Patents

Literature

1481 results about "Ultrasonic atomization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electronic cigarette with solid heating function and solid tobacco product

ActiveCN103919279AAvoid the disadvantages of multiple filling of smoke liquid and easy leakageAvoid disadvantages such as easy leakageTobacco treatmentTobacco pipesSolid massLiquid smoke

The invention discloses an electronic cigarette with a solid heating function and a solid tobacco product. A unique method with solid heating and ultrasonic atomization combined is adopted to heat the specially-made solid tobacco product and produce a tobacco fragrance. Different from a traditional liquid electronic cigarette, the electronic cigarette will not bring discomfort, caused by atomization of a large amount of solvent in tobacco liquid of the traditional liquid electronic cigarette, to a user. Furthermore, liquid ultrasonic atomization is adopted on the basis of solid heating, and solid heating and tobacco liquid ultrasonic atomization can be carried out independently as well as synchronously.

Owner:上海德明生物科技有限公司

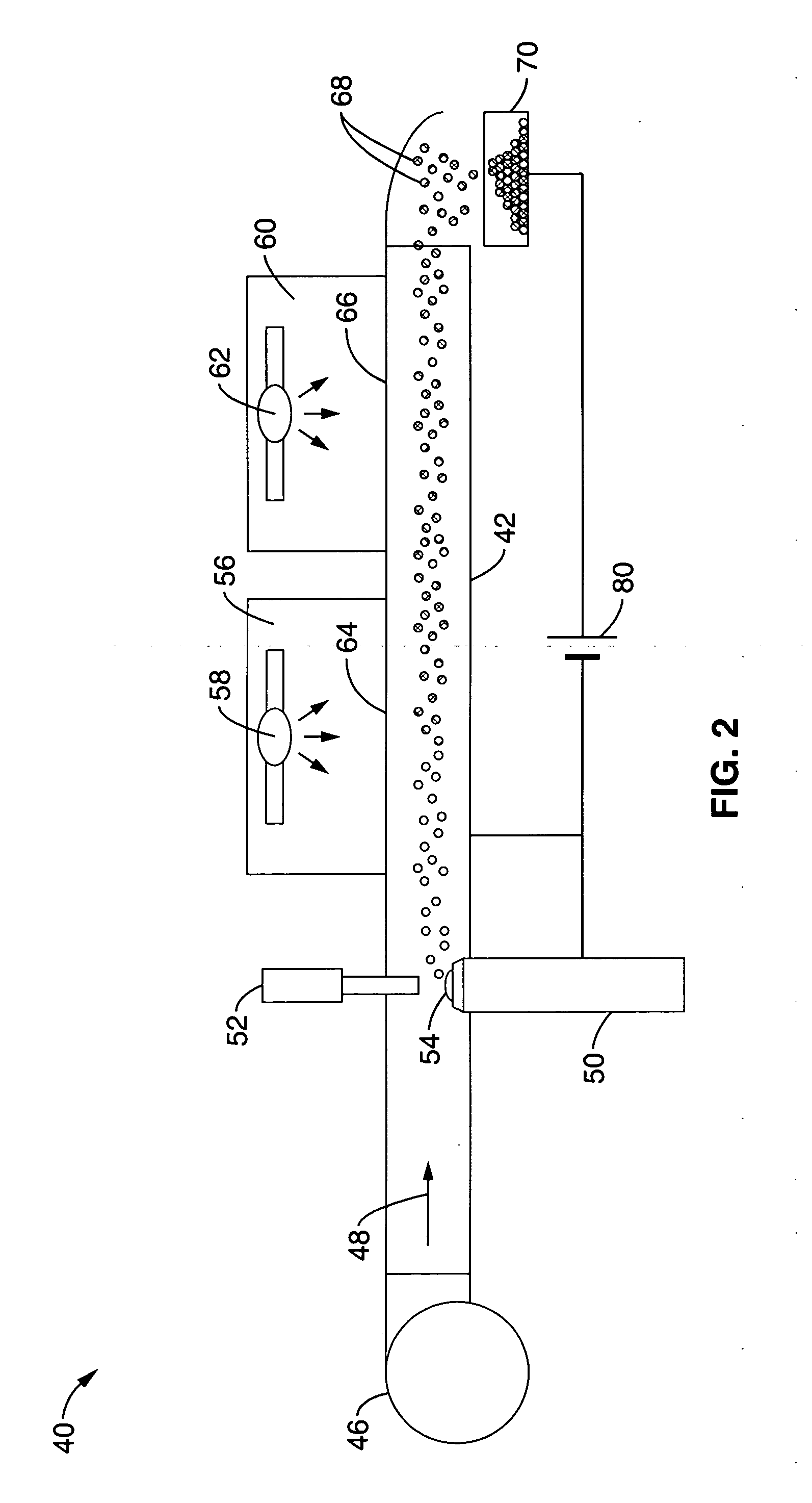

Method and apparatus for liquid microencapsulation with polymers using ultrasonic atomization

InactiveUS20060071357A1Minimize surface depositionEasy to collectPharmaceutical product form changeMicroballoon preparationEmulsionUltraviolet lights

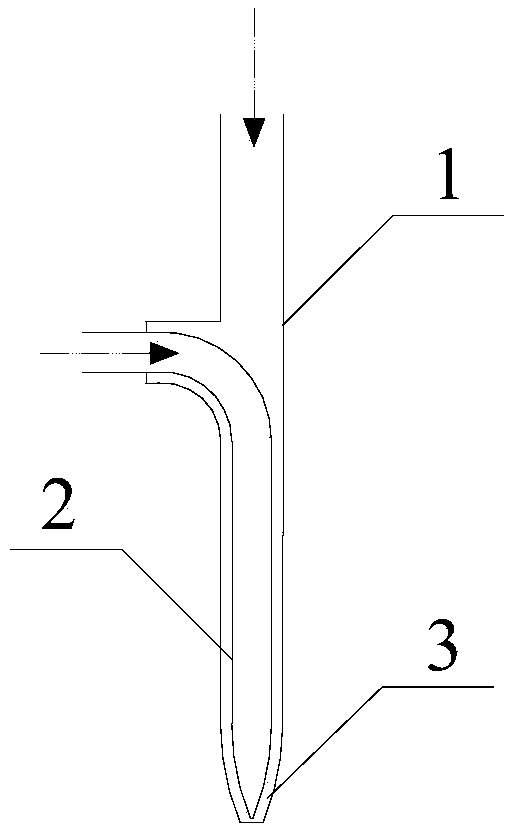

An apparatus and method for encapsulating a liquid or suspension within a polymeric shell to form a microcapsule of a selected size ranging from approximately 0.1 μm to 1000 μm in diameter. The apparatus preferably has a laminar flow of air through a channel and ultrasonic atomizer with the head oriented at approximately ninety degrees from the laminar flow. Emulsions, liquids or thin films of core and shell materials are atomized and the formed microcapsules are exposed to ultraviolet light or additionally infrared light to cure the polymer shell and then are collected. A variety of capsule morphologies can be created by the choice of materials and process conditions to achieve desired controlled or programmed release kinetics. Surface functionalization of the outer shell of the microcapsules capsules can also be achieved to facilitate targeted delivery.

Owner:RGT UNIV OF CALIFORNIA

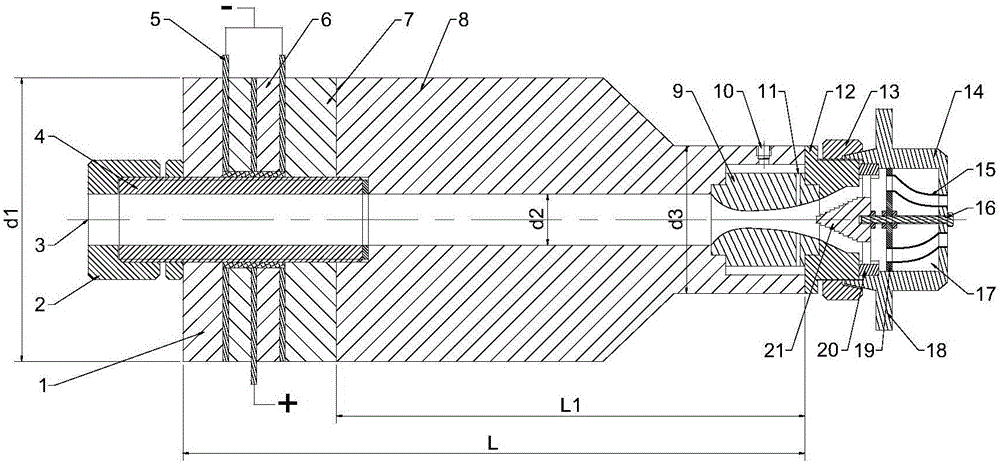

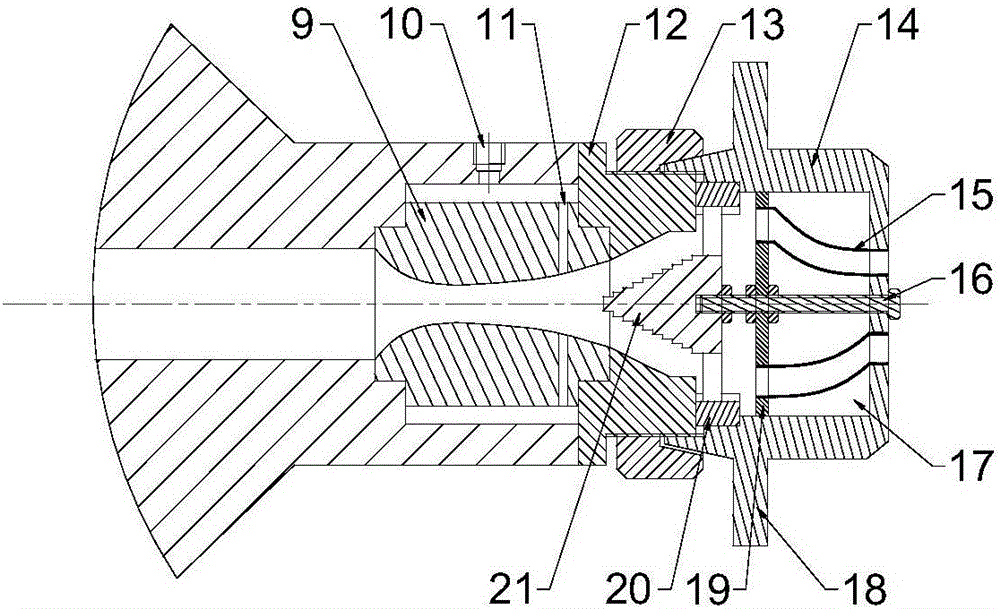

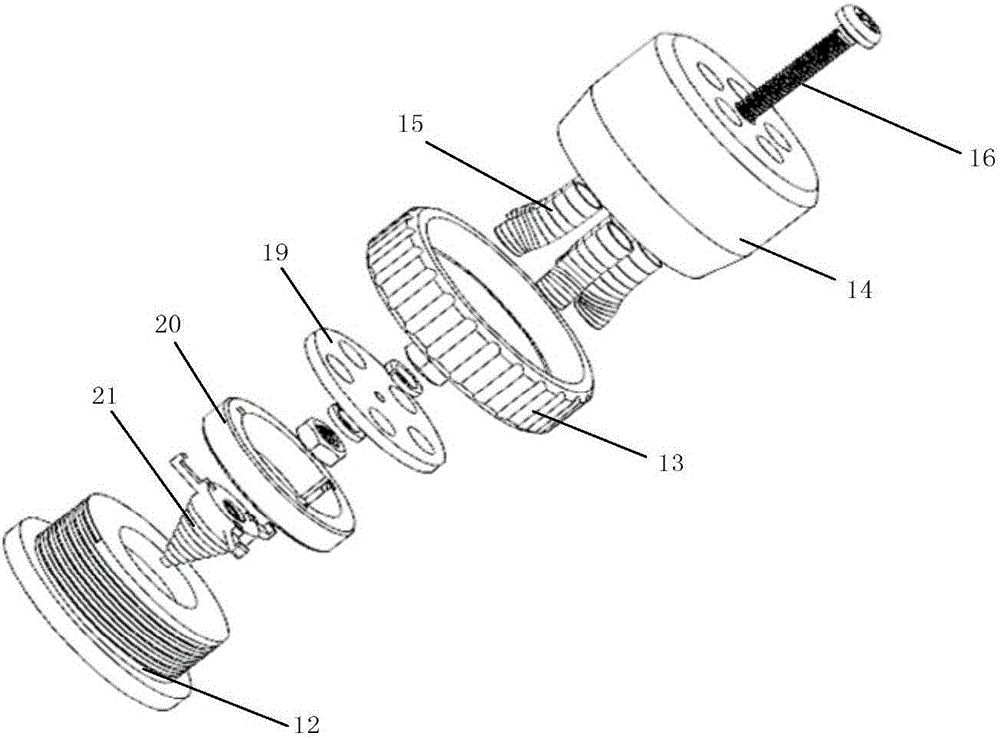

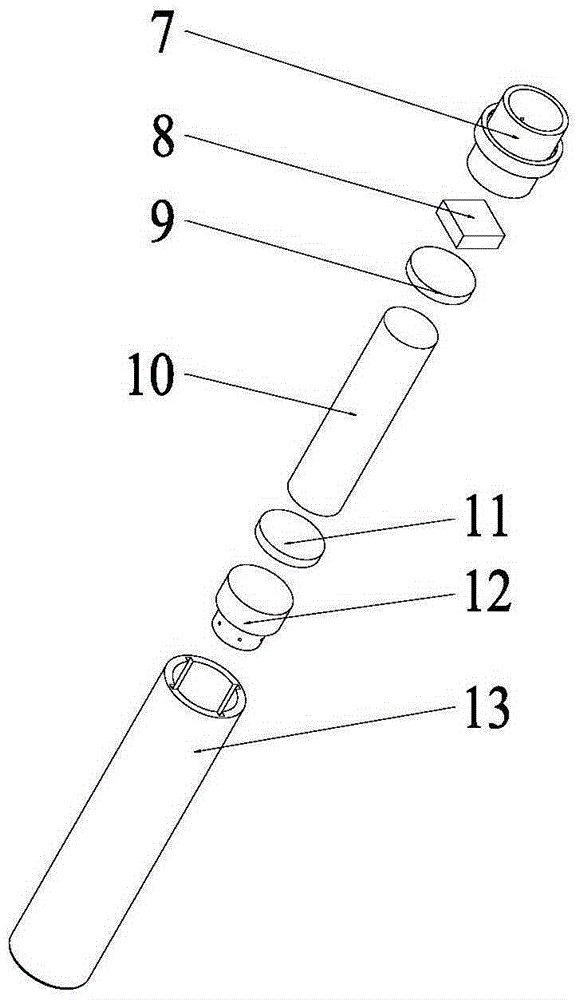

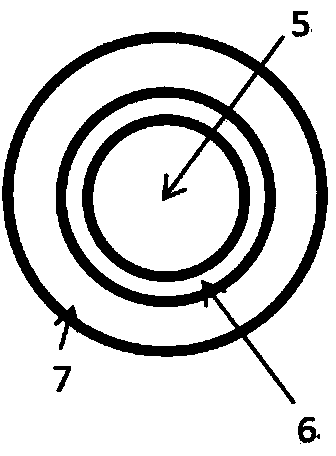

Piezoelectric two-phase flow ultrasonic atomization spraying nozzle

InactiveCN105834054ALarge amount of atomizationSmall dropletLiquid spraying apparatusElectricitySpray nozzle

The invention provides a piezoelectric two-phase flow ultrasonic atomization spraying nozzle. The piezoelectric two-phase flow ultrasonic atomization spraying nozzle comprises a piezoelectric vibrator, an amplitude-change pole, a second end cover and a first end cover; the piezoelectric vibrator and the amplitude-change pole are connected through a connecting bolt; an air inlet connector is installed at the tail of the connecting bolt; the second end cover is fixed to the front end of the amplitude-change pole; a laval type valve element is fixed into a step hole of the amplitude-change pole and a groove of the second end cover; a liquid inlet hole is formed in the hole wall face of the step hole of the amplitude-change pole; a plurality of flow guide holes are formed in the positions, close to an outlet, of the laval type valve element in the radial direction; the first end cover is threaded connection to the second end cover; a radial positioning ring is arranged at the position of a clamping groove in the back end of the first end cover; a step type taper valve is installed on the radial positioning ring; the step type taper valve and a vibration separating plate are connected through an adjusting bolt; a resonance chamber is formed between the vibration separating plate and the top end of the first end cover; and a plurality of flexible pipes are arranged in the resonance chamber. According to the piezoelectric two-phase flow ultrasonic atomization spraying nozzle, a large number of superfine fog drops are generated under the low-energy working condition, and the shortcoming that large pulverization amount, small grain size, low power dissipation and directed spraying cannot be considered at the same time through in the traditional technology is overcome.

Owner:JIANGSU UNIV

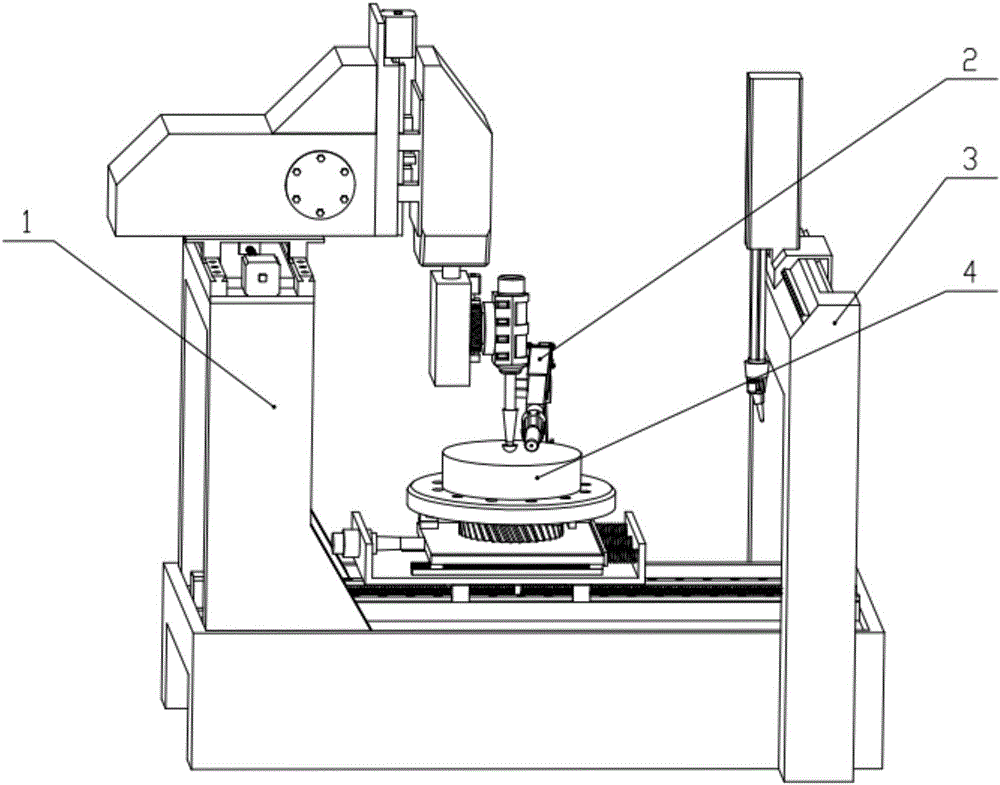

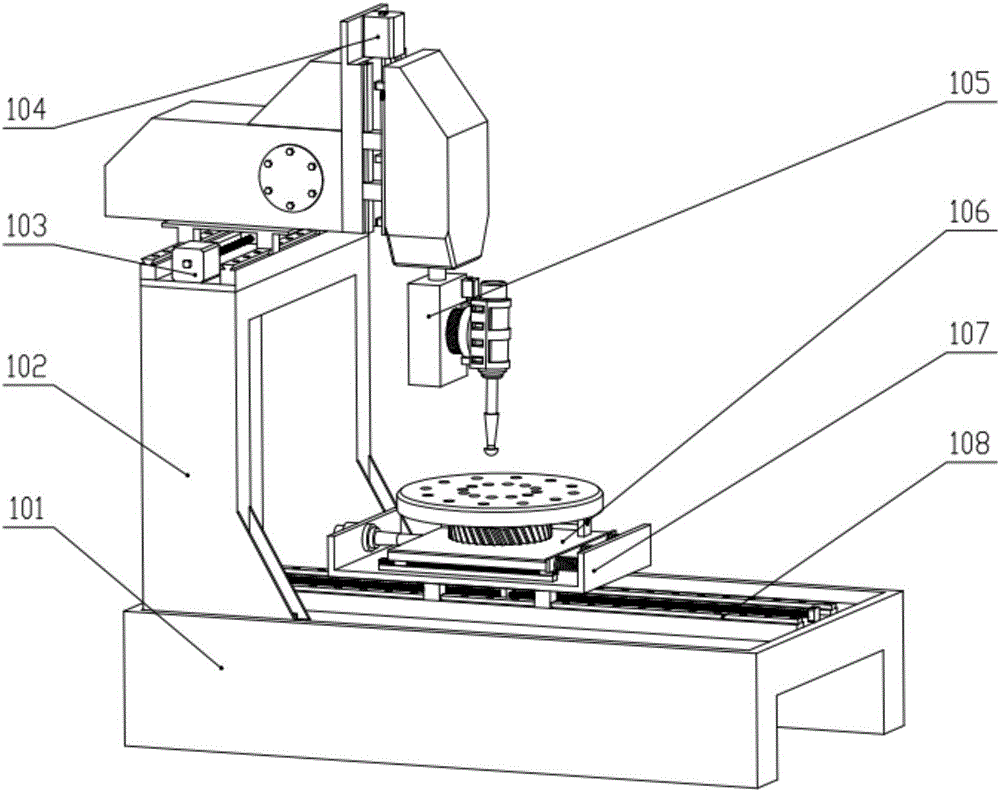

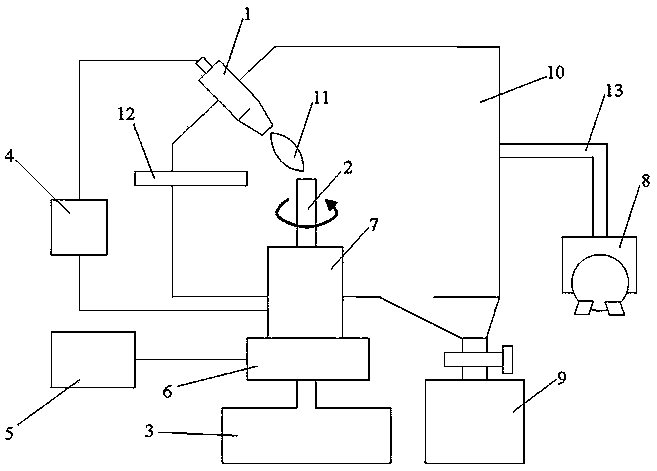

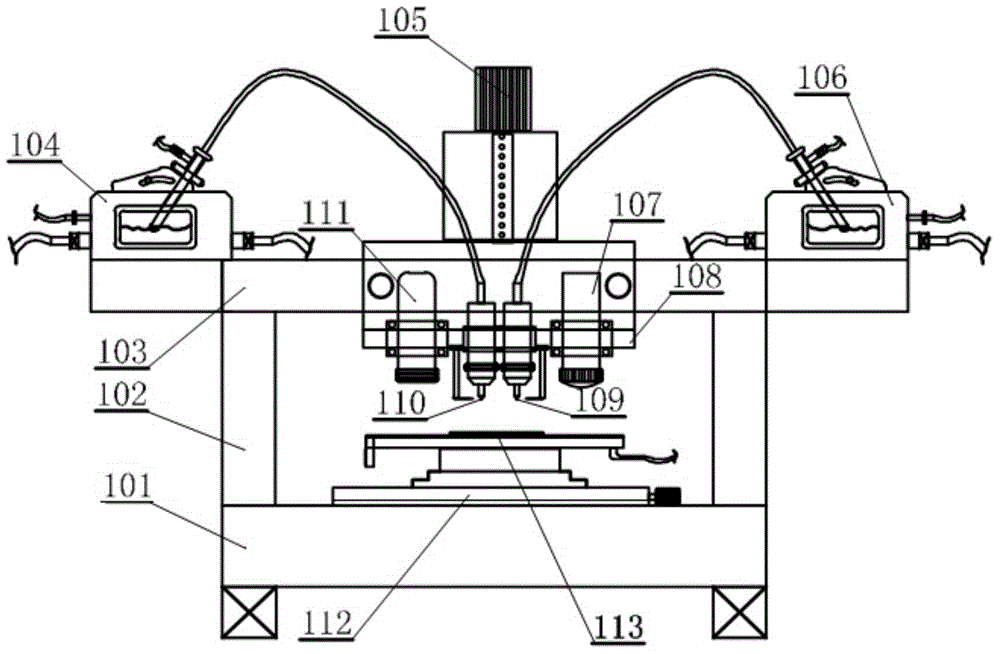

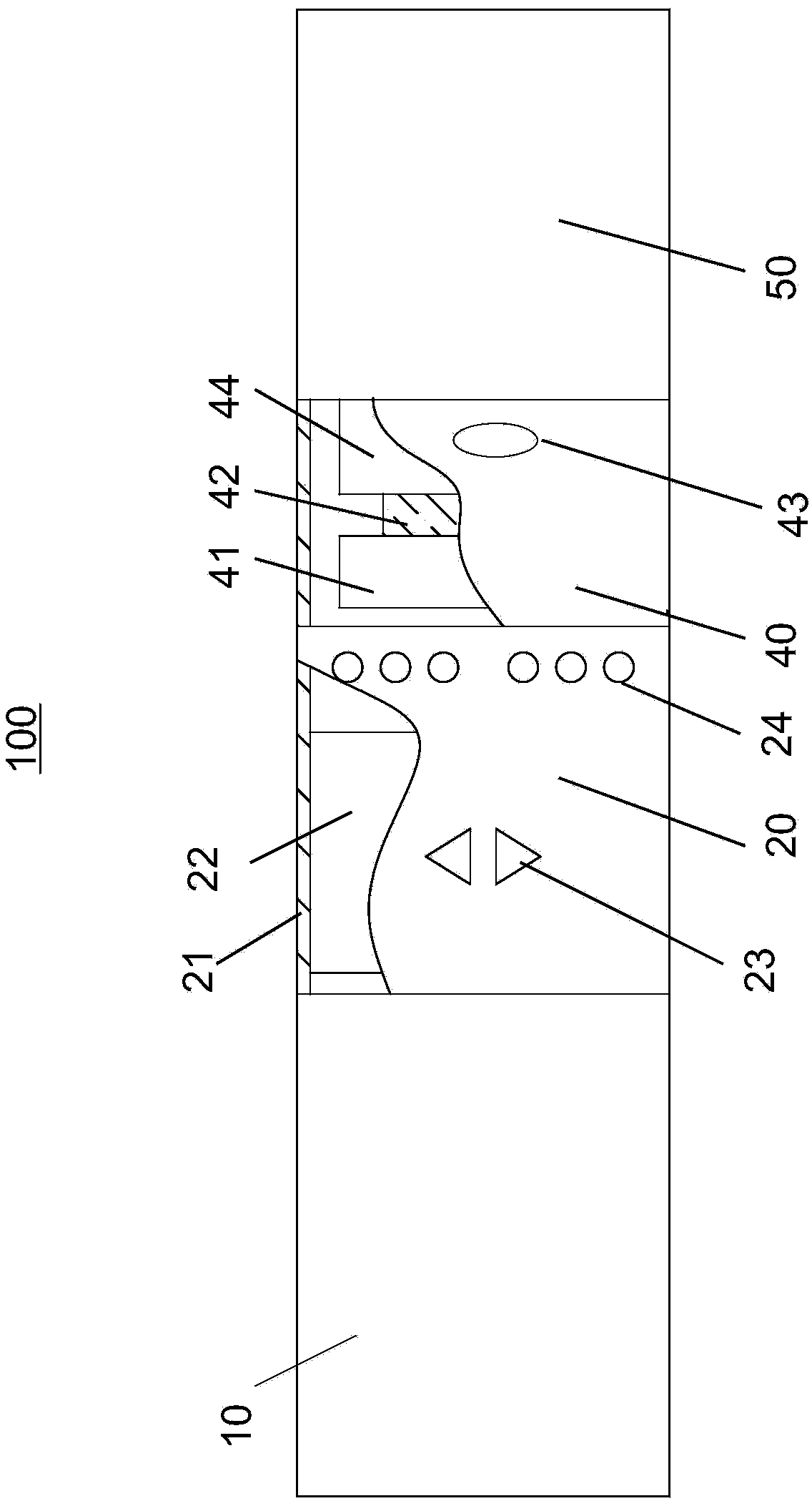

Five-axis three-dimensional ultrasonic polishing machine tool for optical curved surface machining and use method of five-axis three-dimensional ultrasonic polishing machine tool

ActiveCN106736992AGood removal effectImprove efficiencyGrinding carriagesOptical surface grinding machinesUltrasonic vibrationEngineering

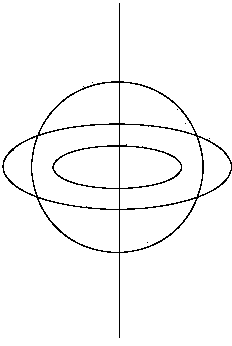

The invention discloses a five-axis three-dimensional ultrasonic polishing machine tool for optical curved surface machining. The five-axis three-dimensional ultrasonic polishing machine tool comprises a machine tool, an ultrasonic atomization device for applying polishing liquid and a workpiece on-line detection device. An X-direction travel mechanism, a Z-direction travel mechanism and a Y-direction travel mechanism are arranged on the machine tool; a spindle ultrasonic vibration polishing device is arranged on the Z-direction travel mechanism; a Y-direction ultrasonic vibration device is arranged on the Y-direction travel mechanism; a C-direction rotating work table is arranged on the Y-direction ultrasonic vibration device; the machine tool can enable the axis line direction of a polishing head parallel to the normal line of a polishing point of a workpiece through five-axis linkage; when the polishing head rotates, the ultrasonic wave of the Y-direction ultrasonic vibration device and the ultrasonic wave of the ultrasonic vibration polishing device which swings around the Z direction are vertically coupled in a plane; when the amplitude A1 of the Y-direction ultrasonic vibration device is greater than the amplitude A2 of the ultrasonic vibration polishing device, the polishing head and the workpiece can form an elliptic machining track where a long axis is in the Y-direction and a short axis is in the normal line position of the polishing point of the workpiece, so that the contact area between the polishing head and the workpiece is increased, and the curved surface removal rate and the polishing machining efficiency can be greatly improved.

Owner:NORTHEASTERN UNIV

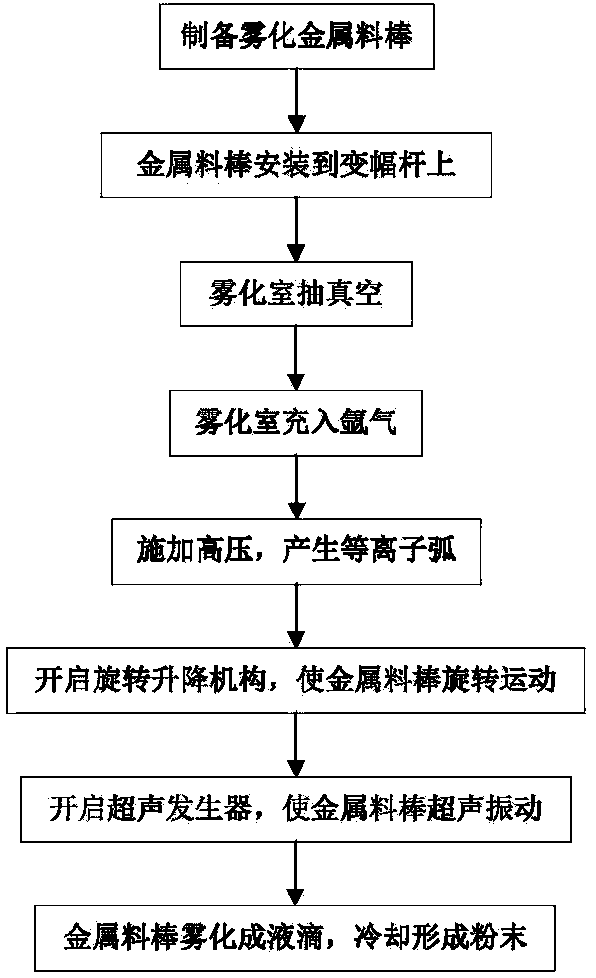

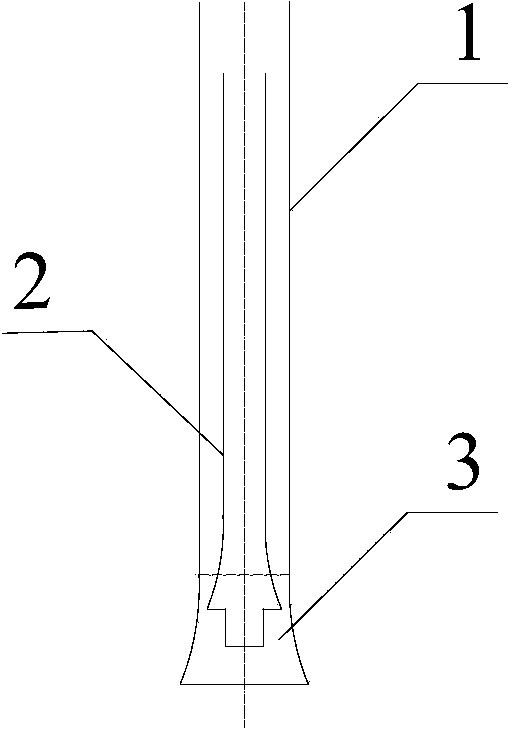

Ultrasonic atomization preparation device and method for spherical metal powder

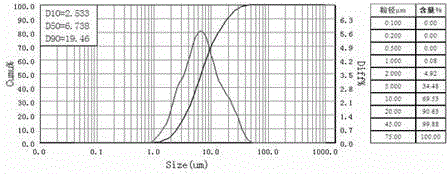

The invention discloses an ultrasonic atomization preparation device and method for spherical metal powder. The ultrasonic atomization preparation device for the spherical metal powder comprises an atomization chamber, metal bar materials arranged inside the atomization chamber, and a plasma arc generation system arranged above the metal bar materials, wherein the metal bar materials are installed on an ultrasonic vibration system, the ultrasonic vibration system is arranged on a rotary lifting mechanism, and a powder collection cylinder is arranged below the metal bar materials. The method comprises the following steps that (1) metal bars are installed; (2) the atomization chamber is vacuumized and then is filled with inert gas; (3) the metal bars are stricken through plasma arcs; (4) the rotary lifting mechanism rotates the metal bars; (5) the ultrasonic vibration system vibrates the metal bars; (6) the metal bars are atomized into metal liquid drops, and the metal liquid drops fly away from the metal bars and are condensed into the metal powder. The ultrasonic atomization preparation device and method for the spherical metal powder can prepare the spherical metal powder with any component, and the metal powder is fine in particle diameter and narrow in particle size distribution.

Owner:航天科工(长沙)新材料研究院有限公司

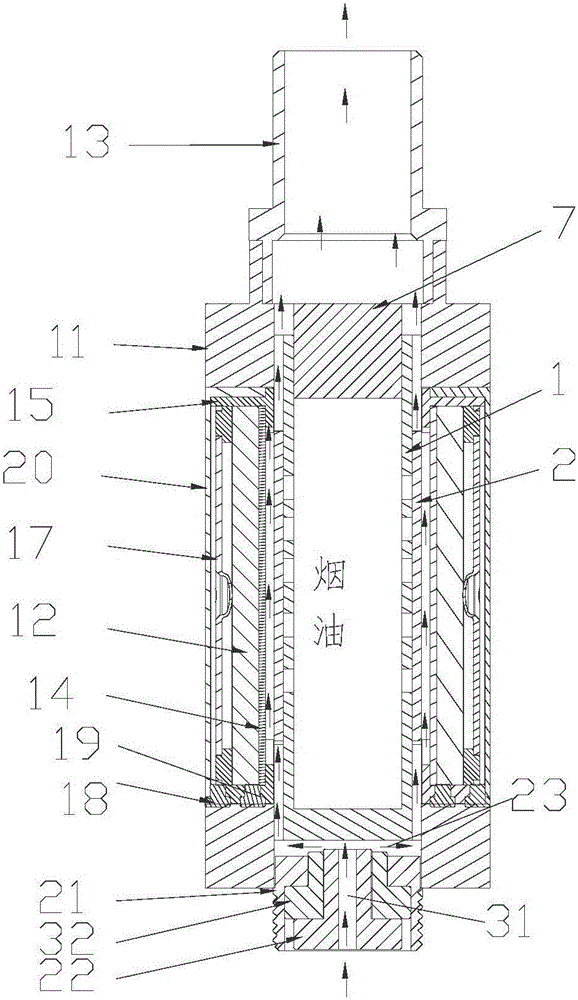

Ultrasonic atomization electronic cigarette

The present invention relates to an ultrasonic atomization electronic cigarette. An upper shell and a lower shell are connected with together through a shell connection component so as to form an integrated body; gas enters from a vent hole on the lower shell and enters a vent groove inside the upper shell through a vent groove in the lower shell and a vent hole inside the shell connection component, and is extracted out from a gas outlet on the upper shell; an ultrasonic atomization sheet and a replaceable cigarette core are installed in the upper shell; the replaceable cigarette core is sleeved with a ceramic heating tube; the ceramic heating tube is fixed in the upper shell through an upper heat insulation gasket and a lower heat insulation gasket; a driving circuit board, an upper gasket, a storage battery, a lower gasket and a pneumatic switch are sequentially installed in the lower shell from top to bottom; the driving circuit board is connected with the ultrasonic atomization sheet, the ceramic heating tube, the storage battery and the pneumatic switch through wires. Ultrasonic atomization is adopted, so that aerosol droplets are small and uniform, and atomization effects are better, and atomization can be realized under a normal temperature condition, and the use of electronic cigarette liquid can be safer.

Owner:深圳熠科电子工业有限公司

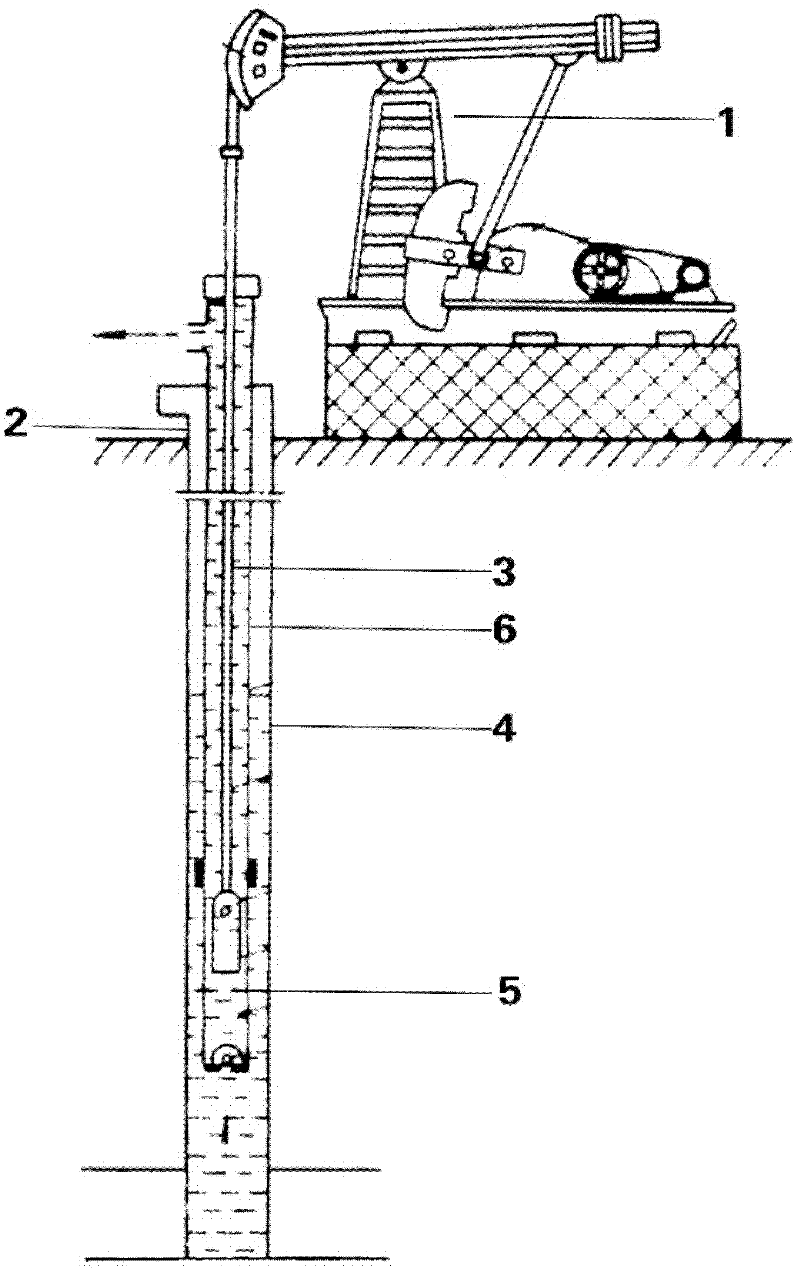

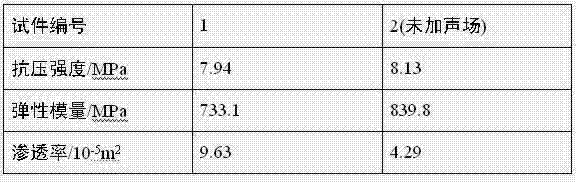

Underground ultrasonic yield-increasing pumping device for coalseam gas

InactiveCN102373908ALow flow resistanceReduce energy consumptionFluid removalSolenoid valveDesorption

The invention discloses an underground ultrasonic yield-increasing and atomized pumping device for coalseam gas. A reciprocating vacuum pump and an underground ultrasonic wave generator are connected by a control cabinet. The underground ultrasonic wave generator is connected to the ultrasonic yield-increasing and atomized pumping device. The reciprocating vacuum pump is connected to oil pipes. A casing pipe provided with an oil pipe is deeply inserted into a coalseam. An oil pipe opening is higher than a casting pipe opening. The ultrasonic yield-increasing and atomized pumping device is installed at the lower end in the oil pipe and used for sealing the oil pipe lower opening. The device includes: a high-power ultrasonic atomization transducer and a yield-increasing device ultrasonic transducer. The lower end of the high-power ultrasonic atomization transducer is connected to the yield-increasing device ultrasonic transducer, and is extended the lower end of the oil pipe opening. An inlet duct communicated with the casting pipe inner chamber is arranged in the oil pipe. A filter screen, a solenoid valve and a liquid level sensor are arranged in the inlet duct. The lower wall of the casting pipe is provided with eyeholes. A coalseam opening is arranged out of the casting pipe above the ground. According to the underground ultrasonic yield-increasing and atomized pumping device disclosed by the invention, the pumping operation for the coalseam gas can be completed, no mechanical motion occurs, and the advantages of saving energy, increasing the total desorption amount of the coalseam gas, reducing the cost and being simple in maintenance are achieved.

Owner:龚大建

Fumigating machine

The invention discloses a fumigation machine, and in particular relates to fumigation equipment with convenient carrying and adjustable fumigation areas and positions, which is particularly suitable for families and individuals and belongs to the field of medical health care instrument. The fumigation equipment mainly comprises a heating component, a heating container, an ultrasonic atomization plate, a pump, an output pipeline, a reflux pipeline, a temperature sensor, a liquid level sensor, a fumigation cover, an ultrasonic guidance head, and a control unit. The fumigation range and the fumigation positions realized by the fumigation equipment can be adjusted by a user, the user can implement the fumigation to the corresponding body surface of the user according to the need at home, and the fumigation equipment also realizes performing cyclic utilization on fumigation gas and restraining the pollution of drugs on the environment, utilizing the atomization effect of ultrasonic wave to fully utilize non-volatile effective constituents of fumigation drugs dissolved in the water to enlarge the varieties of drugs suitable for the fumigation, and combining physical permeation enhancing means such as the ultrasonic wave with the prior fumigation to promote the absorption of human skin to the drugs and improve the effect of the fumigation. The fumigation equipment is applied to treatment, health care, and cosmetology.

Owner:林惠霞

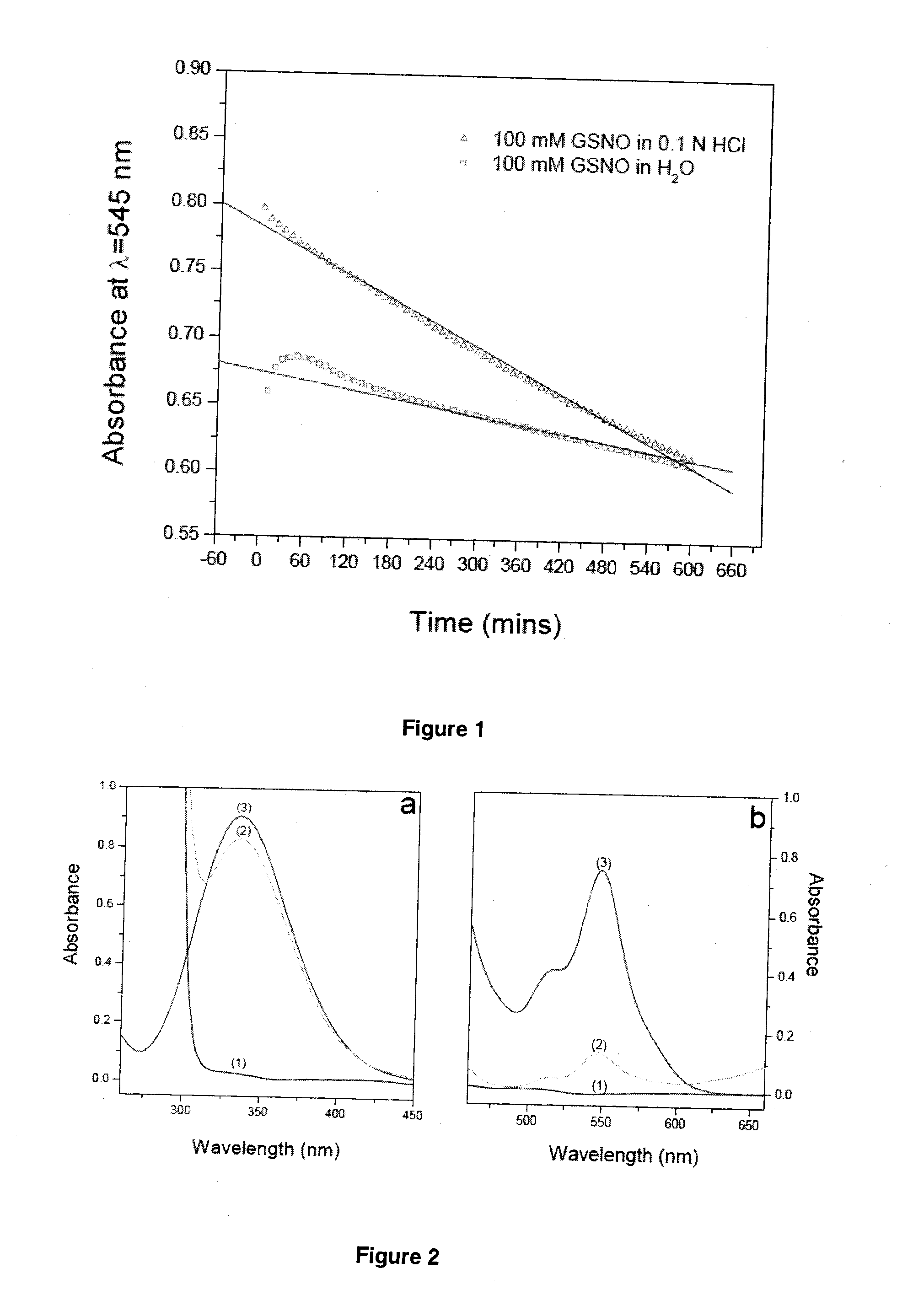

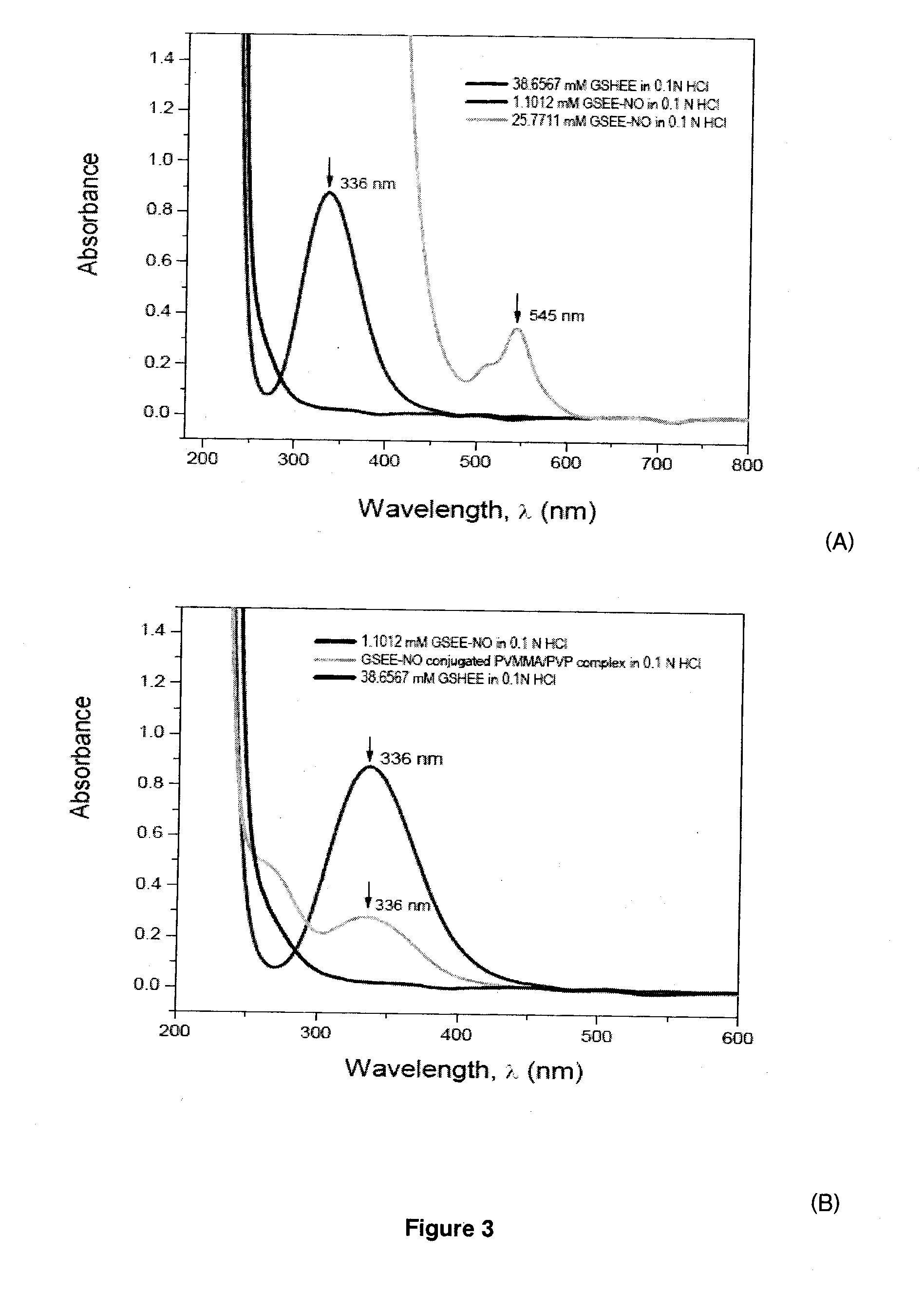

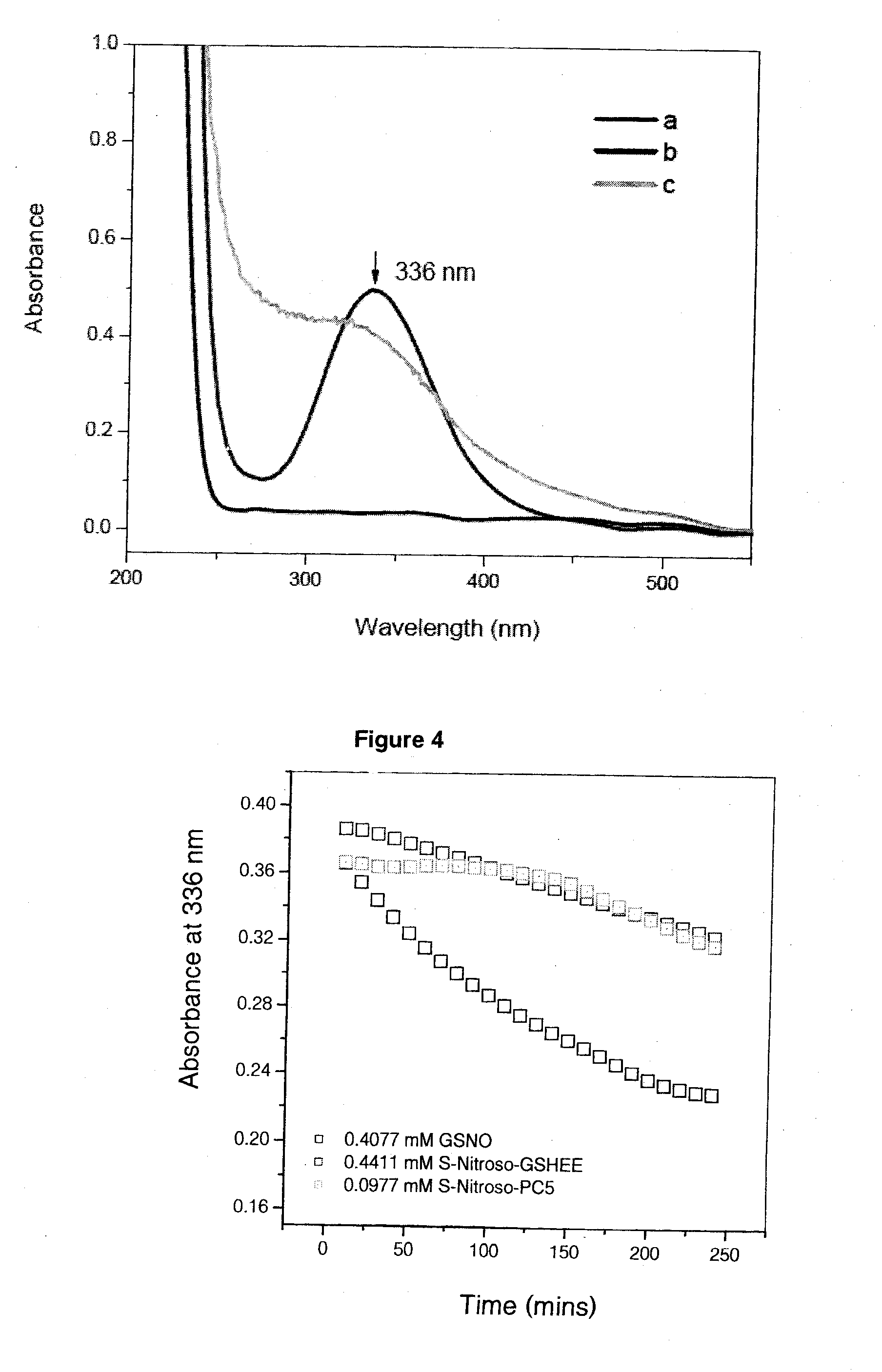

Supramacromolecular polymer complexes providing controlled nitric oxide release for healing wounds

InactiveUS20100303891A1Good storage stabilityOrganic active ingredientsMetabolism disorderAlkaneCarboxylic acid

A bio-adhesive supramacromolecular complex of the general formula:wherein R1 is independently selected from the group consisting of an alkane unsubstituted or substituted with alkoxy groups; R2 is independently selected from the group consisting of C1-6 alkyl; R3 and R4 are independently selected from the group consisting of optionally substituted aliphatic or aromatic alkyl; R5 is independently selected from the group consisting of H or C1-6 alkyl; W is a hydrogen-bond accepting functional group-containing entity; Y is a carboxylic acid ester or amide linkage; R is an independently selected peptide linking group; T1, T2, T3 and T4 are independently selected polymer residues; and m1, m2, m3, n1 and n2 are integers selected from at least 25; and wherein P has a molecular weight of about 1×103 to 1×107 and Q has a molecular weight of about 1×103 to 1×107. The complex provides controlled nitric oxide release over a longer period of time than prior art compounds in the locally delivery systems. Novel compositions, methods of preparation, apparatus including layer-by-layer assemblies coating, electrospinning and ultrasonic atomization, skin coverings containing and medical use of the complexes are described.

Owner:UNIVERSITY OF TORONTO

Textile dyeing method

InactiveCN102002834AIncrease profitSmall particle sizeTextile treatment containersTextile treatment with treating outlet contectFiberTextile printer

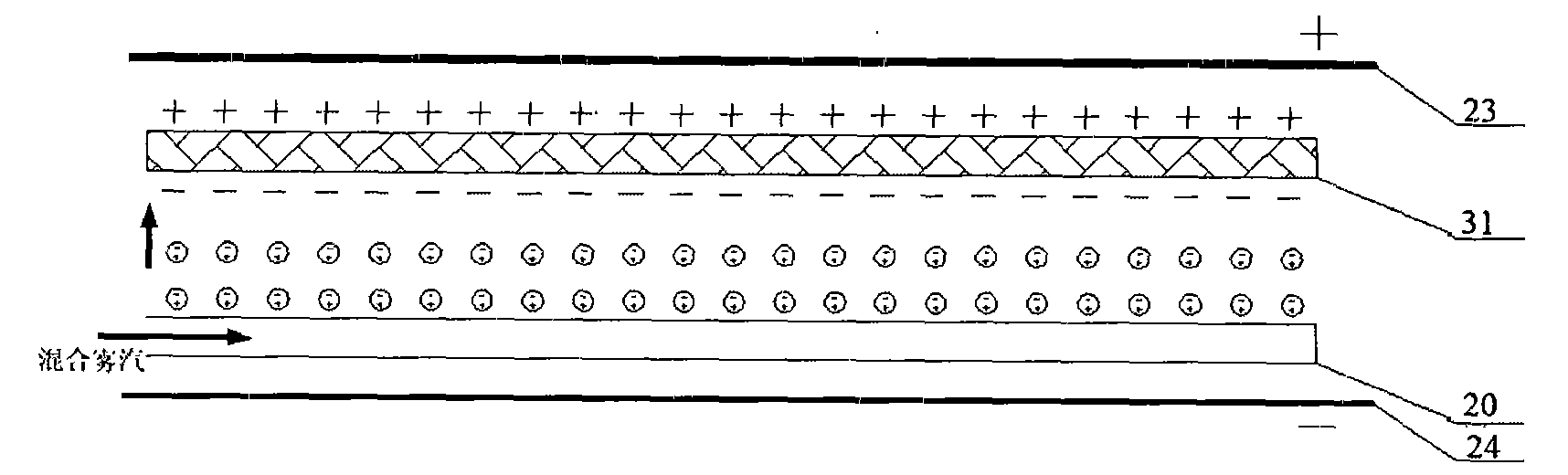

The invention relates to a method for dyeing textile materials and products thereof, and belongs to the field of textile printing and dyeing processing. In the method, prepared dye solution is subjected to ultrasonic atomization to form dye solution microbeads, and the dye solution microbeads directionally infiltrate the textile under the action of certain pressure and an electric field so as to complete the dyeing process. Due to the adoption of the technical scheme, dye solution atomized microbeads prepared from the dye solution through a high-frequency ultrasonic atomizer have smaller grain size, a small dispersion range on the textile and more fine and smooth dyeing effect; the dye solution atomized microbeads enter fibers more easily under the action of the air pressure and the electric field, and have better dyeing effect; and the atomized microbeads carry less solution, the utilization rate of the dye is high, water can be saved and the environmental pollution is lightened. The dyeing method has a wide application range, low energy consumption and light pollution, and is suitable for small-batch and multi-variety printing technology development direction.

Owner:WUHAN TEXTILE UNIV

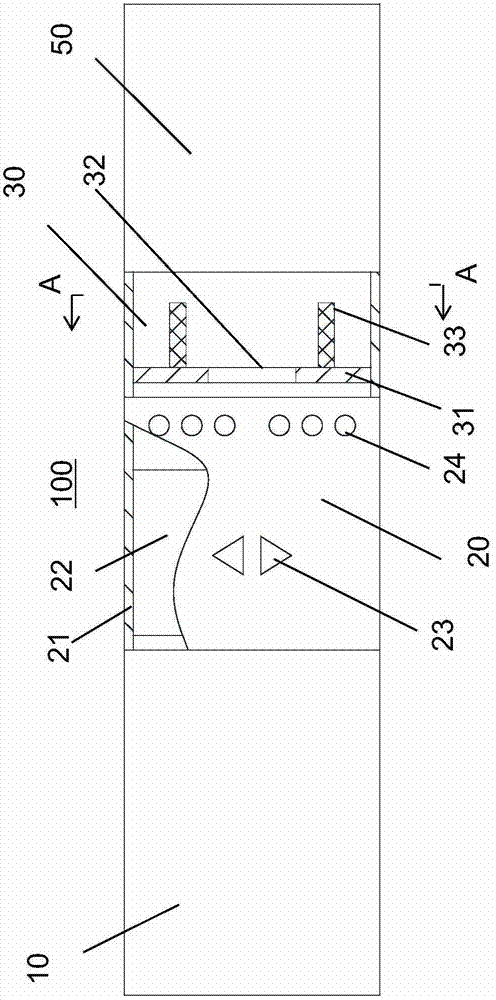

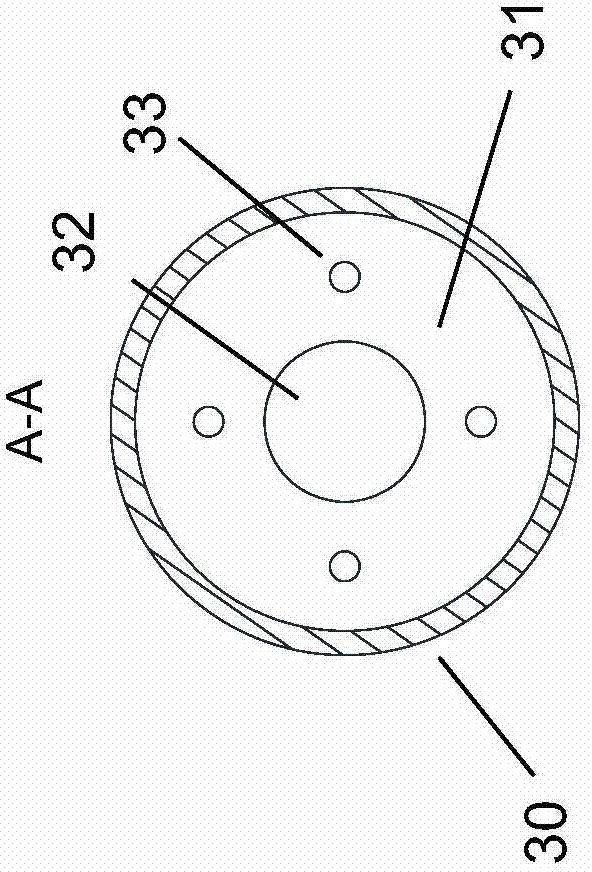

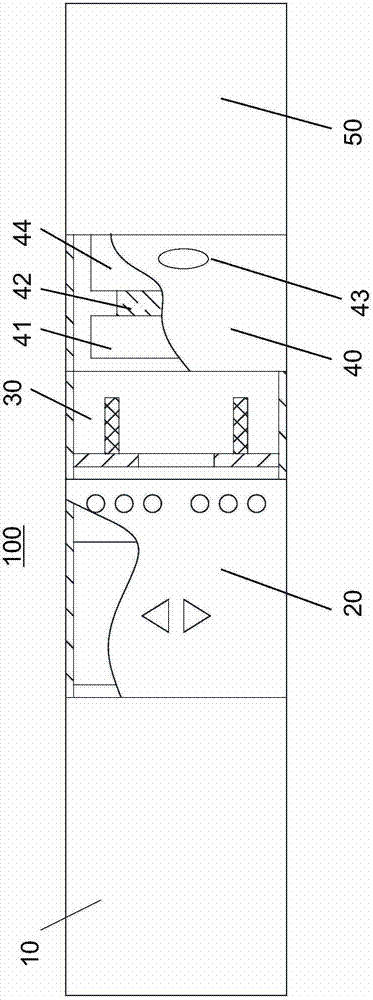

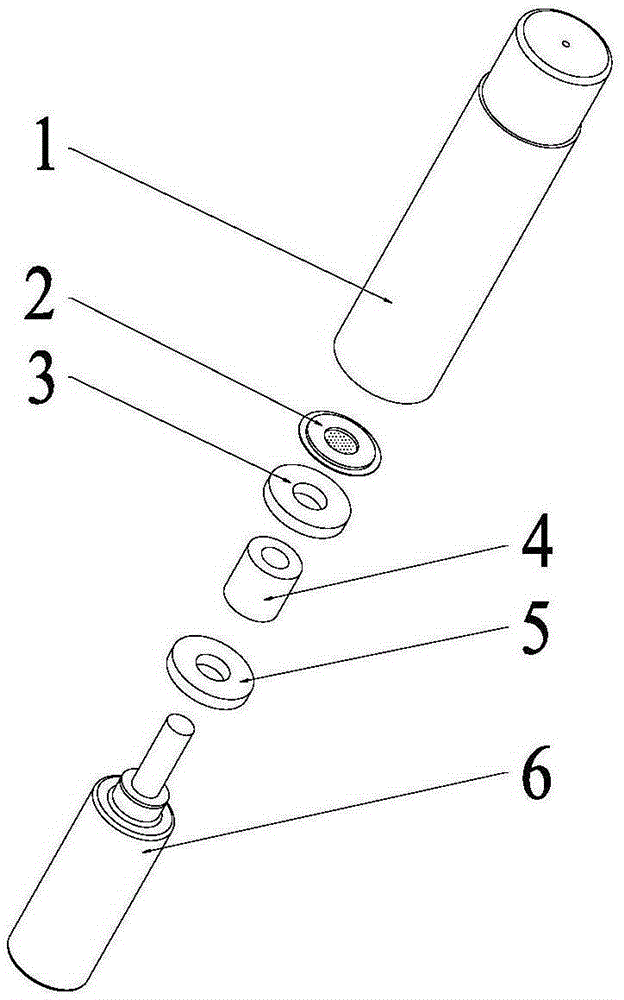

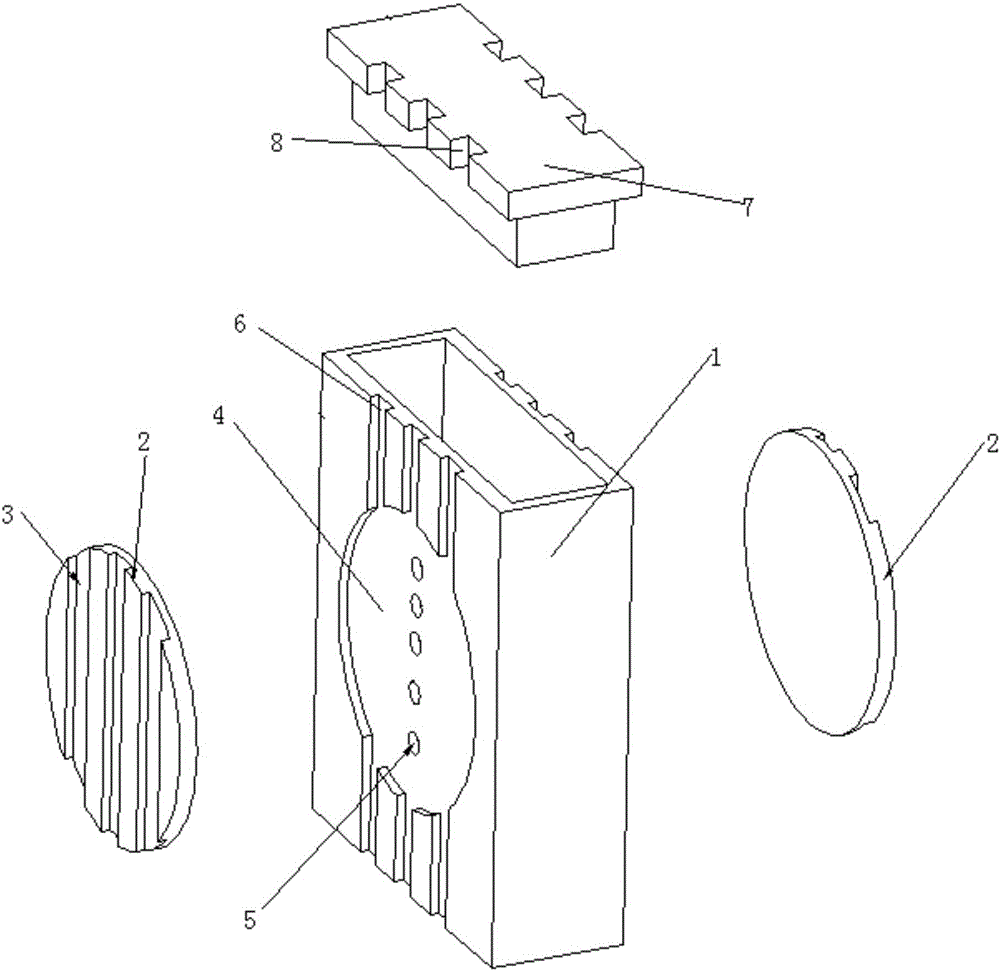

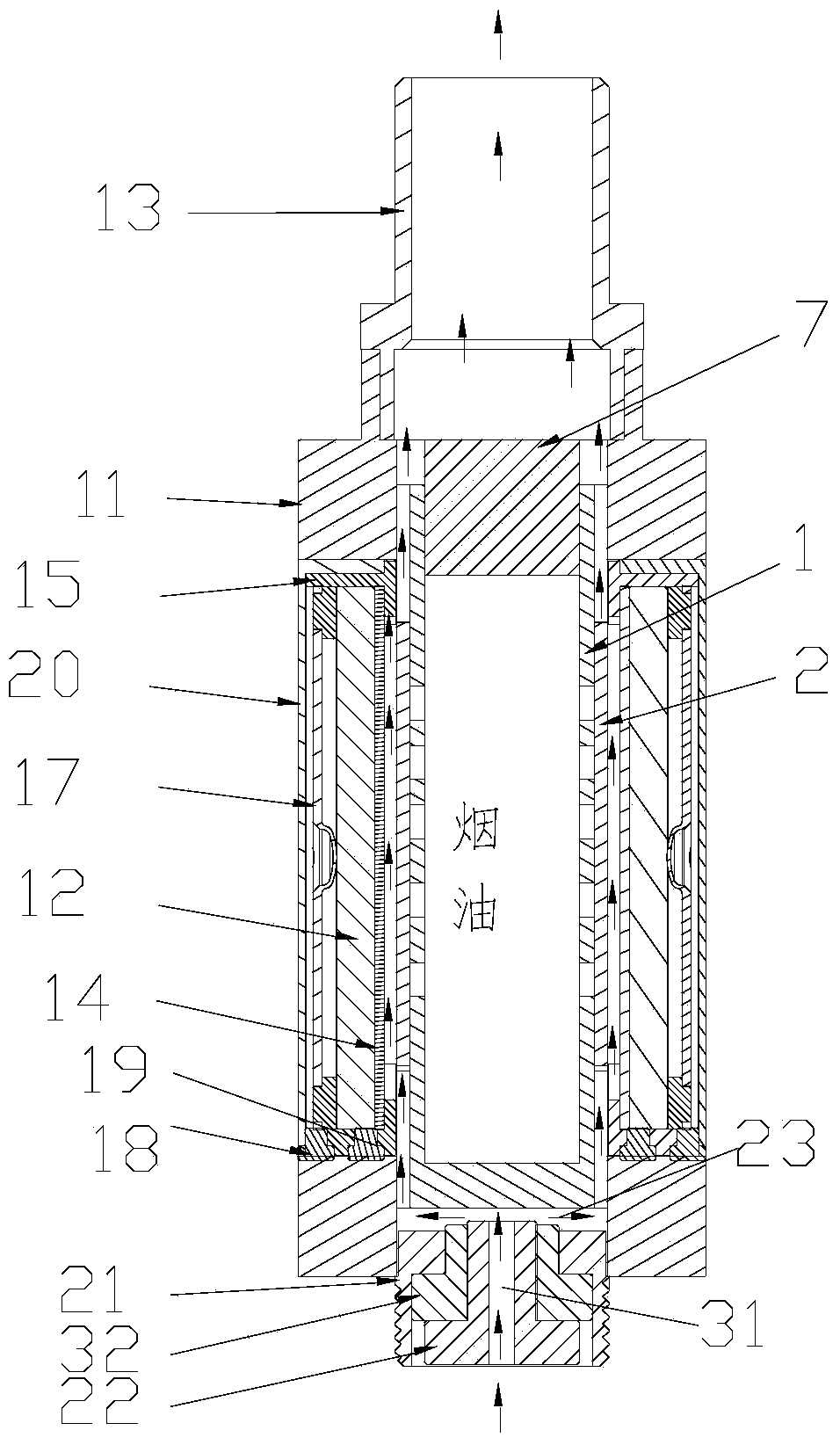

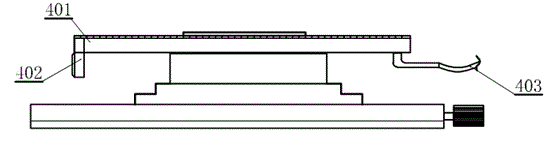

Cigarette liquid storage device, electronic cigarette atomizer and electronic cigarette

ActiveCN105876870ASolve the problem of bad taste of smokingAvoid oil spillsTobacco devicesElectronic cigaretteEngineering

The invention discloses a cigarette liquid storage device, an electronic cigarette atomizer and an electronic cigarette. The cigarette liquid storage device comprises a body, wherein a cigarette liquid guider is fixedly arranged on an outer wall on at least one side of the body; the cigarette liquid guider is communicated with an inner cavity of the body; a vent groove is formed in a surface, far away from the body, of the oil guider. The cigarette liquid storage device provided by the invention is provided with the oil guider; cigarette liquid can be directly conducted to an atomization component through the oil guider; the oil guider can be integrally molded with the body, and can be also fixed in ways of inlaying and the like; the cigarette liquid storage device is simple in structure and is convenient to use; the electronic cigarette atomizer which is provided by the invention adopts an ultrasonic atomization component, is high in capacity usage ratio, and solves a problem that the cigarette liquid heated by an existing heating wire easily generates a burnt smell and causes that a smoking taste becomes poor; meanwhile, the surface of the oil guider is provided with the vent groove which can not only allow a gas to pass through, but also can avoid a phenomenon of liquid leakage caused by too large contact area between a fluid guider and the ultrasonic atomization component; the cigarette liquid storage device, the electronic cigarette atomizer and the electronic cigarette are simple and exquisite in structure, and are convenient to mount and dismount.

Owner:CHINA TOBACCO HUNAN INDAL CORP

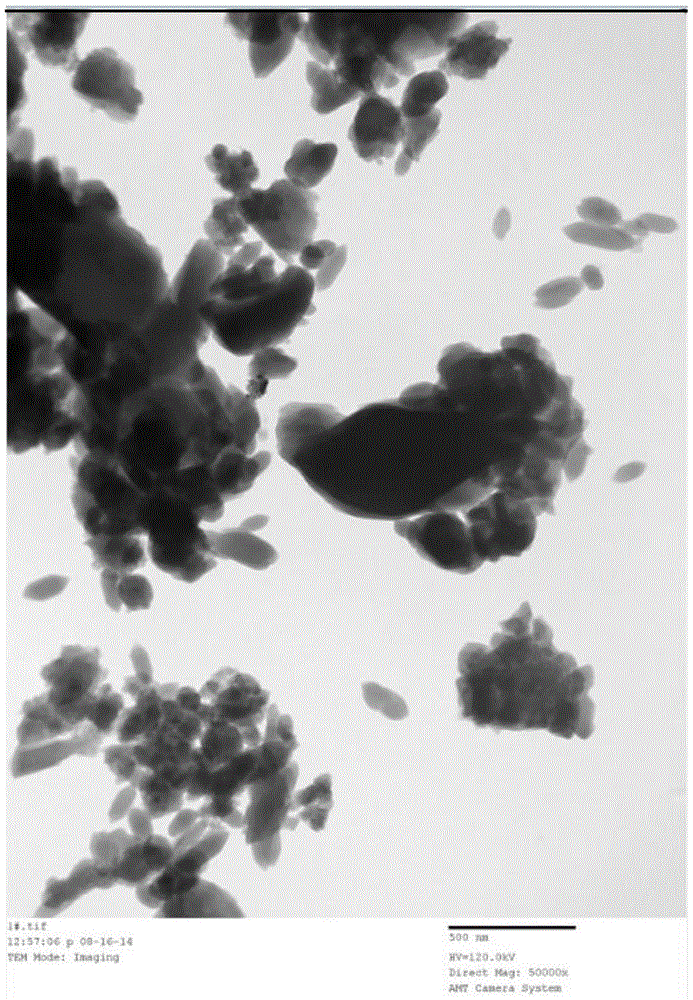

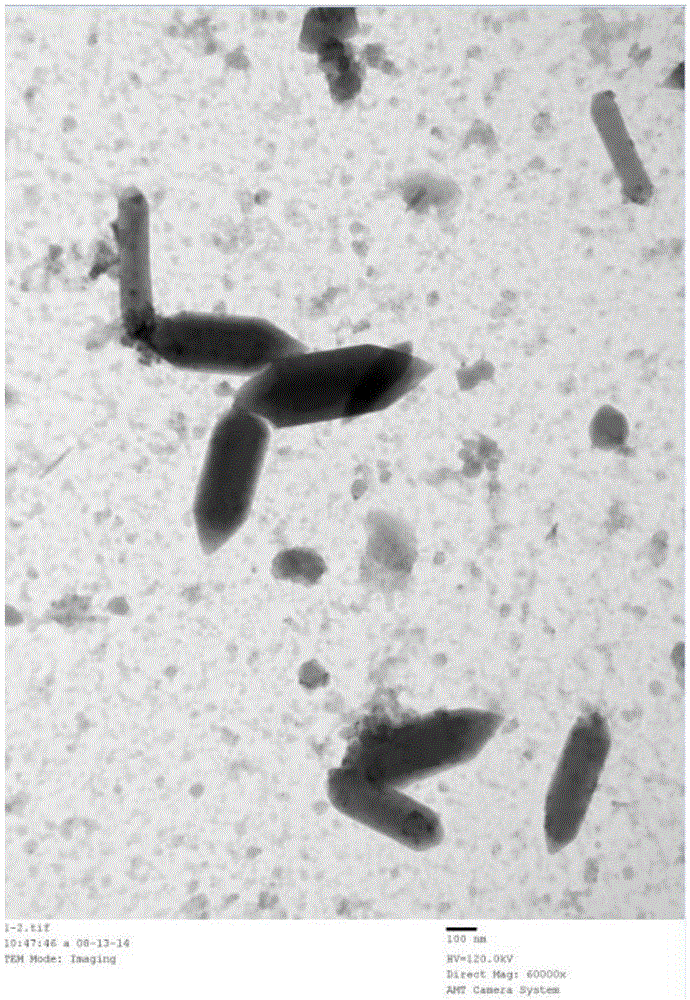

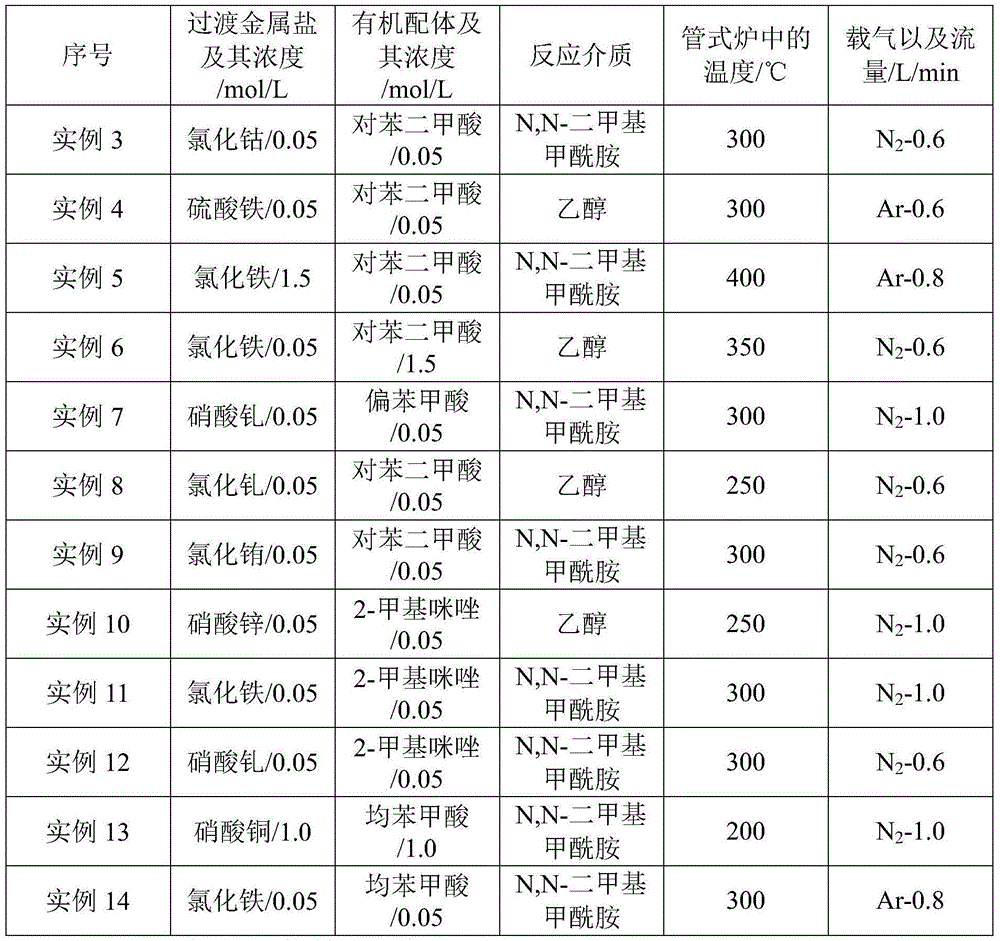

Preparation method for nanometer organic metal framework by ultrasonic atomization

The invention provides a preparation method for a nanometer organic metal framework by ultrasonic atomization. The method comprises the following steps: dissolving a soluble metal salt and an organic ligand in a certain solvent, carrying out ultrasonic atomization so as to produce liquid drops, introducing inert carrier gas so as to bring the liquid drops to a tubular furnace preset with a certain temperature, and carrying out a reaction so as to prepare the nanoscale organic metal framework. The method provided by the invention is simple to operate and can realize continuous reaction to prepare the nanoscale organic metal framework.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

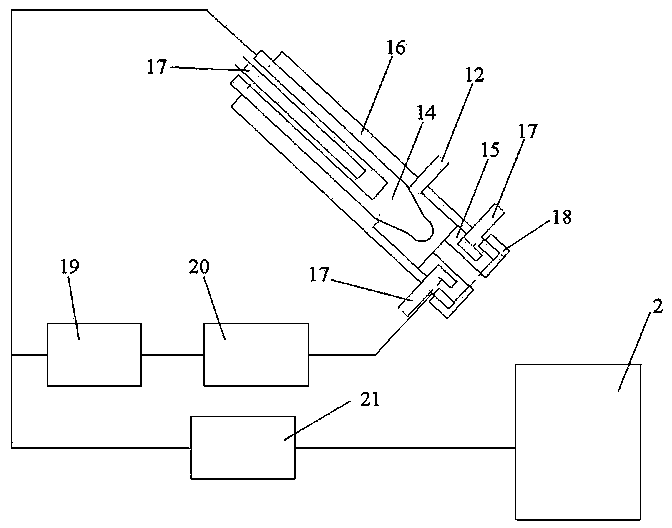

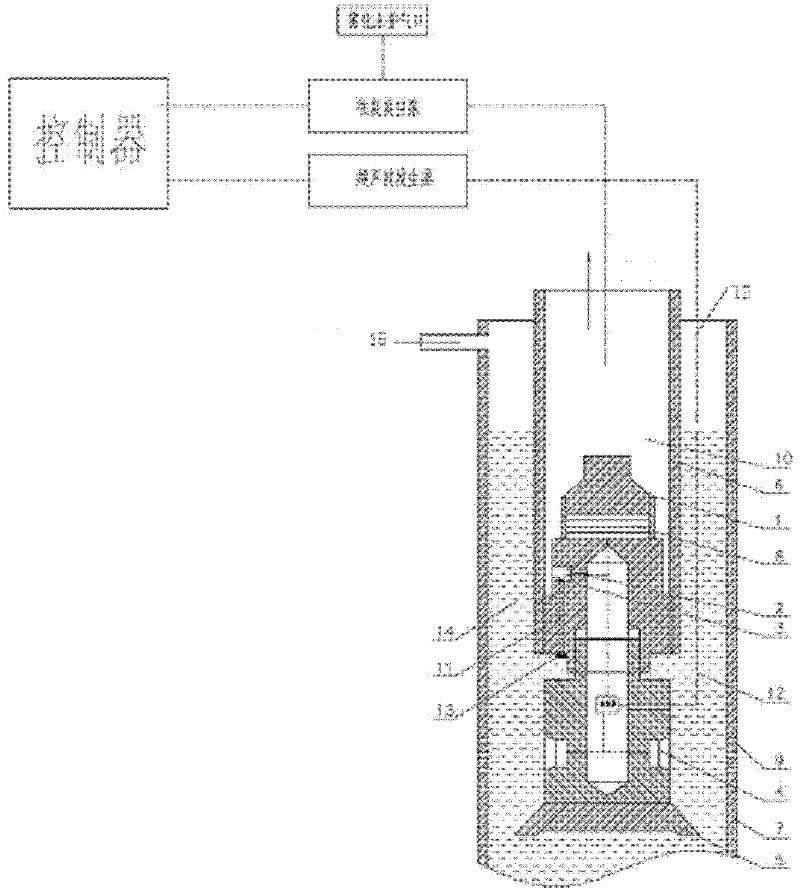

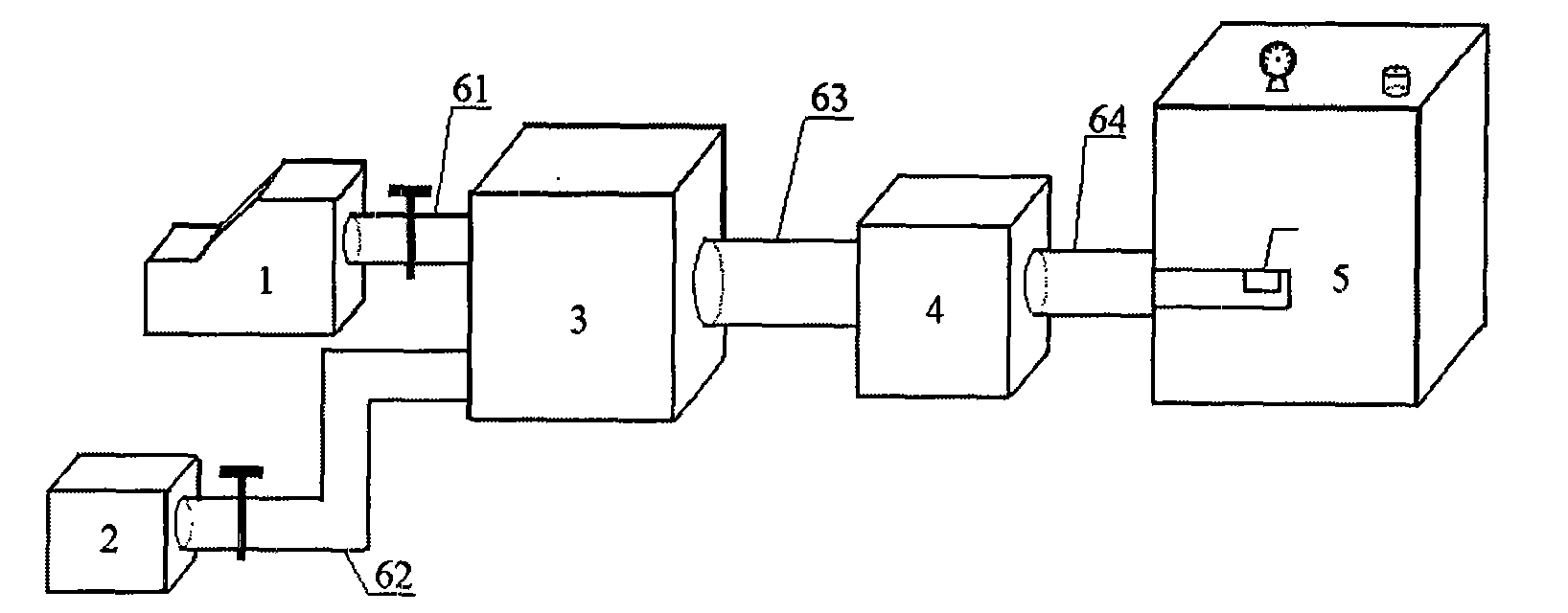

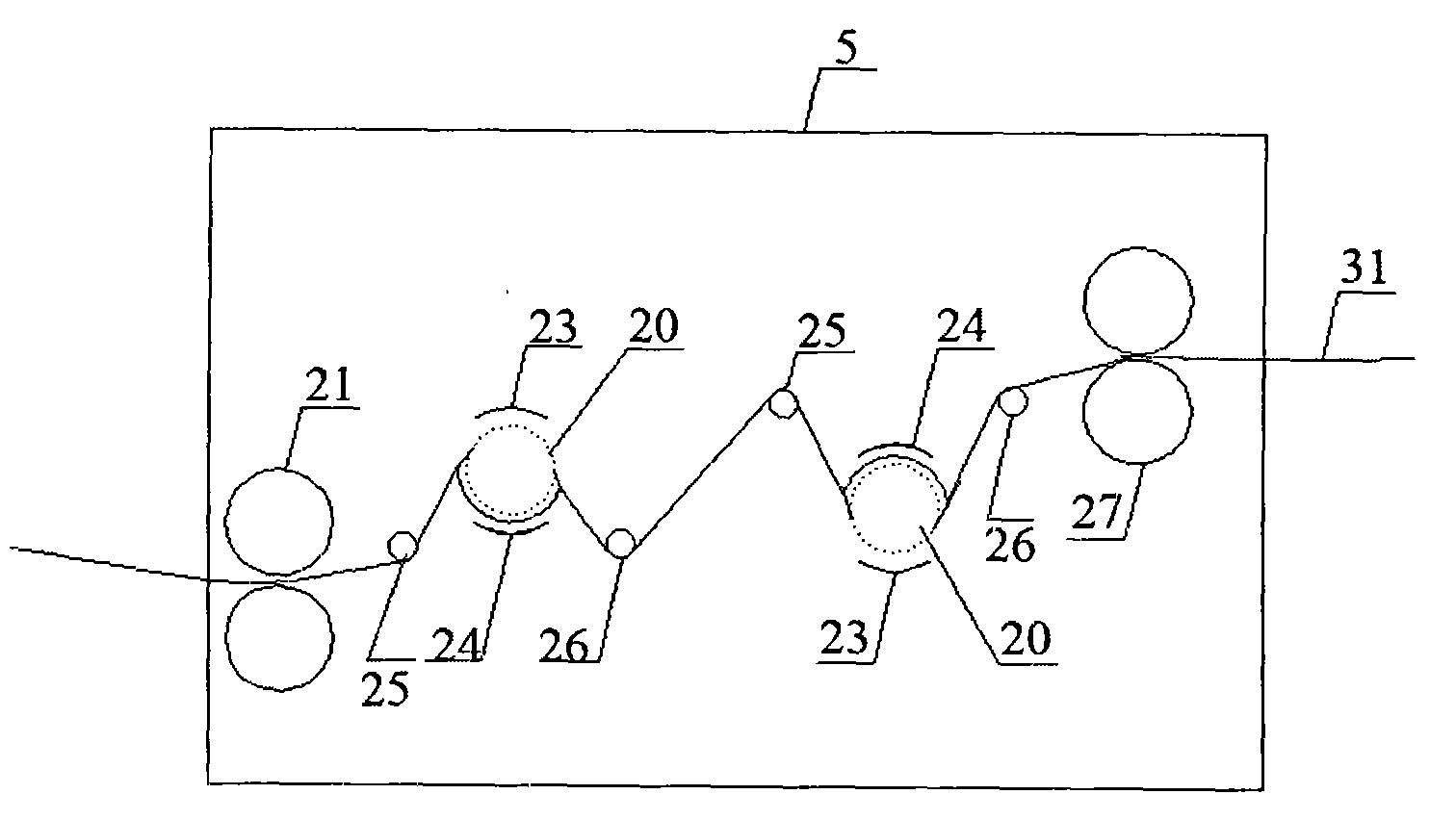

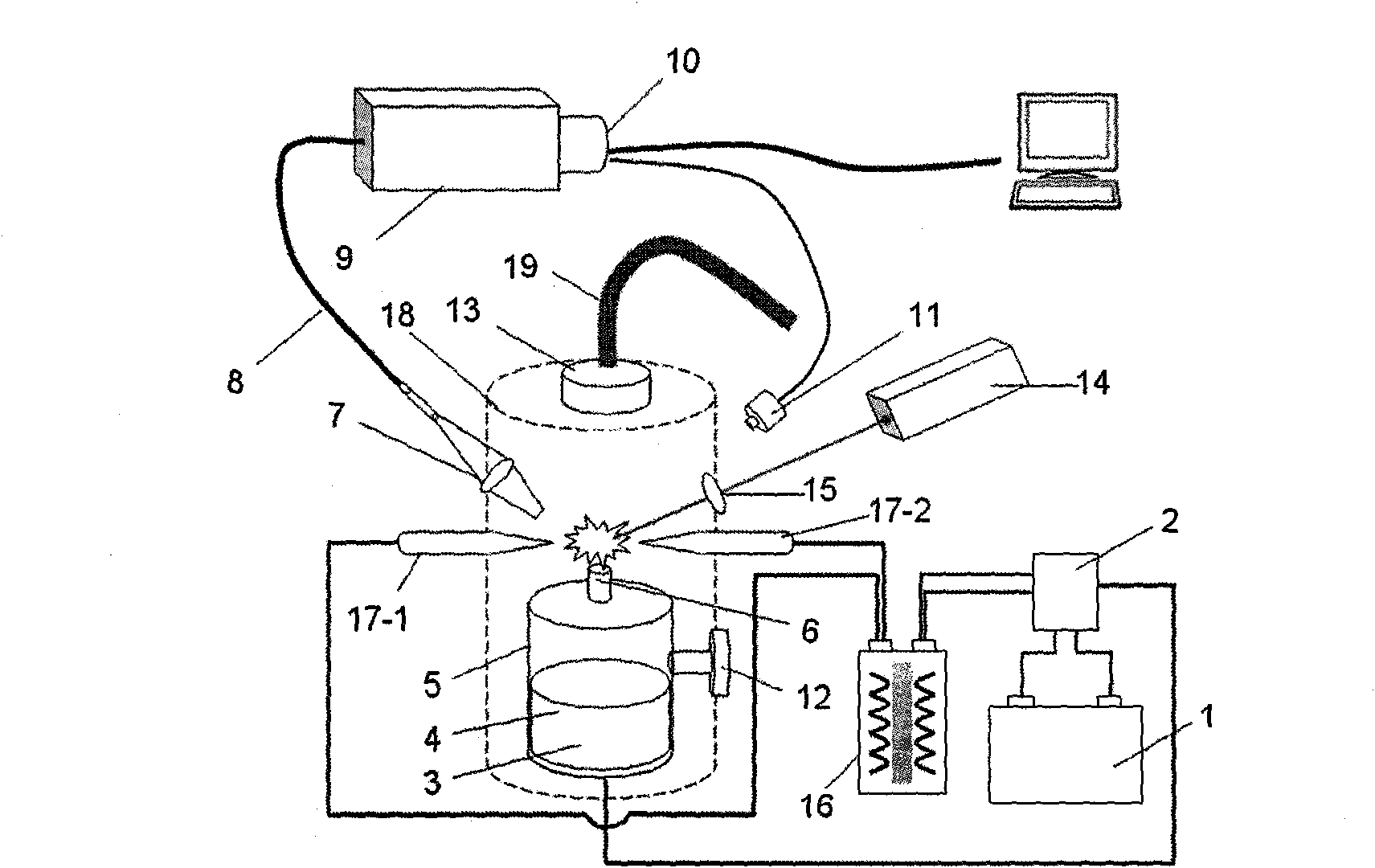

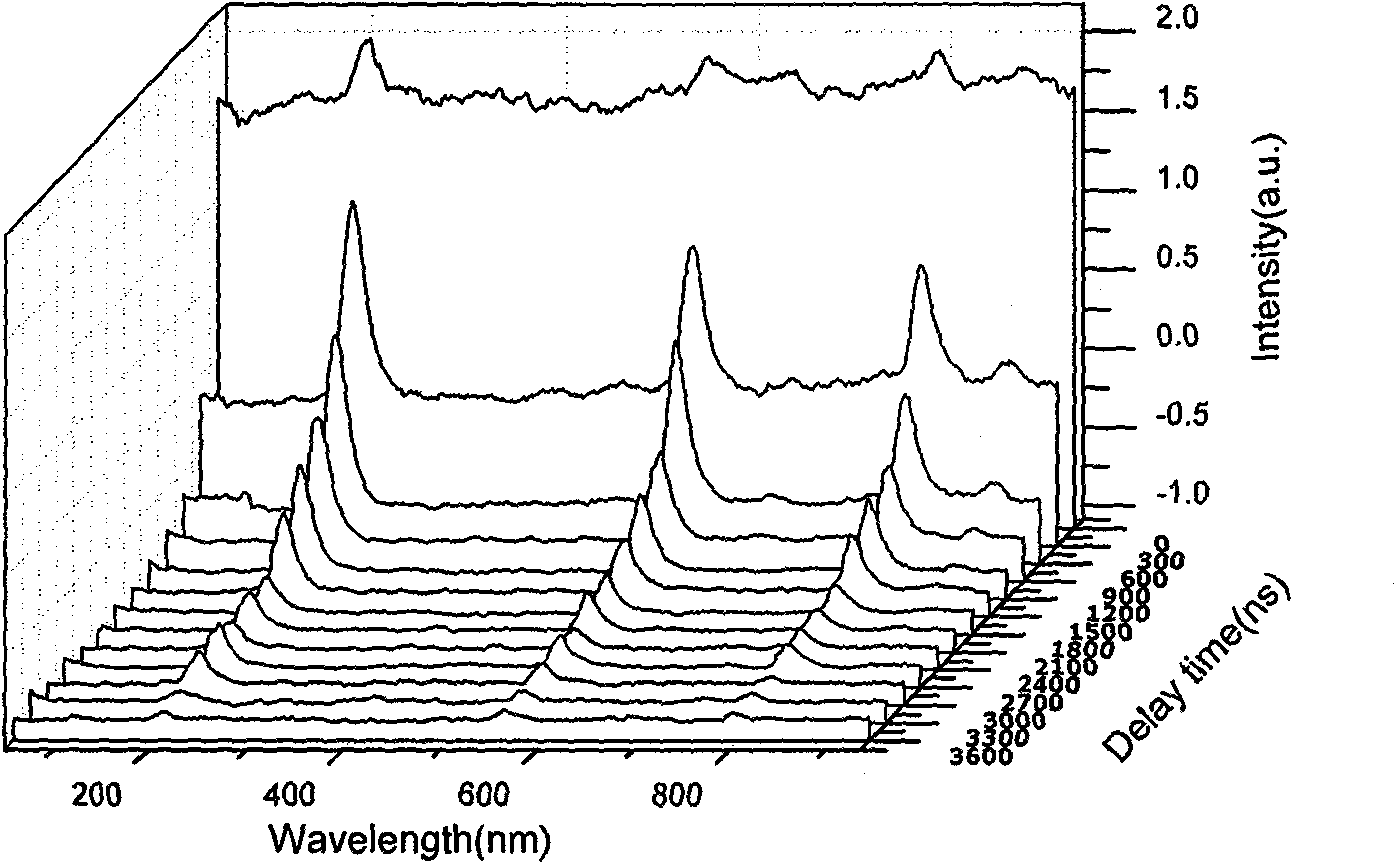

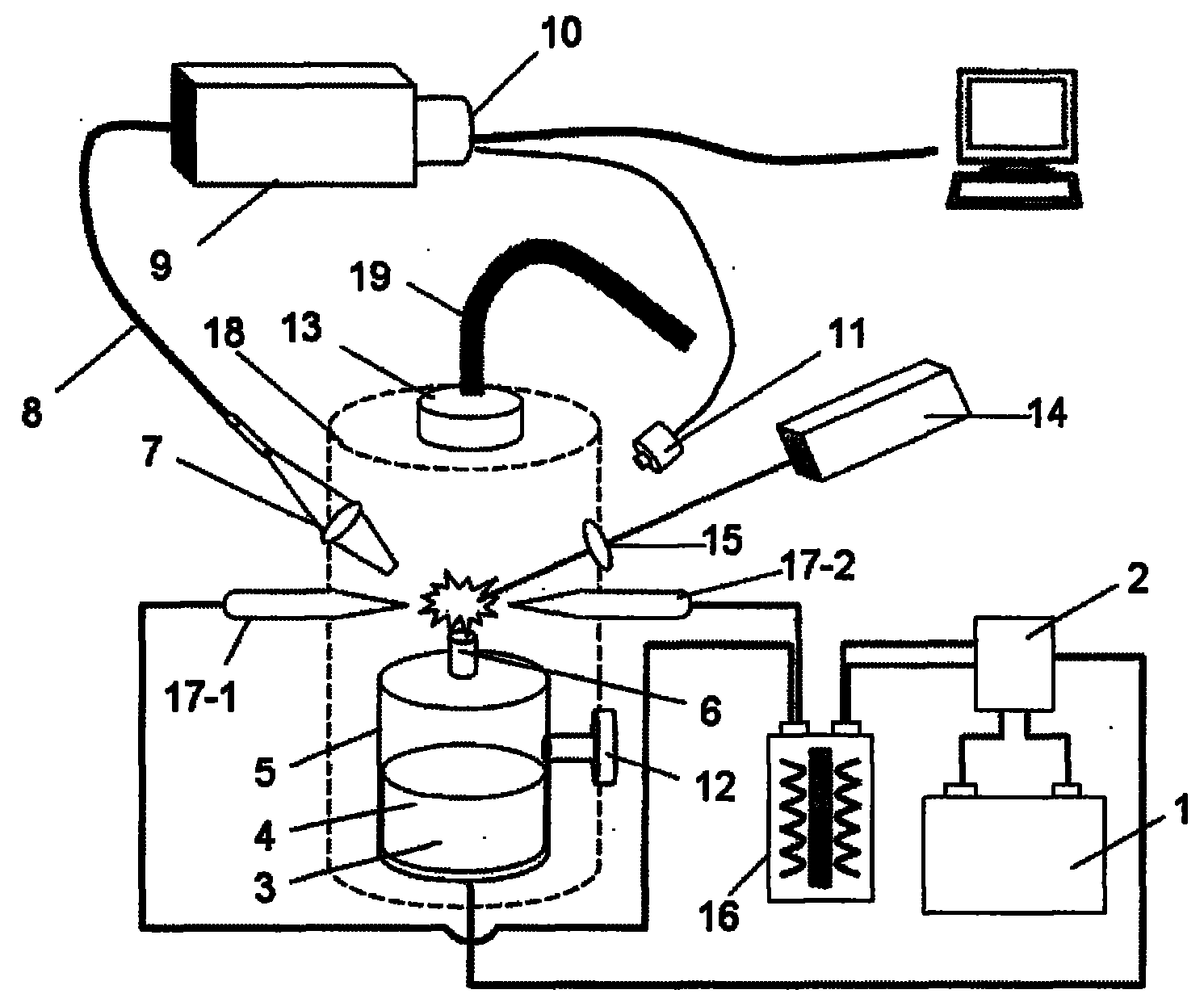

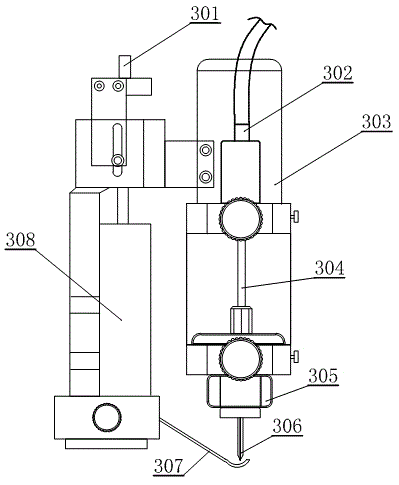

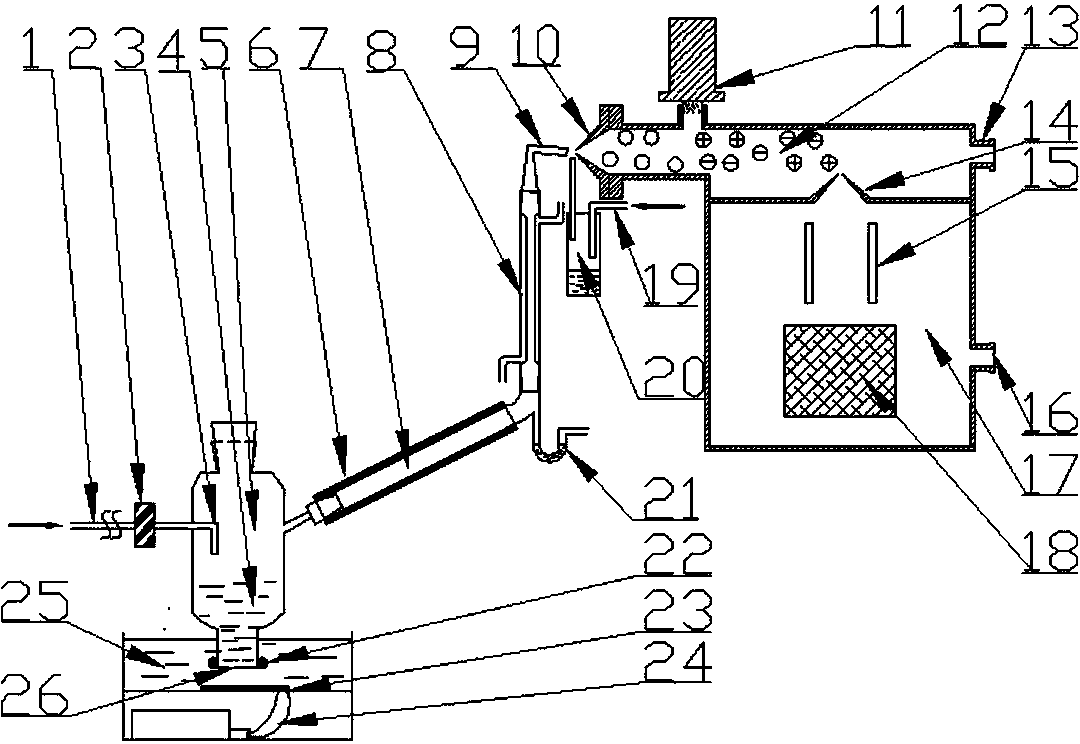

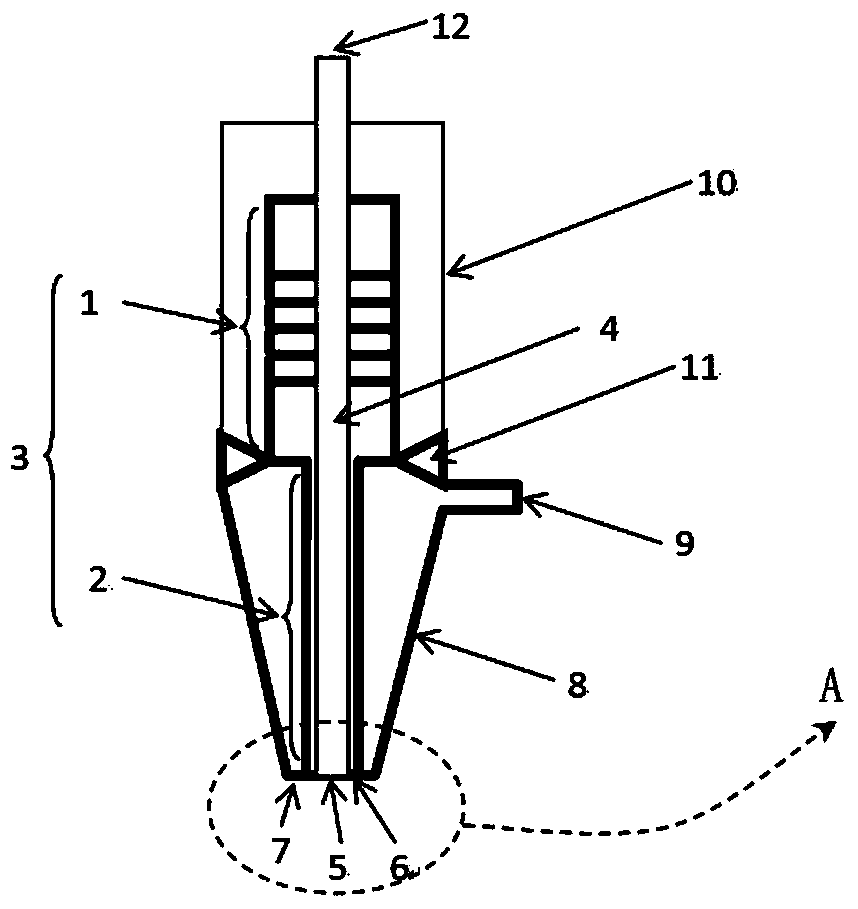

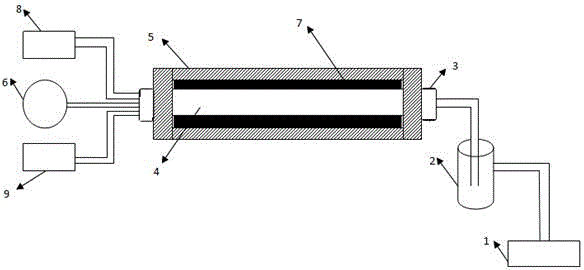

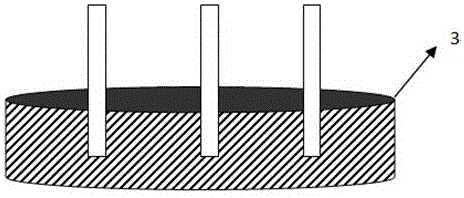

Method and device for detecting liquid sample by using ultrasonic atomization and breakdown spectroscopy

InactiveCN101788487AExtend your lifeHigh sensitivityAnalysis by thermal excitationSpectroscopySpectrograph

The invention relates to a method and device for detecting liquid samples by using breakdown spectroscopy. The device utilizes the ultrasonic atomization method to atomize the liquid samples to form massive and dense droplets in the air, breaks down and induces plasma and radiates an emission spectra signal. The method comprises the following steps: high-frequency oscillation is generated by the ultrasonic transducer (3) of the device of the invention to ensure that the liquid samples (4) in a sample cell (5) generate fog droplets, with the aid of a supply fan and an exhaust fan (13), columnar mist is generated above an air duct (6); plasma is generated at the edge of the columnar mist through breakdown, the plasma emission spectra signal is collected by a collection lens (7) and enters a spectrograph (9) through optical fiber (8) to split light; and finally a photoelectric sensor (11) fits with an ICCD detector (10) to collect spectral data. The method of the invention can reduce the breakdown threshold, increase the ablation efficiency and prolong the life of plasma. The detection device is applicable to the field component detection analysis field of the environment and mineral resources and the detection method has higher signal-to-background ratio and lower cost compared with the similar methods.

Owner:OCEAN UNIV OF CHINA

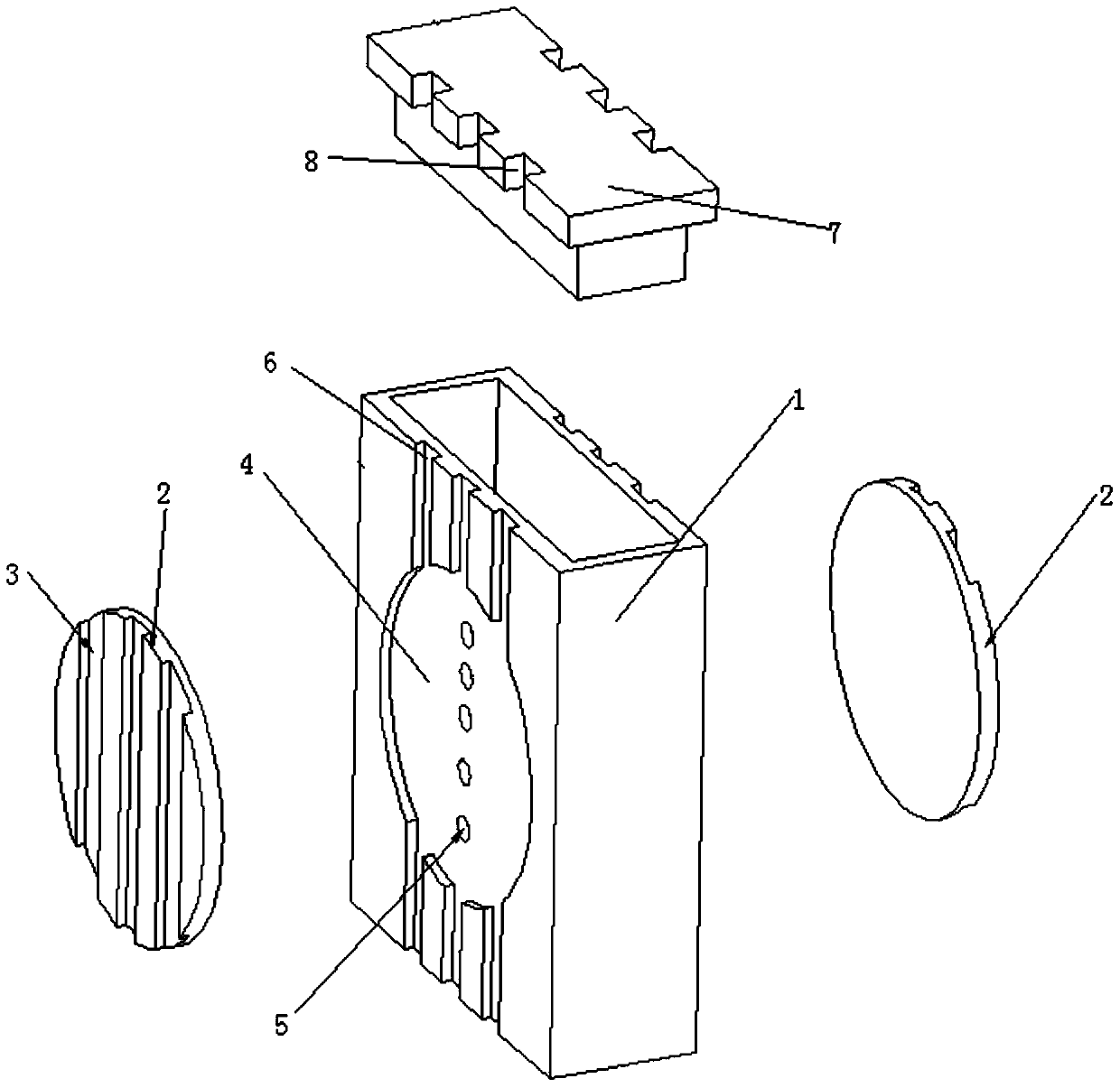

Oil storage device, electronic cigarette atomizer and electronic cigarette

ActiveCN105876870BSolve the problem of bad taste of smokingAvoid oil spillsTobacco devicesEngineeringElectronic cigarette

The invention discloses a cigarette liquid storage device, an electronic cigarette atomizer and an electronic cigarette. The cigarette liquid storage device comprises a body, wherein a cigarette liquid guider is fixedly arranged on an outer wall on at least one side of the body; the cigarette liquid guider is communicated with an inner cavity of the body; a vent groove is formed in a surface, far away from the body, of the oil guider. The cigarette liquid storage device provided by the invention is provided with the oil guider; cigarette liquid can be directly conducted to an atomization component through the oil guider; the oil guider can be integrally molded with the body, and can be also fixed in ways of inlaying and the like; the cigarette liquid storage device is simple in structure and is convenient to use; the electronic cigarette atomizer which is provided by the invention adopts an ultrasonic atomization component, is high in capacity usage ratio, and solves a problem that the cigarette liquid heated by an existing heating wire easily generates a burnt smell and causes that a smoking taste becomes poor; meanwhile, the surface of the oil guider is provided with the vent groove which can not only allow a gas to pass through, but also can avoid a phenomenon of liquid leakage caused by too large contact area between a fluid guider and the ultrasonic atomization component; the cigarette liquid storage device, the electronic cigarette atomizer and the electronic cigarette are simple and exquisite in structure, and are convenient to mount and dismount.

Owner:CHINA TOBACCO HUNAN INDAL CORP

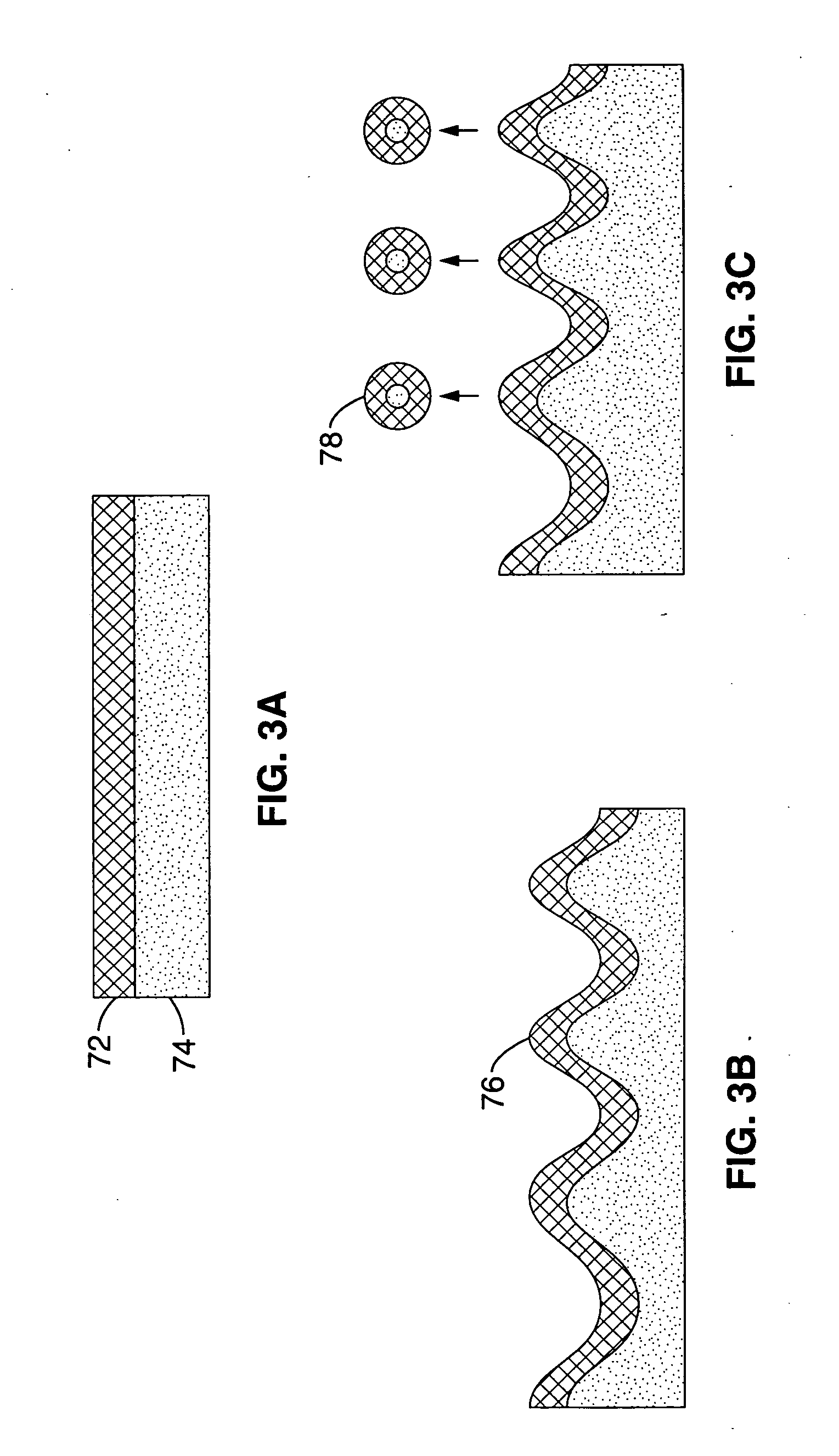

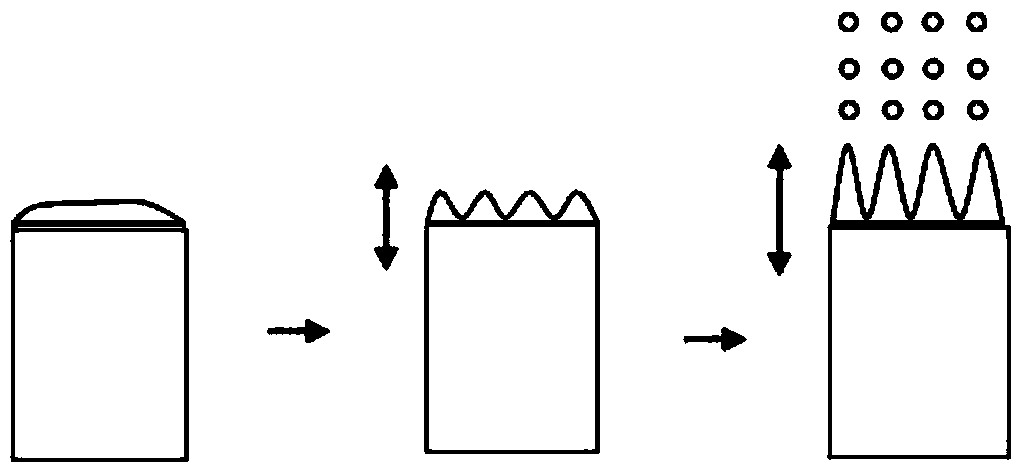

Polycrystalline silicon surface wool manufacturing method

InactiveCN101805929AReduce surface reflectivityEfficient collectionAfter-treatment detailsFinal product manufactureSolar batteryUltrasonic atomization

The invention relates to the manufacturing field of solar batteries, in particular to a polycrystalline silicon surface wool manufacturing method for solar batteries. The invention has the technical scheme that the polycrystalline silicon surface wool manufacturing method is characterized by successively adopting the following steps: 1) pre-cleaning a silicon wafer and removing an affected layer;2) adopting the ultrasonic atomization process or electrostatic spraying process to coat one layer of discontinuous plastic particle film on the surface of the silicon wafer to serve as a masking film; 3) putting the silicon wafer in acid solution and aqueous alkali for corrosion and wool manufacturing; and 4) cleaning the silicon wafer obtained in step 3) with acetone to remove plastic particle films, then cleaning with deionized water, and drying the silicon wafer. By adopting the scheme, the invention overcomes the defects and deficiencies in the prior art, and provides the polycrystallinesilicon surface wool manufacturing method. The method can be used for manufacturing high-performance polycrystalline silicon surface texture, has industrialization prospect and effectively lowers thesurface reflectivity of the silicon wafer.

Owner:SUN POWER PHOTOVOLTAIC SCI & TECH

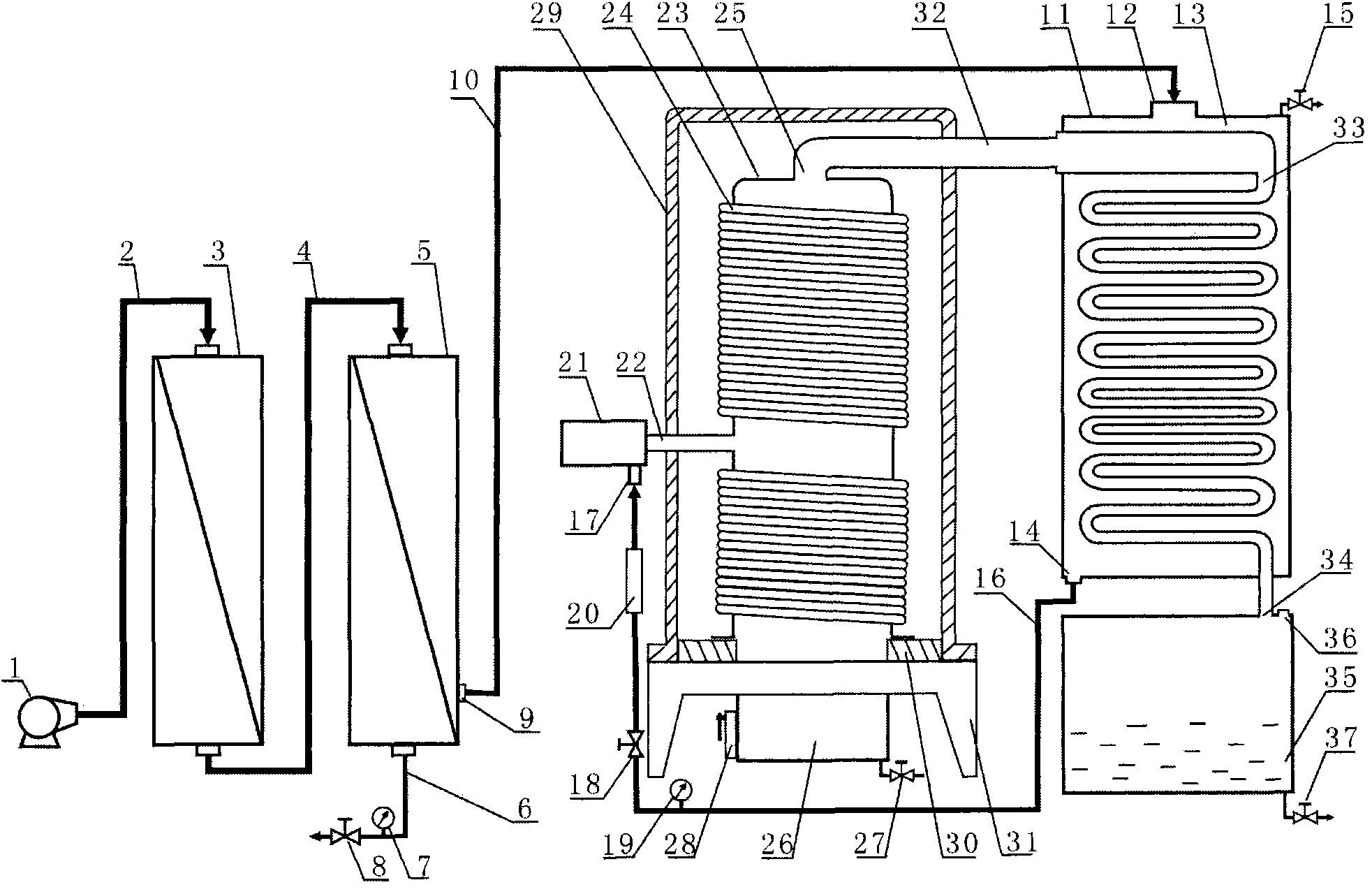

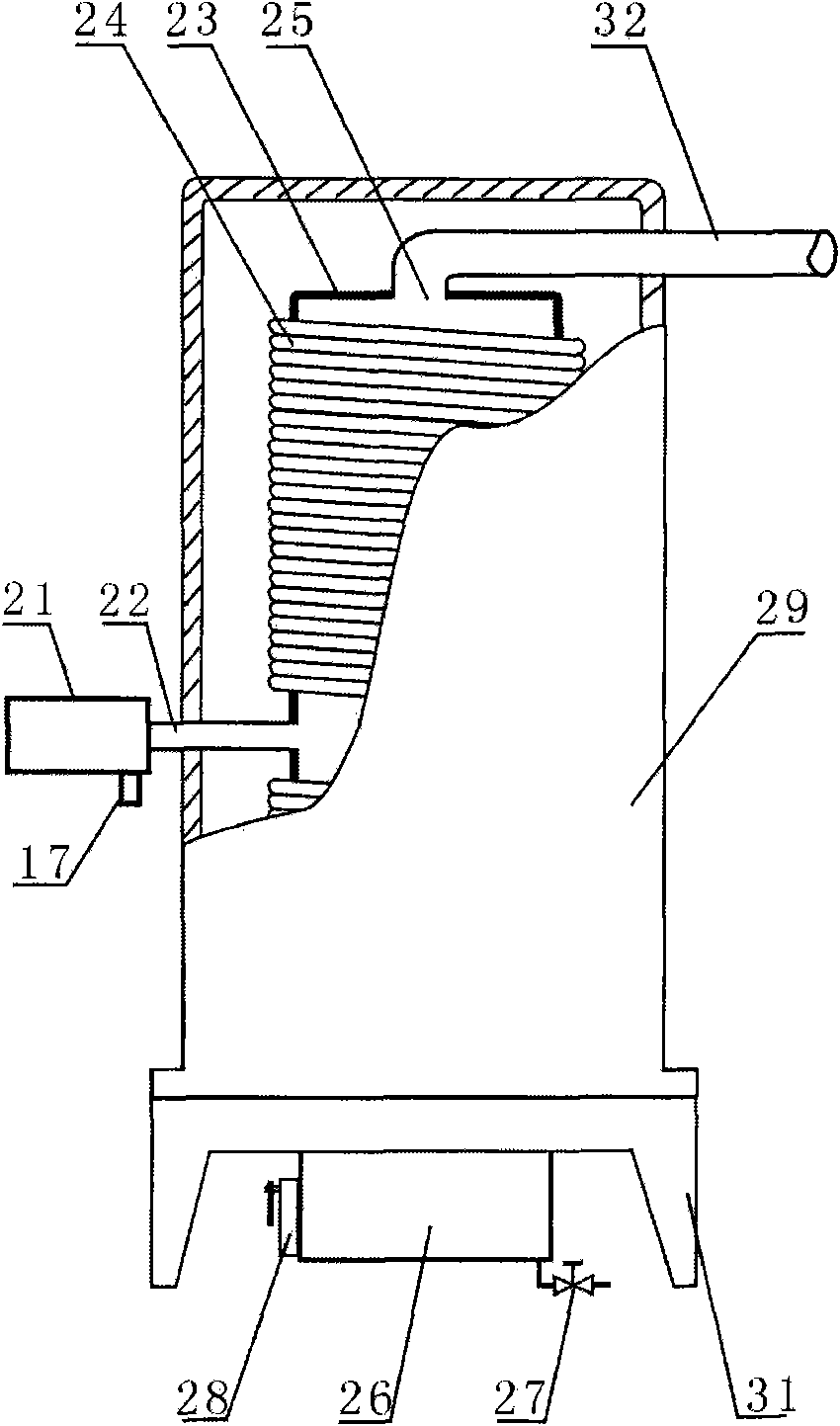

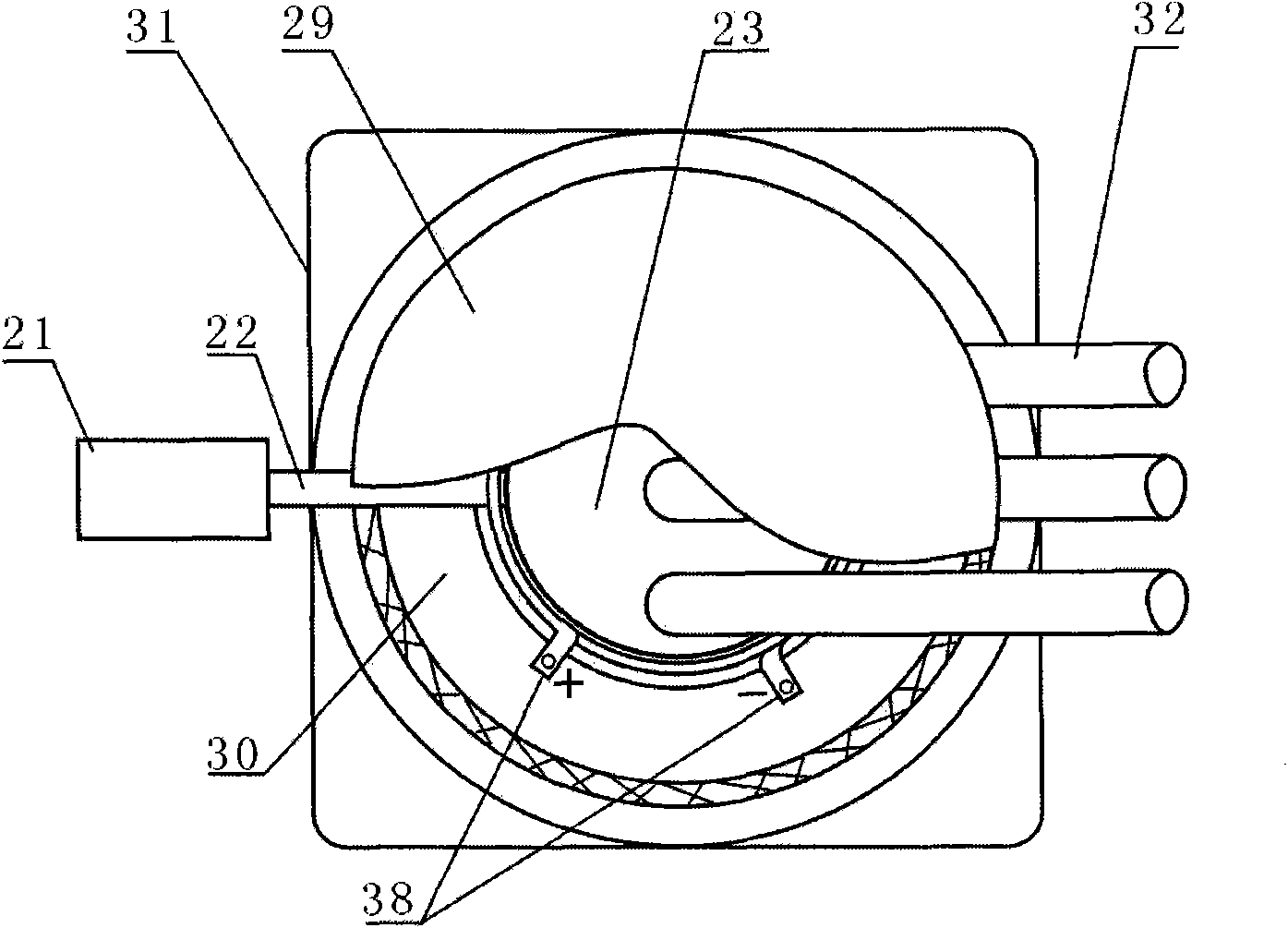

Ultrasonic atomization and vaporization seawater desalination desalting device and method

InactiveCN101838079ALow costLow operation and maintenance costsGeneral water supply conservationSeawater treatmentResonanceFresh water

The invention discloses an ultrasonic atomization and vaporization seawater desalination desalting device comprising a pretreating device, an ultrasonic resonance atomizer, a vaporization furnace, a heat-change condenser and a desalination water tank, wherein the heat-change condenser comprises a cooling medium water tank and a condensing disk intestinal pipe, the condensing disk intestinal pipe is arranged in the cooling medium water tank, a water outlet of the condensing disk intestinal pipe is connected with the desalination water tank, a water outlet of the pretreating device is connected with a water inlet of the cooling medium water tank, a water outlet of the cooling medium water tank is connected with the ultrasonic resonance atomizer, the ultrasonic resonance atomizer is connected with a vaporization furnace body of the vaporization furnace by a spraying pipe, and the vaporization furnace body is connected with the water inlet of the condensing disk intestinal pipe by a vapor transporting pipeline. The ultrasonic atomization and vaporization seawater desalination desalting device can effectively and environmentally extract fresh water from seawater in low energy consumption. The invention also discloses an ultrasonic atomization and vaporization seawater desalination desalting method.

Owner:王剑波

Preparation method for ultrasonic atomization spraying film

ActiveCN103736620ASpeed up the flowUniform and controllable thicknessSpray nozzlesLiquid spraying apparatusProduction rateCoated surface

The invention relates to a preparation method for an ultrasonic atomization spraying film. A simple ultrasonic atomization device is used for atomizing spraying liquid into ultra-fine liquid drops; the ultra-fine liquid drops are uniformly adhered to the surface of a base material by using external auxiliary airflow, so that a coating of which the thickness is uniform and controllable and the appearance quality is high is formed; the problems that in the prior art, the surface uniformity of a coating is poor, a coating effect is low, spraying amount is not controllable, productivity is low and the like are solved; and the purpose of accurate spraying is achieved. Compared with the prior art, the preparation method for the ultrasonic atomization spraying film has the advantages that spraying efficiency is high, the quality of the film is high, the repeatability of products is high, the liquor using rate is also high, the spraying area and the thickness of the coating can be accurately controlled, and the like.

Owner:佛山中科产业技术研究院

3D ink-jet printer for printing electronic circuit board through ultrasonic atomization nanometer suspending liquid

InactiveCN104014790ATroubleshoot direct printing issuesSafe and convenient man-machine operationEvaporationEngineering

The invention discloses a 3D ink-jet printer for printing an electronic circuit board through ultrasonic atomization nanometer suspending liquid. The 3D ink-jet printer comprises an ultrasonic atomization nanometer suspending liquid device, a nanometer fine ink-jet printing device, an industrial positioning camera, a video monitor, an infrared laser micro-fusion-covering device, a heatable vacuum absorption workbench, a three-coordinate movable sliding table and a control portion. According to the 3D ink-jet printer, the nanometer suspending liquid to be printed is atomized based on an ultrasonic double-cavity atomization method, the nanometer suspending liquid is sent to a controllable nanometer fine ink-jet printing device through a guide pipe under the action of auxiliary gas and is directly printed on a substrate in a non-contact mode through a fine ceramic nozzle, the printed nanometer sizing agent is solidified and dried through the method of bottom plate heating or infrared laser micro fusion covering, evaporation of the solvent in the sizing agent, gasification of an organic clad layer and fusion of nanometer particles are accelerated, and therefore the electronic circuit board with high conductivity and micron-size line width is formed. The 3D ink-jet printer can directly print a conducting layer, an insulating layer, a protective layer and a solder mask and can print semiconductor components and parts.

Owner:张远明

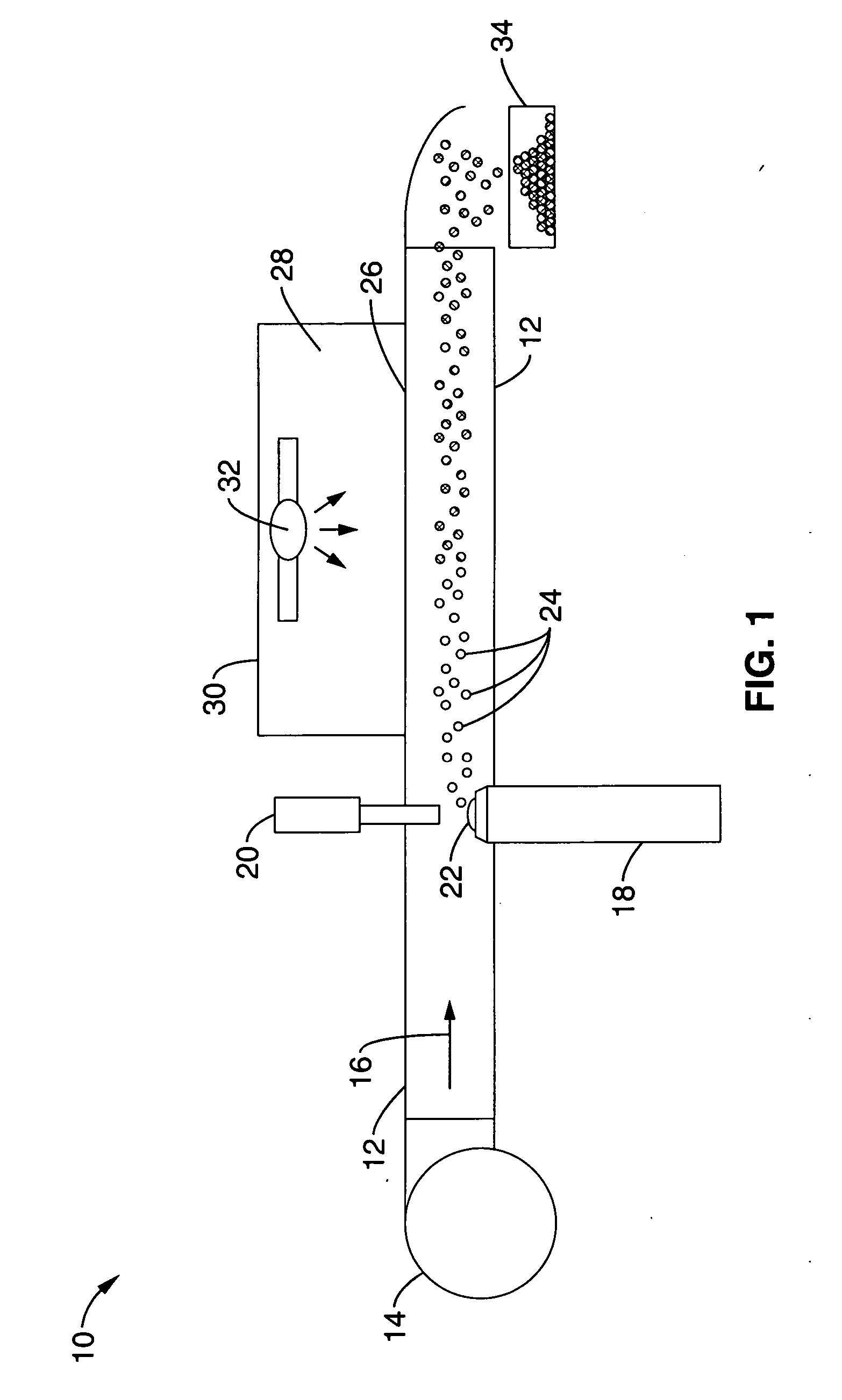

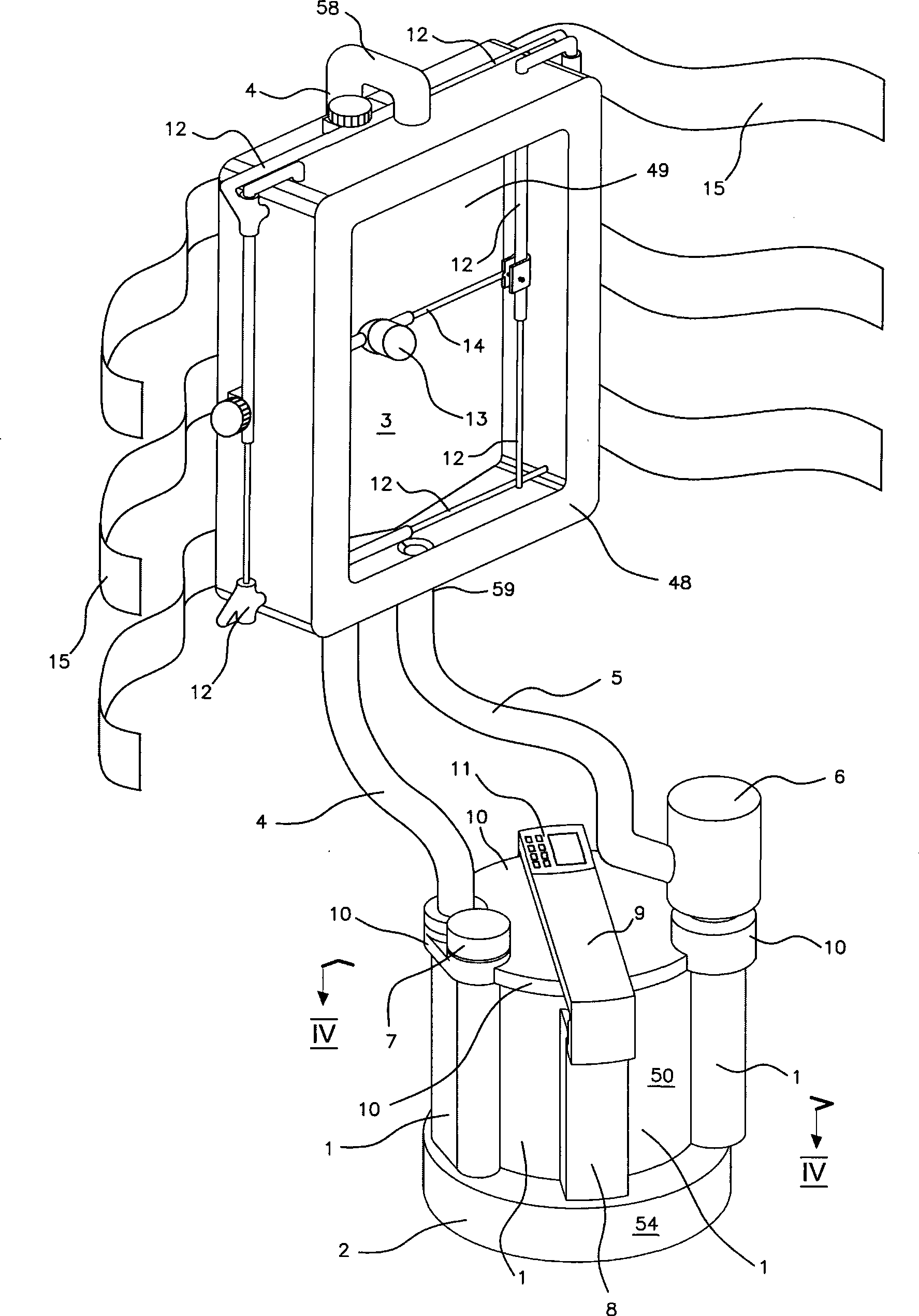

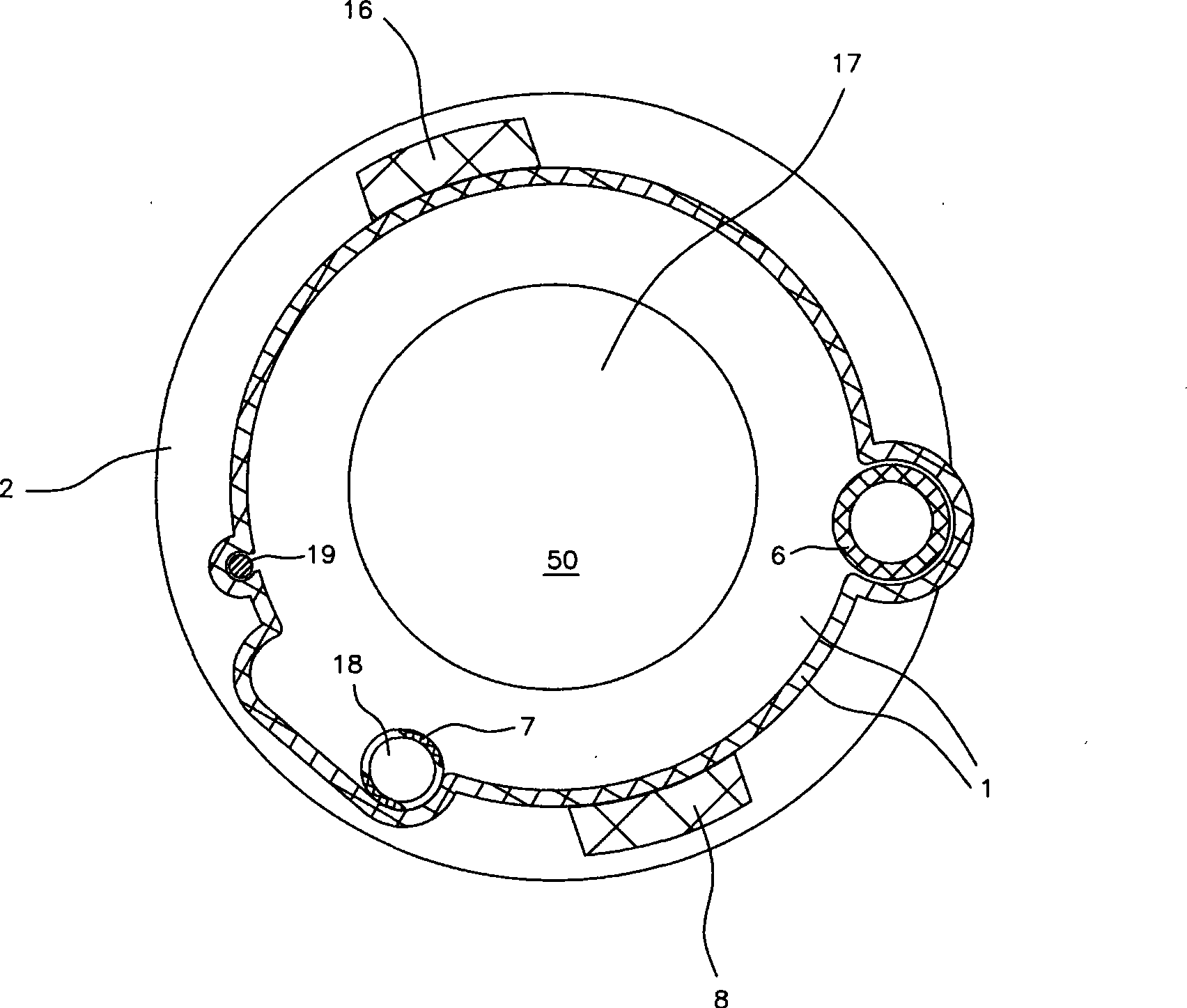

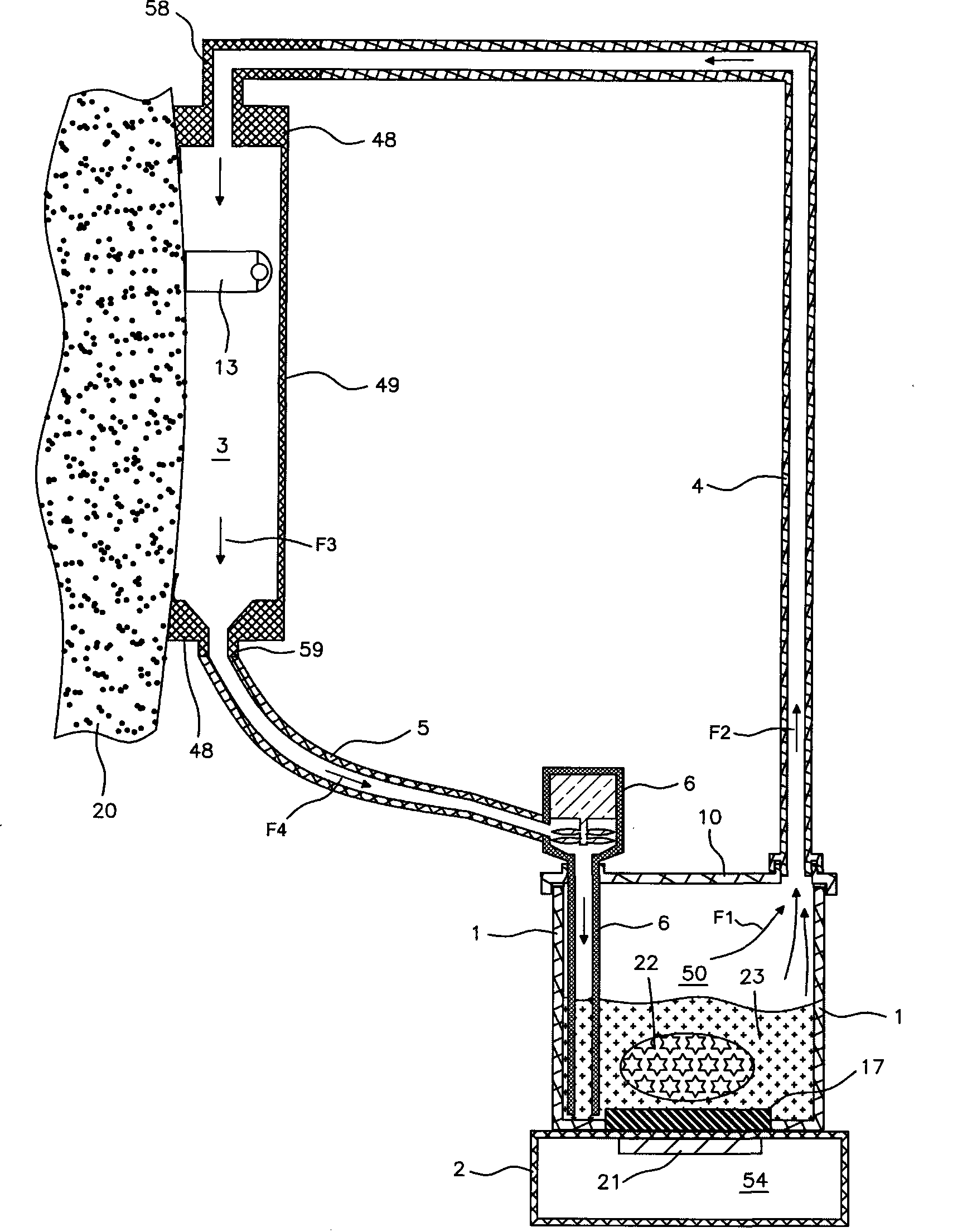

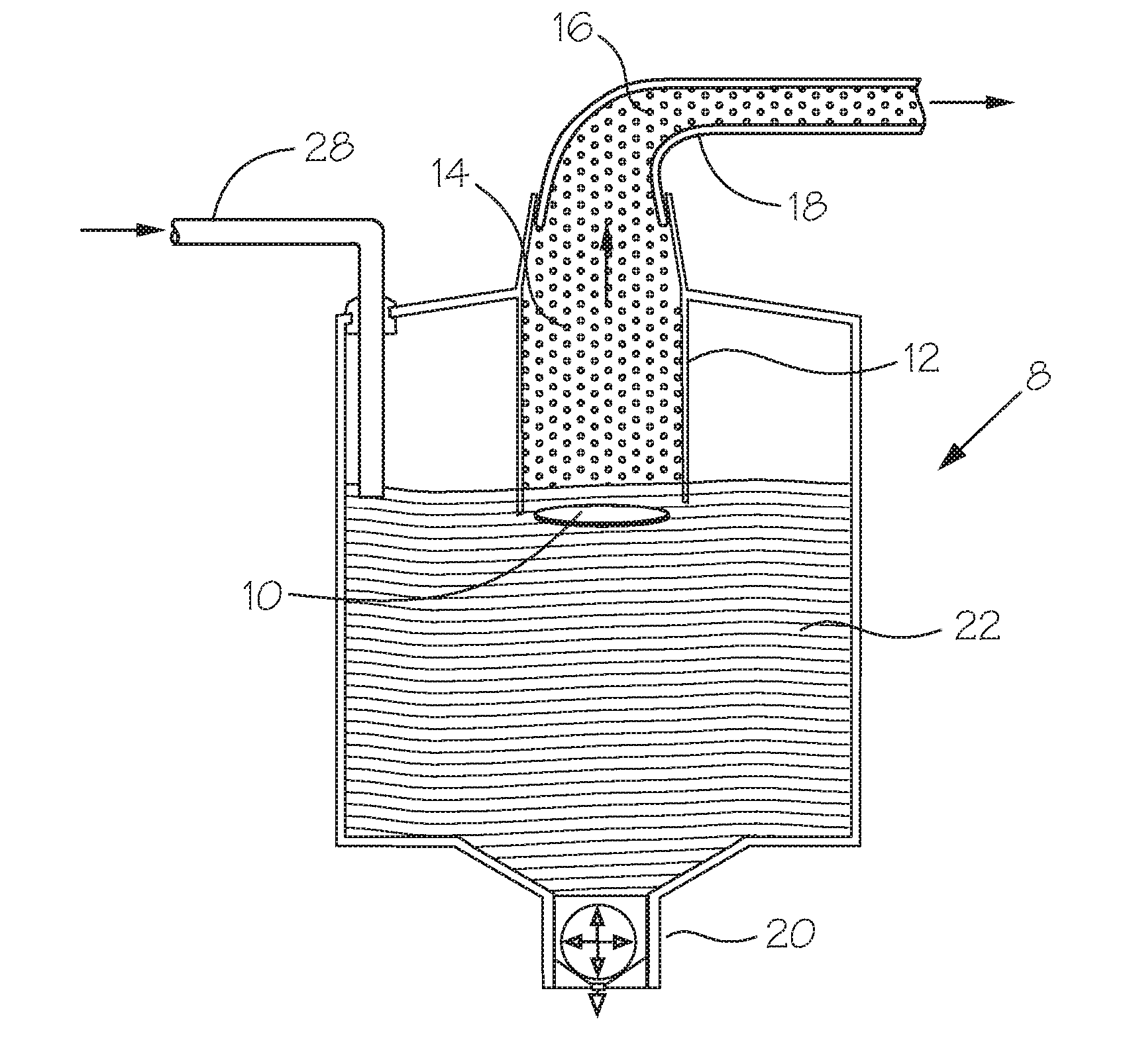

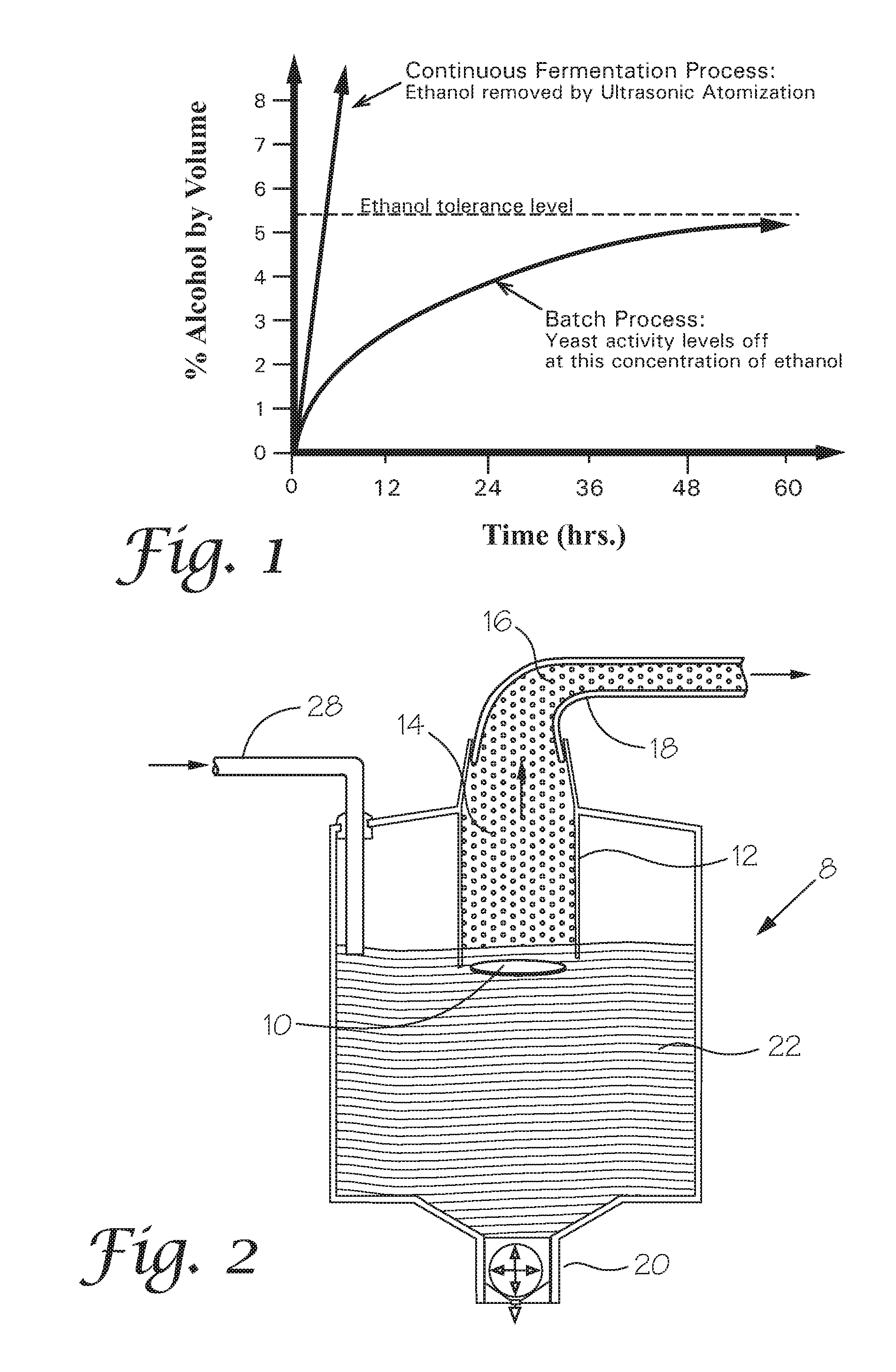

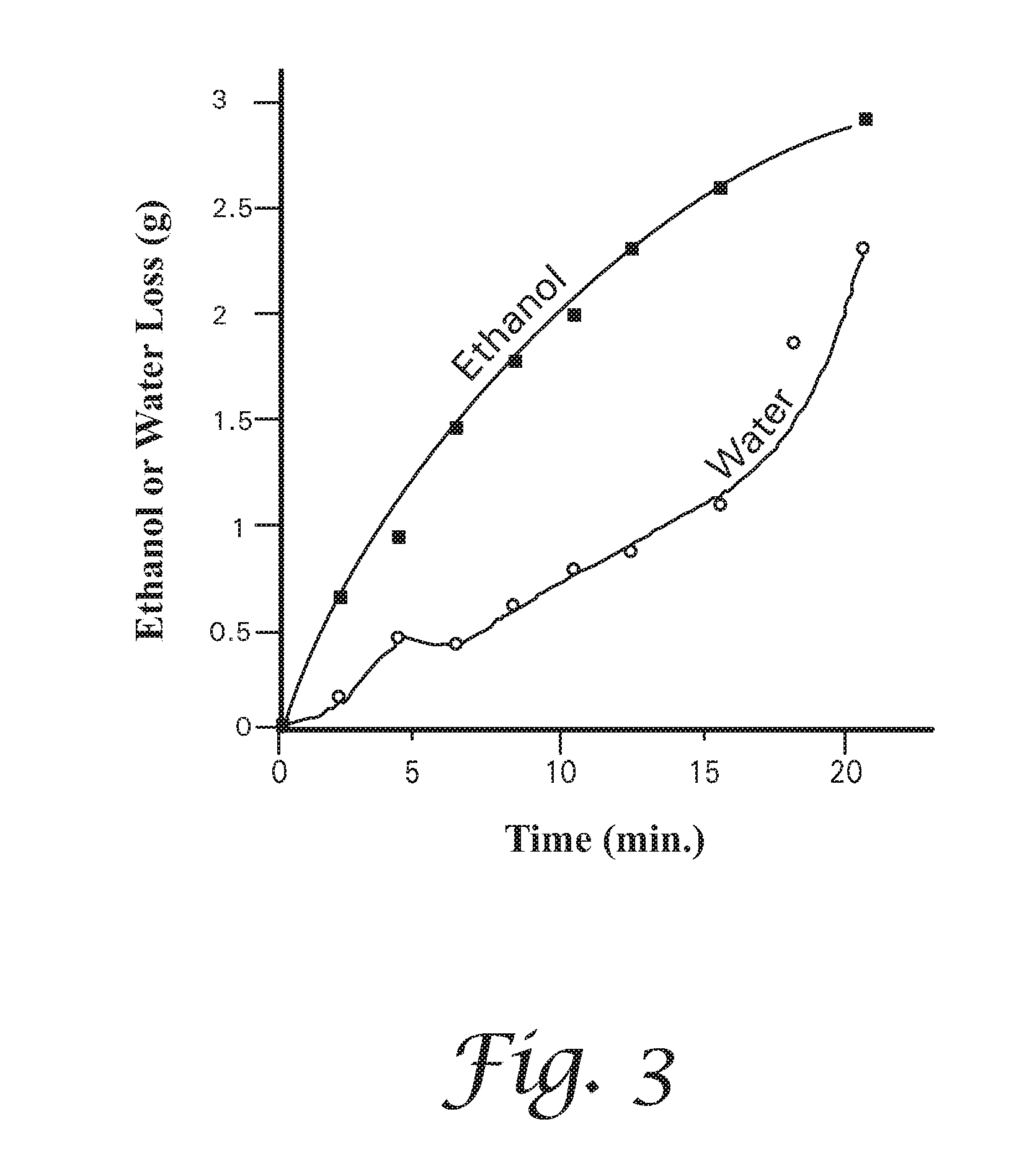

Method and device for improved fermentation process

InactiveUS20070193874A1Prevents exceeding ethanol toleranceSpeed up the processFermented solutions distillation/rectificationBiofuelsContinuous fermentationDistillation

An improved method and device is accomplished for ethanol production using an in-line extraction of ethanol by ultrasonic atomization, thereby removing the effect of the ethanol inhibition factor that adversely affects the rate and yield. The in-line removal of ethanol as it is formed increases the fermentation rate, improves the yield and uses 20-25% of the energy required as compared to thermal distillation processes currently used. The improved method makes sure that ultrasonic vibration does not deactivate enzymes to any significant level. The elimination of the effect of the ethanol inhibition factor allows for a continuous fermentation process as opposed to the costly, time-consuming repeated batch processes.

Owner:ADIGA KAYYANI C +1

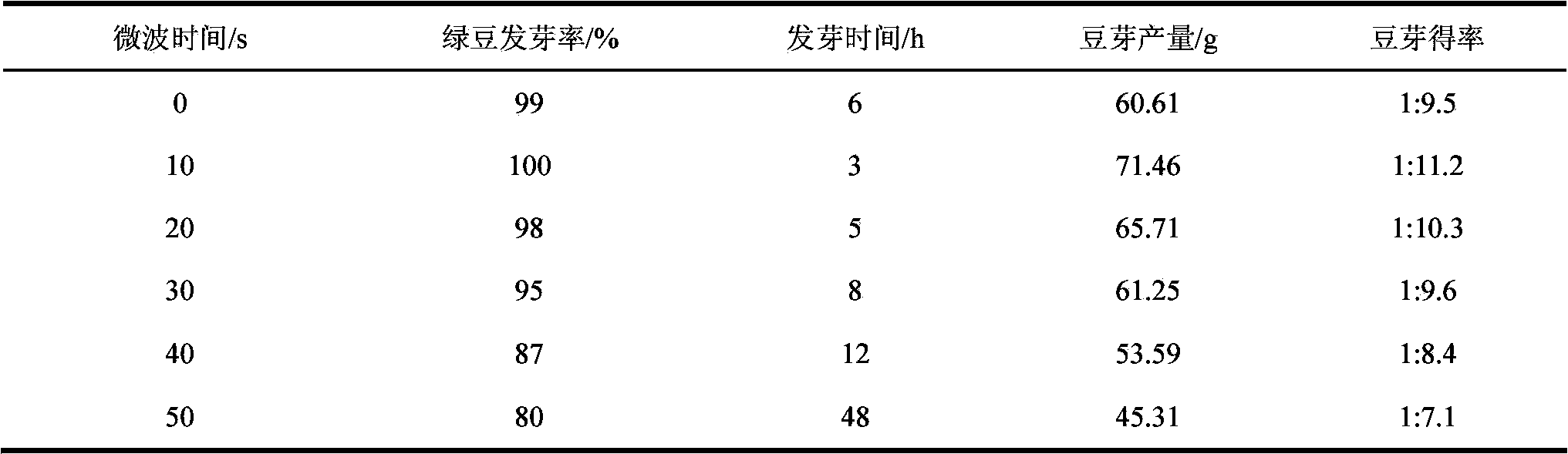

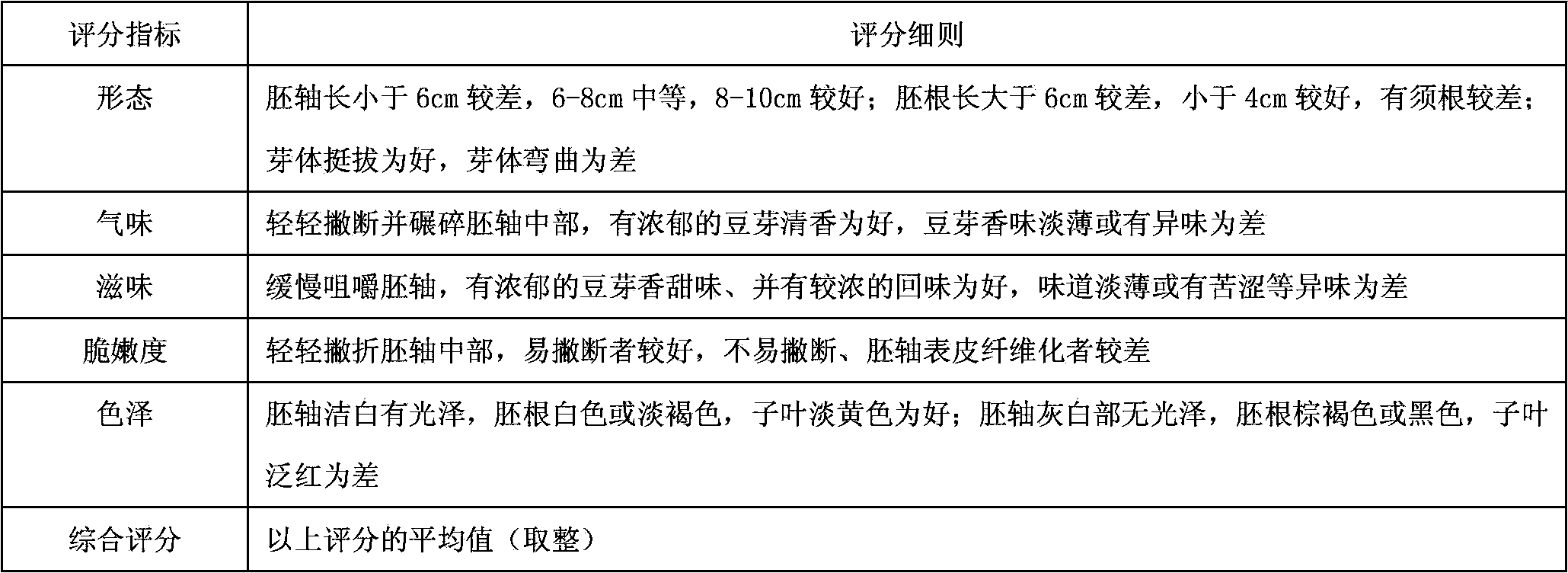

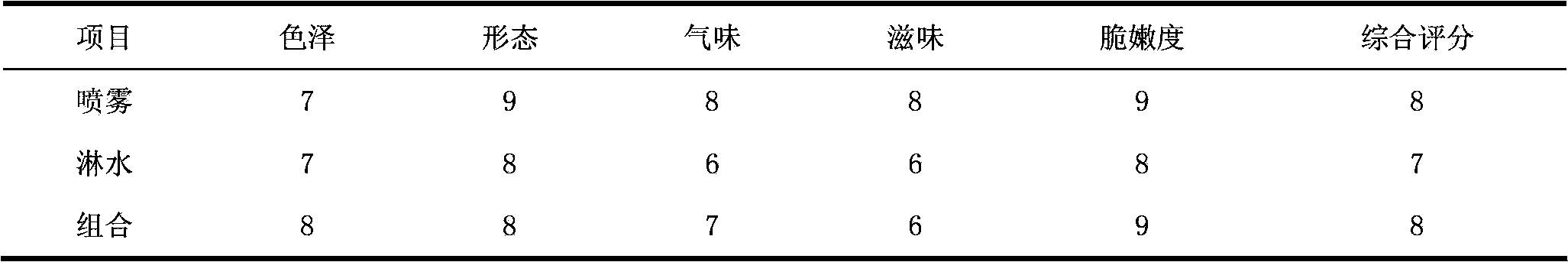

Sprout culture method

InactiveCN103416287AImprove germination rateIncrease productionCultivating equipmentsSoilless cultivationSprouted SeedsEthephon

The invention belongs to the technical field of agricultural product deep processing and particularly relates to a safe sprout culture method. The method is characterized by including: purifying and sterilizing sprout seeds, subjecting the same to microwave treatment, soaking and budding treatment, treating with ethylene during budding, lighting the seeds requiring light, treating with ozone after budding, cleaning with ozone water and clean water after sprout harvesting, and packaging. Microwave treatment can evidently increase budding rate of the sprout seeds and increase sprout yield. Ultrasonic atomization treatment provides even and sufficient moisture for the sprouts to prevent sprout withering during growing. The ethylene and air generated from ethephon solution allows the sprouts to be short in roots and robust and bright in sprout body. The ozone treatment can effectively kill bacteria and remove odor, residue is avoided, the sprout bodies are white in appearance, and the quality of the sprouts is improved.

Owner:WUHAN BOSIDE TECH

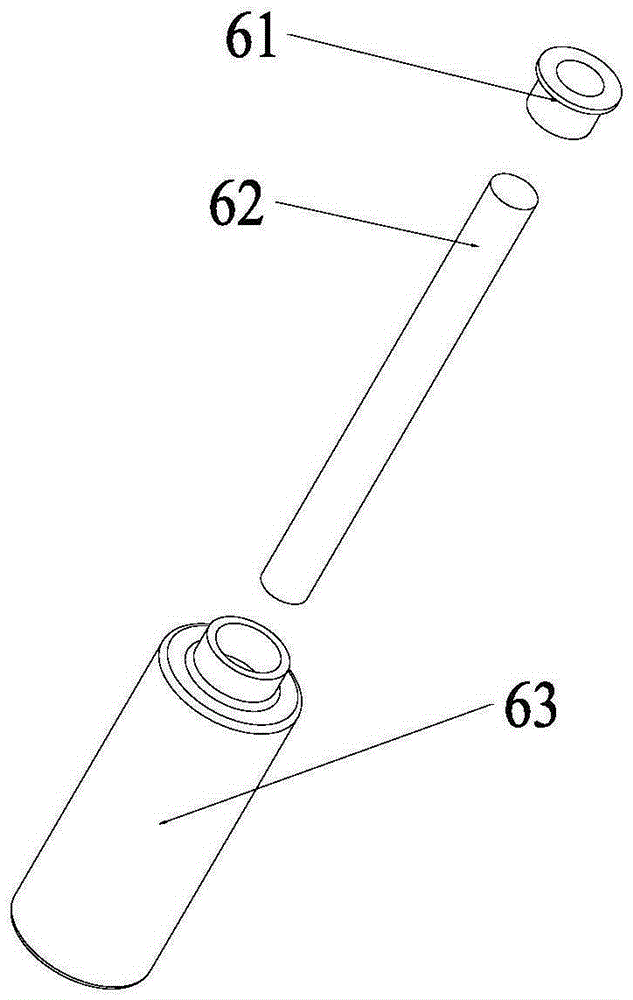

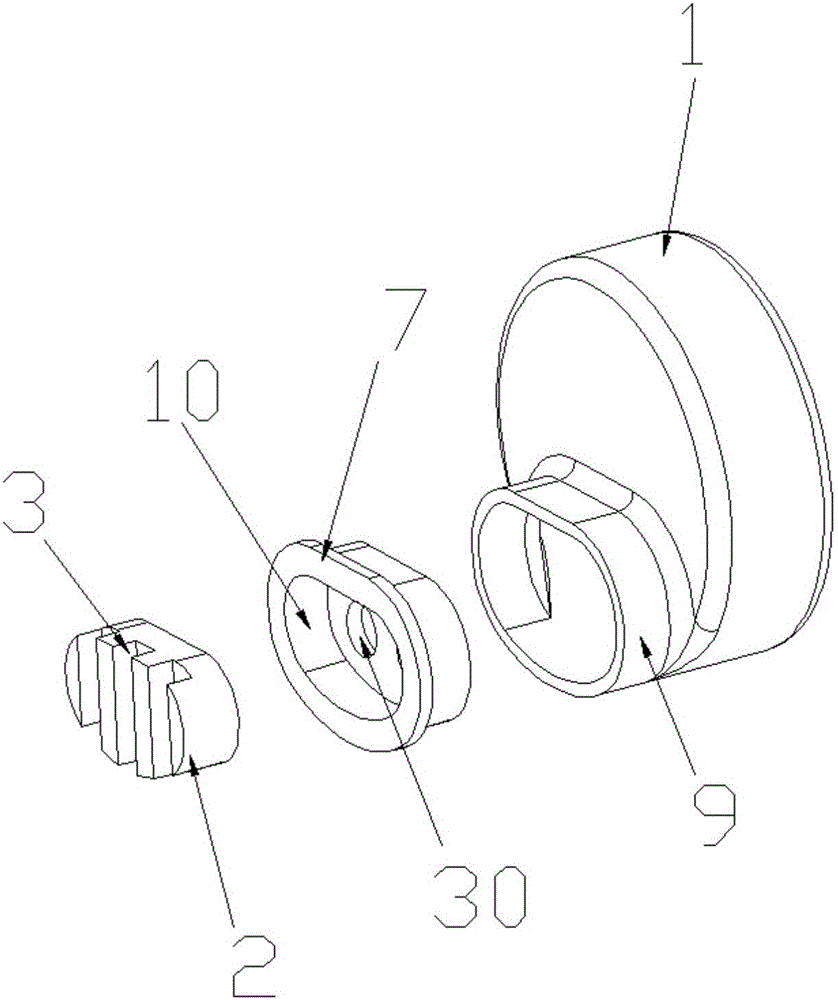

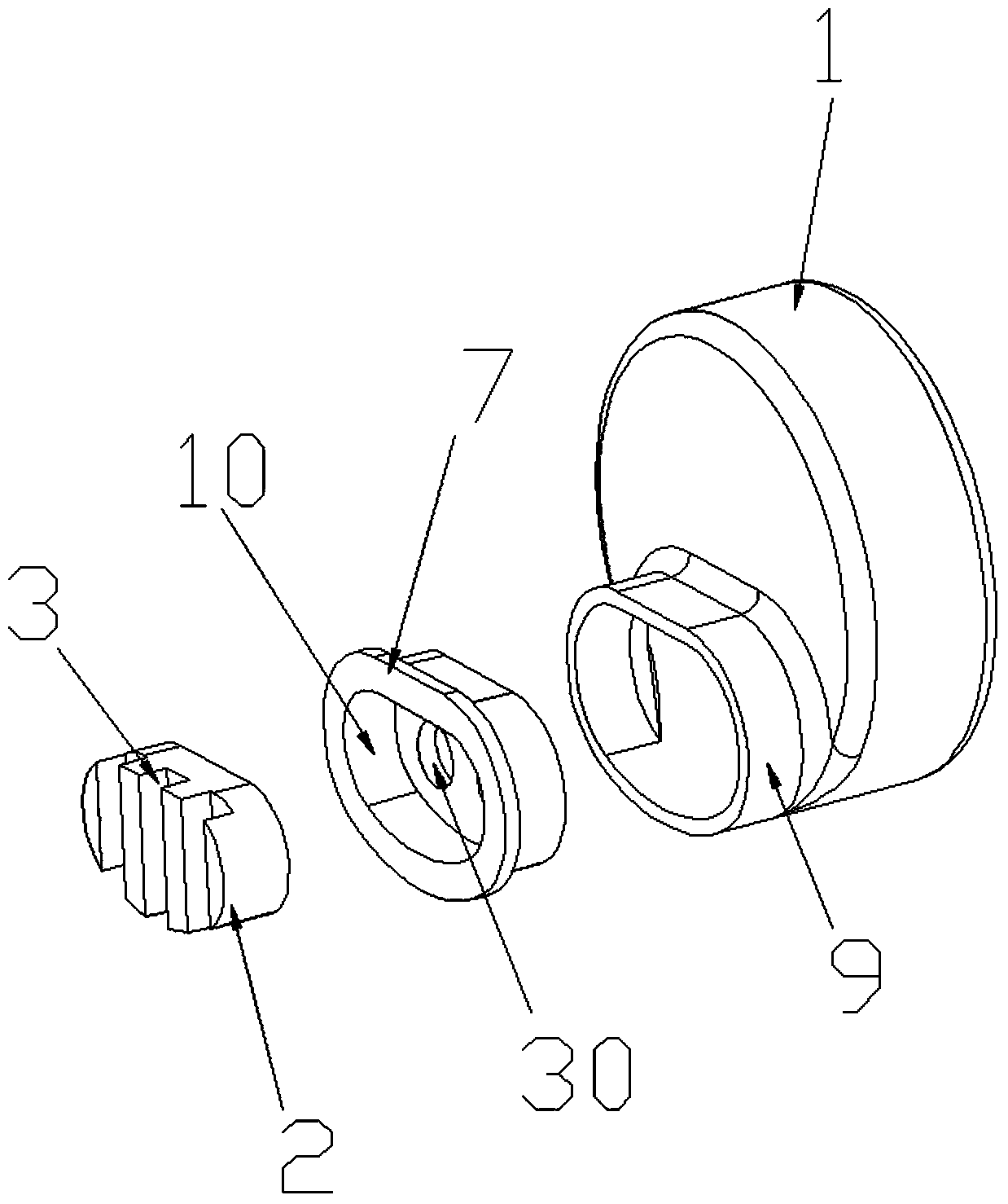

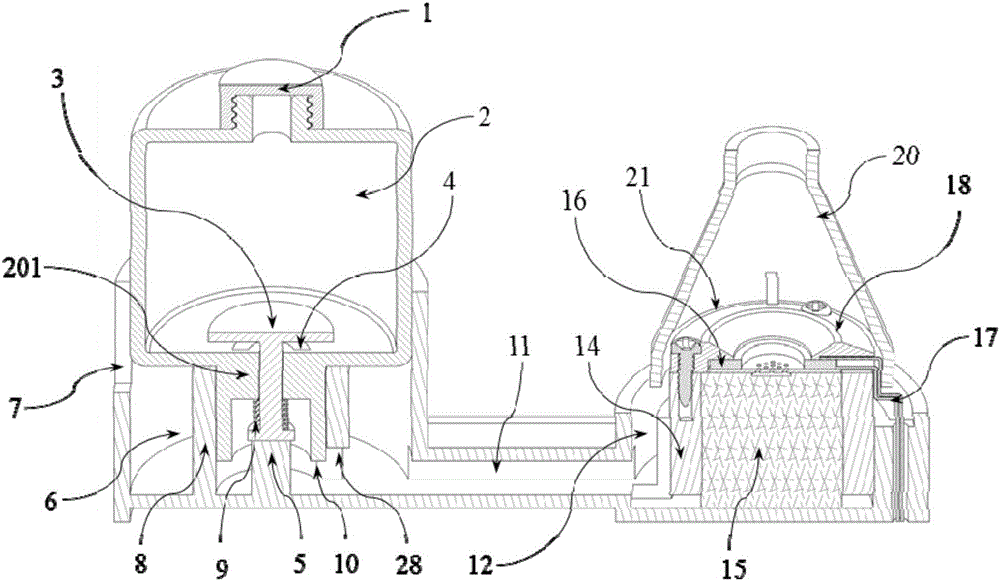

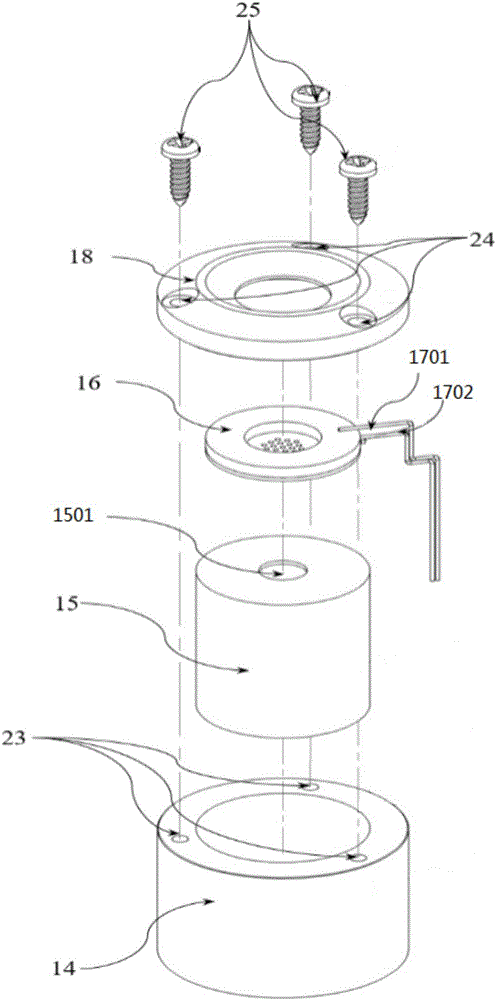

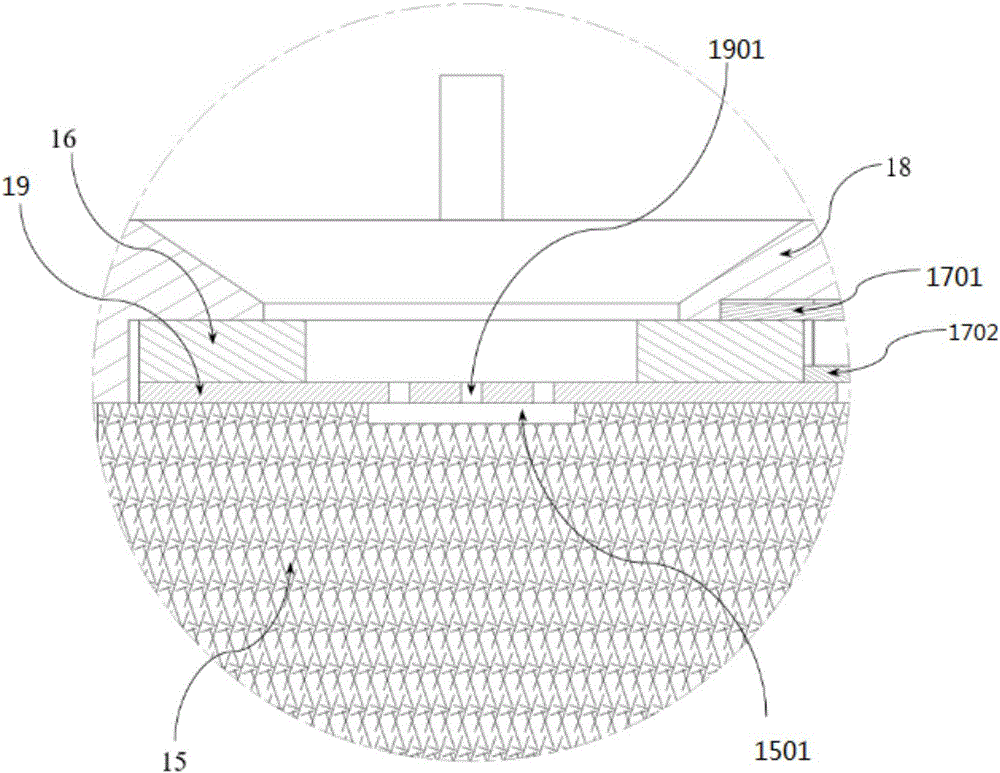

Ultrasonic atomization structure and ultrasonic atomization device using the same

ActiveCN106422005AAvoid overheating problemsChange spray directionEfficient regulation technologiesMedical atomisersEngineeringUltrasonic atomization

The invention discloses an ultrasonic atomization structure and an ultrasonic atomization device using the same. The ultrasonic atomization structure comprises a liquid receiving tank 12, a liquid absorption medium 15 and an atomization unit, wherein the liquid absorption medium 15 is arranged in the liquid receiving tank 12, and the bottom surface of the liquid absorption medium 15 is immersed in liquid in the liquid receiving tank 12. When the ultrasonic atomization structure is used, the liquid absorption medium 15 absorbs the liquid in the liquid receiving tank 12 and conveys the liquid to one end of the liquid imbibition medium 15, far from the bottom surface of the liquid absorption medium 15, the atomization unit is attached to the end of the liquid absorption medium 15, far from the bottom surface of the liquid absorption medium 15, and the end of the liquid absorption medium 15, far from the bottom surface of the liquid absorption medium 15, is provided with a groove 1501. The ultrasonic atomization structure and the ultrasonic atomization device using the same can atomize the high viscosity liquid into fine drops, and can not cause a superheating phenomenon to the atomization unit.

Owner:アコースティックアークインターナショナルリミテッド

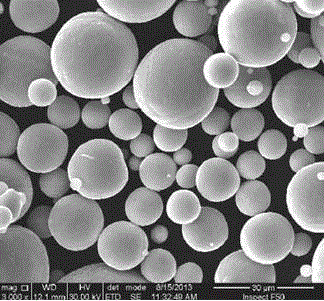

Technique for preparing special Ti6Al4V alloy powder used for material increase manufacturing

The invention discloses a technique for preparing special Ti6Al4V alloy powder used for material increase manufacturing. The technique organically combines vacuumized and water-cooled copper crucible induction smelting with multistage ultrasonic atomization on the basis of ensuring the purity of raw materials, ensures that titanium alloy is not oxidized and metal melt is uniform in temperature and ingredient during smelting to obtain consistent degree of superheat, and can prevent nozzle blockage as well as prevent that liquid drops adhere in the cooling process to from nonspherical particles; powder particles are relatively thinner and uniform and can reach high standards of requirements on particle size distribution, apparent density, oxygen content, liquidity and other performances.

Owner:四川省有色冶金研究院有限公司

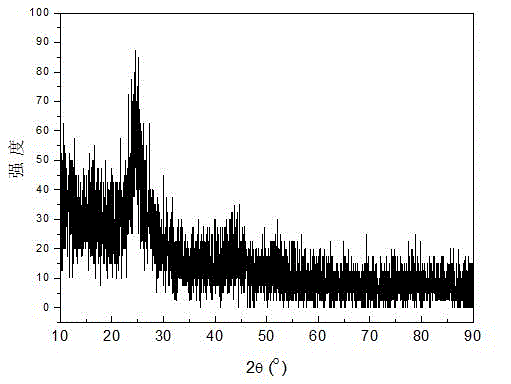

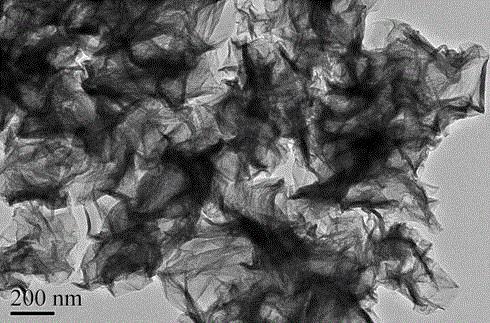

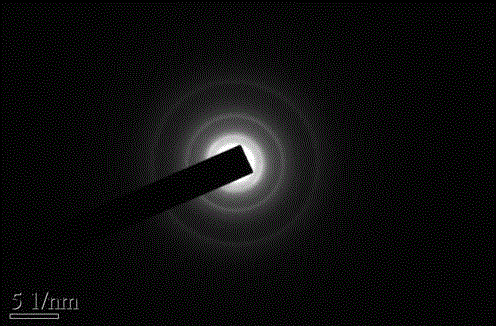

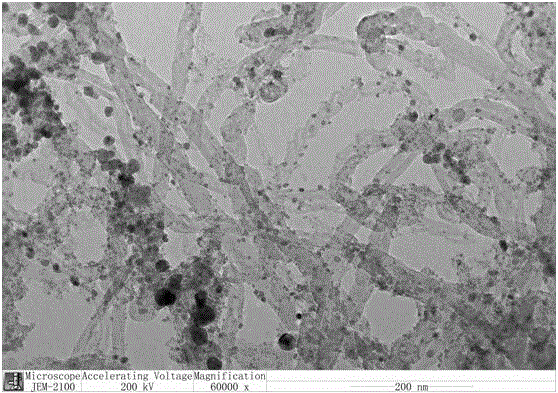

Preparation method of cobalt oxide/graphene composite nano material

InactiveCN103145199ASimple processShort preparation timeMaterial nanotechnologyGrapheneNitrogen gasOrganic fuel

The invention relates to a preparation method of a cobalt oxide / graphene composite nano material, which is characterized by comprising the following steps: (1) preparing a 0.01-1.00 mol / L cobalt nitrate-organic fuel mixed solution, wherein the mol ratio of organic fuel to metal ions is 0.9-2; (2) preparing a 0.1-1.0 mg / ml graphene oxide dispersion solution; (3) calculating the volumes of the mixed solution obtained in the step (1) and the graphene oxide dispersion solution obtained in the step (2) according to the mass ratio of cobalt oxide to graphene in the designed product and the required preparation amounts, and mixing the mixed solution and the graphene oxide dispersion solution by ultrasonic to obtain a dispersion solution for atomization; (4) filling the dispersion solution obtained in the step (3) into an ultrasonic atomization device, carrying the generated atomized liquid drops into a 500-1100 DEG C pipe furnace by argon or nitrogen gas at the flow rate of 0.3-1.2 L / minute, and initiating solution combustion reaction; and (5) collecting the solid reaction product. The invention has the advantages of shorter technical procedure, simple synthesis equipment and continuous preparation process, can directly obtain the final powder product by one step, and can easily implement industrialized preparation.

Owner:NANCHANG UNIV

Electronic cigarette with ultrasonic atomization function and tobacco liquid

The invention discloses an electronic cigarette with an ultrasonic atomization function and tobacco liquid. An ultrasonic liquid atomization mode is set, and compared with general liquid heating atomization, the atomization rate of ultrasonic atomization is improved. Especially, the tobacco liquid is automatically sucked out of a tobacco liquid storage bin through a liquid level adjuster to be atomized by an ultrasonic atomizer, and compared with a current fiber absorption mode and the like, liquid waste is avoided, and meanwhile it can be guaranteed that airflow is sufficient after atomization. Meanwhile, due to the fact that the tobacco liquid directly enters the ultrasonic atomizer, the atomization rate can be further improved, atomization components can be even relatively, and the taste of a smoker can be proper. In addition, high-concentration propylene glycol and glycerin components are removed from the components of the tobacco liquid, and the taste of the smoker can be more comfortable.

Owner:上海德明生物科技有限公司

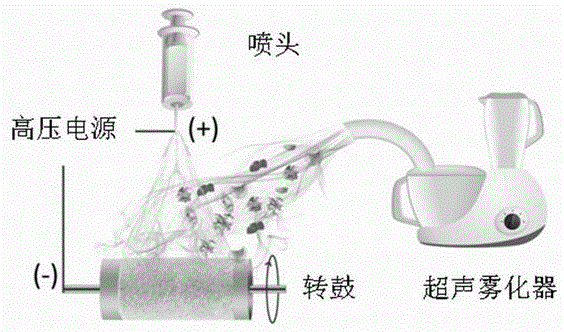

Ultrasonic atomization assisted electrospinning technique

InactiveCN105568401ARealize atomized sprayAchieve cloggingElectro-spinningArtifical filament manufactureFiberSpinning

The invention discloses an ultrasonic atomization assisted electrospinning technique and belongs to the field of preparation and applications of nano materials. According to the technique, prepared graphene, graphene oxide, carbon nano tubes and other nanoparticles are dispersed in a storage tank of an ultrasonic atomizer, atomization spraying of the nanoparticles is realized, and the problem of nanoparticle blocking caused with a conventional mixing method is solved. Ultrasonic atomization and electrospinning techniques are combined for use, a prepared nanoparticle polymer composite film has uniformly mixed nanoparticles, and agglomeration is not easily caused. The polymer fiber film prepared with the technique has high separation efficiency, good strength and excellent water resistance, and the physical and chemical properties of the composite film material are improved. Compared with a conventional electrospinning technique, graphene and the carbon nano tubes can be mixed in any ratio, the conventional blocking problem of an electrospinning sprayer is solved, and the technique has important application prospect in environment treatment and electrode material preparation.

Owner:DALIAN UNIV OF TECH

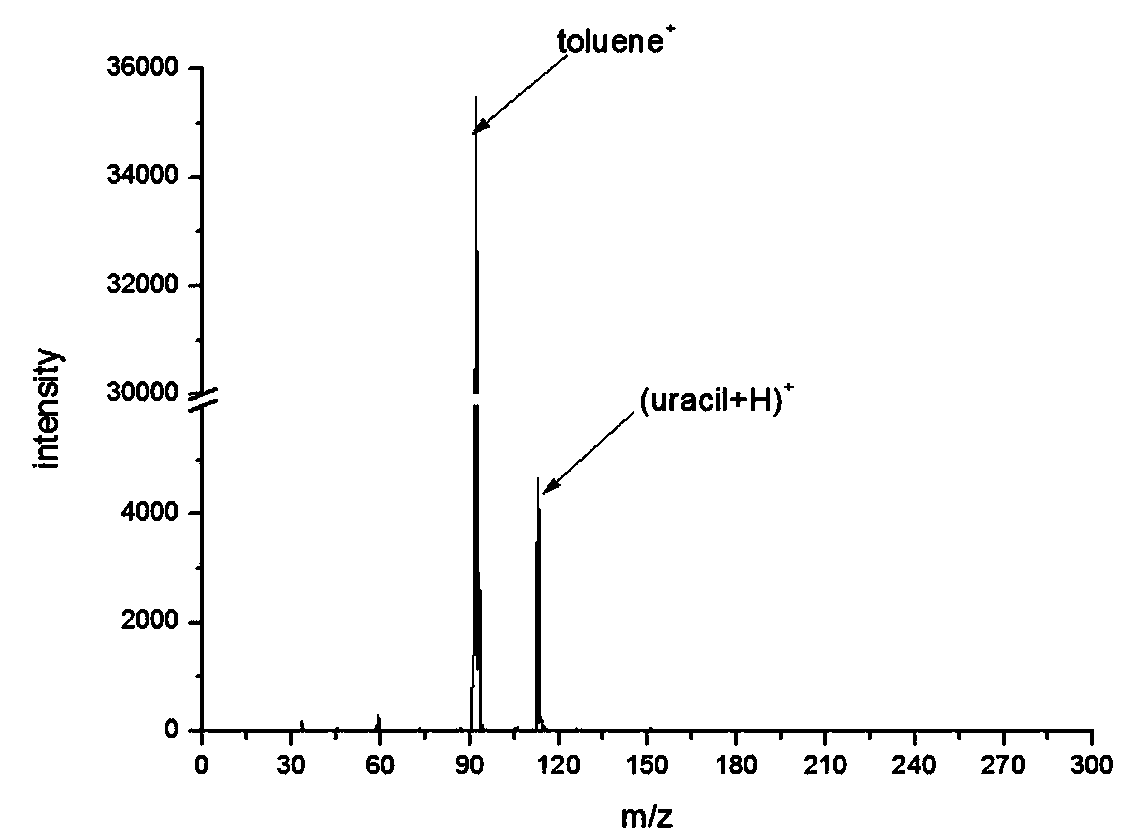

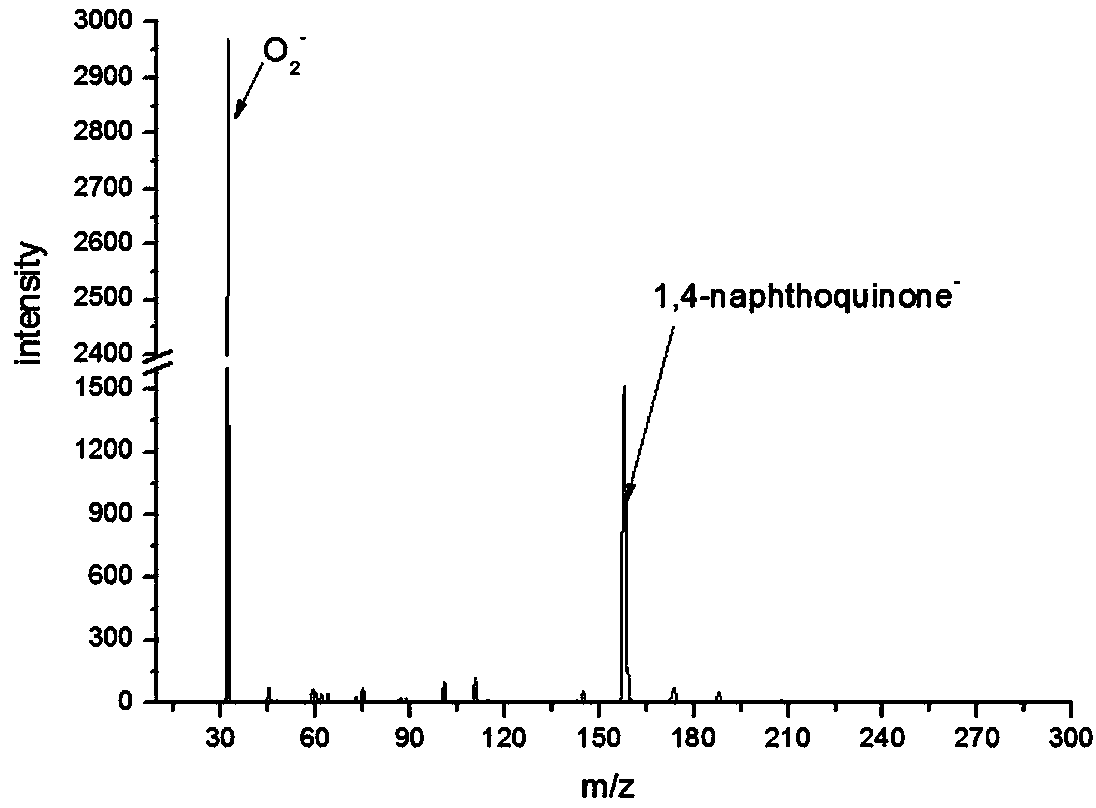

Ultrasonic atomization sample introduction volatile solvent assisting ionization low-pressure photo ionization mass spectrum device

ActiveCN103762150AGreat application potentialNot volatileSamples introduction/extractionIon sources/gunsMass analyzerPhoto ionization

The invention relates to an ultrasonic atomization sample introduction volatile solvent assisting ionization low-pressure photo ionization mass spectrum device. The device comprises a mass spectrum mechanism. The mass spectrum mechanism comprises a mass spectrum room and a photo ionization room, wherein the mass spectrum room and the photo ionization room are adjacent to each other and are connected together. A rear sampling cone is arranged on one side wall of the mass spectrum room, a mass spectrum room vacuum pump connector is arranged on the other side wall of the mass spectrum room, an ion conveying system and a mass analyzer are arranged in the mass spectrum room, the rear sampling cone stretches into the photo ionization room, a front sampling cone is arranged on one side of the photo ionization room, a photo ionization room vacuum connector is arranged on the other side of the photo ionization room, and a vacuum ultraviolet light source is arranged on the top of the photo ionization room. The device further comprises an ultrasonic atomization mechanism, a heating and gasification mechanism and a volatile solvent introducing mechanism. Objects, not prone to volatilization, to be measured are directly sampled through ultrasonic atomization and heating and gasifying of desolventizing agents without preprocessing, and therefore flexible and fast mass spectrum analysis is achieved, and the device has wide application prospects in aspects like food, pesticides and environment fast mass spectrum analysis.

Owner:UNIV OF SCI & TECH OF CHINA

Natural focusing type ultrasonic atomization nozzle

ActiveCN104324839AReduce volumeEvenly distributedLiquid spraying apparatusPrintingTransformerEngineering

Owner:千藤(南京)环保科技有限公司

Composite medium film material based on polyvinylidene fluoride and graphene, and preparation method thereof

InactiveCN102729562AStay flexibleEasy to processSynthetic resin layered productsComposite mediaPolyvinylidene difluoride

The invention which discloses a composite medium film material based on polyvinylidene fluoride and graphene, and a preparation method thereof belongs to the technical field of electric functional materials. The composite medium film is obtained through compounding polyvinylidene fluoride and graphene, wherein the graphene mass percent content is 0.5-3% of the mass of the composite medium film. The preparation method comprises the following steps: preparing an organic solution (a system A) of polyvinylidene fluoride powder; adding graphene powder to the system A to obtain a system B; spraying the system B on the surface of a substrate through adopting an ultrasonic atomization technology; and drying the system B sprayed on the surface of the substrate to obtain the composite medium film material based on the polyvinylidene fluoride and the graphene. According to the invention, the graphene which approaches and does not exceed a percolation threshold is added to a polyvinylidene fluoride film to obtain the composite medium film material with the dielectric constant 100% higher than that of the pure polyvinylidene fluoride film material, and the original flexibility and the easy processability are maintained; and the preparation method has the advantages of simplicity, easy control and low cost.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method and device for uniformly cladding metallic silver on surface of carbon nano tube

ActiveCN106270500ASimplify the experimental processEasy to realize continuous preparationTransportation and packagingMetal-working apparatusChemical platingDecomposition

The invention discloses a method and a device for uniformly cladding metallic silver on the surface of a carbon nano tube. The method comprises the steps of preprocessing the carbon nano tube, preparing a silver-ammonia solution and a chemical plating solution, and adopting the device provided by the invention to carry out chemical plating, wherein the device comprises a vacuum pump, a collection bottle, a quartz tube, an ultrasonic atomizer, a microwave-assisted heater, a microwave leakage prevention device and a carrier gas conveyor device; carrying out ultrasonic atomization on the two solutions, contacting and mixing the two atomized matters to react, repetitively washing powder to be neutral, and drying to obtain the carbon nano tube with the surface uniformly cladded by the metallic silver. The carbon nano tube is dispersed in spray droplets, so that the dispersibility of the carbon nano tube and silver plating is improved, the phenomenon of self-decomposition of the solution in a conventional chemical plating method, the generation of large-particle monomer silver and the occurrence of silver mirror reaction are avoided, the prepared cladding layer is uniform, and the sliver particle size is nano-scaled; the whole process is simple, the device is simple and convenient, convenient to operate, and energy-saving and environmental-friendly, and mass production can be realized.

Owner:KUNMING UNIV OF SCI & TECH

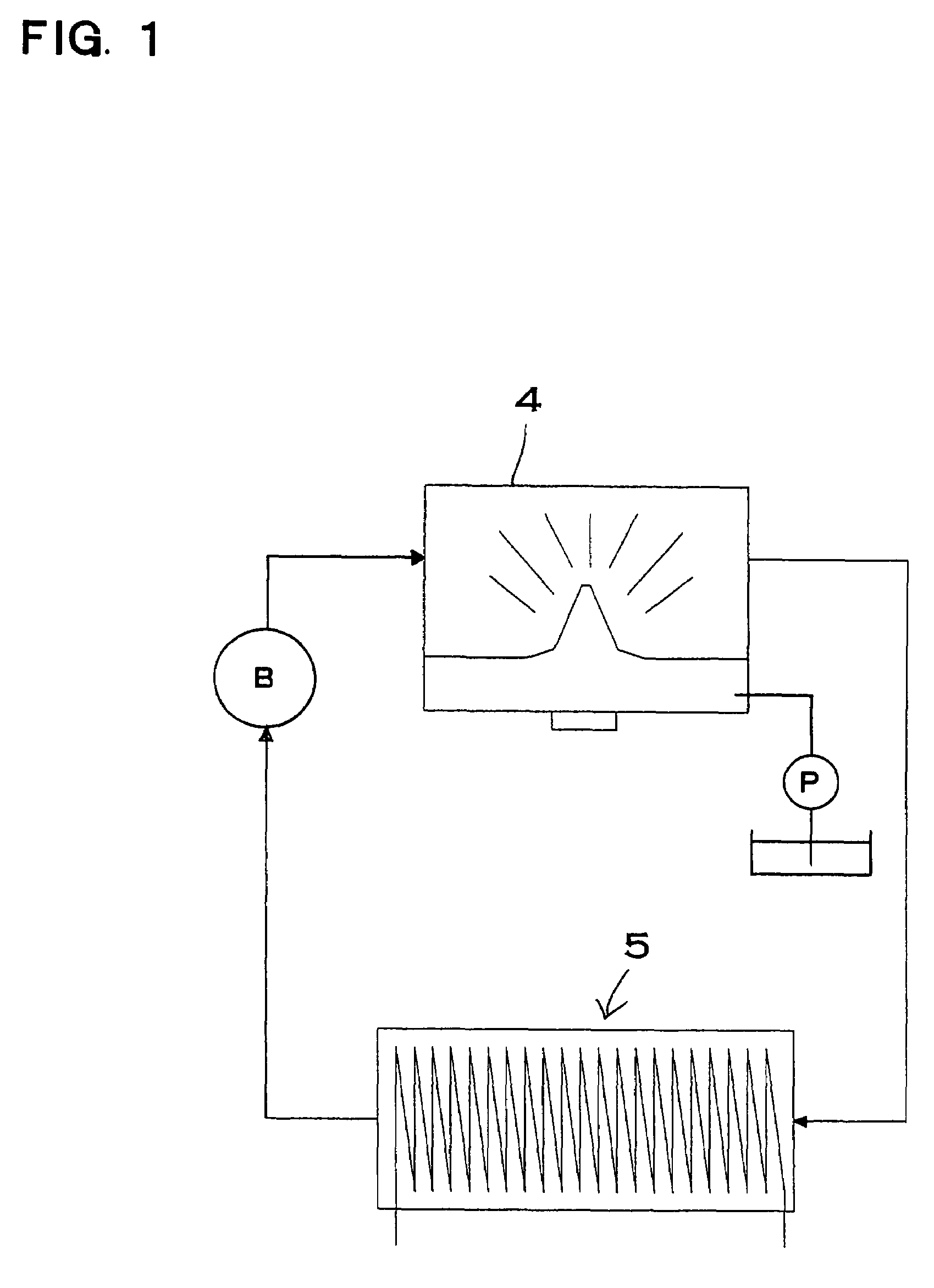

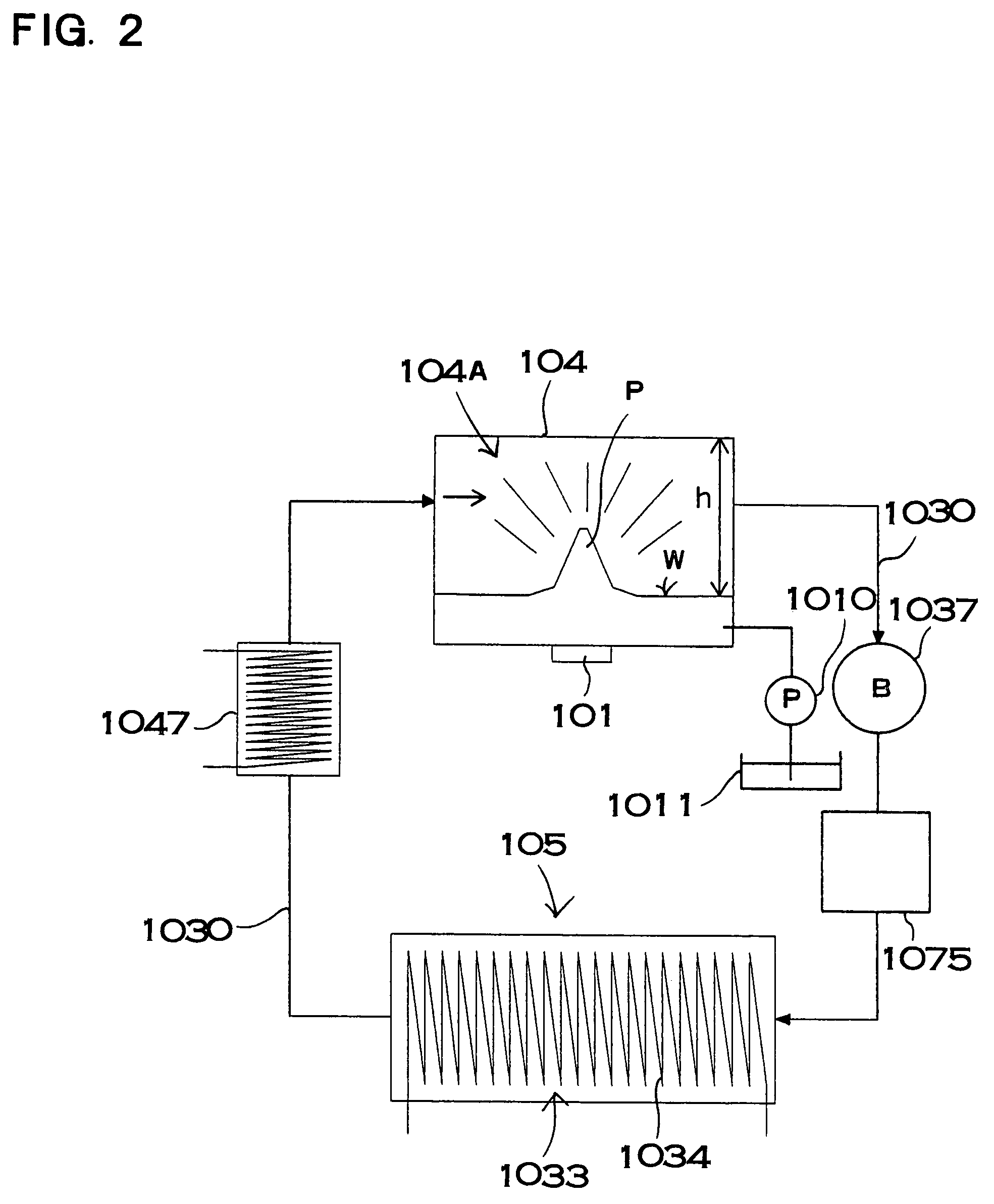

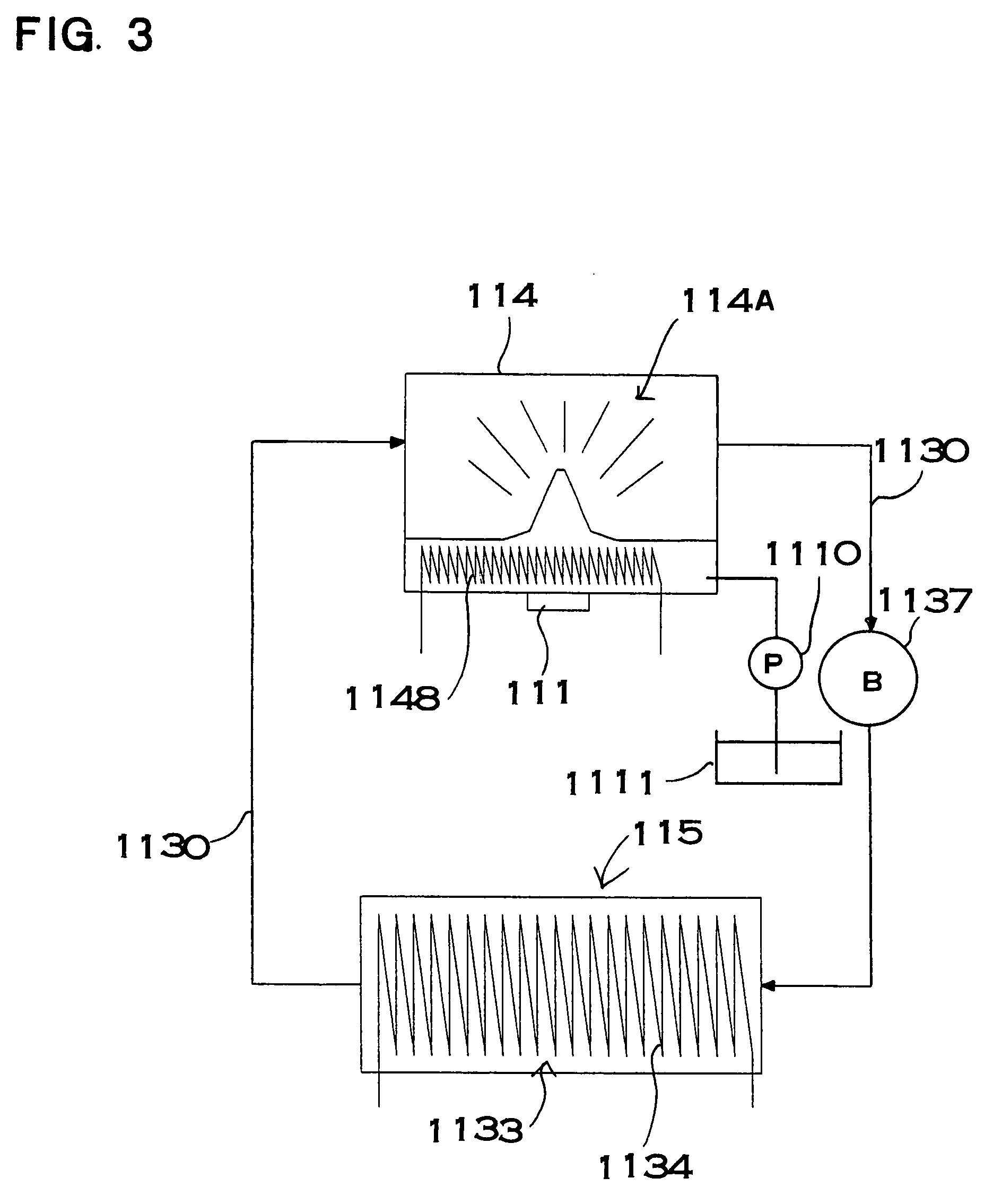

Ultrasonic solution separator

ActiveUS7347889B2Efficient productionEfficient separationThermo-electric condensationCombination devicesHigh frequency powerUltrasonic atomization

An ultrasonic solution separator including an ultrasonic atomization chamber supplied with a solution containing a target material; an ultrasonic oscillator producing mist from the solution in the ultrasonic atomization chamber with ultrasonic oscillation; a power supply for ultrasonics connected to the ultrasonic oscillator, and a collection portion transporting the mist produced by the ultrasonic oscillator with a carrier gas and aggregating and collecting the mist included in the carrier gas. The power supply supplying high-frequency power to the ultrasonic oscillator so that the ultrasonic oscillator oscillates at an ultrasonic frequency. The ultrasonic separator aggregates and collects the mist produced in the ultrasonic atomization chamber by means of the collection portion. With this ultrasonic solution separator, the temperature of carrier gas in the ultrasonic atomization chamber is at least 5° C. higher than the carrier gas in the collection portion.

Owner:ULTRASOUND BREWERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com