Patents

Literature

350 results about "Drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Food drying is a method of food preservation in which food is dried (dehydrated or desiccated). Drying inhibits the growth of bacteria, yeasts, and mold through the removal of water. Dehydration has been used widely for this purpose since ancient times; the earliest known practice is 12,000 B.C. by inhabitants of the modern Middle East and Asia regions. Water is traditionally removed through evaporation (air drying, sun drying, smoking or wind drying), although today electric food dehydrators or freeze-drying can be used to speed the drying process and ensure more consistent results.

Cultures Encapsulated With Compound Fat Breakfast Cereals Coated With Compound Fat and Methods of Preparation

InactiveUS20080305210A1Improve the level ofSufficient amountMilk preparationEdible oils/fats ingredientsWater activityDrying

Food products are provided comprising a food base and the compound fat encapsulated pro-biotic as a coating or portion or phase of the food product. The food base can include the compound fat encapsulated pro-biotic as a topical coating or phase or portion. The food base or foodstuff is dried and has a water activity ranging from about 0.1 to about 0.35. The weight ratio of food base to compound fat encapsulated pro-biotic ranges from about 100:1 to about 100:400. The pieces of the coated food base can be admixed with pieces of uncoated dried food base of the same or different composition to provide desired levels of pro-biotic fortification

Owner:GENERAL MILLS INC

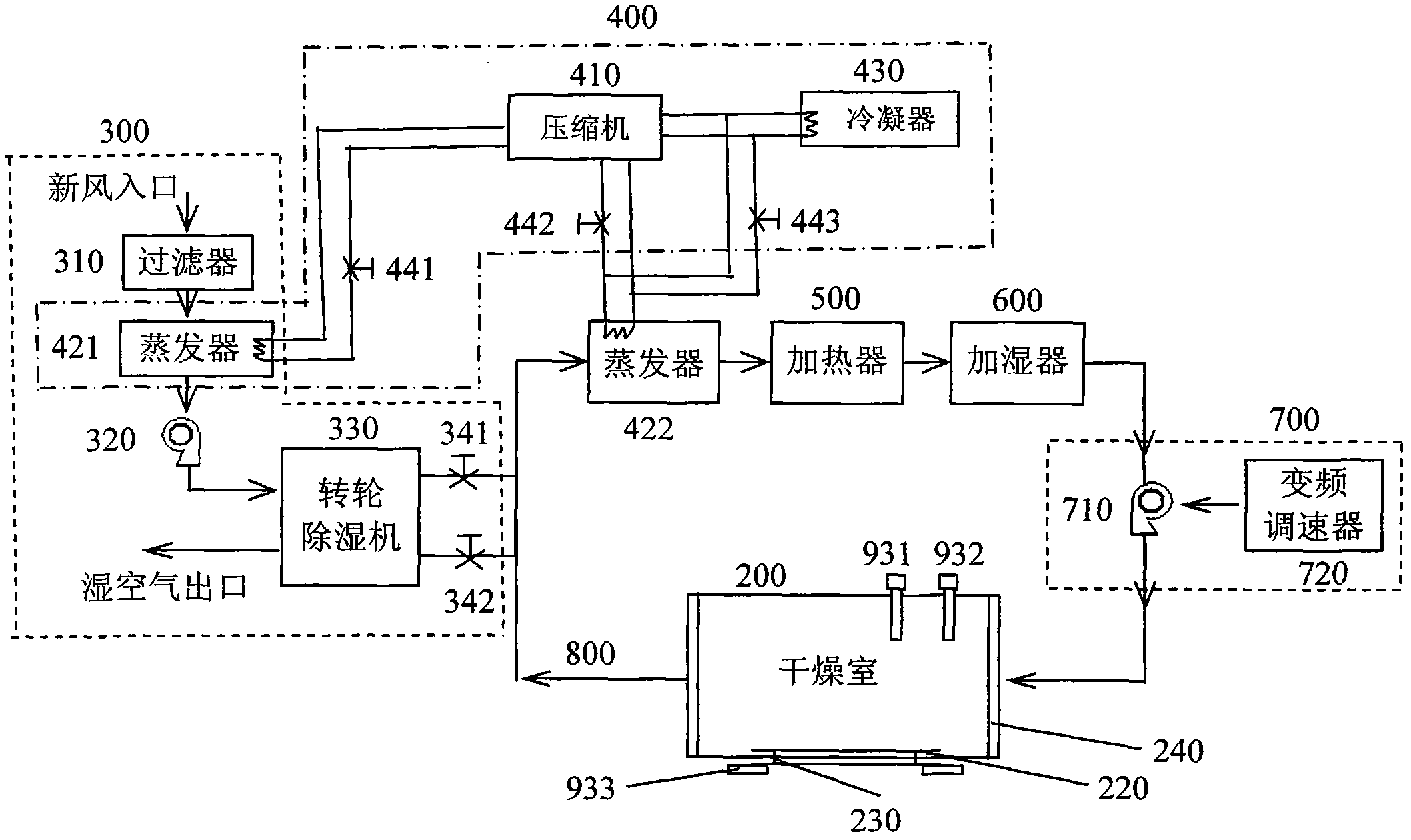

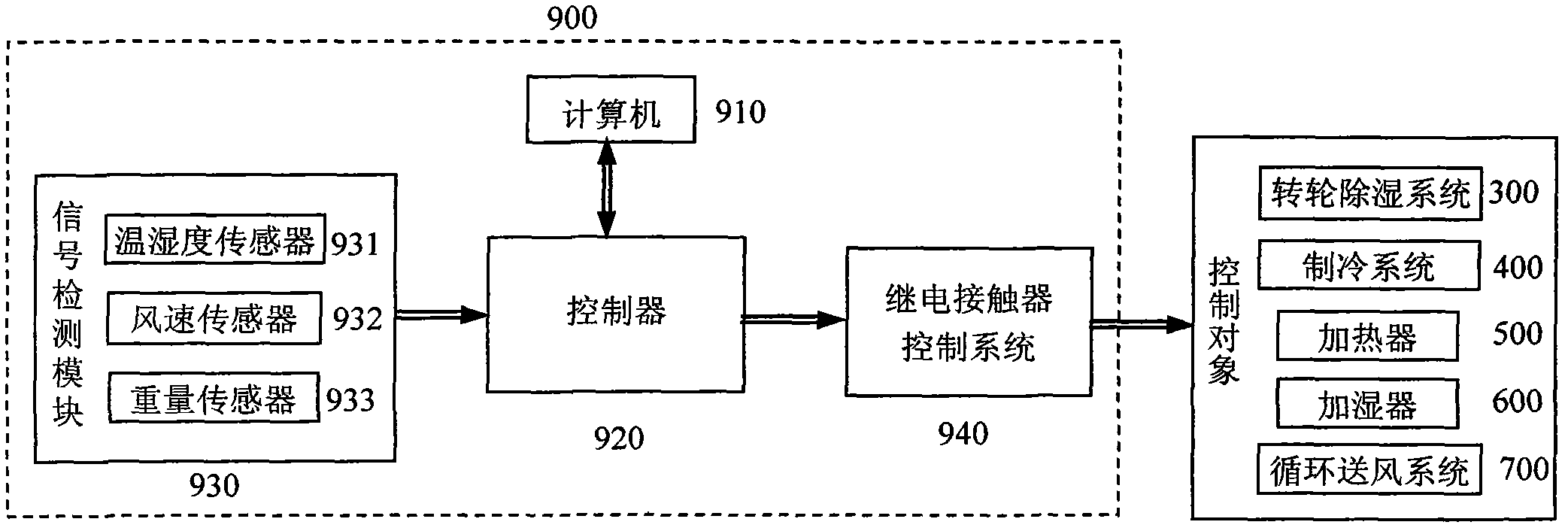

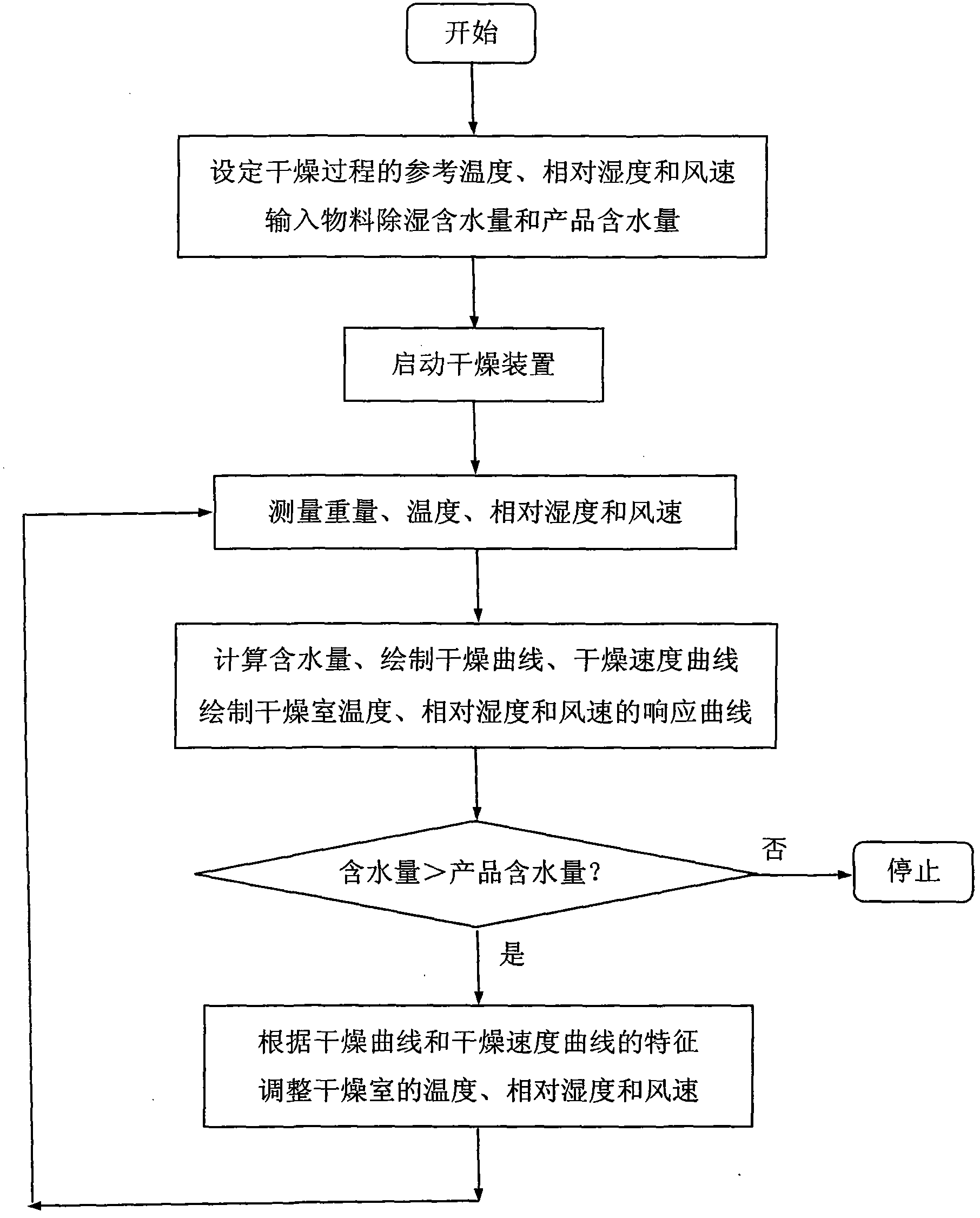

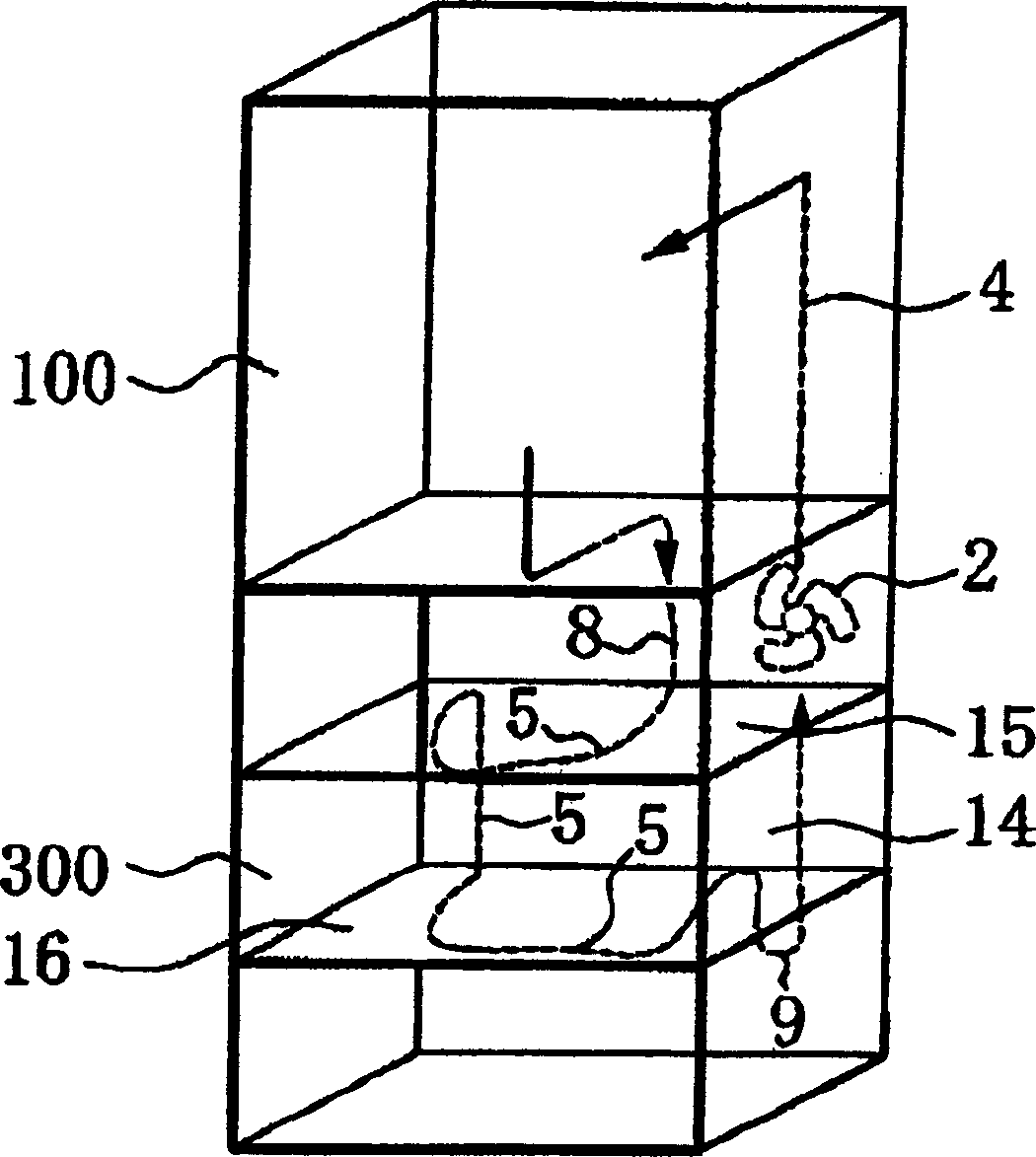

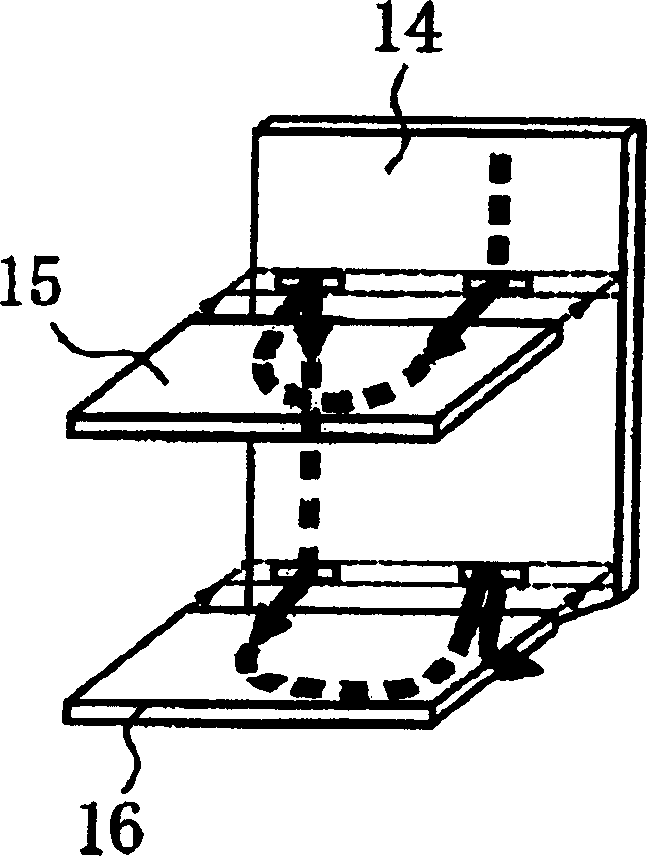

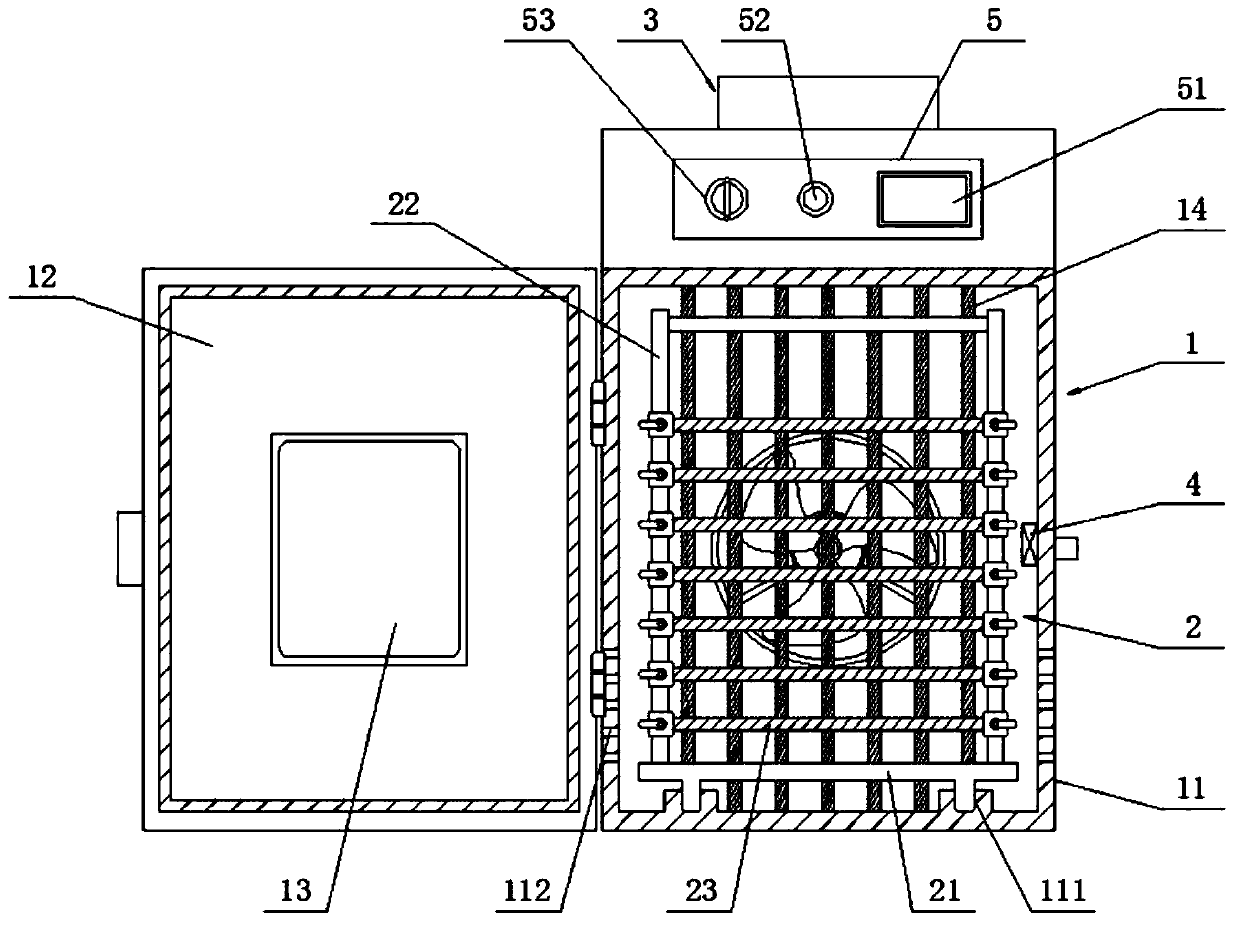

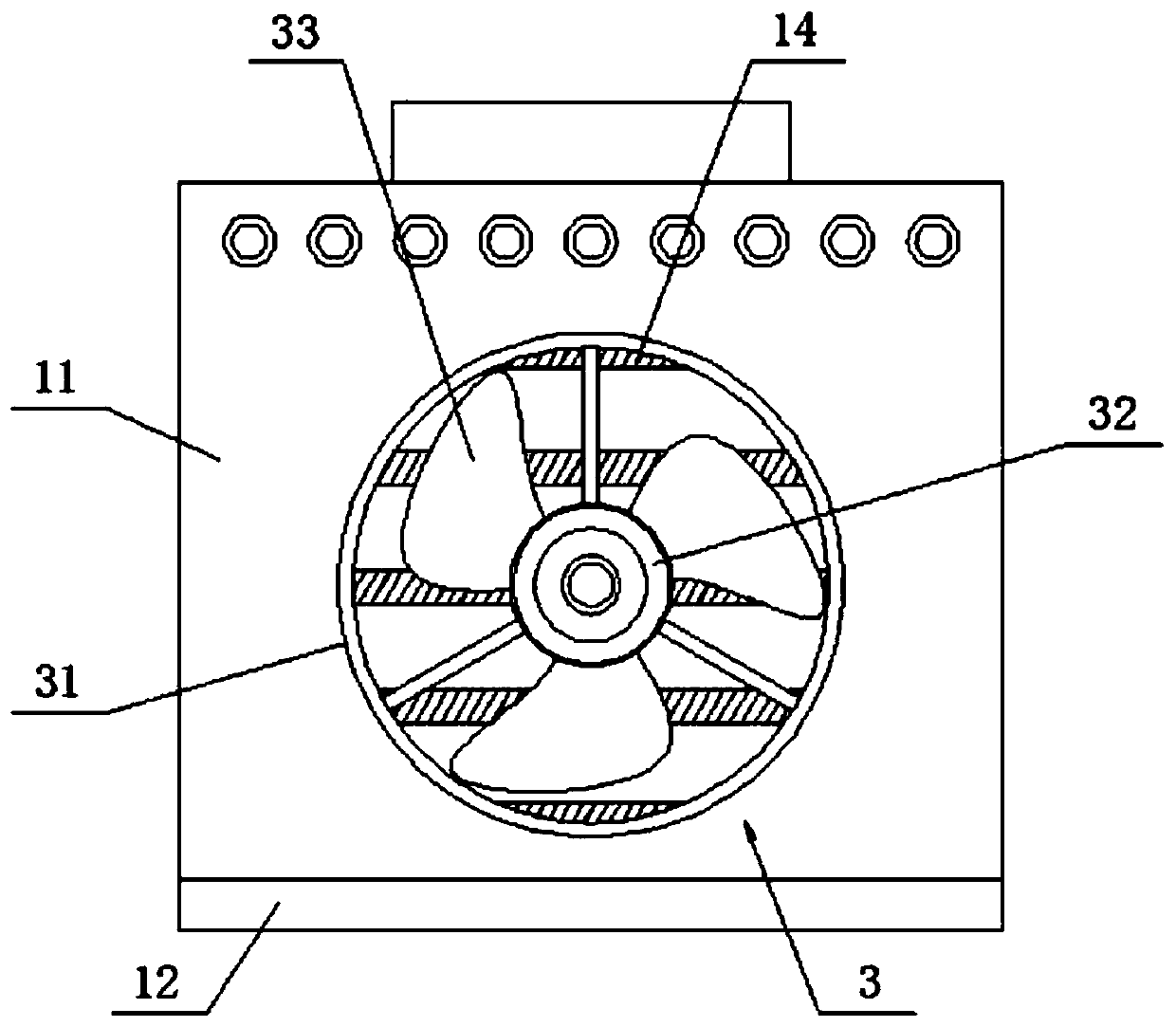

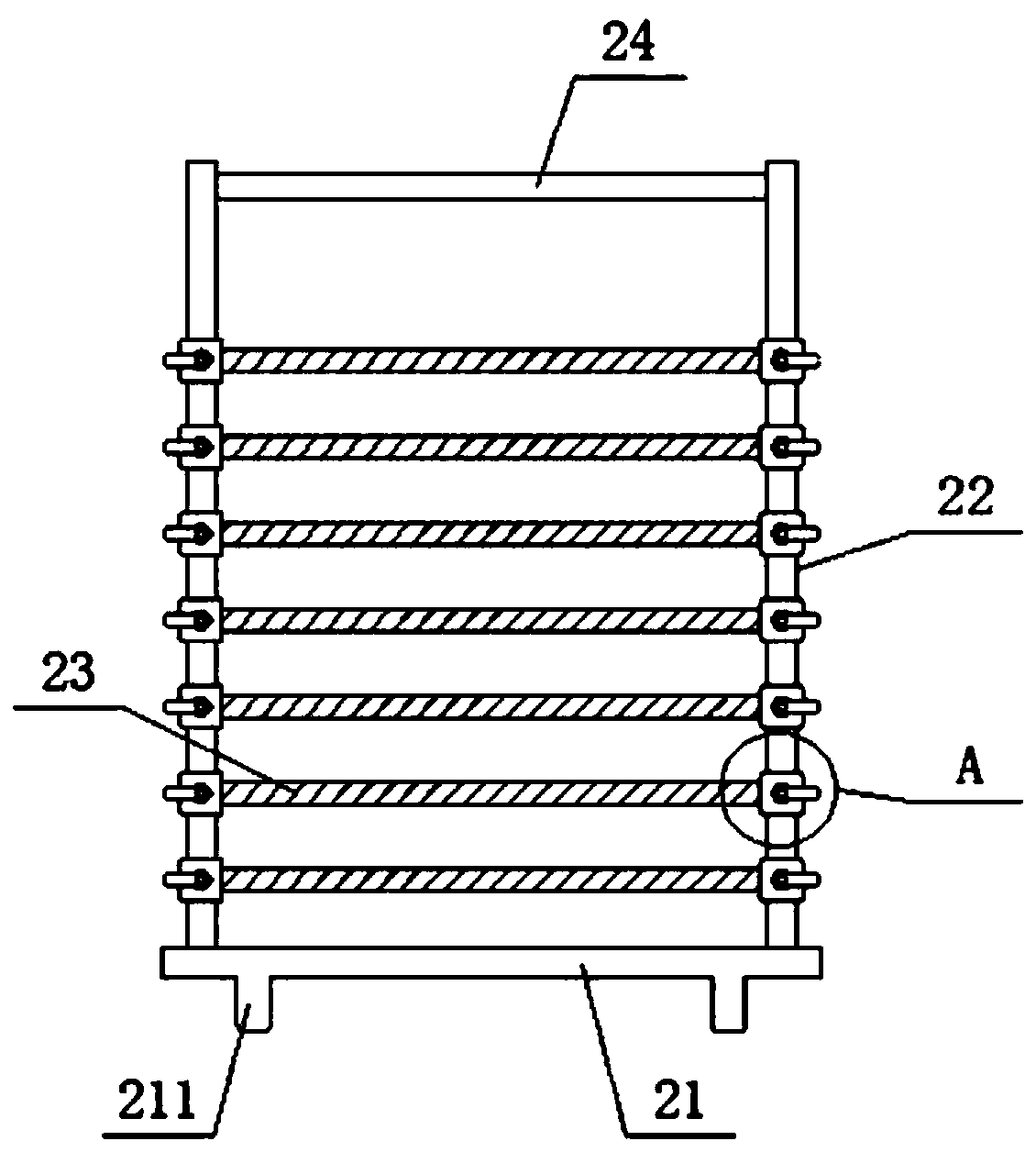

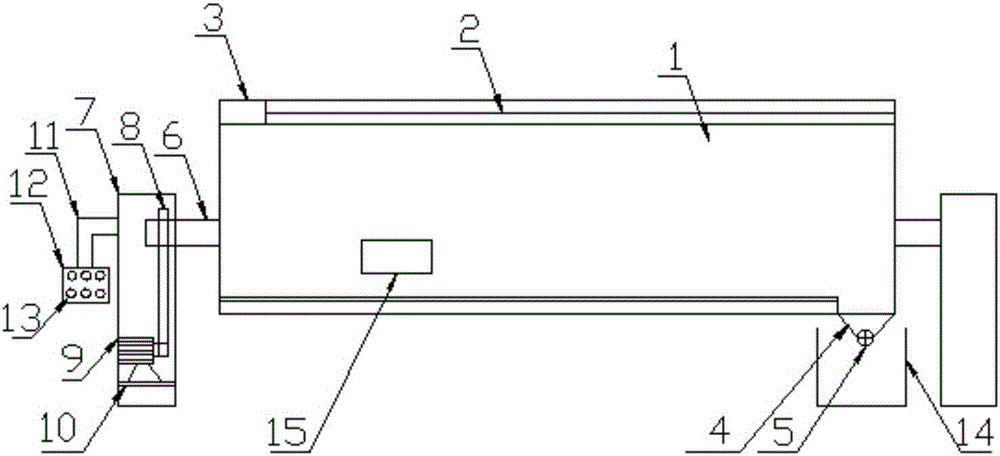

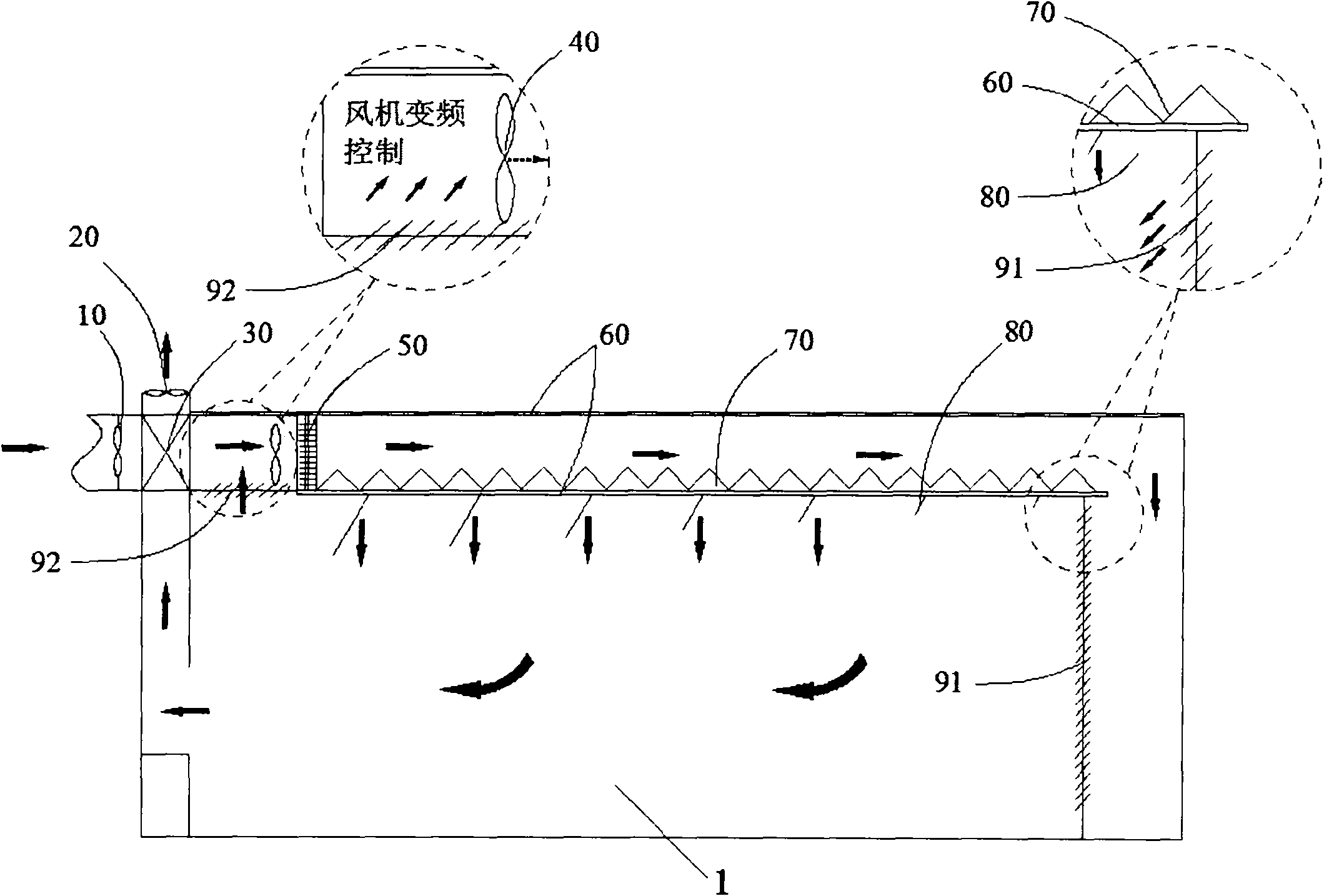

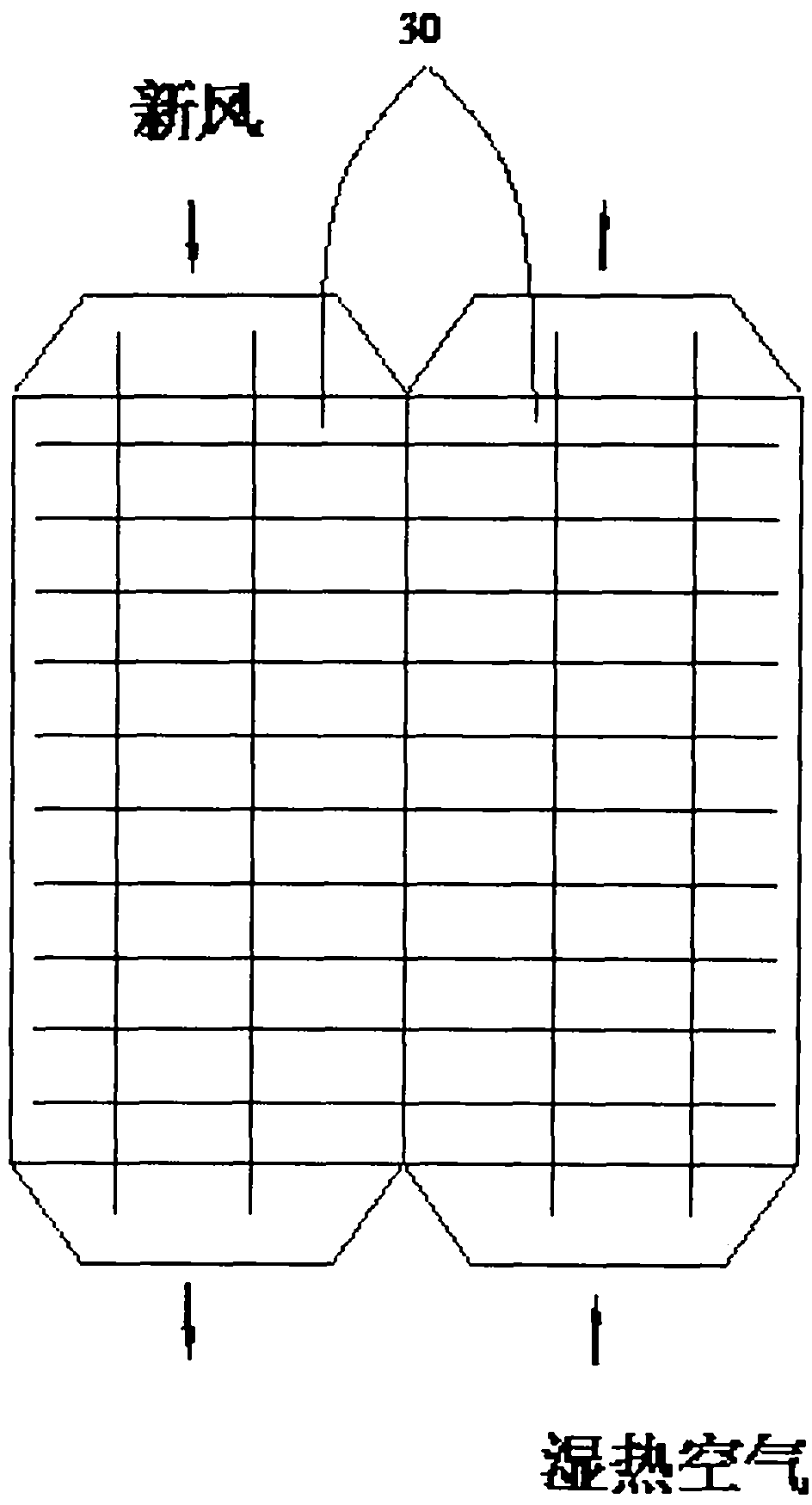

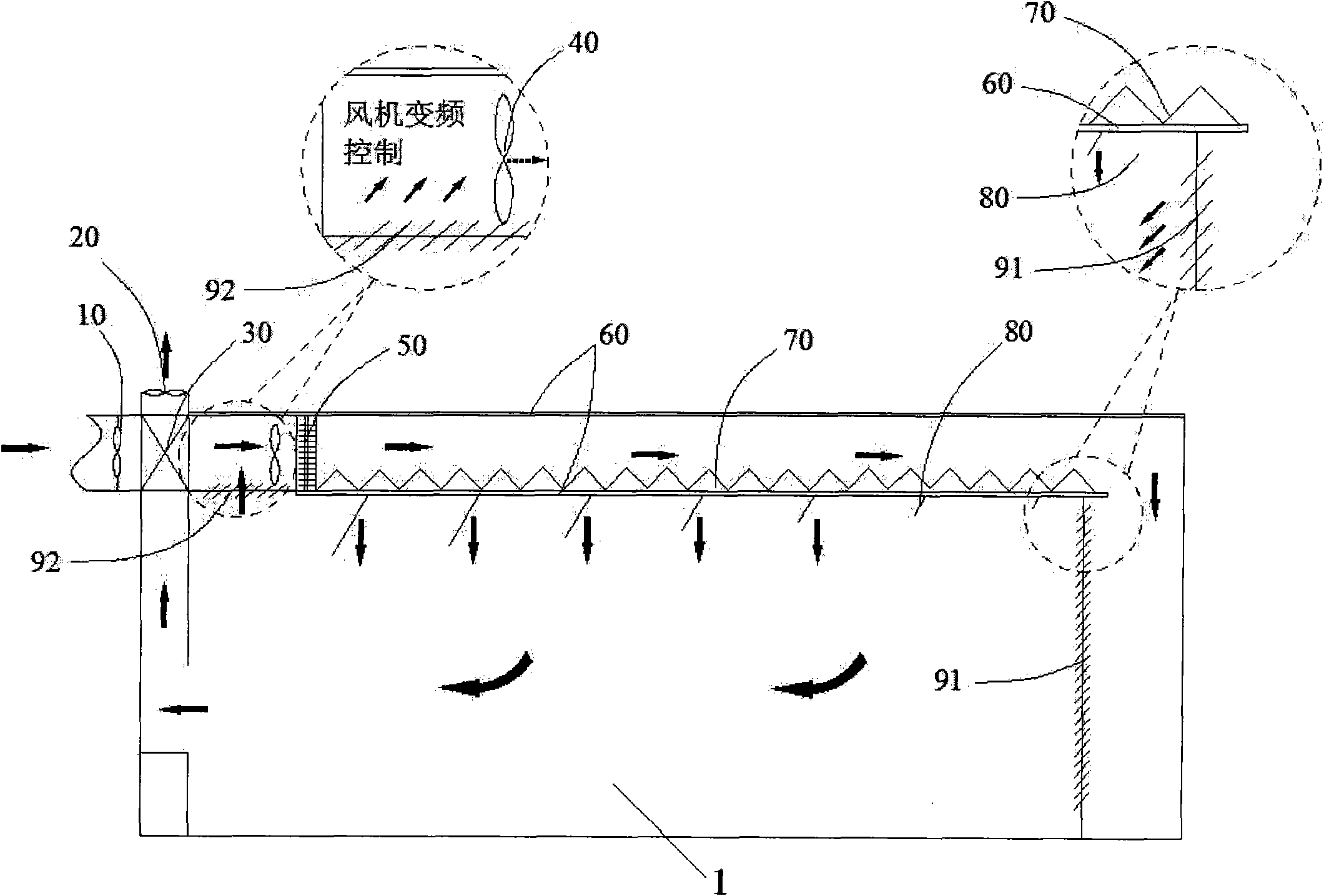

Drying device suitable for food and food drying method thereof

InactiveCN102871201ALarge adjustment rangeImprove uniformityFood preservationAgricultural scienceAir velocity

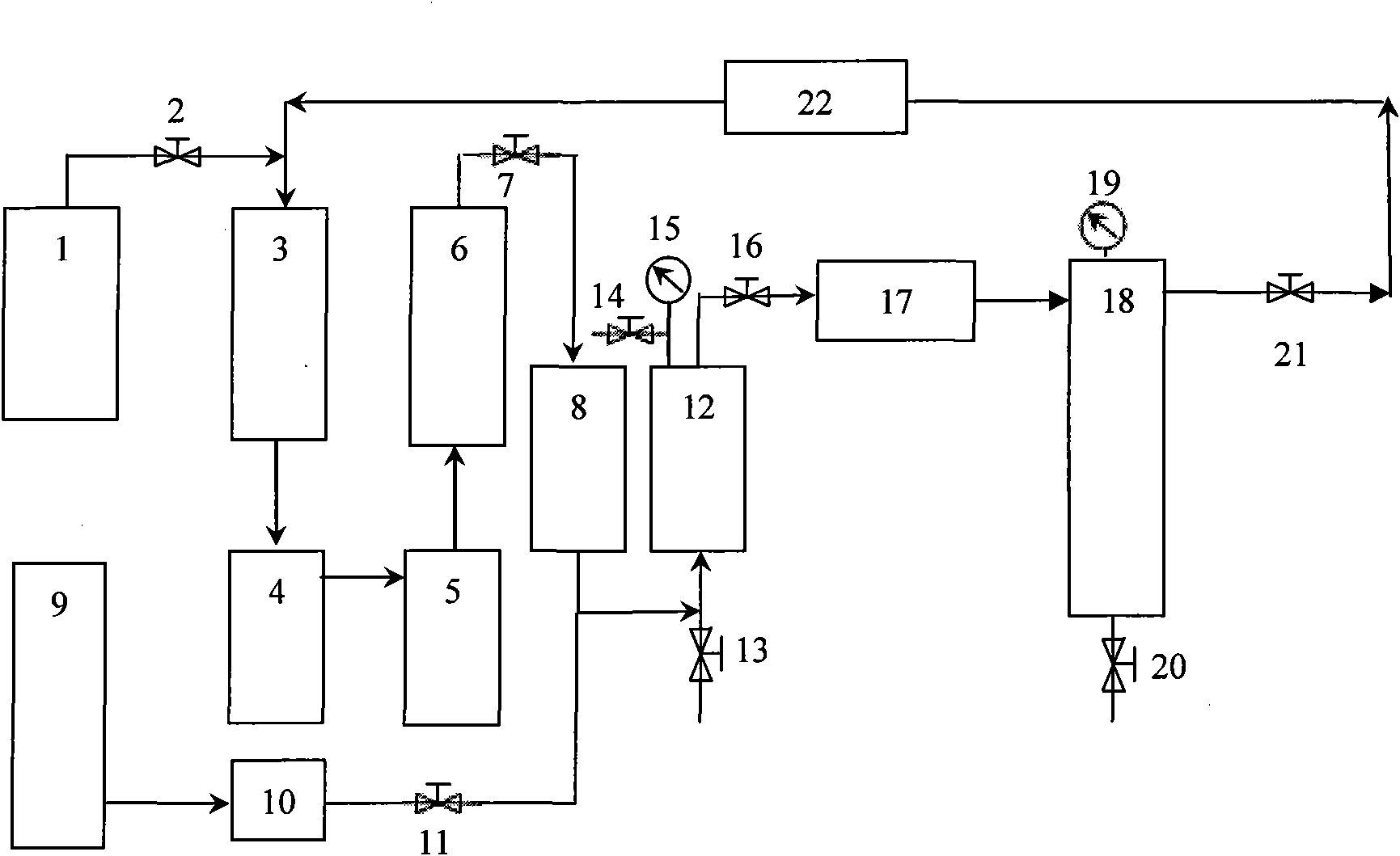

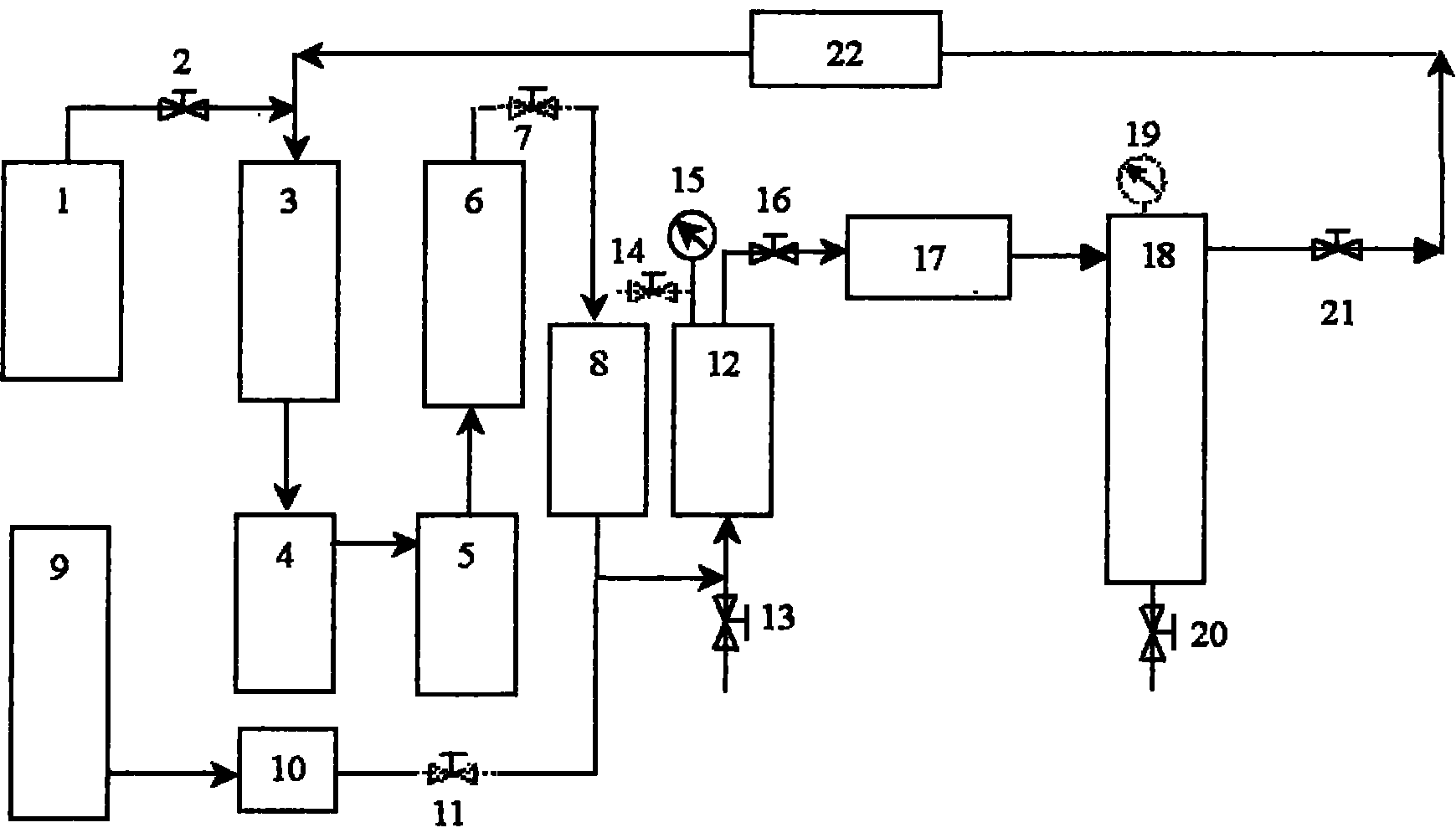

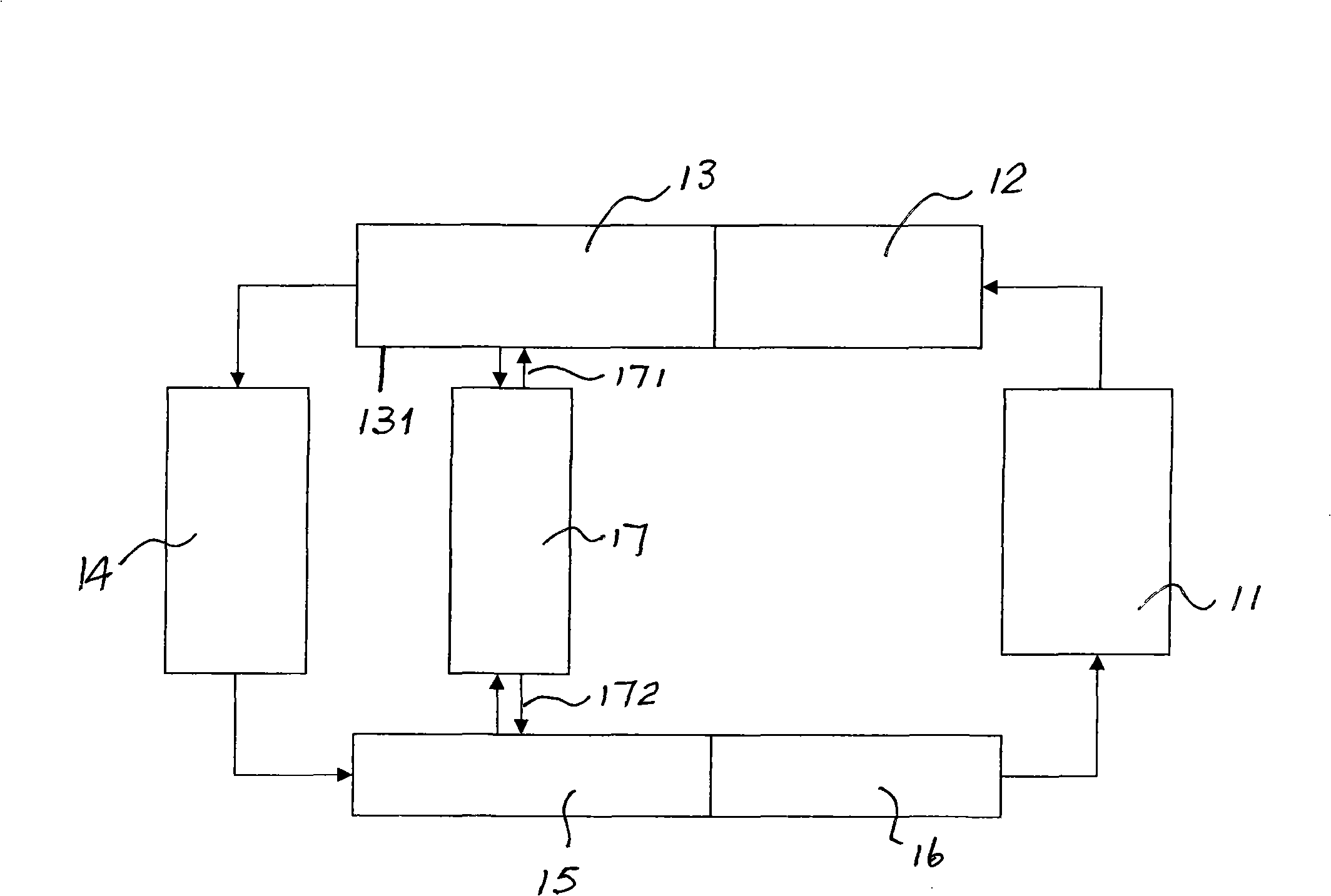

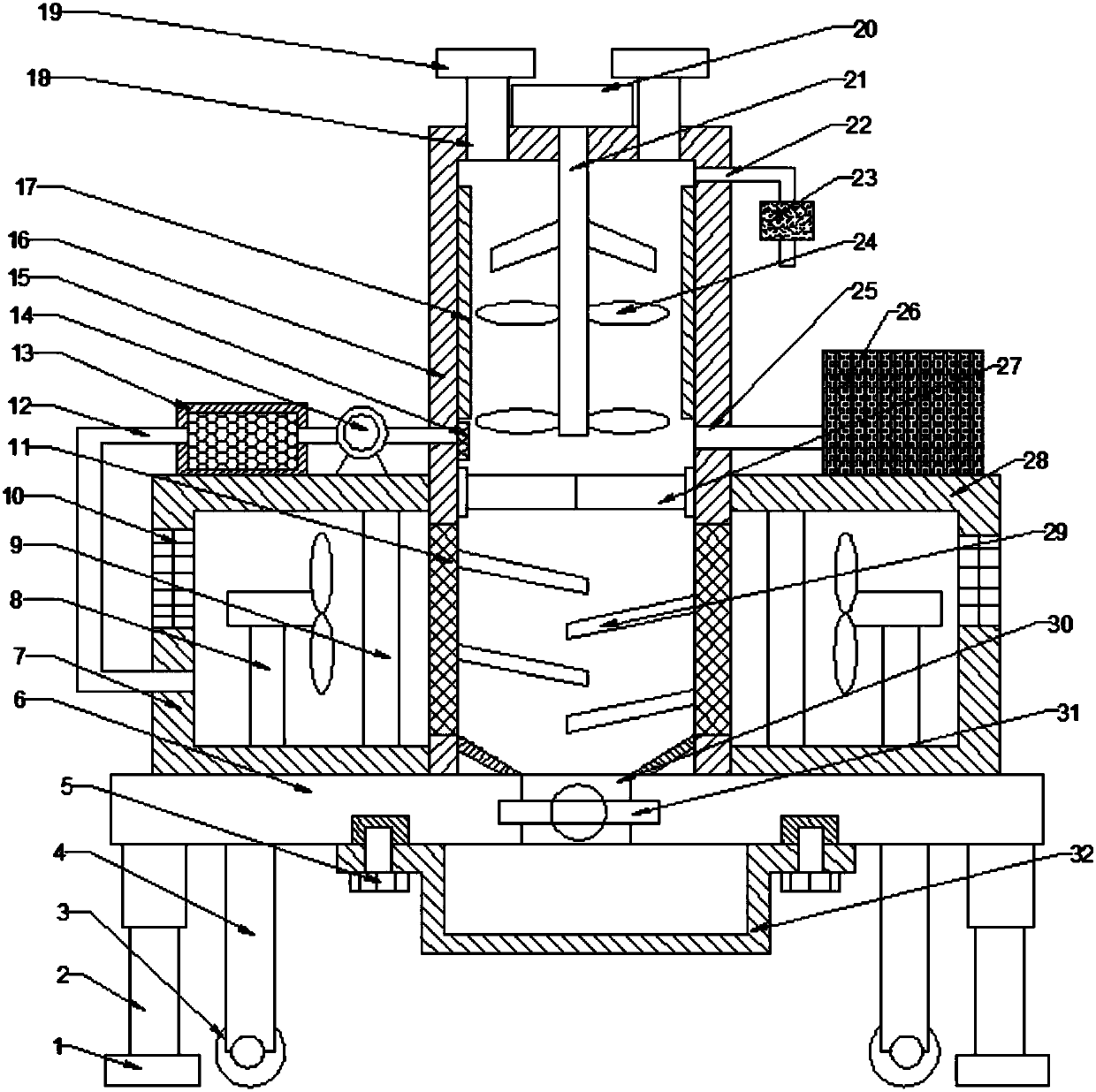

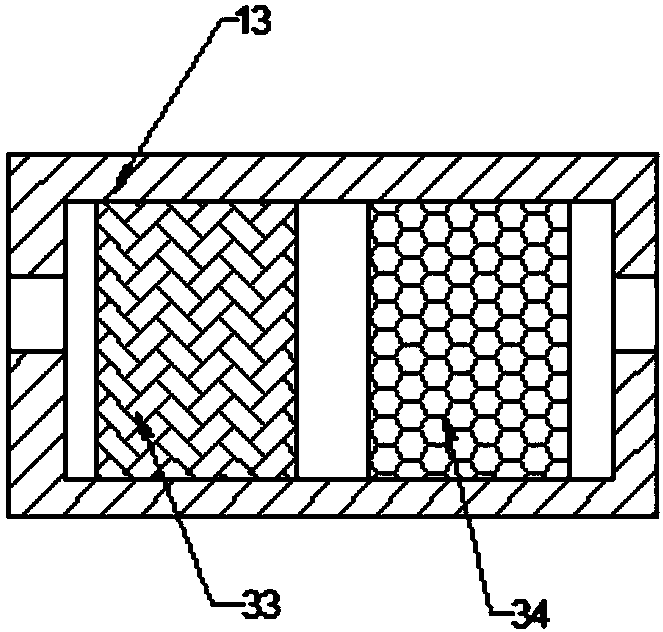

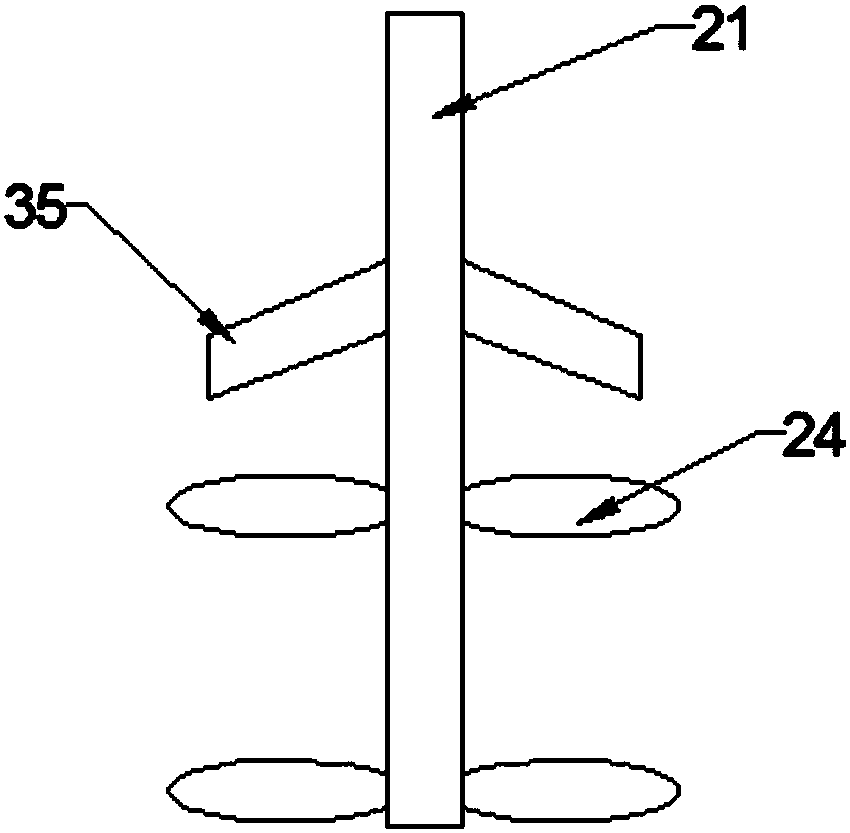

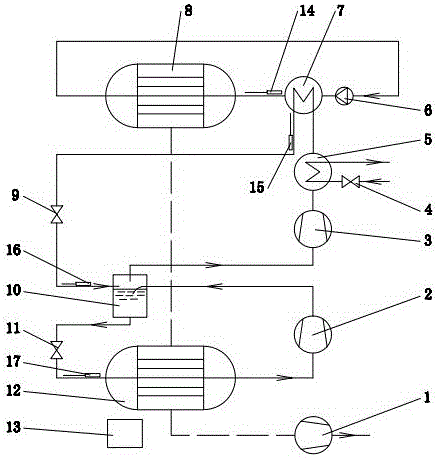

The invention belongs to a drying device suitable for food. The device comprises a drying chamber, a rotating wheel dehumidification system, a refrigerating system, a heater, a humidifier, a circulating air supply system, a main air path and a control system. The drying chamber, a refrigerating system evaporator, the heater, the humidifier, and a circulating fan are connected by air pipes in order so as to form the main air path. The rotating wheel dehumidification system and the main air path are in parallel connection. A food drying method of the drying device provided in the invention consists of: according to a drying curve and a drying rate curve, adjusting the drying chamber temperature, the relative humidity and the air speed, and comparing an actual water content with a product water content to determine whether ending the drying process. Heating dehumidification, evaporator dewing dehumidification, and adsorbing dehumidification by a rotating wheel dehumidifier are employed to realize drying chamber humidity control. The device has the characteristics of wide temperature and humidity control range, good uniformity, and adjustable air speed, can monitor the weight of a dried material in real time, control the drying process, lower energy consumption, and can be used for drying fruits and vegetables, spices, fish, meat, egg products, gel products or / and cereals.

Owner:HUAZHONG AGRI UNIV

Preparing water soluble chitosan or in small molecular weight through radiation method

The invention belongs to a method for preparing small molecular weight or water-solubility chitosan by using radiation process. It is characterized by that a refined high molecular weight chitosan solid or solution can be irradiated by using 60 Co gamma-rays and degraded, and the degradation product is undergone the after-treatment steps of dissolution and decolouration, etc. so as to obtain the invented small molecular weight or water-solubility chitosan. Said chitosan has several purposes, can be used as agricultural production-increasing agent, food drying agent, natural anti-bacterial material and bio-medicine material, etc.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Cultures Encapsulated With Chocolate Food Products Coated With Chocolate And Method Of Preparation

InactiveUS20080102163A1Improve the level ofSufficient amountMilk preparationCocoaButter cocoaWater activity

Food products are provided comprising a food base and the chocolate or cocoa butter encapsulated pro-biotic, especially lactic acid forming cultures, as a coating or portion or phase of the food product. The food base can include the chocolate or cocoa butter encapsulated pro-biotic as a topical coating or phase or portion. The food base or foodstuff is dried and has a water activity ranging from about 0.1 to about 0.35. The weight ratio of food base to chocolate or cocoa butter encapsulated pro-biotic ranges from about 100:1 to about 100:400. The pieces of the coated food base can be admixed with pieces of uncoated dried food base of the same or different composition to provide desired levels of pro-biotic fortification.

Owner:GENERAL MILLS INC

Method for swelling and watering fruit or vegetable type food at ambient temp.

ActiveCN1792284ANo pollution in the processNo generationFruits/vegetable preservation by dehydrationAdditive ingredientDrying

Owner:JIANGSUCHINA PALARICH

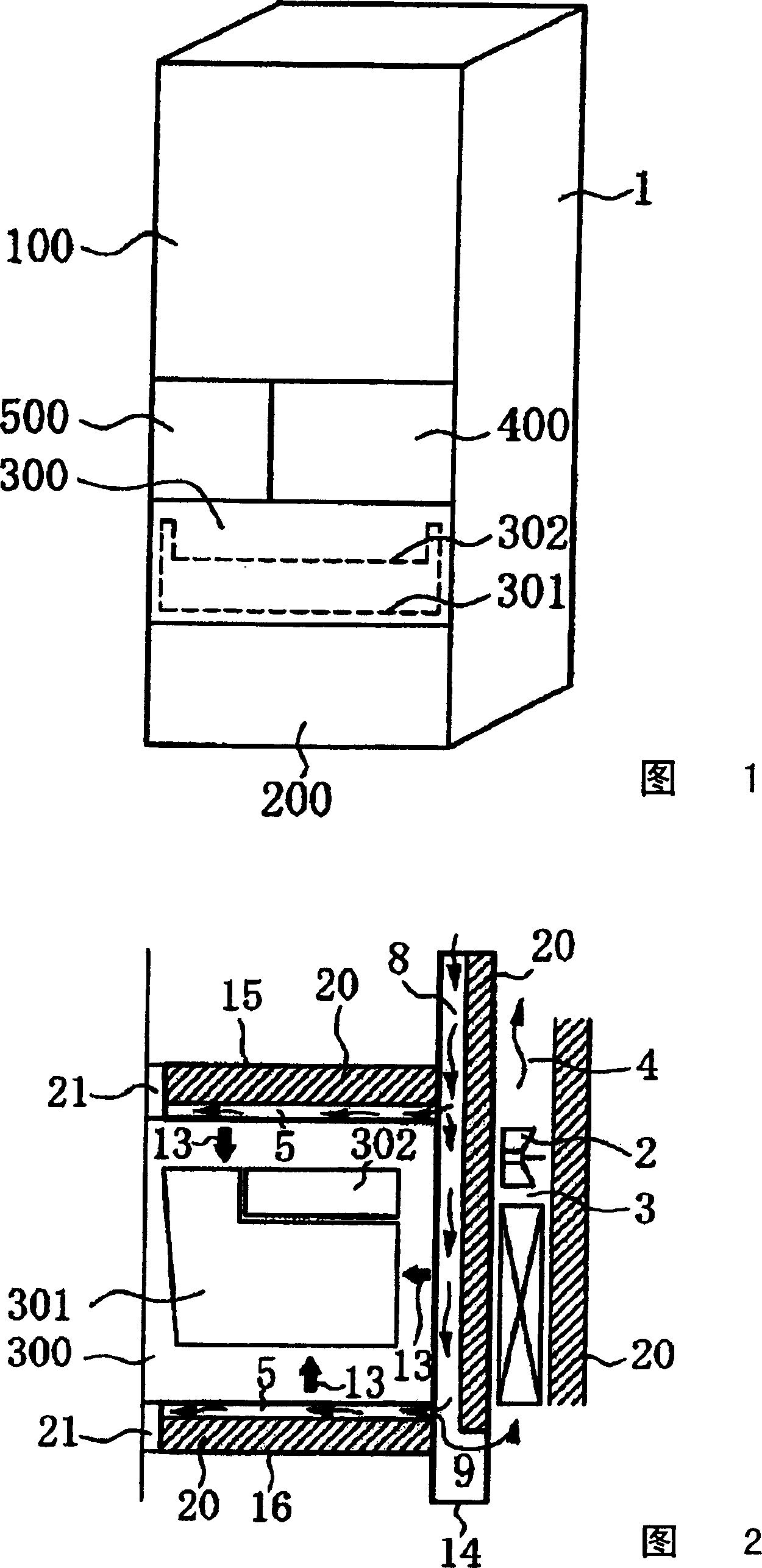

Refrigerator

InactiveCN1397780AImprove hydrophilicityIncrease humidityLighting and heating apparatusDomestic refrigeratorsDryingEngineering

A refrigerator which may allow vegetables kept more fresh by minimizing temperature fluctuations in a vegetable compartment. The refrigerator minimizes dehydration in food stored in the vegetable compartment, so that vegetables are kept fresh longer. The vegetable compartment is arranged so as to be surrounded by freezing temperatures, and cooled through radiation cooling without receiving blowing cool air thereto to minimize temperature fluctuations, so that vegetables may be keep more fresh. At the same time, the vegetable compartment is sealed so that convection does not occur thereby minimizing dehydration in food, so that food is allowed to be kept fresh longer. Furthermore, the refrigerator is provided with compartments whose temperatures may be set to freezing temperatures. The vegetable compartment is arranged so as to be surrounded by compartments whose temperatures are freezing temperatures via partition parts.

Owner:MITSUBISHI ELECTRIC CORP

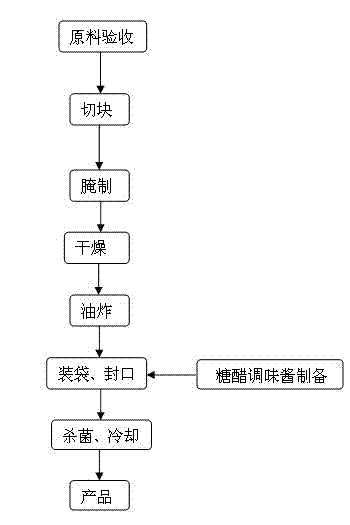

Processing method of instant sweet and sour fish capable of being preserved at normal temperature

The invention provides a processing method of instant sweet and sour fish capable of being preserved at normal temperature and relates to the technical field of food processing and preservation. Fresh and alive freshwater fish is used as a raw material, stripped and sliced, cured, dried, fried, packed, sealed in vacuum mode, sterilized and cooled to be manufactured into an instant sweet and sour fish food. The contemporary food drying and sterilizing processing technology is combined on the basis of a traditional sweet and sour fish manufacturing process to obtain the sweet and sour fish food capable of being preserved at the normal temperature, no chemical preservative is added in a machining process, the produced sweet and sour fish food can well maintain specific flavor, texture, color and nutritional quality of the traditional sweet and sour fish and is convenient and safe to eat, shelf life of the sweet and sour fish food at the normal temperature can reach above 12 months, requirements of consumers for safety, delicacy and convenience of contemporary food are met, industrial production is easy to achieve, and market prospect is wide.

Owner:劲仔食品集团股份有限公司

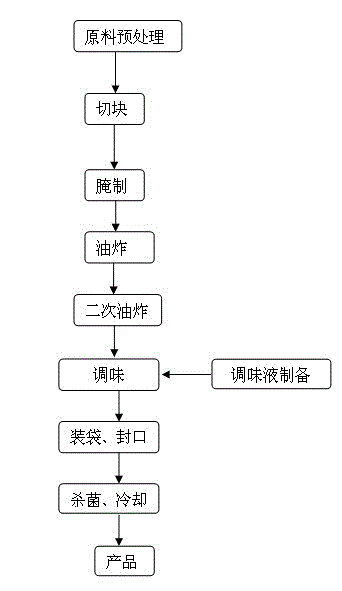

Processing method of normal-temperature preserved instant bloated fish food

The invention relates to a processing method of a normal-temperature preserved instant bloated fish food, belonging to the technical field of food processing and preservation. The normal-temperature preserved instant bloated fish food is prepared through the steps of dicing, curing, frying, secondary frying, seasoning, bagging, vacuum seal, sterilization and cooling by taking fresh and alive freshwater fishes as raw materials. The processing method disclosed by the invention obtains the normal-temperature preserved instant bloated fish food on the basis of the traditional bloated fish making process by combining with a modern food drying and sterilization processing technology; the product is short in production period and simple in process and can realize standardized large-scale industrialized production; and the produced normal-temperature preserved instant bloated fish food can better keep the specific flavor, texture, color and nutritional quality of the traditional bloated fish, is convenient and safe to eat, achieves the normal-temperature quality guarantee period more than one year, meets the requirements of consumers on the safety, delicacy and convenience on modern foods and is wide in market prospect.

Owner:JIANGNAN UNIV

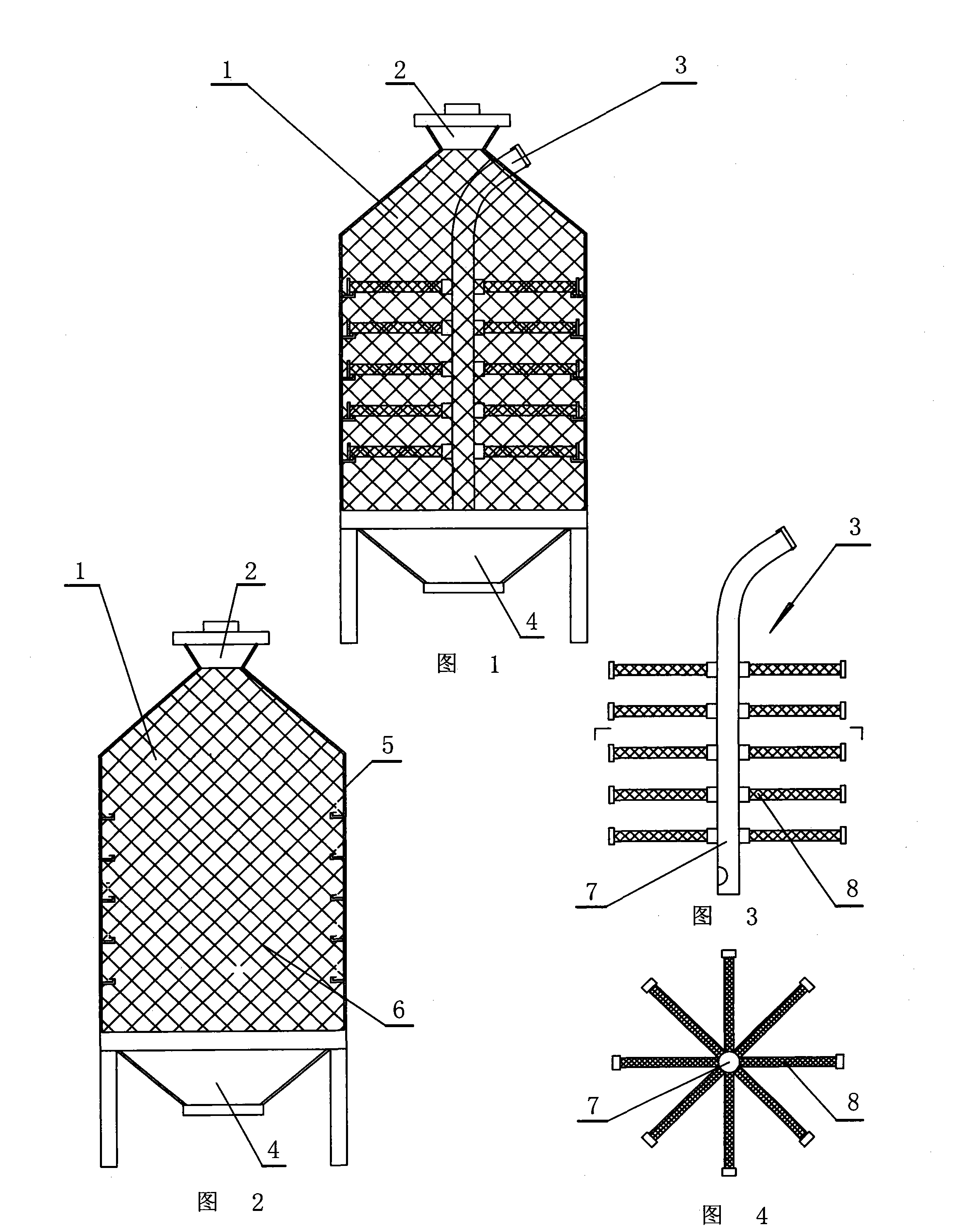

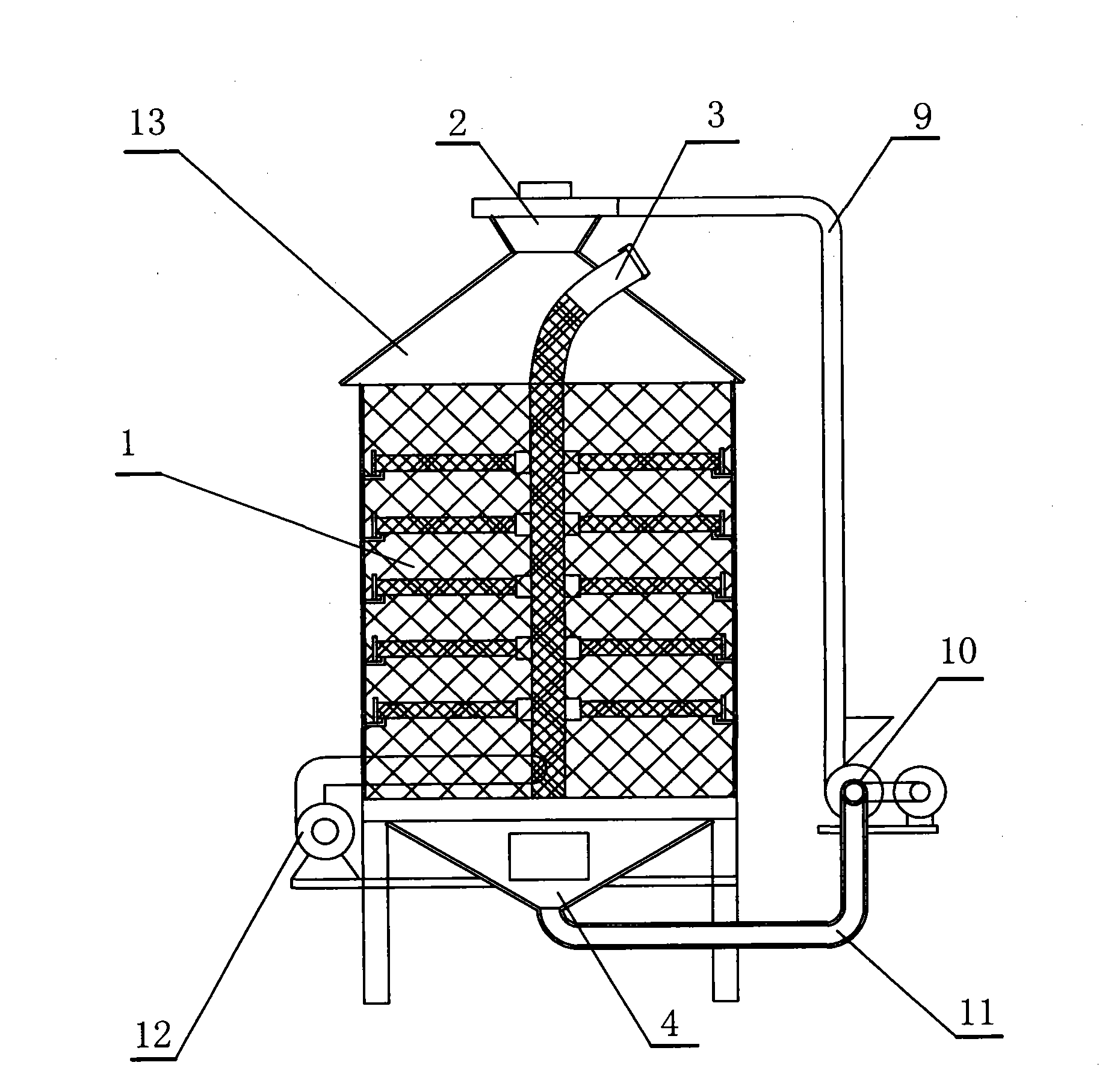

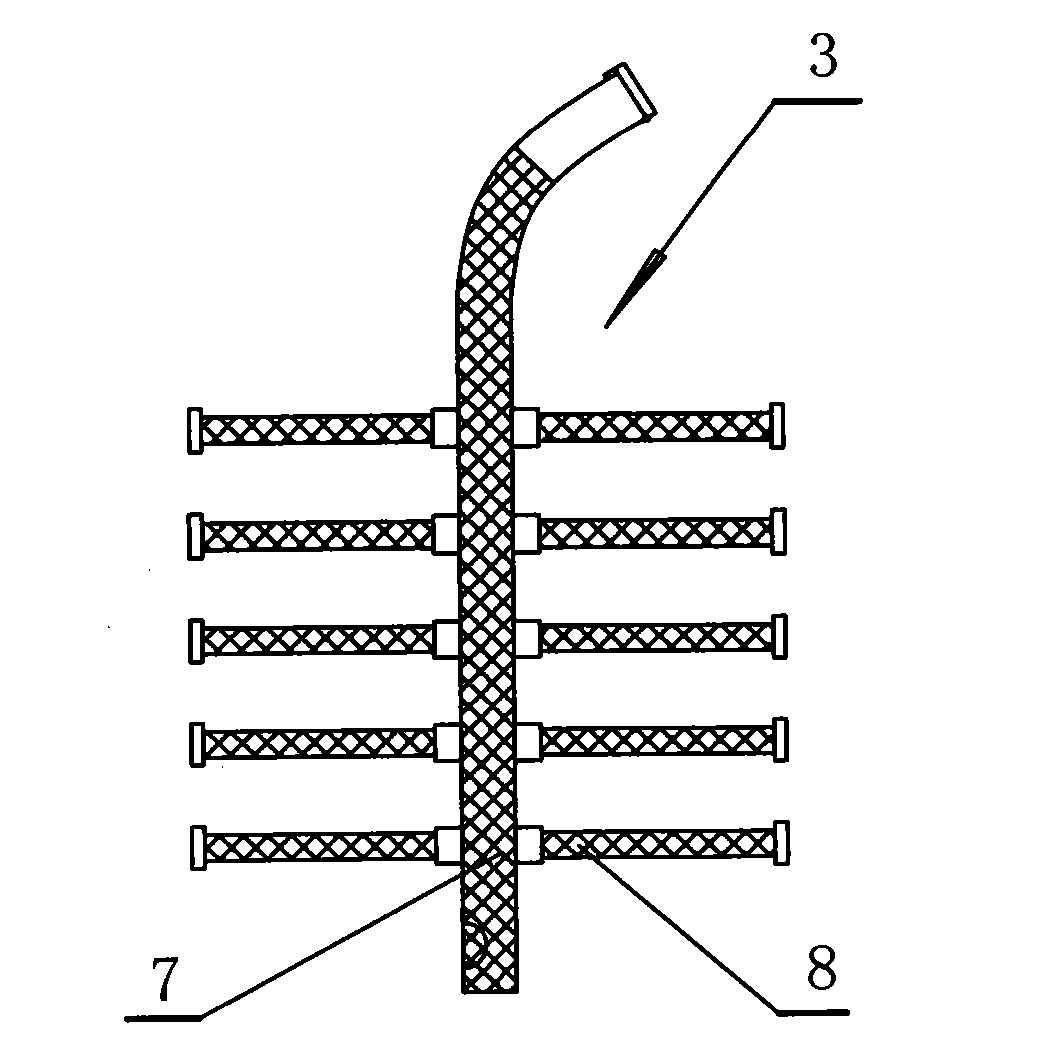

Straw drying warehouse

Owner:通辽市乡天环保设备制造有限公司

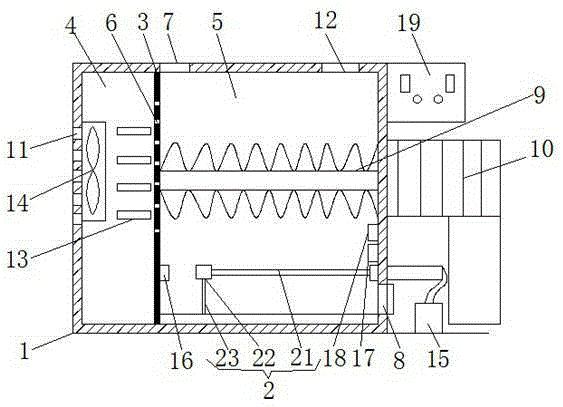

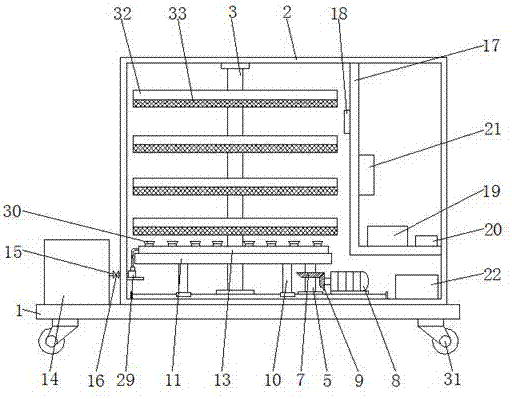

Food processing dryer

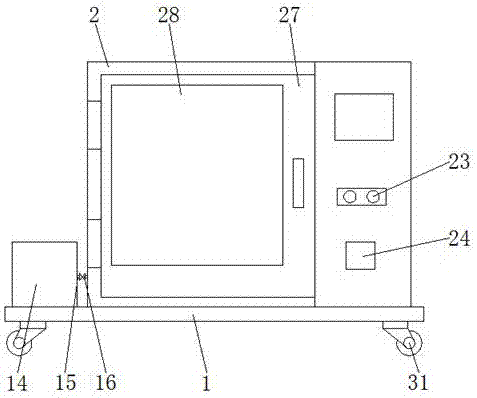

InactiveCN105258472AMonitor temperature in real timeReal-time monitoring of humidityDrying gas arrangementsDrying solid materialsCouplingDrying

The invention discloses a food processing dryer. The food processing dryer comprises a machine body and a discharging device, wherein the machine body is divided into an outer shell and an inner shell; the interior of the machine body is divided into the machine body into a heating chamber formed in the left side of a partition plate and a drying chamber formed in the right side of the partition plate by the separation plate; a vent hole is formed in the partition plate; a filter screen is formed in the vent hole; a feeding opening is formed in the top of the drying chamber; a discharging opening is formed in the right side of a drying box; a stirring device is arranged in the drying chamber; one end of the stirring device is connected with an output shaft of a motor located at the right side of the drying chamber; an air inlet is formed in the left side of the heating chamber. Through the food processing dryer, the discharging device is arranged, so that the food can be automatically discharged out after the food is dried; the trouble of manual operation is eliminated; the food processing dryer is simple and practical; a temperature sensor and a humidity sensor are arranged, so that the temperature and the humidity in the drying chamber can be monitored in time; the food processing dryer is capable of avoiding the breakage of the structure of the food because of over-high temperature.

Owner:蓝玉

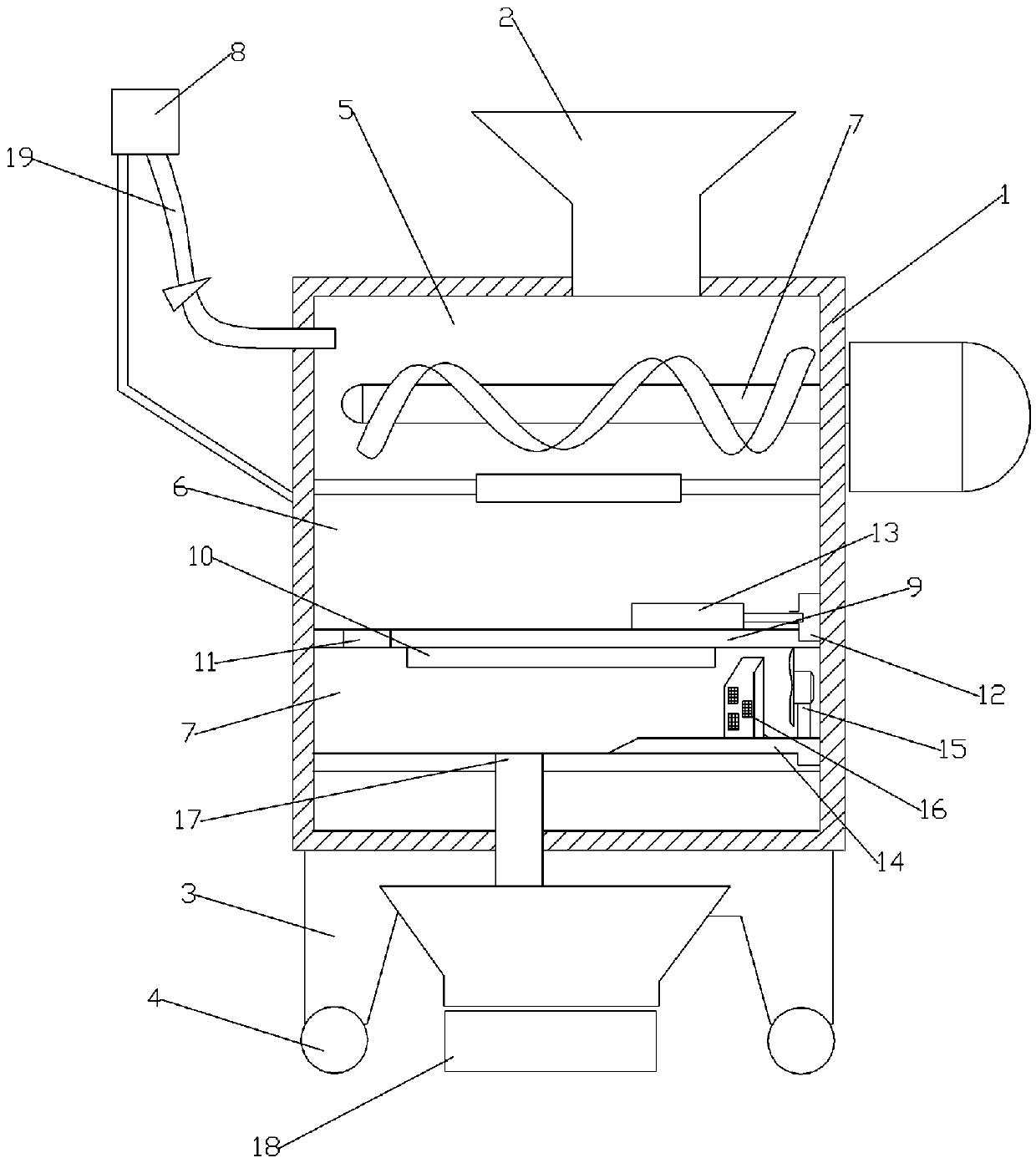

Device and method for drying food by supercritical carbon dioxide

InactiveCN102113699AReduce the temperatureFood treatmentFruits/vegetable preservation by dehydrationCarbon dioxide cylinderFresh food

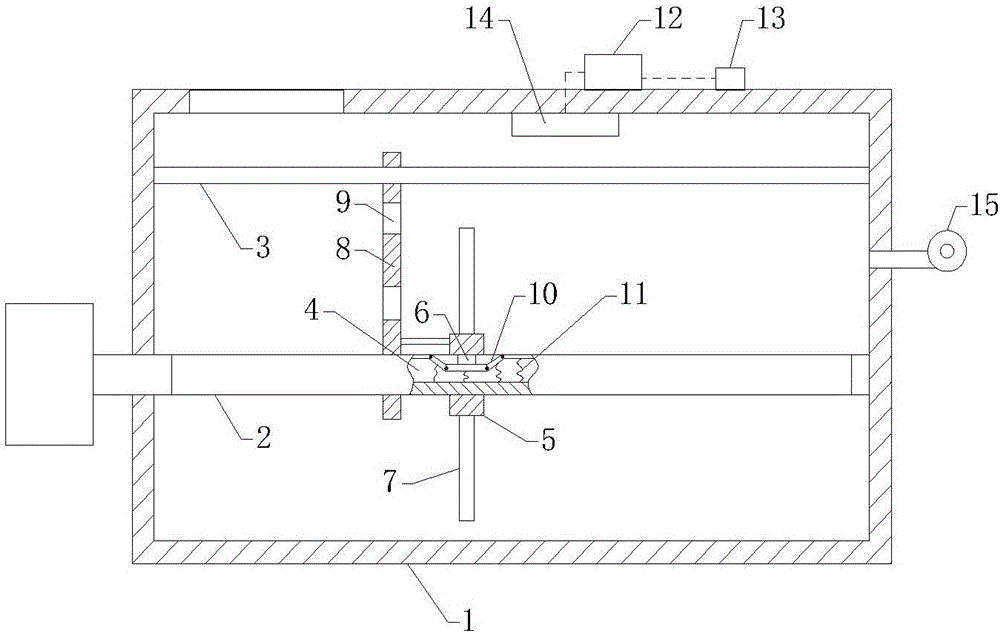

The invention relates to a device and a method for drying food by supercritical carbon dioxide. In a device consisting of a carbon dioxide steel cylinder, a purifier, a refrigerating system, a high-pressure pump, a heater, a drying chamber, a drying agent reaction chamber, a carrying agent storage tank, a pump and a valve, fresh food materials are sliced into slices, the slices are put on a stainless steel screen mesh of the drying chamber, and the drying chamber is sealed; and dried carbon dioxide is introduced to the drying chamber, and is heated under the pressure, so that the carbon dioxide is in the supercritical state to dry the food. The device is suitable for drying vegetables and fruit slices (carrot slices, potato slices, apple slices and the like), and is also suitable for drying fillets. The device and the method have the advantages of simple process flow, high drying efficiency and high quality of products.

Owner:GUANGDONG OCEAN UNIVERSITY

Drying device used for food processing

ActiveCN107062825ADries quickly and thoroughlyRealize hot air dryingDrying gas arrangementsDrying chambers/containersMicrowaveDrying

The invention discloses a drying device used for food processing and relates to the technical field of food processing facilities. The drying device comprises a bottom plate. The top of the bottom plate is fixedly connected with a tank. The bottom of the inner wall of the tank is rotationally connected with a rotary shaft through a bearing pedestal. The top end of the rotary shaft is rotationally connected with the top of the inner wall of the tank through a bearing. The outer surface of the bottom end of the rotary shaft is sleeved with a first transmission gear. A rotary rod is rotationally connected with the bottom of the inner wall of the tank through a bearing and located at one side of the rotary shaft. By adoption of the drying device used for food processing, food can be dried through hot air and microwaves, the drying effect is greatly improved, the drying efficiency is improved, the purpose of fast and thorough drying of the food is better achieved, food drying does not need to take much working time of food processing workers, the production efficiency of the food processing workers is greatly improved, and the drying cost of food processing enterprises is reduced.

Owner:HUNAN UNIV OF ARTS & SCI

Processing device for food drying and packaging

InactiveCN105501480ADry evenlySolve the problem of easy sticking to the bottom wallRotary stirring mixersDrying gas arrangementsProgrammable logic controllerDrying

The invention discloses a processing device for food drying and packaging. The processing device comprises a machine box body and a feeding hopper arranged on the top of the machine box body, wherein the bottom of a weighing chamber is provided with a bottom plate; a pressure sensor is mounted under the bottom plate; the pressure sensor is in signal connection to a PLC (programmable logic controller) control unit; one side of the bottom plate is provided with a material dropping hole; the other side of the bottom plate is provided with a pushing mechanism for pushing food to the material dropping hole; the PLC control unit is in signal connection to the pushing mechanism; the dropping hole is communicated with a drying chamber; one side in the drying chamber is provided with a supporting plate; a fan is mounted on the supporting plate; an electric heater fixed on the supporting plate is mounted in front of the fan; the bottom end of the middle part of the drying chamber is provided with a discharge hole; and a hole sealer mounted on the bottom of the machine box body is arranged under the discharge hole. The invention aims to provide the processing device for food drying and packaging, and the processing device is used for solving the problems of a single function, low production efficiency and high cost of a current food packaging device.

Owner:CHONGQING QINFA FOOD

Food drying method

InactiveCN101288498AReduce or eliminate pollution channelsEasy to operateFruit and vegetables preservationSeed preservation by dryingAir filterDrying

The invention discloses a method for drying food, which adopts the following steps: step 1: an intercommunicating airtight system consisting of a drying chamber, an air cleaner, an air dehumidifier, a blower, a heater and a piping is established, and the food is put into the dry chamber; step 2: the blower is turned on, the air pressure in the airtight system is kept between 95kPa and 100kPa, and the air cleaner in the drying chamber is turned on; step 3: the air dehumidifier is turned on to dehumidifying the air, and the air dehumidifier is provided with a drainage outlet through which condensation water can be discharged; step 4: the heater in the drying chamber is turned on; the temperature of the air dehumidifier is controlled between -2 DEG C and 10 DEG C; the temperature of circulating air in the drying chamber is controlled between 40 DEG C and 120 DEG C. The method for drying food has the advantages of simple equipment, low investment, high quality, small energy consumption, no electromagnetism radiation and reduces or precludes pollution to food. The method also has special efficacy in drying foods that are difficult to be dried, thus being applicable to the foggy and wet areas.

Owner:许圣华 +1

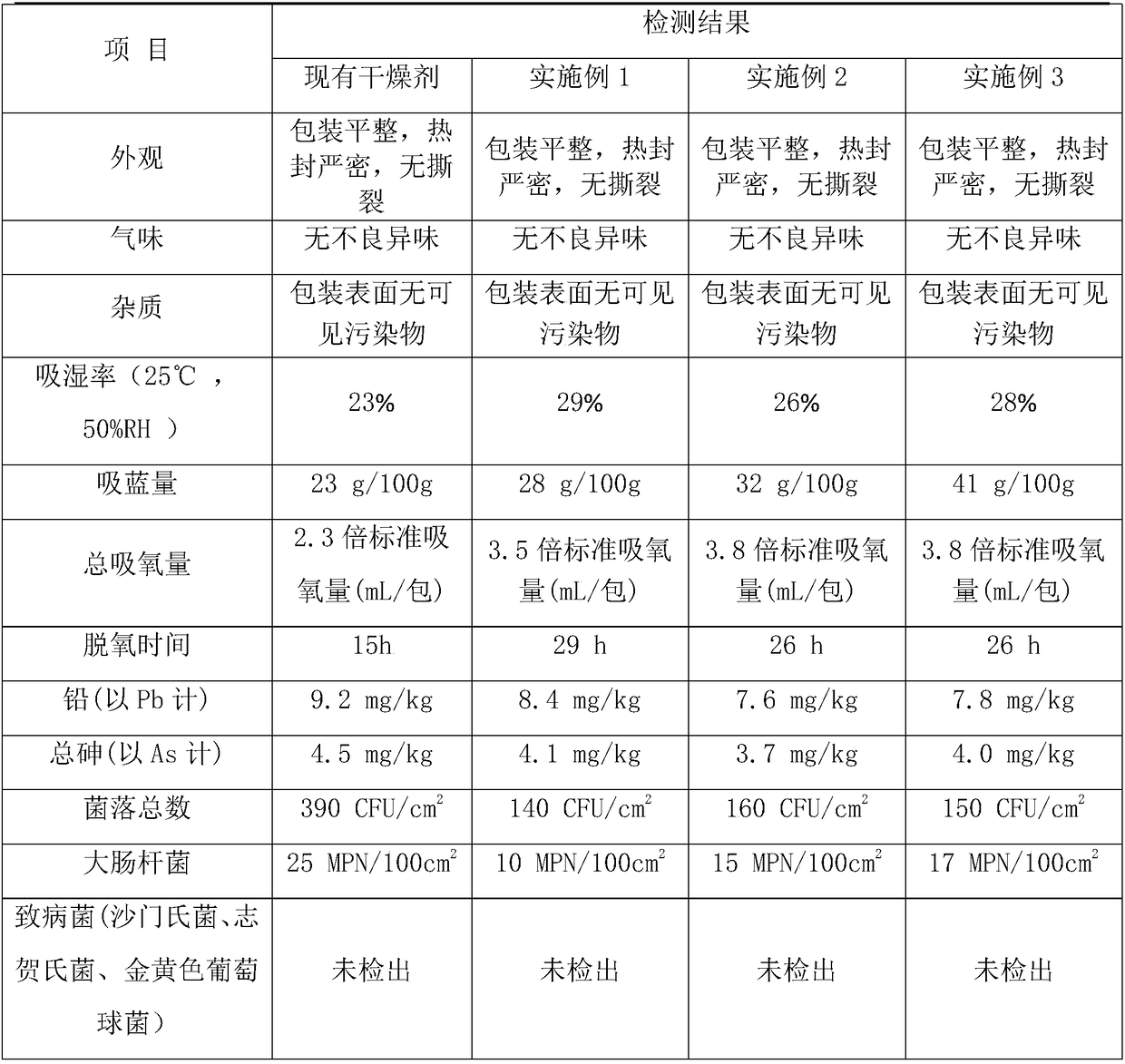

Safe food desiccant composition

The invention provides a safe food desiccant composition belonging to the technical field of food desiccants. The safe food desiccant composition comprises polyacrylamide starch, corncob meal or soybean seed coats, wherein the weight ratio of the polyacrylamide starch to the corncob meal or the soybean seed coats is (1:1)-(1:9); and the polyacrylamide starch is prepared by carrying out graft copolymerization on starch and acrylamide under conditions of catalysis of ammonium persulfate and crosslinking of N,N'-methylene-bis-acrylamide. The safe food desiccant composition provided by the invention is a safe food desiccant with high moisture absorption quantity higher than the moisture absorption quantities of quick lime and silica gel; and the safe food desiccant composition causes no damage to a human body while in contact with the human body. Because the components of the safe food desiccant composition are biodegradable, the safe food desiccant composition is beneficial for environmental protection. The raw materials of the safe food desiccant composition are from side products obtained through agricultural product processing and have a wide source range, and the safe food desiccant composition has the advantages of low cost and scientific manufacturing process and can be industrially produced on a large scale.

Owner:程坷伟 +1

Energy-saving food drying device with recyclable hot gas

InactiveCN107691971AKeep dryConvenient whereaboutsFood processingDrying gas arrangementsDryingPulp and paper industry

The invention provides an energy-saving food drying device with recyclable hot gas, and belongs to the technical field of processing of foods. The energy-saving food drying device comprises a supporting device and a drying device, wherein a box body is fixedly welded at the middle part of the upper surface of a bottom plate through welding; electric heating pieces are fixedly arranged on the leftside and the right side of an inner cavity of the box body; an electric expansion plate is arranged in the inner cavity of the box body; a fan is arranged on the left side of the inner cavity of a first drying box; an electrical heating rod is arranged on the right side of the fan; a suction blower is fixedly welded to the right side of the upper part of the first drying box; and a filter is arranged on an exhaust pipe. According to the energy-saving food drying device disclosed by the invention, the left end of a moisture absorbing machine is connected with the first drying box through a circulating pipe, so that the energy-saving food drying device has the function of performing dampness removing on waste heat in the box body for cyclic utilization; feeding plates are obliquely arrangedon the inner side of a wind net, so that the energy-saving food drying device has the function that the foods can conveniently fall down to be dried; and the energy-saving food drying device has the characteristics of being simple in structure, high in practicality and good in drying effect.

Owner:ZHENGZHOU AIMOFU INFORMATION TECH CO LTD

Method for preparing water-soluble chitosan through radiation process

The invention belongs to a method for preparing water-soluble chitosan through a radiation process. Small molecular weight or water-soluble chitosan is obtained by carrying out radiation degradation on a refined solid or solution of high molecular weight chitosan by using 60Cogamma rays, and carrying out post-processing steps of a degradation product, such as dissolving, decolourizing and the like. The method is convenient to operate, rapid, simple, convenient, high in yield, good in repeatability, easy to control molecular weight, environment-friendly, low in pollution and low in cost. The method not only can be used for rapidly preparing a few water-soluble chitosan samples but also has further industrial possibility. The obtained chitosan is multifunctional and can be used as an agricultural output increasing agent, a food drying agent, a natural antibacterial material, a biomedical material and the like.

Owner:DALIAN CHUANGDA TECH TRADE MARKET

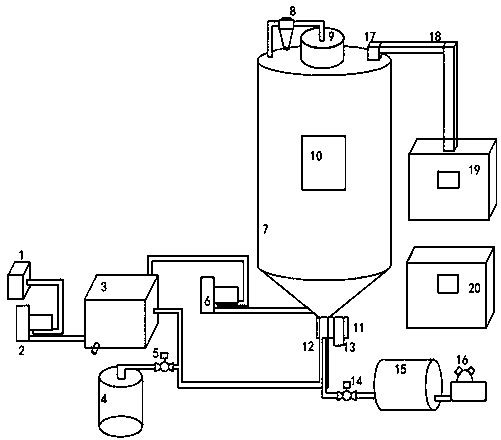

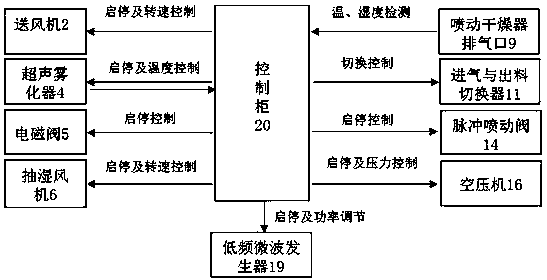

Constant-pressure ultrasound atomizing-low-frequency microwave pulse spouting and drying device for conditioning fruits and vegetables, and application of constant-pressure ultrasound atomizing-low-frequency microwave pulse spouting and drying device

The invention relates to a constant-pressure ultrasound atomizing-low-frequency microwave pulse spouting and drying device for conditioning fruits and vegetables and an application of the constant-pressure ultrasound atomizing-low-frequency microwave pulse spouting and drying device, and belongs to the field of a drying and processing technology and mechanical equipment manufacturing of agricultural products and foods. According to the constant-pressure ultrasound atomizing-low-frequency microwave pulse spouting and drying device disclosed by the invention, a suction filter is connected with ablowing machine; the blowing machine is connected with a heat exchanger; the heat exchanger and an ultrasound atomizer are connected with the bottom of a spouted bed dryer through a gas inlet pipe; an interlayer at the lower part of the spouted bed dryer is connected with the heat exchanger through a dehumidifying fan; the spouted bed dryer is also connected with a compressed air storing tank; the compressed air storing tank is connected with an air compressor; the upper end of the spouted bed dryer is connected with a low-frequency microwave source; and the low-frequency microwave source isconnected with a control cabinet. According to the constant-pressure ultrasound atomizing-low-frequency microwave pulse spouting and drying device disclosed by the invention, an ultrasound atomizing,low-frequency microwave and pulse spouted bed combined drying manner is adopted, so that the drying efficiency of conditioned fruits and vegetables is improved, the drying time is shortened, the drying energy consumption is reduced, the drying quality is improved, the problems that high-glucose conditioned fruits and vegetables are adhered and poor in quality when being dried, and time and labor are consumed are solved, and the constant-pressure high-efficiency energy-saving high-quality drying of the conditioned fruit and vegetable materials is realized.

Owner:JIANGNAN UNIV +1

Manufacturing method of nostoc flagelliforme product

InactiveCN103976411APromote absorptionGood for healthFood homogenisationFood dryingBiotechnologyNutrition

The invention belongs to the food drying and processing technical field, and particularly relates to a manufacturing method of a nostoc flagelliforme product. The manufacturing method comprises eight steps of culturing nostoc flagelliforme cells, scalding and blanching, beating to obtain a nostoc flagelliforme cell filtrate, blending, homogenizing, concentrating, sterilizing, and spray-drying. A culture medium added with a soil extraction liquid and a strontium solution with the mass concentration of 2 mg / L is inoculated with the nostoc flagelliforme cells, so that the absorption of the nostoc flagelliforme cells on strontium is greatly promoted, and besides, effects of prevention and treatment of cardiovascular diseases and promotion of human body health are played. With adopting of the spray drying method, the manufacturing method has the advantages of large evaporation area, fast drying speed, low material temperature, and easy continuous production; based on reservation of the material original nutritional organization composition and flavor to a greatest degree, the drying efficiency is greatly improved; and moreover, with utilization of the spray drying method, a nostoc flagelliforme cell slurry can be quickly dried into a powder, the powder collecting rate is high, the damage rate of the composition of the nostoc flagelliforme cells is reduced, and the original nutrients and flavor of the nostoc flagelliforme cells are relatively well maintained.

Owner:HENAN UNIV OF SCI & TECH

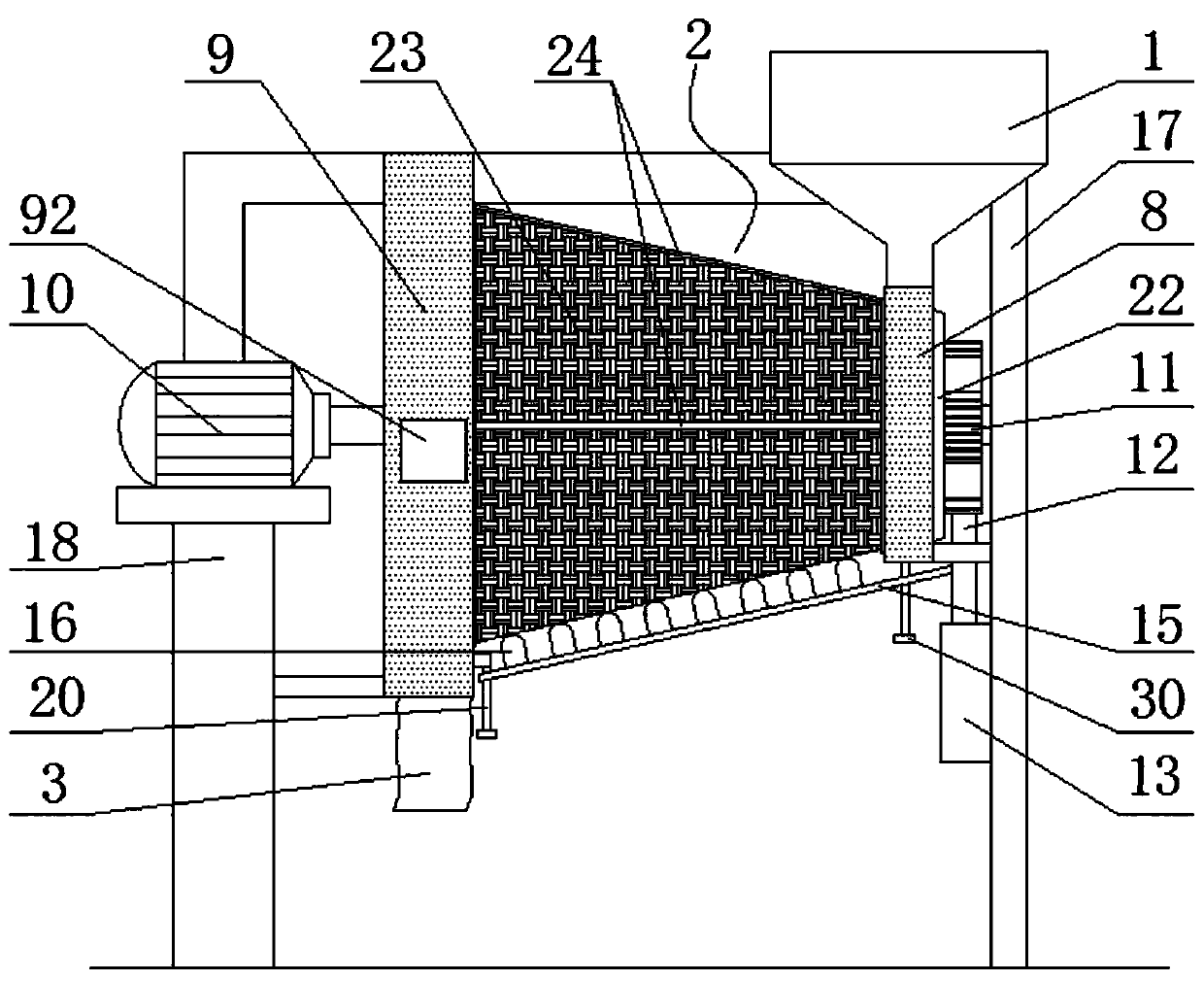

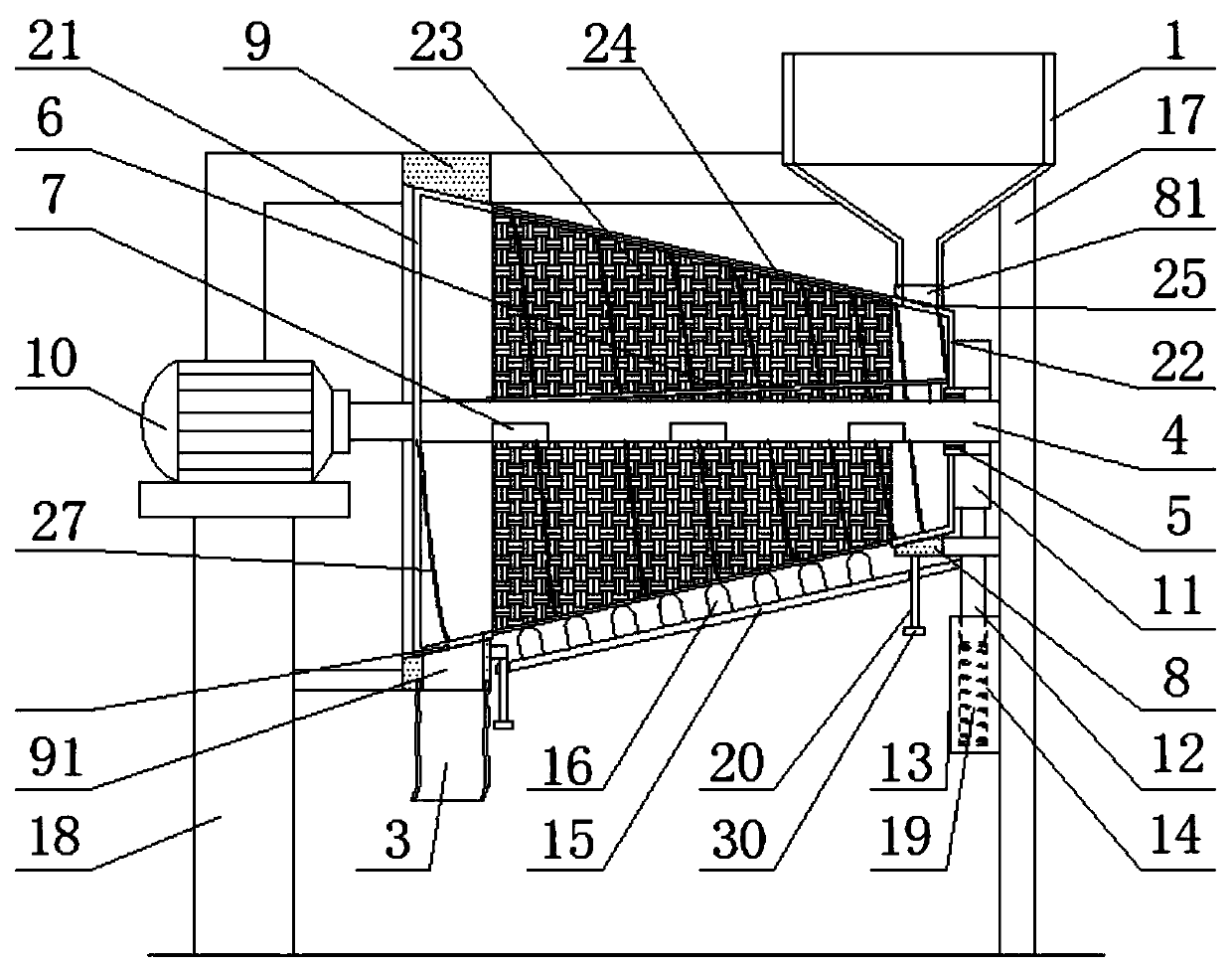

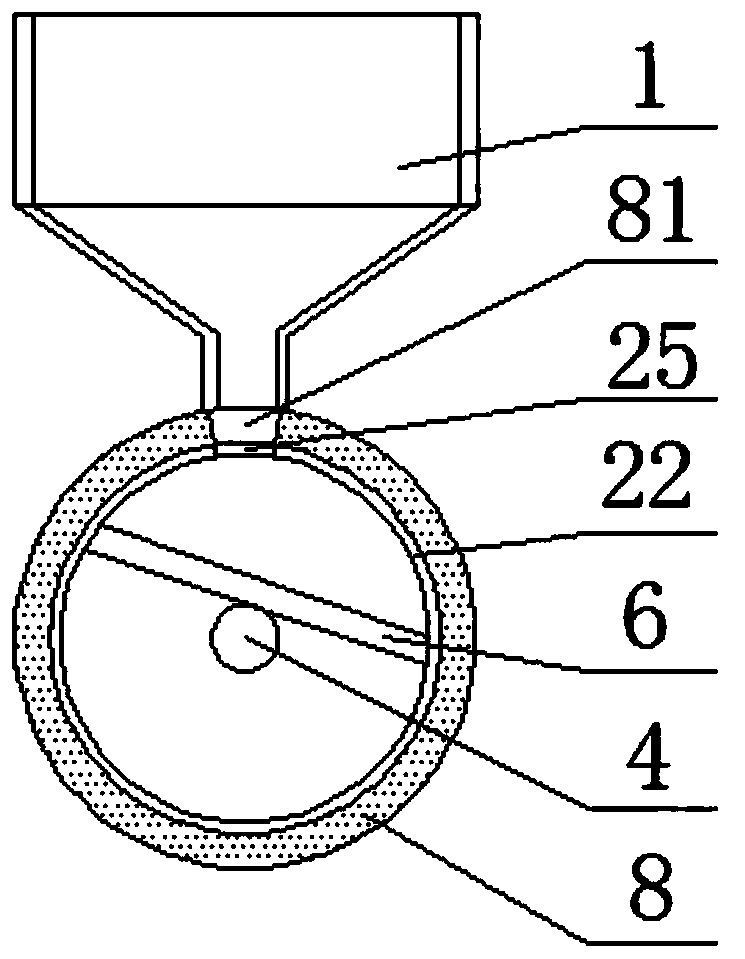

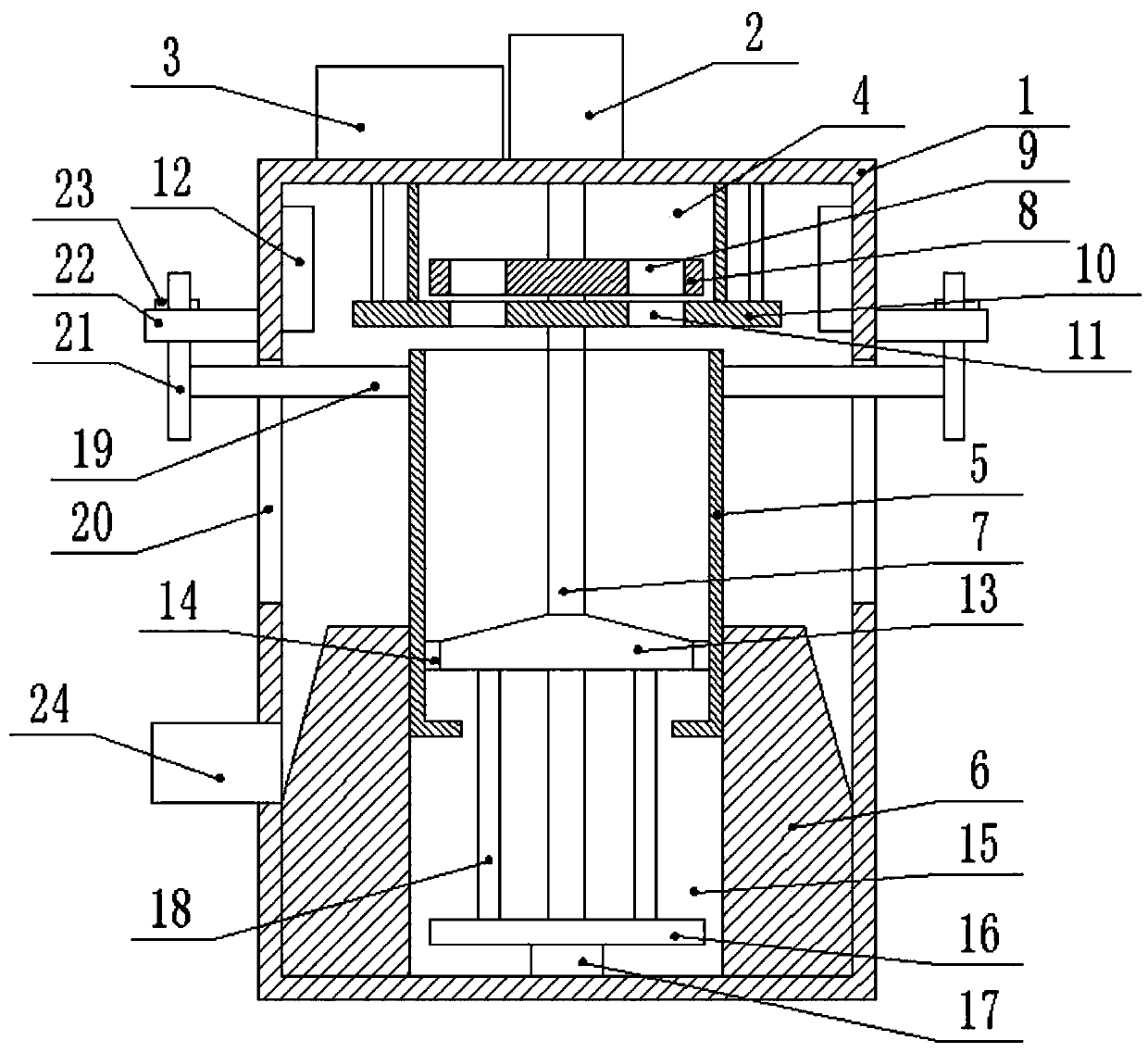

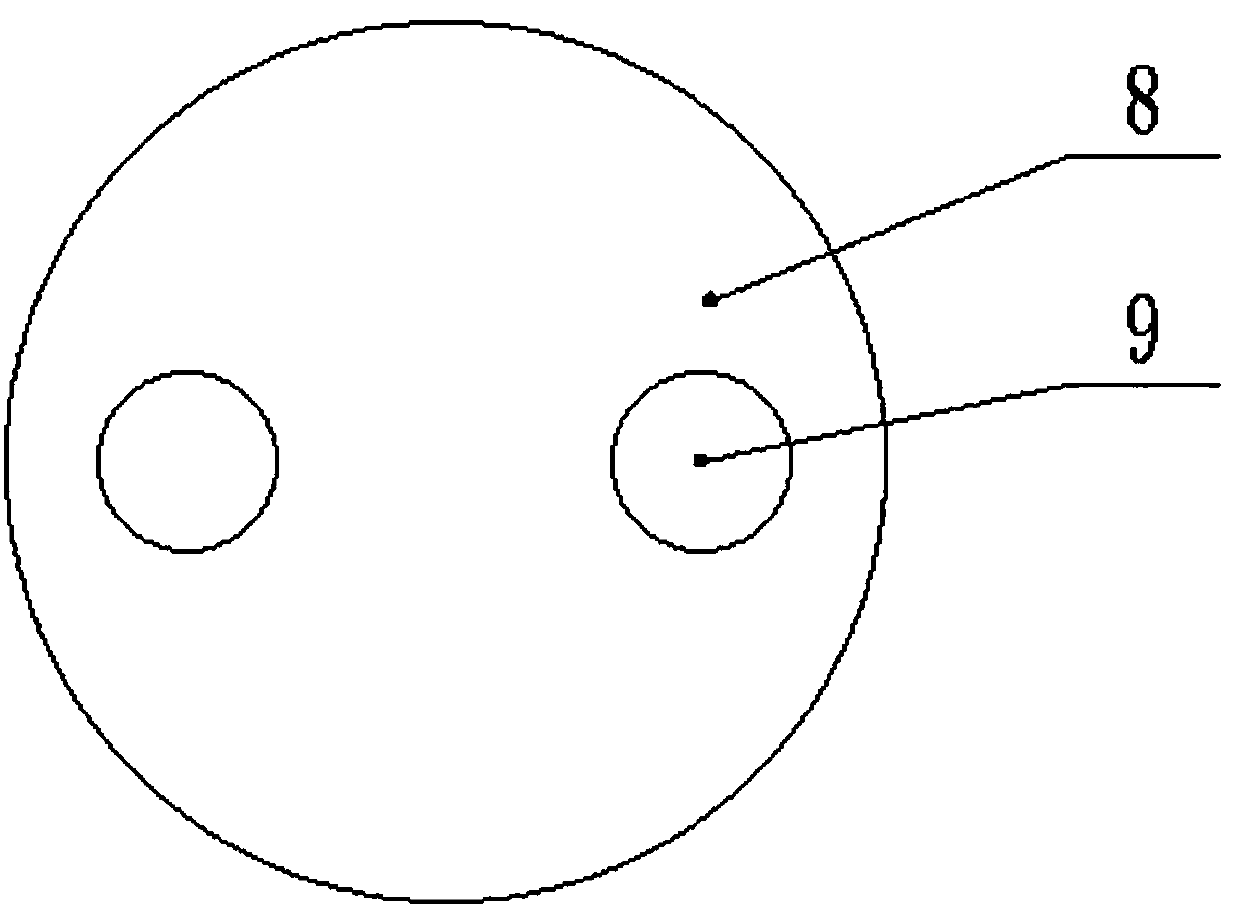

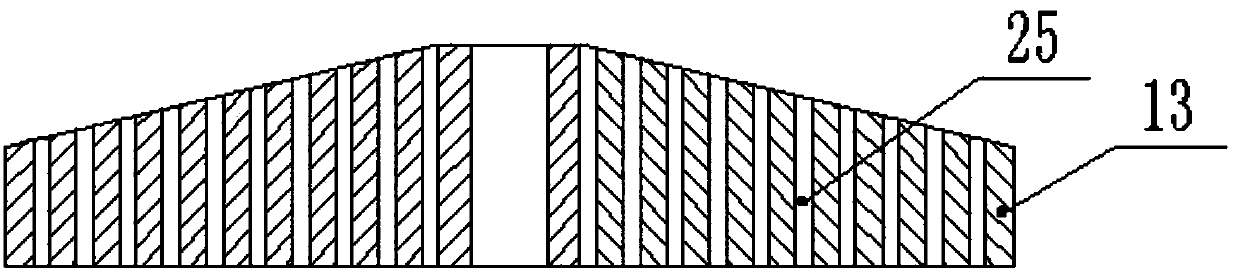

Vibrated food microwave drying device

ActiveCN110617684AAvoid cloggingAvoid affecting the drying effectSievingDrying solid materials with heatMicrowaveStone particle

The invention discloses a vibrated food microwave drying device, and belongs to the technical field of food drying. The vibrated food microwave drying device comprises a feeding hopper, a drying box and a discharging pipe; the drying box takes the shape of a horizontal circular truncated cone, and comprises a left bracket, a right bracket and a cylindrical filter screen connected between the leftbracket and the right bracket; a first feeding opening is formed in the top of the right bracket; a small plugging ring body connected to the bottom of the feeding hopper is arranged outside the rightbracket in an attaching manner; a second feeding opening is formed in the top of the small plugging ring body; an upper filter plate arranged in an inclining manner is arranged in the cylindrical filter screen; a first discharging opening is formed in the bottom of the left bracket; a large plugging ring body is arranged outside the right bracket in an attaching manner; a second discharging opening is formed in the bottom of the large plugging ring body; a small stone outlet is formed in the front side of the large plugging ring body; and a lifting plate parallel to the bottom of the drying box is arranged at the bottom of the drying box. The vibrated food microwave drying device can realize periodic and intermittent feeding synchronously, performs fractional separation and separate discharging on stone particles, generates an overturning effect on food, and can generate impact and vibration effects on the drying box.

Owner:哈尔滨土丰农业机械设备有限公司

Drying equipment with convenient discharging function for agricultural grain processing

InactiveCN107560362ALess impuritiesQuick pourDrying gas arrangementsDrying chambers/containersDrive shaftDrying

The invention discloses a drying equipment for agricultural grain processing with convenient discharging, which comprises a casing, a motor, a feeding hopper and a drying cylinder; the transmission shaft passes through the material storage box and the drying cylinder sequentially from top to bottom; A horizontal fixed plate is arranged at the bottom of the material storage box, and a fixed feeding port is opened on the fixed plate. A turntable fixed on the transmission shaft is arranged in the corresponding material storage box above the fixed plate. a rotating feeding port; the drying cylinder is located directly below the material storage box; a movable bottom plate with a circular frustum structure is fixedly installed on the transmission shaft in the drying cylinder. In the invention, the set turntable follows the rotation of the motor, so that the grain in the storage box falls slowly, makes the grain fully contact with the hot air, makes the grain dry step by step, and ensures the stability of drying; by manually adjusting the height of the drying cylinder, it is convenient to carry out grain drying. It is dry, and can quickly pour out the internal grain, which is convenient and quick to take out, saving time and effort.

Owner:蒋嫚

Meat drying device for food processing

InactiveCN109990580AEvenly heatedImprove work efficiencyDrying gas arrangementsDrying chambers/containersDryingEngineering

The invention discloses a meat drying device for food processing, and belongs to the field of food drying equipment. The meat drying device comprises a drying box, a storage frame, fans, a temperaturesensor and a control panel, wherein the storage frame is positioned inside the drying box, the control panel is fixedly installed on a front surface of an upper end of the drying box, a display screen is embedded in a front surface of the control panel, a switch b is arranged on one side of the display screen, the switch b is in key connection with the control panel, and a switch a is arranged onone side, away from the display screen, of the switch b; the two fans are fixedly arranged on a top surface of the drying box and a back surface of the drying box correspondingly, and the two fans are both electrically connected with the switch b. The meat drying device is uniformly heated, can quickly dissipate heat after being dried, is high in working efficiency and can effectively monitor the temperature in the box body, the state of a drying room food can be observed in real time, the use is safe, the structure is simple, the operation is convenient, and the space utilization rate is high.

Owner:LUDONG UNIVERSITY

Preparation method of pucker-free non-cleaning dried jujubes

ActiveCN103843875AImprove qualitySolve the darkening of jujube skinFruits/vegetable preservation by dehydrationCold airPhysical chemistry

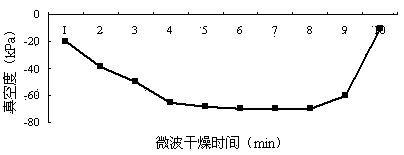

The invention discloses a preparation method of pucker-free non-cleaning dried jujubes, belongs to the technical field of food drying processing, and relates to a method of carrying out microwave vacuum puffing drying on red dates, aiming at solving the technical problems that jujube skin pucker, surface color darkening, nutritional ingredient loss, and the like appearing in a drying process of the red dates. According to the adopted technical scheme, the preparation method of the pucker-free non-cleaning dried jujubes comprises the following steps: pickling jujubes, grading the jujubes, rejecting defective fruits and impurities in materials; cleaning jujubes; drying water on the surfaces of the red dates by an air knife after cleaning the red dates; pre-drying for 3 hours-6 hours by cold air, regulating moisture of the red dates, and keeping the moisture of the red dates uniform, so that moisture content of the red dates reaches 35%-38%; carrying out microwave vacuum puffing drying on the red dates; spreading materials which are pre-dried by the cold air in a tray of a microwave vacuum unit, exhausting and then reducing pressure, wherein the conditions for carrying out the microwave vacuum puffing drying are as follows: vacuum degree is 65kPa-75kPa, microwave power is 6W / g-10W / g, drying time is 5 minutes-10 minutes, and final moisture content is controlled at 20%-25%.

Owner:交城天娇红农业科技有限公司

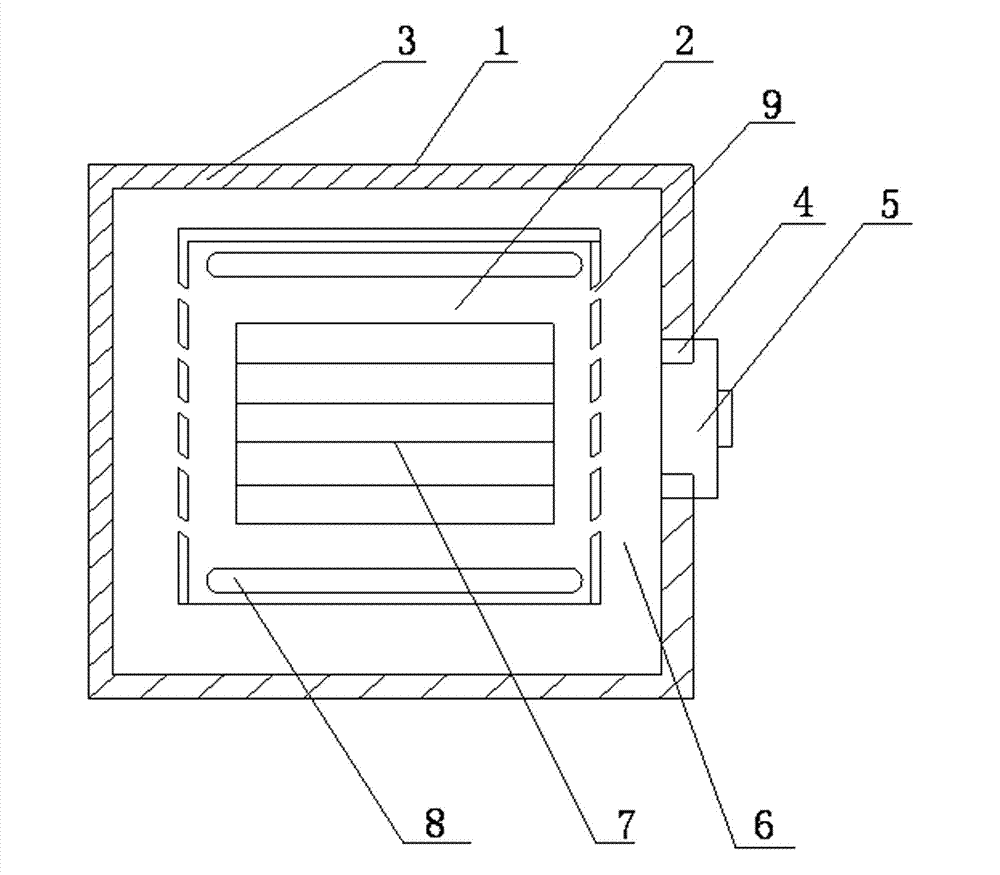

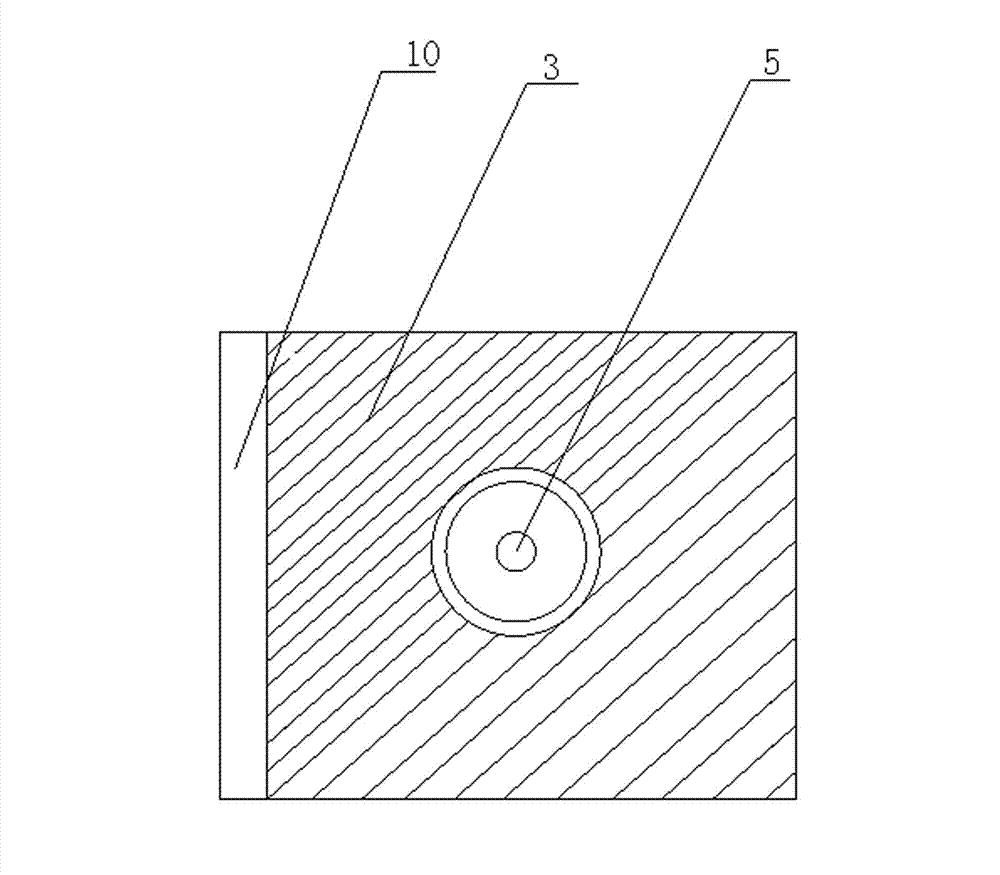

Improved food drying box

InactiveCN103190679AExtended service lifeSave energyFood processingFood preservationDryingEngineering

The invention discloses an improved food drying box. The food drying box comprises an external chamber of the drying box and an inner chamber of the drying box. The food drying box is characterized in that a thermal insulating layer is arranged outside the external chamber of the drying box. A heat dissipating device is arranged on one side face of the external chamber of the drying box and is sealed by a sealing element. A hot air channel is arranged between the inner chamber of the drying box and the external chamber of the drying box. A stuff supporter is arranged in the middle of the internal chamber of the drying box. Heating sources are arranged at the upper face and the lower face of the stuff supporter. Air vents are arranged at the left face and right face of the stuff supporter. A sealing door is arranged at the front side of the external chamber of the drying box. The food drying box has the advantages that the heat generated by heating tubes can be circulated into the hot air channel by the air vents, retained temperature can be utilized to dry the food in the inner chamber of the drying box and energy sources are saved; and heat dissipating holes on the external chamber of the drying box can be used for dissipating heat and the service life of the drying box is prolonged.

Owner:沈南飞

Drum-type food drying machine

The invention discloses a drum-type food drying machine which comprises a food drying machine body and supporting legs. A feeding port is formed in the top end of the food drying machine body, a discharging port is formed in the bottom end of the food drying machine body, a discharging valve is arranged at one end of the discharging port, a heater is arranged inside the food drying machine body, an observing port is formed in the surface of the food drying machine body, the food drying machine body is connected with the supporting legs through a rotary shaft, the rotary shaft is connected with a motor through a belt, a supporting plate is arranged at the bottom end of the motor, a connecting rod is arranged on one side of one supporting leg, a control panel is arranged at one end of the connecting rod, and buttons are arranged on the surface of the control panel. The drum-type food drying machine facilitates even food heating during food drying performed by people and is simple in structure and suitable for popularization, the control panel can also control the rotation speed of the motor and the temperature of the heater, and adjustment can be performed according to different crops.

Owner:合肥朝霞机械科技有限公司

Energy-saving food drying baking room

ActiveCN101884425AReduce consumptionIncrease profitFood processingFood preservationAir volumeHigh energy

The invention discloses an energy-saving food drying baking room. The room comprises a baking room, an air inlet and an air outlet, wherein a first scavenging valve is arranged at the air inlet; a second scavenging valve is arranged at the air outlet; a heat-pipe heat exchanger is arranged between the air outlet and the air inlet and used for recycling waste heat; a variable-frequency circulating fan is arranged between the top layer of the baking room and a ceiling and used for controlling the air quantity in the drying baking room; and a heater is arranged in front of the circulating fan and used for raising the temperature in the drying baking room. The baking room has the advantages of overcoming the defects of high energy consumption, high pollutant discharge and the like in the conventional food drying process, enhancing energy utilization ratio, further reducing energy consumption and lowering cost.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Energy-saving control method of twin-stage compression type heat pump vacuum freeze drying combined device

ActiveCN105962005AOptimum evaporating temperatureRun energy savingHeat pumpsFood processingFreeze-dryingDrying

The present invention relates to an energy-saving control method of a twin-stage compression type heat pump vacuum freeze drying combined device. The energy-saving control method of a control system is characterized by comprising the steps that according to the requirements of the food drying processes, temperature T1 of a heating medium entering drying chamber heating division plates is determined; according to the vacuum degree requirements of the combined device and the changes of the thickness of a frost layer on the surface of a water catcher in the operation process of the combined device, a functional expression of the change of an evaporation temperature T4 of the water catcher with an operation time t during the operation process of the combined device is determined; according to the evaporation temperature T4 of the water catcher in a low-pressure stage refrigeration system and a condensing temperature T2 of a high-pressure stage condenser, an optimum intermediate temperature T3 of an intercooler is determined; according to the functional expression of the change of the evaporator temperature T4 of the water catcher with the operation time t, the temperature is realized by adjusting the opening degree of a low-pressure stage throttle valve and the rotation speed of a low-pressure stage compressor; and according to the calculation of a functional expression, the optimal intermediate temperature T3 of the intercooler is determined and realized by adjusting the opening degree of a high-pressure stage throttle valve and the rotation speed of a high-pressure compressor. The advantages are as follows: the heat supply temperature and heat of the drying chamber can be adjusted, the optimum evaporation temperature of the water catcher can be determined, and the optimum intermediate temperature of the intercooler can be determined, and the combined device is energy-saving in operation.

Owner:SHUNDE POLYTECHNIC

Food desiccant

The invention relates to food desiccant. The food desiccant is a solid substance which is made of natural and harmless materials through processing and has a porous structure. Compared with the priorart, the food desiccant is cheap, natural and safe, is made of the natural and harmless materials through processing and is harmless to a human body. People are not injured even if the food desiccantis eaten by chance or is fallen into eyes carelessly, and simultaneously, the food desiccant can keep the quality of food without polluting and damaging the food.

Owner:SHANGHAI CITY CHANGNING DISTRICT JUNIOR SCI &TECH GUIDANCE STATION +2

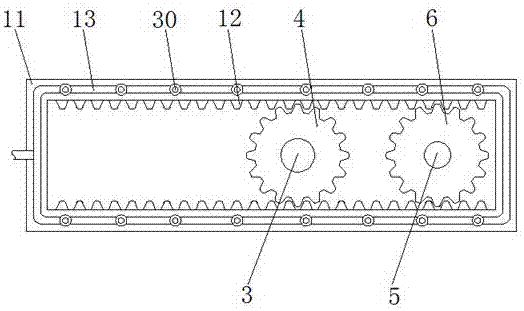

Food drying device

InactiveCN106839697AImprove drying efficiencyImprove drying effectDrying gas arrangementsDrying solid materialsDryingEngineering

The invention discloses a food drying device. The food drying device comprises a drying room. A screw rod and a guide rod are arranged in the drying room in parallel. Two ends of the screw rod are rotationally connected with the left side and the right side of the drying room correspondingly. Two ends of the guide rod are connected with the left side and the right side of the drying room. Sliding chute, extending in the axial direction, is formed on the outer wall of the screw rod. A sleeve is arranged out of the screw rod in a sleeving mode. A sliding block, slidably connected with the sliding chute, is arranged on the inner wall of the sleeve. A plurality of rabbles are evenly arranged, in the circumferential direction, on the outer wall of the sleeve. A push plate is arranged on one side of the sleeve, and the push plate is connected with the sleeve. Meshes are formed in the push plate. The screw rod penetrates through the push plate and is connected with the push plate in a threaded mode. The guide rod penetrates through the push plate and is slidably connected with the push plate. The food drying device, provided with the structure, has the advantages of being high in the drying efficiency and good in the drying effect.

Owner:CHONGQING SHUNYUANTONG FOOD

Food desiccant and preparation method thereof

InactiveCN108464430AReduce packaging pollutionGood deoxidation effectFood preservationActivated carbonIron powder

The invention discloses a food desiccant and a preparation method thereof. The food desiccant comprises the following components in parts by weight: 20-40 parts of super water-absorbent resin, 1-10 parts of calcium chloride, 1-5 parts of iron powder, 1-5 parts of powdered activated carbon, 0.01-1 part of a mildew inhibitor and 0.01-1 part of an adhesive. The preparation method comprises the following steps: (1) pulverizing the super water-absorbent resin into powder of 40-60 meshes in particle size, and then performing mixing with the calcium chloride and the iron powder; and (2) continuing adding the powdered activated carbon, the mildew inhibitor and the adhesive, performing mixing, adding water, performing stirring, granulating and forming, performing drying in vacuum and performing cooling to room temperature to obtain the food desiccant. The food desiccant prepared by the preparation method can be used for performing desiccation, preservation and mold prevention on food and is nonhazardous to a human body.

Owner:袁国森

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com