Patents

Literature

1014 results about "Mooney viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mooney viscosity is a measure of viscosity commonly used for rubbers taken at a certain temperature, it is named after Melvin Mooney. It is measured by a mooney viscometer and is defined as the torque on instrument's rotating spindle within heated dies. The unit for mooney viscosity is mooney units.

Golf ball

InactiveUS6921345B2Solid comfortable feelGood rebound characteristicsGolf ballsSolid ballsPolymer scienceAntioxidant

A golf ball includes a hot-molded product of a rubber composition comprising a base rubber composed of (a) 20-100 wt % of a polybutadiene having a high cis-1,4 content, a minimal 1,2 vinyl content, and a viscosity η of up to 600 mPa·s at 25° C. as a 5 wt % toluene solution, and satisfying a certain relationship between Mooney viscosity and polydispersity index Mw / Mn, in combination with (b) 0-80 wt % of another diene rubber, (c) an unsaturated carboxylic acid, (d) an organosulfur compound, (e) an inorganic filler, (f) an organic peroxide, and optionally, (g) an antioxidant. The hot-molded product has a difference in JIS-C hardness between the center and surface thereof of up to 15 units. The composition and hardness characteristics of the hot-molded product provide the golf ball with a solid comfortable feel upon impact and an excellent rebound.

Owner:BRIDGESTONE SPORTS

Golf ball

InactiveUS6837803B2Excellent in preventing burnReduced characteristicsGolf ballsSolid ballsPolymer scienceAntioxidant

A golf ball includes, as a composing element, a hot-molded product of a rubber composition. The rubber composition contains a polybutadiene having 60 wt % or more of cis-1,4-bonds and 40 or more of a Mooney viscosity (ML1+4(100° C.)), unsaturated carboxylic acid and / or a metal salt thereof, an organic peroxide, and a monophenol based antioxidant. The golf ball can be produced with good workability because of no burn at the time of kneading the rubber composition, while preventing a reduction in rebound characteristic.

Owner:BRIDGESTONE SPORTS

Method and apparatus for producing and treating novel elastomer composites

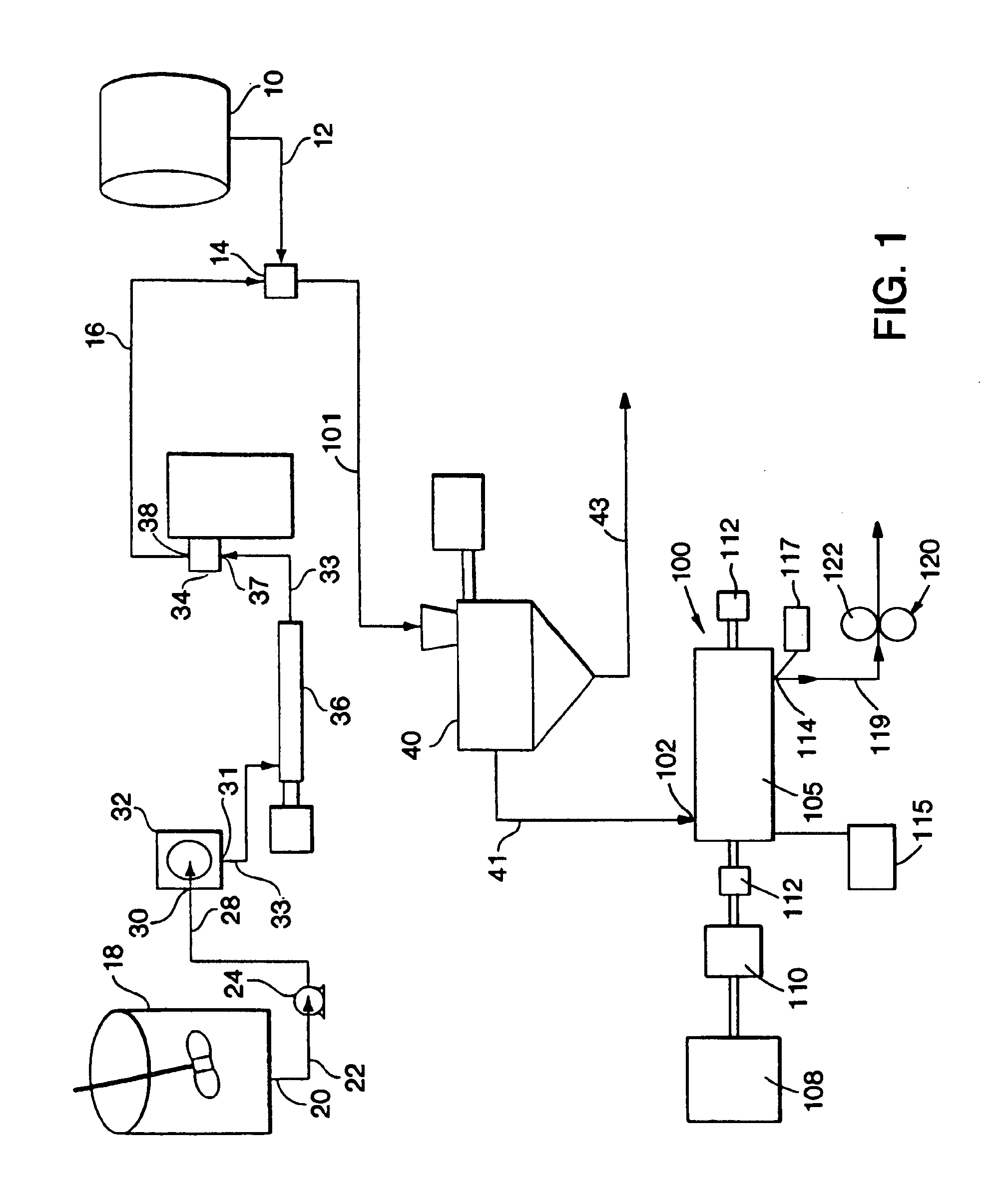

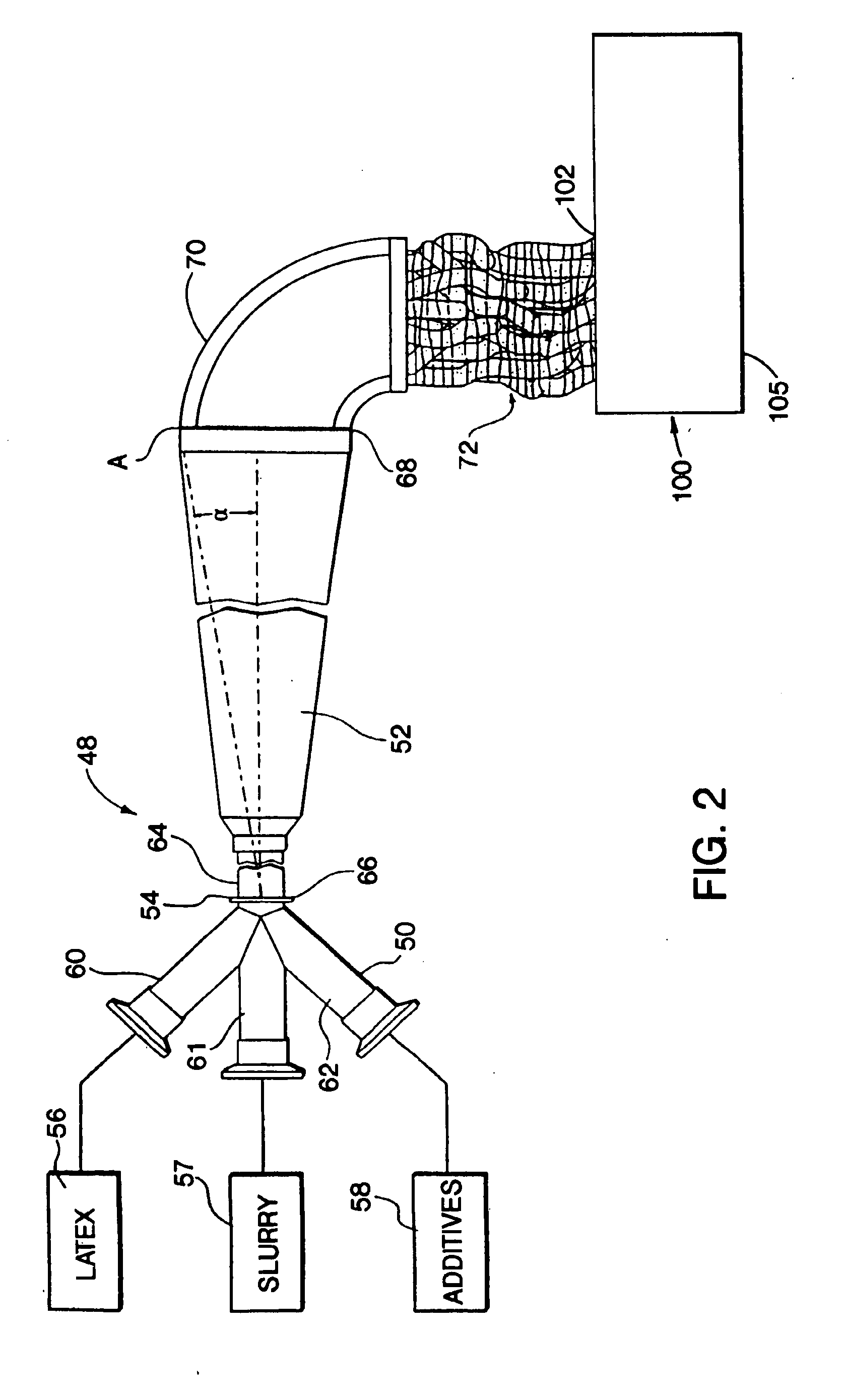

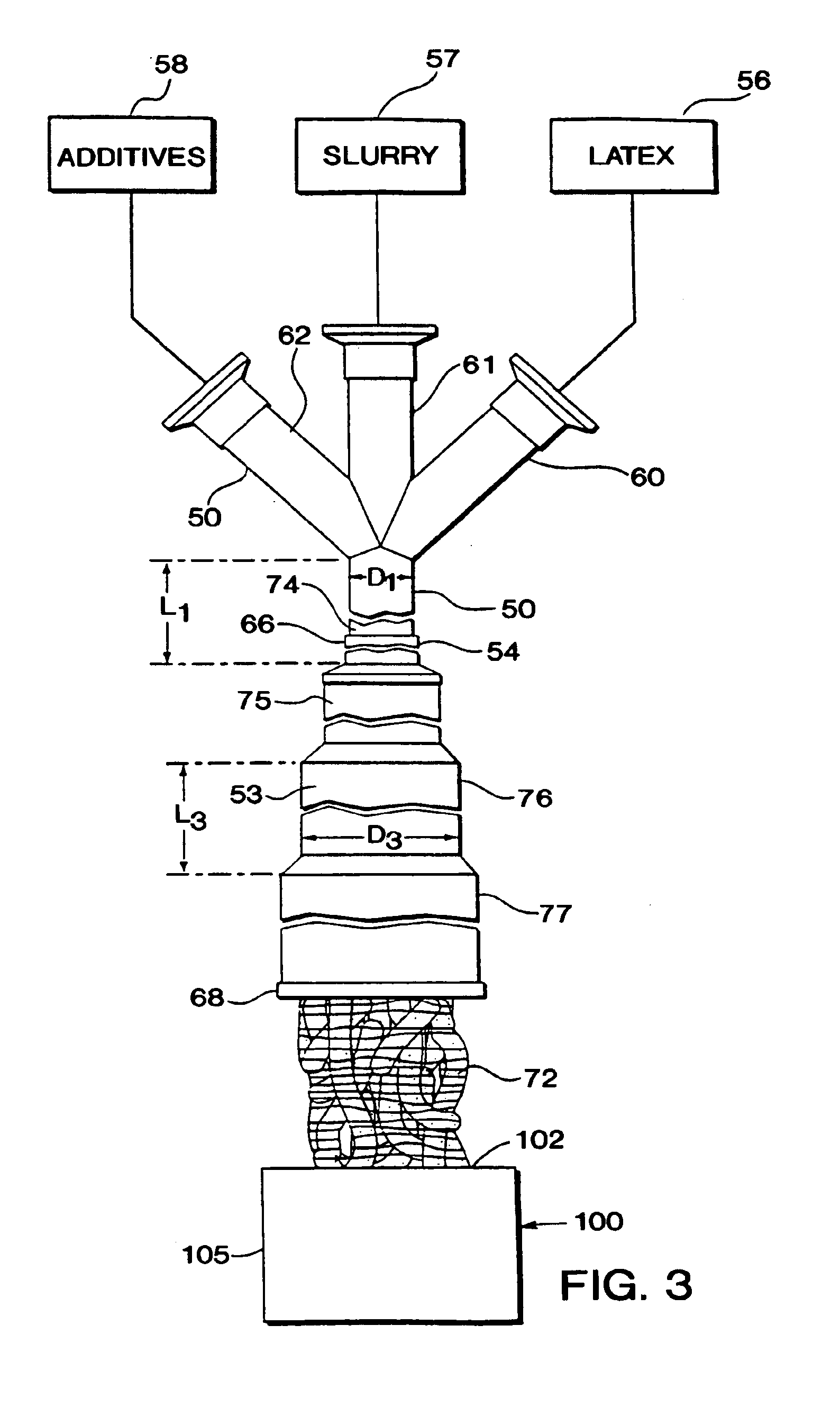

InactiveUS6929783B2Facilitate controlling and changing operating parameterImprove economyLiquid degasificationSpecial tyresParticulatesMasterbatch

Elastomer masterbatch is processed in a continuous compounder having multiple parallel elongate rotors axially oriented in an elongate processing chamber. Optionally, additional materials are compounded into the masterbatch, e.g., additives, other elastomeric compositions, etc. Preferably, the masterbatch then is further processed in an open mill. Excellent control of Mooney Viscosity is achieved.In certain preferred embodiments, elastomer composites are produced by novel continuous flow methods and apparatus in which fluid streams of particulate filler and elastomer latex are fed to the mixing zone of a coagulum reactor to form a coagulated mixture in semi-confined flow continuously from the mixing zone through a coagulum zone to a discharge end of the reactor. The particulate filler fluid is fed under high pressure to the mixing zone, such as to form a jet stream to entrain elastomer latex fluid sufficiently energetically to substantially completely coagulate the elastomer with the particulate filler prior to the discharge end without need of adding acid or salt solution or other coagulation step. The coagulated elastomer and particulate filler composite is fed into the aforesaid continuous compounder for processing and control of its moisture level and Mooney Viscosity. Novel elastomer composites are produced. Such novel elastomer composites combine material properties and characteristics, such as choice of filler, elastomer, level of filler loading, moisture level, Mooney Viscosity, balance between molecular weight and amount of bound rubber, and macro-dispersion not previously achieved.

Owner:CABOT CORP

Golf ball

InactiveUS7226367B2Improve productivityIncrease elasticityGolf ballsSolid ballsPtru catalystEngineering

A golf ball comprises a solid core consisting of a center core and an outer core, wherein at least one of cores is made of a rubber composition comprising 100 parts by weight of a base rubber including. 60 to 100% by weight of a polybutadiene containing at least 60% by weight of cis-1,4-bond, having a Mooney viscosity (ML1+4 (100° C.)) of at least 52, and synthesized using a rare-earth catalyst, 10 to 60 parts by weight of an unsaturated carboxylic acid and / or a metal salt thereof, 5 to 80 parts by weight of an-inorganic filler, and an organic peroxide, and wherein the center core has a JIS-C hardness of 40 to 60 on its center and a JIS-C hardness of 55 to 75 on its surface and the difference therebetween is at least 10, the outer core is harder than the surface hardness of the center core, the cross-sectional hardness of 1 mm outside from the border between the center core and the outer core is from 65 to 85 on a JIS-C hardness, the surface of the outer core has a JIS-C hardness of 75 to 95.

Owner:BRIDGESTONE SPORTS

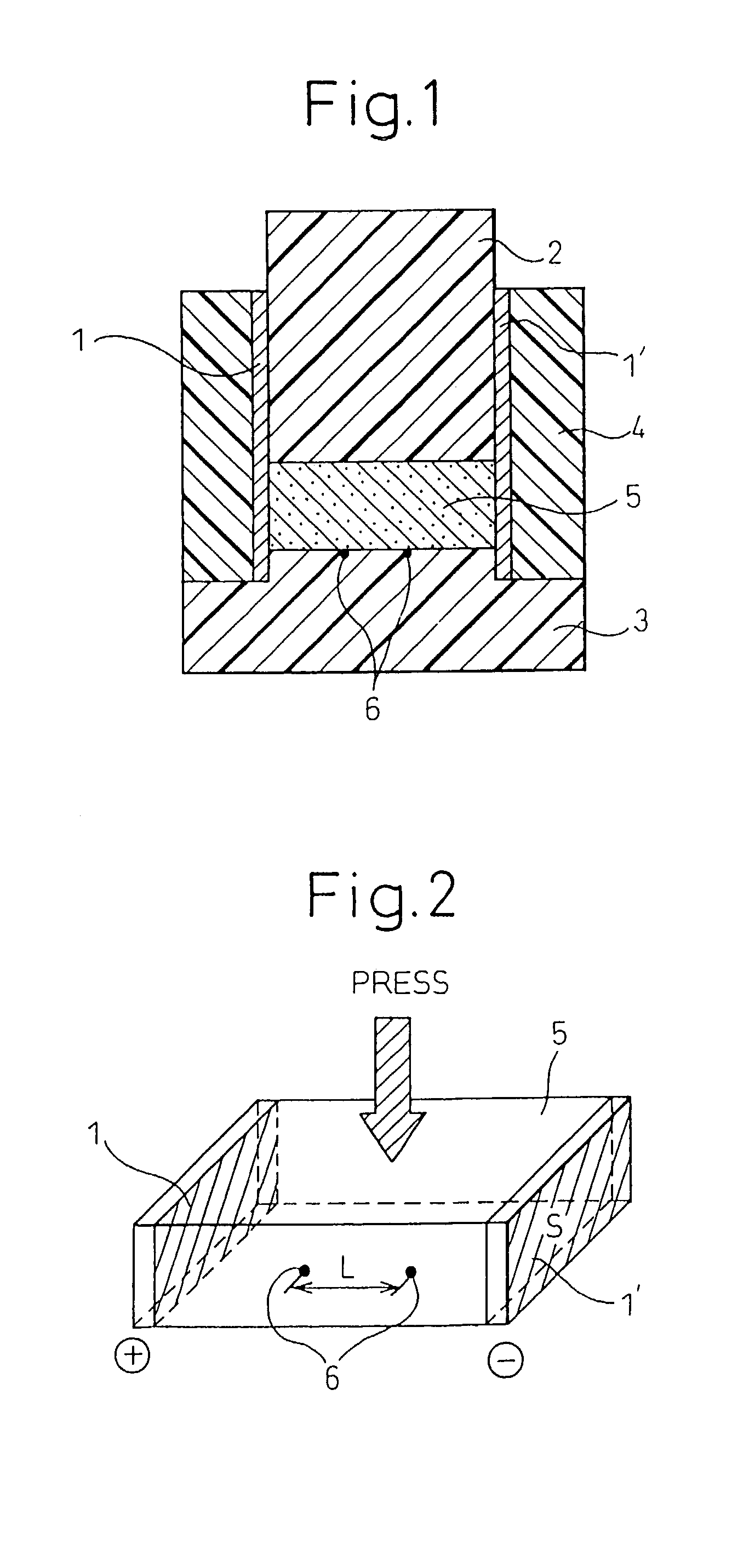

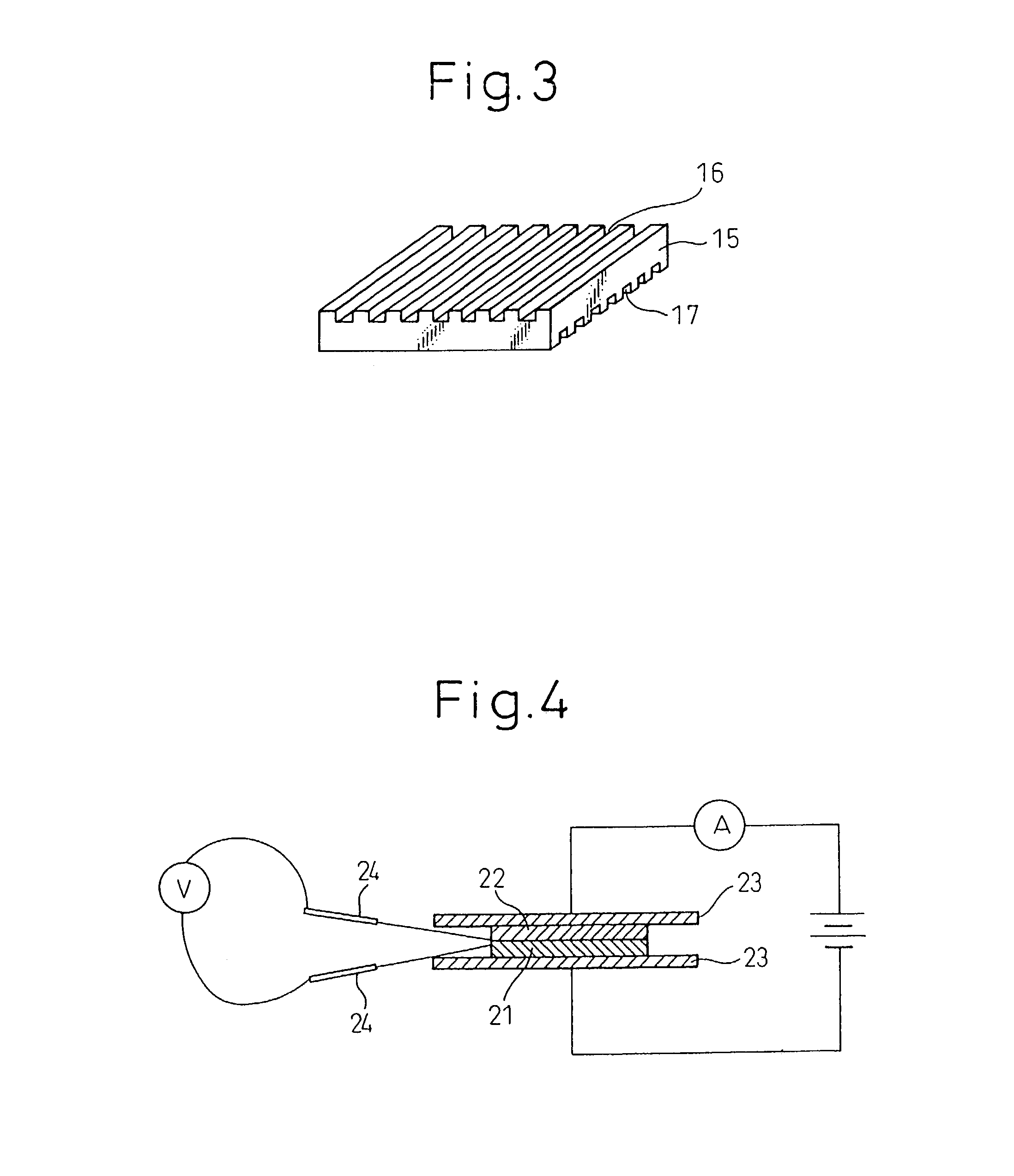

Conductive curable resin composition and separator for fuel cell

InactiveUS7329698B2Improve conductivityMaintain good propertiesMaterial nanotechnologyFinal product manufactureElastomerPolymer science

There is provided a conductive curable resin composition comprising (A) a curable resin composition comprising an elastomer with a Mooney viscosity (ML1+4 (100° C.)) of 25 or greater at 2-80 wt % and (B) a carbon material, with a weight ratio of component (A) to component (B) of 70-5:30-95. The curable resin composition of component (A) preferably comprises (A1) an elastomer at 80-2 wt %, (A2) a radical reactive resin at 20-98 wt % and (A3) an organic peroxide at 0.2-10 parts by weight to 100 parts by weight of (A1+A2). Also provided are a process for production of a conductive cured resin by shaping and curing of the conductive curable resin composition, and a fuel cell separator, an assembly for a cell, an electrode or a heat releasing plate, obtained thereby.

Owner:SHOWA DENKO KK

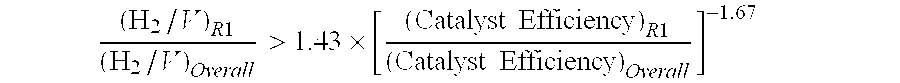

Multimodal ethylene-alpha-olefin elastomers and process for making

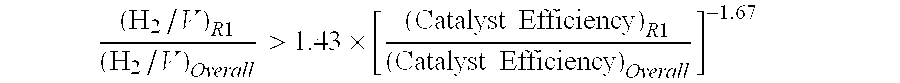

Disclosed herein is a multimodal polymer composition comprising 45 to 75 wt % of a first polymer fraction, 25 to 55 wt % of a second polymer fraction, and from 10-50 phr of an extender oil. The multimodal polymer composition has an overall Mooney viscosity of less than 90 ML(1+4@125° C.), and each polymer fraction comprises an ethylene, C3-C10 alpha-olefin, non-conjugated diene polymer, wherein the first polymer fraction has a Mooney viscosity of greater than or equal to about 150 ML(1+4@125° C.), the second polymer fraction has a Mooney viscosity from about 20 to about 120 ML(1+4@125° C.). A process for making the multimodal polymer composition comprising a process utilizing two or more reactors in series is also disclosed.

Owner:EXXONMOBIL CHEM PAT INC

Thermoplastic vulcanizate composition

The instant disclosure is directed to a thermoplastic vulcanizate composition comprising a dynamically-cured rubber; from about 20 to about 300 parts by weight of a thermoplastic resin per 100 parts by weight rubber and from about 30 to about 250 parts by weight additional oil per 100 parts by weight rubber; wherein the rubber comprises a multimodal polymer composition cured with a curing agent, the multimodal polymer composition comprising 45 to 75 wt% of a first polymer fraction and 25 to 55 wt % of a second polymer fraction, each comprising ethylene, a C3-C10 alpha-olefin, and a non-conjugated diene, wherein the polymer fractions have been polymerized using a Ziegler-Natta catalyst system, wherein the first polymer fraction has a Mooney viscosity of greater than or equal to about 150 ML(1+4@125° C.), and the second polymer fraction has a Mooney viscosity of about 20 ML to about 120 ML; and about 10 phr to about 50 phr of an extender oil. A method of producing the thermoplastic vulcanizate is also disclosed.

Owner:CELANESE INT CORP

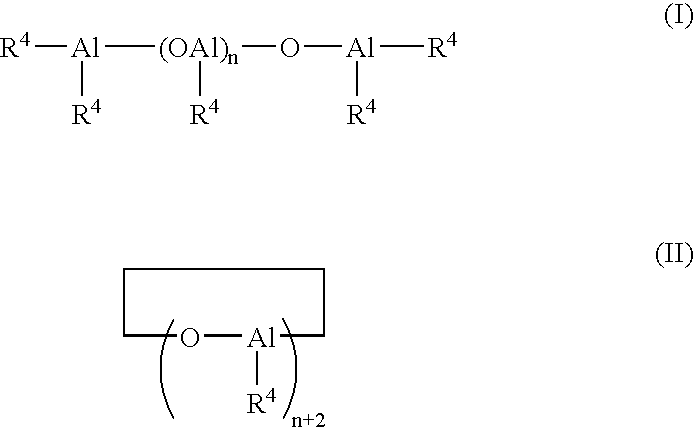

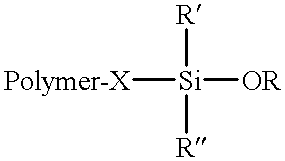

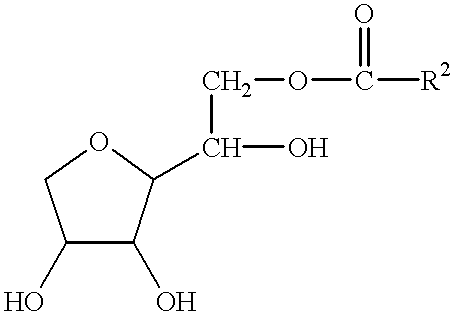

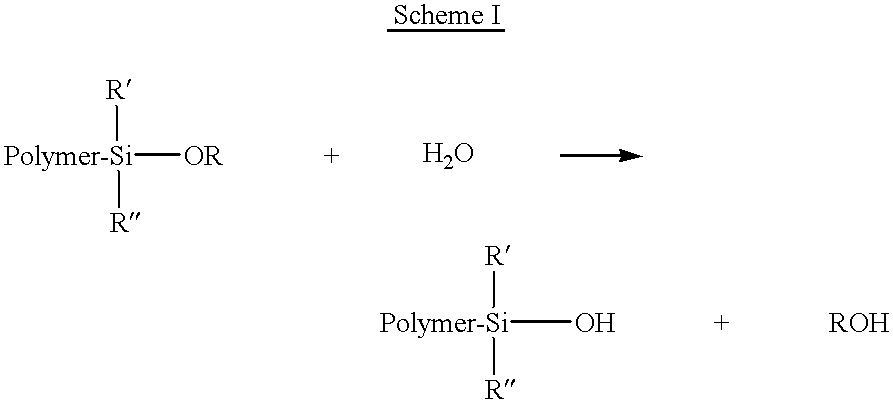

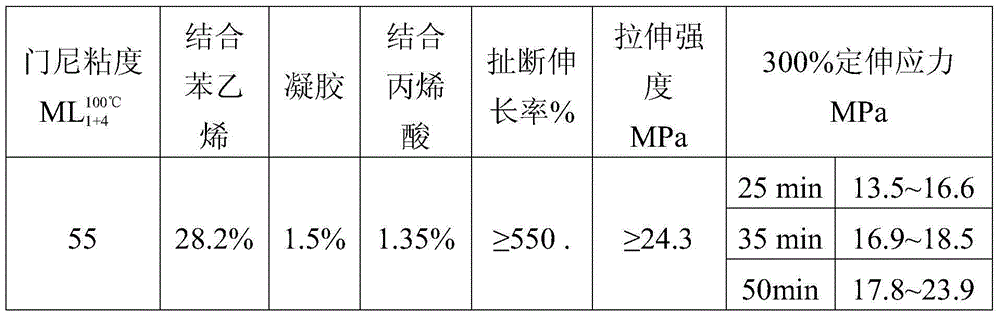

Method to control increase in viscosity during aging of siloxane modified polymers

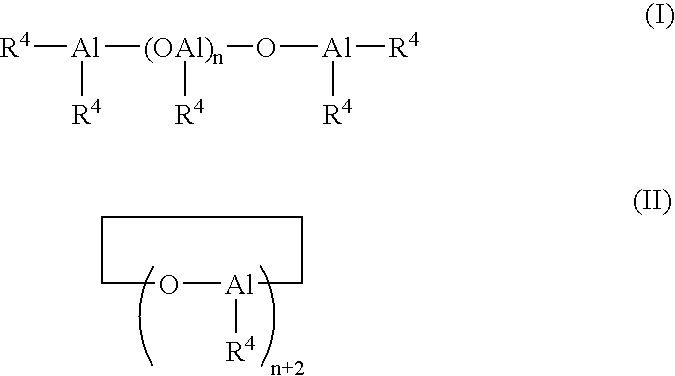

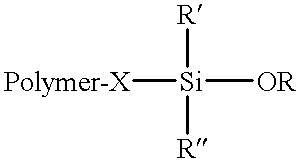

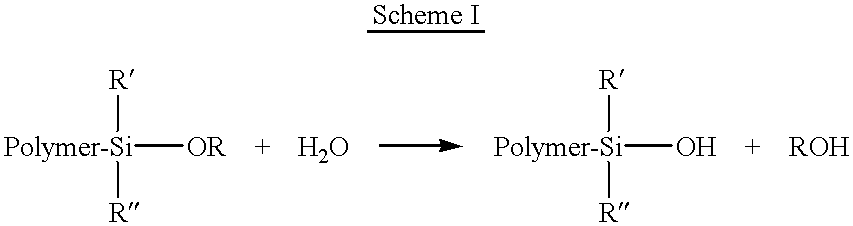

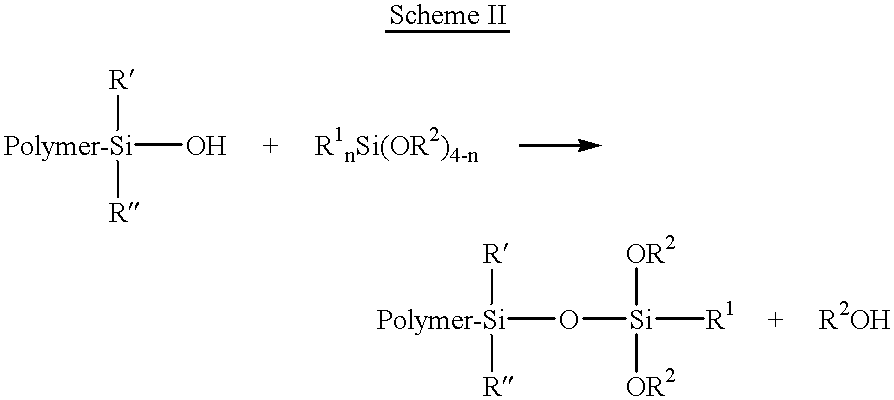

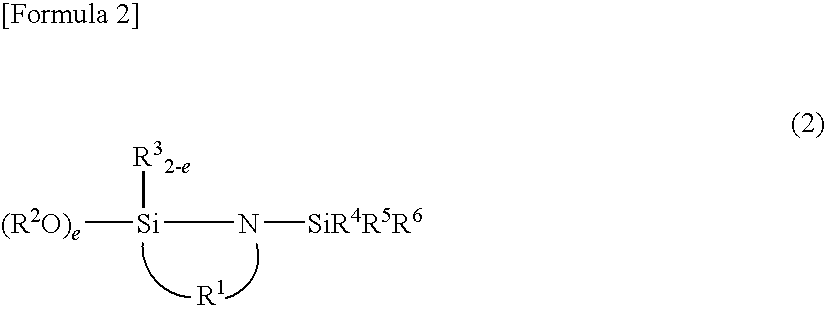

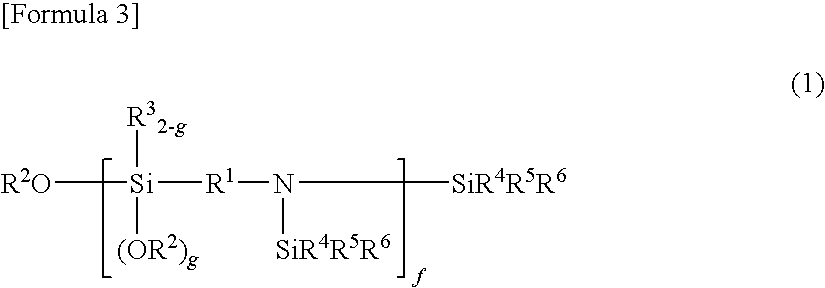

A method for controlling any increase in Mooney viscosity during aging of siloxane-functionalized polymers includes the step of adding a viscosity stabilizing effective amount of a viscosity stabilizing agent selected from the group consisting of alkyl alkoxysilanes of the structural formulawherein R1 is selected from the group consisting of C1 to C20 alkyl, C4 to C10 cycloalkyl, or C5 to C20 aromatic groups, wherein R2 may be the same as or different from R1 and is selected from the group consisting of C1 to C20 alkyl, C4 to C10 cycloalkyl, or C5 to C20 aromatic groups, and wherein n is an integer from 1 to 3. The method provides for the stabilization of Mooney viscosity of siloxane-functionalized polymers at any given level upon aging. The viscosity stabilizing agents react with the siloxane-functionalized polymers during hydrolysis of the siloxane end groups to form moisture stabilized polymers.

Owner:BRIDGESTONE CORP

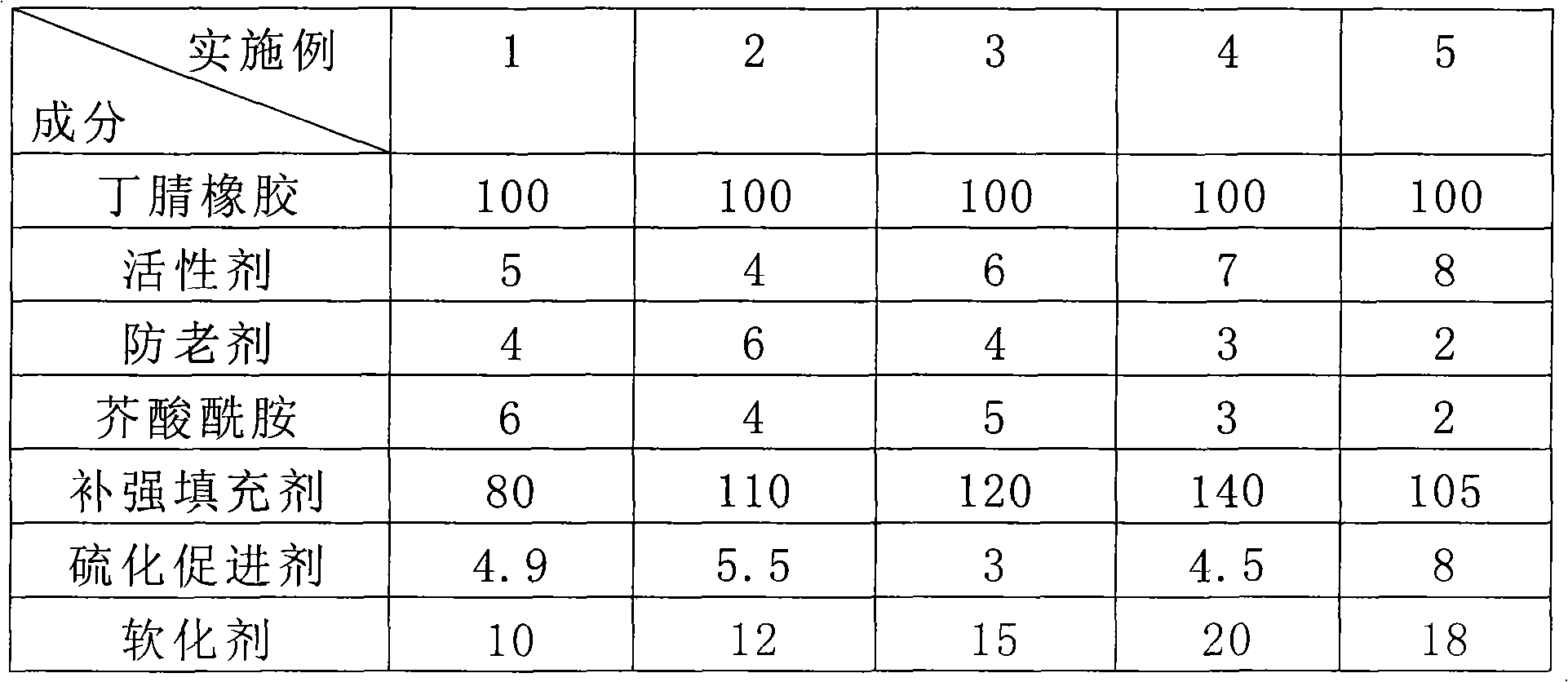

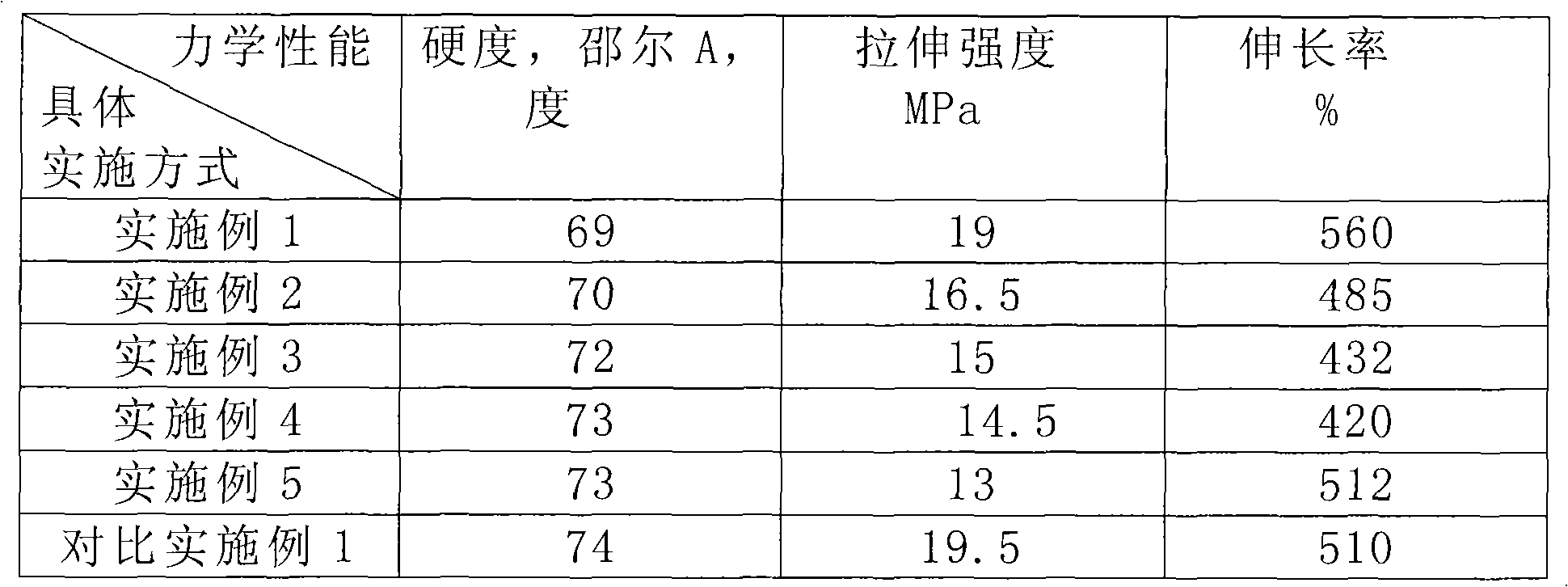

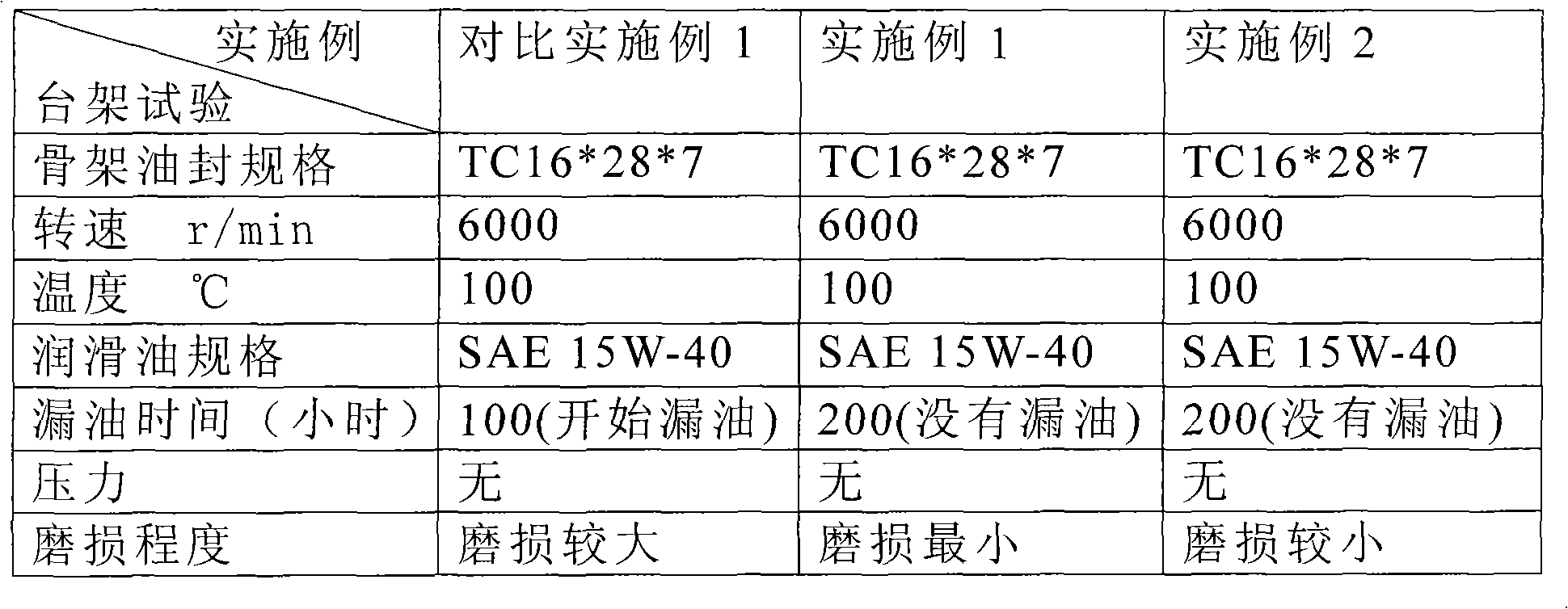

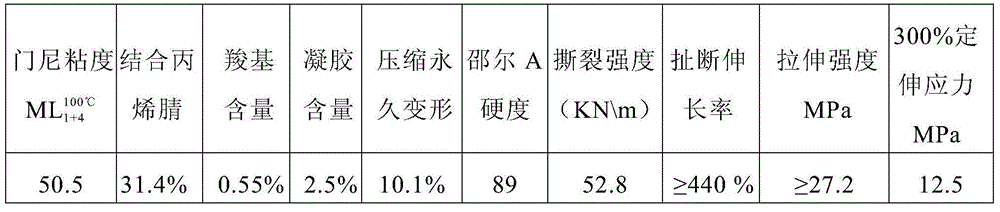

Highly-abrasion-resistant butadiene-acrylonitrile-rubber vulcanized rubber and preparation method thereof

InactiveCN101597391AThe ingredients are well matchedReduce coefficient of frictionNitrile rubberVulcanization

The invention provides a highly-abrasion-resistant butadiene-acrylonitrile-rubber vulcanized rubber and a preparation method thereof. The highly-abrasion-resistant butadiene-acrylonitrile-rubber vulcanized rubber comprises the following components according to parts by weight: 100 parts of butadiene-acrylonitrile rubber, 3-8 parts of active agent, 1-6 parts of antiager, 2-6 parts of erucamide, 50-150 parts of reinforcing filler and 3-8 parts of vulcanizing accelerator, wherein acrylonitrile content in the butadiene-acrylonitrile rubber is 34-41 percent by weight, and Mooney viscosity (ML[1+4] of the butadiene-acrylonitrile rubber is 45-70. The preparation method of the butadiene-acrylonitrile-rubber vulcanized rubber comprises the steps of A. mixing and processing and B. recycled processing and vulcanization. The butadiene-acrylonitrile-rubber vulcanized rubber has reasonable component mixing and higher abrasion resistance. The highly-abrasion-resistant butadiene-acrylonitrile-rubber vulcanized rubber prepared according to the method has high elongation and long service life.

Owner:ANHUI RUNKANG RUBBER & PLASTIC TECH CO LTD

One-piece solid golf ball

InactiveUS20020052253A1Improve featuresIncreased durabilityGolf ballsSolid ballsVulcanizationPolymer science

The present invention provides a one-piece solid golf ball having excellent rebound characteristics and good shot feel, while maintaining excellent processability and durability. The present invention relates to a one-piece solid golf ball formed from a rubber composition comprising a mixture consisting of polybutadiene (a) synthesized using nickel-containing catalyst and polybutadiene (b) synthesized using cobalt-containing catalyst and hydroquinone or derivatives thereof as a vulcanization stabilizer, wherein a Mooney viscosity and a weight ratio of the polybutadienes (a) and (b), an amount of the vulcanization stabilizer, a center hardness (the minimum hardness in the golf ball) and surface hardness of the golf ball, and a difference between the maximum hardness and minimum hardness in the golf ball are adjusted to a specified range.

Owner:SUMITOMO RUBBER IND LTD

Multimodal ethylene-alpha-olefin elastomers and process for making

Disclosed herein is a multimodal polymer composition comprising 45 to 75 wt % of a first polymer fraction, 25 to 55 wt % of a second polymer fraction, and from 10-50 phr of an extender oil. The multimodal polymer composition has an overall Mooney viscosity of less than 90 ML(1+4@125° C.), and each polymer fraction comprises an ethylene, C3-C10 alpha-olefin, non-conjugated diene polymer, wherein the first polymer fraction has a Mooney viscosity of greater than or equal to about 150 ML(1+4@125° C.), the second polymer fraction has a Mooney viscosity from about 20 to about 120 ML(1+4@125° C.). A process for making the multimodal polymer composition comprising a process utilizing two or more reactors in series is also disclosed.

Owner:EXXONMOBIL CHEM PAT INC

Solid golf ball

ActiveUS20060128900A1Soft touchGood rebound characteristicsGolf ballsSolid ballsRare earthCarboxylic acid

The present invention provides a solid golf ball comprising a hot-molded product of a rubber composition comprising (a) 100 parts by weight of a polybutadiene synthesized using a rare-earth catalyst and having a cis-1,4 content of at least 60% and a 1,2 vinyl content of at most 2%, having a viscosity η at 25° C. as a 5 wt % solution in toluene of up to 600 mPa·s, and having Mooney viscosity (ML1+4 (100° C.)) of more than 30, (b) 0.01 to 0.5 parts by weight of a sulfur, (c) 10 to 60 parts by weight of an unsaturated carboxylic acid and / or a metal salt thereof, (d) 0.1 to 5 parts by weight of an organosulfur compound, (e) 5 to 80 parts by weight of an inorganic filler, and (f) 0.1 to 5 parts by weight of an organic peroxide, wherein the hot-molded product has a difference in JIS-C hardness between the center and surface thereof of more than 20 and up to 40. The solid golf balls of the invention have a soft feel upon impact and excellent rebound characteristics. Moreover, the solid golf balls are improved in flight performance by making its spin rate reduced when shot with a driver.

Owner:BRIDGESTONE SPORTS

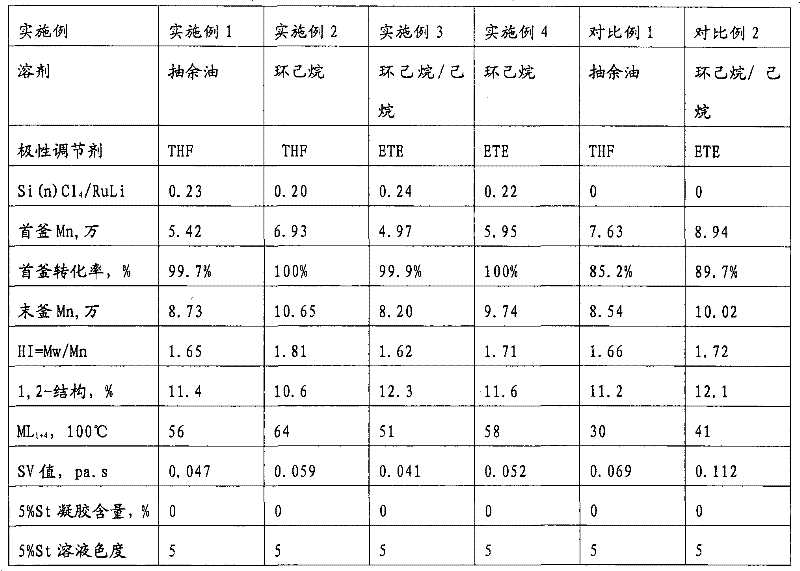

Low cis-polybutadiene rubber as well as preparation method and application thereof

The invention relates to a low cis-polybutadiene rubber as well as a preparation method and application thereof. The preparation method is characterized in that in a polymerization system formed by connecting at least two polymerization reaction kettles in series, in a non-polar solvent containing a structure regulating agent, an stable single-functionality initiator is adopted to initiate the polymerization of polybutadiene and then a conventional chain-end coupling technology is combined, so as to prepare the low cis-polybutadiene rubber having high Mooney viscosity and low SV (styrene viscosity) value (5% rubber-styrene solution viscosity at 25 DEG C). The properties of the prepared low cis-polybutadiene rubber are as follows: (1) the content of the vinyl group in a monomer unit is 8-14%wt; (2) a number-average molecular weight range is 80,000-110,000; (3) the Mooney viscosity ML[1+4] at the temperature of 100 DEG C is 45-65; (4) molecular weight distribution is 1.5-1.8; and (5) the SV value is 0.04-0.059Pa.s. The low cis-polybutadiene rubber synthesized by using the method can be applied to the field of plastic modification, and is especially suitable for preparation of a high-impact high-gloss grade polystyrene (PS) resin.

Owner:CHINA PETROLEUM & CHEM CORP +1

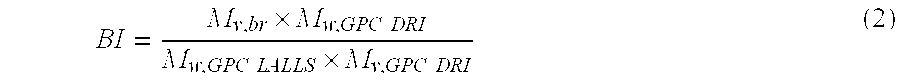

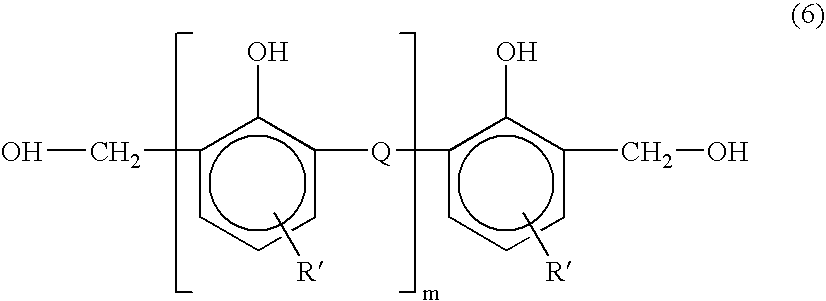

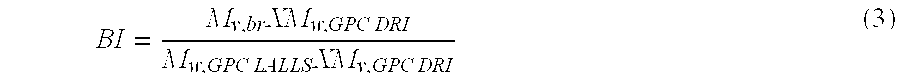

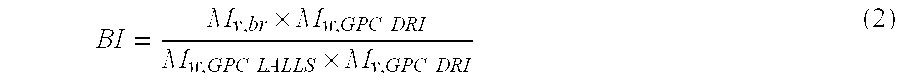

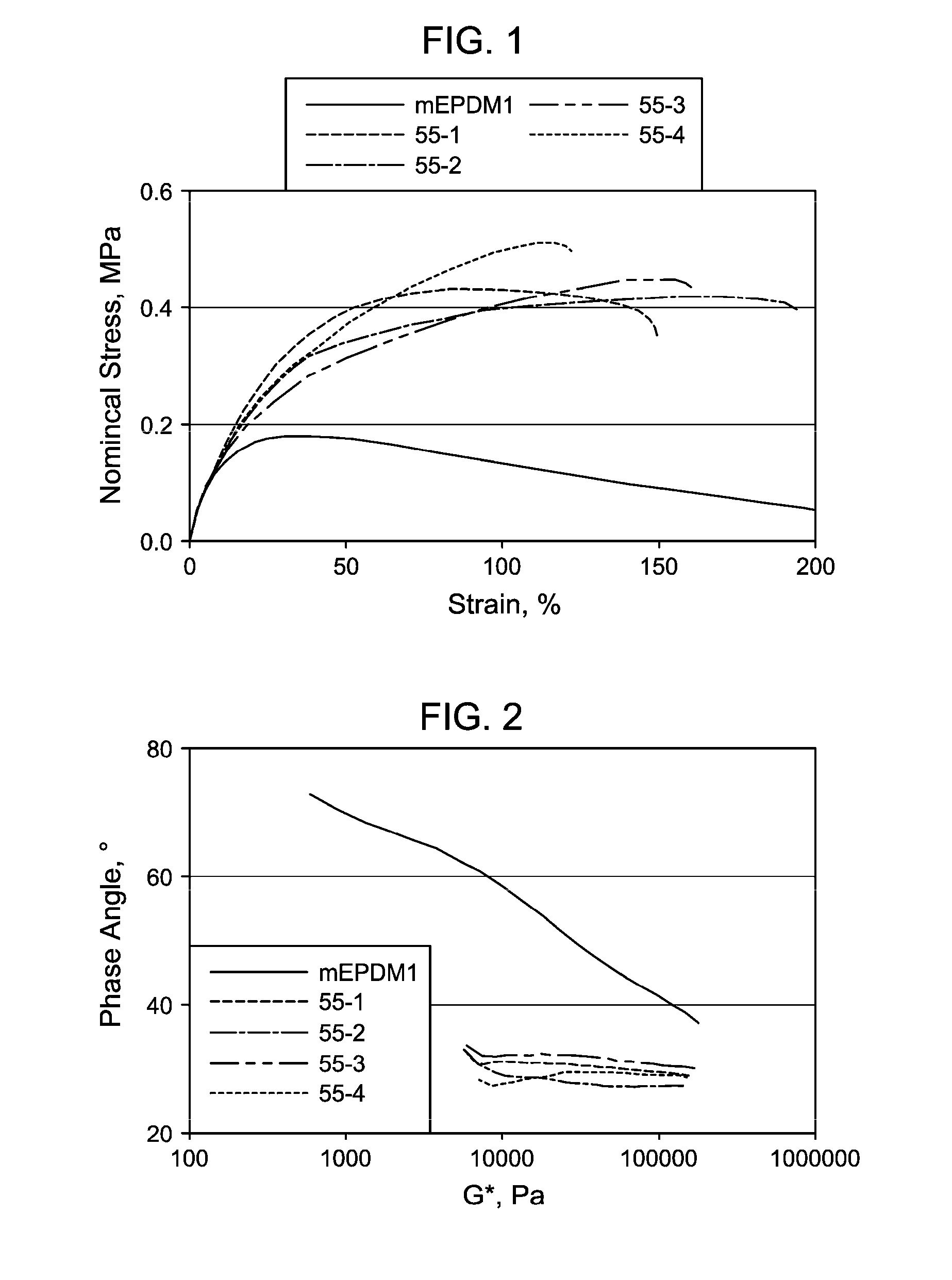

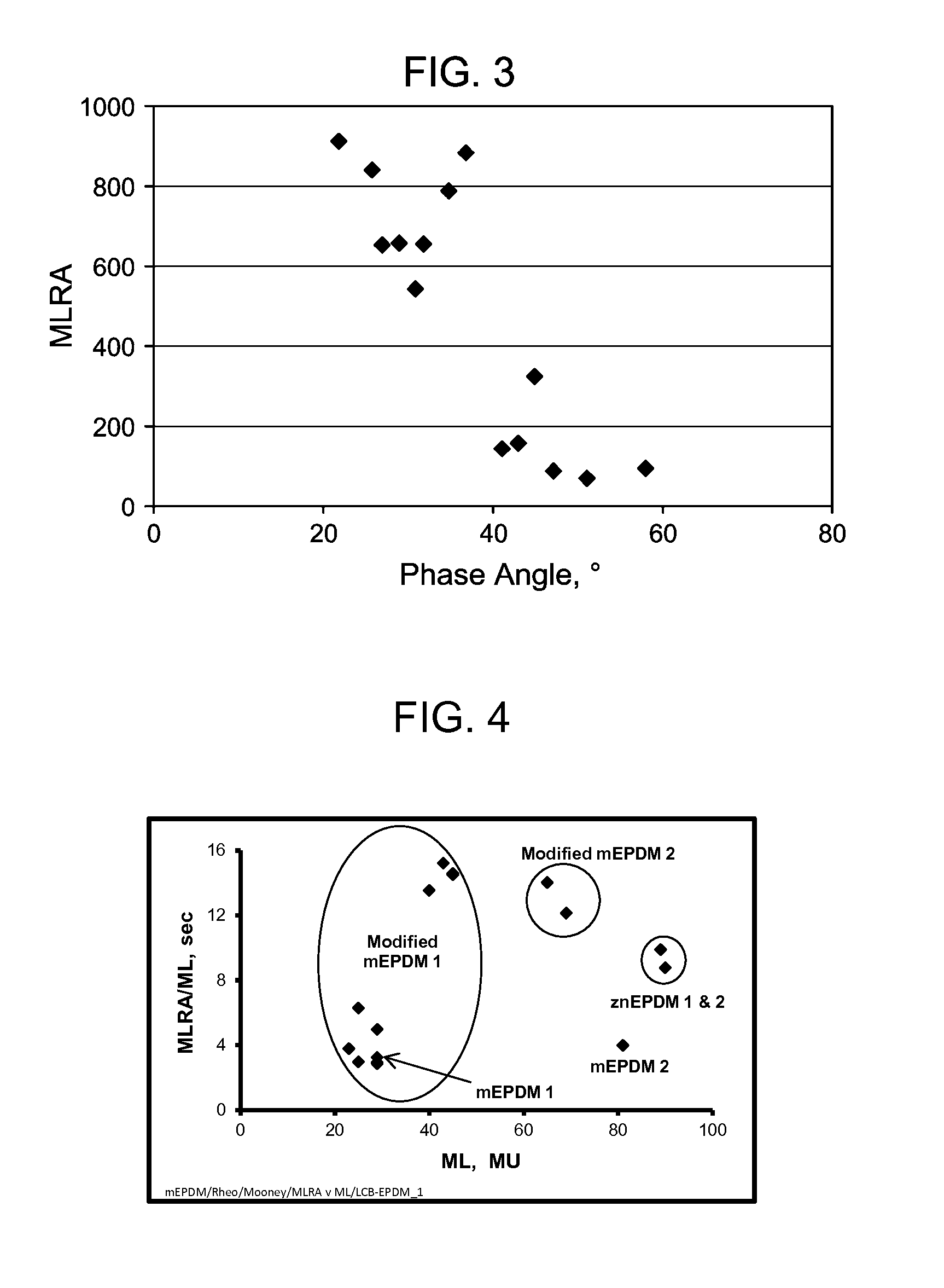

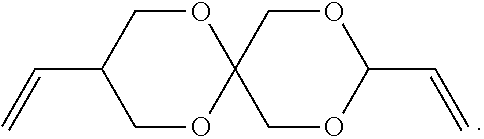

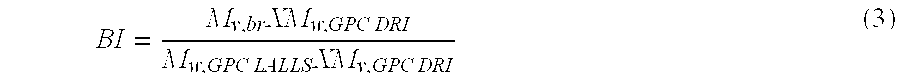

Long Chain Branched EPDM Compositions and Processes for Production Thereof

Highly branched compositions including: (i) from about 96 wt % to about 99.9 wt % metallocene catalyzed ethylene propylene diene derived units; and (ii) from about 0.1 wt % to about 4 wt % multifunctional monomer derived units, wherein the highly branched composition has: (a) a Mooney viscosity ML (1+4) at 125° C. of about 30 to 100 MU, (b) a Mooney relaxation area MLRA of about 100 to about 1000, (c) a branching index, g′(vis) of less than about 0.9, (d) a phase angle, δ, of less than about 55 degrees at a complex modulus of 10 kPa, measured at 190° C., and (e) a degree of shear thinning greater than about 0.95, measured at 190° C., are disclosed herein. Homogeneous blends including this composition are also described. Processes to make the highly branched composition and the homogeneous blend are also described herein.

Owner:EXXONMOBIL CHEM PAT INC

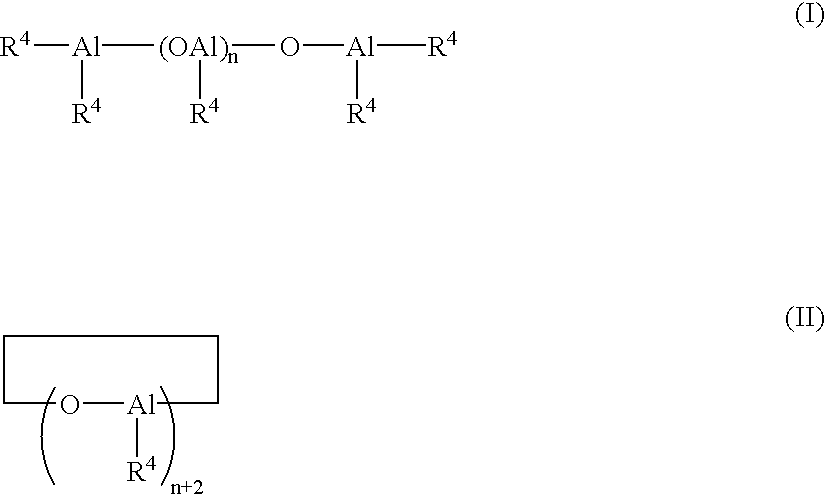

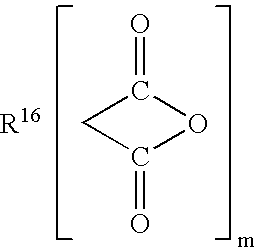

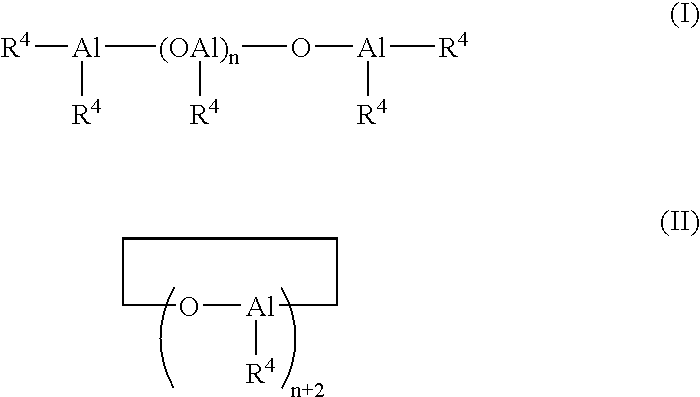

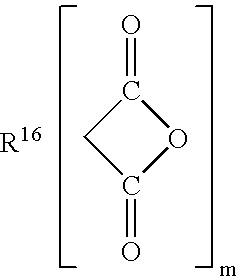

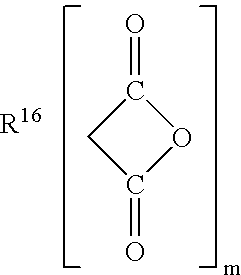

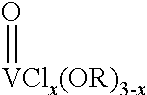

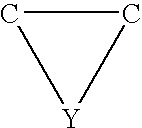

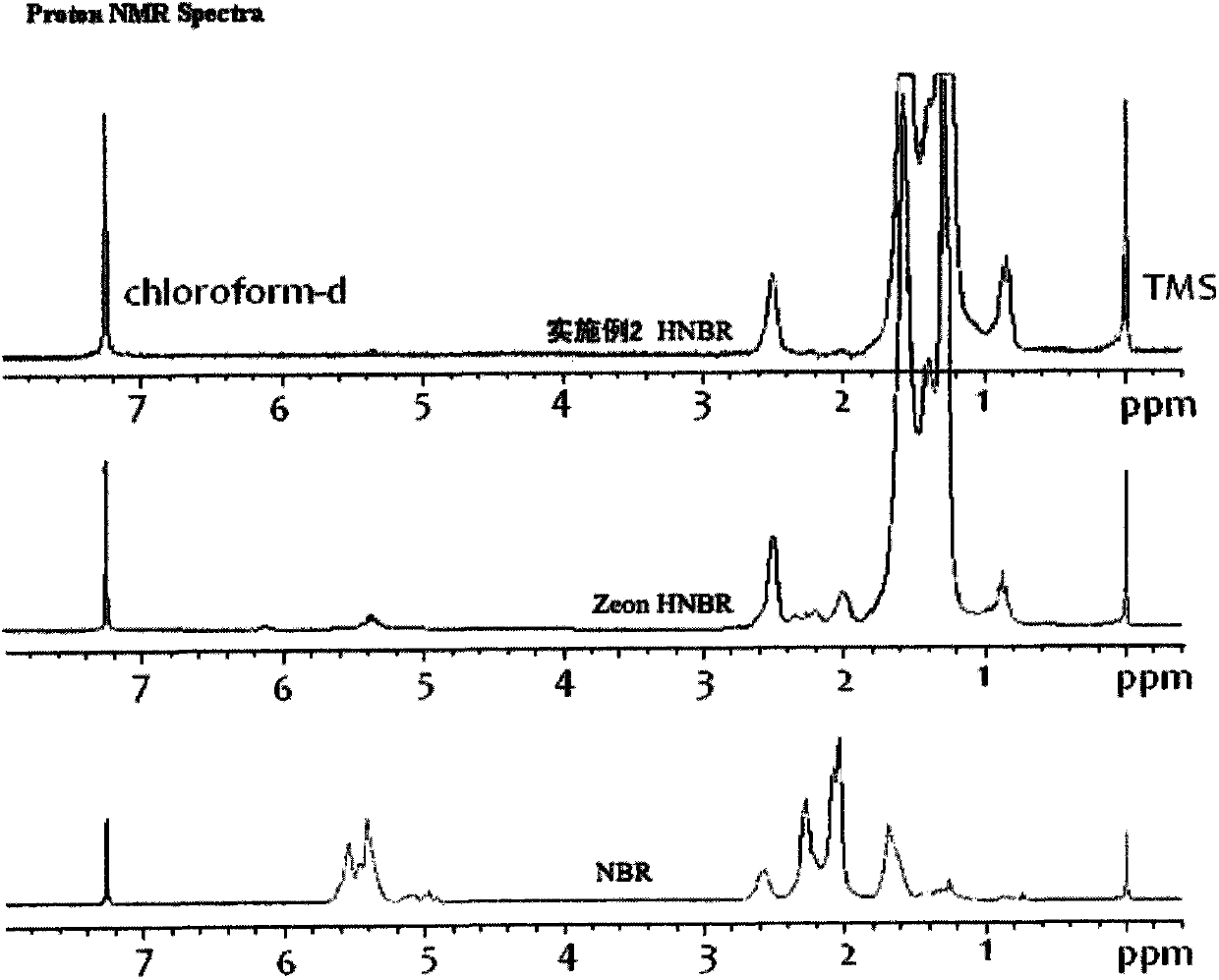

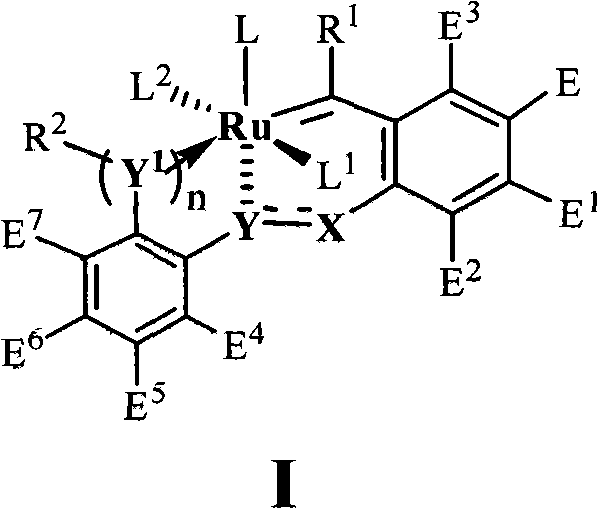

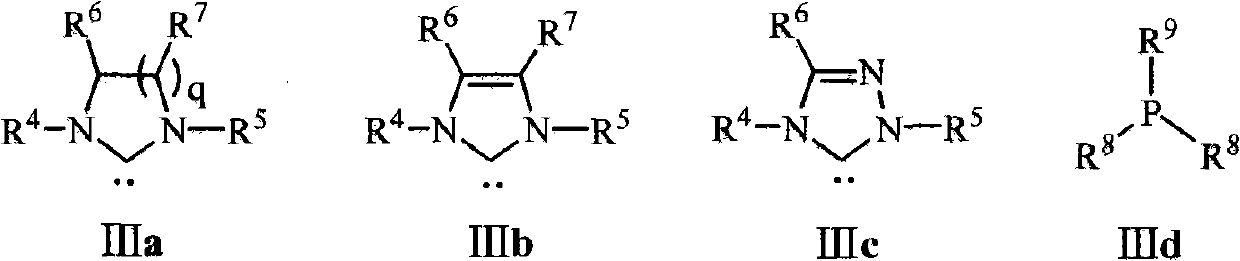

Preparation method of hydrogenated nitrile rubber and degradation and hydrogenation method of butadiene type rubber

The invention discloses a preparation method of hydrogenated butadiene special rubber, which comprises the following steps: subjecting butadiene rubber to a degradation reaction and a hydrogenation reaction under an action of a Zhan Catalyst as showed in the general formula I to obtain hydrogenated butadiene special rubber. The invention also provides a degradation reaction of the butadiene rubber, which is also under the action of a Zhan Catalyst as showed in the general formula I. The preparation method provided by the invention overcomes the shortcomings that the existing various types of catalysts can not be applicable to the preparation of low Mooney viscosity and high Mooney viscosity hydrogenated butadiene special rubber at the same time, so as to provide a preparation method of high-performance hydrogenated butadiene special rubber with a wide controllable Mooney viscosity range of 5-130. The catalyst used in the invention is the catalyst for both rubber degradation and hydrogenation reduction, so as to avoid a process requiring addition of the catalysts with different catalytic activities in two times respectively in the prior art. The method is simple, and easy to operate.

Owner:ZANNAN SCITECH

High-performance, low-pollution and recovering metal ligand cross-linked nitrile rubber materials

High performance, low pollution and regenerated metal coordinative cross linked acrylonitrile-butadiene rubber comprises acrylic nitrile 18 - 50wt%, acrylonitrile-butadiene rubber with Mooney viscosity of 20 - 100, liquid butyronitrile, carboxylic butyronitrile, hydrogenated butyronitrile, powdery butylonitrile, a butyronitrile contained mixture or / and nitrile containing copolymer or grafts and halides of transition metals or / and oxygen containing salts, and is obtained by cross reacting at 200deg.C for 5 - 60minutes. Its advantages include no harmful materials used in production, good mechanical performance without carbon black added, oil-resistant, good adhesion with metals and regenerating ability.

Owner:EAST CHINA UNIV OF SCI & TECH

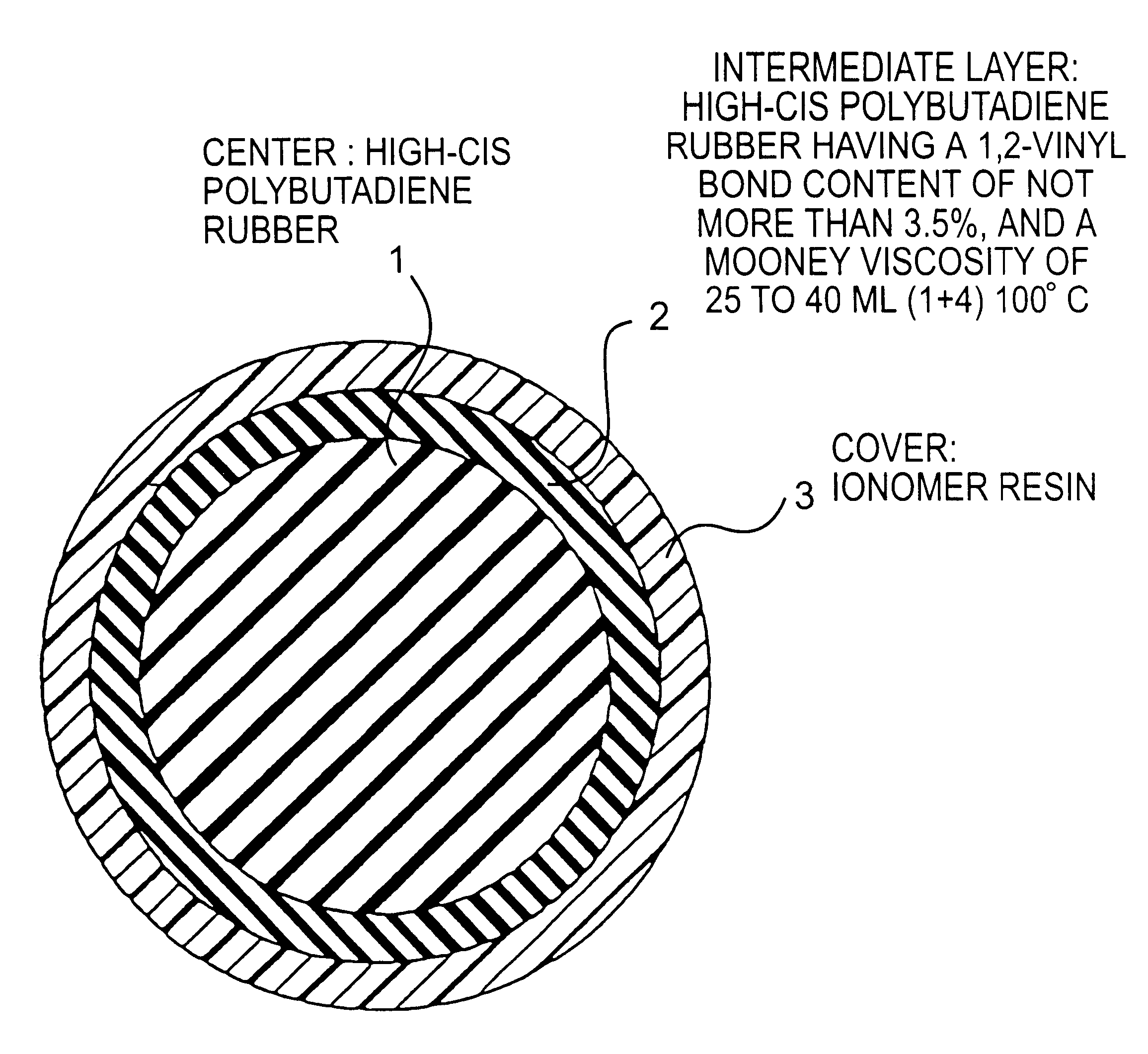

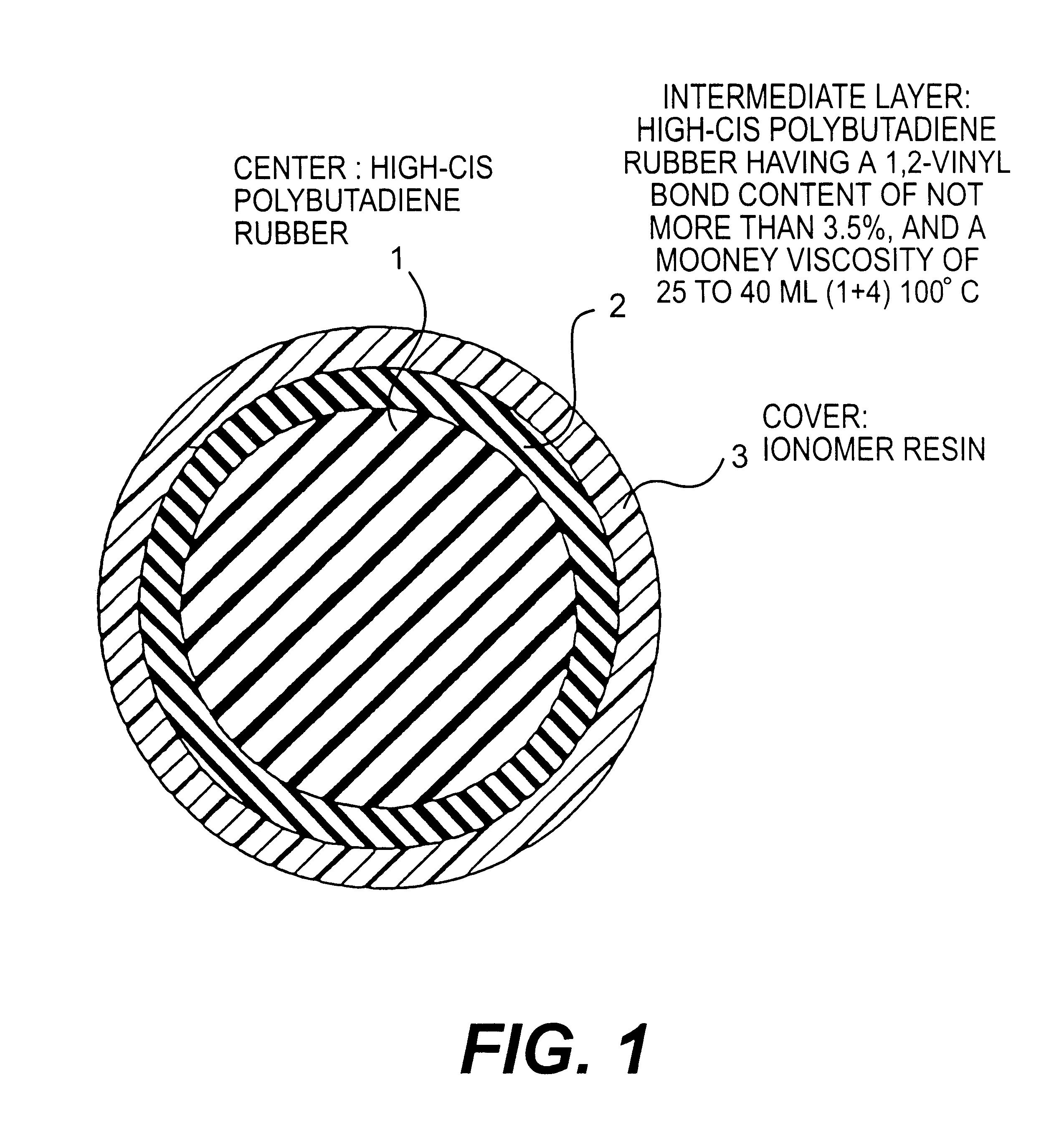

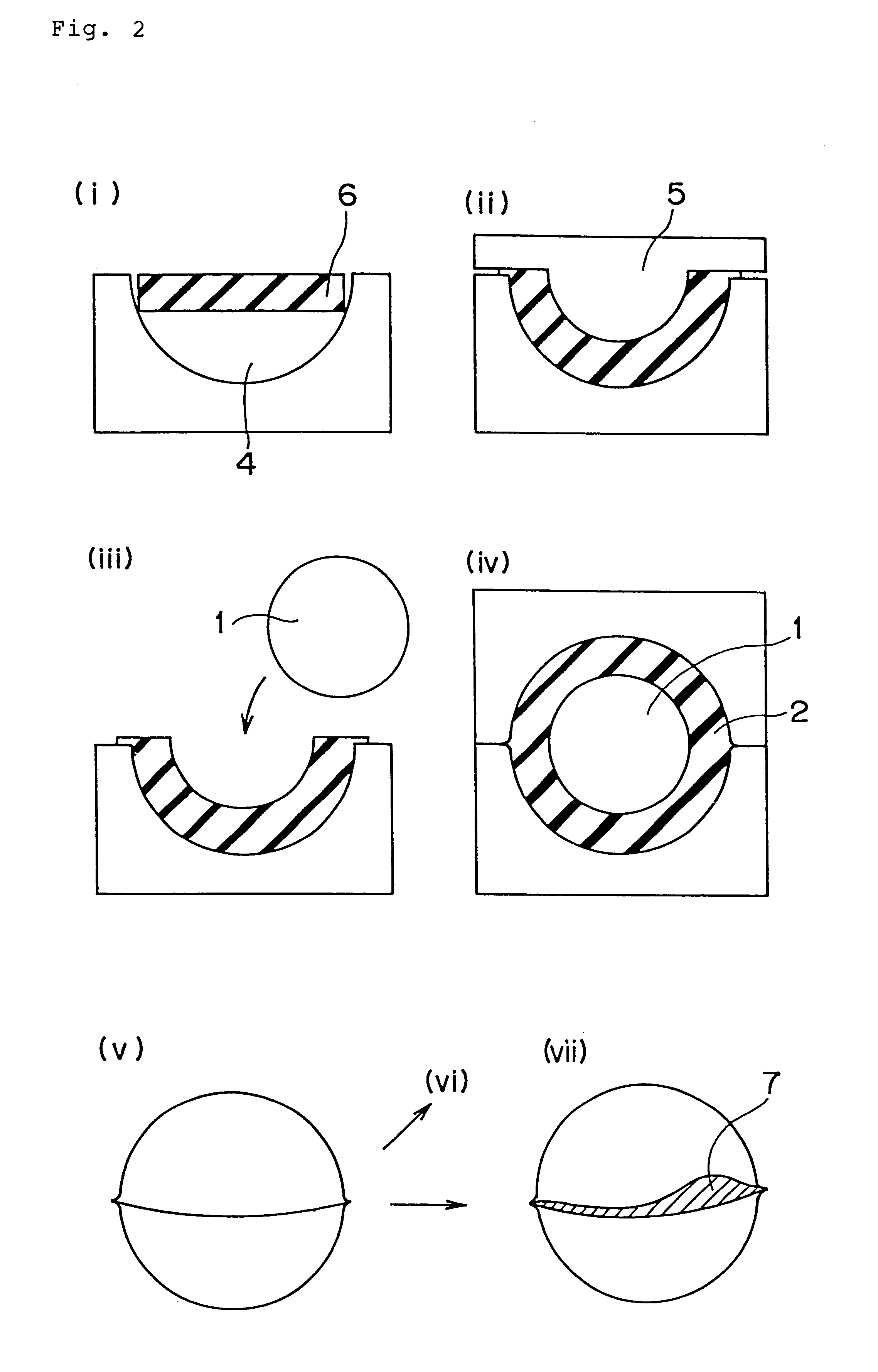

Multi-piece solid golf ball

InactiveUS6312346B1Little unevennessLittle unevenness in physical propertyGolf ballsSolid ballsMooney viscosityEngineering

The present invention provides a multi-piece solid golf ball having little unevenness in physical properties. The present invention relates to a multi-piece solid golf ball comprising a center, an intermediate layer formed on the center, and a cover covering the intermediate layer, wherein the intermediate layer is composed of one or more layers mainly containing a rubber component, the rubber component for the intermediate layer has a Mooney viscosity of 25 to 40 ML(1+4)100° C.

Owner:DUNLOP SPORTS CO LTD

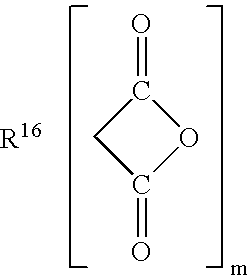

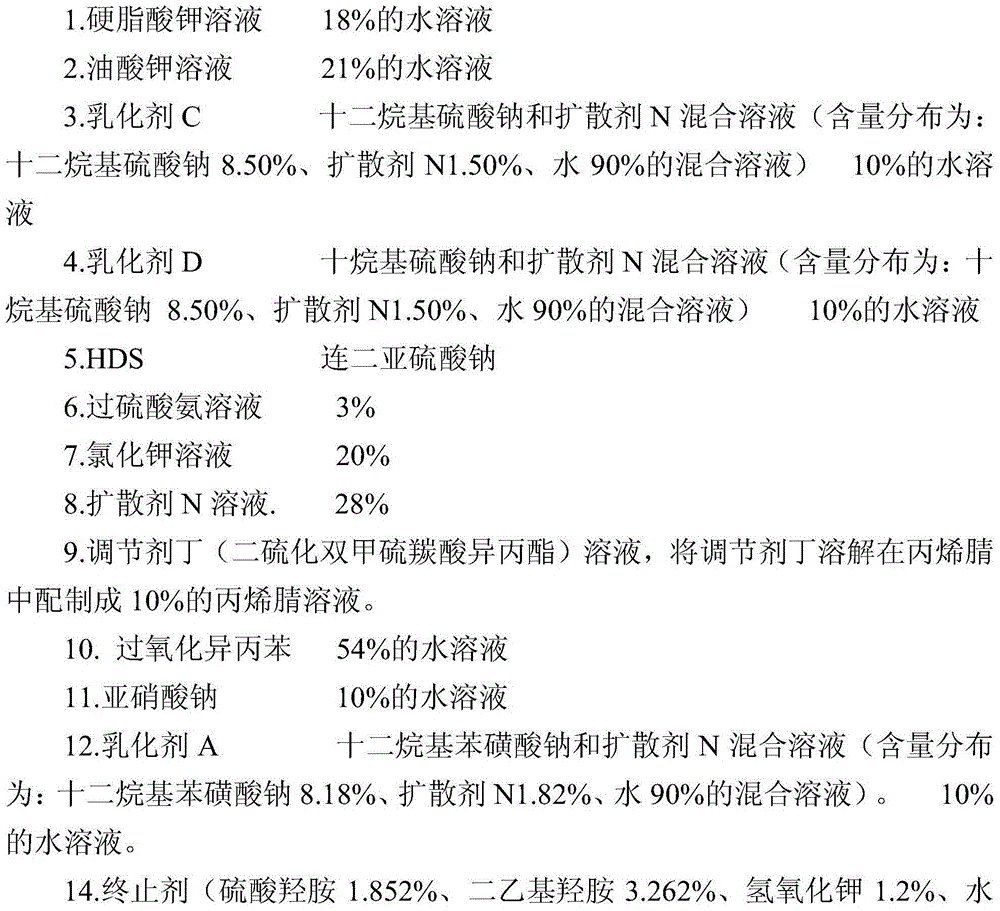

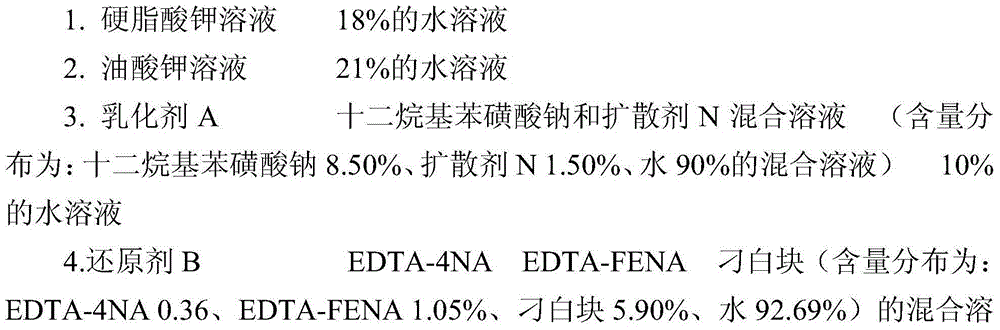

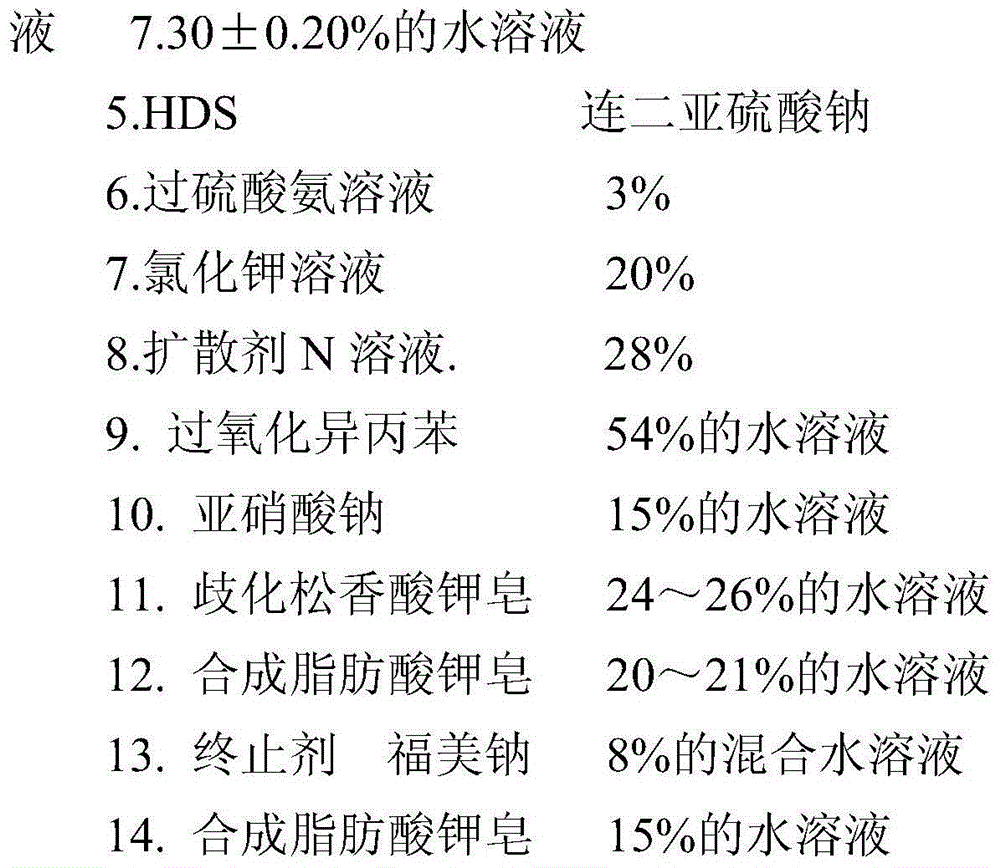

Preparation method of carboxyl nitrile rubber through emulsion polymerization

The invention relates to a preparation method of carboxyl nitrile rubber through emulsion polymerization. According to the preparation method, acrylonitrile, an emulsifier, an adjusting agent, and an initiator are added into a polymerization kettle, then butadiene is added, emulsion polymerization is carried out under stirring, and in the late phase of emulsion polymerization, unsaturated carboxylic acid and / or anhydride thereof is added into the polymerization kettle. The obtained carboxyl nitrile rubber has a low content of gel and a two-layer molecular structure, the index of conjugated acid is controllable; during the processing process, a three-dimensional network structure can be easily formed, thus the mechanical and physical properties of rubber products made of the carboxyl nitrile rubber are good; after processing, the Mooney viscosity is increased, the crosslinking degree of finished products is good, and especially, the elongation at break is prominently improved.

Owner:PETROCHINA CO LTD

Method to control increase in viscosity during aging of siloxane modified polymers

InactiveUS6279632B1Reduce rateReduce hydrolysis rateSilicon organic compoundsSpecial tyresEnd-groupMooney viscosity

A method for controlling any increase in Mooney viscosity during aging of siloxane-functionalized polymers includes the step of adding a viscosity stabilizing effective amount of a long chain alcohol preferably selected from the group consisting of aliphatic, cycloaliphatic, and aromatic alcohols having more carbon atoms than the hydrolyzable substituent on the siloxane end groups. The method provides for the stabilization of Mooney viscosity of siloxane-functionalized polymers at any given level upon aging. The long chain alcohols react with the siloxane-functionalized polymers prior to hydrolysis of the siloxane end groups to form moisture stabilized polymers.

Owner:BRIDGESTONE CORP

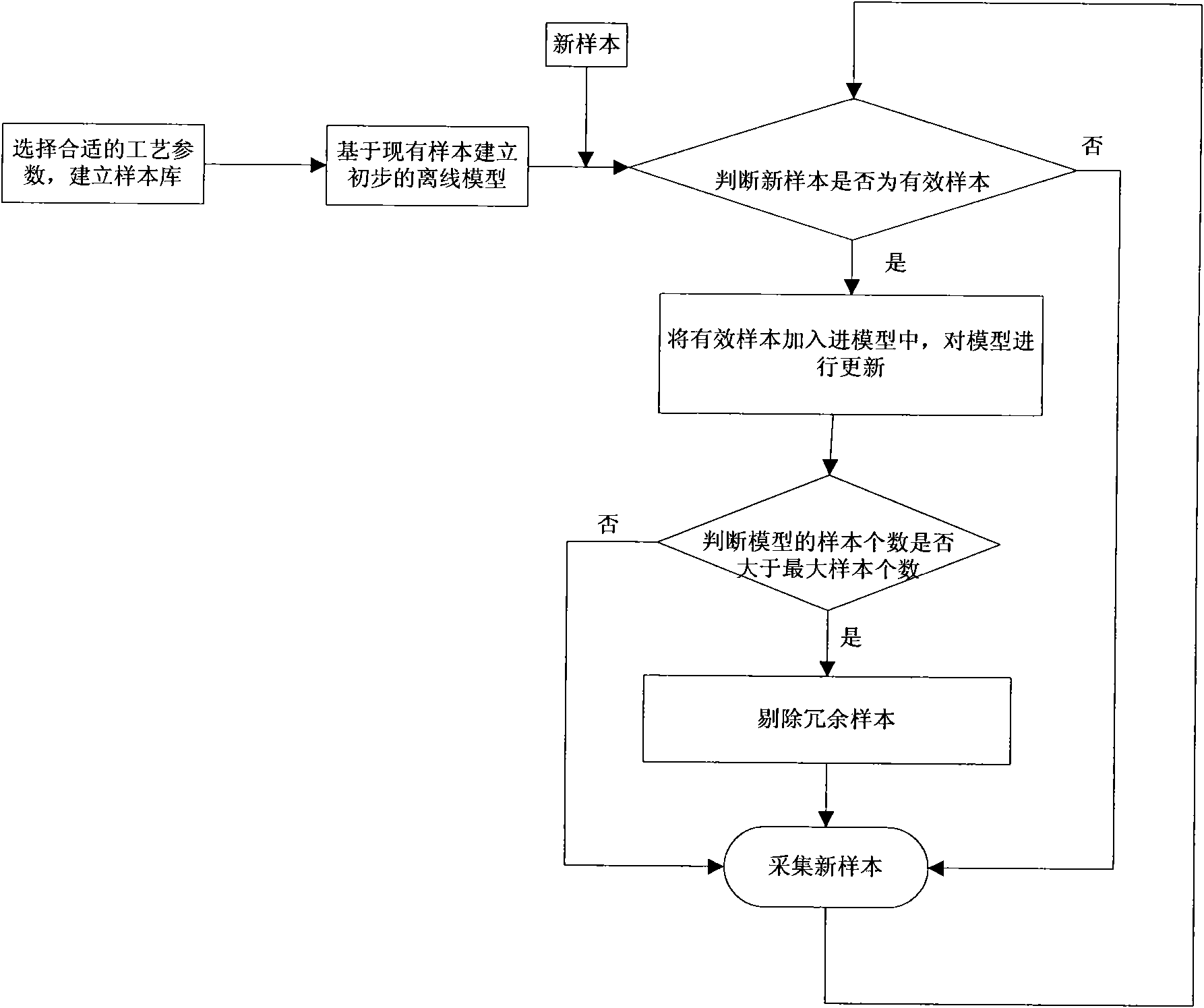

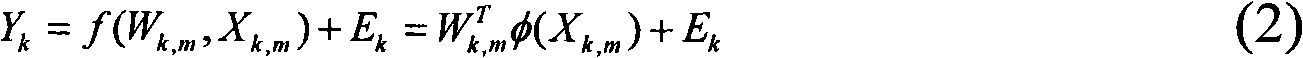

Method for forecasting Mooney viscosity in rubber mixing process

The invention discloses a method for forecasting a Mooney viscosity in a rubber mixing process, which comprises the following steps of: establishing an initial off-line model by using a process parameter and a Mooney viscosity accumulated in the process production as a data sample, then applying the off-line model to a practical process line, and acquiring new sample data; if the forecasting error of the model on the new sample exceeds a forecasting error threshold value, judging the sample as a valid sample, and adding the valid sample into the model; performing on-line dynamic update on model parameters; and when the number of the samples in the model exceeds the preset maximum sample number, removing the redundant samples in the model so that the number of the samples of the model is controlled within the maximum sample number. The method continually improves the precision of the model based on the cutting technology, and can effectively control the complexity of the model at the same time; the model has good convergence effect; and the method reduces the calculation quantity of the conventional model, and can provide accurate on-line real-time forecast for the Mooney viscosity in the rubber mixing process.

Owner:ZHEJIANG UNIV

Method for preparing thermoplastic vulcanizates with improved extrusion surfaces

The invention described is a process for the preparation of dynamically vulcanized thermoplastic elastomers comprising melt processing under shearing conditions in melt reaction extruder, A) at least one thermoplastic resin, B) at least one vulcanizable gas-phase elastomer having a Mooney viscosity (ML1+4(125° C.)) of from about 65 to about 450, C) a curing agent or agents, and D) process oil, wherein said process oil D) is added to the extruder in at least three oil injection positions located a) at least one location before or within the first 15% of the total length of the extruder; b) at least one other location prior to, at or within 10% total extruder length after the onset of the vulcanization of said gas-phase elastomer; and c) at least one location subsequent to the location of the point at which the vulcanization of said gas-phase elastomer is substantially completed; wherein the direct oil injection locations into the extruder are positioned at or immediately before one or more distributive mixing elements, which distributive mixing elements are immediately followed by one or more dispersive mixing elements. Thermoplastic vulcanizates capable of being extrusion molded with a smooth surface and low surface spot count, in addition to excellent elastomeric properties, are obtained through the use of the process described.

Owner:EXXONMOBIL CHEM PAT INC

Layered product olefin foam and use

The foamed laminate based on olefin according to the present invention is composed of a substrate layer of a foamed body made of either an ethylenic thermoplastic elastomer comprising a polyethylene resin and an ethylene / α-olefin copolymer having a Mooney viscosity ML1+4 (100° C.) of 90-250 and an ethylene content of 70-95 mole % or an ethylenic thermoplastic elastomer composition comprising 100 parts by weight of an olefinic thermoplastic elastomer and 1-20 parts by weight of an olefinic thermoplastic resin and, under lamination thereon, a skin layer made of either an ultrahigh molecular weight polyolefin resin having an intrinsic viscosity of 3.5-8.3 dl / g or made of an olefinic thermoplastic elastomer composition comprising an olefinic thermoplastic elastomer and a lubricant. The foamed laminate according to the present invention is easy in recycled use, obtainable at a high foaming expansion ratio with soft hand touch and is superior in the appearance, abrasion resistance, durability and sliding performance.

Owner:MITSUI CHEM INC

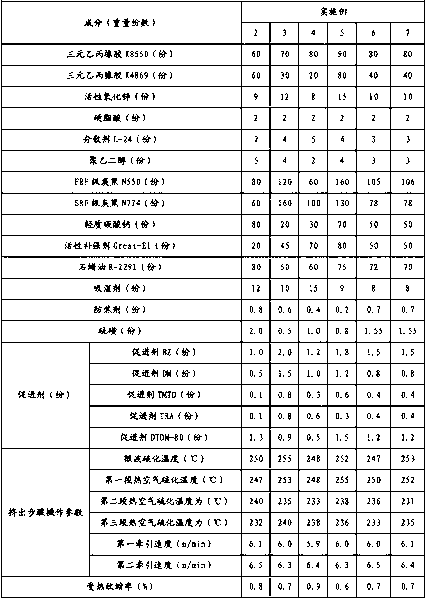

Automobile door glass guide groove seal bar adhesive material and applications thereof

ActiveCN103194155AGuaranteed StrengthMeet performance requirementsNon-macromolecular adhesive additivesVulcanizationMooney viscosity

The invention discloses an automobile door glass guide groove seal bar adhesive material and applications thereof. Crude adhesive with high mooney viscosity and low ethylene content is adopted as a main raw material; a great quantity of high-structure fillers and high-flash-point paroline are added, and semi-effective vulcanized system vulcanized by sulphur is matched, so that the heated contraction rate of seal bar materials is controlled to be within 1%. The conventional physical performance of seal bars can meet the performance requirement of automobile door glass guide groove seal bars on materials, and the secondary baking step required in the subsequent process of the existing seal bars is omitted, so that energy sources are saved, and the waste caused by scrappage for poor size is eradicated. The adhesive material provided by the invention is used for preparing the automobile door glass guide groove seal bars, and is further applied to automobile doors and automobiles.

Owner:NUOBO RUBBER PRODION

Low gloss thermoplastic polyolefin composition

The present invention relates to an impact resistant composition having a polyolefin, an elastomer with a Mooney viscosity of greater than about 40 and an elastomer with a Mooney viscosity of less than about 40. The present invention also relates to an impact resistant composition having a polyolefin and a coupled elastomer with a Mooney viscosity of greater than about 40. Further, the present invention relates to compositions having a polypropylene blend with a heat of crystallization of greater than about 150° C., a coupled ethylene-α-olefin with a Mooney viscosity of greater than about 40 and an ethylene-α-olefin with a Mooney viscosity of between about 30 and about 40.

Owner:DOW GLOBAL TECH LLC

Homogenous neodymium-based rare earth catalyst, and its preparation method and application

The invention relates to a novel homogenous neodymium-based rare earth catalyst, and a preparation method of the catalyst and application in polymerization of conjugated diene. The synthesis method of the catalyst is simple and easy to control, thus the obtained catalyst has high activity and good stability. By using the inventive homogenous neodymium-based rare earth catalyst for catalyzing polymerization of isoprene, the polymerization process is stable, easy to control, and suitable for continuous operation, and polyisoprene with a cis structure content higher than 98% and adjustable Mooney viscosity range within 60-100 can be synthesized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of preparing carboxyl styrene butadiene rubber through emulsion polymerization

The invention relates to a method of preparing carboxyl styrene butadiene rubber through emulsion polymerization. According to the method, styrene, an emulsifier, a conditioning agent, and an initiator are added into a polymerization kettle, then butadiene is added to carry out emulsion polymerization under stirring, and in the later period of reactions, unsaturated carboxylic acid and / or unsaturated carboxylic anhydride are added into the polymerization kettle. The prepared carboxyl styrene butadiene rubber has a low gel content, a controllable combined acid index, and a dual layer molecular structure; during the processing process, a three dimensional net-like structure can be formed easily; the mechanical and physical properties of rubber product are good, after processing, Mooney viscosity is increased, the crosslinking degree of finished product is good, and especially, the elongation at break is obviously improved.

Owner:PETROCHINA CO LTD

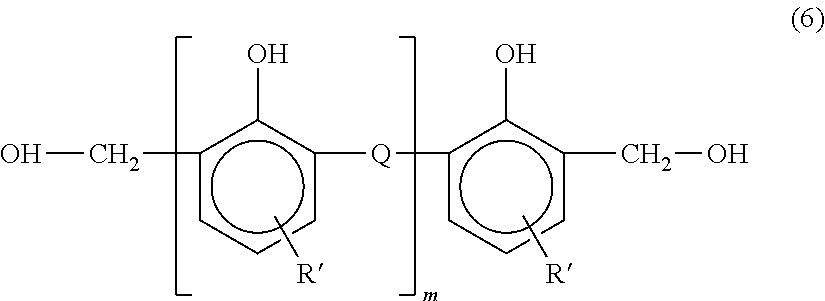

Method for producing modified conjugated diene based (CO)polymer, modified conjugated diene based (CO)polymer, and rubber composition

The method for producing a modified conjugated diene based (co)polymer, according to the present invention comprises a step of reacting a conjugated diene based (co)polymer with a metal halide compound to obtain a modified conjugated diene based (co)polymer, the conjugated diene based (co)polymer having a weight-average molecular weight of 150,000 to 2,000,000 and being obtained by bonding, to a polymer having at least a conjugated diene unit, an alkoxysilyl group and an optionally protected primary amino group. The method can satisfactorily produce a conjugated diene based (co)polymer which has a high Mooney viscosity, excellent shape stability and good processability.

Owner:ENEOS MATERIALS CORP

Thermoplastic vulcanizate composition

The instant disclosure is directed to a thermoplastic vulcanizate composition comprising a dynamically-cured rubber; from about 20 to about 300 parts by weight of a thermoplastic resin per 100 parts by weight rubber and from about 30 to about 250 parts by weight additional oil per 100 parts by weight rubber; wherein the rubber comprises a multimodal polymer composition cured with a curing agent, the multimodal polymer composition comprising 45 to 75 wt % of a first polymer fraction and 25 to 55 wt % of a second polymer fraction, each comprising ethylene, a C3-C10 alpha-olefin, and a non-conjugated diene, wherein the polymer fractions have been polymerized using a Ziegler-Natta catalyst system, wherein the first polymer fraction has a Mooney viscosity of greater than or equal to about 150 ML(1+4@125° C.), and the second polymer fraction has a Mooney viscosity of about 20 ML to about 120 ML; and about 10 phr to about 50 phr of an extender oil. A method of producing the thermoplastic vulcanizate is also disclosed.

Owner:CELANESE INT CORP

Plastic elastomer compositions and air bag cover

A resin composition for impact-resistant moldings with high low-temperature impact strength, and an air bag cover made of this resin composition are provided. The resin composition, or a thermoplastic elastomer composition for impact-resistant moldings, is produced by a process comprising subjecting 15 to 40% by weight of component (A), 15 to 40% by weight of component (B) and 20 to 70% by weight of component (C) (taking the total of the components (A), (B) and (C) as 100% by weigh) to a dynamic heat treatment in the presence of a crosslinking agent, said components being as specified below:(A): an ethylene-α-olefin-non-conjugated diene copolymer rubber having a density of 850 to 900 kg / m3, a Mooney viscosity (ML1+4(100° C.)) of 30 to 150, and an ethylene unit content of 30 to 90;(B): an ethylene-α-olefin-non-conjugated diene copolymer rubber having a density of 850 to 900 kg / m3 and a Mooney viscosity (ML1+4(100° C.)) of 30 to 150, and an ethylene unit content which is 0.50 to 0.95 time that of the component (A) or an iodine value which is 0.25 to 0.95 time that of the component (A);(C): a polypropylene resin.

Owner:SUMITOMO CHEM CO LTD

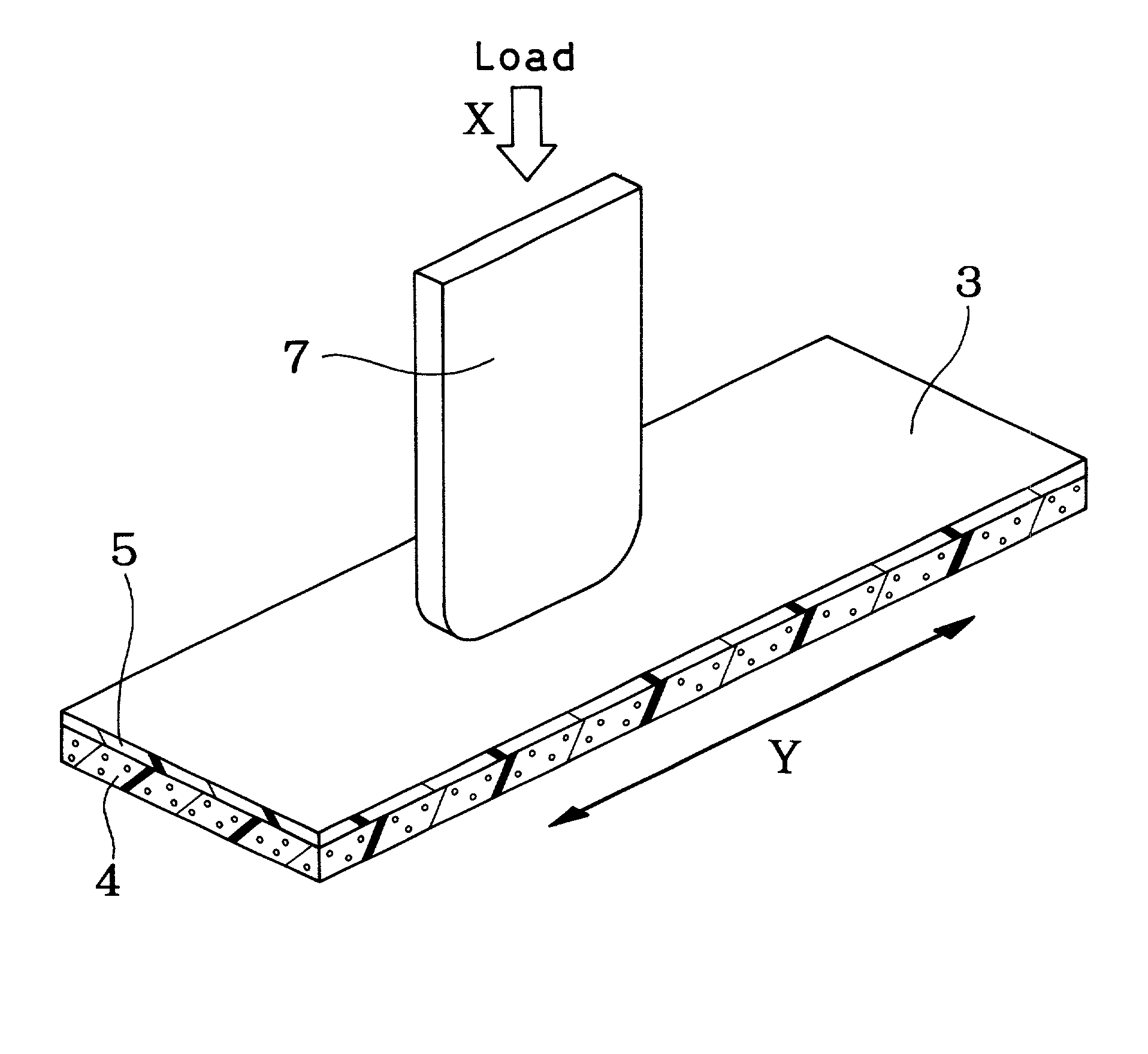

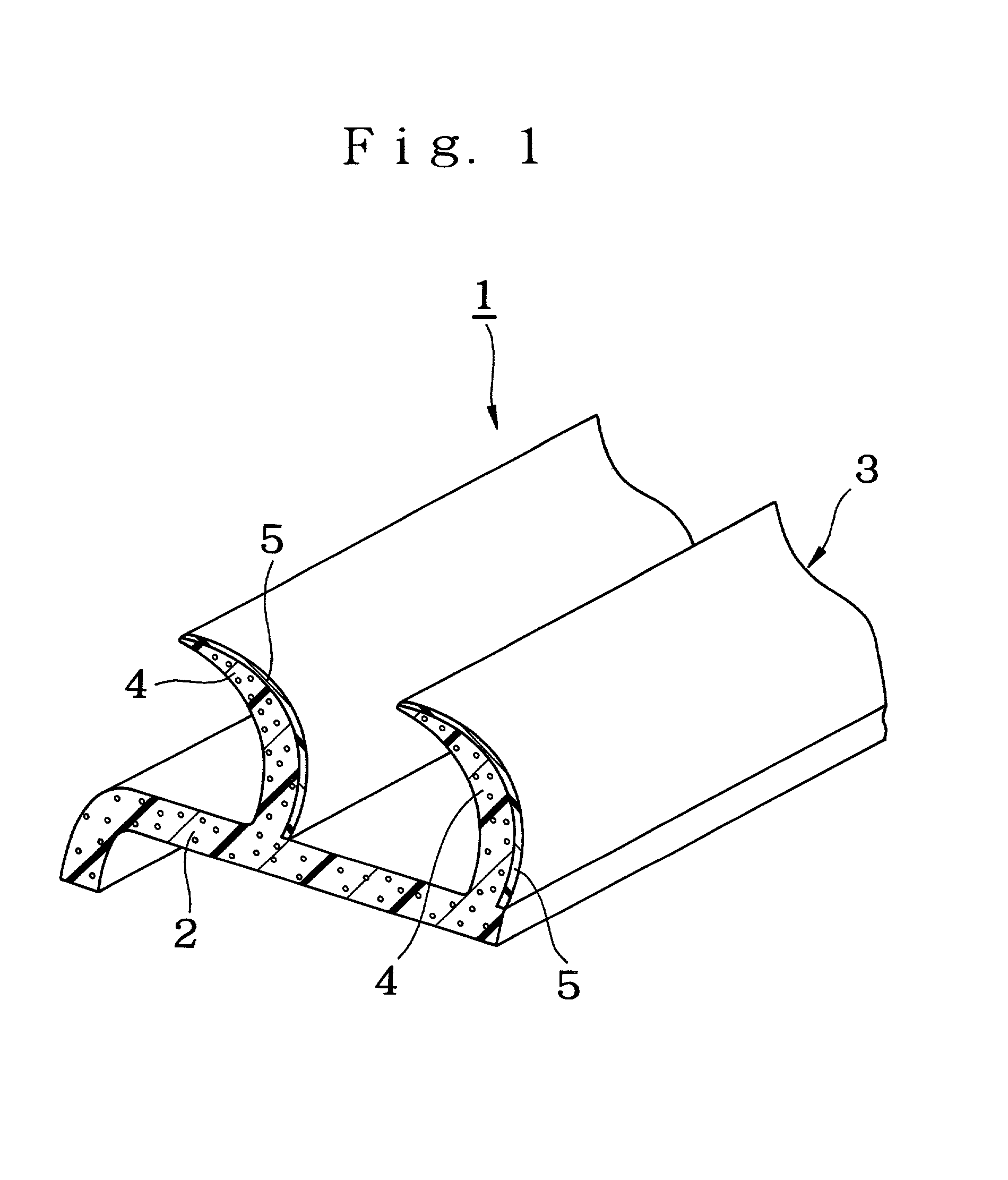

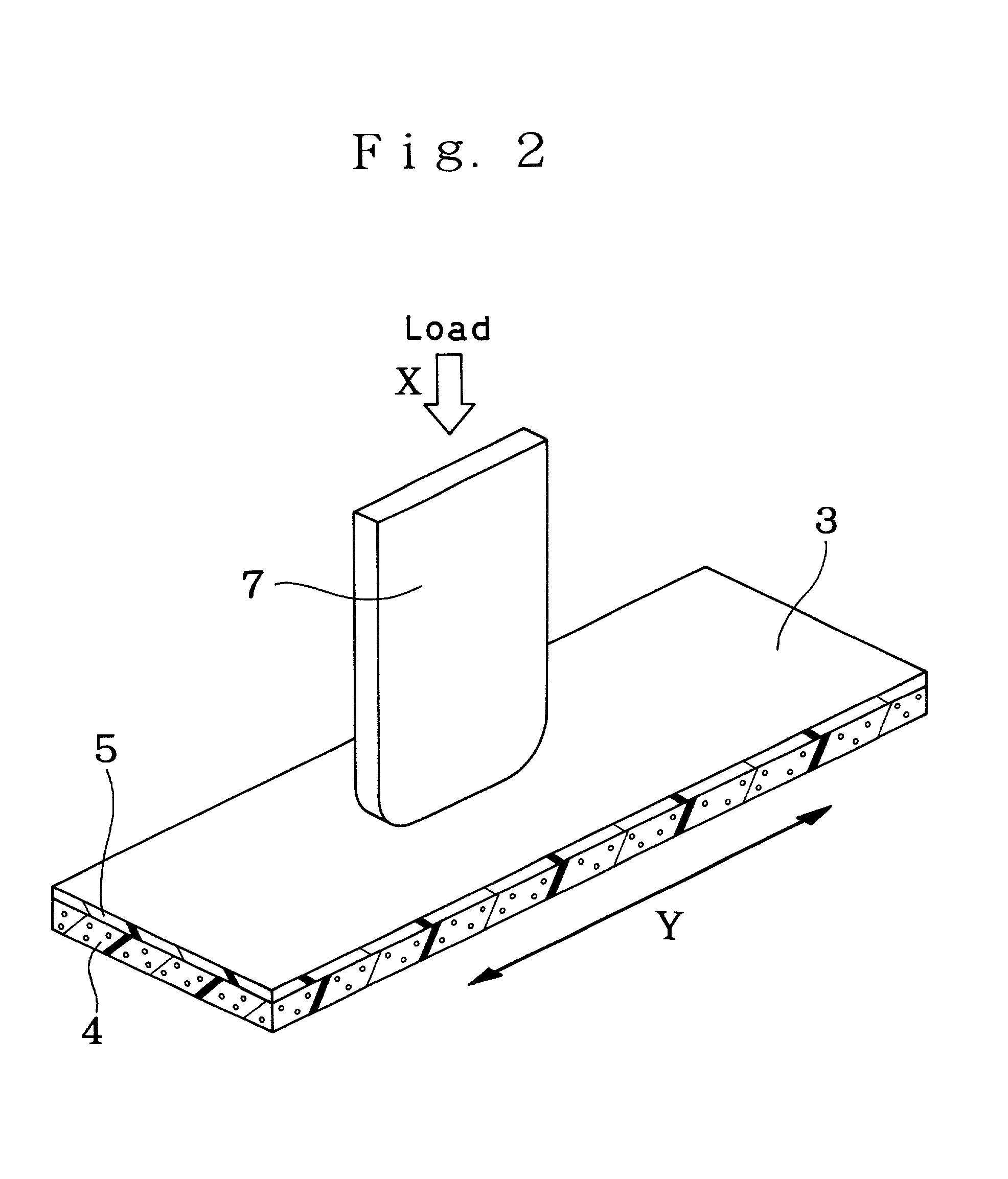

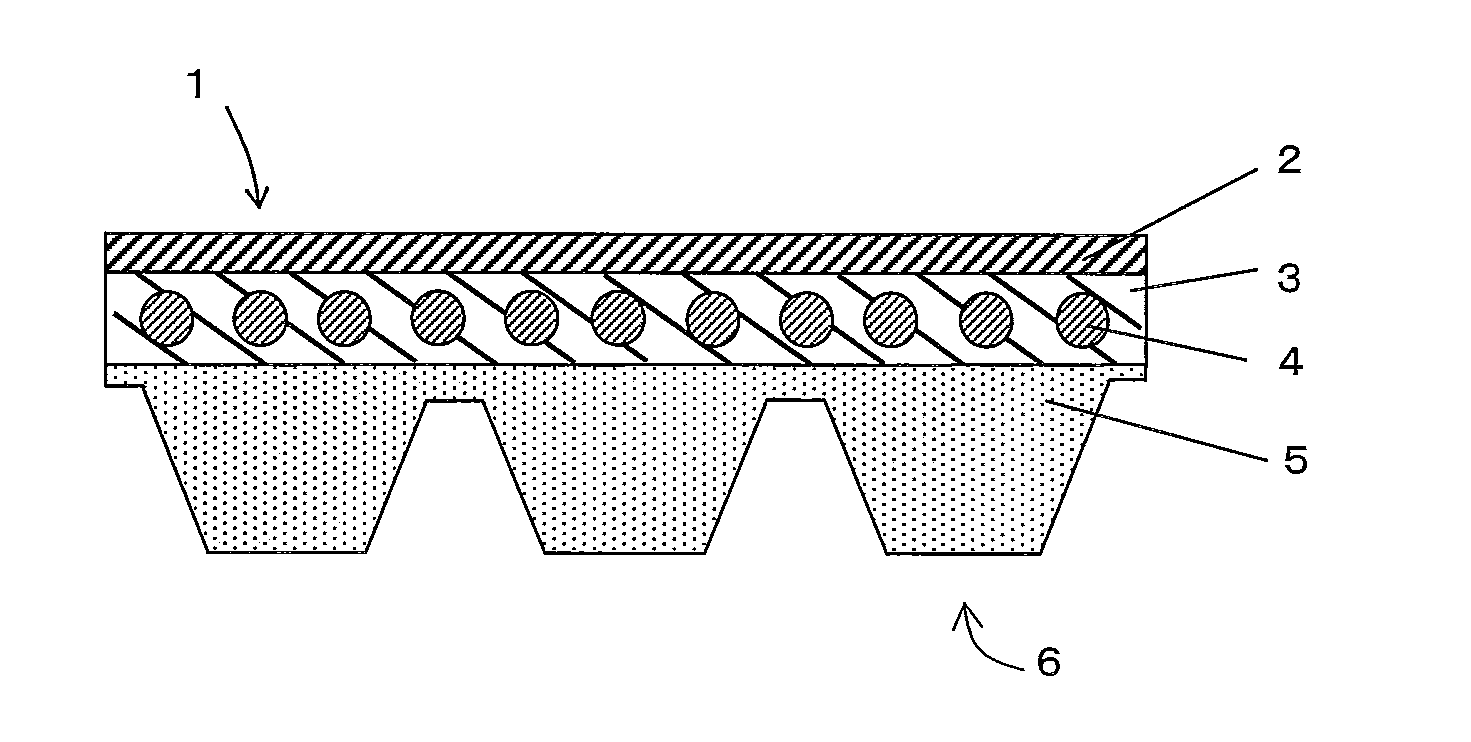

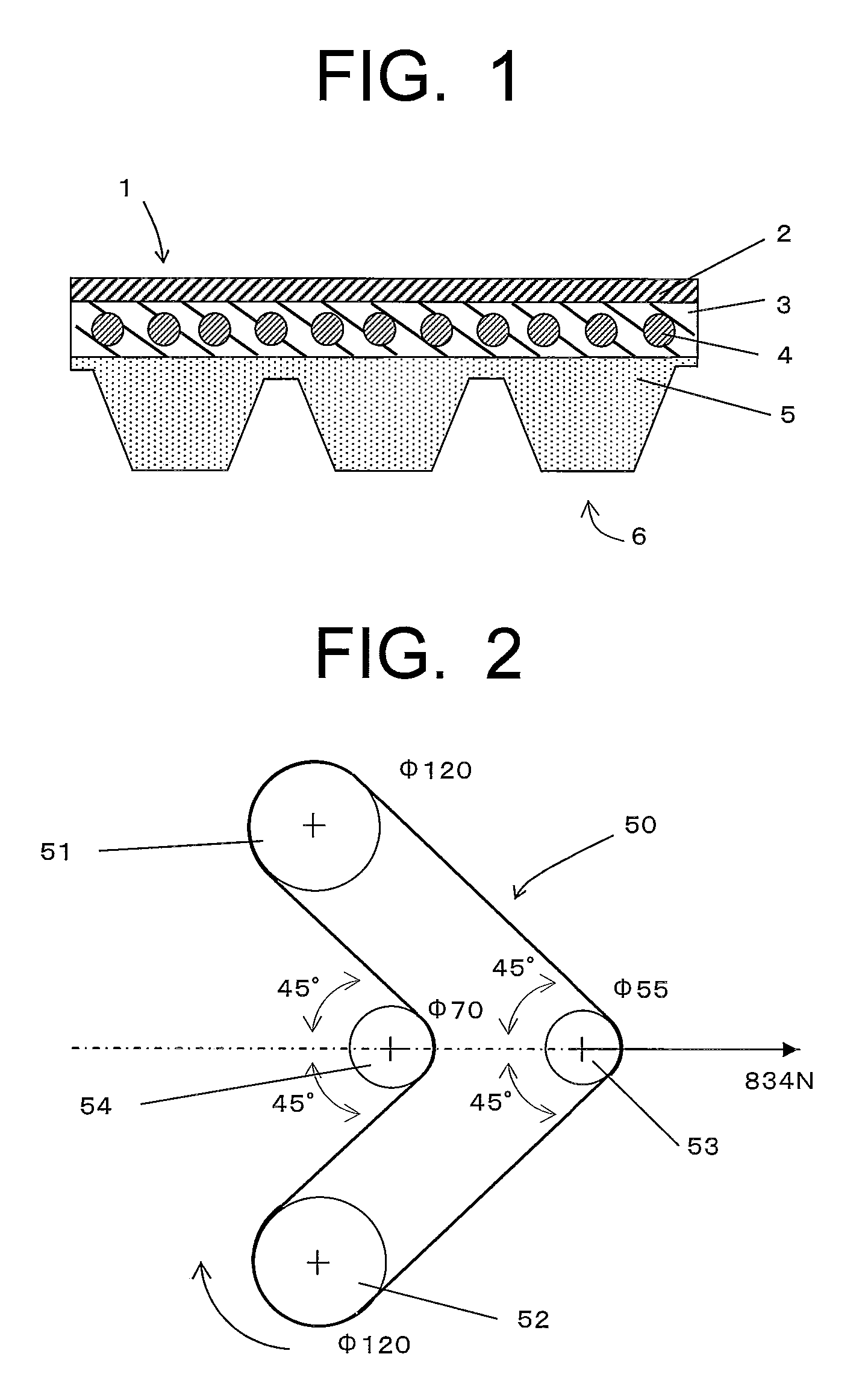

Rubber Composition and Rubber Belt

InactiveUS20100240809A1Improve mechanical propertiesGood molding effectV-beltsDriving beltsClay mineralsPolymer science

An object is to provide a rubber composition that is capable of significantly improving mechanical properties. Another object is to provide a rubber belt that has excellent mechanical properties. Provided are a rubber composition, and a rubber belt formed by using the rubber composition, which is incorporated with a rubber component containing an ethylene / α-olefin copolymer, and an organically treated clay mineral organically treated with an organic ammonium ion, wherein the ethylene content of the ethylene / α-olefin copolymer is in a range of 60-85% by mass, the rubber component has a Mooney viscosity of 10-55 at 125° C., and the organically treated clay mineral is incorporated in 6-30 parts by mass per 100 parts by mass of the rubber component.

Owner:BANDO CHEM IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com