Patents

Literature

3511 results about "Caking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Caking is a powder's tendency to form lumps or masses. The formation of lumps interferes with packaging, transport, flowability, and consumption. Usually caking is undesirable, but it is useful when pressing powdered substances into pills or briquettes. Granular materials can also be subject to caking, particularly those that are hygroscopic such as salt, sugar, and many chemical fertilizers. Anticaking agents are commonly added to control caking.

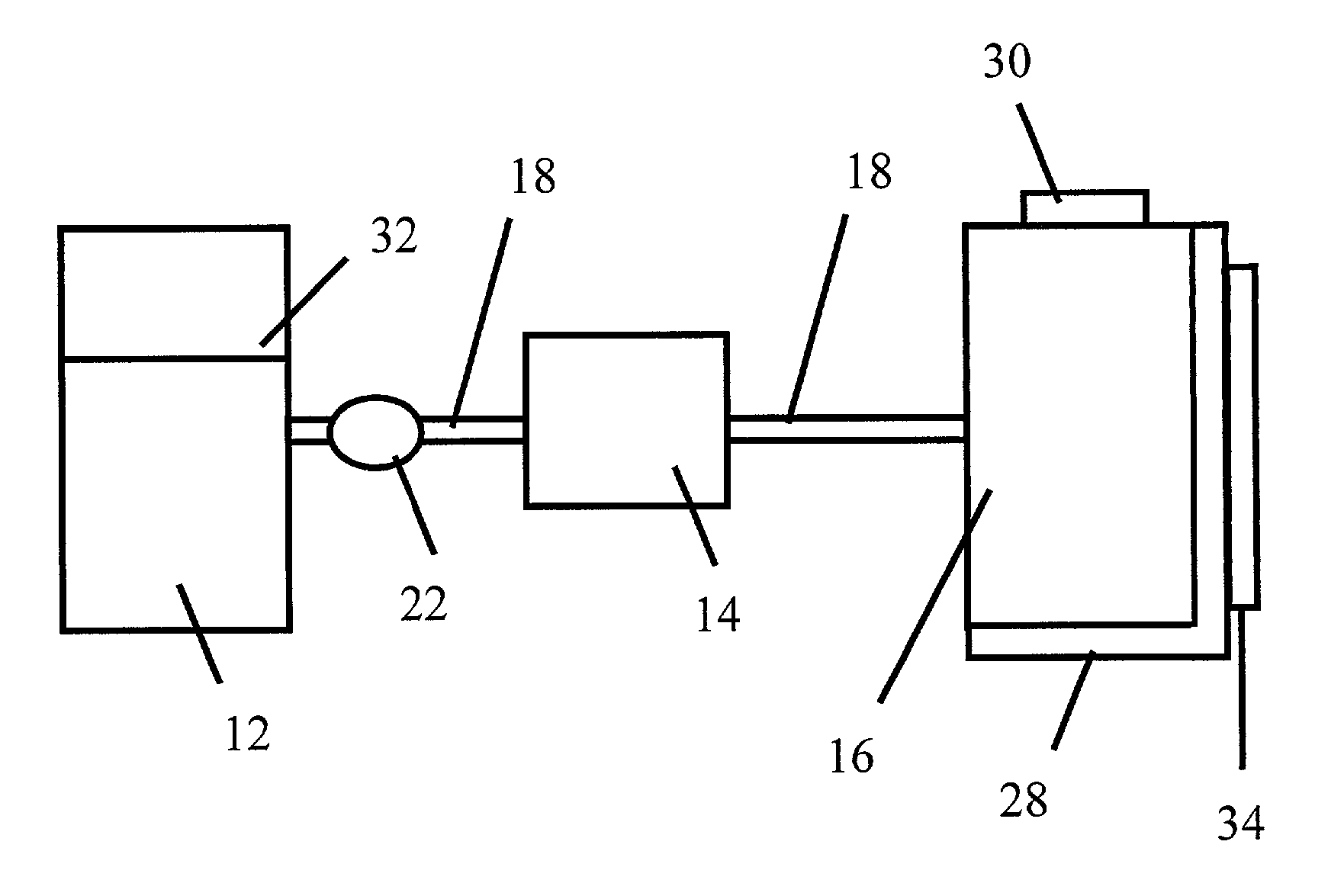

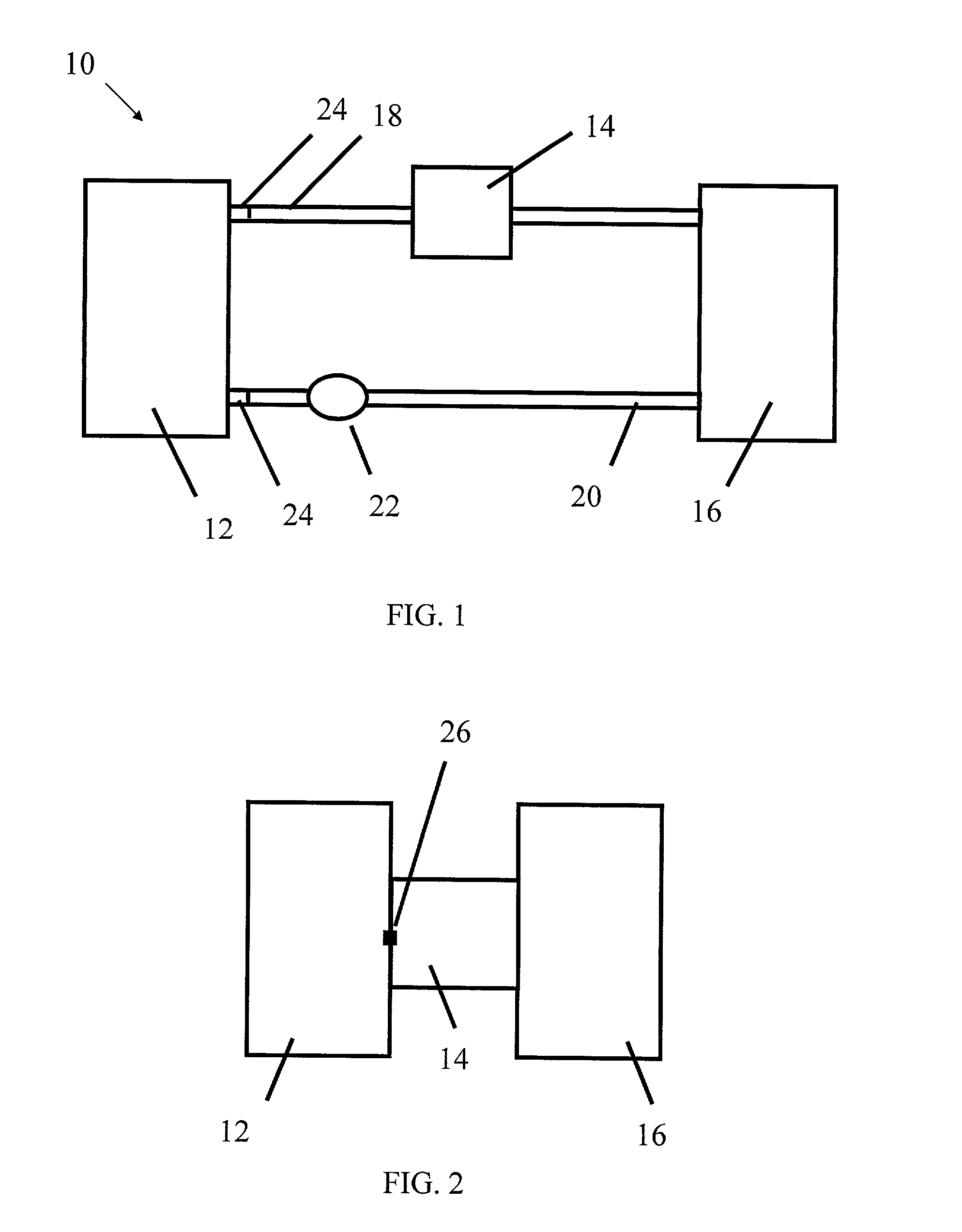

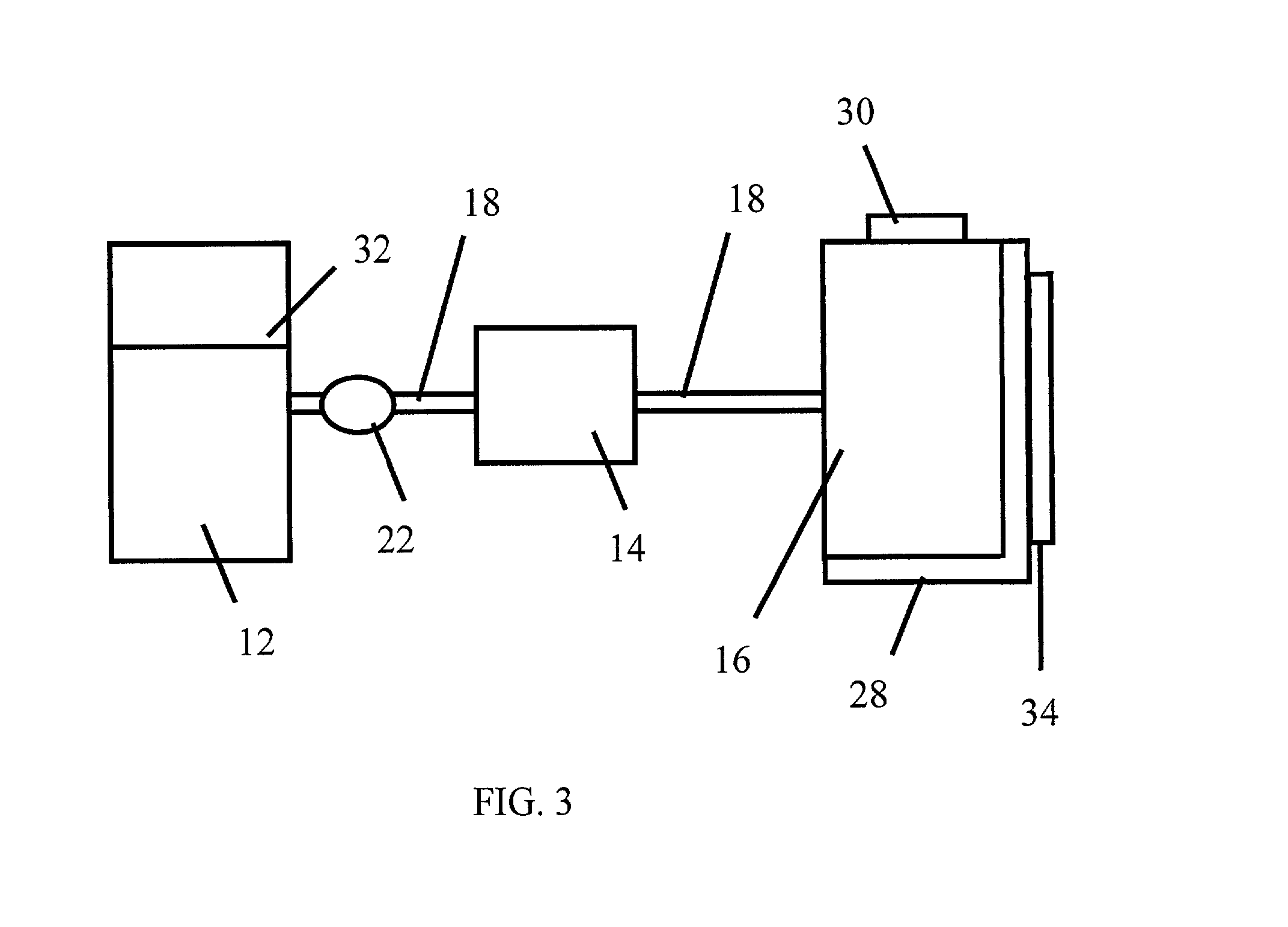

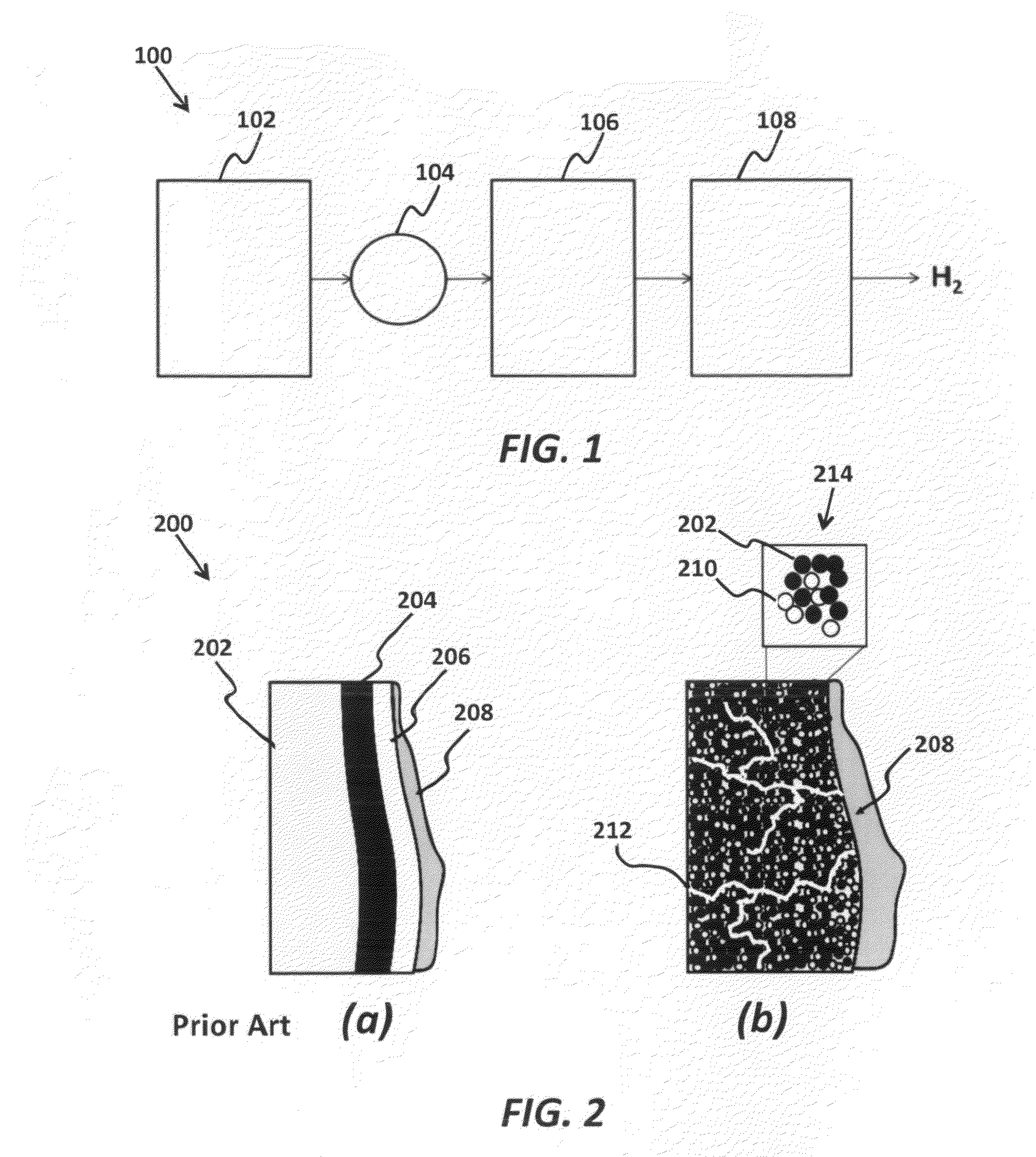

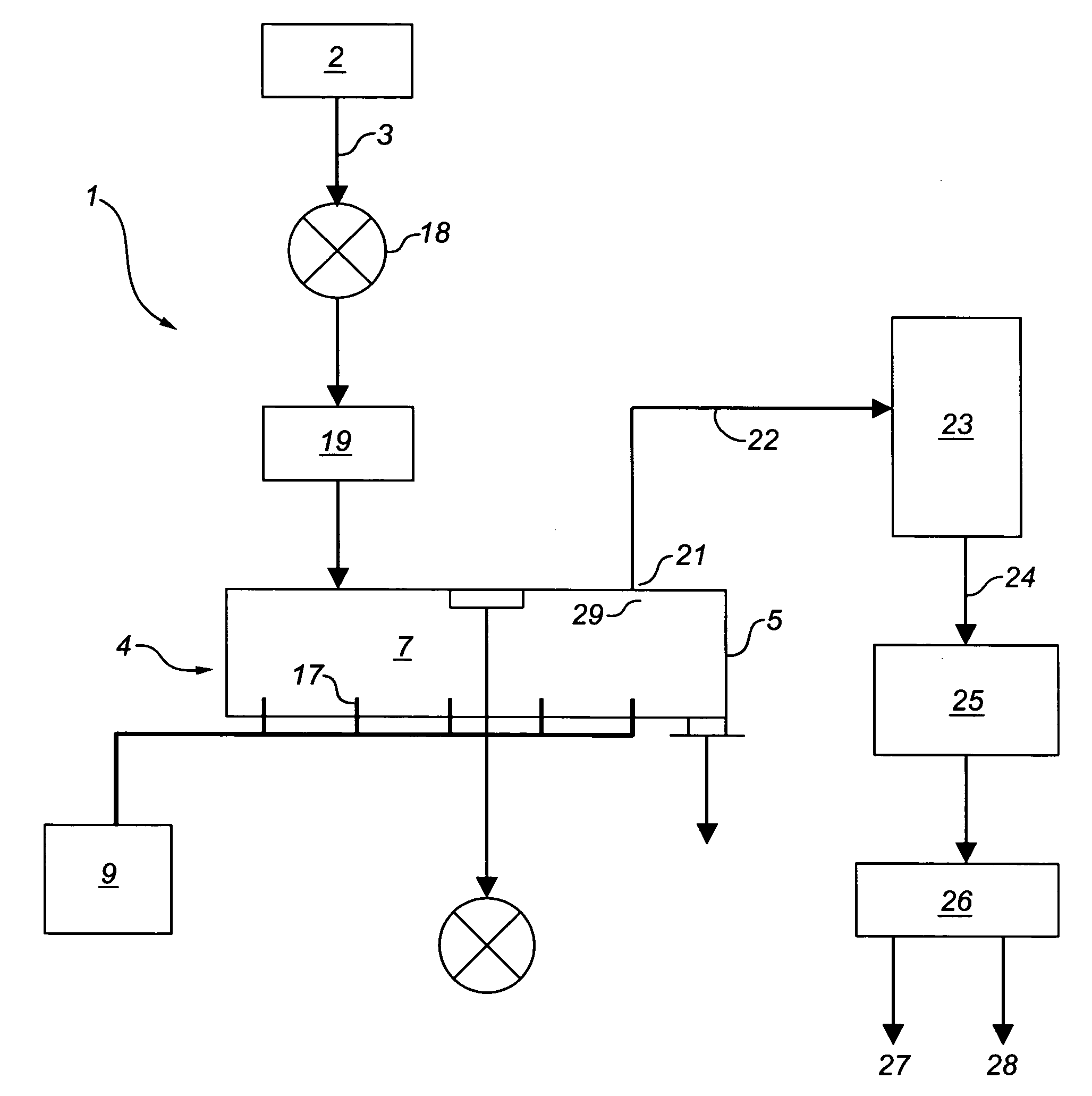

Water vapor transport power generator

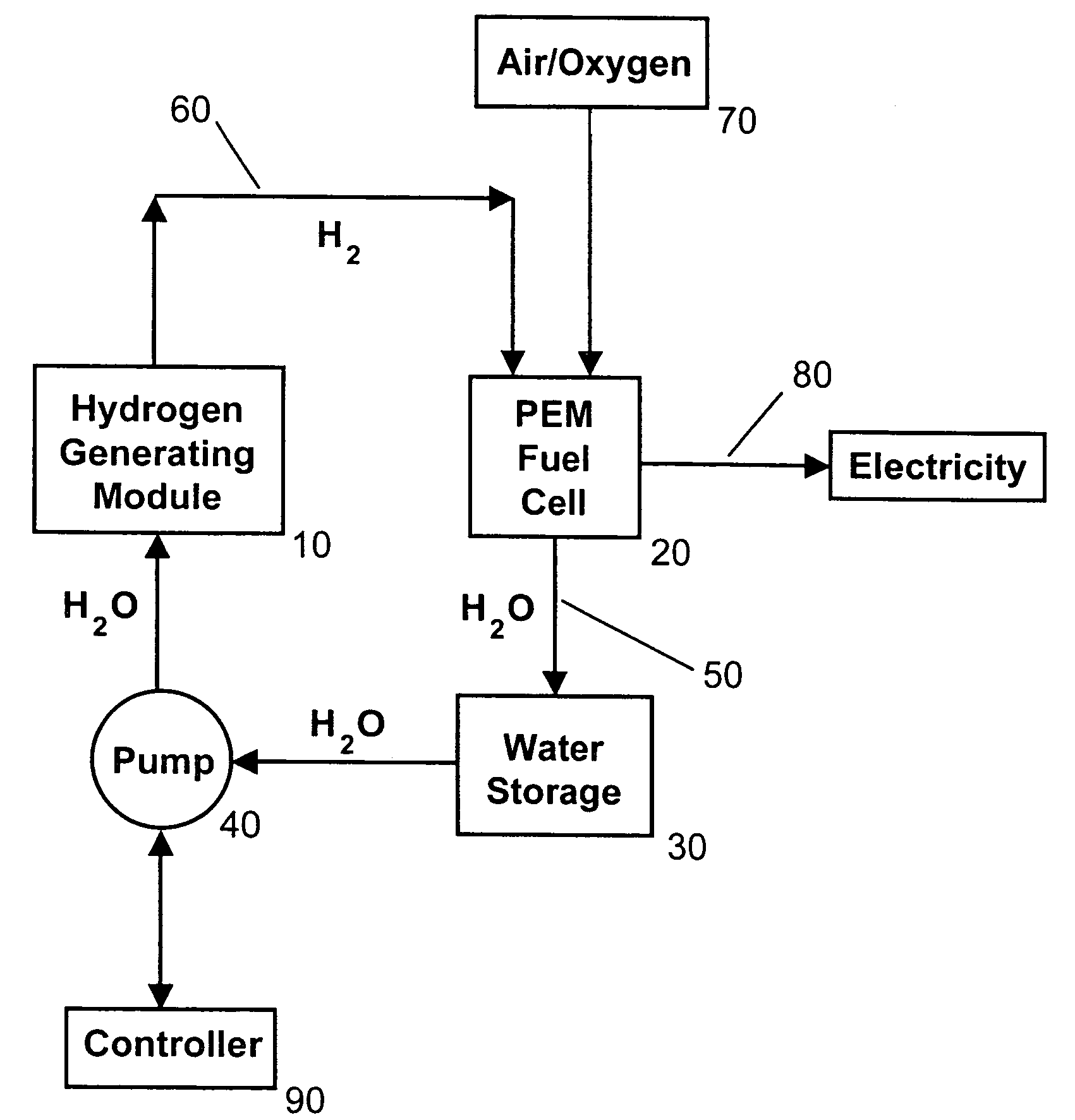

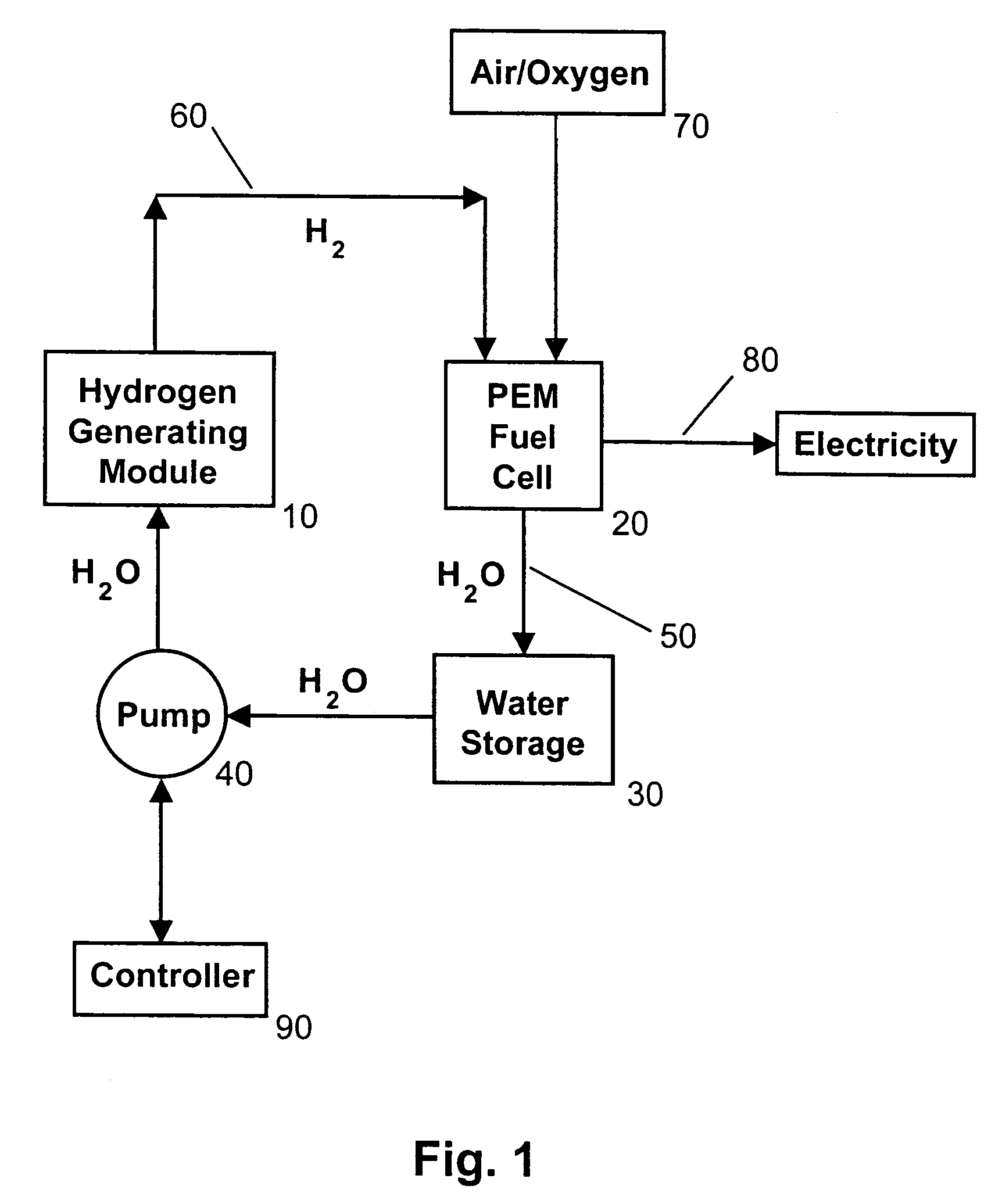

An improved system for generating electrical power using a fuel cell. More particularly, a system for generating hydrogen gas by reacting water vapor with a substantially non-fluid substance and transporting the generated hydrogen gas to the fuel cell which generates electrical power. Reacting water vapor with the non-fluid hydrogen generating substance rather than liquid water prevents caking of the non-fluid substance and deposition of byproducts onto the non-fluid substance that interfere with continued generation of hydrogen gas.

Owner:HONEYWELL INT INC

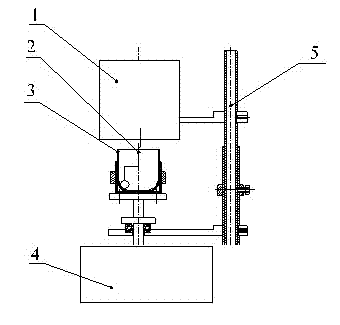

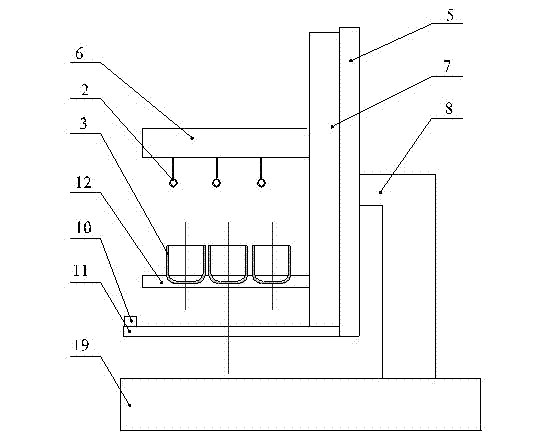

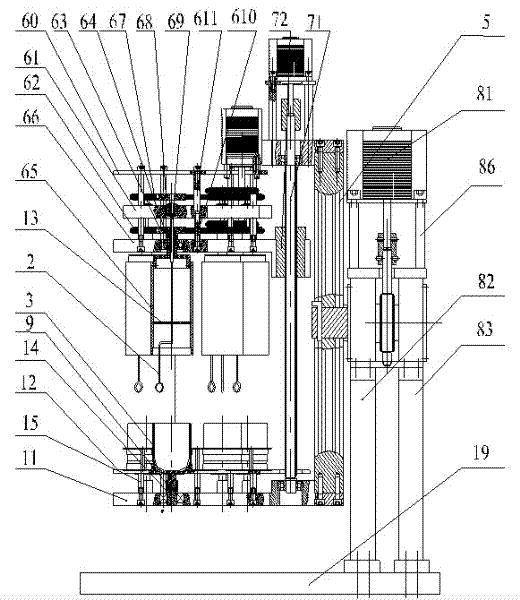

Stirring device with transmission type multi-crucible

ActiveCN102380328AIncrease profitAvoid unstable rotationMixing methodsMixer accessoriesBiochemical engineeringCrucible

The invention discloses a stirring device with a transmission type multi-crucible, which is characterized that a control mechanism is fixed on a bottom plate, a lifting device, an inclination device, a heterodromous rotation device and a crucible tray are fixed on the bottom plate. The transmission driven crucible and the heterodromous rotation device capable of heterodromously rotating a mixing wire are arranged on the upper part of the lifting device, the crucible tray capable of placing the multi-crucible is placed on the lower part of the lifting device, the inclination device fixed on the fixed pedestal is communicated with the heterodromous rotation device. The stirring device of the invention has the advantages of simple and compact structure, and simple operation, and is capable of effectively solving the problem for batch producing anthracite samples, and increasing the production number and the quality of the anthracite caking index samples.

Owner:江苏双星特钢有限公司

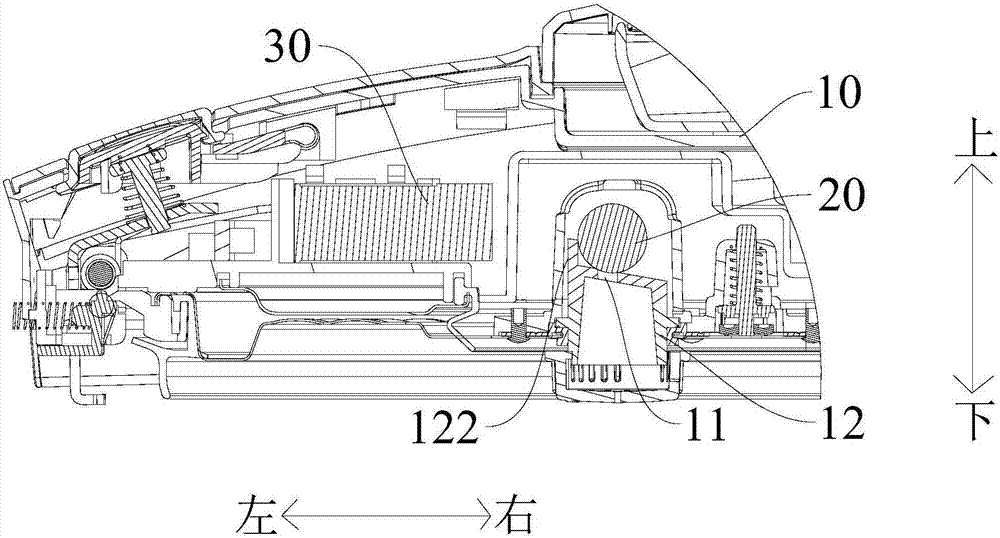

Electric cooker

ActiveCN107874601ASimple structureSimple pressure relief operationPressure-cookersElectricityEngineering

The invention discloses an electric cooker. The electric cooker comprises a cooker body, a cooker lid, a magnetic plugging structure and an electromagnetic driving device; a cooking cavity is definedin the cooker body; the cooker lid is arranged on the cooker body to open or close the cooking cavity and provided with a pressure relief opening; the magnetic plugging structure opens the pressure relief opening under the action of the gravity of the magnetic plugging structure; the electromagnetic driving device is arranged at one side of the magnetic plugging structure and used for generating magnetic force in an energized state so that the magnetic plugging structure can close the pressure relief opening. The electric cooker can achieve instantaneous pressure relief so that food can roll and be prevented from caking, and therefore the taste of the food can be improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Machine-transplanted rice seedling raising ground substance and production method thereof

ActiveCN101507410AGood qualityNo soreBio-organic fraction processingOrganic fertiliser preparationMicroorganismCaking

The invention relates to a rice seedling raising substrate and a production method thereof, in particular to a rice seedling raising substrate taking agricultural and forestal wastes as materials and mechanically transplanting rice seedlings, and a production method thereof. In the invention, organic wastes such as straws are taken as raw materials, fermented by various beneficial microorganisms, and prepared into an organic substrate with a fertilizer slow release and caking agent and a water retention agent. The rice seedling raising substrate has strong stress resistance and strong compatibility with mechanical rice transplanting technology, and makes the rice seedlings have good quality; and the technology of raising the rice seedlings by the substrate is simple, and has low cost and high success ratio.

Owner:HUNAN CHAIMIHE AGRI TECH DEV

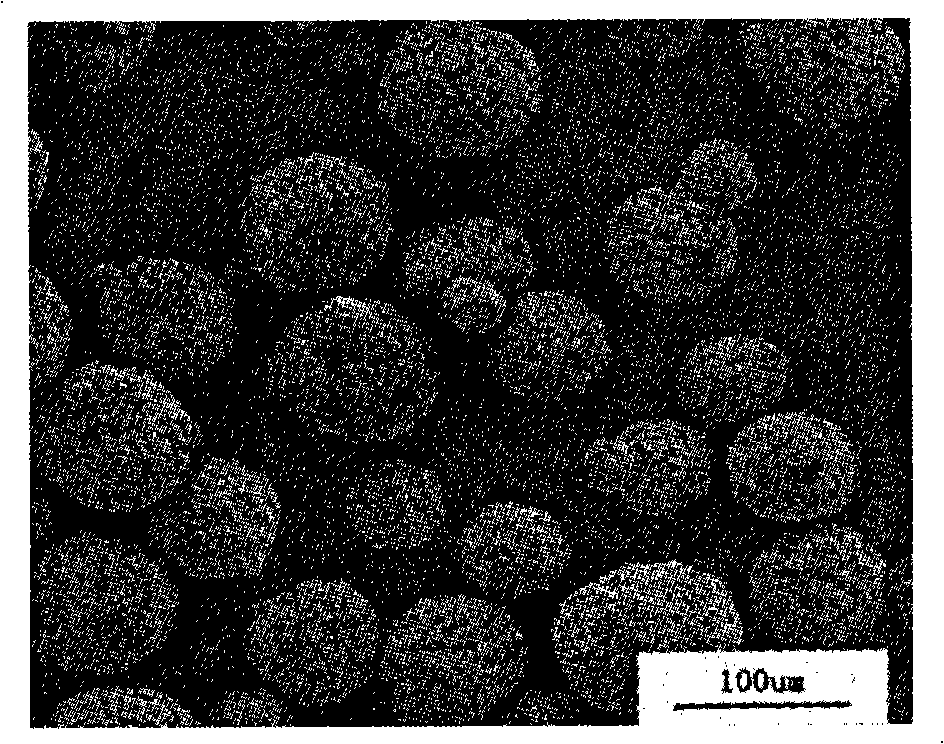

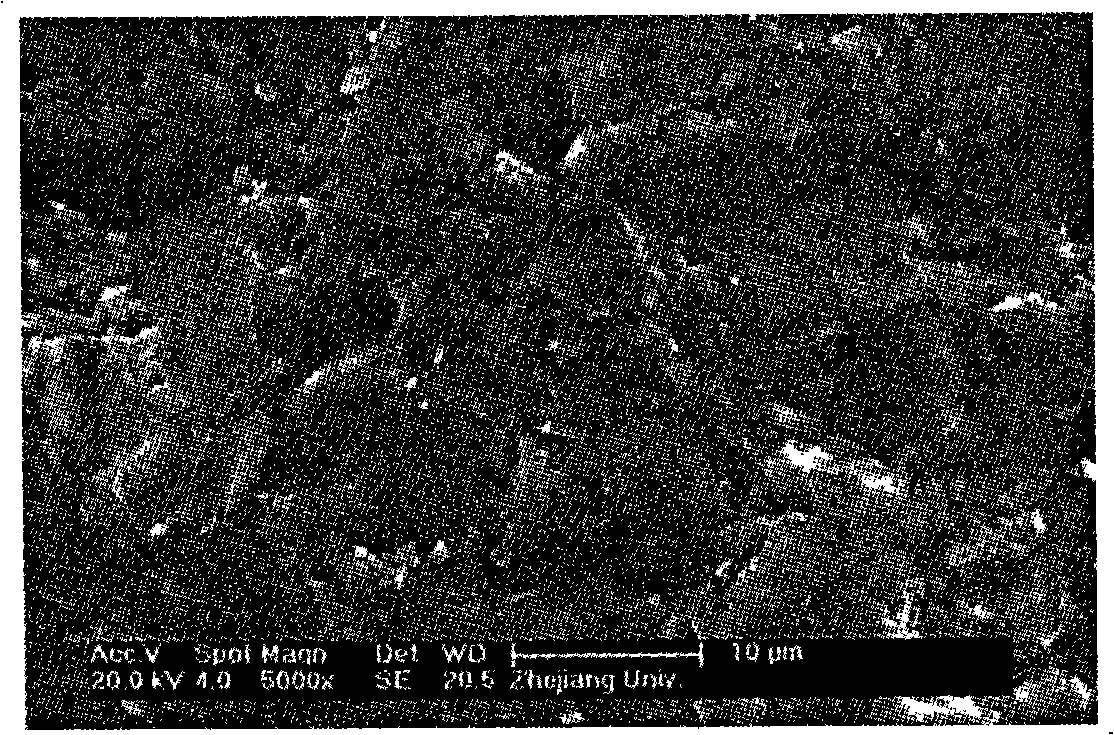

Reaction sintering silicon carbide ceramic and production method thereof

The invention relates to reactive sintering carborundum ceramics, which is characterized in that the weight percentages of the components are as following: carborundum is 80 to 95 percent, powdered carbon is 5 to 20 percent, and sintering accessory ingredient is 1 to 2 percent. The preparation method is as following: the raw materials are put into de-ionized water and caking agent, water-soluble macromolecule mixture collosol and dispersant are added; mixing by ball milling is carried out for 5 to 20 hours to form water-based carborundum sizing agent; spray dry technique is adopted to carry out spraying and drying the sizing agent, thereby obtaining carborundum compound powder amyloplastid; the amyloplastid is carried out dry pressing to obtain carborundum ceramics biscuits; the biscuits are put into a vacuum response sintering furnace for siliconizing and sintering; preparing the reactive sintering silicon carbide ceramics at the temperature of 1500 to 1800 DEG C after heat preservation for 1 to 5 hours. The reactive sintering silicon carbide ceramics of the invention has the advantages of scientific and rational raw materials and mixture ratio, safe production method and low cost. The prepared carborundum ceramics can meet requirements of mechanical seal under special working conditions.

Owner:浙江东新新材料科技有限公司

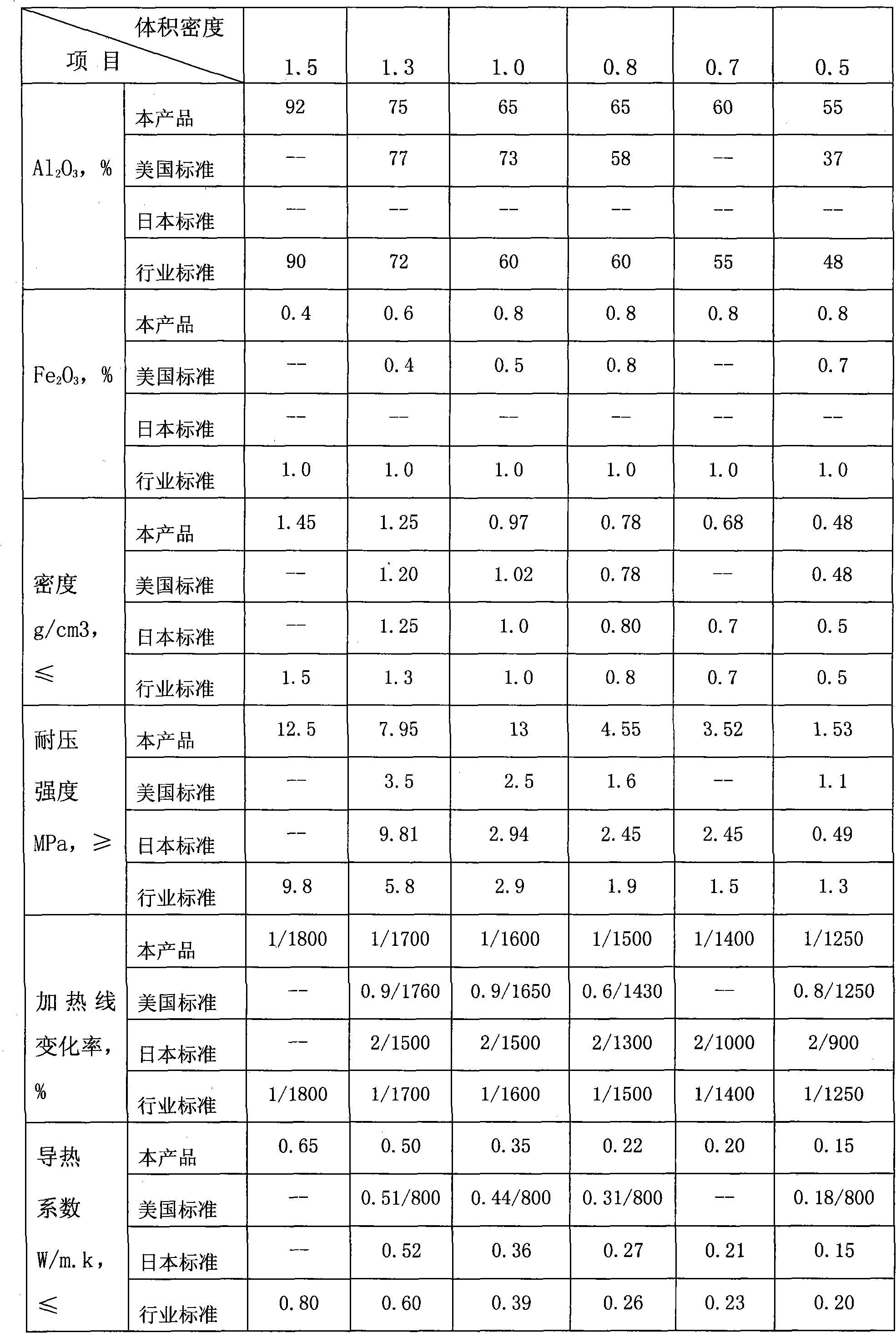

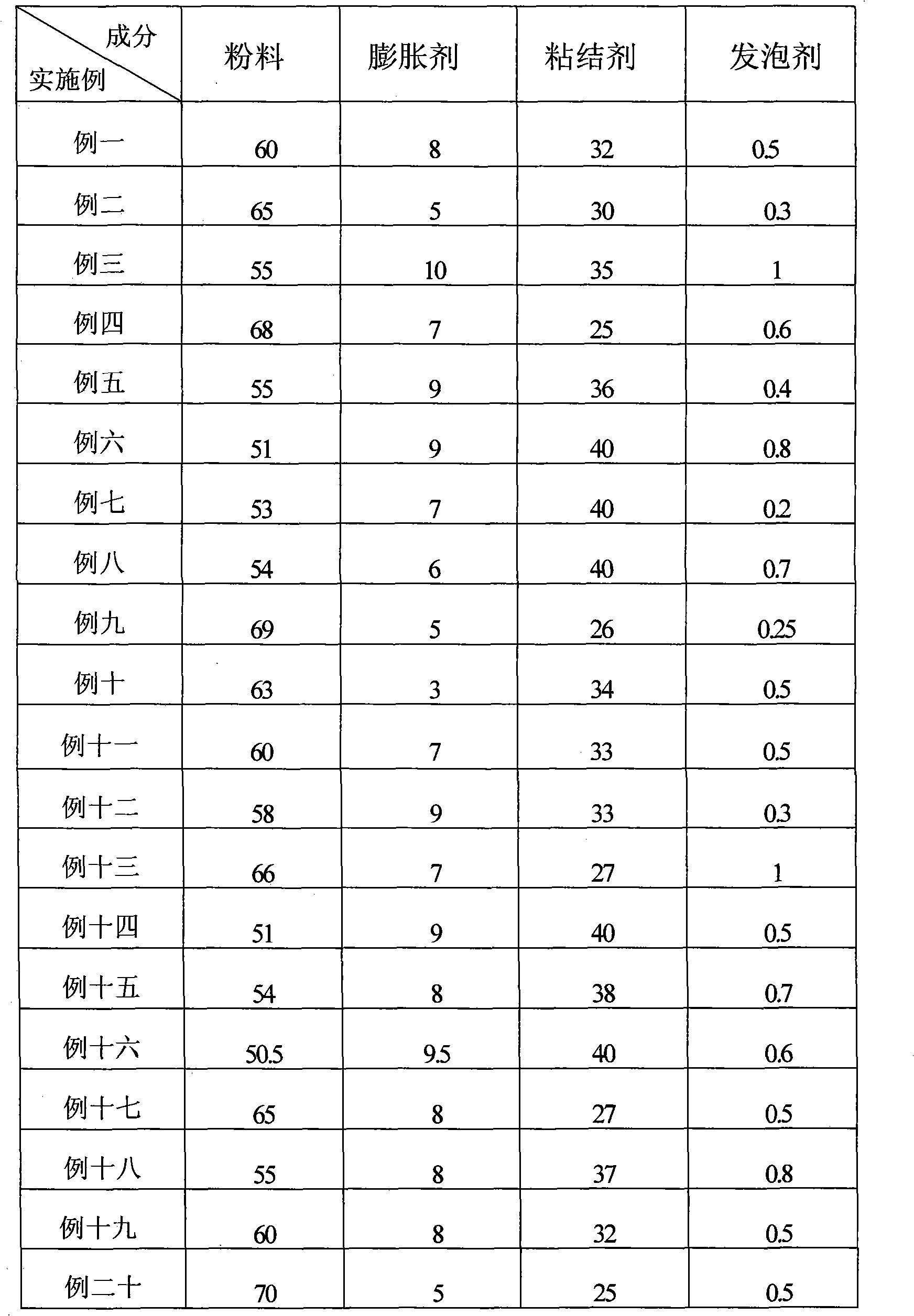

Ultra-microporous lightweight insulated firebrick and manufacture method thereof

The invention discloses an ultra-microporous lightweight insulated firebrick and a manufacture method thereof. The ultra-microporous lightweight insulated firebrick is prepared by the following raw materials in percentage by weight: powder mainly comprising 50-70 Al2O3 and SiO2, 5-10 expanding agent, 25-40 caking agent and 0.2-1.0 external foaming agent. The manufacture method comprises the following steps: uniformly mixing and stirring the raw materials into pasty material; mixing the foaming agent and water according to a ratio of 1: (15-20); adding the mixture to the pasty material to mix uniformly; then, casting into brick blanks; and drying and keeping the brick blanks at a temperature of 1200-1600 DEG C for 6-8 hours. The firebrick has the advantages of high compressive strength, low coefficient of heat conductivity and low linear change ratio and can be directly used for a fireproof coating of thermal equipment so that the product has the lightweight insulation and fireproofness functions and good insulation effect and is beneficial to energy saving and environmental protection. Compared with the prior art, the invention has obvious economic benefits.

Owner:郑州东方炉衬材料有限公司

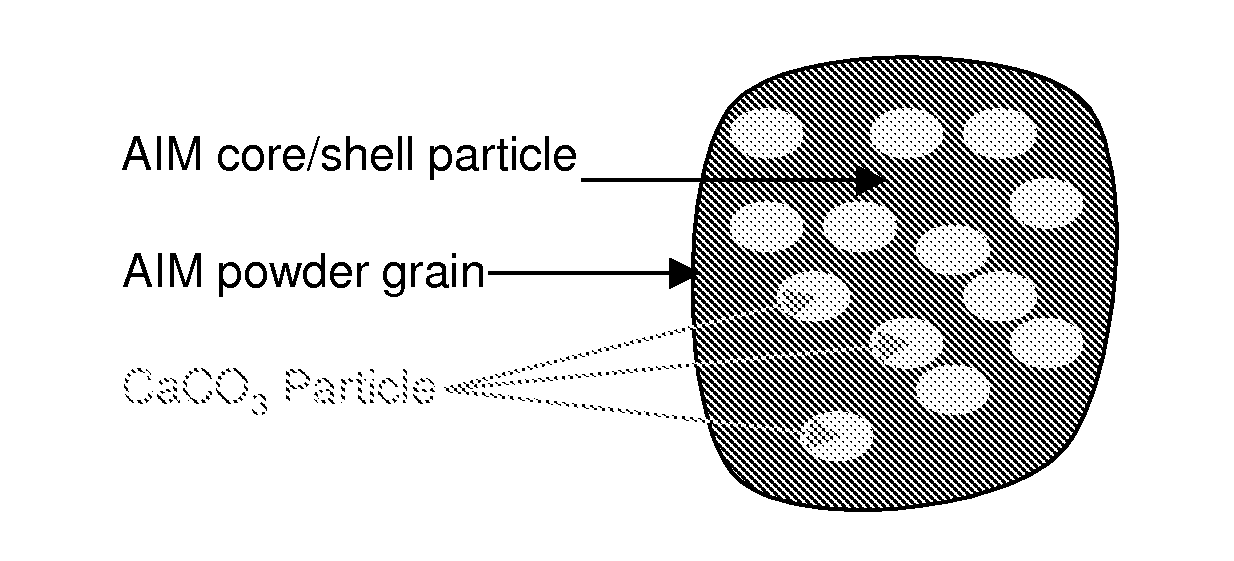

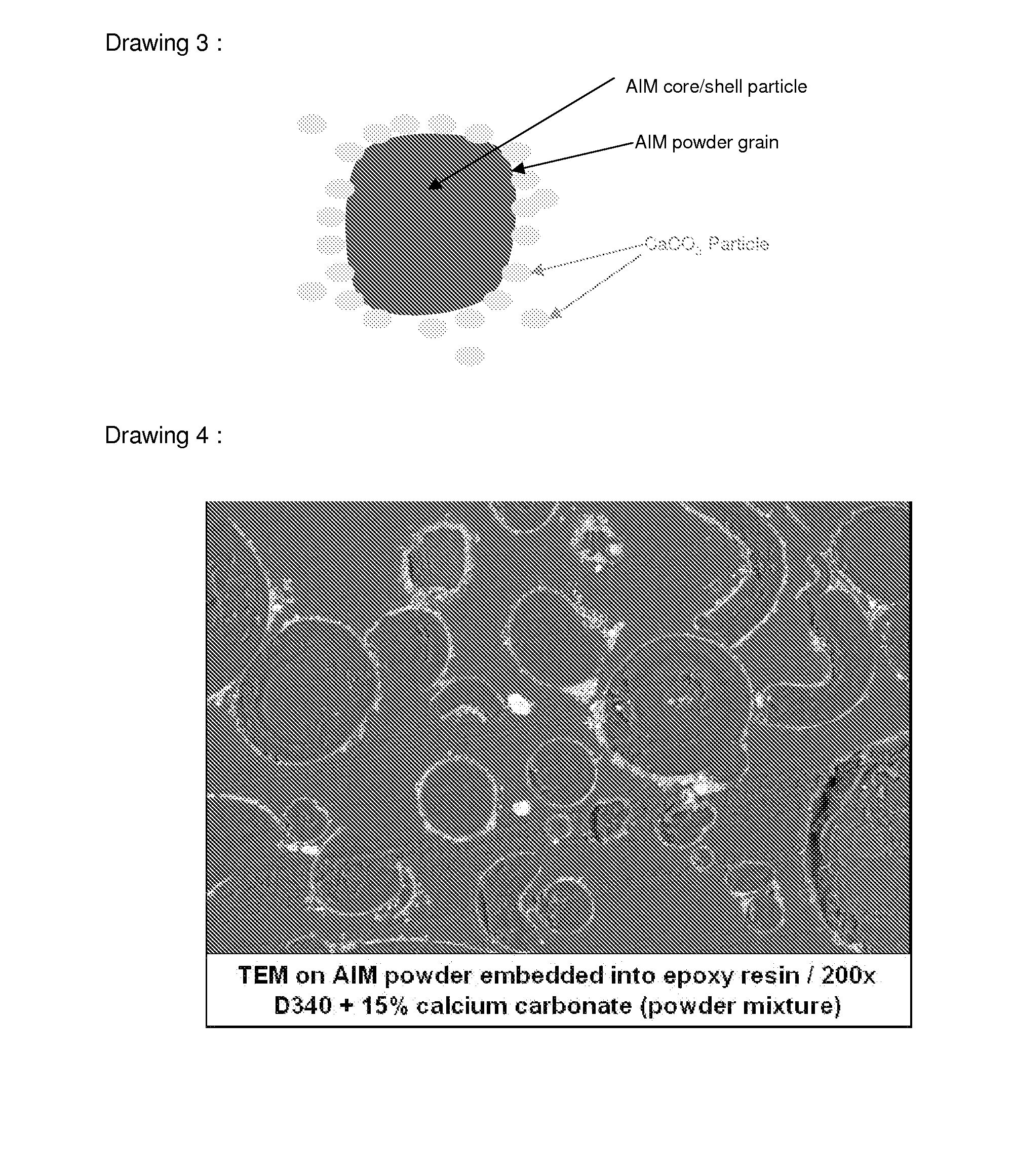

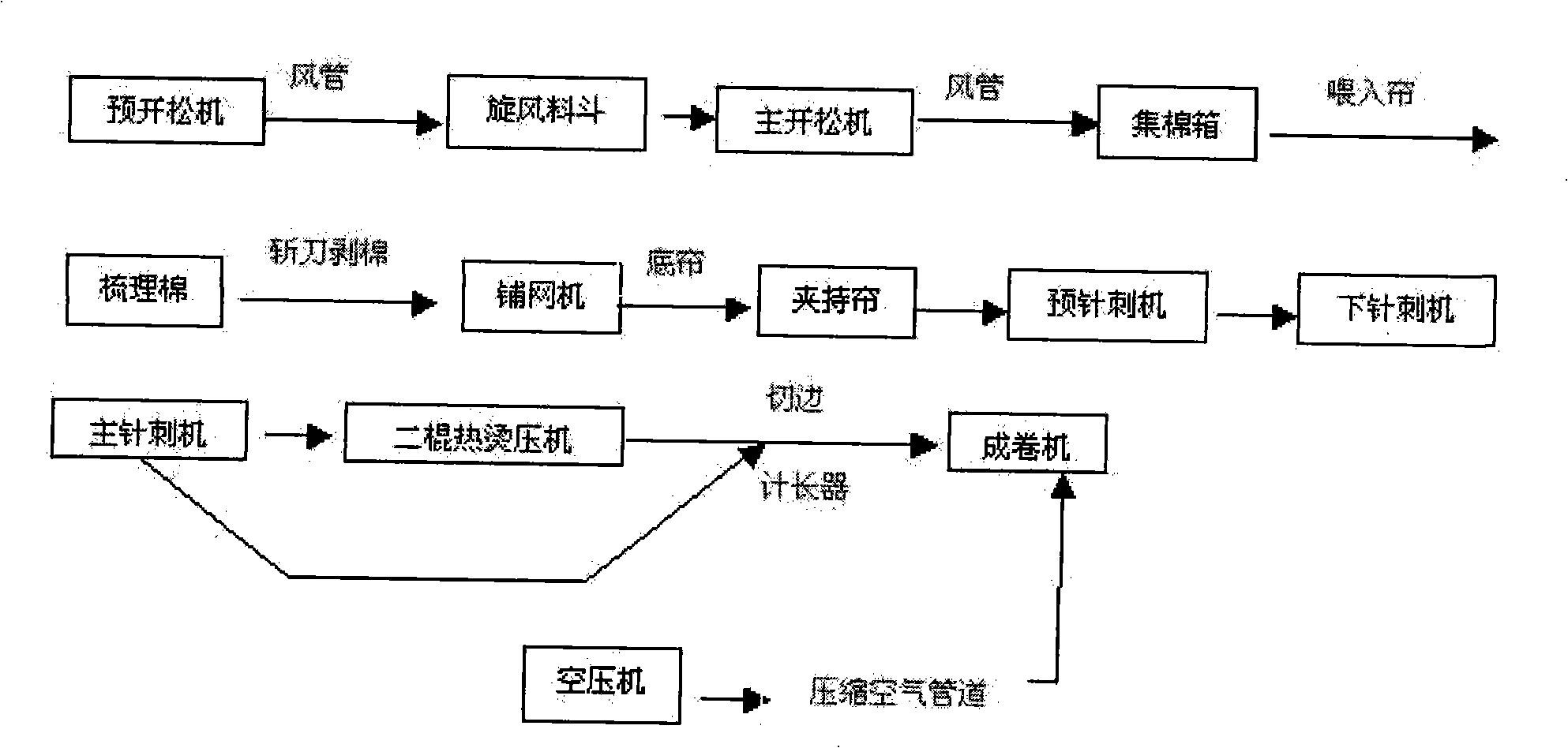

Hybrid impact modifiers and method for preparing the same

ActiveUS20090018248A1Improve impact performanceGood effectNanotechnologyPigment pastesThermoplasticRecovery method

The present invention relates to hybrid impact modifiers prepared by:either spray drying, coagulation, freeze coagulation or other known recovery methods of a mixture of a latex or slurry of standard impact modifiers and a slurry of a mineral filler,either simultaneous drying (by spray-drying, coagulation other known recovery possible methods) of (i) a latex or slurry of standard impact modifiers and of (ii) a slurry of a mineral filler,further to the coagulation or freeze coagulation, if any, there is a filtration and drying step to recover these hybrid impact modifiers as a powder.The host polymers to be impact modified, can be any thermoplastic. Advantageously it can be polyvinyl chloride (PVC), polyamide (PA), polymethyl methacrylate (PMMA), polystyrene (PS), polycarbonate (PC), thermoplastic polyesters such as polyethylene terephthalate (PET), polybutylene terephthalate (PBT), polycyclohexanedimethanol terephthalate, and polyolefins such as polyethylene (PE), polypropylene (PP), and any other matrix polymer which can be improved by an impact modifier.The present invention also relates to the use of said hybrid impact modifiers in thermoplastic polymers.The present invention also relates to a thermoplastic polymer containing said hybrid impact modifiers.The present invention also relates to hybrid impact modifiers having improved powder properties (flowability, lumping / caking resistance, segregation between the organic and the mineral parts).The present invention also relates to a thermoplastic polymer containing said hybrid impact modifiers with better dispersion homogeneities.

Owner:ARKEMA FRANCE SA

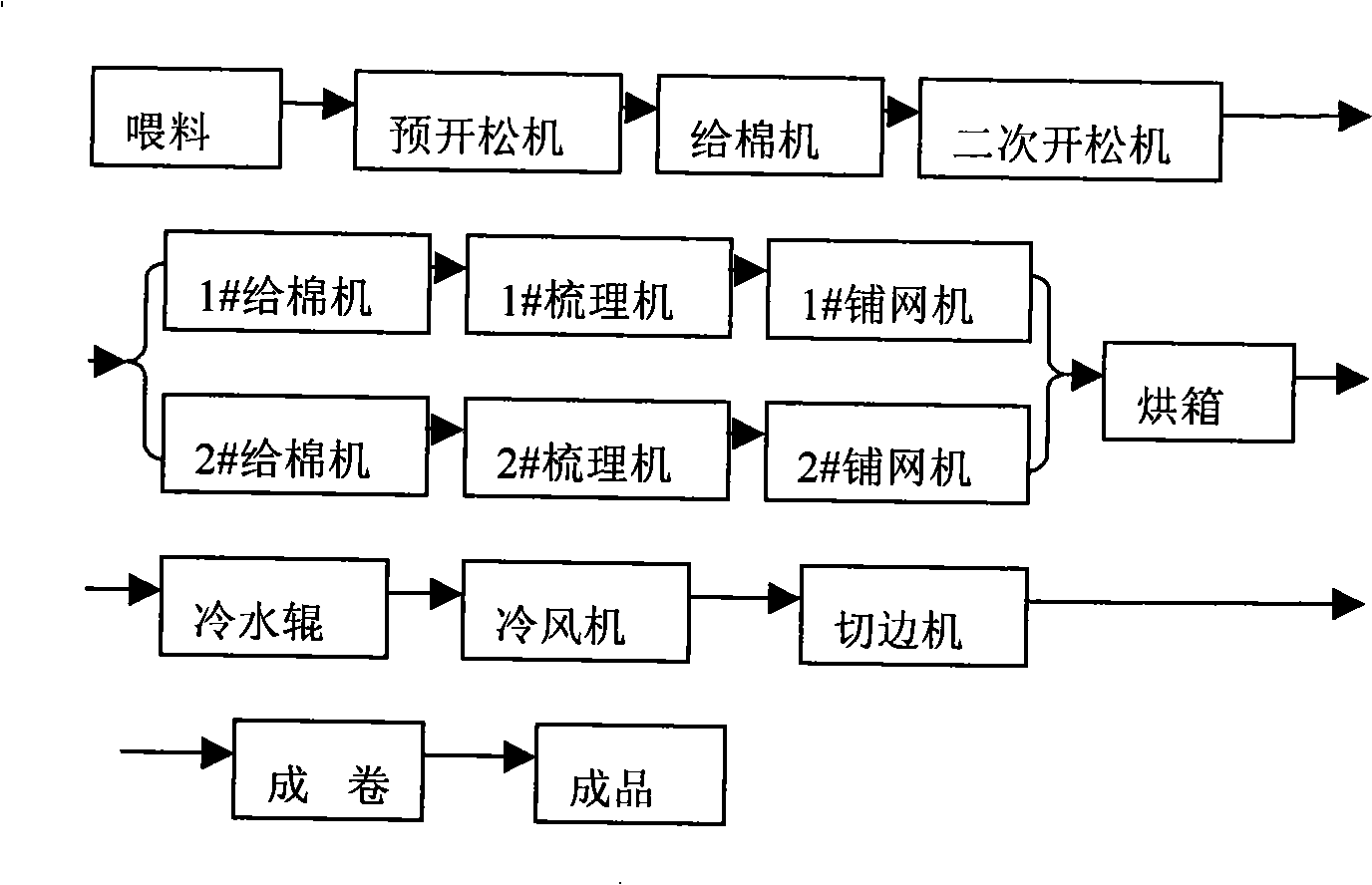

Fire retardant cotton nonwoven fabrics and manufacture method thereof

InactiveCN101307528AImprove flame retardant performanceGood anti-melting effectHeating/cooling textile fabricsNon-woven fabricsCardingPolymer science

The invention discloses an flame retardant non-woven cotton fabric, comprising anti-fcell flame retardant fiber and washing / washing composite hot melting short fiber, wherein, the weight percentage of the anti-fcell flame retardant fiber is between 70 and 90 percent, the balance is the washing / washing composite hot melting short fiber; the two fibers are stuck into an integrated whole by the hot wind heating and / or are penetrated together by prickling fibers to combine into the non-woven fabric. The method for producing the non-woven cotton fabric comprises the processes of mixing, opening, carding, mesh placing, moulding processing, etc. The moulding processing method has the needle point method and the through-air method. The flame retardant non-woven cotton fabric adopts the prescription of mainly taking the anti-fcell flame retardant fiber and solves the problems of the flammability of the terylene, dropping of the fusion and the flammability of the viscose. The washing / washing composite hot melting short fiber is added to increase the caking coefficient so that the fibers are conglutinated evenly. The unique processing flow ensures that the inflaming retarding non-woven cotton fabric has high tension intensity and anti-breakage intensity as well as certain elasticity and bulkiness.

Owner:DONGGUAN LIANYING NONWOVEN TECH

Method for manufacturing rigid carbon fiber heat insulating material and surface treatment method

The invention relates to method for manufacturing a rigid carbon fiber heat insulating material and a surface treatment method. In the method, mashed carbon fiber and caking agent are fully mixed with dispersant solution and molded by vacuum filtration and compression; infusibilization and carbonization treatment are carried out on the preformed product to obtain a rigid heat insulating material with high strength, low heat conductivity and low density. Surface treatment is carried out on the rigid heat insulating material for improving the surface properties, including surface polishing, graphite paper and carbon cloth paste, surface coating high-temperature hardening treatment, and the like. The rigid heat insulating material prepared by the method has the advantages of good performance of heat insulation, low heat capacity, low density, high strength, and the like.

Owner:辽宁奥亿达新材料股份有限公司

Magnesium-alloy metal-type casting coating and preparation method thereof

ActiveCN101658899ASimple componentsEasy to prepareFoundry mouldsFoundry coresSodium BentoniteSuspending Agents

The invention relates to a magnesium-alloy metal-type casting coating and a preparation method thereof. Magnesia and forsterite are used as refractory aggregates; titania, asbestos powder or talcum powder or diatomite, and the like are added as heat-insulation aggregates; a mixed caking agent with favorable high-temperature caking property and a compound suspending agent are selected; and boric acid is added as a flame retardant. The preparation method comprises the following steps: mixing the magnesia, the forsterite, the titania, and the asbestos powder or talcum powder or diatomite, and preparing A after ball milling; mixing the caking agent and bentonite, and adding water to activate so as to obtain B; mixing the boric acid, sodium carboxymethyl cellulose and polyacrylamide, and addingwater to activate so as to obtain C; and finally, mixing A, B and C, and carrying out ball milling or colloid milling for more than 30 minutes to obtain the magnesium-alloy metal-type casting coating. The coating has the advantages of favorable heat insulation, caking property, coating property, flame retardance, stability and durability, is beneficial to continuous production and convenient forobtaining magnesium-alloy metal-type castings with favorable surface quality and superior performance, and prolongs the service life of moulds.

Owner:SHANGHAI JIAO TONG UNIV

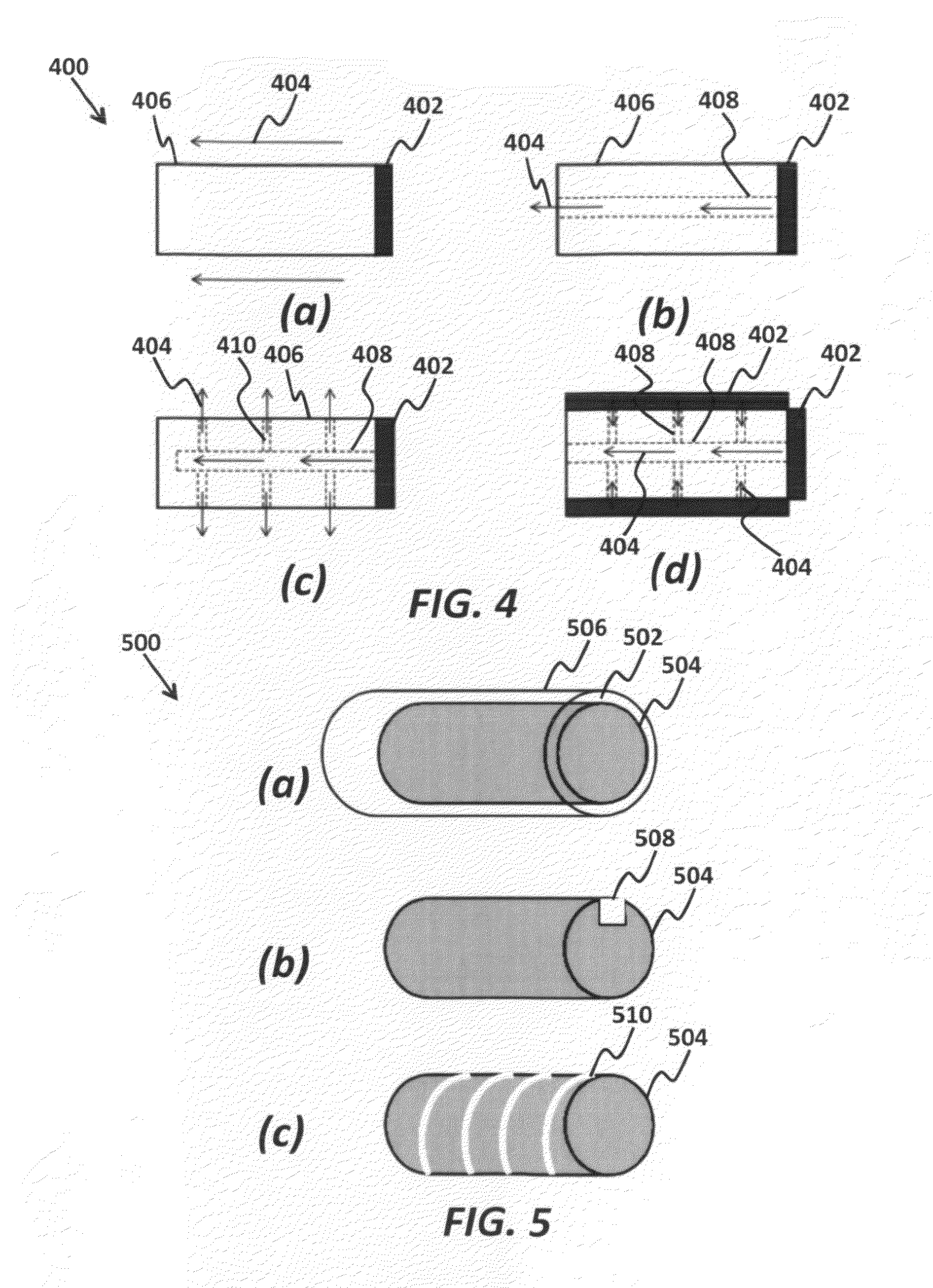

Method of generating hydrogen gas from sodium borohydride

ActiveUS7306780B1Rapid and complete reactionEliminate needPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical/physical/physico-chemical microreactorsClosed loopCobalt

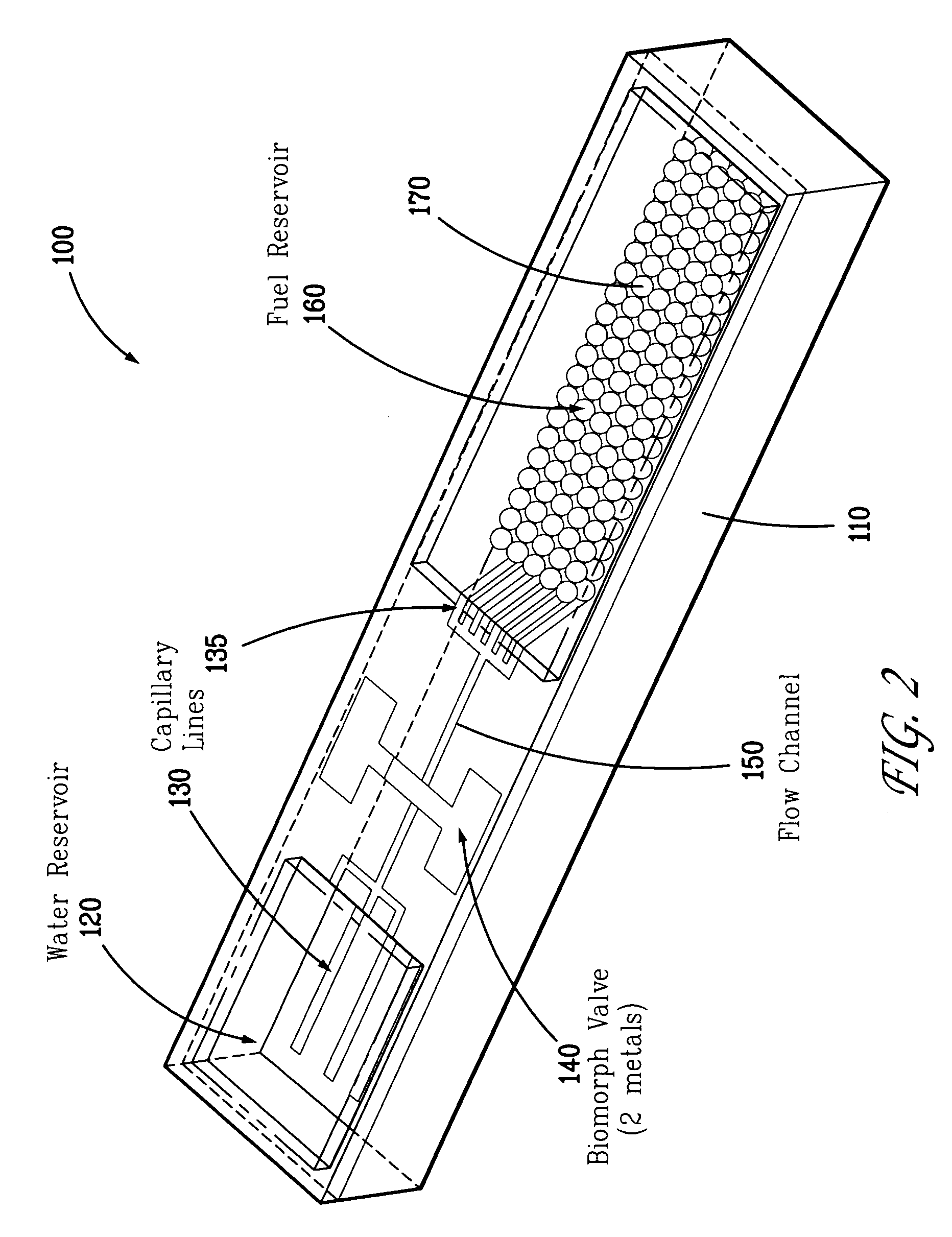

A compact solid source of hydrogen gas, where the gas is generated by contacting water with micro-disperse particles of sodium borohydride in the presence of a catalyst, such as cobalt or ruthenium. The micro-disperse particles can have a substantially uniform diameter of 1-10 microns, and preferably about 3-5 microns. Ruthenium or cobalt catalytic nanoparticles can be incorporated in the micro-disperse particles of sodium borohydride, which allows a rapid and complete reaction to occur without the problems associated with caking and scaling of the surface by the reactant product sodium metaborate. A closed loop water management system can be used to recycle wastewater from a PEM fuel cell to supply water for reacting with the micro-disperse particles of sodium borohydride in a compact hydrogen gas generator. Capillary forces can wick water from a water reservoir into a packed bed of micro-disperse fuel particles, eliminating the need for using an active pump.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

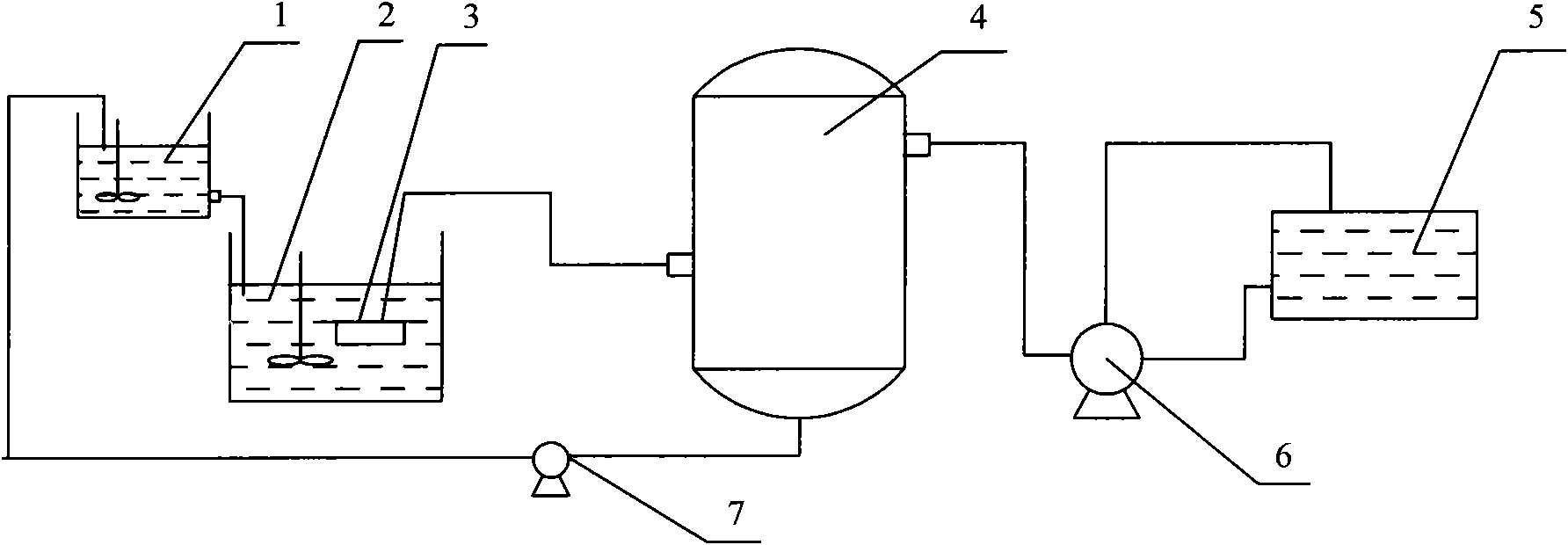

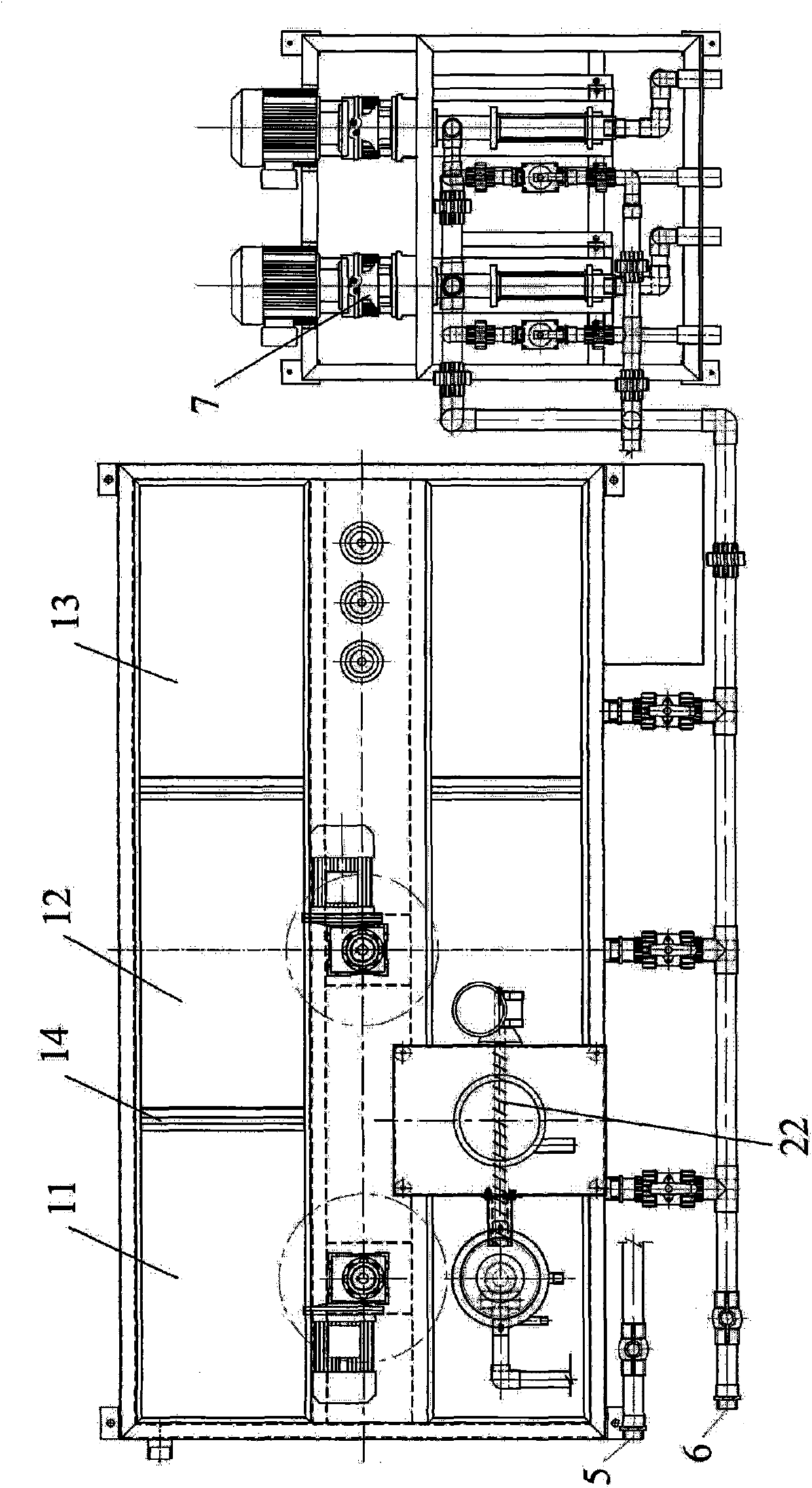

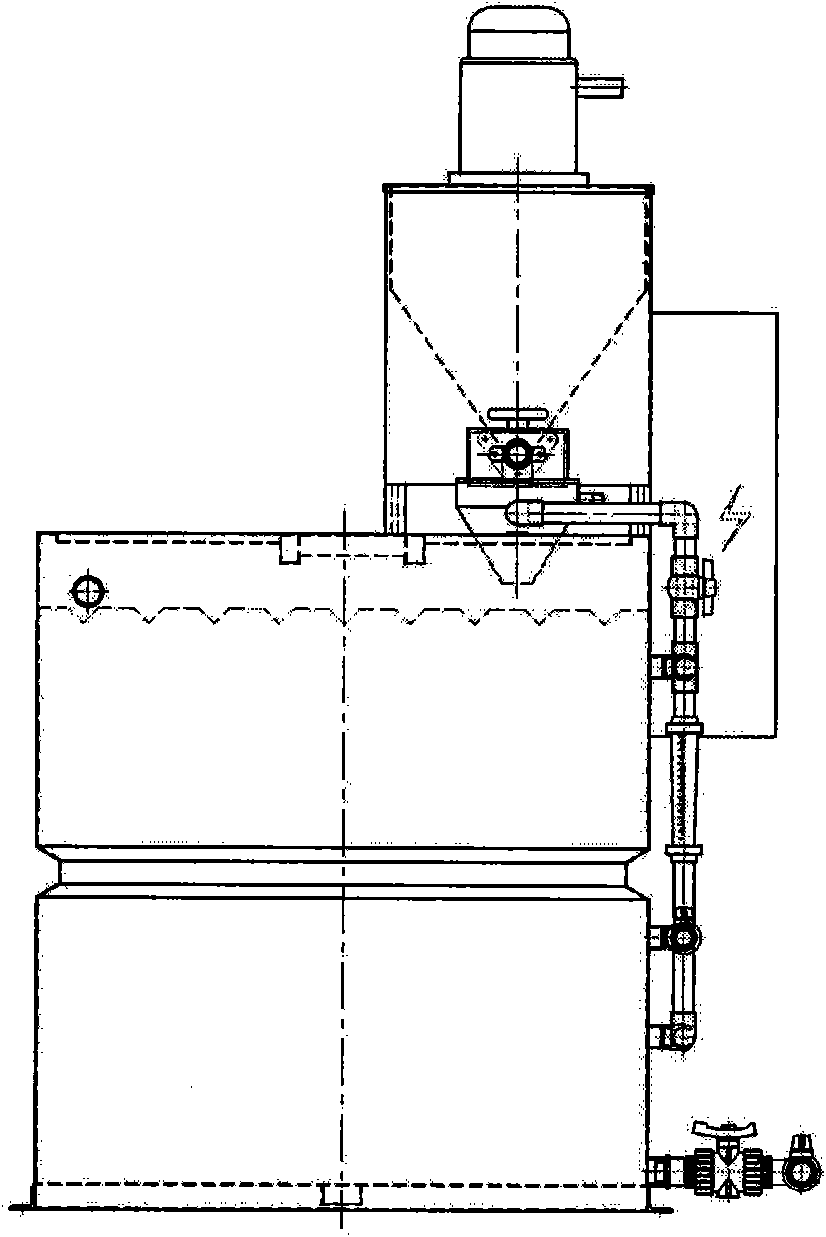

Automatic dosing device for sewage treatment

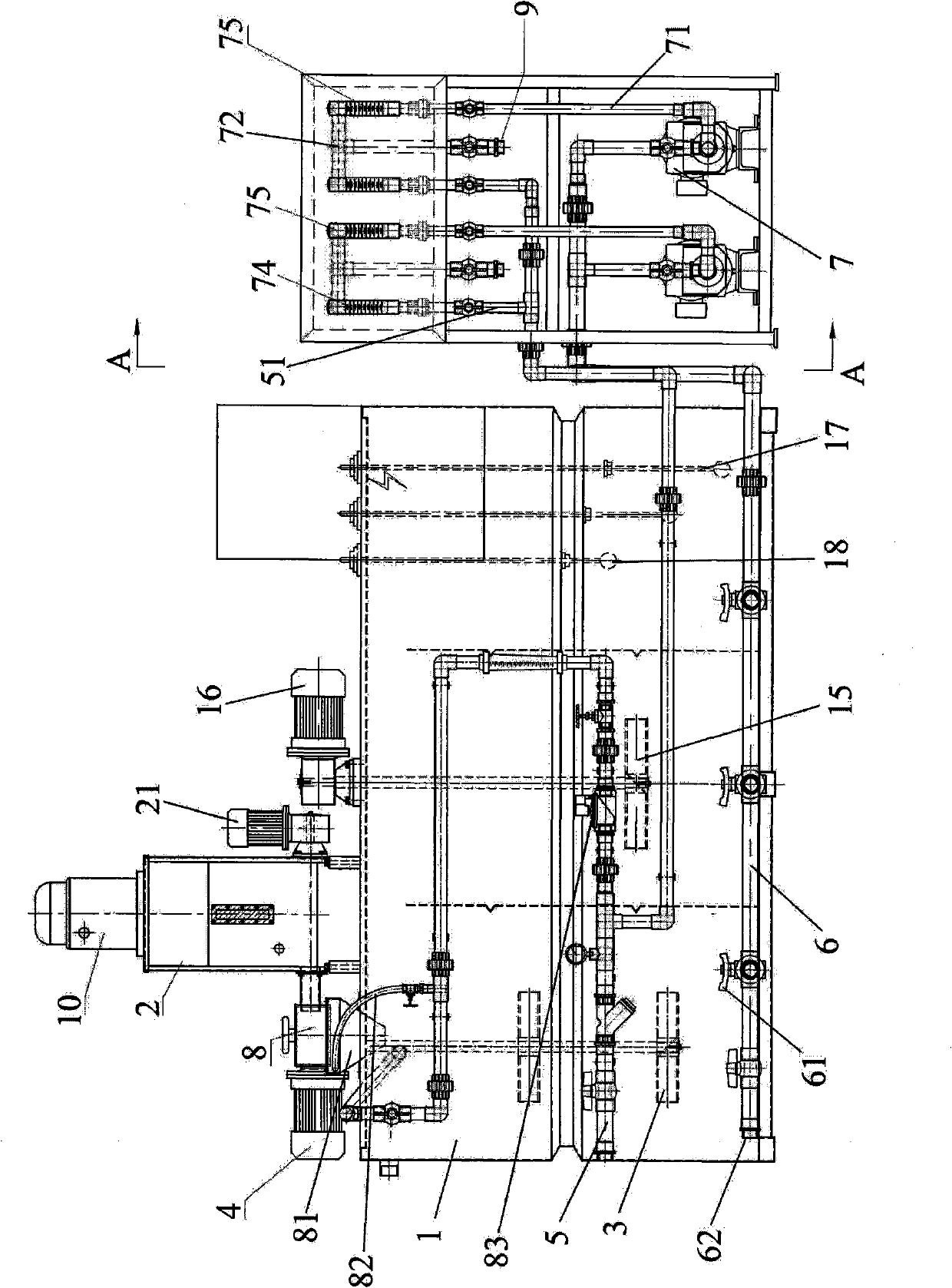

InactiveCN102020406AStir wellStable concentrationSludge treatment by de-watering/drying/thickeningLow speedMedicine

The invention discloses an automatic dosing device for sewage treatment, which consists of a medicine dissolving box, a medicinal powder dosing device, a medicine dissolving mixer, a mixer driving motor, a water inlet pipe, a medicine outlet pipe and a dosing pump. A pre-infiltrating device is arranged between the medicinal powder dosing device and the medicine dissolving box; the medicine dissolving box are separated by two overflow weirs to form a dissolving tank, a curing tank and a storing tank which are adjacent in turn; and a homogenizing stirrer is arranged in the curing tank. The pre-infiltrating device is arranged in the automatic dosing device for sewage treatment and is used for soaking dry flocculant powder, medicine solution flows into the dissolving tank by means of gravity and is stirred and mixed, the curing tank and the storing tank are arranged, low-speed stirring is carried out in the curing tank, and medicine solution meets the requirements of homogenization, curing and activity; the medicine solution passes through the overflow weirs to flow into the solution storing tank, so that the dissolving and stirring of the dry powder, the homogenization and curing of the solution and the dosing of the liquid medicine are synchronously carried out, and the efficiency and the liquid medicine utilization rate are improved; and the dry powder is accurately weighed, the caking of the dry powder is avoided, the concentration of the liquid medicine is ensured, and the medicine solution can be diluted on line according to requirement of actual application concentration.

Owner:开源环保(集团)有限公司

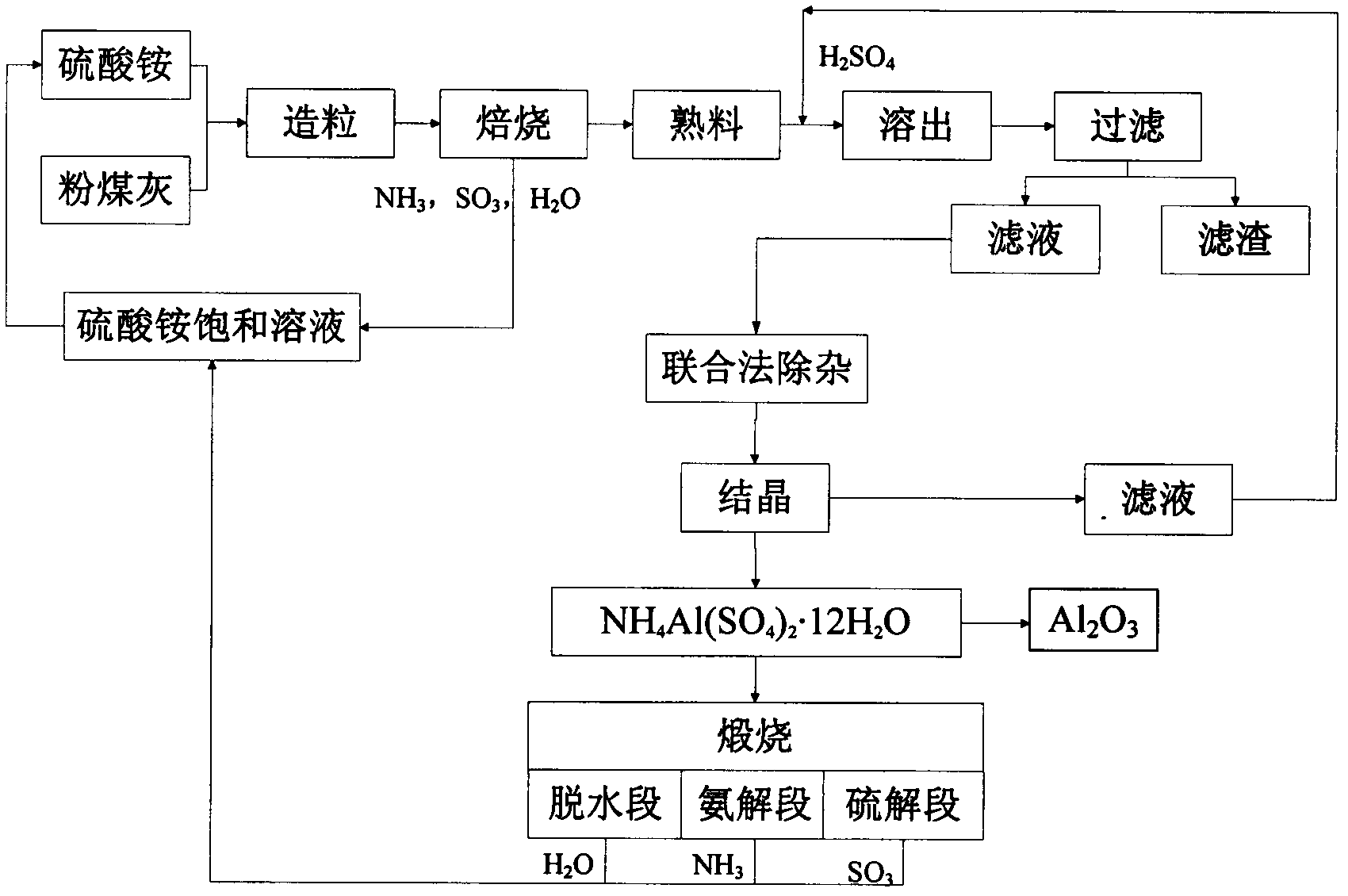

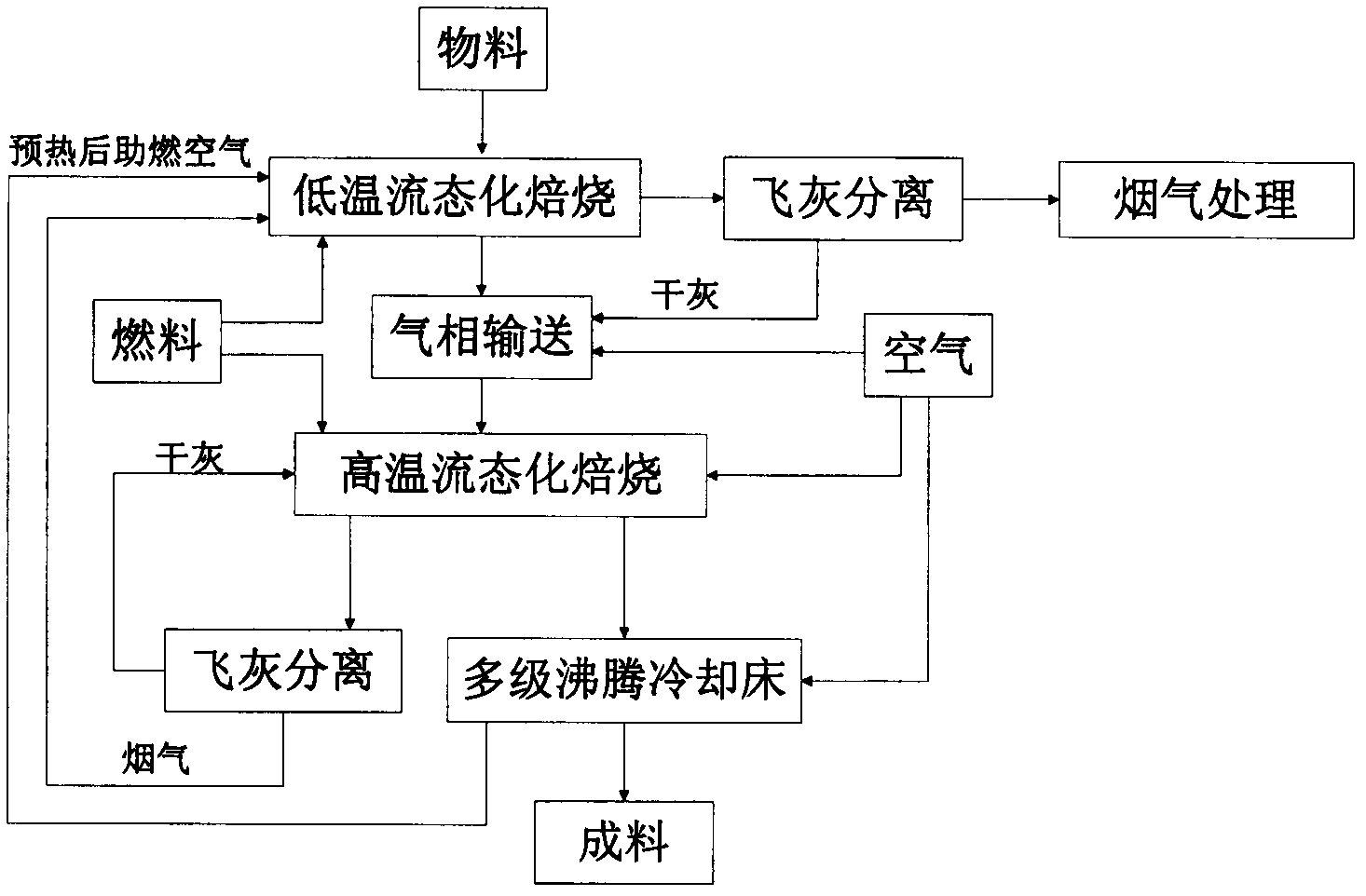

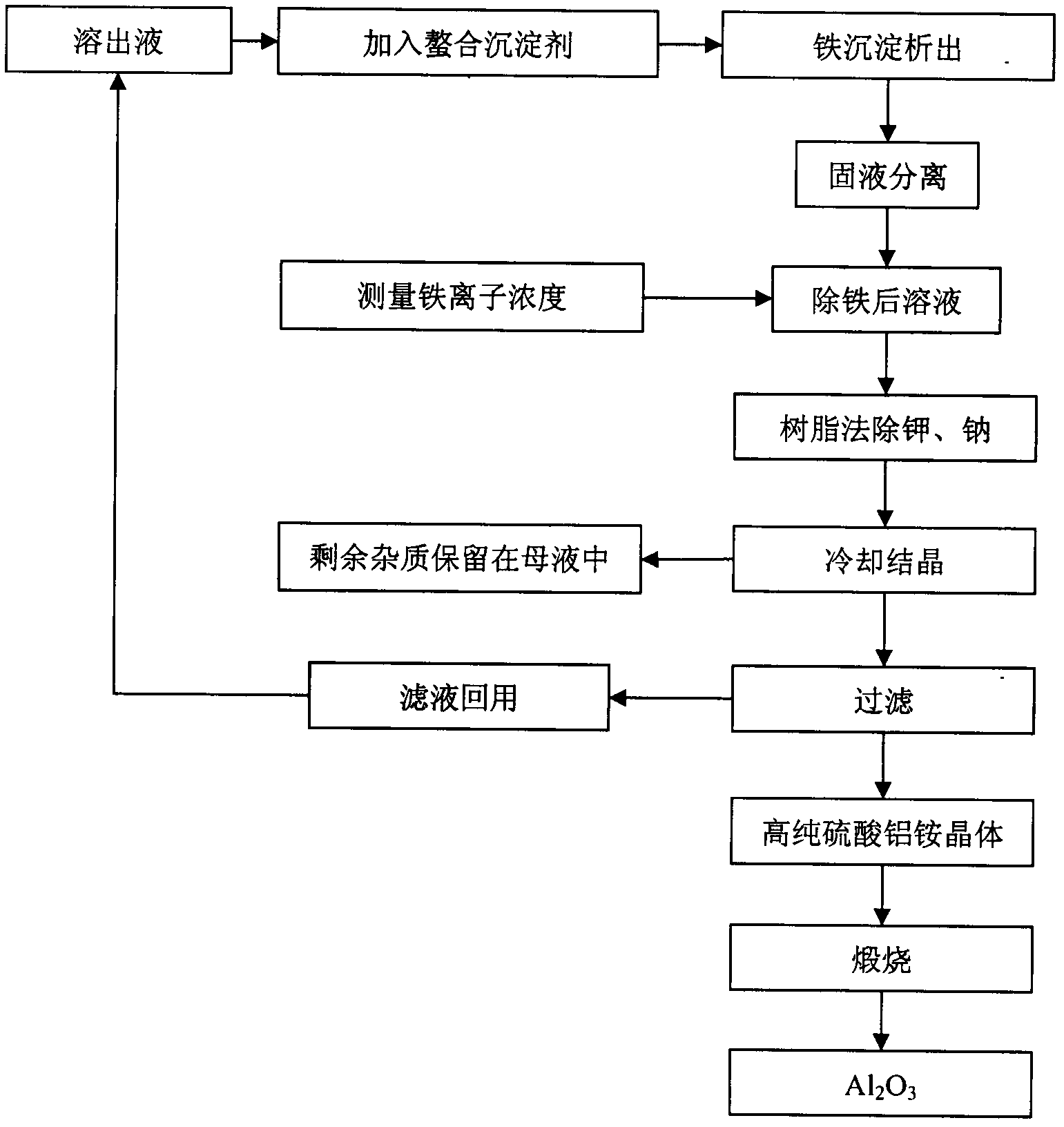

Method for extracting aluminum oxide from fly ash based on ammonium sulfate activation process

The invention relates to a method for extracting aluminum oxide from fly ash based on an ammonium sulfate activation process. By adopting roasting of the fly ash and ammonium sulfate, combined impurity removal and a two-section fluidized roasting system, the problem of high corrosion of equipment in the background technology is solved; a process chain of a main flow is shortened; through the roasting system, the roasting process is low in energy consumption, economic and low in cost by using methods such as two-section cyclic fluidized roasting and dense phase transportation; and the technical problem of material melting, wall sticking, caking or ring forming is solved.

Owner:CHINA SHENHUA ENERGY CO LTD +2

Conditioned urea-based granular fertilizers and methods of making thereof

InactiveUS20130174623A1High trafficOrganic phosphatic fertilisersAgriculture gas emission reductionCakingChemistry

The present invention provides methods for preparing flowable urea-based granular fertilizers, wherein the urea-based granular fertilizer has become wet; comprising contacting the urea-based granular fertilizer with a conditioner; and optionally other components to form a more flowable urea-base granular fertilizer. Methods for preventing urea-based granular fertilizer caking and urea-based granular fertilizer compositions are also disclosed.

Owner:KOCH AGRONOMIC SERVICES LLC

Method for preparing surface-modified proppant

ActiveCN101665686AImprove corrosion resistanceGood dispersionFluid removalDrilling compositionCakingPolyresin

The invention relates to a method for preparing a surface-modified proppant, which comprises the following steps: (a) heating a proppant substrate to 100 to 240 DEG C; (b) adding resin into the heated matrix with stirring to form a mixture to allow the resin to be coated on the surface of the substrate and adding a macromolecular surfactant and a curing agent with stirring to cure the resin coated on the substrate; (c) adding lubricant and hydrophobic macromolecules before the caking of the mixture of the resin and the substrate; and (d) obtaining the proppant by cooling, crushing and screening the mixture obtained by the step c. The proppant prepared by the method has the advantage of stable environment corrosion resistance.

Owner:BEIJING RECHSAND SCI & TECH GRP

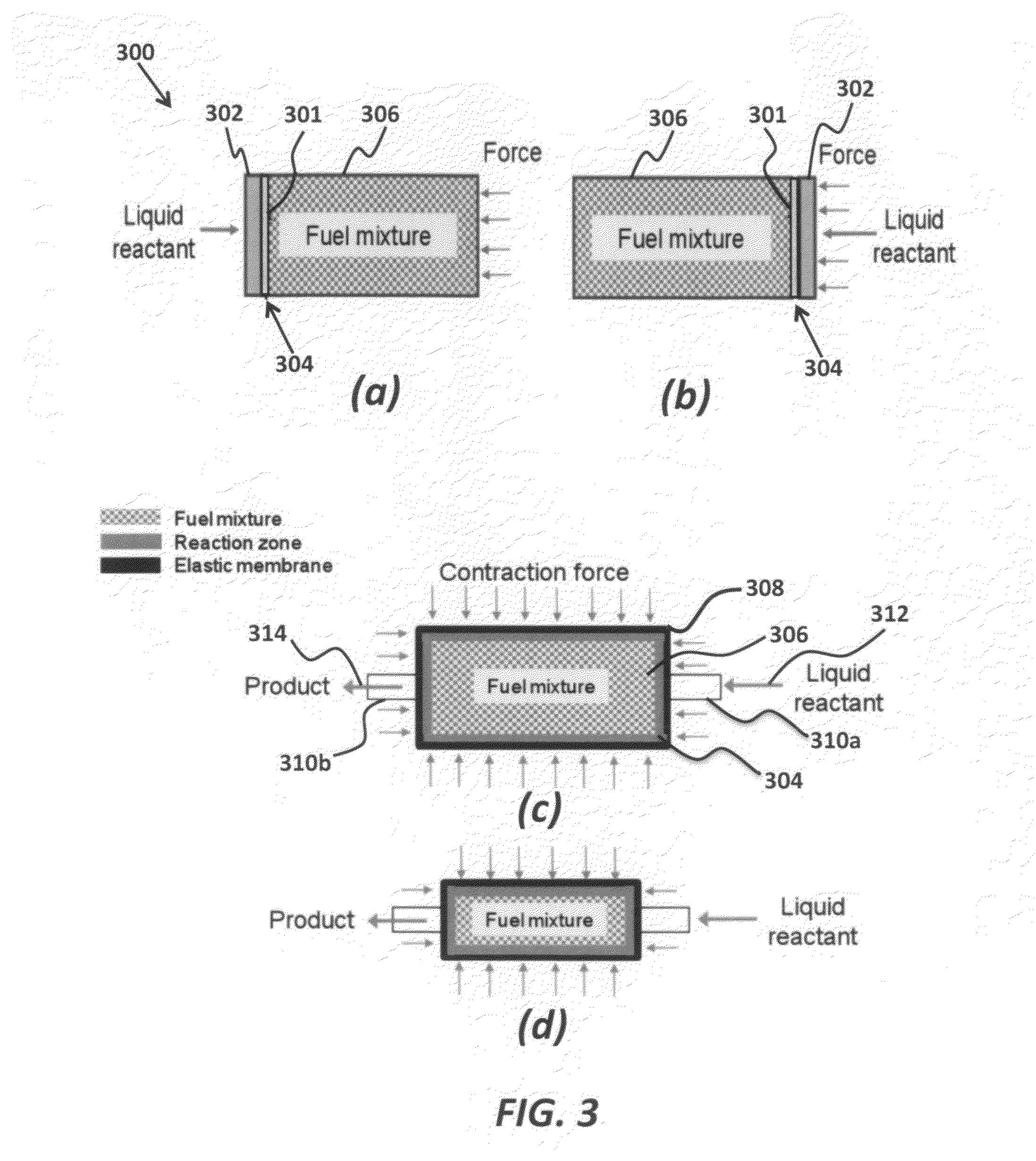

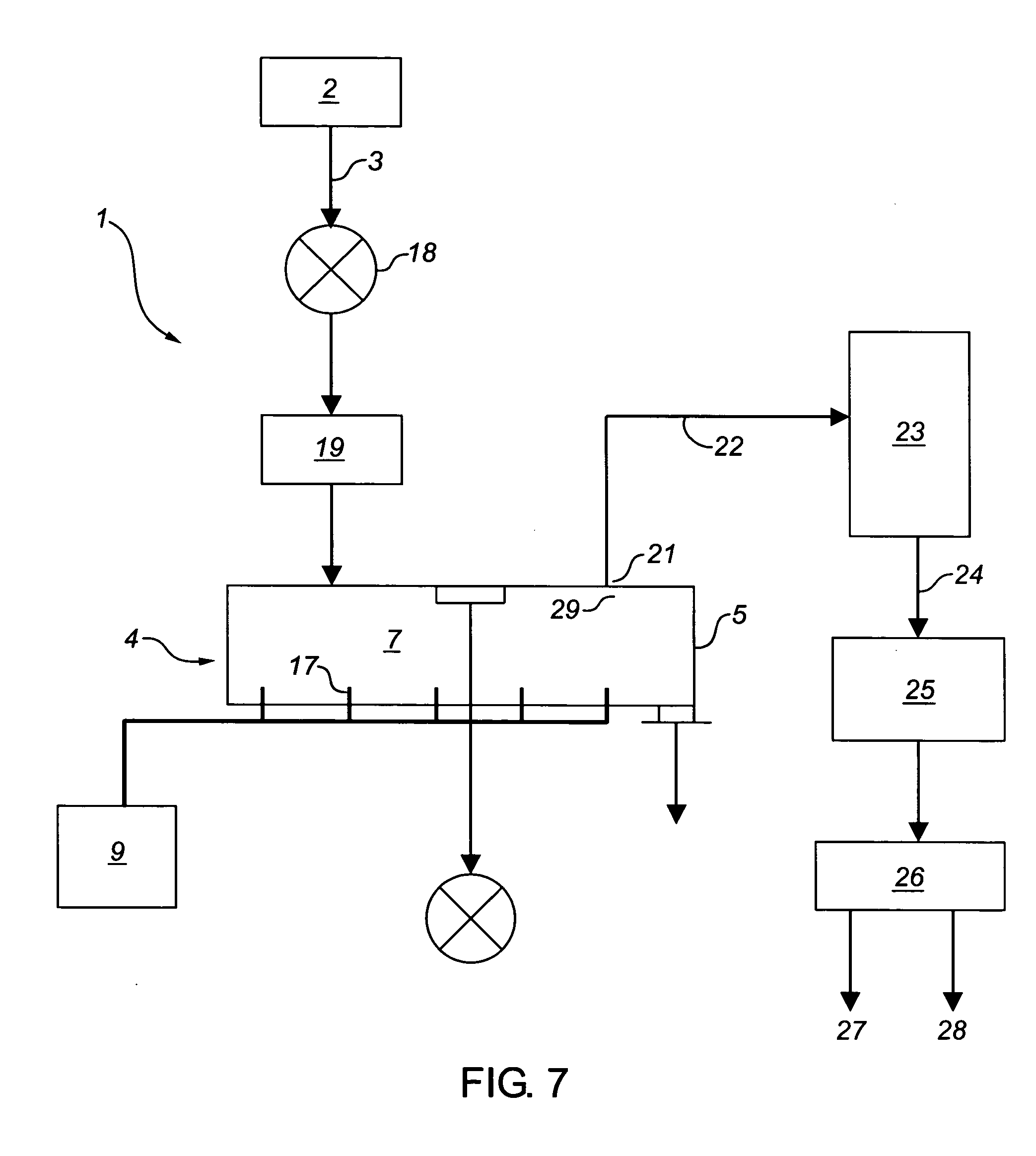

Chemical hydride formulation and system design for controlled generation of hydrogen

A chemical hydride liquid reactant distribution mixture is provided. The mixture includes a fuel mixture having at least one hydride and at least one activating agent. The invention further includes a liquid-distributing agent (LDA), a form-stabilizing agent, and at least one anti-caking agent. The liquid reactant distribution mixture reduces caking and precipitation while promoting liquid reactant distribution, where the chemical hydride liquid reactant distribution mixture generates hydrogen via hydrolysis.

Owner:INTELLIGENT ENERGY LTD

Apparatus and process for removing liquids from drill cuttings

InactiveUS7337860B2Reduce cakingReduce resultSolid waste disposalHollow article cleaningCombustionProduct gas

Owner:CLEANCUT TECH LTD

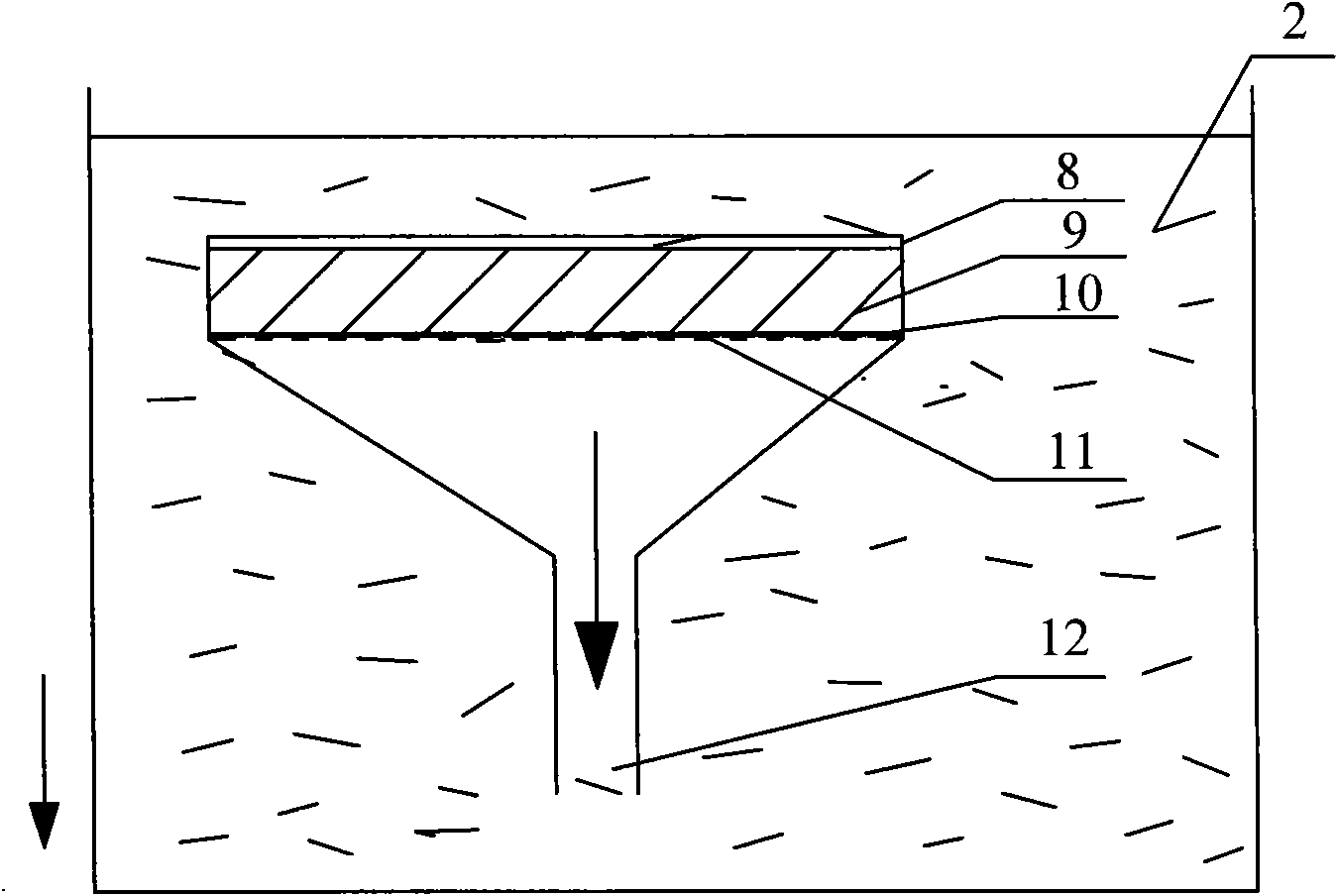

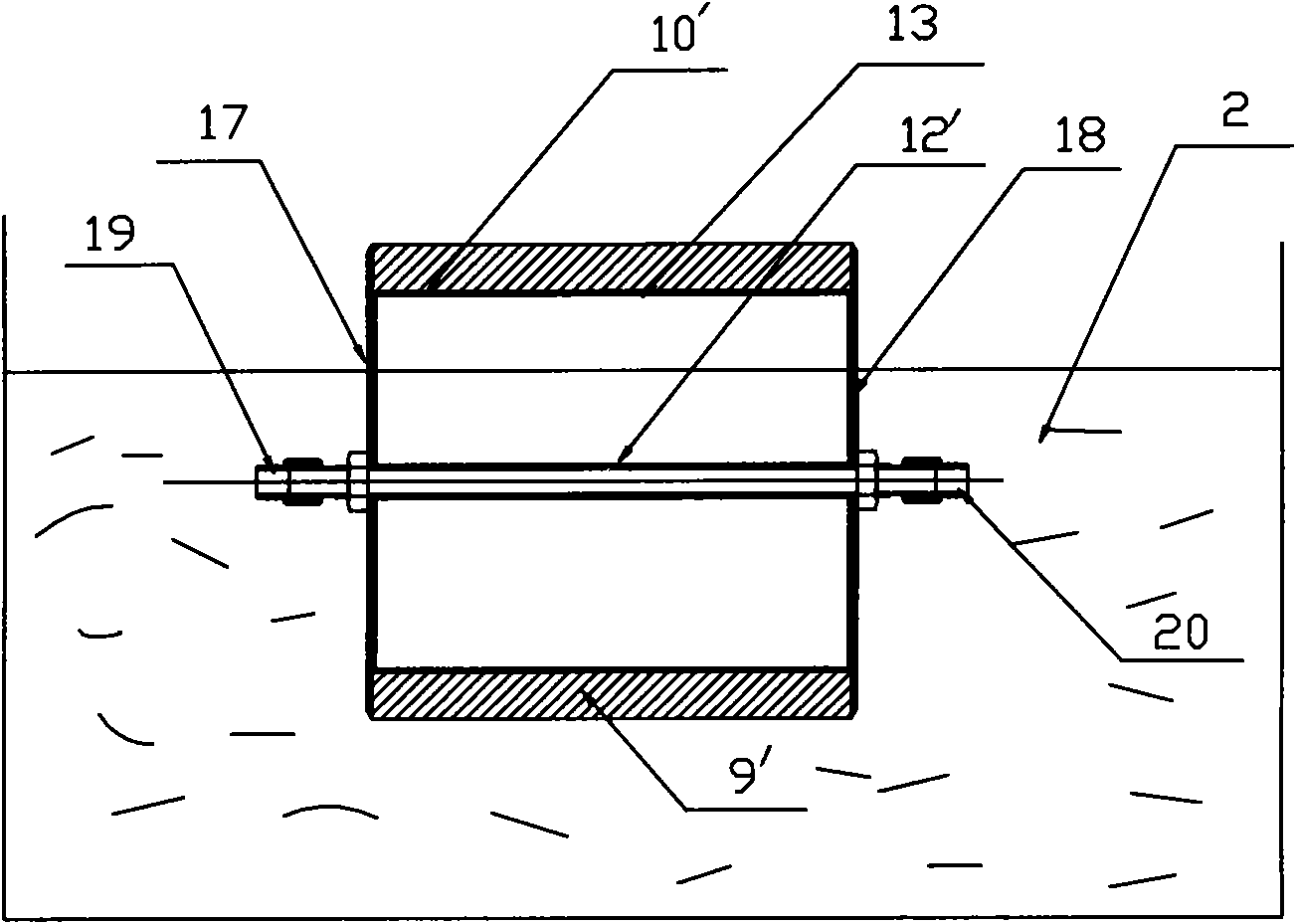

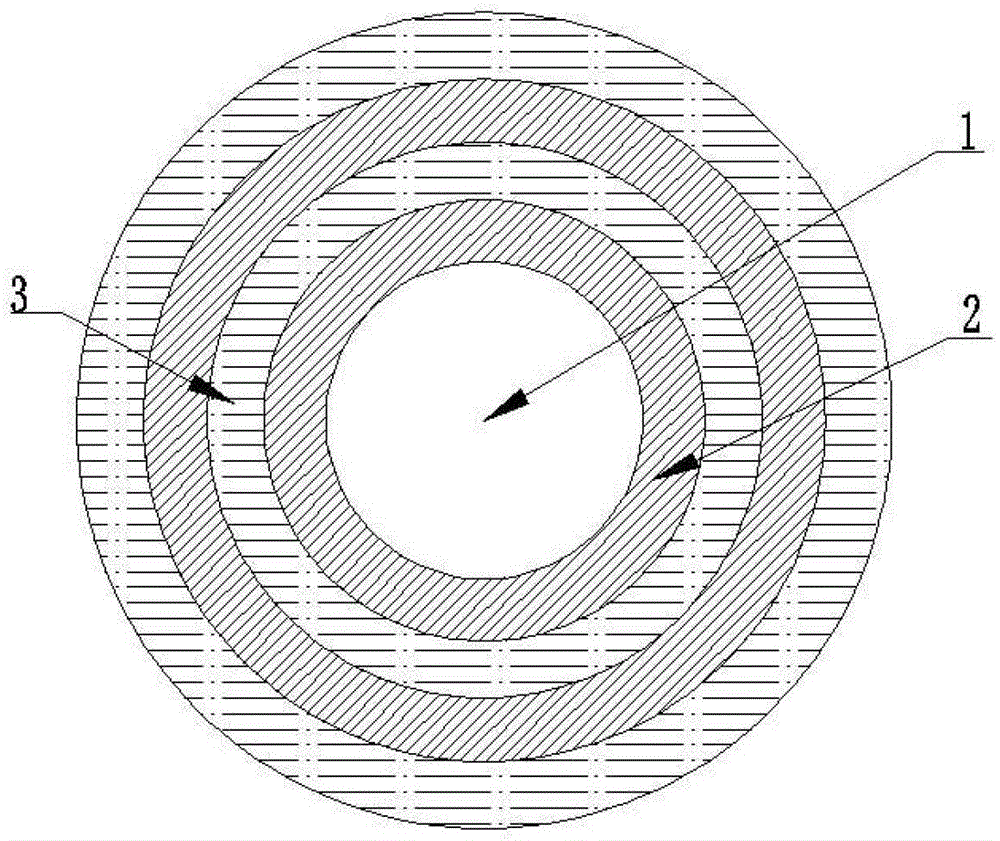

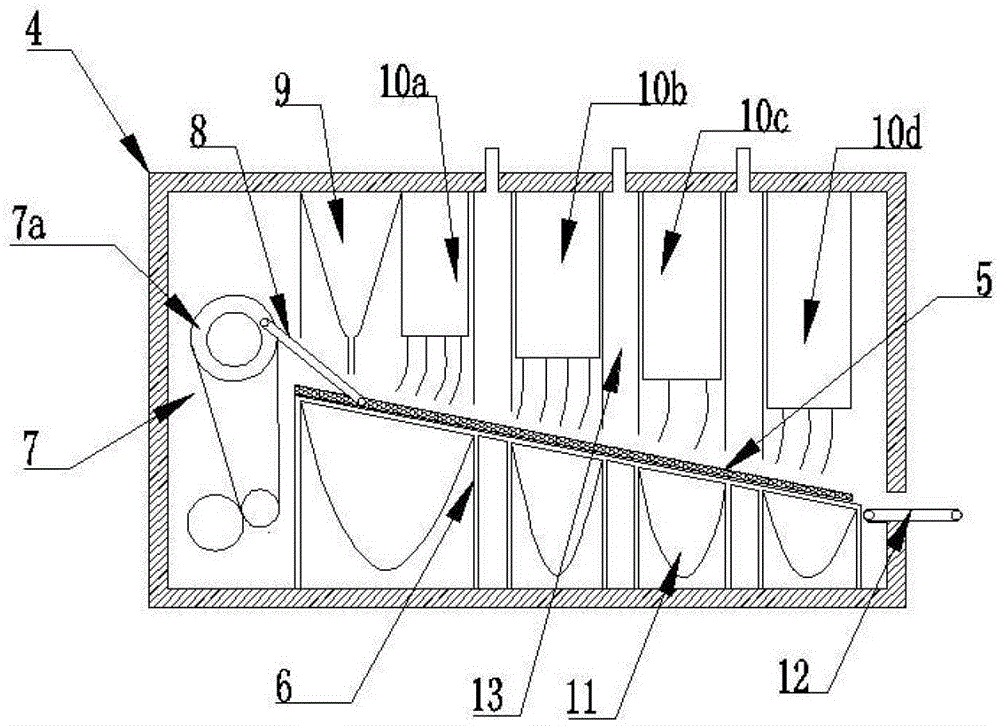

Large-particle slow/controlled-release fertilizer with multi-layer coating structure and coating equipment of fertilizer

ActiveCN102910978ABeautiful appearanceHave no ripsFertiliser formsFertilizer mixturesSoil scienceCaking

The invention relates to a large-particle slow / controlled-release fertilizer with a multi-layer coating structure and coating equipment of the fertilizer. According to the invention, a sulfur coating is coated outside the large-particle fertilizer, and a fertilizer coating is coated outside the sulfur coating. The coating equipment consists of a heating incubator, a screen and the like, wherein one end of the screen (5) is high, and the other end of the screen (5) is low; a particle funnel (9) and 2-10 spray boxes (10) are successively arranged above the screen (5) from the high end to the low end; 2-10 recovery tanks (11) are arranged under the screen (5) in turn from the high end to the low end; and the low end of the screen (5) is provided with a conveying belt (12). The obtained fertilizer can realize the different requirements of various growth periods on NPK elements through adjustment of fertilizer formula of each layer of coating, so that the sulfur coating is well ensured not to fall or be damaged; and simultaneously, the fertilizer has the advantages of beautiful appearance, no crack, no adhesion, no caking and the like.

Owner:CHONGQING JINMANDI FERTILIZER

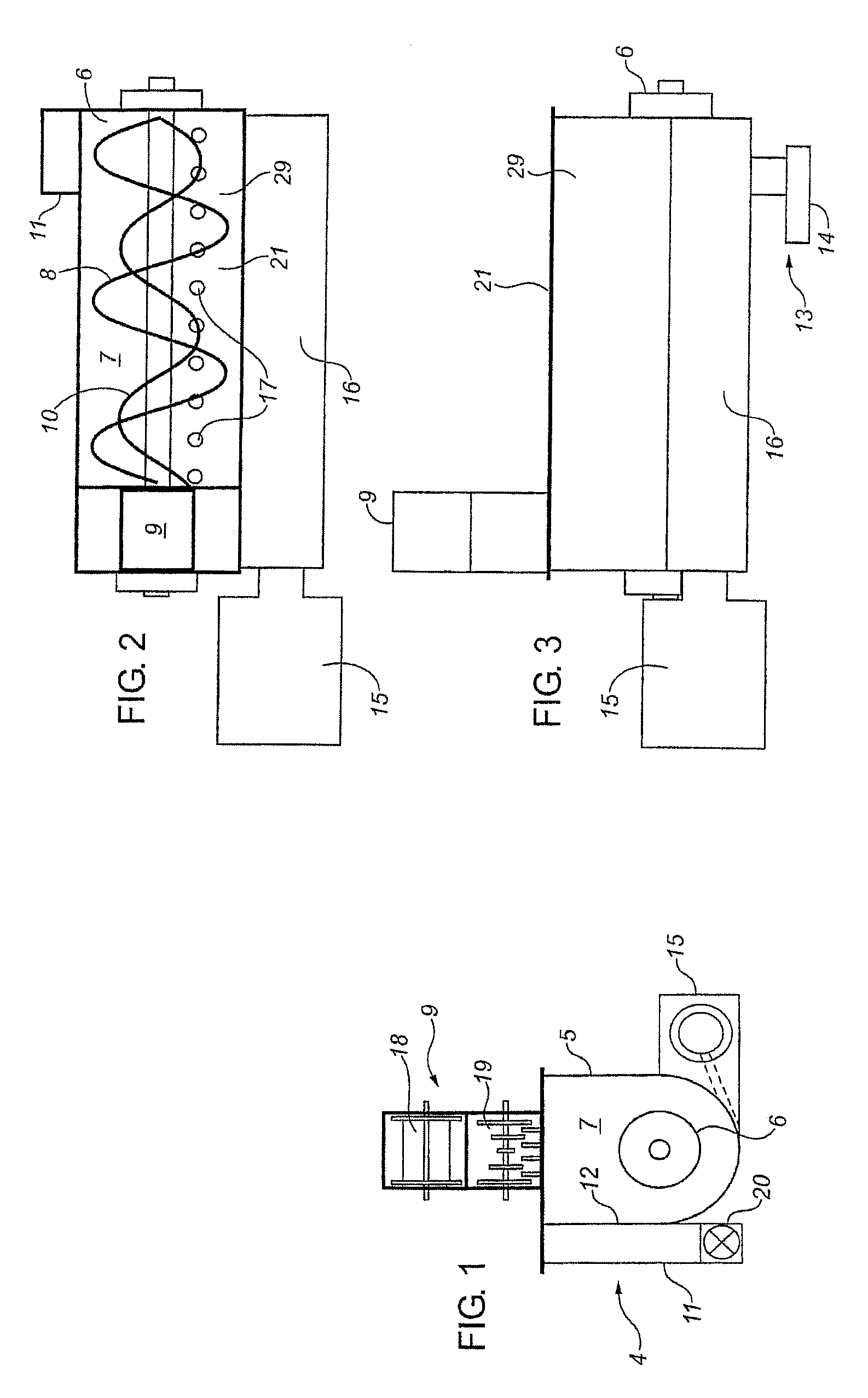

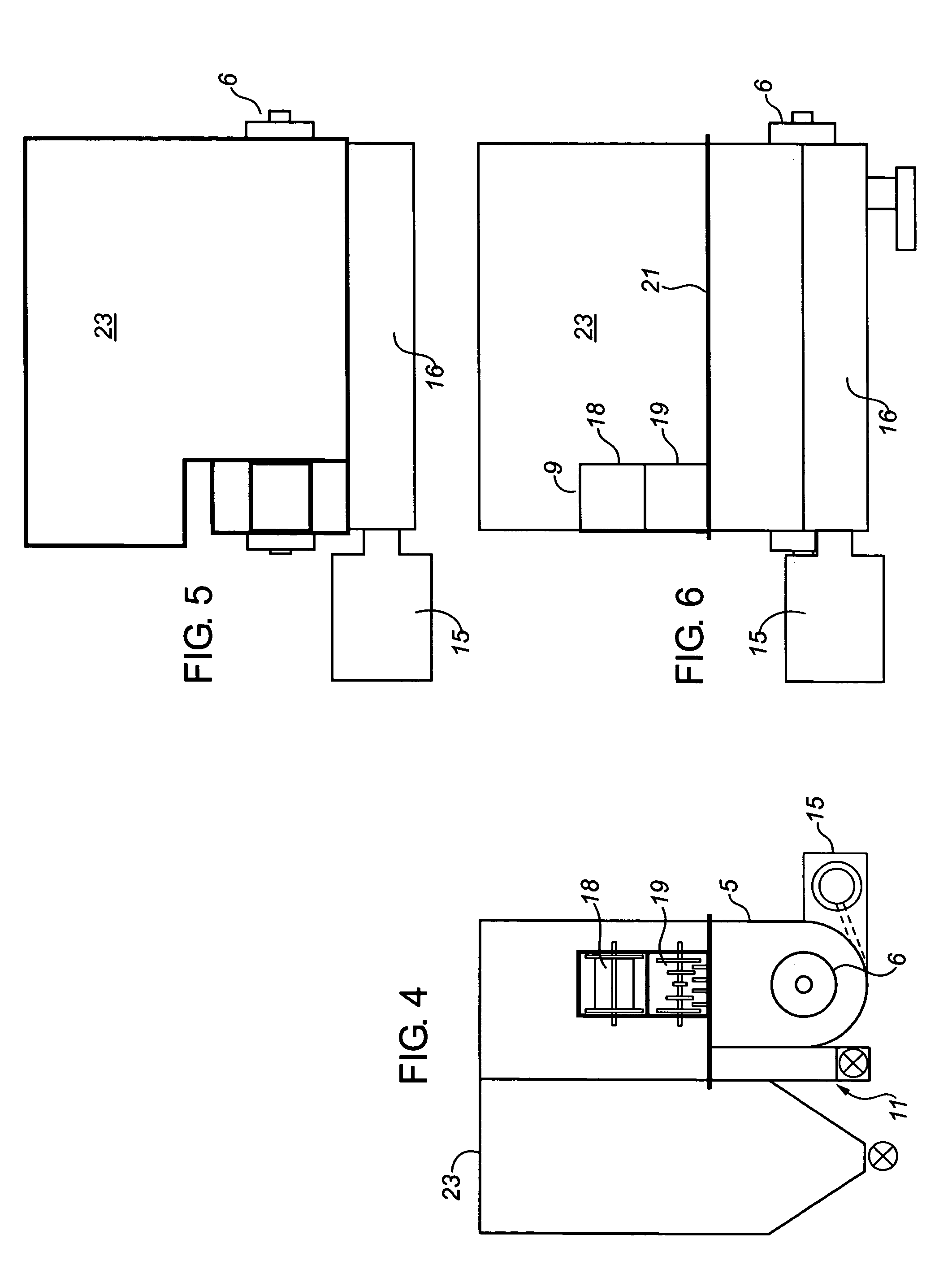

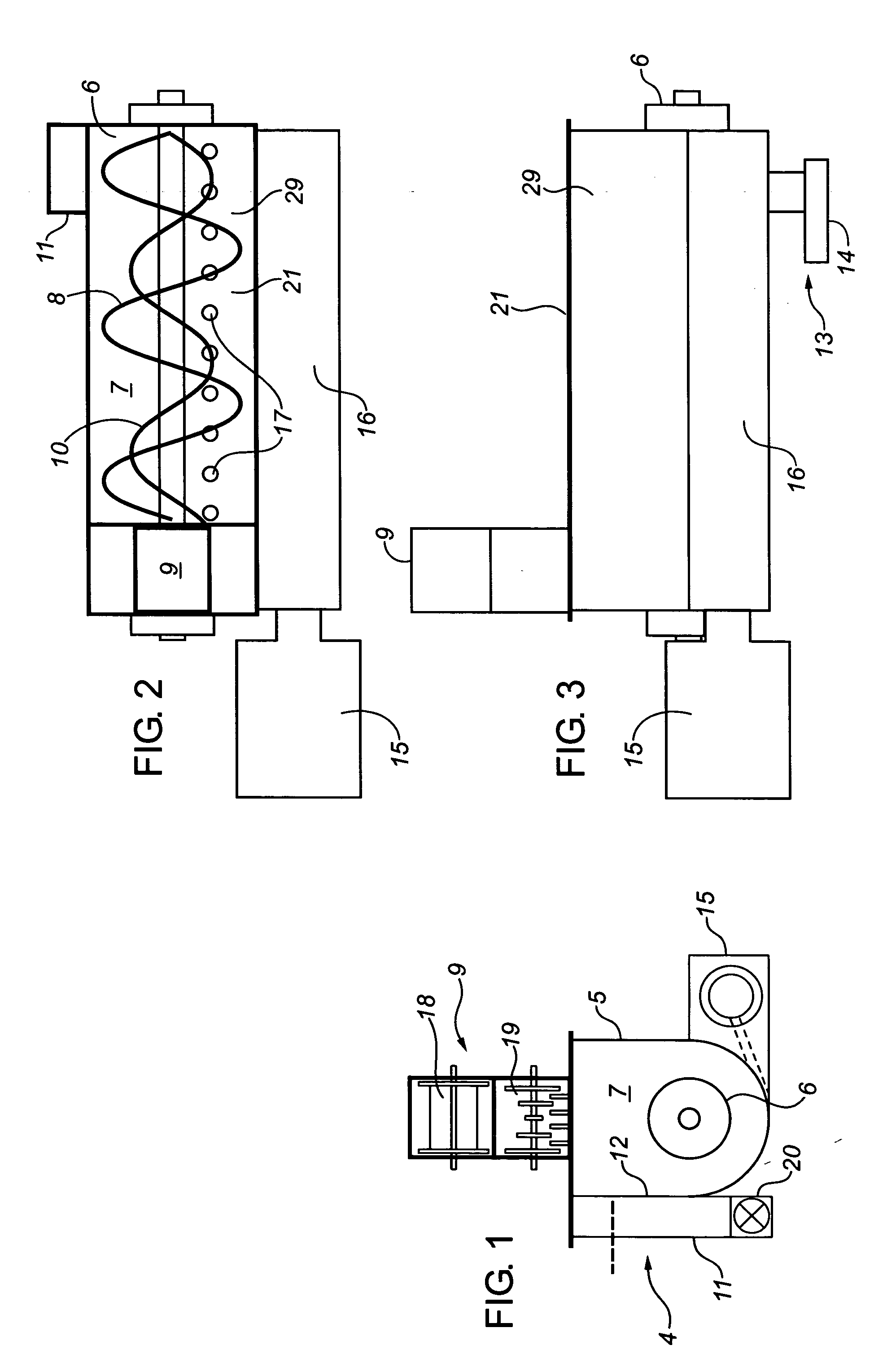

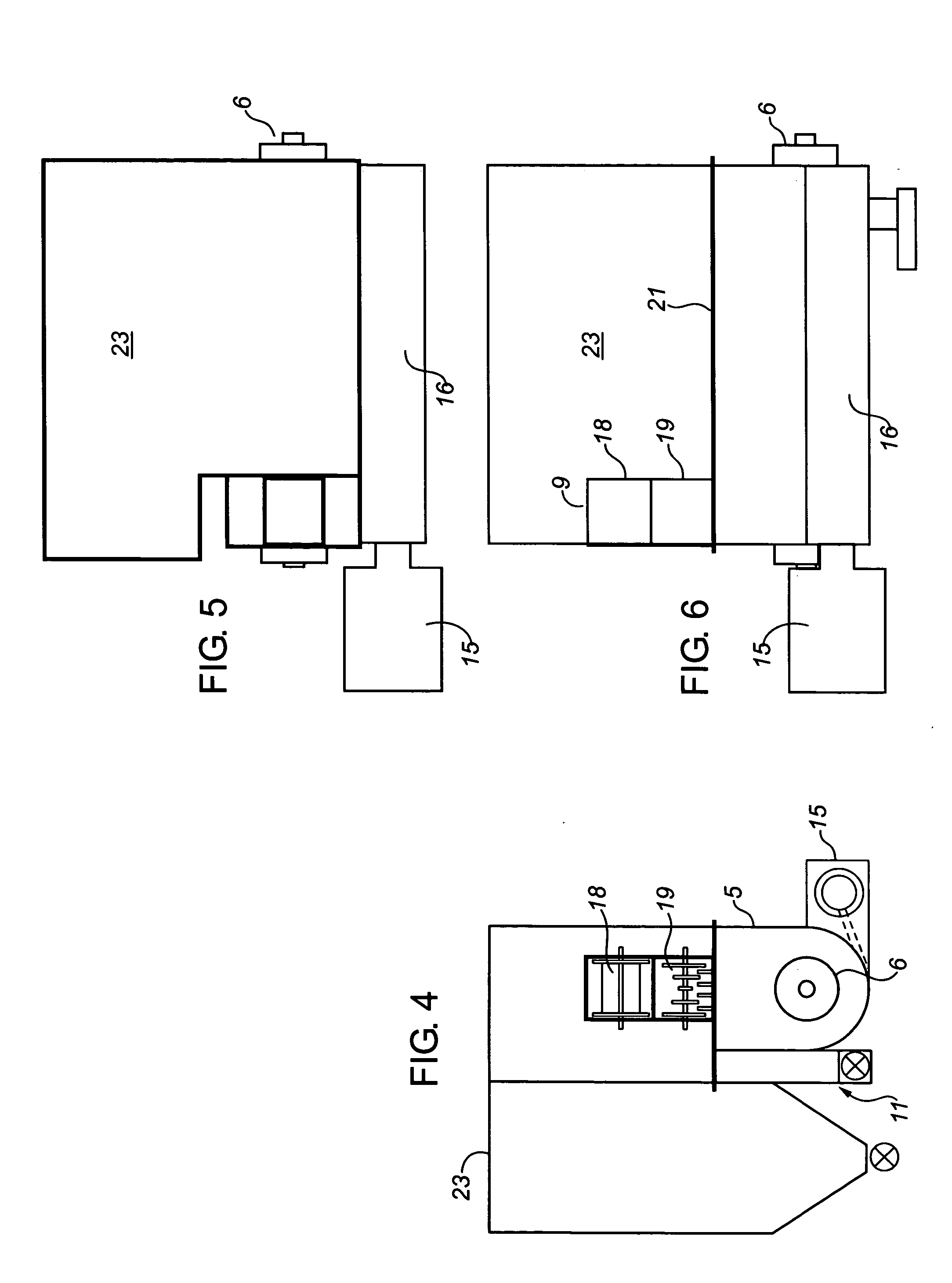

Apparatus and process for removing liquids from drill cuttings

InactiveUS20050153844A1Reduce cakingReduce resultSolid waste disposalHollow article cleaningCombustionEngineering

Drill cuttings associated with drilling fluid are thermally cleaned. The wet cuttings are fed into a vessel chamber having mechanical mixers, such as ribbon blenders, extending lengthwise of the chamber. Direct heating is applied to the chamber contents by introducing hot combustion gas from a heater. A combination of direct heating and mechanical back mixing of wet colder cuttings with drier hotter cuttings results in conditioning and conduction heating of the wet cuttings. The drilling fluid is evaporated and removed as gas. Dried cuttings are separately recovered. Caking and agglomeration of the solids is reduced.

Owner:CLEANCUT TECH LTD

Process for preparing multifunctional carbon nanotube for epoxy resin nano composites

The invention belongs to the nano-material technical sphere, especially it relates to a method for preparation of triplefunction carbon nano-tube used in epoxide resin nano-recombination. The invention adopts molecular design conception, namely that after the suface-definite quantity carboxylation and chloridization, the long-chain diamine with a character construction is introduced into the purified carbon nano-tube, then the grafted carbon nano-tube with a quantitative active amidol on surface is obtained. Making use of the chemical attraction of the construction to the base resin and the chemical reaction with the base resin, we can better the dispersibility of the carbon nano-tube and improve the basal binding strength with the base resin. At the same time the carbon nano-tube can exert multiple functions, for example, it is easy to disperse, its interfacial caking capacity is fine, and it is reinforced and solidified. So the obtained triplefunction carbon nano-tube used in epoxide resin nano-recombination is good to improve the bulk property of the carbon nano-tube / epoxide resin composite and is suitable for industrial use for carbon nano-tube.

Owner:TONGJI UNIV

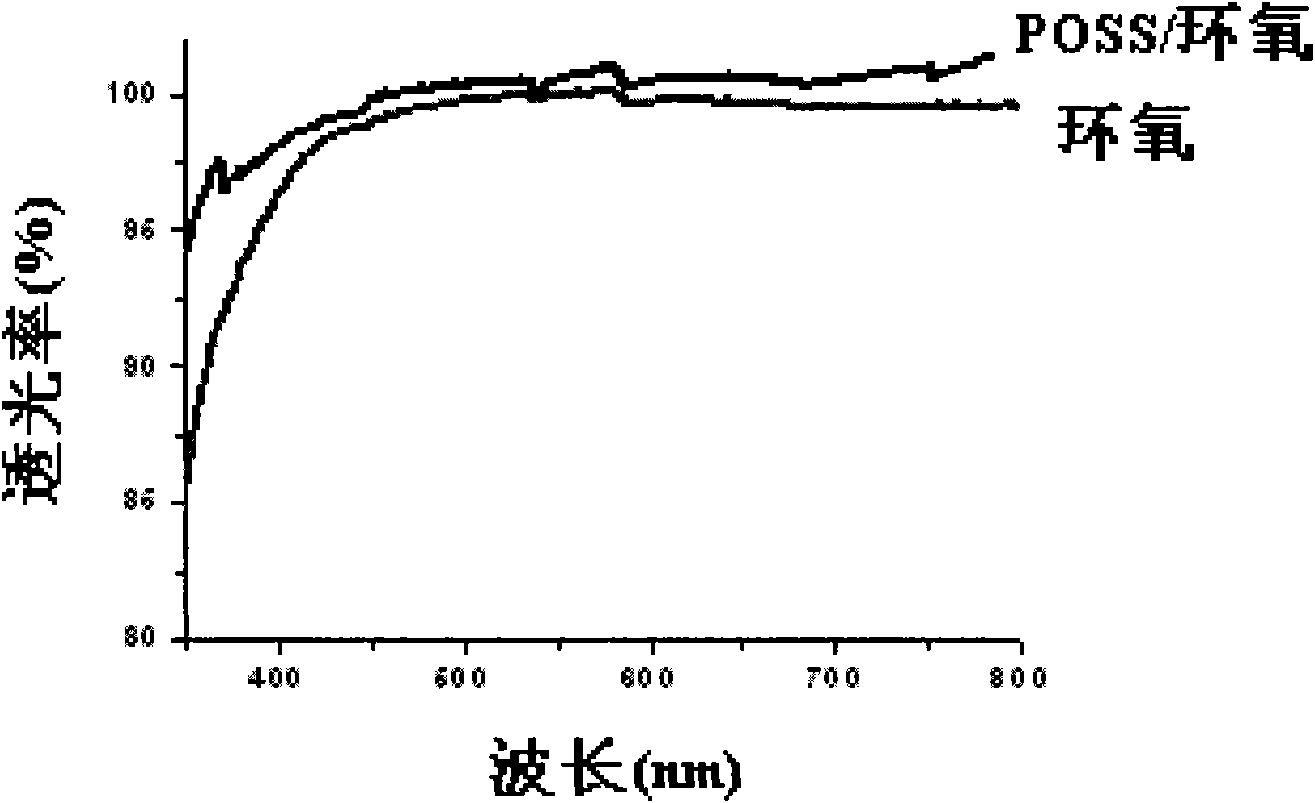

POSS/epoxy nanometer hybrid material and preparation method and application thereof

InactiveCN101985513AImprove heat resistanceImprove aging resistancePlastic/resin/waxes insulatorsSemiconductor/solid-state device detailsChemical industryEpoxy

The invention belongs to the technical field of chemical industry and photoelectricity, and in particular relates to a high-heat-resistant POSS / epoxy nanometer hybrid material and a preparation method and application thereof. The high-heat-resistant POSS / epoxy nanometer hybrid material comprises (a) at least one epoxy resin, (b) at least one polyhedral oligomeric silsesquioxane (POSS), (c) at least one acidic curing agent, (d) unnecessary organosilane, and (e) an unnecessary auxiliary agent. The POSS / epoxy nanometer hybrid material prepared by the method does not have a phase separation phenomenon, has the characteristics of the epoxy resin such as high caking property, mechanical strength, shearing strength and processability, and has the characteristics of the POSS such as high heat resistance, insulating property, elasticity, ageing resistance and transparency; the production and preparation process is simple, and easy to control; a solvent is not used in the production process; and the method is an environmental-friendly and energy-saving method for synthesizing the POSS / epoxy nanometer hybrid material. The POSS / epoxy nanometer hybrid material is used for an adhesive, an LED packaging material, a photoelectric conversion material, an insulating material, a coating material, a circuit protection material, an optical protection material and the like.

Owner:FUDAN UNIV +1

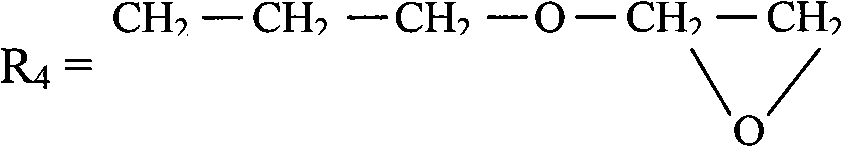

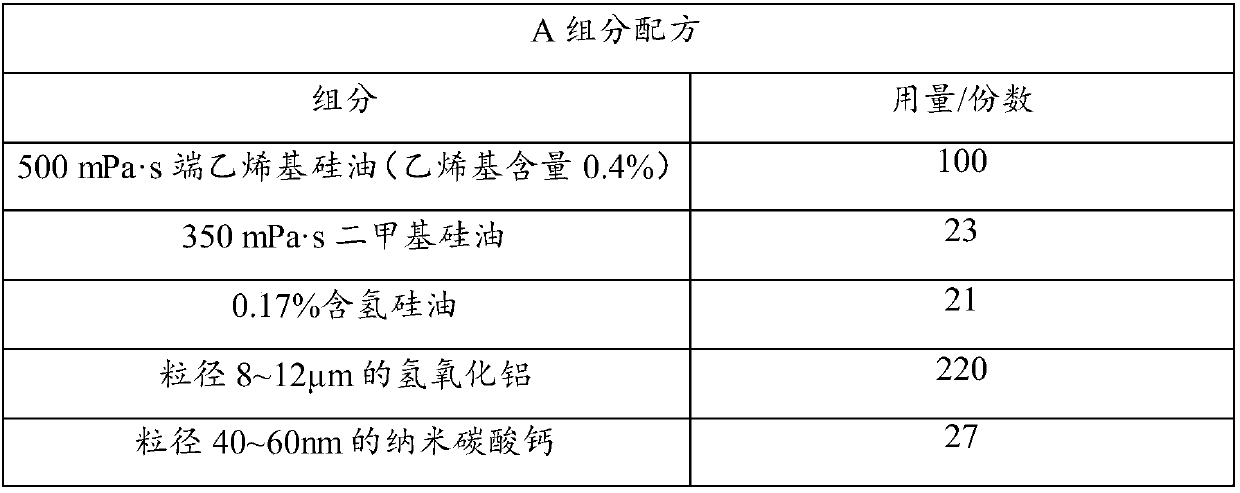

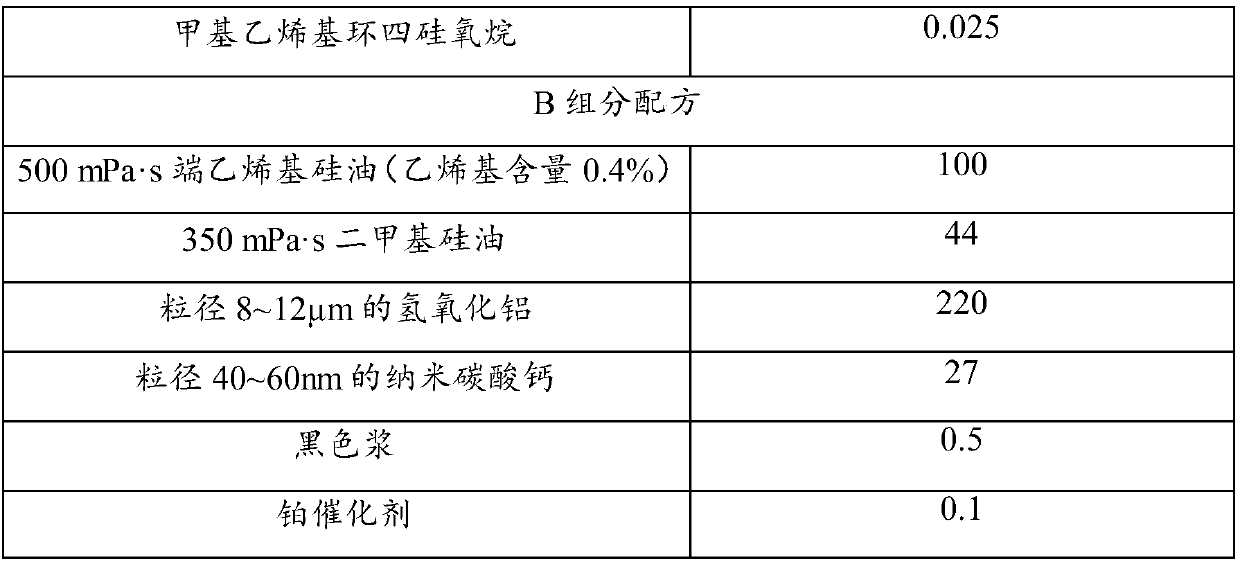

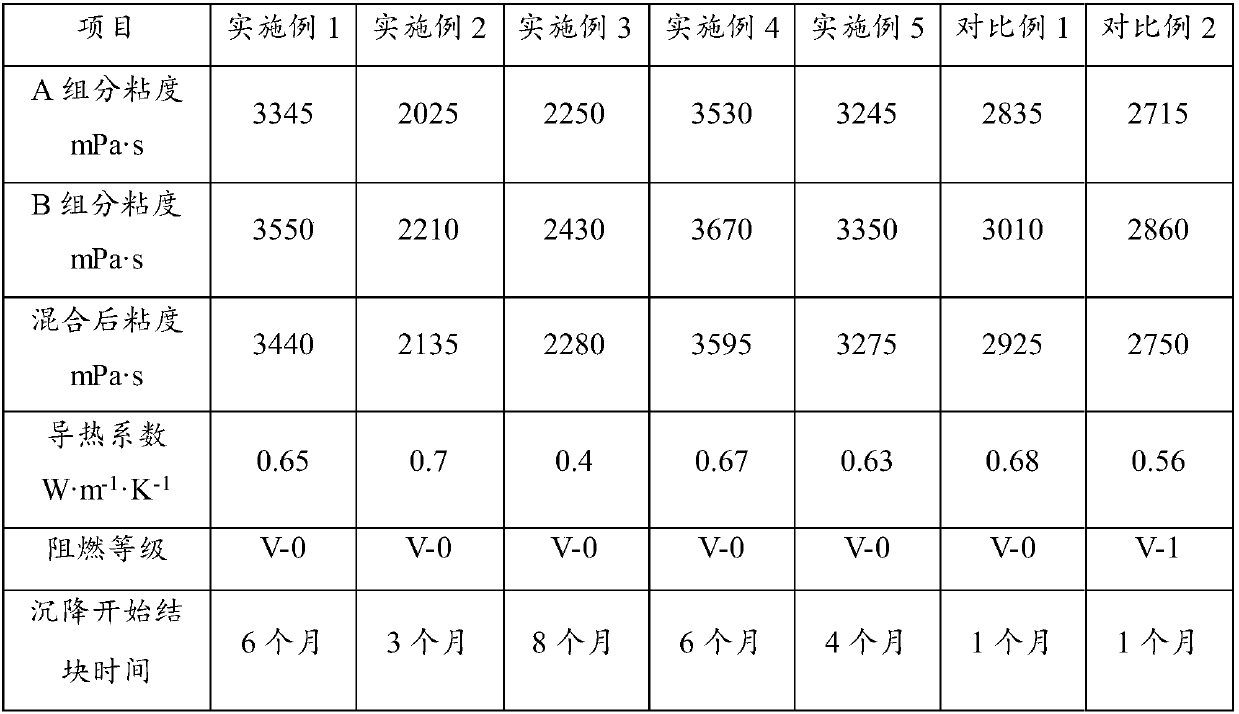

Addition-type organic silicon pouring sealant and preparation method thereof

ActiveCN107793992AGood anti-sedimentationImprove thermal conductivityNon-macromolecular adhesive additivesHydrogenSealant

The invention provides an addition-type organic silicon pouring sealant and a preparation method thereof. The pouring sealant is prepared from a component A and a component B in parts by weight, wherein the component A comprises the following raw materials in parts by weight: 100 parts of vinyl silicone oil, 0-100 parts of dimethyl silicone oil, 1-50 parts of hydrogen-containing silicone oil, 20-250 parts of aluminum hydroxide, 0-200 parts of heat conduction fillers, 1-50 parts of nano-calcium carbonate and 0.01-1 part of an inhibitor; and the component B comprises the following raw materialsin parts by weight: 100 parts of vinyl silicone oil, 0-100 parts of dimethyl silicone oil, 20-250 parts of aluminum hydroxide, 0-200 parts of heat conduction fillers, 1-50 parts of nano-calcium carbonate, 0.01-1 part of a platinum catalyst and 0-10 parts of color paste. Through the synergistic effect of the components, the pouring sealant is high in sedimentation resistance, thermal conductivity and flame retardance. The caking time is at least more than three months after the pouring sealant starts settling, the heat conductivity coefficient is 0.4-0.7 W.m<-1>.k<-1>, and the flame retardant rating reaches V-0.

Owner:HANGZHOU ZHIJIANG SILICONE CHEM +1

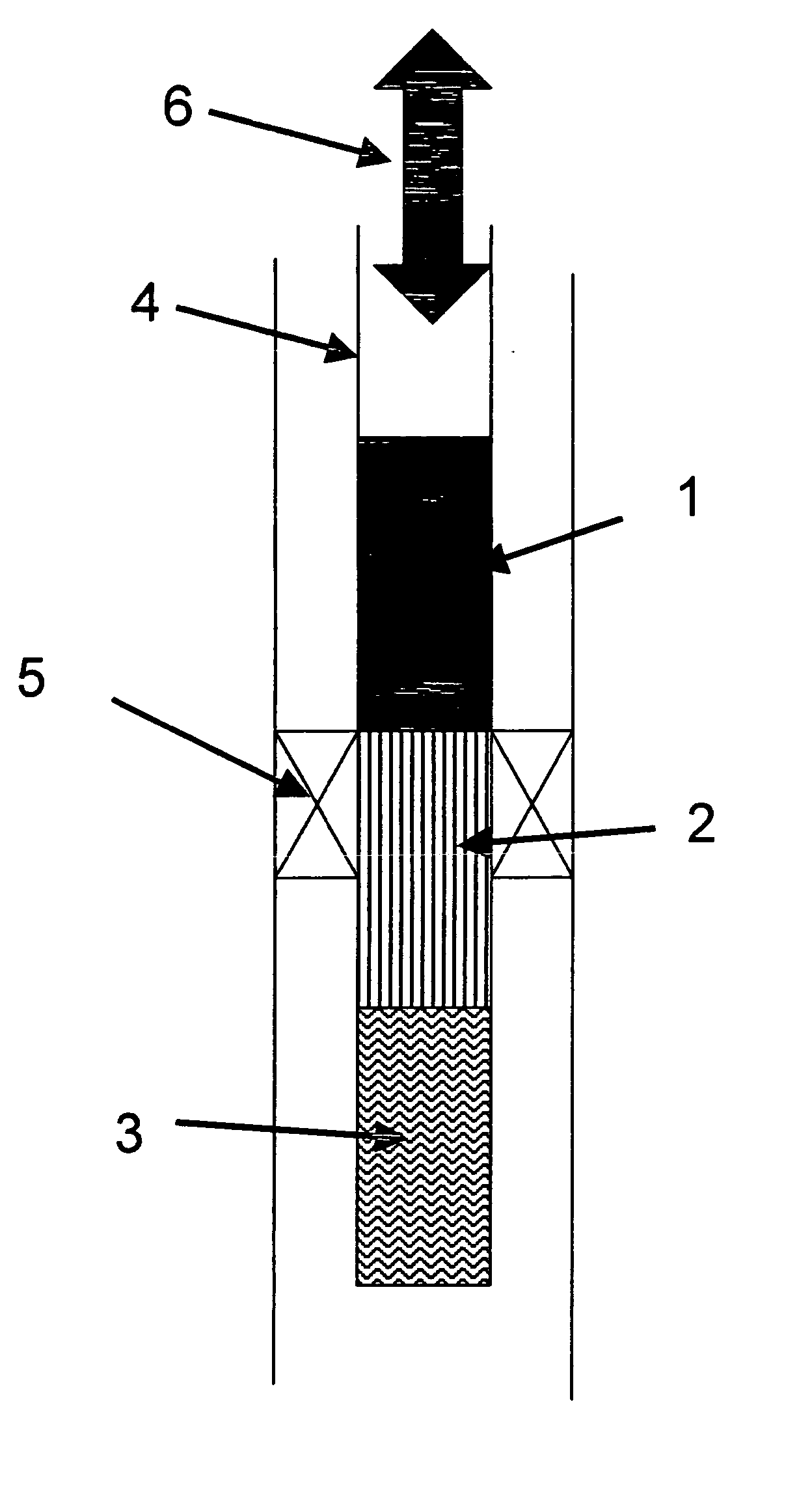

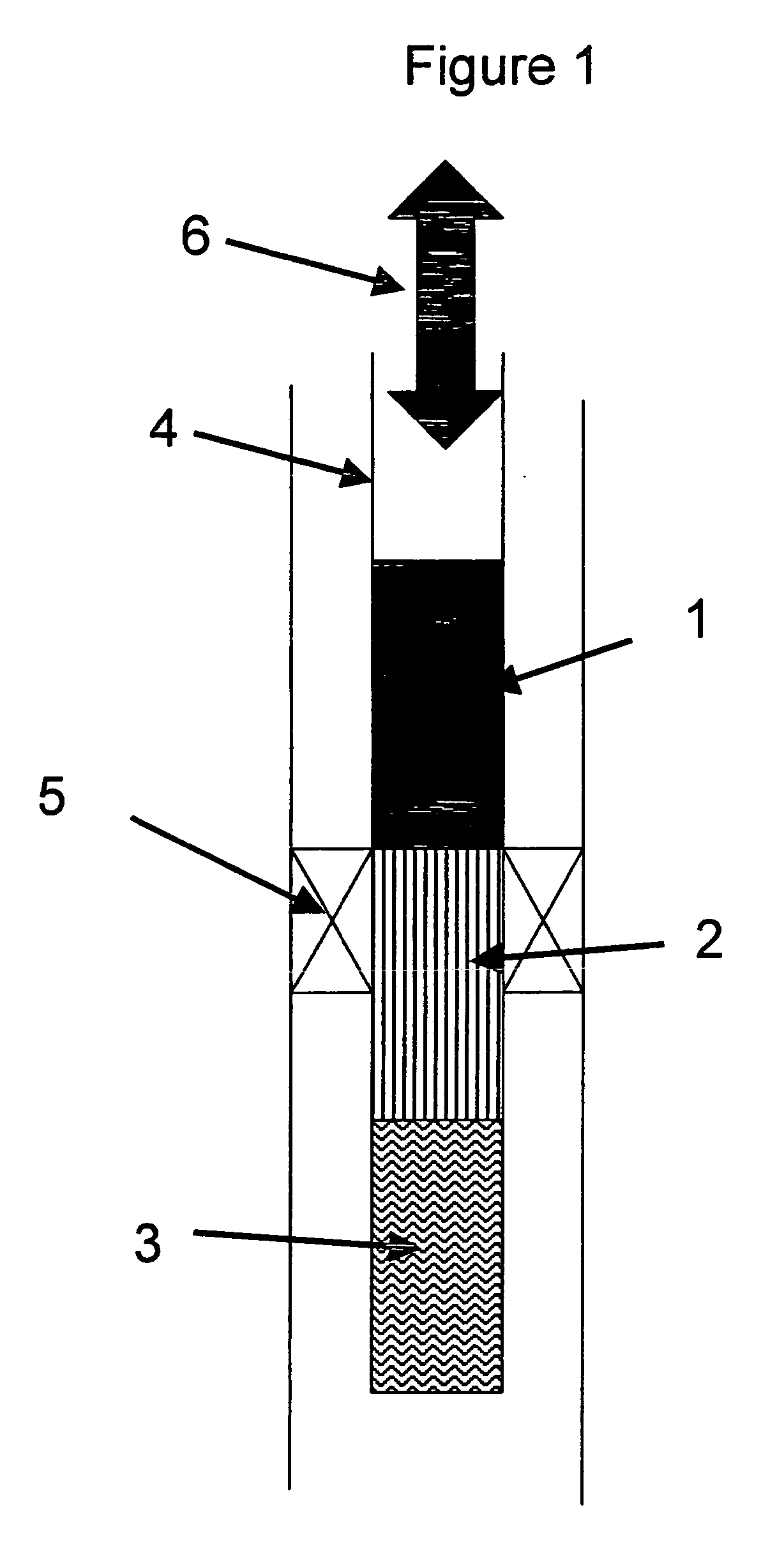

Downhole ultrasonic well cleaning device

InactiveUS20050269078A1Easy to cleanCleaning apparatusHollow article cleaningMechanical energyEngineering

Disclosed is a cleaning apparatus for any structure where caking of particles may affect productivity, particularly a subterranean formation or wellbore, characterized in that it requires no external electrical source and includes the following elements: At least one ultrasonic energy sonde for converting an alternating electric power signal at a selected voltage into ultrasound energy; At least one ultrasonic generator that conditions electrical power to the signal required to energize the ultrasonic energy sonde; At least one apparatus which converts mechanical energy into electrical energy, preferably a piezoelectric generator, in a configuration and with appropriate circuitry to provide electrical power to said ultrasonic generator(s); and A means for applying mechanical force to said apparatus to generate electricity to power said generator.

Owner:SHELL OIL CO

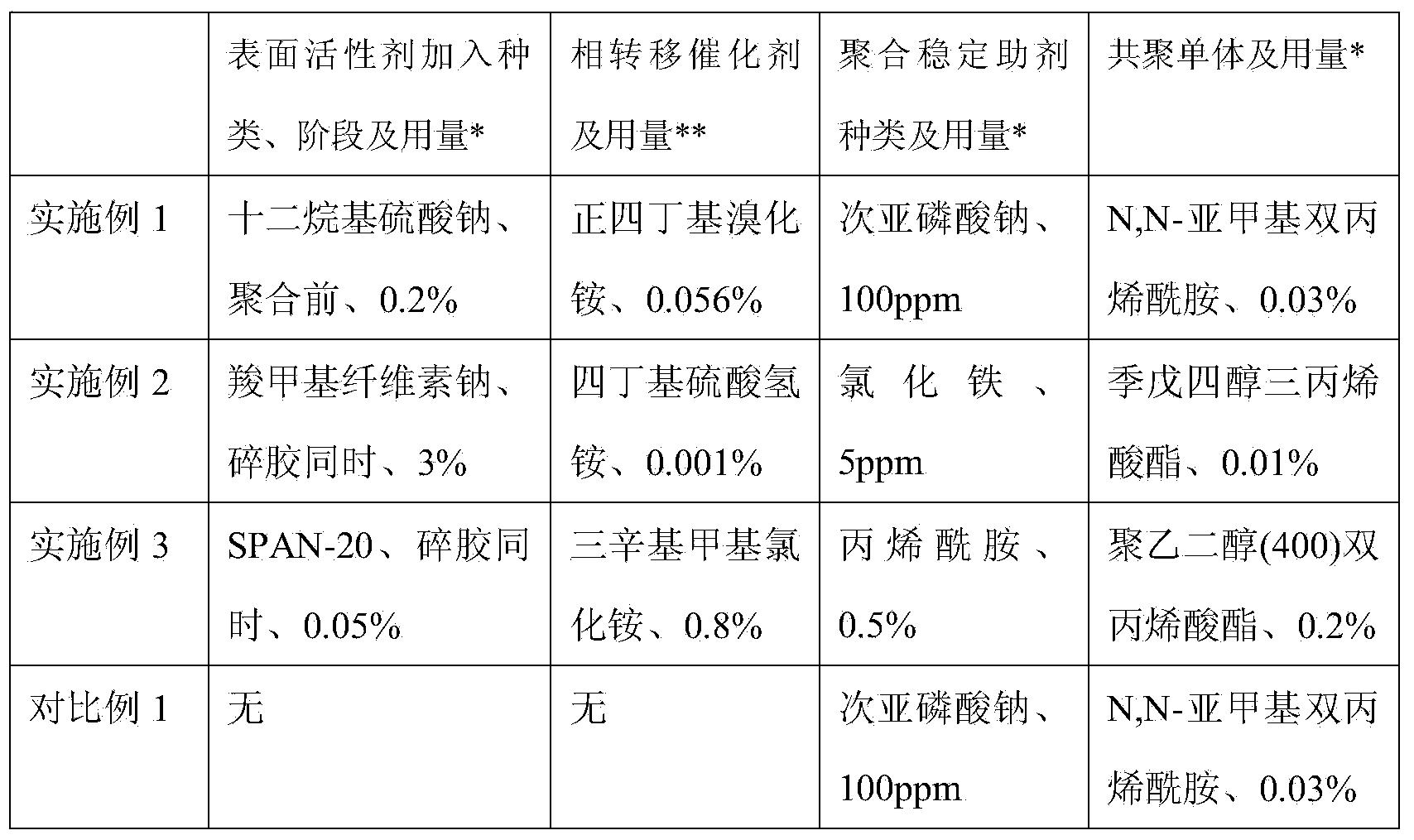

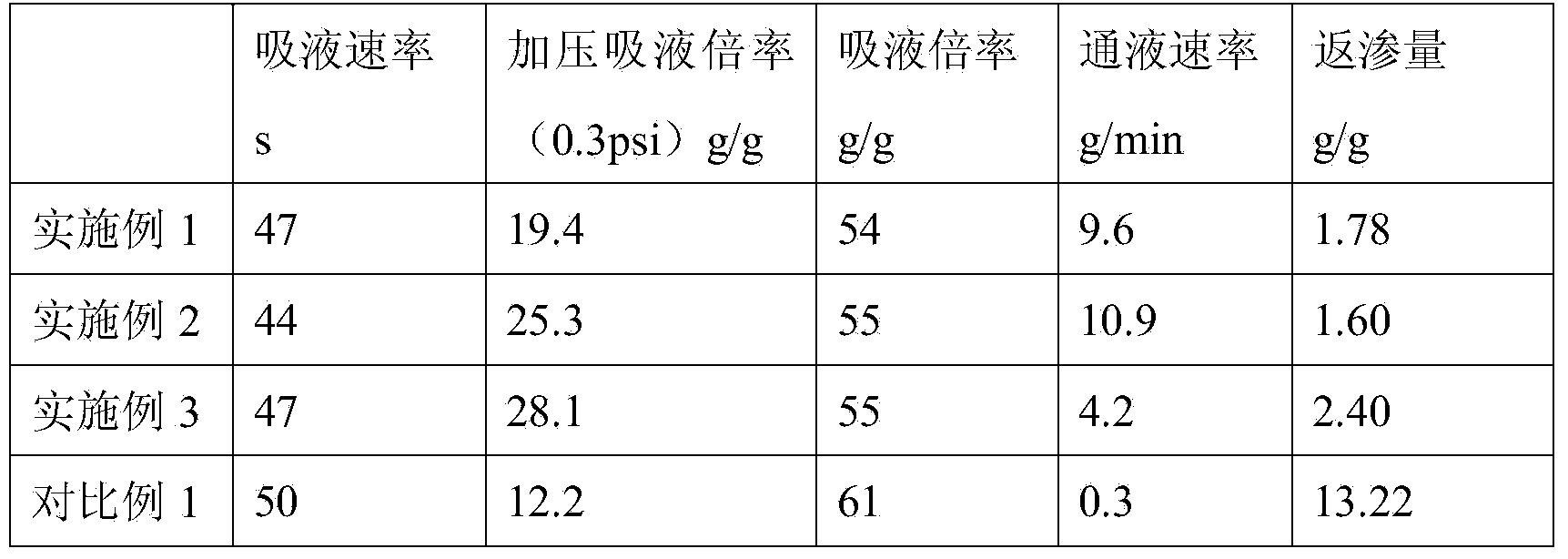

Preparation method of macromolecular water-absorbent resin with low reverse osmosis

ActiveCN103910896AImprove liquid absorption capacityImprove anti-reverse seepage abilityCoatingsPolymer scienceReverse osmosis

The invention provides a preparation method of macromolecular water-absorbent resin with low reverse osmosis. According to the method, a polymerization stabilizing additive is added and process conditions are reasonably controlled during a polymerization process, so that the polymerization reaction is stable and the process is simple. A surfactant is added before the surface crosslinking of water-absorbent resin powder; meanwhile, a phase transfer catalyst is added during the surface crosslinking. Thus, the phenomenon of caking of the water-absorbent resin powder during the surface crosslinking is avoided, so that surface crosslinking solution is uniformly distributed. Therefore, the solution absorbing ability and the reverse osmosis resisting ability of the water-absorbent resin are greatly improved. The water-absorbent resin is suitable for physical hygiene products.

Owner:WANHUA CHEM GRP CO LTD +1

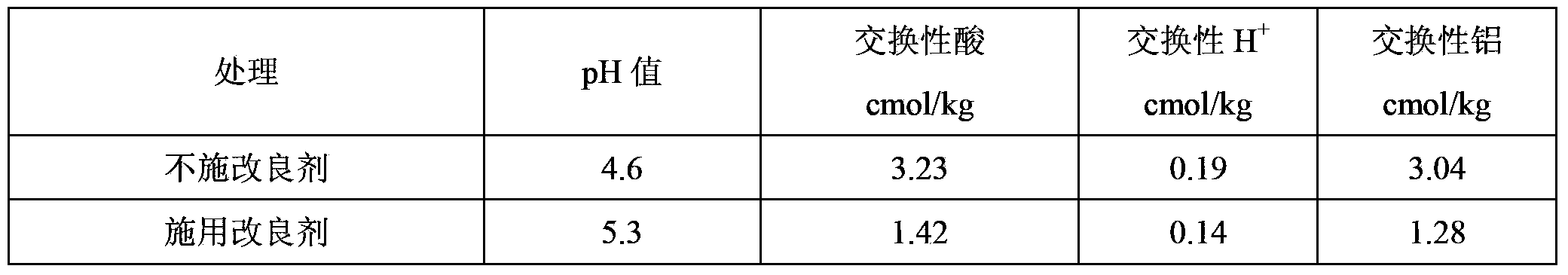

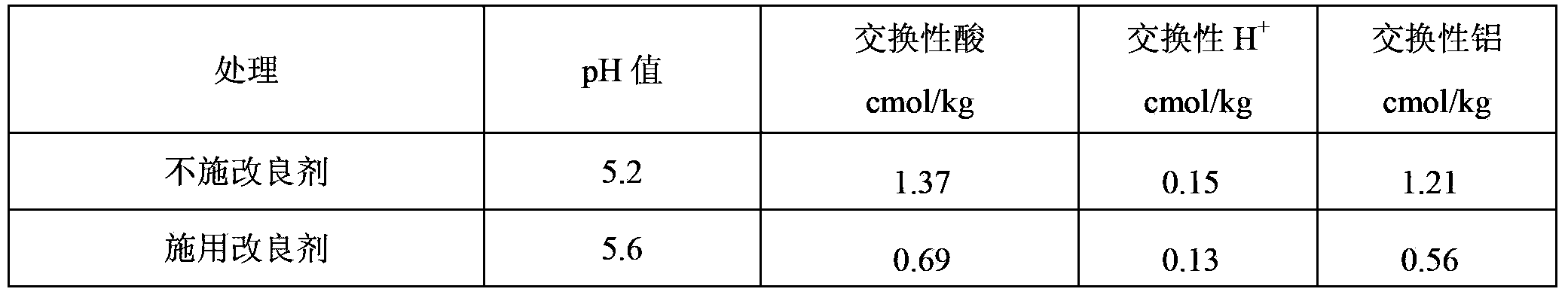

Tobacco plantation soil acidification improver and application method thereof

InactiveCN103409143AEasy to getSuitable for self-configurationOther chemical processesOrganic fertilisersDiseasePeat

The invention relates to a tobacco plantation soil acidification improver and an application method thereof. The improver is prepared from the raw materials of: 20-30wt% of quick lime, 50-60wt% of dolomite powder, 5-10% of lime nitrogen, and 10-15wt% of peat. The application method comprises the steps that: (1) the soil is sampled, and pH value is measured; and (2) according to different pH values, the improver with different dose is applied. With the soil improvement structure, soil caking is prevented, soil organics are supplemented, and soil-borne diseases of tobaccos can be comprehensively controlled. The improver has the advantages of simple preparation method, easy-to-obtain raw materials, and low cost.

Owner:INST OF PLANT PROTECTION & SOIL FERTILIZER HUBEI ACAD OF AGRI SCI

Preparation method of propylene random copolymer

The invention relates to a preparation method of a propylene-butylene-1 random copolymer. The preparation method comprises a step that the propylene-butylene-1 random copolymer is obtained through carrying out a copolymerization reaction of propylene and butylene-1 by adjusting the addition amount of the copolymerization monomer butylene-1 in a reactor at a polymerization temperature under a proper hydrogen content in the presence of a selected Ziegler-Natta catalyst. The preparation method has an easy polymerization process and can avoid the appearance of sticky kettle, caking, incompletely-removed residual monomers and the like, and the prepared propylene-butylene-1 random copolymer has a high relative butylene-1 dispersion degree and a low room-temperature xylene soluble substance content.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fast dissolving water-soluble fertilizer formulations and methods and uses thereof

ActiveUS20100186471A1Fast preparationReadily and rapidly compoundBiocideAmmonium nitratesFree solutionWater soluble

Improved, solid water-soluble fertilizer (WSF) compositions are presented which comprise at least one acid (optionally nutritive) and at least one basic fertilizer component. In one or more embodiments of the present invention, the WSF compositions demonstrate improved solubility of one or more nutrients or additives in solution, do not require additional dissolution aids or anti-caking agents, demonstrate fast dissolution times, produce precipitate free solutions, are readily compounded without intermediate wetting or drying steps, do not generate gas, and demonstrate improved stability under typical usage conditions. Finally, the WSF compositions may be used in improved processes for the creation of stock solutions, optionally with cold water, and / or delivery of nutrients to plants.

Owner:EVERRIS INT

Geopolymer composite material for 3D printing and preparation method and application thereof

ActiveCN106082898ASave energyEnvironmentally friendlyAdditive manufacturing apparatusSolid waste managementAdditive ingredientSlag

A geopolymer composite material for 3D printing and a preparation method and application thereof are disclosed. The geopolymer composite material comprises the following ingredients (by weight): 20-25% of water-quenched granulated blast furnace slag powder, 10-15% of ground steel slag, 0-5% of fly ash, 33-45% of tailings machine-made sand, 3-5% of a composite activator, 2.5-3% of a high-molecular polymer, 1-3% of a volume stabilizer, 1-2% of a thixotropic agent, 0.05-0.1% of an antifoaming agent and 13.9-12.45% of mixing water. The above ingredients are fully and uniformly stirred and then the mixture is subsequently pumped into a 3D printer for construction. The geopolymer composite material has good caking property, strong stability and has good pump-out morphology maintaining capability and bond property. Printed buildings have good morphology and volume stability, and houses and buildings have good overall stability and use security.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

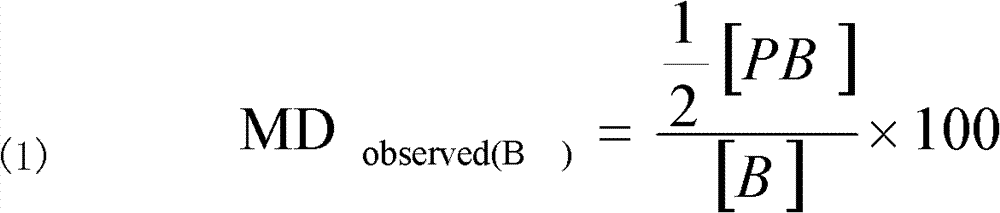

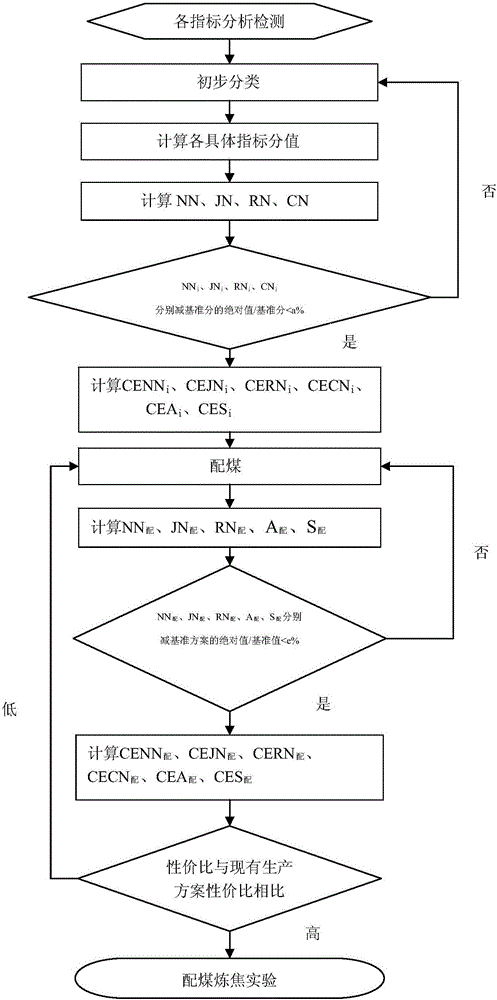

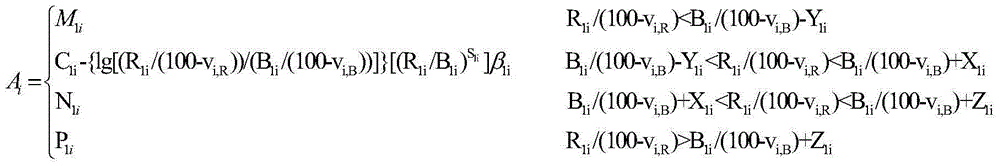

Coking raw material applicability classification, comprehensive quality evaluation and coal blending guiding method

ActiveCN105062531ASolve the problem of huge quality gapMeet the need to control the thermal properties of cokeCoke ovensProcess engineeringCaking

The invention provides a coking raw material applicability classification, comprehensive quality evaluation and coal blending guiding method. According to the method, specific indexes of coking raw materials and the mass index of solid products obtained from coking of the coking raw materials are integrated into three single indexes including caking capacity, coking capacity and a thermal property index according to the corresponding relations with coke quality indexes, and applicability classification is performed on the coking raw materials; the three single indexes are then integrated with ash content and sulfur content value indexes into an comprehensive capacity index, and six price-performance ratio indexes are formed through correlation between the three single indexes, the one comprehensive capacity index, the ash content and sulfur content value indexes and the price; after the applicability classification, coking coal blending is performed according to the three single indexes of the coking raw materials, the one comprehensive capacity index and the ash content and sulfur content value indexes, the six indexes for coal blending are controlled to be within plus / minus e%*a reference scheme score (e ranges from 5 to 10), the price-performance ratio of the six indexes for coal blending is calculated, an optimal coal blending scheme is determined, and refined and optimized coal blending is realized.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

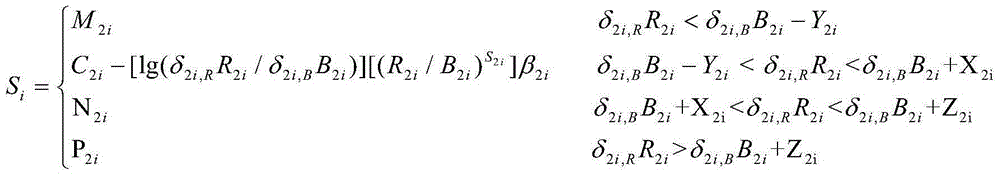

Biologic organic bamboo charcoal fertilizer and production method thereof

The invention discloses a biologic organic bamboo charcoal fertilizer which comprises the following components in parts by weight: 10-30 parts of bamboo charcoal powder, 15-30 parts of bamboo powder, 8-15 parts of bean pulp, 30-50 parts of organic yeast material and 0.2-1 part of biologic culture, wherein the biologic organic bamboo charcoal fertilizer is made into powder or grains. The invention further provides a production method of the biologic organic bamboo charcoal fertilizer. The production method comprises the following steps: weighing the bamboo charcoal powder, the bamboo powder, the bean pulp, the organic yeast material and the biologic culture according to a production ratio, mixing by using a stirring machine so as to obtain the biologic organic bamboo charcoal fertilizer, or adding an adhesive into the components, and pelleting by using a pelleting machine so as to obtain the biologic organic bamboo charcoal fertilizer. The invention provides an environment-friendly solving way for treatment on waste of bamboo products, the prepared biologic organic bamboo charcoal fertilizer has the effects of completeness in nutrition elements, freedom of chemical residue, soil heavy metal and pesticide residue adsorption, soil environment improvement, soil caking prevention, disease resistance improvement, crop quality improvement, and the like.

Owner:时科生物科技(上海)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com