Patents

Literature

5229results about How to "Improve machinability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

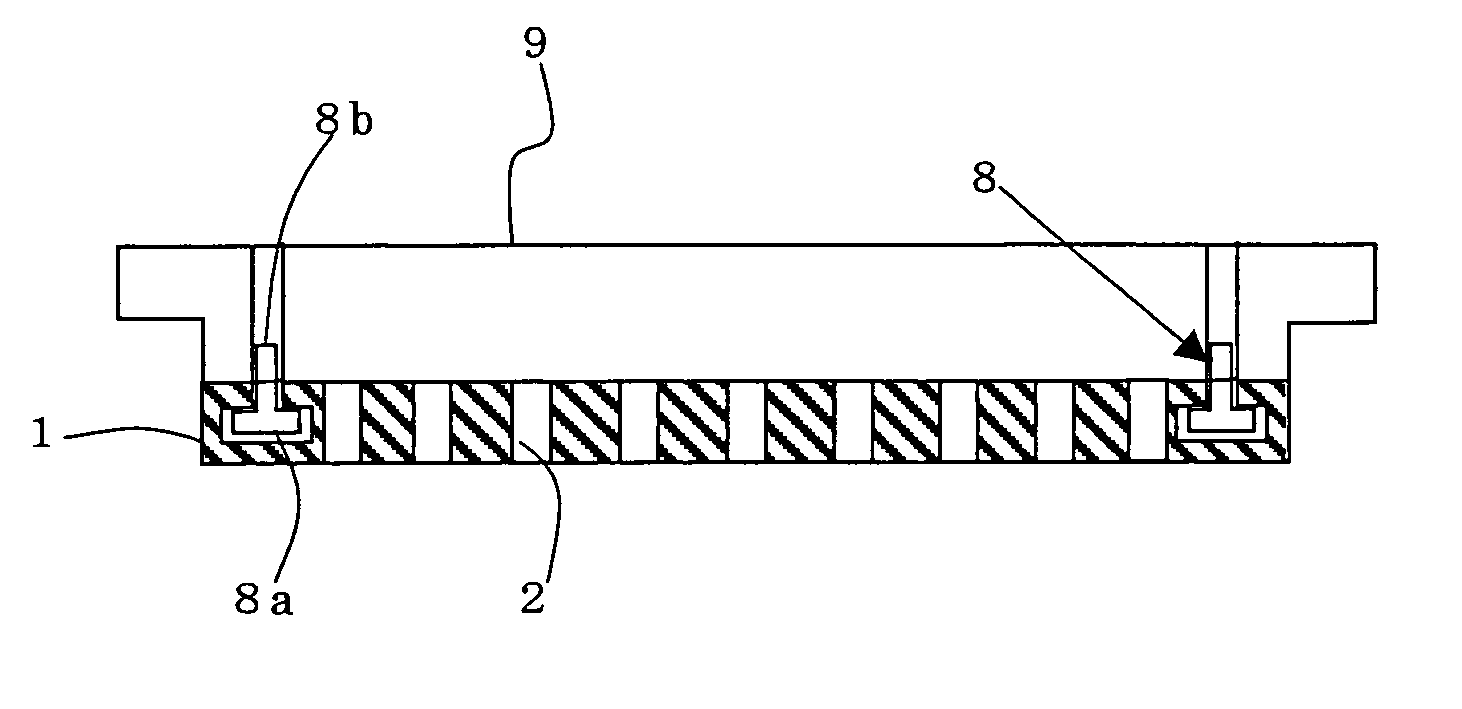

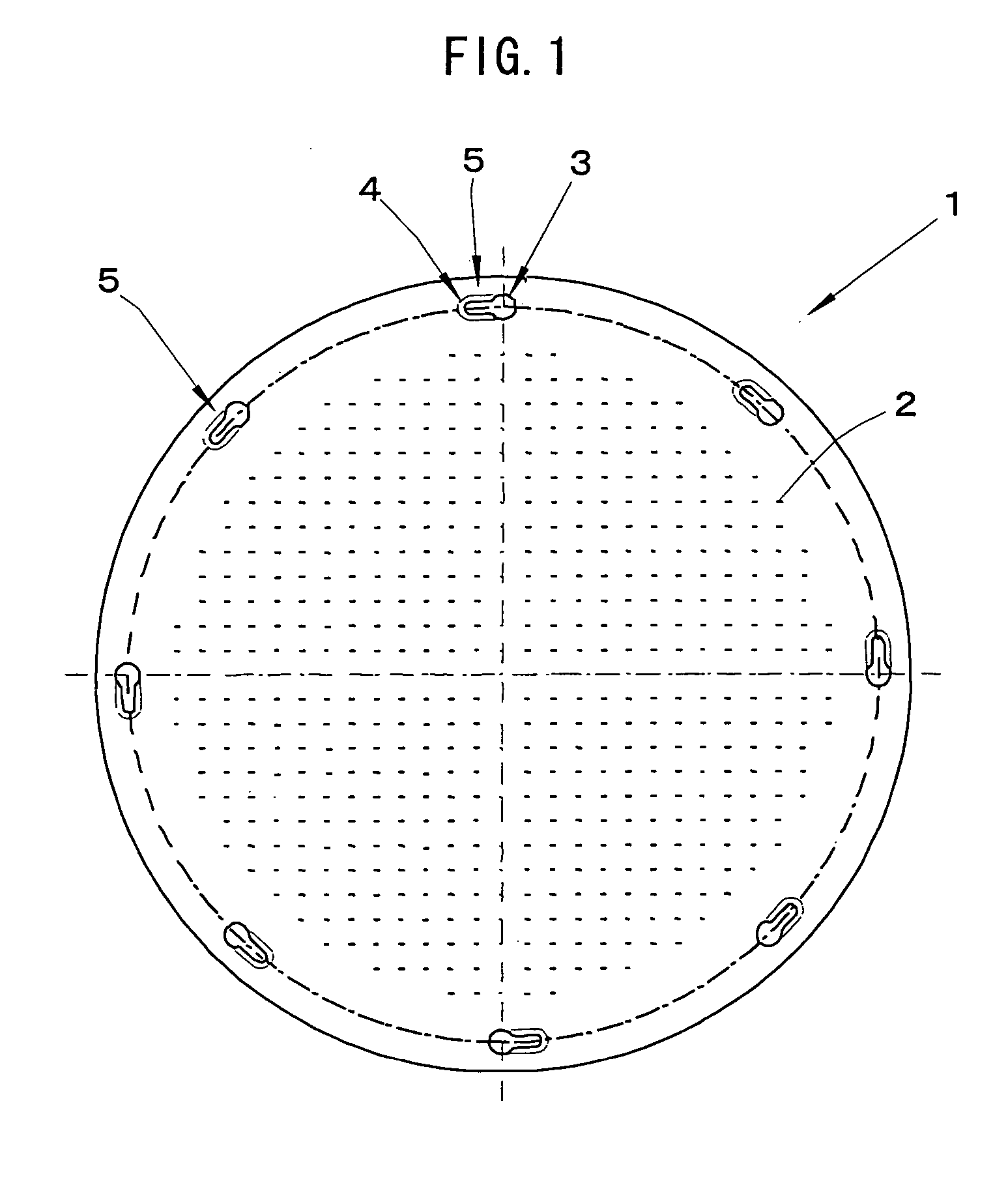

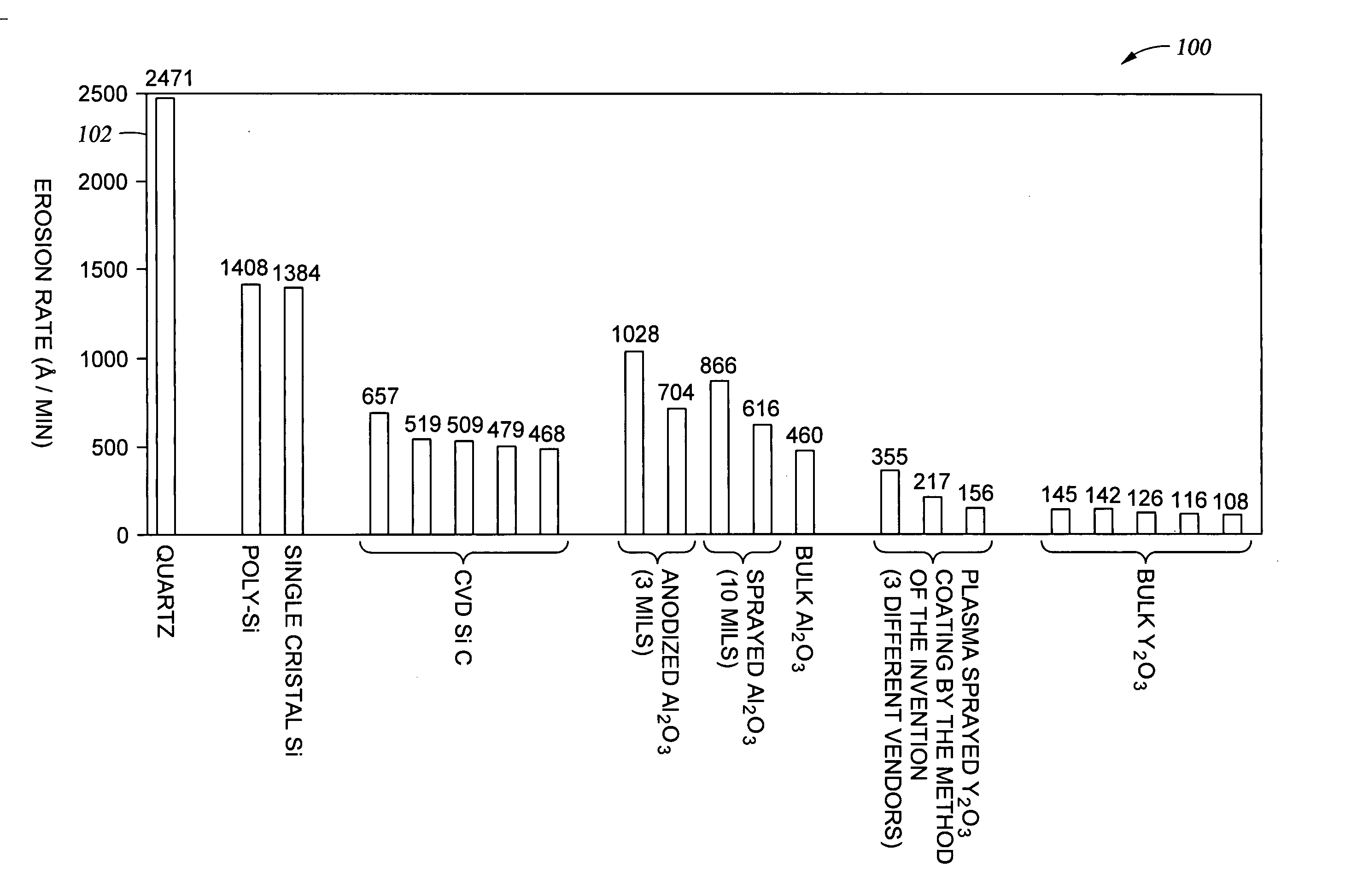

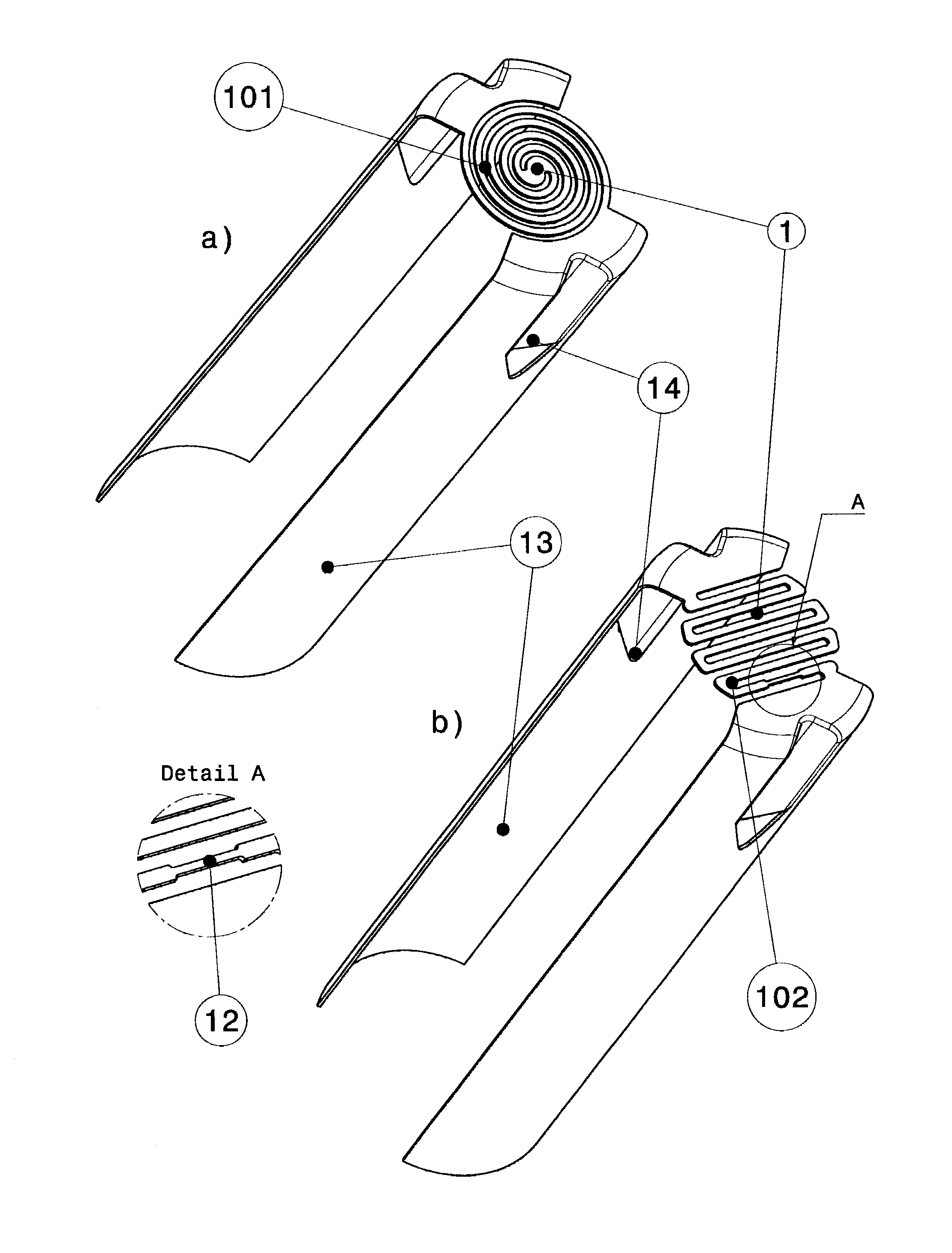

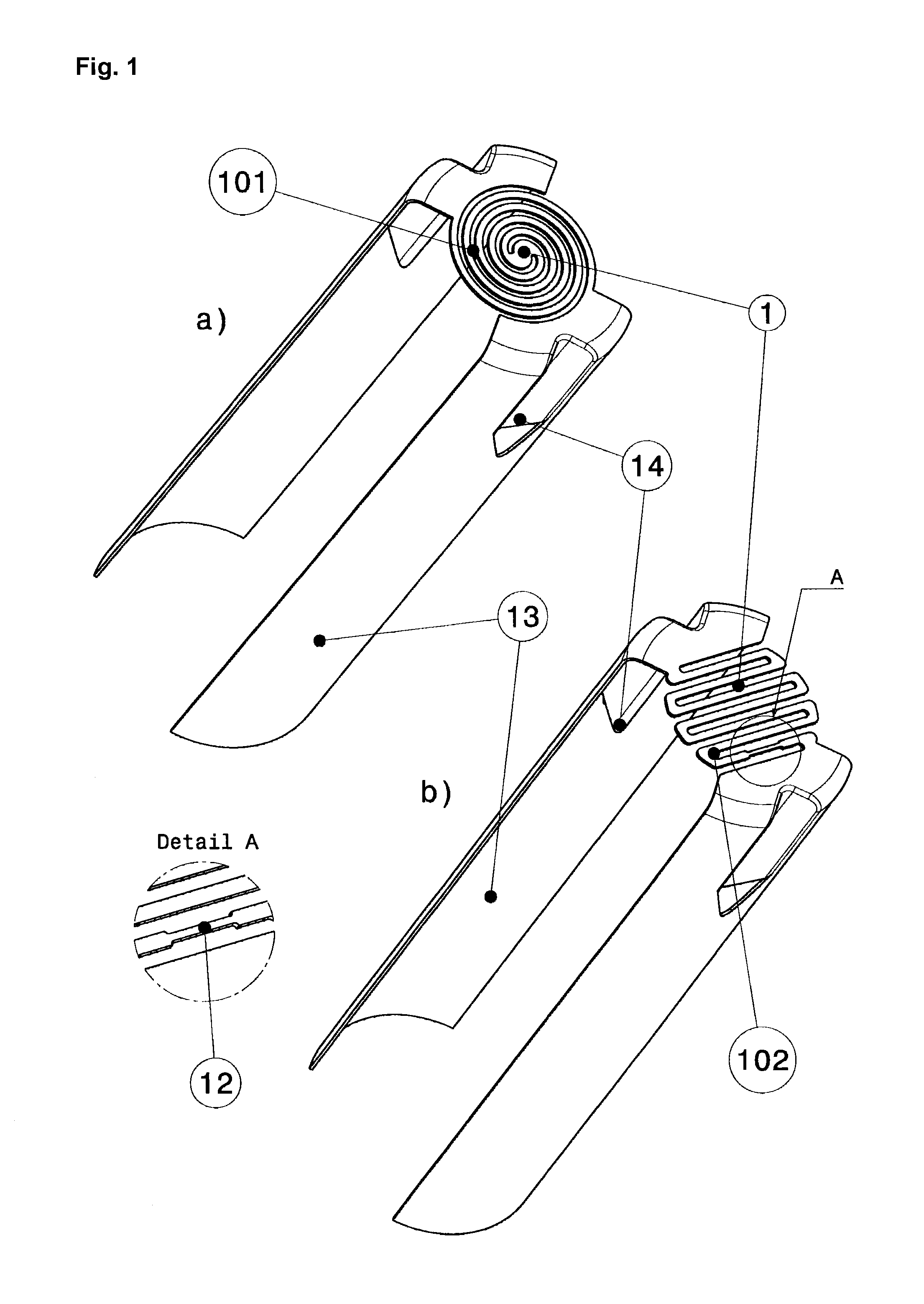

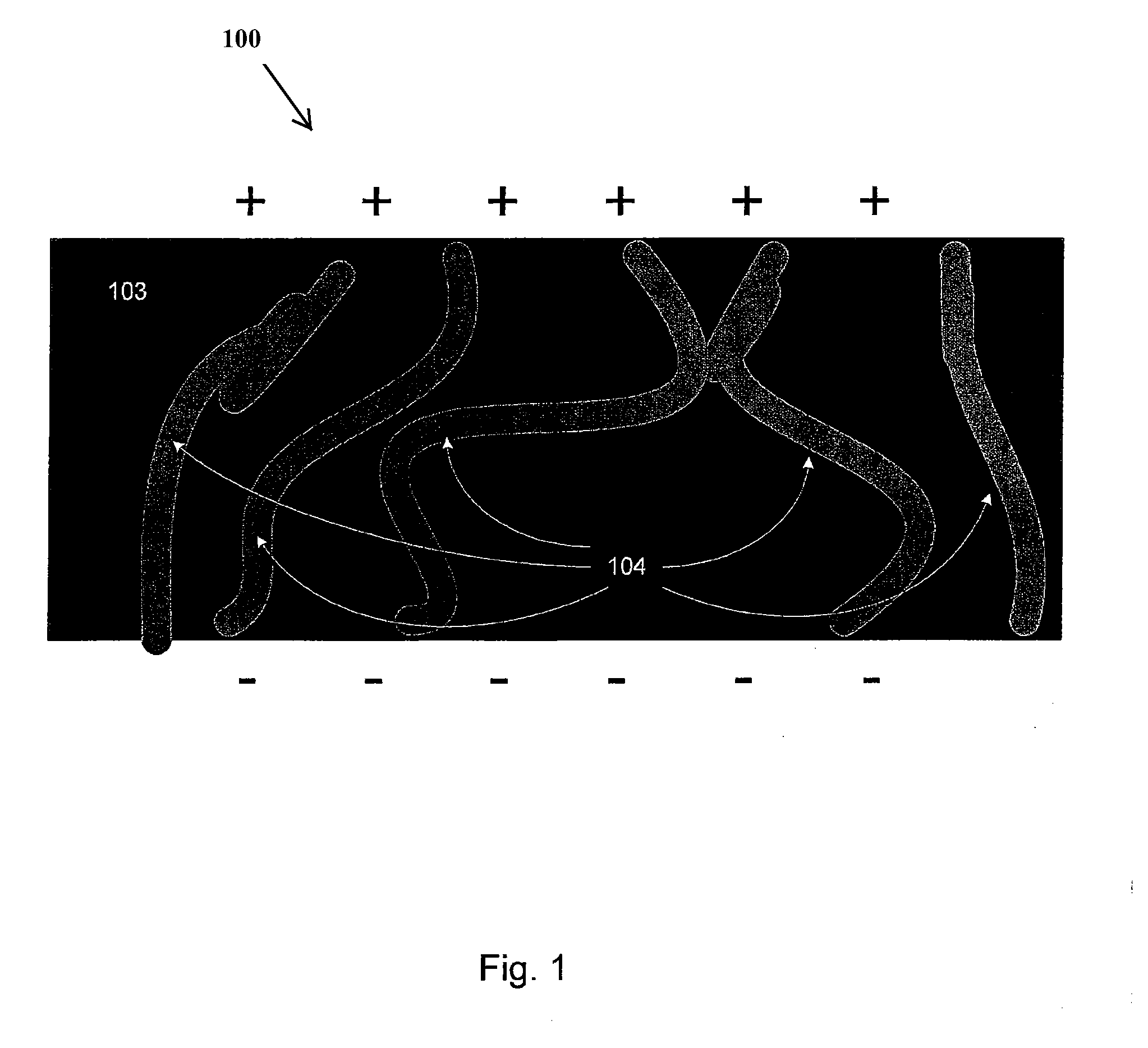

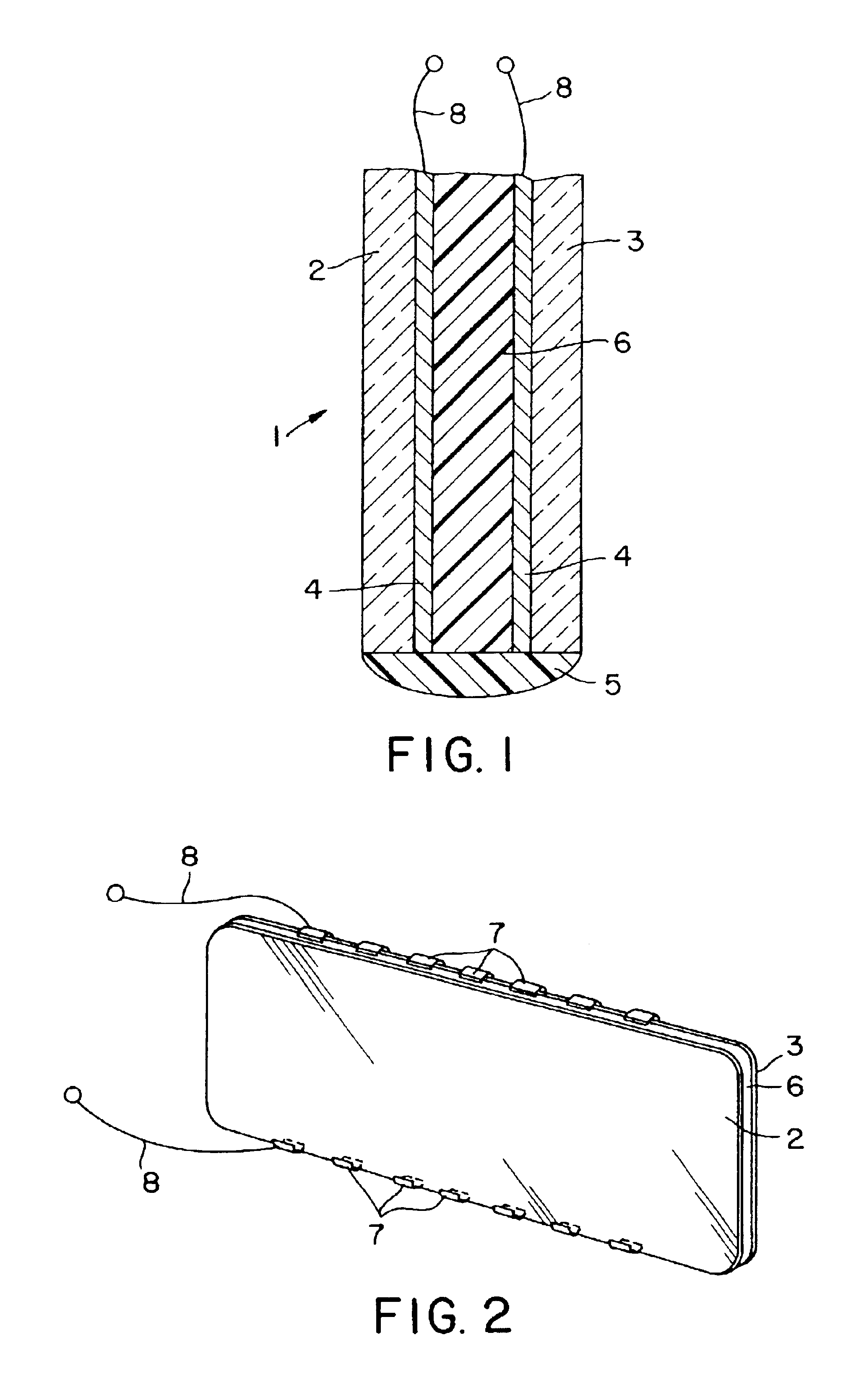

Shower plate for plasma processing apparatus and plasma processing apparatus

InactiveUS20050258280A1Easy to manufactureAvoid pollutionElectric discharge tubesMovable spraying apparatusEngineeringContamination

There is disclosed a shower plate 1, wherein the shower plate has a plurality of holes 3 for inserting the head of the fastening member and holes 4 for fitting the head are formed integrally along a concentric circle in the outside region of the gas feeding holes 2 on a side facing the supporting member, each hole for fitting extending in one direction of the concentric circle from each hole for insertion, each hole for fitting has a groove portion 4b through which the shank of the fastening member is to pass and a fitting portion 4a which is wider than the groove portion and in which the head of the fastening member is to be fitted, and the head of the fastening member fixed in the supporting member is inserted into the hole for insertion of the shower plate and the shower plate is turned so that the head of the fastening member is fitted in the fitting portion, and thereby the shower plate is supported by the supporting member without exposure of the fastening member. There can be provided a shower plate for a plasma processing apparatus, wherein effective diameter is large enough, contamination of a substrate to be treated can be prevented, it is easy to manufacture, and it is easy to fix to a supporting member.

Owner:SHIN ETSU CHEM IND CO LTD

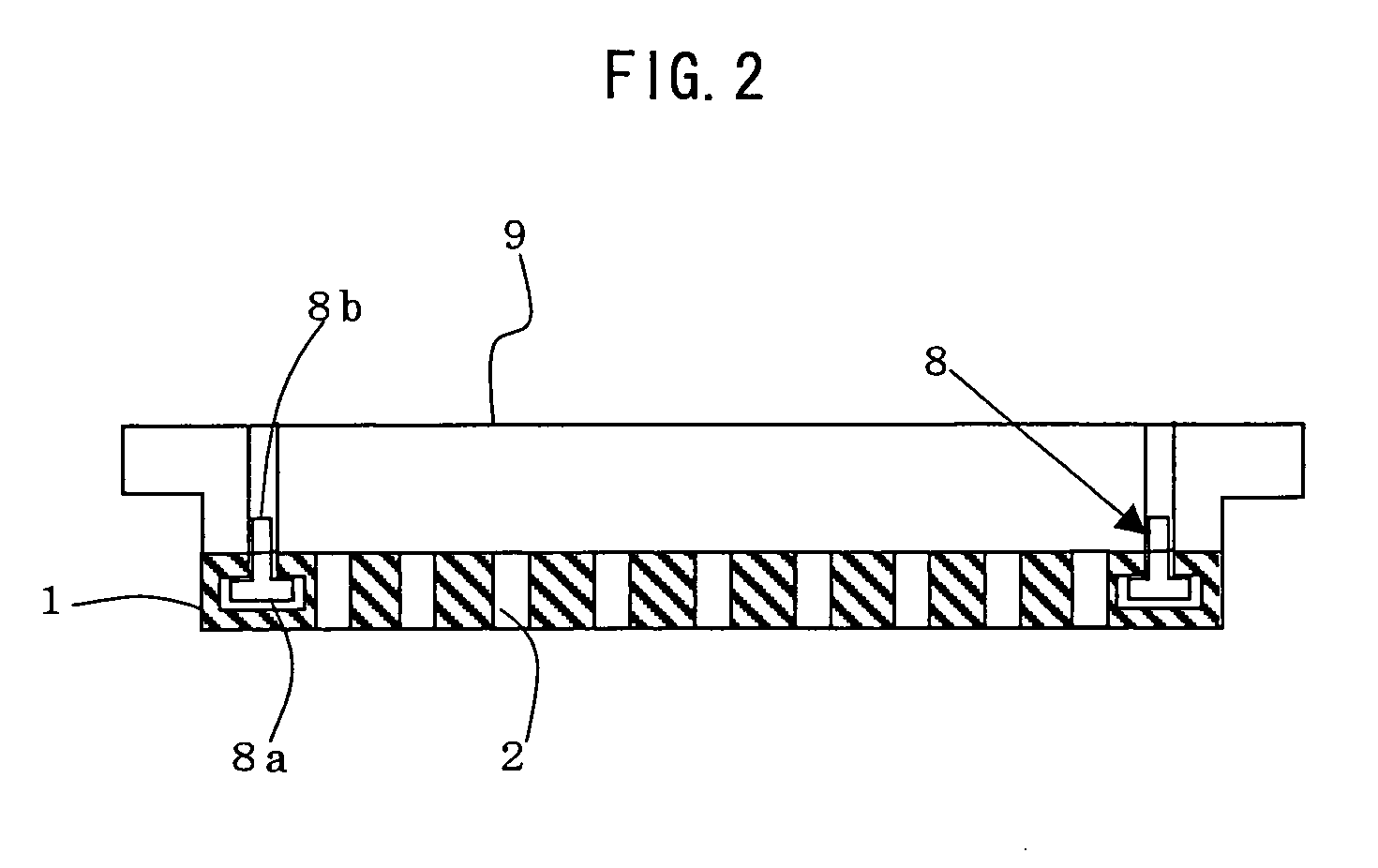

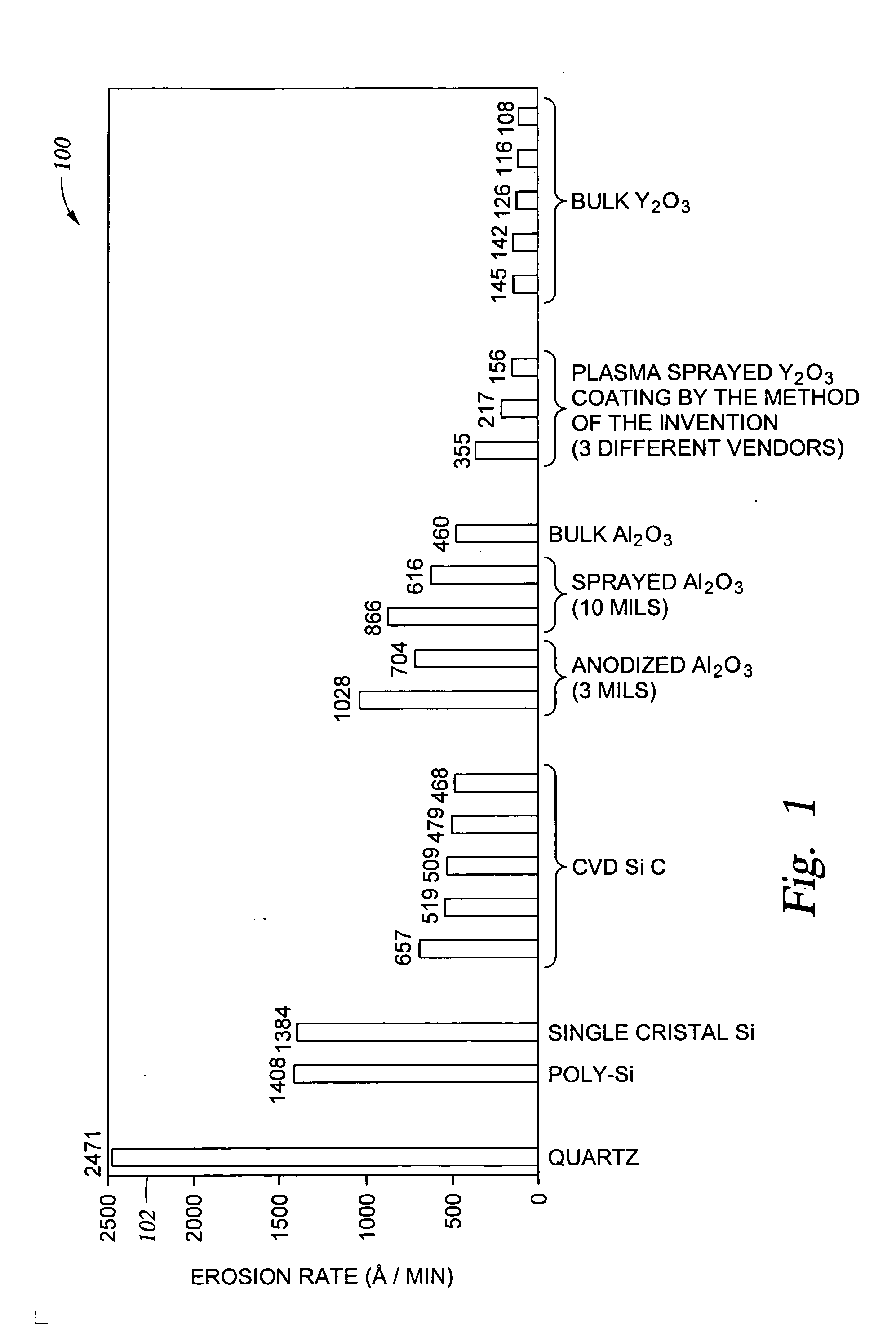

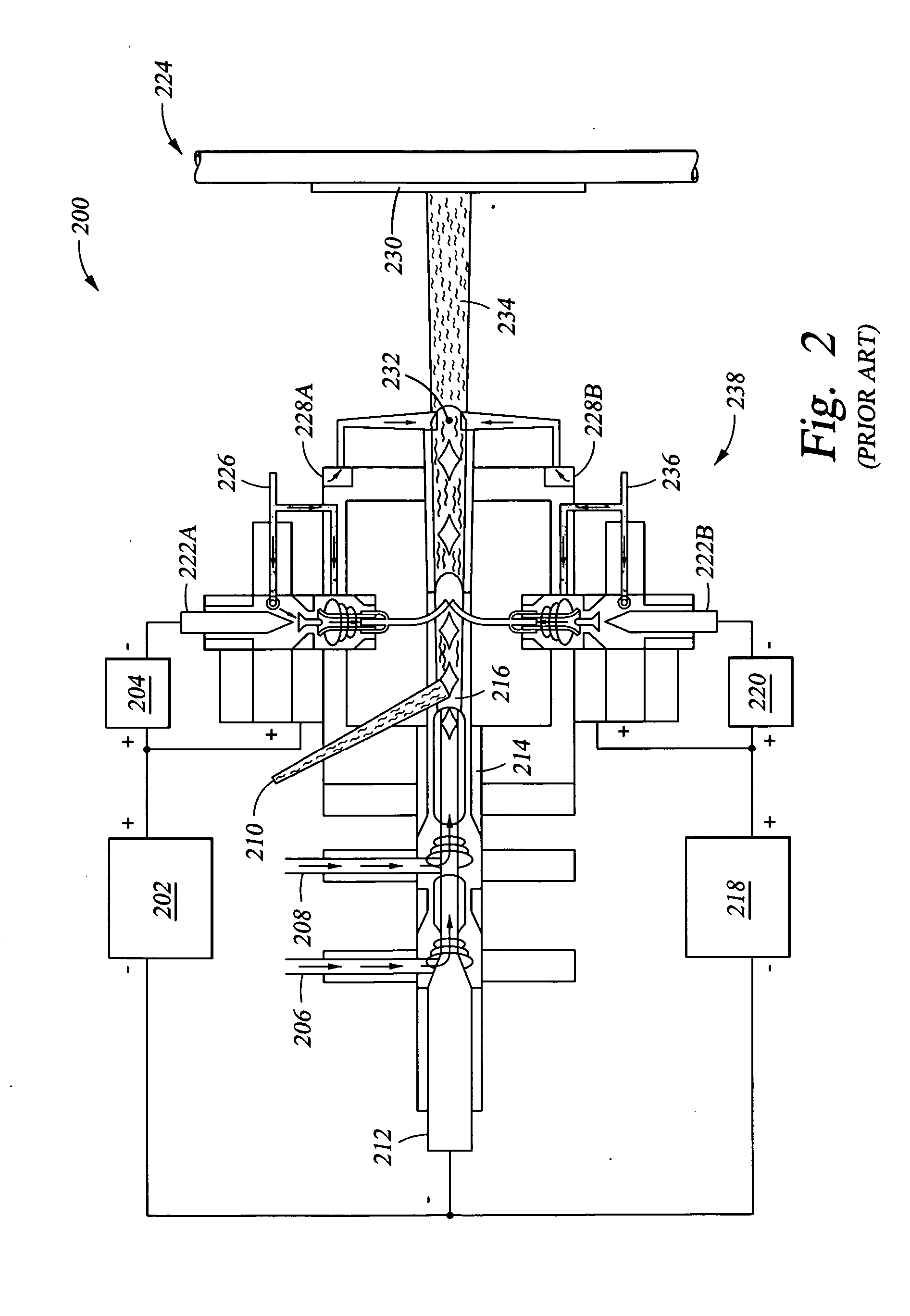

Clean, dense yttrium oxide coating protecting semiconductor processing apparatus

ActiveUS20050037193A1Extended service lifeExcellent plasma corrosion-resistanceLiquid surface applicatorsMolten spray coatingPlasma coatingChemical vapor deposition

Disclosed herein is a method for applying plasma-resistant coatings for use in semiconductor processing apparatus. The coatings are applied over a substrate which typically comprises an aluminum alloy of the 2000 series or the 5000 through 7000 series. The coating typically comprises an oxide or a fluoride of Y, Sc, La, Ce, Eu, Dy, or the like, or yttrium-aluminum-garnet (YAG). The coating may further comprise about 20 volume % or less of Al2O3. The coatings are typically applied to a surface of an aluminum alloy substrate or an anodized aluminum alloy substrate using a technique selected from the group consisting of thermal / flame spraying, plasma spraying, sputtering, and chemical vapor deposition (CVD). To provide the desired corrosion resistance, it is necessary to place the coating in compression. This is accomplished by controlling deposition conditions during application of the coating.

Owner:APPLIED MATERIALS INC

Permeable electric thermal resistor foil for vaporizing fluids from single-use mouthpieces with vaporizer membranes

ActiveUS20140305454A1Low costReduce material usageTobacco pipesTobacco devicesMetallic foilDual coil

A vaporizer device for vaporizing substances is provided, containing active and / or aroma materials, including a mouthpiece with a fluid inlet and a fluid outlet, and including: a heating device with a thermal resistor being a metallic foil or a thin sheet configured as a dual coil and / or sinuous line with two ends and dimensions of the cross-section of a cigarette or a small cigar, wherein the interspaces of the dual coil and / or sinuous line allow fluid flow therethrough, contact tabs are connected to respective opposed ends of the dual coil and / or sinuous line and are not in direct contact with one another, and at least one permeable and wettable vaporizer membrane in large-area contact with the thermal resistor, wherein the thermal resistor and the at least one vaporizer membrane are arranged orthogonally or at an angle to the direction of the fluids passing through the mouthpiece.

Owner:PHILIP MORRIS PROD SA

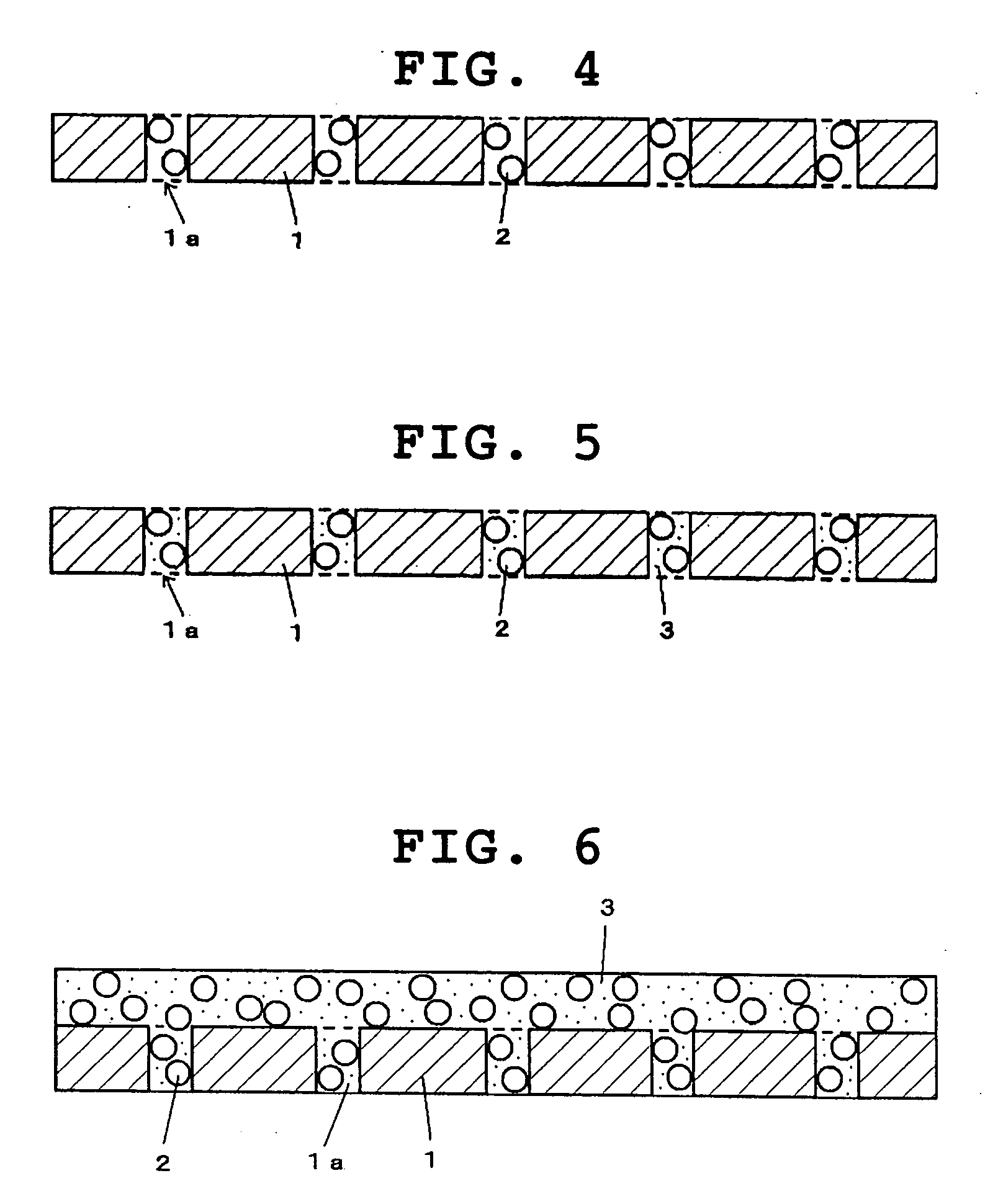

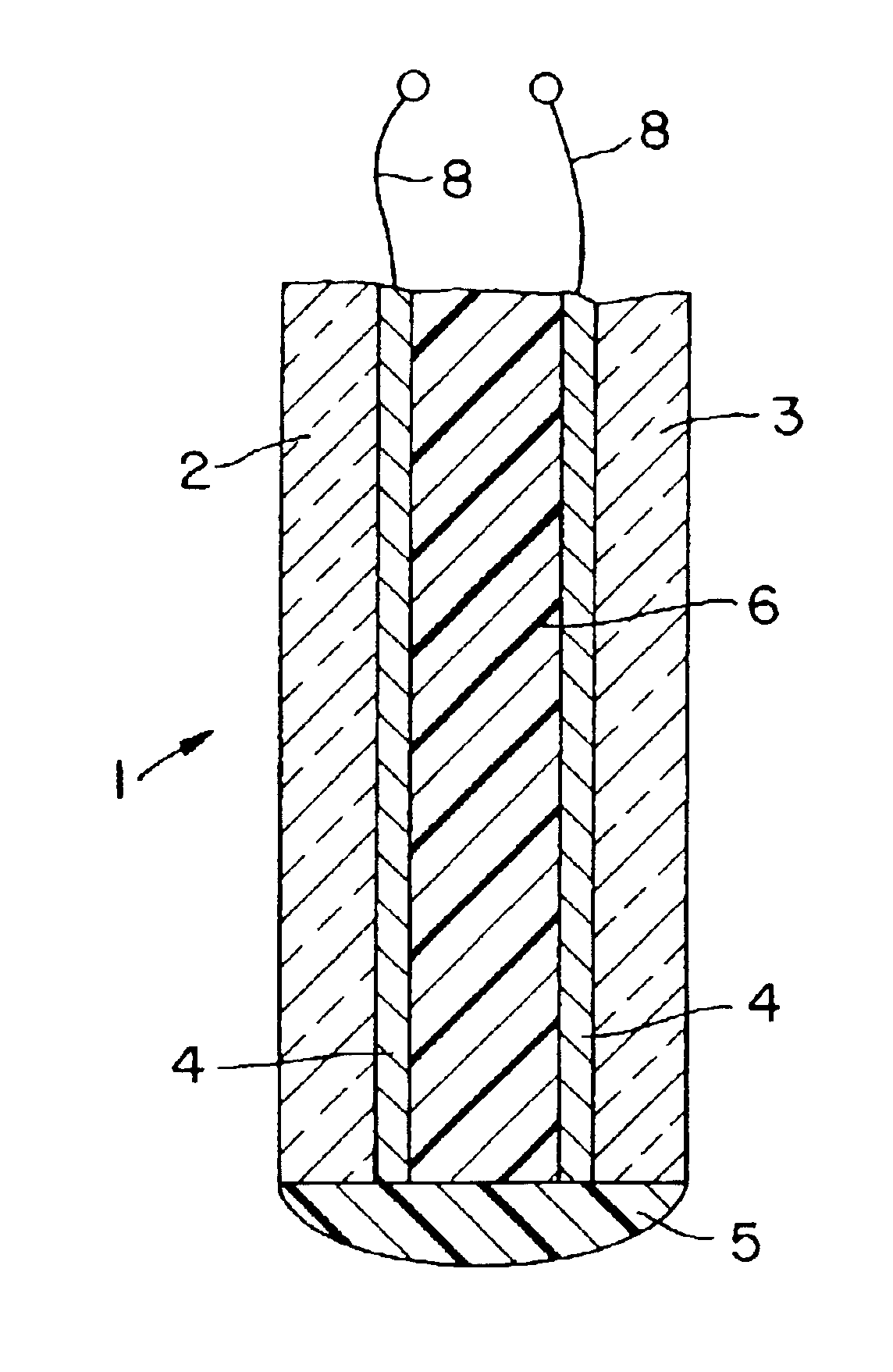

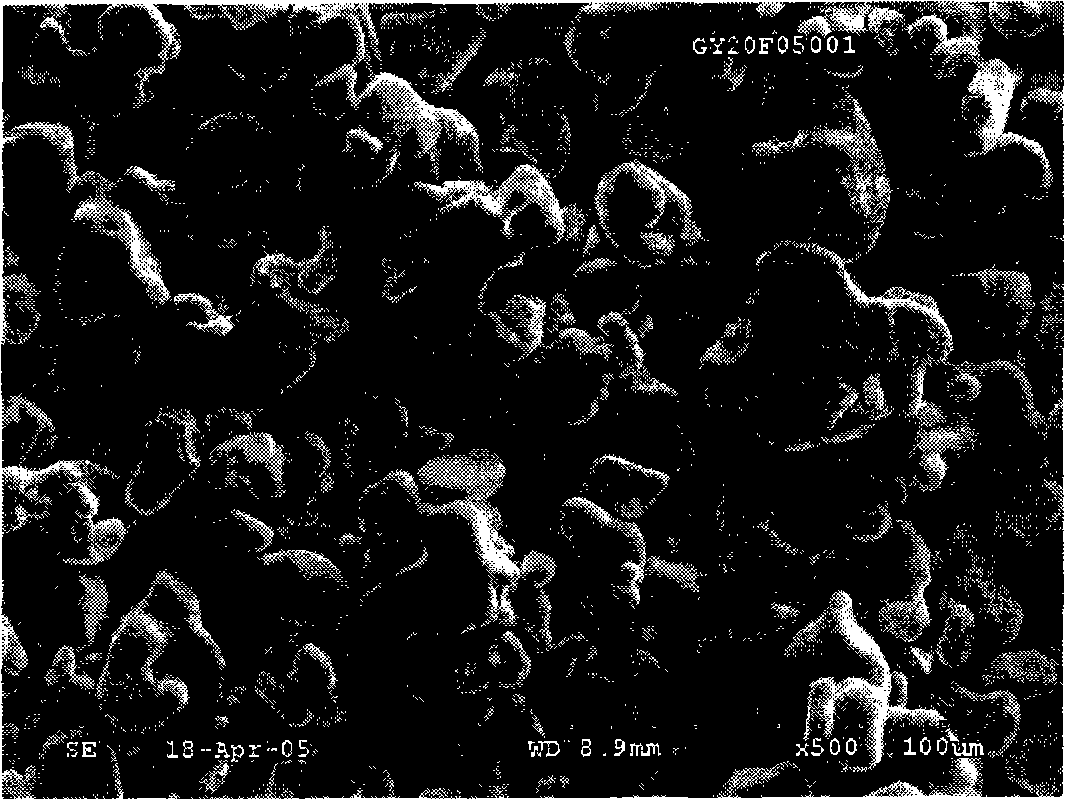

Electronic component separator and method for producing the same

InactiveUS20050208383A1Improve reliabilityImprove machinabilityHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersLithiumElectronic component

The present invention provides a separator that, when used in a lithium ion secondary battery, polymer lithium secondary battery, aluminum electrolytic capacitor or electric double-layer capacitor, offers desired levels of various practical characteristics, undergoes minimal heat shrinkage even when overheated, and exhibits high reliability and excellent workability. The electronic component separator proposed by the present invention comprises a porous base made of a substance having a melting point of 180° C. or above, and a resin structure provided on at least one side of and / or inside the porous base, and the porous base and / or resin structure contains filler grains.

Owner:TOMOEGAWA PAPER CO LTD

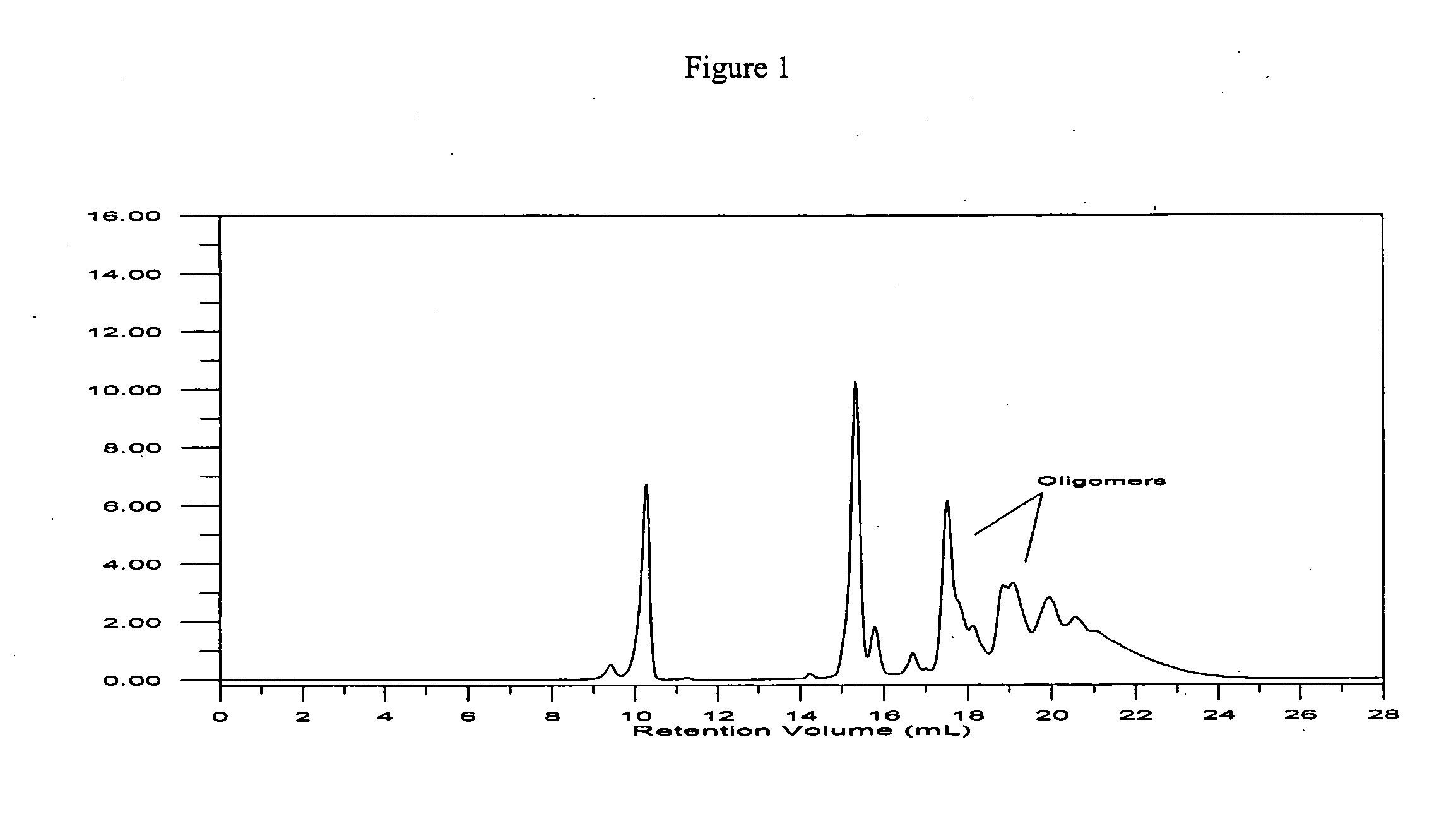

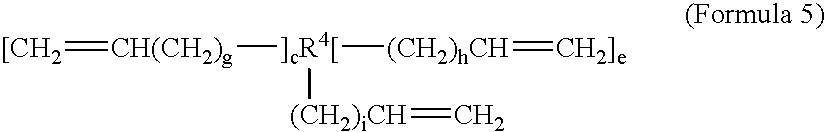

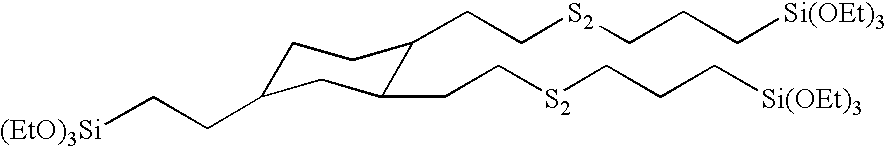

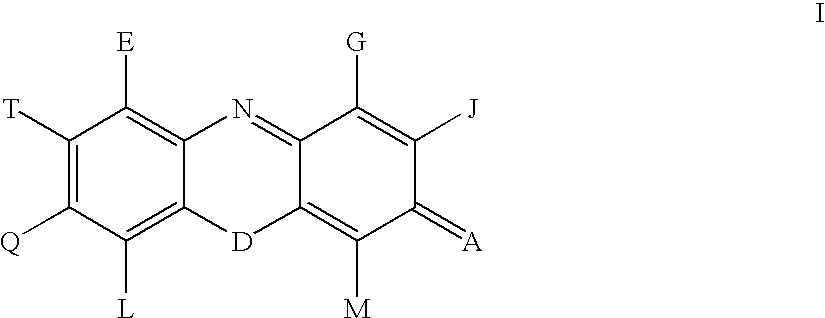

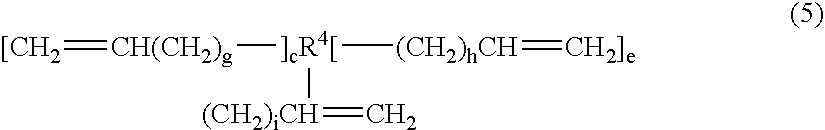

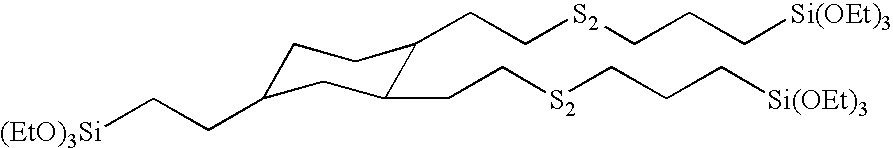

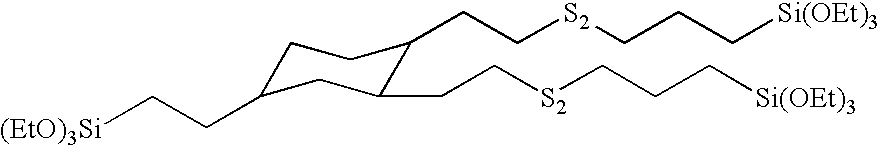

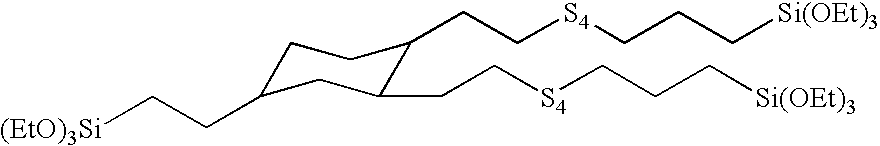

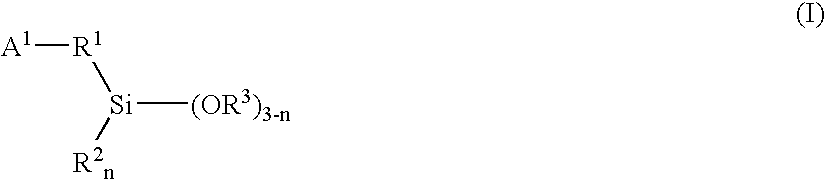

Silated core polysulfides, their preparation and use in filled elastomer compositions

ActiveUS20080161477A1Good dispersion of fillerImprove productivityGroup 4/14 element organic compoundsSpecial tyresElastomerSilanes

This invention relates to novel sulfur-containing silane coupling agents, and organic polymers containing carbon-carbon double bonds. These novel silanes can be carried on organic and inorganic fillers. The invention also relates to articles of manufacture, particularly tires, made from the elastomer compositions described herein.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

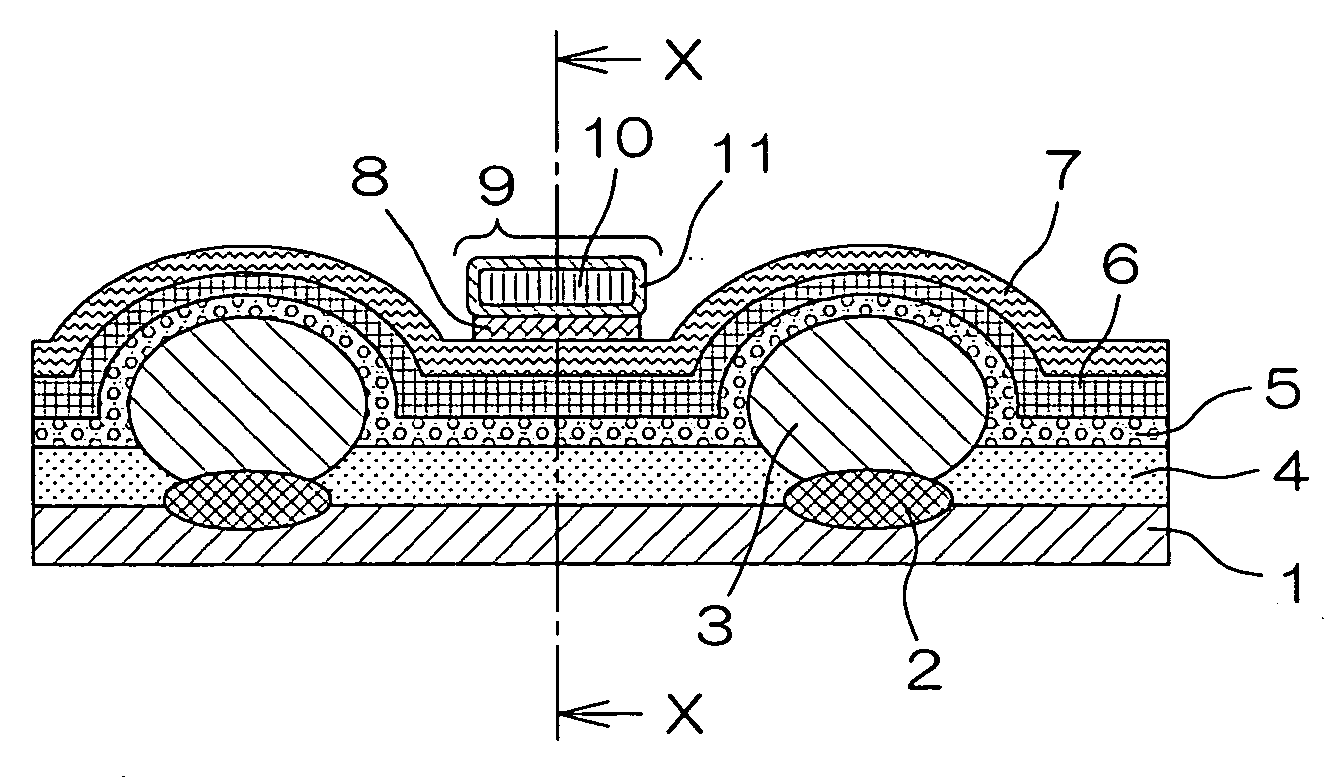

Photo-electric conversion cell and array, and photo-electric generation system

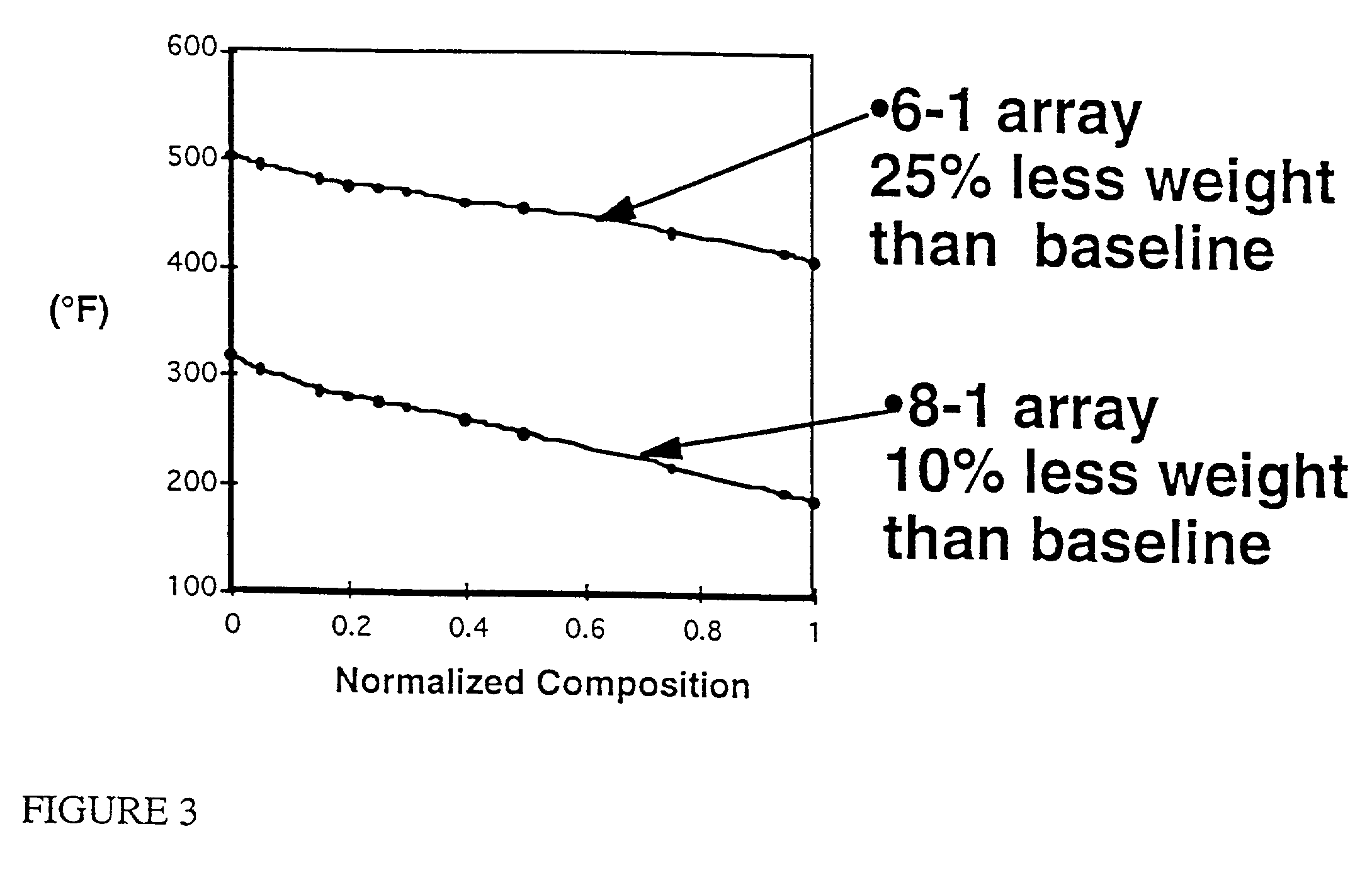

InactiveUS20050115602A1Practical to useHigh economic valuePV power plantsPhotovoltaic energy generationElectricityElectrical conductor

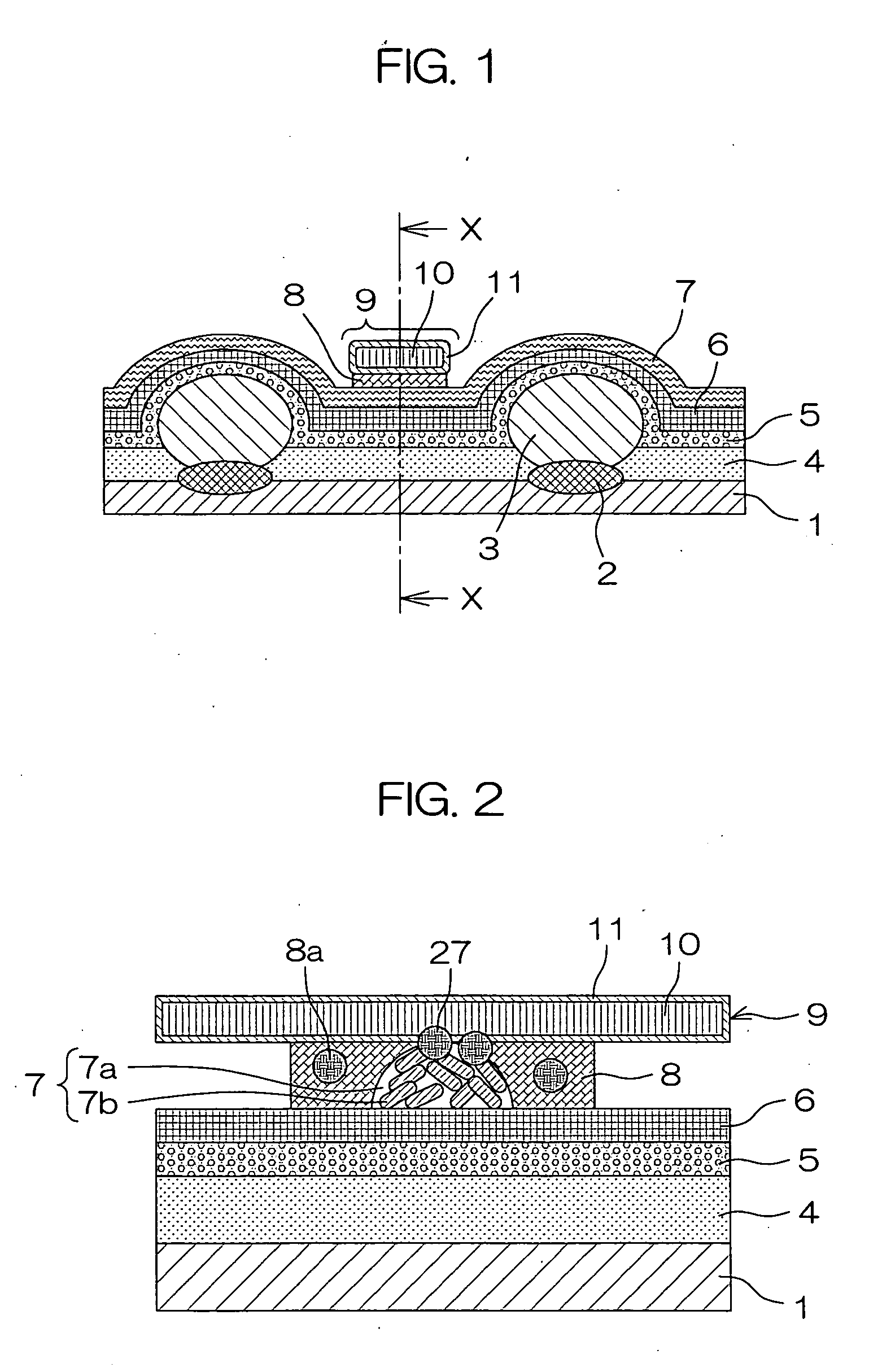

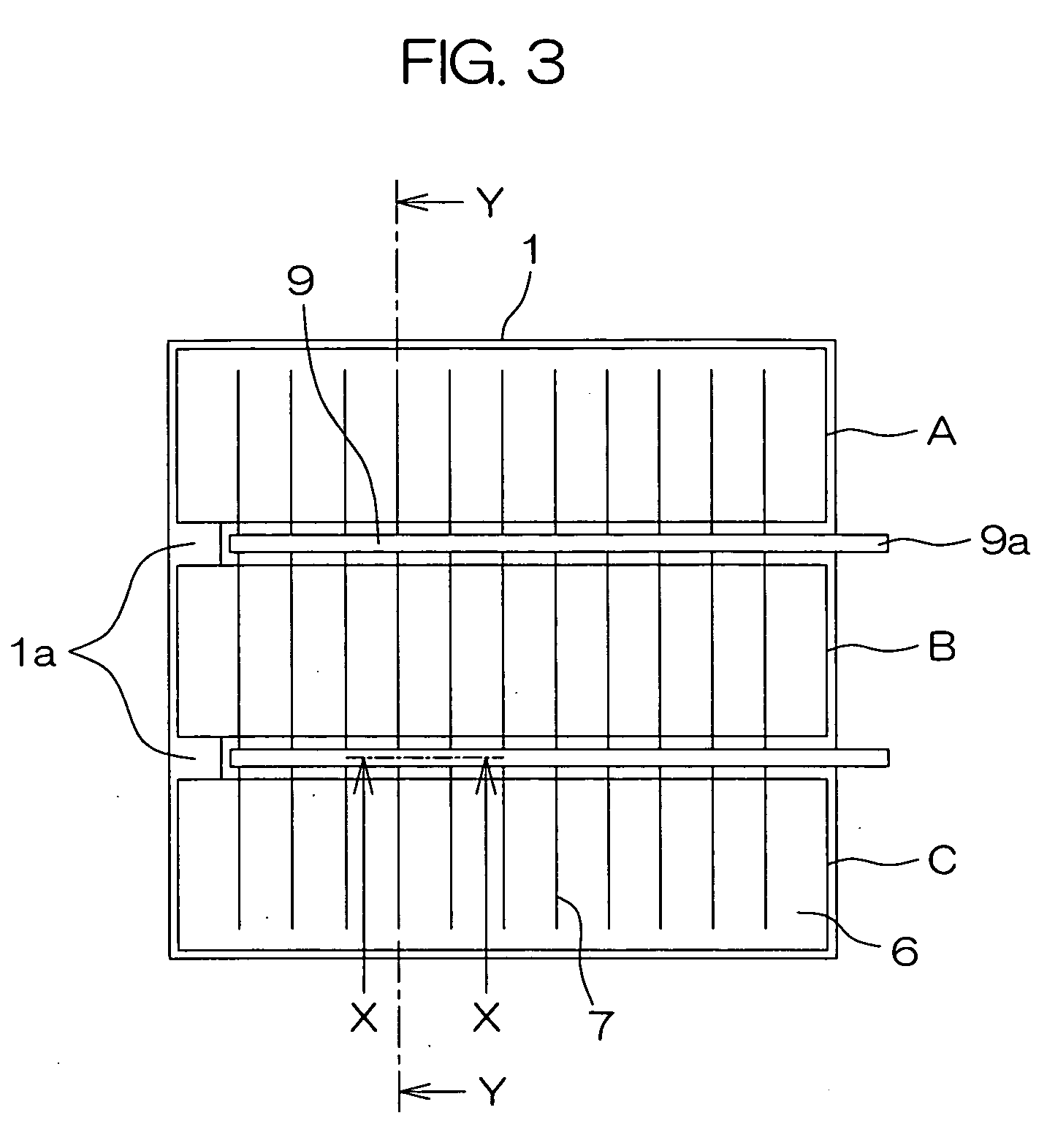

A photo-electric conversion array is formed by connecting photo-electric conversion cells in series. Each photo-electric conversion cell includes: a substrate, at least one main surface of which is made of a conductor layer; plural crystalline semiconductor particles provided on the conductor surface of the substrate; an insulation layer filled in clearances among the crystalline semiconductor particles; a transparent electric conducting layer provided above the plural crystalline semiconductor particles; a collector electrode, formed on the transparent electric conducting layer, to collect electricity from the transparent electric conducting layer. The substrate is provided with a substrate electrode portion at one end portion, through which the conductor surface of the substrate is exposed, and a connection electrode is formed by extending the collector electrode, so that the connection electrode in a given photo-electric conversion cell is connected to the substrate electrode portion in another photo-electric conversion cell. It is thus possible to provide a photo-electric conversion array capable of maintaining the reliability as to the adhesion strength, with a good outward appearance as well as excellent reliability and power generation efficiency.

Owner:KYOCERA CORP

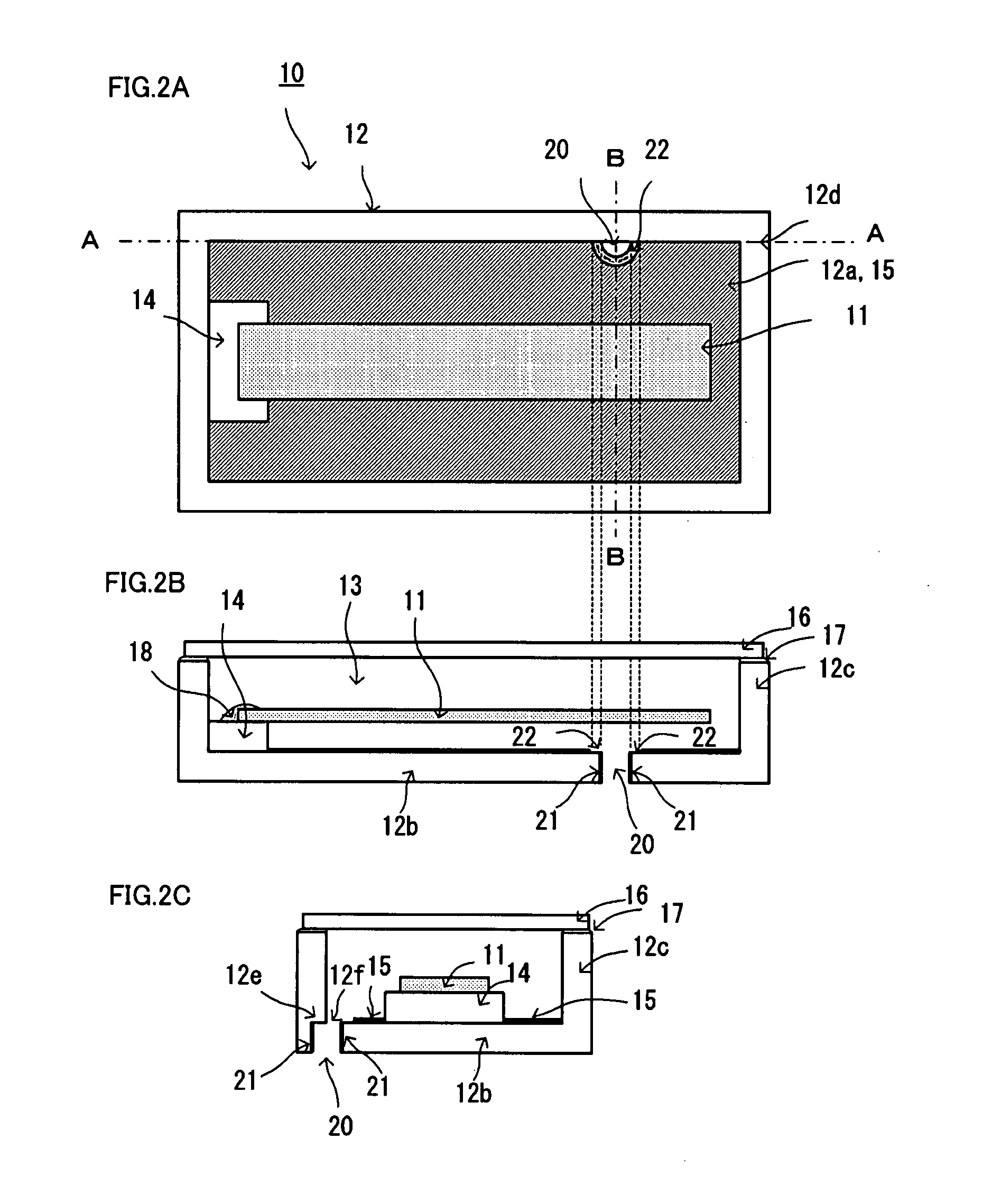

Electronic component package

InactiveUS20070182289A1Reduce impactFavorable in detection sensitivity behavior and starting characteristicImpedence networksPiezoelectric/electrostriction/magnetostriction machinesEngineeringElectronic component

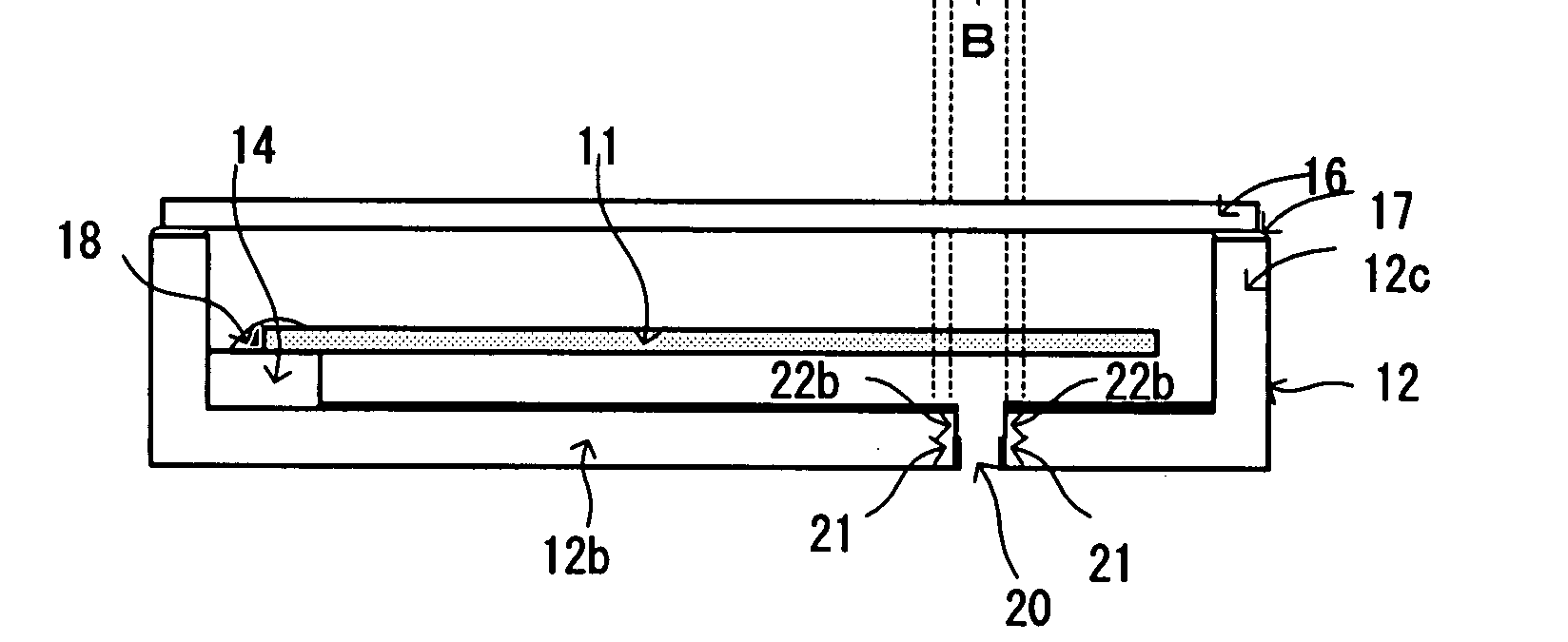

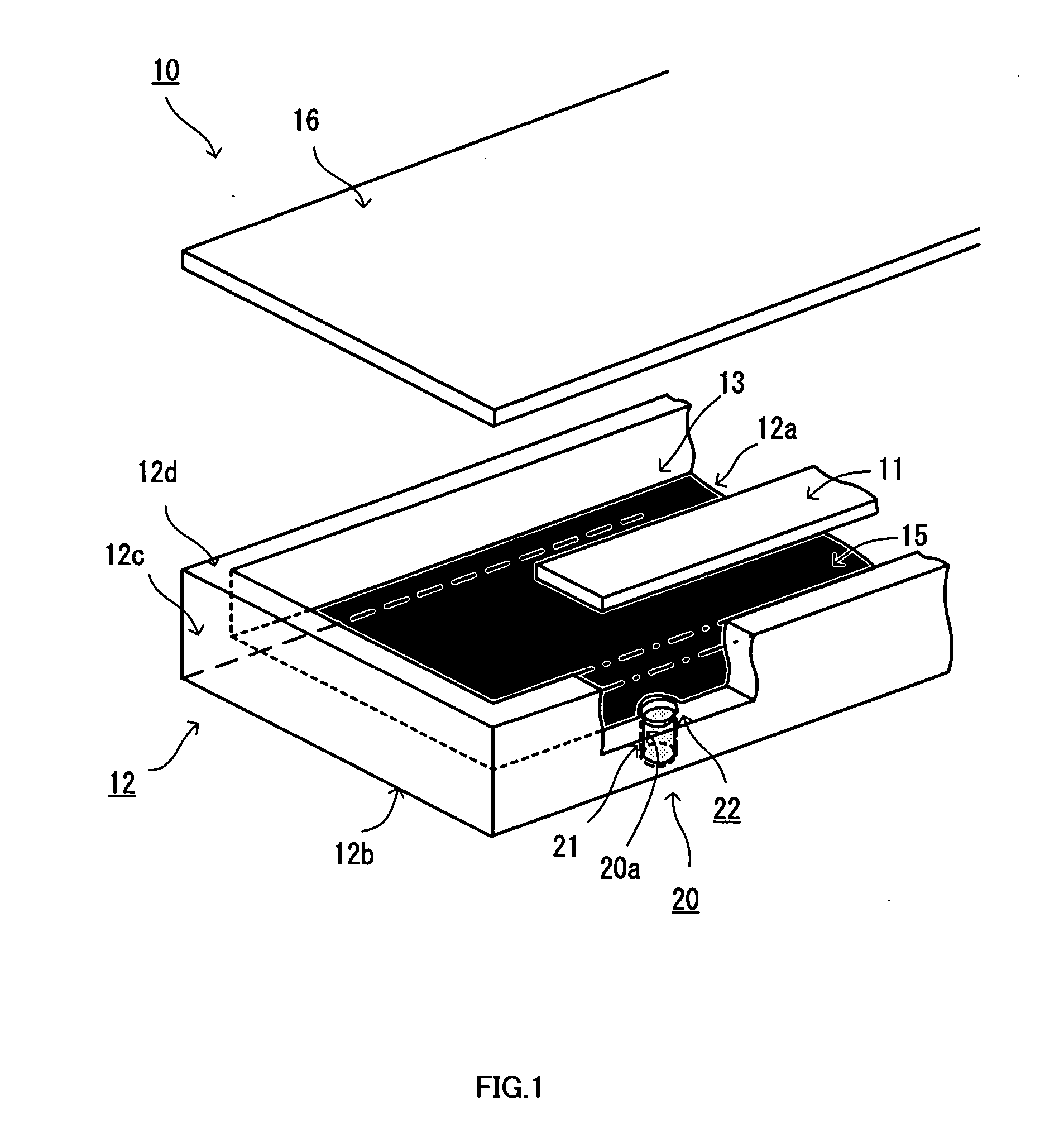

The present invention is to prevent melted sealant from flowing into the interior of a case of an electronic component package that is provided with a shielding electrode on the inner surface of the case, fill a through-hole with the sealant with reliability, and perform vacuum airtight sealing. The electronic component package 10 has a case 12 that has an opening and stores an electronic component (piezoelectric oscillator 11) in the storage inside, and a lid 16 that is joined to the rim of the opening to cover the opening, and airtightly seals a through-hole 20 provided on the bottom part 12b of the case 12 to communicate with the outside, by using a sealant 30. The electronic component package is provided with a shielding electrode 15 on the inner surface of the case to remove a noise influence, and further provided with a configuration to set a part (nonmetal part 22) between the through-hole 20 and the shielding electrode 15, the part being low in wettability with the melted sealant 30, thereby making it difficult to flow the melted sealant 30 from the through-hole 20 into the case 12 along the shielding electrode 15, preventing the melted sealant 30 from flowing into the case 12.

Owner:CITIZEN WATCH CO LTD

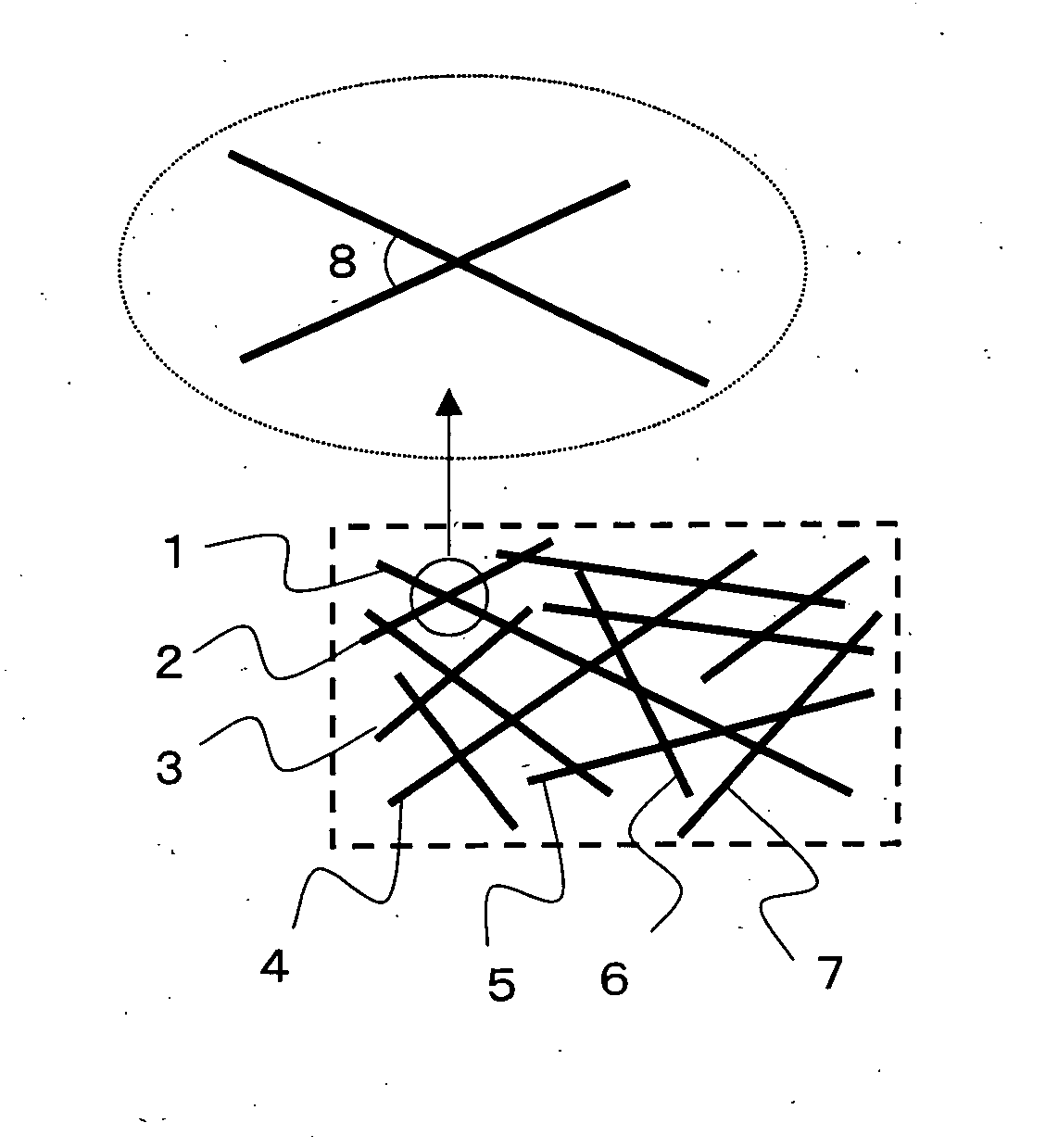

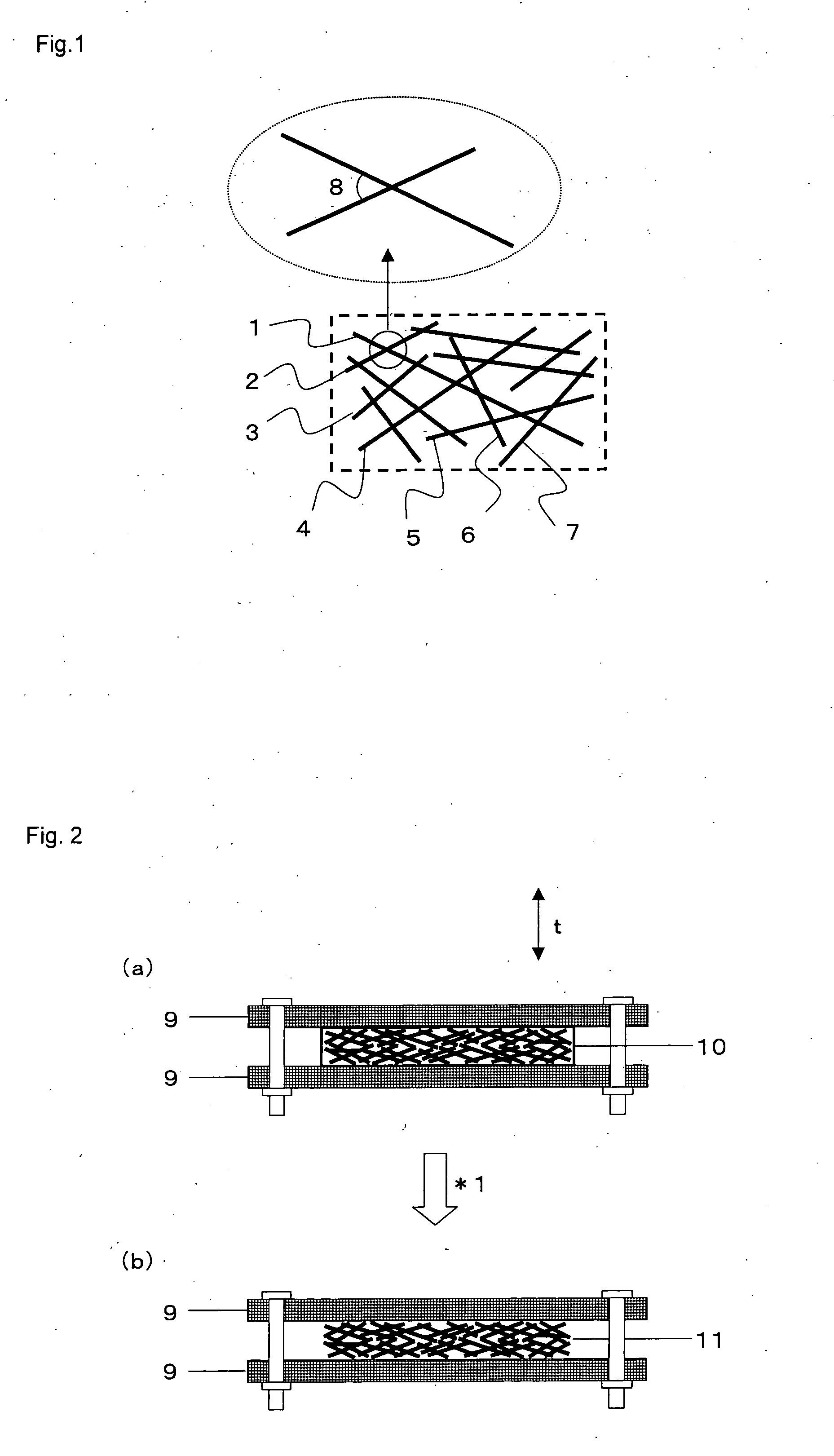

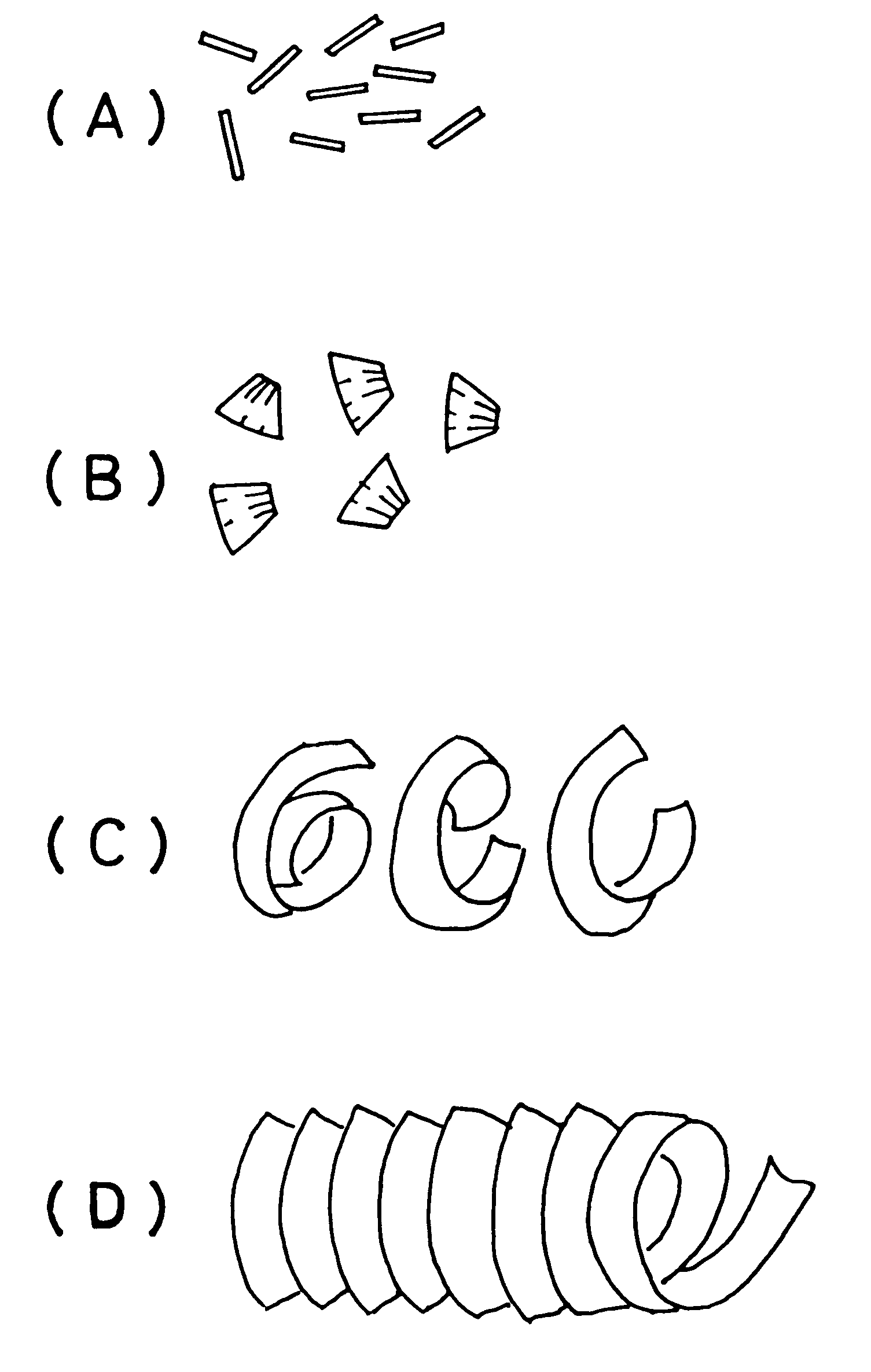

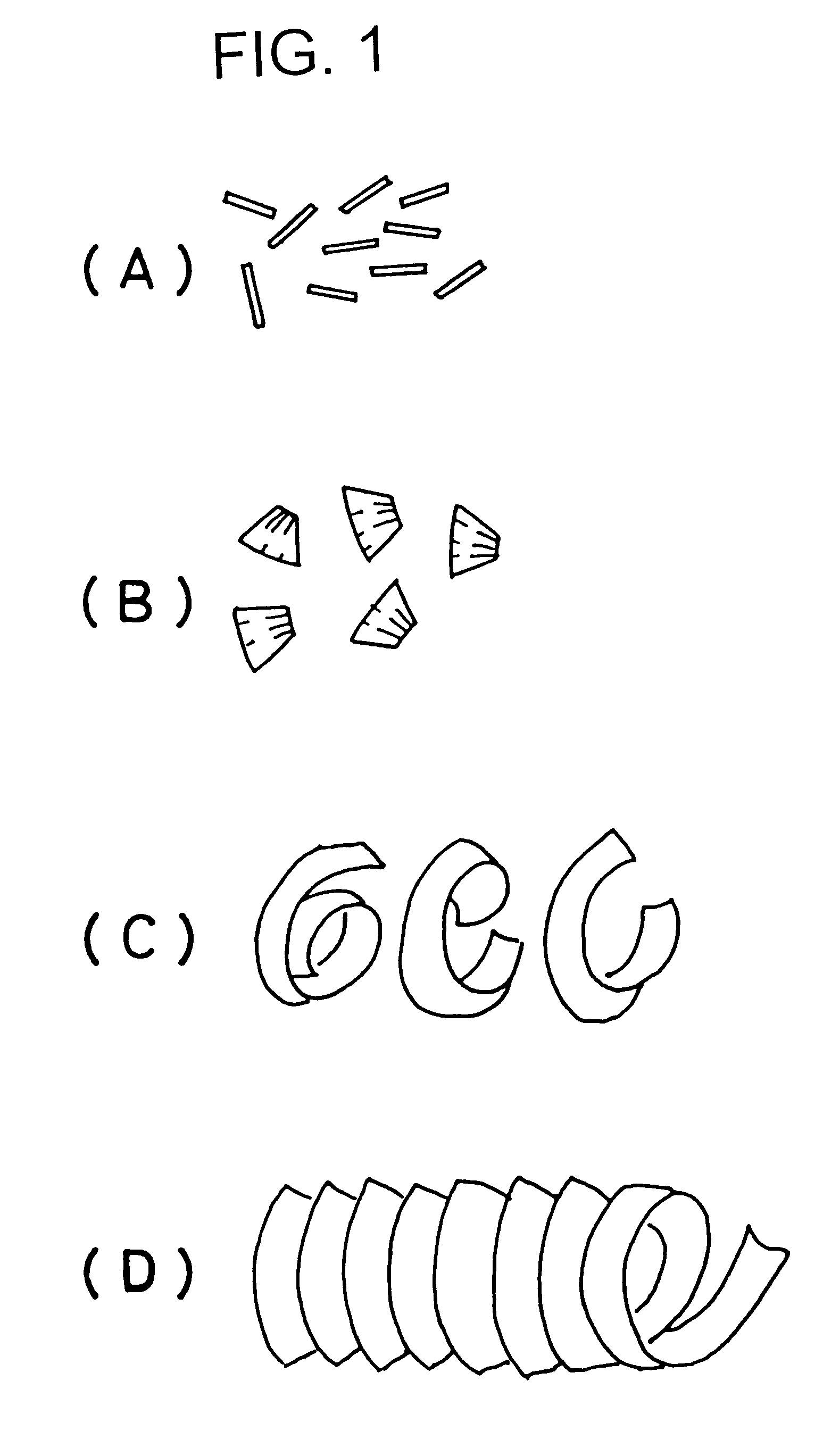

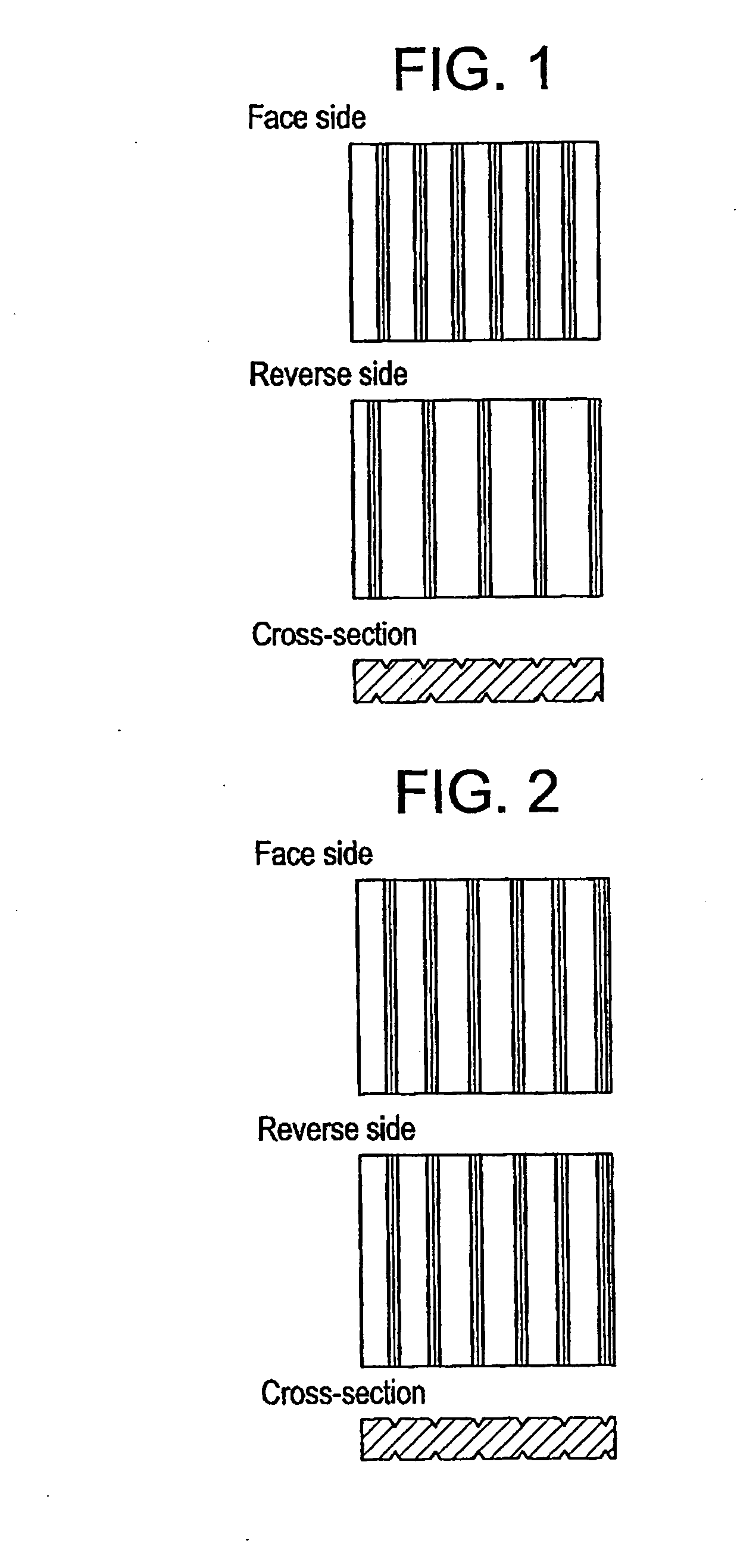

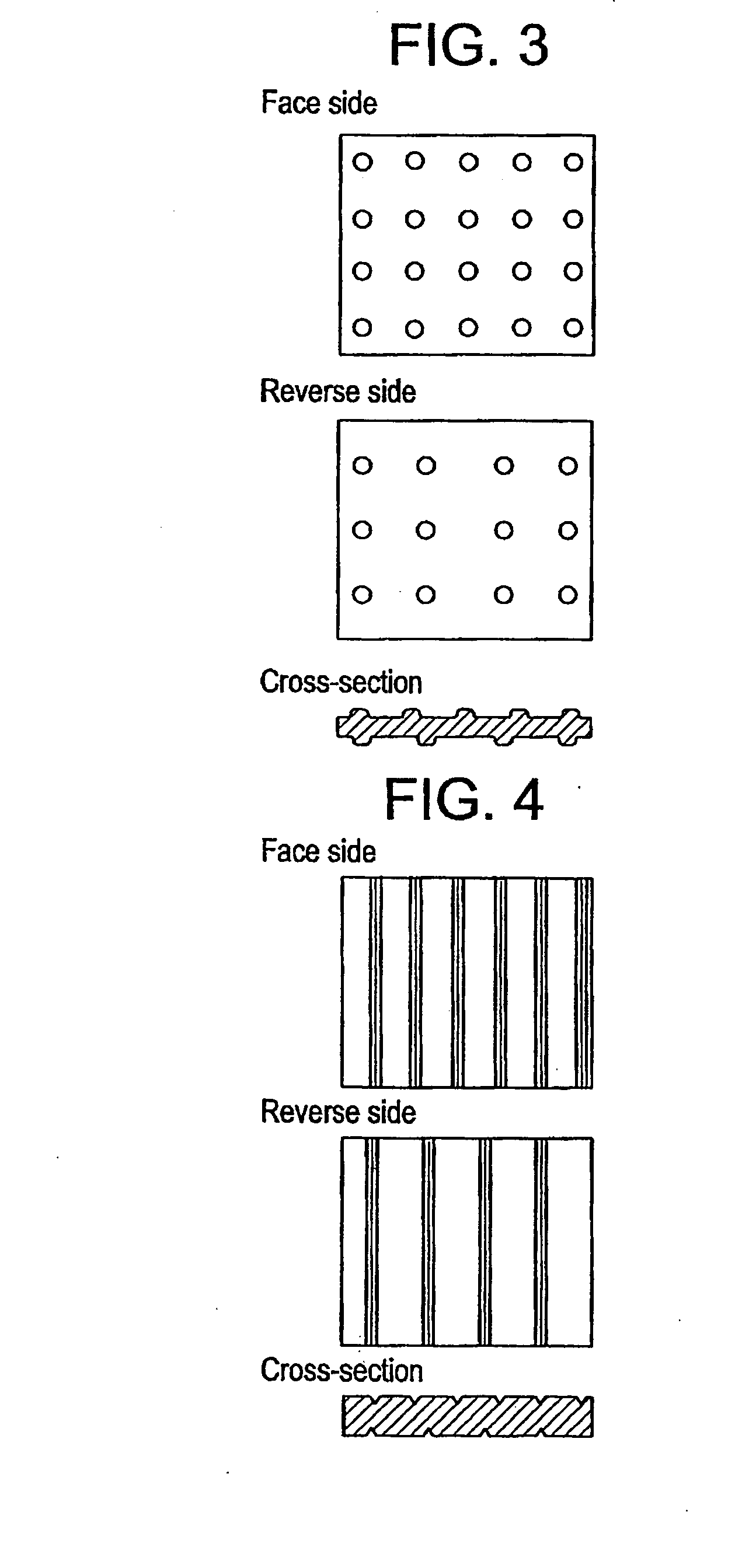

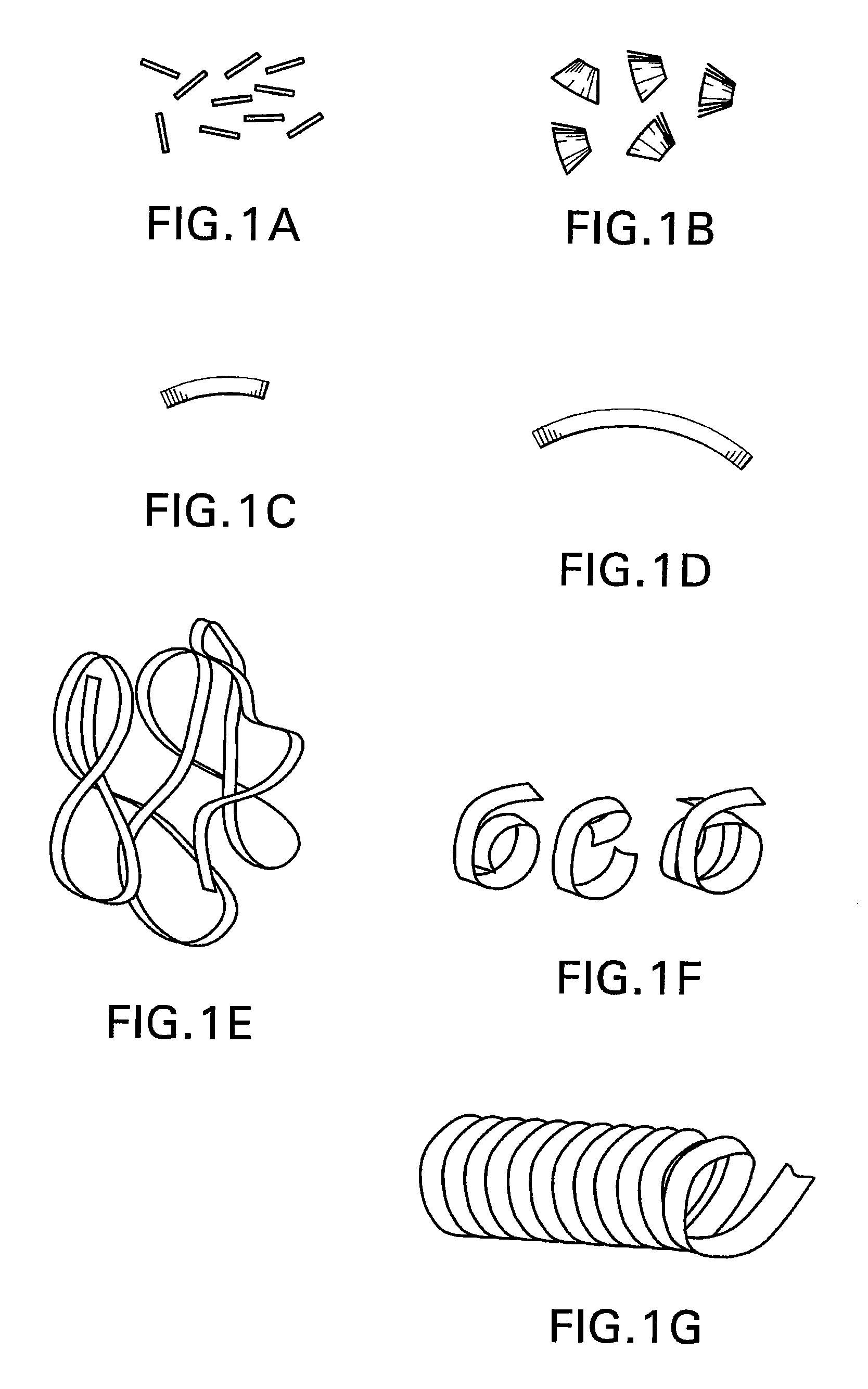

Prepreg, preform, molded product, and method for manufacturing prepreg

ActiveUS20110143110A1Reduce proportionEnhance effectSynthetic resin layered productsLaminationMechanical propertyIsotropy

This invention is A prepreg comprising a reinforcing fiber base material impregnated with a thermoplastic resin, wherein the reinforcing fiber base material comprises from 0 to 50% by mass of reinforcing fibers each having a fiber length of more than 10 mm, from 50 to 100% by mass of reinforcing fibers each having a fiber length of from 2 to 10 mm, and from 0 to 50% by mass of reinforcing fibers each having a fiber length of less than 2 mm, the average of two-dimensional orientation angles each formed by a reinforcing filament (a) and a reinforcing filament (b) intersecting the reinforcing filament (a) is from 10 to 80°, the thickness h0 (mm) at 23° C. is 0.03 to 1 mm, and the tensile strength σ is 0.01 MPa or more.The prepreg can be applied for thin molded products which have been considered unsuitable as a laminated molded product and can provide molded products that have a complicated shape and have isotropically high mechanical properties.

Owner:TORAY IND INC

Solid Electrolyte Material Manufacturable by Polymer Processing Methods

ActiveUS20090075176A1Enhanced securityLow manufacturing costSolid electrolytesAlkaline accumulatorsElastic modulusHigh energy

The present invention relates generally to electrolyte materials. According to an embodiment, the present invention provides for a solid polymer electrolyte material that is ionically conductive, mechanically robust, and can be formed into desirable shapes using conventional polymer processing methods. An exemplary polymer electrolyte material has an elastic modulus in excess of 1×106 Pa at 90 degrees C. and is characterized by an ionic conductivity of at least 1×10−5 Scm−1 at 90 degrees C. An exemplary material can be characterized by a two domain or three domain material system. An exemplary material can include material components made of diblock polymers or triblock polymers. Many uses are contemplated for the solid polymer electrolyte materials. For example, the present invention can be applied to improve Li-based batteries by means of enabling higher energy density, better thermal and environmental stability, lower rates of self-discharge, enhanced safety, lower manufacturing costs, and novel form factors.

Owner:RGT UNIV OF CALIFORNIA +1

Method for lathing silicone hydrogel lenses

ActiveUS20060001184A1High oxygen permeabilityImprove machinabilityOptical articlesCeramic shaping apparatusRoom temperaturePolymer chemistry

The present invention provides methods for lathing at room temperature a silicone hydrogel material, in particular silicone hydrogel material having a high oxygen permeability and made of a polymerizable composition containing a relative large amount of oxyperm component, into contact lenses.

Owner:ALCON INC

Electrochromic polymeric solid films, manufacturing electrochromic devices using such solid films, and processes for making such solid films and devices

InactiveUS6855431B2Minimal shrinkageImprove adhesionOptical signallingGlass/slag layered productsMonomer compositionInherent safety

The present invention relates to electrochromic polymeric solid films, manufacturing electrochromic devices using such solid films and processes for making such solid films and devices. The electrochromic polymeric solid films of the present invention exhibit beneficial properties and characteristics, especially when compared to known electrochromic media. The electrochromic polymeric solid films are transformed in situ from a low viscosity electrochromic monomer composition by exposure to electromagnetic radiation, and in so doing minimum shrinkage occurs. The electrochromic polymeric solid films of the present invention also perform well under prolonged coloration, outdoor weathering and all-climate exposure, and provide an inherent safety aspect not known to electrochromic media heretofore.

Owner:DONNELLY CORP

Tire compositions and components containing silated core polysulfides

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

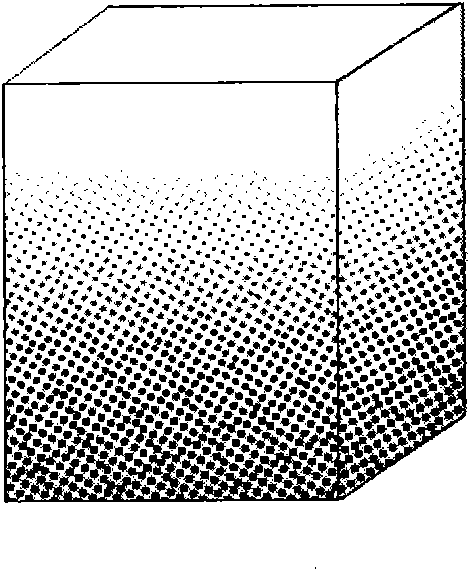

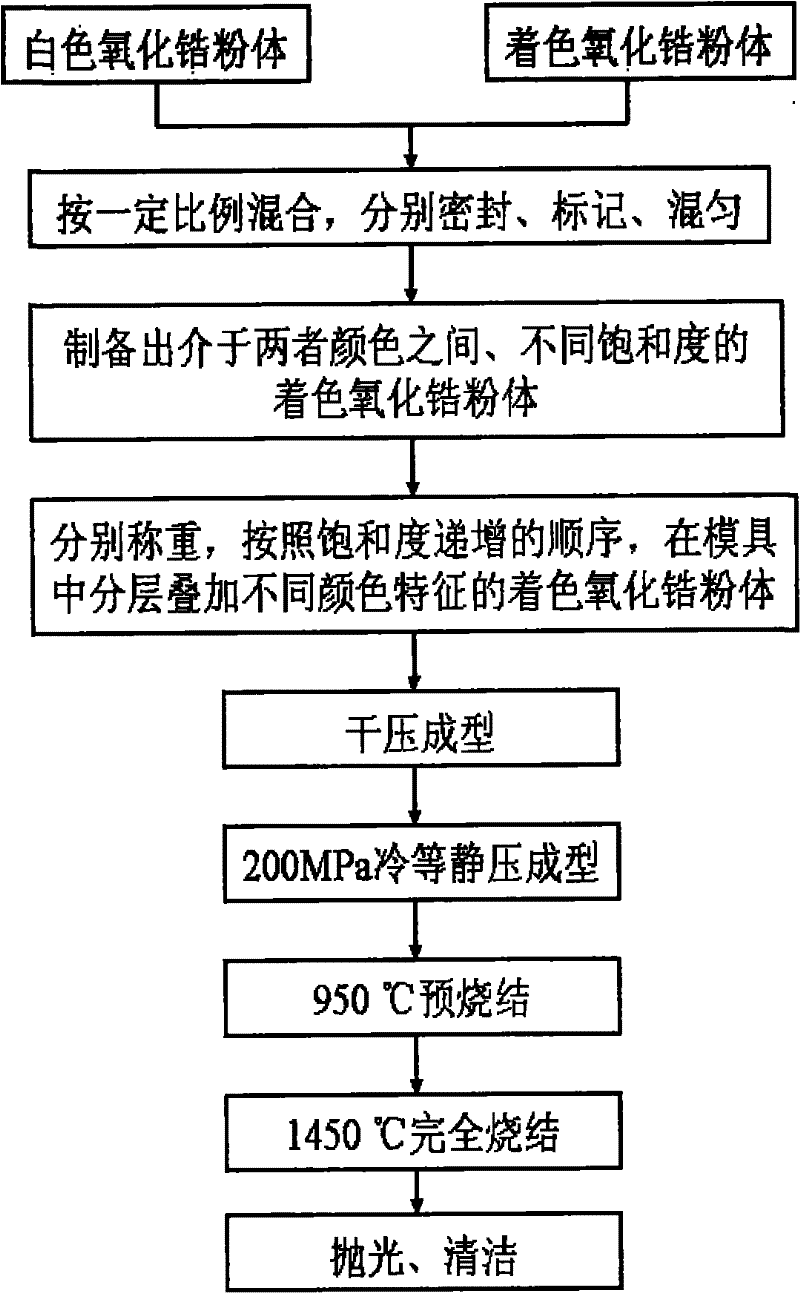

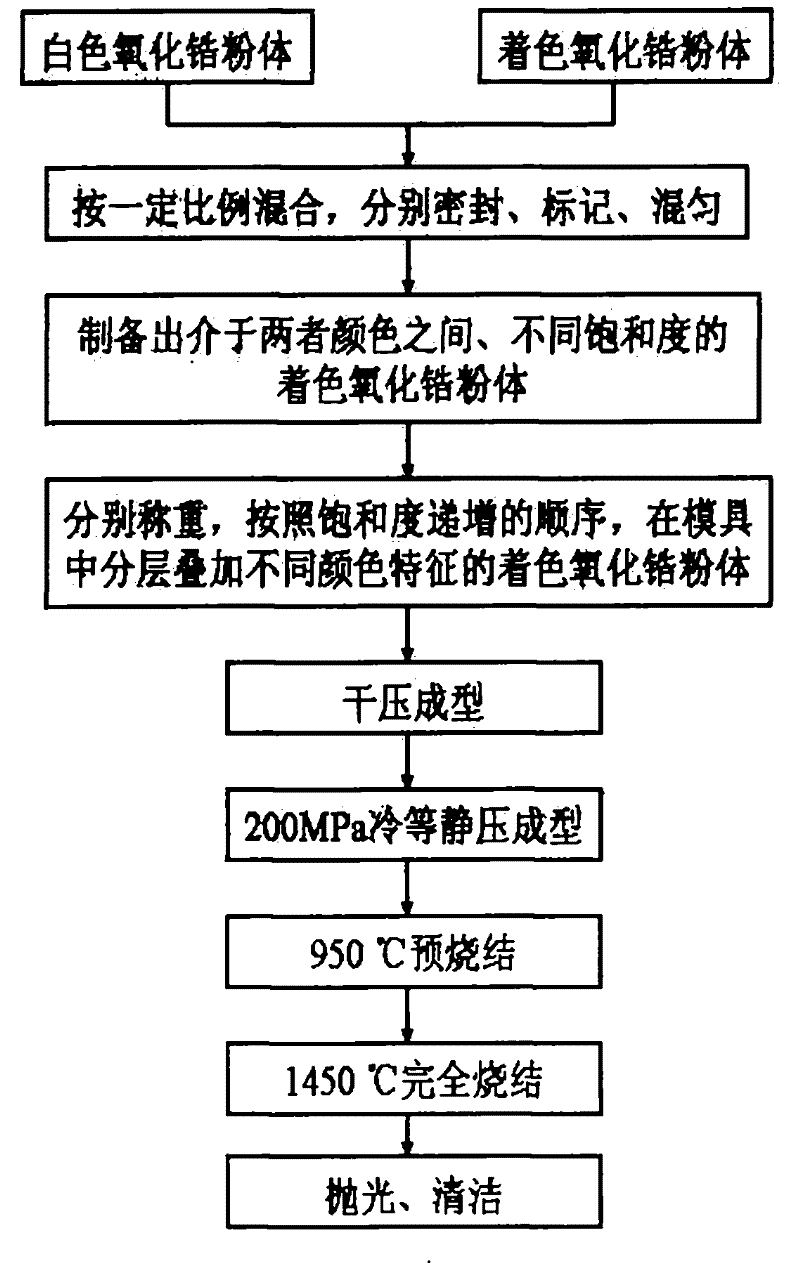

Dental complex color machinable zirconia ceramics and preparation method

InactiveCN102285795AHigh simulationFull aestheticsImpression capsDentistry preparationsAll ceramicAbutment

A dental multi-color machinable zirconia ceramic and its preparation method. The zirconia ceramic has the characteristics of translucence and color gradient, and contains more than five porcelain layers with the same hue and different saturation. The lightness gradually decreases from the top of the ceramic to the bottom layer, and the saturation The density gradually increases, and the color transitions naturally with a sense of hierarchy; the pre-sintered porous ceramic body of the zirconia ceramic is easy to cut and shape, and can be used to make personalized and beautiful dental zirconia all-ceramic restorations through the CAD / CAM system, which is conducive to preserving the abutment teeth. Improve the repair success rate. The preparation method of the dental complex color machinable zirconia ceramic is simple, effective and easy to popularize.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY +1

Rubber composition and cross-linked rubber

InactiveUS20130280459A1Improve machinabilityImprove cold resistanceClosuresLayered productsCross-linkHalogen

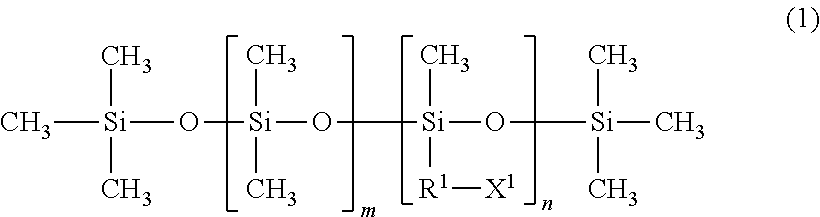

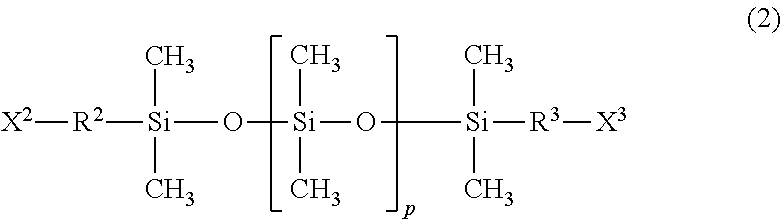

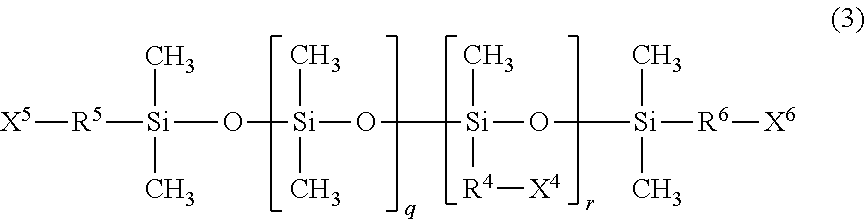

A nitrile rubber composition containing a carboxyl group-containing nitrile rubber and a reactive silicone oil and cross-linked rubber obtained by using that nitrile rubber composition are provided. Further, a rubber composition for sliding member use containing a carboxyl group-containing rubber which contains carboxyl group-containing monomer units in a ratio of 0.1 to 20 wt %, a content ratio of monomer units which have unsaturated carbon-carbon double bonds of 20 wt % or less, and a content ratio of monomer units which have halogen atoms of 5 wt % or less and a reactive silicone oil is provided.

Owner:ZEON CORP

Tire compositions and components containing free-flowing filler compositions

ActiveUS20080161475A1Better wear characteristicsImprove rolling resistanceSpecial tyresSulfur containingOrganic chemistry

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

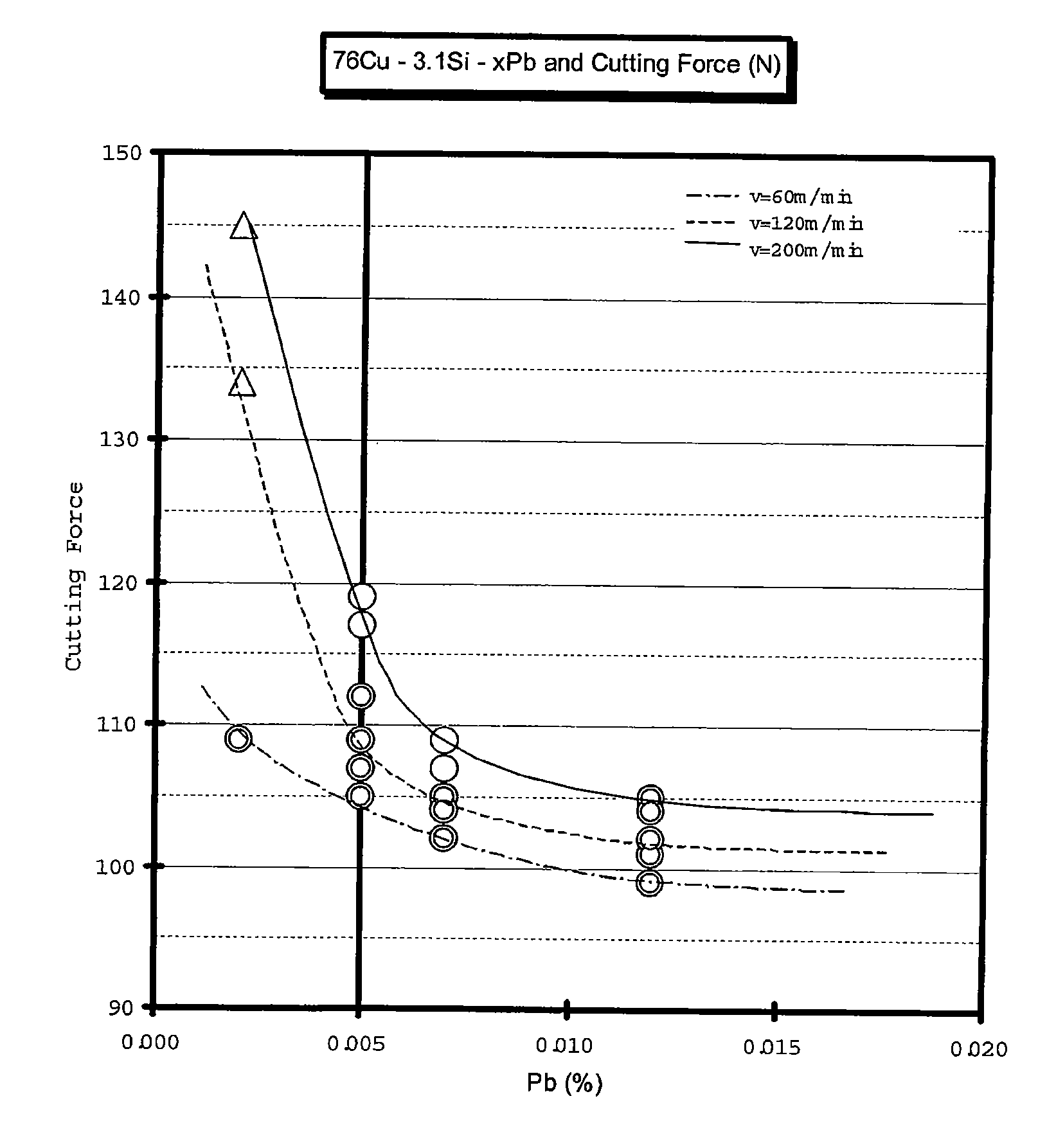

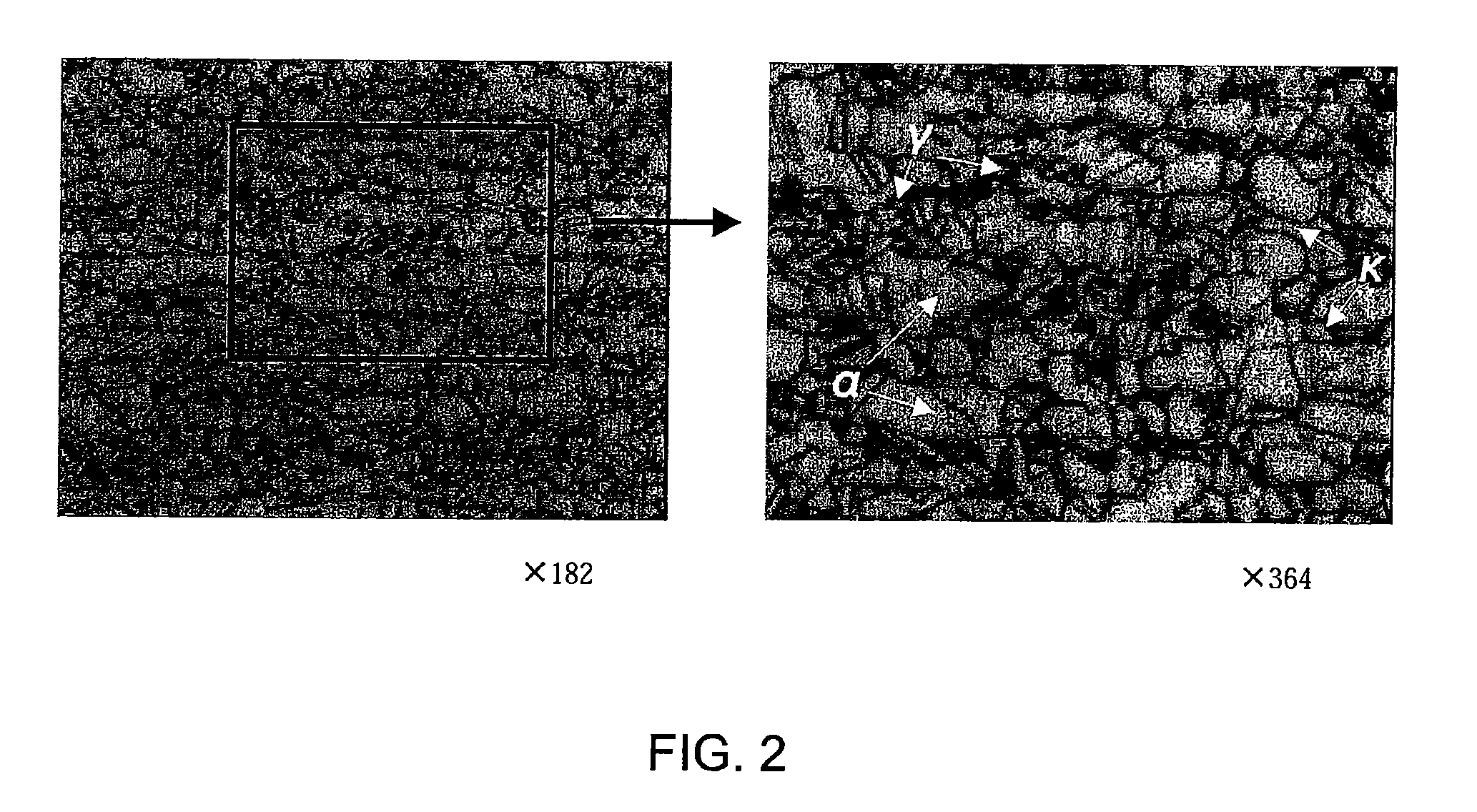

Lead-free free-cutting copper alloys

A lead-free free-cutting copper alloy having 69 to 79 percent, by weight, of copper; greater than 3 percent, by weight, of silicon; and a remaining percent, by weight, of zinc. The alloy preferable has greater than 3.0 percent and less than or equal to 4.0 percent, by weight, of silicon; and at least one element selected from among 0.02 to 0.4 percent, by weight, of bismuth, 0.02 to 0.4 percent, by weight, of tellurium, and 0.02 to 0.4 percent, by weight, of selenium. The alloy also preferable has at least one element selected from among 0.3 to 3.5 percent, by weight, of tin, 1.0 to 3.5 percent, by weight, of aluminum, and 0.02 to 0.25 percent, by weight, of phosphorus. In further embodiments, the alloy has at least one element selected from among 0.02 to 0.15 percent, by weight, of antimony, and 0.02 to 0.15 percent, by weight, of arsenic.

Owner:MITSUBISHI SHINDOH CO LTD

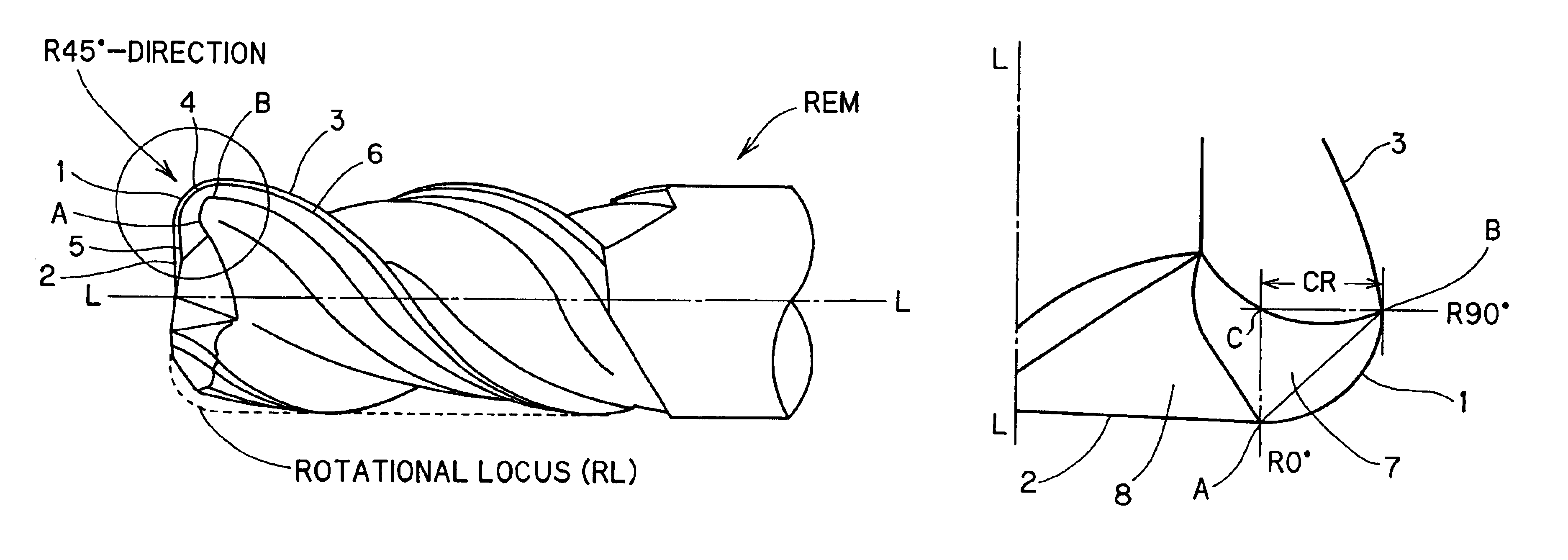

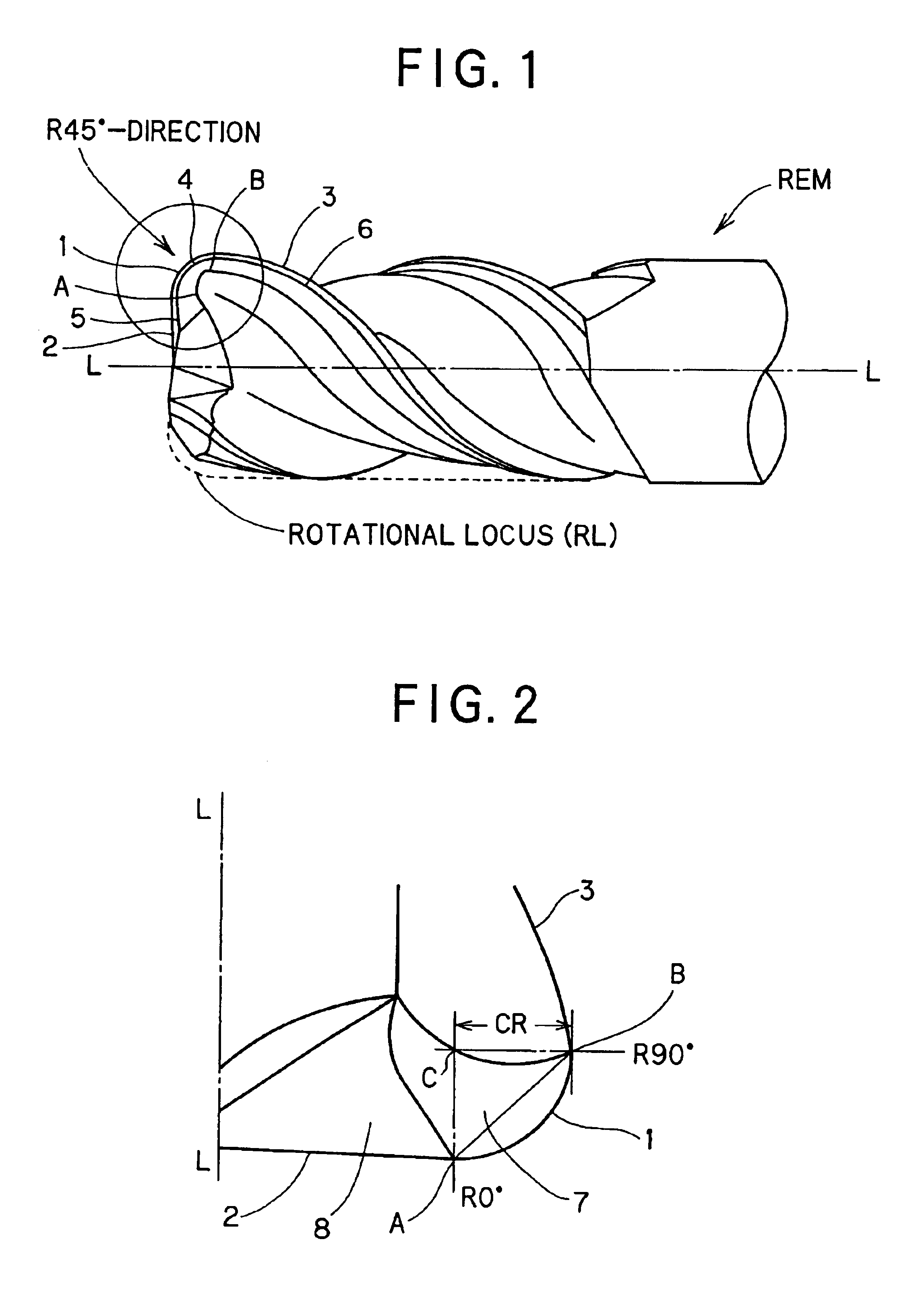

Radius end mill having radius edge enhanced in resistance to chipping and fracture

InactiveUS6846135B2Suppress chipping and fractureHigh-feed cuttingMilling cuttersWorkpiecesEngineeringCurve line

In a radius end mill having a bottom edge formed on the end face thereof, a radius edge designed in a substantially quarter arc shape and formed at a corner portion thereof, and an outer peripheral edge formed spirally on the side surface thereof, the bottom edge and the radius edge being continuously connected to each other at a connecting point A while the radius edge is continuously connected to each other at a connecting point B, when a view taken along a plane that passes through the connecting points A and B and crosses a rake face of the radius edge is represented by an R cross-sectional view, the rake face of the radius edge is designed to have a convex curved line extending from the connecting point A to the connecting point B in the R cross-sectional view.

Owner:HITACHI TOOL ENG LTD

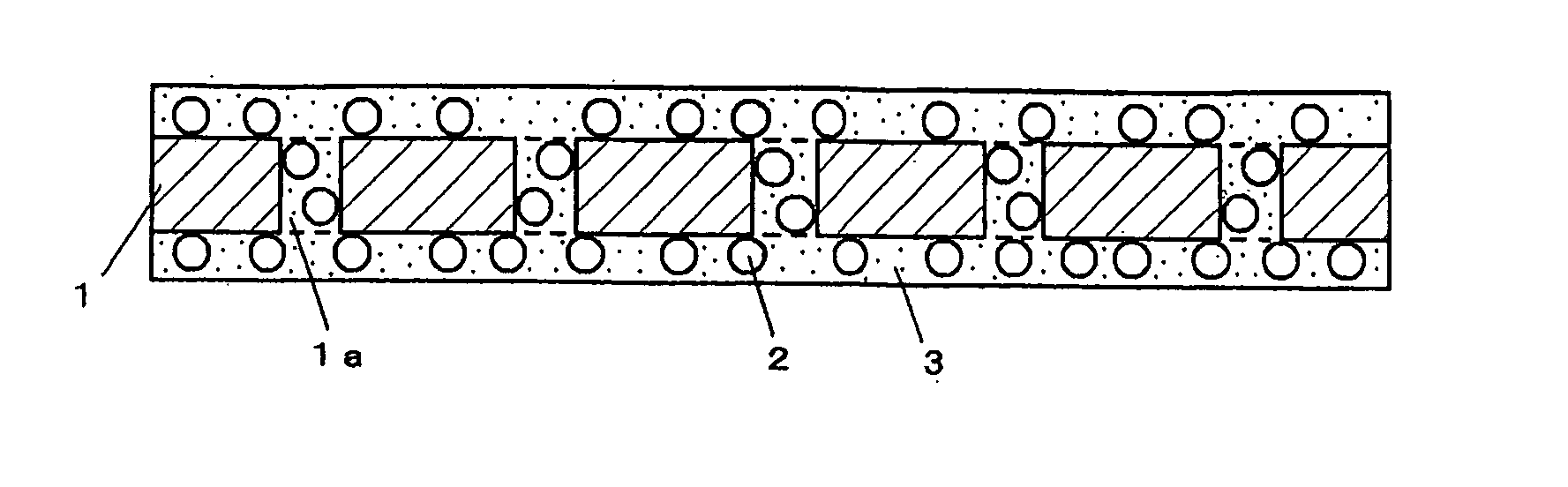

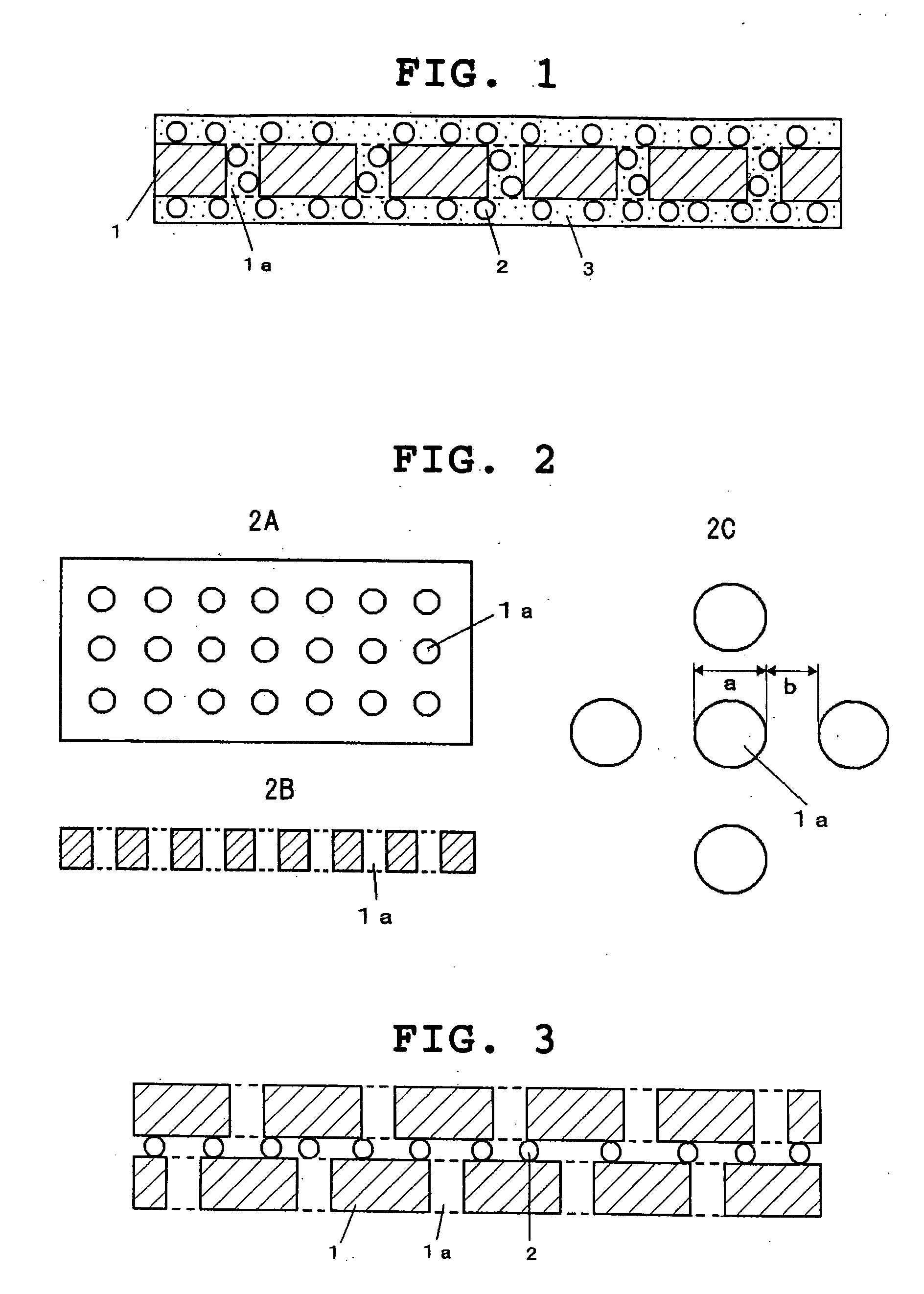

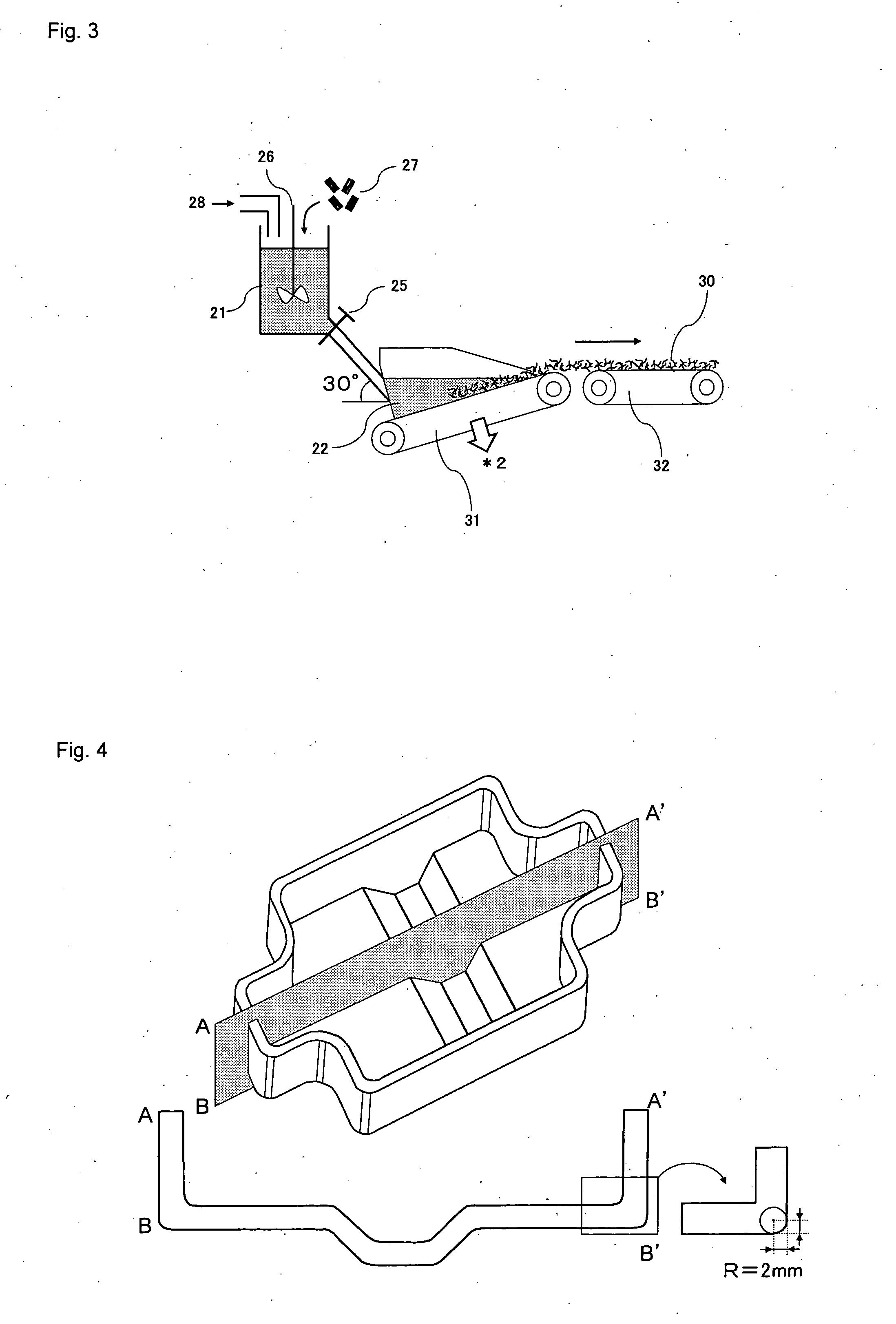

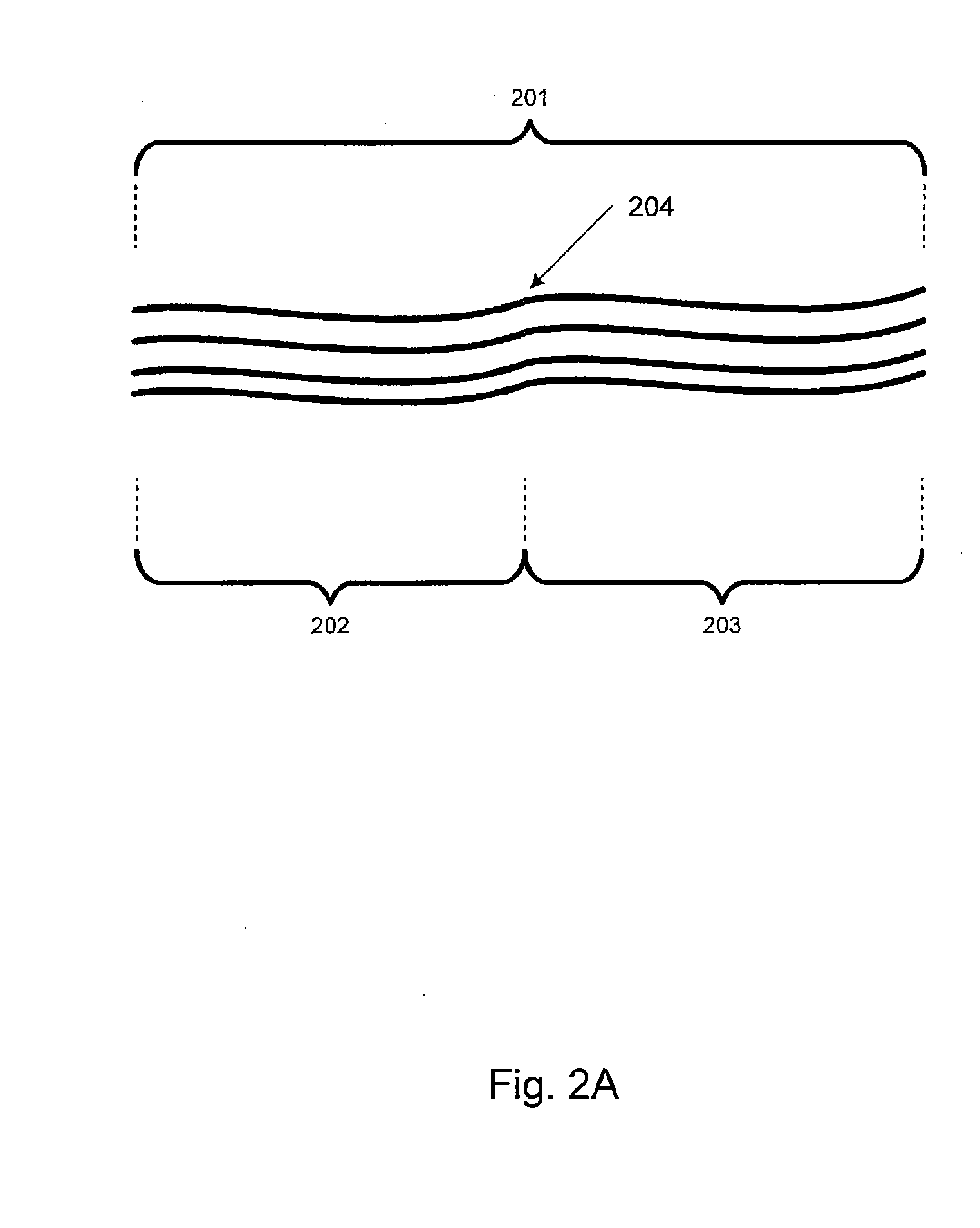

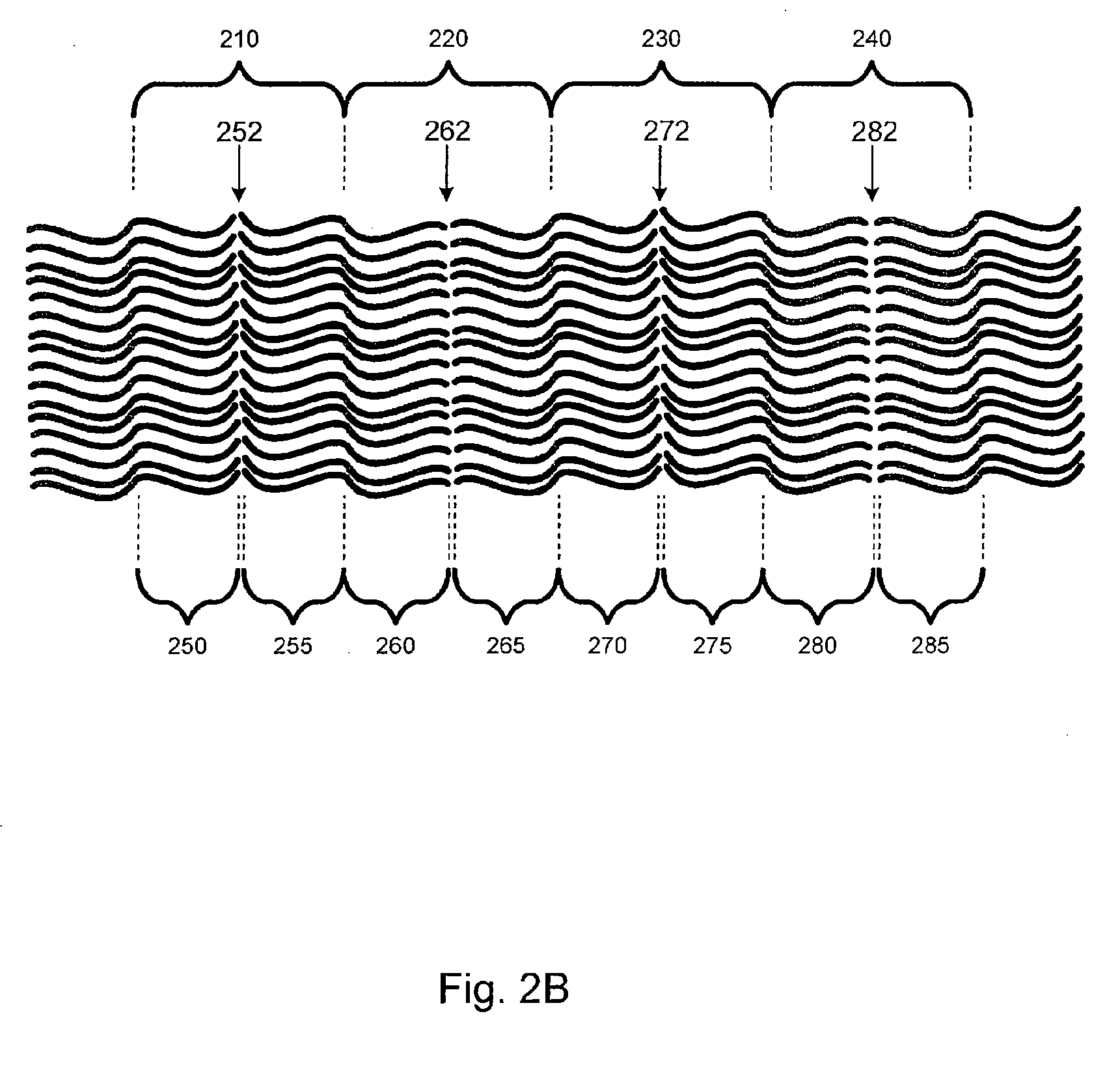

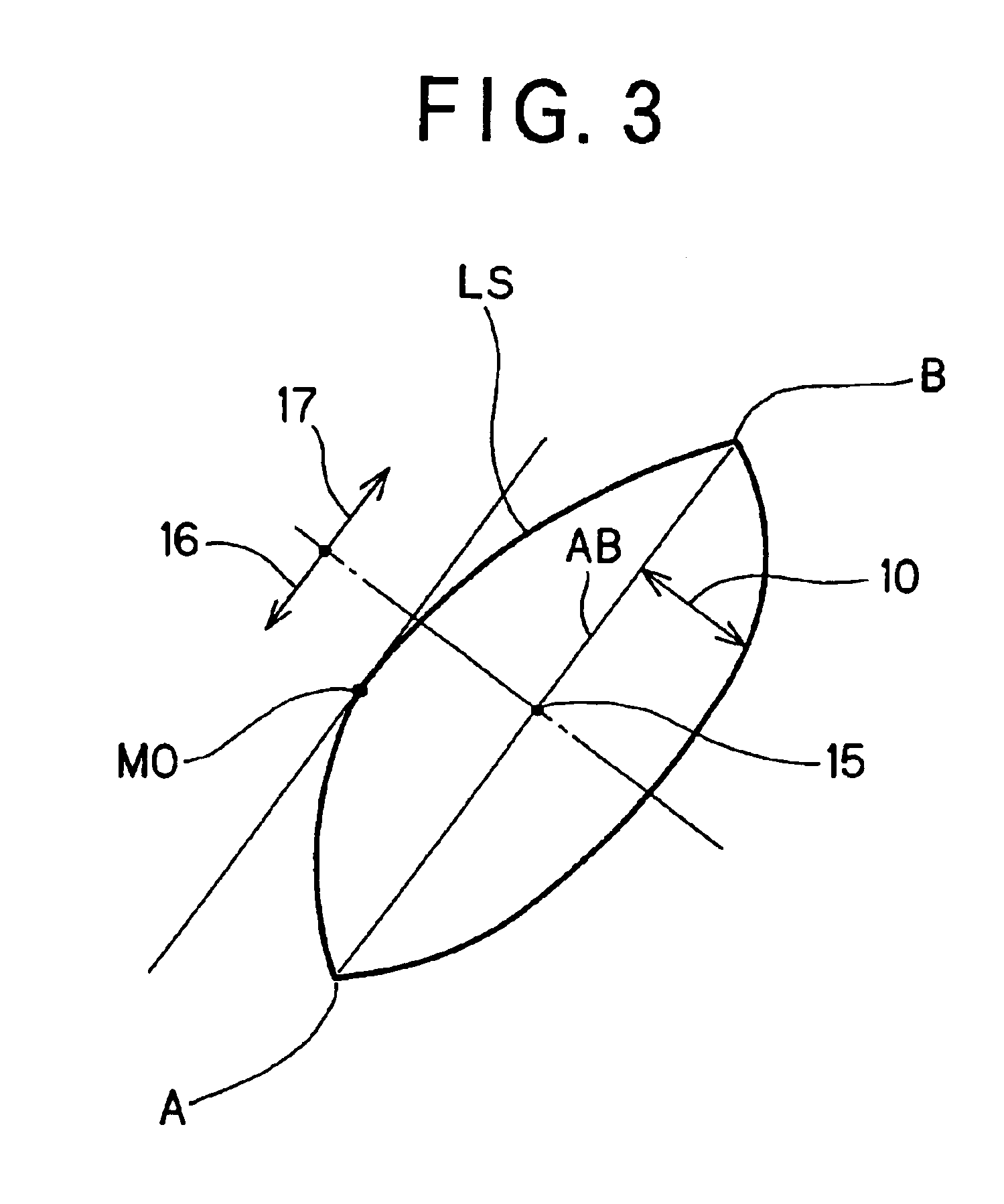

Interlayer for laminated glass and laminated glass

InactiveUS20040191482A1Improve machinabilityPromote degassingGlass/slag layered productsThin material handlingInter layerAir bubble

The present invention provides an interlayer for a laminated glass which does not give rise to the moiré phenomenon even when the arrangement and pitch of its embossments are orderly, hence providing for good workability in cutting and laminating operations and good deaeration in preliminary contact bonding, thus insuring the production of a laminated glass of high quality with a minimum of rejects for reasons of air bubbles, and a laminated glass containing said interlayer. The invention also provides an interlayer for a laminated glass which provides for good deaeration without a risk for premature marginal sealing even if the temperature at initiation of deaeration at preliminary contact bonding is not critically controlled and which does not require raising of temperature for achieving a marginal seal of the glass-interlayer assembly, and a laminated glass containing said interlayer.

Owner:SEKISUI CHEM CO LTD

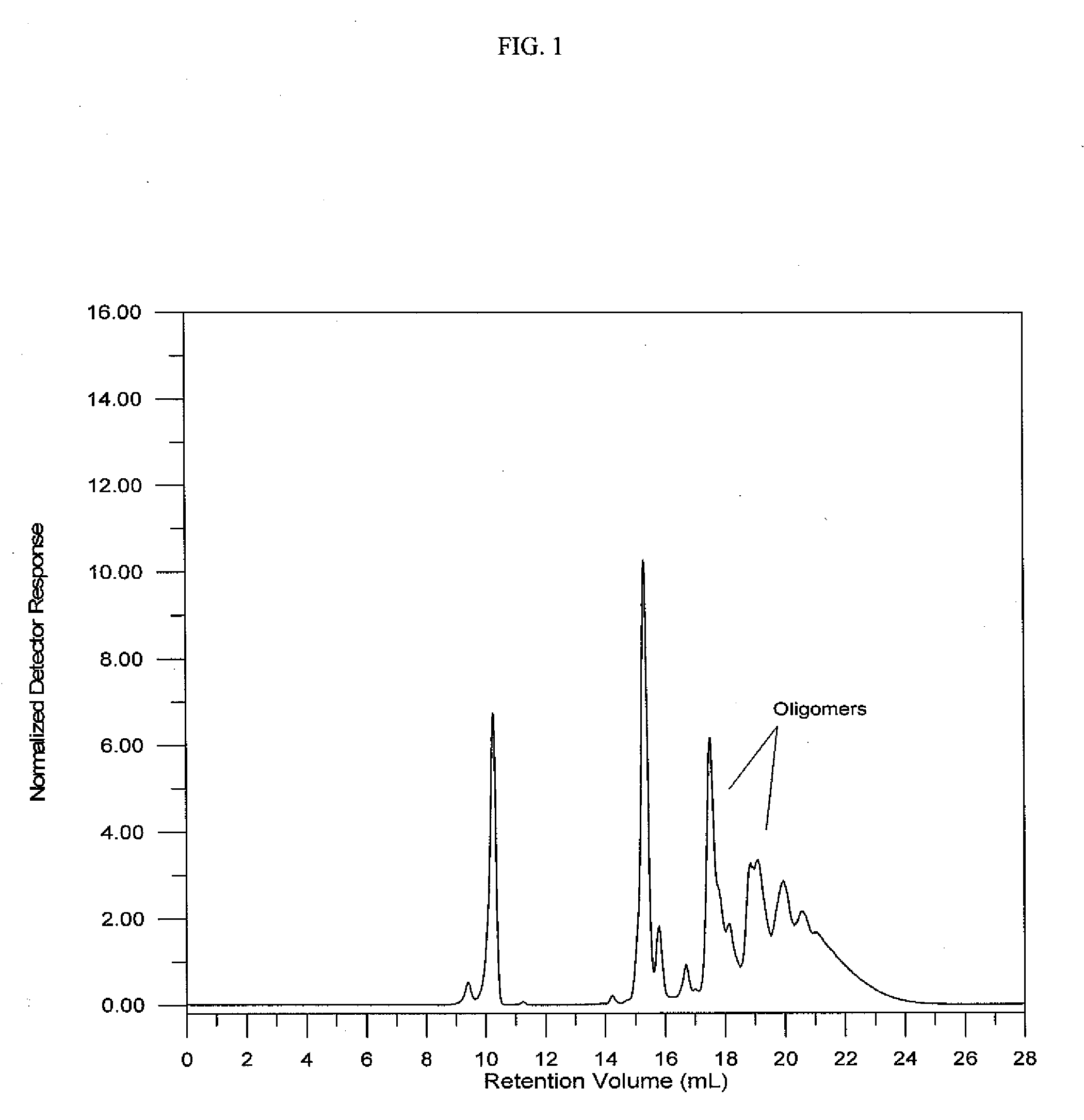

Process for producing polyurethane foam

InactiveUS6777455B2Get stableFine and uniform cellsAbrasion apparatusLapping toolsHydrogenReactive gas

A process for producing a finely cellular polyurethane foam by mixing a first ingredient comprising an isocyanate compound and a second ingredient comprising a compound containing an active hydrogen group, characterized by comprising adding a nonionic silicone surfactant containing no hydroxyl group to at least one of the first ingredient and the second ingredient in an amount of 0.1 to 5 wt %, excluding 5 wt %, based on the total amount of the first ingredient and the second ingredient, subsequently agitating the surfactant containing ingredient together with an unreactive gas, which has no reactivity to isocyanate group or active hydrogen group, to disperse the unreactive gas as fine bubbles to prepare a bubble dispersion and then mixing the bubble dispersion with the remaining ingredient to cure the resultant mixture and forming finely cellular structure into the resultant polyurethane foam by the fine bubbles of the bubble dispersion.

Owner:TOYOBO CO LTD +1

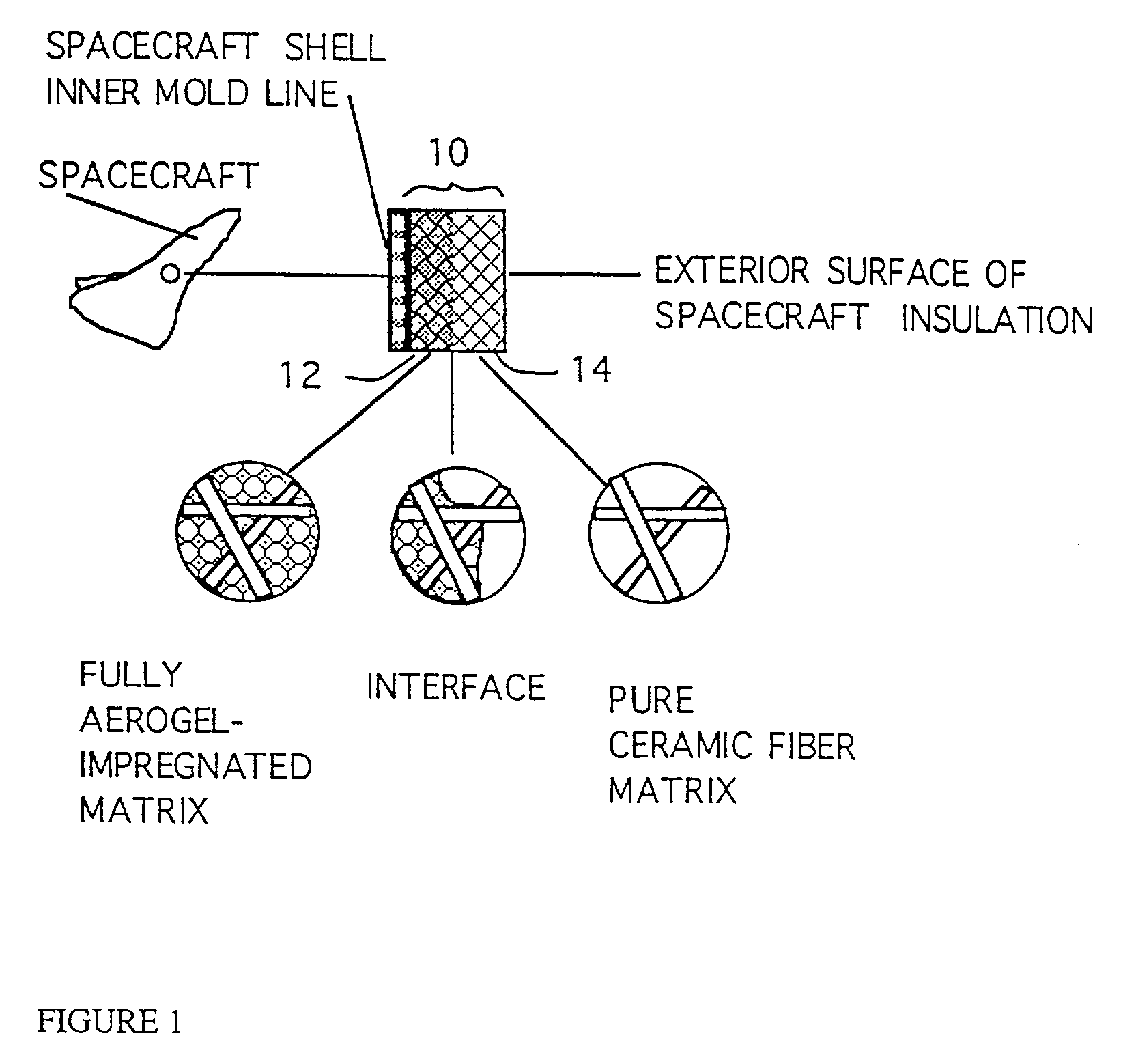

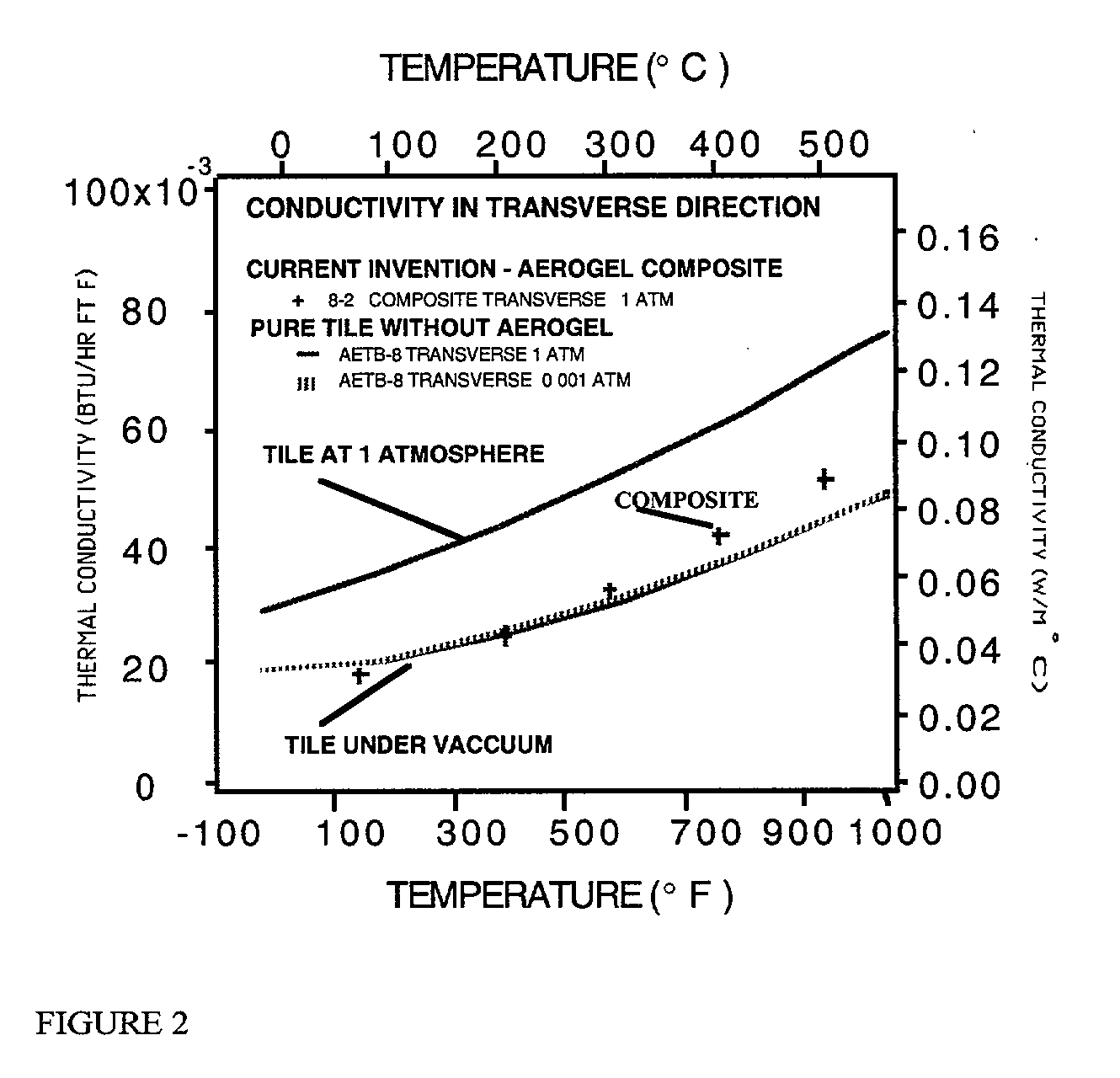

Aerogel loaded tile composite material

InactiveUS20020061396A1Avoid condensationImprove insulation performanceSynthetic resin layered productsCeramic layered productsTotal thicknessFiber matrix

A composite material having a preferably rigid preformed ceramic fiber matrix at least partially impregnated with an aerogel and forming a multi-layered material. The matrix is impregnated with an aerogel material which forms a layer having a total thickness r where r is less than t or equal to t, where t is the thickness of the matrix, thus forming a single or multilayered composite material. The material may be formed with numerous layers s1, s2, S3, . . . snn where r=SIGMAsn and r is less than or equal to t. Thus, a multi-layered material is formed. Alternatively, the aerogel / fiber matrix composite has channels devoid of aerogel.

Owner:NASA

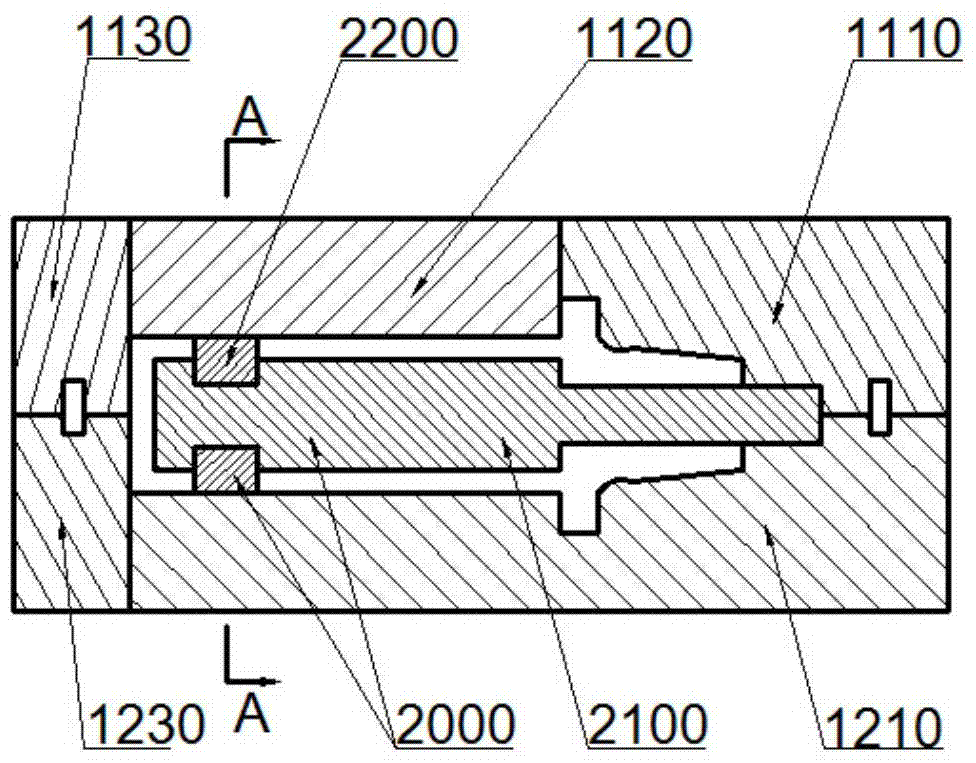

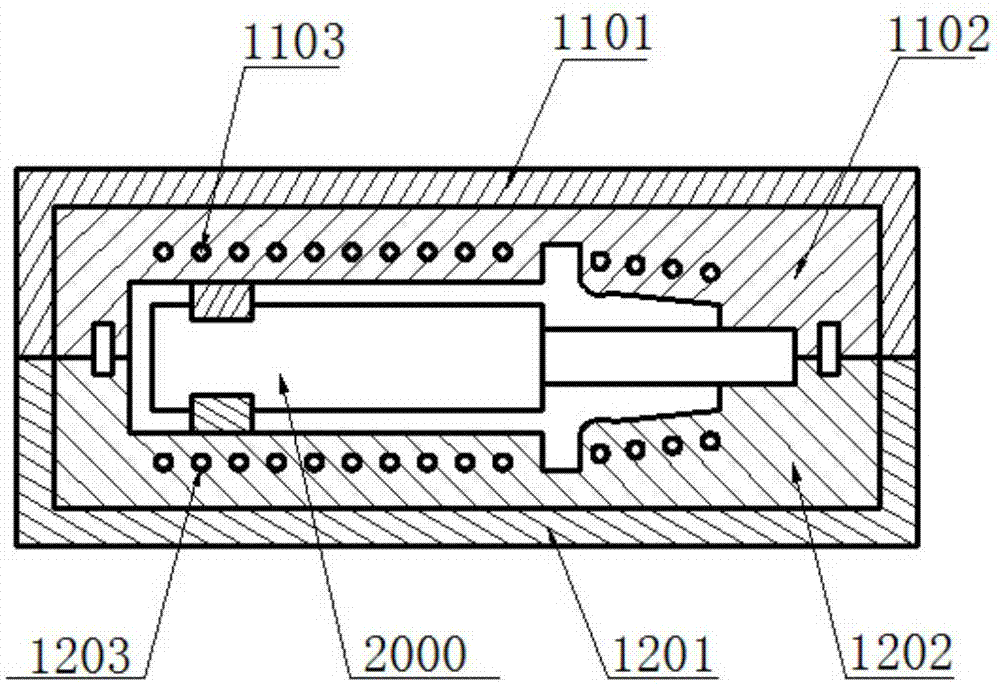

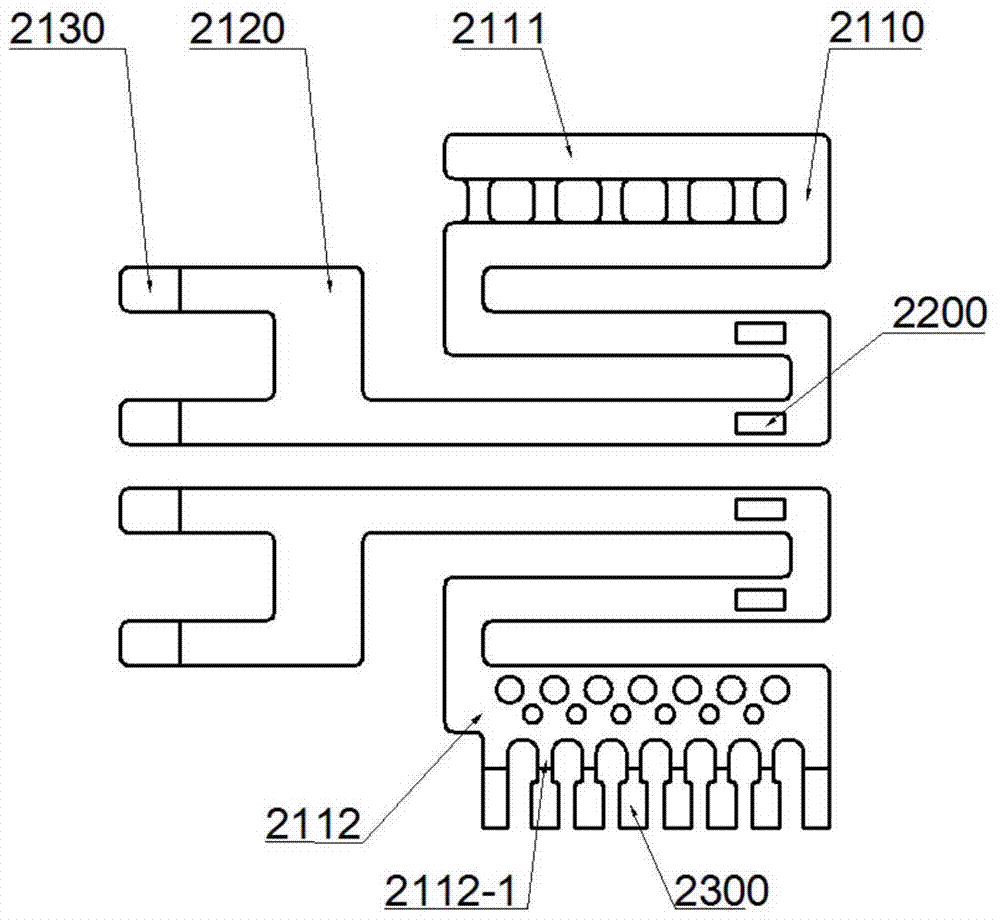

Wax injection mold for investment casting of hollow turbine blades and method for rapidly manufacturing wax injection mold

The invention discloses a wax injection mold for investment casting of hollow turbine blades and a method for rapidly and accurately manufacturing the wax injection mold. The mold consists of a cavity mold, a mold core and an accessory structure, wherein the cavity mold comprises an upper mold and a lower mold of a combined structure; each mold block forming the cavity mold consists of an external aluminum mold frame, an internal cast zinc alloy inlay and a conformal cooling copper pipe embedded into the inlay; a mold core positioning piece which can be decomposed at a high temperature is arranged on a longitudinal rib of the mold core; and water-soluble core blocks used for forming exhaust openings in the rear edges of the turbine blades are arranged on rear edge ribs of the mold core. The matching precision of the mold core positioning piece and the cavity mold is guaranteed by adopting a cavity mold interior running-in method, and the matching precision of the water-soluble core blocks and the cavity mold is guaranteed by adopting a cavity mold interior adhesion method. The wax injection mold disclosed by the invention is low in manufacturing cost and short in period, and the high wax pattern precision and core positioning precision can be obtained.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Free-cutting copper alloy containing very low lead

The free-cutting copper alloy according to the present invention contains a greatly reduced amount of lead in comparison with conventional free-cutting copper alloys, but provides industrially satisfactory machinability. The free-cutting alloys comprise 71.5 to 78.5 percent, by weight, of copper, 2.0 to 4.5 percent, by weight, of silicon, 0.005 percent up to but less than 0.02, by weight, of lead, and the remaining percent, by weight, of zinc.

Owner:SANBO SHINDO KOGYO CO LTD

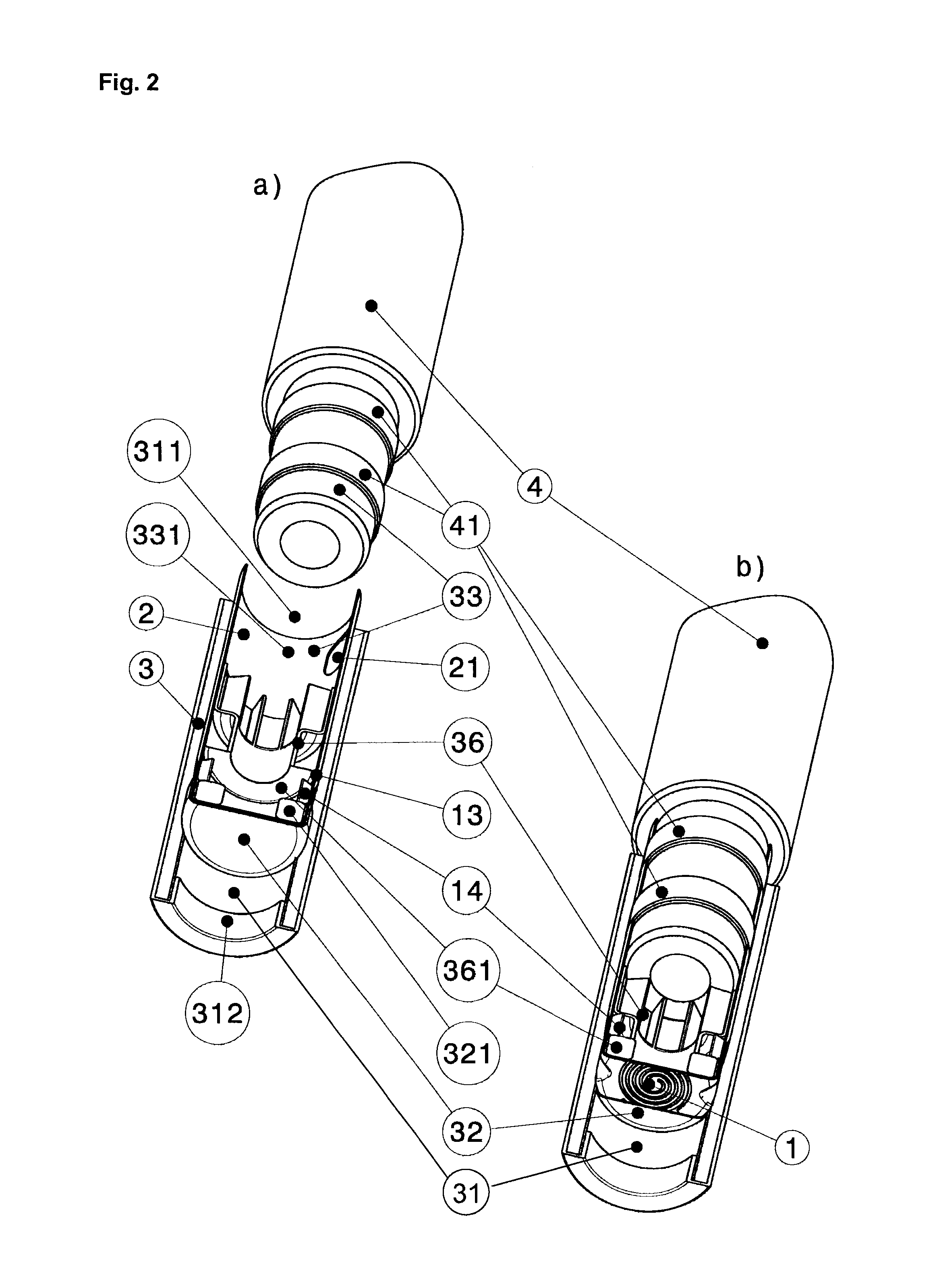

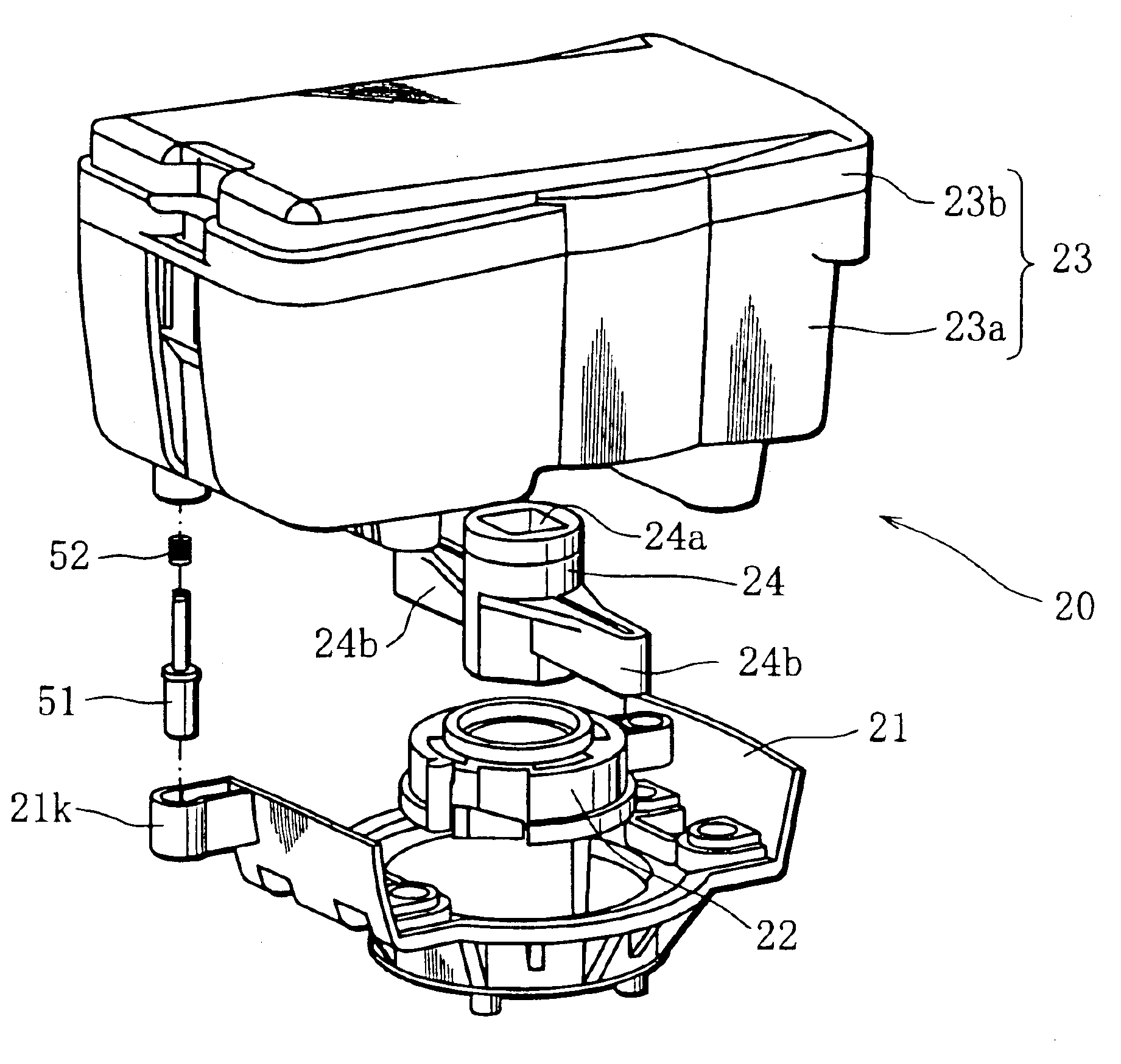

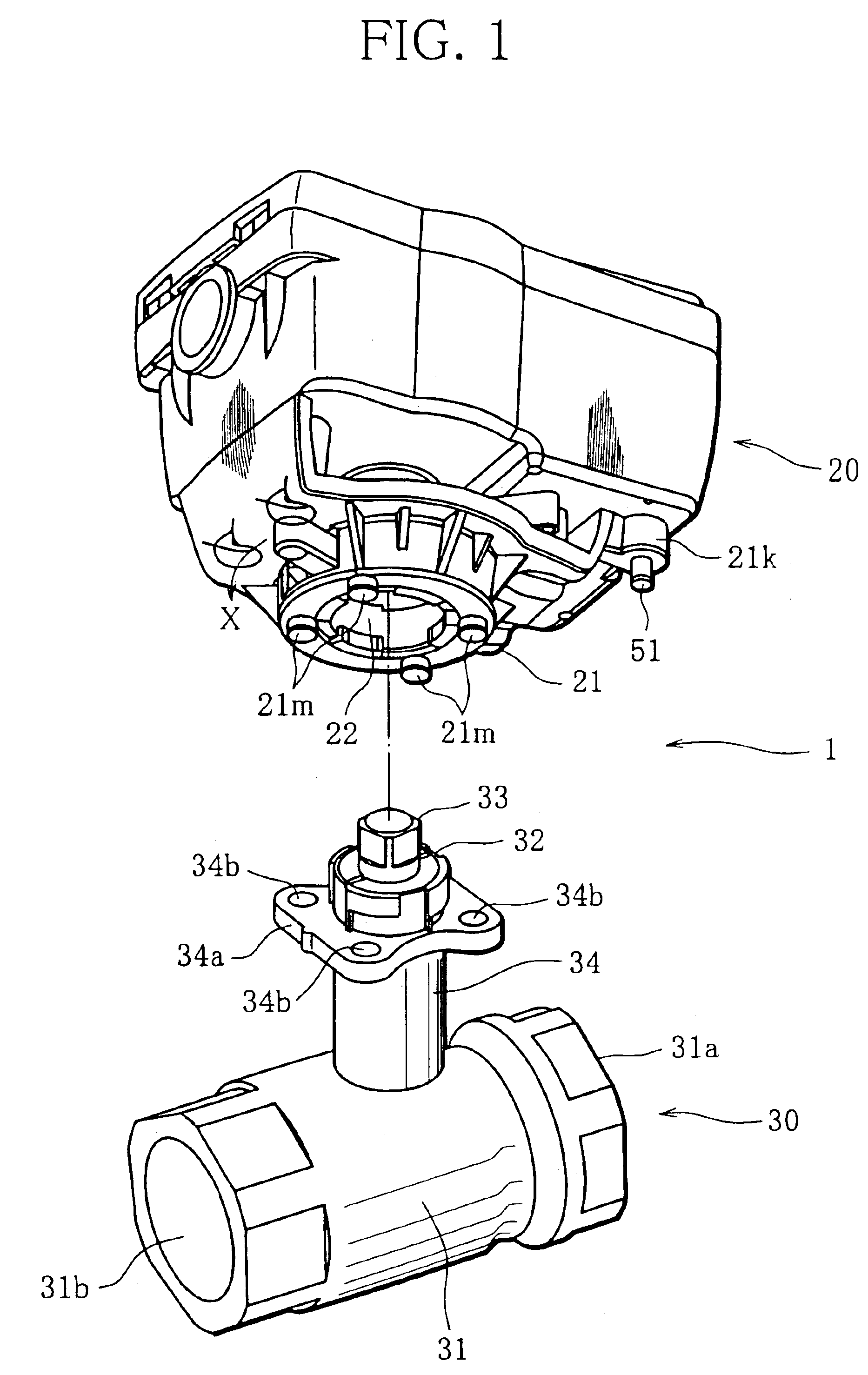

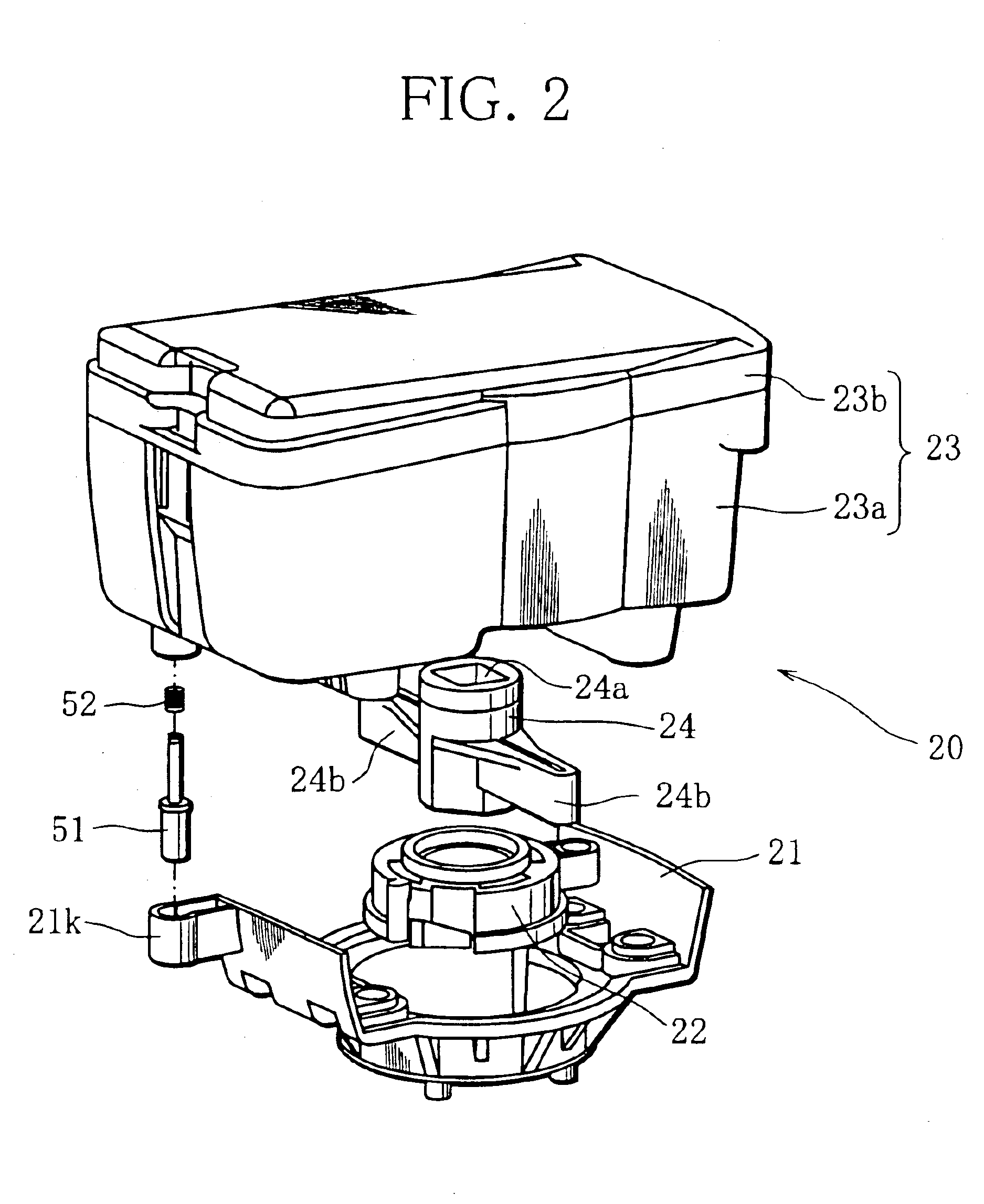

Actuator for driving rotary valve actuator and valve device with the actuator

InactiveUS6880806B2Improve securityImprove machinabilityOperating means/releasing devices for valvesPipeline systemsRotary valveEngineering

A valve gear includes a valve (30), which controls a flow rate of a fluid and an opening of which is determined according to a rotational position of a valve element, an actuator (20) for providing a rotational force to a rotary valve shaft that changes the opening of the valve (30), and attaching / detaching means. The attaching / detaching means includes a locking element (32) formed at its prescribed positions with locking concave / convex portions and an engaging element (22) formed at its prescribed positions with engaging concave / convex portions. The locking element (32) and the engaging element (22) are relatively rotatable around the rotary valve shaft up to a prescribed angle, and prevent the actuator (20) from coming off the valve (30) at an engaging position where the engaging concave / convex portions and the locking concave / convex portions are engaged with one another, and allow the actuator (20) and the valve (30) to be detached from each other at a disengaging position.

Owner:YAMATAKE HONEYWELL CO LTD

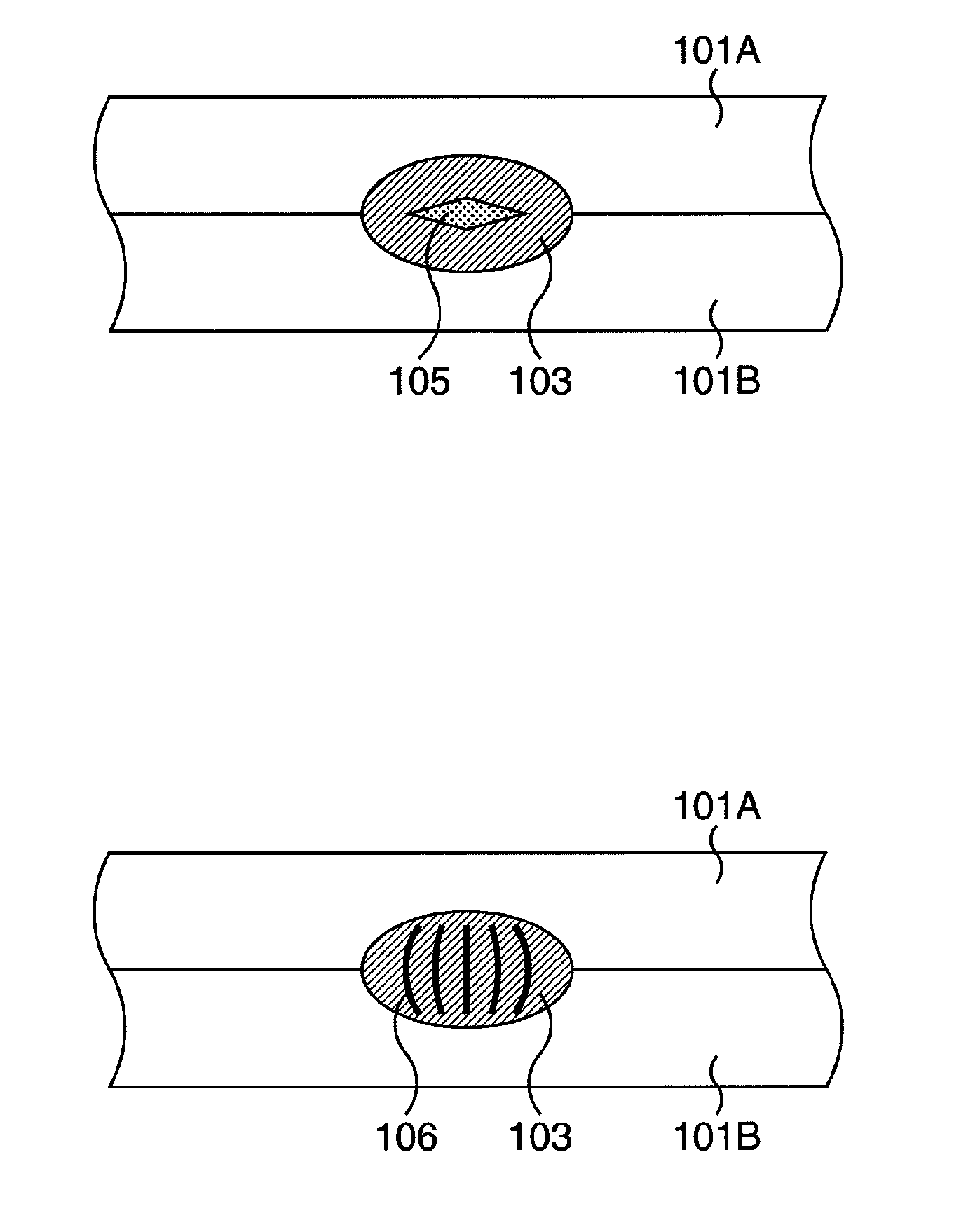

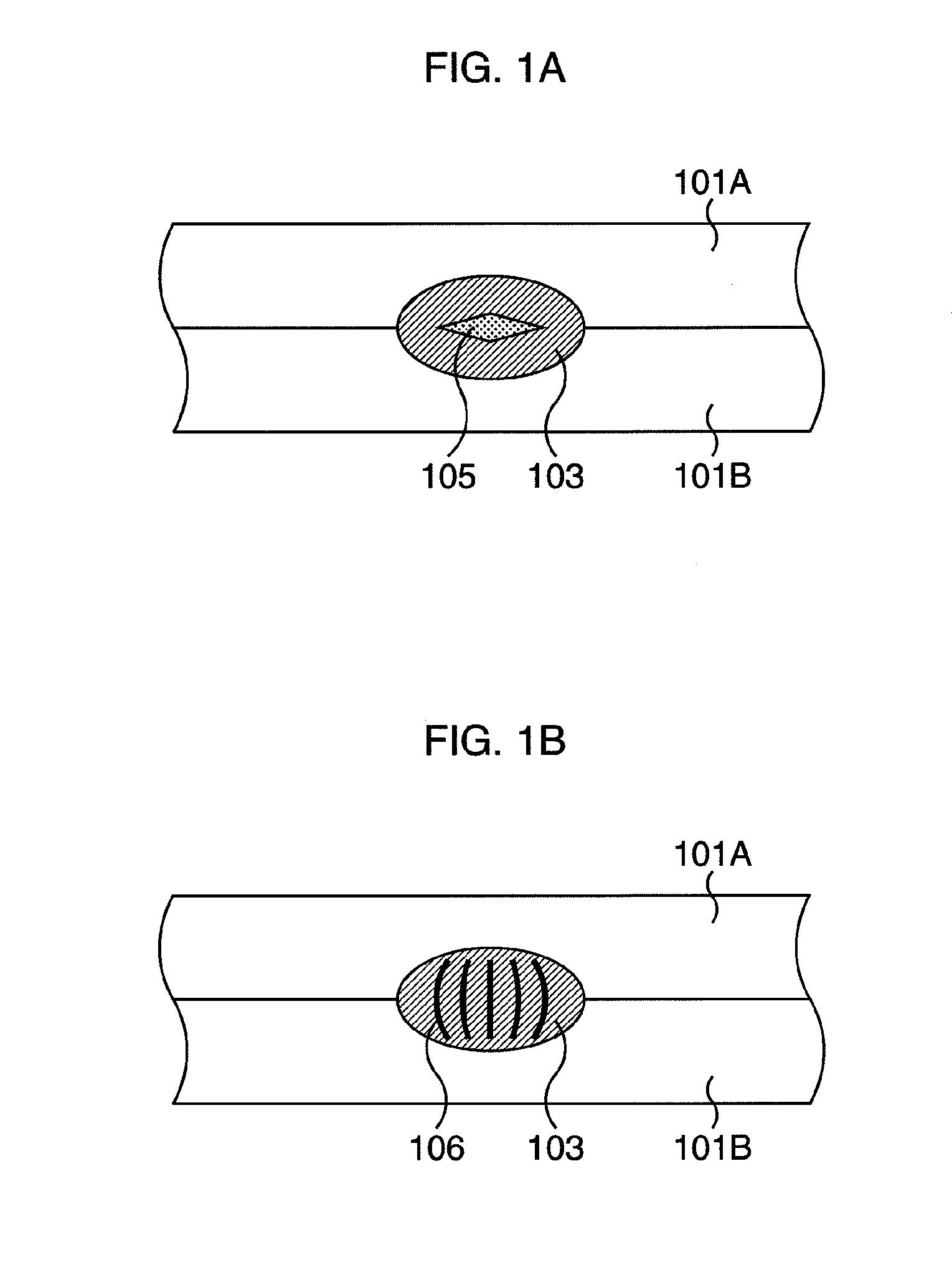

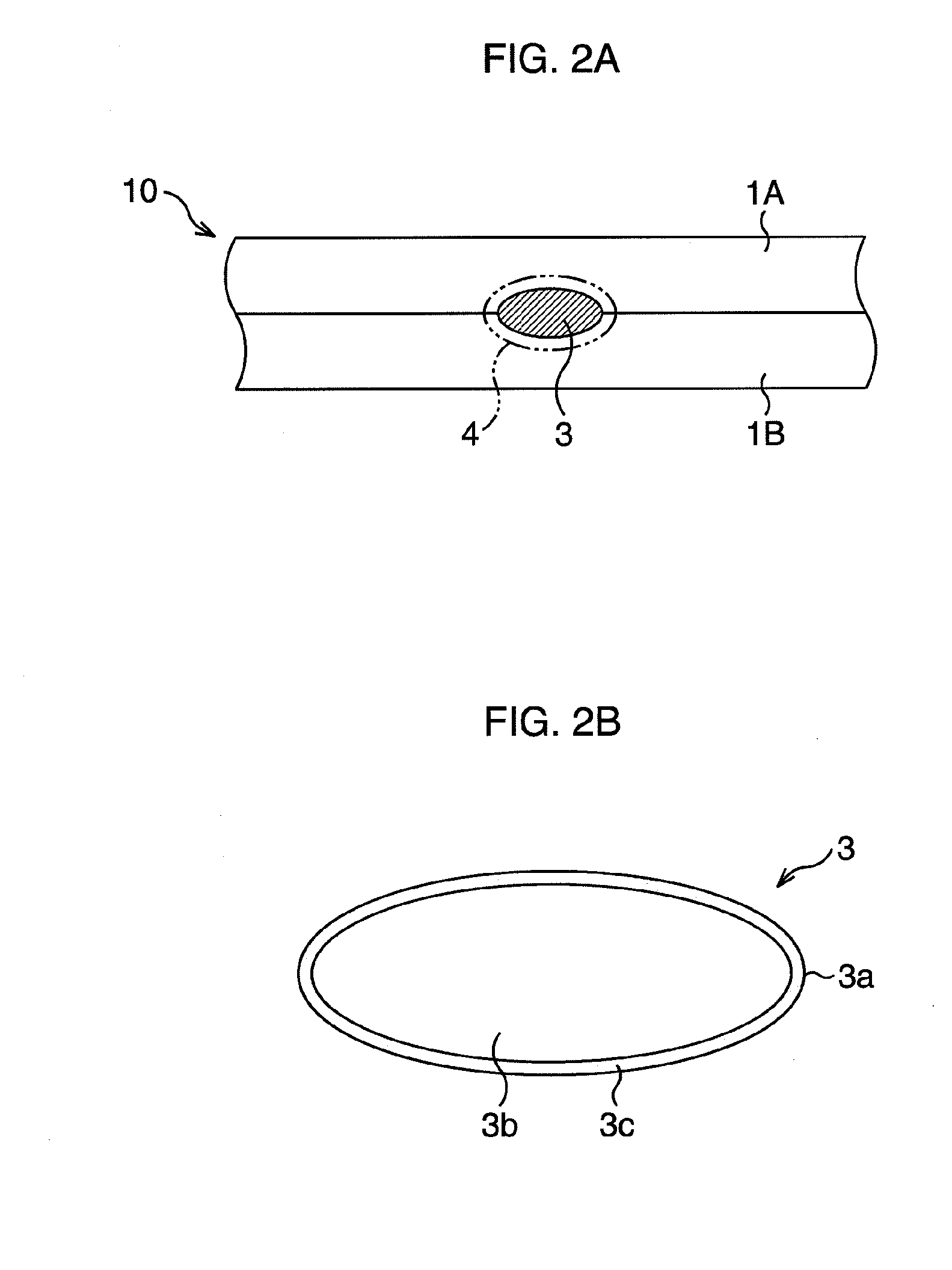

Spot welded joint and spot welding method

ActiveUS20120141829A1Improve machinabilityImprove reliabilityArc welding apparatusWelding/soldering/cutting articlesNumber densityCarbide

Provided is a spot welded joint (10) which includes at least one thin steel plate with a tensile strength of 750 MPa to 1850 MPa and a carbon equivalent Ceq of equal to or more than 0.22 mass % to 0.55 mass % and in which a nugget (3) is formed in an interface of the thin steel plates (1A, 1B). In a nugget outer layer zone, a microstructure consists of a dendrite structure in which an average value of arm intervals is equal to or less than 12 μm, an average grain diameter of carbides contained in the microstructure is 5 nm to 100 nm, and a number density of carbides is equal to or more than 2×106 / mm2.

Owner:NIPPON STEEL CORP

Anode active material, preparation method of anode active material, high-performance anode slurry containing anode active material, and all-solid-state lithium ion battery

ActiveCN106784798AImprove mobilityImprove electrochemical performanceCell electrodesSecondary cellsInorganic compoundSulfide

The invention relates to an anode active material, a preparation method of the anode active material, high-performance anode slurry containing the anode active material, and an all-solid-state lithium ion battery. The anode active material is a nickel-rich type core-shell structure particle or a nickel-rich type core-shell structure particle coated with an inorganic compound coating layer at the surface; an inner core of the nickel-rich type core-shell structure particle is LiNixCoyMn1-x-yO2; the shell is nickel cobalt lithium aluminate. The invention also provides the high-performance anode slurry, which comprises the anode active material, a composite conductive agent, a composite bonding agent, an additive and an organic solvent, wherein the additive is sulfide solid electrolyte; the anode slurry is used for preparing an anode plate consisting of an anode current collector, an anode slurry layer and a modification layer; the anode plate, the sulfide solid electrolyte and a cathode plate are assembled into the all-solid-state lithium ion battery. The all-solid-state lithium ion battery has the prominent advantages of high mass specific energy, high volumetric specific energy, good rate capability, good cycle performance, high safety and the like, and has wide application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Hot melt adhesive composition containing alpha-olefin/aromatic vinyl compound random copolymer

A hot melt adhesive composition exhibiting excellent adhesive strength and which is useful as an adhesive for styrene resins contains (B) tackifier and (C) ethylene / C3-C20 alpha-olefin / aromatic vinyl compound random copolymer and, in some embodiments also (A) base polymer, such as polyolefin, polar group-containing polymer and aromatic vinyl compound / conjugated diene copolymer. A low molecular weight polyolefin may also be included in all embodiments. The randon copolymer (C) may be prepared by polymerizing the alpha-olefin and aromatic vinyl compound in the presence of a metallocene containing catalyst. In addition to excellent adhesive strength the hot melt adhesives have improved workability.

Owner:MITSUI CHEM INC

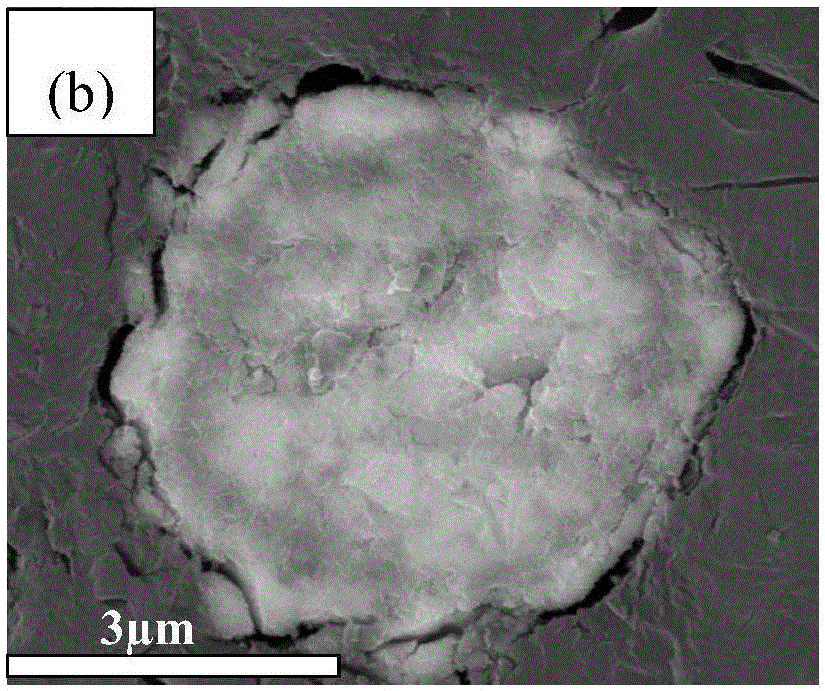

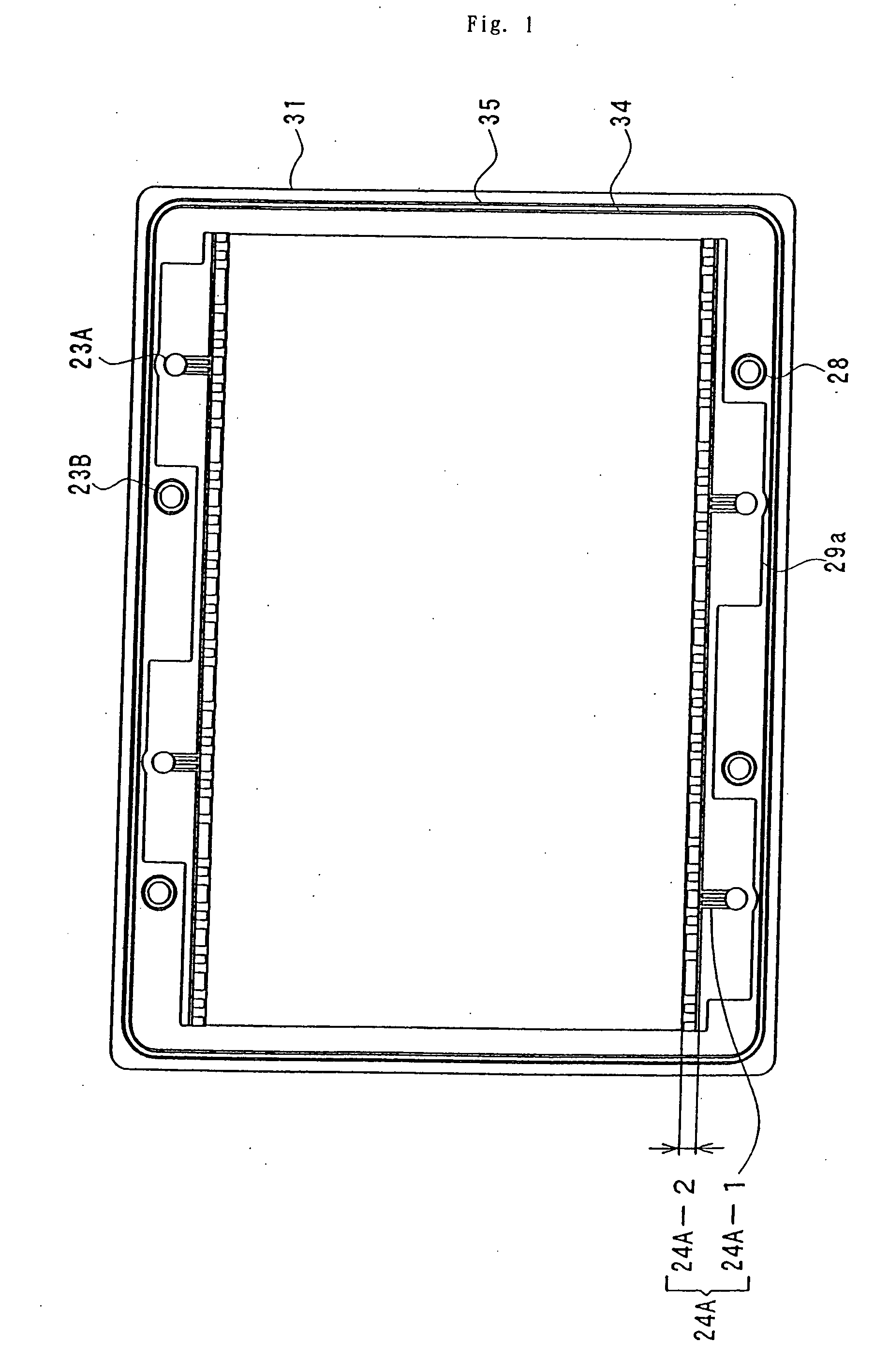

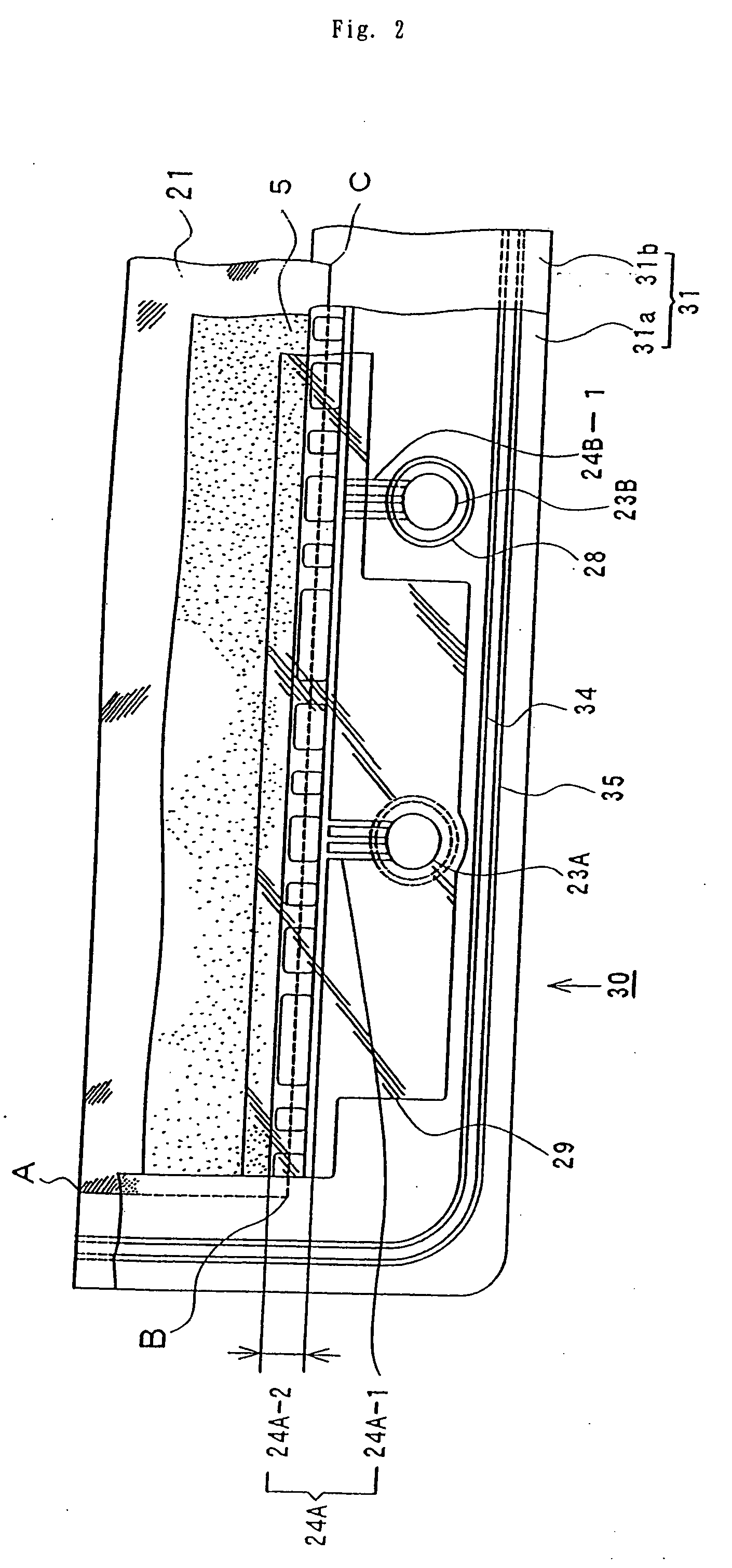

Cell frame for redox flow battery, and redox flow battery

InactiveUS20080081247A1Avoid breakingPrevent a break in the membraneElectrolyte holding meansEngine sealsElectrolyte leakageOxidation-Reduction Agent

This invention provides a cell frame for a redox flow battery that prevents leakage of electrolyte out of the cell frame and also provides a good workability in assembling the redox flow battery. Also, this invention provides a redox flow battery using the cell frame. In the cell frame 30 for the redox flow battery 30 comprising a bipolar plate 21 and a frame 31 fitted around a periphery of the bipolar plate 21, the frame 31 has, on each side thereof, an inner seal and an outer seal to press-contact with a membrane and also seal electrolyte. The frame 31 has, on each side thereof, an inner seal groove 34 and an outer seal groove 35 for placing therein the inner seal and the outer seal, respectively, to prevent the electrolyte from leaking out, and O-rings are placed in the respective seal grooves.

Owner:SUMITOMO ELECTRIC IND LTD +1

Process for producing modified polymer, modified polymer obtained by the process, and rubber composition

InactiveUS20050159554A1Raise fracture characteristicExcellent abrasion resistanceSpecial tyresPolymer scienceActive site

The present invention relates to a process for producing a modified polymer, comprising modifying a polymer having an active site of an organometal type in a molecule by reacting the site thereof with a hydrocarbyloxysilane compound and adding a condensation accelerator to the reaction system in the middle of the above reaction and / or after completion thereof and a rubber composition comprising the modified polymer obtained by the process described above, preferably a rubber composition comprising 100 parts by weight of (A) a rubber component containing at least 3% by weight of the above modified polymer and 10 to 100 parts by weight of (B) silica and / or carbon black. According to the present invention, capable of being provided is a silica and / or carbon black-blended rubber composition which enhances interaction with silica and carbon black and which elevates the fracture characteristic, the abrasion resistance and the low heat buildup property and can exhibit a good workability.

Owner:BRIDGESTONE CORP

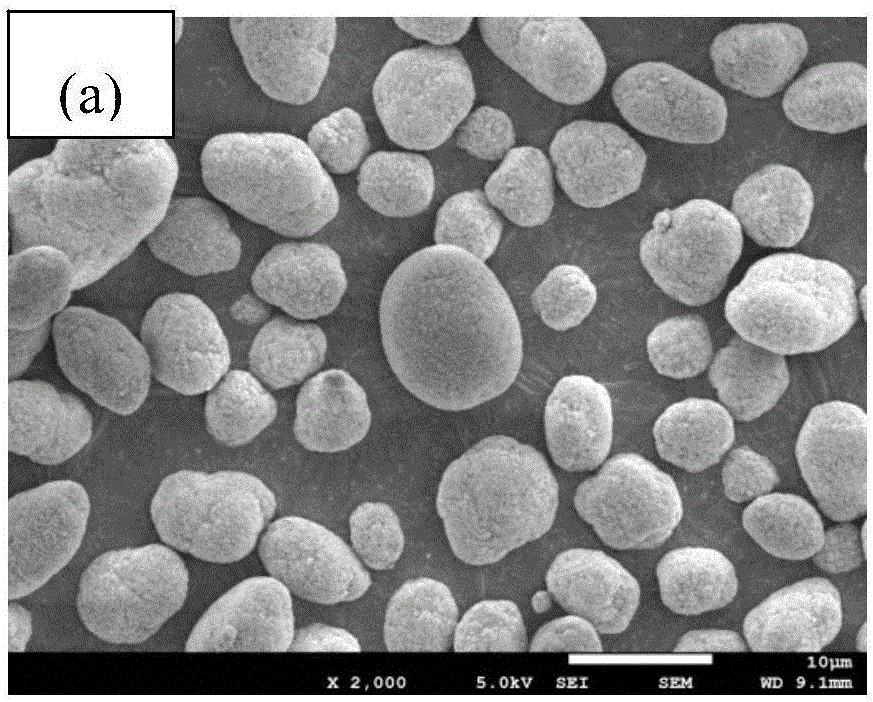

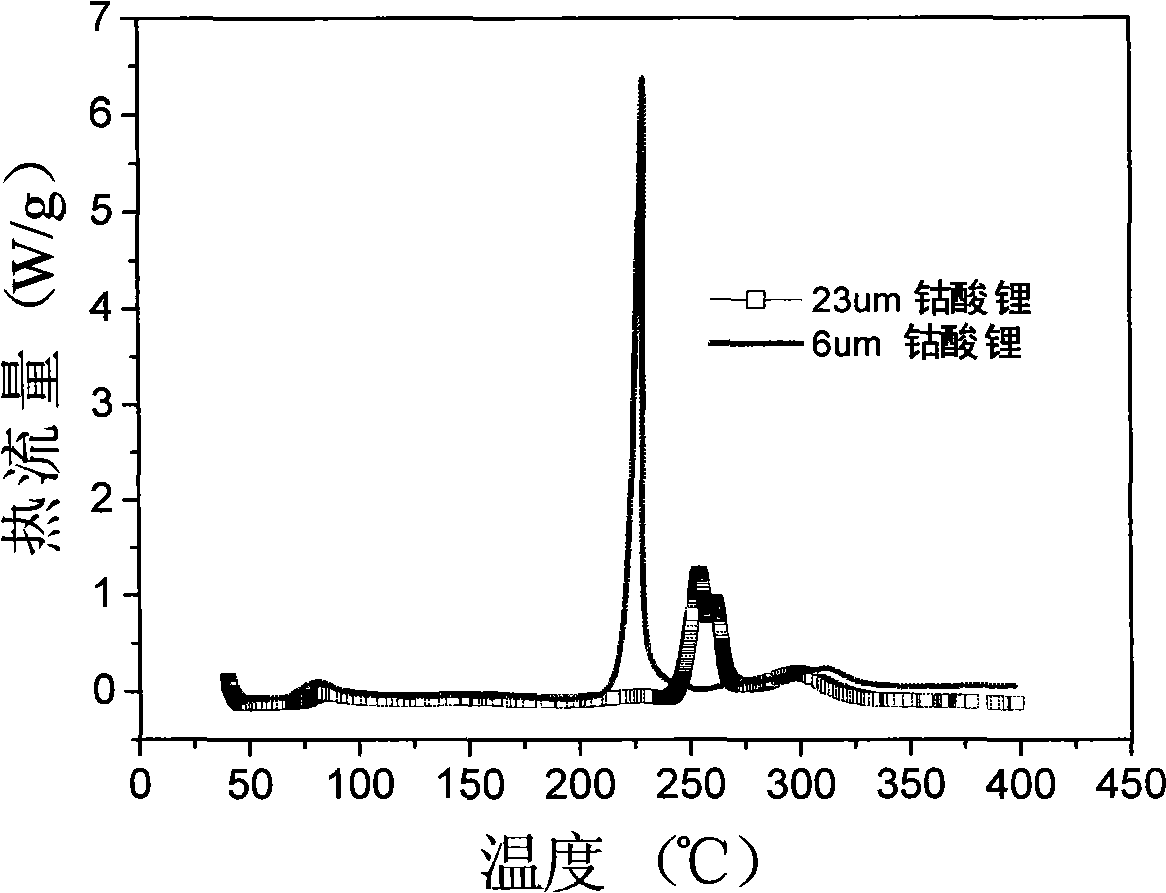

Super-size and high-density lithium cobalt oxide and method for preparing the same

ActiveCN101284681ALarge particle sizeHigh tap densityCell electrodesLithium compoundsHigh densityThermal impact

The invention relates to a high-density lithium cobalt oxide power material with a super-large grain diameter. The method comprises the steps of mixing a cobalt compound, a lithium compound or meanwhile a small amount of doping element compounds; sintering for 3 to 30 hours at the high temperature of 950 to 1,100 DEG C to form a block sintered product; crushing and grading the product to obtain the lithium cobalt oxide power material (molecular formula is LiaCo1-bMbO2), wherein, when b is not equal to 0, the middle diameter of the lithium cobalt oxide containing the doping elements is larger than or equal to 15 Mum, and the tap density is higher than or equal to 2.5g / cm<3>; when b is equal to 0, the middle diameter of the lithium cobalt oxide without the doping elements is larger than 20 Mum, and the tap density is higher than or equal to 2.6g / cm<3>. the 3.6V platform capacity rate of the material as the anode active substance for a lithium battery is higher than or equal to 75%; in the thermal impact test in a 150 DEG C thermotank, the lithium battery with the material is free from leakage and does not catch fire or explode for 60 minutes; the 1C5A specific capacity of the material in the battery is larger than or equal to 135mAh / g.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

Jade-type glass-ceramic and preparation method thereof

The invention relates to a jade-type glass-ceramic and a preparation method thereof. The jade-type glass-ceramic contains a main crystal phase and can also contain a secondary crystal phase, wherein the maximum crystallite dimension of the secondary crystal phase is equal to or smaller than visible wavelength, the jade-type glass-ceramic contains the following components in percentage by weight: 45.0-75.0% of SiO2, 1.0-25.0% of Al2O3, 0-20.0% of alkaline earth metal oxide, 3.0-15.0% of alkali metal oxide, 0-4.0% of TiO2, 0-2.5% of ZrO2, 0-8.0% of F and the balance of flux and clarifier. The preparation method of the jade-type glass-ceramic comprises the steps that the main raw materials and the auxiliary materials are mixed uniformly and then are melted at high temperature to form molten glass, then the molten glass is thermally treated after being cooled and molded so as to form an organization structure beneficial to the penetration of the visible light part in molten glass, and after thermal treatment, the glass-ceramic is in a semitransparent neftdegil shape and becomes a jade-type glass-ceramic. The jade-type glass-ceramic has delicate texture, is translucent, can be widely used as a decorative plate, and can also be carved into handicrafts and prepared into tableware and sanitary ware.

Owner:香港福山实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com