Patents

Literature

24670results about How to "Low viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

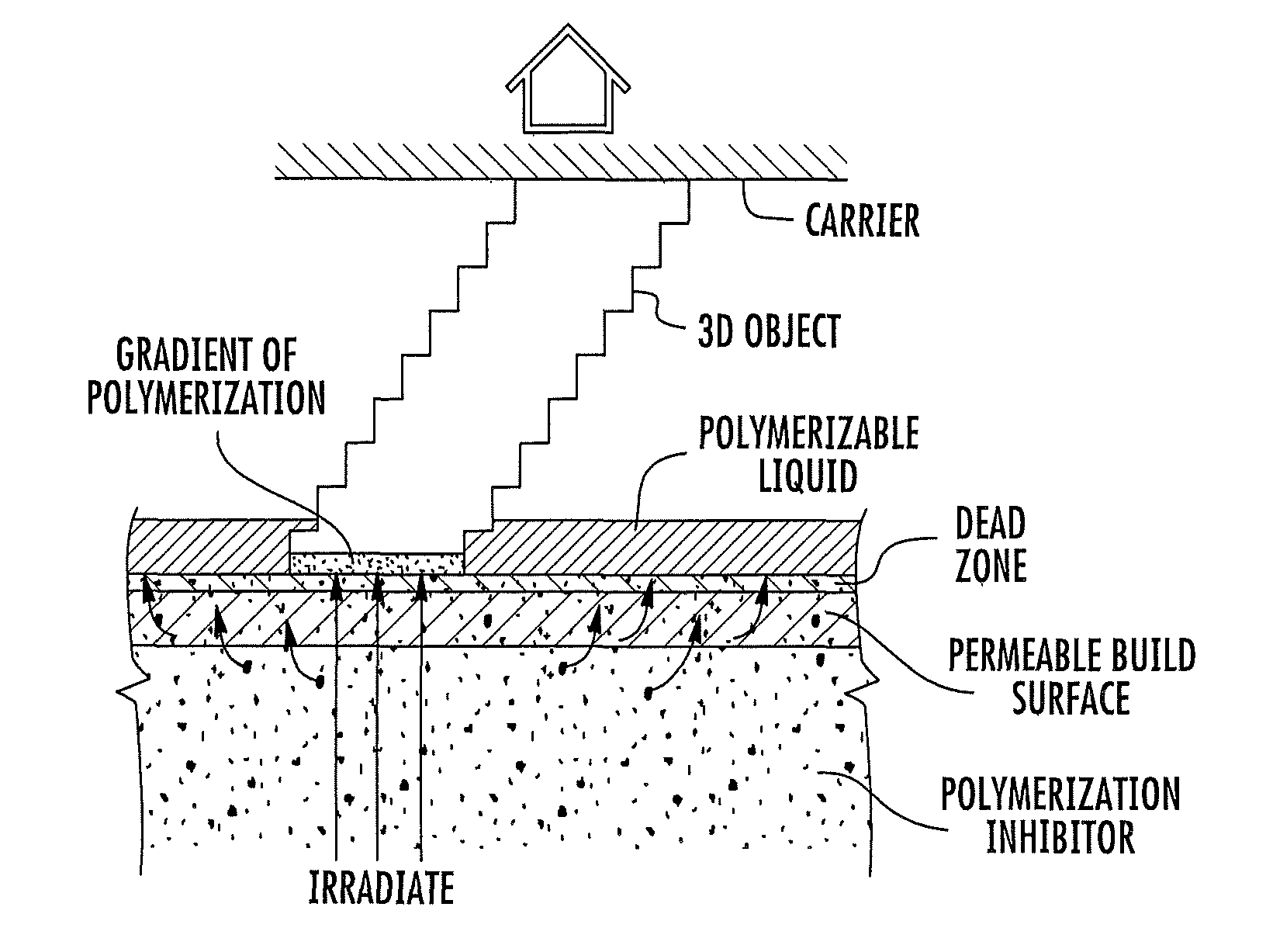

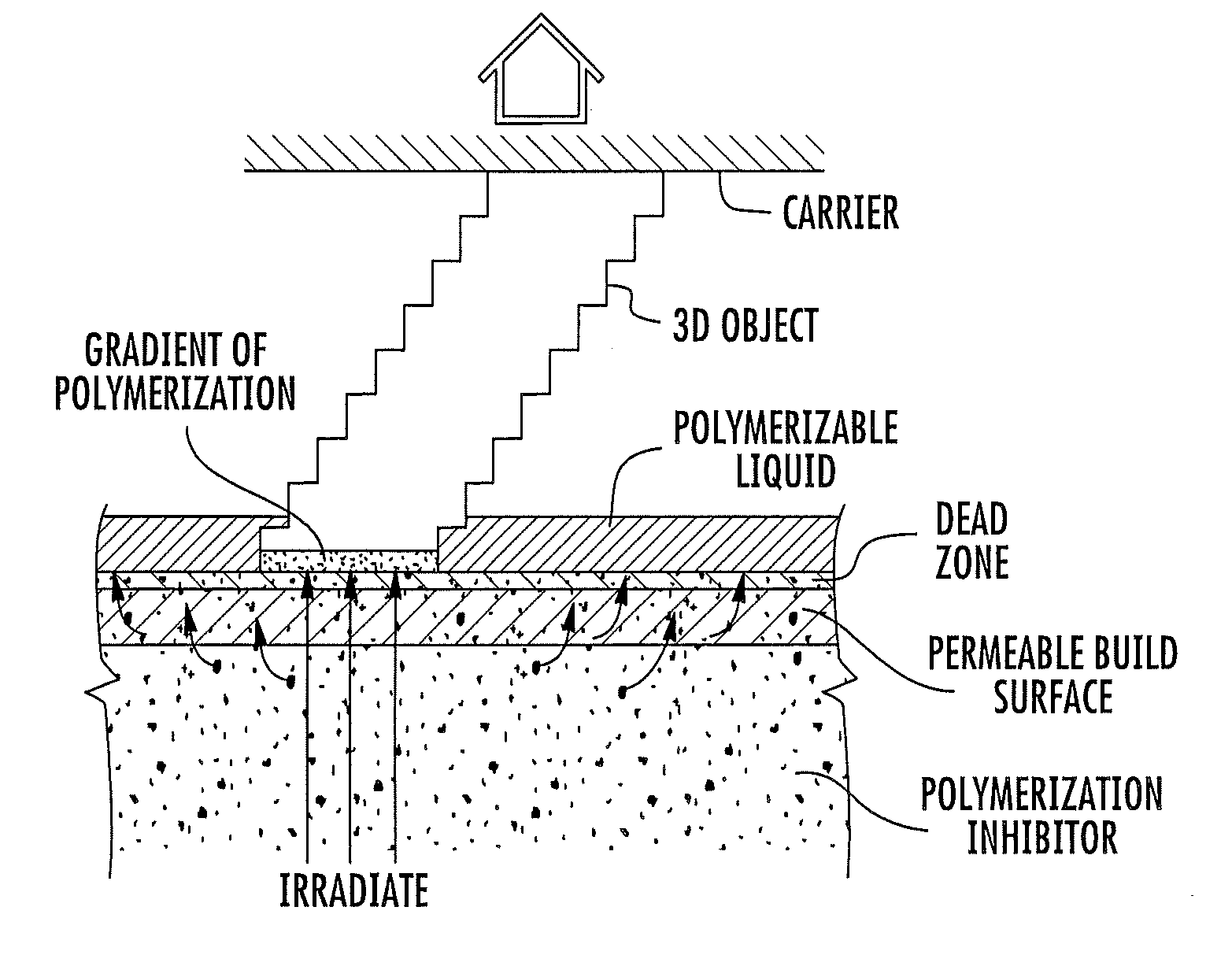

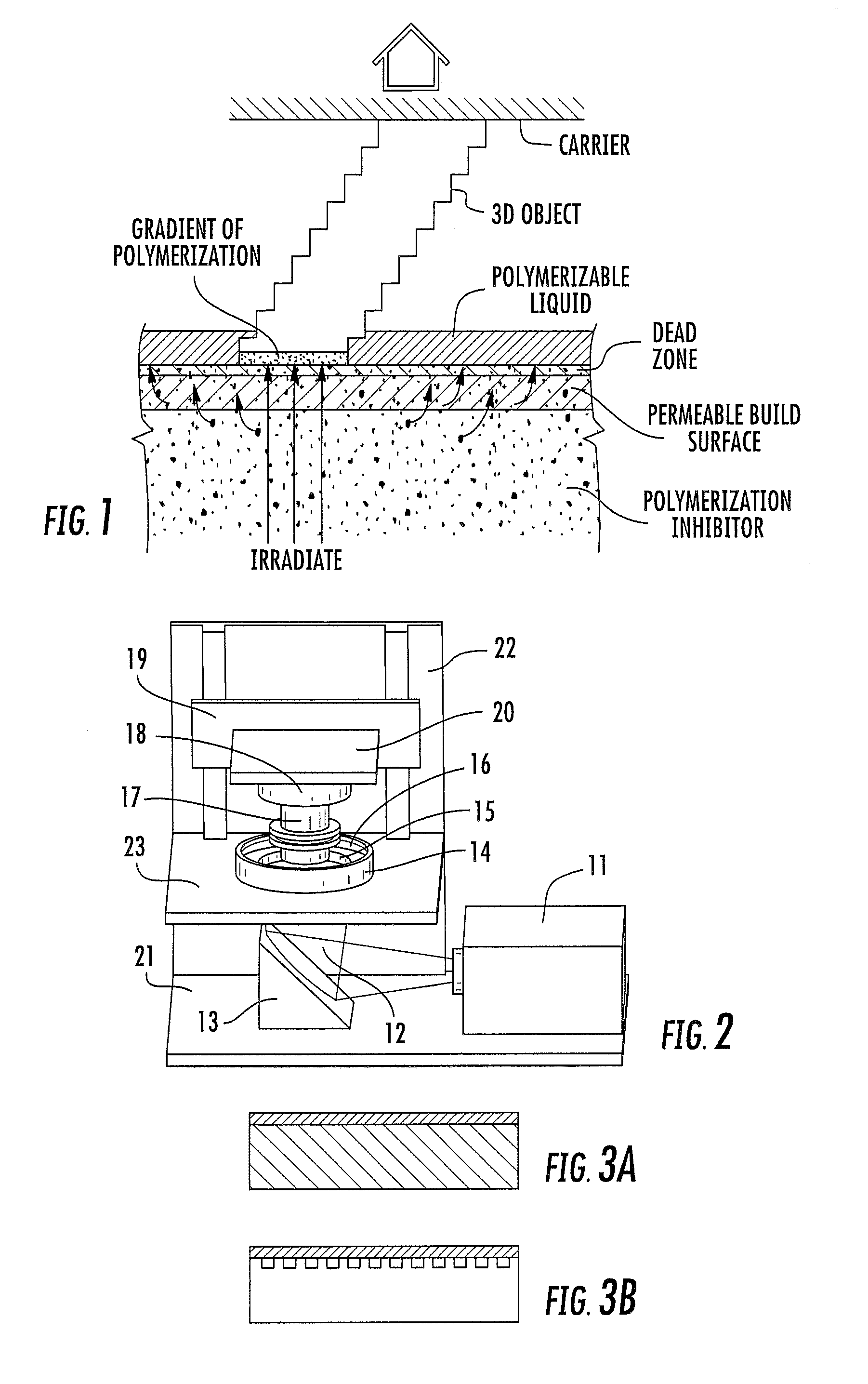

Continuous liquid interphase printing

A method of forming a three-dimensional object, comprises providing a carrier and an optically transparent member having a build surface, the carrier and the build surface defining a build region therebetween; filling the build region with a polymerizable liquid; irradiating the build region through the optically transparent member to form a solid polymer from the polymerizable liquid while concurrently advancing the carrier away from the build surface to form the three-dimensional object from the solid polymer, while also concurrently: (i) continuously maintaining a dead zone of polymerizable liquid in contact with the build surface, and (ii) continuously maintaining a gradient of polymerization zone between the dead zone and the solid polymer and in contact with each thereof, the gradient of polymerization zone comprising the polymerizable liquid in partially cured form. Apparatus for carrying out the method is also described.

Owner:CARBON INC

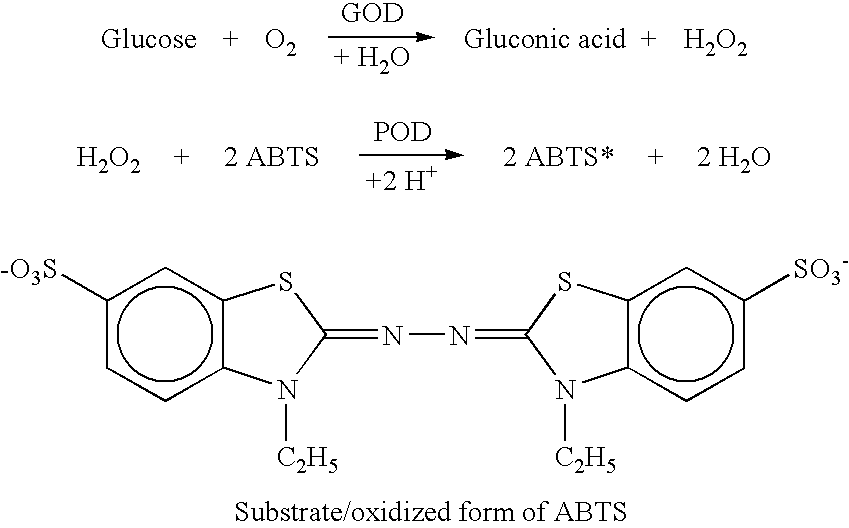

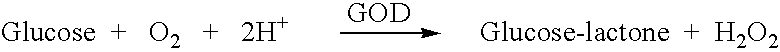

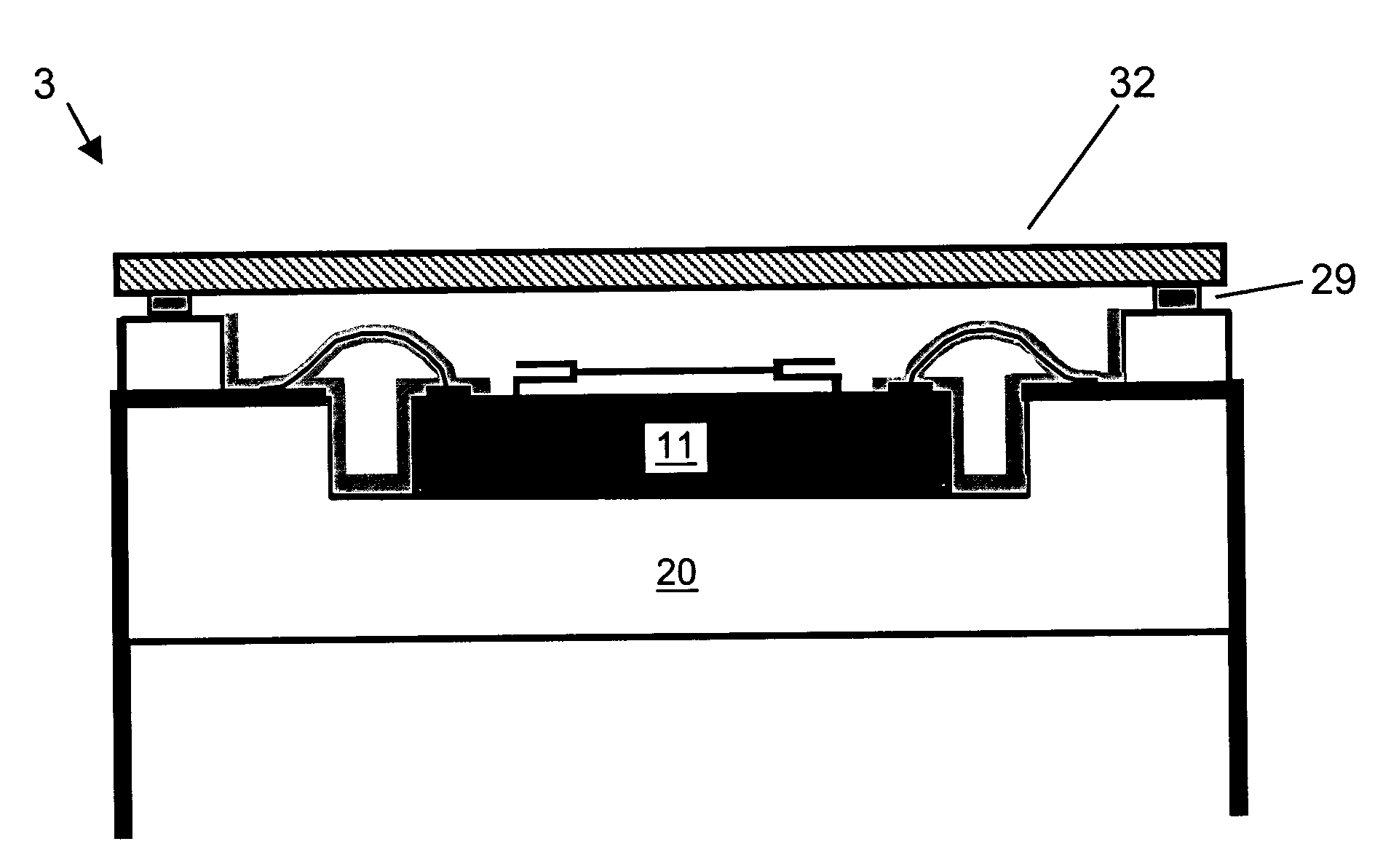

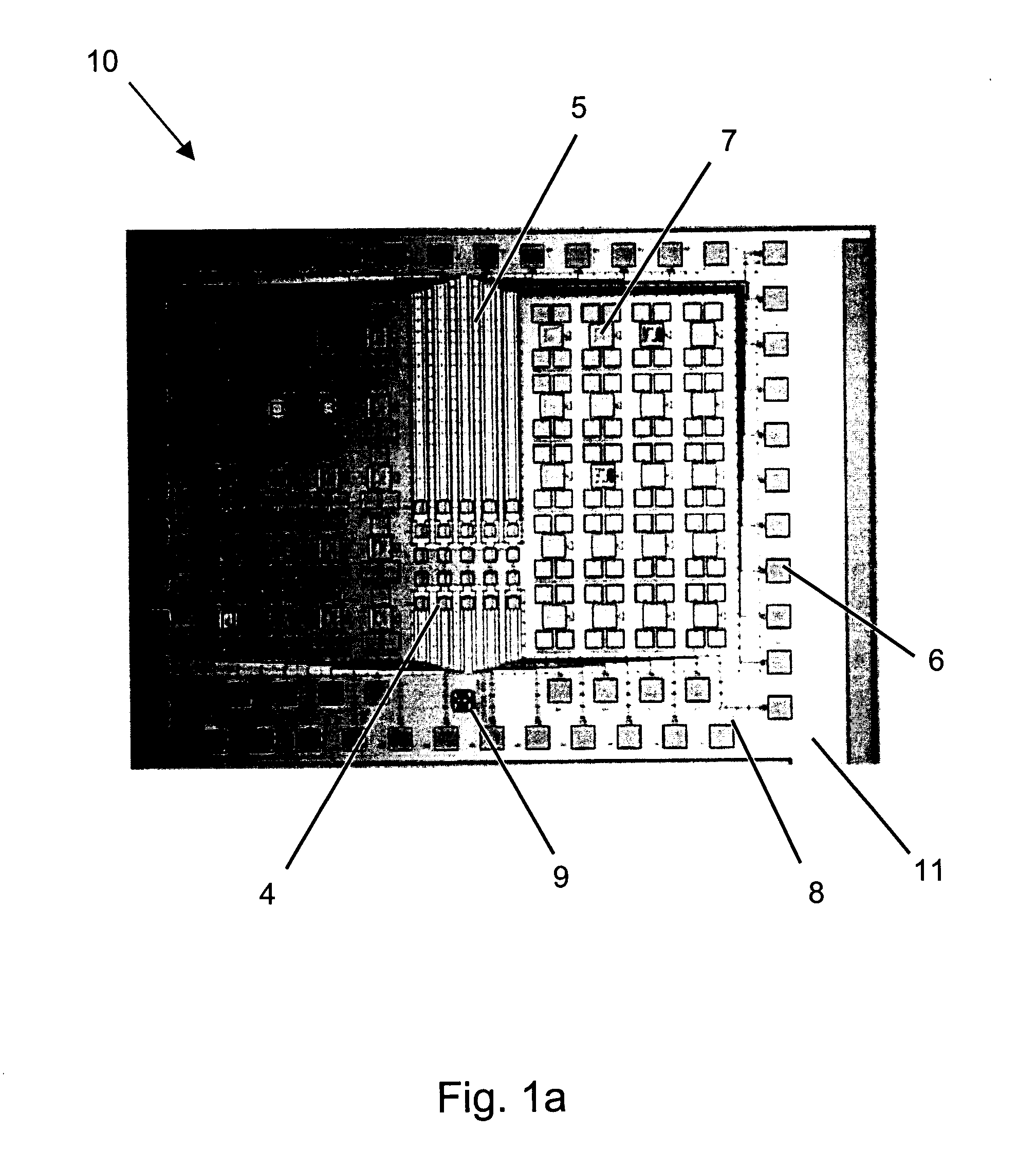

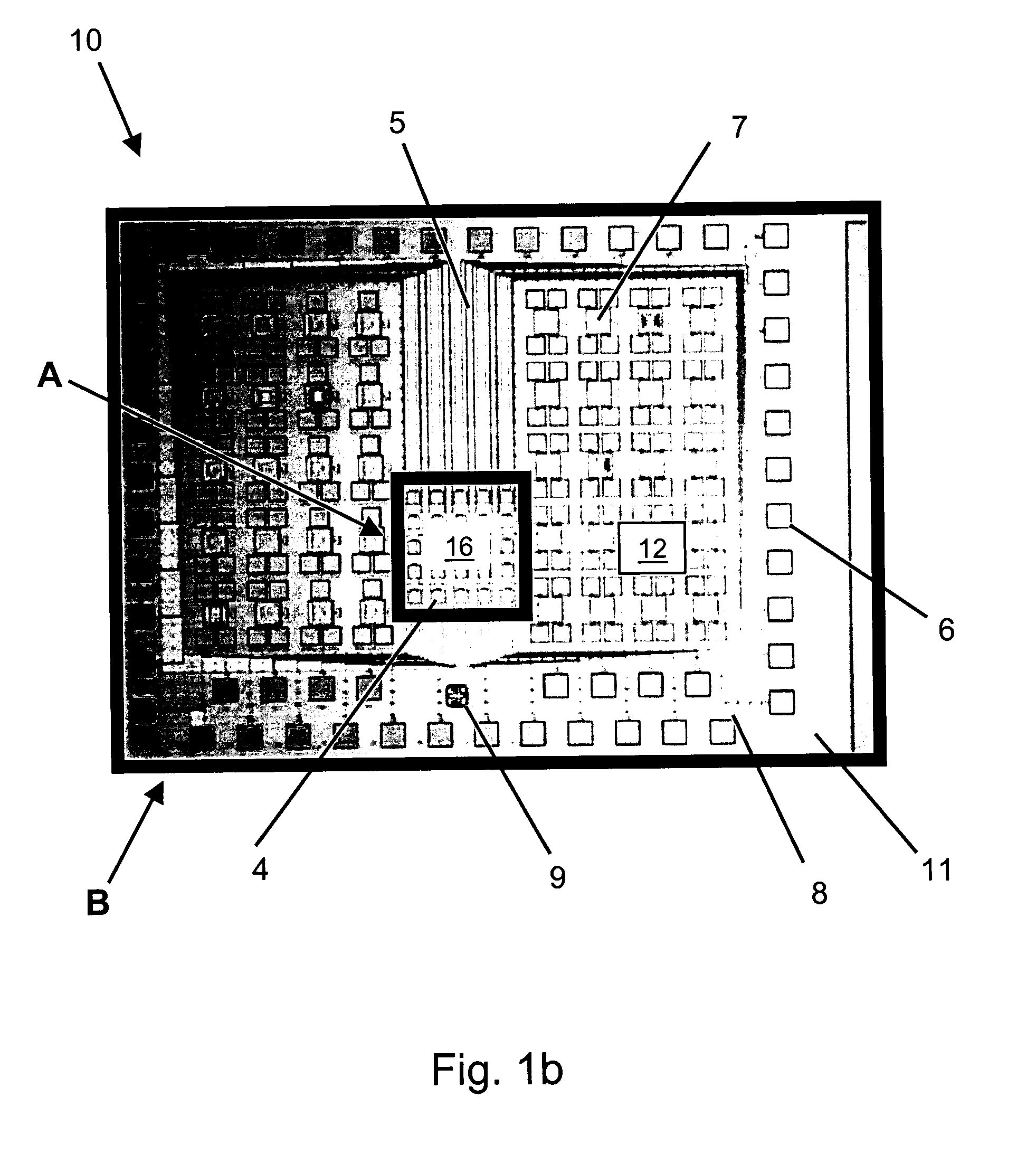

Analyte measurement

InactiveUS20040096959A1Low viscosityMore suitedBioreactor/fermenter combinationsBiological substance pretreatmentsElectrochemical detectorAnalyte

A glucose sensor in the form of a skin patch 2 has a microneedle 4 which painlessly penetrates the skin to draw out interstitial fluid. The interstitial fluid passes to a common entrance port 7. A series of microchannels 8 is provided on the skin patch. The fluid drawn onto the patch is selectively switched between a number of microchannels 8 by means of electro-osmotic pumps 10 and hydrophobic gates 12. Each microchannel 8 has an electrochemical detector 11 for sensing gluocse concentration. Also disclosed is a monlithic device with an integrated lance 83.

Owner:LIFESCAN IP HLDG LLC +1

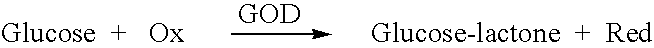

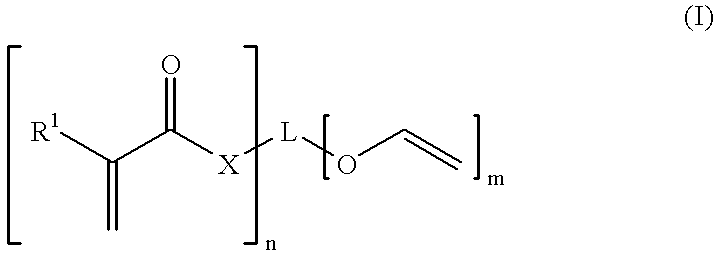

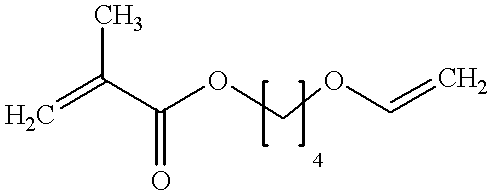

Ink compositions for ink jet printing

InactiveUS6310115B1Reduce viscosityLow viscosityLiquid surface applicatorsOrganic chemistryPolymer chemistryAcrylate

Owner:AGFA NV

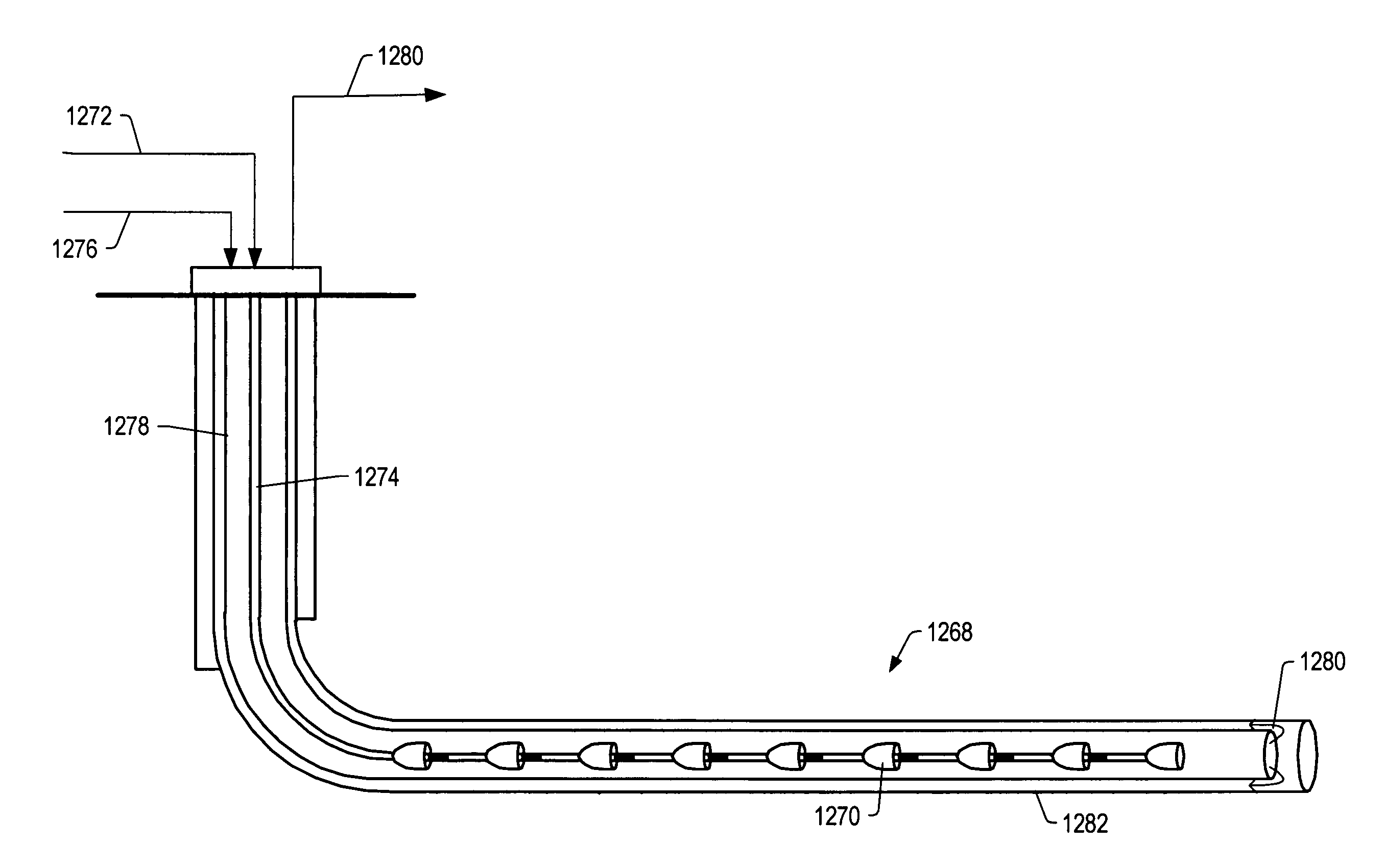

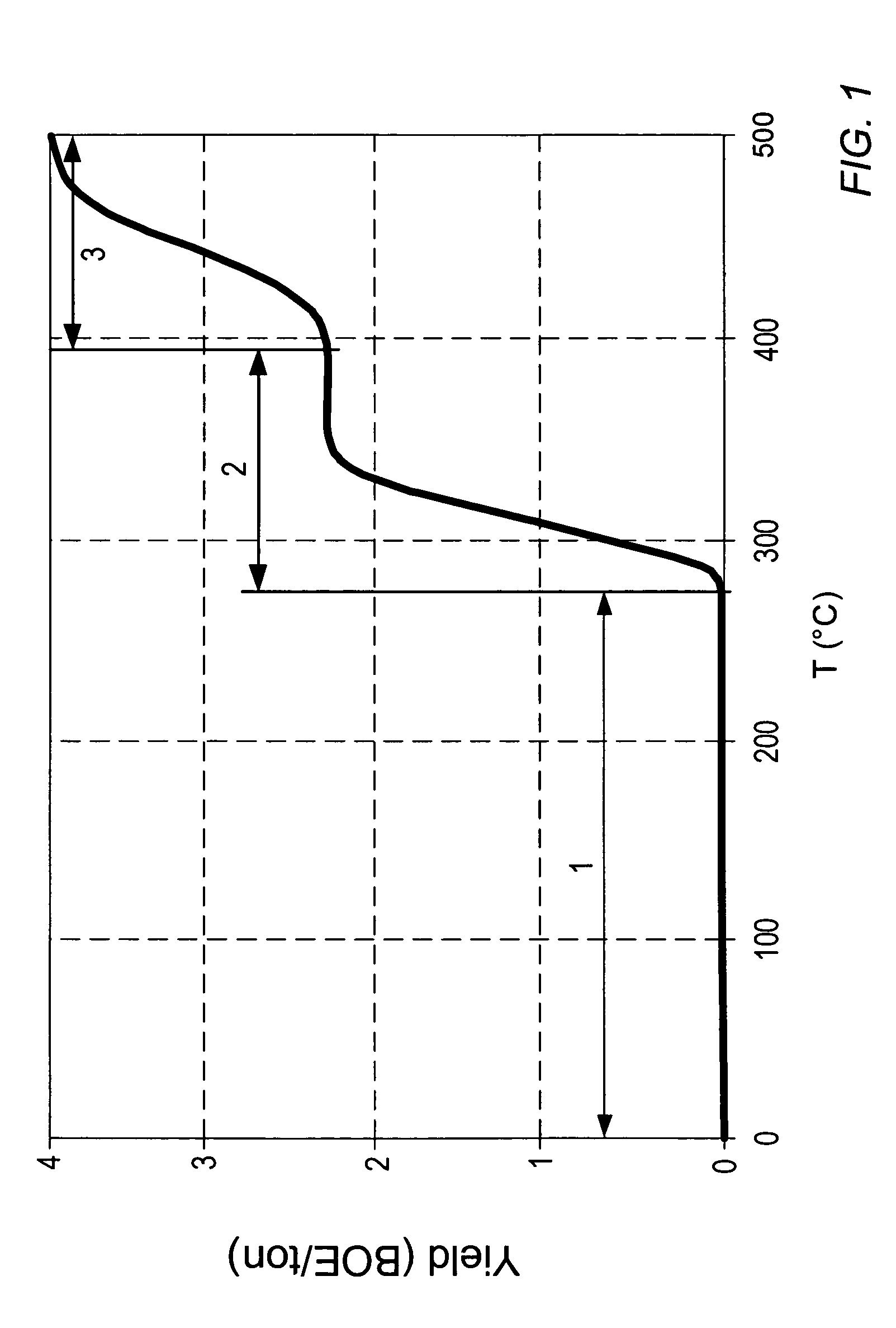

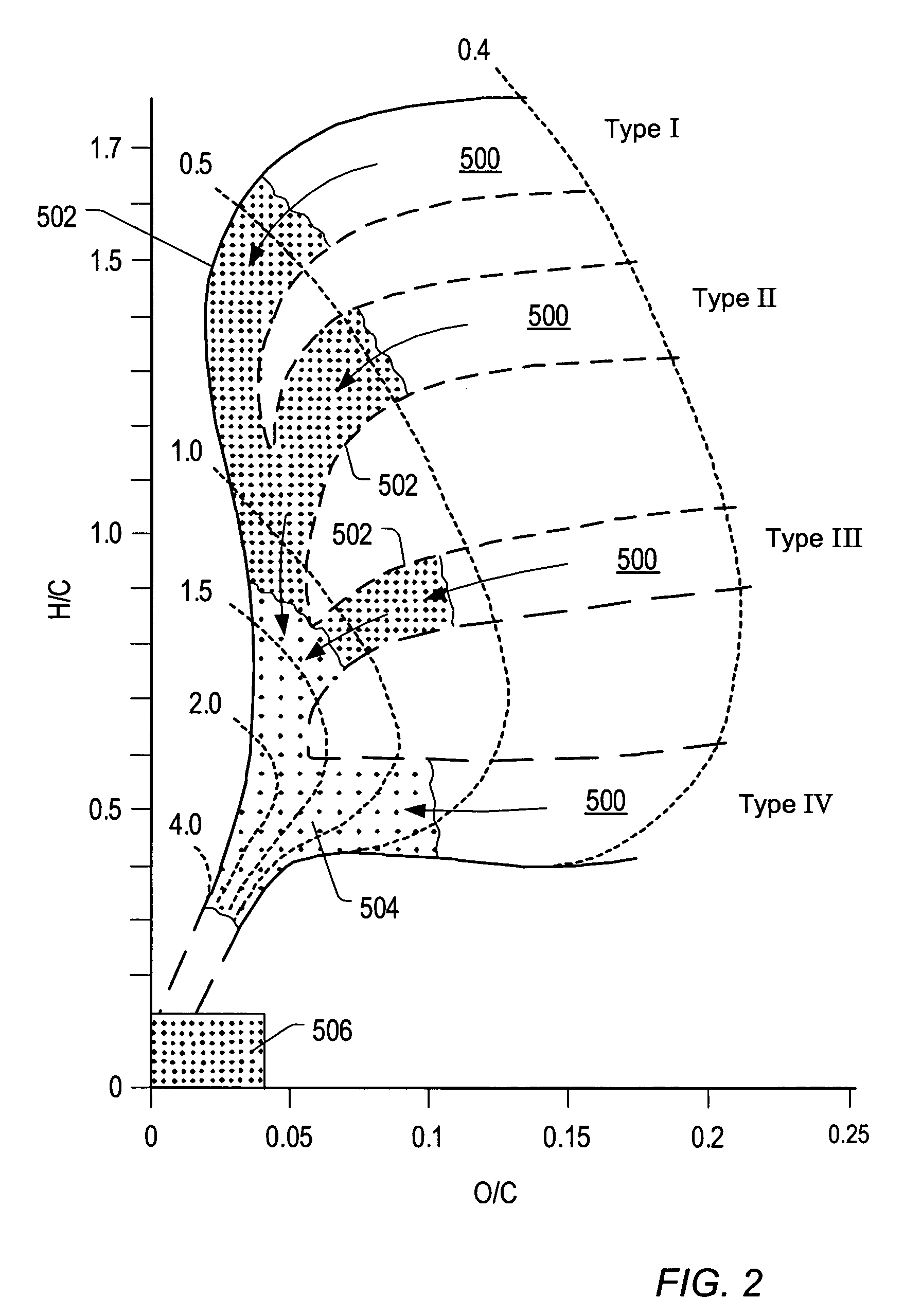

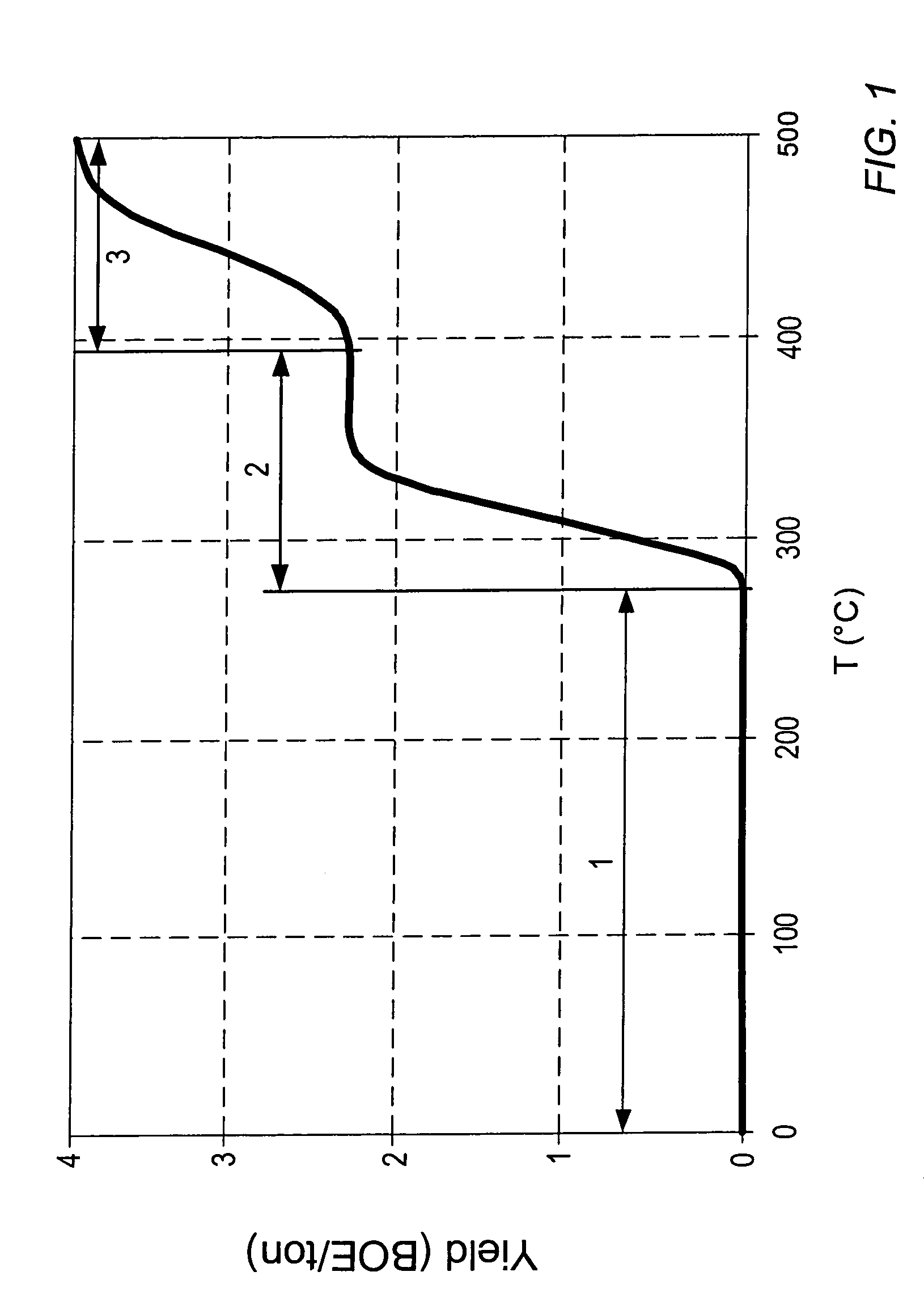

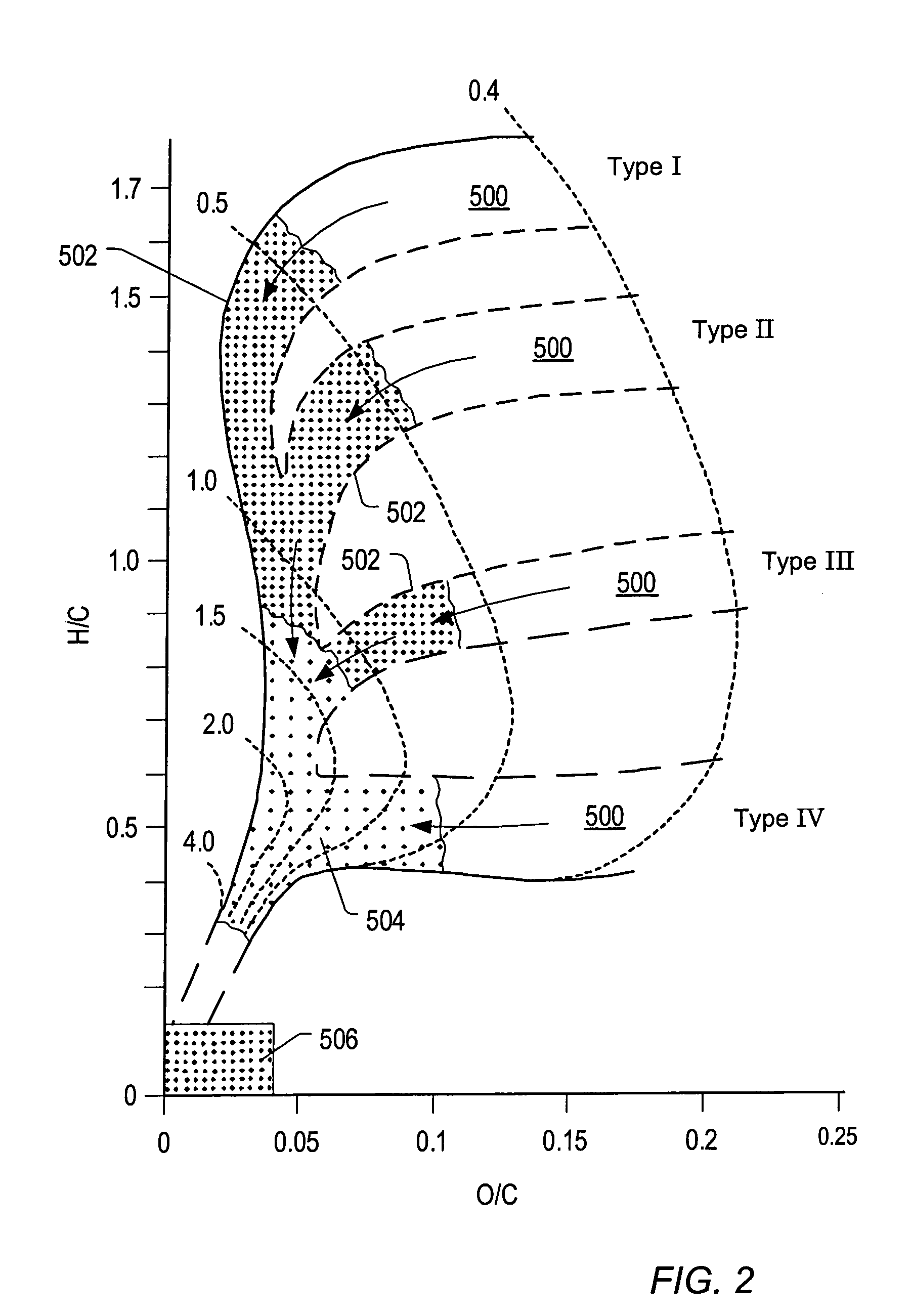

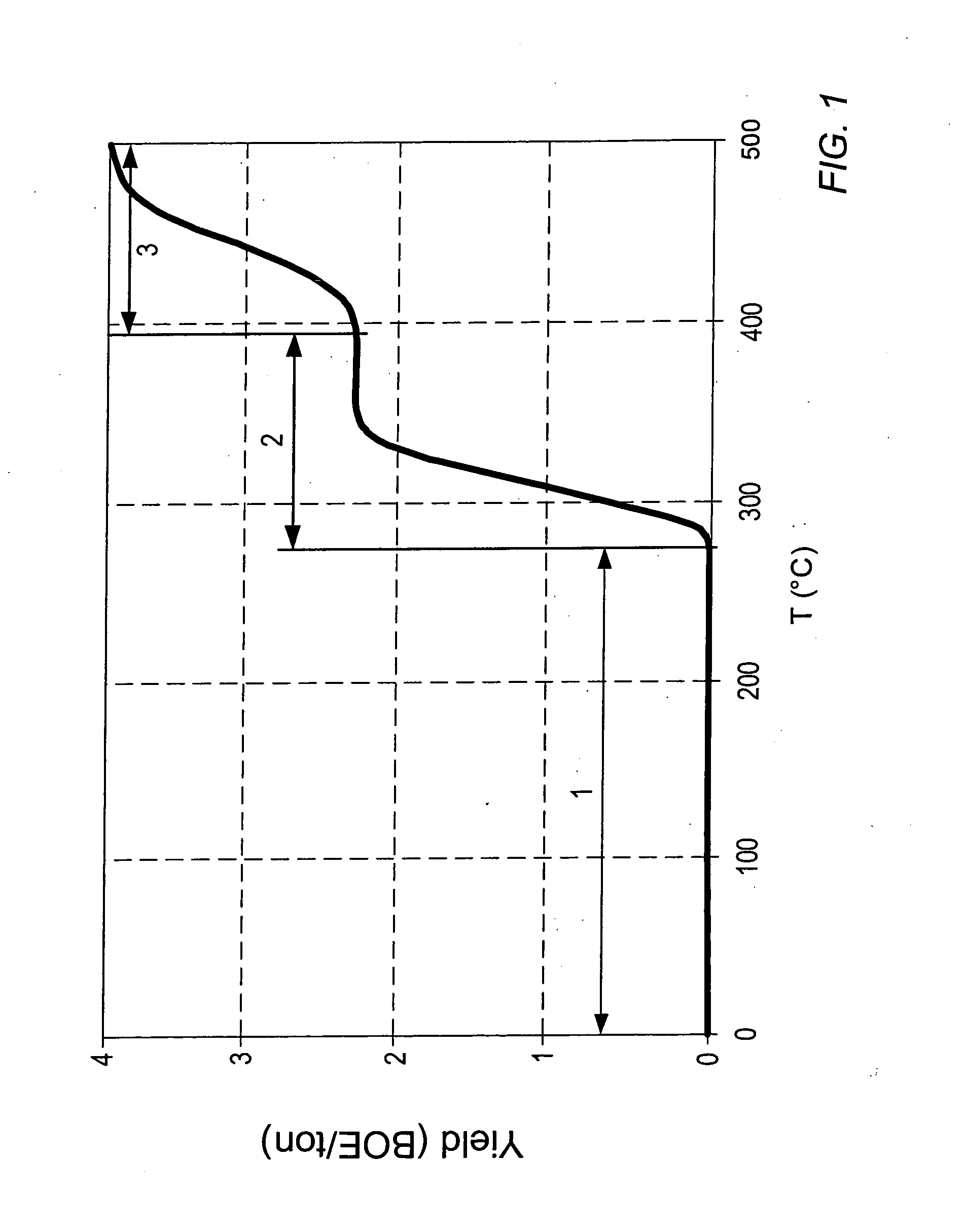

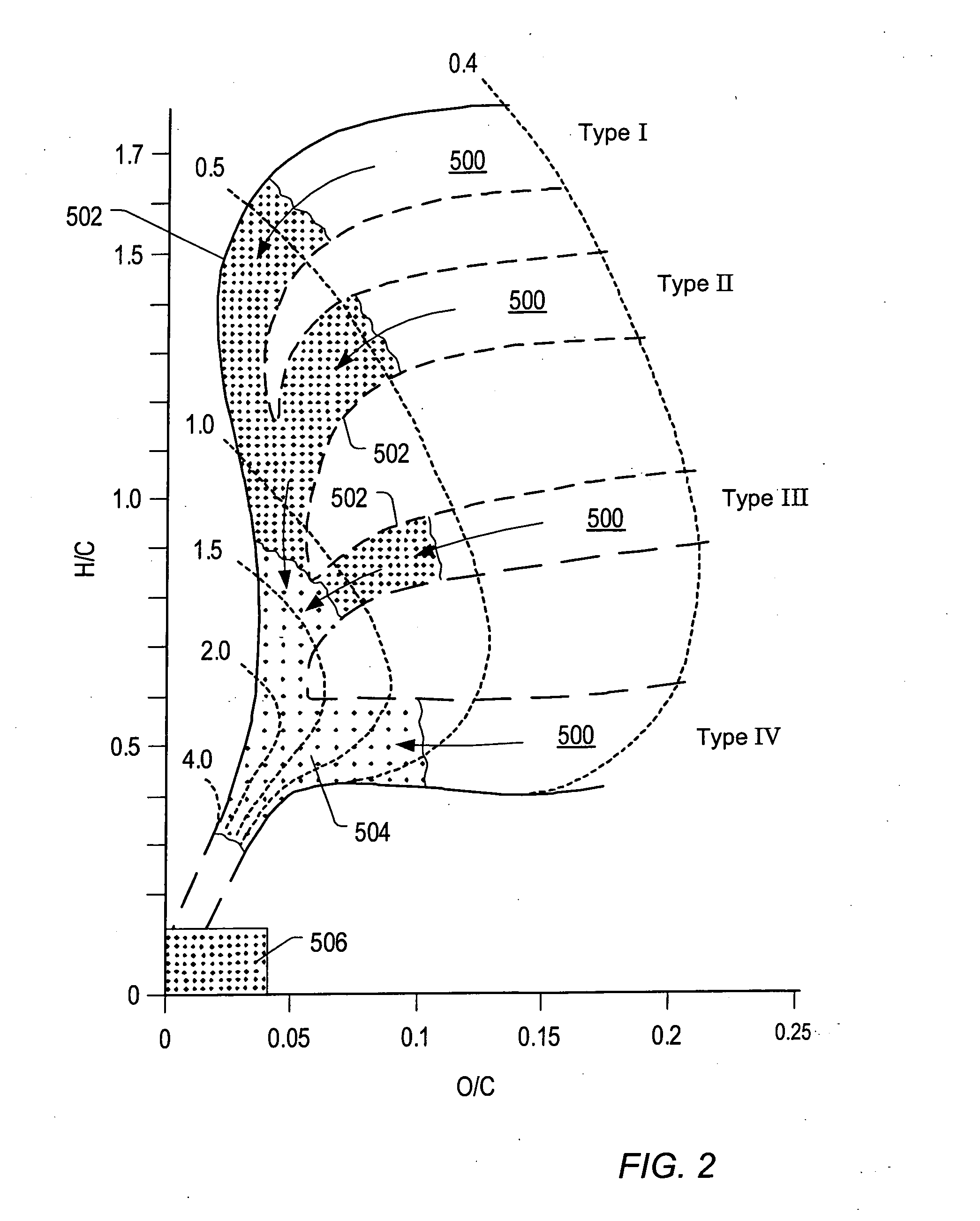

Thermal processes for subsurface formations

A process may include providing heat from one or more heaters to at least a portion of a subsurface formation. Heat may transfer from one or more heaters to a part of a formation. In some embodiments, heat from the one or more heat sources may pyrolyze at least some hydrocarbons in a part of a subsurface formation. Hydrocarbons and / or other products may be produced from a subsurface formation. Certain embodiments describe apparatus, methods, and / or processes used in treating a subsurface or hydrocarbon containing formation.

Owner:SHELL OIL CO

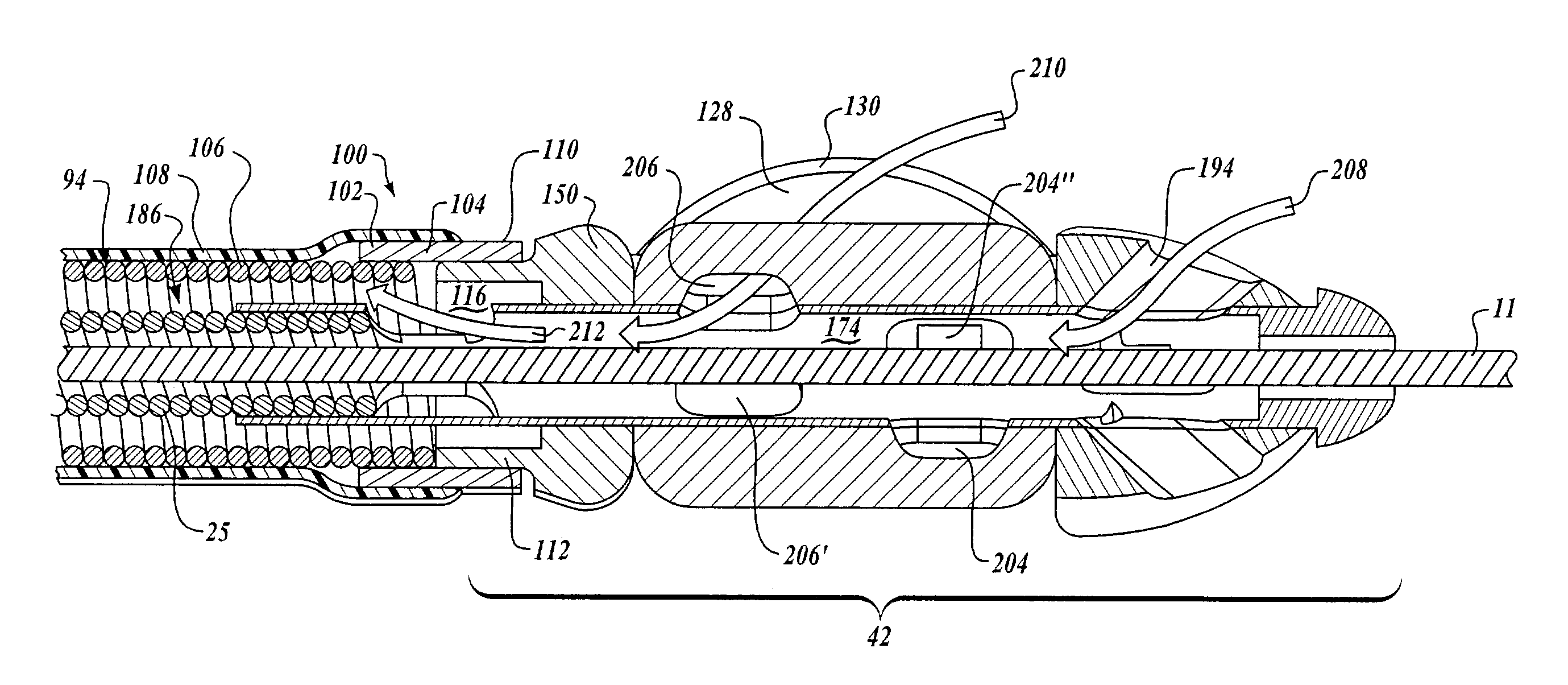

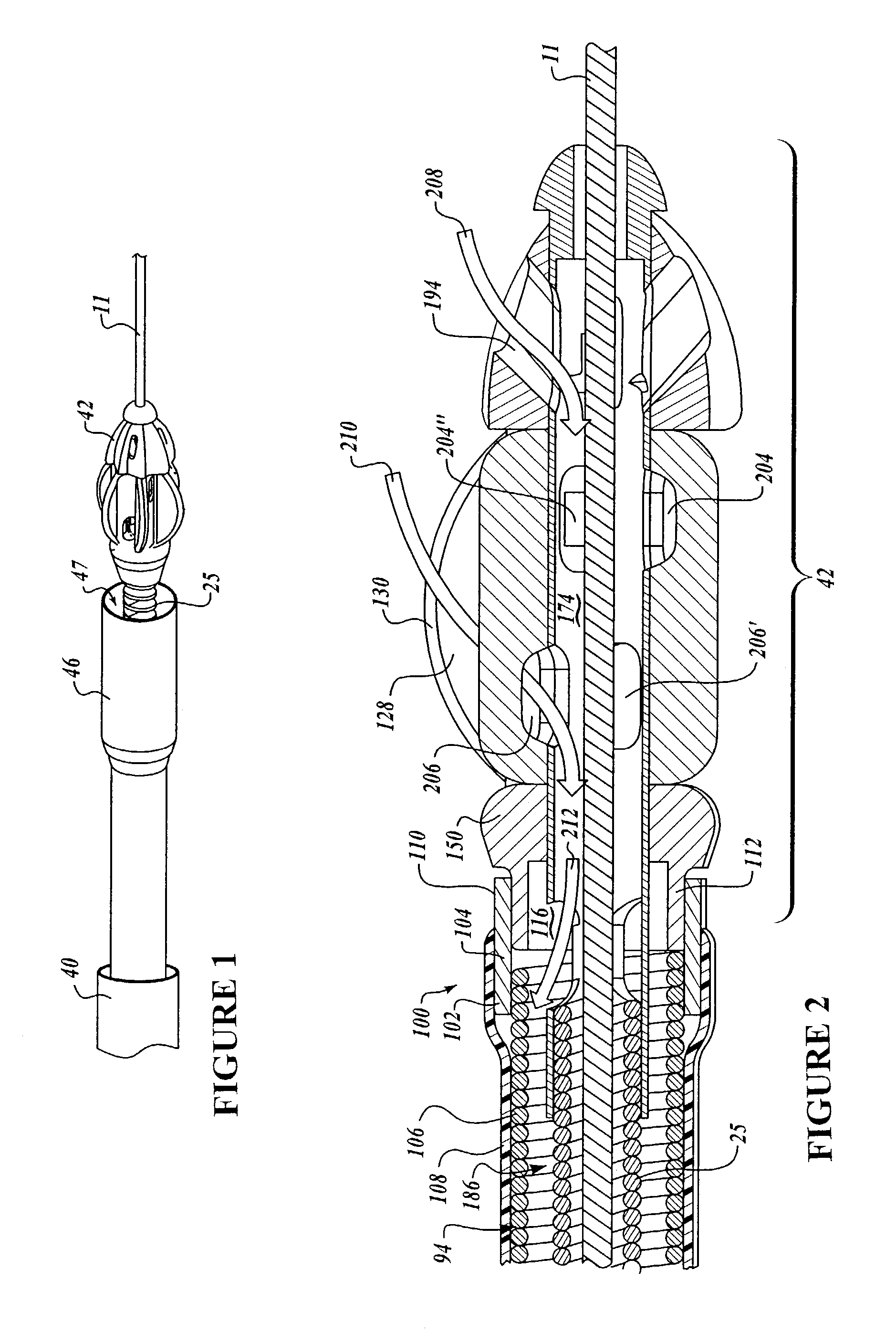

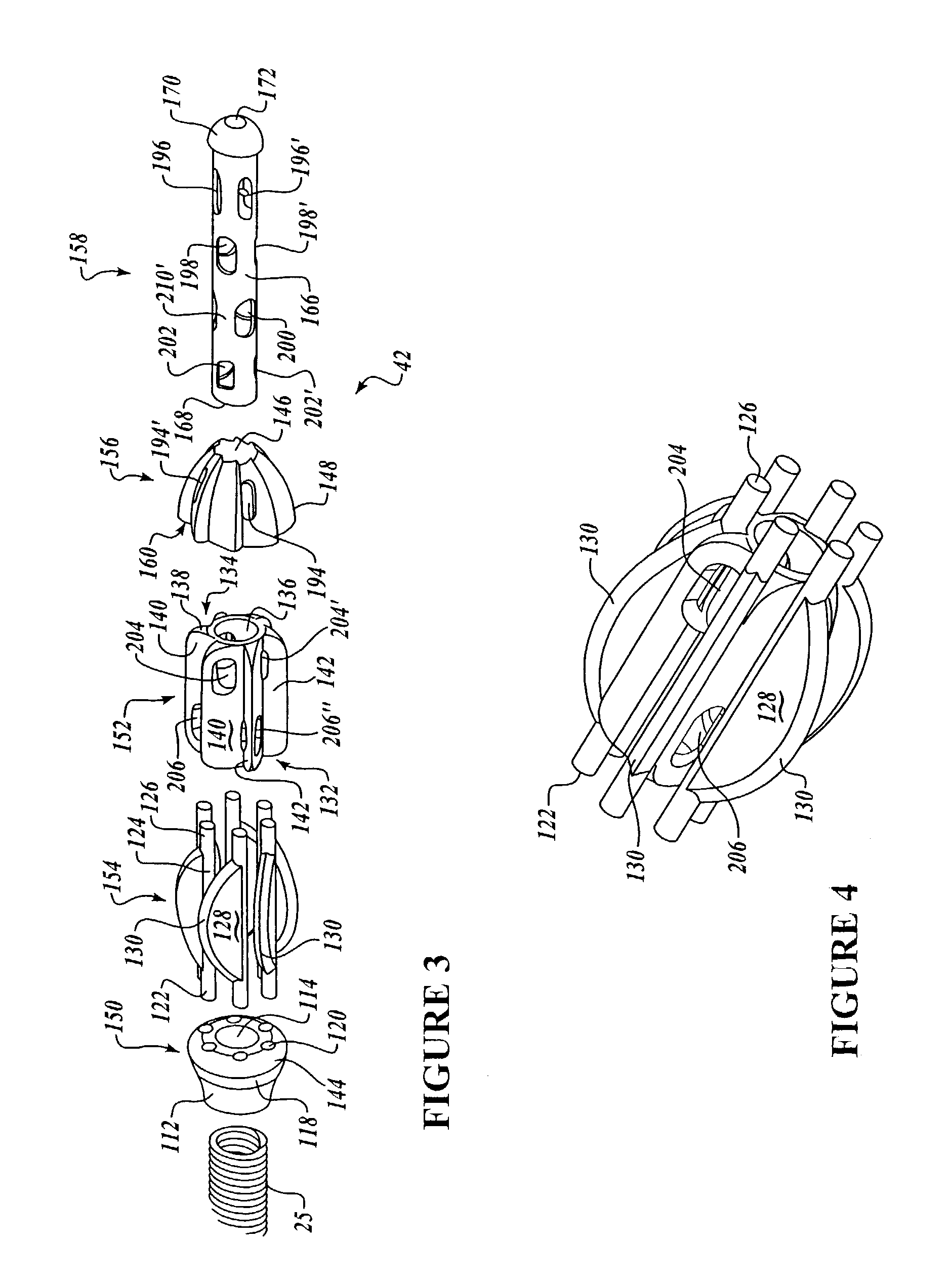

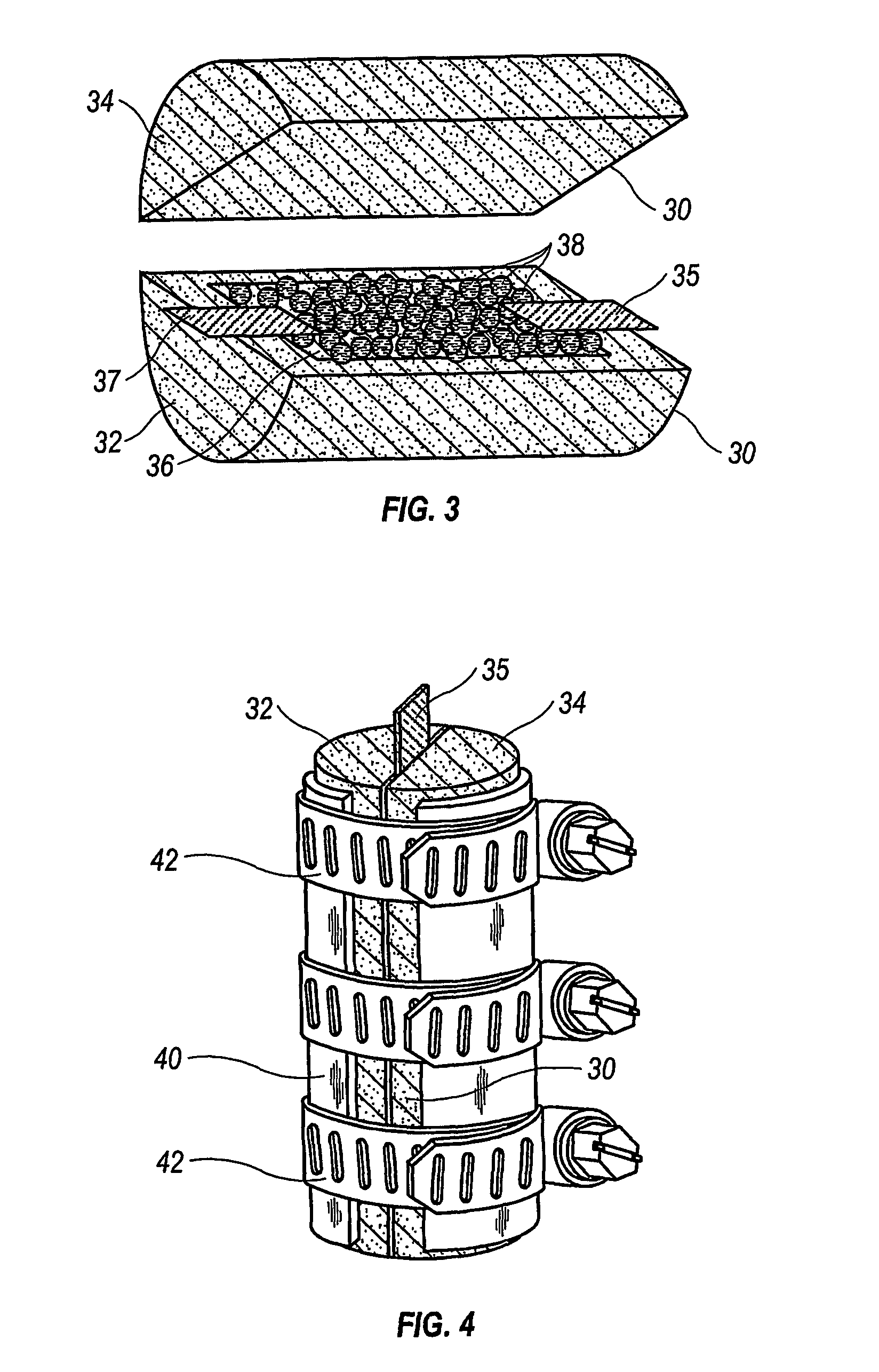

Intralumenal material removal using a cutting device for differential cutting

InactiveUS7344546B2Minimal damageFacilitates translation and navigationUltrasonic/sonic/infrasonic diagnosticsCannulasDrive shaftMaterial removal

Intralumenal material removal systems are provided using an advanceable and rotatable cutter assembly designed for differential cutting. The intralumenal material removal system includes a cutter assembly positionable in the body cavity of a mammalian subject. One embodiment of the cutter assembly includes a cutter with blades that are designed and arranged to form an acute blade angle of attack with the matter-to-be-removed. The cutter assembly is axially advanceable by translating the drive shaft and rotatable by rotating the drive shaft. The occlusive material is scraped by the cutter assembly and may be aspirated to remove the material from the body cavity. The cutter assembly may provide aspiration ports positioned between facing surfaces of the blades.

Owner:BOSTON SCI LTD

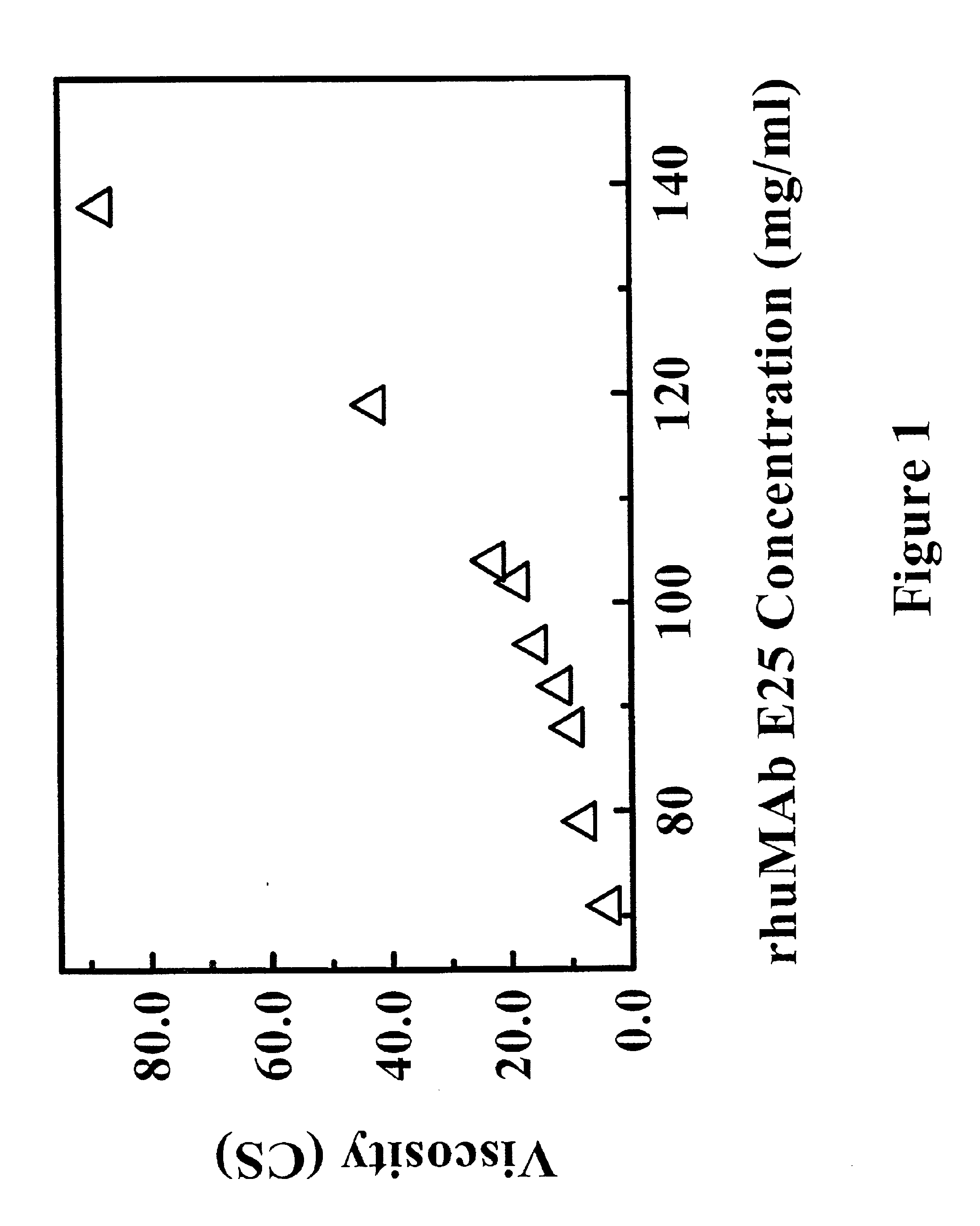

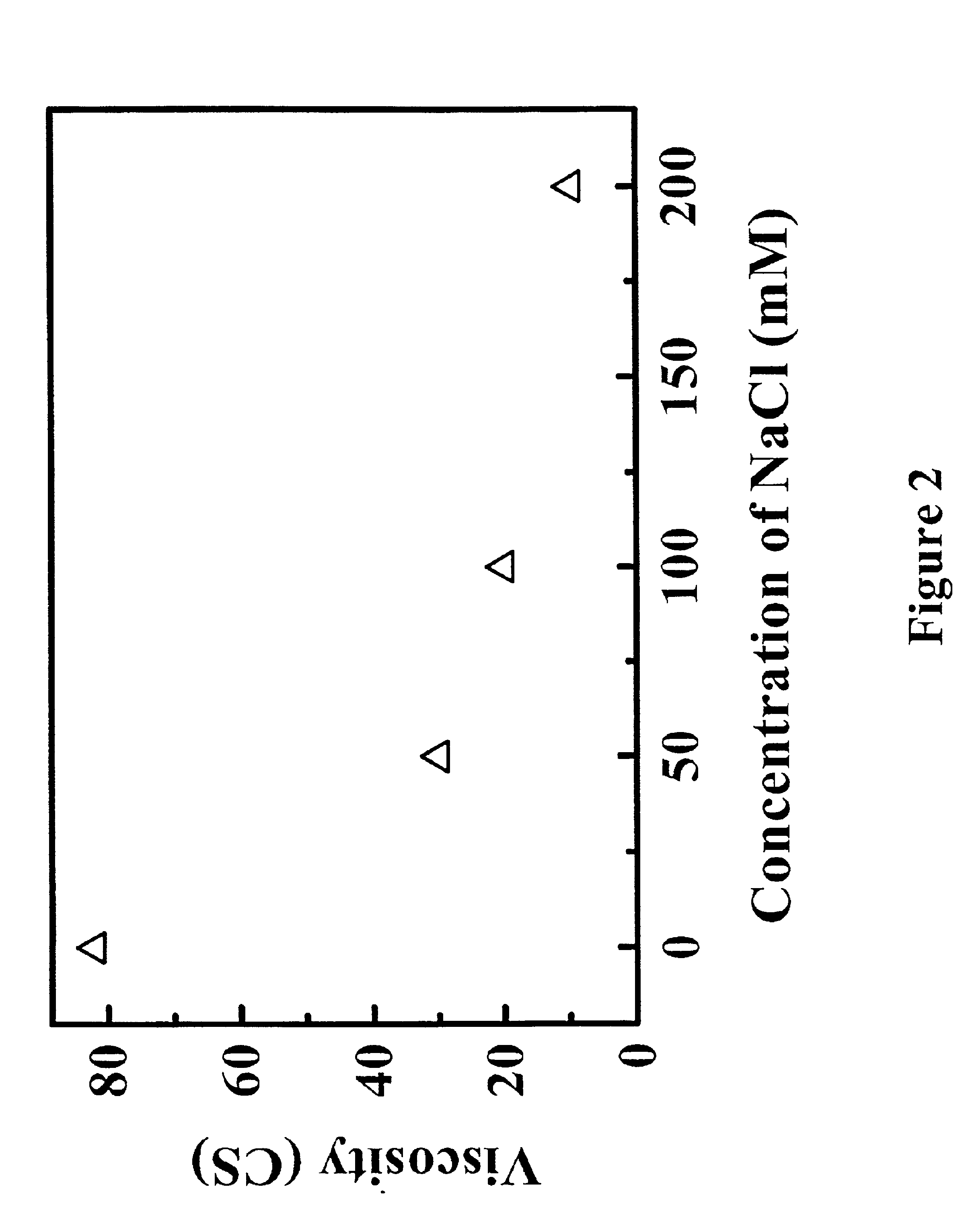

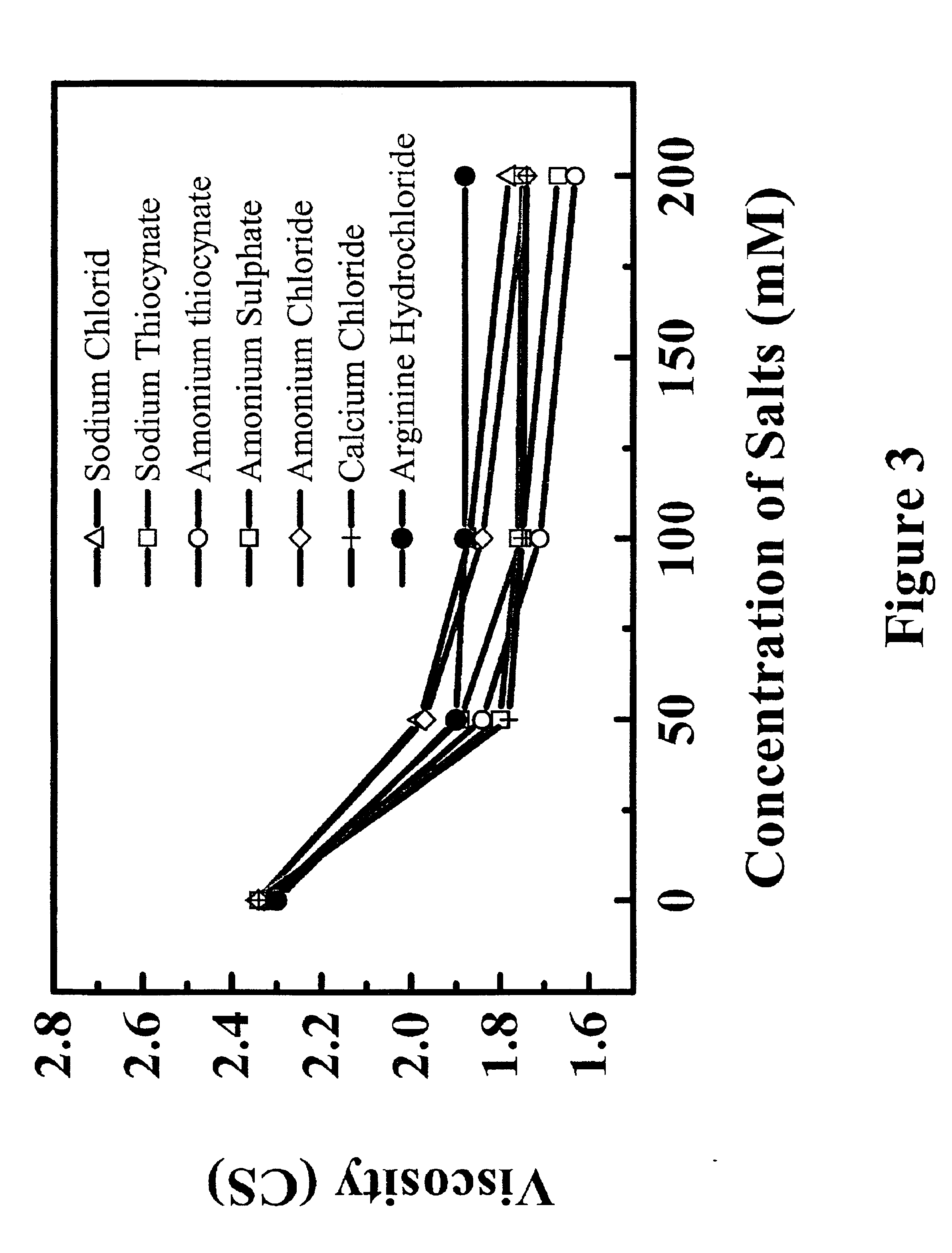

Reduced-viscosity concentrated protein formulations

InactiveUS6875432B2Low viscosityCompromising stability and biological activityPeptide/protein ingredientsInorganic non-active ingredientsConcentration proteinChemistry

The present application concerns concentrated protein formulations with reduced viscosity, which are particularly suitable for subcutaneous administration. The application further concerns a method for reducing the viscosity of concentrated protein formulations.

Owner:GENENTECH INC +1

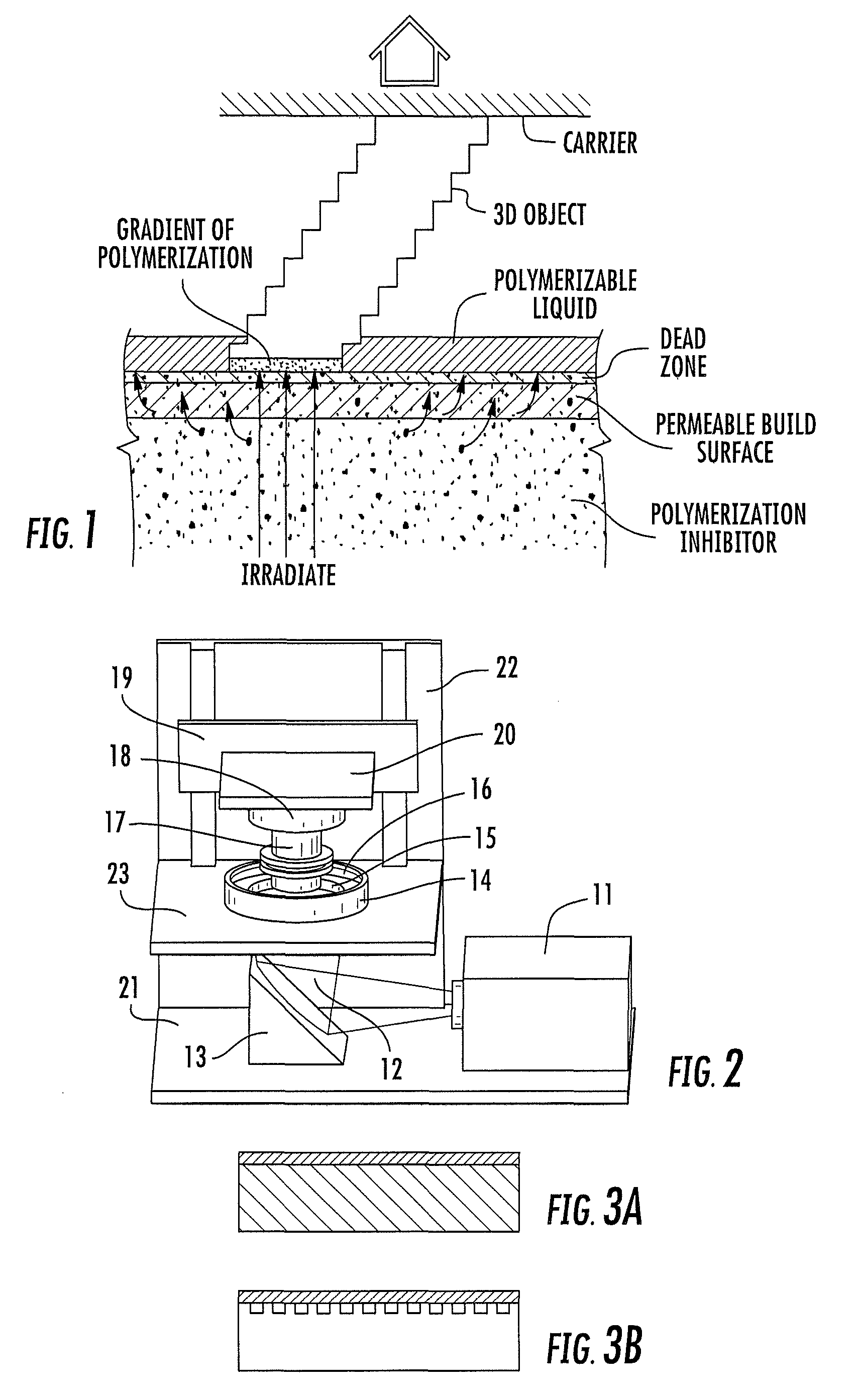

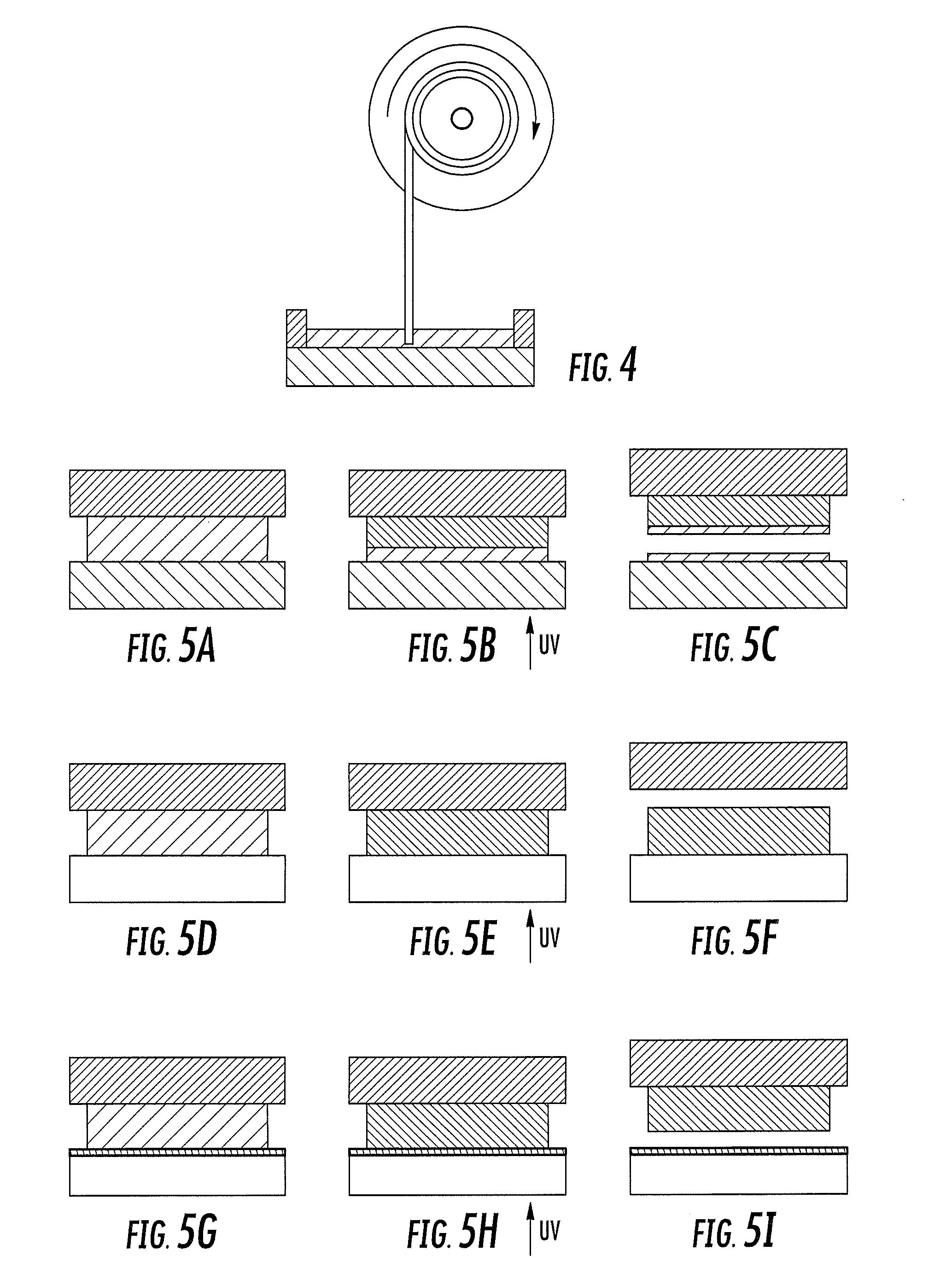

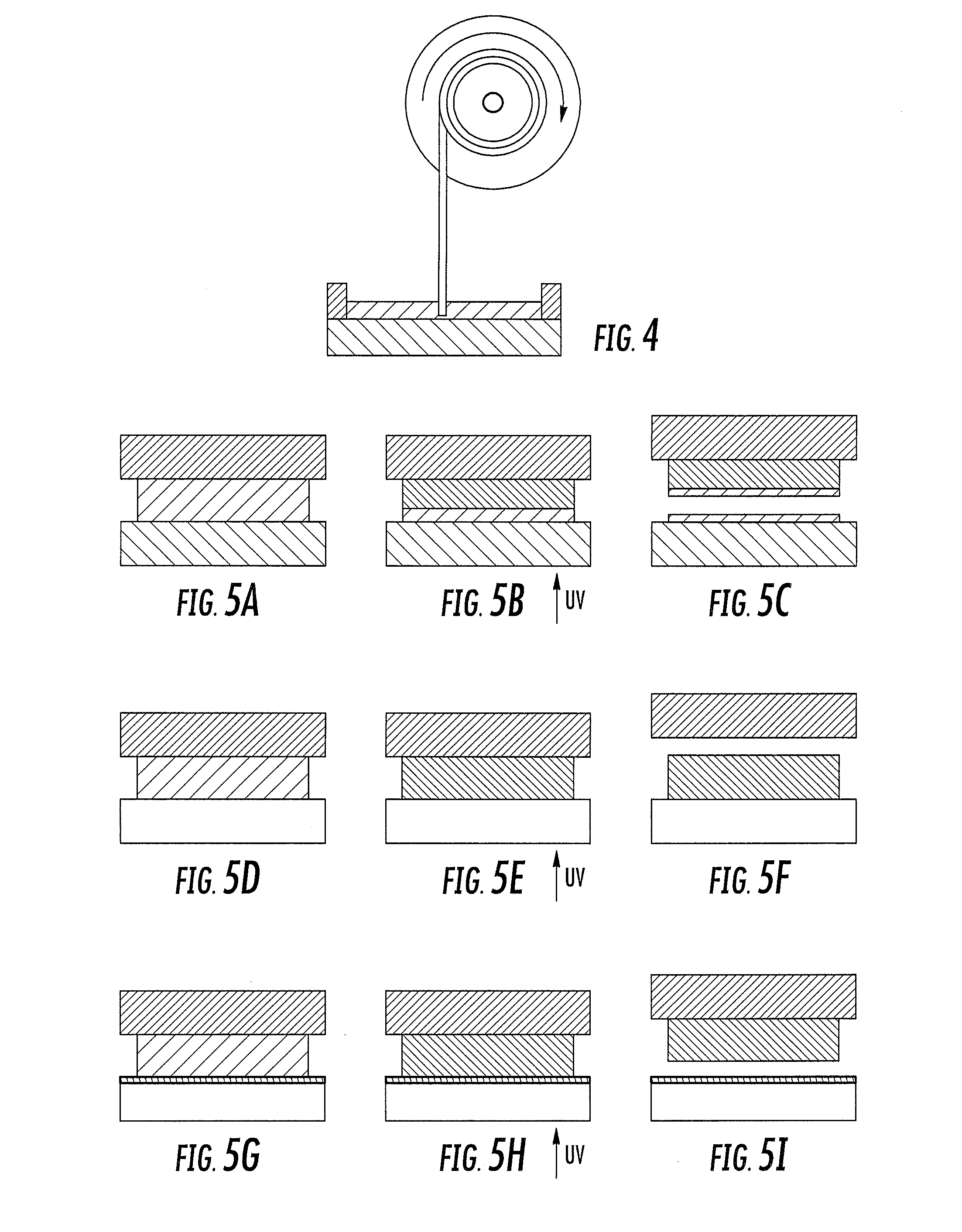

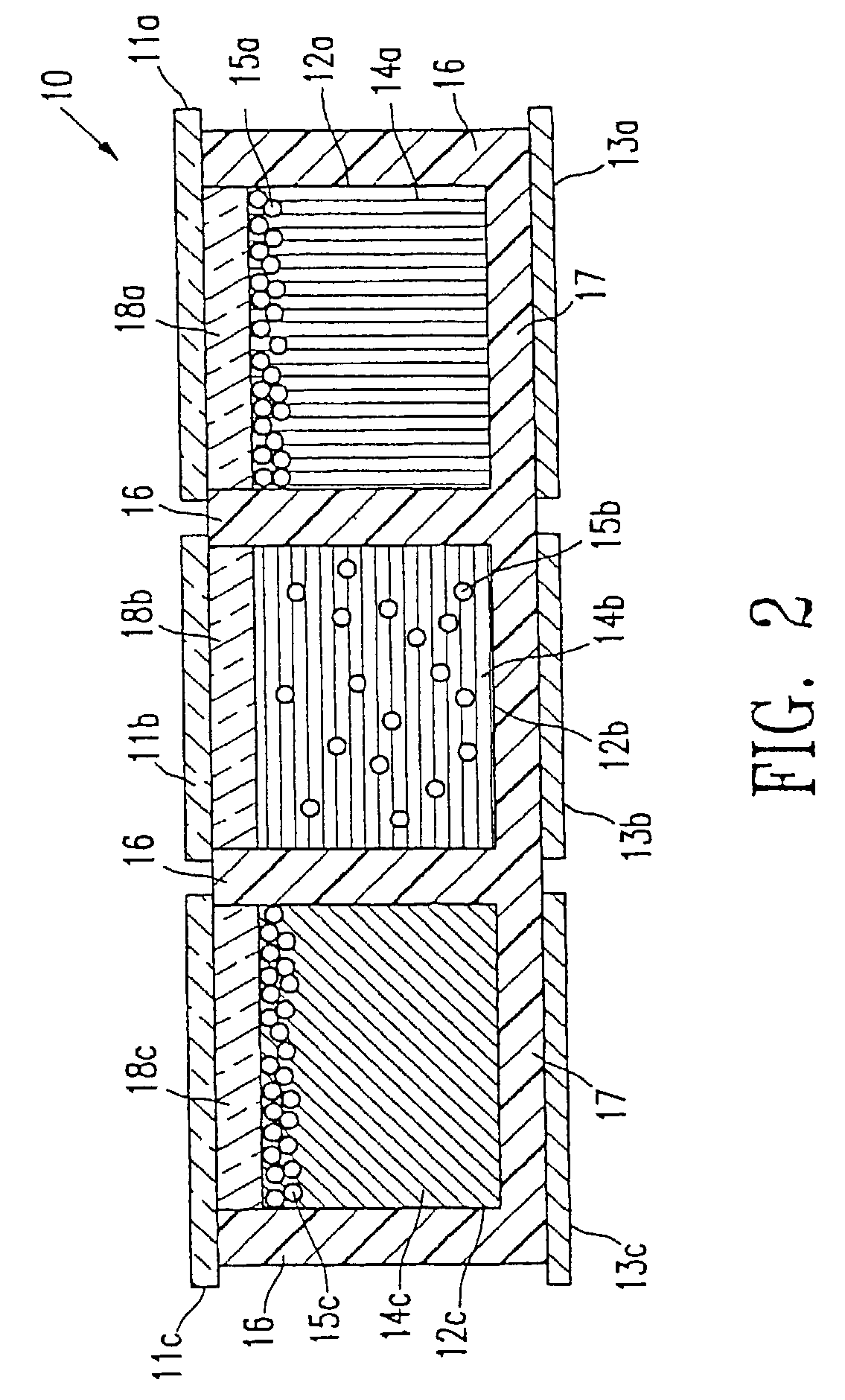

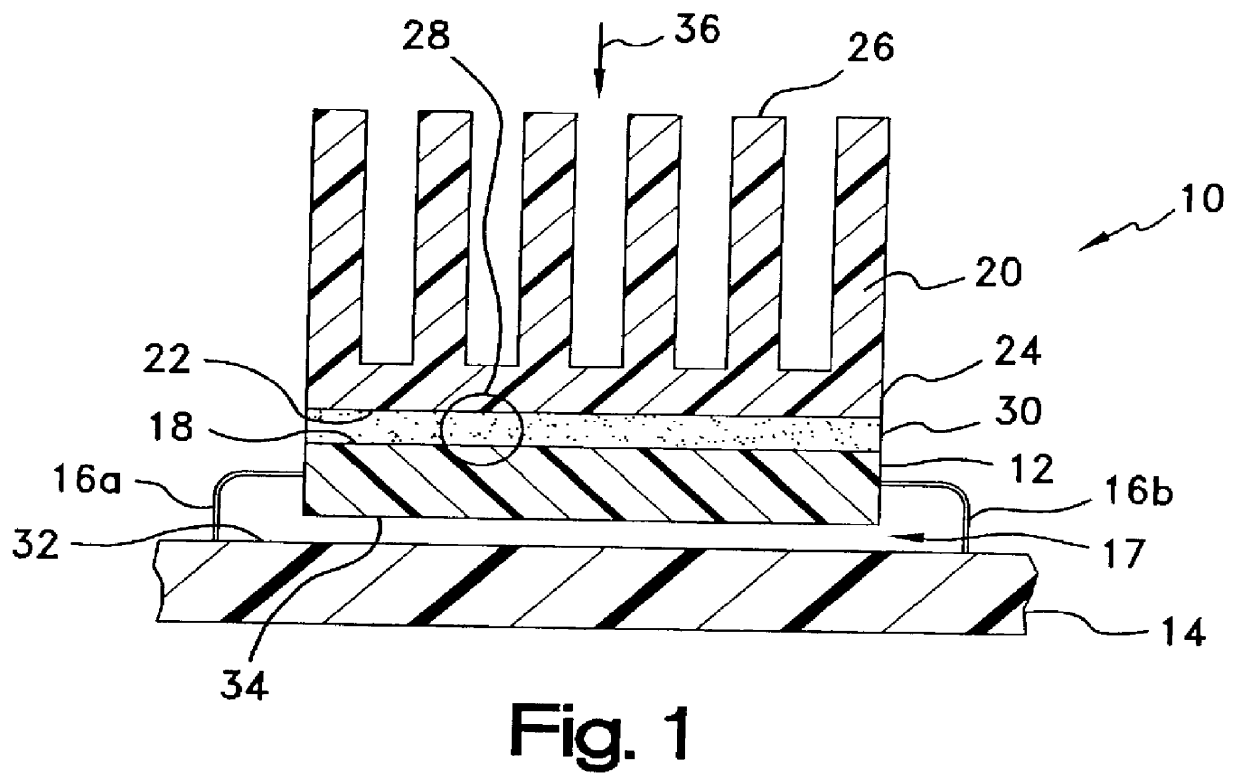

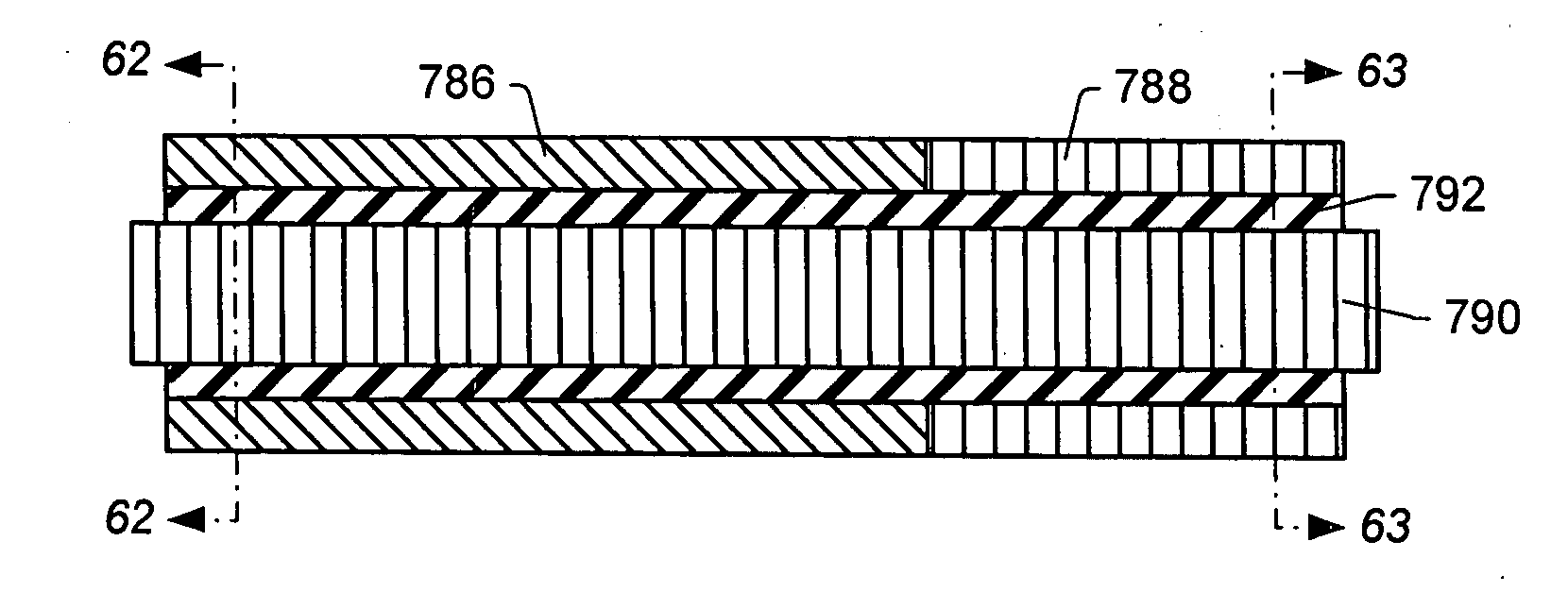

Method and apparatus for three-dimensional fabrication with feed through carrier

A method of forming a three-dimensional object, is carried out by (a) providing a carrier and a build plate, the build plate comprising a semipermeable member, the semipermeable member comprising a build surface with the build surface and the carrier defining a build region therebetween, and with the build surface in fluid communication by way of the semipermeable member with a source of polymerization inhibitor; (b) filling the build region with a polymerizable liquid, the polymerizable liquid contacting the build surface; (c) irradiating the build region through the build plate to produce a solid polymerized region in the build region, while forming or maintaining a liquid film release layer comprised of the polymerizable liquid formed between the solid polymerized region and the build surface, the polymerization of which liquid film is inhibited by the polymerization inhibitor; and (d) advancing the carrier with the polymerized region adhered thereto away from the build surface on the build plate to create a subsequent build region between the polymerized region and the build surface; (e) wherein the carrier has at least one channel formed therein, and the filling step is carried out by passing or forcing the polymerizable liquid into the build region through the at least one channel. Apparatus for carrying out the method is also described

Owner:CARBON INC

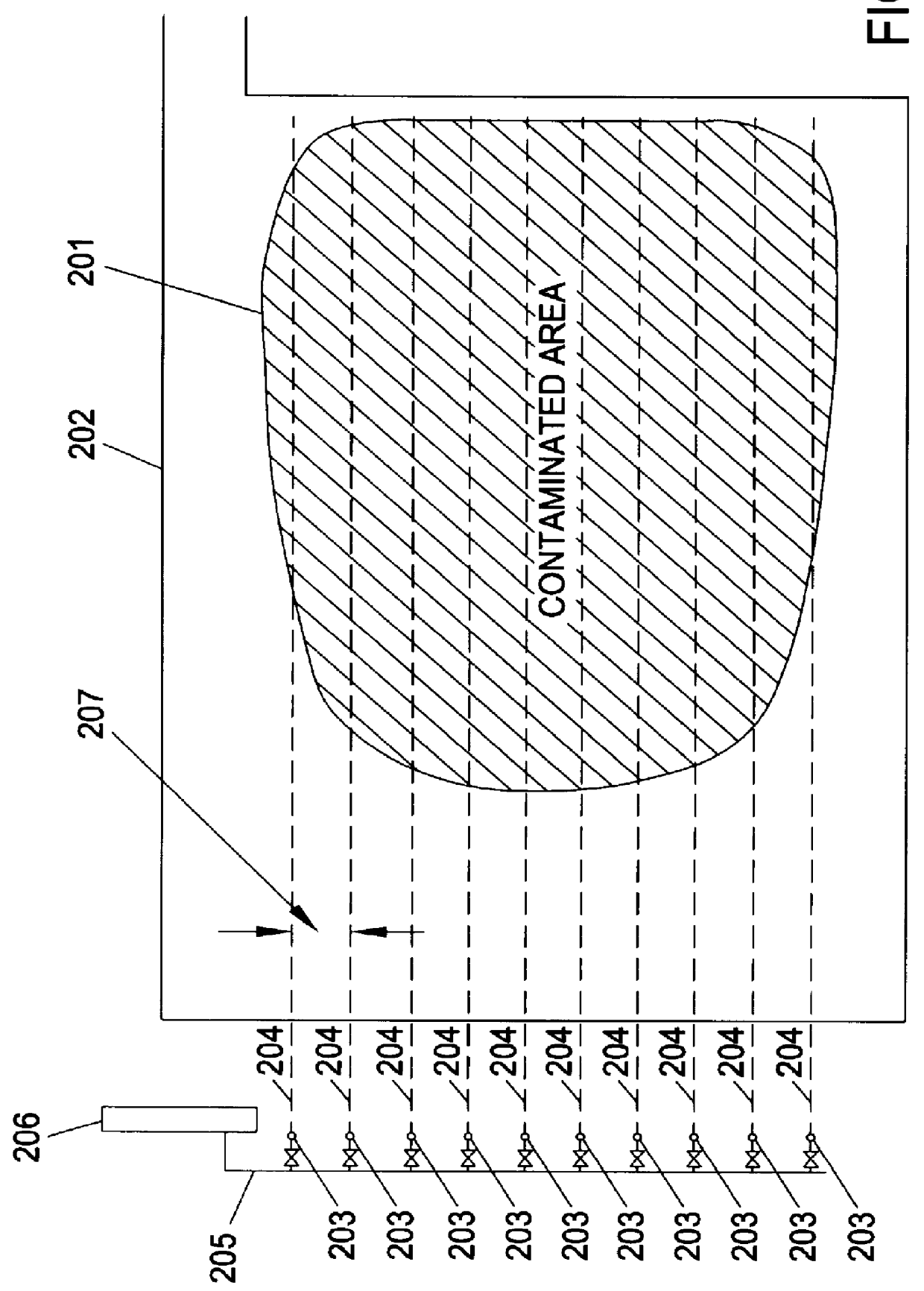

Remediation method

InactiveUS6102622AHigh concentration of pollutantsLow viscosityConstructionsSolid waste disposalPollutantWellhead

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Staged and/or patterned heating during in situ thermal processing of a hydrocarbon containing formation

A method for treating a hydrocarbon containing formation is described. The method for treating a hydrocarbon containing formation may include heating a first volume of the formation using a first set of heaters. A second volume of the formation may be heated using a second set of heaters. The first volume may be spaced apart from the second volume by a third volume of the formation. The first volume, second volume, and / or third volume may be sized, shaped, and / or located to inhibit deformation of subsurface equipment caused by geomechanical motion of the formation during heating.

Owner:SHELL OIL CO

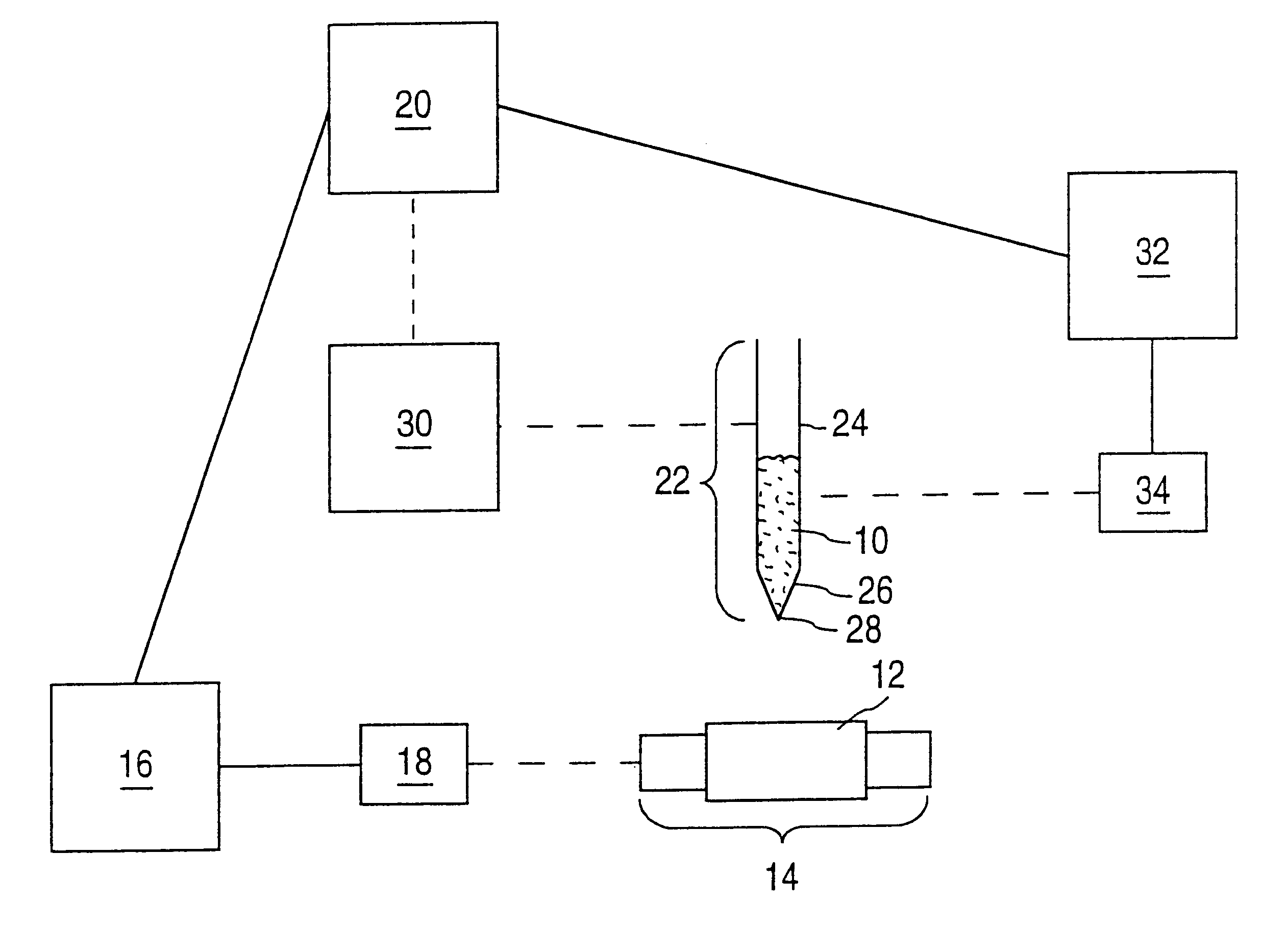

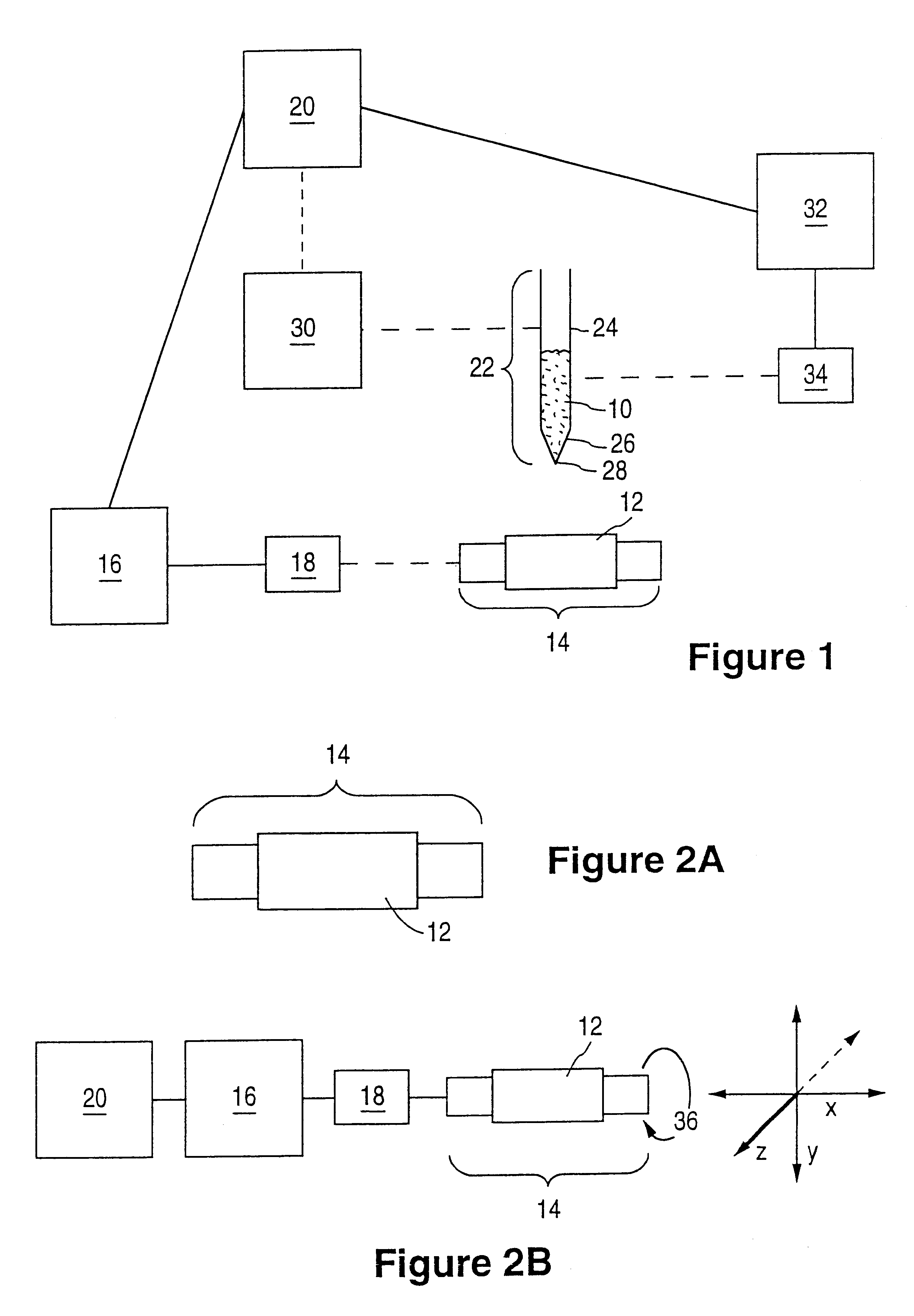

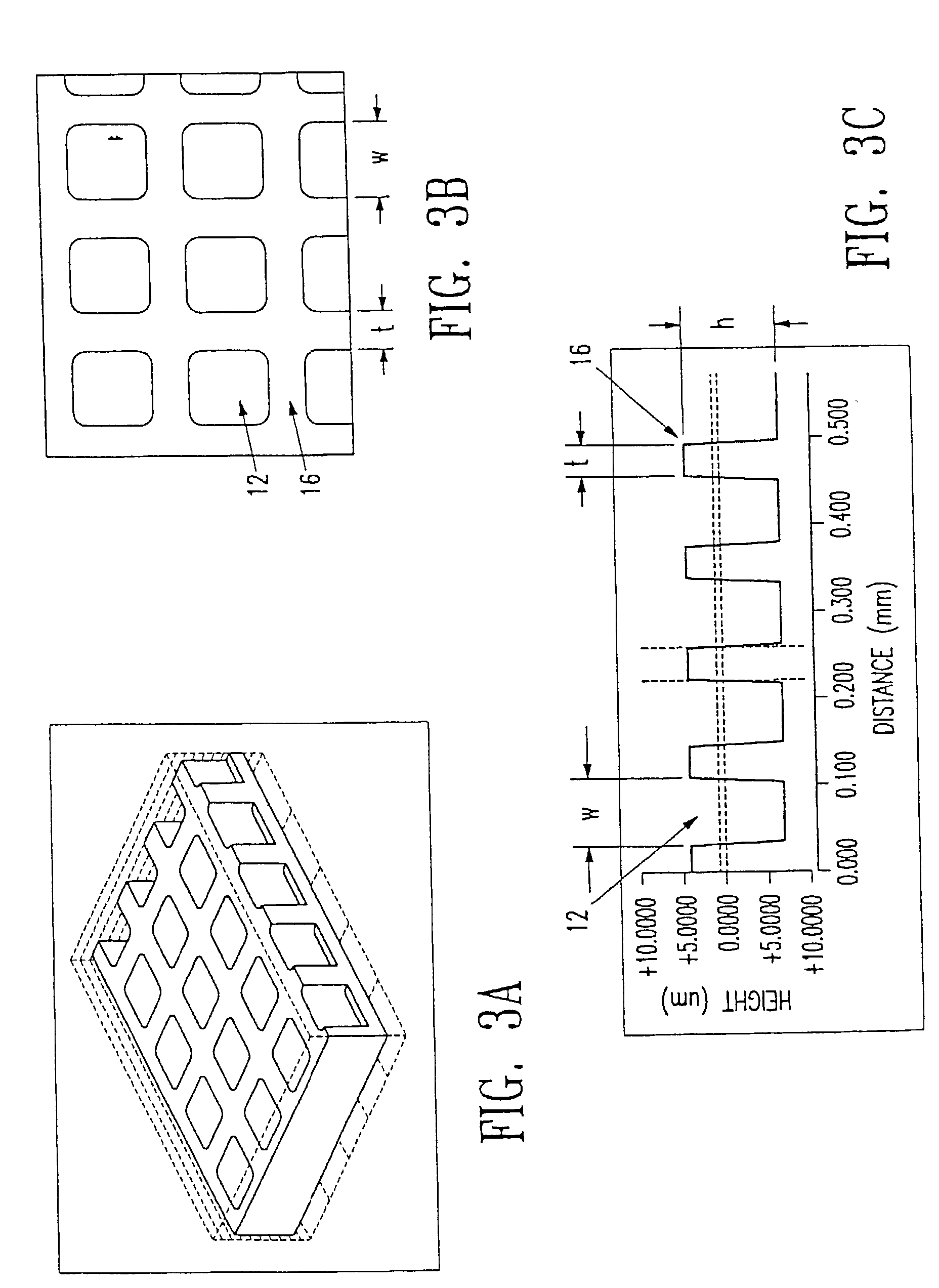

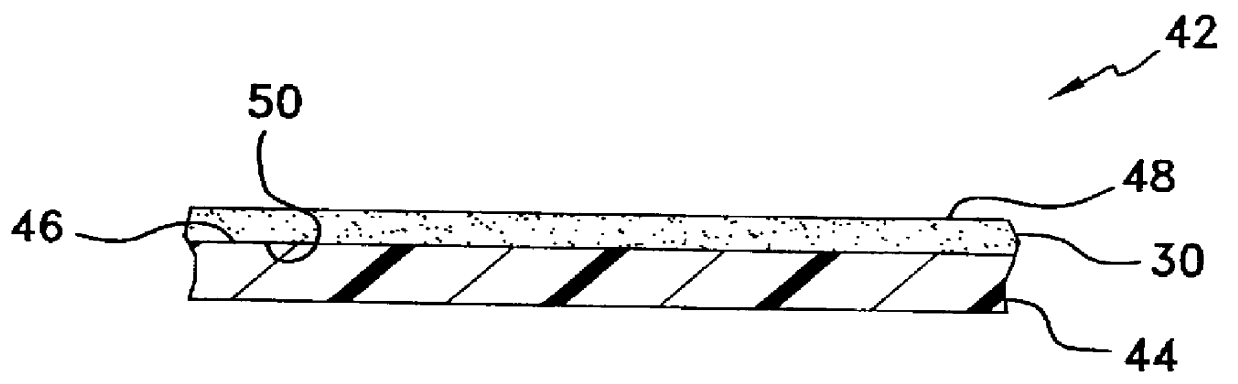

Apparatus and method for depositing a coating onto a surface of a prosthesis

A patterned coating on a prosthesis, for example a stent, and a method for forming the coating are disclosed. Additionally, an apparatus for forming the patterned coating is disclosed.

Owner:ABBOTT CARDIOVASCULAR

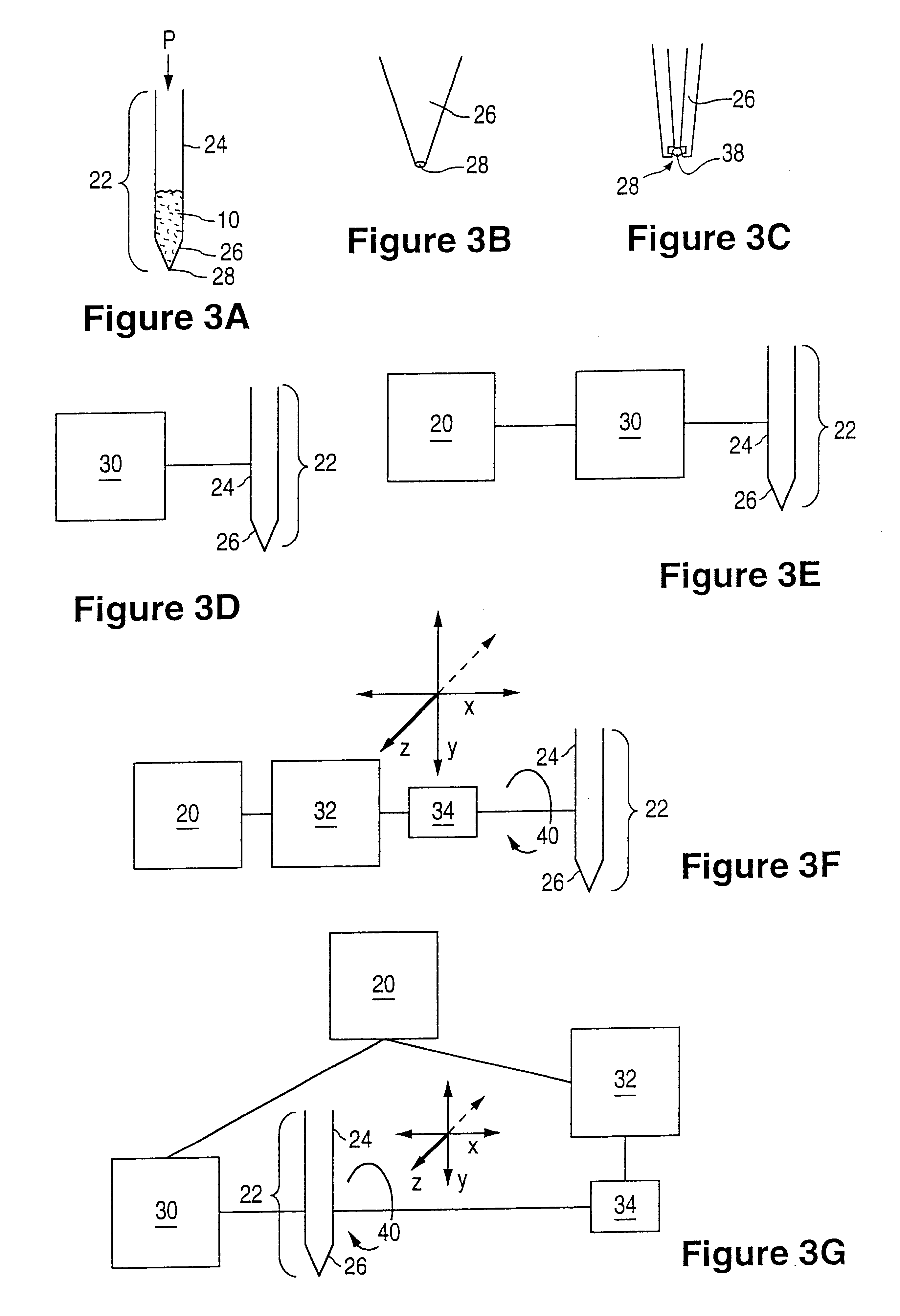

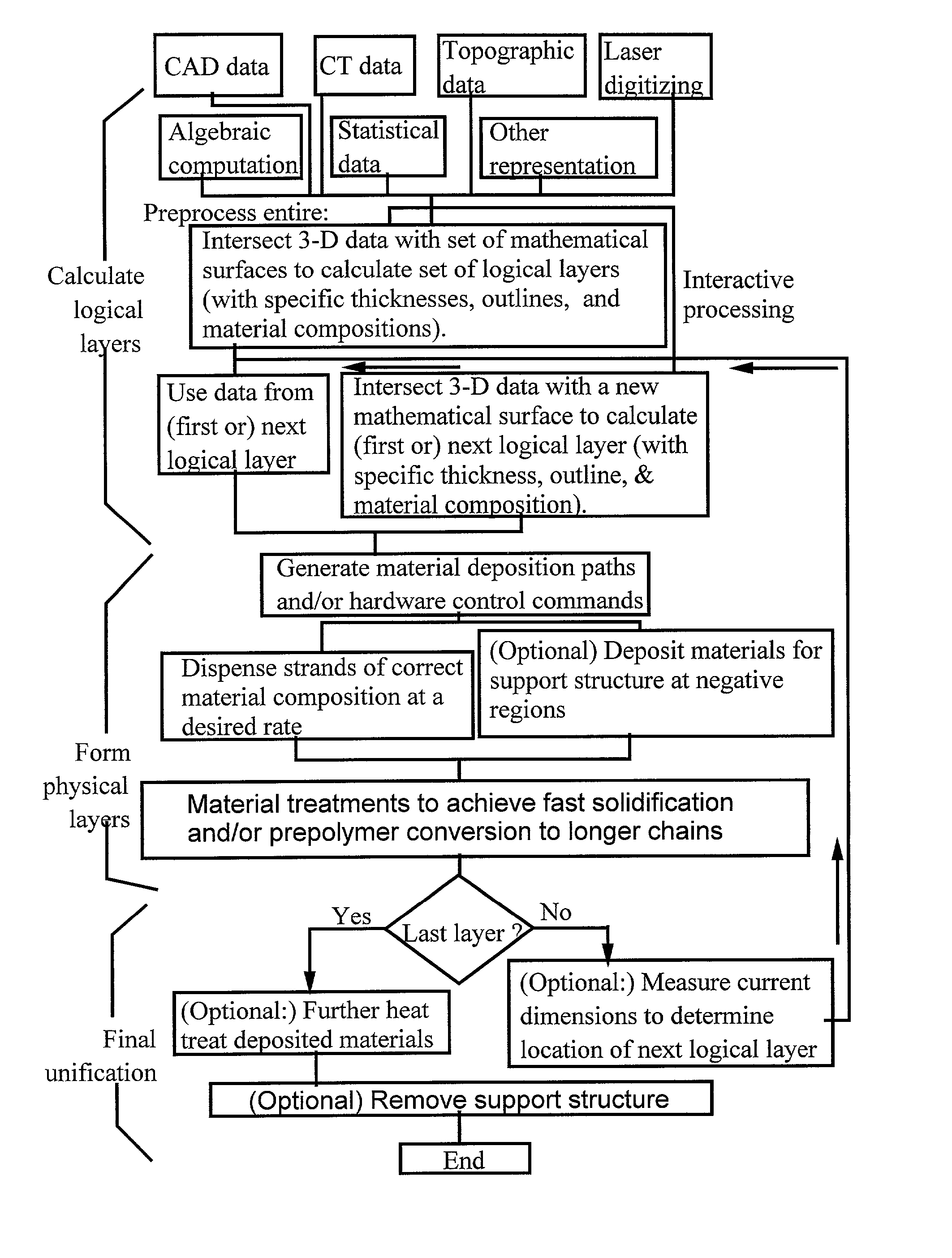

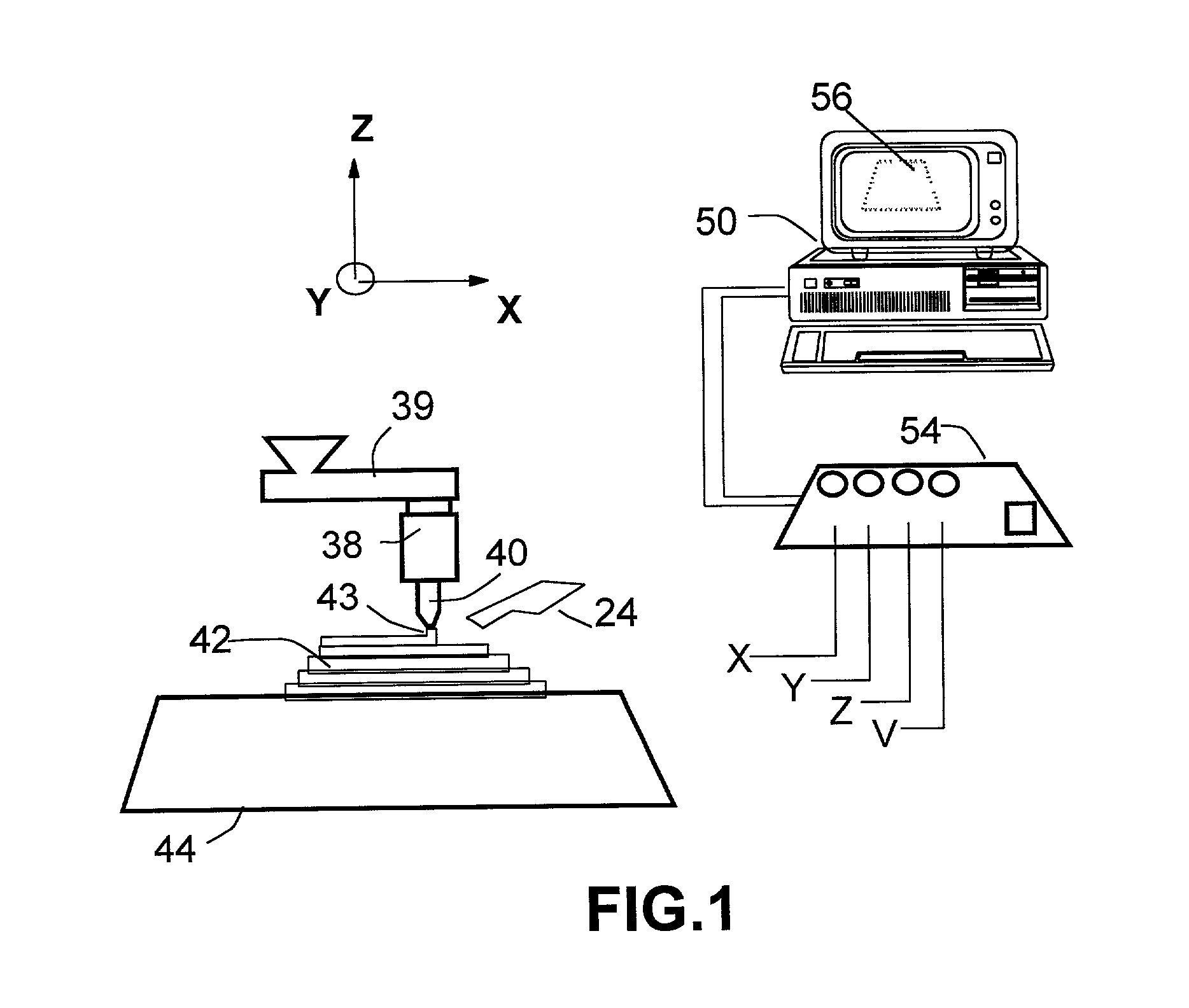

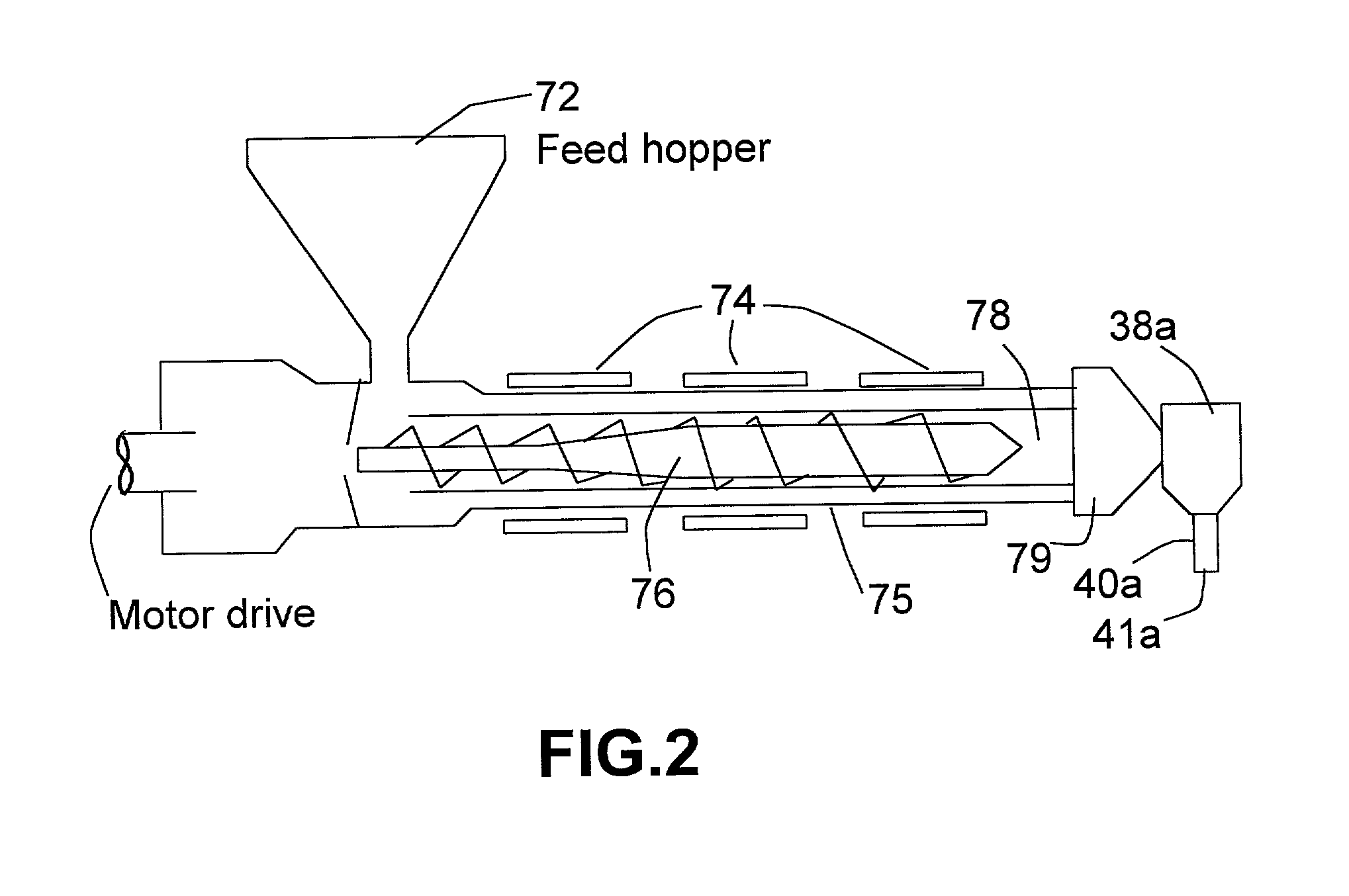

Freeform fabrication method using extrusion of non-cross-linking reactive prepolymers

InactiveUS20020113331A1Fast formingDifficult to prepareProgramme controlComputer controlCross-linkThermoplastic

An extrusion-based freeform fabrication method for making a three-dimensional object from a design created on a computer, including (a) providing a support member; (b) operating a dispensing head having at least one dispensing nozzle with a discharge orifice for dispensing continuous strands of a material composition in a fluent state at a first temperature onto the support member, the material composition including a reactive prepolymer with a melting point above 23° C. and the first temperature being greater than the prepolymer melting point; (c) operating material treatment devices for causing the dispensed strands of material composition to rapidly achieve a rigid state in which the material composition is substantially solidified to build up the 3-D object, the material treatment devices also working to convert the reactive prepolymer to a higher molecular weight thermoplastic resin; and (d) operating control devices for generating control signals in response to coordinates of the object design to control the movement of the dispensing nozzle relative to the support member and for controlling the strand dispensing of the material composition to construct the 3-D object.

Owner:ZHANG TAN +3

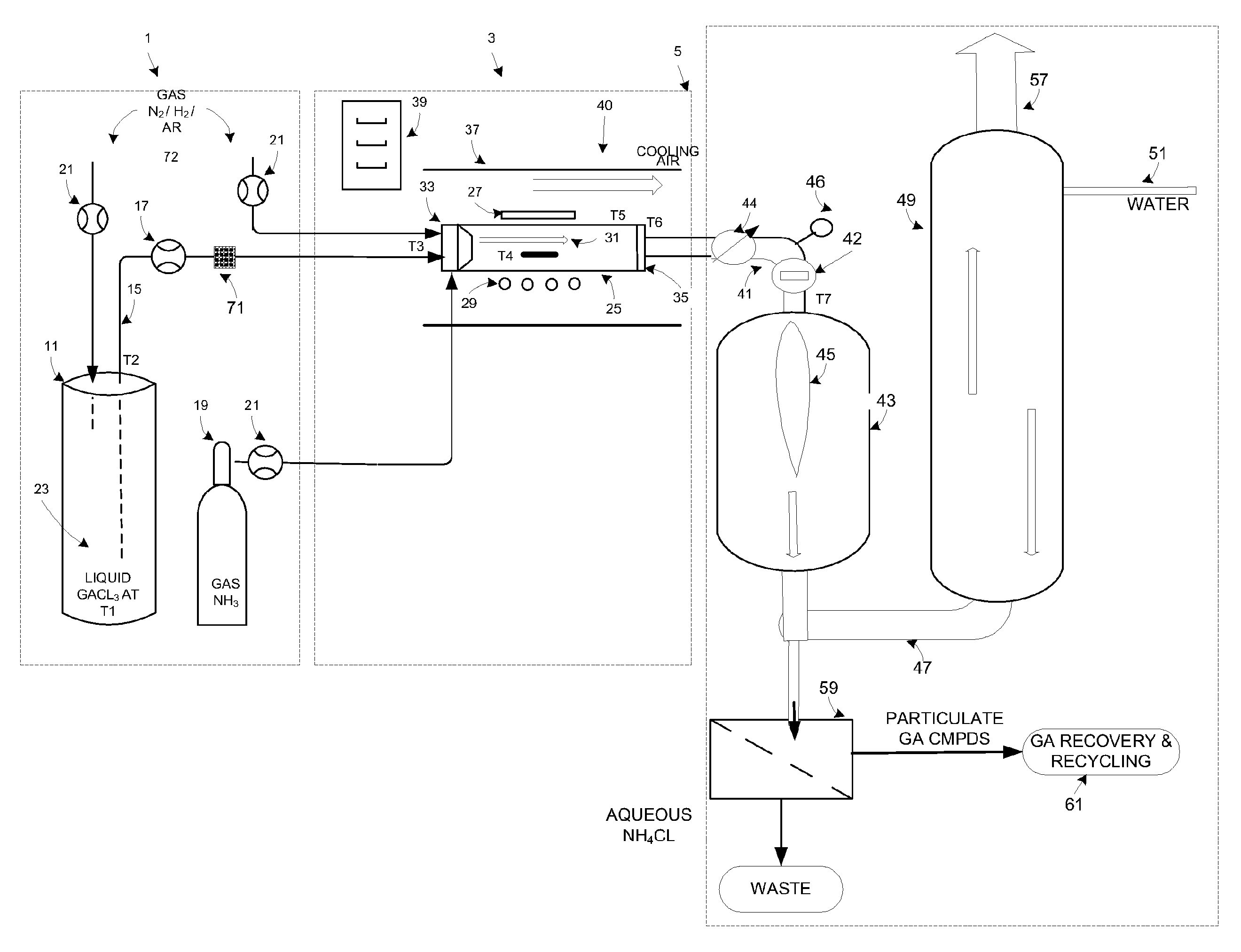

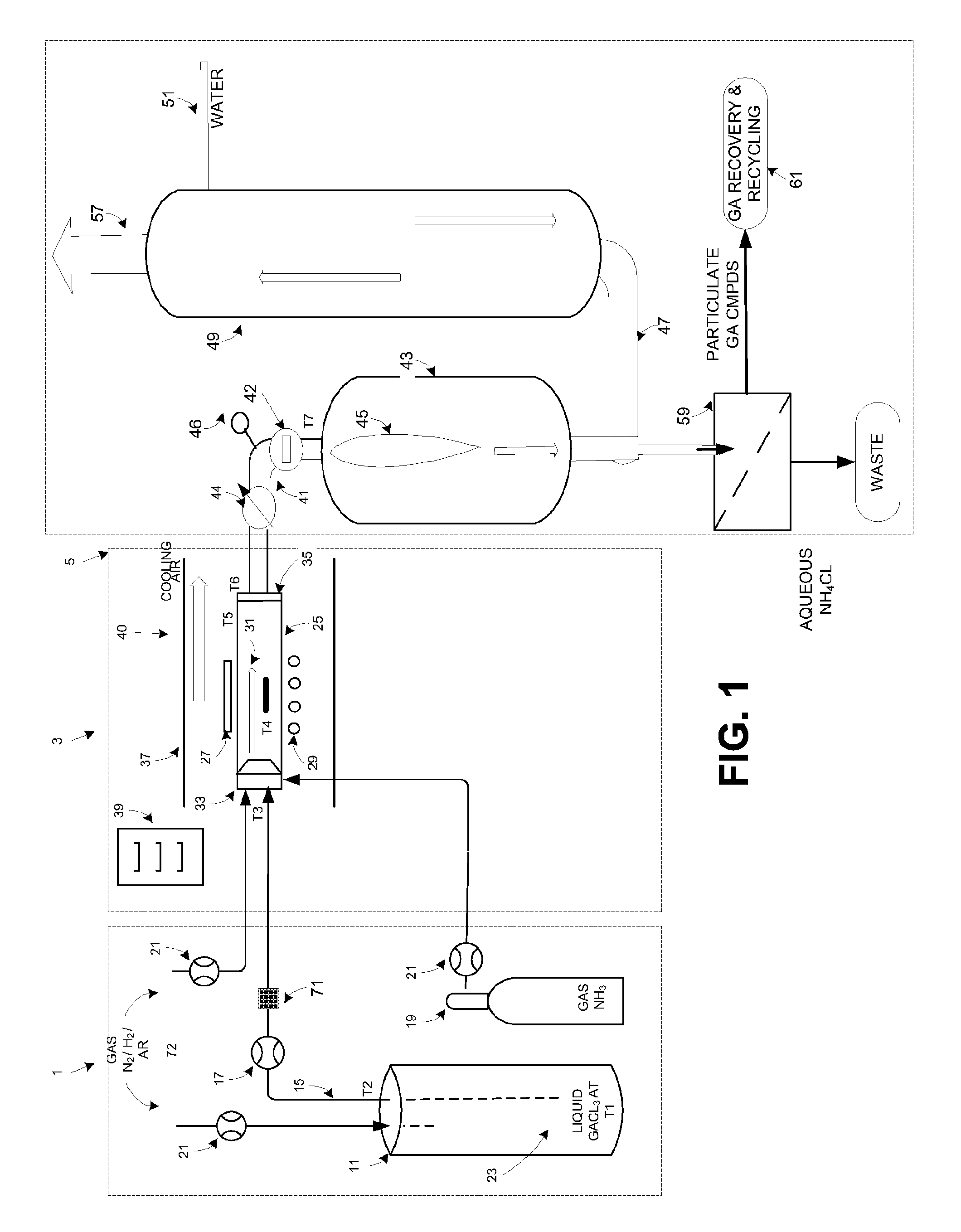

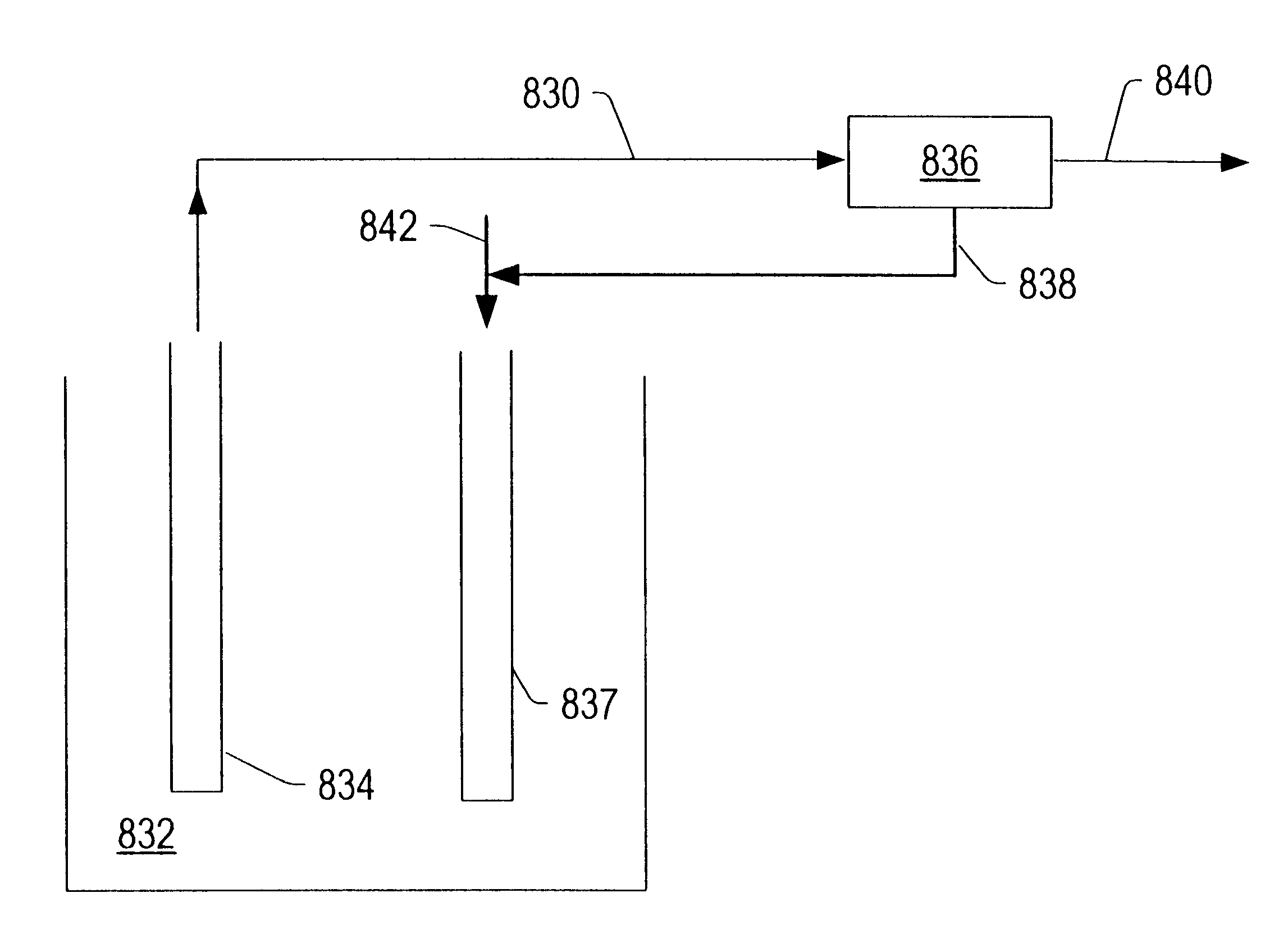

High volume delivery system for gallium trichloride

InactiveUS20090223441A1High manufacturing processEasy to prepare in large batchesPolycrystalline material growthSemiconductor/solid-state device manufacturingHigh volume manufacturingSemiconductor materials

The present invention is related to the field of semiconductor processing equipment and methods and provides, in particular, methods and equipment for the sustained, high-volume production of Group III-V compound semiconductor material suitable for fabrication of optic and electronic components, for use as substrates for epitaxial deposition, for wafers and so forth. In preferred embodiments, these methods and equipment are optimized for producing Group III-N (nitrogen) compound semiconductor wafers and specifically for producing GaN wafers. Specifically, the precursor is provided at a mass flow of at least 50 g Group III element / hour for a time of at least 48 hours to facilitate high volume manufacture of the semiconductor material. Advantageously, the mass flow of the gaseous Group III precursor is controlled to deliver the desired amount.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

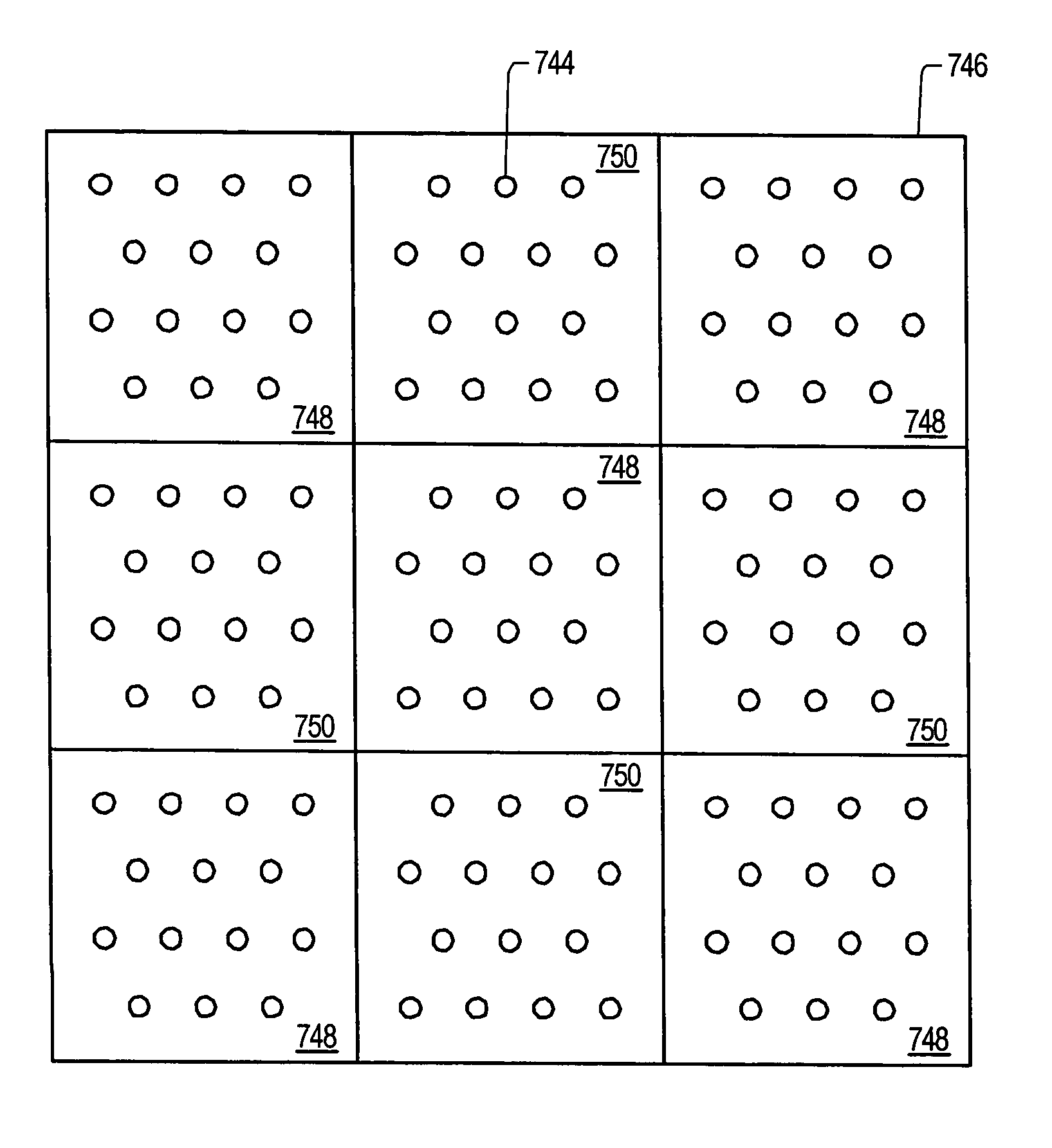

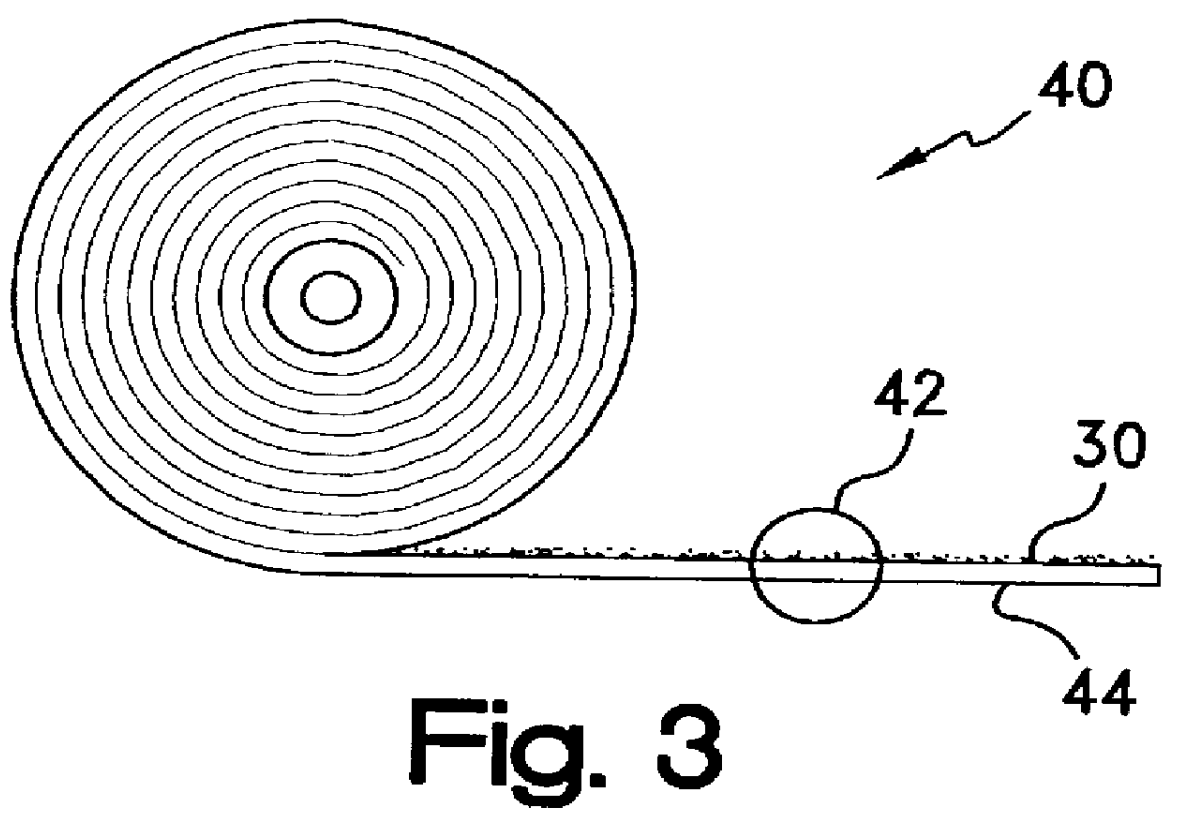

Composition and process for the sealing of microcups in roll-to-roll display manufacturing

InactiveUS7144942B2Improve adhesionQuality improvementLamination ancillary operationsLaminationCrystallographyElectrophoresis

Owner:E INK CALIFORNIA

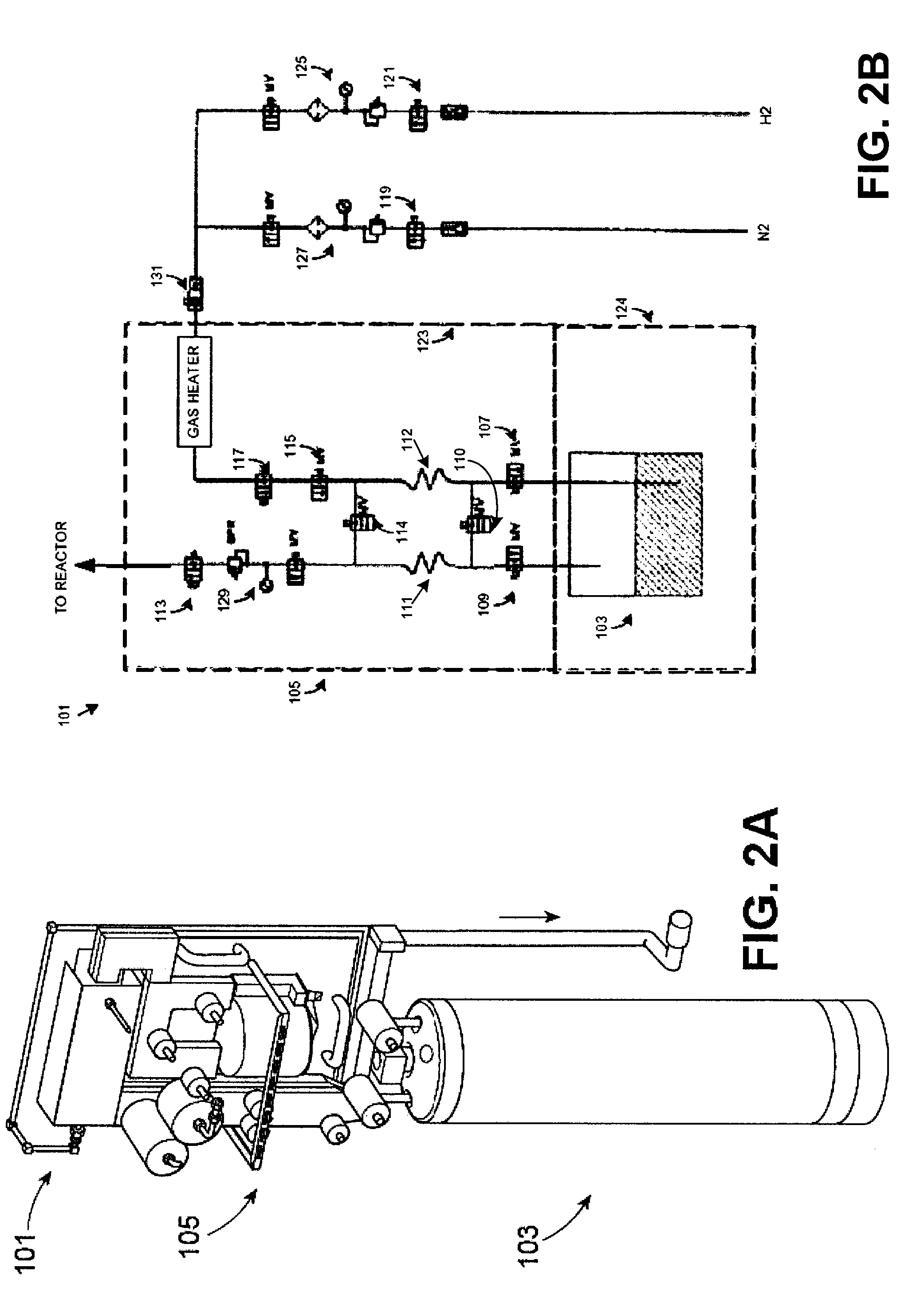

Conformal thermal interface material for electronic components

InactiveUS6054198AOptimize allocationReadily apparentSemiconductor/solid-state device detailsSolid-state devicesRoom temperatureConductive materials

A thermally-conductive interface for conductively cooling a heat-generating electronic component having an associated thermal dissipation member such as a heat sink. The interface is formed as a self-supporting layer of a thermally-conductive material which is form-stable at normal room temperature in a first phase and substantially conformable in a second phase to the interface surfaces of the electronic component and thermal dissipation member. The material has a transition temperature from the first phase to the second phase which is within the operating temperature range of the electronic component.

Owner:PARKER INTANGIBLES LLC

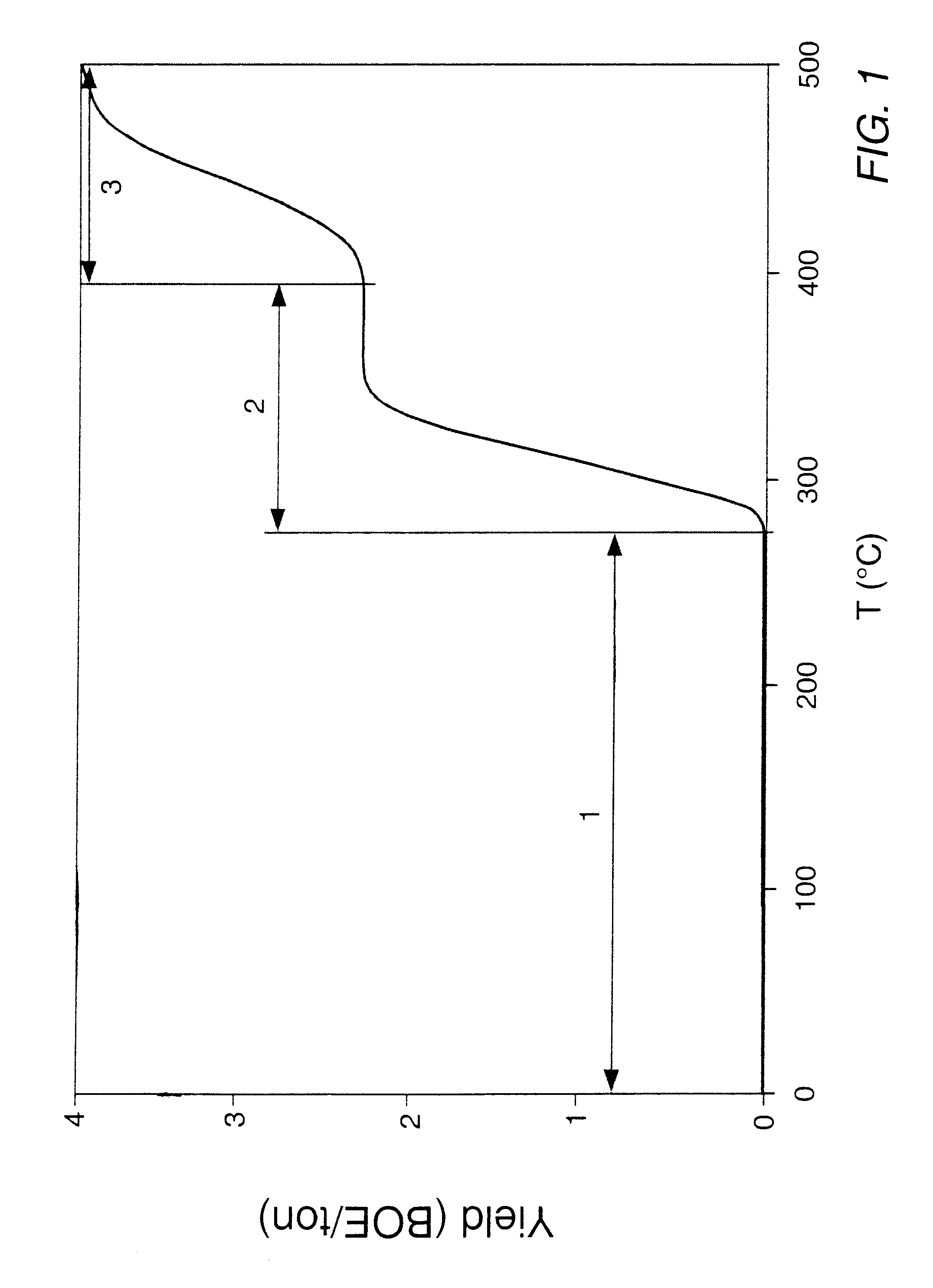

In situ thermal processing of a hydrocarbon containing formation using a controlled heating rate

InactiveUS6745837B2High calorific valueImprove the heating effectSurveyCombustion processFormation fluidHeat energy

A hydrocarbon containing formation may be treated using an in situ thermal process. A mixture of hydrocarbons, H.sub.2, and / or other formation fluids may be produced from the formation. Heat may be applied to the formation to raise a temperature of a portion of the formation to a pyrolysis temperature. A heating rate to a selected volume of the formation may be controlled by altering an amount of heating energy per day that is provided to the selected volume.

Owner:SALAMANDER SOLUTIONS INC

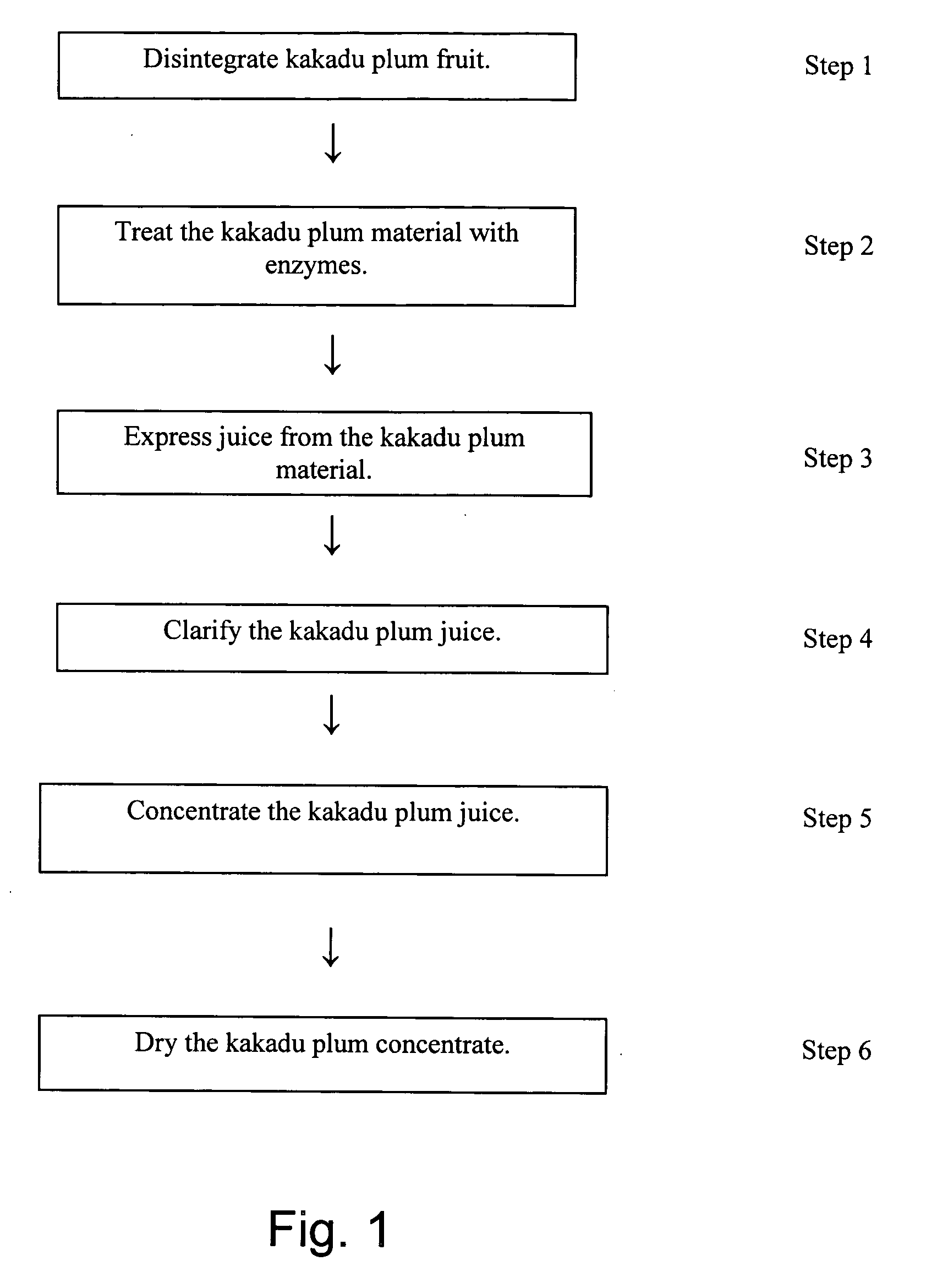

Method of preparing kakadu plum powder

ActiveUS20050163880A1High viscosityImpede efficient processingBiocideUnknown materialsAbsorption capacityUltrafiltration

A process for producing a kakadu plum powder having an increased amount of naturally occurring ascorbic acid and high ORAC value. The process of preparing the extract includes the following: disintegrating kakadu plum fruit; treating the disintegrated kakadu plum material with enzymes to at least partially digest the material; juicing the kakadu plum material and drying the juice to produce a powder. In a preferred embodiment, the kakadu plum juice is further clarified with ultrafiltration and concentrated by performing reverse osmosis on the kakadu plum juice. The resultant kakadu plum powder has a natural ascorbic acid content of at least about 15% and a naturally occurring Oxygen Reduction Absorption Capacity value of at least 1500.

Owner:ACCESS BUSINESS GRP INT LLC +1

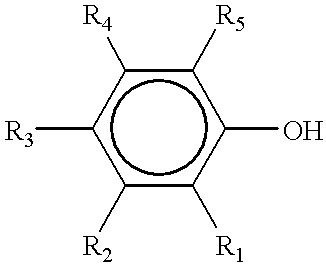

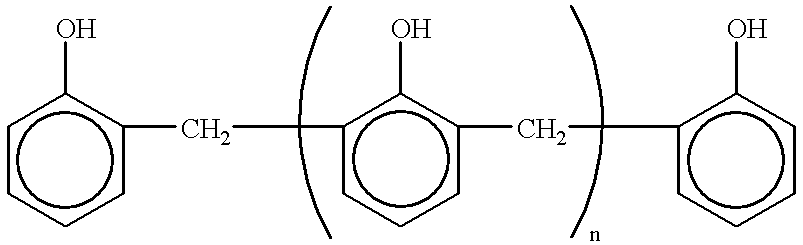

Ternary systems of benzoxazine, epoxy, and phenolic resins

Low viscosity ternary mixtures of benzoxazine, epoxy and phenolic resins have been developed. The blends render homogeneous and void free cured specimen with a wide range of properties. Melt viscosity values as low as 0.3 Pa.s at 100° C. can be achieved. The phenolic resin acts as a cure accelerator to the system, besides its typical function as a hardener of epoxy resin. Glass transition temperatures Tg as high as 170° C. can also be obtained.

Owner:EDISON POLYMER INNOVATION EPIC

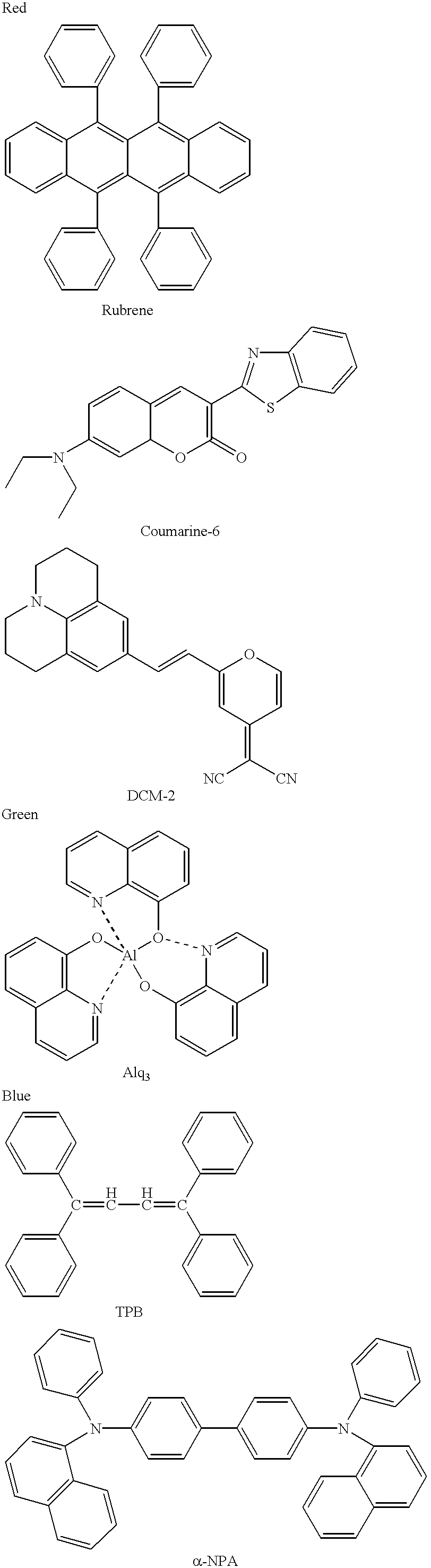

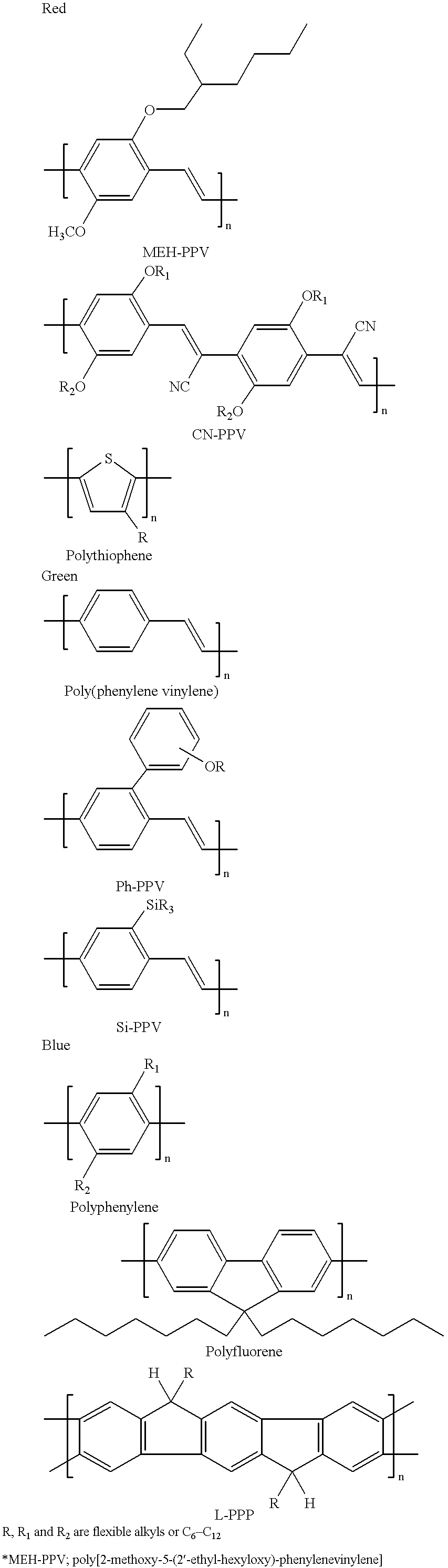

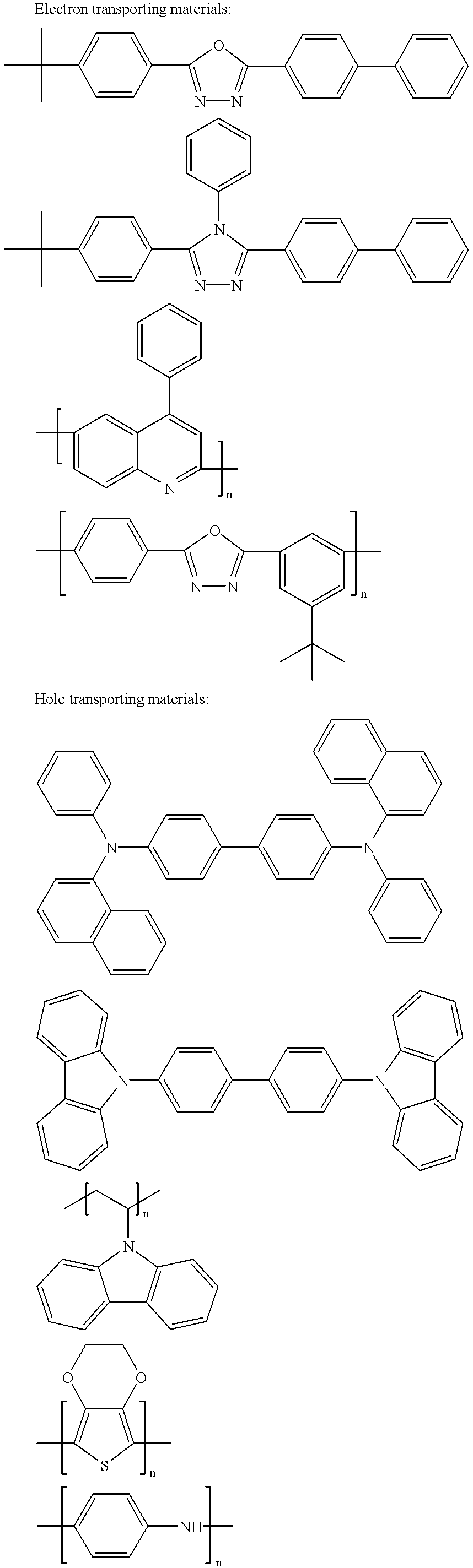

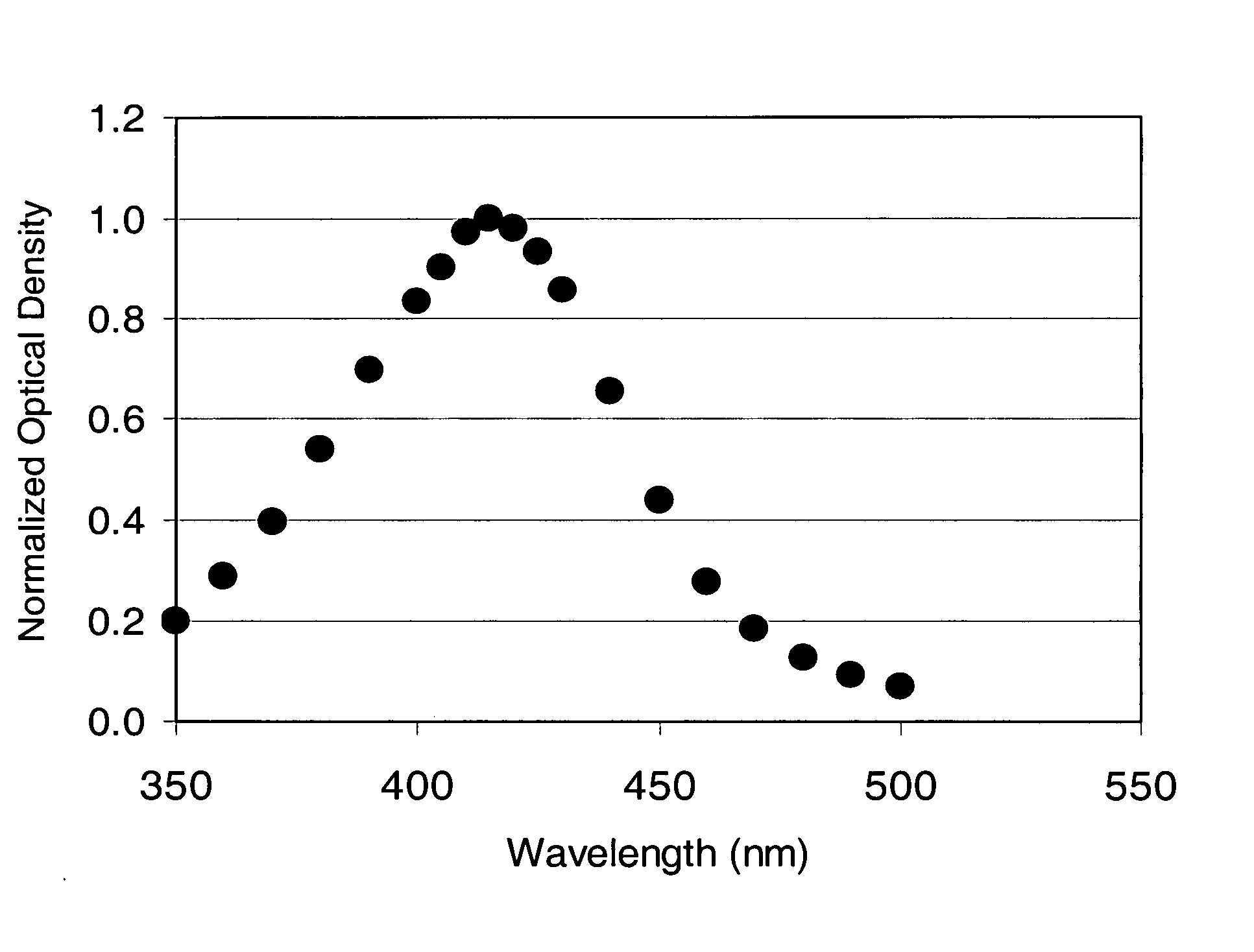

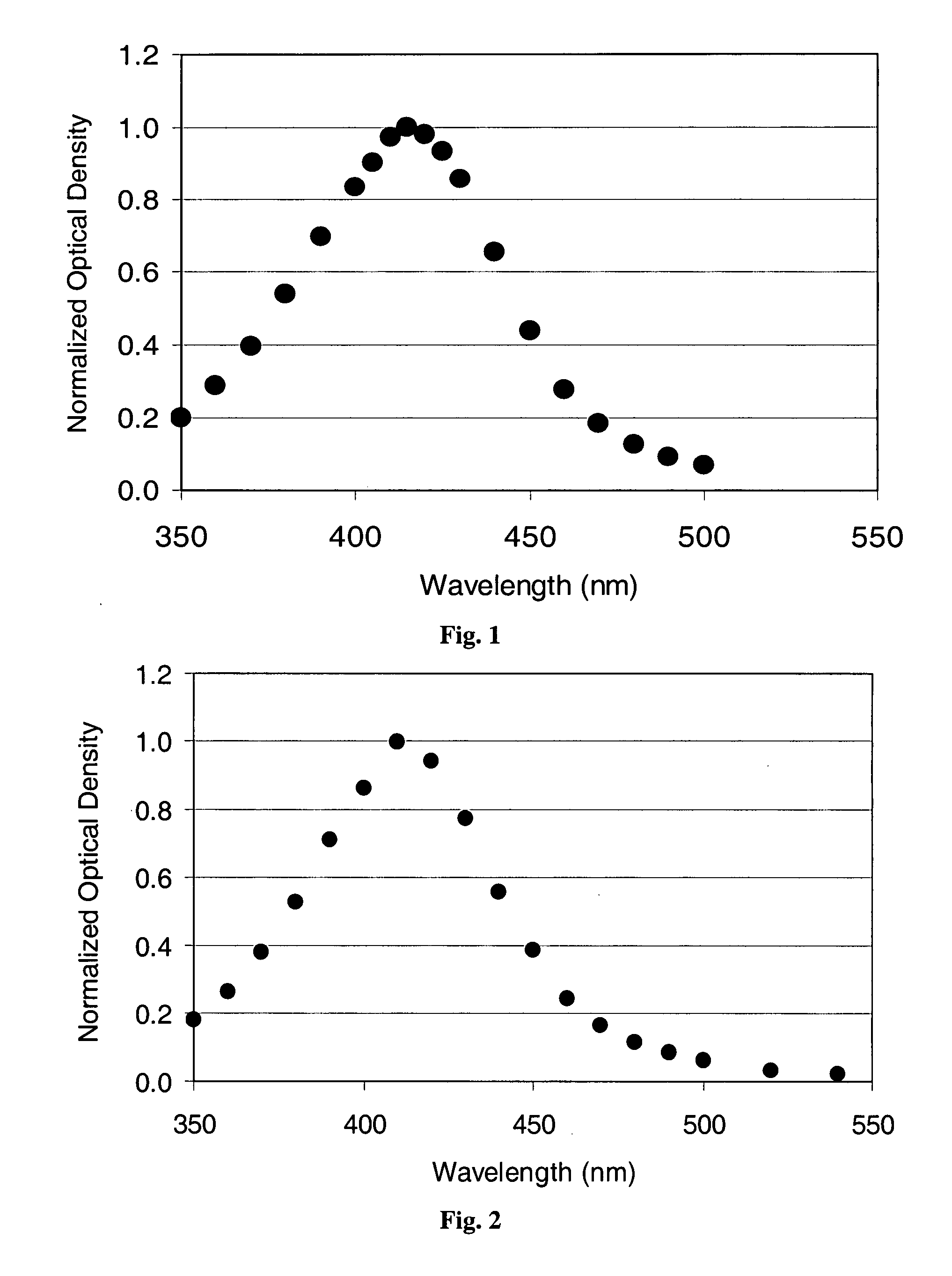

Luminescent ink for printing of organic luminescent devices

InactiveUS6372154B1Improve efficiencyEasy transitionSolid-state devicesSemiconductor/solid-state device manufacturingSolventOrganic compound

Organic luminescent ink (L-ink) is disclosed for use in printing thin films of organic luminescent material. The L-ink is particularly useful in fabricating organic optoelectronic devices, e.g. organic luminescent devices. The L-ink contains at least one organic luminescent material mixed with a solvent and other functional additives to provide the necessary optical, electronic and morphological properties for light-emitting devices (LEDs). The additives play an important role either for enhanced thin film printing or for better performance of the optoelectronic device. The functional additives may be chemically bound to the luminescent compounds or polymers. Luminescent organic compounds, oligomers, or polymers with relatively low solution viscosity, good thin film formability, and good charge transporting properties, are preferred. The L-inks can be cross-linked under certain conditions to enhance thin film properties. The L-ink can be used in various printing methods, such as screen printing, stamp printing, and preferably ink-jet printing (including bubble-jet printing).

Owner:CANON KK

Variable frequency temperature limited heaters

InactiveUS20050006097A1Avoid deformationReduce heatThermal drillingInsulationElectrical resistance and conductancePower flow

A heater system may include an alternating current supply and an electrical conductor. Alternating current may be applied to one or more electrical conductors at a frequency between about 100 Hz and about 1000 Hz. The electrical conductors may be located in a formation. The electrical conductors may resistively heat upon application of the alternating electrical current. At least one of the electrical conductors may include an electrically resistive ferromagnetic material. The electrical conductor may provide a reduced amount of heat above or near a selected temperature. Heat may transfer from the electrical conductor to a part of formation.

Owner:SHELL OIL CO

Effervescent granules and methods for their preparation

InactiveUS6071539AMinimize degradationMelt and soften binderPowder deliveryPill deliveryPlasticizerHot melt

According to the present invent, effervescent granules having a controllable rate of effervescence are provided. Such granules comprise an acidic agent, an alkaline agent, a hot-melt extrudable binder capable of forming a eutectic mixture with the acidic agent and, optionally, a plasticizer. The effervescent granules are made by a hot-melt extrusion process.

Owner:ETHYPHARM SA

Methods and compositions for metal nanoparticle treated surfaces

ActiveUS20070207335A1Extended shelf lifeConvenient coatingMaterial nanotechnologyBiocidePolyamideSolvent

The present invention comprises methods and compositions comprising metal nanoparticles. The invention comprises metal nanoparticles and surfaces treated with a metal nanoparticle coating. The present invention further comprises compositions for preparing nanoparticles comprising at least one stabilizing agent, one or more metal compounds, at least one reducing agent and a solvent. In one aspect, the stabilizing agent comprises a surfactant or a polymer. The polymer may comprise polymers such as polyacrylamides, polyurethanes, and polyamides. In one aspect, the metal compound comprises a salt comprising a metal cation and an anion. The anion may comprise saccharinate derivatives, long chain fatty acids, and alkyl dicarboxylates.

Owner:AVENT INC

Jettable compositions

ActiveUS20050171237A1Prevent long-term corrosionReaction is slowAdditive manufacturing apparatusLiquid surface applicatorsMeth-Oligomer

A fully curable jettable composition having a viscosity less than 30 cps at a temperature within the range of 15-180° C., more preferably at a temperature of 15-100° C., e.g. 60-80° C. the composition comprising: (A) at least one low viscosity reactive resin selected from the group consisting of compounds containing an oxetane ring, cycloaliphatic epoxy resins, tetrahydrofurans, hexahydropyrans and mono-functional (meth)acrylates, said resin having a molecular weight of not greater than 300 Daltons, e.g. 250 Daltons or less, and a viscosity at a temperature in the said range of less than 30 cps, e.g. 5 to 15 cps; (B) at least one higher viscosity resin selected from the group consisting of epoxy resins, compounds containing an oxetane ring and acrylates, which resin acts to thicken the low viscosity resin and strengthen a jetted deposit of the composition, the higher viscosity resin having: a viscosity greater than twice that of the low viscosity resin at the said temperature in the range stated above, and a functionality of greater than or equal to 2; (C) at least one curable toughener, preferably having a functionality of at least 2, such as hydroxy, epoxy, acrylic or other reactive functionalised polymer / oligomer (e.g. derived by functionalising poly(tetrahydrofuran), polycaprolactone, polycarbonate diol, or a dendrimeric polyol; (D) at least one initiator for the polymerisation of the resins, and (E) at least one stabiliser for delaying the curing of the resins of the composition; wherein the low viscosity resin is slower to react than the higher viscosity resin and acts to solvate the higher viscosity resin prior to curing and at least partly during curing and wherein at least 30% of the components A and B are cationically curable resins. The composition can be jetted from piezo electric printing heads under the control of a computer program to form a multi-layered article, e.g. a three dimensional article, in which the adjacent droplets merge and are cured homogeneously together.

Owner:3D SYST INC +1

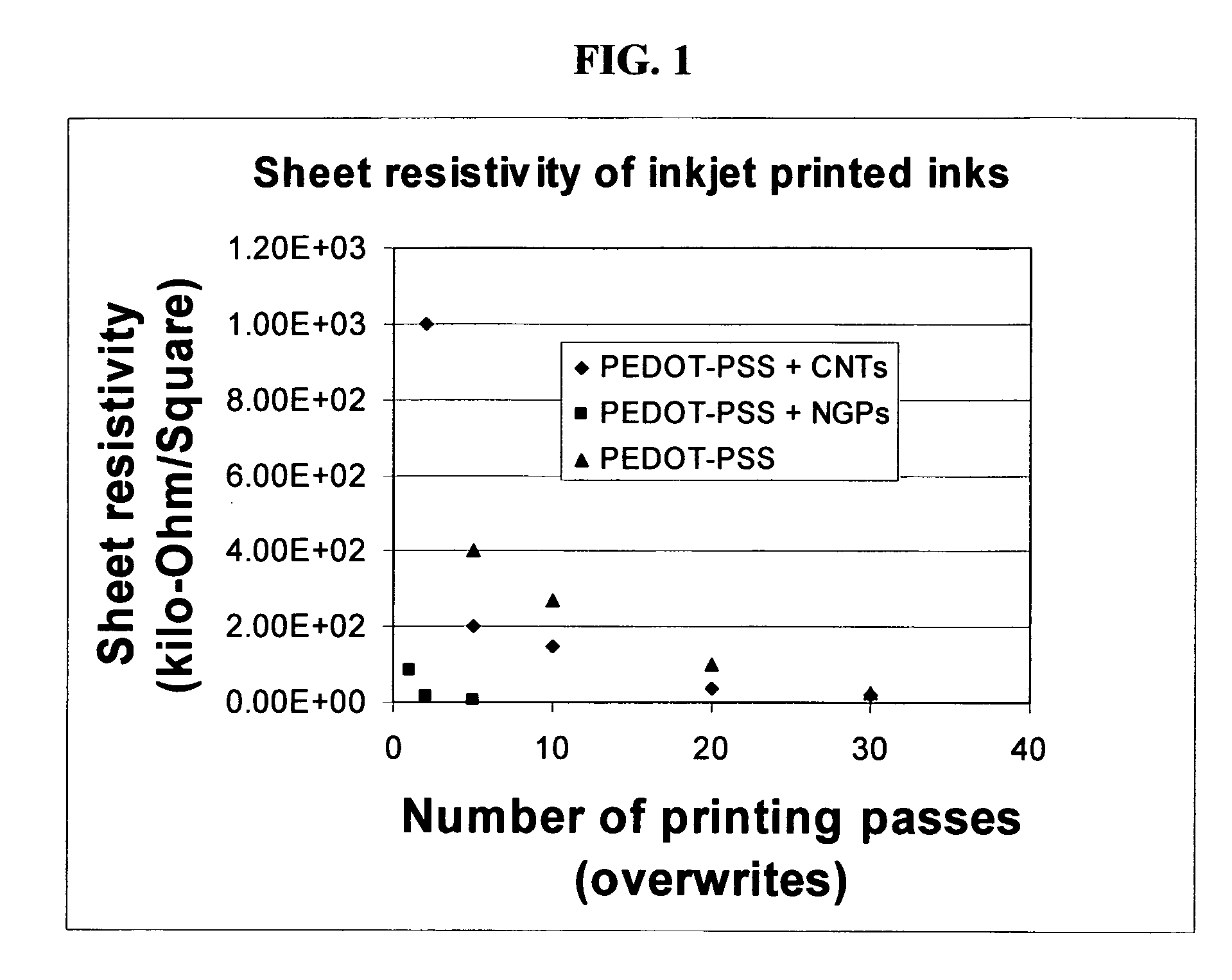

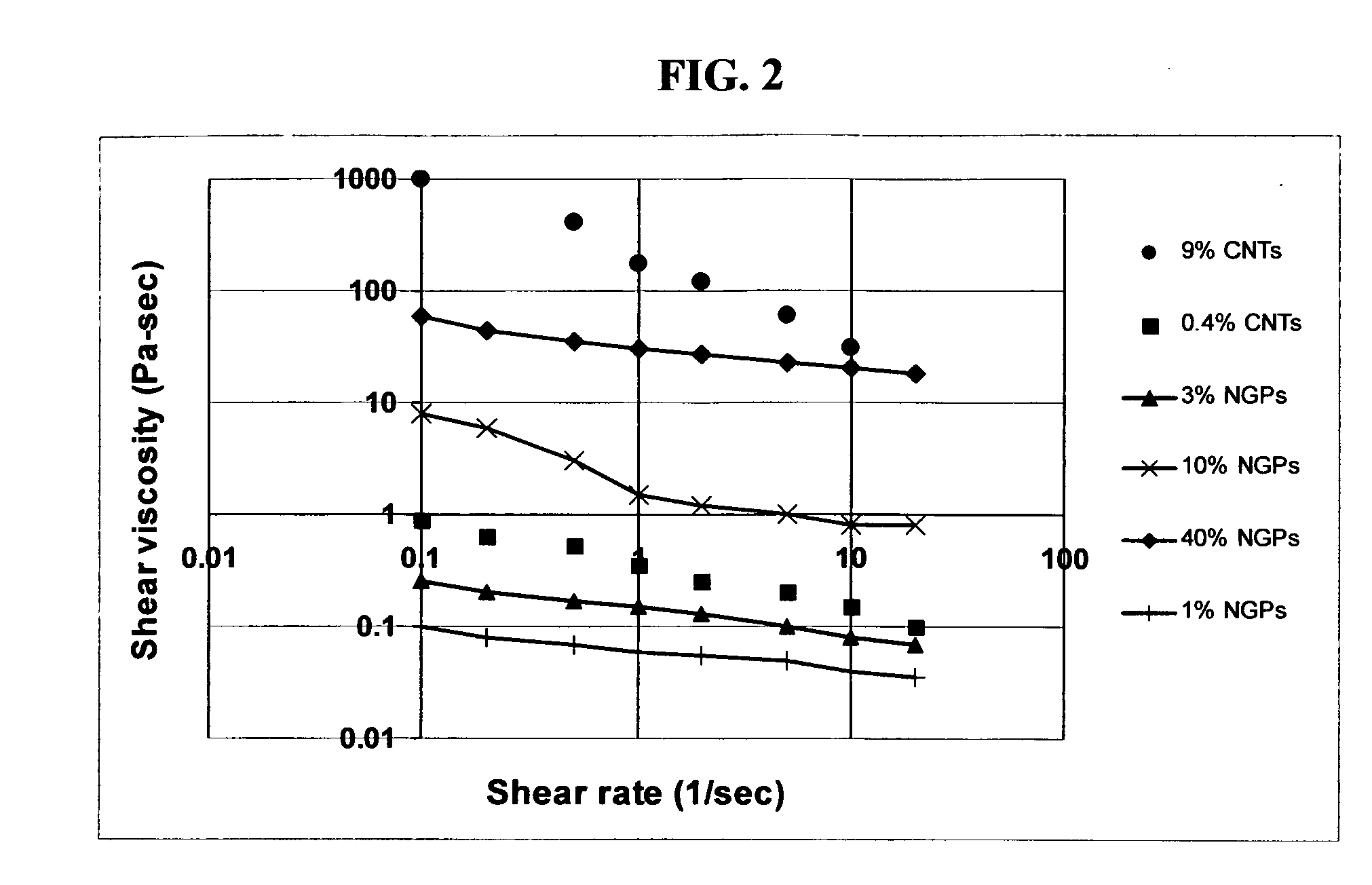

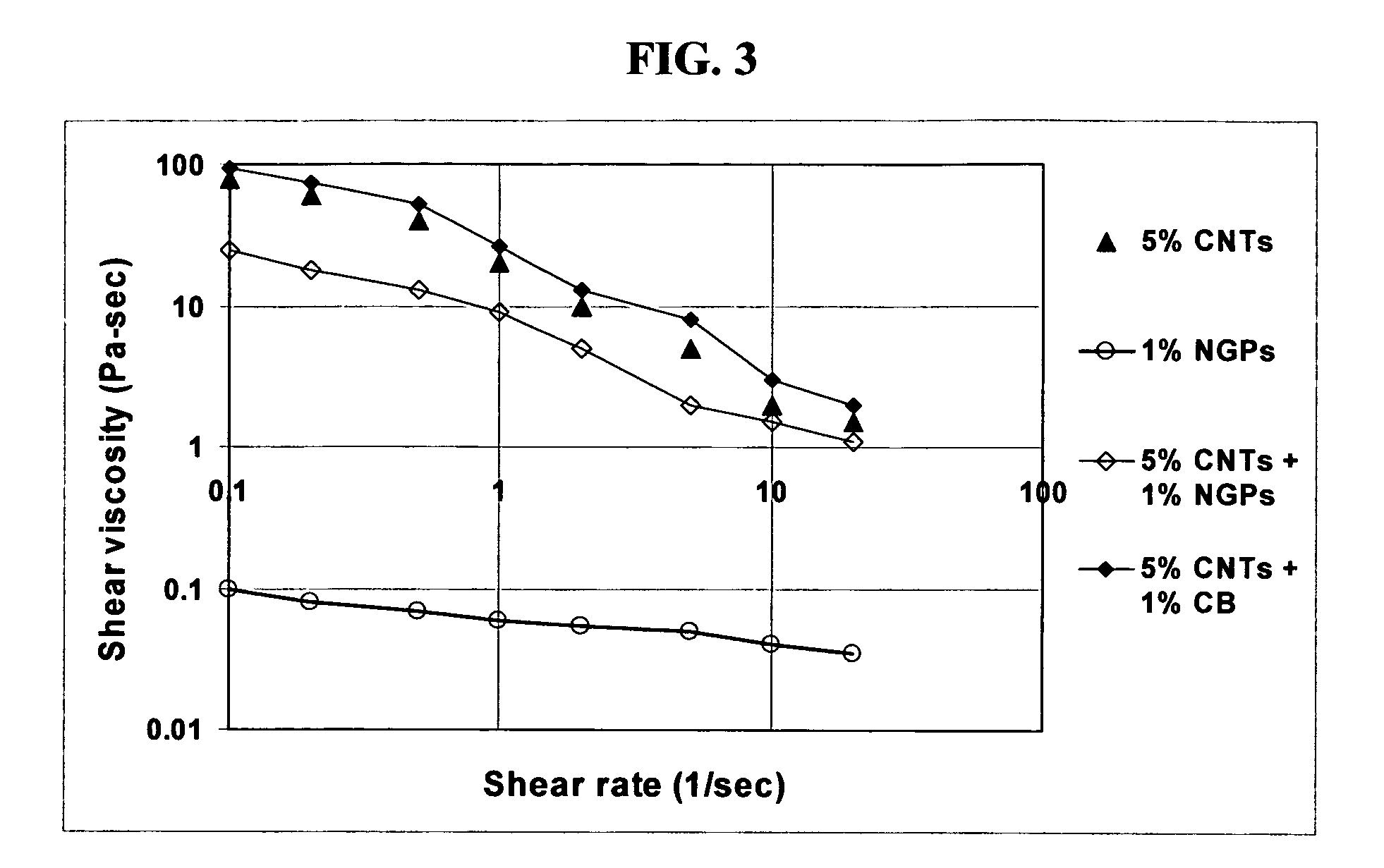

Nano graphene platelet-based conductive inks

InactiveUS20100000441A1Cost-effectiveLow viscosityMaterial nanotechnologyMagnetic/electric field screeningCarbon blackCarbon nanofiber

A nano graphene platelet-based conductive ink comprising: (a) nano graphene platelets (preferably un-oxidized or pristine graphene), and (b) a liquid medium in which the nano graphene platelets are dispersed, wherein the nano graphene platelets occupy a proportion of at least 0.001% by volume based on the total ink volume. The ink can also contain a binder or matrix material and / or a surfactant. The ink may further comprise other fillers, such as carbon nanotubes, carbon nano-fibers, metal nano particles, carbon black, conductive organic species, etc. The graphene platelets preferably have an average thickness no greater than 10 nm and more preferably no greater than 1 nm. These inks can be printed to form a range of electrically or thermally conductive components.

Owner:GLOBAL GRAPHENE GRP INC

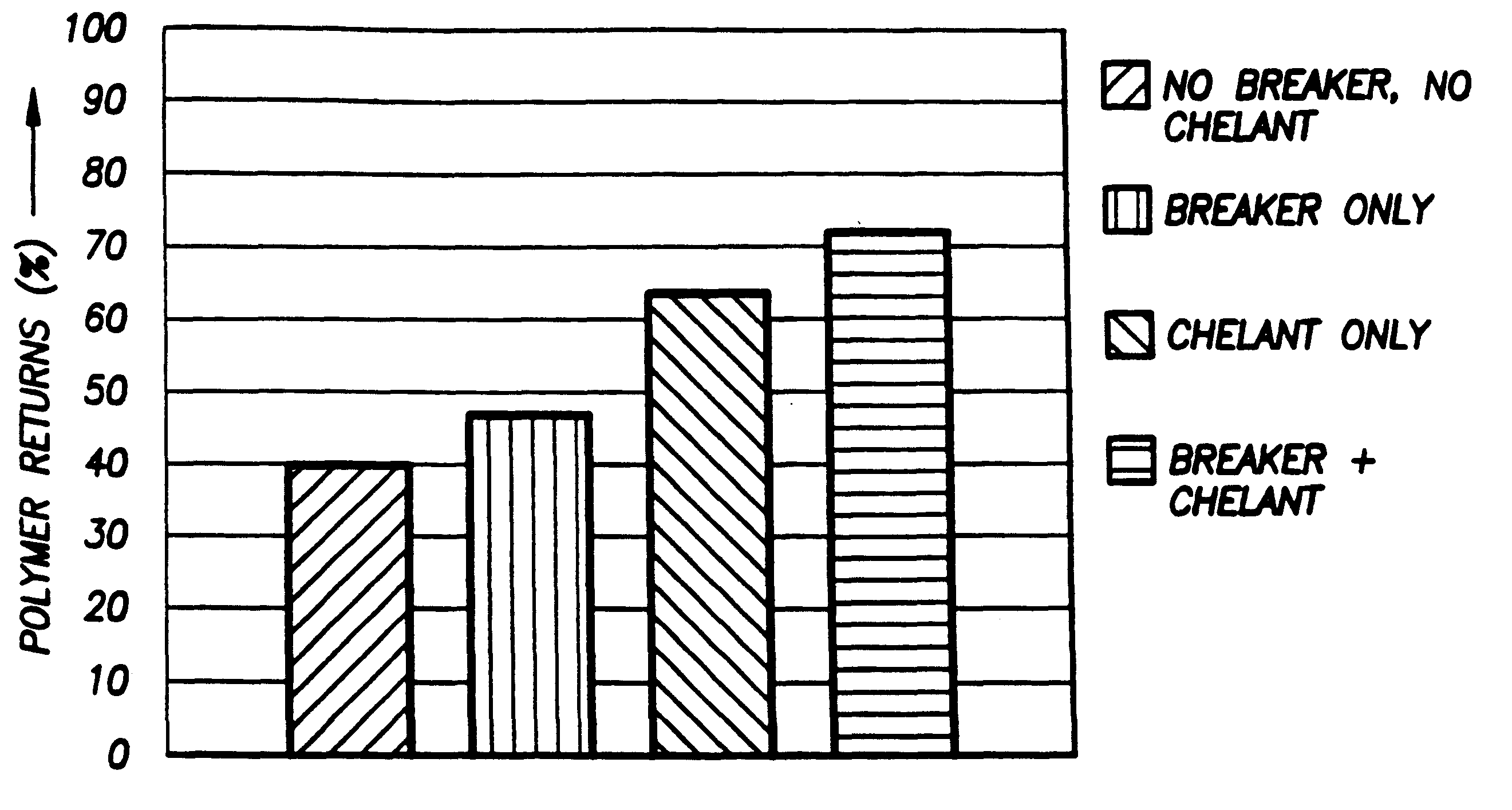

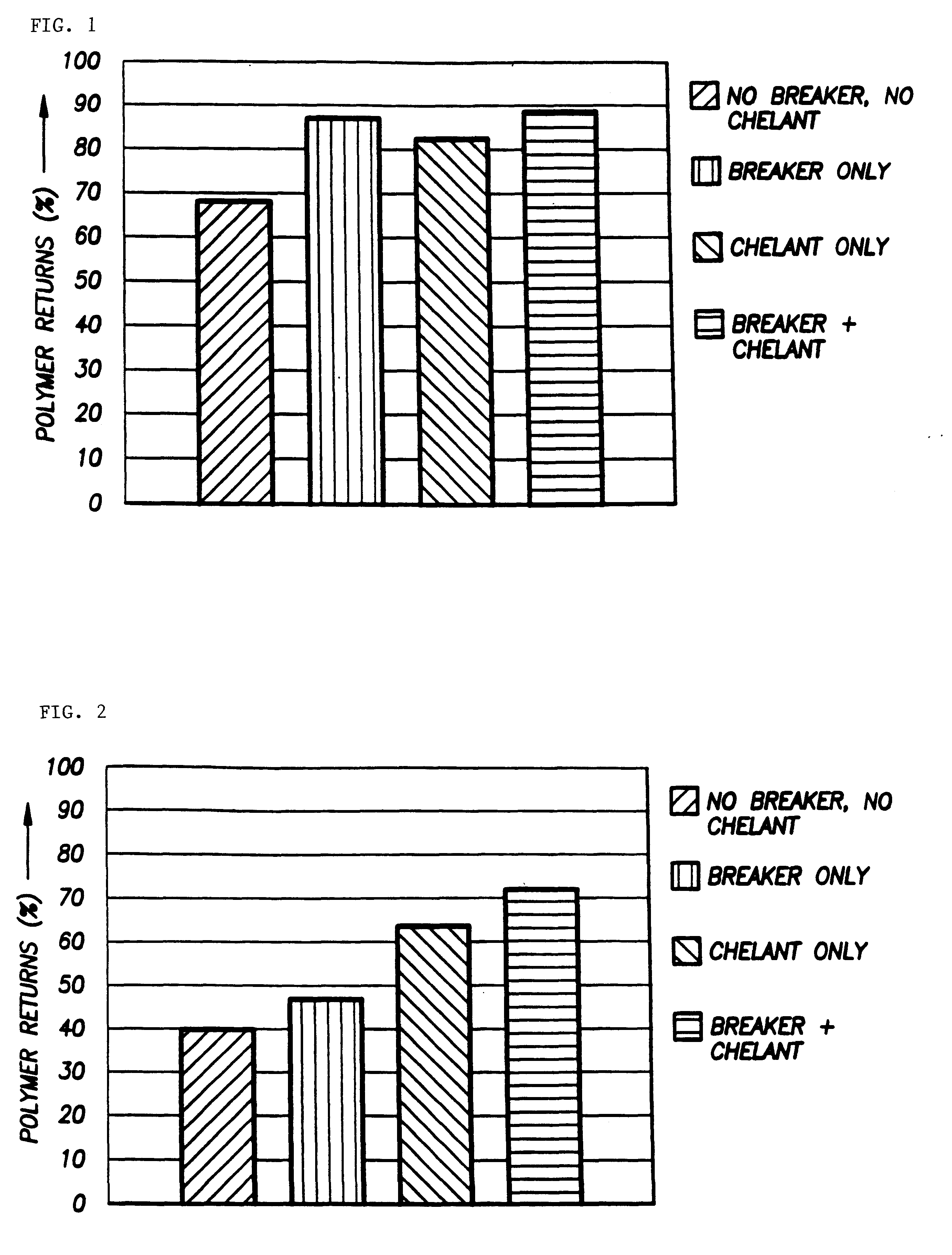

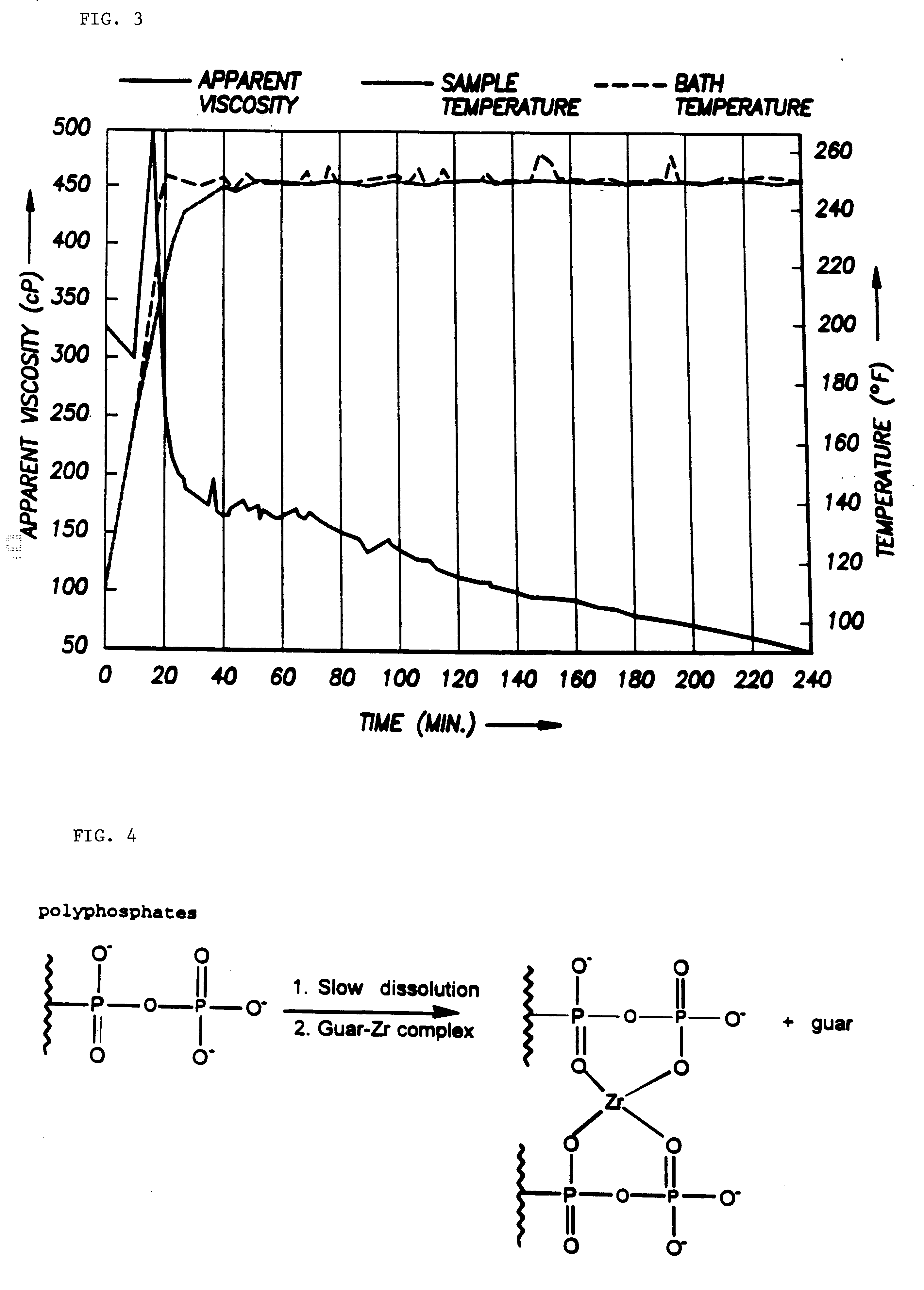

Cleanup additive

InactiveUS6242390B1Low viscosityEasy to disassembleOther chemical processesFluid removalSolubilityHydraulic fracturing

According to the present invention, a composition and method for hydraulically fracturing a subterranean formation is provided. The composition comprises an aqueous mixture of a hydrated polysaccharide, preferably a galactomannan gum, the hydrated polysaccharide having a plurality of bonding sites; a crosslinking agent for crosslinking the hydrated polysaccharide at the bonding sites at the conditions of the subterranean formation with a polyvalent metal ion to form a polyvalent metal crosslink, thereby increasing the viscosity of the hydrated polysaccharide; and a controlled solubility compound for releasing a chelating agent for controllably breaking the polyvalent metal crosslink and bonding with the polyvalent metal ion released by breaking the crosslink, thereby decreasing the viscosity of the hydrated polysaccharide. The method comprises the steps of injecting the above-described composition into the subterranean formation at fracturing pressures; allowing the controlled solubility compound to begin breaking the polyvalent metal crosslink, thereby reducing the viscosity of the hydrated polysaccharide and yielding a lower viscosity fluid; and removing the lower viscosity fluid from the subterranean formation.

Owner:SCHLUMBERGER TECH CORP

Solvent-free expansion type fire-proof epoxy coating and its preparation method

The invention discloses the inflatable fire-resisting paint, comprising A and B. The A comprises epoxide resin, modified resin, catalyst, foamable agent, fire retarding agent, fluxing agent, color filler and smog inhibiting agent, and the B comprises color filler, curing agent and auxiliary agent. The fire-resisting paint has the advantages of good heat-insulating property, adhesion force and intensity. The coating has good water resistance, acid- alkali resistance, corrosion resistance and tenacity, and is not easy to drop. The paint can be used in rolled steel and aluminum products, especially the fireproof situation of oil factories.

Owner:MARINE CHEM RES INST

Structural modified epoxy adhesive compositions

InactiveUS6572971B2Raise the ratioReduce opening timeSynthetic resin layered productsEpoxy resin adhesivesFirming agentAliphatic amine

The present invention is directed to an adhesive composition, which comprises an epoxy resin, a coupling agent, filler, and an effective amount of an amine-curing agent or curative for said epoxy resin. Advantageously, tri-functional and / or tetrafunctional epoxy resins and / or acrylate monomers will be incorporated into the adhesive composition in order to reduce open time and enhance substrate adhesion. Advantageously, a mixture of amines will be used in the curative including aliphatic amines, which have low viscosities and efficiently wet the substrate for enhancing adhesion; polyamines, which can be used to manipulate open time and allow for improved ratio tolerance of the adhesive system; and amine-terminated rubbers (ATBN), which can improve impact resistance and the toughness of the cured adhesive. Preferred coupling agents are silanes.

Owner:ASHLAND LICENSING & INTPROP LLC

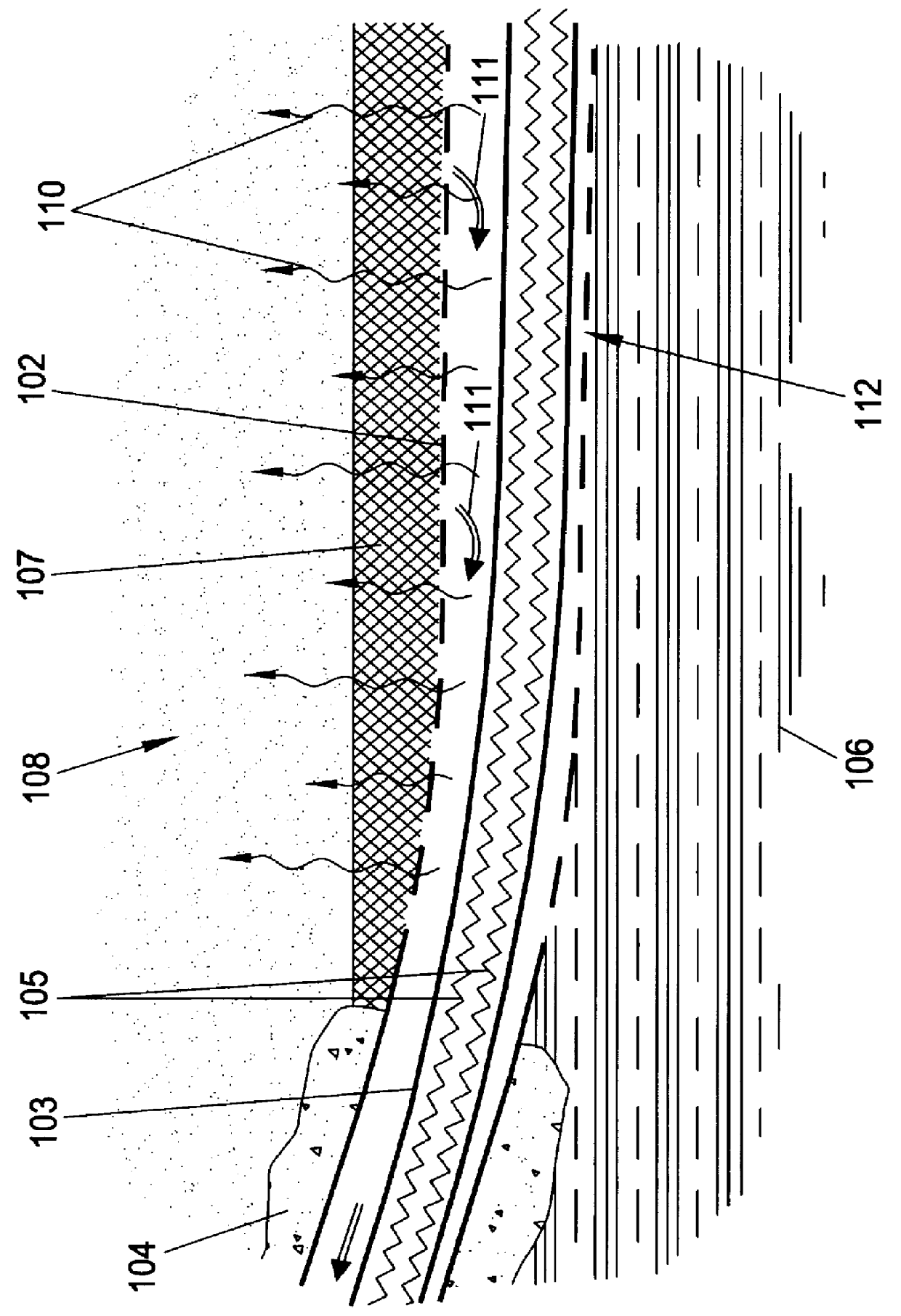

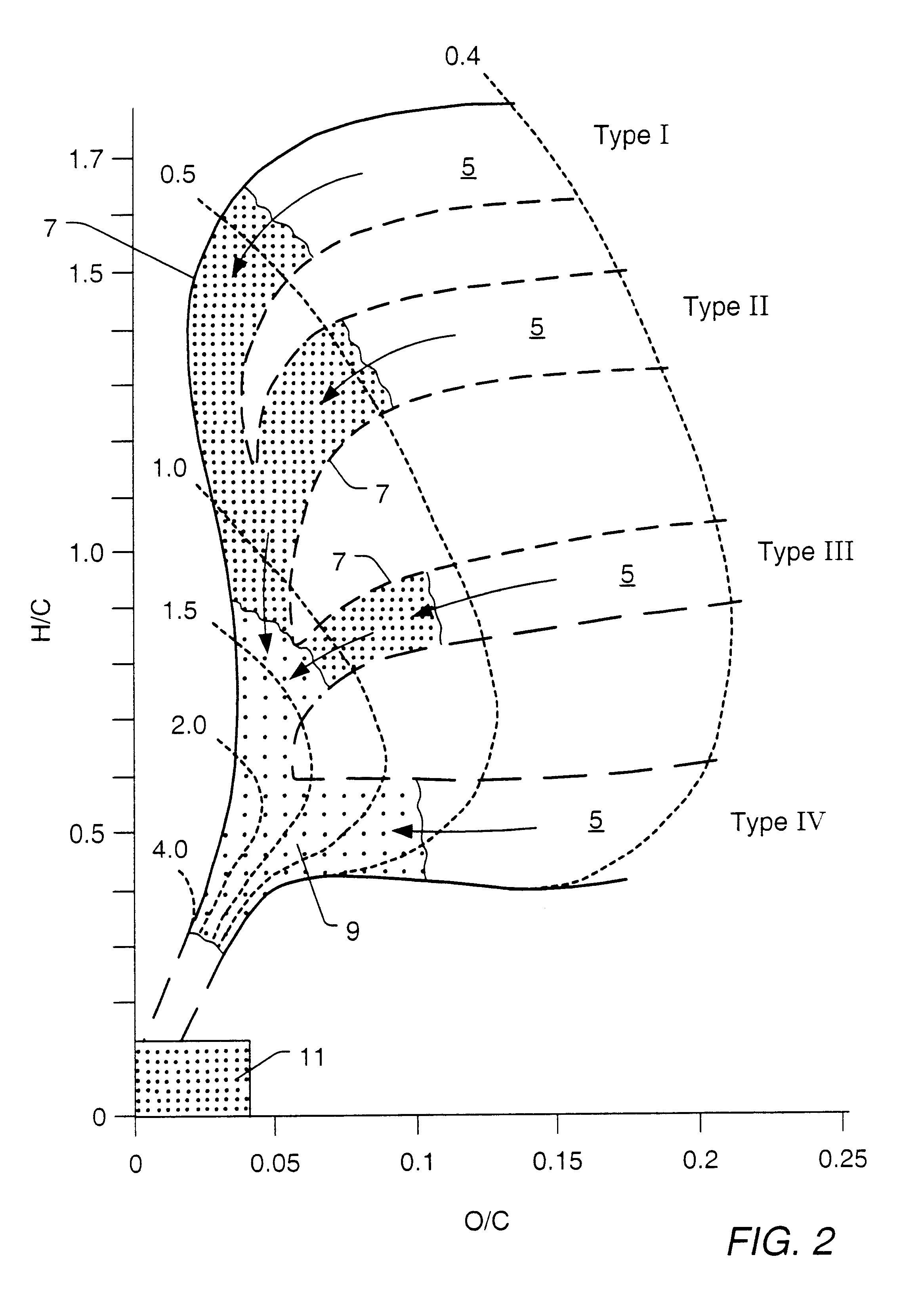

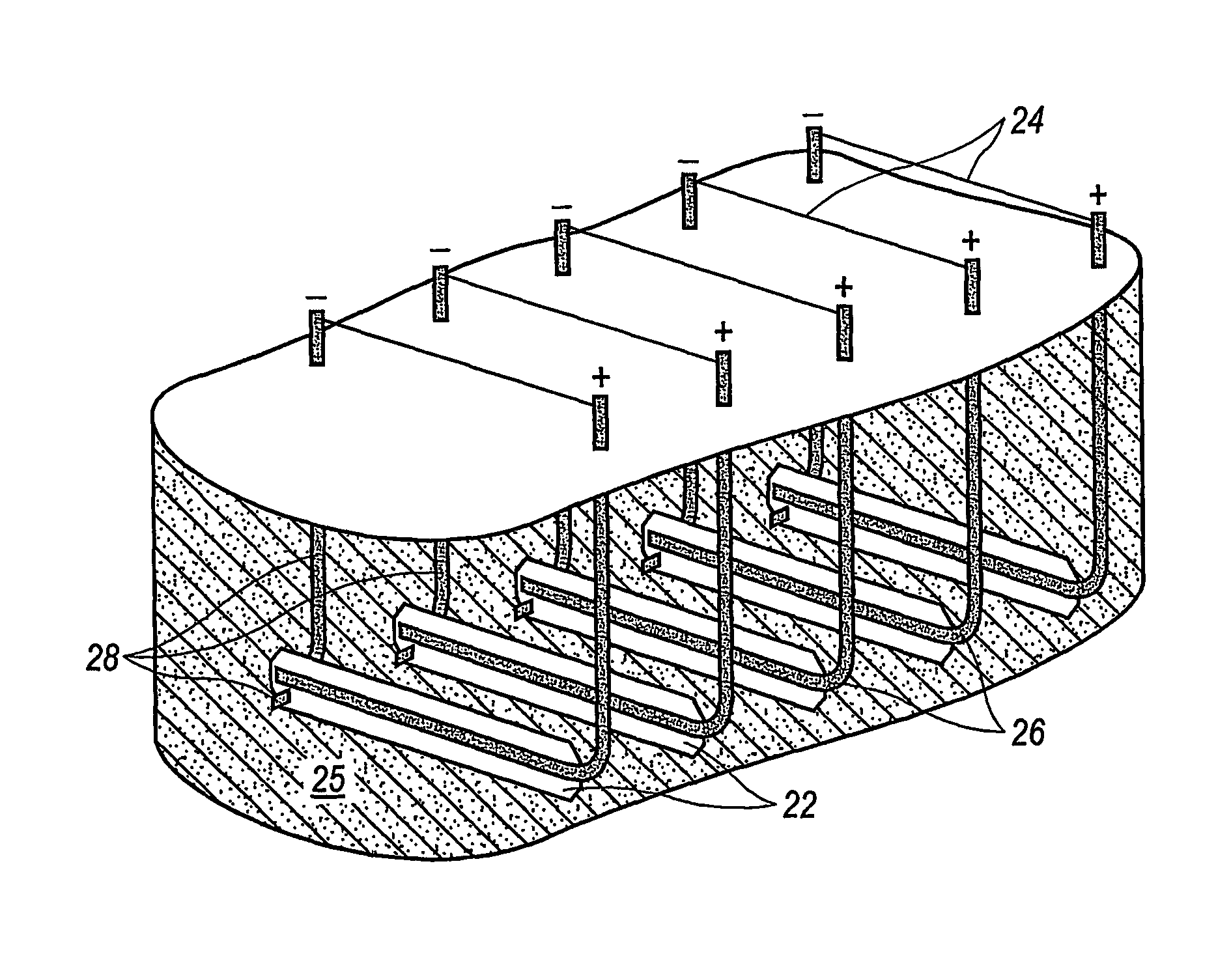

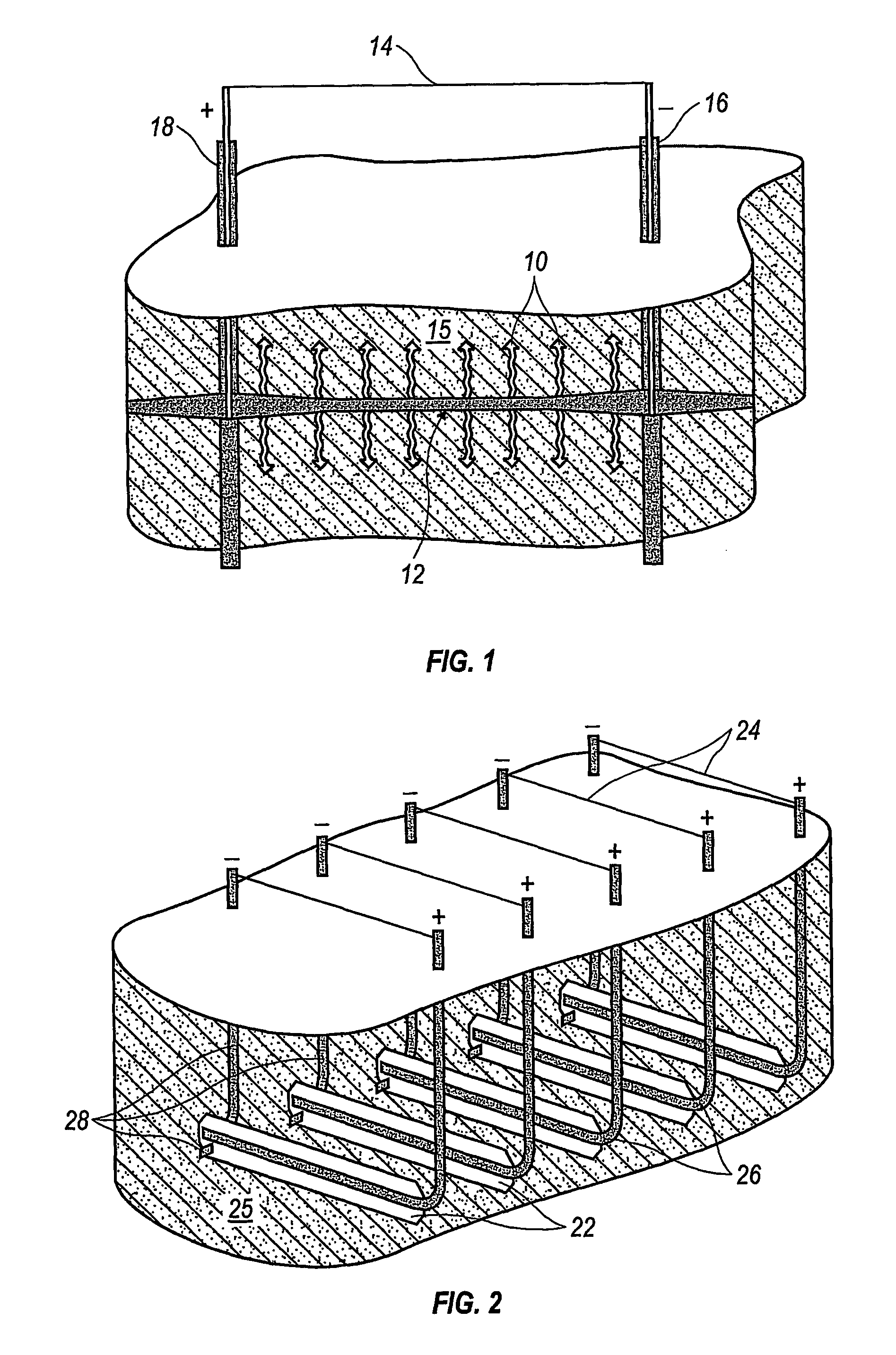

Methods of treating a subterranean formation to convert organic matter into producible hydrocarbons

ActiveUS7331385B2Low viscosityAvoid insufficient heatingFluid removalSoil organic matterConductive materials

Methods are provided that include the steps of providing wells in a formation, establishing one or more fractures (12) in the formation, such that each fracture intersects at least one of the wells (16, 18), placing electrically conductive material in the fractures, and generating electric current through the fractures and through the material such that sufficient heat (10) is generated by electrical resistivity within the material to pyrolyze organic matter in the formation into producible hydrocarbons.

Owner:EXXONMOBIL UPSTREAM RES CO

Encapsulants for protecting MEMS devices during post-packaging release etch

InactiveUS6956283B1Easily photodefined and then removedLow viscosityDecorative surface effectsSemiconductor/solid-state device detailsEngineeringElectrical and Electronics engineering

The present invention relates to methods to protect a MEMS or microsensor device through one or more release or activation steps in a “package first, release later” manufacturing scheme: This method of fabrication permits wirebonds, other interconnects, packaging materials, lines, bond pads, and other structures on the die to be protected from physical, chemical, or electrical damage during the release etch(es) or other packaging steps. Metallic structures (e.g., gold, aluminum, copper) on the device are also protected from galvanic attack because they are protected from contact with HF or HCL-bearing solutions.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

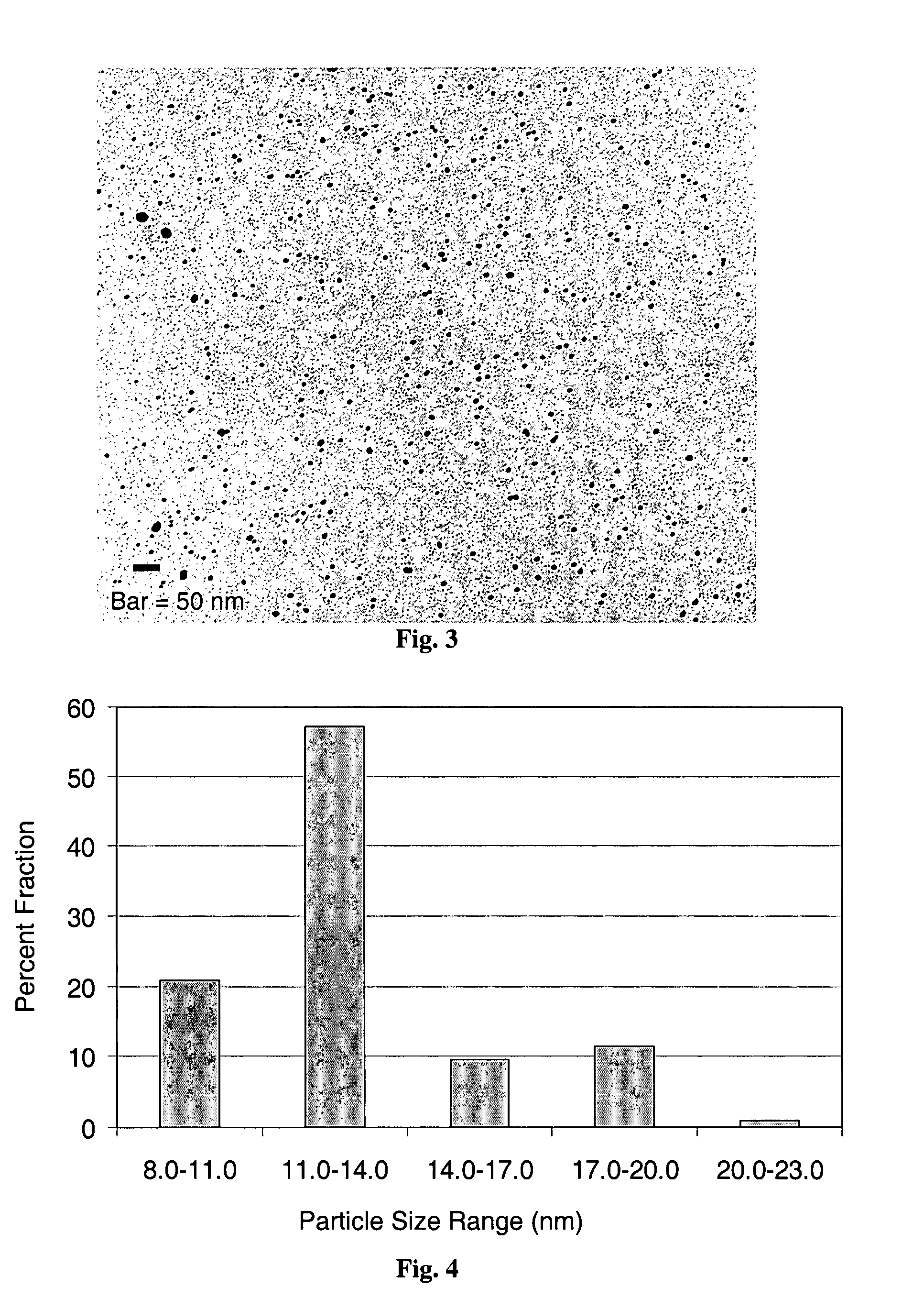

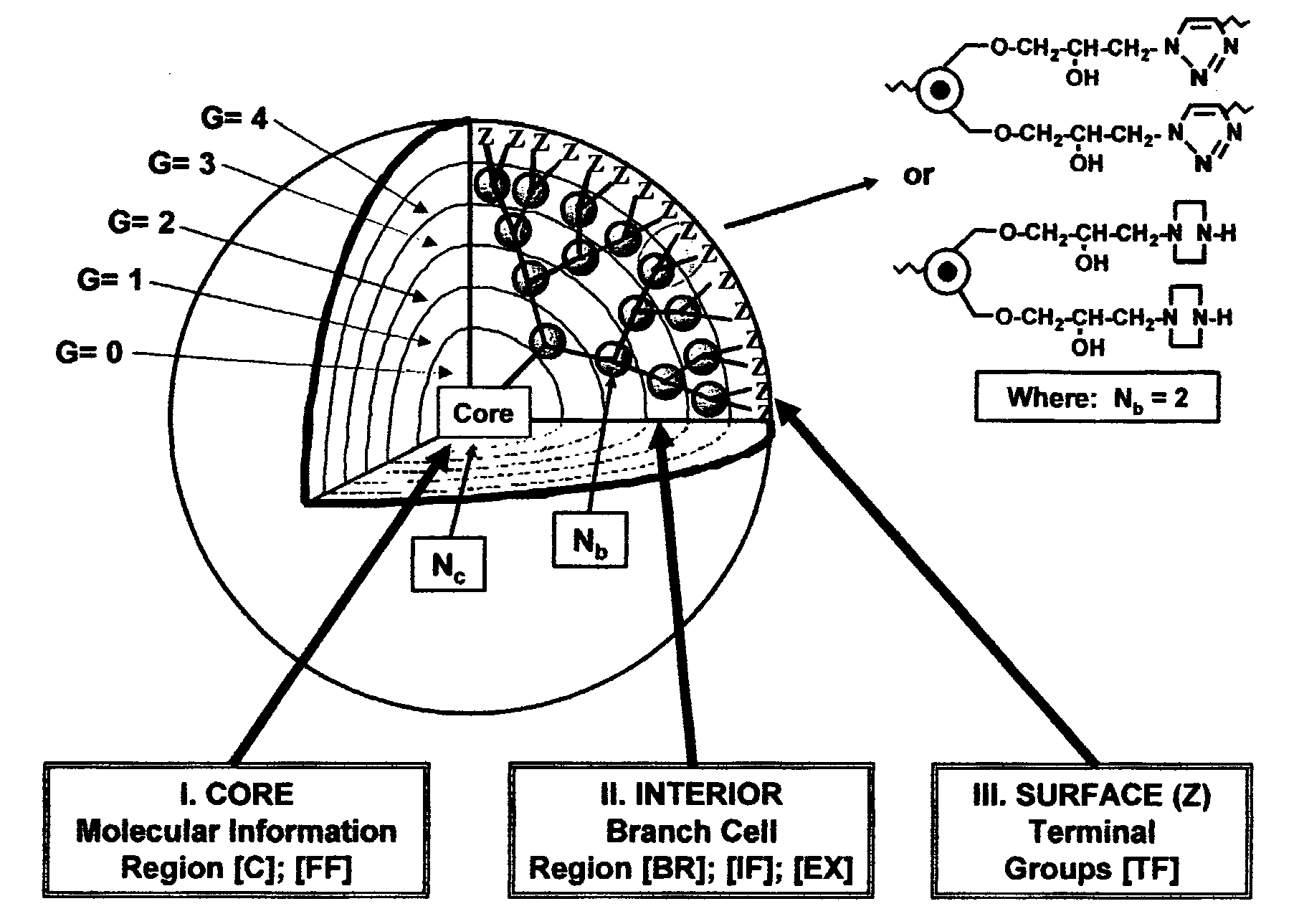

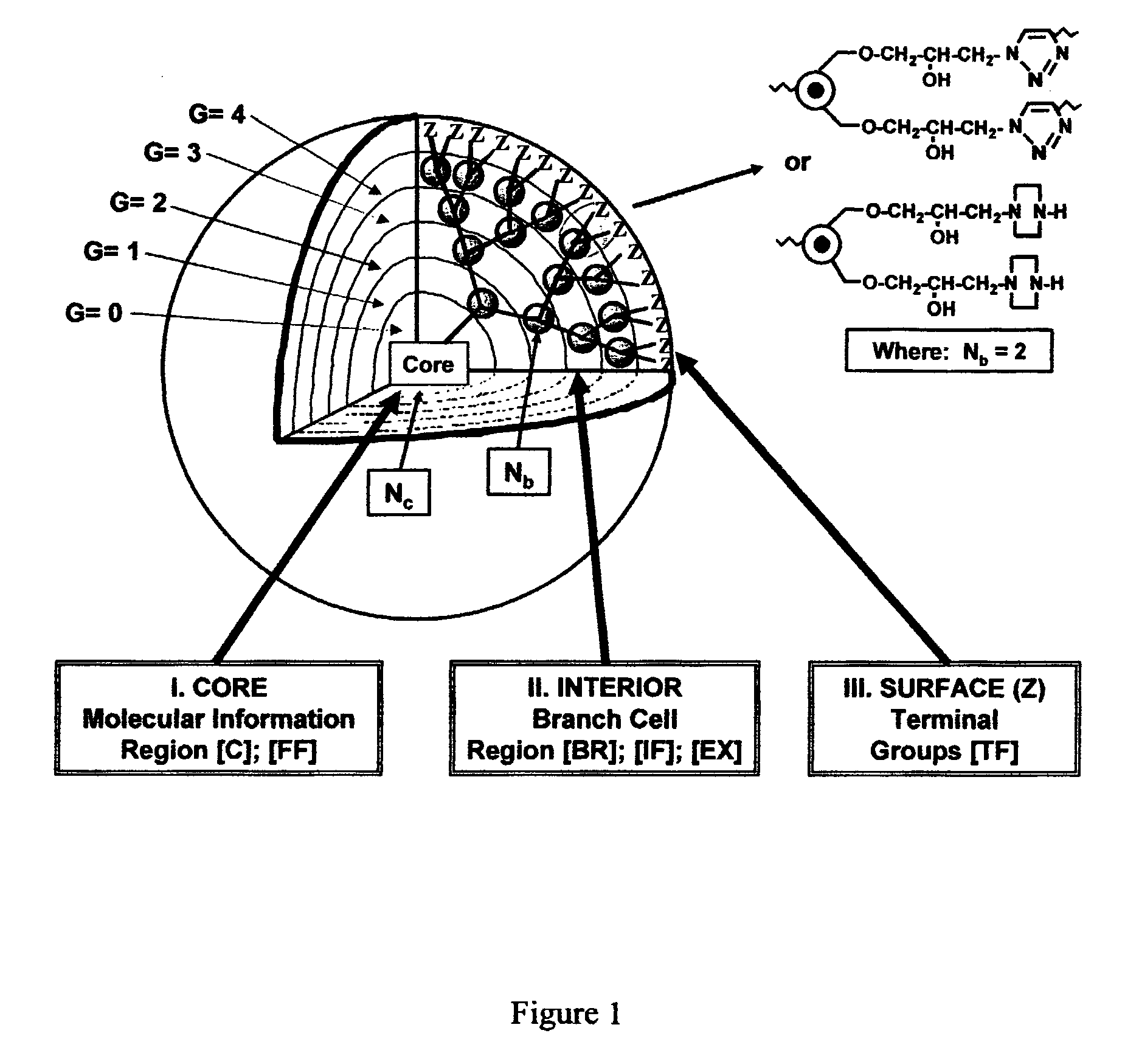

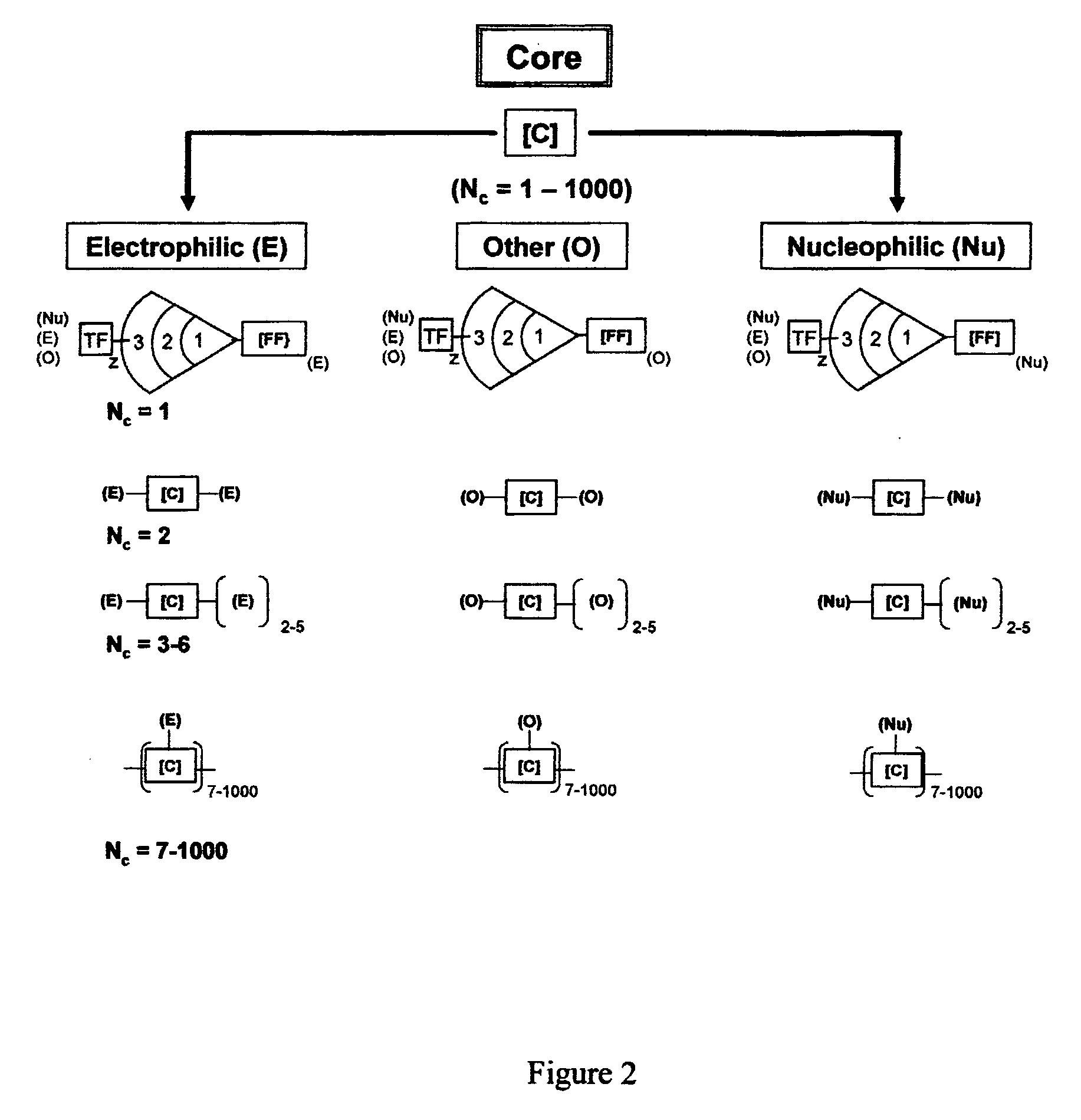

Dendritic Polymers With Enhanced Amplification and Interior Functionality

ActiveUS20070298006A1Reduced responseSizePowder deliveryOrganic active ingredientsCross-linkScavenger

Dendritic polymers with enhanced amplification and interior functionality are disclosed. These dendritic polymers are made by use of fast, reactive ring-opening chemistry (or other fast reactions) combined with the use of branch cell reagents in a controlled way to rapidly and precisely build dendritic structures, generation by generation, with cleaner chemistry, often single products, lower excesses of reagents, lower levels of dilution, higher capacity method, more easily scaled to commercial dimensions, new ranges of materials, and lower cost. The dendritic compositions prepared have novel internal functionality, greater stability (e.g., thermal stability and less or no reverse Michael's reaction), and reach encapsulation surface densities at lower generations. Unexpectedly, these reactions of polyfunctional branch cell reagents with polyfunctional cores do not create cross-linked materials. Such dendritic polymers are useful as demulsifiers for oil / water emulsions, wet strength agents in the manufacture of paper, proton scavengers, polymers, nanoscale monomers, calibration standards for electron microscopy, making size selective membranes, and agents for modifying viscosity in aqueous formulations such as paint. When these dendritic polymers have a carried material associated with their surface and / or interior, then these dendritic polymers have additional properties for carrying materials due to the unique characteristics of the dendritic polymer, such as for drug delivery, transfection, and diagnostics.

Owner:DENDRITIC NANO TECH INC

Ceramic slurry preparation and 3D (three dimensional) printing light curing molding method

ActiveCN106810215ALow viscosityHigh solid contentAdditive manufacturing apparatusCeramic shaping apparatusFlexural strengthVolumetric Mass Density

The invention provides a ceramic slurry preparation and 3D (three dimensional) printing light curing molding method. 25-85vol% of ceramic powder and 15-75vol% of an optical resin premix solution are mainly involved, and the method includes: A), preparation of the optical resin premix : namely stirring a low polymer, a reactive diluent, a photoinitiator, a dispersing agent, a photosensitizer and a sensitizer according to a certain proportion under intermediate speed for 0.5-3 hours to enable the components to be mixed evenly; B), placing the premix solution and the ceramic powder in a ball mill according to certain volume for ball-milling for 5-15 hours to prepare the ceramic slurry high in solid content and low in viscosity; subjecting the ceramic slurry to curing molding layer by layer gradually on a 3D light curing molding machine to obtain a ceramic green body prior to aftertreatment of drying, degreasing, sintering and the like to obtain ceramic part. The method is high in preparation molding precision and free of molds to prepare complex structure parts, the ceramic product can reach more than 92% in density, 320-1750MPa in flexural strength and 1800-4500MPa in compression strength.

Owner:重庆摩方科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com