Patents

Literature

64results about How to "Improve texture quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

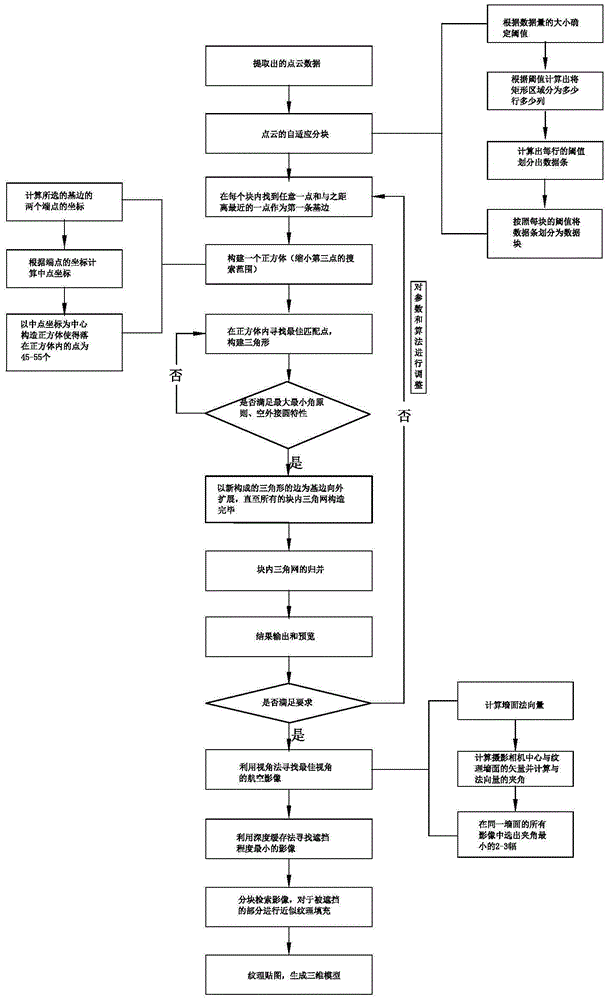

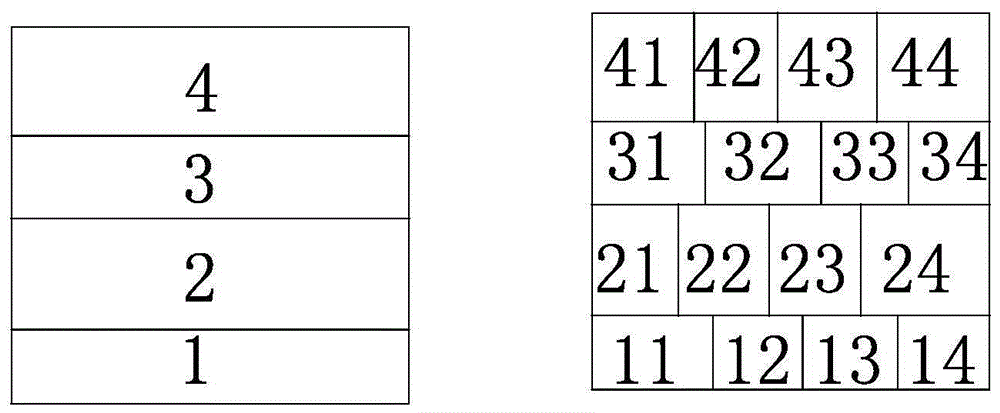

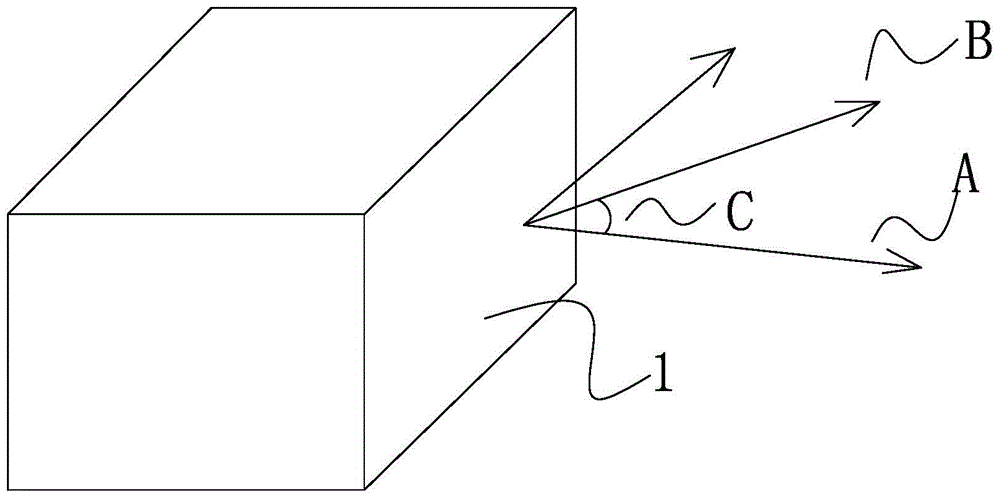

Dense-point-cloud-based rapid construction method of urban three-dimensional model

The invention, which belongs to the technical field of construction of an urban three-dimensional model, especially relates to a dense-point-cloud-based rapid construction method of an urban three-dimensional model. With the method, technical problems of low efficiency and the like in the prior art can be solved. The dense-point-cloud-based rapid construction method comprises: A, carrying out adaptive blocking on point cloud data; B, carrying out three-dimensional TIN model construction on the divided blocks; C, selecting an image with the best quality from a multi-view slanted image for each surface of the three-dimensional TIN model and using the image as a texture data source; D, after selection of the texture data sources with the best qualities, carrying out texture extraction; E, carrying out substitution of textures of shielded parts to complete vulnerability repairing of the textures; and F, pasting the preferably selected textures to the surface of the three-dimensional TIN model to generate a three-dimensional model with a lifelike effect. The method has advantages: firstly, the construction efficiency is high; and secondly, the texture quality is improved and the lifelike effect is realized.

Owner:浙江中测新图地理信息技术有限公司

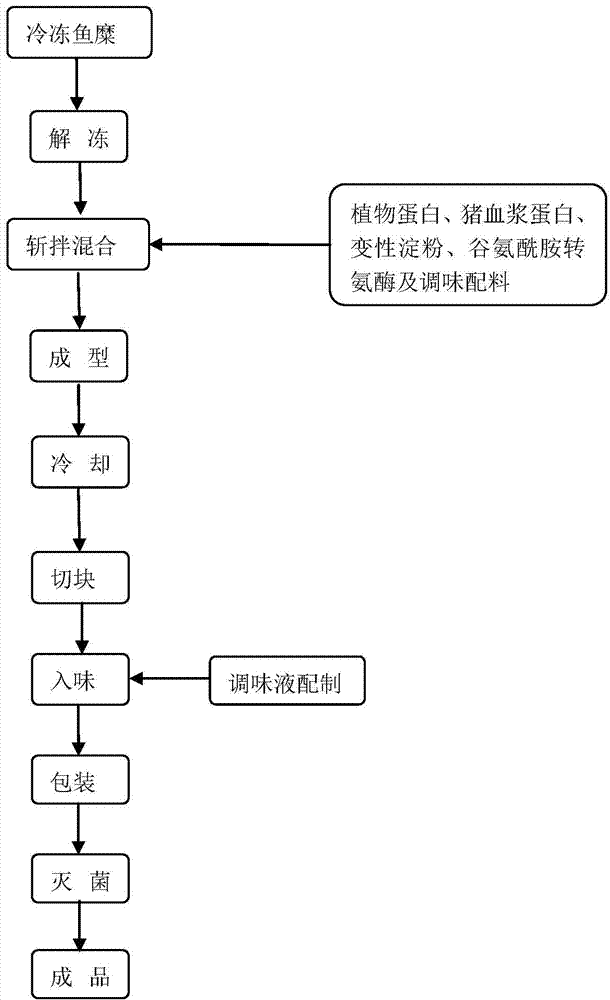

Method for processing instant flavor fish bean curd with high fish protein preserved at normal temperature

InactiveCN103932240AHigh protein contentHigh nutritional valueFood preparationConsumer demandPlasma glucose

The invention discloses a method for processing instant flavor fish bean curd with high fish protein preserved at normal temperature. The method comprises the following steps: taking frozen minced fillet as a main raw material; chopping, mixing, molding, cooling, slicing, pickling, packaging and sterilizing to prepare the instant flavor fish bean curd preserved at normal temperature. The texture taste of the sterilized minced fillet product is improved by integrating a bio-enzyme crosslinking technology, an inhibiting effect of the plasma protein on an endogenous enzyme, a polysaccharide structure modifying technology and a variable temperature sterilization technology, long-term preservation of the product under a normal-temperature condition is achieved, and the product is convenient to eat and carry. Meanwhile, the fish protein content in the fish bean curd product is significantly improved by integrated application of the technologies, the product has high nutrient value and good flavor taste, is broad in market prospect, and the consumer demands of consumers on convenience, daintiness, nutrition and safety of the food are met.

Owner:JIANGNAN UNIV +1

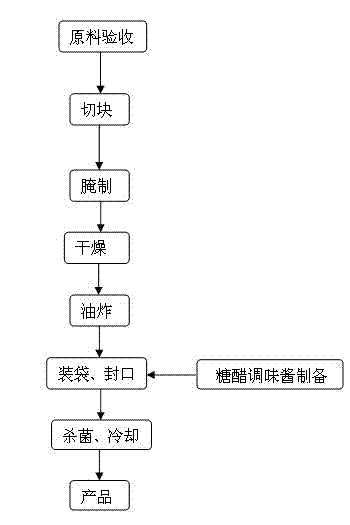

Processing method of instant sweet and sour fish capable of being preserved at normal temperature

The invention provides a processing method of instant sweet and sour fish capable of being preserved at normal temperature and relates to the technical field of food processing and preservation. Fresh and alive freshwater fish is used as a raw material, stripped and sliced, cured, dried, fried, packed, sealed in vacuum mode, sterilized and cooled to be manufactured into an instant sweet and sour fish food. The contemporary food drying and sterilizing processing technology is combined on the basis of a traditional sweet and sour fish manufacturing process to obtain the sweet and sour fish food capable of being preserved at the normal temperature, no chemical preservative is added in a machining process, the produced sweet and sour fish food can well maintain specific flavor, texture, color and nutritional quality of the traditional sweet and sour fish and is convenient and safe to eat, shelf life of the sweet and sour fish food at the normal temperature can reach above 12 months, requirements of consumers for safety, delicacy and convenience of contemporary food are met, industrial production is easy to achieve, and market prospect is wide.

Owner:劲仔食品集团股份有限公司

Plant-based artificial meat pie and preparation process thereof

PendingCN112841398AStable structureIncrease juicinessProteins working-up by texturisingVegetable proteins working-upBiotechnologyFood additive

The invention discloses a plant-based artificial meat pie and a preparation process thereof, and the plant-based artificial meat pie mainly comprises the following raw materials: soybean drawing protein, soybean protein isolate, vegetable oil, water, a vegetable protein source, soy sauce, L-cysteine, Tg enzyme, a food gelling agent, plant-based auxiliary materials, seasonings and a food additive. Raw materials are subjected to wiredrawing protein rehydration, dehydration, shred removal, blending, mixing and stirring, compression molding, enzyme crosslinking, cooking, quick freezing and like, and plant-based artificial meat pie is prepared. The production process is clear, parameters are accurate, the utilization rate of raw materials is high, the taste and color of the prepared plant-based artificial meat pie can well simulate those of a real meat pie, and the plant-based artificial meat pie is rich in dietary fibers and proteins and almost does not contain cholesterol.

Owner:SICHUAN HUIJI FOOD +2

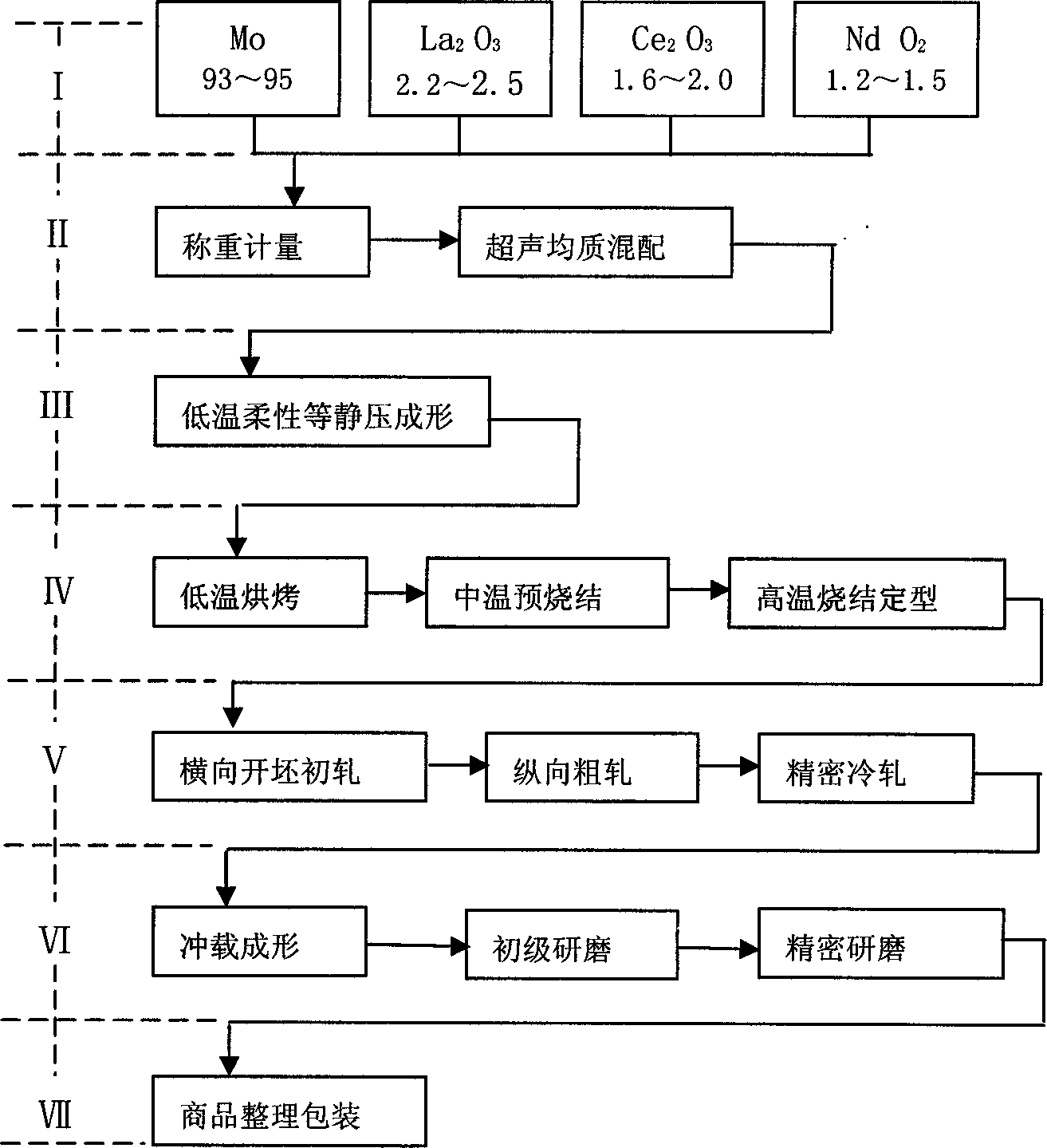

Molybdenum-based rare earth oxide powder metallurgical alloy wafer and preparing method thereof

ActiveCN102728838AHigh strengthImprove toughnessTurbinesOther manufacturing equipments/toolsRare-earth elementAlloy

The invention discloses a molybdenum-based rare earth oxide powder metallurgical alloy wafer and a preparing method thereof. The method adopts material blending technology of directly mixing three types of rare earth oxide powder in a high proportion into pure molybdenum powder, and employs characteristics of rare earth elements such as long big linkage grains, anti-sag performance and good creep performance and the characteristic that the rare earth element can exert strong dispersion strengthening effects and wrapping effects after adding and compounding to effectively improve the recrystallization temperature of molybdenum and improve the mechanical physical properties of the molybdenum-based alloy material. The method adopts preparing process procedures such as ultrasonic solid phase homogenizing and blending, low-temperature flexible isostatic pressing forming, step-by-step continuous sintering shaping, stagewise multi-pass rolling, and fine processing and grinding, and mating special technical equipment and execution process technical parameters. The method has the characteristics of advanced technology, complete configuration, reliable operation and low cost, and can prepare a molybdenum-based rare earth oxide powder metallurgical alloy wafer with excellent technical performance and high and fine surface quality.

Owner:四平市北威钼业有限公司

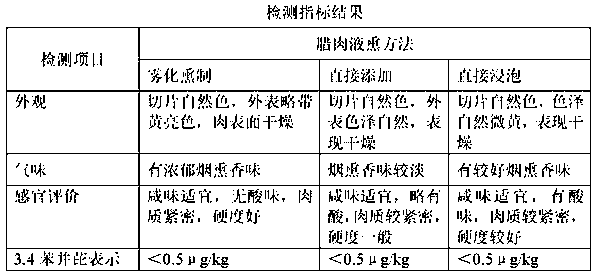

Method for atomization smoke curing of meat products by liquid smoke

InactiveCN107668553AEasy to solveImprove texture qualityFood scienceLiquid smokeUltrasonic atomization

The invention relates to a method for atomization smoke curing of meat products by liquid smoke. According to the method, after pre-roasting of the meat products, a high-and low-frequency ultrasonic alternate atomization process is combined with a hermetic and ventilated smoke curing combined process to realize atomization smoke curing of to-be-smoked meat products, and the smoked products subjected to smoke curing with the liquid smoke have strong smoke curing flavor, and the benzopyrene content is smaller than or equal to 0.5 microgram / kg. By ultrasonic atomization of the liquid smoke, the meat products are smoked by mist droplets of the liquid smoke, and the problem of texture quality decline of the products due to direct adding of the liquid smoke and long-time soaking of the meat products is avoided. In addition, by smoke curing of the meat products with the liquid smoke atomized through an ultrasonic device, high flavor and color stability of the products can be guaranteed.

Owner:HEFEI UNIV OF TECH

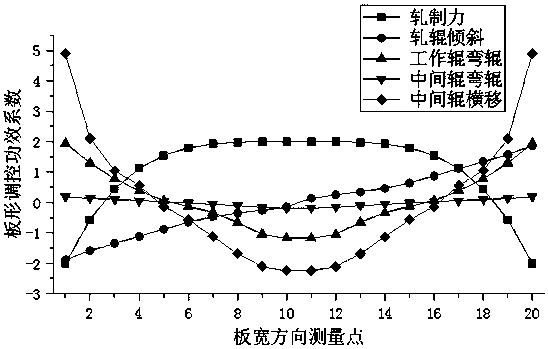

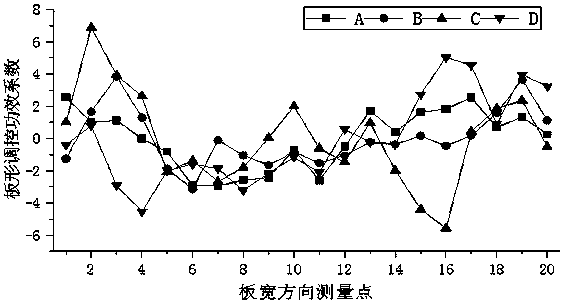

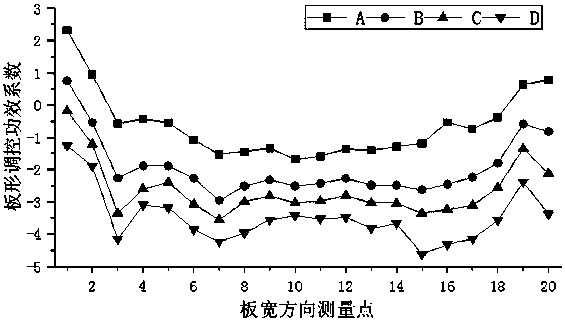

Method for processing measured data of plate shape regulation and control effect coefficient

ActiveCN110773573AImprove controlImprove texture qualityProfile control deviceComplex mathematical operationsShape controlEngineering

The invention discloses a method for processing measured data of a plate shape regulation and control effect coefficient, and belongs to the technical field of metallurgical rolling. The method comprises the following steps that S1, the measured values of the plate shape regulation and control effect coefficient are calculated; S2, the measured plate shape regulation and control effect coefficients are ranked; S3, each group of plate shape regulation and control effect coefficients is subjected to weight allocation after ranking is carried out, and a weighted plate shape regulation and controleffect coefficient is calculated; S4, weighted plate shape regulation and control effect coefficient calculation result data fitting is carried out; and S5, whether the fitted plate shape regulationand control effect coefficient meets requirements or not is judged. According to the method, the measured data are processed through a variable weighting calculating method, and therefore the accurateplate shape regulation and control effect coefficient is obtained, the plate shape regulation and control effect coefficient is closer to the actual condition, the control capability of an automaticplate shape control system can be improved, and the quality of exported strips can be improved.

Owner:康硕(山西)低应力制造系统技术研究院有限公司

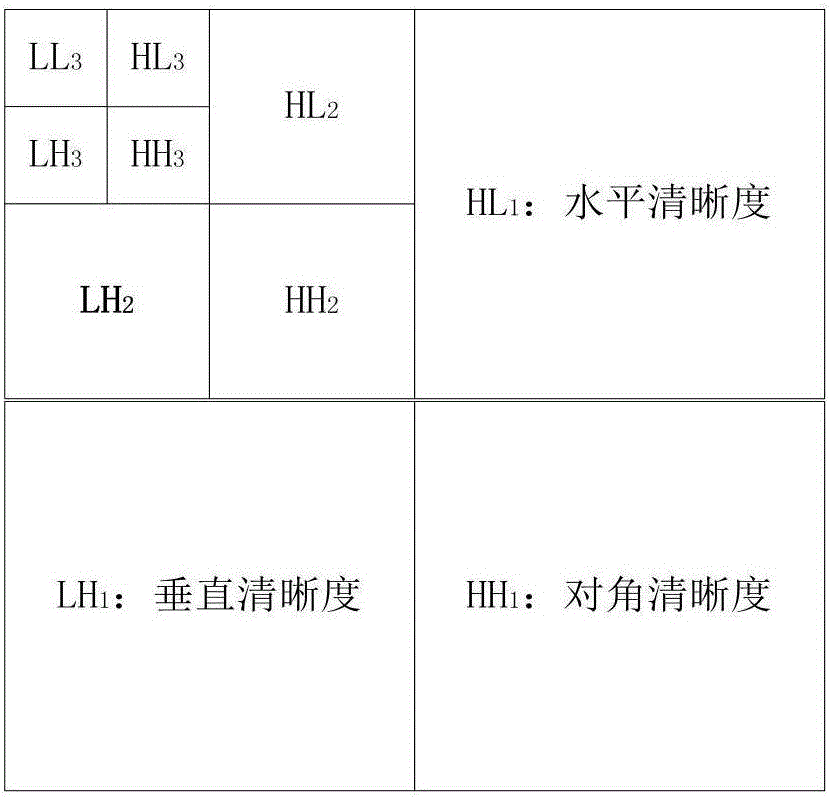

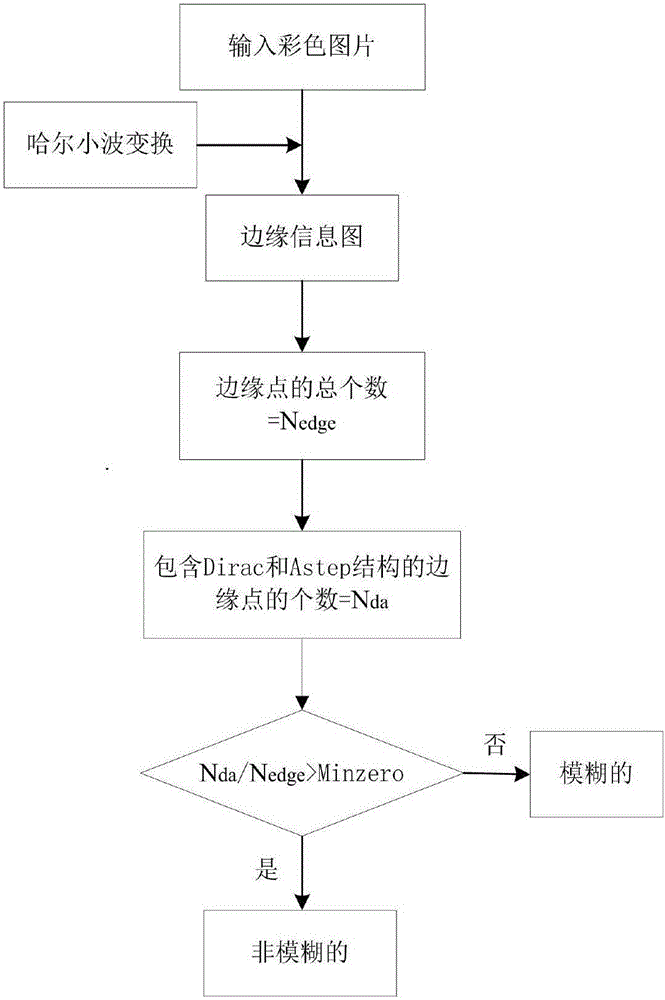

High-quality 3D texture reconstruction method

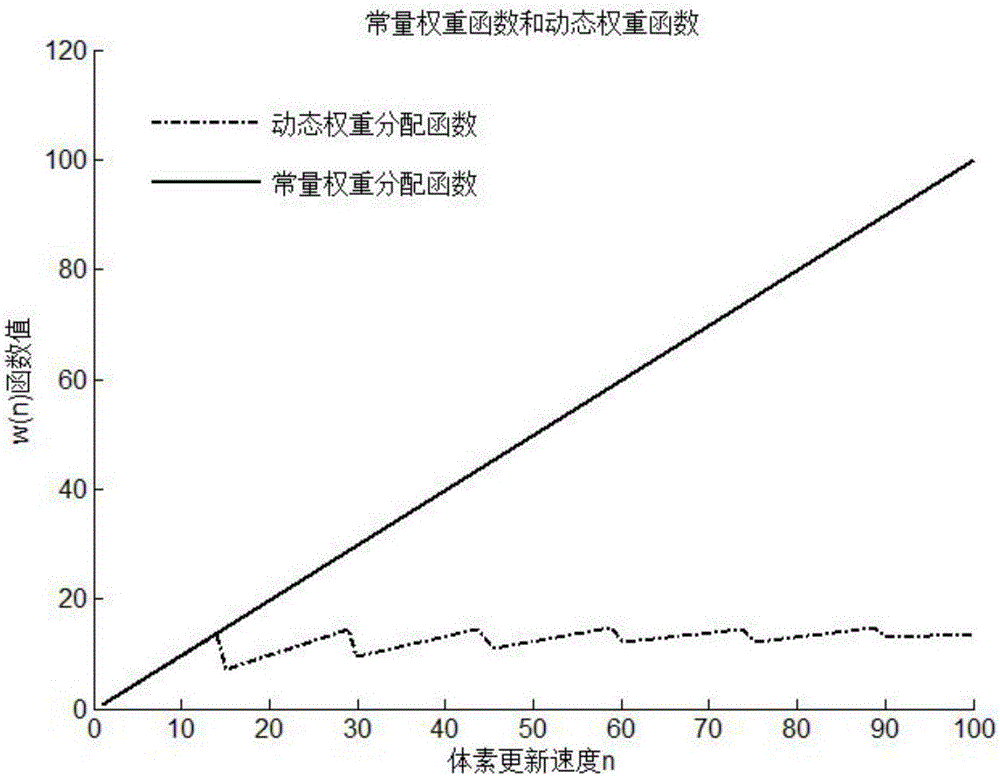

ActiveCN106548508AValid updateNo ghosting issues with colorsDetails involving processing steps3D modellingPattern recognitionVoxel

The invention relates to a high-quality 3D texture reconstruction method. According to the high-quality 3D texture reconstruction method, a fuzzy detection module and a dynamic color weight distribution function are additionally adopted in texture reconstruction; a fuzzy detection algorithm is adopted to set a certain fuzzy threshold value, so that fuzzy pictures inputted into a system are removed; and the dynamic color weight distribution function is designed so as to dynamically distribute color weights for newly acquired color pictures, so that color information stored in voxels can be updated. With the high-quality 3D texture reconstruction method adopted, the problem of color edge ghosting can be solved, and the texture quality of a reconstructed 3D model can be greatly improved to a certain extent.

Owner:胡海兵

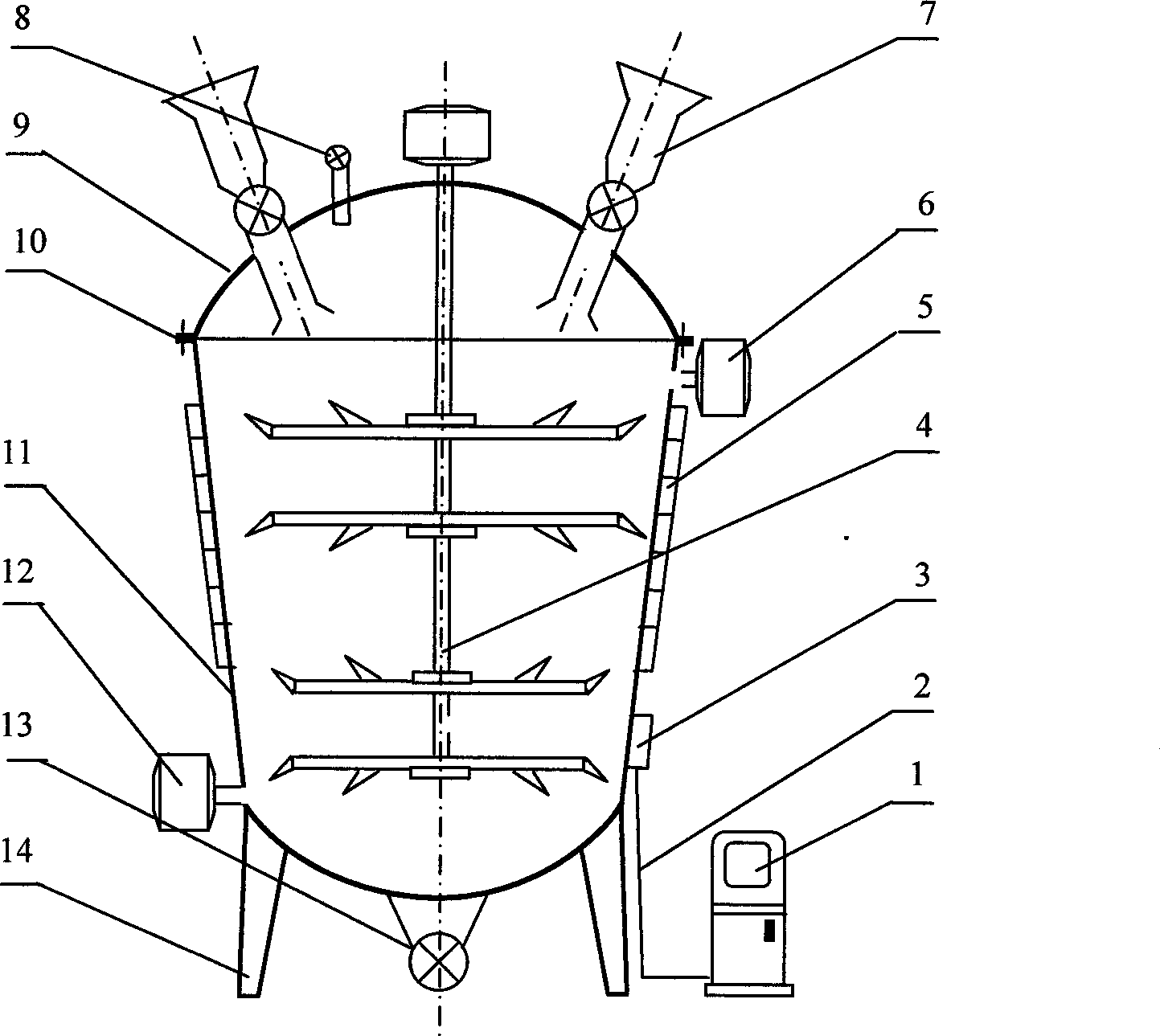

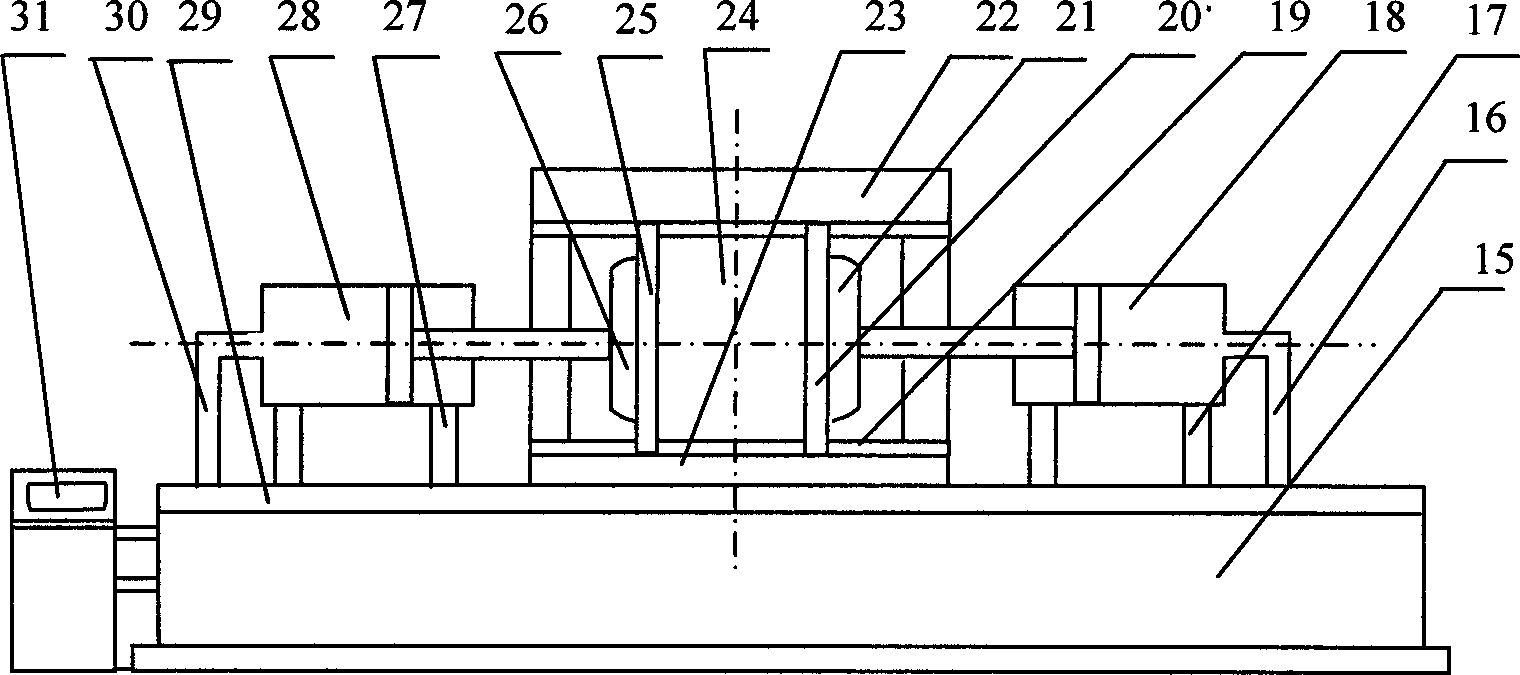

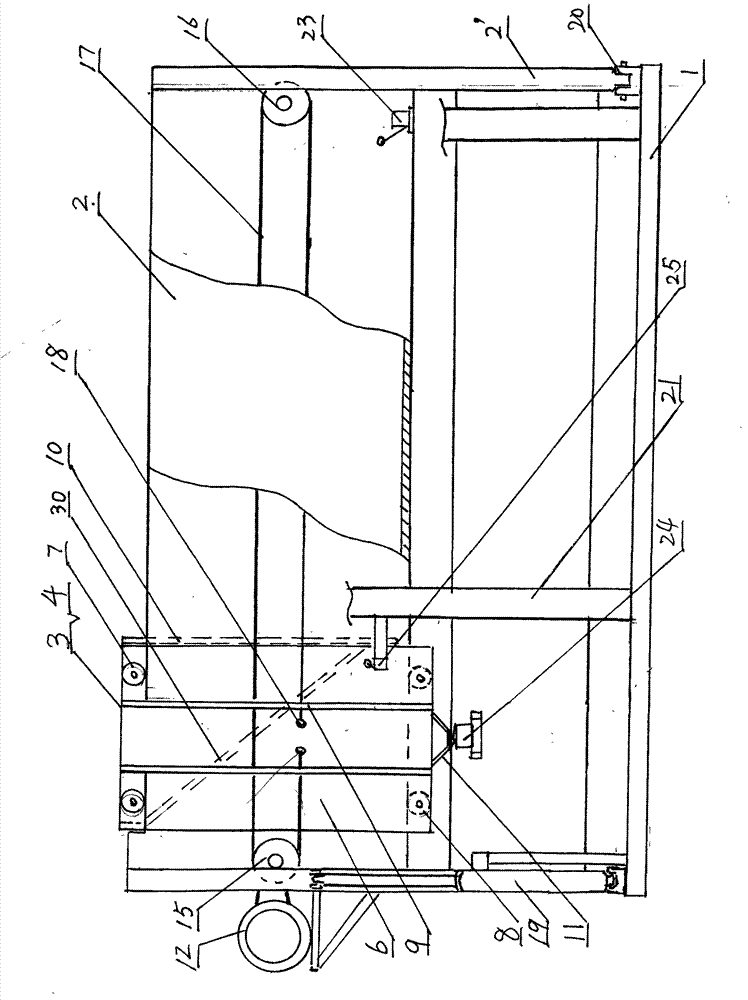

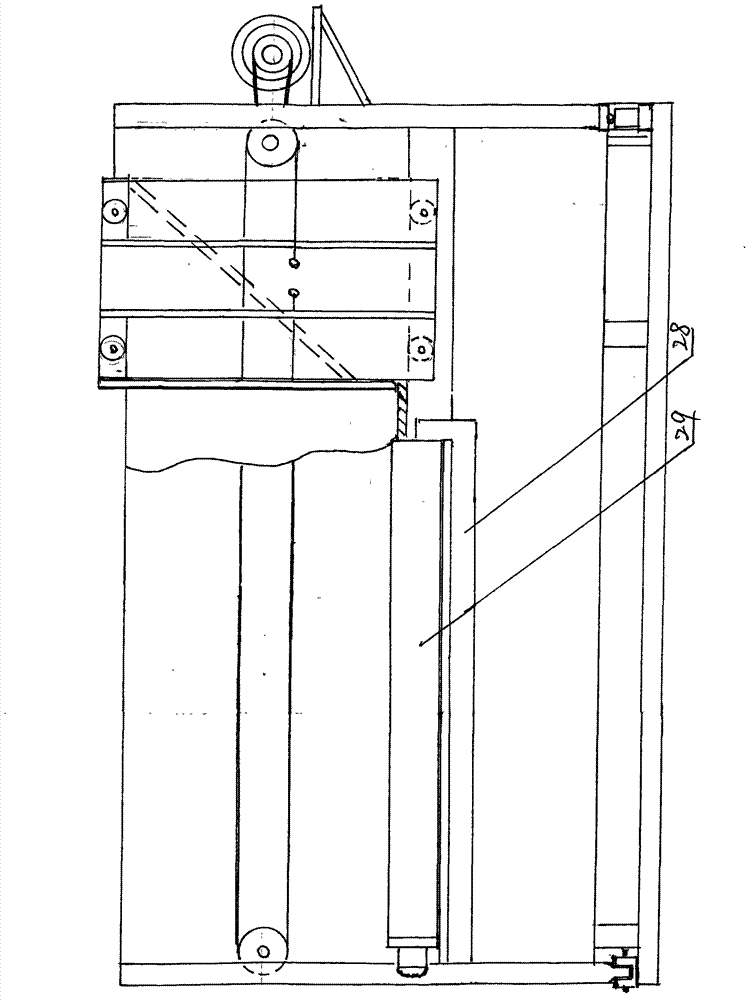

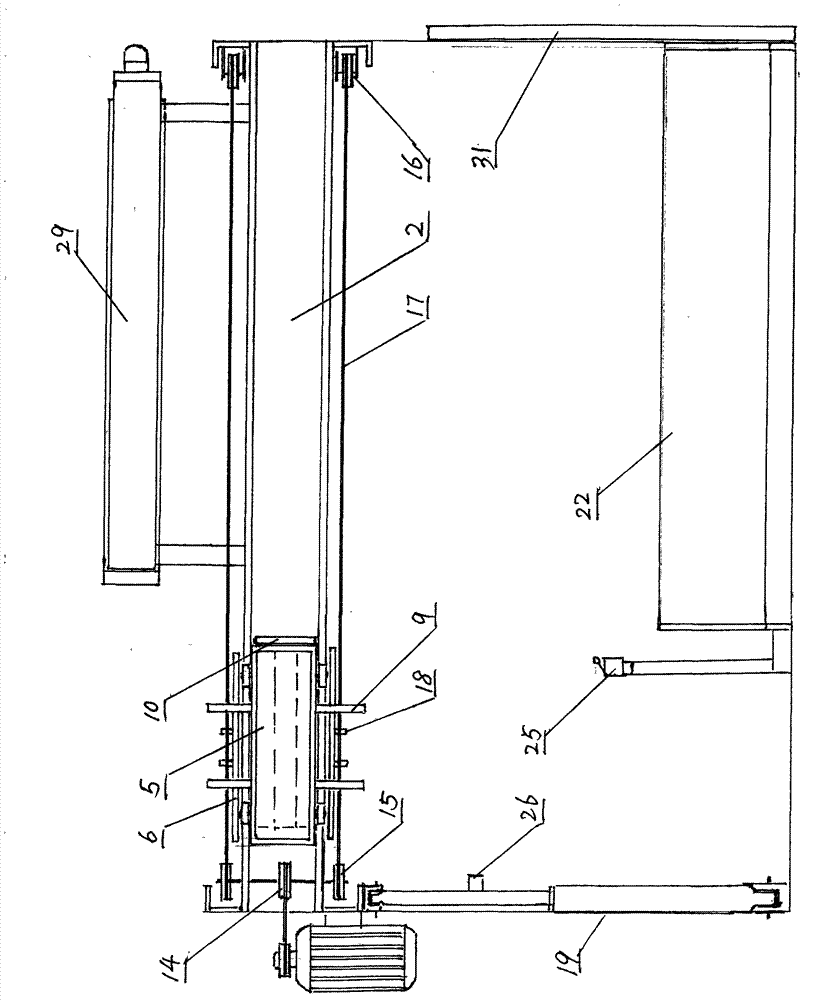

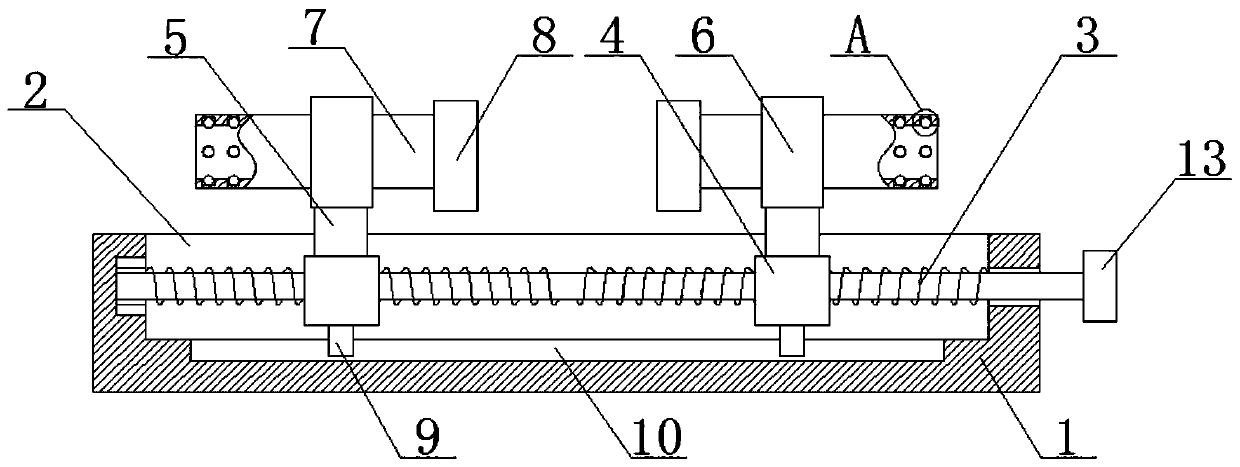

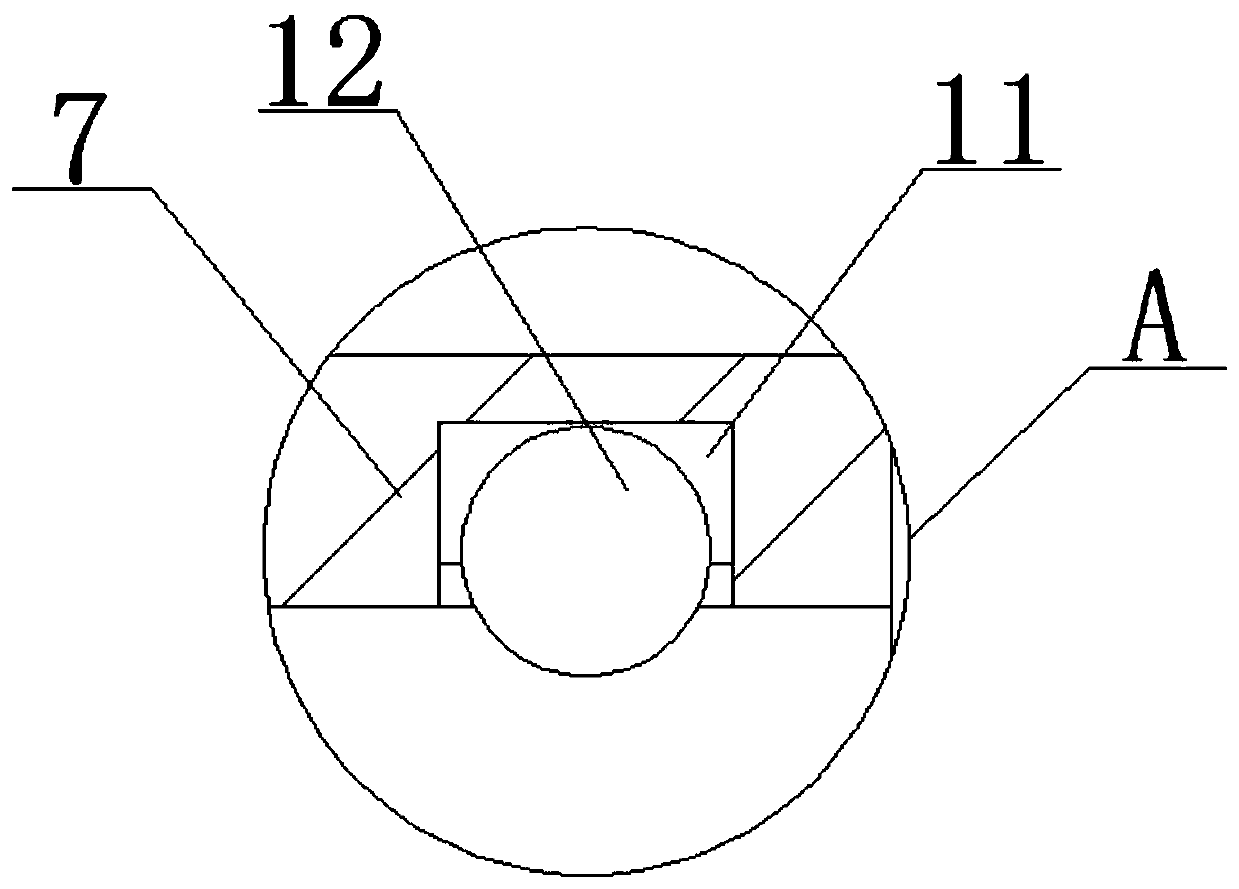

Bamboo recombination material hydraulic unit loading and mode pushing combination device

InactiveCN102729298ANo dopingReduce interventionPlywood pressesVeneer pressesProcess equipmentControl signal

The invention relates to a bamboo recombination material hydraulic unit loading and mode pushing combination device, and relates to bamboo recombination material pressing process equipment. The bamboo recombination material hydraulic unit comprises a base plate seat 1, a charging box 2, a feeder push 3 and an electric control device, wherein the charging box is articulated with the base plate seat, and an inclining reposition oil cylinder 19 is arranged between the charging box and the base plate seat; the feeder push 3 is composed of a guide frame 4 and a material pushing plate 10, and the guide frame 4 is provided with a chain drive device; the front side of the charging box is provided with a lean charging plate 22, and the rear side of the charging box is provided with a mould pushing oil cylinder 29; and the electric control device comprises an electric cabinet, and a PLC(programmable logic controller), wherein the input end of a PCL (printer control language)PLC is connected with the relative input signal, and the output end of the PCL PLC outputs the relative control signal so as to be electrically connected with an executive component. The bamboo recombination material hydraulic unit loading and mode pushing combination device provided by the invention has the beneficial effects that a material bumping process measure is adopted, the material is neat, and the sectional material quality after pressing is improved. The charging box charges material, meanwhile, the mould pushing oil cylinder executes a module pushing motion, and the equipment utilization rate is improved. By using PCL control circuit, the automaticity is high, and the production efficiency is improved.

Owner:QINGDAO GUOSEN MACHINERY

Nutrition-enhanced chewy rice noodles and preparation method thereof

InactiveCN107361290ANutrient enhancers, a wide varietyOvercome single nutritionFood ingredient functionsSodium CaseinateDigestion

The invention discloses nutrition-enhanced chewy rice noodles and a preparation method thereof. The nutrition-enhanced chewy rice noodles comprise the following raw materials: rice flour, sweet potato flour, egg meal, gluten flour, papaya powder, strawberry powder, lotus root starch, kudzuvine root powder, ginger powder, honeysuckle flower powder, liquorice root powder, xylitol, lactitol, sodium caseinate, sodium stearoyl lactylate, sorbitan monooleate, an enzyme preparation, a nutrition enhancer, diammonium phosphate, and sodium alginate. The nutrition-enhanced chewy rice noodles and the preparation method thereof disclosed by the invention are characterized in that the preparation processes are simple; and the prepared nutrition-enhanced chewy rice noodles have the advantages of rich nutrition, easy absorption and digestion, and good health-care effects; moreover, the rice noodles are fine in flexibility, chewy, long-lasting in flavor and good in taste after being cooked, and thus, appetite of people can be easily stimulated.

Owner:安徽省富邦天成食品有限公司

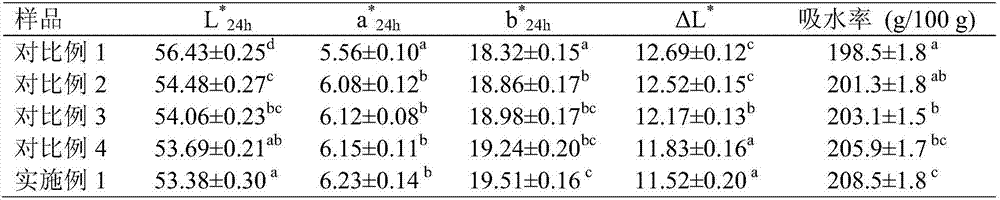

Flour for whole-wheat fresh wet noodles, whole-wheat fresh wet noodles and preparation method thereof

The invention relates to the technical field of food processing, and particularly relates to flour for whole-wheat fresh wet noodles, the whole-wheat fresh wet noodles and a preparation method thereof. The flour is prepared from whole-wheat flour processed by waxy wheat and whole-wheat flour processed by non-waxy wheat in a mass ratio of 3:1-7:1. The flour can be used for preparing whole-wheat flour, and two kinds of wheat flours are synergized and combined in the range of limited mixing proportions, so that the flour pasting viscosity can be improved, the hardness of noodles can be reduced, browning of the whole-wheat fresh wet noodles in the storing process can be reduced, formation of a gluten matrix structure can be improved, the gluten strength can be reinforced, the elasticity of noodles can be improved, and the texture quality of the whole-wheat fresh wet noodles can be comprehensively improved.

Owner:河南省大程粮油集团股份有限公司

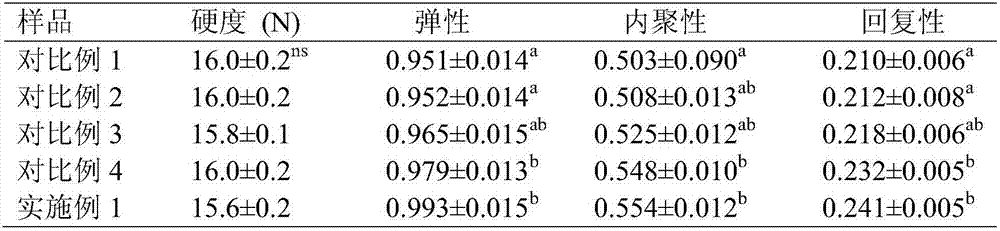

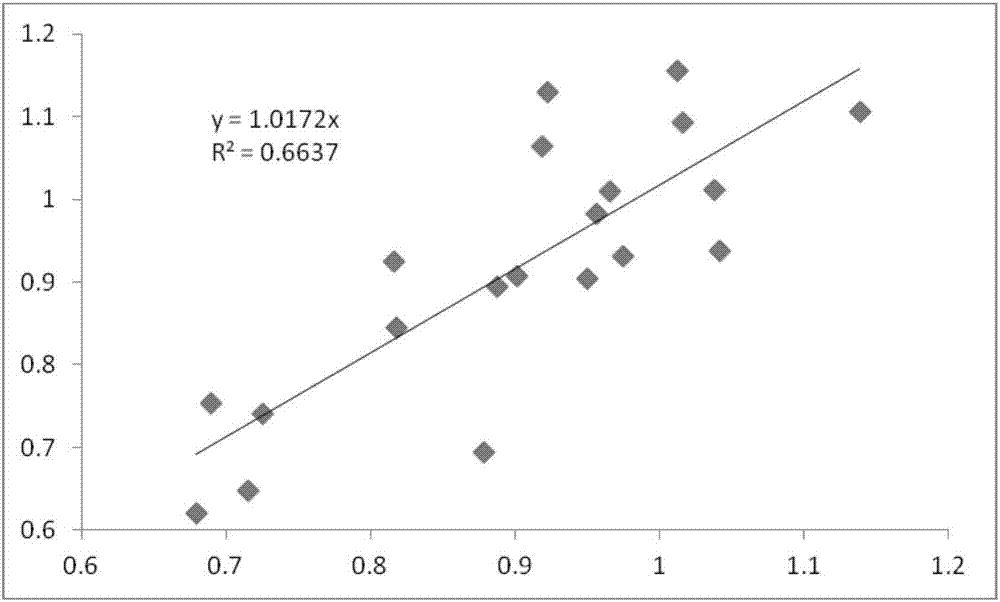

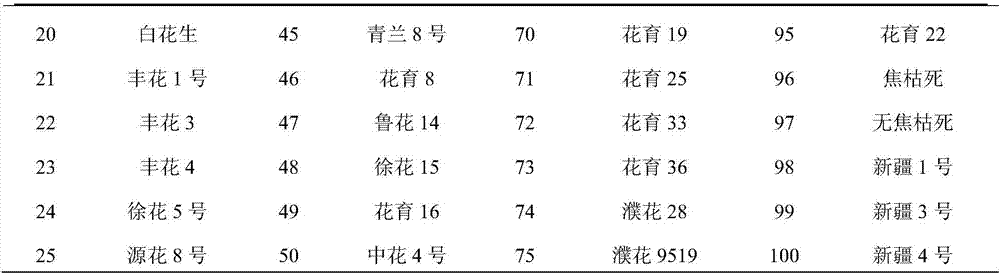

Method for measuring and evaluating quality of peanut raw material for protein processing

ActiveCN107228924ANo damageReduce analysis stepsWeighing by removing componentMaterial analysis by electric/magnetic meansBiotechnologyPROTEIN S HEERLEN

The invention discloses a method for measuring and evaluating quality of a peanut raw material for protein processing. The method for measuring comprises measuring a fruit shape score, total protein content, leucine content, arginine content, conarachin I content and mass percentage content of subunit having molecular weight of 23.5 kDa in total proteins of a peanut sample to be measured, substituting the above measured values into the formula (1) and acquiring protein powder quality of the peanut sample to be measured. The method reduces analysis steps and is suitable for enterprise application. A peanut protein processing raw material quality evaluation model is built. Through six peanut quality characteristics, the peanut protein powder quality is determined. A near-infrared analyzer can conveniently and fast forecast indexes such as amino acids in the model. Through near-infrared analyzing detection of peanut kernels, all indexes in the forecasting model can be acquired simultaneously and the damage to peanut kernels is avoided. The method is convenient and fast.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

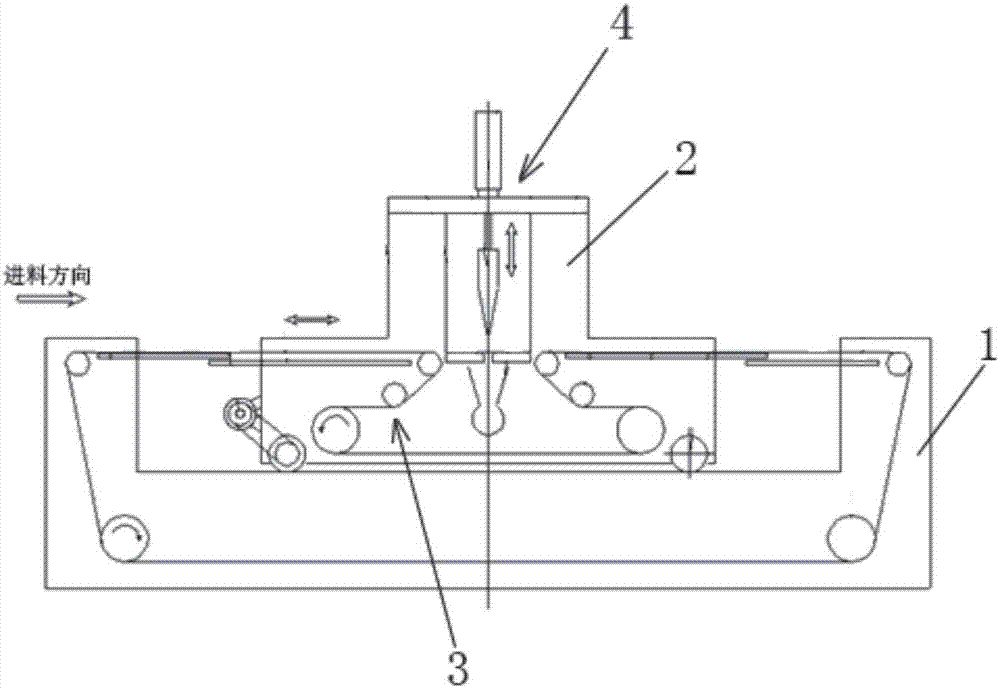

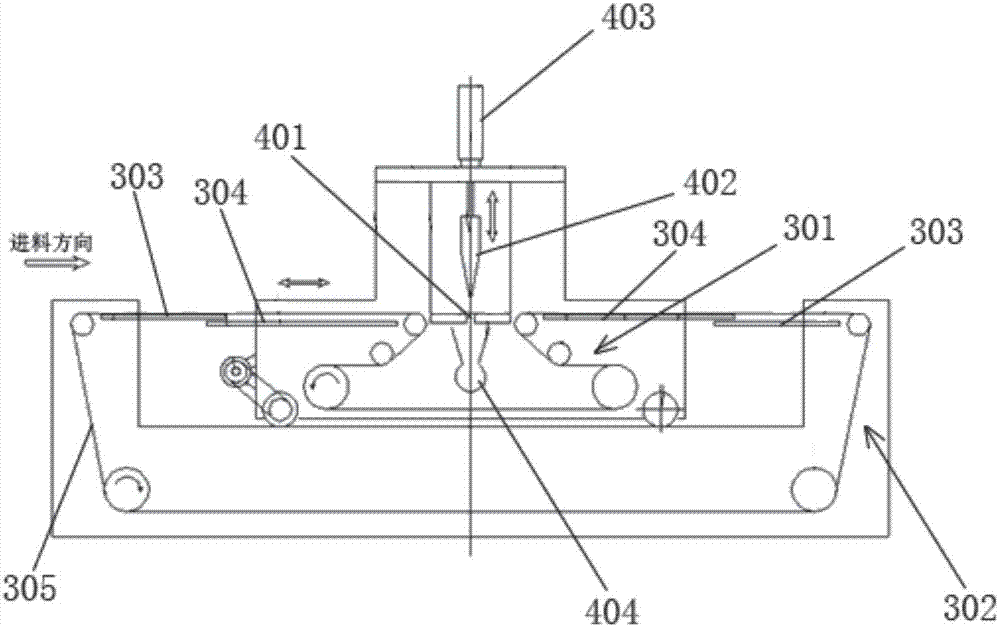

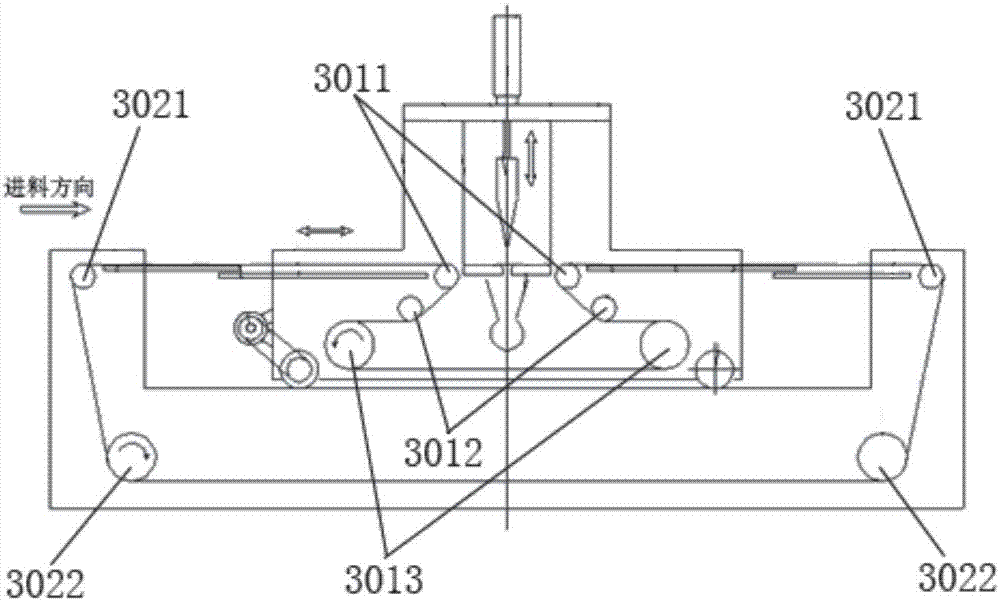

Continuous slab cutting equipment and method thereof for cutting continuous slab

ActiveCN107081816AAvoid Splash DefectsImprove texture qualityProfiling/shaping machinesEngineeringReciprocating motion

The invention discloses continuous slab cutting equipment. The continuous slab cutting equipment comprises a rack, a movement bracket, a transmission unit and a cutting unit, wherein the movement bracket is supported on the rack and can do a linear reciprocating motion on the rack, the transmission unit is used for transmitting materials and is connected with the rack and the movement bracket in series, the cutting unit is used for cutting the materials, and the cutting unit is supported on the movement bracket and can do a linear reciprocating motion along with the movement bracket. According to the continuous slab cutting equipment, the continuous slab is accurately cut to the required length in a cutting mode by adopting a cutter, so that shavings are effectively prevented from splashing, and the quality of shaving boards is increased.

Owner:ZHENJIANG ZHONGFOMA MACHINERY

Technological method for improving furniture pipe quality

InactiveCN110181152AImprove texture qualityQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesNano al2o3Engineering

The invention relates to the technical field of pipe production technologies and discloses a technological method for improving the furniture pipe quality. The technological method for improving the furniture pipe quality comprises the following steps that S1, whether the surfaces of pipe workpieces are moist or not is detected, if the surfaces of the pipe workpieces are moist, welding is conducted after drying, S2, the welded portion of the to-be-welded pipes are polished with an abrasive wheel, impurities on the surface of the welded surface are removed, and the to-be-welded face is guaranteed to be horizontal; S3, the pipes polished by the abrasive wheel are placed on a welding device to undergo welding treatment; S4, the welded pipes are taken down from the welding device, and the surfaces of the welded pipes are painted; S5, a stainless steel pickling solution and a nanometer aluminum oxide particles are mixed to obtain a treatment solution, the treatment solution is heated to 70DEG C, the treatment solution is circularly pumped into the pipes by a water pump and circulates for 0.5 min. By the adoption of the technological method for improving the furniture pipe quality, theproblems that at present, since the connection portions between the two pipes are difficult to align, so that the connection portion between the welded two pipes is not flat, and the welding quality is influenced can be solved.

Owner:张家港市鸿盛精密制管有限公司

Processing method of high-protein, low-fat and low-temperature instant chicken meat

InactiveCN107969642AMaintain essential fat contentAvoid frying and spoilageFood scienceChicken breastFat content

The invention discloses a processing method of high-protein, low-fat and low-temperature instant chicken meat. The processing method is characterized in that frozen skinless chicken breast is used asa main raw material, and the processing method comprises the steps of cutting, tumbling, flavoring, steam boiling, trimming, packaging, sterilizing, freezing and the like. The processing method of thehigh-protein, low-fat and low-temperature instant chicken meat has the following beneficial effects: the processing method does not adopt frying, maintains the basic fat content of the raw material,avoids over-frying and deterioration of protein under high temperature and reduction of nutritional value, avoids damage of fat-soluble vitamins in the food and promotes absorption and utilization ofthe fat-soluble vitamins of a human body.

Owner:诸城外贸有限责任公司

Method for improving reheating quality of crab cream and crabmeat through freezing conditioning

InactiveCN108353998AGood antibacterial effectImproves water retention and retentionMeat/fish preservation by coatingMeat/fish preservation by freezing/coolingRadio frequencyBiology

The invention discloses a method for improving reheating quality of crab cream and crabmeat through freezing conditioning, and belongs to the technical feed of processing of aquatic products. The method comprises the steps of using crab cream and crab meat which are obtained by the processing course of steaming for cooking, stripping and the like as raw materials, adding a composite fresh keepingagent to the crab cream in a spraying manner, applying a recompounded water retaining agent for the crabmeat, performing vacuum packing on the treated crab cream or the crabmeat to obtain packed crabcream or packed crabmeat, placing the packed crab cream or the packed crabmeat in a blower instant freezer for low-temperature freezing for 2 hours, and then placing the frozen crab cream or the frozen crabmeat in a freezer of minus 18 DEG C for long-term preservation. The reheating course comprises early-stage frequency-conversion ultrasonic wave-soaking combined unfreezing and later-stage radio-frequency quick reheating. The method integrates fresh keeping, water retention and a reheating technique, so that the flavor and the quality frozen storage cooked crab cream can be improved to the maximum extent, the texture quality of the crabmeat is improved to the maximum extent, massive frozen crab cream and massive frozen crabmeat can be reheated once, and later-stage industrialized production is facilitated.

Owner:YANGZHOU YECHUN FOOD PRODN & DISTRIBUTION INC CO +1

Shredded pigskin with pickled peppers and making method of shredded pigskin with pickled peppers

InactiveCN107495144AImprove crispnessFacilitates flavor entryFood scienceSodium bicarbonateMonosodium glutamate

The invention relates to the technical field of food processing, in particular to shredded pigskin with pickled peppers and a making method of the shredded pigskin with pickled peppers. The shredded pigskin with pickled peppers is prepared from the following raw materials of shredded pigskin, seasoning liquid, pickled pepper water and pickled peppers, wherein the shredded pigskin is prepared by putting the shredded pigskin in water containing sodium bicarbonate and citric acid, and performing boiling; the seasoning water is prepared from the following raw materials of edible salt, white granulated sugar, monosodium glutamate, sodium tripolyphosphate, citric acid, star aniseeds, Chinese prickly ash, bay leaves, Chinese cinnamon, ginger juice and water; the pickled peppers are prepared from the following raw materials of chili peppers, water, edible salt, white granulated sugar, citric acid, glacial acetic acid, Baijiu, calcium chloride, and D-sodium erythorbate; the pickled pepper water is water prepared by diluting the pickled material water and water in proportion. The formula and the process of the shredded pigskin with pickled peppers are optimized, so that the shredded pigskin with pickled peppers can be adapted to industrial scale production. Compared with the shredded pigskin with pickled peppers made in a workshop-based manner, the shredded pigskin with pickled peppers has the advantages that the color, the flavor and the mouth feel of the shredded pigskin are improved, the color is bright, the flavor is sour, refreshing and hot, the mouth feel is elastic and crispy, and the shredded pigskin with pickled peppers imparts and inherits leisure meat product foods.

Owner:HENAN ZHONGPIN FOOD IND

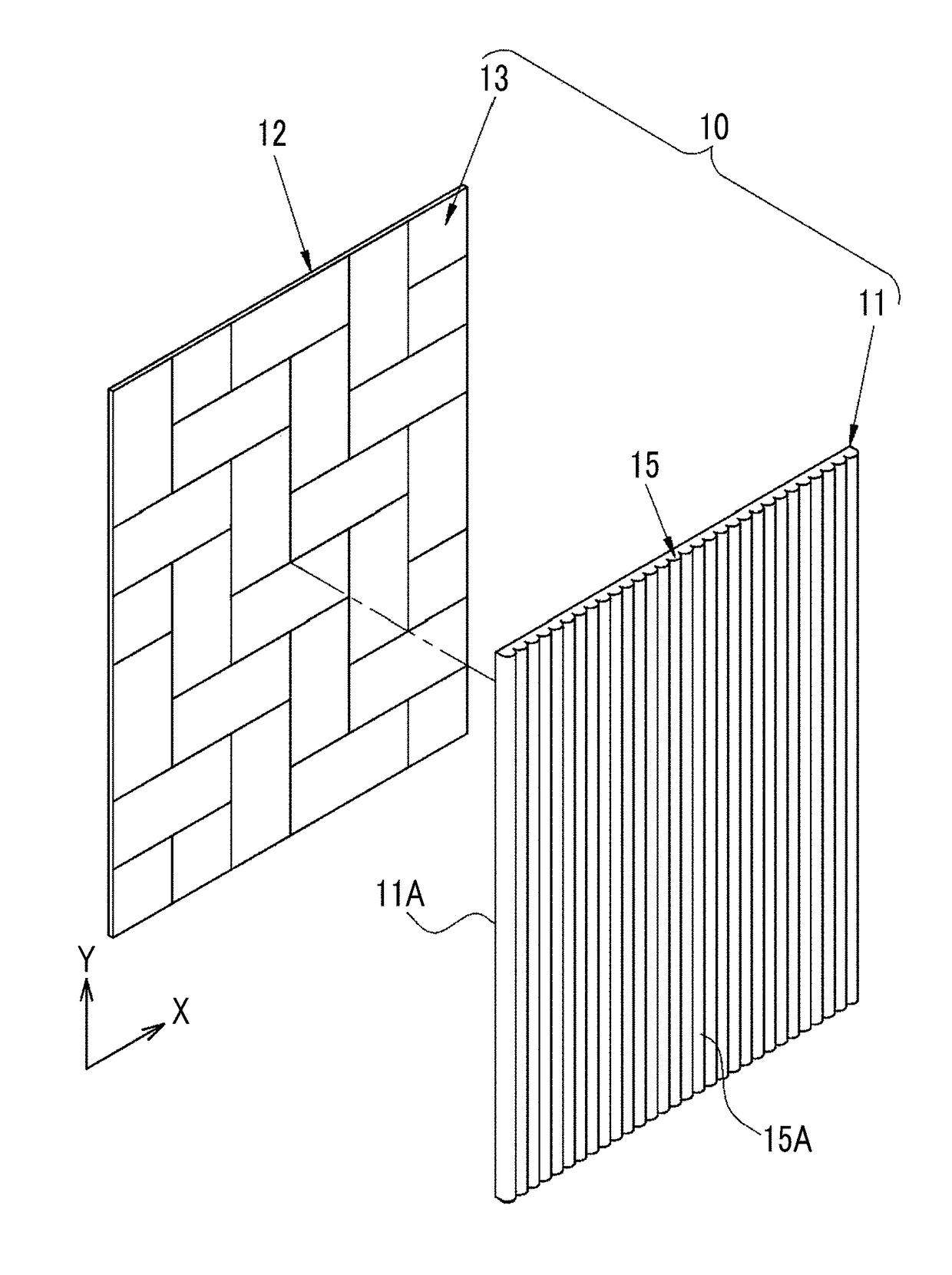

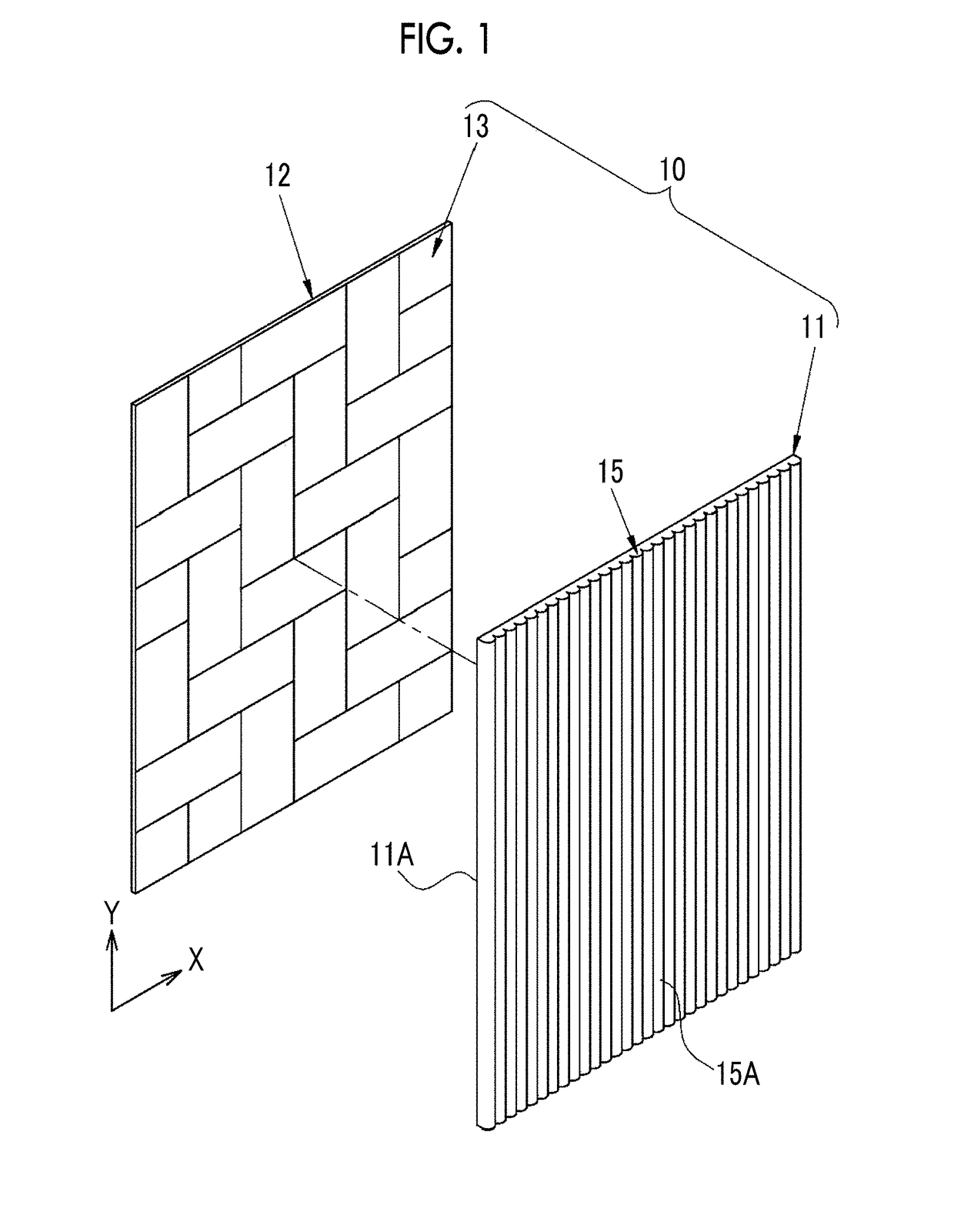

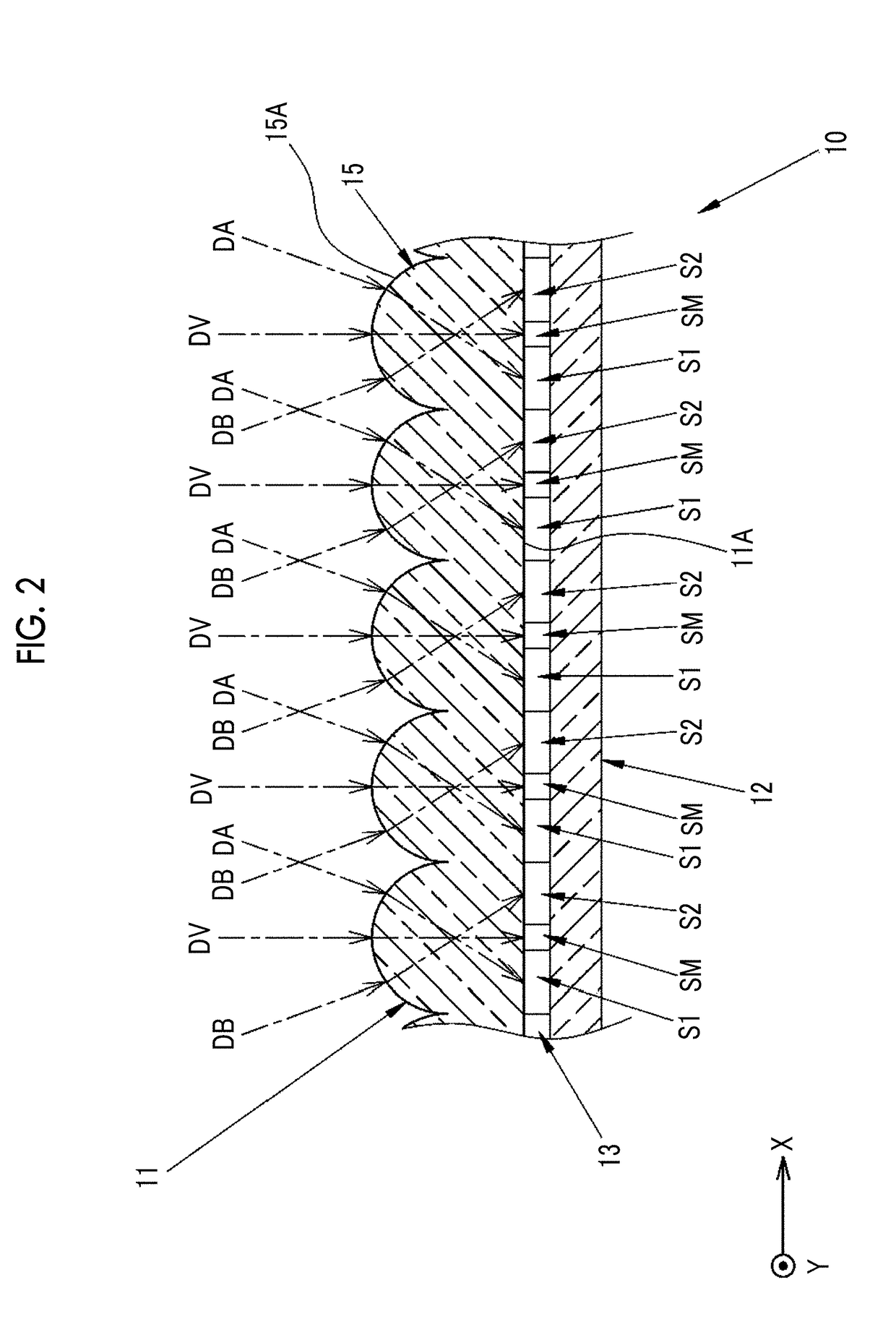

Decorative sheet

InactiveUS20180039089A1Improve texture qualityQuality is obtainedSynthetic resin layered productsSuperstructure subunitsFiberBand shape

Provided is a decorative sheet capable of obtaining an equivalent or higher quality texture than that of a real carbon fiber sheet. The decorative sheet (10) includes a lenticular lens sheet (11) and an image forming layer (13). The lenticular lens sheet includes a plurality of cylindrical lenses (15). The image forming layer includes a first sub-divided region (Si), a second sub-divided region (S2), and an intermediate region (SM) in a unit region corresponding to each of the cylindrical lenses. By changing an observation direction of the decorative sheet, a first-design (P1), a gradation-design (PG), and a second-design (P2) are sequentially observed. The first-design and the second-design have mutually inverted densities. Images of the first-design, the second-design, and the gradation-design are formed in the first sub-divided region, the second sub-divided region, and the intermediate region, respectively, in a state where they are sub-divided in a belt shape.

Owner:FUJIFILM CORP

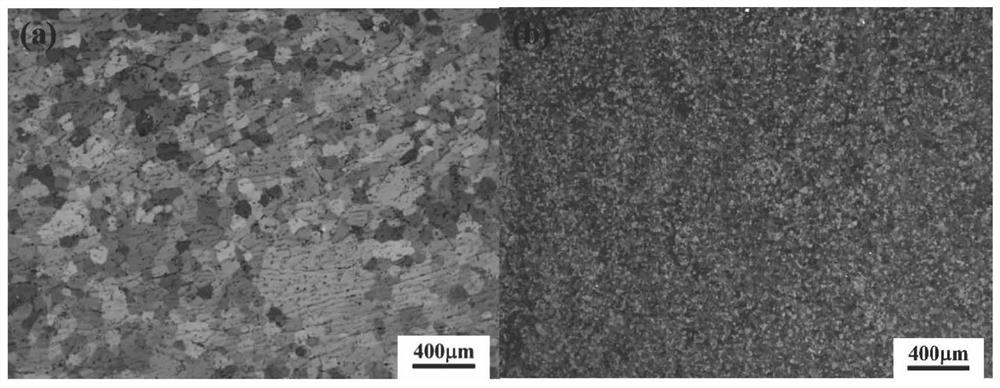

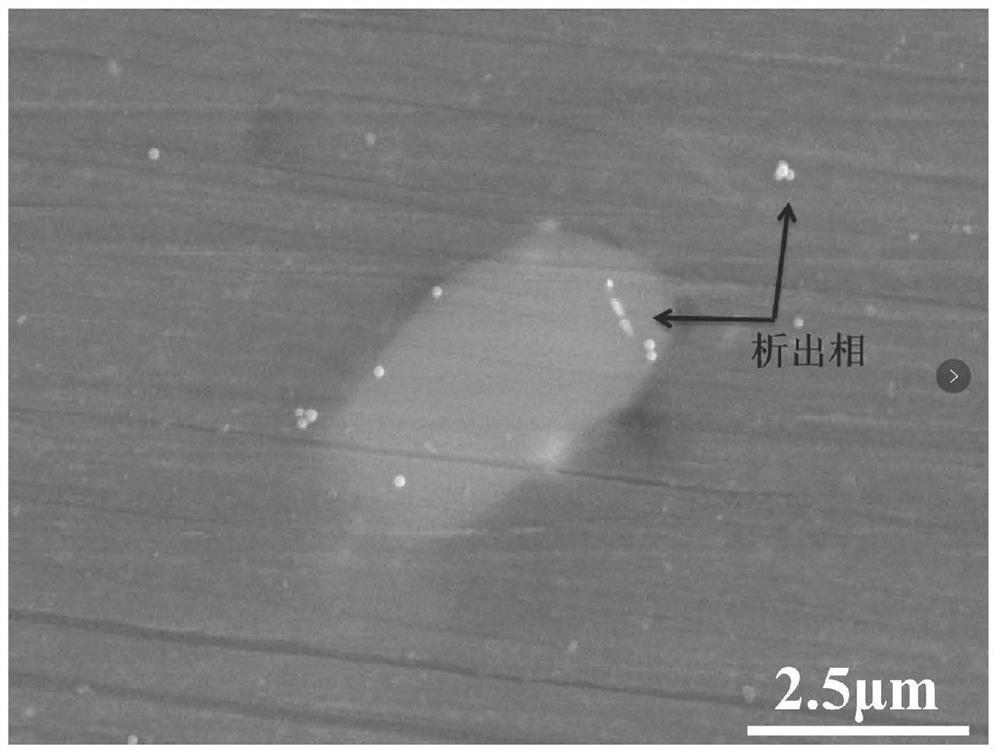

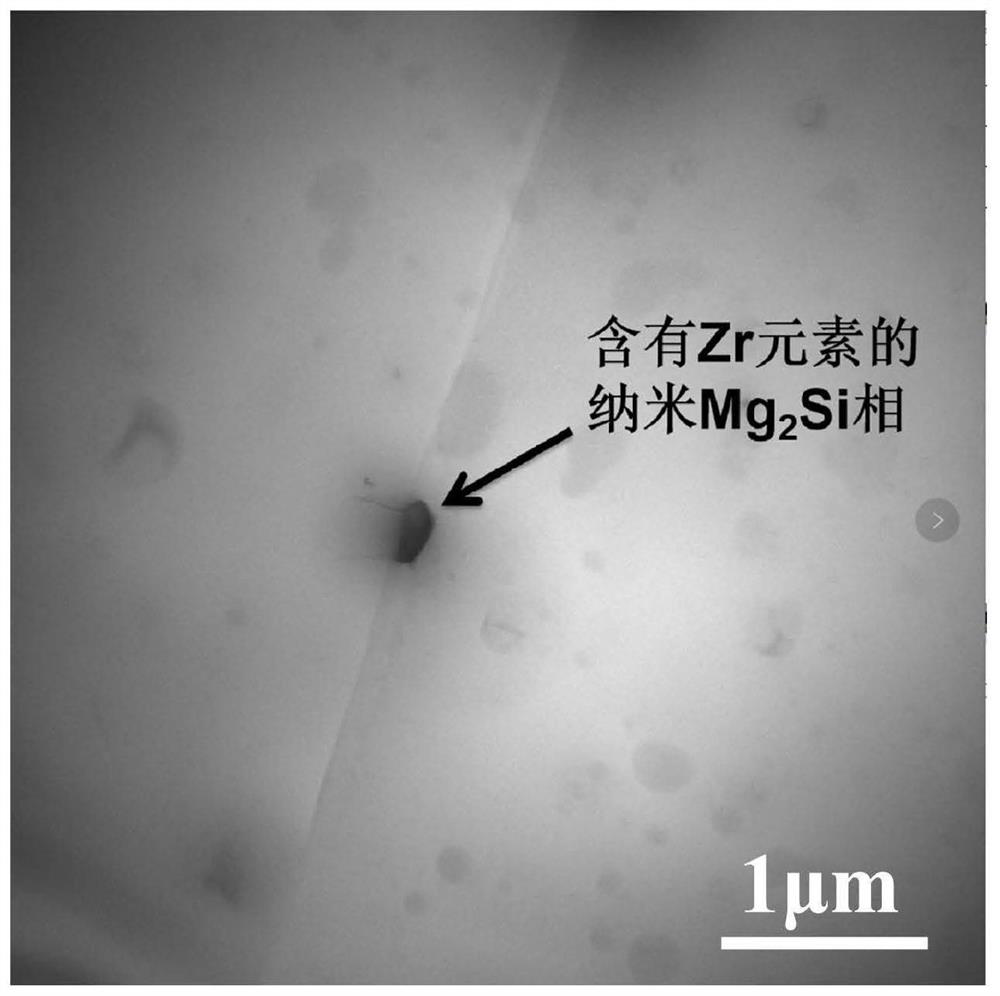

High-performance Al-Mg-Si alloy and preparation method thereof

ActiveCN112522553AImprove thermal stabilityHigh yield strengthHeat stabilitySupersaturated solid solution

The invention discloses a high-performance Al-Mg-Si alloy and a preparation method thereof. The alloy is composed of the following components in percentage by mass of 0.50 to 0.85% of Mg, 0.80 to 1.30% of Si, 0.10 to 0.35% of Fe, 0.03-0.25% of Ti, 0.03-0.30% of Zr, smaller than or equal to 0.15% of the sum of inevitable impurities and the balance Al. The alloy preparation method is a short-processsub-rapid solidification cast-rolling preparation method and comprises the five steps of alloy smelting, water-cooling copper roller cast-rolling, multi-pass cold rolling, solid solution heat treatment and artificial aging. The preparation method has the advantages that a formed Al-Ti-Zr ternary phase effectively inhibits abnormal growth of crystal grains in the Al-Mg-Si alloy, the thermal stability of the alloy is remarkably improved, the distribution and the size of a precipitated phase are improved, and precipitation strengthening is improved; a supersaturated solid solution Zr element isintroduced to participate in the nano Mg2Si phase precipitation process through sub-rapid solidification cast rolling, the aging dynamics is promoted, and the age hardening response is improved; and after artificial aging, alloy grains are uniform and fine, the yield strength is high and reaches 312 MPa, and meanwhile high plasticity is kept. According to the preparation method, the technologicalprocess steps and time are shortened, the quality of a plate strip is high, and the yield is high.

Owner:JILIN UNIV

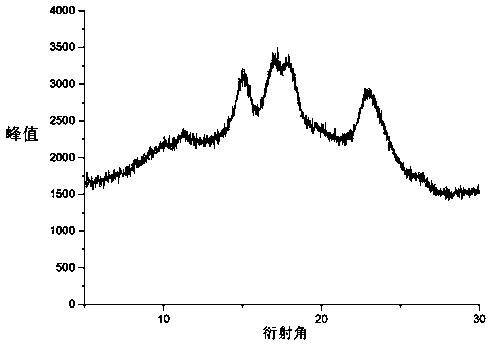

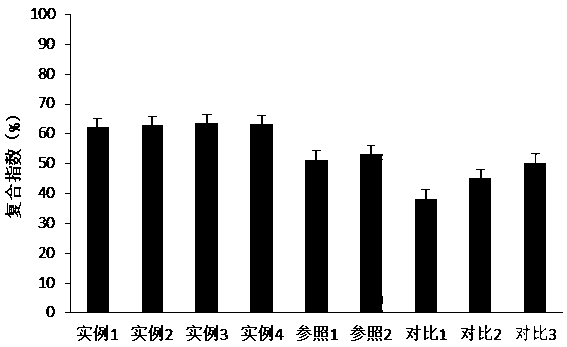

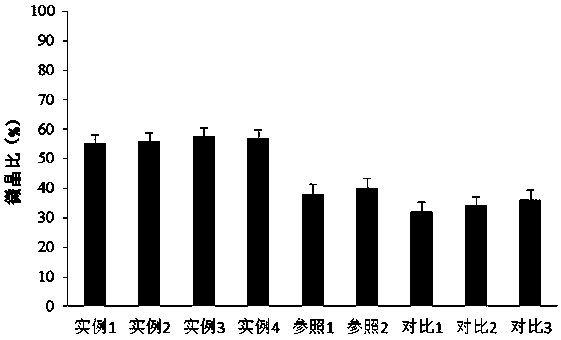

Processing method of high-stability lotus seed starch-soybean lecithin compound

ActiveCN109288035AAvoid heavy useEnsure safetyFood preservationFood ingredientsStability indexFreeze-drying

The invention relates to a processing method of a high-stability lotus seed starch-soybean lecithin compound, and belongs to the field of processing of modified starch. According to the method, lotusseed starch is used as a raw material, lecithin is used as a ligand substance, and through processing steps of vibration type ultramicro crushing, high-pressure micro jet homogenizing and compounding,liquid nitrogen spraying, cooling and crystallization, water washing and centrifuging, freeze drying, crushing and packaging, the lotus seed starch-soybean lecithin compound is prepared. Through theadoption of the method disclosed by the invention, the retrogradation stability of original lotus seed starch can be improved, the compounding indexes and the minicrystal ratio of the lotus seed starch compound can also be increased, high-quality production of lotus seed starach-lecithin compounds is realized, and products have the characteristics of quickly dissolving, being uniform to disperse,being high in safety and the like. The compounding indexes of the obtained lotus seed starch-lecithin compound are 55-70%, the minicrystal ratio is 50-60%, and the stability indexes are 60-75%.

Owner:FUJIAN AGRI & FORESTRY UNIV

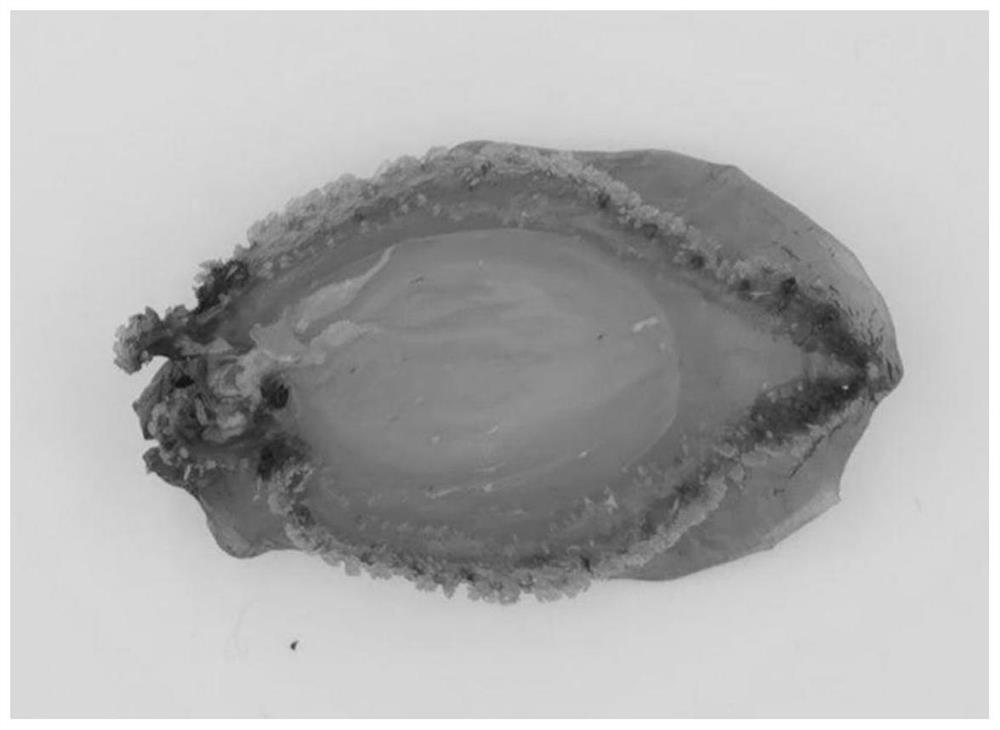

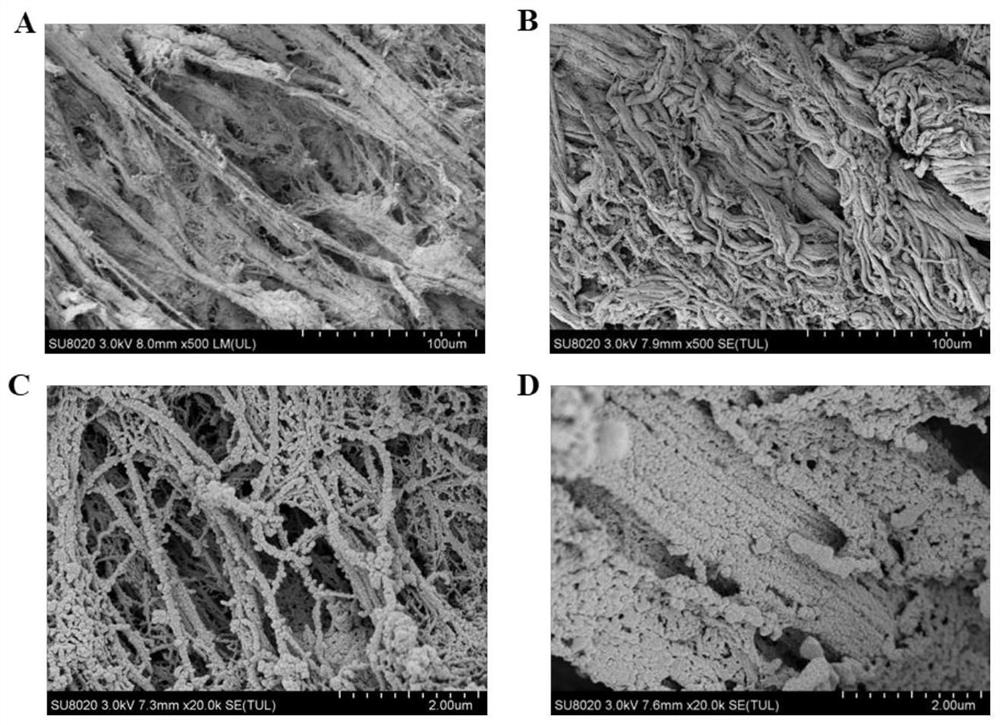

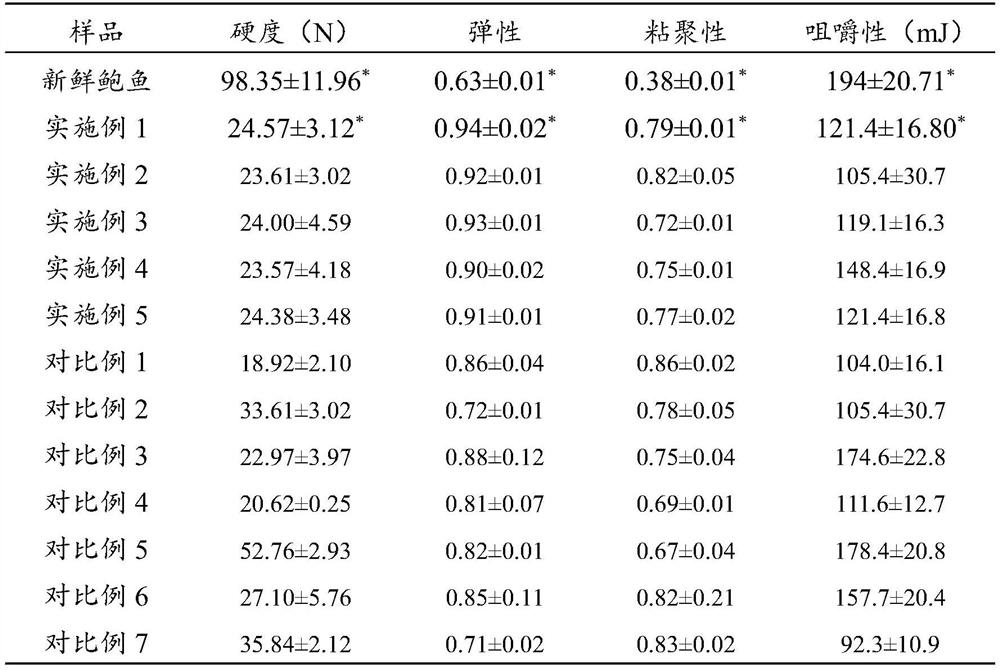

Soft boiled dried abalone and preparation method thereof

PendingCN113519793AImprove texture qualityImprove qualityFood dryingMeat/fish preservation by dryingBiotechnologyProtein molecules

The invention provides soft boiled dried abalone and a preparation method thereof, and belongs to the technical field of food processing. According to the method, the abalones are subjected to enzymolysis treatment through protease, so that protein molecules in the abalones form isopeptide bonds in the molecules or among the molecules, crosslinking is performed, the network structure strength of abalone muscles is greatly improved, the viscosity of abalone products is improved, the flavor and taste are improved, and the phenomenon of edge breaking in the abalone drying process is avoided. The soft boiled dry abalones obtained by the preparation method provided by the invention not only have complete surfaces and good texture quality, but also are easy to water-swollen, so that the quality of the dry abalones is greatly improved; meanwhile, the preparation method provided by the invention is simple in process, easy in control of production conditions, short in preparation period and suitable for industrial mass production.

Owner:CHINA AGRI UNIV

Plant-based snowflake-like chicken nuggets and preparation process thereof

PendingCN112841396AThe formula and process are scientific and reasonableGood organizationProteins working-up by texturisingVegetable proteins working-upDietary fibresMouthfeel

The invention discloses plant-based snowflake-like chicken nuggets and the preparation process thereof, soybean drawing protein and peanut drawing protein are adopted as main raw material formulas, and through the synergistic effect of various ingredients, the product has good tissue form, taste and flavor. The production process is clear, the parameters are accurate, the utilization rate of raw materials is high, the taste and color of the prepared snowflake-like chicken nuggets can well simulate those of really fried chicken nuggets, and the snowflake-like chicken nuggets are rich in dietary fibers and proteins and do not contain cholesterol.

Owner:SICHUAN HUIJI FOOD +2

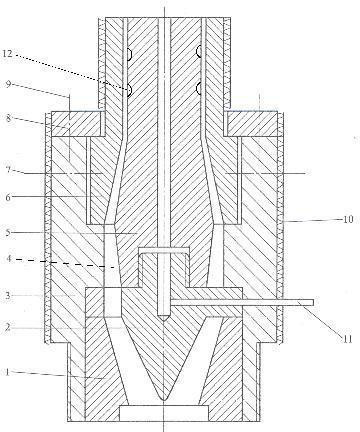

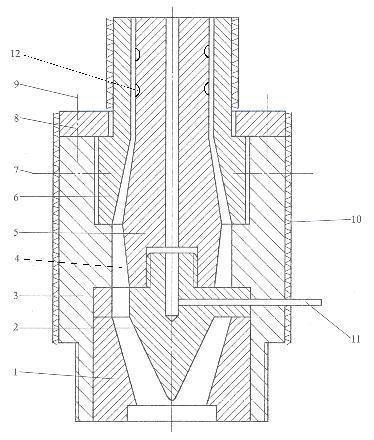

Buffer runner rhombic core model plastic hard tube extruder head

InactiveCN102463664AUniform plasticizationQuality improvementTubular articlesEngineeringMechanical engineering

The invention discloses a buffer runner rhombic core model plastic hard tube extruder head, comprising a cushion block, a diverter, a die body, a core model, a die, and an air intake lever, wherein, the cushion block, the diverter, the die body, the core model, and the die form a melt channel, the outer side of the die body is provided with a heating ring, the die body is connected with the die through an adjusting screw; the outer side of the die body and the die is provided with a gland, the gland is connected with the die body through a fixed screw; the core model is rhombic, and the outlet end which belongs to the core model and is corresponding to the die is provided with at least one buffer groove. According to the invention, the advantage of simple structure is achieved, a through filtering plastic tube extruder head with high quality of plastic tubes and cost saving property is produced, thus the problems of nonuniform wall thickness, corrugated tube inner wall, traction spin and the like are solved.

Owner:束方才

Pre-cleaning process before texturing process

ActiveCN104835717AReduce pollutionImprove texture qualityFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringWater tanks

The present invention discloses a pre-cleaning process before a texturing process. The process comprises the steps that (1) an automatic feeding machine transmits silicon slices to five rails separately; (2) the silicon slices enter a pre-cleaning water tank for cleaning according to the set speeds under the driving of rollers; (3) after cleaning, the residual water on the silicon slices is extruded by a soft roller at the tail end of the water tank; (4) the silicon slices are fed to an air knife groove, so that the silicon slices of which the surfaces are wet are dried under N2 atmosphere; (5) the silicon slices having hidden cracking severely in the step (4) are blown to crack, and the small broken silicon slices drop into an air knife groove body, and the large broken silicon slices enter a next slice pickup groove under the driving of the rollers; (6) cleaning and picking out the broken silicon slices in the step (5), and feeding the pre-cleaned silicon slices to the etching groove to carry out the cleaning and texturing. The silicon slices of the present invention is washed in the pre-cleaning water tank, then are dried in the air knife groove, so that the surfaces of the silicon slices entering the etching groove are guaranteed to be dry and clean, and the water is prevented from being brought to the etching groove to reduce the concentration of the medicine liquid in the etching groove.

Owner:JETION SOLAR HLDG

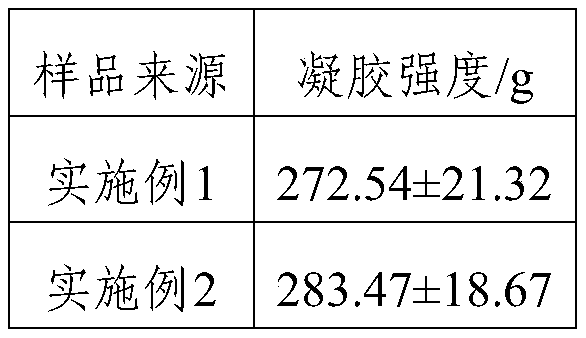

Method for improving gel strength of fibrillin and application of method

InactiveCN111109427AHigh gel strengthImprove texture qualityFood thermal treatmentProteins working-up by texturisingBiotechnologyEngineering

The invention belongs to the field of processing of meat products, and particularly relates to a method for improving the gel strength of fibrillin and application of the method. The method includes the steps: (1) mixing fibrillin and gel-type isolated soybean protein in a solvent so as to form a composite protein colloid; (2) mixing the composite protein colloid with grease so as to form a blended emulsion; and (3) heating the blended emulsion in a mod of sectional-type gradient heating so as to prepare gel. Through the method for improving the gel strength of fibrillin, not only can the gelstrength of fibrillin be improved effectively, but also the method can have a simple process and convenient operation; and when the method is applied to meat products, the texture quality of the meatproducts can be improved, and a good application effect is achieved.

Owner:CHINA MEAT RES CENT +1

Spicy mushy salted egg yolk preparation method and usage method thereof

InactiveCN107432435AAdd flavorGreat tasteFood ingredient as taste affecting agentEggs preservationFlavorAnimal science

The invention relates to a spicy mushy salted egg yolk preparation method and a usage method thereof, which relate to the spicy mushy salted egg yolk preparation method and the usage method thereof. The invention aims at limited application of the current salted egg yolks. The preparation method comprises the following steps: 1) preparing raw materials; 2) boiling the salted egg yolk; 3) mushing the salted egg yolk to obtain the fine mushy salted egg yolk; 4) mixing the mushy salted egg yolk to obtain a blended mixture; 5) performing loading, sterilization, cooling and inspection on the mixture to obtain the spicy salted egg yolk. The application method is characterized by comprising direct eating or cooking as a seasoner. The spicy mushy salted egg yolk has better physical property and local flavor, enhances the health care function of antioxidation and blood fat regulation, and enlarges the application scope of the salted egg yolk. The method is mainly used for preparing the spicy mushy salted egg yolk.

Owner:哈尔滨鸿羽食品有限公司

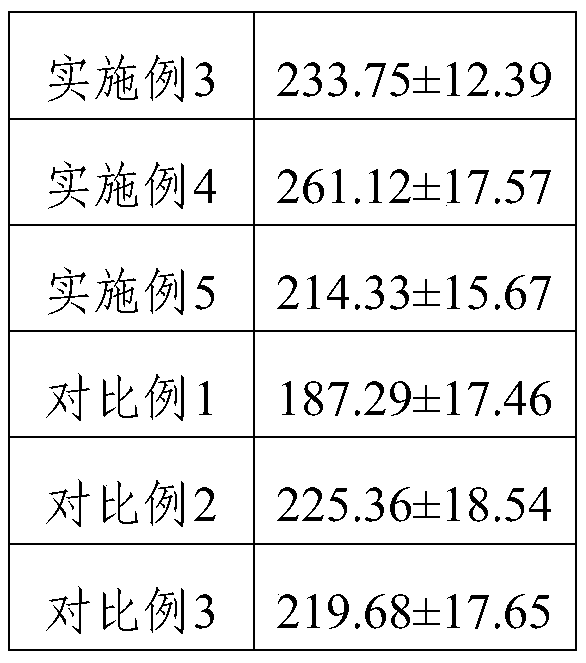

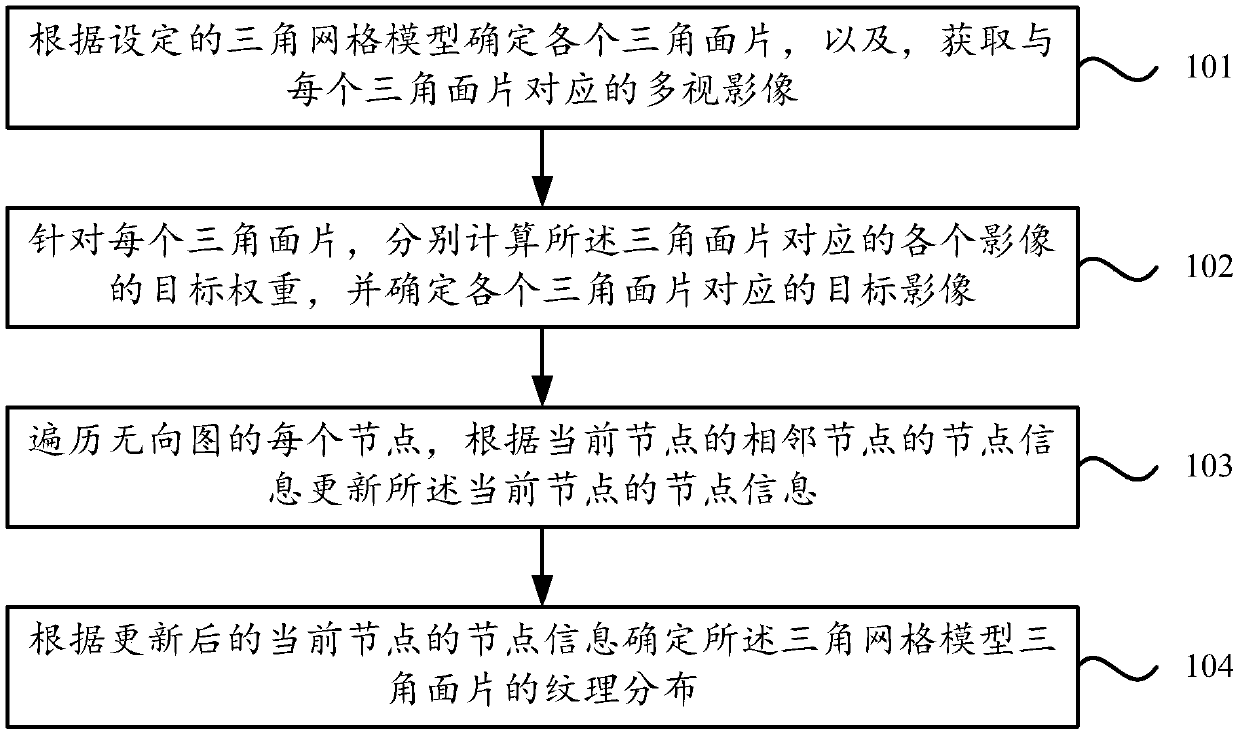

Multi-view image texture distribution determination method and device, equipment and storage medium

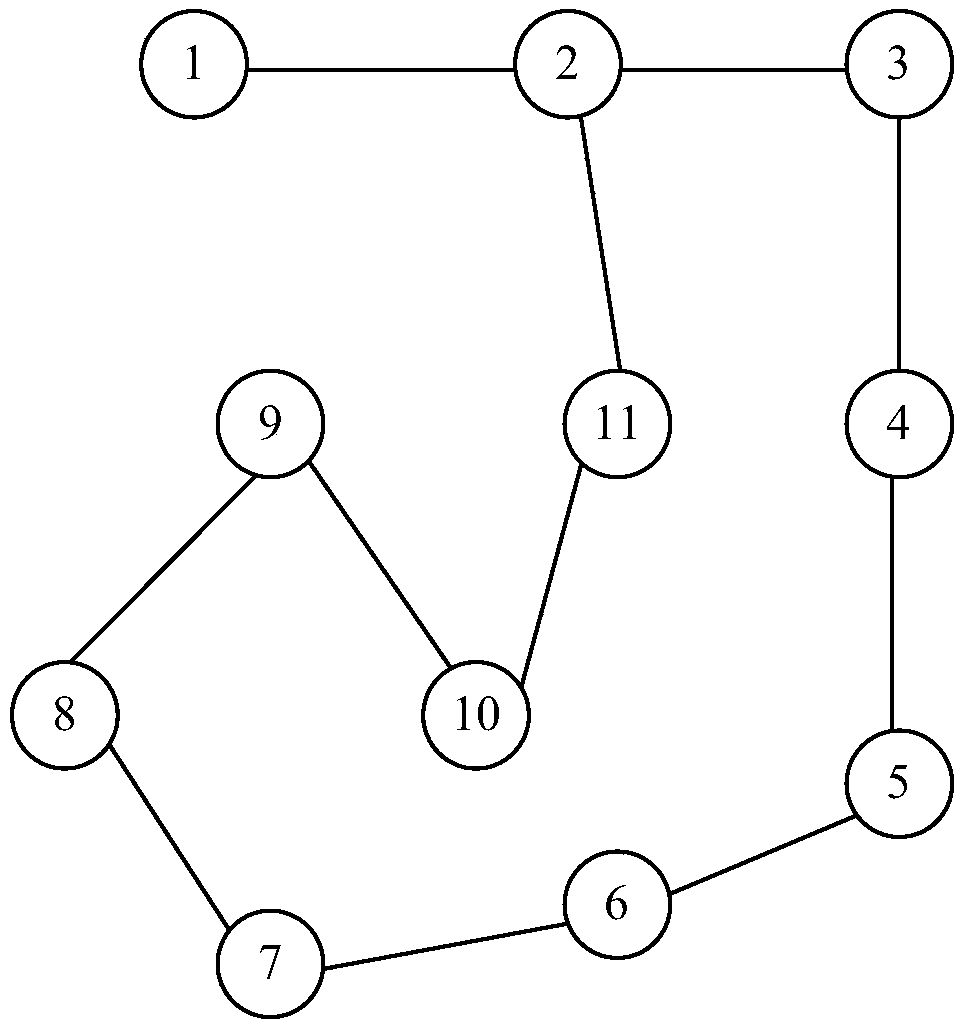

PendingCN109685879AImprove texture qualityQuality improvement3D-image rendering3D modellingUndirected graphAlgorithm

The embodiment of the invention discloses a multi-view image texture distribution determination method and device, equipment and a storage medium, and the method comprises the steps: determining eachtriangular patch according to a set triangular grid model, and obtaining a multi-view image corresponding to each triangular patch; Respectively calculating the target weight of each image corresponding to the triangular patch, and determining the target image corresponding to each triangular patch; Traversing each node of the undirected graph, and updating the node information of the current nodeaccording to the node information of the adjacent node of the current node; Wherein the node information of the adjacent node and the node information of the current node respectively comprise a nodevalue and a label, the node value comprises a target image corresponding to a triangular patch of the node, and the label comprises a target image meeting a set condition in the target image; And determining the texture distribution of the triangular patch of the triangular mesh model according to the updated node information of the current node. The texture quality during reconstruction of a natural scene in the multi-view image is improved, and the texture mapping effect is enhanced.

Owner:广东启慧城市信息有限公司

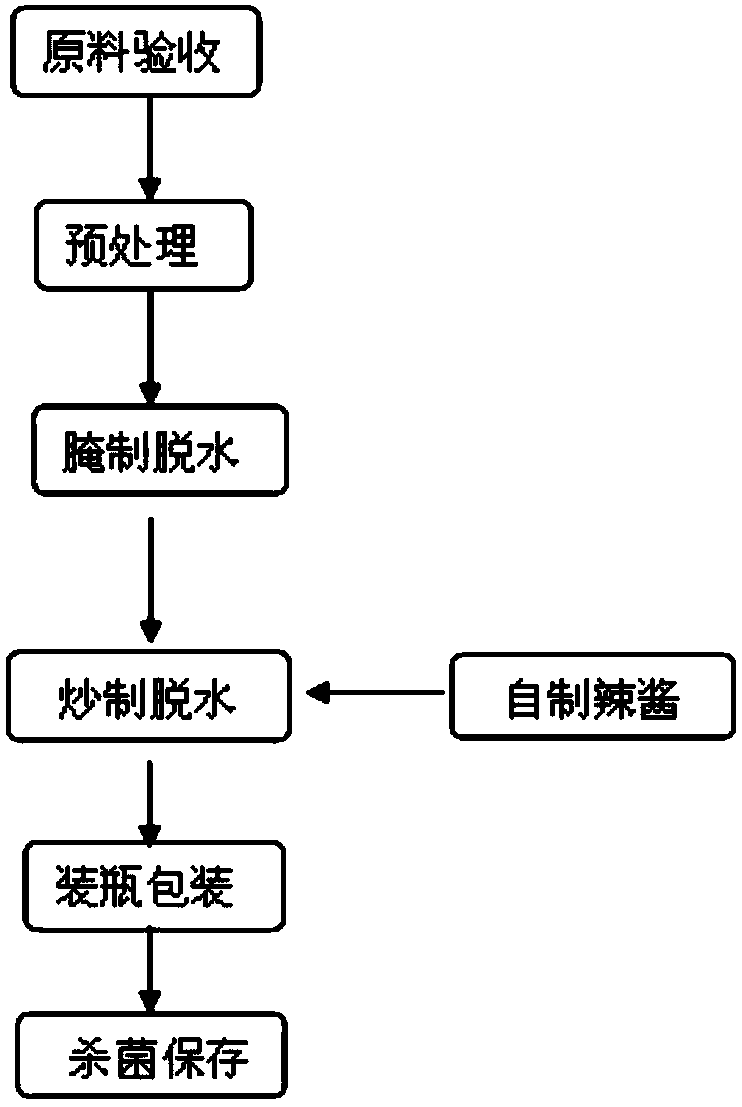

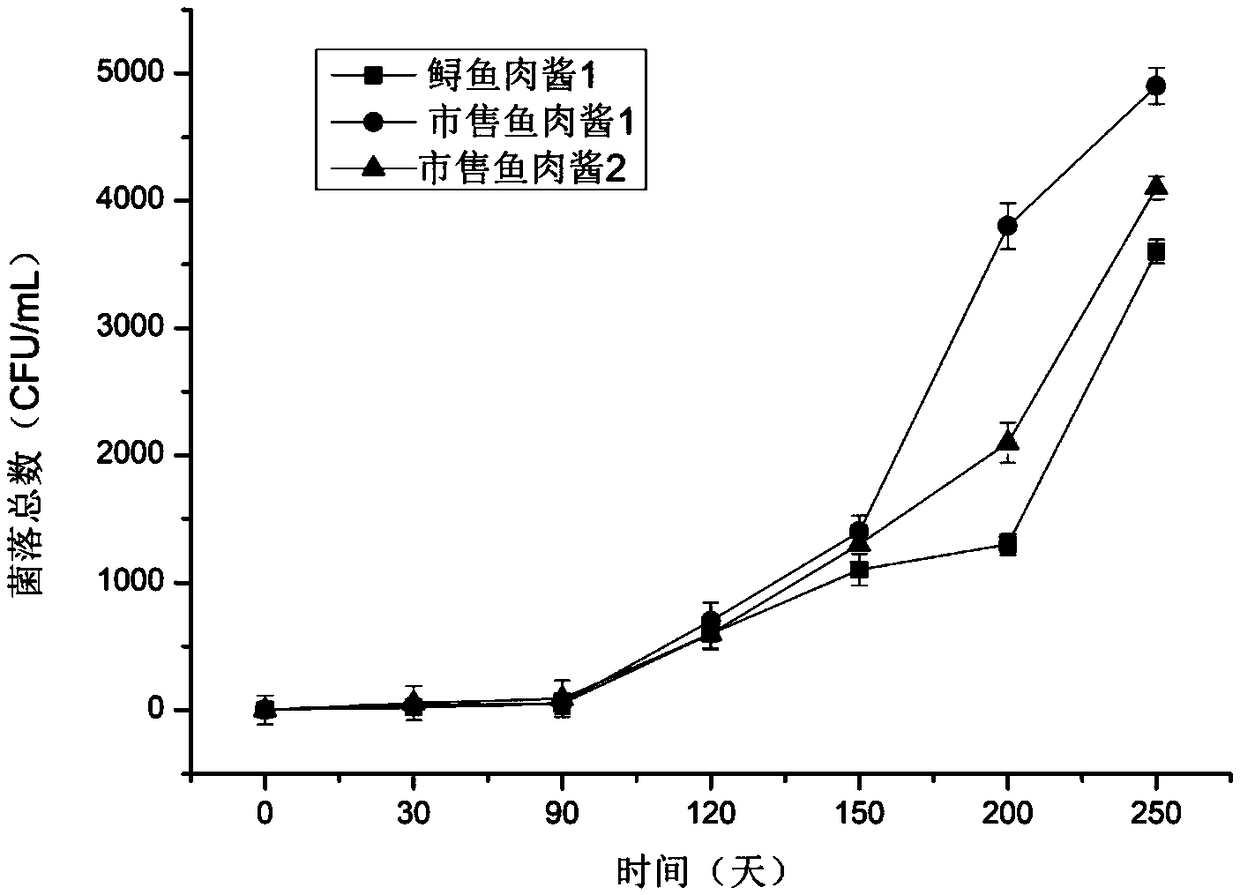

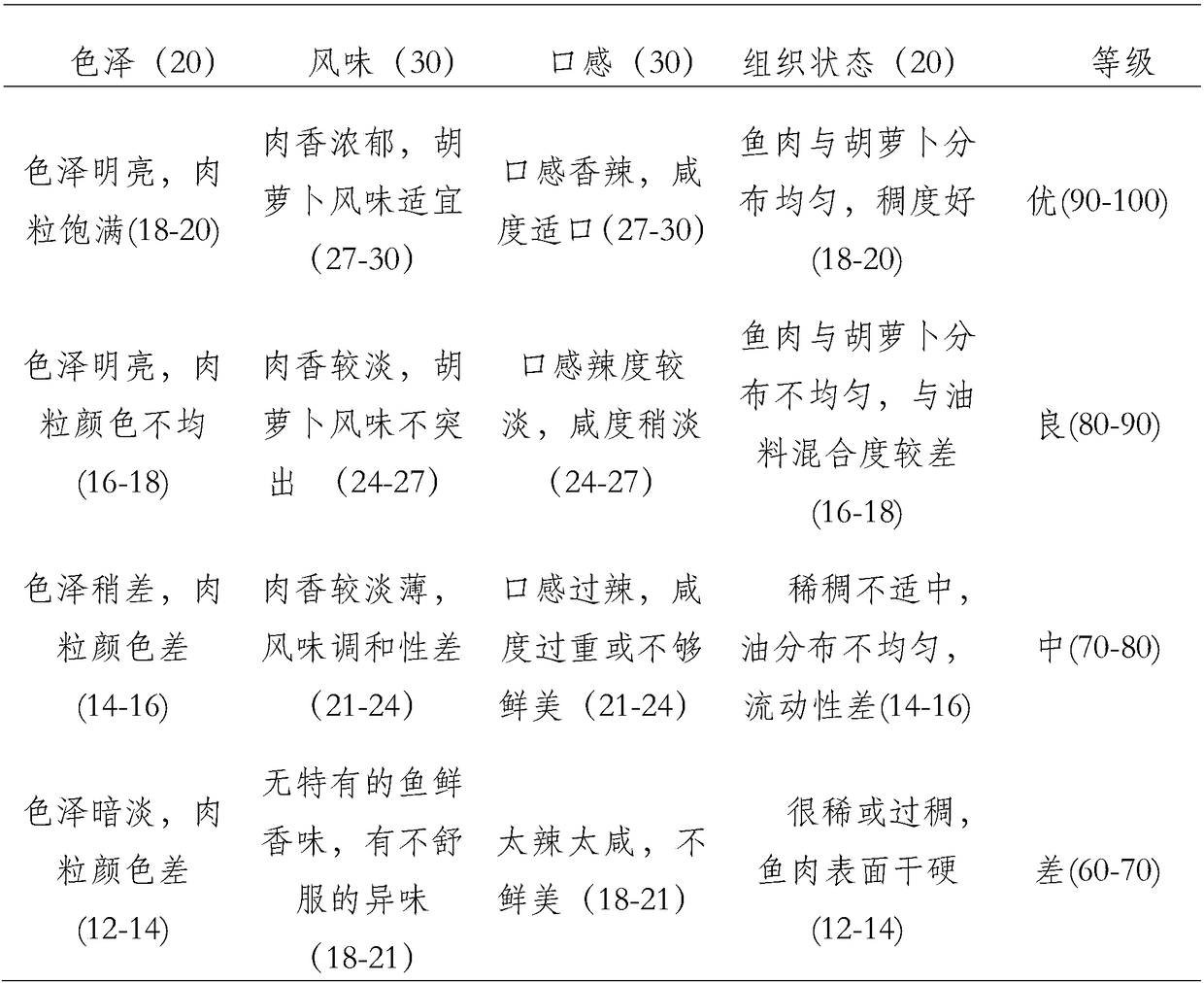

Method for processing instant fish sauce

PendingCN109090506AImprove overall utilizationRich varietyFood ingredient functionsAquatic productRapeseed

The invention discloses a method for processing an instant fish sauce. The method includes placing fish pieces in a deodorization liquid for curing and then mixing and frying rapeseed oil, garlic, fermented soya beans, chili powder, shiitake mushroom, peanut and bean paste to obtain a homemade hot sauce; adding the homemade hot sauce to the fish pieces subjected to deodorization curing, then adding oil, carrot, red pepper and the homemade hot sauce for mixing and then frying for dehydration to obtain the fish sauce. According to the method, the problem that aquatic products are soft in textureafter cured by high salt is solved by means of the synergistic effect of raw material pretreatment, frying dehydration, canning and sterilization, the product texture quality is improved, and the fish umami taste is maintained to the largest extent. Carrot raw materials are added to the product, and the effect of improving eyesight and nurturing the soul can be improved if a user eats the fish sauce frequently. The instant canned product is convenient to eat and carry, spicy in taste and rich in nutrient.

Owner:JIANGNAN UNIV

Novel rapid bright quenching oil

The invention discloses novel rapid bright quenching oil. The oil comprises, by weight fraction, base oil, a catalyst cold agent, an antioxidant, a scaling inhibitor, animal and vegetable oil and a brightening agent. The scaling inhibitor is a single-handing ash-free dispersing agent T151 or polyisobutene bissuccinimide T154 or high molecular weight polyisobutene bissuccinimide T16, the brightening agent is Mirilline oleate or mushroom ene acetic acid or zinc butyl octyl dithiophosphate T202; the antioxidant is a mixture of an amine antioxidant and a phenolic antioxidant; the amine antioxidantis selected from at least one of alkylated diphenylamines, alkyl phenyl-alpha-naphthylamine or N-phenyl group-N'-alkyl group-P-phenylene dI amine. Through sintering, the oil has the good cooling, brightness and thermal oxidation stability, the cooling time is short, the cooling capacity is good, meanwhile, the brightness level can reach A, the metal luster can be effectively improved, the qualityof the treated metal is improved, and a quenched workpiece is bright in surface and free of cracking.

Owner:广州市蓝化润滑科技有限公司

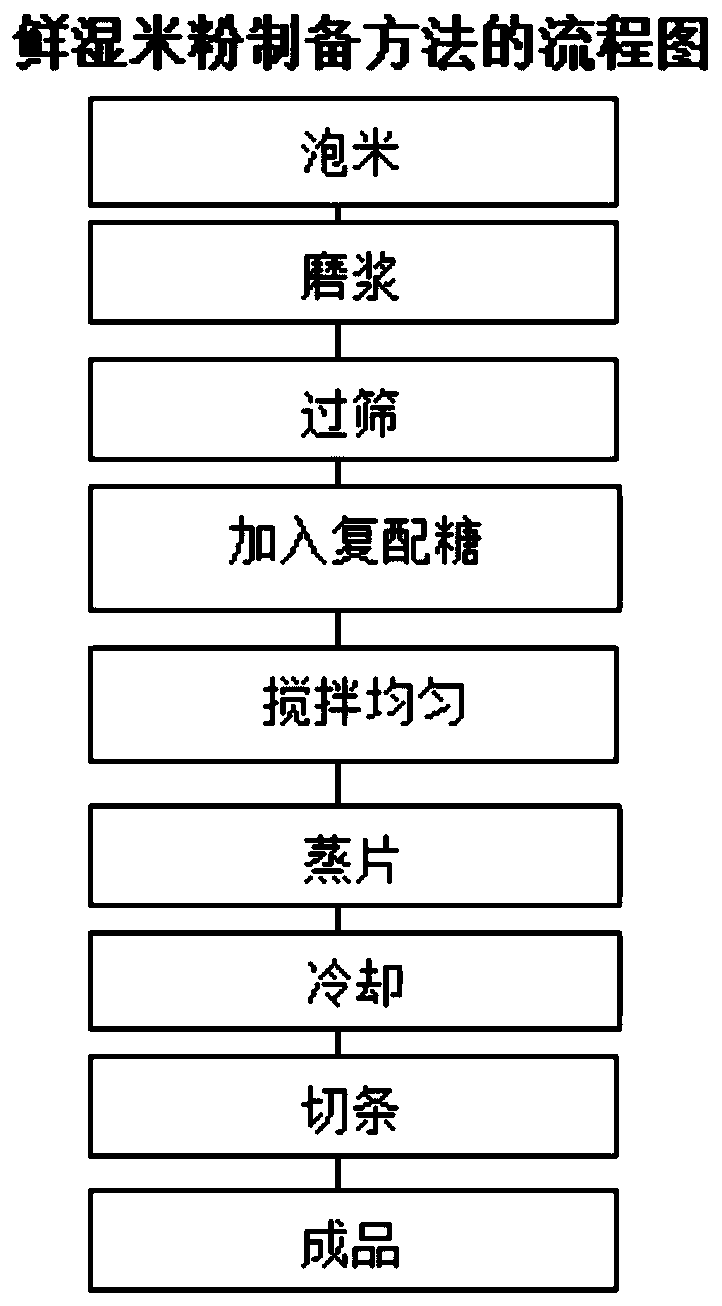

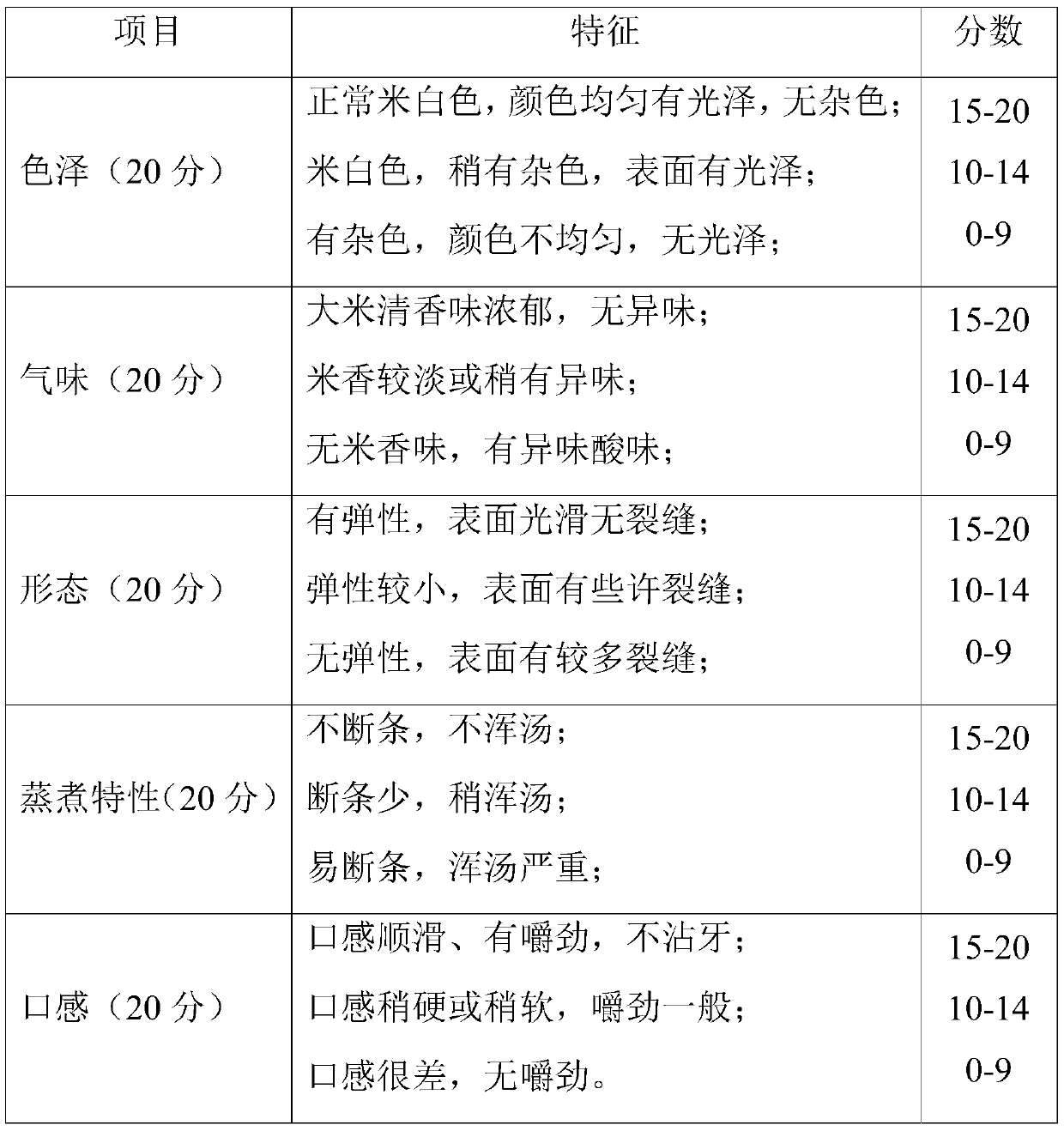

Production method of fresh wet rice noodles

InactiveCN110200209AImprove anti-aging propertiesImprove texture qualityFood scienceSucroseGlucose polymers

The invention relates to the technical field of grain processing and discloses a production method of fresh wet rice noodles, which comprises the steps of (1) soaking rice, grinding the rice, and screening to obtain rice pulp; (2) mixing the rice pulp of the step (1) with compound sugar, and stirring well to obtain a slurry; and (3) steaming a sheet of the slurry of the step (2), cooling the sheet, and cutting the sheet into strips to obtain the fresh wet rice noodles, wherein the compound sugar comprises at least two of trehalose, glucose, sucrose and xylitol. The compound sugar is added after grinding and screening according to the production method, anti-aging action of starch in the fresh wet rice noodles is improved; a starch hydrate system is changed, so that the rice noodles are more elastic, the taste of the rice noodles is improved, all texture quality, sensory quality and boiling quality of the fresh wet rice noodles in the storage stage can be improved, and aging of the fresh wet rice noodles can be retarded.

Owner:HUNAN AGRICULTURAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com