Patents

Literature

22596results about How to "Achieve recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

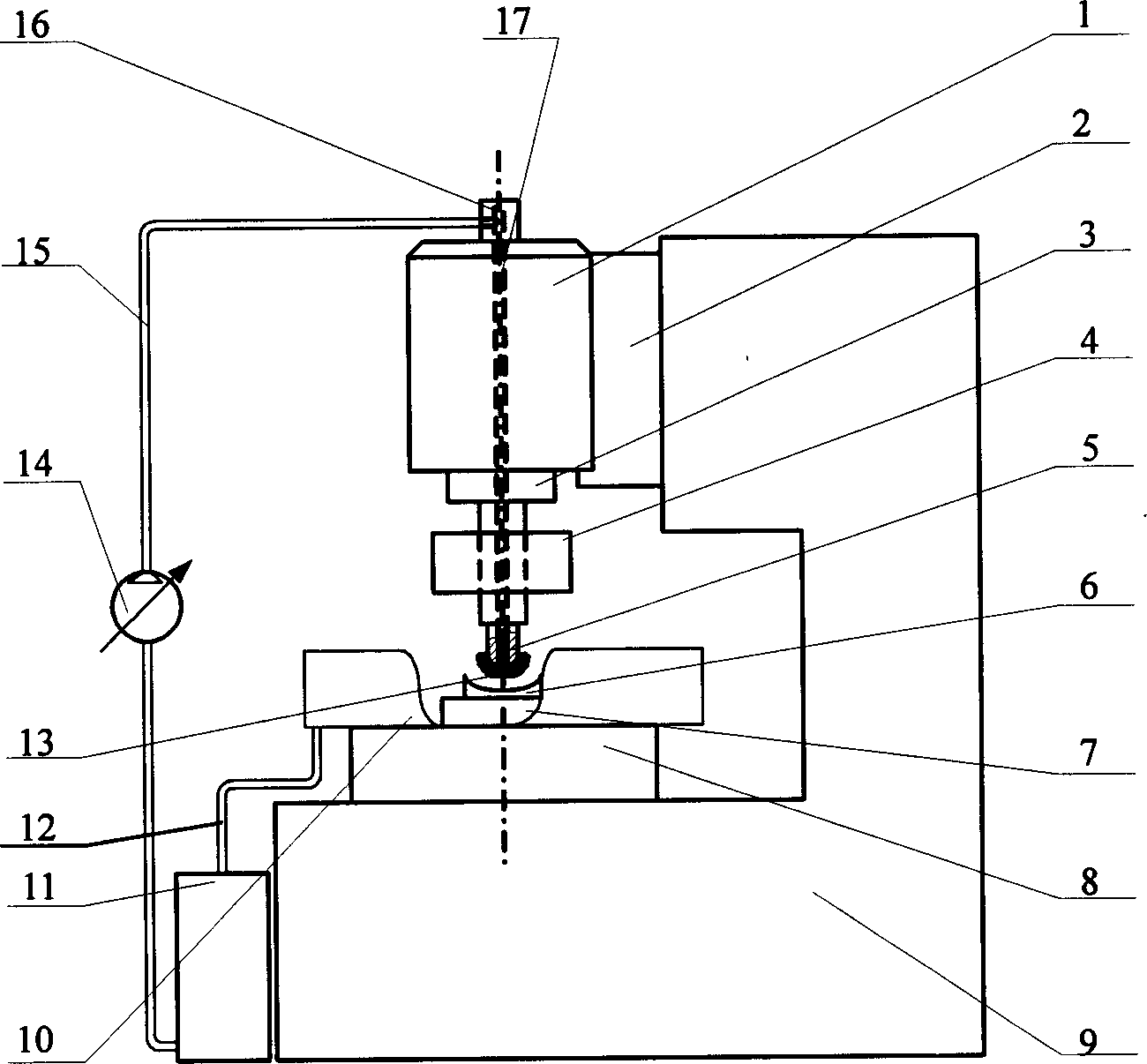

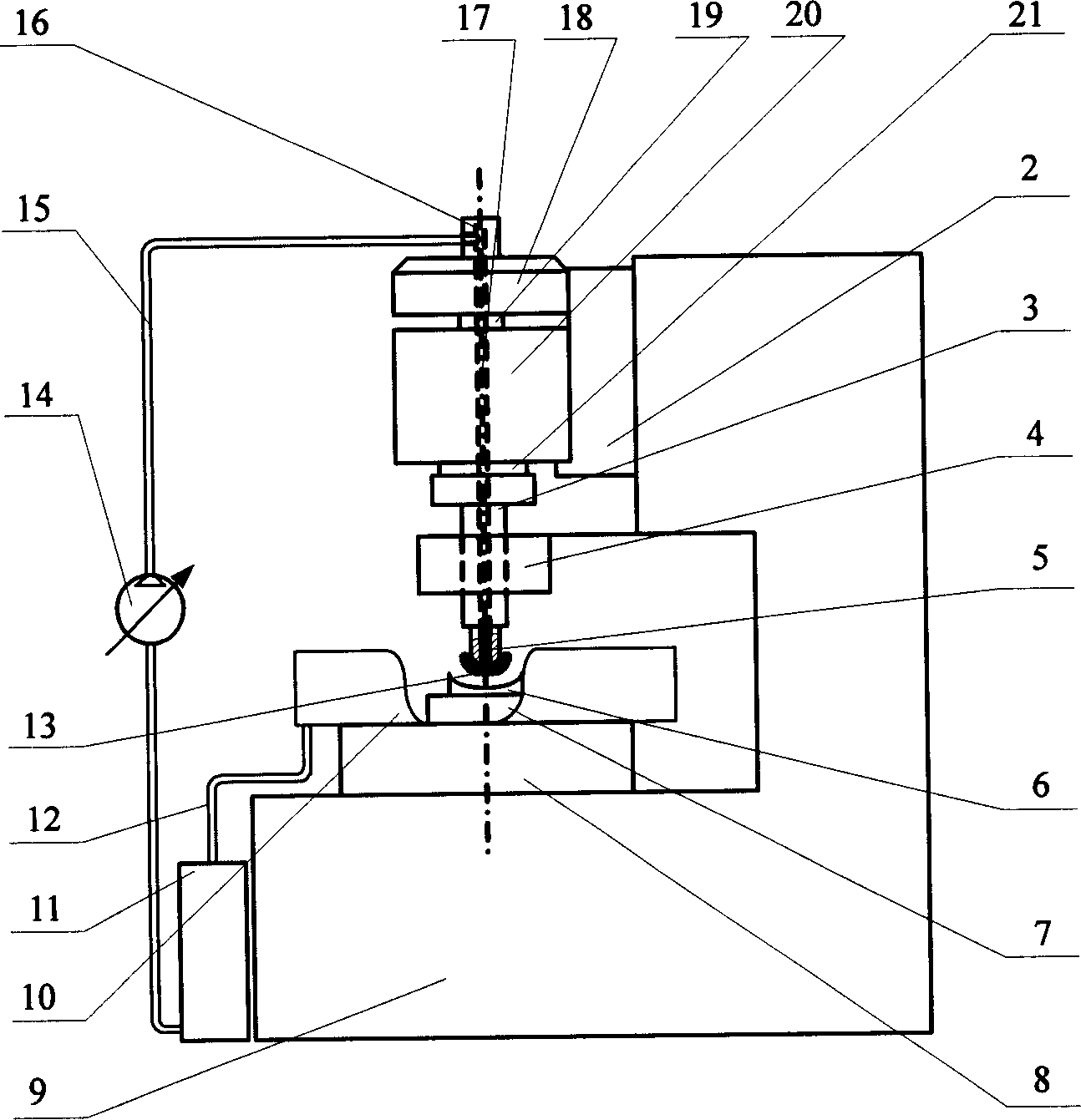

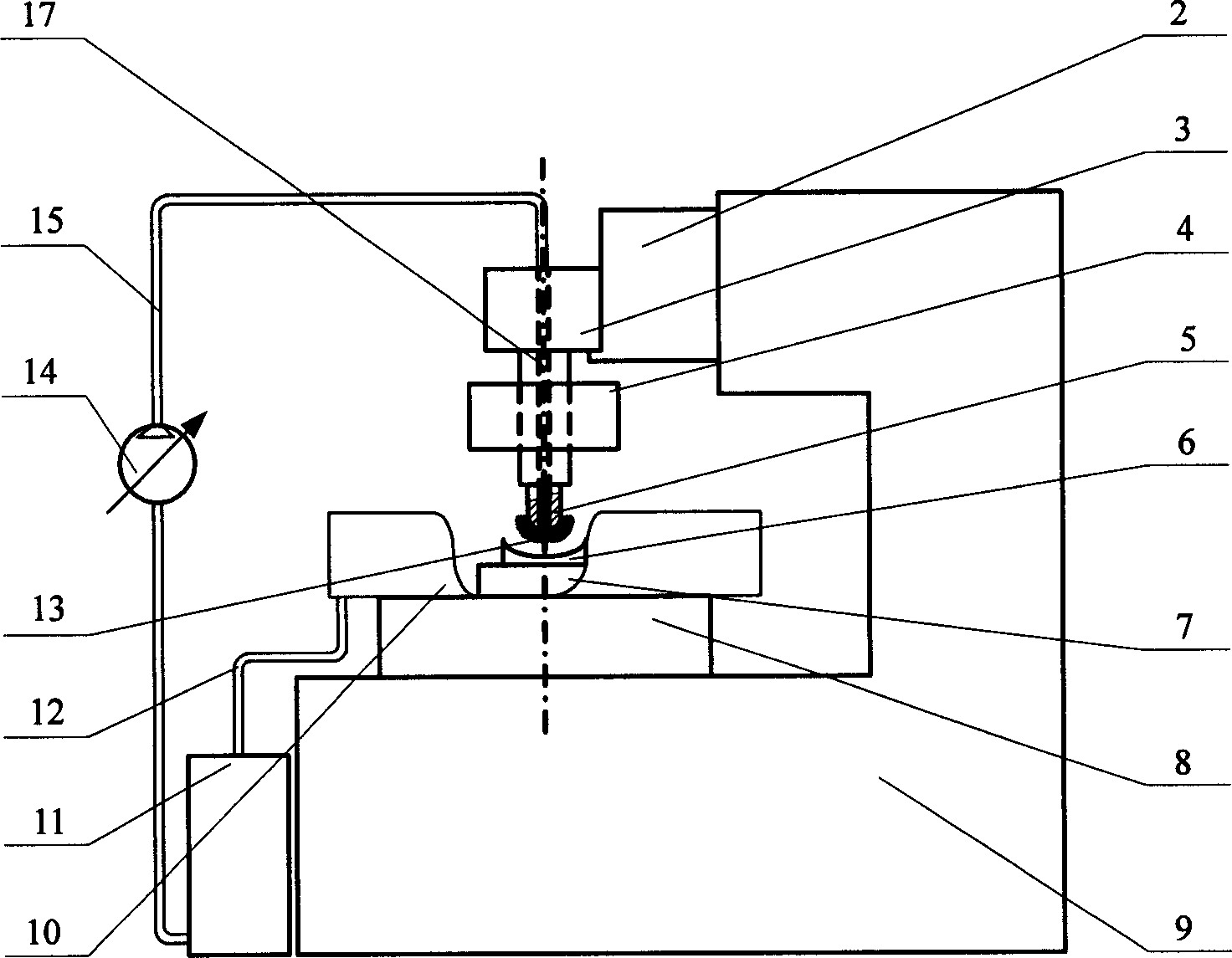

Ultrasonic magnetic rheological composite polishing method and polisher thereof

InactiveCN1613605AAchieve recyclingStable Polishing PropertiesOptical surface grinding machinesUltrasonic vibrationEngineering

An ultrasonic-magnetorheologic polishing method features that the mixture of abrasive material and magnetorheologic liquid is filled in a small-diameter rotary hollow polishing head and a magnetic field is applied to it to make the magnetorheologic liquid become flexible polishing liquid on the polishing head while the ultrasonic vibration is applied to it for higher polishing effect. Its apparatus is composed of polishing head, ultrasonic generator, and electromagnet.

Owner:HARBIN INST OF TECH

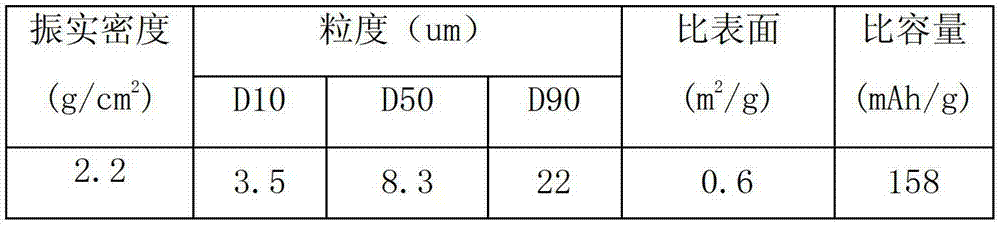

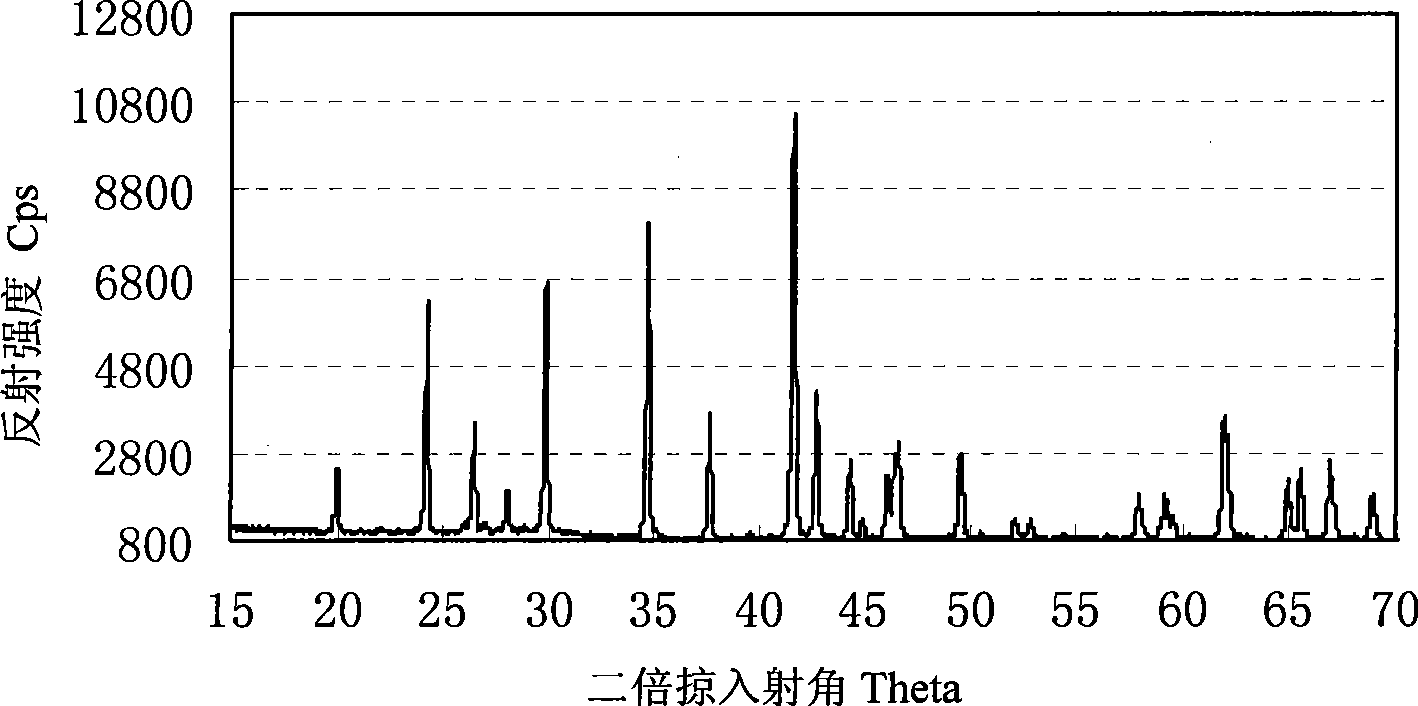

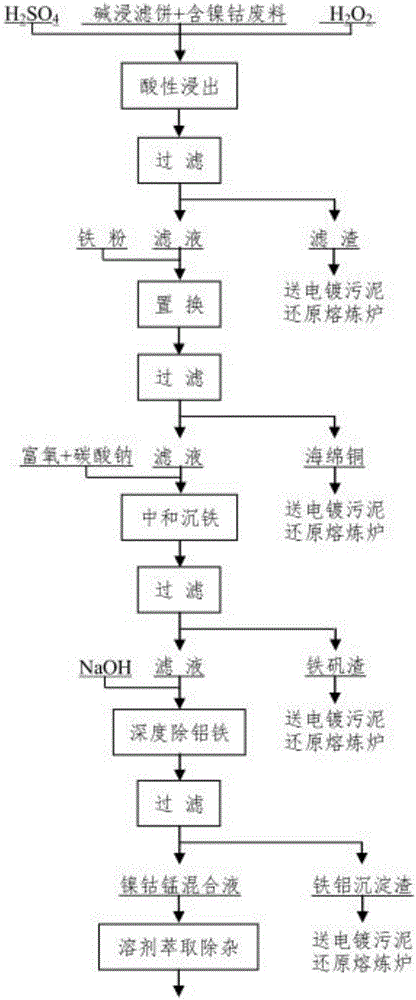

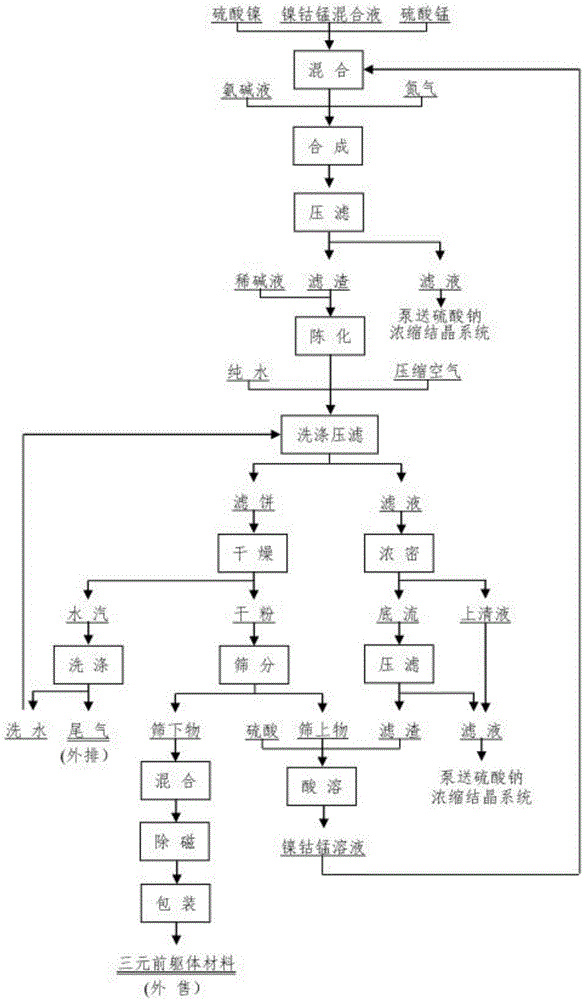

Method for recycling nickel-cobalt-manganese ternary anode material

ActiveCN103199320AAchieve recyclingPromote sustainable developmentWaste accumulators reclaimingNickel compoundsManganeseCobalt

The invention relates to a method for recycling a nickel-cobalt-manganese ternary anode material, belongs to the technical field of recovery of waste cells, and solves the technical problem that a method for recycling the nickel-cobalt-manganese ternary anode material is provided. The method for recycling the nickel-cobalt-manganese ternary anode material comprises a step of removing a binder from the positiveplate of the nickel-cobalt-manganese ternary material by thermal treatment, and the method for removing the binder in the positive plate of the nickel-cobalt-manganese ternary material is thermal treatment of the positive plate of the nickel-cobalt-manganese ternary anode material at 400-1000 DEG C for 0.5-5 hours.

Owner:天齐锂业(江苏)有限公司 +2

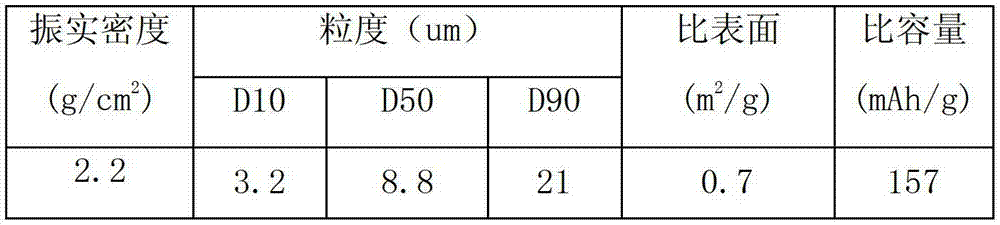

Method for zero emission treatment of desulfurization waste water based on flue gas waste heat evaporation

InactiveCN105481157AReduce membrane fouling and cloggingExtend membrane lifeGeneral water supply conservationWater contaminantsZero emissionFlue gas

The invention discloses a method for zero emission treatment of desulfurization waste water based on flue gas waste heat evaporation. In the method, three systems, namely a double-alkali method pretreatment system, a membrane filtration desalination concentration decrement system and a flue gas bypass evaporation tower evaporation zero emission system, are used. The method is characterized in that the double-alkali method pretreatment is adopted to soften, flocculate and clarify the desulfurization waste water, membrane filtration desalination is utilized to perform desalination concentration decrement for clarified liquor, demineralized water is recyclable, concentrated liquor is sent to the flue gas bypass evaporation tower to be evaporated by boiler flue gas waste heat, gas state vapor enters a desulfurizing absorption tower along with the flue gas to perform condensation recovery, crystal substances and coal ash are discharged together, the purpose of completely recycling the desulfurization waste water is achieved, and the zero emission of the desulfurization waste water and high salinity wastewater is achieved. The method has the advantages that the technology is simple, the boiler flue gas waste heat is utilized to perform evaporation, and the method is low in investment and operation cost and high in practicability. The method achieves low cost zero emission of the desulfurization waste water and has wide popularization and utilization value.

Owner:王辛平

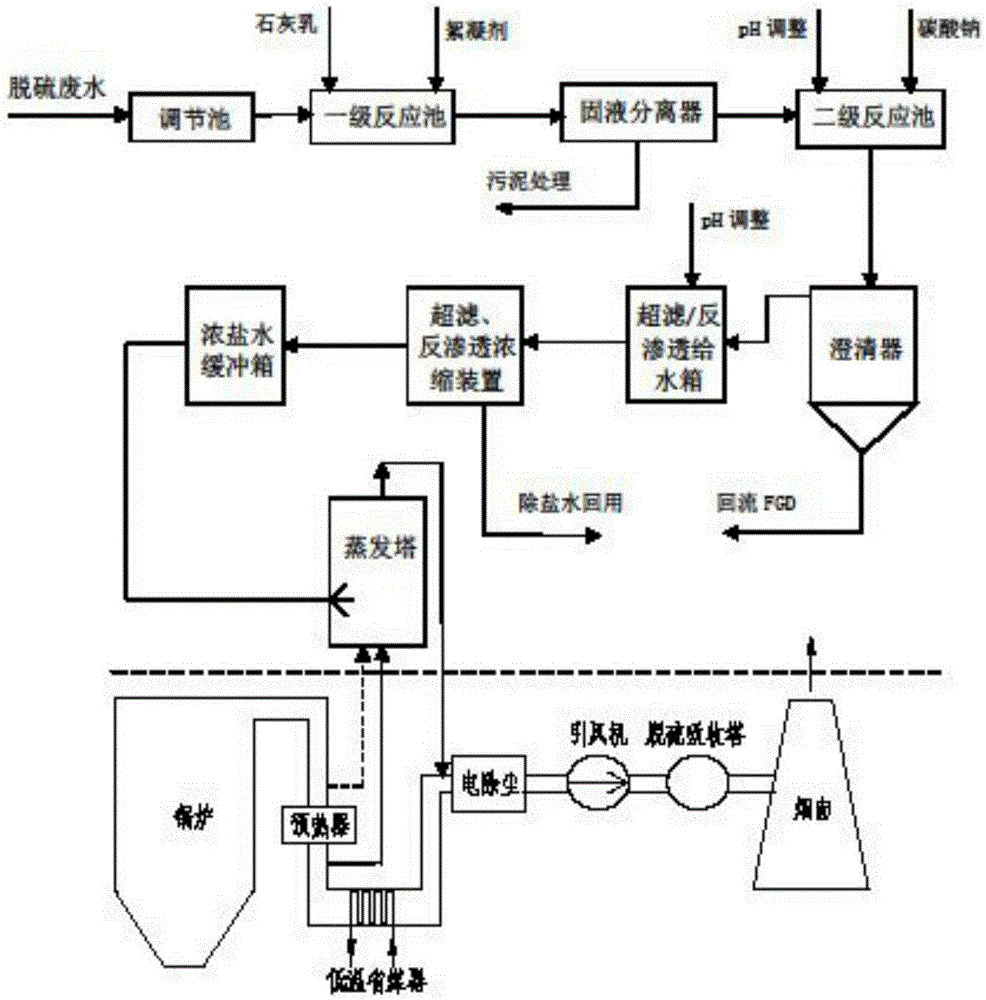

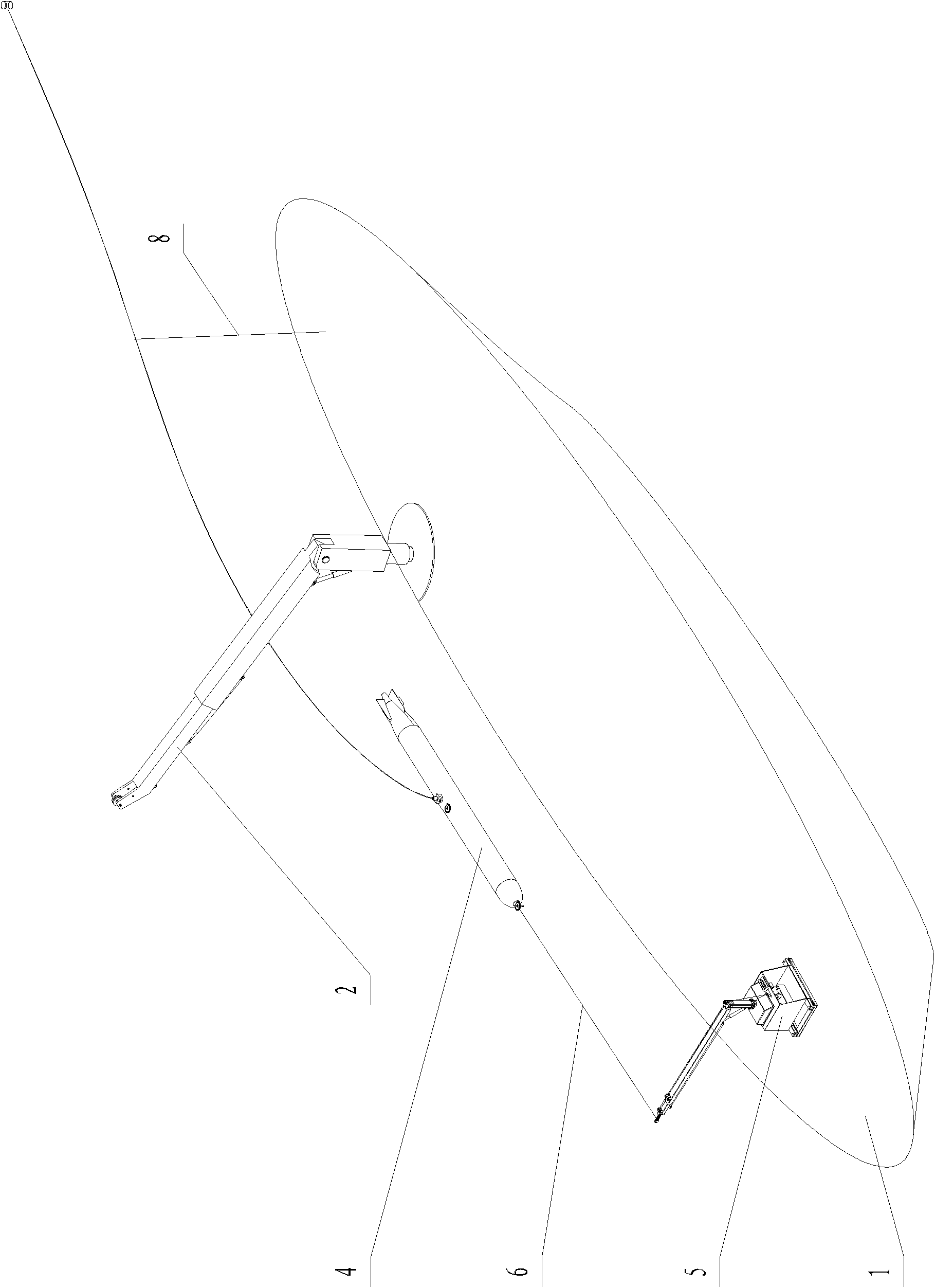

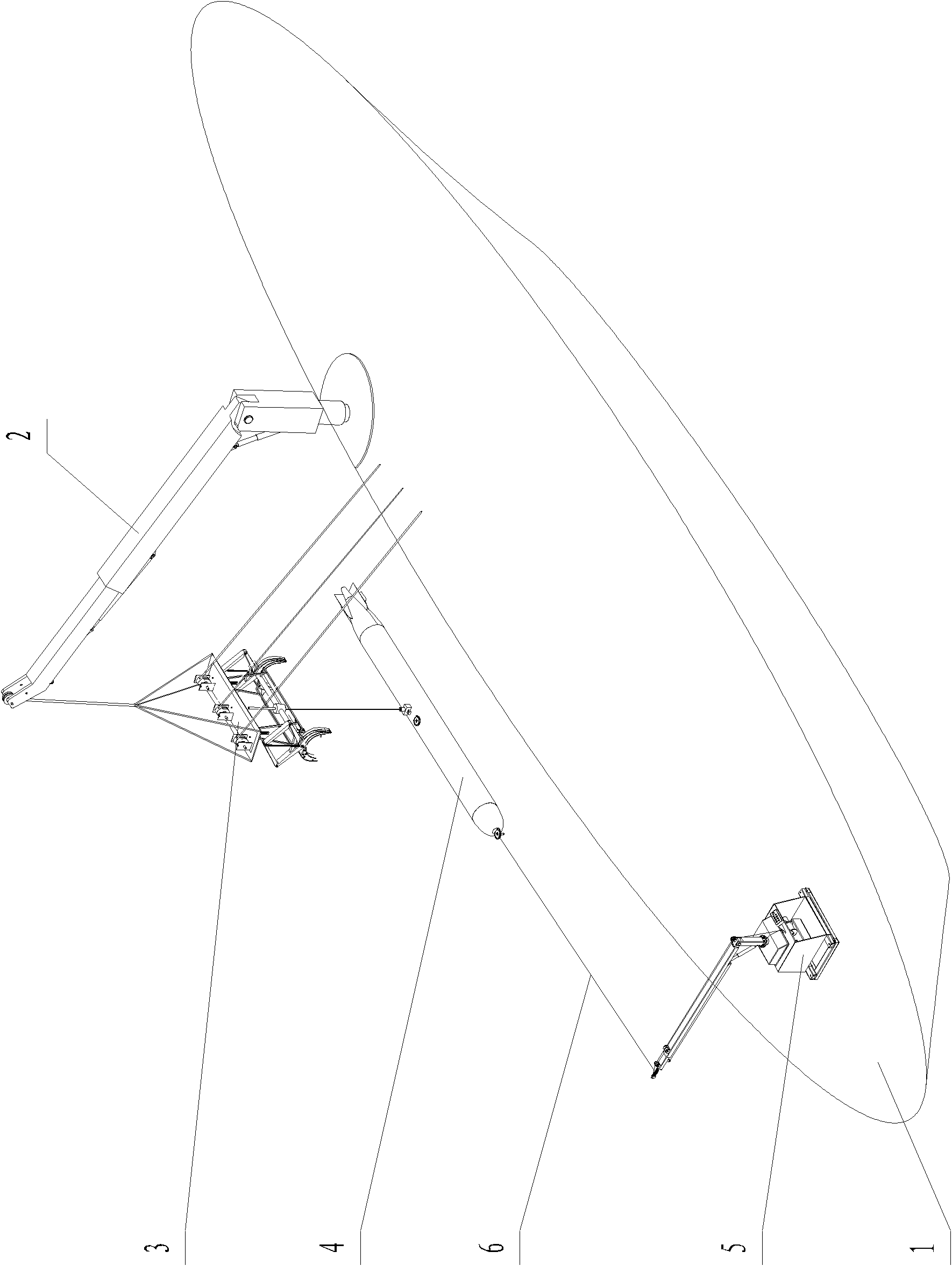

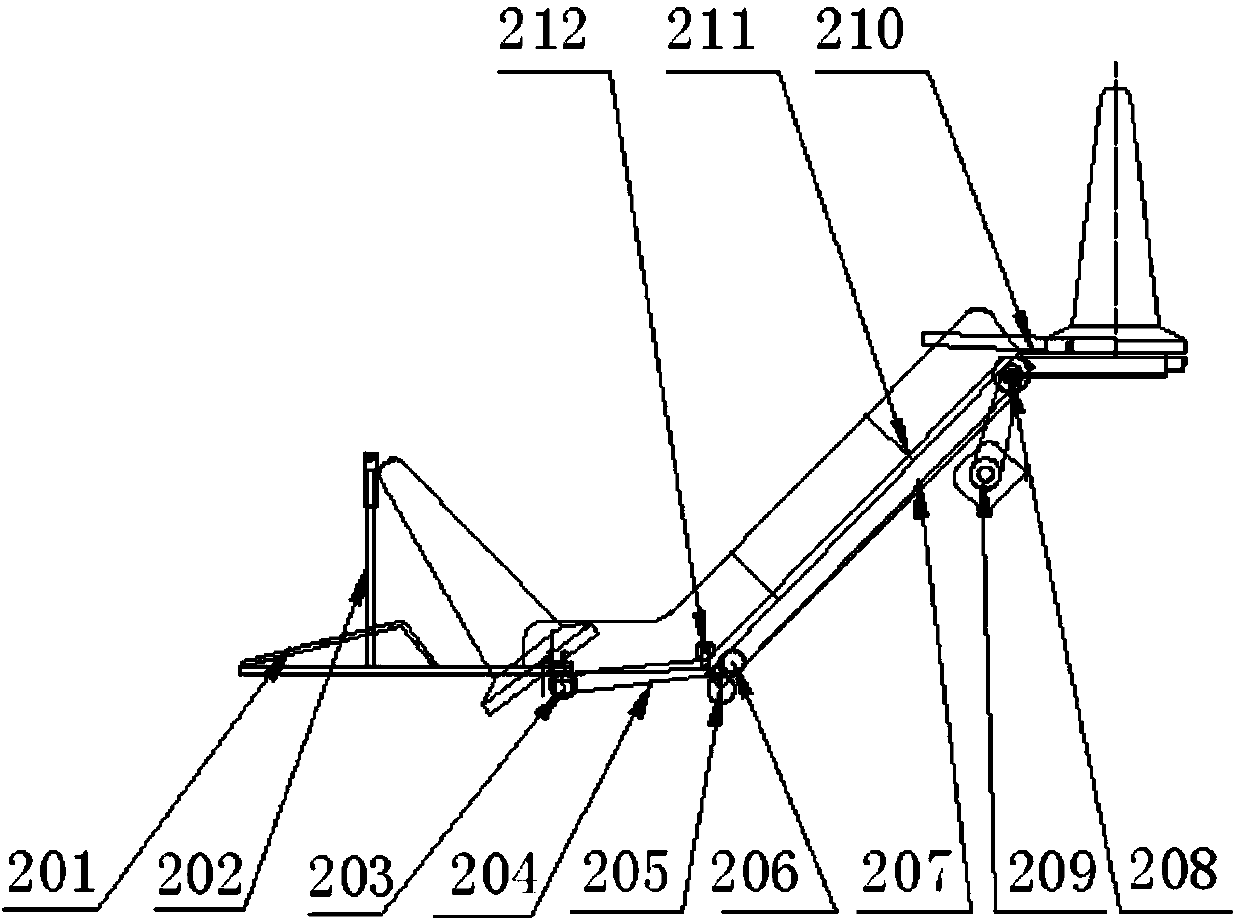

Underwater robot recovery system and recovery method thereof

The invention belongs to the field of underwater robots, and specifically relates to an underwater robot recovery system and a recovery method thereof. The system includes a mother ship, an underwater robot, an automatic line throwing device and a lifting seat arranged on the underwater robot, a butting lifting device and a draw gear. After the underwater robot completes the mission, a haulage rope is thrown out from the ship bow. The staff on the mother ship picks up the haulage rope through a rope picking device, and then the rope is traversed through the draw gear. The underwater robot is driven by the mother ship for navigation to overcome the effects of waves in the sea. A guidance rope is thrown by a remote control command. The butting lifting device is driven by a hoist installed on the mother ship, and falls down along the guidance rope to abut with the underwater robot and clamp. The whole recycling process is realized. The underwater robot recovery system of the present invention has the characteristics of compact structure, convenient operation, safety and reliability, small influence by the sea state, no transform to the hoist, and small requirement to the mother ship, and can achieve the laying and recovering by the same system for the underwater robot under four grade sea conditions.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

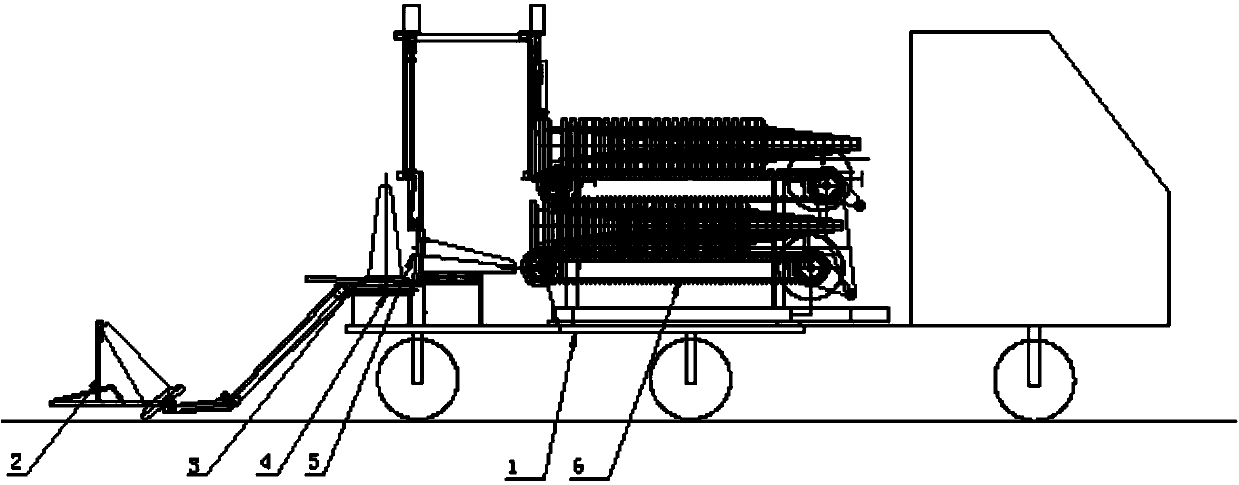

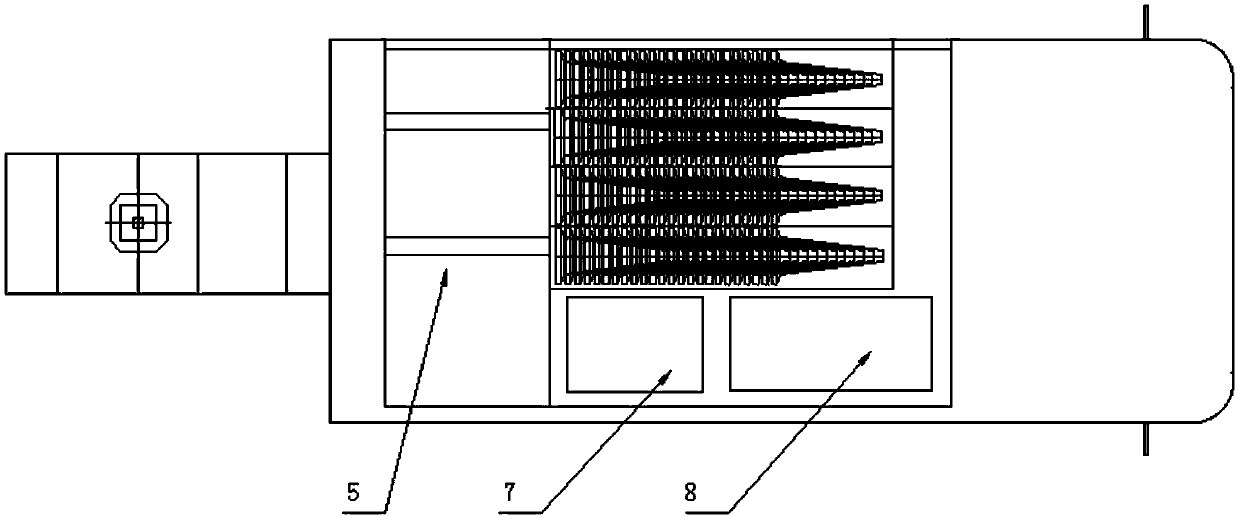

Full automatic traffic cone discharging, collecting and storing special vehicle

ActiveCN103469740ACompact structureEasy to controlTraffic signalsRoad signsDistribution power systemEngineering

The invention discloses a full automatic traffic cone discharging, collecting and storing special vehicle which comprises a discharging and collecting device arranged at the rear end of the vehicle-mounted chassis rear end and connected with a moving device controlling the discharging and collecting device to move. A traffic cone position entering device is arranged on a vehicle-mounted chassis, a conveying device is arranged between the discharging and collecting device and the traffic cone position entering device, and the traffic cone position entering device is connected with a storing device which is of a multi-layer structure and arranged on the vehicle-mounted chassis. The discharging device, the moving device, the conveying device, the traffic cone position entering device and the storing device are connected with an intelligent control system and a power supply and distribution system. The full automatic traffic cone discharging, collecting and storing special vehicle can finish full-automatic discharging, collecting and storing operation of traffic cones at any position in a road and can store a large number of traffic cones automatically to meet traffic cone discharging requirements for short intervals and large strokes, is especially suitable for automatic discharging and collecting of the traffic cones during traffic guiding and temporary road sealing for high ways and urban express ways with large traffic flow.

Owner:BEIJING SHENJIANG AIR COOLED ENGINE +1

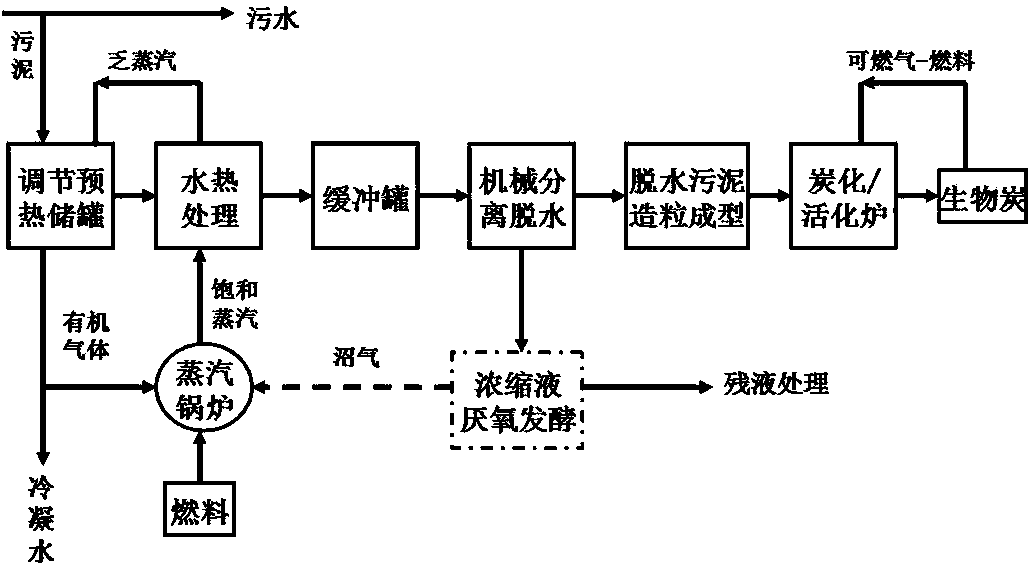

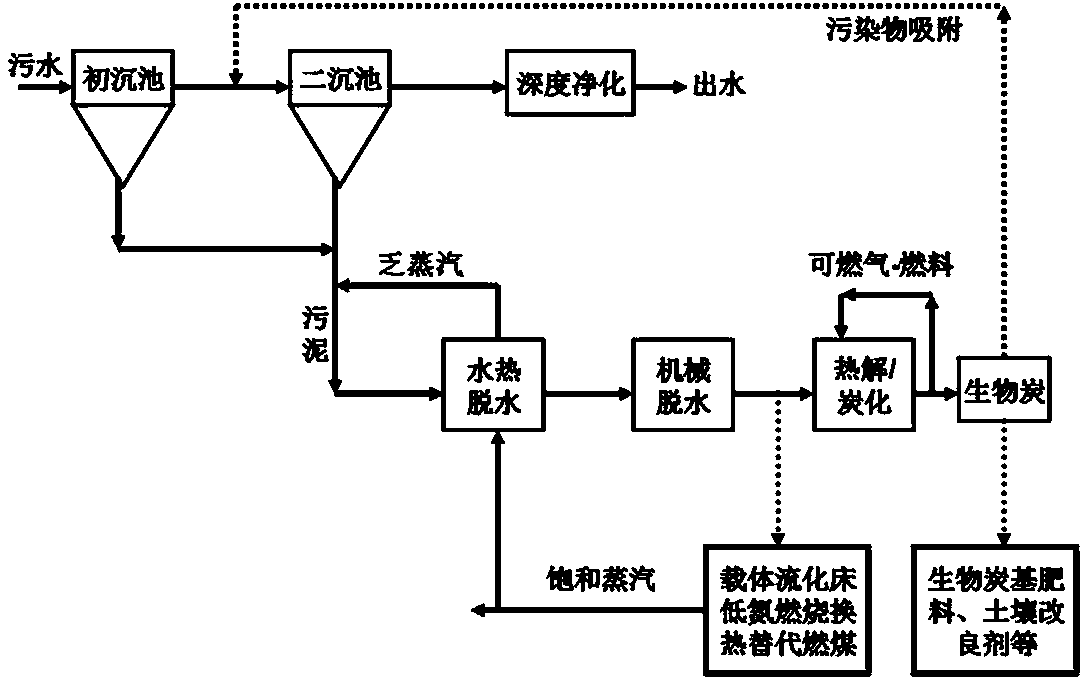

Method for preparing carbon materials by use of sludge

ActiveCN103396815AReduce moisture contentEasy to separateSludge treatment by de-watering/drying/thickeningOther chemical processesEnvironmental chemistryDewatered sludge

The invention provides a method for preparing carbon materials by use of sludge. The method comprises the following steps: preheating of high-water-content sludge to obtain preheated sludge; primary separation of water and solid particles: viscous organic matters in the preheated sludge are hydrolyzed, colloid structures and cell membrane walls of the sludge are destroyed, so that the bound water and the solid particles can be effectively separated; secondary separation of the water and the solid particles; dewatering to obtain dewatered sludge with the water content down to about 40%; and carbonization: preparation of biological carbon. The method also comprises further modification treatment of the biological carbon to prepare adsorption carbon materials. The method also comprises anaerobic fermentation of the dewatered sludge to produce biogas. The adsorption carbon materials prepared by the method can be recycled to a wastewater treatment plant for the adsorption of heavy metals, nitrogen and phosphorus and the organic matters in sewage, and cyclic utilization of the sludge in the wastewater treatment plant can be realized; and the combustible gas generated in the process can be used as a supplementary fuel of a pyrolysis carbonization furnace. The method has the advantages of cyclic utilization, recycle of waste materials and ecological environmental friendliness.

Owner:中科核润(陕西)生态环境有限公司

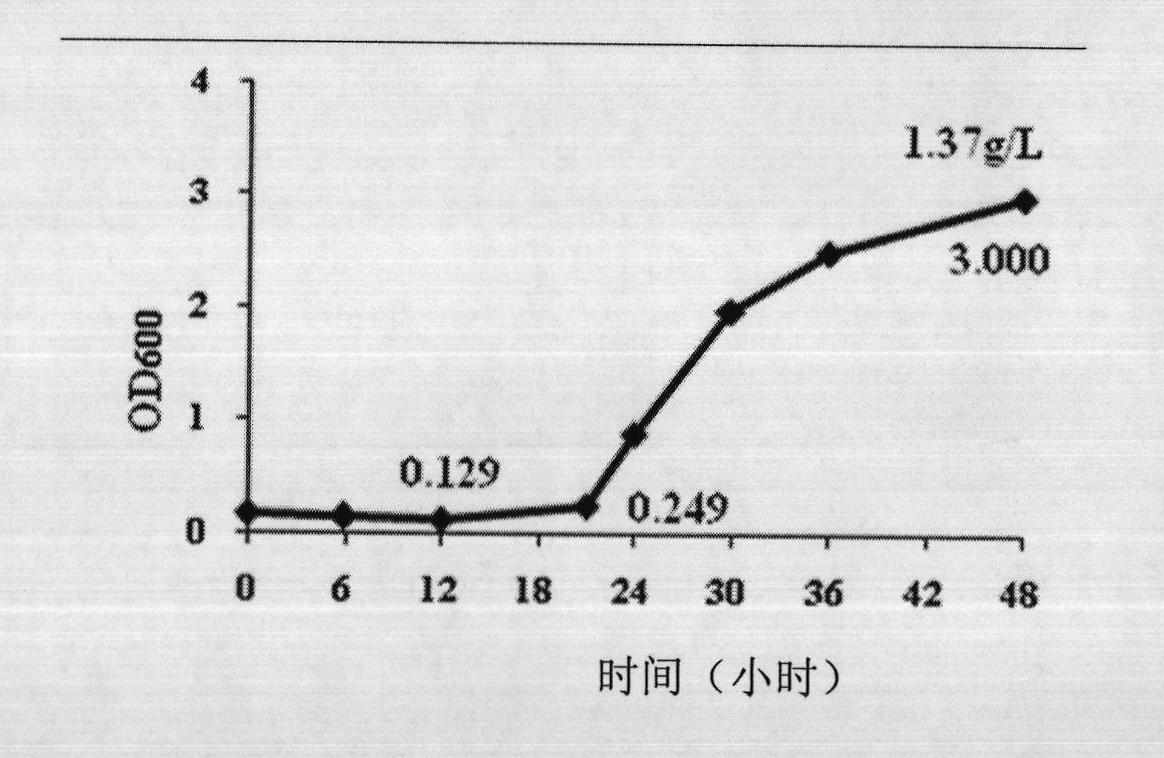

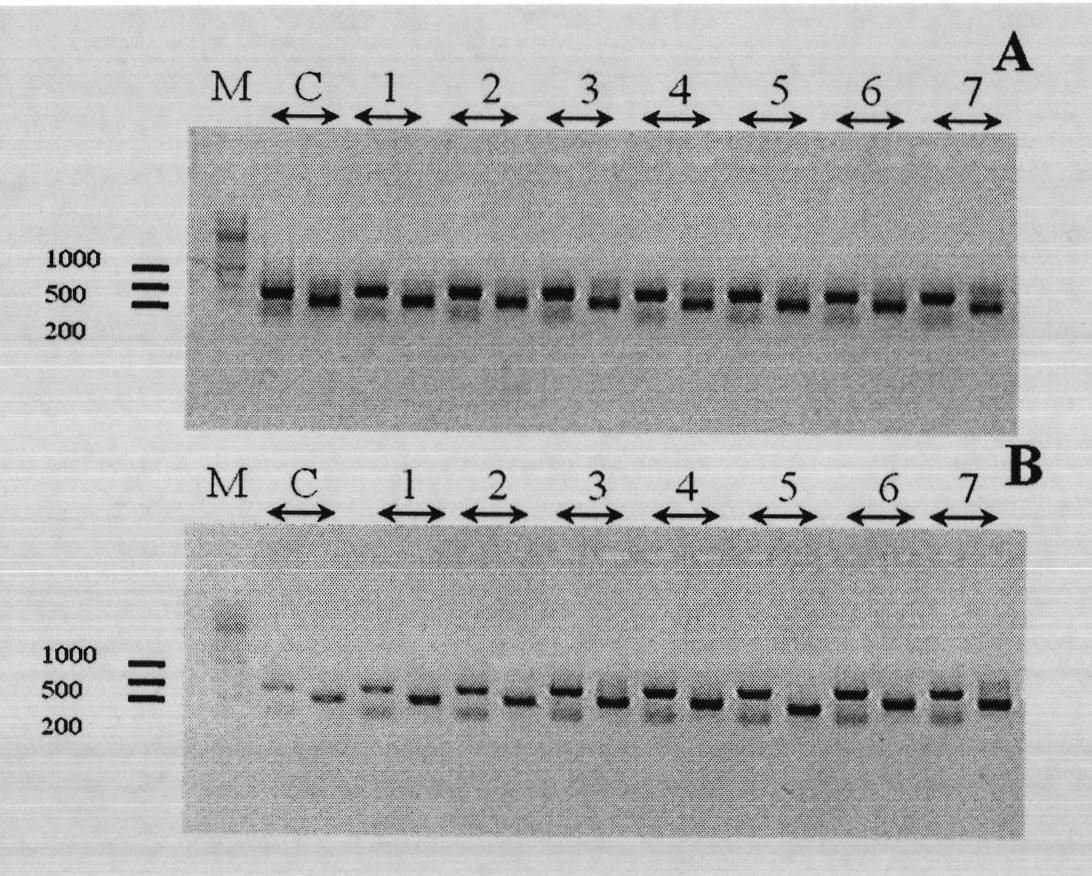

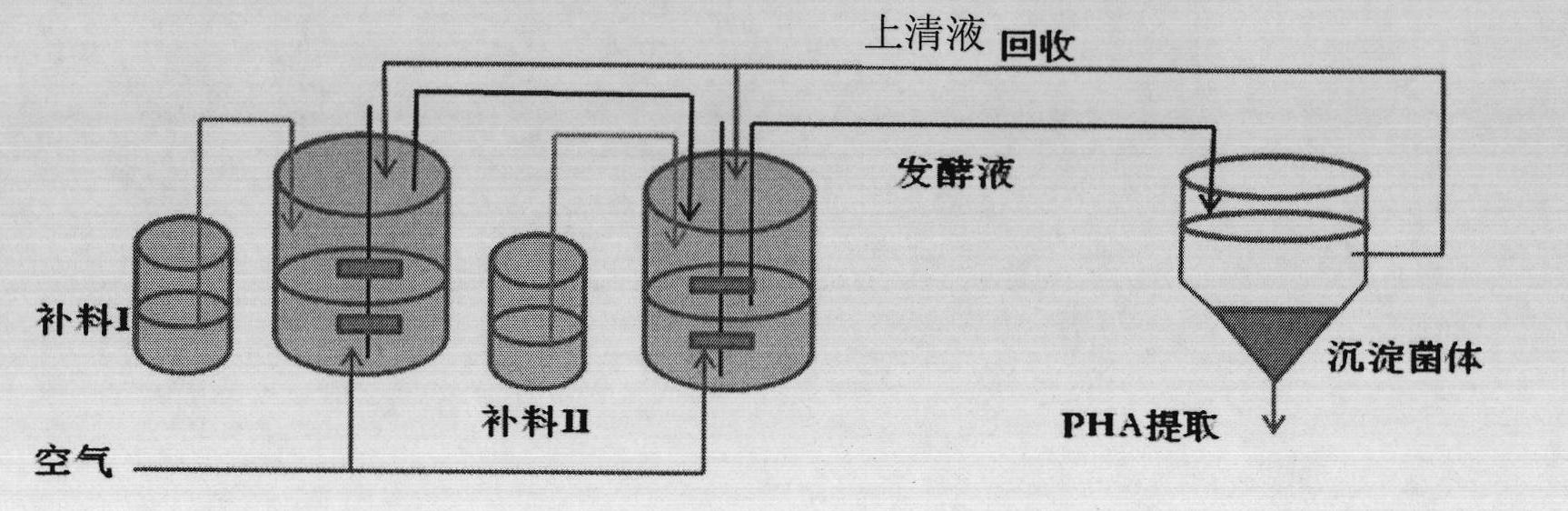

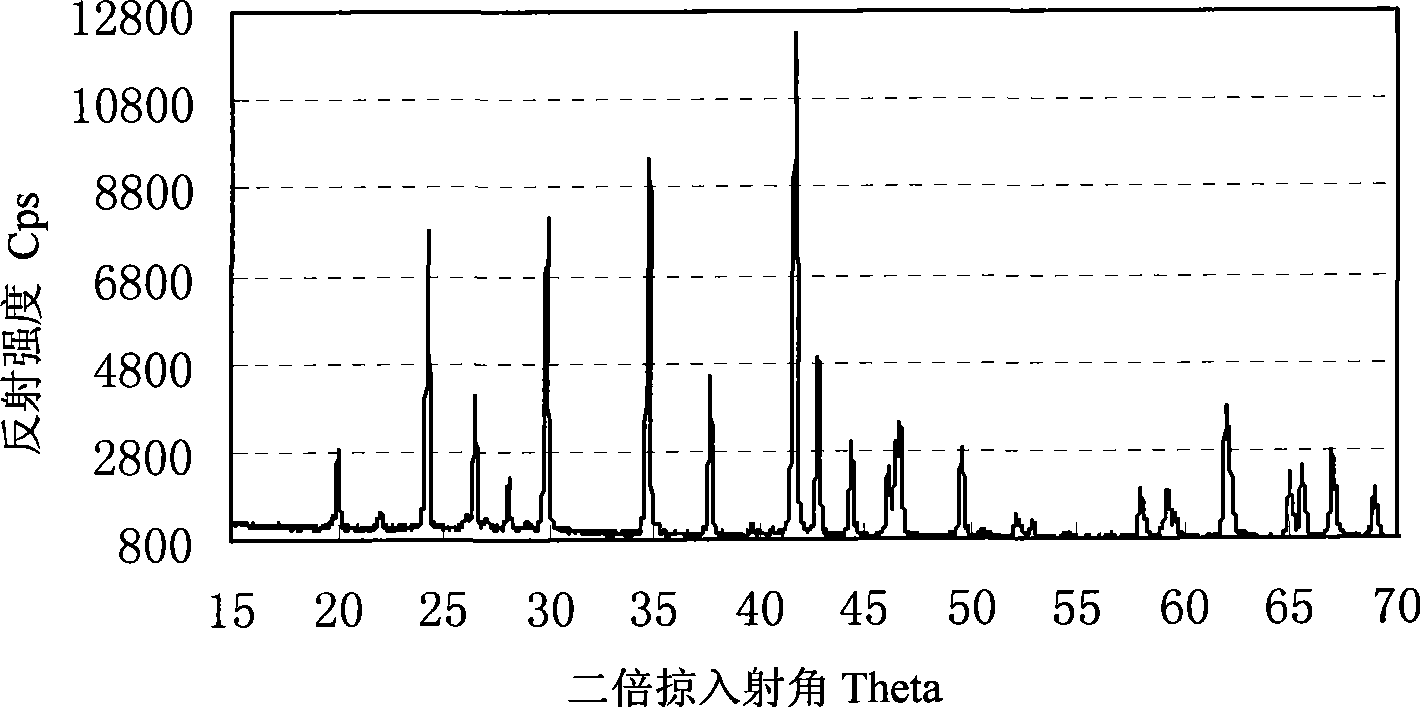

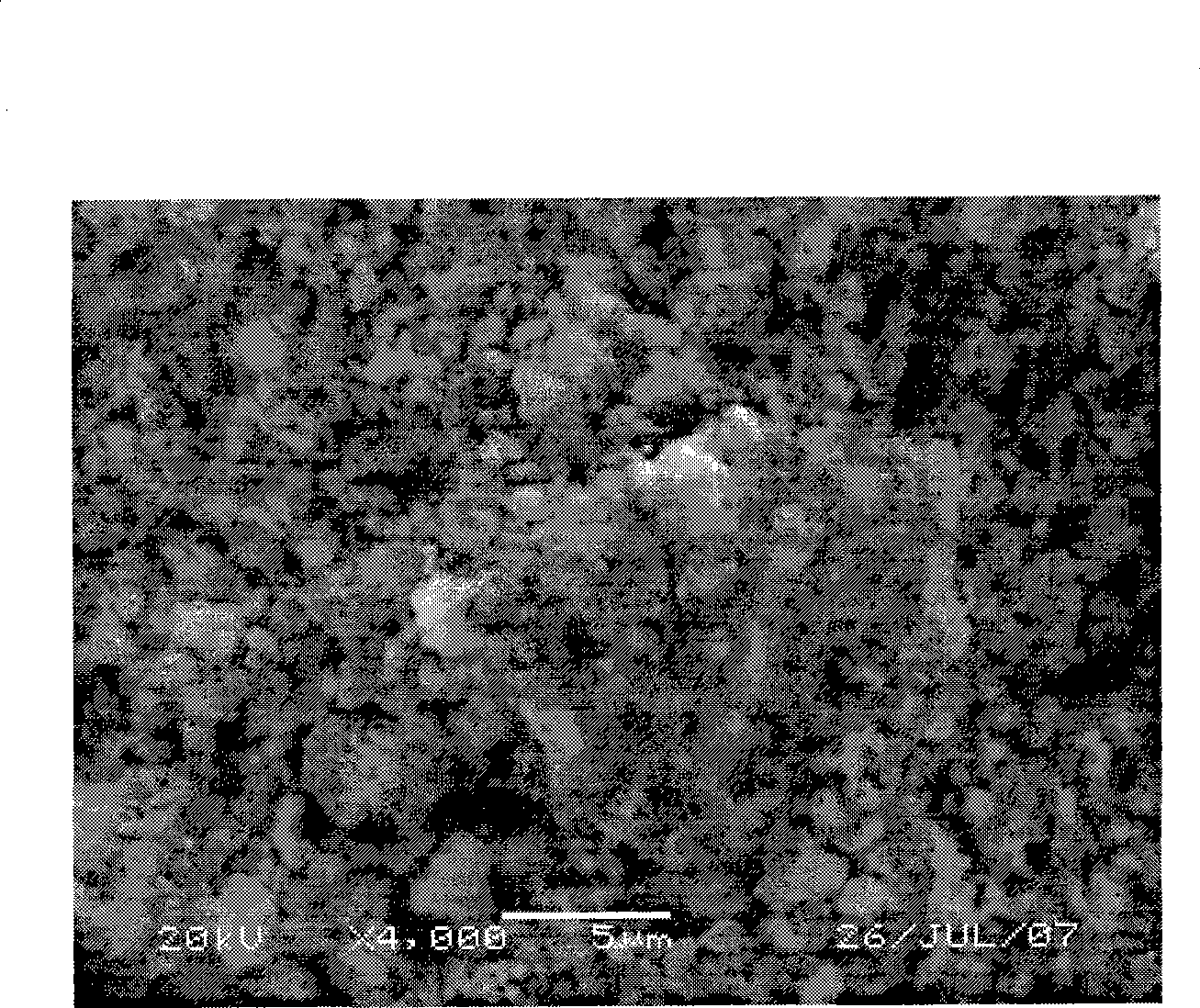

Halomonas strain and application thereof

ActiveCN102120973AIncrease productionReduce manufacturing costBacteriaFermentationBiotechnologyNutrient

The invention discloses a halomonas strain and application thereof. The halomonas strain is a halomonas sp. TD01 with a preservation number of CGMCC NO.4353. Experiments indicate that the halomonas sp. TD01 can effectively accumulate polyhydroxyalkanoates (PHA) in a mineral medium (MM) and provides a better guarantee for the biosynthesis of the PHA and PHBV (poly(hydroxybutyrate-hydroxyvalerate)). The halomonas strain has the advantages of simple nutrient requirement, no need of sterilization in a fermenting process, capability of continuous implantation and simpleness and easiness in control. Methods for preparing the PHA by using the halomonas sp. TD01 all lower the production cost from varying degrees and increase the yield of the PHA; and the obtained PHA has the molecular weight of above 500kDa and has an industrial application value.

Owner:BLUEPHA CO LTD

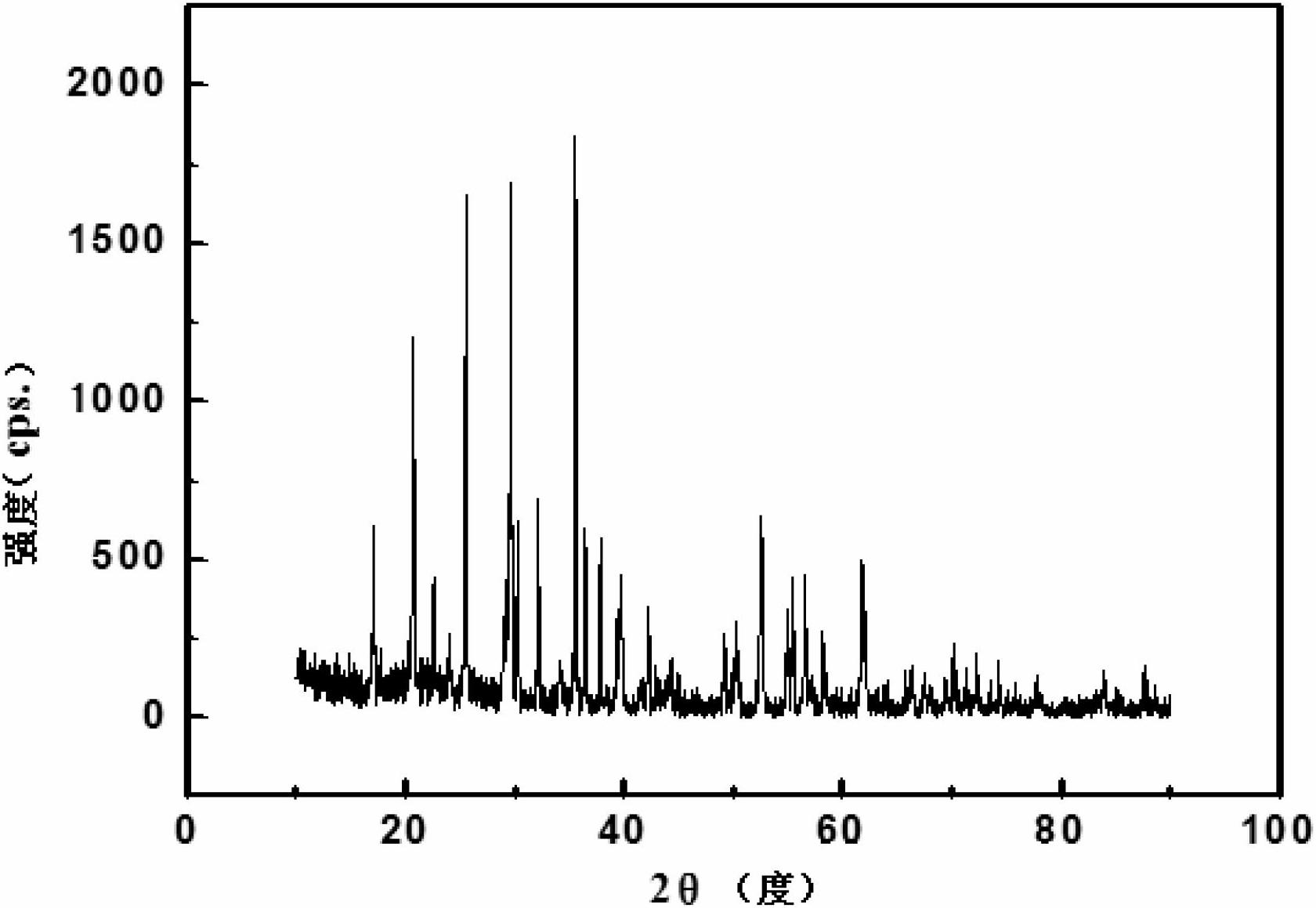

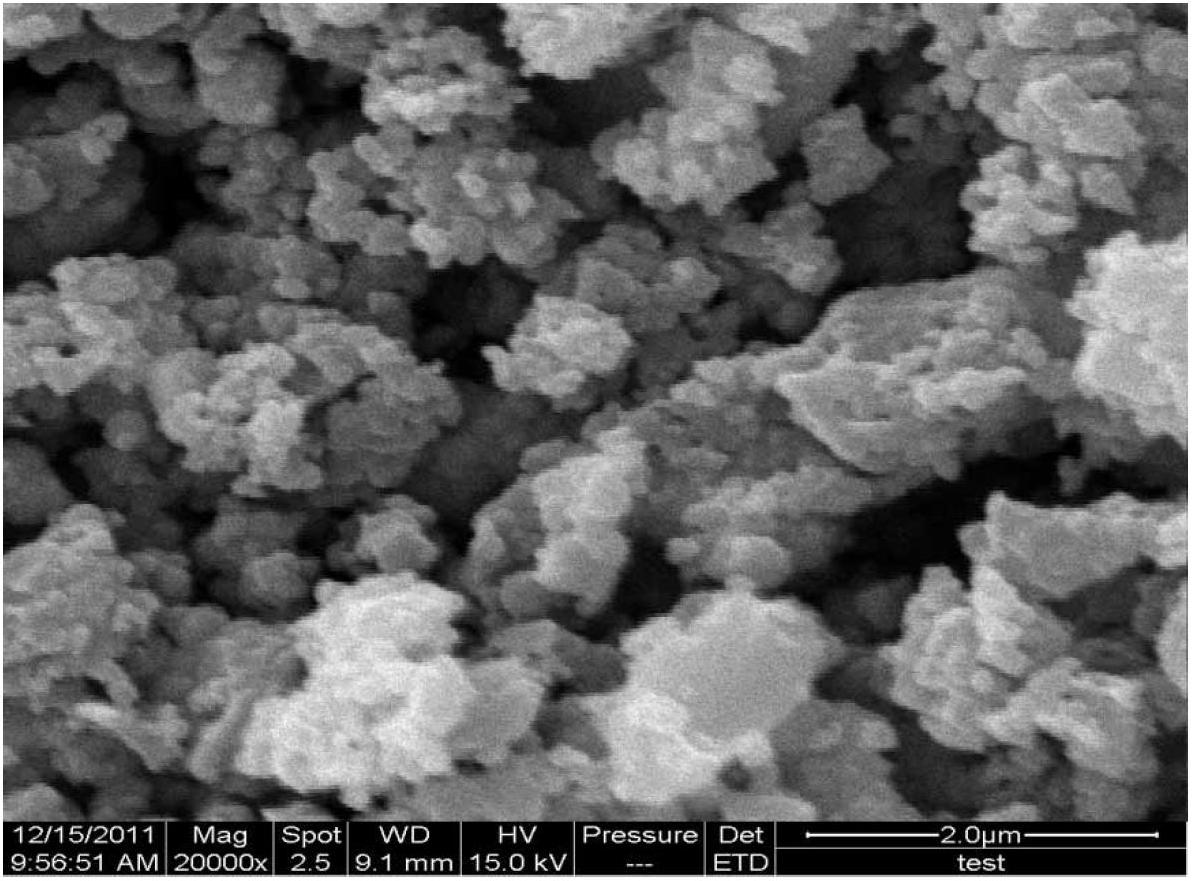

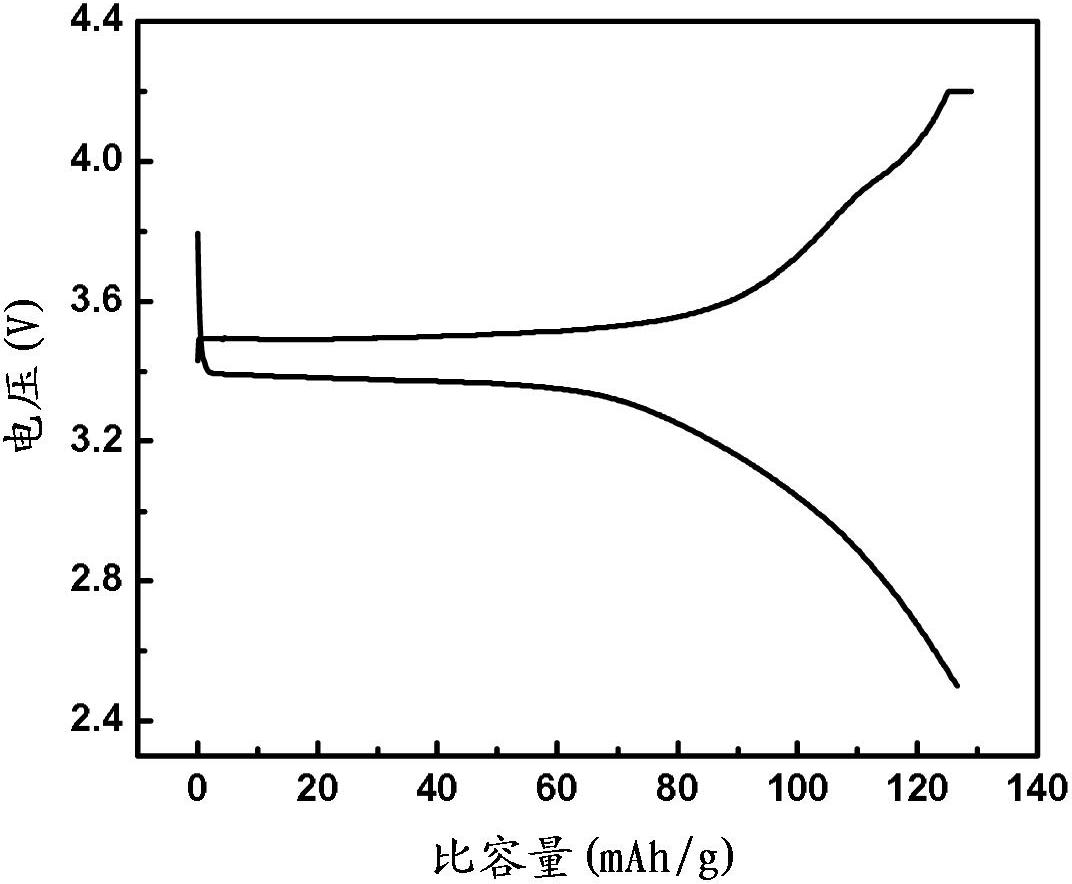

Synthetic recovering method for positive pole waste tablet from ferric phosphate lithium cell

ActiveCN101383441AReduce manufacturing costAchieve recyclingElectrode manufacturing processesSolid waste disposalRecovery methodPhosphate

The invention relates to a synthesized recovery method for waste positive plates of iron phosphate lithium batteries. The method comprises the following steps: collected waste positive plate material is mechanically crashed into fragments; the fragments are positioned in a welding furnace which is protected by vacuum atmosphere, inert gases and / or reducing gases and / or nitrogen and are heat processed in the temperature of 150-750 DEG C; aluminum foil basal bodies are separated from the fragments after heat process by adopting mechanical separation or ultrasonic concussion to obtain a mixture of iron phosphate lithium positive material, conduction agent and caking agent giblets; the mixture of iron phosphate lithium anode material, conduction agent and caking agent giblets is roasted for 8-24 hrs in 80-150 DRG C; the mixture after roasting is classified to control the grain diameter of the powder material to be not more than 20 microns, and the D50 is controlled to be 3-10 microns so as to obtain iron phosphate lithium positive recovery material. The method has simple technique, takes effect fast and reduces the material consumption and production cost of a manufacturer.

Owner:ZHENGZHOU BAK BATTERY CO LTD

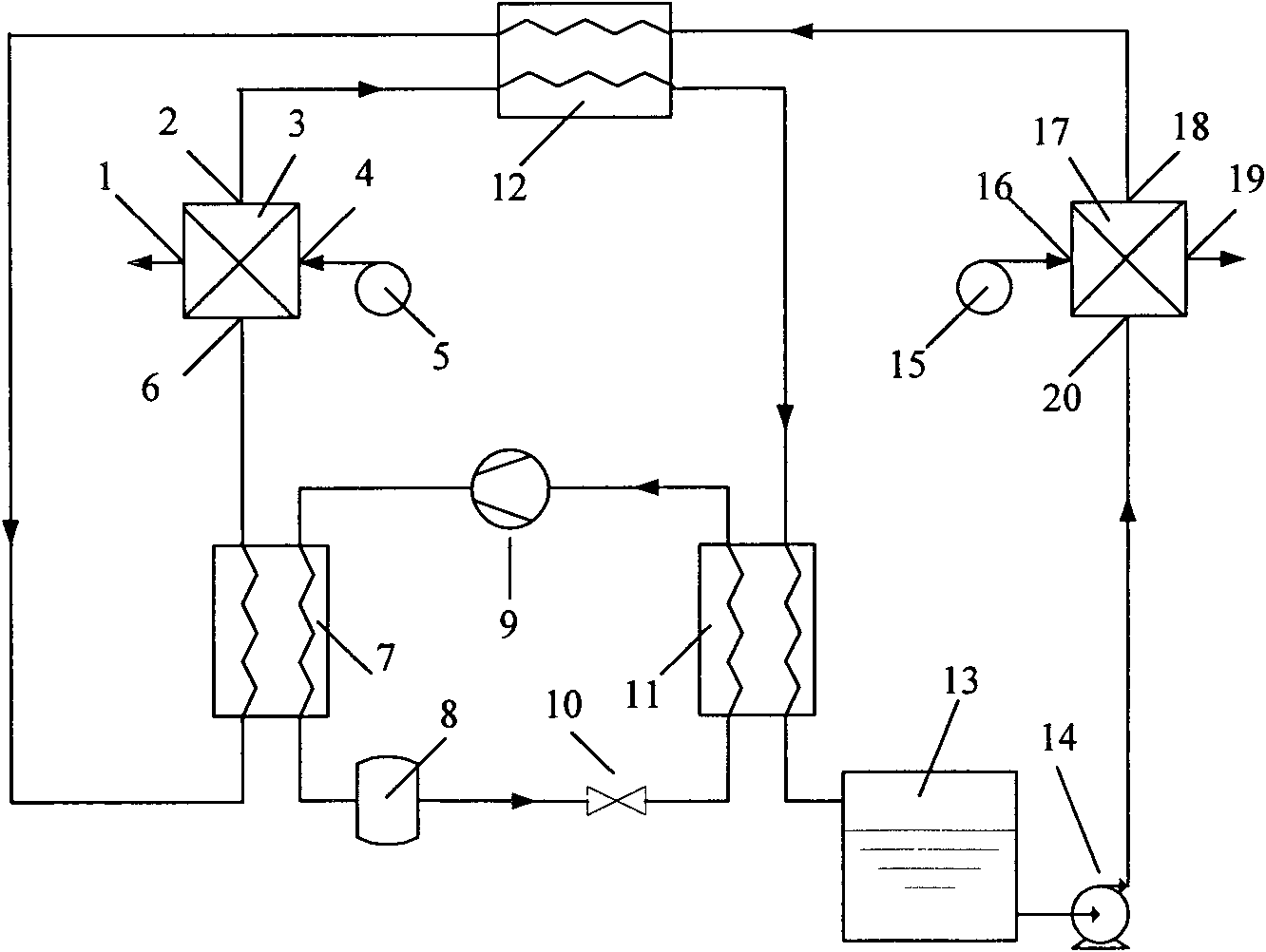

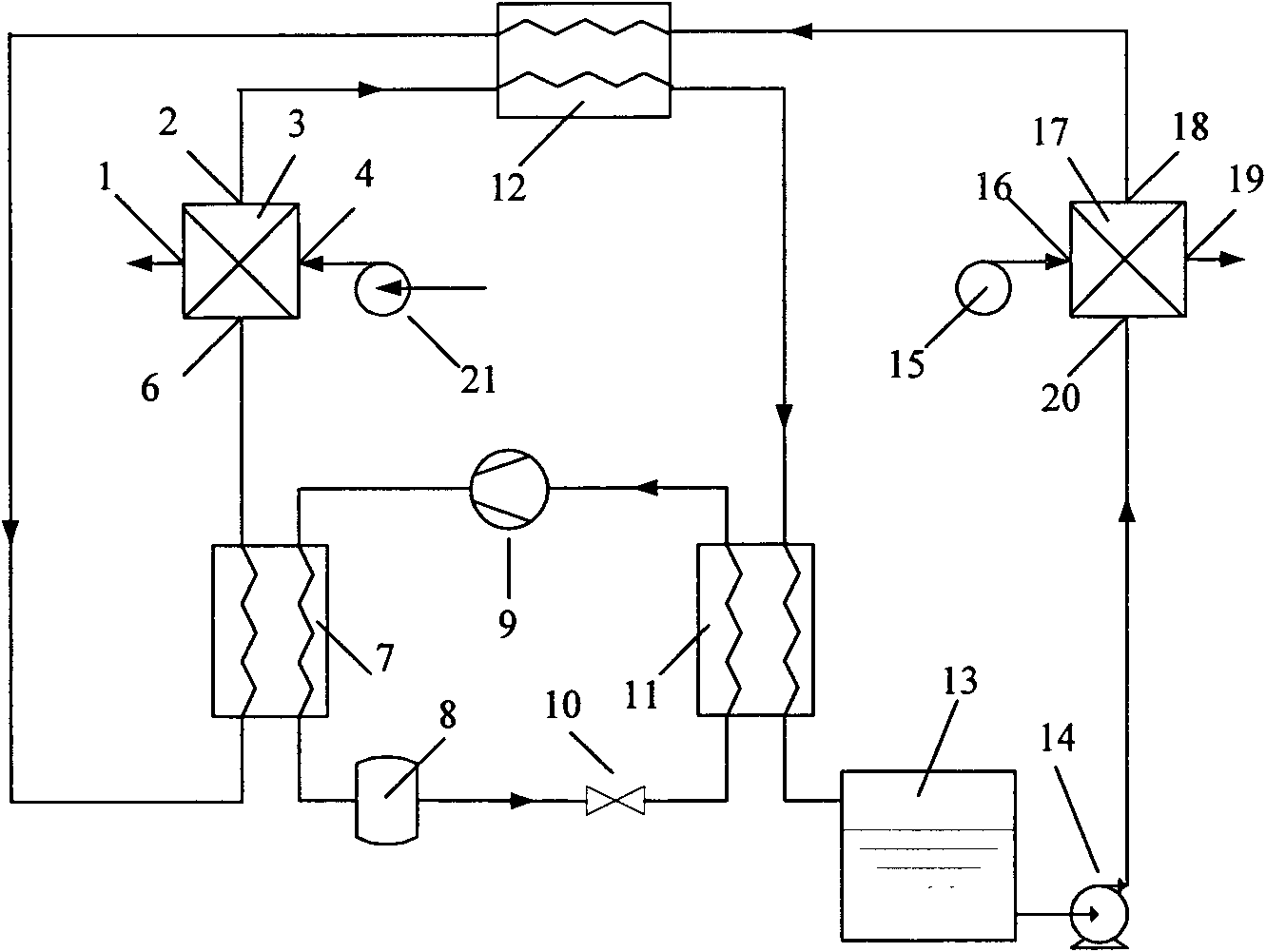

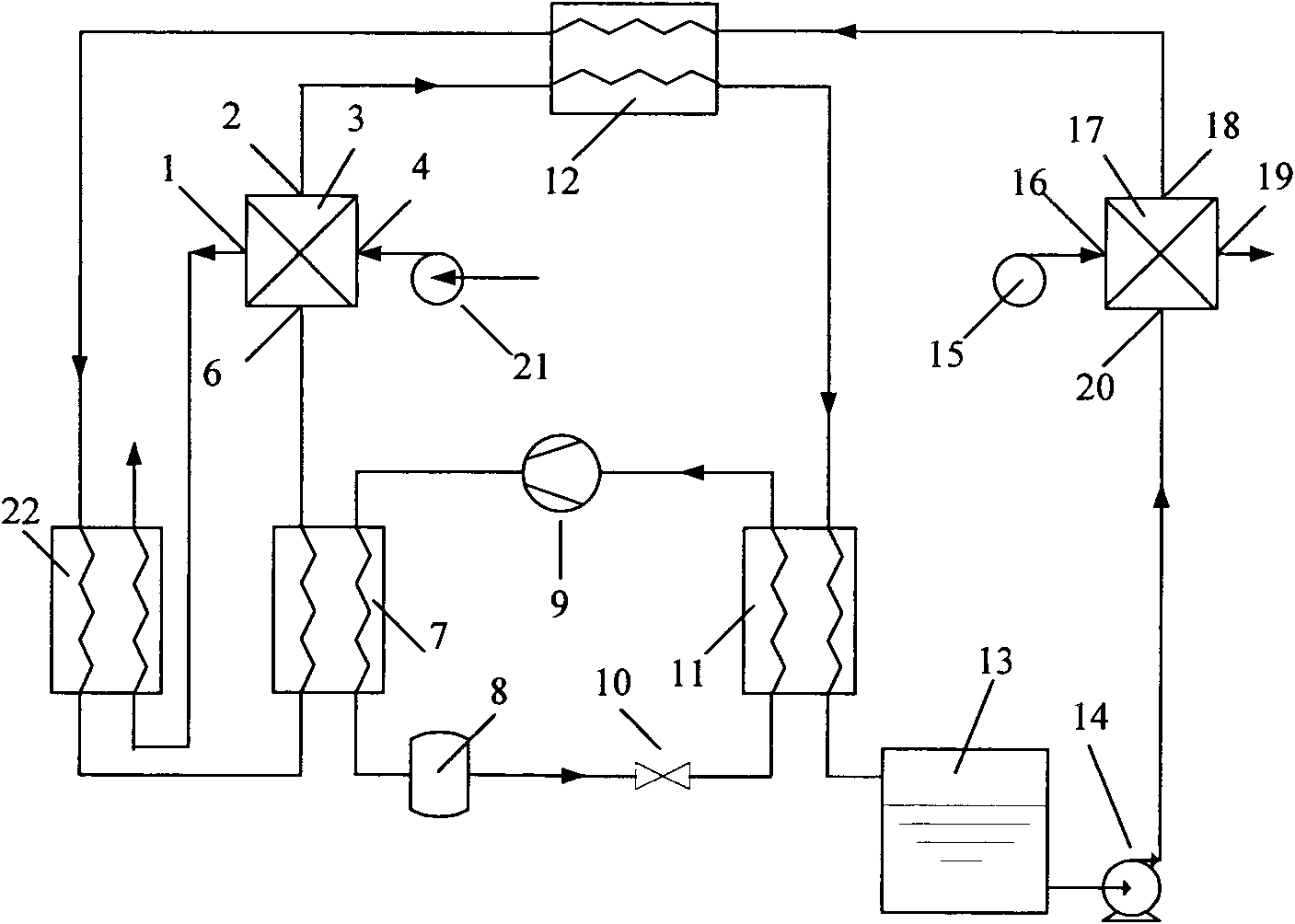

Heat pump-driven membrane-type liquid dehumidification and energy storage device

InactiveCN101975421AAchieve dehumidificationAvoid enteringHeat recovery systemsLighting and heating apparatusWater vaporEngineering

The invention discloses a heat pump-driven membrane-type liquid dehumidification and energy storage device which comprises a dehumidification solution storage tank, a solution pump, a dehumidifier, a first heat exchanger, a fan, a regenerator and a heat pump. The heat pump is a closed circulation loop composed of an evaporator, a compressor, a condenser, a refrigerant reservoir and an expansion valve or a capillary tube which are connected in turn; the dehumidification solution storage tank is connected with the dehumidifier through the solution pump; the dehumidifier is connected with the first heat exchanger and the condenser of the heat pump in turn and then is connected with the liquid inlet of the regenerator; the liquid outlet of the regenerator is connected with the first heat exchanger and the evaporator of the heat pump in turn and then is connected with the dehumidification solution storage tank; the air inlets of the dehumidifier and the regenerator are both connected with the fan; and the dehumidifier and the regenerator are both membrane components capable of isolating the dehumidification solution flowing through the membrane components from the air. The membrane has selective permeability, only allows steam to permeate and can effectively prevent the tiny droplets of the dehumidification solution from being carried in the air; and moreover, the device has the advantage of high utilization rate of energy.

Owner:SOUTH CHINA UNIV OF TECH

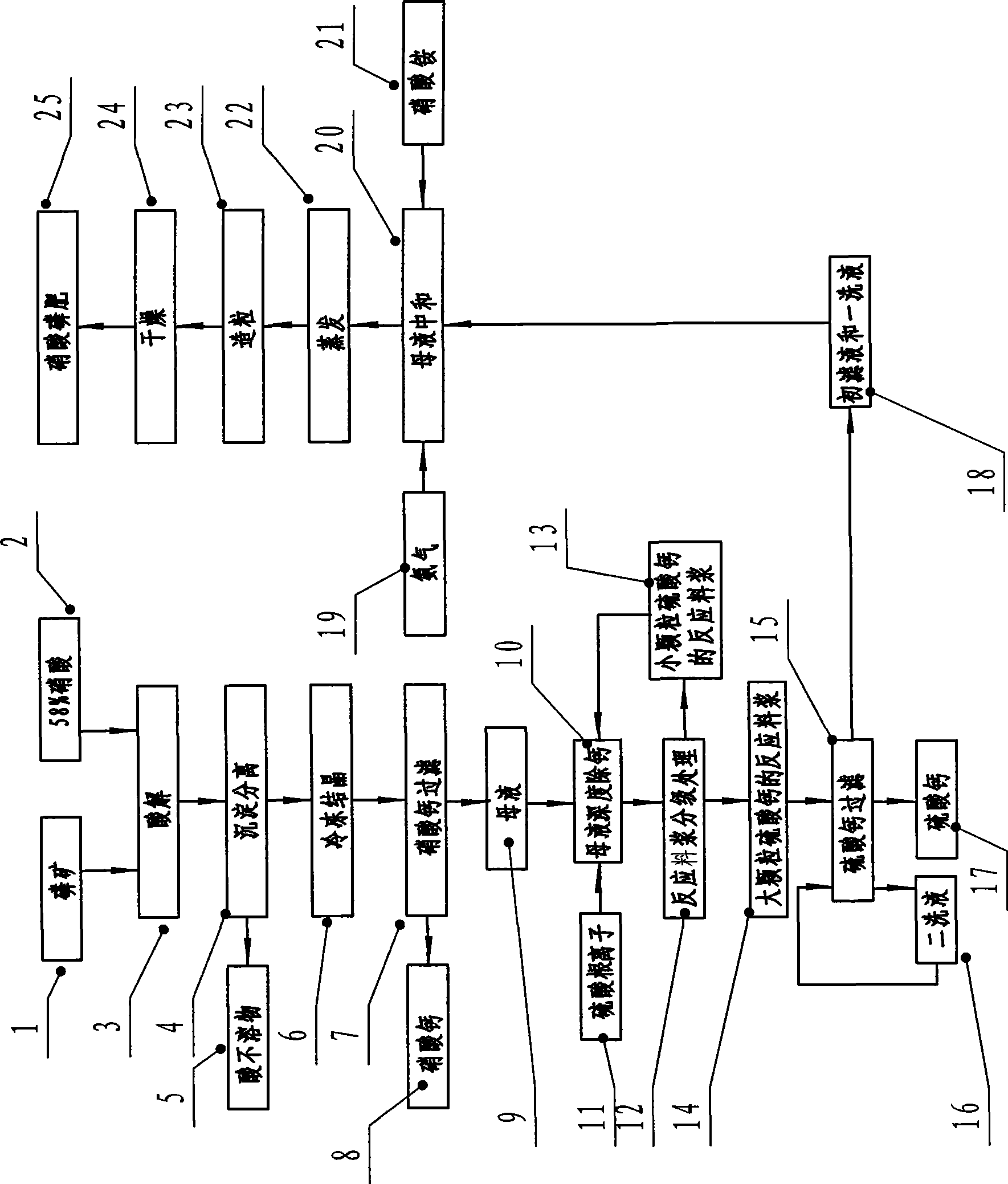

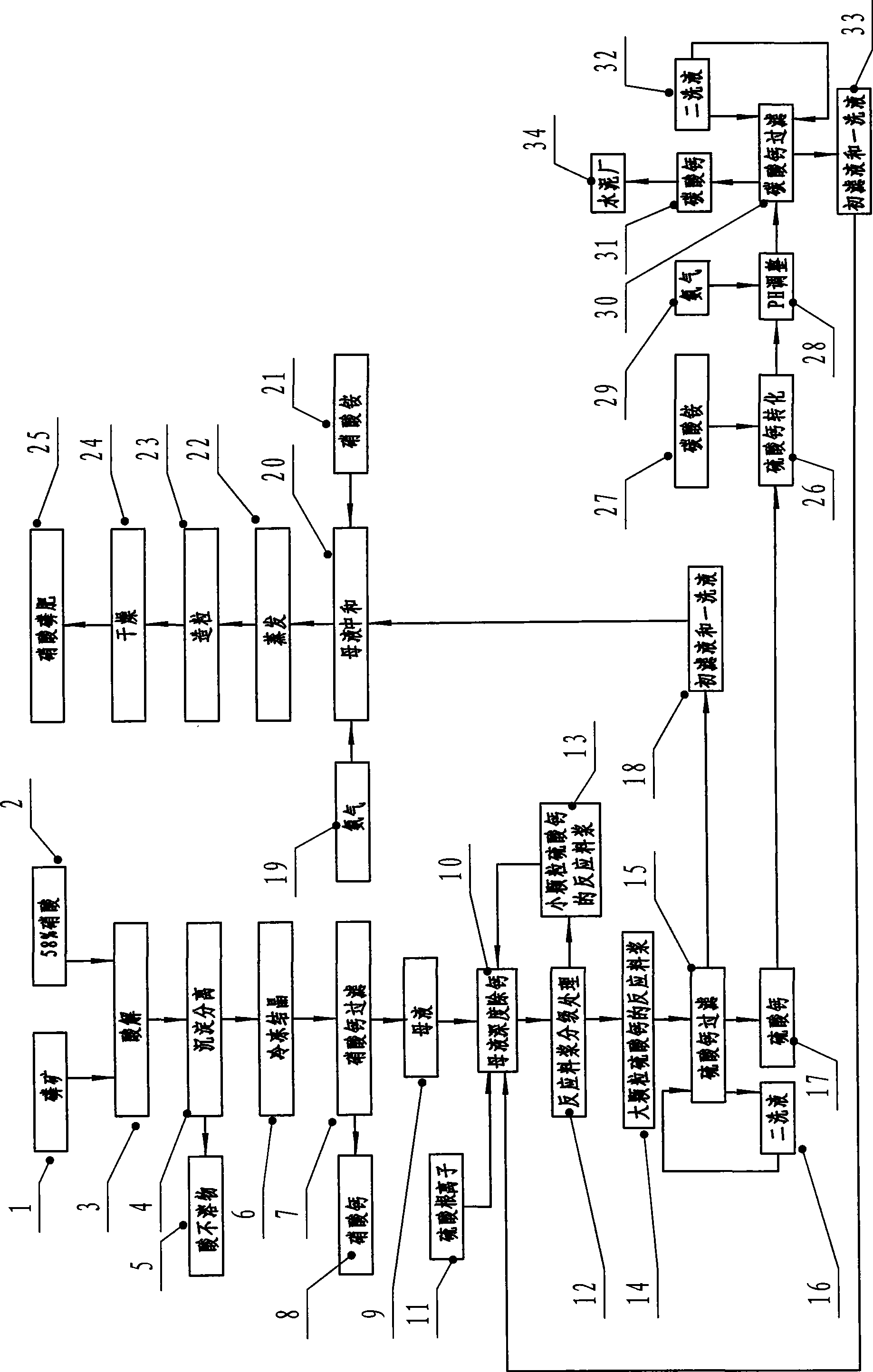

Technological process for producing high concentration nitric-phosphate fertilizer

The invention discloses a technique method for producing high-concentration nitric phosphate, which comprises the following steps of: adding nitric acid into phosphorus ore for acidolysis, depositing and separating acid non-soluble substance, freezing and crystallizing calcium nitrate, filtering the calcium nitrate, neutralizing the mother liquid, vaporization, pelleting and drying. The invention is characterized in that: a step of thoroughly removing the calcium of the mother liquid is arranged between the steps of filtering the calcium nitrate, and neutralizing the mother liquid. The steps comprise the following steps of: I) thoroughly removing the calcium of the mother liquid and adding sulfuric acid or ammonium sulfate; the calcium ions and the sulfate ions in the mother liquid generate dihydrate calcium sulfate crystal; II) the grading processing of reaction slurry: employing a grading device to carry out grading processing to the reaction slurry; returning the reaction slurry provided with small grain calcium sulfate to the mother liquid for thoroughly removing the calcium, and feeding the reaction slurry provided with large grain calcium sulfate to the calcium sulfate for filtering; and III) filtering and washing the filtering reaction slurry of calcium sulfate by a filter, feeding the primary filtrate and the primary lavage fluid into the working procedure of neutralizing, and returning the secondary lavage fluid to the filter. The invention has the advantage of using middle-low quality phosphorite to prepare the high-concentration nitric phosphate.

Owner:TIANJI COAL CHEM IND GROUP +1

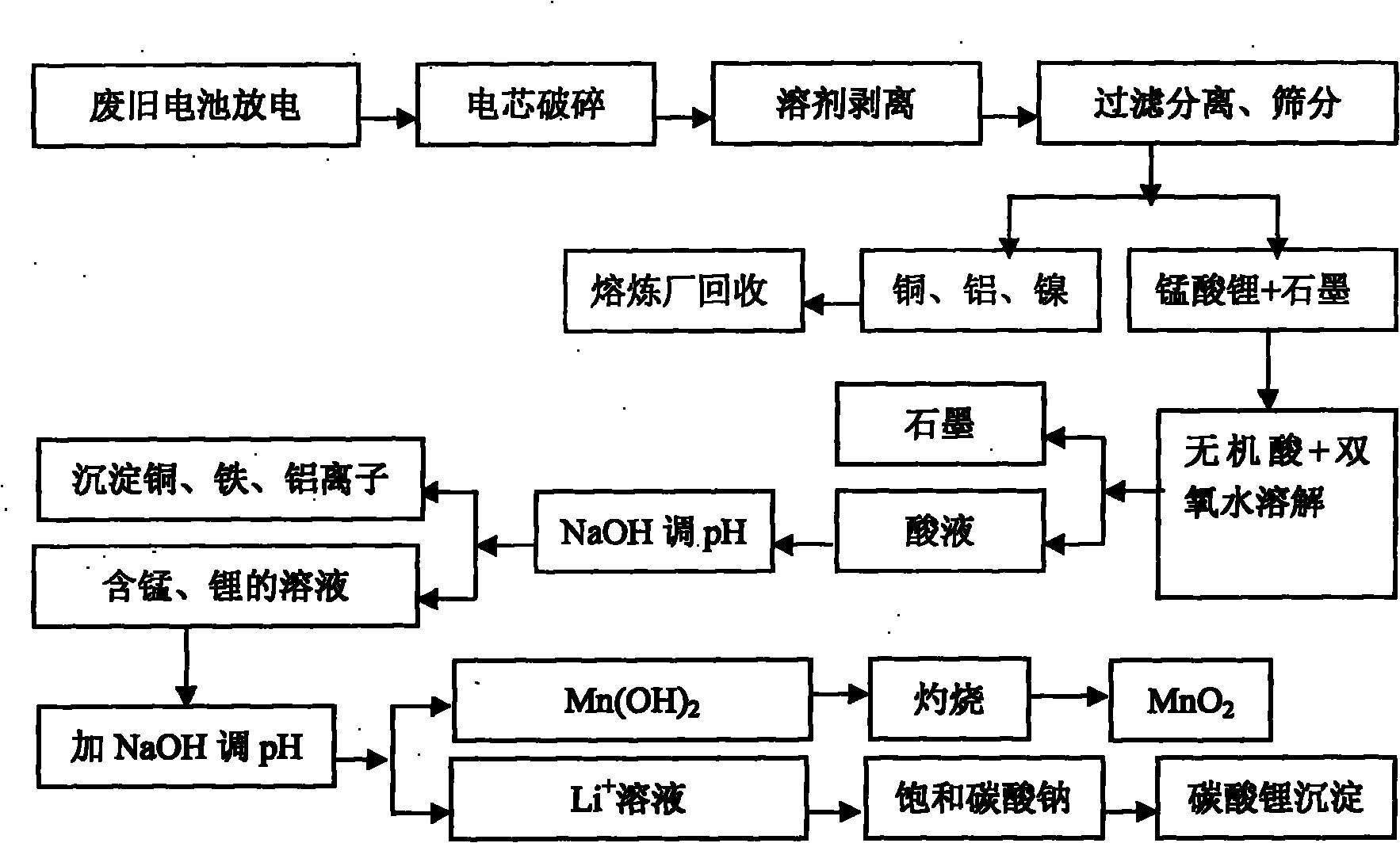

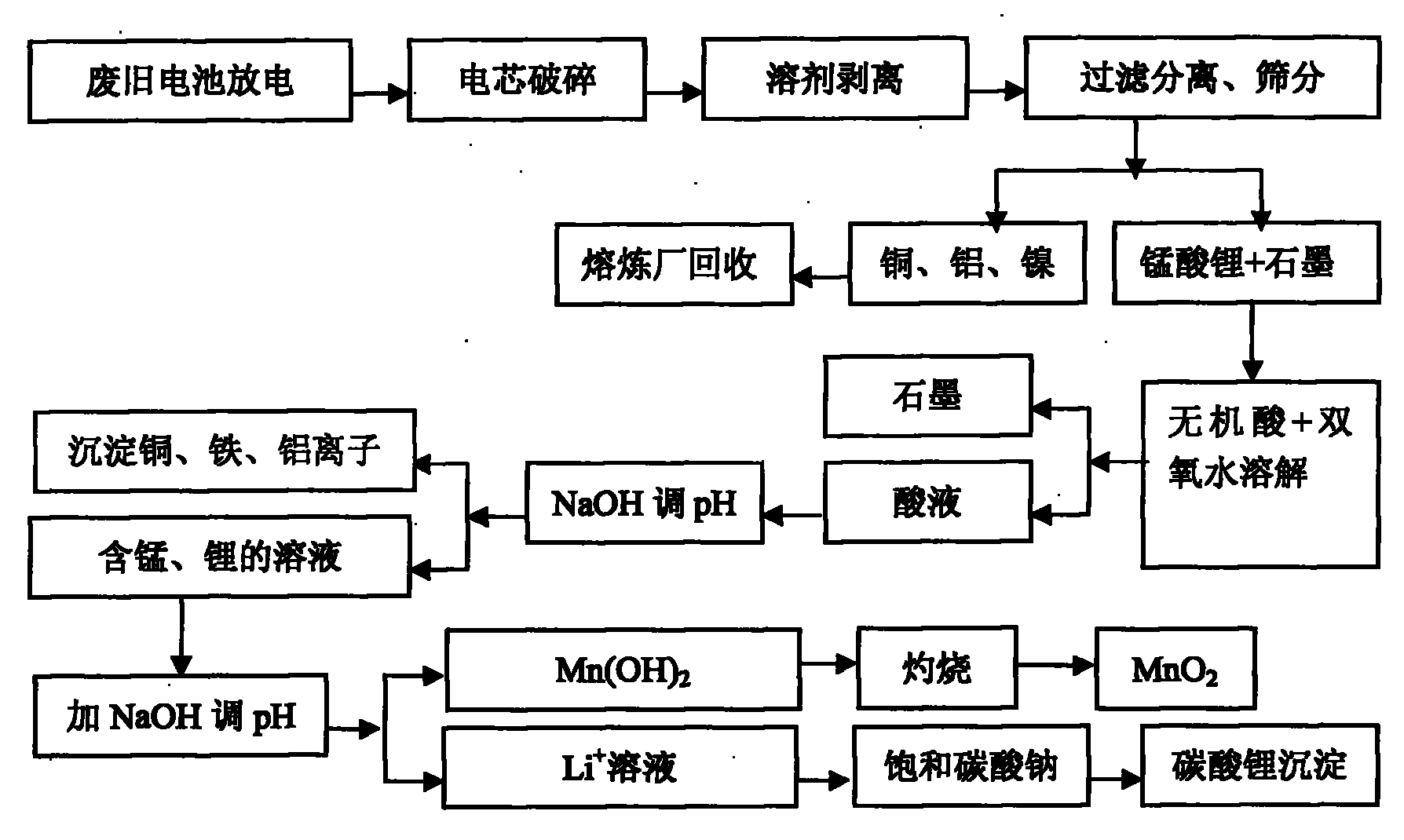

Method for recovering valuable metals from waste lithium manganese oxide battery

ActiveCN101831548ASimple processLow costProcess efficiency improvementLithium carbonateSodium carbonate

The invention provides a method for recovering valuable metals from a waste lithium manganese oxide battery with simple process, low cost and high purification purity to comprehensively metals such as manganese, lithium, aluminum, copper nickel and the like. The method comprises the following steps of: soaking and peeling off active substances of the battery in organic solvent to directly obtain clean aluminum, copper, nickel foils and diaphragms; reacting acid solution with LiMn2O4 in a battery electrical core to generate soluble salts of the lithium and the manganese; regulating a pH value to 5-7 by using NaOH solution or ammonia water to enable iron ions, aluminum ions and copper ions in the solution to be wholly deposited, filtering and separating; regulating the pH value to 10-12 by using the NaOH solution or the ammonia water, and depositing and filtering to obtain manganous hydroxide solids and lithium containing filtrate; and finally, firing the manganous hydroxide solids to obtain MnO2, reacting the lithium containing filtrate with sodium carbonate to generate lithium carbonate, and filtering, washing and drying the lithium carbonate to obtain pure lithium carbonate. Through the steps, the recovery rate of the lithium in the battery is higher than 85 percent.

Owner:CHERY AUTOMOBILE CO LTD

Oil-containing sludge treating method

InactiveCN1488591AImprove processing efficiencyGood deliverySludge treatment by de-watering/drying/thickeningSolventSolid phases

The invention discloses a treatment method for oily mud. The invention carries on mechanical dehydration to oily mud, then blends with extracted solvent oil and preheats them, then carries on heat extraction and dehydration, carries on solid-liquid separation, the liquid phase enters the coking device, the solid phase can be used as fuel. The gas phase is carried on oil and water separation, the water can be discharged into the waste water treatment field; oil is carried on further treatment. The method is simple and easy to be operated.

Owner:CHINA PETROLEUM & CHEM CORP +1

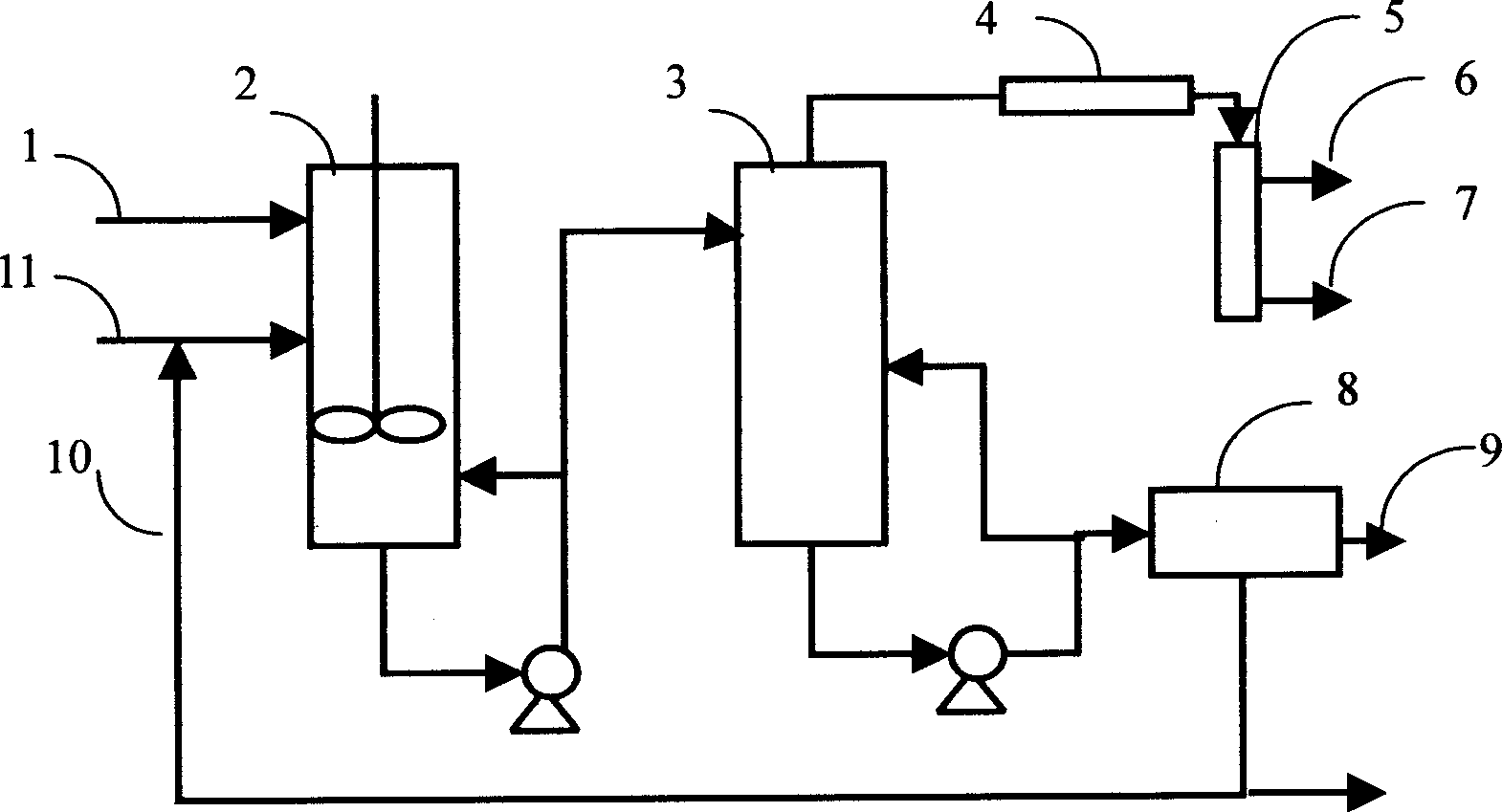

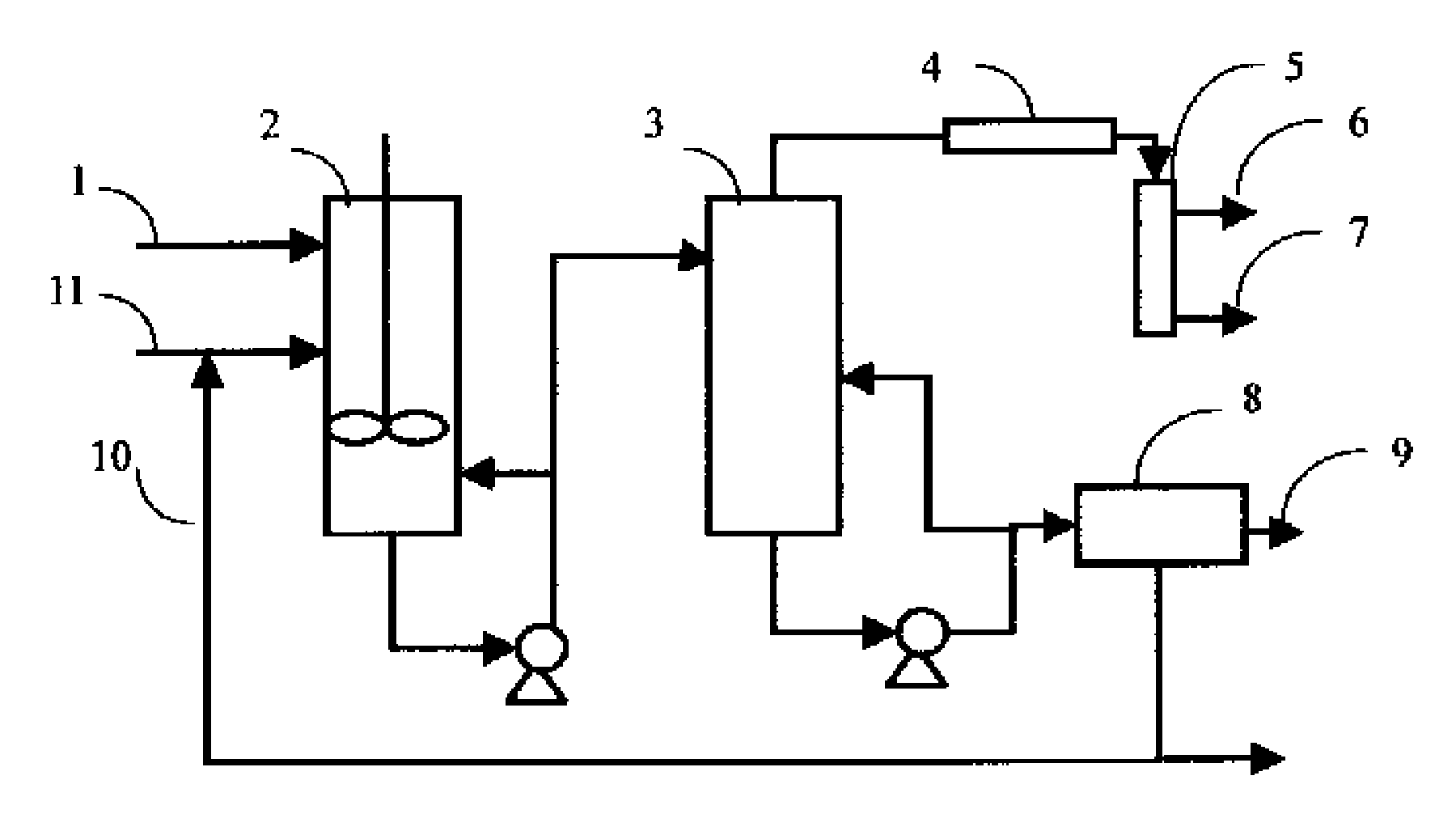

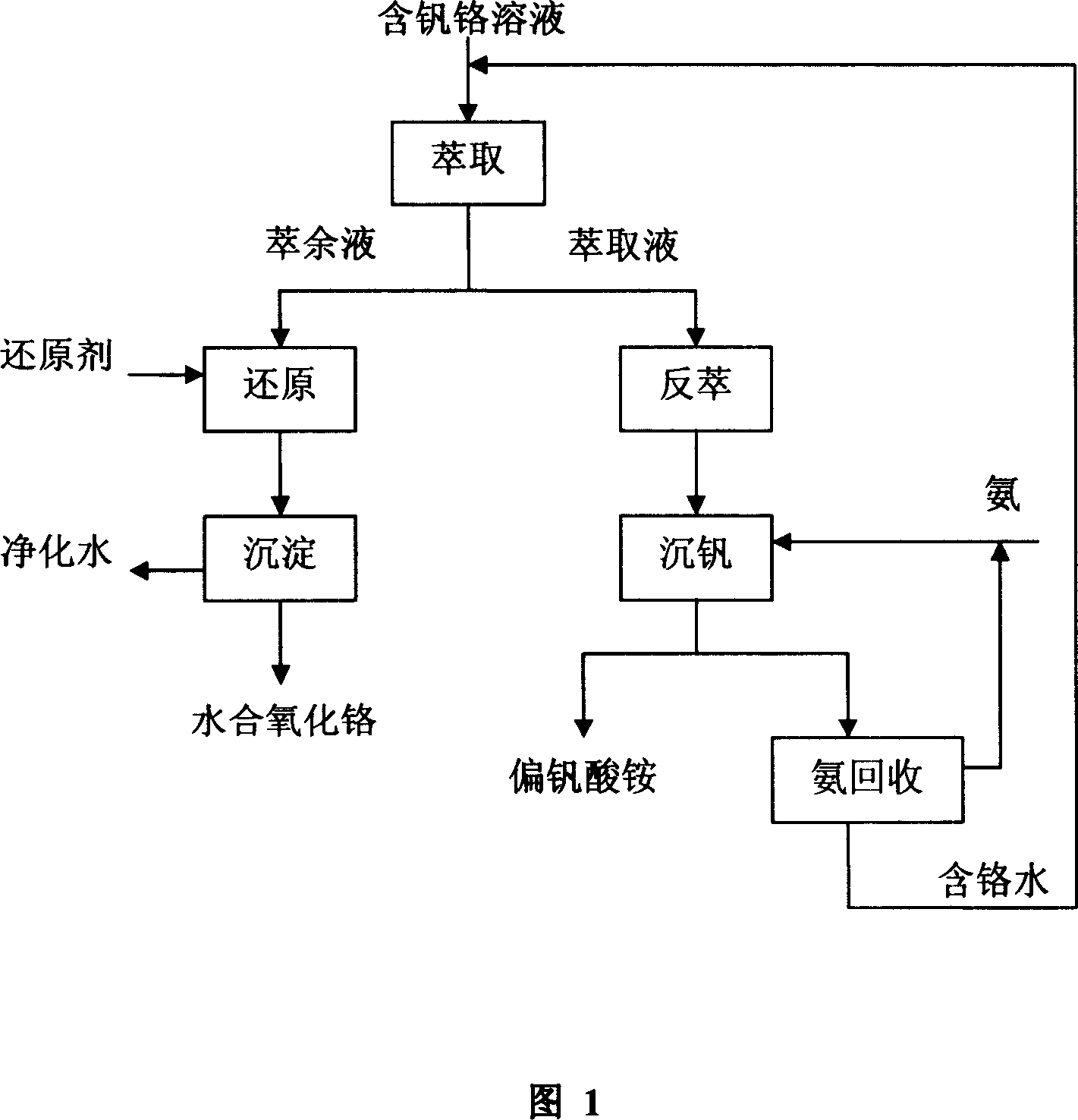

Method for separating and reclaiming vanadium and chromium from solution containing vanadium and chromium

ActiveCN101121962ALow costSimple processProcess efficiency improvementHydration reactionDistillation

This invention relates to an entirely new technology of completely recovering chromium and vanadium from vanadium-chromium miscible liquid. The main procedures include: first a primary-secondary compound amine extracting agent contacts the vanadium-chromium miscible liquid by means of countercurrent contact and extract, so as to extract most of vanadium and a small amount of chromium into a organic phase while most of chromium stays into a aqueous phase; and a reduction reaction is conducted with pH of acid adjustable faffinate (aqueous phase) and a certain amount of a reducing agent; the sodium hydroxide is used for adjusting pH value of the solution and filter, and finally the product is hydrous chromium oxide; at that time, the lye is used as a stripping agent; the vanadium is stripped from the vanadium-rich organic phase into water in the manner of countercurrent contact; and the vanadium is separated from the solution witthe method of ammonium precipitation and in the form of ammonium metavanadate; and finally the supernatant clear solution of the one is processed with deposited vanadium with a high-efficient distillation technology, and the strong aqua ammonia is left in the tower top and deamidization solution is left in the tower bottom until the extraction process is reached. The invention uses the primary-secondary compound amine as the extracting agent, extracts and separates vanadium and chromium selectively at a low temperature. The invention not only has a simple process flow, but also is low-cost, quite applicable in large-scale industrial production. In addition, the invention also provides high-purity ammonium metavanadate and 16 percentage strong aqua ammonia, and makes sure the vanadium and chromium can be completely recovered through re-use of the solution.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

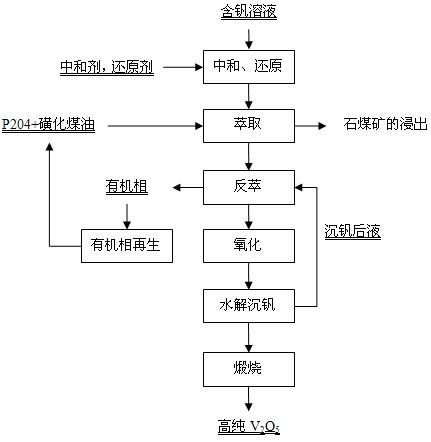

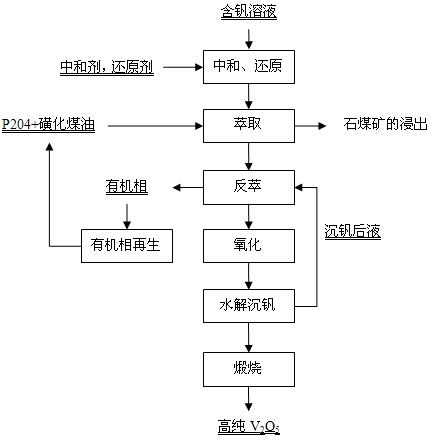

Method for preparing vanadium pentoxide from sulfuric acid leach liquor of stone coal vanadium ore

The invention relates to a method for preparing vanadium pentoxide from sulfuric acid leach liquor of stone coal vanadium ore, particularly a method for preparing high-purity vanadium pentoxide from sulfuric acid leach liquor of low-impurity-content stone coal vanadium ore. The method is characterized by sequentially comprising the following steps: (1) extracting leach liquor, which is obtained by leaching stone coal vanadium ore with sulfuric acid, to remove impurities; (2) carrying out back extraction on sulfuric acid to carry an organic phase; (3) oxidizing the back extraction liquor; (4) carrying out hydrolysis to precipitate vanadium; and (5) calcining the vanadium precipitate slag to obtain the vanadium pentoxide. Compared with the traditional technique, by using oxydol, persulfuric acid and the like as oxidants in the oxidation process, the method provided by the invention can avoid introducing other impurity cations, thereby ensuring the purity of the product vanadium pentoxide. Compared with the traditional ammonium-salt vanadium-precipitation technique, the method provided by the invention saves the alkali consumption required by neutralization. The purity of the prepared vanadium pentoxide is up to 99.9%, and the recovery rate of vanadium is up to above 98%; and meanwhile, the invention can implement no pollution and cyclic utilization of the back extraction agent.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Production method of biodiesel oil using high acid ralue animal and vegetable grease

InactiveCN1556174AAchieve cycleAchieve recyclingBiofuelsLiquid hydrocarbon mixture productionOil and greaseAlcohol

A process for preparing the biological diesel oil from the animal fat or vegetative oil with high acid number includes esterifying by glycerine under existance of strong acid catalyst, distilling in azeotropic solvent for removing water, mixing with methanol, transesterifying reacting to remove glycerine, water washing, and low-temp treating for removing high-smelting-point substances to obtain methyl ester of fatty acid, which is just the biological diesel oil.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

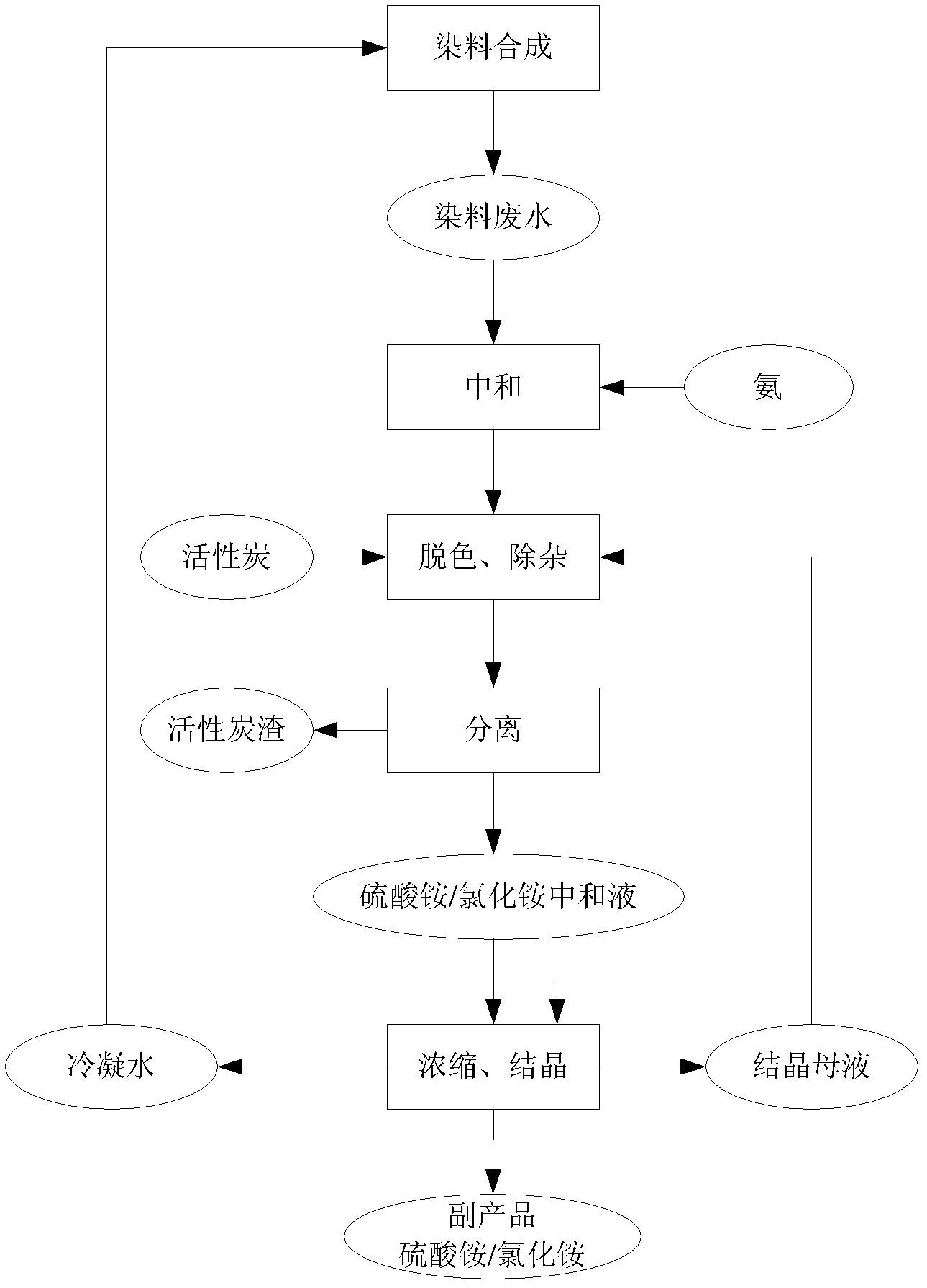

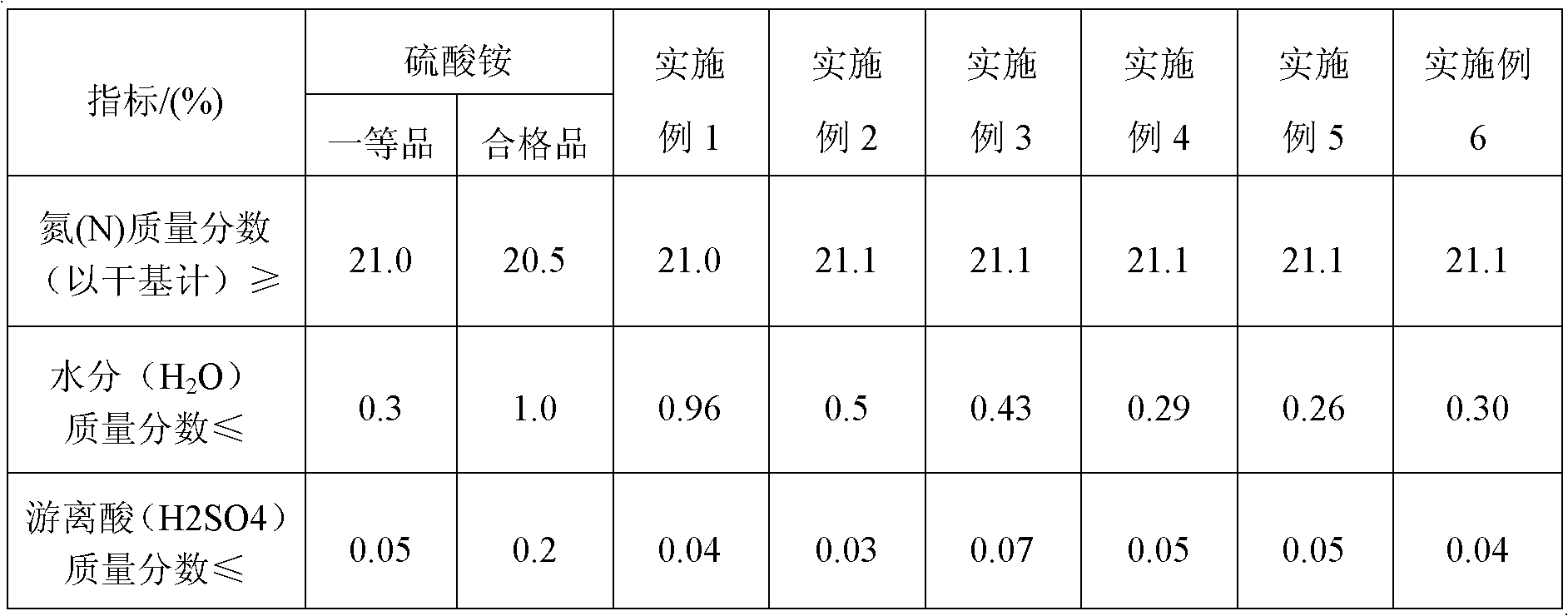

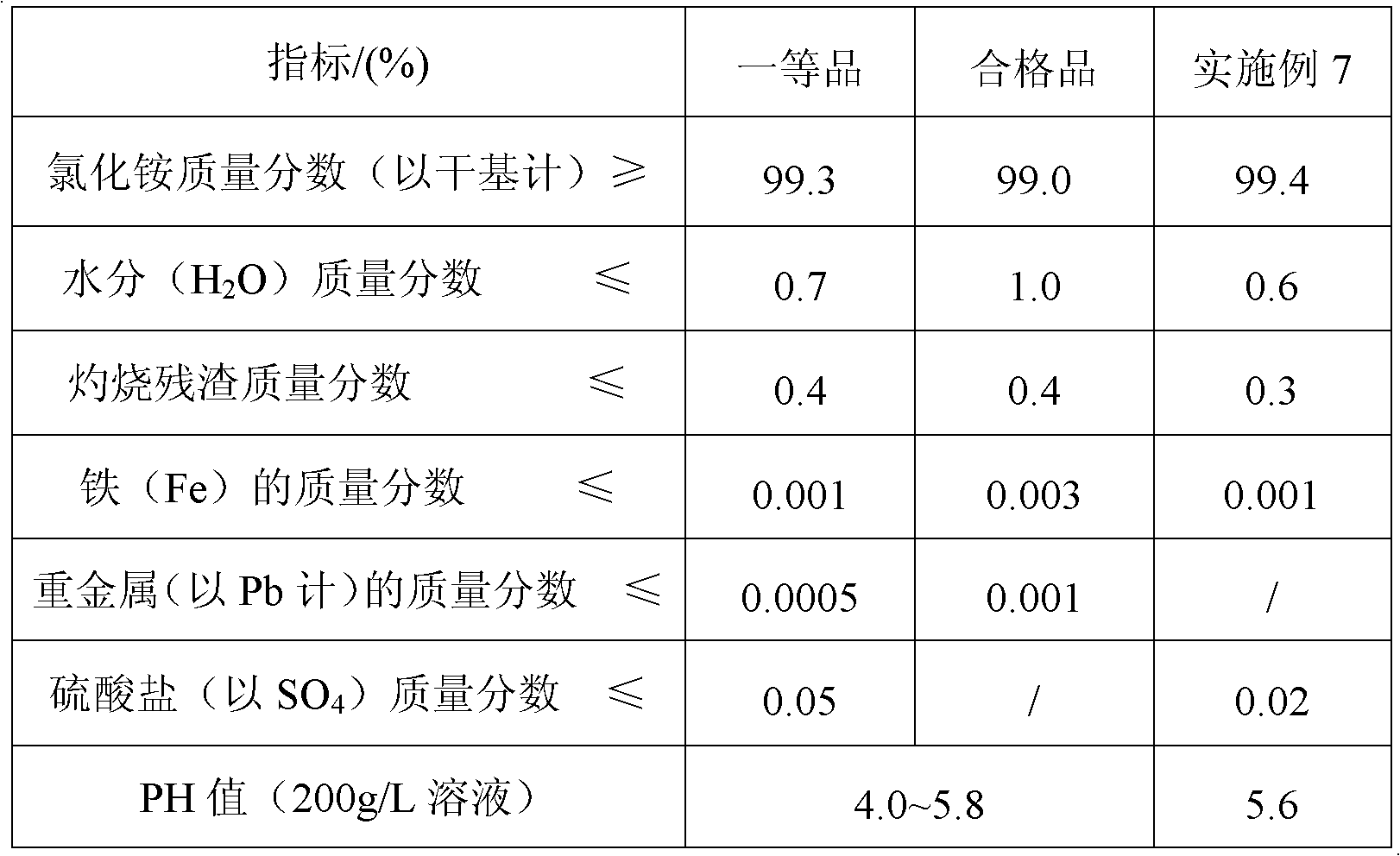

Cleaning treatment method of dying industrial acidic wastewater

ActiveCN102826673AAchieve recyclingAvoid it happening againAmmonium sulfatesMultistage water/sewage treatmentSulfateWastewater

The invention provides a cleaning treatment method of dying industrial acidic wastewater. After purified by measurements of neutralization, decolouring, oxidation, condensation, separation and the like, wastewater is reused as synthetic bottom water and dye filter cake washing water for dye production, thus avoiding discharge of a lot of colored wastewater with high COD value during a traditional dye production process. By a method of using a by-product ammonium sulfate or ammonium chloride, generation of calcium sulfate is avoided during neutralization of wastewater by the use of lime. Therefore, the dangerous solid waste calcium sulfate slug treatment problem is solved, and the cleaning production purposes of water saving, emission reduction and synergy are reflected.

Owner:ZHEJIANG LONGSHENG GROUP +1

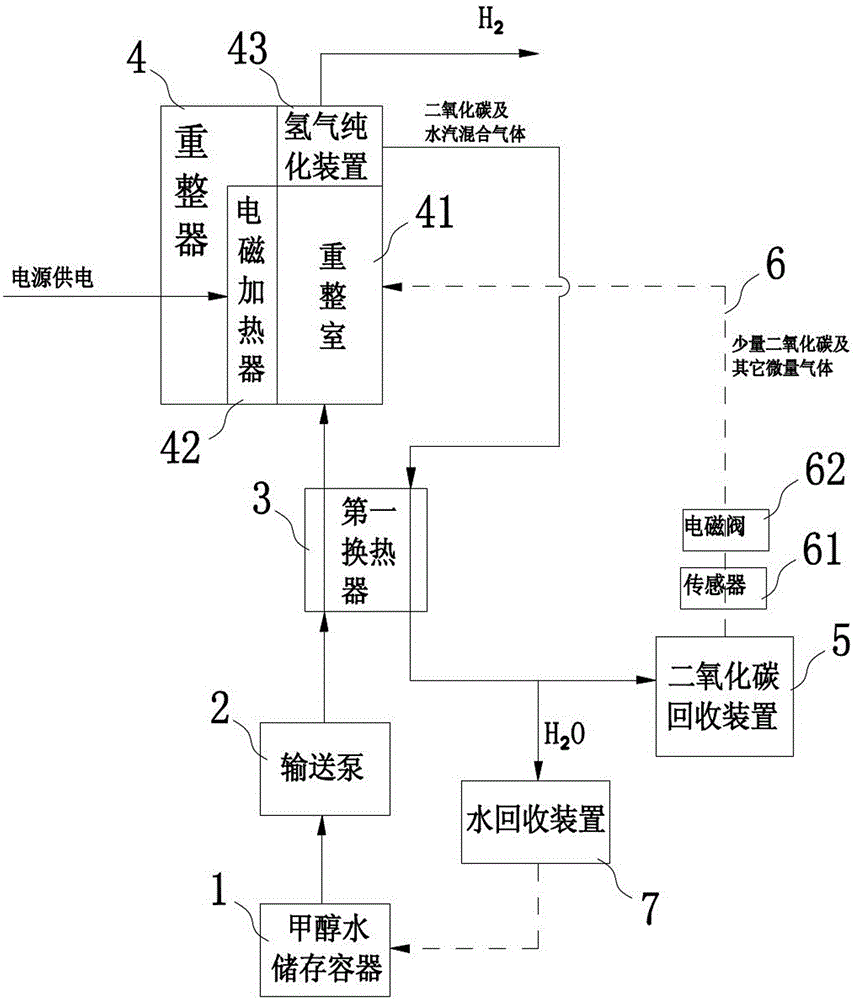

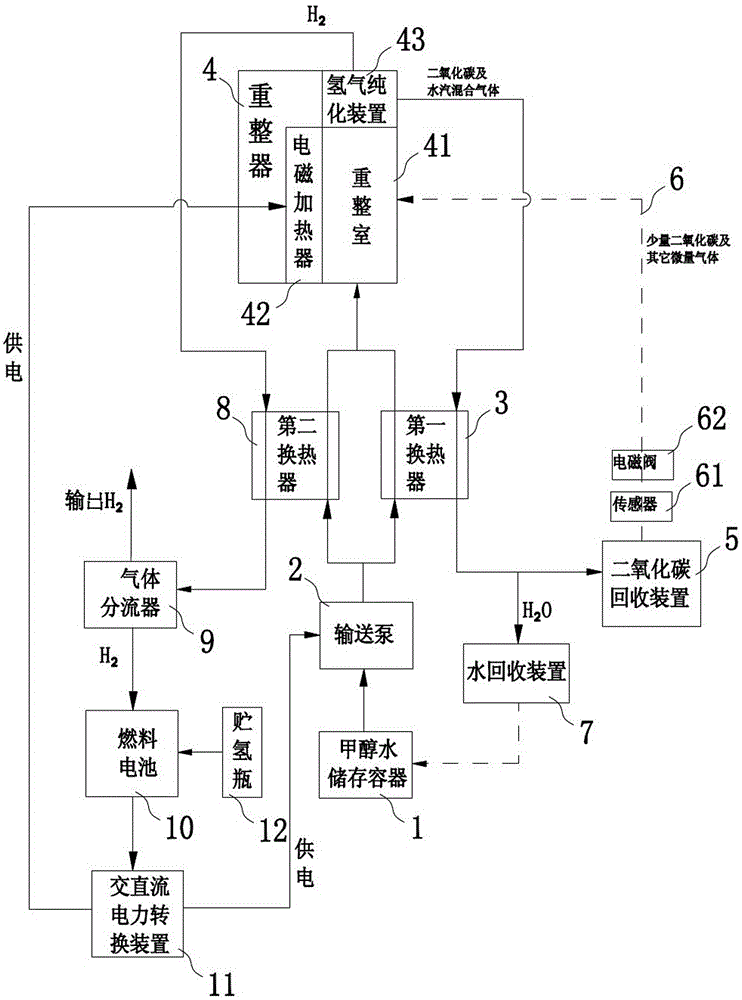

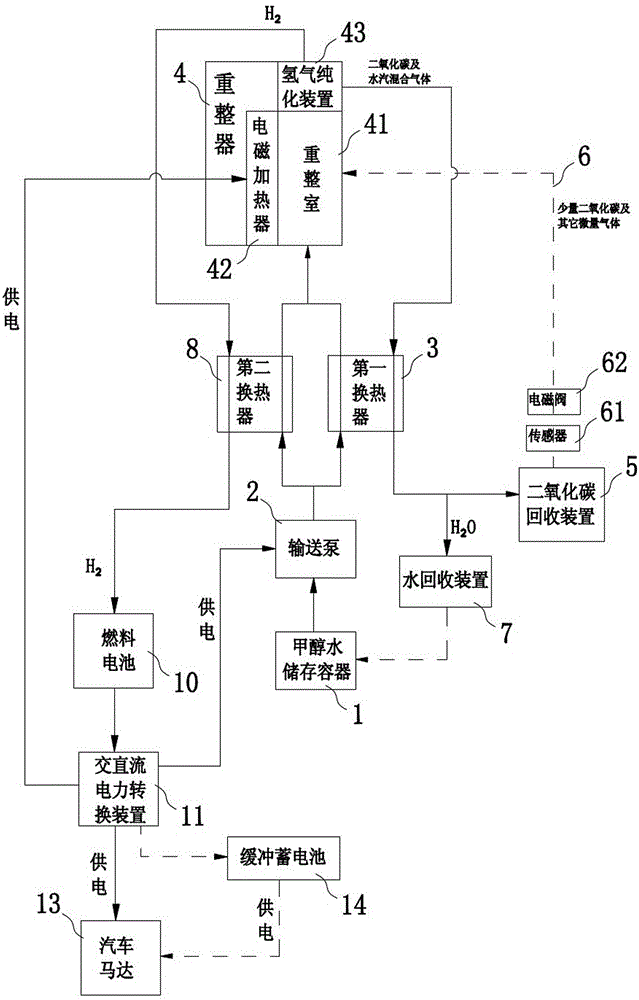

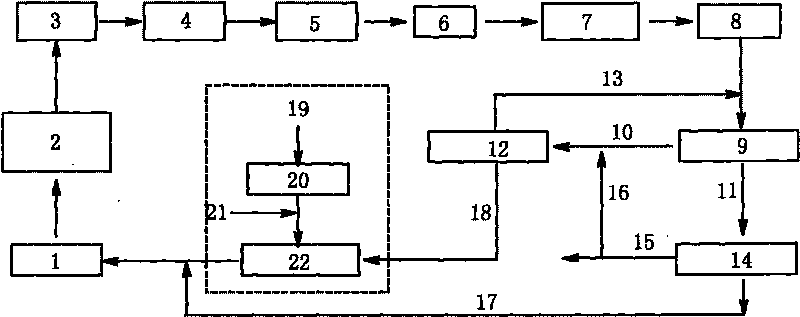

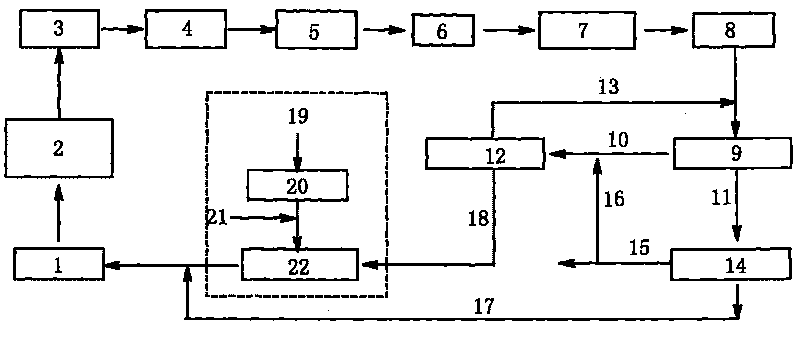

Zero-carbon-emission hydrogen production system by methanol water reforming as well as application and hydrogen production method thereof

The invention discloses a zero-carbon-emission hydrogen production system by methanol water reforming and application and a hydrogen production method thereof. The hydrogen production system comprises a methanol water storage vessel, a delivery pump, a first heat exchanger, a reformer and a carbon dioxide recovery device, wherein the reformer is provided with a reforming chamber, an electromagnetic heater and a hydrogen purification device; the electromagnetic heater provides heat energy for the reforming chamber; the reforming chamber is used for hydrogen production reaction of methanol and water by reforming to obtain carbon dioxide and hydrogen; carbon dioxide and hydrogen are mixed with water vapor to form high-temperature mixed gas, and the high-temperature mixed gas is delivered into the hydrogen purification device; after purification and separation, hydrogen is delivered out, at the same time carbon dioxide and unreacted water vapor mixed gas are also delivered out, and then carbon dioxide and unreacted water vapor mixed gas are delivered into the carbon dioxide recovery device after passing through the first heat exchanger; the carbon dioxide recovery device is a replaceable modular carbon dioxide recovery device and used for recovering carbon dioxide and part of the water vapor. The zero-carbon-emission hydrogen production system provided by the invention can recover carbon dioxide, has no impact on the environment and causes no harm to the hydrogen production system self and is beneficial for popularization and application in the field of new energy resources such as fuel cell cars.

Owner:GUANGDONG HYDROGEN ENERGY SCI & TECH

Method for reclaiming carbon fiber reinforced epoxy resin composite material

ActiveCN102181071ARelieve stressImprove degradation efficiencyPlastic recyclingBulk chemical productionEpoxyPhosphomolybdic acid

The invention relates to a method for reclaiming a carbon fiber reinforced epoxy resin composite material. The conventional method is high in equipment requirement and high in reclamation cost. The method comprises the following steps of: adding a catalyst into an organic reagent to prepare supercritical CO2 composite solution; putting the carbon fiber reinforced epoxy resin composite material tobe decomposed into a reaction kettle, and adding the supercritical CO2 composite solution; and reacting for 1 to 24 hours at the temperature of between 100 and 250 DEG C under the pressure of 7.5 to 25.0MPa, cooling the product to normal temperature, washing and drying the solid product in the product to obtain carbon fibers, and performing reduced pressure distillation on the liquid product in the product to obtain phenol and derivatives thereof. The catalyst is one or two of liquid super acid, solid super acid, phosphotungstic acid, phosphomolybdic acid, acetic acid, formic acid, hydrochloric acid, sulfuric acid and nitric acid. The method has the advantages of high degradation efficiency, environmental friendliness, low cost and the like, and is a green method for reclaiming the waste and old carbon fiber reinforced epoxy resin composite material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

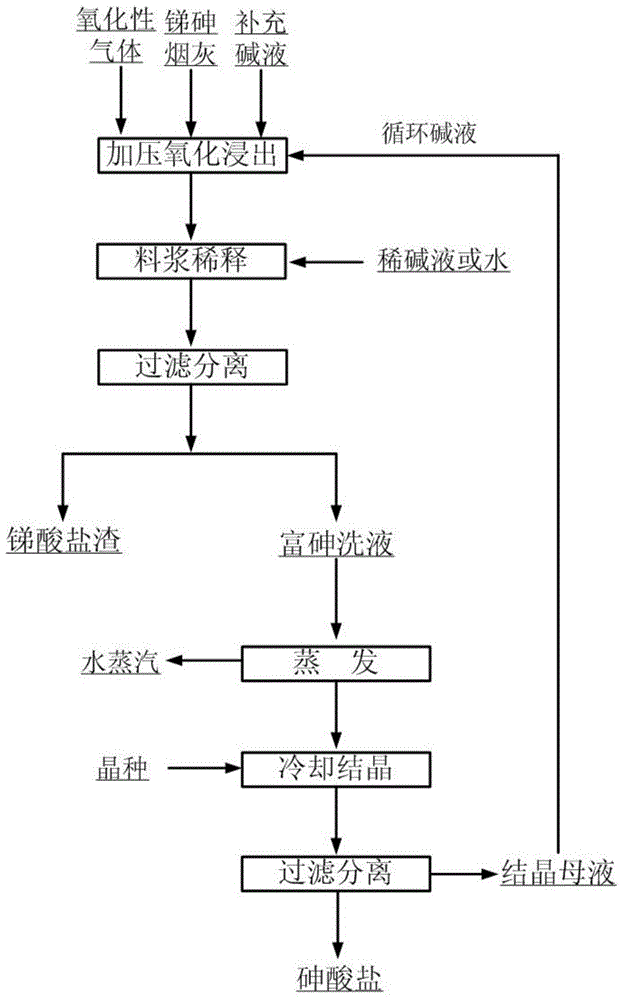

Method for separating antimony from arsenic in antimony-arsenic soot

The invention relates to a method for separating antimony from arsenic in antimony-arsenic soot through oxidation alkaline leaching. The method specifically includes the steps that the antimony-arsenic soot and an alkali solution of a certain concentration are mixed and placed in an alkali-resisting and pressure-resisting reaction still, a gas oxidizing agent of certain pressure is introduced, and a reaction is carried out at a certain temperature; after the reaction, the alkali concentration is adjusted to be below 150 g / L with water or dilute alkali, liquid and solid are separated, an arsenic-rich leaching solution and antimonate slags are obtained, and the antimonate slags can be used for preparation of antimonious oxide powder as antimony concentrate; the arsenic-rich leaching solution is evaporated and added with little seed crystals for cooling crystallization, arsenate crystal products are obtained, and crystallization mother liquor returns to the leaching process of the antimony-arsenic soot. The method is simple in process, capable of separating antimony and arsenic thoroughly and short in flow path; and the method can also avoid arsenic volatilization of the roasting process and harm caused by arsenic hydride gas of the acid leaching process, thereby being environmentally friendly.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Method for recycling waste lithium iron phosphate batteries

InactiveCN102664294AAchieve recyclingImprove electrochemical performanceWaste accumulators reclaimingBattery recyclingLithium iron phosphateEngineering

A method for recycling waste lithium iron phosphate batteries relates to a battery recycling method. The method provided by the invention aims to provide a battery recycling method which is simple in process and low in cost. The method comprises the following steps of: removing residual electric quantity of a waste lithium iron phosphate battery, taking out the cell of the battery and crashing the cell into fragments, soaking the cell fragments in sodium hydroxide solution and stirring; and then performing filtering, washing, drying and vibratory screening so as to obtain pure alumium, pure copper and a diaphragm on a screen, recycling alumium and copper through smelting so as to obtain mixed powder under the screen, cleaning the mixed powder by using acidic solution, performing drying and thermal treatment, adjusting the mol ratio of lithium to iron to phosphorus to carbon, and then performing ball milling, drying and roasting, thereby obtaining a lithium iron phosphate anode material. The method for efficiently recycling the waste lithium iron phosphate batteries provided by the invention is simple in process, low in production cost and quick in taking effect.

Owner:HARBIN INST OF TECH

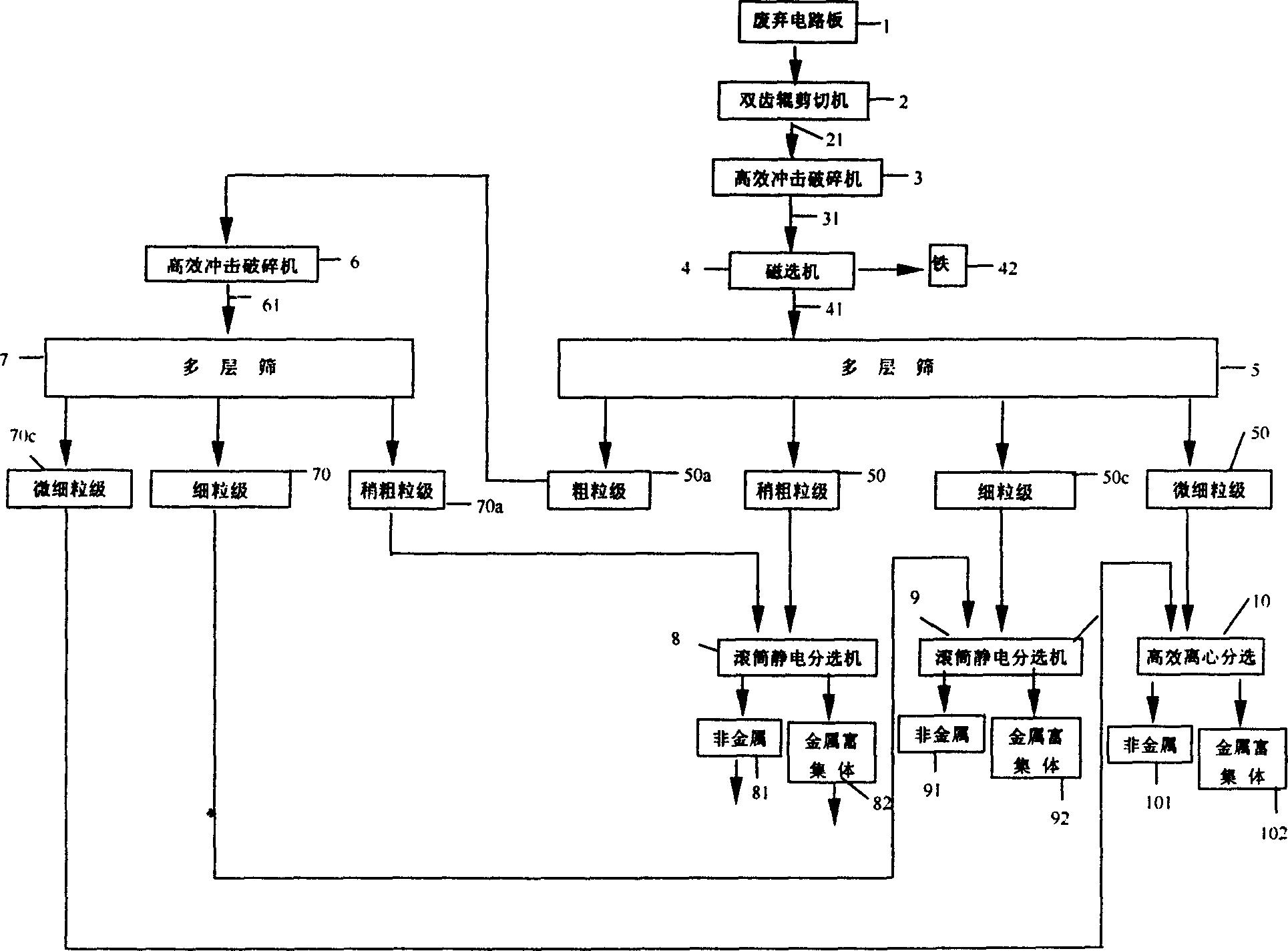

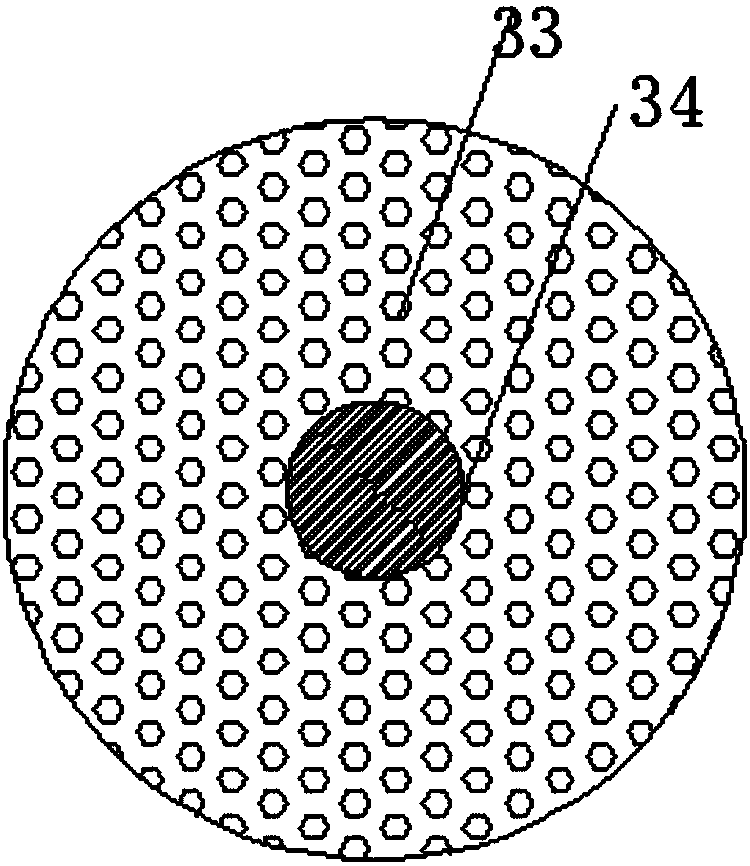

Techhnique for reclaiming metal concentrate in obsolete PCB physically

InactiveCN1563440ASolve resource problemsAchieve recyclingSolid waste disposalProcess efficiency improvementDouble teethMagnetic separator

A physical recovery technology of metal enriched materials from waste CB applies a mechnanical and physical sorting method to cut, crush, screen, sort and separate the waste CB by a double tooth roll shearer, a punch crusher, a magnetic separator, a separating screen, a rotary static separator, high efficient centrifugal separator to get a multicomponent of metal rich collection and a nonmetal enriched material to recover all valuable components from waste CB.

Owner:CHINA UNIV OF MINING & TECH

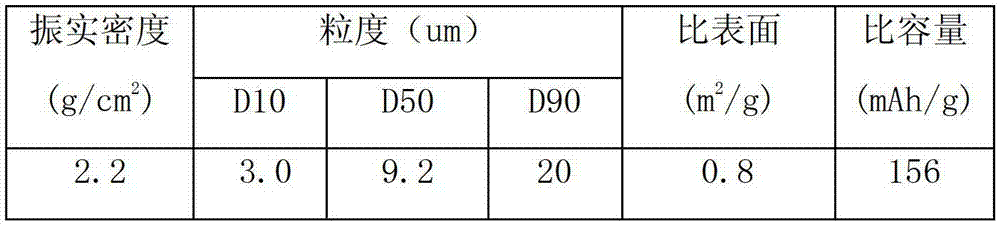

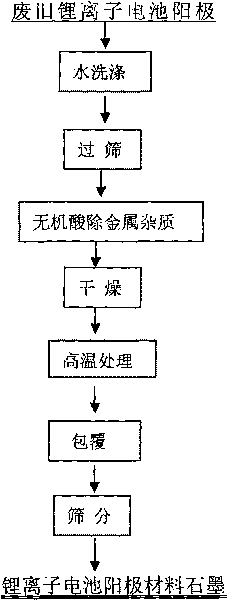

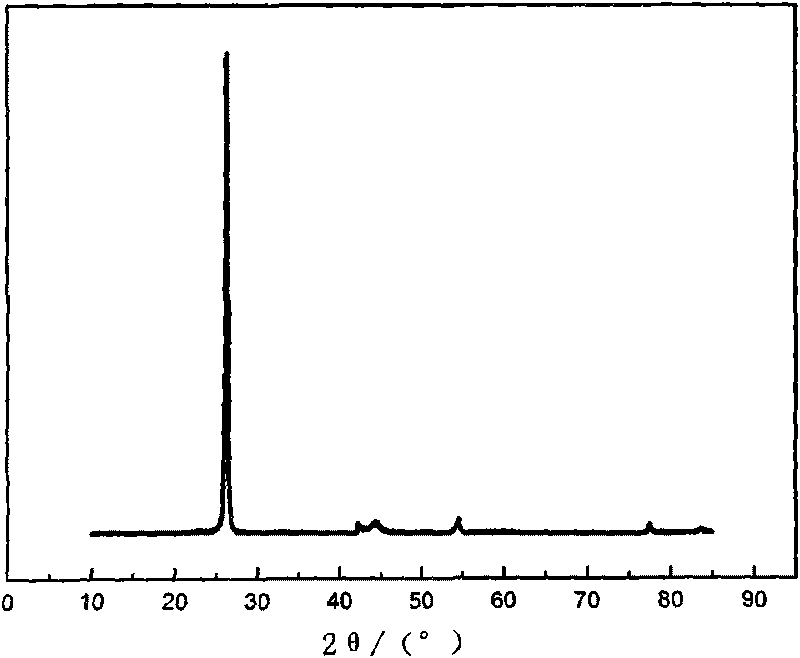

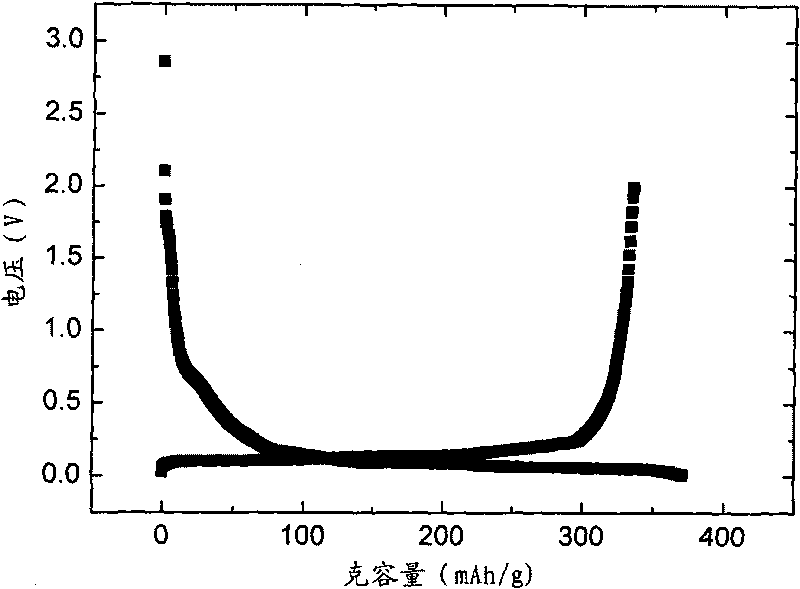

Method for recovering and restoring anode material graphite of waste lithium ion battery

ActiveCN101710632AAchieve recyclingAchieve fixWaste accumulators reclaimingBattery recyclingCharge dischargeCopper foil

The invention discloses a method for recovering and restoring anode material graphite of a waste lithium ion battery, which belongs to the technical fields of resource cyclic utilization and inorganic material restoration. The method comprises the following steps: (1) separating graphite from copper foil to obtain crude anode material graphite; (2) removing lithium, copper and other metallic impurities in the crude anode material graphite; (3) removing acetylene black and residual organic substances, oxidizing the surface of the graphite; and (4) coating and surface-finishing. The tap density of the graphite obtained in the invention reaches 1.07 g / cm<3>; the first discharge capacity is 335.7 mAb / g; the first charge-discharge efficiency is 90.5%; after circulations for 54 times, the capacity conservation rate is 97.23%; and the properties of the graphite obtained in the invention correspond to the properties of graphite of lithium ion batteries in the market. The invention has the advantages of high graphite recovery rate, high raw material purity, simple technology, low energy consumption and the like, has economic benefit, and also has social benefit of saving finite graphite resources, reducing environmental pollution and the like.

Owner:HUNAN BRUNP RECYCLING TECH

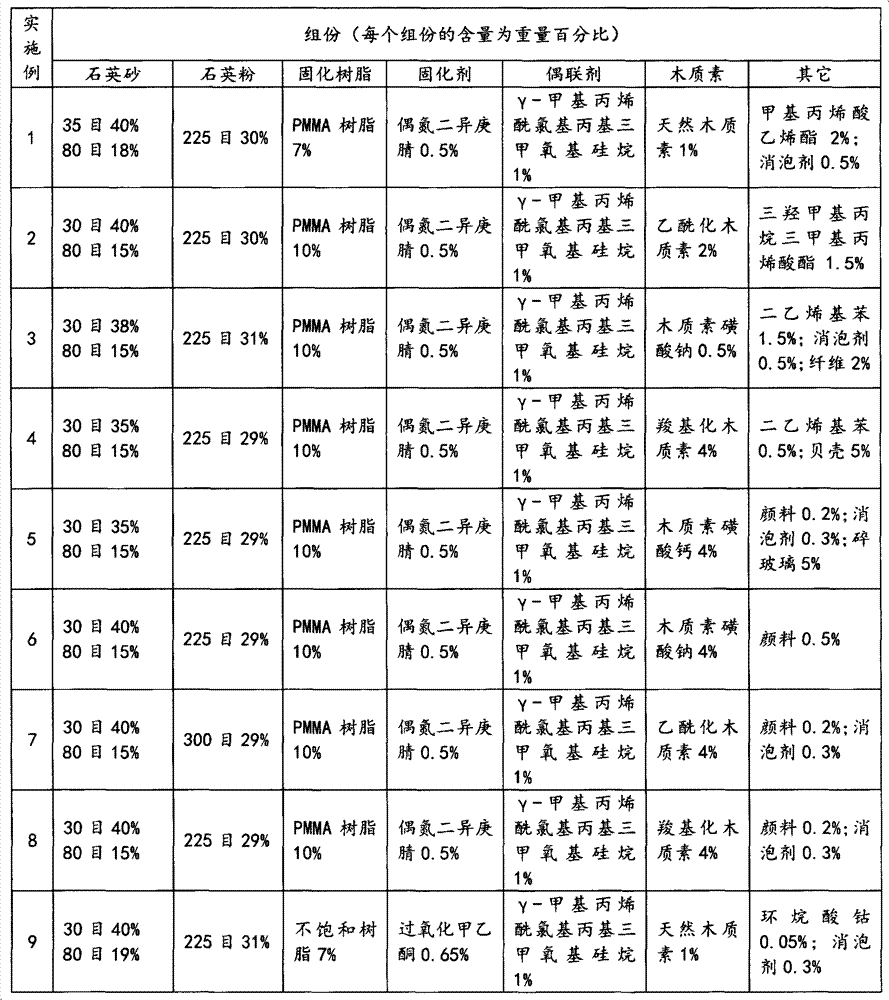

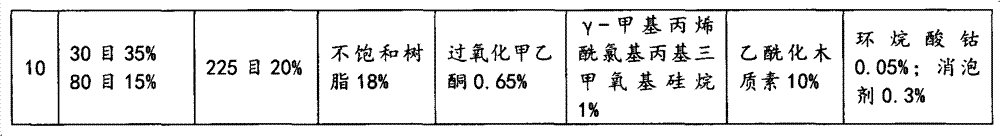

Bio-based artificial quartz stone and production process thereof

ActiveCN102898070AReduce environmental pollution problemsAchieve recyclingCeramic shaping apparatusWeather resistanceDefoaming Agents

A bio-based artificial quartz stone and a production process thereof are disclosed. The bio-based artificial quartz stone includes the following components by weight: 0-80% of quartz sand; 10-70% of quartz powder; 3-20% of curable resin; 0.05-3% of a curing agent; 0.01-40% of lignin; 0-5% of a crosslinking agent; 0.05-5% of a coupling agent; 0-1% of a promoter; 0-2% of a pigment; and 0-3% of a defoaming agent. According to the invention, the lignin is used in the artificial quartz, the environmental pollution of the lignin is reduced, the cost of the artificial quartz is reduced, and at the same time the weather resistance and light stability of the artificial quartz are improved, thus the artificial quartz has antibacterial ability, is green and environmental-friendly, and is suitable for using in building decoration of living environments.

Owner:SUZHOU TOPOLINE TECH

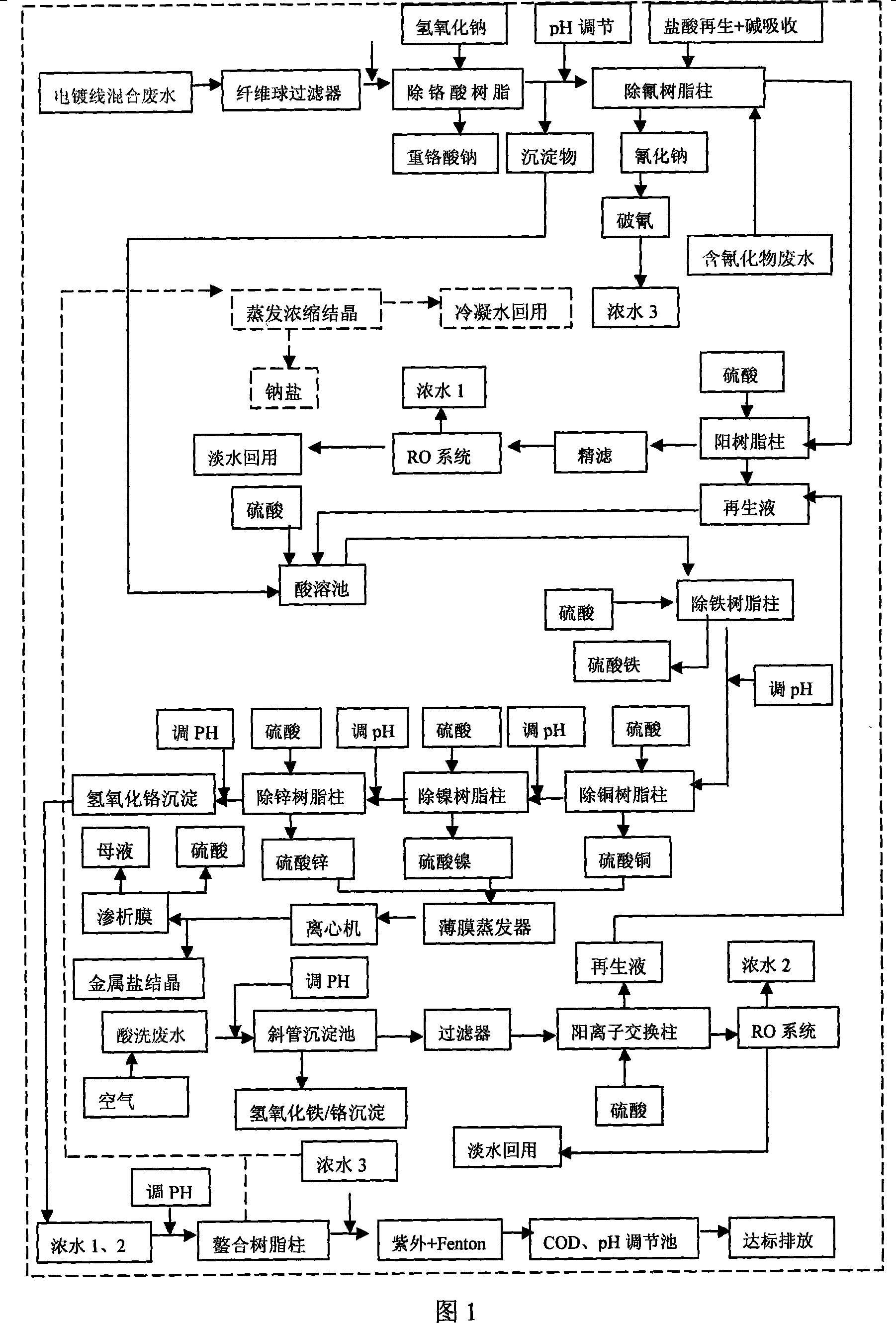

Electroplating wastewater zero-discharge or low-discharge handling method

InactiveCN101157509ASolve pollutionReduce processing costsFatty/oily/floating substances removal devicesWater/sewage treatment by irradiationIonAutomatic control

The invention provides a processing method for zero draining or low draining of electroplating wastewater. The method adopts an integrative technique, such as barrier concentration, barrier separation, ion exchange, and ultraviolet light catalytic oxidation, etc. The following steps are adopted: the pretreatment of the electroplating wastewater; the treatment for the three types of wastewater including pickling wastewater, wastewater containing cyanide and passivating and electroplating rinsing composite wastewater; and the treatment for the wastewater in an acid-soluble pool. Compared with the wastewater in an integrative electroplating plant with universal generic multi-plating species, only the prior water separation method with no need to control the troubled water strictly can realize : first, zero draining of the electroplating wastewater is performed; second, when operating in the low energy consumption way, 65 to 85 percent of water recovery is realized, the left wastewater which can not be recovered is discharged when reaching the primary discharge standard of National Standard; third, the processing cost is reduced; fourth, the metallic ion in the wastewater can be effectively recovered and utilized, at the same time, the benefit disinvestment cost is produced; fifth, the amount for causing solid waste is reduced; sixth, the invention is advantageous to realize the automatic control and the operation.

Owner:SURFACE & INTERFACE CHEM ENG TECH RES CENT NANJING UNIV +1

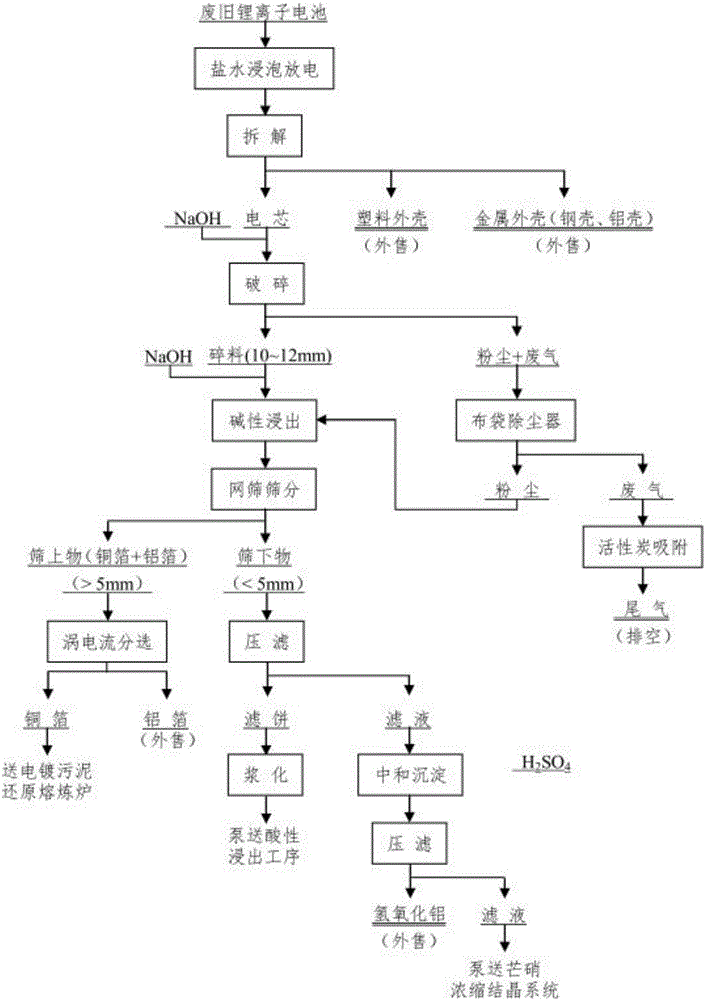

Environmentally-friendly and highly-efficient recovery and separation technology of lithium ion batteries in waste mobile phones

ActiveCN106558739ACause secondary pollutionAchieve recyclingWaste accumulators reclaimingBattery recyclingSeparation technologyLithium-ion battery

The invention discloses an environmentally-friendly and highly-efficient recovery and separation technology of lithium ion batteries in waste mobile phones. The technology mainly comprises brine discharge, disassembling and crushing, alkaline leaching, acidic leaching, iron powder displacement copper precipitation, purification and impurity removal, and precursor synthesis. The technology has the characteristics of advanced process, low cost, high efficiency, substantial economic and social benefits, no discharge of three wastes, no secondary pollution to environment, and realization of cycling of mobile phone resources, so the earth is well protected.

Owner:安徽得盈再生资源回收有限公司

Method for treating solid organic wastes by biological method

InactiveCN101709006AAchieve recyclingAchieve reductionBio-organic fraction processingAnimal corpse fertilisersEcological environmentFermentation

The invention relates to a process for treating solid organic waste resources (food residues, domestic garbage, vegetable market garbage, wastes and leftovers of slaughter houses and food products factories, beer lees, distilled spirit lees, stevia rebaudiana residues, Chinese medicinal herbal dregs and the like), which comprises the following steps of: removing impurities (plastic bags, bottle caps, napkins, metals and the like) from solid organic wastes; adding mixed bacteria, an enzyme preparation and auxiliary materials into the organic wastes; stirring the mixture and controlling the temperature by hot blast; performing fermentation treatment on the mixture by adopting a staged temperature raising method; and drying and crushing the mixture to obtain an organic fertilizer. The invention finds a process capable of effectively treating the solid organic wastes, which can convert the solid organic wastes into the organic fertilizer by using microorganisms to change the organic wastes into valuable and realize the recycling use and the quantity reduction of waste resources; besides, the used microorganisms are harmless to human and the ecological environment.

Owner:TIANJIN UNIV OF SCI & TECH

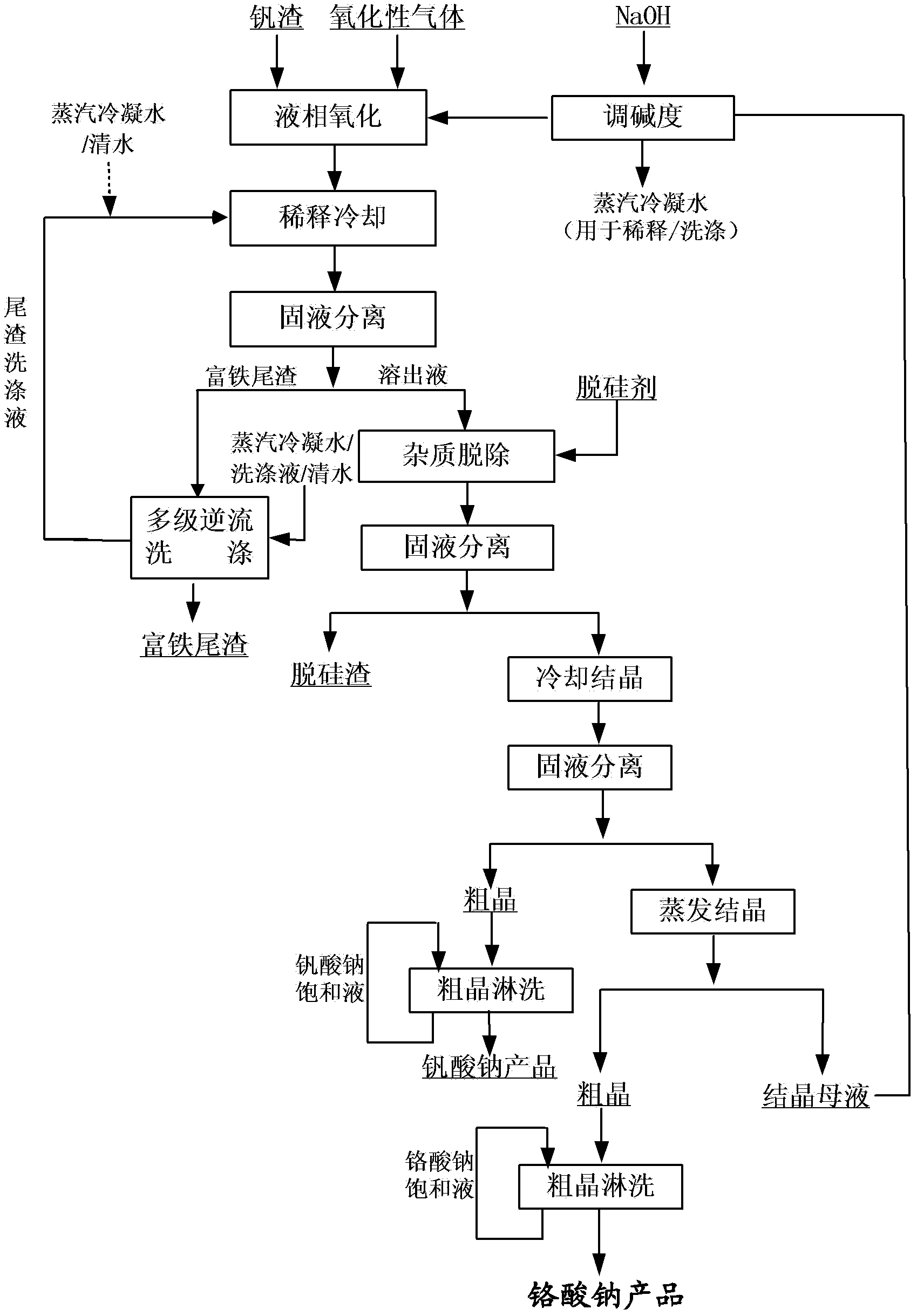

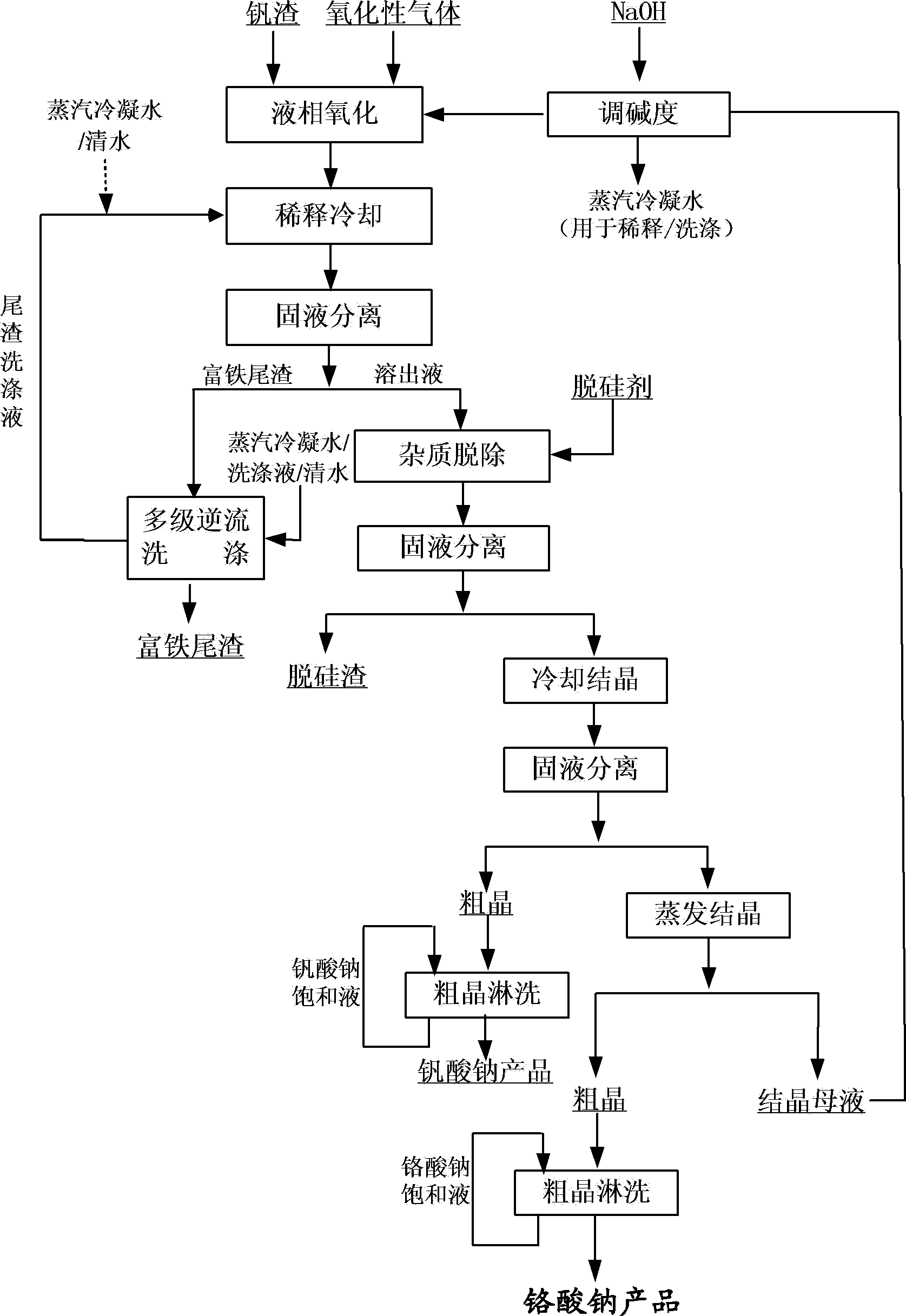

Method for cleaner production of sodium vanadate and sodium chromate by pressure leaching of vanadium slag

ActiveCN102531056ASimple ingredientsAchieve separationChromates/bichromatesVanadium compoundsSlagSlurry

The invention relates to a method for cleaner production of sodium vanadate and sodium chromate by pressure leaching of vanadium slag. The method comprises the following steps of: (1) mixing materials, namely mixing the vanadium slag and a solution of NaOH to obtain a reaction material; (2) reacting, namely performing oxidization reaction on the vanadium slag and oxidizing gas in the solution of NaOH under high pressure to obtain solid-liquid mixed slurry of a solution containing NaOH, Na3VO4, Na2CrO4 and water-soluble impurity components, and iron-rich tailings; (3) performing solid-liquid separation; (4) removing impurities; (5) crystallizing sodium vanadate; and (6) crystallizing sodium chromate. The method is easy to operate and is high in safety; and the operating temperature is greatly lower than the temperature of the traditional vanadium extraction process, energy consumption is low, the high-efficiency co-extraction of vanadium and chromium is realized, and the extraction rate of vanadium and chromium is over 95 percent.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

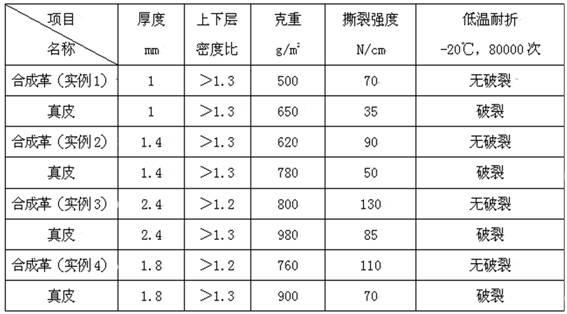

Preparation method of superfine fiber high-imitation grain synthetic leather

ActiveCN102304858AUniform cell size and distributionImprove qualityLamination ancillary operationsSynthetic resin layered productsWoven fabricDimethylformamide

The invention discloses a preparation method of superfine fiber high-imitation grain synthetic leather. The preparation method comprises the following steps of: spinning sea-island composite fibers by utilizing nylon 6 and low-density polythene as raw materials, manufacturing non-woven fabric by utilizing the sea-island composite fibers, coating one surface of the non-woven fabric by utilizing high-solid-concentration polyurethane slurry, infiltrating the non-woven fabric by utilizing low-solid-concentration polyurethane slurry, enabling the non-woven fabric to pass through an aqueous solution of dimethylformamide after infiltrating, solidifying polyurethane and forming a cellular structure to obtain synthetic leather semi-finished products, enabling the synthetic leather semi-finished products to pass through methylbenzene to separate sea-component low-density polythene out of the sea-island fibers, peeling off the sea-island composite fibers to be superfine fibers, washing away methylbenzene through boiling water, and drying to obtain the superfine fiber high-imitation grain synthetic leather. The product manufactured by the method disclosed by the invention has the advantages of strong gradient, abundant hand feeling, fine and smooth surface wrinkles and strong toughness after being bent, and has the beneficial effects on aspects of pollution reduction, animal protection, ecological protection and the like.

Owner:SHANDONG TONGDA ISLAND NEW MATERIALS

Method for producing propylene oxide

ActiveCN101735177AReduce investmentAchieve recyclingOrganic chemistryDispersed particle separationProcess designSodium hydroxide

The invention discloses a chemical production method, in particular a novel green production process for propylene oxide. In the method, the process design is carried out by using bipolar membrane, electrodialysis, antiosmosis, air flotation, heat exchange, oxidation, and other technology. In the production process, sodium hydroxide replaces the conventional calcium hydroxide and generates sodium chloride through reaction; the sodium chloride generates hydrochloric acid and sodium hydroxide by the bipolar membrane technology; and the hydrochloric acid is recovered, and the sodium hydroxide and water can be recycled. Therefore, no new sodium hydroxide is needed and no wastewater is discharged in the production of the propylene oxide. The sodium hydroxide is added at the preliminary stage of the production of the propylene oxide, and the input amount of the sodium hydroxide is controlled between 5 and 15 percent. The novel green production process for the propylene oxide has the advantages that: the recycling of the water, sodium chloride and sodium hydroxide is realized, the effects of zero discharge and input reduction of production materials are substantially achieved, and finally better social and economic benefits are achieved. The novel green production process for the propylene oxide can be widely applied to the chlorohydrin production in China.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

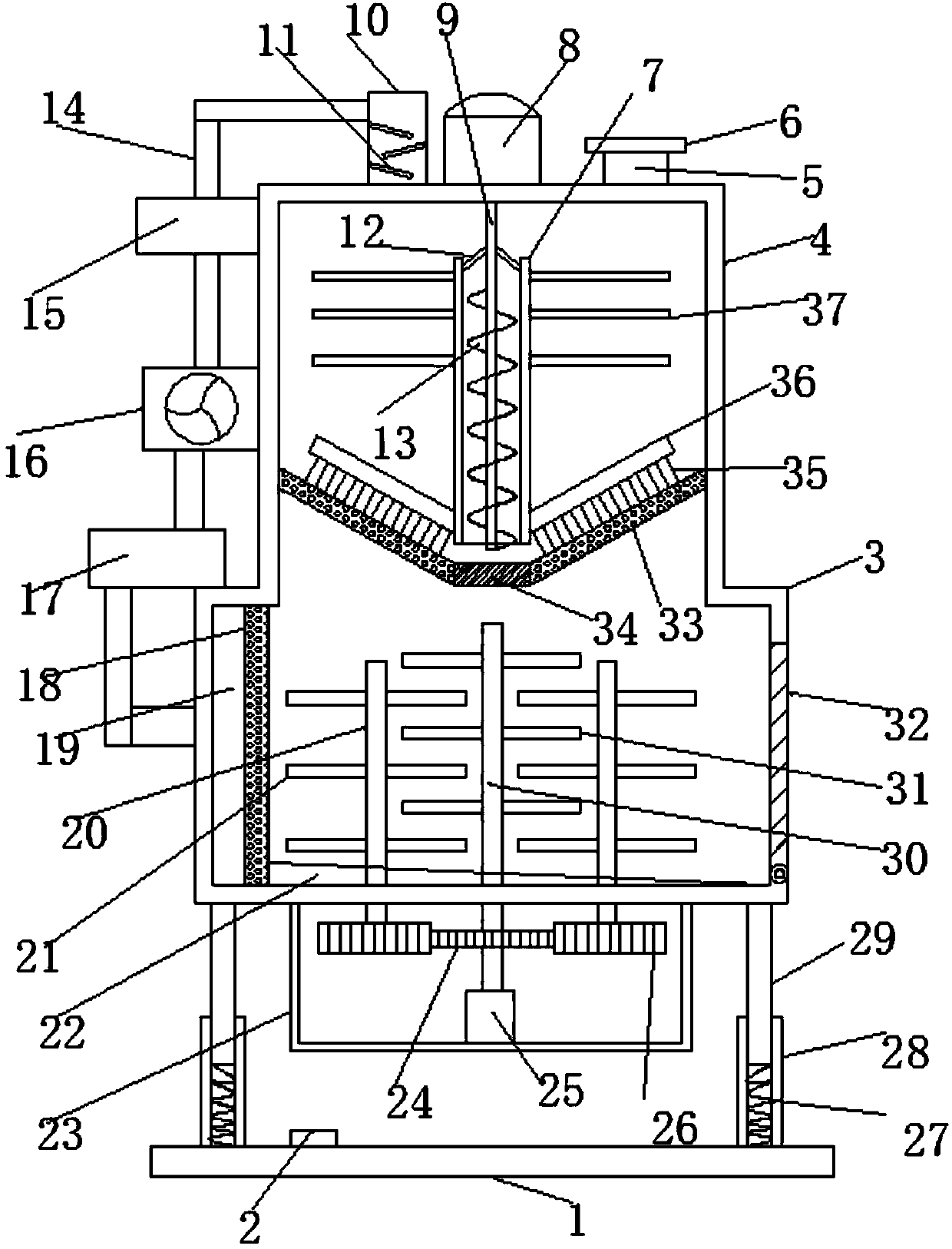

Rapid traditional Chinese medicine drying device facilitating material taking

InactiveCN107560373ARealize internal circulation crushingTimely processingDrying gas arrangementsDrying solid materialsInner loopEngineering

The invention discloses a quick drying device for traditional Chinese medicine which is convenient for taking materials. It comprises a base, a No. 2 cylinder body and a No. 1 cylinder body. The No. 2 cylinder body is connected, and the No. 2 cylinder body and the No. 1 cylinder body are both cylindrical cylinder bodies. The diameter of the No. 2 cylinder body is larger than that of the No. 1 cylinder body. Support rods are symmetrically arranged on both sides of the lower end of the No. 2 cylinder body, and the lower end of the support rod slides The sleeve is provided with a support sleeve, and the inside of the support sleeve is provided with a built-in shock absorbing spring, which connects and fixes the support rod with the base. A crushing motor is fixed in the middle of the upper end of the No. 1 barrel. The structure of the present invention is simple and reasonable, and the shock absorbing effect is Well, the internal circulation of materials is realized, so that unqualified materials can be processed in time, and the heat in the exhausted hot air can be recovered and utilized. This internal circulation drying also reduces the pollution of the device to the environment and facilitates the discharge of materials.

Owner:ZHENGZHOU SOUQU INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com