Epoxy resin composition, preparation method thereof, laminated material and copper-clad laminated board manufactured by adopting epoxy resin composition

一种环氧树脂、组合物的技术,应用在电路基板材料、化学仪器和方法、织物等方向,能够解决Df高、高频线路板信号传速不利等问题,达到良好耐热性、有利于信号传输、制备过程简单方便的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

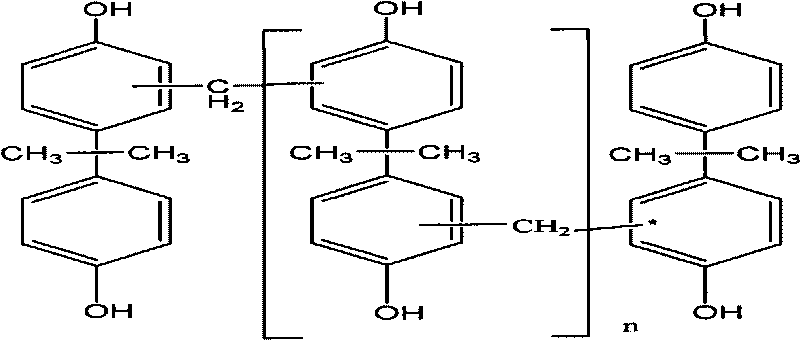

[0058] A novolac resin with a softening point of 45±2°C and a degree of polymerization of 1.5 was used as a chain scission agent to prepare a polyphenylene ether resin with a new structure. 1000 parts of polyphenylene ether resin (SUBIC company, number average molecular weight is 16000), 120 parts of novolac resin (KOLON, brand KPE-2100) and heated to dissolve, add 35 parts of benzoyl peroxide, and stir while heating Redistribution reaction; the reaction temperature is 95°C, and the time is 2h. The number average molecular weight of the reaction product was measured to be 4540 by gel permeation chromatography (Waters GPC2000).

[0059] Use 100 parts of polyphenylene ether resin prepared above (calculated according to the weight of the composition), add 150 parts of epoxy resin, then add epoxy resin curing agent, accelerator and other auxiliary agents, stir at room temperature or under heating for 30-120min , to obtain the above-mentioned epoxy resin composition.

Embodiment 2

[0061] A novolac resin with a softening point of 45±2°C and a degree of polymerization of 1.5 was used as a chain scission agent to prepare a polyphenylene ether resin with a new structure. 1000 parts of polyphenylene ether resin (SUBIC company, number average molecular weight is 16000), 160 parts of novolac resin (KOLON, brand KPE-2100) and heated to dissolve, add 25 parts of benzoyl peroxide, and stir while heating Redistribution reaction; the reaction temperature is 95°C, and the time is 2h. The number average molecular weight of the reaction product was measured to be 4080 by gel permeation chromatography (Waters GPC2000).

[0062] Use 100 parts of polyphenylene ether resin prepared above (calculated according to the weight of the composition), add 150 parts of epoxy resin, then add epoxy resin curing agent, accelerator and other auxiliary agents, stir at room temperature or under heating for 30-120min , to obtain the above-mentioned epoxy resin composition.

Embodiment 3

[0064] A novolac resin with a softening point of 65±2°C and a degree of polymerization of 2 was used as a chain scission agent to prepare a polyphenylene ether resin with a new structure. After 2400 parts of polyphenylene ether resin (SUBIC company, number average molecular weight is 16000), 360 parts of novolac resin (KOLON, brand KPE-2000) and heating and dissolving, add 20 parts of benzoyl peroxide and stir while heating Redistribution reaction; the reaction temperature is 95°C, and the time is 2h. The number average molecular weight of the reaction product was measured to be 4842 by gel permeation chromatography (Waters GPC2000).

[0065] Use 100 parts of polyphenylene ether resin prepared above (calculated according to the weight of the composition), add 150 parts of epoxy resin, then add epoxy resin curing agent, accelerator and other auxiliary agents, stir at room temperature or under heating for 30-120min , to obtain the above-mentioned epoxy resin composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com