Patents

Literature

8834 results about "Hot blast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot blast refers to the preheating of air blown into a blast furnace or other metallurgical process. As this considerably reduced the fuel consumed, hot blast was one of the most important technologies developed during the Industrial Revolution. Hot blast also allowed higher furnace temperatures, which increased the capacity of furnaces.

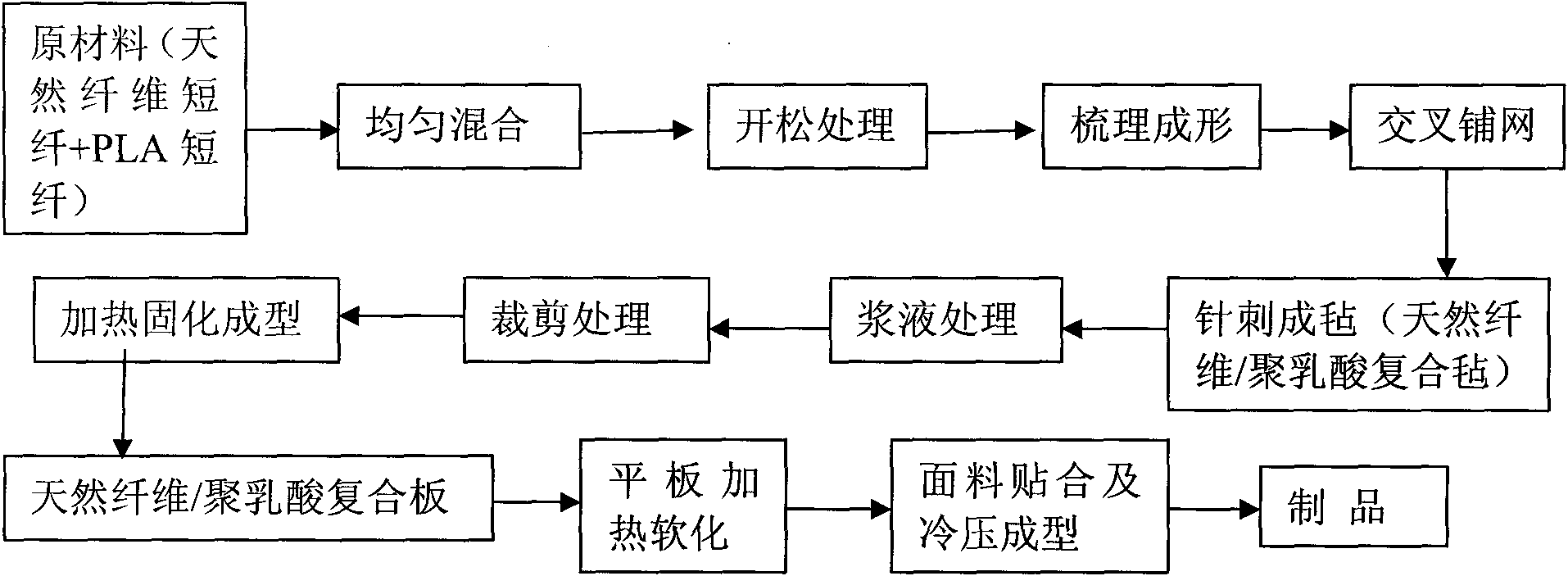

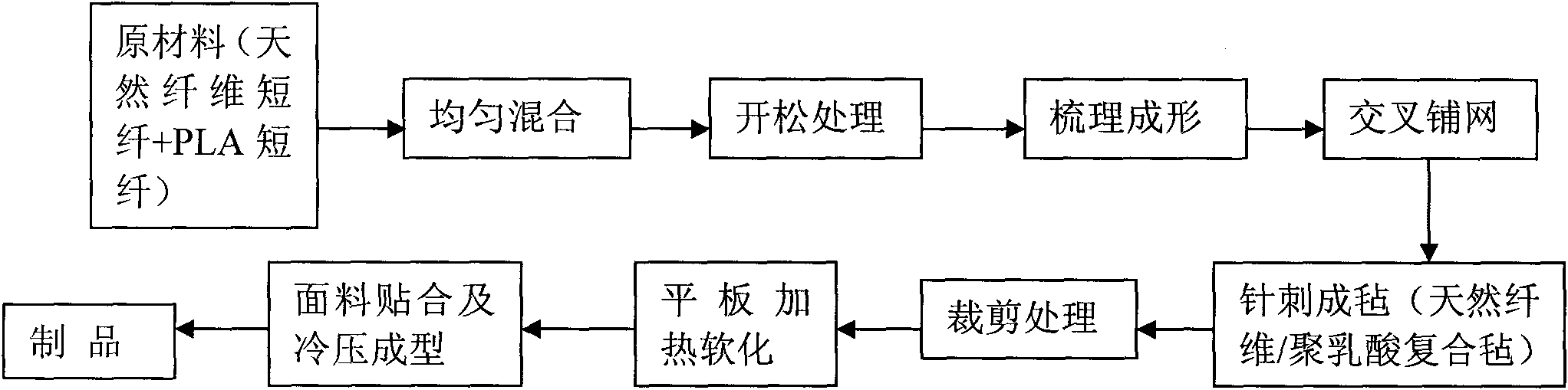

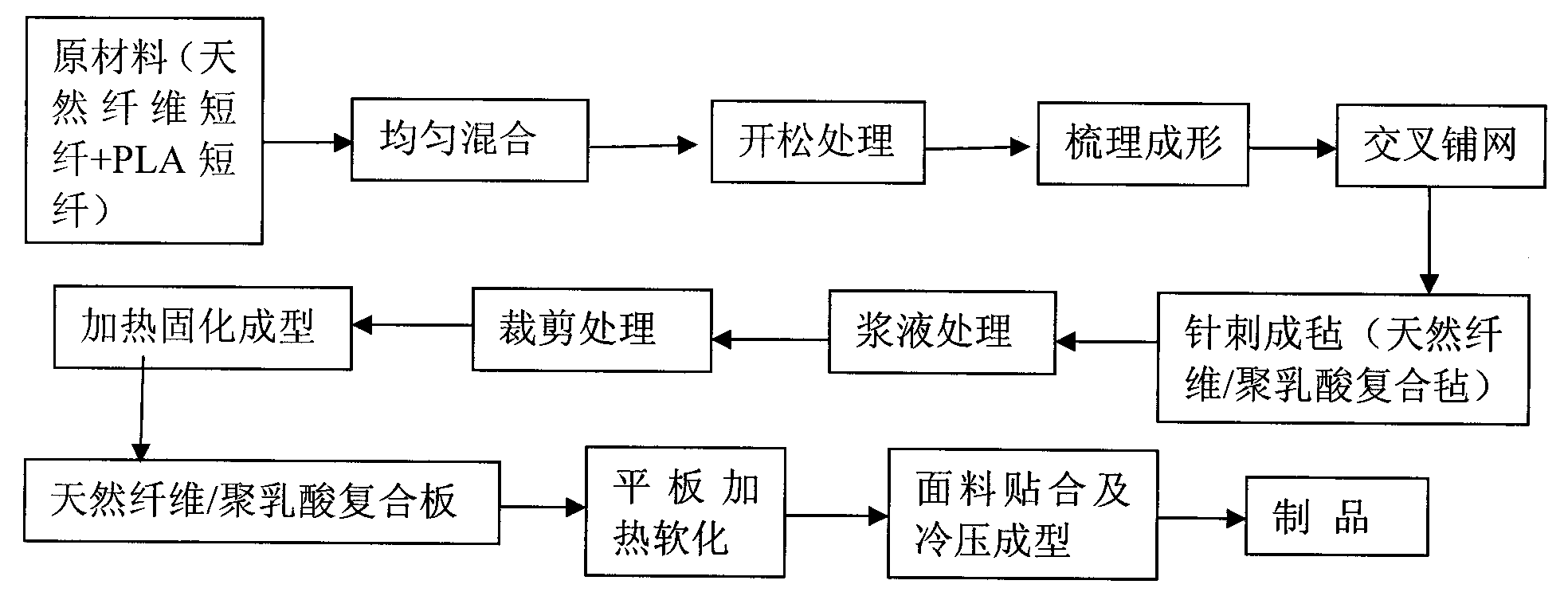

Composite material for automobile interior part and production method thereof

ActiveCN101812773ANo pollution in the processReduce lossVehicle componentsNon-woven fabricsMetallurgySlurry

The invention discloses a formula of a composite material for an automobile interior part. The formula consists of the following materials in percentage by weight: 40 to 60 percent of polylactic acid fiber and 40 to 60 percent of natural fiber. The production method of the invention comprises the following steps: uniformly mixing the raw materials; putting the mixture into an opener for opening, combing and shaping the obtained product, feeding the product into a lapping machine for cross lapping and feeding the cross-lapped product into a needling machine for needling to form a felt; immersing the fiber felt into a processing slurry; drying the immersed coiled material through hot blast and cutting the dried material into pieces of required size; placing the cut material into a mould for curing and shaping by heating; demoulding the material to form a composite plate; and softening the composite plate by flat panel heating, covering the plate with a surface decorative layer and performing cold molding on the plate through a product mould to manufacture the finished product finally; or softening the cut fiber felt by the flat panel heating directly, covering the plate with the surface decorative layer and performing the cold molding to manufacture the finished product finally. The composite material for the automobile interior part of the invention has the advantages of no toxicity, no pollution, simple processing technique, small energy consumption and high environment protection performance.

Owner:CHERY COMML VEHICLE ANHUI

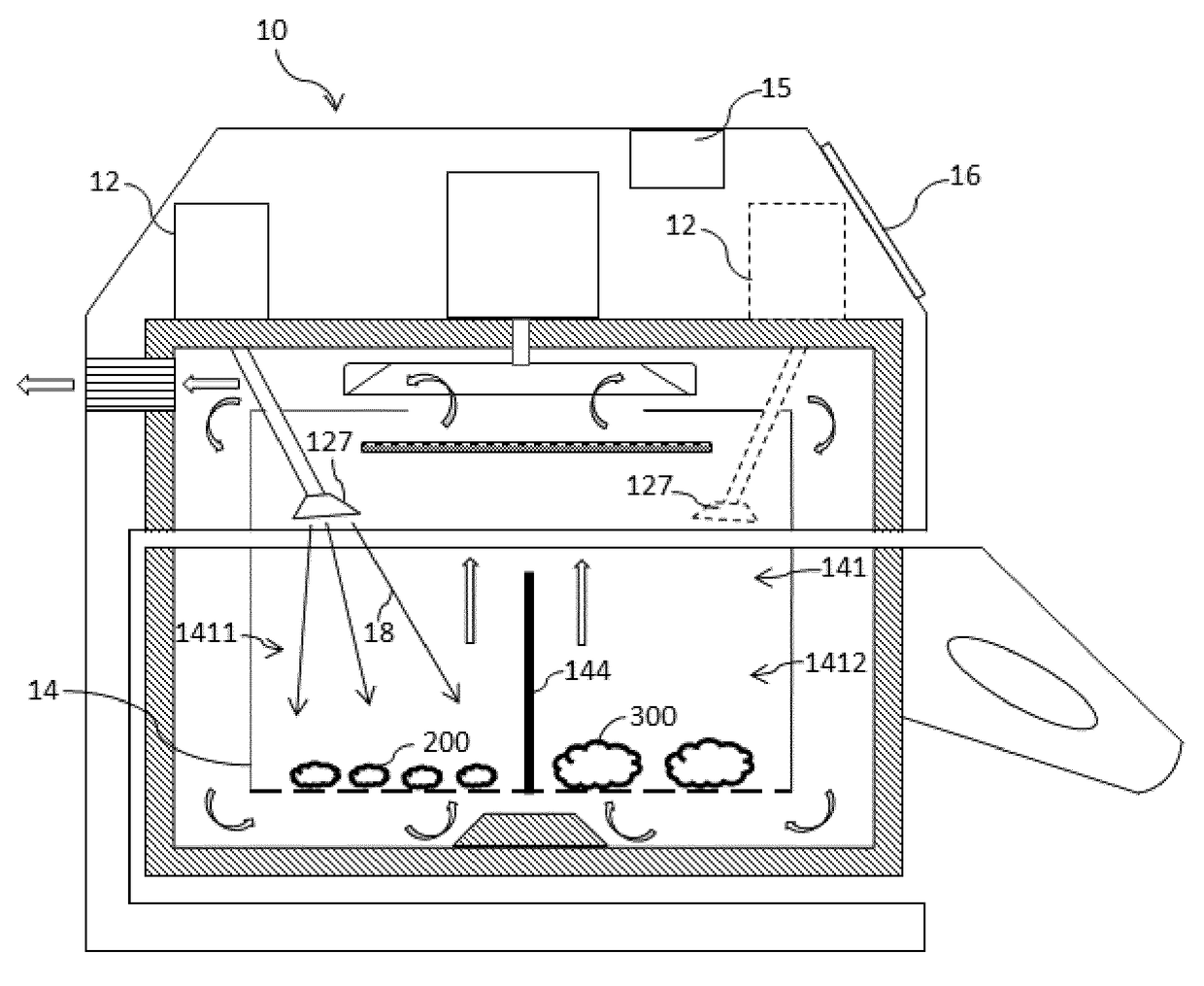

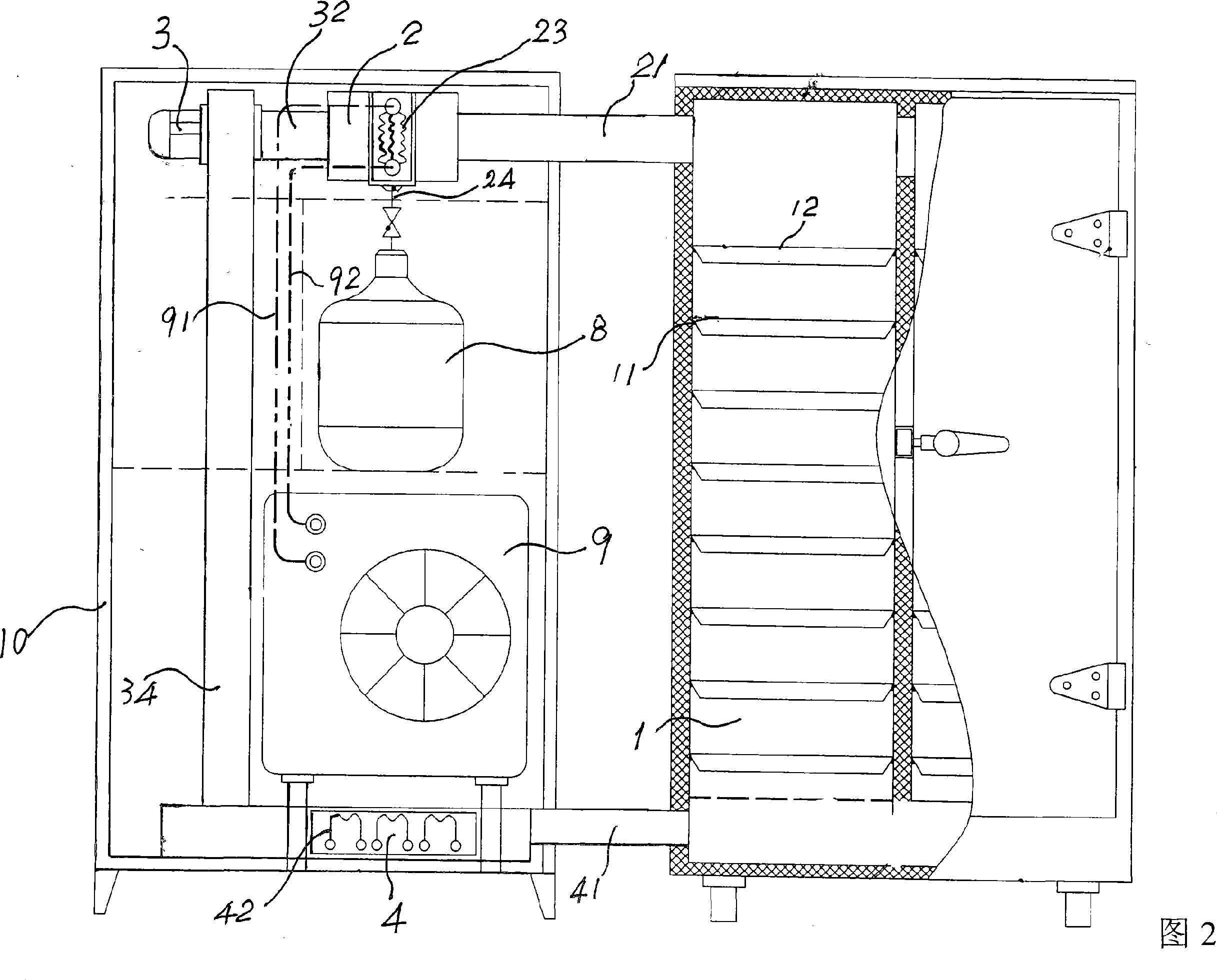

Apparatus and method for preparing food

ActiveUS20170245683A1Reduce surface moisture contentImprove propertiesDomestic stoves or rangesOven air-treatment devicesAir heaterEngineering

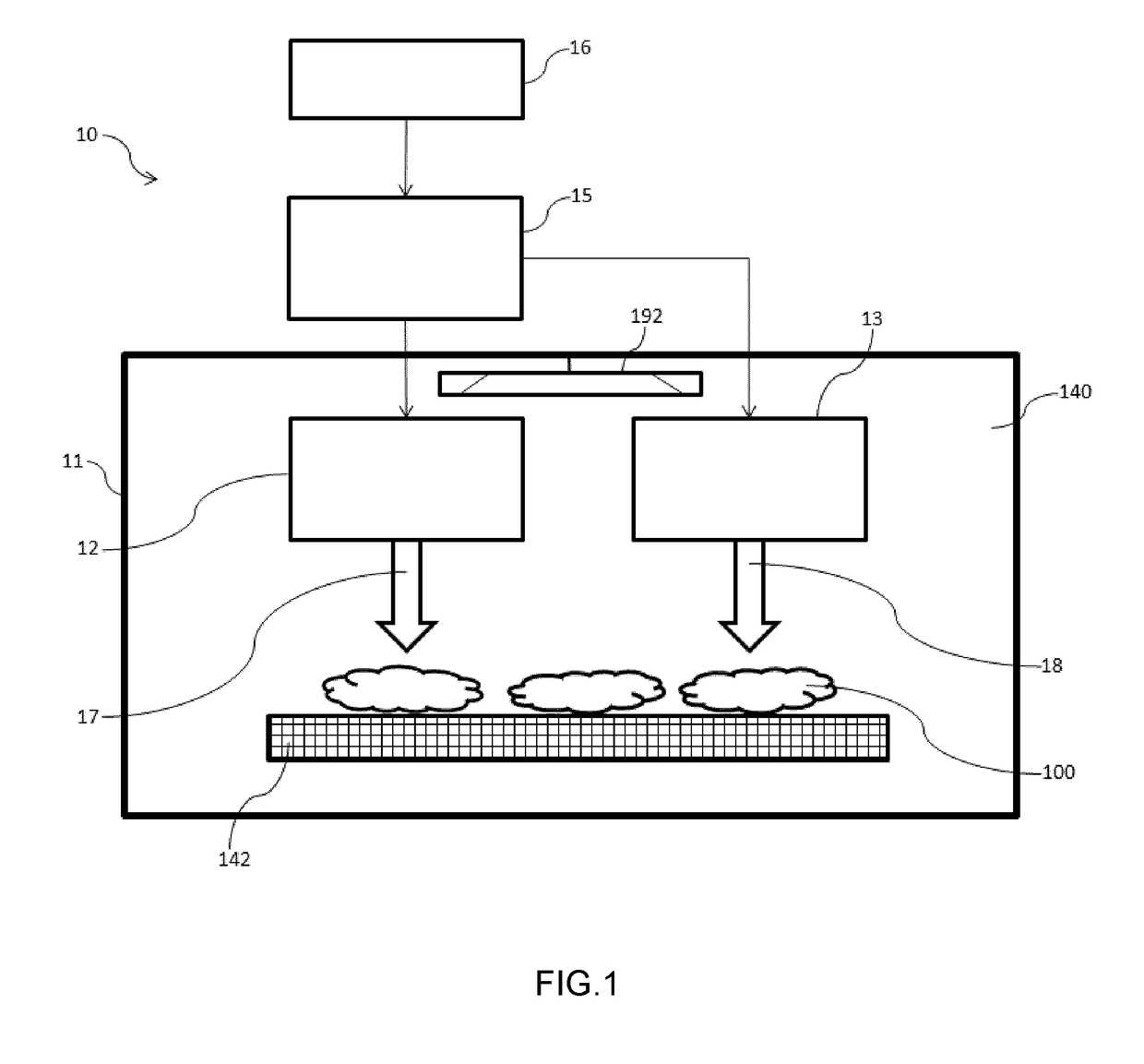

The present invention relates to an air-based flyer (10) apparatus comprising a food preparation chamber (140) comprising an outer wall (11), an inner wall (14) defining a food receiving space (141) with an air inlet (142) and an air discharge opening (145), and a circulation channel (113) defined between the outer wall (11) and the inner wall (14). The apparatus also comprises an air heater (13) for heating air in the food preparation chamber (140), a fan (192) for moving a flow of hot air successively through the air inlet (142), the food receiving space (141), the discharge opening (145), and the channel (113). The apparatus also comprises a steam generator (12) comprising at least one nozzle (127) extending into the food receiving space (141) for spraying temperature-controlled steam (18) onto the food; and a controller (15) adapted to control the steam generator to spray steam to food placed in the food receiving space (141) for a first predetermined period, and to control the air heater (13) and the fan (192) to circulate hot air to the food for a subsequent second predetermined period. This apparatus allows keeping the tenderness or crunchiness of the food during subsequent hot air cooking.

Owner:KONINKLJIJKE PHILIPS NV

Polyhydroxylkanoates as well as blending modification for copolymer thereof and polylactic acid

The invention discloses a PHBV with good performance and a copolymer of PHBV and PLA and the preparation technique method. The invention is characterized in that 1 per cent to 99 per cent of PHAs, 1 per cent to 99 per cent of PLA1 and other additives 0-40 per cent are put in a mixer for 1 to 30 minutes, and then put in an electricity hot blast drying oven a temperature ranging from 40 to 100 DEG C for 2 to 48 hours after being mixed equally. The dried compound is plastified in a double screw extruder, the highest temperature of the double screw extruder is between 90 and 180 DEG C according to the the different content of PHAs and the temperature of the mouth mold is between110 to 170 DEG C. The material extruded from a die head is cooled, stretched and grained to form the complete biodegradation aggregate. The resin consisting of PHBV and copolymer of PHBV and PLA is able to be used for producing the thin films, plates and sheet materials and injected mold to plastic materials. The compound has biological degradability and good machining performance. The target product of the compound has excellent mechanical properties and can be used for replacing the petroleum base plastic to be widely used for packing, agriculture, medical material, electron, chemical industry concerning products for daily use, etc.

Owner:深圳市奥贝尔科技有限公司

Iron coke for blast furnace and preparing method thereof

InactiveCN103468289AEnsure Strength IndexBest heating speedCoke ovensBlast furnace detailsCoke ovenUltimate tensile strength

The invention relates to iron coke for a blast furnace and a preparing method thereof. The iron coke comprises 5wt%-20wt% of iron ore powder and 80wt%-95wt% of mixed coal; the mixed coal is formed by mixing 25wt%-29wt% of one third of coking coal, 40wt%-44wt% of coking coal, 7wt%-11wt% of lean coal, 6wt%-10wt% of gas-fat coal and 12wt%-16wt% of fat coal; the iron ore powder and the mixed coal are mixed uniformly with water and tamped before entering the blast furnace, and are placed into the blast furnace when the temperature is 800 DEG C, the temperature is increased at the speed of 2 DEG C per minute to 3 DEG C per minute, the iron ore powder and the mixed coal are discharged from the blast furnace when the temperature is 950-1050 DEG C, and the iron coke is obtained by adopting a wet way of quenching the coke. According to the iron coke and the preparing method, the performance, the ratio, the particle size and the composition and the like of the iron ore powder and the mixed coal are optimized, and the strength and the reactivity of the iron coke can meet the requirement of the blast furnace process under the circumstance of not adding binding agents.

Owner:WUHAN UNIV OF SCI & TECH

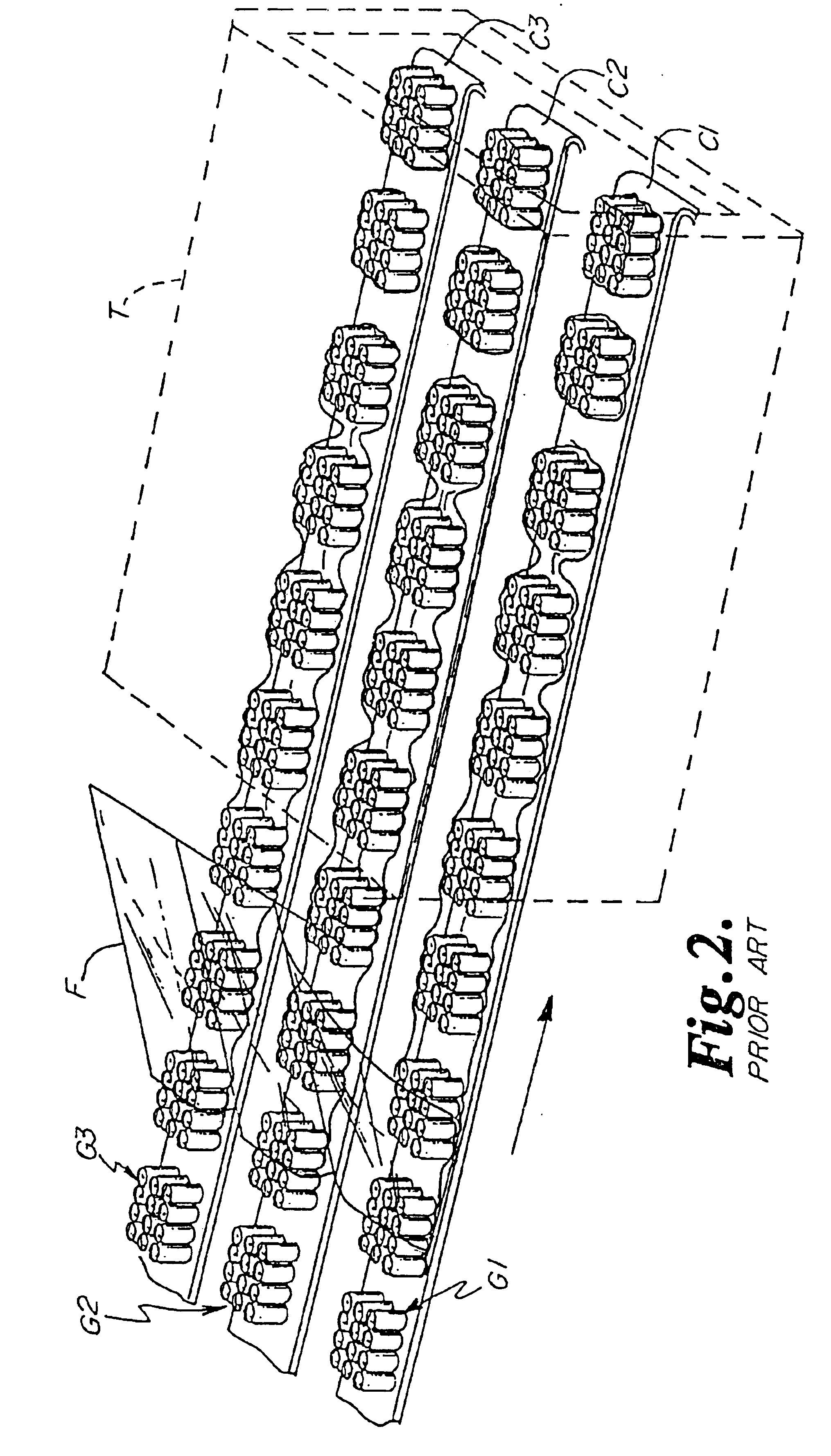

Heat tunnel for film shrinking

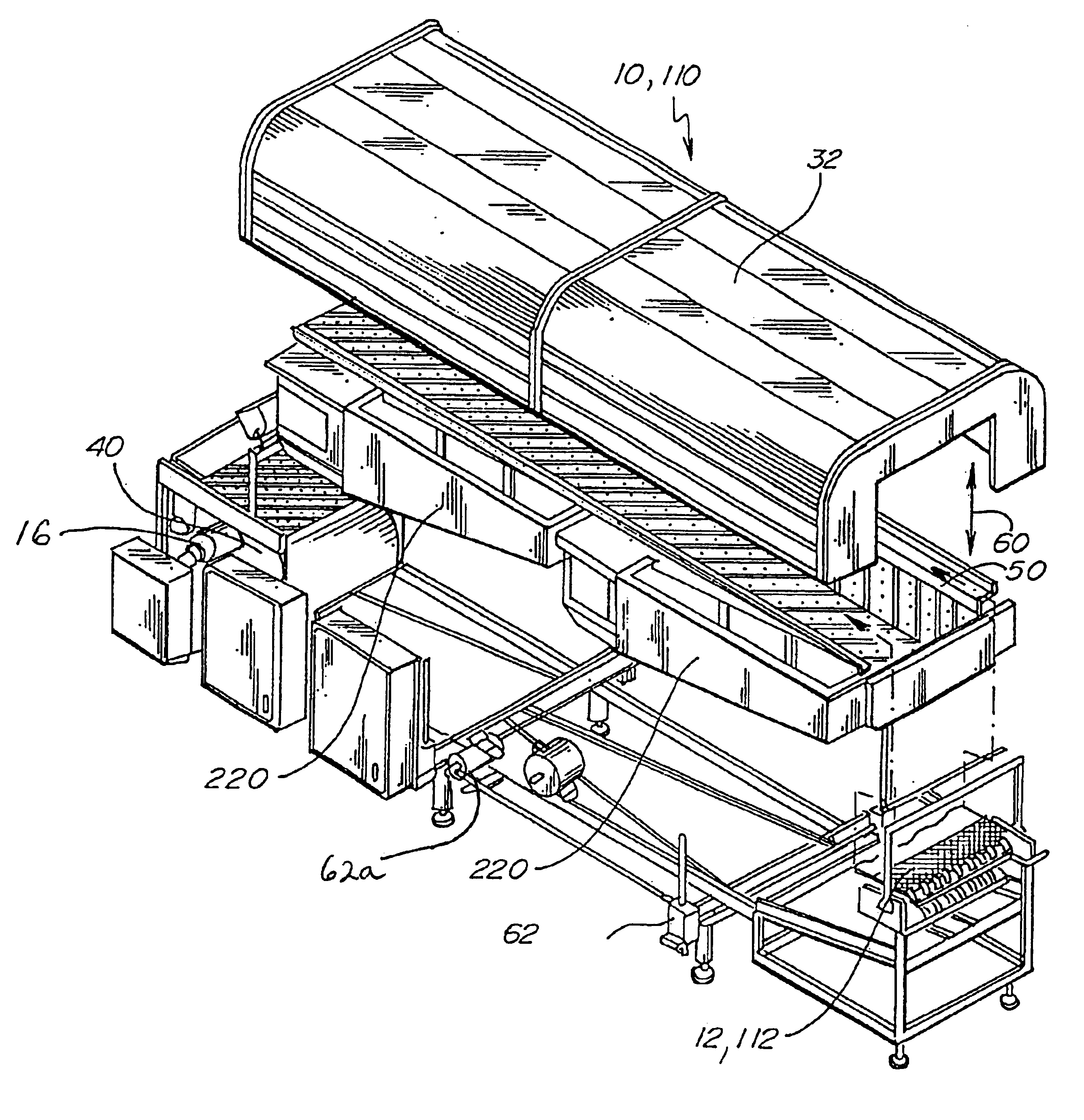

InactiveUS7155876B2Minimal distortionMinimum of wrinkles.Wrappers shrinkageFurnace componentsProcess engineeringShrink wrap

Owner:DOUGLAS MACHINE LIABILITY

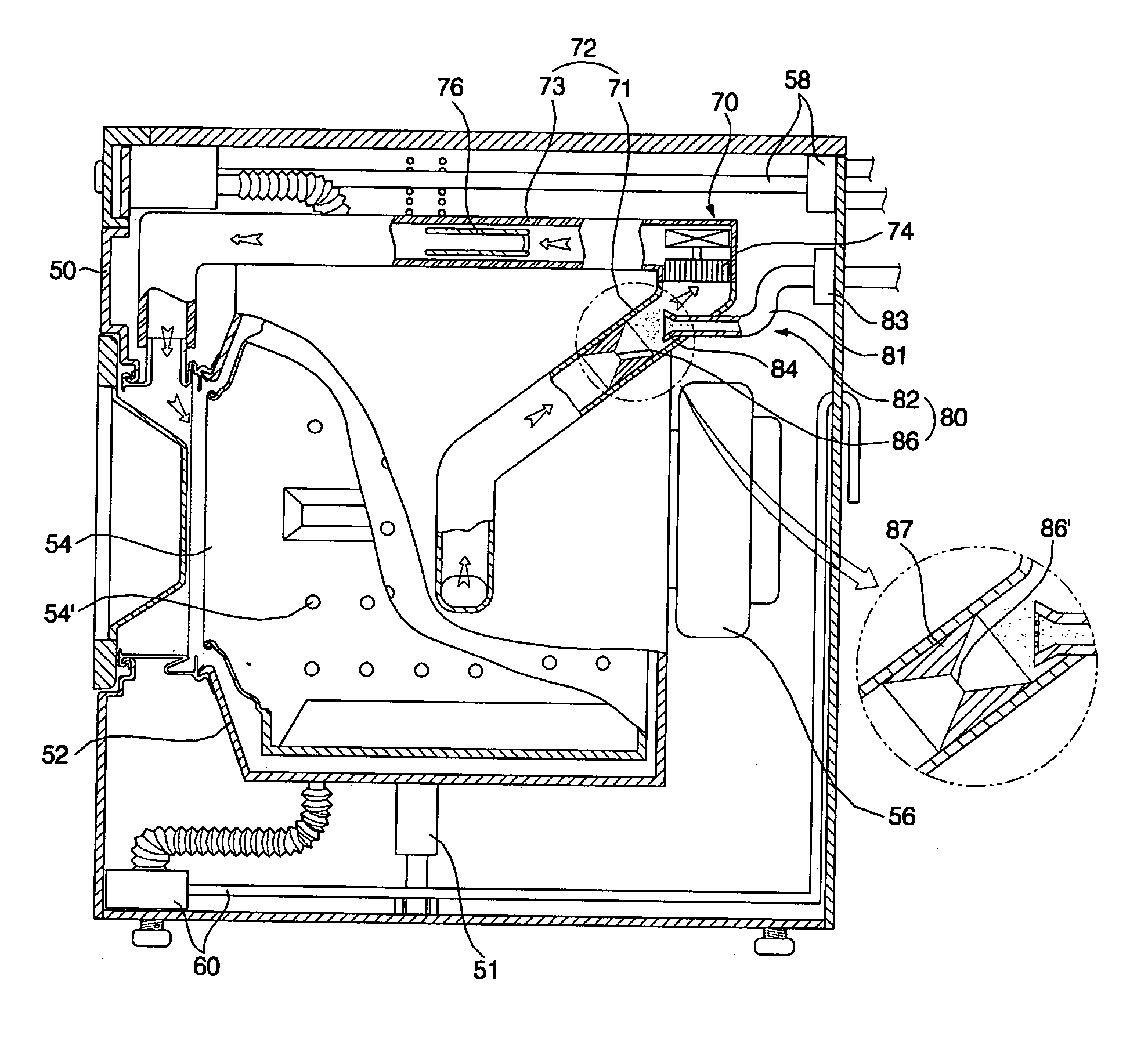

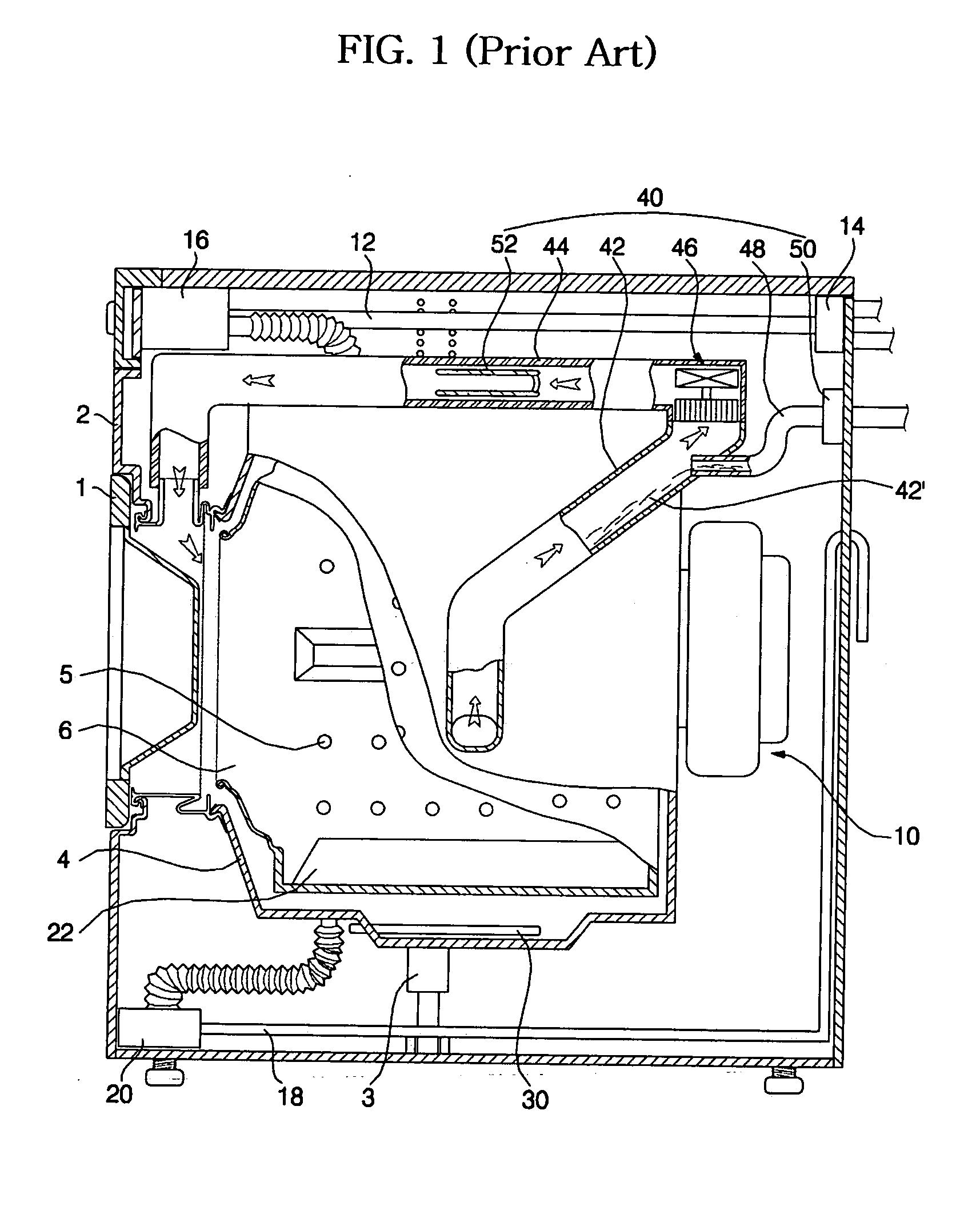

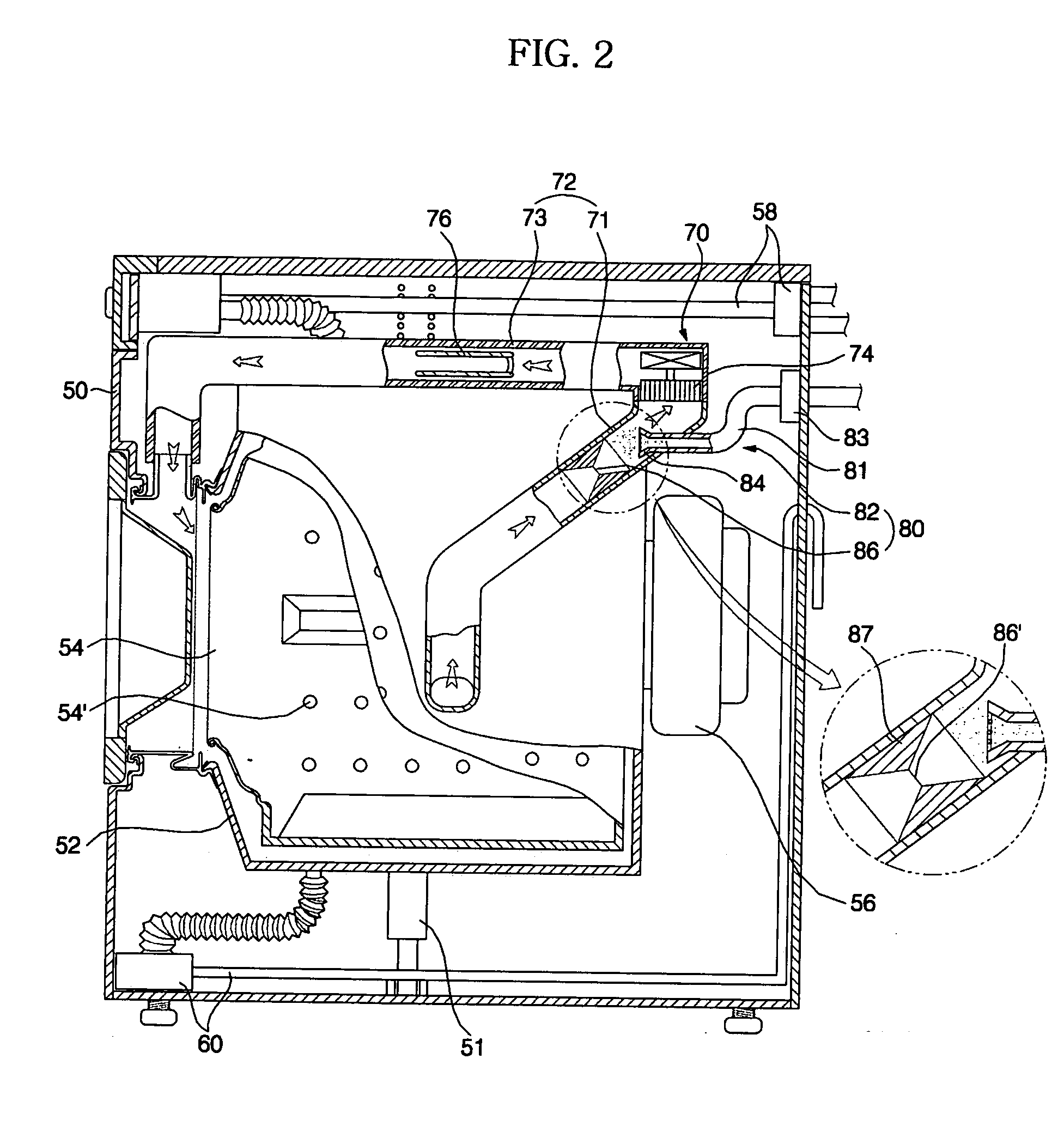

Heating apparatus of washing machine and washing method thereof

InactiveUS20050223503A1Improve washing effectLow production costOther washing machinesWashing machine with receptaclesProcess engineeringAir blower

A heating apparatus of a washing machine and a washing method thereof. The heating apparatus includes a circulation channel installed outside a tub for connecting one side of the tub to the other side of the tub, and an orifice, water drop supply device for supplying water, an air blower for circulating the water, and a heater, which are sequentially installed in the circulation channel. The heating apparatus supplies steam or hot wind to the tub in a washing or rinsing operation, thereby improving the washing capacity of the washing machine, minimizing the time taken to perform the washing or rinsing operation and an energy consumption rate, and allows the washing machine to perform a drying operation using hot wind without any additional element, thereby diversifying its functions and minimizing production costs.

Owner:LG ELECTRONICS INC

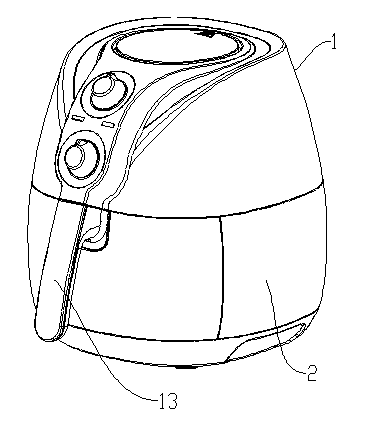

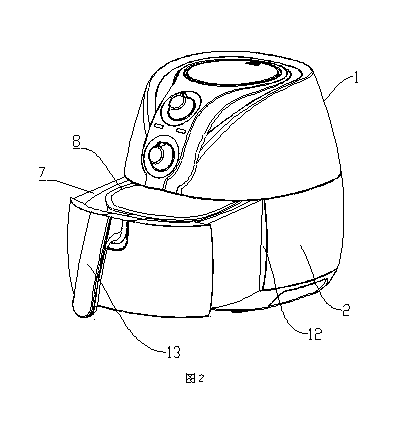

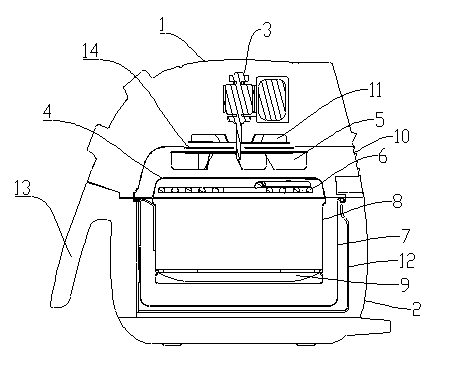

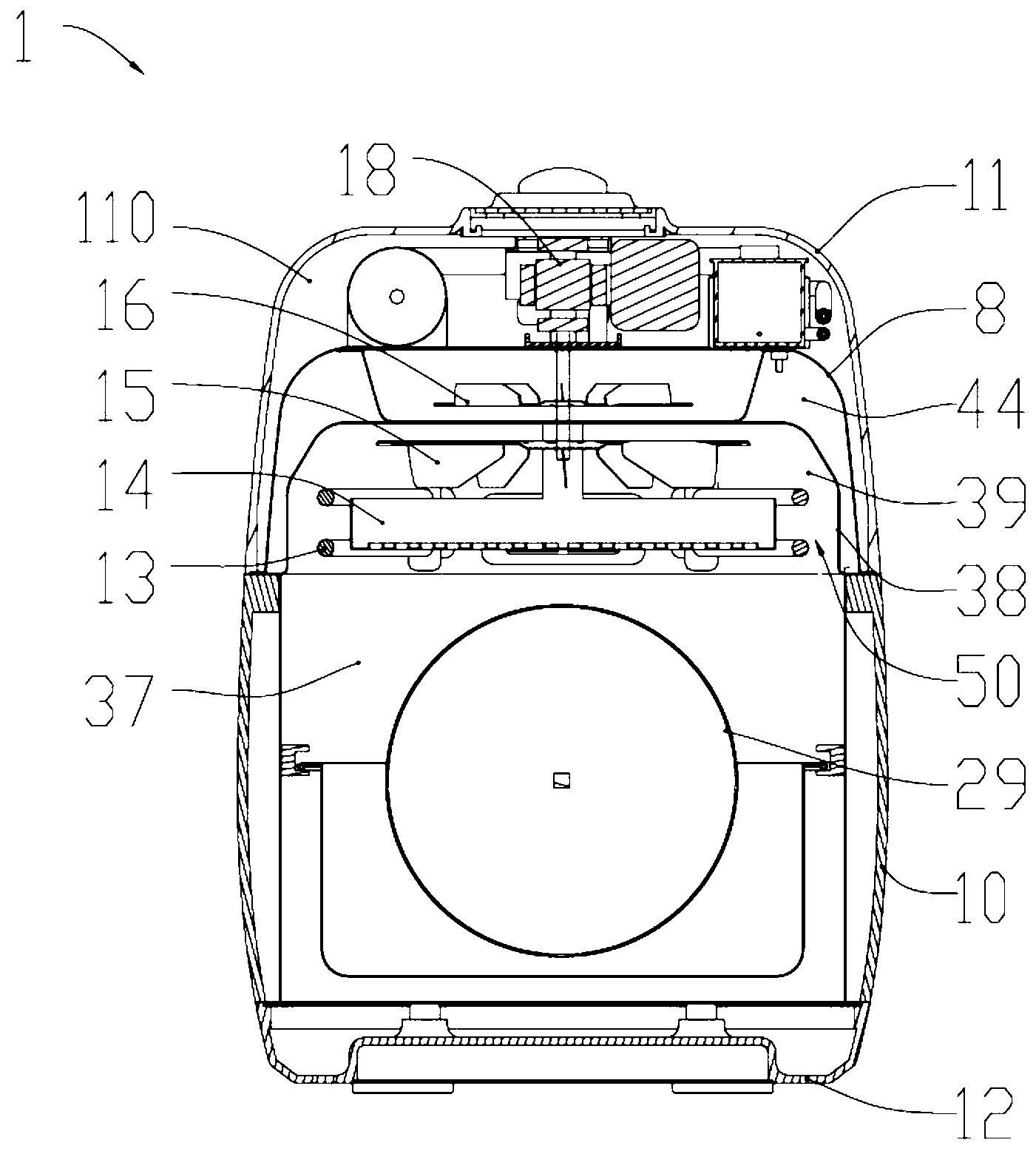

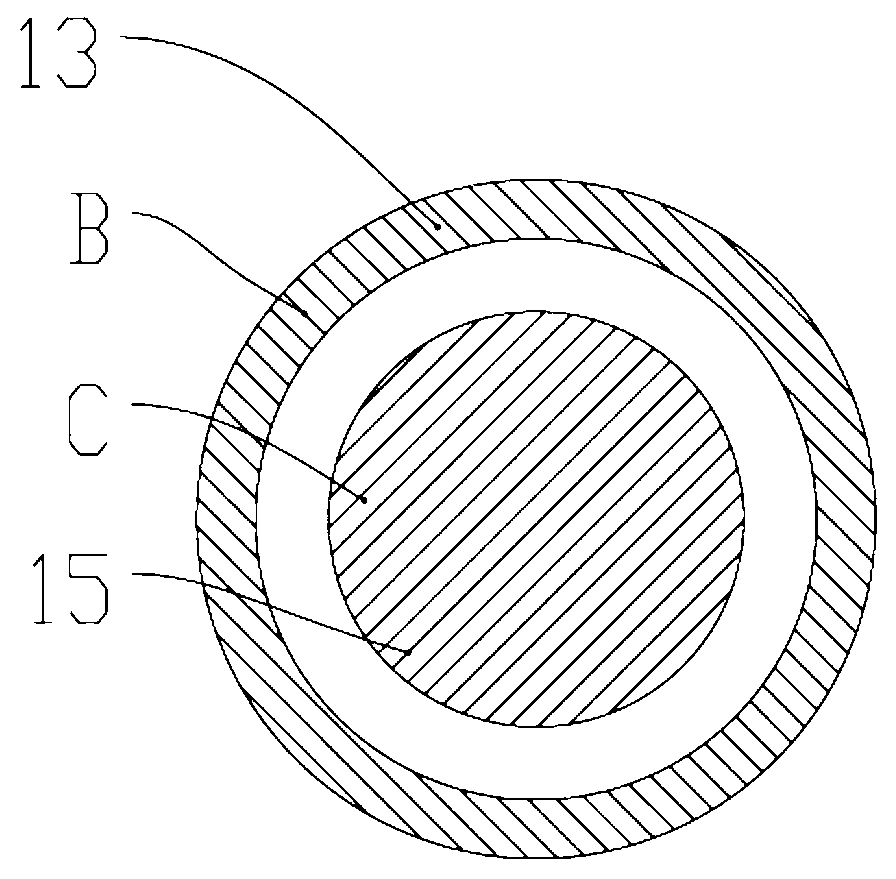

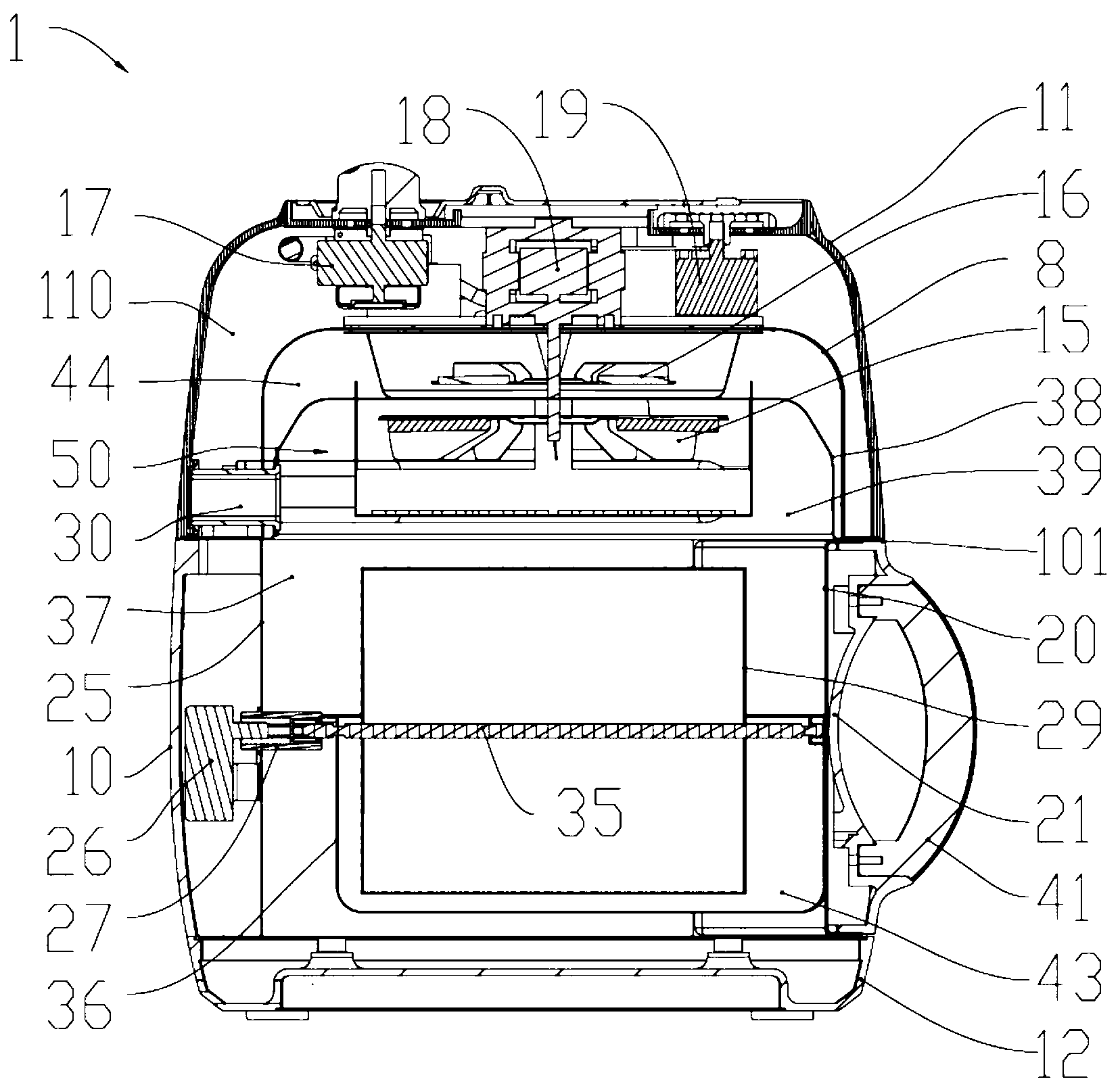

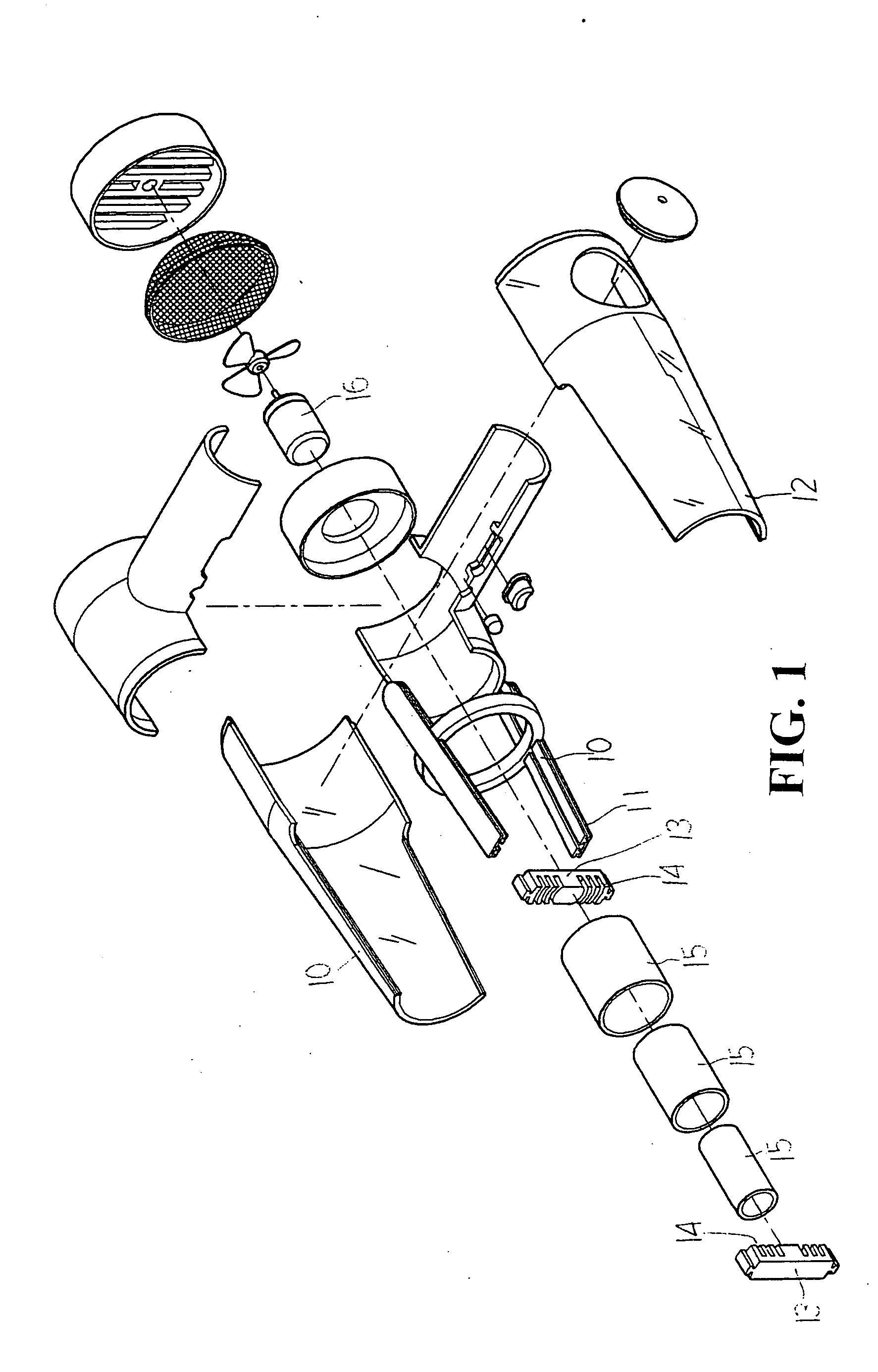

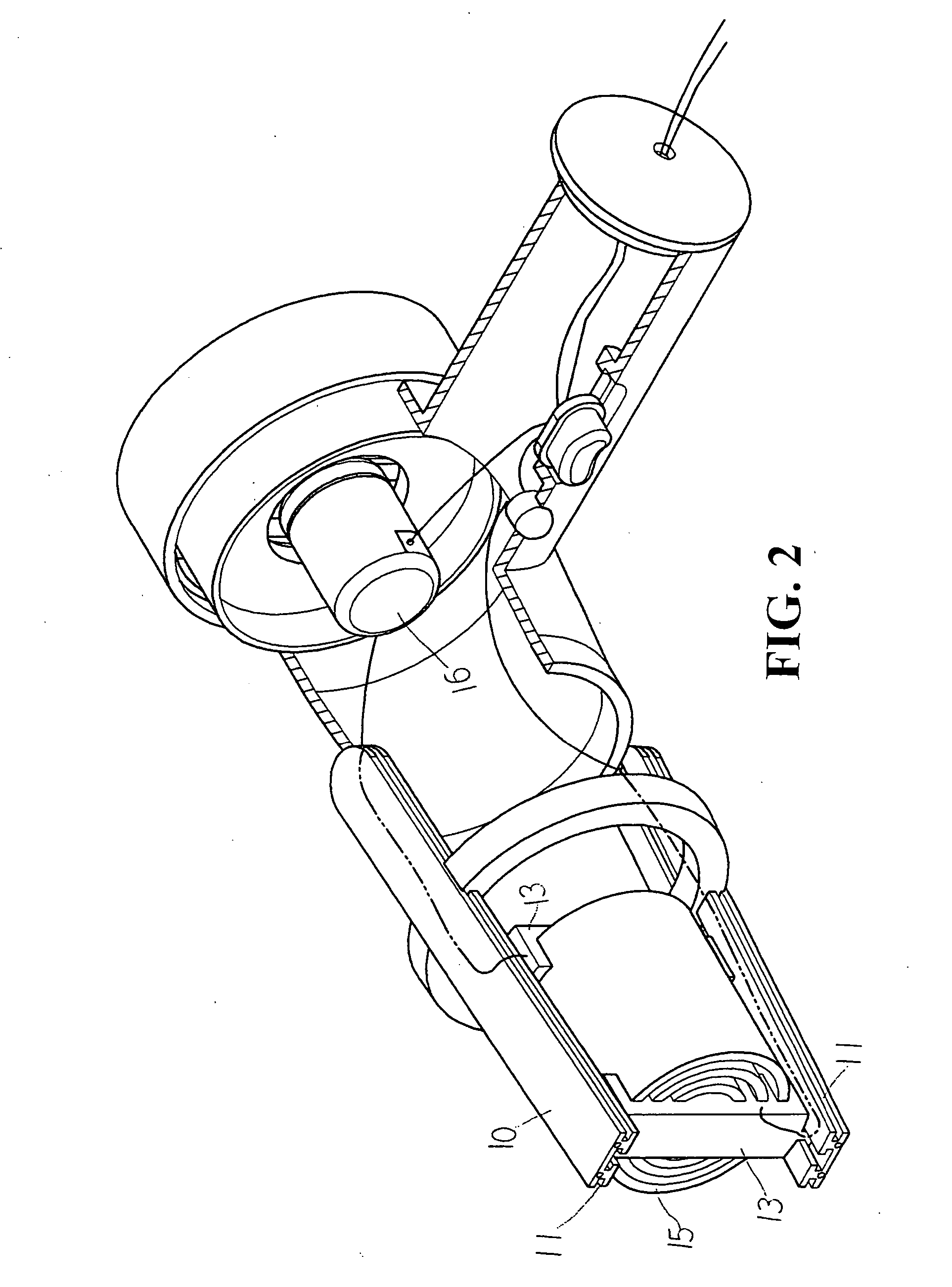

Air frying pan

The invention discloses an air frying pan and aims at providing an improved air frying pan. The air frying pan comprises a furnace head and a housing, and is characterized in that a motor and a heating tube cover are arranged in the furnace head; the tail end of a motor shaft is connected with hot air blades in a thread matching manner; the heating tube cover is provided with a heating tube; an object disc is arranged in the housing; the object disc and an inner container are connected; the top and bottom of the inner container are hollow; and a filter screen is arranged inside the inner container. The air frying pan is mainly used for cooking food.

Owner:杨振巧

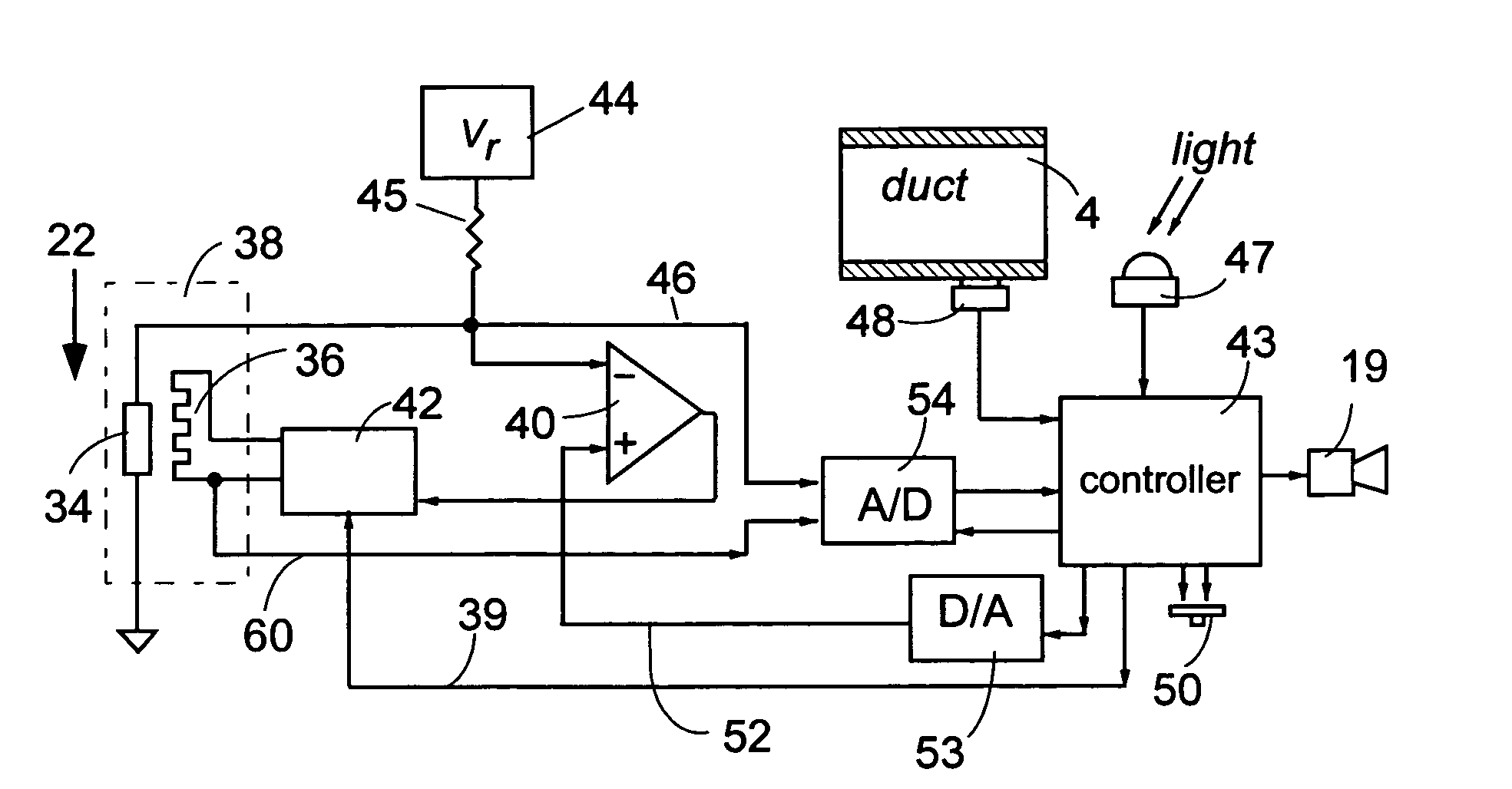

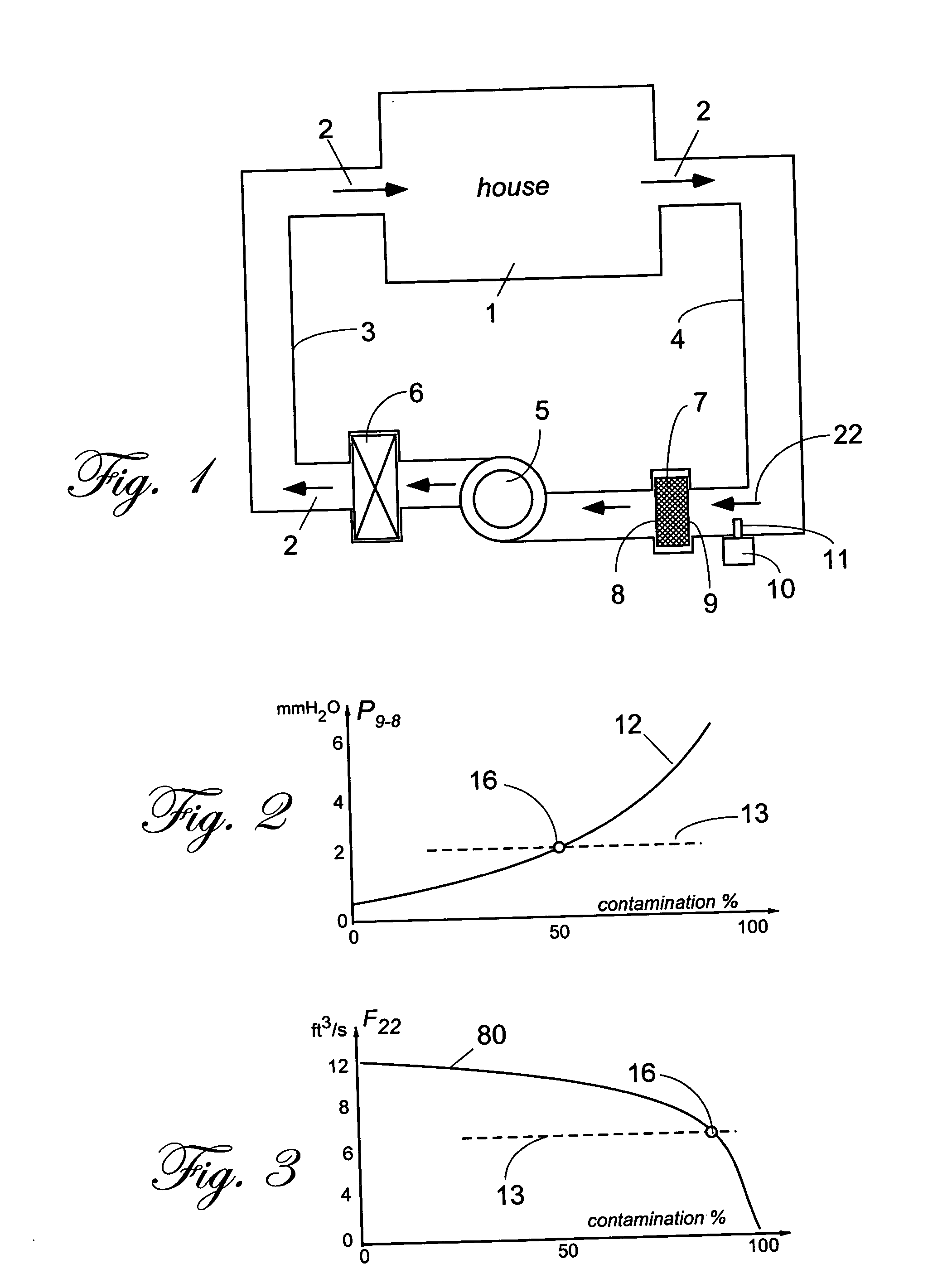

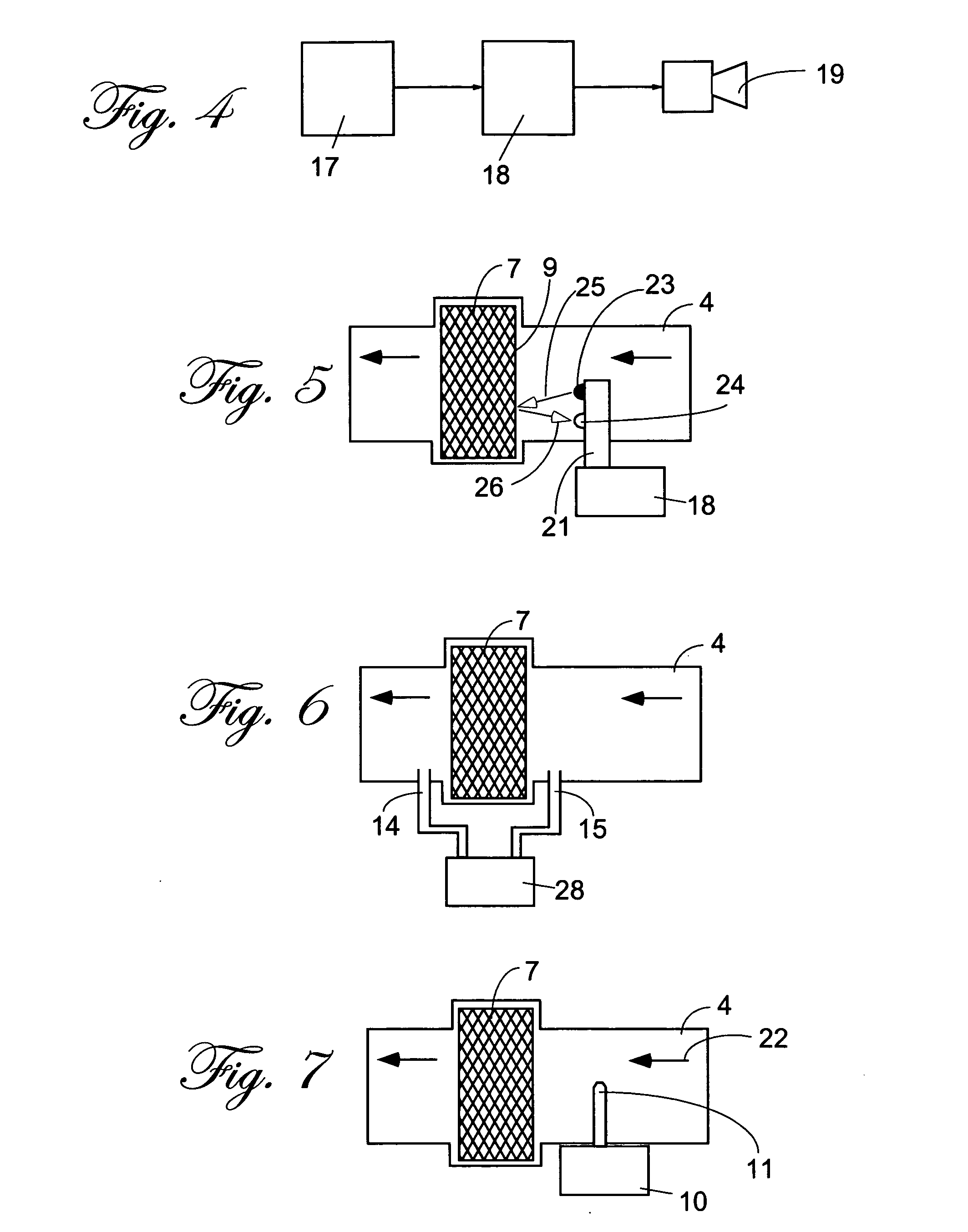

Clogging detector for air filter

The detector for monitoring decrease in air flow rate due to air filter clogging. It is based on combination of three essential components: the air flow sensor, a threshold detector and an indicator. The air flow sensor is built in form of a novel thermo-anemometer which contains a thermistor, a heating element, and a thermal insulator. Temperature of the sensor is maintained above the air temperature by a constant value by means of an electronic servo circuit. The threshold detector is implemented either in a hardware or software. A novel design of a thermo-anemometer (closely related to a hot wire anemometer) automatically compensates for variations in the air temperatures. The thermo-anemometer triggers the threshold circuit when air flow rate drops below a preset level. For reduction of power consumption, the detector may employ two additional sensors: one is for detection of the blower operation and the other is a presence detector to enable the alarm in presence of people to perceive the alarm. The device automatically calibrates itself upon installation of a new or cleaned air filter. The applications include residential and commercial air conditioners, air heaters, internal combustion engines, vacuum cleaners and other systems where air filters are employed.

Owner:CLEAN ALERT

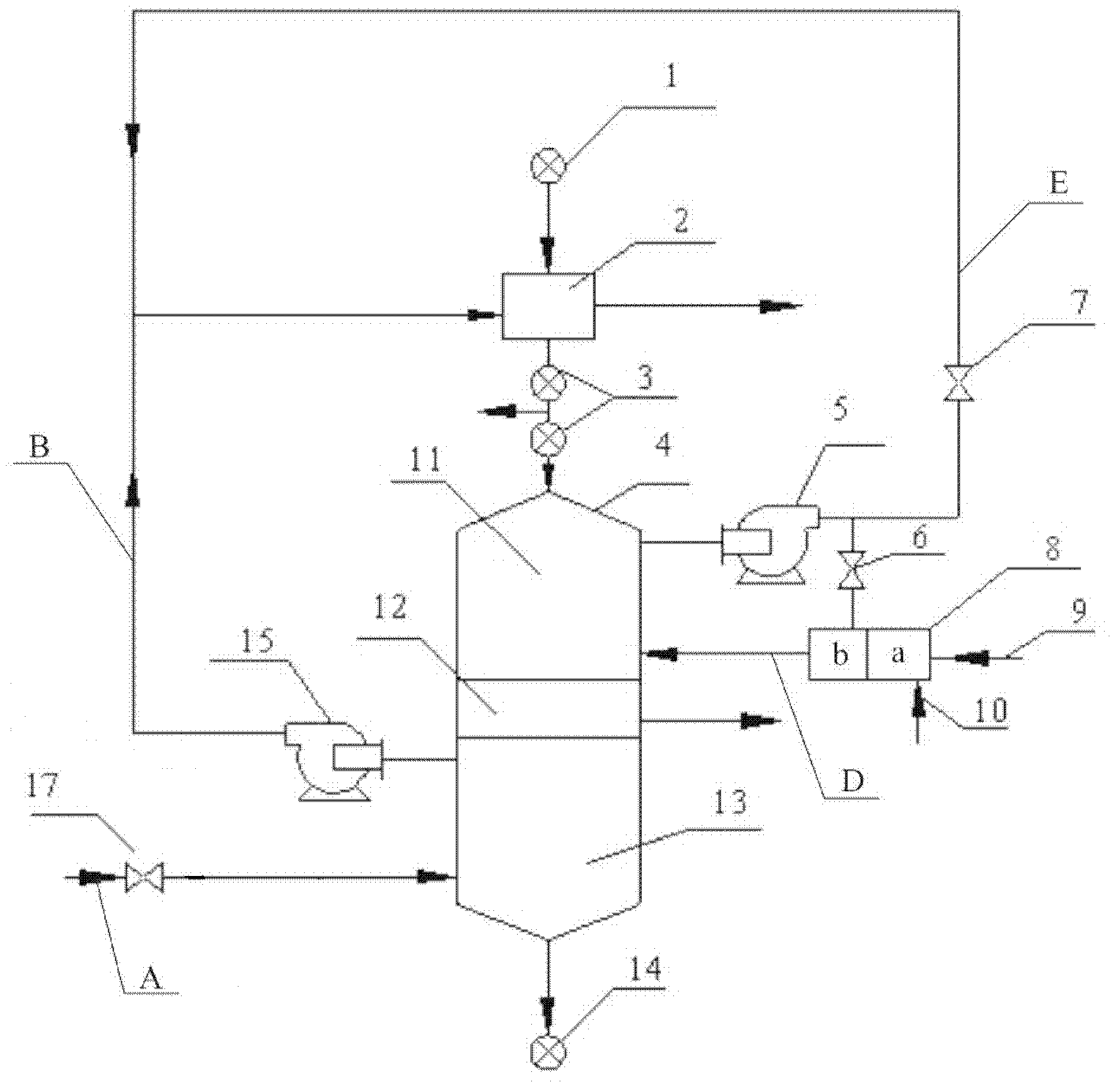

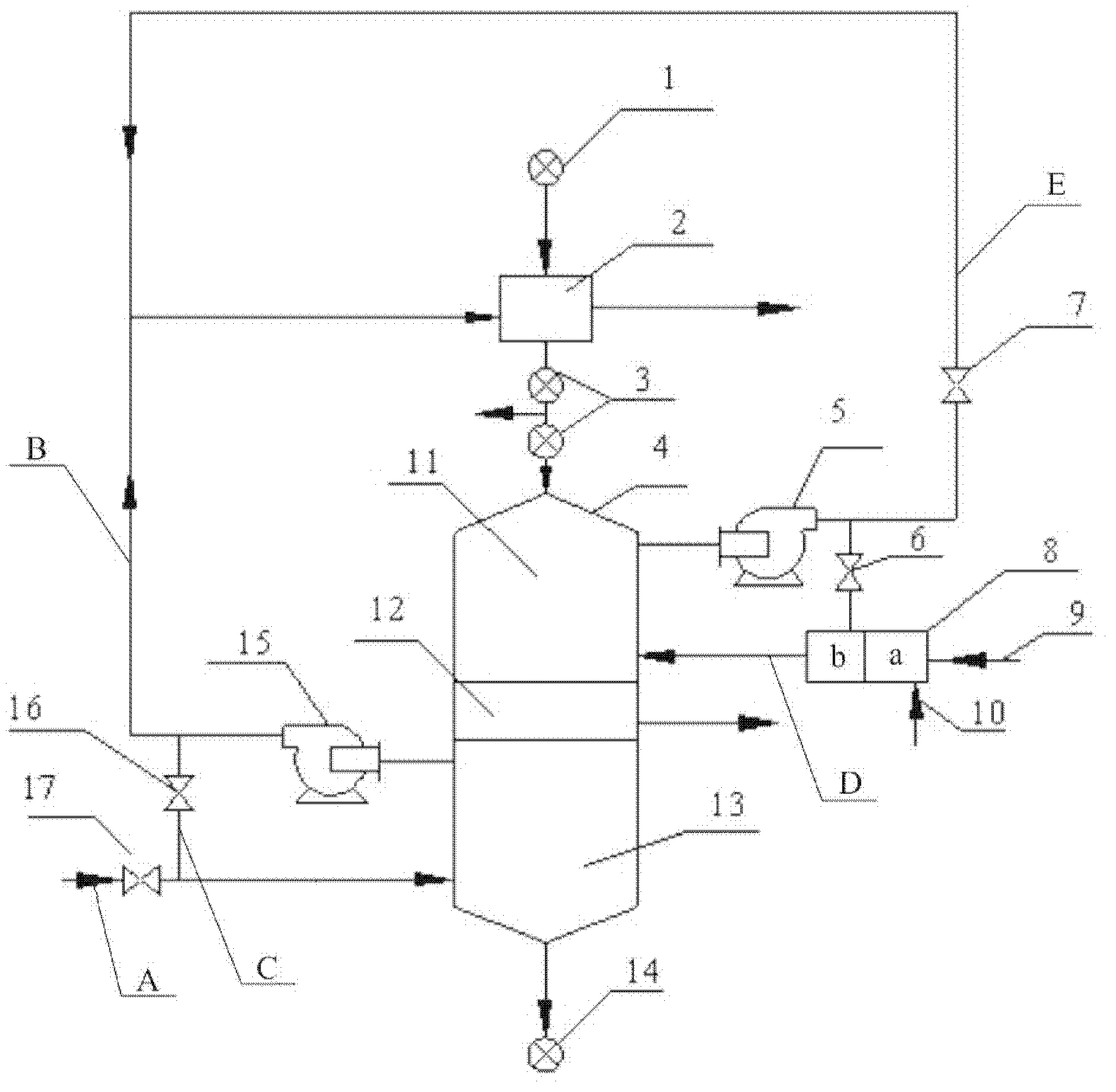

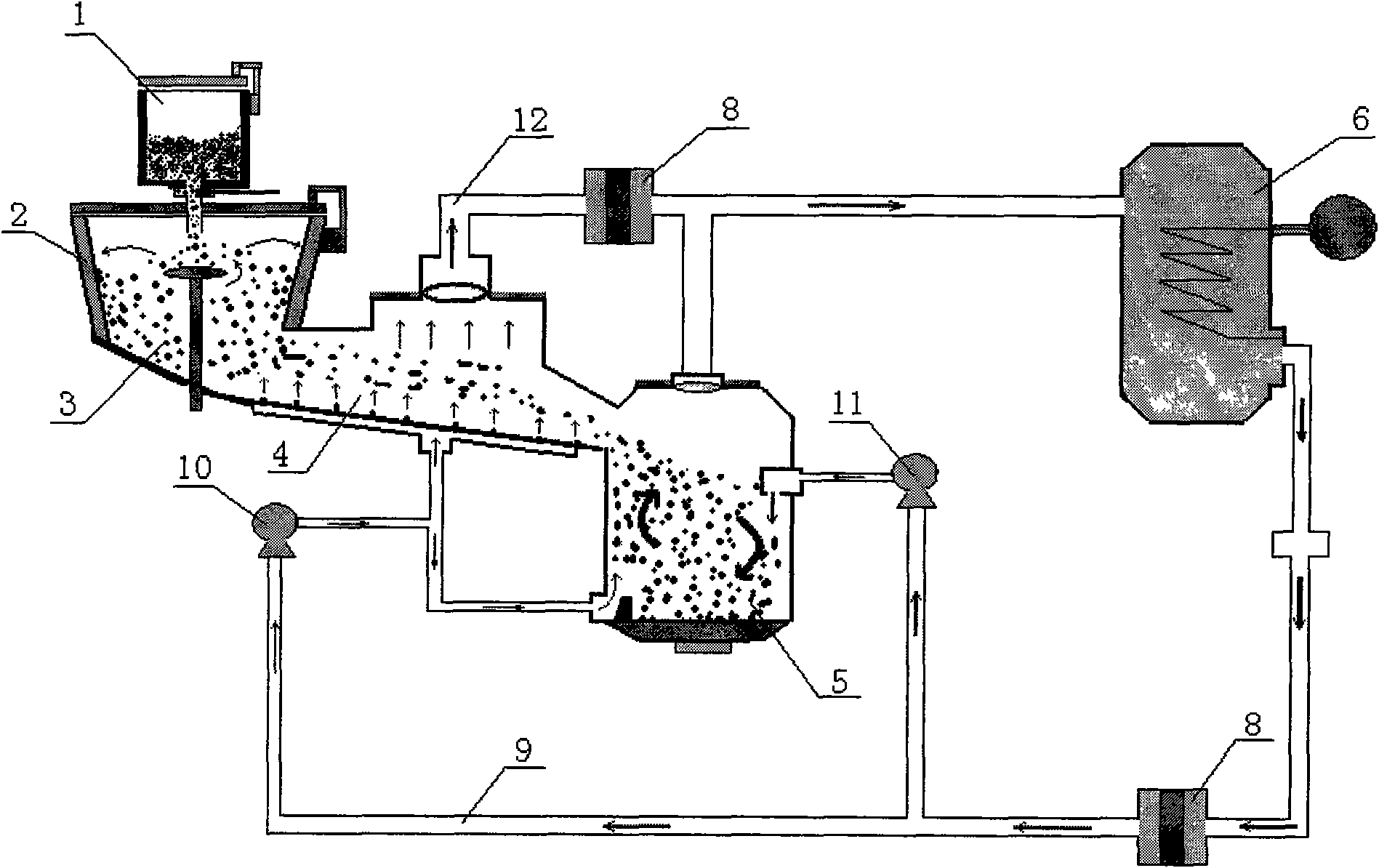

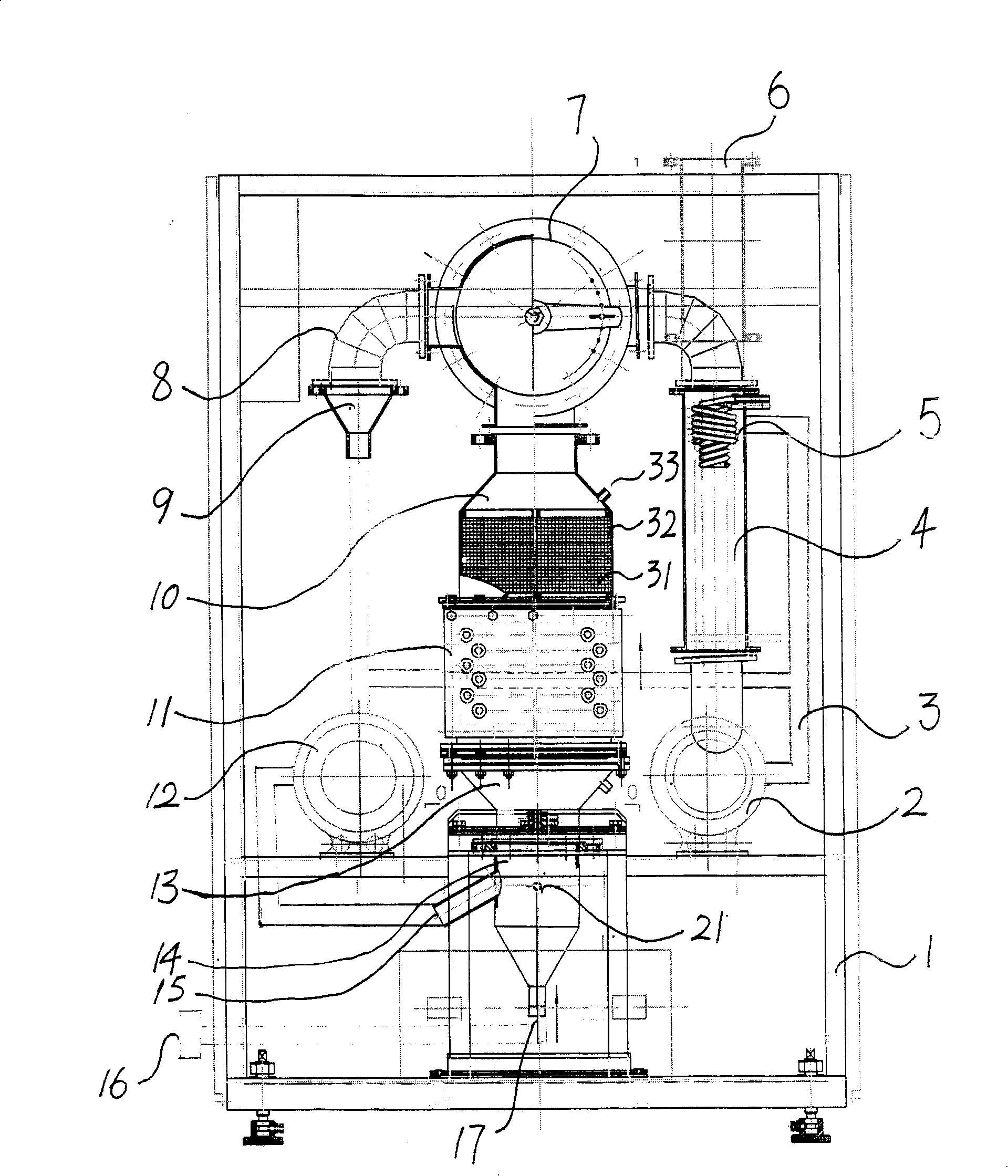

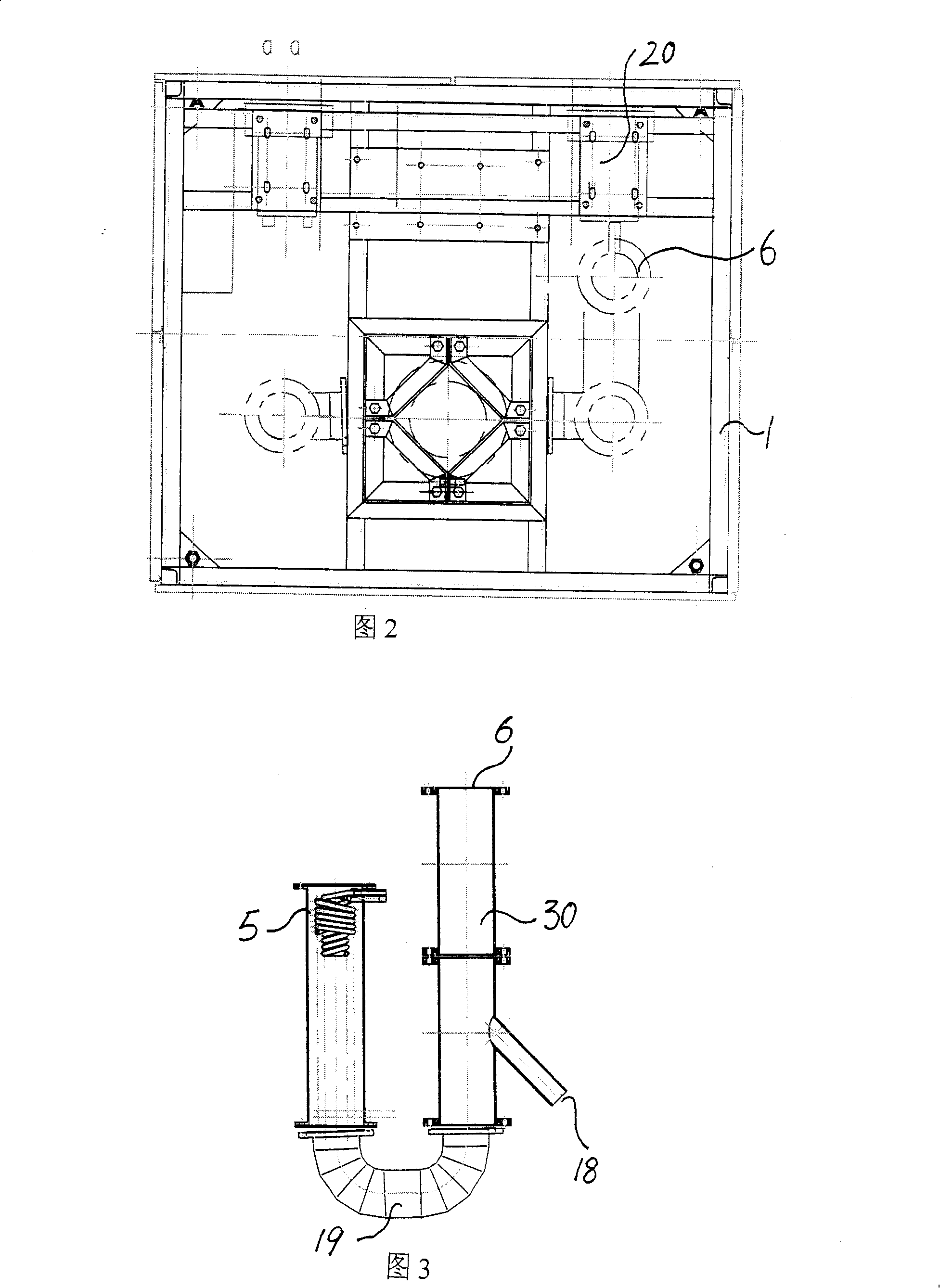

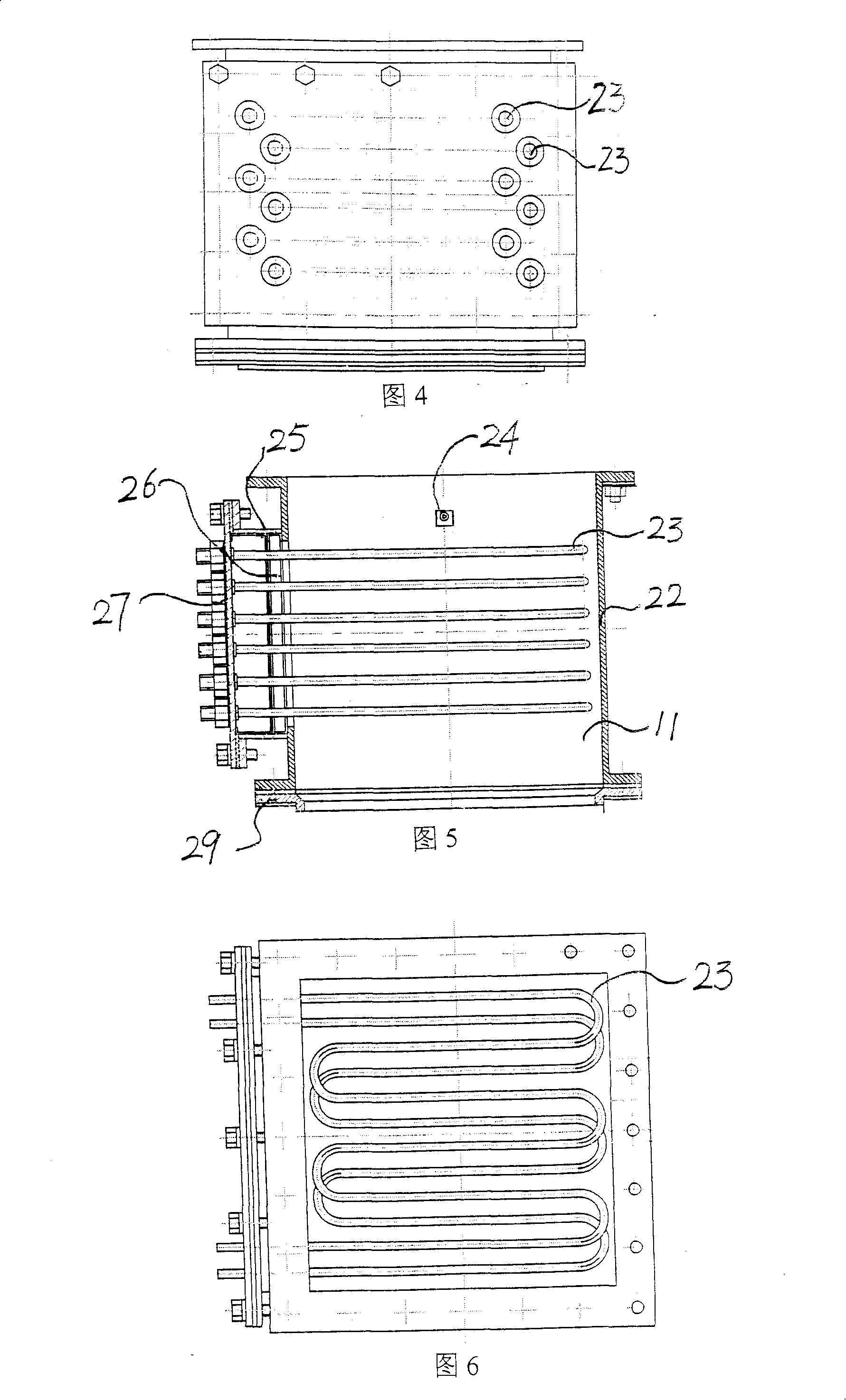

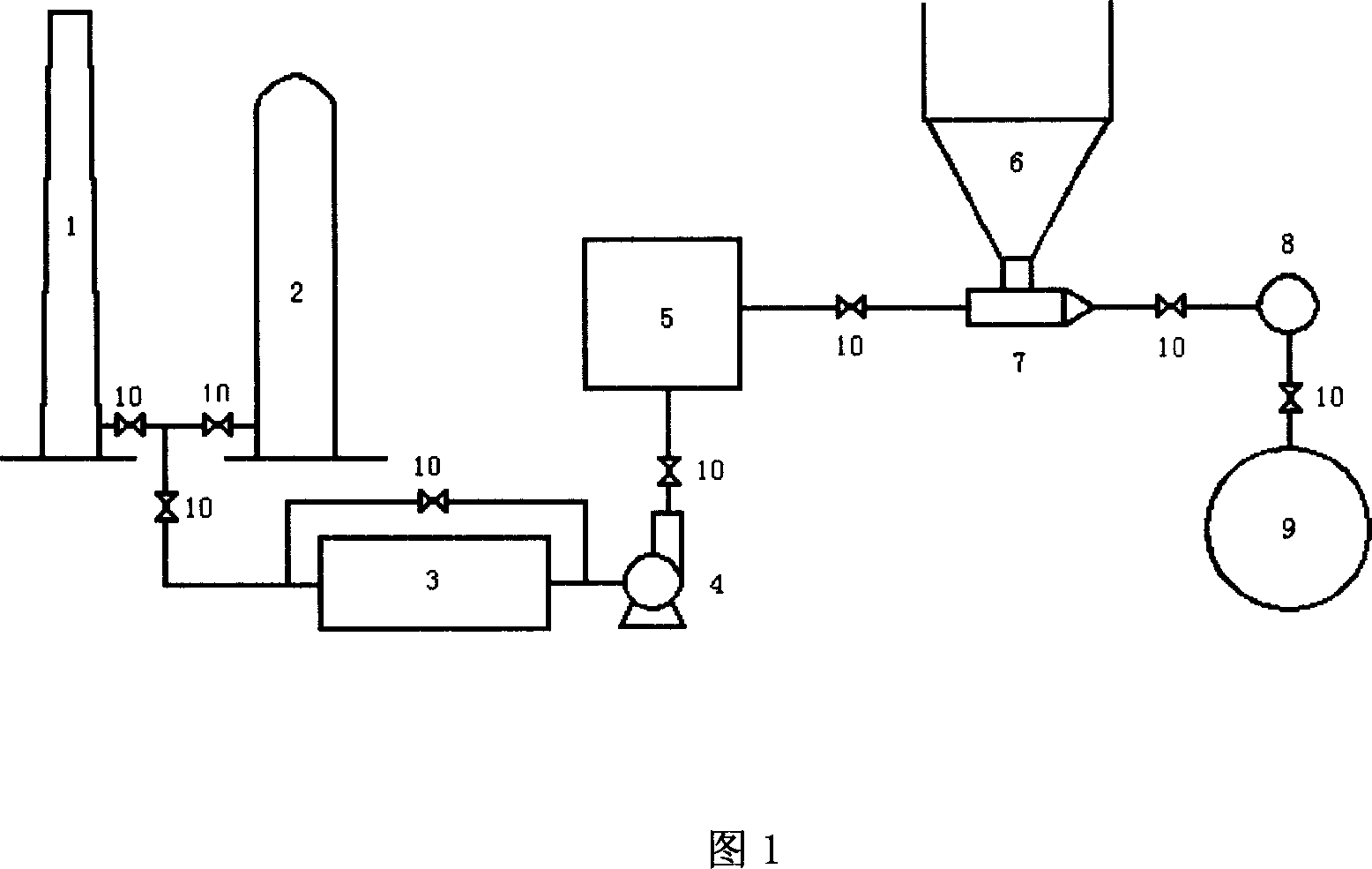

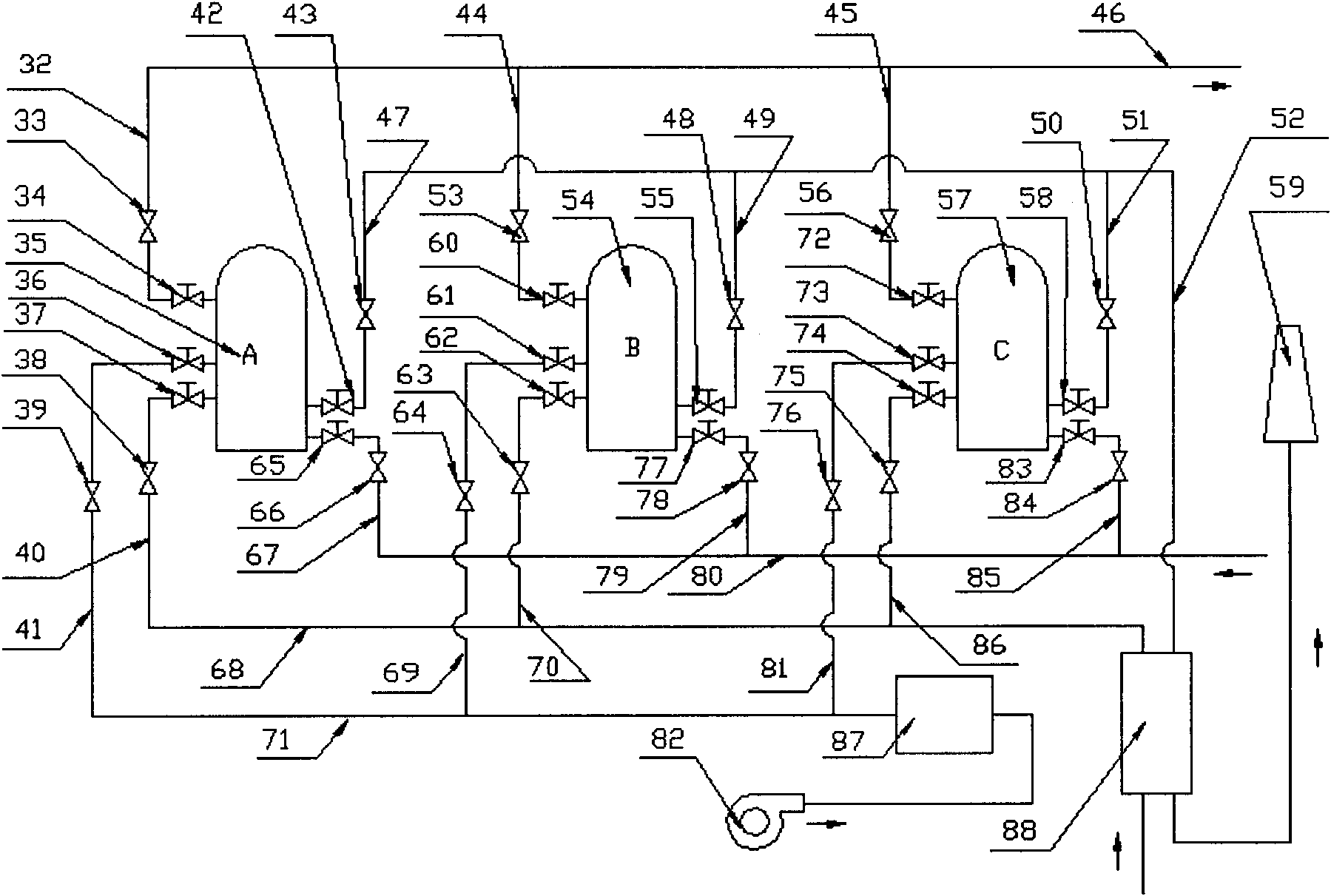

Comprehensive heat energy utilizing type active coke purifying and regenerating process system and active coke purifying and regenerating process method

ActiveCN102580705AImprove regeneration efficiencyIncrease profitOther chemical processesDispersed particle separationProcess systemsHeat conducting

The invention discloses a comprehensive heat energy utilizing type active coke purifying and regenerating process system and an active coke purifying and generating process method. The process system comprises a regenerating device, a preheating device, a heating device and a heat exchanging device, wherein the regenerating device comprises a regenerating tower; the preheating device comprises a drying tower; the heating device comprises a hot-blast stove and a first fan; and the heat exchanging device comprises a second fan, a normal-temperature air input pipeline and a hot air output pipeline, wherein the second fan is used for sending the hot air after heat exchange to the drying tower so as to preheat the active coke. The method comprises the following steps: (1) preheating: preheating the active coke in the drying tower; (b) heating: heating the active coke due to the action of a high-temperature heat-conducting medium; (c) regenerating; and (d) cooling: cooling the regenerated active coke entering a cooling section. The system and method disclosed by the invention are suitable for restoring and regenerating the active coke.

Owner:SHANGHAI CLEAR ENVIRONMENTAL PROTECTION SCI & TECH

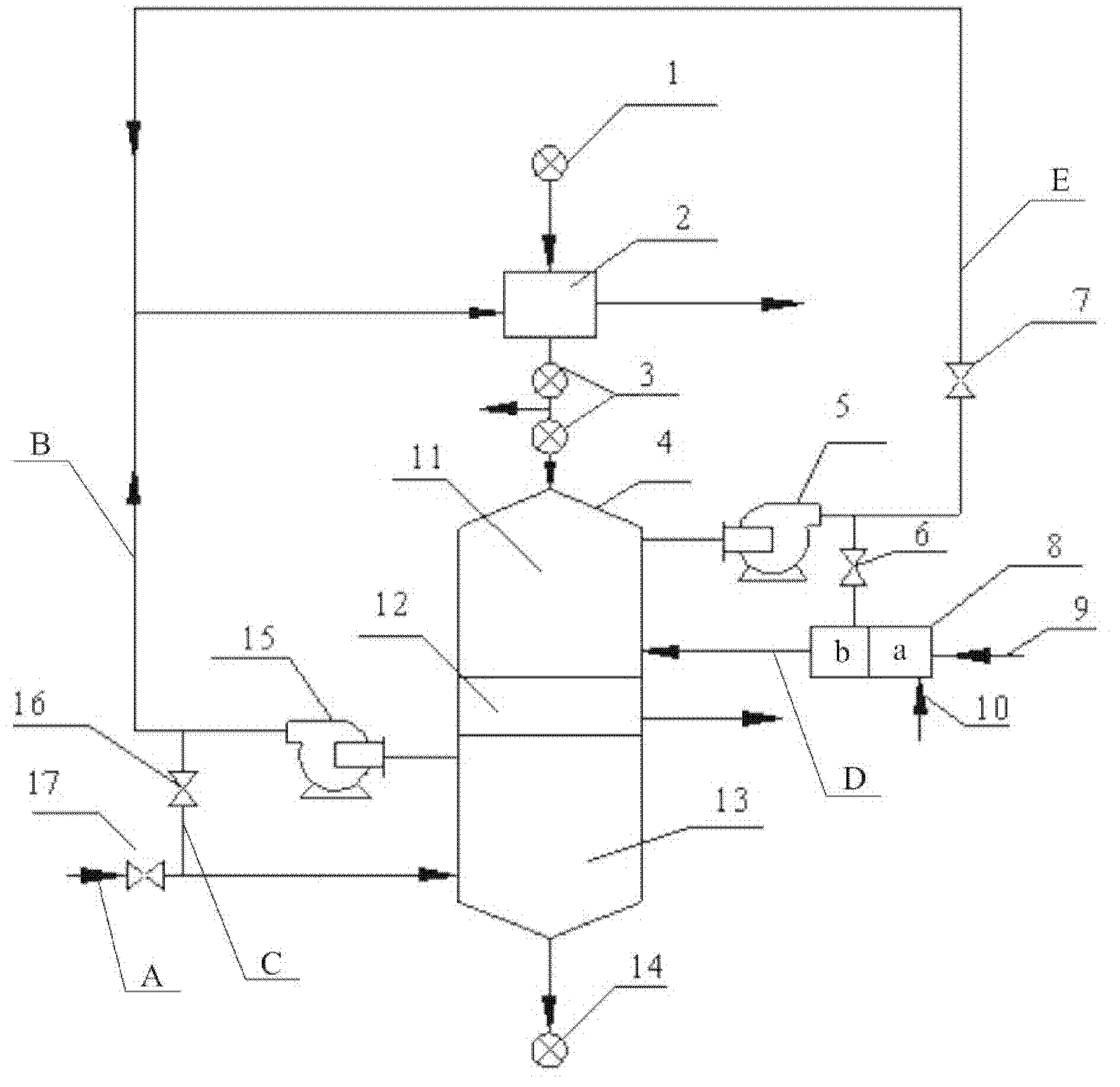

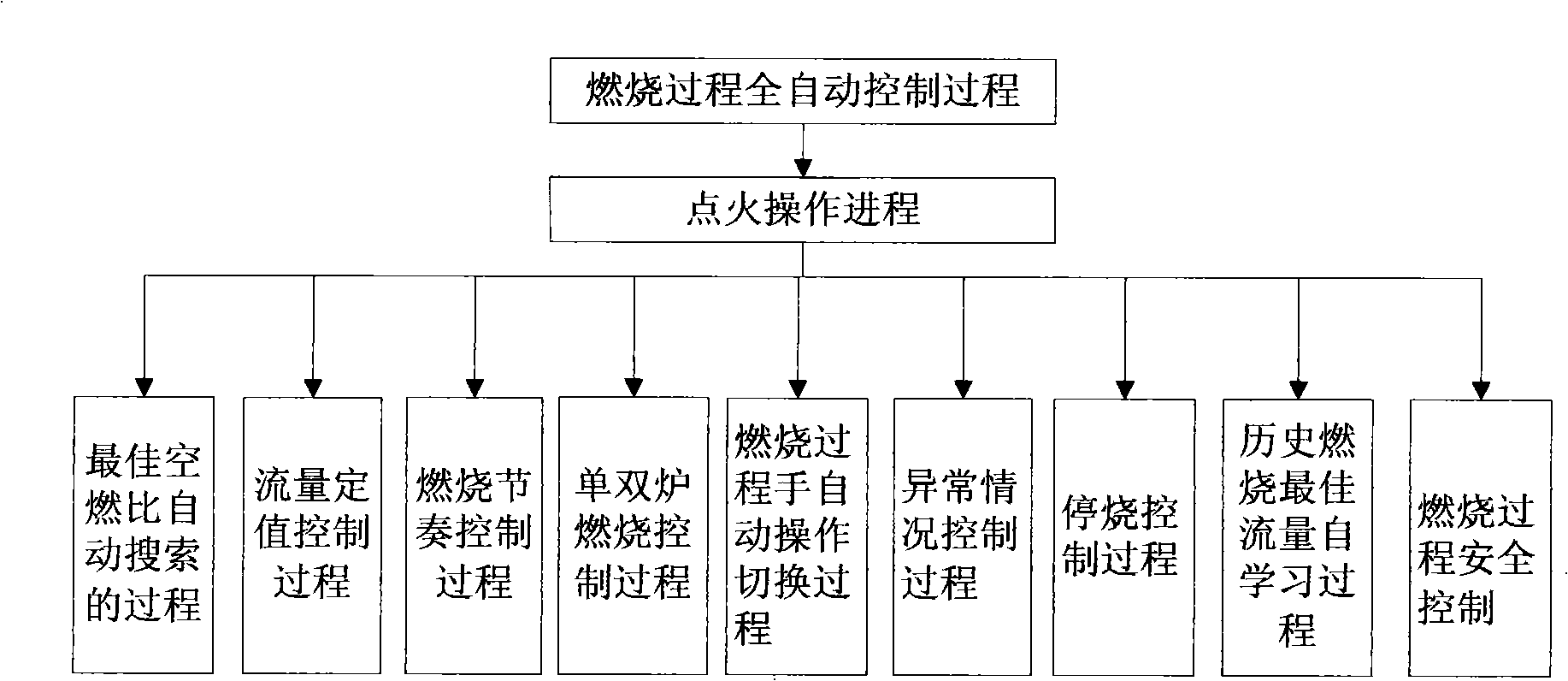

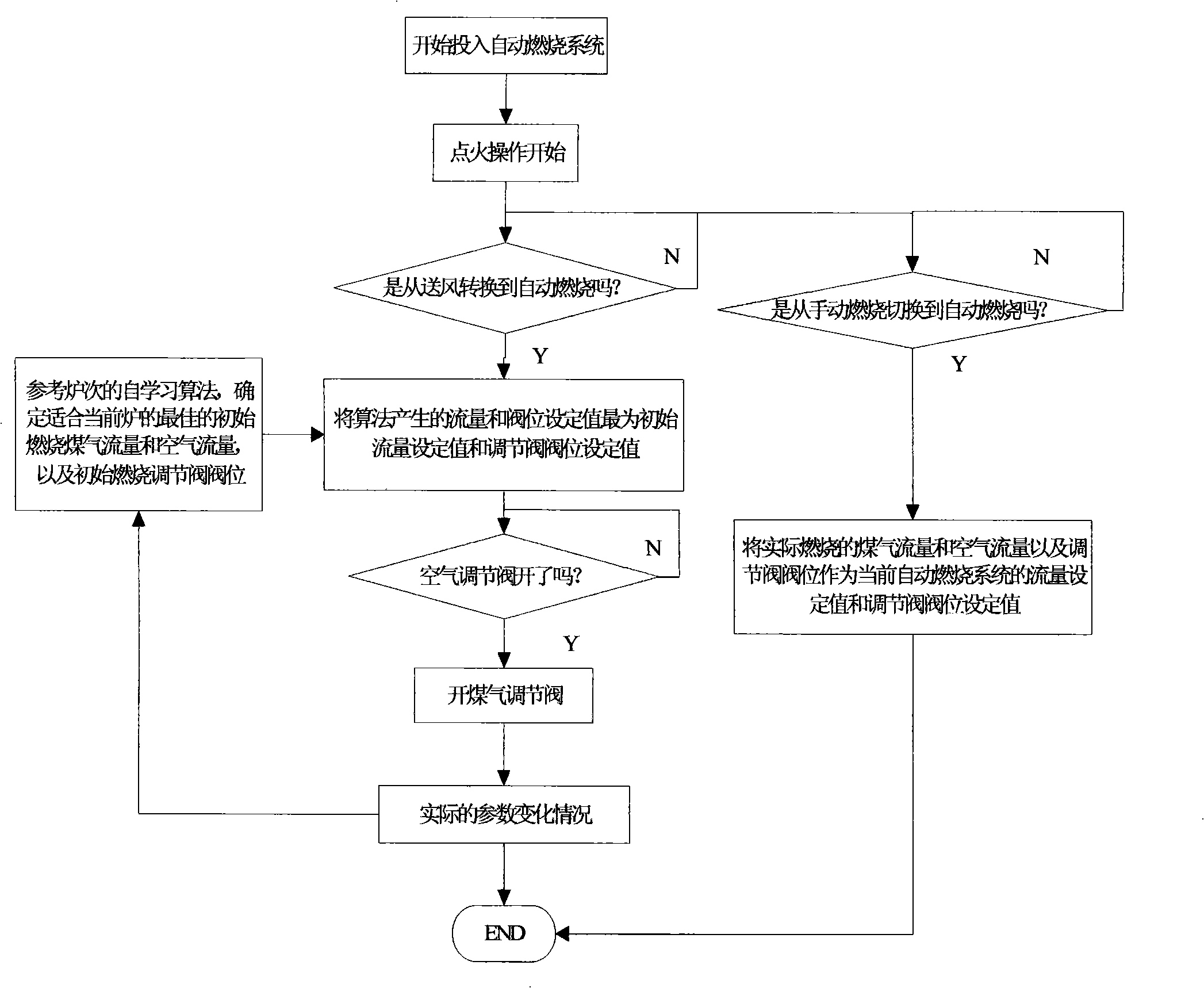

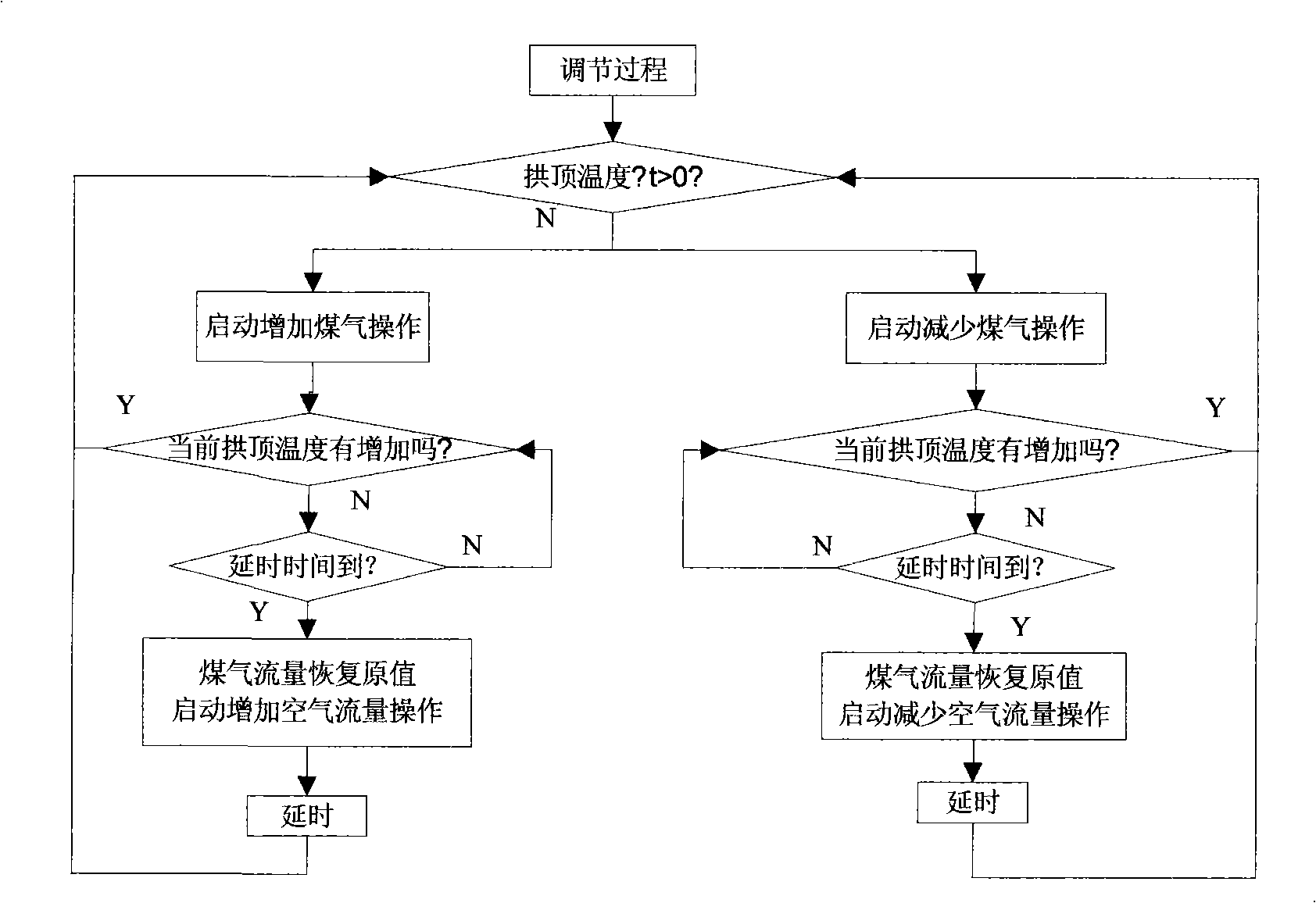

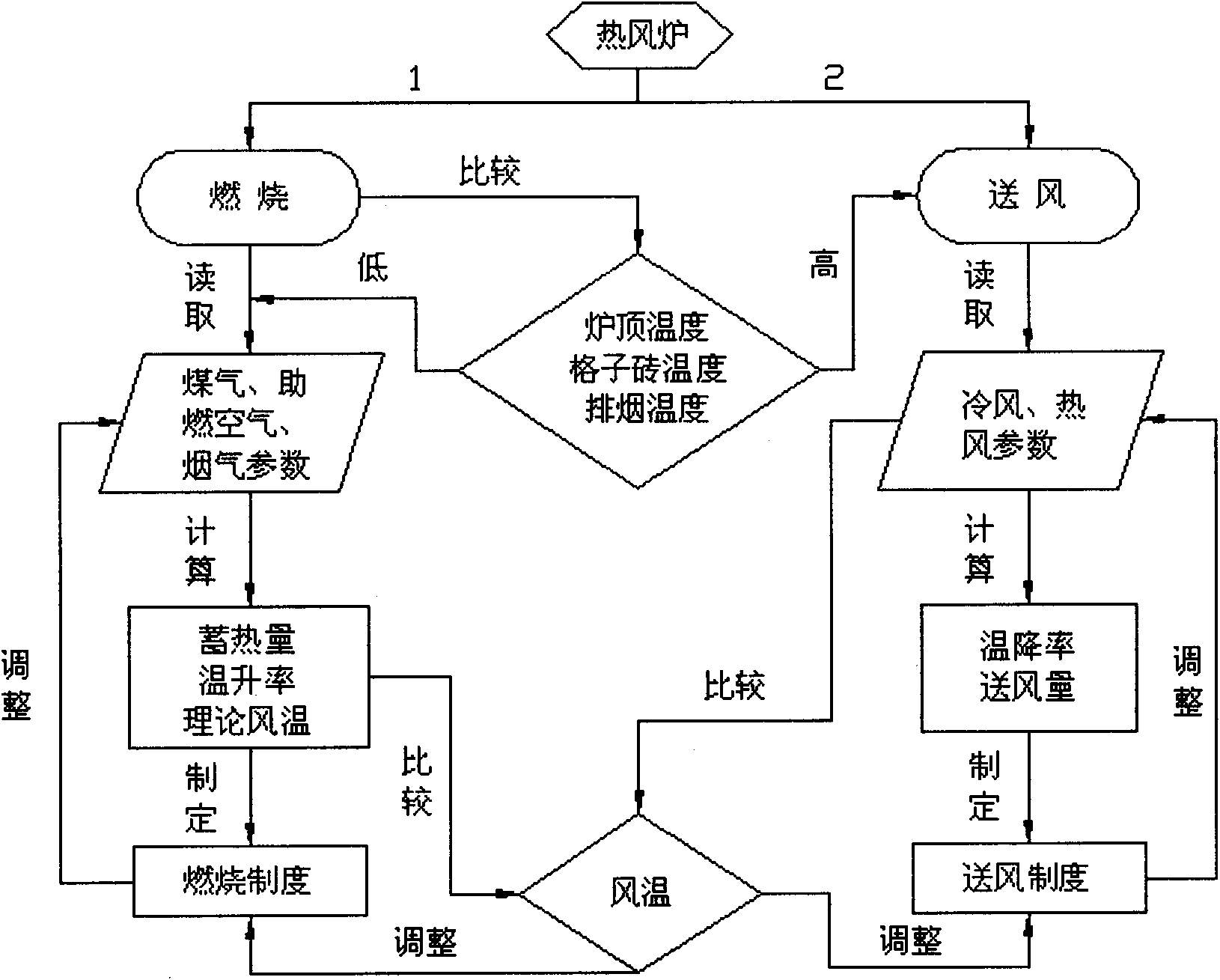

Automatic control system of blast furnace hot blast stove combustion process

ActiveCN101408314AGuaranteed air-fuel ratioQuick controlFuel supply regulationCombustion chamberAutomatic control

The invention relates to an automatic control system during the combustion process of a hot air furnace of a blast furnace, belonging to the field of automatic combustion control technique of the hot air furnace of the blast furnace. Firstly, the system self-learns the historical combustion data of the furnace according to the specified conditions, and determines the best coal gas and air flux of the furnace and the best initial openness of an adjusting valve to be as the initial parameters of the next combustion period. During the normal combustion stage, a control method that fuzzy control is combined with self-optimization control is adopted, the fastest increment of the temperature at the arch is taken as the object, and the air combustion proportion coefficient is quickly optimized according to the temperature change of the combustion chamber. Simultaneously, by adopting a non-difference self-adaptive single closed ring control system combined with the methods such as fuzzy control, self-learning and pulse driving and the like, the action of the adjusting valve can be effectively controlled, and precise and quick adjustment and control of the flux are realized. According to the trend change of the temperature of the waste gas, the system adopts the fuzzy control arithmetic to control the combustion rhythm. Simultaneously, the system comprehensively summarizes the manual combustion experience and achieves the object of completely automatic control without man-watching during the whole combustion process.

Owner:SHOUGANG CORPORATION +1

Method for treating solid organic wastes by biological method

InactiveCN101709006AAchieve recyclingAchieve reductionBio-organic fraction processingAnimal corpse fertilisersEcological environmentFermentation

The invention relates to a process for treating solid organic waste resources (food residues, domestic garbage, vegetable market garbage, wastes and leftovers of slaughter houses and food products factories, beer lees, distilled spirit lees, stevia rebaudiana residues, Chinese medicinal herbal dregs and the like), which comprises the following steps of: removing impurities (plastic bags, bottle caps, napkins, metals and the like) from solid organic wastes; adding mixed bacteria, an enzyme preparation and auxiliary materials into the organic wastes; stirring the mixture and controlling the temperature by hot blast; performing fermentation treatment on the mixture by adopting a staged temperature raising method; and drying and crushing the mixture to obtain an organic fertilizer. The invention finds a process capable of effectively treating the solid organic wastes, which can convert the solid organic wastes into the organic fertilizer by using microorganisms to change the organic wastes into valuable and realize the recycling use and the quantity reduction of waste resources; besides, the used microorganisms are harmless to human and the ecological environment.

Owner:TIANJIN UNIV OF SCI & TECH

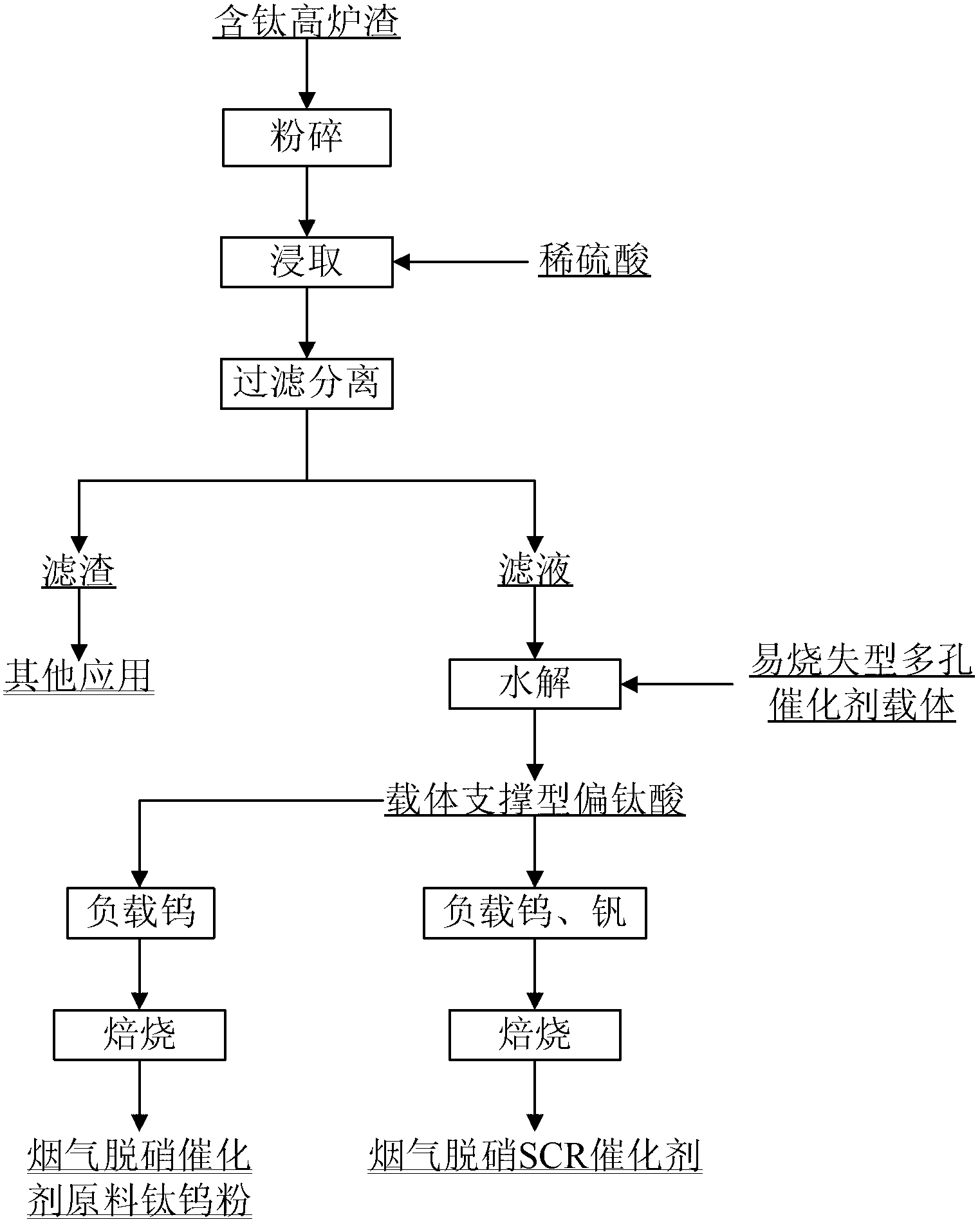

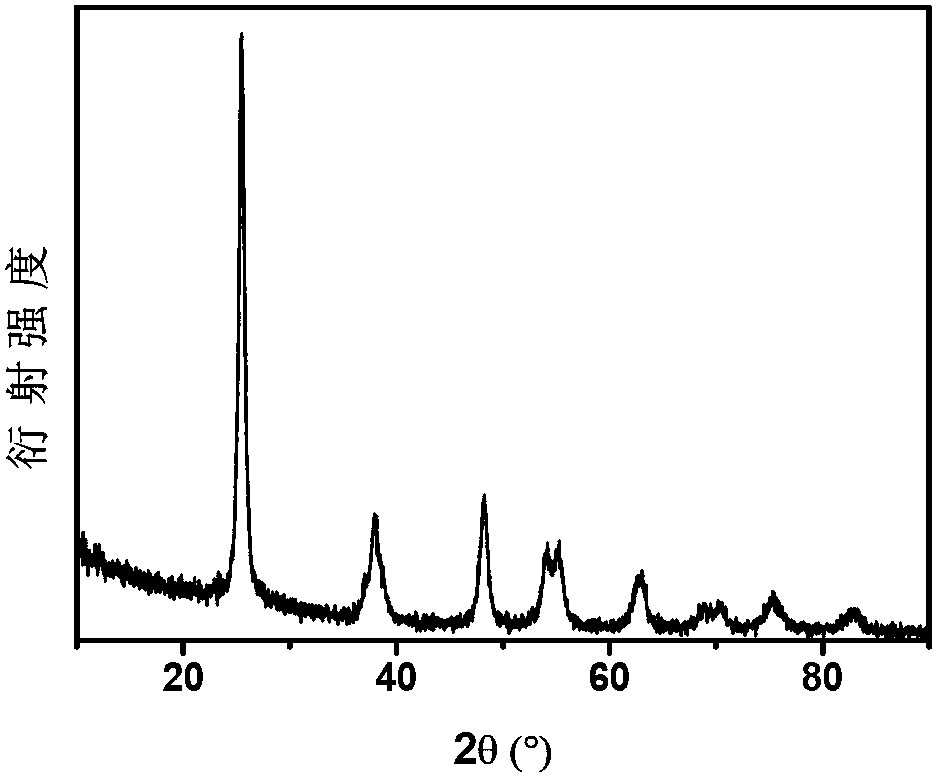

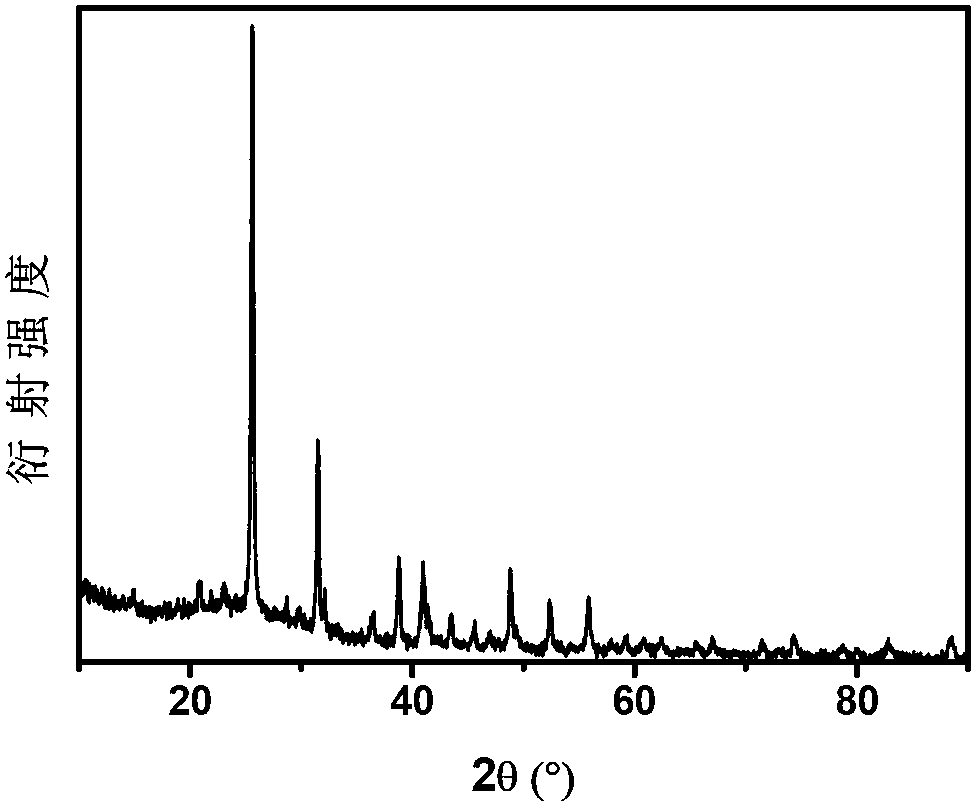

Method for preparing selective catalytic reduction SCR flue gas denitration catalyst and method for preparing raw material titanium-tungsten powder of SCR flue gas denitration catalyst

ActiveCN102698737AReduce manufacturing costAlleviate the pricey situationDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPorous catalystSlag

The invention relates to a method for preparing a selective catalytic reduction SCR flue gas denitration catalyst and a method for preparing a raw material titanium-tungsten powder of the SCR flue gas denitration catalyst. The method for preparing the SCR flue gas denitration catalyst comprises the followings: smashing titanium-bearing blast furnace slag, leaching TiO2 in the smashed titanium-bearing blast furnace slag with dilute sulphuric acid, filtering and separating the mixture to obtain residues and titanium solution, adding a porous catalyst carrier which is easy to be burnt off into the titanium solution and hydrolyzing the mixture; filtering, washing and drying the hydrolyzed product to obtain a carrier supported metatitanic acid, and further loading tungsten and vanadium on the metatitanic acid, and baking the obtained product to obtain a vanadium-tungsten-titanium SCR denitration catalyst. The method not only effectively utilizes valuable elements in blast furnace slag, solves the problems that the titanium dioxide product is extracted, separated and purified difficultly from the blast furnace slag, and the quality of the product cannot meet the standard easily, and also greatly reduces the production cost of the vanadium-tungsten-titanium SCR denitration catalyst and has a broad application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

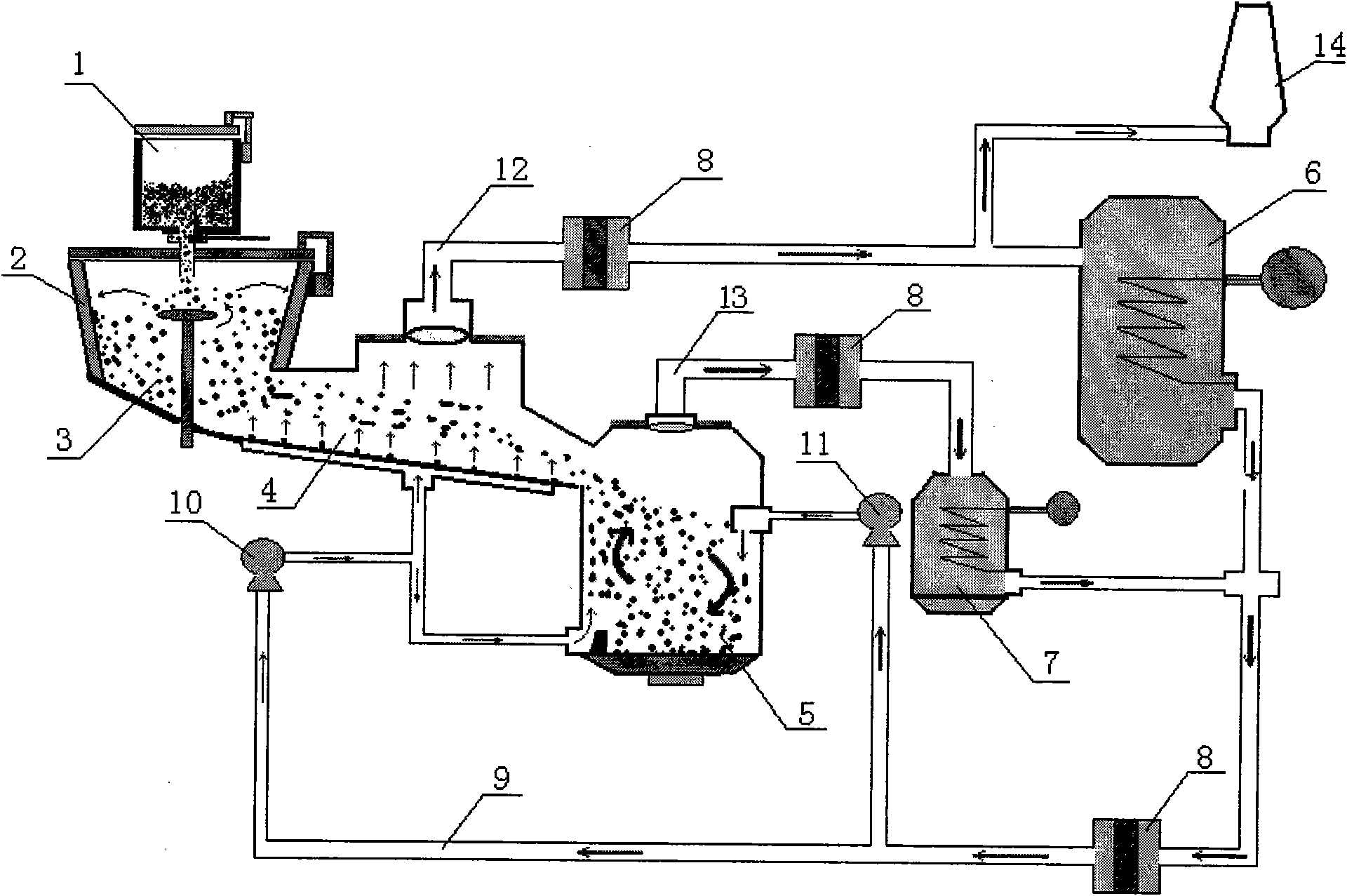

Molten blast furnace slag sensible heat recovery method and device

InactiveCN101660014ASave energyRecycling and recovery technologiesProcess efficiency improvementRecovery methodThermal energy

The invention relates to the field of energy recovery utilization and in particular to a molten blast furnace slag sensible heat recovery method and a device; the method is characterized in that: themolten blast furnace slag carries out a first heat recovery in a granulator, and then a second heat recovery is carried out by a vibrated bed, and then a third heat recovery is carried out in a fluidized bed, and the reclaimed heat energy is reutilized or converted in a hot air or power generating way; the realization steps are that: 1) the molten blast furnace slag is arranged in the granulator for granulation; 2) the blast furnace slag granules carry out heat exchange in the vibrated bed; 3) the blast furnace slag granules carry out heat exchange in the fluidized bed; 4) after heat exchangeis carried out, the heat is used for power generation from air or is directly utilized in a hot wind way. The method has the beneficial effects that: the sensible heat of the molten blast furnace slagis utilized respectively in a way of waste heat stream power generation and in a way of blast furnace hot wind, compared with the existing water quenching method, 1.0-1.2t of fresh water can be savedwhen processing 1t of molten slag, and sulfides H2S and SO2 are not produced, and energy equivalent to 47kg of standard coal is saved.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

Cleaning agent and cleaning method for air conditioner

InactiveCN101475878AImprove heating efficiencyImprove cooling efficiencyNon-ionic surface-active compoundsFlush cleaningStrong acidsHigh pressure water

The invention discloses a detergent and a cleaning method for a complete air-conditioner, which not only can uniformly and completely remove dirt but also cannot strongly corrupt components and parts such as aluminum, copper and stainless steel, are time-saving and labor saving, safe and reliable, and pollution-free, and have low cost. Raw materials of the detergent are at least two compositions of citric acid, inorganic weak acid and inorganic strong acid; a non-ionic surfactant or a non-ionic surfactant is mixed with an anionic surfactant; and the detergent comprises an oxygen solvent, an acid corrosion inhibitor, and the balance being water. The cleaning method comprises: disassembling a motor and a fan, and taking off the motor and the fan for independent cleaning; preparing the detergent into an aqueous solution according to the proportion of between 10 and 15 percent, hanging the complete air-conditioner after disassembly of the motor and the fan into a cleaning tank, soaking the complete air-conditioner for 30 minutes at normal temperature, and starting ultrasonic waves to clean for 10 to 30 minutes; placing the complete air-conditioner into a washing tank, and using a high-pressure water gun to spray the surface and the inside of the air-conditioner; and using hot blast to dry the air-conditioner at a temperature of 80 DEG C.

Owner:DALIAN SANDAAOKE CHEM

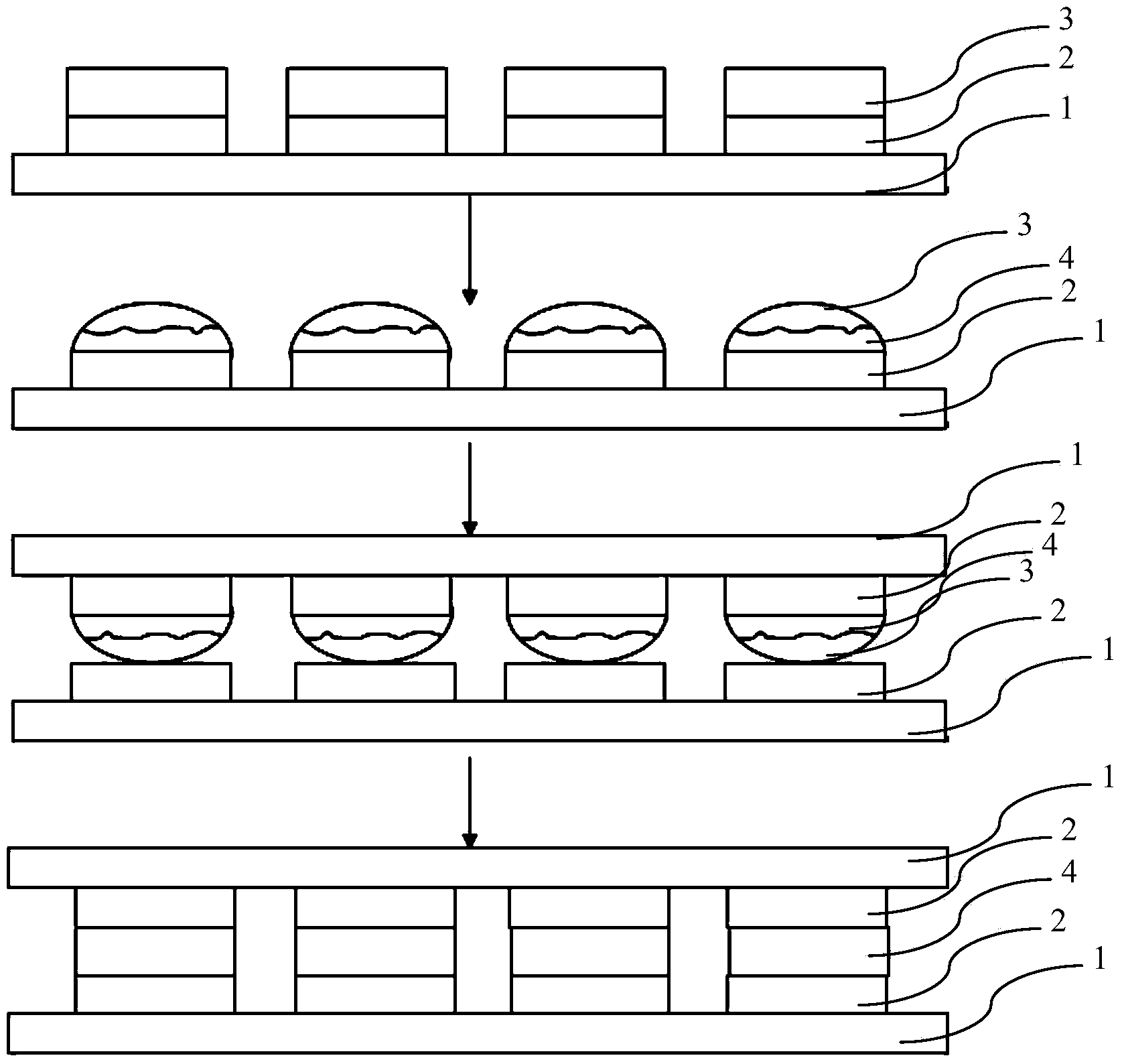

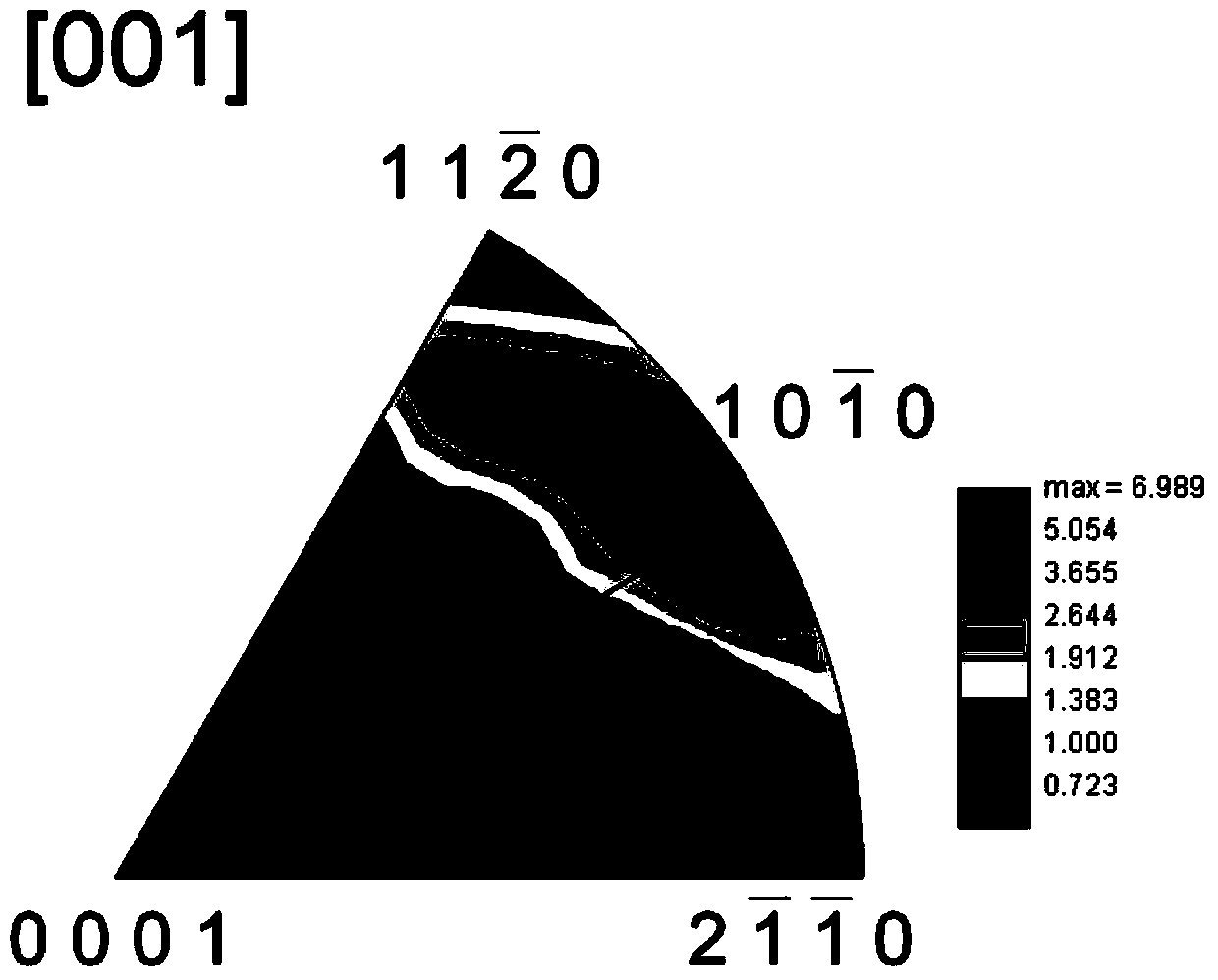

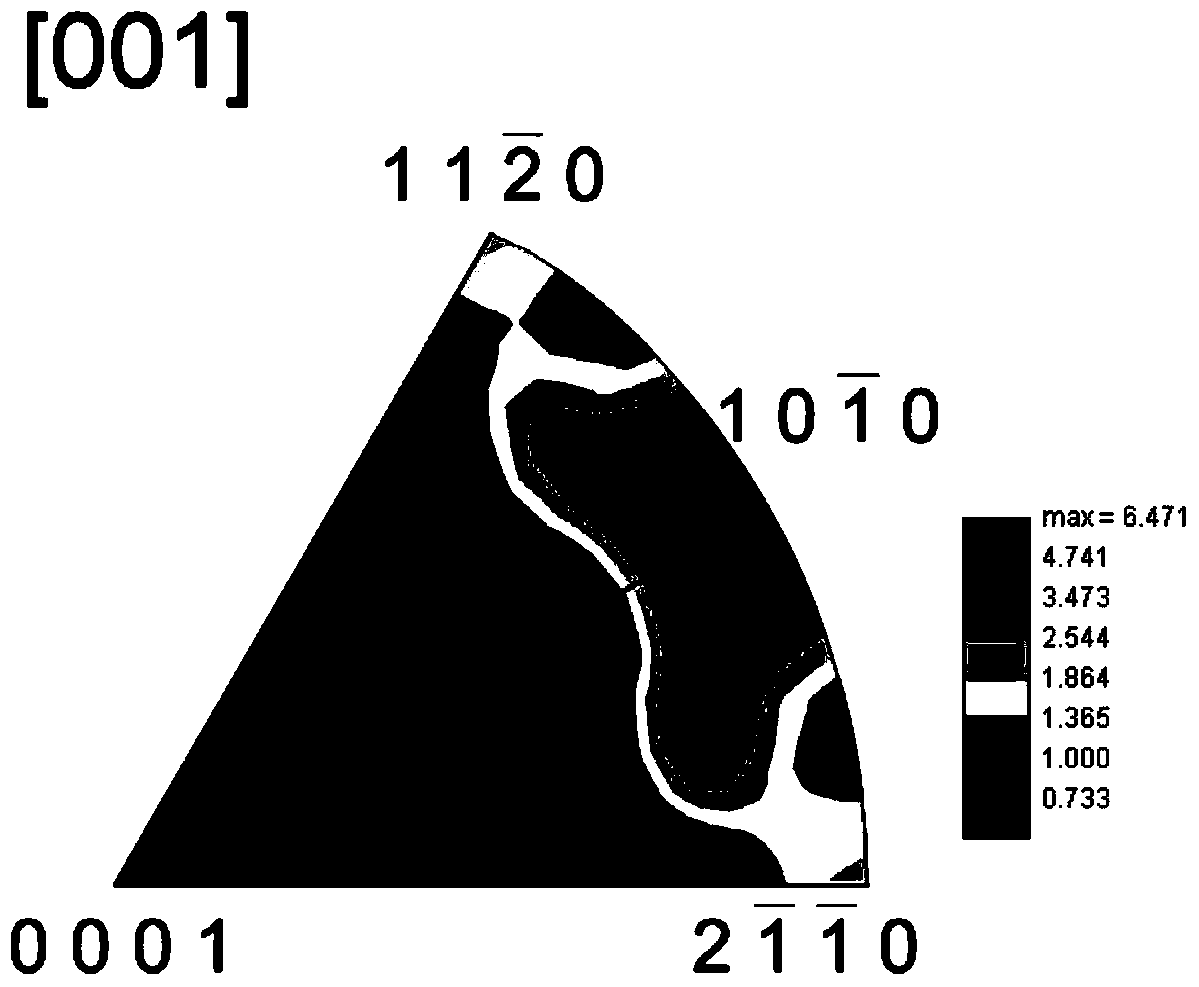

Method for preparing and applying single orientation Cu6Sn5 intermetallic compound micro-interconnecting welding point structure

ActiveCN103658899AAvoid premature failureUniform orientation distributionSolid-state devicesSemiconductor/solid-state device manufacturingProcess conditionsIntermetallic

The invention provides a method for preparing and applying a single orientation Cu6Sn5 intermetallic compound micro-interconnecting welding point structure. The method for preparing the single orientation Cu6Sn5 intermetallic compound micro-interconnecting welding point structure comprises the first step of arraying a Cu welding disc on a wafer through the electroplating technology, the second step of manufacturing bosses by preparing brazing filler metal prepared on the Cu welding disc, the third step of carrying out hot-wind remelting on the manufactured bosses for 30s-120s, the fourth step of carrying out solid-phase aging processes on chips obtained in the third step, the fifth step of placing the welding point bosses prepared in the fourth step into hydrochloric acid, oscillating the welding point bosses through ultrasound, washing and drying the welding point bosses to obtain a preferred orientation Cu6Sn5 welding disc, the sixth step of reversely buckling the welding point bosses prepared in the fifth step into a corresponding circuit board Cu metal layer, and obtaining the single orientation Cu6Sn5 intermetallic compound micro-interconnecting welding point structure through the reflow welding technology. Uniform and stable welding point structure can be obtained when the single orientation Cu6Sn5 intermetallic compound micro-interconnecting welding point structure is applied to large two-level packaging at the appropriate conditions.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL +3

Ethylene oxide exhaust gas processor

InactiveCN101224381AReduce concentrationSave energyDispersed particle separationIncinerator apparatusCombustion chamberEthylene oxide

The invention relates to an ethylene oxide exhaust gas processor. A pre-mixing chamber, a pre-heating chamber, a firebox, an adsorption chamber, a gas-distributing regulator and a cooling chamber which are mutually communicated are sequentially arranged upwards from an inlet of ethylene oxide exhaust gas. The gas-distributing regulator is communicated with the cooling chamber and is also communicated with a circulation fan. A jet circulation air intake and a vacuumizing port are arranged on the pre-mixing chamber. Heating pipes are arranged in the firebox and are interlaced orderly into layers, and the firebox is communicated with the adsorption chamber. A plurality of adsorbing layers are arranged in the internal part of the adsorption chamber, and a porous clapboard is respectively arranged between two layers, and the upper part of the adsorption is communicated with the gas-distributing regulator which can regulate the flow of high temperature purifying gas and circulation hot gas. The invention not only can lead the sterilized ethylene oxide gas to be thoroughly decomposed into carbon dioxide and water and lead the concentration of disposed and purified ethylene oxide nearly to be 0ppm which is further less than 1ppm regulated by the international standard, but also can lead the hot air to be recycled so as to conserve energy. The operation of the invention is convenient, and can be carried out together with sterilizing so as to avoid the secondary pollution.

Owner:吕延利

Method for processing leisure seasoning dewatered fruit and vegetable

InactiveCN1554292AIncreased drying costsLittle increase in drying costsFood preservationFood preparationPre treatmentHot blast

The present invention relates to the production process of seasoned dewatered fruit and vegetable as snack, and belongs to the field of fruit and vegetable food producing technology. The production process includes selecting vegetable, meat, edible fungus and other material, peeling, washing, slicing, scalding to kill enzyme, color keeping, hot blast drying to safe water content of 5-7%, re-combining with water inside seasoning liquid for 30-60 min to increase the water content to 20-60%, vacuum drying to water content of 3-7%, and nitrogen-filling or vacuum packing. The product is puffy and tasty and is used as snack.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD +1

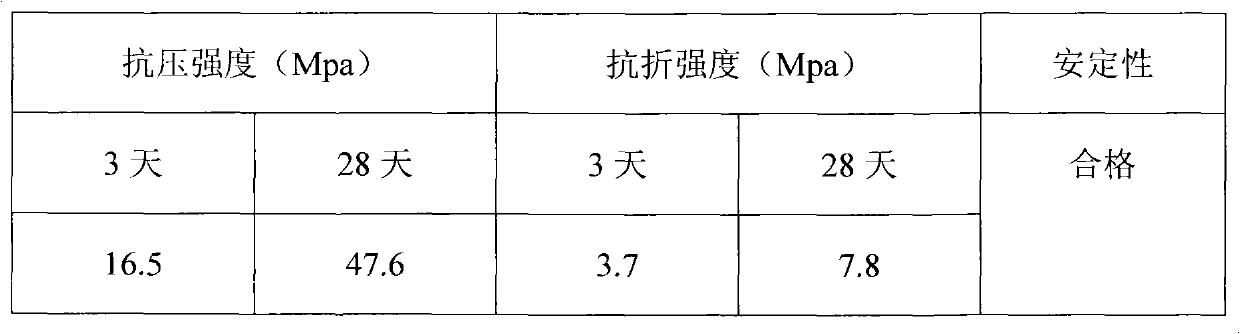

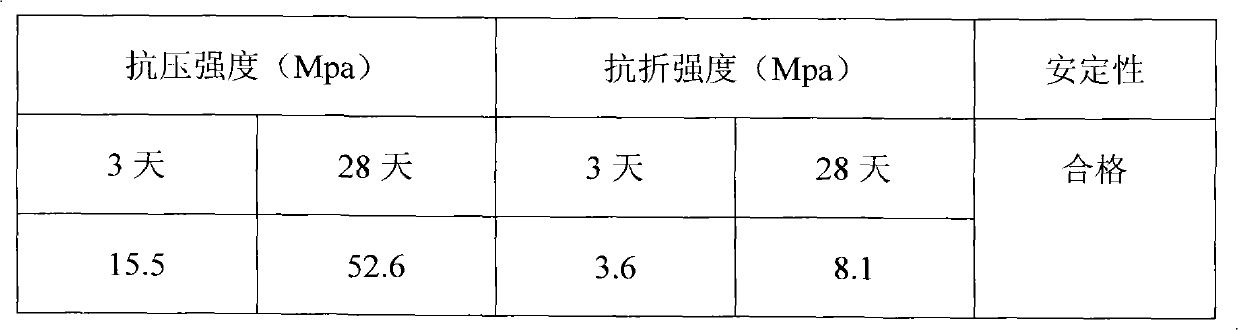

Method for preparing electrolytic manganese slag ecological cement

The invention discloses a method for preparing electrolytic manganese slag ecological cement, and belongs to the field of building materials and environment protection. The cement is characterized by consisting of calcined electrolytic manganese slag, blast furnace slag, a clinker, gypsum and an additive. The method comprises the following steps of: crushing the electrolytic manganese slag and then calcining the crushed slag at the temperature of between 500 and 900 DEG C, wherein the activity of the slag is increased to be close to that of fly ash from zero activity of volcanic ash; and grinding the blast furnace slag, the clinker, the fly ash or steel slag, the gypsum and the additive together or respectively according to a certain proportion and uniformly mixing the materials to prepare the electrolytic manganese slag ecological cement, wherein the amount of the calcined electrolytic manganese slag in the mixture is 10 to 50 percent. The method has the advantages of circularly utilizing a great amount of accumulated electrolytic manganese slag on a large scale and relieving serious damage of the electrolytic manganese slag to the environment, along with simple process, high product quality, low production cost and high economic, environmental and social benefit.

Owner:UNIV OF SCI & TECH BEIJING

Former hot blast and latter vacuum microwave combining drying process of producing crisp fruit and vegetable grains

InactiveCN1672531AReduce drying loadReduced moisture removal requirementsFruits/vegetable preservation by dehydrationWater contentFood processing

The present invention is former hot blast and latter vacuum microwave combining drying process of producing fruit and vegetable grains, and belongs to the field of fruit and vegetable food processing technology. The drying process includes the steps of: washing fruit and vegetable material, dicing, scalding to killing enzyme, cooling in flow water, draining, optional fast freezing and defrosting, soaking with seasoning, draining, pre-dewatering with hot blast to obtain semi-finished product with water content of 40-60 %, and final vacuum microwave drying to obtain product with water content of 2-5 %. The said process has the nutritious components and color well maintained, crisp product, short production period, low cost, high product quality and other features.

Owner:JIANGNAN UNIV

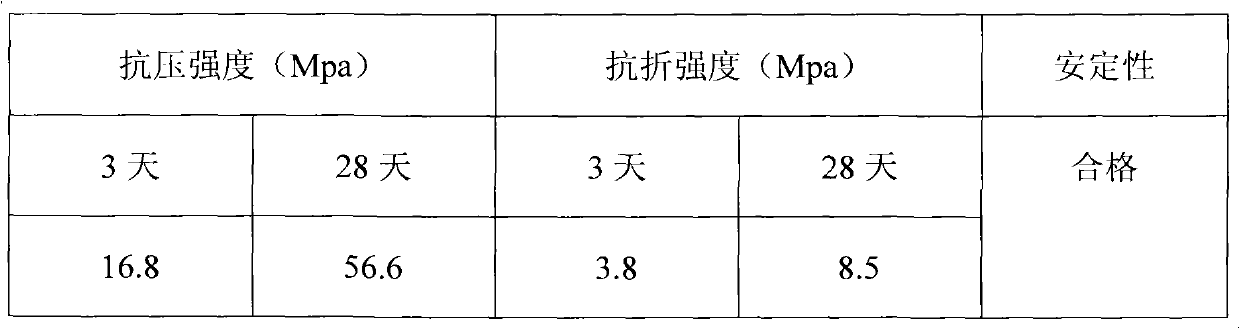

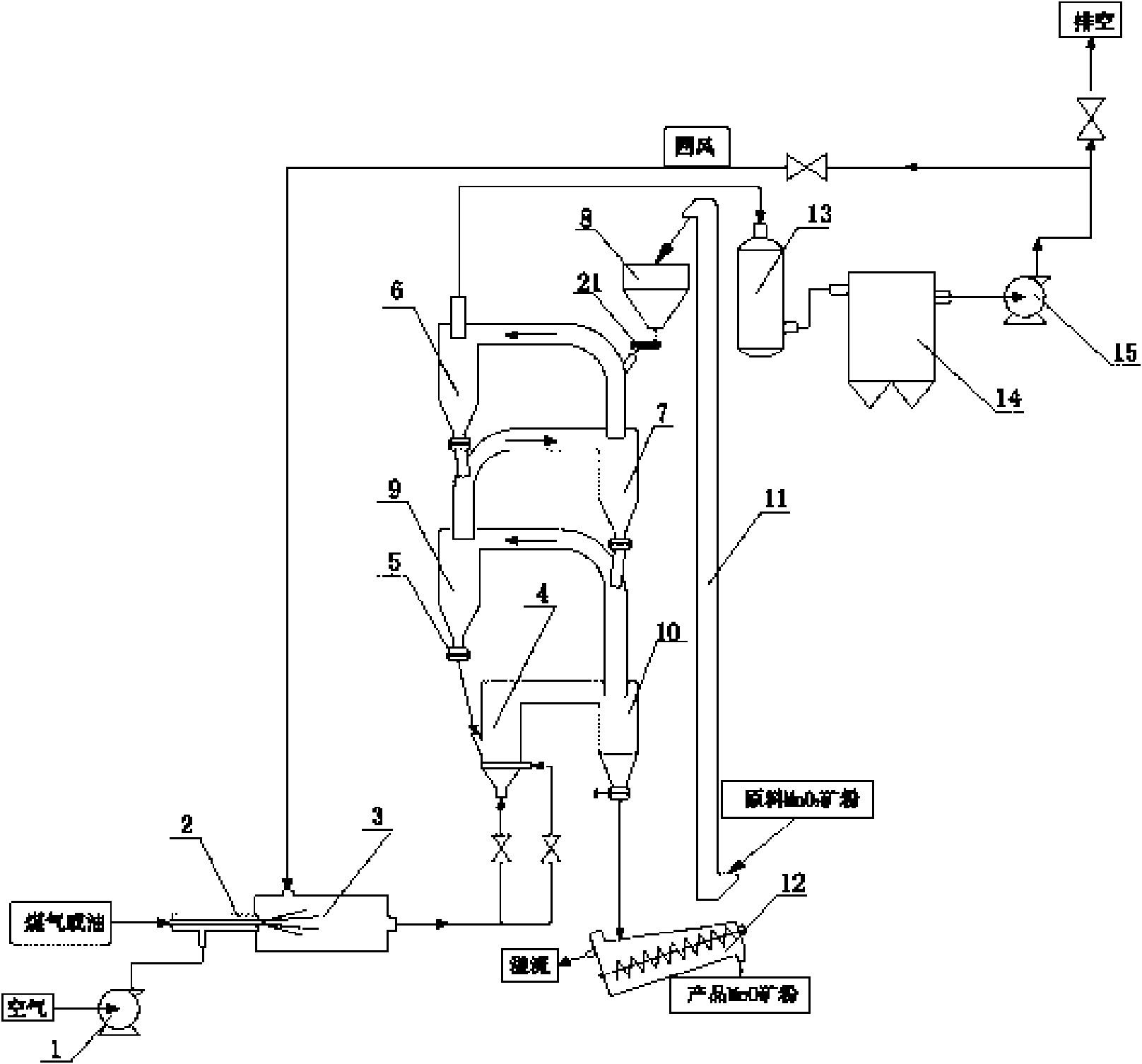

Method and device for reducing and baking for high-valent manganese minerals

The invention provides a method and a device for reducing and baking for high-valent manganese minerals. The method comprises the following steps: (1) combusting combustible gas and air in a hot blast furnace through a nozzle, controlling coefficient of excess air to ensure that the gas of the hot blast furnace is required reduction atmosphere and temperature, and introducing a fluidized roaster; (2) finely grinding manganese minerals, feeding the manganese minerals into a suspension preheat assembly for sufficient heat exchange in several times, separating gas and mineral powder granules, and feeding the granules into the fluidized roaster for a reduction reaction; and (3) controlling the CO content and solid-gas ratio in the fluidized roaster; reducing manganese mineral powder in the fluidized roaster into acidsoluble manganous oxide, and discharging the manganous oxide from a solid material outlet of a cyclone preheater in the last stage. The device comprises a feed assembly, the suspension preheat assembly, the fluidized roaster, a dust-removal exhaust assembly, a gas feed assembly and a combustion assembly. The method and the device have the advantages of simple and compact structure, low cost, simple and convenient operation, good reduction effect, low energy consumption and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Blast-furnace coal powder injection method using waste gas of hot-blast stove flue as carrier

InactiveCN101000141AAvoid large emissionsReduce pollutionLump/pulverulent fuel feeder/distributionHot blastPrimary energy

The invention provides a blast furnace coal spraying method using flue gas of hot-air furnace, concretely using induced draft fan to draw the flue gas of hot-air furnace through special pipeline and control valve out of the flue, cooling by heat exchanger to enter air compressor, after compression, using coal feeder to blow the pulverized coal inputted by blowing tank to distributor, and thus spraying the pulverized coal into the blast furnace from each tuyere. And it implements waste gas utilization, saving primary energy sources; and helps indirect reduction reaction in furnace, so that secondary energy sources can be utilized; besides, largely avoids waste gas CO2 exhaust, reducing atmospheric pollution; can preheat pulverized coal, increasing combustion speed; and has the same system safety as N2 carrier, especially suitable for large scale blast furnace applications and having extremely remarkable energy saving and environmental protection effects.

Owner:ANGANG STEEL CO LTD

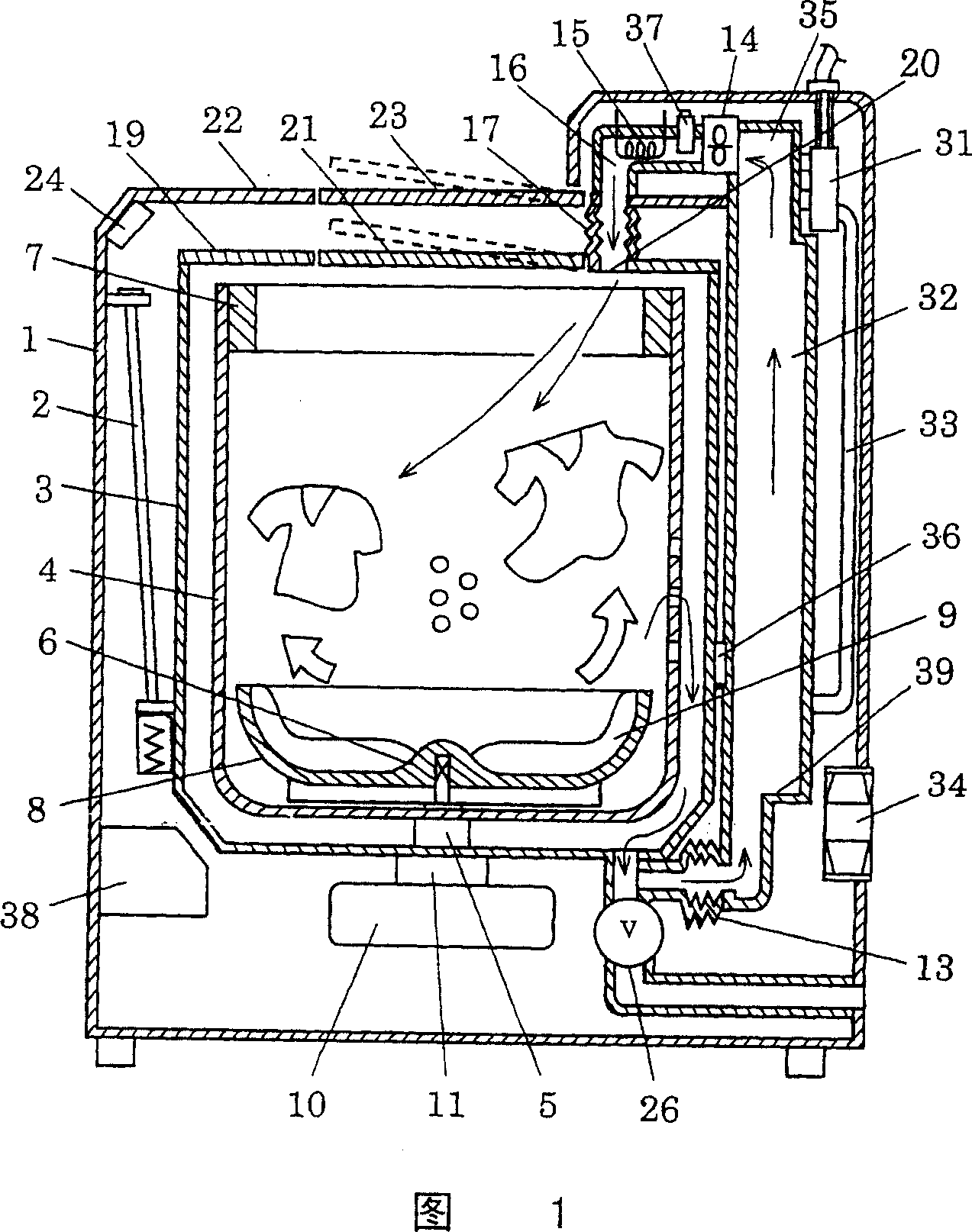

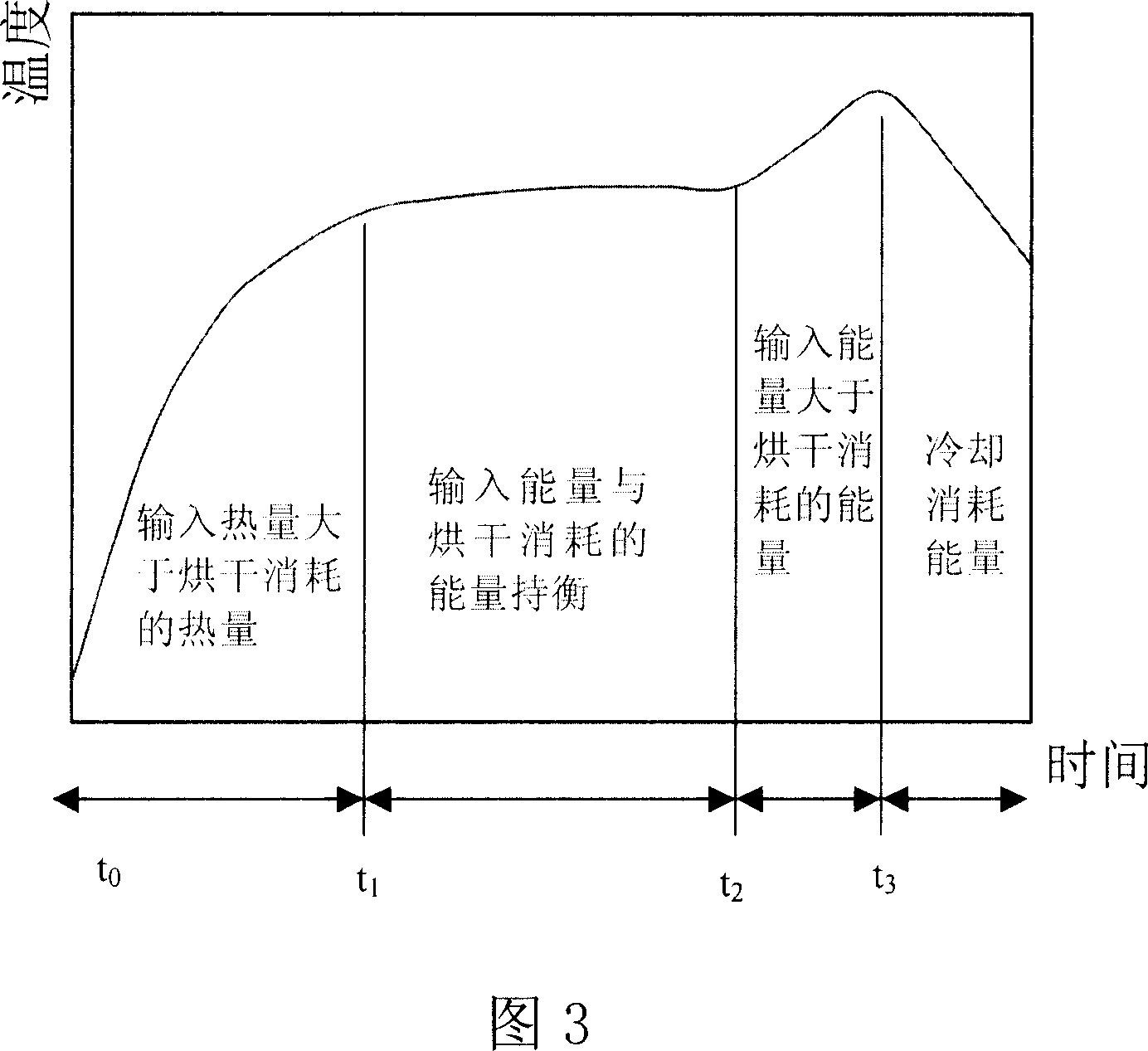

Drum washing-drying machine and drying time determining method

ActiveCN1978731ADryness controlRealize the effect of stopping when the clothes are dryWashing machine with receptaclesTextiles and paperEngineeringDrying time

The invention relates to drum-type washing drying machine. It includes outer drum set in case a drum set in the outer drum, observation port set at the front of the case; a drainage system connected with the outlet of the outer drum bottom, a drying system set at its one side; re-circulating air formed by drying device upper shell, hot-blast tube, and condenser; the condenser includes a air inlet and outlet, condenser tube, and condensed water adjustor; the heating air duct is set fan and heating tube connected with the heating air duct and the outer drum. Its feature is that temperature sensor is close to the air outlet in the condenser.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

Steam fryer

The invention relates to a steam fryer comprising a body and a heating space formed in the body. A rotating baking basket is accommodated in the heating space. The body is provided with an air heater capable of providing hot air for the heating space. The steam fryer is characterized in that the body is further provided with a mist generator capable of providing atomized steam for the heating space. Therefore, the steam fryer is applicable to oil-free steam frying of foods such as potato strips, meat, and pizza.

Owner:伊立浦集团股份有限公司

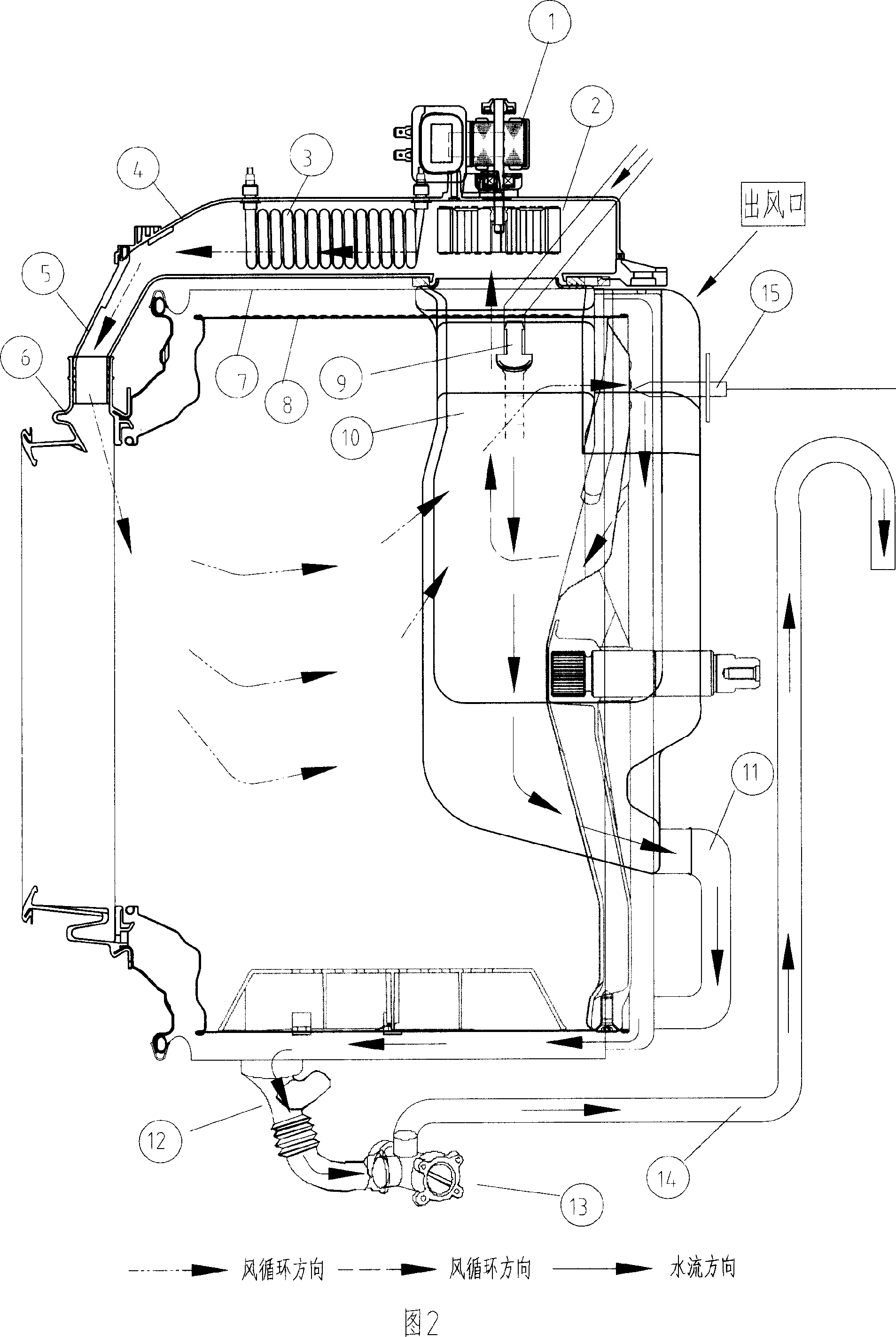

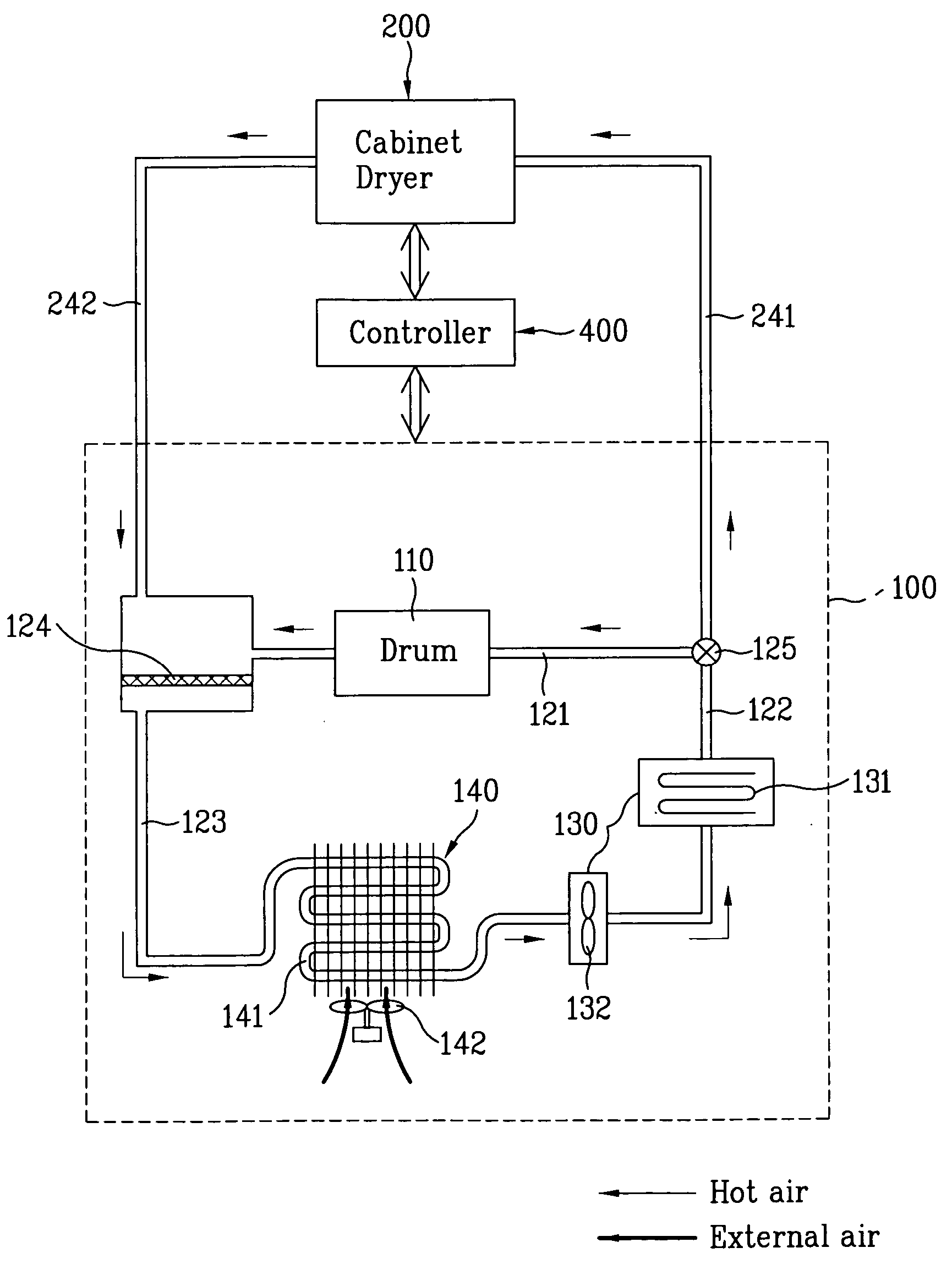

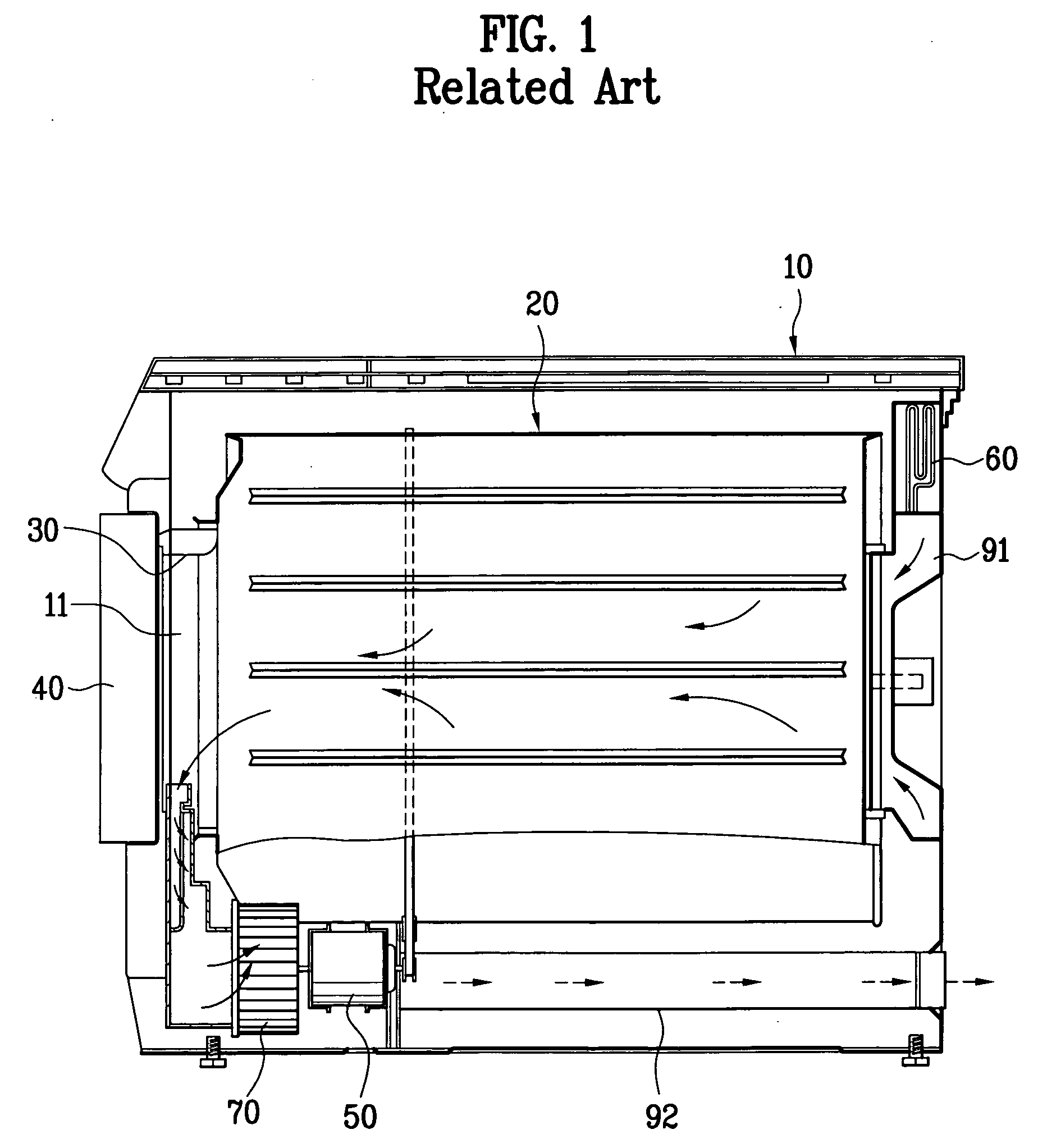

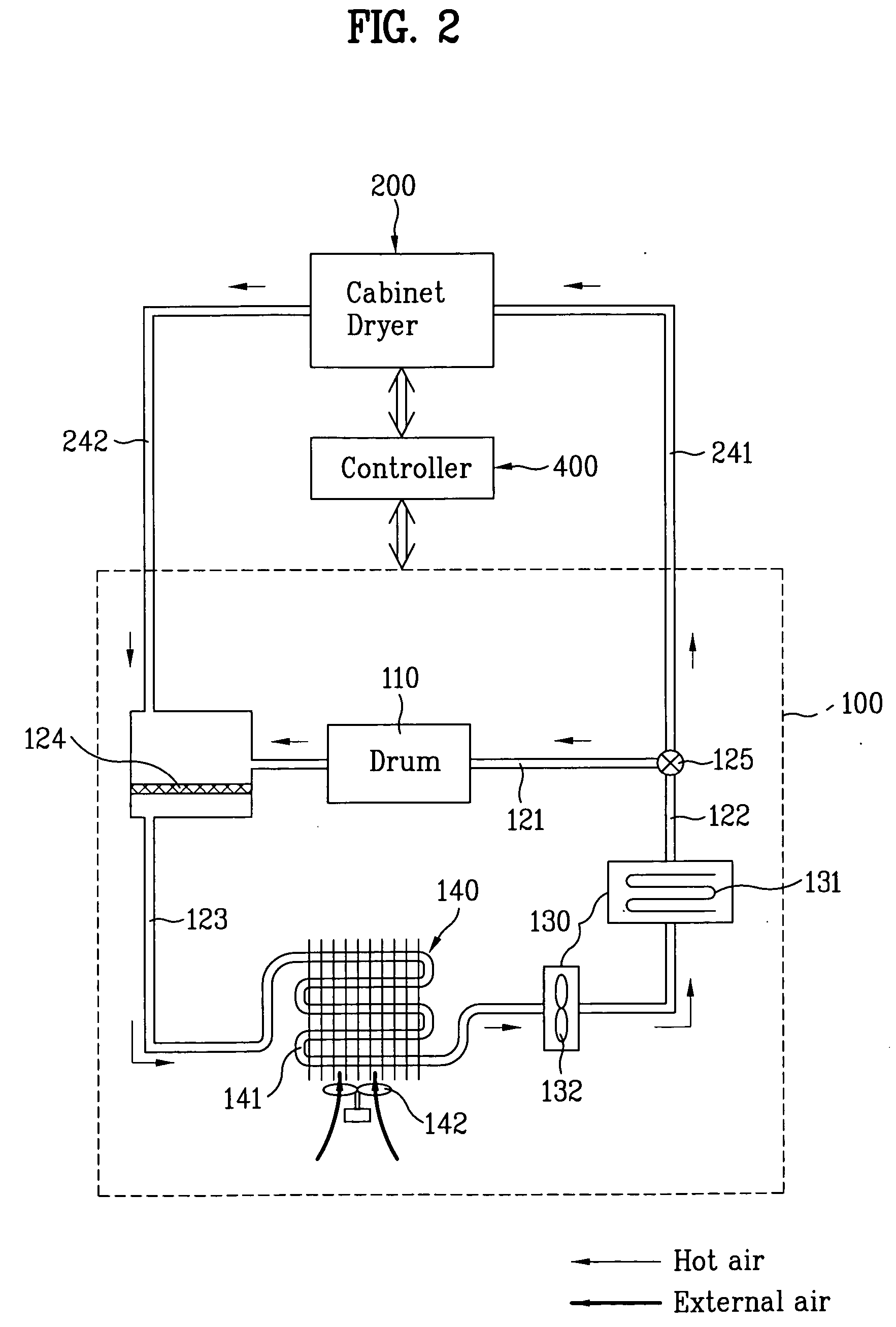

Composite washing system

A composite washing system is disclosed which is capable of continuously circulating laundry-drying air through dryers while obtaining a more efficient drying effect, so that the composite washing system has a suitable built-in structure having minimal influence on the indoor environment. The composite washing system includes a drum dryer which dries laundry to be dried, and includes a drying drum adapted to receive the laundry, a hot air supply path adapted to guide a flow of hot air, a hot air supplier arranged in the hot air supply path to generate the hot air, and an air condenser adapted to condense the hot air, a cabinet dryer which is coupled to one side of the drum dryer, and is defined with a laundry receiving compartment, the cabinet dryer including a hot air inlet duct adapted to receive the hot air flowing through the hot air supply path, and a hot air supplying device which is arranged in the cabinet dryer to receive the hot air from the hot air inlet duct and to supply the received hot air to an inside of the laundry.

Owner:LG ELECTRONICS INC

Method for preparing coductive fiber and its product

The present invention relates to conductive fiber preparing process and product. The preparation process includes the following steps: 1. pre-treating base fiber of polyester, viscose or wool successively with acetone, ethanol and distilled water under room temperature condition; 2. compounding fiber treating liquid with oxidant ferric trichloride or ammonium persulfate 2-32 wt%, dopant ammonium cetyl trimethyl bromide or hydrochloric acid 0.1-7 wt% and distilled water; and soaking the base fiber inside the fiber treating liquid for 30 min; and 3. making conductive fiber via coating conducting liquid of aniline, pyrrole or thiophene onto the base fiber inside a continuous coating machine of 1-10 m / min speed, washing with hot water at 50-90 deg.c and drying with hot blast at 60 deg.c to obtain the conductive fiber.

Owner:TIANJIN POLYTECHNIC UNIV

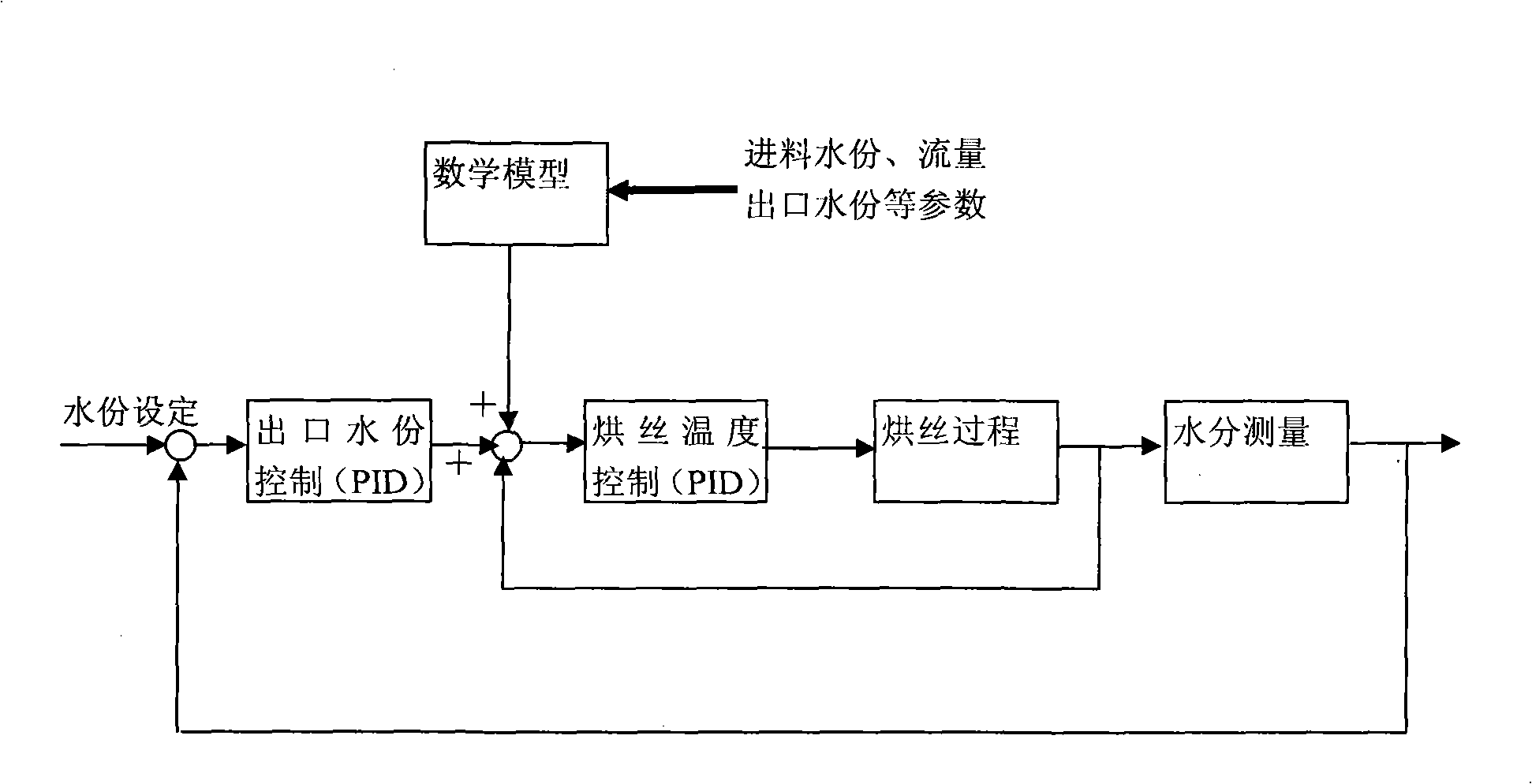

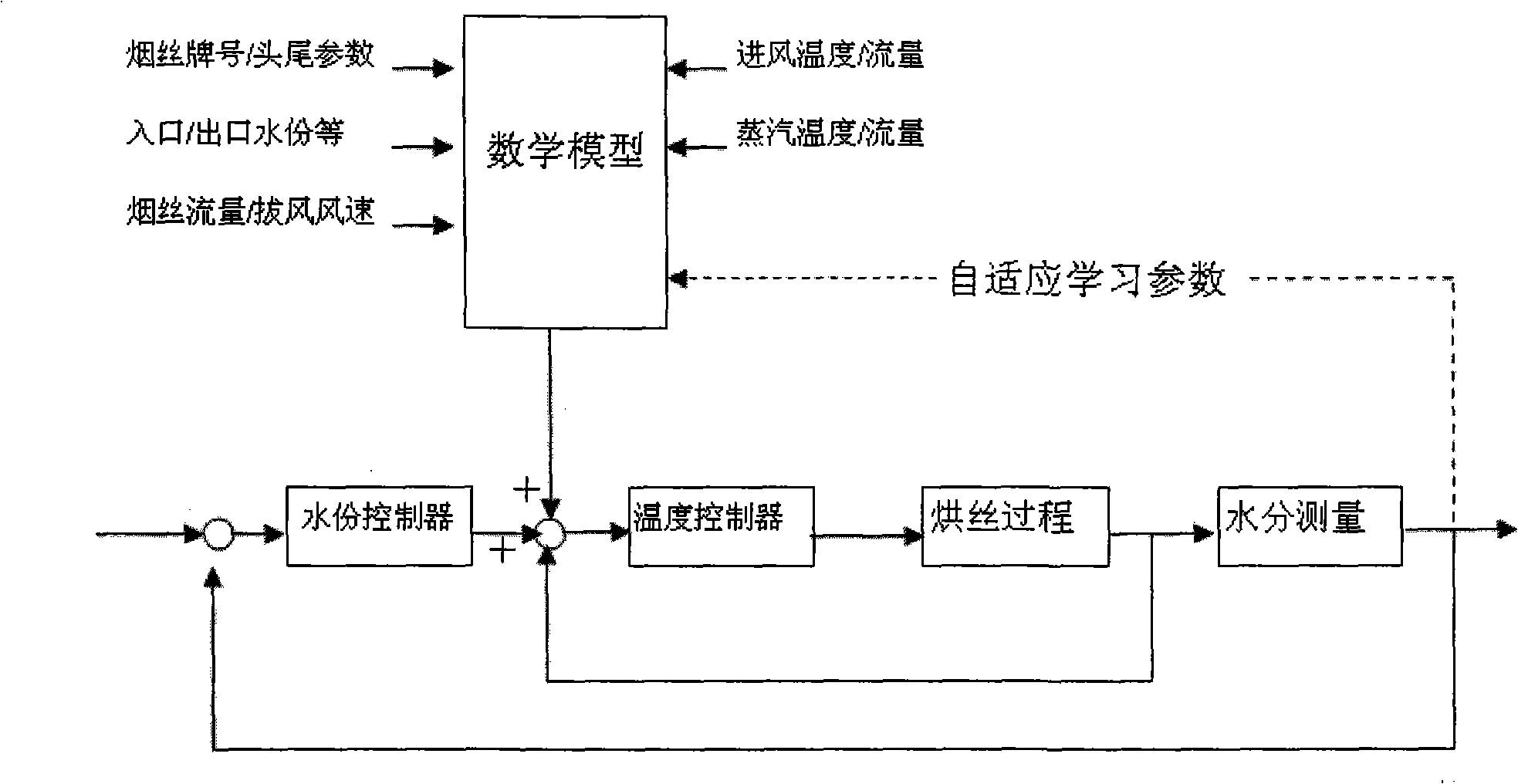

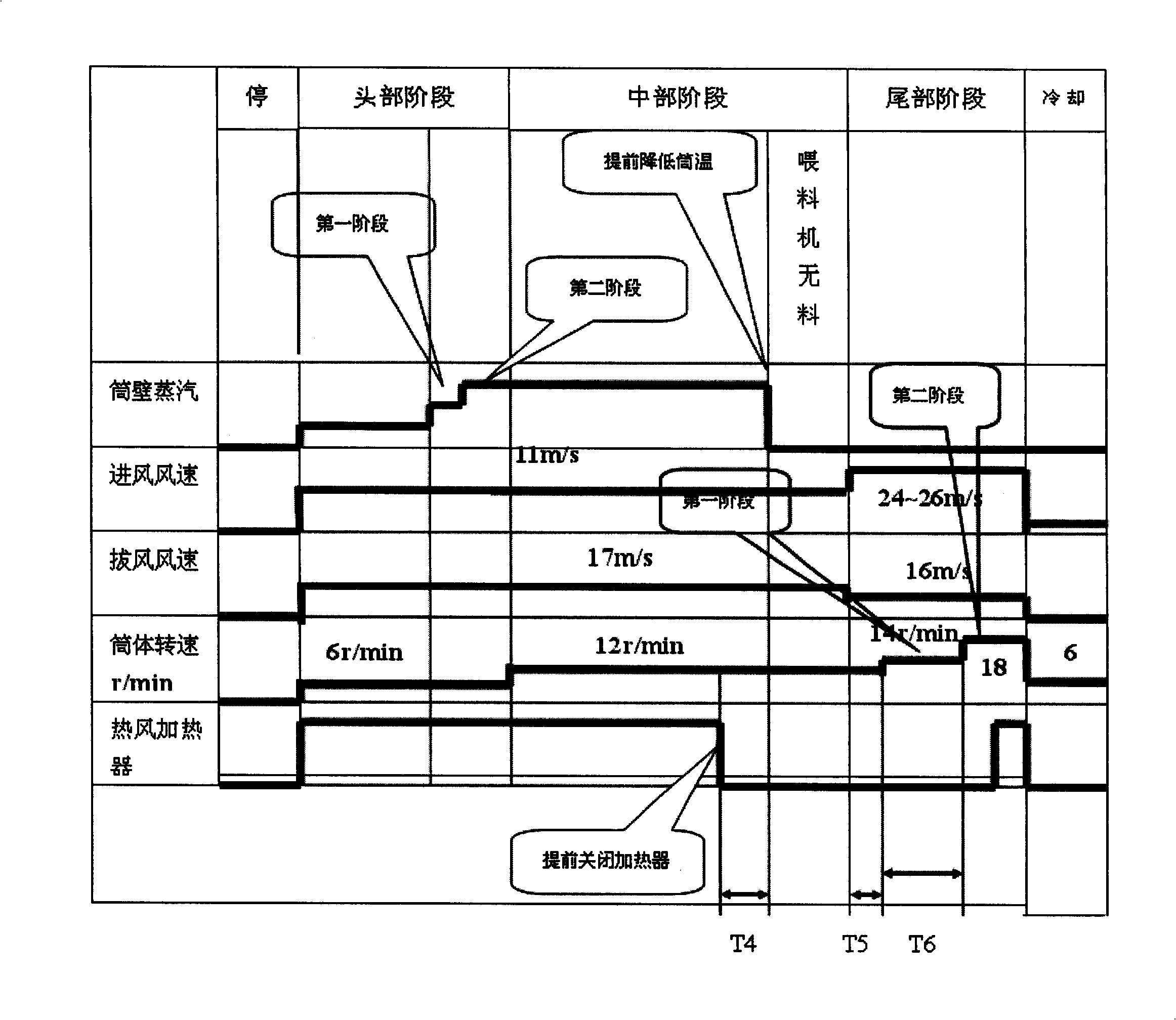

Thread baking thread process control method

ActiveCN101254020AAvoid influenceImprove anti-interference abilityTobacco preparationHot blastIntermediate stage

The invention relates to a method for controlling the tobacco drying process, which is characterized in that the whole tobacco drying process is divided into a head stage, a middle stage, and a tail stage; the head stage adopts an adaptive learning temperature rising control method, a control system automatically adjusts the temperature in the next temperature rising according to the previous humidity control effect, and the low drum speed is adopted in the heat stage; the middle stage leads water parameters at an outlet into the control system, forecast PID control is adopted to feed back and correct to realize the automatic control for the temperature of the cylinder wall of a tobacco drying cylinder; the tail stage lowers the temperature of the tobacco drying cylinder in advance, closes a steam heater on the cylinder wall and a cyclic hot blast heater in advance, increases the air intake speed, reduces the drawing air speed, and accelerates the drum speed. The tobacco drying process controlling means has the advantages that the influence on the moisture content at the tobacco drying outlet caused by the nonlinearity and the large time delay during the original tobacco drying procedure control process is overcome, the anti-interference ability is strong, various changes of operation conditions can be adapted, and the control of the moisture content at the tobacco drying outlet can be led to achieve higher control precision.

Owner:SHANGHAI TOBACCO GRP CO LTD

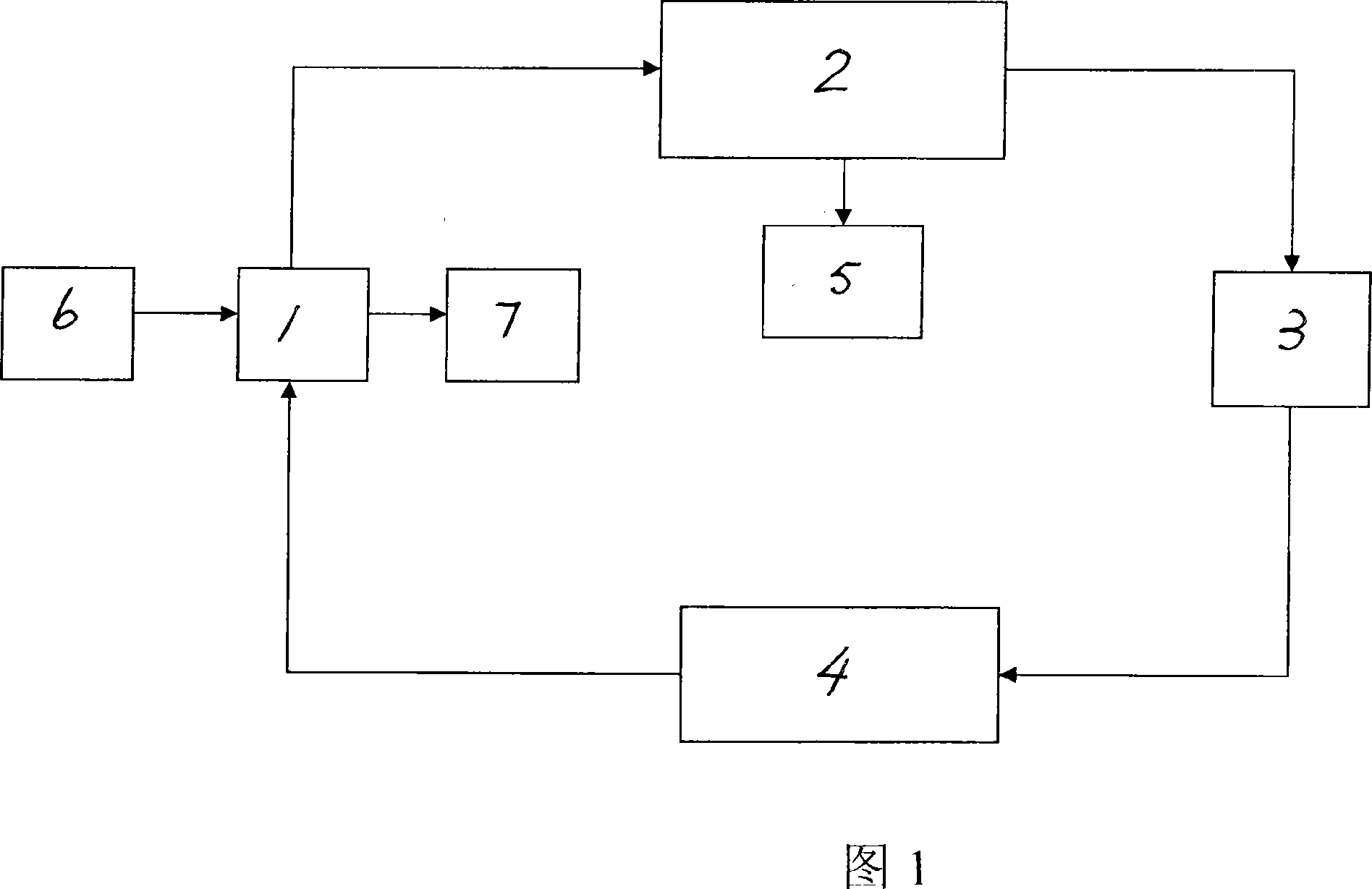

Method for extracting fragrant liquor and essential oil from aromatic plants by dry-process

InactiveCN101117614AReduce volumeSimple processEssential-oils/perfumesAgricultural engineeringPollution

The present invention discloses a dry method for refining balsam and essential oil from aromatic plants, aromatic plants are refined and put in a device, a heating chamber (4) is connected with an evaporating chamber (1) through a pipeline, the evaporating chamber (1) is connected with an extraction chamber (2) through a pipeline, the extraction chamber (2) is connected with a blower (3) through a pipeline, the blower (3) is connected with the heating chamber (4) through a pipeline, and a sealed circulation loop device is formed. The hot blast temperature is controlled between 60 DEG C and 90 DEG C, the wind speed is controlled at 1 meter to 15 meters per minutes, the inlet temperature of a condensing reed pipe (23) is 3 DEG C to 25 DEG C, and balsam and essential oil can be collected in a discharge pipe(24). In the present invention, no water, special gas and organic solvent are added into raw material, balsam and essential oil which are refined are uncorrupt in smell, small in equipment volume, simply in art, high in efficiency, low in energy consumption, simply in operation and high in production efficiency; no pollution material is discharged, no cooking water and steam are consumed, balsam after being refined can be used as additive of food, drink and condiment, and used for hairdressing, face-painting, bath, and health care, in addition, the aromatic plants after being refined balsam and essential oil is in the dry shape and reserved in a whole, then can be used sequentially, thereby saving resources.

Owner:宋永快 +1

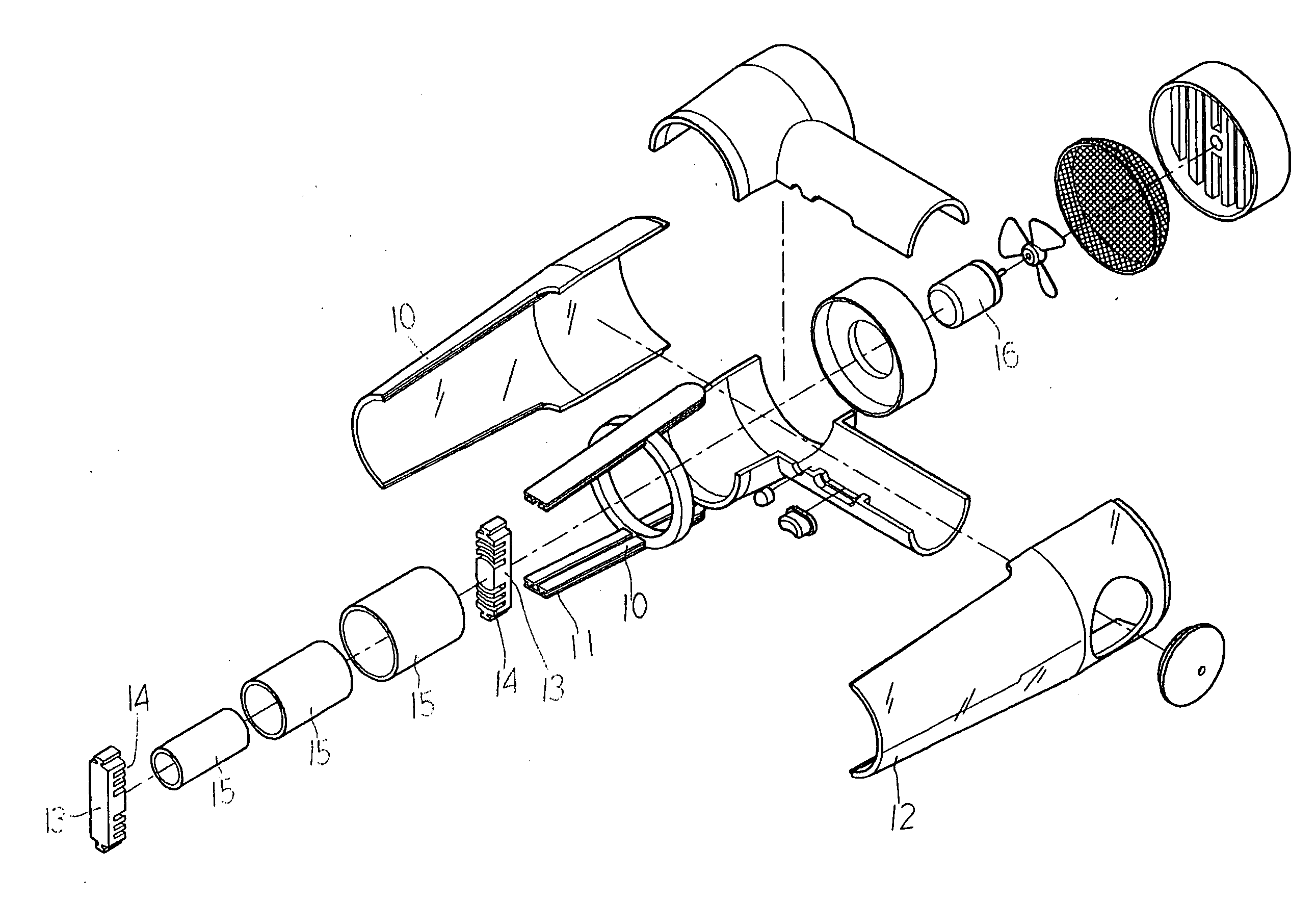

Hair drier hot air generator retainer

InactiveUS20060075654A1Easy constructionEasy to assembleDrying solid materials with heatDrying gas arrangementsElectrical conductorVoltage drop

A hair dryer hot air generator retainer allowing compact design, production cost reduction, and see-through attractive appearance containing a built-in hot air generator in homogenous voltage drop design; including a barrel in two separate halves and an H shape frame; multiple vitreous hot air generation devices sandwiched by two retaining members adapted with relative electrodes also for conduction; all ends of conductors connected to a DC motor concealed inside the frame for hot air generation devices to achieve homogenous voltage drop for use.

Owner:LIN HSIN YUN

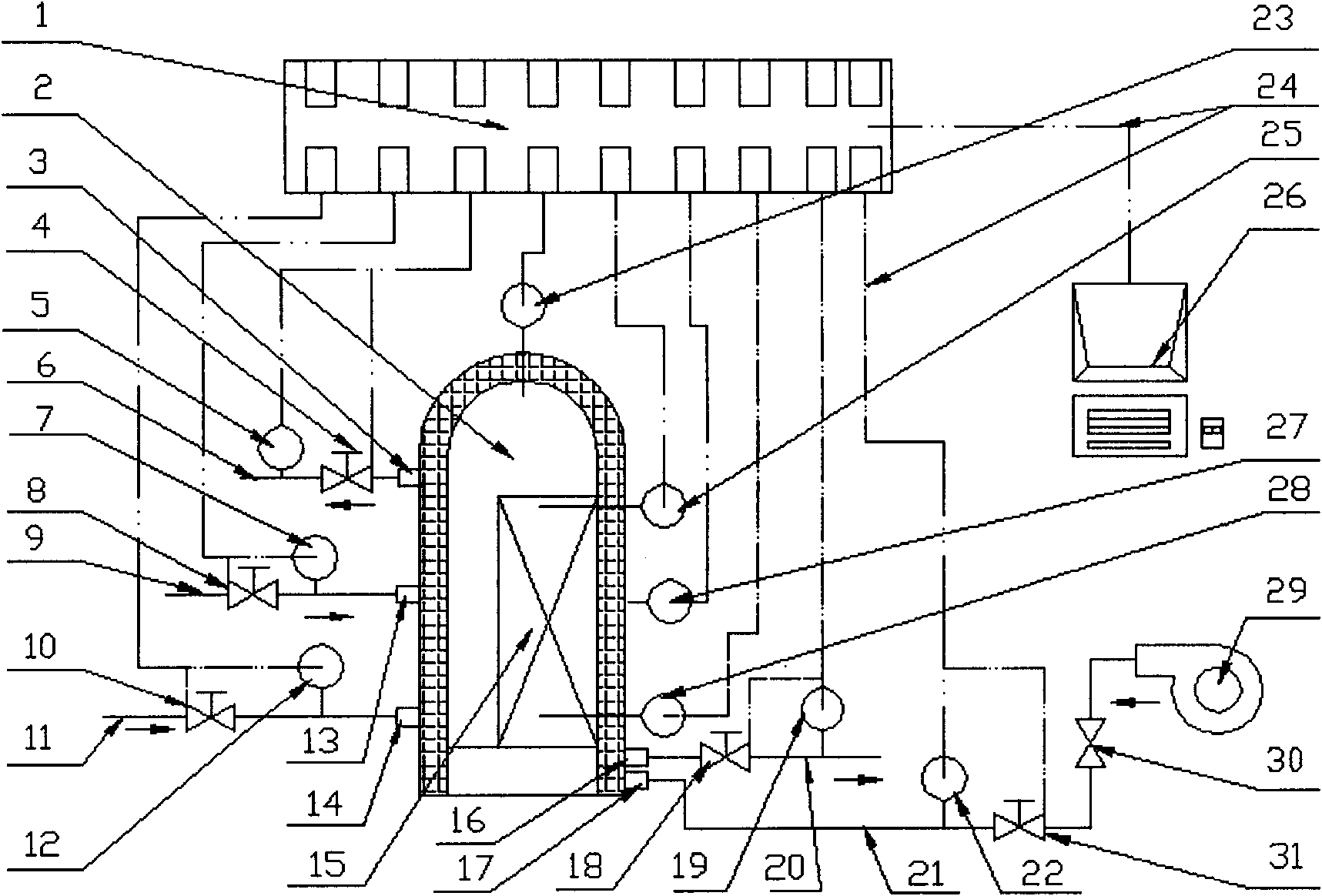

Constant wind temperature control system for hot blast stove

ActiveCN101892338ARegulating pressureAdjustable temperatureBlast furnace detailsHeating stovesBrickAir volume

The invention provides a constant wind temperature control system for a hot blast stove, comprising the hot blast stove (2), a detection element, a regulating valve, a data acquisition unit (1) and a computer (26). The control method of the control system comprises the following processes: detection of fluid parameters and valve location signals, data acquisition, data transmission, data comparison and data correction and control adjustment, wherein the detection element and the regulating valve are arranged in a pipeline, and temperature measuring equipment is arranged on the surface of a stove body. Specific steps are as follows: dynamically calculating parameters such as the heat storage capacity of checker bricks, temperature-rise ratio, theoretical wind temperature and the like during the combustion process, and carrying out on-line adjustment of parameters such as combustion air and gas flow, preheating temperature and the like; controlling direction change of the hot blast stove by the highest setting temperature of the checker bricks, a stove top and fume; and during the air supply period, taking hot blast temperature control as a target to determine an air supply curve and air supply time. The method based on calculation of dynamic balance of on-line energy of the hot blast stove effectively controls the heat storage capacity of the checker bricks of the hot blast stove, adjusts air supply quantity and air supply time, and ensures stable output of wind temperature of the hot blast stove.

Owner:SHOUGANG CORPORATION

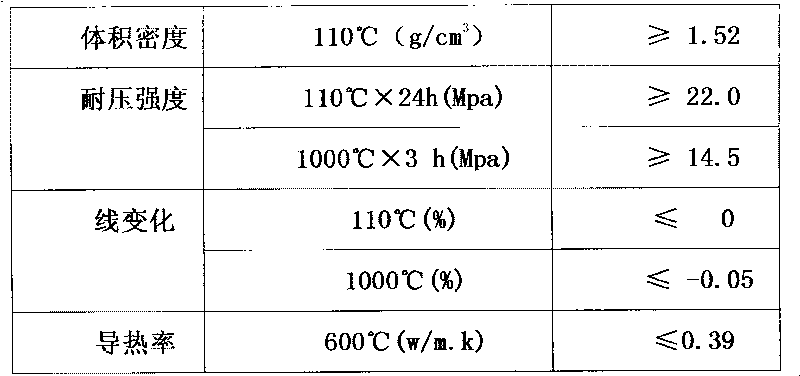

Alumina bubble lightweight insulating refractory casting material

The invention discloses an alumina bubble lightweight insulating refractory casting material, which comprises the following components in percentage by weight: 10 to 50 percent of alumina bubbles, 5 to 15 percent of mullite with the grain diameter of 5 to 3 millimeters, 5 to 20 percent of mullite with the grain diameter of 1 to 3 millimeters, 10 to 20 percent of mullite with the grain diameter of 0 to 1 millimeter, 1 to 13 percent of swelling agent, 10 to 25 percent of fine powder, 10 to 20 percent of micro powder, 0.1 to 1 percent of water reducing agent and 5 to 20 percent of composite aluminate cement. The casting material has the characteristics of carrier weight reduction, high temperature resistance, good heat insulation effect, large strength, convenient and practical operation, and suitability for being used at the temperature of between 1,000 and 2,000, can be used for integrally casting, spraying, coating and repairing, and not only meet the requirement of smelting special steel, but also meet the requirements of refractory materials for hot-blast stoves, furnace tops, furnace walls, petrochemical cracking furnaces, systems for chlorine and sulfur removal, slag discharge and catalytic cracking, electric fluidized bed boilers, flues and the like.

Owner:营口丰华耐火材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com