Patents

Literature

51results about How to "Fine and uniform cells" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for producing polyurethane foam

InactiveUS6777455B2Get stableFine and uniform cellsAbrasion apparatusLapping toolsHydrogenReactive gas

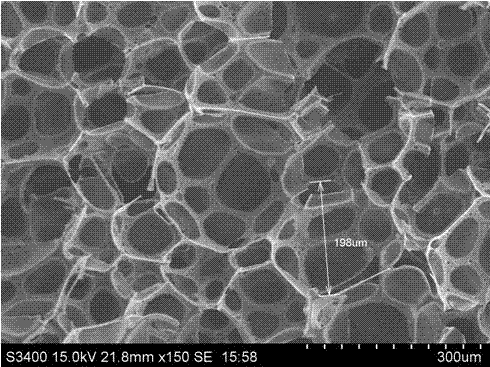

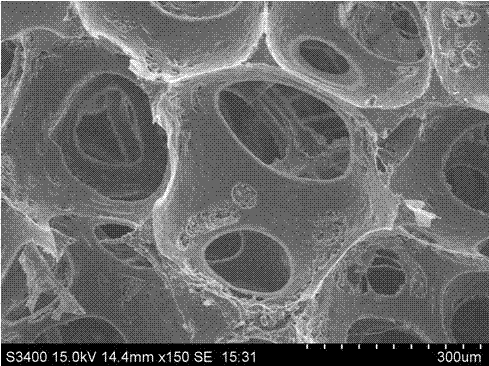

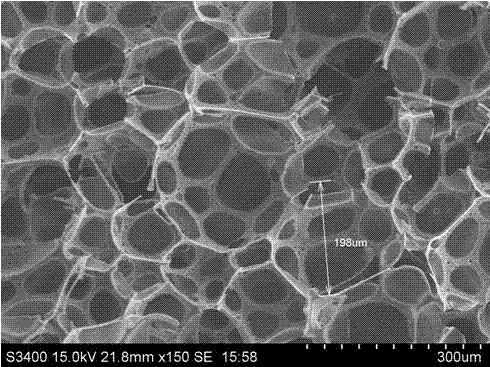

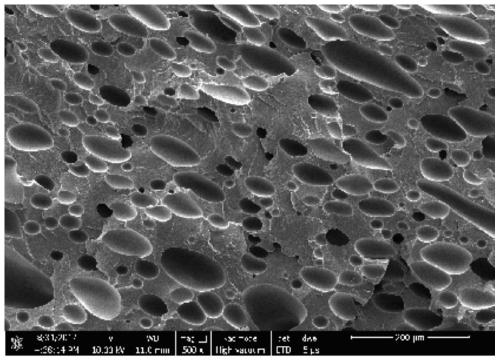

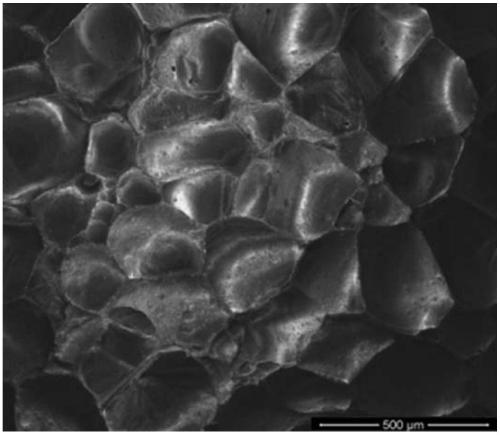

A process for producing a finely cellular polyurethane foam by mixing a first ingredient comprising an isocyanate compound and a second ingredient comprising a compound containing an active hydrogen group, characterized by comprising adding a nonionic silicone surfactant containing no hydroxyl group to at least one of the first ingredient and the second ingredient in an amount of 0.1 to 5 wt %, excluding 5 wt %, based on the total amount of the first ingredient and the second ingredient, subsequently agitating the surfactant containing ingredient together with an unreactive gas, which has no reactivity to isocyanate group or active hydrogen group, to disperse the unreactive gas as fine bubbles to prepare a bubble dispersion and then mixing the bubble dispersion with the remaining ingredient to cure the resultant mixture and forming finely cellular structure into the resultant polyurethane foam by the fine bubbles of the bubble dispersion.

Owner:TOYOBO CO LTD +1

Process for producing polyurethane foam, polyurethane foam, and abrasive sheet

InactiveUS20020183409A1Get stableFine and uniform cellsAbrasion apparatusLapping toolsChemical reactionAdditive ingredient

A process for producing a finely cellular polyurethane foam by mixing a first ingredient comprisi an isocyanate compound and a second ingredient comprising a compound containing an active hydrogen group, characterized by comprising adding a nonionic silicone surfactant containing no hydroxyl group to at least one of the first ingredient and the second ingredient in an amount of 0.1 to 5 wt %, excluding 5 wt %, based on the total amount of the first ingredient and the second ingredient, subsequently agitating the surfactant containing ingredient together with an unreactive gas to disperse the unreactive gas as fine bubbles to prepare a bubble dispersion and then mixing the bubble dispersion with the remaining ingredient to cure the resultant mixture. Thus, a polyurethane foam having uniform fine cells and a higher hardness than ones having the same density can be produced without using a chemically reactive blowing agent such as water, vaporizable expandable blowing agent such as fluorocarbon, or other substance such as a finely particulate hollow foam or solvent soluble substance.

Owner:TOYOBO CO LTD +1

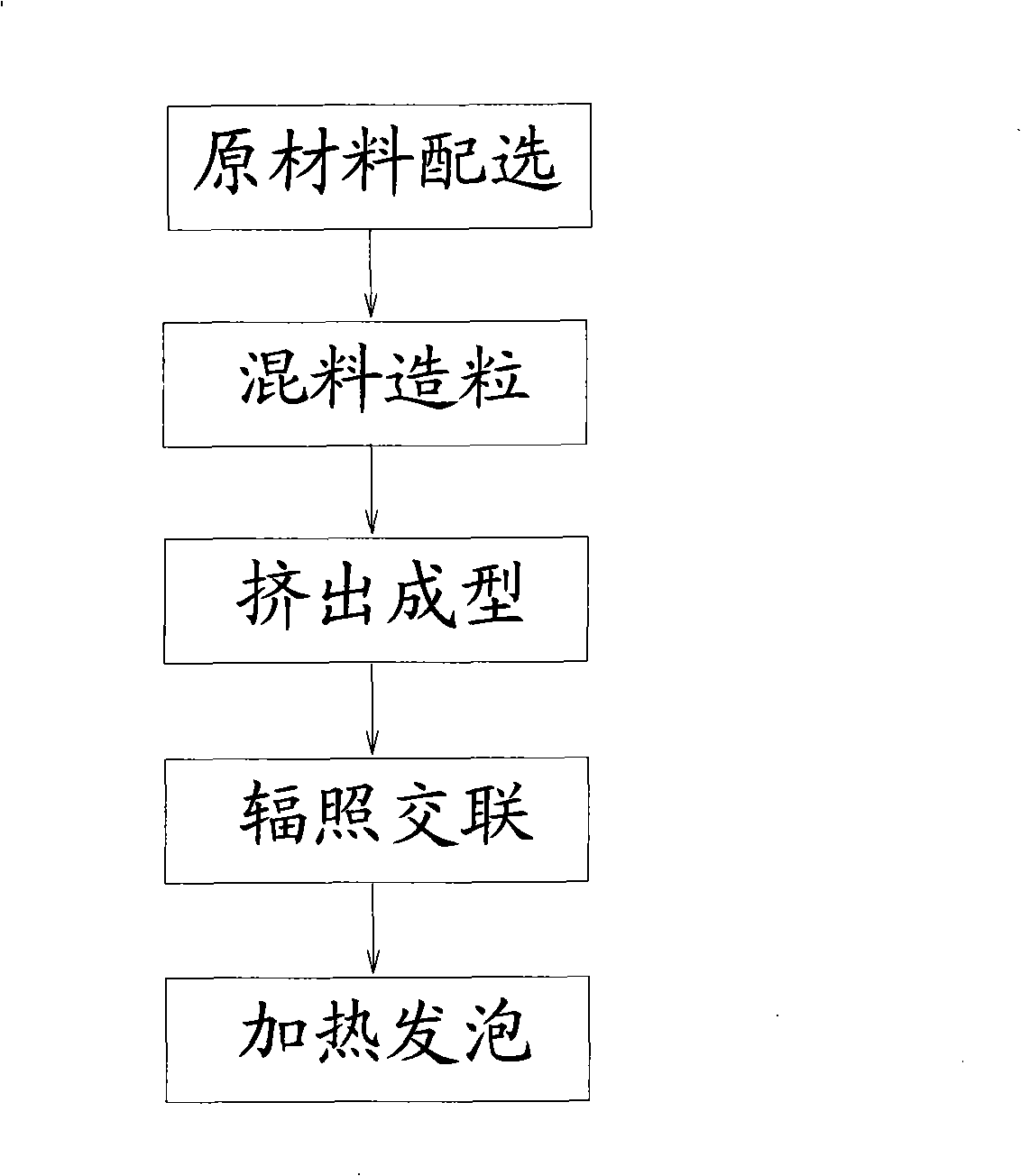

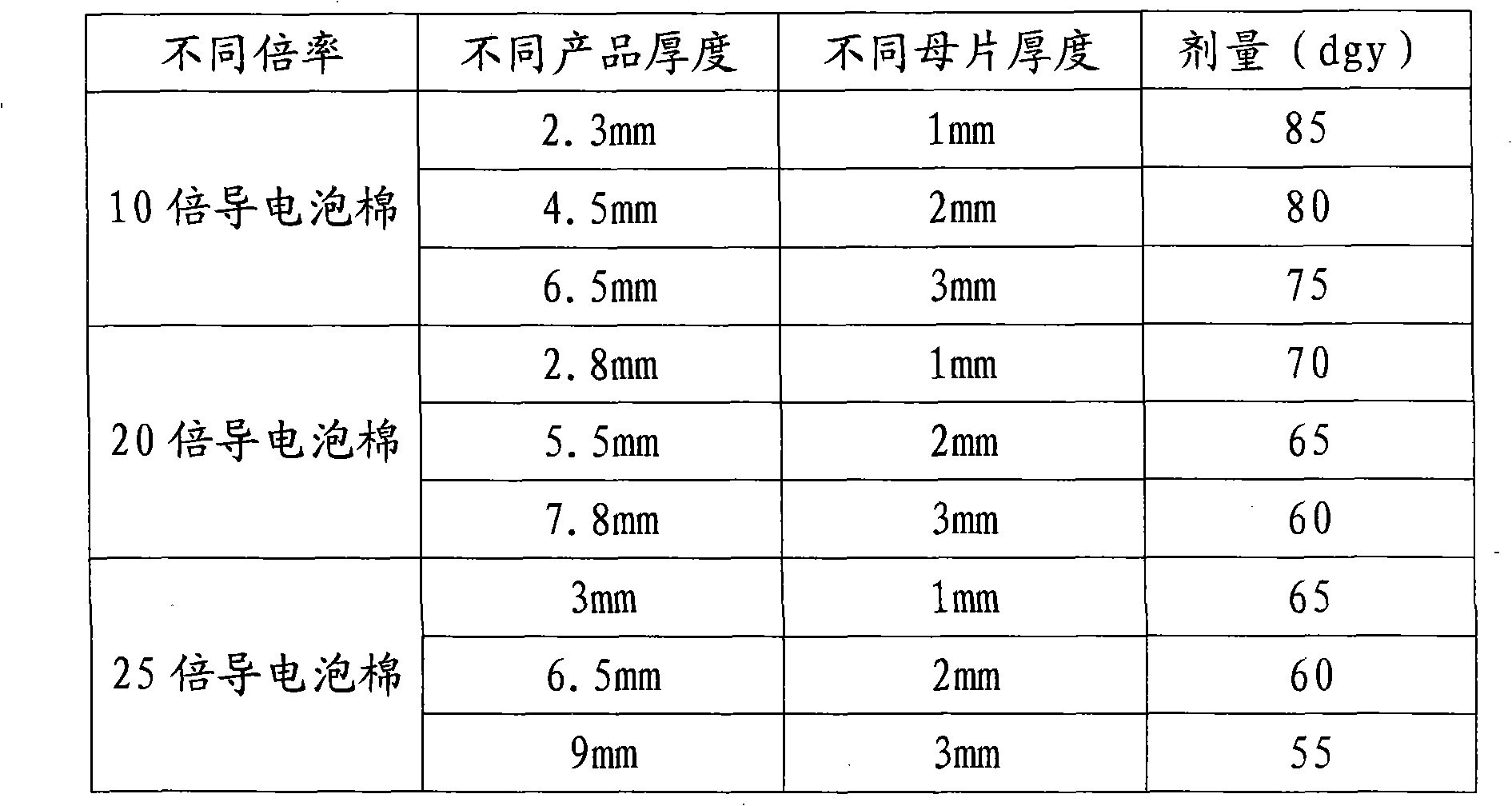

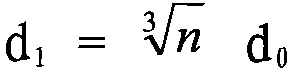

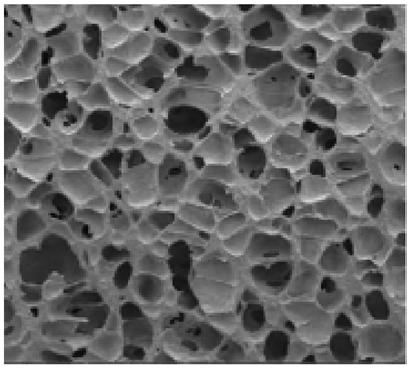

IXPE electron radiation on crosslinking polyethylene conductive foam and preparation method thereof

The invention relates to an IXPE electronic radiation crosslinked polyethylene conductive foam and a preparation method thereof. The IXPE electronic radiation crosslinked polyethylene conductive foam mainly contains the mother batch: low density polyethylene; accessories: ethylene-vinyl acetate copolymer, azodicarbonamide blowing agent, polyethylene wax lubrication additive, titanate ester coupling agent and conductive carbon black which are mixed for processing, extruded for molding, radiated for crosslinking, heated for foaming, and treated by secondary processing, etc, to produce the IXPE electronic radiation crosslinked polyethylene conductive foam. The crosslinking of the product of the invention can be easily controlled, the foaming process is stable, the foam pores are fine and even, the quality of the surface is high without unpleasant odor, the foam pores are obstructed, the production can be carried out continually, the electrical conductivity is stable, the product is lightweight, non-toxic, extremely less absorbent; the thermal conductivity is slow, aging resistant, chemical corrosion resistant, pulverization resistant, and a plurality of porous foam materials can be easily achieved; in addition, the product has good properties to be treated by the secondary processing procedures, such as bonding, machining, hot forming, etc.

Owner:SHENZHEN CHANGYUAN TEFA TECH CO LTD

Porcelainized fireproof and heat insulation foamed silicone rubber and preparation method thereof

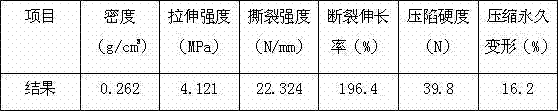

The invention discloses porcelainized fireproof and heat insulation foamed silicone rubber and a preparation method thereof. The rubber comprises the following raw materials in parts by weight: 100 parts of base rubber, 10 to 60 parts of porcelain forming filler, 0.1 to 0.5 part of a platinum catalyst, 0.5 to 1.5 parts of silicone oil, 2 to 10 parts of a foaming agent, 0.1 to 0.5 part of a vulcanizing agent, and 0.1 to 0.4 part of a vulcanization accelerator. The foamed silicone rubber has good ceramic effect, does not have surface cracks, is hard in texture, keeps a complete foam structure, ensures that the volume retention rate is 85% or higher, and is excellent in fireproof performance.

Owner:WUHU YANGZHAN NEW MATERIAL TECH SERVICE CO LTD

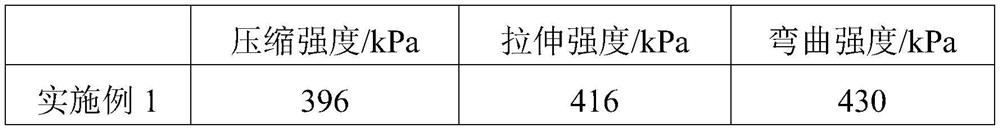

Lignin-based phenolic foam material and preparation method thereof

The invention discloses a lignin-based phenolic heat insulating material and a preparation method thereof. The preparation method comprises the following steps of: uniformly stirring expandable lignin basic phenolic resin with the conventional pH adjusting agent and a surfactant; adding a foaming agent and rapidly and uniformly stirring; adding a curing agent lastly; and uniformly stirring, and rapidly pouring into a specified enclosed container for foaming to the obtain lignin-based phenolic heat insulating material, wherein the used curing agent is a compound curing agent obtained by mixing toluenesulfonic acid and phosphoric acid in the mass ratio of 1.5:1. The foaming multiplying power of the lignin-based phenolic foam material is adjustable, the form hole fineness uniform density is 40-60 kg / m<3>, the compression strength is 0.07-0.45MPa, and the water absorbing rate is 7-15.5 percent.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

EPE material for crawling pad, preparation method of EPE material and crawling pad

InactiveCN104403173AFine and uniform cellsFlexibleSynthetic resin layered productsLow-density polyethyleneFoaming agent

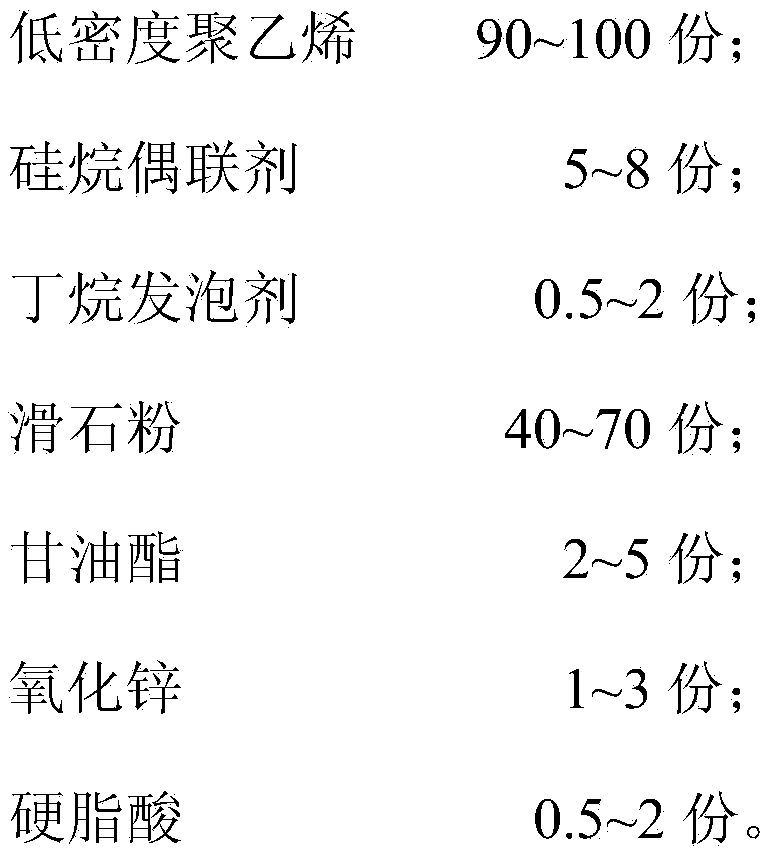

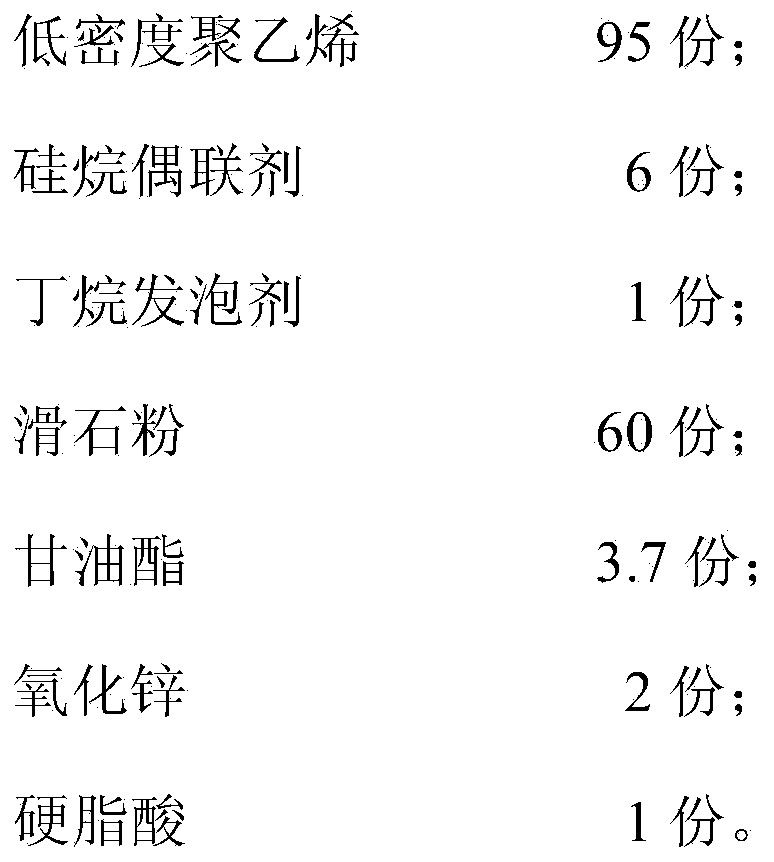

The invention discloses an EPE material for a crawling pad, a preparation method of the EPE material and the crawling pad. The EPE material comprises the following components in parts by mass: 90-100 parts of low density polyethylene, 5-8 parts of a silane coupling agent, 0.5-2 parts of a butane foaming agent, 40-70 parts of talcum powder, 2-5 parts of glyceride, 1-3 parts of zinc oxide and 0.5-2 parts of stearic acid. The crawling pad prepared from the EPE material is favorable in water resistance, is flexible, light and elastic, can absorb and disperse external impact force through bending to achieve a buffer effect, overcomes the defects of deformation and poor rebound resilience, and meanwhile, has a thermal insulating effect and is easy to clean.

Owner:SUZHOU JIUDING

Pre-foamed organic silicone foam material as well as preparation method and application thereof

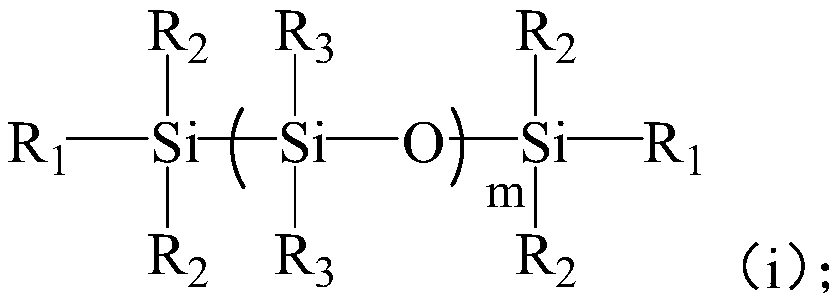

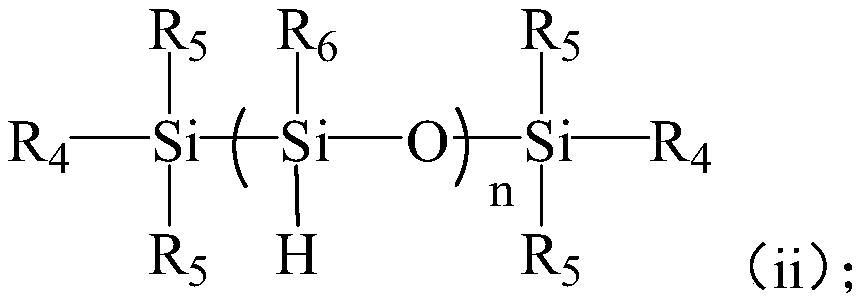

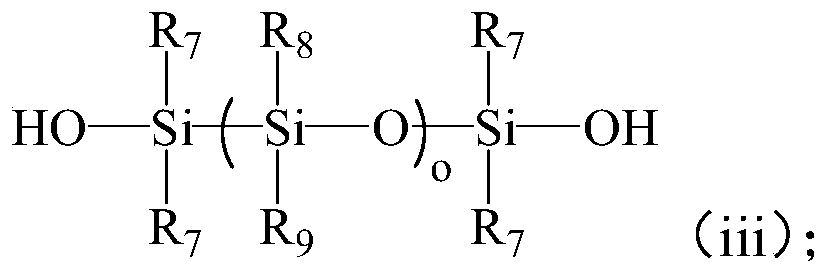

The invention provides a pre-foamed organic silicone foam material as well as a preparation method and application thereof. The pre-foamed organic silicone foam material disclosed by the invention comprises the following raw materials: methyl and / or vinyl-terminated organopolysiloxane, hydrogen-containing polysiloxane, hydroxyl silicone oil, a pre-foaming agent, an alcohol substance, a surfactant, a filler, a catalyst and a vulcanization inhibitor. According to the pre-foamed organic silicone foam material disclosed by the invention, the pre-foaming agent and the alcohol substance are adopted for performing auxiliary foaming on the basis of dehydrogenation foaming of hydroxyl silicone oil, foaming can be performed before a dehydrogenation reaction, tiny bubble nucleuses are formed, gas volumes and foaming ratios can be effectively increased, the dosage of the hydroxyl silicone oil is reduced, thixotropy is reduced, and processability is improved. Meanwhile, by adding aids such as the surfactant, compatibility of the components can be improved, and stability in the foaming process is improved, so that the prepared foam material is fine and uniform in pore and low in density.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Open-pore chemical-crosslinked polyolefin foam material and preparation method therefor

The invention relates to the technical field of macromolecular materials and particularly discloses an open-pore chemical-crosslinked polyolefin foam material and a preparation method therefor. The open-pore chemical-crosslinked polyolefin foam material is characterized by being obtained through subjecting a closed-pore chemical-crosslinked polyolefin foam material to repeated calendering by a double-roller calender, wherein the closed-pore chemical-crosslinked polyolefin foam material is prepared through carrying out internal mixing on polyolefin, a main foamer, an auxiliary foamer, a foamer activator, a crosslinker, a crosslinking accelerant, a lubricant and an inorganic filler according to a certain weight ratio, and carrying out extruding, calendering, foaming, edge trimming and winding. According to the open-pore chemical-crosslinked polyolefin foam material and the preparation method therefor, the production process is simple, restriction on raw materials is absent, the production cost is reduced, excessive dependency on foamer kinds and foaming multiplying factor of the open-pore chemical-crosslinked polyolefin foam material is lowered, and the resilience and maximum impact acceleration of the crosslinked polyolefin foam material are lowered.

Owner:TAISHAN SPORTS IND GRP +1

Polyurethane resin used for slow-recovery sponge, and preparation method and application thereof

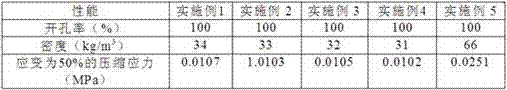

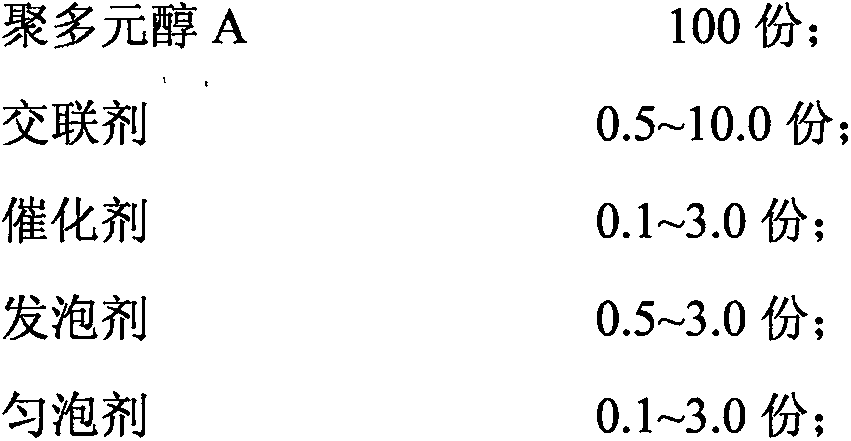

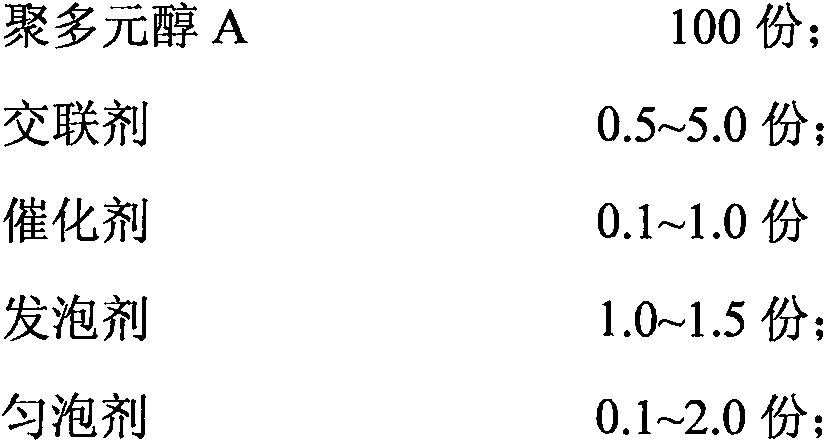

The invention discloses a polyurethane resin used for slow-recovery sponge, and a preparation method and an application thereof. The resin comprises a resin A component, a resin B1 component and a resin B2 component, and the resin A component comprises polyol A, a cross-linking agent, a catalyst, a foaming agent and a foam stabilizer; the resin B1 comprises 100 parts of isocyanate B1, 10-40 parts of polyol B1 and 0.002-0.010 parts of a side reaction inhibitor, the resin B2 comprises 100 parts of isocyanate B2, 50-100 parts of polyol B2 and 0.002-0.010 parts of the side reaction inhibitor, the isocyanate B1 is methyl diphenylene diisocyanate, carbodiimide modified methyl diphenylene diisocyanate, toluene diisocyanate or diisocyanatonaphthalene, the polyol B1 is polyether triol, the isocyanate B2 is methyl diphenylene diisocyanate, carbodiimide modified methyl diphenylene diisocyanate, toluene diisocyanate or diisocyanatonaphthalene, and the polyol B2 is polyether polyol. Slow-recovery polyurethane sponge with different hardness values can be produced, and the cost is low.

Owner:ZHEJIANG HUAFON NEW MATERIALS CO LTD

XPE (crosslinked polyethylene) foaming material and preparation method thereof

InactiveCN108314824AGood compatibilityWell mixedLow-density polyethyleneLinear low-density polyethylene

The invention belongs to the field of macromolecule foaming materials, and particularly relates to an XPE (crosslinked polyethylene) foaming material and a preparation method thereof. The XPE foamingmaterial is prepared from the following raw materials in parts by weight: 35 to 65 parts of low density polyethylene, 26 to 36 parts of linear low density polyethylene, 5 to 30 parts of modified foaming agent, 0.5 to 1 part of crosslinking agent, 0.1 to 0.5 part of assistant crosslinker, and 1 to 3 parts of master batch, wherein the weight ratio of a foaming agent OBSH to a foaming agent BIH40 toa curing agent to a compound foaming additive to a surfactant in the modified foaming agent is 12:(6 to 10):(0.3 to 1):(0.8 to 2):(1 to 3); the total content of citric acid and carbonate in the foaming agent BIH40 is 50% or above. The invention also provides the preparation method of the XPE foaming material. The XPE foaming material has the advantages that the healthy and environment-friendly effects are realized, and the foam holes are uniform and dense.

Owner:FUJIAN SANSHENG IND

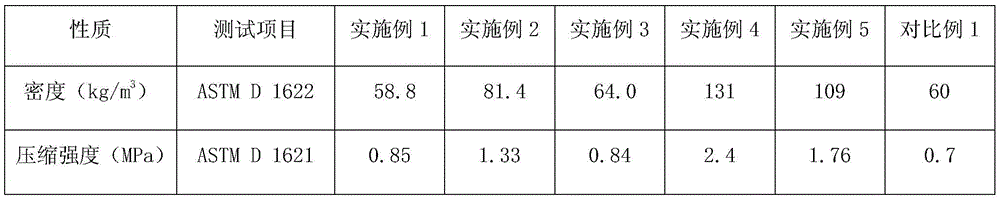

High temperature-resistant imide-polyvinyl chloride alloy structure foam and preparation method thereof

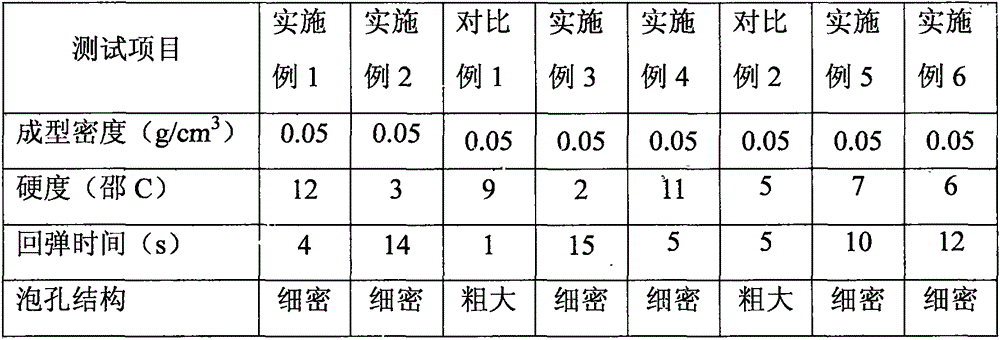

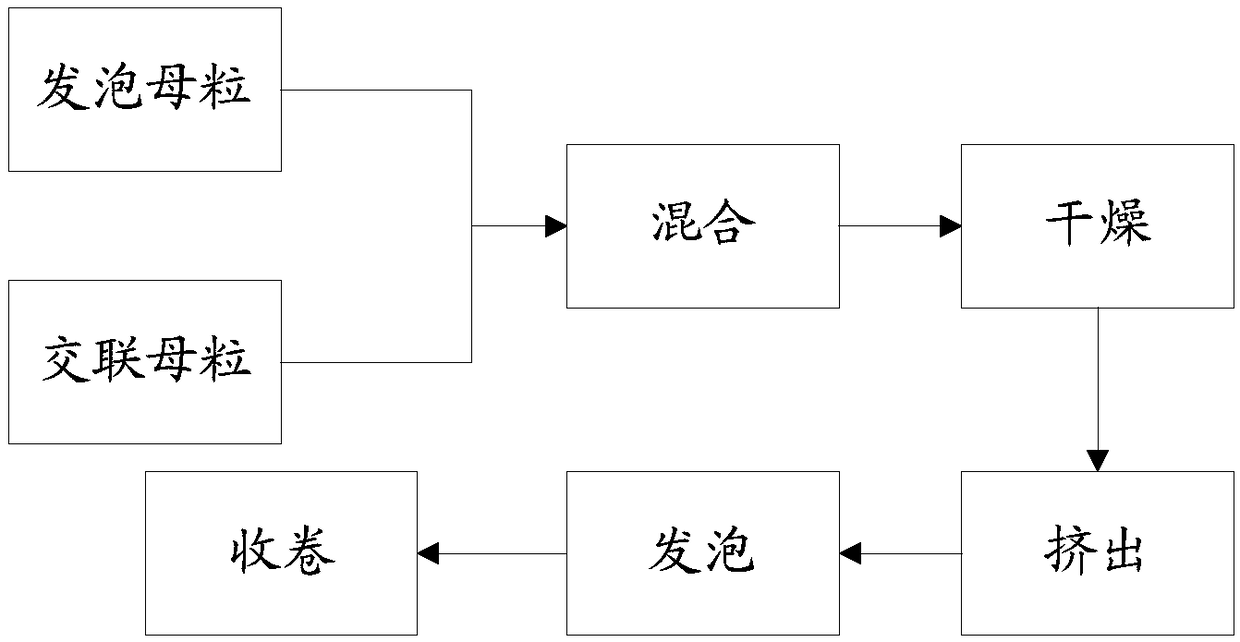

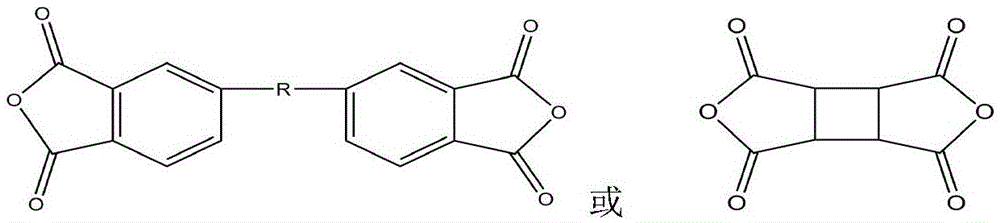

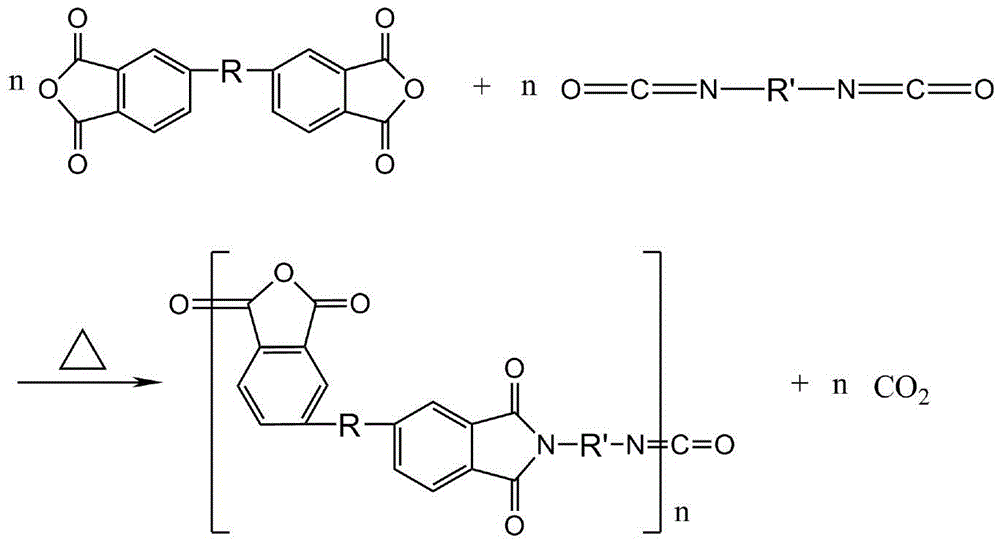

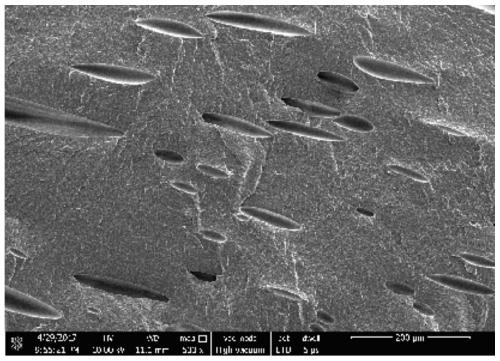

ActiveCN105542335AFine and uniform cellsGood physical and mechanical propertiesIsocyanate compoundImide

The invention belongs to the technical field of novel materials and relates to high temperature-resistant imide-polyvinyl chloride alloy structure foam and a preparation method thereof. The high temperature-resistant imide-polyvinyl chloride alloy structure foam comprises, by weight, 100 parts of polyvinyl chloride resin, 1-30 parts of organic dianhydride, 30-150 parts of isocyanate, 0-10 parts of a stabilizer and 1-12 parts of an initiator. The high temperature-resistant imide-polyvinyl chloride alloy structure foam has uniform foam apertures, excellent mechanical properties, closed porosity of 97% or more, density of 60kg / m<3> and compression strength of 0.8-1.2MPa. Compared with the common polyvinyl chloride structure foam, the high temperature-resistant imide-polyvinyl chloride alloy structure foam has better temperature resistance and improves a processing temperature upper limit by 30-40%. The high temperature-resistant imide-polyvinyl chloride alloy structure foam provides a strong support for use in a preimpregnation process and development of an advanced composite material technology.

Owner:CHANGZHOU TIANSHENG NEW MATERIALS

Light weight PU plate special for passenger vehicle skylight sunshading boards

The invention discloses a light weight PU plate special for passenger vehicle skylight sunshading boards. The light weight PU plate is characterized in that it is prepared from the following raw materials by weight: a component A, which is prepared by uniform mixing of 35-50 parts of soft foam polyether, 50-65 parts of low viscosity hard foam polyether, 1-2 parts of mixed silicone oil, 0.8-1.5 parts of a reaction catalyst, 5-7.5 parts of a foaming agent, 1-2 parts of a mixed hole opening agent and 1-2.5 parts of an antioxidant; and 165-190 parts of a component B. The component A and the component B are subjected to foaming reaction to form a PU semi-hard large foam block, and after slicing, the light weight PU plate can be obtained. With a density of 20-22Kg / m<3> and a foam block utilization rate up to 90%, the foam cells are fine and uniform, have high hole opening rate and good air permeability, and can be used for the wet making process of passenger vehicle skylight sunshading boards. The product has the characteristics of light weight, low VOC and high yield.

Owner:YANTAI ZHENGHAI HIGH TECH

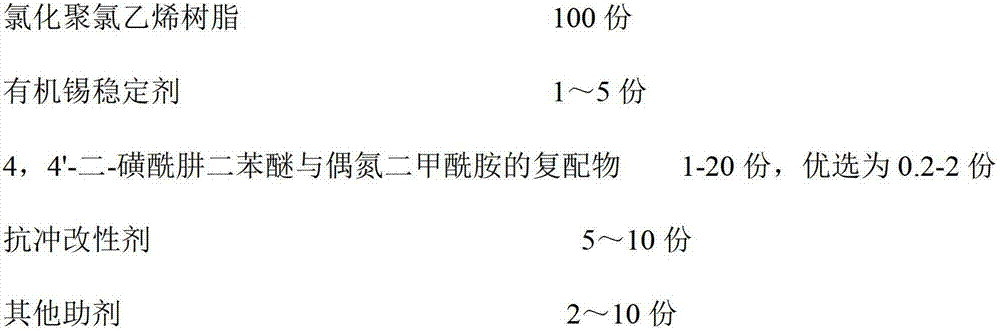

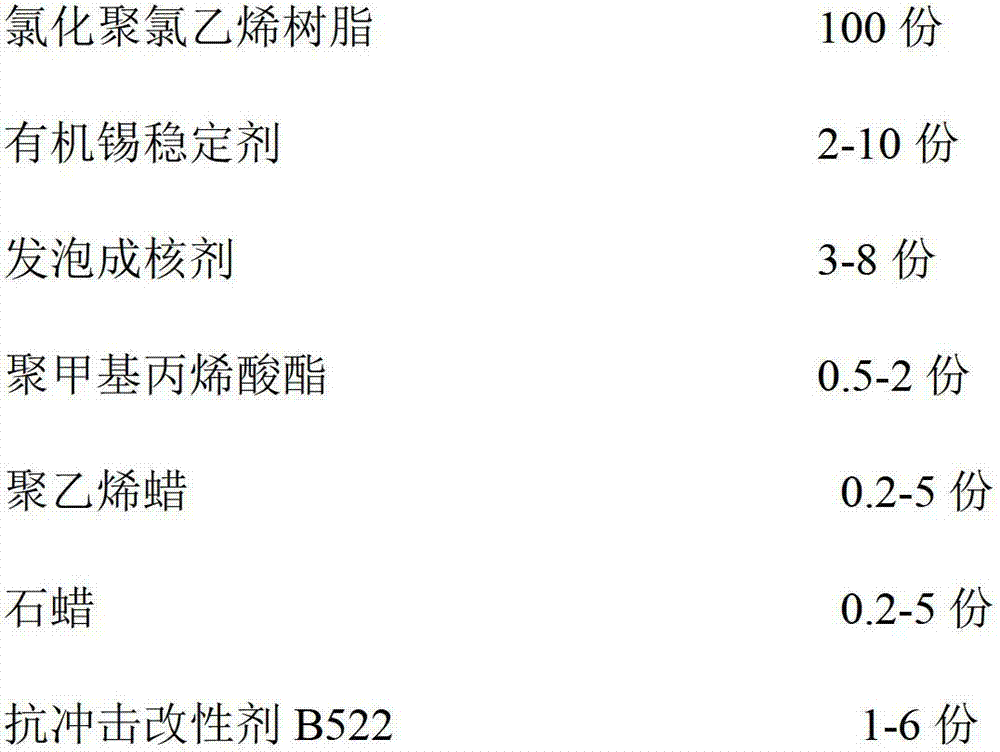

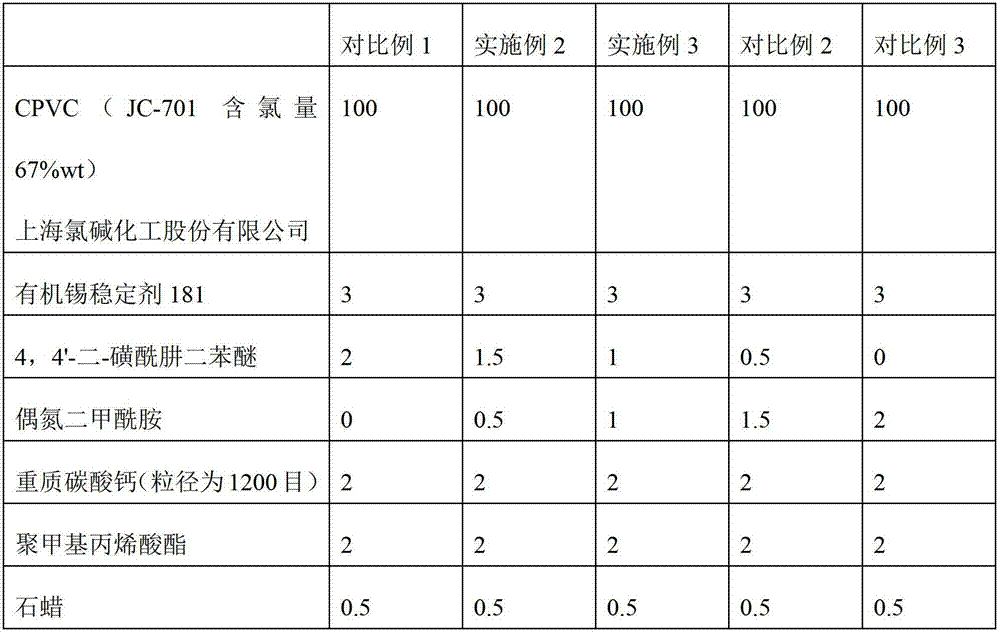

Preparation method for chlorinated polyvinyl chloride foaming board

InactiveCN102816400AFine and uniform cellsHigh tensile strengthFoaming agentChlorinated polyvinyl chloride

The invention discloses a preparation method for a chlorinated polyvinyl chloride foaming board. The preparation method comprises the following steps of: heating chlorinated polyvinyl chloride resin, organic tin stabilizer, composite foaming agent of 4,4'-oxybis (benzenesulfonyl hydrazine)and azobisformamide, and other additives except anti-impact modifier to 80-90 DEG C, adding the anti-impact modifier and heating until 100 DEG C to 120 DEG C, cooling to 25 DEG C to 45 DEG C, granulating after discharging, delivering the particles into an extruding machine, and shaping after extrusion to obtain the chlorinated polyvinyl chloride foaming board; and the composite foaming agent is a composite of 4,4'-oxybis benzenesulfonyl hydrazine and azobisformamide, and the weight ratio of 4,4'-oxybis benzenesulfonyl hydrazine to azobisformamide is (3-1):1. The chlorinated polyvinyl chloride (CPVC) foaming bard obtained via the preparation method is provided with an expansion rate of 300 percent, and the obtained board product is provided with a remarkable mechanical force property.

Owner:SHANGHAI CHLOR ALKALI CHEM

Preparation method of foamed nylon plate

The invention discloses a preparation method of a foamed nylon plate. The preparation method comprises the following steps: premixing nylon, a toughening agent, a chemical foaming agent, a nucleating agent, a lubricant and a crosslinking agent according to a formula, adding the obtained mixture into an extensional rheological plasticization and extrusion device, using an extensional deformation-based flow field to make nylon melted and plasticized and a gas formed after decomposition of the foaming agent mixed and dispersed in a polymer melt, performing extrusion through a foamed sheet die, and carrying out three-roller pressing to obtain the foamed nylon sheet. Addition of a small amount of the crosslinking agent can significantly improve the melt strength of PA, and the nylon plate produced through the preparation method by adopting the extensional rheological plasticization and extrusion device has the advantages of uniform and fine cells, high foaming rate, low aperture ratio, excellent performances, good processing performance, simple process flow, high production efficiency, suitableness for industrial scale production, and wide application prospect.

Owner:SIIICO TECH CO LTD

High-molecular foaming material and preparation method thereof

The invention provides a high-molecular foaming material and a preparation method thereof. The high-molecular foaming material is prepared from base resin, a cross-linking agent, a foaming agent, a cell nucleating agent and an antioxidant, wherein the base resin is high-molecular resin or modified high-molecular resin having end groups with active hydrogen. Based on the total weight, the content of the base resin is 93.5-97.4 wt% by weight, the content of the cross-linking agent is 0.38-1.92 wt%, the content of the foaming agent is 0.94-1.93 wt%, the content of the cell nucleating agent is 1.14-2.31 wt%, and the content of the antioxidant is 0.09-0.48 wt%. The invention also provides the preparation method of the high-molecular foaming material. The foaming system has a flame-retardant property, and the high-molecular foaming material also has better apparent mass and foaming rate.

Owner:SHENZHEN POLYTECHNIC

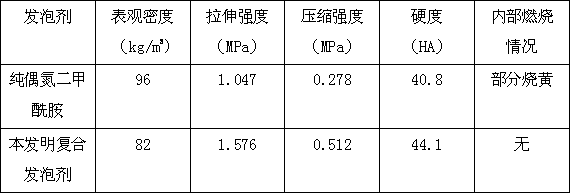

Composite foaming agent for soft PVC foam material

The invention discloses a composite foaming agent for soft PVC foam material. The foaming agent comprises the following raw materials, by weight: 4-6 parts of azobisformamide, 1-3 parts of N,N'-dinitrosopentamethylene tetraamine, 1-2 parts of cetyl trimethyl ammonium bromide, 2-3 parts of sodium bicarbonate, 2-3 parts of sodium citrate, 1-2 parts of zinc carbonate, 0.5-1.5 parts of chromium sulfate, 0.5-0.8 part of lead stearate, 2-4 parts of glycerine, and 10-15 parts of poly propylene glycol. Compound of azoformamide, N, N'-dinitrosopentamethylene tetraamine, cetyl trimethyl ammonium bromide and other raw materials improves defects of single azoformamide, such as strong heat release, strong burstiness and rapid dissociation. The composite foaming agent provided by the invention gently decomposes and releases less heat when heated; and the obtained material has uniform and fine pores, improved performance, and especially increased tear strength and elongation at break.

Owner:安徽艾柯泡塑股份有限公司

Composite foaming agent for rigid PVC foam material

The invention discloses a composite foaming agent for a rigid PVC foam material. The foaming agent comprises the following raw materials, by weight: 5-10 parts of azodicarbonamide, 2-4 parts of diethyl azodicarboxylate, 2-3 parts of OBSH, 0.5-1.5 parts of lauryl sodium sulfate, 1-2 parts of sodium bicarbonate, 1-2 parts of zinc carbonate, 1-3 parts of urea, 0.5-0.8 part of lead stearate, 2-4 parts of citric acid, and 15-20 parts of glycol propyl ether. According to the invention, raw materials including urea, zinc carbonate, sodium bicarbonate, sodium dodecyl sulfate are adopted for modification of azodicarbonamide to prepare the composite foaming agent for rigid PVC foam material; and the composite foaming agent has advantages of decomposition temperature within the range of molding processing of rigid PVC foam material, basically balanced heat absorption-release, smooth decomposition rate, large deflating amount and no abruptness. The rigid PVC material prepared from the composite foaming agent has good mechanical properties, uniform and fine pores, thin pore wall, easily controlled processing conditions, and no emergence of burning.

Owner:安徽艾柯泡塑股份有限公司

Foaming agent for NBR sponge rubber

ActiveCN102964619BRaise the foaming temperatureStrong foaming powerRubber materialSodium bicarbonate

The invention discloses a foaming agent for NBR sponge rubber. The foaming agent comprises the following raw materials, by weight: 6-12 parts of azobisformamide, 4-8 parts of 4, 4 '-oxydibenzenesulfonyl hydrazide, 2-5 parts of p-toluenesulfonohydrazide, 3-6 parts of DNPT, 4-8 parts of modified sodium bicarbonate, 20-30 parts of polyethylene glycol, 5-10 parts of triethanolamine, 2-5 parts of salicylic acid, 1-2 parts of zinc stearate, and 0.5-1.5 parts of calcium oxide. The foaming agent produced by the invention has excellent foaming capacity and foam stability; and the produced foam has advantages of good temperature adaptability, uniform dispersion, low cost and easiness for usage. The NBR sponge rubber material prepared by the foaming agent has good mechanical performance, small density and fine and uniform pore.

Owner:安徽艾柯泡塑股份有限公司

PVC structural foam and preparation method thereof

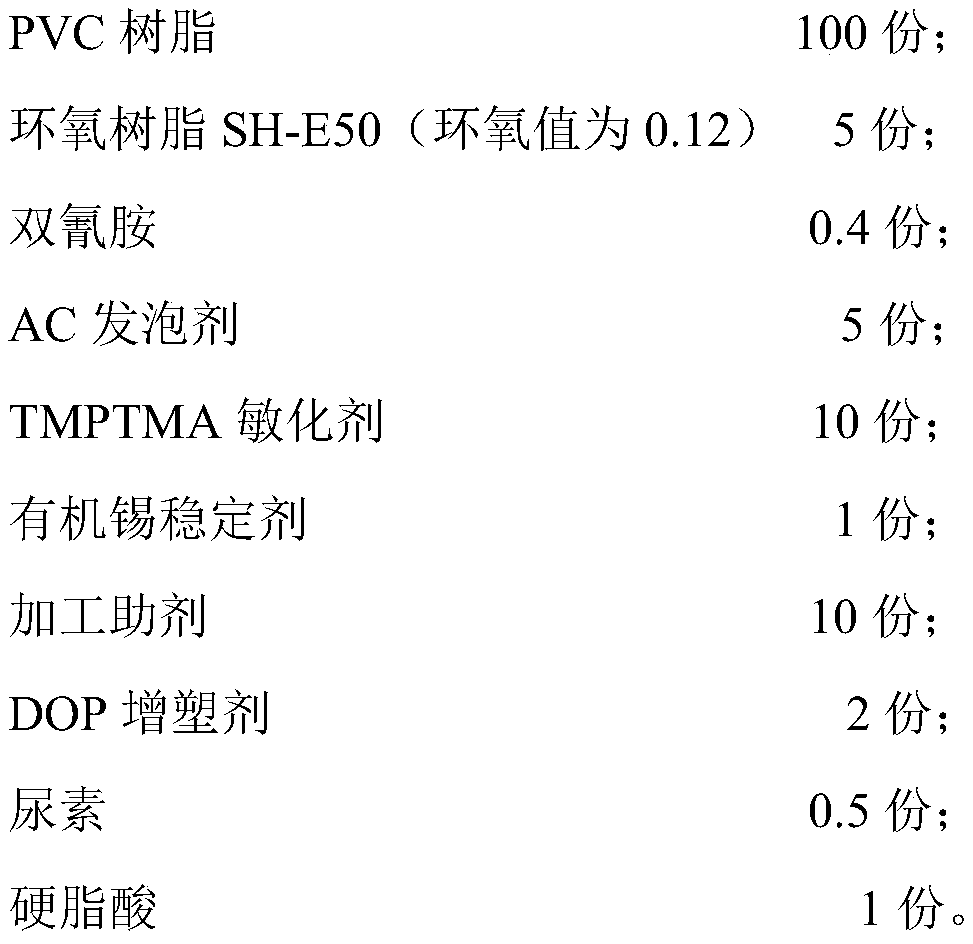

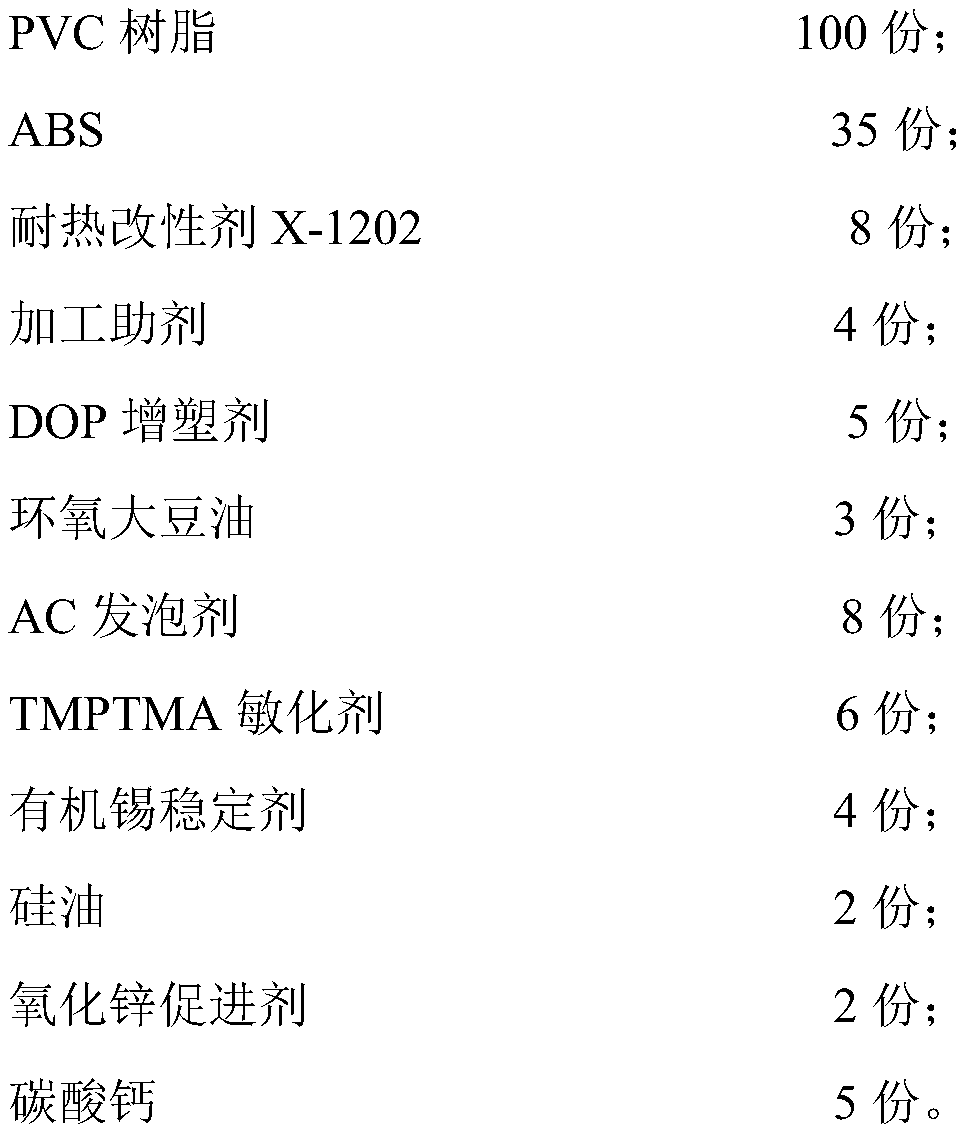

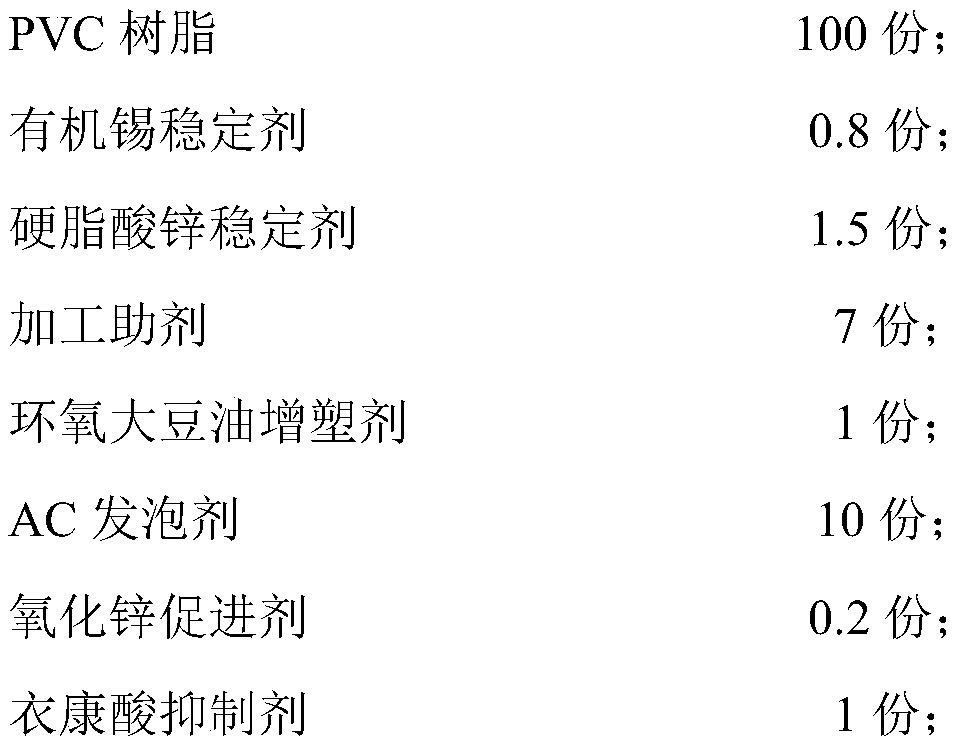

The invention discloses PVC structural foam which comprises the following raw material components in parts by weight: 100 parts of PVC resin, 5-80 parts of epoxy resin, 0.4-24 parts of an epoxy curingagent, 5-20 parts of a foaming agent, 3-20 parts of a sensitizer, 1-8 parts of a stabilizer and 5-15 parts of a processing aid. Through special setting of the raw material components and the ratio, an epoxy resin crosslinking system is introduced, and after irradiation foaming, a double-crosslinking system with two interpenetrated resin systems with a PVC resin crosslinking system is formed; on the basis of ensuring the uniformity of the PVC crosslinking system and obtaining foam with fine and uniform cells, high closed-cell rate and low water absorption, the rigidity of a crosslinking structure is enhanced by utilizing an epoxy resin system, and the crosslinking density and the crosslinking strength of the whole system are greatly improved, so that the mechanical property and the heat resistance of the prepared structural foam are greatly improved. The invention also discloses a preparation method for the PVC structural foam.

Owner:FSPG HI TECH +1

Variable-density ethylene propylene diene monomer thermal insulation functional material and preparation method thereof

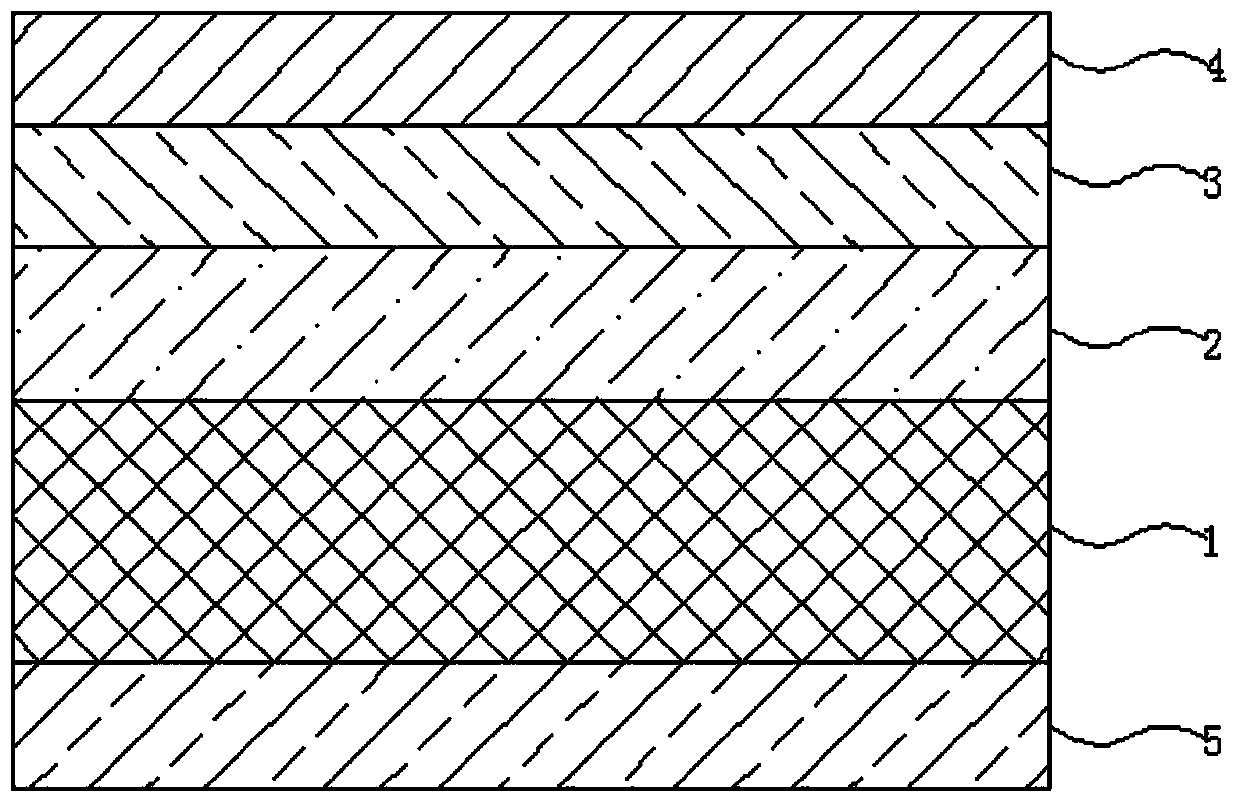

ActiveCN111086298AHigh densityLow densityVehicle componentsRubber layered productsFiberPolymer science

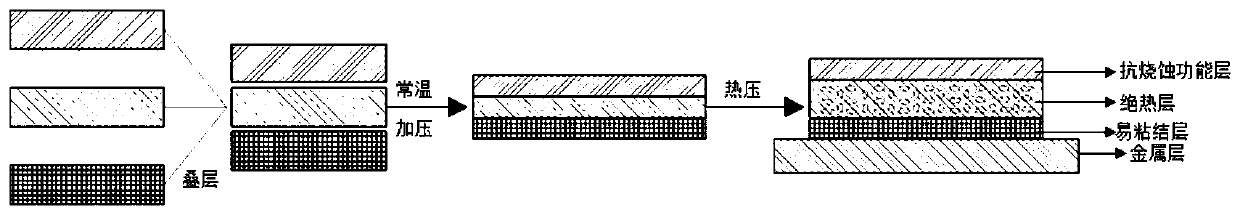

The invention relates to a variable-density ethylene propylene diene monomer thermal insulation functional material and a preparation method thereof. The thermal insulation functional material is composed of an anti-ablation functional layer, a heat-insulating layer and an easy-to-bond layer, wherein chopped fibers and a functional filler are added to the anti-ablation functional layer to improvethe ablation resistance of the anti-ablation functional layer, a foaming agent is added to the heat-insulating layer to reduce the density and enhance heat insulation, and a tackifier is added to theeasy-to-bond layer to enhance the bonding effect with a substrate material. The preparation method comprises the following steps: sequentially adding the raw materials of the anti-ablation functionallayer, the heat-insulating layer and the easy-to-bond layer into an open mill, mixing to obtain a mixed rubber sheet, then processing the obtained three layers of the mixed rubber sheets into an integral composite laminated raw rubber sheet by using a flat plate laminating pressurizing method, and carrying out integral pressurizing vulcanization forming in a using process to obtain the rubber heatinsulation layer with the multi-layer functional characteristic. The thermal insulation functional material reduces the overall average density of the material, highly resists impact of high-temperature flame, can efficiently isolate heat, has strong binding force with a substrate material, and is suitable for harsh use environments.

Owner:WUHAN UNIV OF TECH

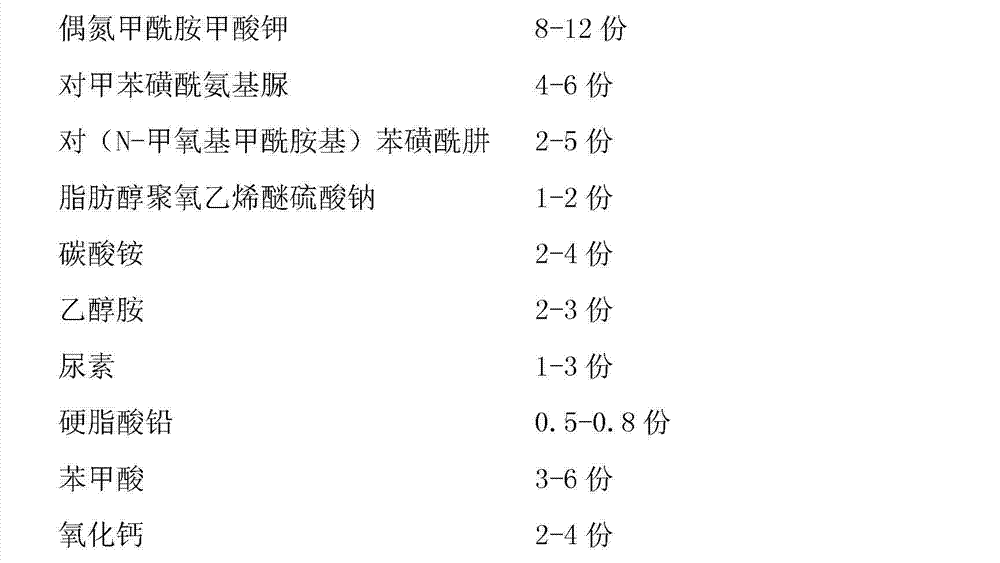

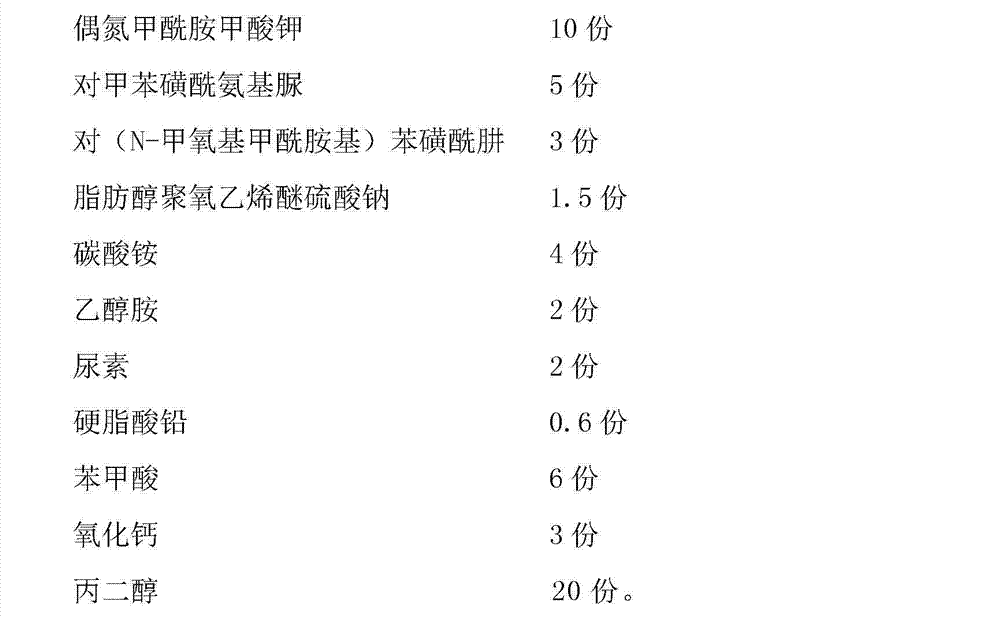

Foaming agent for PVC foamed plastic

The invention discloses a foaming agent for PVC foamed plastic. The foaming agent consists of the following raw materials by weight: 8-12 parts of azoformamide potassium formate, 4-6 parts of p-toluenesulfonyl semicarbazide, 2-5 parts of p-(N-methoxy formamido) benzene sulfonyl hydrazide, 1-2 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 2-4 parts of ammonium carbonate, 2-3 parts of ethanolamine, 1-3 parts of urea, 0.5-0.8 part of lead stearate, 3-6 parts of benzoic acid, 2-4 parts of calcium oxide and 15-20 parts of propylene glycol. The foaming agent for PVC foamed plastic provided by the invention has decomposition temperature in the molding processing range of rigid PVC foam material, basically balanced heat absorption, smooth decomposition rate, large amount of gas release and no burstiness. The foamed plastic prepared from the composite foaming agent has good mechanical property, uniform and fine bubble hole, thin hole wall, easily controllable processing conditions, and no occurrence of burning and charring.

Owner:鲁奎

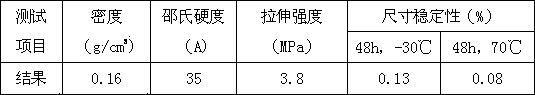

Dampproof silence pad and preparation process thereof

InactiveCN104974405ASmooth appearanceFeel comfortableFlat articlesFlooring insulationsLow-density polyethyleneLinear low-density polyethylene

The invention discloses a dampproof silence pad and a preparation process thereof. The preparation process comprises the following steps: mixing low density polyethylene and a hollow material and performing banburying to obtain semi-finished product particles A; mixing low density polyethylene, a foaming agent, an antioxidant and a coupling agent and performing banburying to obtain semi-finished product particles B; mixing low density polyethylene, a toughening agent and a lubricant and performing banburying to obtain semi-finished product particles C; mixing low density polyethylene and a coloring agent and performing banburying to obtain semi-finished product particles D; drying the semi-finished product particles A, B, C and D, stirring and mixing uniformly, and extruding into a sheet E by a single screw extruder; performing radiation crosslinking of the sheet E through a high-frequency high-voltage electron accelerator to obtain a foaming master slice F; preheating the master slice F by a horizontal foaming furnace, performing high-temperature foaming in a vertical foaming furnace, and sequentially performing the processes of calendering setting, corona, punching, trimming and coiling to obtain a coil of the dampproof silence pad; and performing thermal compounding between the coil G and PE films different in thickness on a compound machine with a heating device, and performing online slitting and coiling to obtain the dampproof silence pad.

Owner:SUZHOU GOOD NEW MATERIAL TECH CO LTD

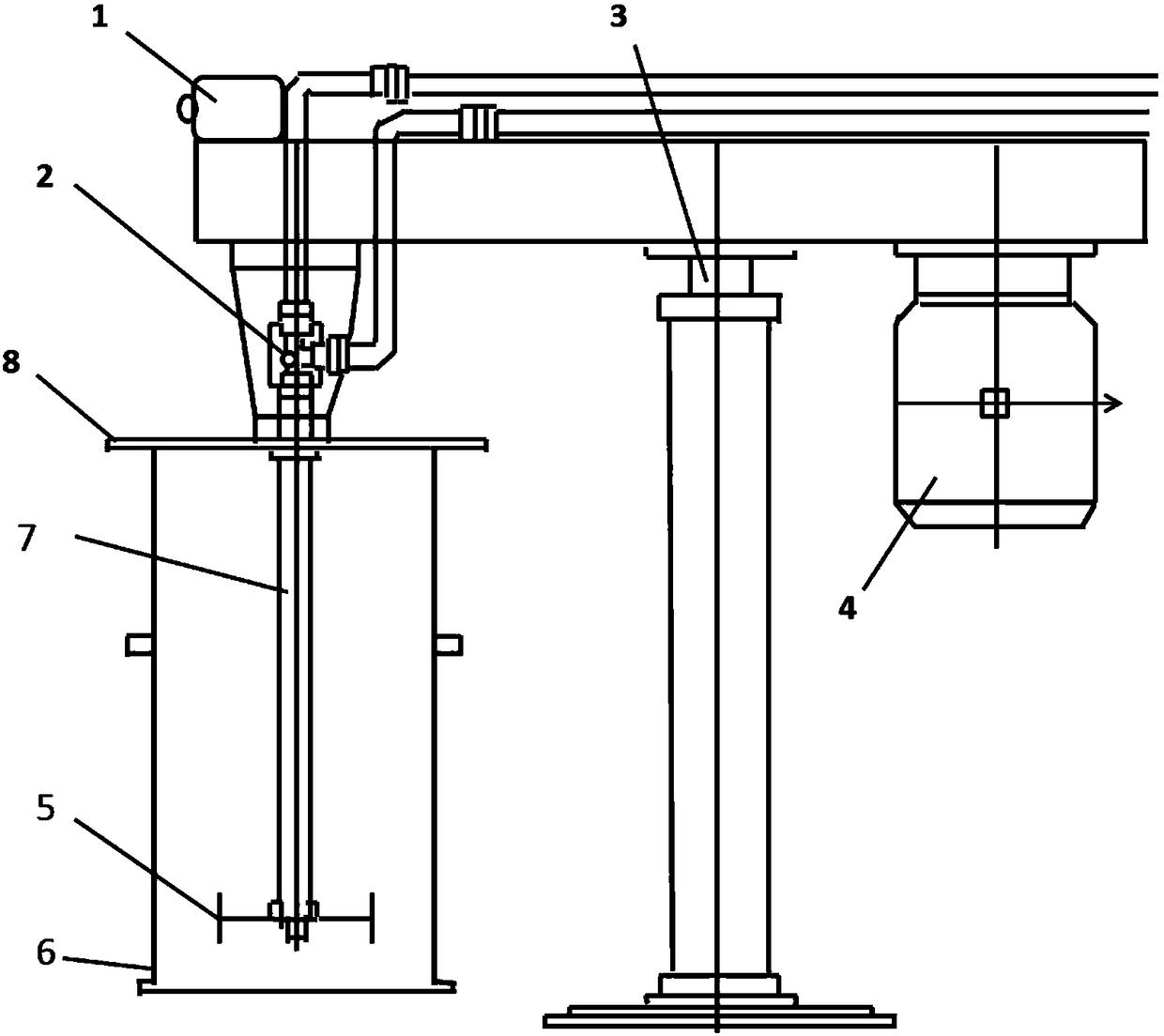

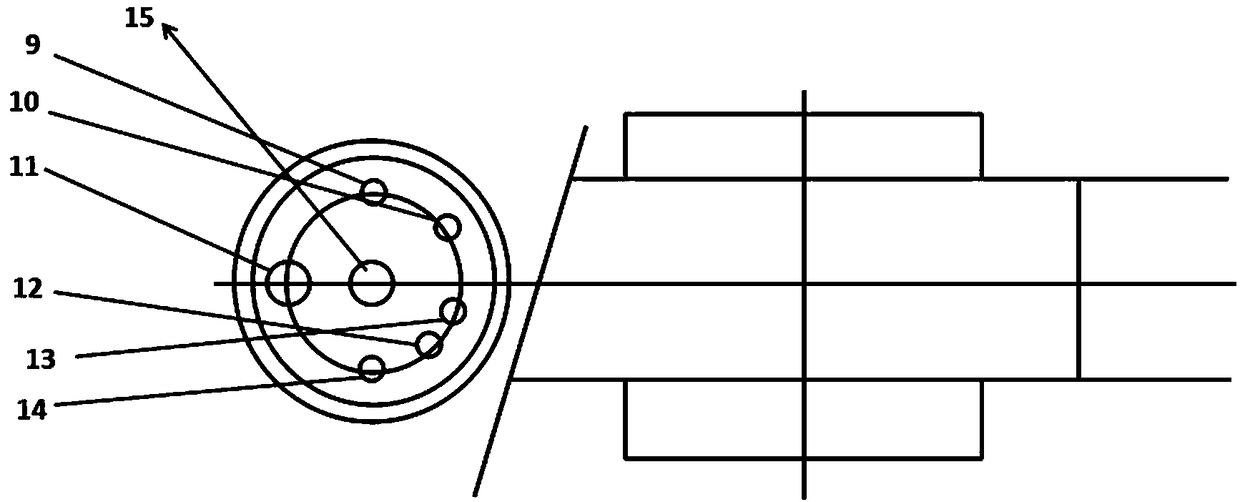

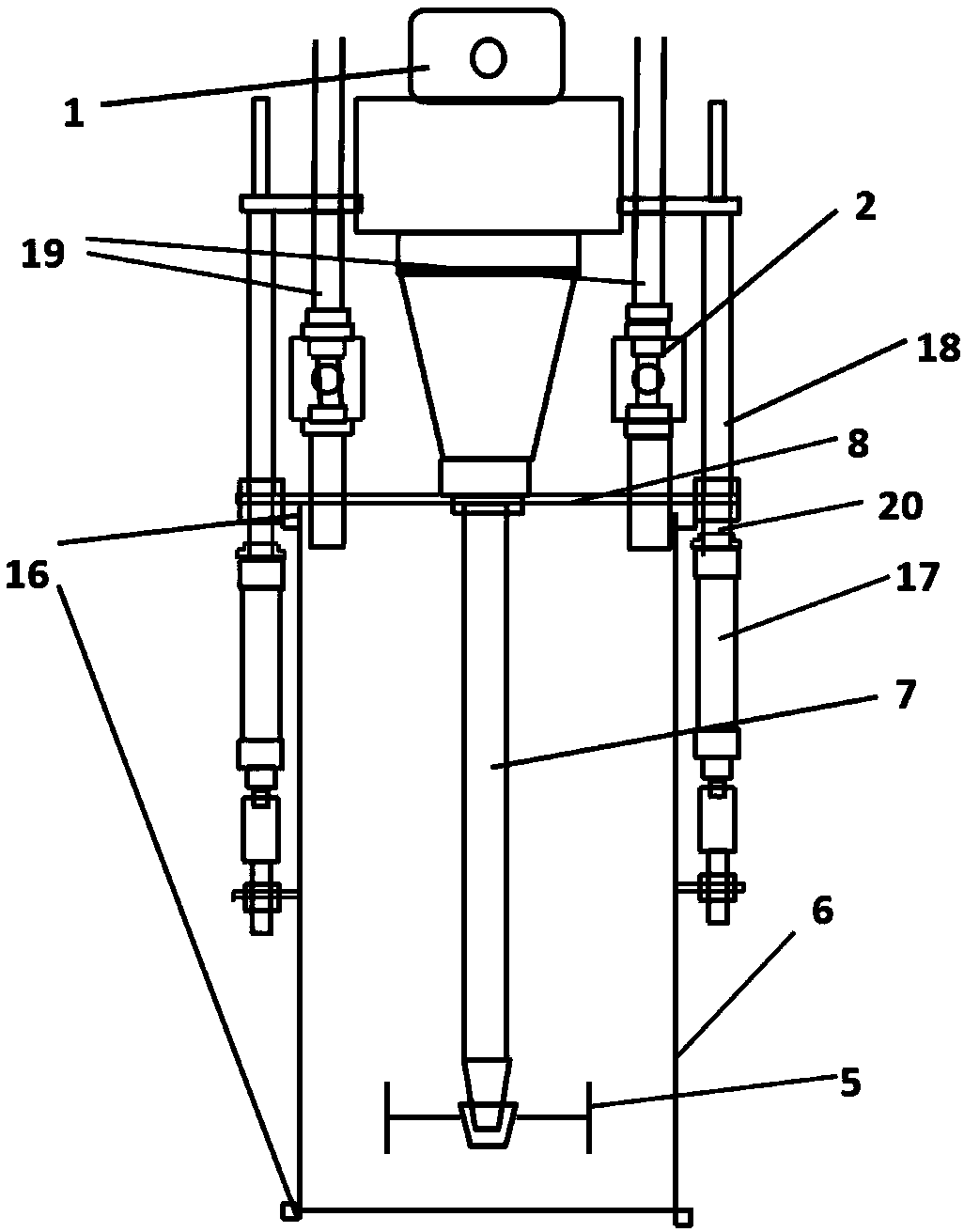

Separable negative pressure foaming machine with bottomless bucket, and preparation method thereof

The invention discloses a separable negative pressure foaming machine with a bottomless bucket, and a preparation method thereof. The separable negative pressure foaming machine comprises a stirring device, a hydraulic lifting device, a negative pressure air extraction device, a separable stirring bucket and a discharge device, wherein the separable stirring bucket comprises the bottomless bucketand a sealing cover; the hydraulic lifting device is fixedly connected with the sealing cover through an upper pull rod; the sealing cover is movably connected with the bottomless bucket through a cylinder and a lower pull rod; and the cylinder realizes the closure and separation of the sealing cover and the bottomless bucket. The separable negative pressure foaming machine disclosed by the invention overcomes the technical problems that the internal structure defects of a product are caused due to air mixing during stirring, and the inner wall of a bucket bottom cannot be self-cleaned and residues exist, so that the production efficiency is reduced, in the prior art, and the provided foaming equipment with the polyurethane bottomless bucket and a negative pressure defoaming stirring device realizes that the next foaming can be carried out without the need of cleaning for a bucket body, and continuous industrial production is efficient and rapid; and meanwhile, the foam holes of foam are fine and uniform, so that the perforation and structure defects are greatly reduced, the mechanical strength of the product is increased, and the appearance quality of the product is improved.

Owner:浙江华江科技股份有限公司

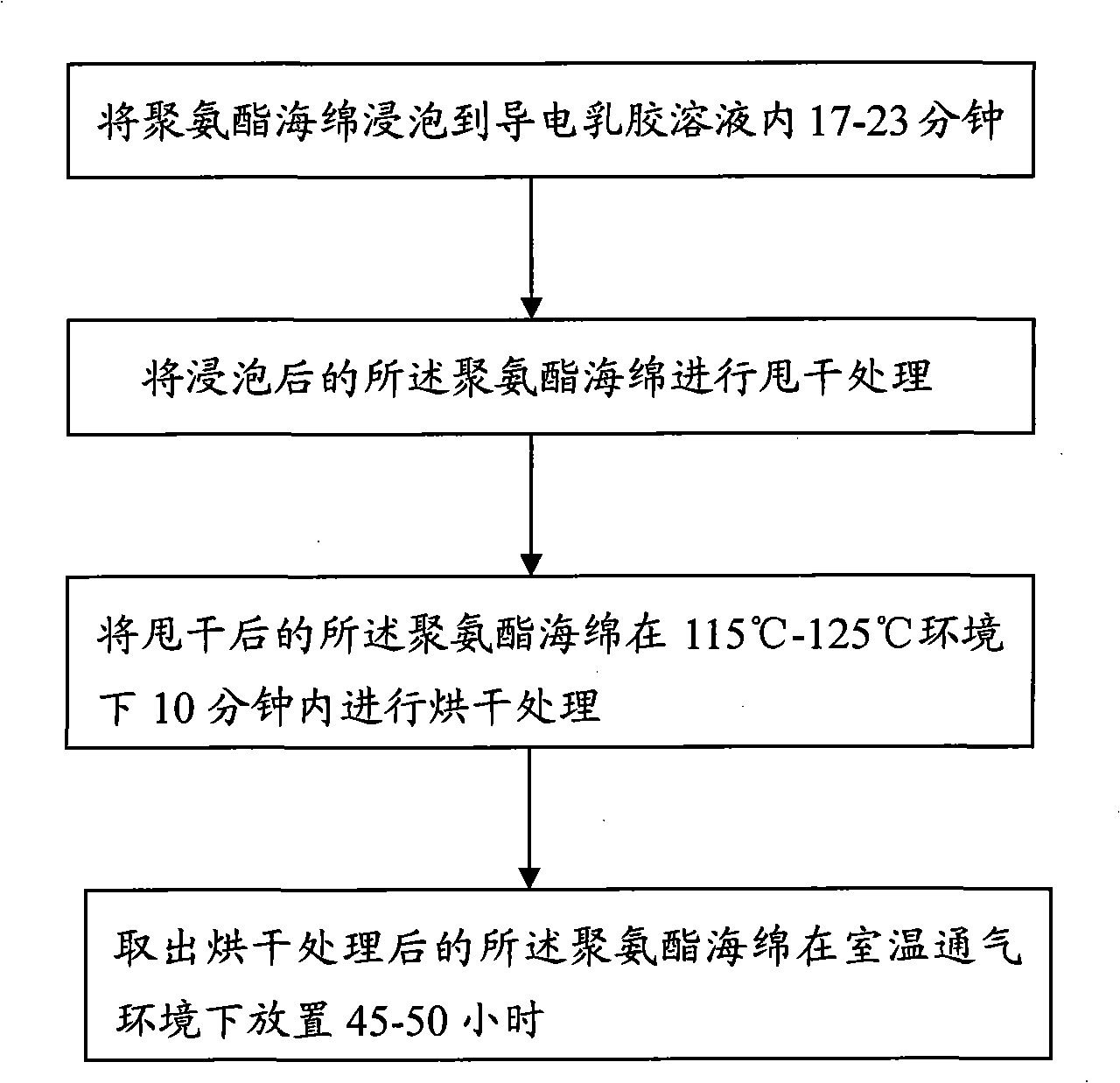

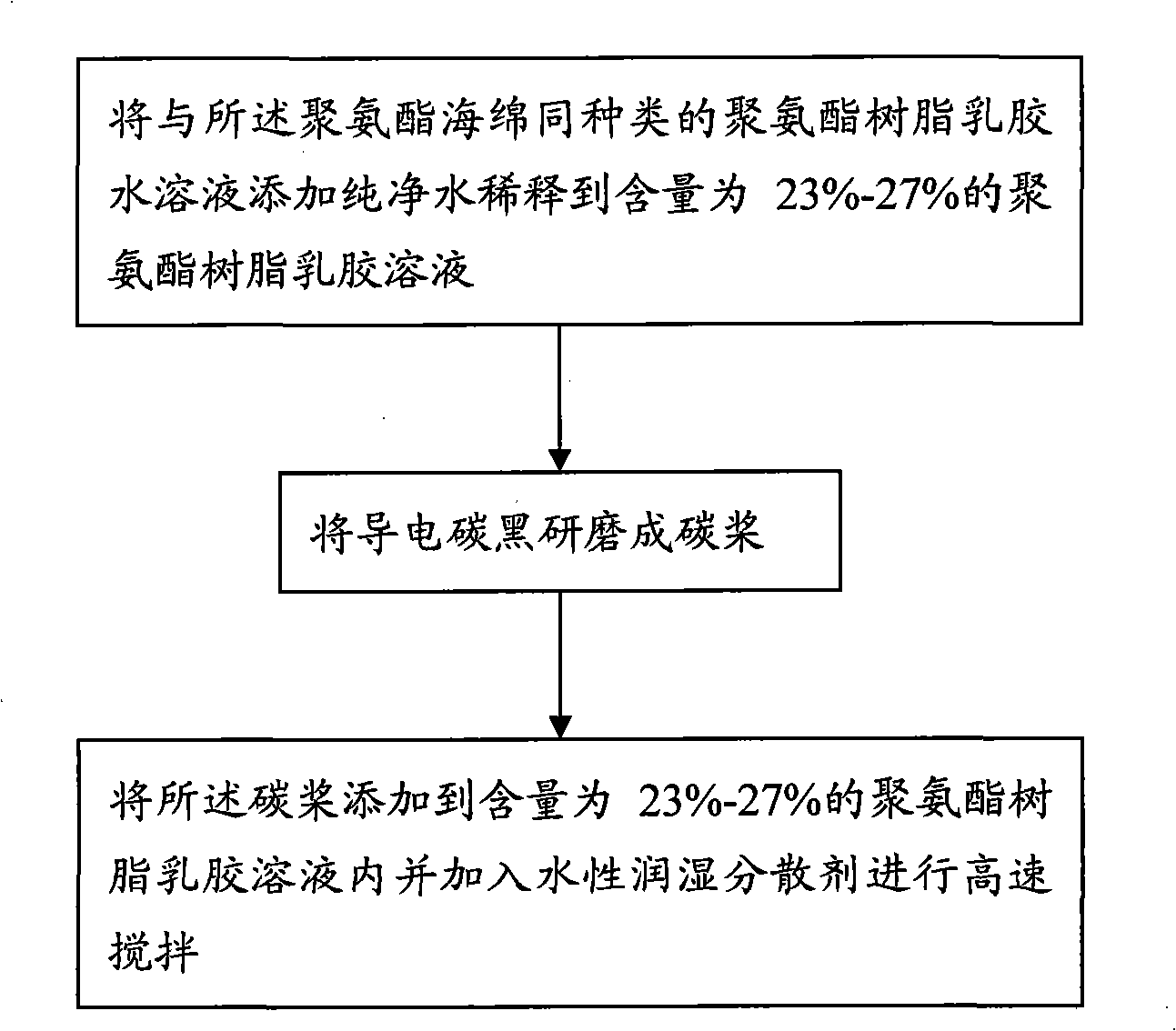

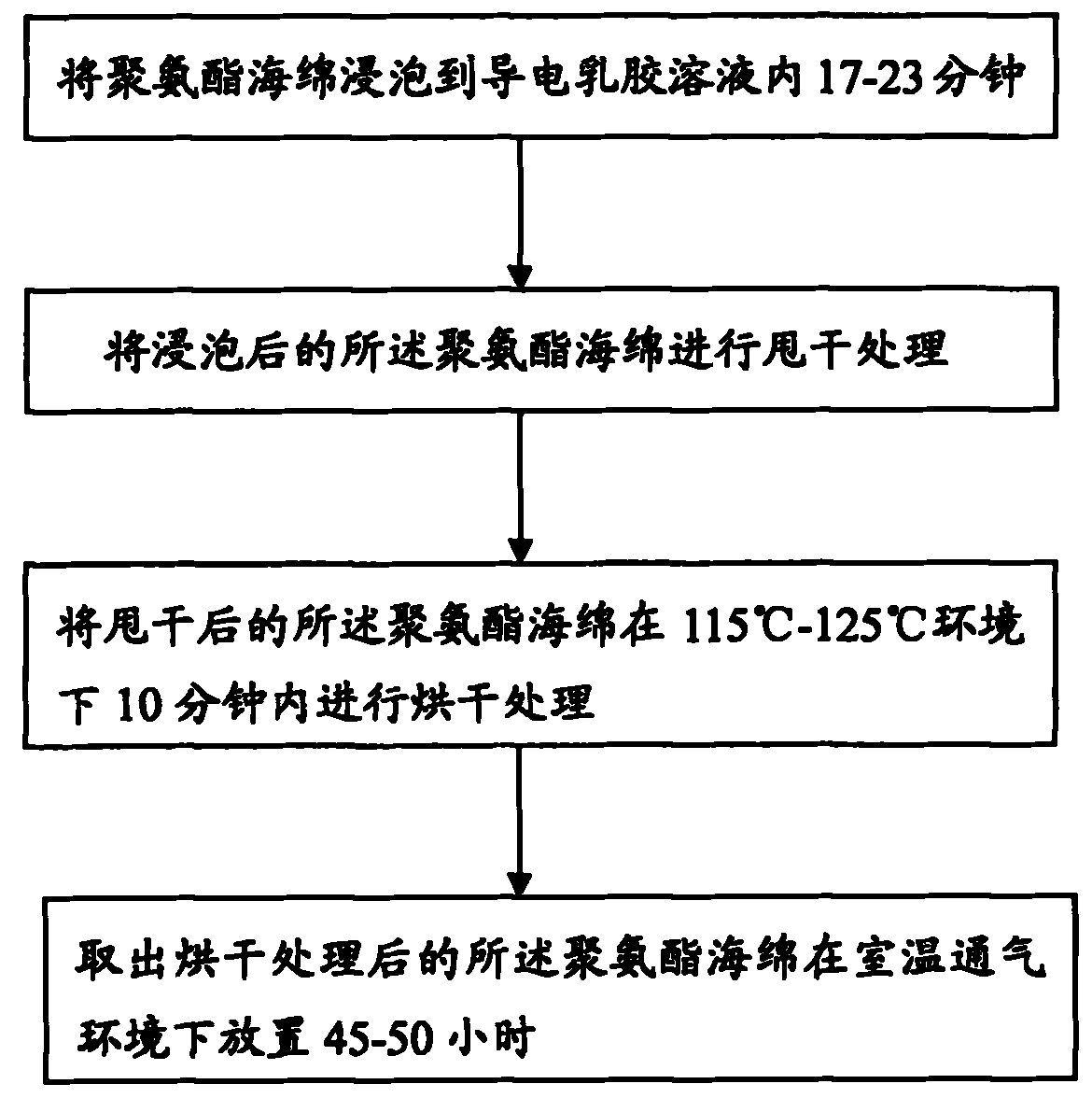

Preparations of conductive sponge and conductive latex solution

ActiveCN101481467BFine and uniform cellsHigh compressive strengthEnvironmental resistancePolymer science

The invention relates to a preparation method for conductive sponge and conductive emulsion solution. The preparation method for the conductive sponge comprises steps: firstly, polyurethane sponge is dipped in the conductive emulsion solution for 17-23 minutes; secondly, shaking drying treatment is carried out; thirdly, drying treatment is carried out; fourthly, the dried polyurethane sponge is placed for 48 hours in the room temperature ventilation environment. The preparation method of the conductive emulsion solution is that firstly, urethane resin emulsion solution with 25% contents is preformed; secondly, conductive carbon black is ground into carbon paste; finally, the carbon paste is added into the urethane resin emulsion solution with 25% contents, added with water borne wetting-dispersing agent and stirred in high speed. The conductive sponge prepared by the technical proposal of the invention has fine and uniform cells, and good compressive strength. The sponge materials cannot be corroded in the dipping and drying process. The better rebound resilience of the sponge is reserved. The conductive sponge does not fall crumbs, does not bring about pollution to devices, doesnot volatilize solvents to pollute environment, has the advantages of environmental protection, innocuity, odorlessness and no three wastes generation.

Owner:SHENZHEN CHANGYUAN TEFA TECH CO LTD

Preparation method of intercalated and modified organic montmorillonite composite foaming agent for polyvinyl chloride

The invention discloses a preparation method of an intercalated and modified organic montmorillonite composite foaming agent for polyvinyl chloride. The method comprises the steps of firstly carrying out organic modification on montmorillonite by using benzyl triphenyl phosphonium chloride; secondly carrying out intercalation on the modified montmorillonite by using azodicarbonamide and achieving uniform dispersion of the azodicarbonamide between montmorillonite laminates through control of a series of technological conditions; and finally further reducing the decomposition temperature of the foaming agent through coordinating with addition of a proper amount of zinc oxide and sodium bicarbonate, adding the foaming agent to polyvinyl chloride, thereby avoiding the phenomenon of pasting of the polyvinyl chloride. Industrial control is facilitated by a synthetic process of a product produced by the process, the production cost is reduced, the foaming temperature is moderate, the product is very suitable for a foaming process of the polyvinyl chloride and is not decomposed or pasted in the foaming process, a foaming material formed by the foaming agent is stable in quality, dense and uniform in cells and excellent in heat preservation effect, and has a certain flame-retarding effect.

Owner:CHUZHOU HONGYUAN SPRAYING

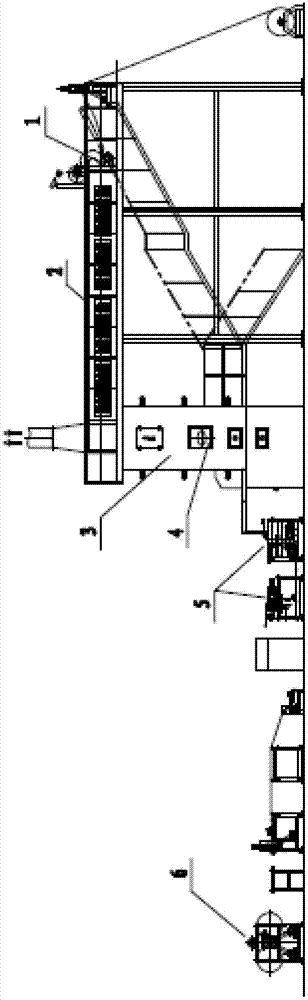

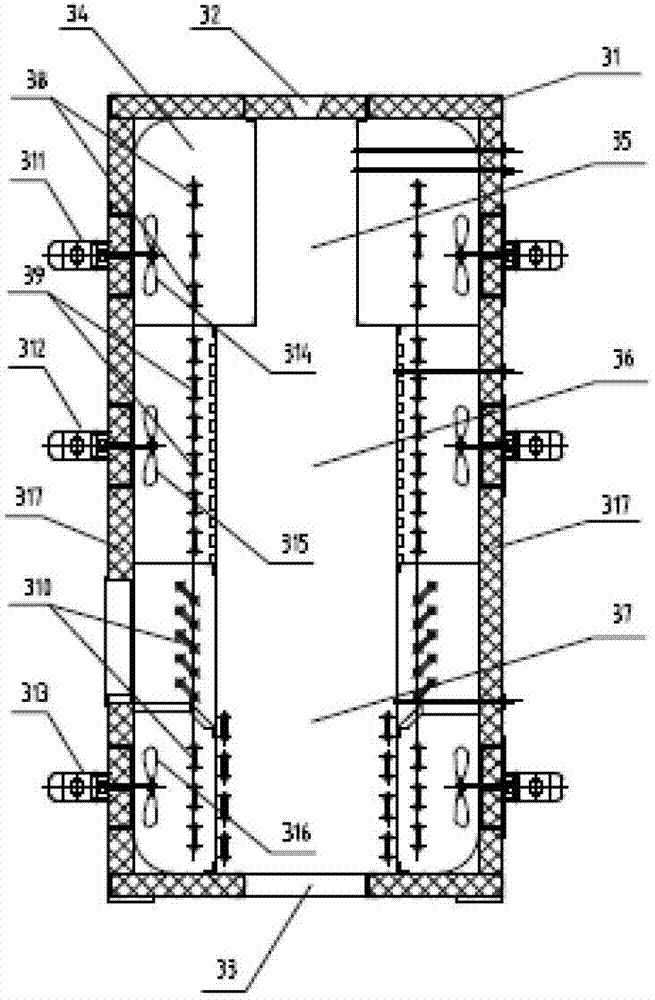

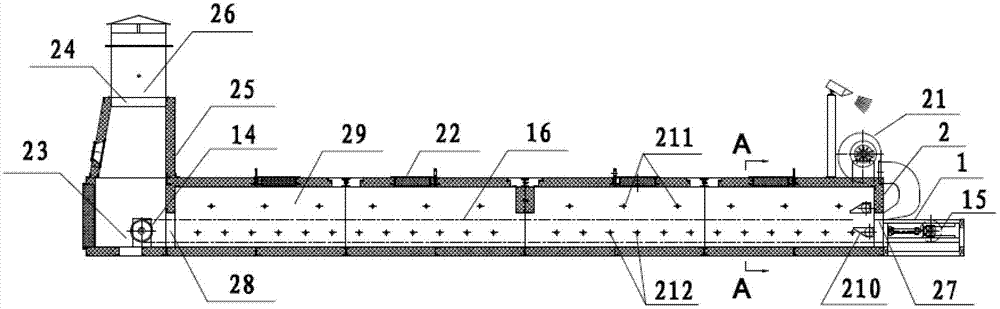

Electronic irradiating crosslinked polyethylene foaming machine

The invention relates to an electronic irradiating crosslinked polyethylene foaming machine, which comprises a horizontal conveying device, a horizontal preheating device, a vertical foaming device, an unfolding device, a positive and negative calendaring device and a coiling device which are successively arranged. The electronic irradiating crosslinked polyethylene foaming machine is characterized in that the vertical foaming device comprises a vertical foaming furnace; the vertical foaming furnace is provided with a transition area, a pre-foaming area and a foaming area; a plurality of first electric heating tubes, a plurality of second electric heating tubes, a plurality of third electric heating tubes, a plurality of first hot air circulating fans, a plurality of second hot air circulating fans and a plurality of third hot air circulating fans are arranged in the vertical foaming furnace; the first electric heating tubes and the first hot air circulating fans are located in the transition area; the second electric heating tubes and the second hot air circulating fans are located in the pre-foaming area; and the third electric heating tubes and the third hot air circulating fans are located in the foaming area. After the electronic irradiating crosslinked polyethylene foaming machine provided by the invention is adopted, the production efficiency and yield of the polyethylene foamed products are greatly increased.

Owner:宁波辉门科技有限公司

Styrofoam plastic with antibacterial and antifungal functions

ActiveCN113429538BSimple processWith antibacterial and anti-mildew functionBiotechnologyMicrobiology

The invention discloses a foamed plastic with antibacterial and antimildew functions and a preparation method thereof. The foamed plastic is prepared by a one-step method, the process is simple, low energy consumption and few steps; the obtained foamed plastic with the antibacterial and antimildew function has fine and uniform high-quality cells , good mechanical properties, excellent and durable antibacterial and antifungal effect.

Owner:揭阳市宏信塑胶制品有限公司

A kind of open cell chemically cross-linked polyolefin foam material and preparation method thereof

The invention relates to the technical field of macromolecular materials and particularly discloses an open-pore chemical-crosslinked polyolefin foam material and a preparation method therefor. The open-pore chemical-crosslinked polyolefin foam material is characterized by being obtained through subjecting a closed-pore chemical-crosslinked polyolefin foam material to repeated calendering by a double-roller calender, wherein the closed-pore chemical-crosslinked polyolefin foam material is prepared through carrying out internal mixing on polyolefin, a main foamer, an auxiliary foamer, a foamer activator, a crosslinker, a crosslinking accelerant, a lubricant and an inorganic filler according to a certain weight ratio, and carrying out extruding, calendering, foaming, edge trimming and winding. According to the open-pore chemical-crosslinked polyolefin foam material and the preparation method therefor, the production process is simple, restriction on raw materials is absent, the production cost is reduced, excessive dependency on foamer kinds and foaming multiplying factor of the open-pore chemical-crosslinked polyolefin foam material is lowered, and the resilience and maximum impact acceleration of the crosslinked polyolefin foam material are lowered.

Owner:TAISHAN SPORTS IND GRP +1

Modified latex masterbatch/styrene butadiene rubber foam material

The invention discloses a modified latex masterbatch / styrene butadiene rubber foam material and relates to the field of rubber foam materials. The modified latex masterbatch / styrene butadiene rubber foam material comprises styrene butadiene rubber, modified latex masterbatch, a vulcanizer, a plasticizer, an activator and an anti-aging agent. The modified latex masterbatch is made by adding a foaming agent and a reinforcing filler into latex (styrene butadiene latex or natural latex and the like), liquid mixing, coagulating, granulating and drying. Specifically, the foam material herein comprises 100 parts of styrene butadiene rubber, 20-40 parts of modified latex masterbatch, 1.0-2.0 parts of a vulcanizer, 10-15 parts of a plasticizer, 10-20 parts of an activator, and 1-3 parts of an anti-aging agent. The modified latex masterbatch / styrene butadiene rubber foam material features fine and uniform cells and good mechanical strength, and is expectedly applicable to diving suits, heat insulation materials and cushion tools.

Owner:SOUTH CHINA UNIV OF TECH

Composition for preparing sponge powder puff and preparation method of composition

ActiveCN102942673BImprove hydrophilicityImprove comfortPackaging toiletriesPackaging cosmeticsPolyolFoaming agent

The invention belongs to the field of polymer synthesis and particularly relates to a composition for preparing sponge powder puff and a preparation method of the composition. The composition consists of prepolymer ingredients and foaming agent ingredients according to a mass ratio being 100:(50-100), wherein the prepolymer ingredients are prepared from polyether polyol, reaction type hardening agents and toluene di-isocyanate through reaction, NCO is 5.5 to 7.0 percent, and the foaming agent ingredients consist of distilled water and organic silicon surfactants. The preparation method comprises the steps that the polyether polyol and the reaction type hardening agents are placed in a reaction kettle for dehydration, the temperature reduction is carried out, toluene di-isocyanate is added, the temperature rise reaction is carried out, and materials are discharged and are stored in a sealed way; the distilled water and the organic silicon surfactants are mixed, the uniform stirring is carried out, and the mixture is stored in a sealed way; and the prepolymer ingredients and the foaming agent ingredients are uniformly mixed and are cast into a mold for curing, and products are obtained. The sponge powder puff prepared by the composition has the advantages that excellent hydrophily and the hand feeling comfort are realized, the bubble holes are fine, dense and uniform, the powder affinity performance is high, and the use is convenient. The preparation method is simple, and the operation is easy.

Owner:SHANDONG INOV POLYURETHANE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com