Patents

Literature

49 results about "Apparent mass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apparent Mass. (or associated mass), a quantity having the dimensions of the mass that is added to the mass of a body moving nonuniformly in a fluid medium in order to take into account the action of the medium on the body. For example, if a body with mass m moves with translational motion in an ideal fluid under the influence of the force F,...

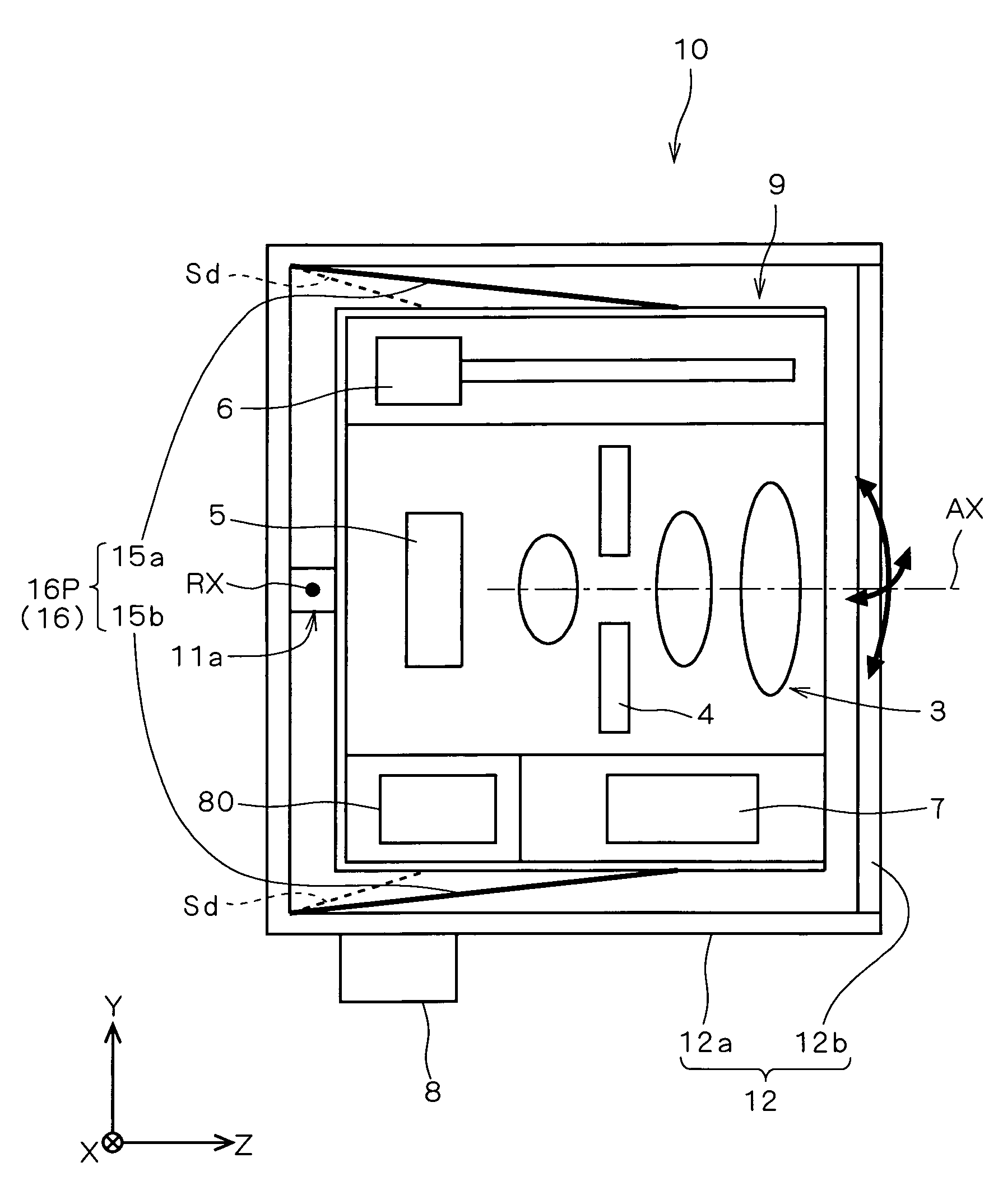

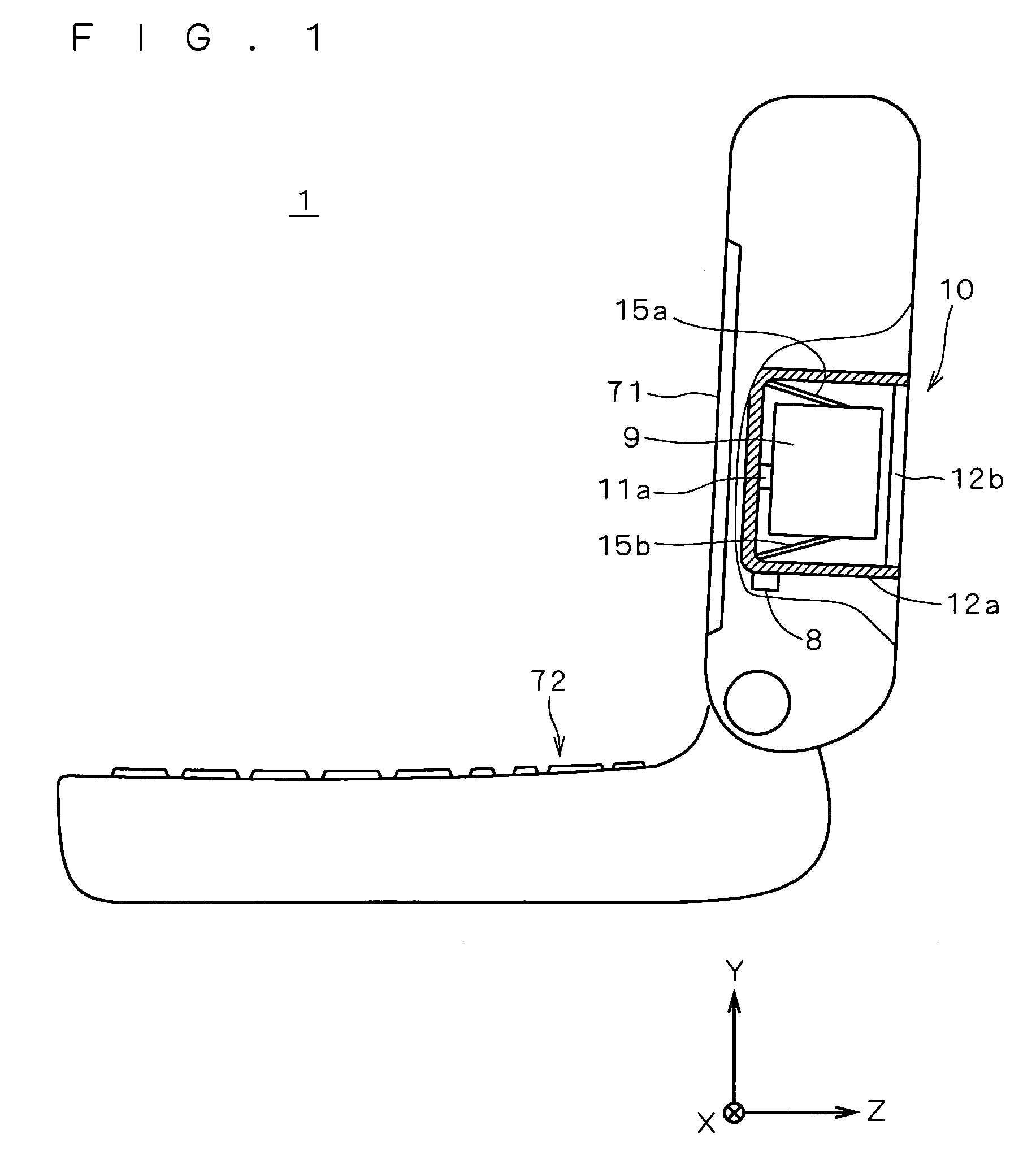

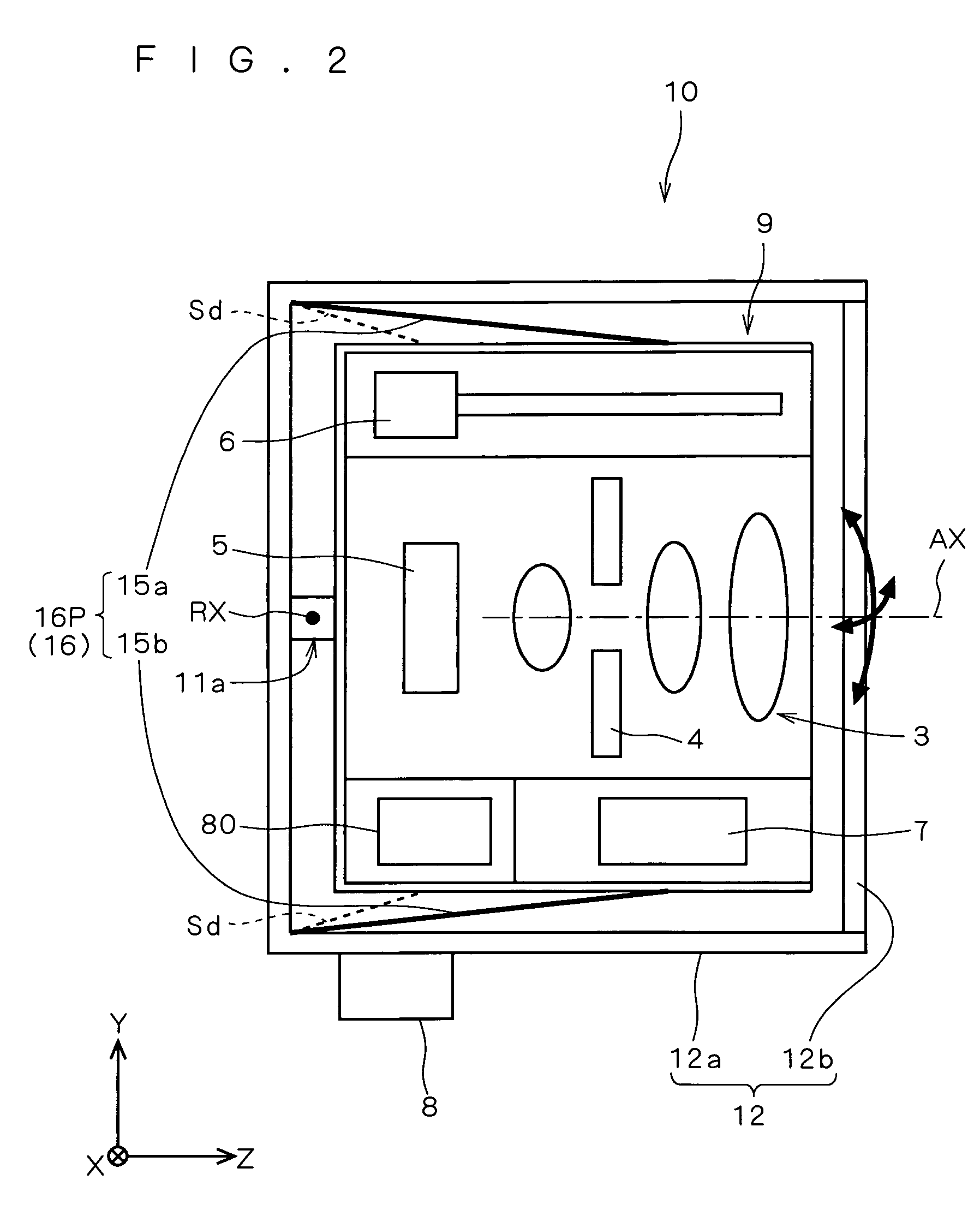

Driving apparatus

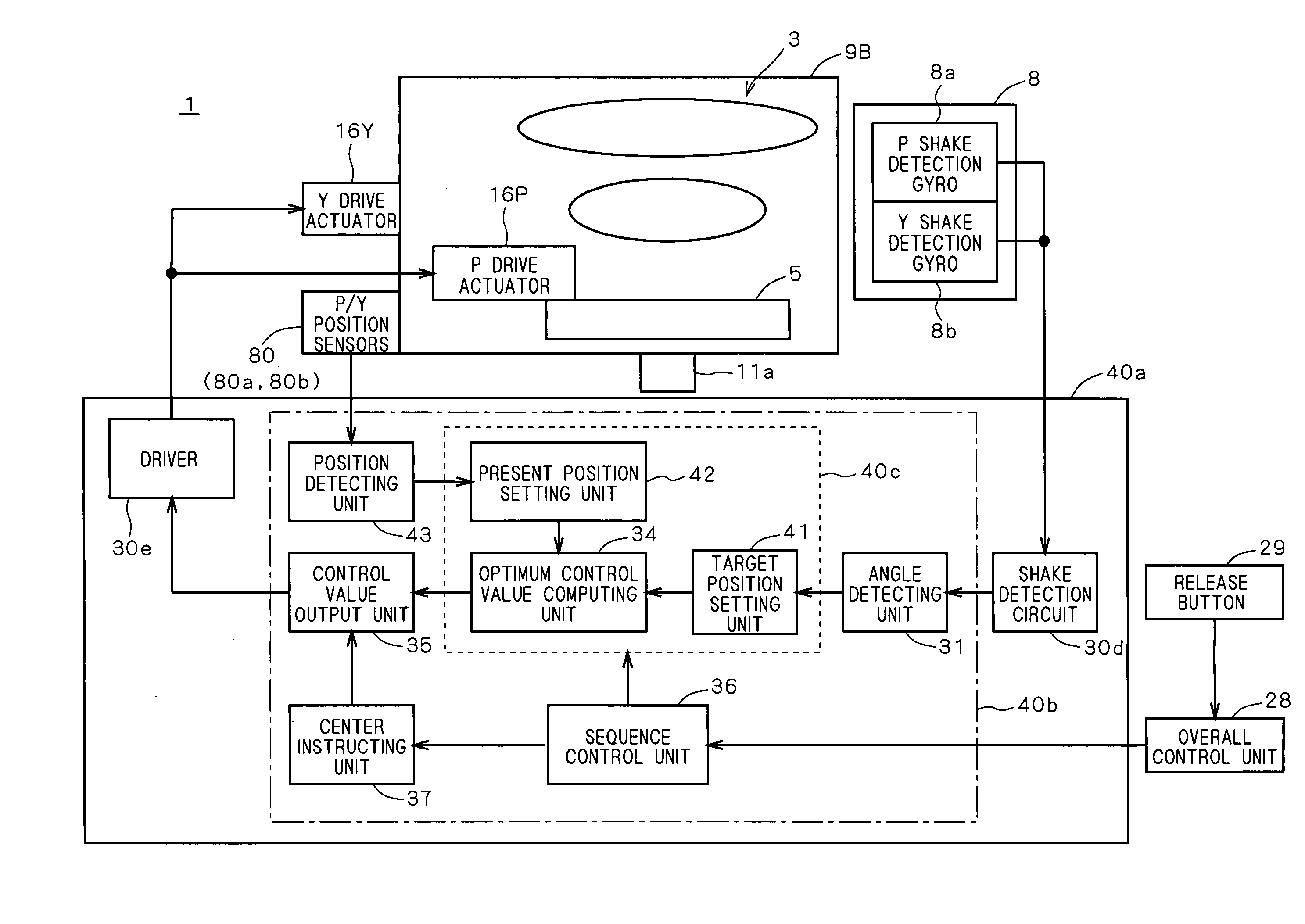

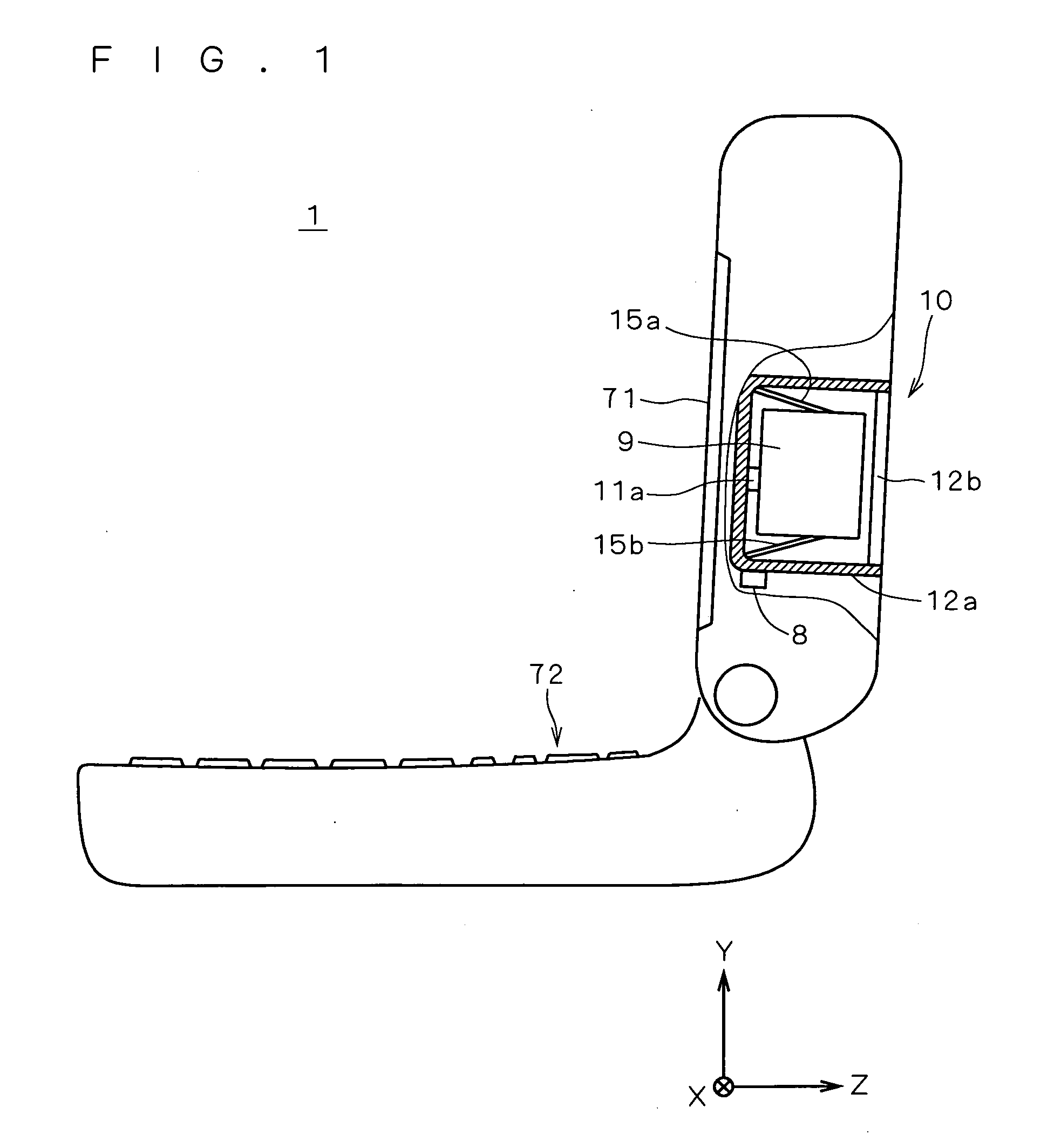

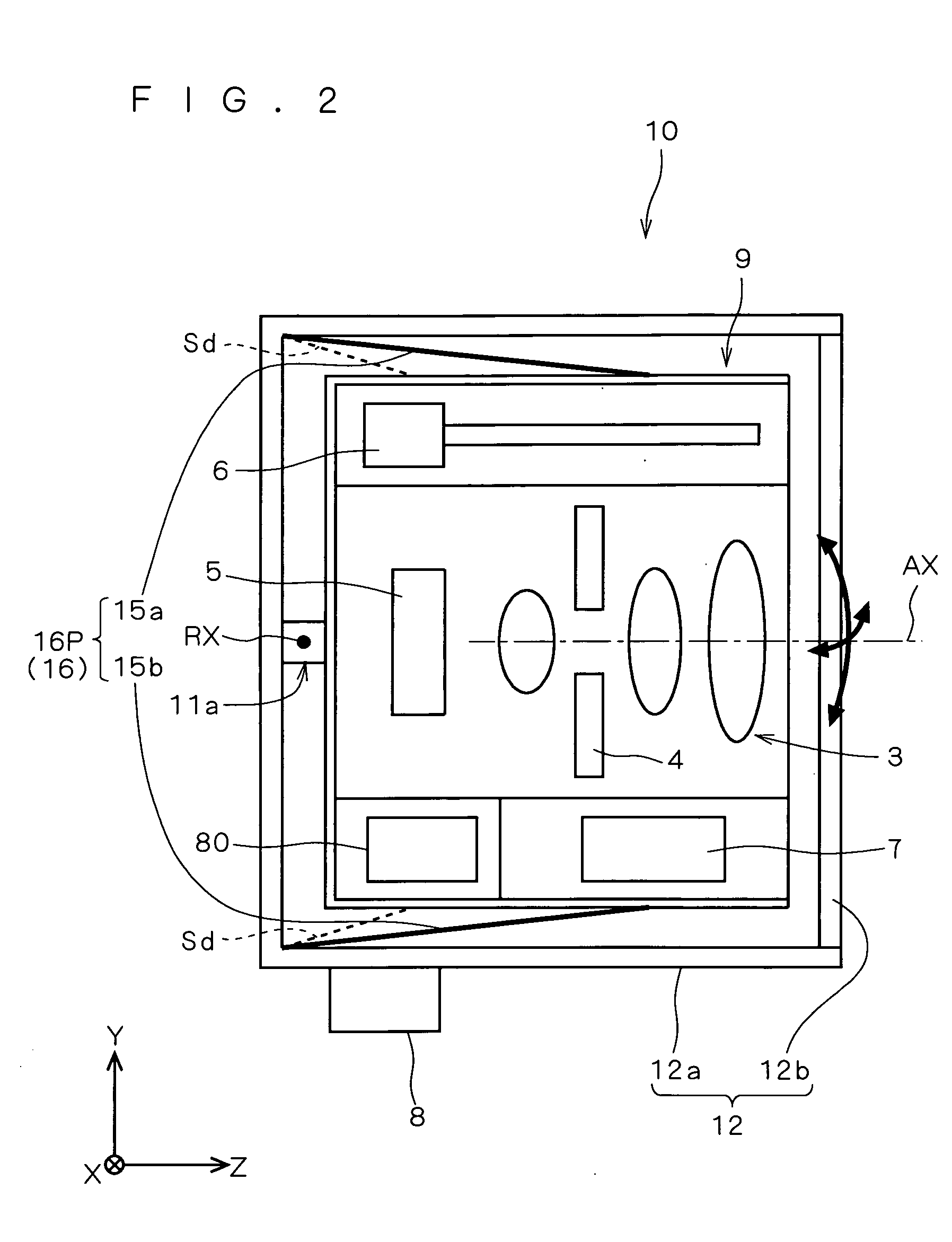

InactiveUS20070109412A1Improve responseImprove cooling effectTelevision system detailsOpticsEllipseImage stabilization

In an auto image stabilization system, a driving member formed as a wire of shape memory alloy (SMA) is retained by a projection of an image capturing unit. A distance Lb from the rotation center of an elastic deforming part to center of gravity (point of application) of the image capturing unit is longer than a distance La from the rotation center of the elastic deforming part to the projection (power point). In the configuration, equivalent mass (apparent mass) of the image capturing unit becomes (Lb / La) times, and it causes deterioration in response. Consequently, the driving member having an ellipse-shaped section in which a value obtained by dividing the width in the longer direction of the section by the width in the shorter direction is 1.3 or larger is employed. As a result, heat dissipation of the driving member increases, so that response in the SMA actuator can be properly improved.

Owner:KONICA MINOLTA INC

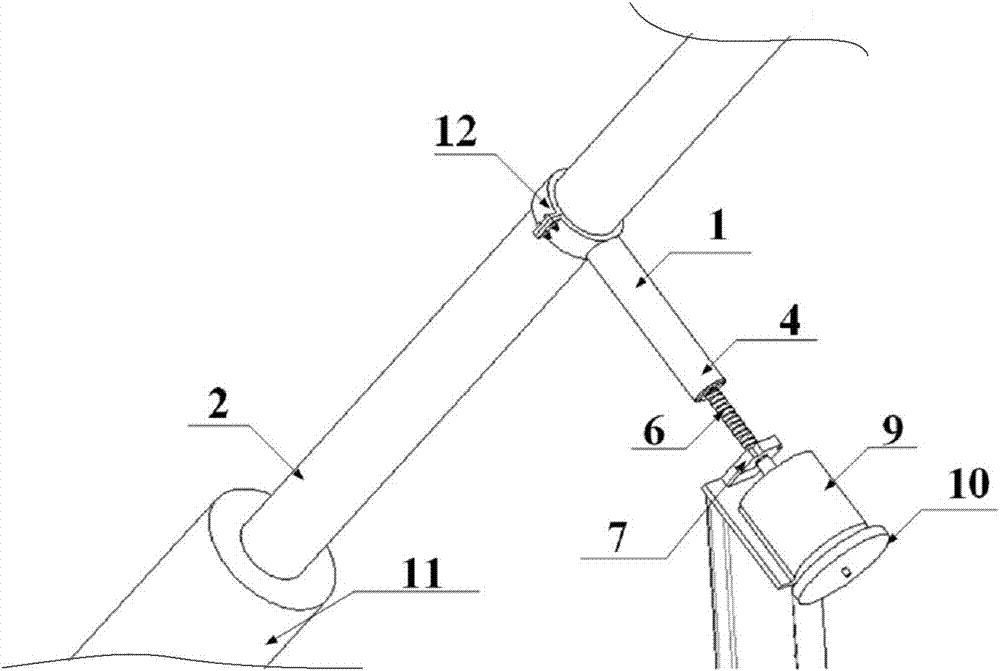

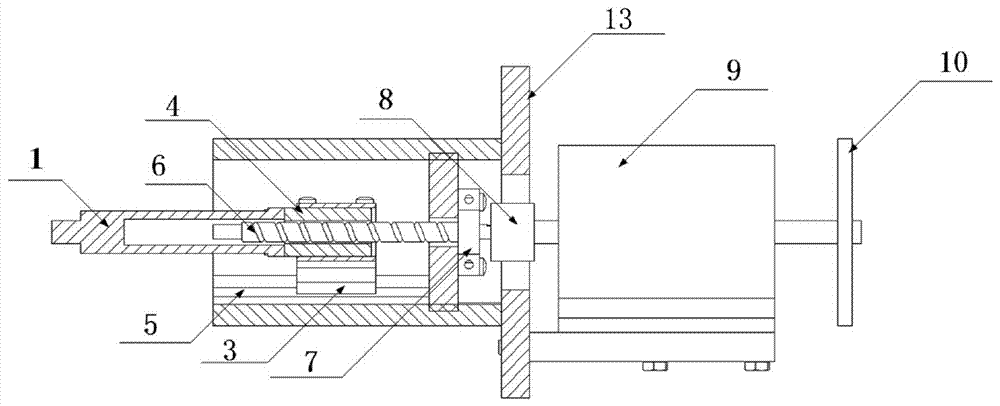

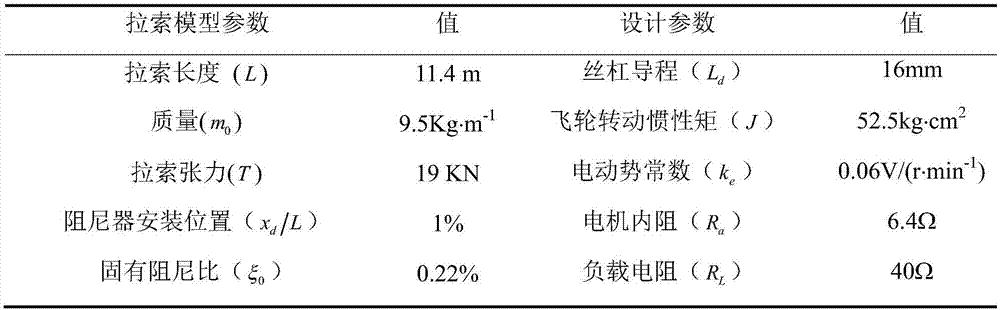

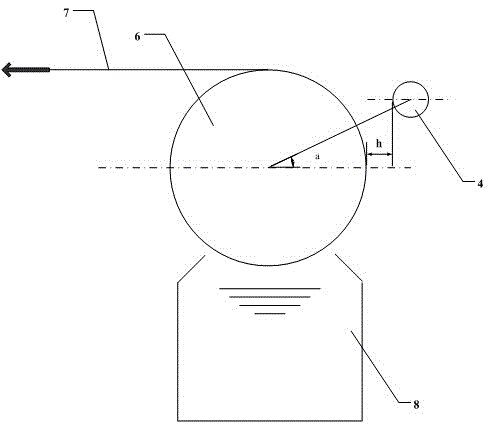

Stayed cable vibration damper and design method for apparent mass rotating electromagnetic damper

ActiveCN107022955AAmplify the speedIncrease the equivalent damping coefficientRotating vibration suppressionFlywheelsDamping factorFundamental frequency

The invention belongs to the technical field of engineering structure control, and in particular relates to a stayed cable vibration damper and a design method for an apparent mass rotating electromagnetic damper. The stayed cable vibration damper comprises a damping device and a transmission mechanism, the transmission mechanism is used for connecting the stayed cable and the damping device, the design method comprises the steps that the fundamental frequency of the stayed cable is determined; the installation location of the apparent mass rotating electromagnetic damper is determined; the damping parameters of the apparent mass rotating electromagnetic damper is calculated; and the stiffness parameters of the apparent mass rotating electromagnetic damper is calculated. According to the stayed cable vibration damper and the design method for the apparent mass rotating electromagnetic damper, a ball screw is utilized to effectively improve the rotational speed of the rotating electromagnetic damper, the equivalent damping coefficient of the damper is improved, and the energy consumption efficiency of the electromagnetic damper is improved; and an inertia flywheel mounted on a rotating shaft of the electromagnetic damper generates an apparent mass effect, the apparent mass effect is amplified through a ball screw mechanism, the stayed cable vibration damping mechanism is provided passive negative stiffness control characteristics, and the vibration damping effect of the stayed cable is effectively improved.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

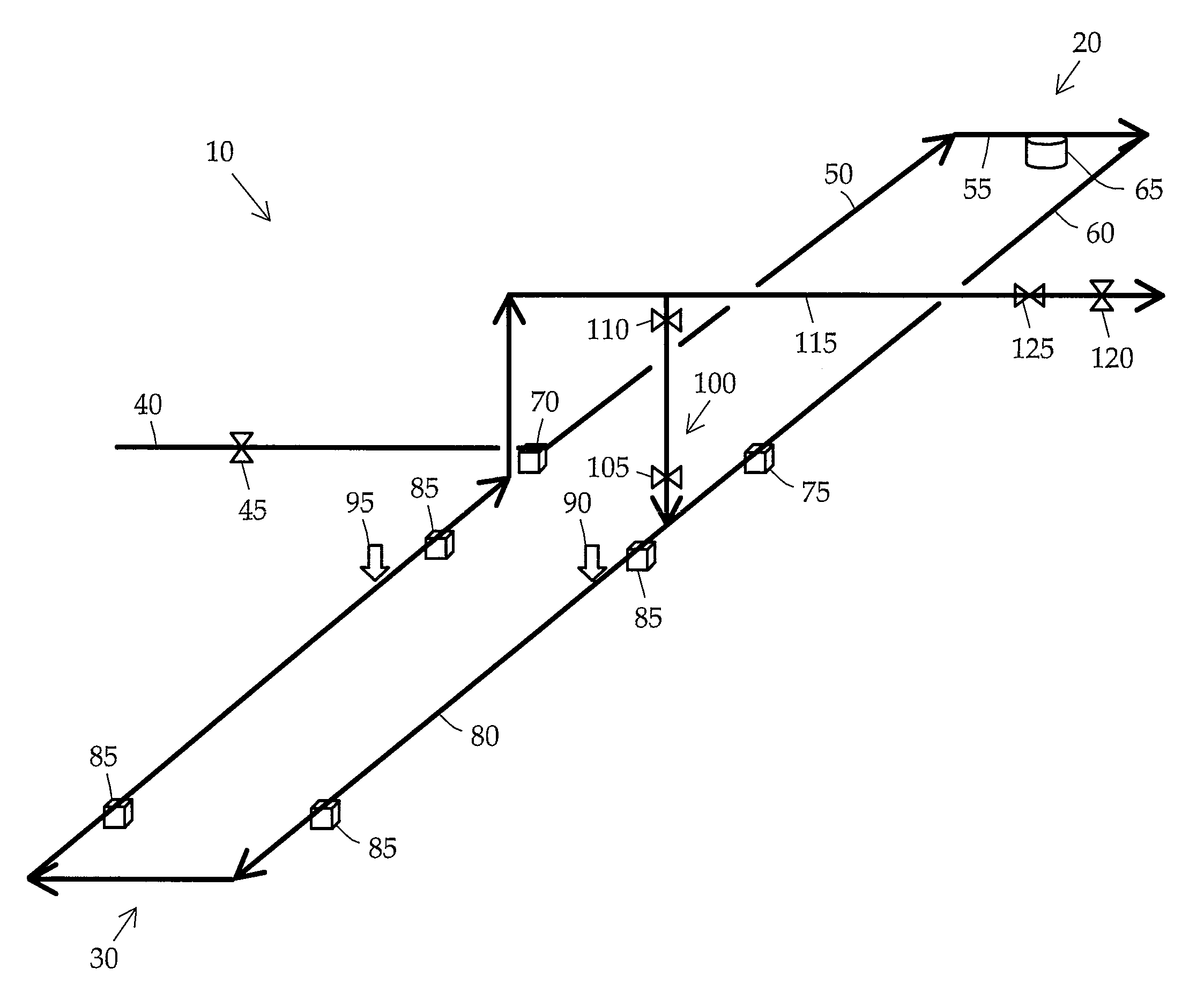

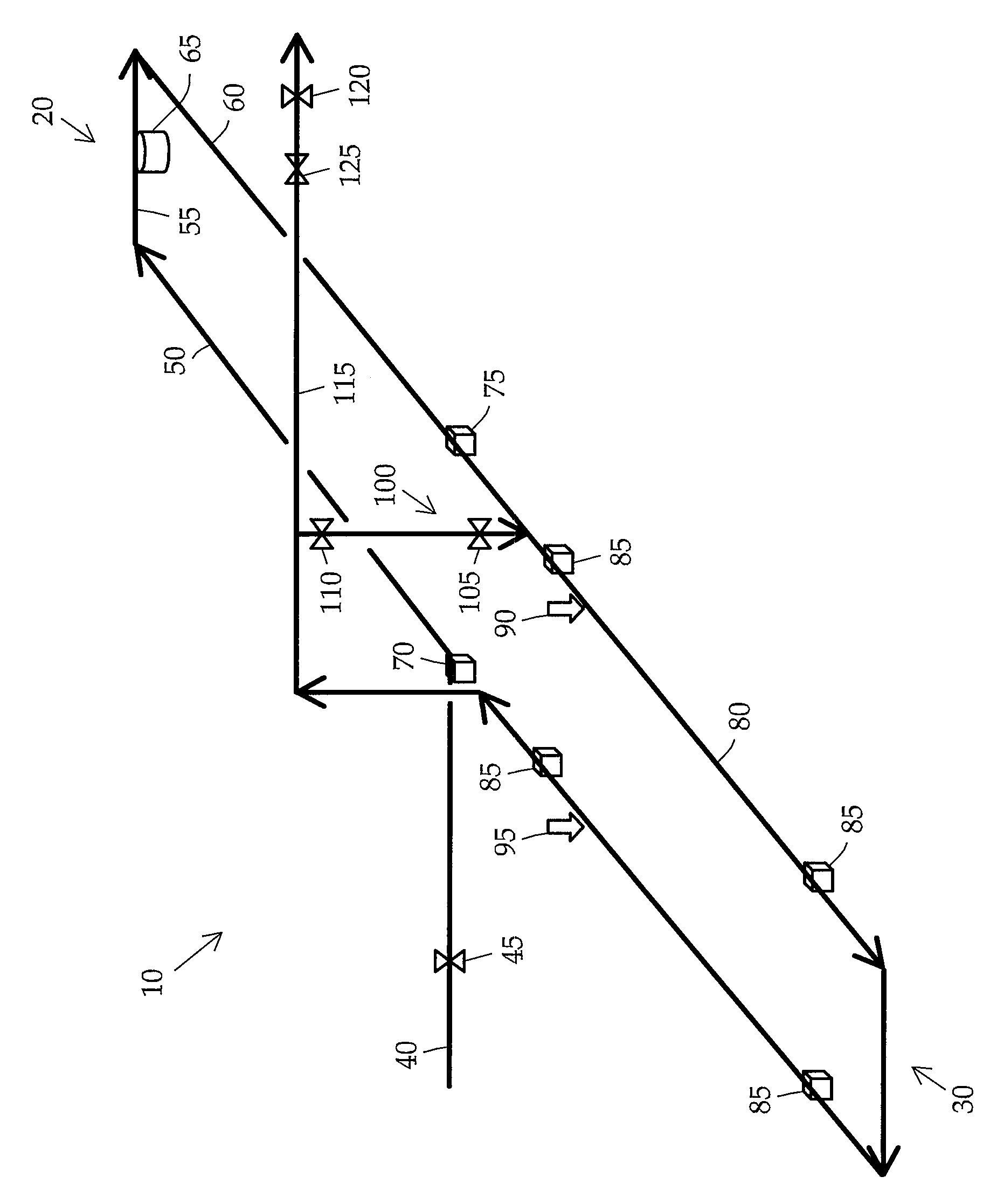

Multiphase mass flow metering system and method using density and volumetric flow rate determination

ActiveUS8915145B1Efficiently determinedShorten speedWeighing apparatus using counterbalanceSurveySupporting systemEngineering

A system and method for calculating the mass flow rate of a fluid stream are presented. The system includes an inlet pipe that receives the fluid stream, a density determination end, a volumetric flow rate determination end, and an outlet pipe. The density determination end may have pipe sections that are connected to each other, a weighing system to determine the apparent mass of the fluid stream, and inlet and outlet supports. The volumetric flow rate determination end of the system may be a piping system, displacer, displacer position sensors and a piping support system designed to determine the average flowing velocity of the fluid stream. The resulting density and volumetric flow rate measurements are multiplied to determine the mass flow rate of the fluid stream. The system and method are applicable to both single- and multi-phase streams and can be used in onshore and offshore applications.

Owner:VAN ORSDOL FRED G

Mass scale alignment of time-of-flight mass spectra

ActiveUS7391017B2Improve comparabilityImprove matchThermometer detailsTime-of-flight spectrometersDesorptionMass analyzer

The invention generates mass scale comparability between mass spectra which are acquired in time-of-flight mass spectrometers, particularly with ionization by matrix-assisted laser desorption. Always slightly distorted mass scales of different mass spectra from the same type of sample can be aligned. The flight times of identical ions always differ slightly from one mass spectrum to the next due to non-reproducible processes in the ionization method. Thus the apparent mass values of ion signals of identical substances in different mass spectra do not match even if the flight times are converted into mass values with the identical calibration equation. After alignment of the mass scales, mass spectra can be reliably compared with respect to deviations in intensities of bio-makers, or be added together without deterioration in the mass resolution, and improved reference spectrum libraries can be created. Furthermore, the invention allows more reliable library searches to be carried out.

Owner:BRUKER DALTONIK GMBH & CO KG

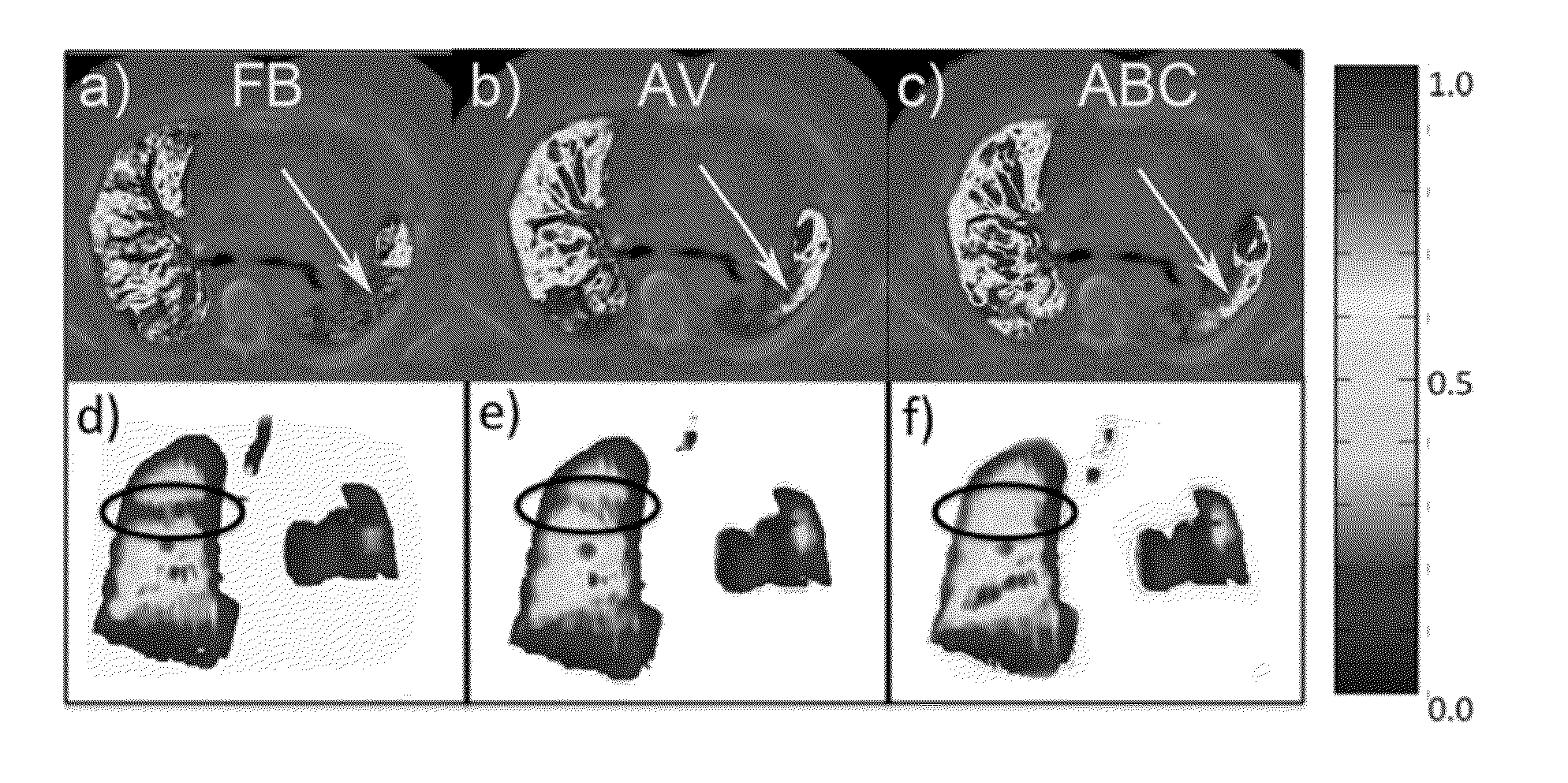

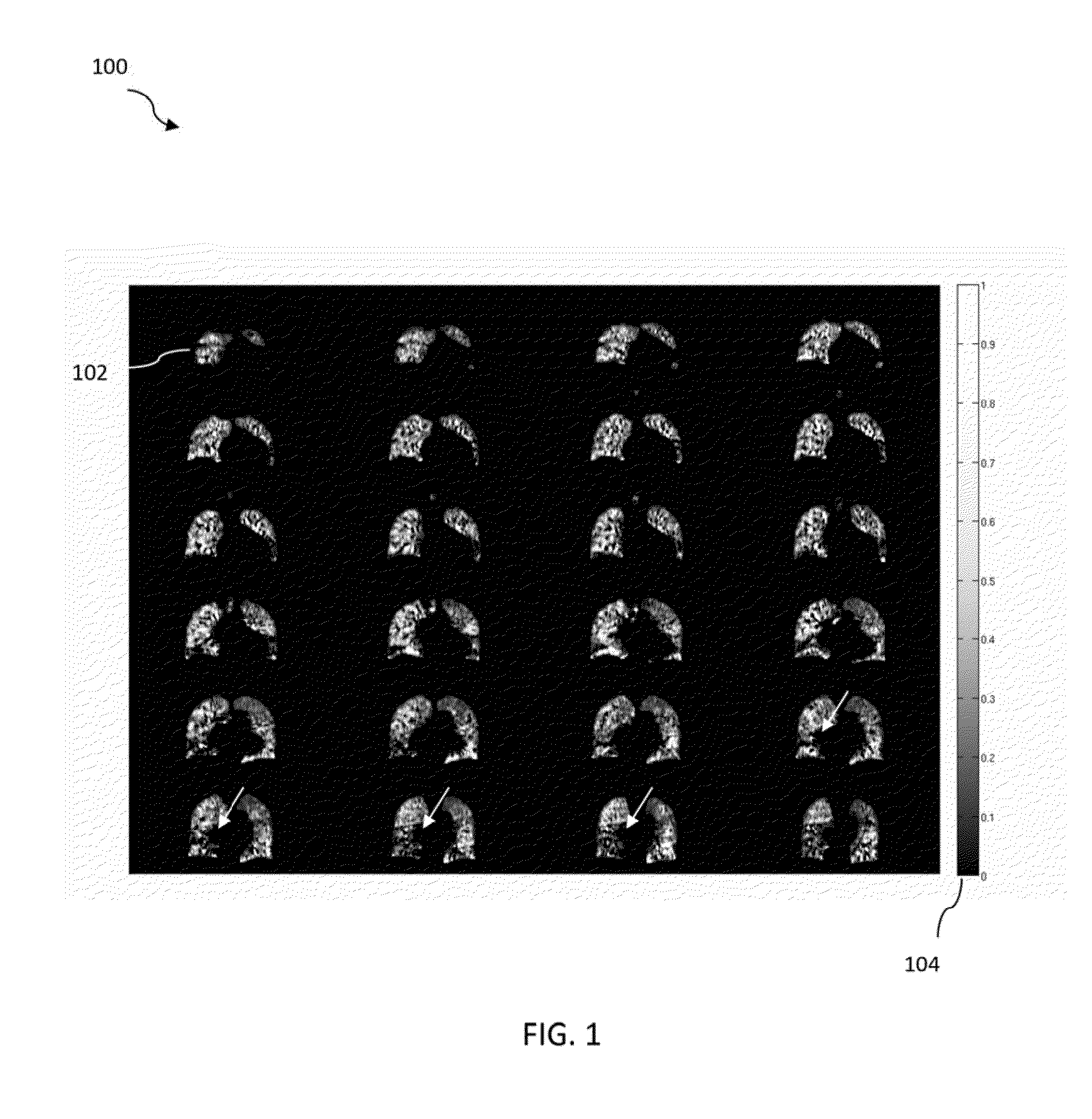

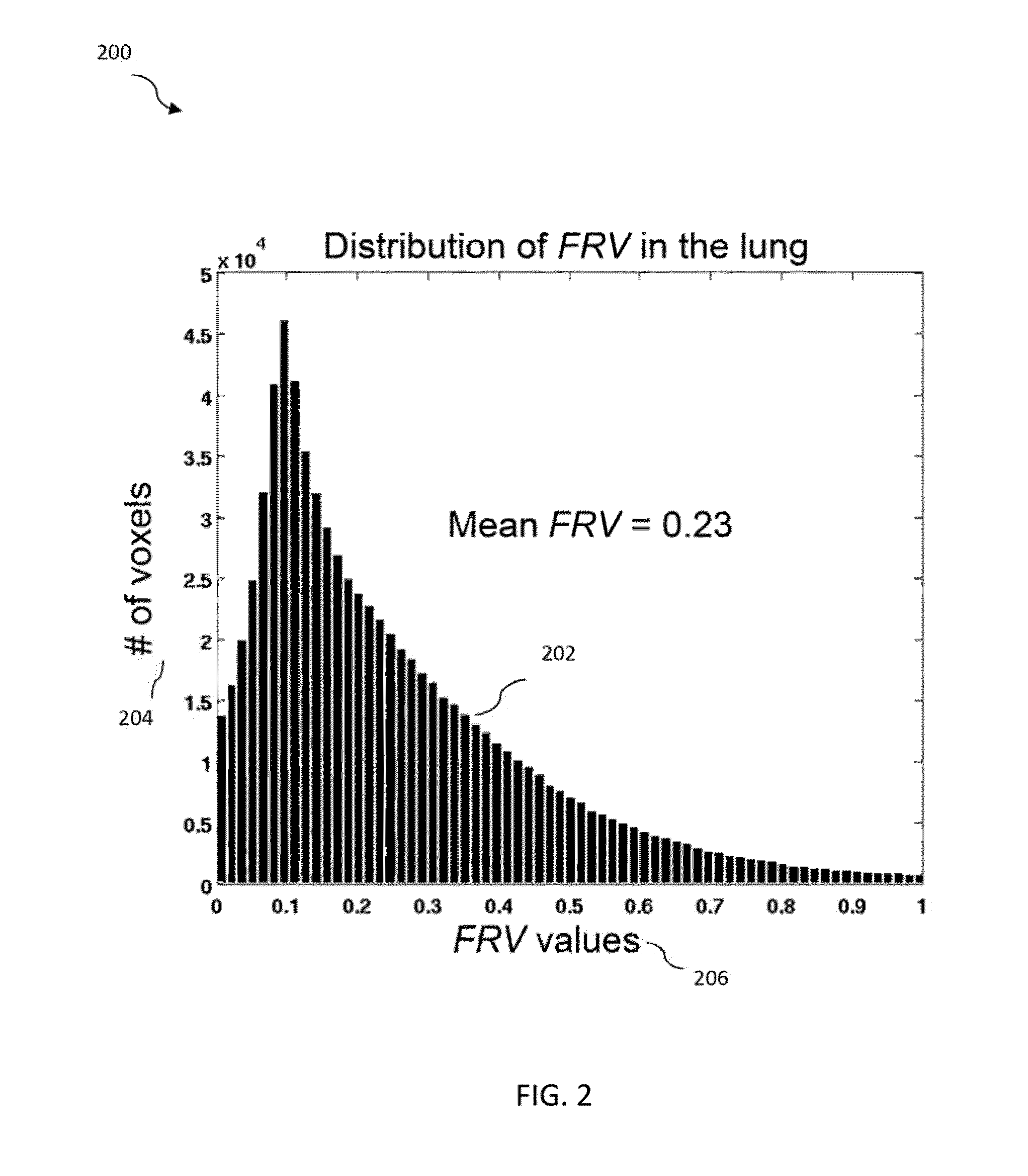

Quantitative evaluation of fractional regional ventilation using four-dimensional computed tomography

InactiveUS20130303899A1Noise minimizationHealth-index calculationDiagnostic recording/measuringVoxelRadiology

Methods and systems for determining fractional regional ventilation are disclosed. A method includes obtaining first and second lung image data indicative of a first phase and a second phase of a respiratory cycle, respectively, determining an apparent mass ratio k based on the first lung image data and the second lung image data, determining first and second spatially matched lung image data, each including N voxels, based on the first lung image data and the second lung image data, and determining at least one fractional regional ventilation value (FRV value), in accordance with a first equation FRV(n)=(k·ρ2_n−ρ1_n) / ρ1_n. The value of n is a voxel index, ρ1_n is indicative of a density of a voxel n of the first spatially matched lung image data, and ρ2_n is indicative of a density of a voxel n of the second spatially matched lung image data.

Owner:UNIV OF MARYLAND

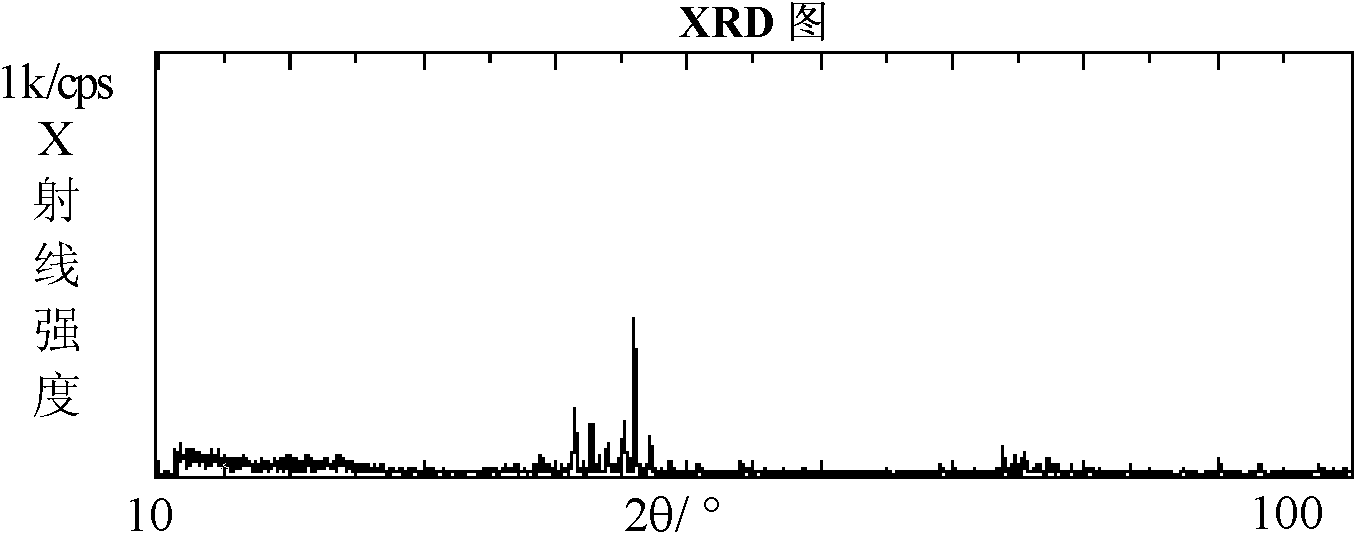

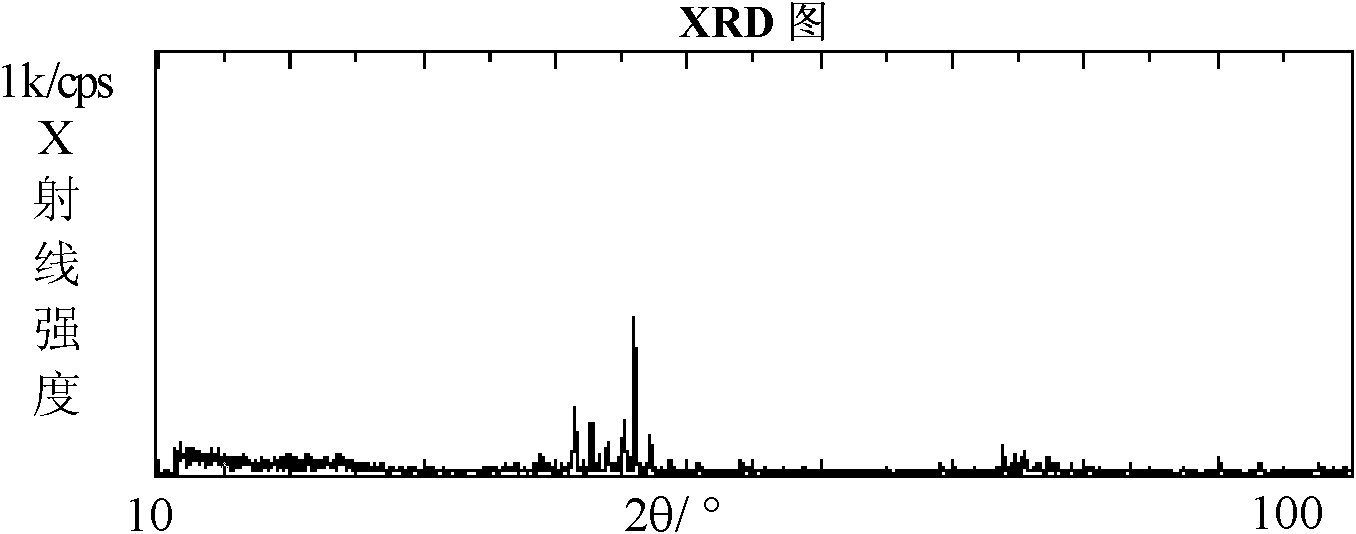

Method for preparing sigma-phase FeV50

The invention belongs to the field of metallurgy and relates to a method for preparing sigma-phase FeV50. The technical problem to the solved of the invention is to provide a method for preparing the sigma-phase FeV50 which has good apparent mass and is easy to break. In the adopted technical scheme, the sigma-phase FeV50 is obtained by uniformly mixing vanadium oxide, aluminum, iron and lime serving as raw materials, feeding the mixture into a furnace and smelting the mixture in an electric arc furnace by an electro-aluminothermic process. The method comprises the following steps of: a, adding excess aluminum into the raw materials while proportioning so as to reduce the vanadium oxide, melting a furnace charge down, depleting slag until vanadium content is low and removing lean slag; and b, adding an appropriate amount of vanadium oxide into alloy liquor from which the slag is removed to remove the excess aluminum, discharging and casting when the temperature and aluminum content ofthe alloy liquor meet requirements and cooling so as to obtain a product, namely, the sigma-phase FeV50. The crush strength of the sigma-phase FeV50 produced by the process is less than 510 MPa and convenience can be brought to vanadium iron manufacturers and customers in the crushing, sampling and using processes of vanadium iron.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Mass scale alignment of time-of-flight mass spectra

ActiveUS20060095212A1Improve matchImprove comparabilityThermometer detailsTime-of-flight spectrometersDesorptionMass analyzer

The invention generates mass scale comparability between mass spectra which are acquired in time-of-flight mass spectrometers, particularly with ionization by matrix-assisted laser desorption. Always slightly distorted mass scales of different mass spectra from the same type of sample can be aligned. The flight times of identical ions always differ slightly from one mass spectrum to the next due to non-reproducible processes in the ionization method. Thus the apparent mass values of ion signals of identical substances in different mass spectra do not match even if the flight times are converted into mass values with the identical calibration equation. After alignment of the mass scales, mass spectra can be reliably compared with respect to deviations in intensities of bio-makers, or be added together without deterioration in the mass resolution, and improved reference spectrum libraries can be created. Furthermore, the invention allows more reliable library searches to be carried out.

Owner:BRUKER DALTONIK GMBH & CO KG

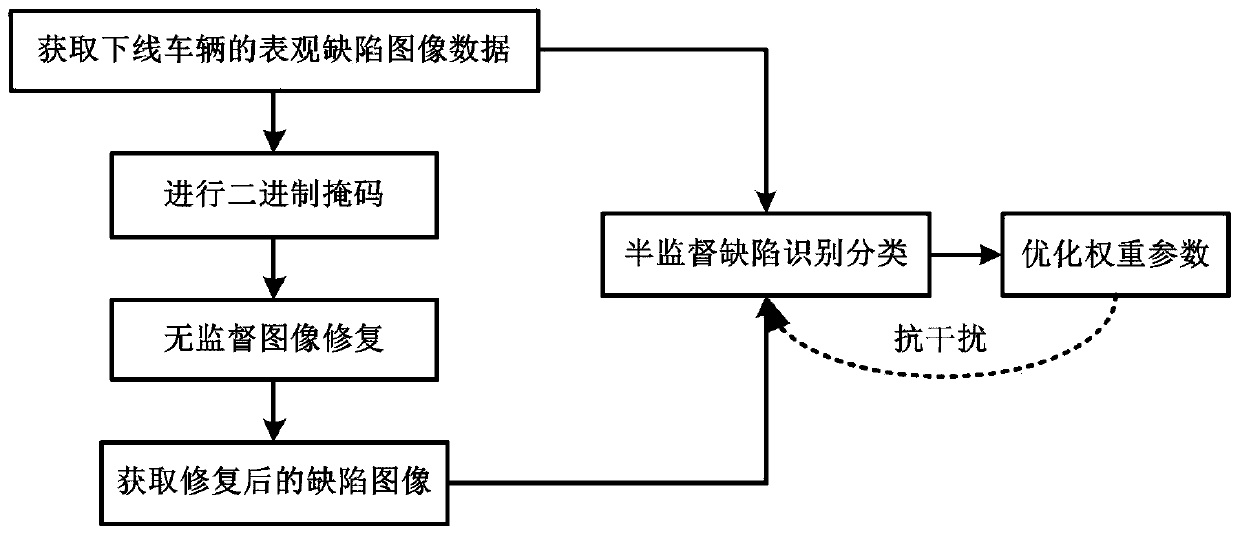

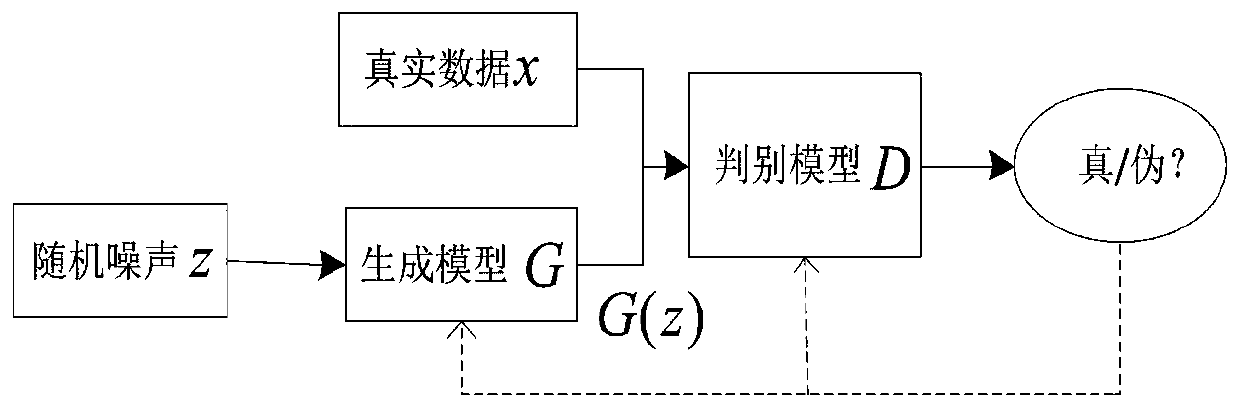

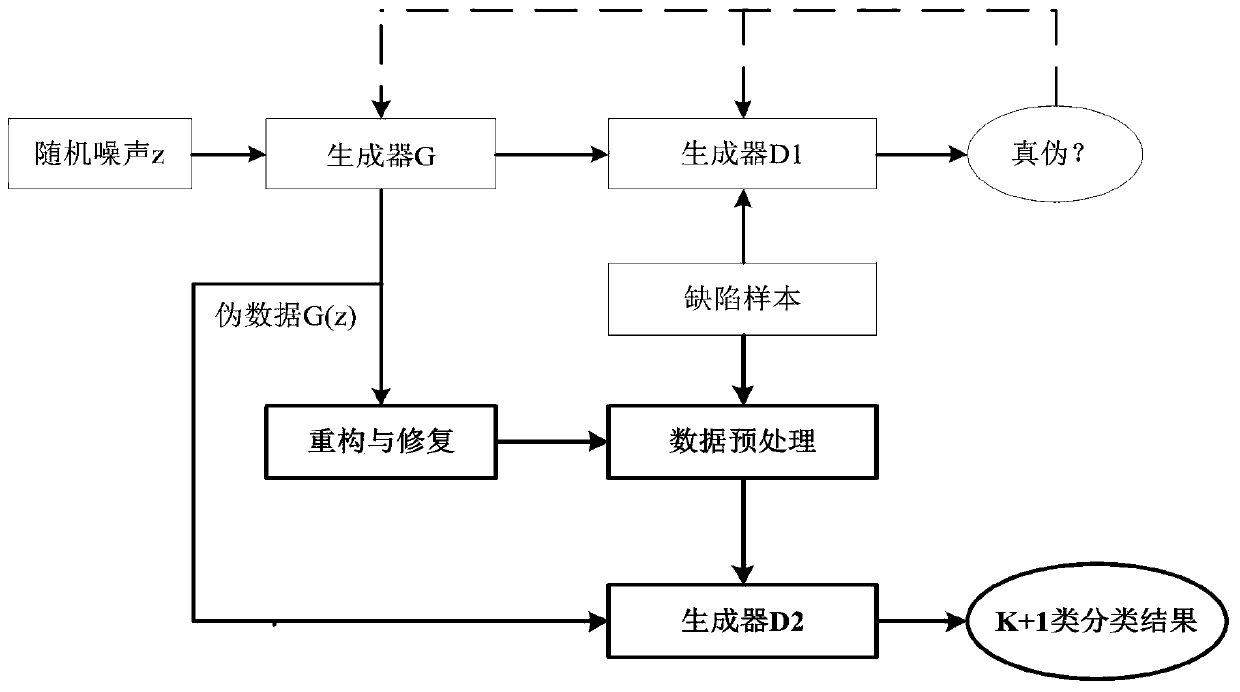

An automobile apparent mass detection method based on a generative adversarial network

ActiveCN109741328AAvoid influenceImage enhancementImage analysisNetwork structureGenerative adversarial network

The invention relates to an automobile apparent quality detection method based on a generative adversarial network. The method comprises the following steps: acquiring apparent defect image data suchas surface pit packages, scratches, geometric dimension gaps and surface differences of offline vehicles; in consideration of the existence of shelters such as mud points, rain points and oil stains on the surface of the actual defect, performing random binary mask equivalent processing on the acquired defect data to complete an image restoration task based on unsupervised learning; the repaired defect data and the unprocessed defect data are used for training the generative adversarial network, and a defect recognition and classification task based on semi-supervised learning is completed; and optimizing the weight parameters in the generative adversarial network training process by using an interval optimization algorithm. The network structure of the generative adversarial network provided by the invention is used for unsupervised authenticity discrimination to assist in completing an image restoration task. And finally, defect shielding object removal can be carried out simultaneously to complete image restoration and automobile apparent defect identification and classification multitask.

Owner:NORTHEASTERN UNIV

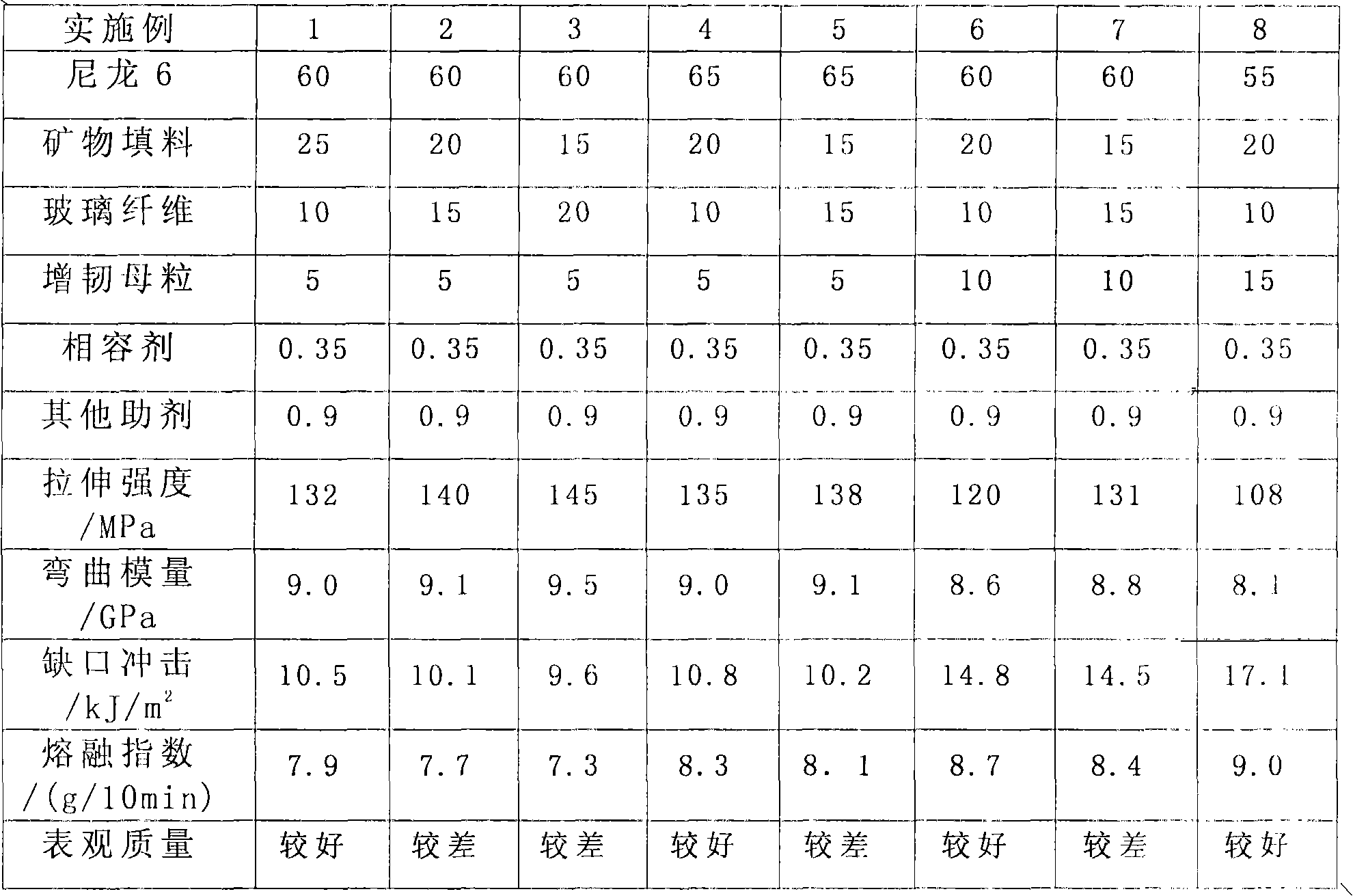

Glass fiber/mineral composite reinforced modified nylon-6 material and preparation method thereof

The invention belongs to the field of reinforced modified nylon-6 composite materials and relates to a glass fiber / mineral composite reinforced modified nylon-6 material suitable for manufacturing an automobile interior trim part. The material comprises the following components in parts by weight: 45-85 parts of nylon-6, 5-30 parts of mineral filler, 5-30 parts of glass fiber, 5-30 parts of toughened master batch, 0.1-5 parts of compatilizer and 0.1-5 parts of other auxiliary agents. In the invention, the glass fibers and the mineral fillers are simultaneously used for filling the modified nylon-6, and the toughened master batches and a series of auxiliary agents are also added, thus the manufactured product not only obviously improves the strength, the rigidity and the thermal property of the material, but also has better apparent mass.

Owner:SUZHOU SUNWAY POLYMER

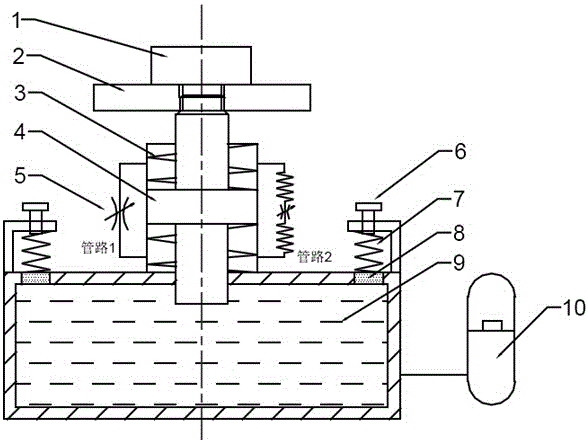

Composite semi-active ultralow-frequency vibration isolating device

InactiveCN105782333ALower natural frequencyAdaptableSpringsVibration suppression adjustmentsSemi activeShape-memory alloy

The invention discloses a composite semi-active ultralow-frequency vibration isolating device. The composite semi-active ultralow-frequency vibration isolating device is mainly composed of a connecting plate, an inerter, hydraulic buffer devices, shape memory alloy springs, movable films, adjusting screws and other components. According to the ultralow-frequency vibration isolating device, the apparent mass of a system is increased through the hydraulic inerter, a quasi-zero stiffness characteristic is provided for the system based on the hydraulic buffer theory, the hydraulic inerter and the quasi-zero stiffness characteristic are organically combined, and therefore the effect of ultralow-frequency vibration isolating is achieved.

Owner:ZHEJIANG UNIV

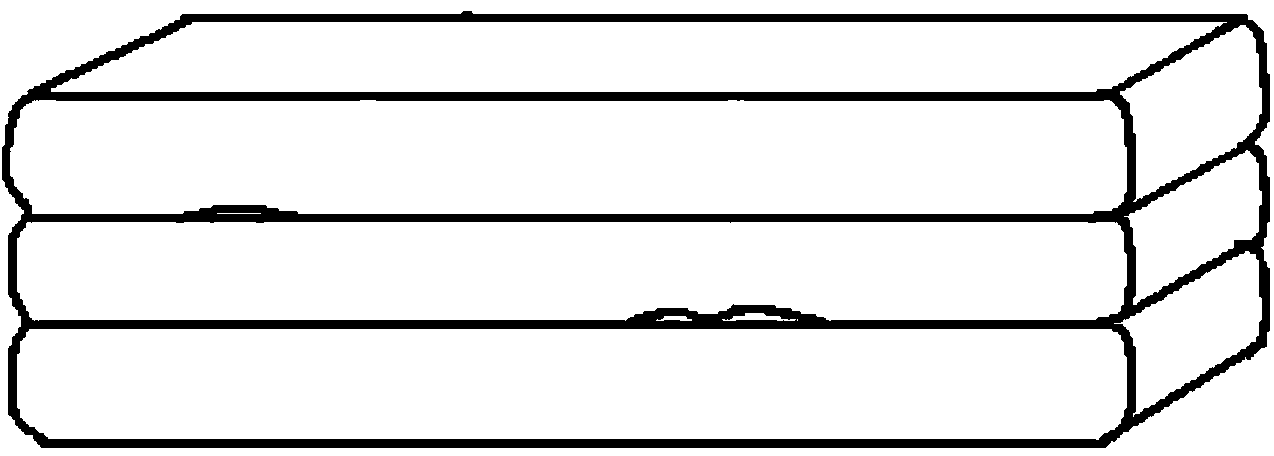

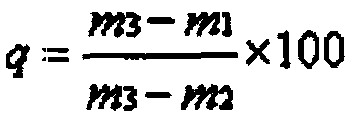

Testing method for cohesion performance of 3D printing building mortar

ActiveCN104297097AMeet performance requirementsWeighing by removing componentPermeability/surface area analysisVoid ratioEngineering

The invention relates to a testing method for cohesion performance of 3D printing building mortar. The method comprises the two steps of preparation of a test specimen and testing of voidage, wherein the testing of voidage comprises the steps of determination of drying quality, dipping of the test specimen, determination of apparent mass of a saturated specimen, quality determination of the saturated specimen, voidage calculation and the like. Compared with the prior art, the method provided by the invention can be used for effectively representing the layer cohesion performance (voidage) of different kinds of printing mortar, i.e., while the voidage is lowered, the compactness is increased, and thus less defects exist between each two adjacent layers. According to the method, the quantitative index to the layer cohesion performance of the 3D printing mortar can be given so as to provide a basis for evaluating the performance of the 3D printing material. By testing the layer cohesion performance of the printing material via the method, the compositions of the material can be blended, so that the requirements on the performance of the printing material in different environments and under different working conditions can be met.

Owner:SHANGHAI LIVABLE BUILDING SCI & TECH CO LTD

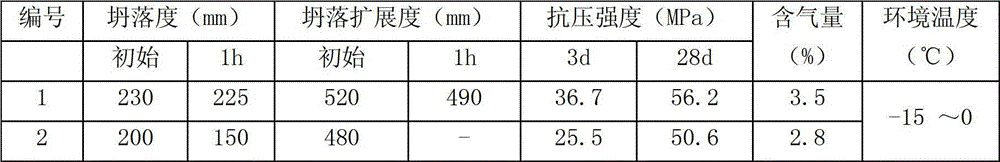

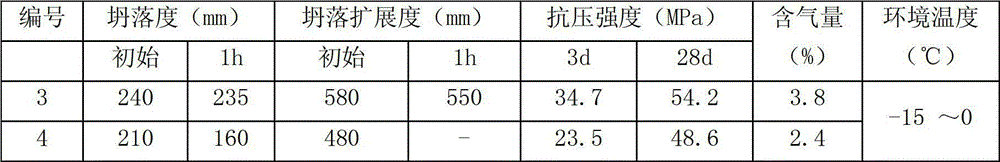

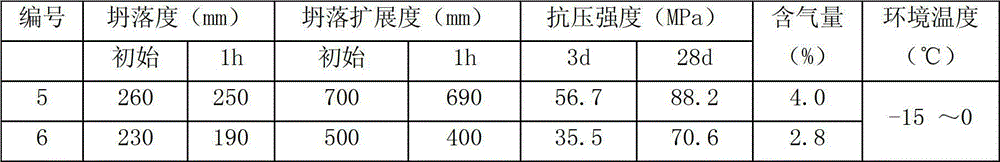

Compound admixture for heat curing-free concrete in winter construction

The invention discloses a compound admixture for heat curing-free concrete in winter construction. The compound admixture consists of the following components in parts by mass: 28-40 percent of high performance superplasticizer, 3-10 percent of early strength admixture, 5-15 percent of antifreezing agent, 3-7 percent of plant fiber intermediate-acting water-reducing agent MPA for retaining plastic and controlling the thickening, 0.02-0.5 percent of defoaming agent, 0.02-0.1 percent of PC-II for bleeding air and the balance of water. The compound admixture disclosed by the invention can be used for concrete with the intensity of C35 and over C35, does not need heat curing during winter construction and has the addition amount of 1-2 percent of that of gel material; and the compound admixture has the advantages of enabling the concrete to have upper flow regime, favorable cohesiveness, favorable water-retaining property, favorable slump loss, early strength under low temperature, good apparent mass of concrete and the like. According to the compound admixture, the initial slump flow is over 500mm, the early strength is obviously increased without influencing the development of later strength, the template cycle is prolonged and the curing cost of the concrete is reduced.

Owner:TIANJIN RES INST OF BUILDING SCI

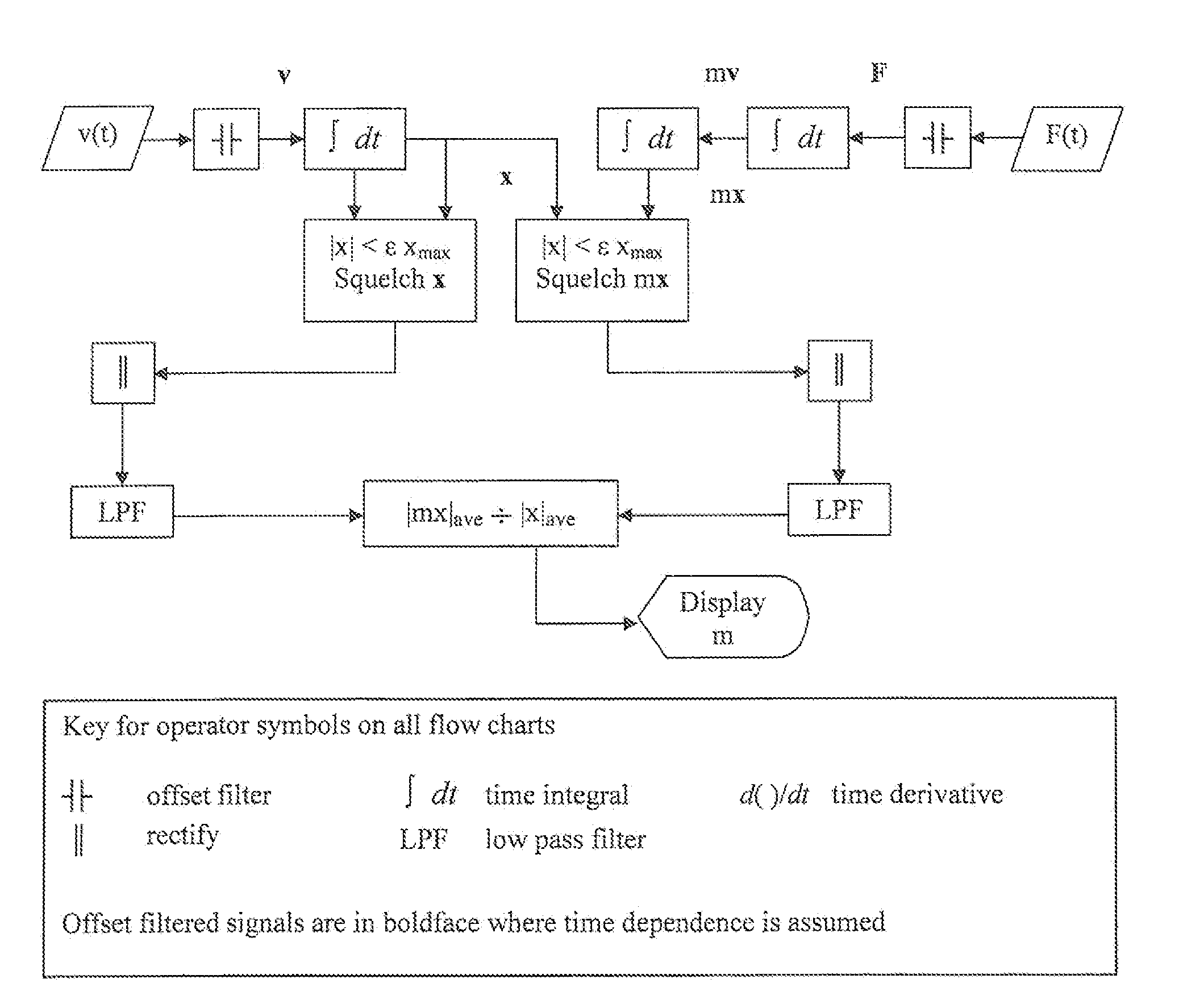

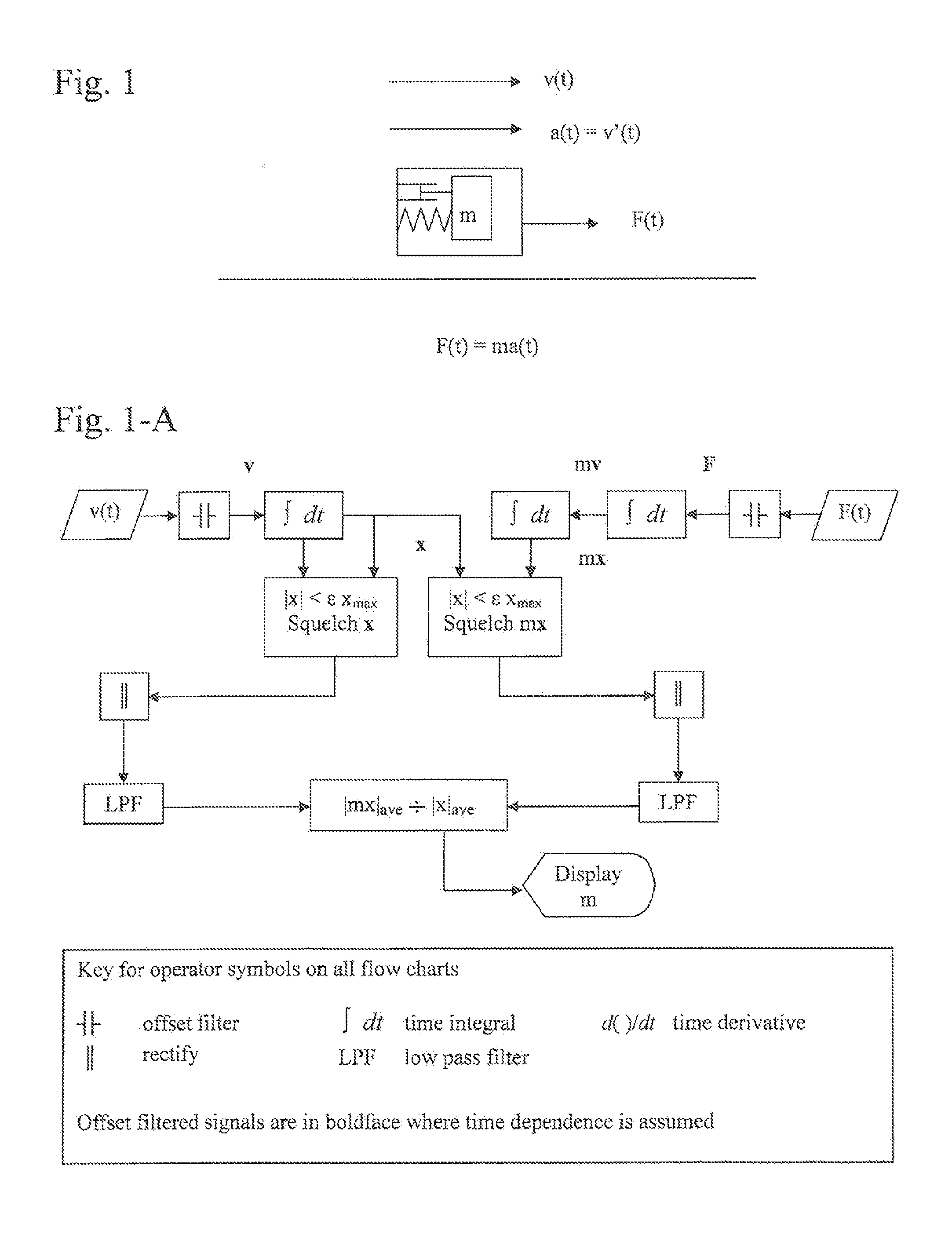

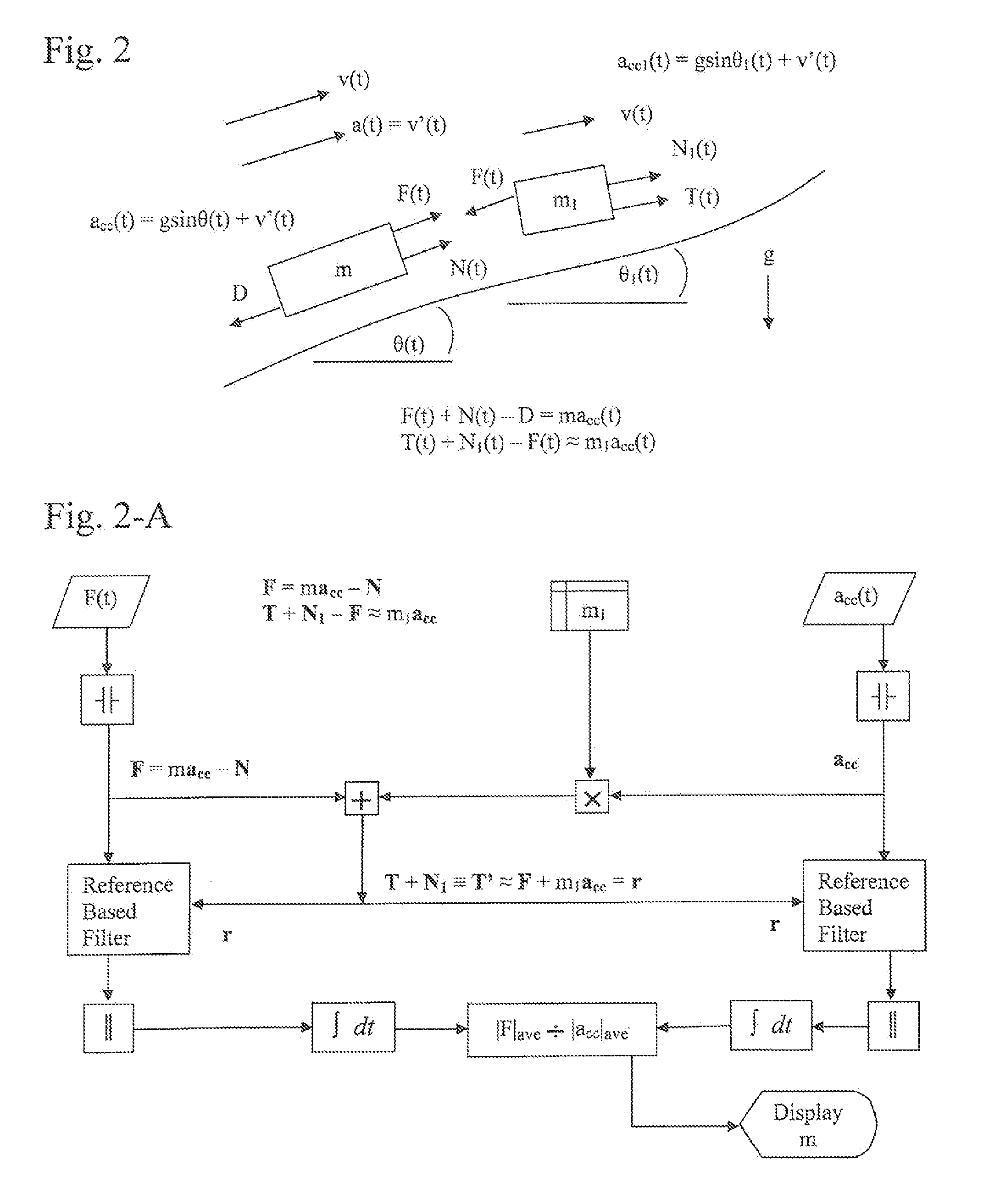

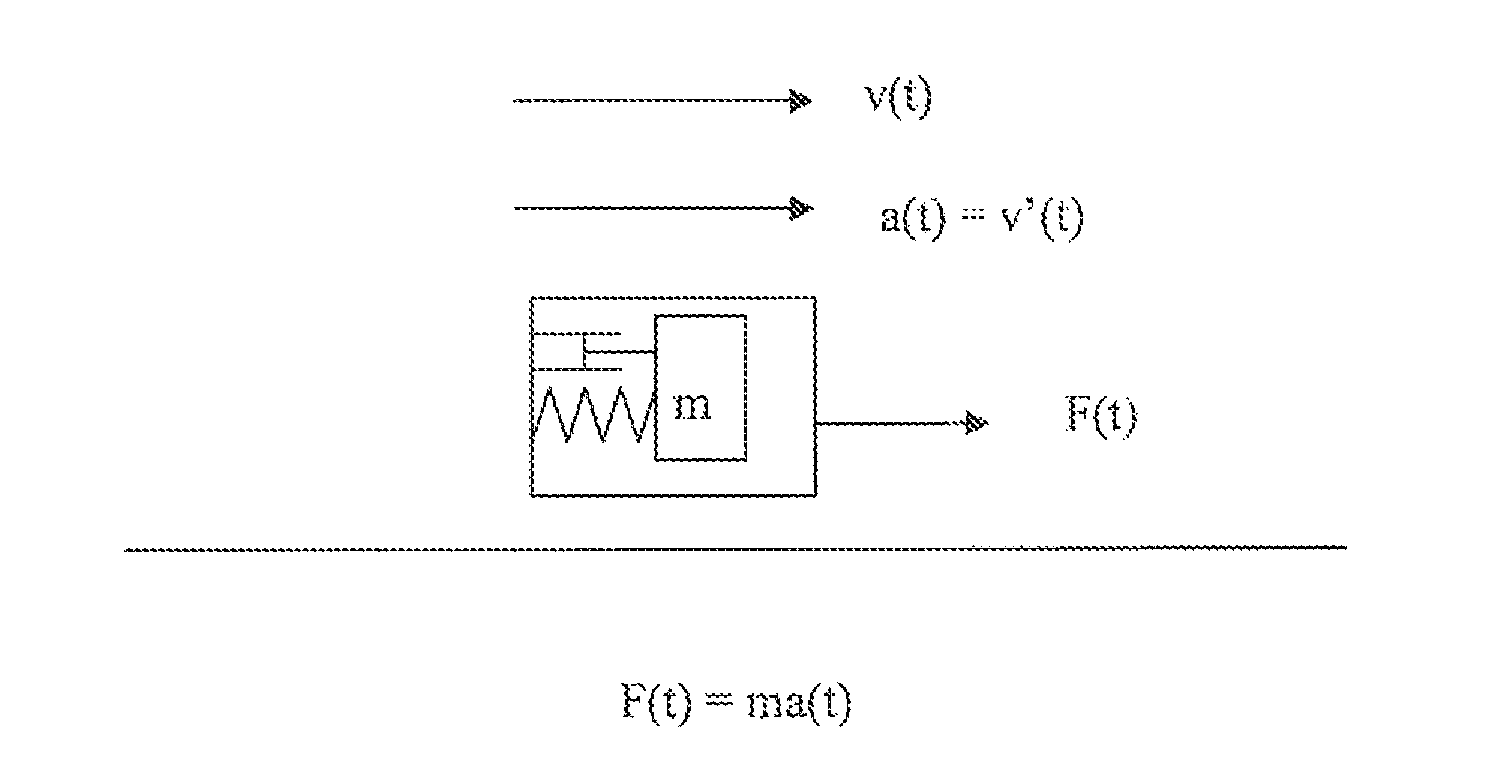

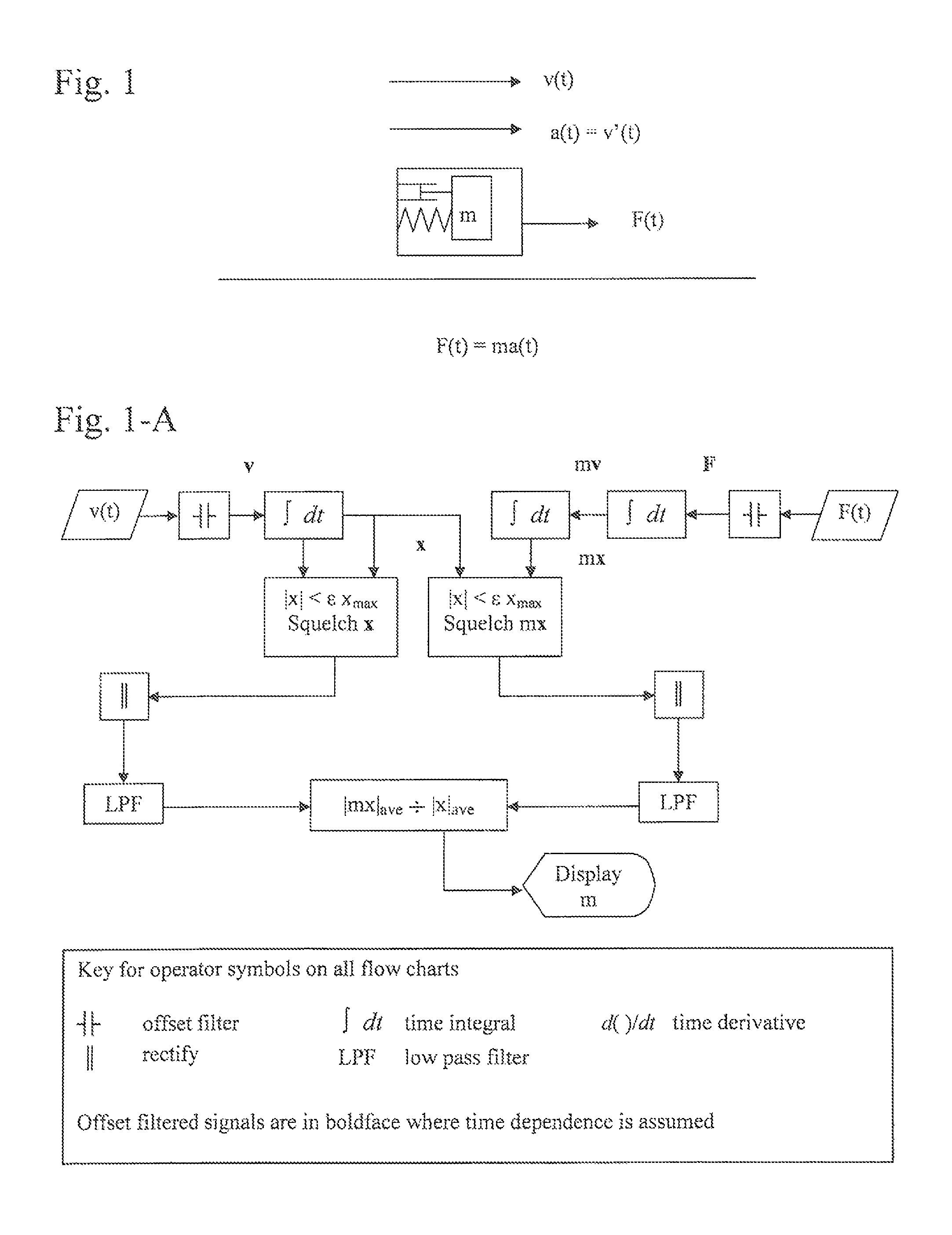

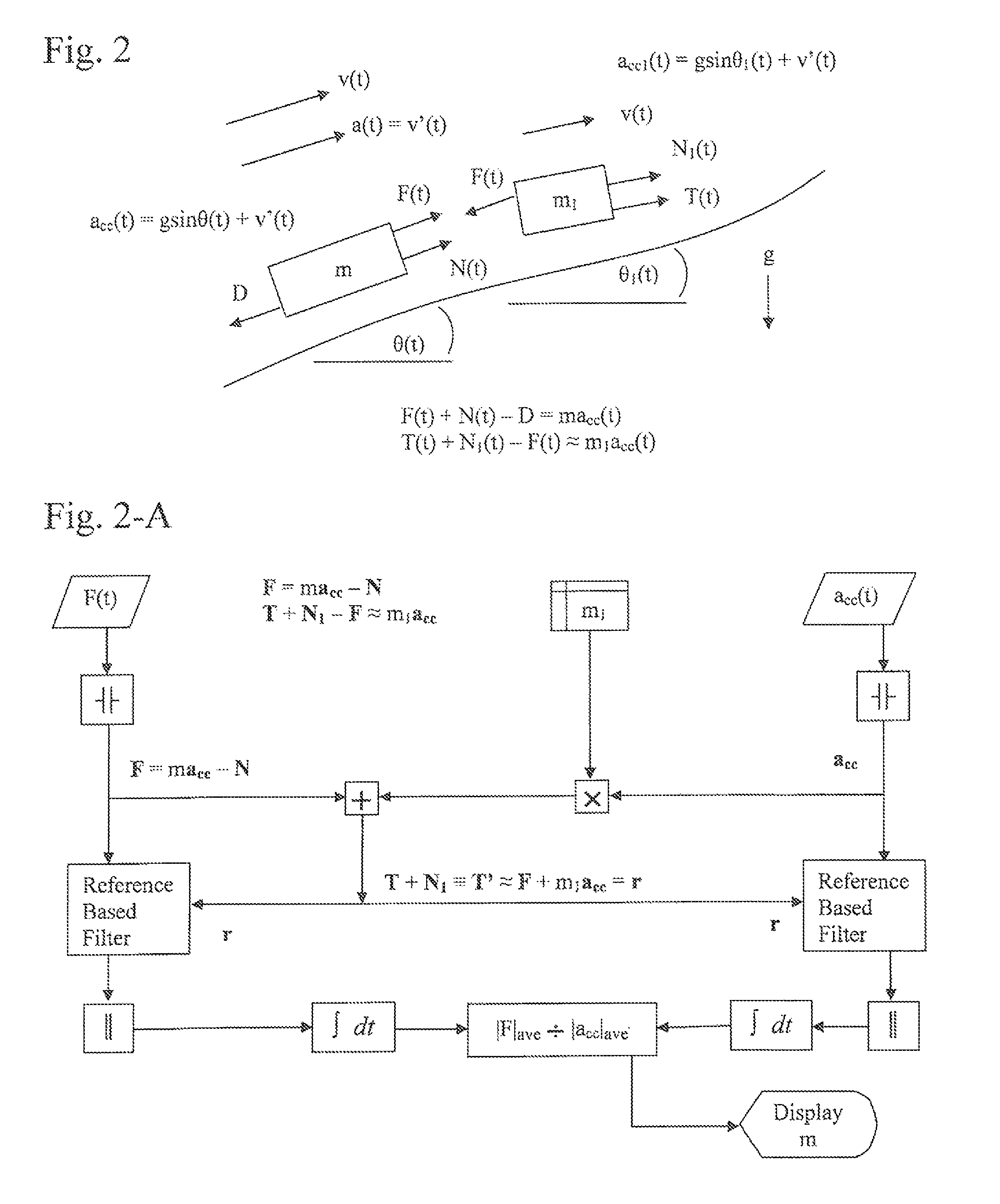

Method for Dynamic Determination of the True Mass of a Non Rigid Body Subject To Low Frequency Noise

A dynamic method to accurately determine the mass of a vehicle which deforms on acceleration and is subject to low frequency noise is disclosed. Only the greater than zero hertz frequencies of the signals are processed. Both signals are squelched during periods of high jerk to reduce the error between true mass and apparent mass. For a single body or combination vehicle such as a semi-rig with a propulsive body of known mass a reference for matched or Wiener filtering is constructed from the noisy signals to filter low frequency noise. A towing vehicle with a fifth wheel mounted on a dedicated load sensing apparatus can, therefore, determine the weight of any semi-trailer towed on any terrain of any inclination and any changing inclination with the greatest precision in the shortest possible time.

Owner:CAHILL BRET E

Driving apparatus

InactiveUS7640741B2Improve responseImprove cooling effectTelevision system detailsOpticsEllipseAlloy

Owner:KONICA MINOLTA INC

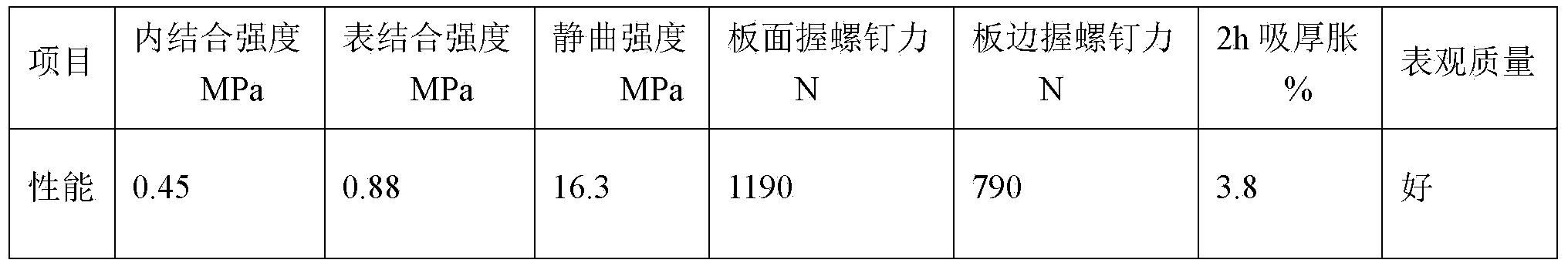

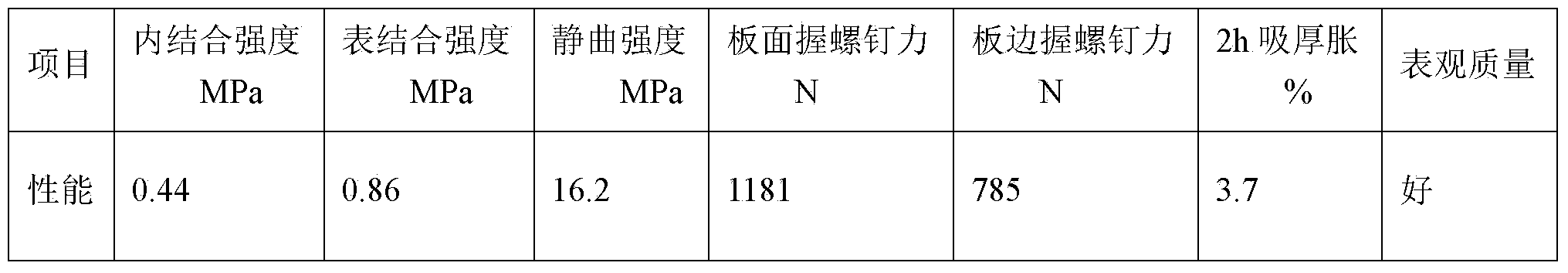

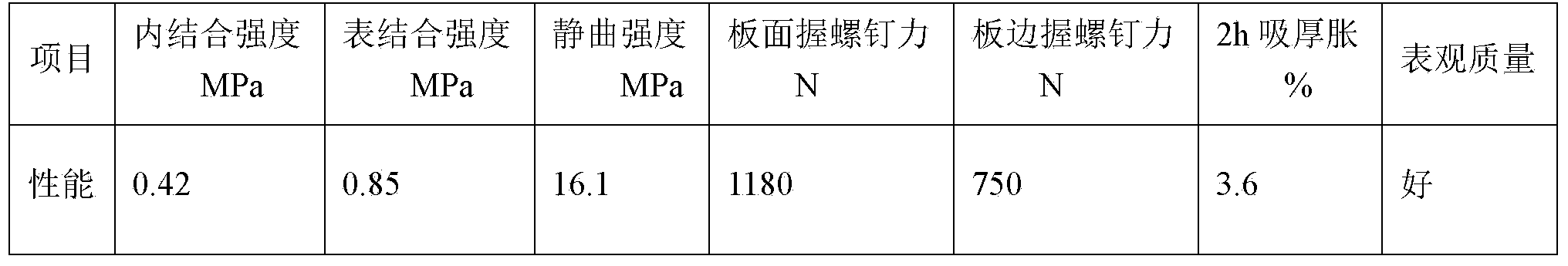

Crop straw manmade board and production method thereof

InactiveCN104385424AHigh yieldReduce energy consumptionDomestic articlesFlat articlesFiberEngineering

The invention discloses a crop straw manmade board and a production method thereof. The production method comprises the steps of (1) cutting straws of which the moisture content is 20%-30% into straw sections of which the length is 10-100 mm; (2) uniformly drying the straw sections by adopting drying equipment, and enabling the moisture content of the straw sections to be reduced to 3%-20%; then removing sundries in the straw sections; (3) pulverizing the straw sections by adopting a pulverizer; (4) screening pulverized fiber into coarse materials and fine materials by adopting screening equipment; (5) taking the coarse materials as raw materials of a core layer and the fine materials as the raw materials of a surface layer, sequentially carrying out sizing, mat formation, pre-pressing, hot pressing and post-processing, and obtaining the crop straw manmade board. According to the crop straw manmade board and the production method, disclosed by the invention, the straws are cut into the straw sections, and feeding, drying and pulverizing are easy; the energy consumption of the pulverizer can be reduced due to dry and clean straw sections, and the production efficiency is substantially increased; meanwhile, the fault rate of the pulverizer is greatly reduced, and continuous and stable production is ensured; the straw yield is increased, the shapes of wood shavings are uniform, and the apparent mass and the physical and chemical performance of a straw board are ensured.

Owner:万华生态科技(烟台)有限公司 +1

White laser labeled glass fiber reinforced nylon 6 composite material and preparation method thereof

ActiveCN101633776AChange the stacking methodImprove durabilityAblative recordingGlass fiberPlastic injection molding

The invention discloses a white laser labeled glass fiber reinforced nylon 6 composite material and a preparation method thereof. The composite material comprises the following components in percentage by weight: 50 to 88 percent of nylon 6 resin, 10 to 45 percent of glass fiber, 0.5 to 10 percent of color development filler, and 0.5 to 5 percent of other additives. The method comprises the following steps: weighing various materials except the glass fiber; mixing the materials in a material mixer for 3 to 5 minutes; adding the evenly mixed material into a double screw extruder, wherein the glass fiber is added from the first air outlet, the temperatures from a feed inlet to an extrusion die head are between 160 and 180 DEG C, between 190 and 220 DEG C, between 210 and 240 DEG C, between 220 and 250 DEG C, and between 210 and 240 DEG C respectively, and the rotating speed of a host machine is between 20 and 50 hertz; and then using a plastic injection molding machine to prepare samples. The composite material has the advantages of good apparent mass, obvious white laser labels, abrasion resistance, durability and easy processing.

Owner:CHONGQNG PRET NEW MATERIAL +2

Method for dynamic determination of the true mass of a non rigid body subject to low frequency noise

Owner:CAHILL BRET E

Method for improving quality of continuous casting hollow bloom by applying composite alternating electromagnetic field and device

InactiveCN101298094AImprove appearance qualityImprove circumferential uniformityAlloyElectromagnetic field

The invention discloses a method and a device for improving the quality of continuously cast hollow billets by imposing a compound alternating electromagnetic field, which pertains to the technical field of the preparation of metal materials. The method and the device of the invention are that the outside of a slotted outer crystallizer is provided with electromagnetic coils with medium frequency and high frequency and the liquid surface is kept parallel to the central plane of the coins, with an error not exceeding plus or minus 5mm; meanwhile, a convex magnetic field generator with low and medium frequency is arranged in the cooling water sheath inside an inner crystallizer, which is adjacent to a initially solidified shell. The method and the device of the invention have the advantages that: (1) the surface vibration mark caused by the vibration of crystallizers is settled and the segregation tumors, cracks and other defects on the inner and outer surface of the hollow billets are eliminated, thus having good apparent mass; (2) the solidification structure has good homogenization and fine crystal grain and can be directly rolled in a as-cast state; (3) the placement of the convex magnetic field generator in the inner crystallizer simplifies the design of the magnetic field generator and saves the space of industrialized operations, which is especially beneficial to the production of the large-caliber hollow billets. The method of the invention is applicable to the production of various alloy hollow billets.

Owner:DALIAN UNIV OF TECH

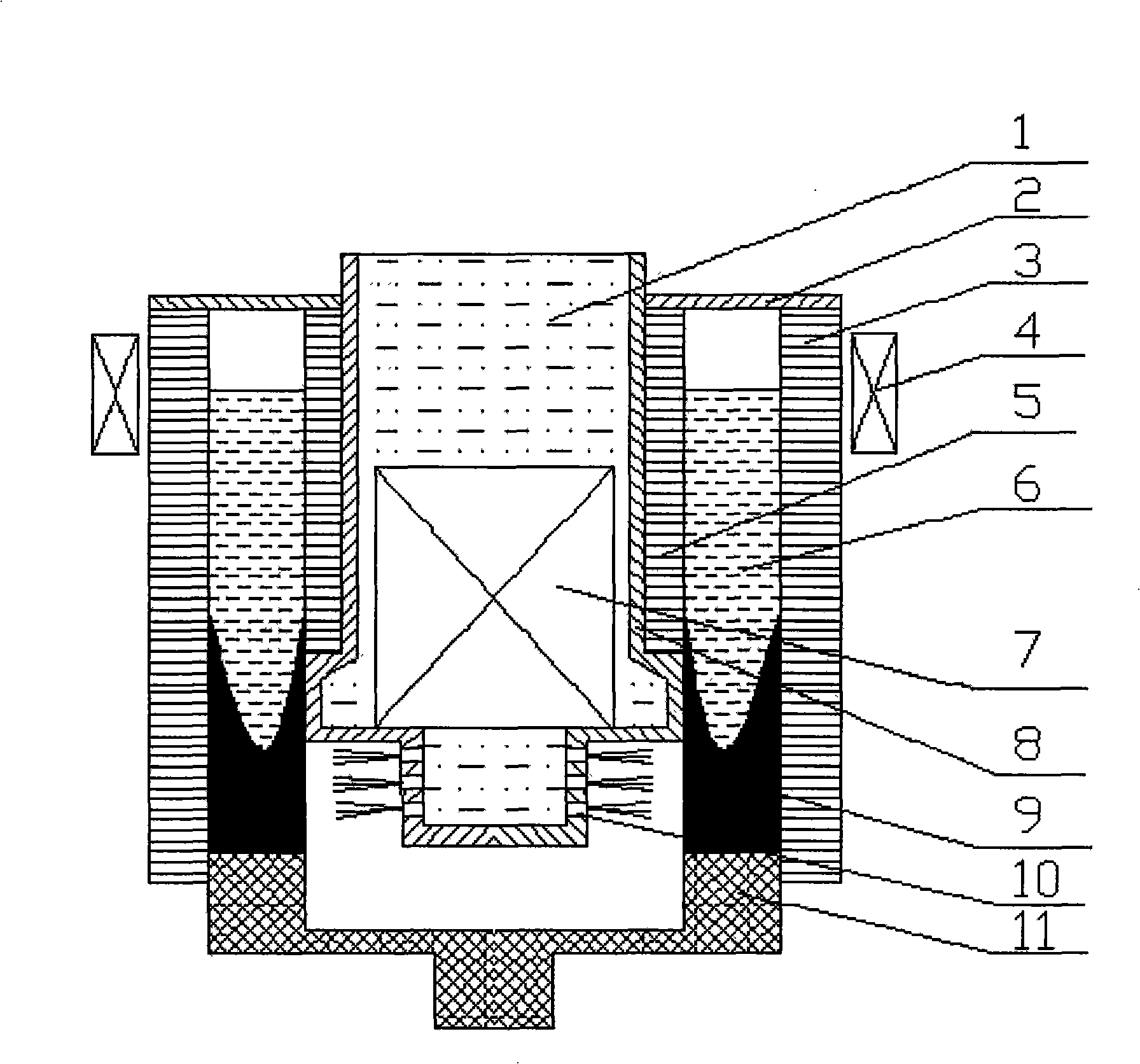

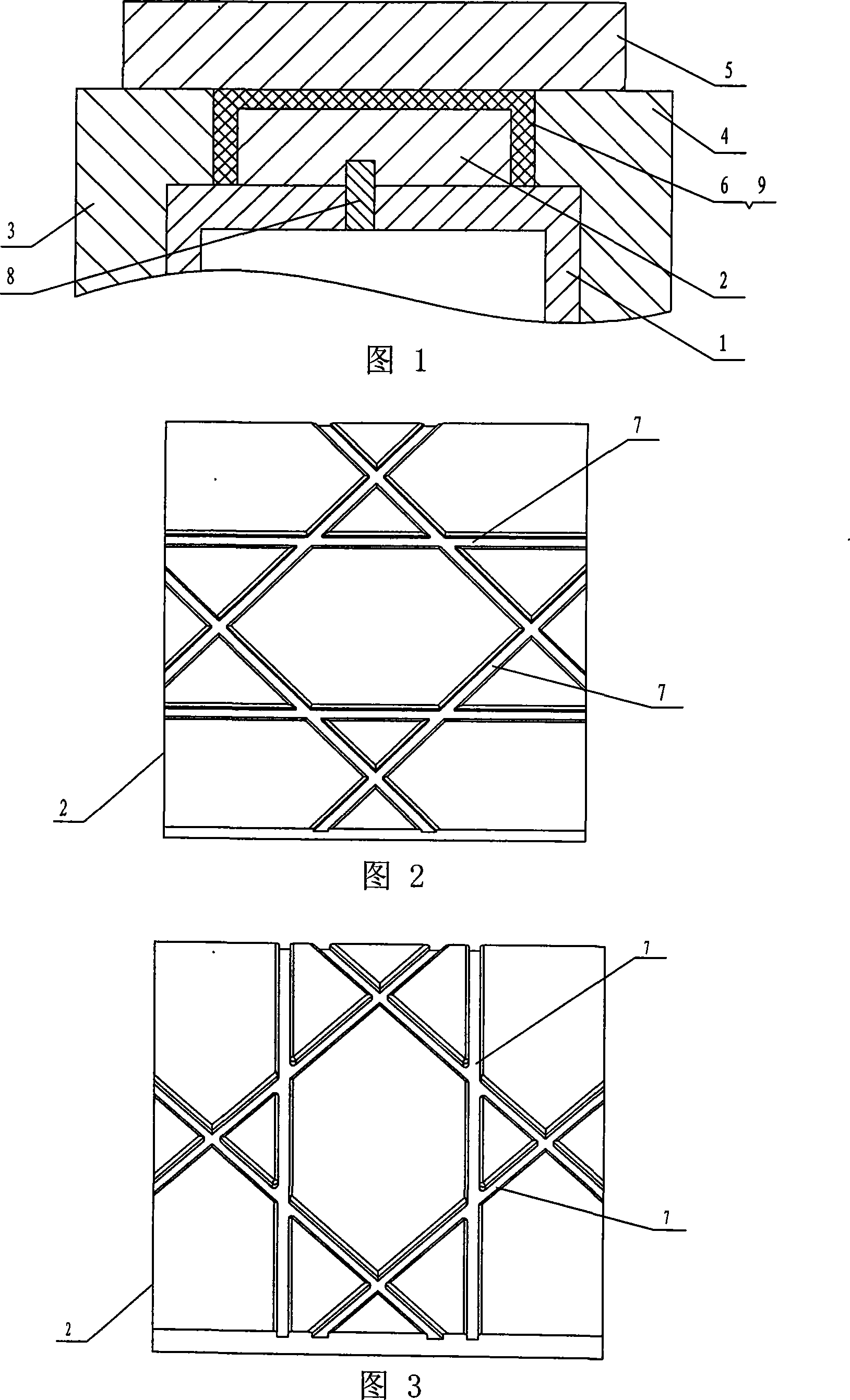

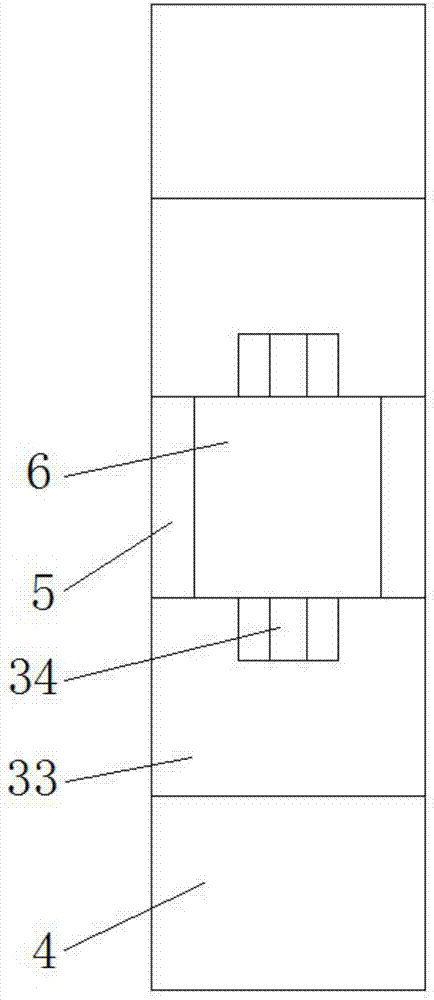

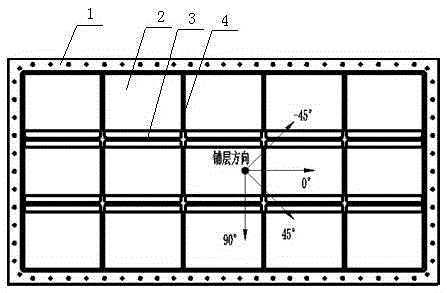

Mold of resin base complex material inner gridding skeletal rod structure and shaping method thereof

The invention discloses a mold and a component forming method of a resin-based composite material internal grid reinforcement structure, which relates to a mold of a fiber composite material component and a forming method of the component. It solves the problems of low precision, low production efficiency, high cost, poor apparent quality and difficult demoulding in the existing forming method. In the present invention, an inner grid reinforcement member of a resin-based composite material is surrounded by an inner mold (1), a split mold (2), a left flange (3), a right flange (4) and an outer mold (5). The cavity (6), the outer surface of the split mold (2) has a plurality of grooves (7), the split mold (2) and the inner mold (1) are positioned by positioning pins (8), and are connected by bolts and inner molds. Die 1 is firmly connected. The method is as follows: 1. Designing a mould; 2. Winding or laying convex ribs in the cavity; 3. Winding or laying continuous fibers impregnated with resin base in the cavity (6); 4. Forming. The invention has the advantages of high product precision, high production efficiency, reduced production cost, good apparent quality of components, easy demoulding and the like.

Owner:HARBIN FRP INST

Vacuum brazing method for radio fuze antenna radiator

The invention provides a vacuum brazing method for a radio fuze antenna radiator. The vacuum brazing method comprises the following steps: 1) preparing a soldering lug by adopting a linear cutting mode; 2) assembling a cavity and a cover plate of the radiator according to requirements; 3) designing a welding process box and a welding tool, putting the assembled radiator into the process box, and then, putting the process box onto the welding tool which is put into a vacuum furnace in advance; 4) carrying out vacuum brazing on the radiator; and 5) carrying out thermal treatment on the brazed radiator. According to the vacuum brazing method, the soldering lug is prepared by adopting the linear cutting mode, so that break-off is avoided, and the time is saved; the soldering lug is fixed by four locating pins on a welding step, and the vacuum welding tool is supplemented, so that the welding defects of uneven welding flux filling, soldering skips and the like are greatly avoided, and the apparent mass is improved; according to the optimized process, a thermal treatment process is independent, thereby shortening the vacuum brazing and cooling time, and greatly improving the vacuum brazing efficiency.

Owner:GUIZHOU AEROSPACE ELECTRONICS TECH

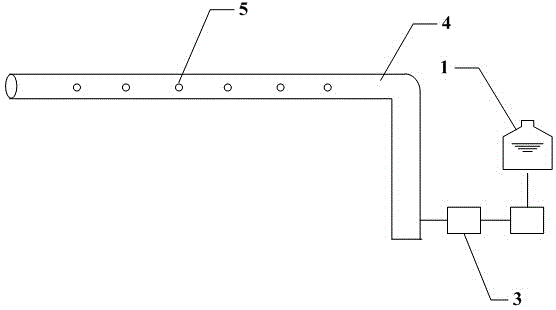

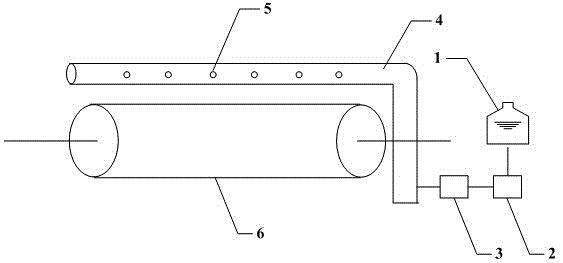

High-apparent mass blowing micro foaming automotive air duct material and preparation method thereof

The invention discloses a high-apparent mass blowing micro foaming automotive air duct material and a preparation method thereof. The material disclosed by the invention contains the following components in parts by weight: 60-85 parts of polyethylene, 1-10 parts of a filling agent, 1-10 parts of a hyperdispersant, 5-20 parts of a flexibilizer, 1-10 parts of a foaming agent, 5-15 parts of a blowing promoter, 1-5 parts of a nucleating agent and 0.5-2 parts of other additives. The invention further discloses a preparation method of the high-apparent mass blowing micro foaming automotive air ductmaterial. The material disclosed by the invention has the characteristics that the molded foam is small in particle size, the foam density is high, the inner and outer walls of blowing air duct products have high apparent mass and the like, and wind resistance of the product is reduced; the product has the characteristics of being light in weight, excellent in dimensional stability, short in molding cycle, high in molding yield and the like; and meanwhile, the performance requirements on odor and VOC (Volatile Organic Compounds) in automotive original equipment manufacturers are met.

Owner:NANJING JULONG SCI&TECH CO LTD

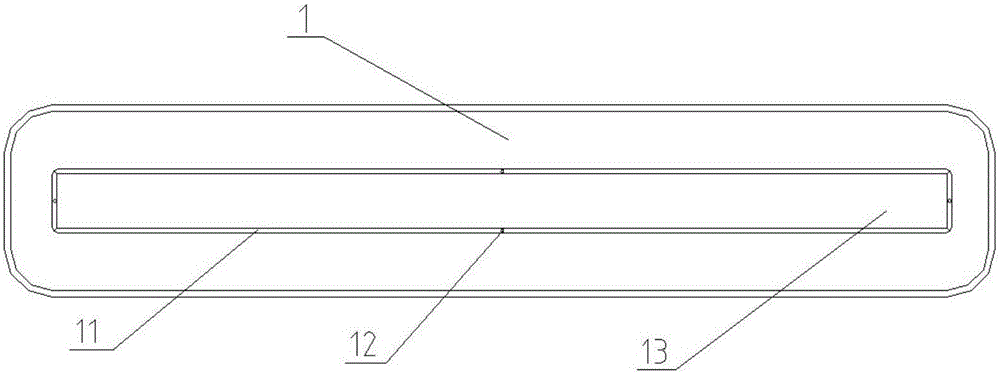

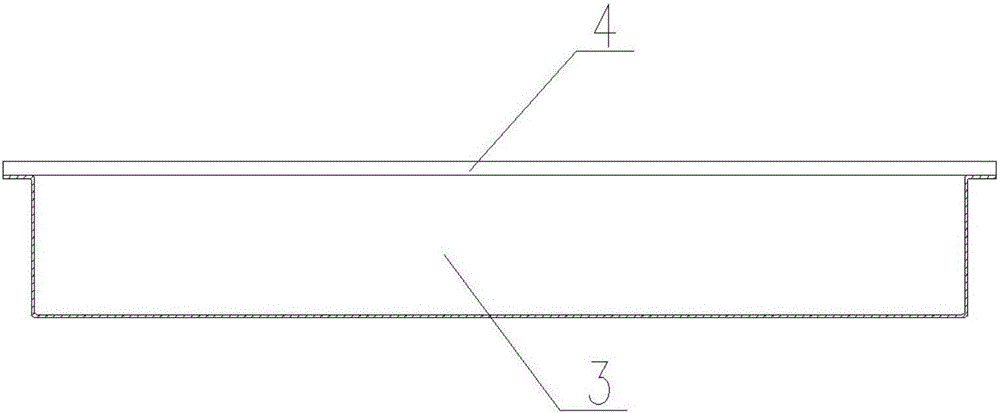

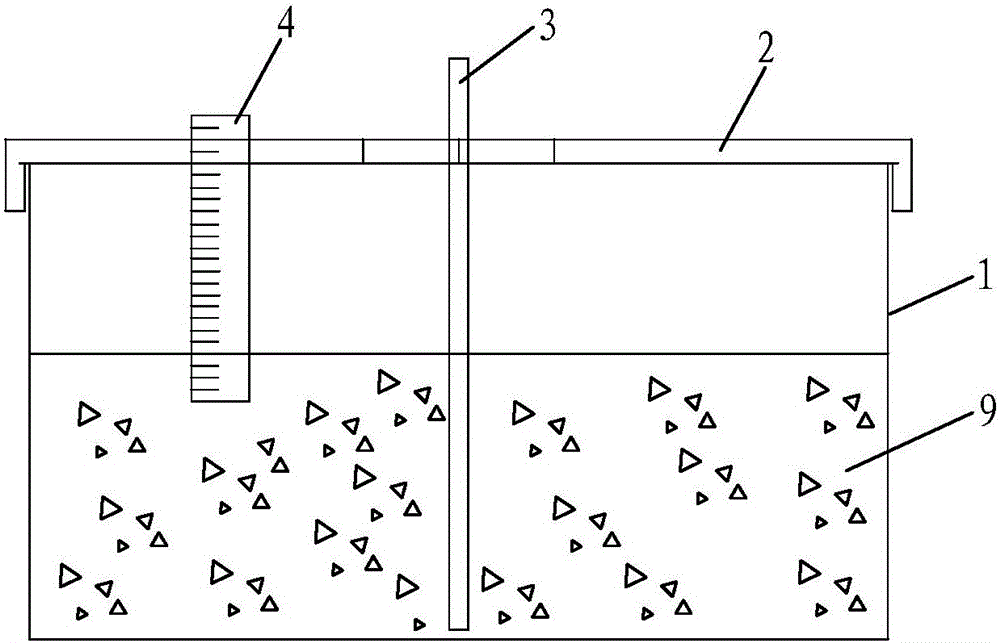

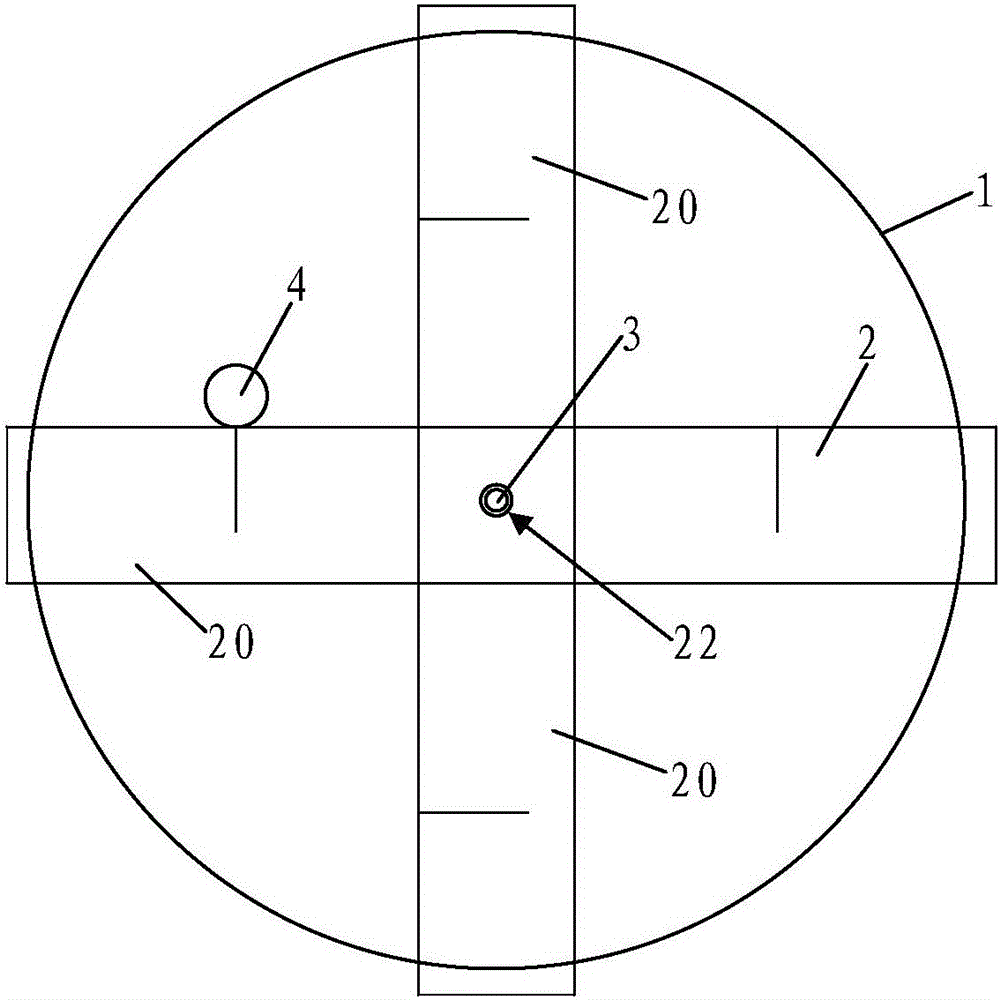

Device and method for testing apparent mass of bare concrete

The invention provides a device and method for testing the apparent mass of bare concrete. The device comprises a transparent container used for accommodating the bare concrete, a support erected on the top surface of the transparent container, a vibration rod which is arranged at the center of the support in a penetrating mode and stretches into the bare concrete, and a scale measurement bar sinking into the bare concrete from different positions so as to record the depth in the vibrated bare concrete. A scientific test standard is formed, and the blank of the prior art is filled in.

Owner:SHANDONG JIANZE CONCRETE

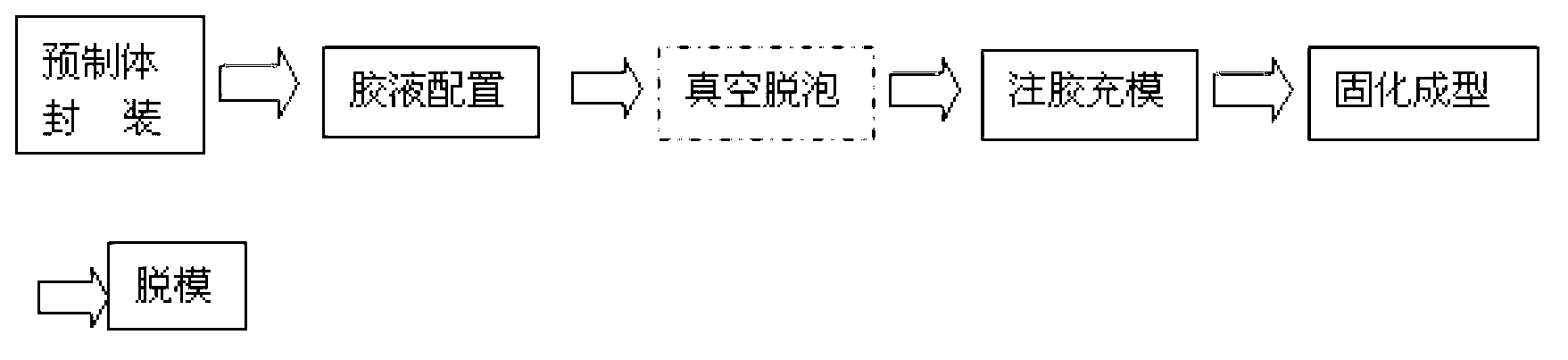

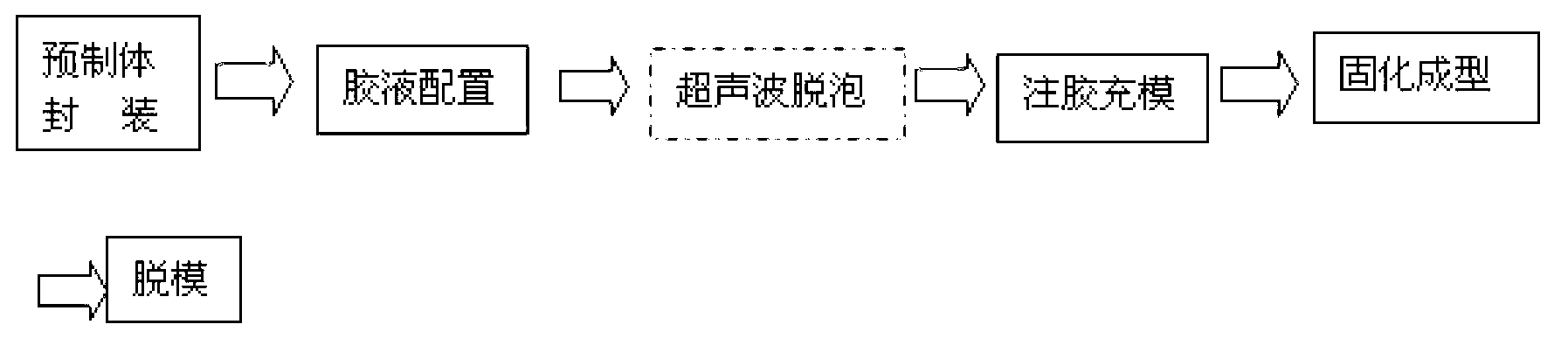

Vacuum infusion process for forming composite material and composite material

The invention discloses a vacuum infusion process for forming a composite material and the composite material. The vacuum infusion process comprises the following steps of: injecting raw materials for preparing the composite material for performing mold filling; and defoaming the raw materials before the raw materials are injected into the mold for performing mold filling. According to the process, the air bubbles in the raw materials for preparing the composite material are reduced, so that the porosity in the formed composite material is reduced, and the apparent mass and mechanical properties of the prepared composite material are improved. The method for defoaming the raw materials for preparing the composite material before mold filling is simple and easy to implement.

Owner:CHERY AUTOMOBILE CO LTD

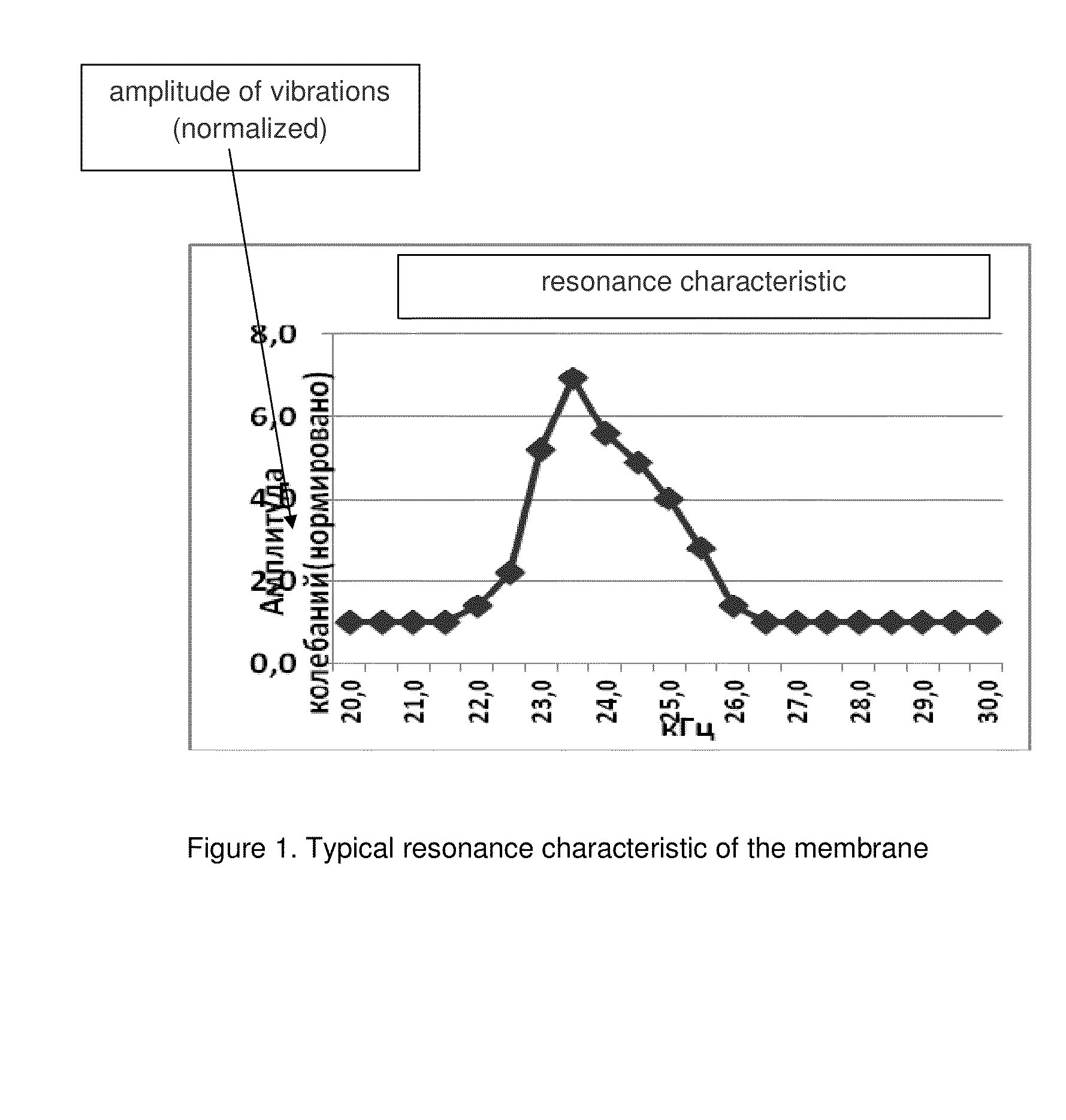

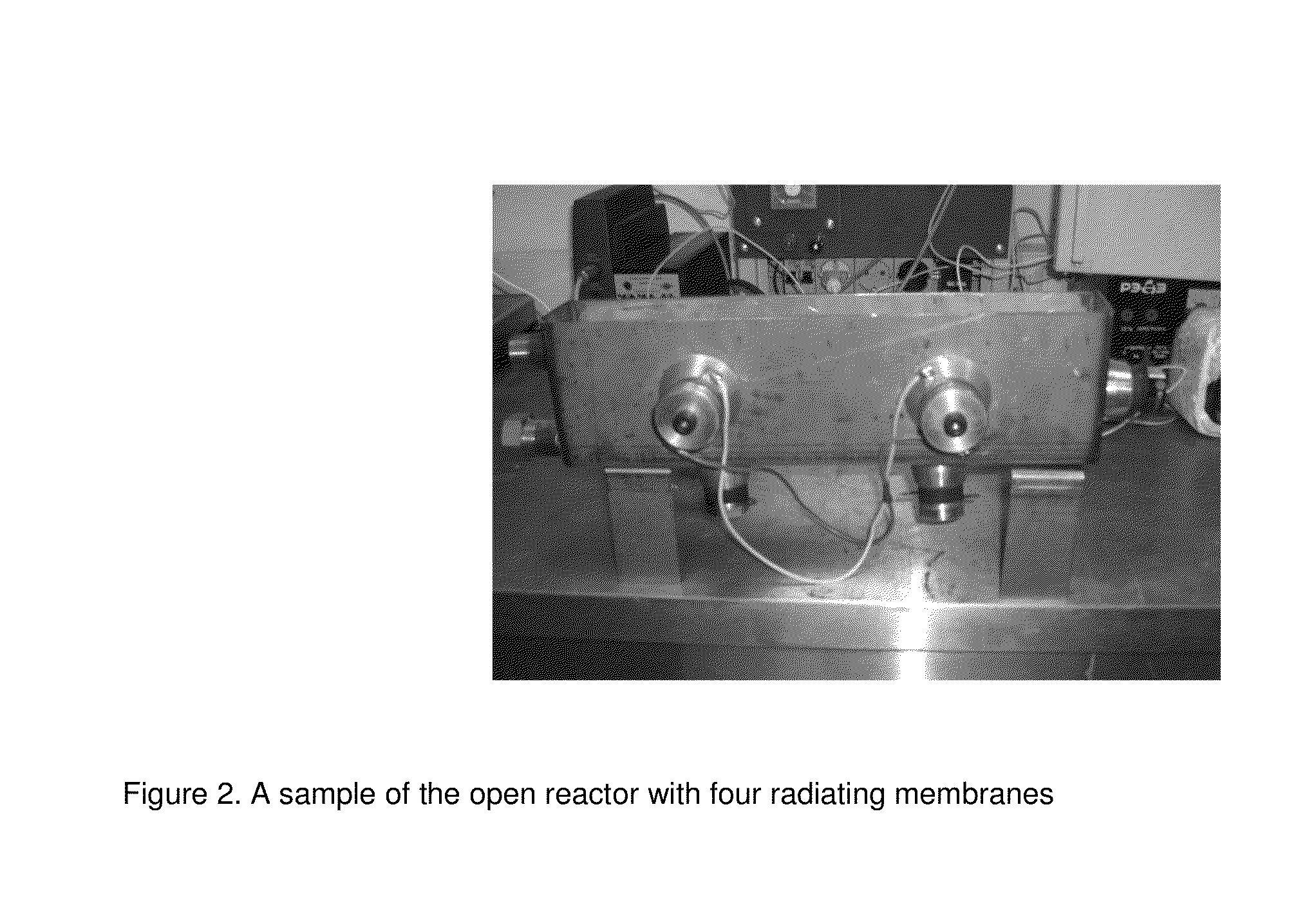

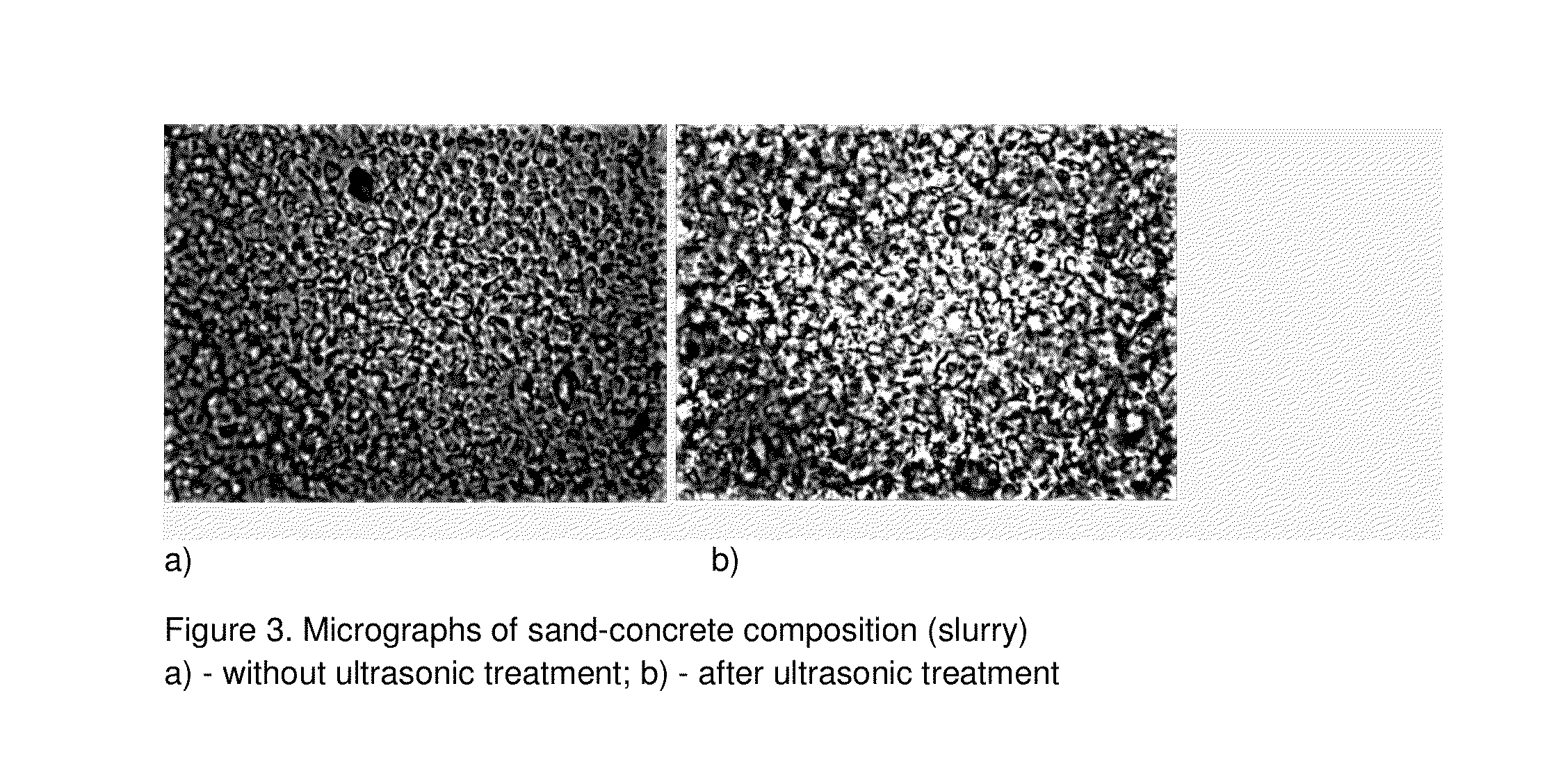

Method of ultrasonic cavitation treatment of liquid media and the objects placed therein

InactiveUS20130315025A1Increase amplitudeImprove efficiencyShaking/oscillating/vibrating mixersDiagnosticsLiquid mediumUltrasonic cavitation

The invention relates to the field of cavitation treatment of liquid media as well as media, where the density of water or other liquid phase is over 65-70% of the total weight as well as to treatment of the objects placed in the treated liquid media. The method cavitation treatment consists of the vibration system with the liquid medium and the placed objects consisting of the wall-surfaces, each surface of the system is the membrane fixed outline. For example on a rigid frame, having a natural frequency with due consideration of the apparent mass of the vibration generator equal to the fundamental mode, the radiation of ultrasonic waves to the liquid media is carried out simultaneously by all membranes of the vibration system, providing in the treated media the effect of superposition of waves with forming a standing acoustic wave or multiple waves with different frequencies. The amplitude of resonant vibrations of each membrane is above the threshold of acoustic cavitation for the liquid media with objects located therein. The vibrations frequencies and phase characteristics of the membranes are chosen so that they can be the same or different in order to maximize the desired cavitation effect factoring in the characteristics of the treated media. The vibration system can be of any shape, flowing or steady state mode of motion of the liquid media. The method improves the efficiency (power and amplitude of the acoustic wave, coherence) of cavitation effect on the treated liquid media and the objects placed therein while limiting the power of ultrasonic radiators.

Owner:CAVITANICA

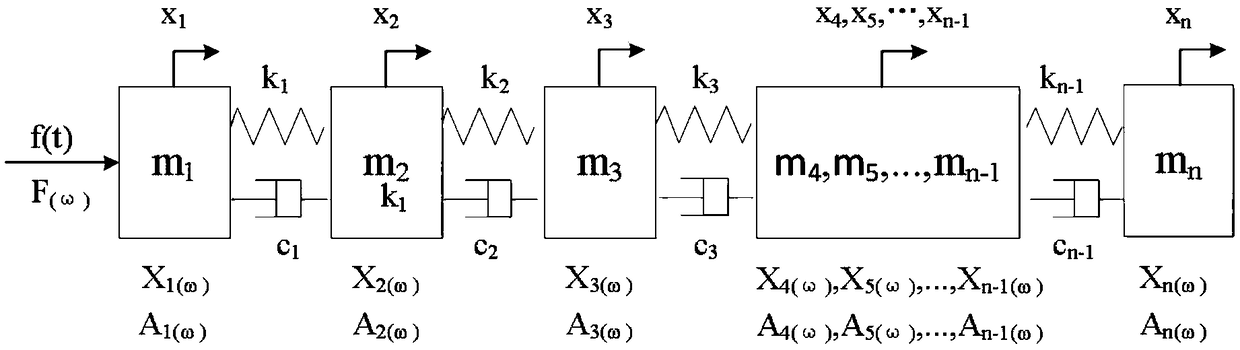

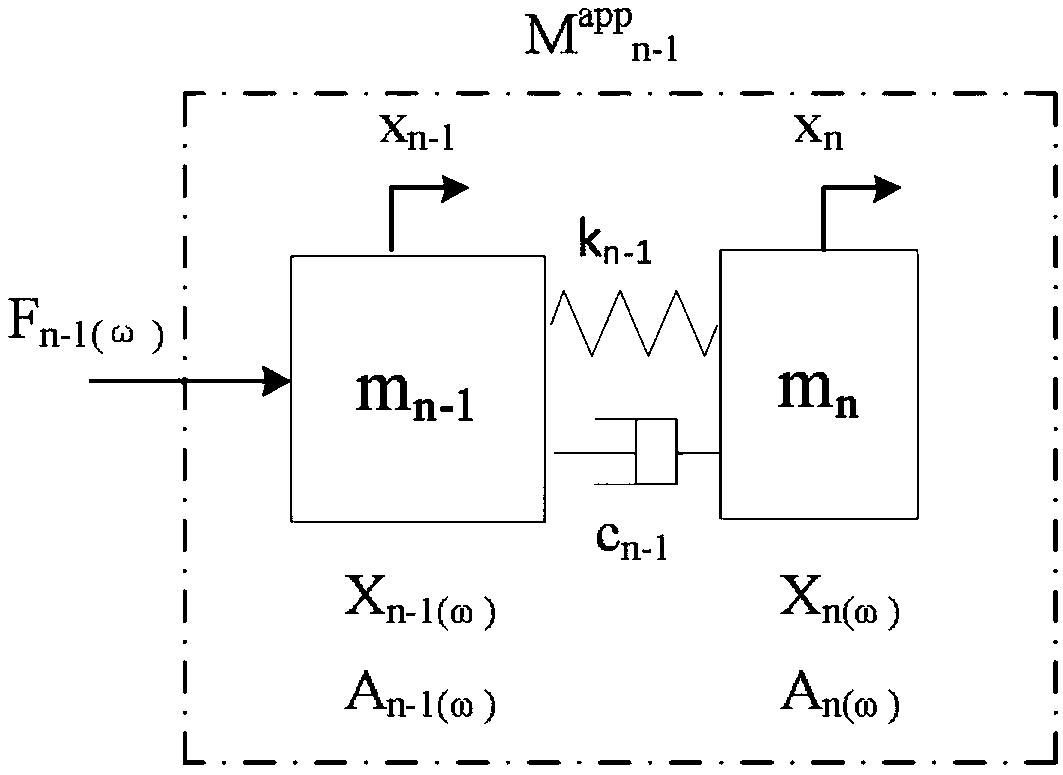

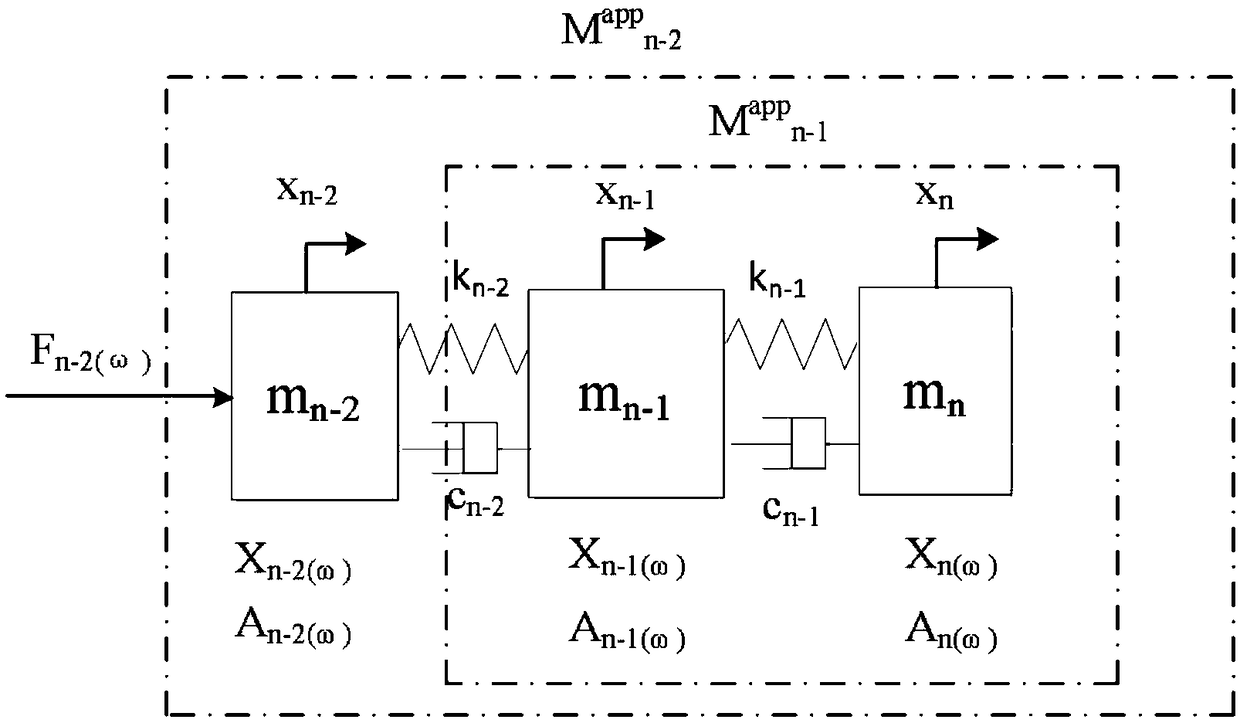

A displacement frequency response calculation method of series multi-degree-of-freedom system

ActiveCN108984879ASustainable transportationDesign optimisation/simulationTransfer function modelDynamic models

The invention discloses a displacement frequency response calculation method of a series multi-degree-of-freedom system. The method includes: through modeling of a series multi-degree-of-freedom system, obtaining a series multi-degree-of-freedom system model; establishing a displacement transfer function model; establishing an apparent quality model; establishing an acceleration frequency responsemodel; establishing a displacement frequency response model and obtaining the displacement frequency response. Through apparent mass, the kinematic relationship between adjacent mass points in the system is established. On the premise of not establishing the whole system dynamics model, the displacement transfer function and acceleration transfer function between adjacent mass points are established from back to front and step by step, and the apparent mass of each mass point is obtained. The apparent mass of the first mass point is combined with the boundary condition to obtain the displacement frequency response and acceleration frequency response of the first mass point. The displacement frequency response and acceleration frequency response of all the mass points are obtained by the transfer function between the adjacent mass points.

Owner:BEIJING INST OF ELECTRONICS SYST ENG

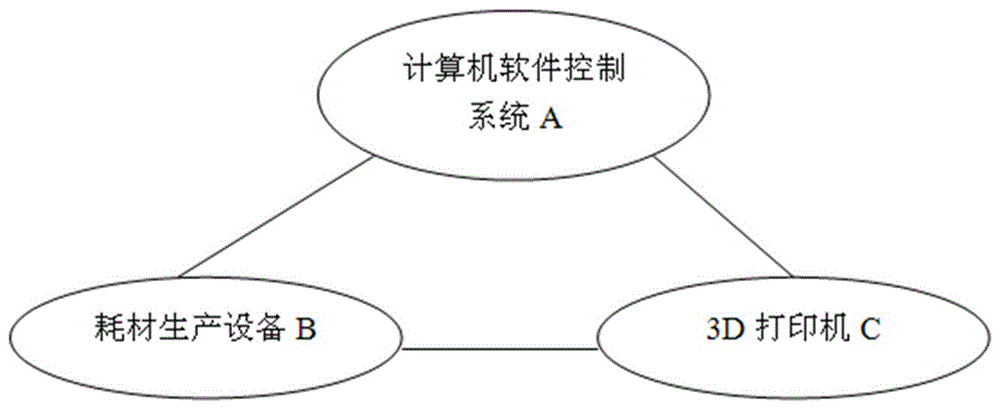

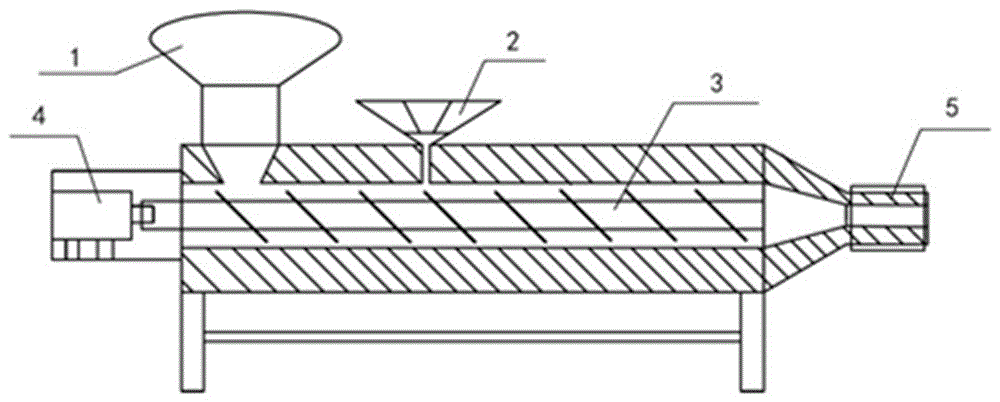

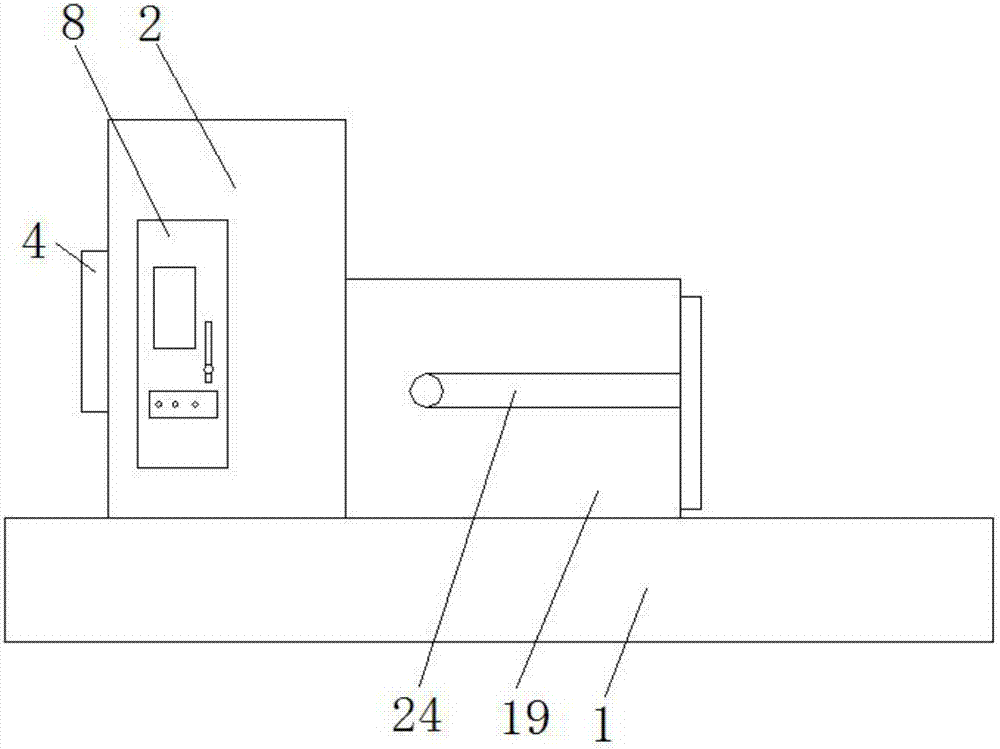

Integrated full-color 3D printing equipment and method

InactiveCN105799174ASolve the problem of uneven color mixingMeet the needs of printing personalized full-color productsAdditive manufacturing apparatusPersonalizationControl system

The invention relates to full-color 3D printing equipment which comprises a computer software control system, consumable item production equipment and a 3D printer. The computer software control system comprises three-dimensional model design software and a central pivot structure; by means of the three-dimensional model design software, design of a full-color 3D product model can be achieved, and the red, yellow and blue proportion of corresponding colors on a product is automatically calculated; and by means of the central pivot structure, a computer, the consumable item production equipment and the 3D printer are connected together. Consumable item on-line integrated production can be carried out according to different color requirements of the product, the product is molded through the 3D printer in real time, different colors can be designed at different portions of the product according to customer demands, and the full-color product in any color combination is printed. According to the full-color 3D printing equipment, a multi-head printer or a printer with a multi-inlet one-outlet printing head is avoided, the problem that mixing of colors of the printing head is uneven is solved, the printing accuracy and the product apparent mass can be improved, and the requirement of vast users to print individual full-color products is truly met. In addition, the desktop stage consumable item production equipment and the desktop stage 3D printer are adopted, so that the using occasions of the 3D printing equipment are greatly increased.

Owner:QUZHOU UNIV

Vision robot for checking surface texture and apparent mass of textiles

InactiveCN107449784APrevent affecting the results of the testEasy to take off the jobMaterial analysis by optical meansDrive wheelDrive motor

The invention discloses a visual robot for inspecting the surface texture and apparent quality of textiles. It comprises a base, and a test box is fixedly installed on the top of the base. A baffle is fixedly installed on one side of the box, and the baffle is located at the opening on one side of the through groove, and a chute connecting the through groove is opened on the baffle, and a limit plate is slidably installed inside the chute, and the One side of the limiting plate is fixedly connected with one end of the electric push rod. In the present invention, the community drive box is started by the drive motor in the drive box, and through the cooperation of the driving wheel and the driven wheel, when the drive motor is started, the first rotating shaft and the second rotating shaft will rotate in opposite directions at the same time, when the first rotating shaft When rotating with the second rotating shaft, the textiles will be moved to the inside of the inspection box, and the textiles will be flattened, so as to avoid the inaccurate inspection structure caused by the unevenness of the textiles.

Owner:ZHEJIANG YUEJIAN INTELLIGENT EQUIP CO LTD

Method to improve apparent mass of film coating

InactiveCN104307707AImprove stabilityReduce the temperatureLiquid surface applicatorsCoatingsWater storage tankSpray nozzle

A method to improve apparent mass a film coating includes the steps of: coating, drying and rolling. A humidifying device is arranged on at least one side of a gravure roller in the coating process; the device is composed of a water storage tank, an ultrasonic oscillator, a wind feeding device, a spray pipe and a spray nozzle; and the spray pipe and the gravure roller have a distance of 10-50 mm, and the ligature of the spray pipe axis and the gravure roll axis has an included angle with the horizontal direction of 30 to 60 DEG. The invention solves the problem that temperature rise of the roller surface causes accelerated volatilization of local coating liquid aqueous solution on the roller surface, which further causes solid precipitation; the method plays good wetting effect, avoids the phenomenon of paste roller caused by clogging of precipitated solid on the gravure roller surface groove and mesh, and improves the coating stability and apparent mass of film coating.

Owner:HEFEI LUCKY SCI & TECH IND +2

Hood adopting longitudinal-transverse reinforced rib structure and adopting RTM entire shaping technology and manufacturing method of hood

InactiveCN105423116AReduce porosityImprove surface qualityElongated constructional elementsFiberPorosity

The invention provides a hood adopting a longitudinal-transverse reinforced rib structure and adopting an RTM entire shaping technology and a manufacturing method of the hood. According to the hood, carbon fiber textiles are used as a material, the textiles are fixed by adopting a hot melting type fixative, material preparation is performed according to the design of a paved layer, and the textiles are cut; the cut textiles are paved and pasted to a hood mold for preparing preforms, then the preforms are assembled and matched, the RTM entire shaping technology is adopted, under 2-10 bar pressure, resin is poured into the hood mold in which the preforms are paved, finally the resin is solidified and shaped in a curing furnace, and the shaped resin is demolded after solidification so as to obtain the hood with the longitudinal-transverse reinforced rib structure and adopting the RTM entire shaping technology. According to the hood disclosed by the invention, the precision of external dimensions of products can be guaranteed; the continuity of longitudinal and transverse reinforced ribs and a panel is guaranteed through the entire shaping technology method; besides, second cementation shaping is not needed, the apparent mass is better, the dimensions of the products are high in precision, the fiber volume fraction is high, the porosity is low, and the cost of the mold can be reduced through batch production.

Owner:HENGSHEN

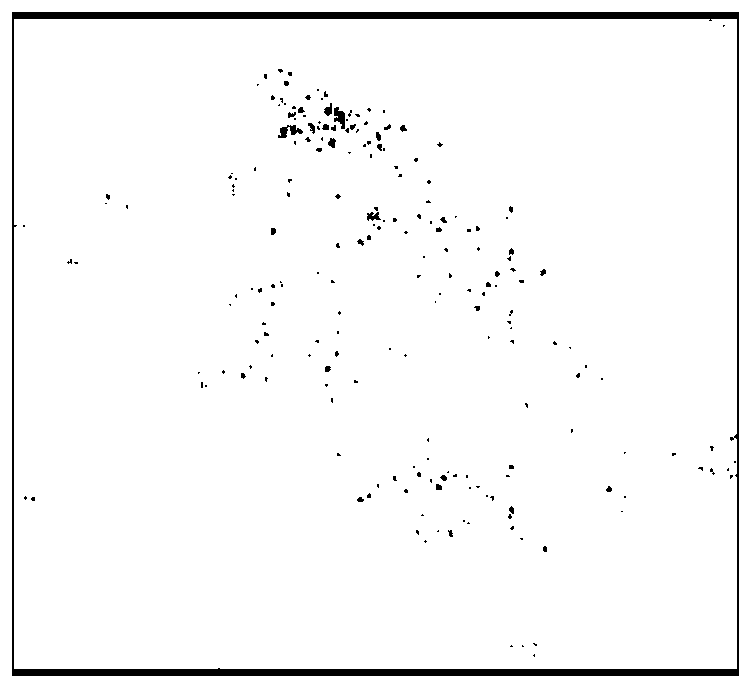

Quantitative evaluation method for apparent mass of fair-faced concrete

InactiveCN110349123AImprove efficiencyPrevent deviationImage enhancementImage analysisComputer softwareArea ratio

The invention discloses a quantitative evaluation method for the apparent mass of fair-faced concrete, which is used for testing a surface pore area ratio of the fair-faced concrete and evaluating theapparent mass of the fair-faced concrete according to the surface pore area ratio, and the quantitative evaluation standard is as follows: the surface pore area ratio is less than or equal to 0.35%;wherein the product is qualified if the content is 0.35%-0.55%; and if not less than 0.55%, the condition is unqualified. The method for testing the surface pore area ratio comprises the following steps: collecting an image of on-site fair-faced concrete by using an unmanned aerial vehicle and processing the fair-faced concrete image ; marking the concrete structure and the pore size; performing gray scale binarization processing on the marked image, and distinguishing pores and concrete on the surface of the image through gray scale difference; measuring and counting the size and quantity ofpores on the surface of the fair-faced concrete through computer software, and calculating the surface pore area ratio of the fair-faced concrete. The apparent mass of the bare concrete is quantitatively evaluated by taking the surface pore area ratio as an evaluation parameter for the first time. The method has the advantages of quantification and high accuracy, and convenience is brought to field engineering.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com