Patents

Literature

973 results about "Polyphenylene oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

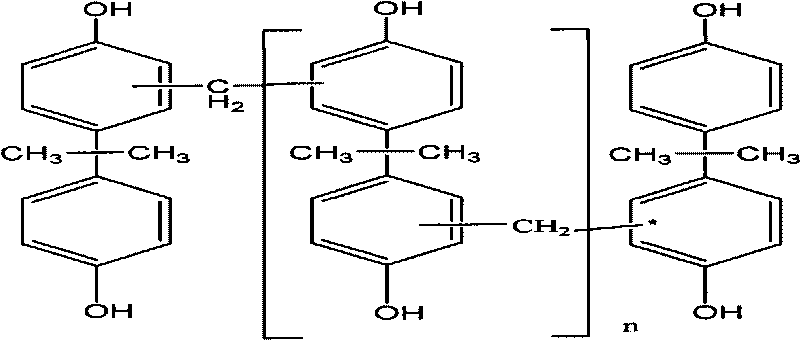

Poly(p-phenylene oxide) or poly(p-phenylene ether) (PPE) is a high-temperature thermoplastic. It is rarely used in its pure form due to difficulties in processing. It is mainly used as blend with polystyrene, high impact styrene-butadiene copolymer or polyamide.

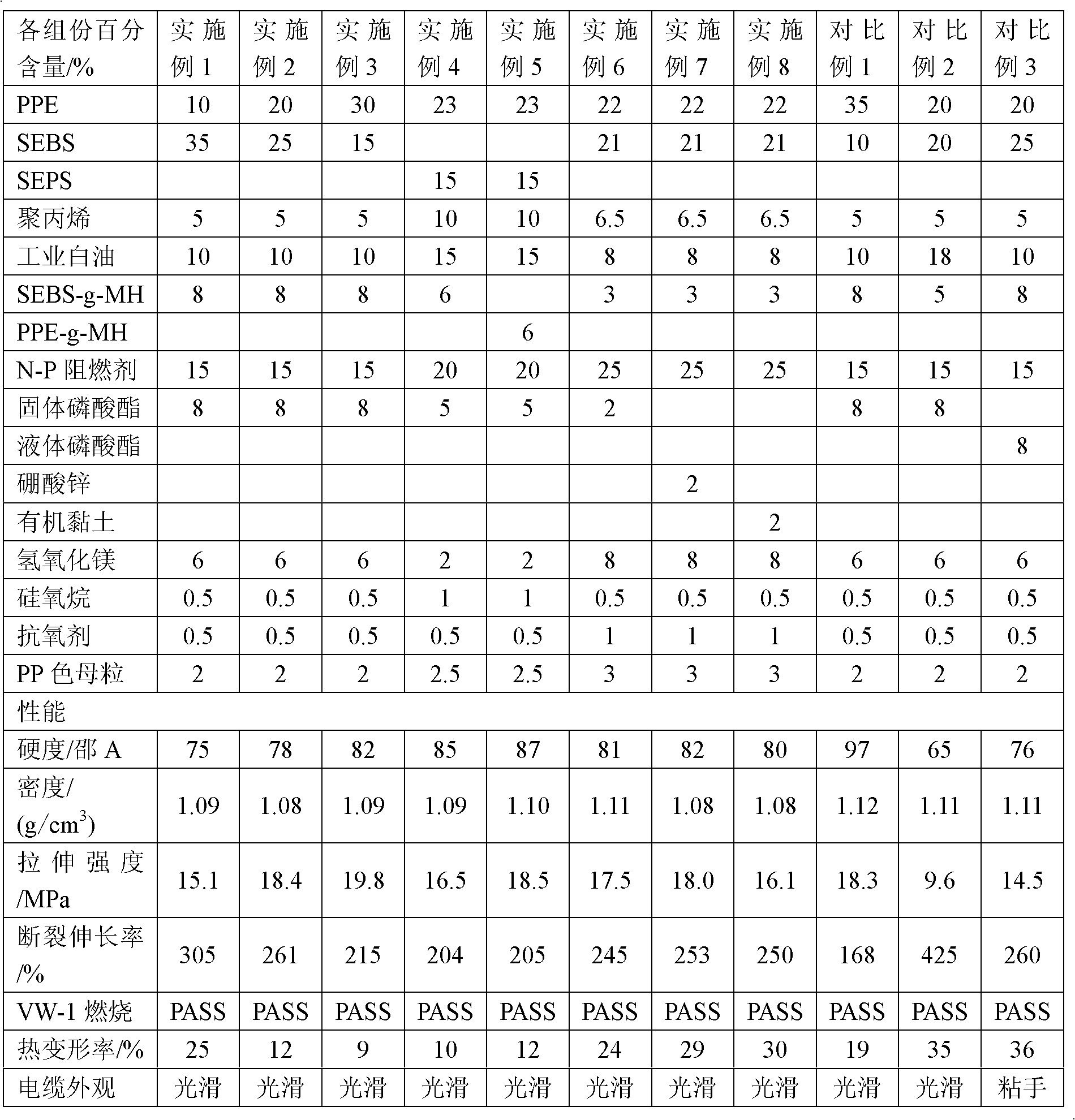

Halogen-free flame-retardant thermoplastic elastomer electrical cable material using polyphenylene ether as base material and preparation method thereof

InactiveCN101358028AGood compatibilityReduce stratificationInsulated cablesInsulated conductorsElastomerPolyphenylene oxide

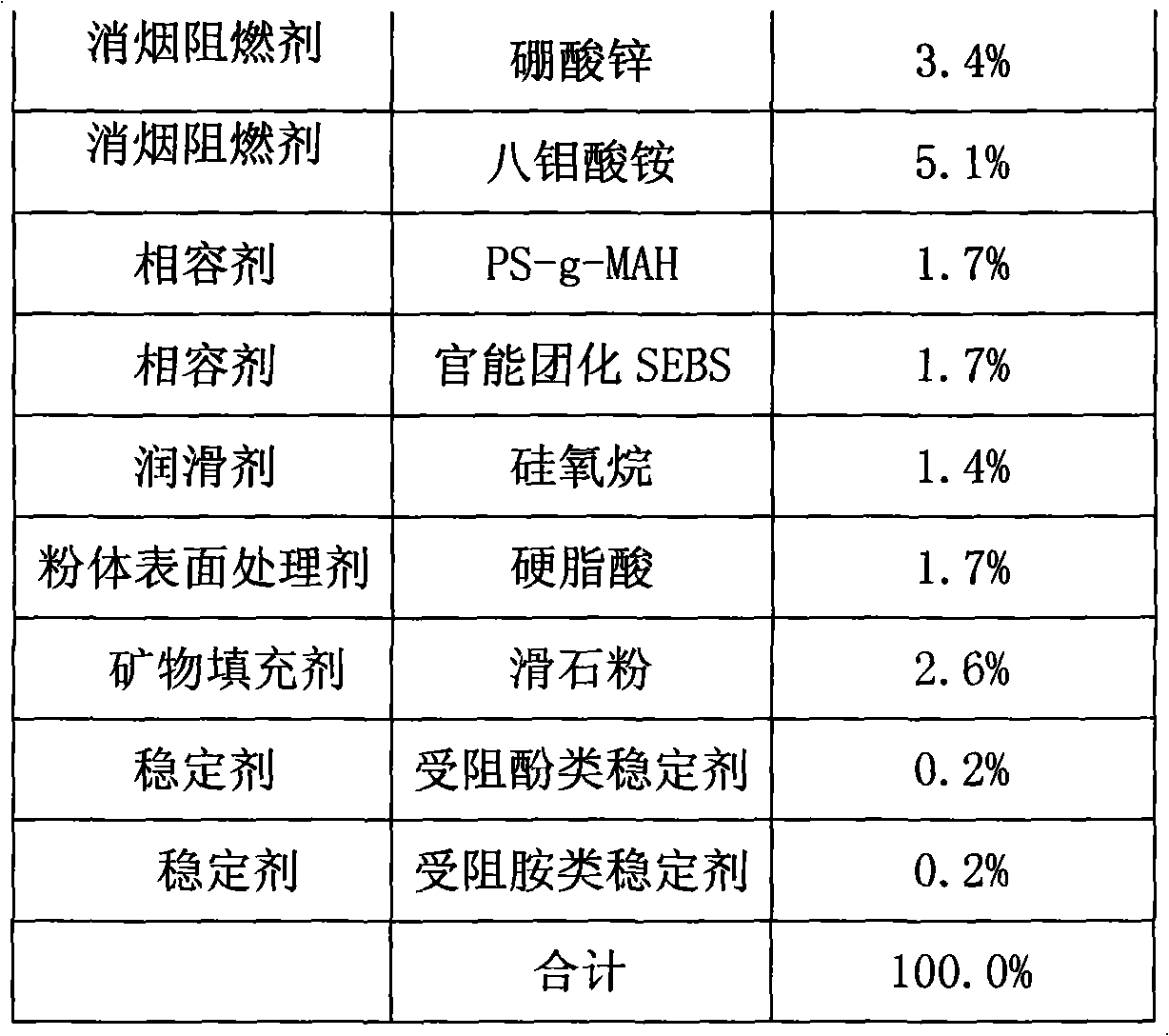

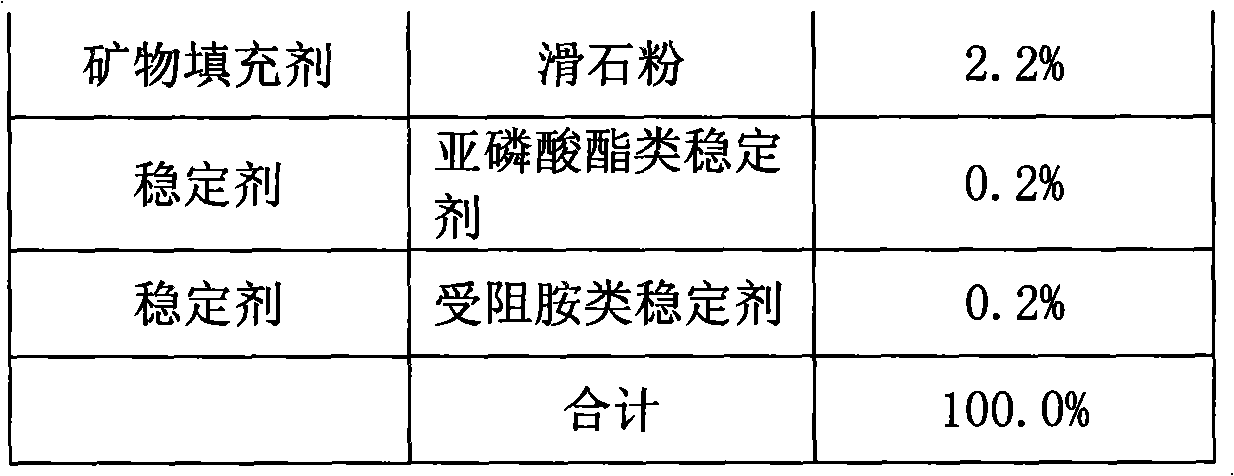

The invention discloses a halogen-free flame-retardant thermoplastic elastomer cable material with polyphenylether as the base materials and a preparation method thereof. The raw material of the cable material contains the components with the following weight percentage: 10 to 35 percent of matrix resin A; 5 to 15 percent of matrix resin B; 10 to 25 percent of elastomer; 5 to 25 percent of softening plasticizer; 8 to 15 percent of flame-retardant plasticizer; 20 to 40 percent of smoke-suppression flame retardant; 3 to 10 percent of compatilizer; 1 to 5 percent of lubricant; 1 to 5 percent of powder surface conditioner; 0 to 10 percent of mineral filler; 0.1 to 1 percent of stabilizing agent. The invention adds matrix resin, polyphenylether of strong polarity and functional group of styrene-ethylene / butylene-styrene segmented copolymer, which effectively improves the compatibility of non-polar elastomer with polyphenylether; the invention also adds plasticizer, which reduces the hardness of the material and increases the flexibility; and through the optimization and interaction of the softening plasticizer and the flame-retardant plasticizer, the invention reduces the hardness and improves the tactility of the material, and the flame retardant performance is excellent.

Owner:NINGBO SHIP PLASTIC CO LTD

High flow polyphenylene ether formulations

A high flow polyphenylene ether resin composition with improved HDT values and flame retardance comprising a blend of at least two polyphenylene ether resins, a first resin having an intrinsic viscosity of at least 0.3 dl / g, and a second resin having an intrinsic viscosity of less than 0.25 dl / g and preferably having a particle size of at least about 100 mum. The composition preferably contains less than 30 wt % of the low viscosity polyphenylene ether based on the weight of the total composition. Fiber reinforced and flame retarded compositions also exhibit high HDT values.

Owner:SABIC INNOVATIVE PLASTICS IP BV

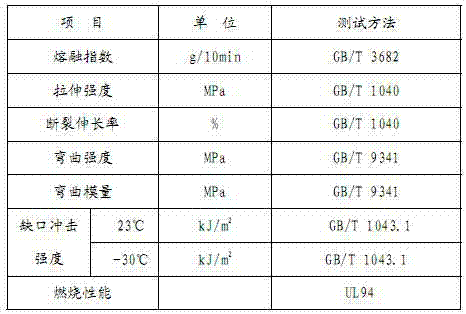

Polyphenylene oxide resin, method of preparing polyphenylene oxide resin, polyphenylene oxide prepolymer and resin composition

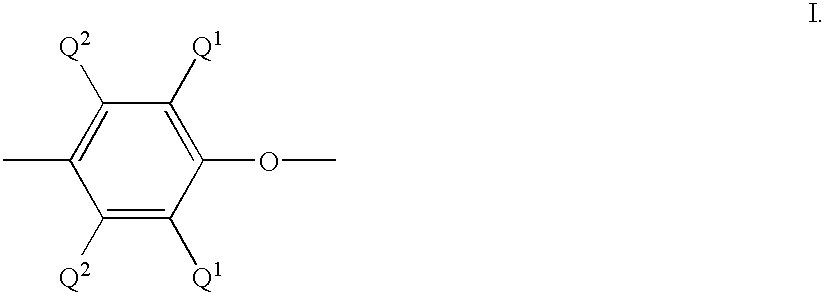

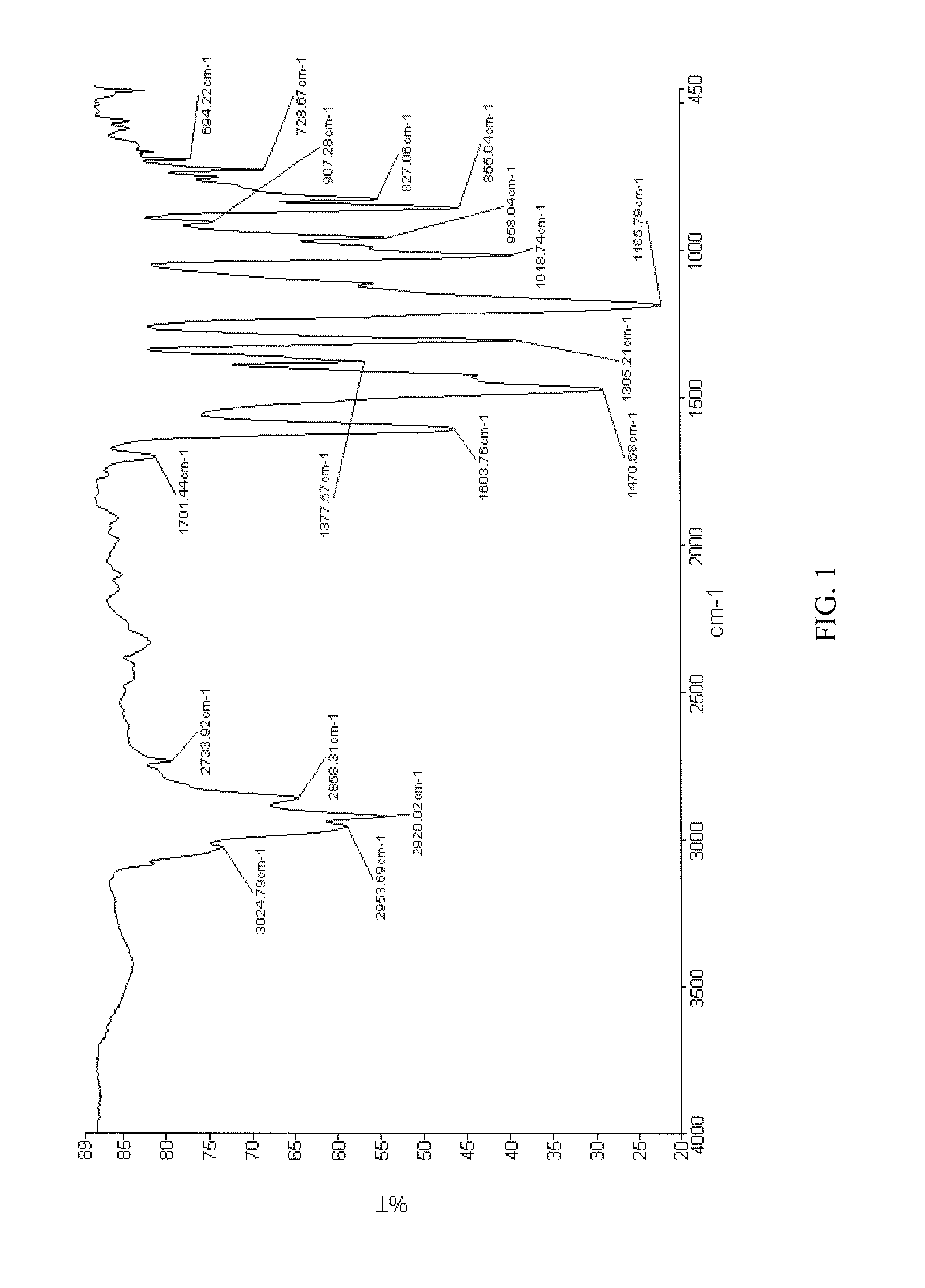

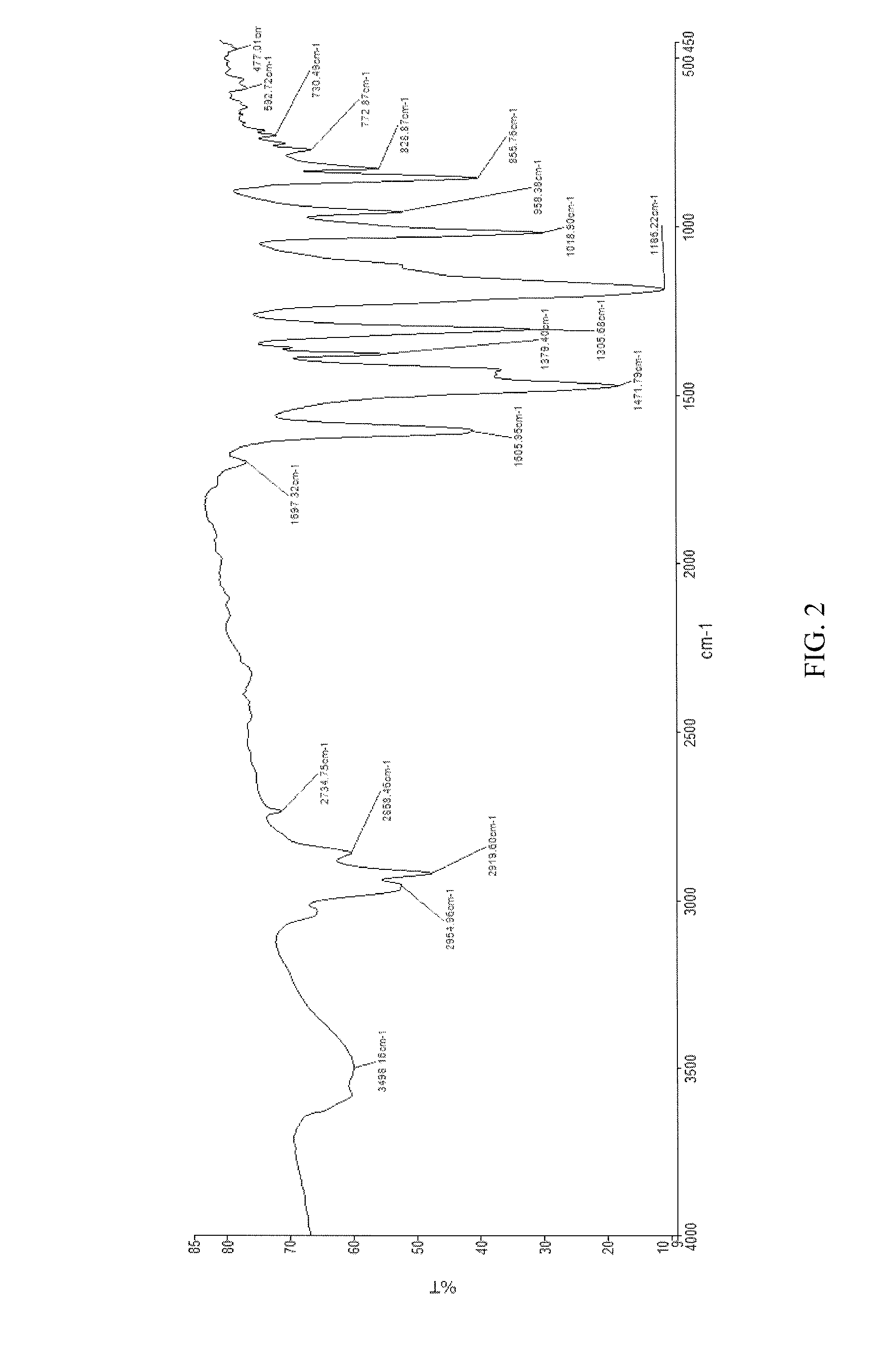

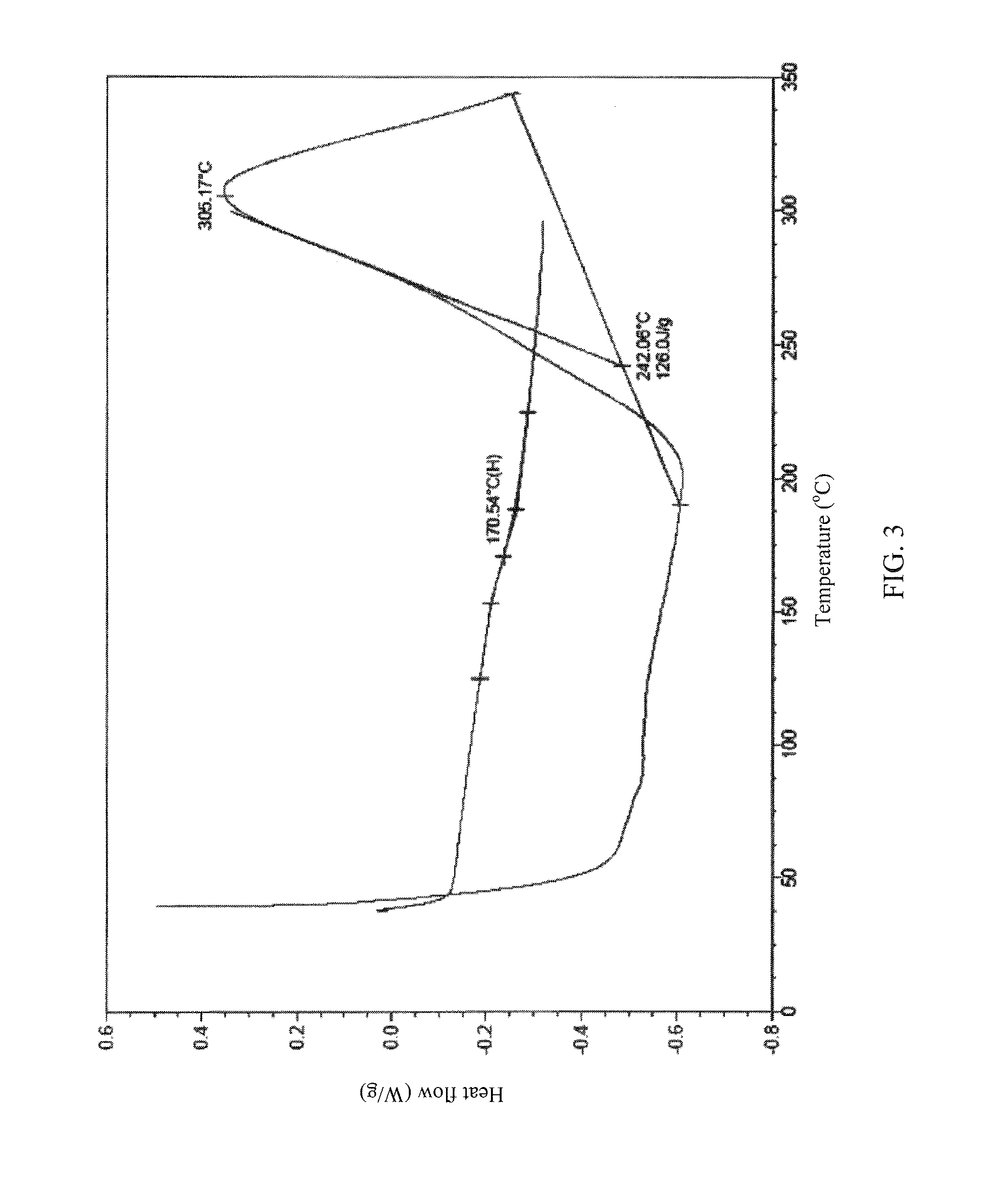

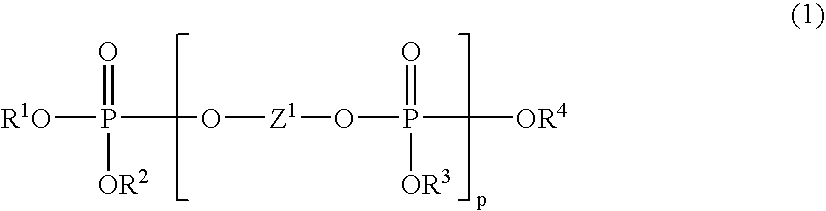

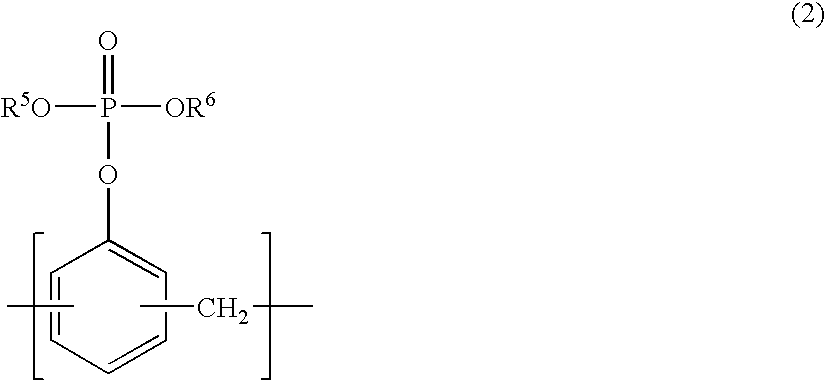

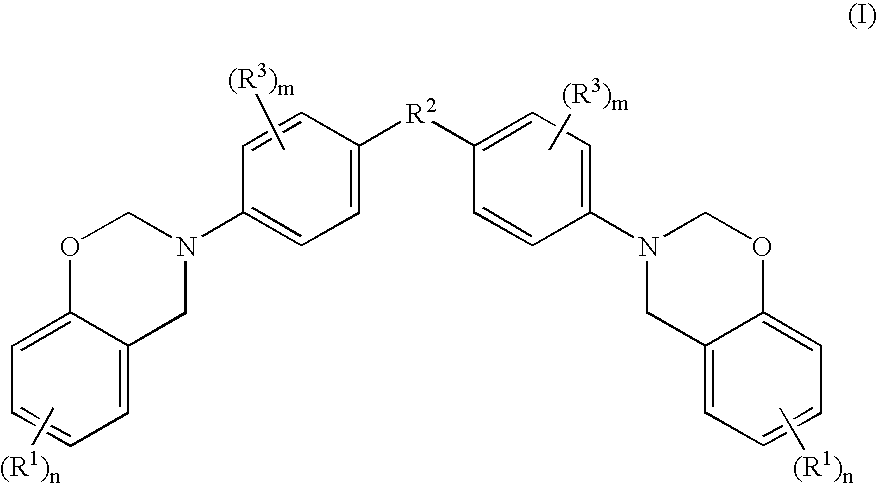

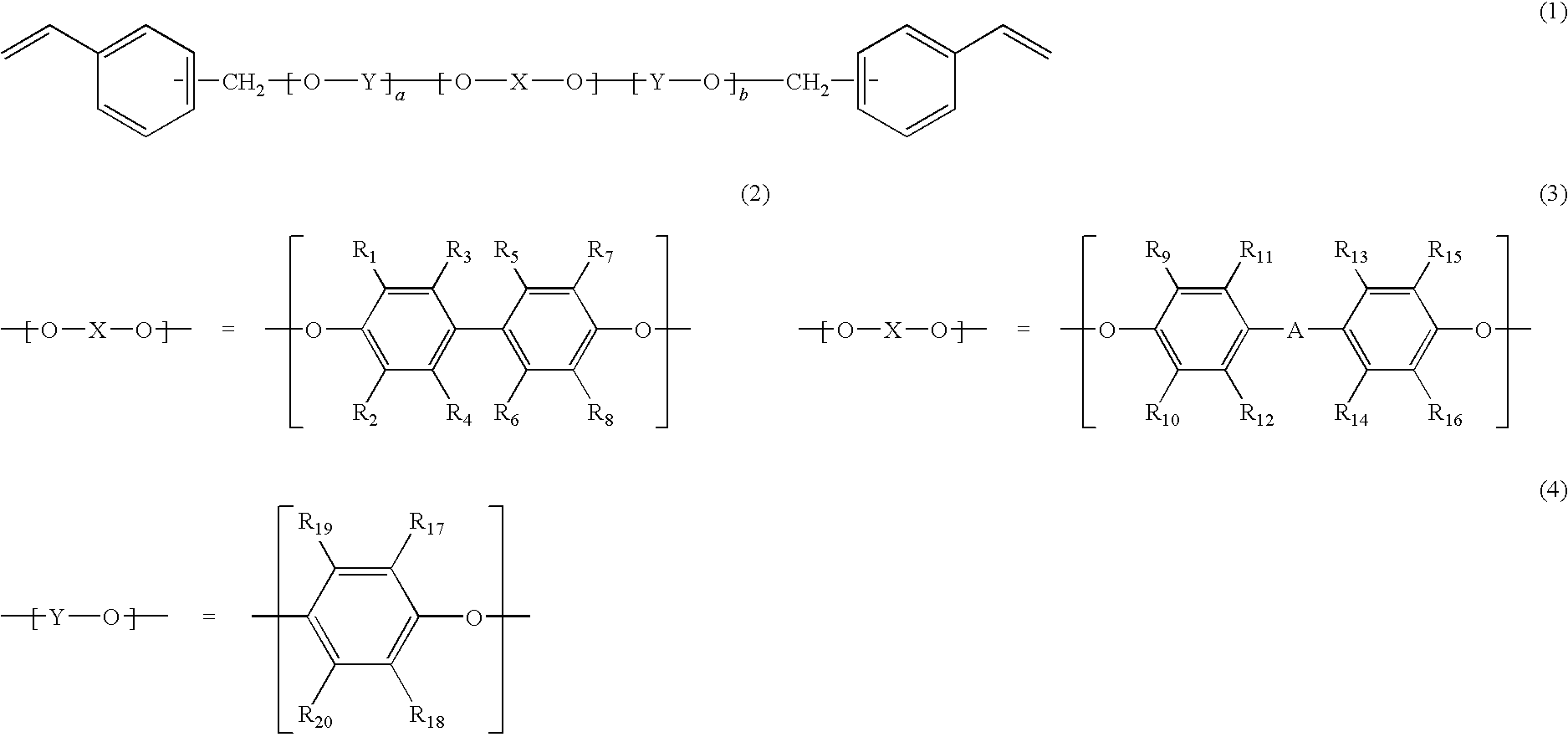

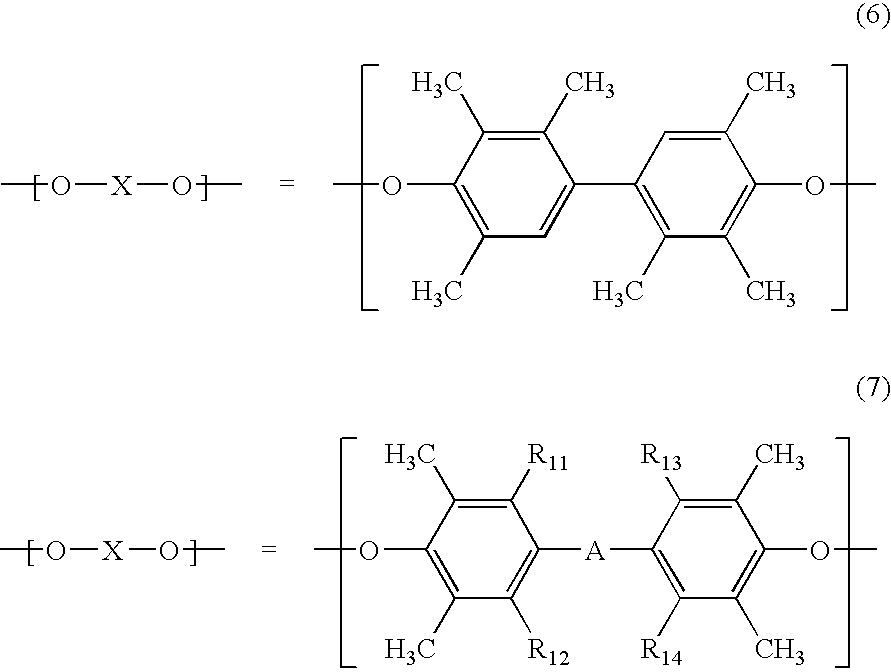

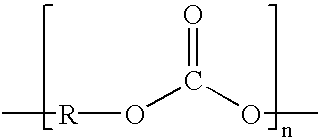

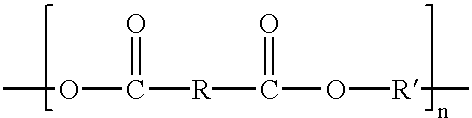

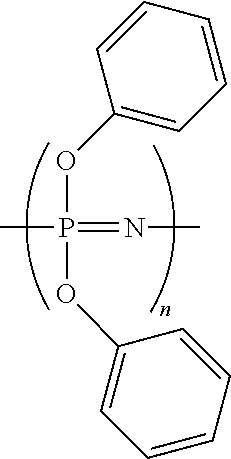

A polyphenylene oxide resin belongs to a polymerized and / or modified thermosetting polyphenylene oxide resin, having a structure represented by formula (I):The polymerized and / or modified thermosetting polyphenylene oxide resin has better flame retardancy, thermal resistance, dielectric constant, dissipation factor, toughness, reactivity, viscosity and solubility. Therefore, the polyphenylene oxide resin is suitable for producing prepregs, resin films, laminates, printed circuit boards and other articles. A method of preparing polyphenylene oxide resins, a prepolymer thereof and a resin composition containing the polyphenylene oxide resin are also provided.

Owner:ELITE ELECTRONICS MATERIAL KUNSHAN

Flame-retardant resin composition

A flame-retardant resin composition comprises 10 to 300 parts by weight of a flame retardant (B) and 1 to 200 parts by weight of an inorganic filler (C) (a glass fiber and / or a glass flake), relative to 100 parts by weight of a base resin (A). The flame retardant (B) comprises a polyphenylene oxide-series resin and / or a polyphenylene sulfide-series resin (B1), a phosphoric ester (B2), and a nitrogen-containing cyclic compound (B3) (for example, a polyphosphate of an amino group-containing triazine compound). The inorganic filler (C) has been treated with a surface-treatment agent or sizing agent containing a novolak epoxy resin. Such a resin composition is useful for obtaining a shaped article which has been inhibited from dripping and to which flame retardancy is highly imparted.

Owner:POLYPLASTICS CO LTD

Halogen-free resin composition and copper clad laminate and printed circuit board using same

ActiveUS20130075138A1Low dissipation factorHigh heat resistancePrinted circuit aspectsSynthetic resin layered productsLow dissipationStyrene maleic anhydride

The halogen-free resin composition comprises (A)100 parts by weight of cyanate ester resin; (B) 5 to 50 parts by weight of styrene-maleic anhydride; (C) 5 to 100 parts by weight of polyphenylene oxide resin; (D) 5 to 100 parts by weight of maleimide; (E) 10 to 150 parts by weight of phosphazene; and (F) 10 to 1000 parts by weight of inorganic filler. By using specific components at specific proportions, the halogen-free resin composition of the invention offers the features of low dielectric constant, low dissipation factor, high heat resistance and high flame retardancy, and can be made into prepreg or resin film, and thereby used in copper clad laminate or printed circuit board.

Owner:ELITE MATERIAL

Halogen-free resin composition

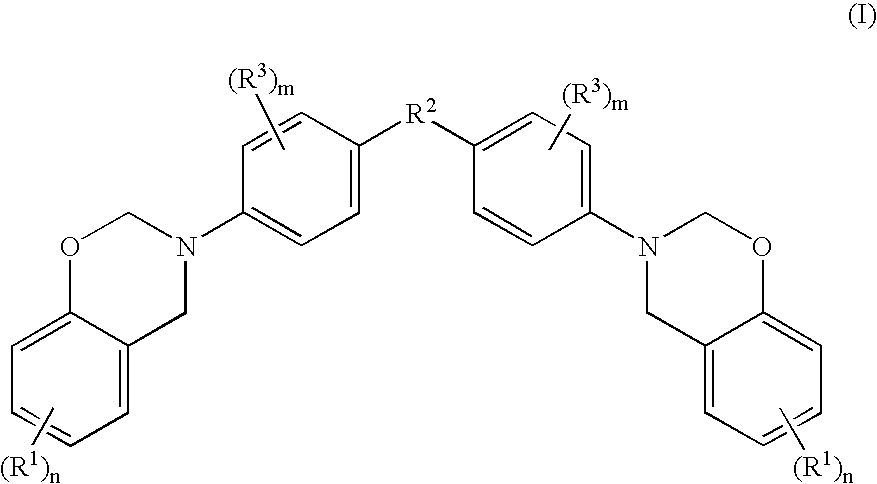

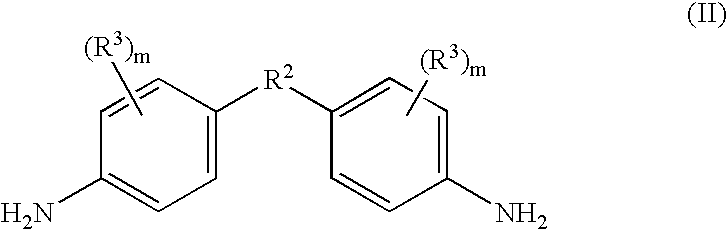

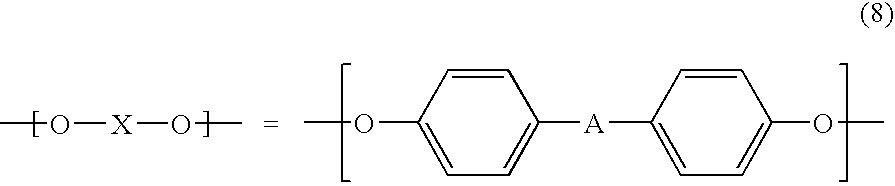

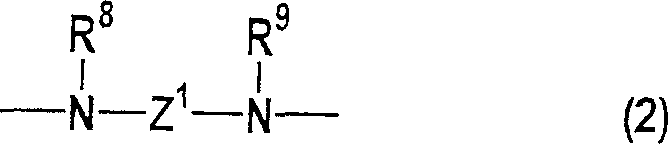

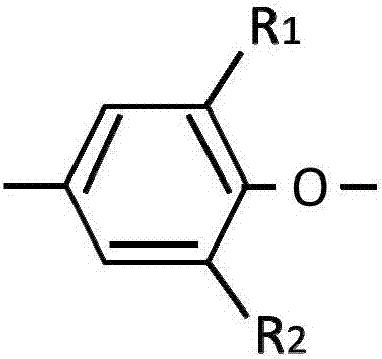

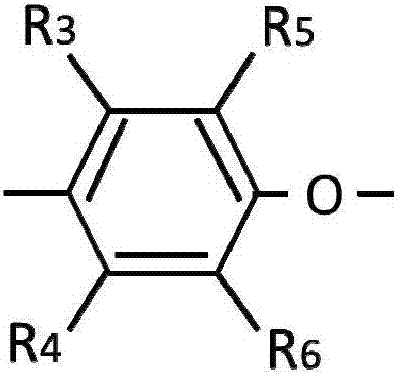

Disclosed is a halogen-free resin composition comprising: (A) one or more phosphorus-containing epoxy resins; (B) a hardener; (C) a hardening accelerator; (D) a polyphenylene oxide resin; and (E) a filling material, wherein the hardener of component B has the structure represented by the following formula (I): wherein each symbol is as defined above. The halogen-free resin composition of the present invention without adding halogen has excellent heat resistance and flame retardant property, and excellent dielectric property. The halogen-free resin composition of the present invention is particularly useful in the application of bonding sheets, composite materials, laminated plates, printed circuit boards, copper foil adhesives, inks used for build-up process, semiconductor packaging materials and the like.

Owner:CHANG CHUN PLASTICS CO LTD

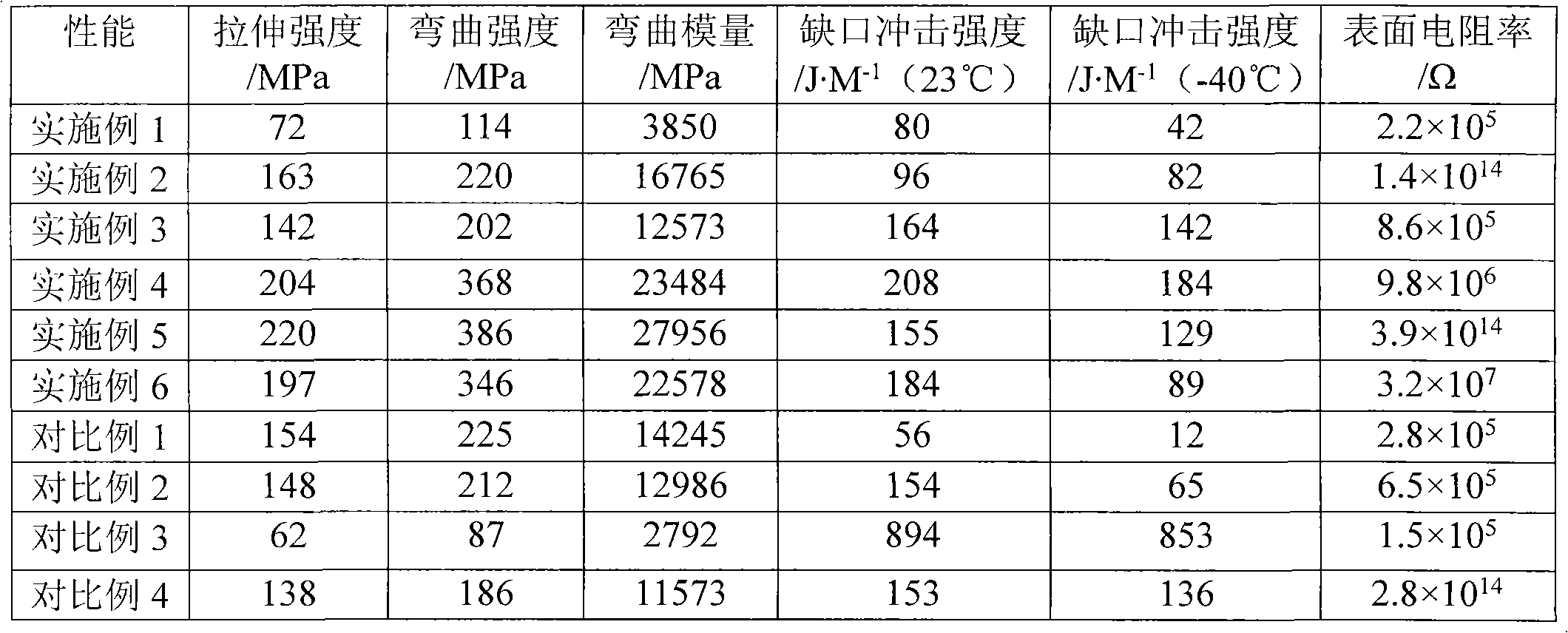

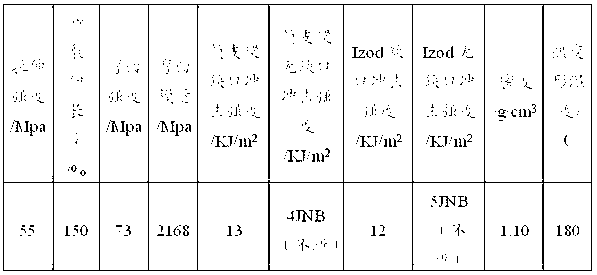

High toughness filling reinforcement poly phenylene sulfide (PPS)/poly-p-phenylene oxide (PPO) alloy and method for preparing same

The invention relates to a high toughness filling reinforcement poly phenylene sulfide (PPS) / poly-p-phenylene oxide (PPO) alloy and a method for preparing the same. The alloy comprises 1-99 parts by weight of polyphenylene sulfide, 99-1 part by weight of polyphenyl ether, 10-200 parts by weight of glass fiber, 1-50 parts by weight of filler, 3-10 parts by weight of compatilizer, 5-30 parts by weight of toughening agent, 0.2-2 parts by weight of coupling agent, 0.2-2 parts by weight of antioxidant and 0.5-3 parts by weight of processing agent, wherein the sum of the parts by weight of the polyphenylene sulfide and the polyphenyl ether is 100 parts by weight. The alloy has the advantages of high toughness, impact cracking resistance, excellent strength and rigidity, excellent compatibility, high temperature resistance, inflaming retardance, chemical corrosion resistance, solvent resistance, stress cracking resistance, excellent processing performance and the like, and can be safely applied to various electrical and electronic equipment parts, vehicle equipment parts and chemical equipment parts and even ships, bridges and building materials.

Owner:张国庆 +1

Low-smoke halogen-freeflame-proof polyphenylene oxide electric wire and cable material, and method for producing the same

InactiveCN101130616AImprove flame retardant performanceImprove toughnessInsulated cablesInsulated conductorsElastomerPliability

The invention discloses a low smoke non-bitter flame-proof polyphenyl ether electric wire and cable material and preparing method, which is characterized by the following: allocating 40-80 wt polyphenyl ether PPO, 20-60 wt high impact polystyrene HIPS, 10-70 wt elastic body, 1-20 wt functional polyphenyl ether, 10-60 wt fire retardant, 5-20 wt smoke suppressor, 1-3 wt anti-oxidant and 3-5 wt environmental protection color master particle; using higher rigidity, good electrical isolation property and water resistance of the polyphenyl ether material; decreasing hardness of blending system; increasing tenacity; adding into inclusive property; increasing cohesion between the PPO and the elastic body; improving combination mechanical property of the blending material. This product is environmental protection product, which possesses good water resistance property and electrical isolation property.

Owner:SHENZHEN KEJU NEW MATERIAL

Resin composition, prepreg and metal-foil-clad laminate

ActiveUS20090247032A1Improve suppression propertiesHigh multilayerPrinted circuit aspectsSynthetic resin layered productsMetal foilCopper foil

A vinyl-compound-based resin composition containing a terminal vinyl compound (a) of a bifunctional phenylene ether oligomer having a polyphenylene ether structure, a naphthol aralkyl type cyanate ester resin (b), a bisphenol A cyanate ester resin (c), a brominated flame retardant (d) and an inorganic filler (e), which resin composition is for use in a printed wiring board for high multilayer and high frequency and is improved in moldability and copper foil peel strength, which are conventional problems, without any decrease in electric characteristics and heat resistance after moisture absorption while keeping flame retardancy, a prepreg comprising the above resin composition and a glass woven fabric, a metal-foil-clad laminate obtained by disposing a metal foil on one side or both sides of a stack of at least one prepreg and laminate-molding the resultant set, and a resin sheet obtained by applying a solution of the above resin composition to a surface of a metal foil or a film.

Owner:MITSUBISHI GAS CHEM CO INC

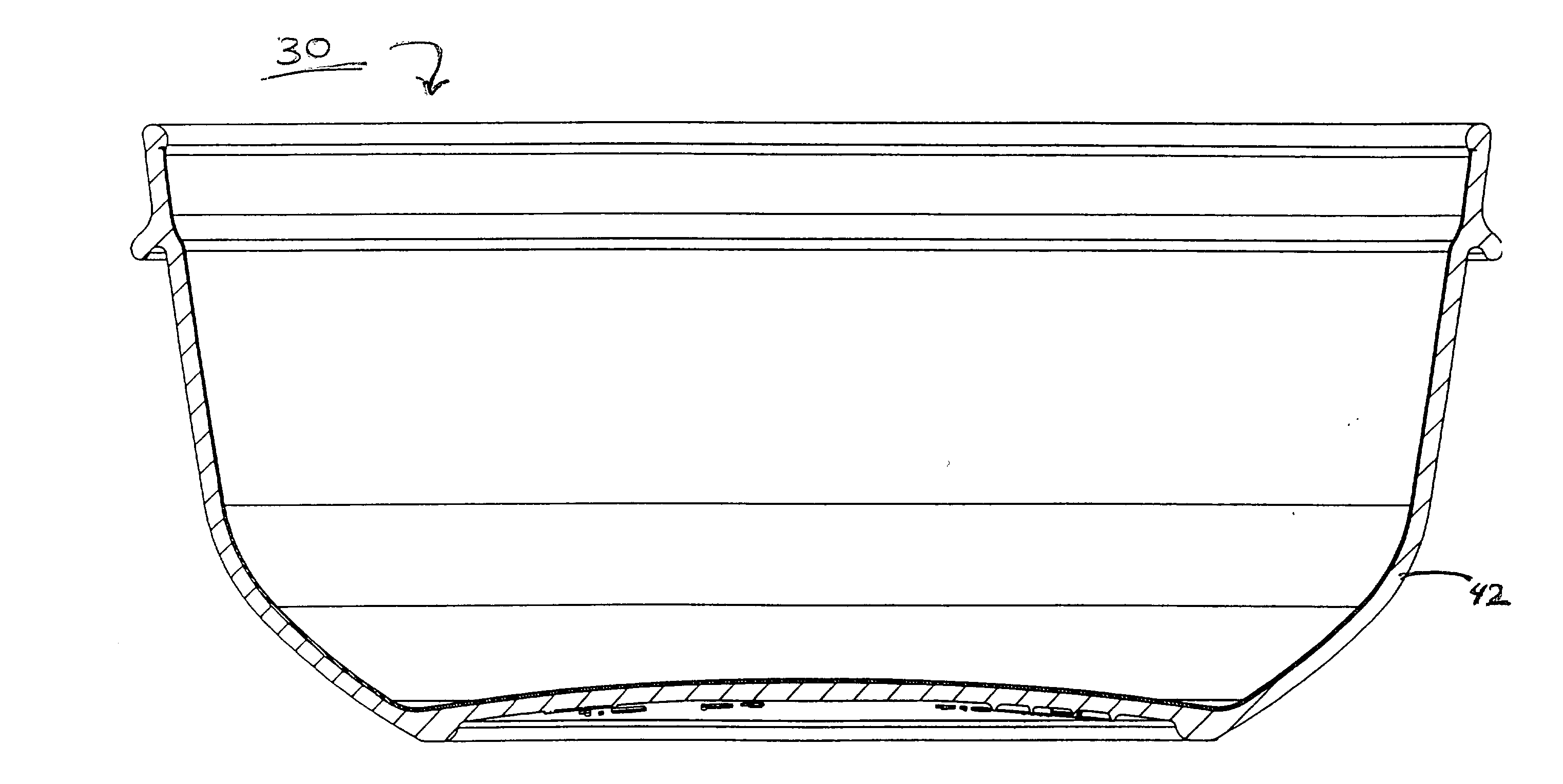

Multi-layer plastic articles and methods of making the same

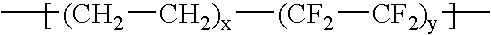

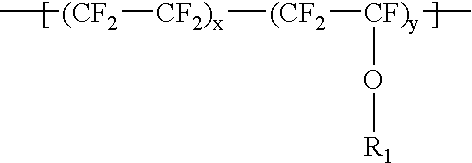

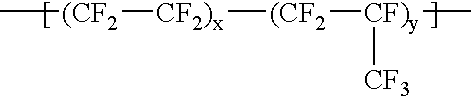

A three-dimensional, multi-layer plastic product that is resistant to damage caused by environmental factors such as heat, chemicals, desiccants, oxygen, and / or weather is disclosed. The multi-layer product includes an engineering resin layer affixed to a commodity resin layer. The engineering resin layer of the multi-layer film may be directly fused to the commodity resin or post-consumer regrind layer. Alternatively, the engineering resin layer may be tied to the commodity resin or post-consumer regrind layer through the use of one or more adhesive and / or tie layers. The commodity resin layer may be manufactured from an economical polymer material such as a polypropylene, polyethylene, polystyrene or post-consumer regrind. Suitable engineering resins may be any of a variety of suitable materials such as a polysulphone, polymethylpentene, polyester, polycarbonate, polyetherimide, nylon, polyarylate, polyphenylenesulphide, polyphenylene oxide, polyethersulphone, aromatic polyketone, liquid crystal polymer, and mixtures thereof, for example, a method for manufacturing a three-dimensional multi-layer plastic product is also disclosed which includes the steps of providing an extruded or laminated sheet comprising an engineering resin layer, thermoforming a three-dimensional shell from the sheet, and injection molding a commodity resin layer onto the thermoformed shell.

Owner:RUBBERMAID

Flexible halogen-free flame-retardant polyphenyl ether electric wire cable shield material and preparation method thereof

InactiveCN102585428ANo migrationImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesElastomerPolyolefin

The invention relates to the field of halogen-free flame-retardant electric wire cable shield materials, in particular to a flexible halogen-free flame-retardant polyphenyl ether electric wire cable shield material and a preparation method thereof. The flexible halogen-free flame-retardant polyphenyl ether electric wire cable shield material is characterized by comprising the following raw materials in percentage: 10 to 30 percent of polyphenyl ether resin; 15 to 35 percent of styrene elastomer; 5 to 10 percent of polyolefin; 8 to 15 percent of plasticizing agent; 3 to 8 percent of compatilizer; 15 to 25 percent of main flame retardant; 2 to 8 percent of synergistic flame retardant; 2 to 8 percent of smoke suppressant; 0.5 to 1 percent of lubricant; 0.5 to 1 percent of antioxygen; and 2 to 3 percent of masterbatch. The flexible halogen-free flame-retardant polyphenyl ether electric wire cable shield material has favorable mechanical property, flexibleness, flame retardant property, heat resistance and processability.

Owner:浙江北化阻燃材料有限公司 +1

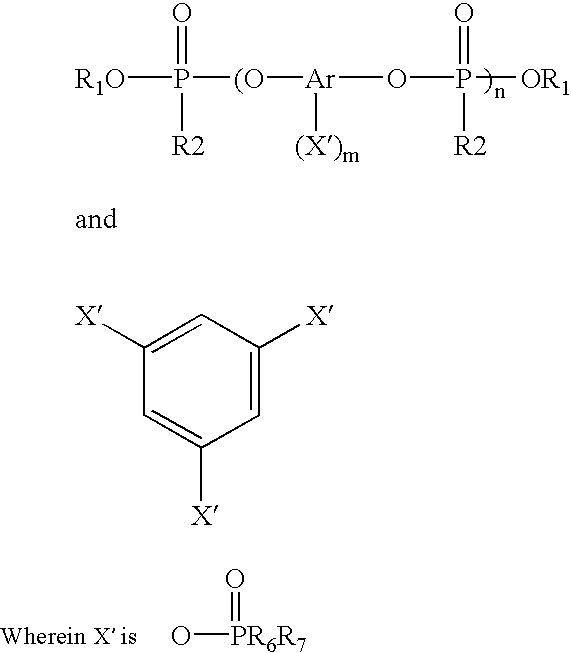

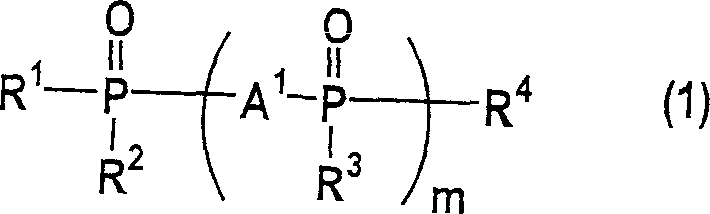

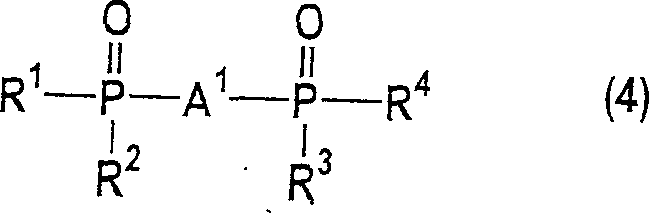

Flame-retardant resin composition

InactiveCN1599776AHigh level of flame retardancyInhibition of hydrolysisPhosphoric Acid EstersOxygen

A flame-retardant resin composition comprises a thermoplastic resin; a flame retardant comprising a phosphorus-containing compound (A), a aromatic resin (B), and at least one flame-retardant auxiliary (C) selected from a nitrogen-containing compound and a metal salt of an inorganic acid; and at least one stabilizer auxiliary (D) selected from a compound having a functional group reactive to an active hydrogen atom and a water-repellent compound. The phosphorus-containing compound may be a phosphoric ester. The aromatic resin may be a polyphenylene sulfide-series resin or a polyphenylene oxide-series resin. The nitrogen-containing compound is a salt of an amino group-containing triazine compound with an oxygen acid, a salt of an amino group-containing triazine compound with a hydroxyl group-containing triazine compound, a polyphosphoric acid amide, a cyclic urea compound, or others. The present invention provides a flame-retardant resin composition which has been flame-retarded without using a halogen-containing flame retardant.

Owner:POLYPLASTICS CO LTD

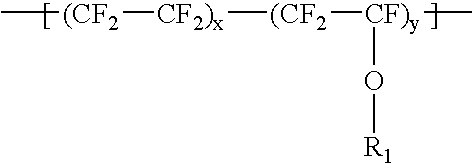

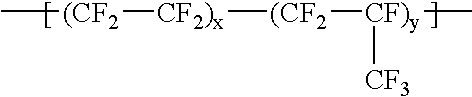

Compositions useful in electronic circuitry type applications, patternable using amplified light, and methods and compositions relating thereto

InactiveUS20060286365A1Synthetic resin layered productsLiquid/solution decomposition chemical coatingPolyesterPolyamide

A light-activatable polymer composition and polymer composite includes a polymer binder selected from epoxy resins, silica filled epoxy, bismaleimide resins, bismaleimide triazines, fluoropolymers, polyesters, polyphenylene oxide / polyphenylene ether resins, polybutadiene / polyisoprene crosslinkable resins (and copolymers), liquid crystal polymers, polyamides, cyanate esters, or combinations thereof, the polymer binder being present in an amount from 40, 45, 50, 55, 60, 65, 70, 75, 80, 85, 90, 95, 96, or 97 weight-percent of the total weight of the polymer composition; a spinel crystal filler present in an amount from 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 20, 25, 30, 35, 40, 45, 50, 55 and 60 weight-percent of the total weight of the polymer composition, and methods for making same are provided.

Owner:EI DU PONT DE NEMOURS & CO

Polyphenyl ether resin material used for processing charger case

The invention discloses a polyphenyl ether resin material used for processing a charger case, which consists of polyphenyl ether resin, polystyrene resin, an elastic body, fire retardants, polyolefin, silicone masterbatch, main antioxidants and auxiliary antioxidants. Through adding proper auxiliary agents into a polyphenyl ether resin composition, the invention improves the surface lubricating effect of manufactured elements, reduces the pressure required during welding, and solves the problems of impression, scratches and the like occurring during the ultrasonic welding of products. The products are mainly applied to the fields requiring the ultrasonic welding, such as charger cases, wiring cases and the like.

Owner:NANTONG XINGCHEN SYNTHETIC MATERIAL +1

Compositions useful in electronic circuitry type applications, patternable using amplified light, and methods and compositions relating thereto

A light-activatable polymer composition and polymer composite includes a polymer binder selected from epoxy resins, silica filled epoxy, bismaleimide resins, bismaleimide triazines, fluoropolymers, polyesters, polyphenylene oxide / polyphenylene ether resins, polybutadiene / polyisoprene crosslinkable resins (and copolymers), liquid crystal polymers, polyamides, cyanate esters, or combinations thereof, the polymer binder being present in an amount from 40, 45, 50, 55, 60, 65, 70, 75, 80, 85, 90, 95, 96, or 97 weight-percent of the total weight of the polymer composition; a spinel crystal filler present in an amount from 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 20, 25, 30, 35, 40, 45, 50, 55 and 60 weight-percent of the total weight of the polymer composition, and methods for making same are provided.

Owner:EI DU PONT DE NEMOURS & CO

Polyphenylene oxide/polyamide 6 blend alloy as well as preparation method and application for same

The invention discloses a polyphenylene oxide / polyamide 6 blend alloy. The polyphenylene oxide / polyamide 6 blend alloy is prepared from the components in the following parts by weight: 20-80 parts of polyphenylene oxide, 10-40 parts of polyamide 6, 5-35 parts of compatilizer, 5-15 parts of toughener, 0.2-0.5 parts of antioxidant, 0.2-0.7 parts of lubricant, and 3-35.5 parts of auxiliaries. The invention further discloses a preparation method for the polyphenylene oxide / polyamide 6 blend alloy and an application for the polyphenylene oxide / polyamide 6 blend alloy as an extruded profile material. The PPO / PA6 (polyphenylene oxide / polyamide 6) blend alloy material disclosed by the invention is high in strength, good in toughness, excellent in corrosion resistance and insulativity, capable of replacing a steel plate or a special engineering plastic, thus realizing the purpose of replacing steel by plastic. Moreover, the PPO / PA6 blend alloy material can be popularized to extruded profiles, as well as is good in wear resistance, heat resistance and dimensional stability, easy to machine and form, and capable of being used by replacing the profiles of stainless steel, PEEK (poly ether ether ketone) and the like in a very large range, thus greatly reducing cost.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

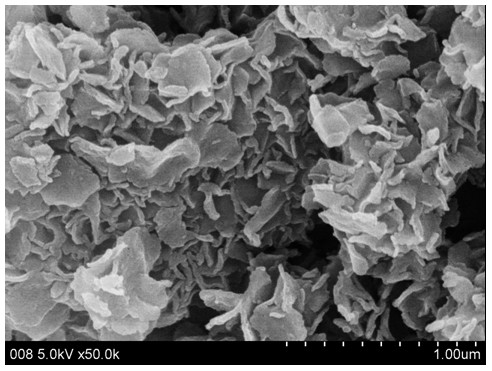

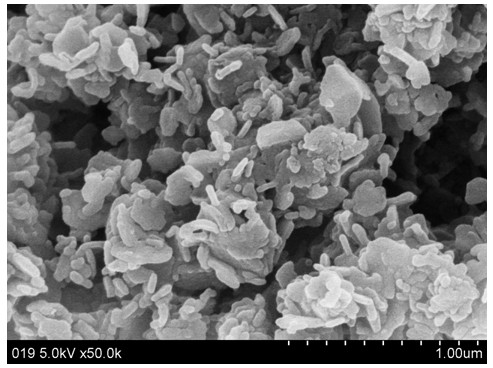

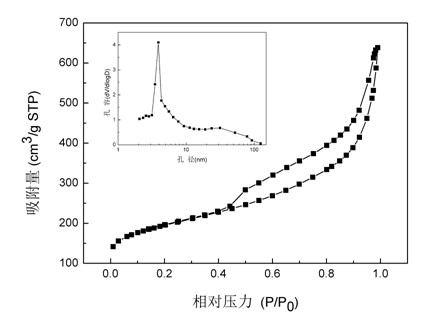

Preparation method of mesoporous carbon nanosheet and application of mesoporous carbon nanosheet as electrode material of super capacitor

ActiveCN102682928AImprove electrochemical performanceImproved magnification performanceElectrolytic capacitorsHybrid capacitor electrodesPolyethylene oxideElectric capacity

The invention relates to preparation of a mesoporous carbon nanosheet and application of the mesoporous carbon nanosheet as an electrode material in a super capacitor. According to the method, a porous magnesium oxide nanosheet is used as a template, dopamine is used as a carbon precursor, a carbon source is uniformly coated on the surface of the magnesium oxide nanosheet to form a complex, the complex is carbonized at a high temperature, and the magnesium oxide of the template is removed with excess sulfuric acid solution to obtain a two-dimensional carbon nanosheet. Triblock copolymer PEO-PPO-PEO (Polyethylene Oxide-Polyphenylene Oxide-Polyethylene Oxide) added in a preparation process is used as a structure directing agent to form a mesoporous structure, so that the specific surface area and the pore capacity of the carbon nanosheet are improved and transmission and diffusion of electrolyte ions are facilitated to improve the electric capacity of the material. The coating thickness of the carbon source on the surface of the template can be effectively controlled by adjusting the mass ratio of the template to the carbon source and the polymerization reaction time of the dopamine, and correspondingly the carbon nanosheets with different thicknesses are obtained, so that the electrochemical performance of the carbon nanosheet is affected.

Owner:EAST CHINA UNIV OF SCI & TECH

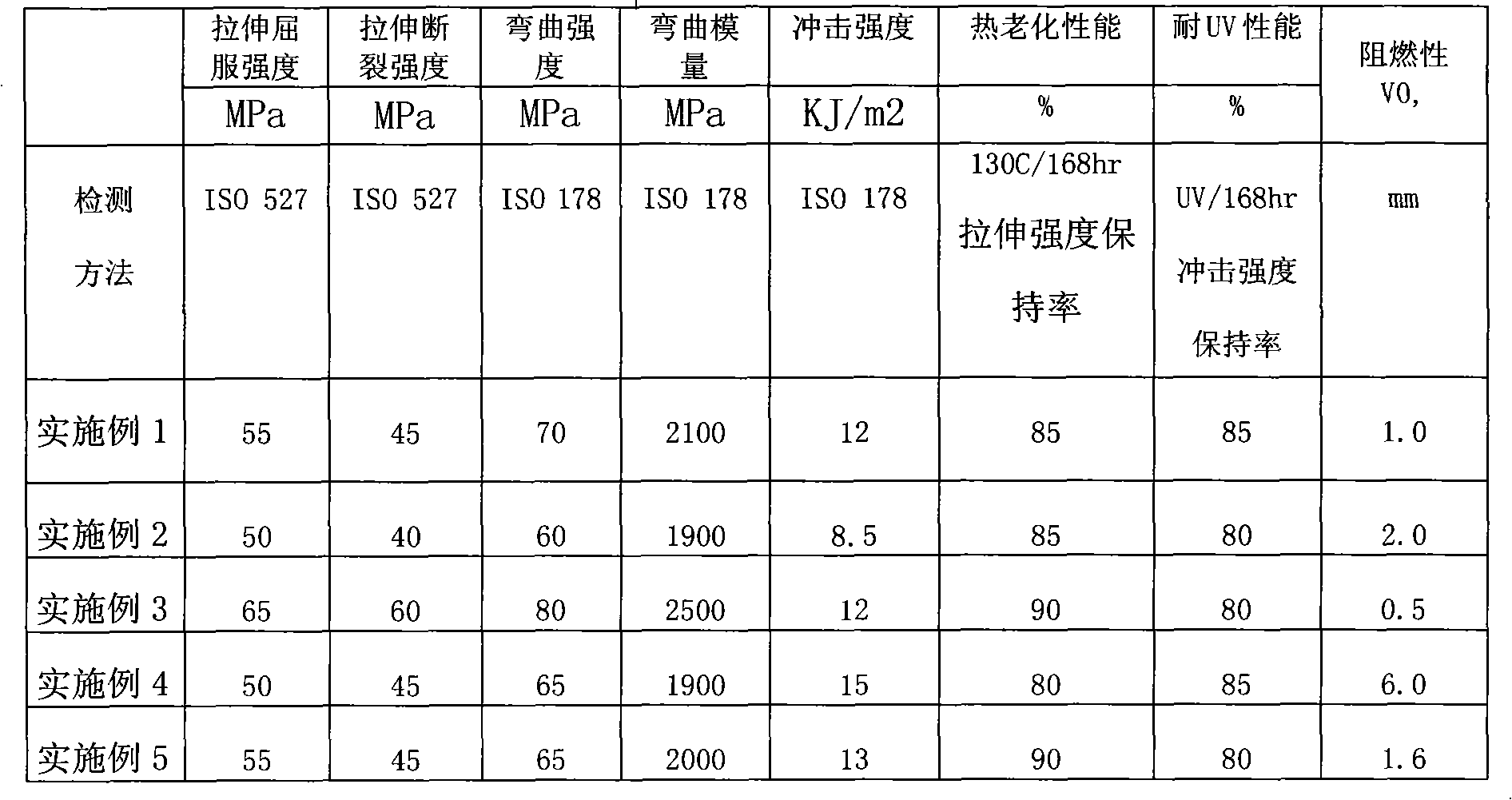

Polyphenylene oxide composition used for photovoltaic junction box

ActiveCN102399433AImprove liquidityGuaranteed toughnessHazardous substanceComparative Tracking Index

The invention provides a polyphenylene oxide composition used for a photovoltaic junction box. The composition comprises the following components by weight: 55-95 parts of polyphenylene oxide, 45-5 parts of styrene resin, 2-10 parts of a flexibilizer, 5-20 parts of a phosphate fire retardant, 0.5-2.5 parts of an acid absorbent, 0.2-0.6 part of a hindered phenol main antioxidant, 0.2-0.6 part of a phosphite auxiliary antioxidant, 0.3-1.5 parts of an ultraviolet absorbent, 0.3-1.5 parts of a hindered amine light stabilizer, 0.1-0.5 part of a lubricating agent, and 0.1-1.0 part of toner. With the characteristics of good flame resistance, thermo-oxidative aging resistance, UV (ultraviolet) resistance, excellent electrical performances, the composition of the invention has flame retardancy up to grade UL945VA, RTI (relative temperature index)=110DEG C, CTI (comparative tracking index) PLC ( programmable logic controller)=2, and GWIT (glow wire ignition temperature)=750DEG C, thus satisfying the requirements in ROHS (restriction of hazardous substances) standard. Thus, the composition provided in the invention can be used for electronic and electrical component production of solar photovoltaic junction boxes, etc.

Owner:广东瑞能新材料有限公司

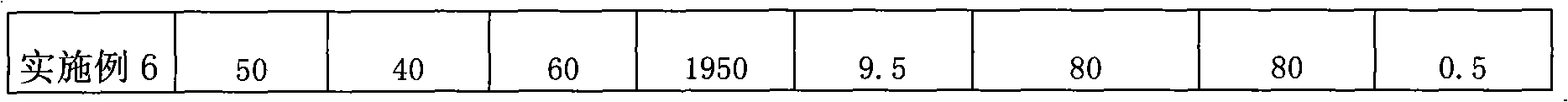

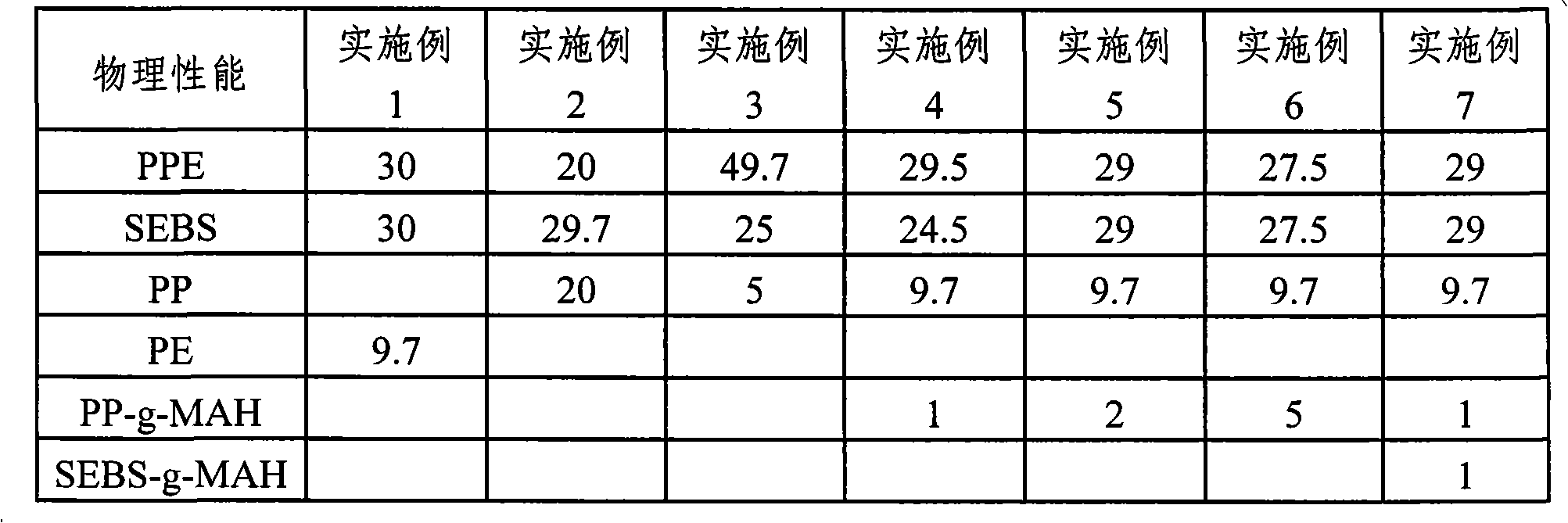

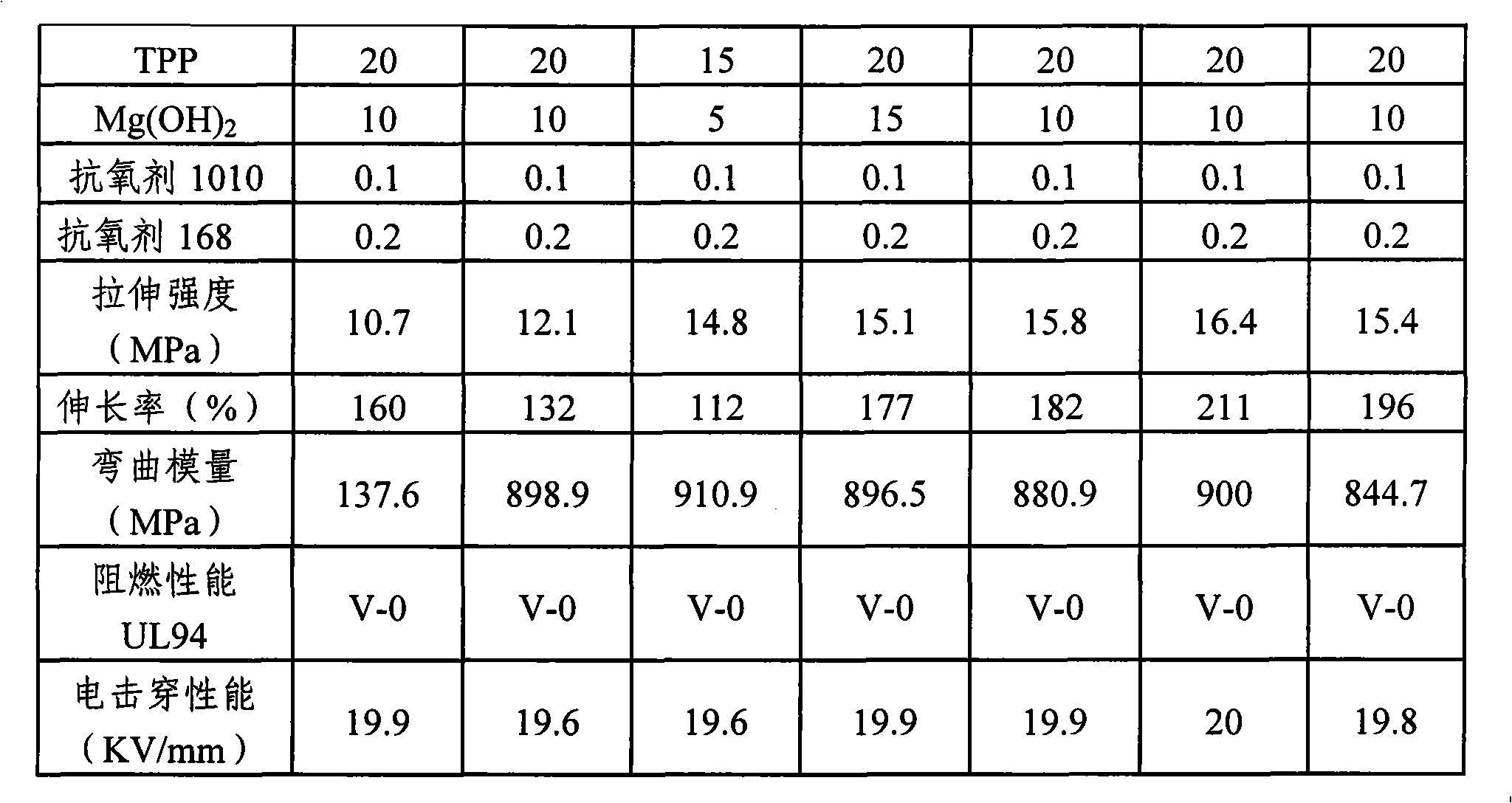

Halogen-free flame retardant polyphenylene oxide polyphenyl ether (PPE) cable material composition and preparation method thereof

ActiveCN102030978AGood flexibilityImprove mechanical propertiesPlastic/resin/waxes insulatorsInsulated cablesElastomerPolyolefin

The invention relates to a halogen-free flame retardant polyphenylene oxide polyphenyl ether (PPE) cable material composition and a preparation method thereof. The composition comprises the following components in percentage by mass: 20 to 50 percent of polyphenylene oxide polyphenyl ether (PPE), 24 to 30 percent of elastomer, 5 to 20 percent of polyolefin, 20 to 35 percent of flame retardant agent, 0 to 5 percent of compatilizer and 0.1 to 1.0 percent of antioxidant. The halogen-free flame retardant PPE cable material composition prepared by the method has the advantages of high flexibility, high mechanical property, high flame retardance, high resilience and the like, does not comprise halogen, is an environmental-friendly product, and can be widely applied to insulation sheaths of halogen-free ultrathin lead connecting leads, direct current electric wires and plugs, electrical product electric wires, telecommunication facility cables, cable sheaths and the like.

Owner:CHINA NAT BLUESTAR GRP CO LTD +1

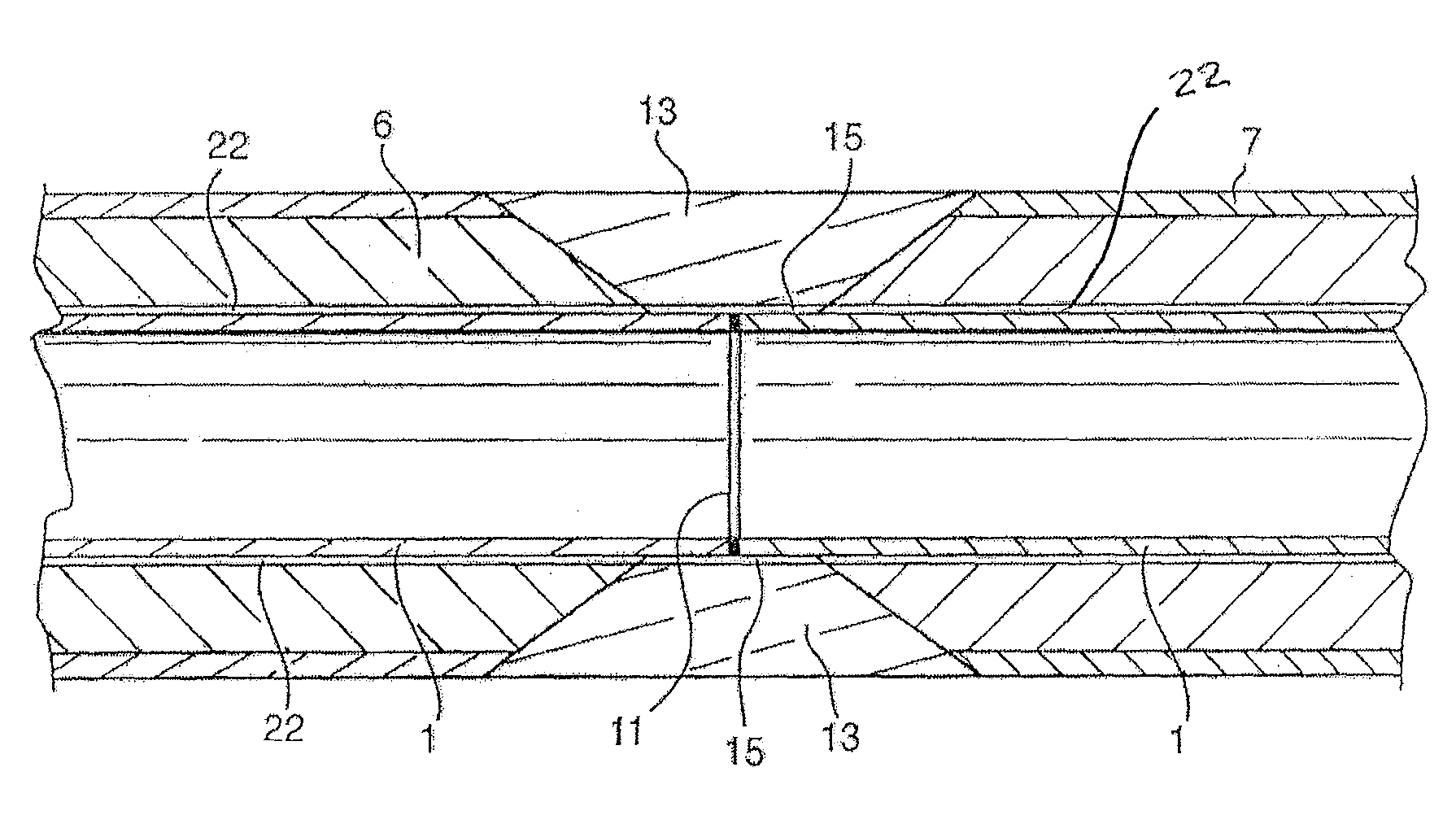

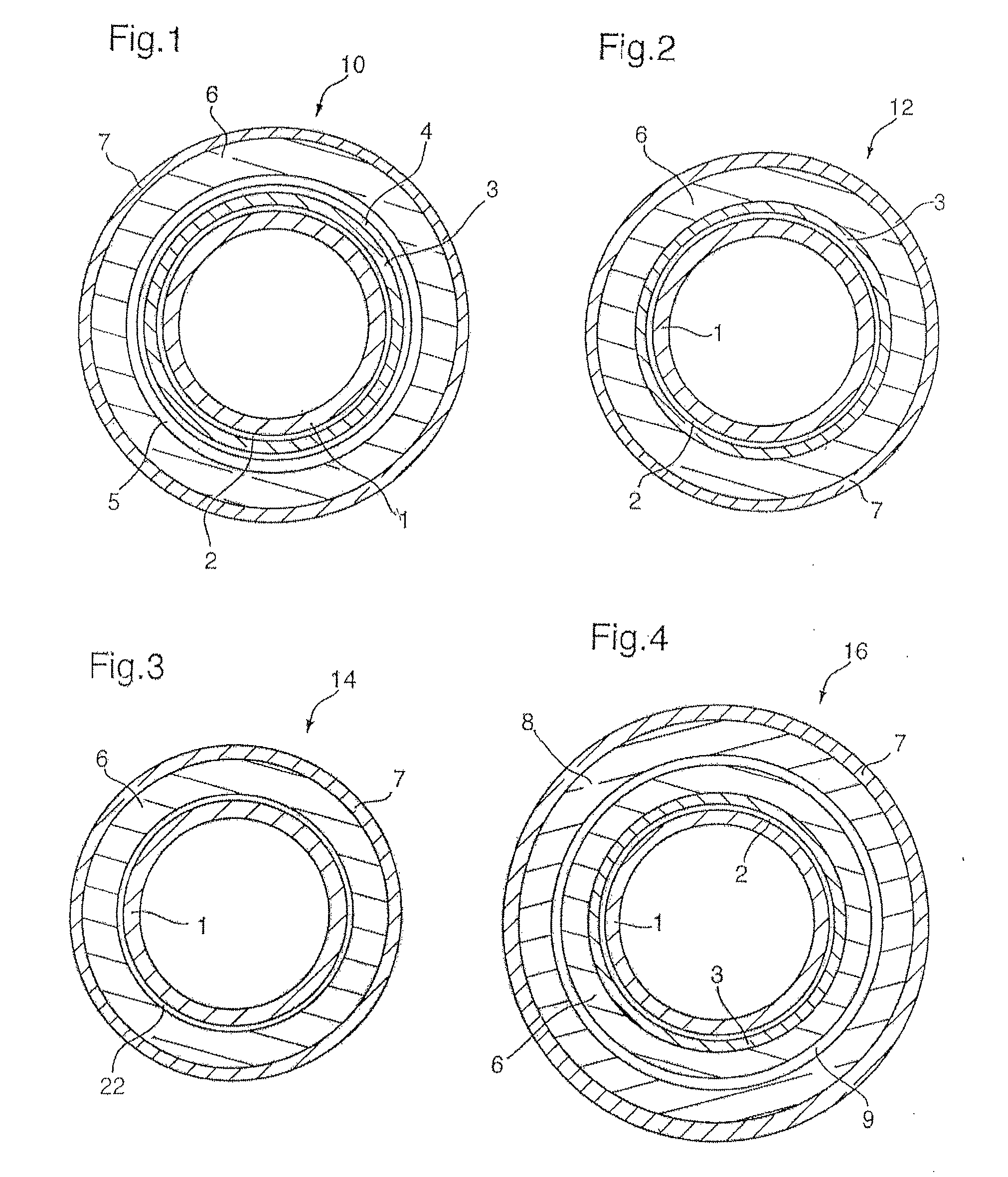

High temperature resistant insulation for pipe

ActiveUS8397765B2Low thermal conductivityImprove thermal stabilityThermal insulationSynthetic resin layered productsElastomerPolyetherimide

A polymeric composition for insulating fluid and / or gas transport conduits, such as off-shore oil and gas pipelines operating at temperatures of 130° C. or higher in water depths above 1,000 meters. The outer surface of the conduit is provided with at least one layer of solid or foam insulation comprising a high temperature resistant thermoplastic having low thermal conductivity, high thermal softening point, high compressive strength and high compressive creep resistance. The high temperature resistant thermoplastic is selected from one or more members of the group comprising: polycarbonate; polyphenylene oxide; polyphenylene oxide blended with polypropylene, polystyrene or polyamide; polycarbonate blended with polybutylene terephthalate, polyethylene terephthalate, acrylonitrile butadiene styrene, acrylonitrile styrene acrylate, or polyetherimide; polyamides, including polyamide 12 and 612 and elastomers thereof; polymethylpentene and blends thereof; cyclic olefin copolymers and blends thereof; and, partially crosslinked thermoplastic elastomers, also known as thermoplastic vulcanizates or dynamically vulcanized elastomers.

Owner:SHAWCOR LTD

High-fluidity environmental protection halogen-free flame-retardant HIPS composite material and its preparation method

The invention belongs to the technical field of macromolecular compound combination and relates to a high-fluidity environmental protection halogen-free flame-retardant HIPS composite material, which is composed of the following components of: by weight, 29-50 parts of high impact polystyrene (HIPS), 15-35 parts of polyphenylene oxide (PPO), 3-12 parts of a flexibilizer, 5-20 parts of a phosphorus flame retardant, 1-7 parts of a flame-retardant synergistic agent, 0.2-1.0 part of a heat stabilizer, 0.2-0.8 part of an antioxidant and 0.5-1.2 parts of a processing aid. The invention also discloses a preparation method of the HIPS composite material. The composite material provided by the invention is a halogen-free flame retardation HIPS / PPO alloy with high fluidity and excellent mechanical properties.

Owner:深圳市比克新材科技有限公司

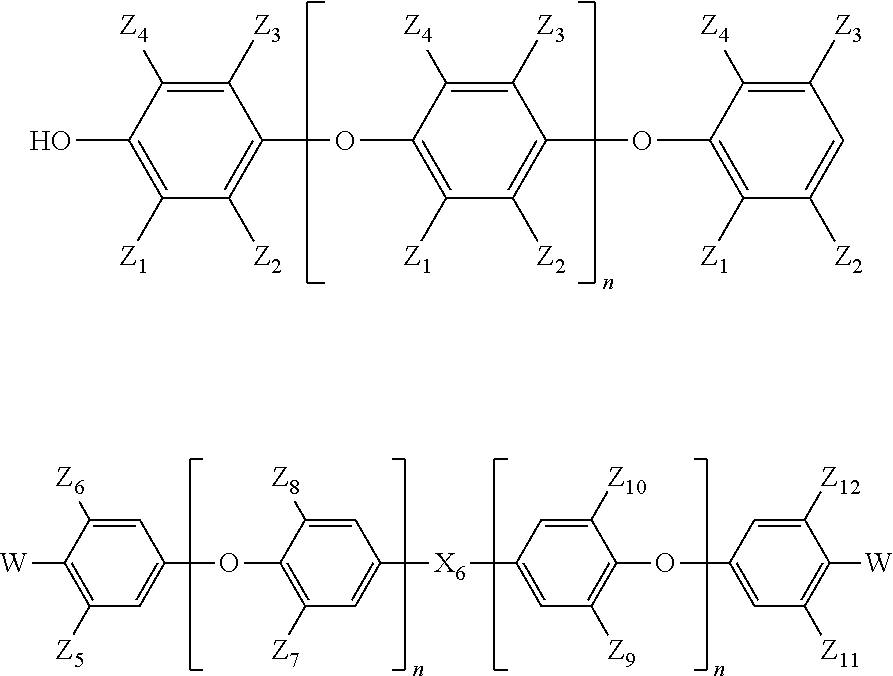

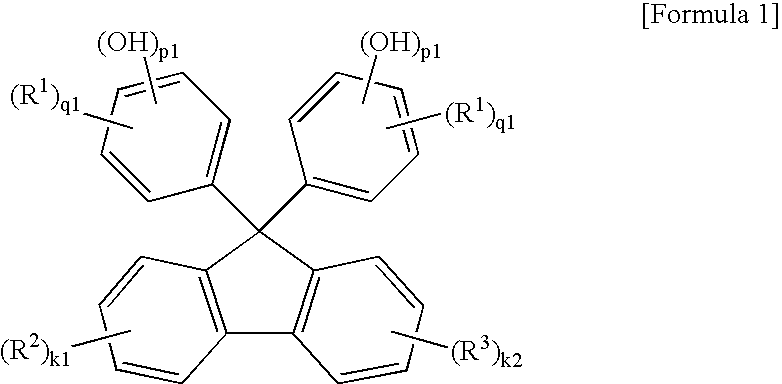

Resine Composition For Printed Circuit Board And Composite Substrate And Copper Laminates Using The Same

InactiveUS20090004484A1Desirable formabilityDesirable processibilitySynthetic resin layered productsElectrical equipmentEpoxyComposite substrate

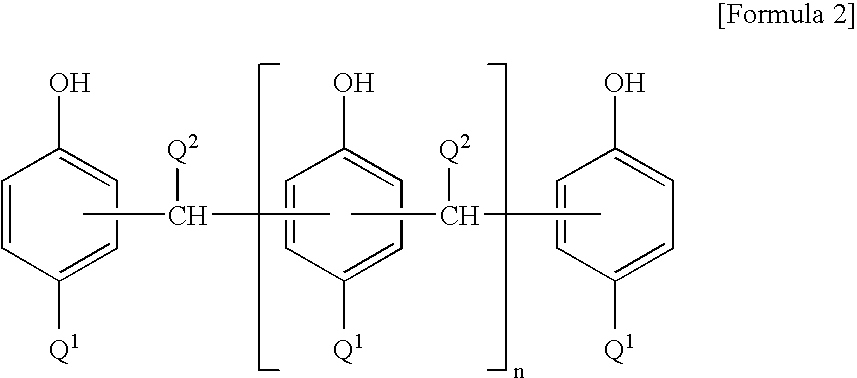

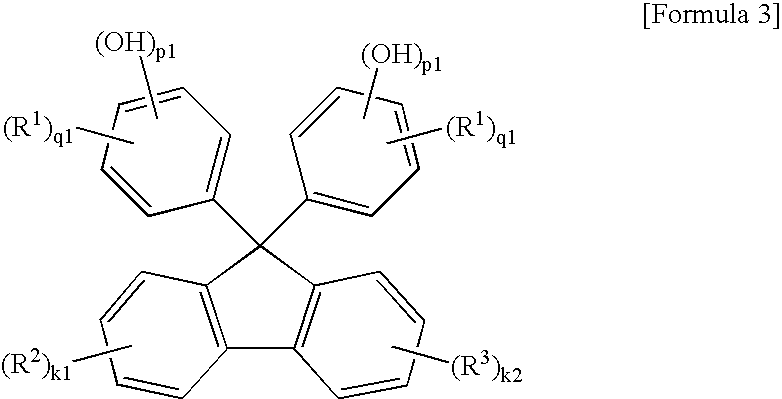

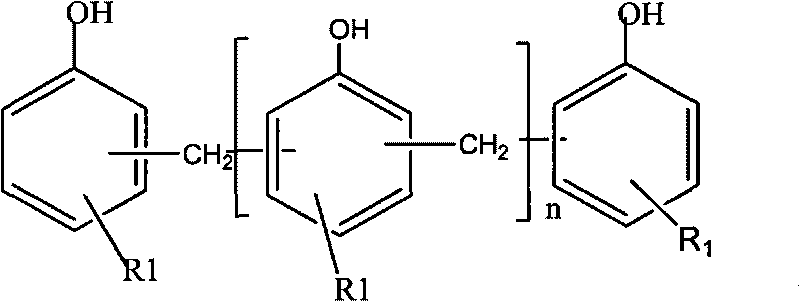

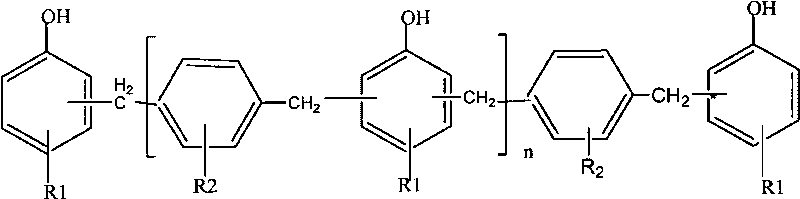

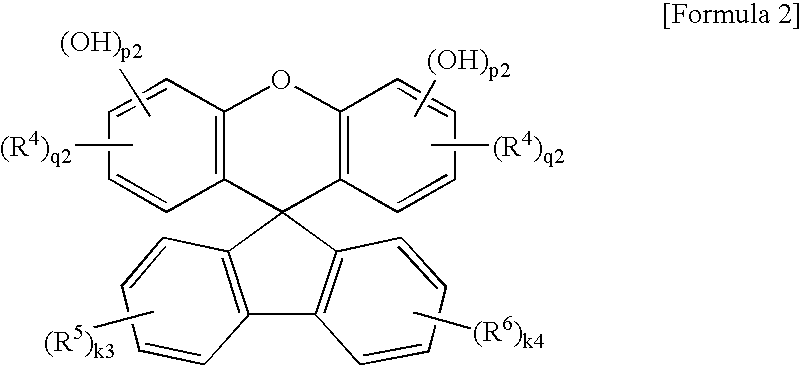

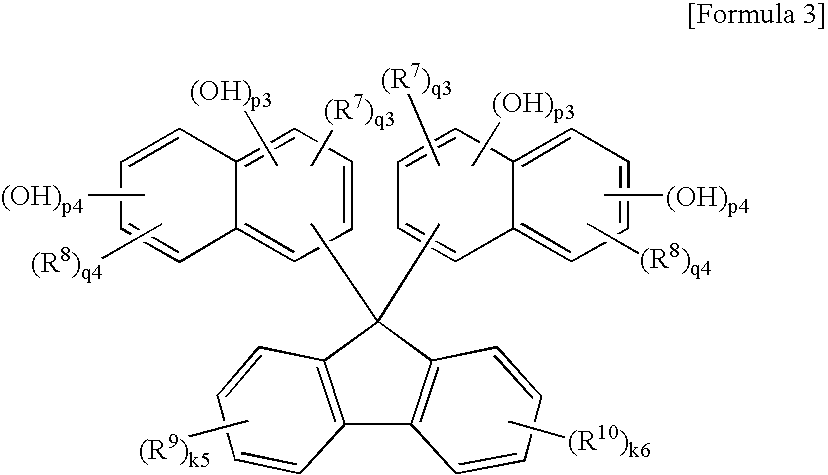

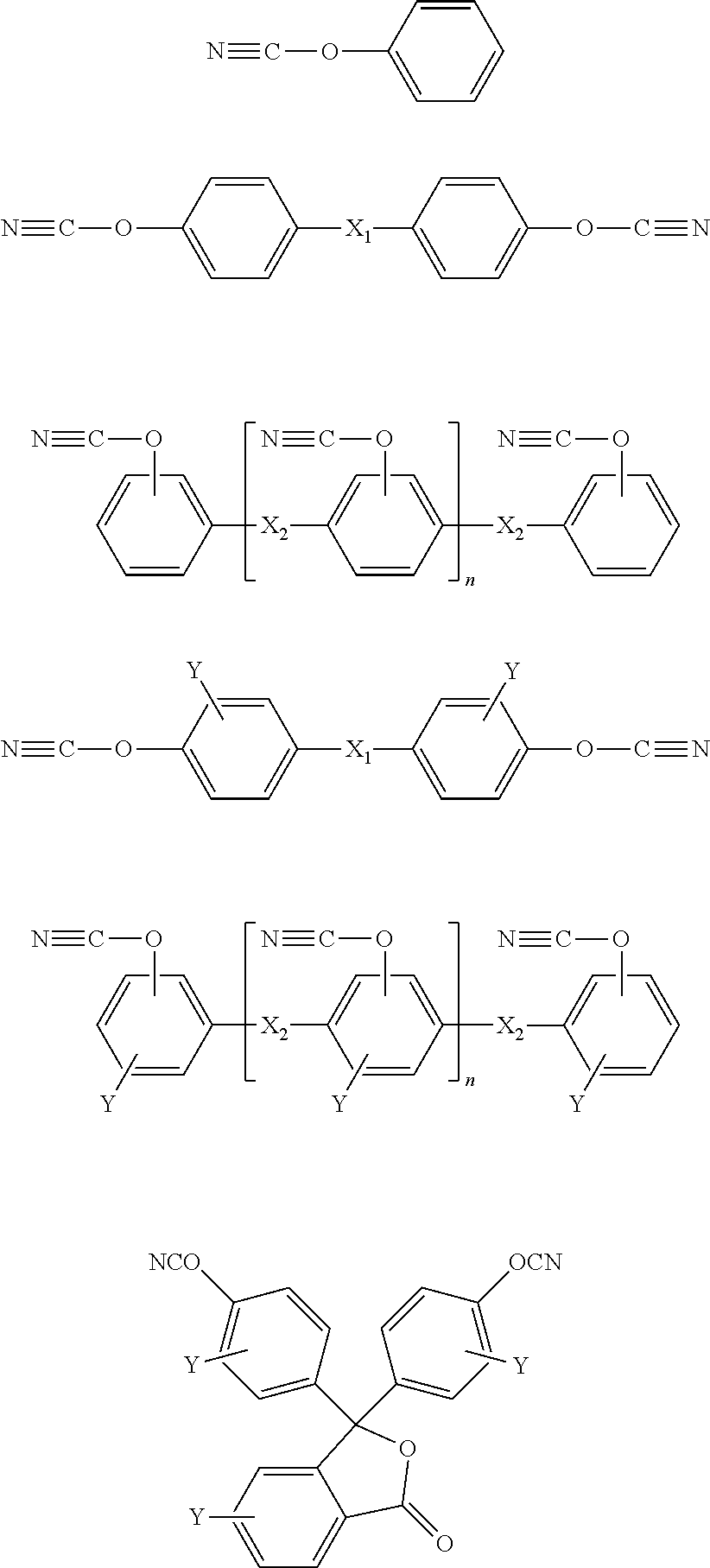

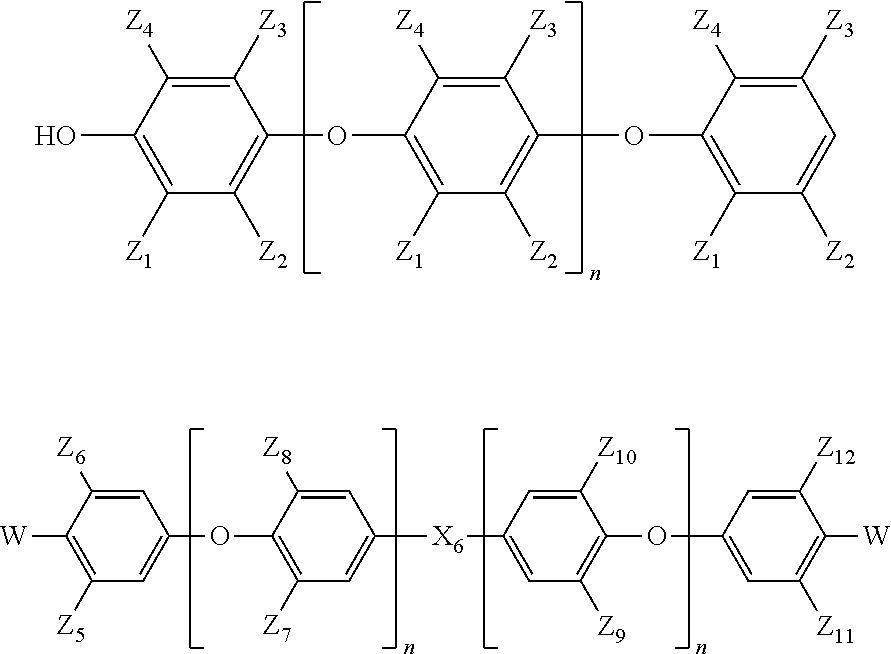

Disclosed is a resin composition for a PCB, the composition including: (a) a polyphenylene ether resin modified via a redistribution reaction of polyphenylene ether in the presence of 9,9-bis(hydroxyaryl)fluorene or 9,10-dihydro-9-oxa-10-(dihydroxyaryl)-10-phosphaphenanthrene 10-oxide; (b) a dicyclopentadiene epoxy resin represented by Formula 1; and (c) an alkylphenol aldehyde novolak curing agent represented by Formula 2, wherein, when the polyphenylene ether resin is modified via a redistribution reaction of the polyphenylene ether in the presence of 9,9-bis(hydroxyaryl)fluorene, the composition further includes (d) a brominated epoxy resin. Also, a composite substrate and a copper laminate using the same are disclosed.

Owner:DOOSAN CORP

Epoxy resin composition, preparation method thereof, laminated material and copper-clad laminated board manufactured by adopting epoxy resin composition

ActiveCN101735562AImprove heat resistanceExcellent dielectric propertiesGlass/slag layered productsWoven fabricsEpoxyHeat resistance

The invention relates to an epoxy resin composition, a preparation method thereof, a laminated material and a copper-clad laminated board manufactured by adopting the epoxy resin composition. The epoxy resin composition comprises the following components in part by mass: 30 to 80 parts of epoxy resin, 20 to 50 parts of polyphenyl ether resin with a novel structure, 0 to 50 parts of filler and 1 to 20 parts of assistant, wherein the polyphenyl ether resin is obtained through redistribution reaction of polyphenyl ether and phenolic resin in the presence of a reaction initiator, and the number-average molecular weight of the polyphenyl ether resin is 1,000 to 5,000. The epoxy resin composition provided by the invention not only has good heat resistance and dielectric property, but also has simple and convenient preparation process and is favorable for industrialized large-scale production; and in addition, the laminated material and the copper-clad laminated board manufactured by using the epoxy resin composition are applied to a printed circuit board, have good heat resistance, dielectric property and machining property, and are favorable for signal transmission of a high-frequency circuit board.

Owner:GUANGDONG SHENGYI SCI TECH

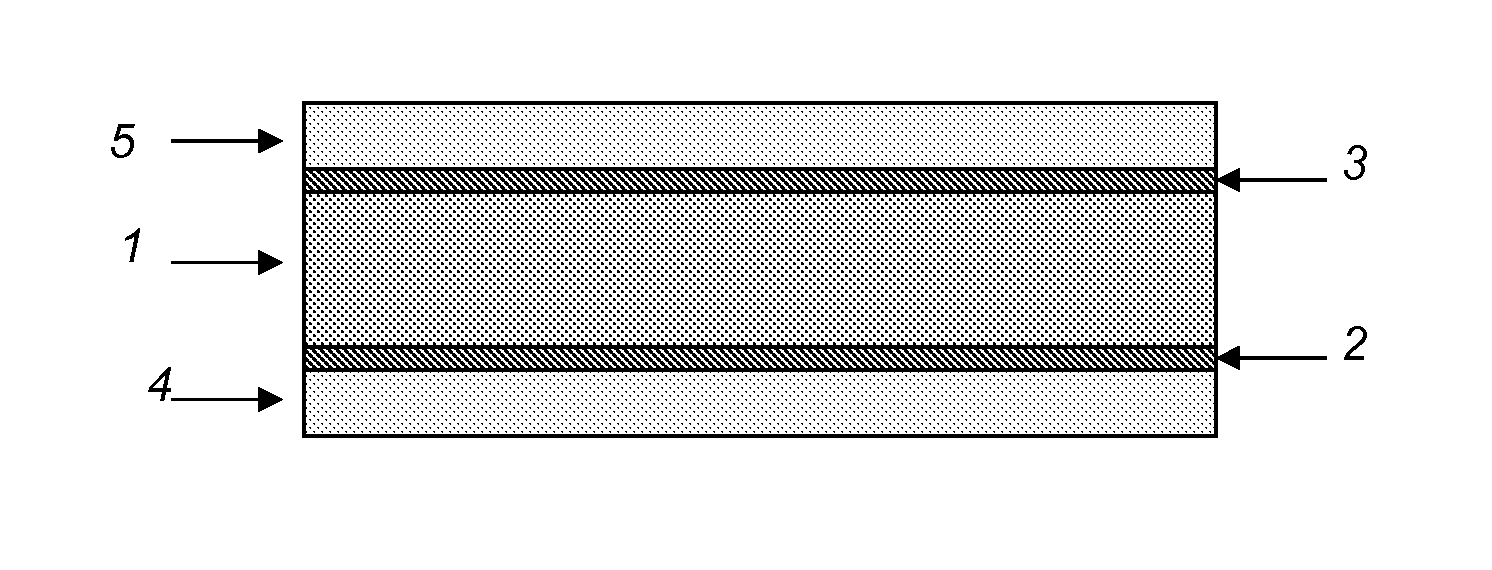

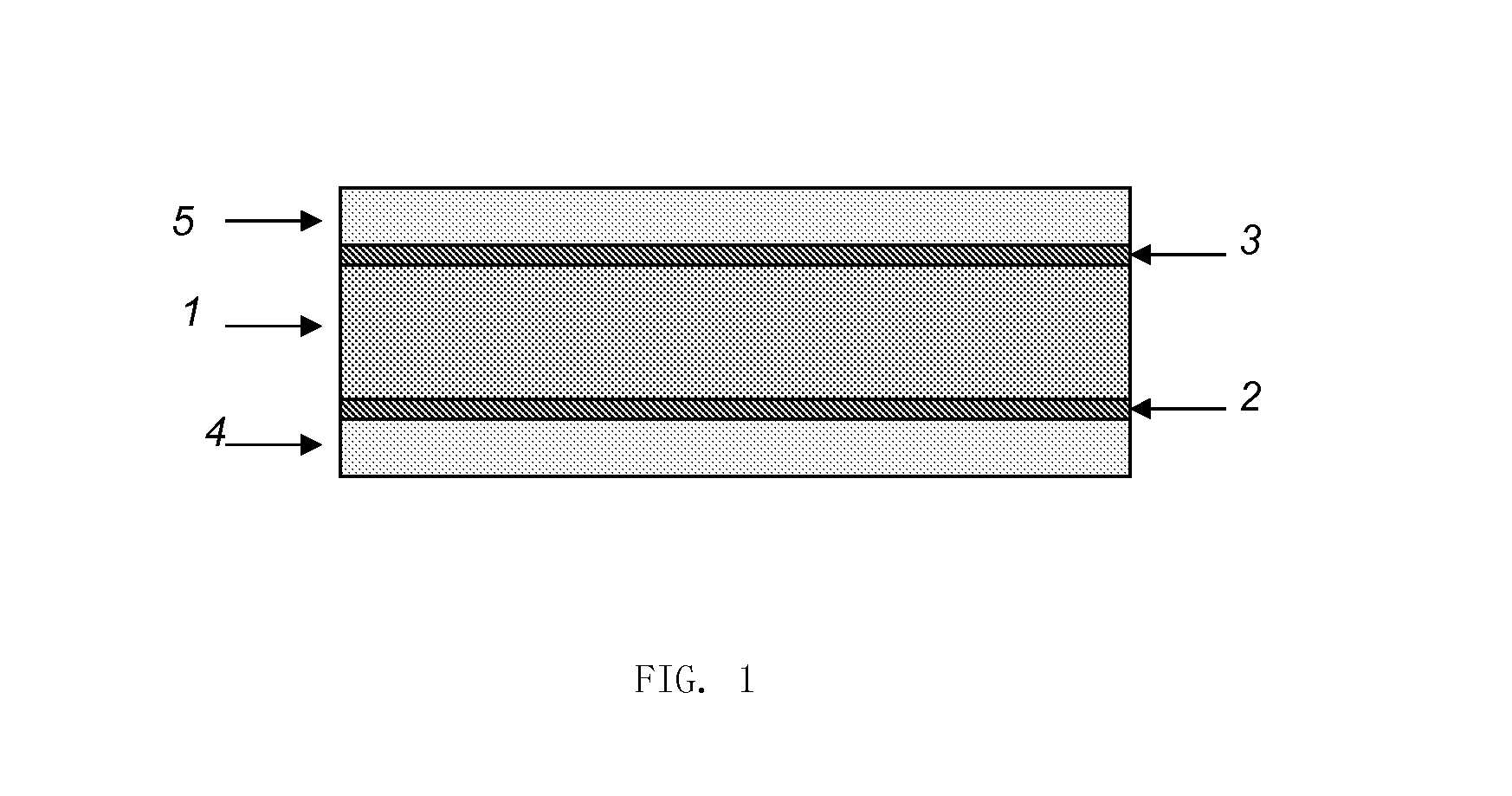

Polymer backsheet of solar cell assembly and manufacturing process thereof

InactiveUS20130209795A1Easy to processExcellent material mechanical performanceFilm/foil adhesivesSynthetic resin layered productsPolymer sciencePolymer alloy

A solar module polymer backsheet comprising a basement layer, tie layer on each side of the basement layer, a fourth film layer and a fifth film layer on the other side of the tie layer, the basement layer comprises at least one of the following components: polyamide polymers, polypropylene and propylene polymers, polyethylene and vinyl polymers, poly(vinylidene chloride), styrene polymers, ABS resins, liquid crystal polymers, acrylic polymers, polyphenylene oxides, polycarbonates, and polymer alloys of polycarbonates with poly(C2-6 alkylene glycol phthalates). The manufacturing process of the backsheet was provided, one polymer or a mixture of more polymers are used to form the film configuration in place of the former PET layer, thus excellent processability, material mechanical performances, barrier property and ageing resistance can be obtained; furthermore, the laminated films of the backsheet are formed via melt co-extrusion or extrusion composite process, which significantly upgraded the adhesion strength between the laminated films, and simplified manufacturing process.

Owner:DSM SUNSHINE SOLAR TECH (SUZHOU) CO LTD

Resine Composition For Printed Circuit Board and Composite Substrate And Copper Laminates Using The Same

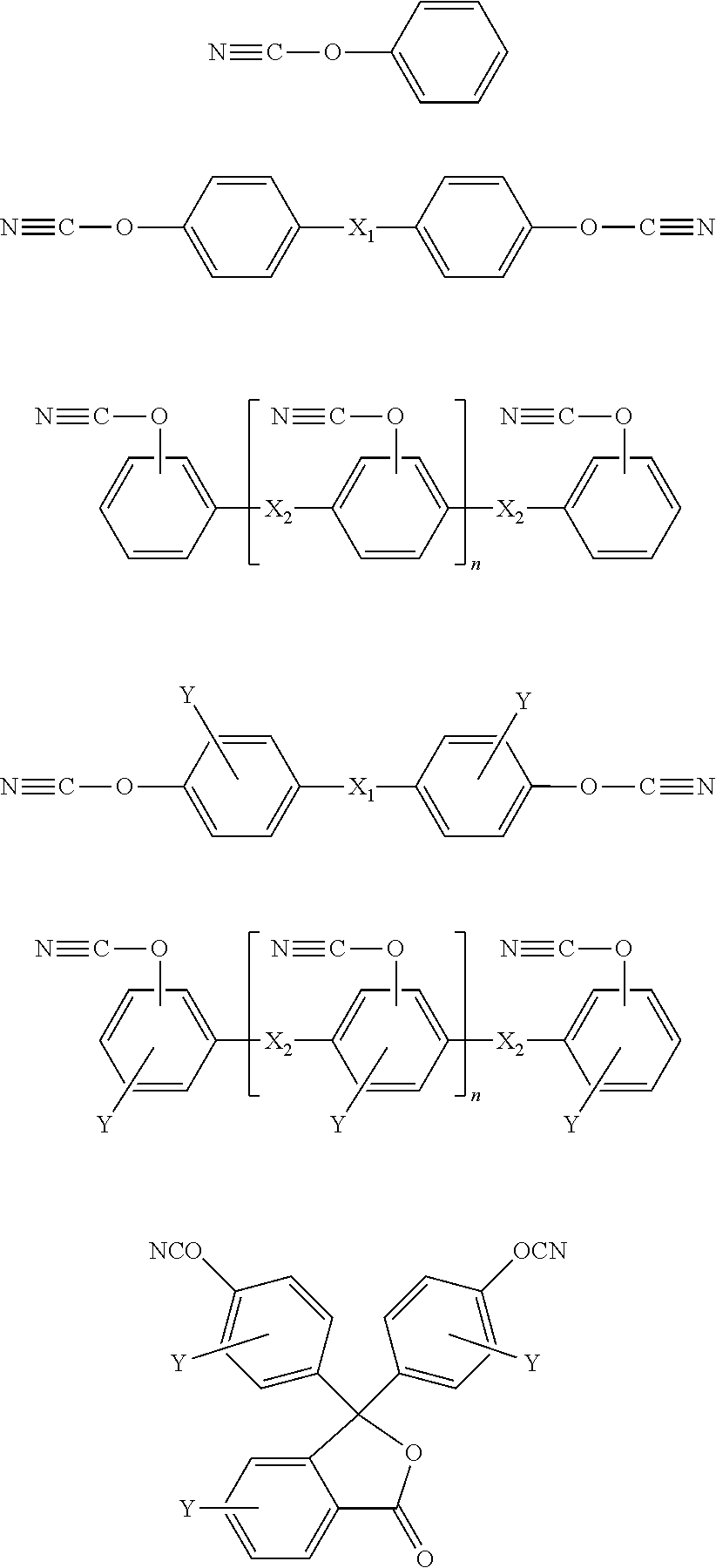

InactiveUS20090004488A1Desirable formabilityDesirable processibilityPrinted circuitsThin material handlingComposite substrateCyanate compound

Disclosed is a resin composition for a PCB, the composition including: (a) a polyphenylene ether resin modified via a redistribution reaction of polyphenylene ether in the presence of 9,9-bis(hydroxyaryl)fluorene or 9,10-dihydro-9-oxa-10-(dihydroxyaryl)-10-phosphaphenanthrene 10-oxide; (b) a polymer binder; and (c) cyanate ester or a prepolymer of the cyanate ester, wherein, when the polyphenylene ether resin is modified via a redistribution reaction of the polyphenylene ether in the presence of 9,9-bis(hydroxyaryl)fluorene, the composition further includes (d) a flame retardant. Also, a composite substrate and a copper laminate using the same are disclosed.

Owner:DOOSAN CORP

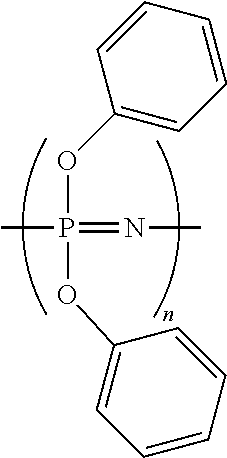

Halogen-free resin composition, and copper clad laminate and printed circuit board using same

ActiveUS20130115472A1Group 5/15 element organic compoundsPrinted circuit aspectsLow dissipationHeat resistance

The halogen-free resin composition comprises (A) 100 parts by weight of cyanate ester resin; (B) 5 to 50 parts by weight of styrene-maleic anhydride; (C) 5 to 100 parts by weight of polyphenylene oxide resin; (D) 10 to 150 parts by weight of phosphazene; and (E) 10 to 1000 parts by weight of inorganic filler. By using specific components at specific proportions, the halogen-free resin composition offers the features of low dielectric constant, low dissipation factor, high heat resistance and high flame retardancy, and can be made into prepreg or resin film, and thereby used in copper clad laminate or printed circuit board.

Owner:ELITE MATERIAL

Thermoplastic resin composition, molded product, and method of producing molded product

ActiveCN106867245AExcellent articulation characteristicsImprove heat resistanceDomestic articlesHeat resistancePolyamide

The thermoplastic resin composition contains (A) a polyamide, (B) a polyphenylene ether, and (C) a compatibilizer. When the thermoplastic resin composition is molded into a specimen, a continuous phase containing the polyamide (A) and a dispersed phase containing the polyphenylene ether (B) are formed in the specimen, and E-20 represents a mean ellipticity of the dispersed phase in region I extending from a surface of the hinge portion to a depth of 20 microns in the thickness direction, and E-mid represents a mean ellipticity of the dispersed phase in region II extending from a distance, measured along the thickness direction from the surface, equal to 48% of the thickness to a distance, measured along the thickness direction from the surface, equal to 52% of the thickness, the following formula (1) is satisfied: 4.0<=(E-20) / (E-mid) (1).

Owner:ASAHI KASEI KK

High-heat resistance halogen-free fire-retarding polyphenylether and polystyrene composite and preparation method thereof

The invention discloses a high-heat resistance halogen-free fire-retarding polyphenylether and polystyrene composite and a preparation method thereof. The composite comprises polyphenylene oxide resin, polystyreneresin, toughener, processing aid and a halogen-free fire retarding agent, wherein the halogen-free fire retarding agent is microencapsulated coated red phosphor and is used in combination with one or more of organic phosphates or phosphite esters in a separate charging mode. The components are subjected to melt blending as well as plasticization and blending in a double screw extruder to form the composite material of the invention. The method is continuous in processing process and high in production efficiency. The composite material of the invention can radically solve the problems of the prior fire retarding art such as halogen content of the fire retarding agent, easy precipitation, low fire retarding level and the like. Products made from the composite material are high in heat resistance, smooth in surface, environmentally-friendly, free from any halogen substance and applicable in the fields of electronic appliances, office equipment, fluid engineering and the like.

Owner:NANJING JULONG SCI&TECH CO LTD

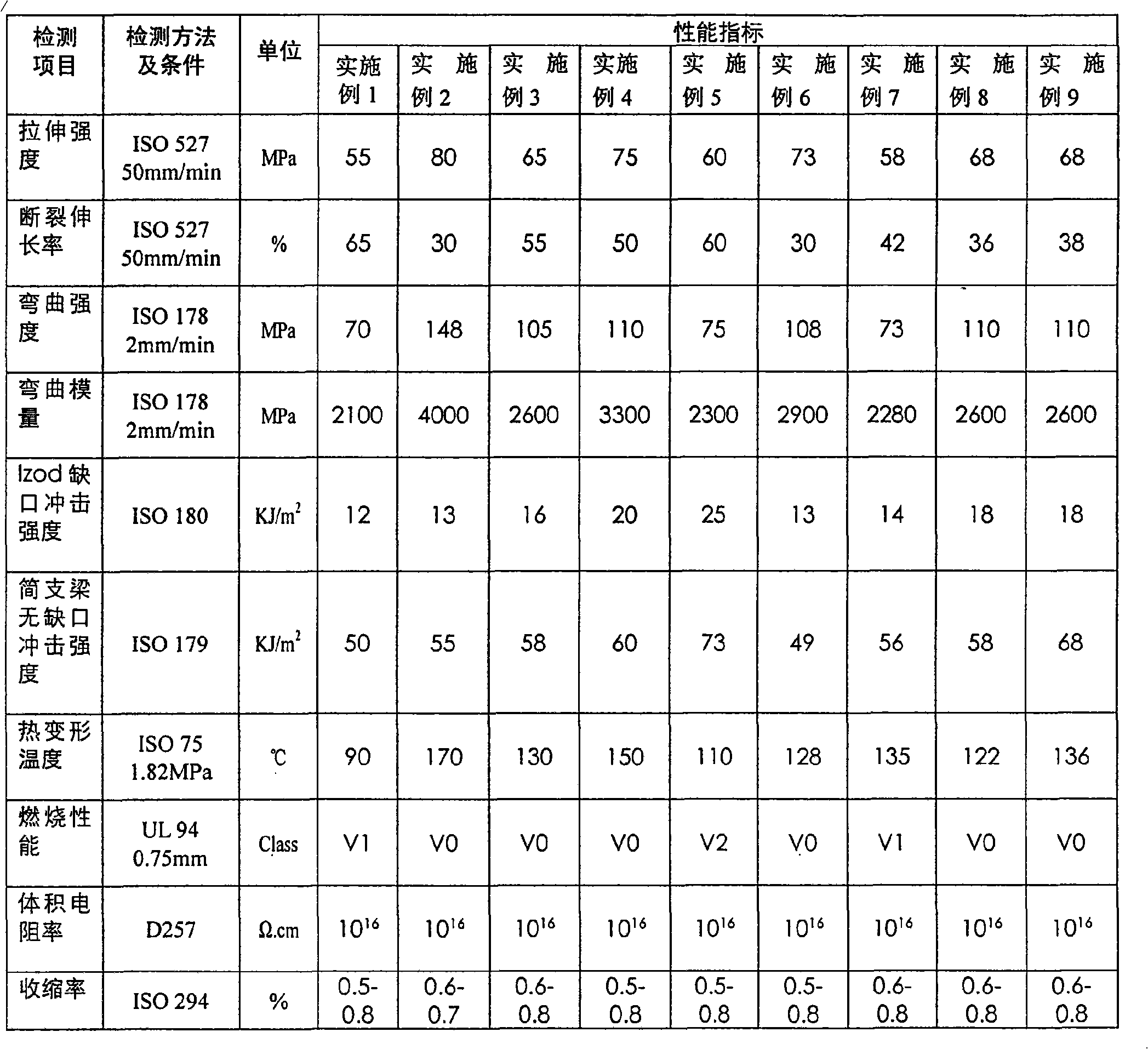

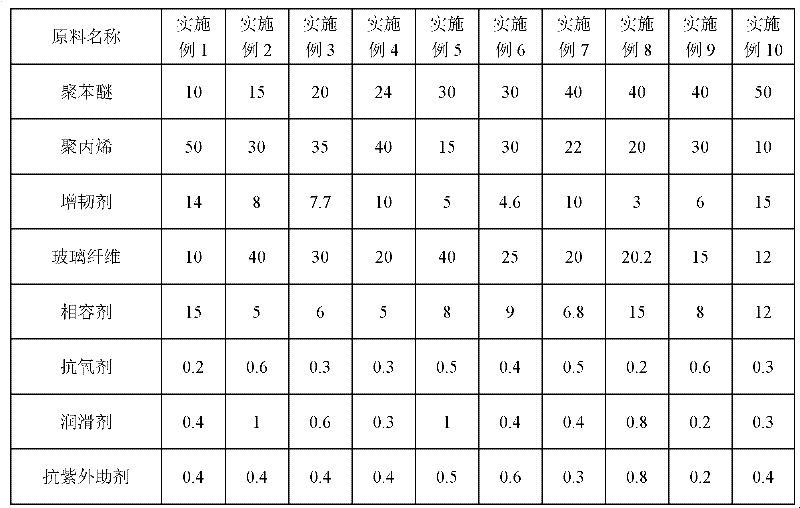

Glass fiber reinforcement polyphenyl ether/polypropylene alloy and production method thereof

InactiveCN102417718AImprove mechanical propertiesGood dimensional stabilityGlass fiberWeather resistance

The invention relates to a glass fiber reinforcement polyphenyl ether / polypropylene alloy and a production method thereof, wherein the alloy comprises the following component in part by weight: 10-50% of polyphenyl ether (PPO), 10-50% of polypropylene (PP), 3-15% of flexibilizer, 10-40% of glass fibre, 5-15% of polyphenyl ether-polypropylene compatilizer, 0.2-0.6% of antioxygen, 0.2-1% of lubricant and 0.2-0.8% of uvioresistant. The production technology comprises the following processes that: firstly, raw materials are mixed according to the proportion, and then are added into a double-screw extruder through a feeder, the long glass fibre is added from the glass fibre inlet of the double-screw extruder and is then granulated, the temperature is controlled between 220-250 DEG C, screws are controlled between 300-600r, so the glass fiber reinforcement polyphenyl ether / polypropylene alloy material can be obtained. The invention has the advantages of good stretching, bending and impacting performance, heat resistance, weather resistance, creep resistance, size stability, easiness in machine shaping and the like, and is applicable to automobile parts, pipe fittings, valve valves and the like.

Owner:SHANGHAI SUNNY

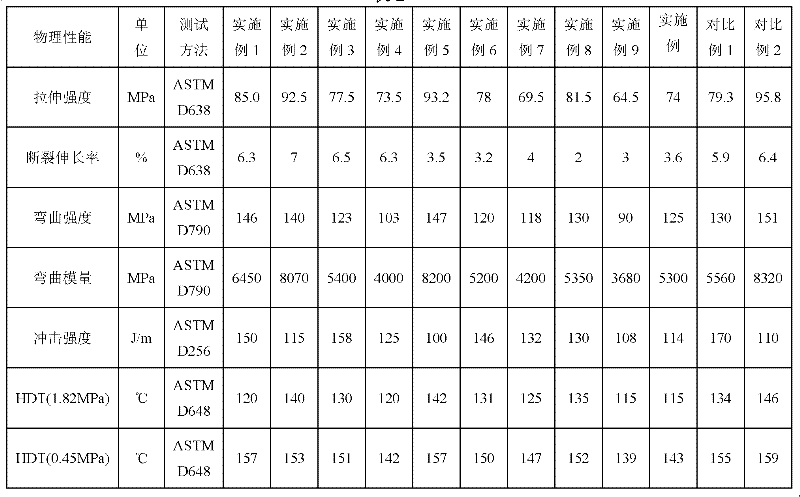

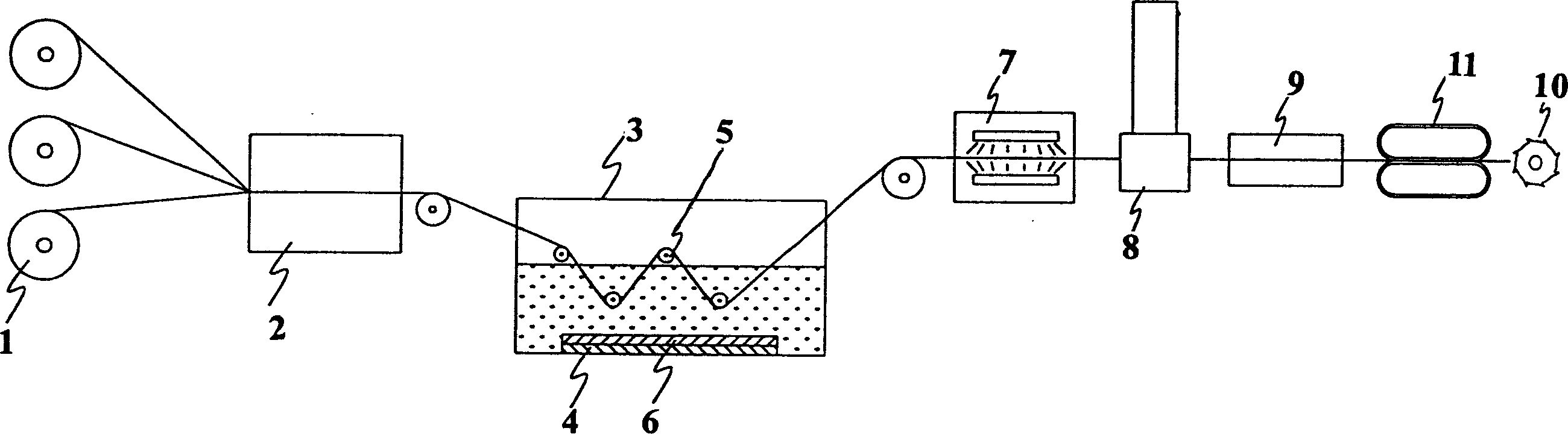

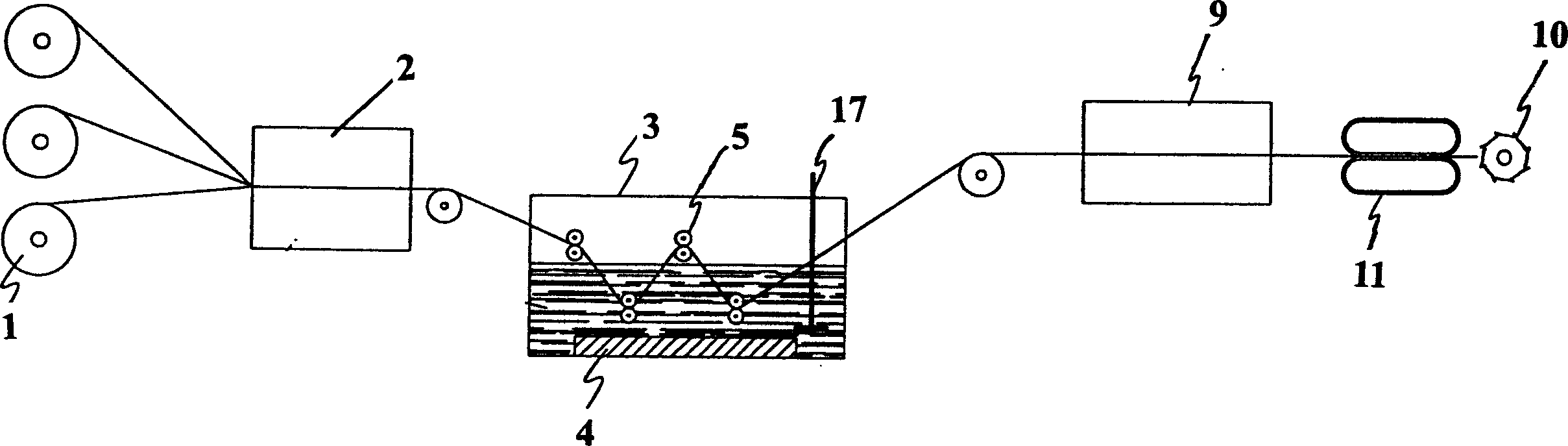

Long fiber reinforced polypropylene/PPE alloy material and its prepn and application

The long fiber reinforced polypropylene / PPE alloy material has oriented fibers in the length over 4 mm and in netted configuration, and thus greatly raised shock resistance, rigidity, creeping resistance and size stability. What is more important is that the material may be mixed with many kinds of other material and thus has wide application range. The material may be prepared through powder soaking process, smelting soaking process, etc. The long fiber reinforced polypropylene / PPE alloy material of the present invention has excellent tensile, bending and anti-shocking performance, and may be used in manufacturing automobile part, pipe, valve part, electric tool, etc.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com