Patents

Literature

272 results about "Contraction rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

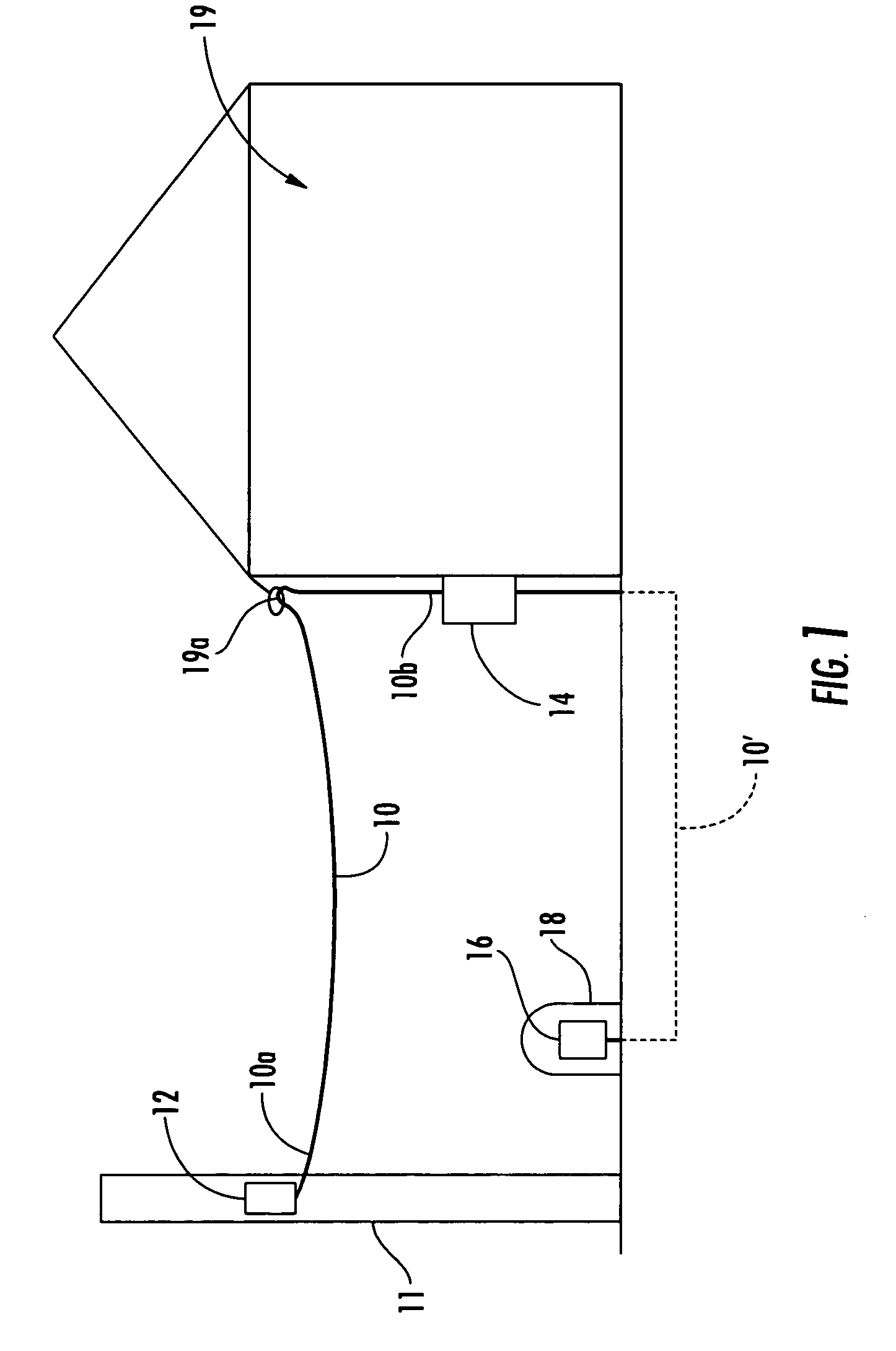

Patent Type

Patent Status

Application Year

Inventor

Lightweight high-performance foam concrete and preparation method thereof

ActiveCN104108912AHigh CaO contentHigh glass bead contentSolid waste managementCeramicwareFoam concreteFiber

The invention discloses a lightweight high-performance foam concrete, which is composed of the following components in parts by weight: 50 to 60 parts of cement, 20 to 35 parts of mineral slag, 15 to 20 parts of fly ash, 5 to 10 parts of gypsum, 60 to 80 parts of fine aggregate, 2.7 to 7.3 parts of additive, 0.1 to 0.2 part of fiber, 32 to 45 parts of water, and 5 to 25 parts of foam. The invention also discloses a preparation method of the foam concrete. The foam concrete has the advantages of small volume-weight, high strength, low water absorption, and small contraction rate, and has the waterproof and anti-cracking functions at the same time.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

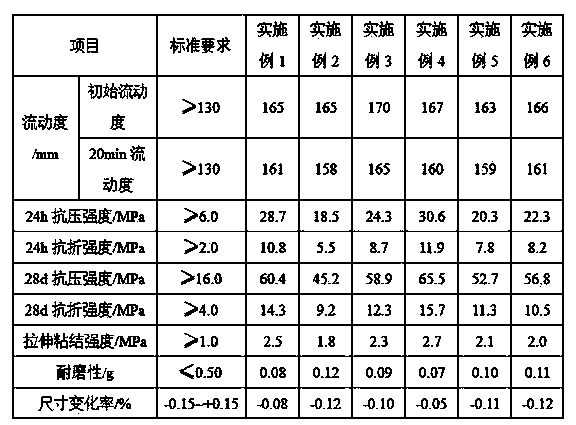

High performance cement-base self-leveling mortar

The invention discloses a high performance cement-base self-leveling mortar. The mortar is characterized by comprising cement, an auxiliary gel material, fine aggregate, a filling material, an additive, and water; wherein the cement is common silicate cement and sulphoaluminate-silicate cement, the auxiliary gel material comprises mineral slag, fly ash, silica fume, and gypsum, and the ratio of common silicate cement to sulphoaluminate-silicate cement to gypsum is equal to 1:0.2-0.6:0.1-0.4. The mortar has a self-leveling function without vibration, so the surface flatness is very high. The curing speed of the mortar is very quick, and after two hours, the strength of the mortar can meet the requirements of subsequent construction. Moreover the mortar has the advantages of low contraction rate, good volume stability, good surface wear resistance, and high compression strength.

Owner:广东省建筑工程监理有限公司

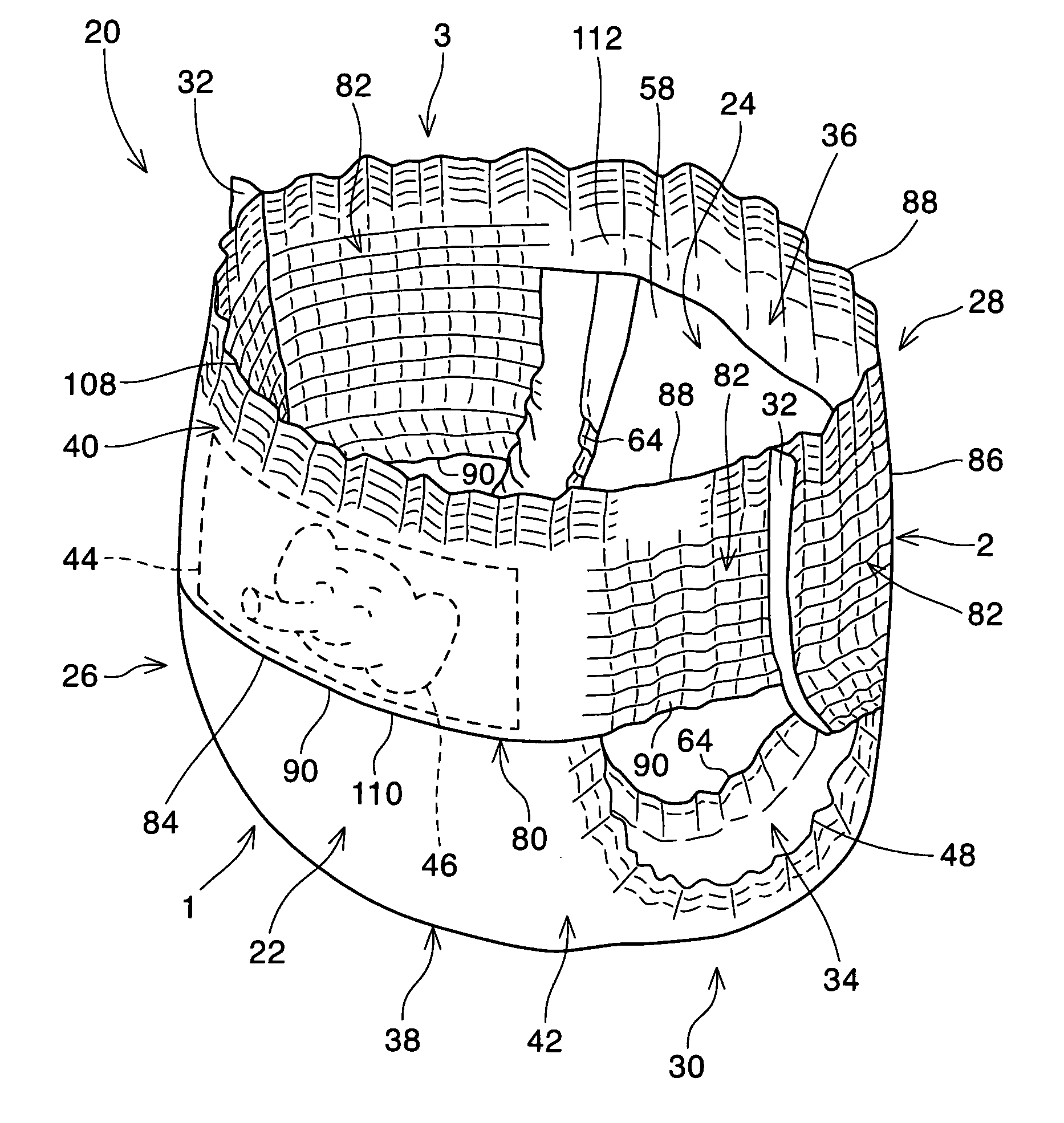

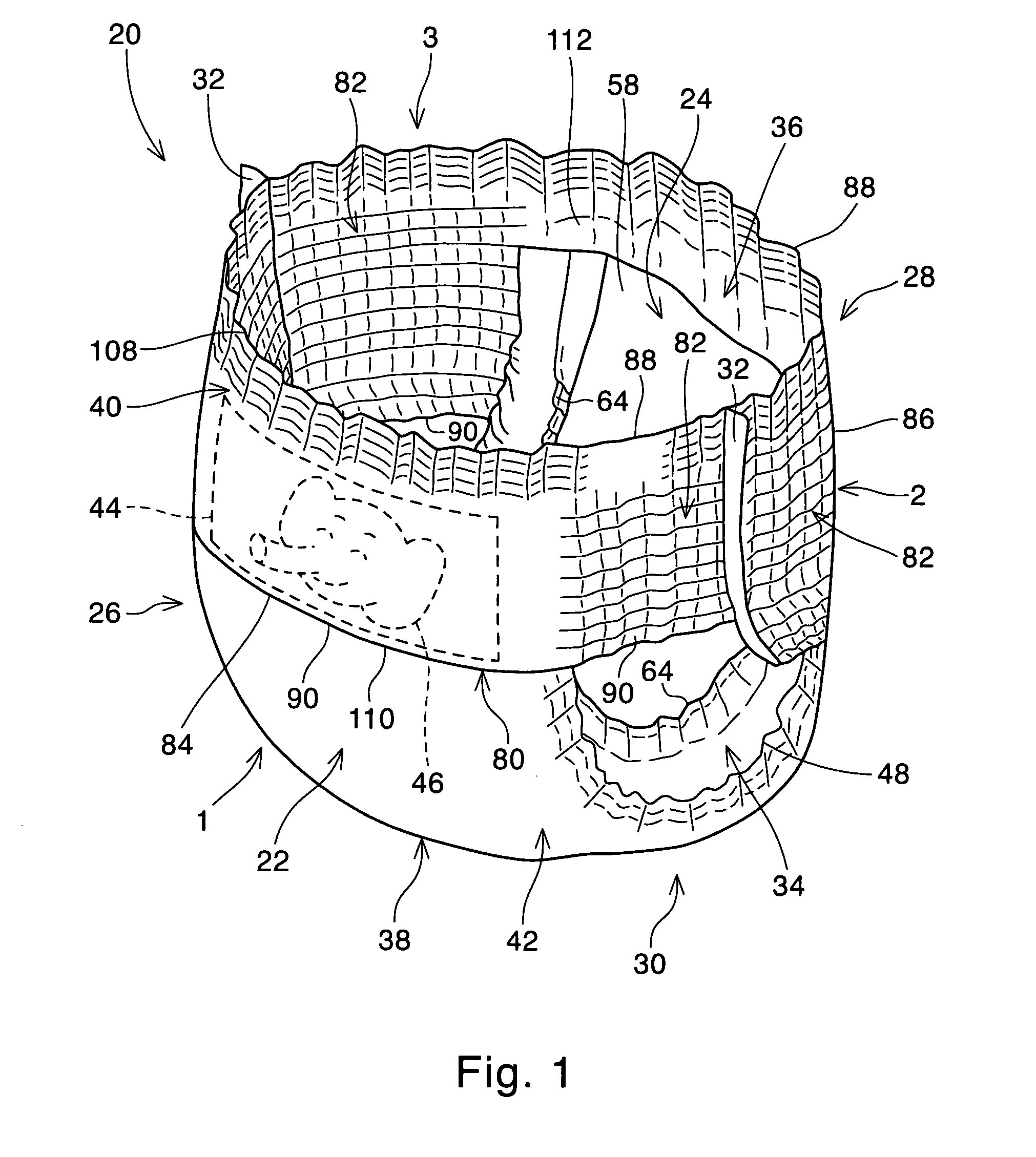

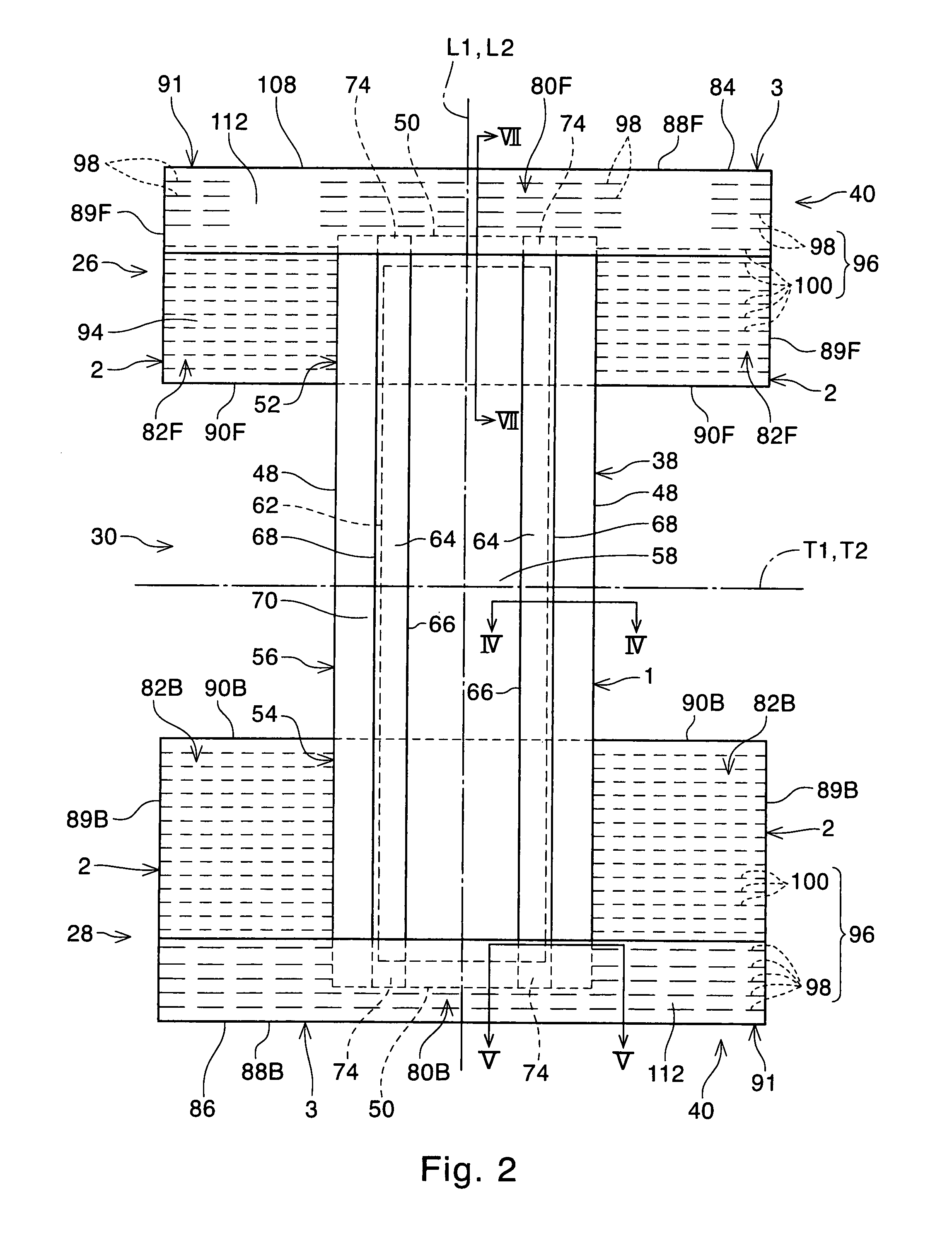

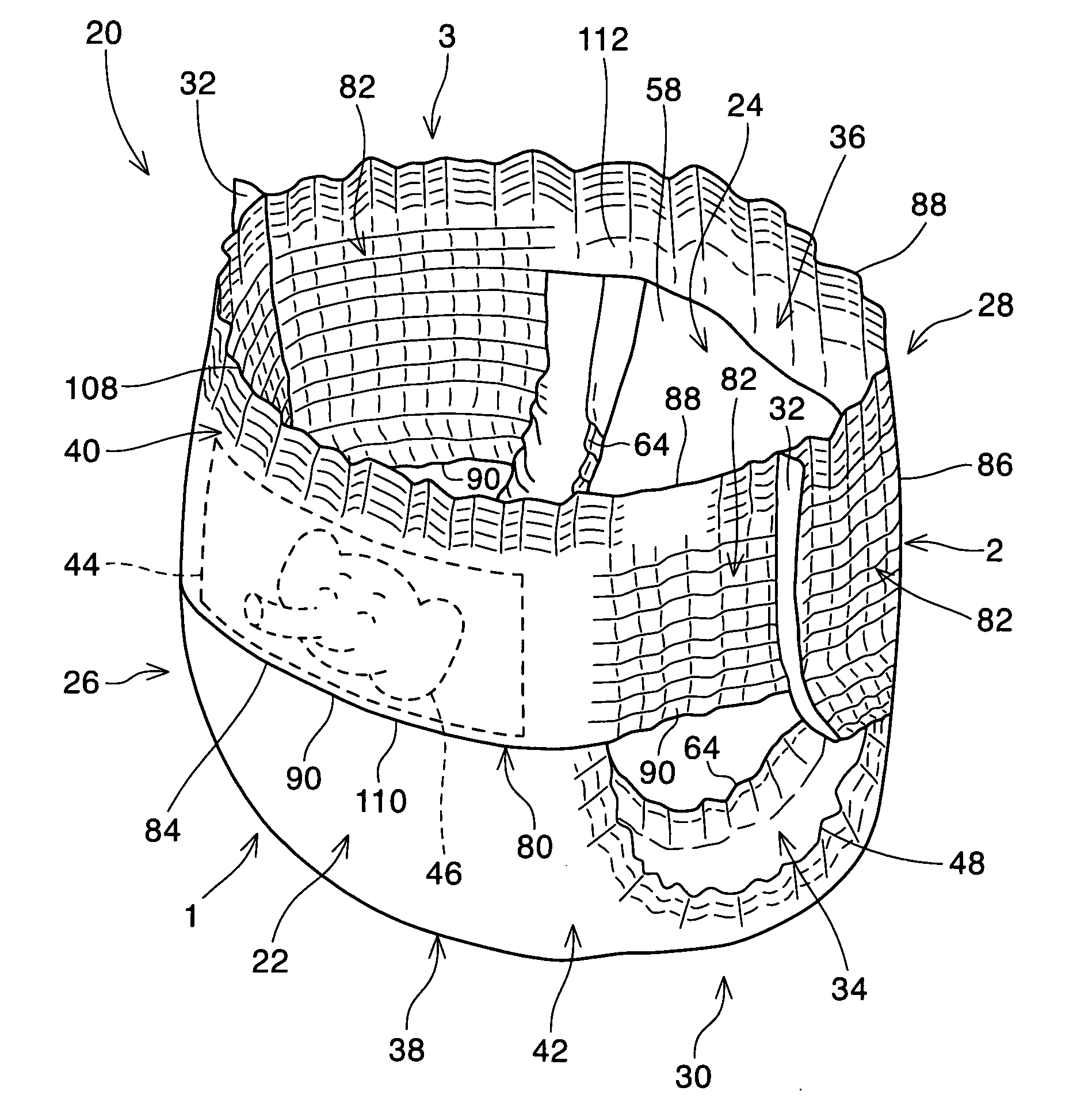

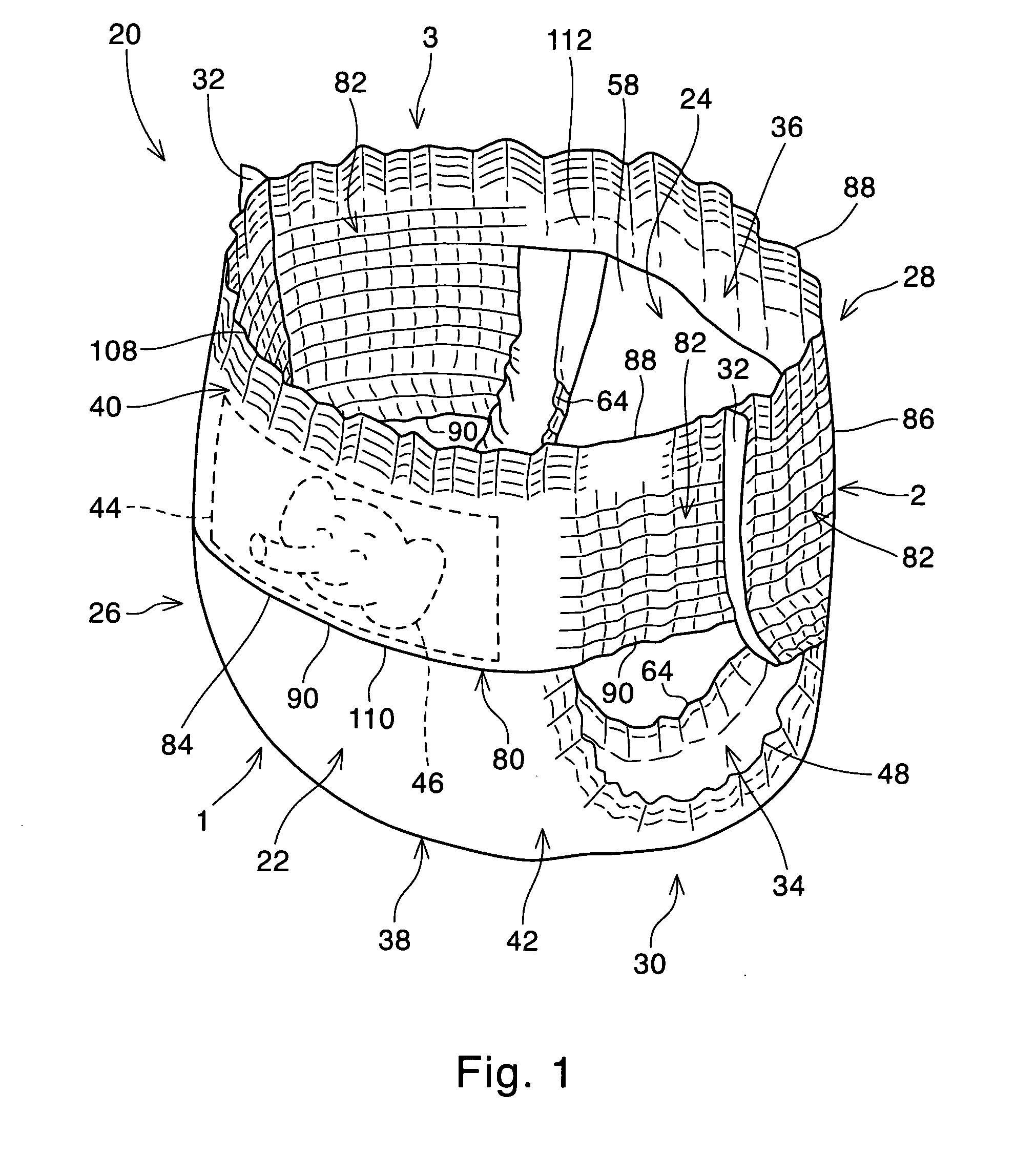

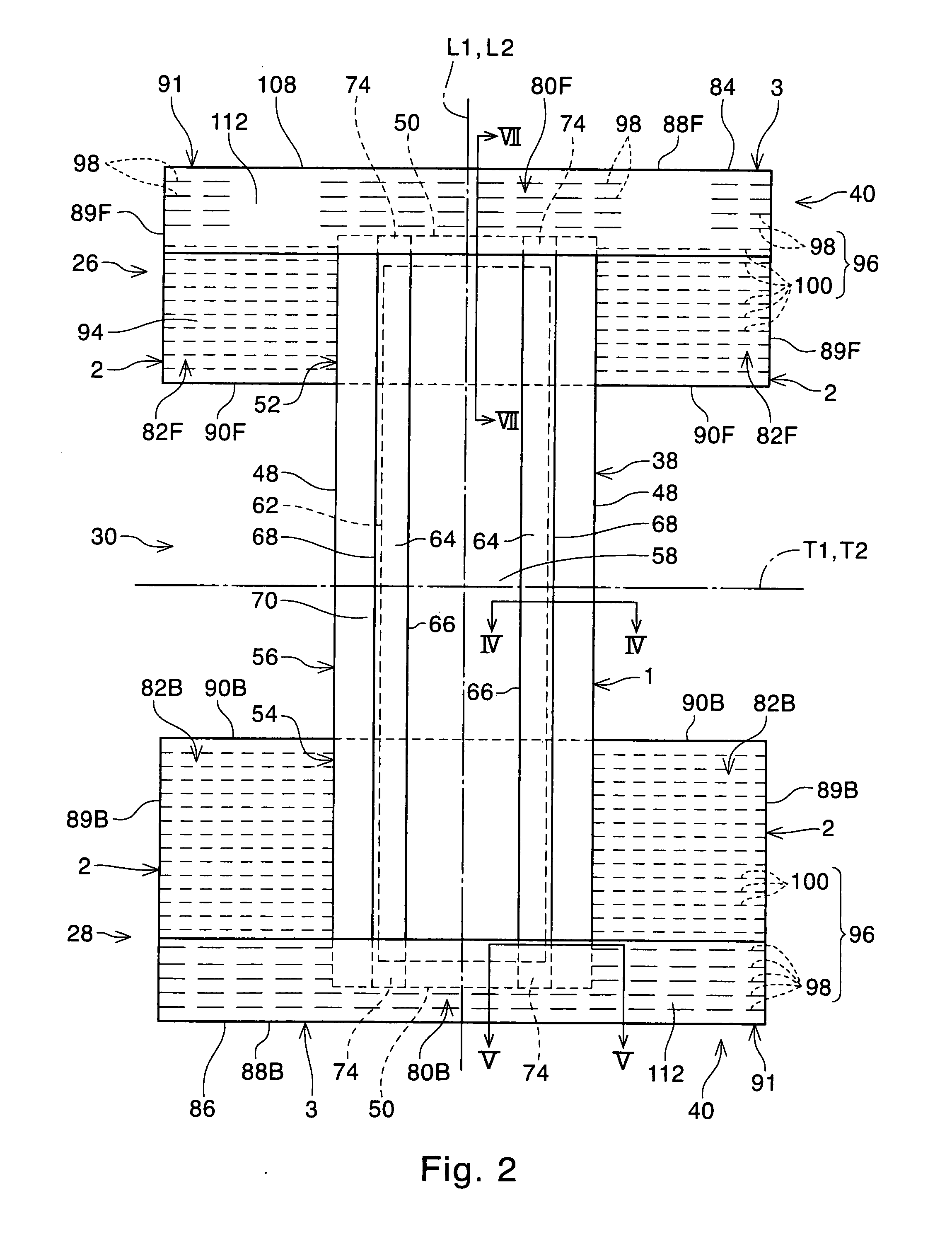

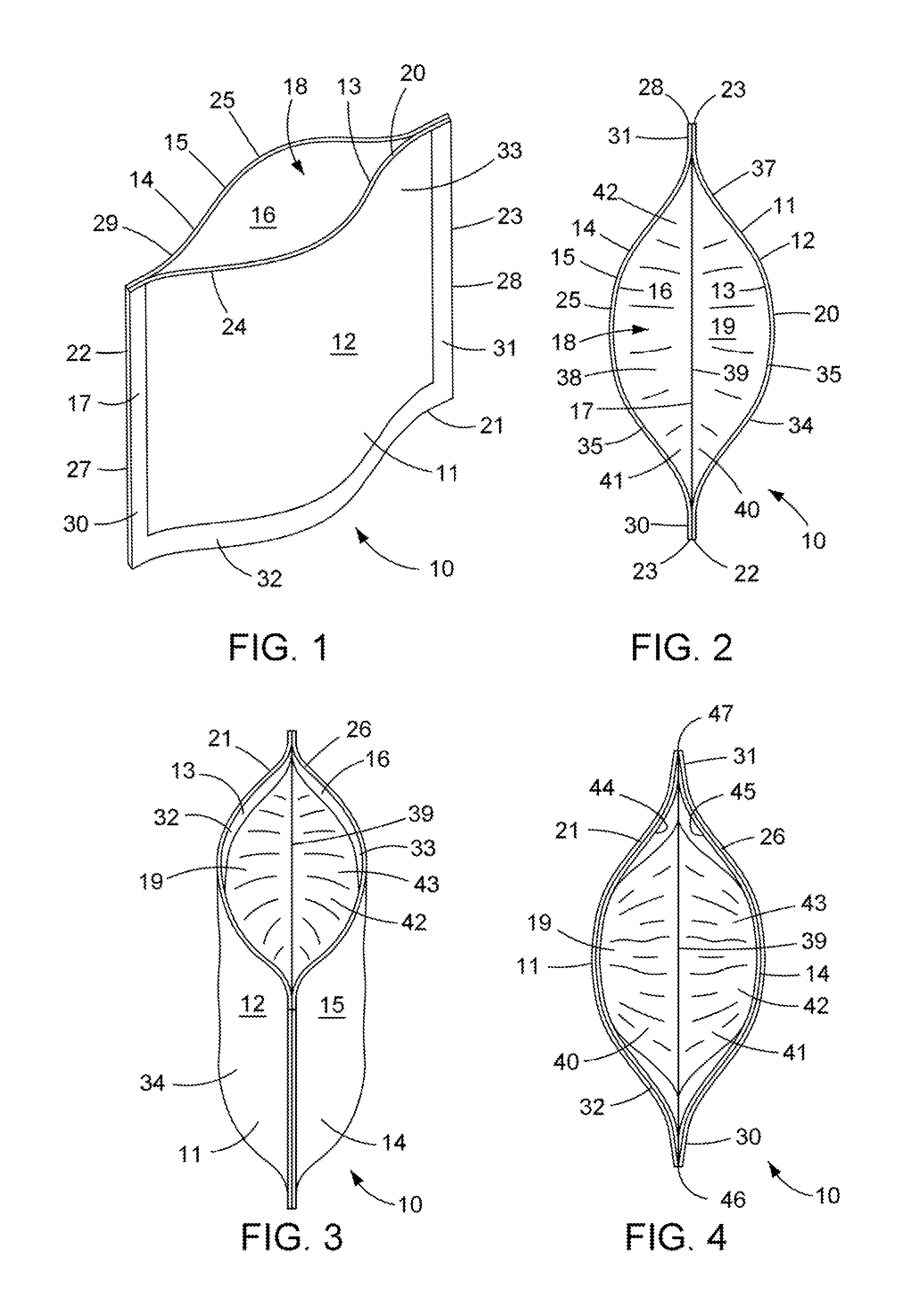

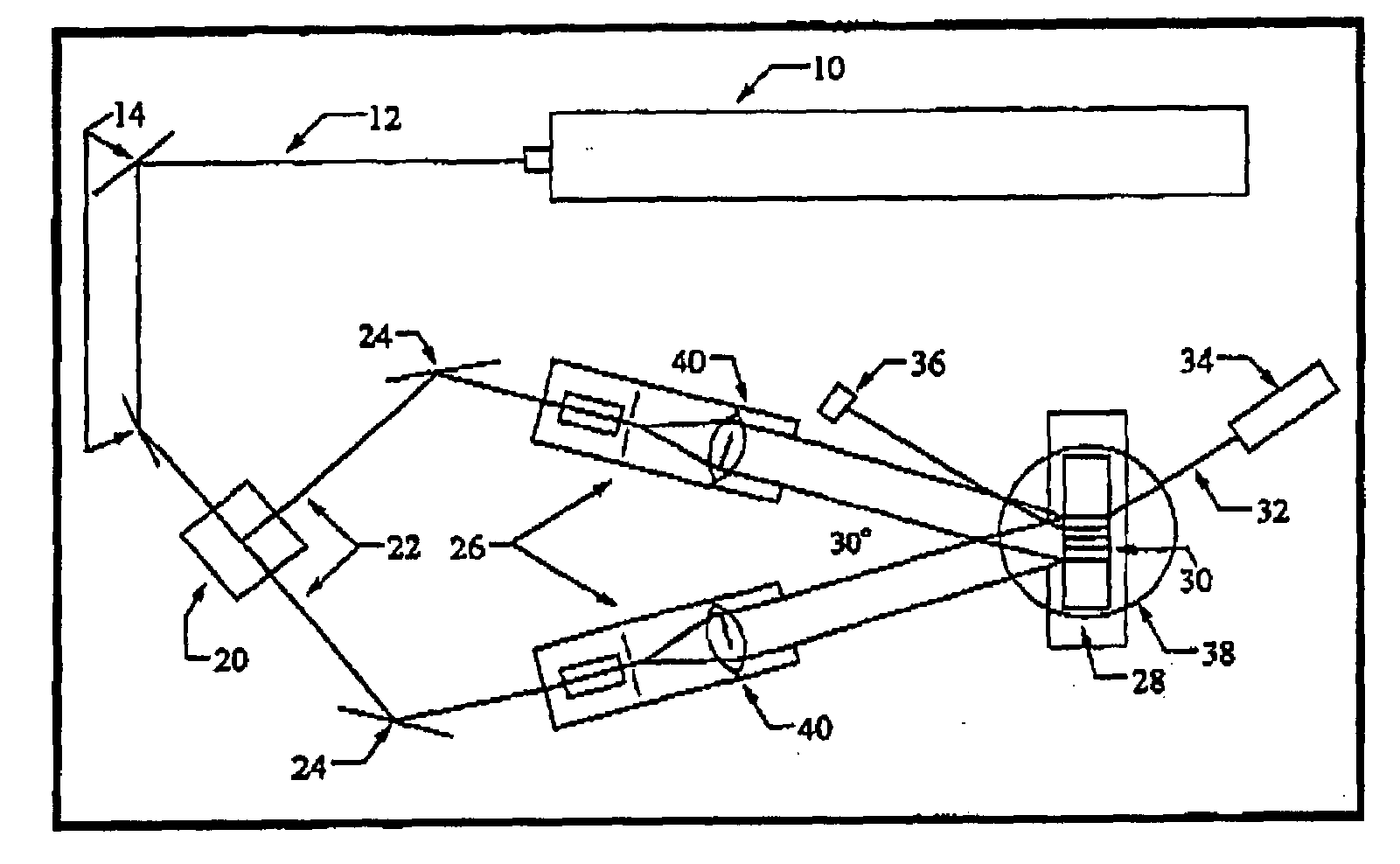

Disposable pull-on garment

The disposable pull-on garment has a longitudinal centerline, a front region, a crotch region, and a back region. The front and back regions are joined at seams to form a waist opening and leg openings. The pull-on garment comprises a main portion, a side portion, and a waist portion. The side portion is disposed transversely outboard of the main portion. The waist portion comprises a center waist portion, an outer side waist portion, and an inner side waist portion. The contraction rate of the inner side waist portion is less than that of the center waist portion, and the contraction rate of the side portion longitudinally inboard of the inner side waist portion is greater than that of the inner side waist portion.

Owner:PROCTER & GAMBLE CO

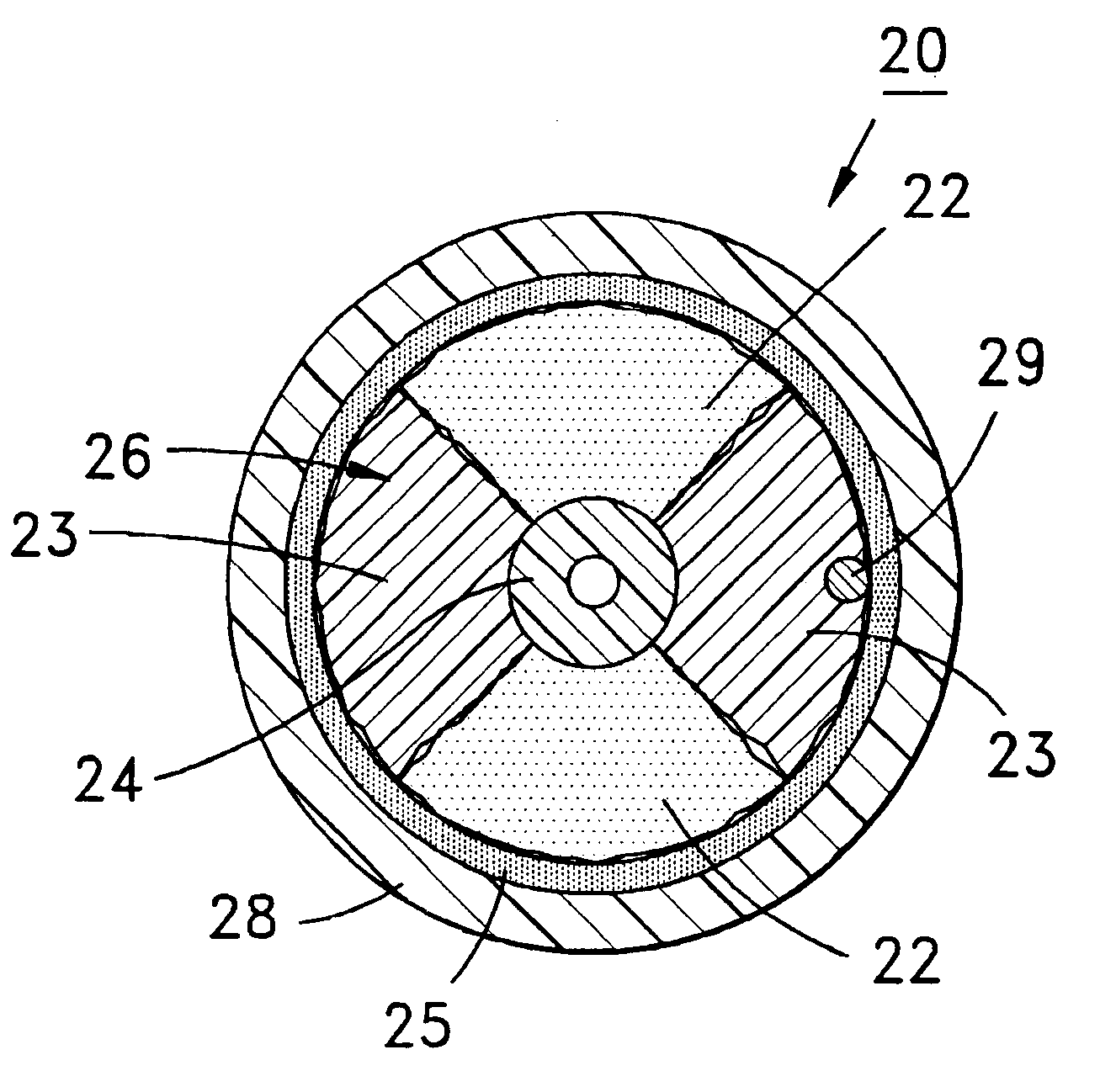

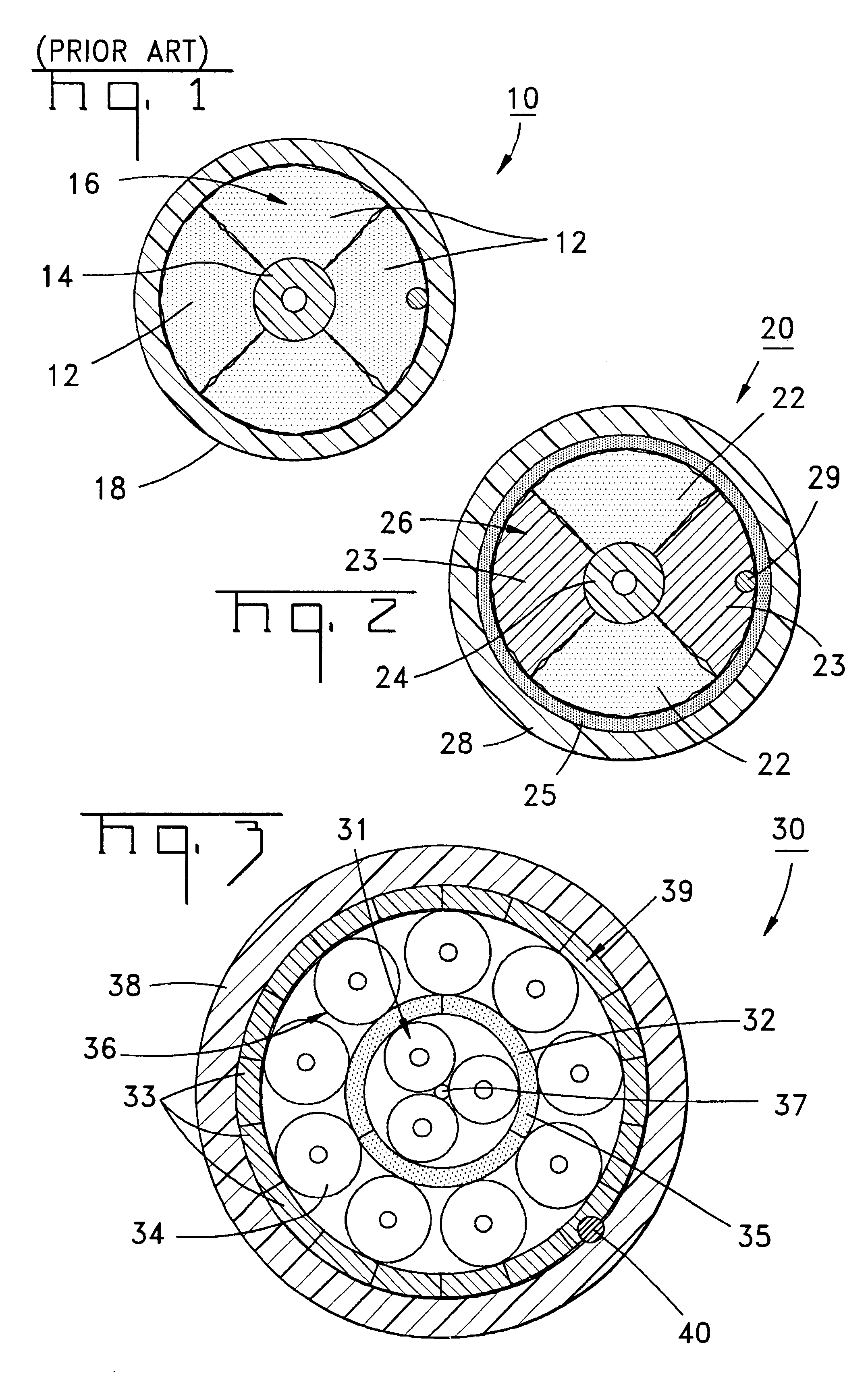

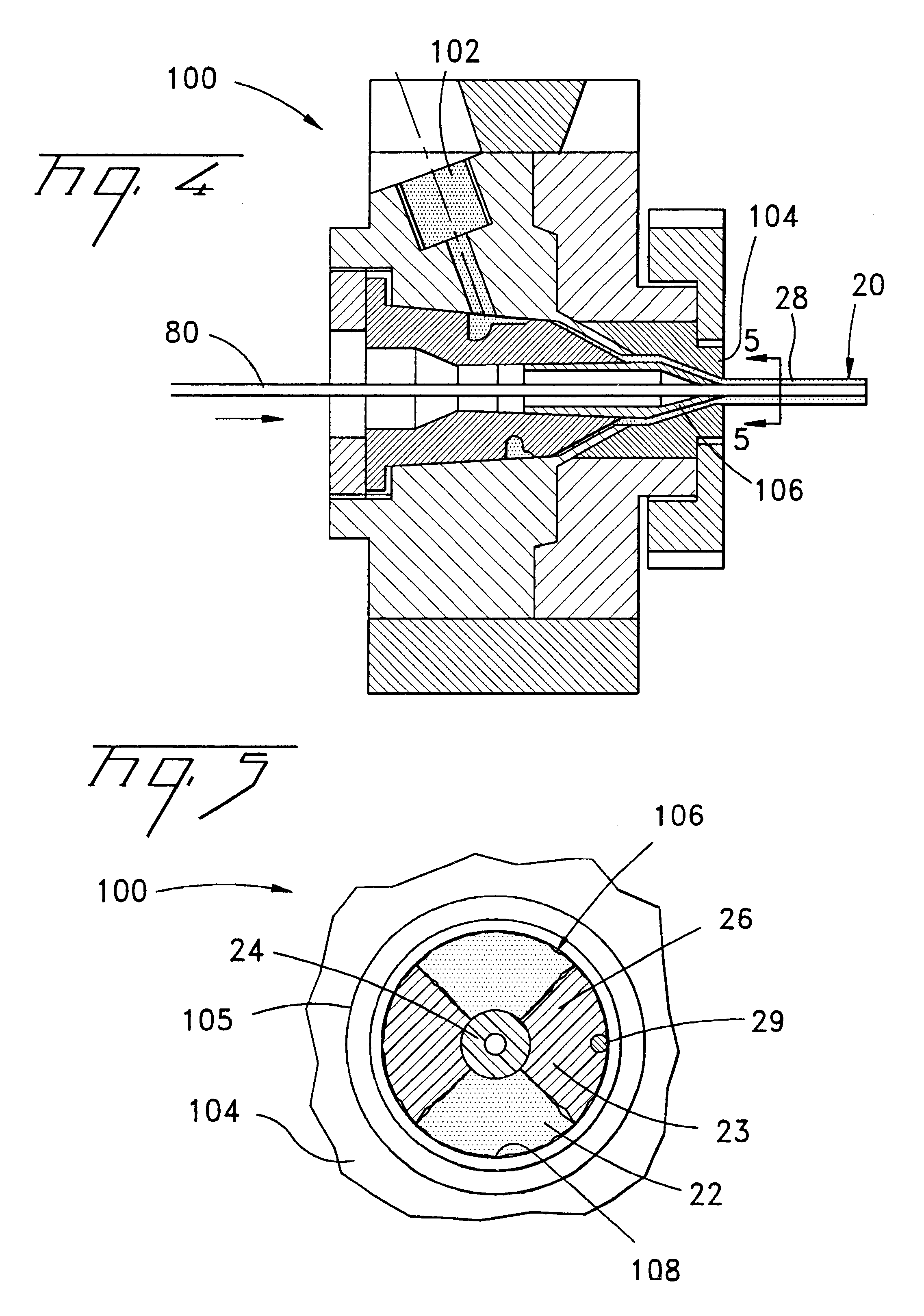

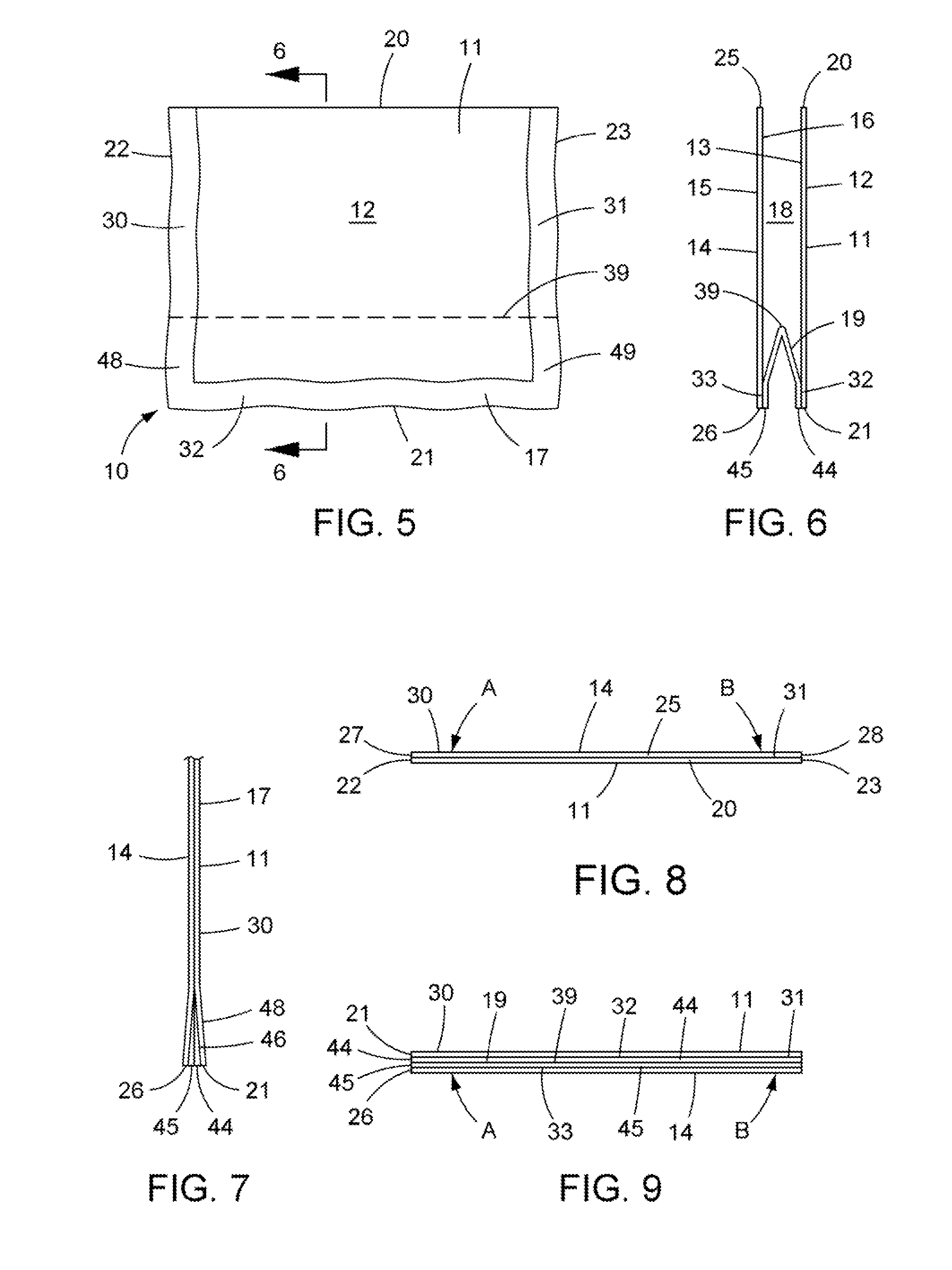

Fiber optic drop cables suitable for outdoor fiber to the subscriber applications

ActiveUS7035513B2Increase bending radiusLower Level RequirementsFibre mechanical structuresUltrasound attenuationFiber

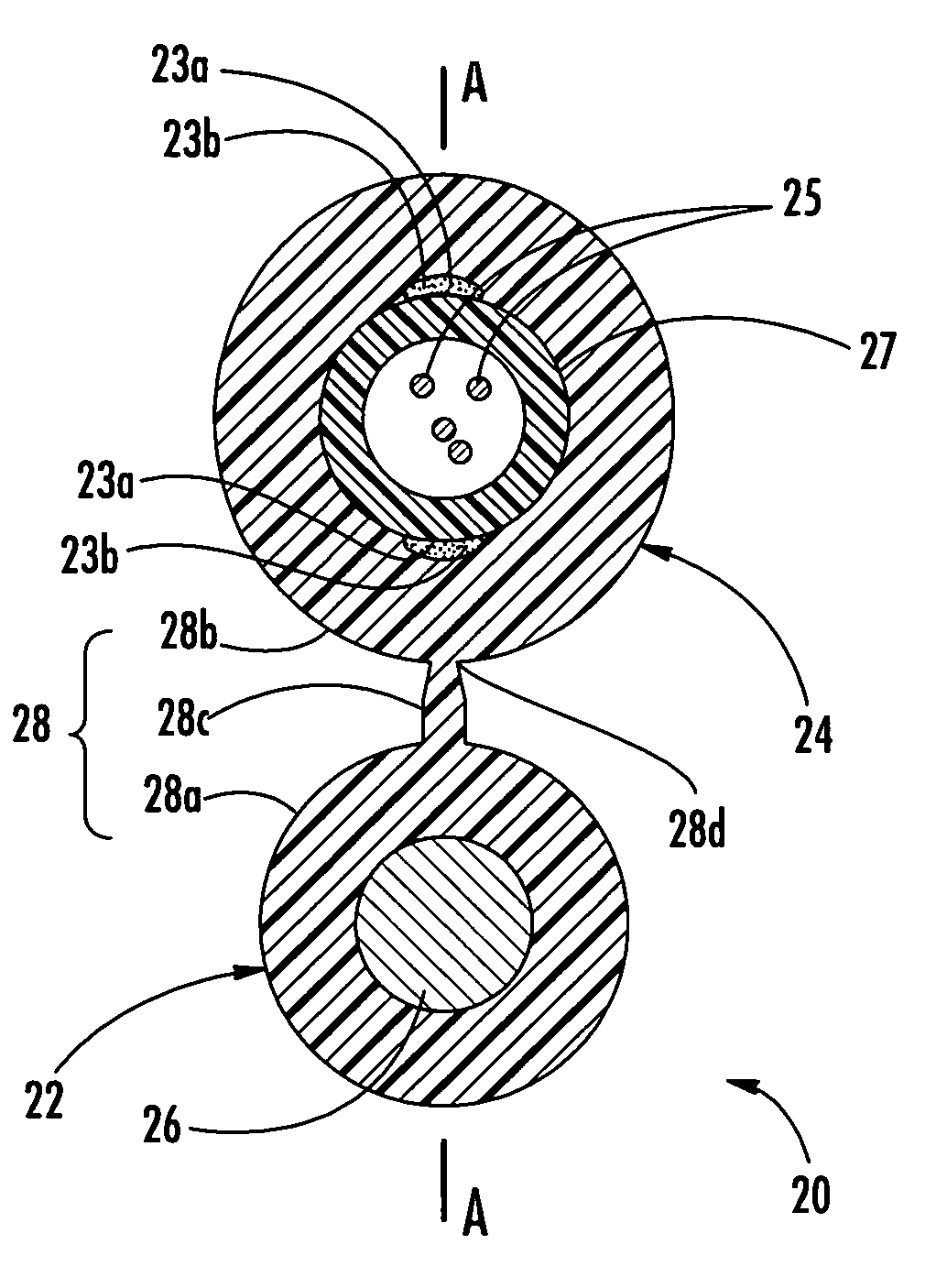

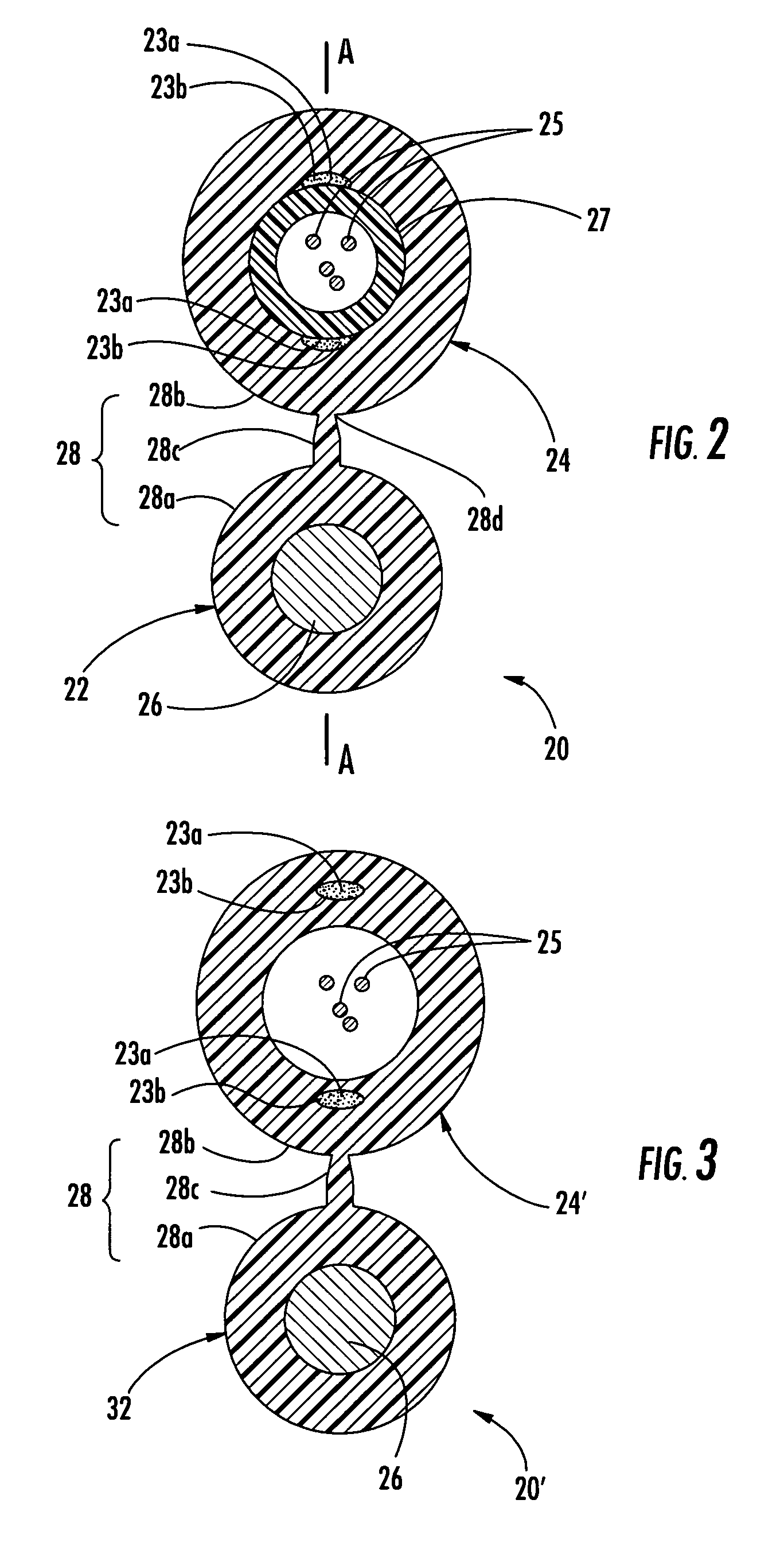

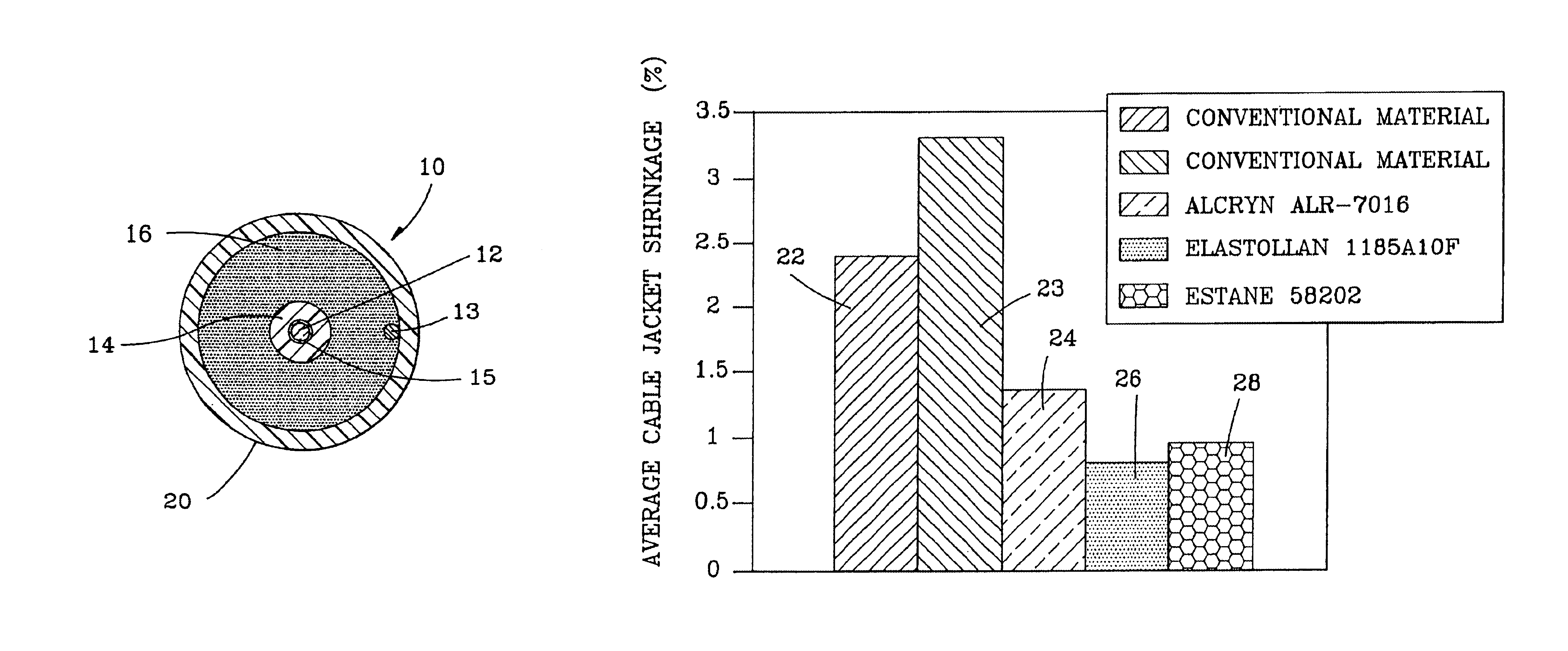

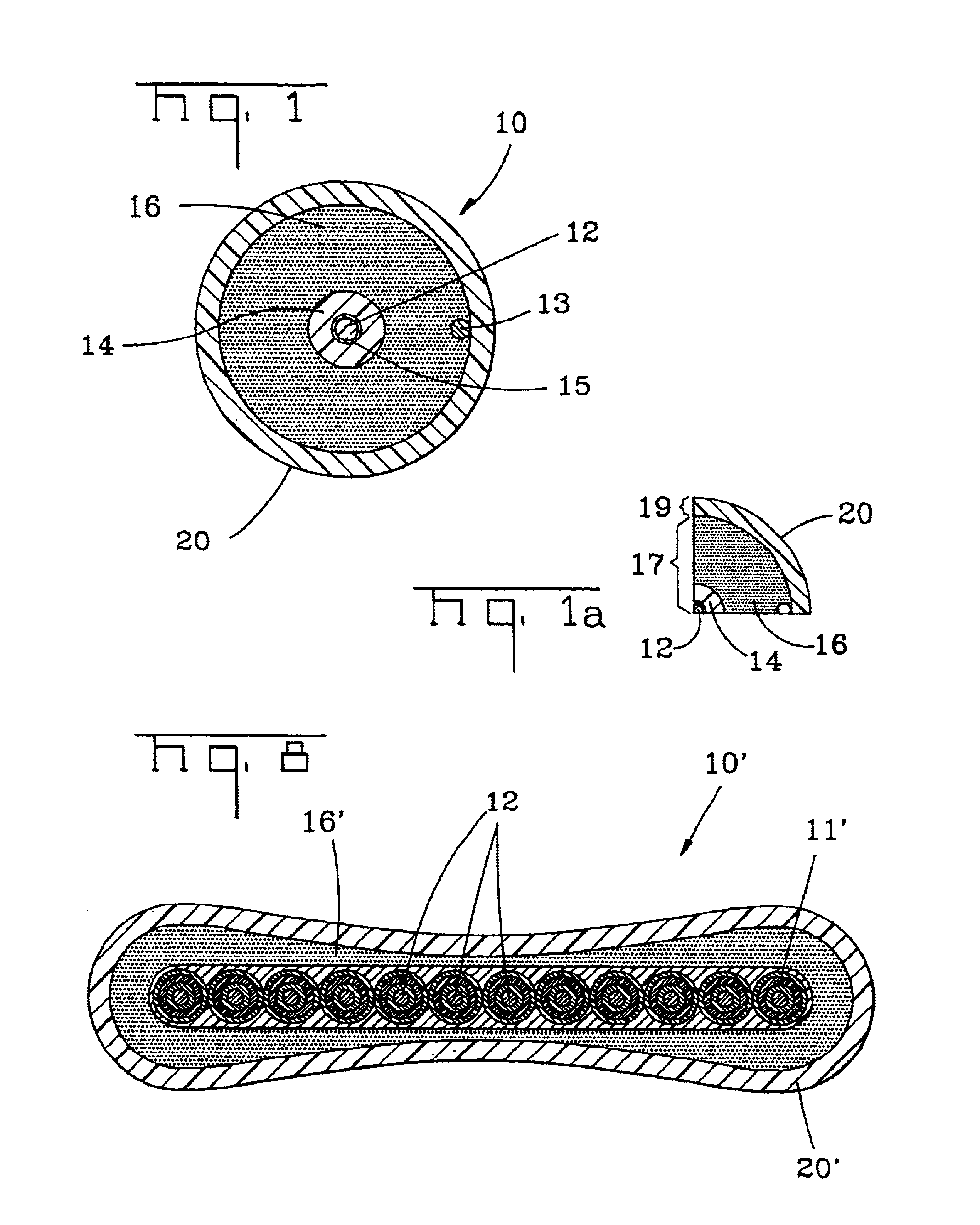

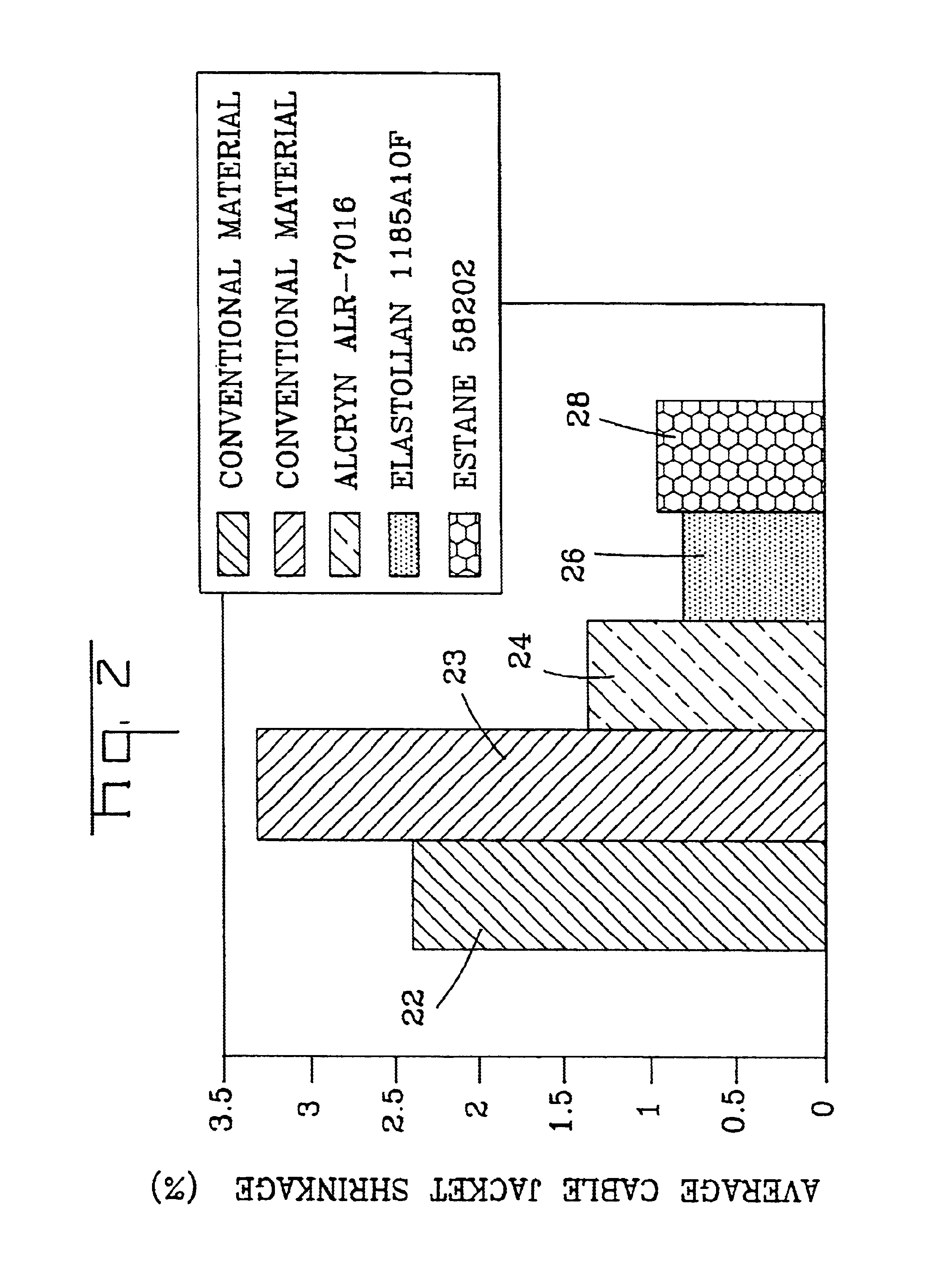

A figure-eight fiber optic drop cable includes a messenger section and a carrier section connected by a web. The carrier section has at least one optical waveguide and at least one roving. In one embodiment, the carrier section has an average shrinkage of about 0.5% or less when separated from the messenger section during an average shrinkage test. Also the carrier section of the figure-eight fiber optic drop cable can have an average coefficient of thermal expansion (CTE) section after being separated from the messenger section of about 5.0×10−3% / ° C. or less for preserving optical performance. Furthermore, a maximum delta attenuation of the at least one optical waveguide during thermal cycling may be about 0.3 dB / 20 meters or less at a reference wavelength of about 1550 nm at a temperature of about −40° C. Other cable configurations are also possible with the invention.

Owner:CORNING OPTICAL COMM LLC

Disposable pull-on garment

The disposable pull-on garment has a longitudinal centerline, a front region, a crotch region, and a back region, the front region and the back region being joined at seams to form a waist opening and leg openings. The pull-on garment comprises a main portion, a side portion, and a waist portion. The side portion is disposed transversely outboard of the main portion. The waist portion comprises a center waist portion, an outer side waist portion, and an inner side waist portion. The center waist portion is disposed longitudinally outboard of the main portion. The outer side waist portion is disposed longitudinally outboard of the side portion, transversely outboard of the center waist portion, and contiguous with the seam. The inner side waist portion is disposed longitudinally outboard of the side portion, transversely inboard of the outer side waist portion, and transversely outboard of the center waist portion. The side portion is elasticized to provide elasticity and comprising a side elastic material to contract and gather at least a portion of the side portion. The waist portion is elasticized to provide elasticity and comprising a waist elastic material to contract and gather at least a portion of the waist portion. Contraction rate of the inner side waist portion is less than that of the center waist portion, and contraction rate of the side portion longitudinally inboard of the inner side waist potion is greater than that of the inner side waist portion.

Owner:THE PROCTER & GAMBLE COMPANY

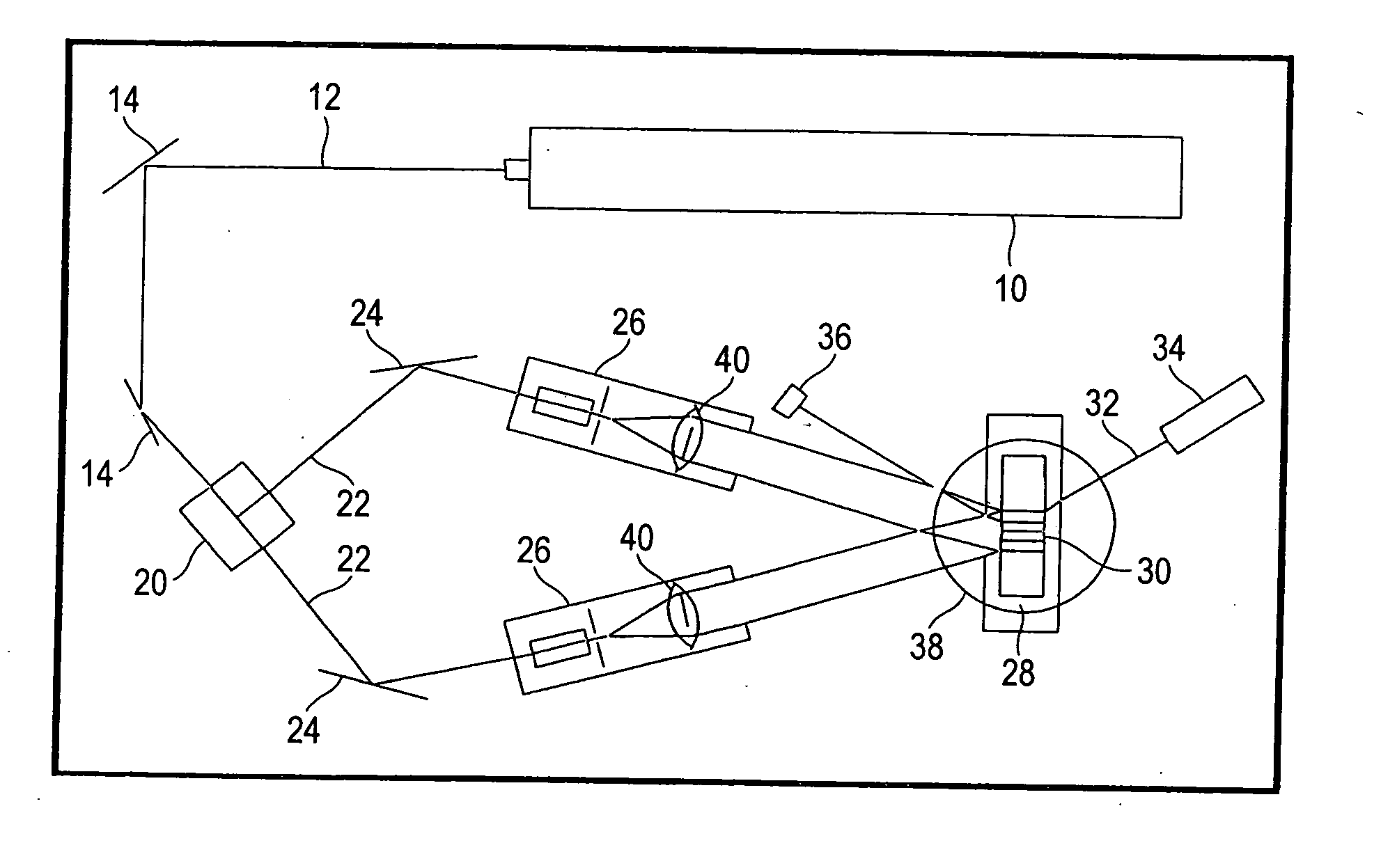

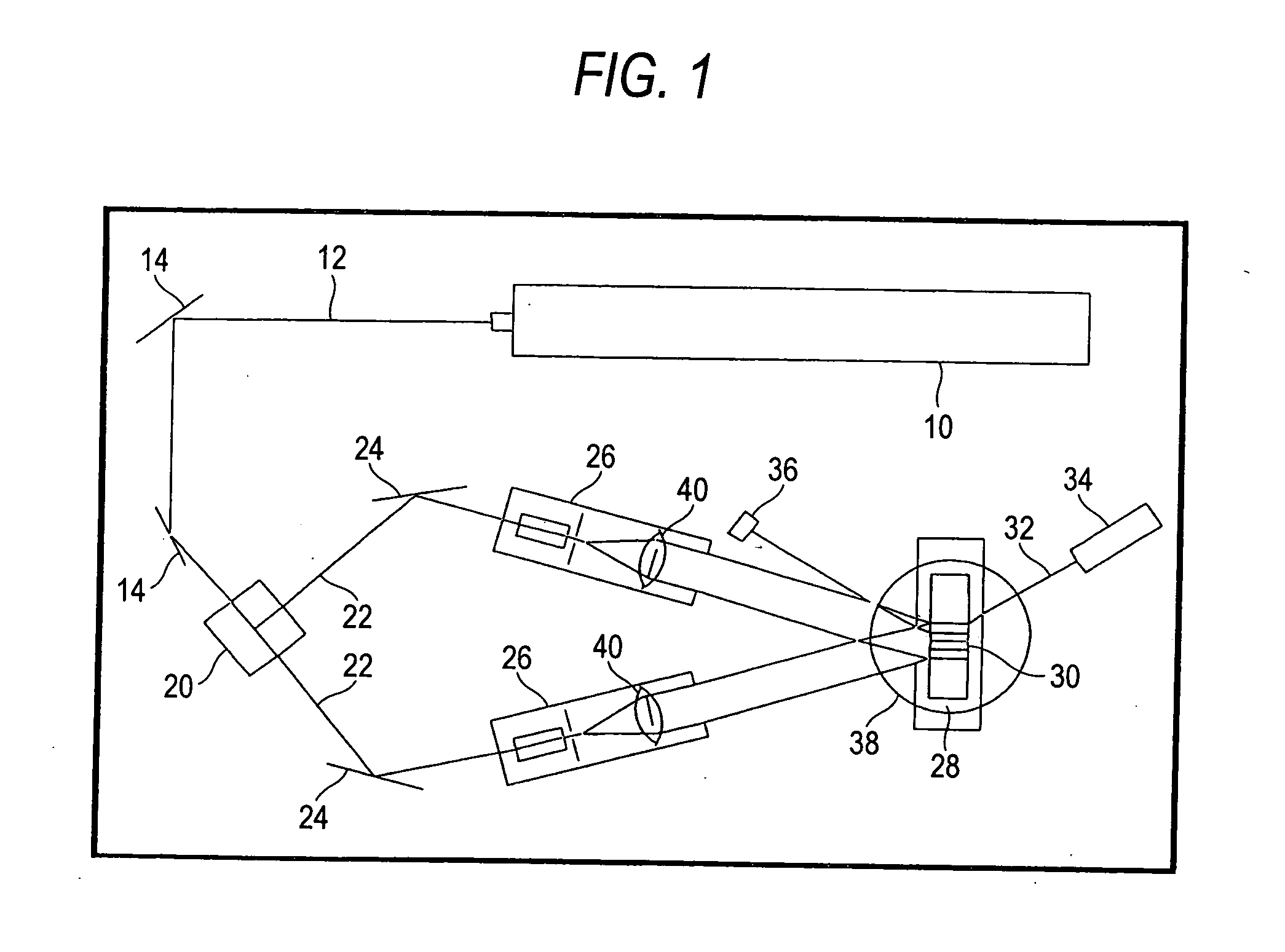

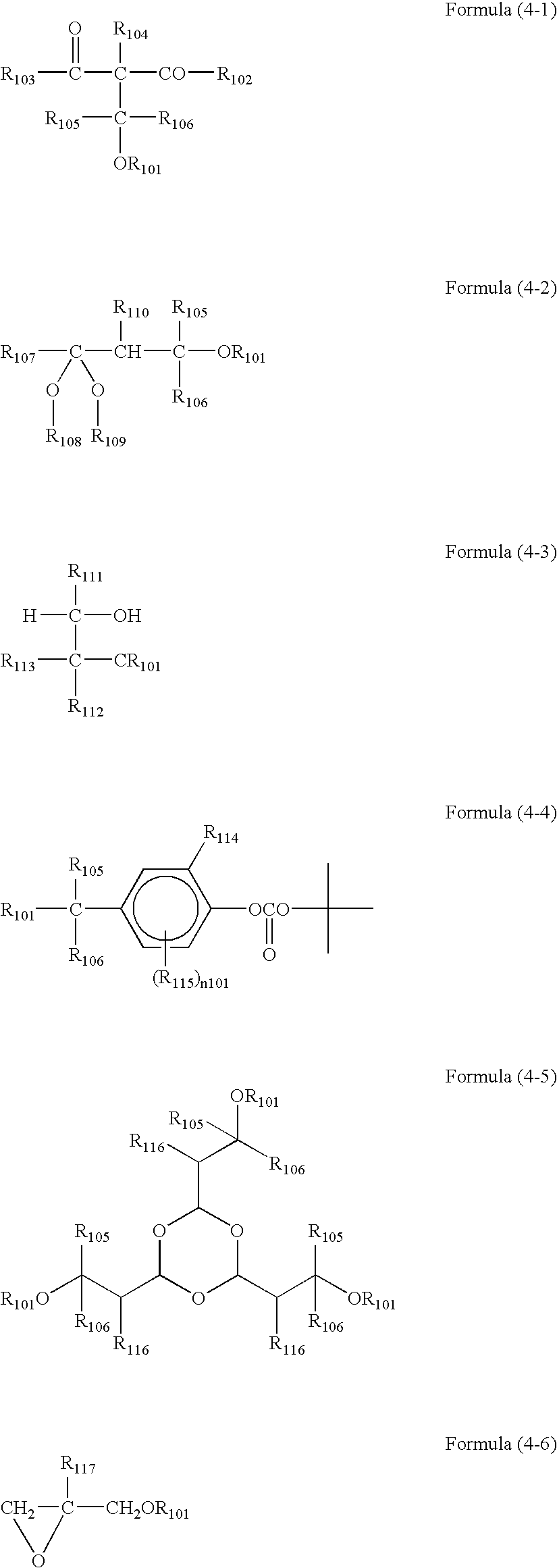

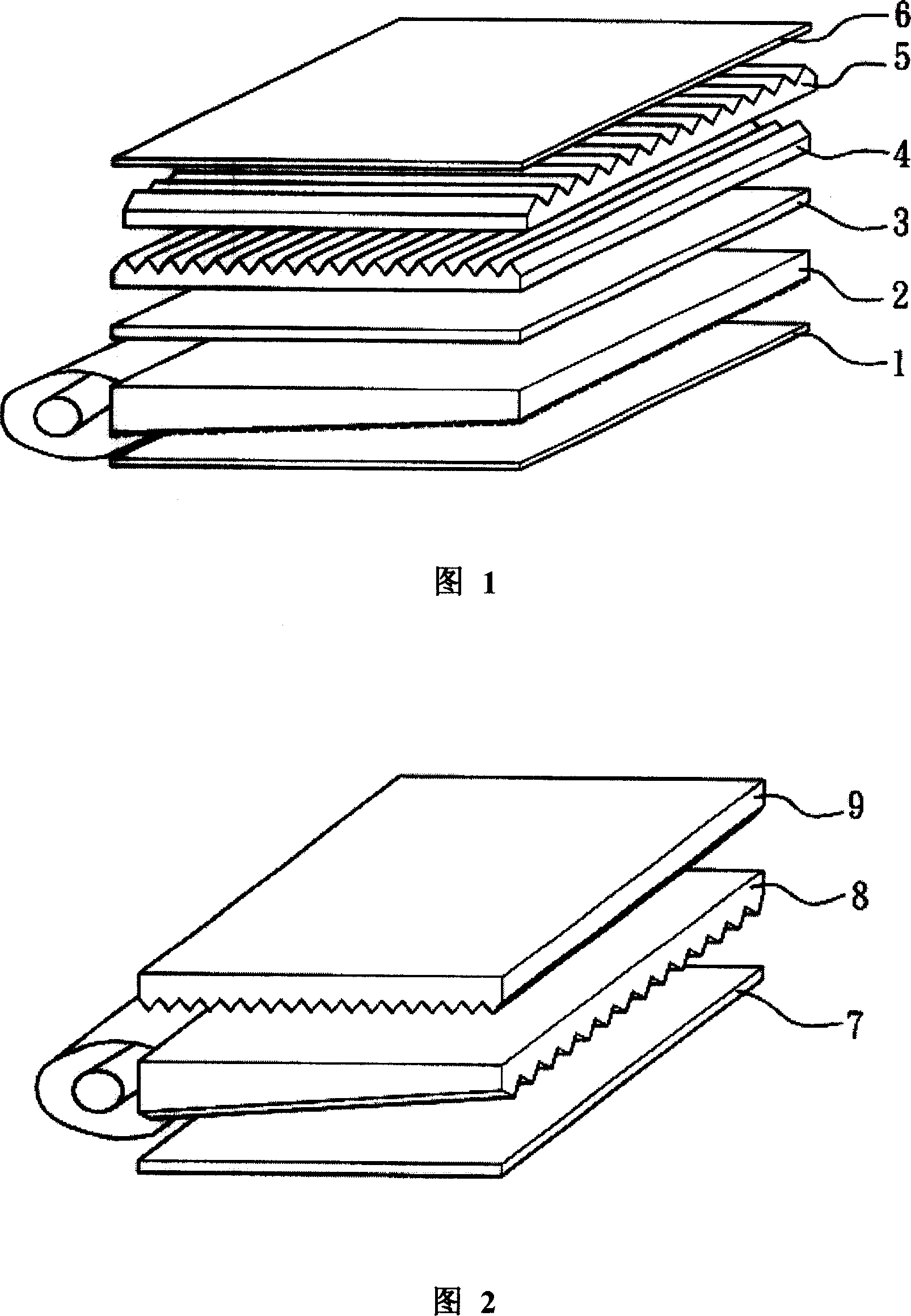

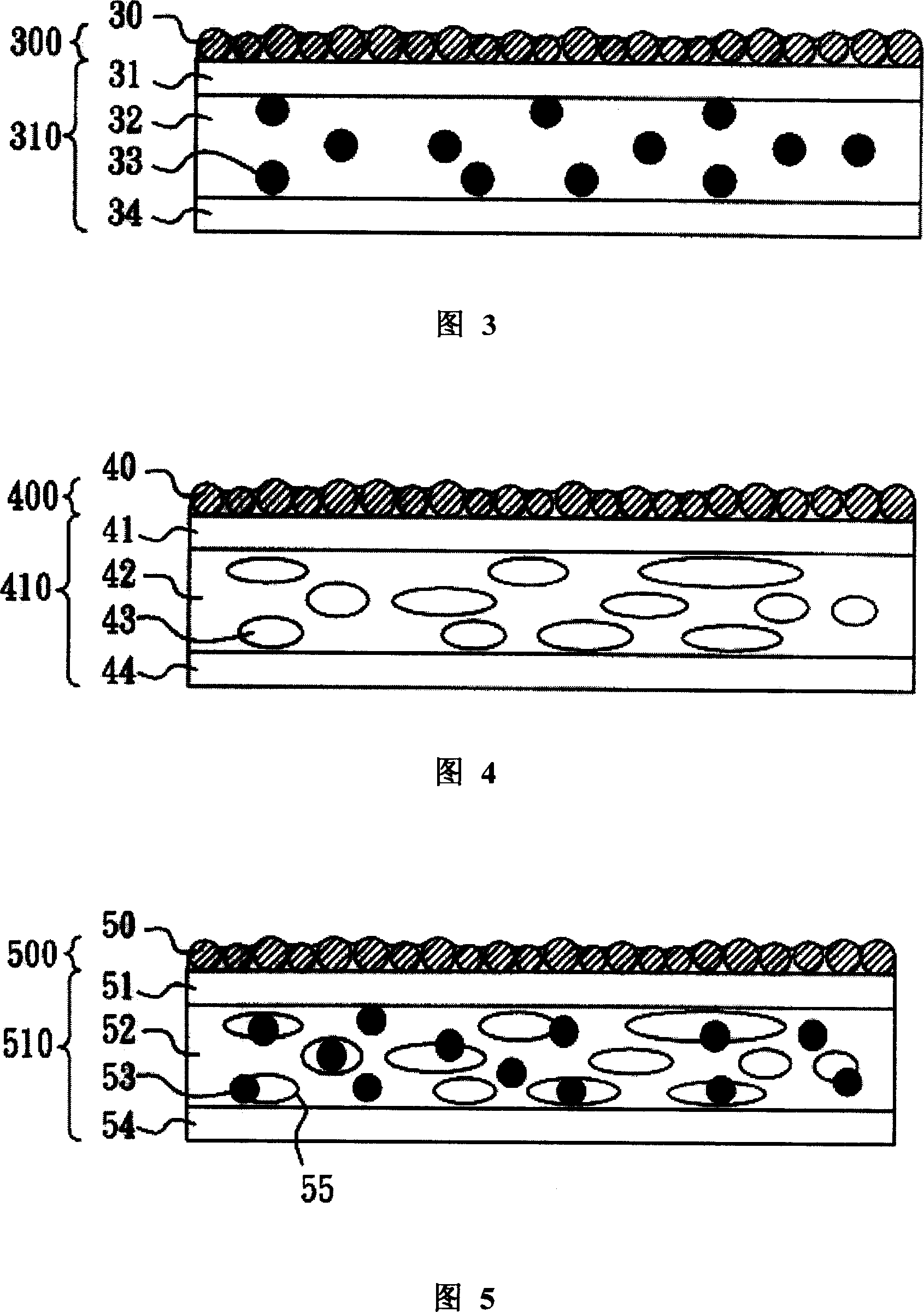

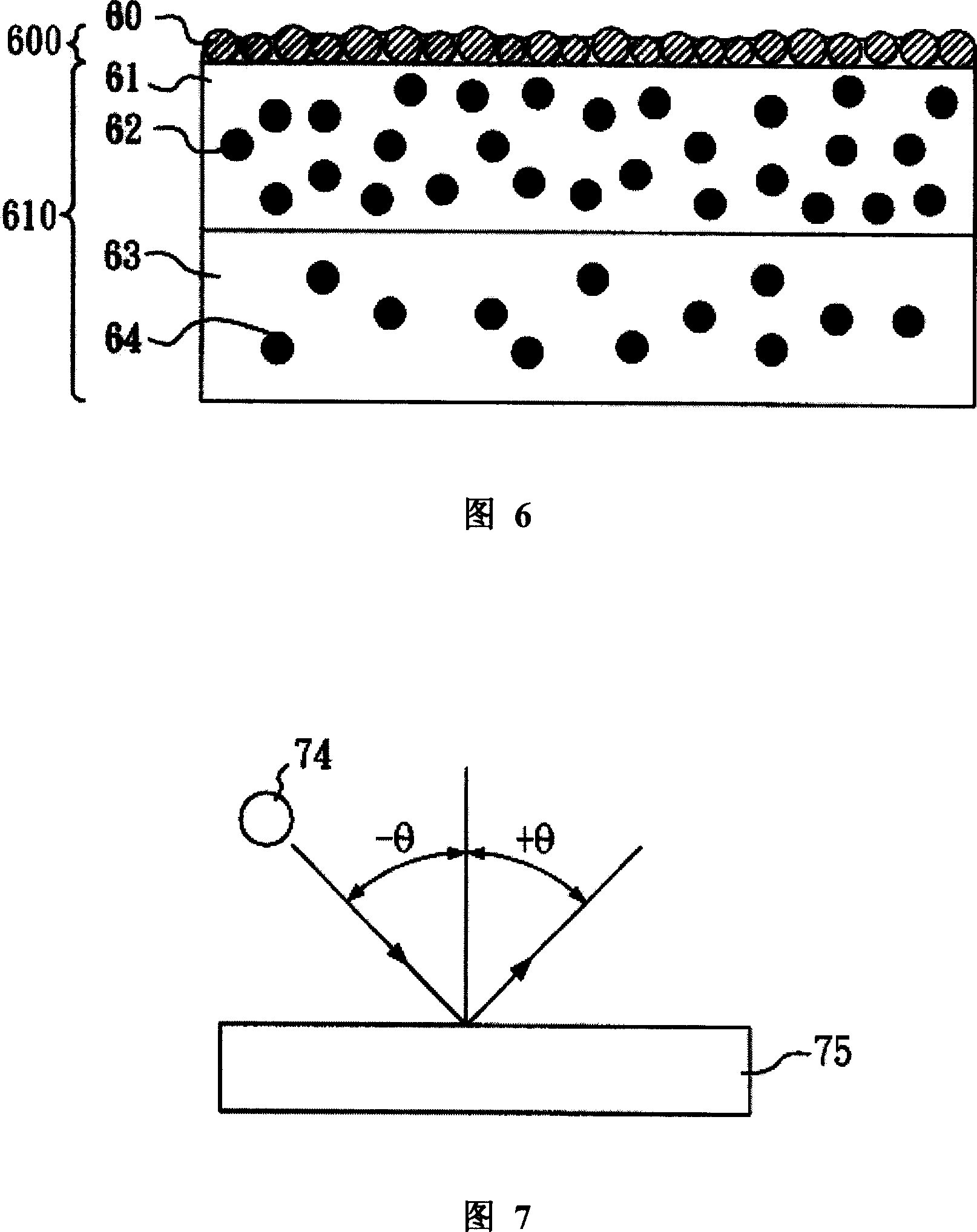

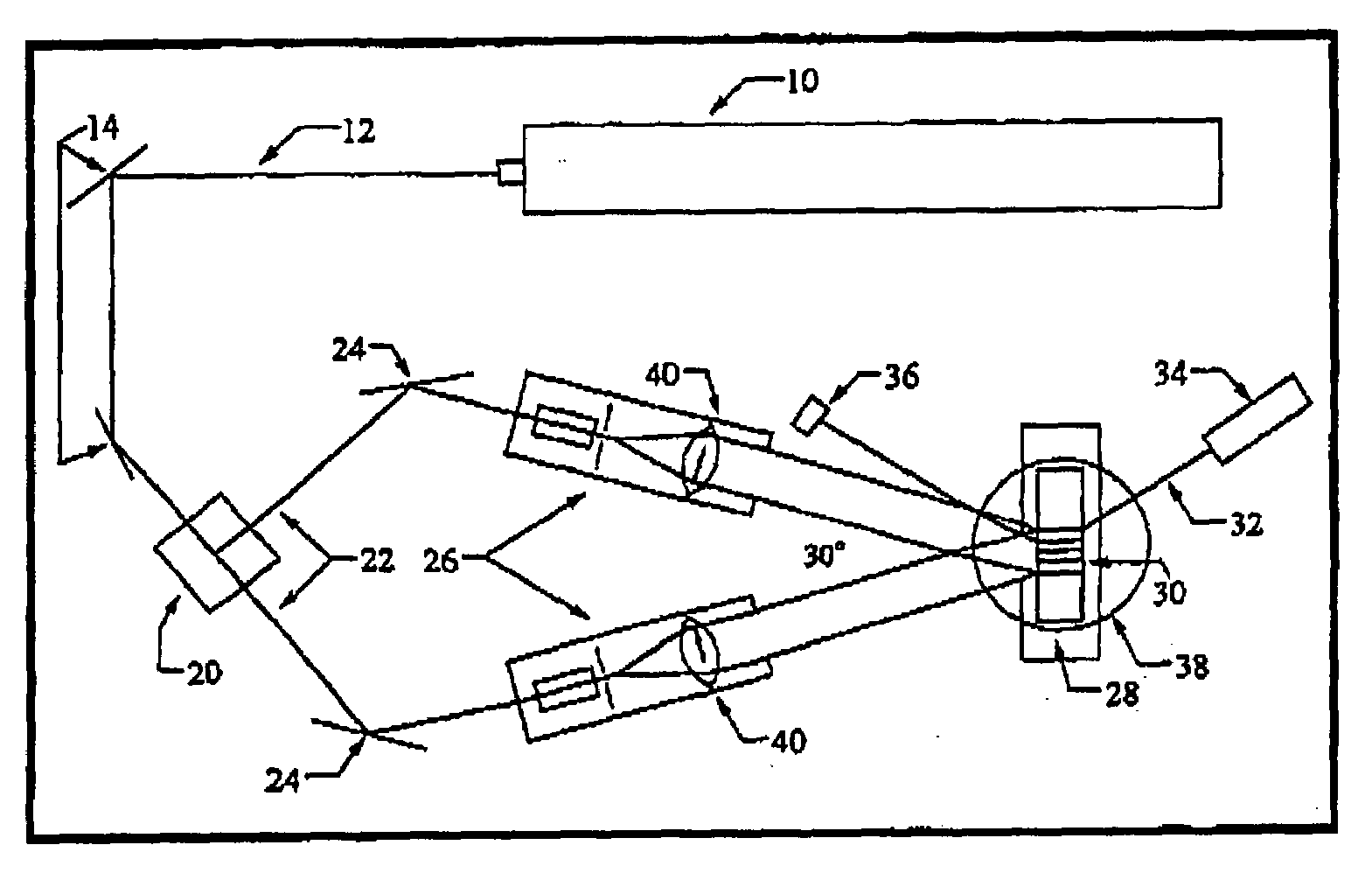

Hologram recording material composition, hologram recording material and hologram recording method

InactiveUS20050046915A1High sensitivityHigh refractive indexPhotomechanical apparatusRecord information storageChemical reactionVolumetric Mass Density

To provide a composition for a hologram recording material, a hologram recording material and a hologram recording method applicable to a high density optical recording medium, a three-dimensional display, a holographic optical element etc. and capable of attaining a high sensitivity, a high diffraction efficiency, a satisfactory storage property, a low shrinkage rate, a dry process, a multiplex recording property and a high recording density. An unrewritable hologram recording method including a step in which a sensitizing dye absorbs light by an exposure to form an excited state, a chemical reaction step including a color forming reaction involving an electron transfer or an energy transfer from such excited state, and a hologram-forming step by such chemical reaction.

Owner:FUJIFILM CORP +1

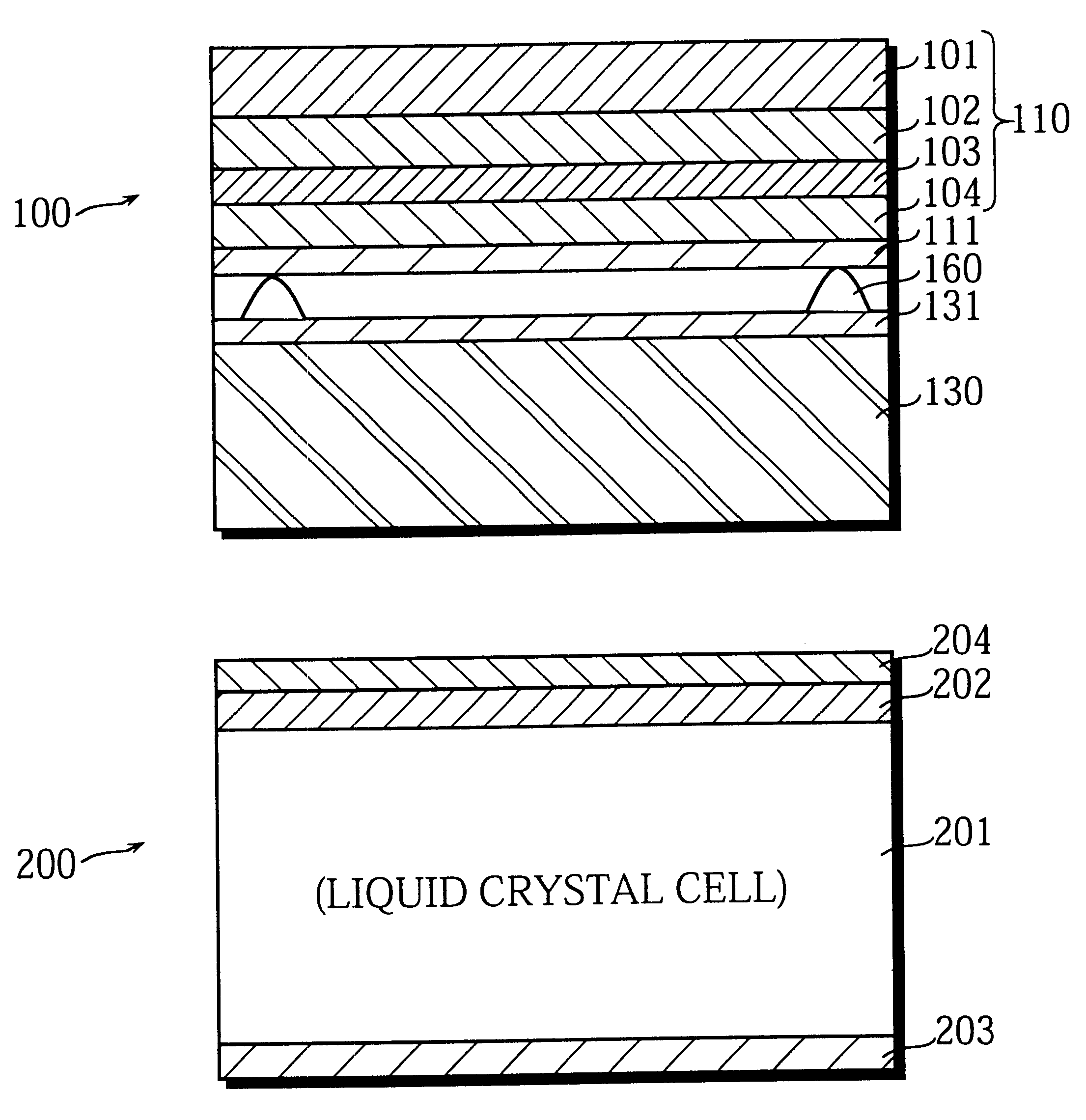

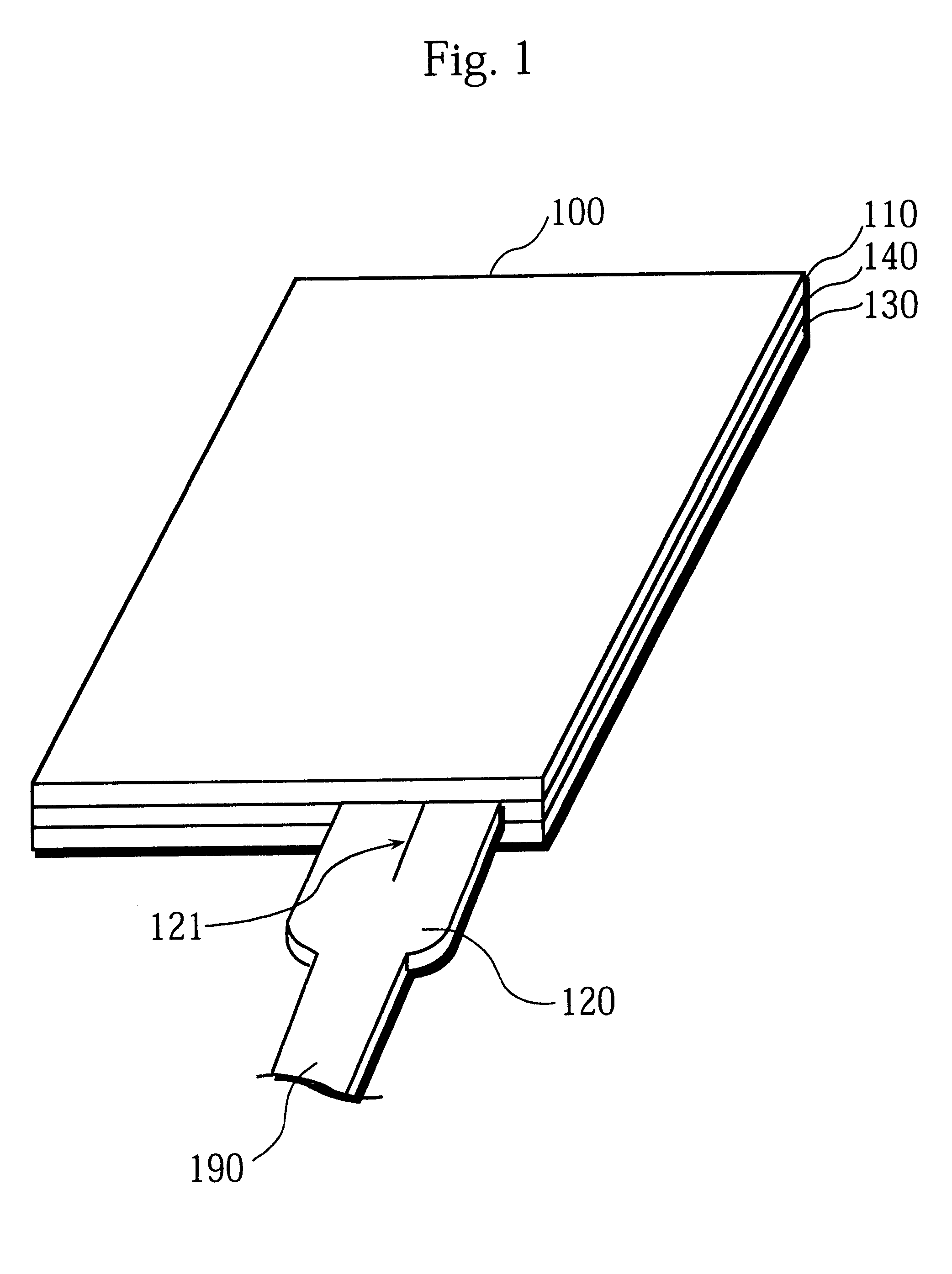

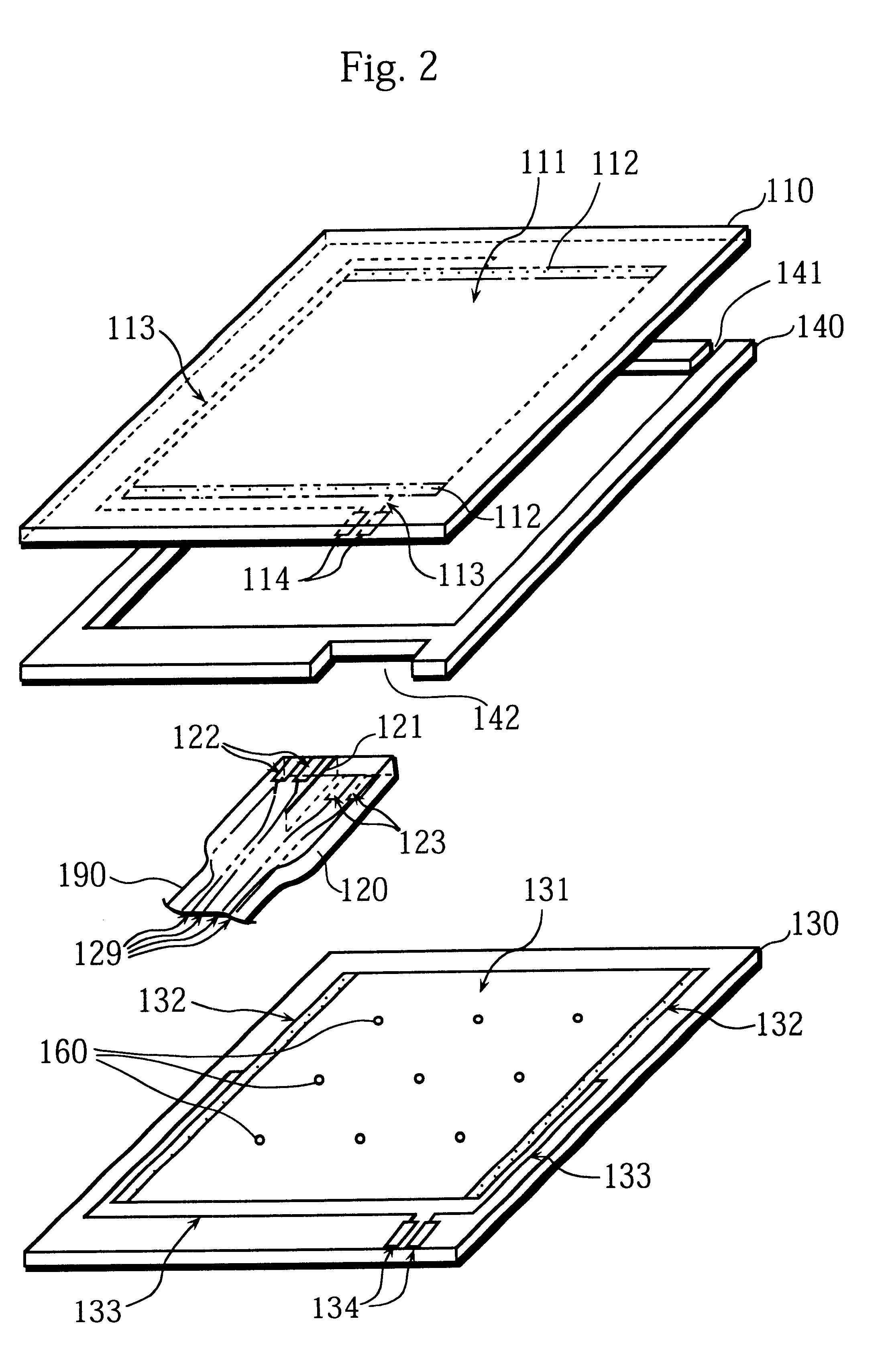

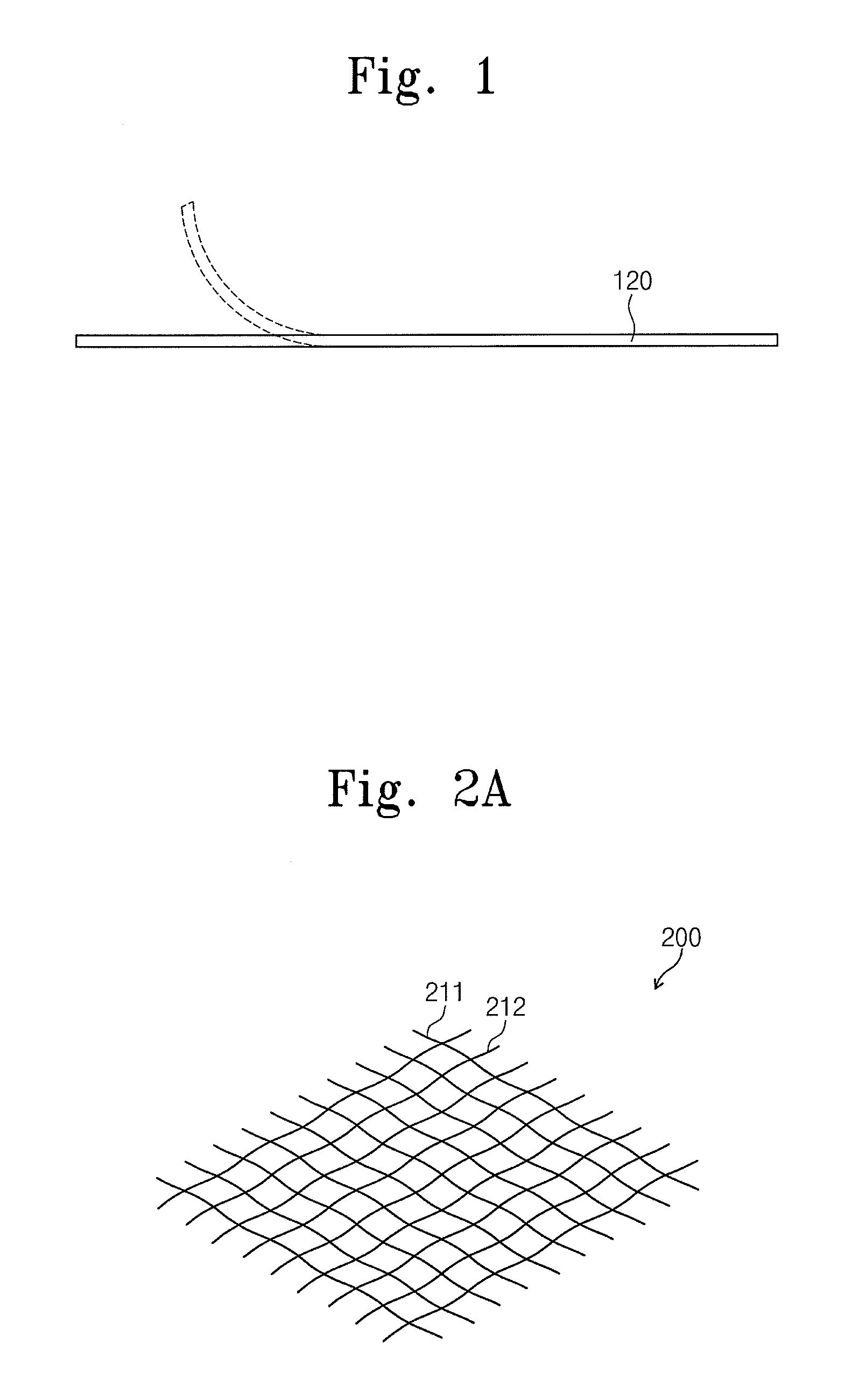

Glare-resistant touch panel

InactiveUS6559834B1Increase awarenessOutward bulge of the touch panel is effectively suppressedTransmission systemsCathode-ray tube indicatorsContraction rateLength wave

A touch panel is constructed of a top sheet member having a resistive membrane on its inner surface and a base sheet member having a resistive membrane on its inner surface, the top and base sheet members facing each other with dot spacers being located in between. The top sheet member is formed by laminating a bulge-resistant film, a polarizing plate, a quarter wavelength plate, and a light isotropic film in this order from above. A PET film which is not heat-treated so as to have a higher thermal contraction rate than the other members of the top sheet member underneath such as the polarizing plate, is used as the bulge-resistant film. Since the bulge-resistant film contracts more than the polarizing plate under a high ambient temperature, after the ambient temperature returns to normal, the bulge-resistant film does not become slack against the polarizing plate. Accordingly, the top sheet member can be kept from bulging outward.

Owner:GUNZE LTD +1

Lithium ion battery electrode slice, electric core and its making method

ActiveCN101150182AImprove high temperature melting strengthLow melt fluidity at high temperatureElectrode carriers/collectorsSecondary cellsCross-linkPolyolefin

This invention discloses pole plates of Li ionic cells, in which, a micro-porous film is set on the pole plate with PVDF as the matrix and chemical gel formed by chimical cross-link is set in the micro-porous film.This invention also discloses a Li-ionic cell core with said pole plates and a preparation method including: the PVDF film forming chemical gel inside by irradiation and cross-link has the heat contraction rate of nearly zero under 100-220deg.C, which can prevent electronic short circuit of positive and negative pole plates caused by over contraction of intensified switchable Polyolefin micro-hole septums under high temperature when being coated on the pole plates.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

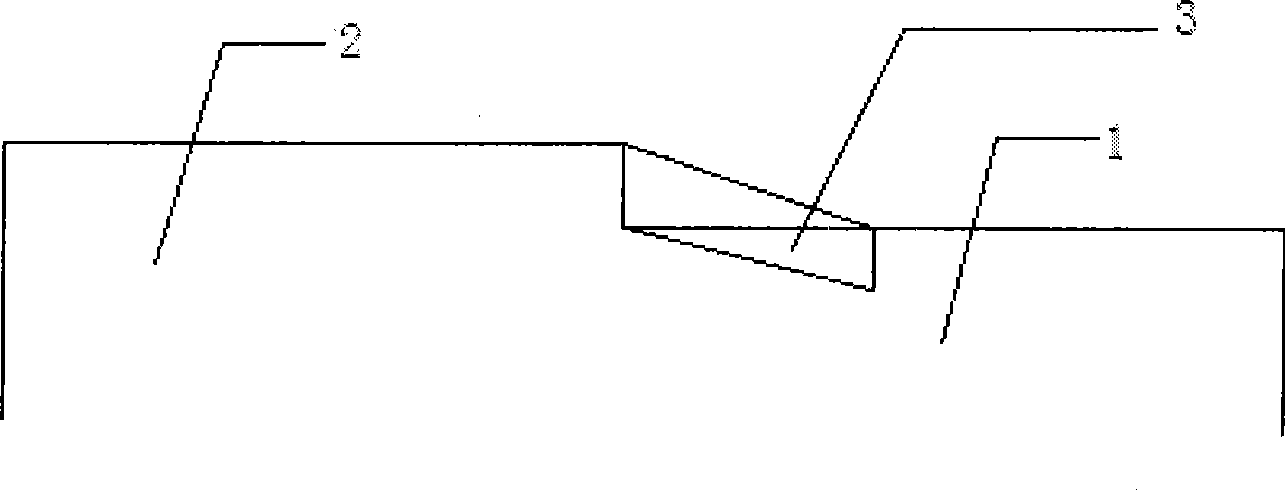

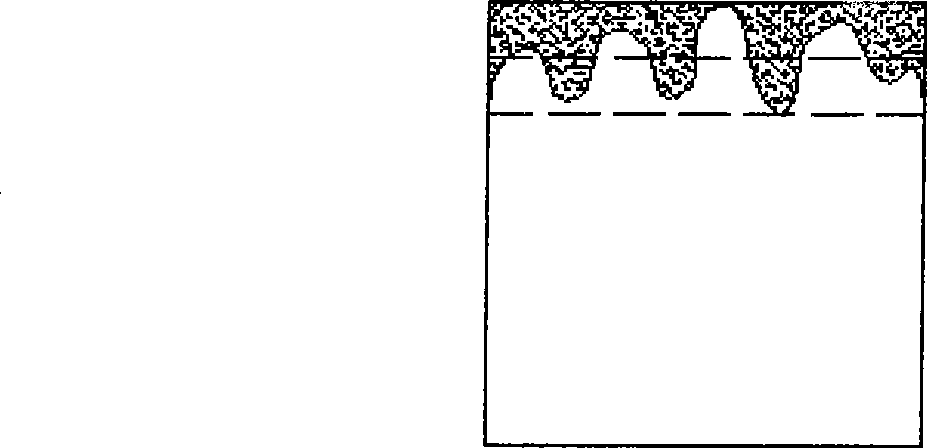

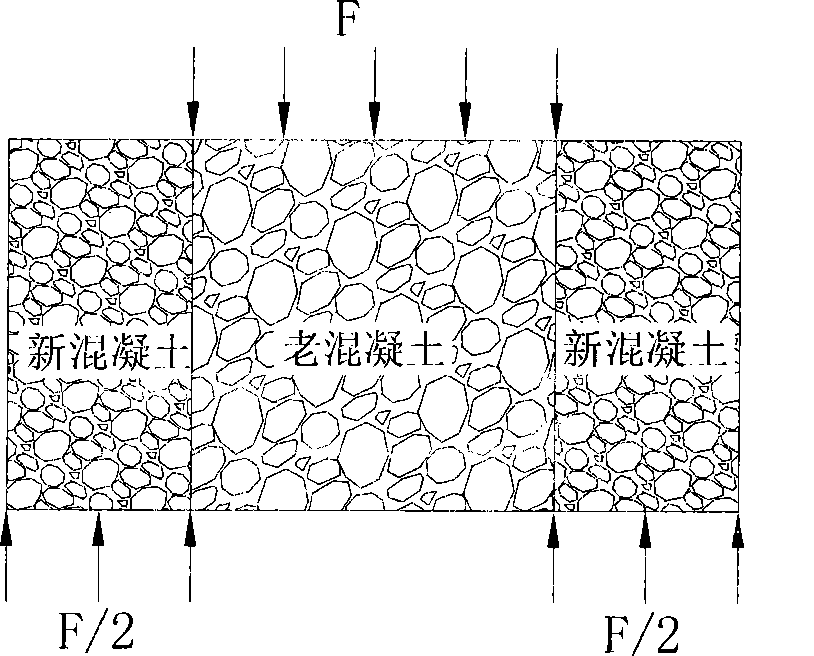

Rapid patching material for cement concrete pavement faulting of slab ends and patching method thereof

The invention discloses a rapid repairing material for table dislocation of a cement concrete road surface, which comprises cement, water, fine aggregate and styrene butadiene latex. The weight ratios of the ingredients are as following: the concrete cement in one cubic meter is less than or equal to 500 kg, the ratio of the water and the cement is from 0.3 to 0.36, the water content in the ratio of the water and the cement contains the water content in the styrene butadiene latex, the solid content in the styrene butadiene latex is 5 percent to 10 percent of the cement, the weight of the repairing material of one cubic meter is about 2400 kg, and the content of the fine aggregate is the weight difference obtained by subtracting the weight of the other ingredients from the total weight of the repairing material of one cubic meter. The invention also discloses a method for rapidly repairing the table dislocation of a cement concrete road surface. The invention has the following advantages that the strength can be rapidly increased, the traffic can be open in 12 hours, the contraction rate is low, and the thin layer repair with the height difference about 1 cm can be carried out.

Owner:CHONGQING JIAOTONG UNIVERSITY +1

Heat-shrinkable polyester film and heat-shrinkable label

A heat-shrinkable polyester film having a multi-layer structure of at least two layers, among which at least one layer is a layer containing a PET bottle-recycled material, wherein a heat shrinkage percentage in a maximum shrinkage direction of a 10 cm square sample cut out from the film is 40% or higher, under the condition that the square sample is immersed in hot water of 95° C. for 10 seconds and then immersed in water of 25° C. for 10 seconds, to provide a heat-shrinkable polyester film which has excellent characteristics and which can be produced at a high rate, even when a PET bottle-recycled material is used.

Owner:TOYOBO CO LTD

Fiber optic cables having ultra-low shrinking filaments and methods of making the same

A fiber optic cable and method of manufacturing the same having at least one optical fiber component, at least one strength member and at least one ultra-low shrinking filament. The at least one ultra-low shrinking filament having a shrinkage of about 0.2% or less when heated and held at about 85° C. for about seven days. At least one strength member and at least one ultra-low shrinking filament being disposed generally between the at least one optical fiber component and a cable jacket. The jacket generally surrounding the at least one optical fiber component, the at least one strength member and the ultra-low shrinking filament. The cable can include an interfacial layer interposed between said at least one optical fiber component and the jacket. Additionally, the cable can be riser or plenum rated.

Owner:CORNING OPTICAL COMM LLC

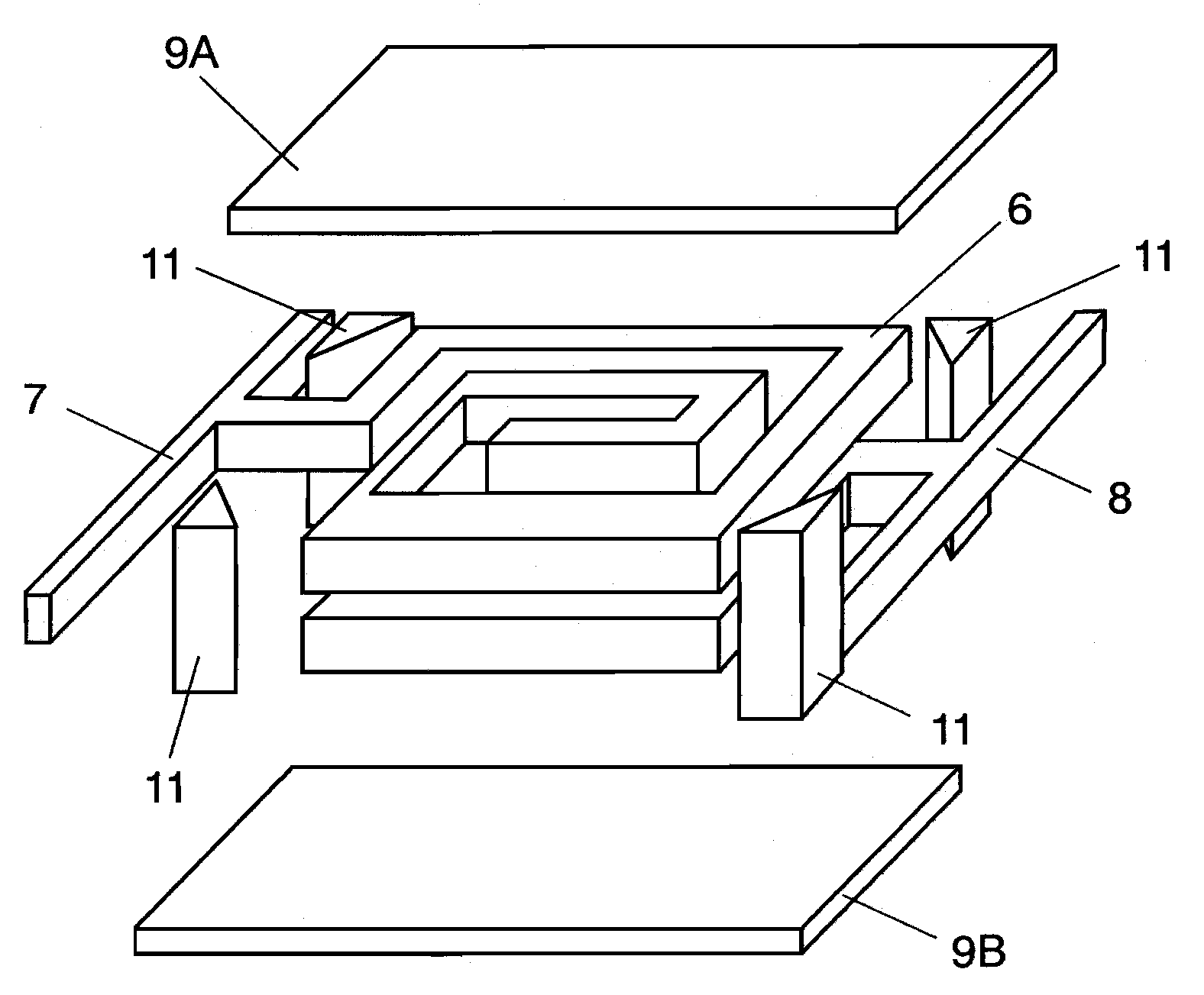

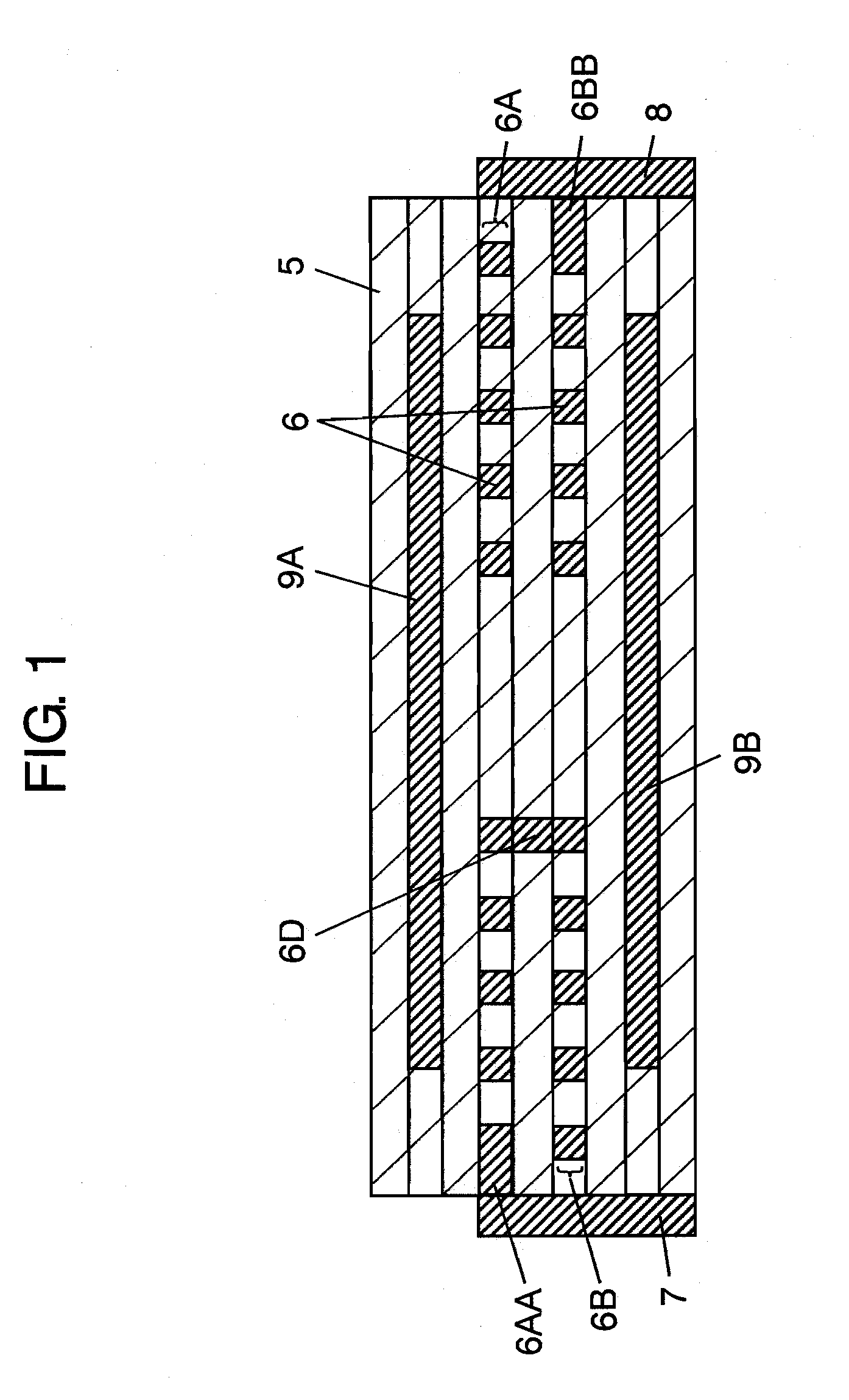

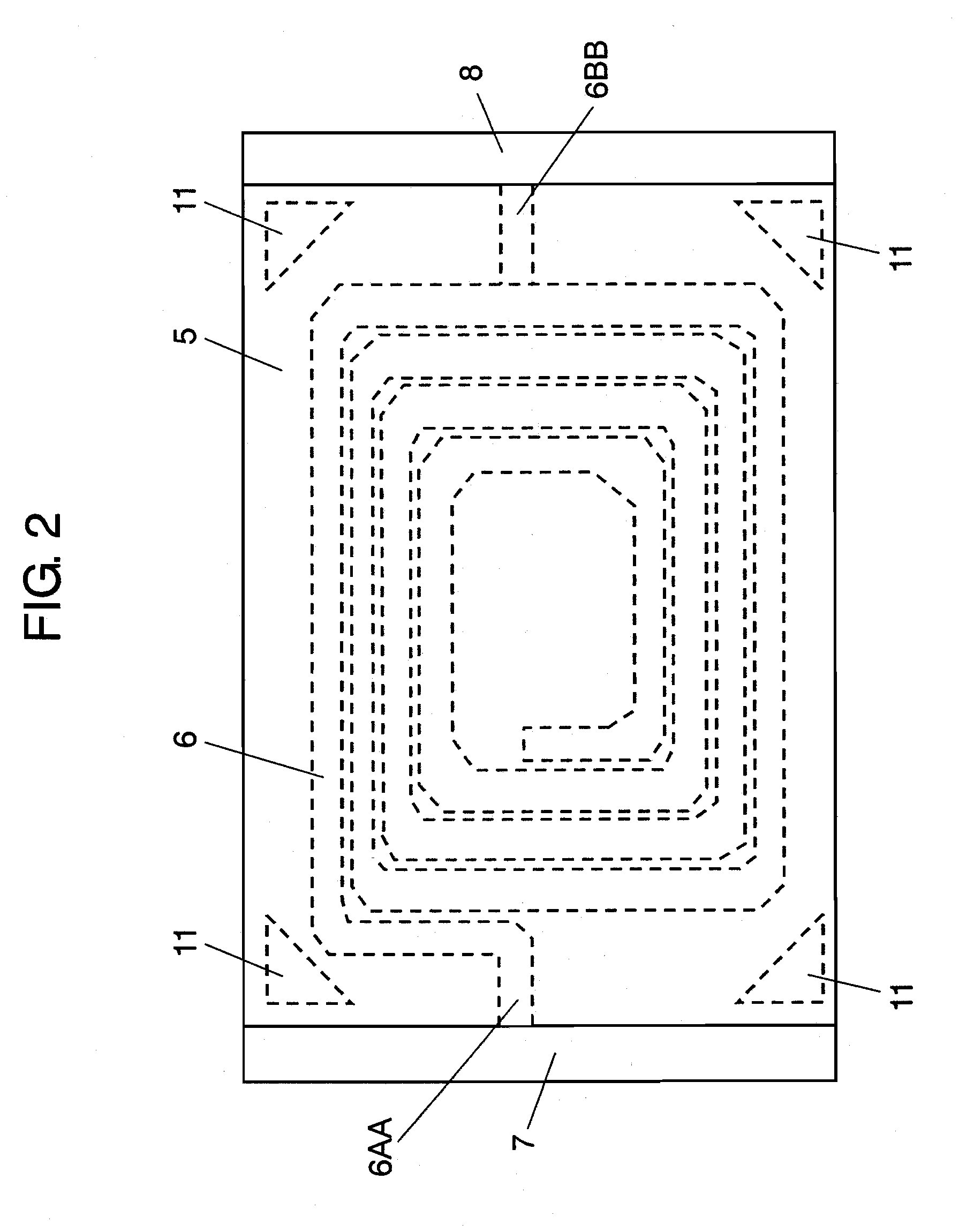

Inductance component

ActiveUS20100182116A1High saturationImprove reliabilityTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureContraction rateThermal expansion

In an inductance component, a stress is not locally applied even in the condition where heat is applied to entire component, such as when implementing soldering, so that high reliability is realized. For realizing this, the component includes element (5), coil (6) formed in element (5), terminals (7, 8) electrically connected to coil (6), and magnetic layers (9A, 9B) arranged so as to be substantially parallel to a winding surface of coil (6) are formed in element (5) and entire magnetic layers (9A, 9B) is covered with a material of which thermal expansion and contraction rates are constant.

Owner:PANASONIC CORP

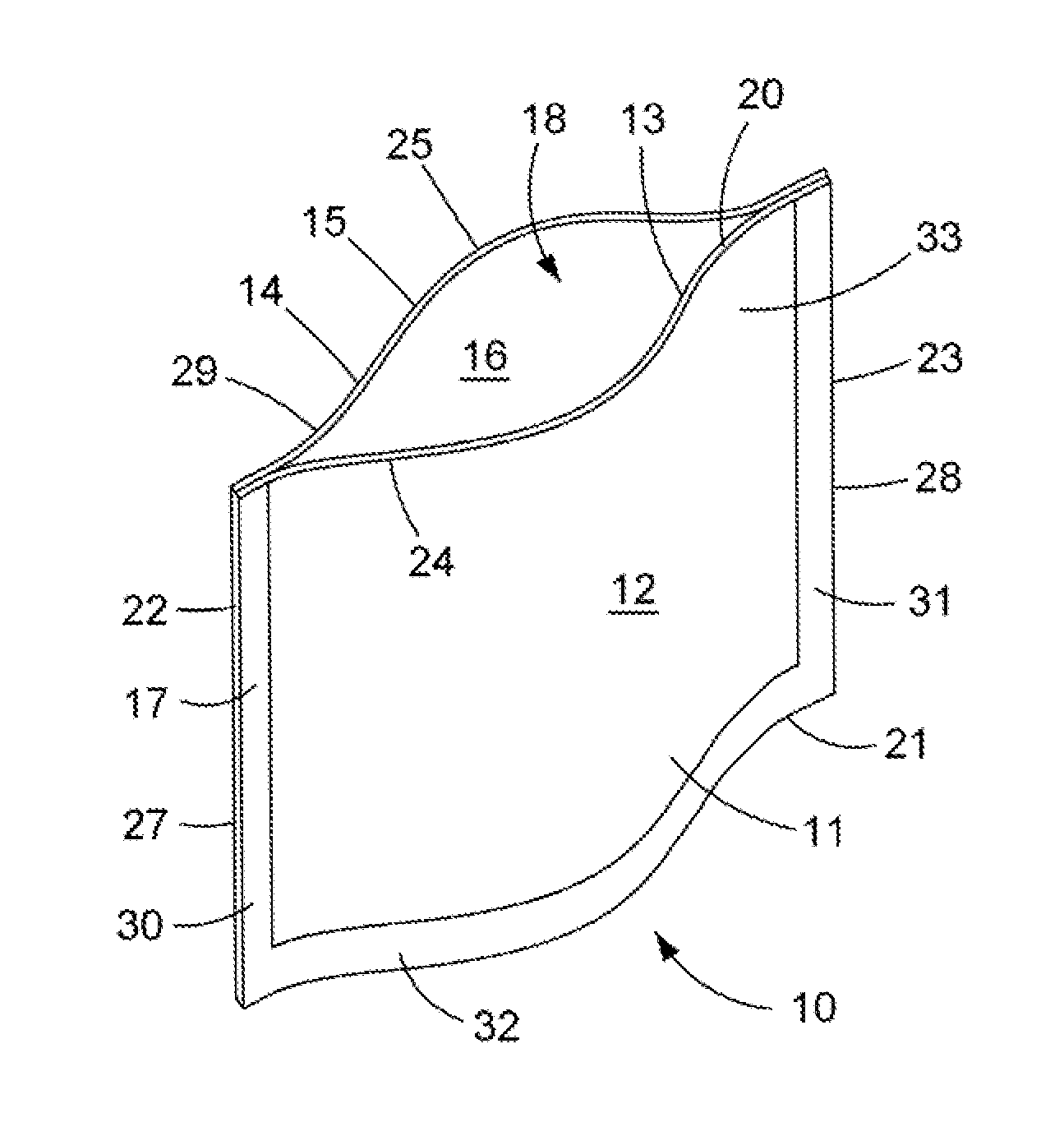

Self-forming container

Owner:BEMIS COMPANY INC

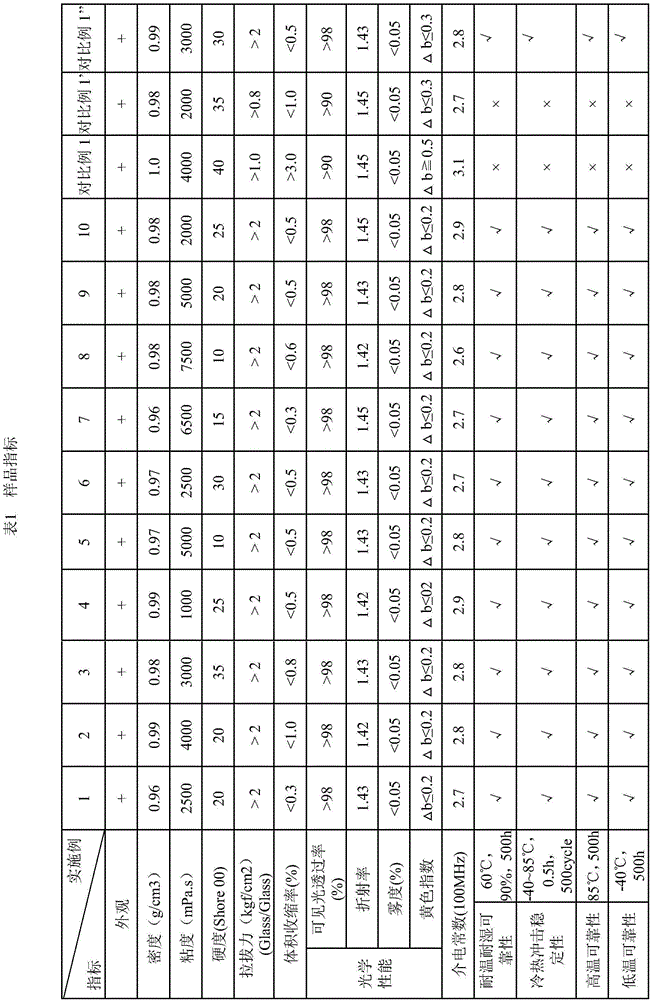

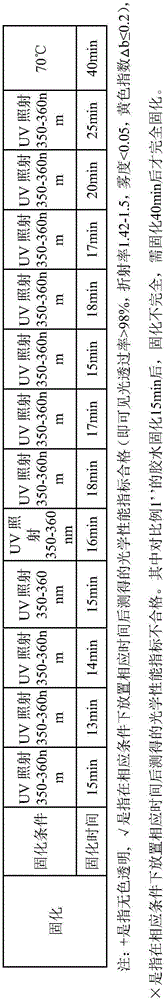

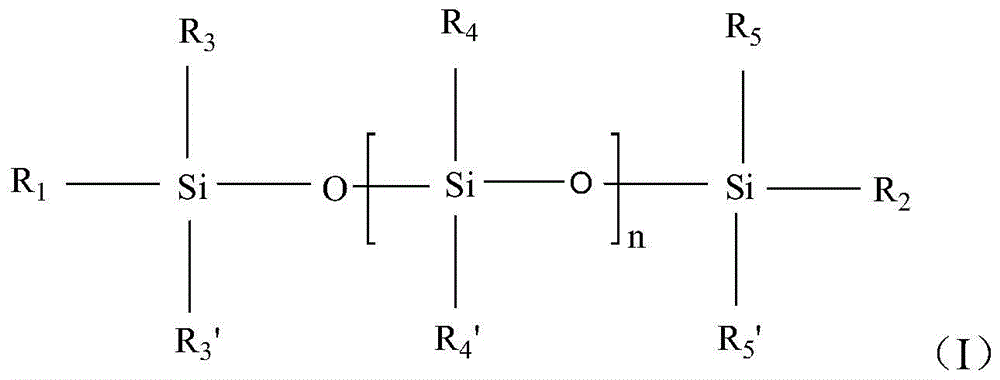

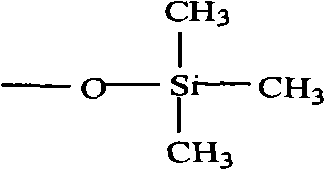

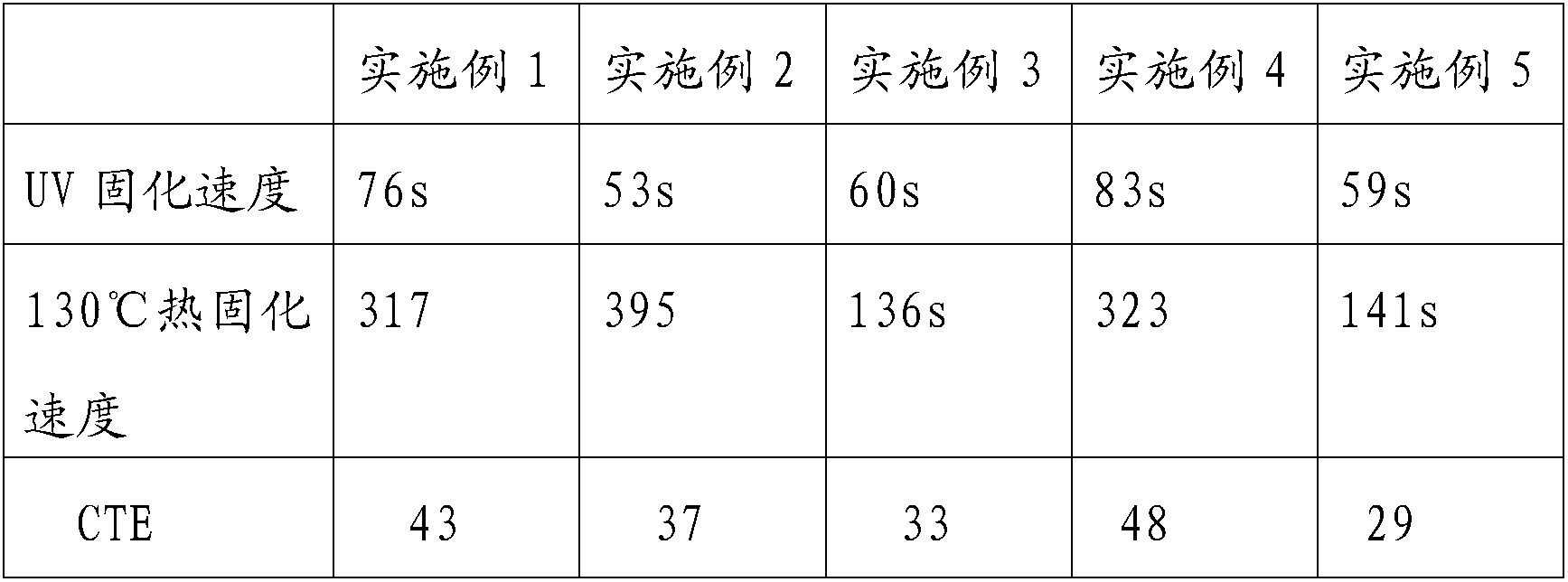

Optically transparent glue composition with organic silicone liquid and method for preparing optically transparent glue composition

ActiveCN105694800AGood effectSatisfy light transmittanceNon-macromolecular adhesive additivesUltravioletTackifier

The invention provides an optically transparent glue composition with organic silicone liquid.The optically transparent glue composition mainly comprises acrylate-terminated vinyl silicone oil, vinyl MQ silicone resin, vinyl MDT silicone oil, tackifiers, hydrogen-containing silicone oil, photoinitiators, catalysts, inhibitors and the like.The invention further provides a method for preparing the optically transparent glue composition.The method includes proportionally preparing materials; blending the materials to obtain mixtures; purifying the mixtures; defoaming the mixtures at high speeds and packaging the mixtures at high speeds.The optically transparent glue composition and the method have the advantages that glue with the organic silicone liquid can be simultaneously subjected to ultraviolet curing and heat curing, accordingly, the problem of incapability of completing curing on the peripheral edges of screens at one step can be solved, production processes and the manufacturing time can be greatly shortened, the reject ratio of finished products can be reduced, and effects of saving energy and time, reducing the production cost and improving the productivity can be realized; the glue is excellent in impact resistance, bending resistance, high-temperature and high-humidity resistance and yellowing resistance and low in dimensional contraction rate after being cured; bubble and impurities in the optically transparent glue with the organic silicone liquid can be prevented by the aid of the method.

Owner:新纶光电材料(深圳)有限公司

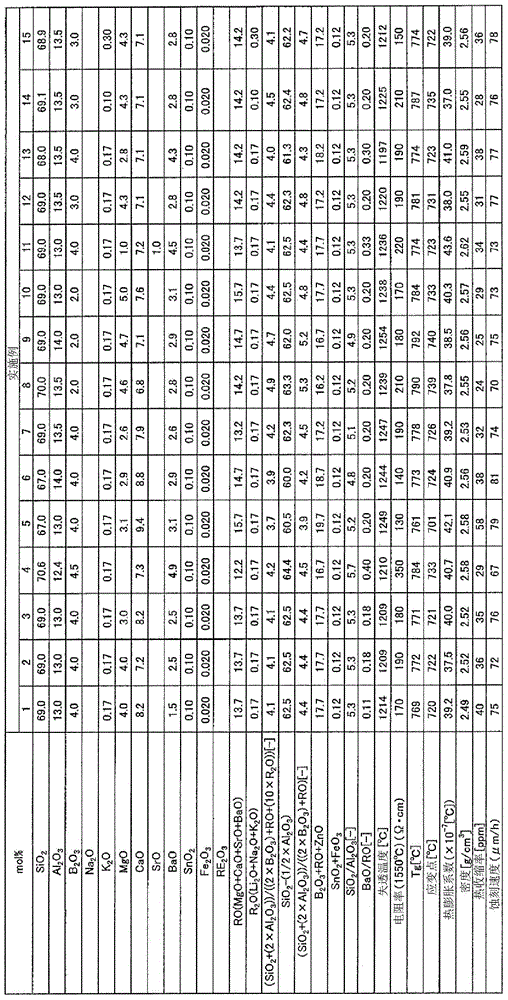

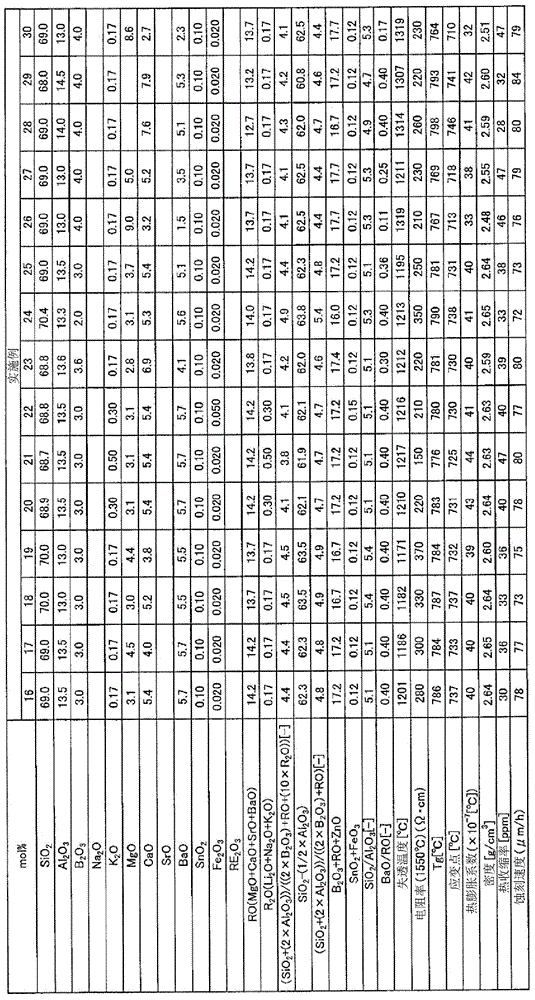

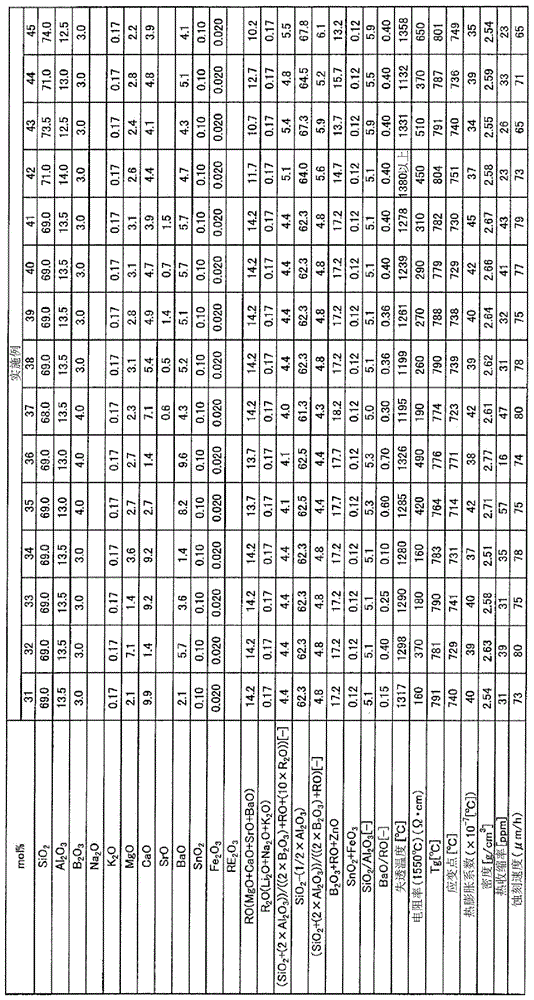

Glass substrate for display device and method for manufacturing same

ActiveCN103910487AInhibit or avoid melt lossInhibit devitrificationGlass productionDevitrificationMelting tank

The invention relates to a glass substrate for display device and a method for manufacturing same and provides a glass substrate which is high in strain point and capable of preventing a melting tank from melting loss, a glass substrate which is high in strain point and capable of suppressing devitrification, a glass substrate which is high in strain point and etching speed, and a method for manufacturing the glass substrate. The glass substrate contains Sio2 and Al2O3, 0-8% of B2O3, 0.01-0.8 % of R2O, and 0.05-1 of BaO / RO in mol%, and the strain point is over 670 DEG C. The glass substrate may contain Sio2, Al2O3 and MgO, 0.1-0.9 of MgO / (RO+ZnO), the strain point is over 700 DEG C, and the contraction rate is 5ppm-75ppm. The glass substrate may contain Sio2, Al2O3 and BaO, 0-7% of B2O3, 1-15% of BaO, and less than 6.0 of Sio2 / Al2O3, and the strain point is over 700 DEG C. RO represents (MgO+CaO+SrO+BaO), and R2O represents (Li2O+Na2O+K2O).

Owner:AVANSTRATE INC

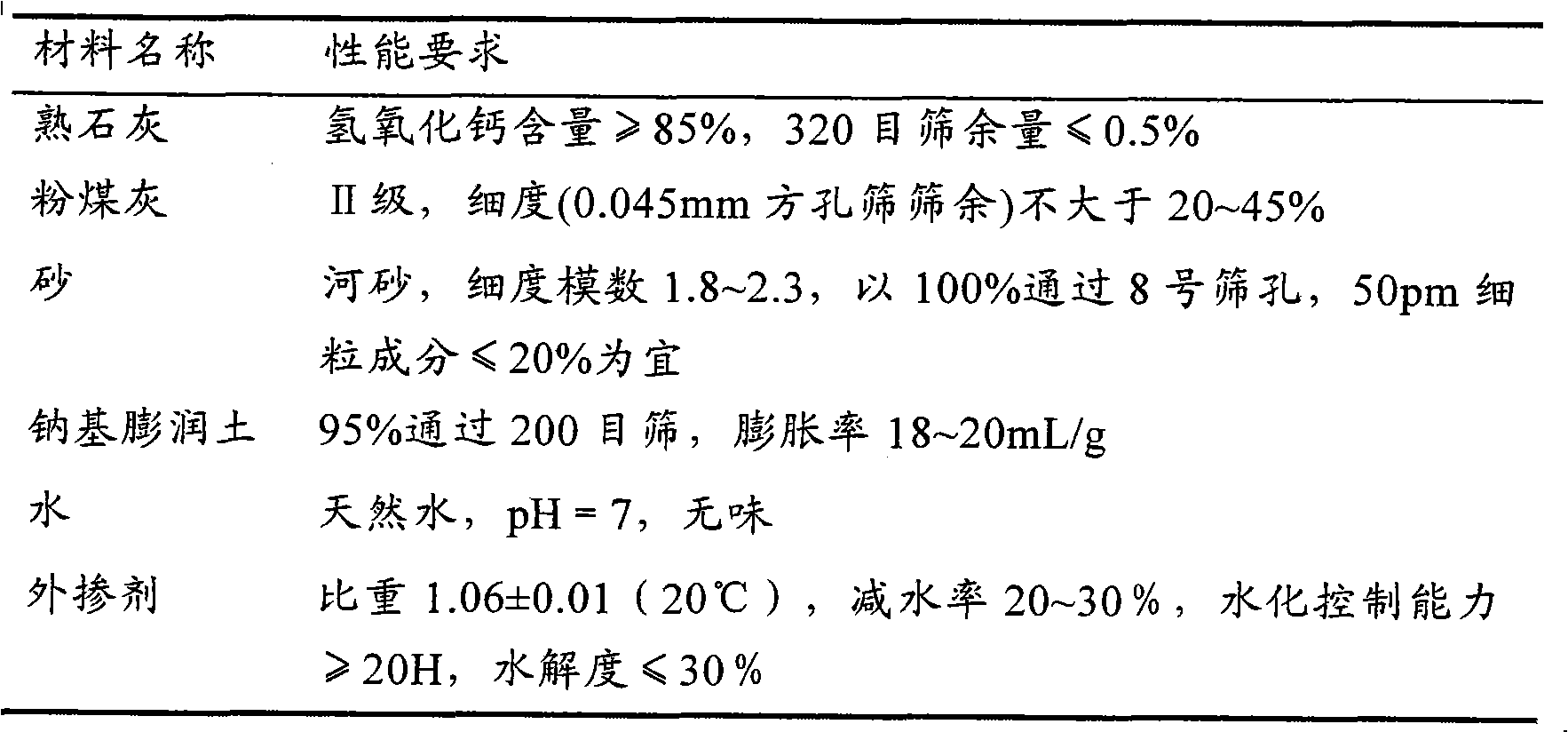

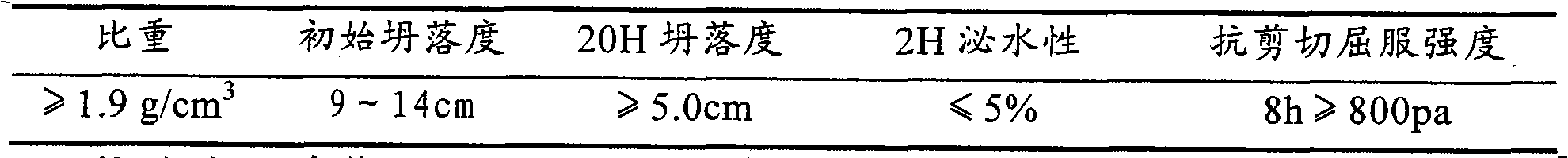

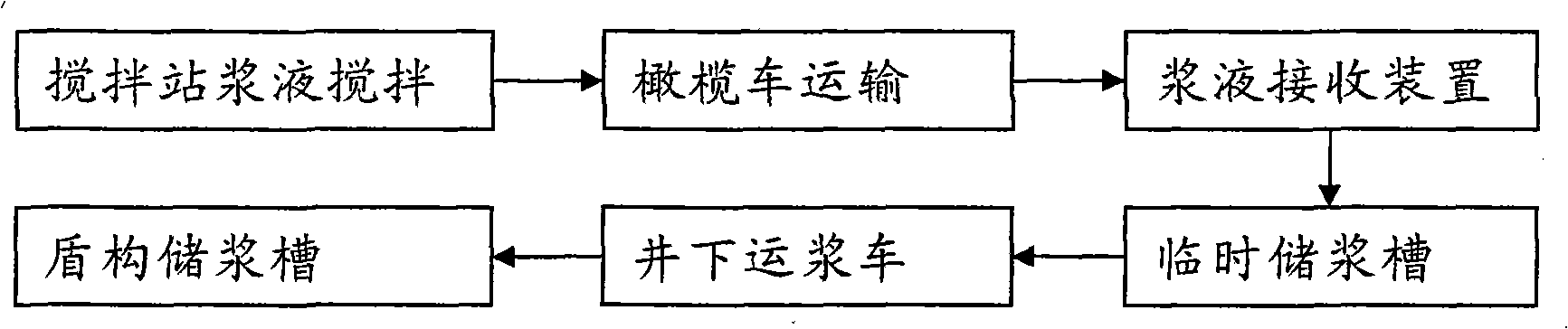

Shield synchronization slip casting construction technology

ActiveCN101603427AHigh shear yield strengthExtended use timeUnderground chambersTunnel liningMetallurgyTransit system

The invention discloses a shield synchronization slip casting construction technology, comprising the following steps: A) stirring the slip casting material into single grout via a grout mix and feeding system of a mixing station; B) conveying the mixed single grout to shield grout groove through a transportation system; and C) conducting synchronous slip casting to tailskin building interspaces through a shield slip casting system; wherein, in step A), the initial slump is 9-14cm, the sand factor is 50-60%, the specific gravity is not less than 1.9kg / L, the bleeding rate is not more than 5%, the anti-cutting yield strength 8h is more than or equal to 800Pa and the later-stage solid shrinkage is not more than 1%; in step C), the slip casting pressure P=P1+P2, wherein, P1 is a water-soil pressure value around the slip casting point and P2 is pressure loss of the slip casting pipe. The grout in the invention has the advantages of higher anti-cutting yield strength, long service time, no occurrence of eduction and pipe blocking and good peaceability and the like. The invention further has the advantages of low production cost of grout, low slip casting rate, low slip casting volume, no need of secondary supplement slip casting, controllable distortion and settlement of completed ground surface and high quality of tunnel circular forming.

Owner:SHANGHAI TUNNEL ENG CO LTD +1

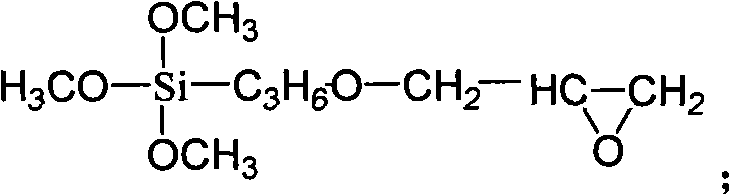

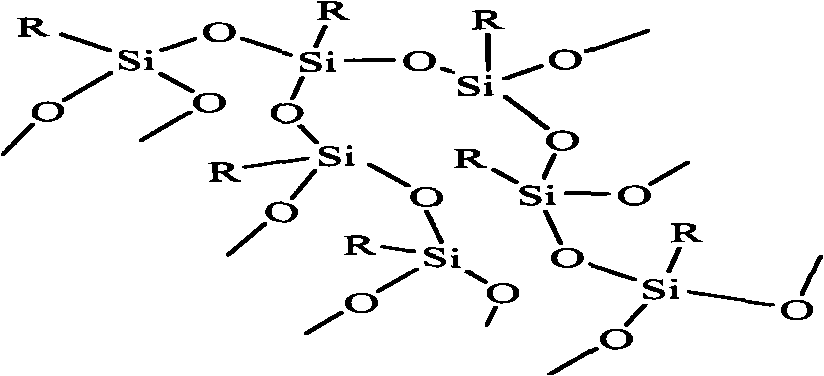

Epoxy silsesquioxane/epoxy resin hybridized glue for packaging photoelectric devices and preparation method thereof

InactiveCN101857789AHigh molecular weightAccelerated corrosionOther chemical processesEpoxy resin adhesivesPolyamideStructural formula

The invention relates to epoxy silsesquioxane / epoxy resin hybridized glue for packaging photoelectric devices and a preparation method thereof. The hybridized glue is prepared by mixing substrate resins, a curing agent and other components, wherein other components comprise the following materials in mass percentage: 12%-18% of modified epoxy silsesquioxane, 36%-42% of bisphenol A type epoxy resins, 30%-38% of polyamide, 5%-10% of N,N-diaminodiphenyl-methane and 0.5%-1.5% of triethylamine, and the structural formula of the modified epoxy silsesquioxane is shown in the specification, wherein Ris shown in the specification. The epoxy silsesquioxane synthesized in the method has high molecular weight, the maximum-average molecular weight reaches 1.1*10<6>, and the weight-average molecular weight reaches 1.21*10<6>. The prepared glue has the advantages of the epoxy silsesquioxane and the epoxy resins and has good heat resistance, cold resistance and corrosion resistance, high bonding performance, low curing contraction rate, good electrical performance, simple preparation process and easy operation of a preparation process, and excellent ultraviolet radiation resistance, chemical corrosion resistance and mechanical performance, wherein the electrical performance achieves the packaging requirements on the photoelectric devices.

Owner:SHANGHAI UNIV

Fiber optic cable having a low-shrink cable jacket and methods of manufacturing the same

A fiber optic cable and methods for manufacturing the same the fiber optic cable including a fiber optic cable core, the fiber optic cable core includes at least one optical fiber and a separation layer. The separation layer generally surrounds the at least one optical fiber, and a cable jacket generally surrounds the separation layer. The cable jacket has an average shrinkage of about 2.0% or less during a cable jacket shrinkage test conducted at a temperature of 110° C. for 2 hours with the cable core removed. The low-shrink characteristic of the cable jacket preserves optical performance during, for example, temperature variations.

Owner:CORNING OPTICAL COMM LLC

Anti scraping thin film, and liquid crystal display

InactiveCN101004461AAvoid optical propertiesHigh hardnessPrismsDiffusing elementsConvex structureLiquid-crystal display

A scratch proof film is prepared for arranging a microstructure layer at bottom side of base material and a scratch proof layer on top side of base material, setting concave-convex structure on scratch proof layer, making scratch proof layer have fog degree of 30-98% and surface resistivity of 10 to the power 8-10 Omega / „ as well as pencil hardness of 3H.

Owner:长兴光学材料(苏州)有限公司

Waterless stemming for blast furnace

InactiveCN1523120AImprove workabilityEasy to squeeze outBlast furnace componentsBlast furnace detailsAnthraceneContraction rate

The present invention provides an anhydrous stemming for blast furnace. Its composition includes (wt%) coarse brown corundun 1-4%, fine brown corundum 2-5%, coarse mullite 7-15%, fine mullite 9-20%, coke powder 15-20%, clay 10-19%, silicon carbide 7-11%, sericite 5-8%, bitumen 2-4% and anthracene oil 15-25%. It has good working property, stable high temperature resistance, excellent caking property, quick agglutinating property, low ton-iron stemming consumption, low contraction rate and high strength, it can raise tap up-to-standard rate to 100% from original 61.5%, can raise production safety of blast furnace, and can raise smelting strength.

Owner:WUKUN STEEL

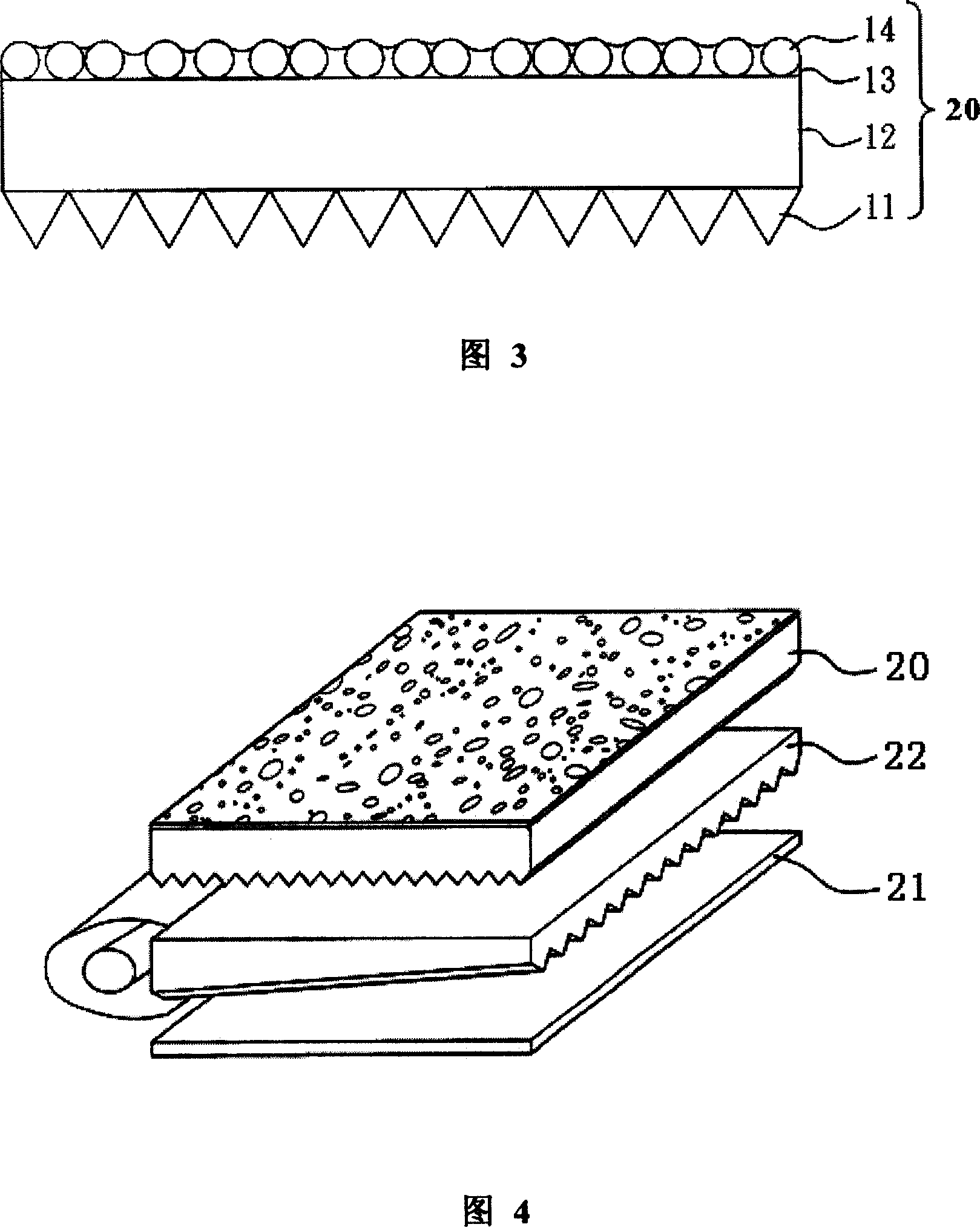

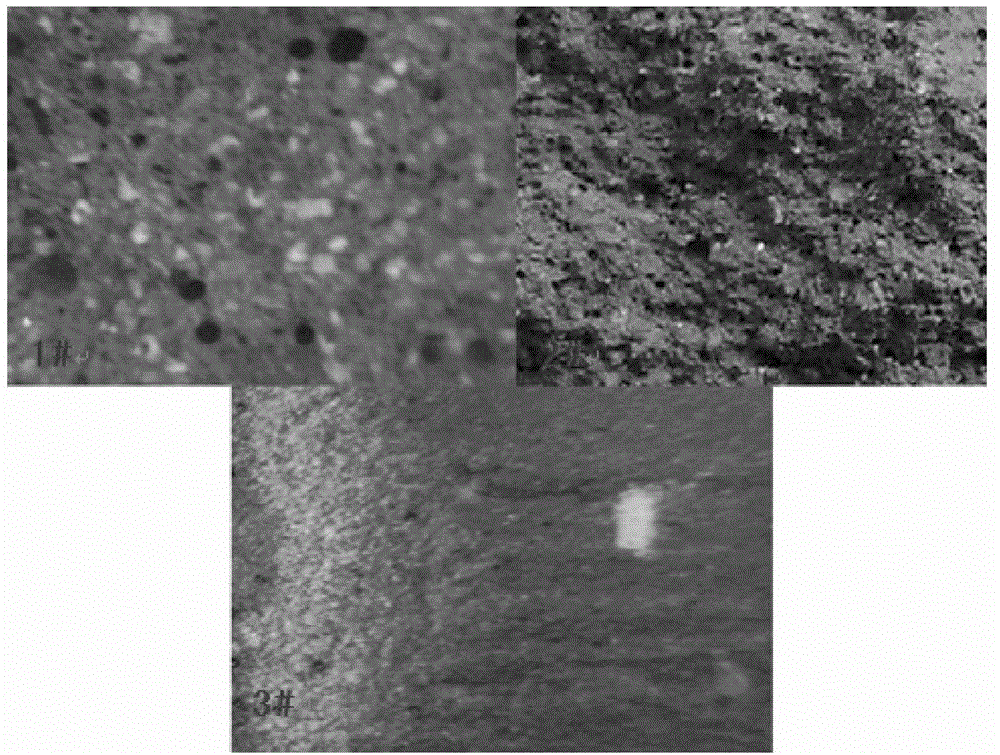

Preparation and construction method of epoxy grouting material for track filling and secondary grouting

The invention relates to preparation and a construction method of a grouting material (referred to as RE-GD) for track filling and secondary grouting. The RE-GD comprises three components, A, B and C. The component A is a modified epoxy resin mixing system, which comprises modified epoxy resin, an active diluent, a toughening agent, an antioxidant, a leveling agent, a defoaming agent and a coupling agent. The component B is a curing agent. The component C is a filler. The high-strength precise non-contraction epoxy resin grouting material for tracking provided by the invention has the advantages of high adhesion to a cement base and a steel base, high strength, good toughness, no expansion, extremely low contraction rate and small amount of dense porosity; excellent properties of polymer material enables the material with characteristics, unmatched by other materials, in corrosion resistance and weatherability performance, and can satisfy usage in different climate environment. The material provided by the invention has long cycle of usage and a general service life of up to 30 years, and can be used as a substitute or be applied to environment and position, which CA mortar or cement base grouting material can not be applied to.

Owner:BEIJING ALLIED RONGDA CONSTR MATERIAL

Double curing encapsulating adhesive and preparation method thereof

InactiveCN102504745ALow shrinkageImprove water resistanceNon-macromolecular adhesive additivesOther chemical processesEpoxyPolyol

The invention relates to a double curing encapsulating adhesive and a preparation method thereof. The double curing encapsulating adhesive comprises the following raw materials in percentage by weight: 35 to 60 percent of epoxy resin, 2 to 20 percent of polyol, 1 to 20 percent of silane coupling agent, 0.1 to 2 percent of photoinitiator, 0.1 to 2 percent of thermal initiator and 30 to 60 percent of filler. The double curing encapsulating adhesive provided by the invention with low contraction rate and high water resistance and cold and heat circulation resistance can effectively guarantee that encapsulated elements are reliable; the adhesive can cure quickly and completely under ultraviolet (UV) and heat while delivering quick positioning and excellent mechanical properties; with light smell after curing, the adhesive is environment-friendly; and with high storage stability, the adhesive is suitable to adhere electronic elements.

Owner:YANTAI DARBOND TECH

Composite floor board and production method thereof

The invention relates to the field of the production of a floor board, and particularly discloses a composite floor with small expansion rate and contraction rate and a production method thereof. The composite floor board comprises a wearable layer, a color film layer and a base material layer from top to bottom in sequence, wherein the base material layer consists of calcium carbonate, PVC (Polyvinyl Chloride), a plasticizer, a stabilizer and a modifier ACR (Acrylics); the production method comprises the steps of processing for shaping, implementing thermal compounding, implementing surface UV (Ultraviolet) and tempering, cooling and finally implementing slicing and grooving. According to the composite floor board and the production method thereof, the calcium carbonate adopted for the composite floor board has a specification of over 500 meshes; the processing temperature is rationally controlled through the production method, so that the contraction rate and the expansion rate can be effectively lowered; consequently, the lowest contraction rate can reach 0.04% and the lowest expansion rate can reach 0.1%; as the volume change of the composite floor board caused by expansion and contraction is greatly decreased, the use performance and the service life of the composite floor board can be effectively improved.

Owner:ZHEJIANG KINGDOM NEW MATERIAL GRP CO LTD

Antiscraping optical film and use thereof

InactiveCN101021644AImprove antistatic performanceExcellent hardness propertiesNon-linear opticsOptical elementsAntistatic agentLiquid-crystal display

The invention provides an anti-scratching optical film and its use. And its characters: at least a surface of its substrate is coated with antistatic anti-scratching layer whose surface resistivity is 108-1012 Ohm / sq and which has the hardness of pencil of 3H or above, according to the measurement by JIS K5400 standard method. And it has low volumetric shrinkage, unable to warp but having good antistatic performance and high hardness, applied to advertising lamp boxes or plane displays and other light source devices, especially applied to an LCD provided with ''V-channel'' light guide plate as anti-scratching reflective film at the bottom of the light guide plate.

Owner:长兴光学材料(苏州)有限公司

Monocomponent polyurethane adhesive and preparation method and use thereof

InactiveCN101139512ALow reaction temperatureShort reaction timePolyureas/polyurethane adhesivesLaminationPolyurethane adhesiveToluene diisocyanate

The invention relates to a single-component polyurethane binder and a preparing method and application of the binder, and pertains to the technical field of chemical binder. The binder is got by the following procedures: mixing low-hydroxyl-value dehydrated castor oil and polyaryl polymethylene isocyanate as main raw materials with toluene diisocyanate, refined castor oil, and trimethylolpropane-oxypropylene polyether troil; using stannous octanoate, triethylenediamine and N, N-dimethylbenzylamine as complexing catalyst, and 4-tert-butyl-catechol as antioxidant, and allowing them reacting under 50-60 DEG C. The single-component polyurethane binder is for binding color steel sheets and polystyrene foam sheets, is a castor oil type single-component polyurethane binder; the curing flexibility is good, and the contraction rate is high; the binder is of high binding strength for two interfacing surfaces, and is of low cost in term of raw materials.

Owner:UNIV OF JINAN

Hologram recording material and hologram recording method

InactiveUS20070207390A1Improve recording densityImprove storabilityPhotosensitive materialsPhotomechanical apparatusHigh densityContraction rate

A hologram recording material with high sensitivity, high diffraction efficiency, good storability, a small shrinkage ratio, dry processing applicability and a multiple recording performance, which is applicable to high density optical recording media and the like, is provided. The hologram recording material contains the specific acid generator of sensitizing dye.

Owner:FUJIFILM CORP

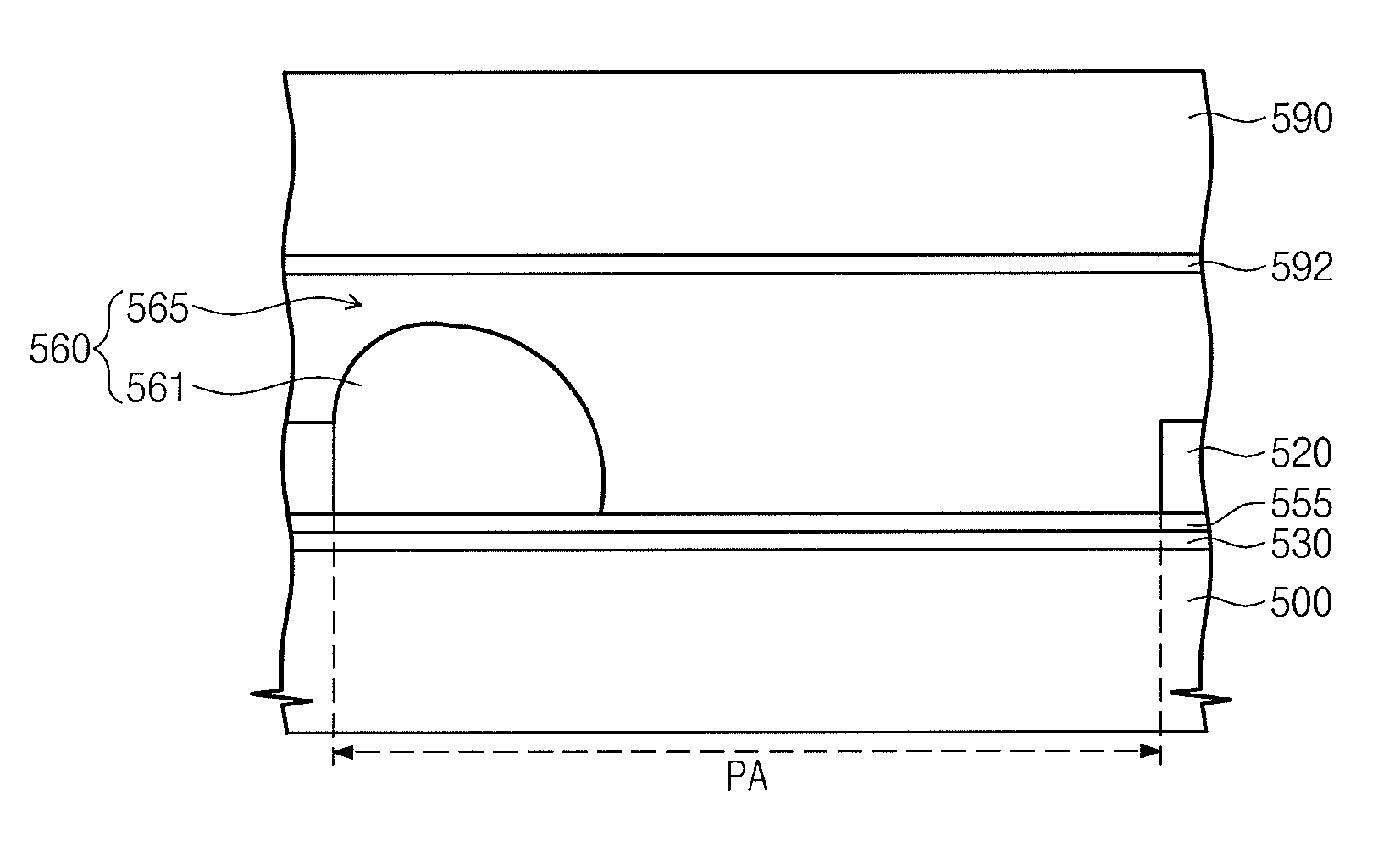

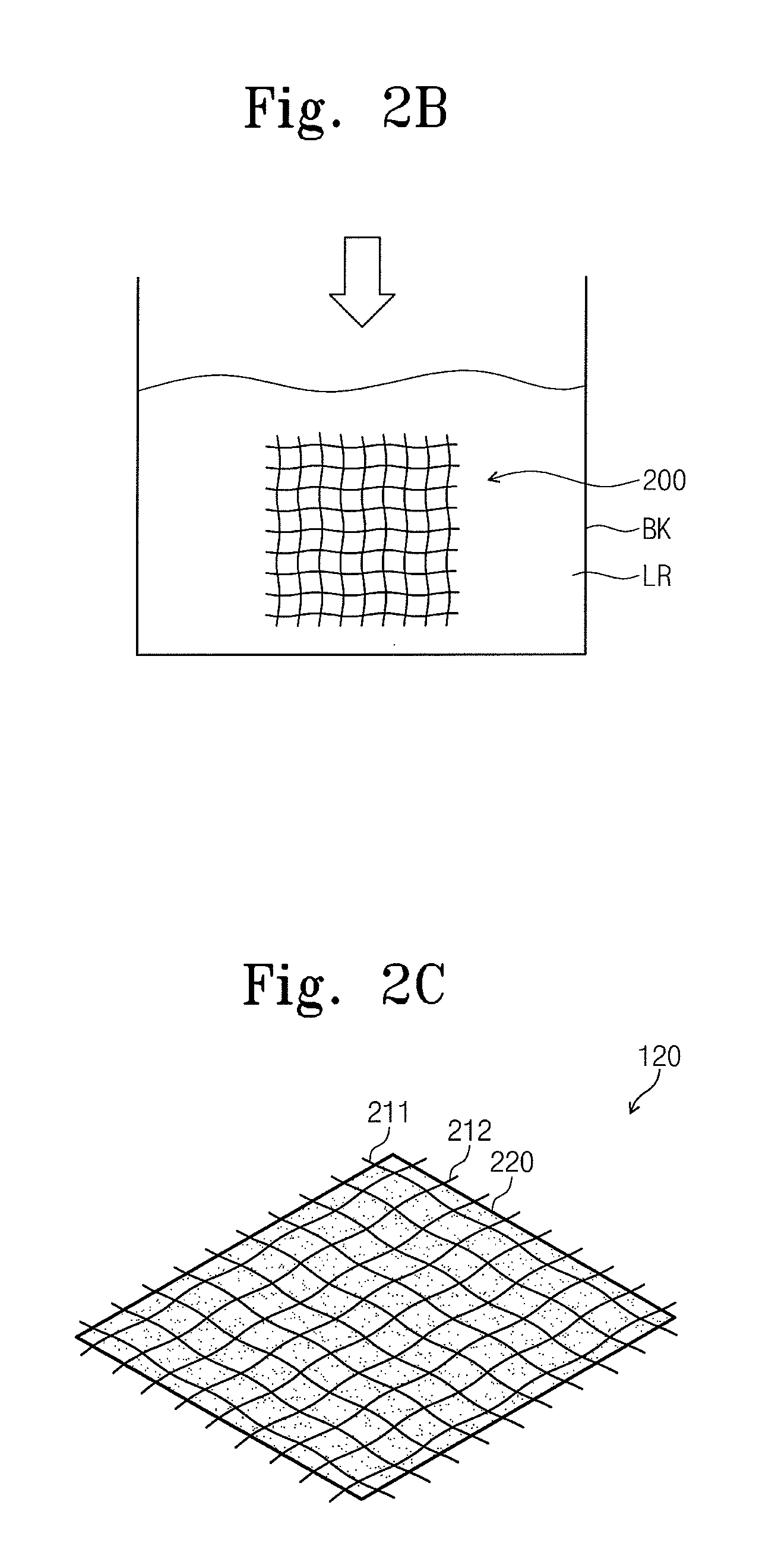

Flexible substrates and method of manufacturing the same

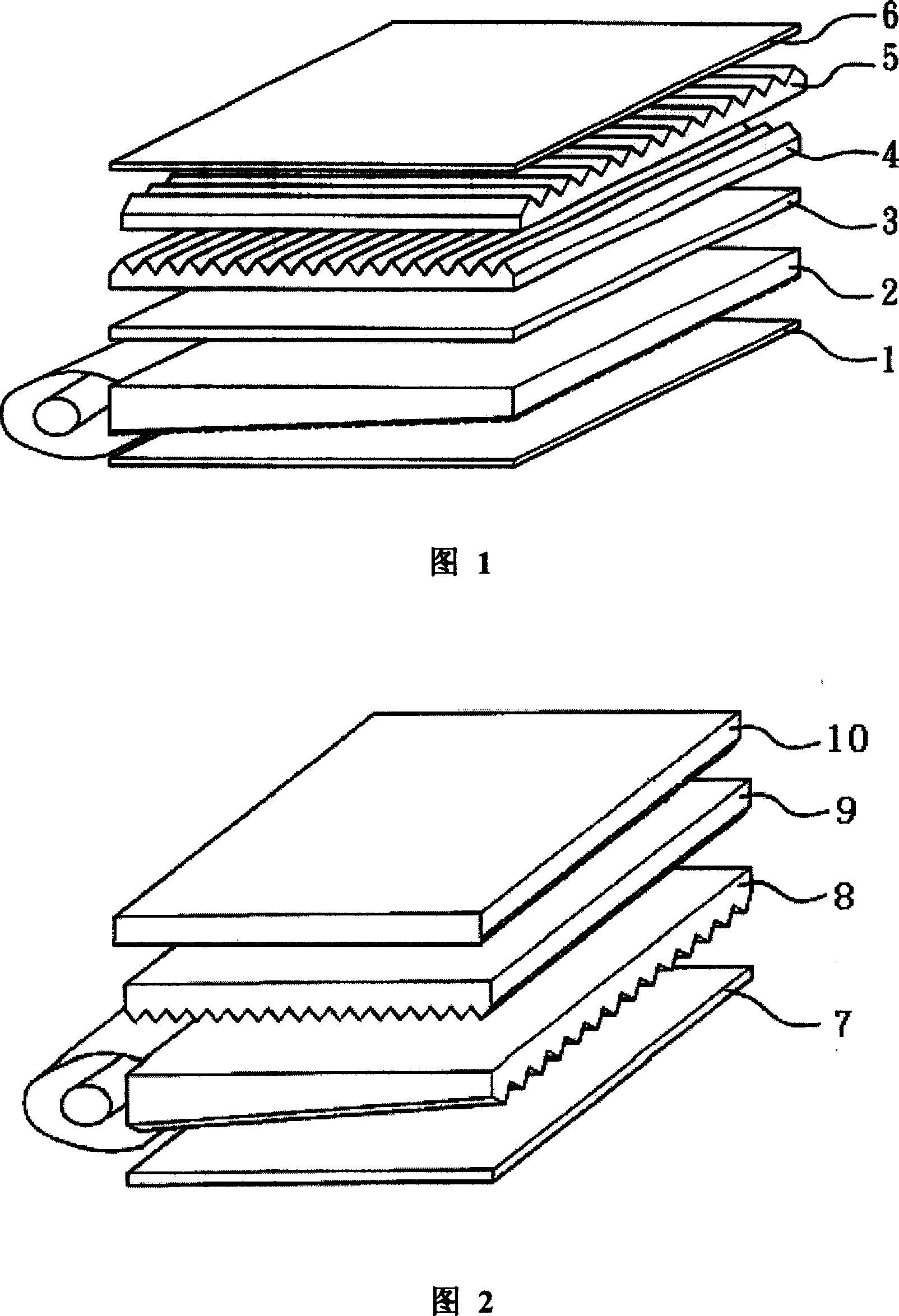

A flexible substrate includes a flexible mother substrate and a planarization layer on the flexible mother substrate. Here, the flexible mother substrate includes a transparent textile and a resin layer. The transparent textile includes a plurality of first transparent fibers and a plurality of second transparent fibers crossing the plurality of first transparent fibers, and the resin layer coats the transparent textile to fill a space between the first and second transparent fibers. The planarization layer includes an organic material having a curable contraction rate of no greater than about 20%.

Owner:SAMSUNG DISPLAY CO LTD

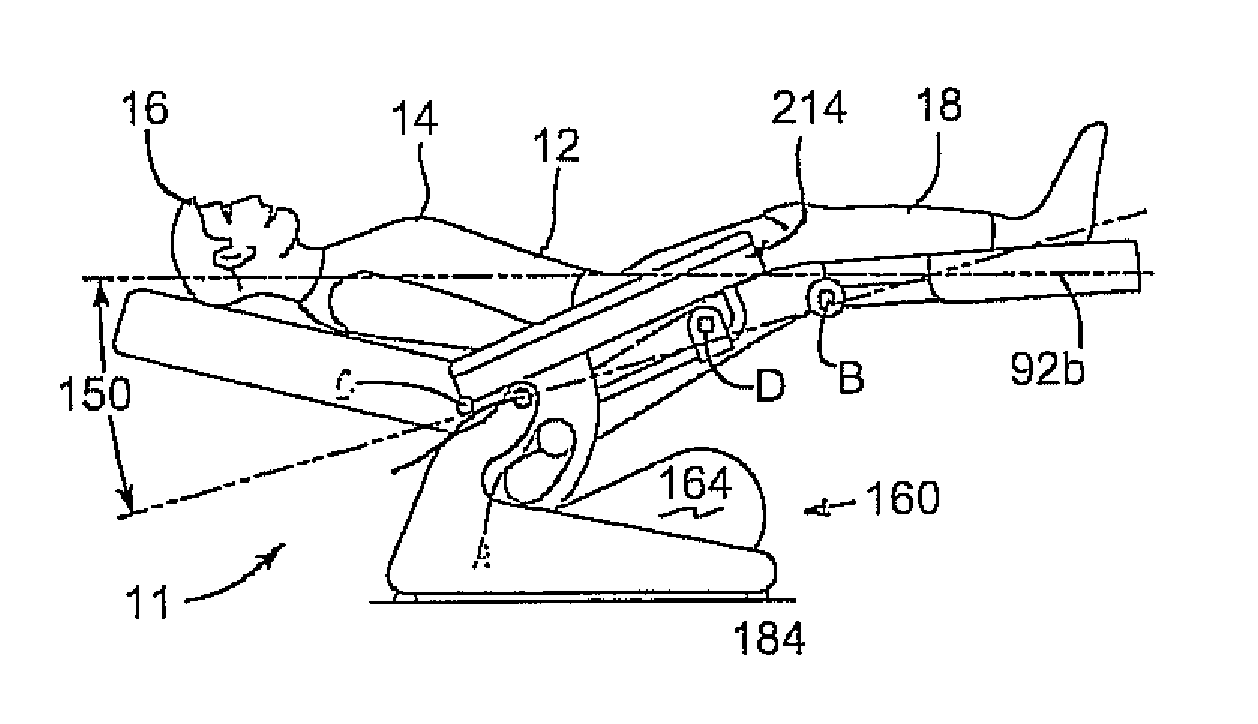

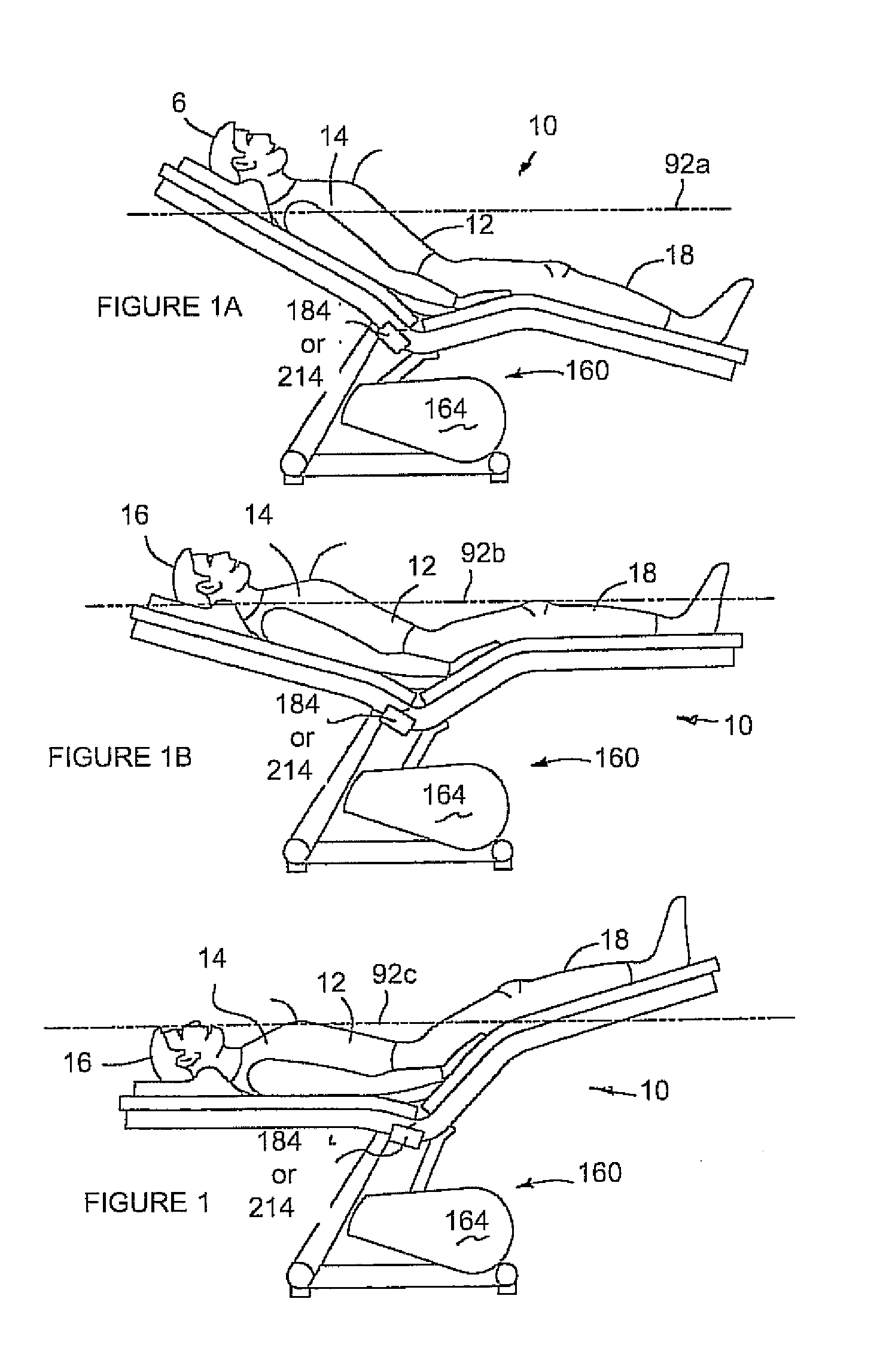

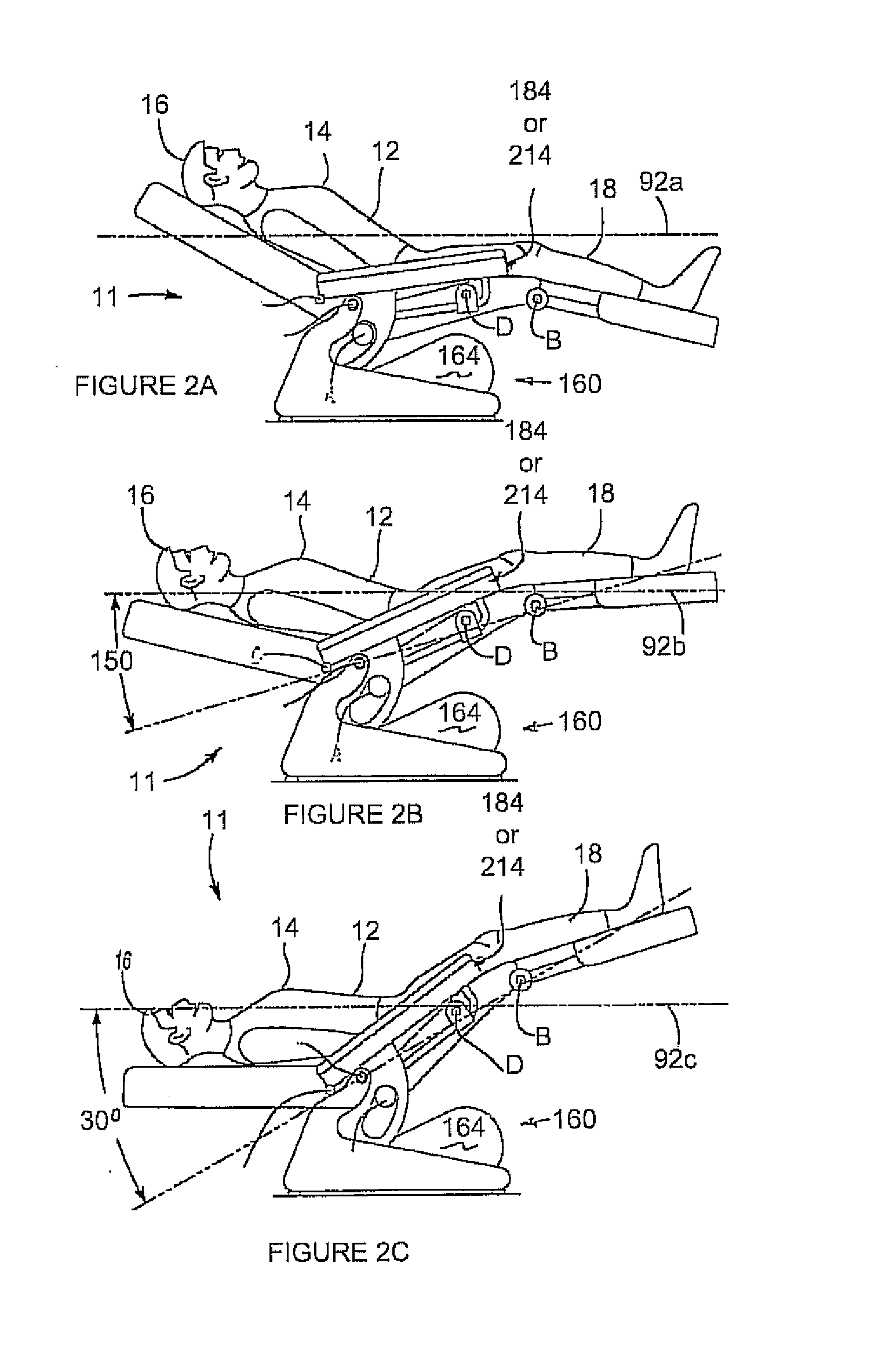

Therapeutic device for inducing blood pressure modulation

InactiveUS20110132377A1Increase blood flowIncrease pressureOperating chairsPneumatic massageTherapeutic DevicesLymphangion

A Kinetic Recliner Bed or Chair apparatus intended for enhancing blood circulation, and lymph and neural fluid flow throughout a person's body. The person is placed supinely in a comfortable and relaxed state on a bed or chair member that is driven, either at the nominal cyclic rate of a human lymph system's normal lymphangion contraction rate divided by 2, or alternately, at the nominal cyclic rate of a human lymph system's normal lymphangion contraction rate, in a cyclic tilting seesaw mode that alternatively raises the person's upper torso and head above his or her lower extremities, and vice-versa.

Owner:PHILLIPS EDWARD H

Composite additive improving self-contraction of concrete

InactiveCN101172803ALow costReduce autogenous shrinkageSolid waste managementDimethyl siloxaneRelative humidity

The invention relates to a compound admixture for improving the self-contraction property of concrete, and belongs to the technical field of the admixture. The prior materials used for improving the self-contraction of the concrete mainly comprise expansion agent, shrinkage reducing agent and fiber, but the materials are not effective when the materials are used solely. The invention is characterized in that the compound admixture is formed by evenly mixing I-class fly ash, milled limestone powder, dihydrate gypsum, raw alum clay and dimethyl siloxane, wherein, the weight percent of each component is showed as follows: 20 to 40 percent of the I-class fly ash, 30 to 60 percent of the milled limestone powder, 5 to 10 percent of the dihydrate gypsum, 10 to 20 percent of the raw alum clay and 3 to 5 percent of the dimethyl siloxane; the finenesses of the milled limestone powder, the dihydrate gypsum and the raw alum clay are larger than 350m2 / kg. When the invention is mixed into the concrete with high strength and large area and the self-compacting concrete, and the relative ambient humidity is less than 50 percent, the invention can obviously reduce the self contraction rate of the concrete by more than 30 percent and improve the strength, the mobility and the durability of the concrete.

Owner:BEIJING UNIV OF TECH

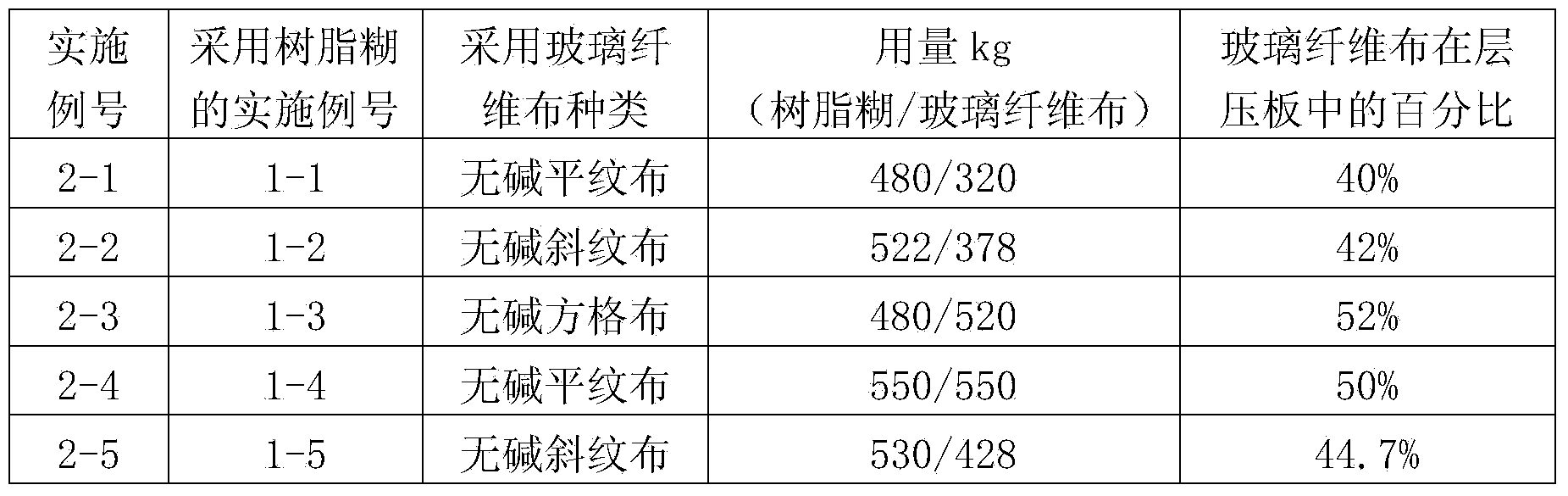

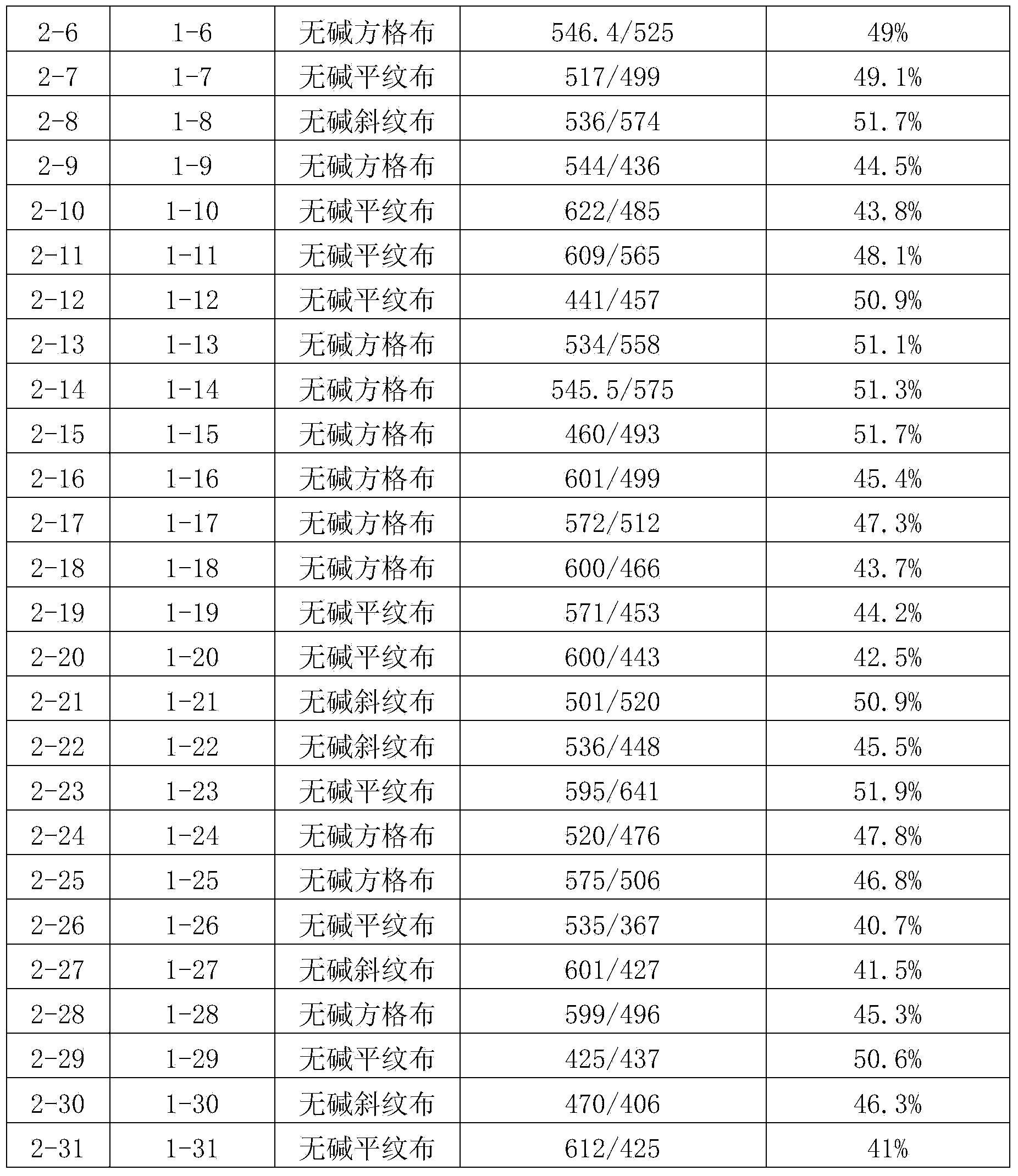

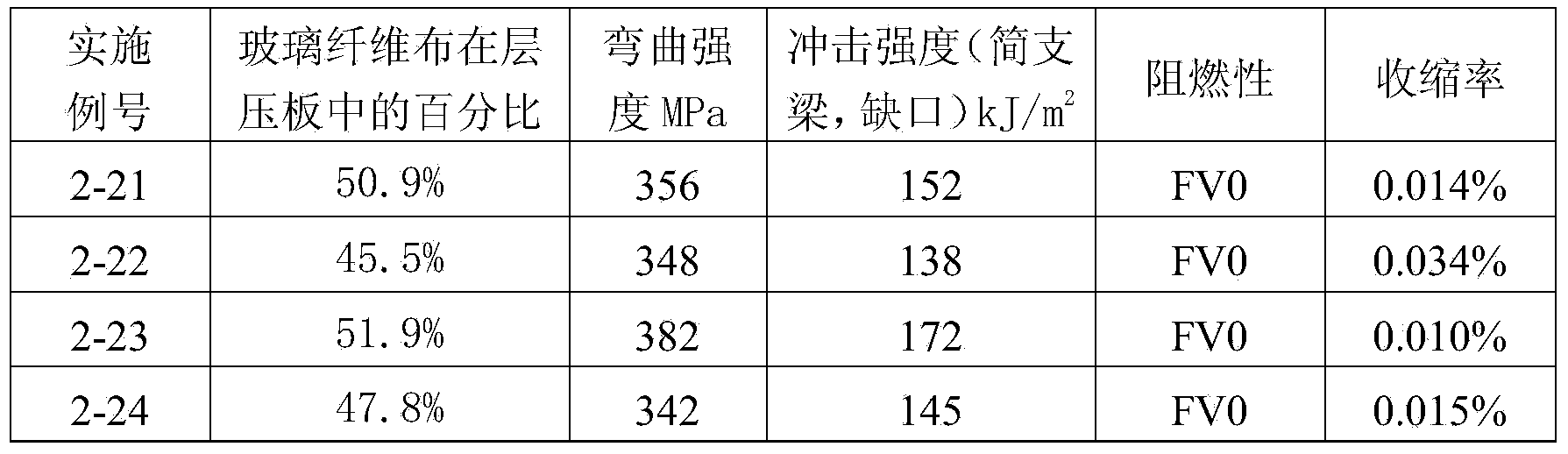

Unsaturated polyester glass fiber cloth laminated board and preparation method thereof

ActiveCN103522680AHigh mechanical strengthPracticalSynthetic resin layered productsLaminationFiberAluminium hydroxide

The invention discloses an unsaturated polyester glass fiber cloth laminated board and a preparation method thereof. The unsaturated polyester glass fiber cloth laminated board is characterized in that the board is formed by hot-pressing more than one layer of overlapped unsaturated polyester glass fiber cloth prepregs; and each layer of the unsaturated polyester glass fiber cloth prepregs comprises a layer of glass fiber cloth and resin paste, and the two surfaces of the glass fiber cloth are coated with the resin paste. The preparation method of the unsaturated polyester glass fiber cloth laminated board is as follows: a styrene solution of an unsaturated polyester resin, a styrene solution of a saturated polyester resin, a styrene solution of polyvinyl acetate, aluminium hydroxide, active magnesium oxide, an initiator, pigment paste and zinc stearate are mixed, so that resin paste is prepared; and the unsaturated polyester glass fiber cloth prepregs are prepared. With the adoption of the unsaturated polyester glass fiber cloth laminated board and the preparation method, the unsaturated polyester glass fiber cloth laminated board has the characteristics that the mechanical strength is high, halogen-free flame retardance is realized, the contraction rate is low, and the like. The unsaturated polyester glass fiber cloth laminated board is suitable for parts with high-strength insulation structures of motors, electrical appliances, high-tension power transmission and transformation equipment and the like.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com