Patents

Literature

7554results about How to "Good physical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plasma protein matrices and methods for their preparation

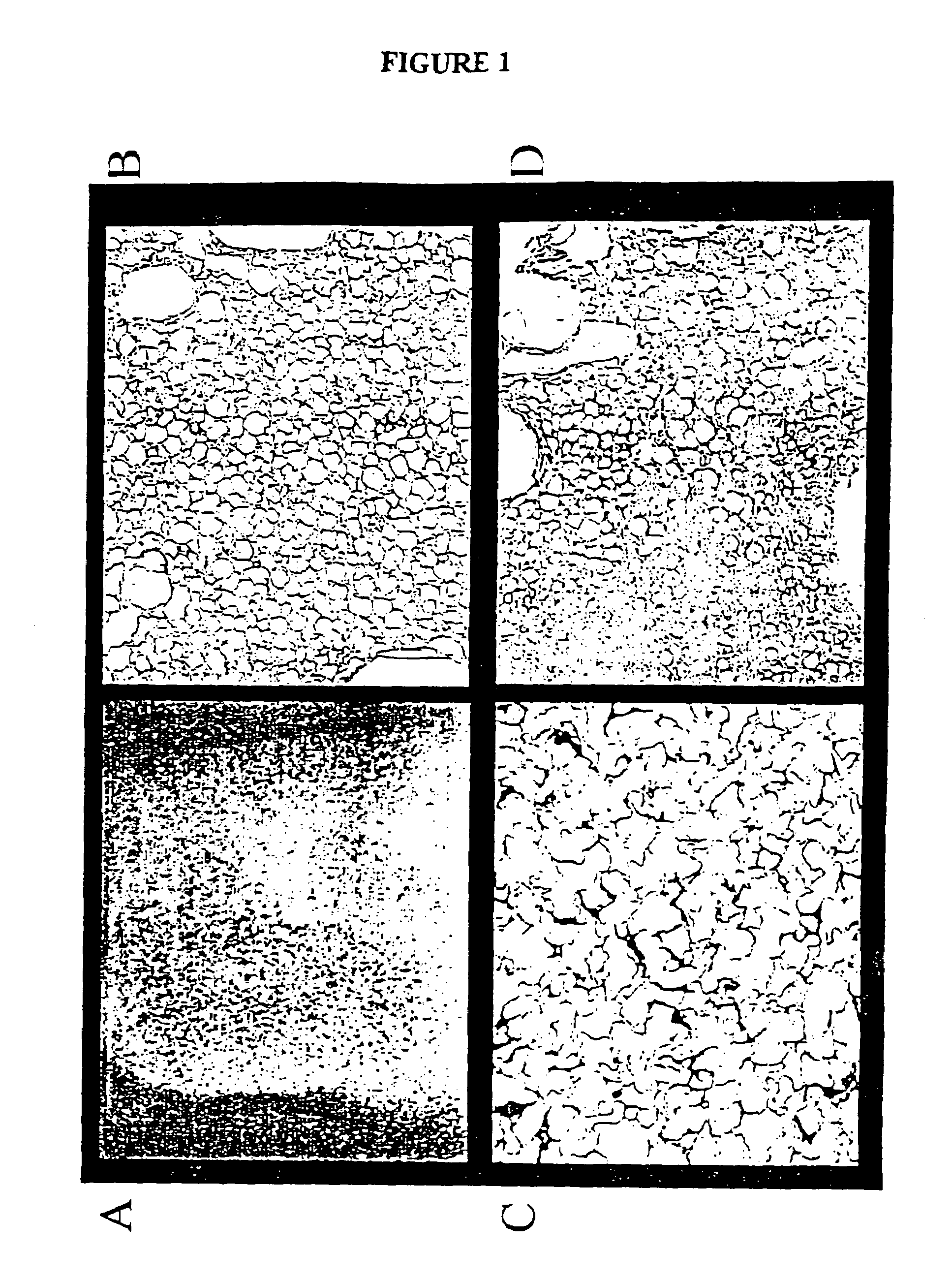

InactiveUS7009039B2Rapid cell growthRapid vascularizationBiocidePeptide/protein ingredientsBiological propertyFreeze-drying

A freeze dried biocompatible matrix comprising plasma proteins, useful as implants for tissue engineering as well as in biotechnology, and methods of producing the matrix are provided. Mechanical and physical parameters can be controlled by use of auxiliary components or additives which may be removed after the matrix is formed in order to improve the biological properties of the matrix. The matrices according to the present invention may be used clinically per se, or as a cell-bearing implant.

Owner:PROCHON BIOTECH

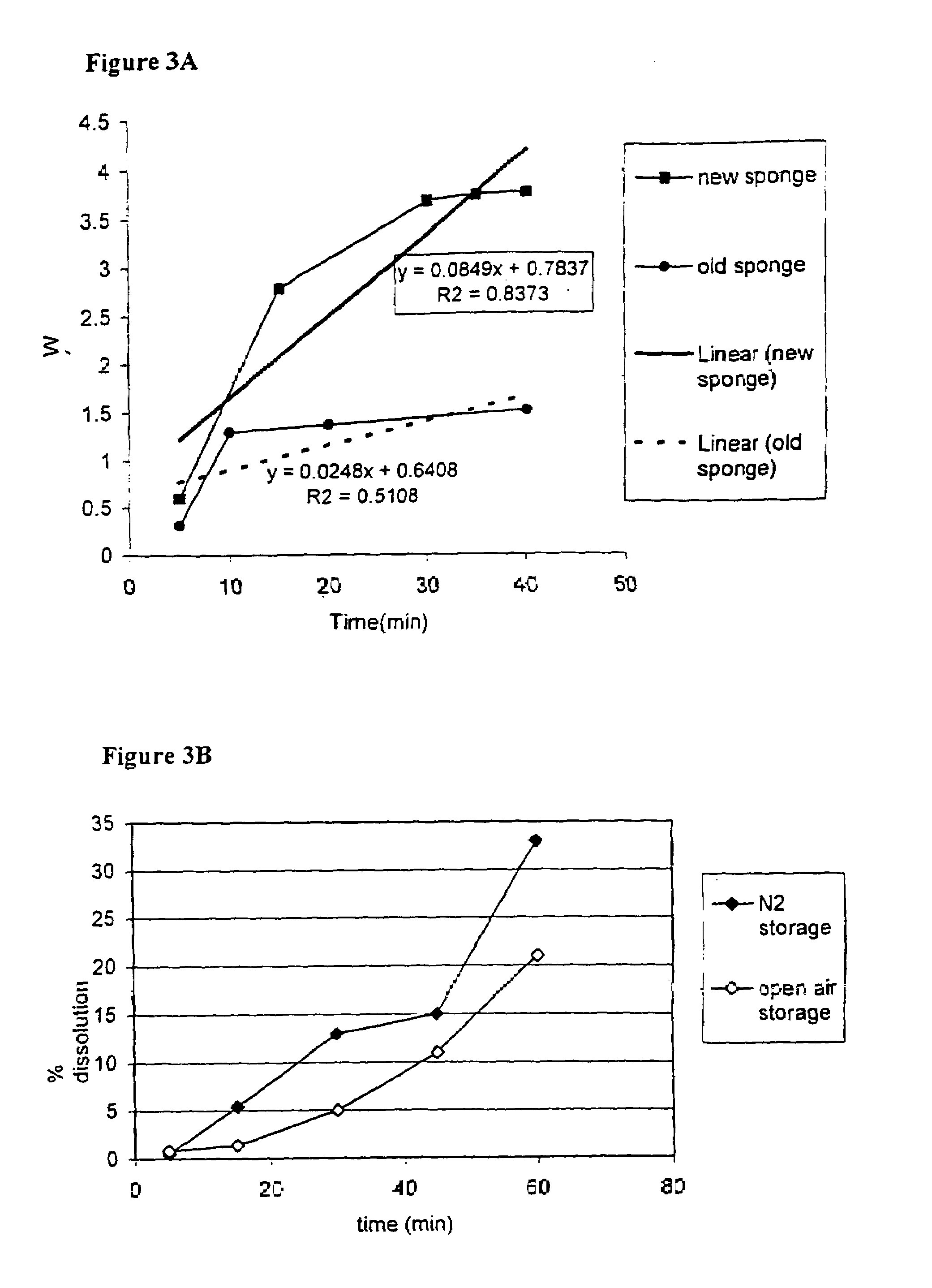

Effervescent granules and methods for their preparation

InactiveUS6071539AMinimize degradationMelt and soften binderPowder deliveryPill deliveryPlasticizerHot melt

According to the present invent, effervescent granules having a controllable rate of effervescence are provided. Such granules comprise an acidic agent, an alkaline agent, a hot-melt extrudable binder capable of forming a eutectic mixture with the acidic agent and, optionally, a plasticizer. The effervescent granules are made by a hot-melt extrusion process.

Owner:ETHYPHARM SA

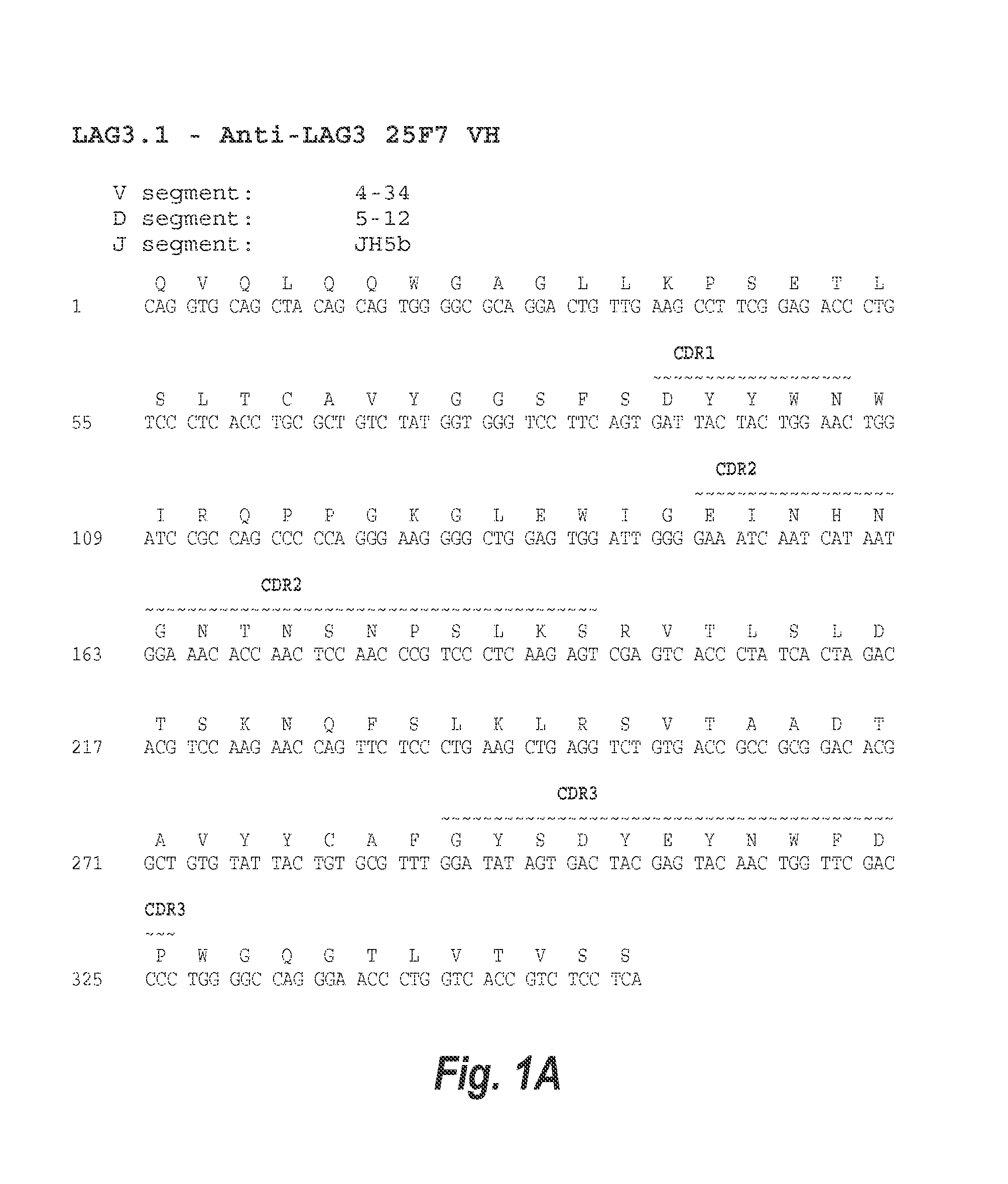

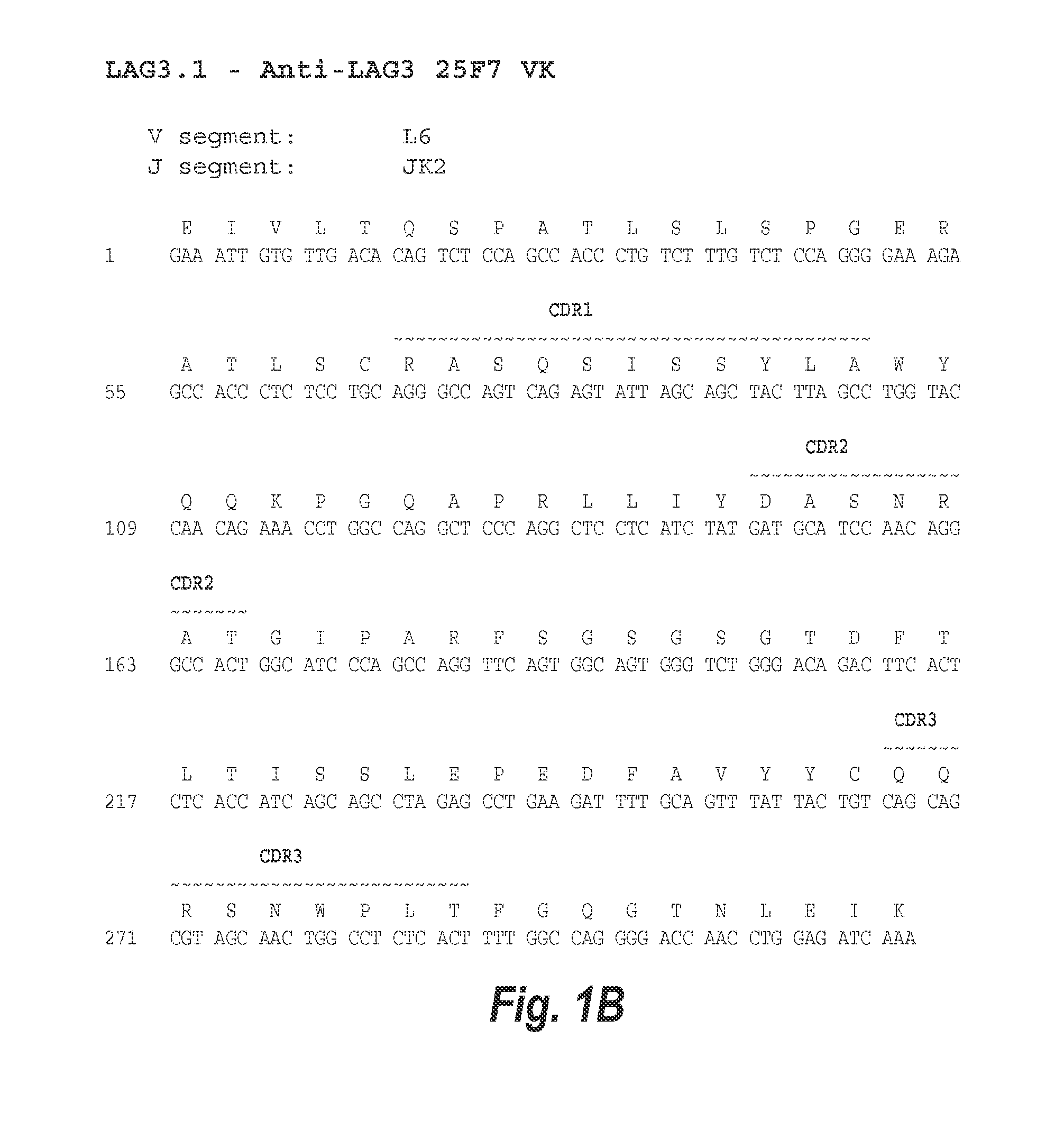

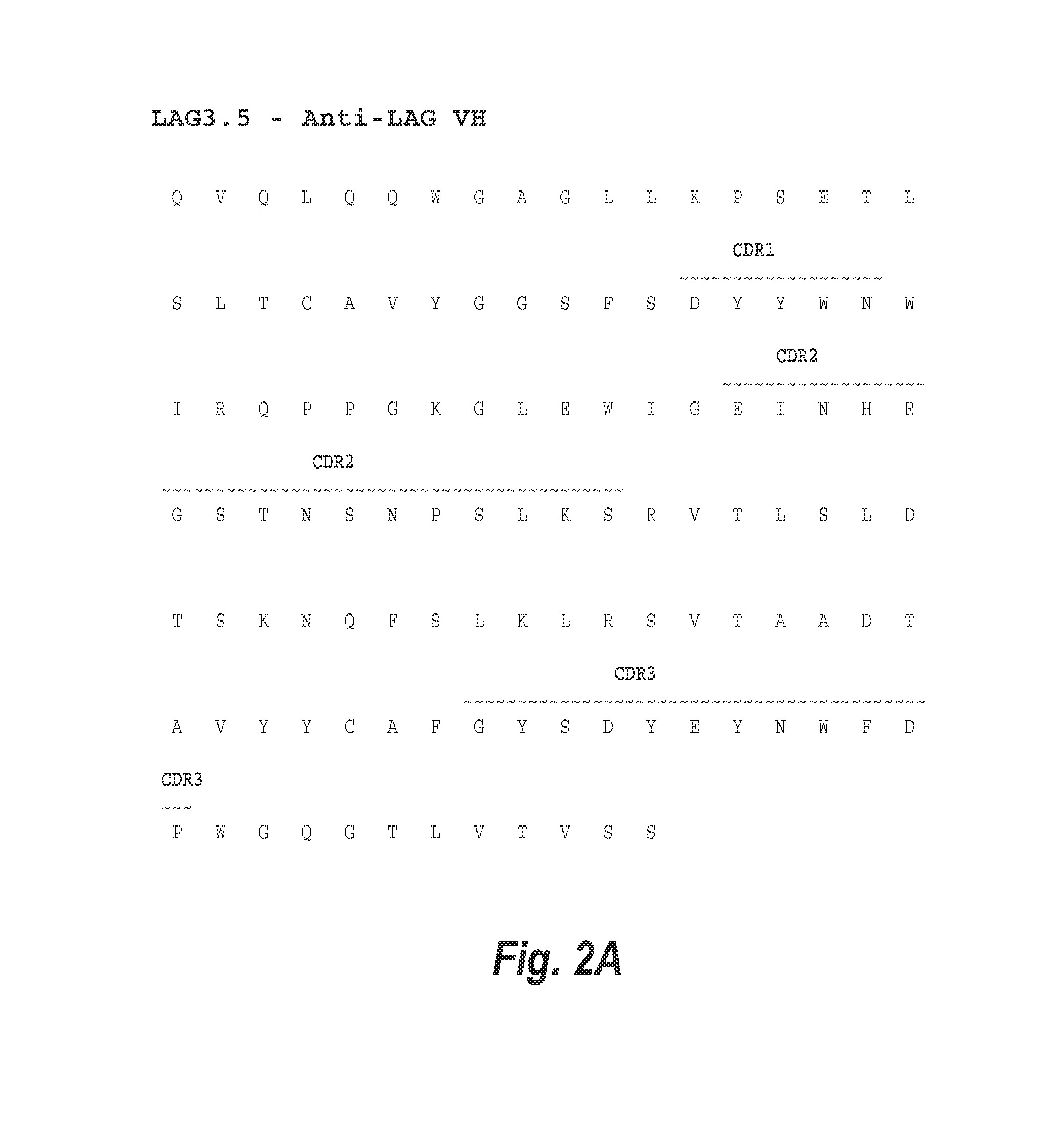

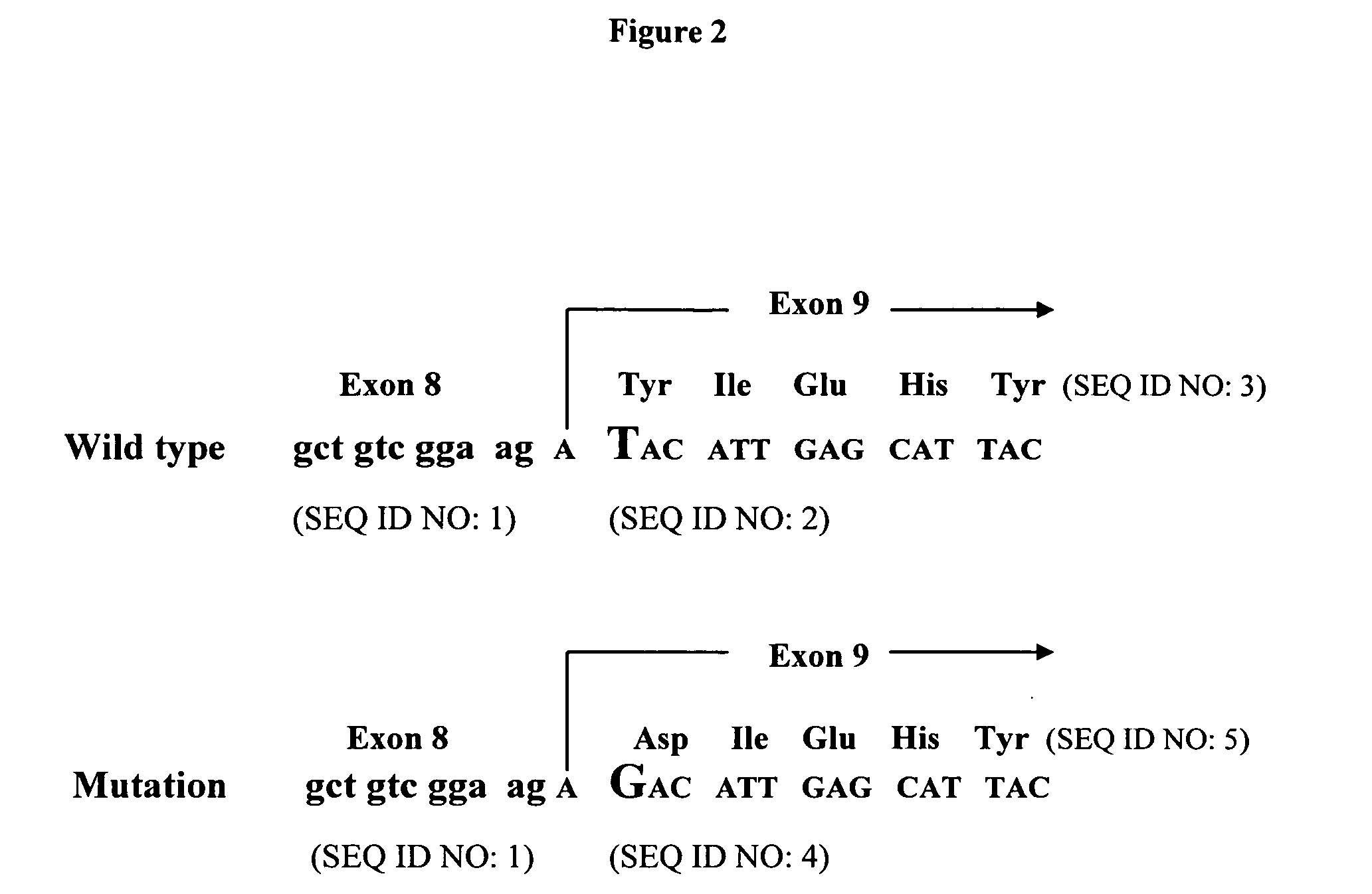

Optimization of antibodies that bind lymphocyte activation gene-3 (lag-3), and uses thereof

ActiveUS20140093511A1Improve physical stabilityGood chemical stabilityImmunoglobulins against cell receptors/antigens/surface-determinantsAntiviralsLymphocyteLymphocyte activation

The present invention provides isolated monoclonal antibodies that specifically bind LAG-3, and have optimized functional properties compared to previously described anti-LAG-3 antibodies, such as antibody 25F7 (US 2011 / 0150892 A1). These properties include reduced deamidation sites, while still retaining high affinity binding to human LAG-3, and physical (i.e., thermal and chemical) stability. Nucleic acid molecules encoding the antibodies of the invention, expression vectors, host cells and methods for expressing the antibodies of the invention are also provided, as well as immunoconjugates, bispecific molecules and pharmaceutical compositions comprising the antibodies. The present invention also provides methods for detecting LAG-3, as well as methods for treating stimulating immune responses using an anti-LAG-3 antibody of the invention. Combination therapy, in which the antibodies are co-administered with at least one additional immunostimulatory antibody, is also provided.

Owner:BRISTOL MYERS SQUIBB CO

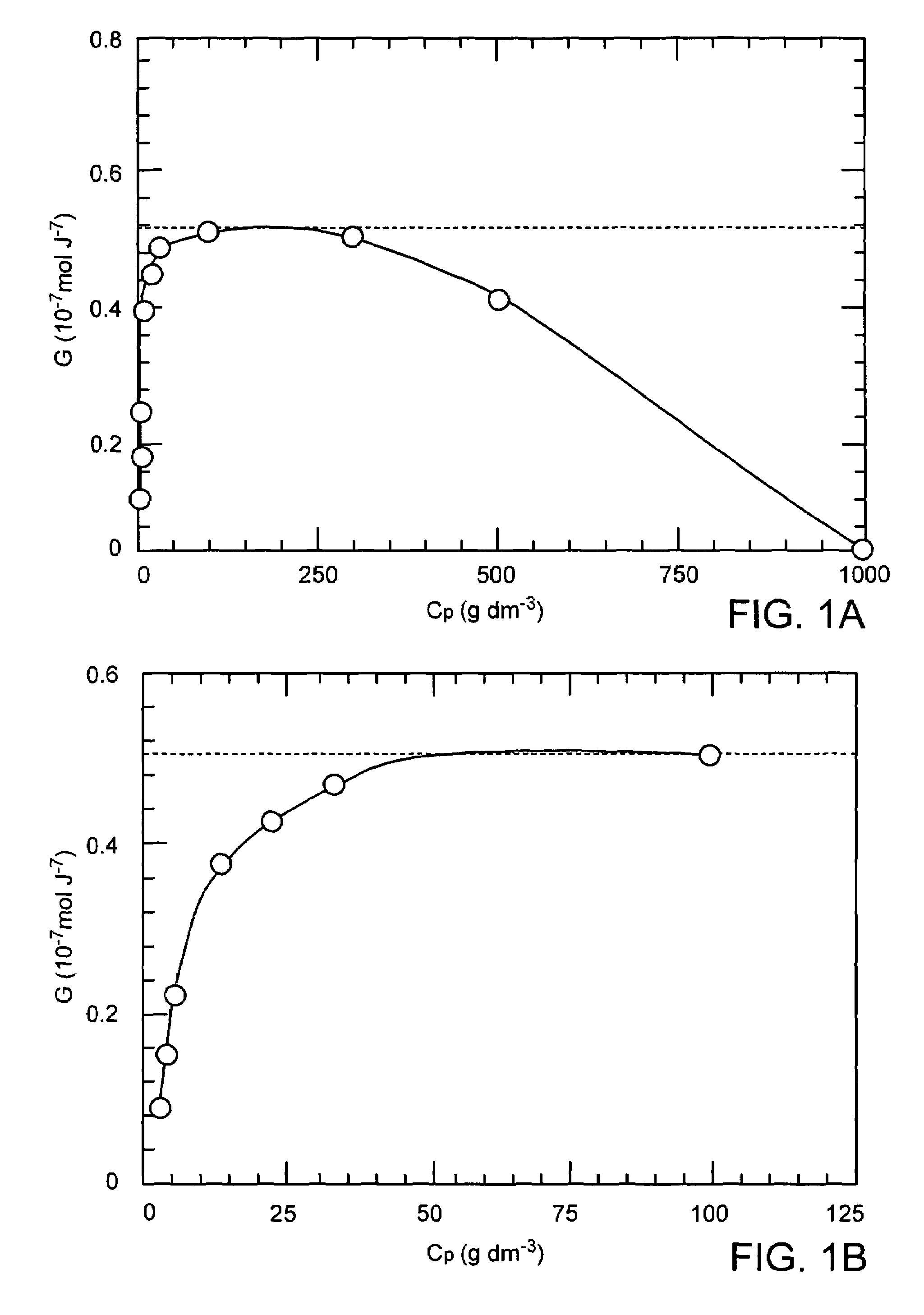

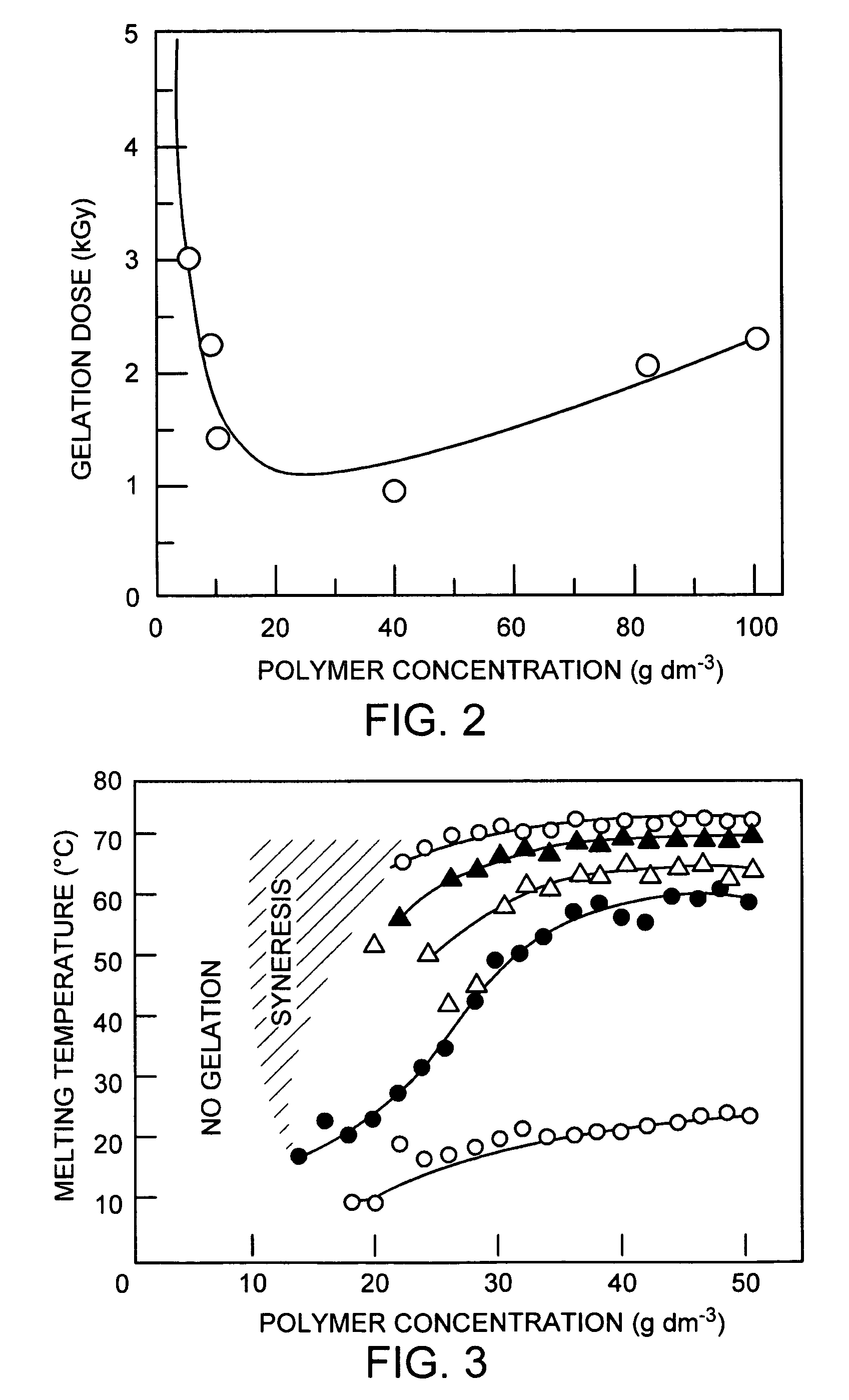

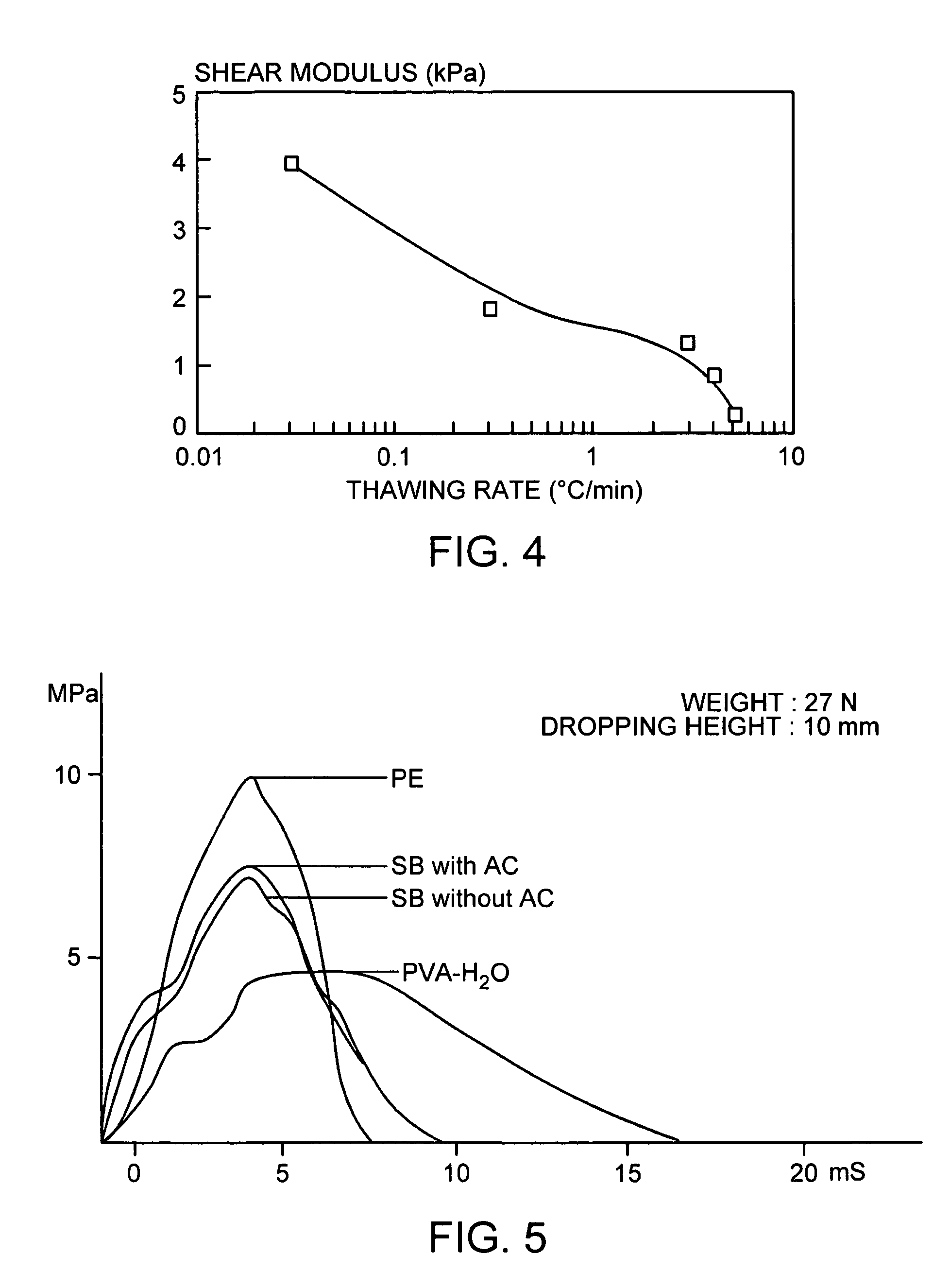

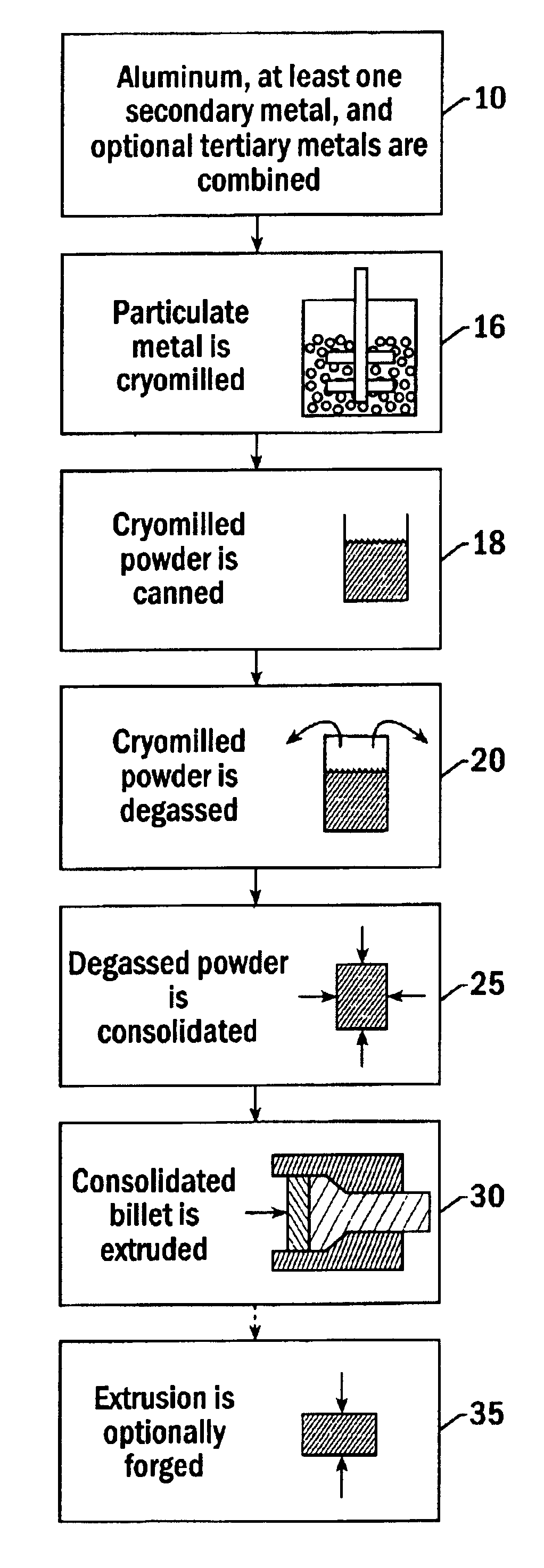

PVA hydrogel

InactiveUS7235592B2Improve physical stabilityGood physical propertiesOrganic chemistryMixing methodsPolymer sciencePolymer

The present invention provides methods of making covalently crosslinked vinyl polymer hydrogels having advantageous physical properties, and covalently crosslinked vinyl polymer hydrogel compositions made by such methods, as well as articles of manufacture comprising such covalently crosslinked vinyl polymer hydrogel compositions. The physical properties of the produced hydrogels can be adjusted by varying controlled parameters such as the proportion of physical associations, the concentration of polymer and the amount of radiation applied. Such covalently crosslinked vinyl polymer hydrogels can be made translucent, preferably transparent, or opaque depending on the processing conditions. The stability of the physical properties of the produced vinyl polymer hydrogel can be enhanced by controlling the amount of covalent crosslinks.

Owner:ZIMMER GMBH

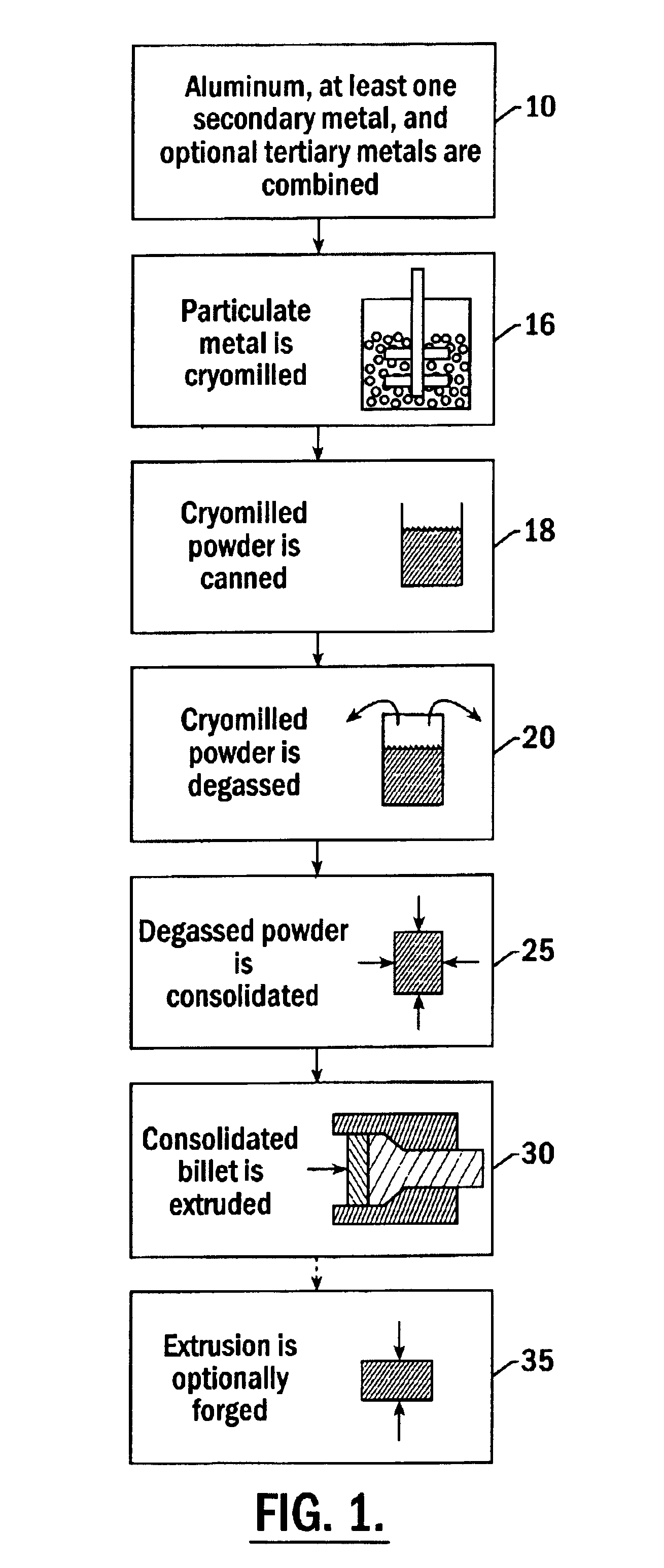

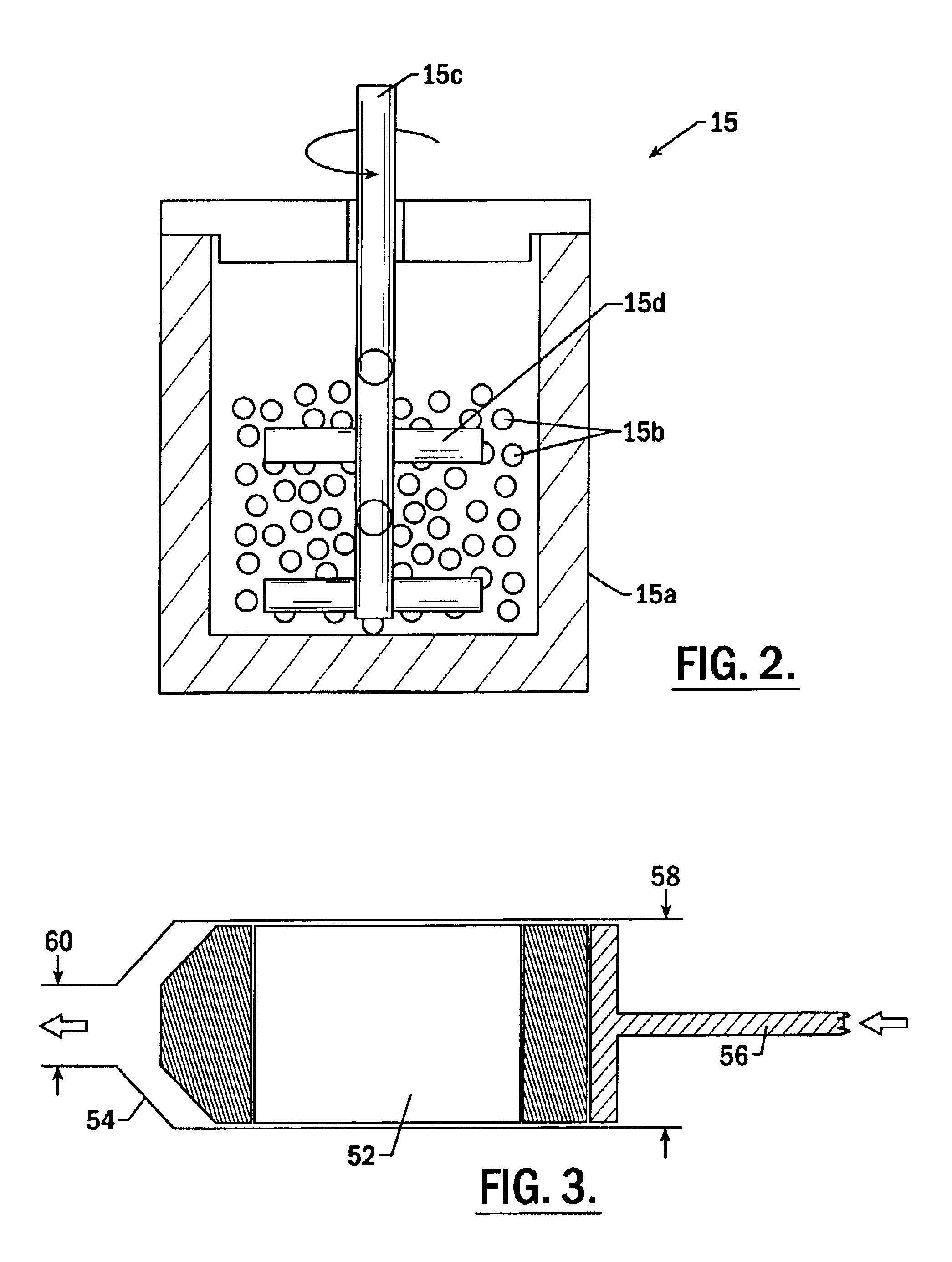

Method for preparing cryomilled aluminum alloys and components extruded and forged therefrom

InactiveUS6902699B2Stable structureHigh strengthTransportation and packagingMetal-working apparatusNanostructureAluminium alloy

High strength aluminum alloy powders, extrusions, and forgings are provided in which the aluminum alloys exhibit high strength at atmospheric temperatures and maintain high strength and ductility at extremely low temperatures. The alloy is produced by blending about 89 atomic % to 99 atomic % aluminum, 1 atomic % to 11 atomic % of a secondary metal selected from the group consisting of magnesium, lithium, silicon, titanium, zirconium, and combinations thereof, and up to about 10 atomic % of a tertiary metal selected from the group consisting of Be, Ca, Sr, Ba, Ra, Sc, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Y, Nb, Mo, Tc, Ru, Rh, Pd, Ag, Cd, W, and combinations thereof. The alloy is produced by nanostructure material synthesis, such as cryomilling, in the absence of refractory dispersoids. The synthesized alloy is then canned, degassed, consolidated, extruded, and optionally forged into a solid metallic component. Grain size within the alloy is less than 0.5 μm, and alloys with grain size less than 0.1 μm may be produced.

Owner:THE BOEING CO

Surface crosslinking treatment method of water-absorbing resin powder

ActiveUS7378453B2Good physical propertiesMade stableAbsorbent padsDyeing processAqueous solutionIndustrial scale

A surface crosslinking treatment method of a water-absorbing resin powder is disclosed that can overcome various problems in production encountered in the production of surface crosslinked water-absorbing resin powders on an industrial scale and can produce a water-absorbing resin powder having excellent physical properties without causing deterioration in physical properties of resin. The surface crosslinking treatment method of a water-absorbing resin powder includes adding a surface crosslinking agent to a water-absorbing resin powder and heat treating the mixture, wherein (1) the water-absorbing resin powder after the heat treatment is stirred and cooled under an air flow; (2) the water-absorbing resin powder after the heat treatment is cooled under an air flow, and at the same time, at least a part of fine particles of the water-absorbing resin powder and / or the residual crosslinking agent is removed by the air flow; or (3) the water-absorbing resin powder after the heat treatment is cooled and simultaneously granulated, and preferably an aqueous solution is added to the water-absorbing resin powder at a temperature of 40-100° C. during the cooling treatment.

Owner:NIPPON SHOKUBAI CO LTD

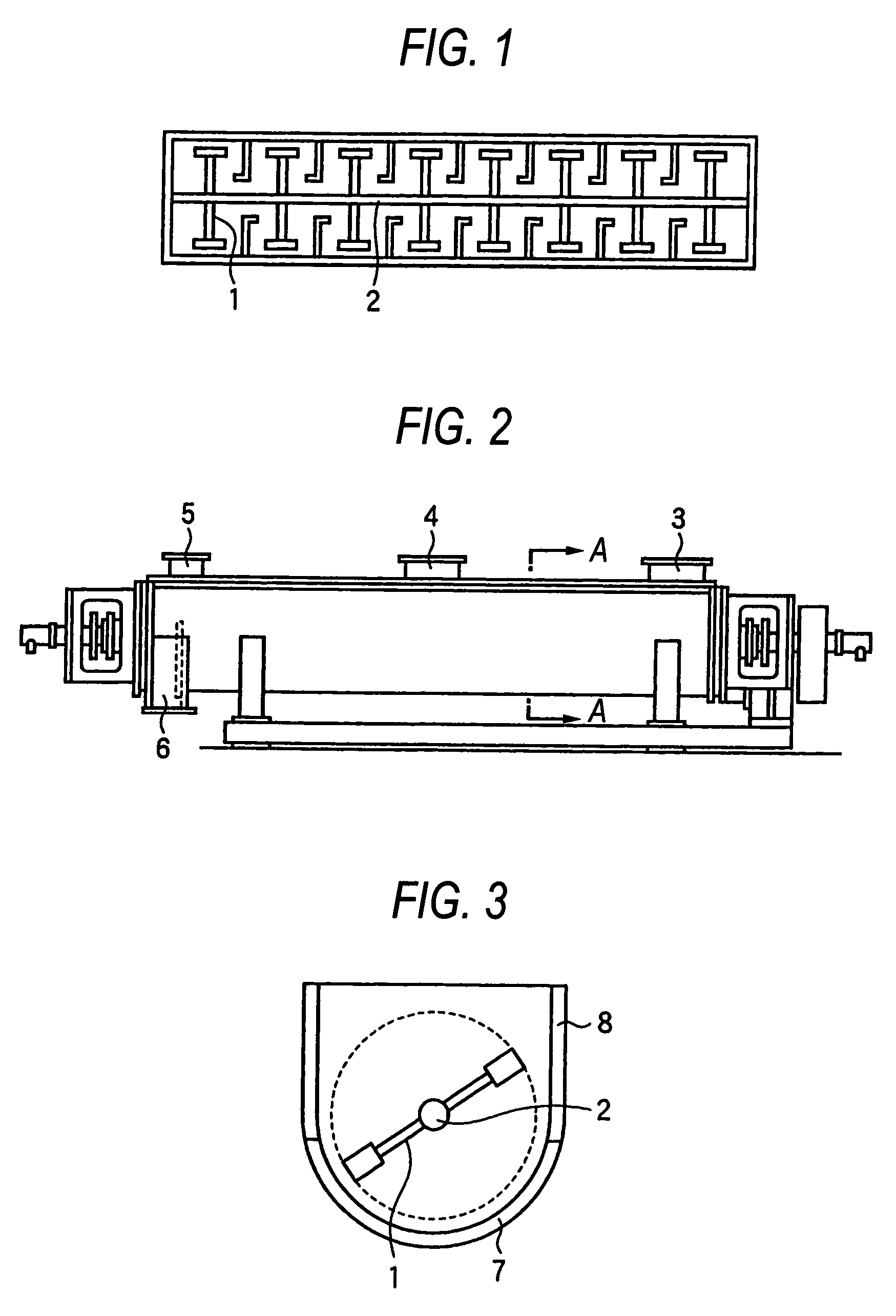

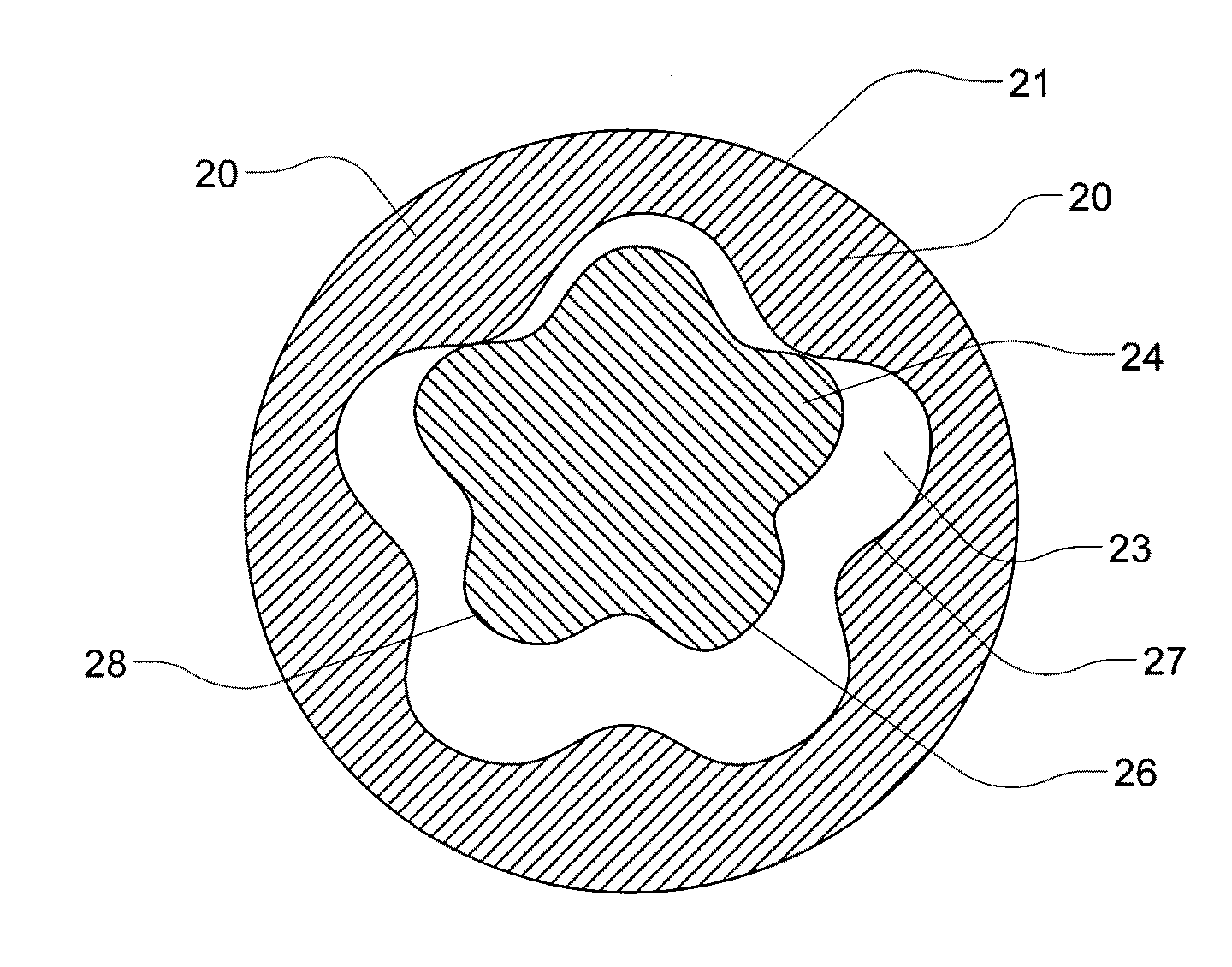

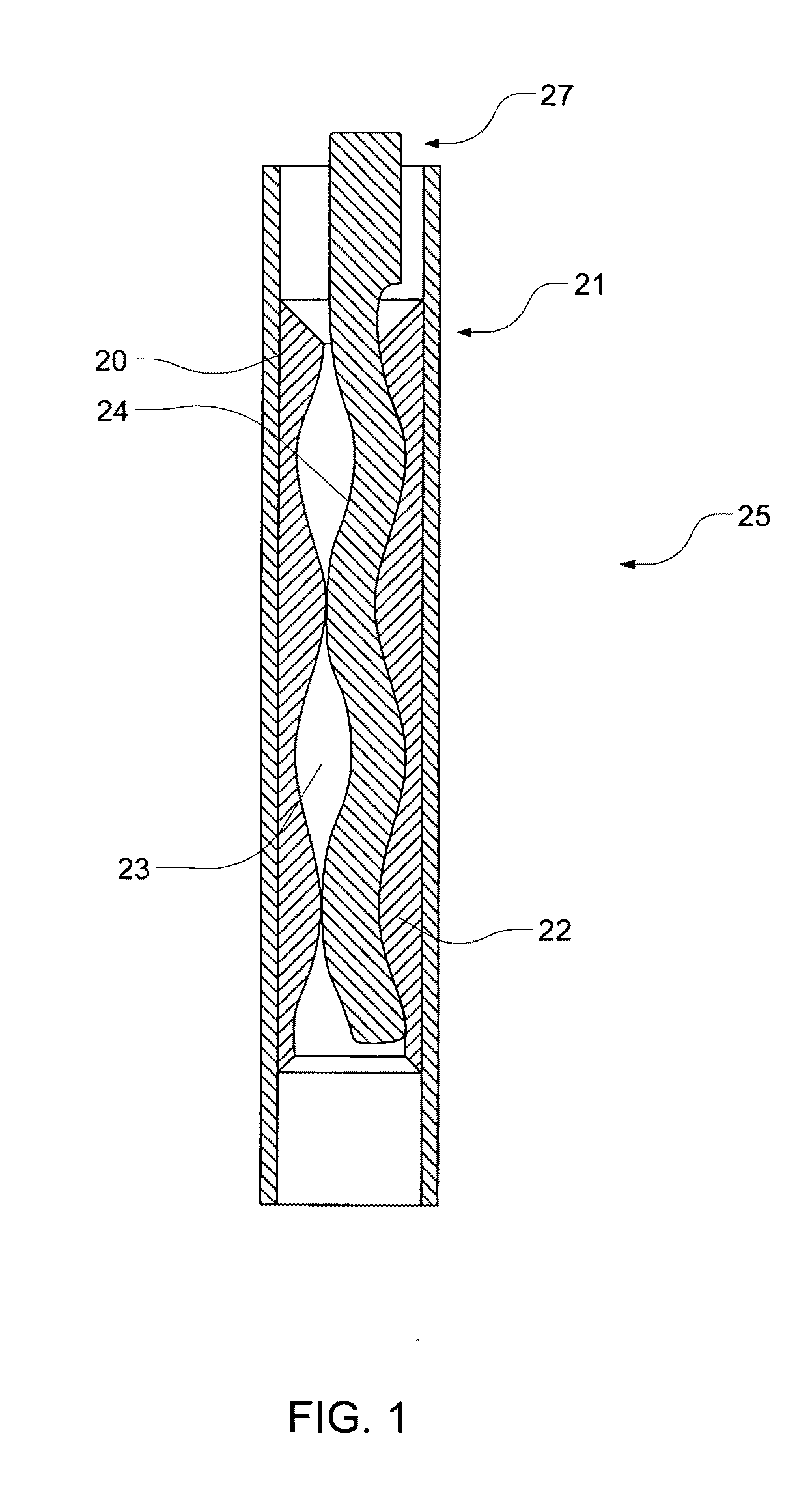

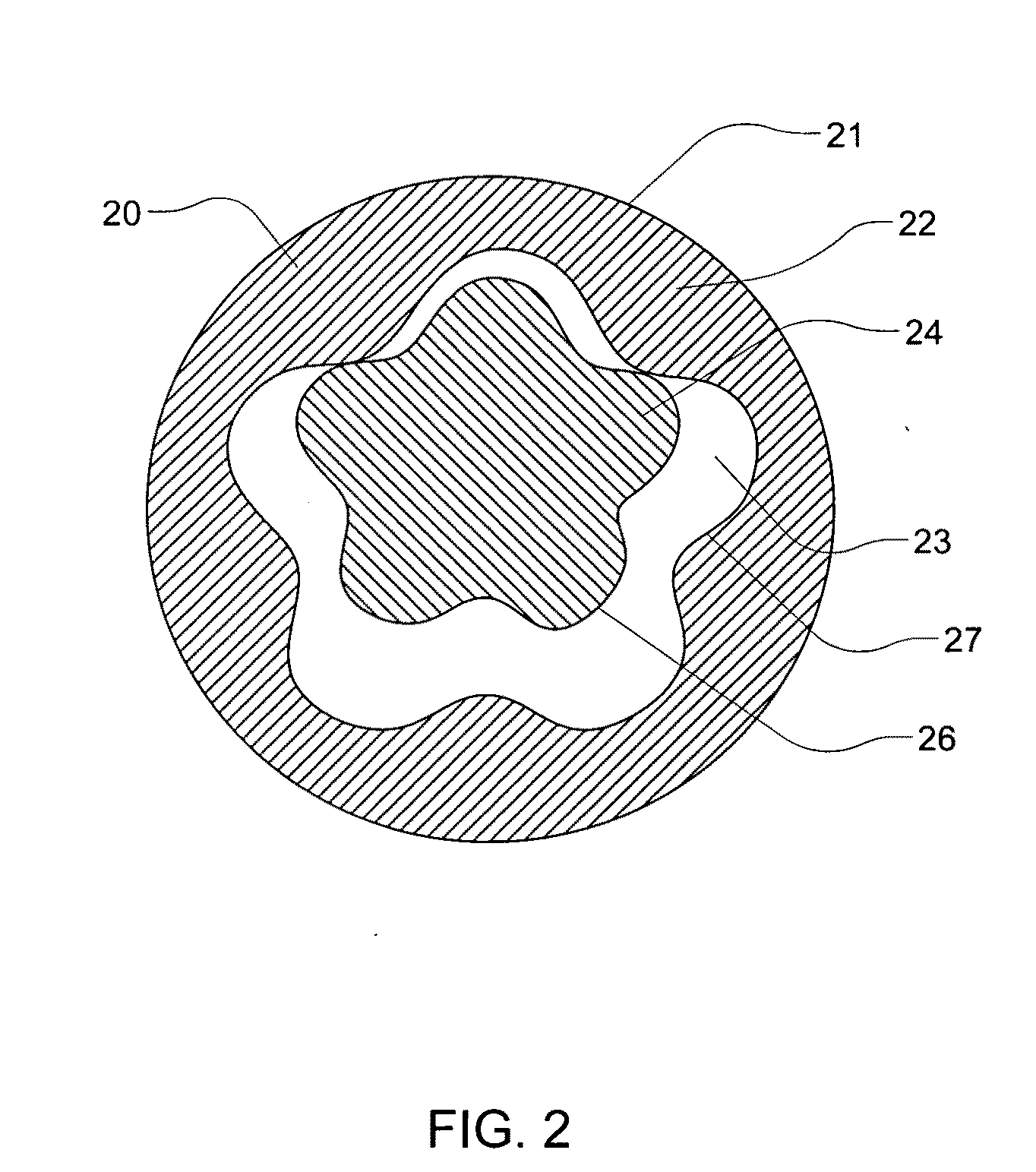

Nano particle reinforced polymer element for stator and rotor assembly

InactiveUS20090152009A1Interfacial interaction be improveImprove resistanceEngine of arcuate-engagement typeOscillating piston enginesNanometreNano sized particle

A nano particle reinforced polymer element of a stator and rotor assembly for a power section of a positive displacement fluid motor or a progressive cavity pump. Nano-sized particles are blended with an uncured polymer to improve the physical and chemical properties of the polymer. The use of nano-sized particles reduces the quantity of reinforcement material required to manufacture the polymer for the stator and rotor assembly and lowers the viscosity of the uncured polymer to improve manufacturing characteristics. The use of chemically functionalized nano particles improves the chemical and physical characteristics of the polymer.

Owner:HALLIBURTON ENERGY SERVICES INC

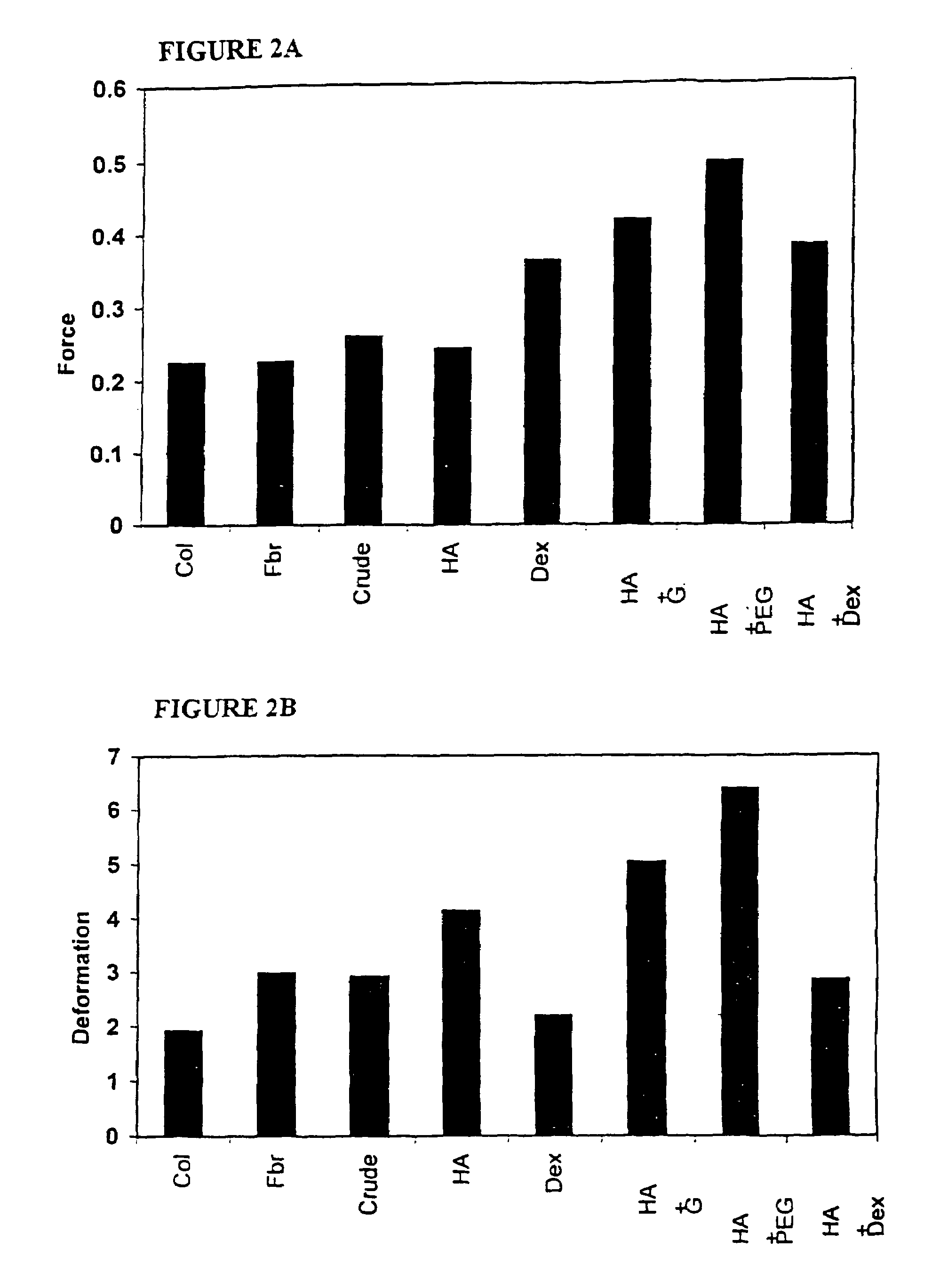

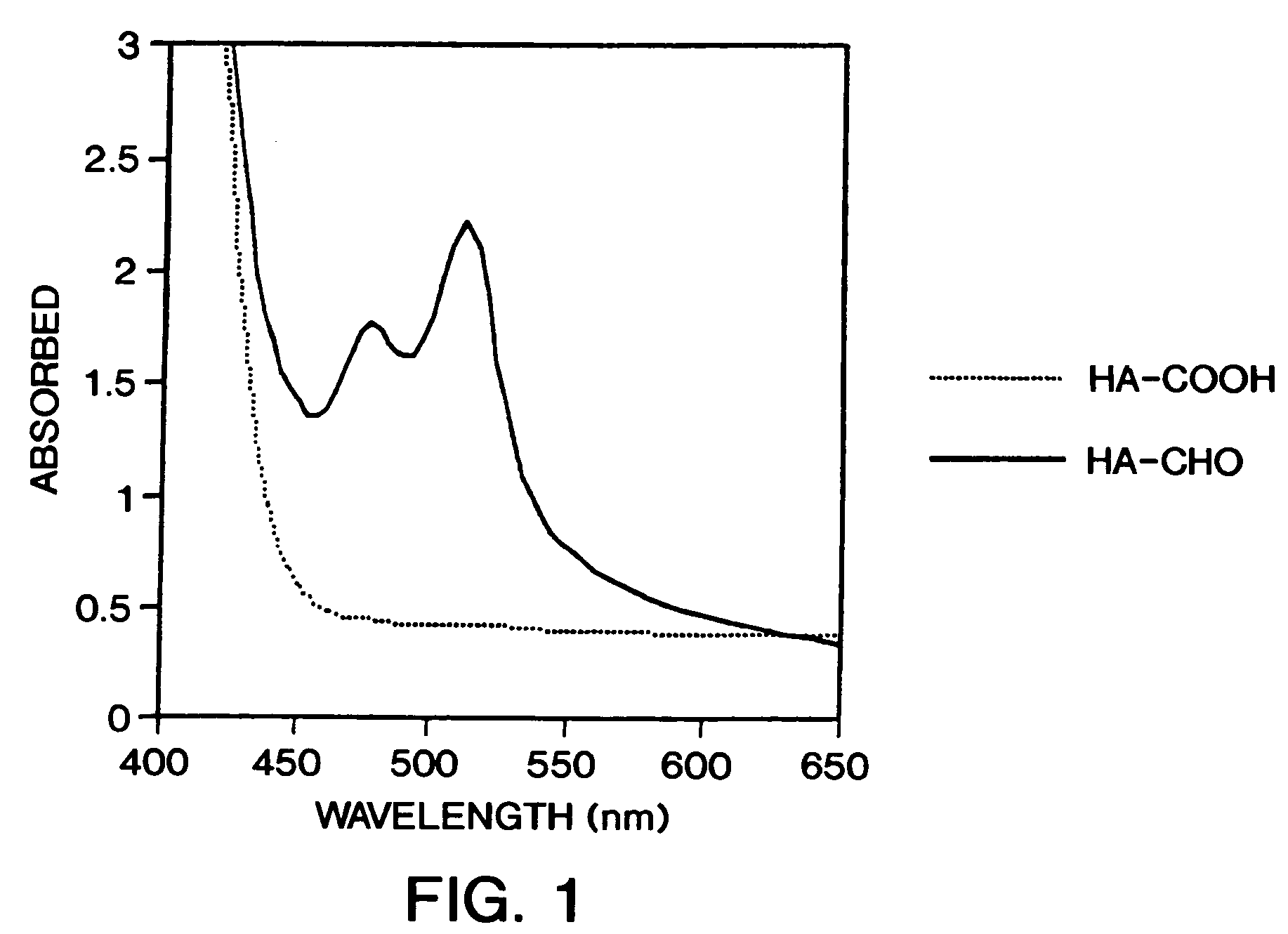

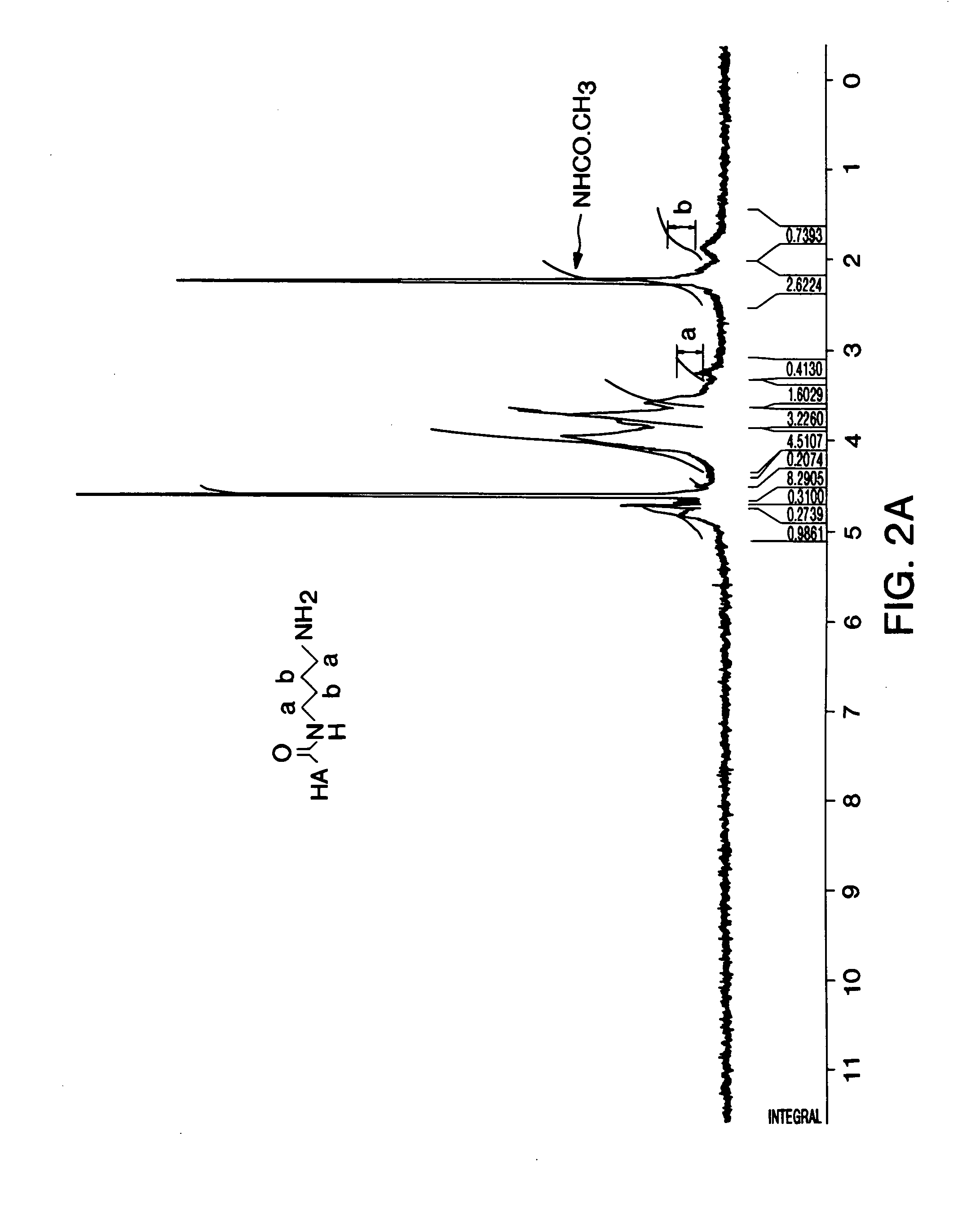

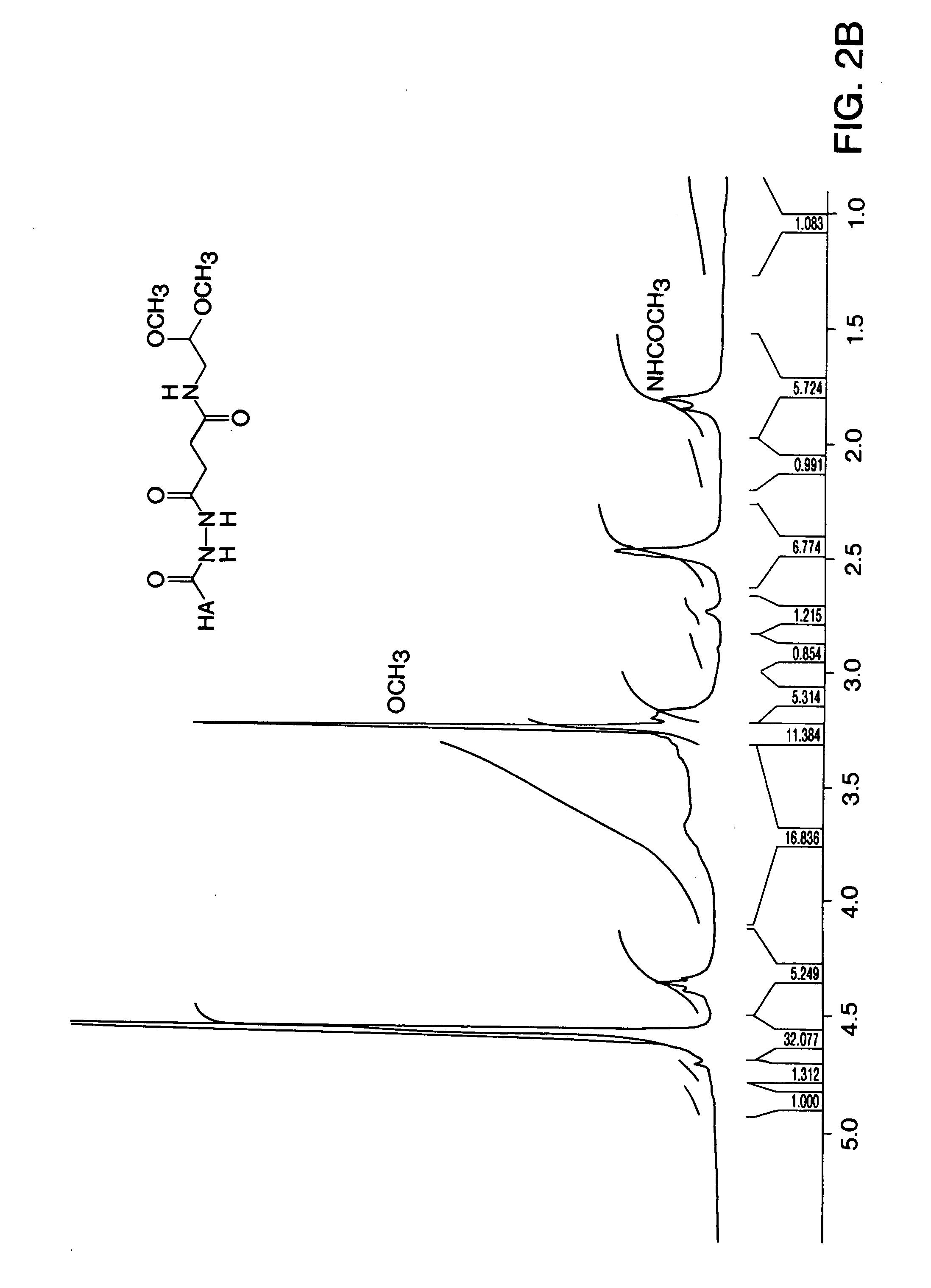

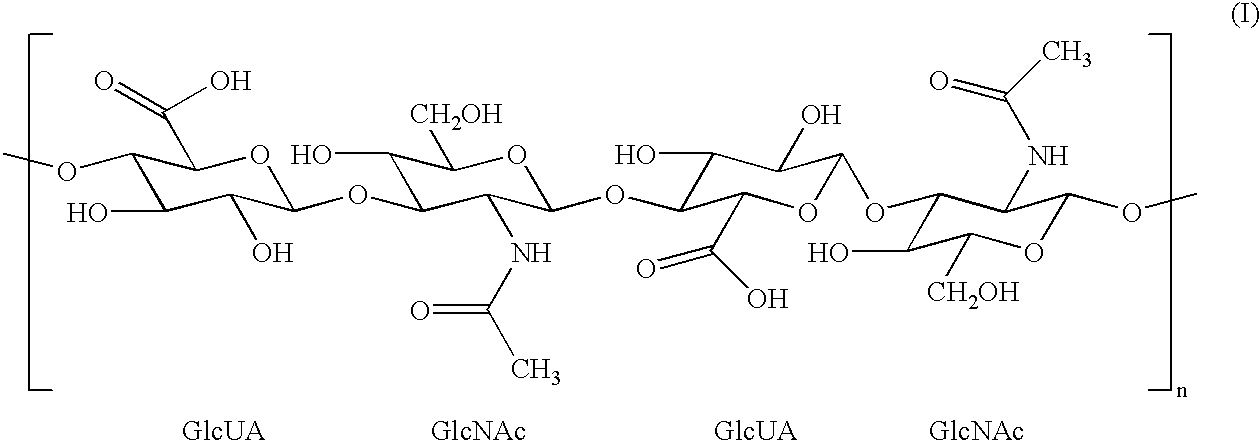

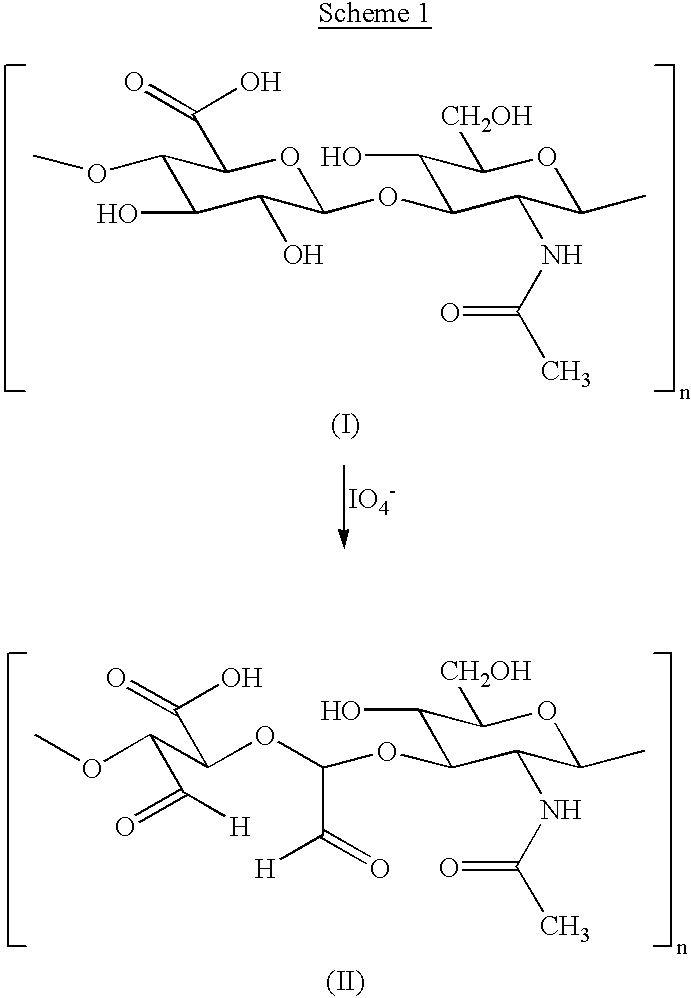

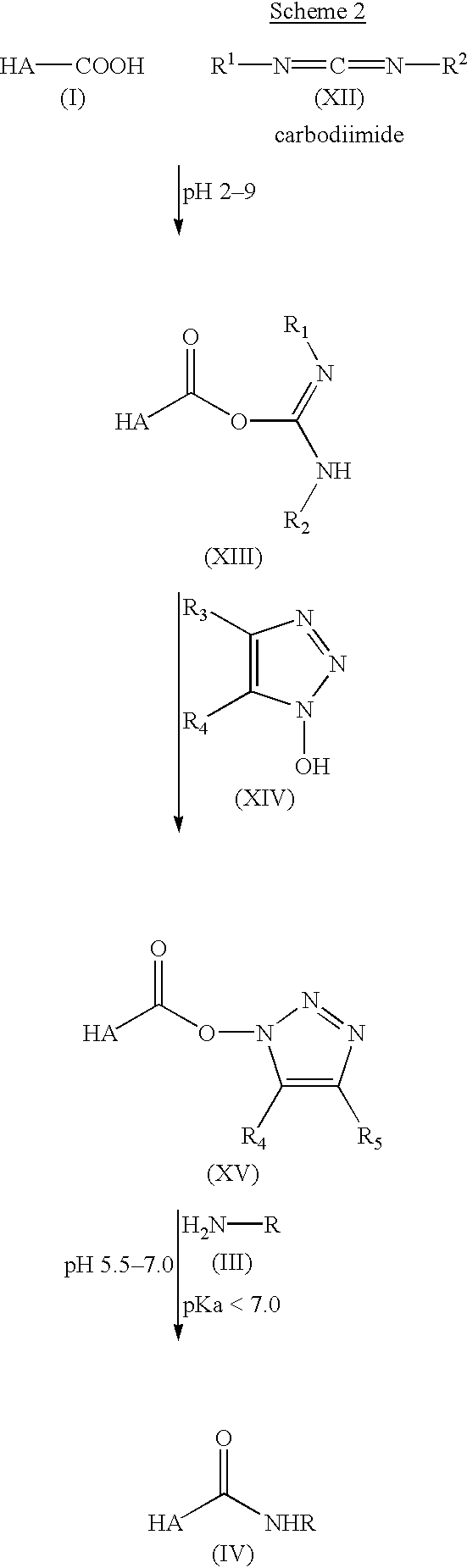

Functionalized derivatives of hyaluronic acid, formation of hydrogels in situ using same, and methods for making and using same

InactiveUS7196180B2Good physical propertiesSimple structureOrganic active ingredientsSugar derivativesCross-linkIn situ polymerization

Methods for chemical modification of hyaluronic acid, formation of amine or aldehyde functionalized hyaluronic acid, and the cross-linking thereof to form hydrogels are provided. Functionalized hyaluronic acid hydrogels of this invention can be polymerized in situ, are biodegradable, and can serve as a tissue adhesive, a tissue separator, a drug delivery system, a matrix for cell cultures, and a temporary scaffold for tissue regeneration.

Owner:ORTHOGENE

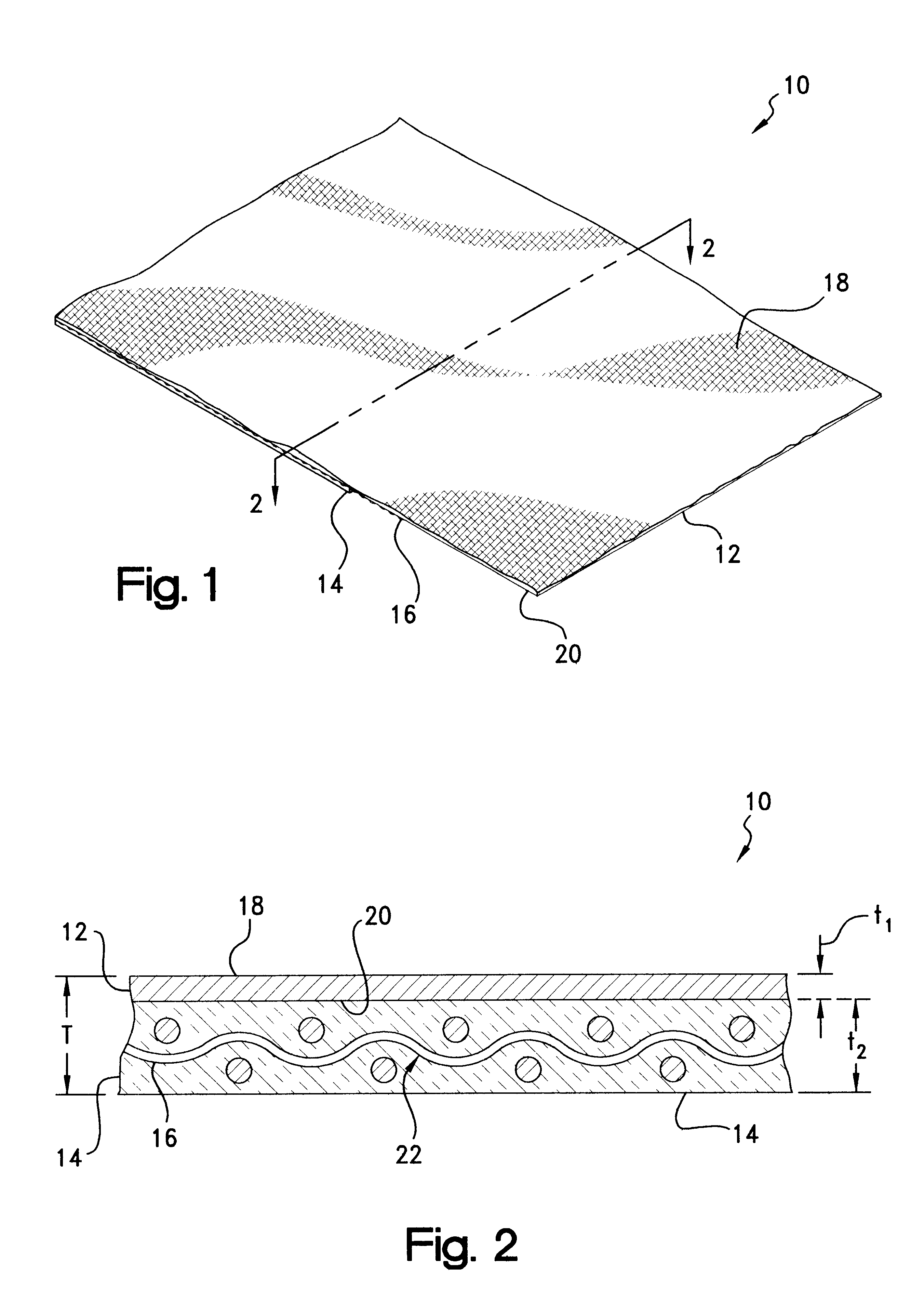

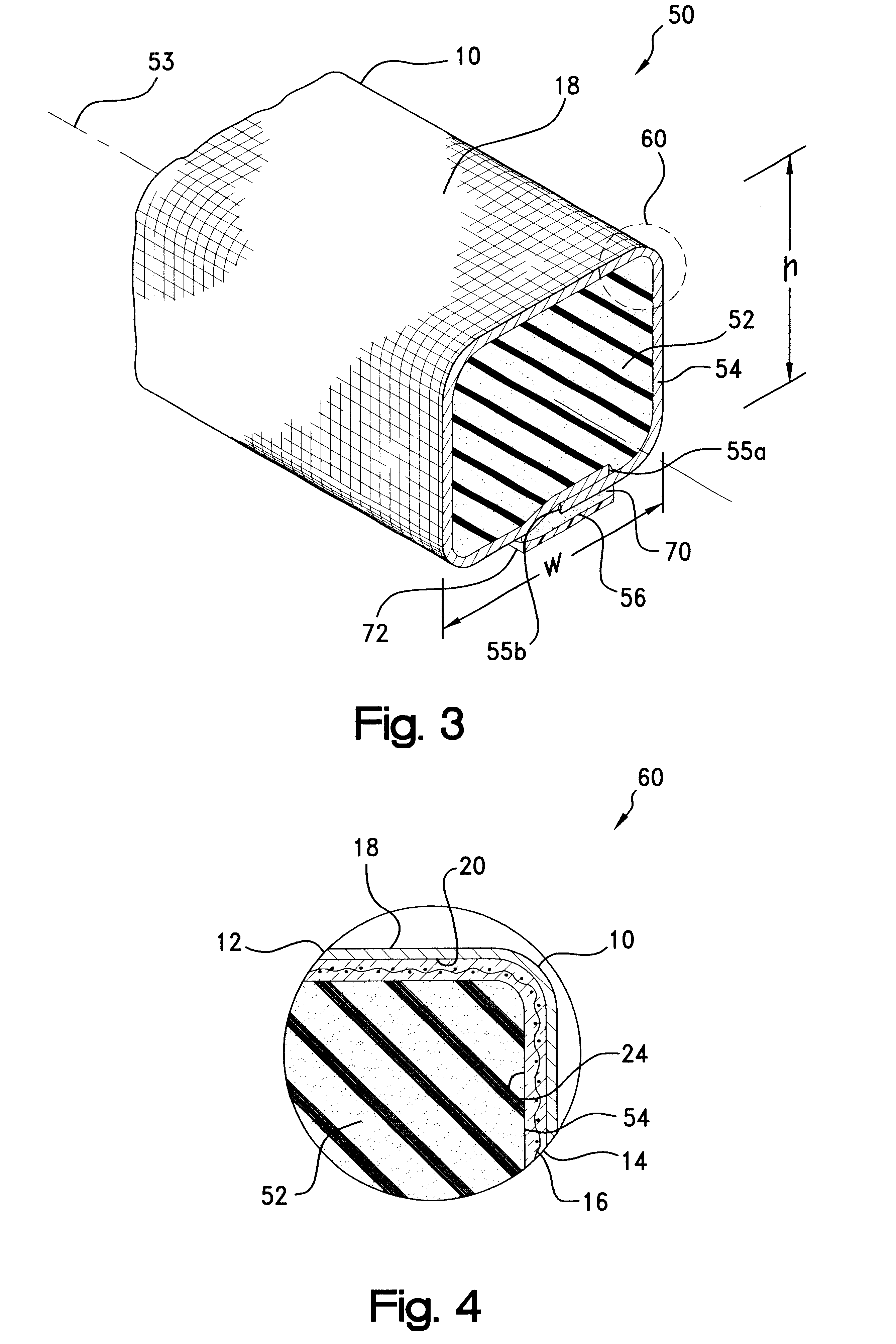

Intumescent, flame retardant pressure sensitive adhesive composition for EMI shielding applications

InactiveUS6410137B1Readily apparentGood physical propertiesScreening gaskets/sealsSynthetic resin layered productsDecabromodiphenyl etherPolybrominated Biphenyls

A flame retardant, intumescent pressure sensitive adhesive (PSA) composition for EMI shielding gaskets, tapes, wraps, and the like. The composition is formulated as an admixture of: (a) a PSA component; (b) a halogenated first flame retardant component; (c) a metal-based second flame retardant component; and (d) a filler component of expandable, intercalated graphite particles. In a representative embodiment the PSA component (a) is acrylic-based, the halogenated first flame retardant component (b) is a polybrominated diphenyl compound such as decabromodiphenyl oxide or decabromodiphenyl ether, the metal oxide-based second flame retardant component (c) is antimony oxide, antimony trioxide, or antimony pentoxide, and the filler component (d) is graphite flake.

Owner:PARKER INTANGIBLES LLC

Functionalized derivatives of hyaluronic acid, formation of hydrogels in situ using same, and methods for making and using same

InactiveUS6630457B1Assay sensitivityPromote regenerationOrganic active ingredientsBiocideDrug deliveryTissue adhesives

Methods for chemical modification of hyaluronic acid, formation of amine or aldehyde functionalized hyaluronic acid, and the cross-linking thereof to form hydrogels are provided. Functionalized hyaluronic acid hydrogels of this invention can be polymerized in situ, are biodegradable, and can serve as a tissue adhesive, a tissue separator, a drug delivery system, a matrix for cell cultures, and a temporary scaffold for tissue regeneration.

Owner:ORTHOGENE

Effervescent granules and methods for their preparation

InactiveUS6649186B1Improve stabilityParticular regionPowder deliveryNervous disorderHYDROMORPHONE HYDROCHLORIDEAlpha adrenergic blockade

Disclosed here are effervescent granules having a controllable rate of effervescence. In some embodiments, the such granules comprise an acidic agent, an alkaline agent, a pharmacologically active agent, hot-melt extrudable binder capable of forming a eutectic mixture with the acidic agent and, optionally, a plasticizer. The effervescent granules are made by a hot-melt extrusion process. The present invention also provides a thermal heat process for preparing a pharmacologically active agent containing effervescent granule. In certain aspects, the granules contain pharmacologically active agents such as narcotics, antidiarrheal agents, antiviral agents, anxiolytic agents, a cholesterol lowering agent, an alpha adrenergic blocking agent, a phenanthrene derivative. By way of example, some of the narcotics that may be included in the granules and in the process of preparing the granules include, by way of example: phenanthrene derivatives (e.g., morphine sulfate), and morphine derivatives (e.g., hydromorphone hydrochloride).

Owner:ETHYPHARM SA

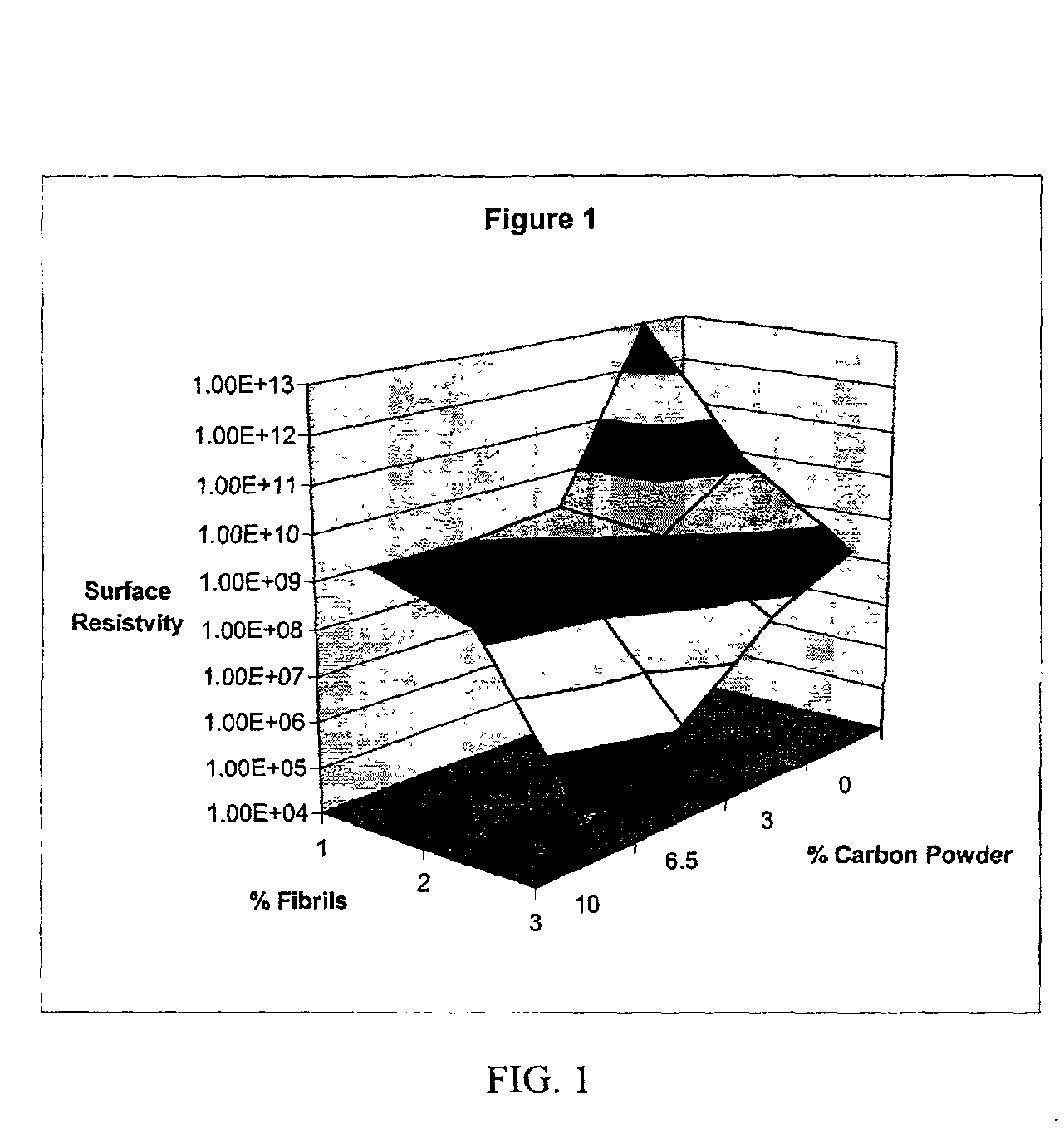

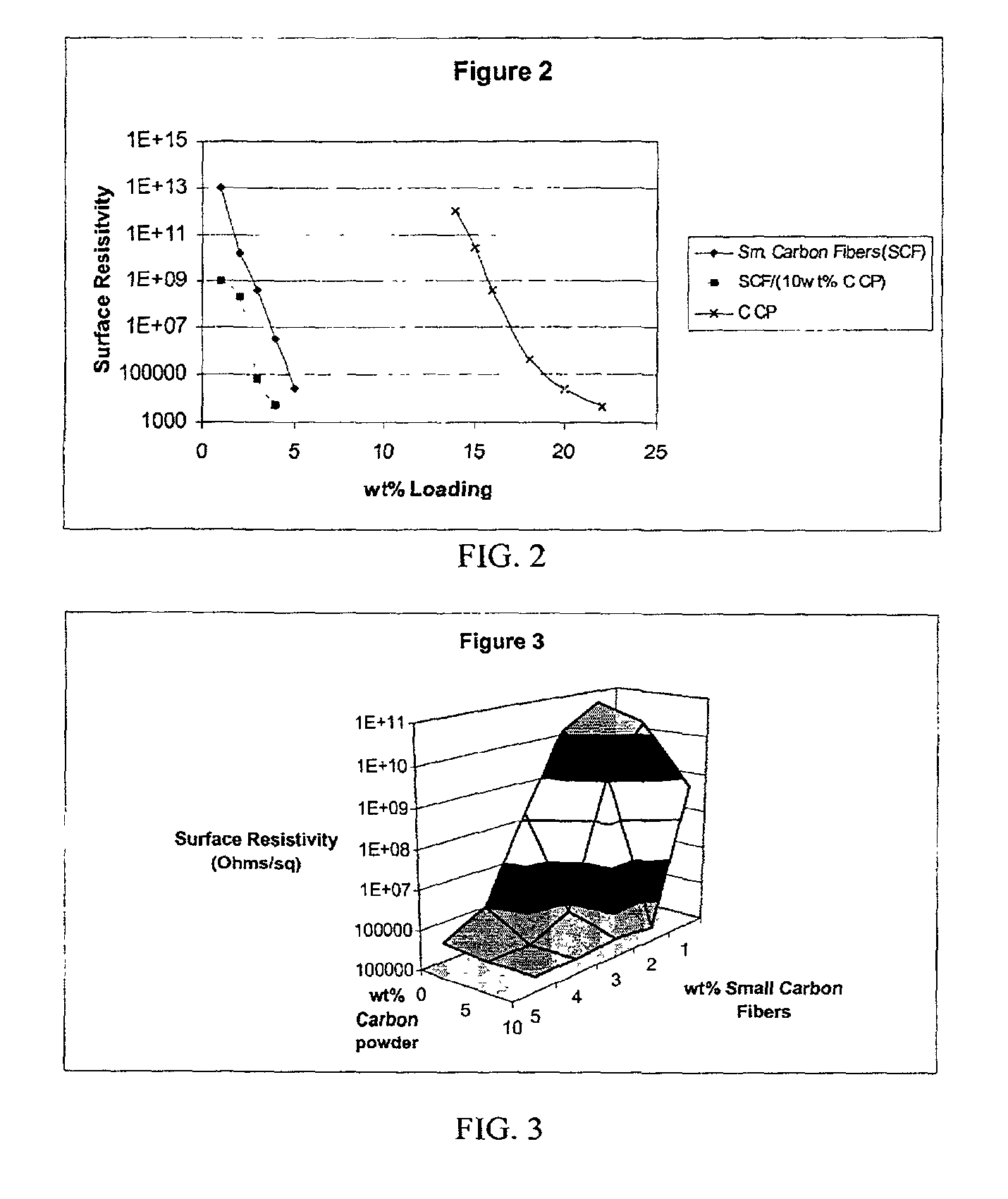

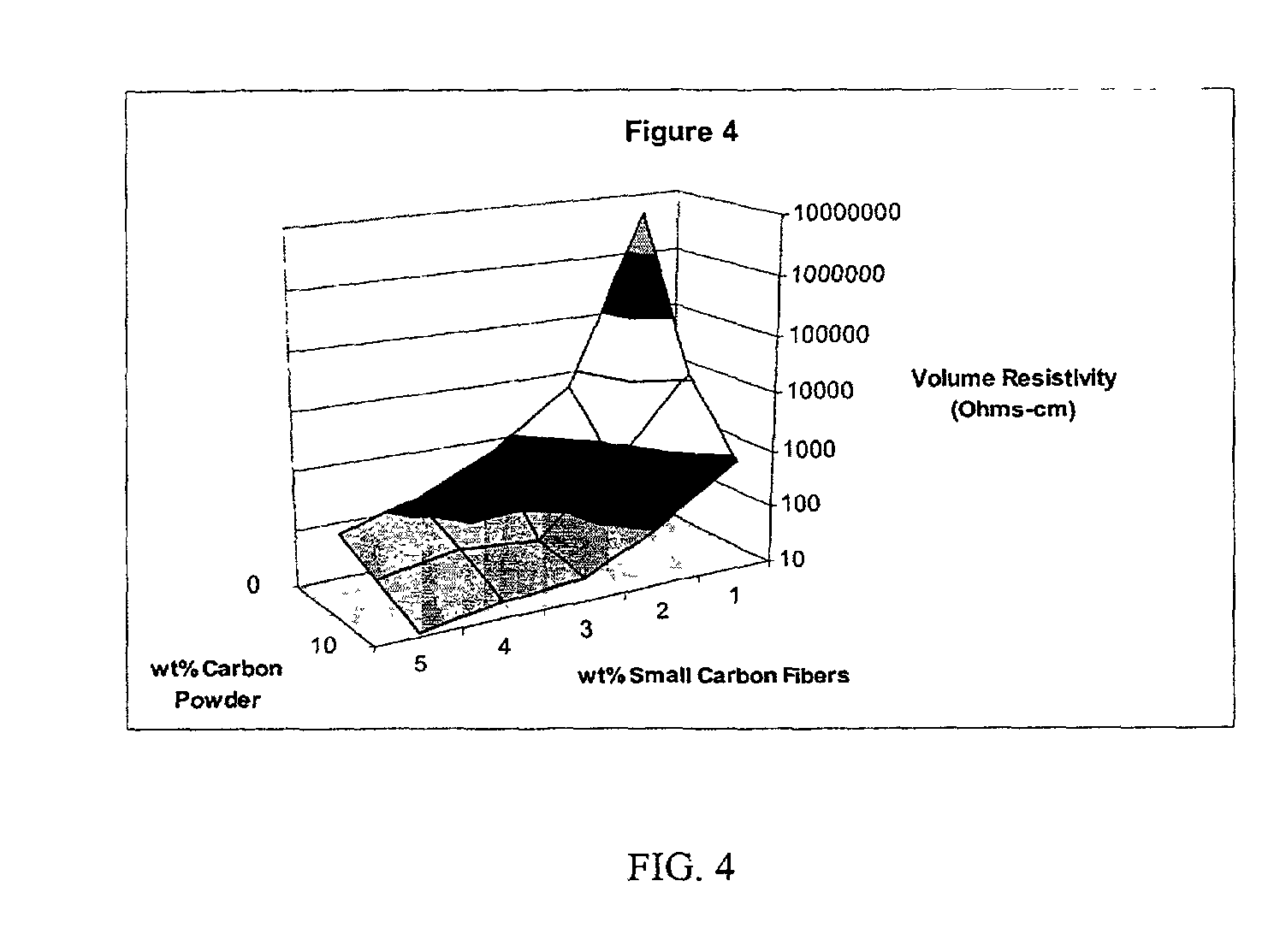

Conductive plastic compositions and method of manufacture thereof

InactiveUS20020183438A1Reduce concentrationSame surface resistivitySpecial tyresNon-conductive material with dispersed conductive materialFiberCarbon fibers

An improved, conductive, polymeric composition comprises a polymeric resin; an electrically conductive filler system comprising small carbon fibers and either carbon powder or fibrous non-conductive filler or a combination of both. The amount of the conductive filler system utilized is dependent upon the desired electrical conductivity (surface and volume conductivity or resistivity) while preferably preserving intrinsic properties of the polymeric resin such as impact, flex modulus, class A finish, and the like. The conductive articles made from these compositions can therefore be used for electromagnetic shielding, electrostatic dissipation or antistatic purposes in packaging, electronic components, housings for electronic components and automotive housings.

Owner:SABIC GLOBAL TECH BV

Effervescent granules and methods for their preparation

InactiveUS6488961B1Improve stabilityParticular regionPowder deliveryBiocideAnesthetic AgentHYDROMORPHONE HYDROCHLORIDE

Disclosed here are effervescent granules having a controllable rate of effervescence. In some embodiments, the such granules comprise an acidic agent, an alkaline agent, a pharmacologically active agent, hot-melt extrudable binder capable of forming a eutectic mixture with the acidic agent and, optionally, a plasticizer. The effervescent granules are made by a hot-melt extrusion process. The present invention also provides a thermal heat process for preparing a pharmacologically active agent containing effervescent granule. In certain aspects, the granules contain pharmacologically active agents such as narcotics, antidiarrheal agents, antiviral agents, anxiolytic agents, a cholesterol lowering agent, an alpha adrenergic blocking agent, a phenanthrene derivative. By way of example, some of the narcotics that may be included in the granules and in the process of preparing the granules include, by way of example: phenanthrene derivatives (e.g., morphine sulfate), and morphine derivatives (e.g., hydromorphone hydrochloride).

Owner:ETHYPHARM SA

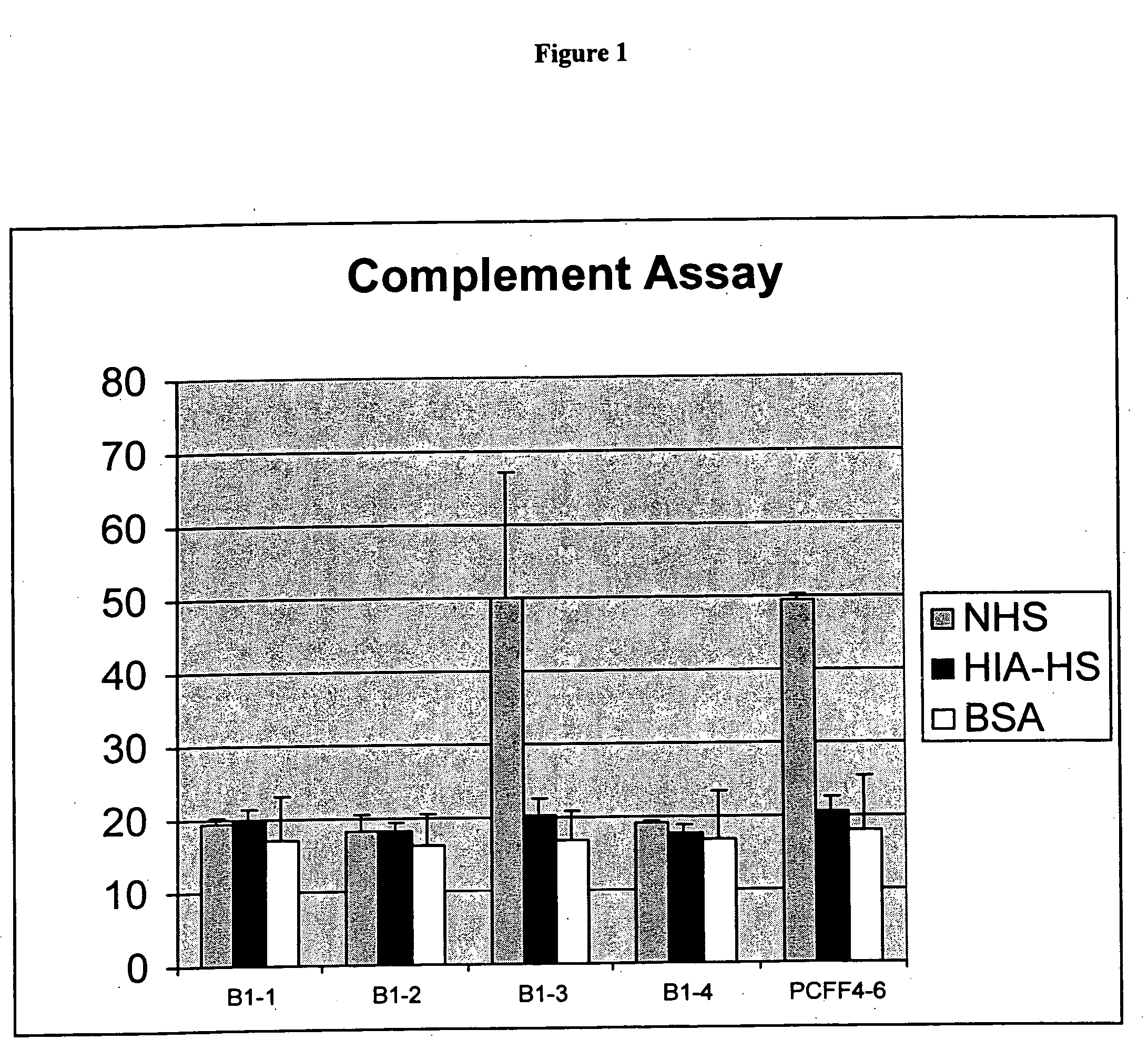

Tissue products derived from animals lacking any expression of functional alpha 1,3 galactosyltransferase

InactiveUS20050260176A1Prevent rejectionPromote wound healingBiocideGenetic material ingredientsTissue repairSkin repair

The present invention provides tissues derived from animals, which lack any expression of functional alpha 1,3 galactosyltransferase (alpha-1,3-GT). Such tissues can be used in the field of xenotransplantation, such as orthopedic reconstruction and repair, skin repair and internal tissue repair or as medical devices.

Owner:REVIVICOR INC

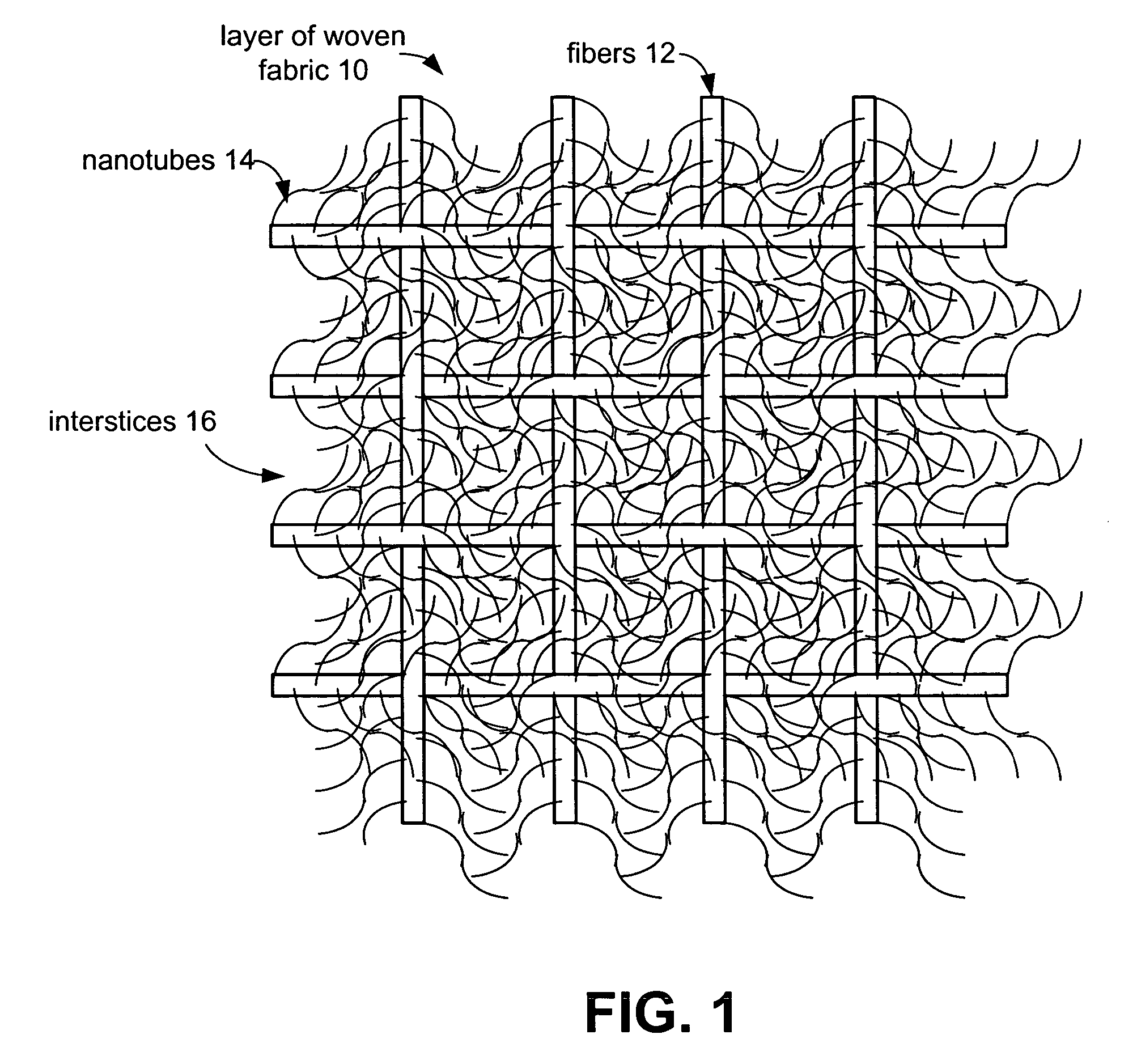

Ballistic fabrics with improved antiballistic properties

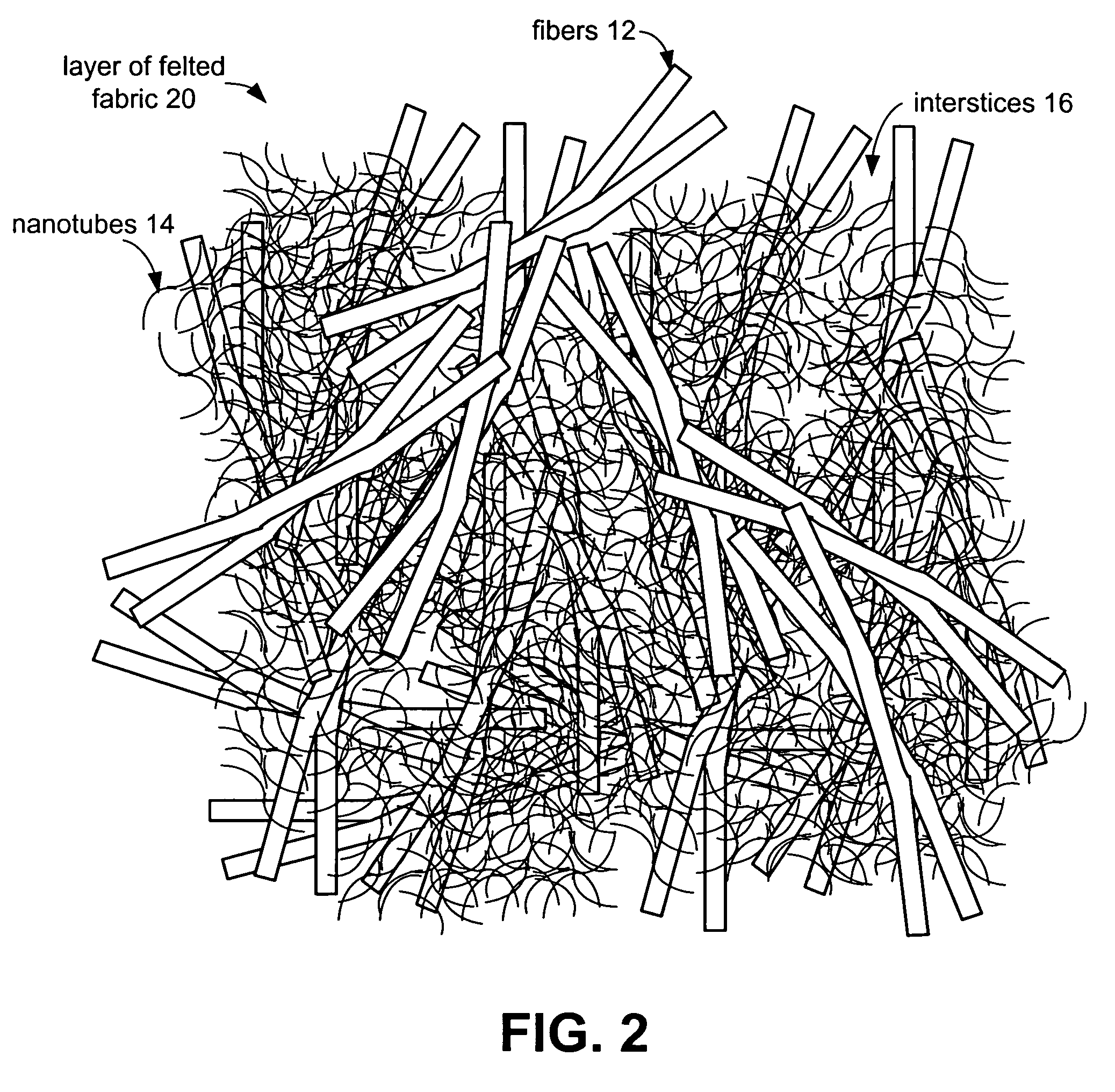

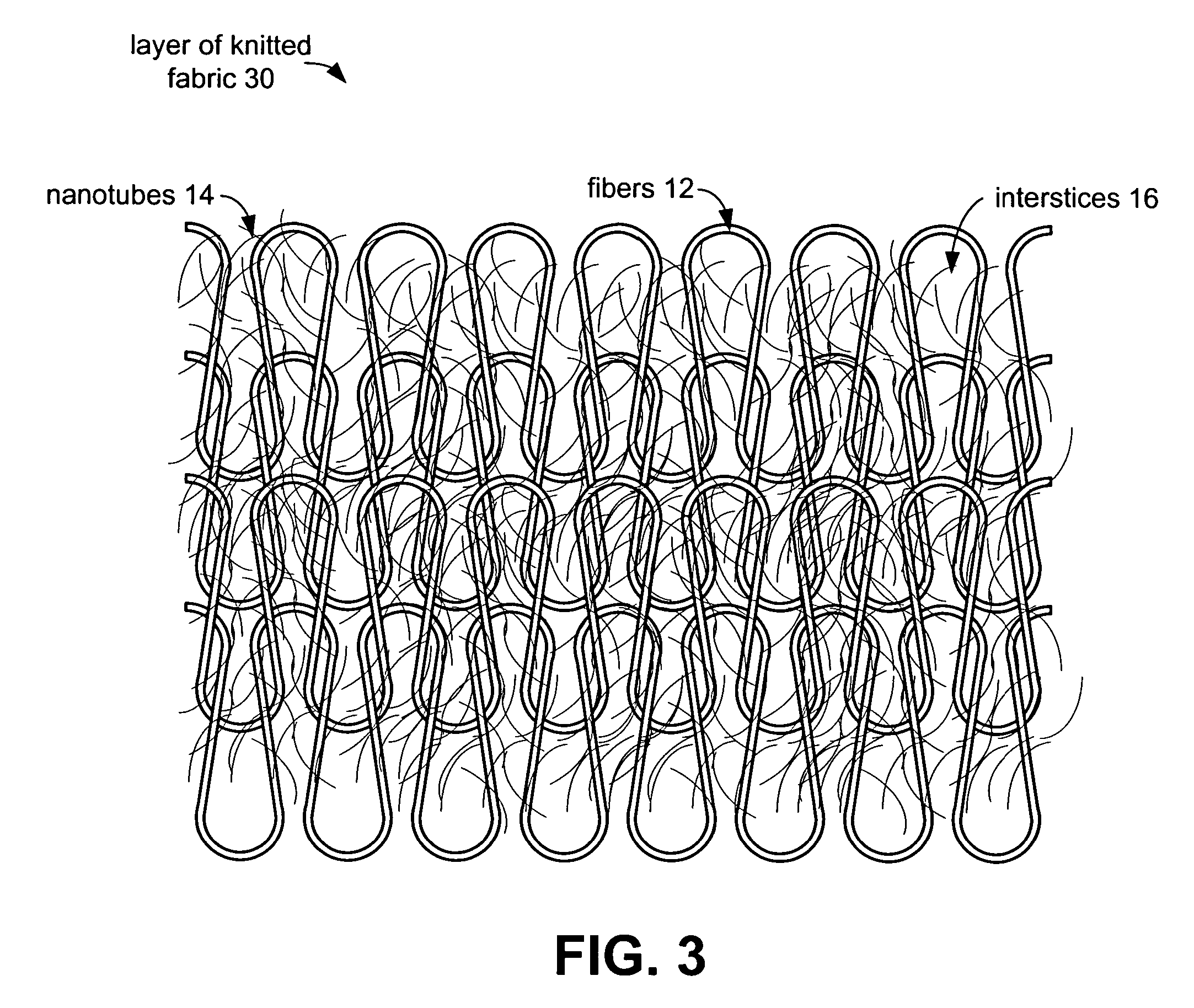

ActiveUS20060062944A1Good physical propertiesImprove propertiesMaterial nanotechnologyWarp knittingFiberYarn

The present invention provides fabrics that have unique mechanical, chemical, electrical, and thermal properties. The fabrics comprise layers of woven, knit or felted fibers, yarns or tow. Interstitially synthesized nanotubes, such as single-walled or multi-walled carbon nanotubes, enhance the fabric's antiballistic properties. These nanotubes may also insulate, semi-conduct or super-conduct electrical charges, or provide enhanced thermal properties of these fabrics which can be layered to form unique garments or structures.

Owner:LOCKHEED MARTIN CORP

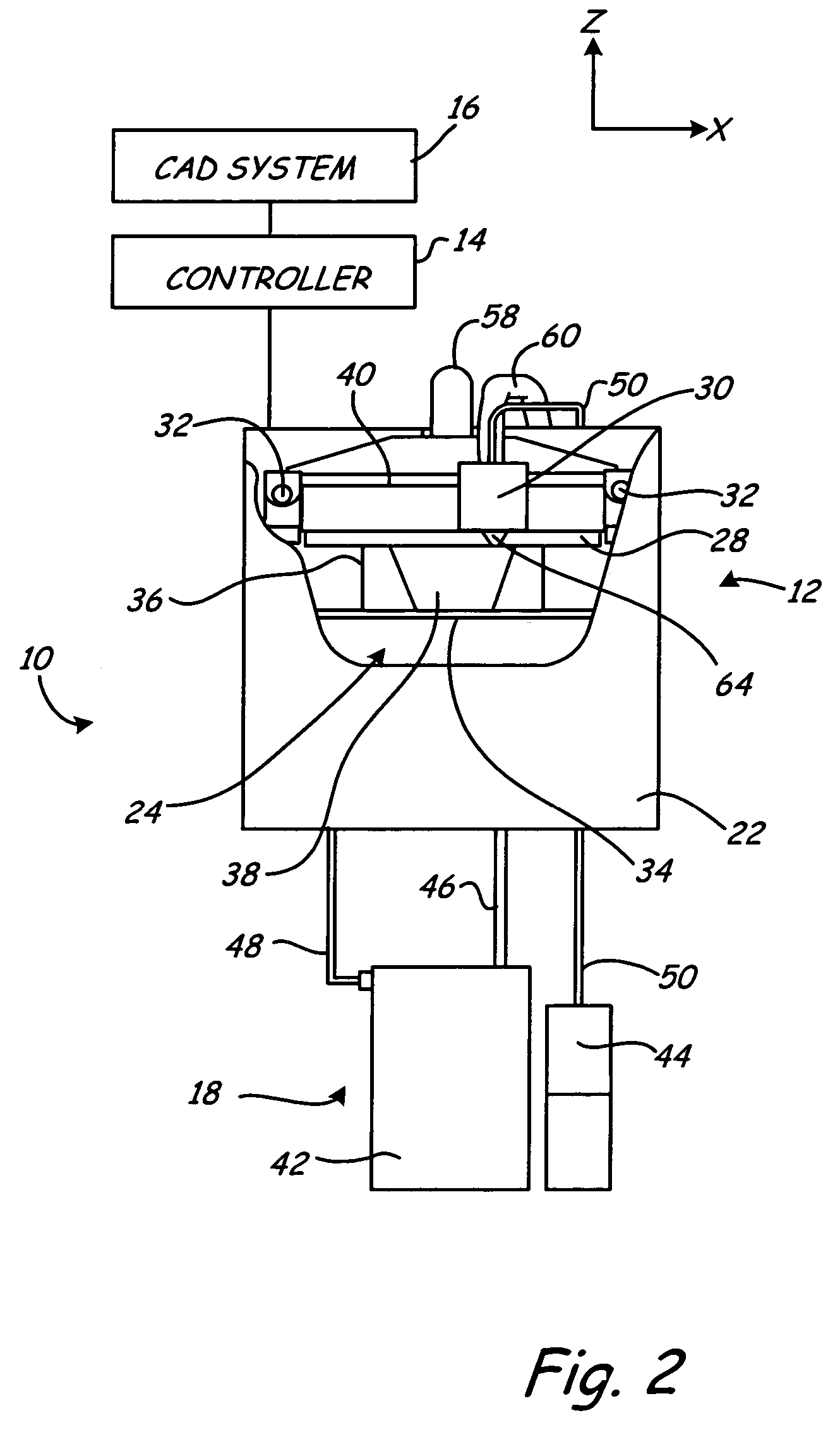

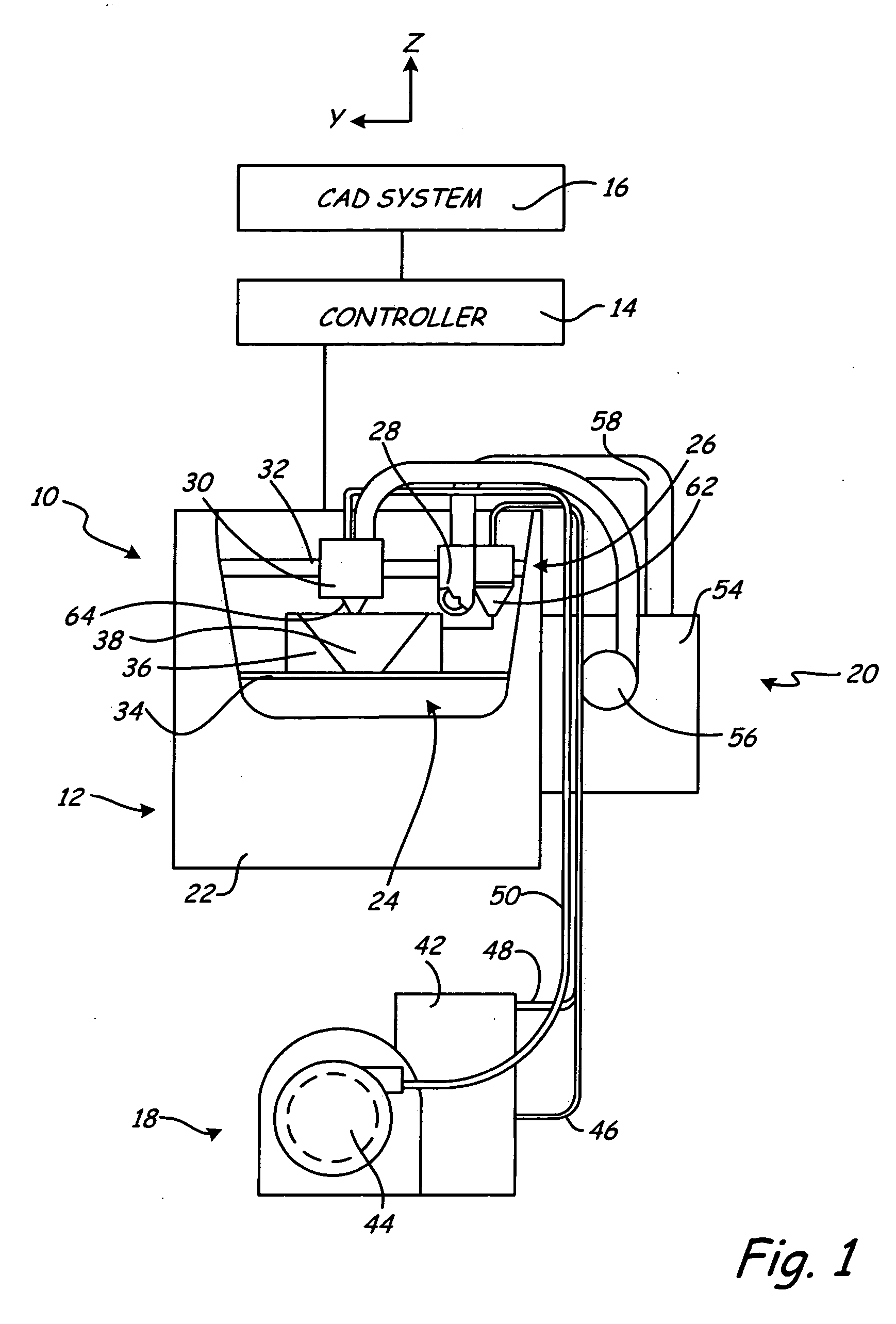

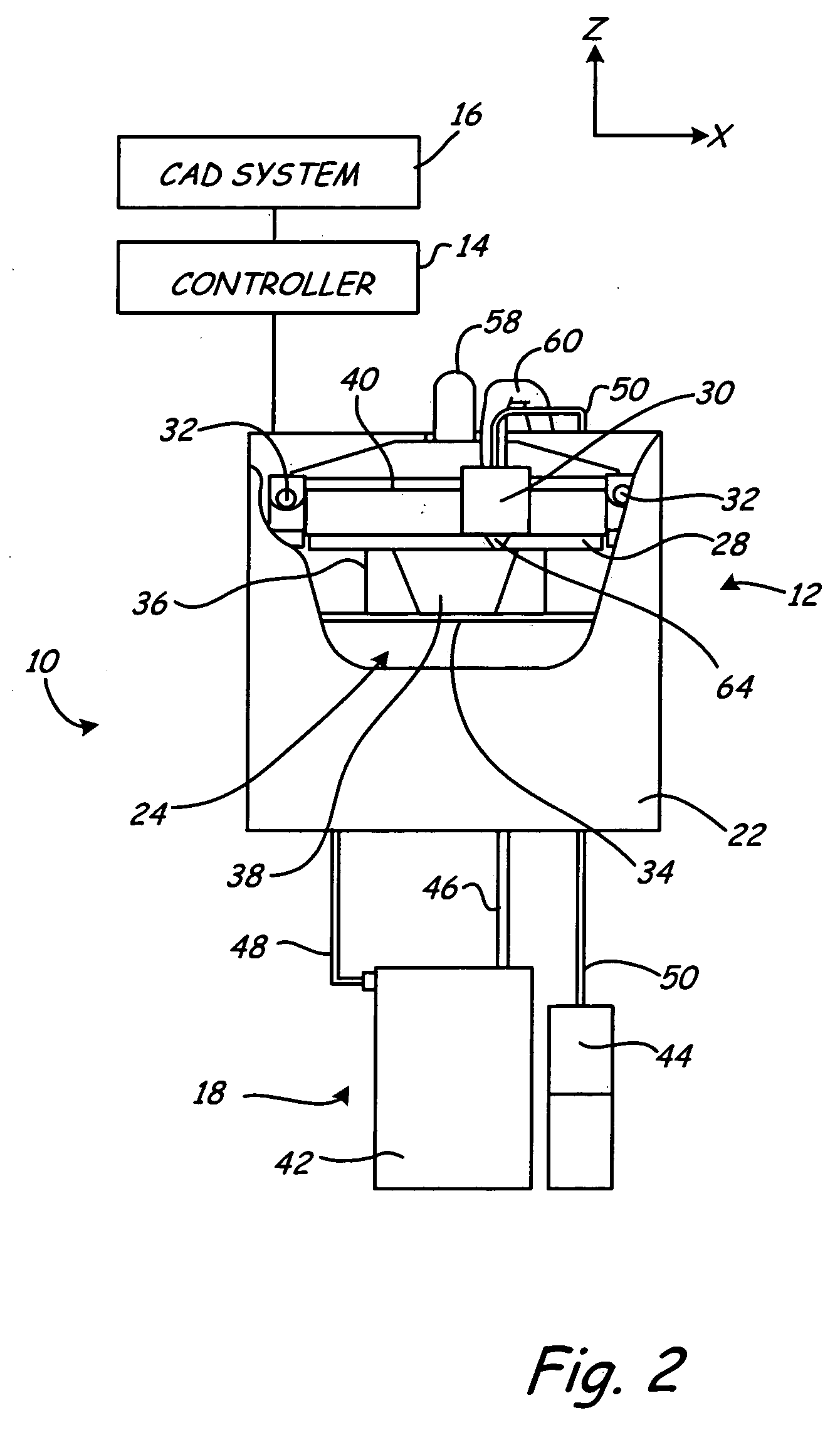

High-resolution rapid manufacturing

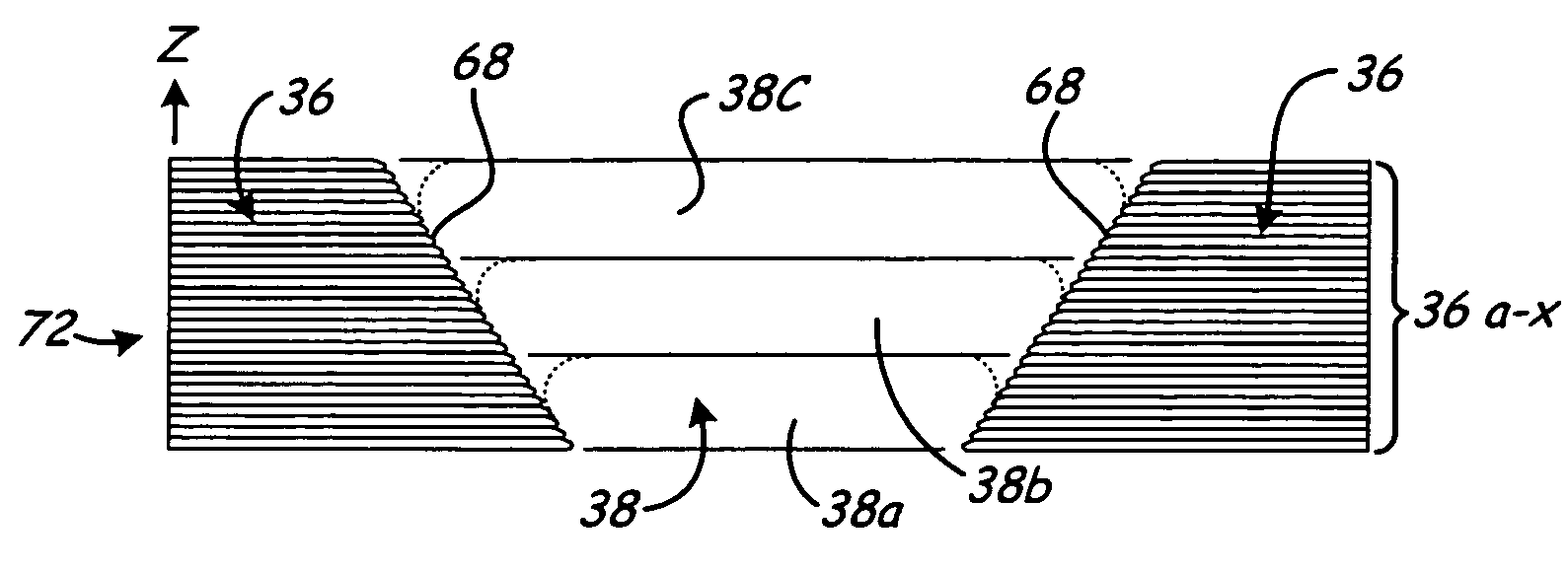

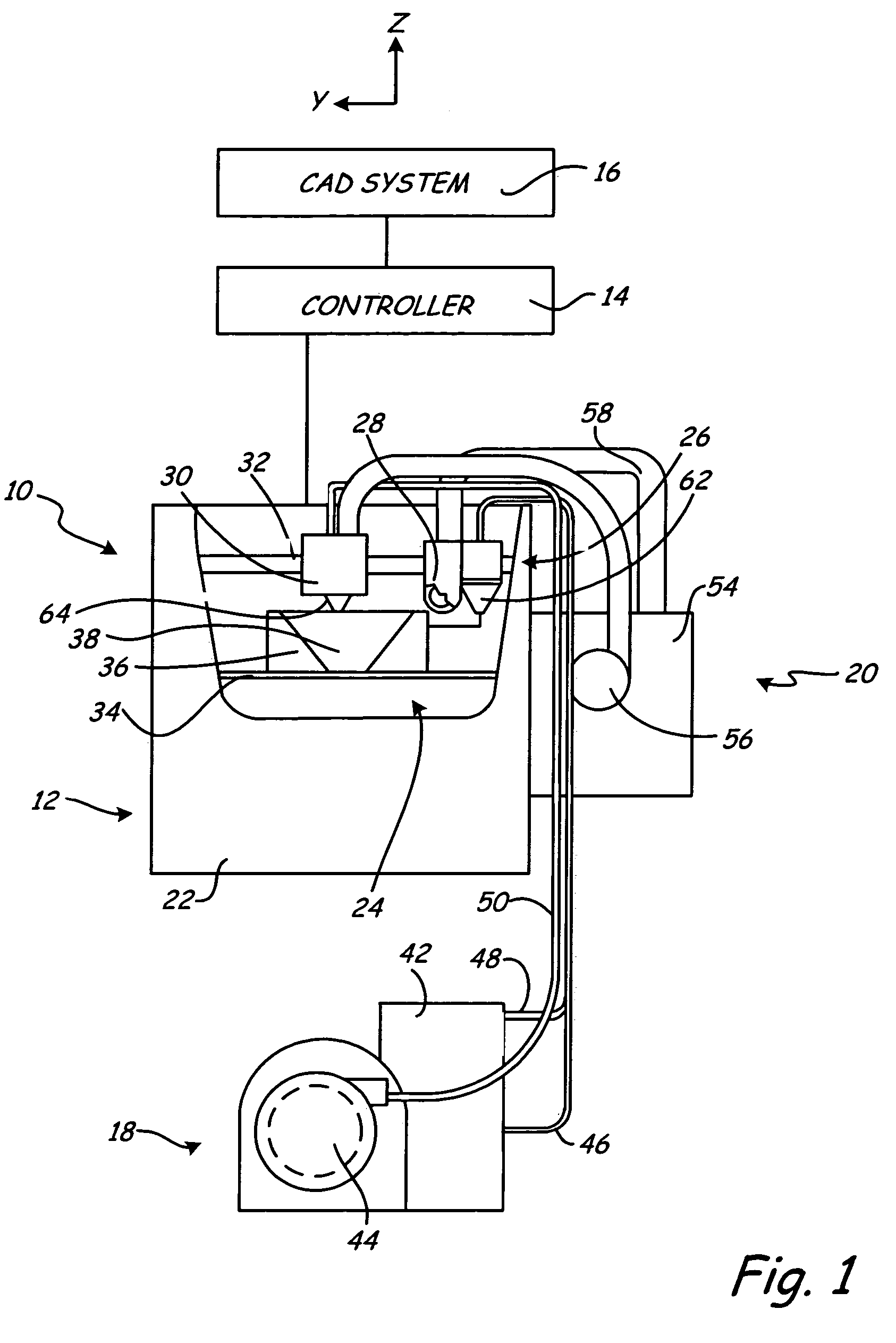

ActiveUS7236166B2Fast preparationGood physical propertiesAdditive manufacturing apparatusWood working apparatusStructural engineeringRapid manufacturing

The present invention is a method for forming an object, the method comprising jetting a first material to form a plurality of layers that define a support structure increment, and extruding a second material to form a layer of the object. The layer of the object substantially conforms to an interior surface of the support structure increment.

Owner:STRATSYS INC

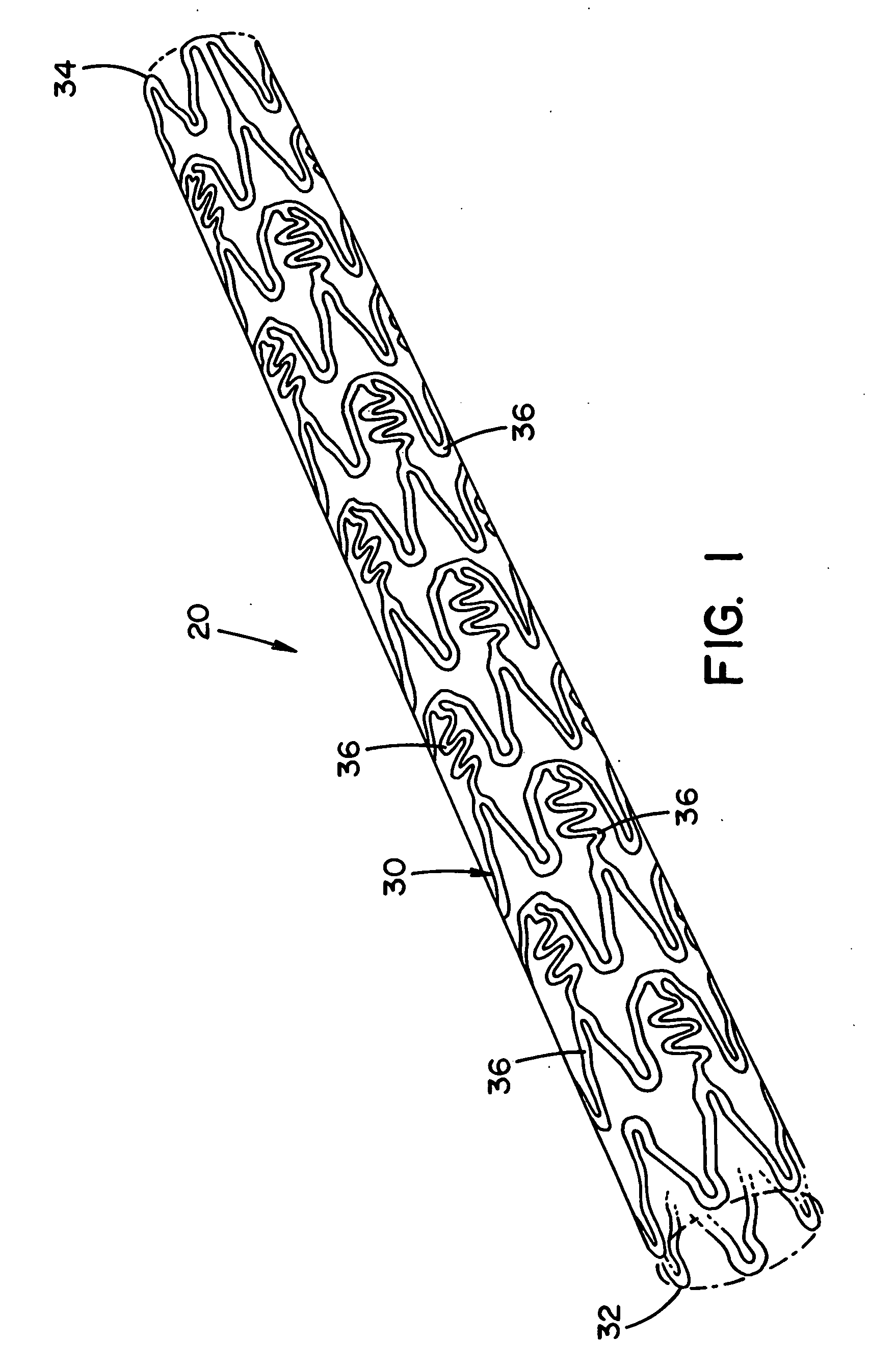

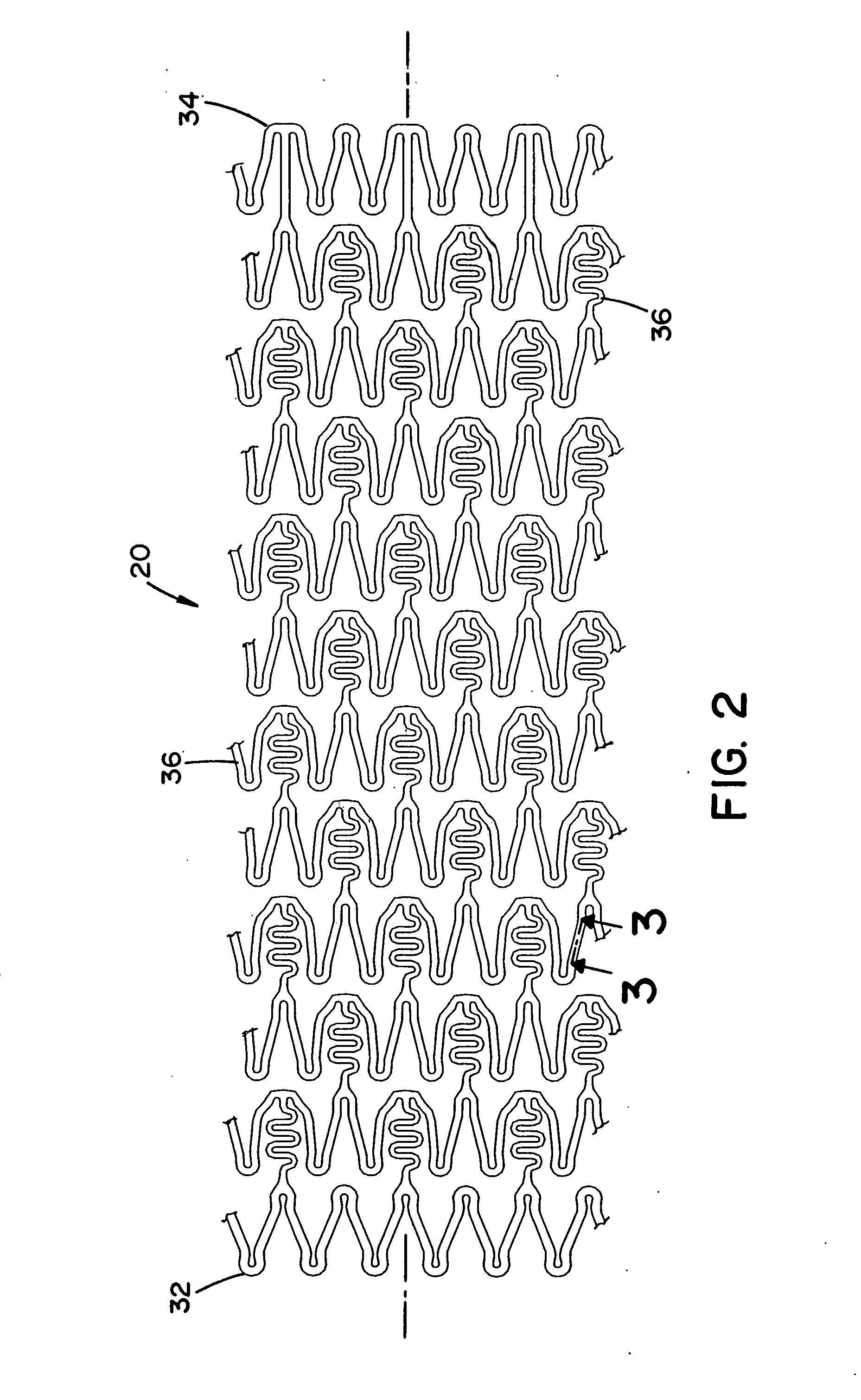

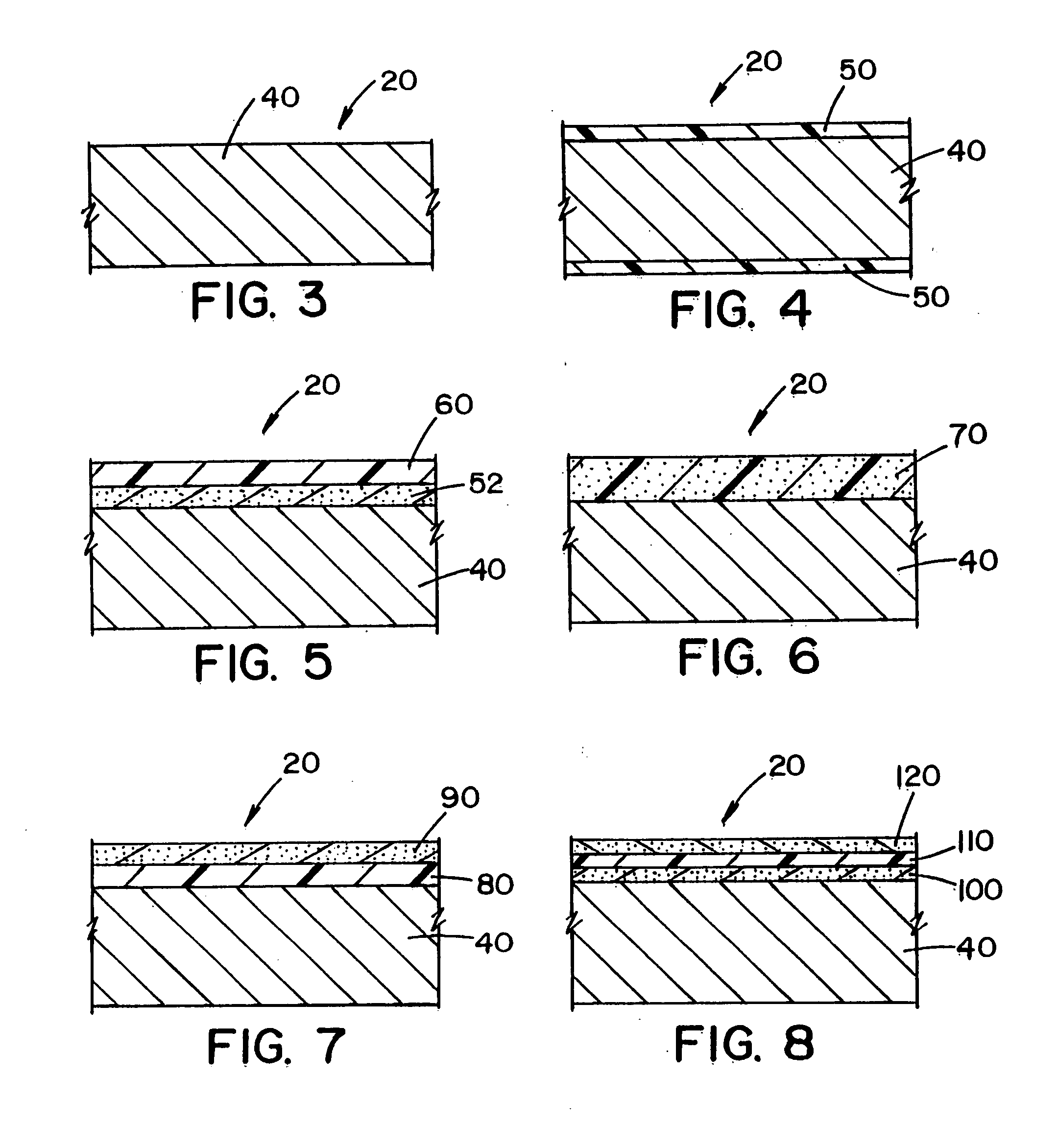

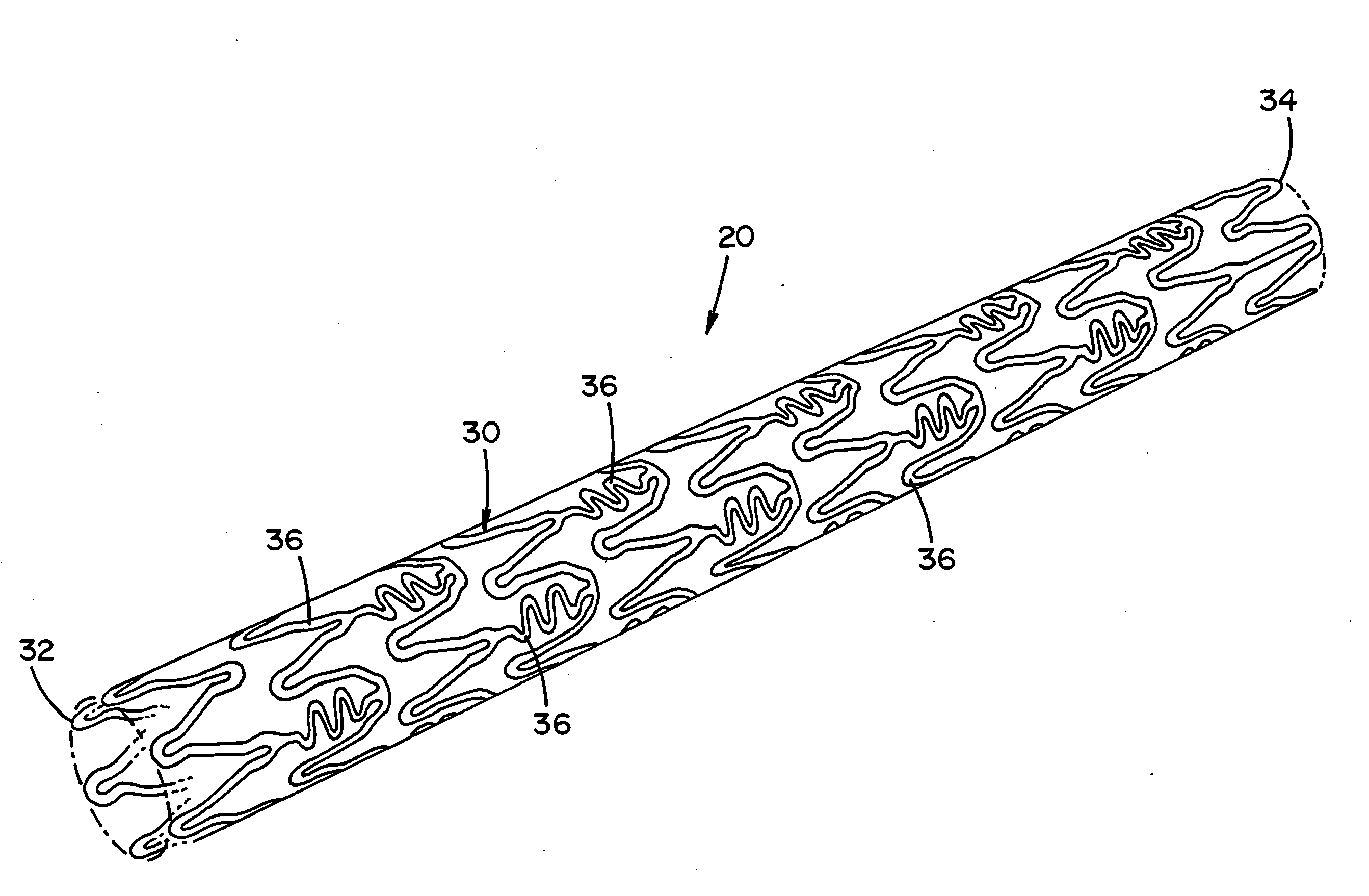

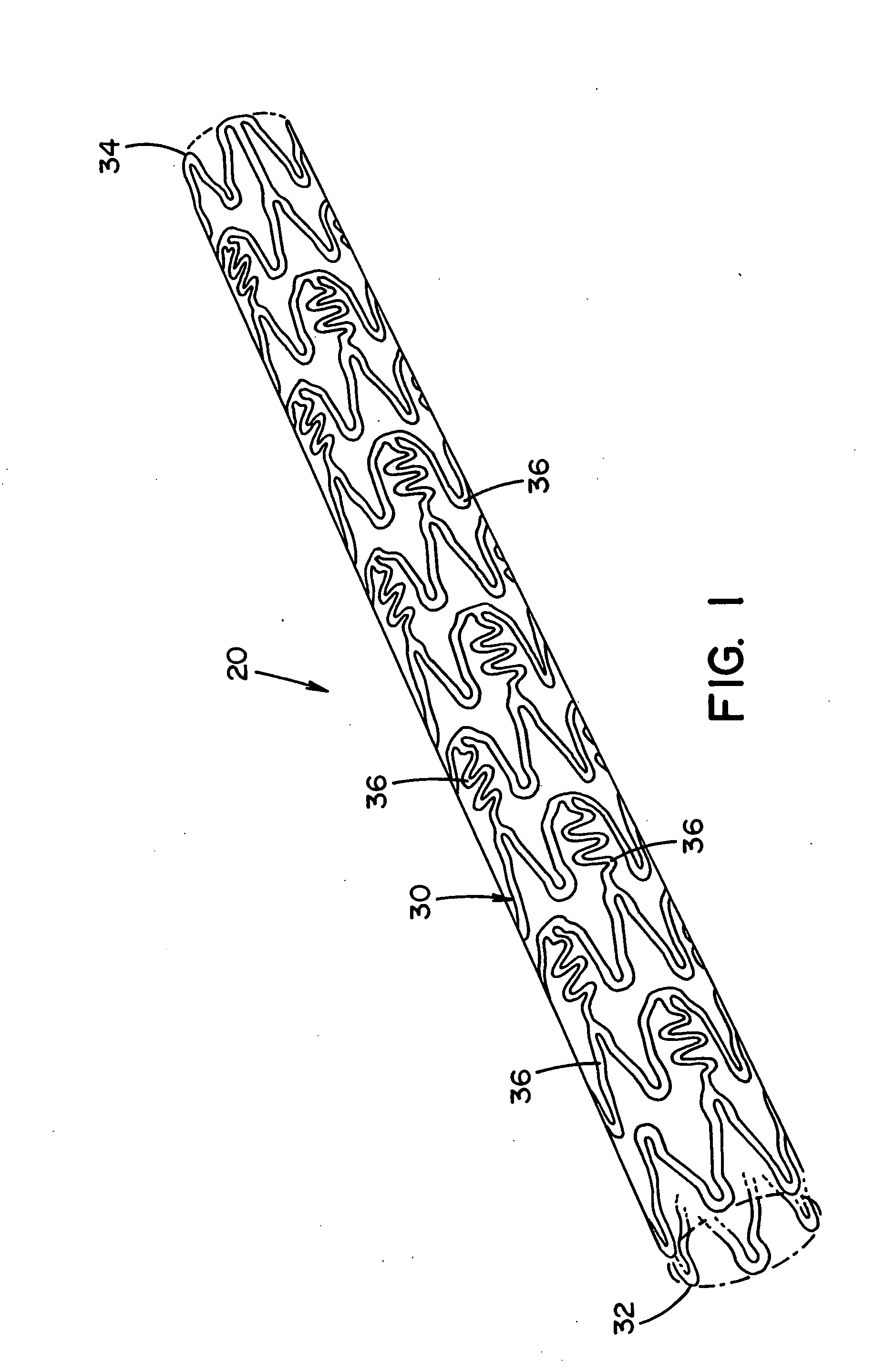

Bioabsorable medical devices

InactiveUS20060198869A1Facilitate deploymentImprove physical propertiesStentsPeptide/protein ingredientsYttriumMagnesium

Owner:ICON MEDICAL CORP

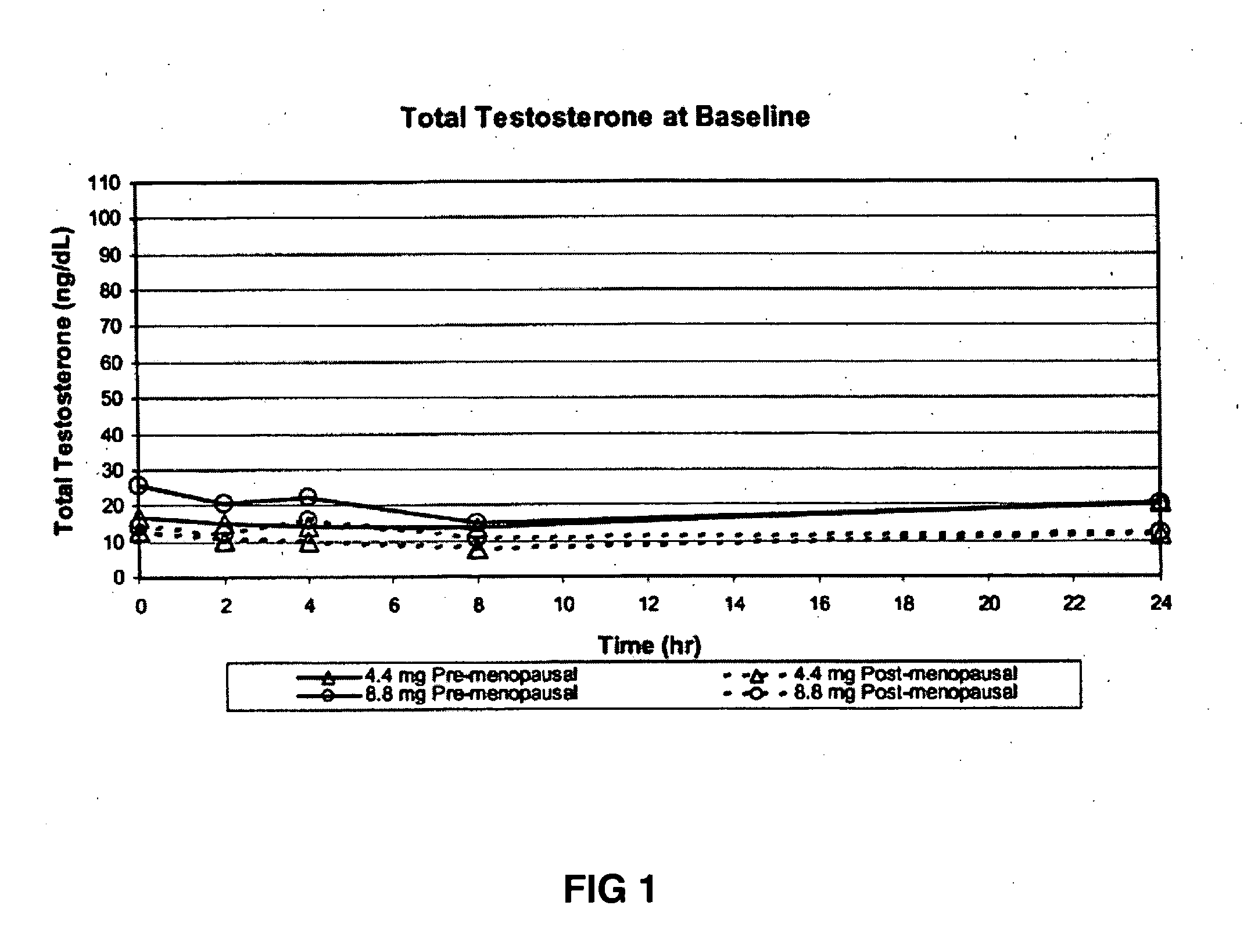

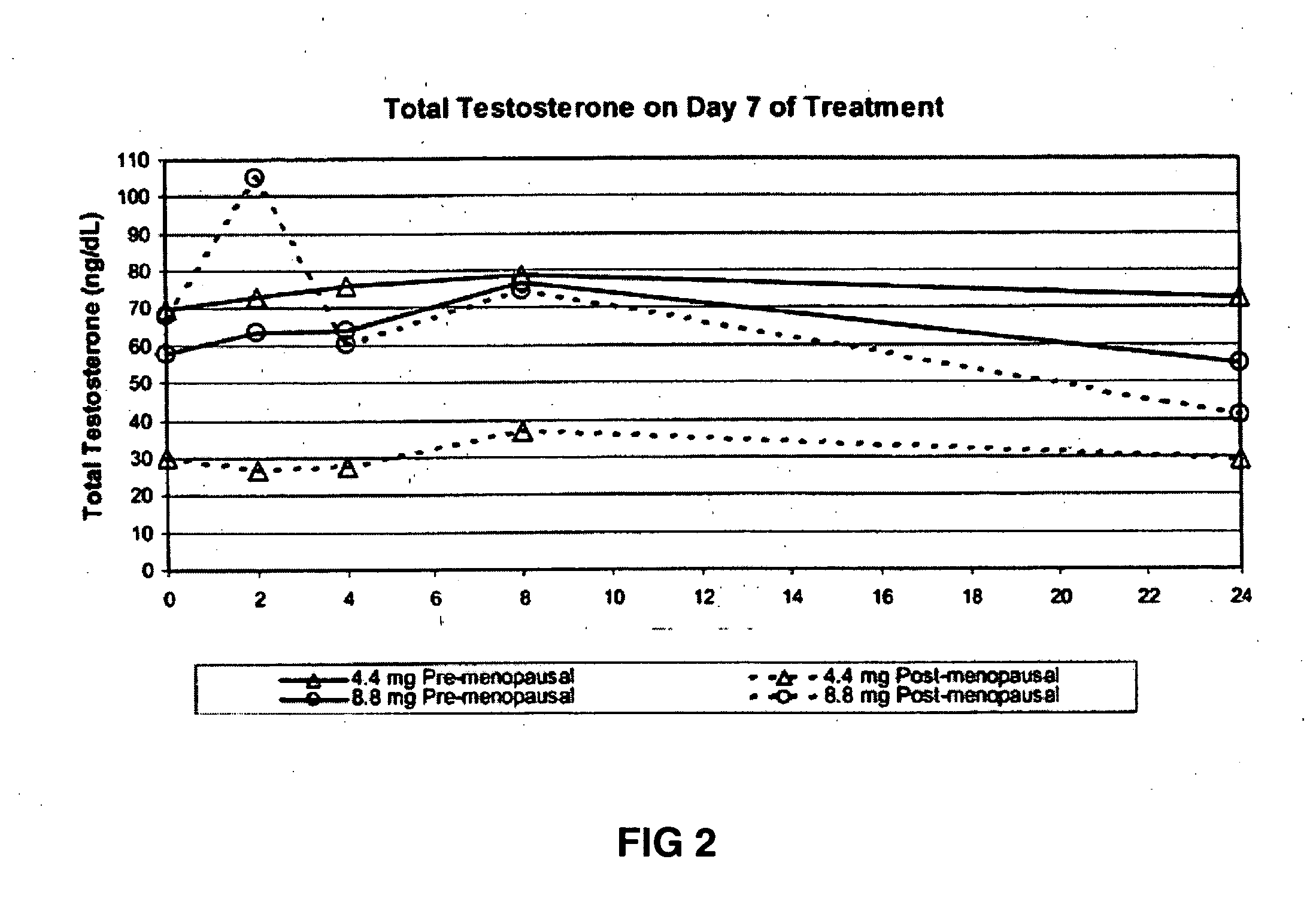

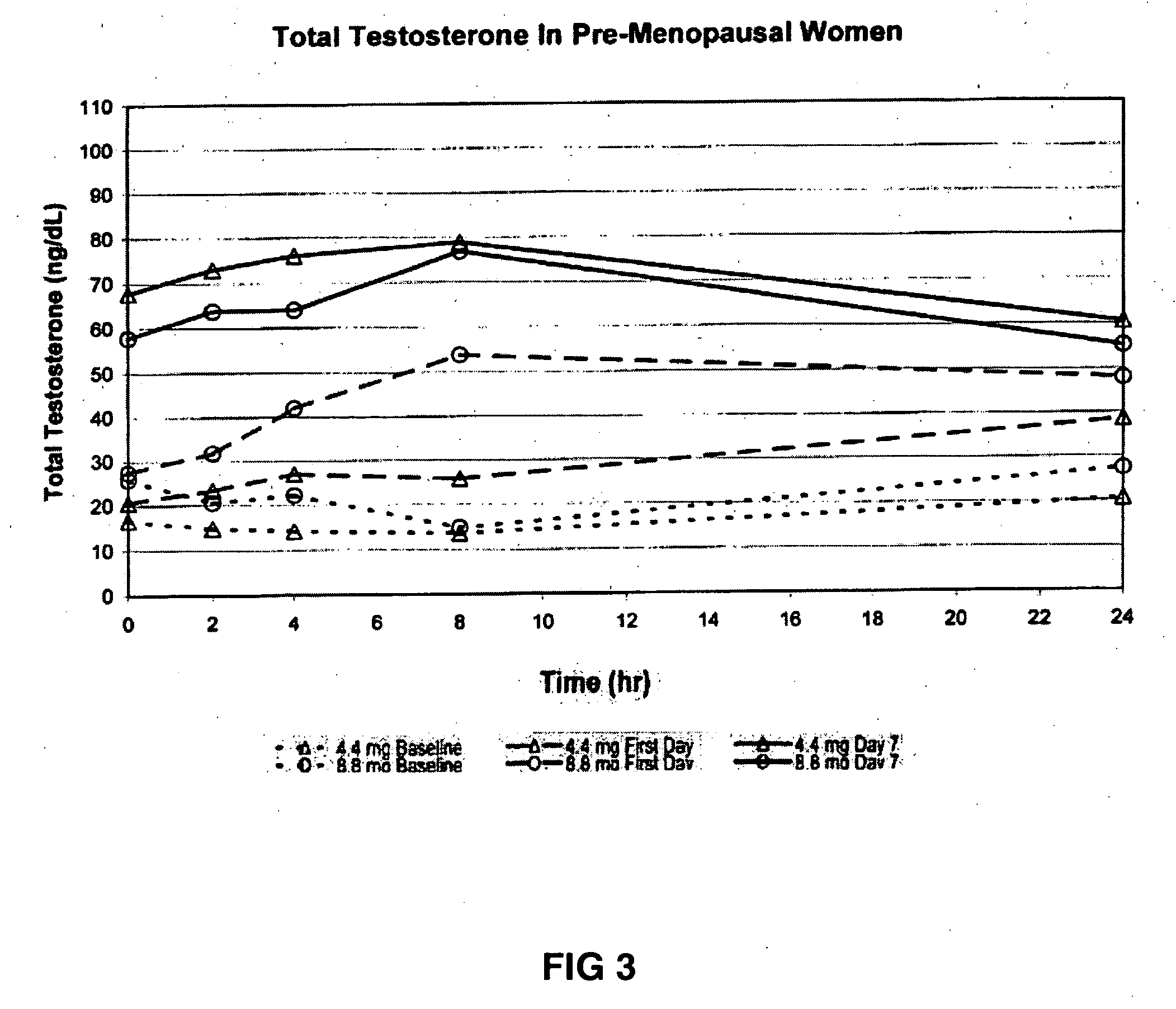

Method of increasing testosterone and related steriod concentrations in women

InactiveUS20070154533A1Improve bioavailabilityGood chemical stabilityOrganic active ingredientsOintment deliveryPhysiologyTestosterone

The present invention relates to methods, kits, combinations, and compositions for treating, preventing or reducing the risk of developing a testosterone-deficient disorder, or the symptoms associated with, or related to a testosterone-deficient disorder in a subject in need thereof. The present invention also relates to a method of administering a steroid in the testosterone synthetic pathway to a subject in need thereof.

Owner:LABORATORIES BESINS INTERNATIONAL SAS

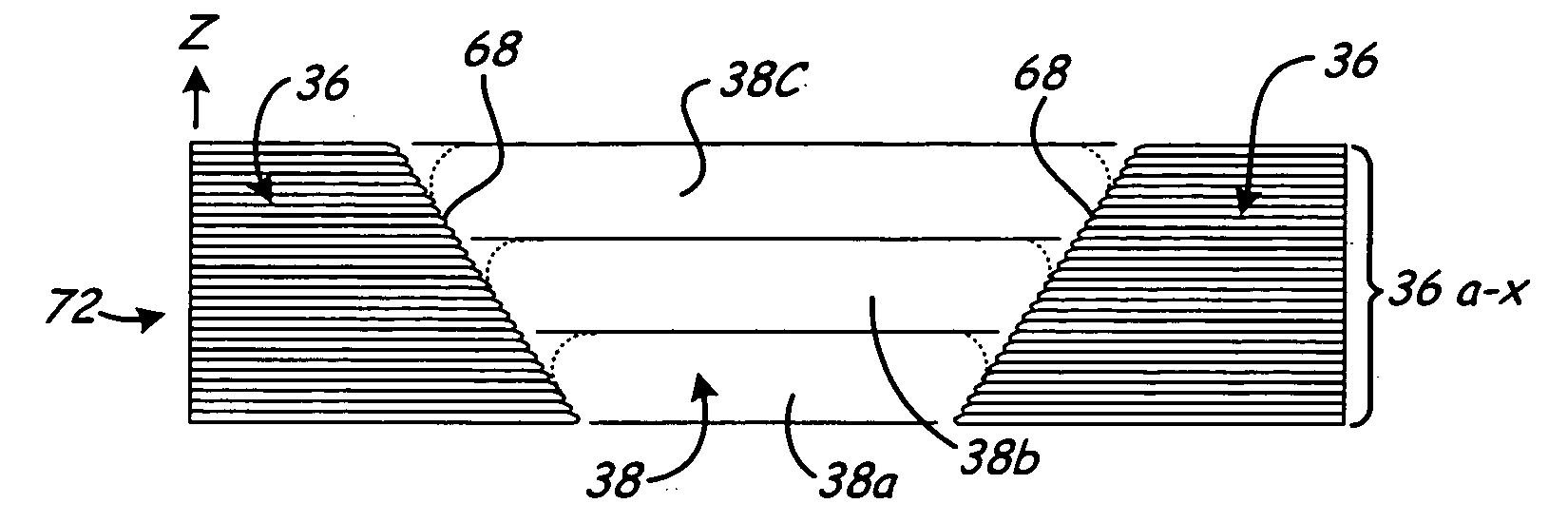

High-resolution rapid manufacturing

ActiveUS20060158456A1Fast preparationGood physical propertiesAdditive manufacturing apparatusWood working apparatusStructural engineeringRapid manufacturing

The present invention is a method for forming an object, the method comprising jetting a first material to form a plurality of layers that define a support structure increment, and extruding a second material to form a layer of the object. The layer of the object substantially conforms to an interior surface of the support structure increment.

Owner:STRATSYS INC

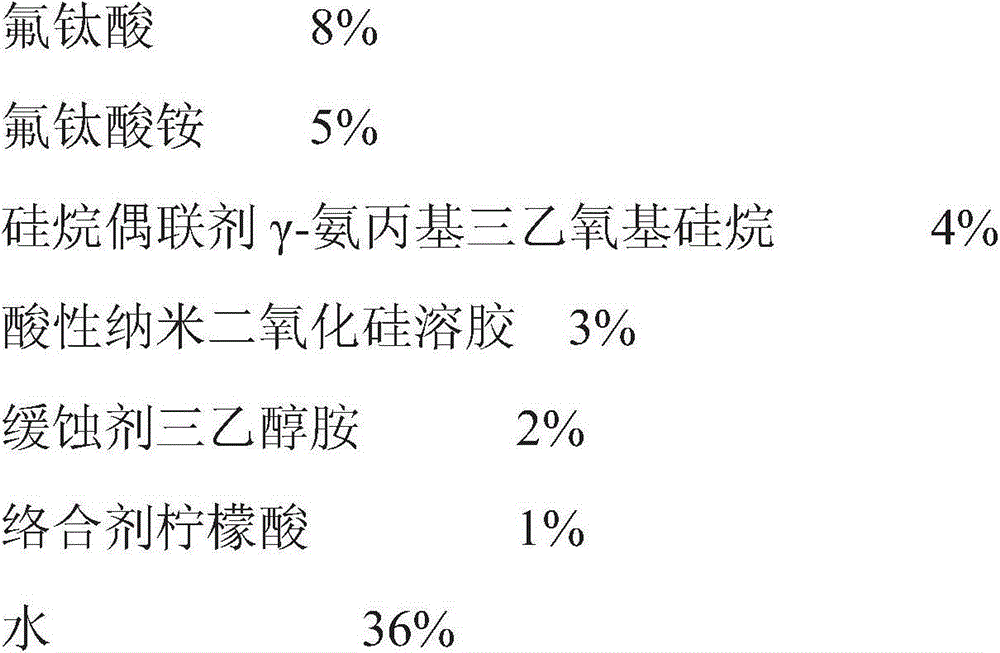

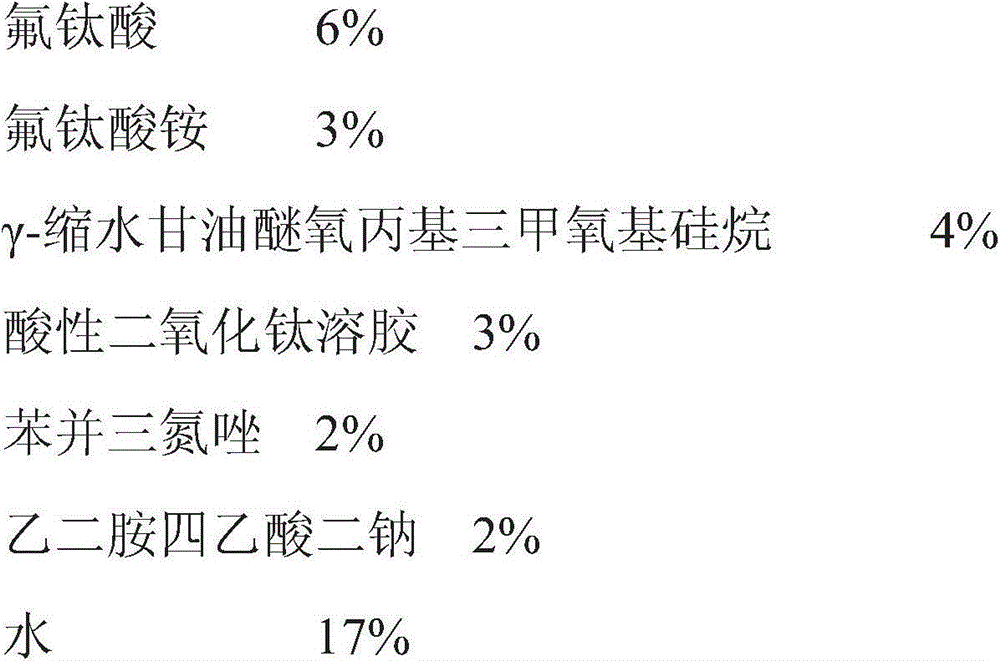

Corrosion-resistant magnesium aluminum alloy chromium-free passivation solution

InactiveCN104561970AHigh hardnessImprove stain resistanceMetallic material coating processesWater basedChromium free

The invention discloses a corrosion-resistant magnesium aluminum alloy chromium-free passivation solution, which comprises the following components: 10-40 parts of water-base resin, 1-10 parts of nanoparticle sol, 1-10 parts of fluoric-containing acid, 1-5 parts of fluoric acid-containing salt, 1-5 parts of a rare earth catalyst, 1-10 parts of a silane coupling agent, 1-5 parts of a corrosion inhibitor, 1-2 parts of a complexing agent and 40-70% of water. The corrosion-resistant magnesium aluminum alloy chromium-free passivation solution does not contain chromium and other toxic and harmful substances, meets the ROHS environmental protection law of the European Union, and meanwhile, can form an organic and inorganic composite passivation film and a thin film on the surface of a magnesium aluminum layer, and the formed composite passivation film has an excellent physical property and corrosion resistance, and has higher corrosion resistance and long salt fog time, so that the corrosion resistance of a magnesium aluminum alloy plate is better improved.

Owner:苏州禾川化学技术服务有限公司

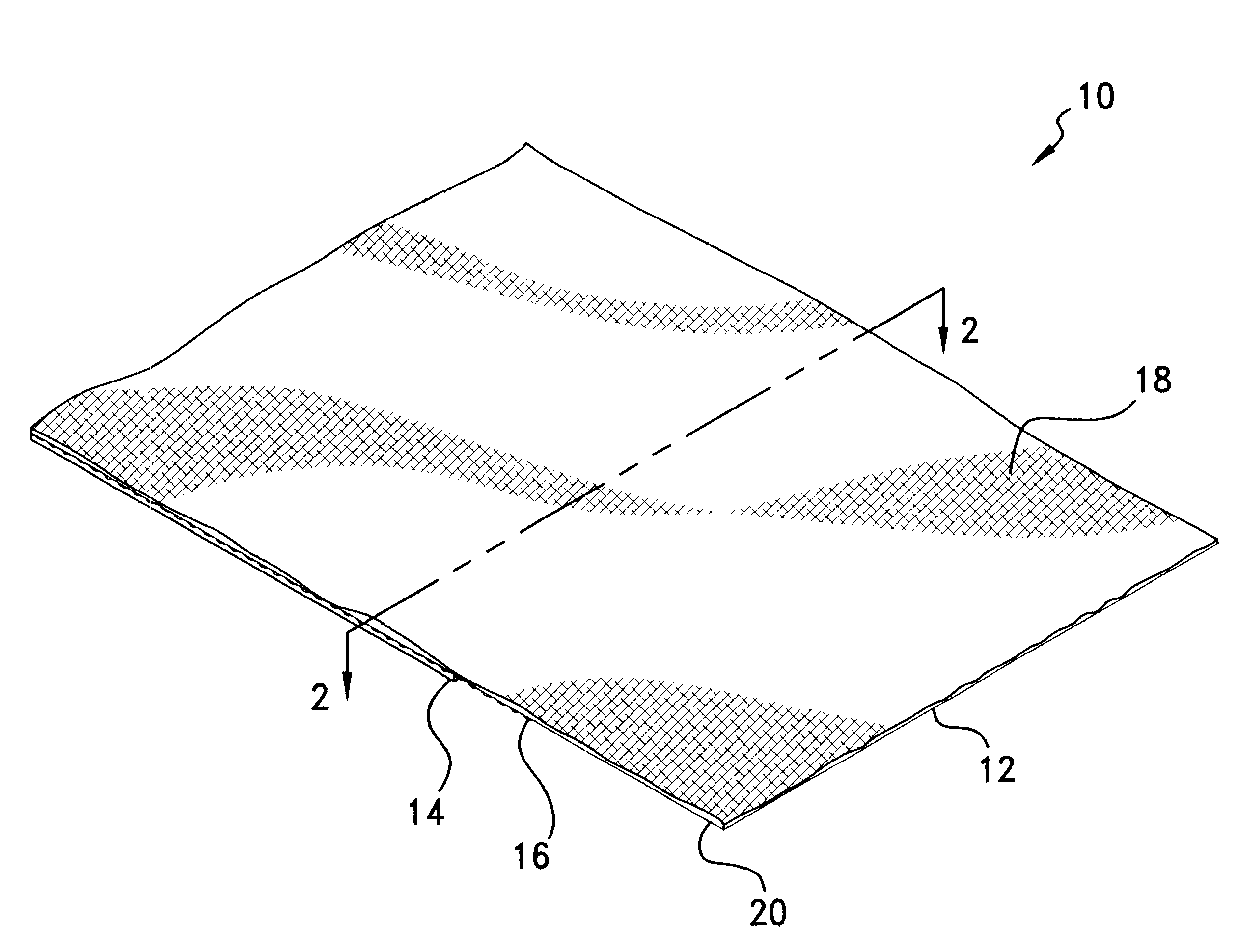

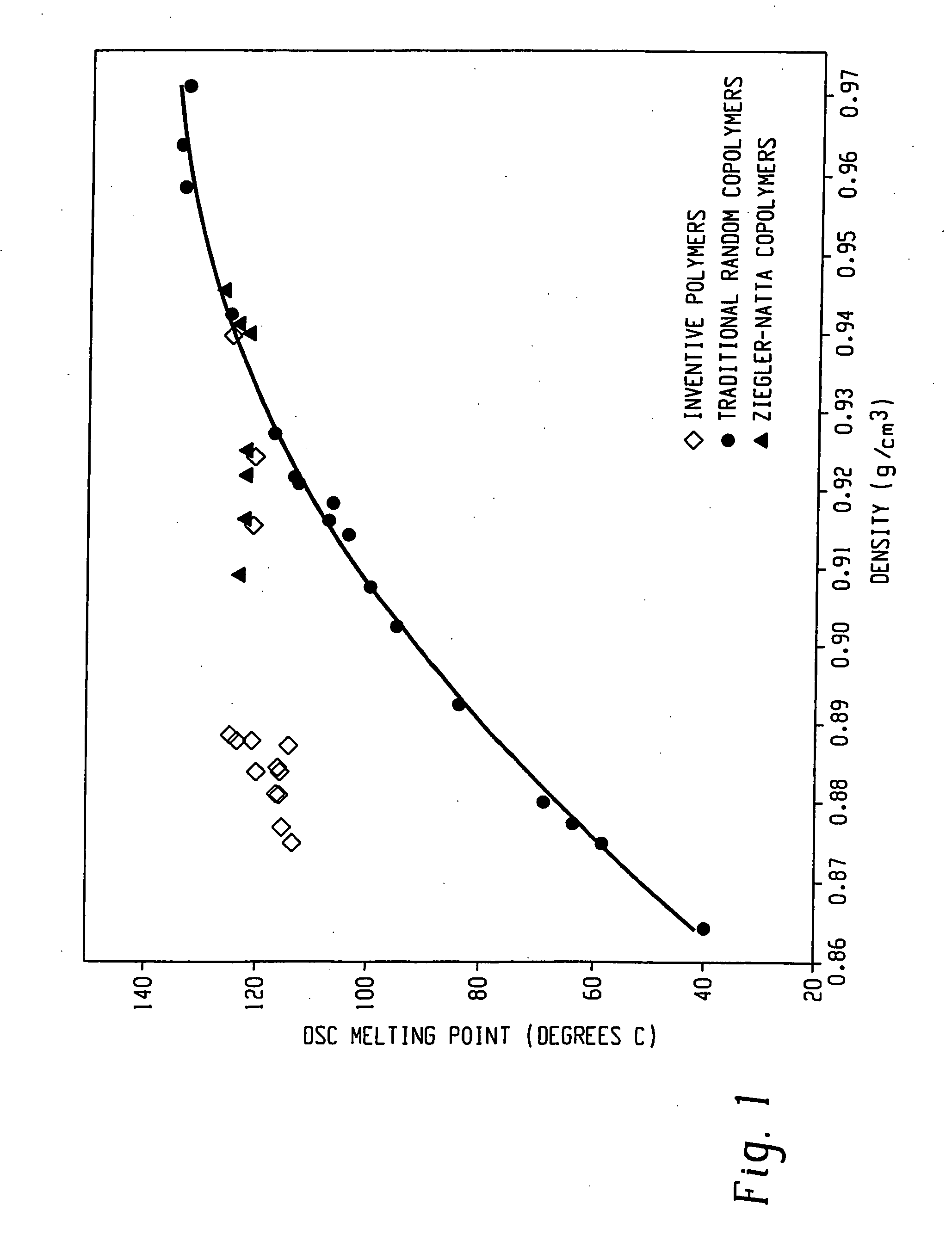

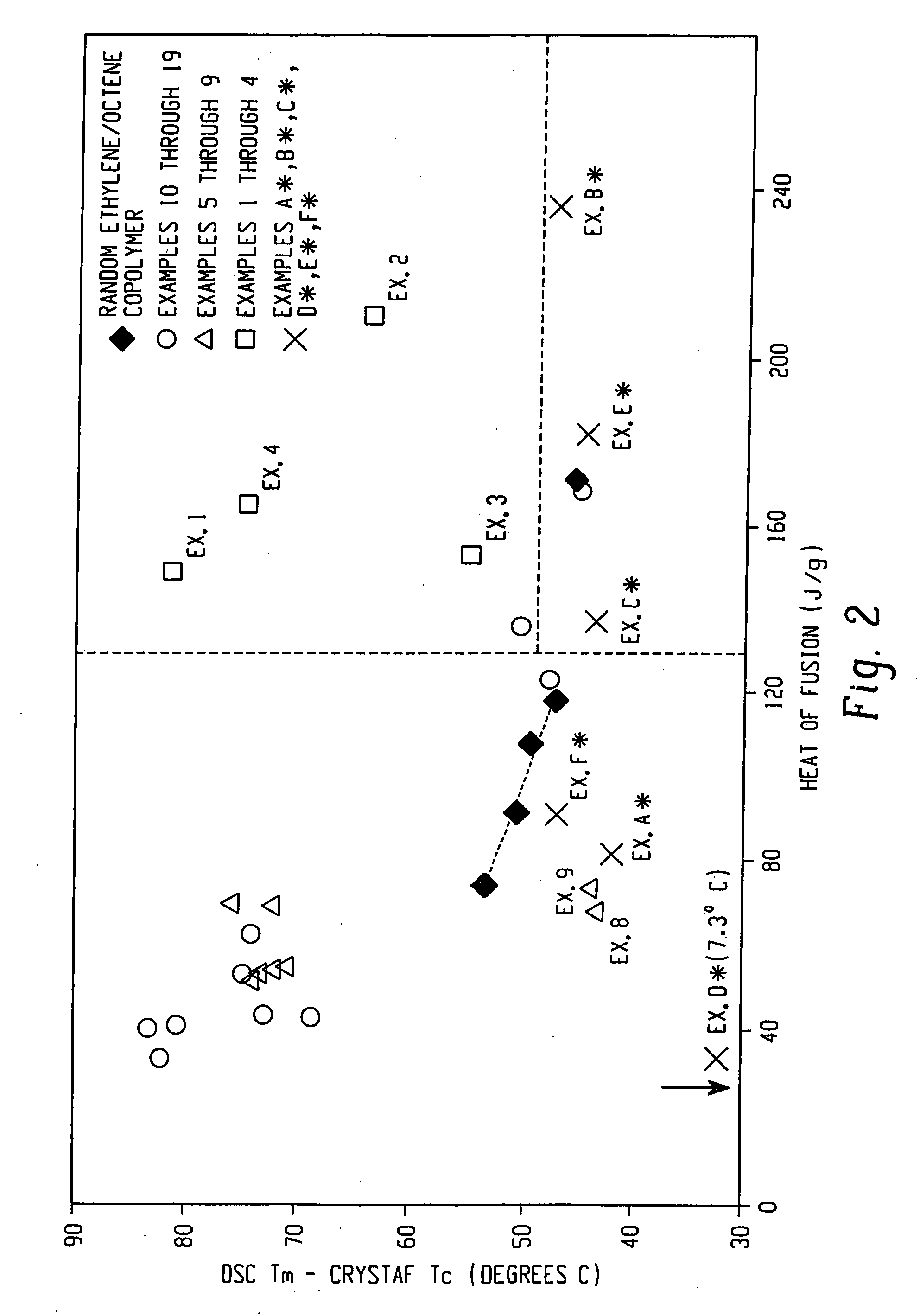

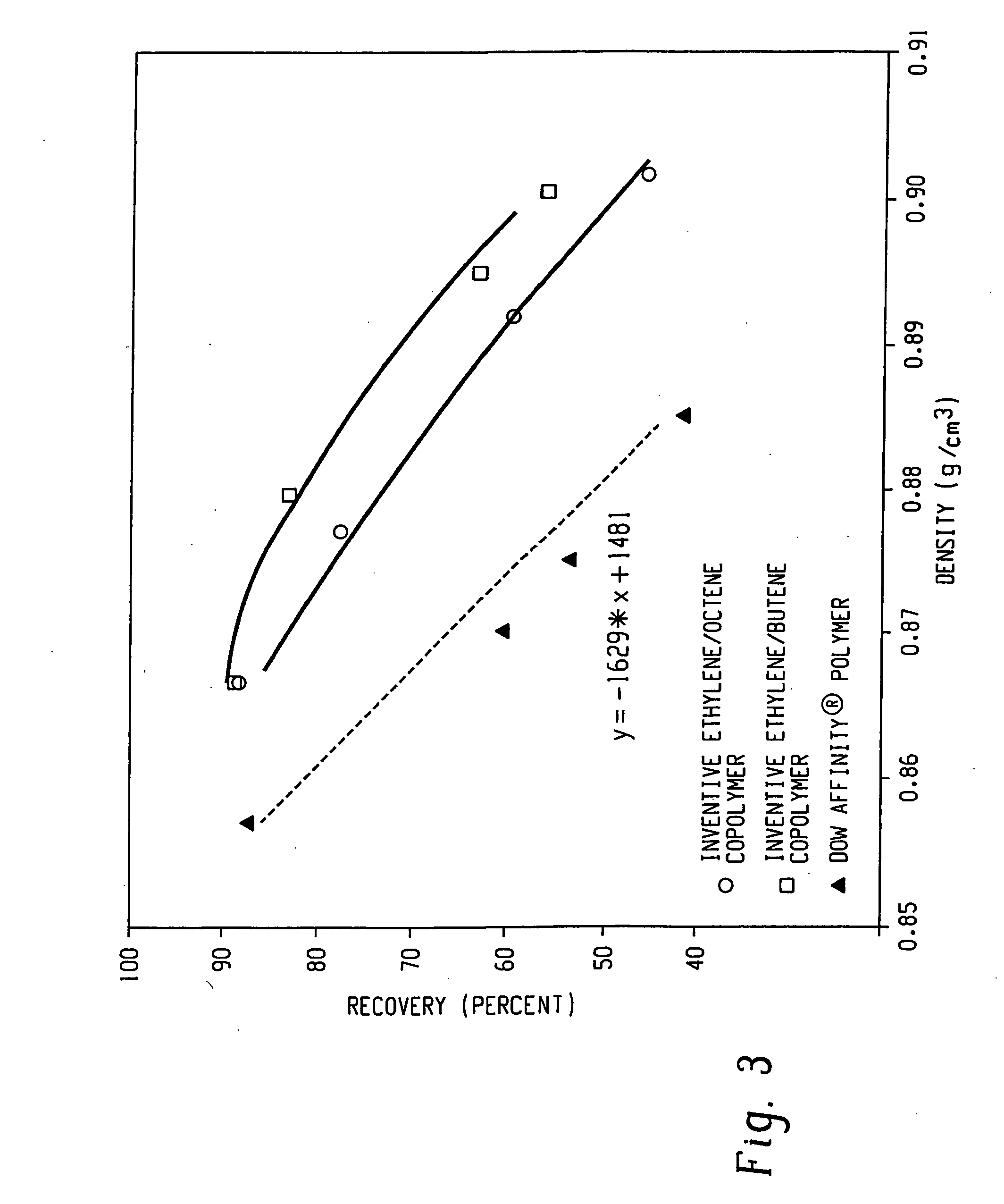

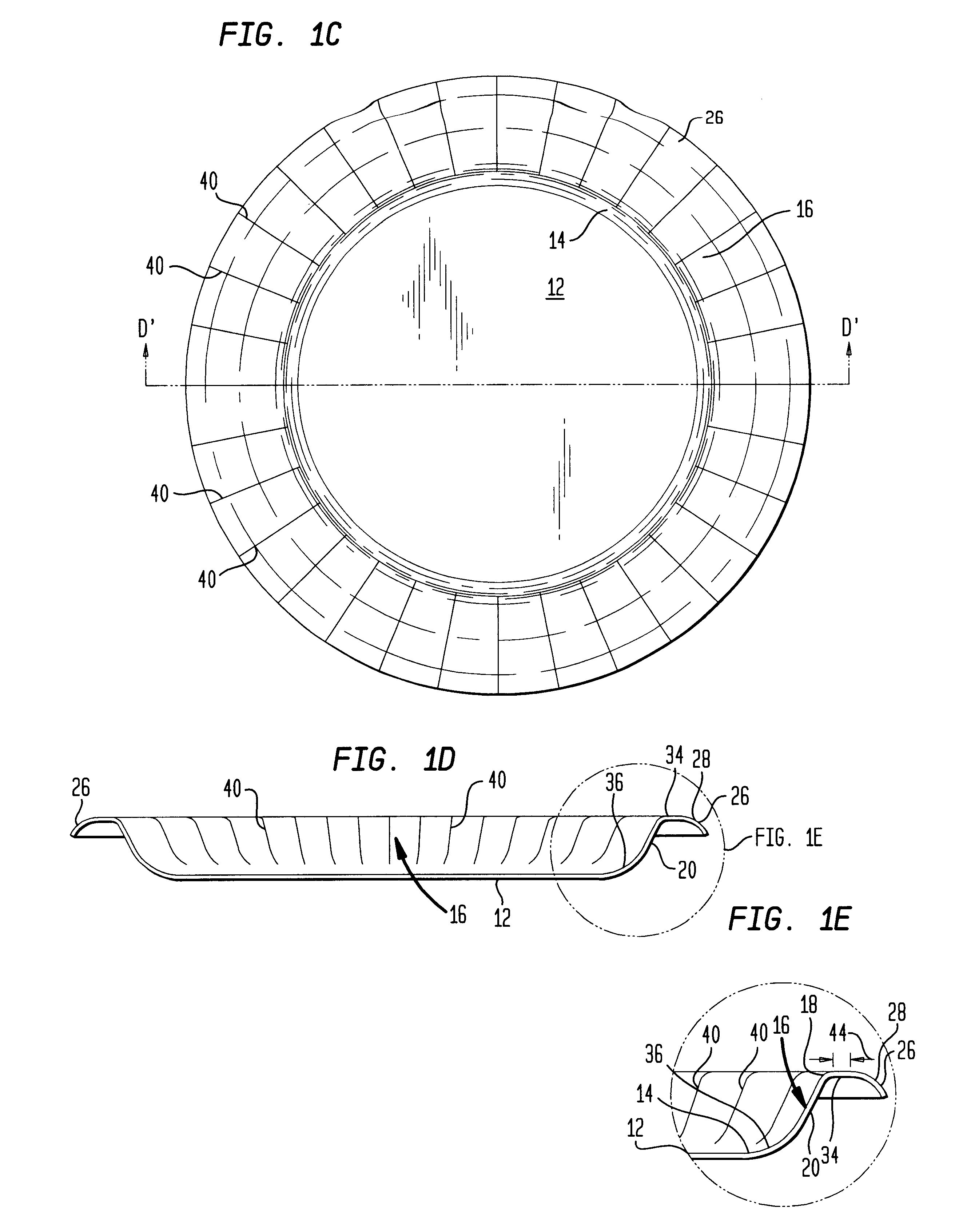

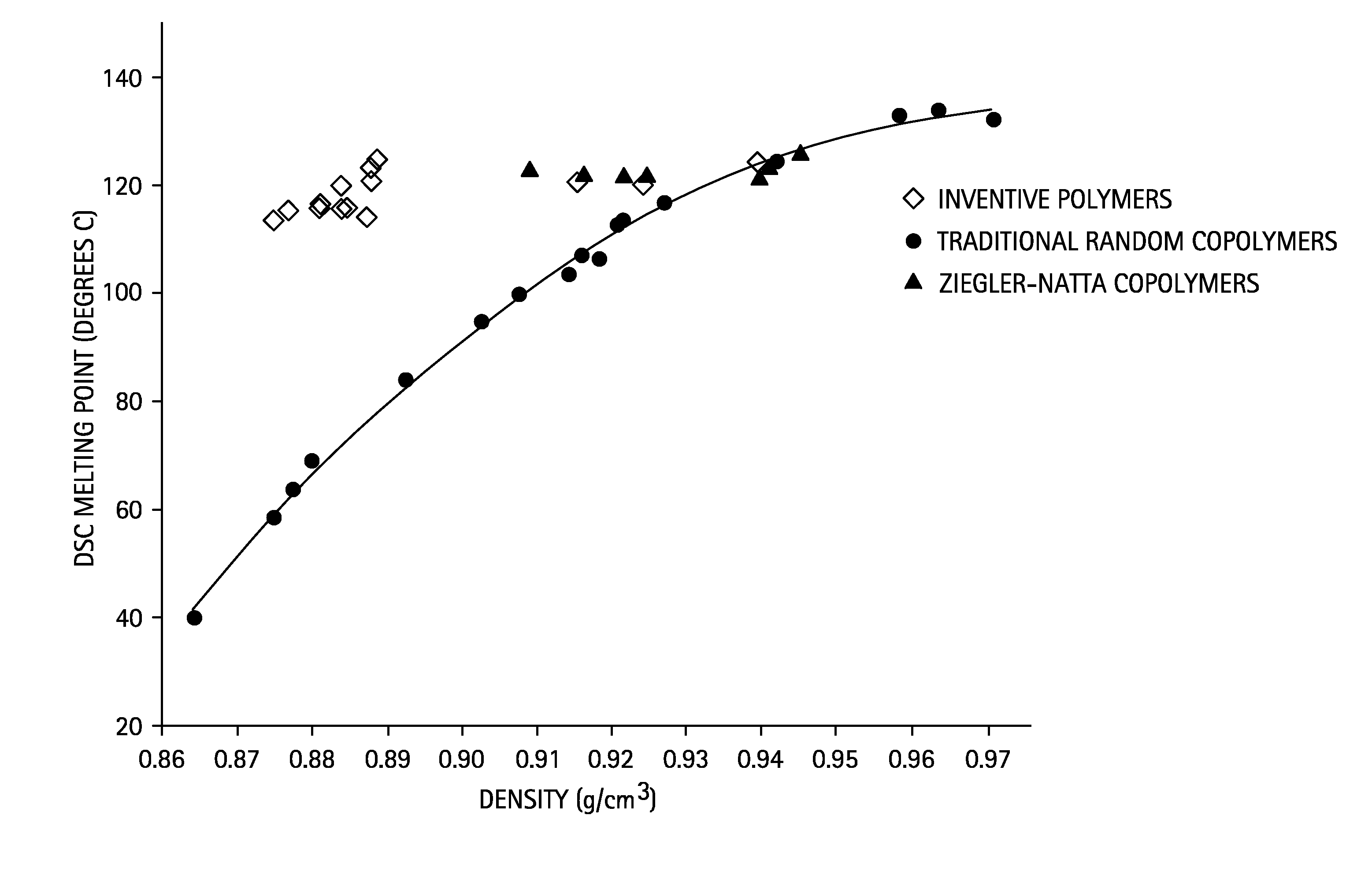

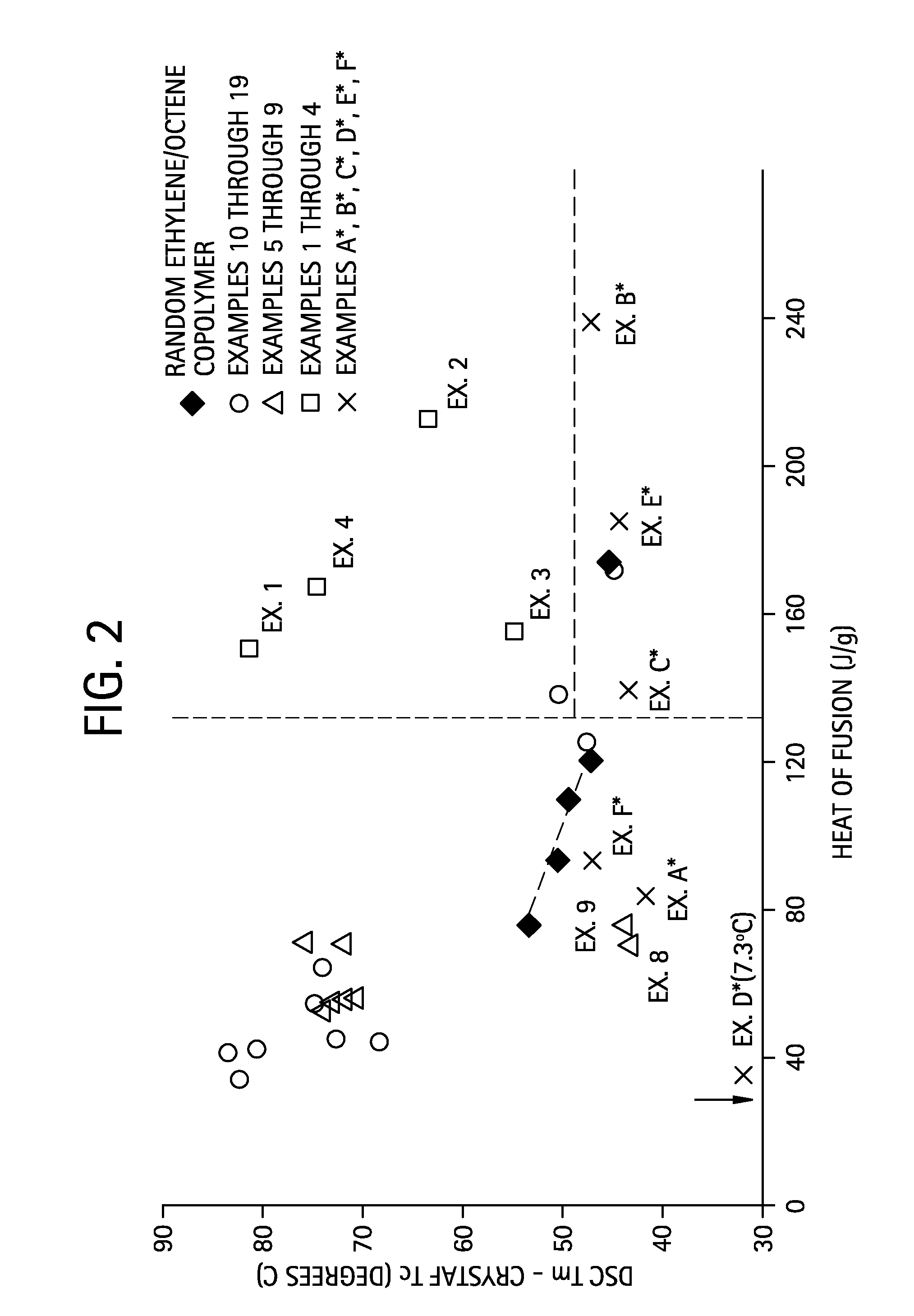

Compositions of ethylene/alpha-olefin multi-block interpolymer for elastic films and laminates

ActiveUS20070155900A1Easy to processHigh tensile strengthPersonal careLayered product treatmentProduction linePolyolefin

This invention relates to polyolefin compositions. In particular, the invention pertains to elastic polymer compositions that can be more easily processed on cast film lines, extrusion lamination or coating lines. The compositions of the present invention preferably comprise an elastomeric polyolefin resin and a high pressure low density type resin.

Owner:DOW GLOBAL TECH LLC

Thrombosis inhibiting graft

InactiveUS20070032864A1Bulk and weightIncrease radiopacityStentsSurgeryThrombosis preventionThrombus

A medical method that is adapted for introducing the medical device into the vascular system of a body which is designed to inhibit or prevent thrombosis after the insertion of the medical device.

Owner:MIRUS LLC

High nutrient compound selenium fertilizer and preparation method thereof

InactiveCN102320879AGood compatibilityPromote degradationFertilizer mixturesTrace element compositionInorganic materials

The invention discloses a high nutrient compound selenium fertilizer comprising selenium, nuisanceless organic material-inorganic material and medium and trace elements, and a preparation method thereof. The high nutrient compound selenium fertilizer comprises 45-60 wt% of organic material, 55-35 wt% of inorganic material, 1-6 wt% of medium and trace elements, and 0.011-0.025 wt% of purified selenium. The fertilizer disclosed in the invention can increase yield efficiently, and allow the applied plant to contain selenium element which has health care effect to human body. The fertilizer adopts a plurality of internal adsorptions to protect selenium to let the selenium in the selenium fertilizer be effective, has good intermiscibility and degradability, keeps selenium from fix, and obviously improves the biological absorption utilization rate of selenium of plants (including tea).

Owner:李子先 +1

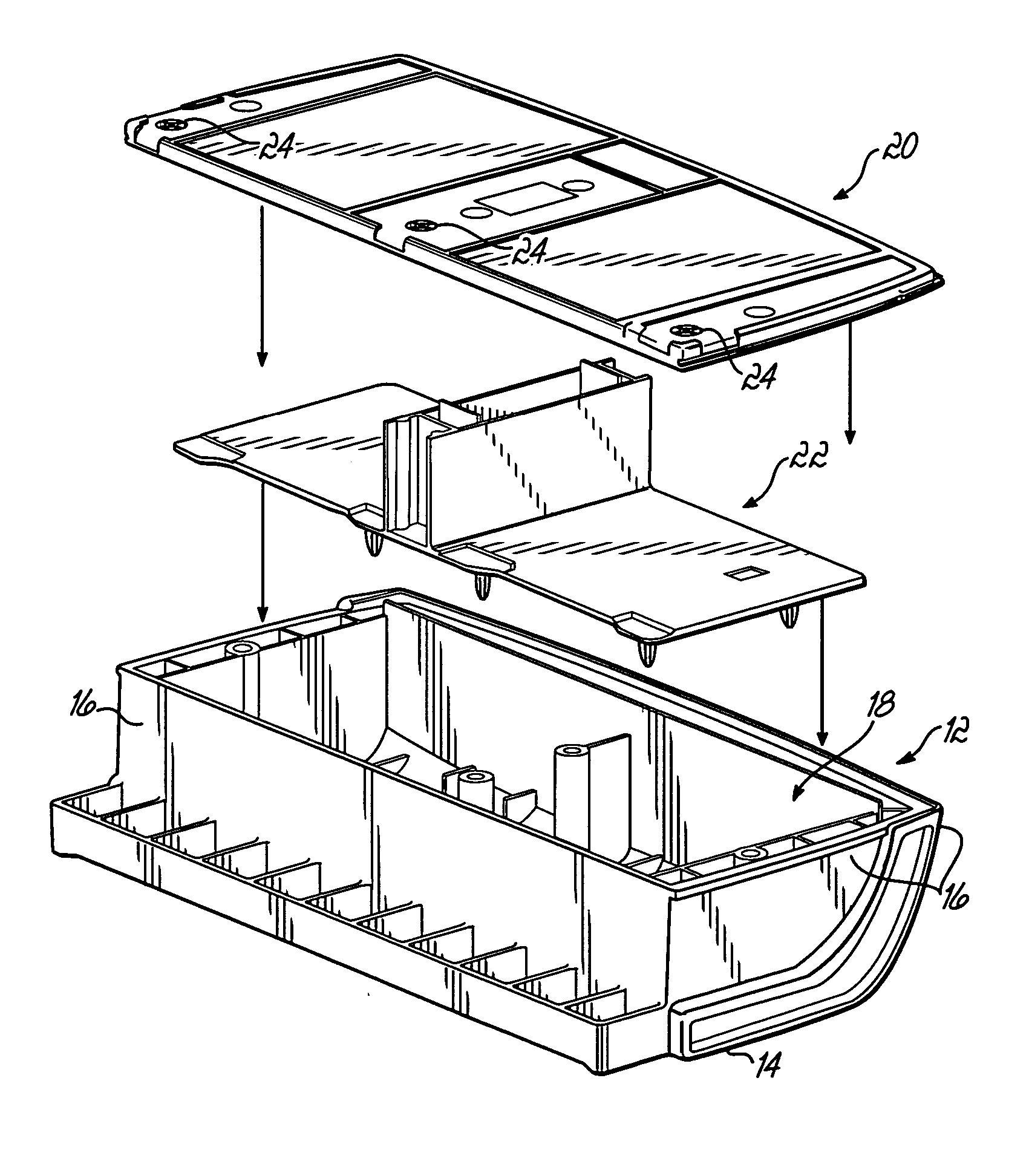

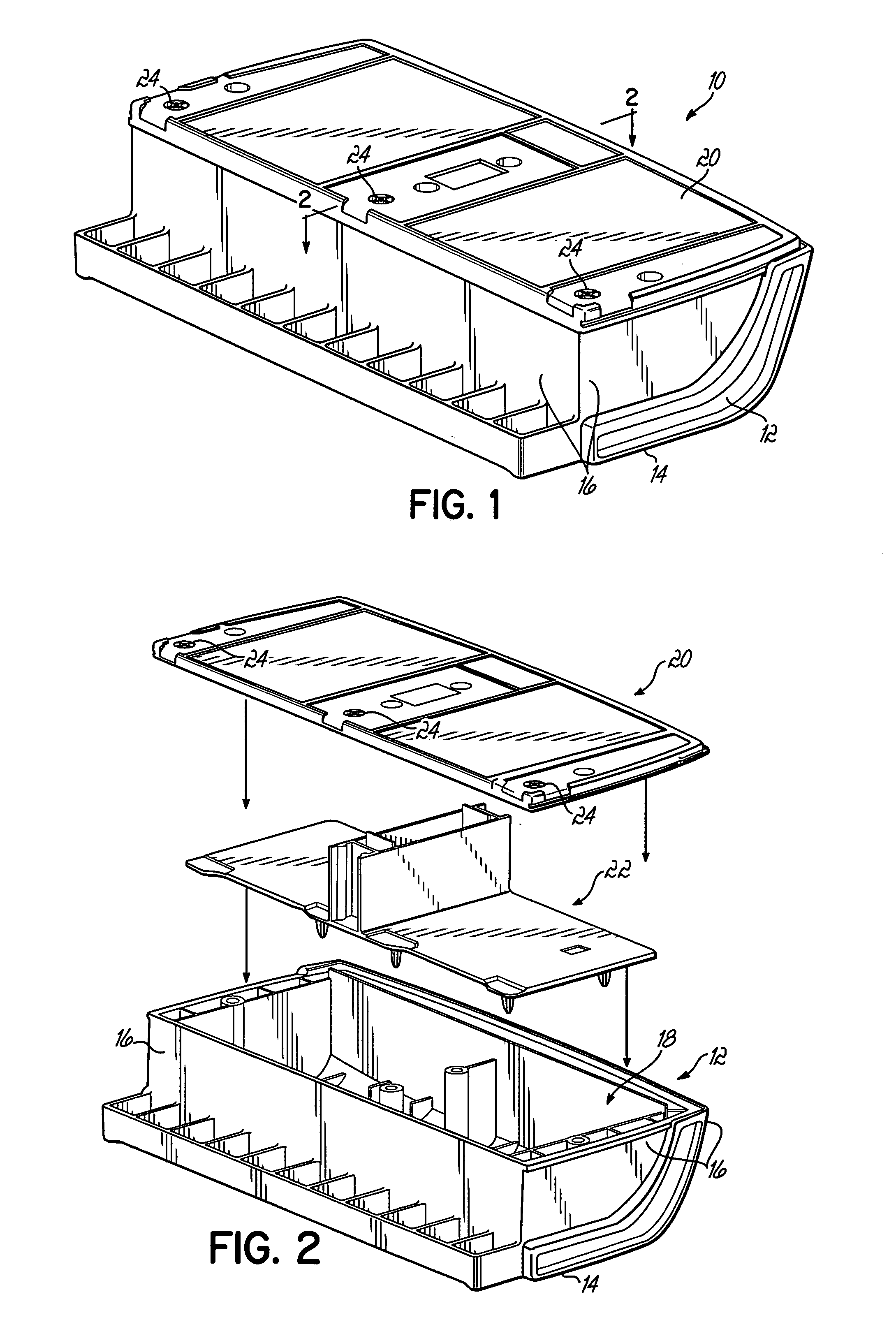

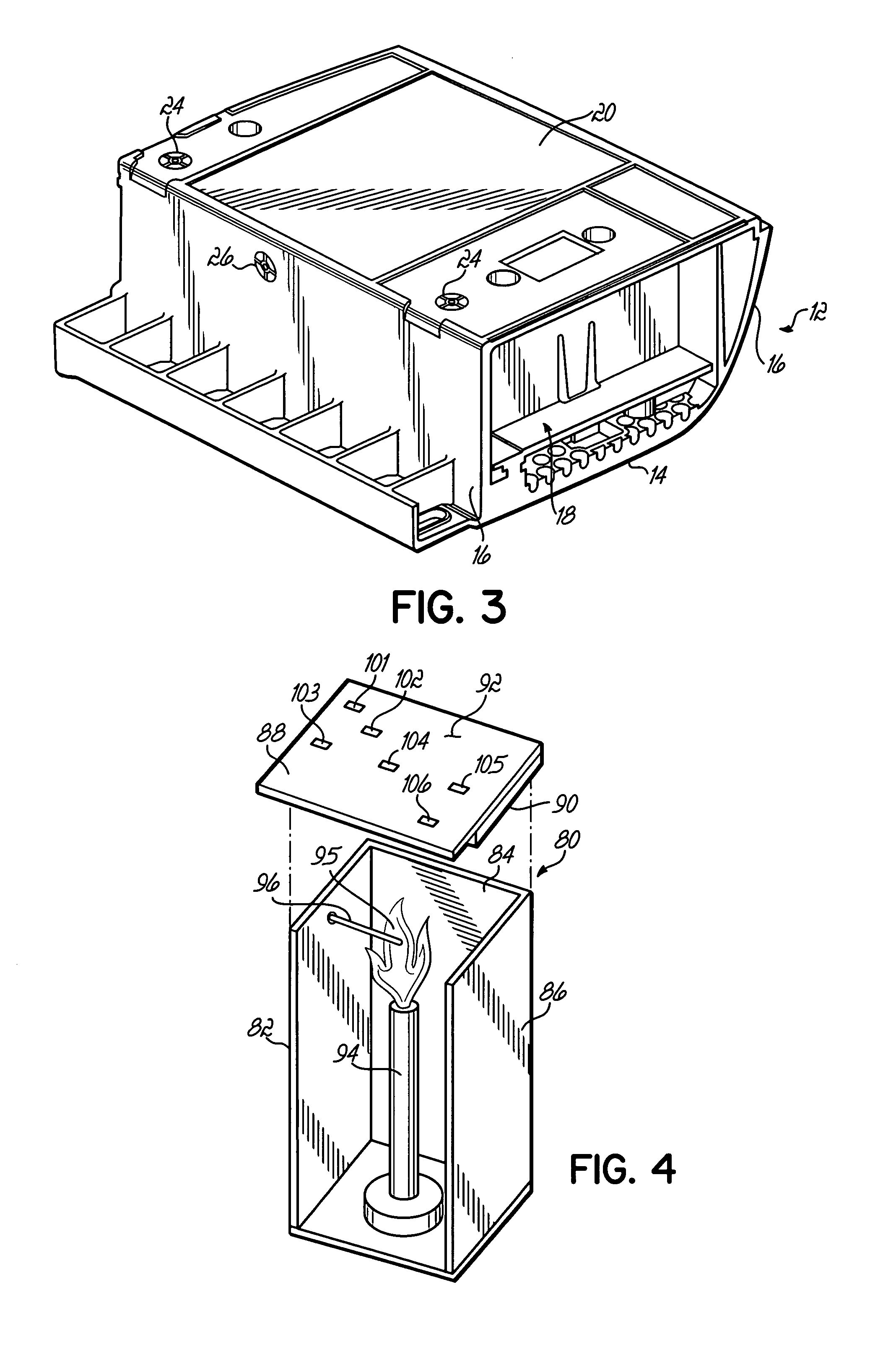

Fire shielding battery case

InactiveUS20050170238A1Low heat release rateReduce pressure build upsBattery isolationJackets/cases materialsPolypropyleneHigh-density polyethylene

A battery case made of an intumescent flame retardant polymeric composition that provides fire shielding, thermal shielding and a low heat release rate. A fire resistant additive is blended with a base polymer to produce the flame retardant polymeric material that is molded into the battery case. In one embodiment, one or more vent holes are provided in the battery case, advantageously in the cover portion, to permit gases to escape. In another embodiment, the fire resistant additive used for the battery case composition comprises a polymeric binder that includes an α-olefin-containing copolymer and a high density polyethylene, a nitrogenous gas-generating agent; a water vapor-generating agent; an antioxidant; and optionally a reinforcing agent. In another embodiment, the base polymer comprises a polyphenylene oxide and polypropylene blend, unfilled or filled with up to 60 wt. % glass fiber.

Owner:ENERDEL

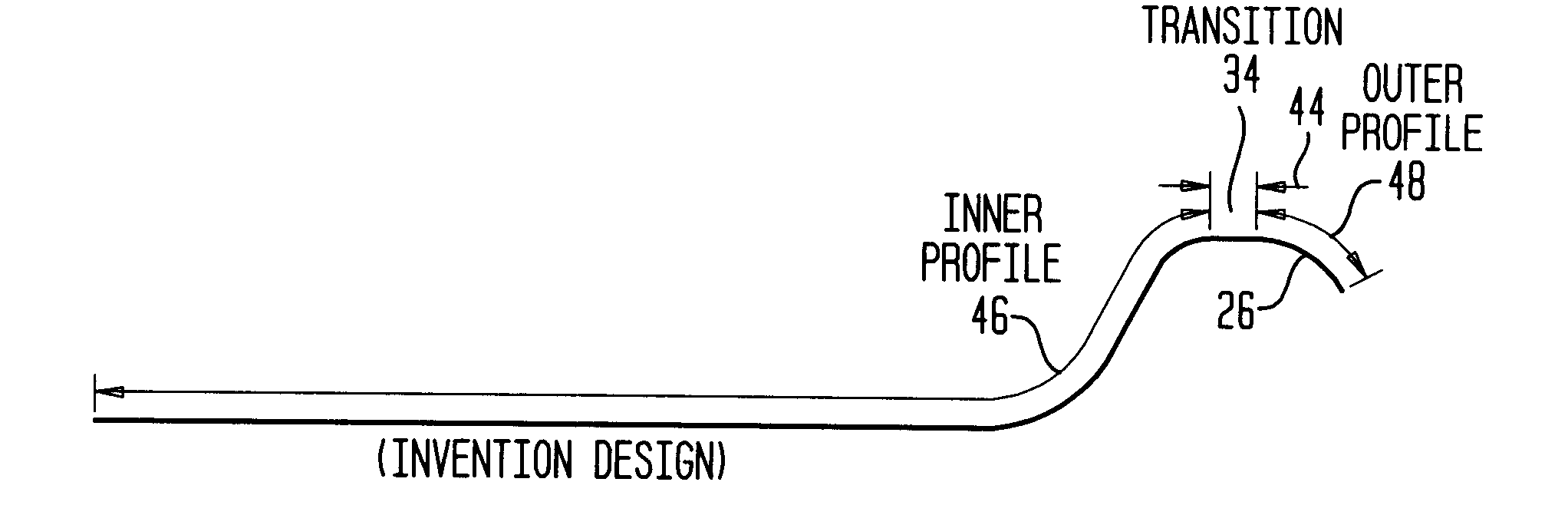

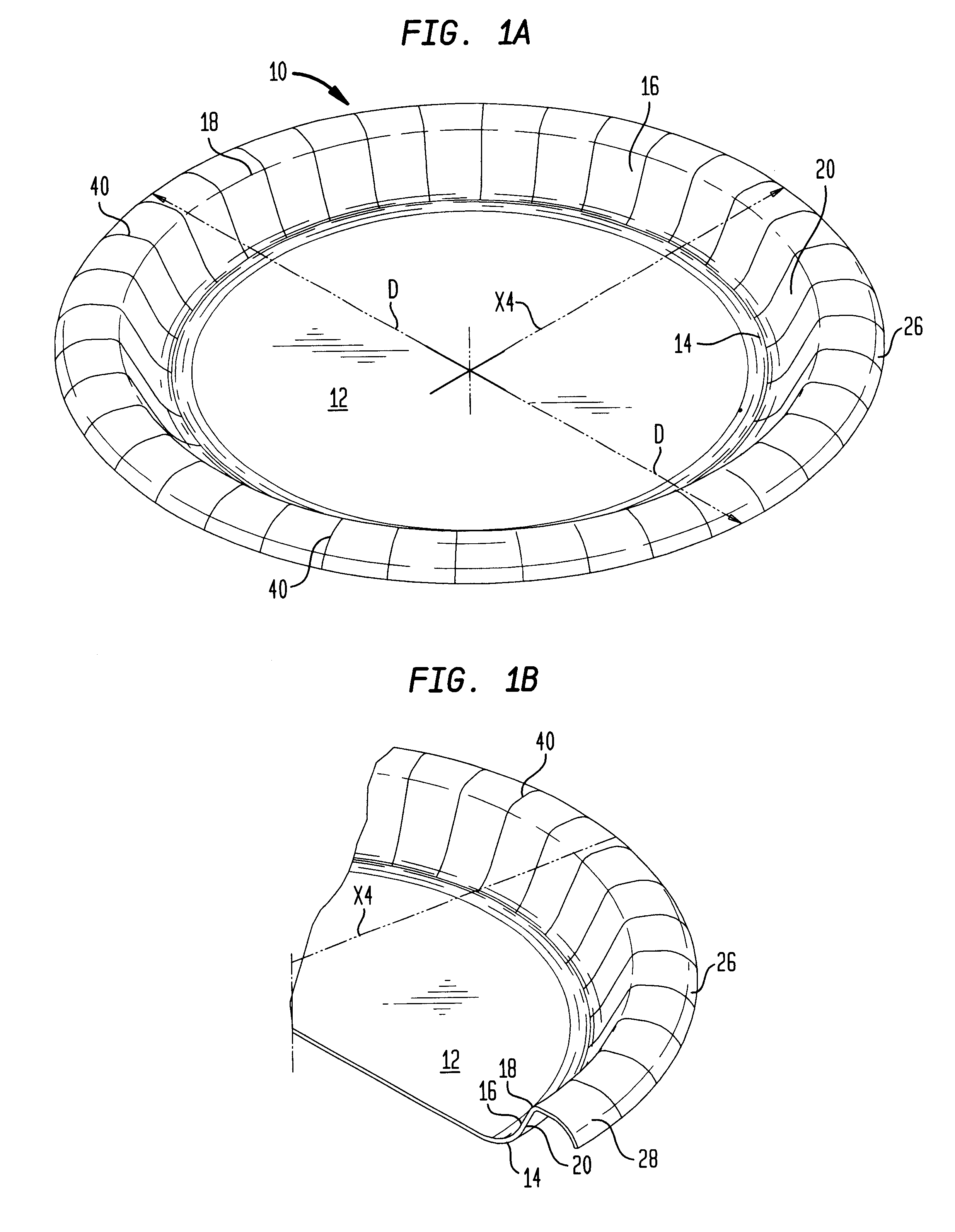

Disposable food container with a linear sidewall profile and an arcuate outer flange

InactiveUS6715630B2Good physical propertiesLose weightEnvelopes/bags making machinerySpecial paperEngineeringUltimate tensile strength

The present invention is directed to rigid disposable food containers provided with a relatively steep sidewall with a generally linear profile and an outwardly flared arcuate flange portion. The containers are further characterized by a flange outer vertical drop wherein the ratio of the length of the vertical drop to the characteristic diameter of the container is greater than about 0.01. By virtue of unique geometry, the containers of the invention exhibit improved rigidity and / or rim stiffness yet have favorable runnability in pressware manufacturing systems characteristic of plates of lower strength.

Owner:GPCP IP HLDG LLC

Compositions of ethylene/alpha-olefin multi-block interpolymer for elastic films and laminates

ActiveUS20080177242A1Good physical propertiesElasticityCosmetic preparationsToilet preparationsElastomerPolyolefin

This invention relates to polyolefin compositions. In particular, the invention pertains to elastic polymer compositions that can be more easily processed on cast film lines, extrusion lamination or coating lines. The compositions of the present invention preferably comprise an elastomeric polyolefin resin and a high pressure low density type resin.

Owner:DOW GLOBAL TECH LLC

Photocurable Compositions

ActiveUS20070205528A1Reduce Shrinkage ProblemsHigh Tg cured propertyAdditive manufacturing apparatusNanostructure manufacturePhysicsRadiation exposure

An optical moulding process is disclosed comprising the sequential steps of: (a)(y) forming a layer of a photocurable composition; and (bXz) irradiating selected areas of the composition in the layer with radiation from a radiation source, thereby curing the composition in said selected areas and repeating the steps a) and b) on top of an earlier cured layer to form a three dimensional structure, wherein the radiation source used in step b) is a non-coherent source of radiation and wherein the photocurable composition comprises at least two curable components: (i) 45%-95% (and preferably at least 50%, more preferably at least 60%, e.g. at least 70%) by weight of the total curable components in the composition is a first component that is photocurable and that is such that, when cured in the presence of a photocuring initiator by exposure to UV radiation having an energy of 30 mJ / cm2, at least 90% of the component is cured within 50 milliseconds; and (ii) 5% to 55% (and preferably 10-40%, more preferably 15 to 30%, e.g. about 20%) by weight of the total curable components in the composition is a second component that results in the composition, on curing, shrinking, in a linear direction, by less than 3% and preferably that results in the composition having, after cure, a Tg of greater than 50° C., preferably at least 100° C. and more preferably at least 120° C.

Owner:3D SYST INC

Polyurethanes obtained from hydroxyalkanoates and isocyanates

A polyurethane is described which is a reaction product of at least one isocyanate containing material having at least two isocyanate groups and at least one compound having at least two hydrogen atoms capable of reacting with the isocyanate. The compound having the at least two hydrogen atoms contains a hydroxyalkanoate, which is preferably a thermally decomposable or a biodegradable polyhydroxyalkanoate. The polyurethane of the present invention can be used in a number of applications and preferably has improved properties such as, but not limited to, improved flexibility and / or improved hydrophobicity. The polyurethanes of the present invention are preferably biodegradable and easily recycled.

Owner:METABOLIX

Foamable interpolymer resin particles containing limonene as a blowing aid

ActiveUS20040152795A1Lower Level RequirementsImprove acceleration performanceFoundry mouldsFoundry coresPolyolefinFoaming agent

Interpolymer resin particles comprised of 20% to 80% by weight polyolefin, e.g. polyethylene and 80% to 20% by weight of an in situ polymerized vinyl aromatic resin, e.g. polystyrene or poly(styrene-butyl acrylate) and forming an interpenetrating network of polyolefin and vinyl aromatic resin particles. The interpolymer particles are impregnated with a volatile hydrocarbon blowing agent, and limonene, e.g. d-limonene, ranging from about 0.1 to about 5 parts, preferably 0.1 to 1 part by weight, based on 100 parts by weight of the interpolymer particles, for improved expandability and a pleasant fragrance.

Owner:BVPV STYRENICS LLC

Method for preparing tobacco sheet and application thereof

ActiveCN101637298AGood physical propertiesExtract completelyTobacco preparationTobacco treatmentMaillard reactionFiber

The invention discloses a method for preparing tobacco sheets and an application of the method. In the method, enzymolysis is implemented when the tobacco stalk and the tobacco powder are soaked, solid-liquid separation is implemented after extraction, the solids are made into fiber sheet substrates, liquid is made into concentrated solution by alcohol precipitation and concentration, the concentrated solution is made into coating liquid by maillard reaction and coated on the fiber sheet substrates, and the fiber sheet substrates are dried and cut into tobacco sheets. In the invention, the macromolecular compounds that influence the quality of the tobacco sheets are sufficiently degraded by enzymolysis, the content of the impure taste in the tobacco sheets is decreased, the internal quality of the tobacco sheets is improved, and better aroma is obtained by the technical solution that produces prospective aroma by the maillard reaction to provide a rich aroma for the tobacco sheets so as to obtain tobacco sheet products fitting different types of cigarette products and having better internal quality. The tobacco sheets prepared by the method have excellent compatibility and harmonywith the conventional raw materials of the cigarettes, and have the advantages of good cigarette taste, various and rich aromas and less impure taste.

Owner:CHINA TOBACCO GUANGDONG IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com