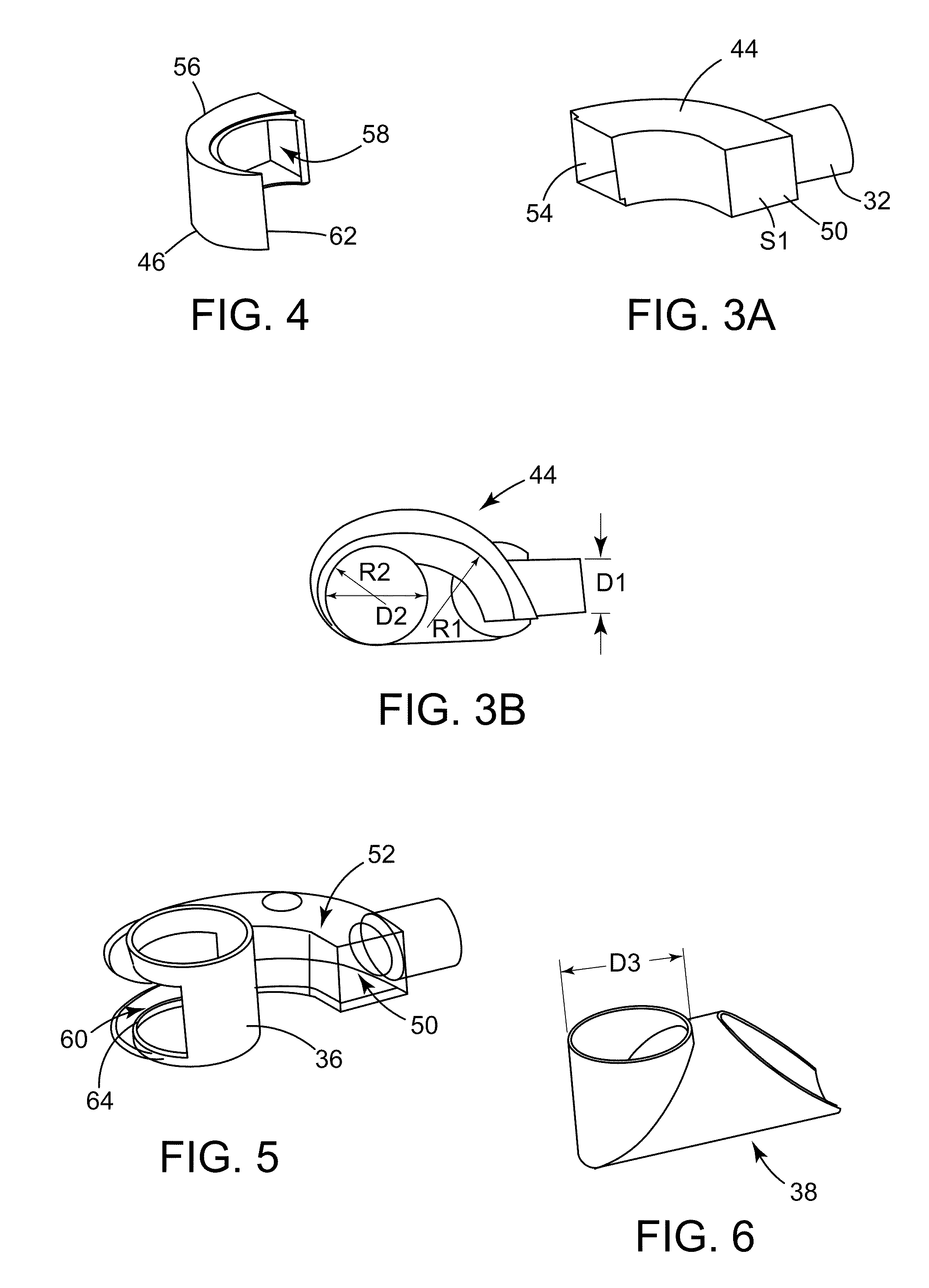

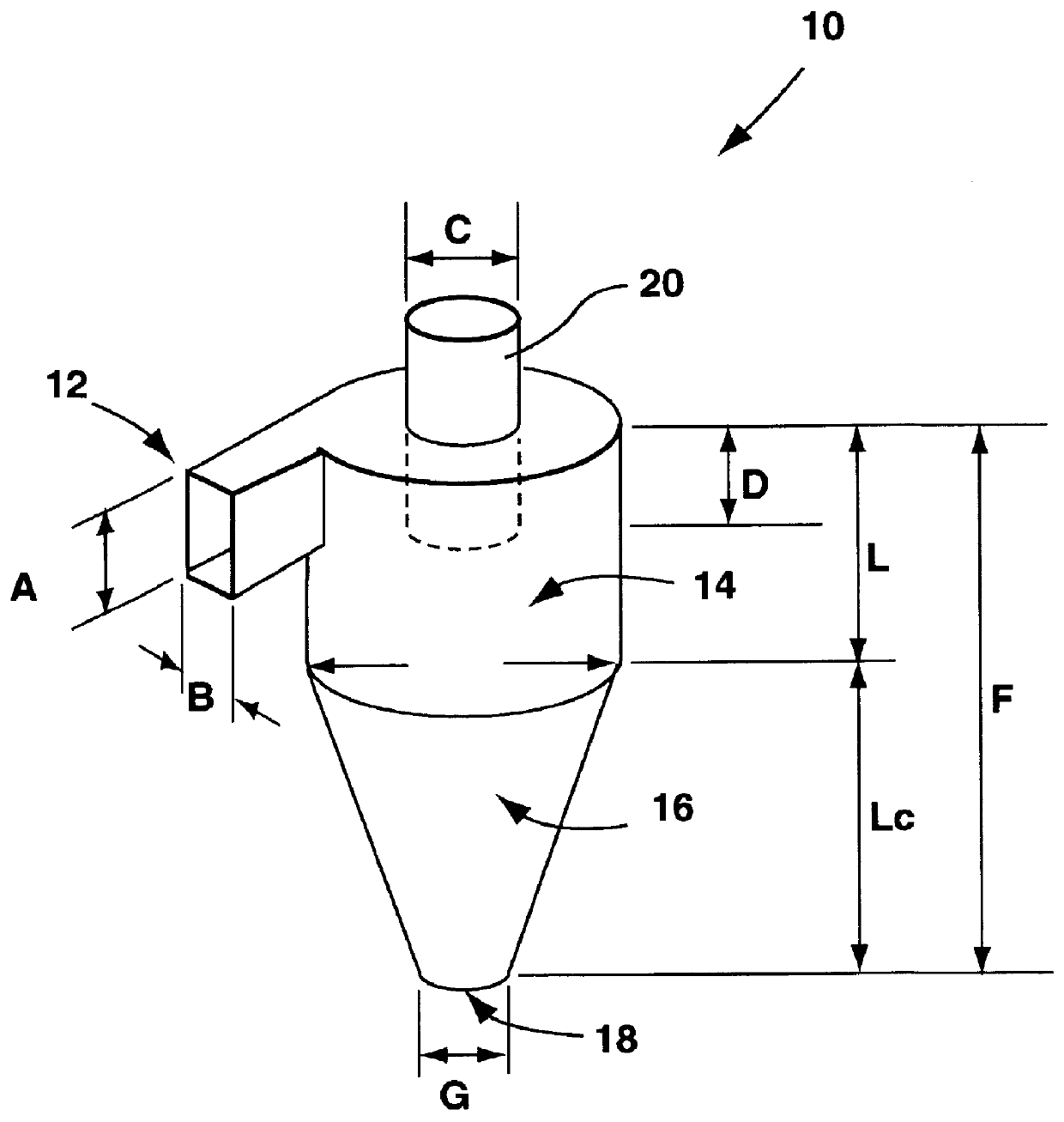

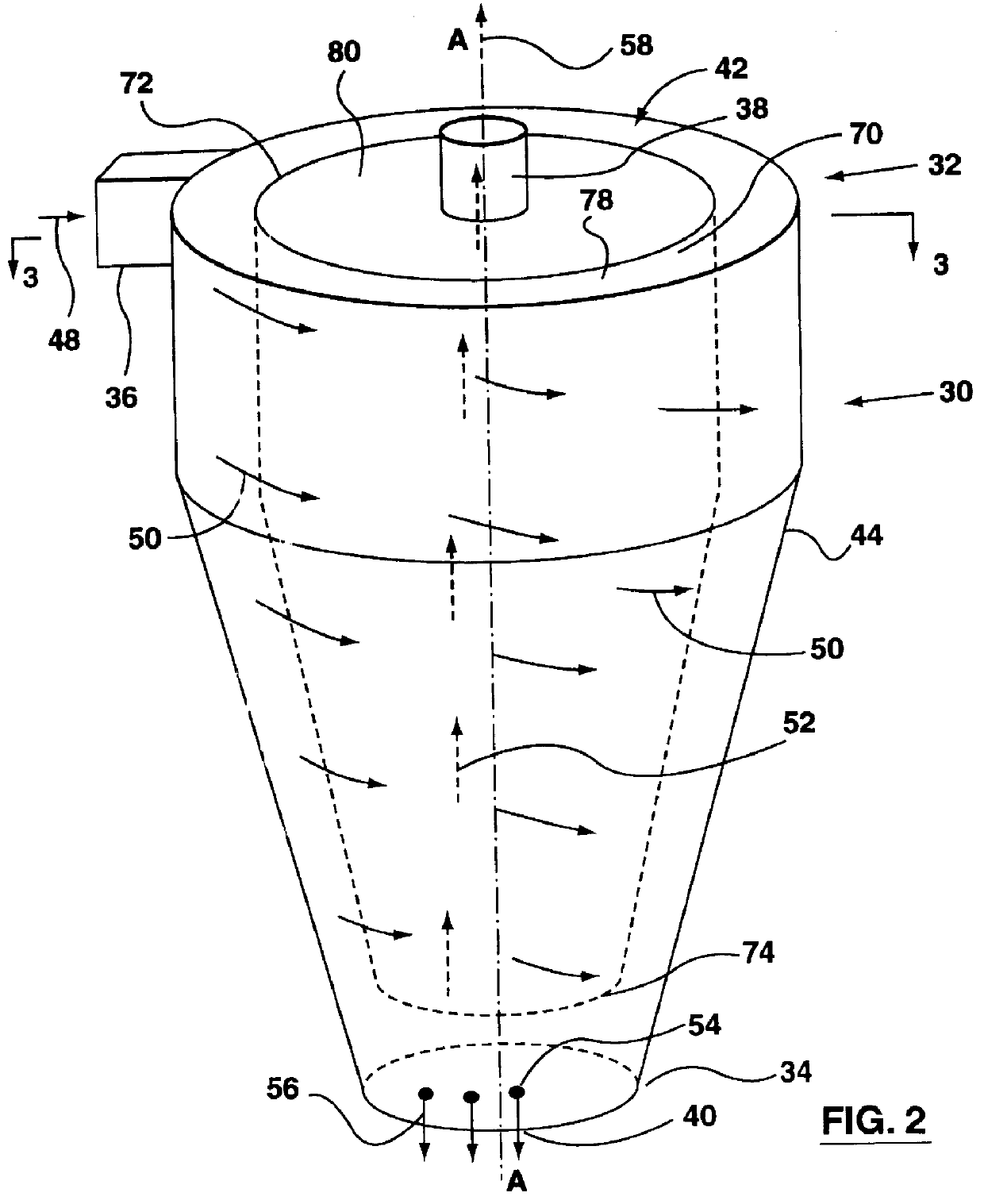

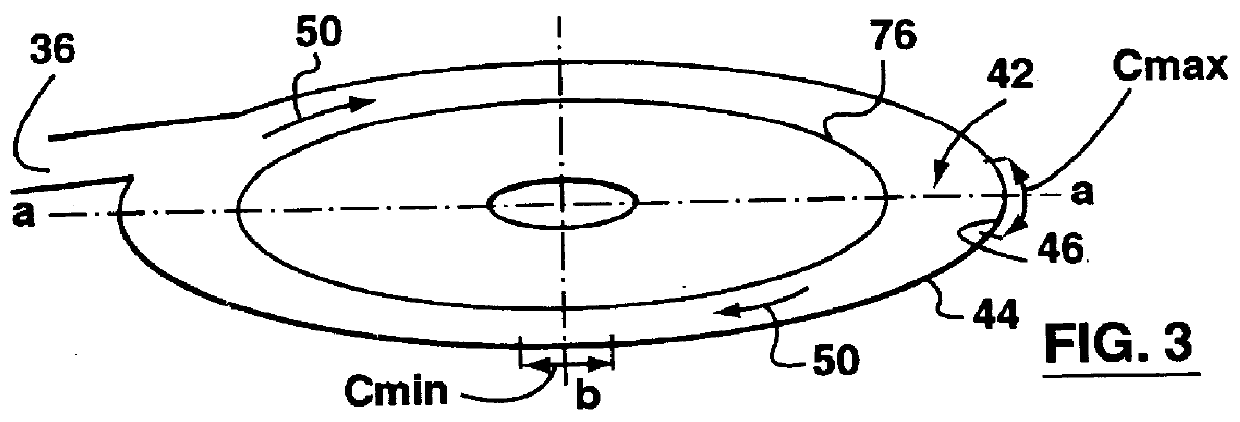

Apparatus for separation of gas-liquid mixtures and promoting coalescence of liquids

ActiveUS20110247500A1Reduce momentumPromote droplet coalescenceLiquid degasificationReversed direction vortexChemical physicsOil separation

Provided herein is a conditioning apparatus that includes a geometrical configuration having an inlet flow deceleration conduit and a cyclonic tube to effectuate both liquid-gas separation and droplet coalescence. The apparatus is typically positioned at the inlet of a separator vessel used for removing water and gas from extracted crude oil containing entrained water and gas. The apparatus promotes droplet coalescence and gas separation for mixed fluids flowing into an existing water and oil separation device.

Owner:SAUDI ARABIAN OIL CO

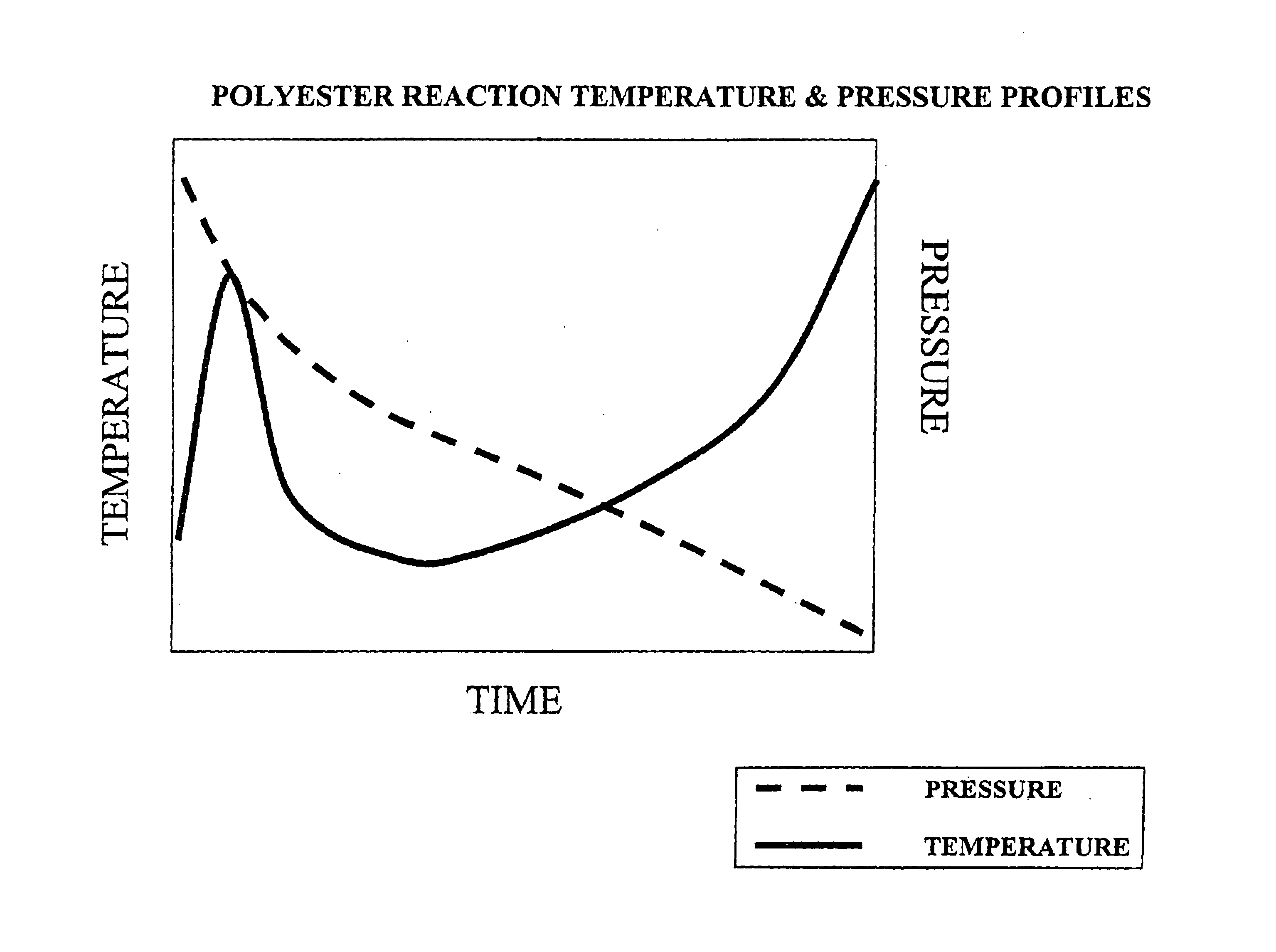

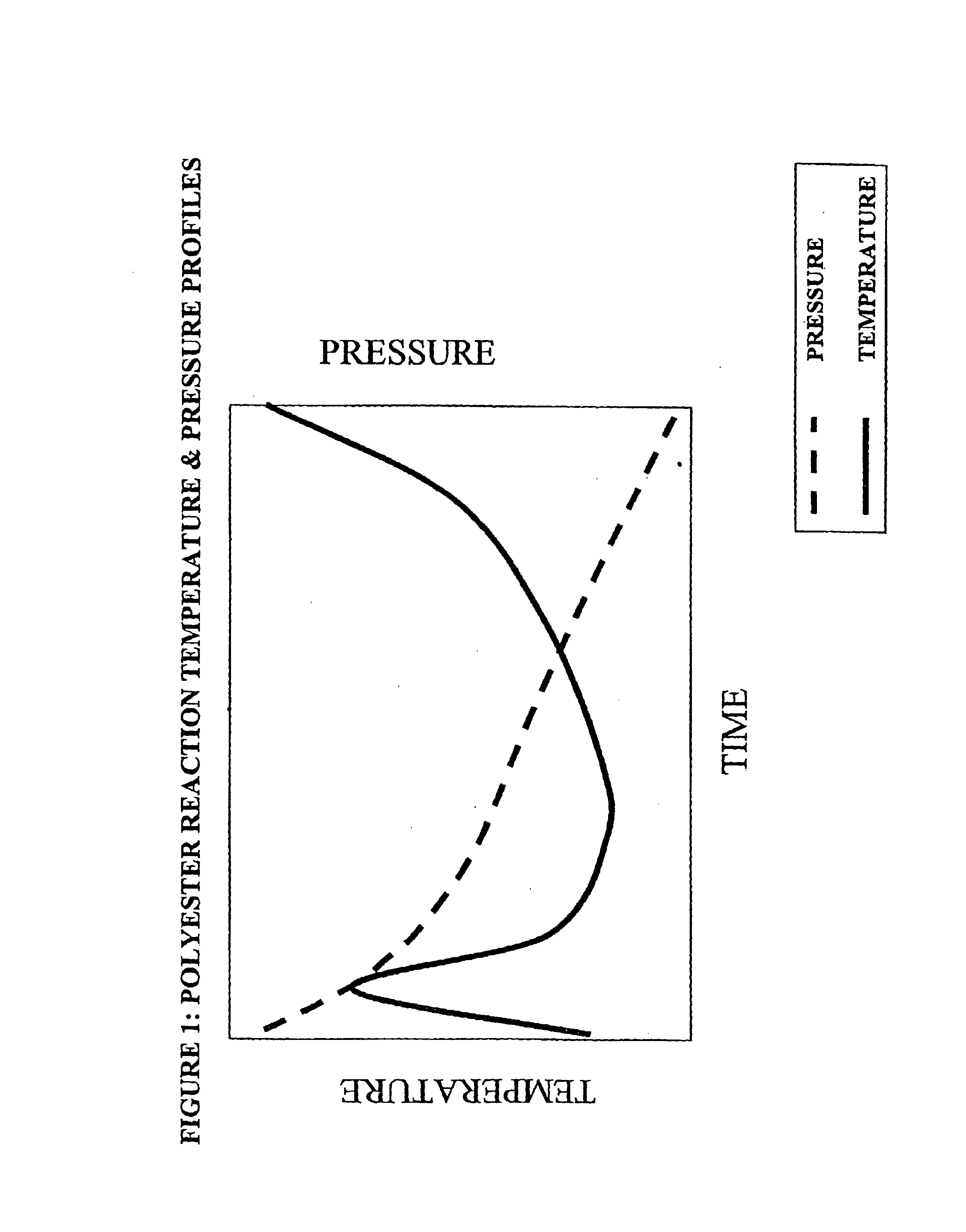

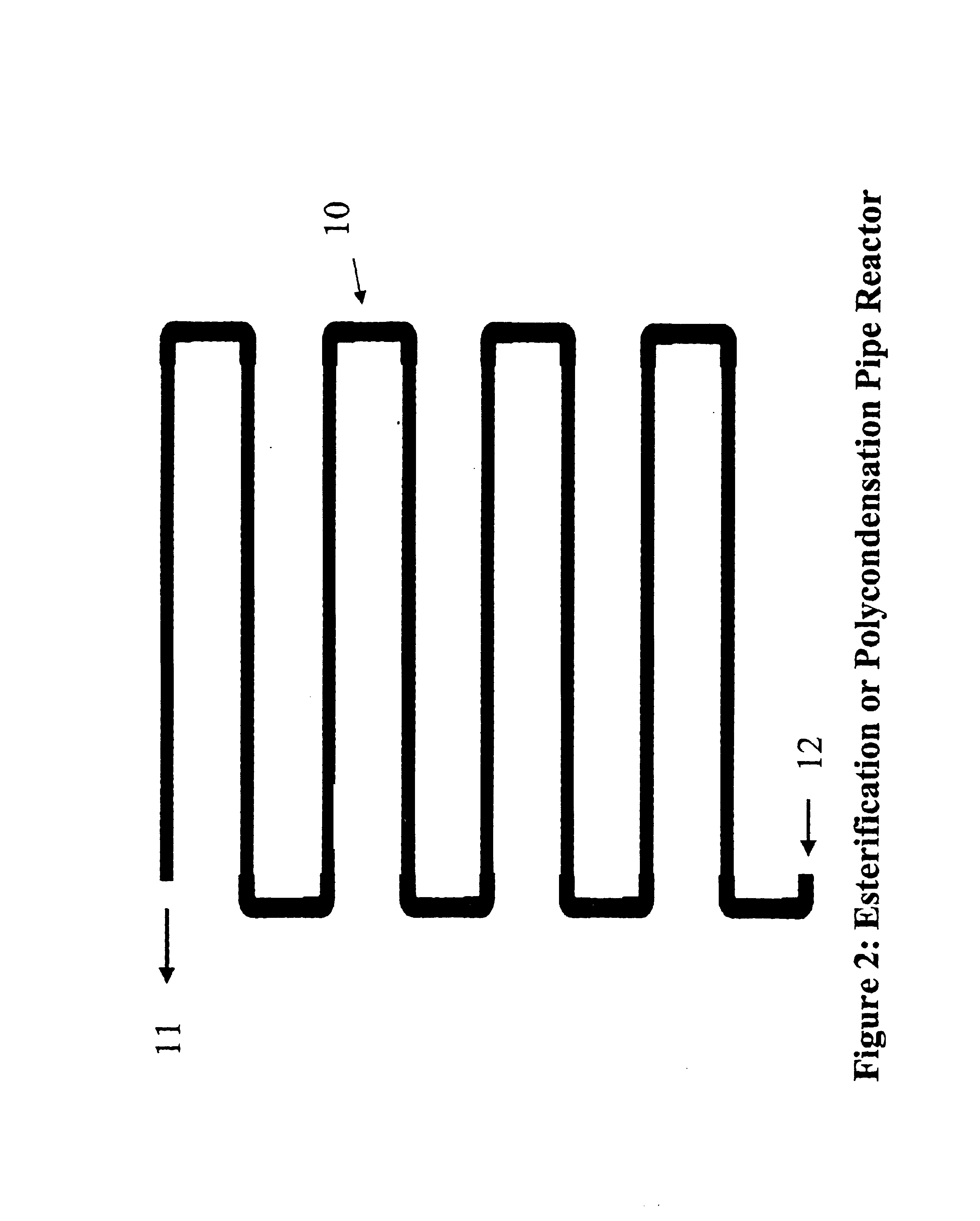

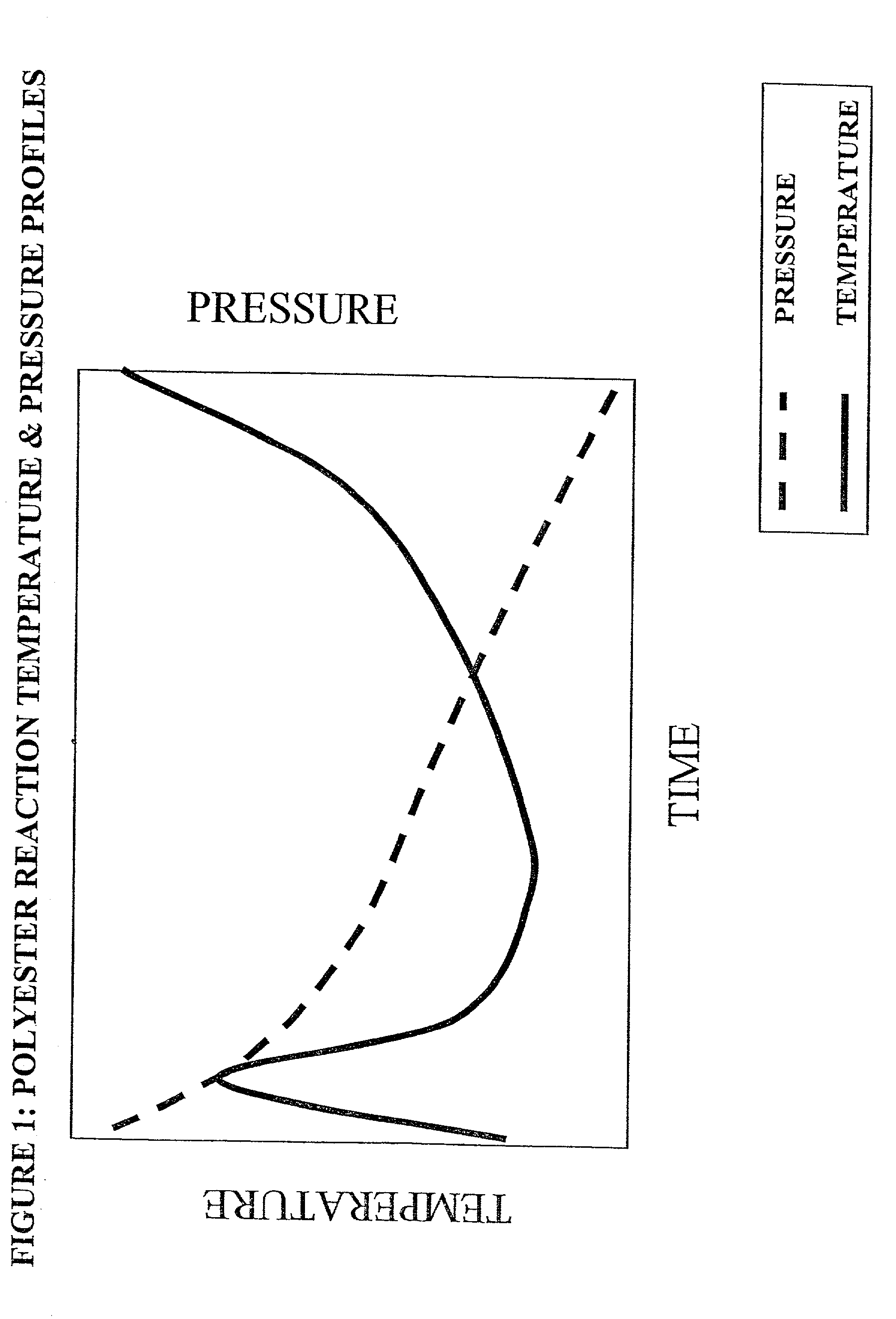

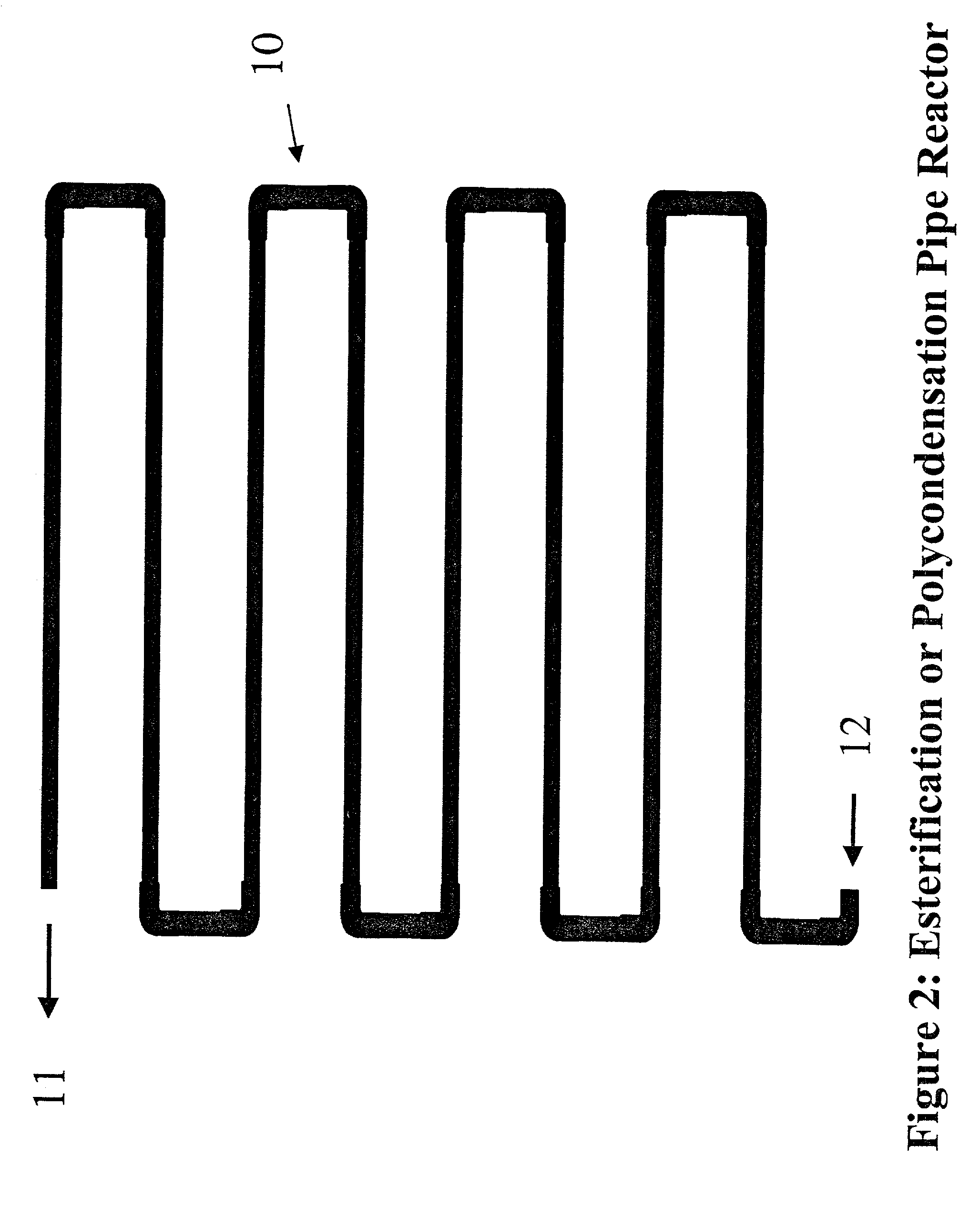

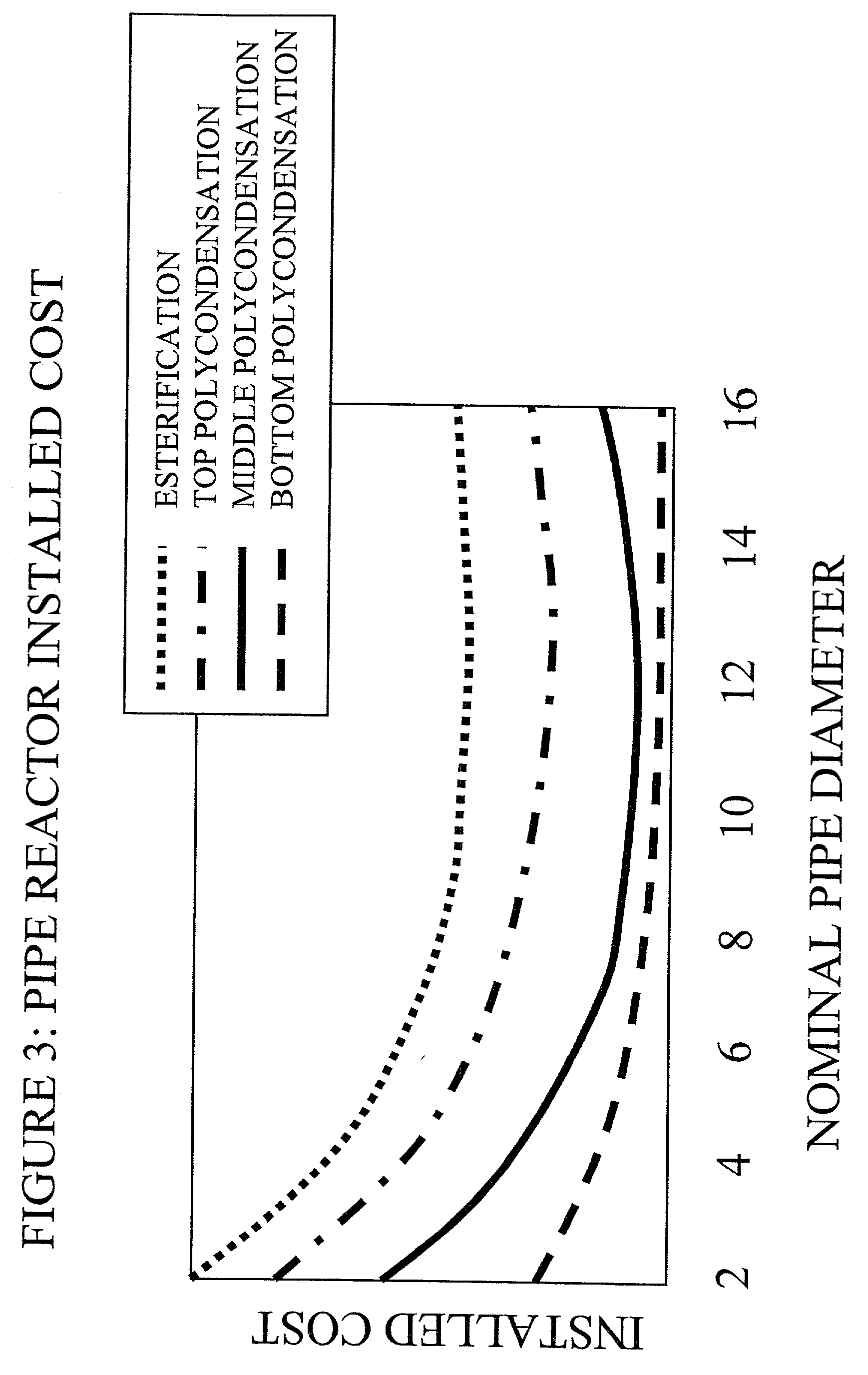

Polyester process using a pipe reactor

InactiveUS6861494B2Reduce pressureEliminate needLiquid degasificationFlow mixersProcess engineeringPolyester resin

Owner:ALPEK POLYESTER SA DE CV

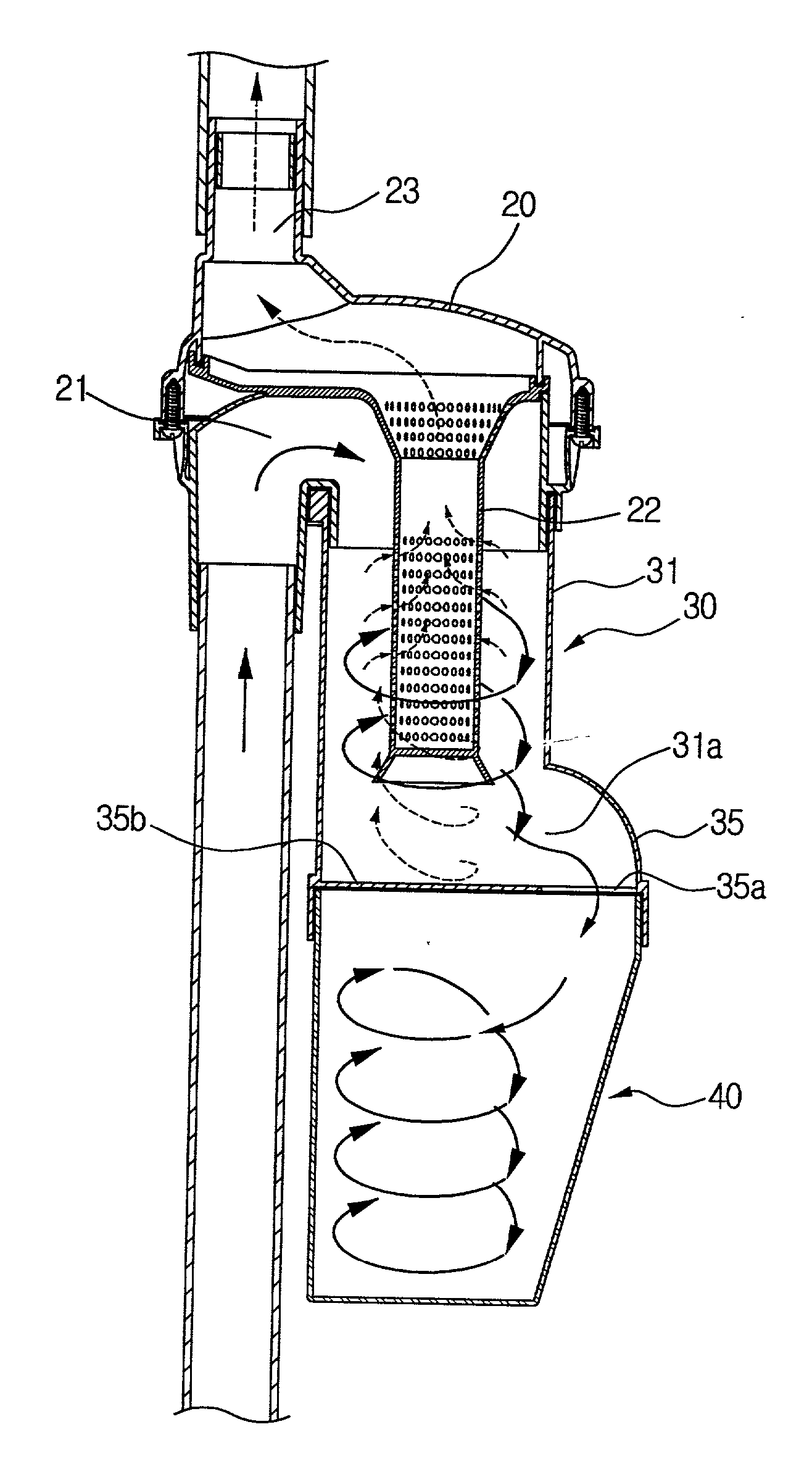

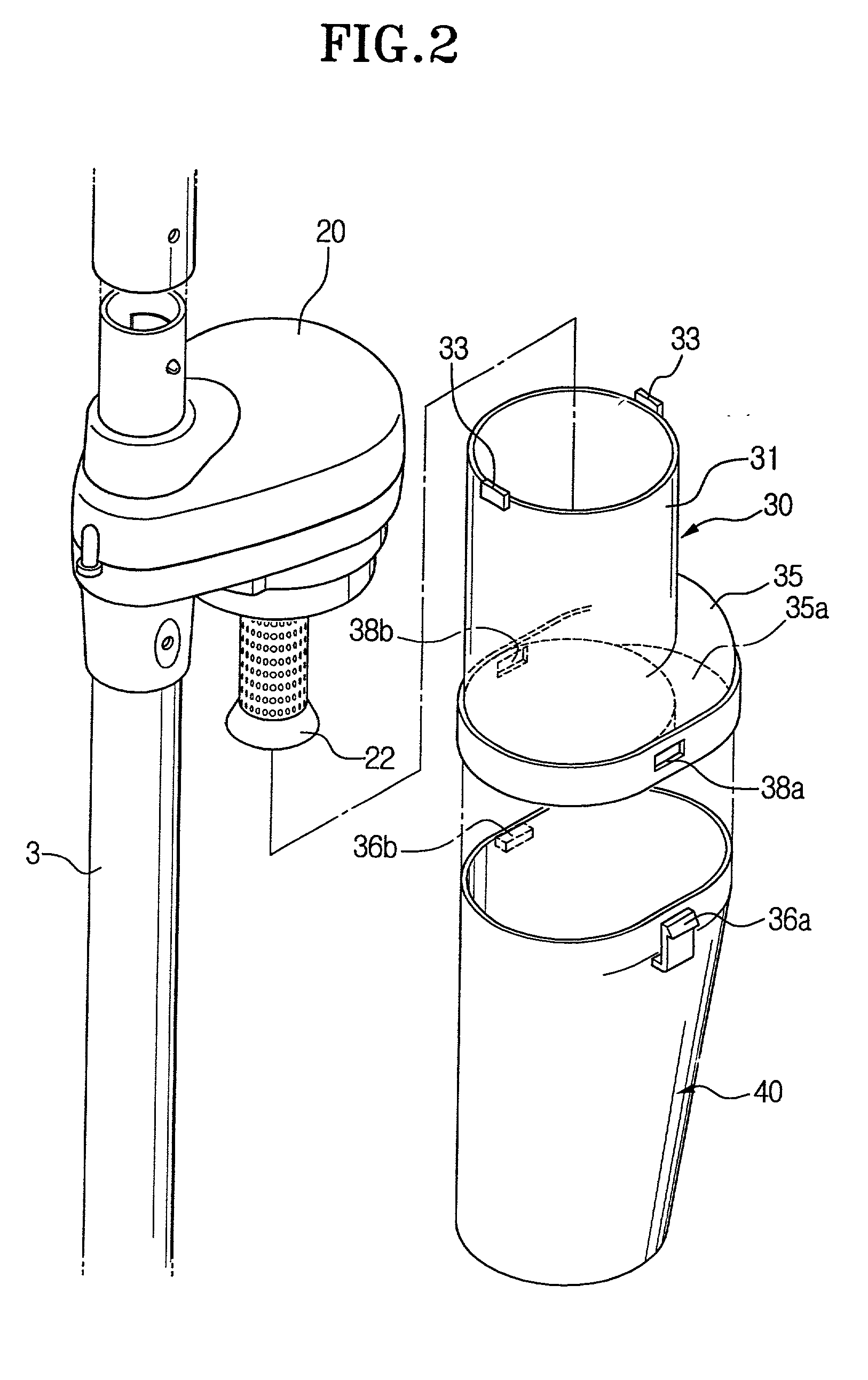

Cyclone dust- collecting apparatus for vacuum cleaner

A cyclone dust-collecting apparatus of a vacuum cleaner includes a cyclone body installed at an extension hose for generating air current of vortex from incoming air, a grill for filtering back drafting current of the air current of vortex, and a cyclone cover including a partly blocked plate, which is placed to correspond to the grill, a filth passage for guiding filth to a filth-collecting container, and a first connection member for connecting the cyclone body with the filth-collecting container. The filth-collecting container has second connection member for connecting with the cyclone cover. Accordingly, it can be prevented a grill from being blocked by back drafting of piled filth in the filth-collecting container regardless of the position of a user. When the user eliminates collected filth, breakage of a grill or falling down of the filth clung to the grill, can also be prevented.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

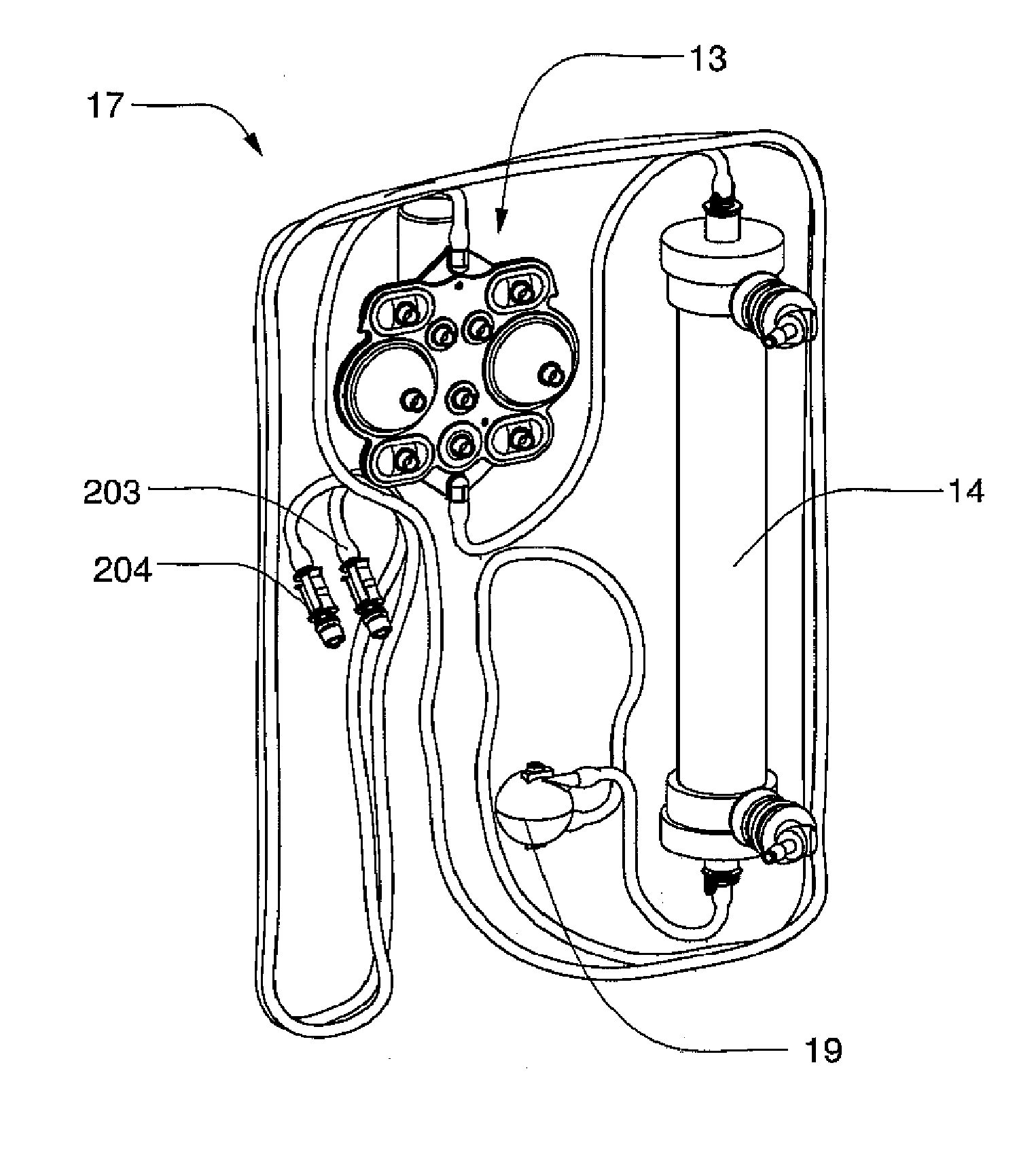

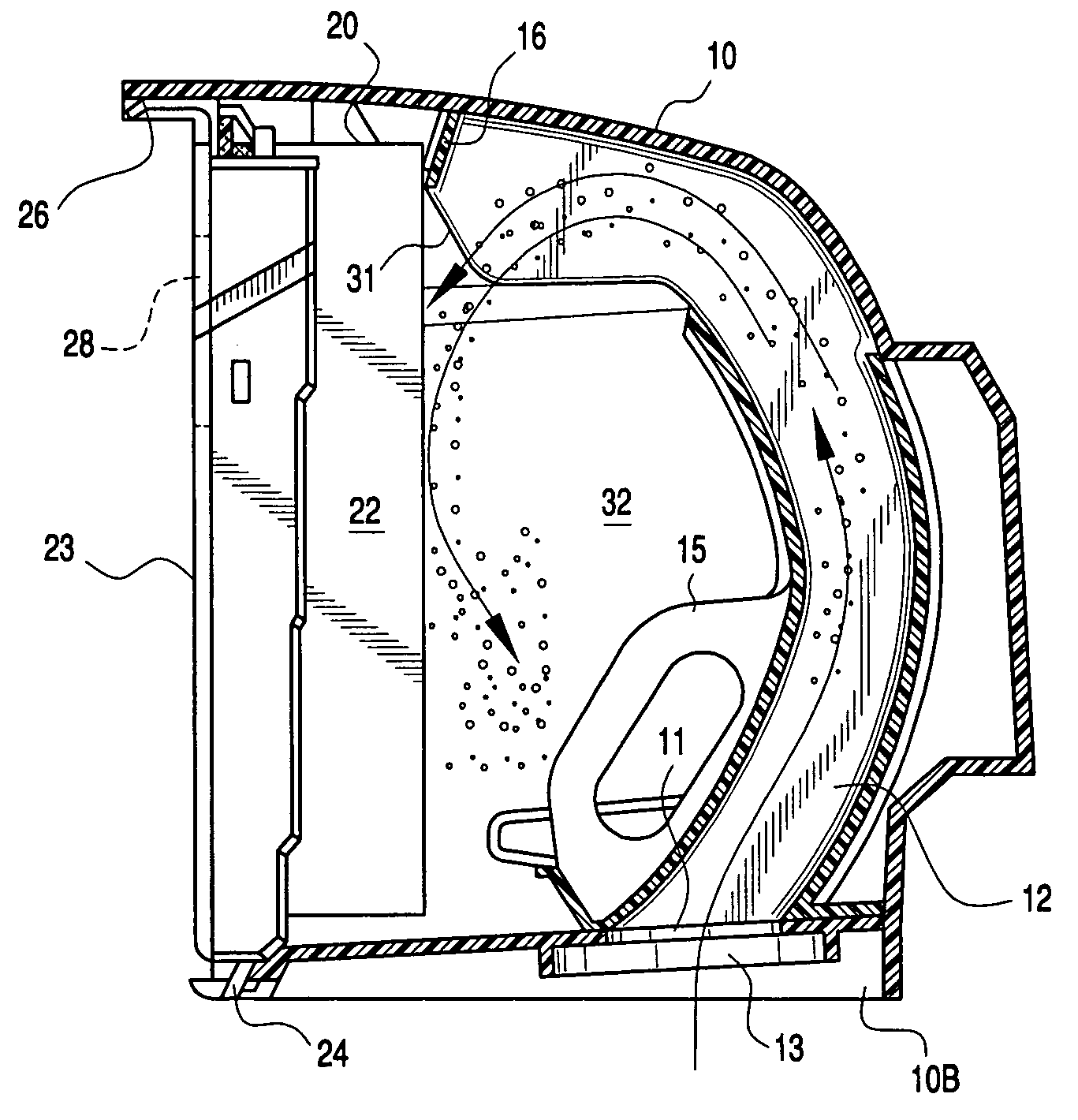

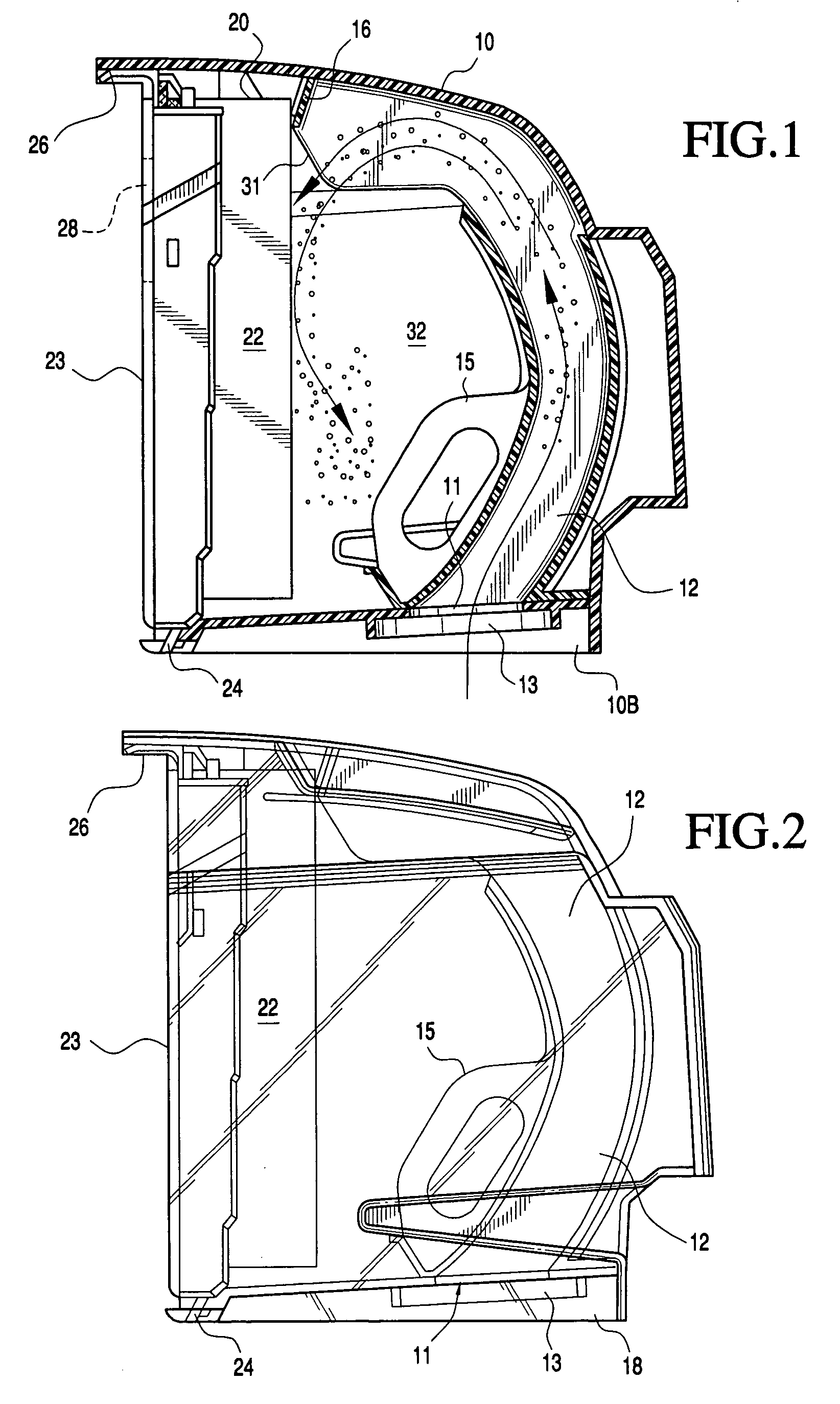

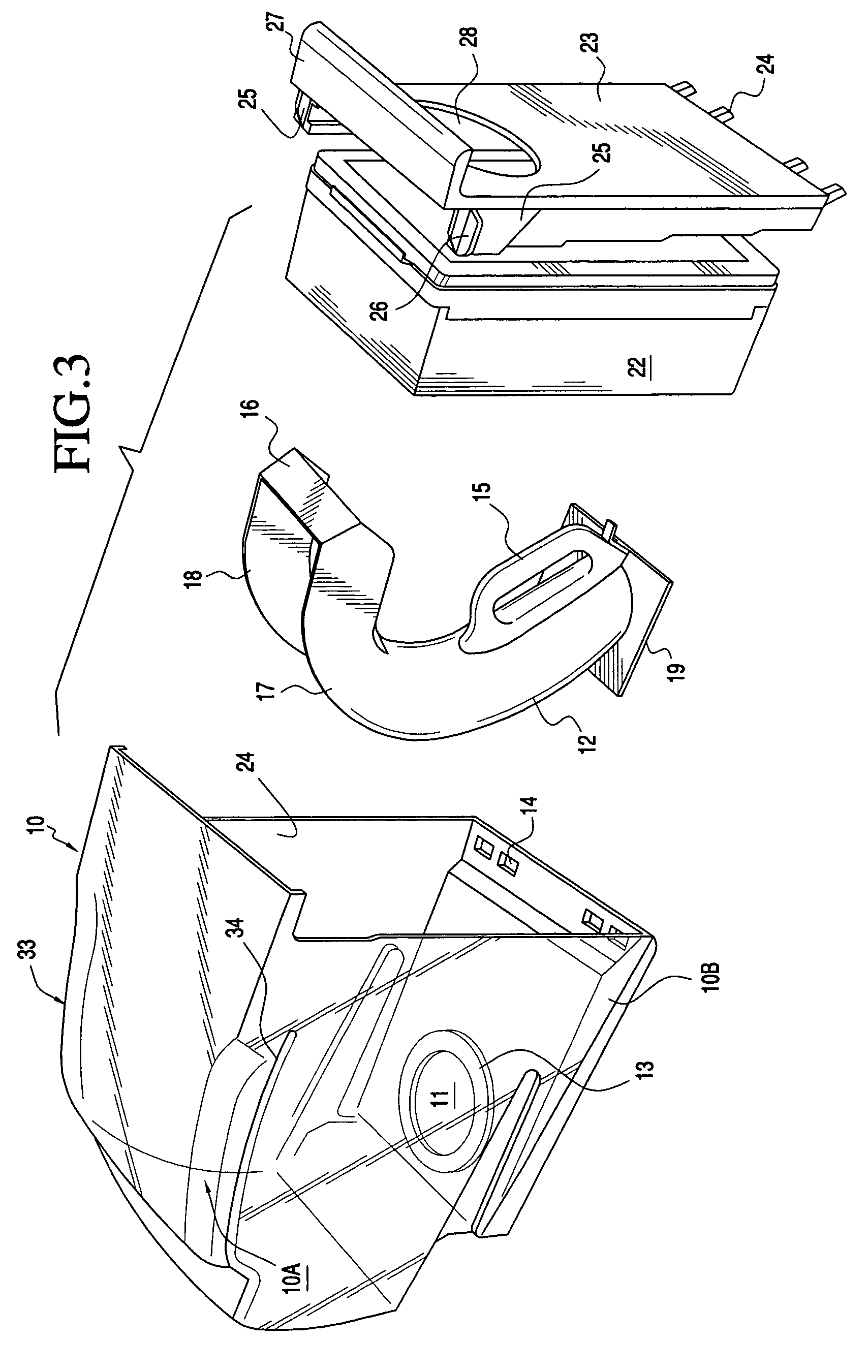

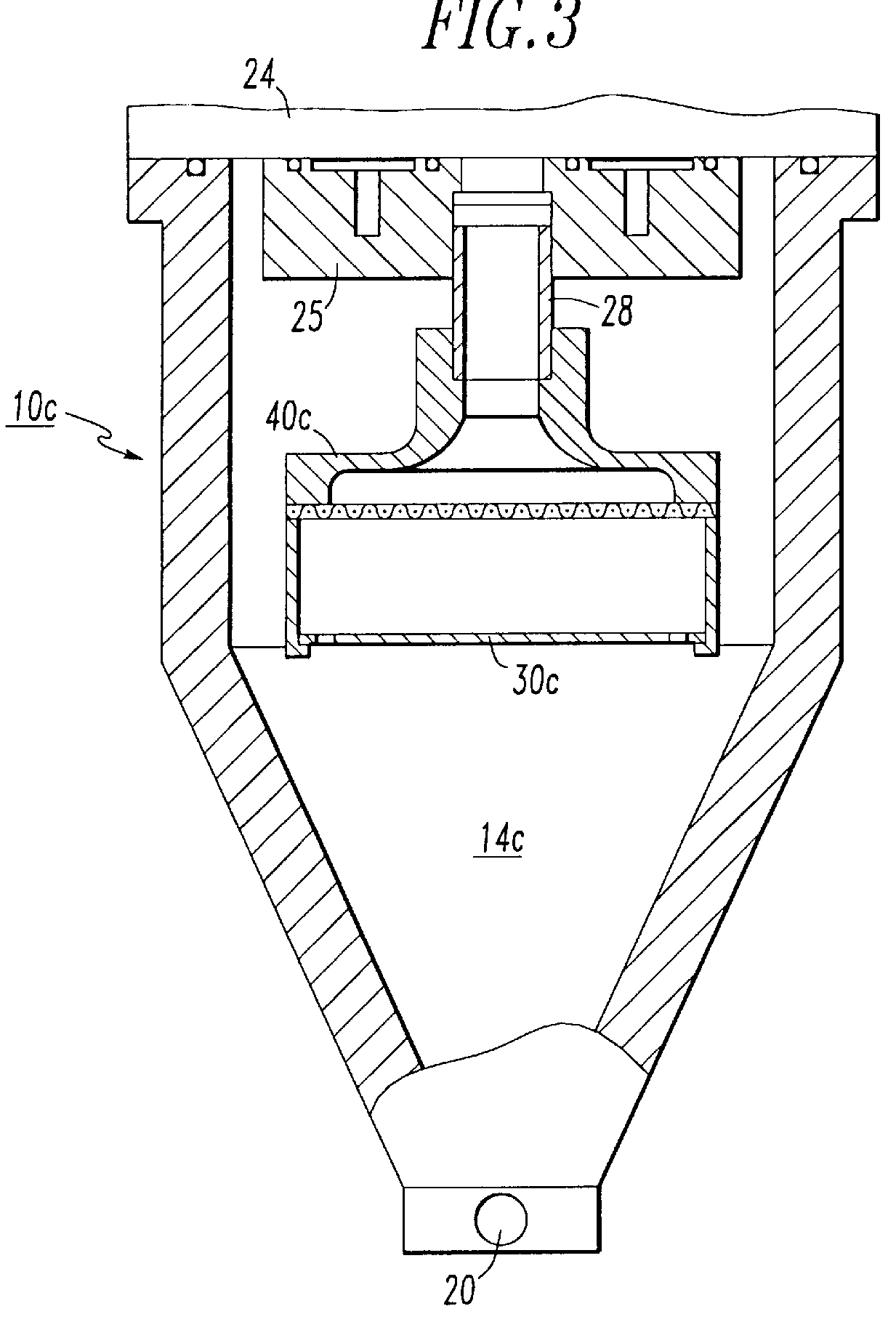

Air trap for a medical infusion device

InactiveUS20090107335A1Easy to useOptimize locationLiquid degasificationDialysis systemsEngineeringVertical axis

An air trap for a blood circuit and method for removing air from blood in a dialysis unit. The air trap may include a blood inlet supply line, a blood outlet supply line, and a container having an approximately spherical internal wall, an inlet at a top end of the container connected to the blood inlet supply line, and an outlet at a bottom end of the container connected to the blood outlet supply line. The inlet may be offset from a vertical axis of the approximately spherical internal wall such that blood entering the container is directed to flow in a spiral-like path. The inlet port may be arranged to introduce blood into the container in a direction that is approximately tangential to the approximately spherical inner wall of the container and / or in a direction that is approximately perpendicular to the vertical axis of the container.

Owner:DEKA PROD LLP

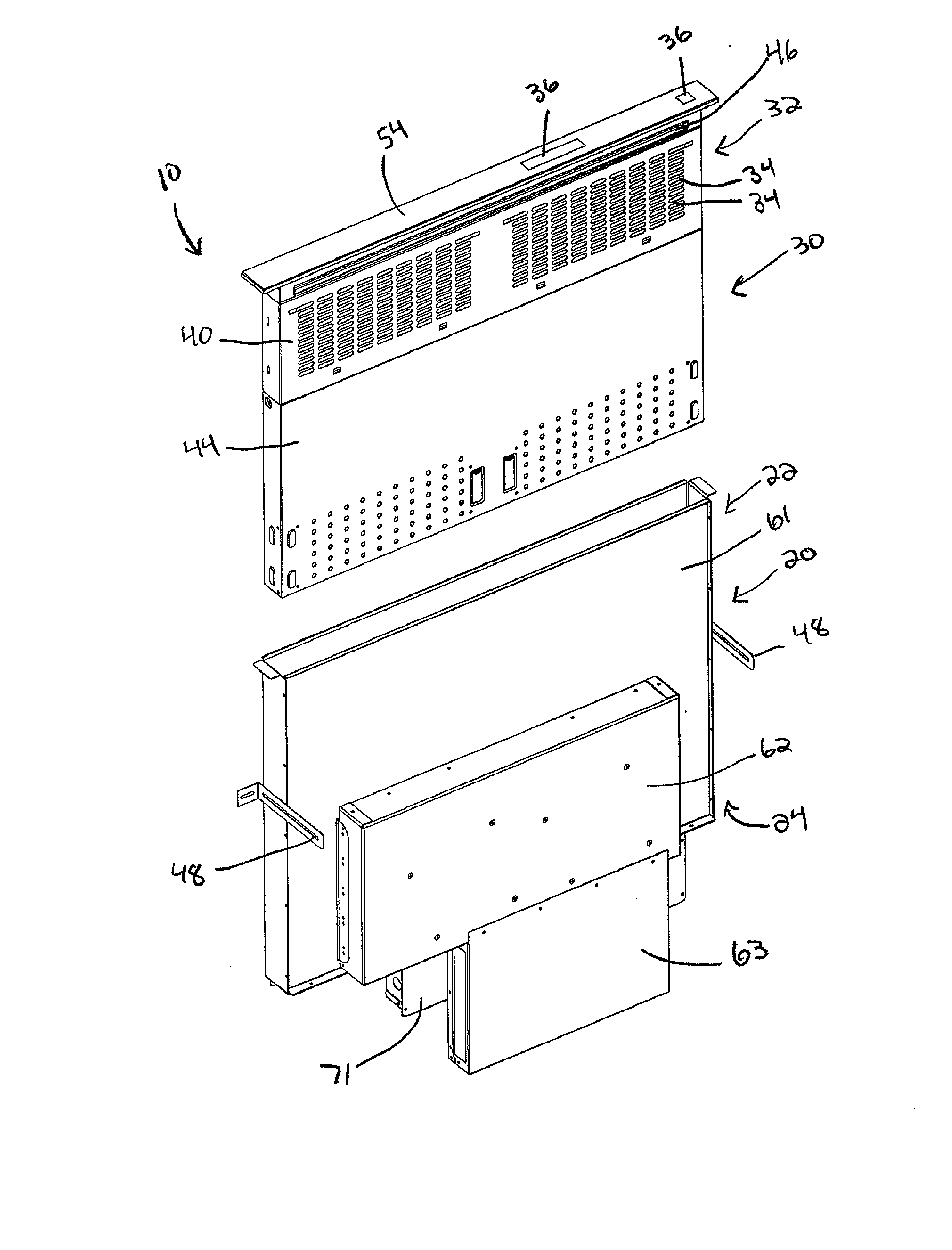

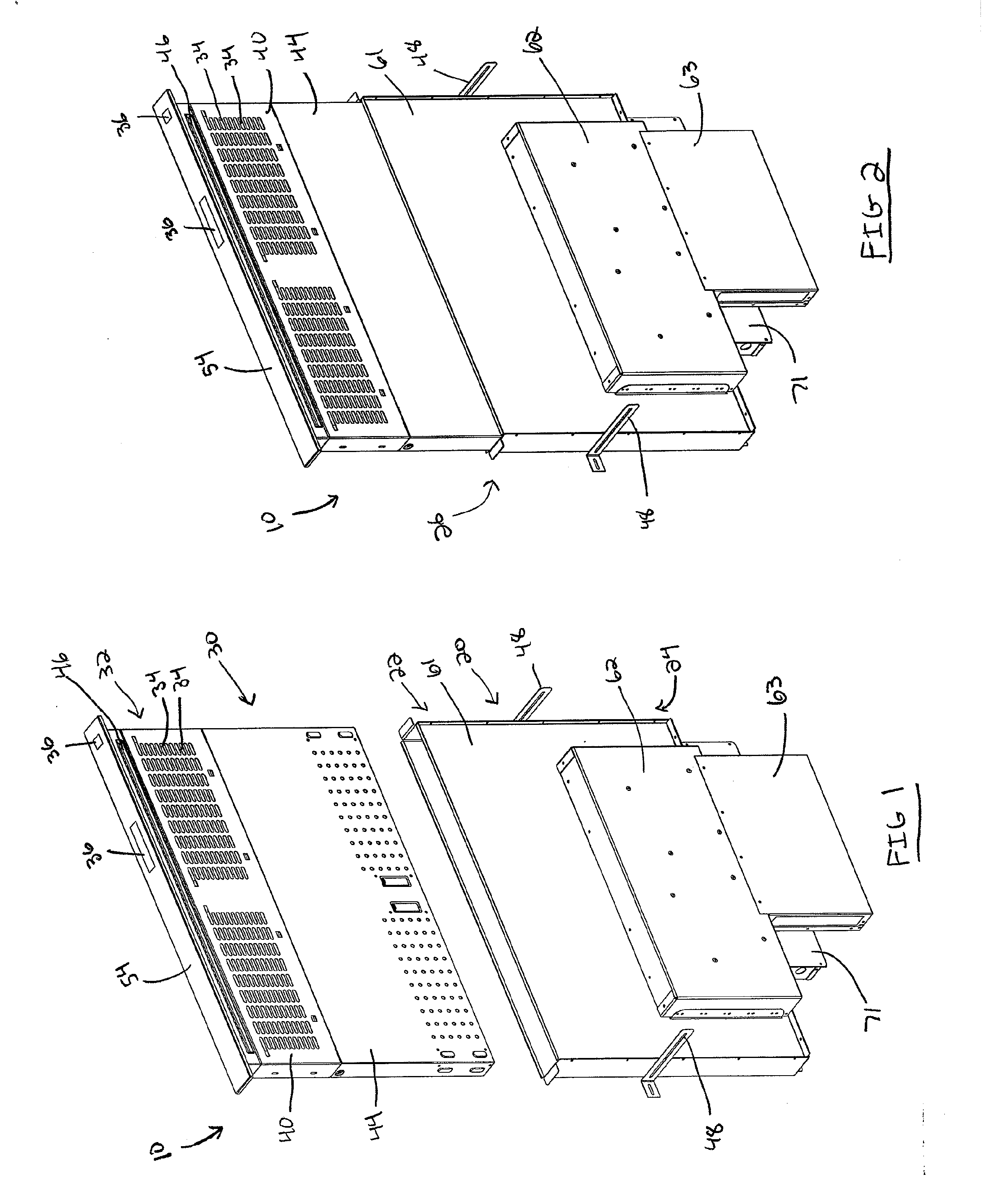

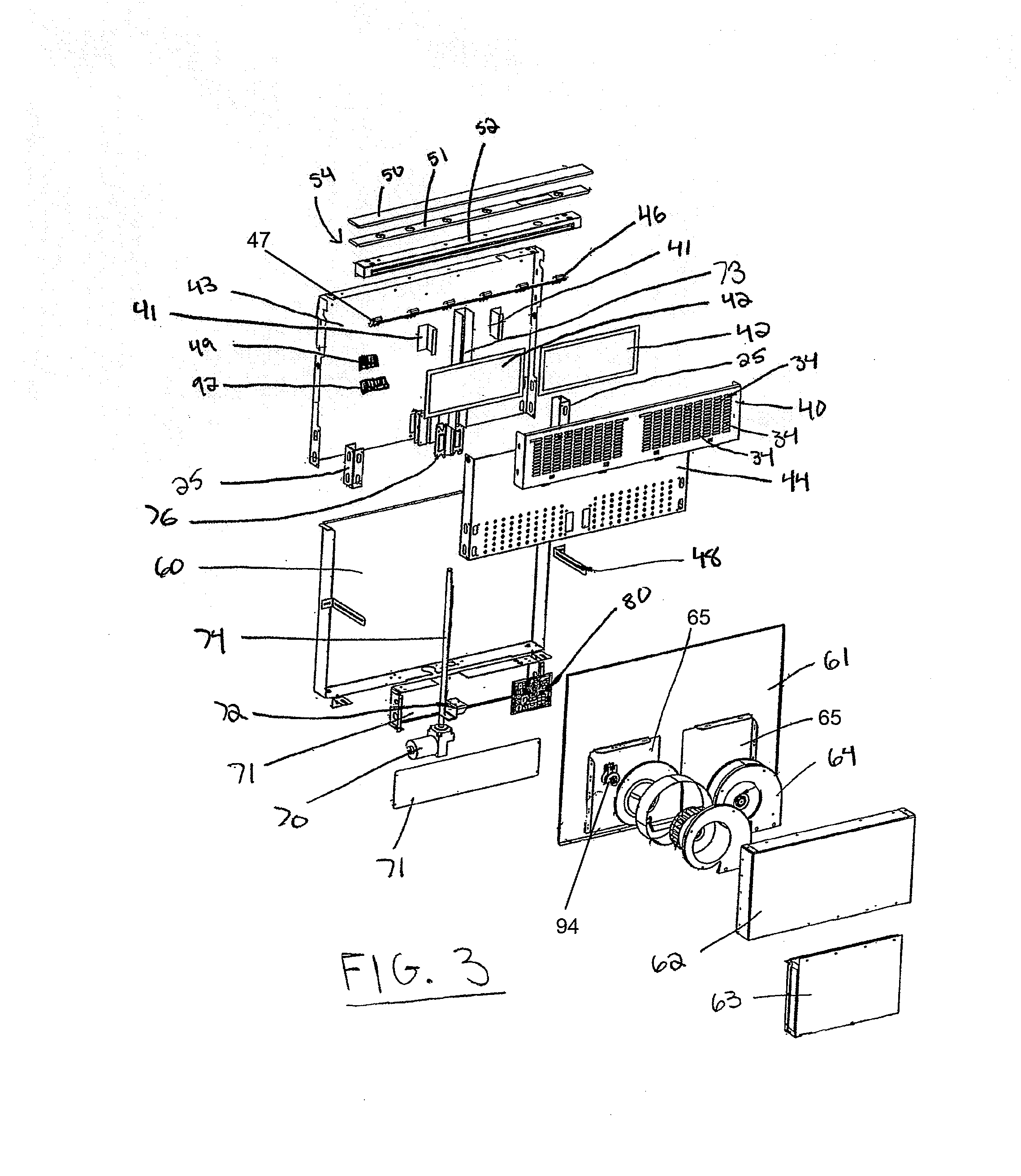

Low Depth Telescoping Downdraft Ventilator

ActiveUS20080029081A1Accuracy in removalEasy to controlCombination devicesLiquid degasificationElectrical resistance and conductanceElectronic controller

A low depth telescoping downdraft ventilator controlled by an electronic controller providing a precisely controlled and efficient way of removing gases and fumes is disclosed. The low depth telescoping downdraft ventilator has the ability to fit behind a built-in oven placed below a cook top unit. The telescoping downdraft ventilator has an almost infinitely selectable range of heights above a cook top with a built in oven. The ventilator collects and draws in exhaust fumes and smoke, filters it and re-circulates or expels it either outdoors or indoors. The inner member of the telescoping ventilator may house the exhaust fans and may move up or down without the use of mechanical switches for elevation detection and stopping. The ventilator may have sensors to detect temperatures, filter change need, fan speeds, telescoping stop points, energy consumption, resistance and voltage, enabling programmable set point operation.

Owner:HAIER US APPLIANCE SOLUTIONS INC D B A GE APPLIANCES

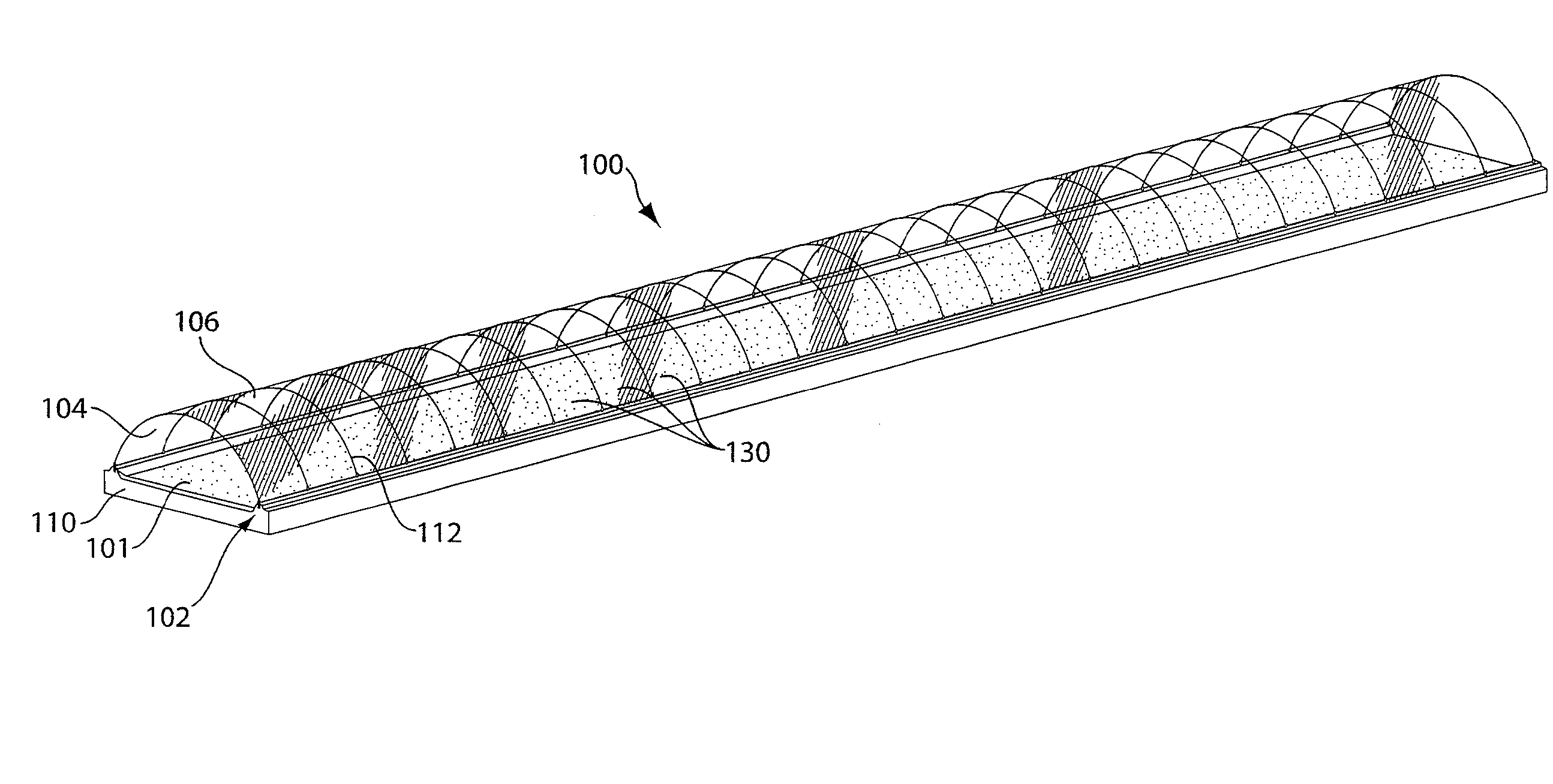

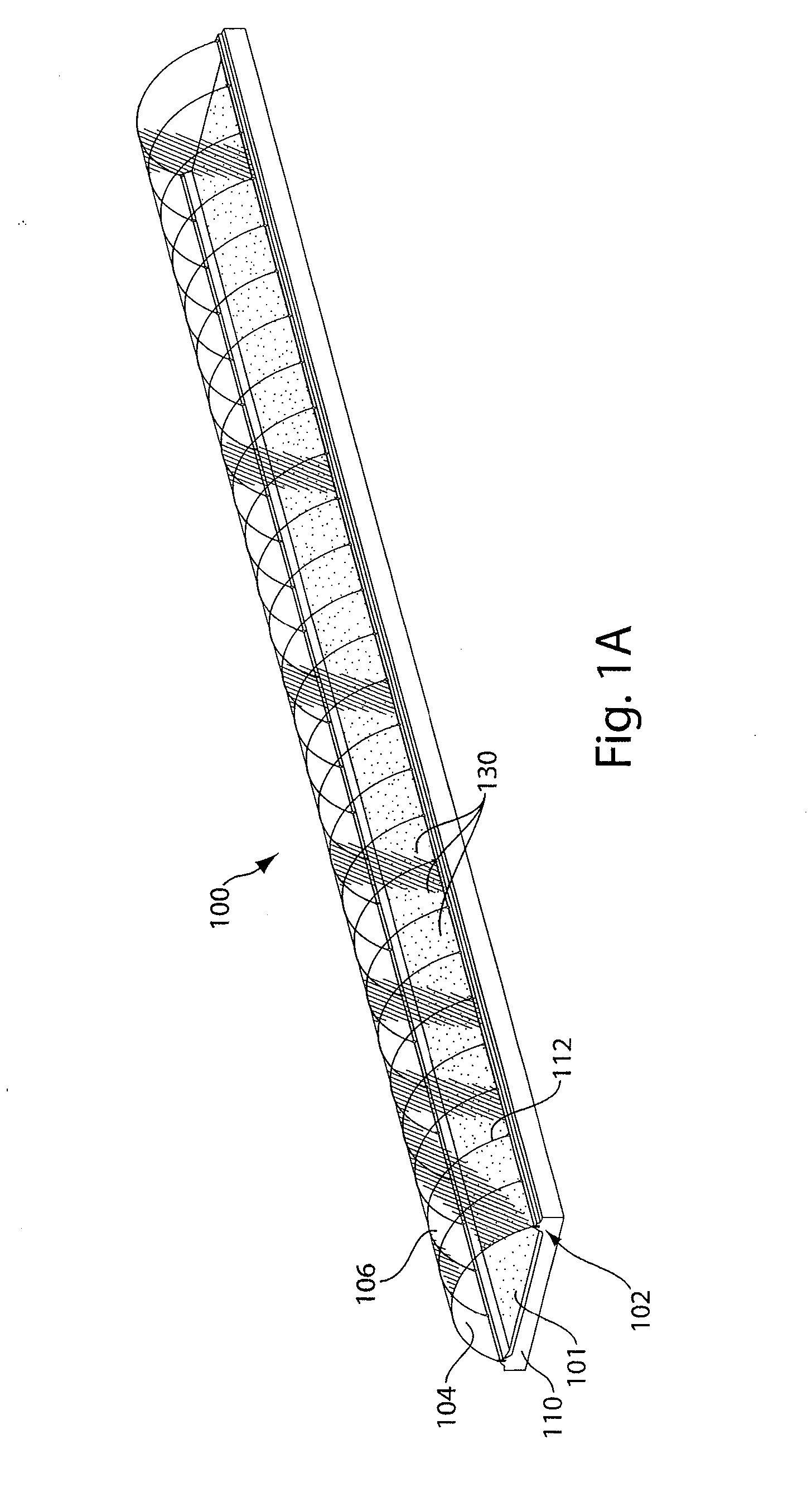

Photobioreactor systems and methods for treating CO2-enriched gas and producing biomass

InactiveUS20080178739A1Facilitate evaporative coolingSupport growthBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid mediumStream flow

Certain embodiments and aspects of the present invention relate to a photobioreactor including covered photobioreactor units through which a liquid medium stream and a gas stream flow. The liquid medium comprises at least one species of phototrophic organism therein. Certain methods of using the photobioreactor system as part of fuel generation system and / or a gas-treatment process or system at least partially remove certain undesirable pollutants from a gas stream. In certain embodiments, a portion of the liquid medium is diverted from a photobioreactor unit and reintroduced upstream of the diversion position. In certain embodiments, the disclosed photobioreactor system, methods of using such systems, and / or gas treatment apparatus and methods provided herein can be used as part of an integrated combustion method and system, wherein photosynthetic organisms used within the photobioreactor are harvested from the photobioreactor, processed, and used as a fuel source for a combustion system such as an electric power plant.

Owner:THE TRON GRP

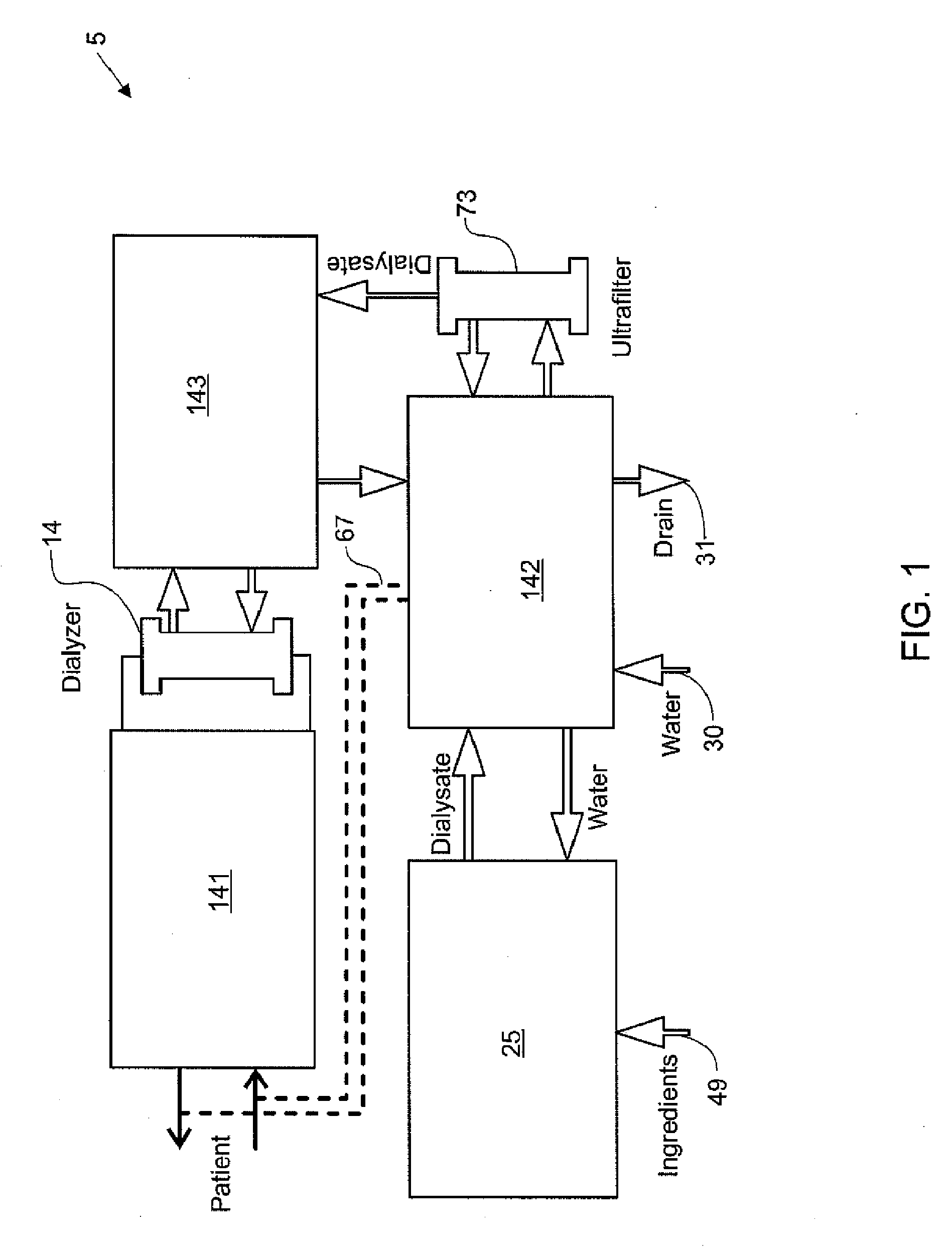

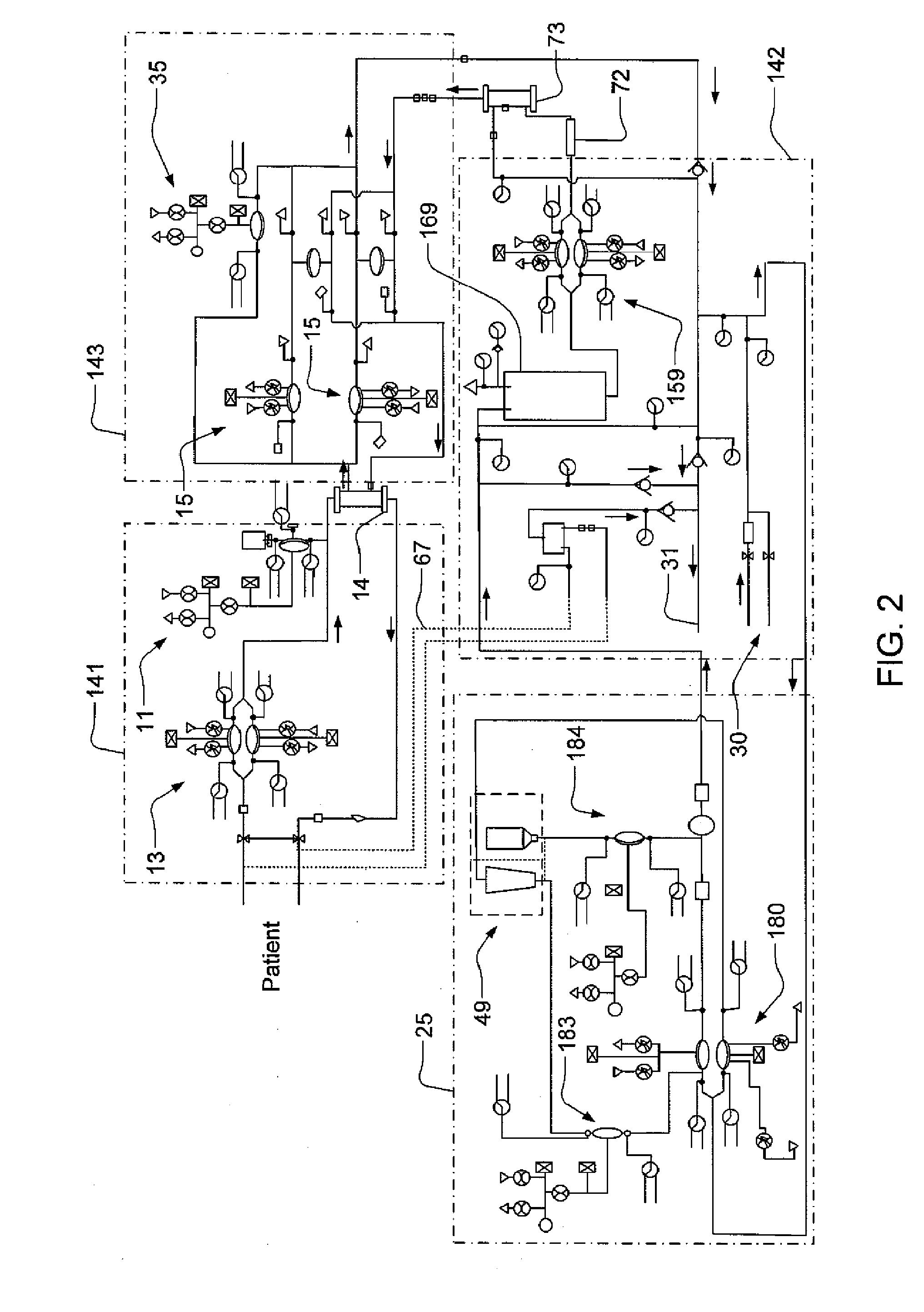

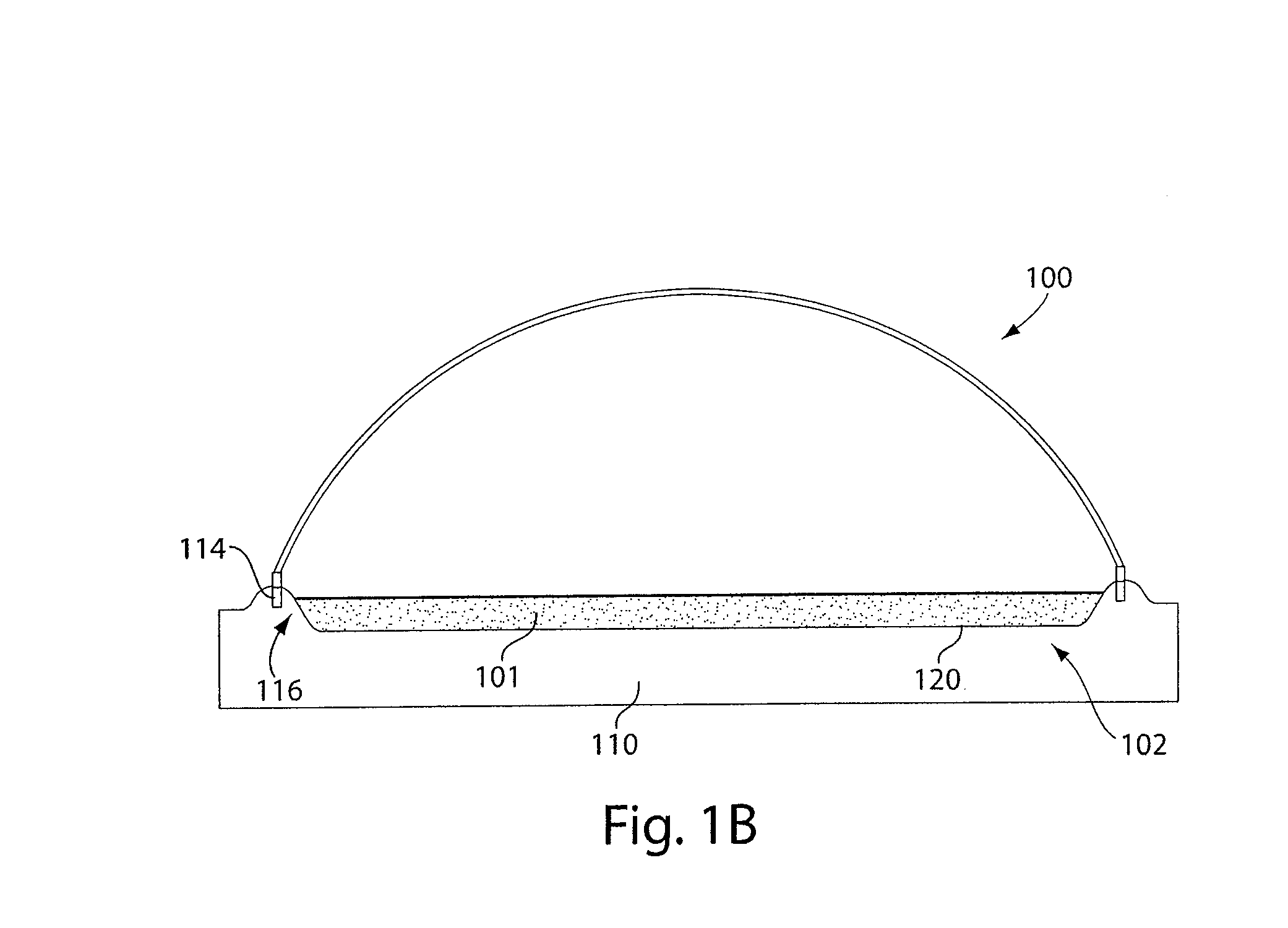

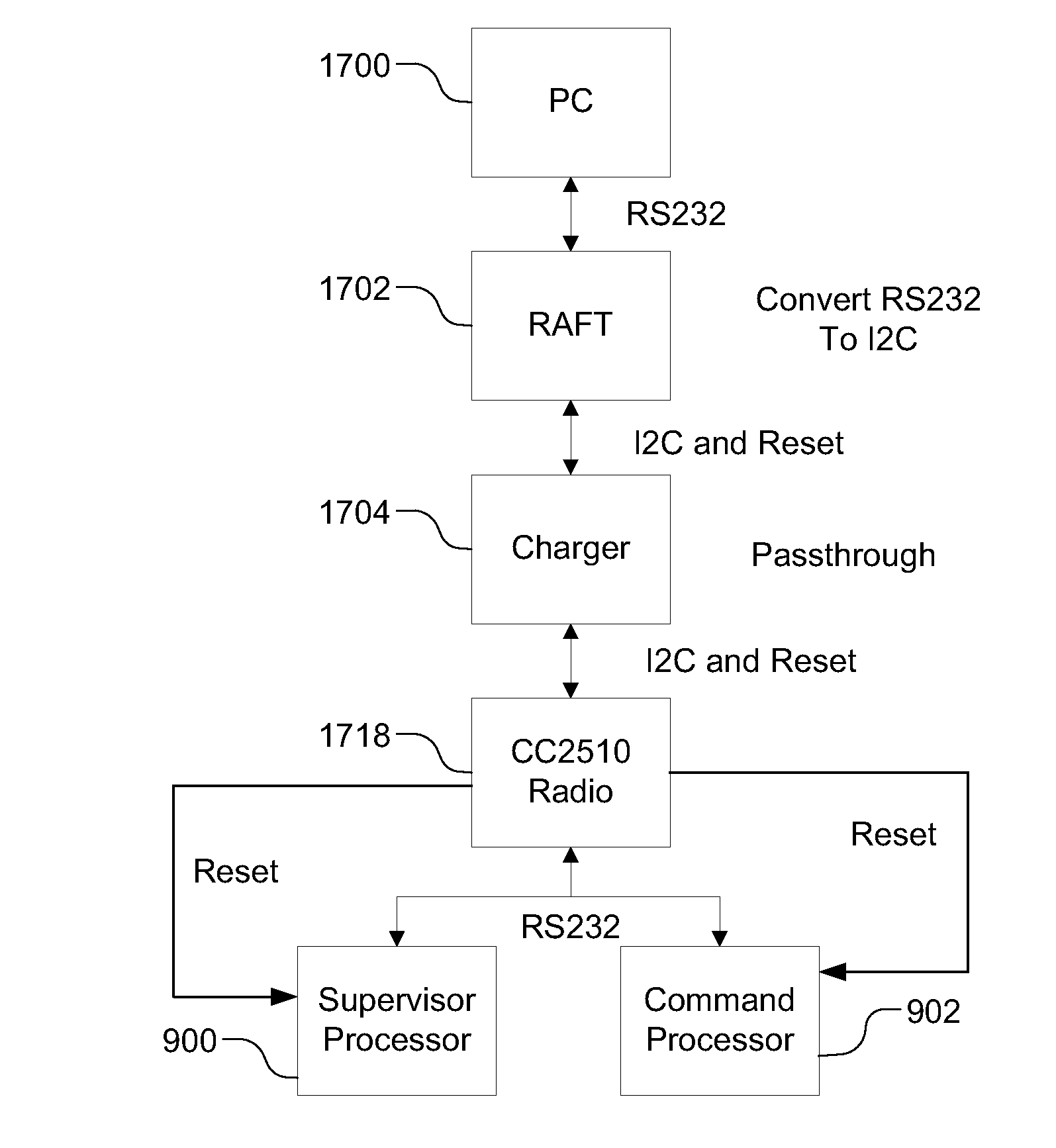

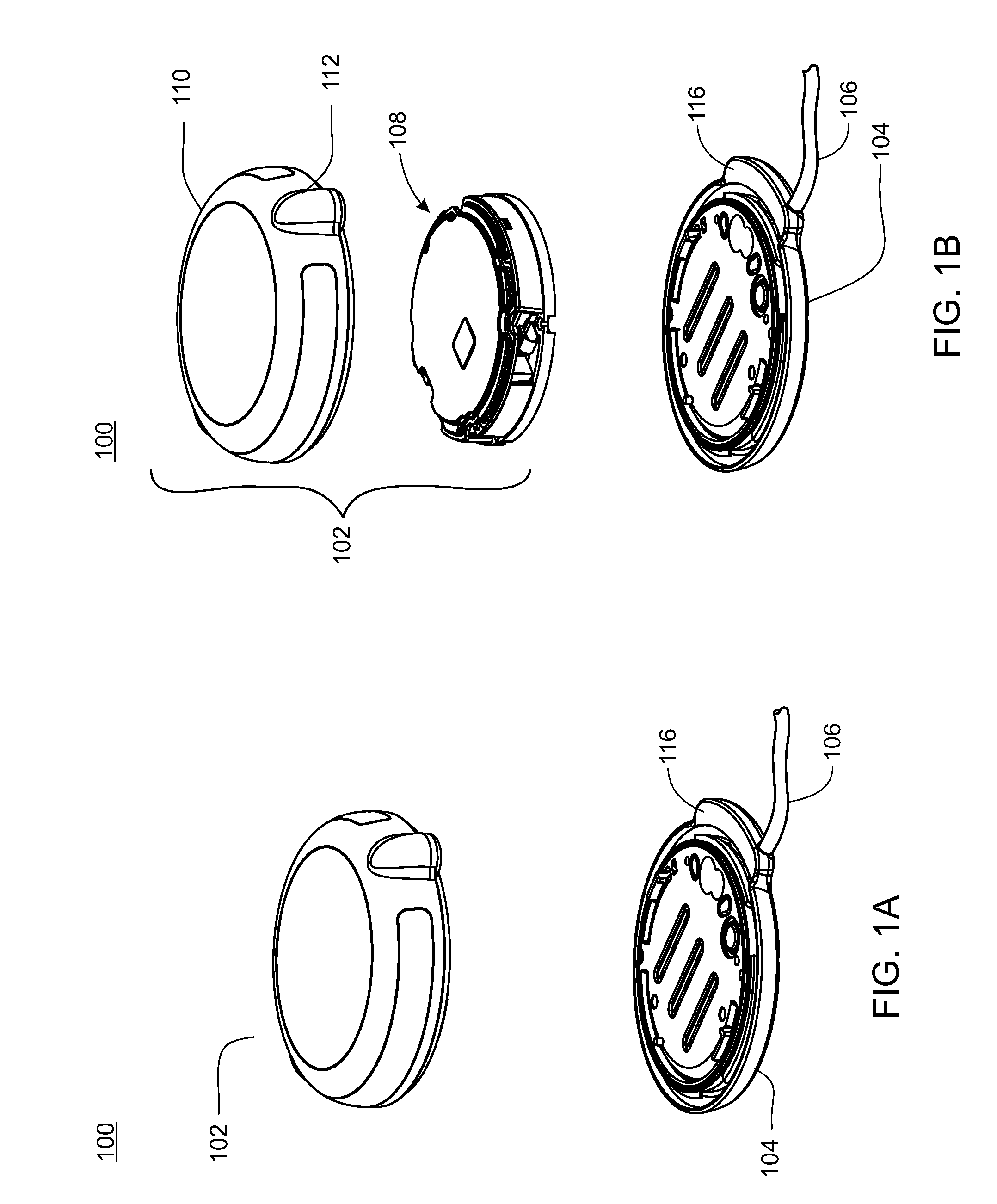

Devices, Methods and Systems for Wireless Control of Medical Devices

A medical device system is disclosed. The medical device system includes a first medical device and a second medical device. A remote interface including a touch screen is also included. The remote interface is in wireless communication with the first medical device and the second medical device. The remote interface is configured to provide a user interface to the first medical device and the second medical device. The remote interface is configured to receive user input through a touch screen. Also, a charging device is included. The charging device is configured to receive at least the first medical device and the remote interface and the charging device is configured to recharge a first medical device battery and the charging device is configured to recharge an interface battery in the remote interface. The charging device is connected to a personal computer wherein the personal computer provides information to the remote interface.

Owner:DEKA PROD LLP

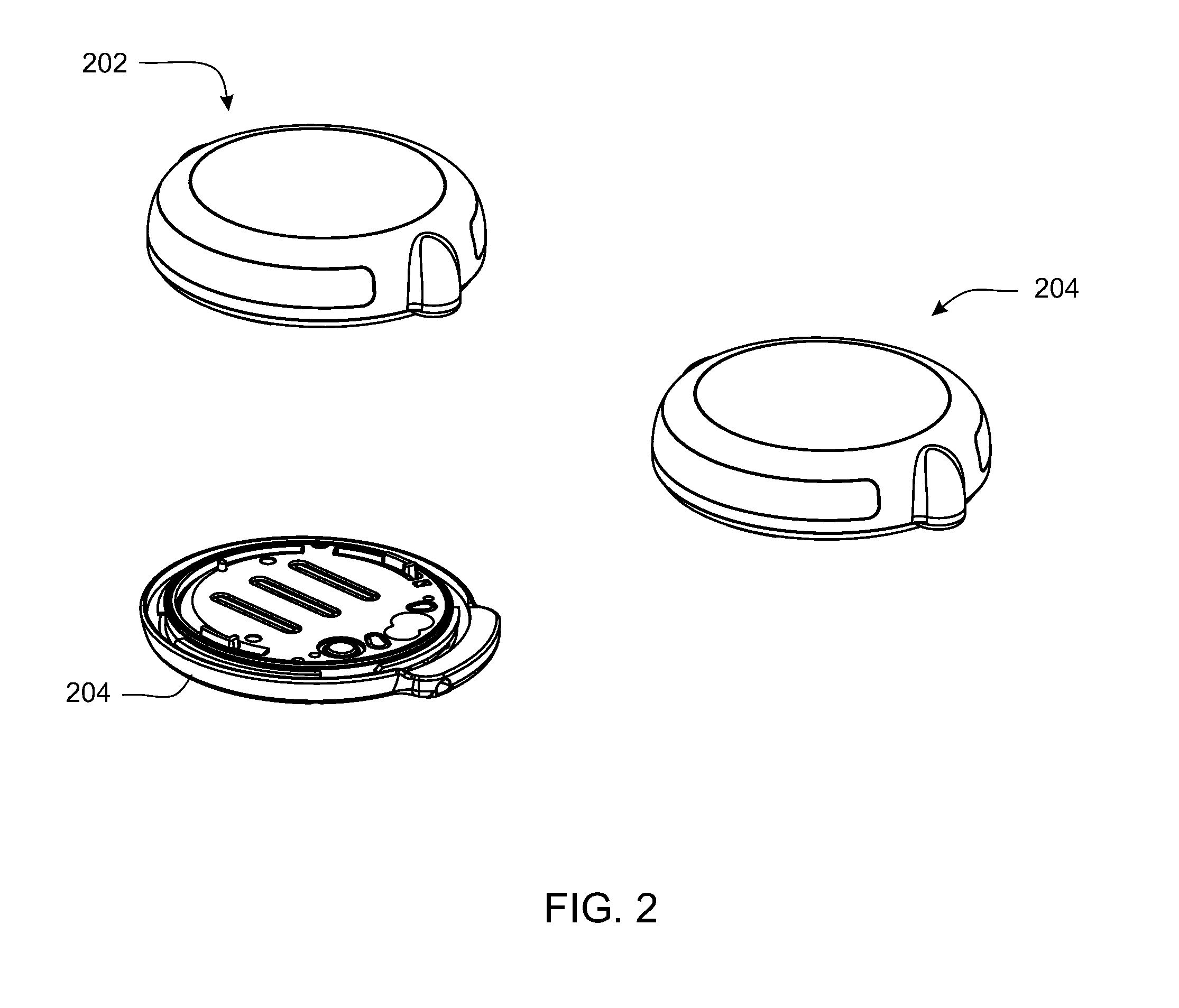

Dust bin and filter for robotic vacuum cleaner

ActiveUS7201786B2No cloggingReduce cleaning frequencyCombination devicesAuxillary pretreatmentEngineeringVacuum cleaner

A detachable dust bin for a vacuum cleaner. A container is provided with a removable sidewall which has an outlet opening which is adapted to be coupled to a source of vacuum. The container includes an inlet for connecting to a passageway which is connected to a vacuum nozzle. A duct extends vertically from the inlet within the container, and then laterally toward the removable sidewall. A filter is supported along the removable sidewall having a front surface facing the outlet of the duct, and a rear surface facing the outlet opening in the removable sidewall. Dirt laden air is drawn through the filter, duct, and vacuum nozzle. Dirt is separated from the air and collected within the container.

Owner:HEALTHY GAIN INVESTMENTS

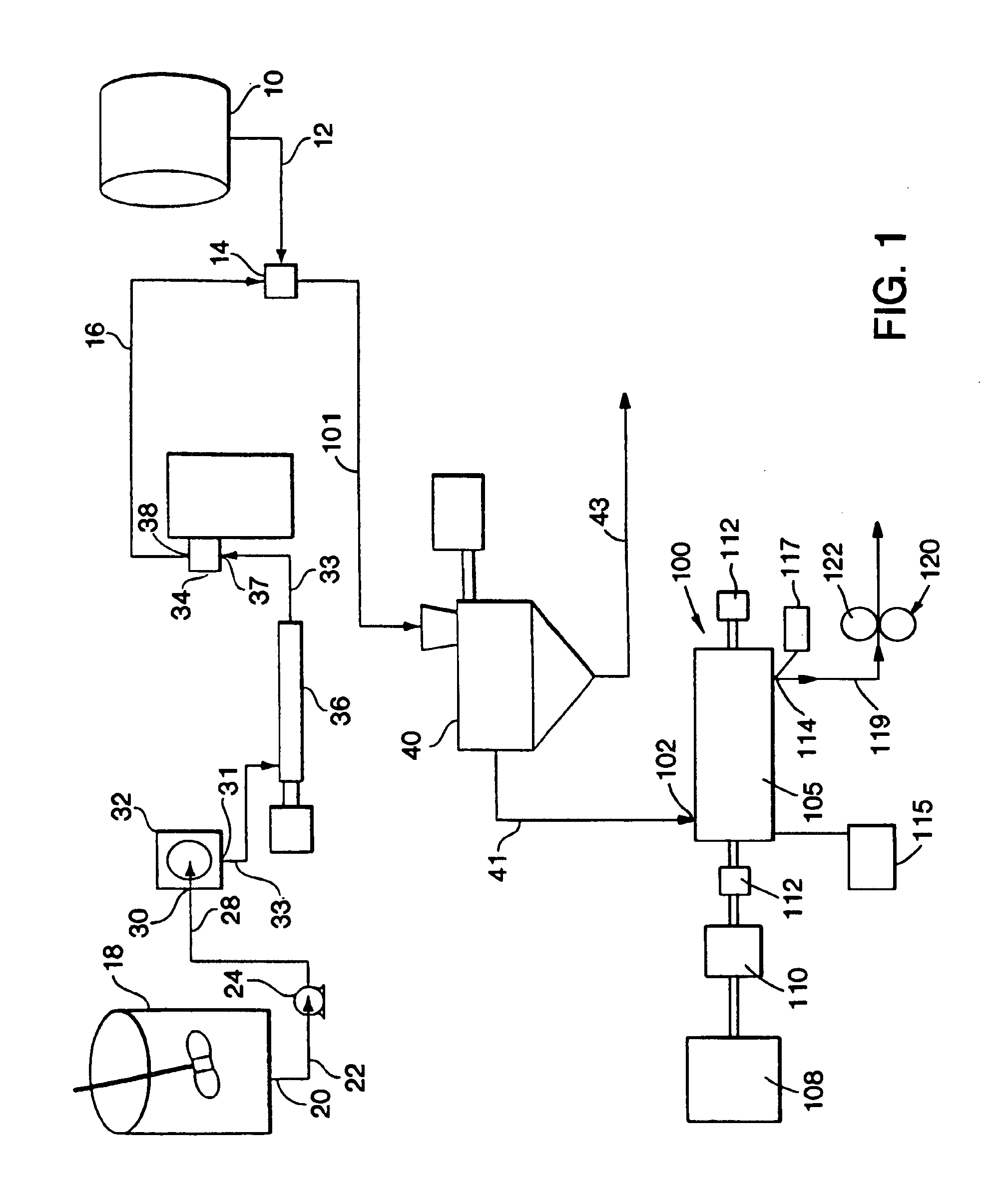

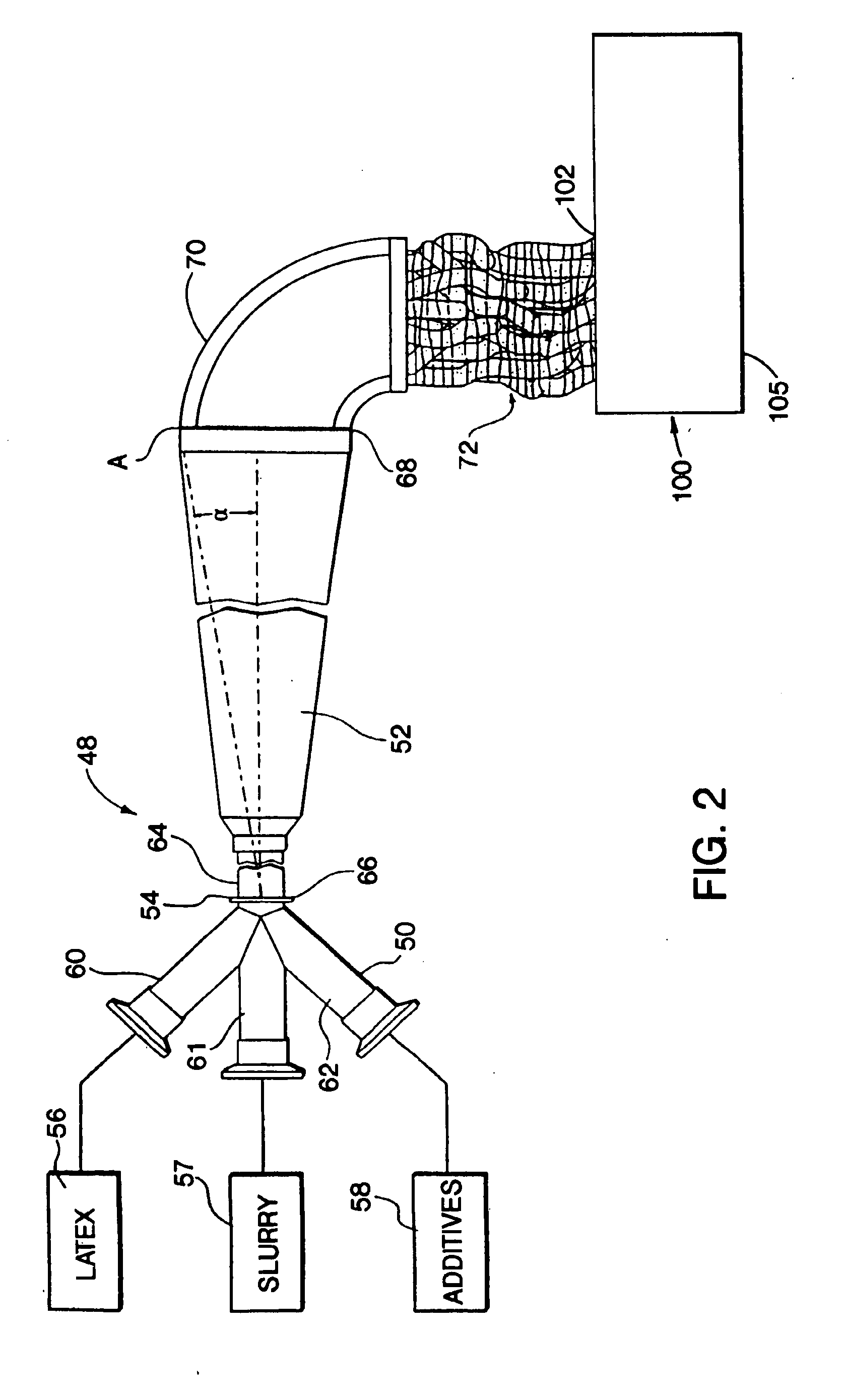

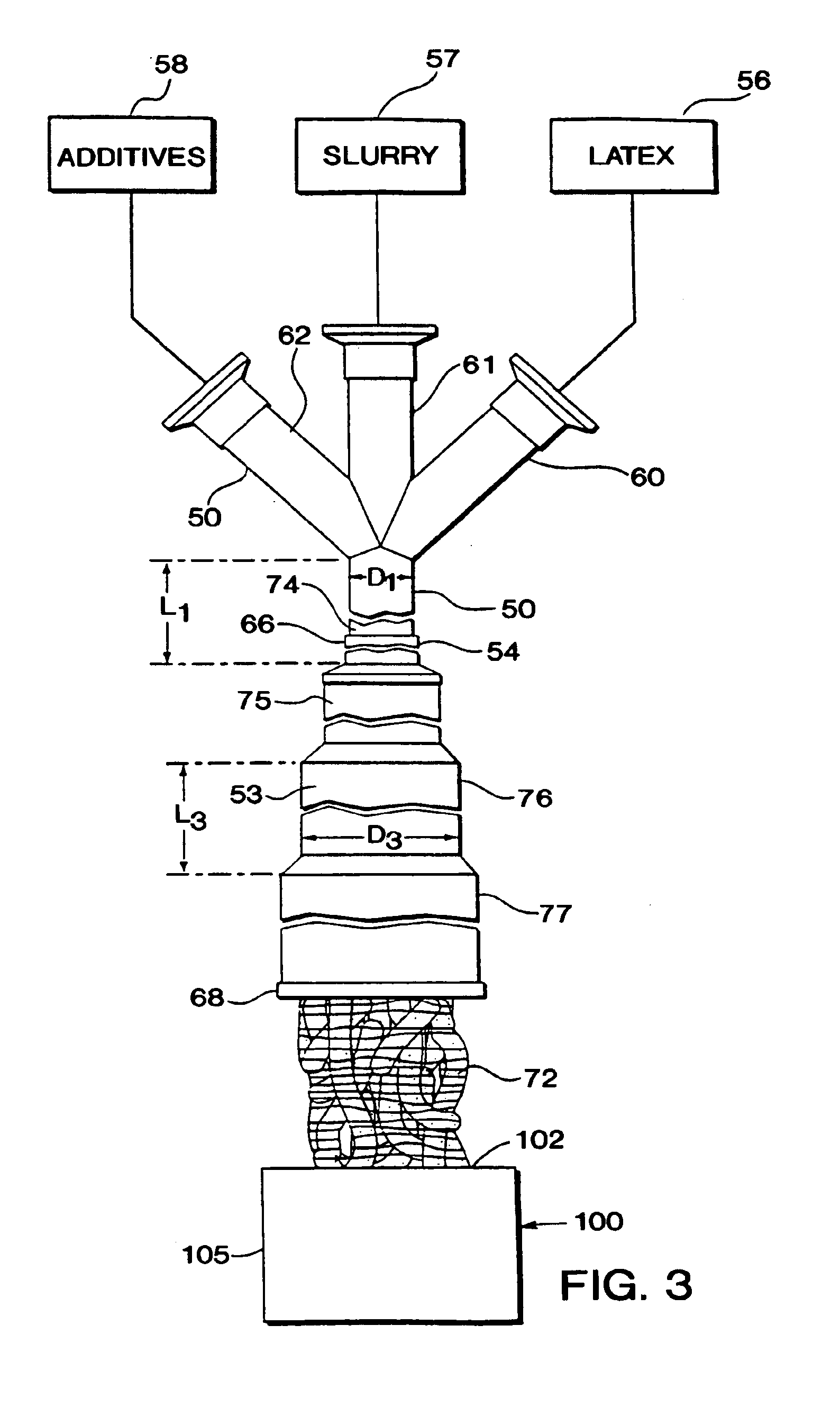

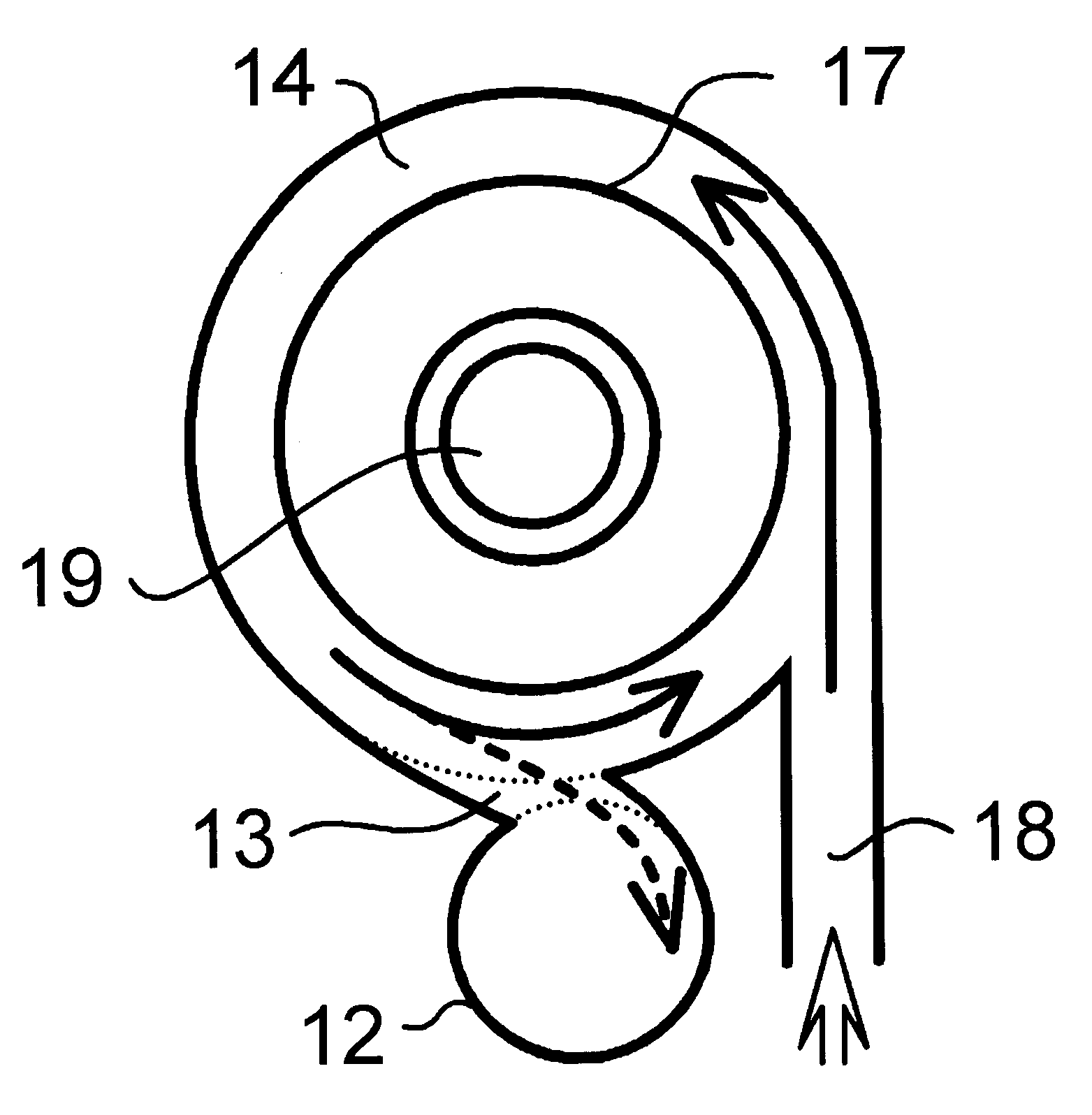

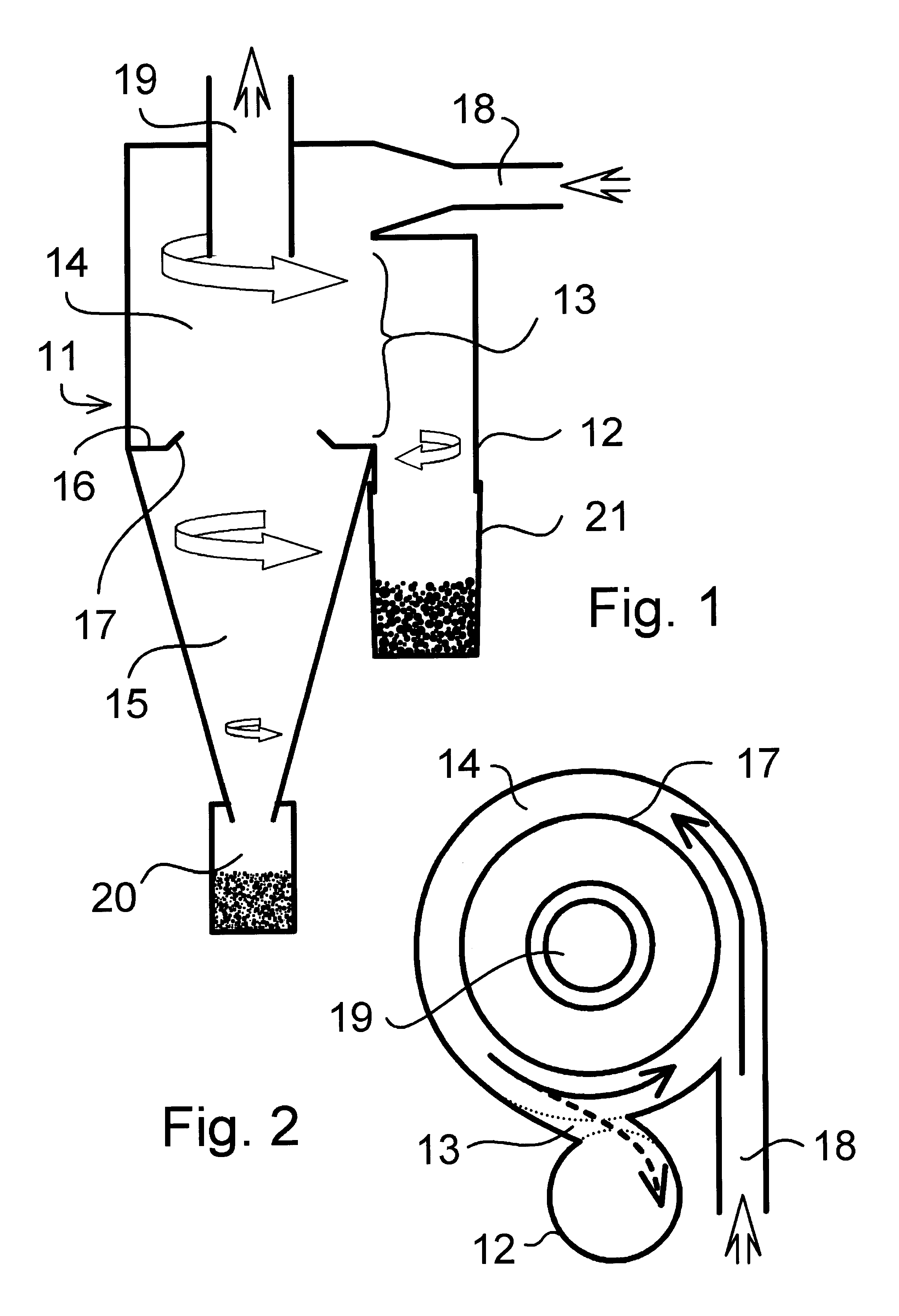

Method and apparatus for producing and treating novel elastomer composites

InactiveUS6929783B2Facilitate controlling and changing operating parameterImprove economyLiquid degasificationSpecial tyresParticulatesMasterbatch

Elastomer masterbatch is processed in a continuous compounder having multiple parallel elongate rotors axially oriented in an elongate processing chamber. Optionally, additional materials are compounded into the masterbatch, e.g., additives, other elastomeric compositions, etc. Preferably, the masterbatch then is further processed in an open mill. Excellent control of Mooney Viscosity is achieved.In certain preferred embodiments, elastomer composites are produced by novel continuous flow methods and apparatus in which fluid streams of particulate filler and elastomer latex are fed to the mixing zone of a coagulum reactor to form a coagulated mixture in semi-confined flow continuously from the mixing zone through a coagulum zone to a discharge end of the reactor. The particulate filler fluid is fed under high pressure to the mixing zone, such as to form a jet stream to entrain elastomer latex fluid sufficiently energetically to substantially completely coagulate the elastomer with the particulate filler prior to the discharge end without need of adding acid or salt solution or other coagulation step. The coagulated elastomer and particulate filler composite is fed into the aforesaid continuous compounder for processing and control of its moisture level and Mooney Viscosity. Novel elastomer composites are produced. Such novel elastomer composites combine material properties and characteristics, such as choice of filler, elastomer, level of filler loading, moisture level, Mooney Viscosity, balance between molecular weight and amount of bound rubber, and macro-dispersion not previously achieved.

Owner:CABOT CORP

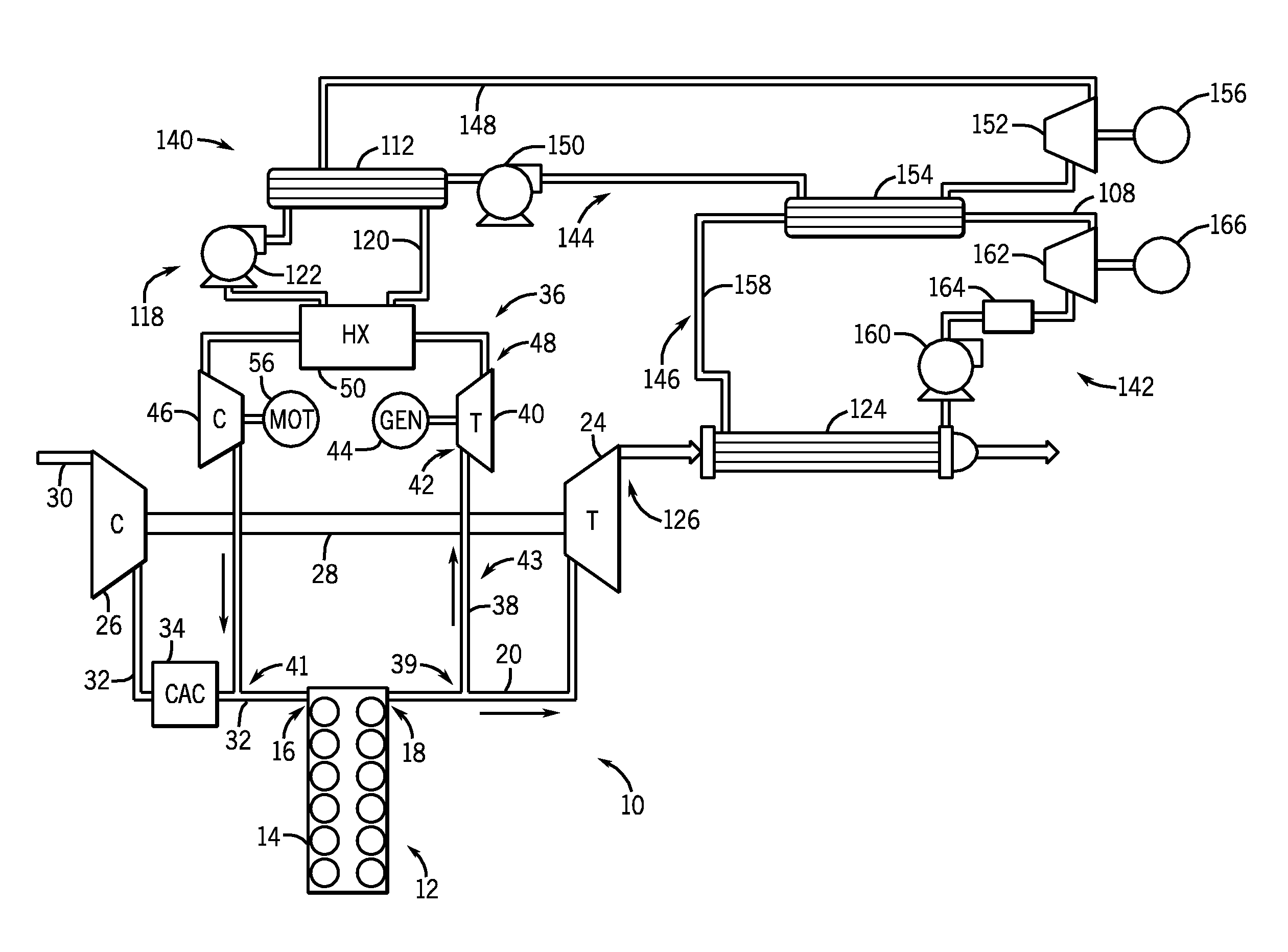

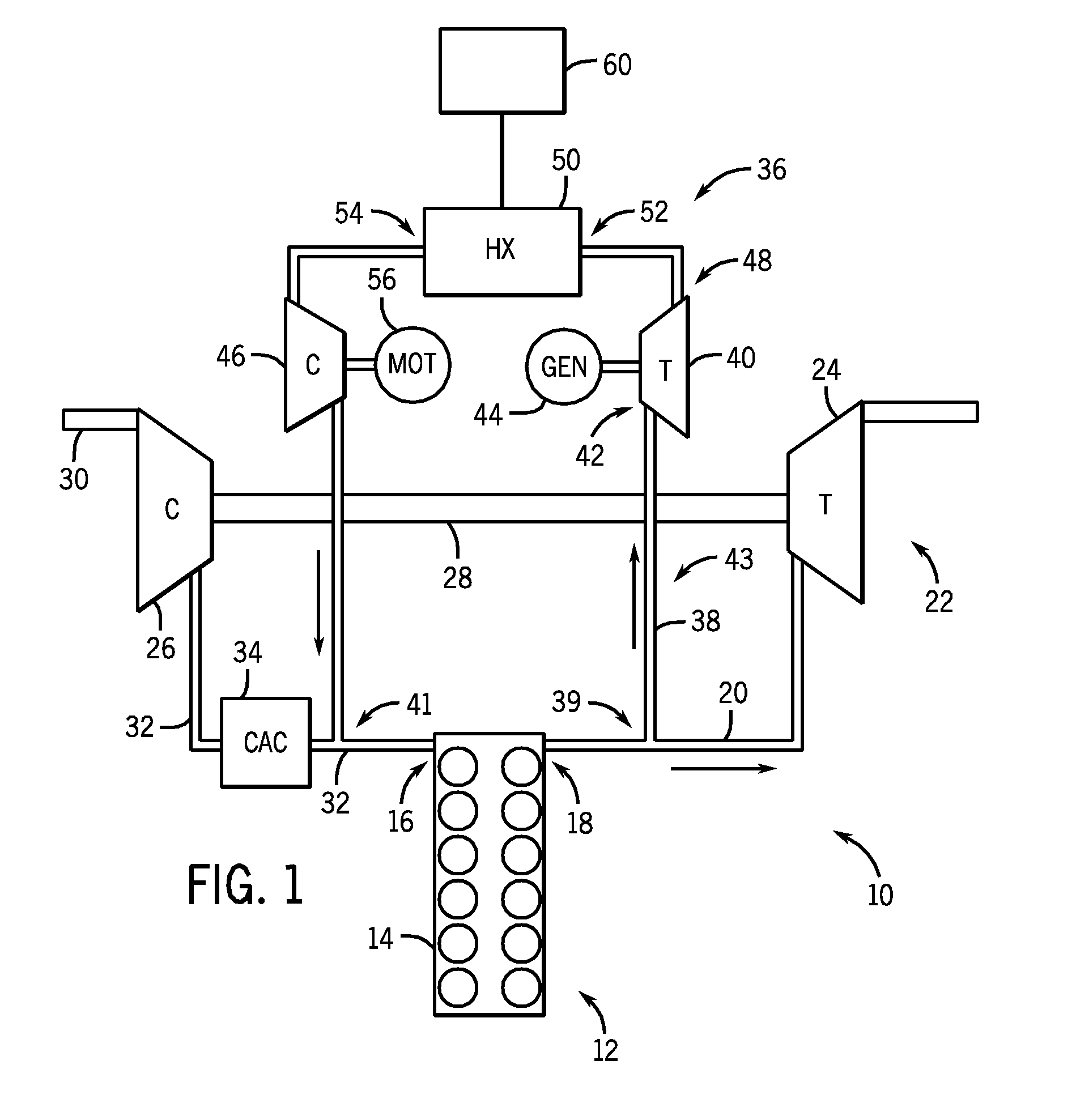

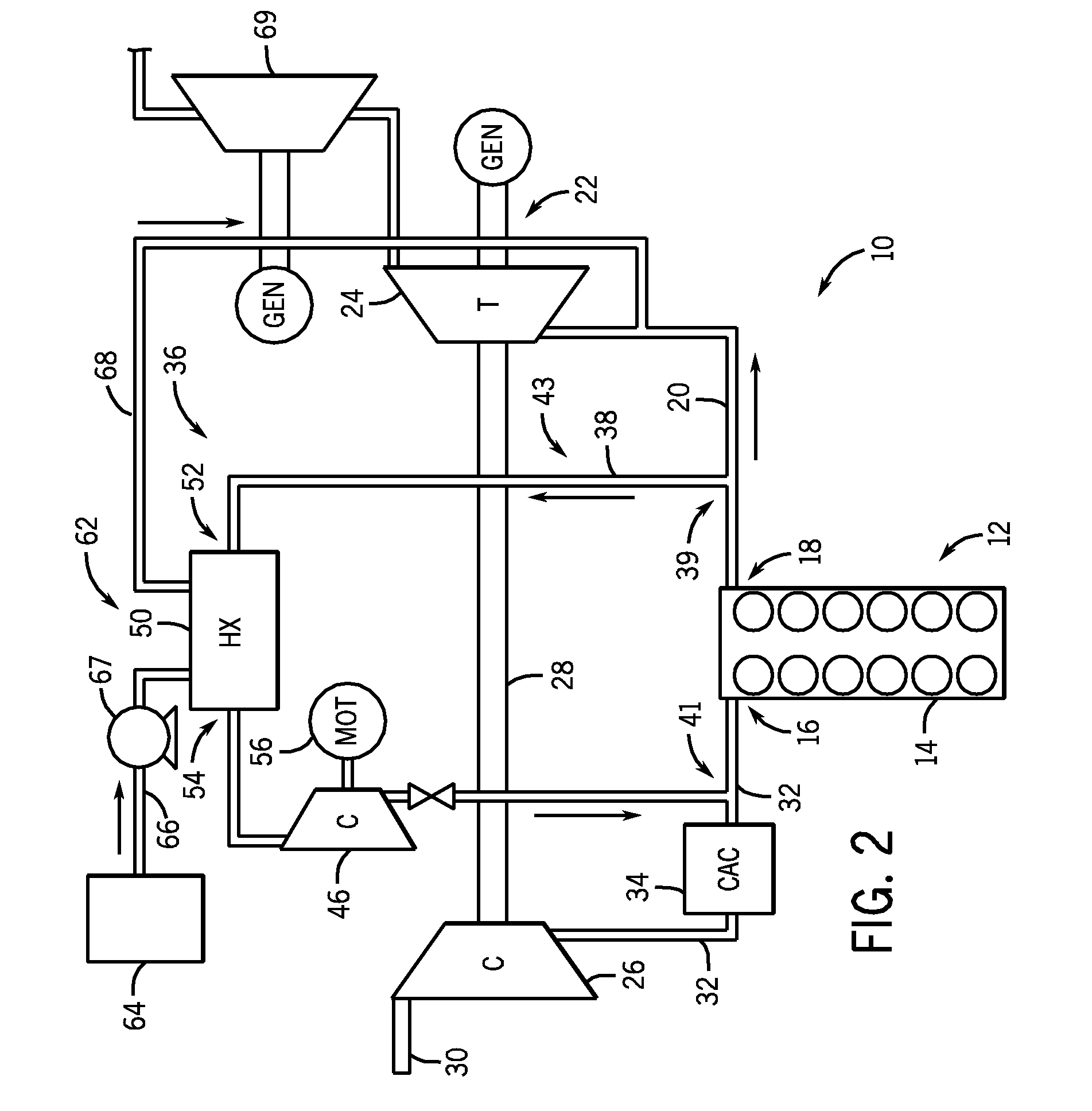

System and method for waste heat recovery in exhaust gas recirculation

InactiveUS20110209473A1Liquid degasificationInternal combustion piston enginesTurbochargerExhaust fumes

A system and method for waste heat recovery in exhaust gas recirculation is disclosed. The system includes an engine having an intake manifold and an exhaust manifold, an exhaust conduit connected to the exhaust manifold, and a turbocharger having a turbine and a compressor, the turbine being connected to the exhaust conduit to receive a portion of the exhaust gas from the exhaust manifold. The system also includes an EGR system connected to the exhaust conduit to receive a portion of the exhaust gas, with the EGR system including an EGR conduit that is connected to the exhaust conduit to receive a portion of the exhaust gas, a heat exchanger connected to the EGR conduit and being configured to extract heat from the exhaust gas, and a waste heat recovery system connected to the heat exchanger and configured to capture the heat extracted by the heat exchanger.

Owner:GENERAL ELECTRIC CO

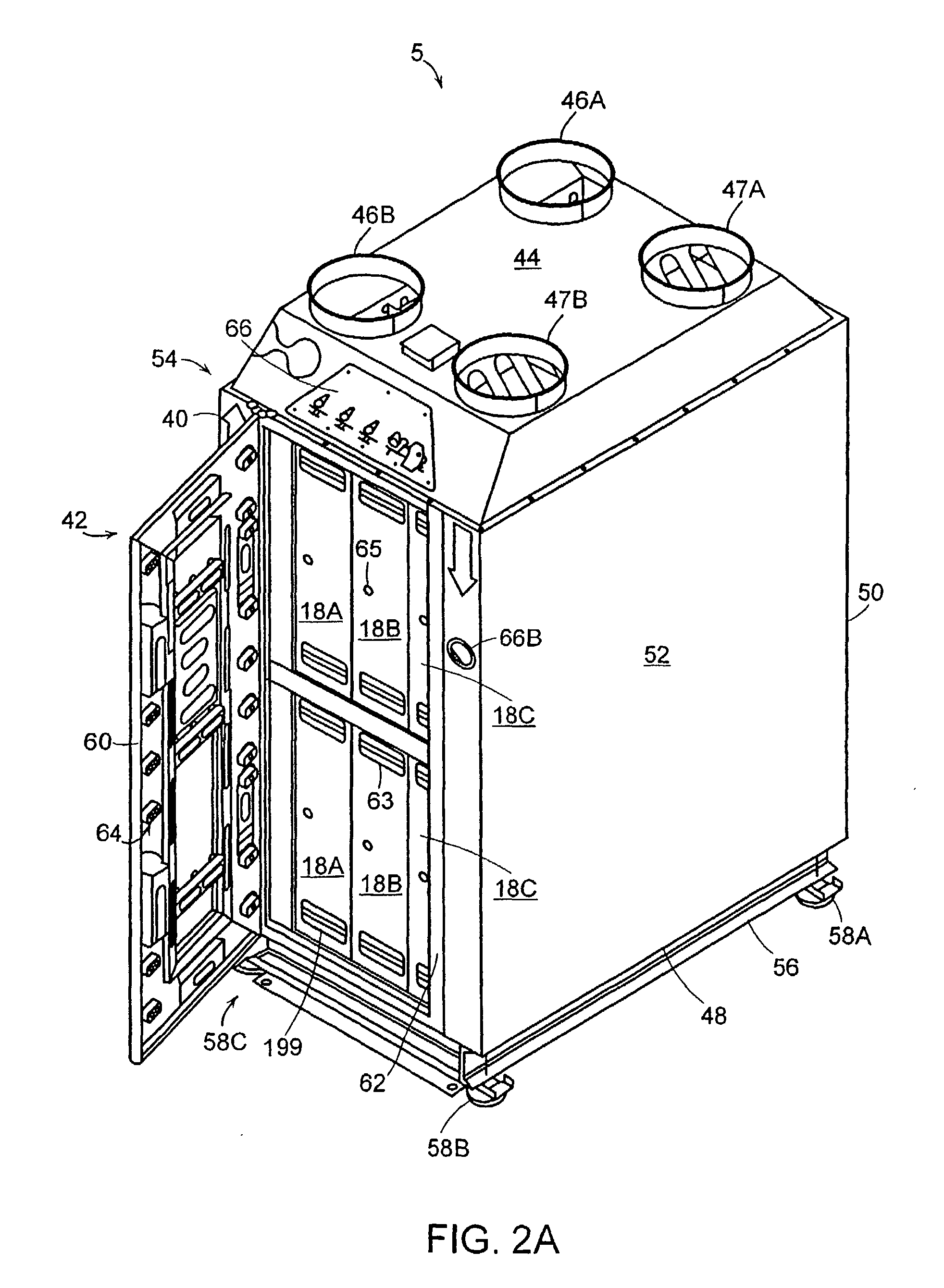

System for inlet air mass enhancement

InactiveUS8414673B2ParasiticImprove carrying capacityCombination devicesAuxillary pretreatmentFiltrationEngineering

Owner:FREUDENBERG FILTRATION TECH INDIA PVT LTD

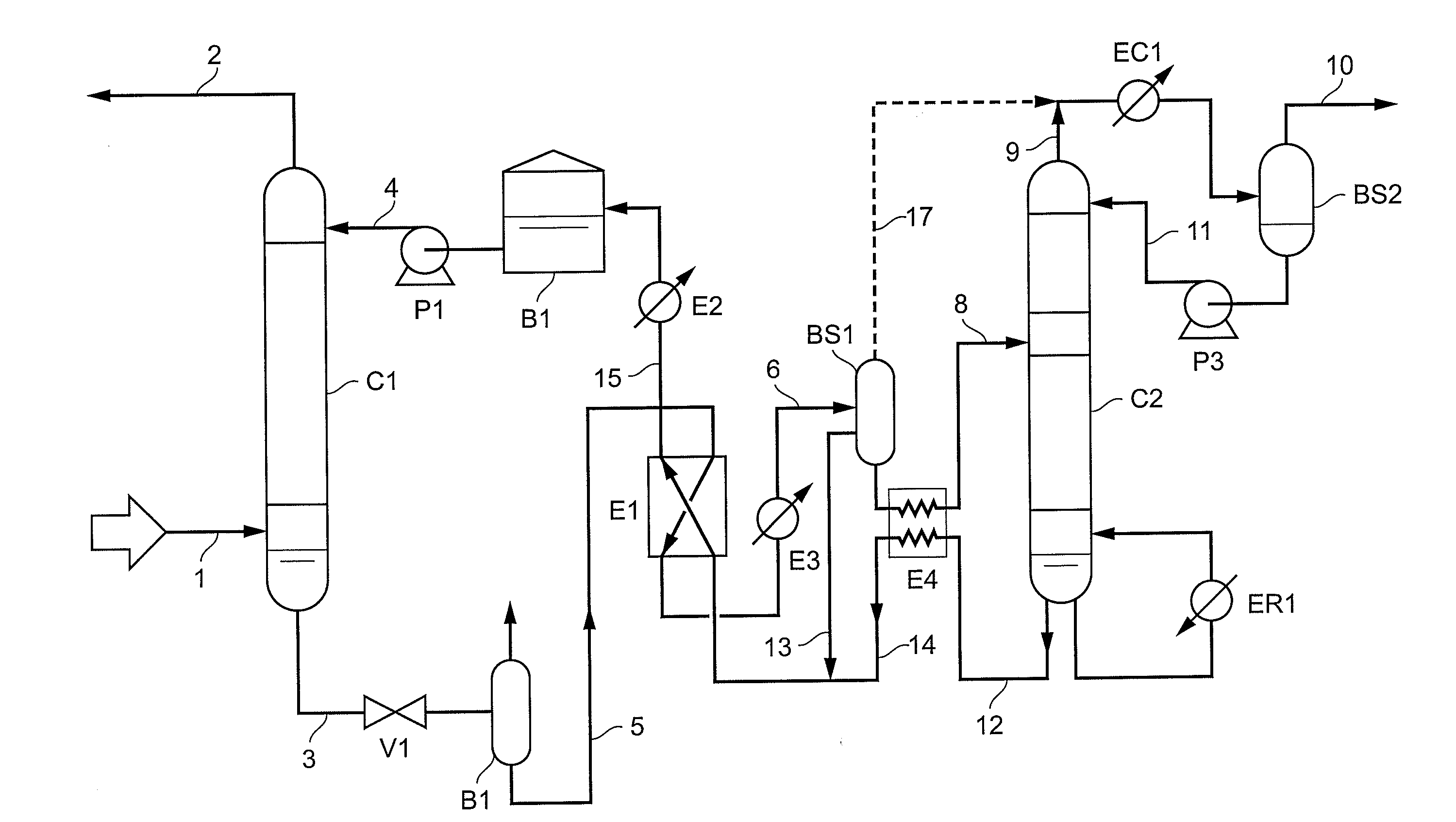

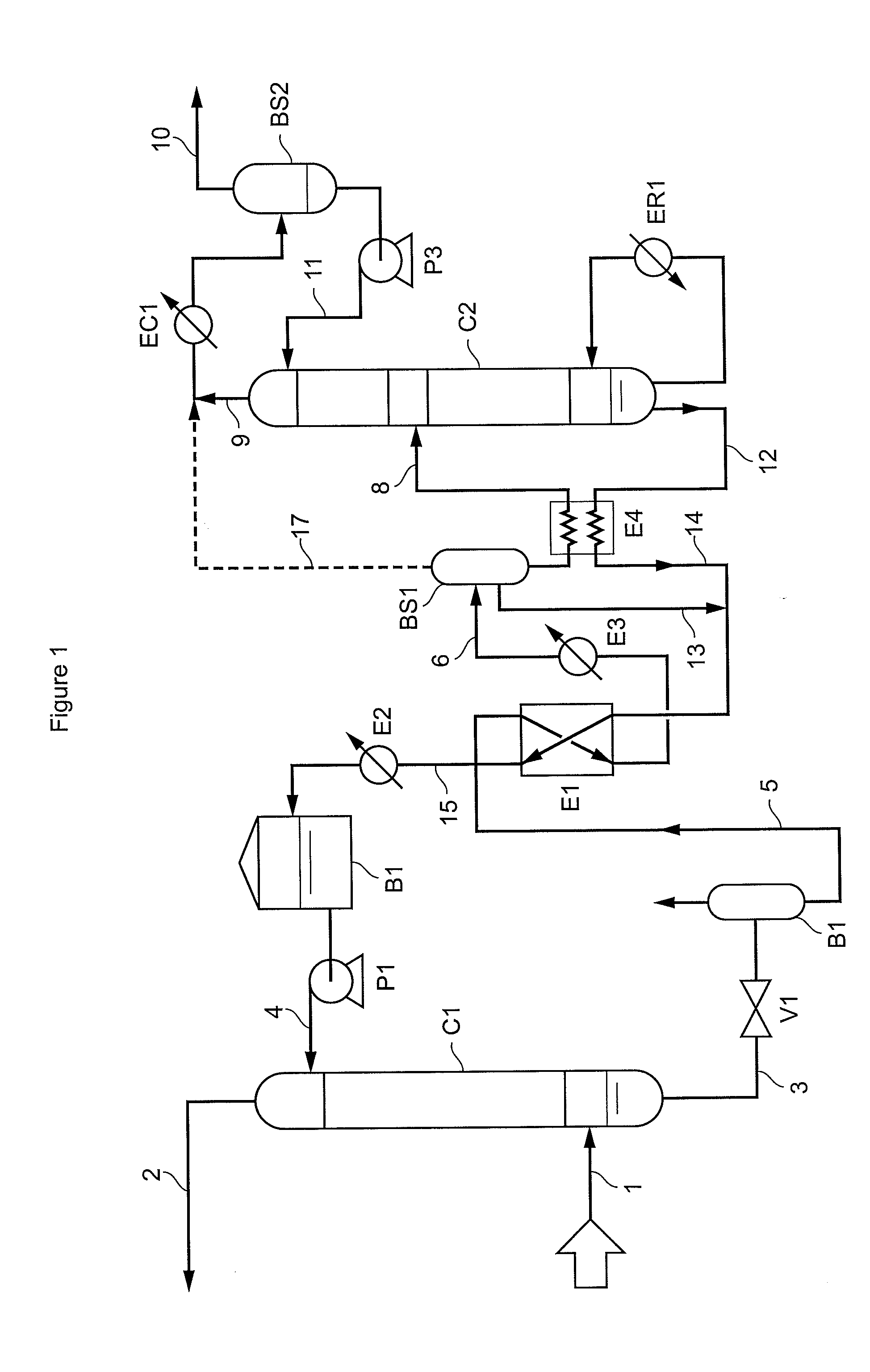

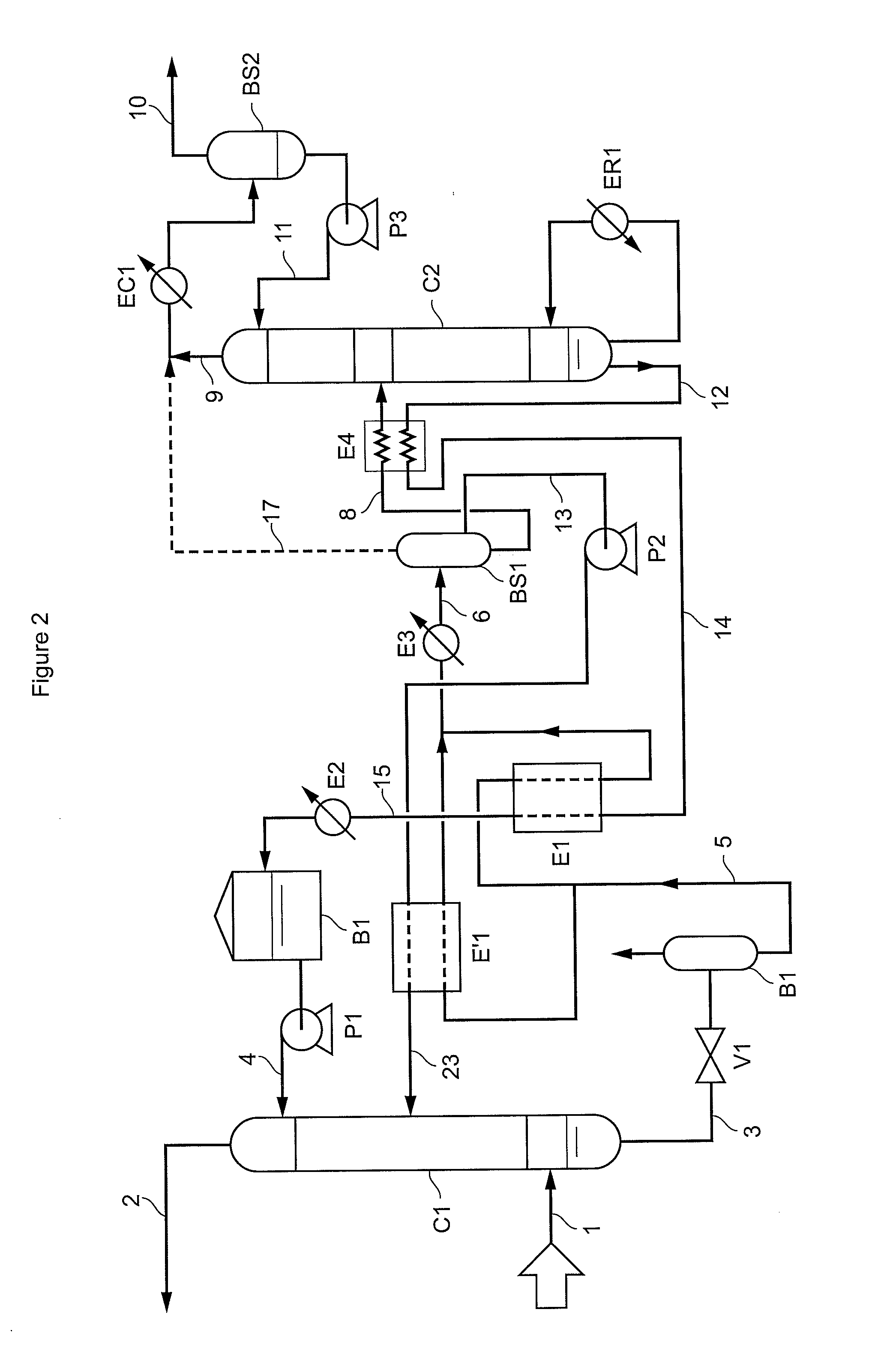

Method of deacidizing a gas by means of an absorbent solution with fractionated regeneration through heating

A method of deacidizing a gaseous effluent comprising acid compounds where the gaseous effluent is contacted in C1 with an adsorbent solution so as to obtain a gaseous effluent depleted in acid compounds and an absorbent solution laden with acid compounds, the absorbent solution being selected for its property of forming two separable phases when it has absorbed an amount of acid compounds and when it is heated. The absorbent solution laden with acid compounds is then heated in E1 and E3 so as to separate two fractions: a first absorbent solution fraction depleted in acid compounds and a second absorbent solution fraction enriched in acid compounds. These two fractions are then separated in BS1. The second fraction is regenerated in C2 so as to release part of the acid compounds, and the first absorbent solution fraction and the regenerated absorbent solution are recycled as absorbent solution.

Owner:INST FR DU PETROLE

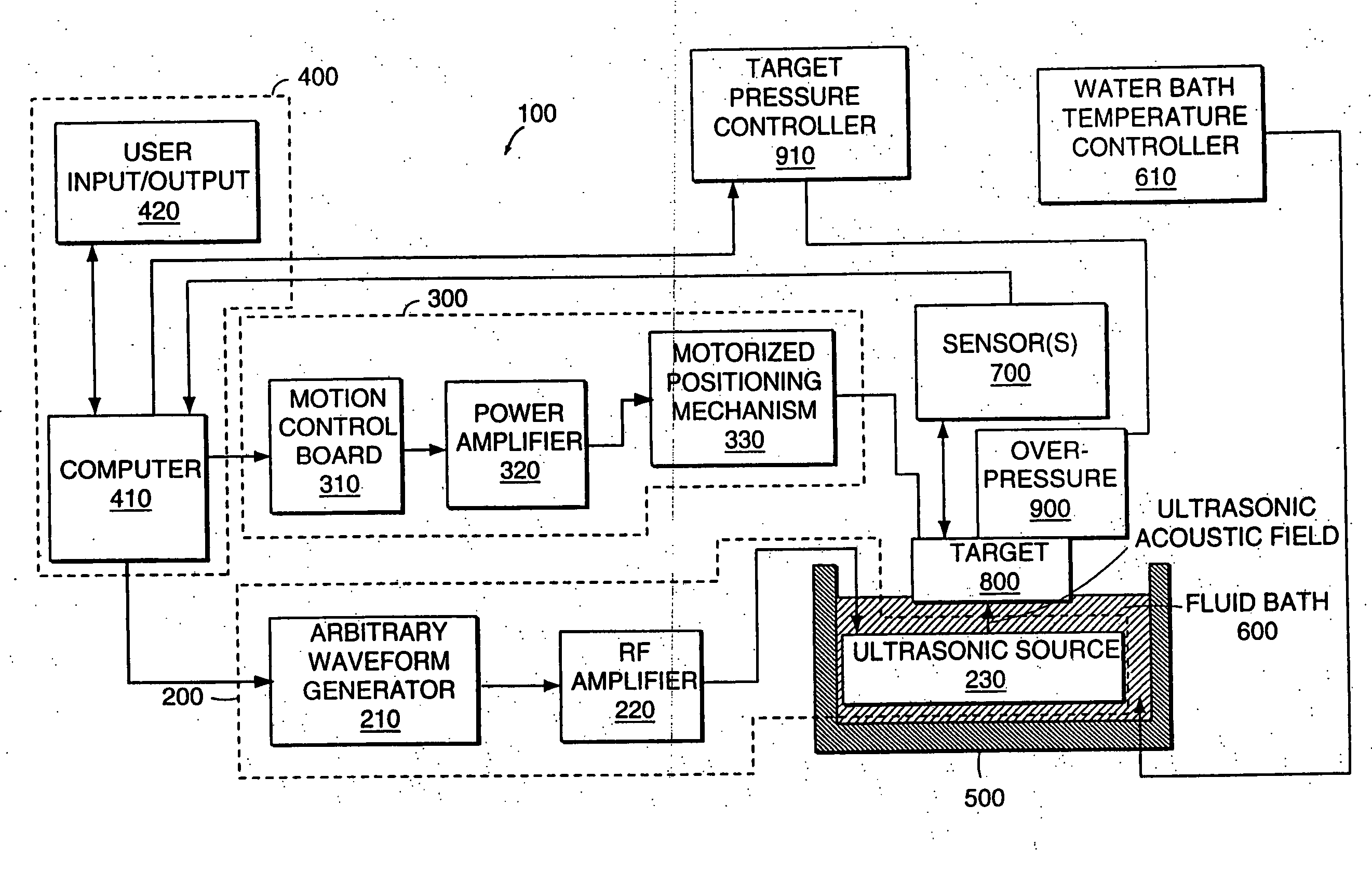

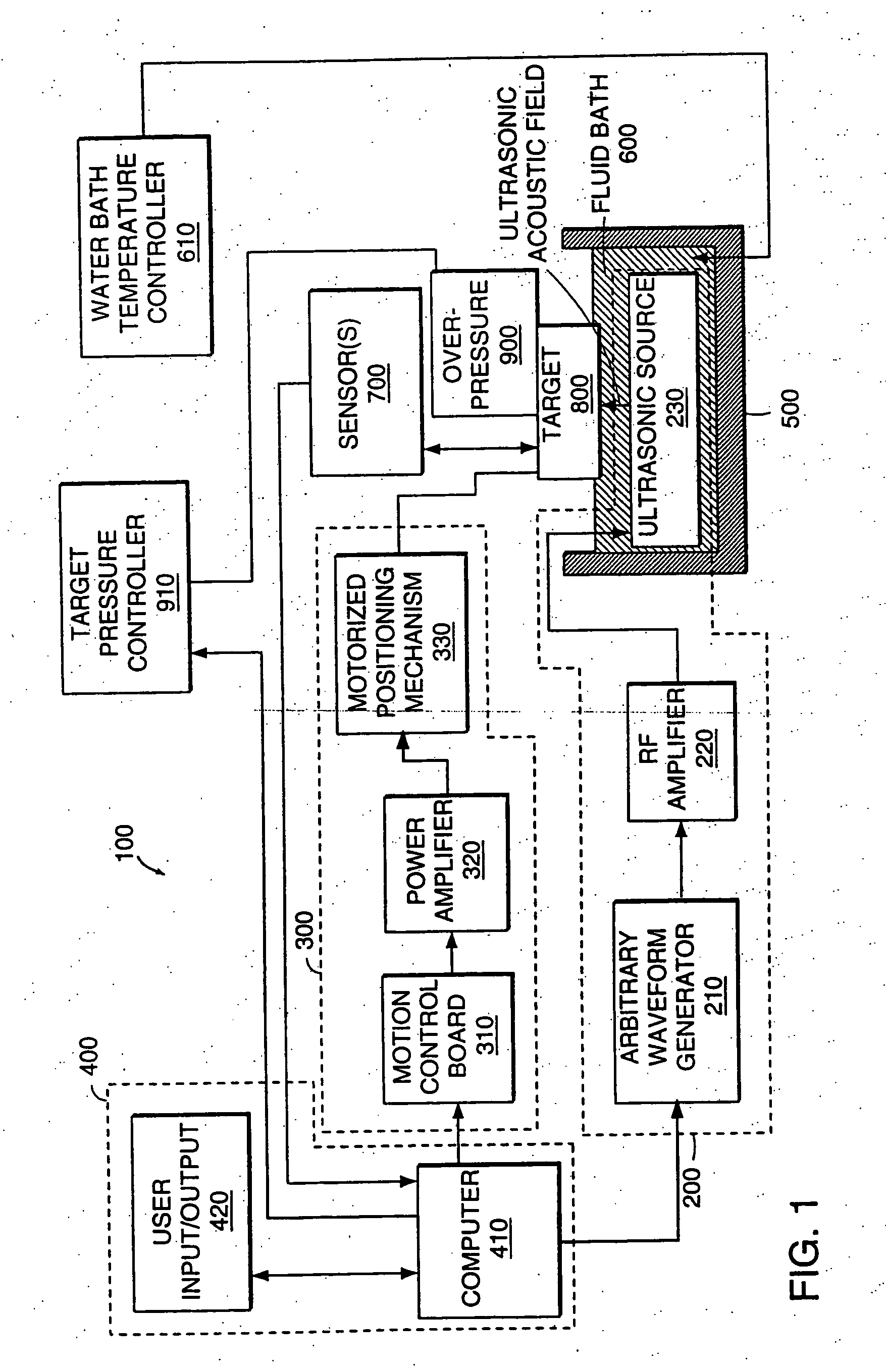

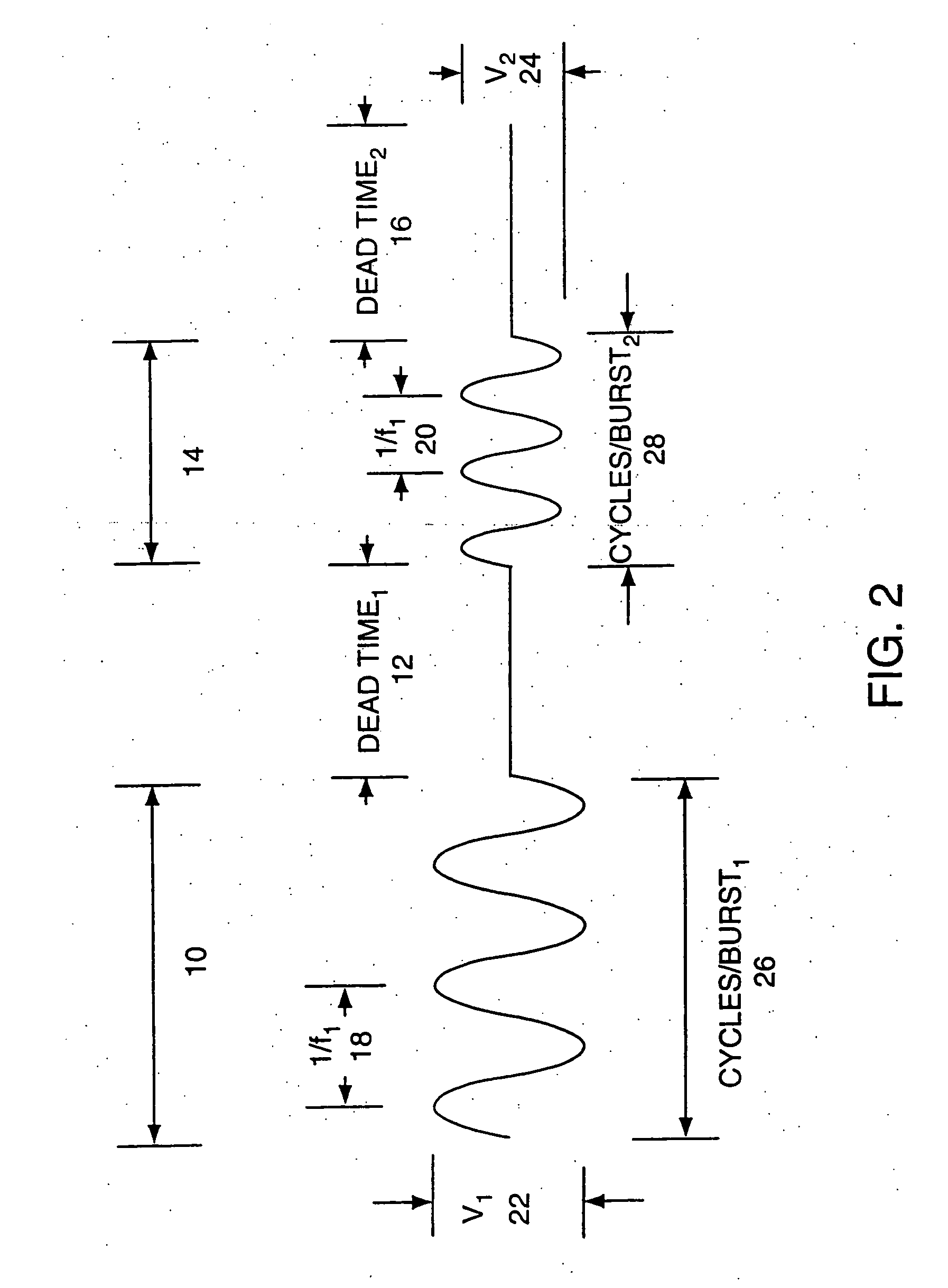

Methods and systems for modulating acoustic energy delivery

InactiveUS20060158956A1Treatment process can be safelySatisfy safety performance requirementsSequential/parallel process reactionsLiquid degasificationAcoustic energy

Owner:COVARIS INC

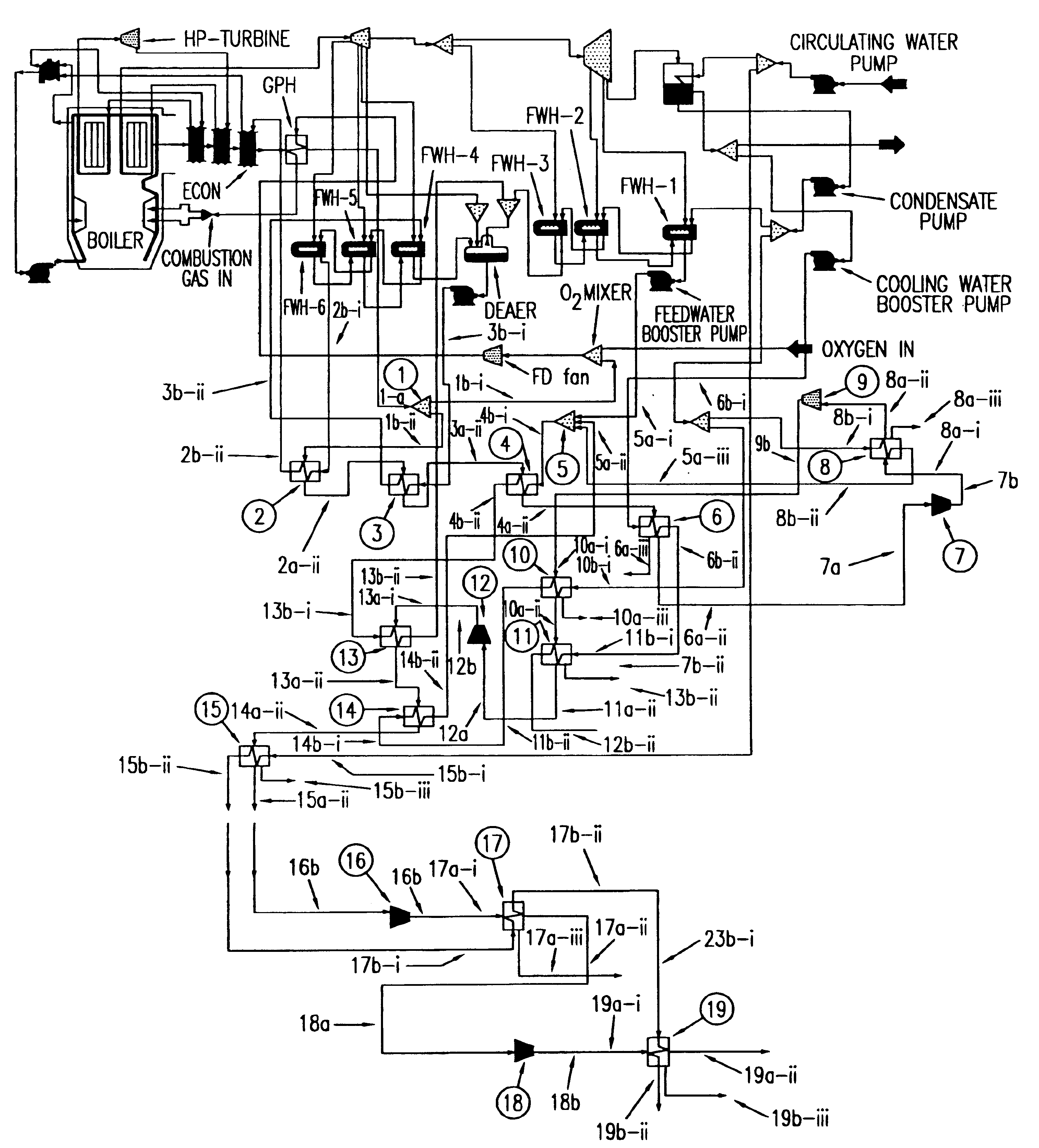

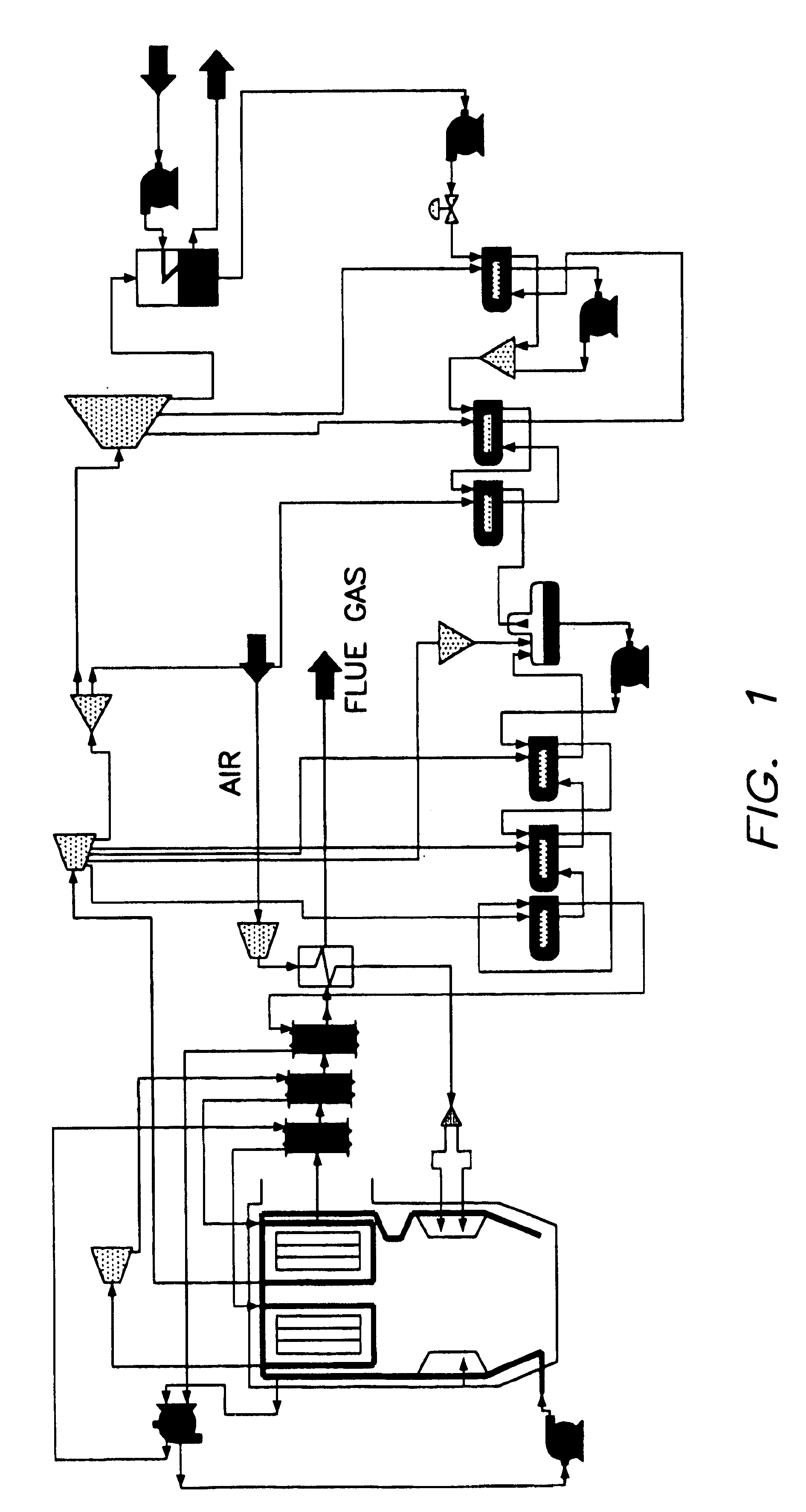

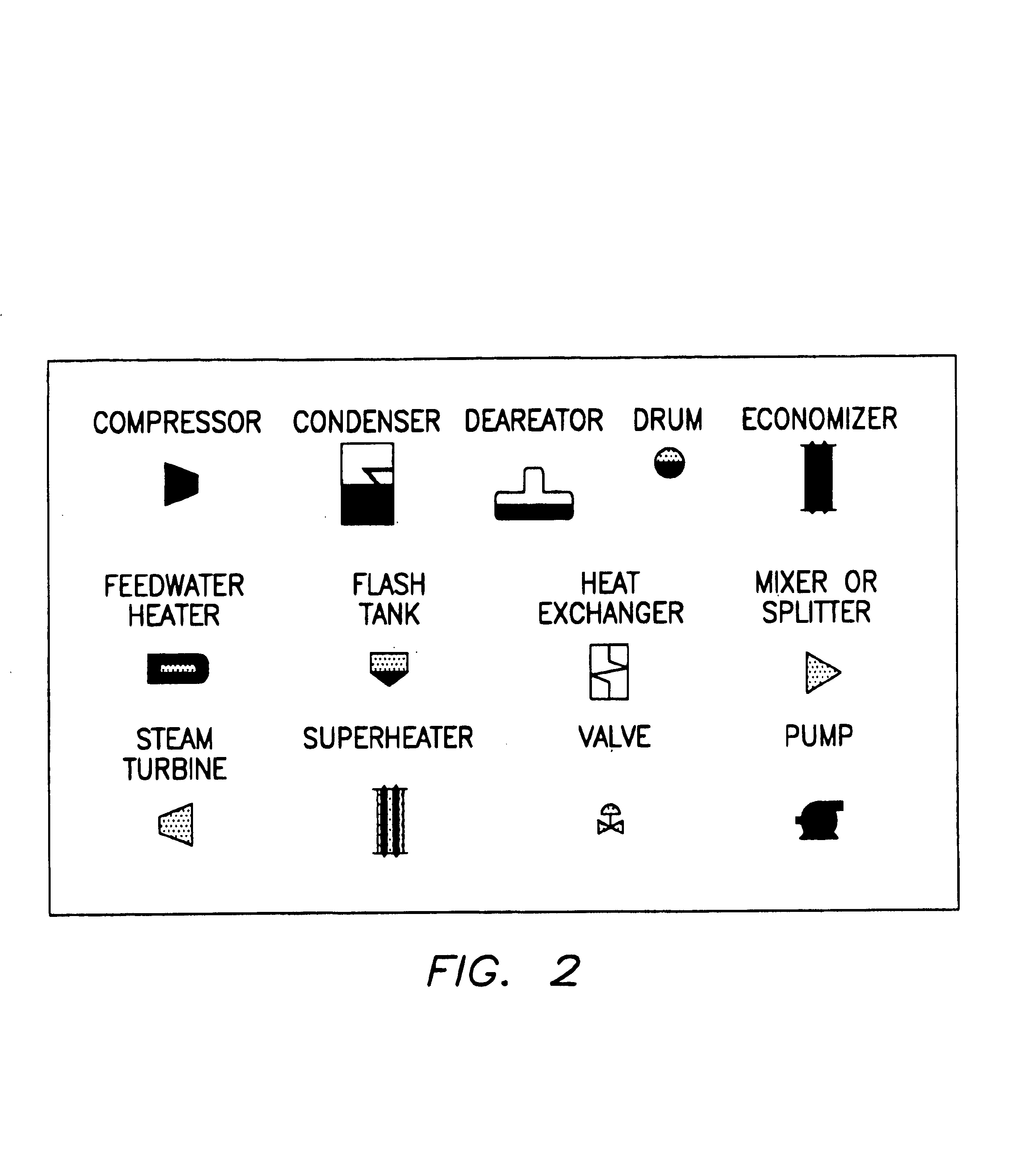

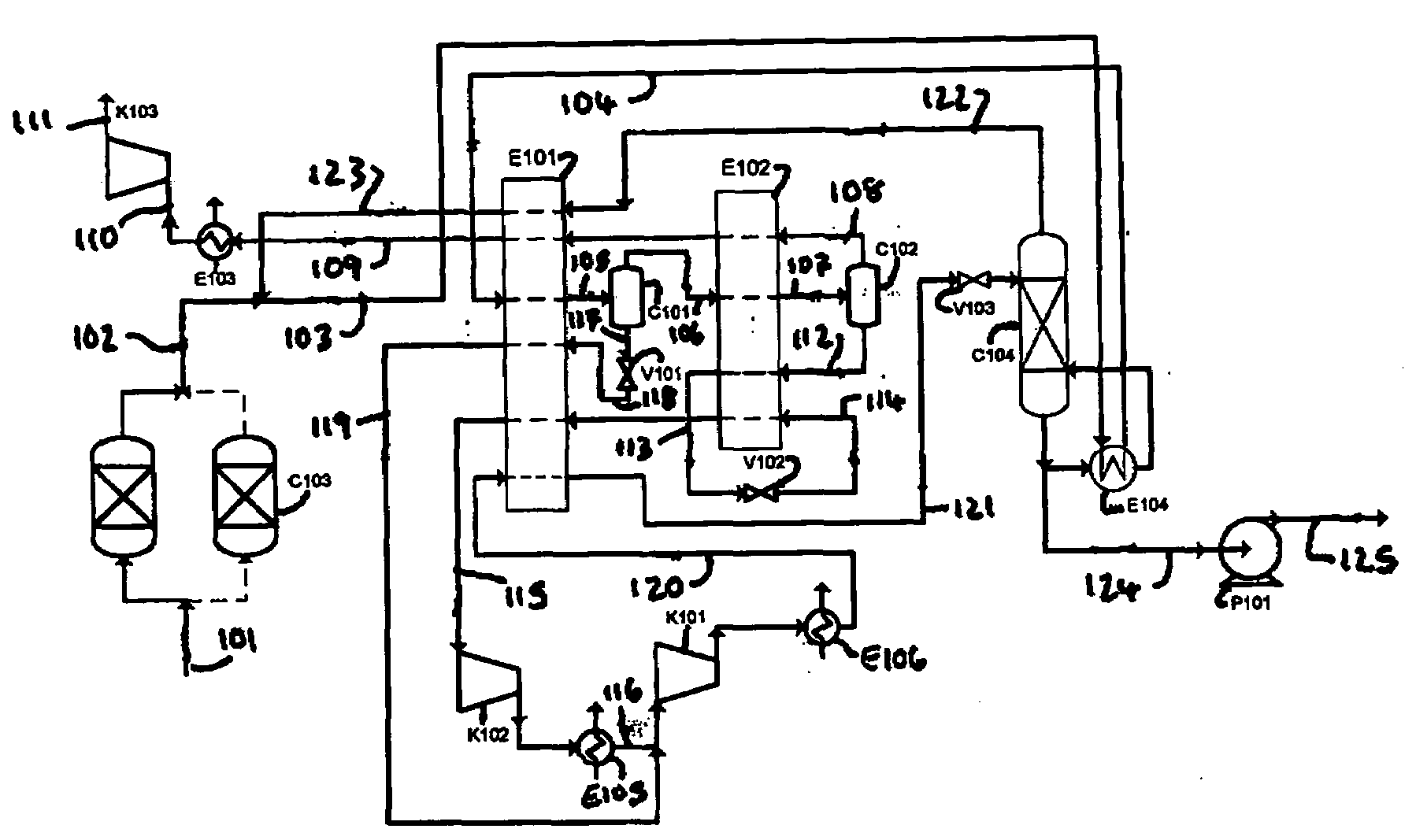

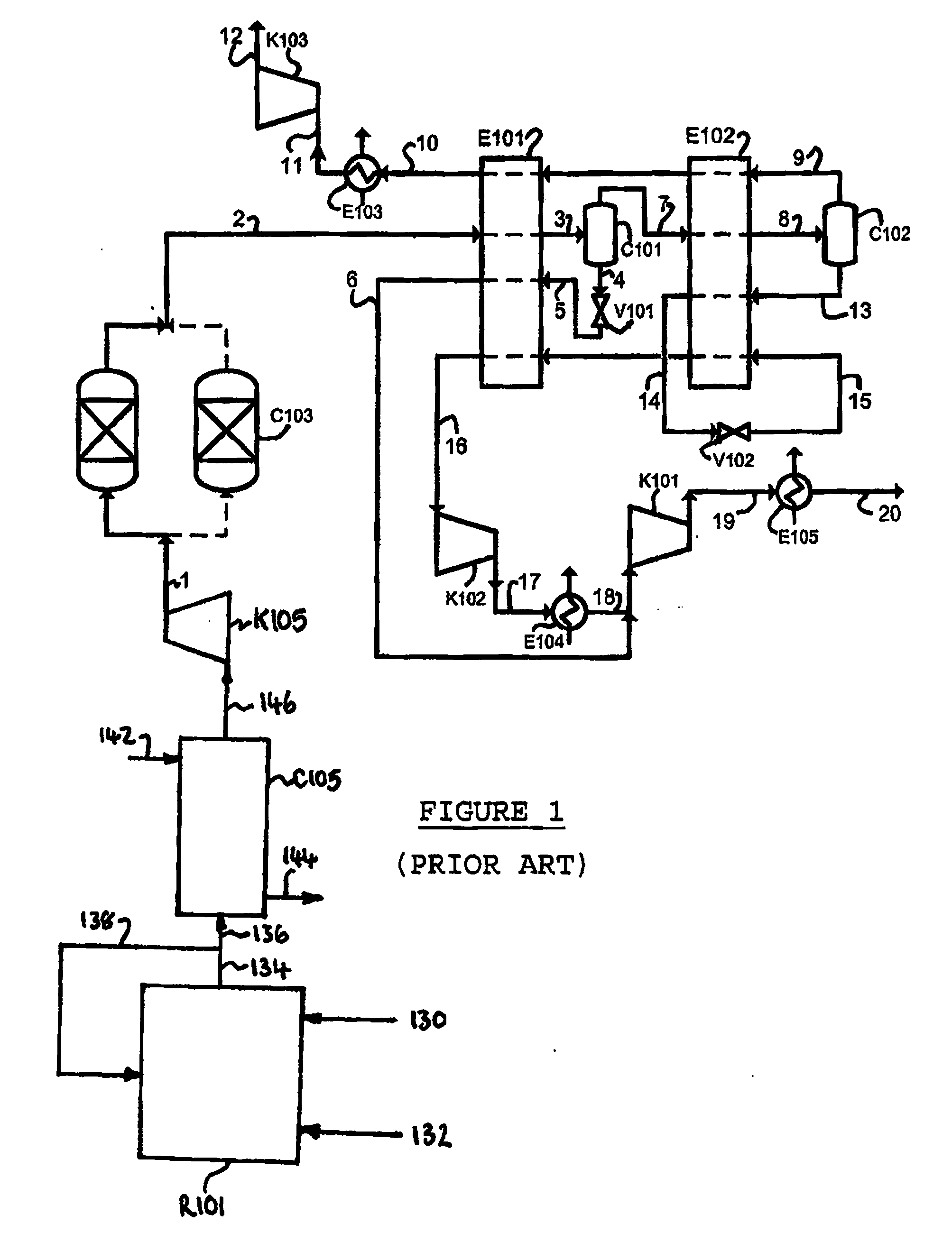

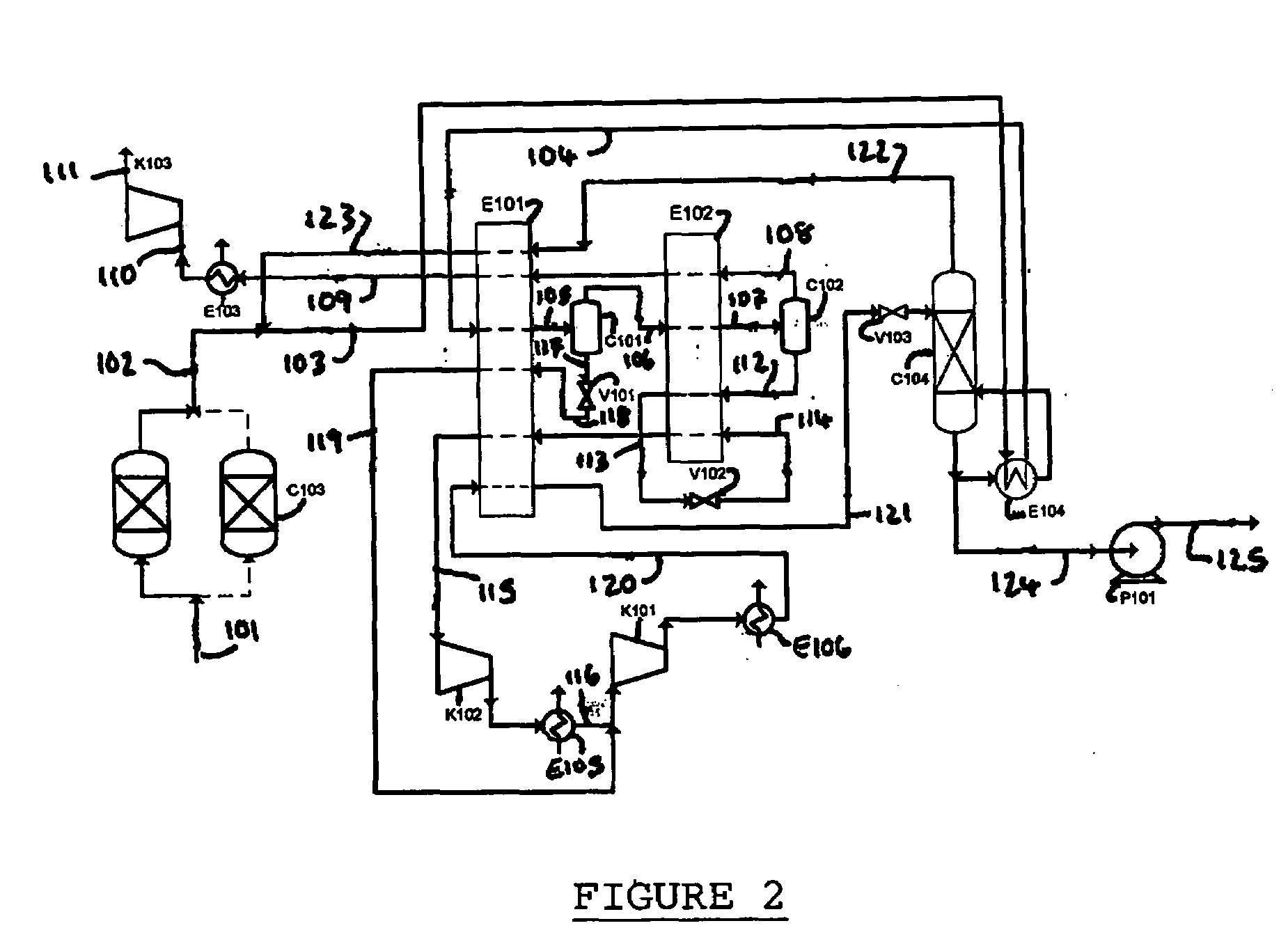

Compression stripping of flue gas with energy recovery

InactiveUS6898936B1Low costReduced Power RequirementsLiquid degasificationSteam regenerationWorking fluidWater vapor

A method of remediating and recovering energy from combustion products from a fossil fuel power plant having at least one fossil fuel combustion chamber, at least one compressor, at least one turbine, at least one heat exchanger and a source of oxygen. Combustion products including non-condensable gases such as oxygen and nitrogen and condensable vapors such as water vapor and acid gases such as SOX and NOX and CO2 and pollutants are produced and energy is recovered during the remediation which recycles combustion products and adds oxygen to support combustion. The temperature and / or pressure of the combustion products are changed by cooling through heat exchange with thermodynamic working fluids in the power generation cycle and / or compressing and / or heating and / or expanding the combustion products to a temperature / pressure combination below the dew point of at least some of the condensable vapors to condense liquid having some acid gases dissolved and / or entrained and / or directly condense acid gas vapors from the combustion products and to entrain and / or dissolve some of the pollutants while recovering sensible and / or latent heat from the combustion products through heat exchange between the combustion products and thermodynamic working fluids and / or cooling fluids used in the power generating cycle. Then the CO2, SO2, and H2O poor and oxygen enriched remediation stream is sent to an exhaust and / or an air separation unit and / or a turbine.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

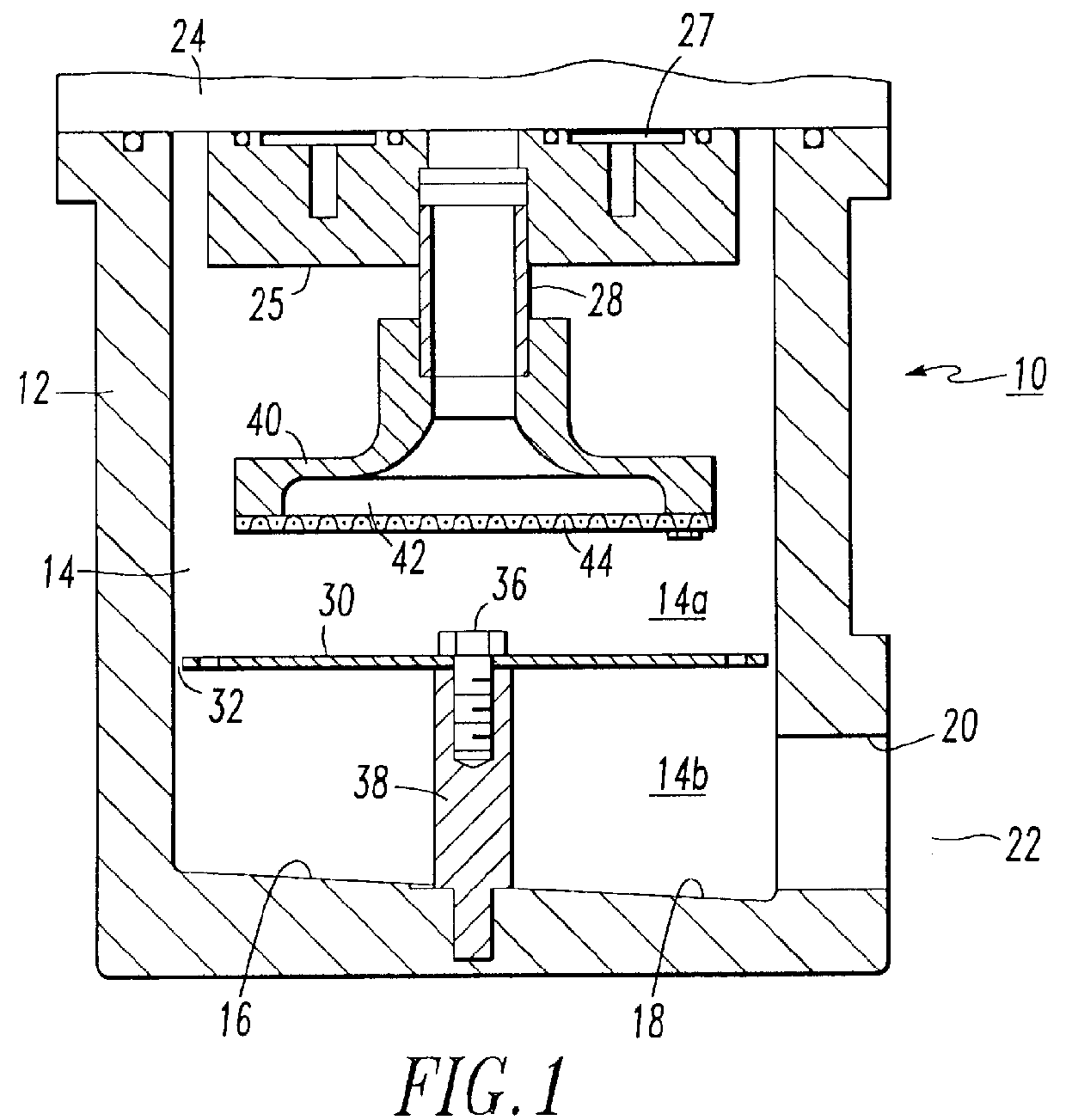

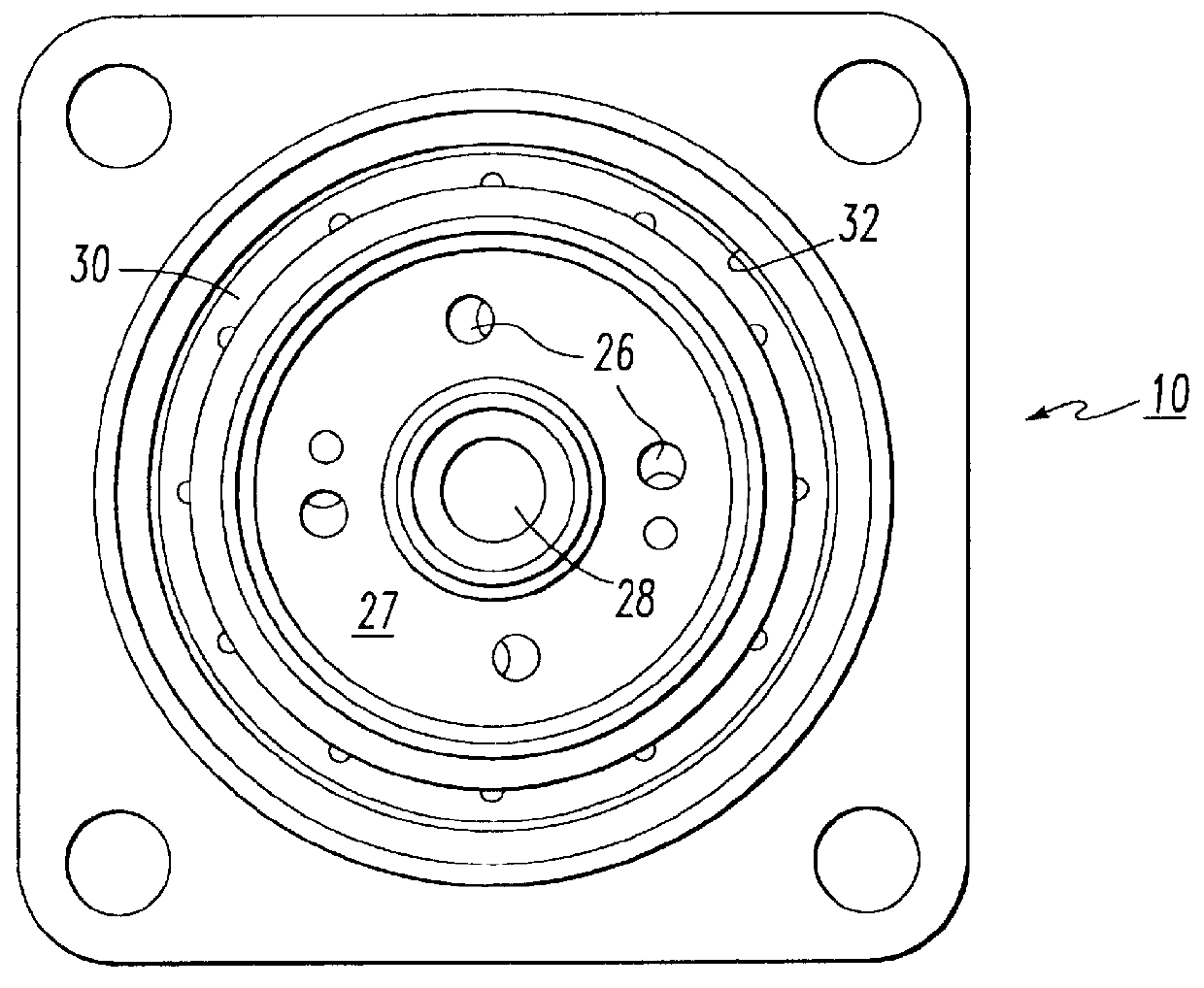

E-1 air dryer liquid separator with baffle

In a centrifugal separator for separating a liquid from a compressed gas, a baffle is provided to separate the centrifugal chamber into an upper sub-chamber and a lower sub-chamber but does not contact the walls of the chamber thereby being insufficient to prevent downward flow of separated liquid along the interior wall of the two sub-chambers, and insufficient to prevent flow of compressed gas from one sub-chamber to the other sub-chamber, the baffle nevertheless being sufficient to prevent turbulent gas flow in the lower sub-chamber when collected liquid is drained therefrom.

Owner:WESTINGHOUSE AIR BRAKE CO

Purification of carbon dioxide

Impure carbon dioxide (“CO2”) comprising a first contaminant selected from the group consisting of oxygen (“O2”) and carbon monoxide (“CO”) is purified by separating expanded impure carbon dioxide liquid in a mass transfer separation column system. The impure carbon dioxide may be derived from, for example, flue gas from an oxyfuel combustion process or waste gas from a hydrogen (“H2”) PSA system.

Owner:AIR PROD & CHEM INC

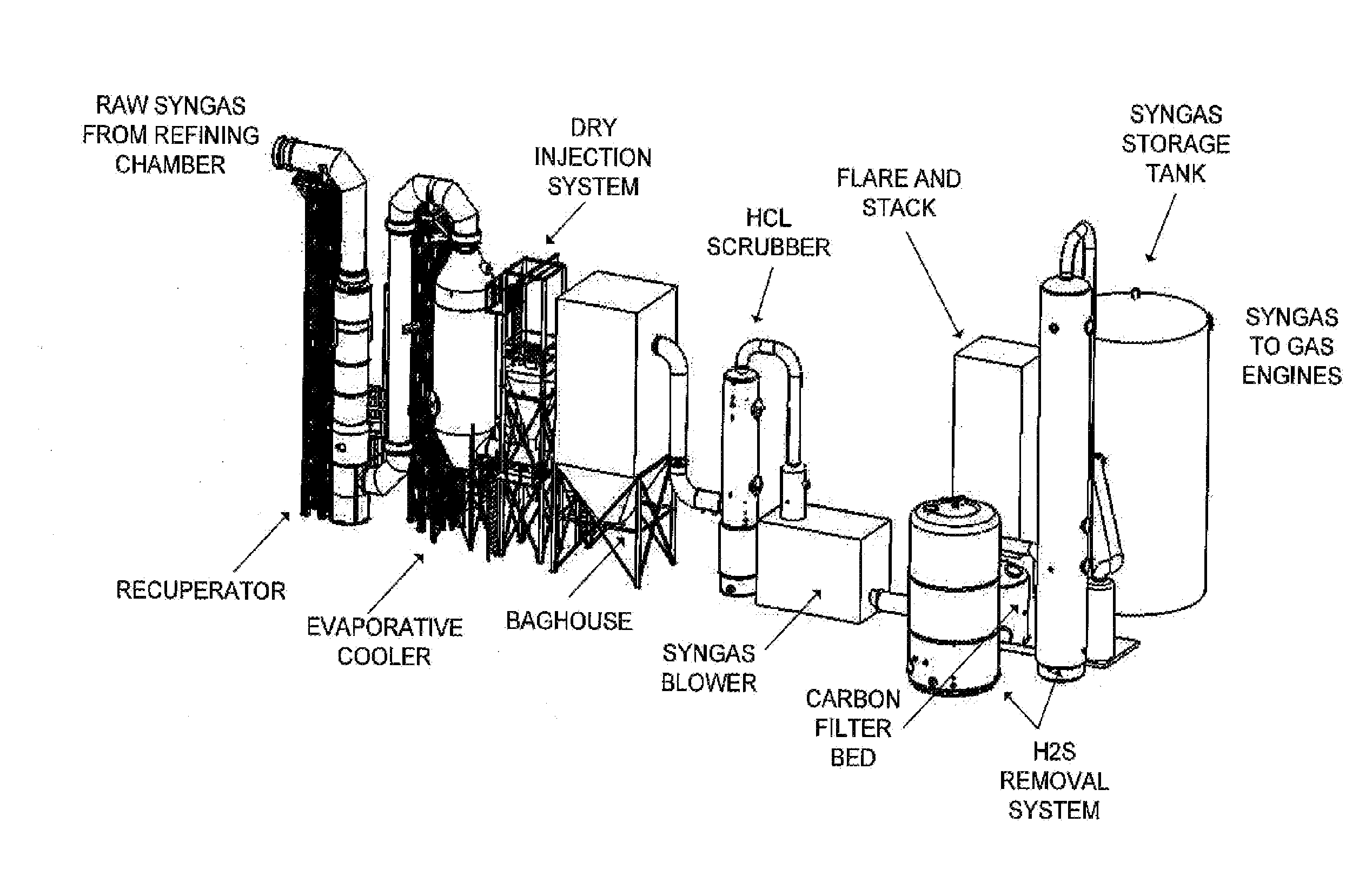

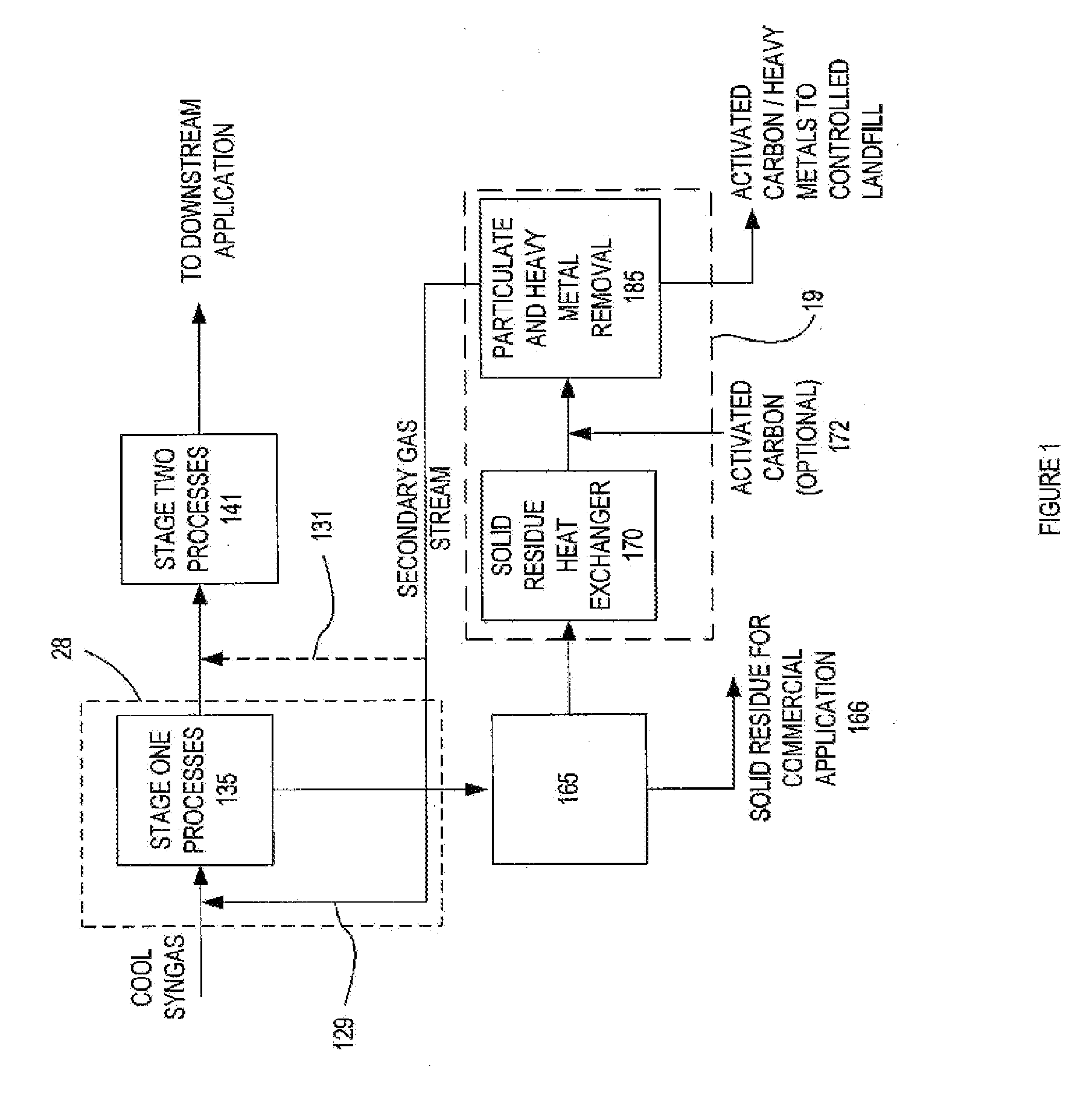

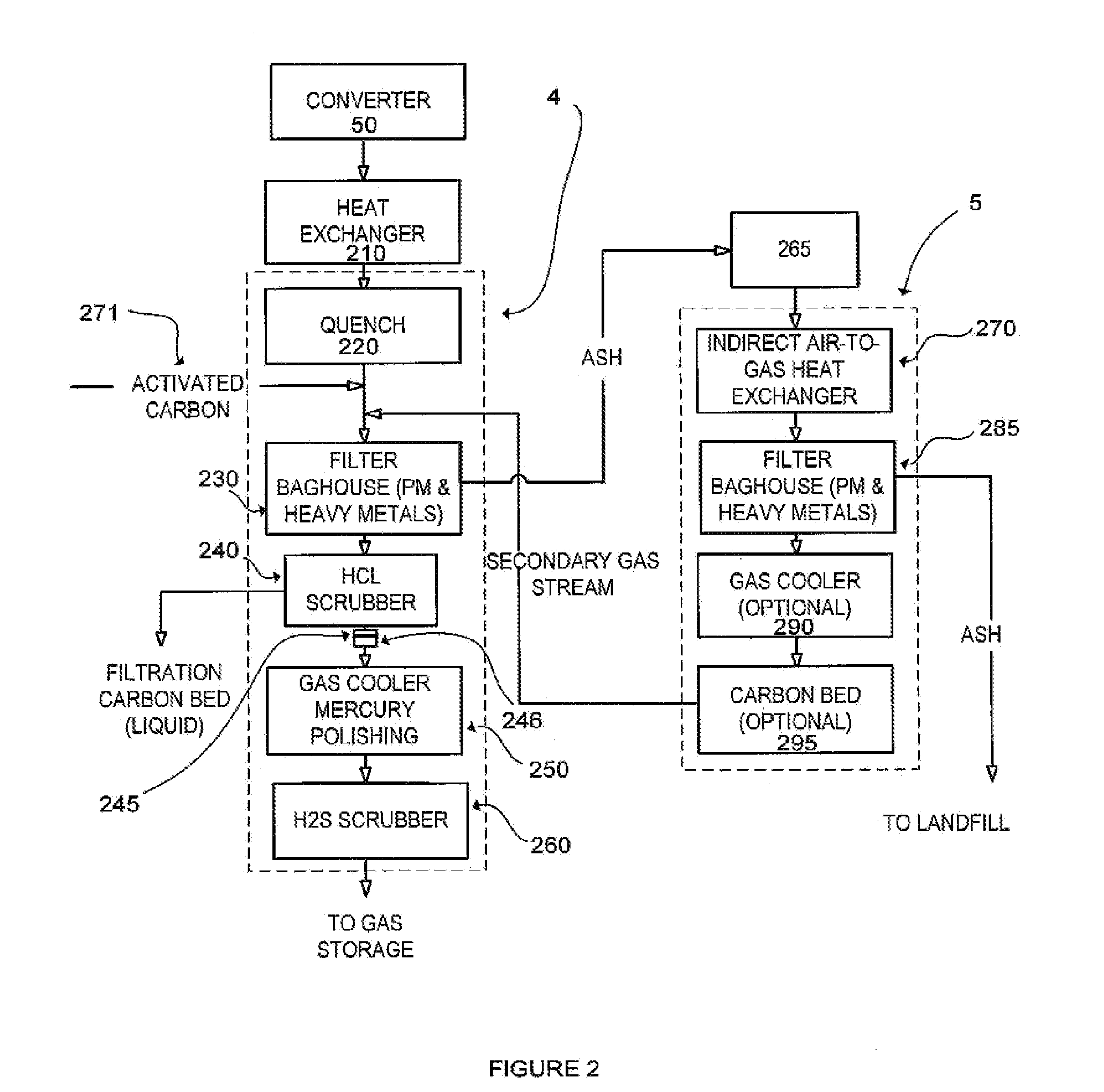

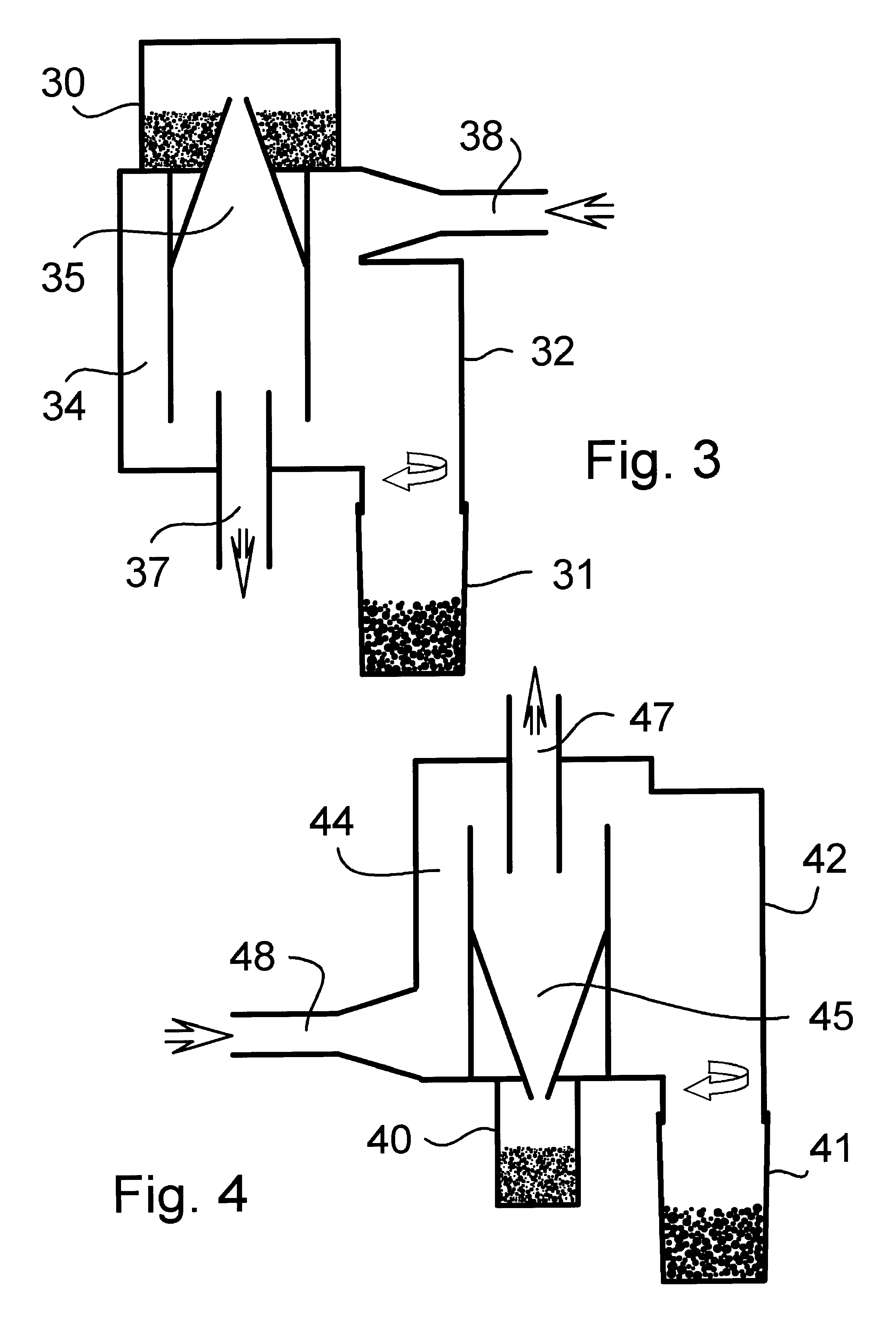

Gas conditioning system

The present invention provides a gas conditioning system for processing an input gas from a low temperature gasification system to an output gas of desired characteristics. The system comprises a two-stage process, the first stage separating heavy metals and particulate matter in a dry phase, and the second stage including further processing steps of removing acid gases, and / or other contaminants. Optional processes include adjusting the humidity and temperature of the input gas as it passes through the gas conditioning system. The presence and sequence of processing steps is determined by the composition of the input gas, the desired composition of output gas for downstream applications, and by efficiency and waste minimization.

Owner:PLASCO ENERGY GROUP INC

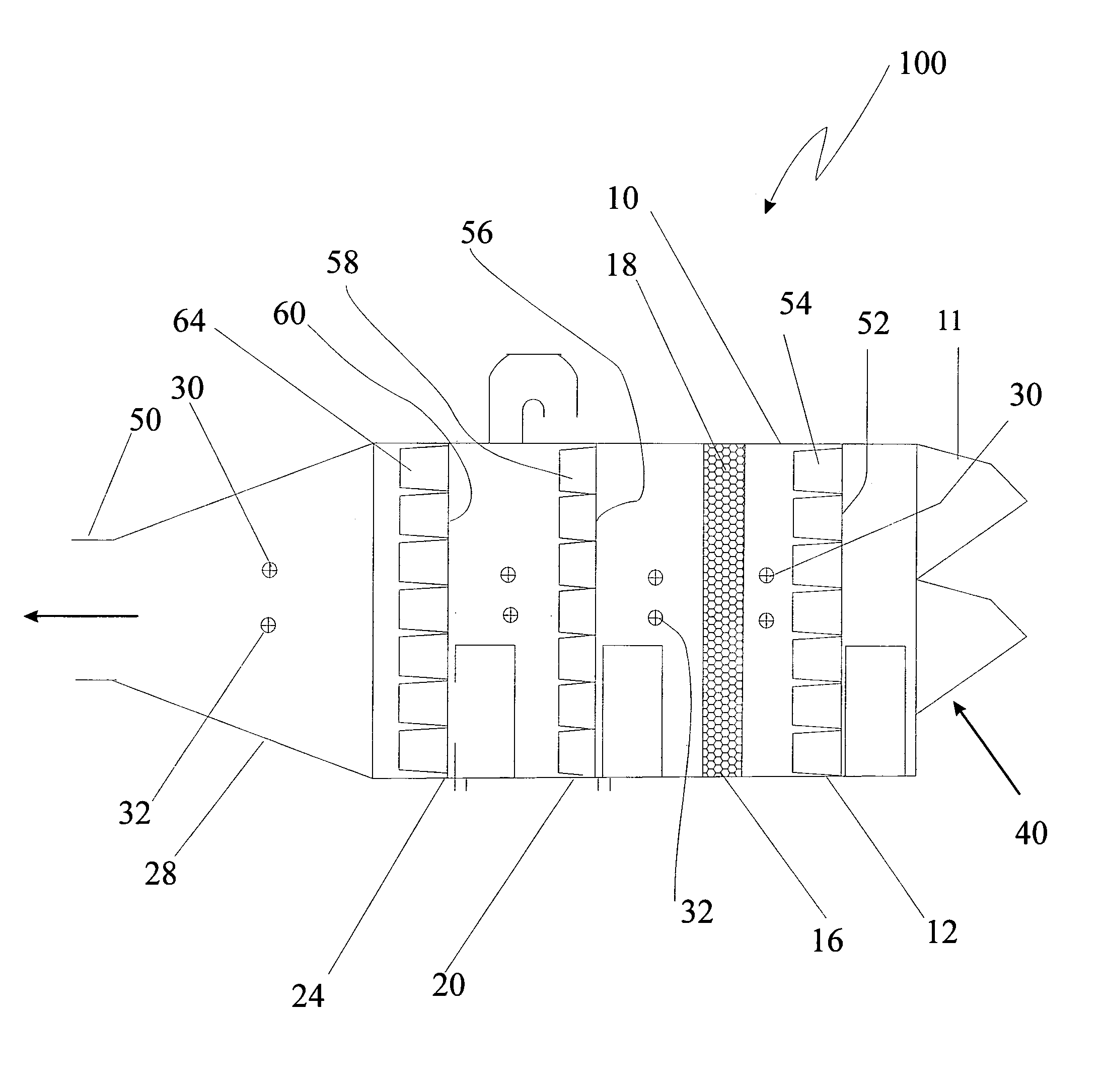

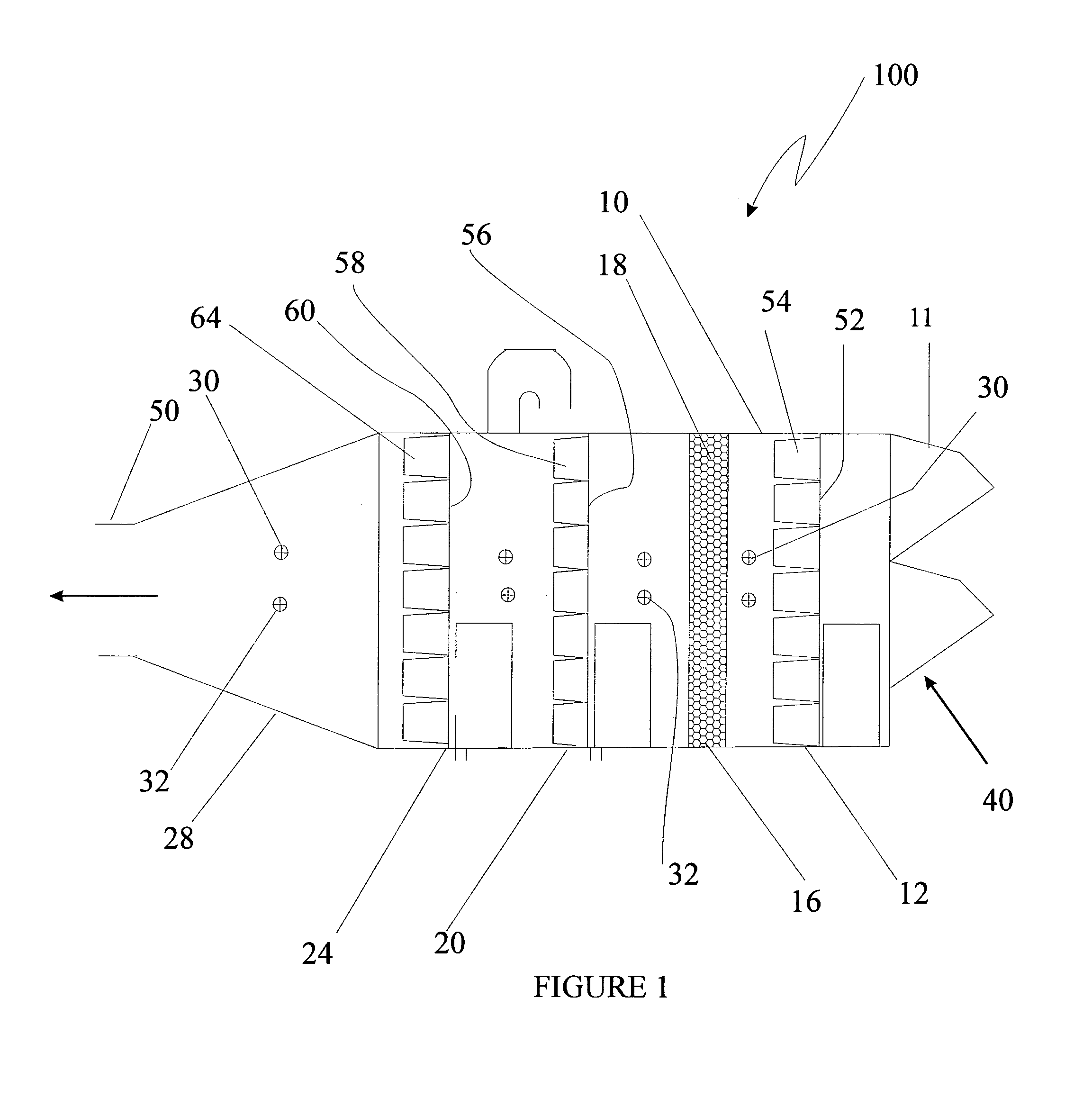

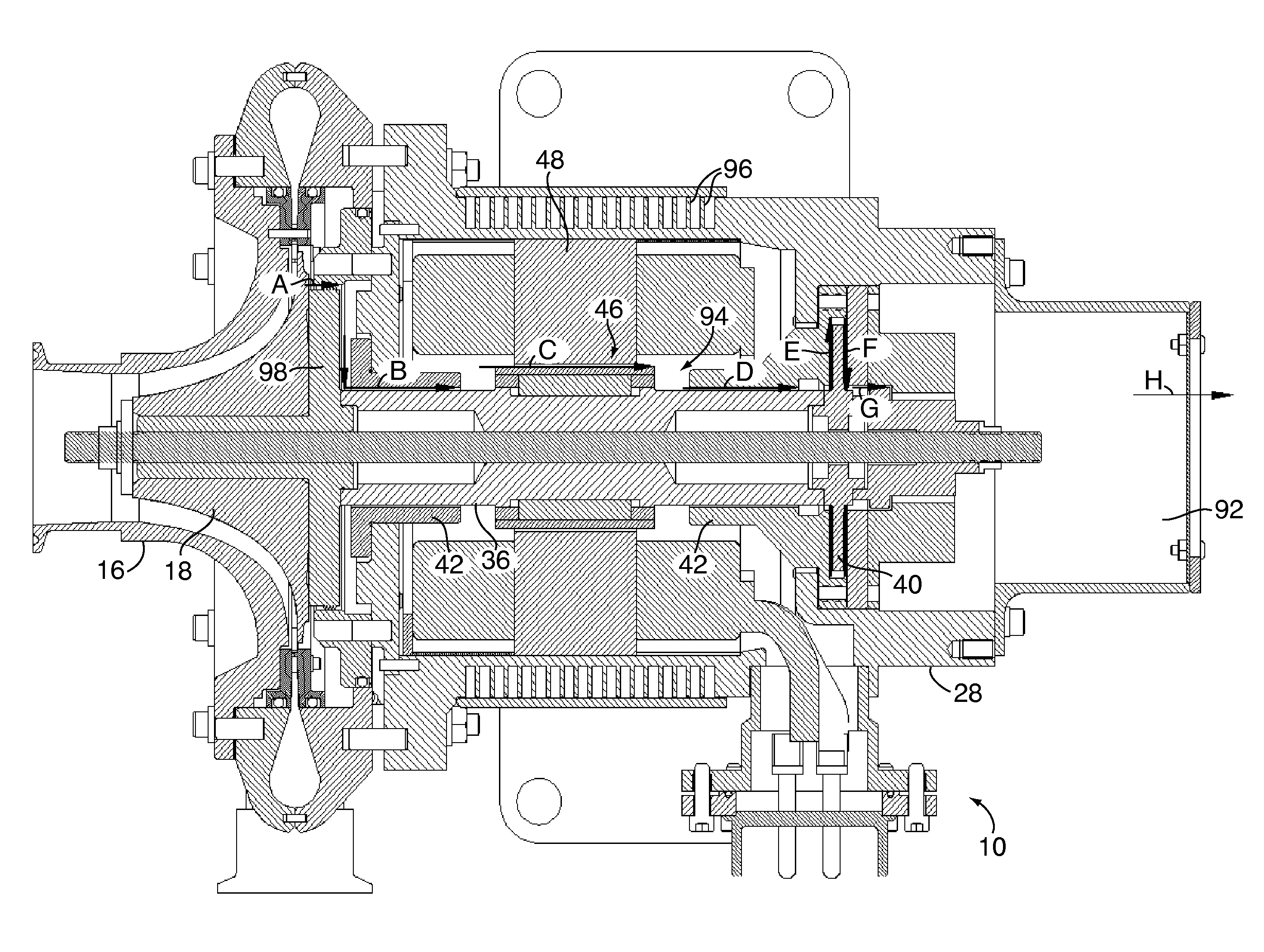

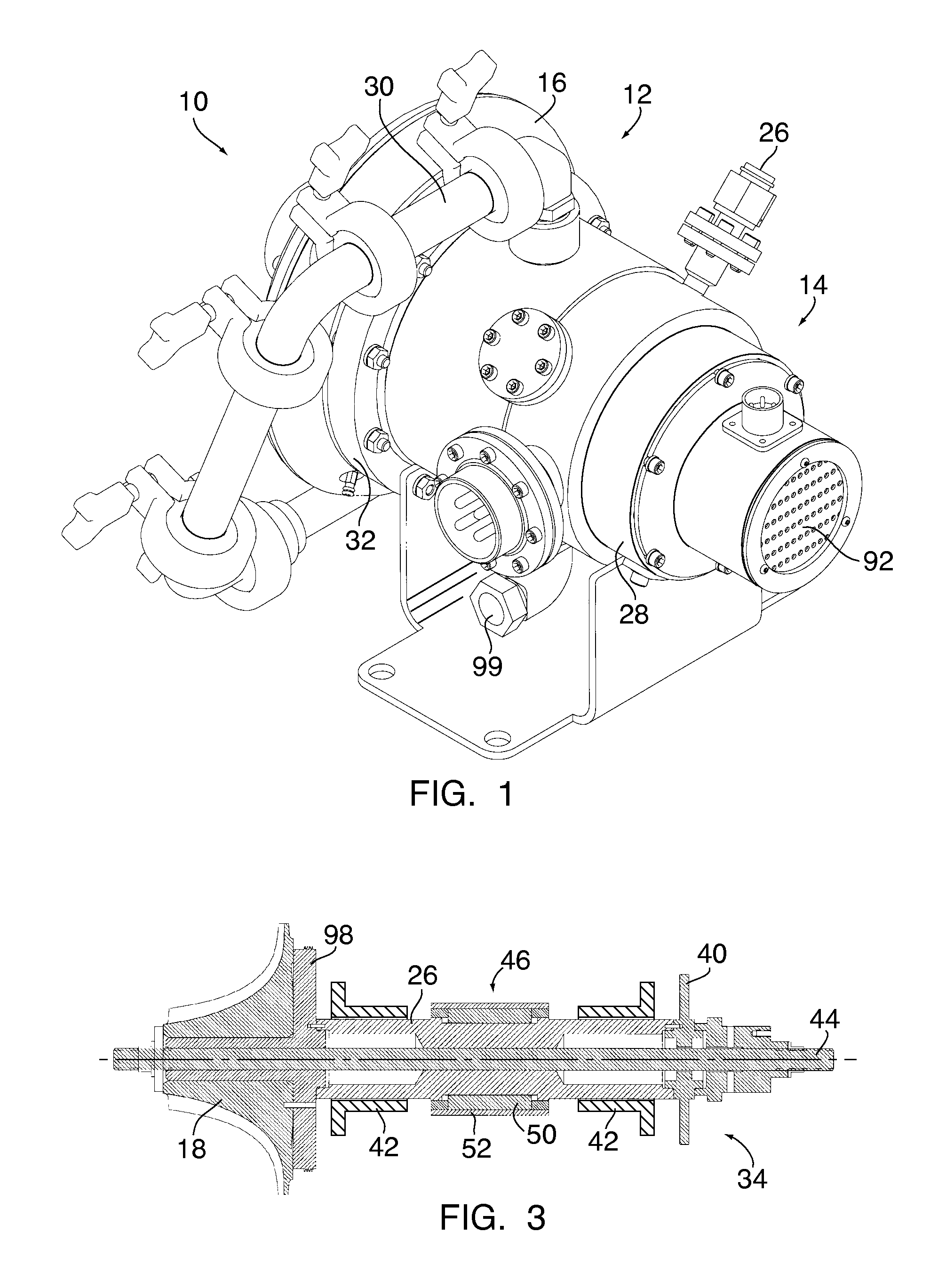

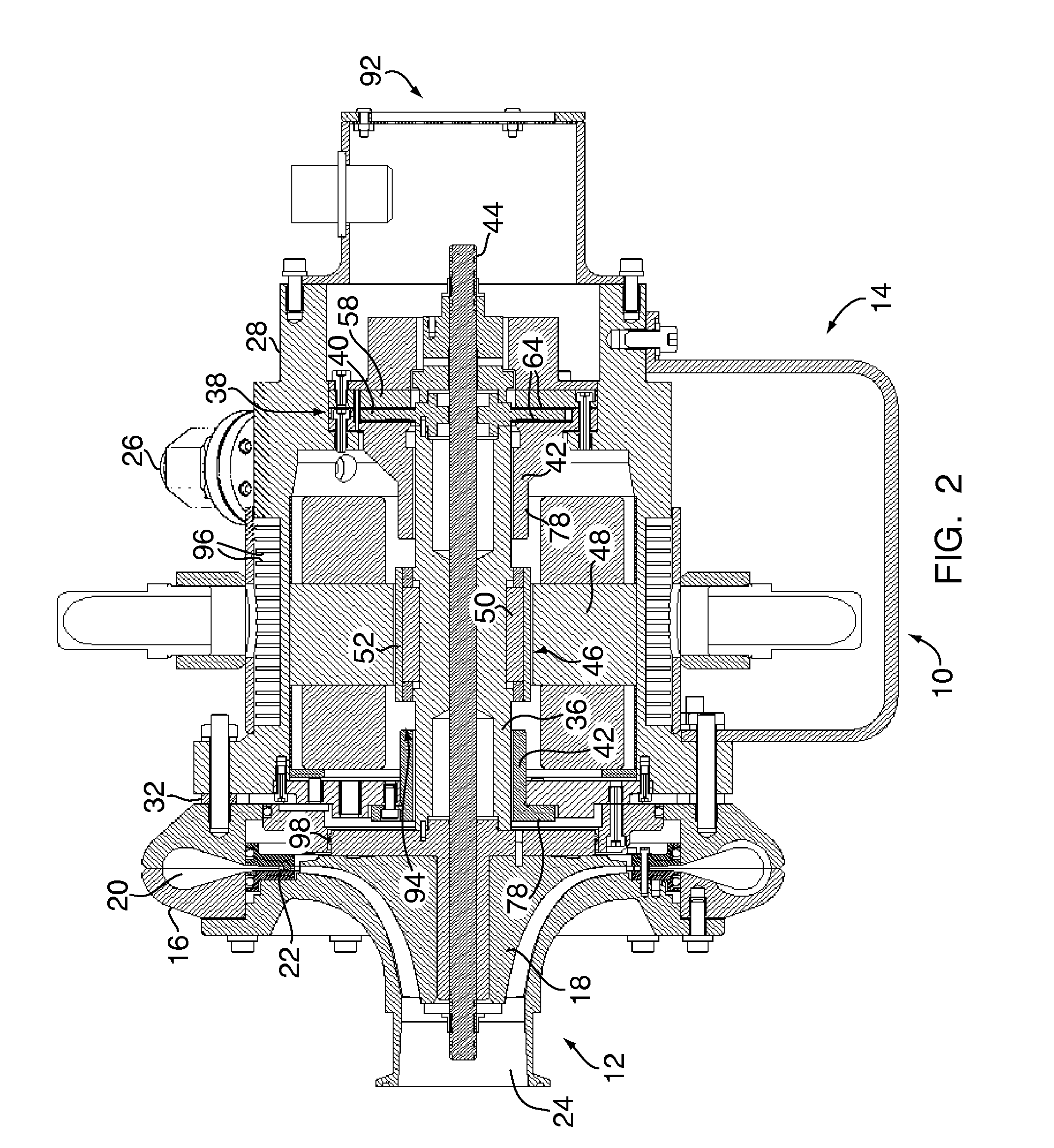

Turboalternator with hydrodynamic bearings

ActiveUS20080246281A1Recovery of wasted energyReduce pressureLiquid degasificationPump componentsStored energyAlternator

This invention provides a small, high efficiency, oil-free turbine-driven alternator (i.e. turboalternator) suitable for conversion of stored energy in a process gas to electrical power, facilitating recapture of energy during operation that would otherwise be wasted. The turboalternator includes a turbine and a generating device operatively connected together by a rotating shaft capable of rotating at high speeds. The rotating shaft is supported by foil gas bearings.

Owner:R & D DYNAMICS

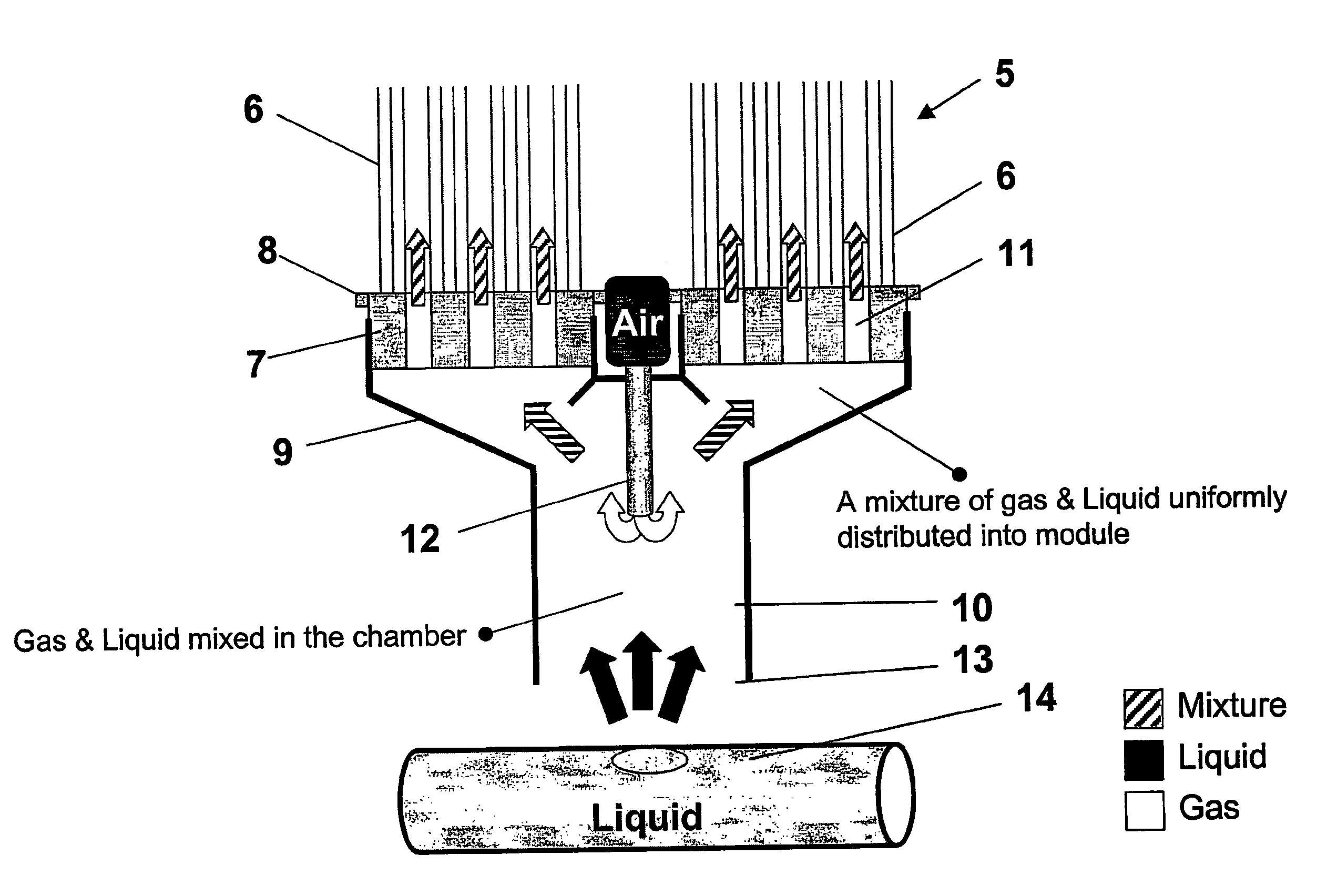

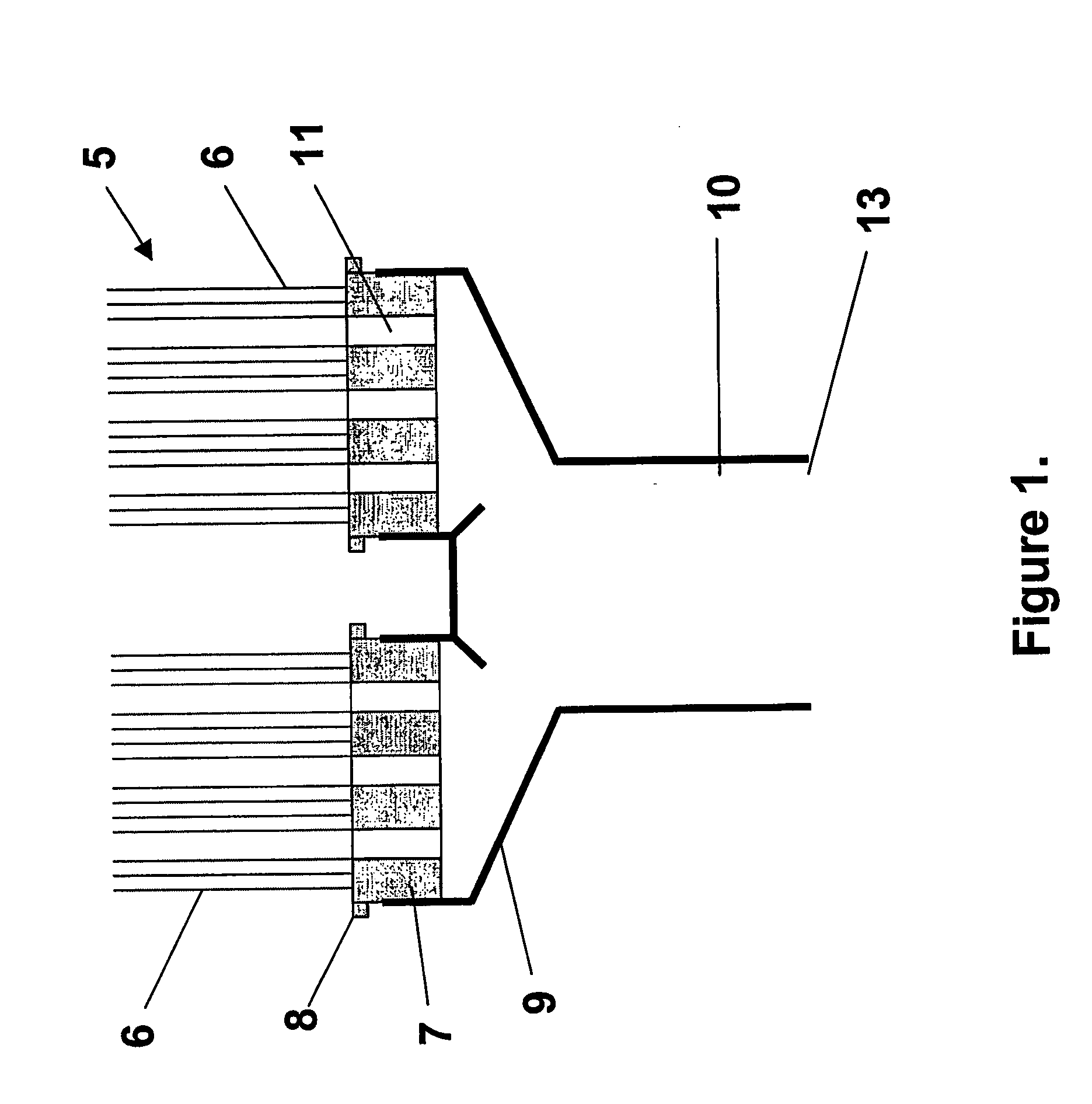

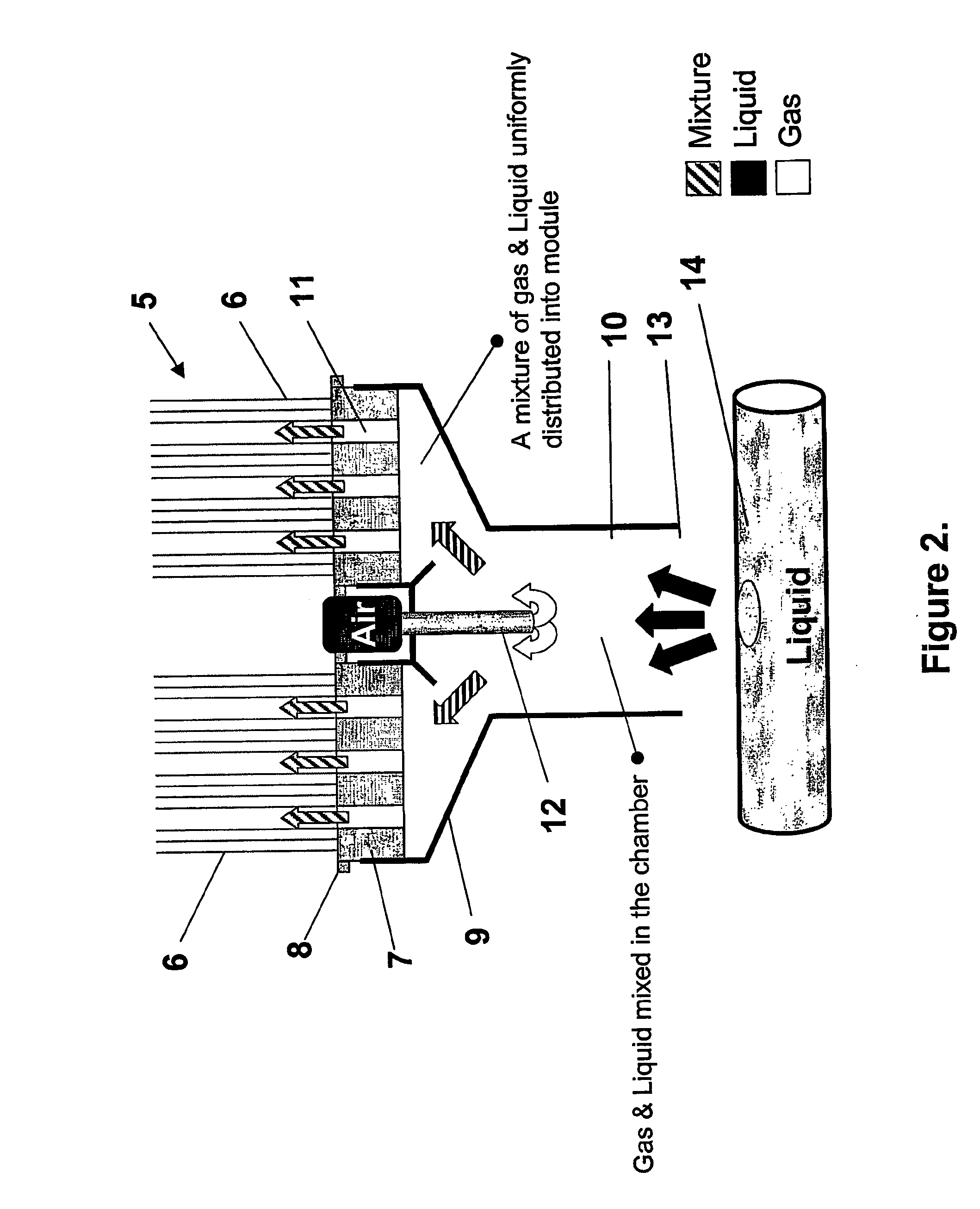

Mixing chamber

ActiveUS20070007214A1Reduce anoxic zoneImprove filtrate qualityMembranesLiquid degasificationPorous membraneBiomedical engineering

Owner:EVOQUA WATER TECH LLC

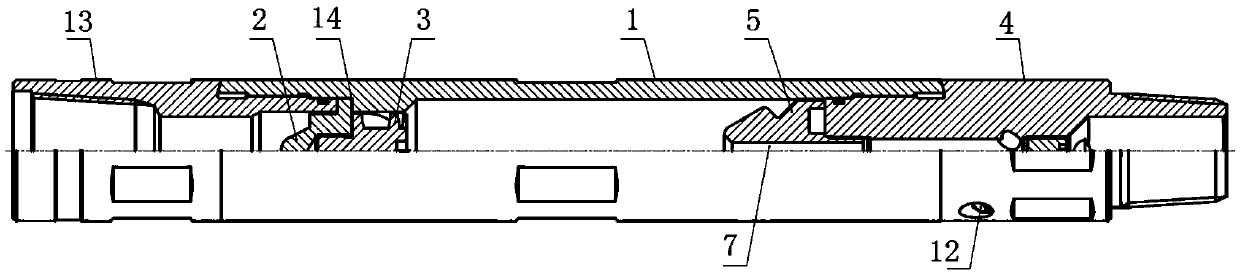

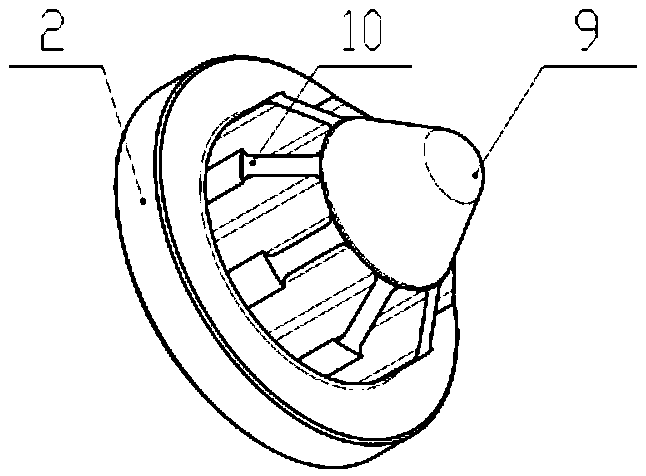

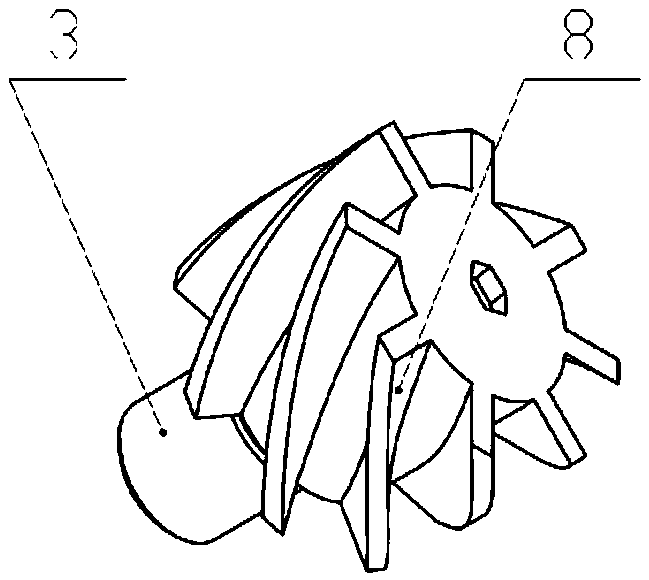

Downhole gas-liquid separation device and working method thereof

ActiveCN105536299AReduce in quantitySimple structureLiquid degasificationSeparation devicesEngineeringProduct gas

A downhole gas-liquid separation device comprises a barrel-shaped body, and a positioning wheel is fixedly installed in the body. A rotatable swirling wheel is installed on the positioning wheel and provided with spiral wheel blades, and the positioning wheel is provided with fluid channels. A lower connector is connected to the body, a diverting joint is arranged at the inner end, located in an inner cavity of the body, of the lower connector, a gas outlet channel is formed in the center of the diverting joint in a coaxial mode, and the outer side of the diverting joint is provided with liquid drainage channels. An interval is formed between the swirling wheel and the diverting joint. The downhole gas-liquid separation device is small in part number, simple in structure and lower in cost; the swirling wheel is driven to rotate when liquid passes through the swirling wheel to enable the liquid to generate centrifugal force and swirlingly flow in the inner cavity in the mode of being attached to the wall, the liquid in gas is gathered to the center, and then the liquid and the gas flow out through the liquid drainage channels formed in the outer side and the gas outlet channel formed in the center respectively, so that gas and liquid separation is achieved; accordingly, the liquid sent to a motor does not contain the gas, damage to the motor is avoided, and the service life of the motor is prolonged.

Owner:JEREH ENERGY SERVICES

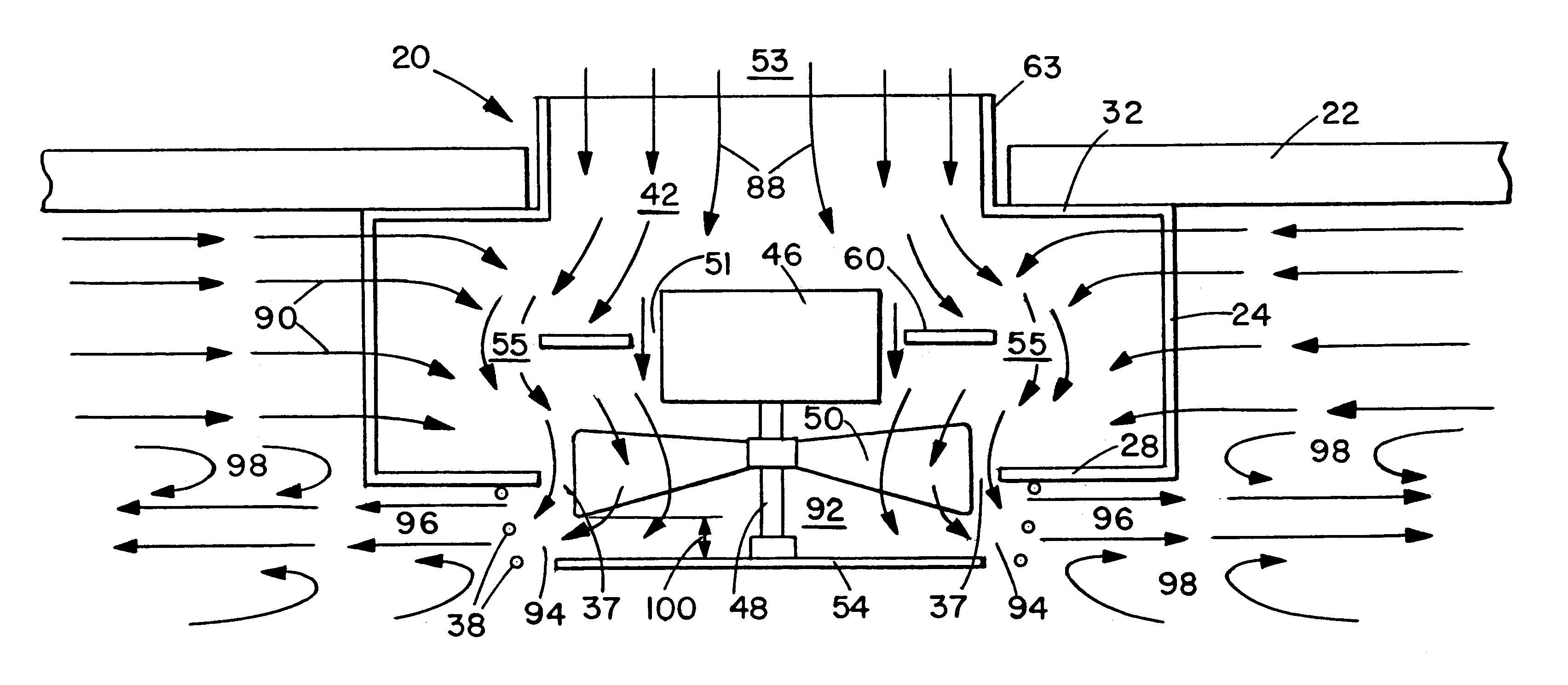

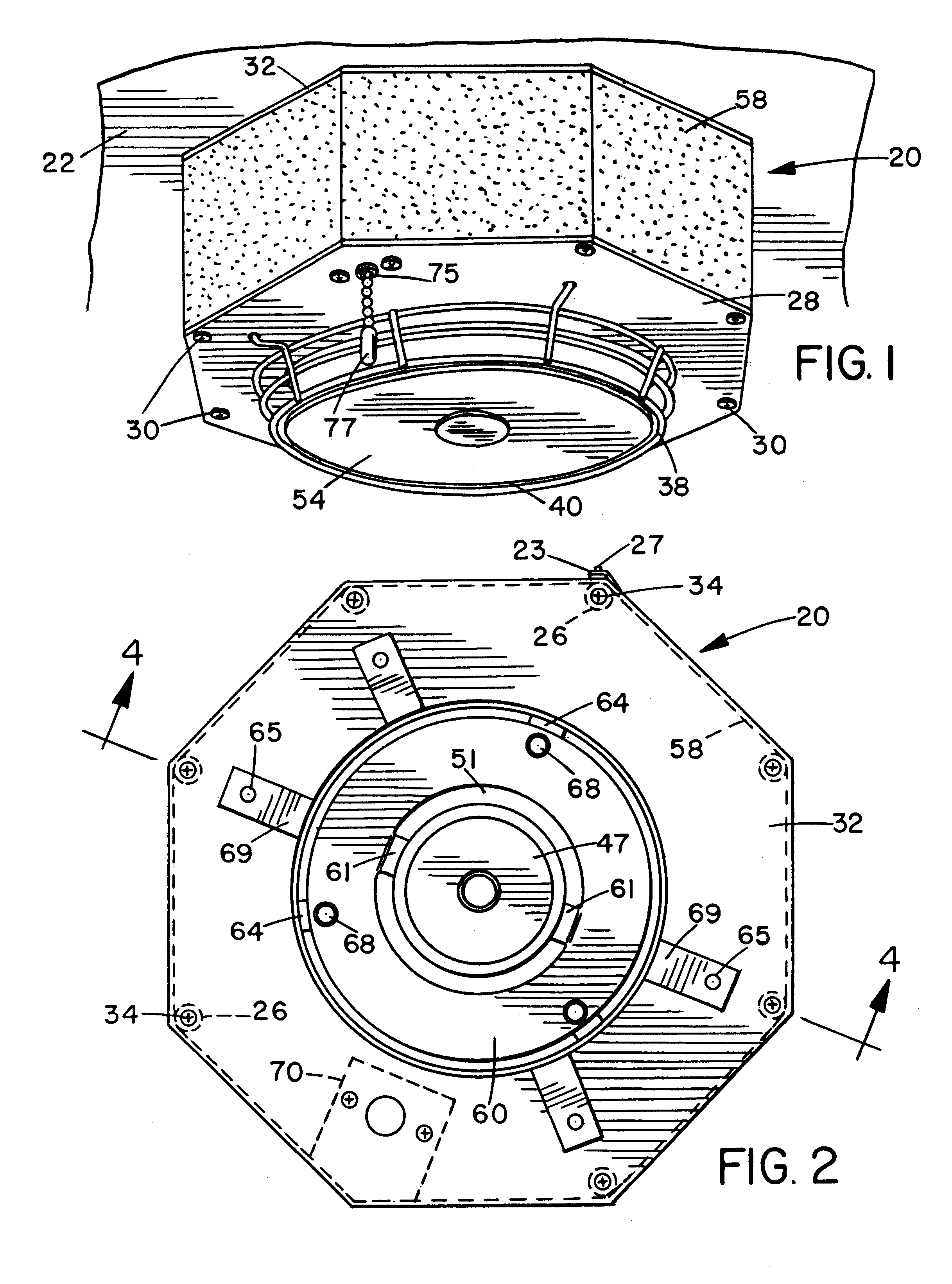

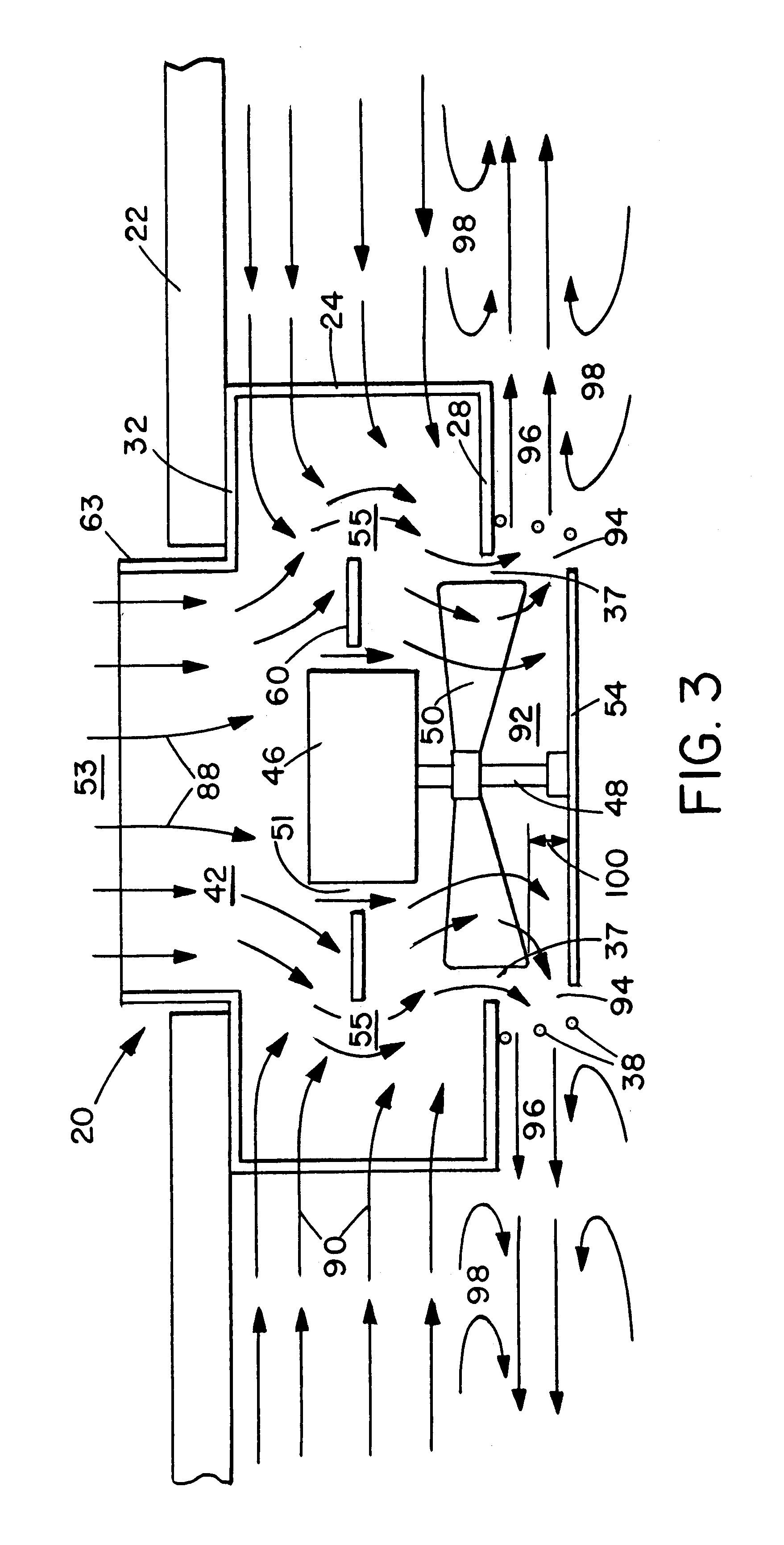

Recirculating air mixer and fan with lateral air flow

An air circulation and mixing device is disclosed which can cover a ceiling air ventilation duct, taking air discharged from the duct and drawing air at the room's ceiling, mixing the two, and redirecting the mixed air so that it is discharged radially and parallel to the ceiling, rather than directly downwardly. The device has an open frame whose sides may be covered with removable air filtration media and which forms a primary interior having a lower aperture and normally an upper aperture. An open-sided grille below the lower aperture forms a secondary space. A fan is mounted within the primary space and turns blades within the lower aperture and a disk at the bottom of the secondary space. An annular plate surrounding the fan housing blocks downward flow of incoming air and forces the air to flow radially outwardly around the edge of the plate, thus also insuring good mixing with the incoming ceiling air. The rotating disk receives air blown downwardly through the lower aperture and redirects it radially outwardly through the openings in the side of the grille, such that airflow becomes horizontal and parallel to the ceiling, so that the air flow slows and the air becomes gradually dispersed throughout the entire room. The device can also be mounted over a through-wall air duct outlet by using a duct extension.

Owner:COOK E F

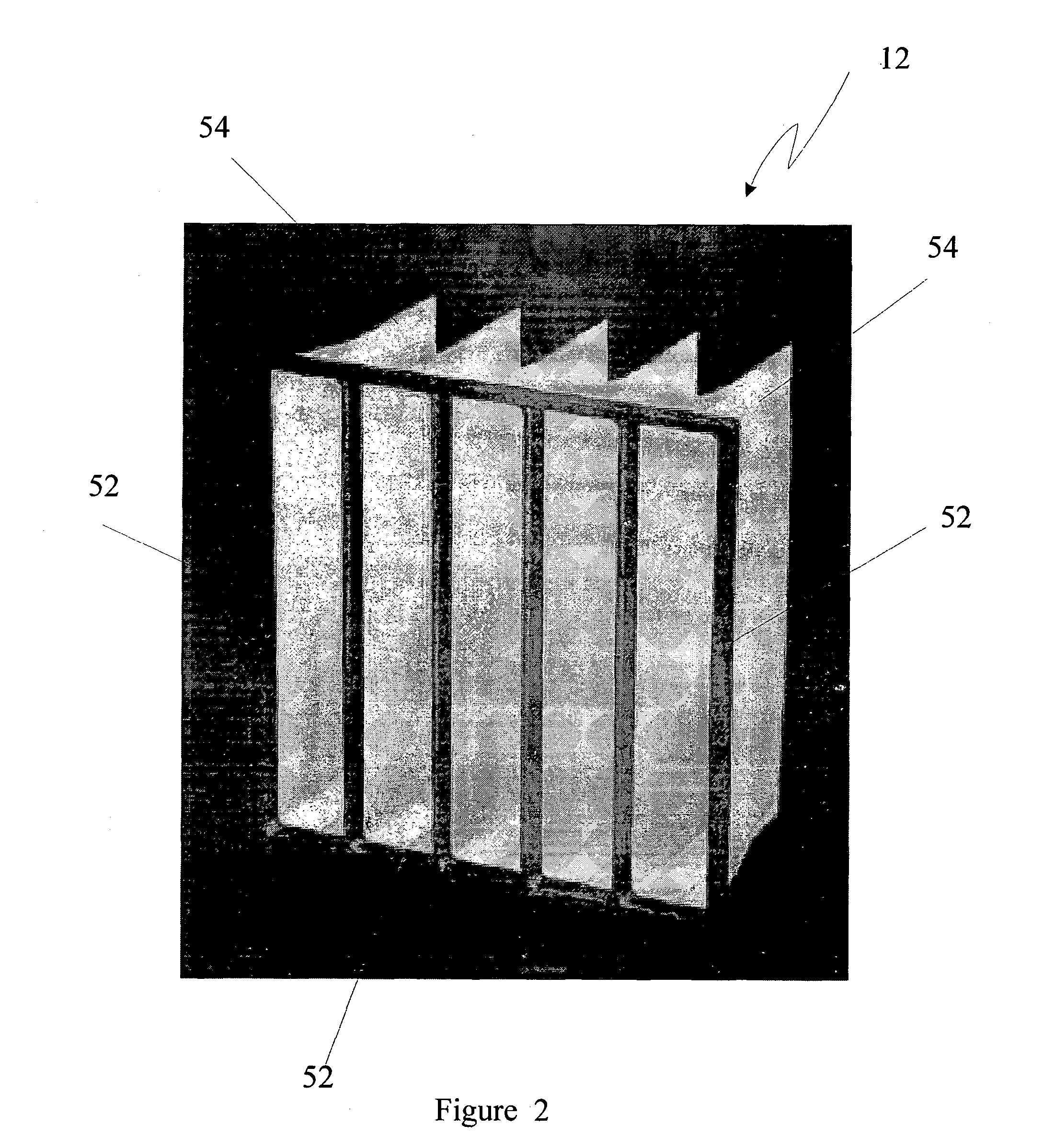

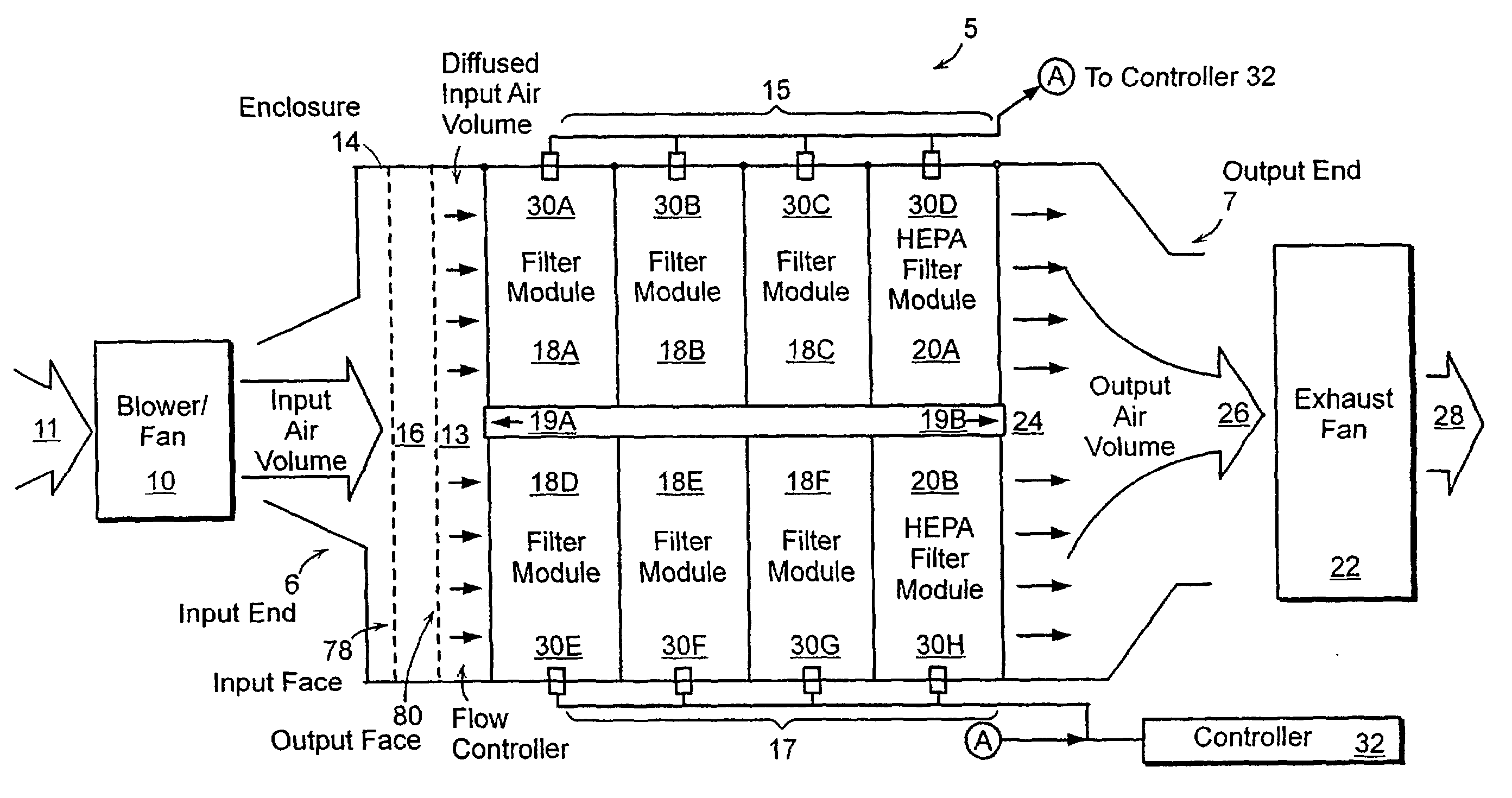

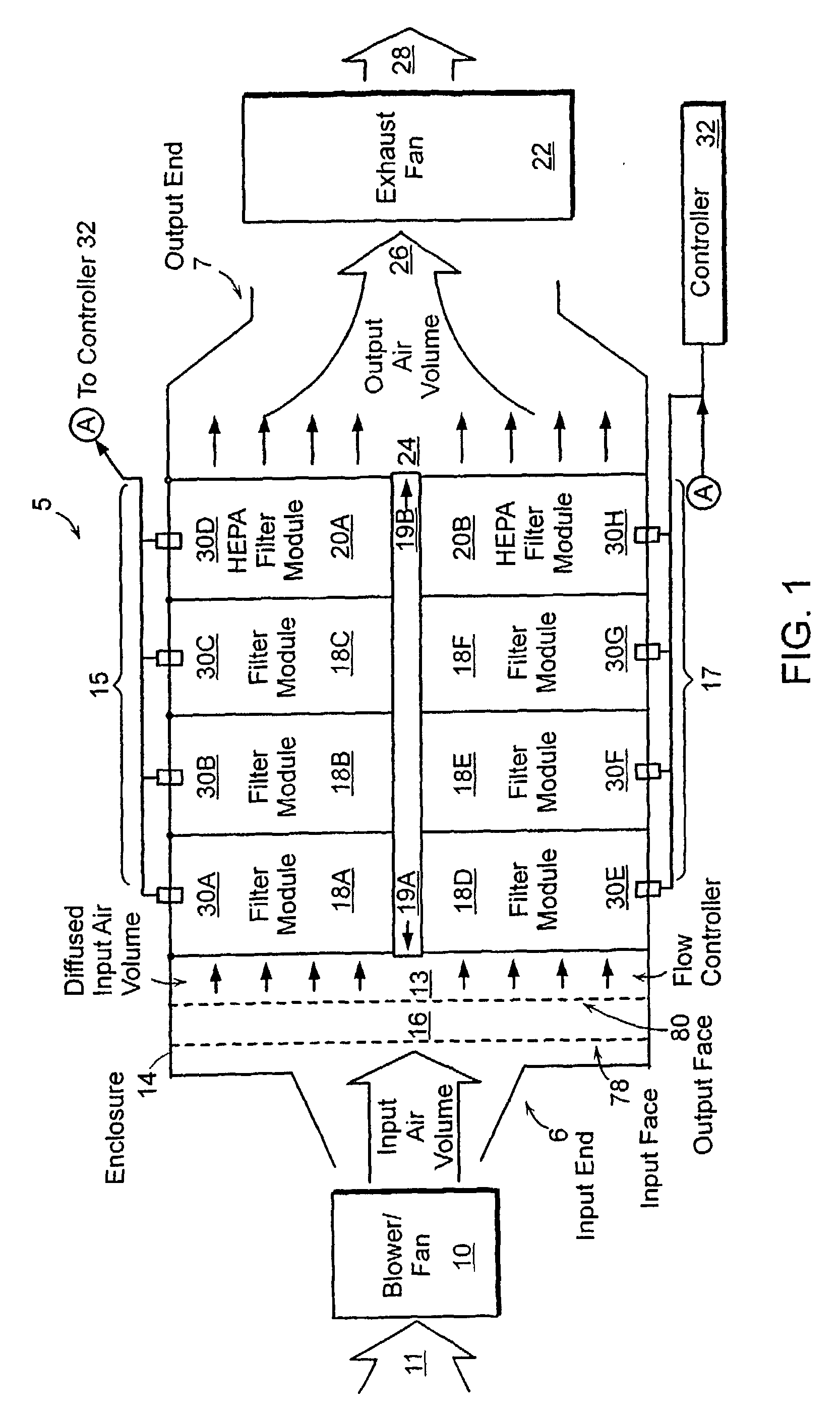

System And Method For Removing Contaminants

ActiveUS20080078289A1Long period of timeHEPA filterAnalysing fluids using sonic/ultrasonic/infrasonic wavesCombination devicesProduct gasProcess engineering

The invention provides a system and method comprising an apparatus for removing contaminants from a gas in a semiconductor processing device, which can include a filter unit having at least two parallel filter stages located therein. The filter stages are designed to remove a least a portion of the contaminants present in the gas flowing through them. The apparatus can also include a flow controller for distributing the gas flow among the filter stages. In one embodiment, the controller may consist of a diffuser plate. The invention also provides a sampling tube orifice for gas flow control in a system or method of the invention. In another embodiment, an apparatus for removing contaminants from a gas in a clean room comprises a filter unit having at least two parallel filter stages, which are used to remove a portion of the contaminants in the gas as it passes through the apparatus.

Owner:ENTEGRIS INC

Cleaning apparatus

InactiveUS6896720B1High retention rateInhibit transferCombination devicesAuxillary pretreatmentParticulatesEngineering

Apparatus for separating particulate matter from an airstream includes a housing including an intake for particulates-containing air and an exhaust for cleaned air, in which the apparatus includes a primary vortex generator in the intake air and the housing includes a separation zone which includes primary and secondary separation chambers each associated with respective particulates collector and including an interconnector adapted to generate a secondary vortex in the secondary separation chamber.

Owner:ARNOLD ADRIAN CHRISTOPHER +1

Terminal insert for a cyclone separator

InactiveUS6129775AReduce the numberEasy to separateCombination devicesSuction filtersEngineeringPhencyclone

A terminal insert for a cyclone separator for separating a material from a fluid. The terminal insert has a distinct member positioned within the cyclone separator to impinge upon at least a portion of the fluid as it rotates within the cyclone separator to destructively interfere with the rotational motion of the fluid within the cyclone separator.

Owner:OMACHRON INTPROP

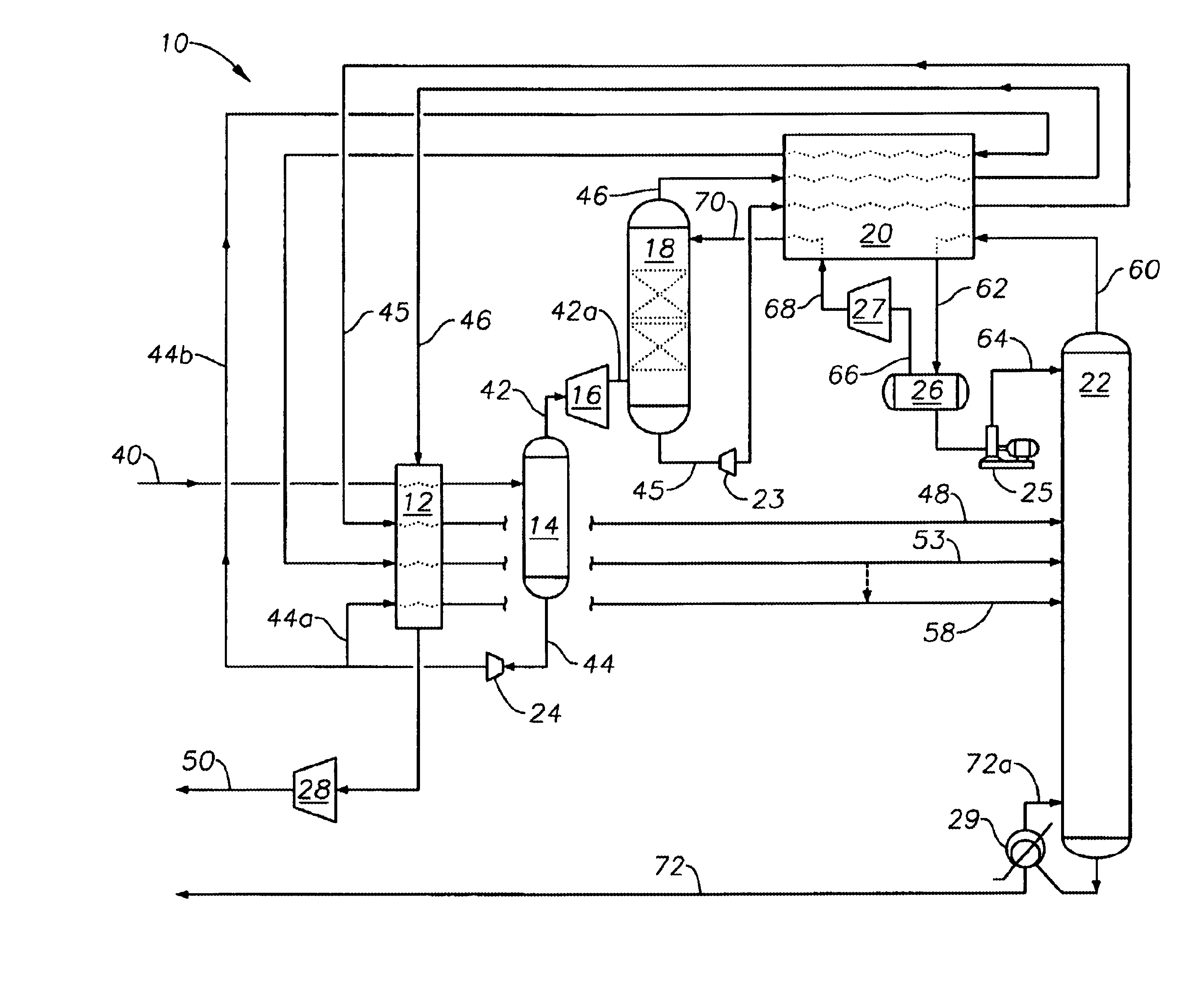

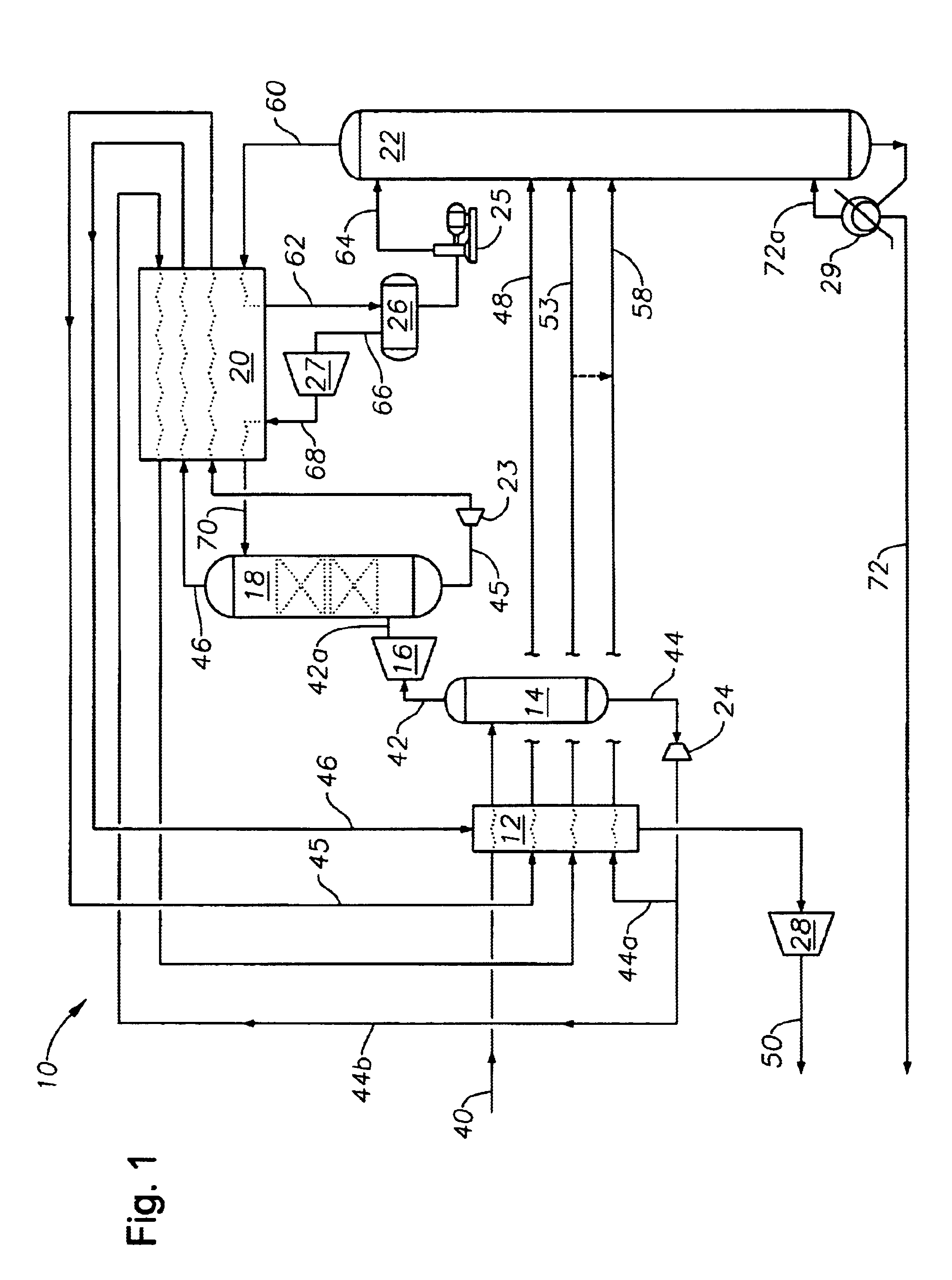

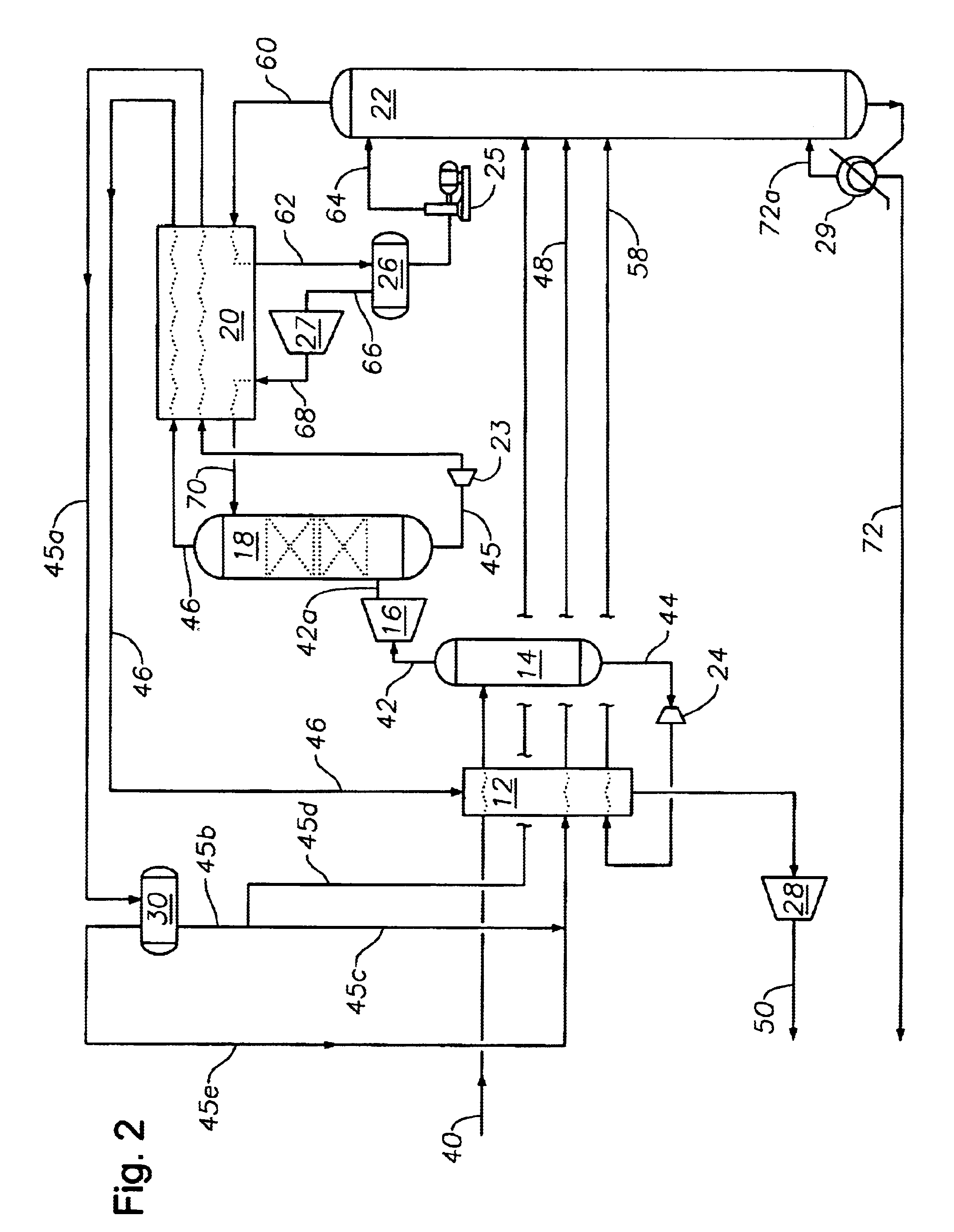

Low cost polyester process using a pipe reactor

InactiveUS20020137877A1Reduce pressureEliminate needLiquid degasificationFlow mixersProcess engineeringVolume control

The invention is directed to polyester processes that utilizes a pipe reactor in the esterification, polycondensation, or both esterification and polycondensation processes. Pipe reactor processes of the present invention have a multitude of advantages over prior art processes including improved heat transfer, volume control, agitation and disengagement functions. The pipe reactor processes and apparatus of the present invention are built and operated at a much lower cost than conventional polyester processes.

Owner:ALPEK POLYESTER SA DE CV

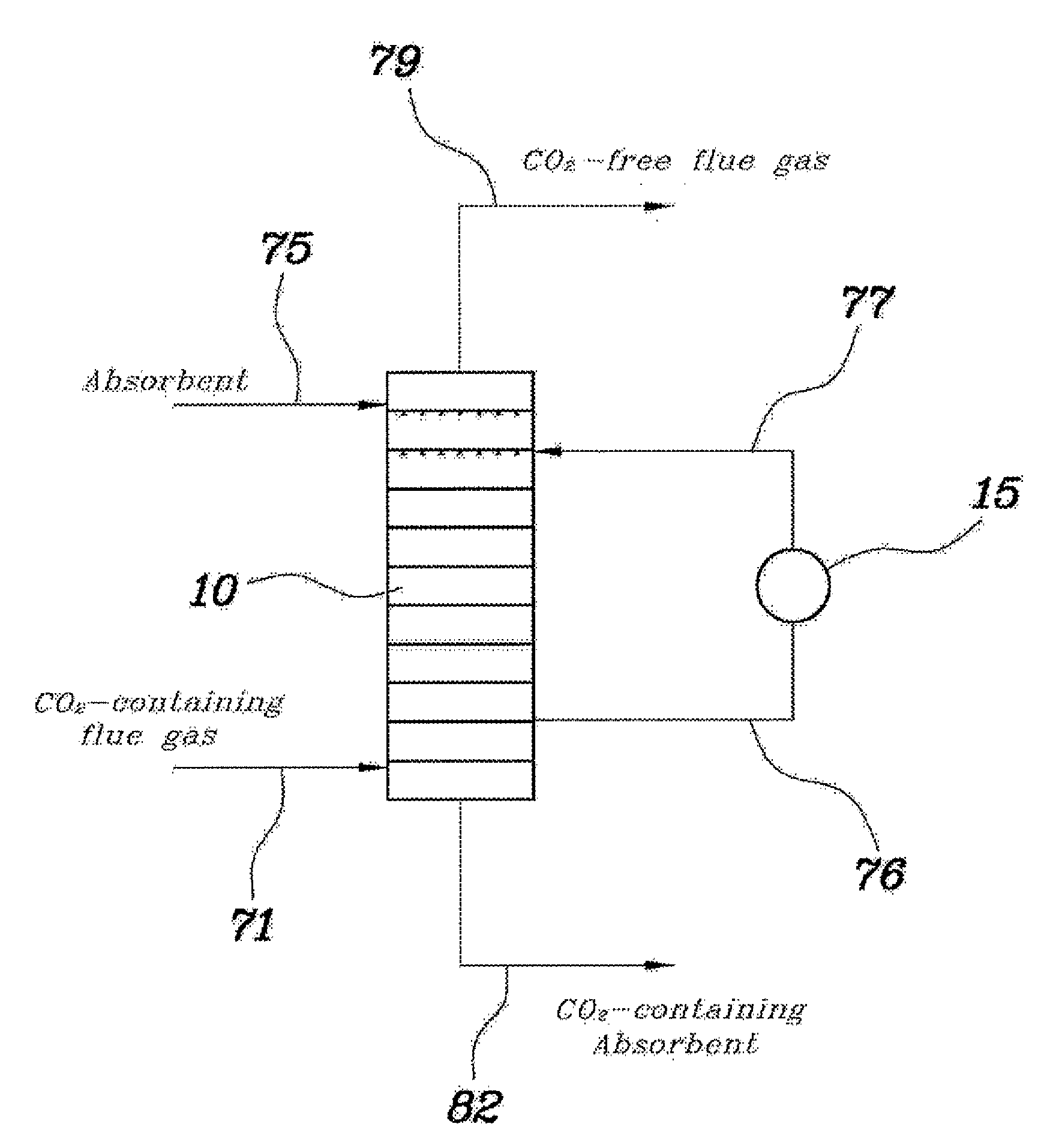

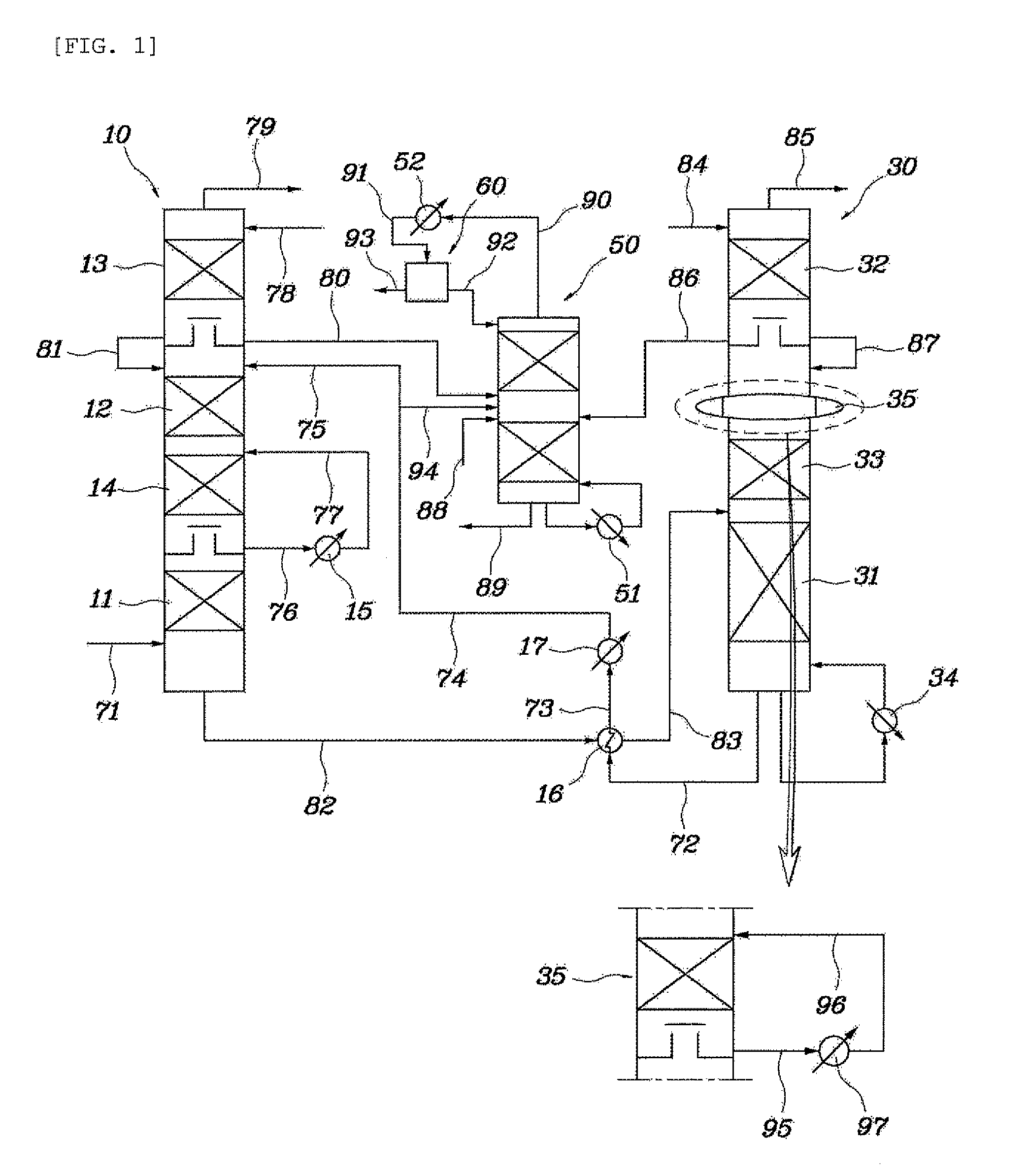

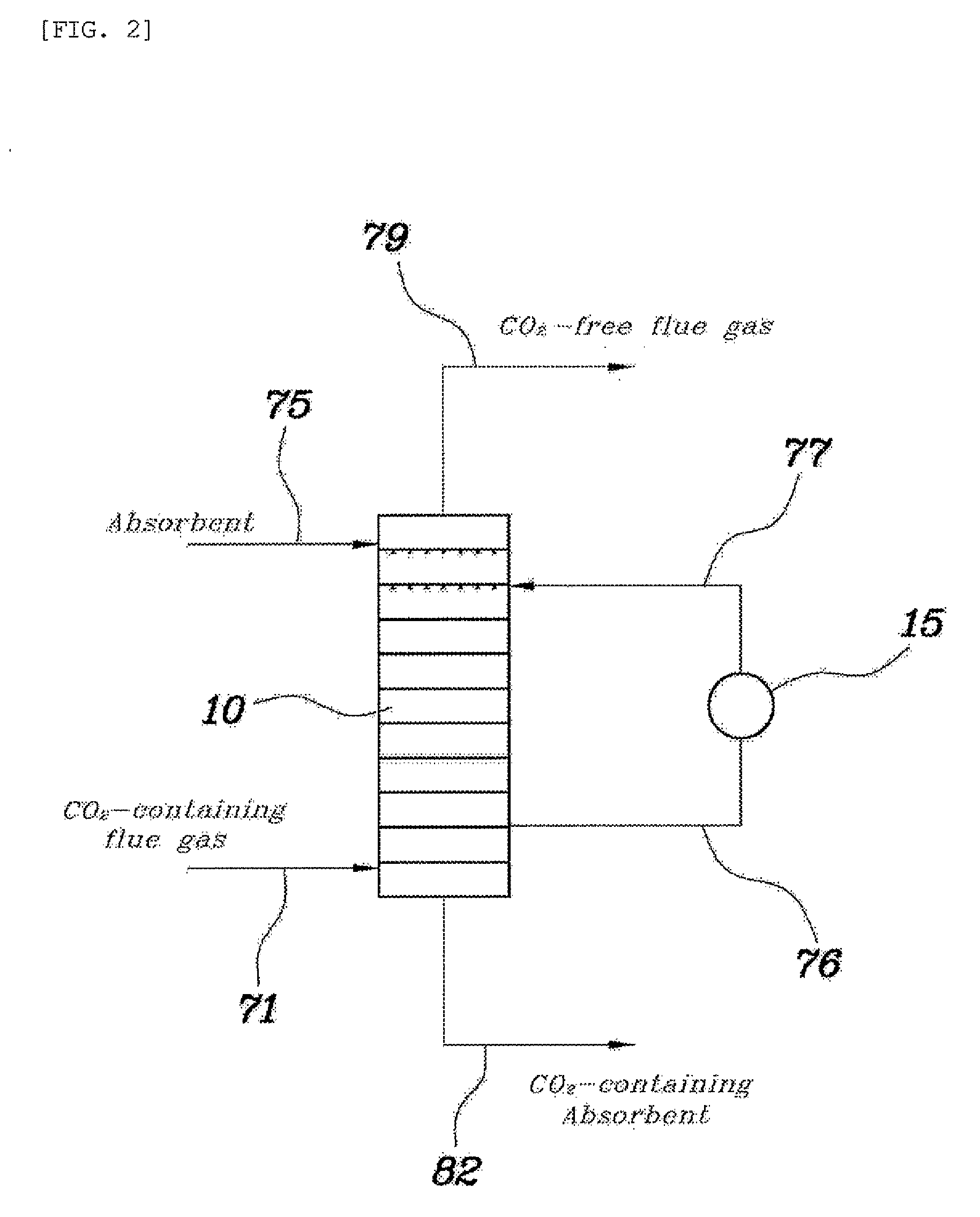

Apparatus and Method for Recovering Carbon Dioxide from Flue Gas Using Ammonia Water

ActiveUS20080307968A1Prevent volatilizationIncreased carbon dioxide absorption efficiencyGas treatmentLiquid degasificationFlue gasAbsorption column

An apparatus and method for absorbing and recovering carbon dioxide from flue gas using ammonia water as an absorbent, including an absorption column and a circulation cooler connected to the absorption column so that a high-temperature absorbent is recovered from the absorption column, cooled to a preset temperature, and then supplied again into the absorption column, in order to dissipate absorptive heat generated when carbon dioxide is absorbed from the flue gas.

Owner:RES INST OF IND SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com