Patents

Literature

106results about How to "Reaction is slow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Jettable compositions

ActiveUS20050171237A1Prevent long-term corrosionReaction is slowAdditive manufacturing apparatusLiquid surface applicatorsMeth-Oligomer

A fully curable jettable composition having a viscosity less than 30 cps at a temperature within the range of 15-180° C., more preferably at a temperature of 15-100° C., e.g. 60-80° C. the composition comprising: (A) at least one low viscosity reactive resin selected from the group consisting of compounds containing an oxetane ring, cycloaliphatic epoxy resins, tetrahydrofurans, hexahydropyrans and mono-functional (meth)acrylates, said resin having a molecular weight of not greater than 300 Daltons, e.g. 250 Daltons or less, and a viscosity at a temperature in the said range of less than 30 cps, e.g. 5 to 15 cps; (B) at least one higher viscosity resin selected from the group consisting of epoxy resins, compounds containing an oxetane ring and acrylates, which resin acts to thicken the low viscosity resin and strengthen a jetted deposit of the composition, the higher viscosity resin having: a viscosity greater than twice that of the low viscosity resin at the said temperature in the range stated above, and a functionality of greater than or equal to 2; (C) at least one curable toughener, preferably having a functionality of at least 2, such as hydroxy, epoxy, acrylic or other reactive functionalised polymer / oligomer (e.g. derived by functionalising poly(tetrahydrofuran), polycaprolactone, polycarbonate diol, or a dendrimeric polyol; (D) at least one initiator for the polymerisation of the resins, and (E) at least one stabiliser for delaying the curing of the resins of the composition; wherein the low viscosity resin is slower to react than the higher viscosity resin and acts to solvate the higher viscosity resin prior to curing and at least partly during curing and wherein at least 30% of the components A and B are cationically curable resins. The composition can be jetted from piezo electric printing heads under the control of a computer program to form a multi-layered article, e.g. a three dimensional article, in which the adjacent droplets merge and are cured homogeneously together.

Owner:3D SYST INC +1

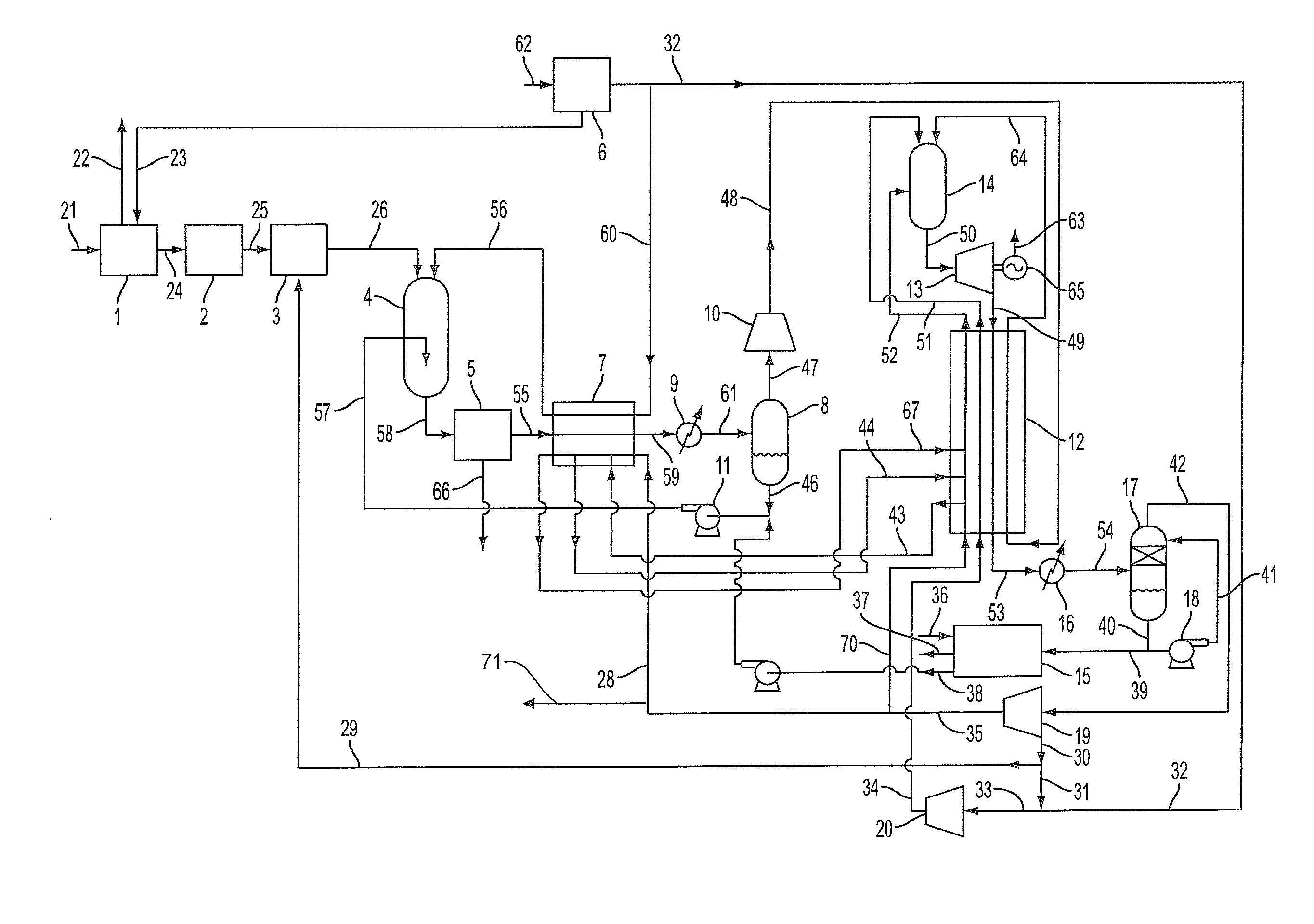

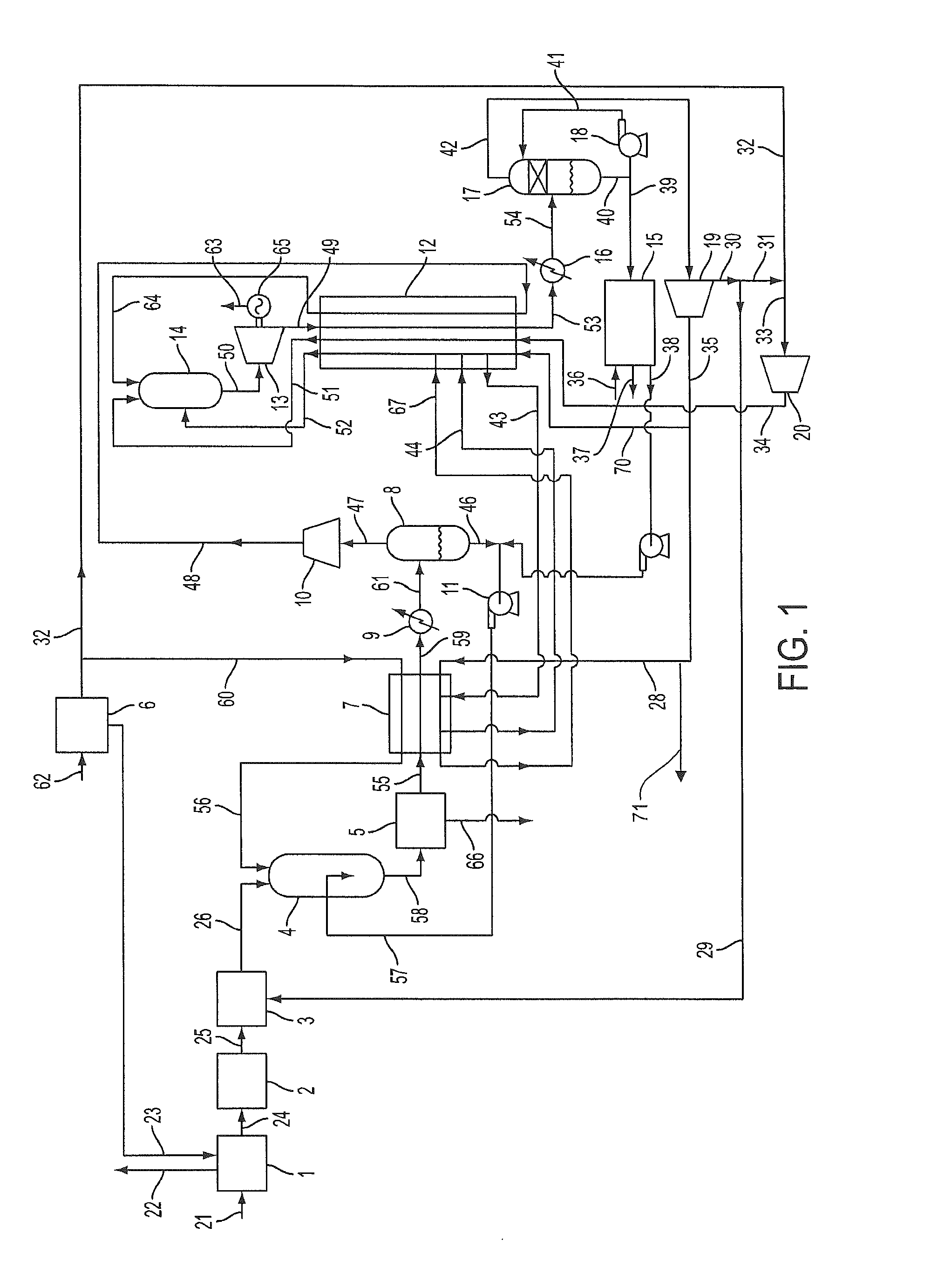

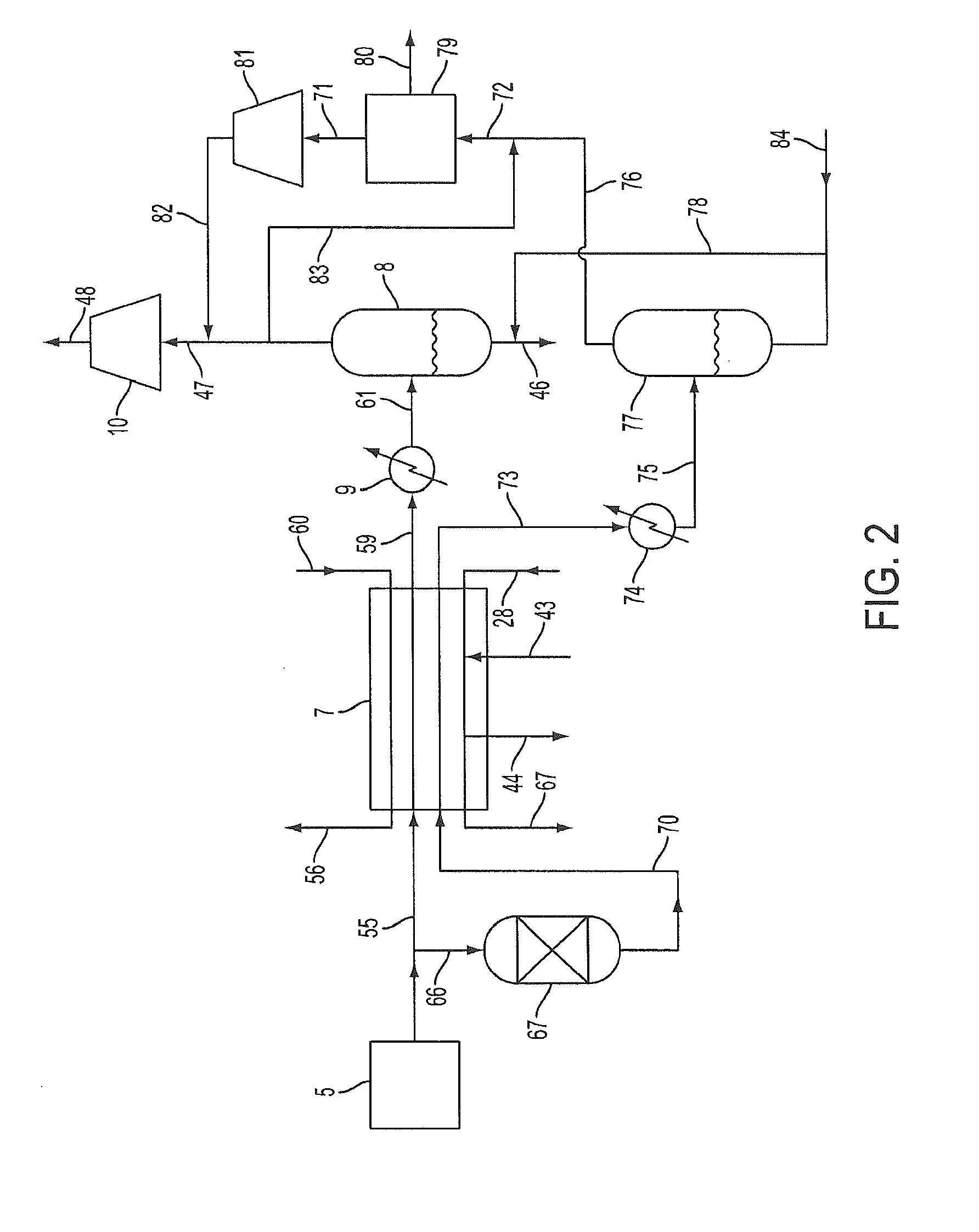

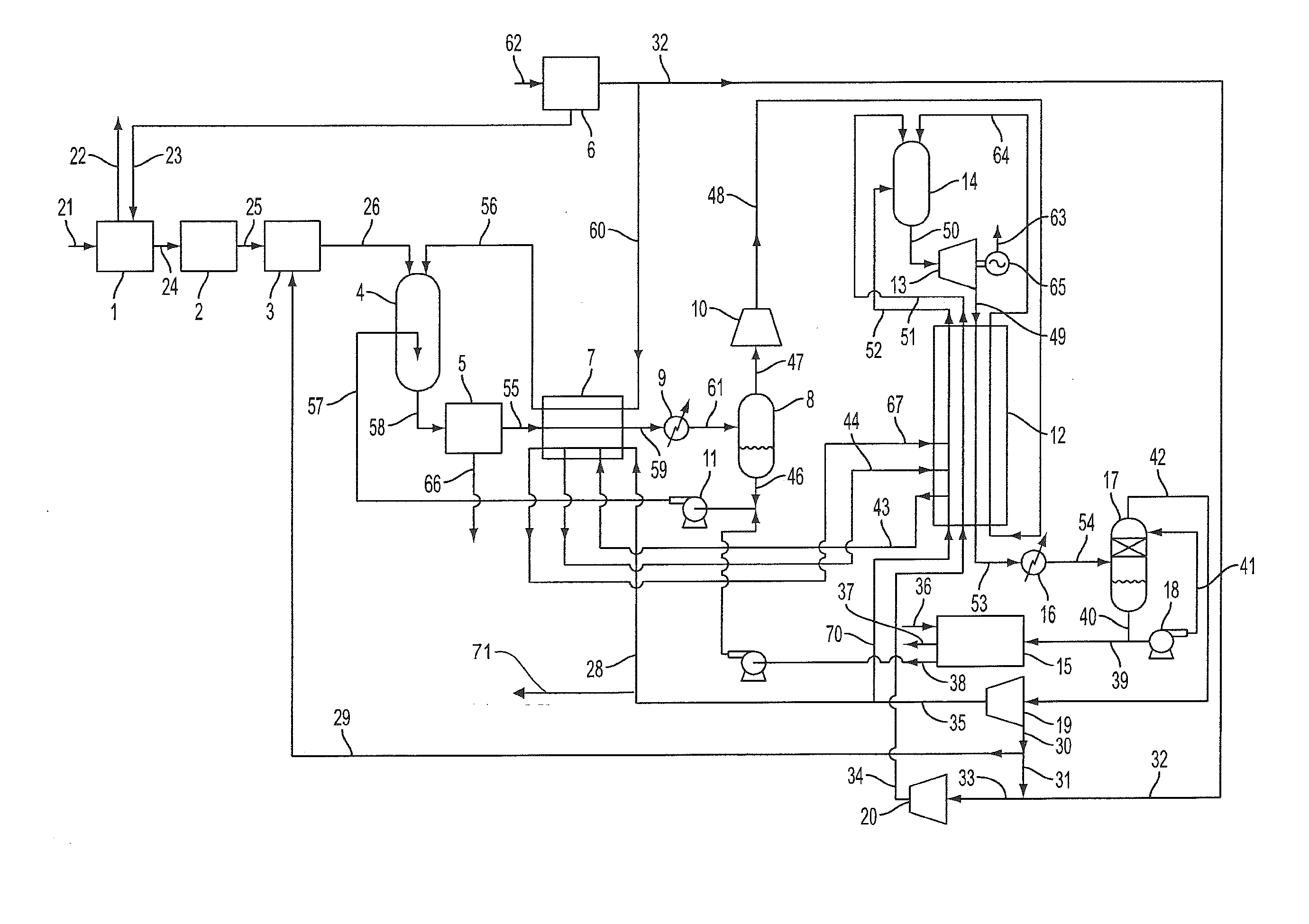

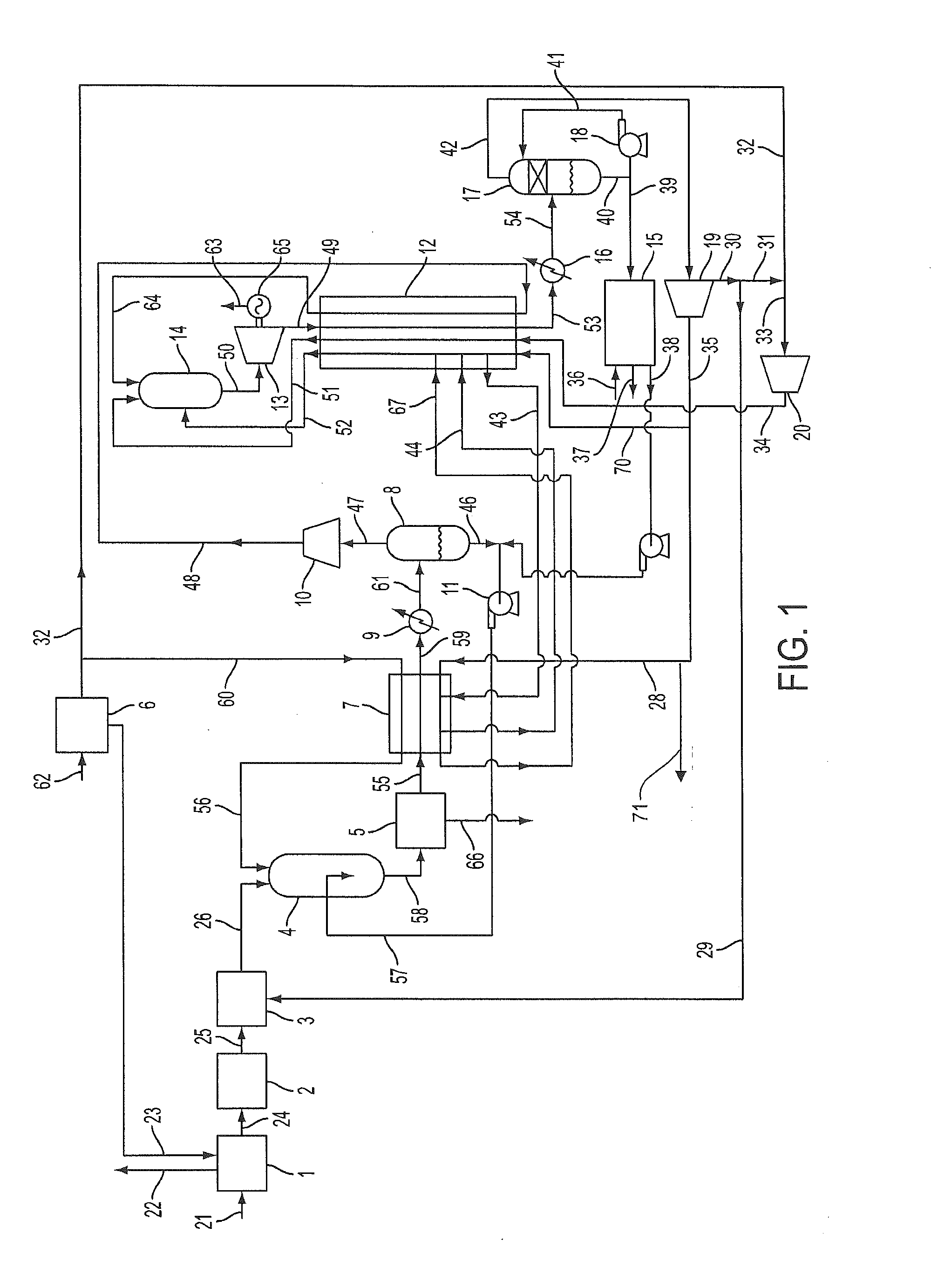

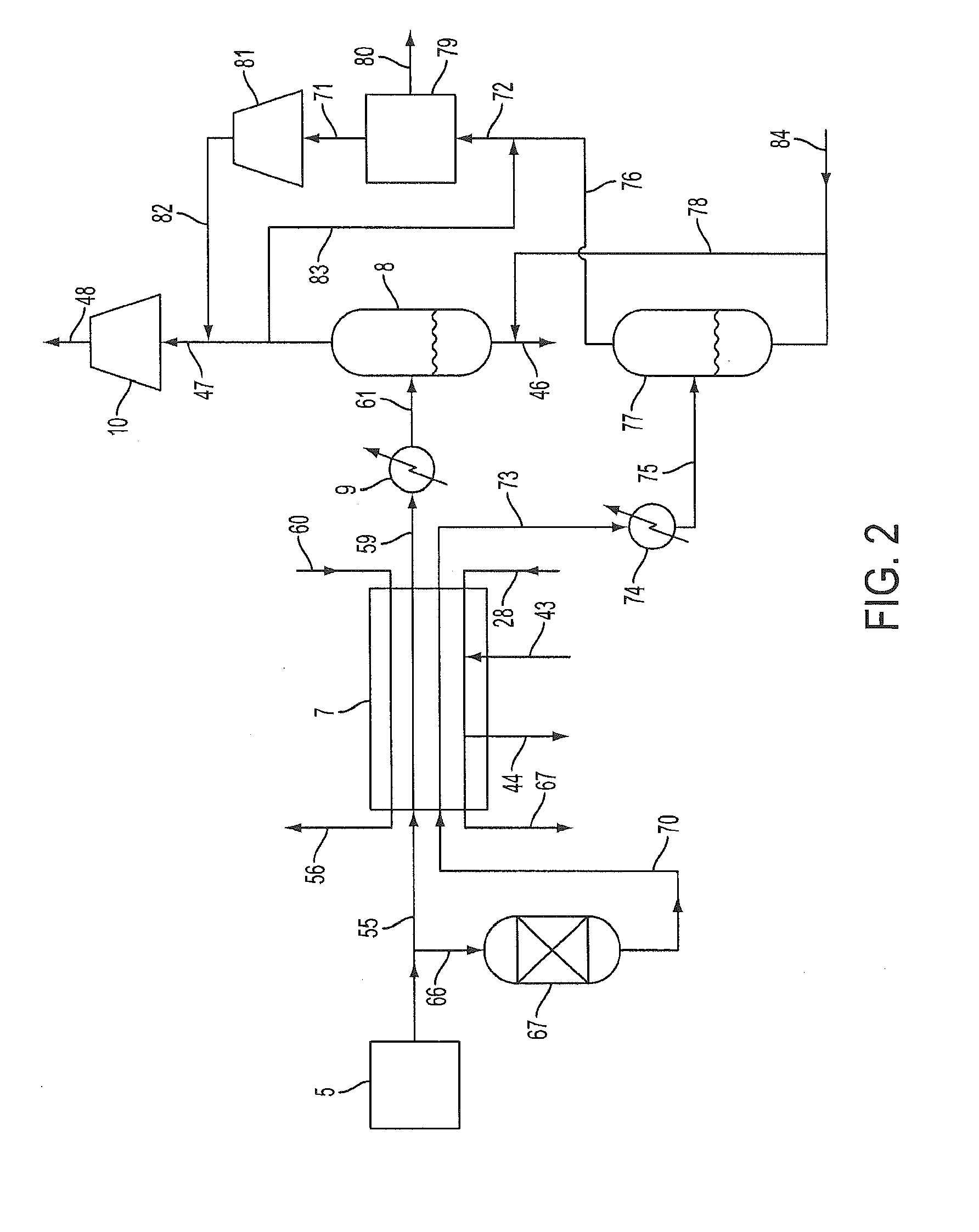

Partial oxidation reaction with closed cycle quench

ActiveUS8776532B2Prevent metal dustingReaction is slowSolidificationLiquefactionPartial oxidationCombustor

The present disclosure relates to a power production system that is adapted to achieve high efficiency power production with complete carbon capture when using a solid or liquid hydrocarbon or carbonaceous fuel. More particularly, the solid or liquid fuel first is partially oxidized in a partial oxidation reactor. The resulting partially oxidized stream that comprises a fuel gas is quenched, filtered, cooled, and then directed to a combustor of a power production system as the combustion fuel. The partially oxidized stream is combined with a compressed recycle CO2 stream and oxygen. The combustion stream is expanded across a turbine to produce power and passed through a recuperator heat exchanger. The expanded and cooled exhaust stream is scrubbed to provide the recycle CO2 stream, which is compressed and passed through the recuperator heat exchanger and the POX heat exchanger in a manner useful to provide increased efficiency to the combined systems.

Owner:8 RIVERS CAPTTAL LLC

Partial oxidation reaction with closed cycle quench

ActiveUS20130205746A1Prevent metal dustingReaction is slowSolidificationLiquefactionPartial oxidationCombustor

The present disclosure relates to a power production system that is adapted to achieve high efficiency power production with complete carbon capture when using a solid or liquid hydrocarbon or carbonaceous fuel. More particularly, the solid or liquid fuel first is partially oxidized in a partial oxidation reactor. The resulting partially oxidized stream that comprises a fuel gas is quenched, filtered, cooled, and then directed to a combustor of a power production system as the combustion fuel. The partially oxidized stream is combined with a compressed recycle CO2 stream and oxygen. The combustion stream is expanded across a turbine to produce power and passed through a recuperator heat exchanger. The expanded and cooled exhaust stream is scrubbed to provide the recycle CO2 stream, which is compressed and passed through the recuperator heat exchanger and the POX heat exchanger in a manner useful to provide increased efficiency to the combined systems.

Owner:8 RIVERS CAPTTAL LLC

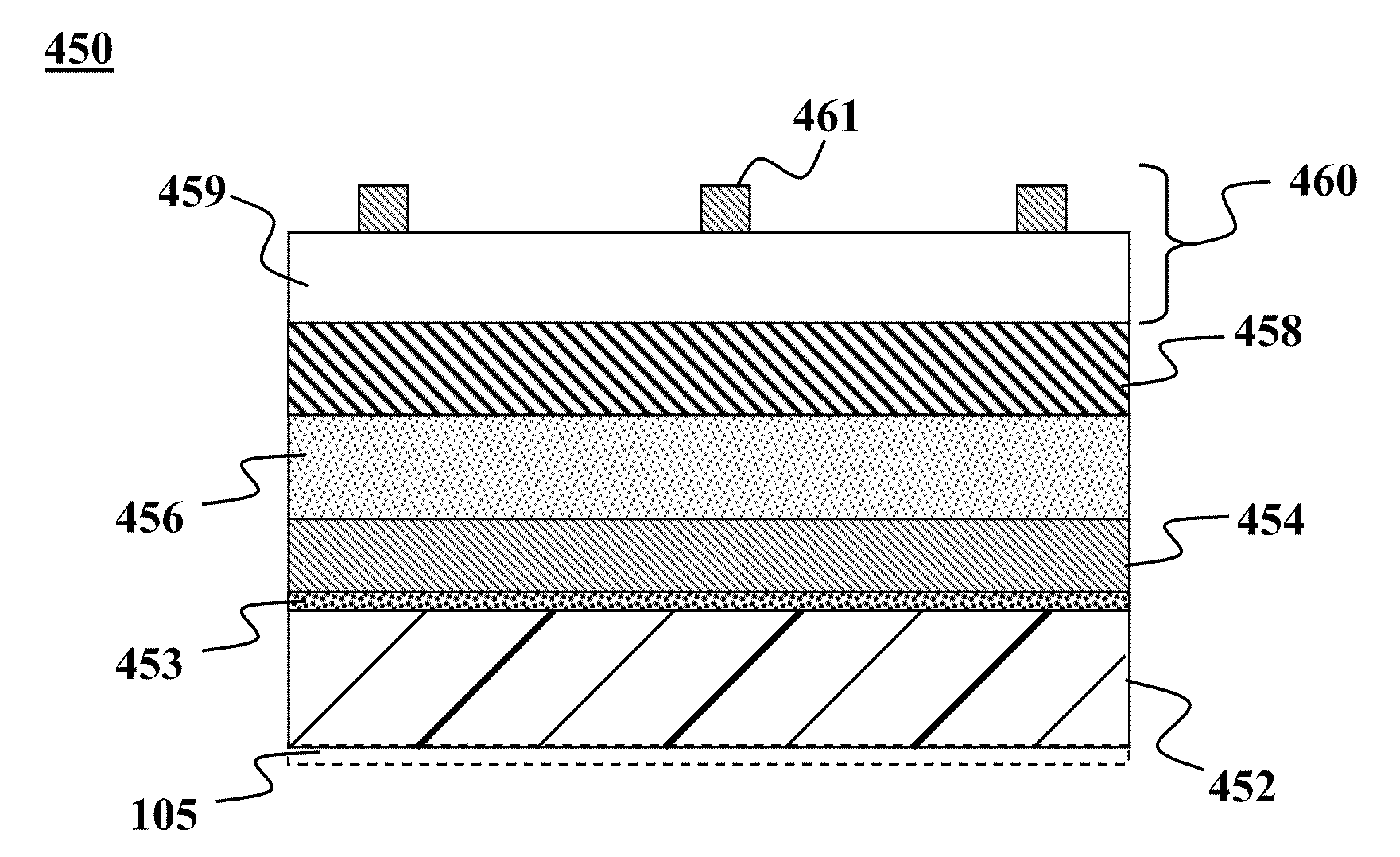

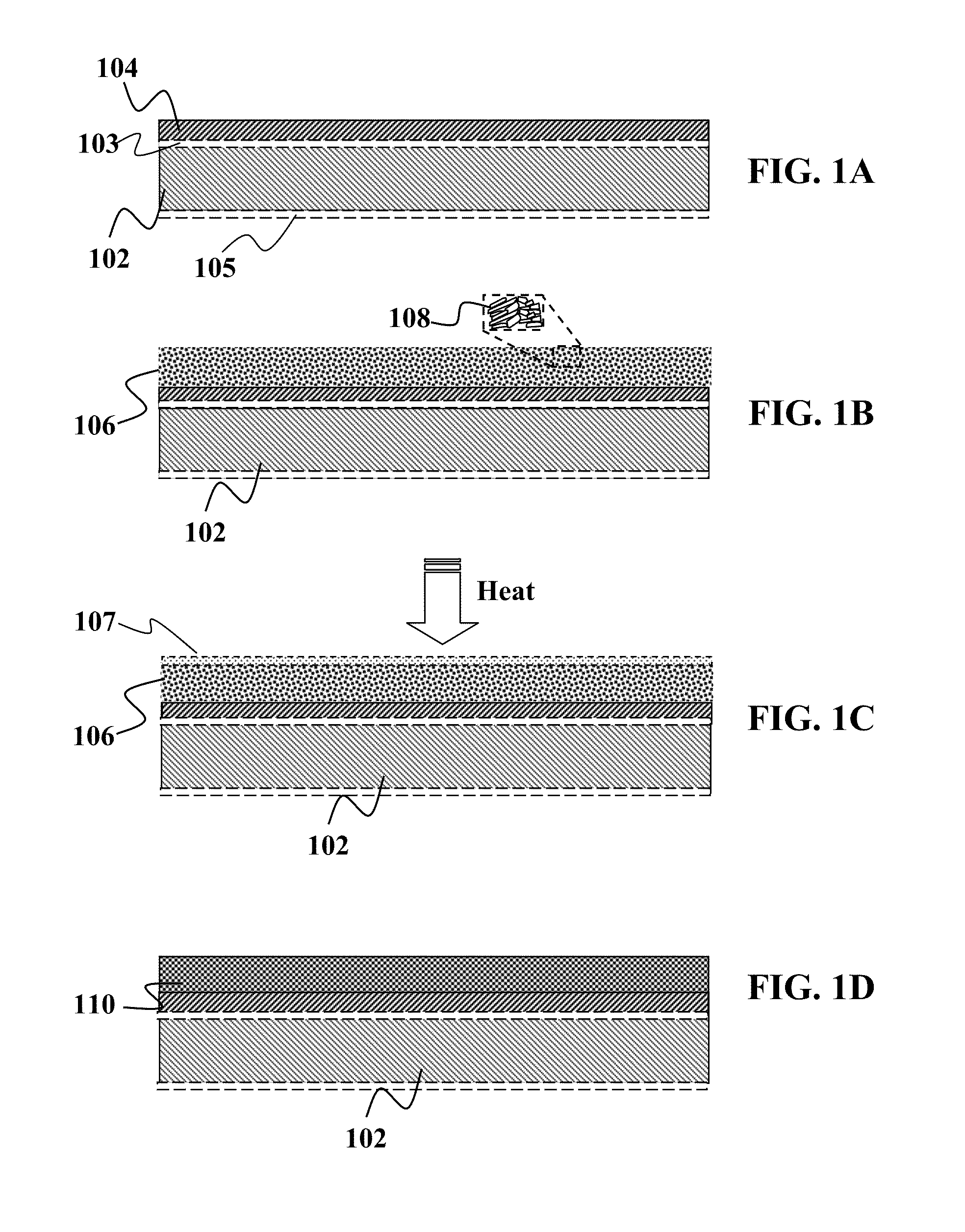

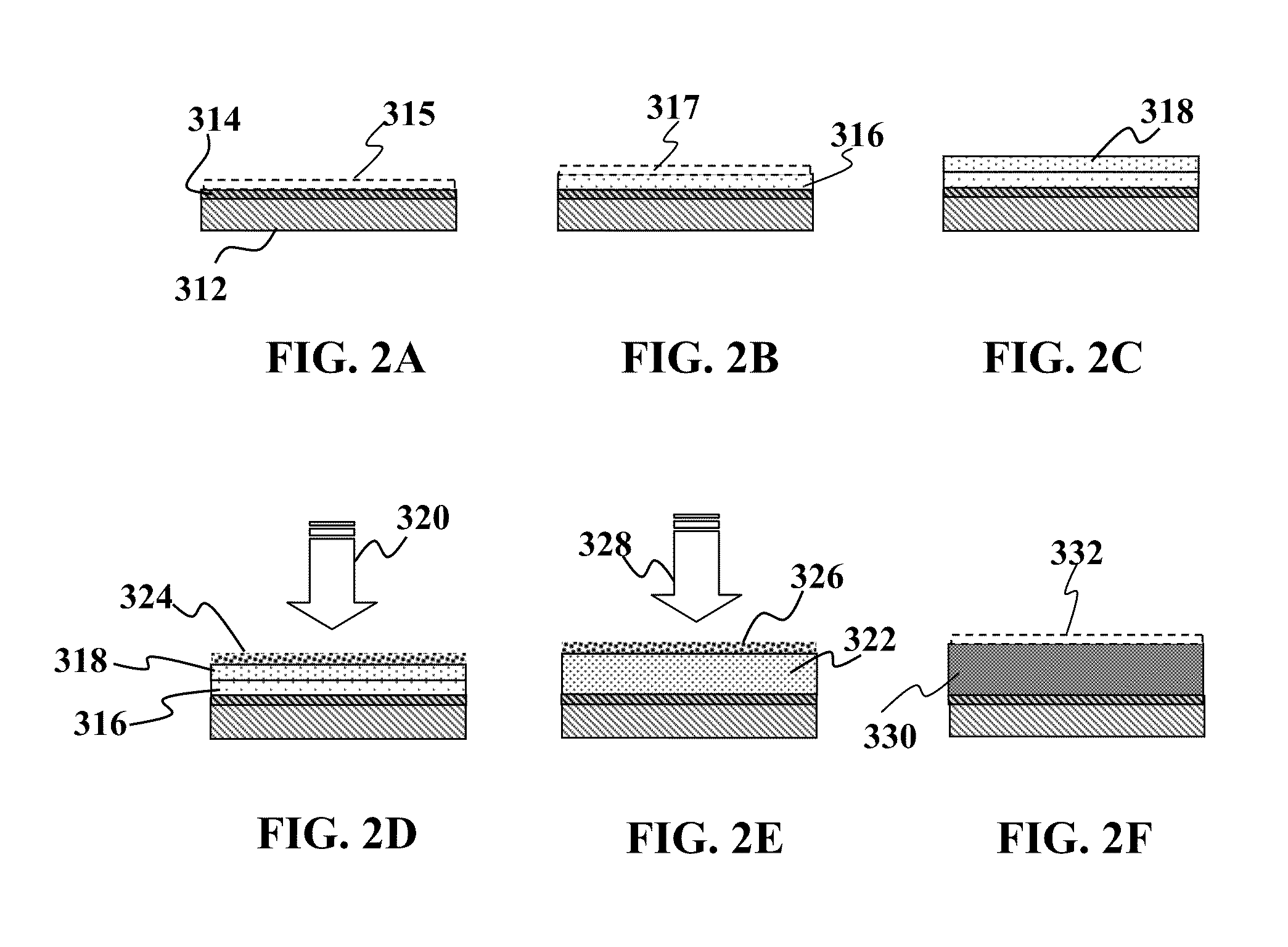

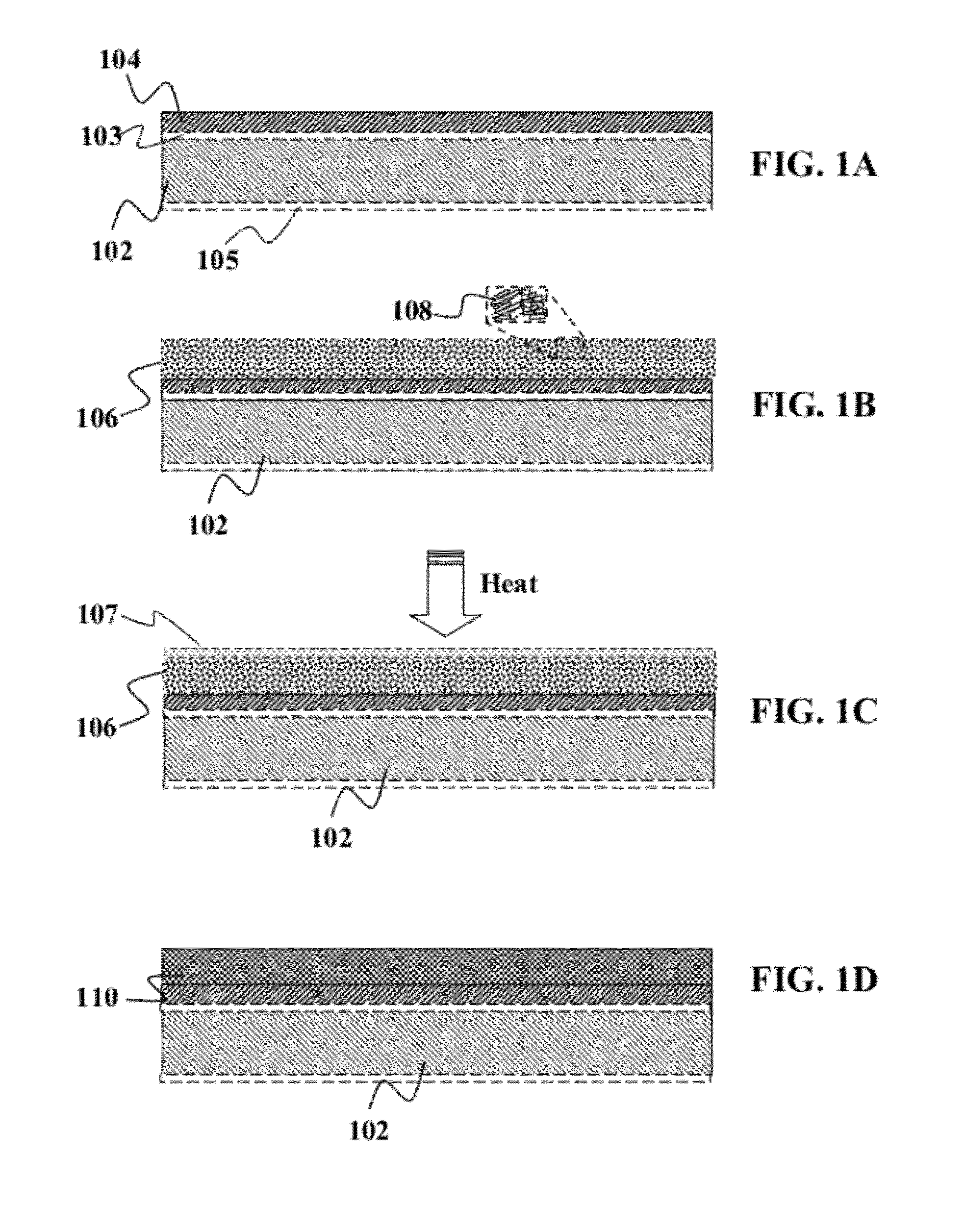

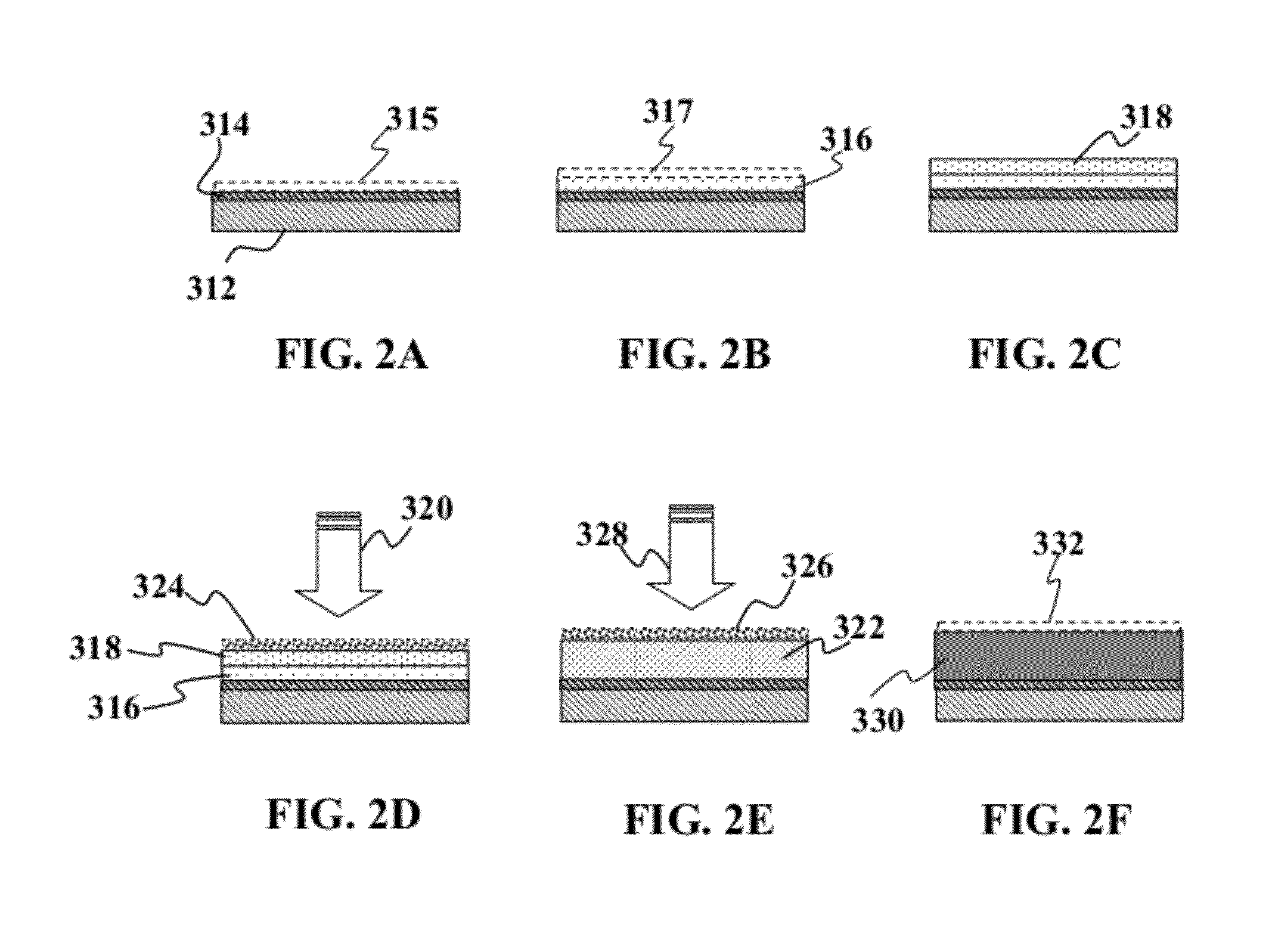

Low cost solar cells formed using a chalcogenization rate modifier

InactiveUS20110294254A1Speed up gallium processingIncrease exposureFinal product manufactureSemiconductor/solid-state device manufacturingAlloySolar cell

Methods and devices are provided for forming an absorber layer. In one embodiment, a method is provided comprising of depositing a precursor material onto a substrate, wherein the precursor material may include or may be used with an additive to minimize concentration of group IIIA material such as Ga in the back portion of the final semiconductor layer. The additive may be a non-copper Group IB additive in elemental or alloy form.

Owner:AERIS CAPITAL SUSTAINABLE IP

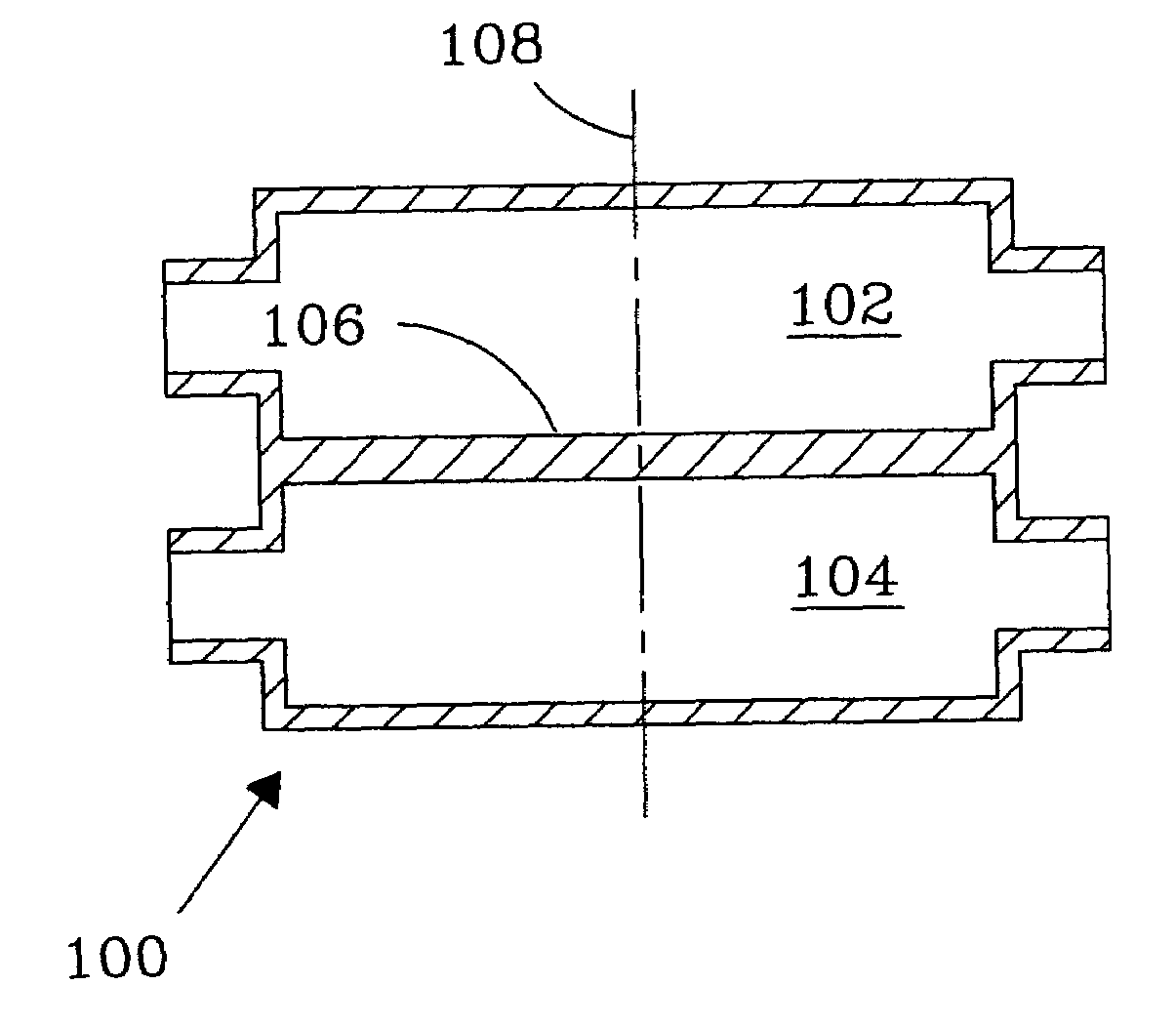

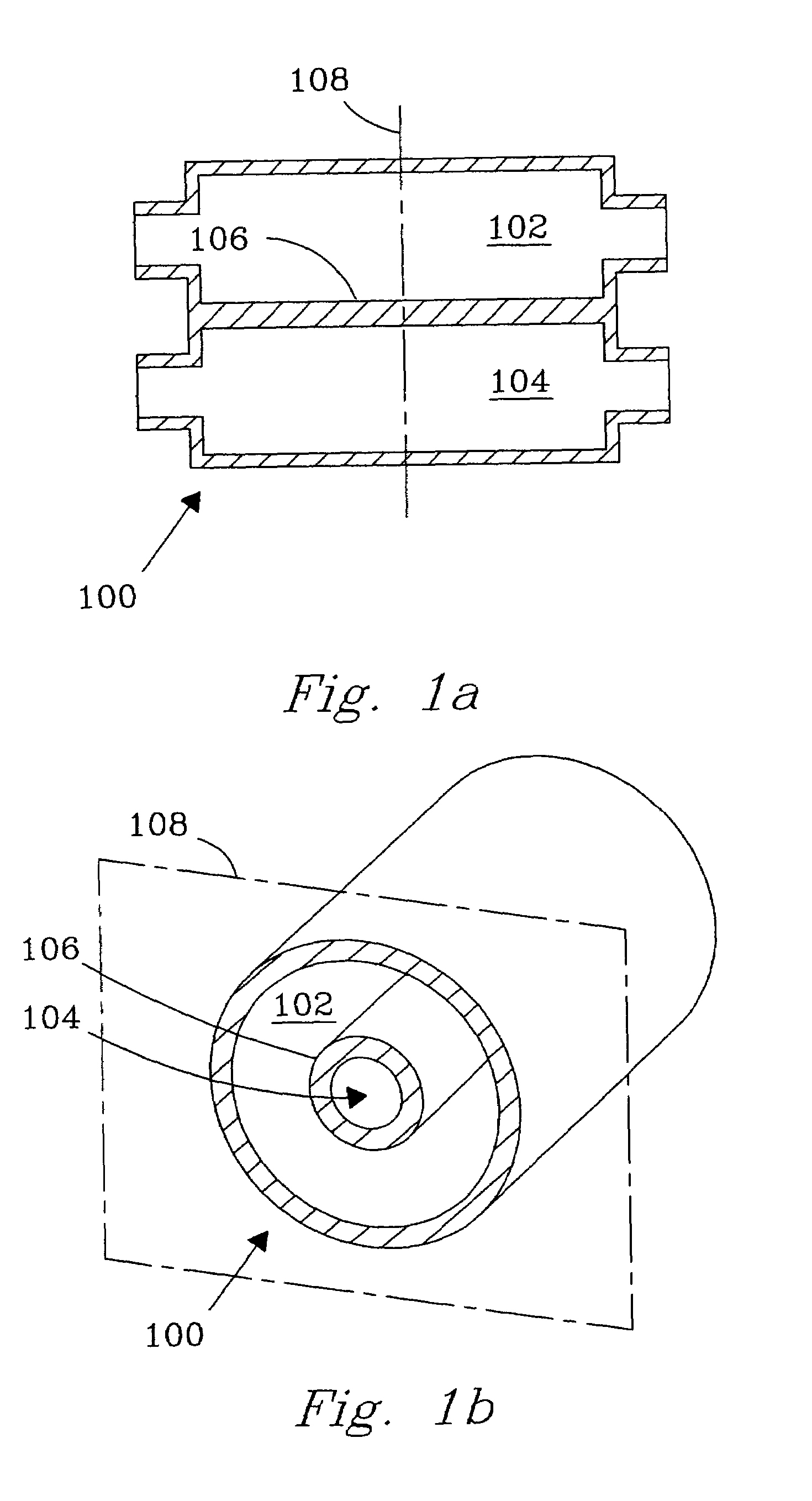

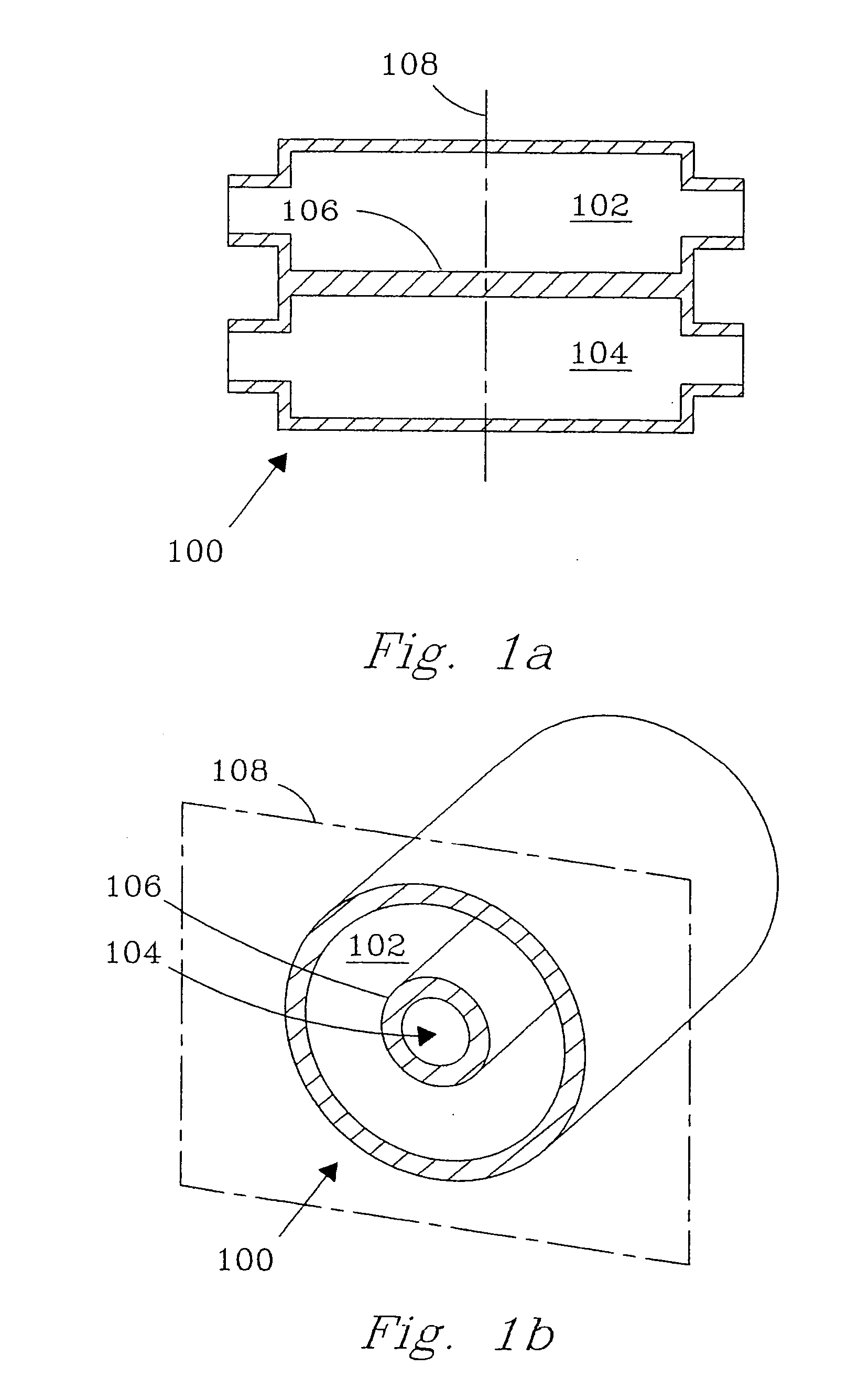

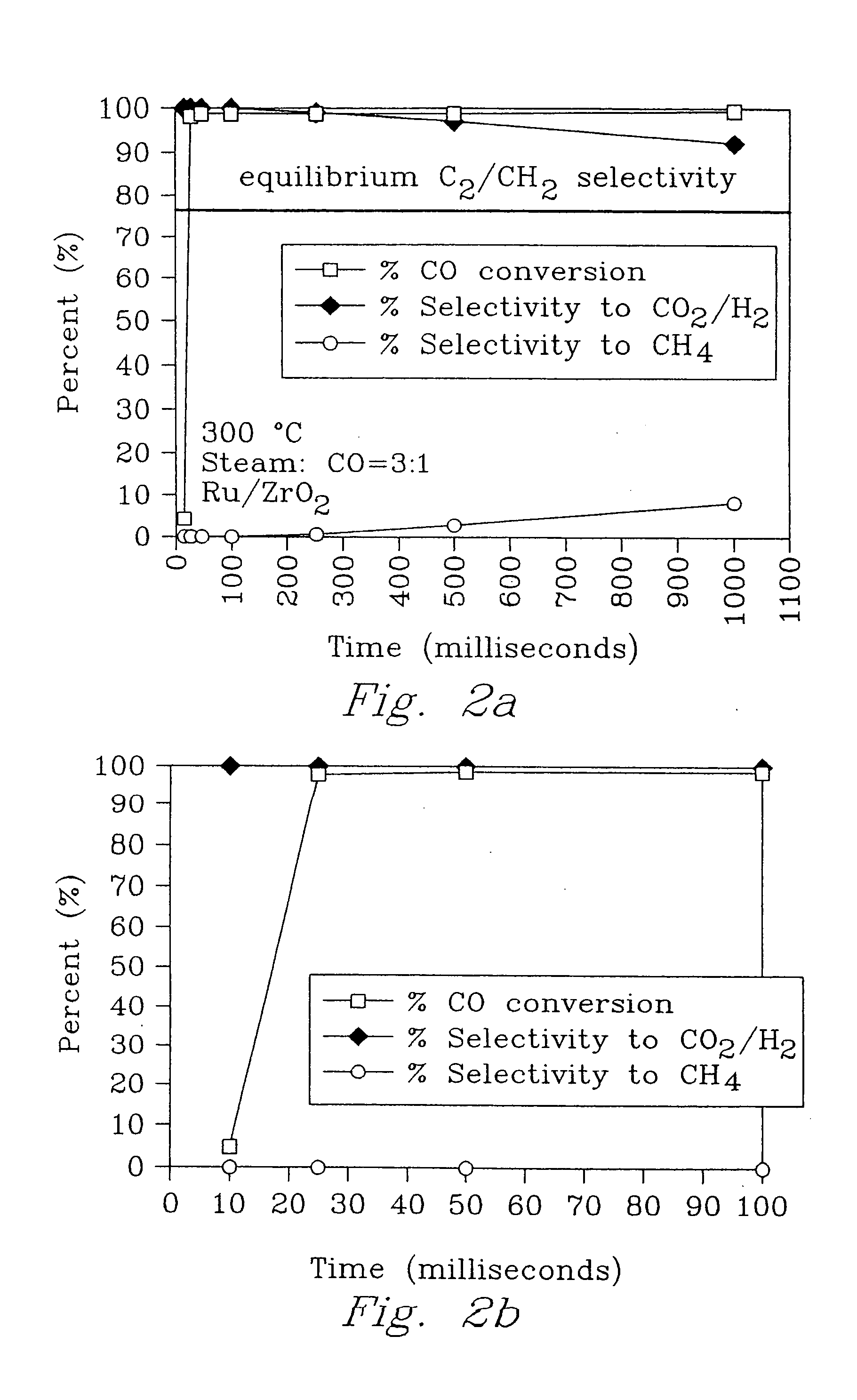

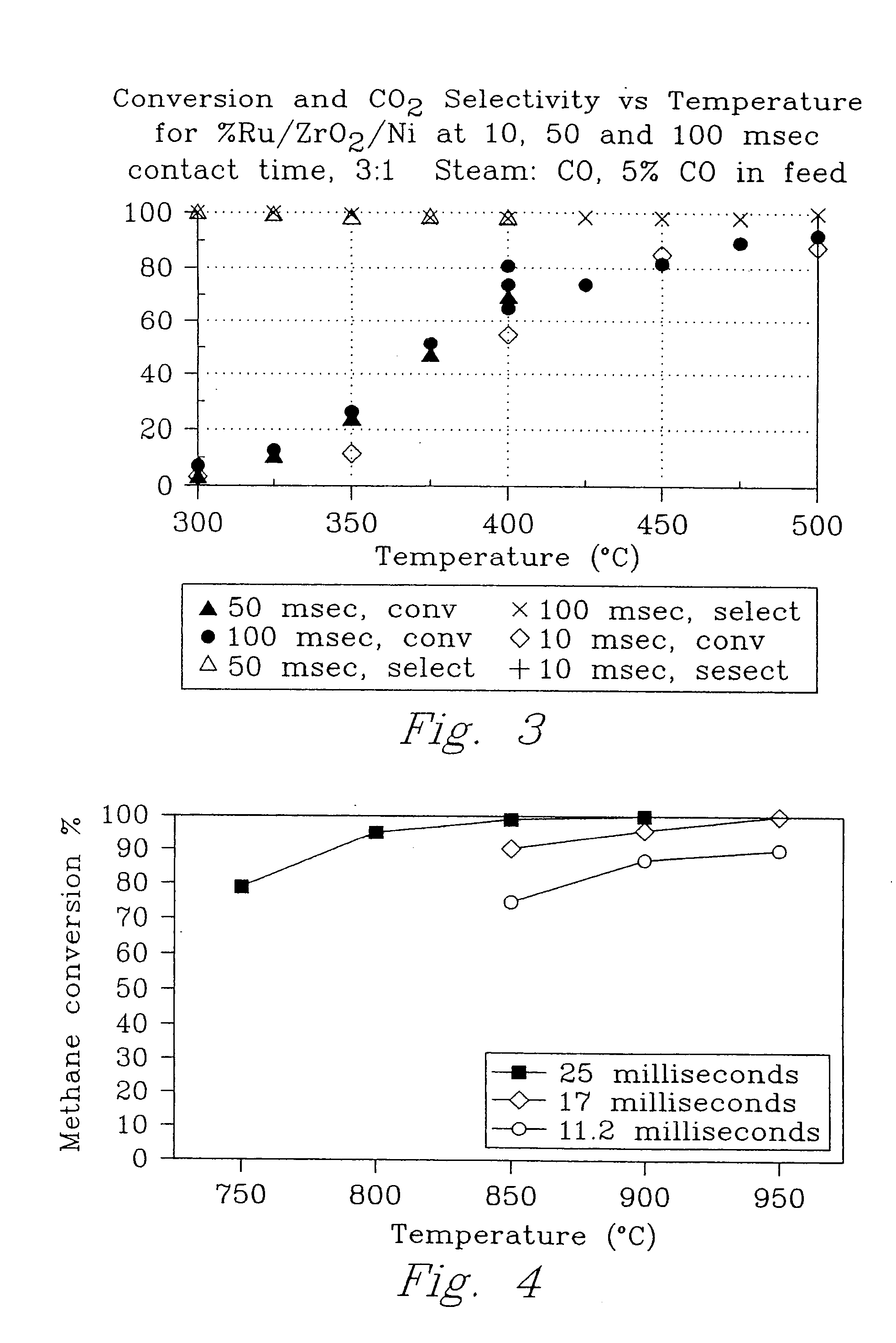

Method and apparatus for obtaining enhanced production rate of thermal chemical reactions

InactiveUS7045114B2Reduce formationReaction is slowOrganic chemistry methodsChemical/physical/physico-chemical microreactorsSteam reformingChemical reaction

Reactors and processes are disclosed that can utilize high heat fluxes to obtain fast, steady-state reaction rates. Porous catalysts used in conjunction with microchannel reactors to obtain high rates of heat transfer are also disclosed. Reactors and processes that utilize short contact times, high heat flux and low pressure drop are described. Improved methods of steam reforming are also provided.

Owner:BATTELLE MEMORIAL INST

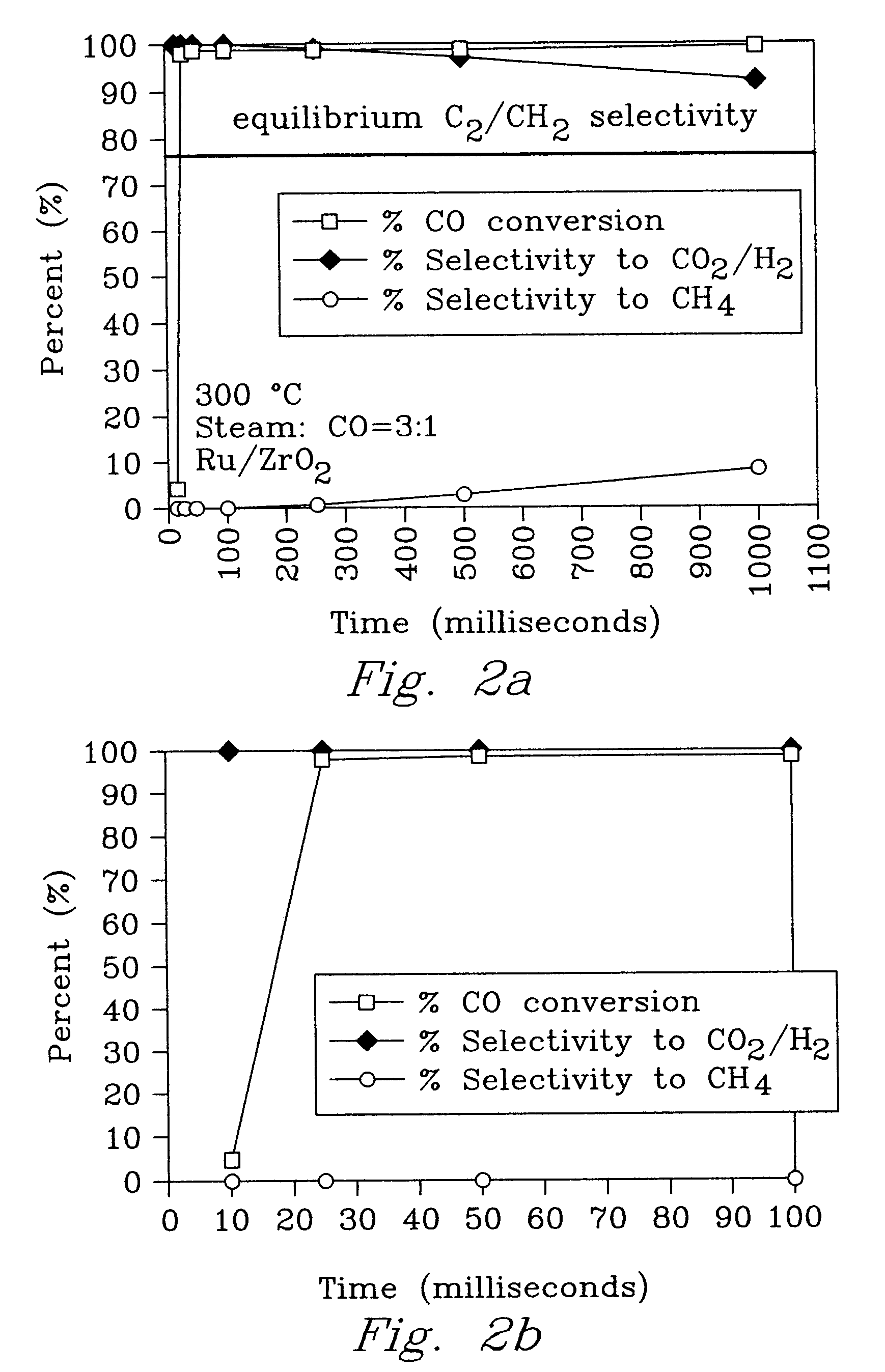

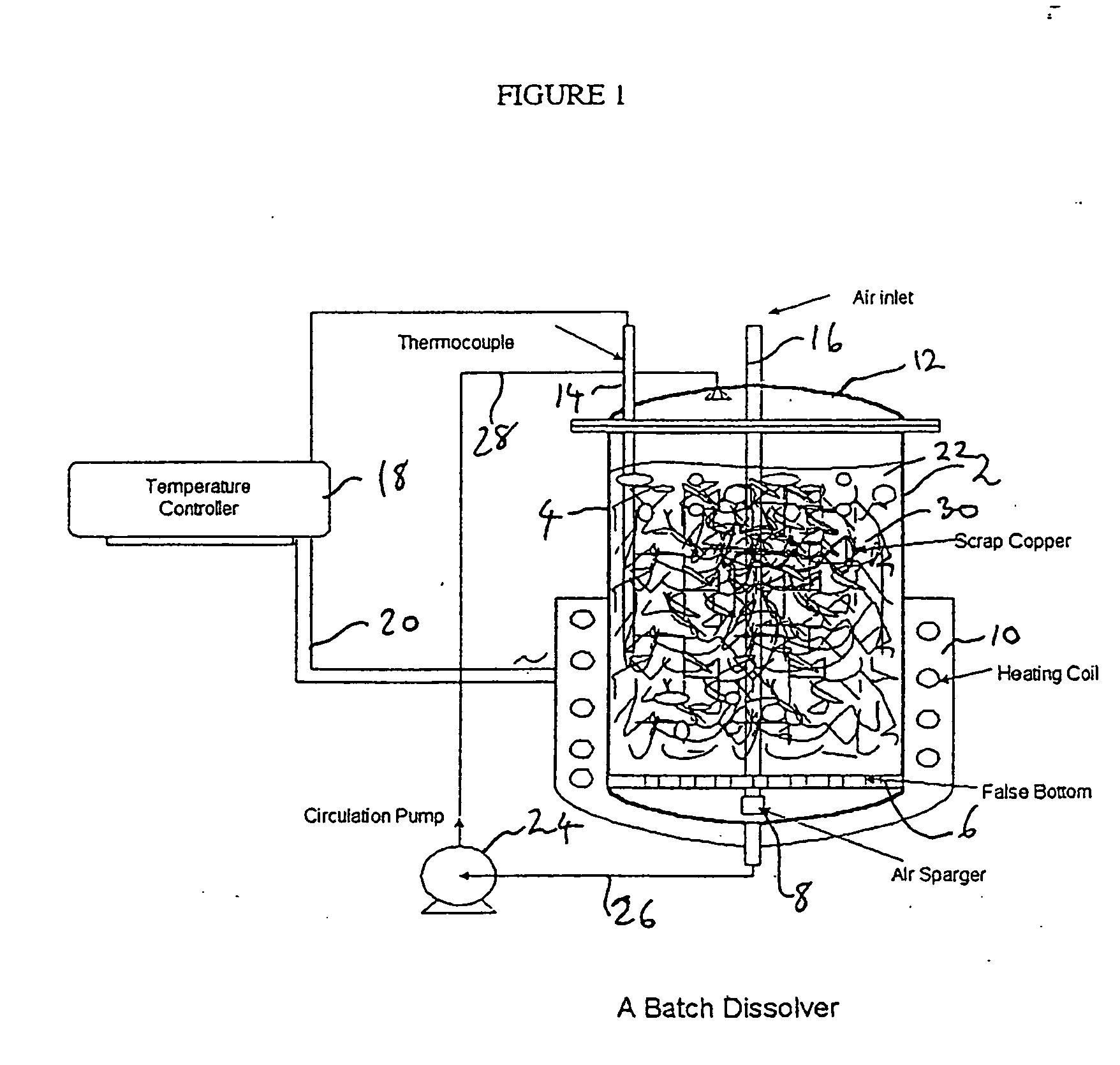

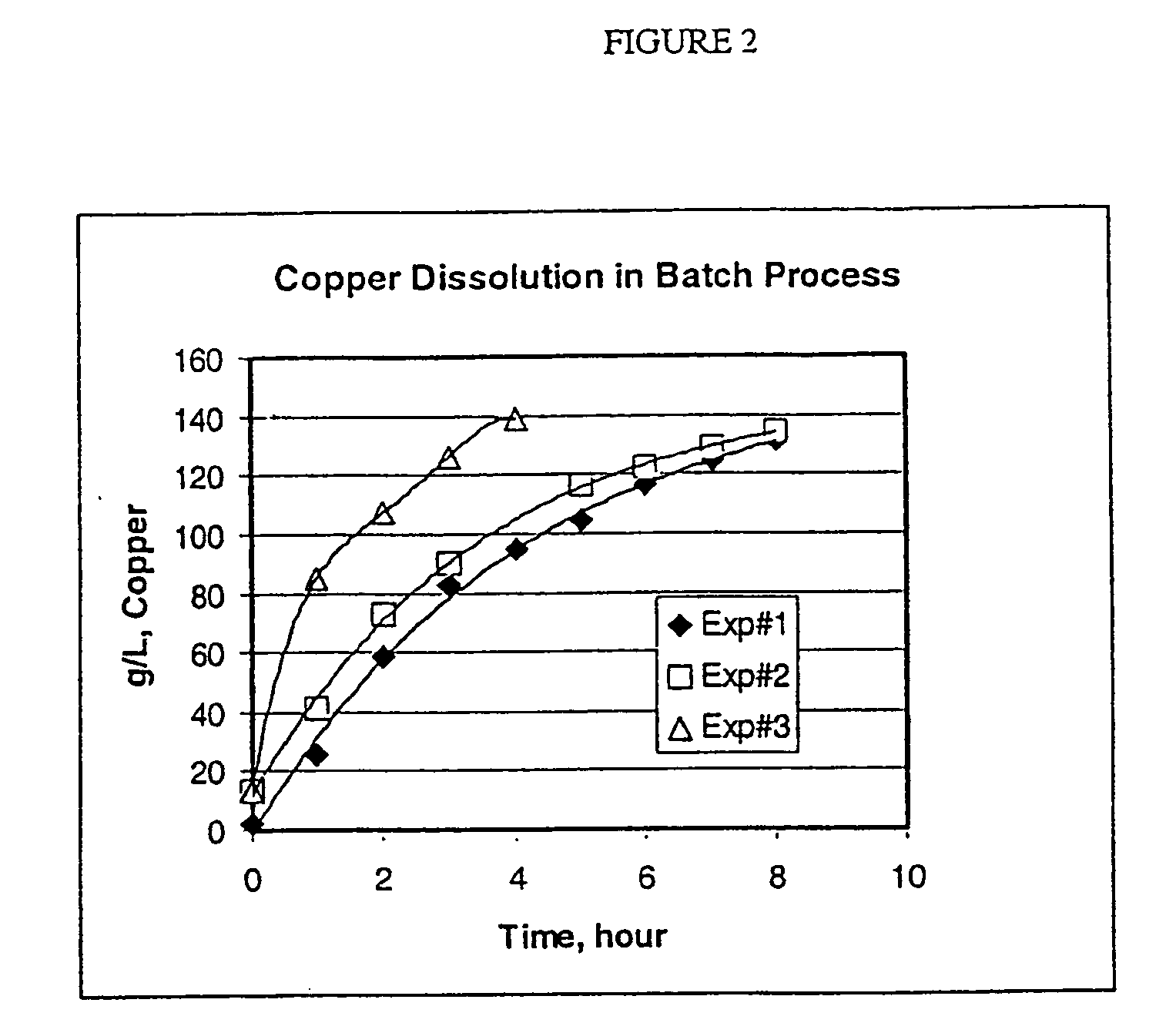

Process for the dissolution of copper metal

ActiveUS20050130866A1High initial dissolution rateShorten the timeGroup 1/11 element organic compoundsSolvent extractionGramEquivalent weight

Process for producing a copper-containing aqueous solution, in which a copper mass is dissolved in the presence of air in an aqueous leach liquor containing monoethanolamine and an acid, wherein the amount of acid equivalents is between 0.05 and about 0.7 times the equivalents of monoethanolamine, and wherein the rate of copper dissolution into the aqueous leach liquor is greater than about 4.3 grams of copper per liter of leach liquor per hour until a product having at least about 80 grams per liter is obtained.

Owner:KOPPERS PERFORMANCE CHEM

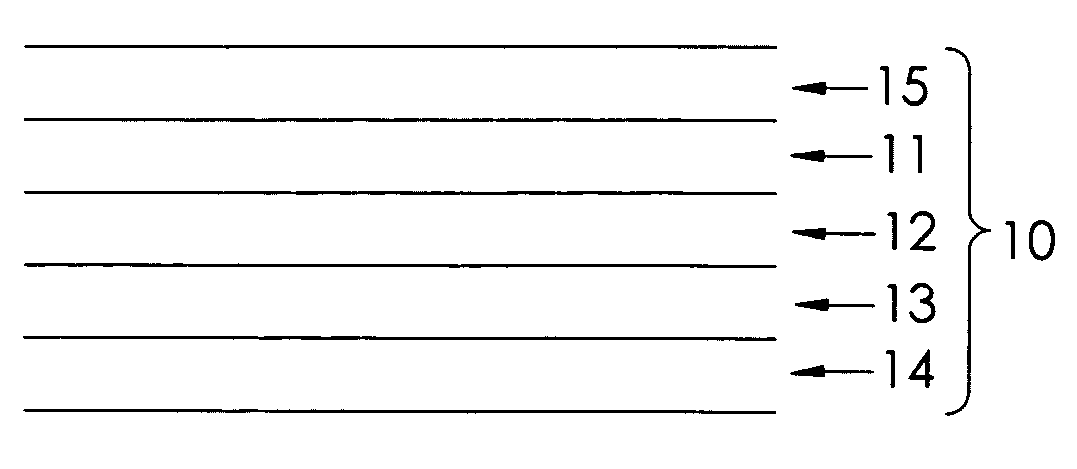

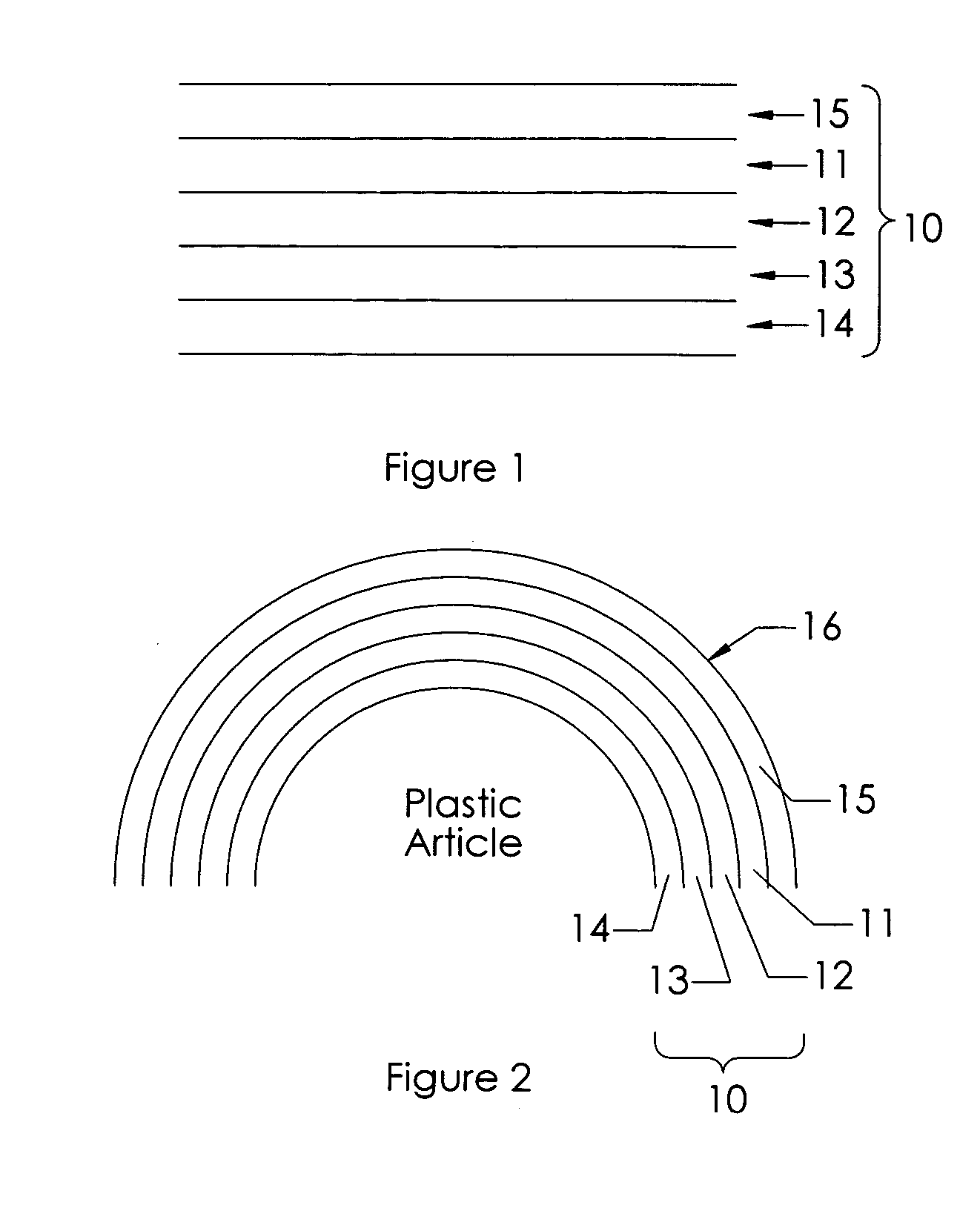

Durable layer composition for in-mold decoration

InactiveUS20050181204A1Improve surface qualityWider geometric toleranceCoatingsThin material handlingMedicinePolymer science

Owner:WANG XIAOJIA +6

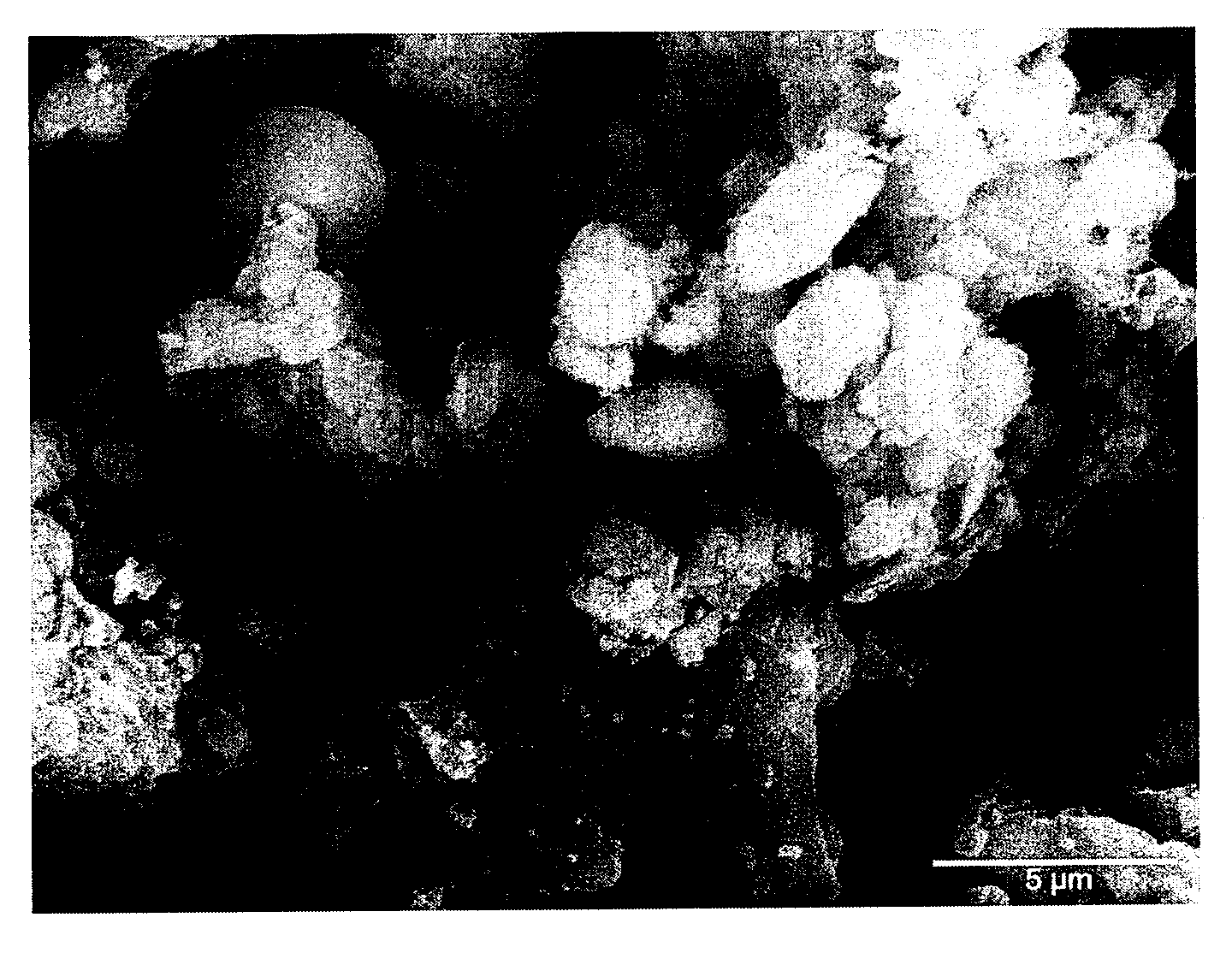

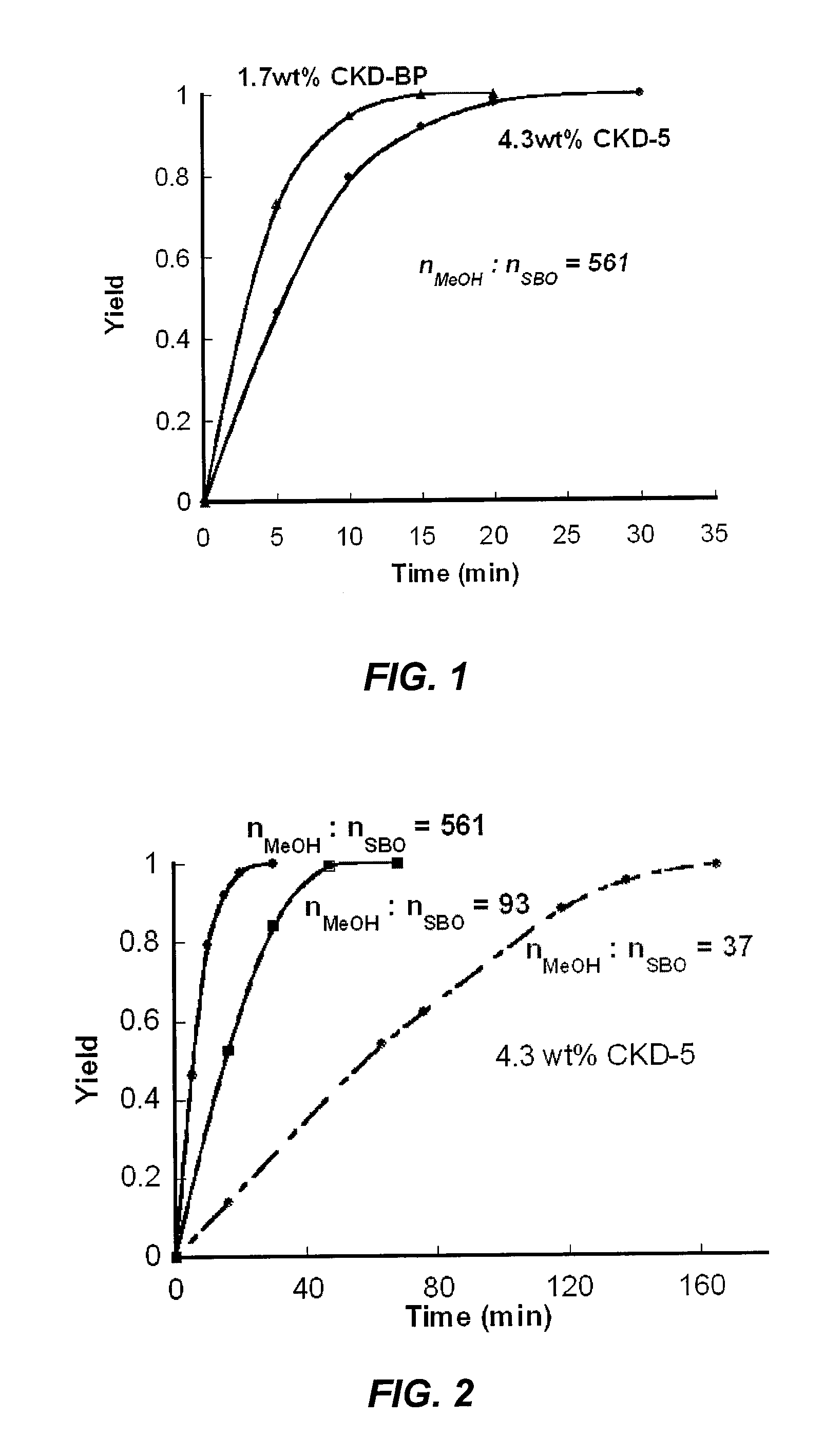

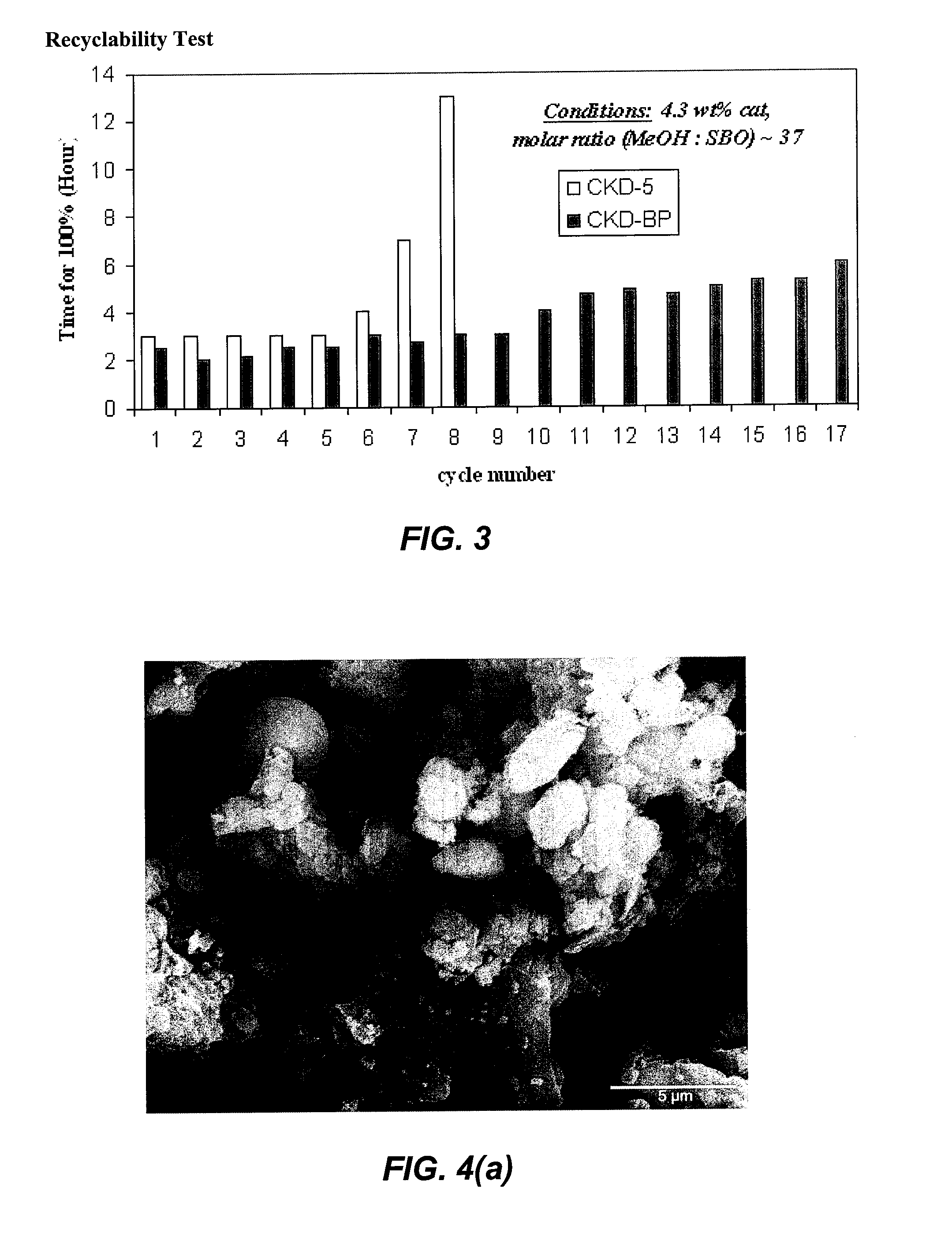

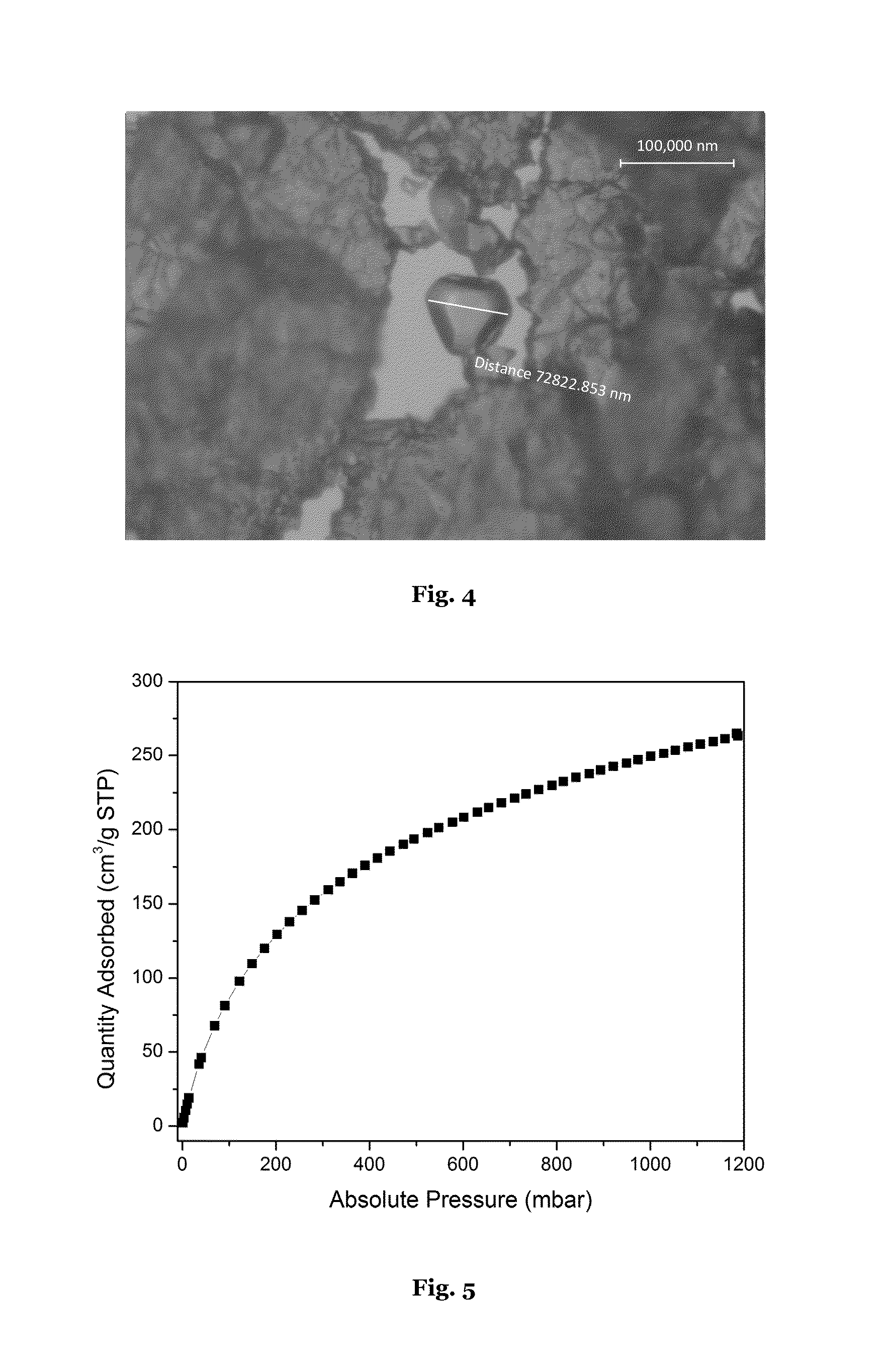

Solid catalyst system for biodiesel production

ActiveUS20090112007A1Increase contact areaRapid responseFatty acid chemical modificationFatty acids production/refiningMETHYL SOYATEVegetable oil

The invention provides efficient, inexpensive, and environmental friendly catalysts and catalyst systems. The catalysts can be used to catalyze esterification and / or transesterification reactions, for example, for the preparation of biodiesel. Kiln dust, such as cement kiln dust (CKD) or lime kiln dust (LKD) can be used to convert a variety of feedstock acids and / or esters to biodiesel in high yield under mild conditions. The CKD and LKD catalyst systems are recyclable esterification or transesterification catalysts that can be used to prepare biodiesel, such as methyl soyate, from various feedstocks, including vegetable oils and animal fats.

Owner:PINNAVAIA THOMAS J PH D +1

Hyaluronic acid-based cross-linked nanoparticles

InactiveUS20070224277A1Reaction is slowReduce crosslink densityBiocideOrganic active ingredientsCross-linkControlled release

Methods are disclosed for preparing novel biodegradable cross-linked nanoparticles based on covalently cross-linking modifications of hyaluronic acid. The final products of the present invention are stable in aqueous media, and may be used as detergents and as additives for pharmaceutical compositions for drug delivery, DNA carrier system and other applications. The nanoparticles made from the biopolymers of the present invention may also be used in controlled release applications, super-absorbent materials as well as biomaterials like enzyme immobilization.

Owner:BORBELY JANOS +3

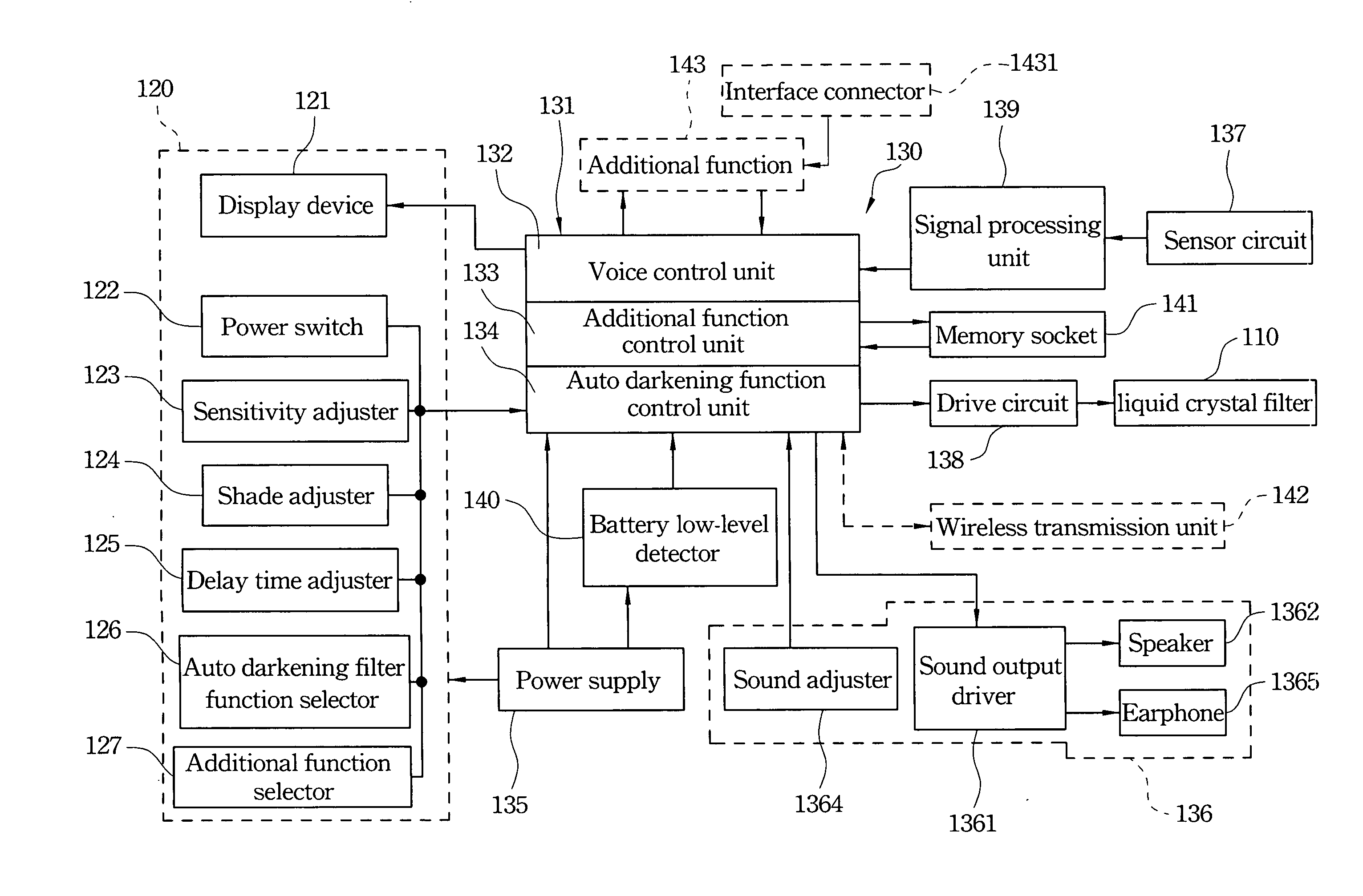

Eye guard with voice indication

InactiveUS20080082179A1Problem be solveReduce thicknessComputer controlSignalling system detailsElectricityEngineering

An eye guard with voice indication is provided, and it includes an eye guard body, a filter, a display device and a voice output device. The display device is mounted inside the eye guard body to display a circumstance value or operating condition information. Furthermore, the voice output device is electrically connected with the display device and includes a main controller, a power supply, a sound output controller, a sensor circuit and a drive circuit. The sensor circuit has at least one sensor exposed on an external surface of the eye guard body and defined in a supposed centerline of the filter to detect the surrounding circumstance. Thus, the circumstance value and the operation condition information are noticed in the form of voice and vision simultaneously for the operators.

Owner:YANG YEA CHYI

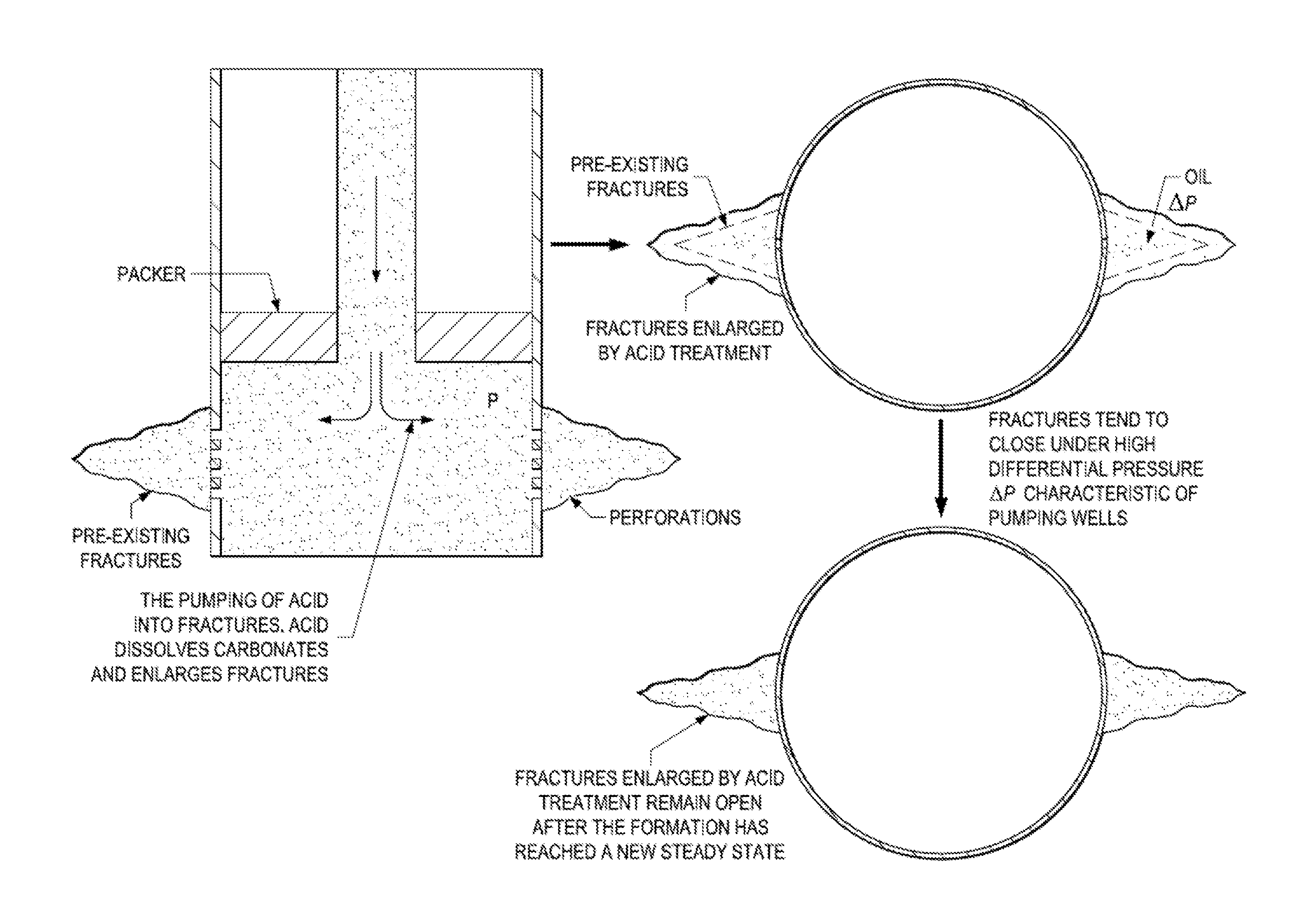

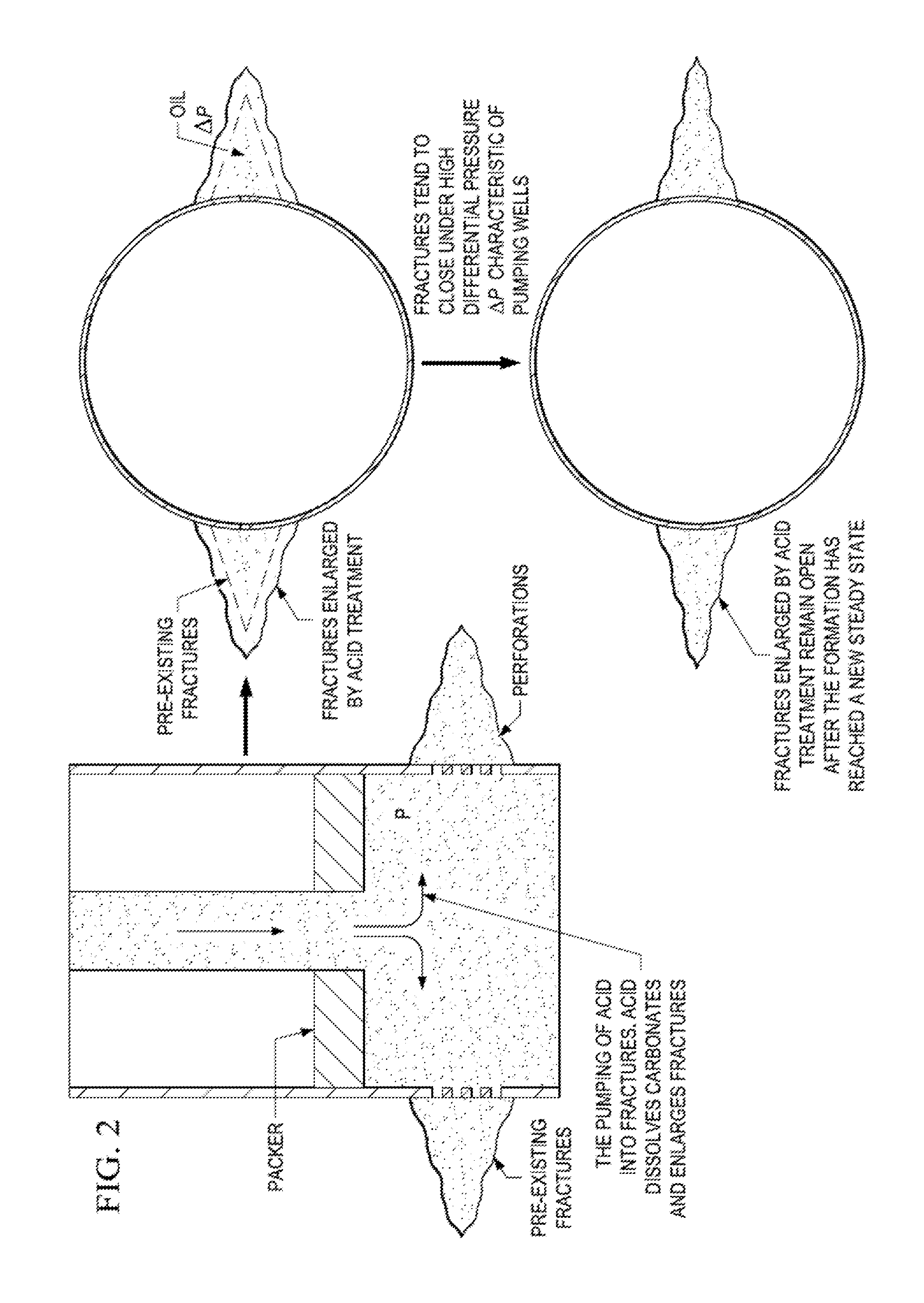

Cryogenic acid frack

ActiveUS20150218439A1Extended reaction timeIncreased penetration distanceFluid removalDrilling compositionOrganic chemistry

A method of fracking carbonate-rich reservoirs, comprising injecting a cryogenic or chilled fluid followed by an acid into said reservoir, allowing the acid to etch said reservoir, and thereby increasing production of a fluid, such as water, oil or gas, from said reservoir.

Owner:CONOCOPHILLIPS CO

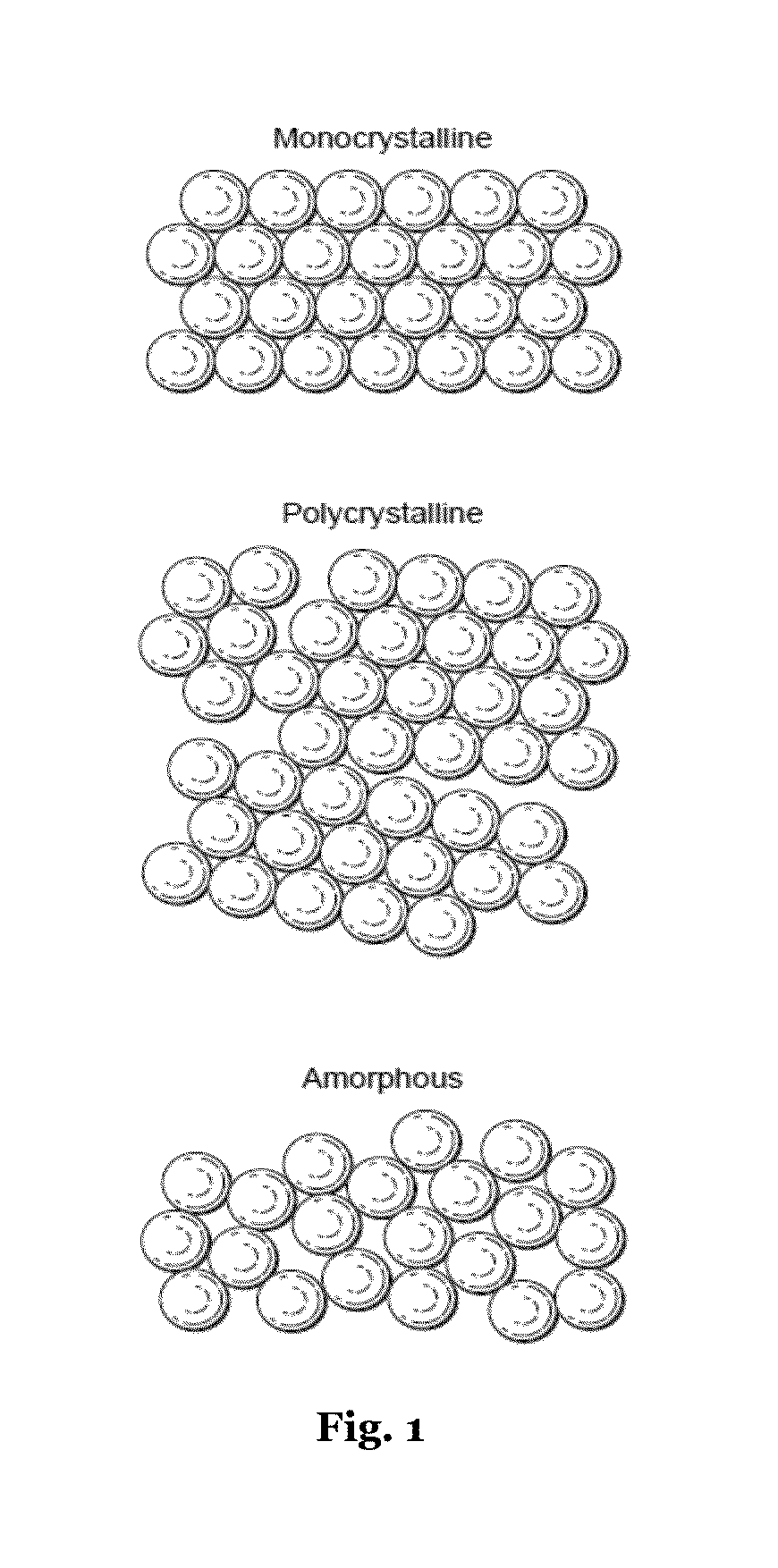

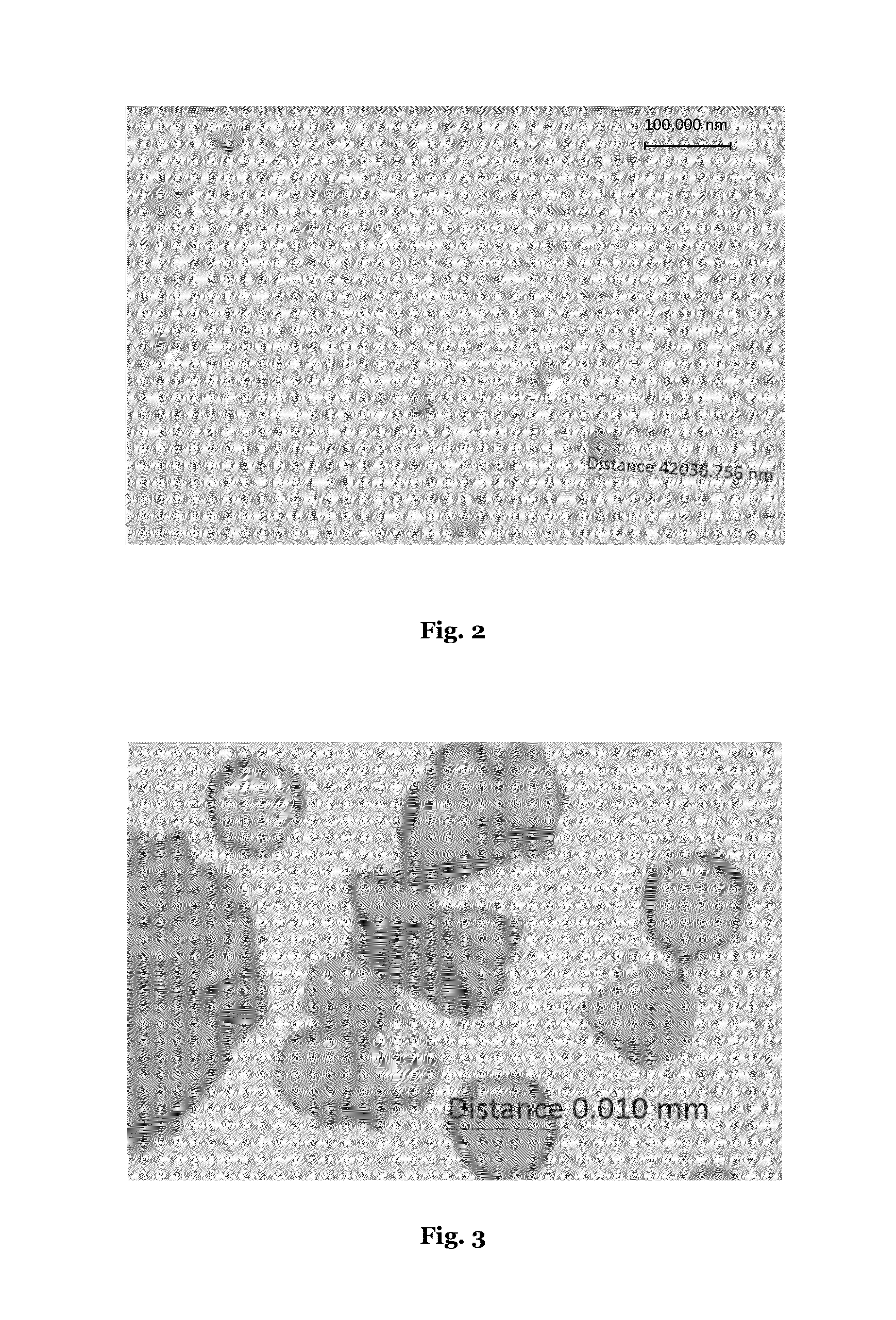

Aluminum metal organic framework materials

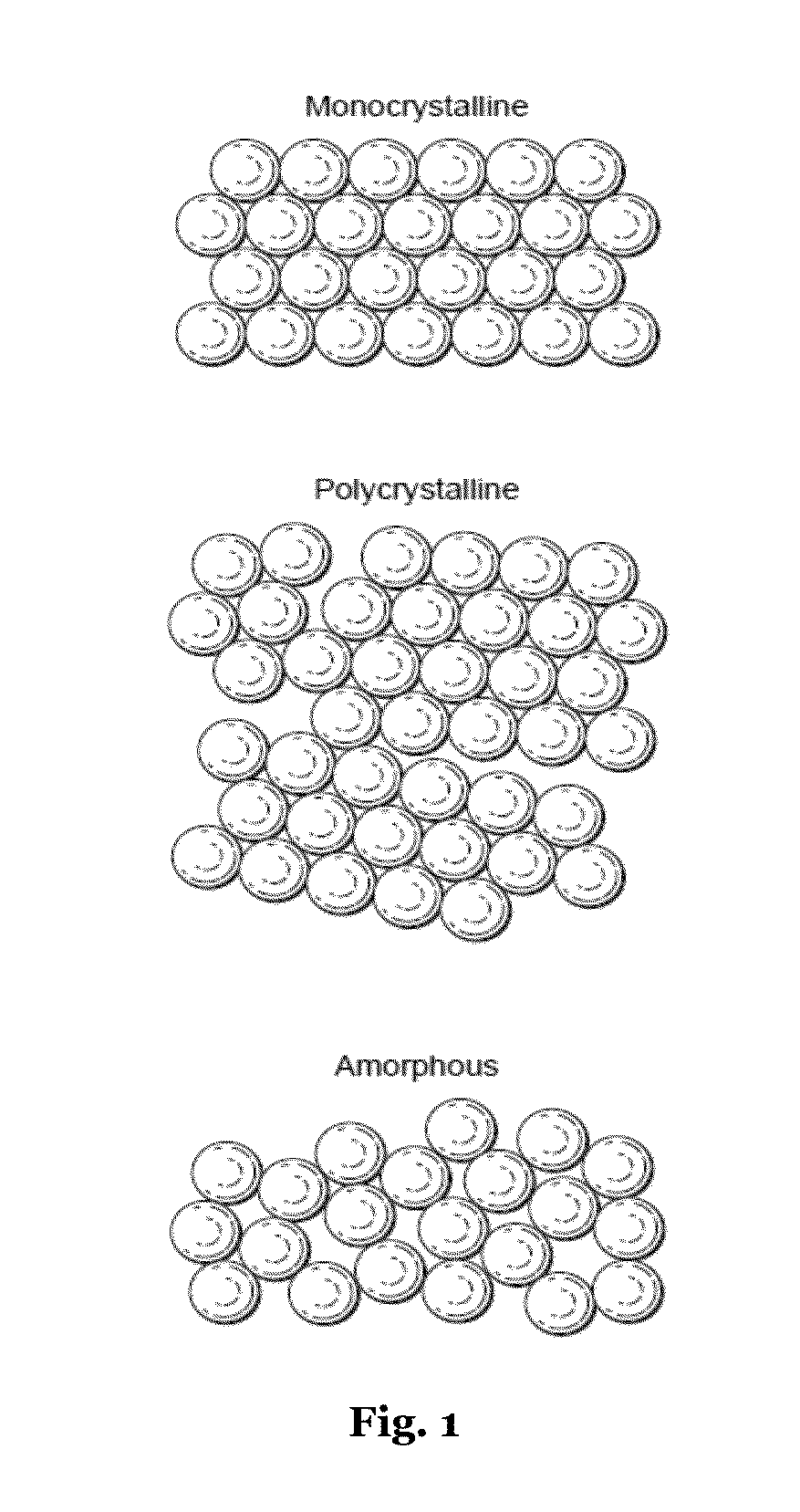

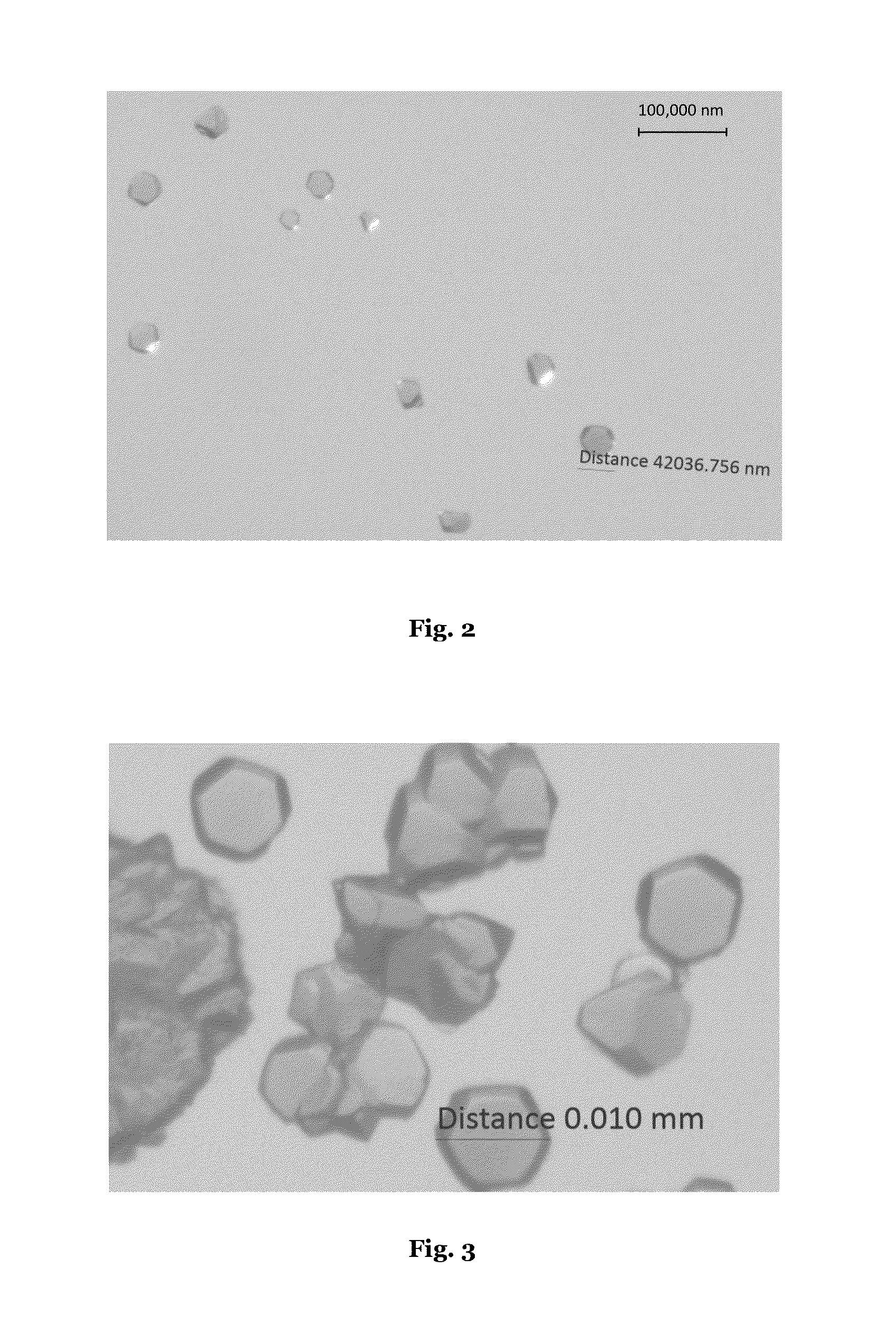

ActiveUS9102691B2Small sizeSlow reaction rateCarbon compoundsNickel organic compoundsPhysical chemistryMetal-organic framework

The invention relates to monocrystalline single crystals of metal-organic framework materials comprising at least one aluminum metal ion, processes for preparing the same, methods for employing the same, and the use thereof. The invention also relates to monocrystalline aluminum metal-organic frameworks.

Owner:TEXAS A&M UNIVERSITY

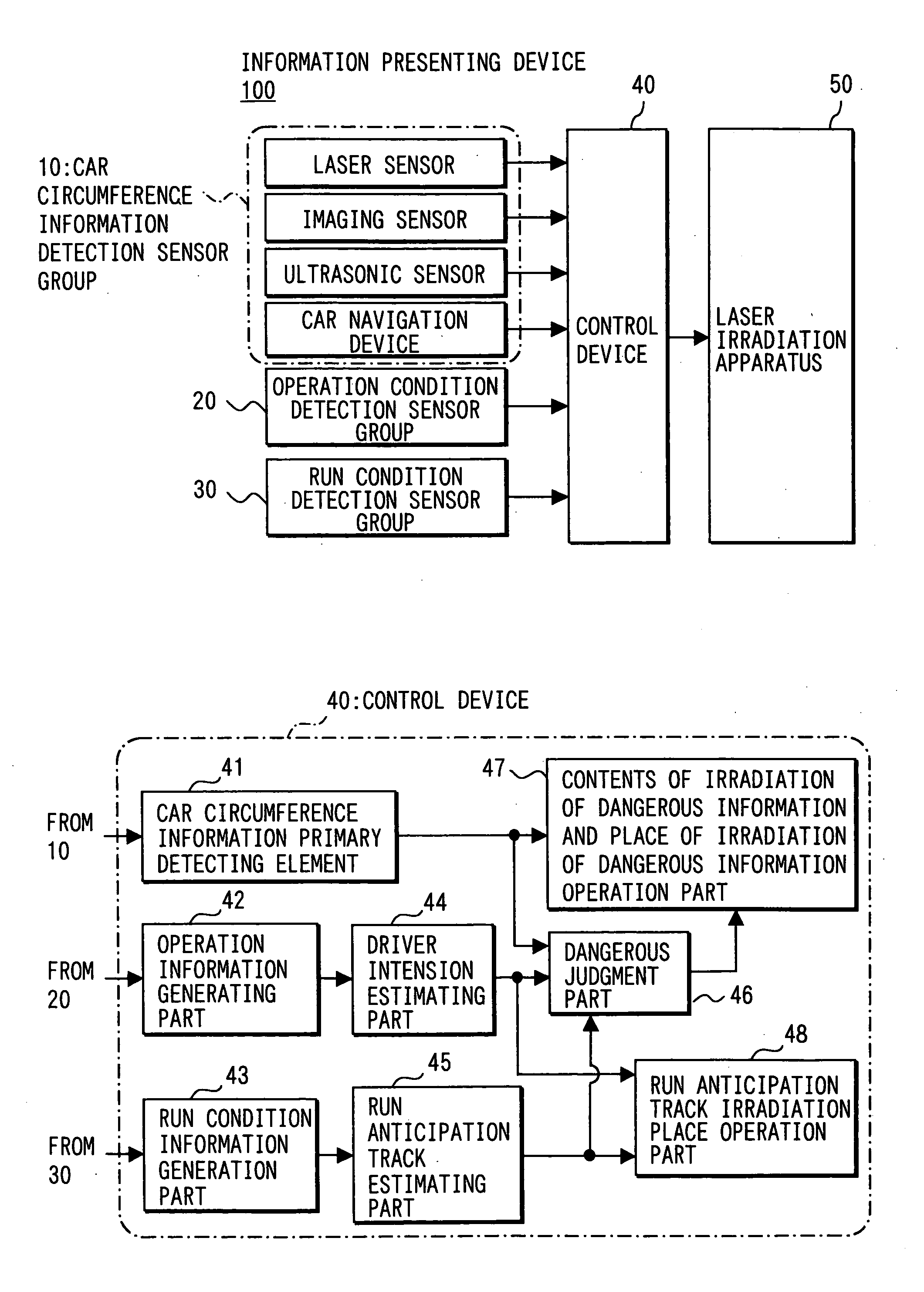

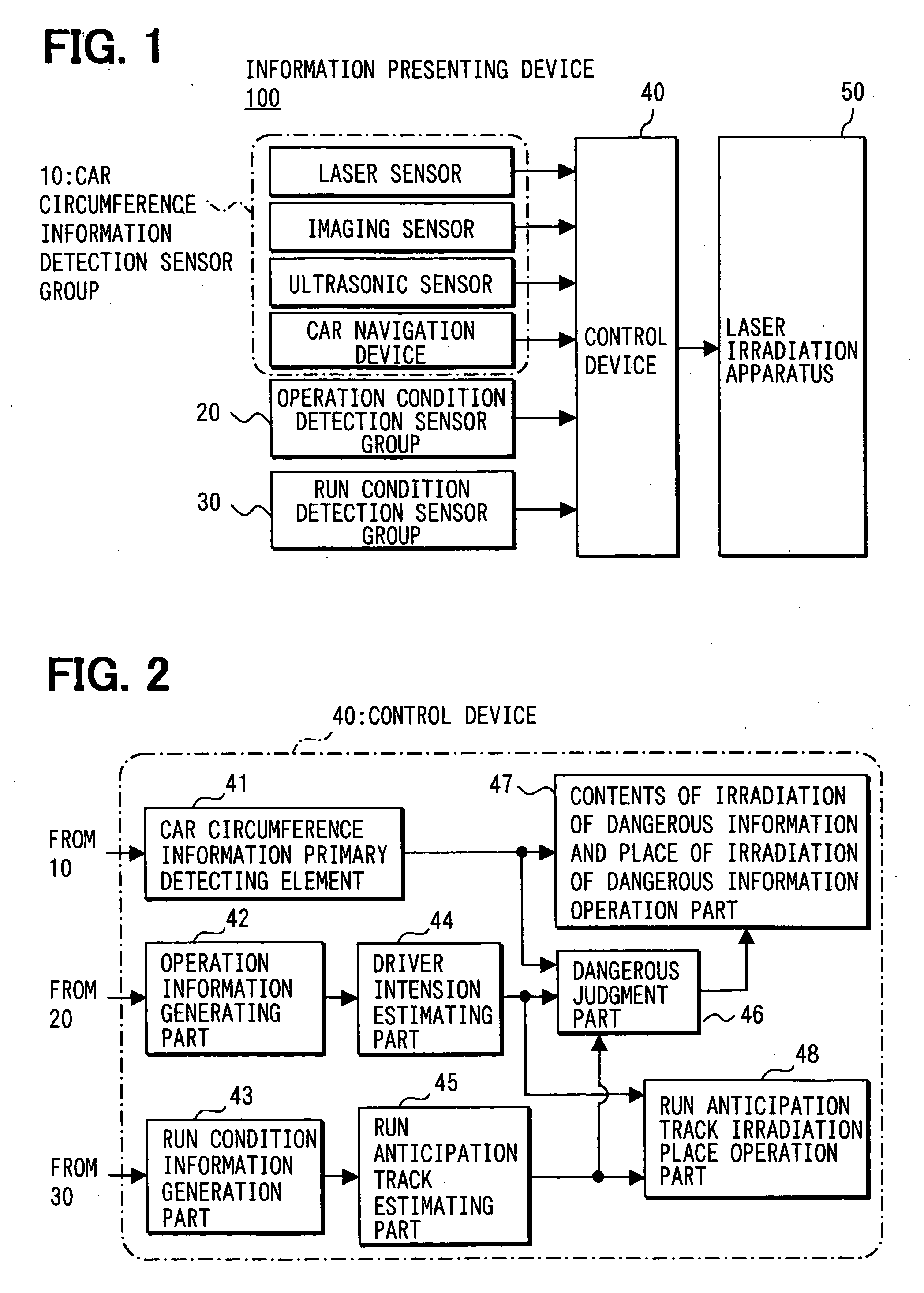

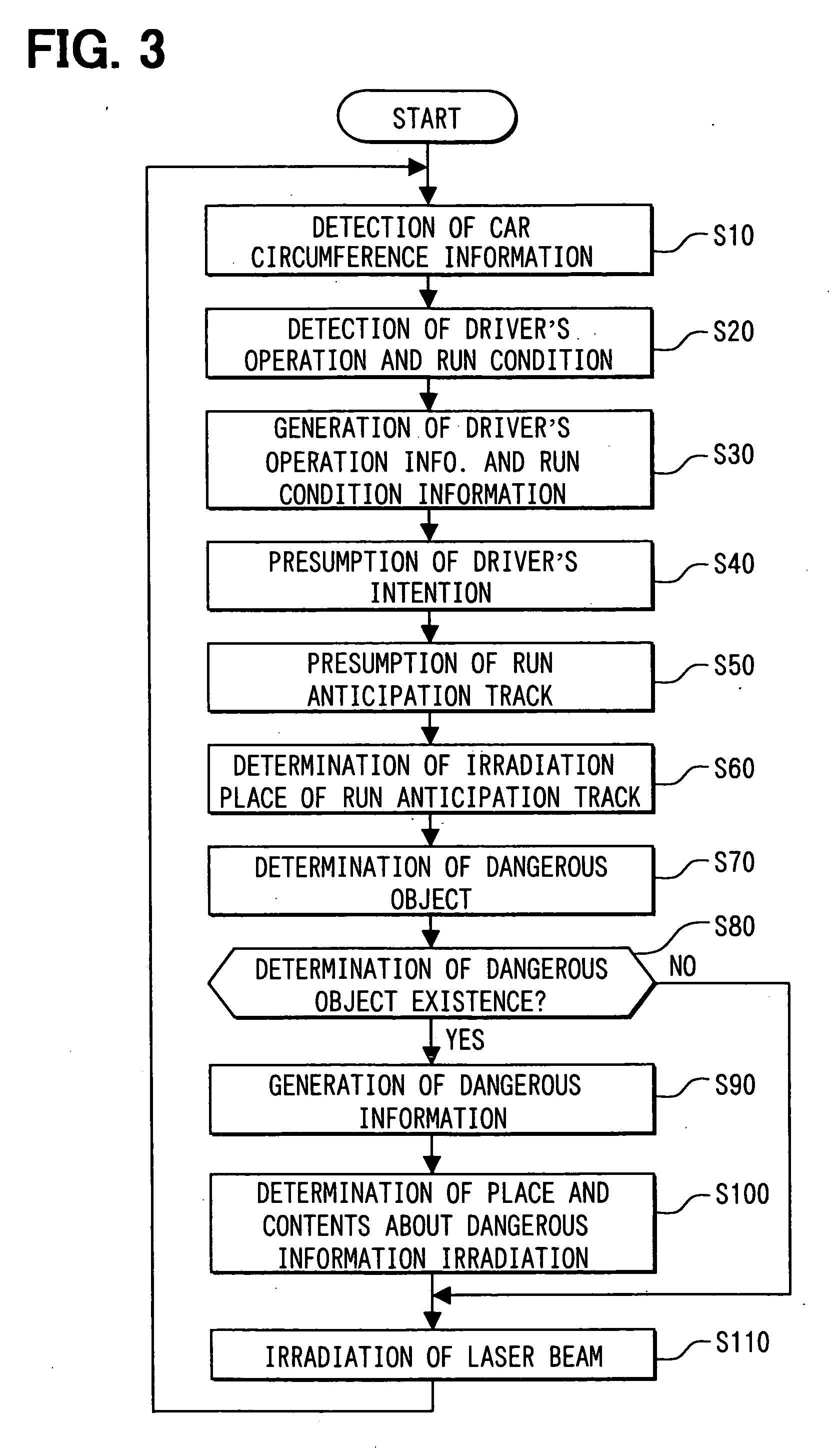

Information presenting apparatus and method

ActiveUS20060097858A1Easy to identifyReduce latencyIndication of parksing free spacesColor television detailsPresent methodComputer graphics (images)

Owner:DENSO CORP

Metal phosphonates and related nanocomposites

InactiveUS20050239938A1Reduce lossesPromote sheddingGroup 5/15 element organic compoundsPolymer scienceNanocomposite

Compositions comprising a polymer and an exfoliated metal phosphonate are provided. Processes for making such polymer compositions and articles formed from such polymer compositions are also provided. Compositions according to the invention are useful in polymer applications in which barrier properties are of concern, such as in plastic food and beverage containers.

Owner:PLASTIC TECH INC

Polyurethane compositions with a low content of diisocyanate monomer(s)

ActiveUS20030162933A1Reaction is slowCarbamic acid derivatives preparationOrganic compound preparationIsocyanateAdhesive

The invention concerns processes for producing polyurethane compositions with a low content of diisocyanate monomer(s), the use of polyurethane compositions produced by these processes, especially in a bonding process or for coating purposes, and adhesives and coating compounds that contain these types of polyurethane compositions.

Owner:JOWAT

Multi-nary group ib and via based semiconductor

InactiveUS20120270363A1Speed processDelay indium processingFinal product manufactureSemiconductor/solid-state device manufacturingSeleniumCopper

Methods and devices are provided for forming an absorber layer. In one embodiment, a method is provided comprising of depositing a precursor material onto a substrate, wherein the precursor material may include or may be used with an additive to minimize concentration of group IIIA material such as Ga in the back portion of the final semiconductor layer. The additive may be a non-copper Group IB additive in elemental or alloy form. Some embodiments may use both selenium and sulfur

Owner:AERIS CAPITAL SUSTAINABLE IP

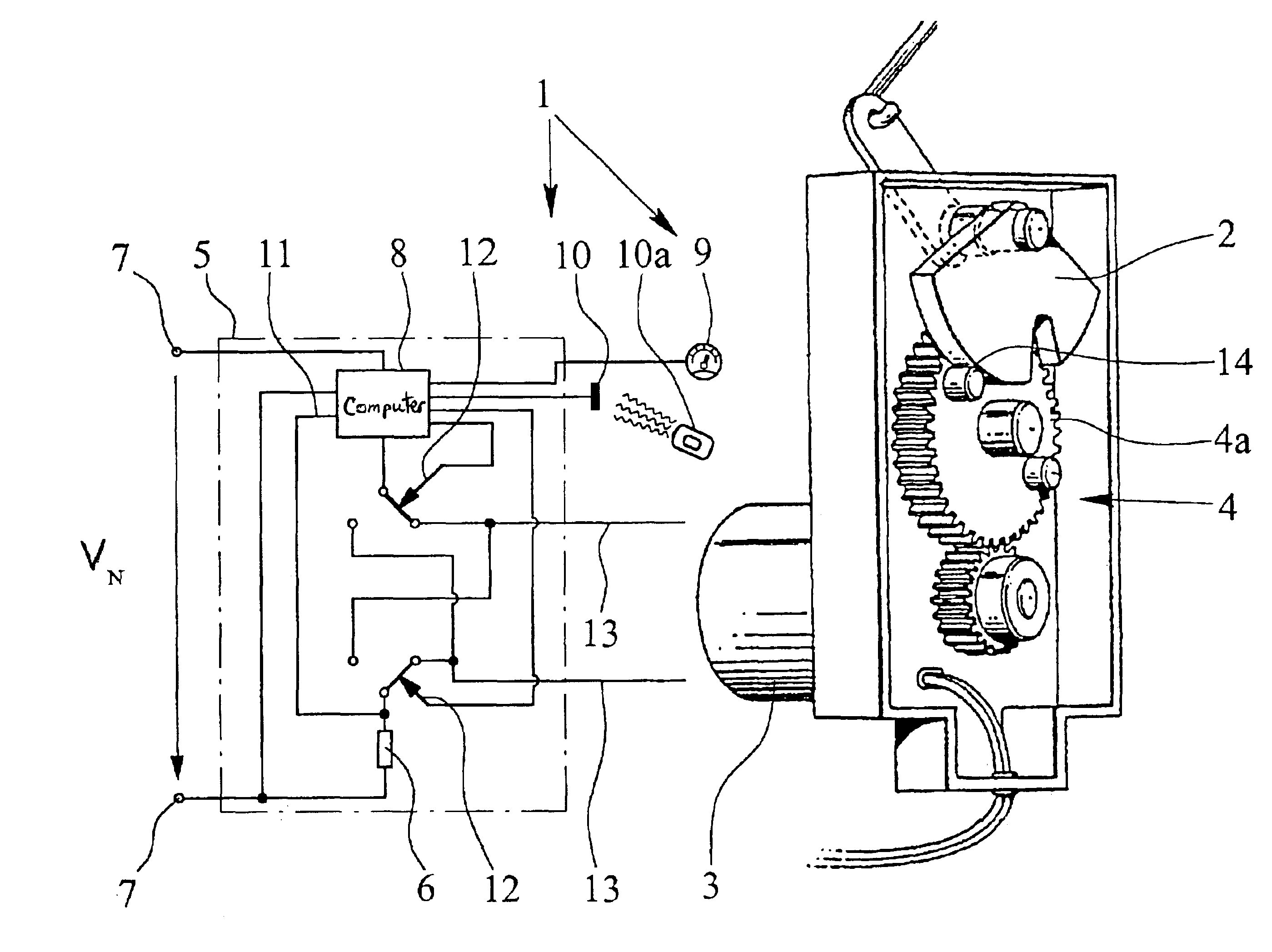

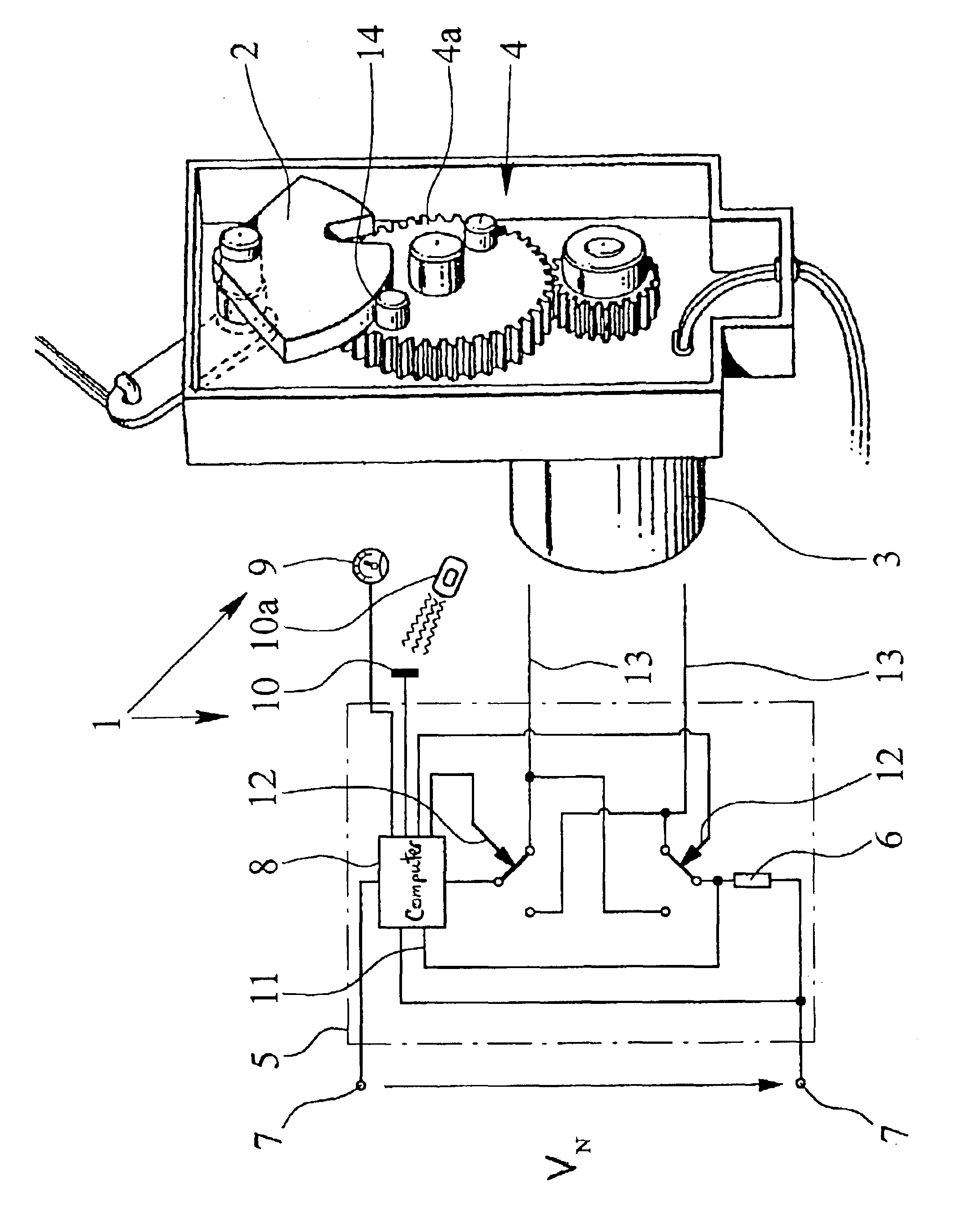

Motor vehicle door lock with an electromechanical central locking system drive

InactiveUS6936983B2Reaction is slowEasy to controlDC motor speed/torque controlNoise-prevention/anti-rattling lockingMotor vehicle partSystem element

A motor vehicle door lock with an electromechanical central locking system drive (1) and a mechanical central locking system element (2) driven by it, the central locking system drive (1) having an electric drive motor (3) and a motor control (5) with a motor state sensor (6). The central locking system element (2) can be moved by the central locking system drive (1) at least into a locked position and the motor control (5) is designed such that it triggers the electric drive motor (3) for driving the central locking system element (2) into the locked position after receiving an actuation signal from an actuation unit, such as a closing cylinder, a locking button, a remote control receiving unit or a handle (inside door handle, outside door handle). Preferably, the motor control 5 is also designed such that it automatically triggers the electric drive motor (3) for driving the central locking system element (2) into the locked position as soon as a certain operating state of the motor vehicle has been reached. Furthermore, significantly, the motor control (5) has a control circuit that includes the motor state sensor (6) and this control circuit is designed such that, when the electric drive motor (3) is triggered, the electric drive motor (3) runs with a low rpm that is controlled using the signal of the motor state sensor (6).

Owner:BROSE SCHLIESSSYSTEME GMBH & CO KG

Aluminum Metal Organic Framework Materials

ActiveUS20150152123A1High symmetryImprove solubilityCarbon compoundsNickel organic compoundsMetal-organic frameworkSingle crystal

The invention relates to monocrystalline single crystals of metal-organic framework materials comprising at least one aluminium metal ion, processes for preparing the same, methods for employing the same, and the use thereof. The invention also relates to monocrystalline aluminium metal-organic frameworks.

Owner:TEXAS A&M UNIVERSITY

Photocurable compositions

ActiveUS8097399B2Fast curingGood physical propertiesAdditive manufacturing apparatusNanostructure manufactureFluenceNon coherent

An optical moulding process is disclosed comprising the sequential steps of: (a)(y) forming a layer of a photocurable composition; and (bXz) irradiating selected areas of the composition in the layer with radiation from a radiation source, thereby curing the composition in said selected areas and repeating the steps a) and b) on top of an earlier cured layer to form a three dimensional structure, wherein the radiation source used in step b) is a non-coherent source of radiation and wherein the photocurable composition comprises at least two curable components: (i) 45%-95% (and preferably at least 50%, more preferably at least 60%, e.g. at least 70%) by weight of the total curable components in the composition is a first component that is photocurable and that is such that, when cured in the presence of a photocuring initiator by exposure to UV radiation having an energy of 30 mJ / cm2, at least 90% of the component is cured within 50 milliseconds; and (ii) 5% to 55% (and preferably 10-40%, more preferably 15 to 30%, e.g. about 20%) by weight of the total curable components in the composition is a second component that results in the composition, on curing, shrinking, in a linear direction, by less than 3% and preferably that results in the composition having, after cure, a Tg of greater than 50° C., preferably at least 100° C. and more preferably at least 120° C.

Owner:3D SYST INC

Oxyalkylene-substituted aminophenol intermediate

InactiveUS6040482AGood choiceLow costOrganic chemistryDiaryl/thriaryl methane dyesM-aminophenolPhenol

This invention relates to very specific oxyalkylene-substituted aminophenol compounds as intermediates for the production of poly(oxyalkylene)-substituted xanthene (or other type) colorants. Such an inventive intermediate compound is produced in a single step by reacting an oxyalkylene oxide having from 3 to 12 carbon atoms (branched or unbranched), glycidol, or a glycidyl directly with aminophenol without the use of a catalyst and at a relatively low temperature. Propylene oxide and m-aminophenol are the preferred reactants. The propylene oxide selectively reacts with the amine group on the m-aminophenol without propoxylating the phenolic hydroxyl group. Such a specific method thus does not require extra time- and cost-consuming steps of protecting the phenolic hydroxyl group from attack. After production, this intermediate may be reacted with suitable compounds to ultimately form any number of different colorants, including xanthenes, oxazines, coumarins, and the like. The resultant oxypropylene groups may subsequently be reacted with electrophile compounds to produce any number of different colorants. Resultant colorants produced through the reaction of the inventive intermediate are also contemplated within this invention.

Owner:MILLIKEN & CO

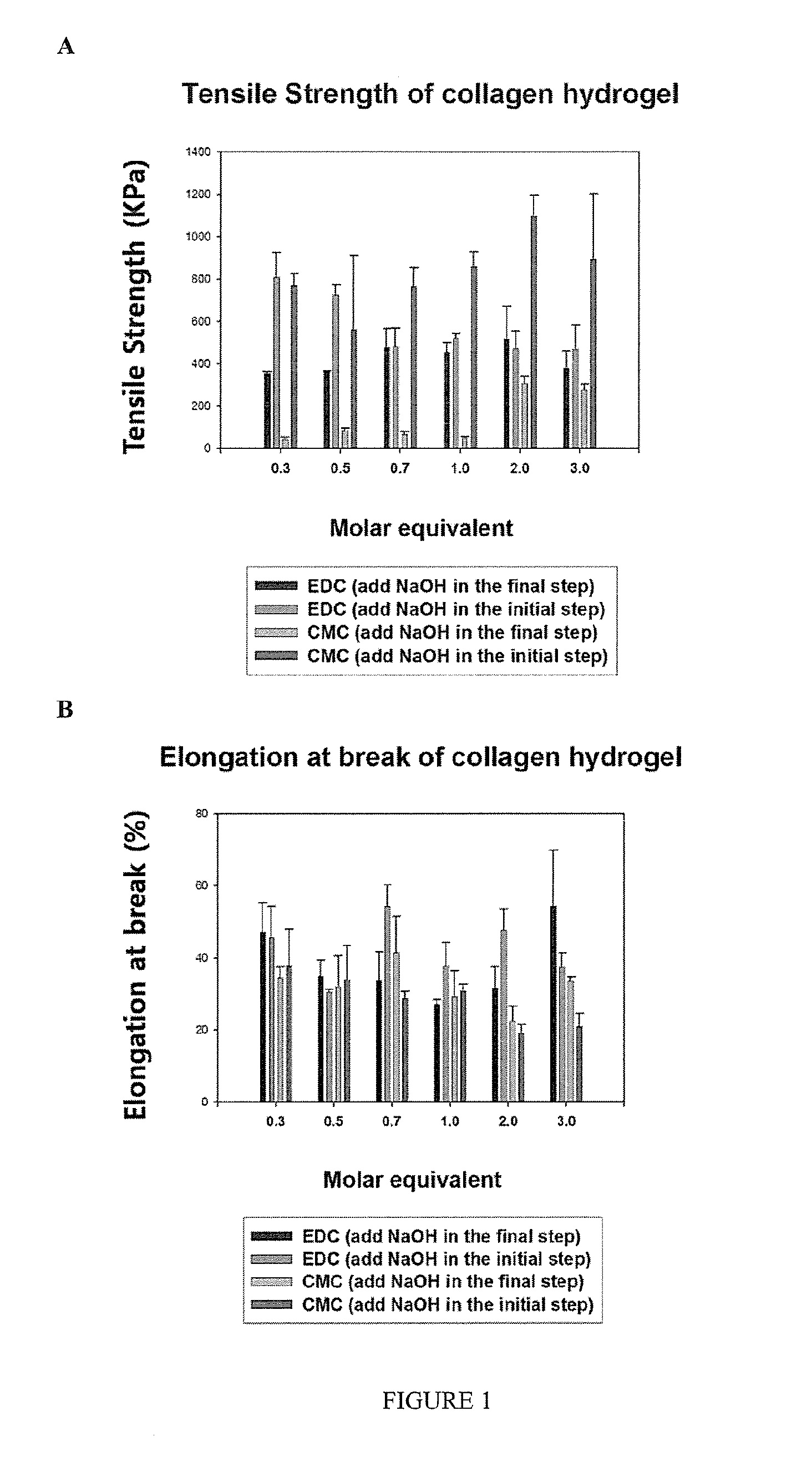

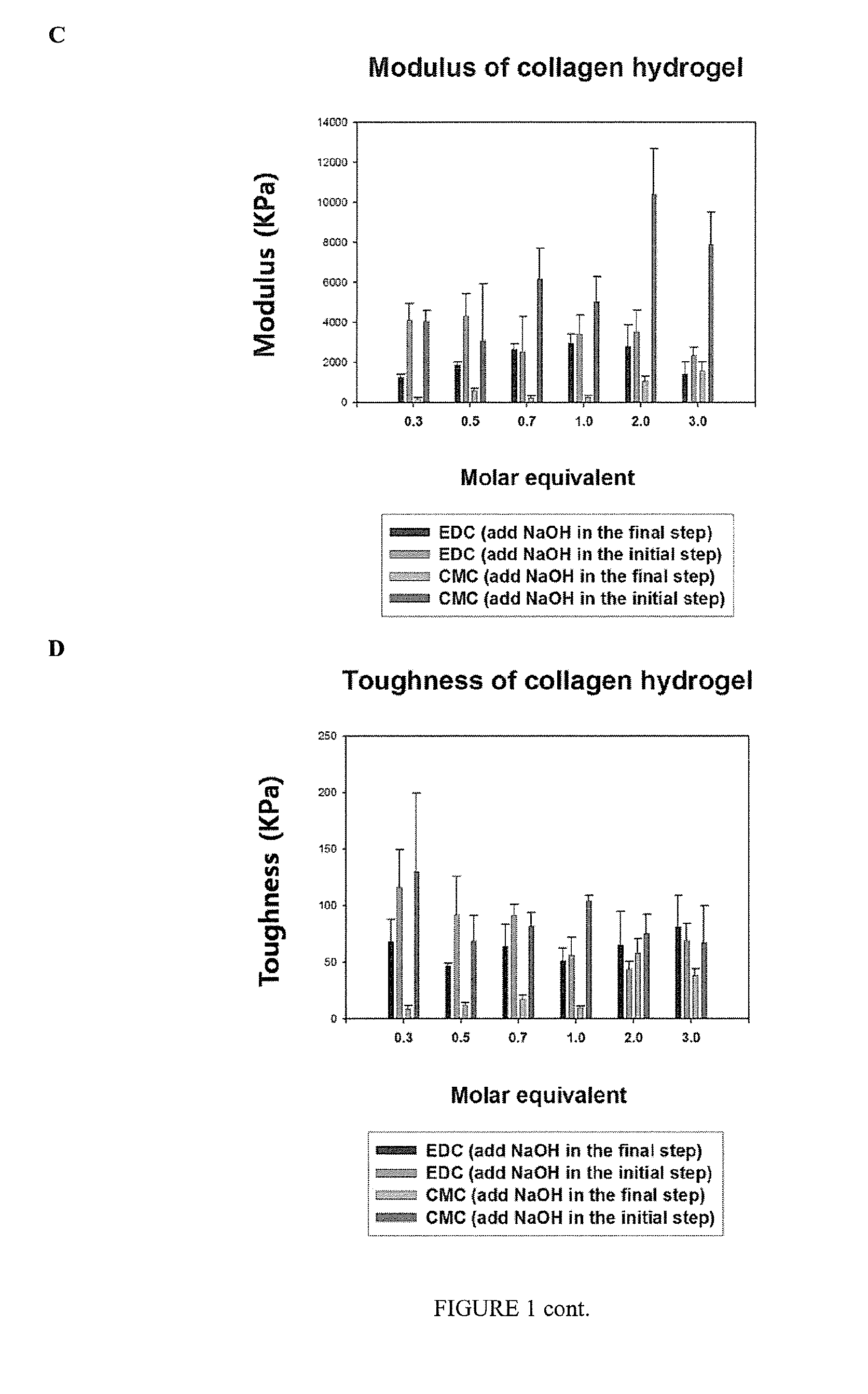

Crosslinked Hydrogels and Related Method of Preparation

InactiveUS20120321585A1Slow down crosslinking reactionReaction is slowSenses disorderDrug photocleavageArylBiopolymer

The present invention provides a method of manufacturing a hydrogel comprising the step of crosslinking a biopolymer using a carbodiimide crosslinker of Formula I wherein at least one of R1 and R2 is a functional group that is a bulky organic functional group. R1 and R2 can each independently be an optionally substituted saturated or unsaturated functional group selected from the group consisting of an alkyl, a cycloalkyl, a heterocyclic, and an aryl. The bulky organic functional group will slow down the crosslinking reaction of carbodiimide due to the steric effects and / or electronic effects, in comparison to a crosslinking reaction using EDC. Also provided are the hydrogels and ophthalmic devices prepared using the method of the invention and uses thereof.

Owner:OTTAWA HOSPITAL RES INST +1

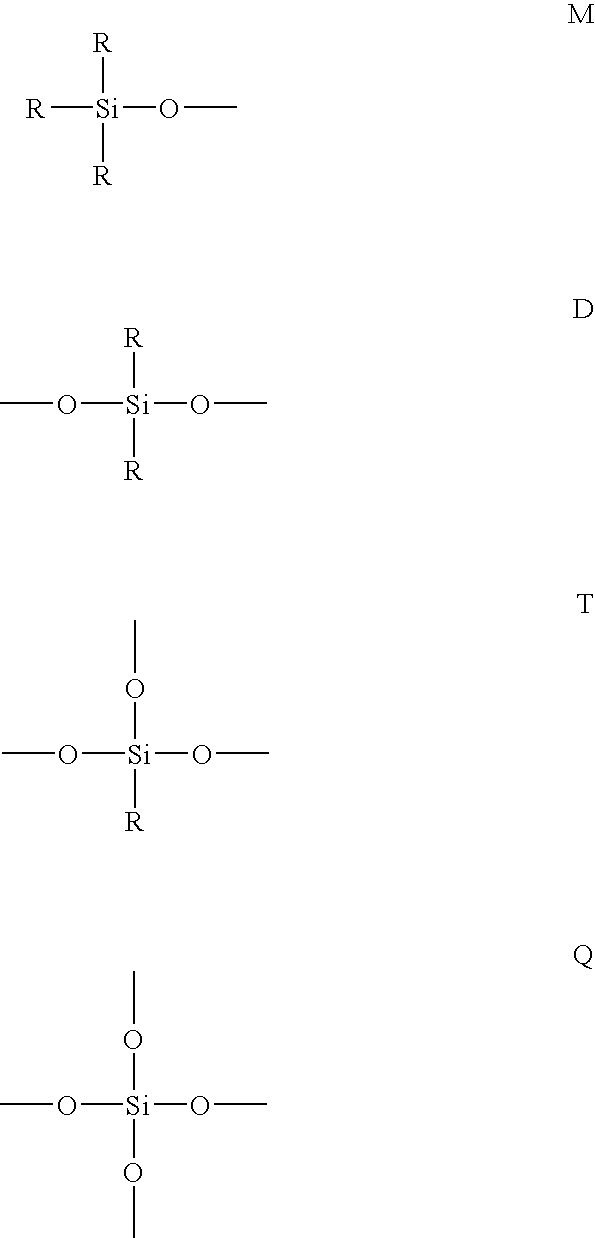

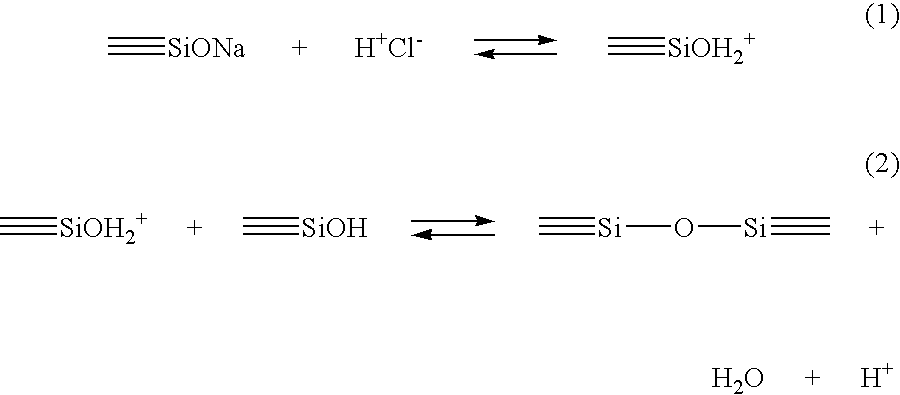

Process for preparing a silicone resin

ActiveUS20090093605A1Reaction is slowGreat latitudeSpecial tyresSilicon compoundsHYDROSOLSodium silicate

The invention relates to, and the general field of the invention is that of, the synthesis of silicone resins, more particularly the synthesis of silicone resins of type MQ. The process relates to the preparation of MQ silicone resins and permits better control of the operating conditions in the step of the polymerization of a sodium silicate (B) in aqueous medium in the presence of an acid (C) to form a silica hydrosol (polysilicic acid). In the course of the polycondensation step the reactants, a sodium silicate and an acid, are mixed, preferably in continuous fashion, dynamically to form a mixture (3), by means of at least one intensive mixing tool (M) producing a power ε per unit volume of more than 10 kW / m3.

Owner:BLUESTAR SILICONES FRANCE SAS

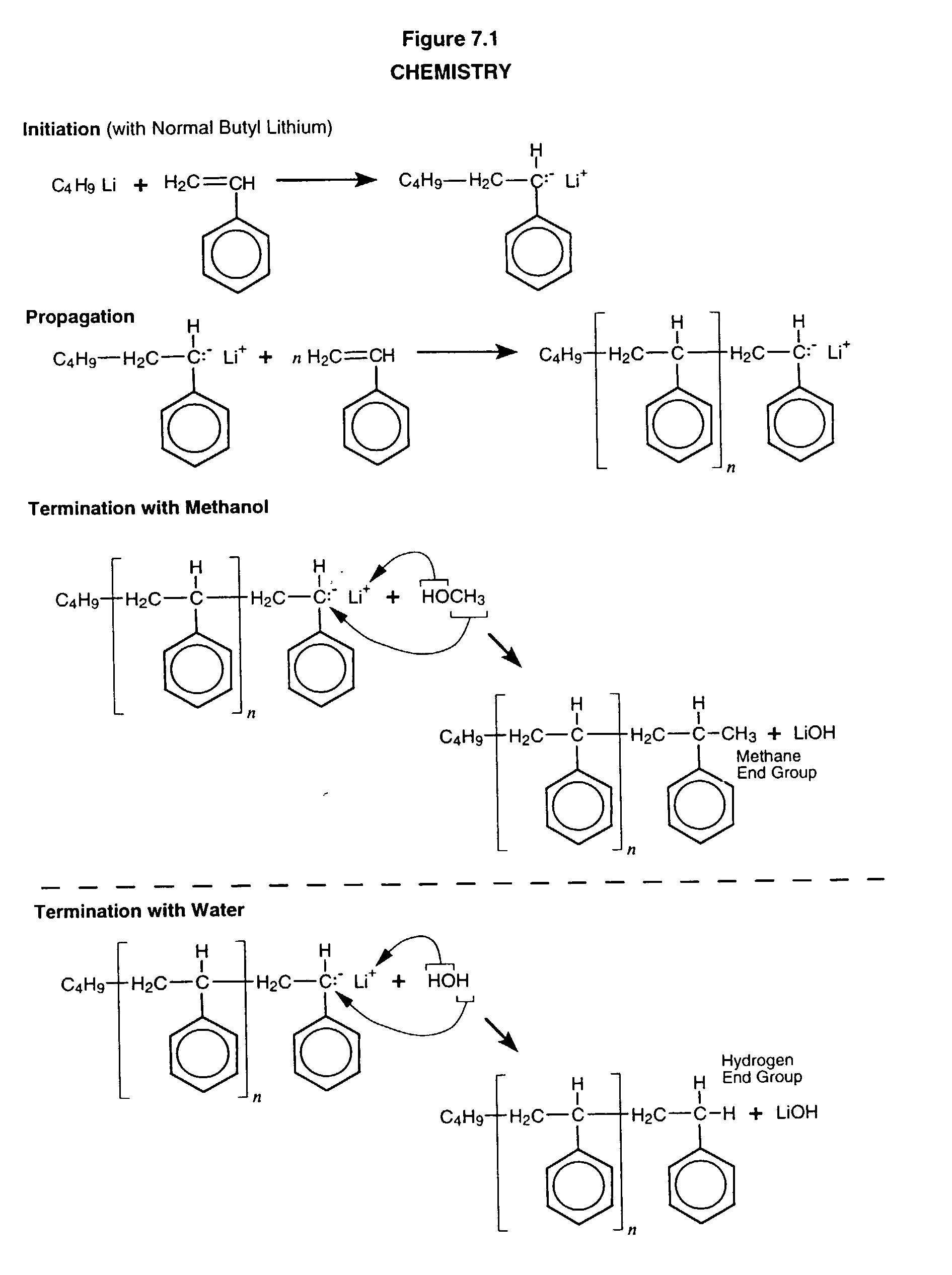

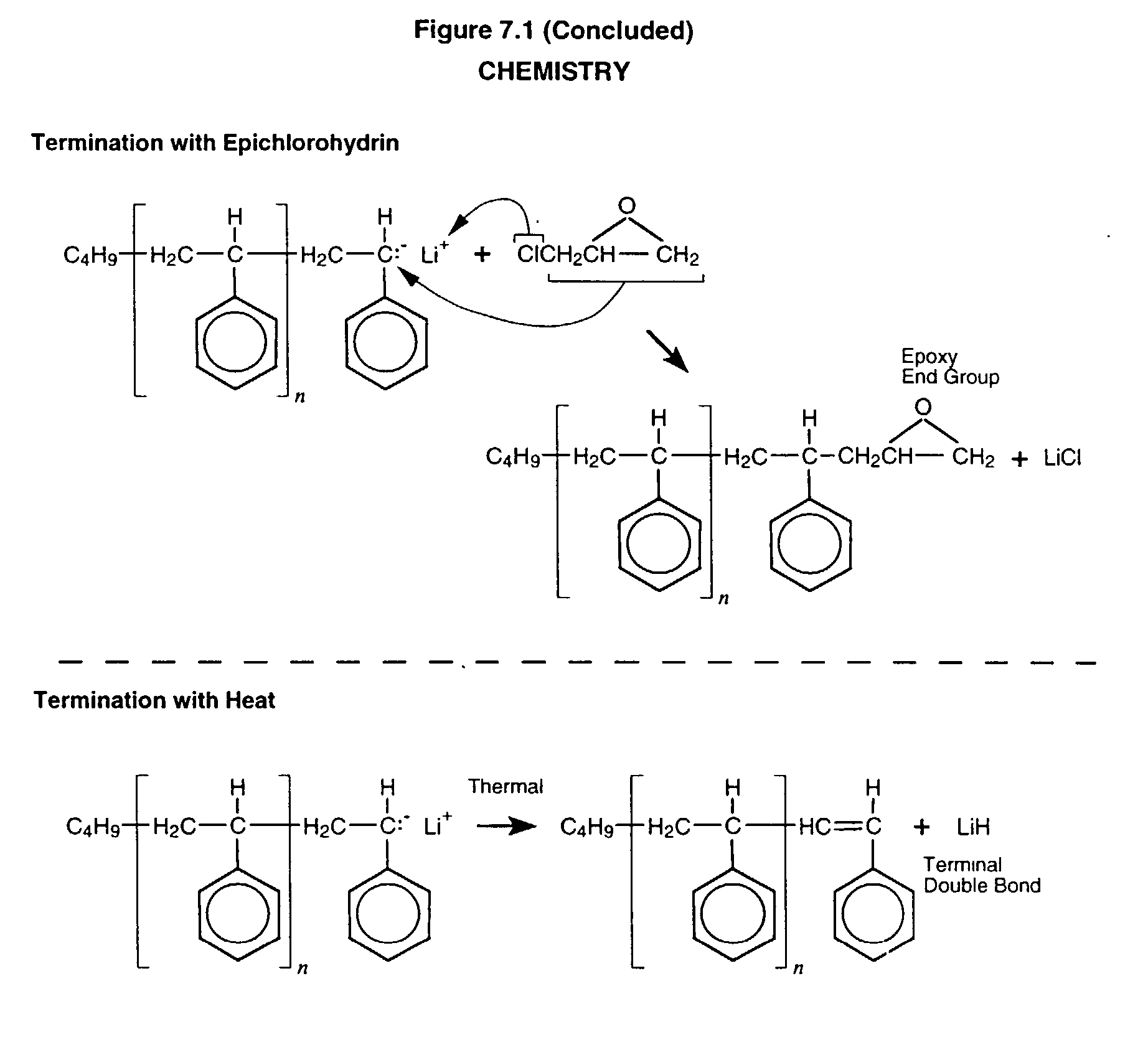

Anionic process design for rapid polymerization of polystyrene without gel formation and product produced there from

The extremely rapid anionic polymerization rate of polystyrene has made polymerization difficult to control and has prevented large-scale development. This invention uses batch polymerization to utilize the rapid rate of polymerization to complete polymerization from zero to 100% conversion in minutes and turns this rapid rate into an advantage. Polystyrene itself is used as a heat sink to limit and control the maximum temperature reached during polymerization. Adiabatic polymerization increases the polymer temperature to the desired processing temperature of the polymer for either removal of volatile compounds or for direct pellet formation when no solvent is employed. The polystyrene to be used as a heat sink is added either as pellets or is first formed at a low controllable temperature. Extremely low levels of residual monomer are found in the product. This invention also demonstrates techniques to prevent gel formation or to reduce formation to an acceptable level.

Owner:CARTILAST

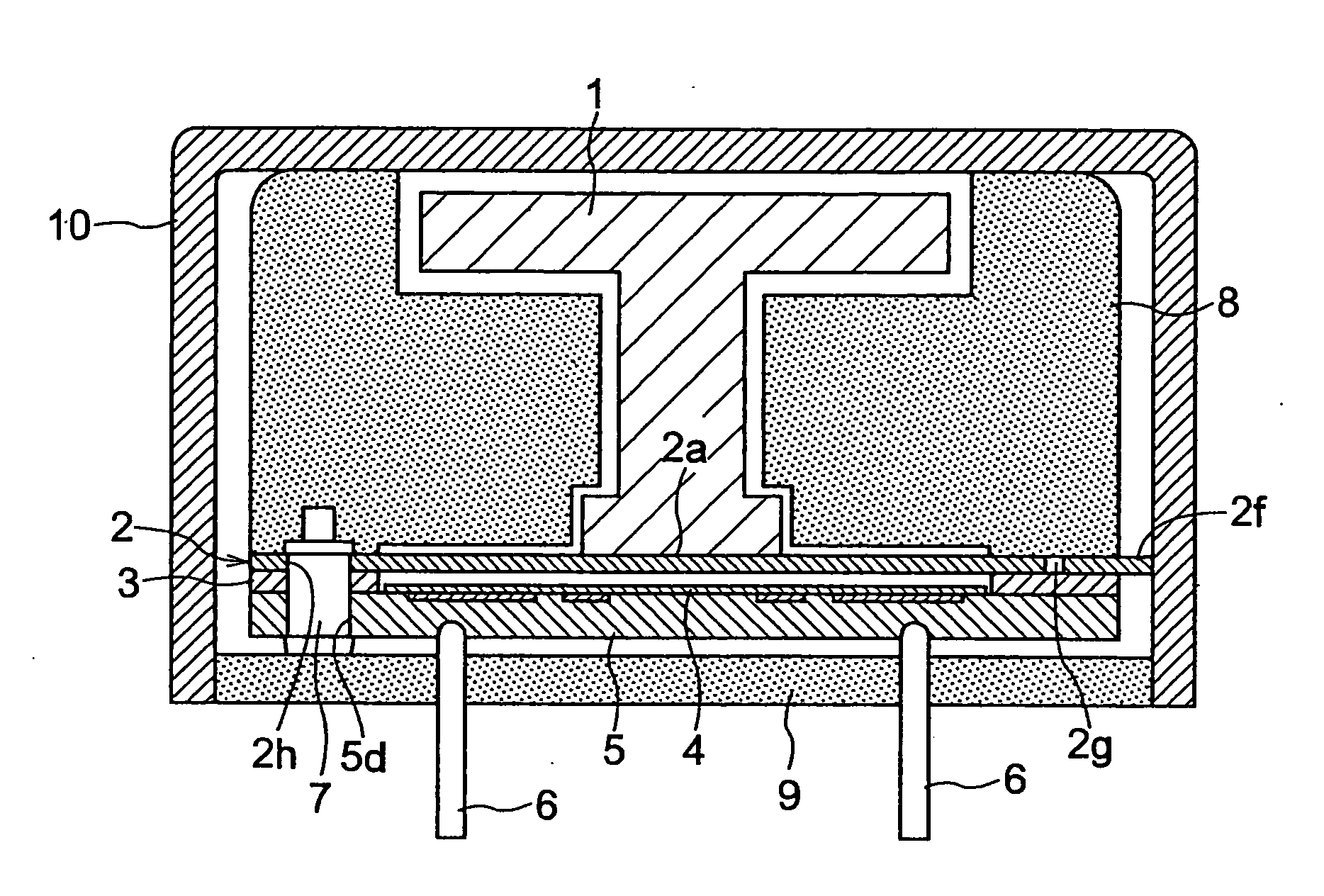

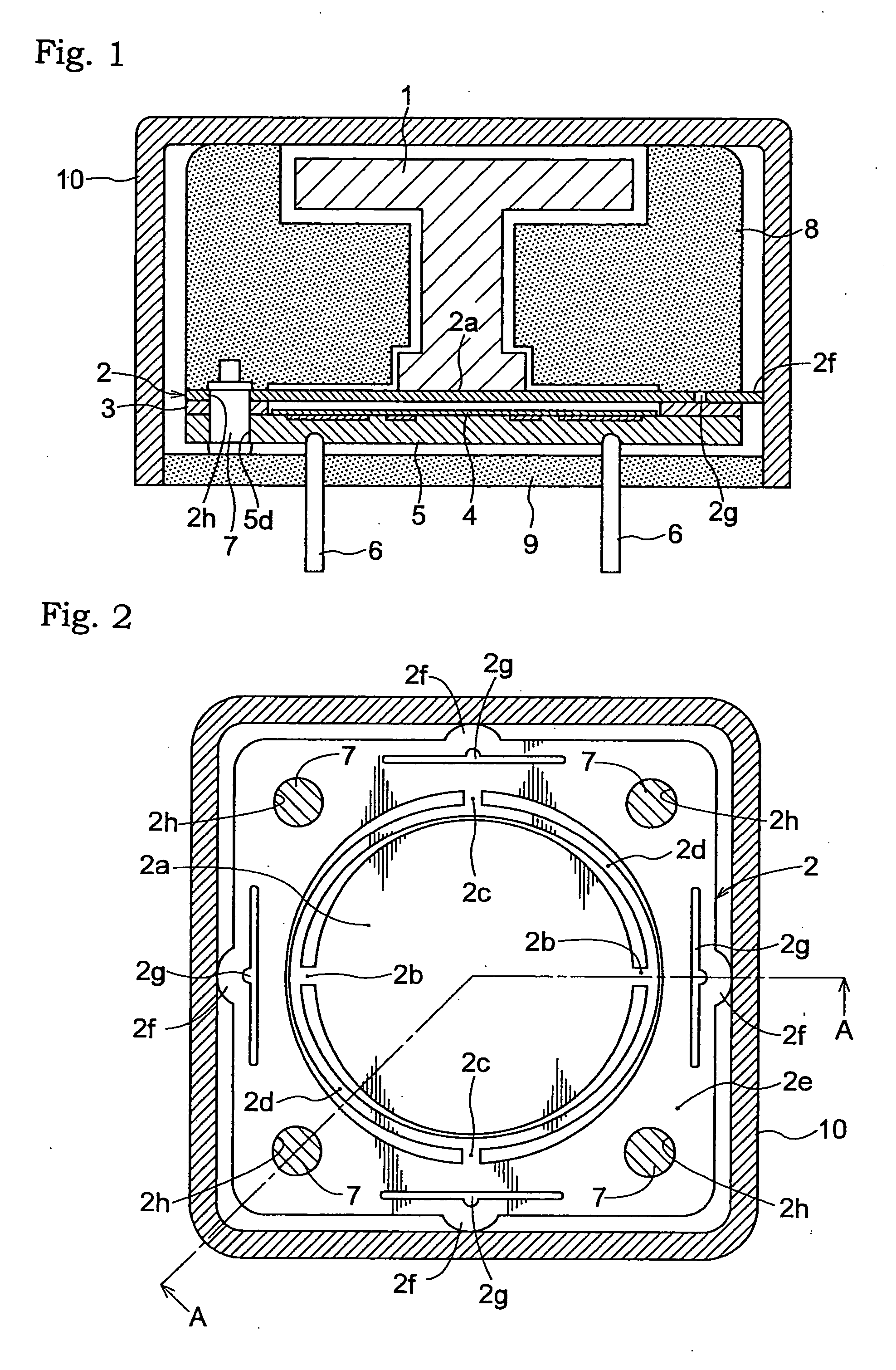

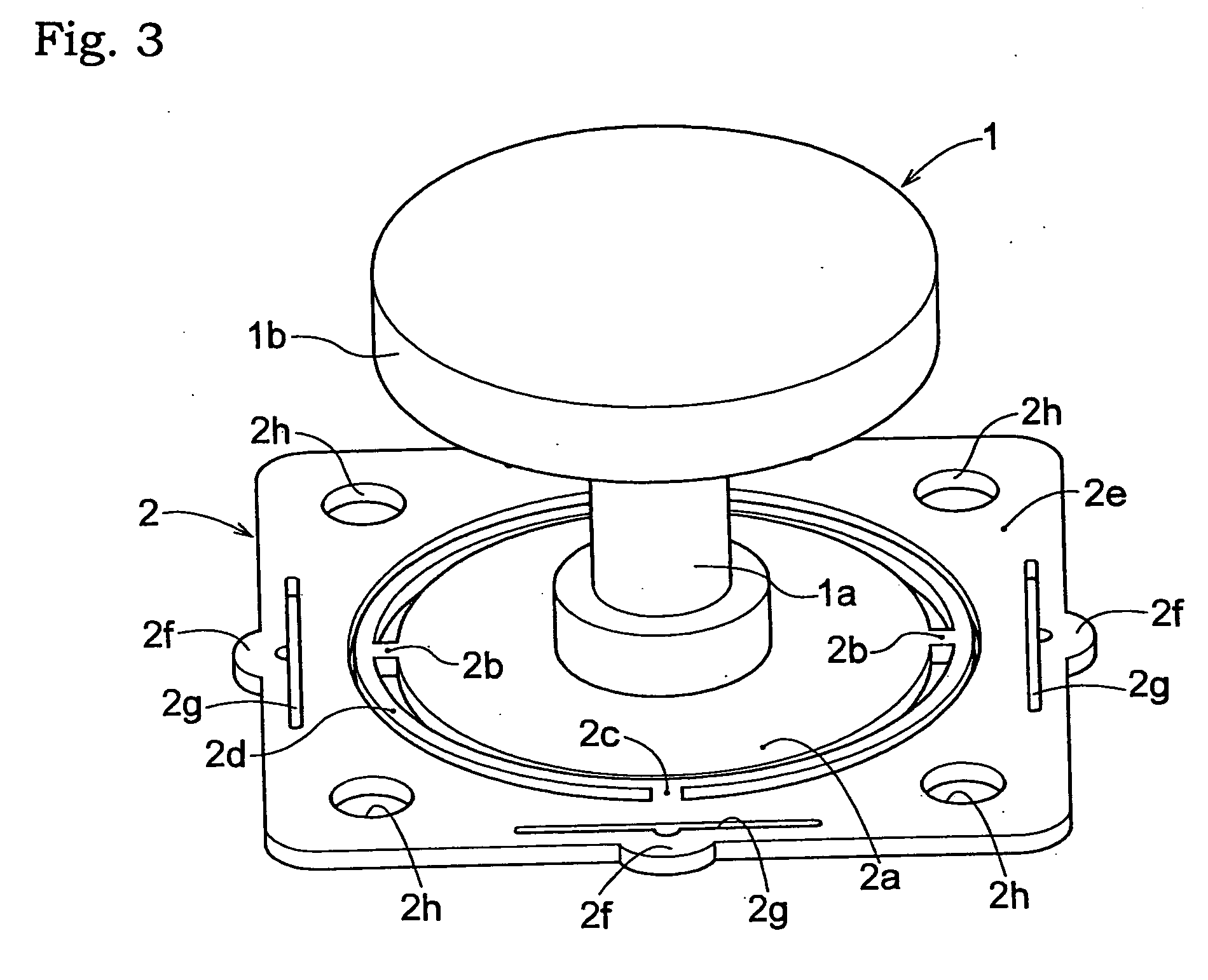

Acceleration sensor

InactiveUS20060053888A1Easy to assembleAccurate detectionAcceleration measurement using interia forcesSubsonic/sonic/ultrasonic wave measurementCapacitanceEngineering

A three-axis acceleration sensor having a simple construction is provided for improving shock resistance without lowering sensor sensitivity. An acceleration sensor for detecting acceleration in three orthogonal directions includes an electrode substrate (5) having fixed electrodes corresponding to three axes, respectively, a diaphragm (2) having one surface thereof opposed to the fixed electrodes acting as a movable electrode, and a weight (1) mounted centrally of the other surface of the diaphragm. Acceleration is detected based on variations in capacitance between the fixed electrodes and diaphragm (2). The electrode substrate (5) has an electret layer (4) formed to cover surfaces of the fixed electrodes.

Owner:HOSIDEN CORP

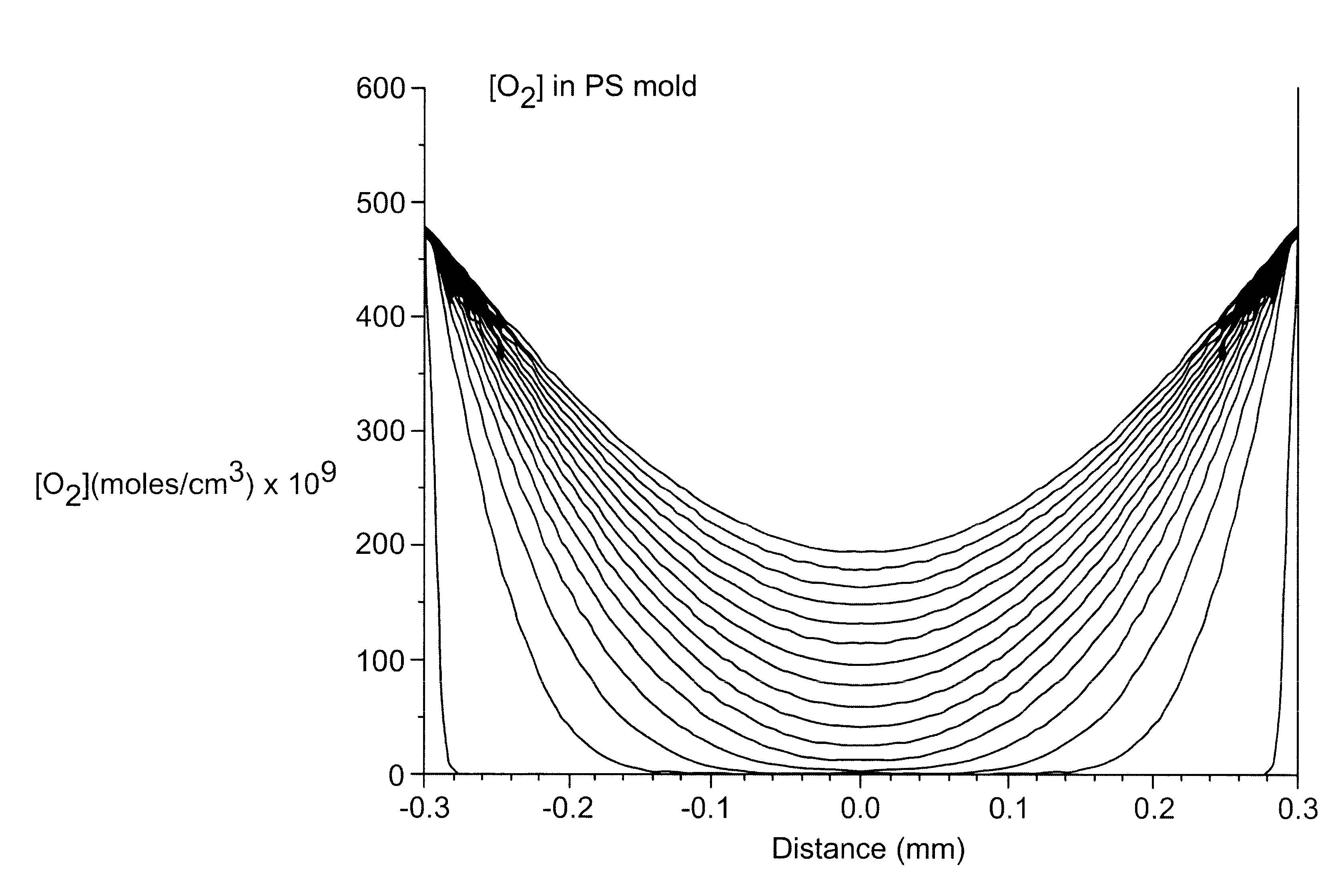

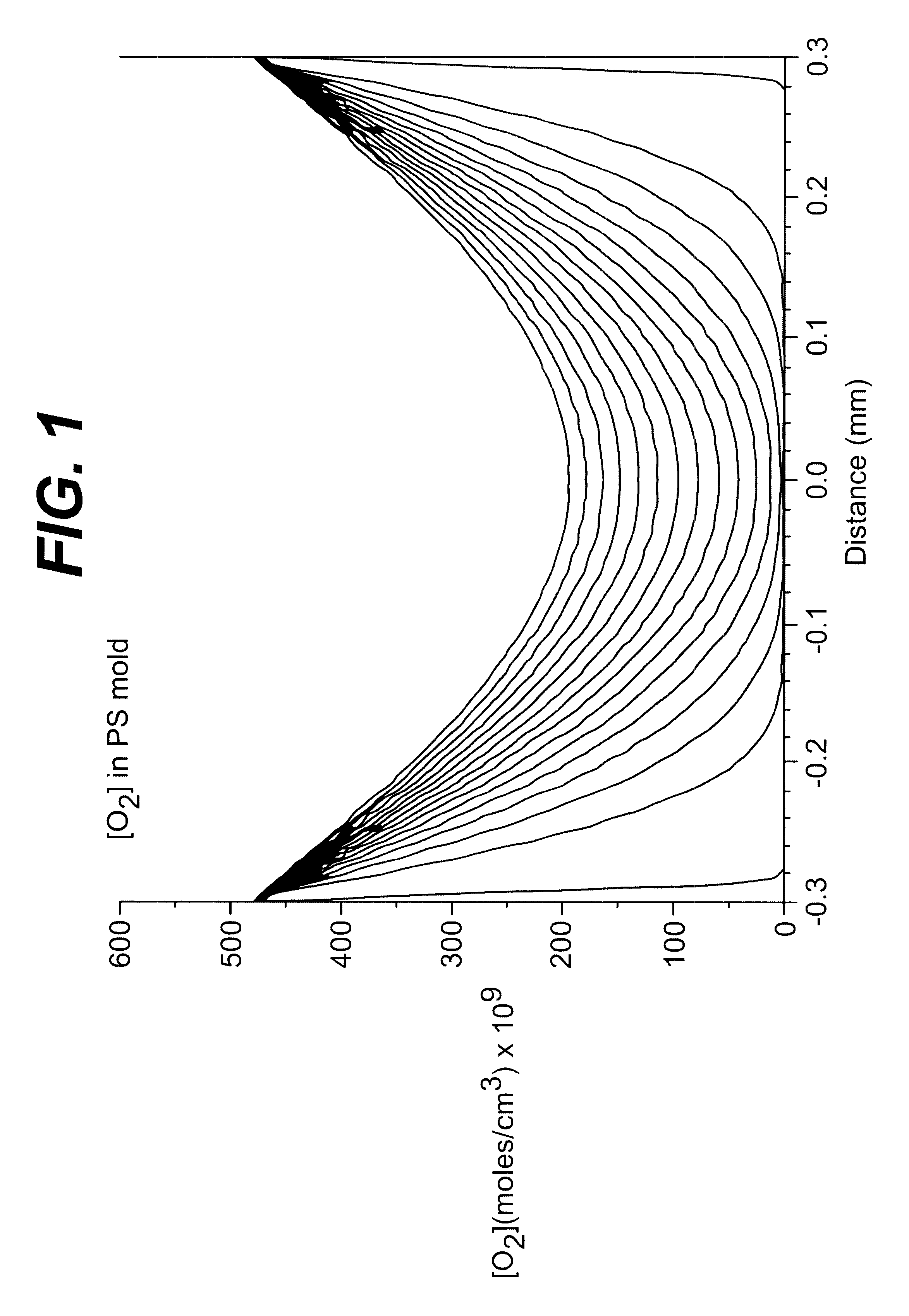

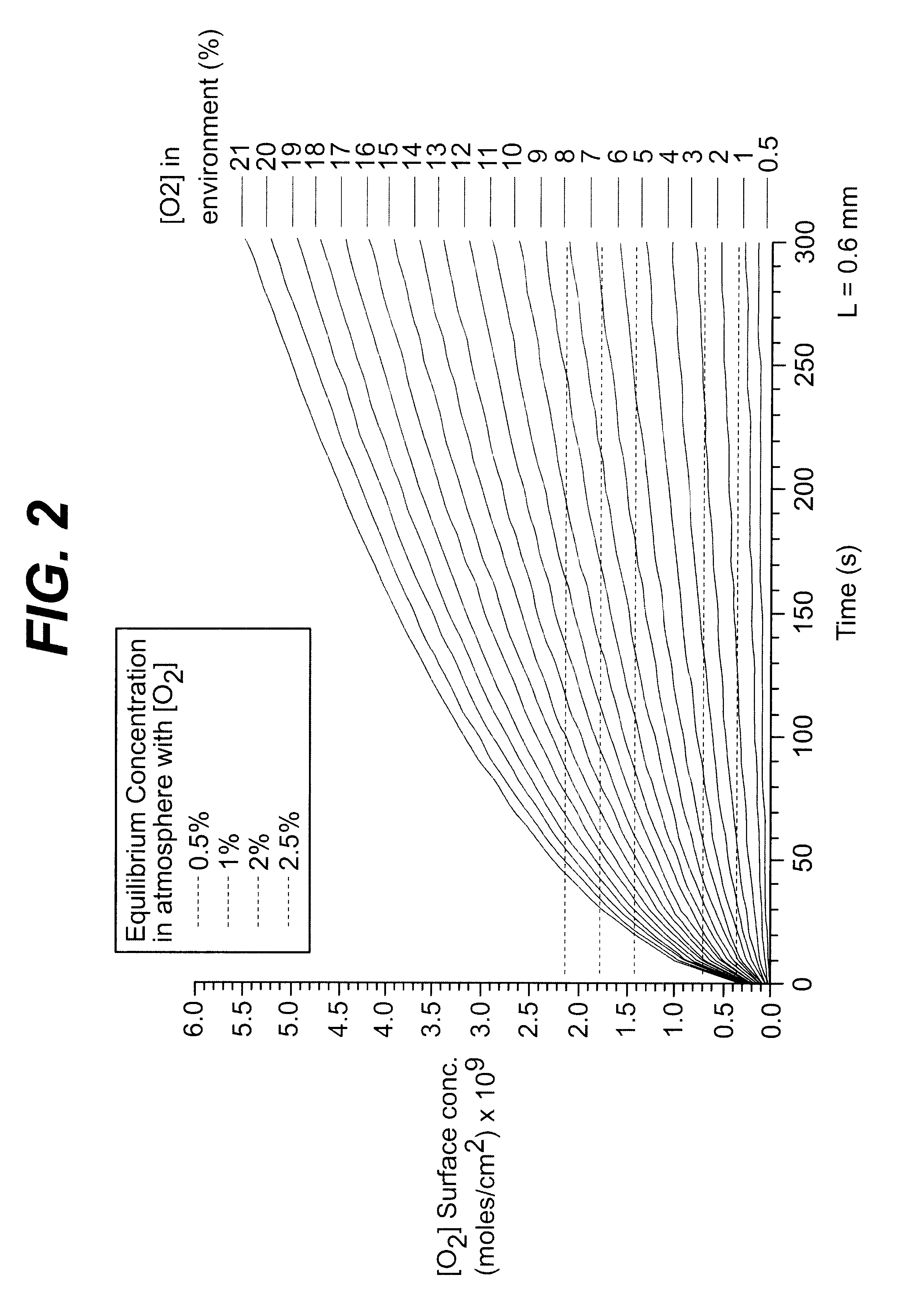

Process of manufacturing contact lenses with measured exposure to oxygen

InactiveUS6610220B1Increase productionLow costOptical articlesDomestic articlesOptoelectronicsOxygen

This invention provides a method of manufacturing a contact lens comprising the step of: dosing a contact lens mold comprising optical mold surfaces with an oxygen-sensitive reaction mixture, wherein said optical surfaces of said contact lens mold have between from 0.13x10-9 to 2.6x10-9 moles / cm2 O2 available to interfere with the reaction of said reaction mixture. This invention further provides a method of manufacturing a contact lens comprising the steps of: dosing a contact lens mold comprising optical mold surfaces with a reaction mixture, and sealing said reaction mixture and said optical mold surfaces away from a gaseous environment, wherein said optical surfaces of said contact lens mold were exposed to said gaseous environment comprising greater than 0.5 percent oxygen just prior to said sealing step.

Owner:JOHNSON & JOHNSON VISION CARE INC

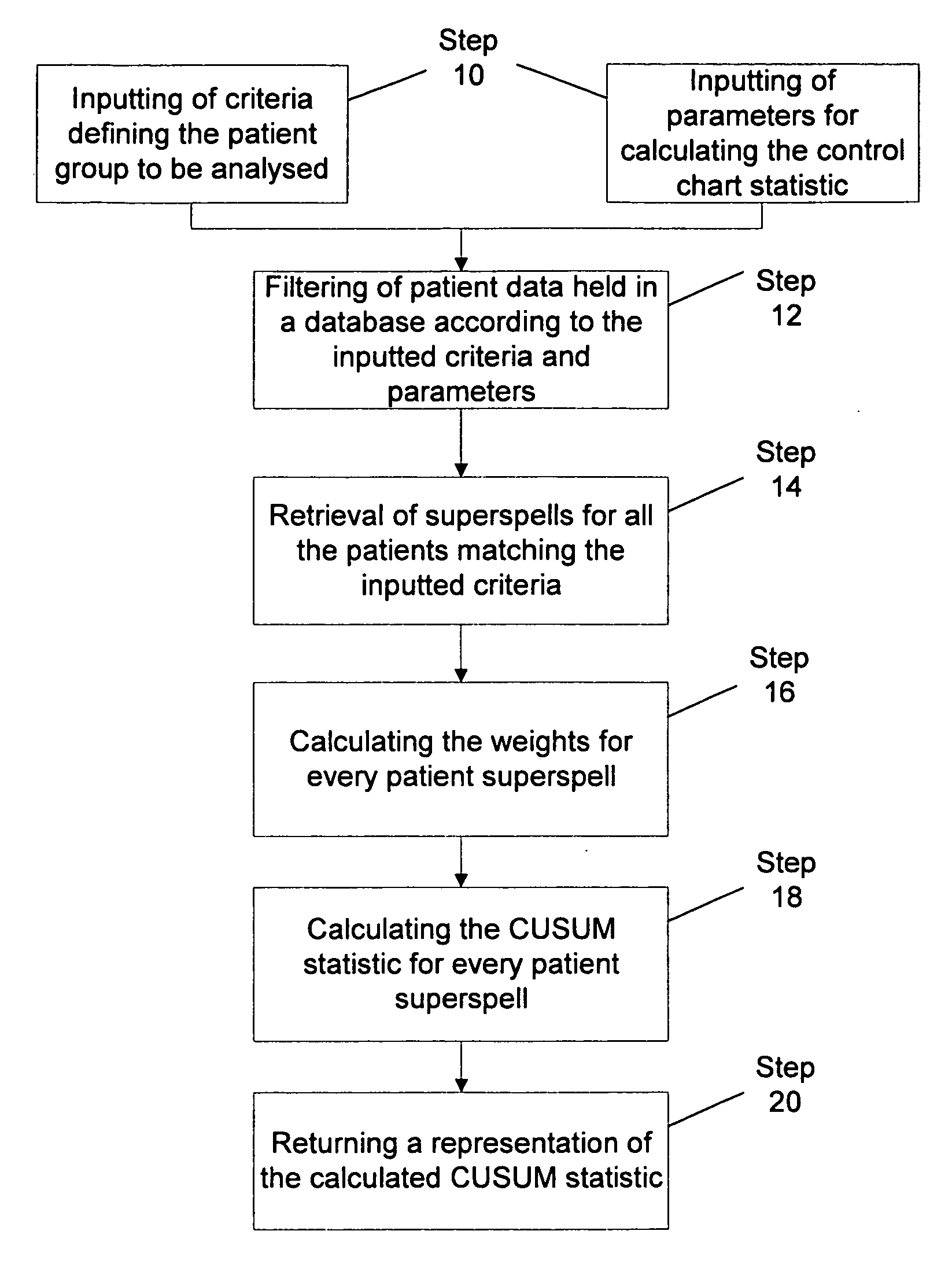

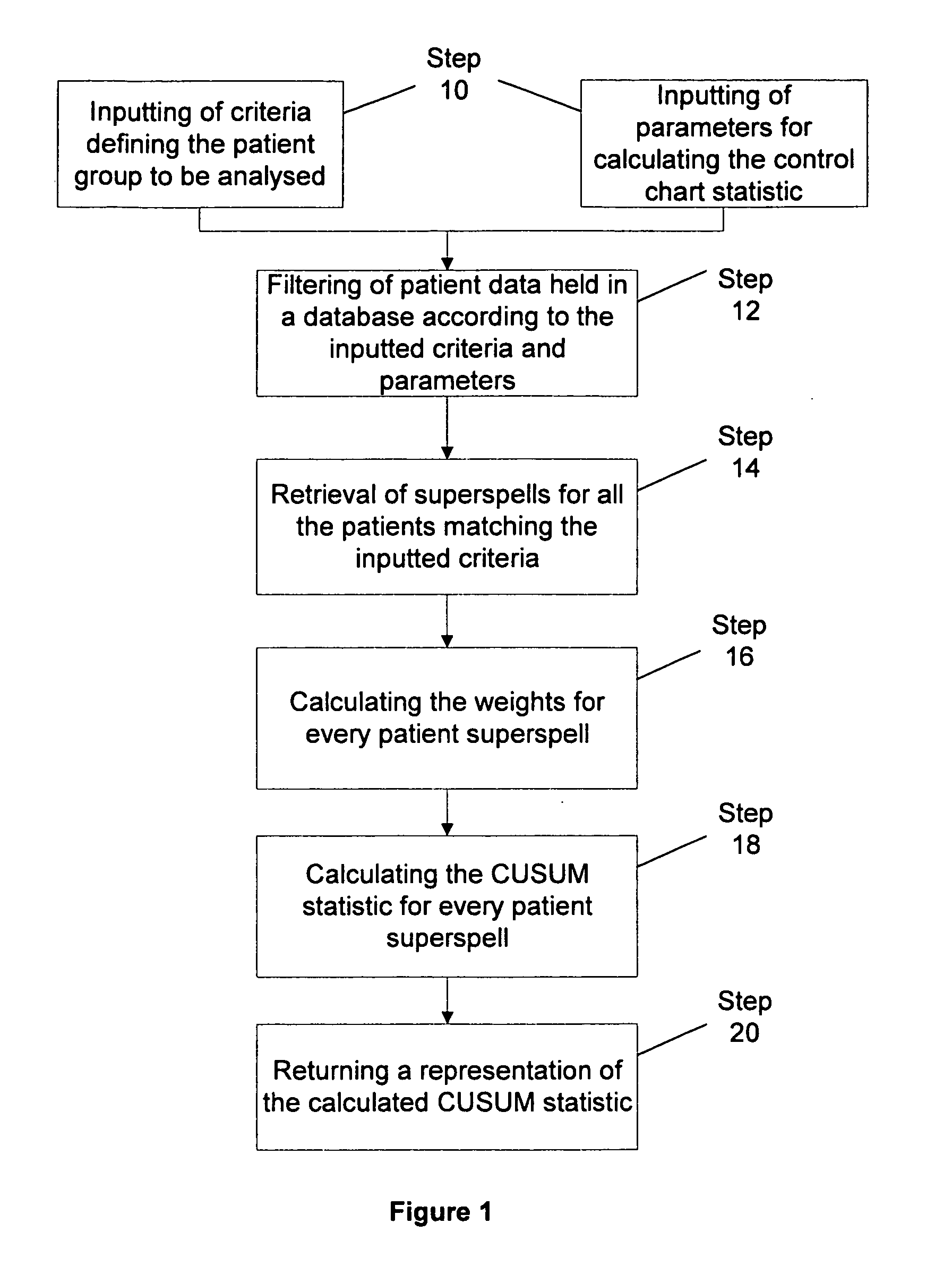

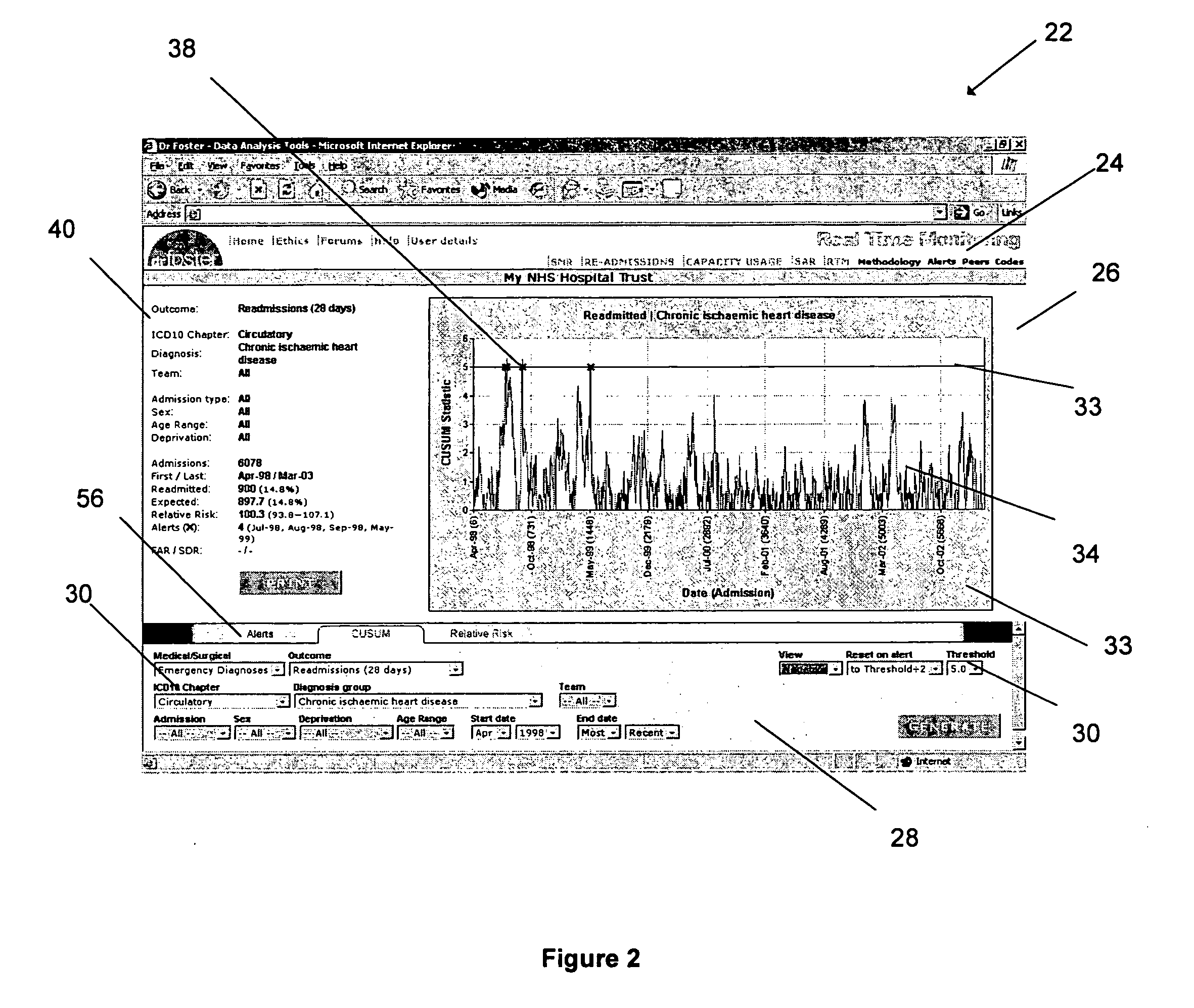

System for data analysis

InactiveUS20060015367A1Minimize dangerReaction is slowMedical data miningData processing applicationsGraphicsAnalysis data

A method and apparatus for analysing data allowing accurate, up to date analysis of the performance of hospitals or hospital trusts as the data is entered into the system. The method and apparatus is optimised for analysing data in such a way as to produce graphical representations allowing easy recognition of groups of patient having or hospitals producing outcomes which have significantly diverged from the desired outcome. The method involves filtering data held within databases to retrieve data belonging to the patient group that is to be analysed. The filtered data is then analysed using statistical calculations and a representation of the analysis is returned to the user for review.

Owner:DR FOSTER

Method and apparatus for obtaining enhanced production rate of thermal chemical reactions

InactiveUS20060029541A1Increase heat transfer rateIncrease ratingsCatalytic gas-gas reactionHydrogenSteam reformingChemical reaction

Reactors and processes are disclosed that can utilize high heat fluxes to obtain fast, steady-state reaction rates. Porous catalysts used in conjunction with microchannel reactors to obtain high rates of heat transfer are also disclosed. Reactors and processes that utilize short contact times, high heat flux and low pressure drop are described. Improved methods of steam reforming are also provided.

Owner:TONKOVICH ANNA LEE Y +3

Hyaluronic acid-based cross-linked nanoparticles

InactiveUS7879818B2Reaction is slowReduce crosslink densityPowder deliveryOrganic active ingredientsCross-linkBiopolymer

Methods are disclosed for preparing novel biodegradable cross-linked nanoparticles based on covalently cross-linking modifications of hyaluronic acid. The final products of the present invention are stable in aqueous media, and may be used as detergents and as additives for pharmaceutical compositions for drug delivery, DNA carrier system and other applications. The nanoparticles made from the biopolymers of the present invention may also be used in controlled release applications, super-absorbent materials as well as biomaterials like enzyme immobilization.

Owner:BORBELY JANOS +3

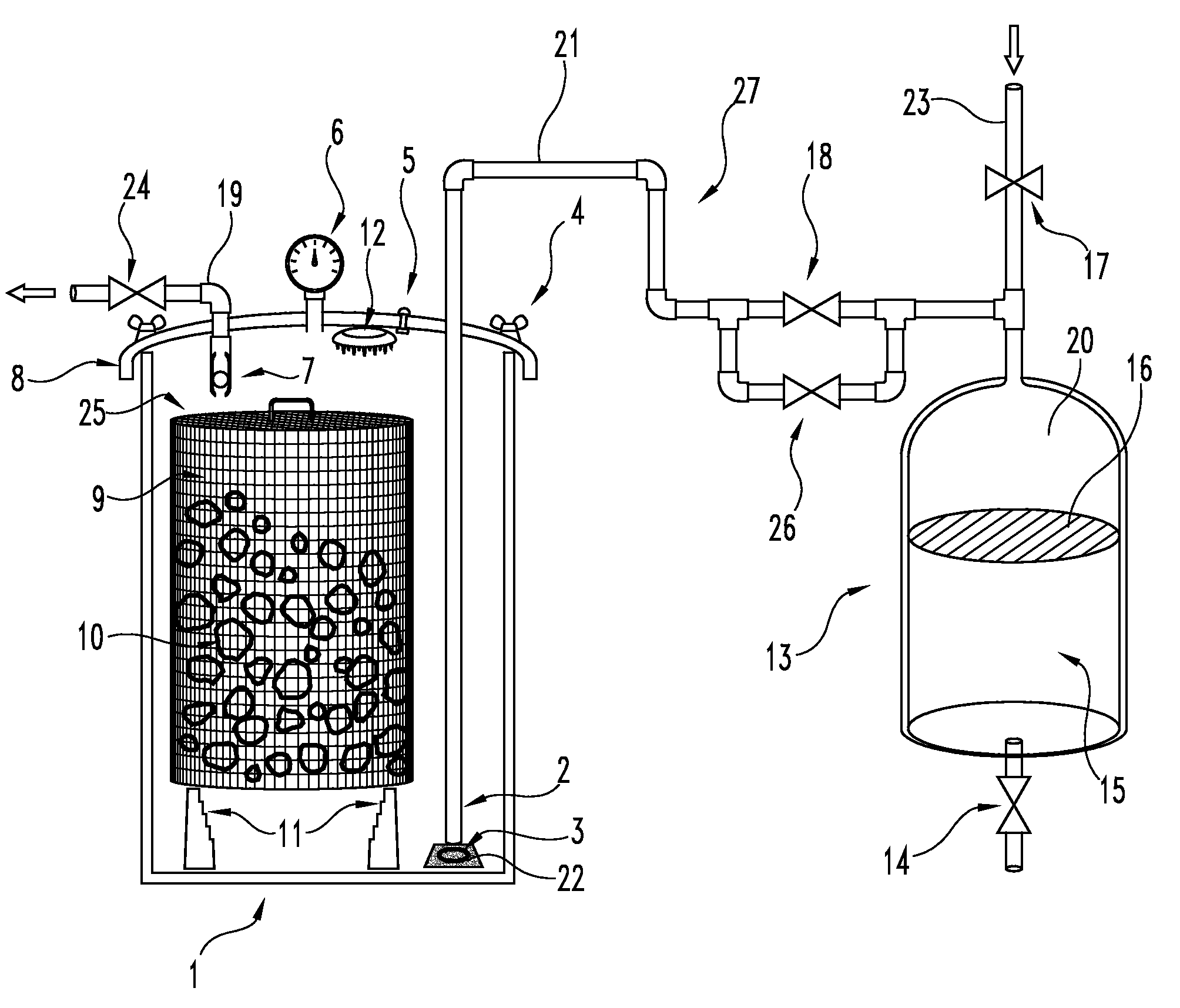

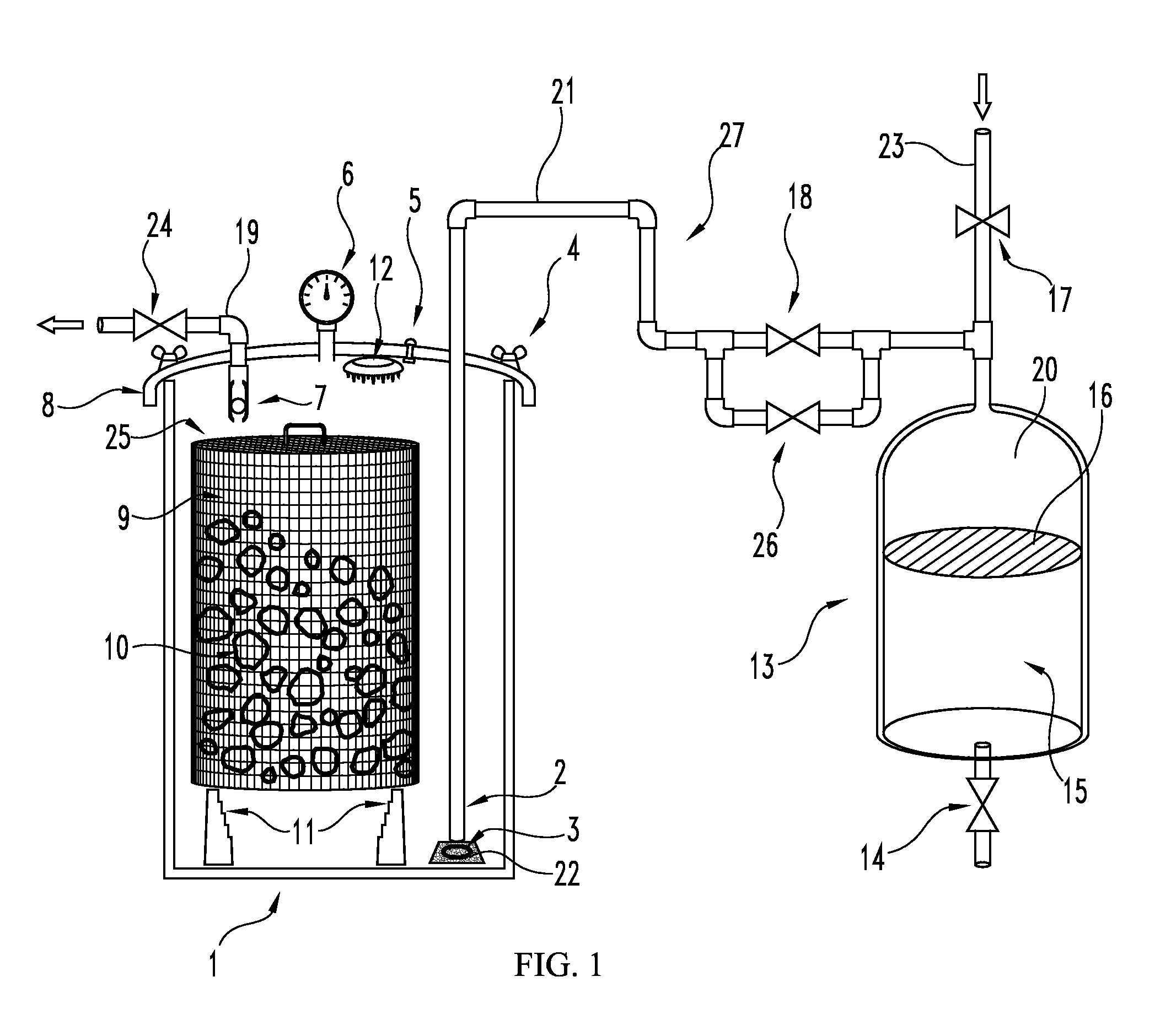

Control system for an on-demand gas generator

InactiveUS20090035214A1Reduce exposureReaction is slowPressurized chemical processPhysical/chemical process catalystsControl systemEngineering

A self-regulating on-demand gas generator. Generation of gas produced from a reaction is selectively, variably, and spontaneously controlled. A variable volume liquid chamber in communication with the pressure pot allows the volume of liquid reactant in the pressure pot to be varied. The amount of product gas generated in the pressure pot depends on the degree of contact between the solid-like reactant and the liquid reactant. The pressure of the product gas regulates the level of liquid in the pressure pot and thereby regulates the degree of contact between the solid-like reactant and the liquid reactant. A sealed gas chamber sharing a flexible diaphragm with the liquid chamber controls the expandability of the liquid chamber. Manipulating the pressure in the sealed gas chamber or the volume of the liquid reactant affects the pressure at which contact by the reactants will be initiated or terminated and thereby provides the ability to control the reaction.

Owner:PURDUE RES FOUND INC

Jettable compositions

ActiveUS7655174B2Reaction is slowLow viscosityAdditive manufacturing apparatusLiquid surface applicatorsMeth-Piezo electric

A fully curable jettable composition having a viscosity less than 30 cps at a temperature within the range of 15-180° C., more preferably at a temperature of 15-100° C., e.g. 60-80° C. the composition comprising: (A) at least one low viscosity reactive resin selected from the group consisting of compounds containing an oxetane ring, cycloaliphatic epoxy resins, tetrahydrofurans, hexahydropyrans and mono-functional (meth)acrylates, said resin having a molecular weight of not greater than 300 Daltons, e.g. 250 Daltons or less, and a viscosity at a temperature in the said range of less than 30 cps, e.g. 5 to 15 cps; (B) at least one higher viscosity resin selected from the group consisting of epoxy resins, compounds containing an oxetane ring and acrylates, which resin acts to thicken the low viscosity resin and strengthen a jetted deposit of the composition, the higher viscosity resin having: a viscosity greater than twice that of the low viscosity resin at the said temperature in the range stated above, and a functionality of greater than or equal to 2; (C) at least one curable toughener, preferably having a functionality of at least 2, such as hydroxy, epoxy, acrylic or other reactive functionalised polymer / oligomer (e.g. derived by functionalising poly(tetrahydrofuran), polycaprolactone, polycarbonate diol, or a dendrimeric polyol; (D) at least one initiator for the polymerisation of the resins, and (E) at least one stabilizer for delaying the curing of the resins of the composition; wherein the low viscosity resin is slower to react than the higher viscosity resin and acts to solvate the higher viscosity resin prior to curing and at least partly during curing and wherein at least 30% of the components A and B are cationically curable resins. The composition can be jetted from piezo electric printing heads under the control of a computer program to form a multi-layered article, e.g. a three dimensional article, in which the adjacent droplets merge and are cured homogeneously together.

Owner:3D SYST INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com