Processing method of instant sweet and sour fish capable of being preserved at normal temperature

A processing method and technology for sweet and sour fish, which are applied in the fields of food processing and preservation, and aquatic product processing, can solve the problems of affecting the flavor and taste of products, large edible limitations, and long processing time, so as to improve economic benefits and market competitiveness. , convenient storage, and the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

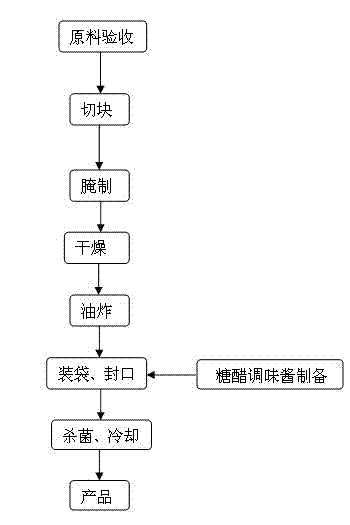

Image

Examples

Embodiment 1

[0023] Fresh and live carp are slaughtered, scaled, viscerated, head and tail removed, washed, drained, cut into fish pieces about 1.5 cm thick, and marinated in the pickling solution for 1 hour. The liquid mass ratio is 1:3. The ratio of pickling solution is: 6% salt, 2% edible vinegar, 0.5% monosodium glutamate, 3% cooking wine, and the rest is water; dehydrate and dry the marinated fish pieces to make the water content reach 70%-72%; Fry in oil at 190°C for 1.0 min. Mix 10% white sugar, 0.5% salt, 0.5% monosodium glutamate, 0.3% citric acid, 2.0% pregelatinized starch, add water to dissolve, add 25% tomato juice concentrate, 5% edible vinegar, 2.0% soy sauce, mix well Add water to make up 100%, stir well to make sweet and sour sauce. Put the processed fish pieces and sweet and sour seasoning sauce into a three-layer aluminum foil bag according to the mass ratio of 1:0.8, carry out vacuum sealing under a vacuum condition of 0.06MPa, and then sterilize at high temperature, ...

Embodiment 2

[0025] Fresh and live grass carp are slaughtered, scaled, viscerated, head and tail removed, washed, drained, cut into fish pieces about 1.5 cm thick, marinated in the pickling solution for 3.0 h, fish pieces and The mass ratio of pickling liquid is 1:3. The ratio of pickling solution is: 3% salt, 5% edible vinegar, 0.2% monosodium glutamate, 1% cooking wine, and the rest is water; dehydrate and dry the marinated fish pieces to make the water content reach 70%-72%; Fry in oil at 160°C for 3.0 min. Mix 5% white sugar, 0.3% salt, 0.2% monosodium glutamate, 0.8% citric acid, 1.0% pregelatinized starch, add water to dissolve, add 10% tomato juice concentrate, 2% edible vinegar, 1.0% soy sauce, mix well Add water to make up 100%, and make sweet and sour sauce. Put the processed fish pieces and sweet and sour seasoning sauce into a three-layer aluminum foil bag according to the mass ratio of 1:1, vacuum seal it under a vacuum condition of 0.08 MPa, and then sterilize it at high te...

Embodiment 3

[0027] Live and fresh bighead carp are slaughtered, scaled, viscerated, head and tail removed, washed, drained, cut into fish pieces about 1.5 cm thick, marinated in the pickling solution for 2.0 h, and the fish pieces are The mass ratio of pickling liquid is 1:3. The ratio of pickling solution is: 4% salt, 5% edible vinegar, 0.2% monosodium glutamate, 1% cooking wine; dehydrate and dry the marinated fish pieces to make the water content reach 70%-72%; Fry for 1.5 minutes. Mix 8% white sugar, 0.4% salt, 0.4% monosodium glutamate, 0.5% citric acid, 1.8% pre-gelatinized starch, add water to dissolve, add 15% tomato juice concentrate, 3% edible vinegar, 1.5% soy sauce, mix well Add water to make up 100%, stir well to make sweet and sour sauce. The processed fish pieces and sweet and sour seasoning sauce are packed into three-layer aluminum foil bags according to the mass ratio of 1:0.9, vacuum-sealed under a vacuum condition of 0.07 MPa, and then sterilized at high temperature,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com