Patents

Literature

5179results about "Animal corpse fertilisers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

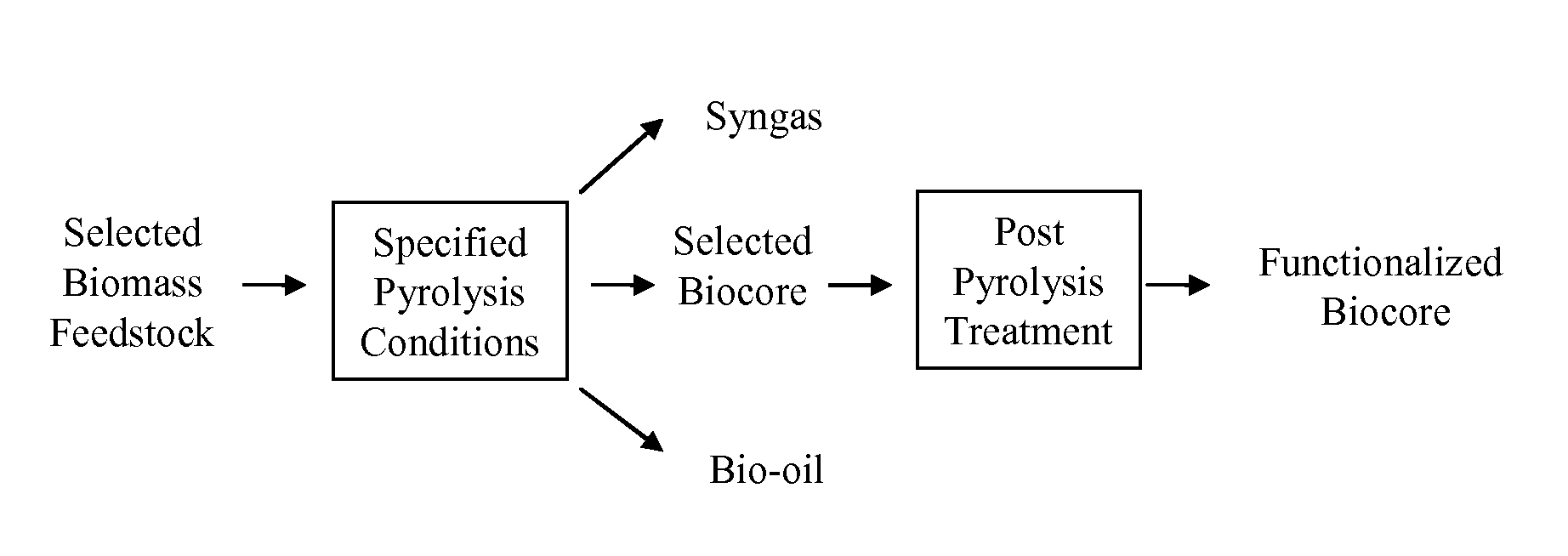

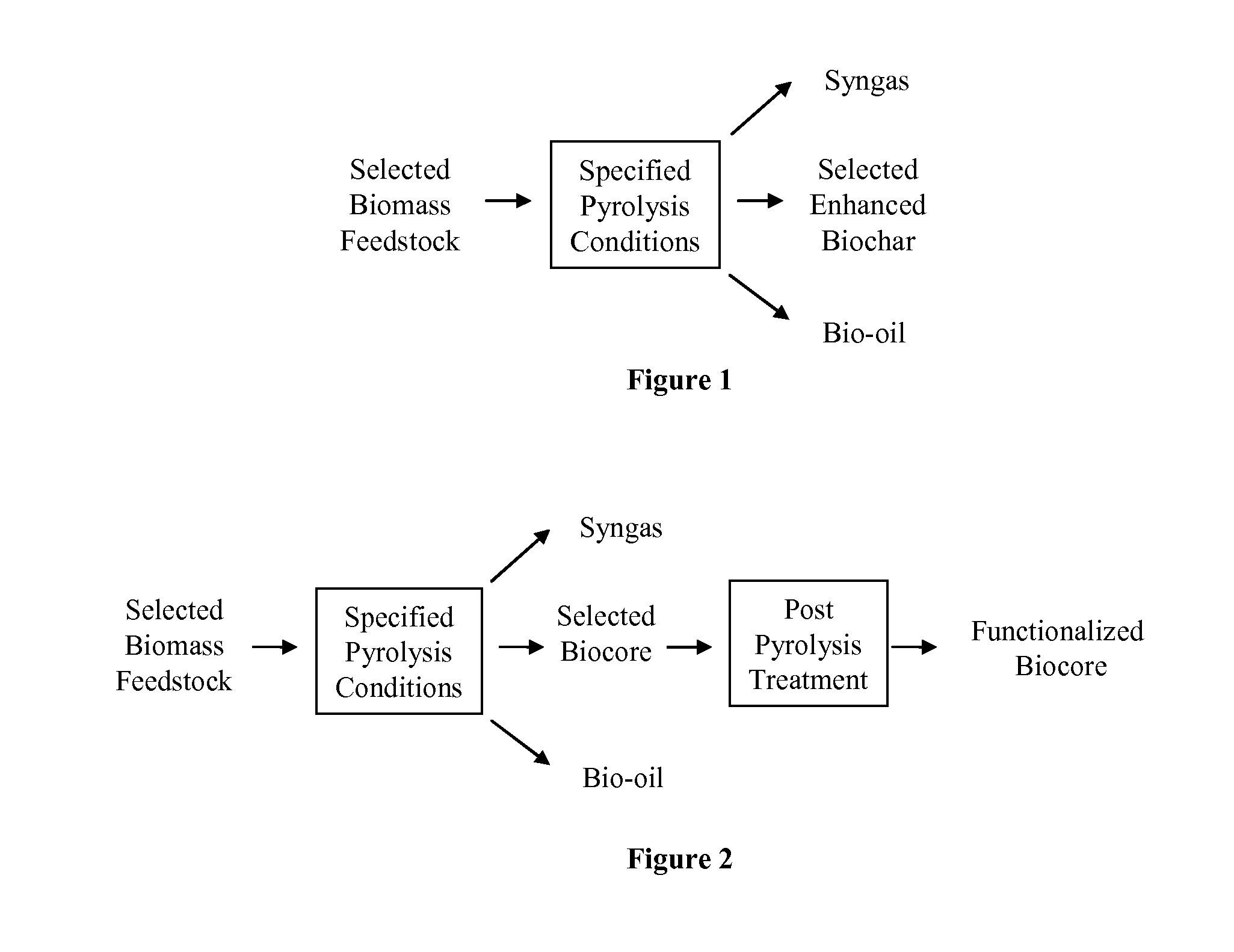

Biochar

ActiveUS8361186B1Enhanced and functionalizedCalcareous fertilisersMagnesium fertilisersForming gasBiological activation

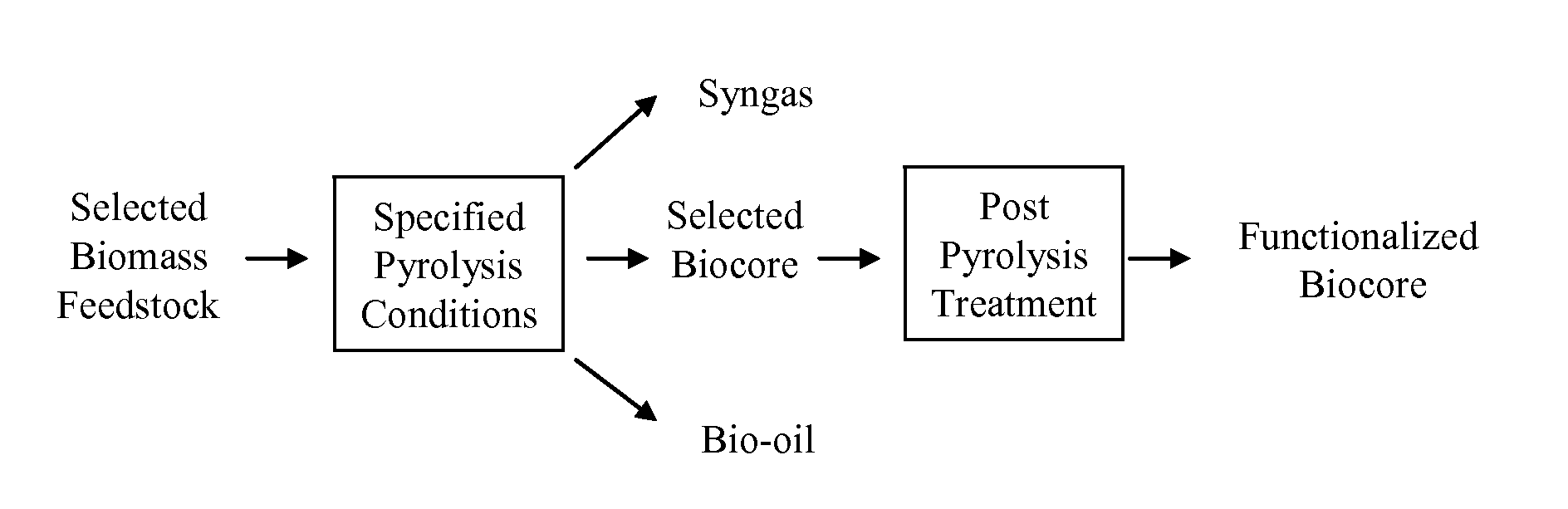

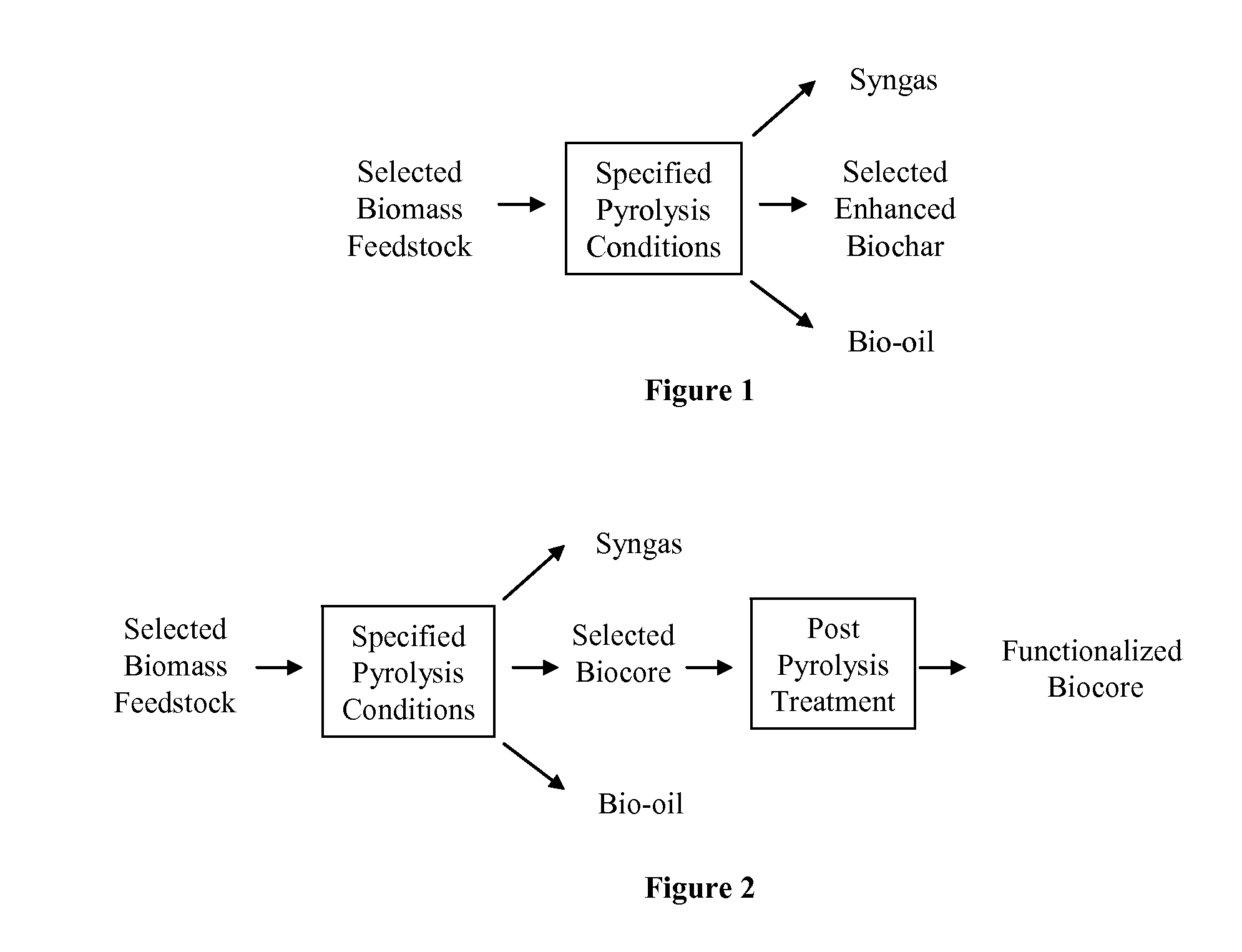

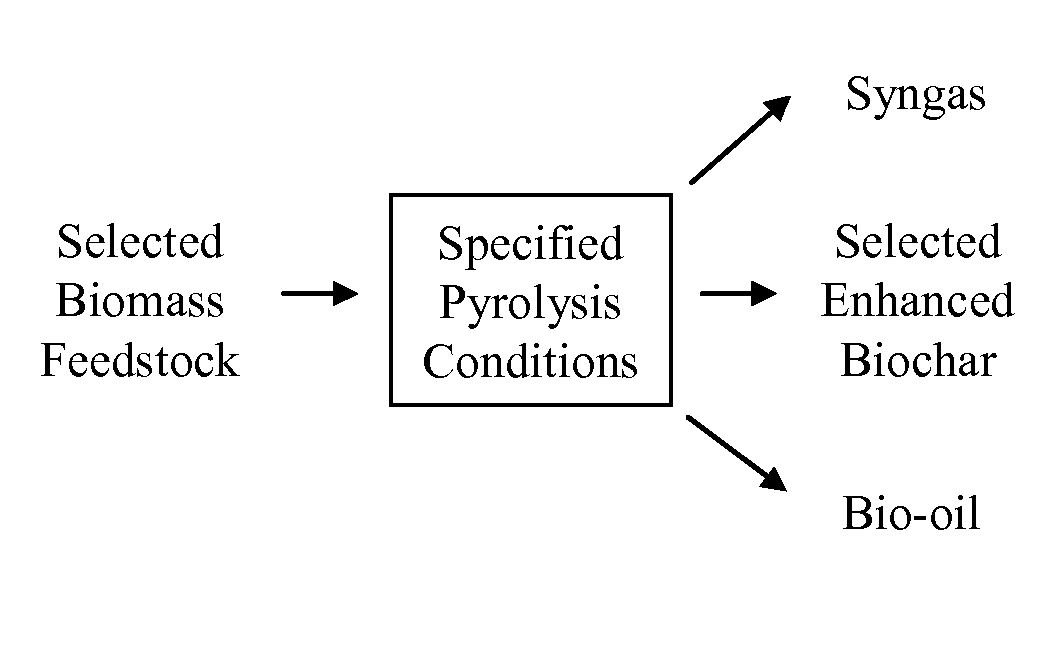

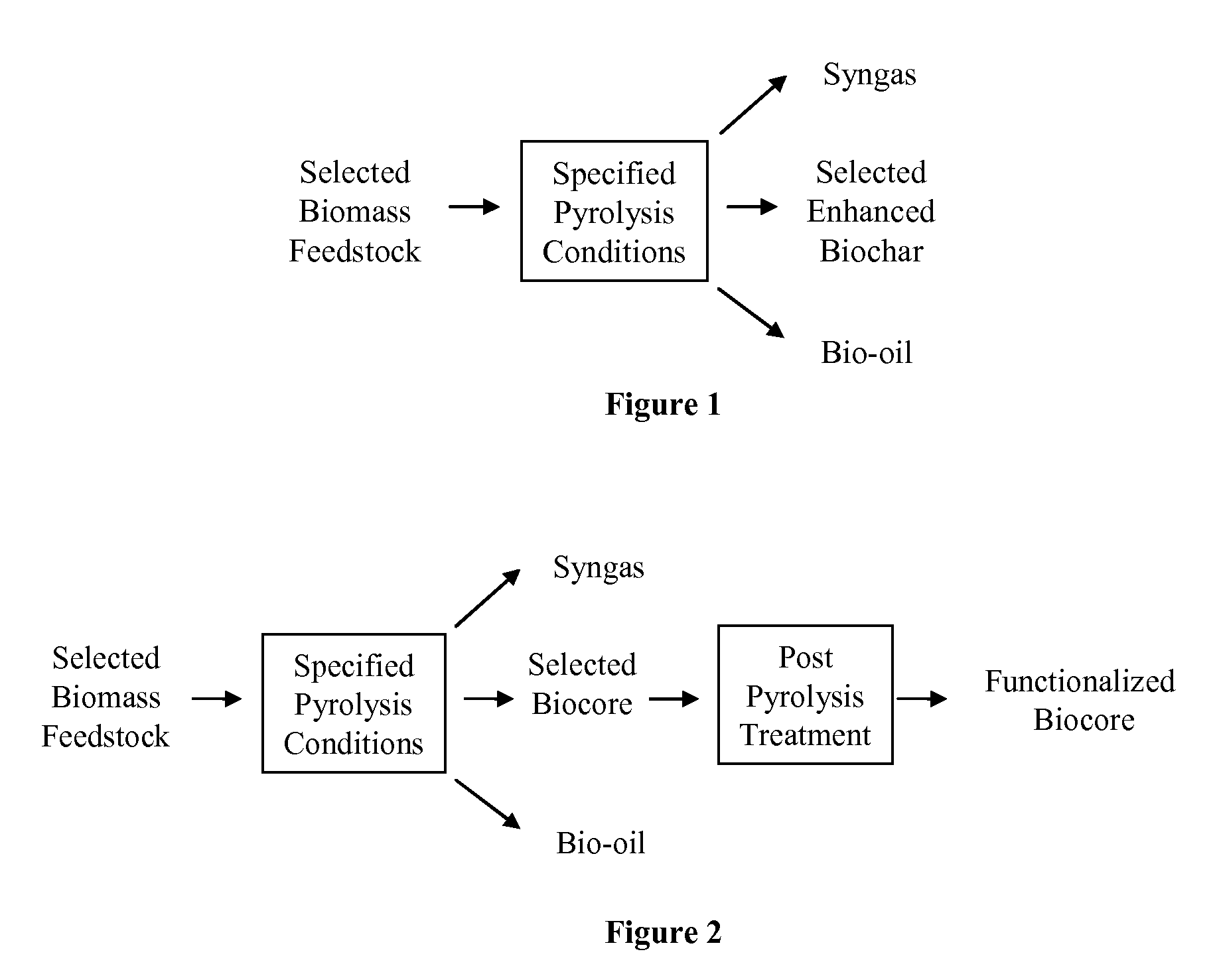

The invention provides for methods, devices, and systems for pyrolyzing biomass. A pyrolysis unit can be used for the pyrolysis of biomass to form gas, liquid, and solid products. The biomass materials can be selected such that an enhanced biochar is formed after pyrolysis. The biomass can be pyrolyzed under specified conditions such that a selected biochar core is formed. The pyrolysis process can form a stable biochar core that is inert and / or resistant to degradation. The biochar or biochar core can be functionalized to form a functionalized biochar or functionalized biochar core. Functionalization can include post-pyrolysis treatments such as supplementation with microbes or physical transformations including annealing and / or activation.

Owner:FULL CIRCLE BIOCHAR

Novel method for innocent treatment and utilization of dead livestock and poultry

InactiveCN101182247ASave energyNo secondary pollutionBio-organic fraction processingInternal combustion piston enginesSlagSludge

The invention discloses a novel method of the harmless treatment and utilization of livestock and poultry which died of disease according to the steps as follows: firstly, various kinds of the animal bodies of the livestock and the poultry which died of disease are collected; secondly, the animal bodies are crushed; thirdly, the crushed animal bodies are sterilized under high temperature and highpressure and separated for filtering, the material of oil and fat flows into a cooling pool, and the material of hair and bone is dried; fourthly, the material of hair and bone after drying is carbonized; fifthly, the material of oil and fat after cooling is added with catalyst, high-efficiency compound microorganism, trash, organic wastewater and sludge; sixthly, the mixed organic material is put into an anaerobic tower to be fermented, and then biogas, biogas slurry and biogas slag are processed for three-phase separation; seventhly, the biogas is used for burning and generating electricity; eighthly, the biogas slurry inside a fertilizer storing pool is used as farmland fertilizer; ninthly, the biogas slag is added with the high-efficiency compound microorganism and the catalyst for secondary ferment; tenthly, the material after the secondary ferment is made into agricultural high-efficiency organic fertilizer. The invention solves the problem of the environmental pollution caused by the livestock and poultry which died of disease and change the waste livestock and poultry which died of disease into valuables.

Owner:浙江威尔斯生物能源开发有限公司

Biochar

The invention provides for methods, devices, and systems for pyrolyzing biomass. A pyrolysis unit can be used for the pyrolysis of biomass to form gas, liquid, and solid products. The biomass materials can be selected such that an enhanced biochar is formed after pyrolysis. The biomass can be pyrolyzed under specified conditions such that a selected biochar core is formed. The pyrolysis process can form a stable biochar core that is inert and / or resistant to degradation. The biochar or biochar core can be functionalized to form a functionalized biochar or functionalized biochar core. Functionalization can include post-pyrolysis treatments such as supplementation with microbes or physical transformations including annealing and / or activation.

Owner:FULL CIRCLE BIOCHAR

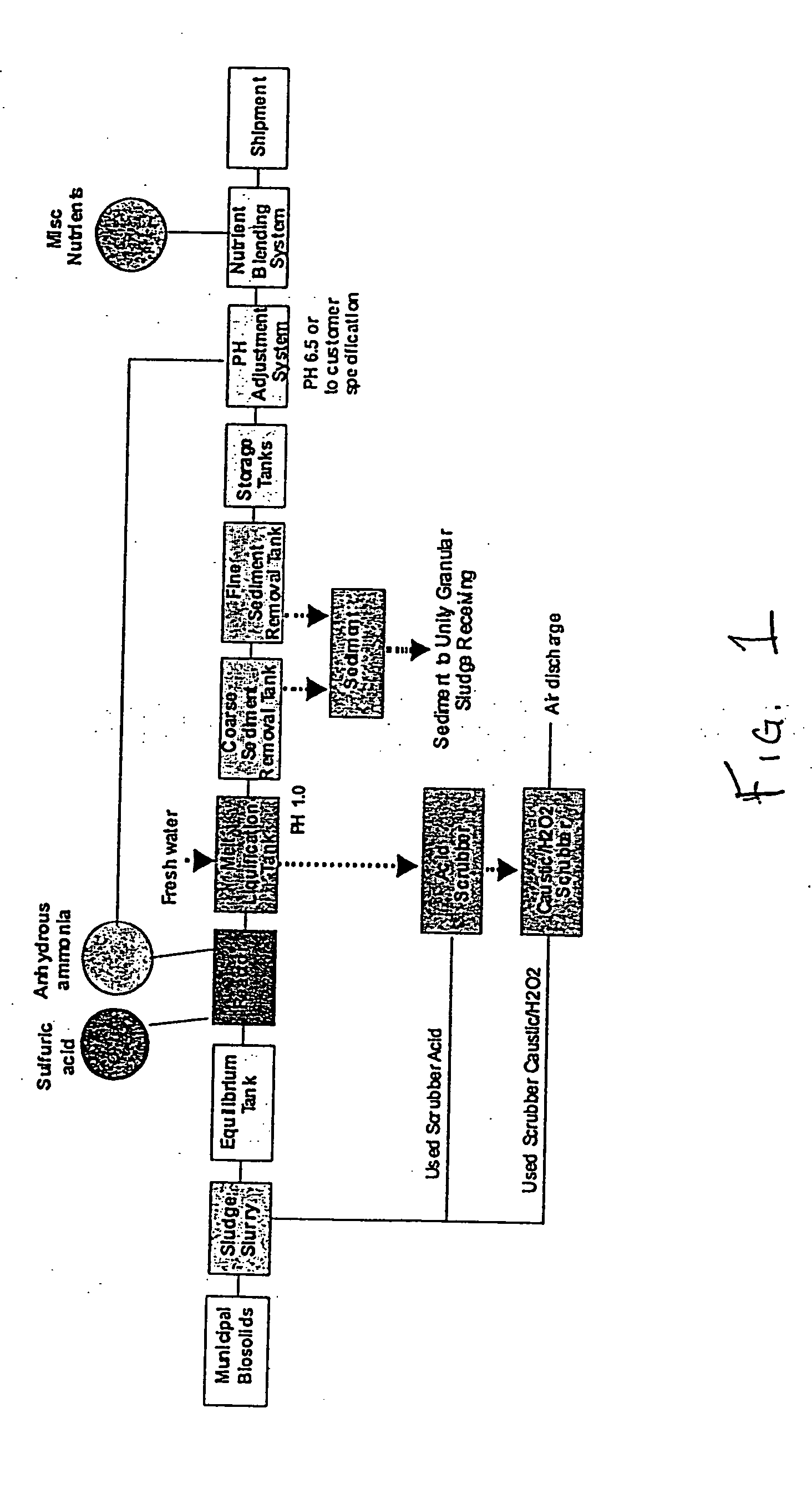

Organic containing sludge to fertilizer alkaline conversion process

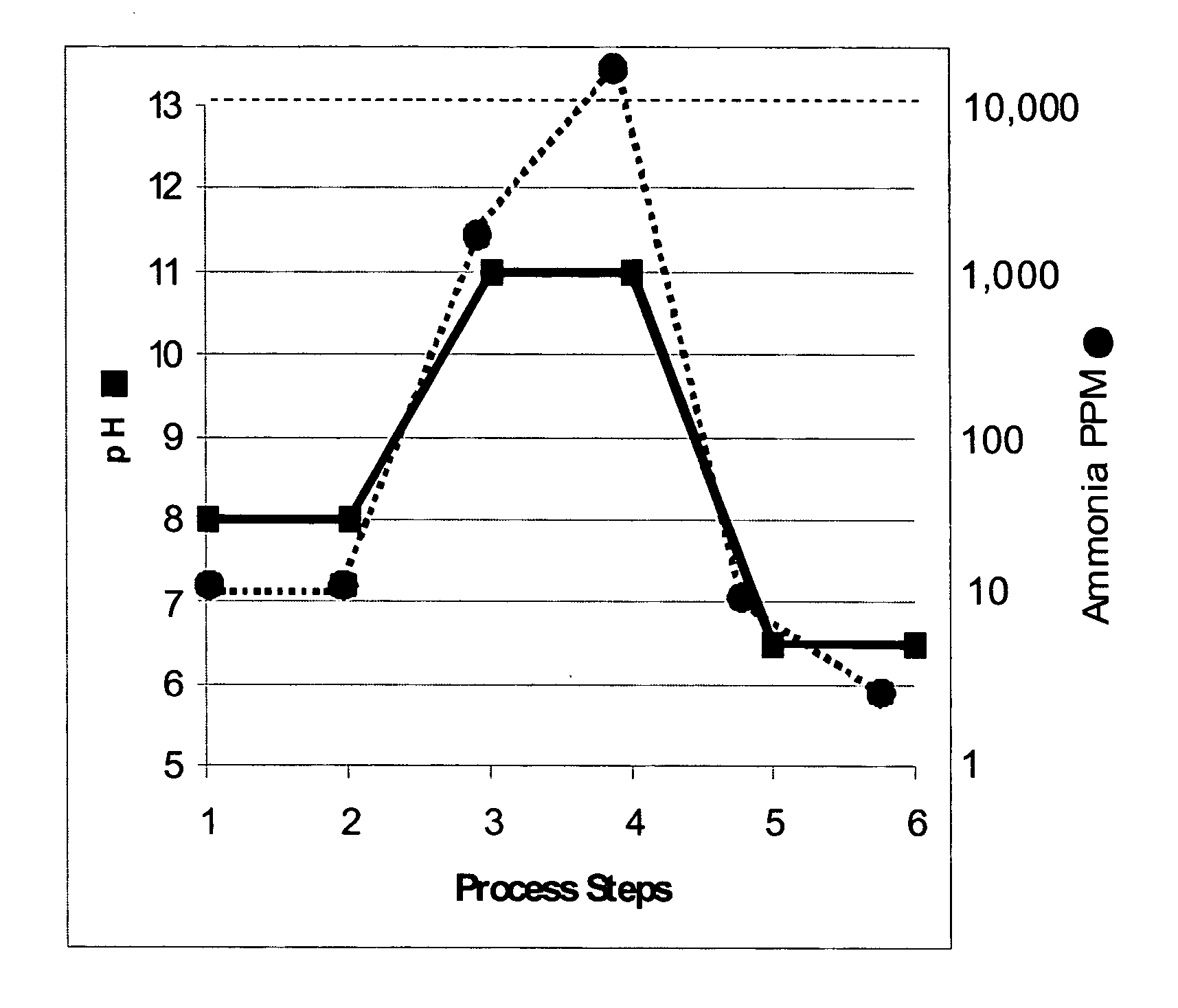

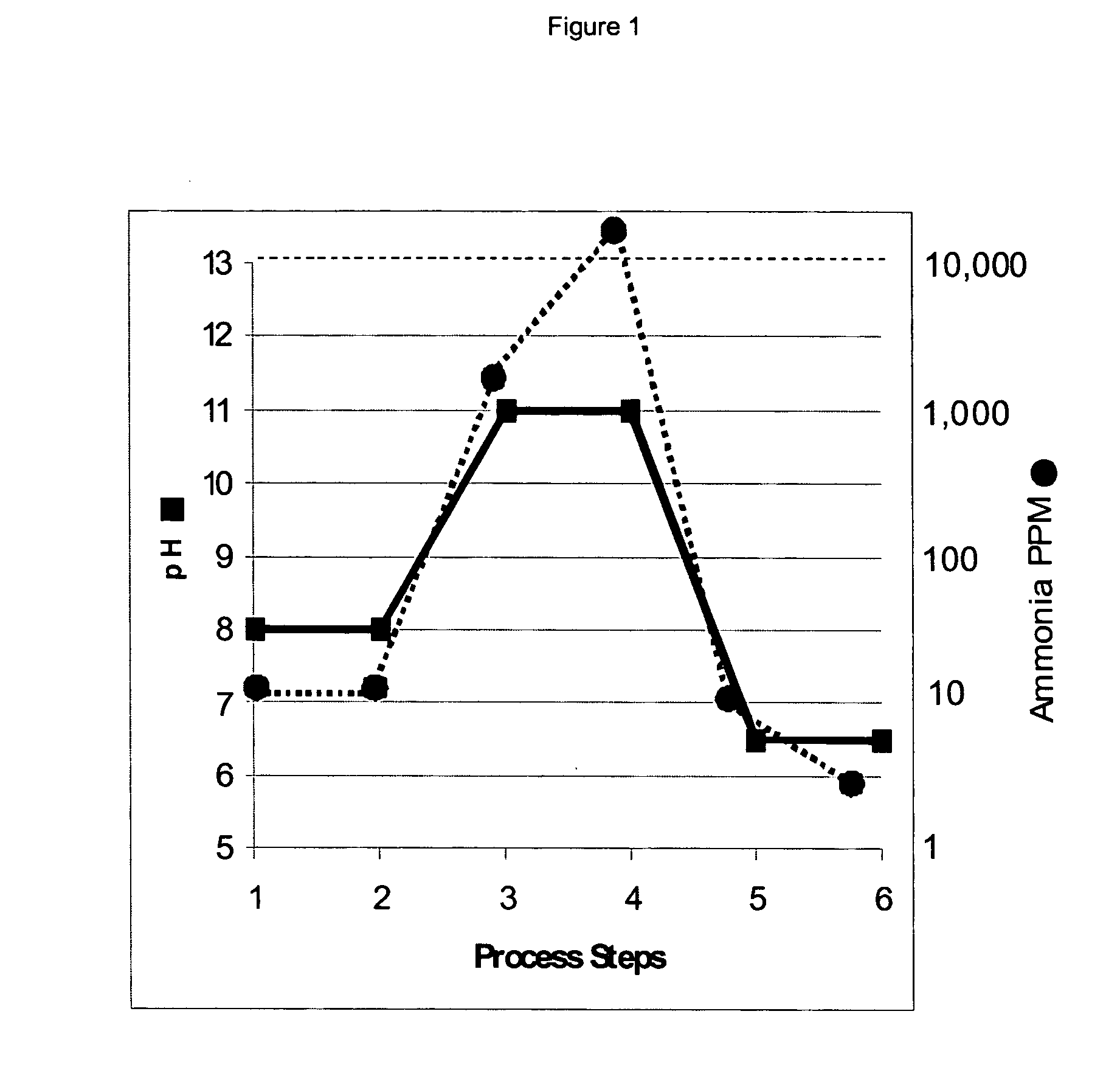

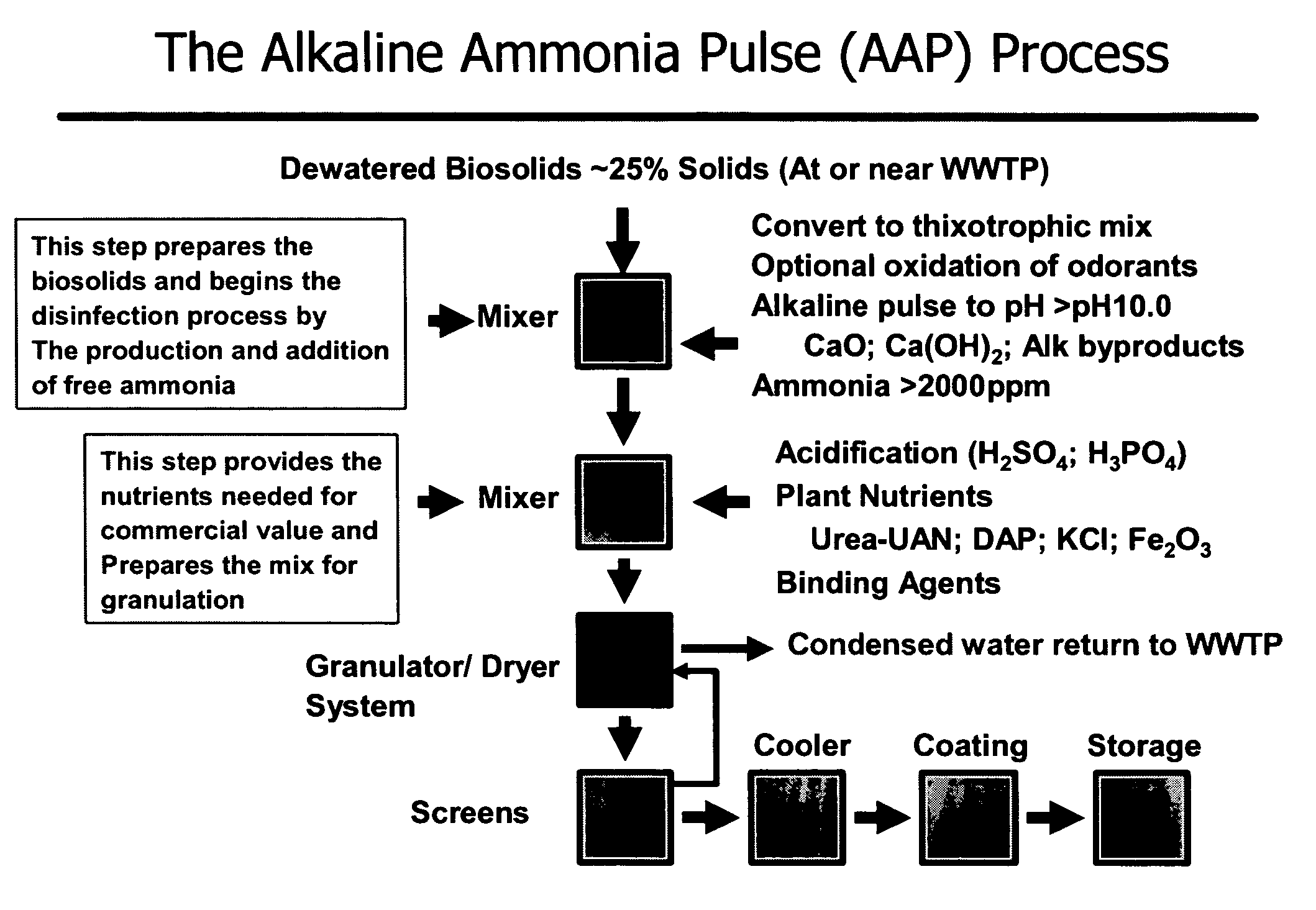

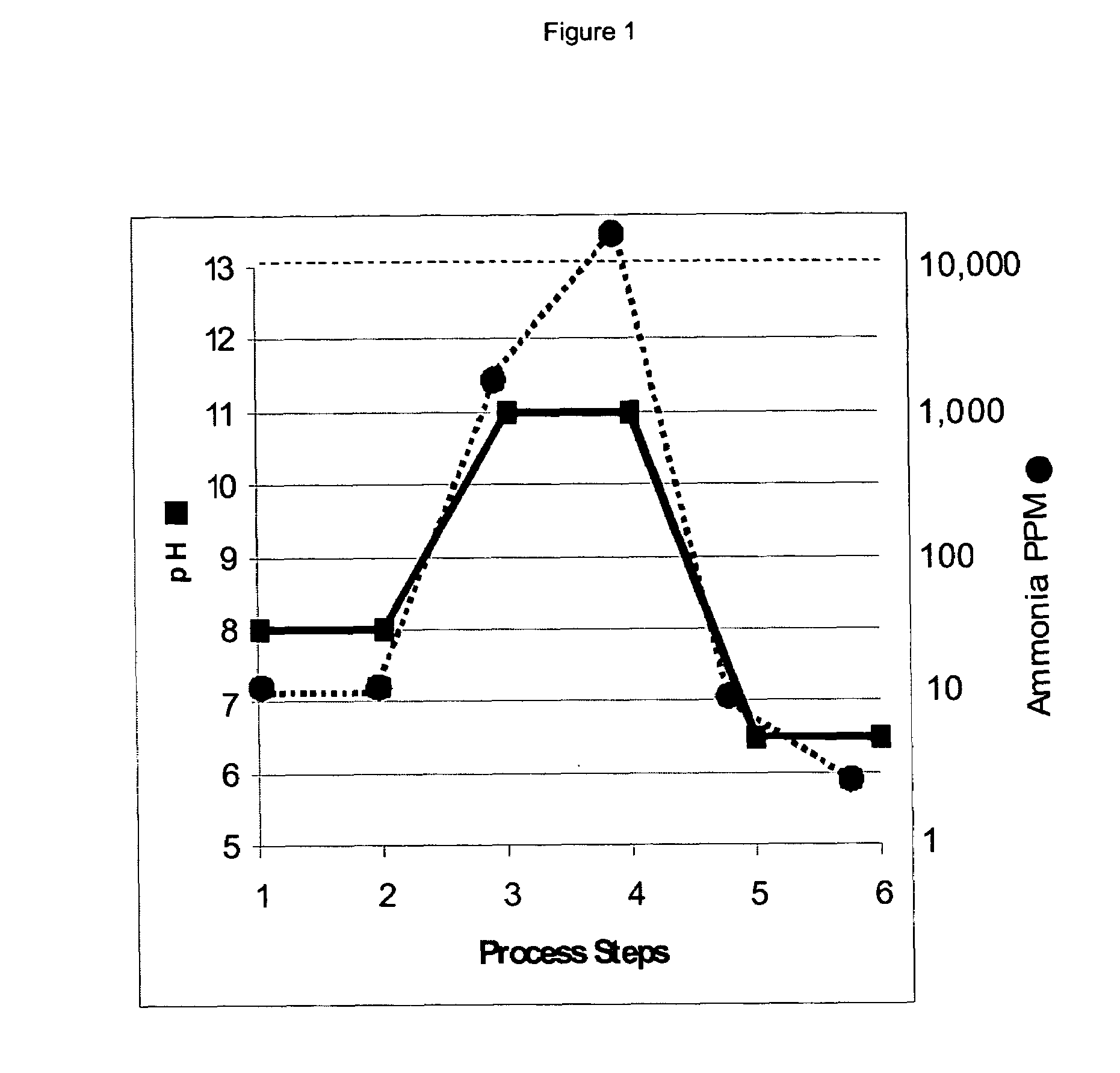

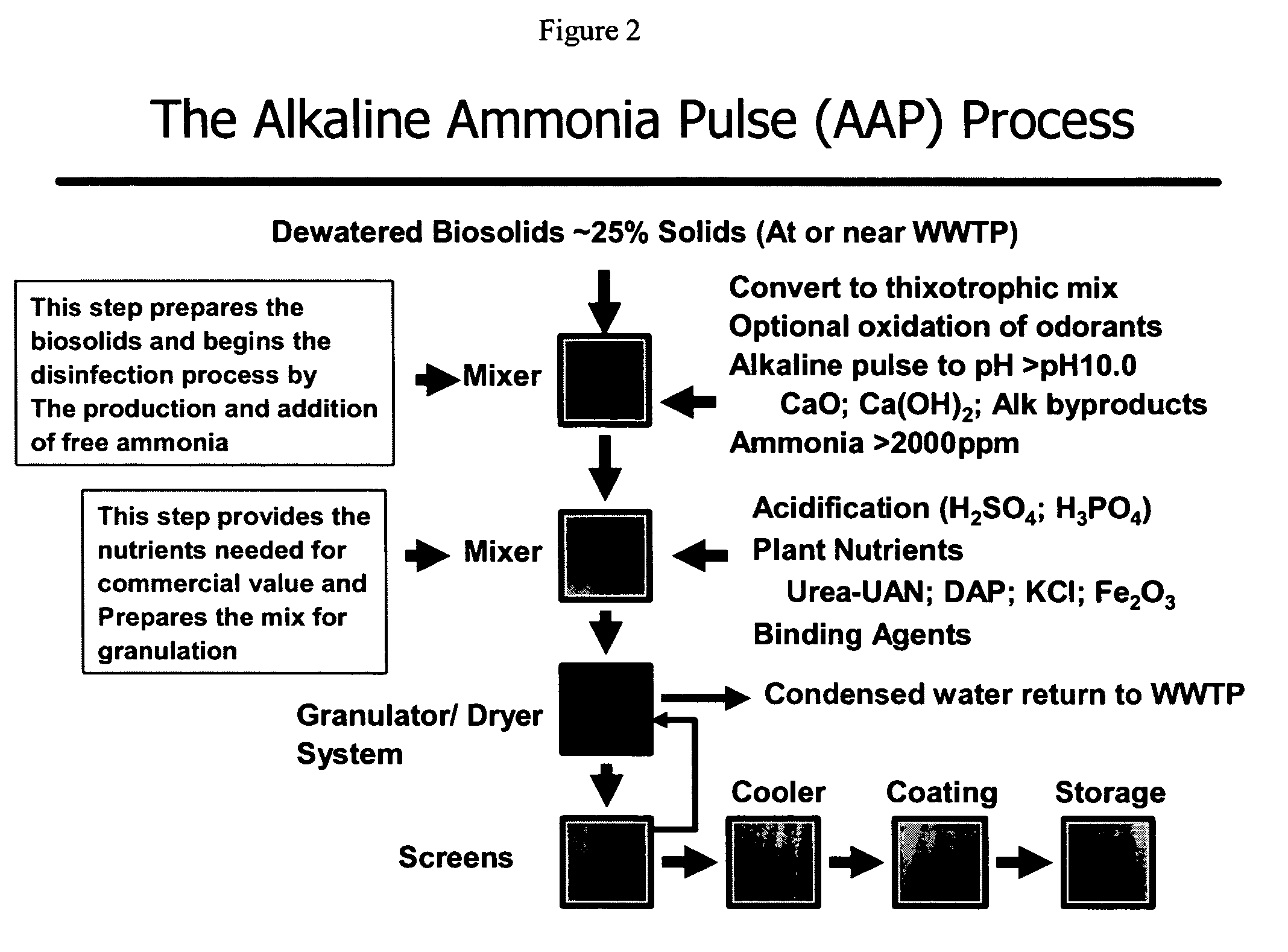

InactiveUS20070062233A1Increases plant nutrient contentReduce odorCalcareous fertilisersBio-organic fraction processingSludgeOrganic manure

This invention is directed to systems, devices and methods for treating organic-containing sludges and converting such sludges to high value fertilizers containing both inorganic and organic fertilizer components, which creates an inorganically-augmented bioorganic fertilizer. The invention describes methods to create a thixotrophic or paste-like material via the application of mixing energy to the organic sludge followed by an alkaline treatment and a subsequent ammoniation. The invention further describes a method to increase the plant nutrient content in the organic containing product to a level which permits the finished granular fertilizer product to compete in the commercial agricultural fertilizer marketplace. Further, the invention reduces odors associated with said organic-containing sludges.

Owner:GENERATE LENDING LLC

Organic-based fertilizer

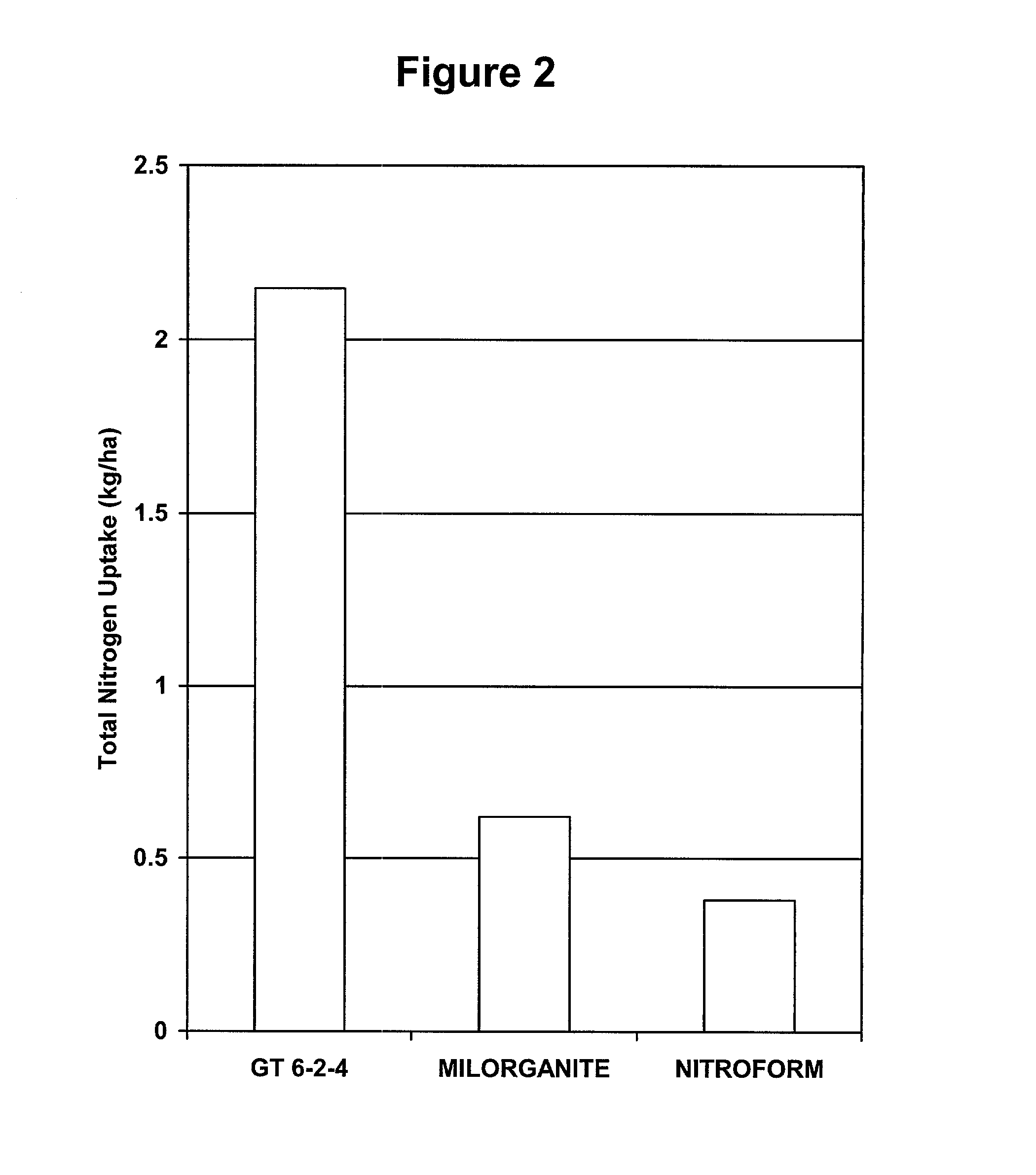

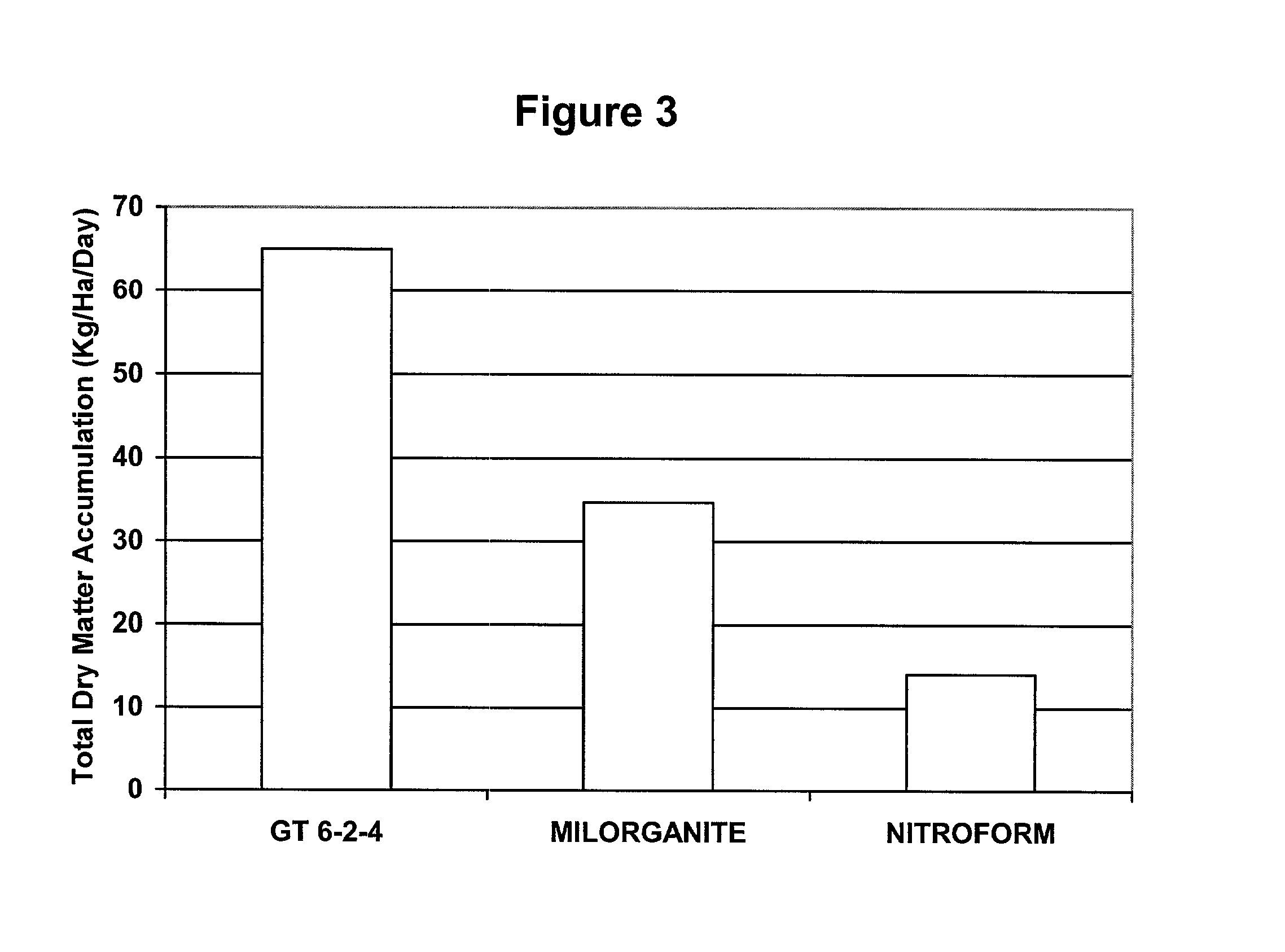

The subject invention provides methods for producing homogenous organic base fertilizer for plant nutrition and soil fertility. Also provided by the subject invention are value added fertilizer products for plant nutrition and soil fertility and concentrated liquid formulations / nutrient supplements that provide the value added nutrients to fertilizer products. Methods according to the invention involve the application of concentrated liquid(s) and / or dry formulation(s) comprising a mixture of one or more plant nutrient(s), one or more additional organic compound(s), one or more penetrate(s), and one or more optional supplement(s) into one or more organic base material(s). These organic base materials include, and are not limited to, biosolids, activated sludge, municipal compost, animal manures (e.g., horse, cow, chicken, pig, and sheep), and composted organic byproducts.

Owner:GREEN TECH LLC

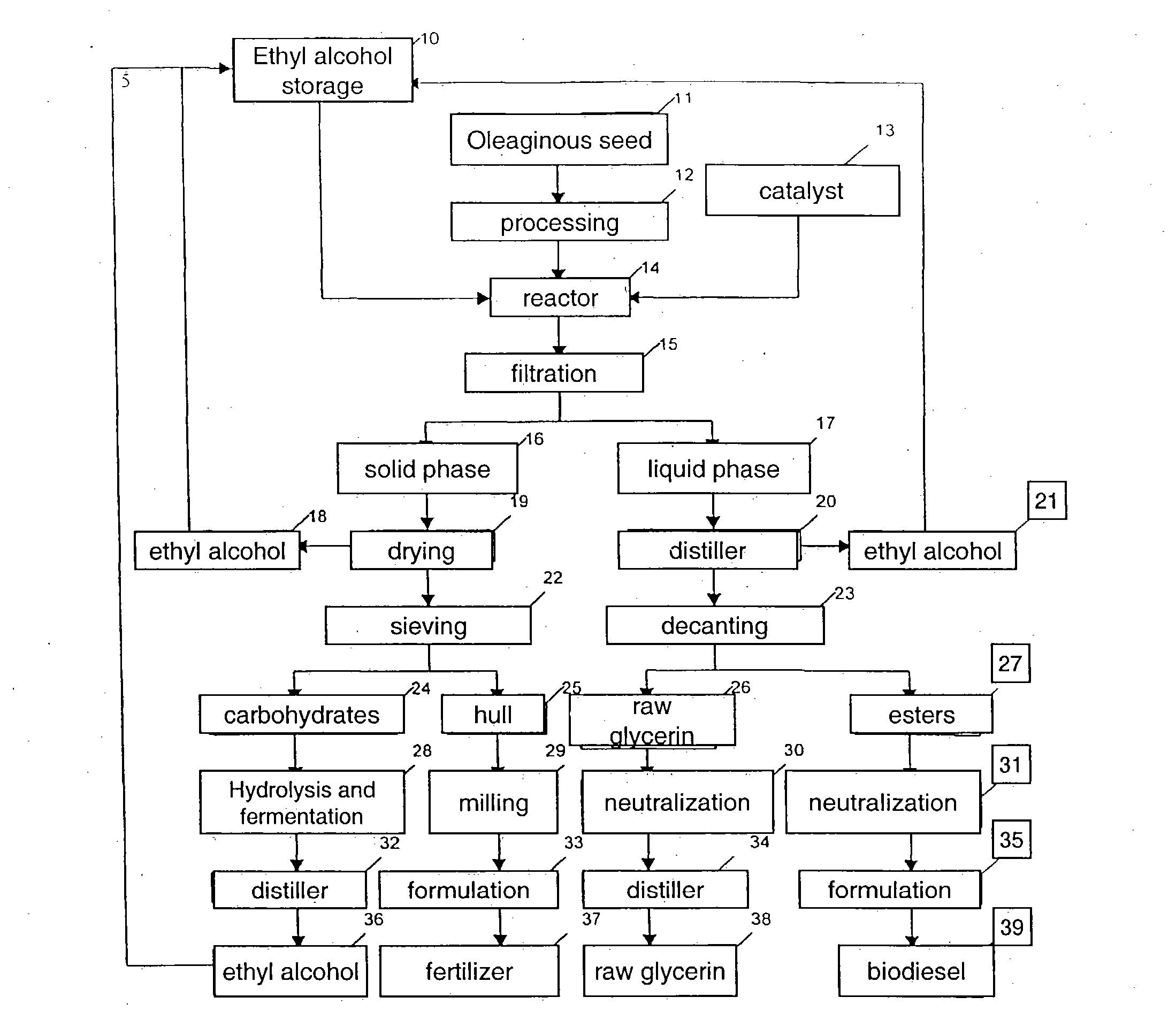

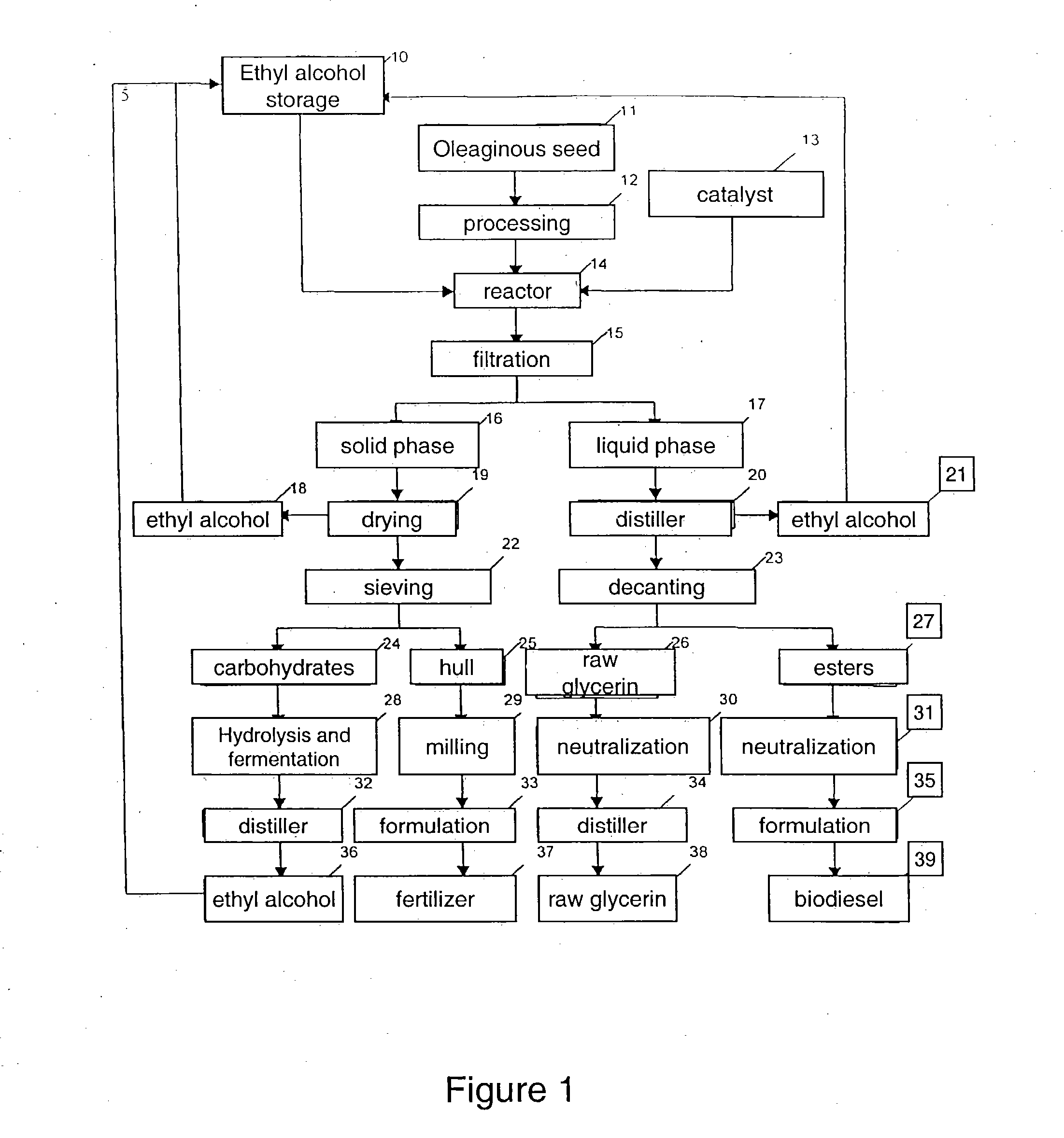

Process for producing biodiesel

InactiveUS20050011112A1Fatty oils/acids recovery from wasteFatty acid esterificationBiodieselSolid fraction

An integrated process is described for producing biodiesel from oleaginous seeds, preferably castor bean seeds, comprising a transesterification reaction where the seeds themselves react with anhydrous ethyl alcohol in the presence of an alkaline catalyst. The resulting ethyl esters are then separated by decantation and neutralized and used as fuel for diesel engines, co-solvents for diesel and gasoline mixtures with anhydrous or hydrated ethyl alcohol. The solid fractions may be used as fertilizers, for feeding cattle and as a raw material for producing ethyl alcohol.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

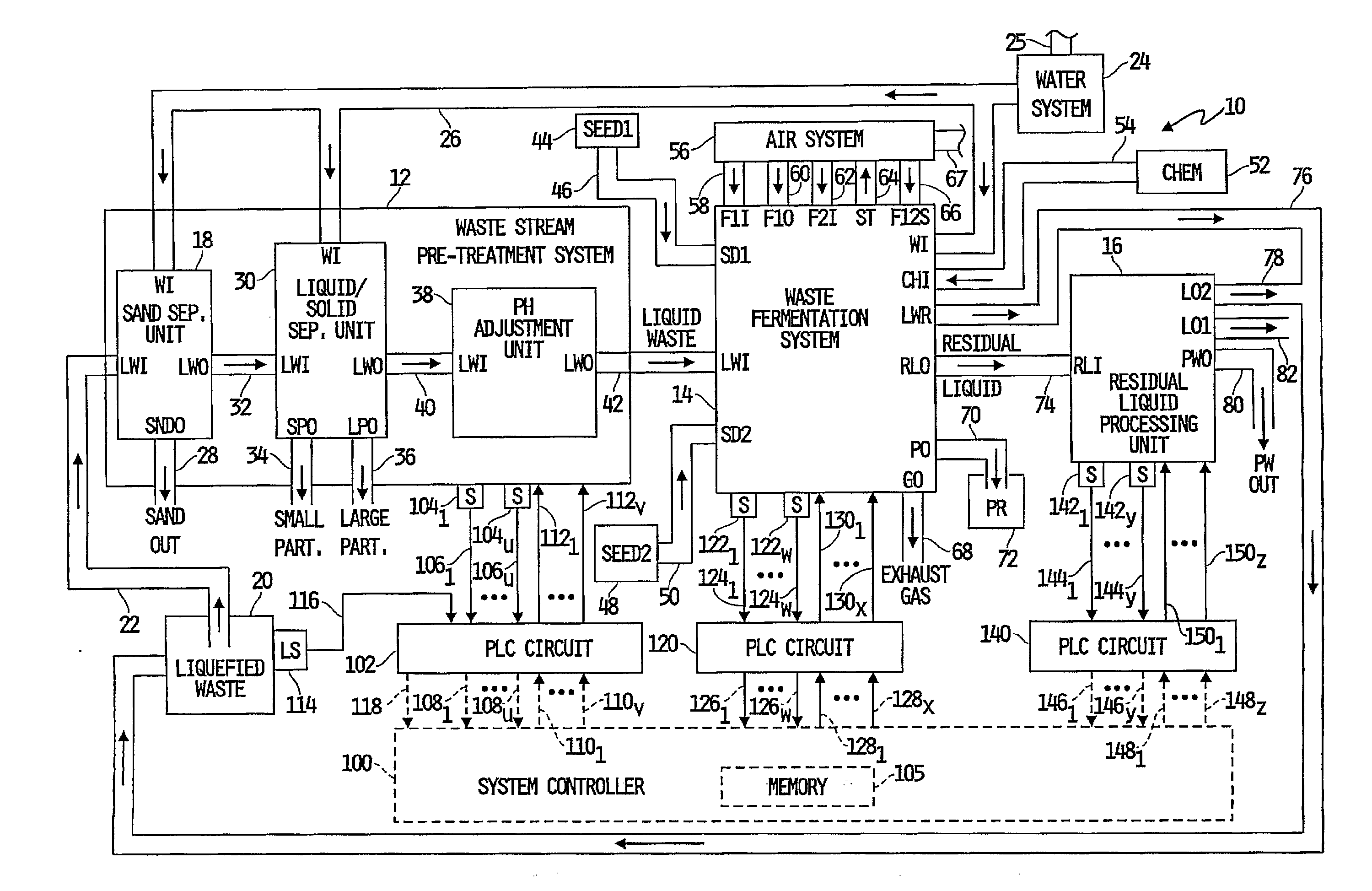

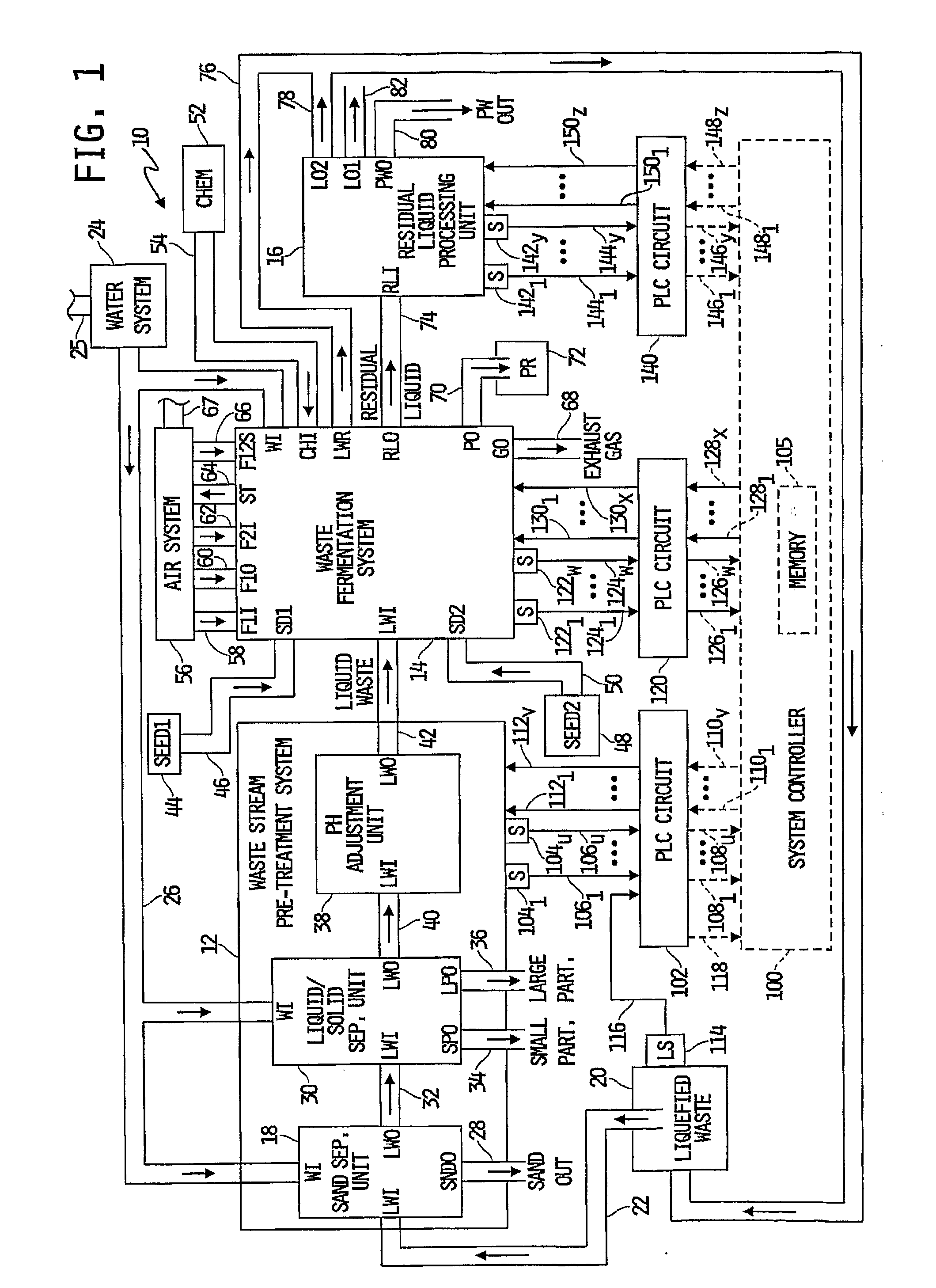

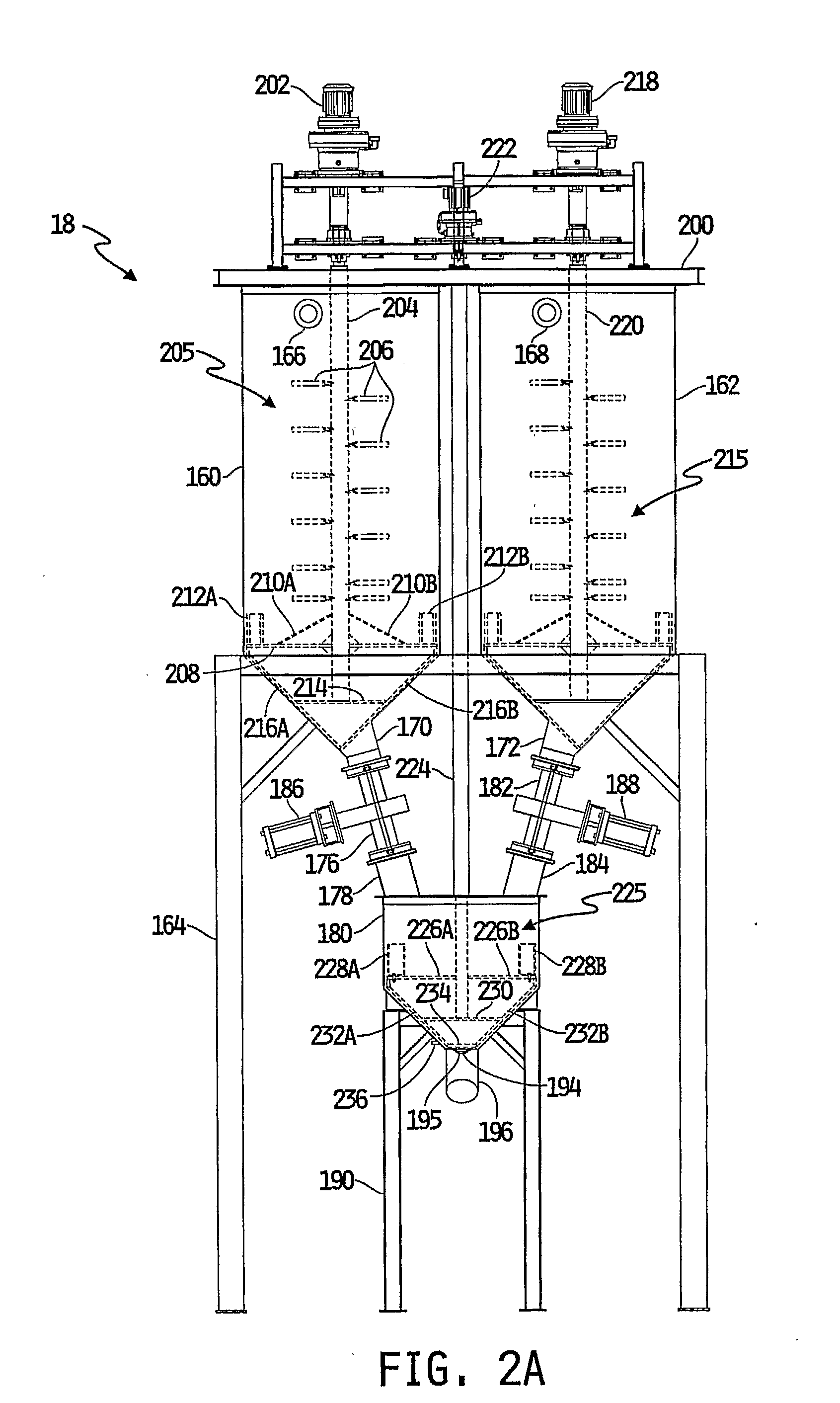

System for the treating biomaterial waste streams

InactiveUS20070175825A1Animal corpse fertilisersExcrement fertilisersWaste streamEnvironmental engineering

A process for treating a biomaterial waste stream is described. The process may form part of a waste fermentation system. The treating process can degrade at least a portion of the biomaterial waste stream into other components or materials. These other components or materials may be reintroduced into a fermentation process as a nutrient for a fermenting organism.

Owner:BIOMASS PROCESSING TECH

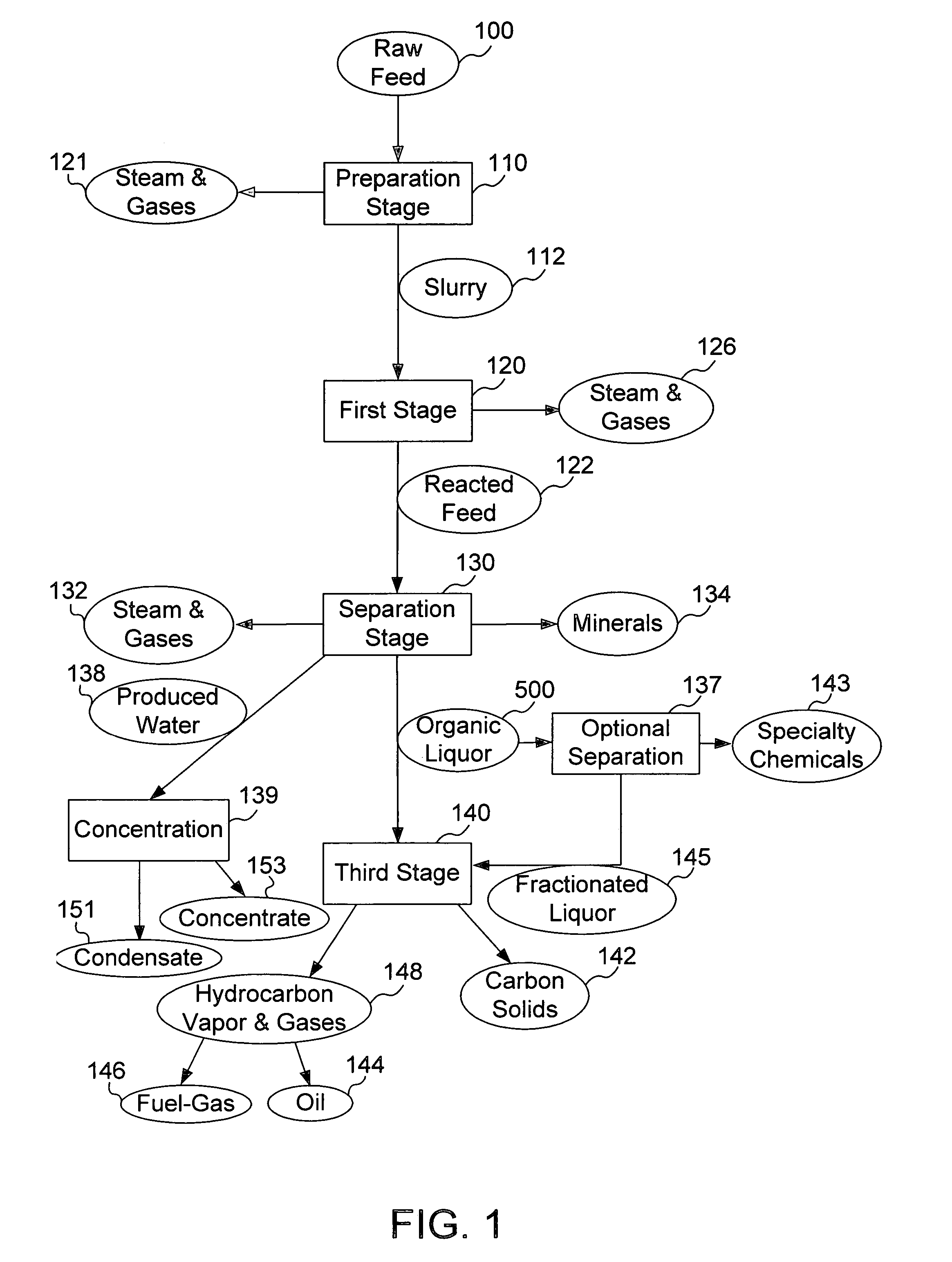

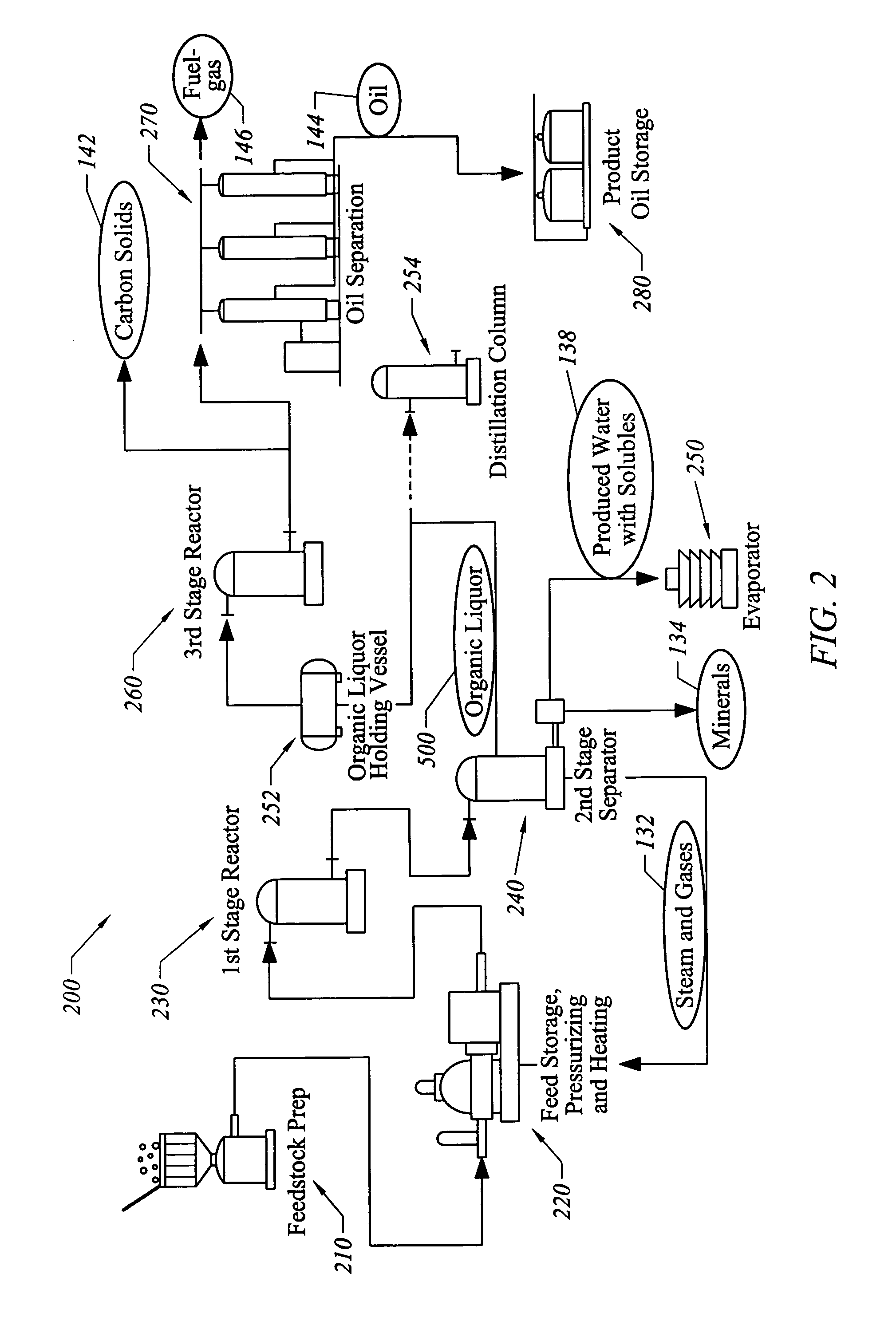

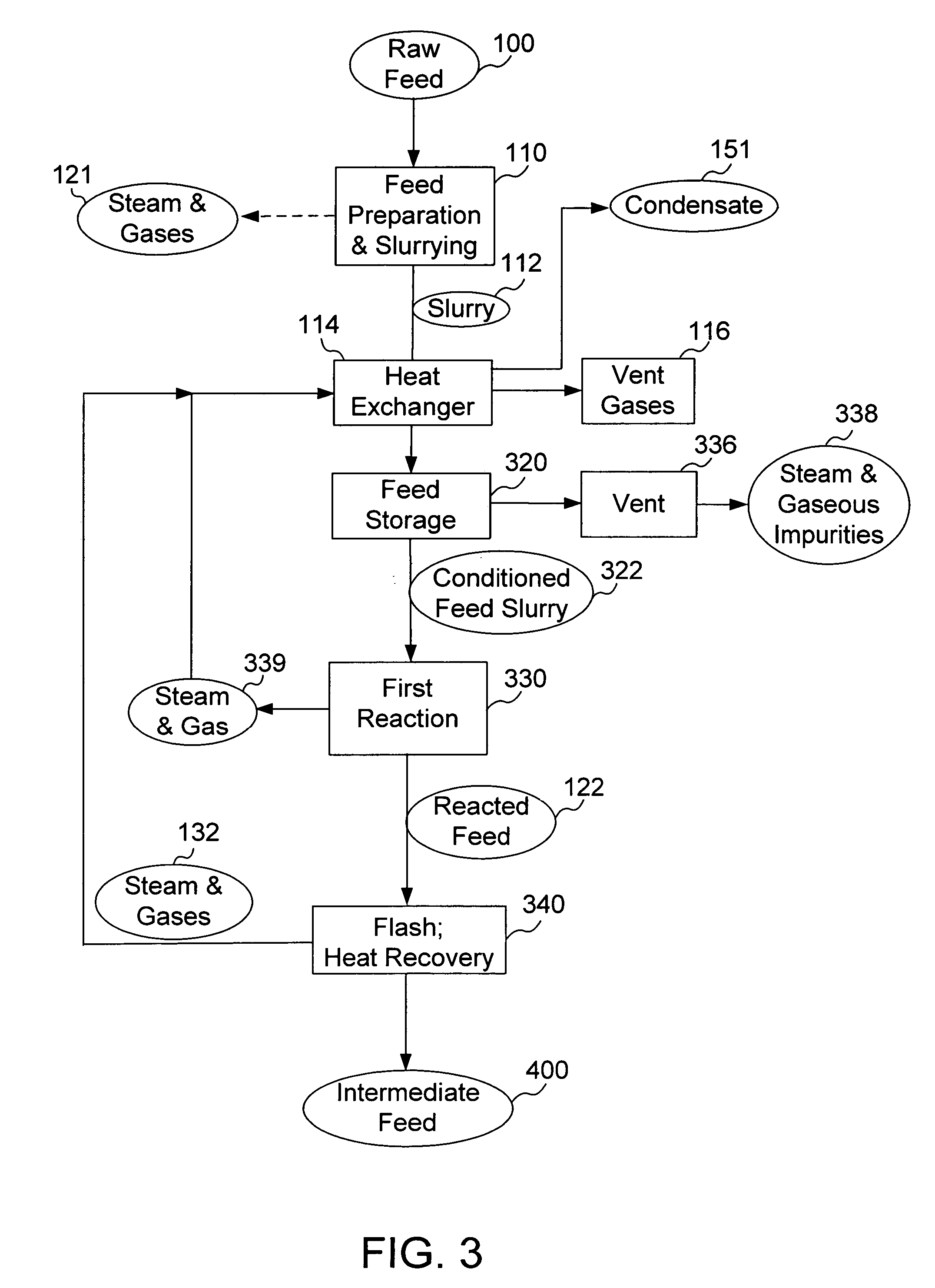

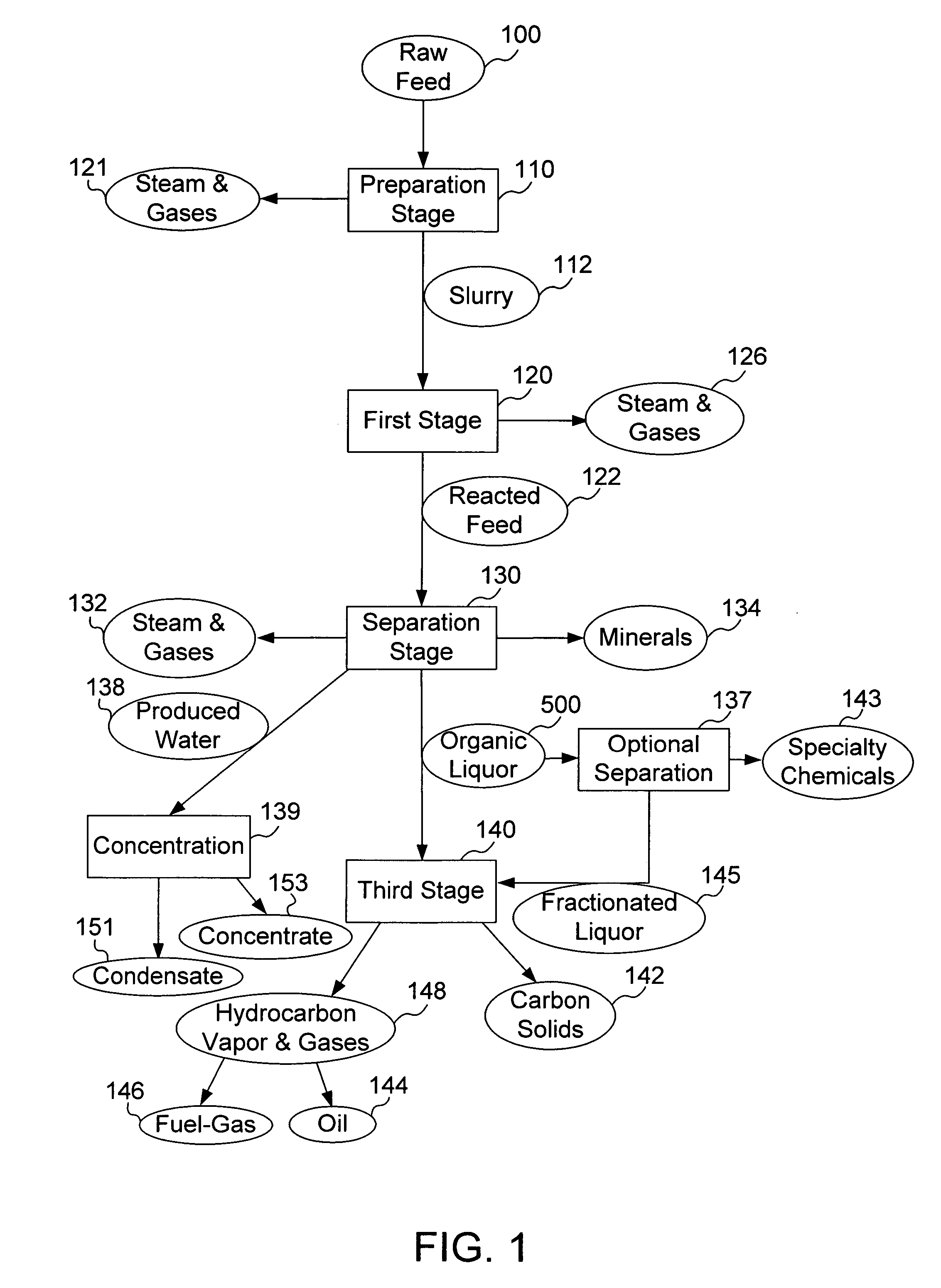

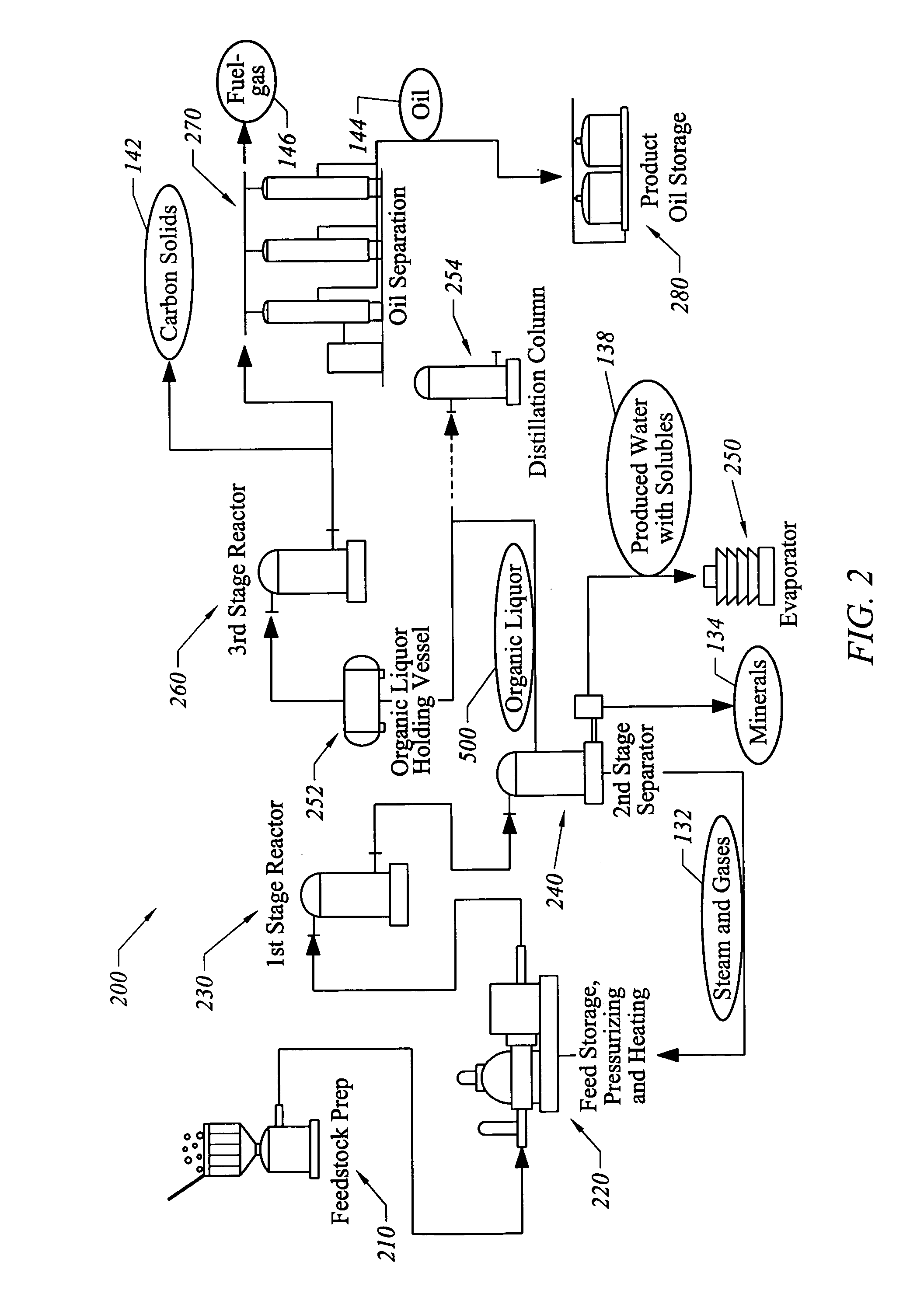

Apparatus and process for converting a mixture of organic materials into hydrocarbons and carbon solids

ActiveUS7476296B2Low viscosityInhibition formationAnimal corpse fertilisersMultiple-effect/fractional condensationSpeciality chemicalsHigh energy

Owner:SYNPET TEKNOLOJI GELISTIRME

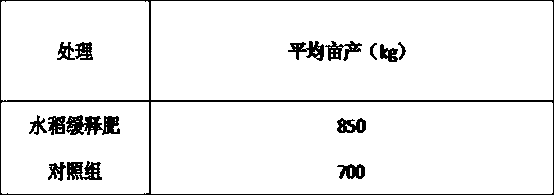

Rice slow-release fertilizer and preparation method thereof

InactiveCN107673927APhysiological characteristics are diverseWidely distributedCalcareous fertilisersMagnesium fertilisersCelluloseTrace element

The invention discloses a rice slow-release fertilizer and a preparation method thereof. The rice slow-release fertilizer comprises the following raw material components by weight: 25-40 parts of compound bacteria, 500-600 parts of an organic material, 800-1200 parts of an inorganic material, 100-150 parts of a fertilizer core, 20-30 parts of trace elements, 120-150 parts of additives, 70-80 partsof cellulose and 2500-3500 parts of a solvent.

Owner:INST OF SOIL FERTILIZER & ENVIRONMENT RESOURCE HEILONGJIANG ACADEMY OF AGRI SCI

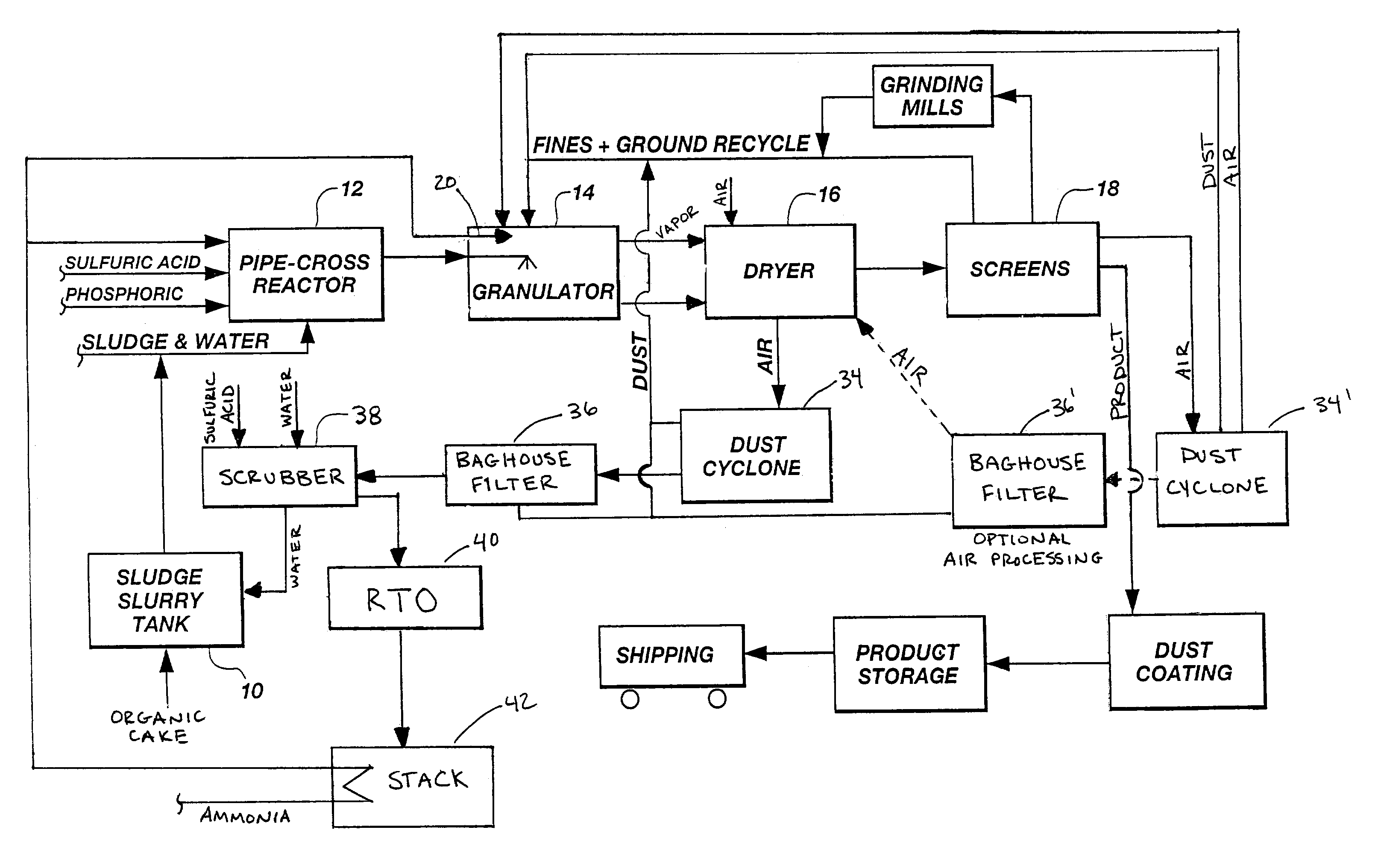

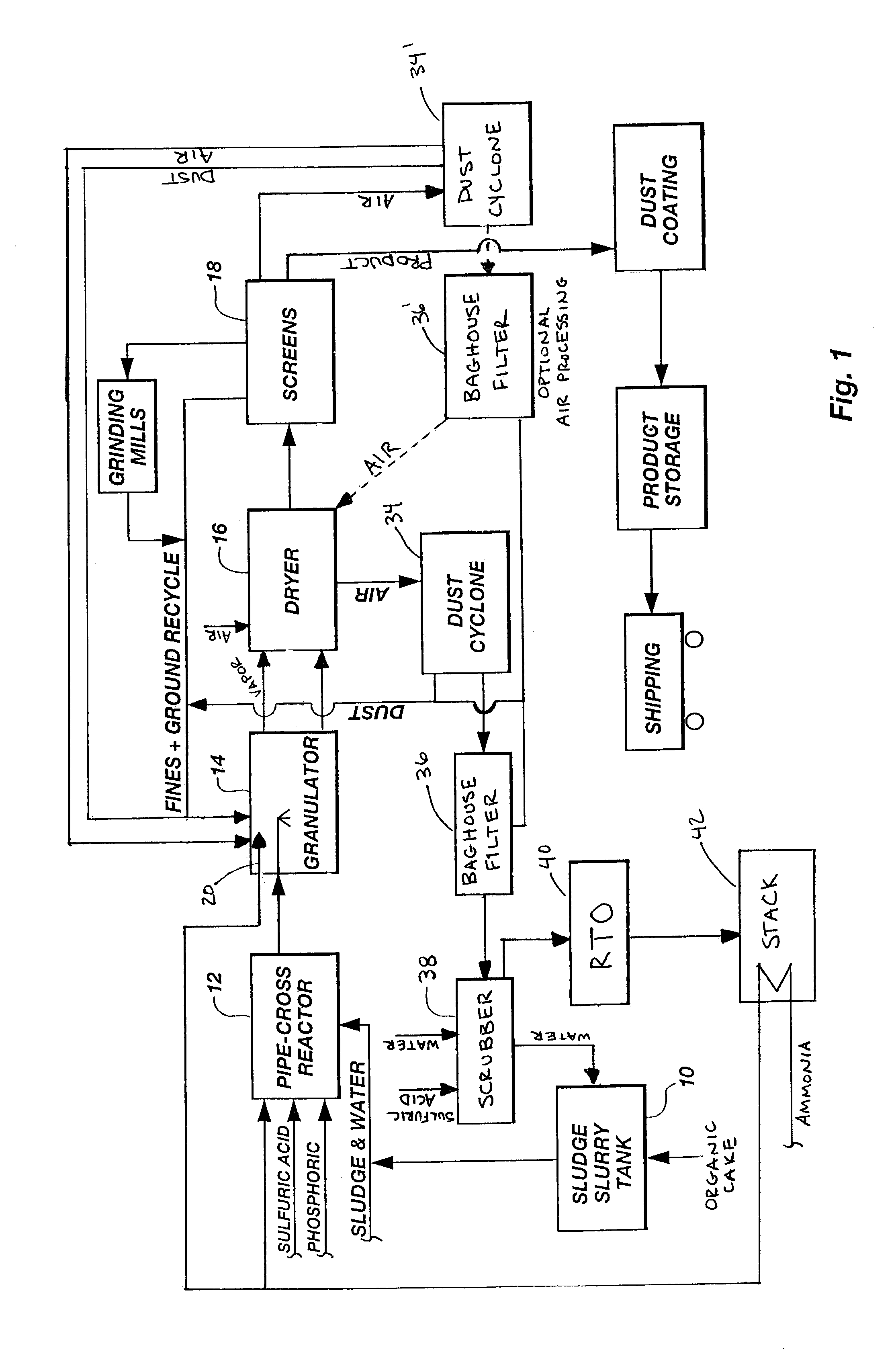

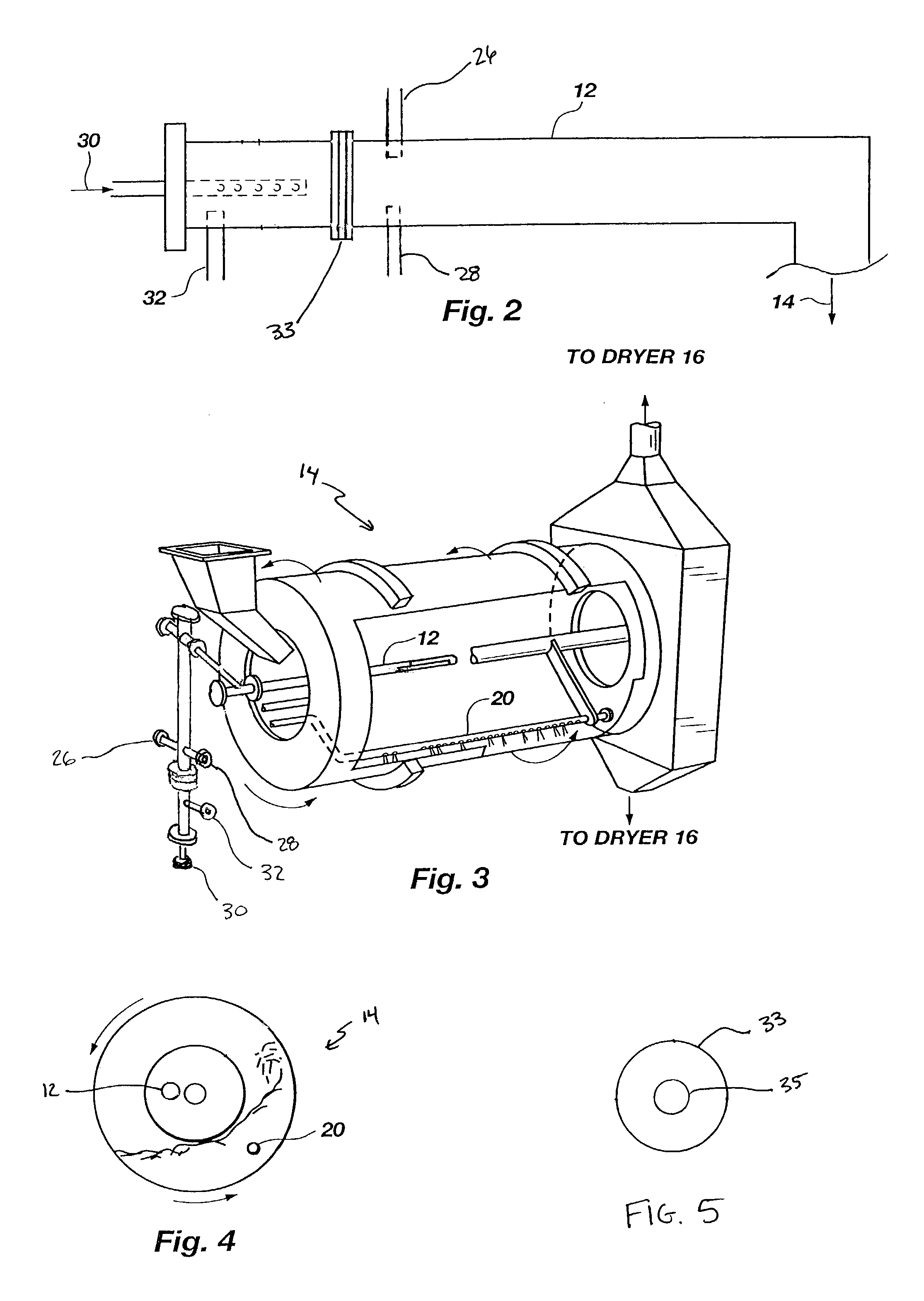

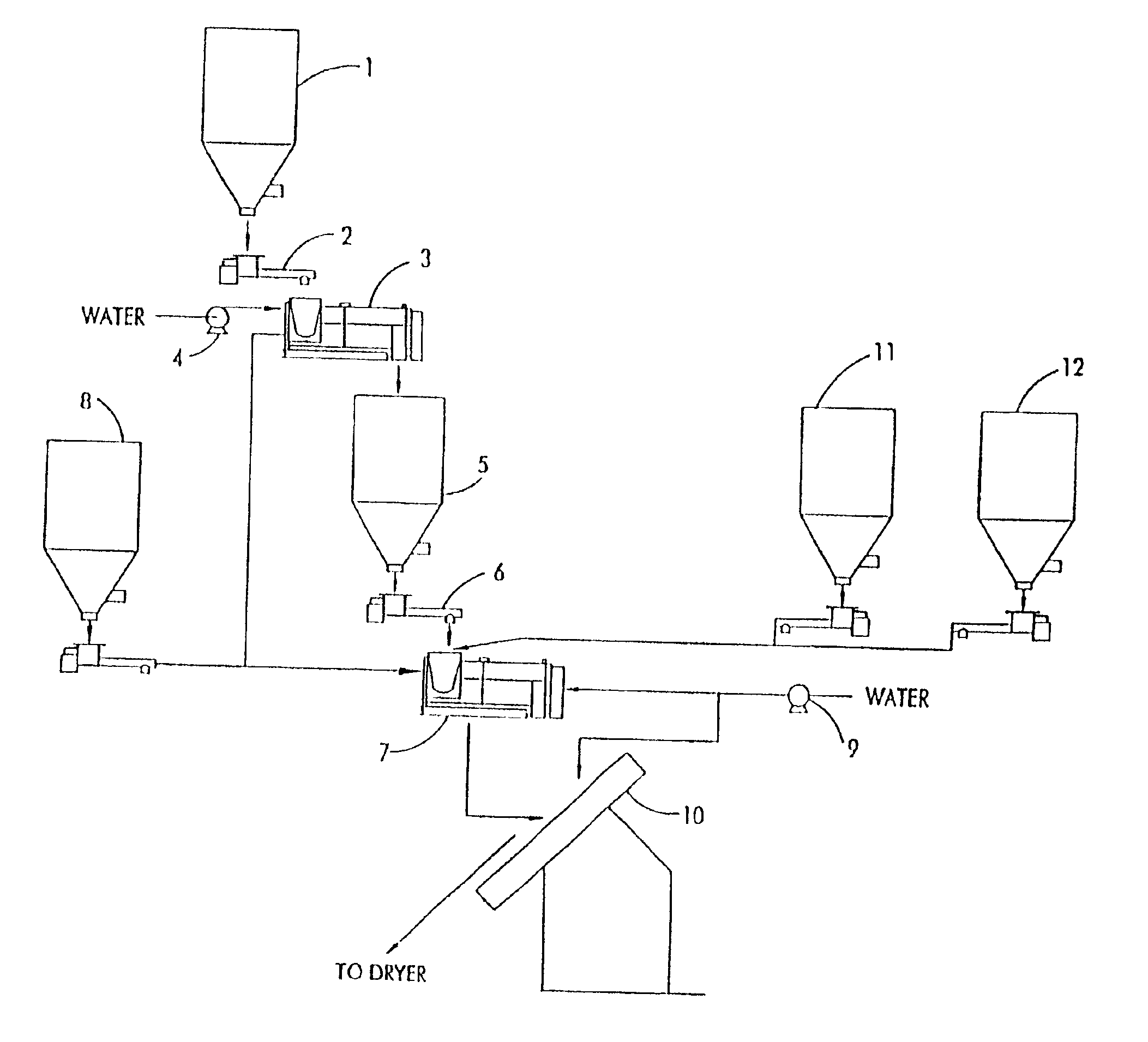

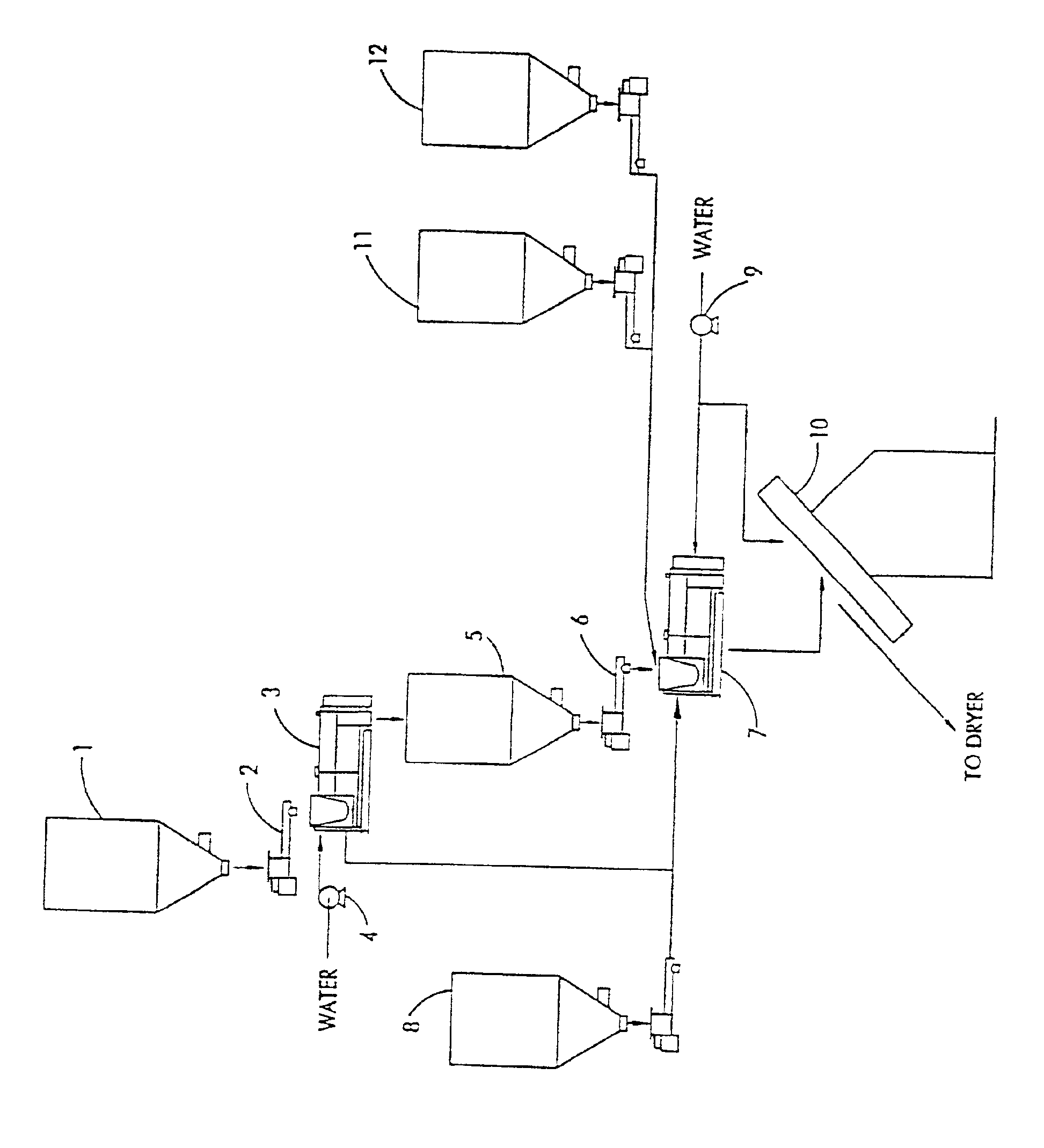

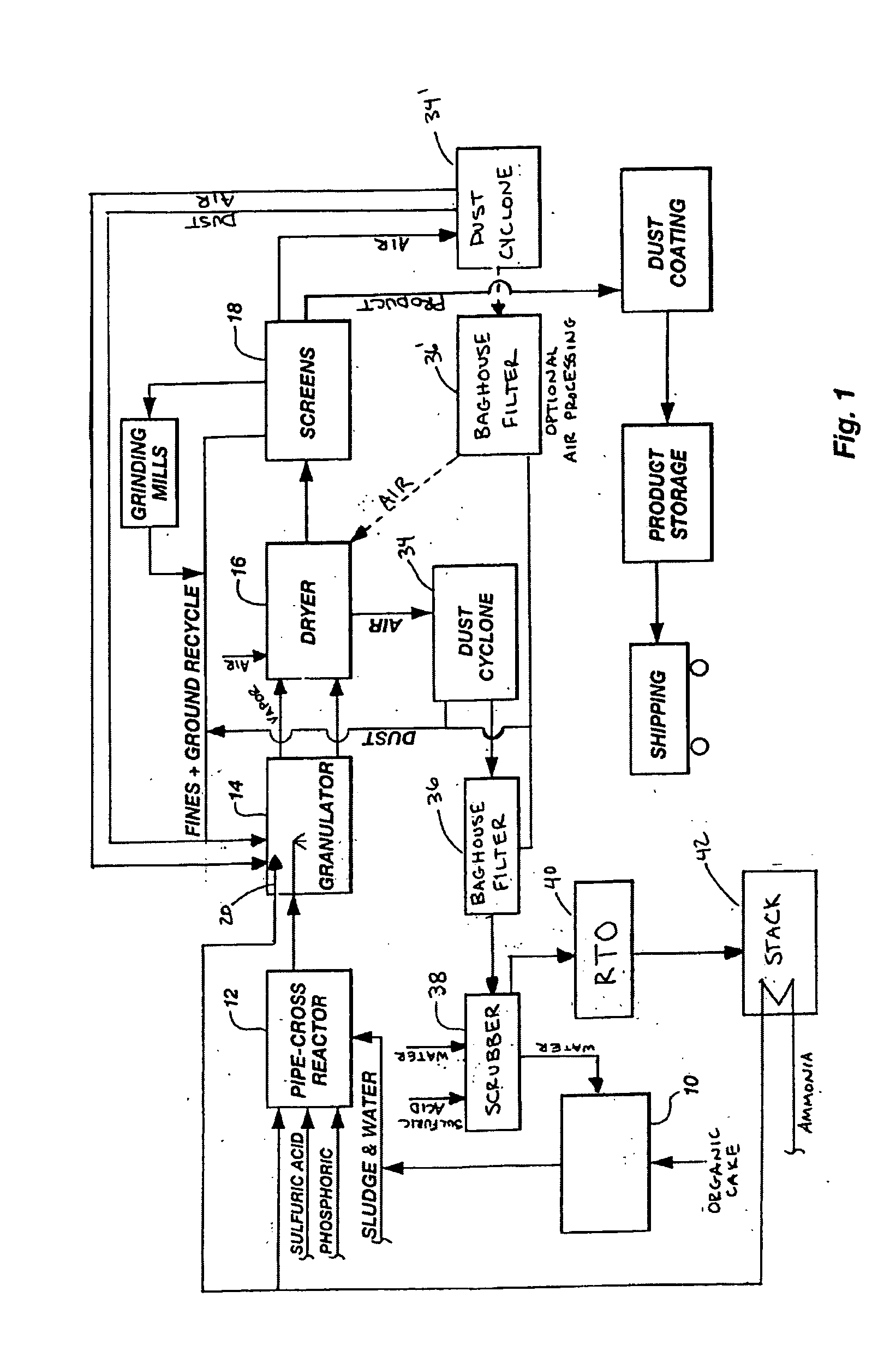

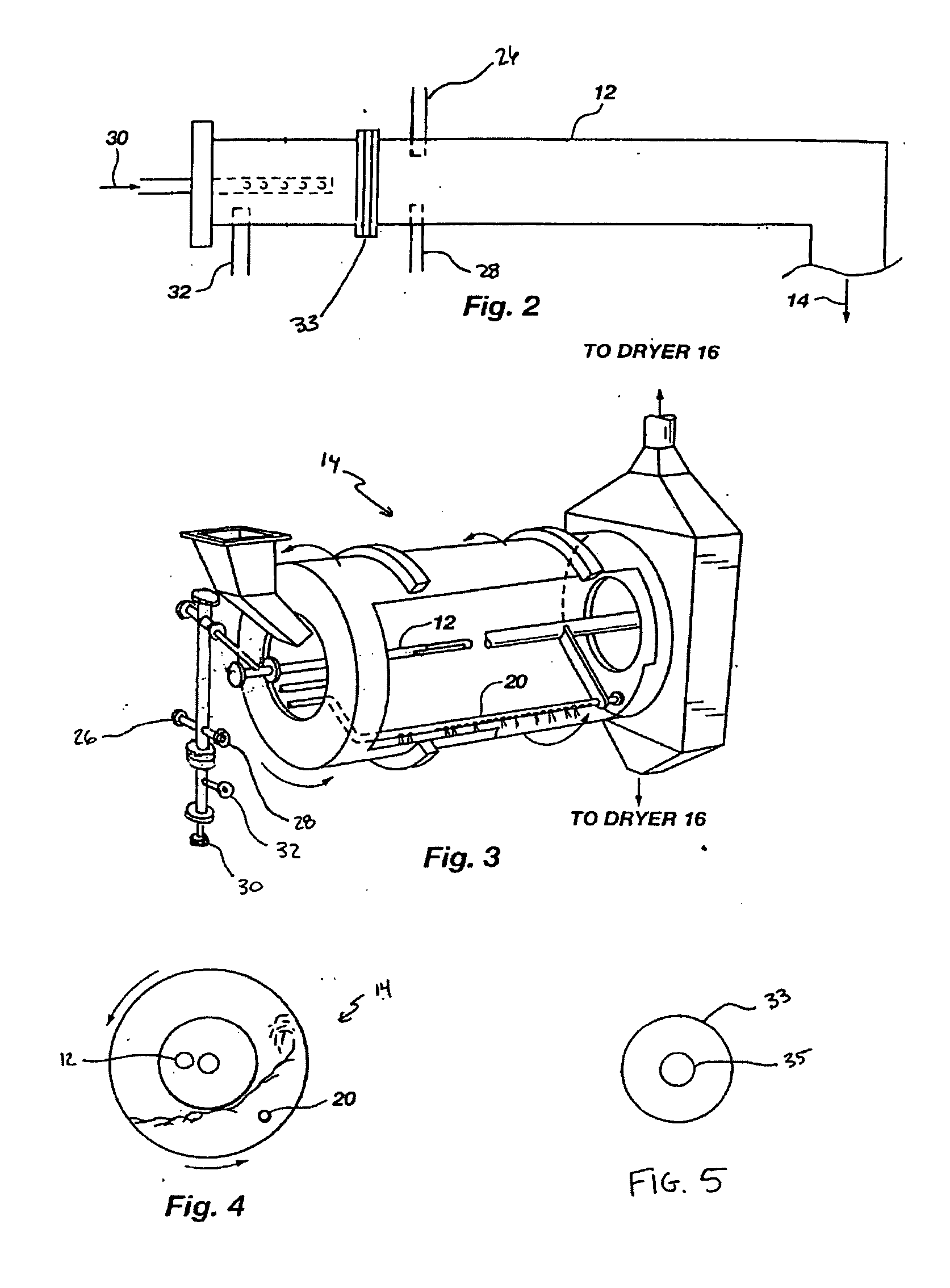

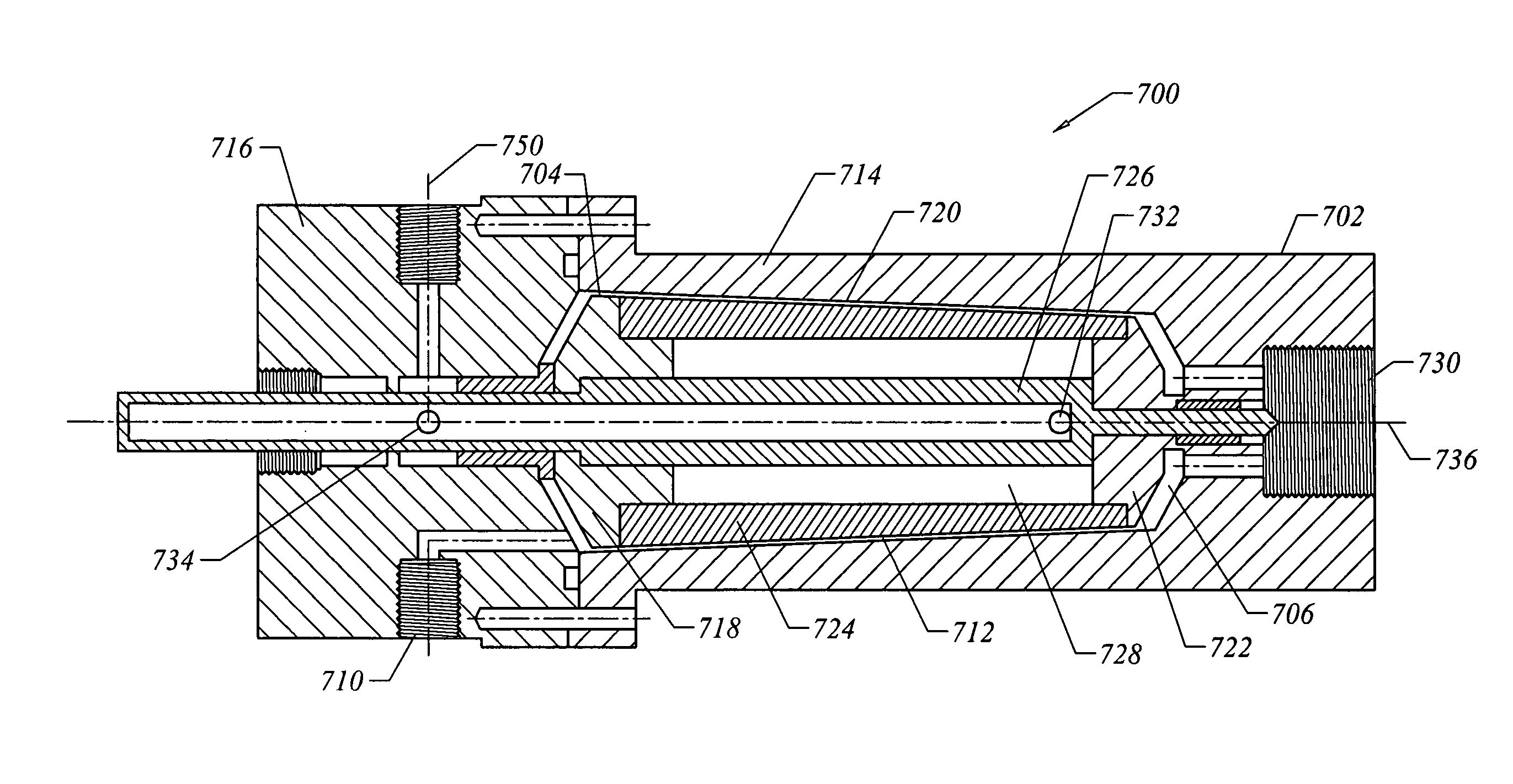

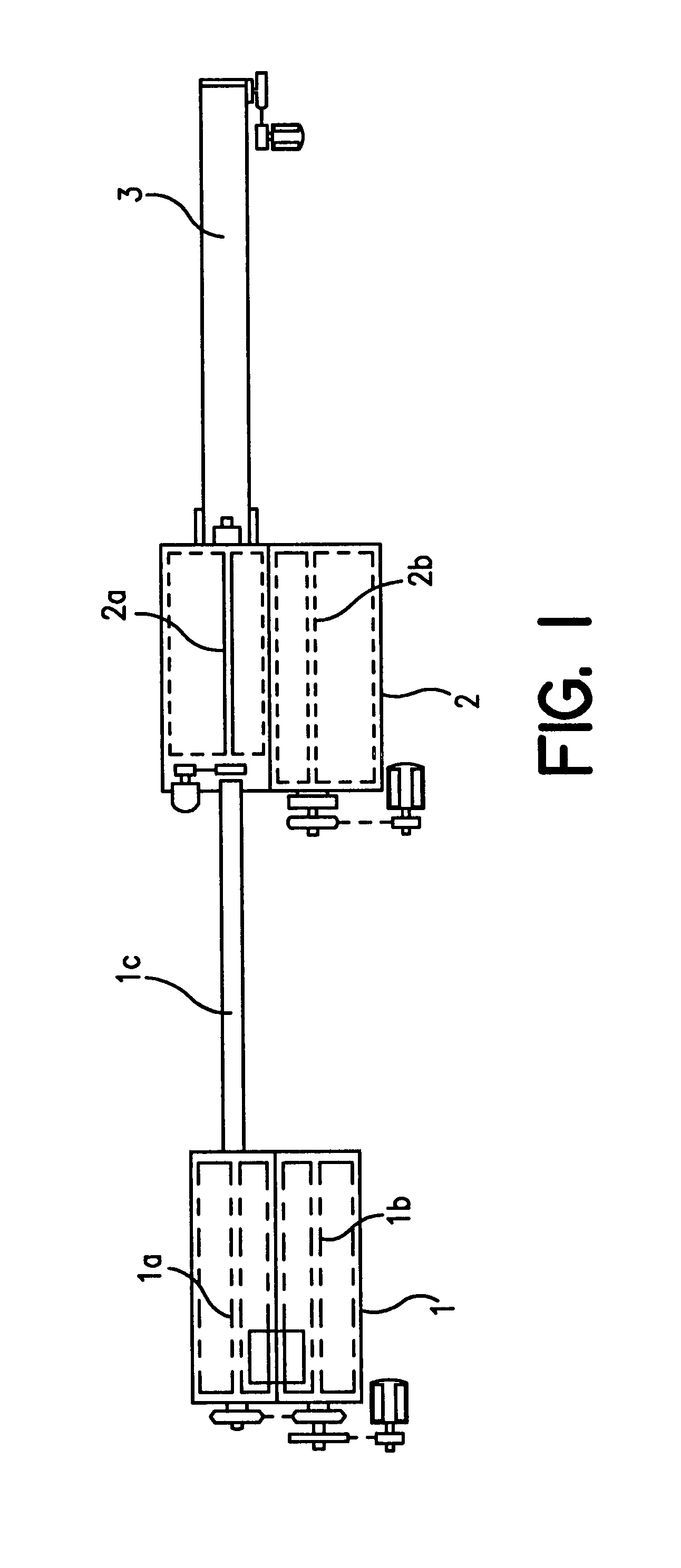

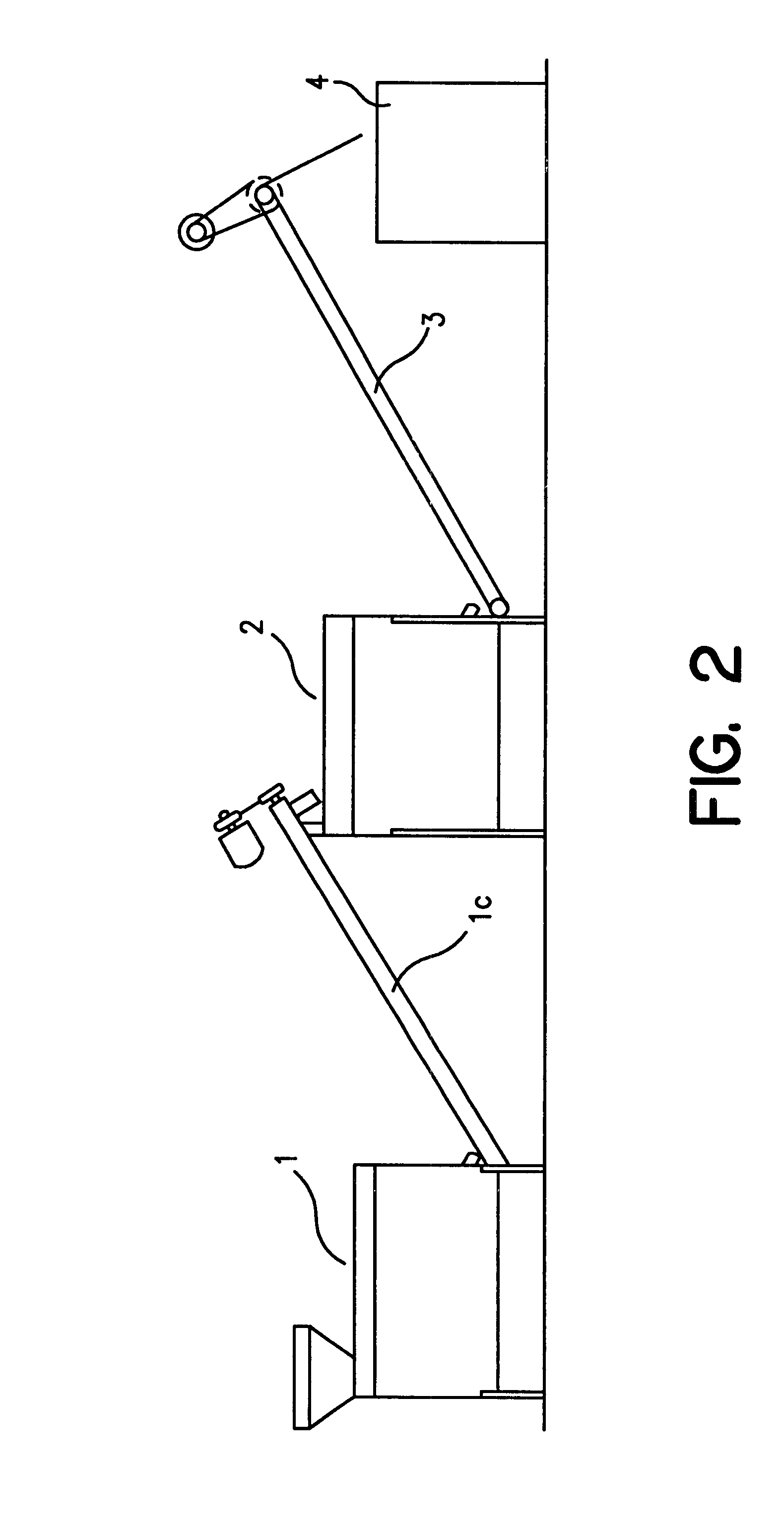

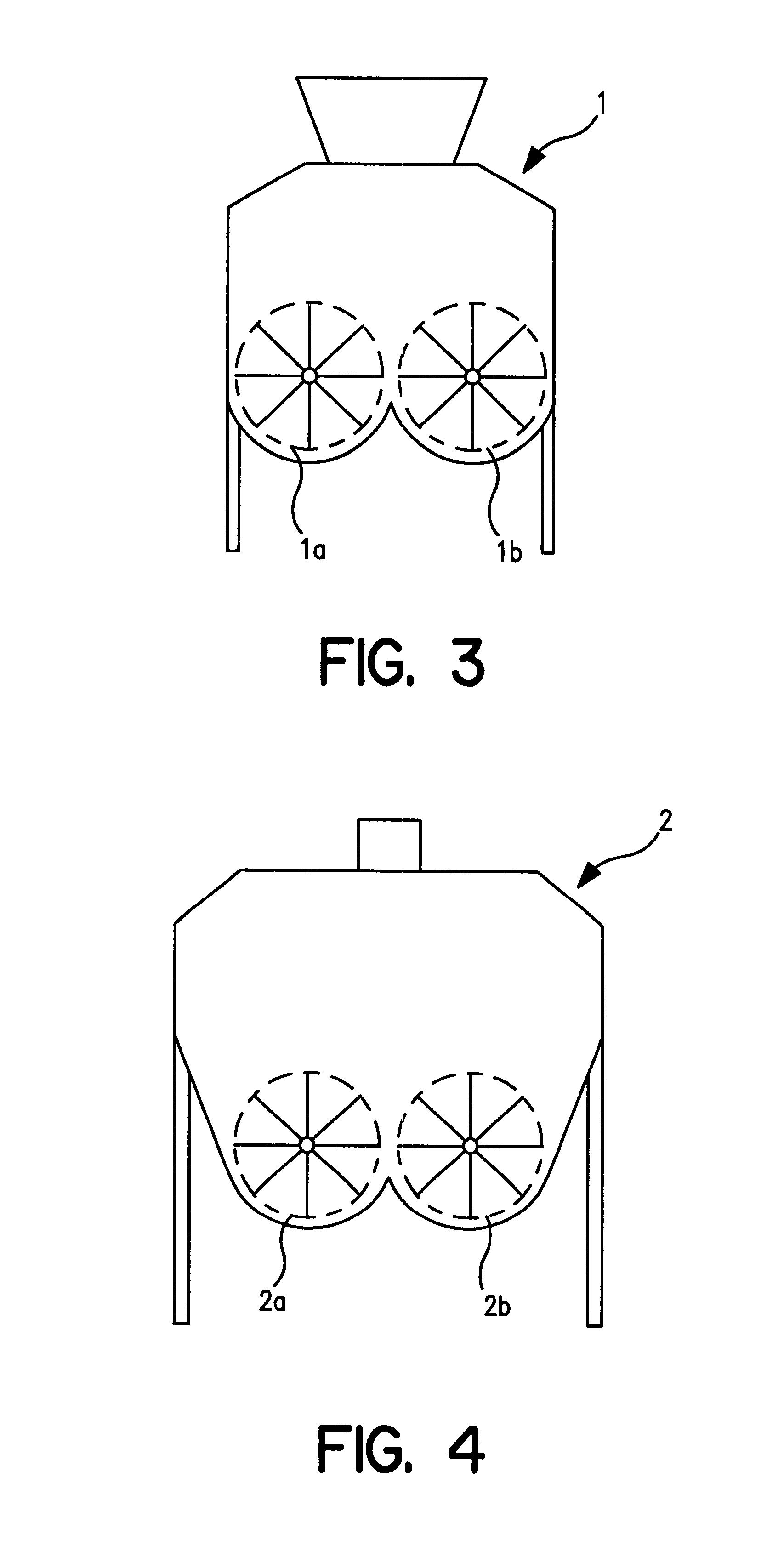

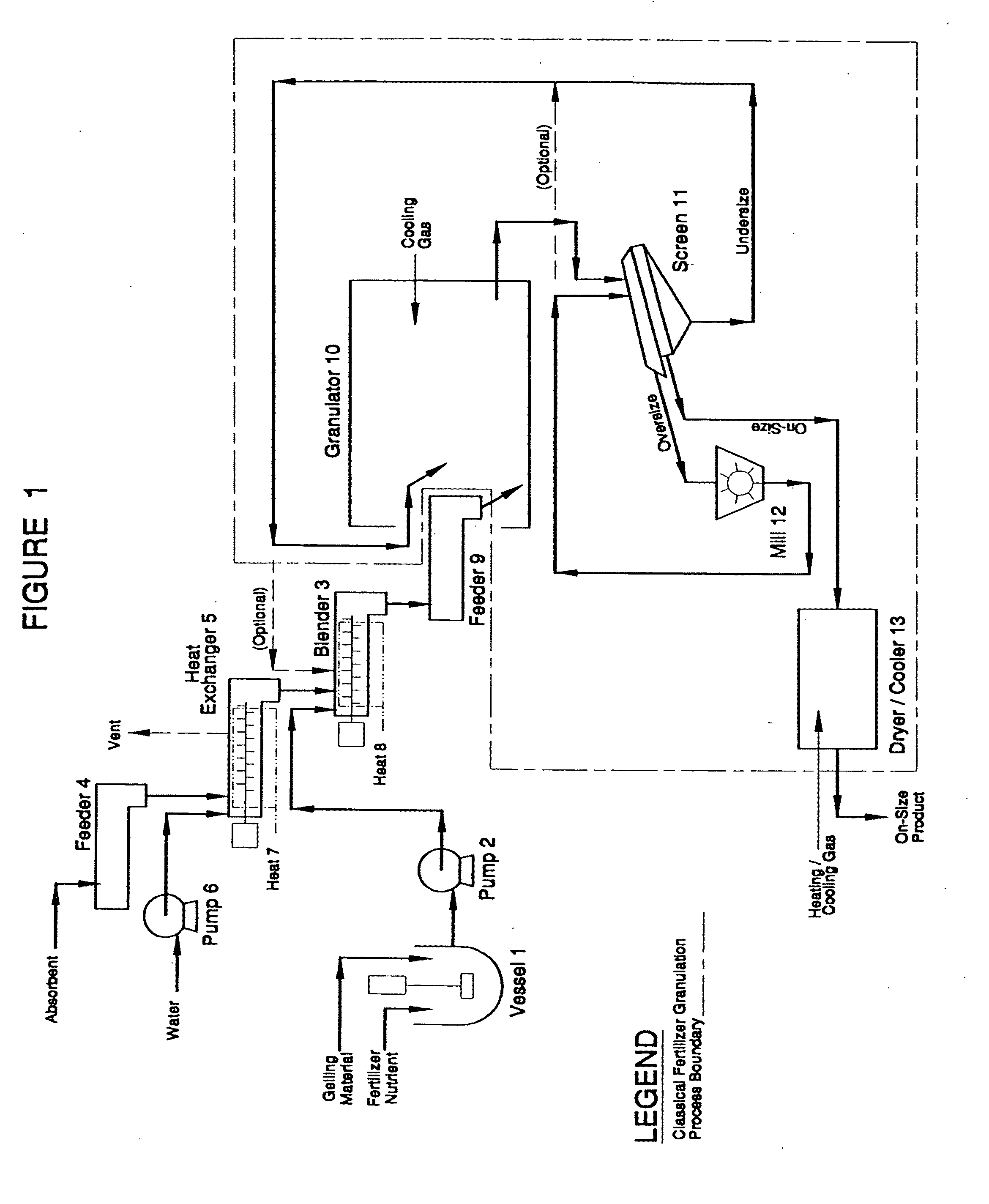

Organic recycling with a pipe-cross or tubular reactor

ActiveUS7128880B2Reduce moisture contentSimple compositionPhosphatesAnimal corpse fertilisersWater vaporSludge

The invention is directed to a process for enhancing the plant nutrient value of relatively low analysis organic waste material (e.g. sewage sludge) involves treating the waste material with an acid and base in a pipe-cross reactor or tubular to form a melt; spraying the melt onto a recycling bed of fines in a granulator and flashing off the water contained in the melt as steam; rolling the melt onto recycled fine particles in a granulator to form granulated particles; and drying these granulated particles to form an enhanced plant nutrient value composition (e.g. a fertilizer or soil conditioner having a greater NPK value than the original relatively low analysis organic waste material). The process further includes drawing off the fumes from the granulator, passing them through a dryer with the granulated particles, and subsequently oxidizing the fumes to eliminate volatile organic compounds and / or gaseous hydrocarbon pollutants be converting such into carbon dioxide and water vapor.

Owner:UNITY FERTILIZER LLC

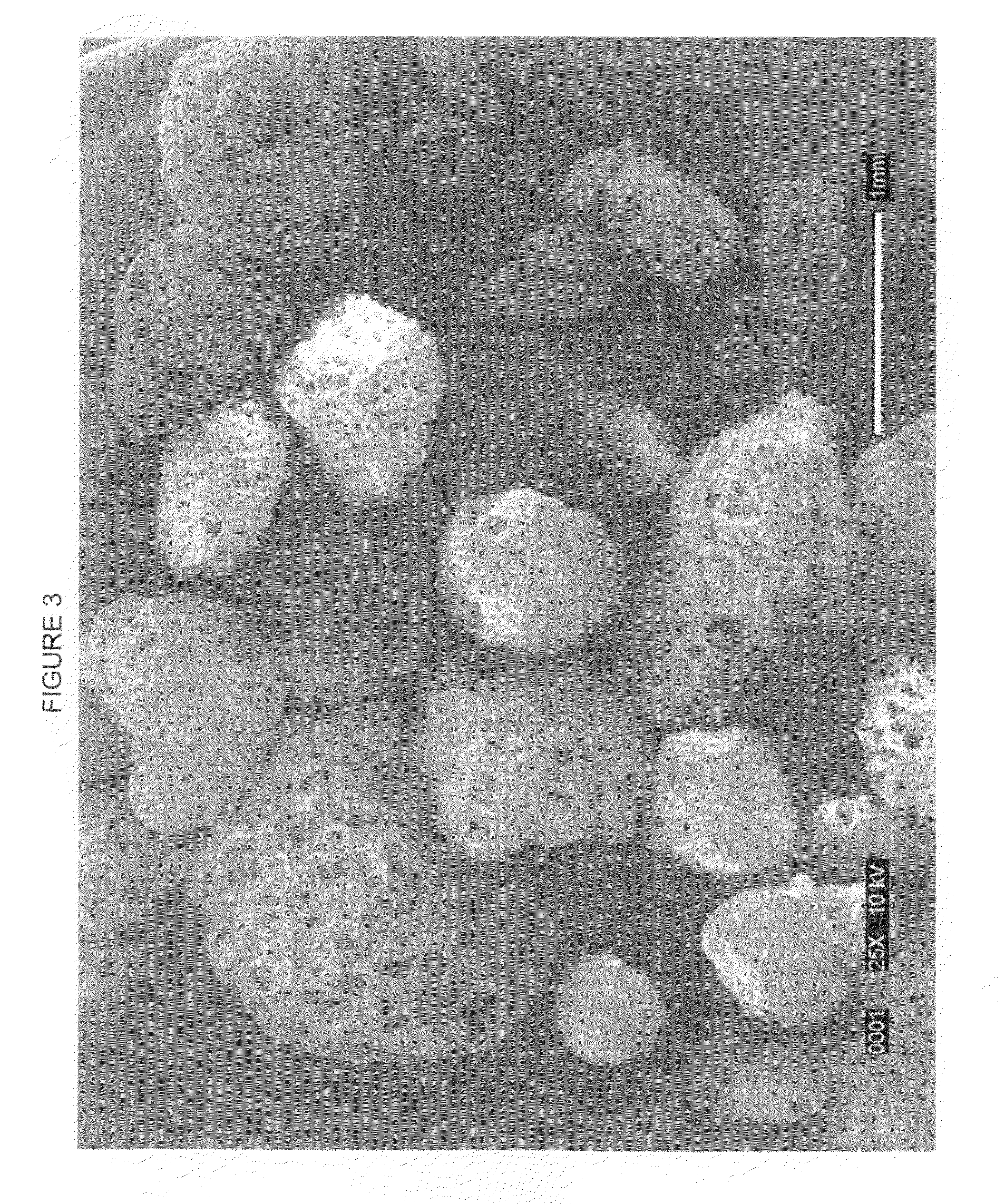

Biochar

The invention provides for methods, devices, and systems for pyrolyzing biomass. A pyrolysis unit can be used for the pyrolysis of biomass to form gas, liquid, and solid products. The biomass materials can be selected such that an enhanced biochar is formed after pyrolysis. The biomass can be pyrolyzed under specified conditions such that a selected biochar core is formed. The pyrolysis process can form a stable biochar core that is inert and / or resistant to degradation. The biochar or biochar core can be functionalized to form a functionalized biochar or functionalized biochar core. Functionalization can include post-pyrolysis treatments such as supplementation with microbes or physical transformations including annealing and / or activation.

Owner:FULL CIRCLE BIOCHAR

Soil conditioning agglomerates containing calcium

InactiveUS6936087B2High mechanical strengthGood curative effectBiocideCalcareous fertilisersParticulatesWater soluble

Mechanically strong, water-disintegrable agglomerates made from a particulate calcium source, a water-soluble binder and optionally containing a primary plant nutrient source and / or micronutrient source and a process for forming such agglomerates are disclosed. The agglomerates may be used as a soil liming agent and for introducing nutrient values into cultivated soil. Also disclosed is a method for introducing nutrient values into cultivated soil so as to inhibit leaching of the nutrient values from the soil and improve utilization of the nutrient values by plants grown in the soil.

Owner:MAGIC GREEN CORP

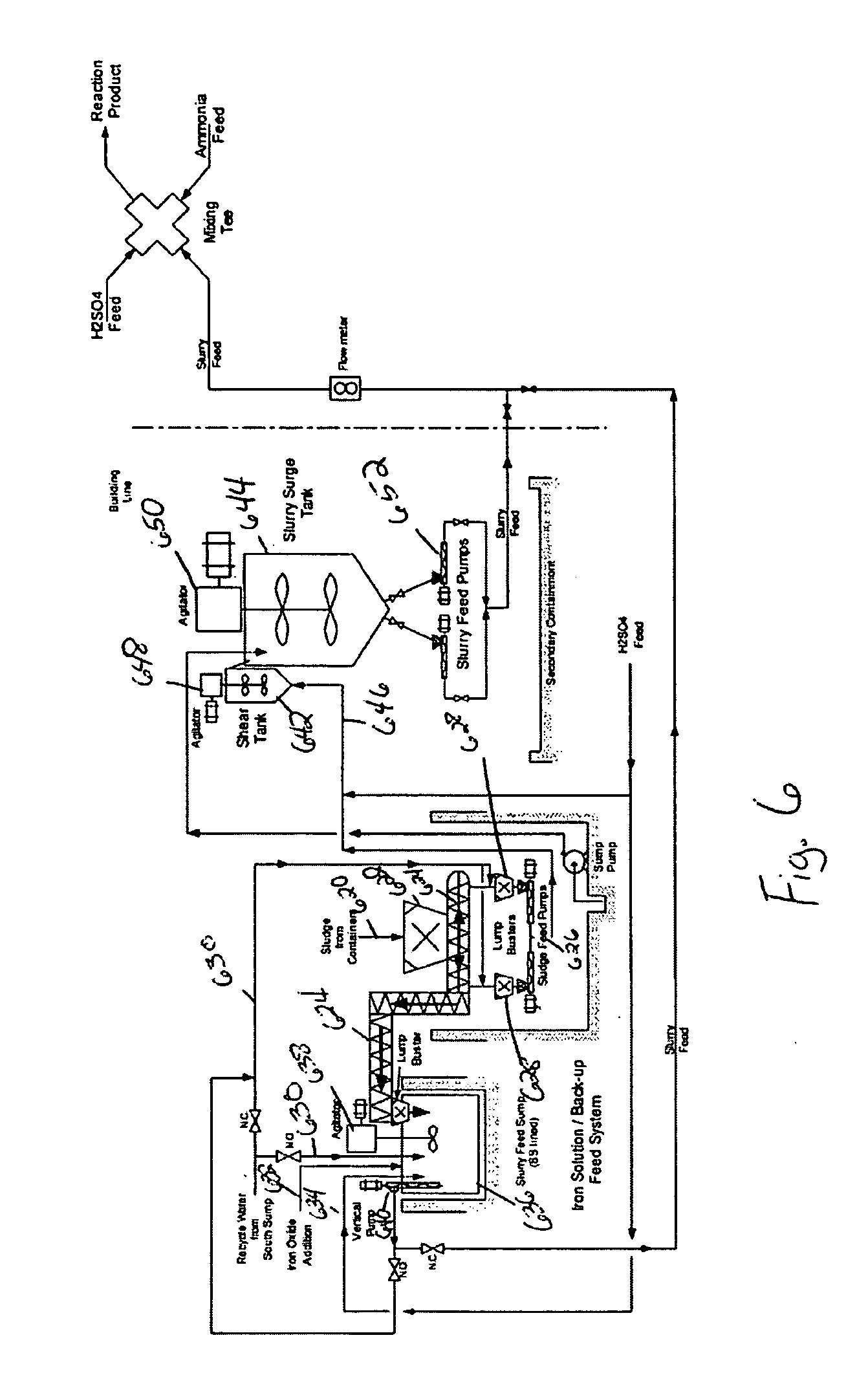

Organic recycling with metal addition

InactiveUS20050039508A1Reduce slurry viscosityAvoid flowAnimal corpse fertilisersAlkali orthophosphate fertiliserSolubilityIron sulfate

The invention is directed to methods for producing a granular nitrogen fertilizer from an organic material comprising adding a metallic salt to said organic material to form a slurry. Preferably the organic material comprises dewatered biosolids and contains water from a scrubber. Metallic salts that can be used comprise a salt of iron, zinc, or a mixture thereof. Preferred iron salts comprises ferric sulfate or ferric oxide, and preferred zinc salts comprises zinc sulfate or zinc oxide. Preferably, the metallic salt is mixed with an acid such as sulfuric acid to form an acidified metal salt. Slurry pH ranges from approximately 2-2.5. The acidified metal salt is added to the organic material in sufficient quantity to lower viscosity of the slurry such that the resulting fluid does not hinder fluid flow during operation. When the metallic salt comprises acidified ferric sulfate or ferrous sulfate, sufficient iron can be present to produce a fertilizer product with 0.1 weight percent to 10 weight percent iron sulfate calculated on a dry weight basis. The invention is also directed to fertilizer products made by the methods of the invention. Preferred products are granules and the metallic salt increases product hardness. Fertilizer granules preferably contain metal that is bioavailable to a plant when used as a fertilizer. Solubility of the metal of the product in water is enhanced, and the product is low staining.

Owner:UNIFIED ENVIRONMENTAL SERVICES GROUP +1

Method for treating solid organic wastes by biological method

InactiveCN101709006AAchieve recyclingAchieve reductionBio-organic fraction processingAnimal corpse fertilisersEcological environmentFermentation

The invention relates to a process for treating solid organic waste resources (food residues, domestic garbage, vegetable market garbage, wastes and leftovers of slaughter houses and food products factories, beer lees, distilled spirit lees, stevia rebaudiana residues, Chinese medicinal herbal dregs and the like), which comprises the following steps of: removing impurities (plastic bags, bottle caps, napkins, metals and the like) from solid organic wastes; adding mixed bacteria, an enzyme preparation and auxiliary materials into the organic wastes; stirring the mixture and controlling the temperature by hot blast; performing fermentation treatment on the mixture by adopting a staged temperature raising method; and drying and crushing the mixture to obtain an organic fertilizer. The invention finds a process capable of effectively treating the solid organic wastes, which can convert the solid organic wastes into the organic fertilizer by using microorganisms to change the organic wastes into valuable and realize the recycling use and the quantity reduction of waste resources; besides, the used microorganisms are harmless to human and the ecological environment.

Owner:TIANJIN UNIV OF SCI & TECH

Apparatus for separating particulates from a suspension, and uses thereof

InactiveUS7179379B2Stir wellDiscouraging decarboxylation reactionMultiple-effect/fractional condensationAnimal corpse fertilisersParticulatesSpeciality chemicals

The present invention includes an apparatus for separating particulates from a fluid in a suspension, comprising: a housing defining a frusto-conically shaped inner chamber with an inner wall, an inlet and a first outlet communicating with the chamber, and a second outlet; and a spinning assembly with a hollow interior mounted in the chamber, the assembly being shaped to define an annular gap with the chamber inner wall, the hollow interior communicating with the second outlet, and the hollow interior communicating with the annular gap for flow of fluid materials from the gap into the interior and out of the second outlet in response to rotation of the spinning assembly. The separator finds application in the preparation of waste products such as municipal sewage sludge for processes that produce useful materials including gas, oil, specialty chemicals, fertilizer, and carbon solids, in reliable purities and compositions, and with high energy efficiency.

Owner:AB CWT LLC

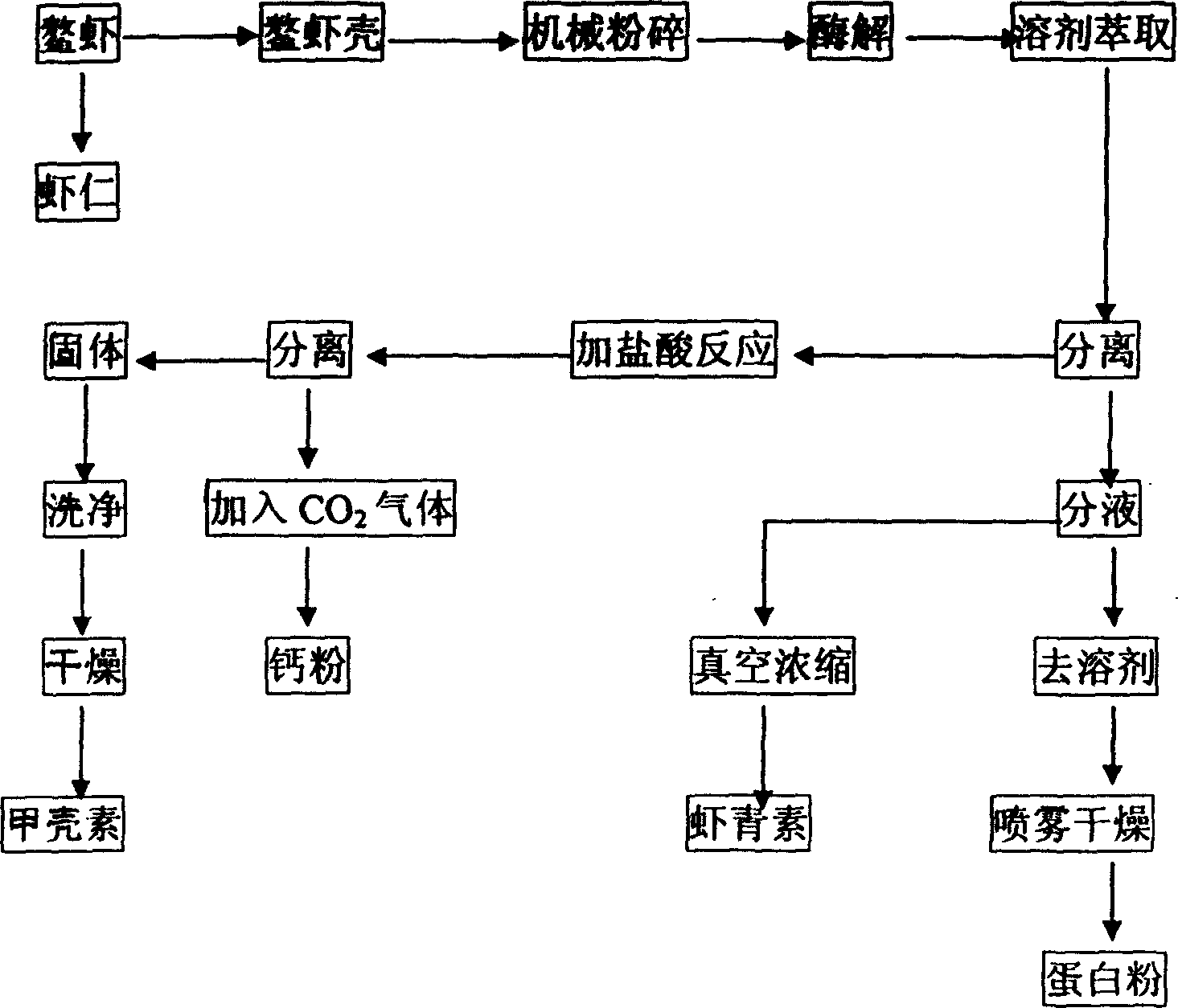

Method for producing chitin, astaxanthin, protein, calcium powder and biological fertilizer from shrimp shell

ActiveCN1715255AReduce pollutionGood effectAnimal corpse fertilisersClimate change adaptationBetaxanthinsPhytic acid

The method of producing chitin, astaxanthin, protein, calcium powder and biofertilizer with shrimp shell includes the following technological steps: crushing shrimp shell, enzymolysis with composite enzyme, extracting with organic solvent, reaction and separating liquid from solid; separating the liquid into hydrolysis liquid and organic liquid ; vacuum concentrating the organic liquid to obtain coarse astaxanthin; eliminating organic solvent from hydrolysis liquid, vacuum concentrating and spray drying to obtain protein powder; soaking the solid in 3 % concentration hydrochloric acid and rinsing to obtain chitin; introducing CO2 gas to the waste acid solution and filtering to obtain active calcium powder; ultrafiltering the coarse astaxanthin liquid to obtain astaxanthin; adding phytic acid and active oligose into the effluent to obtain nutritious liquid as biofertilizer.

Owner:林大昌

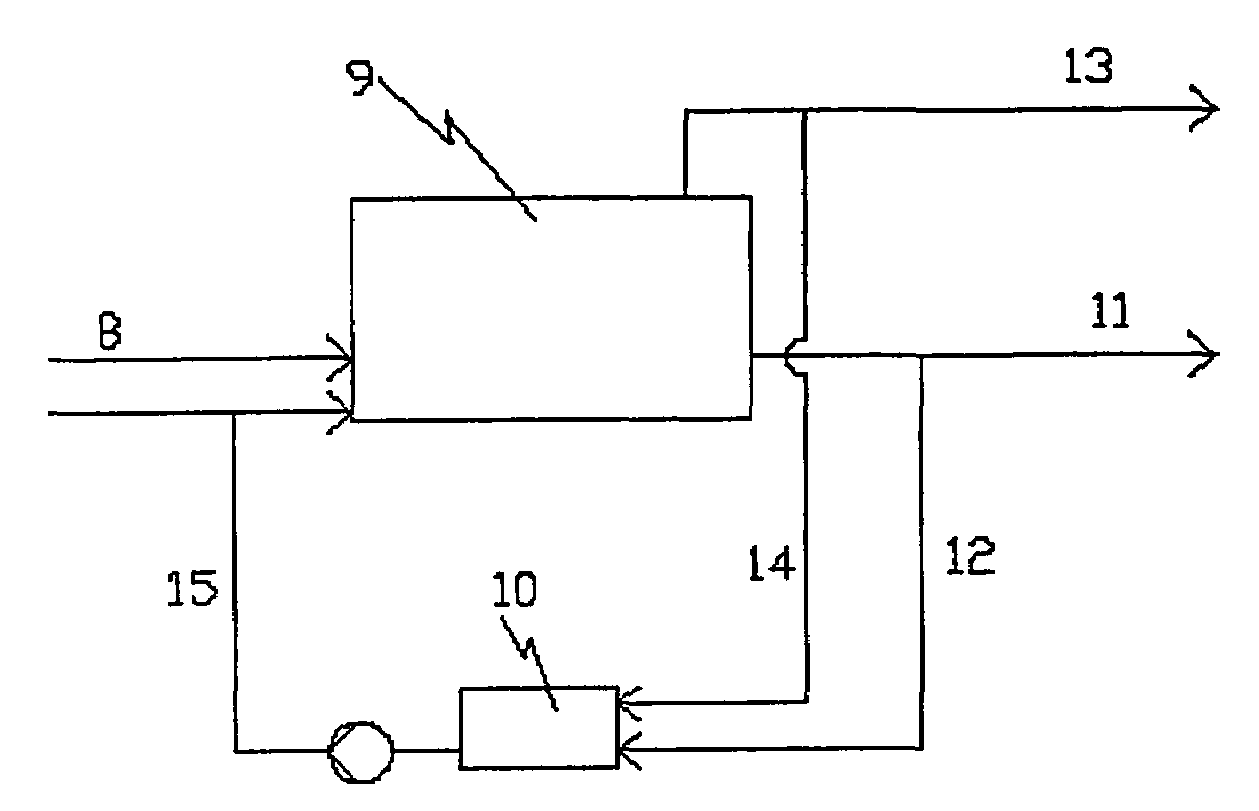

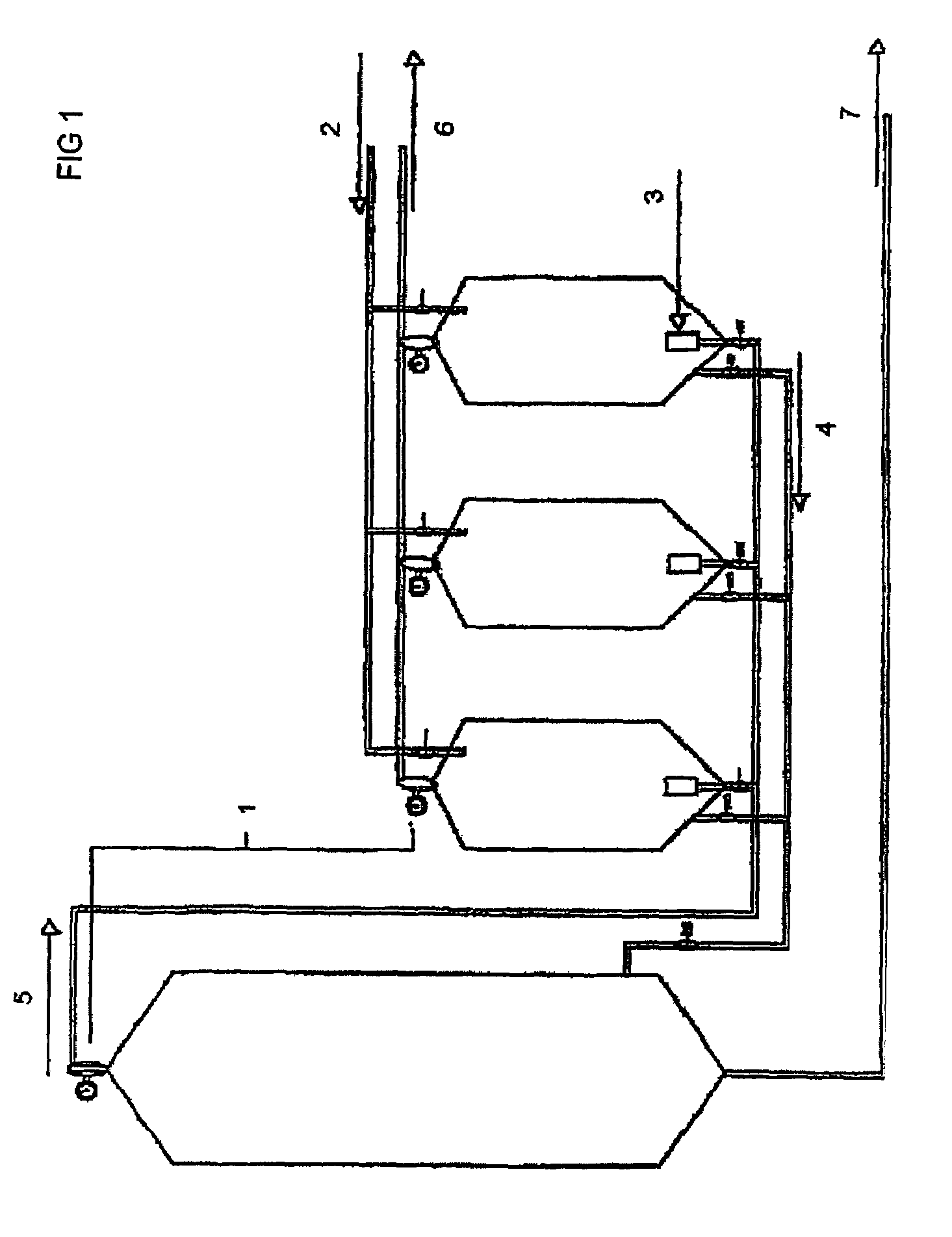

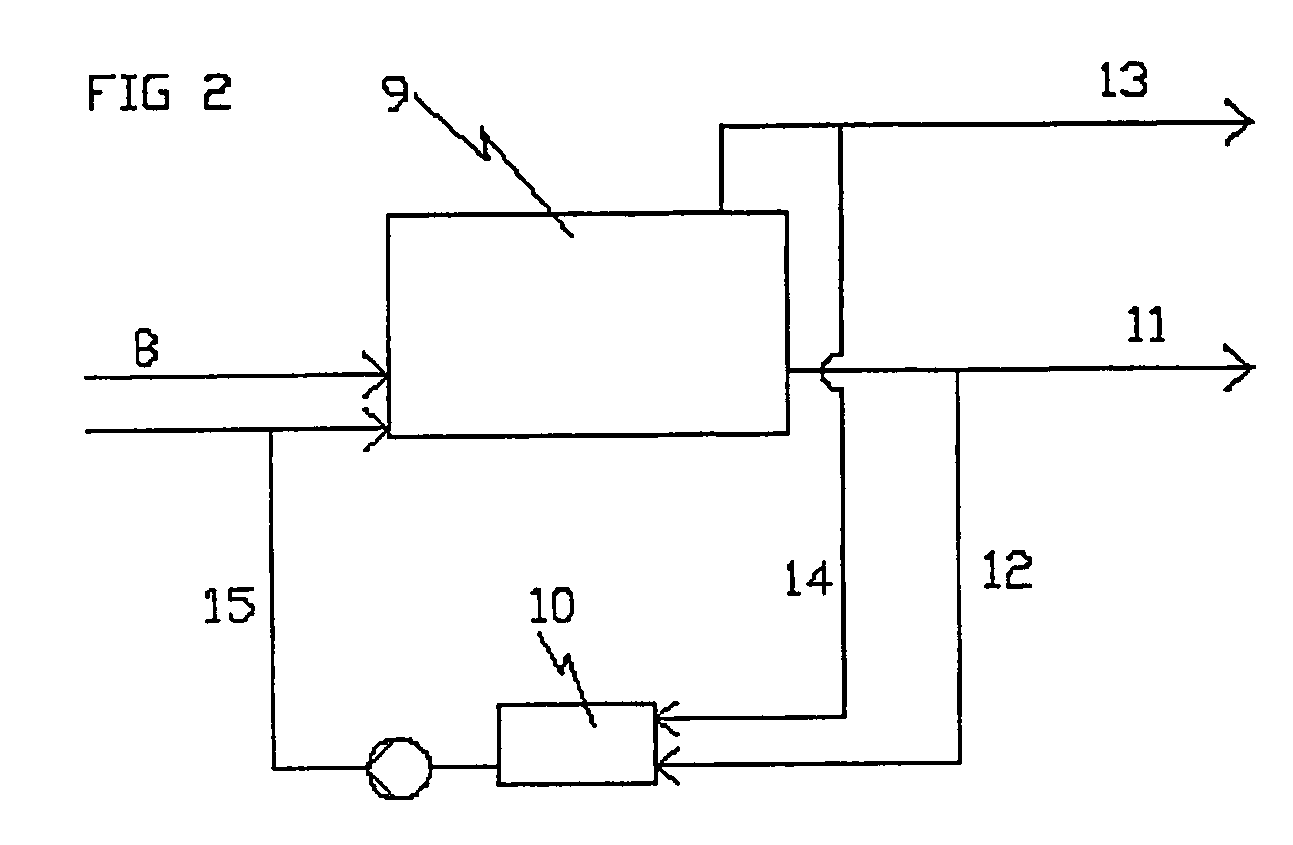

Method and equipment for processing organic material

InactiveUS7160456B2Organic material longerEasy to storeBio-organic fraction processingAnimal corpse fertilisersBuffer solutionAmmonia

A method for processing organic material, in which method bioconversion is performed on the organic material in at least one first reactor, the biogas formed in the bioconversion is treated with ammonia in at least one second reactor and buffer solution produced in the second reactor is recycled to the bioconversion in the first reactor. Thus, the carbon dioxide of the mixed methane / carbon dioxide gas reacts with the ammonia and forms a buffer compound, such as ammonium bicarbonate and / or ammonium carbonate.

Owner:PRESECO

Liquid fertilizer incorporating biosolids and high concentrations of ammonium

InactiveUS20050005660A1High nitrogen contentEasy to transportBio-organic fraction processingAnimal corpse fertilisersHigh concentrationNitrogen

This invention is directed to a method of manufacturing a liquid agricultural fertilizer utilizing biosolids and high concentrations of nitrogen and other essential plant nutrients and the resulting products.

Owner:ENVIRONMENTAL TECH CAPITAL PARTNERS +1

Manufacturing method of fertilizer made from organic wastes

InactiveUS6273927B1Neutralize toxicityHigh in magnesiumCalcareous fertilisersProductsHuman wasteChaff

This invention relates to a method of manufacturing the fertilizer made from organic wastes such as food wastes, human excrements, animal excrements, slaugterhouse waste, henhouse waste, fish and shellfish wastes, vegetable wastes and agricultural wastes. Various wastes are mixed and crushed into certain sizes, processes for adjusting the water content, put into the treating tank and digested by mixing a calcined lime. The present invention utilizes a dolomite or mixture of calcined lime and dolomite to provide the first treatment material. This first treatment material is mixed with the supplement material such as charcoal, saw dust, loess, zoelite, chaff, or shell powder to give compost fertilizer. It is also mixed with agricultural products such a watermelons or melons which ferment to provide a special fertilizer for the agricultural product. The treatment material can be added to water and mixed with mugwort, medicinal herb, zeolite, loess, and then extracted to provide a liquid fertilizer. As the various organic wastes are changed to organic fertilizer, the acidified soil is improved, the environmental contamination can be prevented, and the high moisturizing and the fine porous of the soil prevent drought and fertilizer loss so as to raise fertilizing efficiency.

Owner:JMBIO

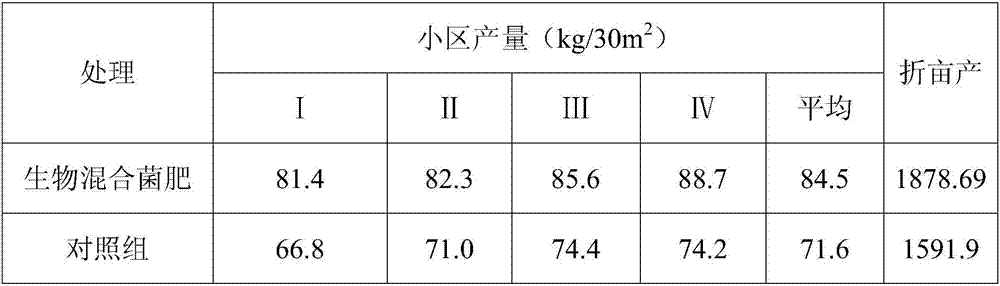

Biological mixed bacterial fertilizer and preparation method and application thereof

InactiveCN107285918AImprove the living environmentEnhanced back soil effectCalcareous fertilisersBio-organic fraction processingTrace elementInorganic materials

The invention discloses a biological mixed bacterial fertilizer and a preparation method and application thereof. The biological mixed bacterial fertilizer is prepared from, by weight, 1-20 parts of a compound bacterial agent, 300-400 parts of organic materials, 500-600 parts of inorganic materials, 800-1000 parts of chemical fertilizers, 5-10 parts of trace elements, 300-500 parts of waste liquid, 30-50 parts of amino acid salts and 50-100 parts of additives.

Owner:英丽华

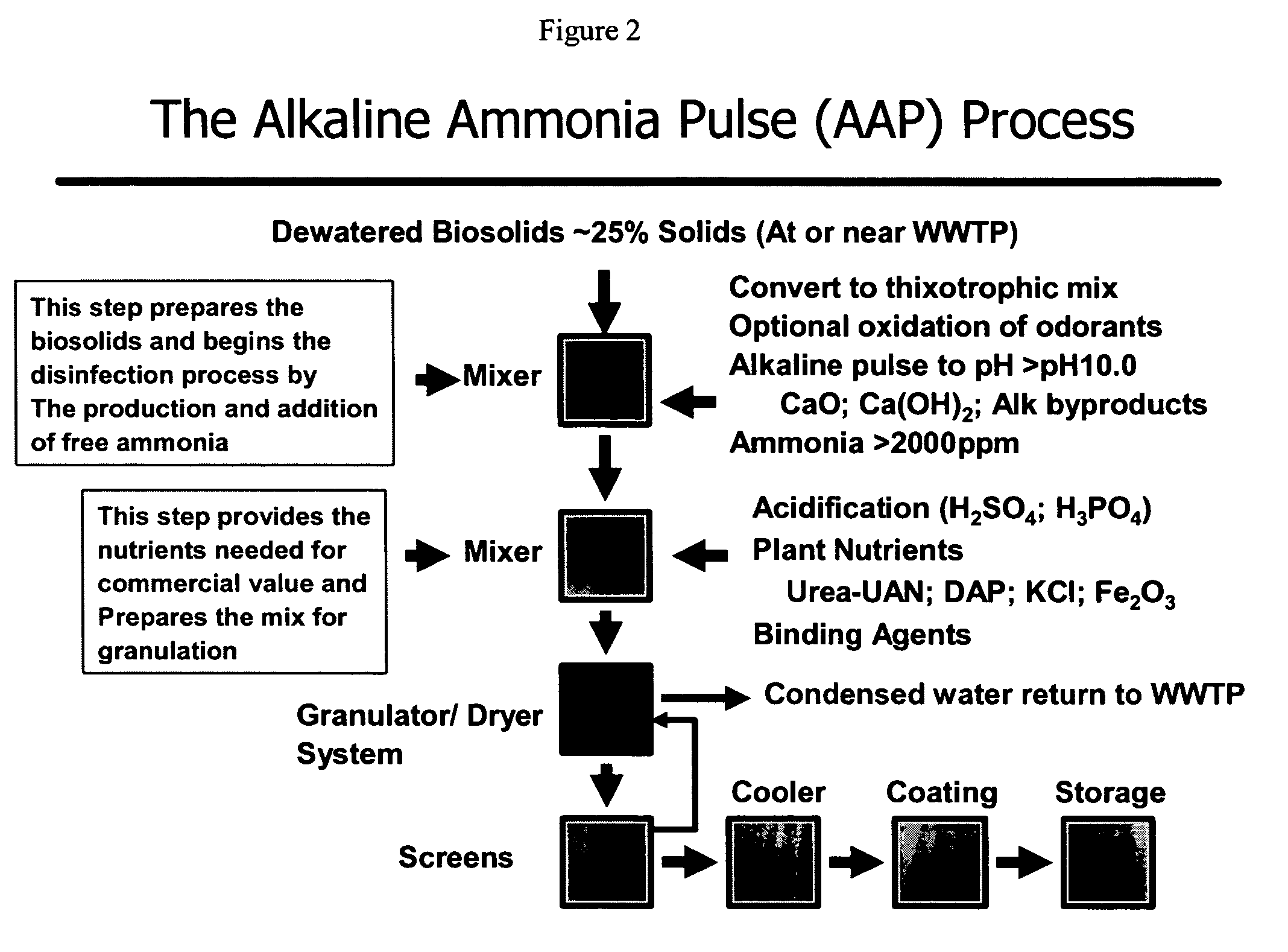

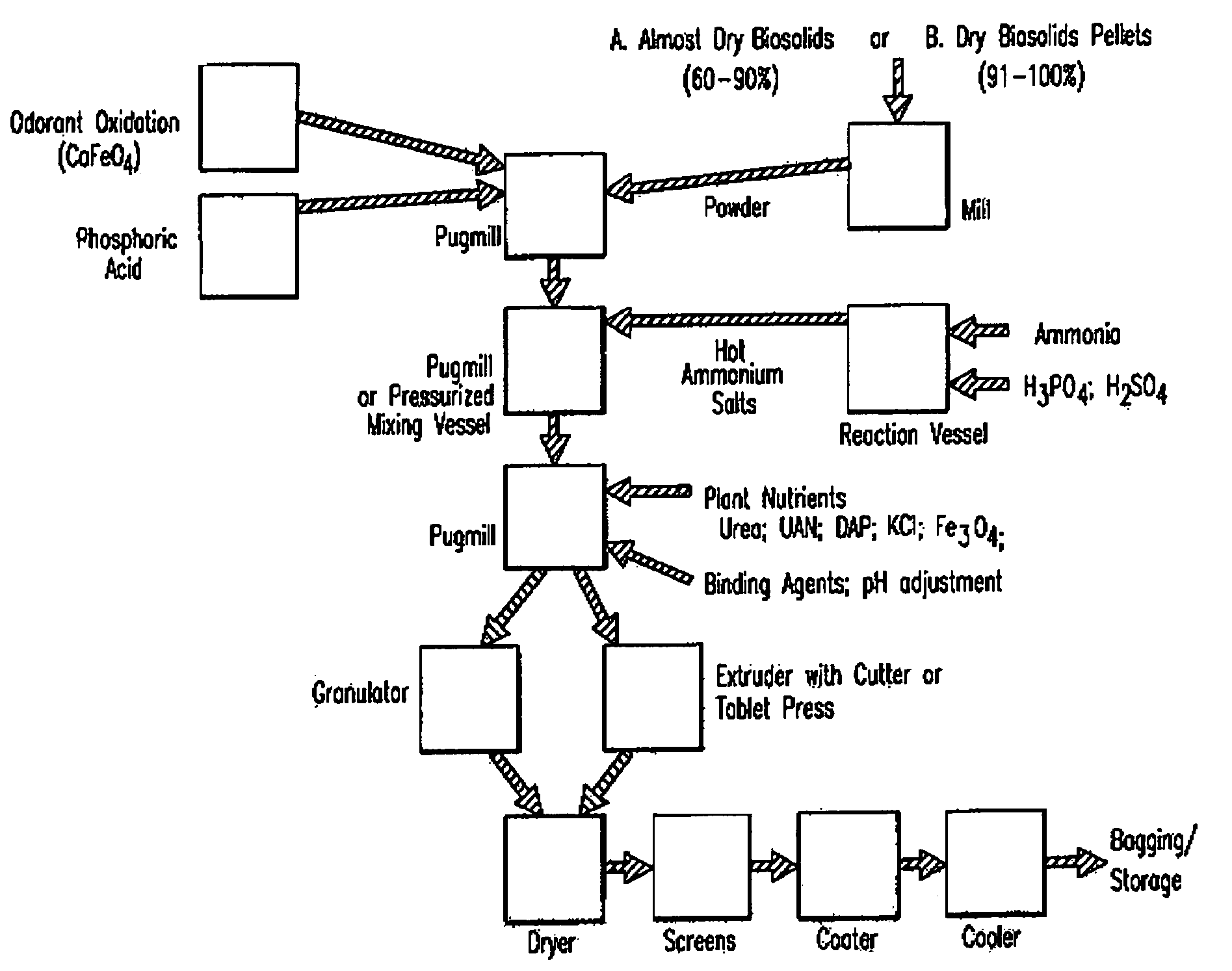

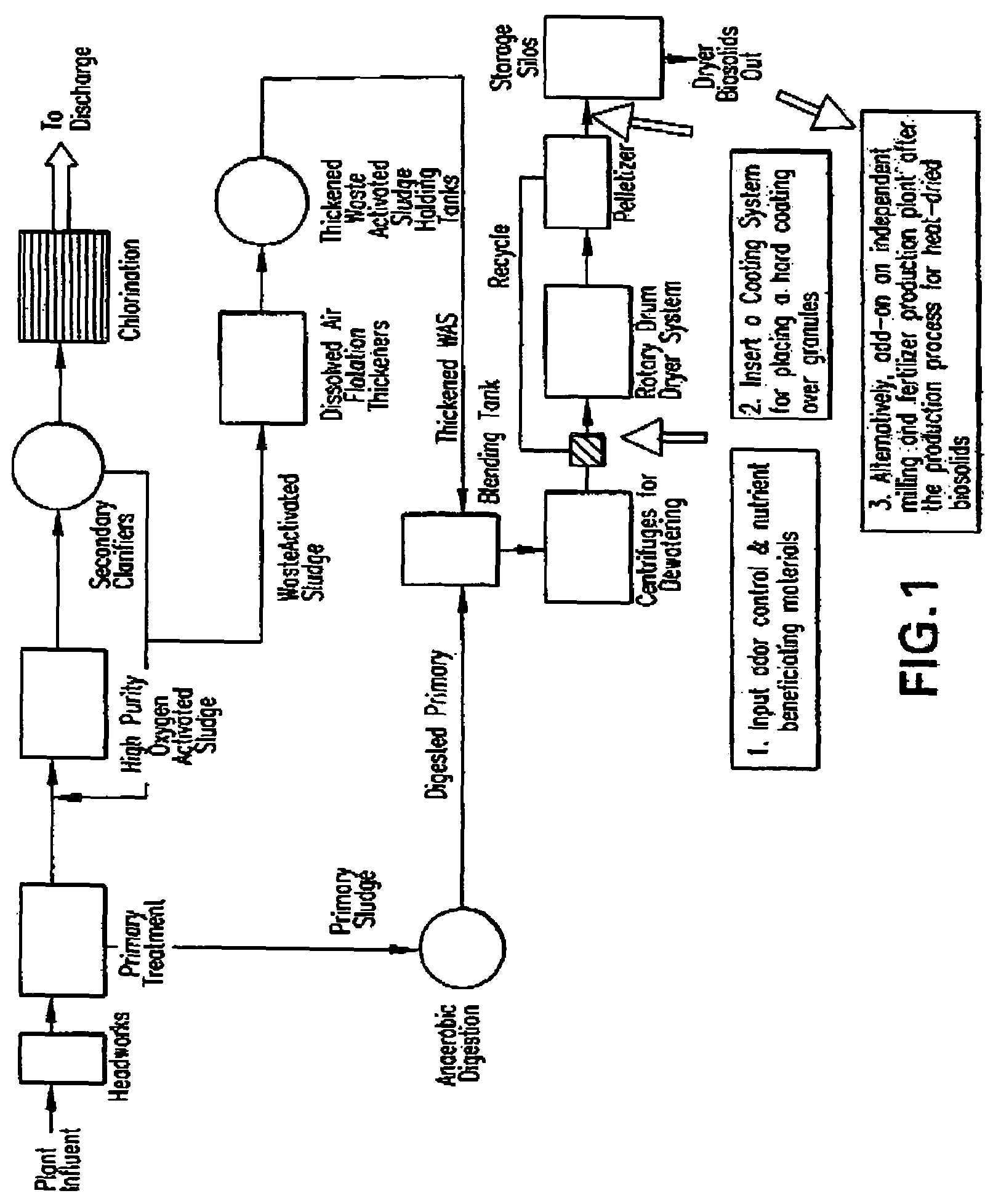

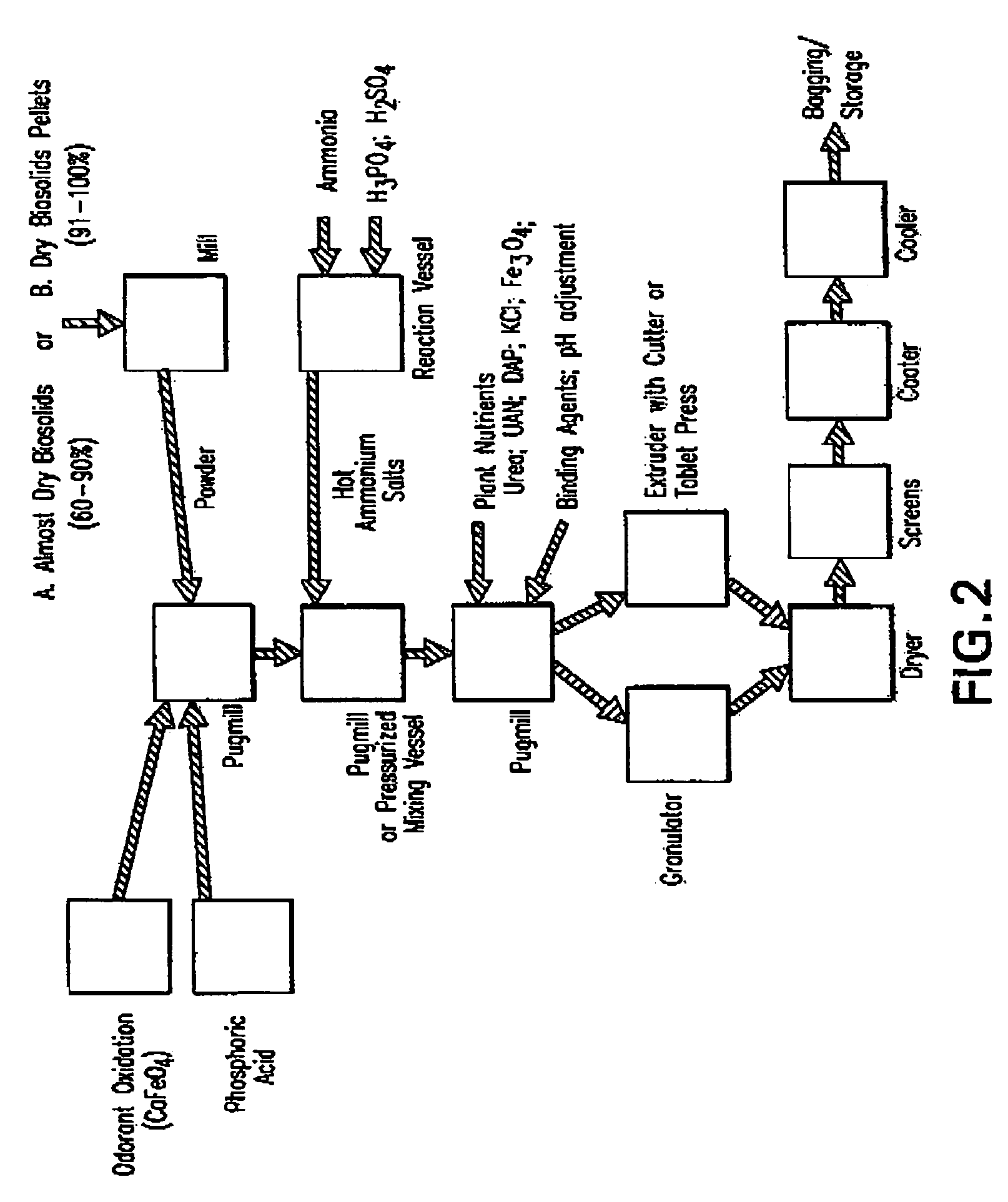

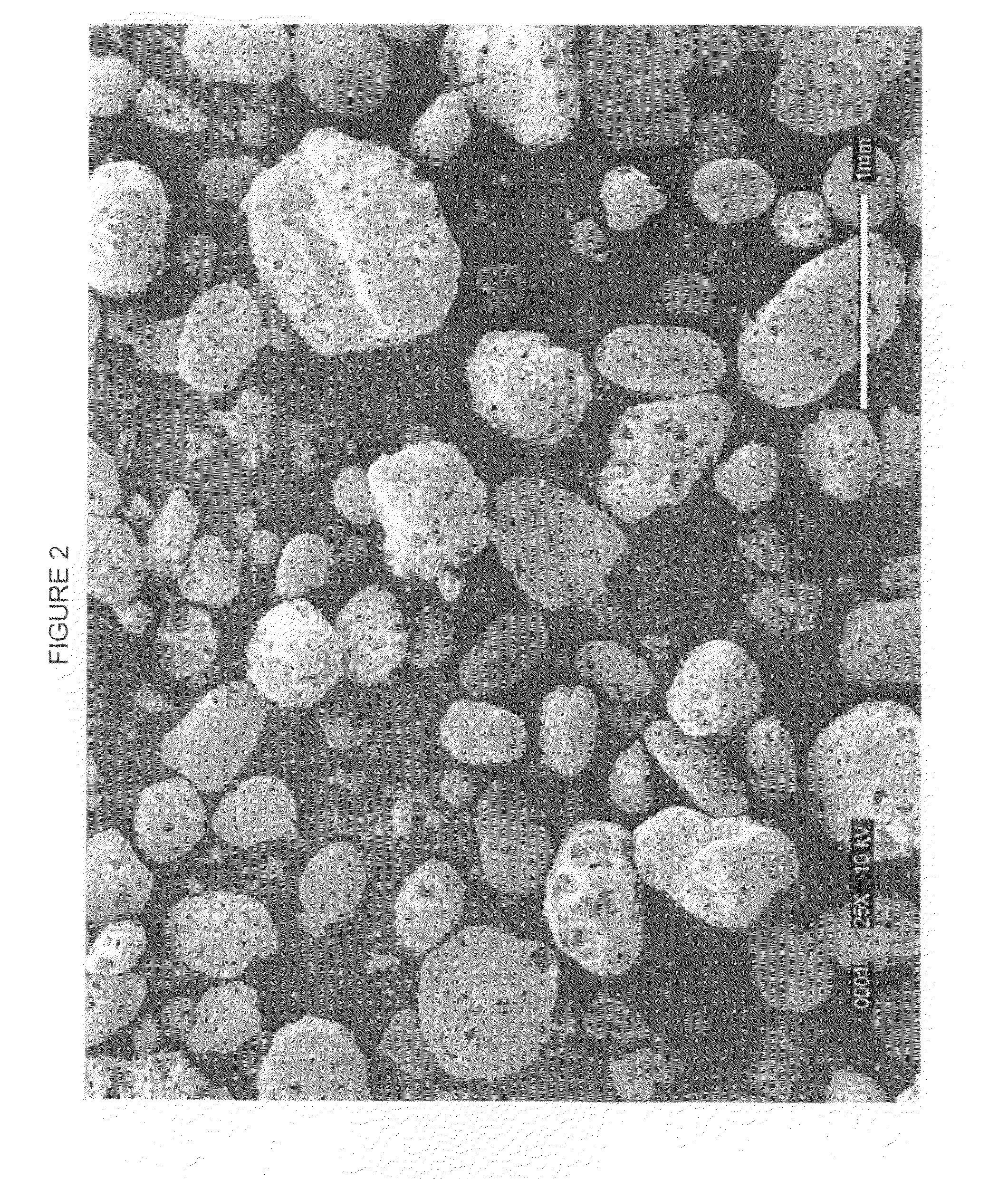

Processes to beneficiate heat-dried biosolid pellets

This invention is directed to systems, devices and methods for modifying the process of producing dried biosolids pellets or granules into beneficiated inorganically-augmented bioorganic fertilizer. The present invention describes a method to beneficiate heat-dried biosolids or sludge pellets or granules as presently manufactured by municipalities or companies from a) dewatered municipal wastewater biosolids or sludges within the municipal wastewater treatment plant heat-dried biosolids production facility or from b) finished dry heat dried biosolids pellets or granules in a separate manufacturing facility from the municipal wastewater treatment plant to produce a fertilizer containing sufficient organic and inorganic plant nutrients to be valuable and saleable into the commercial agricultural industry. The present invention describes beneficiation methods to increase the plant nutrient content to a level which permits the finished beneficiated dried biosolids pellet or granule product to compete in the commercial agricultural fertilizer marketplace and also to reduce the odors associated with traditionally-produced heat dried biosolids.

Owner:GENERATE LENDING LLC +1

Vacuum coated particulate fertilizers

A method of coating fertilizer particles exhibiting porous surfaces under vacuum to form attrition resistant controlled release particulate fertilizers, by drawing a vacuum on the fertilizer particles and applying thereto a water insoluble fluid resin at about atmospheric pressure, so that the fluid resin is forced into the porous surfaces of the fertilizer particles by differences in pressure, and then hardening the fluid resin to form a solid resin, tenaciously bonded onto, and into, the porous surfaces of the fertilizer particles. Porous surfaced water soluble, slow releasing and sulfur coated, fertilizers may be effectively coated. Granular, briquetted, compacted and other special shaped fertilizers may also be effectively vacuum coated to provide controlled release products. Pesticides may also be effectively included in these attrition resistant products. Fertilizers are provided which exhibit substantially improved resistance to attrition.

Owner:B&B INT

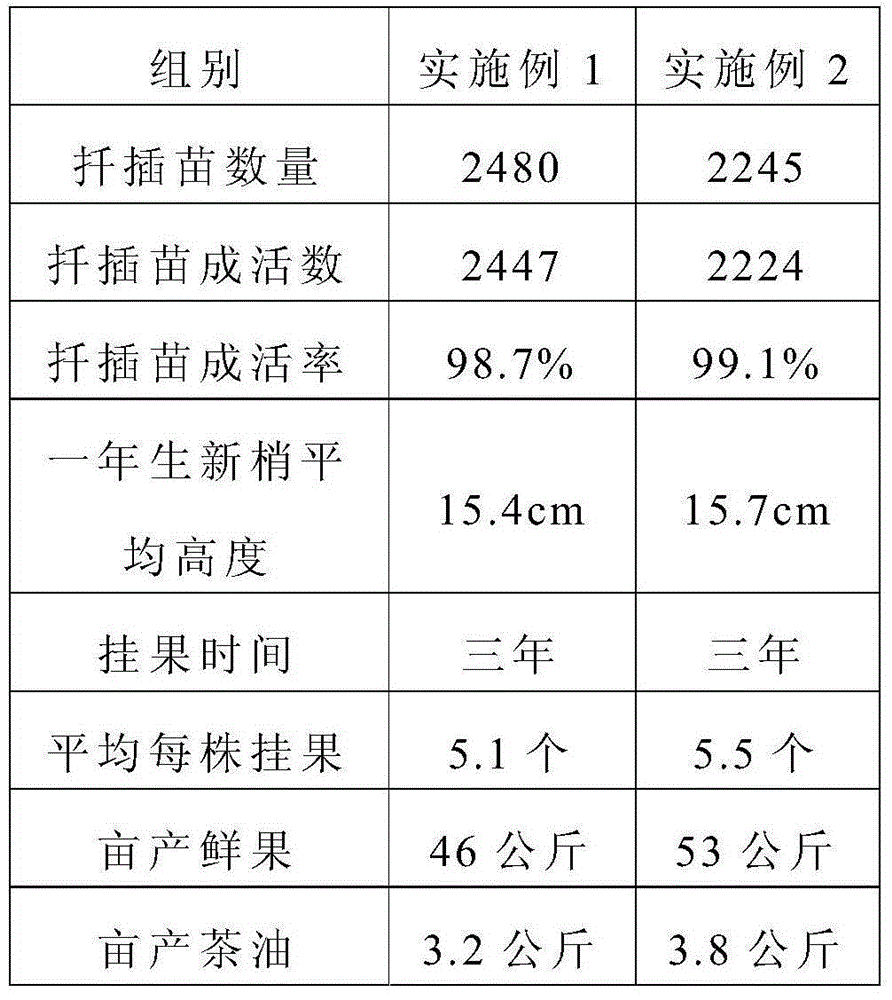

Camellia oleifera Abel planting method

ActiveCN105052655AIncrease growth rateIncrease oil productionCalcareous fertilisersAnimal corpse fertilisersCamellia oleiferaObserved Survival

The invention relates to a camellia oleifera Abel planting method and belongs to the technical field of plant planting. The method comprises the following steps: cutting, cutting management, seedling hardening, management before transplanting, field transplanting and field management. According to the camellia oleifera Abel planting method, through a reasonable cutting management method and camellia oleifera seedling fertilization and topdressing management, the survival rate and growth rate of the cutting seedlings are greatly improved; meanwhile, the camellia oleifera Abel can bear fruits after three years, and enter a full bearing period after five to six years; fruit-bearing rate is high; and oil extraction rate of the fruits is high.

Owner:张家界融和实业有限公司

Composite amino acid ecological nutritious agent

InactiveCN1594232AApparently antiviralObvious antibacterialAnimal corpse fertilisersClimate change adaptationTrace elementFermentation

The invention provides a composite amino acid ecological nutritious agent, which comprises sea weed fermentation liquor, fermentation liquor of animal leftover bits and pieces, trace elements, and biological bacterium. The functions of the agent include stimulating growth, suppressing pathogenic agent and reinforcing immunization.

Owner:李长江

Controlled release fertilizers containing calcium sulfate and processes for making same

Owner:NEW FERTILIZER TECH LLC

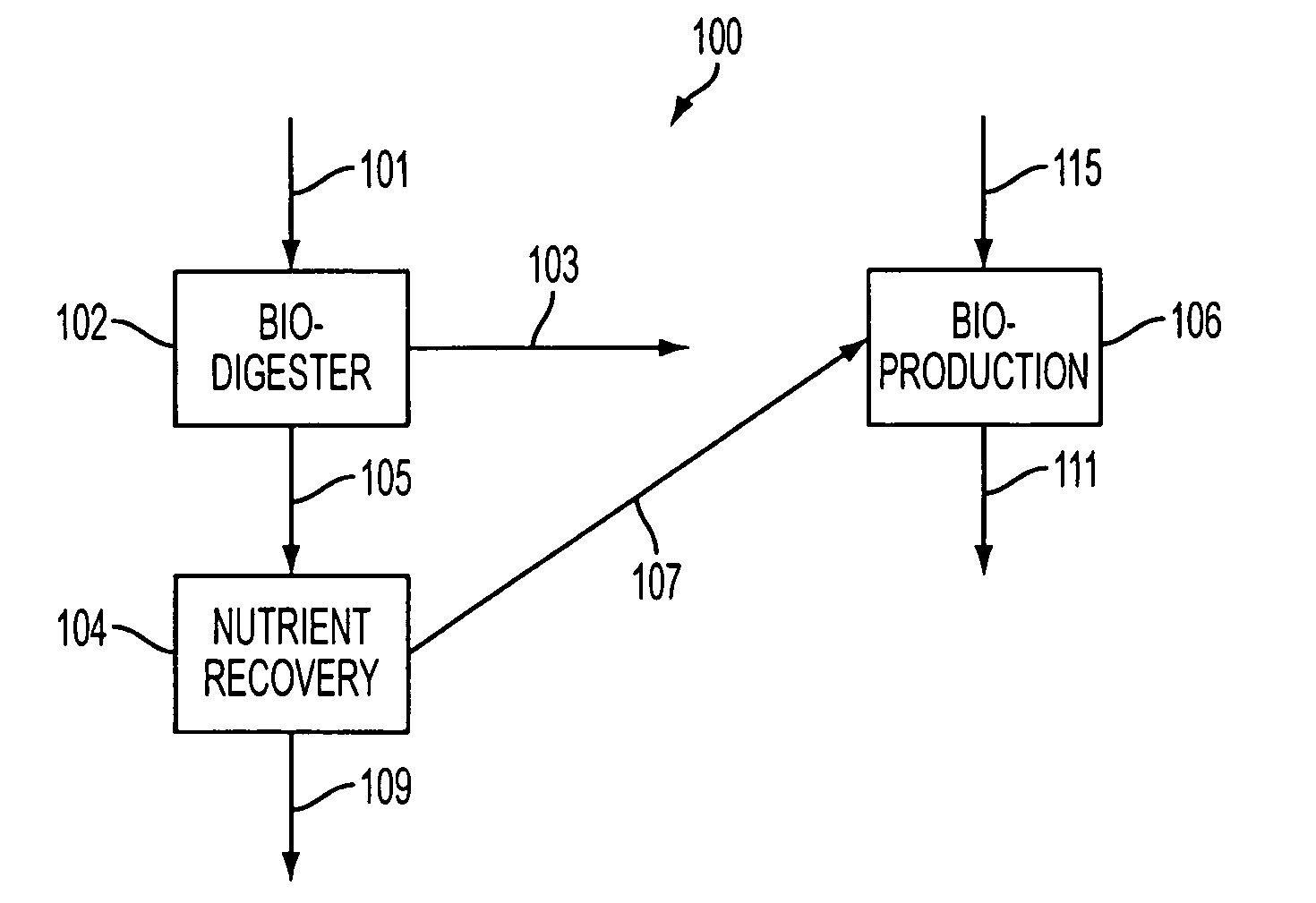

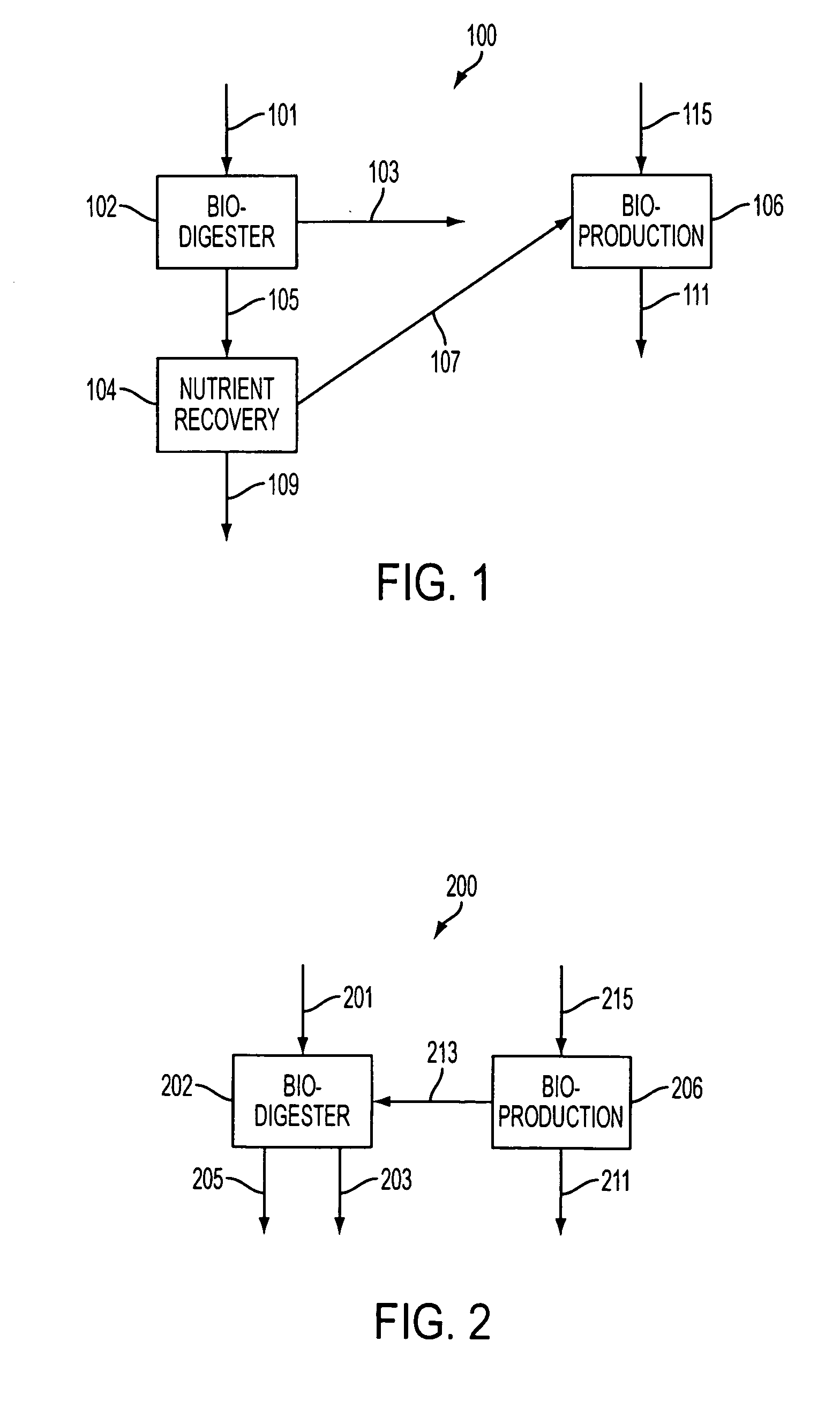

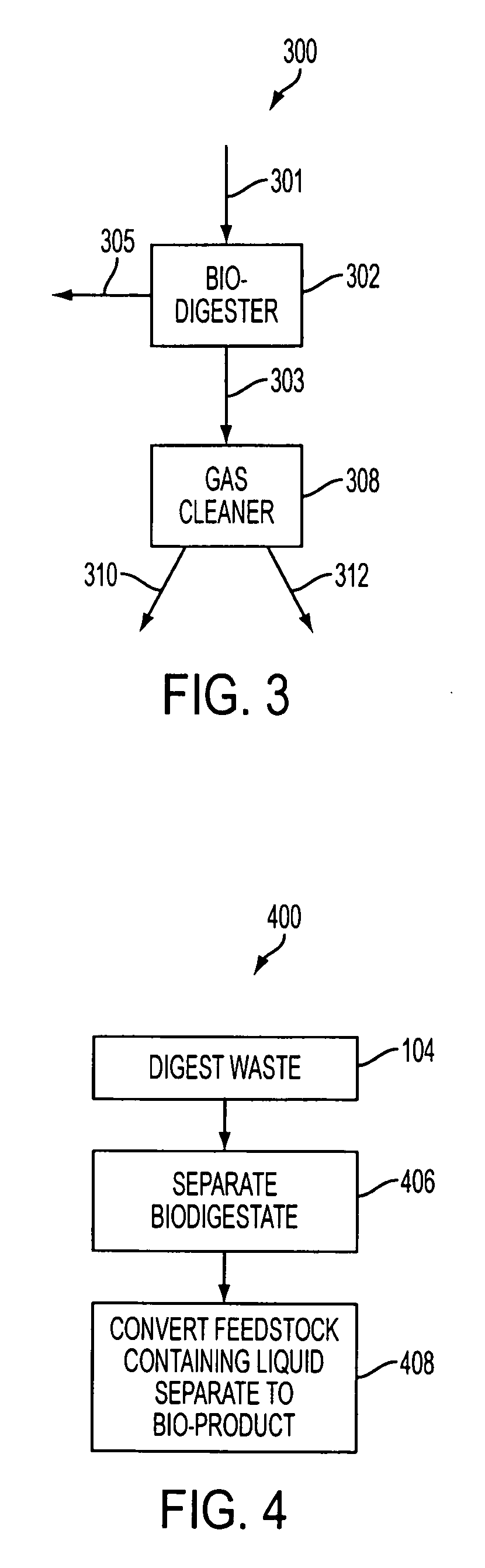

Integrated bio-digestion facility

InactiveUS20090250401A1Fatty acid esterificationAnimal corpse fertilisersEnvironmental engineeringDigestion

Methods and systems for processing organic waste material are provided. These methods and systems include integrating an anaerobic bio-digester and nutrient recovery module with a bio-production facility, which can locally provide feedstock for the bio-production facility, and can locally provide organic material for the anaerobic bio-digester. Methods and systems for integrating an anaerobic bio-digester with a gas cleaner are also provided, which can recover nutrients while cleaning the biogas produced by the anaerobic bio-digester.

Owner:HIGHMARK RENEWABLES RES PARTNERSHIP

Organic containing sludge to fertilizer alkaline conversion process

InactiveUS7662206B2Reduce odorHigh in nutrientsCalcareous fertilisersBio-organic fraction processingSludgeOrganic manure

This invention is directed to systems, devices and methods for treating organic-containing sludges and converting such sludges to high value fertilizers containing both inorganic and organic fertilizer components, which creates an inorganically-augmented bioorganic fertilizer. The invention describes methods to create a thixotrophic or paste-like material via the application of mixing energy to the organic sludge followed by an alkaline treatment and a subsequent ammoniation. The invention further describes a method to increase the plant nutrient content in the organic containing product to a level which permits the finished granular fertilizer product to compete in the commercial agricultural fertilizer marketplace. Further, the invention reduces odors associated with said organic-containing sludges.

Owner:GENERATE LENDING LLC +1

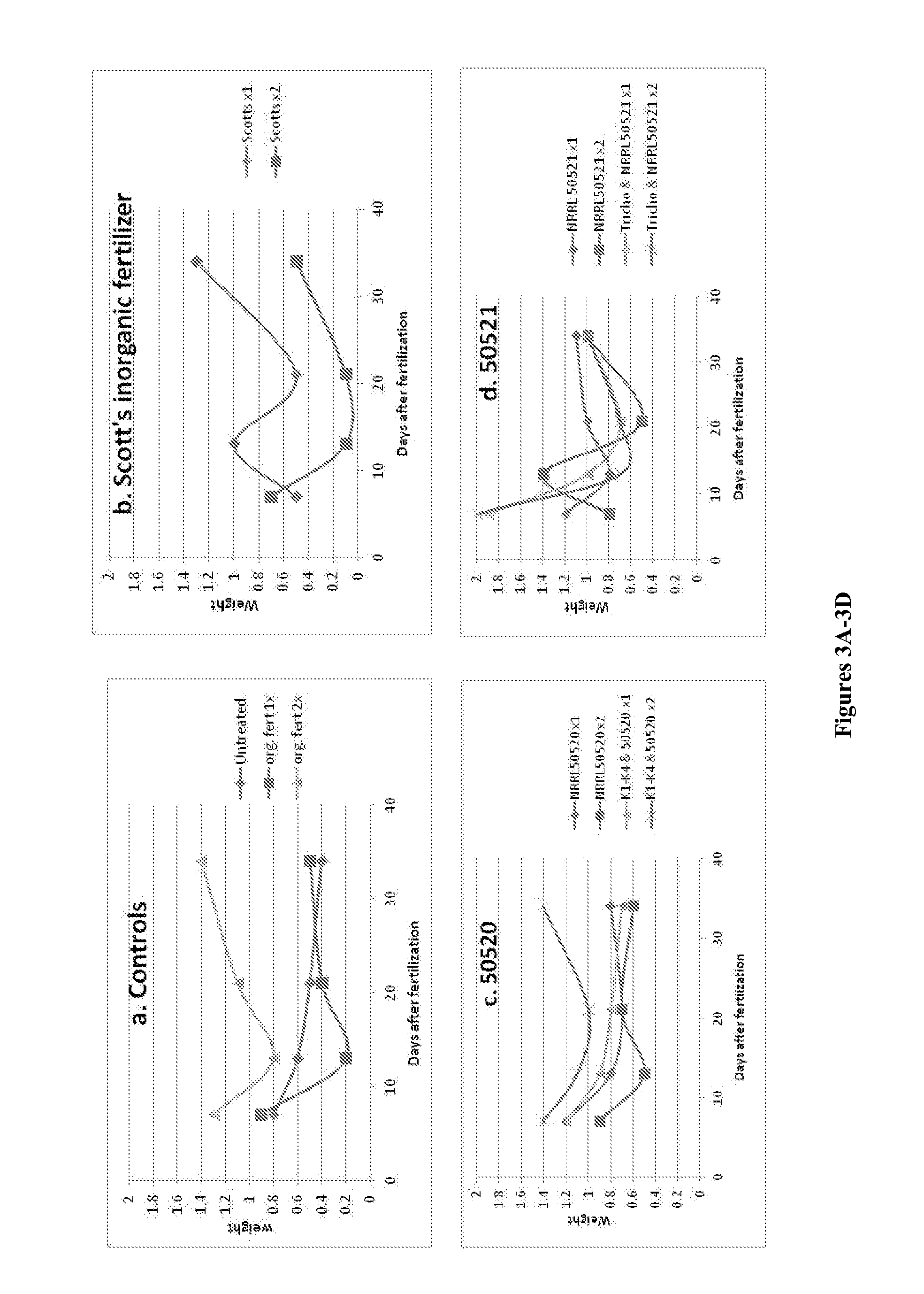

Highly efficient organic fertilizer and components thereof

ActiveUS20140323297A1Minimize and eliminate pollutionEfficient methodCalcareous fertilisersBiocideBiotechnologyMicroorganism

The present invention relates to a fertilizer comprising at least one microbe selected from the group consisting of Trichoderma viride (NRRL B-50520), Scopulariopsis brevicaulis (NRRL B-50521), Scopulariopsis brevicaulis (NRRL B-50522), and combinations thereof, and a substrate which is acted upon by the at least one microbe to release nitrogen. The invention also relates to a fertilizer comprising at least one microbe selected from a keratin degrading microorganism and a keratin substrate which is acted upon by the at least one microbe to release nitrogen. The invention further relates to a method for enhancing growth of plants with the fertilizer, and methods of making a fertilizer. The invention further relates to an isolated Trichoderma viride strain (NRRL B-50520) and two isolated Scopulariopsis brevicaulis strains (NRRL B-50521, NRRL B-50522).

Owner:CORNELL UNIVERSITY

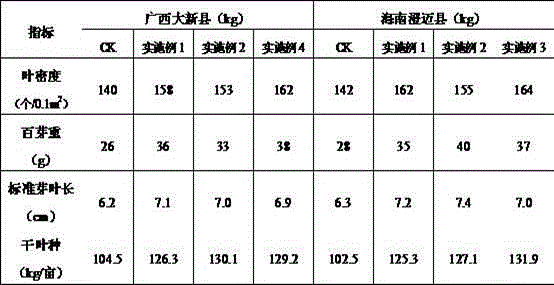

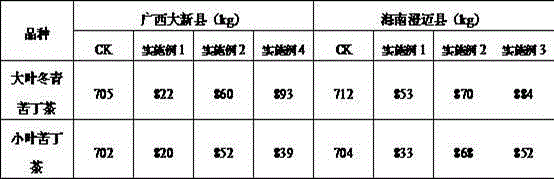

Special composite fertilizer for broadleaf holly leaves and production method of composite fertilizer

InactiveCN104447092AImprove developmentPromote productionAnimal corpse fertilisersBioloigcal waste fertilisersSoil scienceOrganic manure

The invention discloses a special composite fertilizer for broadleaf holly leaves and a production method of the composite fertilizer. The special composite fertilizer is characterized by being prepared from the following raw materials in parts by weight: 40-50 parts of an inorganic fertilizer, 20-30 parts of an organic fertilizer, 5-10 parts of compound amino acid, 0.1-0.5 part of microelements, 0.05-0.1 part of a fertilizer activating agent, 0.1-0.5 part of a water-retaining agent, 0.1-0.5 part of a soil conditioner and 0.05-0.1 part of a pest repellent. The special composite fertilizer disclosed by the invention has the effects of fixing nitrogen, activating phosphorus and dissolving potassium, and also contains the microelements, so that the nutrition of a tea tree in the growth process is timely supplemented; the content of the organic fertilizer in soil can also be improved; the soil environment is improved; injurious insects are avoided; the broadleaf holly leaf tree is good in growth after being fertilized; the quality is improved; the yield is improved by over 10%; and the economic benefits are greatly improved.

Owner:DAXIN PRODIVITY PROMOTING CENT

Fertilizers and methods for using biotic science to feed soils

ActiveUS20090188290A1Improve fertilityEnhanced ChelationCalcareous fertilisersProductsPhylum CyanobacteriaCyanobacteria

Biotic fertilizers are described that build soil nutrients by accelerating the growth of topsoil microorganisms Biotic fertilizers are primarily aimed at increasing populations of cyanobacteria, formally known as blue-green algae, and like organisms that have the ability to engage in photosynthesis reand to engage in the extraction of nitrogen from the atmosphere. Methods of biotic fertilizer manufacture are presented that utilize animal waste product as well as desirable compositions obtained thereby.

Owner:PERFECT BLEND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com