Patents

Literature

523 results about "Negative stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

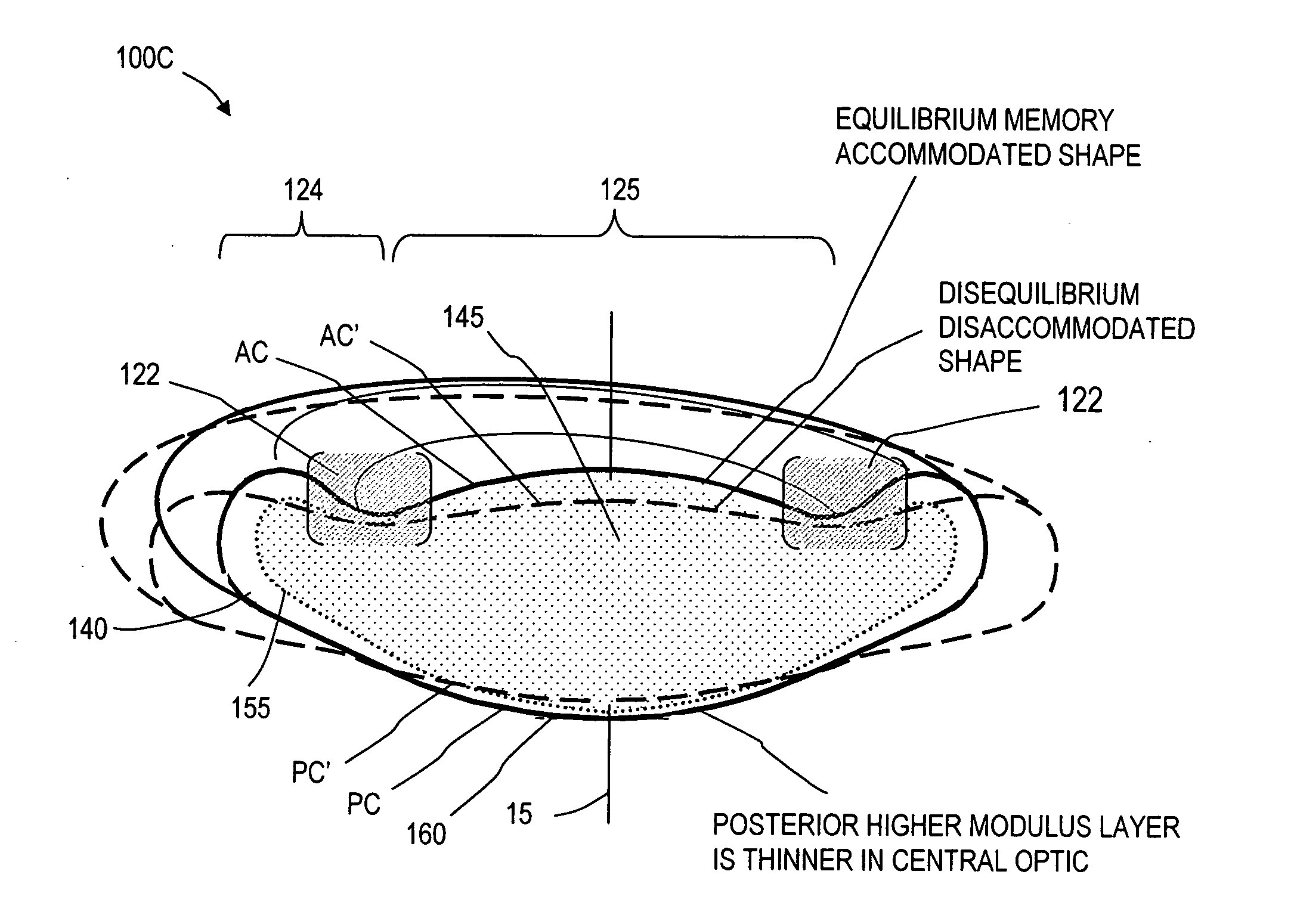

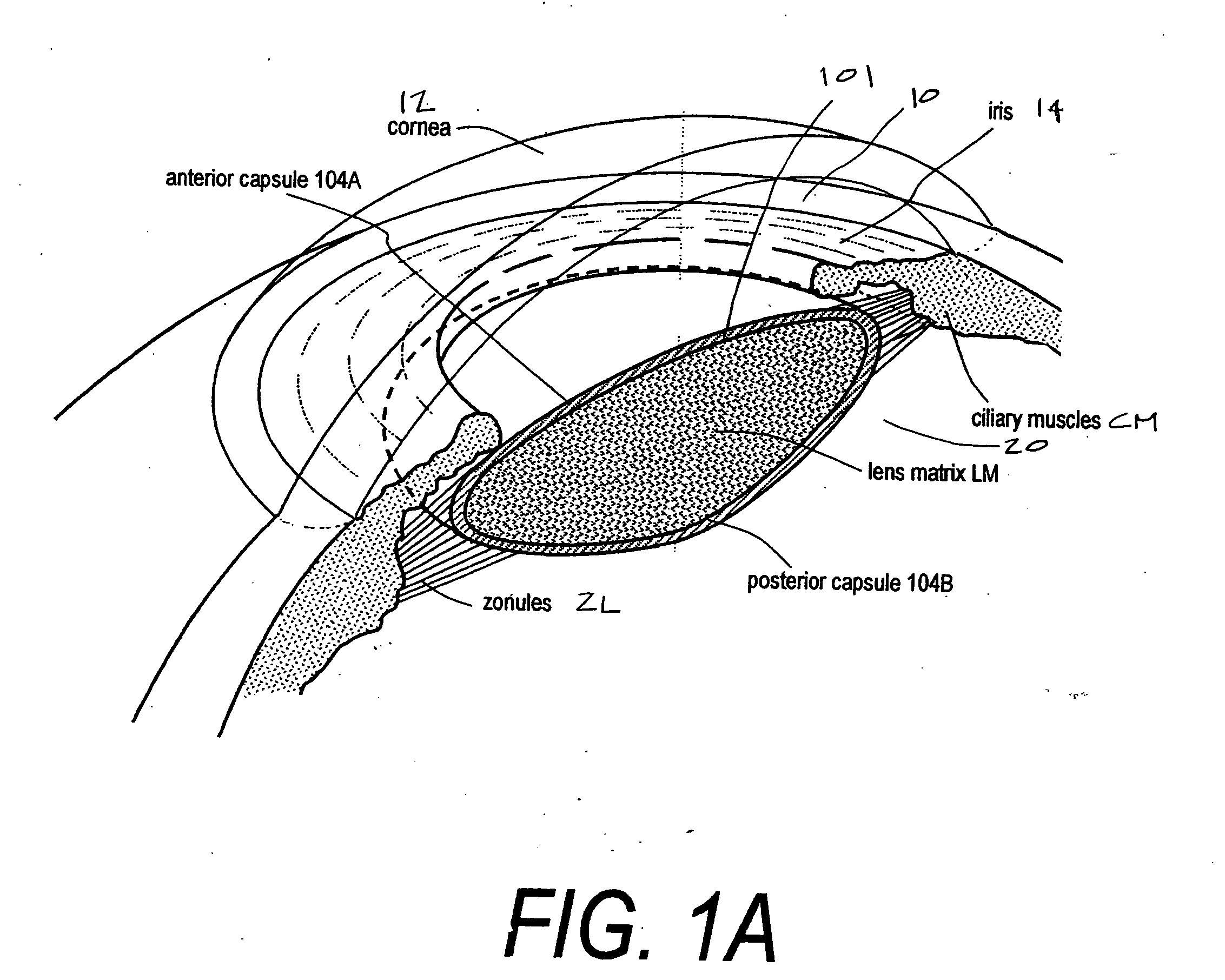

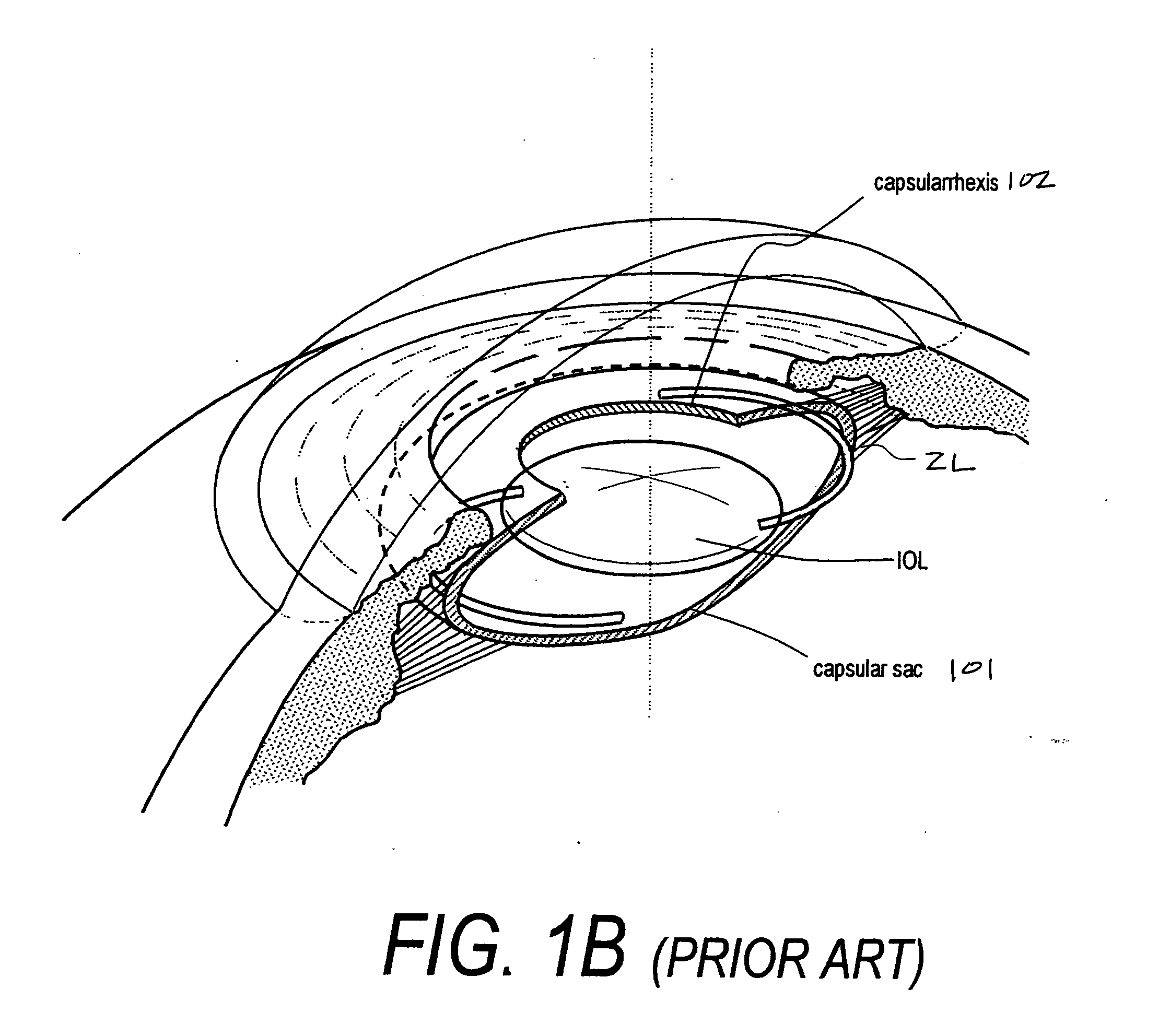

Ophthalmic devices, methods of use and methods of fabrication

InactiveUS20050021139A1Increase the adjustment rangeImproved force transmissionIntraocular lensElastomerYoung's modulus

An adaptive optic for refractive lens exchange or cataract patients. The intracapsular implant comprises an elastomeric monolith with an equilibrium memory shape that imparts to the capsular sac's periphery the natural shape of the capsule in an accommodated state. In one embodiment, the monolith carries a recessed deformable central lens portion having an ultralow modulus that allows for high accommodative amplitude in response to equatorial tensioning. In a preferred embodiment, the adaptive optic defines an anisotropic modulus with a plurality of on-axis, rotationally symmetric elastomer block portions each having a different Young's modulus. The invention further provides composite materials for enhancing deformation of lens curvature, including the use of auxetic polymeric materials and negative stiffness materials. In preferred embodiments, at least a portion of the lens is fabricated of a shape memory polymer that provides a memory shape and a temporary shape with a reduced cross-sectional shape for introduction into the patient's eye.

Owner:POWERVISION

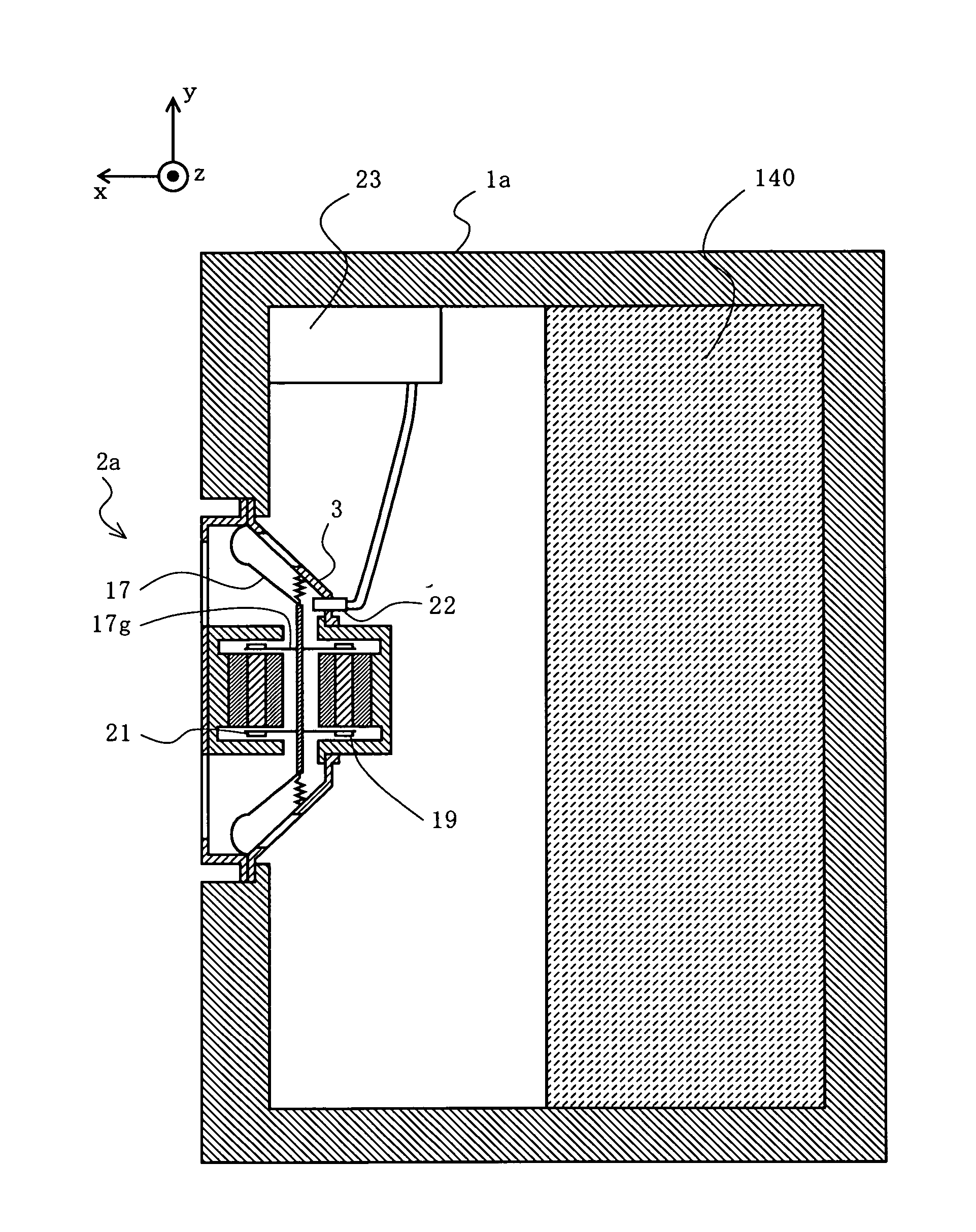

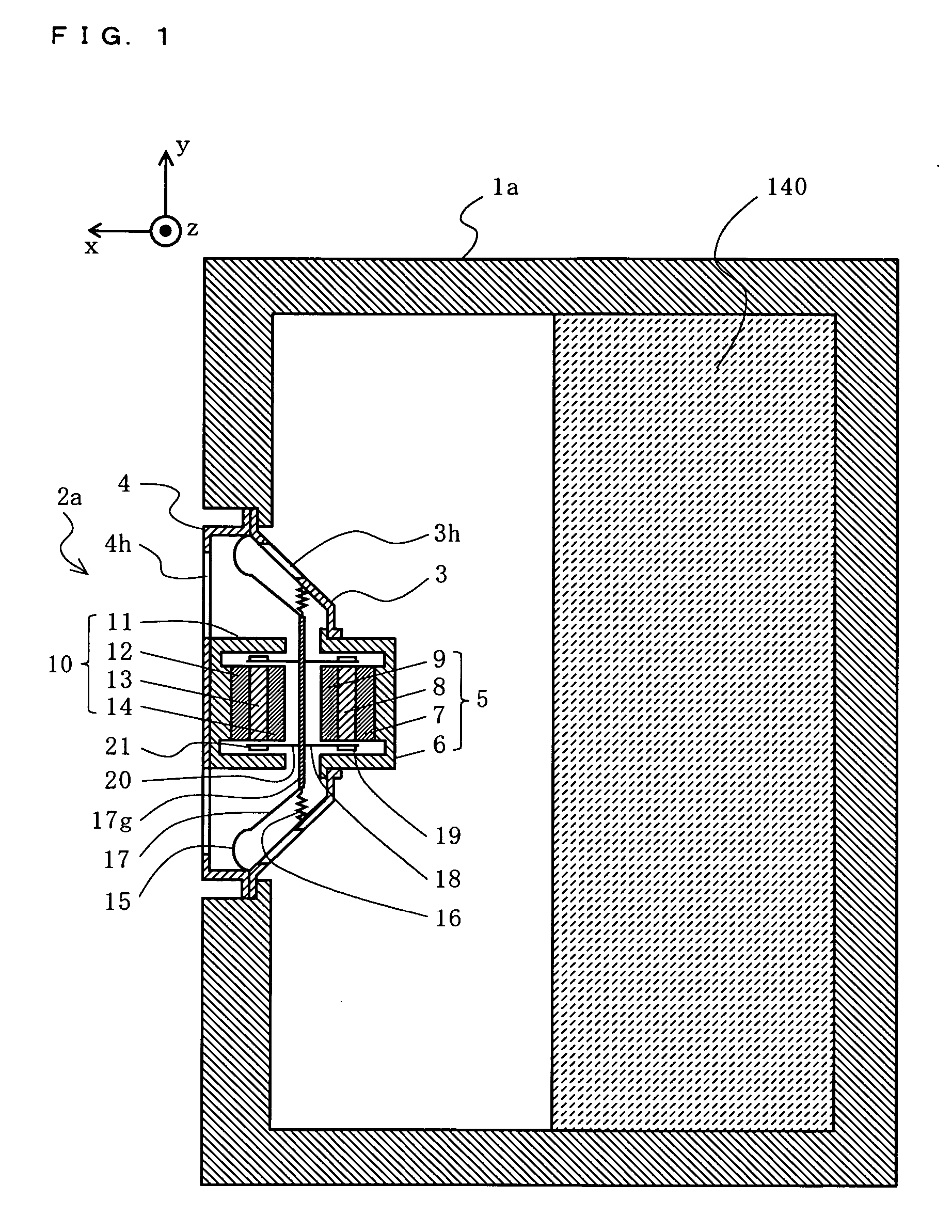

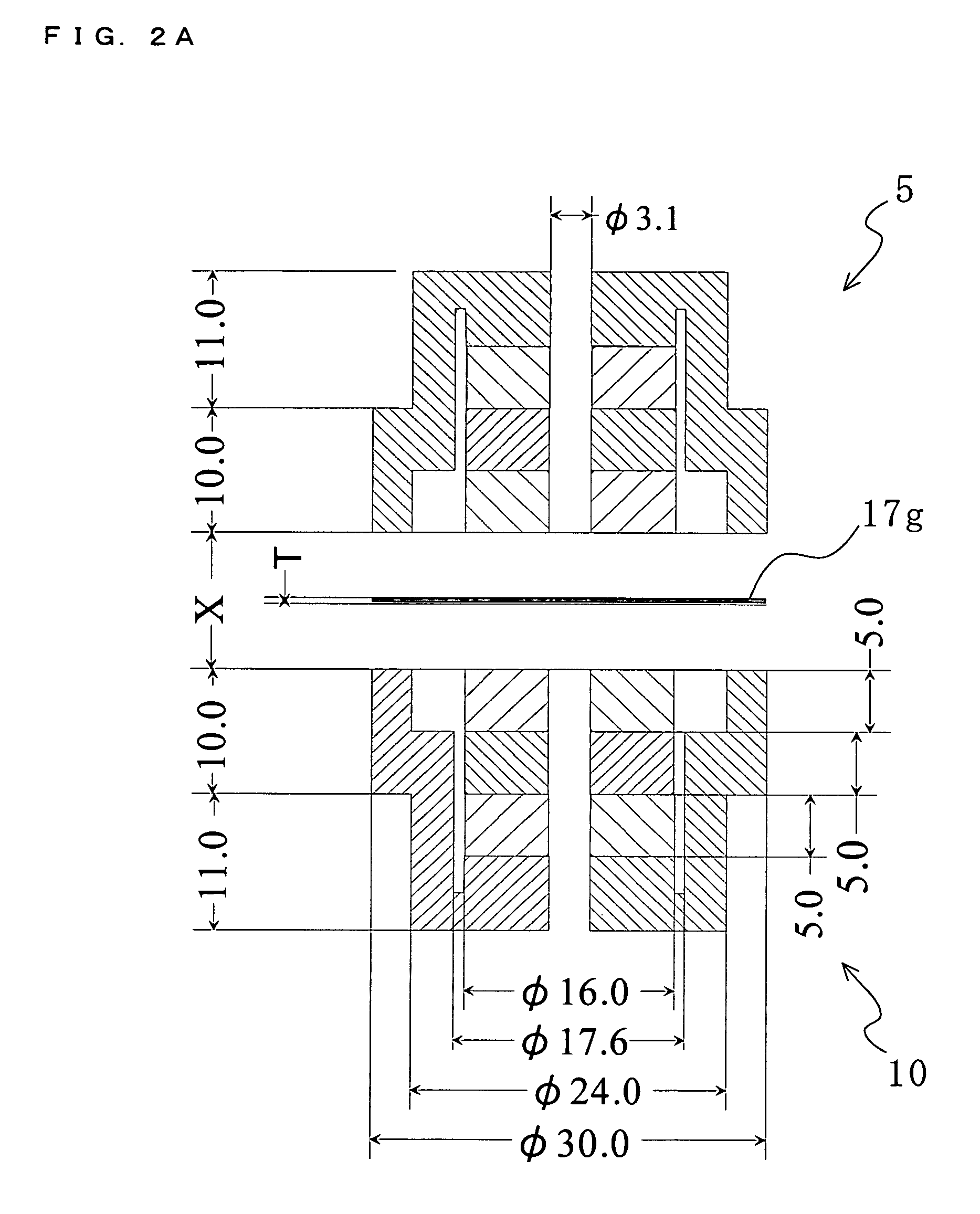

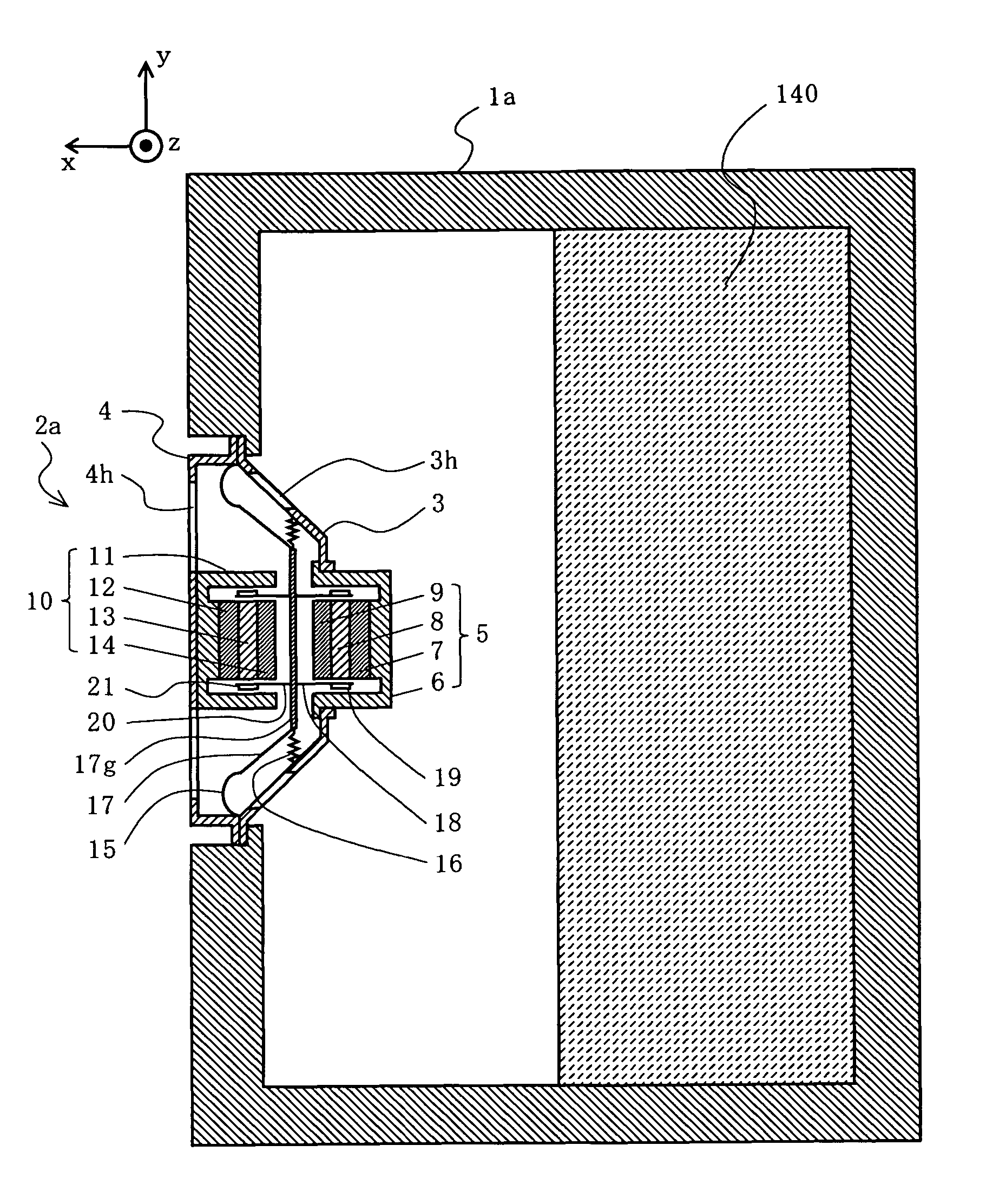

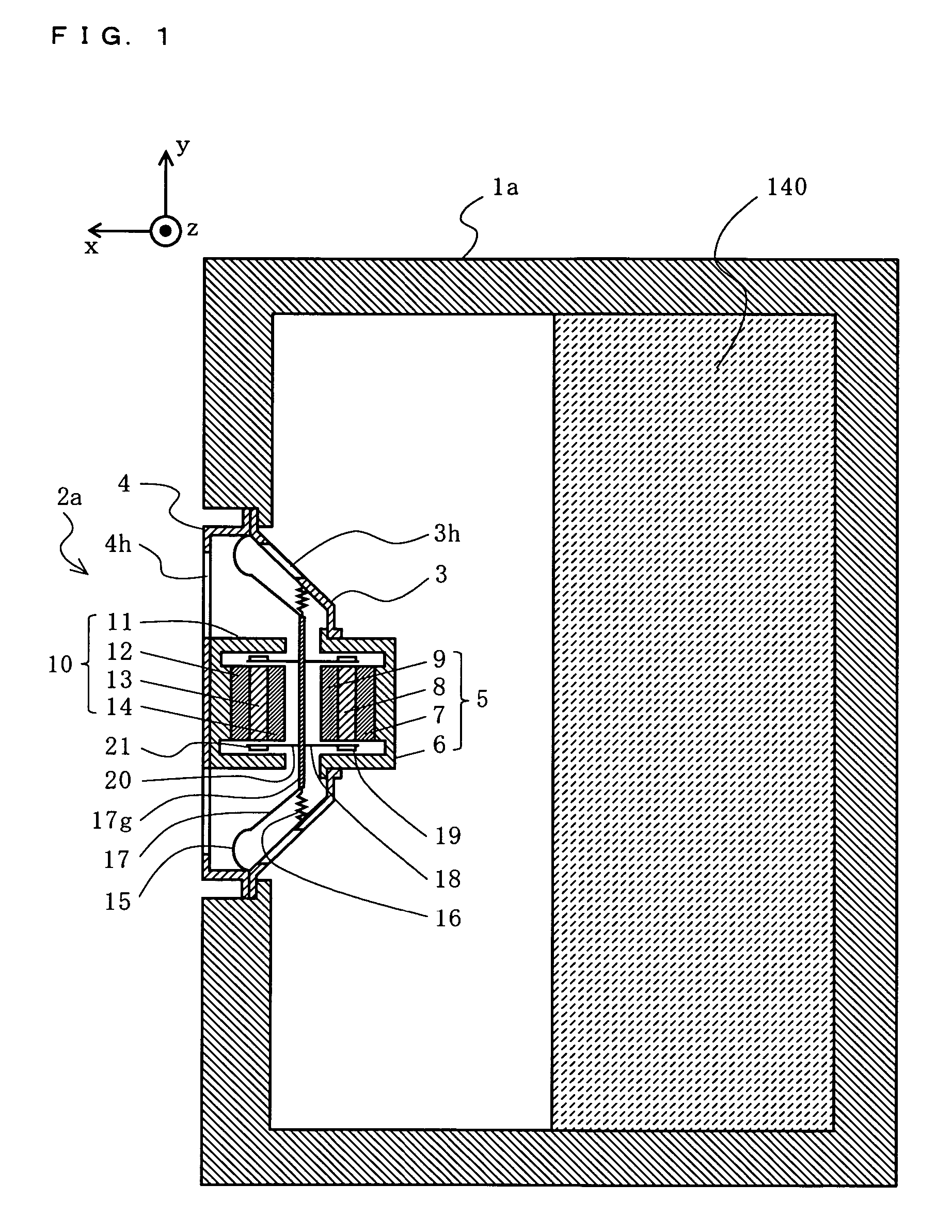

Loudspeaker apparatus

ActiveUS20060269095A1Promote reproductionReduce stiffnessFrequency/directions obtaining arrangementsTransducer casings/cabinets/supportsEngineeringNegative stiffness

A loudspeaker apparatus comprises a housing, an adsorptive material provided inside the housing, for physically adsorbing gas inside the housing, a vibration section including a diaphragm and provided in an opening formed in the housing, a drive section for driving the diaphragm to generate sound from the diaphragm, and a negative stiffness generating mechanism provided inside the housing, for reducing an acoustic stiffness inside the housing, the acoustic stiffness acting on the diaphragm.

Owner:PANASONIC CORP

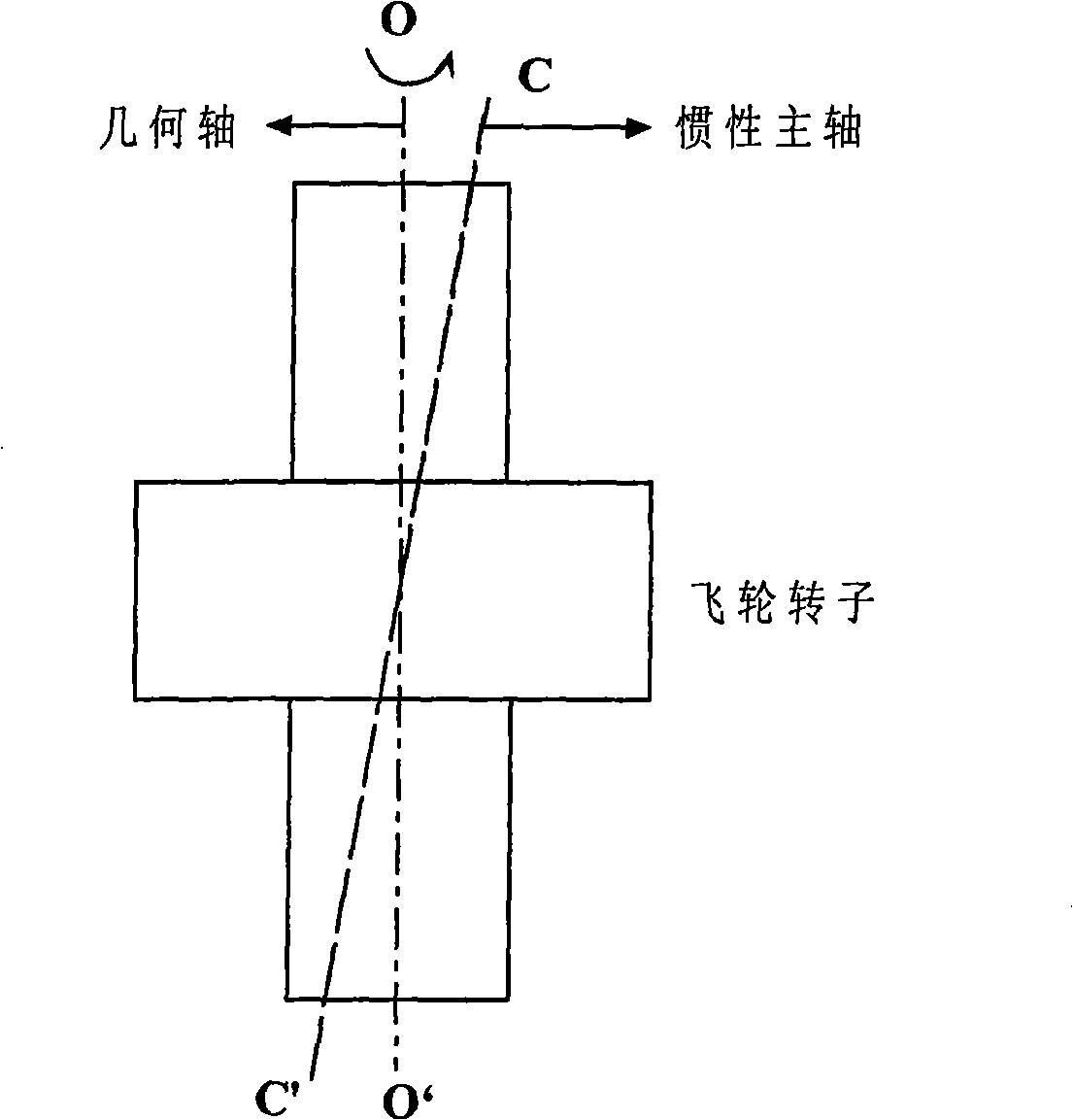

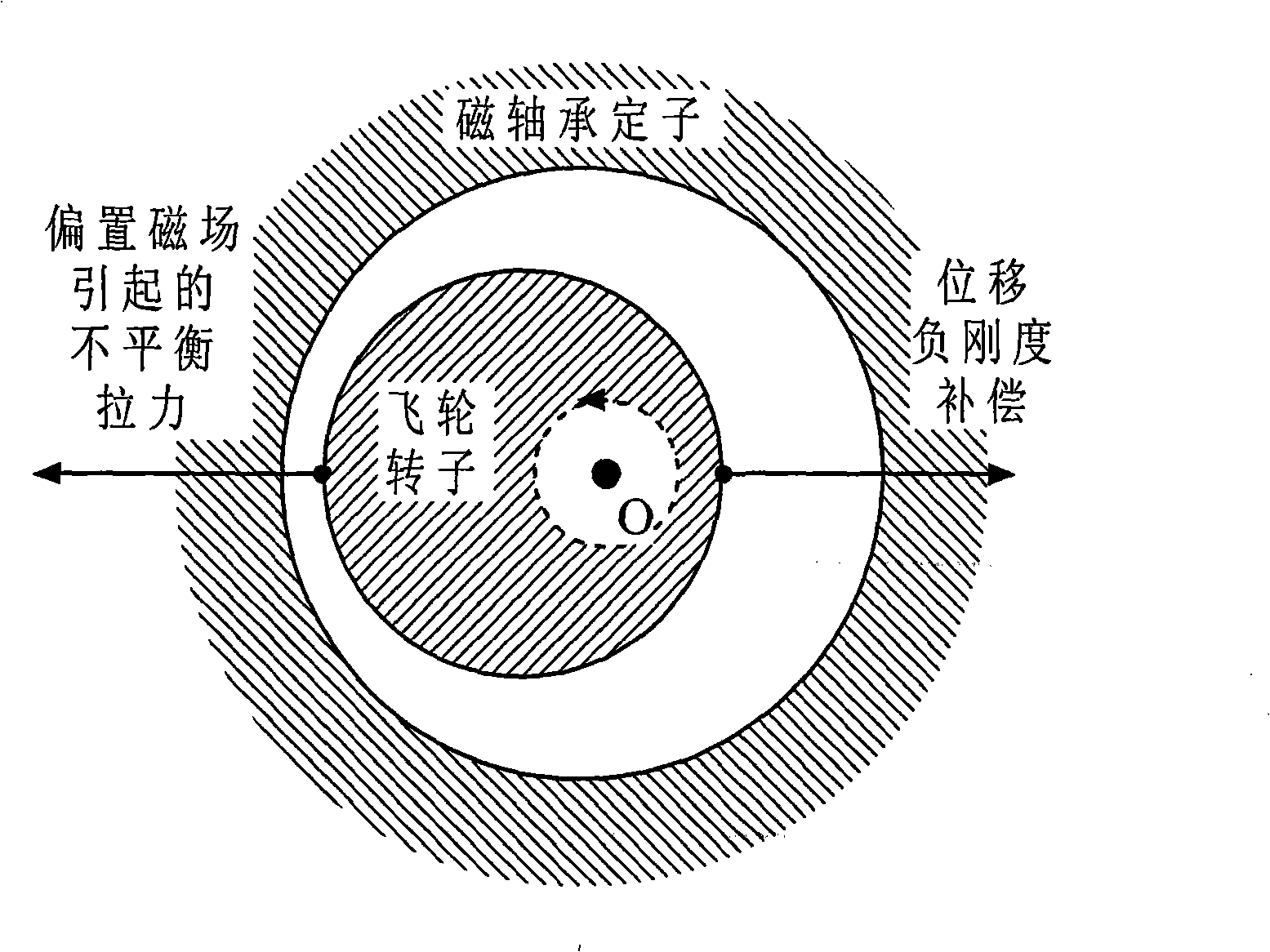

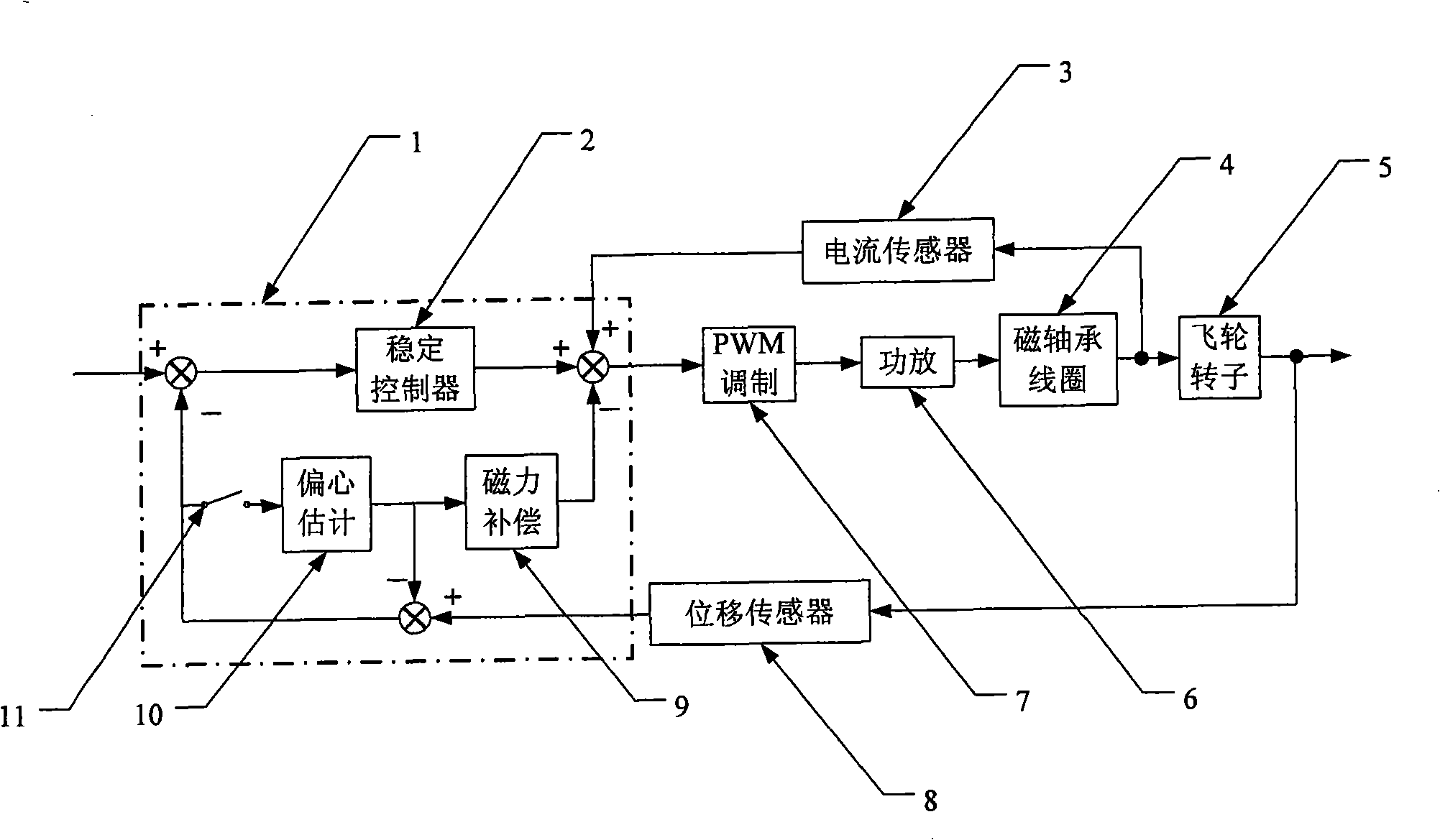

Magnetic levitation flywheel high precision initiative vibration control system

InactiveCN101261496AAchieve high-precision active vibration controlElectric controllersMagnetic tension forceMagnetic bearing

A magnetic levitation flywheel high-precision active vibration control system comprises a displacement sensor, a current sensor, a magnetic bearing controller and a PWM modulation and a power amplifier, wherein, the magnetic bearing controller comprises stabilization of the controller, eccentric estimation, magnetic force compensation and action of a switch. The magnetic levitation flywheel high-precision active vibration control system introduces the eccentric estimation and the magnetic force compensation on the basis of the stable control and utilizes the unbalance vibration parameters of a flywheel to carry out the compensation of the unbalance amount and the displacement negative stiffness of the flywheel within the entire rotation speed range, thus realizing the control of the unbalance vibration of the flywheel within the entire rotation speed range and allowing the flywheel to be operated around a principal axis of inertia with high precision during the whole process of speed increasing and speed reducing.

Owner:BEIHANG UNIV

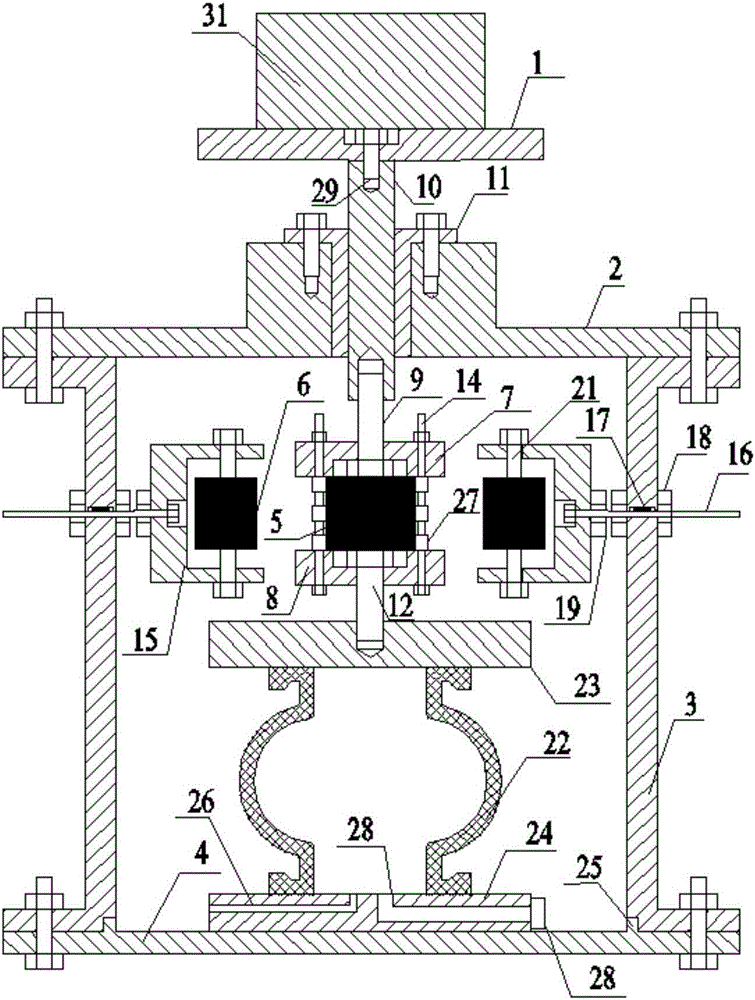

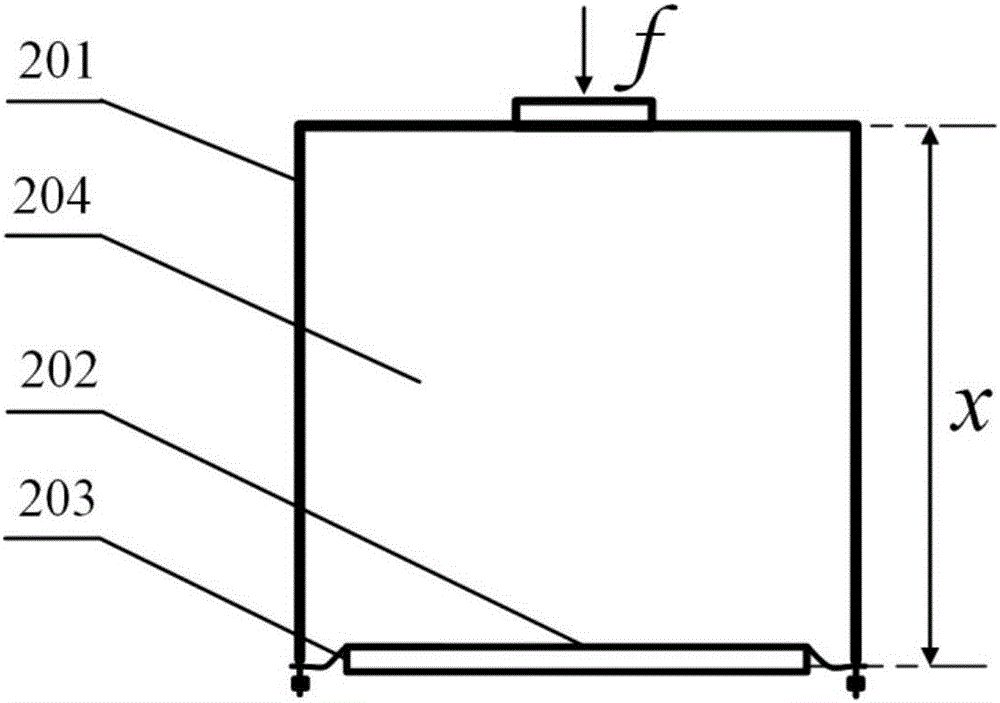

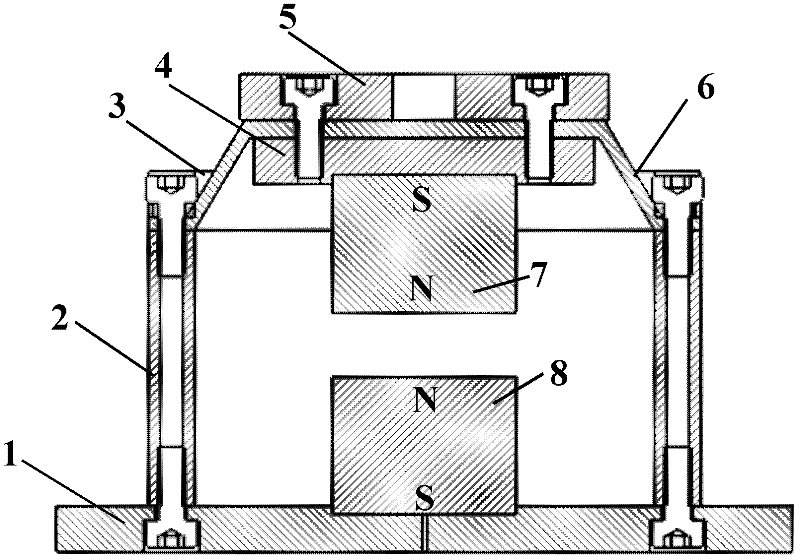

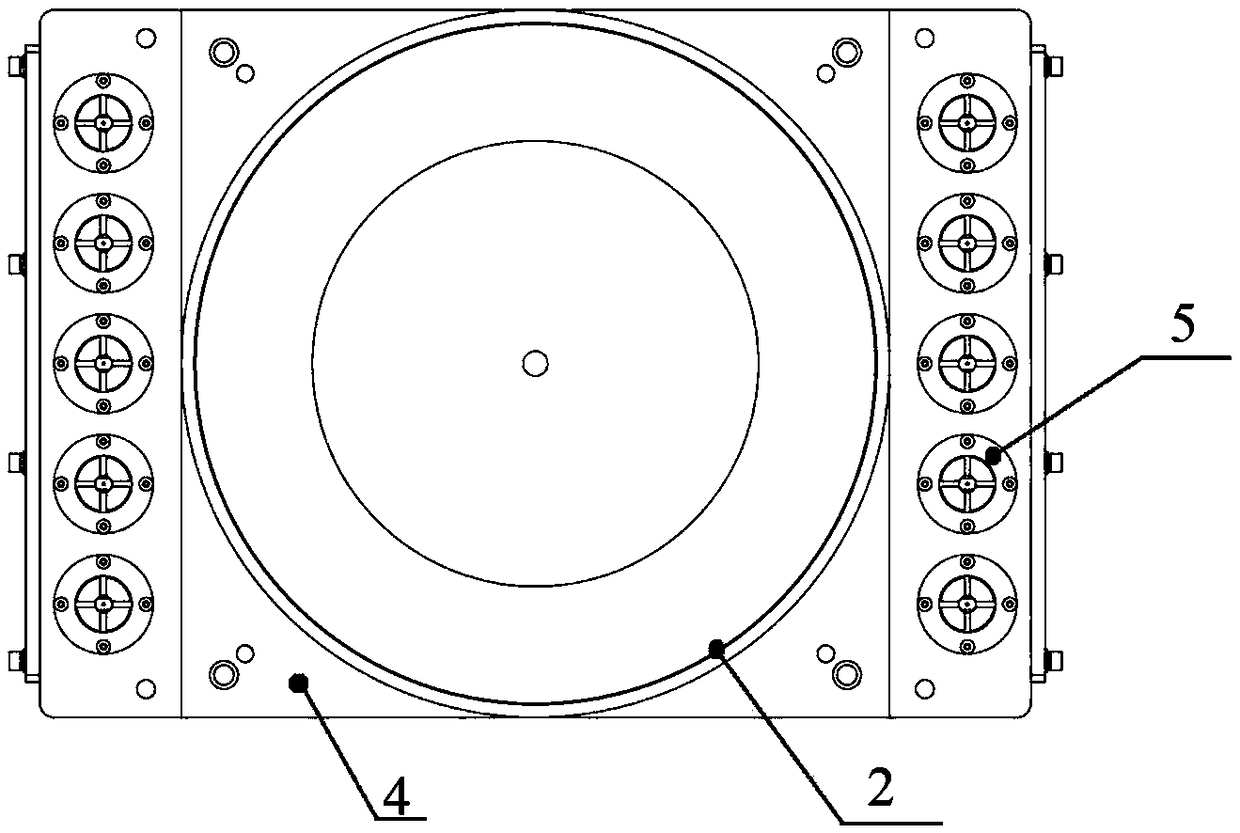

Stiffness-adjustable magnetic vibration isolator with quasi zero stiffness

ActiveCN106402262AImprove carrying capacityEnsure stabilityNon-rotating vibration suppressionNoise controlInternal pressure

The invention belongs to the technical field of vibration and noise control and relates to a relatively-high-applicability passive isolation technology for ultralow-frequency vibration. In order to effectively solve the problem between the low-frequency vibration transmissibility and the high-frequency vibration attenuation rate of the vibration isolator, the invention provides the stiffness-adjustable magnetic vibration isolator with quasi zero stiffness, which adopts rectangular permanent magnets generating negative stiffness and an elastic capsule providing positive stiffness; and when a load is changed, the working position of the elastic capsule is controlled unchanged, the positive stiffness of the elastic capsule is changed because the pressure inside the elastic capsule is changed, and then, the negative stiffness is matched with the positive stiffness through regulating the distance among the rectangular magnets, so that the stiffness-adjustable magnetic vibration isolator with quasi zero stiffness is adaptable to vibration isolation objects with different weights. The stiffness-adjustable magnetic vibration isolator with quasi zero stiffness is simple in structure, convenient to mount, adjustable in bearing capacity, excellent in vibration isolation property, compact in structure, light in weight and suitable for popularization and application.

Owner:NAVAL UNIV OF ENG PLA

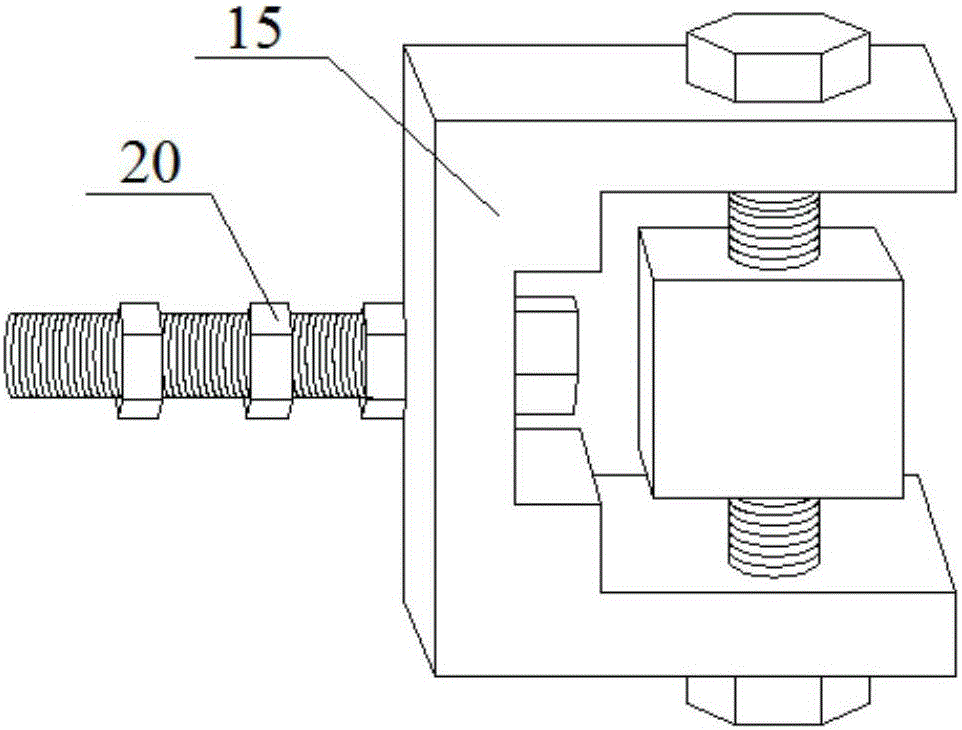

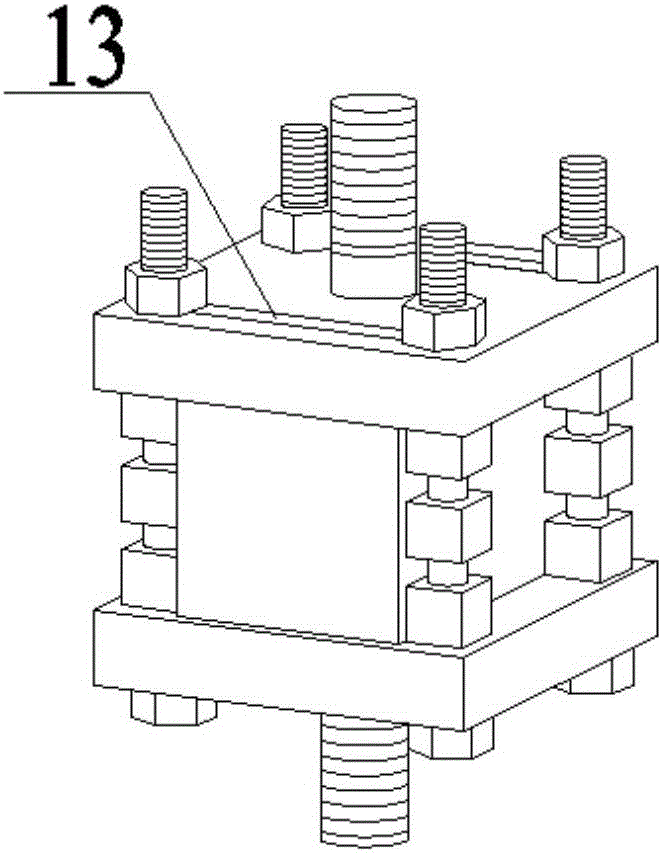

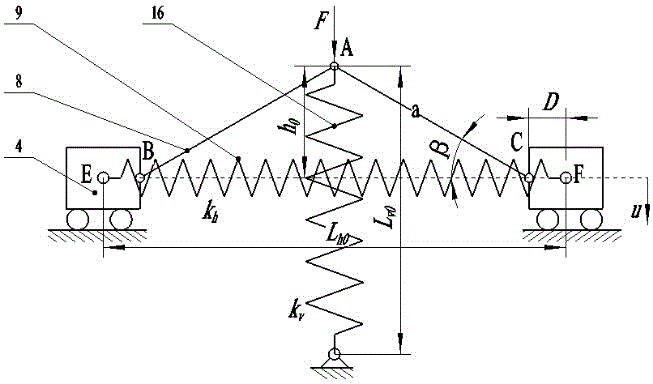

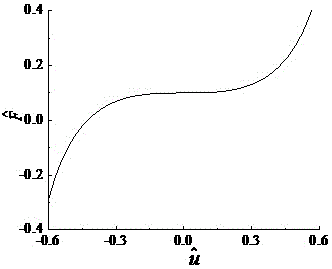

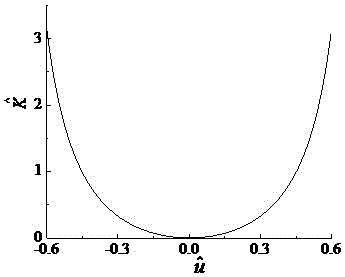

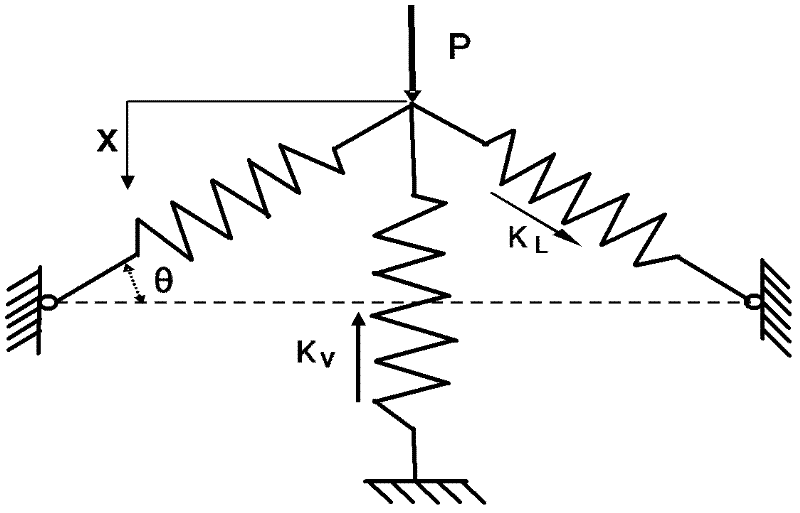

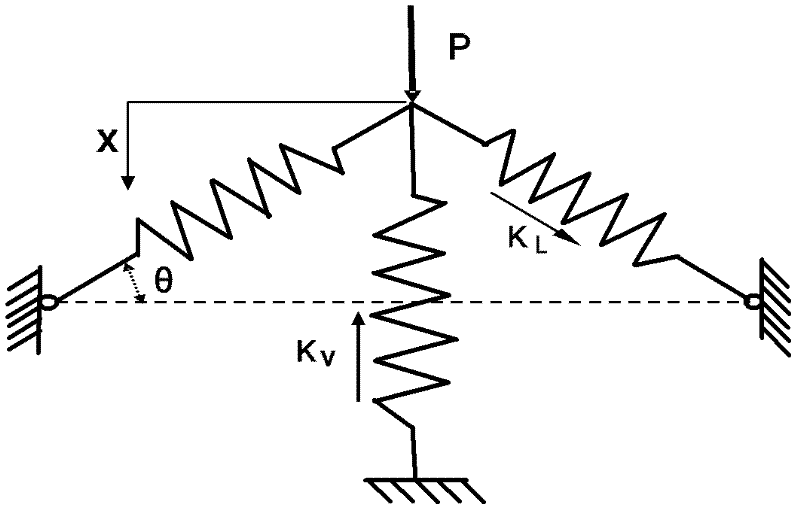

Extension type quasi-zero stiffness vibration isolator and implementation method thereof

InactiveCN106402267AAvoid the disadvantages of instabilityGuaranteed carrying capacityNon-rotating vibration suppressionShock absorbersAviationNegative stiffness

The invention relates to an extension type quasi-zero stiffness vibration isolator and an implementation method thereof. The vibration isolator is formed by a negative stiffness mechanism in parallel connection with a positive stiffness main spring, wherein the negative stiffness mechanism is composed of extension springs, connecting rods, slide blocks and guide rails; negative stiffness can be generated in the vertical direction, and in addition, the defect that compression springs lose stability can be avoided; and it can be guaranteed that the structure is in bilateral symmetry when fine adjustment is conducted in the horizontal direction. On the basis of the principle that positive stiffness and negative stiffness counteract each other, after the negative stiffness mechanism is in parallel connection with the positive stiffness spring, stiffness, at the equilibrium position, of the vibration isolator is close to zero, and inherent frequency is also close to zero, so that starting vibration isolation frequency is greatly reduced; the vibration isolation section is increased; and capability of isolating low frequency or ultralow frequency vibration is achieved. The vibration isolator is simple and compact in structure and convenient to assemble and debug and has certain engineering application value in the fields such as automobiles, precise instruments, sensitive equipment, precision machining and aerospace engineering.

Owner:FUZHOU UNIV

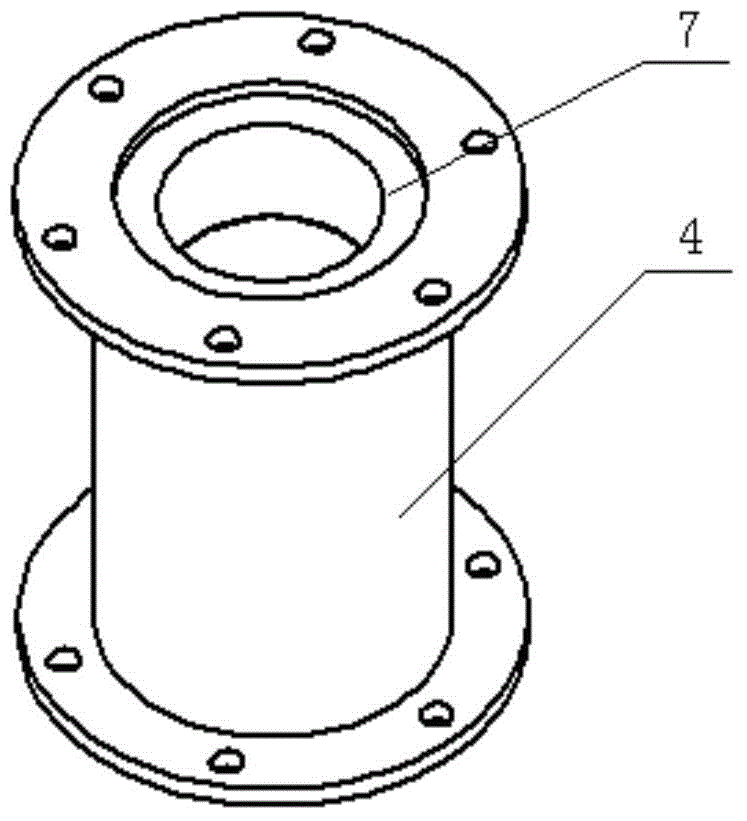

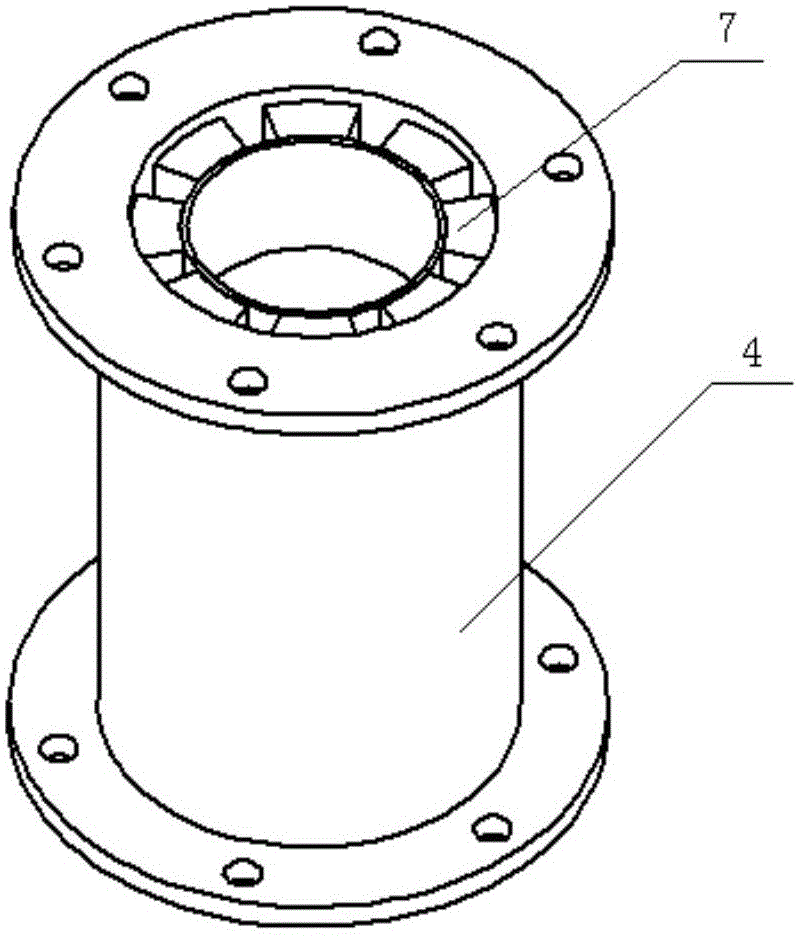

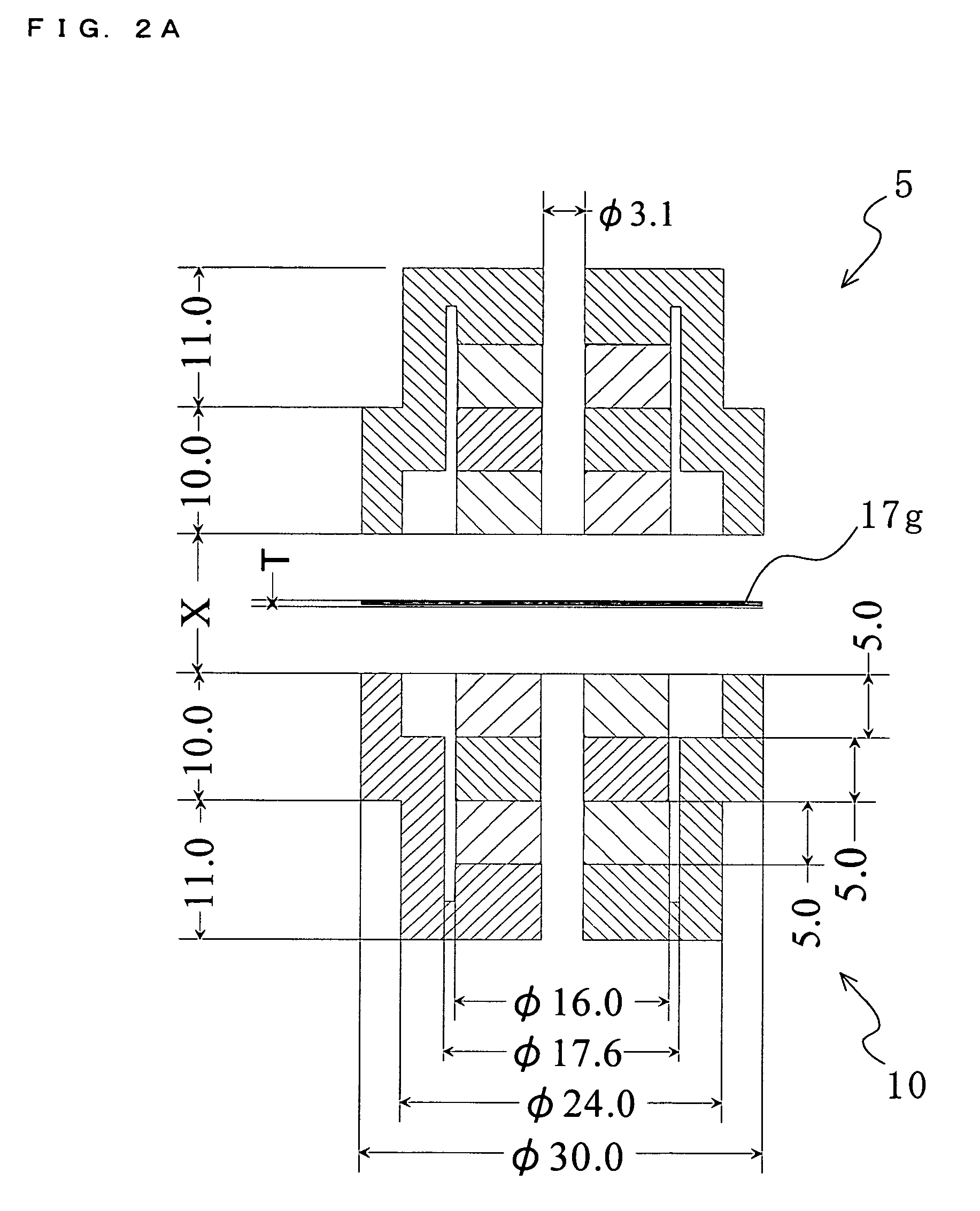

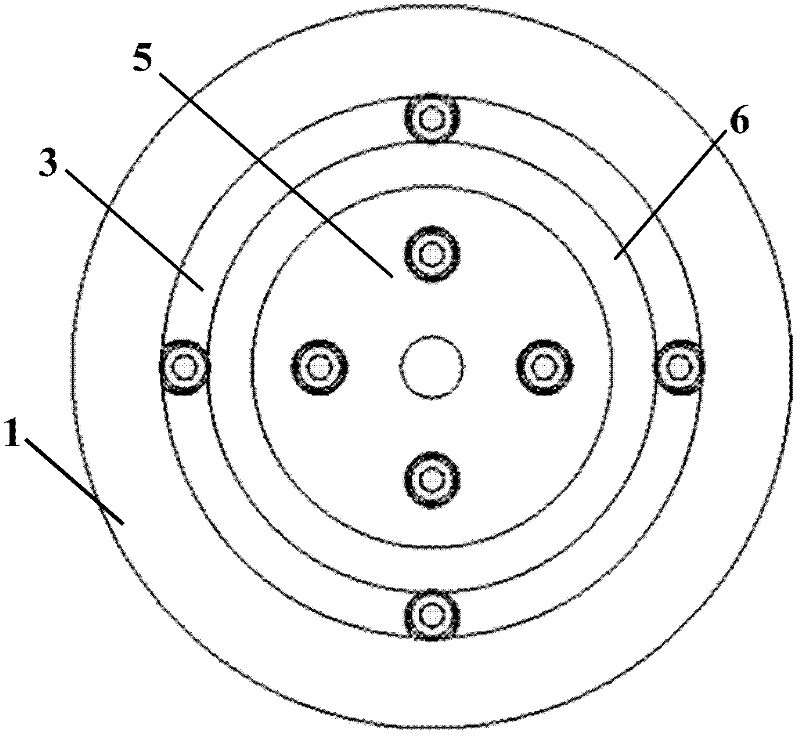

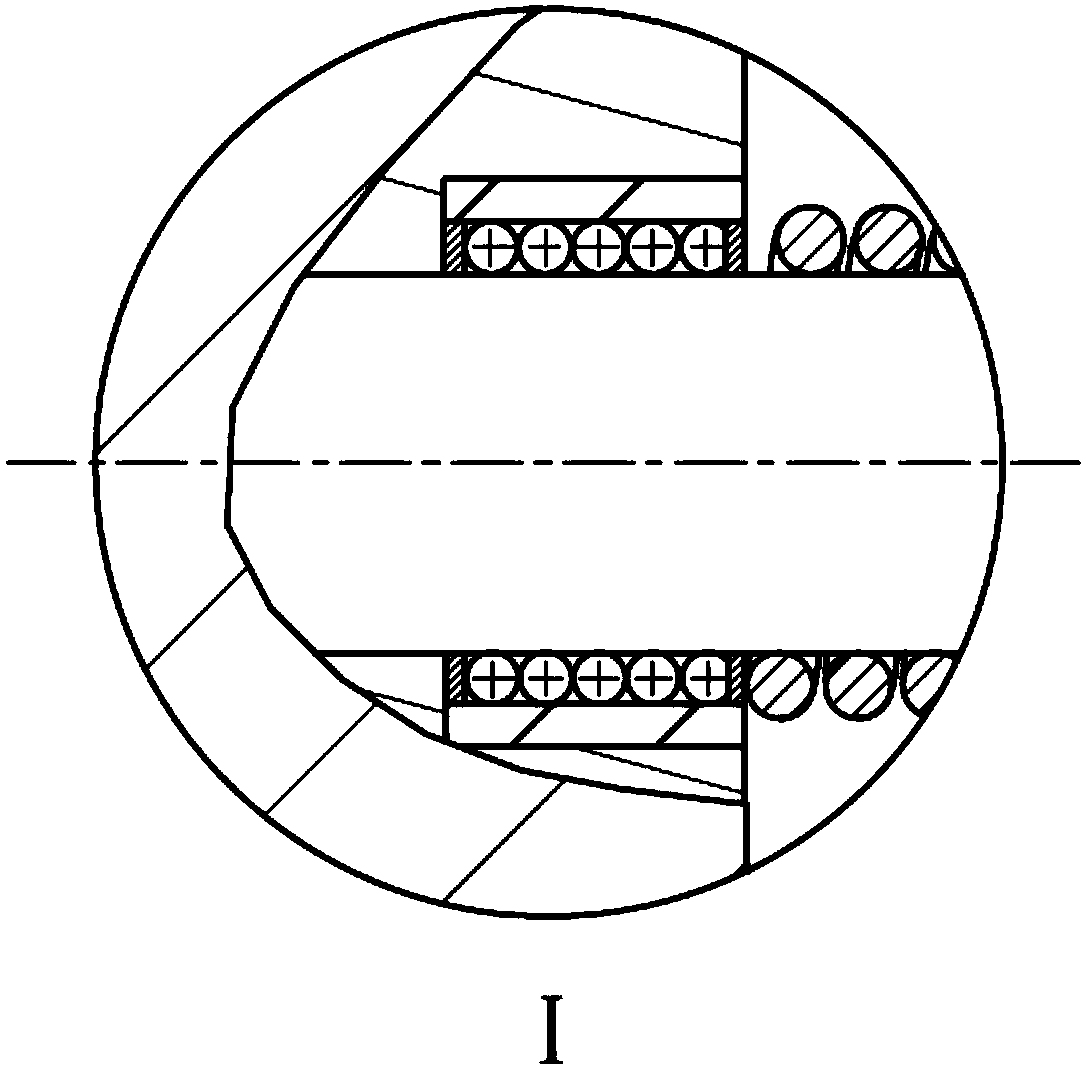

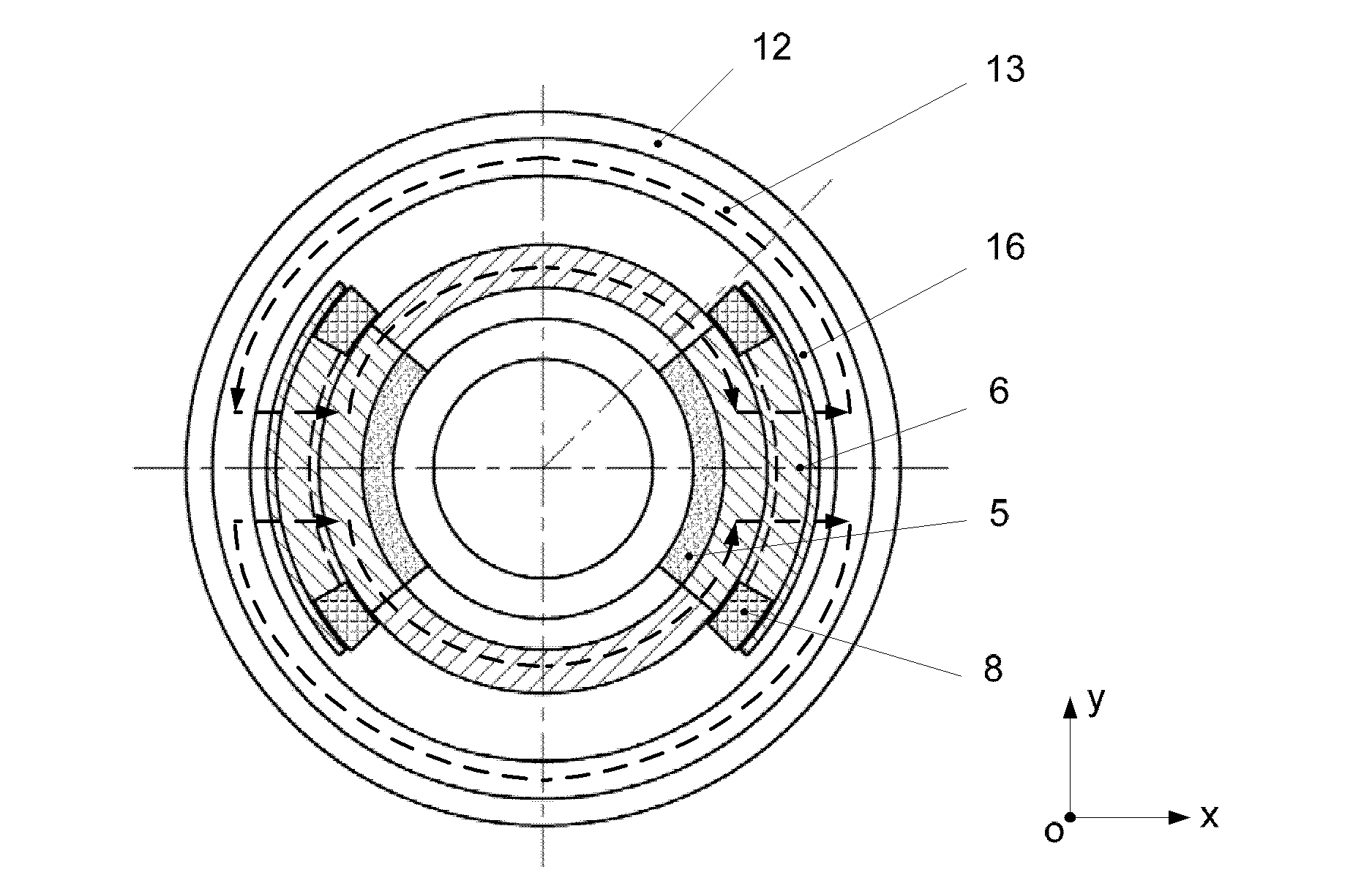

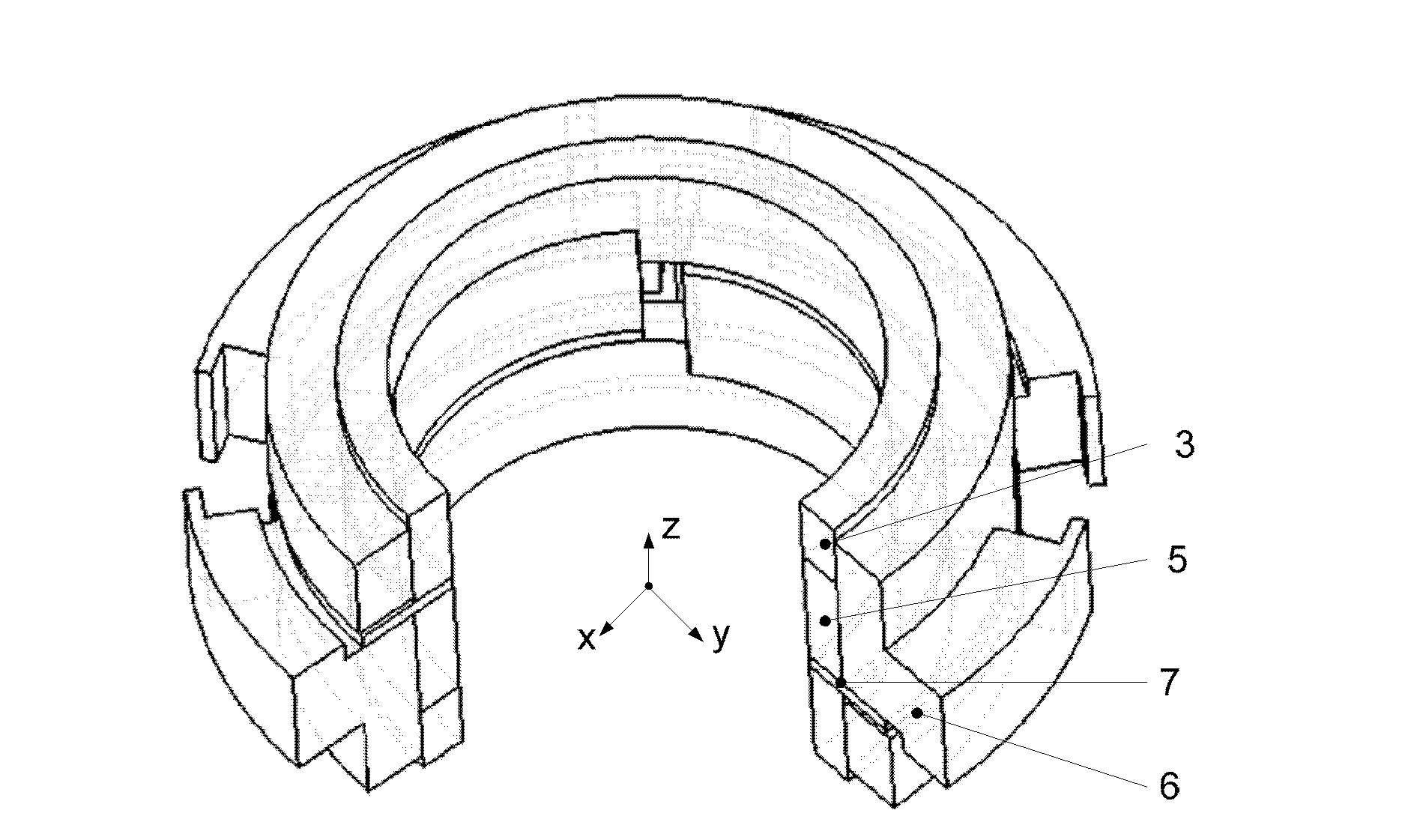

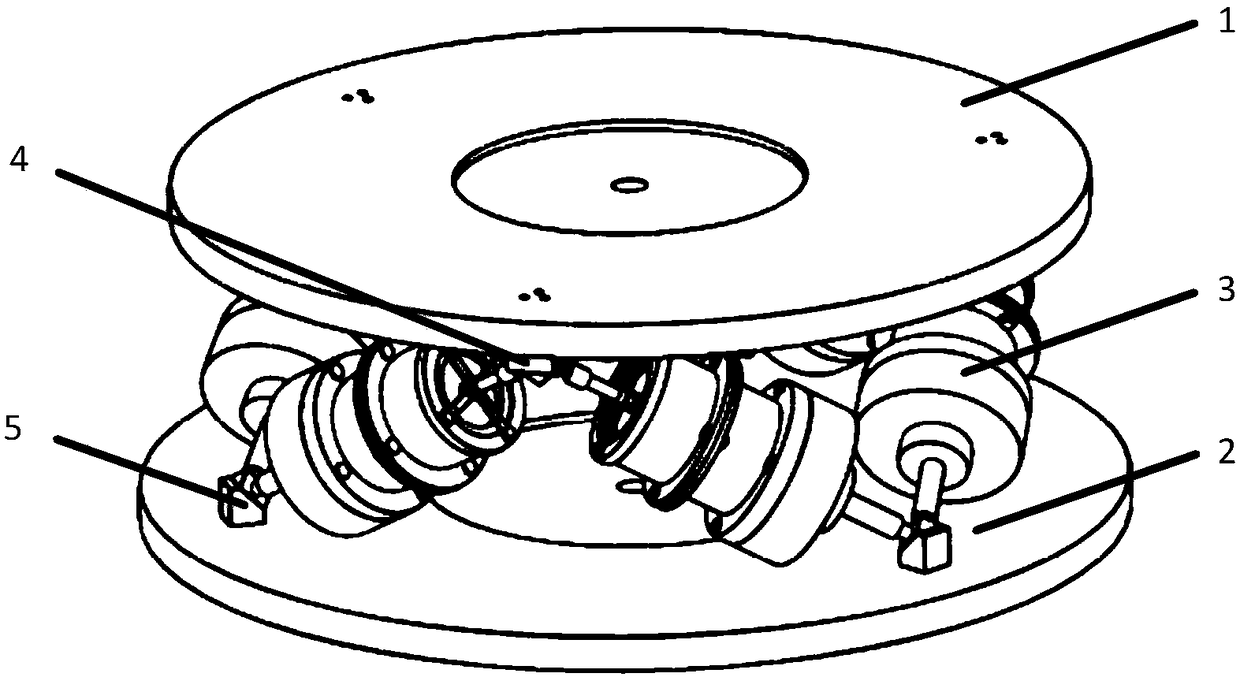

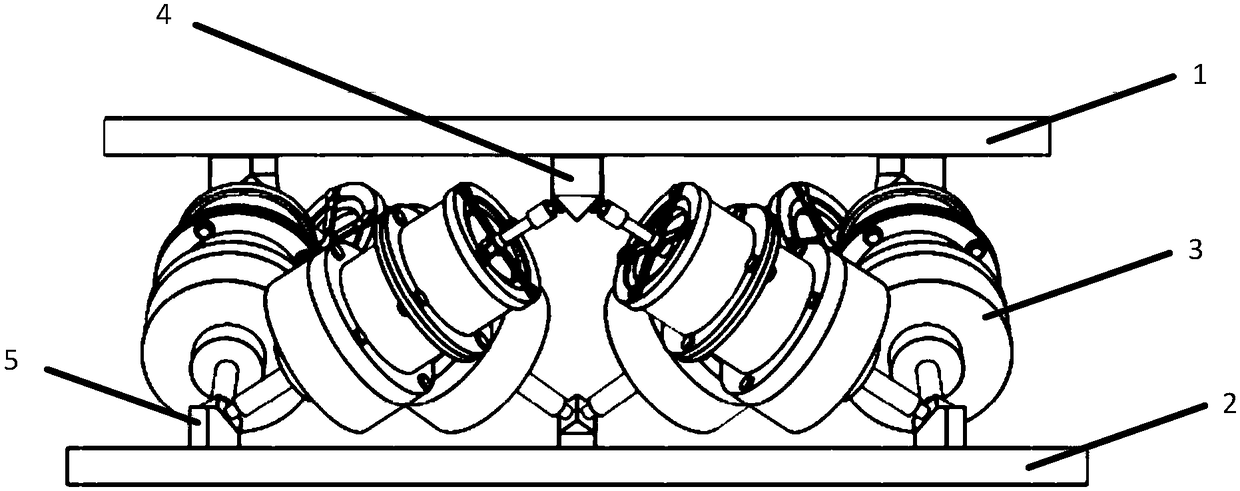

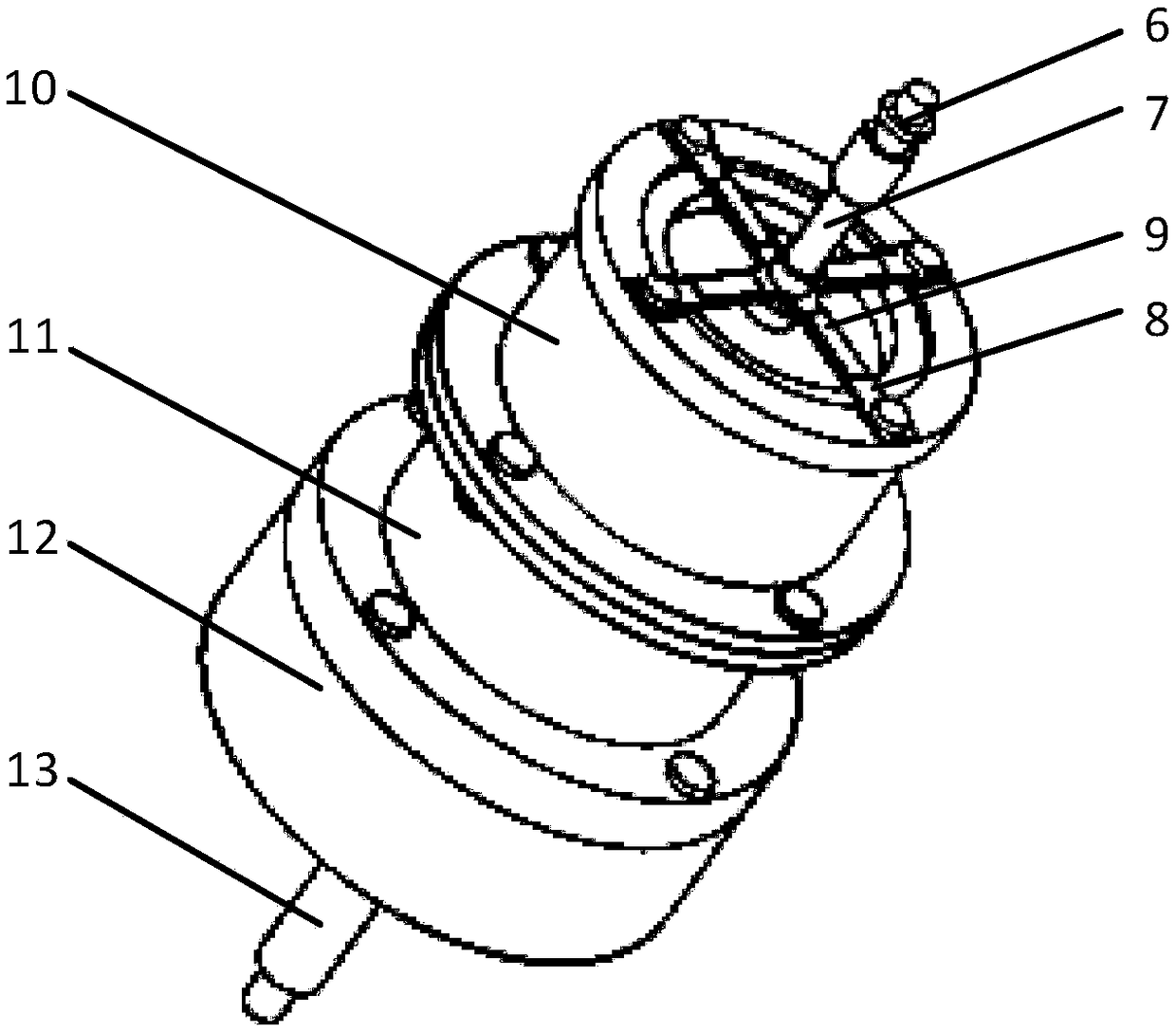

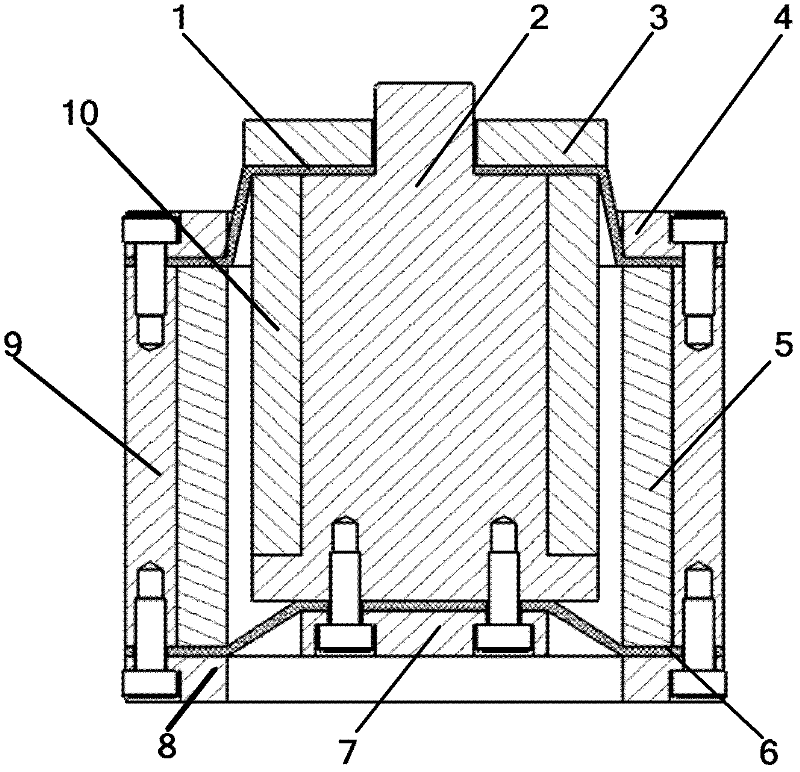

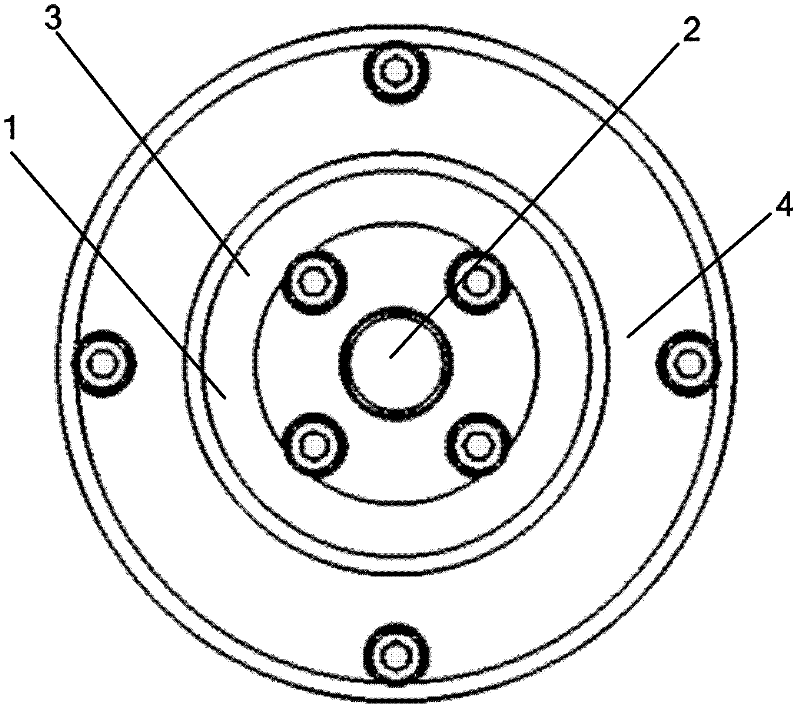

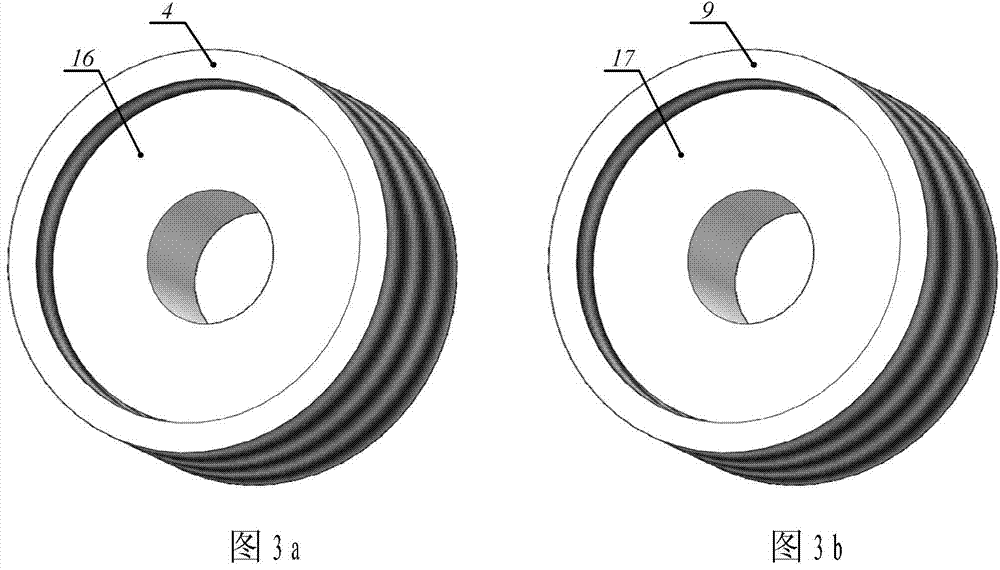

Quasi-zero stiffness vibration isolator with annular permanent magnets used for generating negative stiffness

InactiveCN104455181ALarge negative stiffnessImprove uniformityMagnetic springsShock absorbersDynamic stiffnessNegative stiffness

A quasi-zero stiffness vibration isolator with annular permanent magnets used for generating negative stiffness comprises a base and an outer cylinder connected with the base, the outer permanent magnet is arranged in a top notch of the outer cylinder, an upper cover is connected with the outer cylinder, a sliding bearing is combined with a central hole of the upper cover in a sleeved mode, and a central shaft is sleeved with the sliding bearing and is in clearance fit with the sliding bearing. A sleeve and an adjusting sleeve are sequentially connected to the position, located on the lower portion of the sliding bearing, of the central shaft, and the inner permanent magnet is installed in the sleeve. A spring is arranged at the bottom of the central shaft in a sleeving mode, the bottom end of the spring is fixed to the base, and the top end of the spring is fixed to the adjusting sleeve. A mark line on the central shaft is used for representing the position of the inner permanent magnet relative to the outer permanent magnet. When the mark line coincides with the upper end face of the sliding bearing, the inner permanent magnet exactly faces the outer permanent magnet, and the isolator is in a normal working state. The quasi-zero stiffness vibration isolator has the advantages of being high in static stiffness and low in dynamic stiffness, basic stimulation with large amplitude can be isolated, and the mass of a vibration-isolated objected can be adjusted.

Owner:XI AN JIAOTONG UNIV

Loudspeaker apparatus

ActiveUS7953240B2Promote reproductionReduce stiffnessFrequency/directions obtaining arrangementsTransducer casings/cabinets/supportsEngineeringNegative stiffness

Owner:PANASONIC CORP

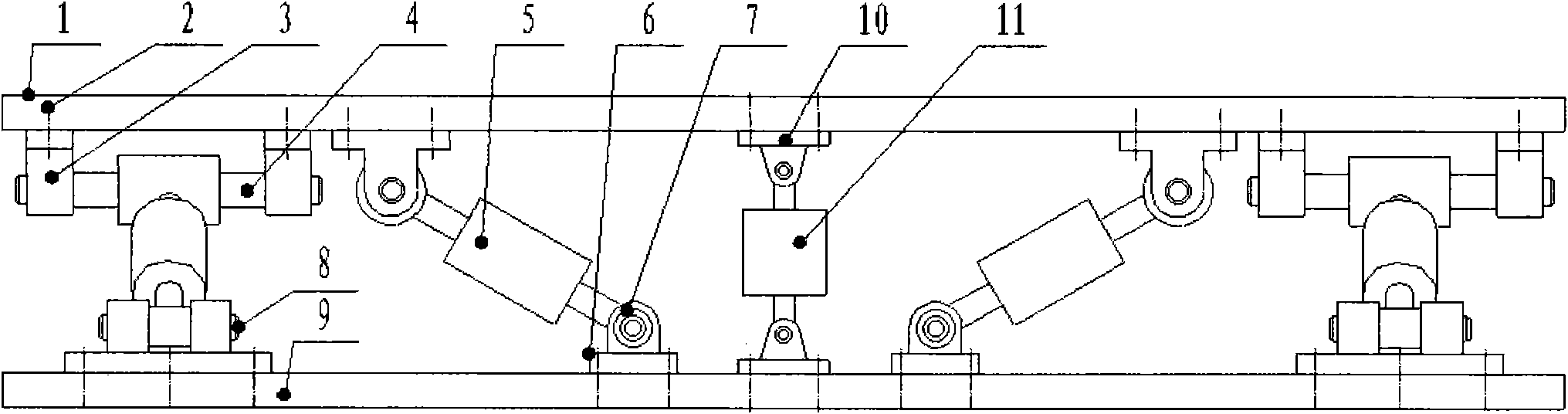

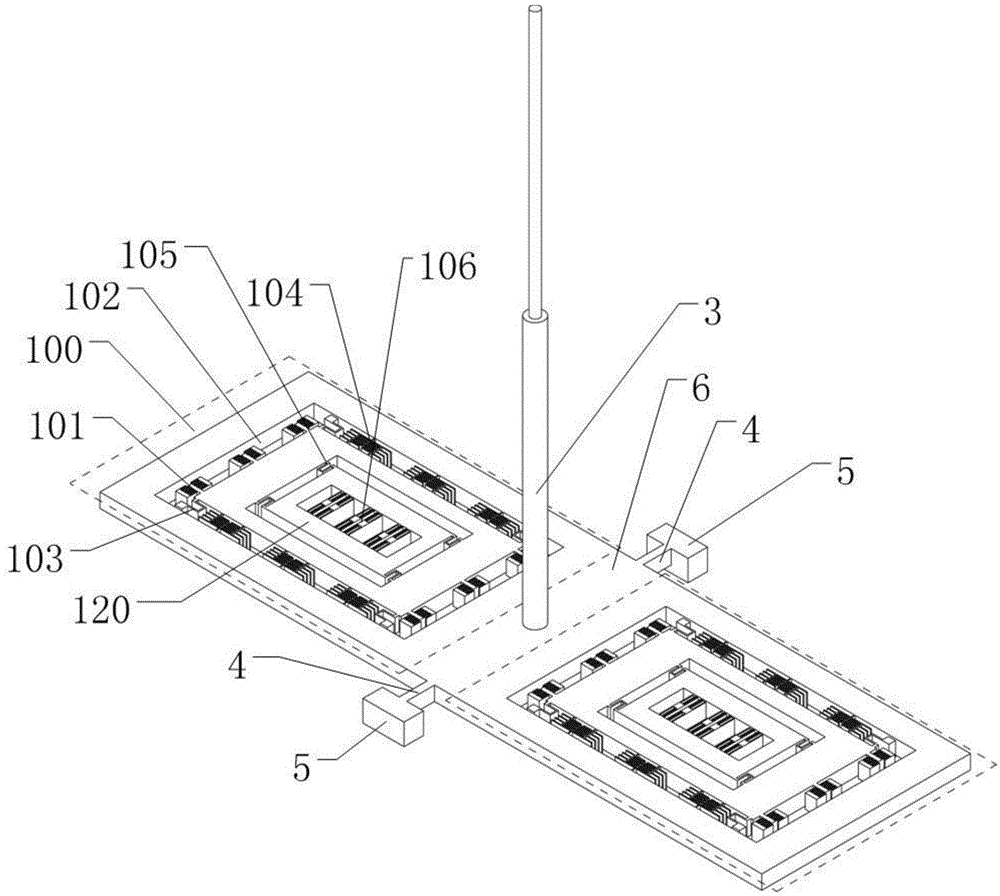

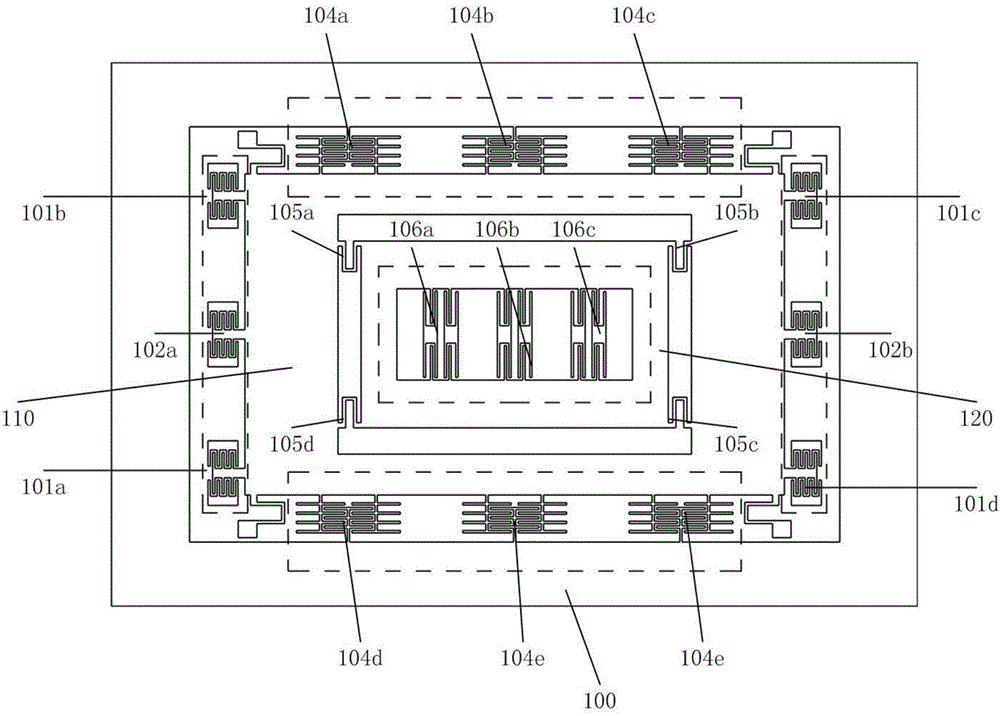

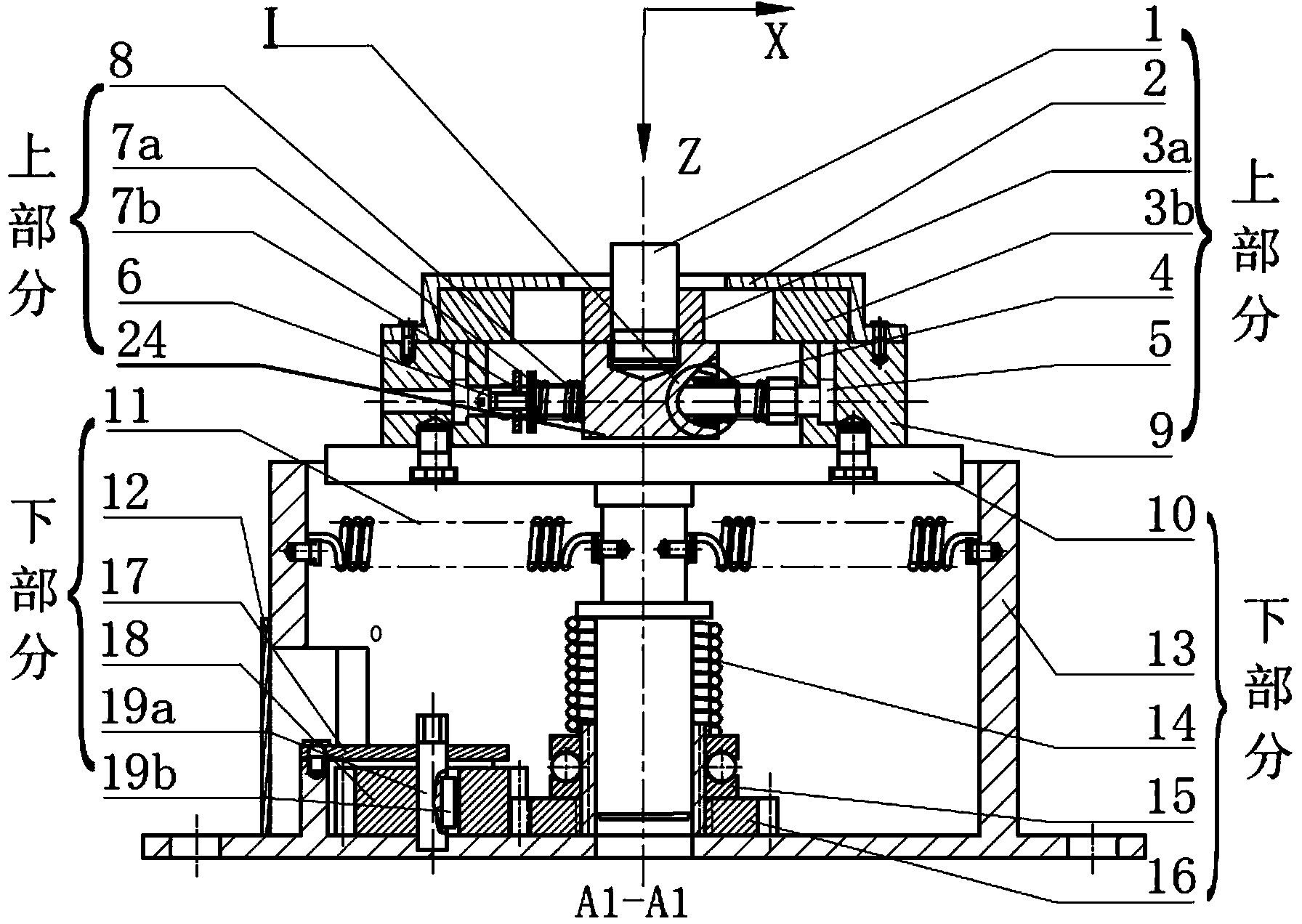

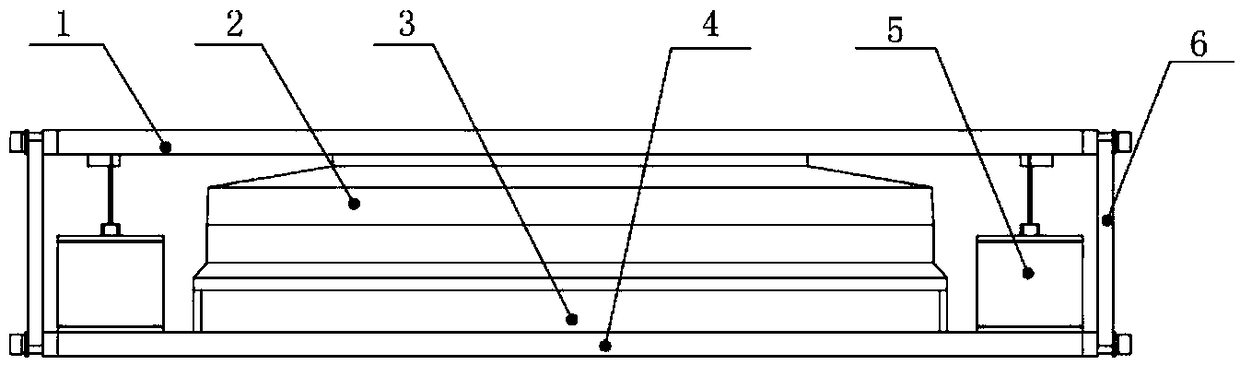

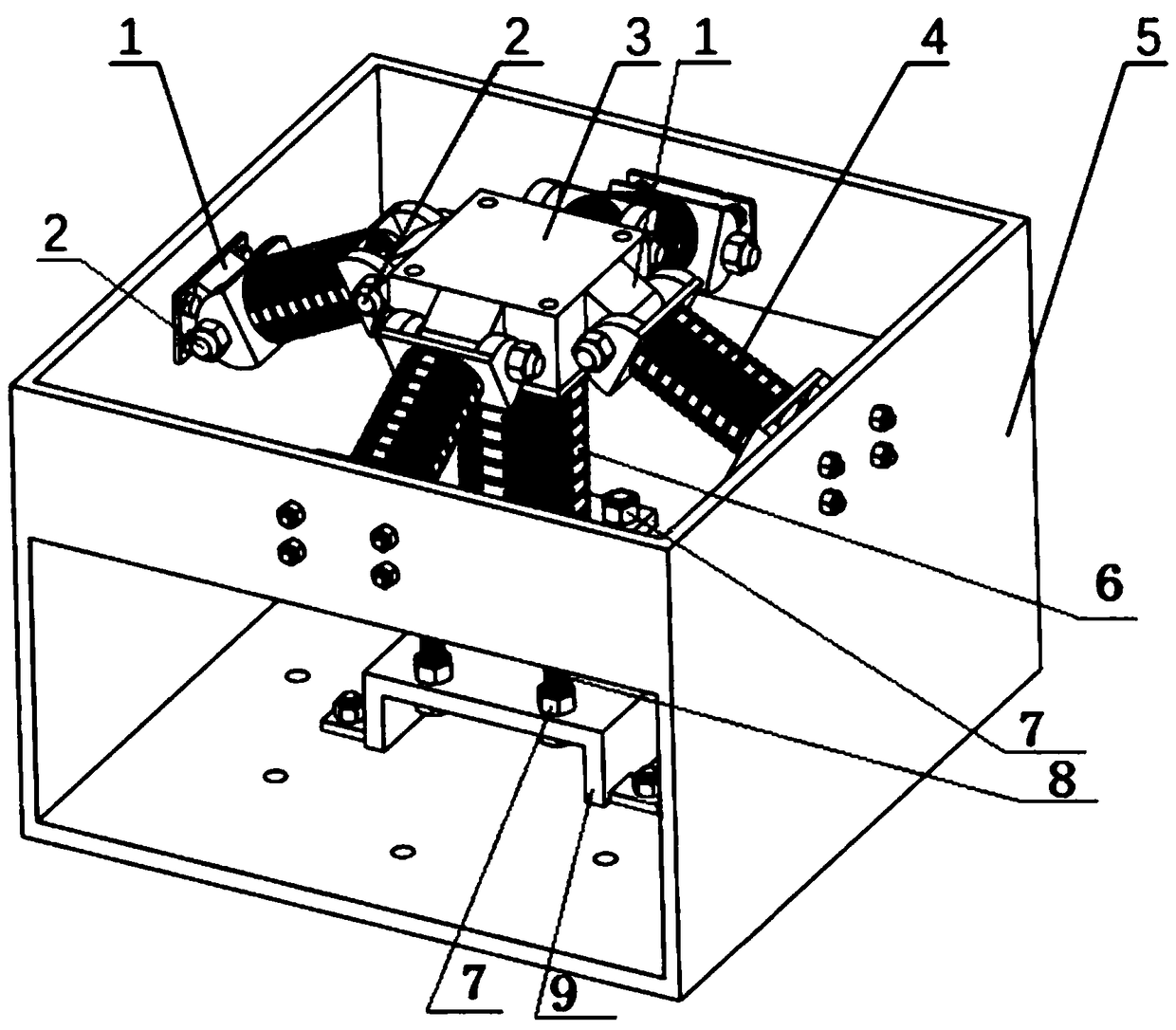

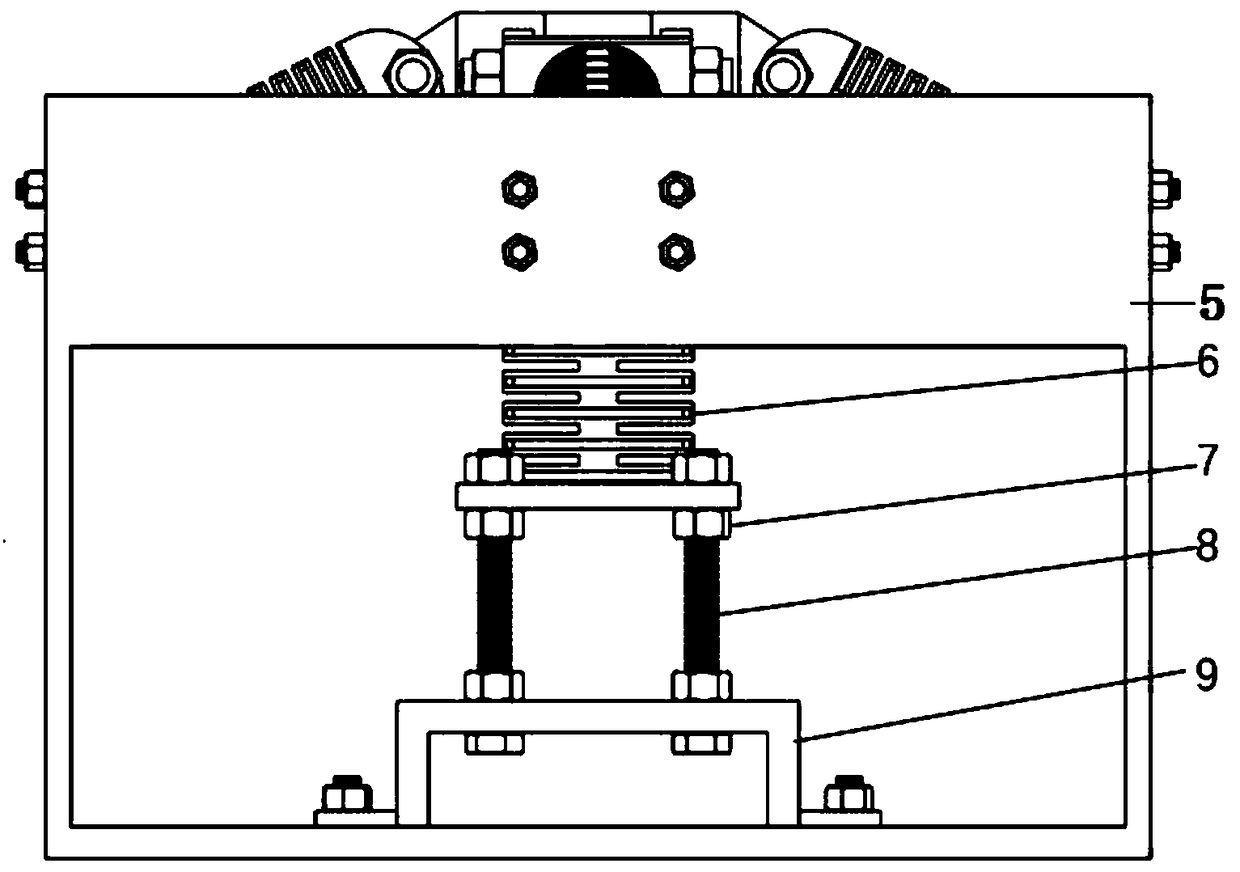

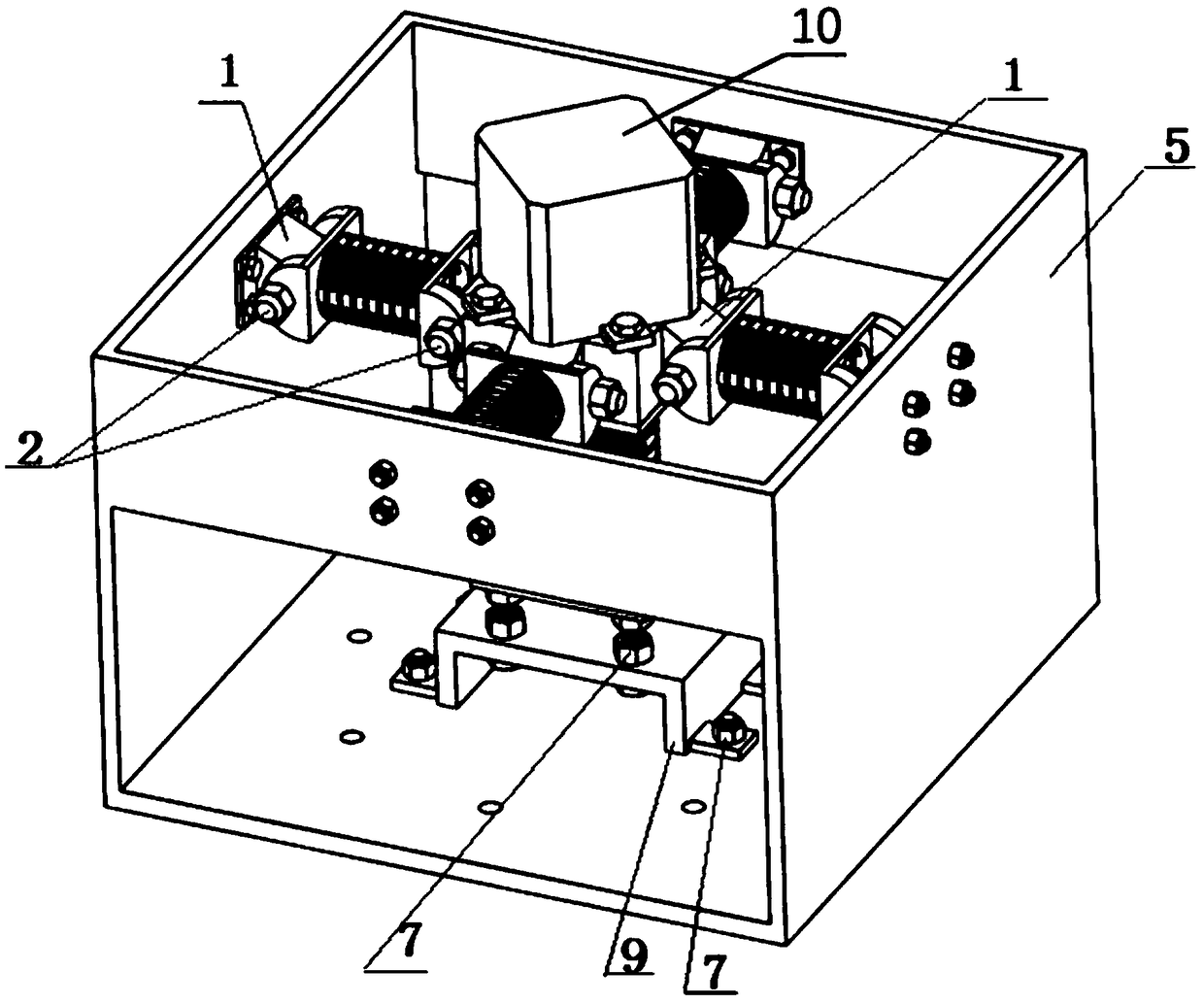

Positive and negative stiffness parallel three-translation vibration and impact isolation platform

InactiveCN101871505AImprove the dynamic environmentGuaranteed operating vibration parametersNon-rotating vibration suppressionAviationVibration control

The invention discloses a positive and negative stiffness parallel three-translation vibration and impact isolation platform, and belongs to the field of the multi-axis vibration control technology and multi-axis vibration control devices, which comprises an upper platform (1), a lower platform (9), eight elastic branched-chain structures and a silica gel magnetorheological damper (11), wherein the eight elastic branched-chain structures are fixed between the upper platform (1) and the lower platform (9) two by two in an orthogonally symmetrical four-point supporting mode; the axes of the two elastic branched-chain structures of each point are vertical mutually; and the silica gel magnetorheological damper (11) is arranged in the geometric center between the upper platform (1) and the lower platform (9). The positive and negative stiffness parallel three-translation vibration and impact isolation platform can be widely used for instruments and equipment in fields of aviation, space flight, weapons, vehicles, ships, construction, nuclear industry, mechanical industry, optical industry, semiconductor industry, photosensitive chemistry and the like, and has the advantages of large carrying capacity, high stability, small volume, low natural frequency, controlled damping, low cost of manufacturing and maintenance and the like.

Owner:SHANGHAI HIGHER MECHANICAL & ELECTRICAL

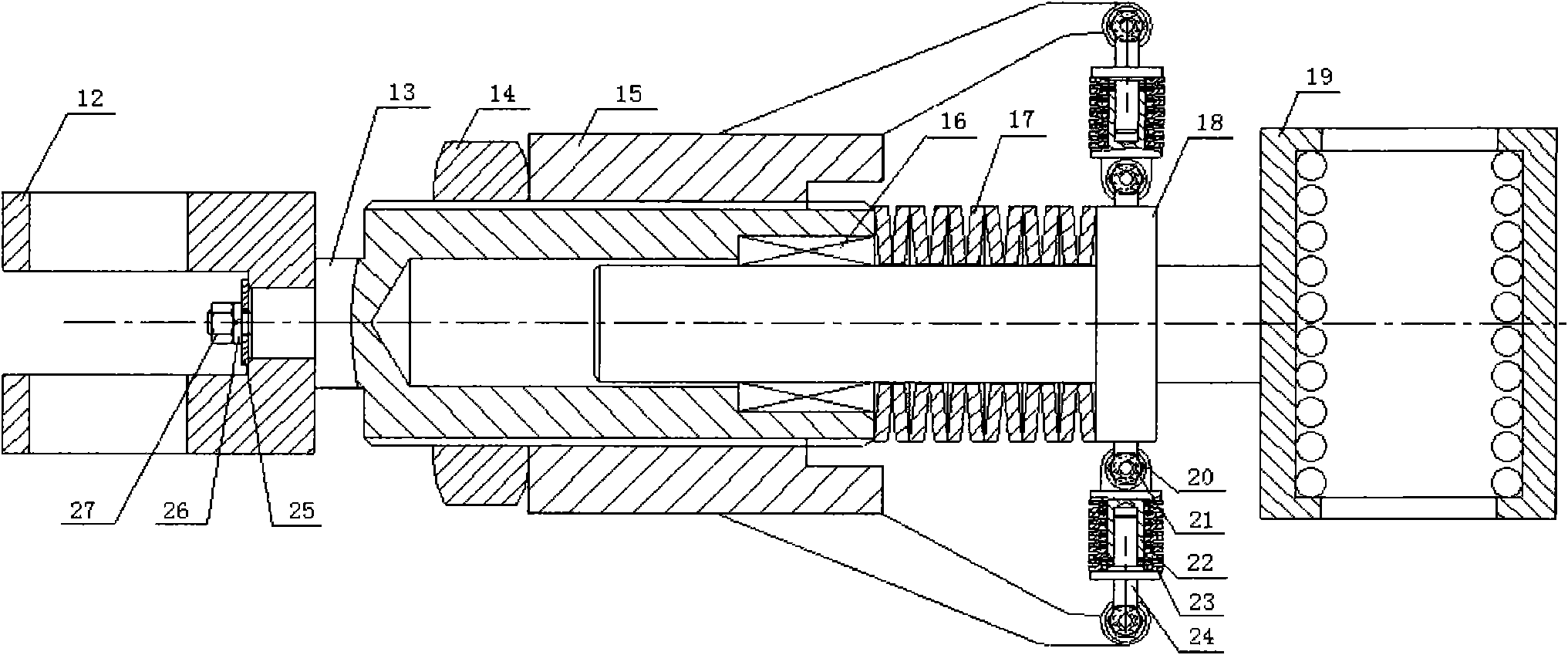

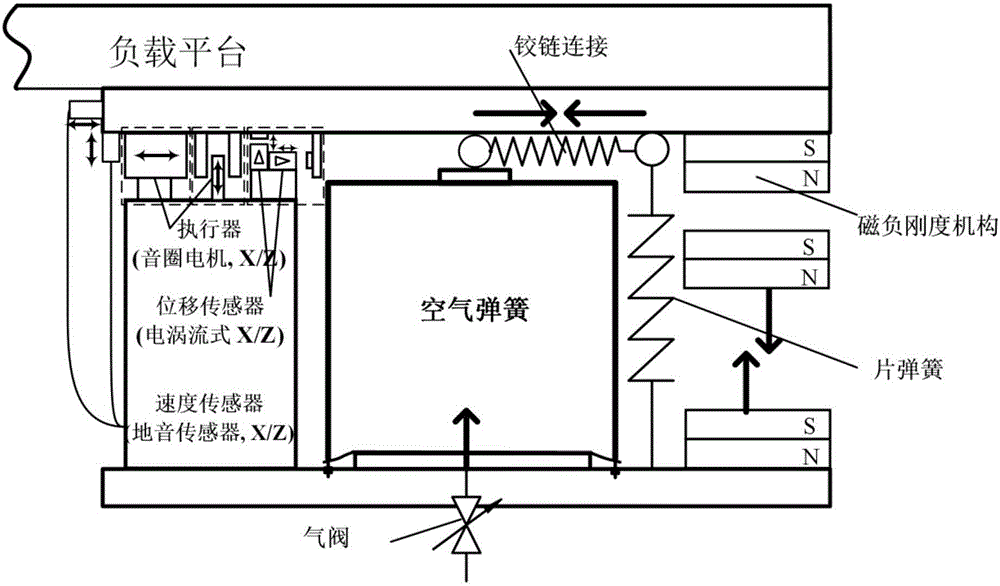

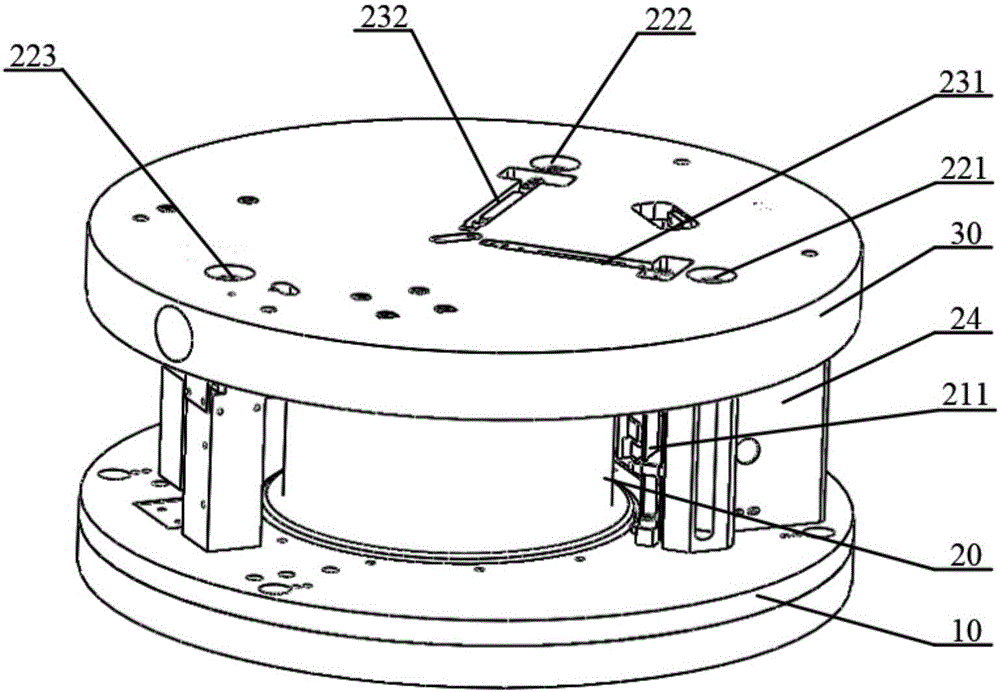

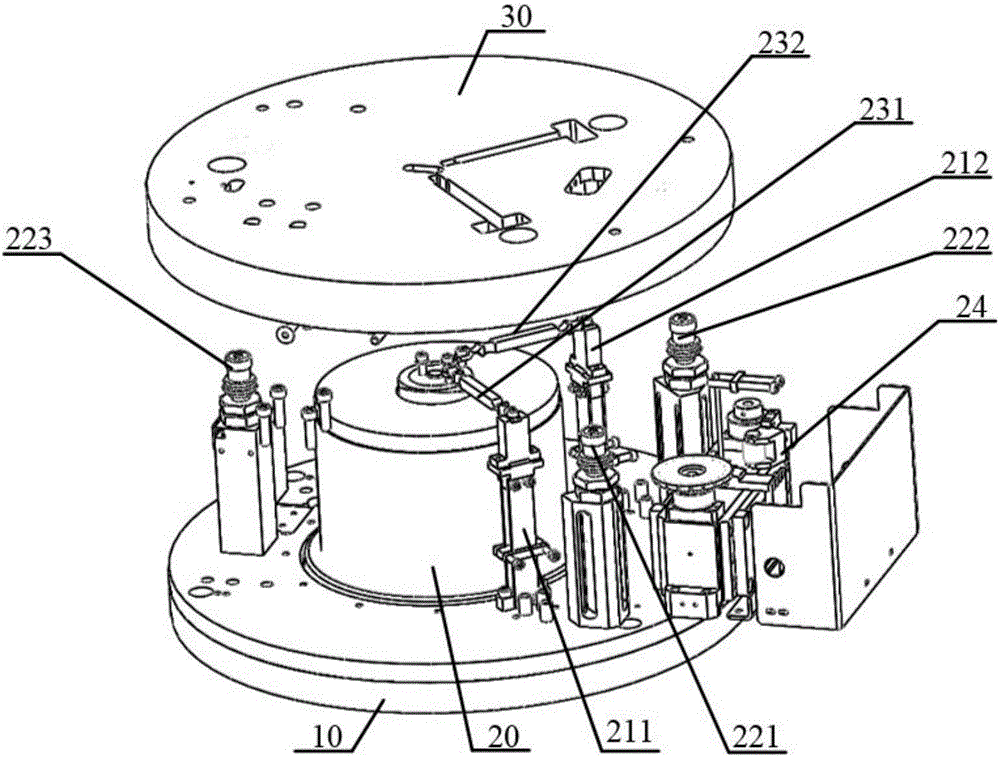

Active-passive combined vibration isolator based on positive-stiffness and negative-stiffness parallel connection

ActiveCN106321719AHigh static stiffnessRaise the natural frequencyMagnetic springsGas based dampersAir springNegative stiffness

The invention discloses an active-passive combined vibration isolator based on positive-stiffness and negative-stiffness parallel connection. The active-passive combined vibration isolator based on positive-stiffness and negative-stiffness parallel connection comprises a basic platform (10), a load-bearing platform (30), a passive vibration isolation unit and an active vibration isolation unit, wherein the passive vibration isolation unit is provided with a positive-stiffness air spring (20) and a magnetic negative-stiffness mechanism (28) with adjustable negative stiffness in the first direction, so that the inherent frequency in the first direction is decreased, and the passive vibration isolation unit is provided with a stiffness-adjustable positive-stiffness leaf spring and a negative-stiffness inverted pendulum in the second direction, so that the inherent frequency in the second direction is decreased; the active vibration isolation unit is arranged at the outer side of the passive vibration isolation unit, the upper end of the active vibration isolation unit is linked with the load-bearing platform (30), and the lower end of the active vibration isolation unit is linked with the basic platform (10); and the active vibration isolation unit comprises displacement sensors, speed sensors, a proportional pressure valve and a voice coil motor, and the voice coil motor is used for fine adjustment of the load-bearing platform, so that vibration is further isolated. The active-passive combined vibration isolator based on positive-stiffness and negative-stiffness parallel connection has high bearing capacity, and active and passive vibration isolation of two degrees of freedom is achieved at the same time.

Owner:HUAZHONG UNIV OF SCI & TECH

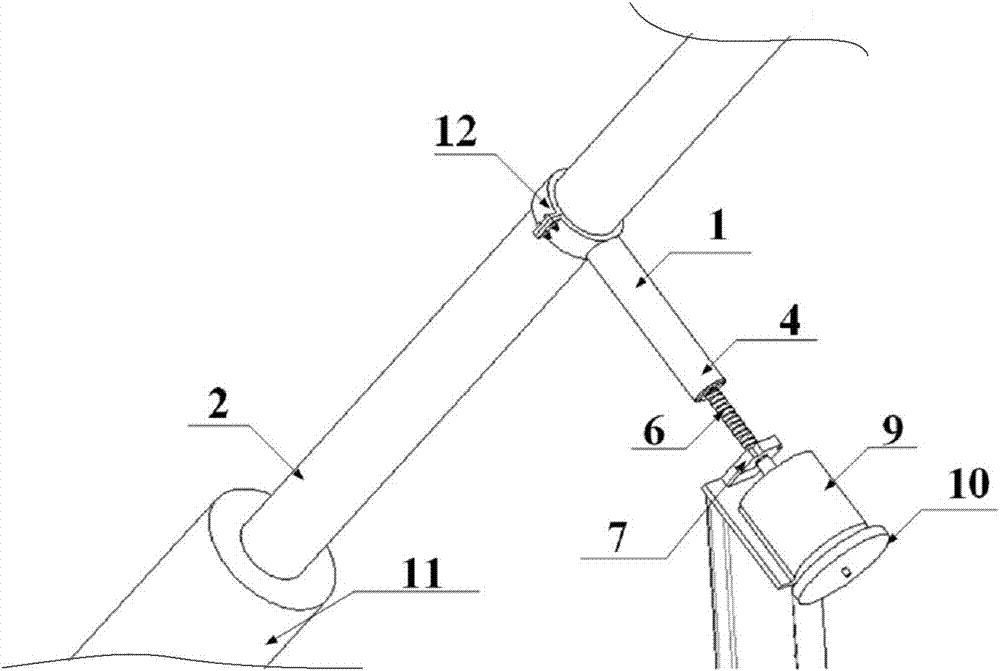

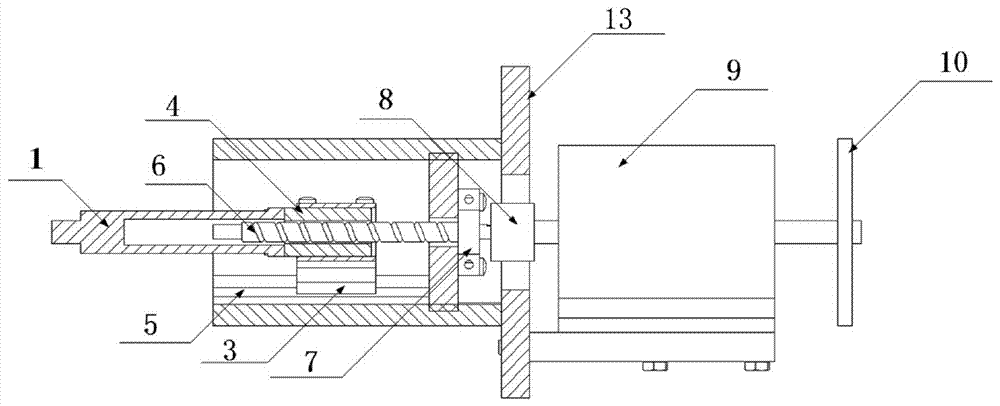

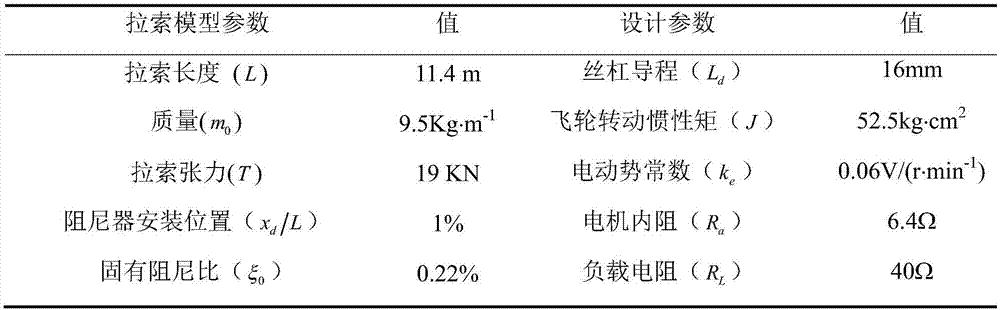

Stayed cable vibration damper and design method for apparent mass rotating electromagnetic damper

ActiveCN107022955AAmplify the speedIncrease the equivalent damping coefficientRotating vibration suppressionFlywheelsDamping factorFundamental frequency

The invention belongs to the technical field of engineering structure control, and in particular relates to a stayed cable vibration damper and a design method for an apparent mass rotating electromagnetic damper. The stayed cable vibration damper comprises a damping device and a transmission mechanism, the transmission mechanism is used for connecting the stayed cable and the damping device, the design method comprises the steps that the fundamental frequency of the stayed cable is determined; the installation location of the apparent mass rotating electromagnetic damper is determined; the damping parameters of the apparent mass rotating electromagnetic damper is calculated; and the stiffness parameters of the apparent mass rotating electromagnetic damper is calculated. According to the stayed cable vibration damper and the design method for the apparent mass rotating electromagnetic damper, a ball screw is utilized to effectively improve the rotational speed of the rotating electromagnetic damper, the equivalent damping coefficient of the damper is improved, and the energy consumption efficiency of the electromagnetic damper is improved; and an inertia flywheel mounted on a rotating shaft of the electromagnetic damper generates an apparent mass effect, the apparent mass effect is amplified through a ball screw mechanism, the stayed cable vibration damping mechanism is provided passive negative stiffness control characteristics, and the vibration damping effect of the stayed cable is effectively improved.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

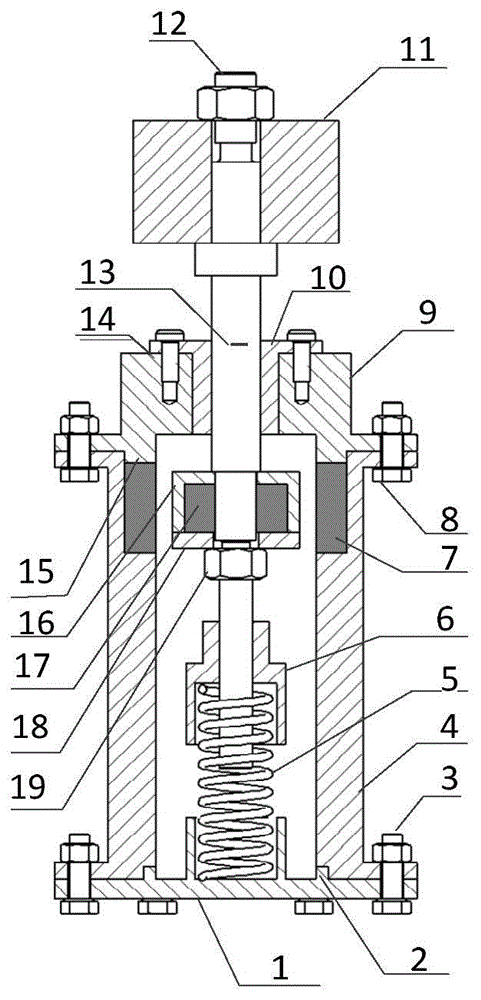

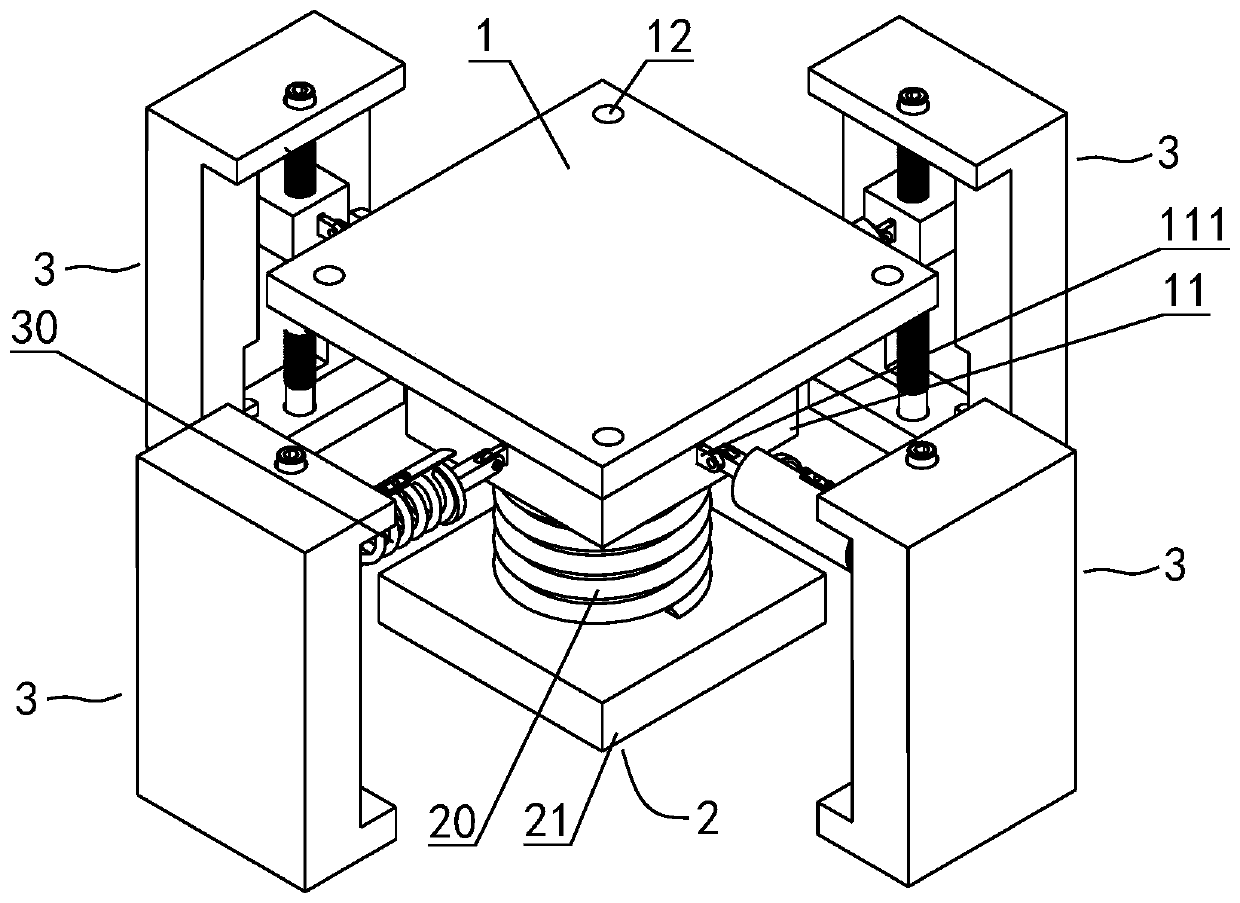

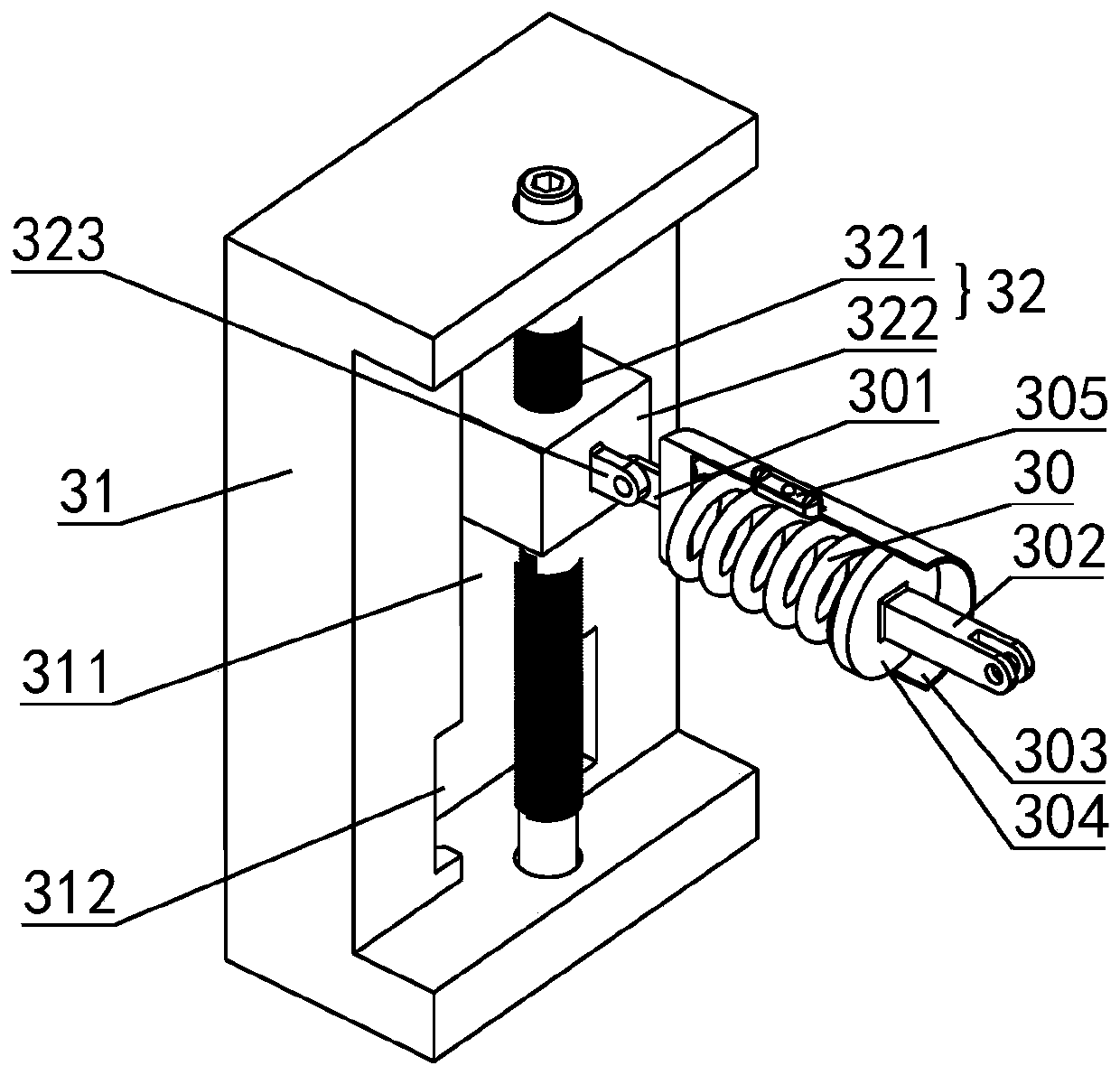

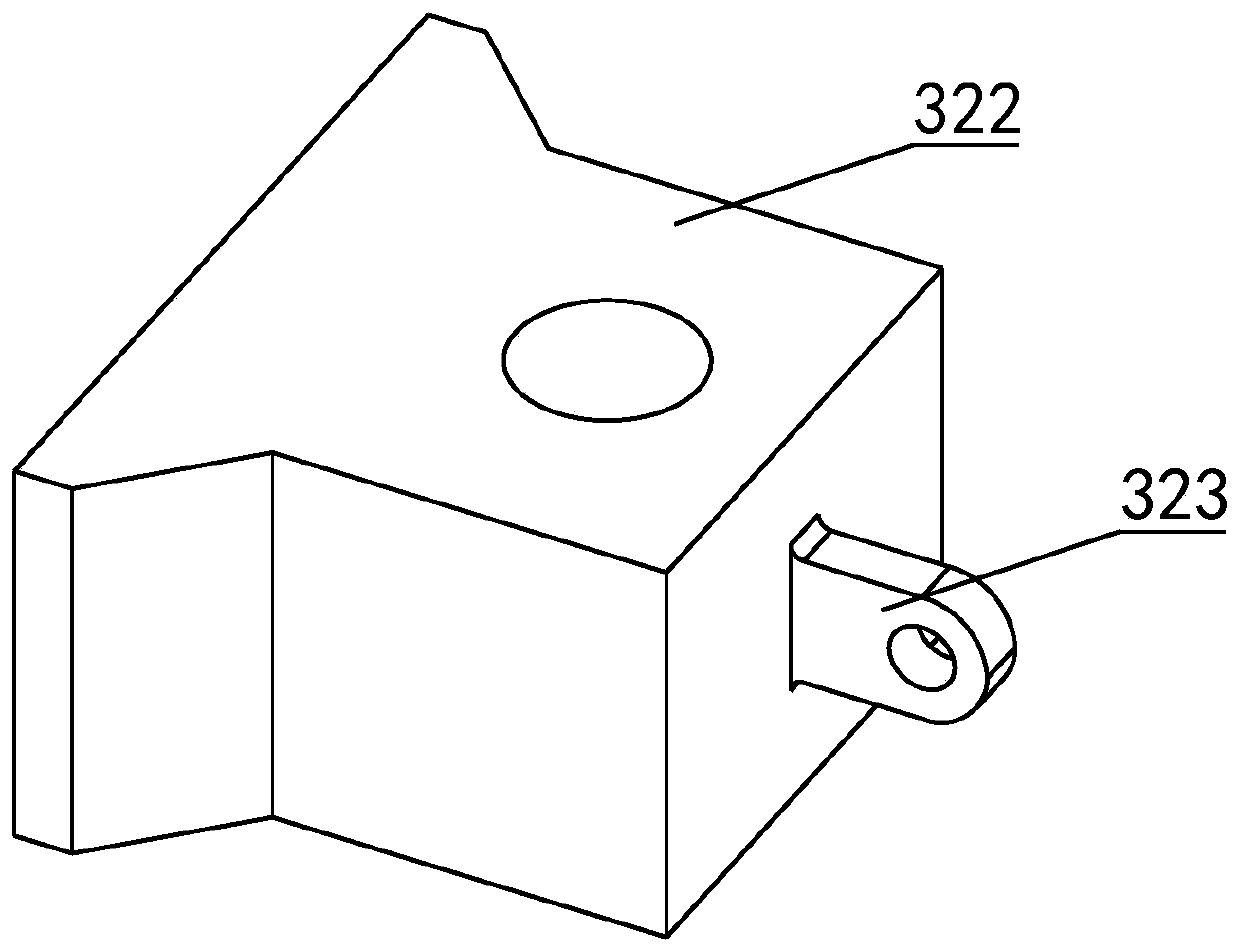

Negative stiffness adjustable zero stiffness vibration isolation device and application method thereof

PendingCN110388408AAvoid failureFlexible adjustment of positive stiffnessNon-rotating vibration suppressionSprings/dampers functional characteristicsDynamic stiffnessEngineering

The invention discloses a negative stiffness adjustable zero stiffness vibration isolation device and an application method thereof, wherein the negative stiffness adjustable zero stiffness vibrationisolation device comprises a bearing table, a positive stiffness mechanism is arranged at the lower side of the bearing table, a plurality of adjustable negative stiffness mechanisms which are centrosymmetrically arranged are connected around the bearing table, the positive stiffness mechanism comprises a vertical elastic element for supporting the bearing table, and the adjustable negative stiffness mechanism comprises a horizontal elastic element for applying horizontal acting force to the bearing table; and the application method comprises the steps of installing a bearing object on the bearing table and then adjusting each height adjusting mechanism to enable the horizontal elastic element to be horizontal. The negative stiffness adjustable zero stiffness vibration isolation device canflexibly adjust the negative stiffness according to the bearing at any time, so that the negative stiffness can be adjusted according to the actual situation after bearing, the negative stiffness adjustable zero stiffness vibration isolation device can be adjusted to ensure that the negative stiffness adjustable zero stiffness vibration isolation device is in an ideal state that the dynamic stiffness is close to zero in a static load state after field installation, the failure of a vibration isolation system can be avoided, and the negative stiffness adjustable zero stiffness vibration isolation device has the advantages of simple structure, easiness in processing, convenience in loading and unloading, reasonable design and easiness in adjustment.

Owner:STATE GRID HUNAN ELECTRIC POWER +2

Ultralow frequency vibration isolator based on parallel connection of positive stiffness spring and negative stiffness spring

InactiveCN102619916AWith ultra-low frequency zero Hz vibration isolation performanceGuaranteed vibration isolation performanceShock absorbersDynamic stiffnessVibration attenuation

The invention discloses an ultralow frequency vibration isolator based on parallel connection of a positive stiffness spring and a negative stiffness spring, comprising a guide post, a sheath cover, a sliding block, a negative stiffness spring, a lower cover, a guide seat, a ball and a main spring. According to the invention, the main spring (a positive stiffness spring) is connected with the negative stiffness spring in parallel, thus a vibration damper can have the characteristics of high static stiffness and low dynamic stiffness, and zero-hertz ultralow frequency vibration isolation is realized; connection of a screw thread pair is adjusted, thus a stiffness curve of a vibration isolator is adjusted according to vibration isolation quality, and vibration isolation performance can be adjustable; and rolling friction is realized by adopting balls, thus frictional resistance is reduced. The ultralow frequency vibration isolator disclosed by the invention can be used as one component and is applicable to an environment under vibrational excitation, especially an environment under low frequency vibrational excitation, such as a vehicle seat, a suspension, precise instrument vibration isolation as well as vibration attenuation and seismic resistance.

Owner:JILIN UNIV

Bionic hair sensor for flow velocity, acceleration and angular velocity sensitivity

ActiveCN104459181ARealize measurementEasy to digitizeFluid speed measurementDevices characerised by mechanical meansSensor arrayCapacitance

The invention relates to a bionic hair sensor for flow velocity, acceleration and angular velocity sensitivity. The bionic hair sensor comprises top hair, a middle silicon micro sensor structure and a bottom signal lead manufactured on a glass substrate. The top hair can drive an outer frame in the silicon micro sensor structure to swing left and right. The negative stiffness effect principle of electrostatic force is used for detecting the acceleration and the flow velocity. A sensor array mode is used for distinguishing the detection of the acceleration and detection of the flow velocity. When external input is acceleration input, all the sensors can be subjected to action to generate torque. Two sub-structures in the silicon micro sensor structure are of gyroscope structures and are used for detecting the external angular velocity, the two sub-structures are arranged in left-and-right symmetry and are two times of a single gyroscope in terms of output signals, a variable-area type capacitor is used for detection, and the interference on detection by the driving movement is relieved.

Owner:SOUTHEAST UNIV

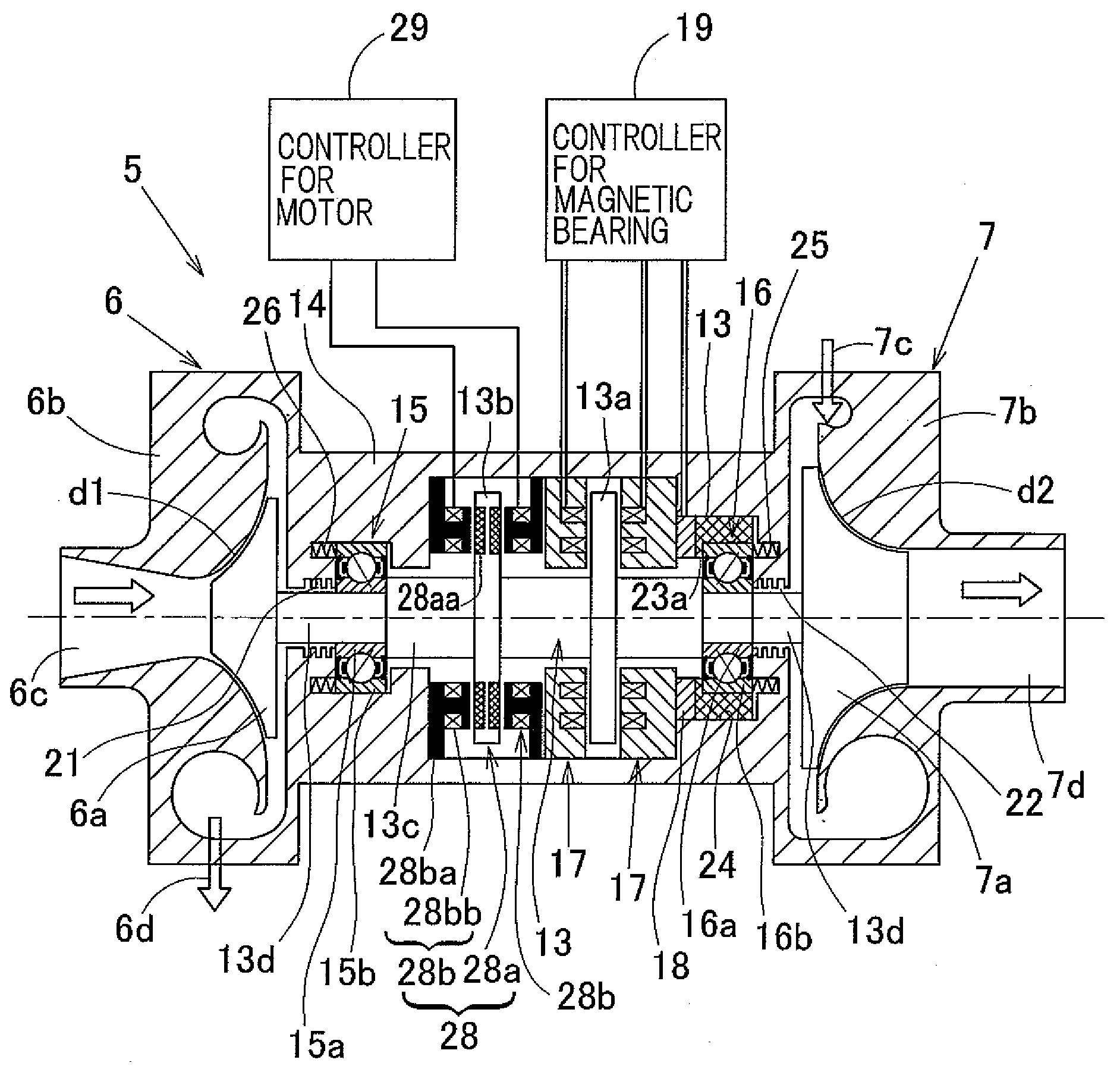

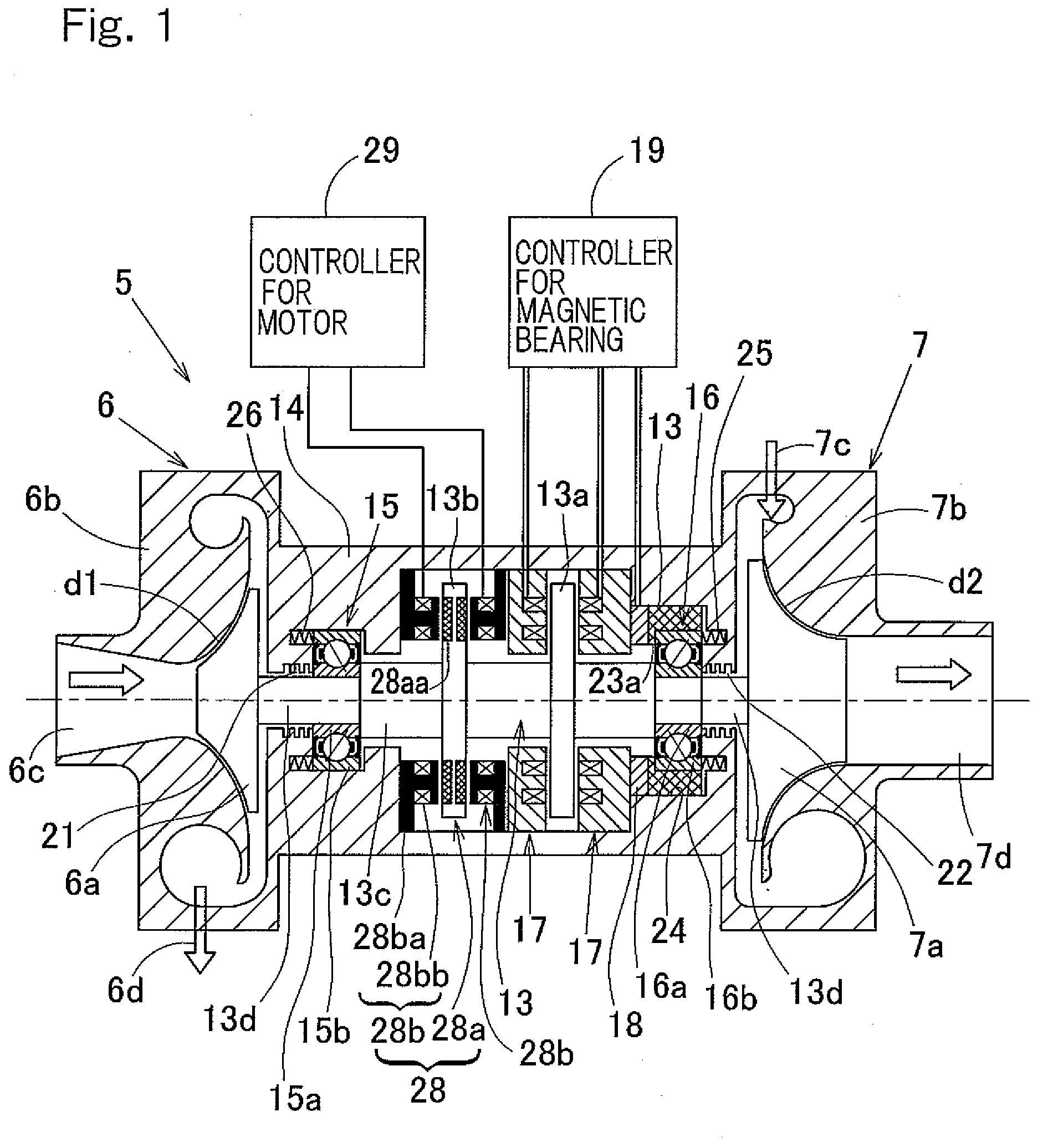

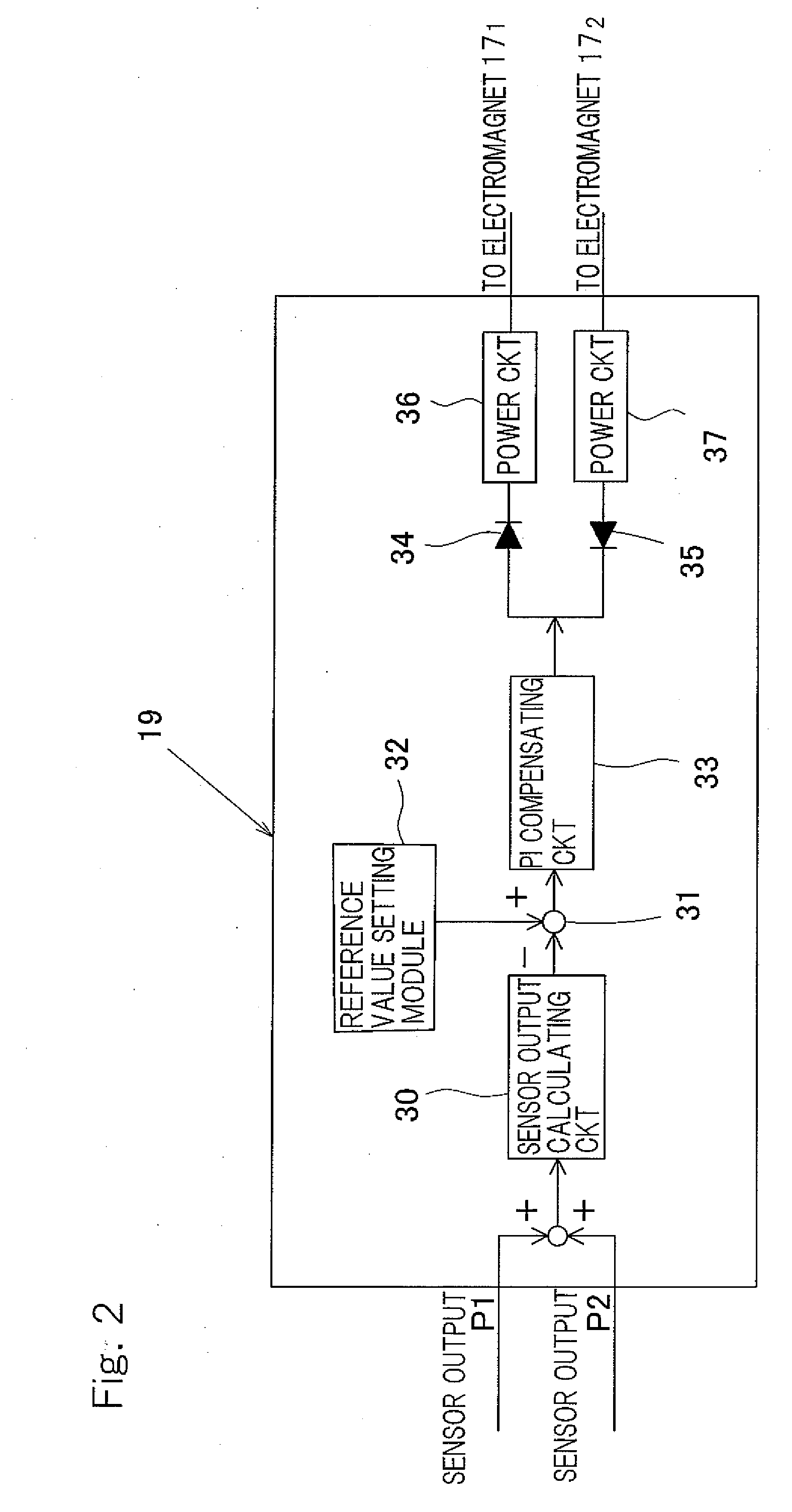

Motor built-in magnetic bearing device

InactiveUS20090127956A1Improve long-term durabilityReliabilityPump componentsFlexible member pumpsSupporting systemMagnetic bearing

The device includes a rolling bearing unit supporting a radial load and a magnetic bearing unit supporting an axial load and / or a bearing preload; an electromagnet fitted to a spindle housing so as to confront, on a non-contact basis, a flange shaped thrust plate mounted on a main shaft; a motor rotor of a motor for driving the shaft, and a motor stator opposed to the rotor, the shaft being driven by magnetic or Lorentz forces developed between the rotor and the stator; and a sensor detecting an axial force acting on the bearing unit, and a controller controlling the electromagnet. In this device, the stiffness of a composite spring formed by the bearing unit and a support system for the bearing unit is chosen to be higher than the negative stiffness of a composite spring of a motor part comprised of the electromagnet and the motor.

Owner:NTN CORP

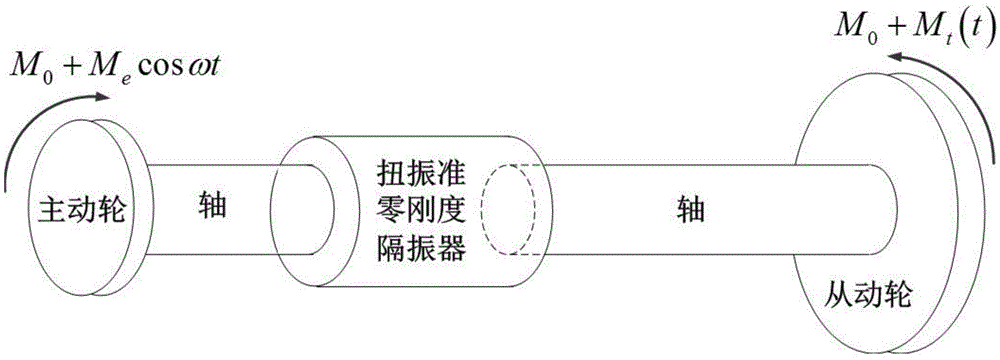

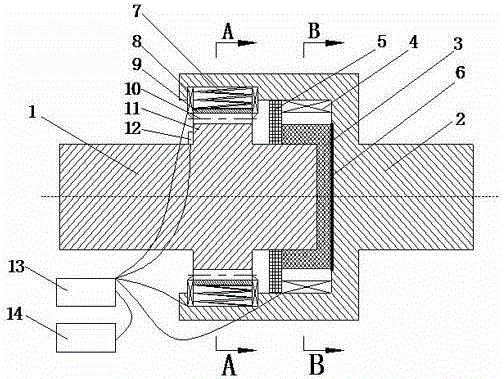

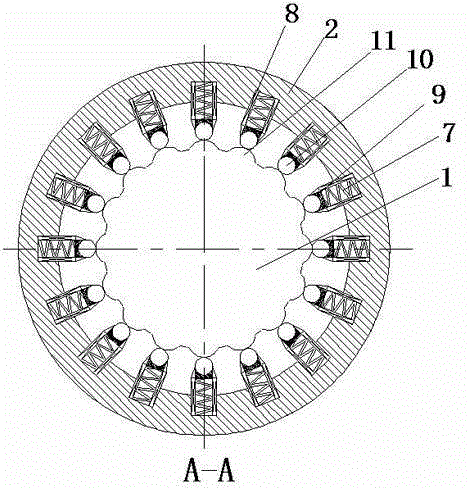

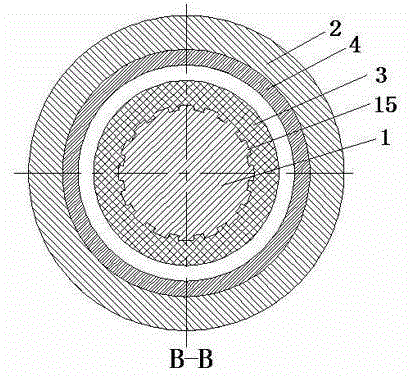

Torsion quasi-zero stiffness vibration isolator

ActiveCN104455199AImprove static stiffnessPositive torsional stiffnessVibration suppression adjustmentsDynamic stiffnessCoupling

The invention discloses a torsion quasi-zero stiffness vibration isolator. The torsion quasi-zero stiffness vibration isolator is mainly composed of a negative-stiffness cam-roller-radial spring mechanism and a positive-stiffness rubber spring vulcanized on a first coupling and a second coupling, and is further provided with a radial spring supporting component used for supporting a radial spring and guaranteeing that the radial spring only deforms in the radial direction. When the first coupling and the second coupling rotate relative to each other, the cam-roller-radial spring mechanism generates negative torsion stiffness, the rubber spring has positive torsion stiffness; under the parallel combination of the positive-stiffness element and the negative-stiffness element, the vibration isolator has the high static stiffness and low dynamic stiffness characteristic that the vibration isolator can bear large static loads, namely, the vibration isolator can transmit large static torque. The stiffness is zero at the static balance position, and the micro stiffness characteristic is shown near the static balance position. Thus, the vibration isolator can isolate ultralow-frequency torsion vibration of a shaft system.

Owner:HUNAN UNIV

Rigidity-adjustable semi-active control type torsional damper for vehicle

ActiveCN104864033AReduce torsional vibrationSolve the transmission torqueInertia force compensationVibration dampersSemi activeDrive shaft

The invention discloses a rigidity-adjustable semi-active control type torsional damper for vehicles. The rigidity-adjustable semi-active control type torsional damper for the vehicles comprises a driving shaft, a driven shaft, a negative stiffness structure, a positive stiffness structure, a damping fin, a displacement sensor, a controller and a power supply. The power supply is connected with the controller, and the controller is respectively connected with the negative stiffness structure, the positive stiffness structure and the displacement sensor. The positive stiffness structure is arranged at the bottom inside the driven shaft and covers the outer portion of the end of the driving shaft, the damping fin is arranged between the positive stiffness structure and the driven shaft, the negative stiffness structure sleeves the outer portion of the driving shaft and is connected between an outer circle of the driving shaft and an inner wall of the driven shaft, and the displacement sensor is arranged on the outer circle of the driving shaft. Compared with the prior art, the rigidity-adjustable semi-active control type torsional damper for the vehicles can guarantee the transmission of required torque and can reduce torsional vibration of a wide band, the problem of contradiction of a traditional torsional damper between torque transmission and vibration reduction is solved, and the rigidity-adjustable semi-active control type torsional damper for the vehicles is favorable for vehicle running safety and comfort.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

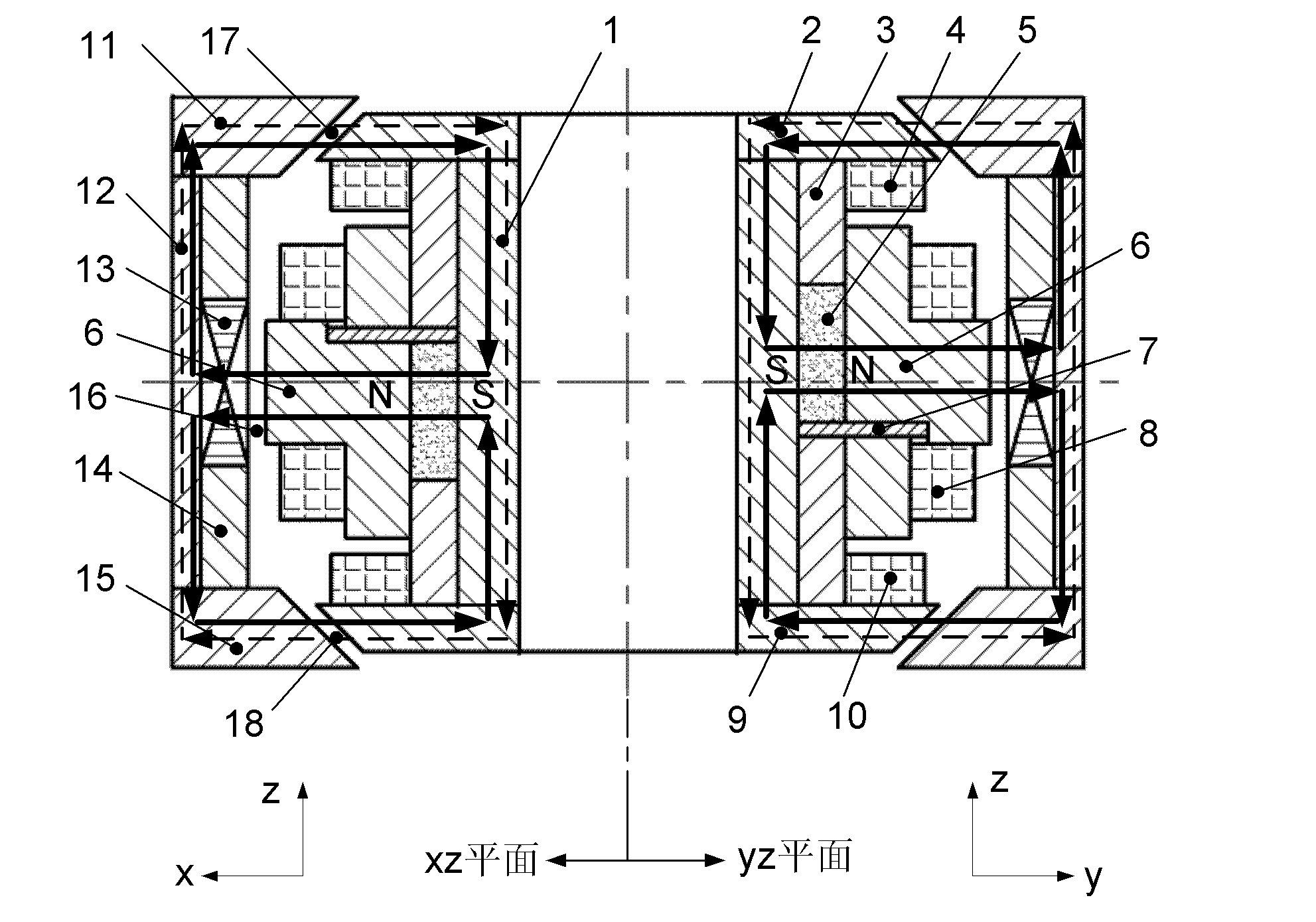

Permanent magnet low-frequency multidegree of freedom vibration isolation mechanism based on negative stiffness principle

InactiveCN102410337ASimple structureLow costNon-rotating vibration suppressionMagnetic springsExternal energyThree degrees of freedom

A permanent magnet low-frequency multidegree of freedom vibration isolation mechanism based on the negative stiffness principle comprises a lower permanent magnet, an upper permanent magnet, a rubber sheet, a lower permanent magnet fixing plate, a rubber fixing seat, an upper permanent magnet fixing plate, a rubber pressure block and a rubber sheet edge fixing pressure ring, wherein the permanent magnets are magnetized in the vertical direction and opposite for same poles. A positive stiffness system is formed by the permanent magnets under the action of repulsive force, the rubber sheet is stretched to a negative stiffness system under the action of repulsive force of the permanent magnets, two systems are combined to form a low-frequency vibration isolation mechanism, the single vibration isolation mechanism can realize three degrees of freedom low-frequency vibration isolation, and three or four systems are combined in parallel to realize the six degrees of freedom low-frequency vibration isolation. The vibration isolation mechanism can be used in vacuum without the input of external energy. The vibration isolation mechanism has the characteristics of simple structure, low cost and easy processing, and can be used in the fields like optics, acoustics, biology, advanced manufacturing equipment, semiconductor manufacturing and precision measurement, etc.

Owner:TSINGHUA UNIV

Three-dimensional vibration isolation device applicable to low-frequency vibration

ActiveCN104033535AAvoid couplingAvoid the phenomenon of aging and fractureNon-rotating vibration suppressionDynamic stiffnessCarrying capacity

The invention aims at providing a three-dimensional vibration isolation device applicable to low-frequency vibration. On a horizontal plane, a decoupling bracket, steel shafts, and an aluminum slide block realizes decoupling of vibration displacement in X and Y directions; a large circular permanent magnet and a small circular permanent magnet serve as negative stiffness elements, and springs serve as positive stiffness elements, thereby forming a low-frequency vibration isolation system of the horizontal plane; in a vertical direction, oblique springs serve as negative stiffness elements due to geometrical characteristics, and a support spring serves as a positive stiffness element to form a low-frequency vibration isolation system in Z direction; and a three-dimensional low-frequency vibration isolation system is formed by combining the two systems. According to the device, the permanent magnets or the springs serve as the negative stiffness elements or positive stiffness elements, lower-frequency vibration isolation is achieved; displacement decoupling in the X, Y and Z directions is achieved; lower dynamic stiffness in the Z direction and an XY plane can be obtained, and a greater carrying capacity can be ensured at the same time; the input energy is not required; and a static balance position can be adjusted to ensure that the vibration occurs near zero stiffness.

Owner:苏州东菱智能减振降噪技术有限公司

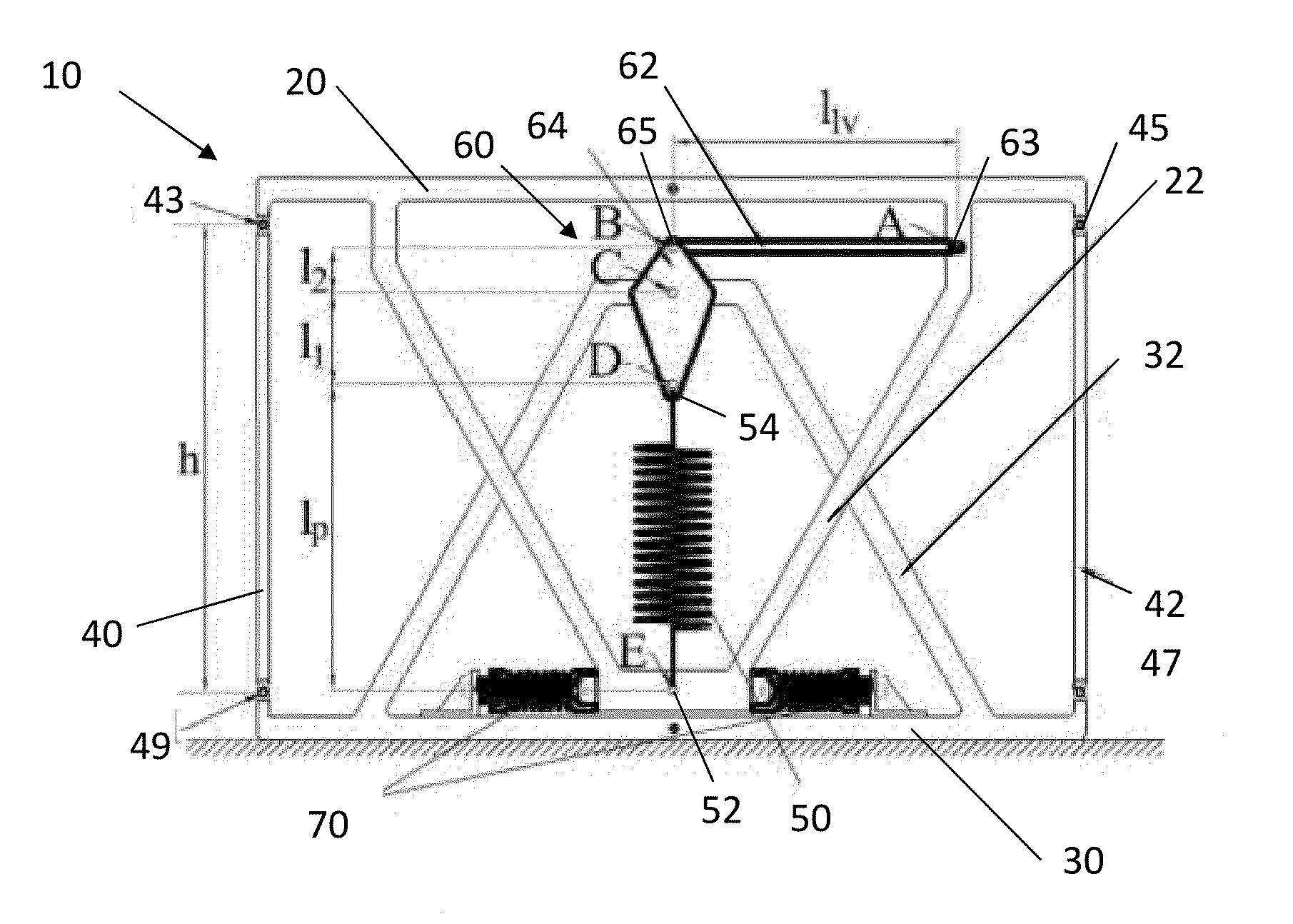

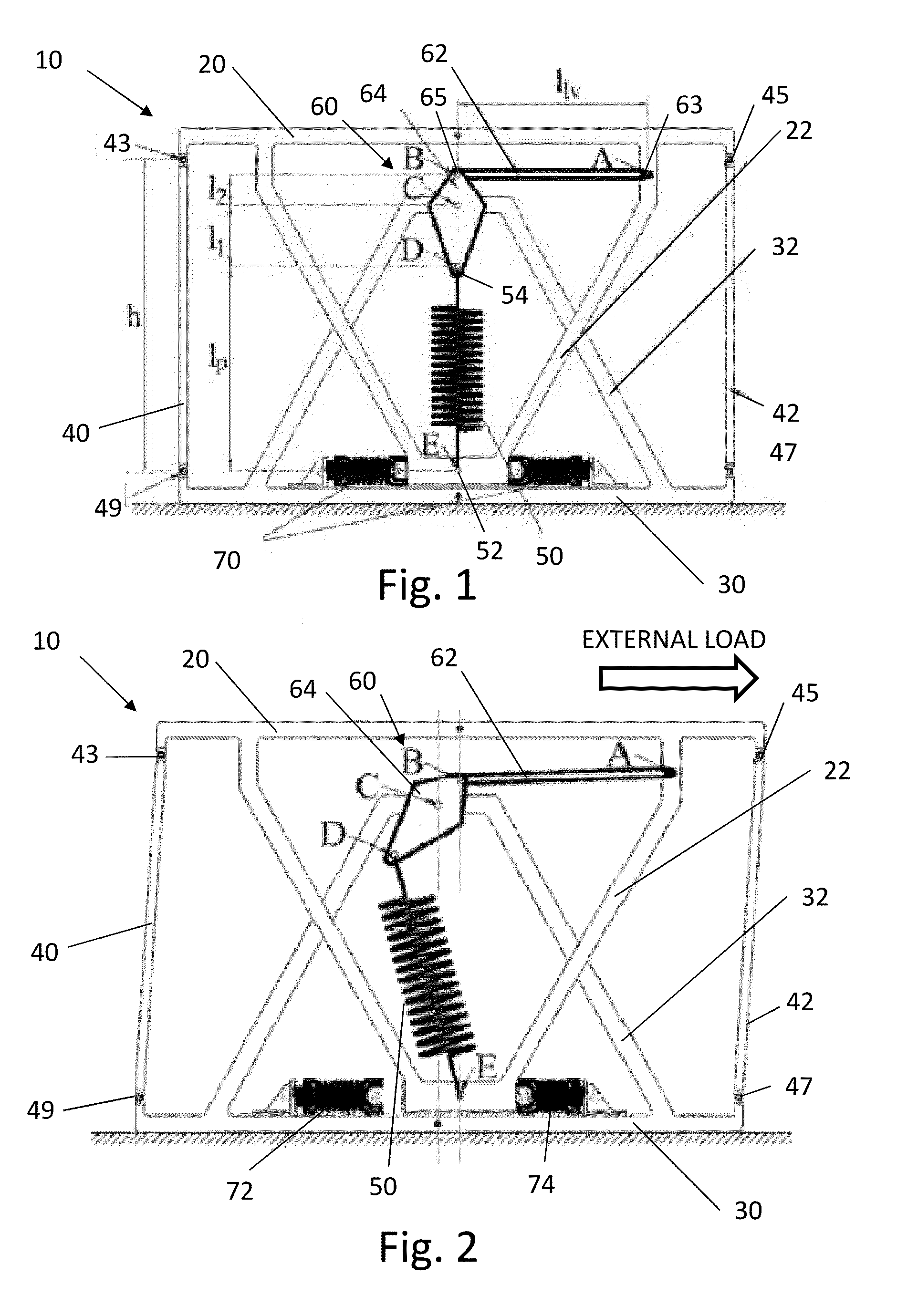

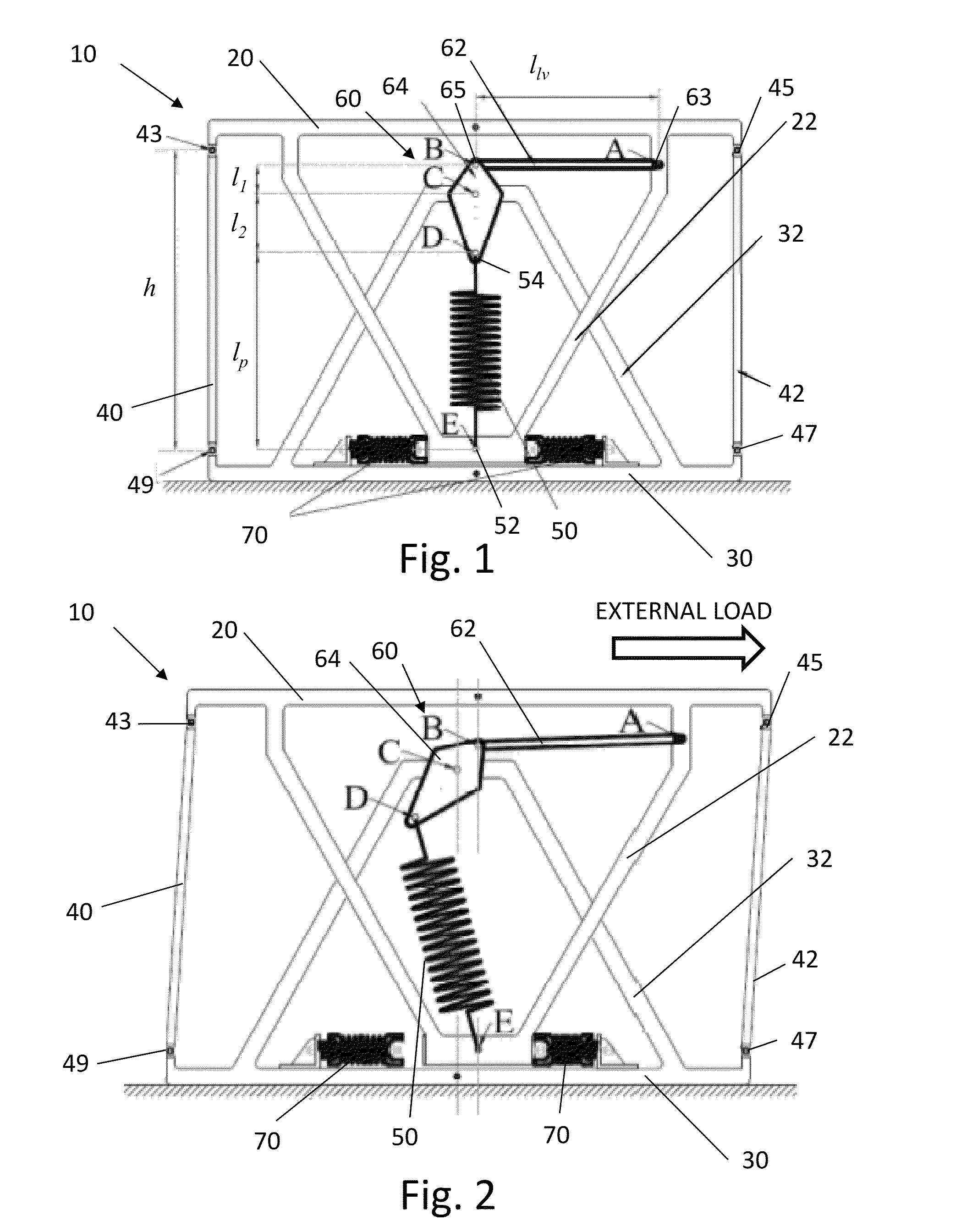

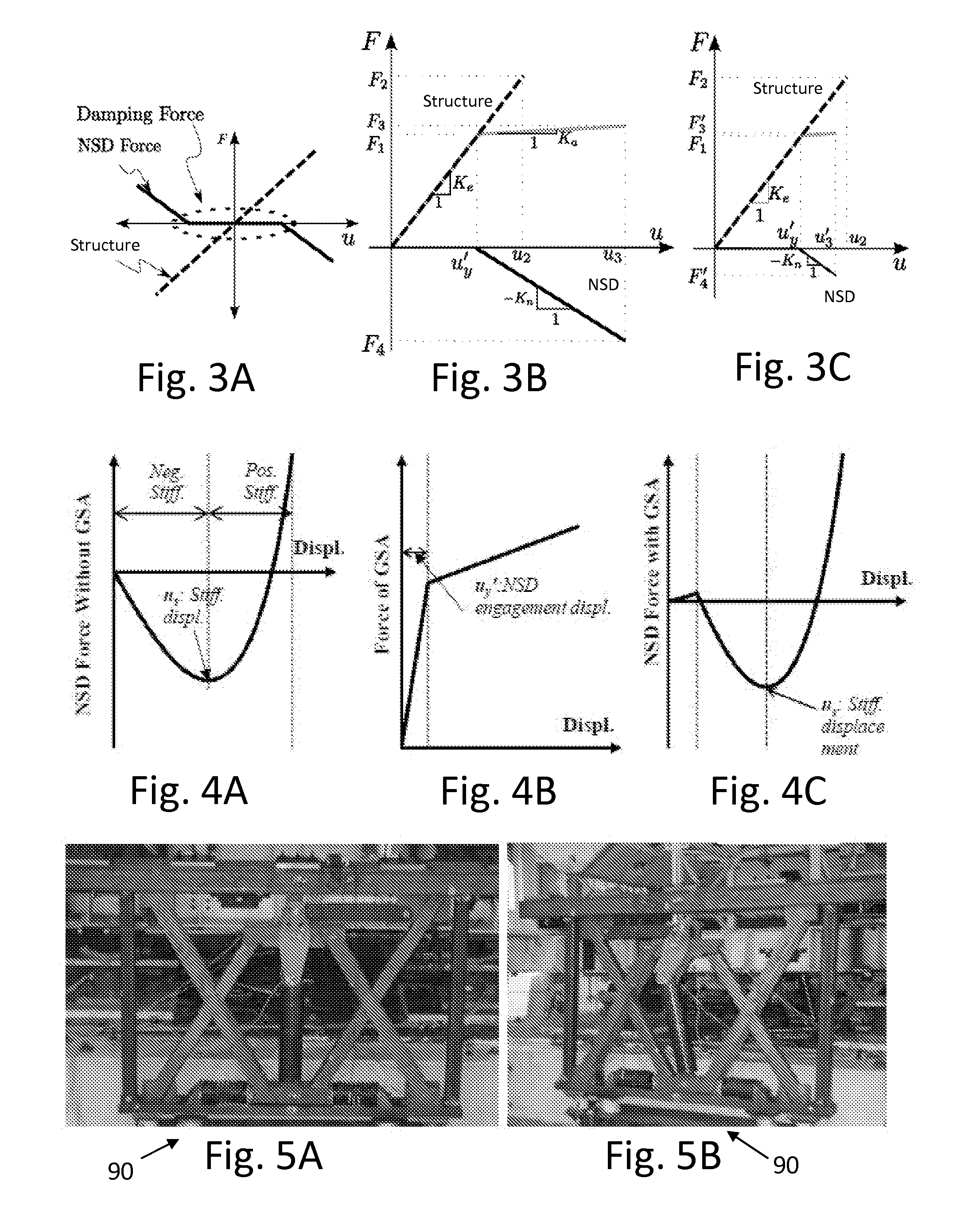

Negative stiffness device and method

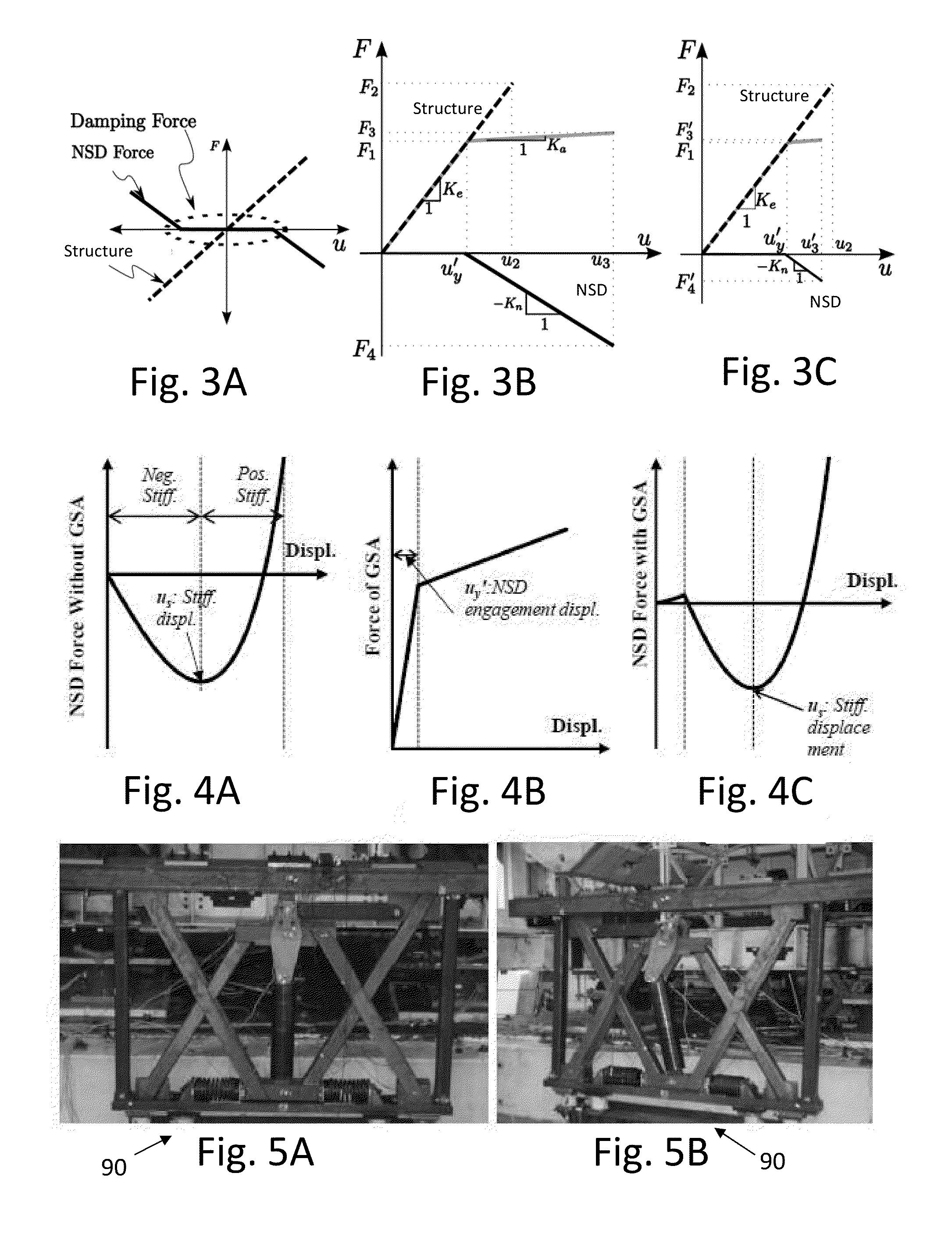

ActiveUS20130118098A1Negative stiffnessReduce demandSprings/dampers functional characteristicsBuilding repairsSeismic protectionSpring force

A negative stiffness device and method for seismic protection of a structure is described. In one embodiment, the device has an anchor frame and a movement frame laterally translatable relative to the anchor frame. The anchor frame and movement frame have respective extension portions. A linkage is pivotably connected to the extension portion of the anchor frame. A compressed spring has a first end is attached to the extension portion of the movement frame and a second end attached to the linkage. The compressed spring has a spring force. In a rest state, the compressed spring does not apply a lateral force to the movement frame. In an engaged state, the compressed spring is configured to apply a lateral force to displace the movement frame in a lateral direction of a seismic load. The spring force is amplified by the linkage when the movement frame is laterally displaced to an amplification point.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK +2

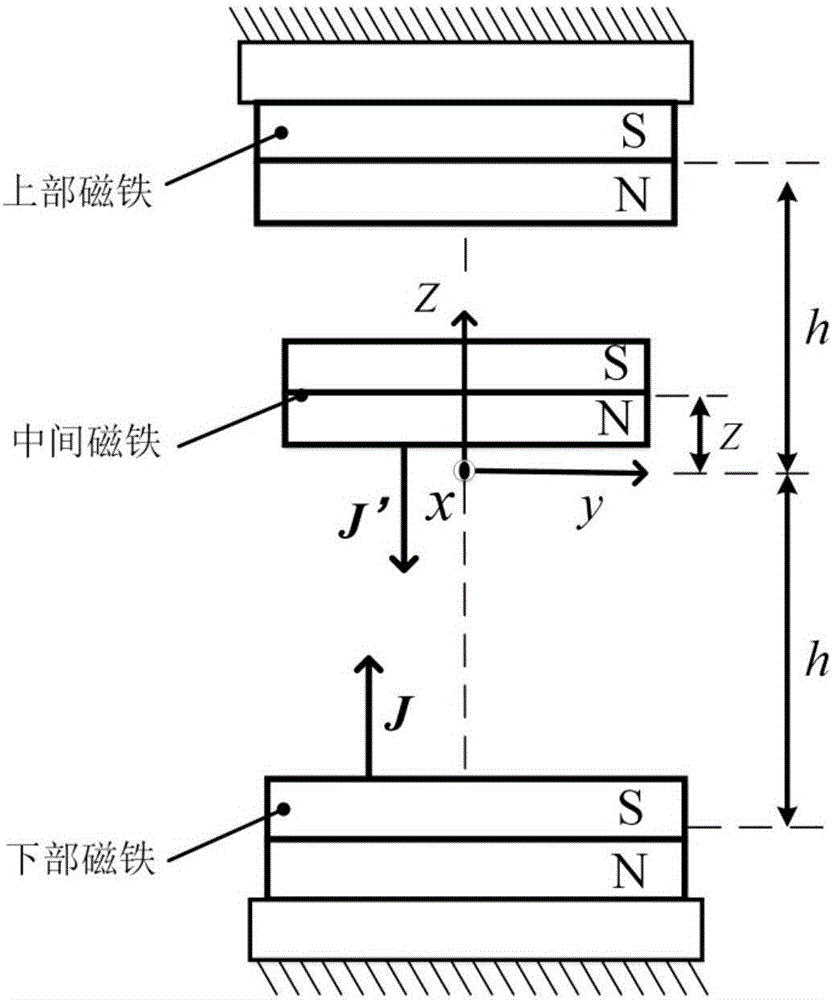

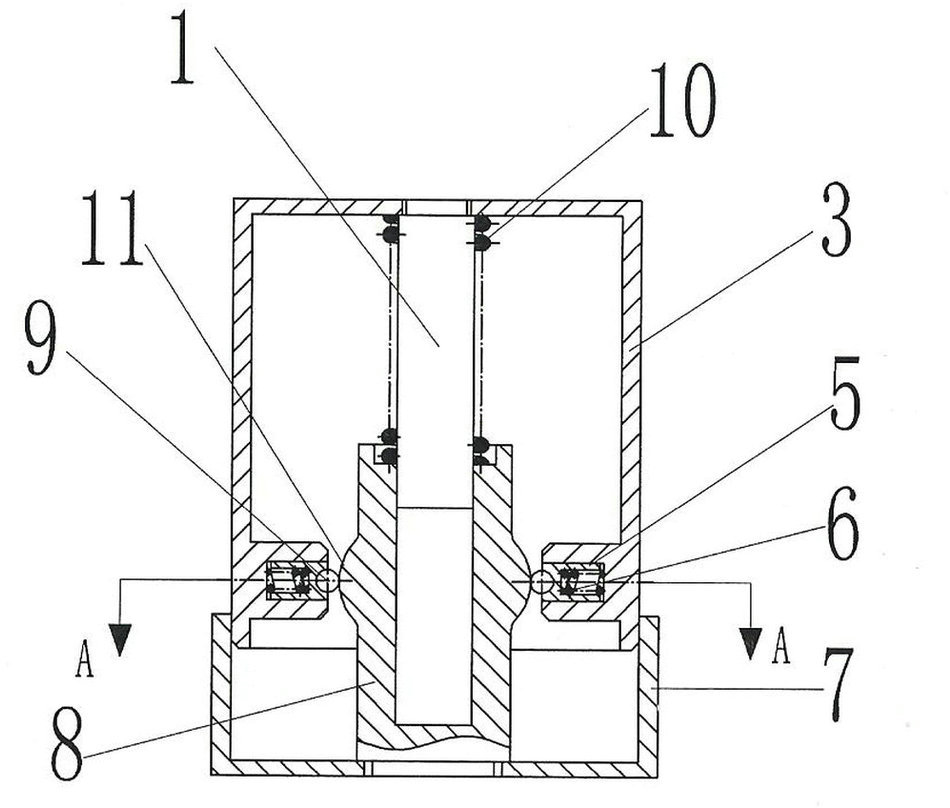

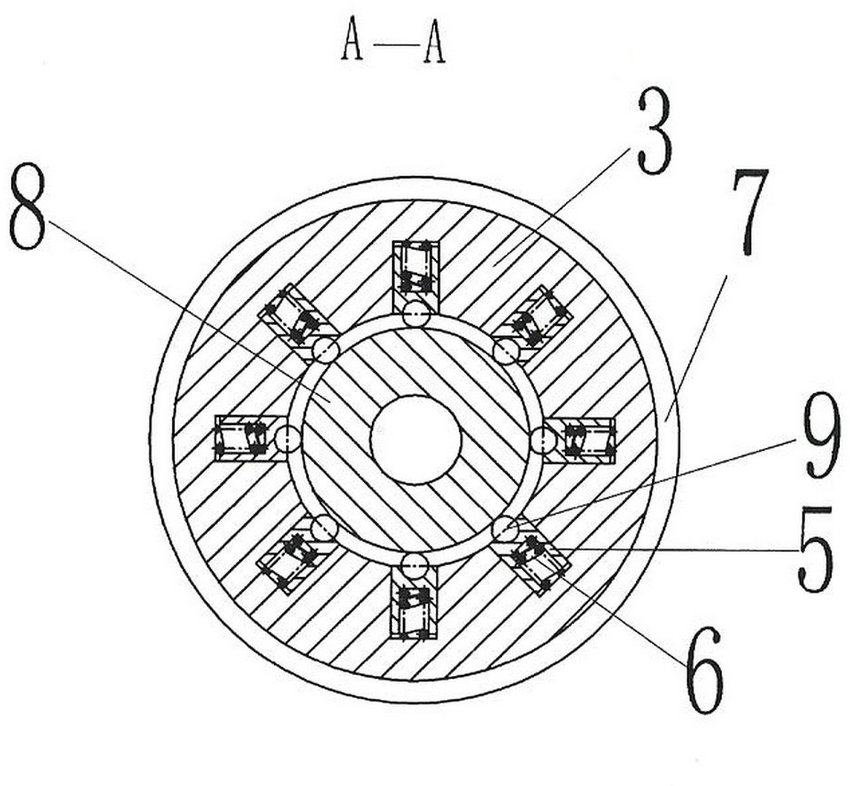

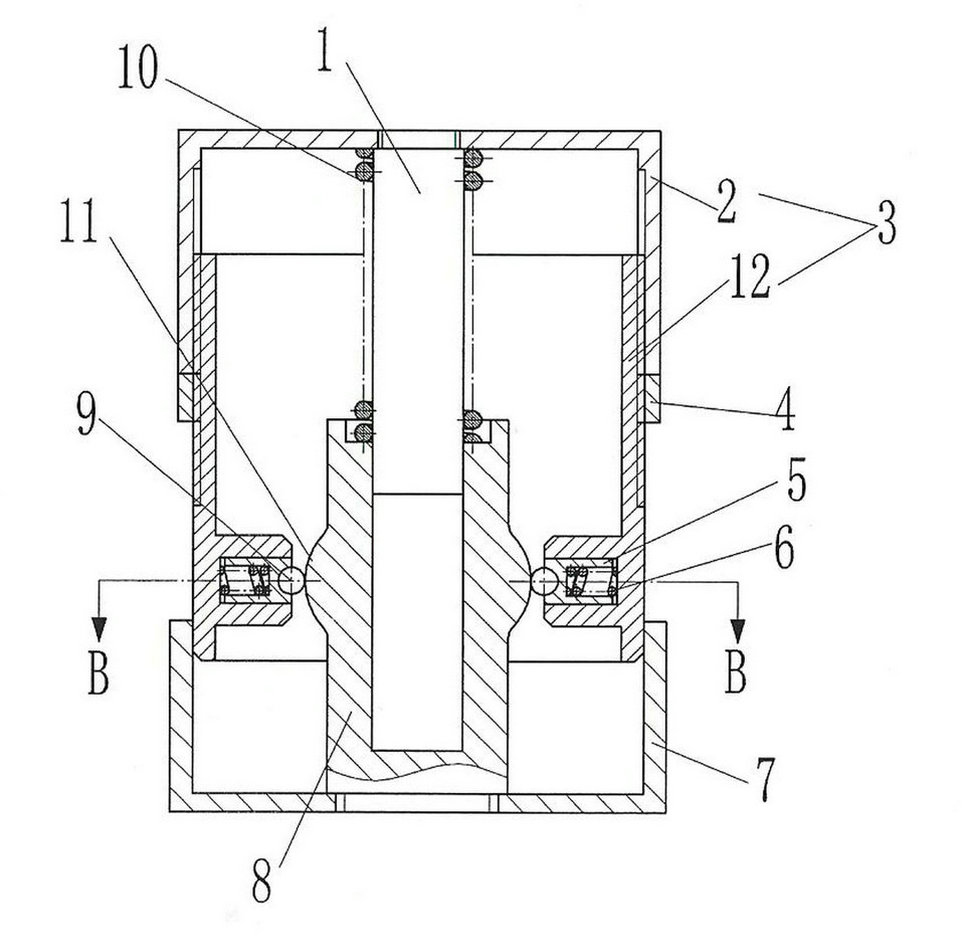

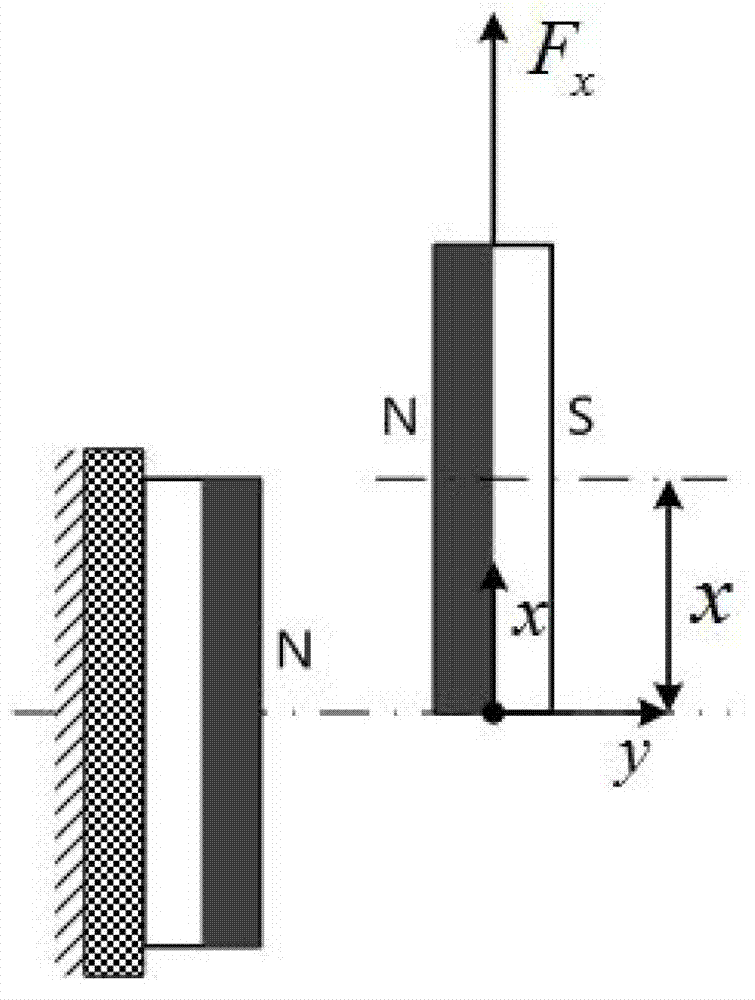

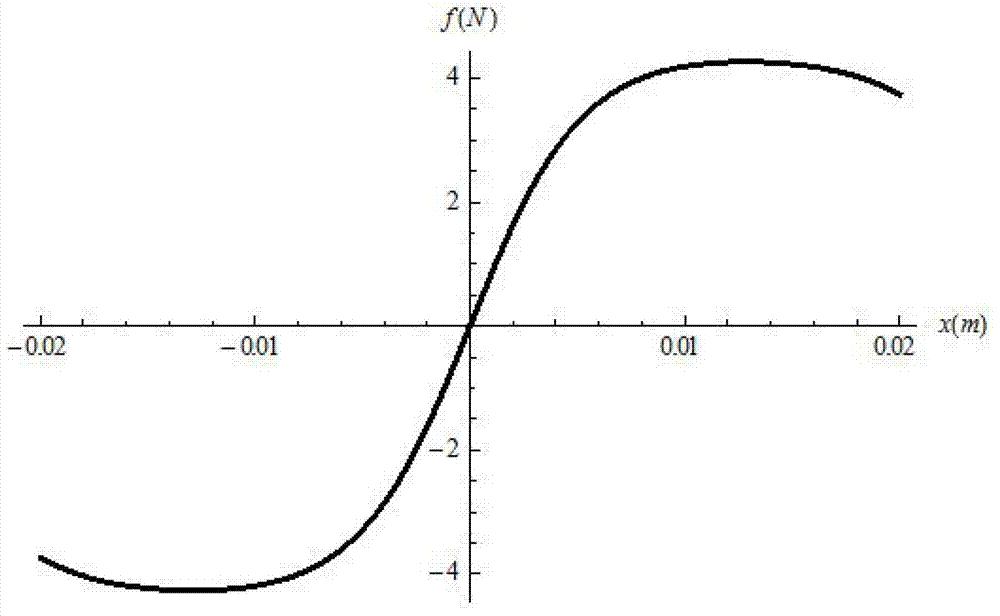

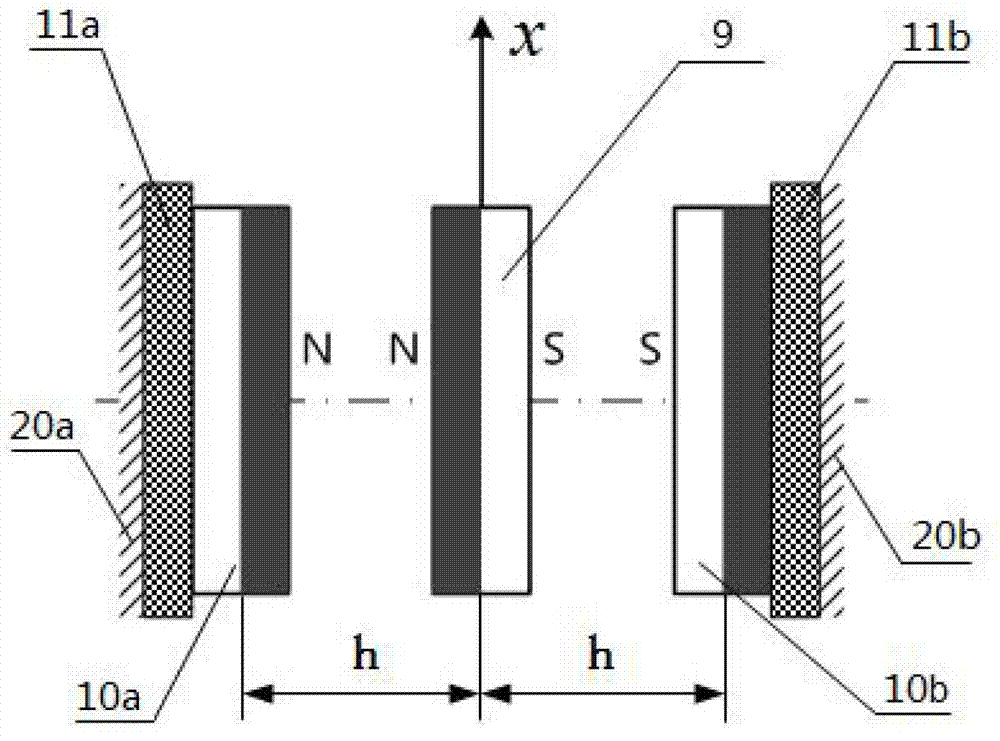

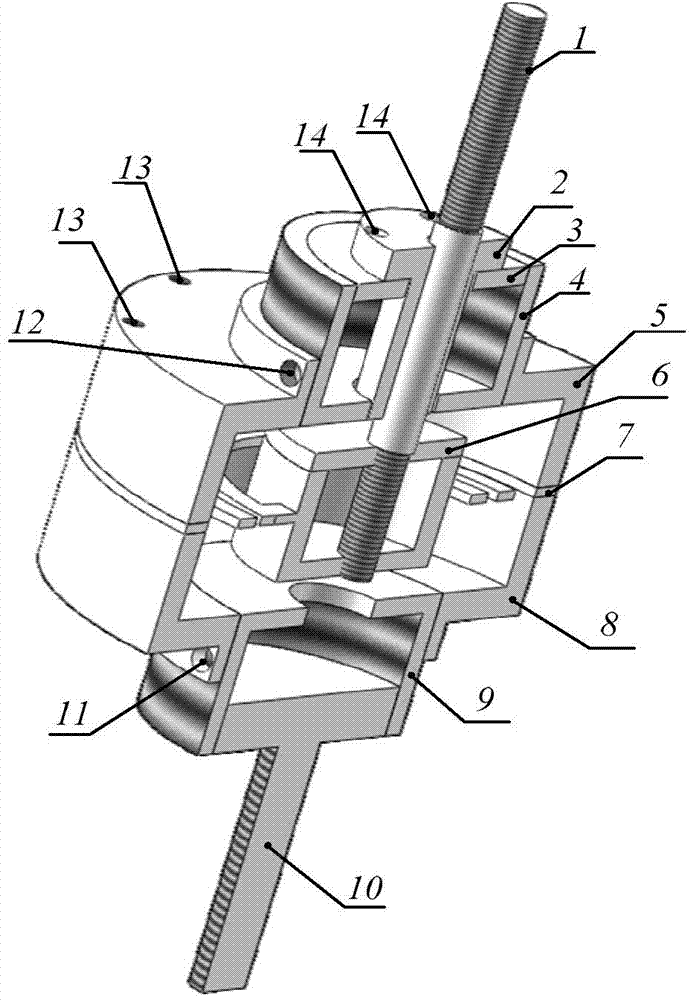

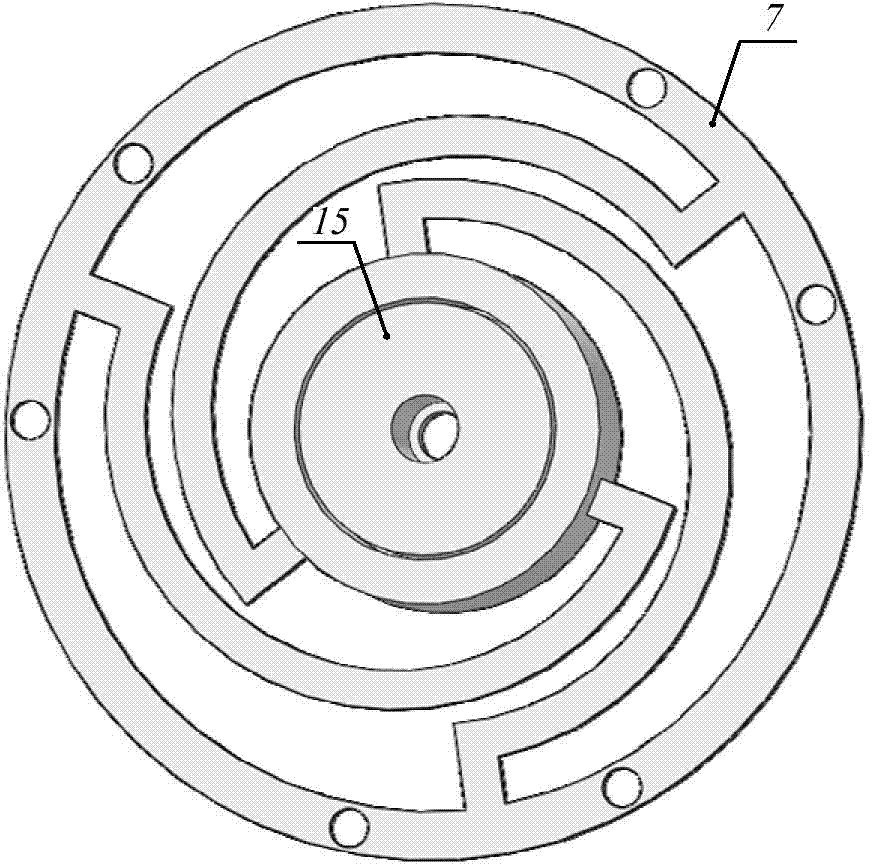

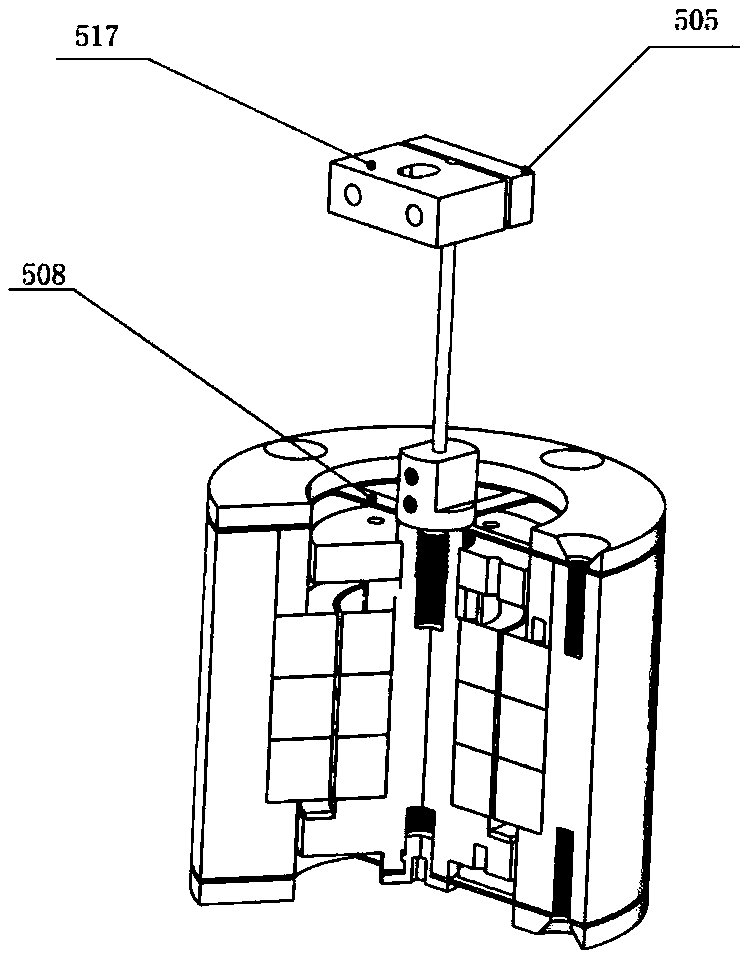

Magnetic negative stiffness mechanism

ActiveCN102808883AOvercome the impossibleOvercome the shortcoming that it is difficult to achieve ultra-low frequency vibration reductionSprings/dampers functional characteristicsMagnetic springsDynamic stiffnessEngineering

The invention provides a magnetic negative stiffness mechanism with a compact structure, and belongs to the field of ultra-precise vibration damping. The magnetic negative stiffness mechanism includes a frame part, a negative stiffness adjusting part, a flexible guiding part and a moving part. The negative stiffness mechanism utilizes the reverse repelling action of the magnet to form the negative stiffness characteristic, and the size of the negative stiffness can be adjusted through the negative stiffness adjusting part. As the ultra-low frequency vibration damper formed by combining the magnetic negative stiffness mechanism and the positive stiffness spring has extremely low dynamic stiffness, the inherent frequency of the ultra-low frequency vibration damper is greatly reduced, as a result, the vibration damper not only has excellent vibration isolation effect towards the high-frequency vibration interference, but also can effectively isolate the ultra-low frequency vibration, and the magnetic negative stiffness mechanism is applicable to the ultra-precise machining and measuring equipment sensitive to the vibration.

Owner:HUAZHONG UNIV OF SCI & TECH

Radial decoupling taper magnetic bearing with three degree of freedom

InactiveCN102322481AIncrease the maximum carrying capacityImprove bearing capacityBearingsMagnetic bearingThree degrees of freedom

The invention discloses a radial decoupling taper magnetic bearing with three degree of freedom, comprising an upper taper stator, a lower taper stator , an upper taper rotor, a lower taper rotor, radial stators, a radial rotor iron core, a field coil, a permanent magnet, a stator magnetic conductive ring and a rotor magnetic conductive ring, wherein, the taper stators and the taper rotors are the structure of integral ring, the suction generated between the taper stator and the taper rotor passes through the rotor barycenter to control the translation in the direction z of the rotor; the tworadial stators comprise stator teeth and stator magnet yokes, the two radial stators are arranged orthogonally when being installed, and a radial stator magnetic isolated ring is arranged between thetwo stators to let the magnetic circuit between the two radial channels be mutually decoupling; the suction generated between the radial stator and the radial rotor iron core is used to control the translation in the direction x and y of the rotor. According to the invention, the suction generated between the taper stator and the taper rotor passes through the rotor barycenter, when the rotor rotates, the length of the arm of force of negative stiffness is reduced, so that negative torsion moment is reduced; simultaneously, the two radial channels are decoupling, so that the radial bearing capacity is increased.

Owner:BEIHANG UNIV

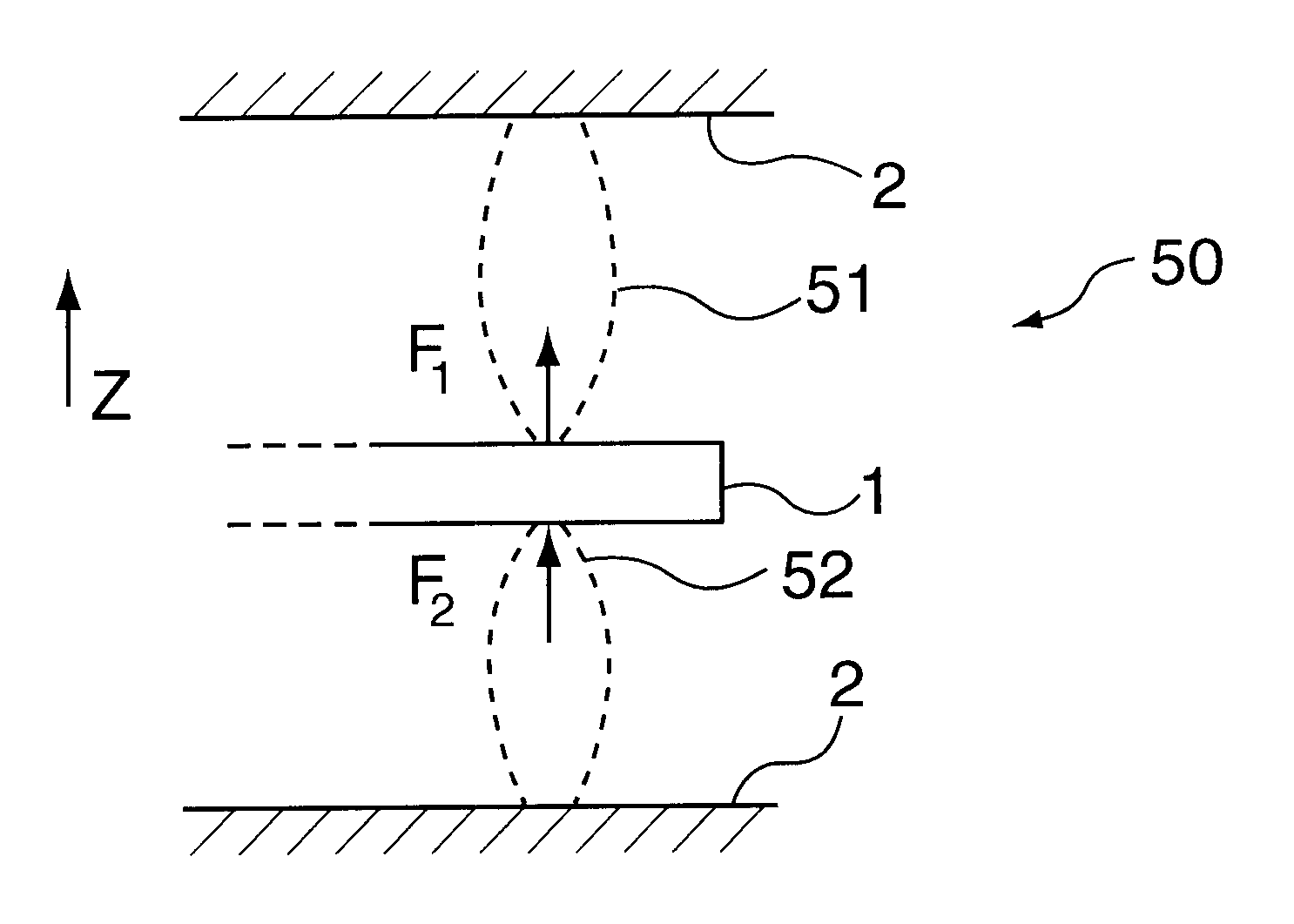

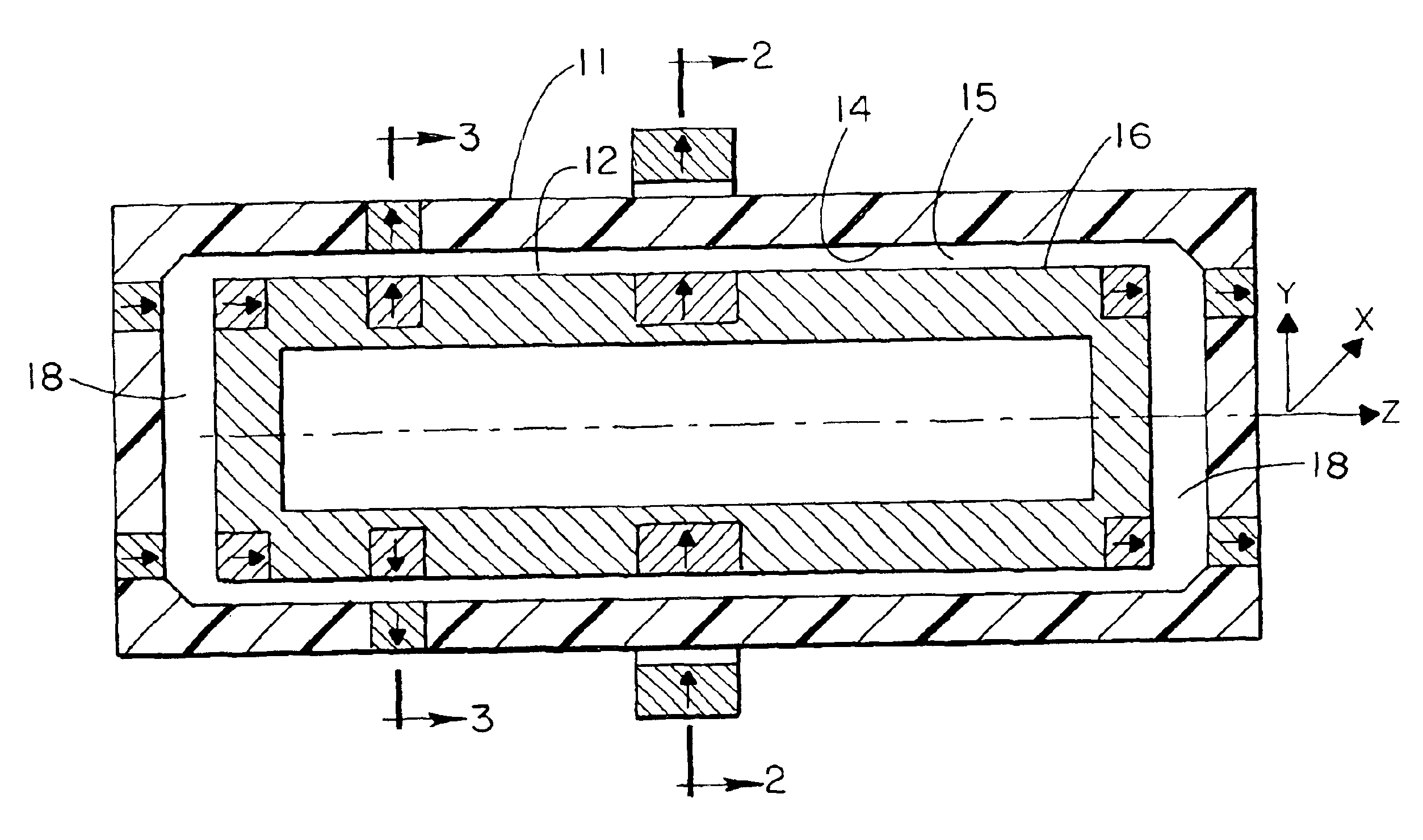

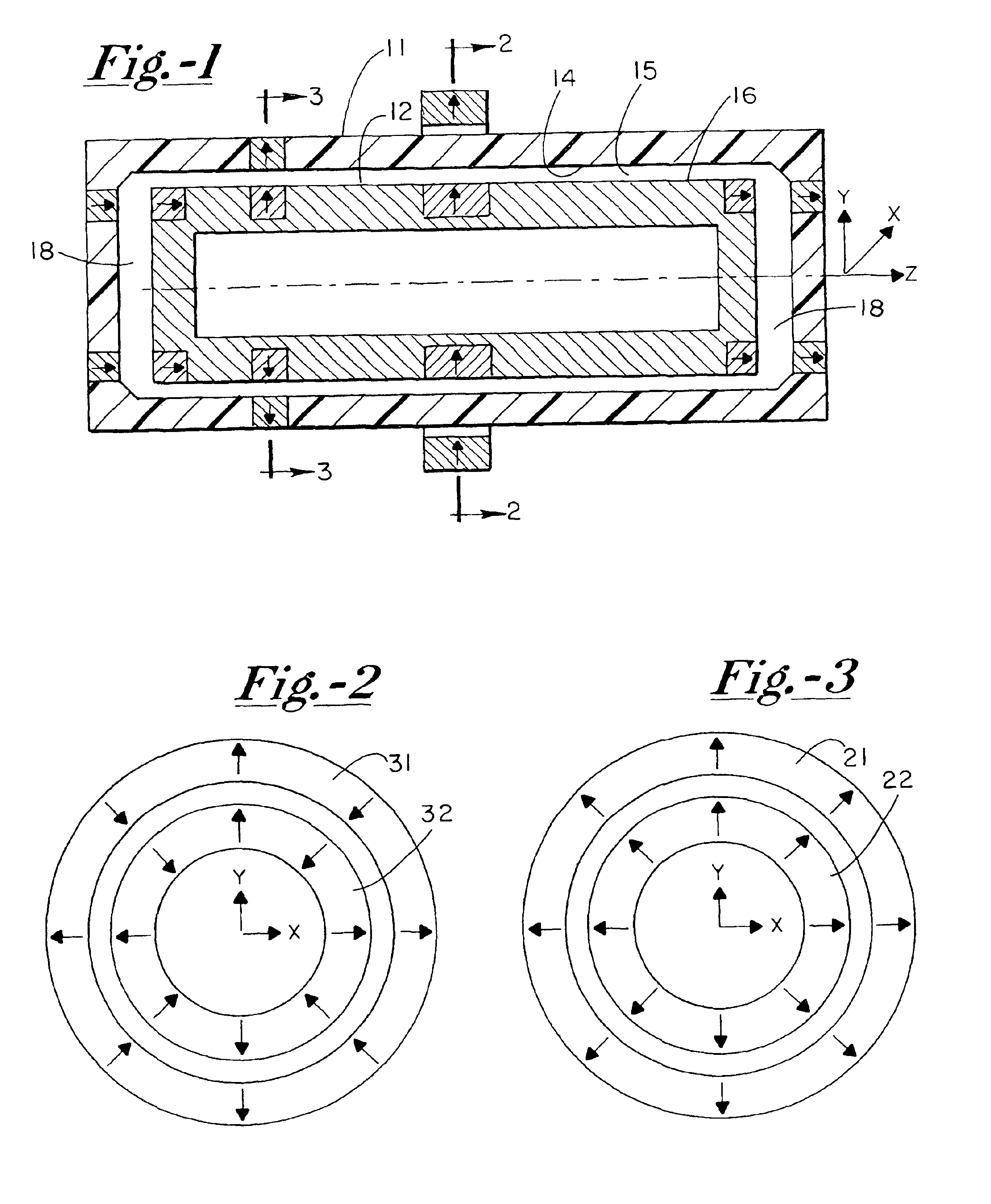

Magnetic support system

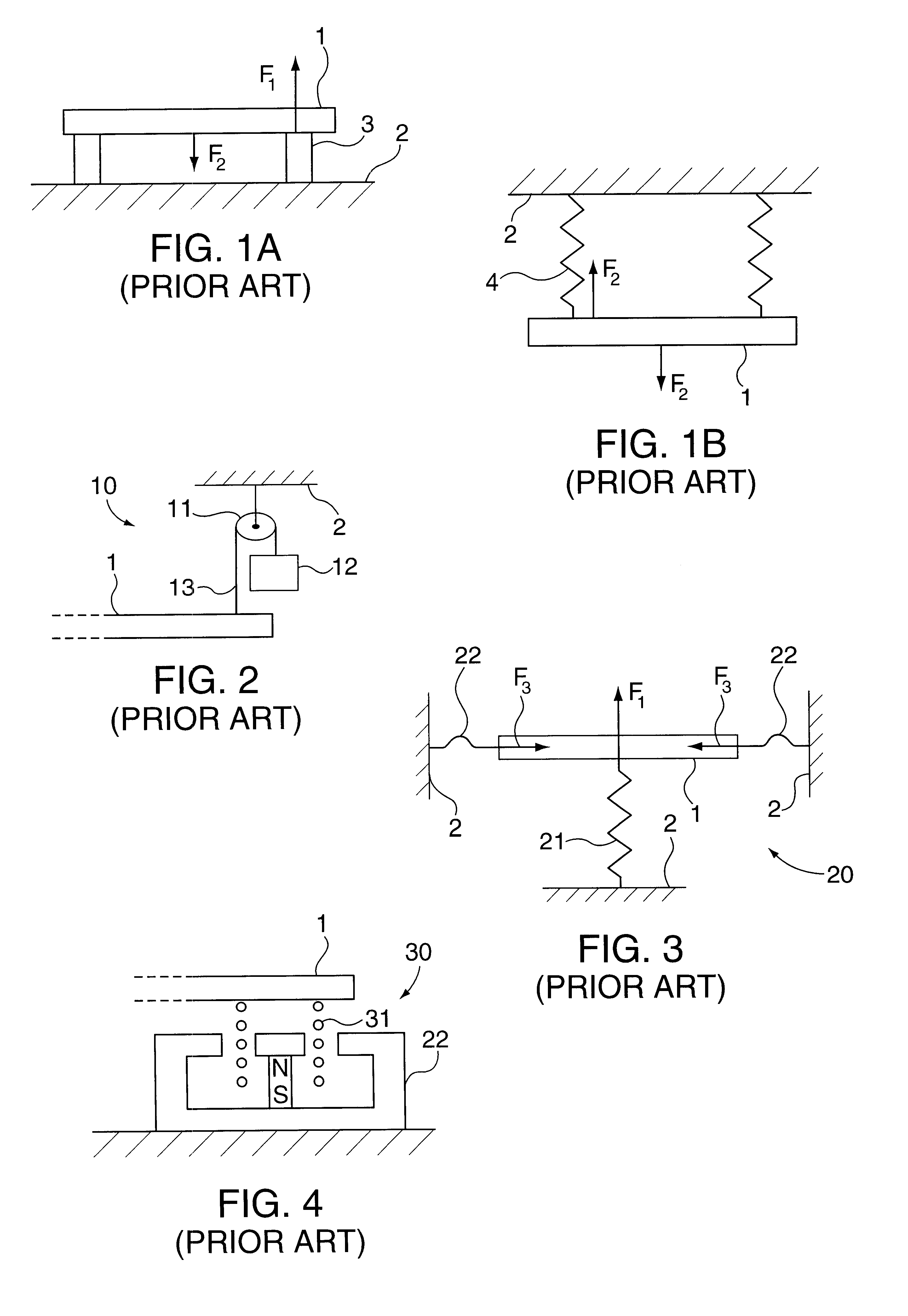

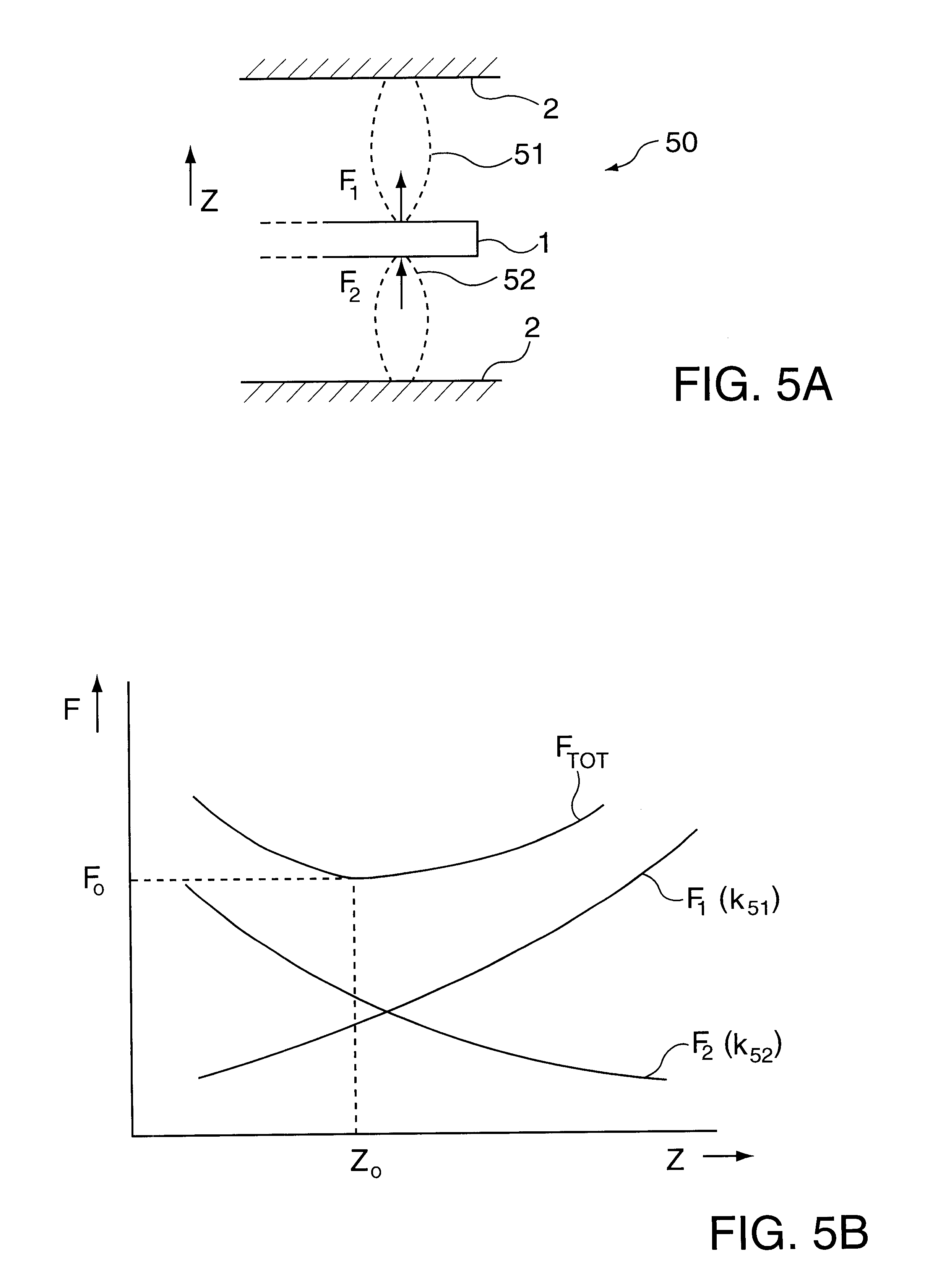

InactiveUS6402118B1Simple and compact structurePortable framesNon-rotating vibration suppressionSupporting systemCoupling

There is described a support system enabling supporting an object such as a platform (1) free from vibration, in that bearing elements (50) have a stiffness (k) which at a working point (z0) equals zero. A bearing element (50) comprises two magnectic couplings (51, 52) provided by permanent magnets (61, 63). One coupling (51) has a positive stiffness (k51), and the other coupling has a negative stiffness (k52); in the working point, the absolute values of those stiffnesses are equally great. Alternatively, electrostatic couplings are used.

Owner:ASML NETHERLANDS BV

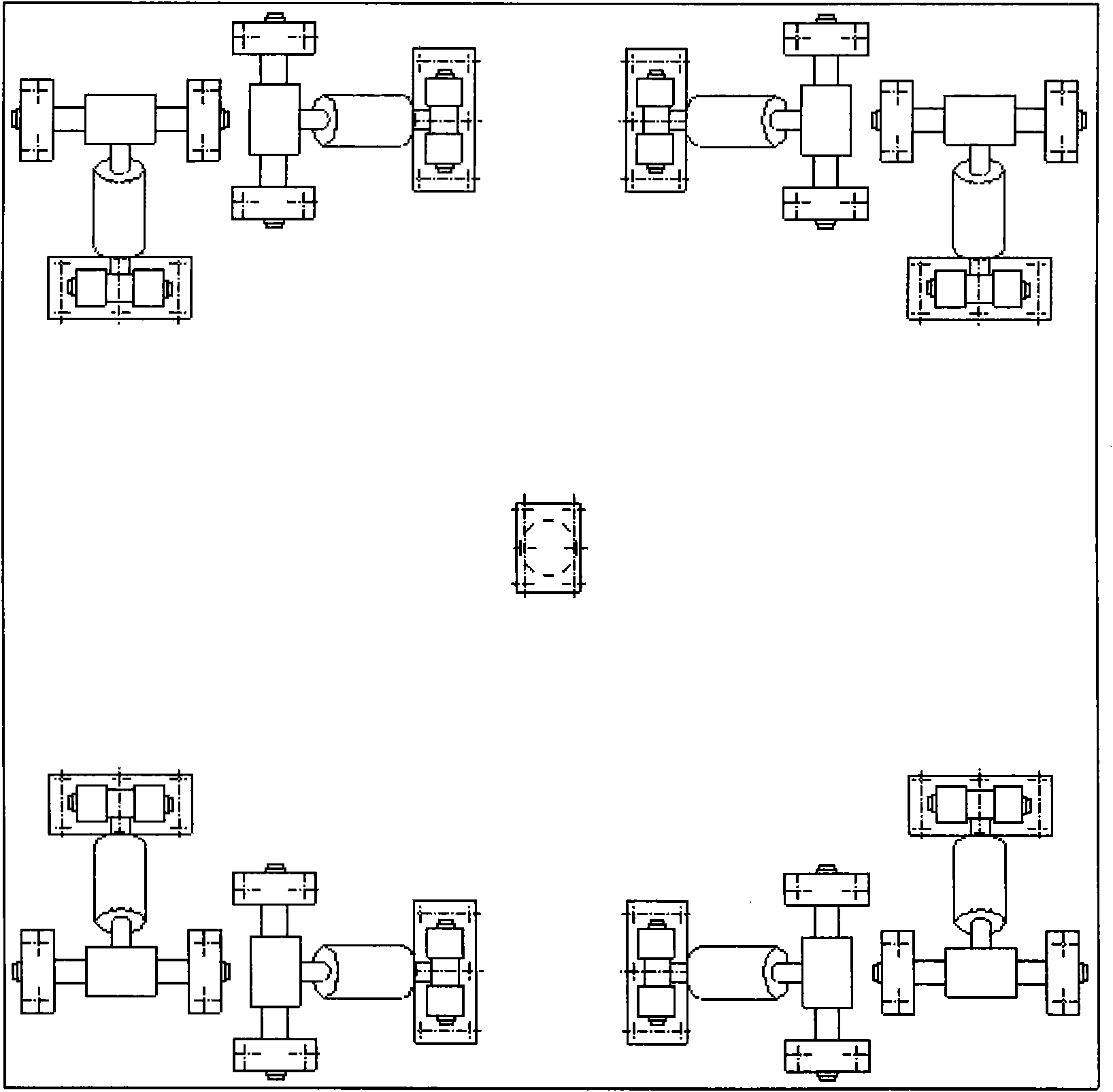

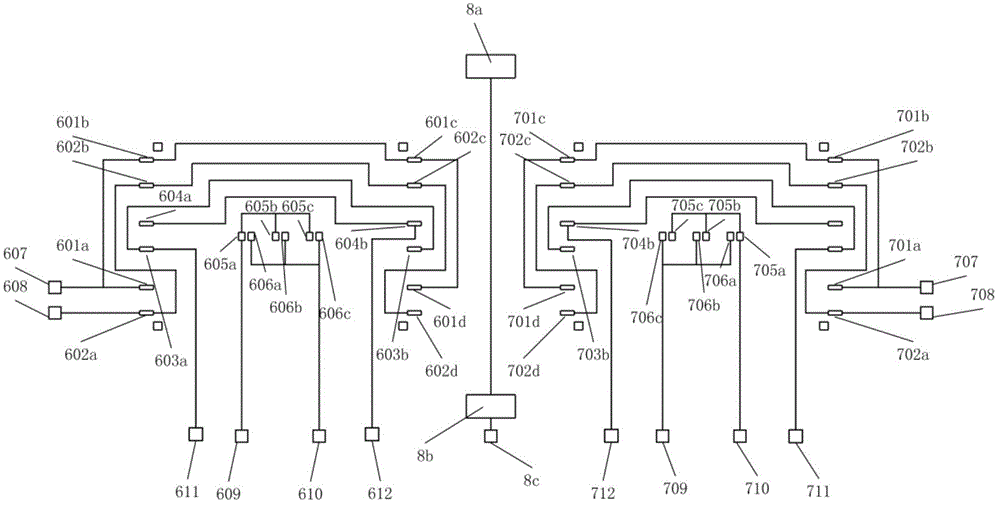

Platform and method of main and passive vibration isolation in space six-degree of freedom based on electromagnetic negative stiffness

ActiveCN108533669AQuick responseGreat driving forceNon-rotating vibration suppressionAxial displacementAviation

The invention discloses a platform and a method of main and passive vibration isolation in space six-degree of freedom based on electromagnetic negative stiffness. The platform comprises a load platform, a foundation platform and six electromagnetic negative stiffness vibration isolators, wherein the six electromagnetic negative stiffness vibration isolators are fixed between the load platform andthe foundation platform through a connecting piece; the two adjacent vibration isolators are perpendicular to each other in the axial direction, and the load platform has six-degree of freedom relative to the foundation platform; each electromagnetic negative stiffness vibration isolator comprises an actuating rod, an upper shell, a lower shell, a combined disc spring, a base, a bottom supportingrod and two sets of excitation devices, wherein the actuating rod is fixedly connected with the upper shell through a cross beam spring piece, a strain sensor is pasted on the cross beam spring piece, and is used for detecting the axial displacement of the actuating rod; each vibration isolator can realize active control of equivalent electromagnetic negative rigidity, so that the vibration isolation platform is of a positive and negative stiffness parallel structure in six-degrees of freedom, the vibration isolators have relatively low resonance frequency and a very wide vibration isolationfrequency band, so that micro-vibrations in the space six-degree of freedom direction can be effectively inhibited. According to the platform and the method, the platform and the method of the main and passive vibration isolation in the space six-degree of freedom based on the electromagnetic negative stiffness are suitable for equipment micro-vibration main and passive vibration isolation in thefield of spaceflight aviation, precise instruments and the like.

Owner:XI AN JIAOTONG UNIV

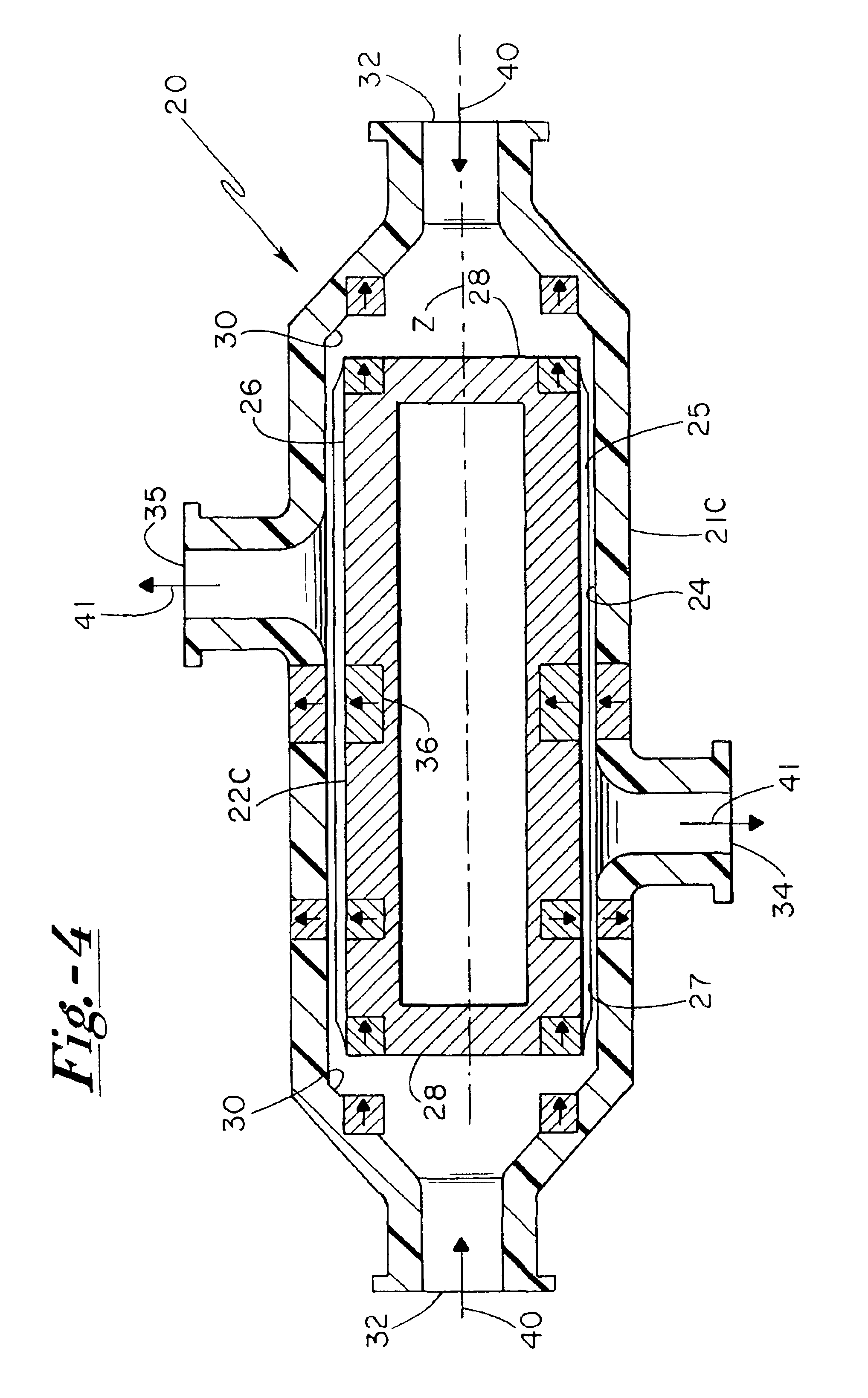

System for passive and stable suspension of a rotor in rotor/stator assemblies

InactiveUS6861778B2Positive stiffnessDynamic interactionPump componentsBlood pumpMagnetic bearingEngineering

A rotary mechanism includes a stator body defining a chamber and an elongated rotor operationally disposed within the chamber. The elongated rotor has opposed ends with a central axis defining an axis of rotation, with magnetic driven elements disposed on the rotor and positioned outwardly of the rotor axis between the opposed ends. Passive magnetic bearing pairs are positioned along opposed ends of the rotor body with each bearing pair being similarly polarized so as to be in mutually attracting or mutually repelling relationship. A third passive magnetic bearing pair is positioned along the rotor axis between the opposed ends with the third bearing pair being magnetically coupled similarly to the first and second bearing pairs, with the passive magnetic bearings creating an unstable negative force in a plane perpendicular to the axis of rotation of the rotor with the negative stiffness being overcome upon rotation of the rotor creating a centrifugal force of a magnitude greater than that of the unstable negative force.

Owner:ADVANCED BIONICS INC

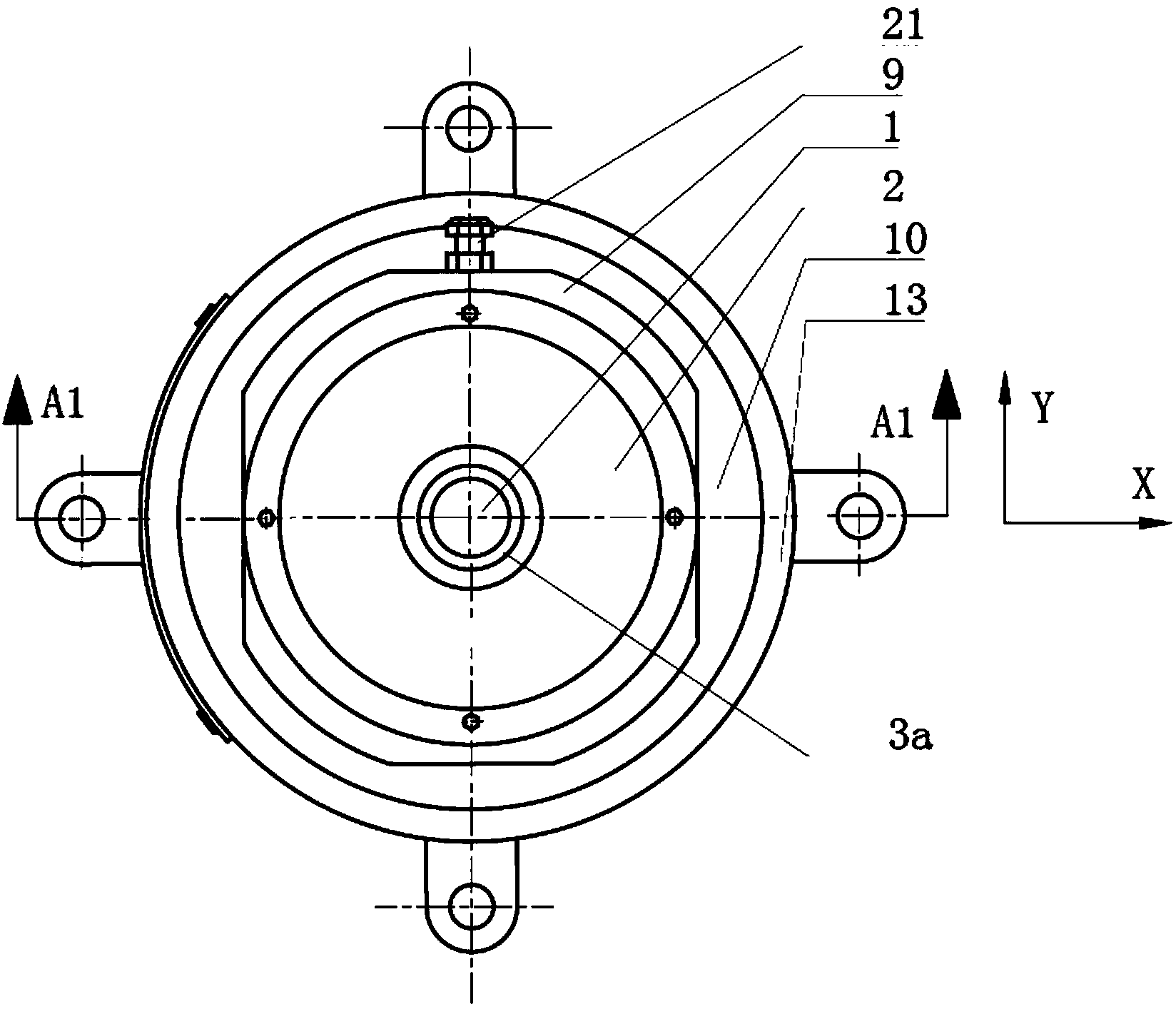

Permanent magnet low frequency single-degree-of-freedom vibration isolation mechanism based on negative stiffness theory

ActiveCN102506110AGood vibration isolationSimple structureSprings/dampers functional characteristicsMagnetic springsThree degrees of freedomSingle degree of freedom

The invention discloses an annular permanent magnet low frequency vibration isolation mechanism based on a negative stiffness theory. The mechanism comprises an upper rubber sheet, an inner annular permanent magnet fixing mandrel, an upper rubber sheet upper pressing ring, an upper rubber sheet outer pressing ring, an outer annular permanent magnet, a lower rubber sheet, a lower rubber sheet inner pressing sheet, a lower rubber sheet outer pressing ring, an outer annular permanent magnet fixing sleeve and an inner annular permanent magnet, wherein the inner annular permanent magnet is magnetized axially; the outer annular permanent magnet is radially magnetized; a positive stiffness system consists of the inner annular permanent magnet and the outer annular permanent magnet; a negative stiffness system consists of the upper rubber sheet and the lower rubber sheet; and the positive stiffness system and the negative stiffness system are used in parallel to form the low frequency vibration isolation mechanism. Three or four single-degree-of-freedom vibration isolation mechanisms are used in parallel to realize three-degree-of-freedom low frequency vibration isolation. When the vibration isolation mechanism has the largest magnetic force, the stiffness of the vibration isolation mechanism approximates to zero. Without an outside air source, the vibration isolation mechanism has a prospect of being used in vacuum, has the characteristics of simple structure and low cost, is easy to process, and can be applied to the fields of optics, acoustics, biologics, semiconductor manufacturing, precise measurement and the like.

Owner:TSINGHUA UNIV +1

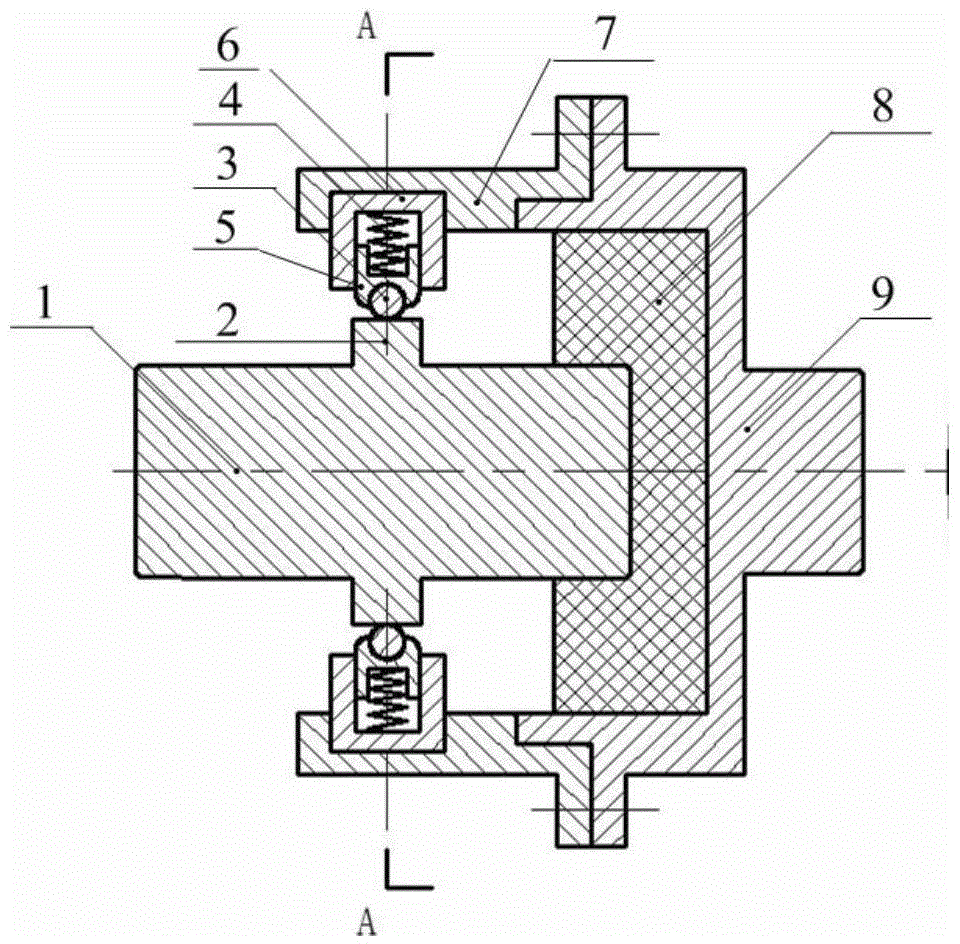

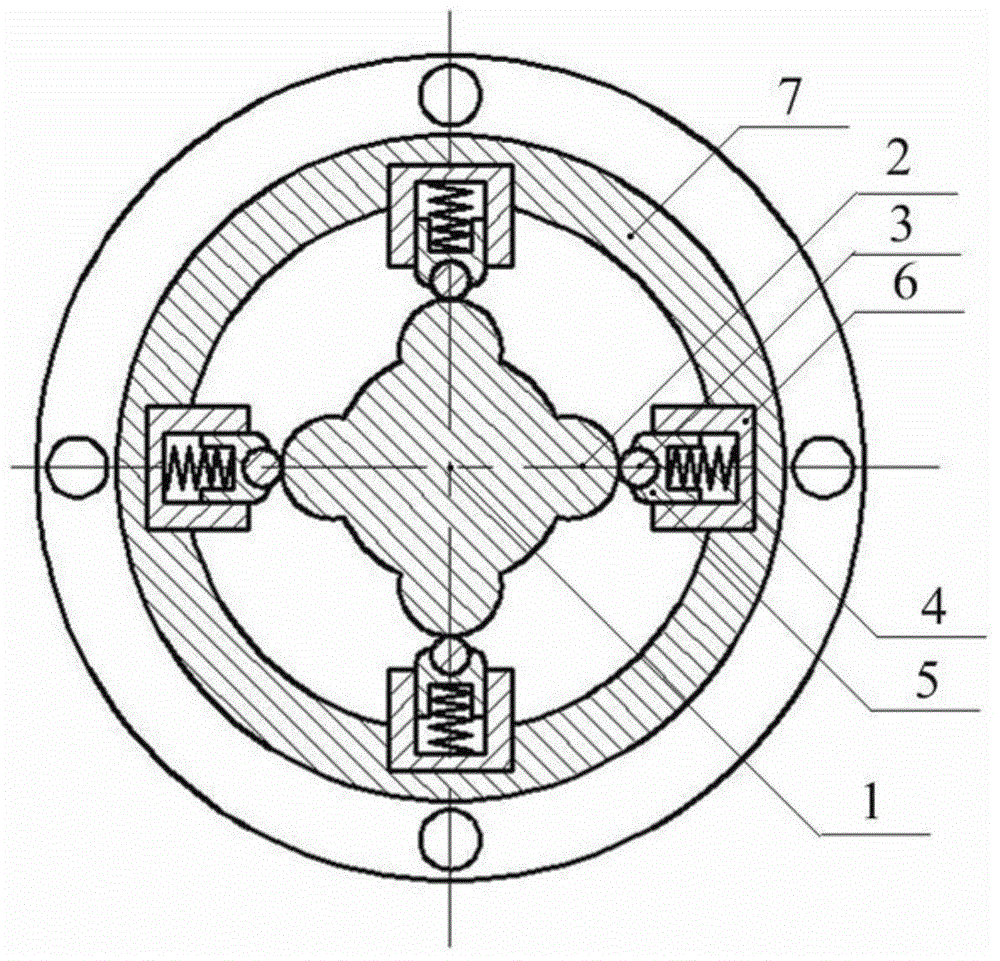

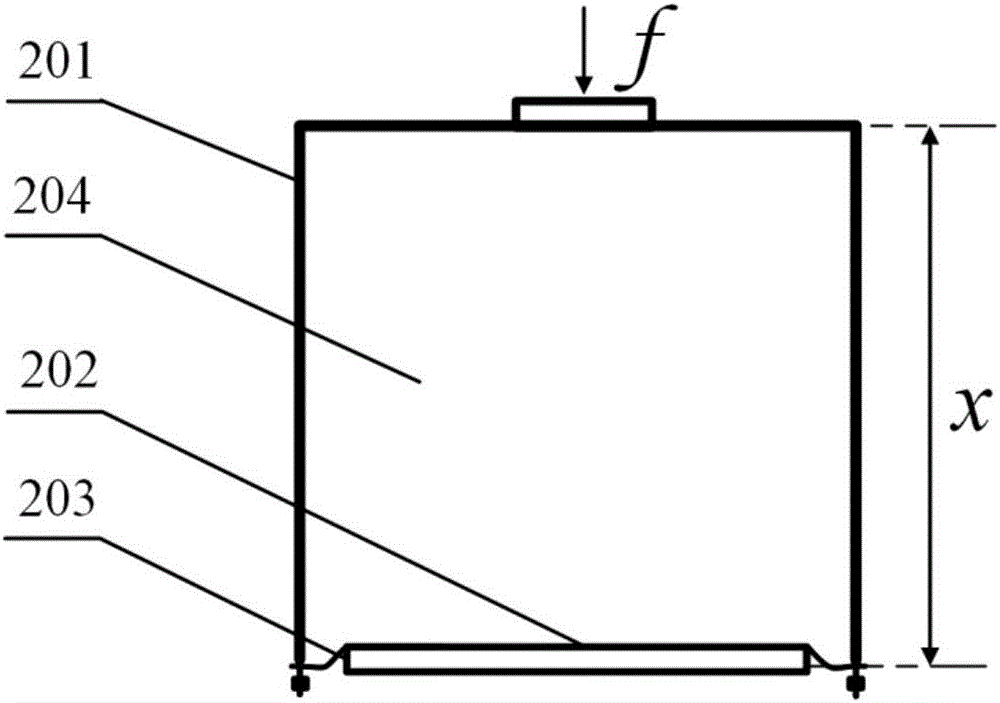

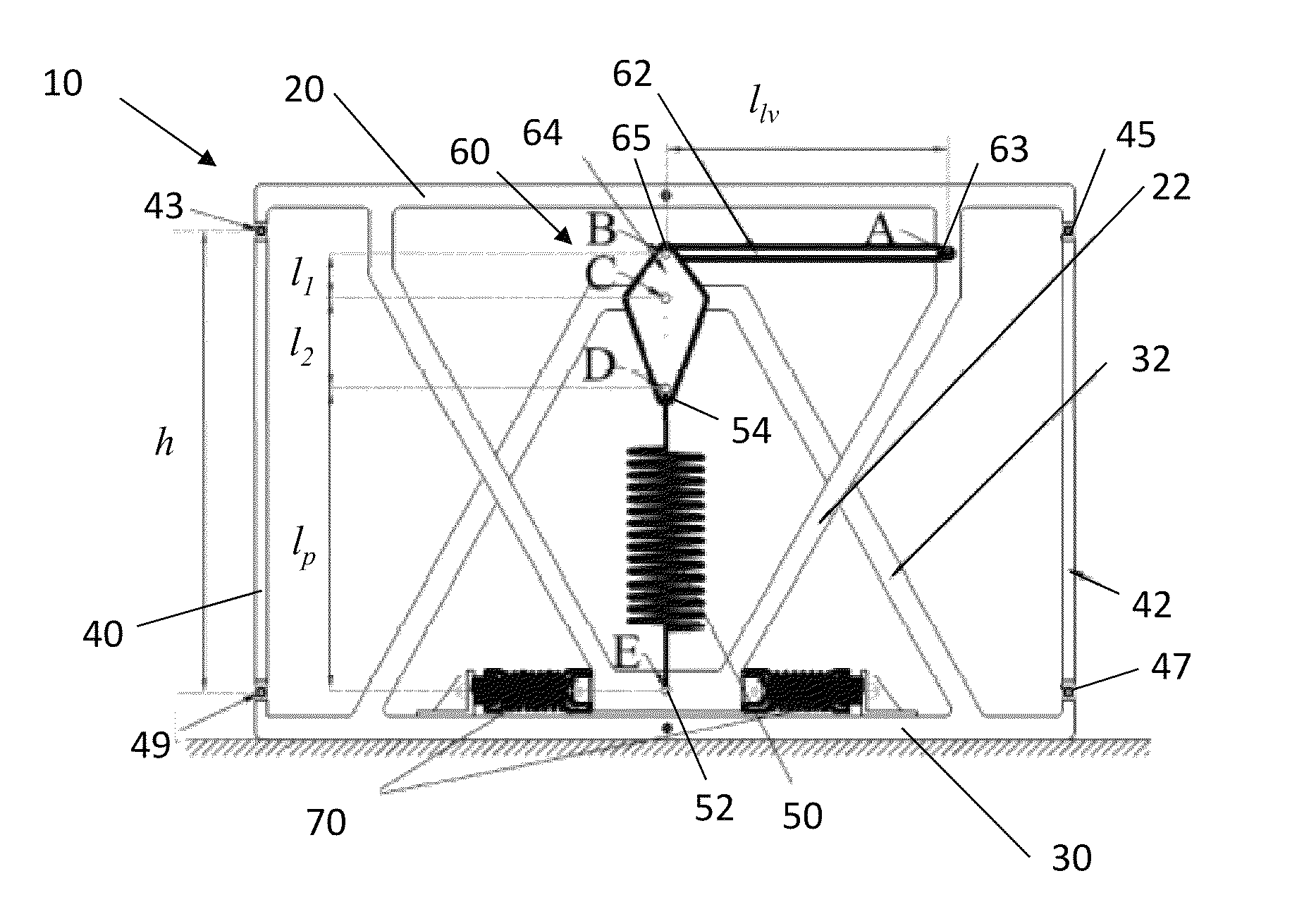

Two-degree-of-freedom ultralow-frequency vibration isolator

ActiveCN106321707ARealization of ultra-low frequency vibration isolation with degrees of freedomVibration isolation achievedNon-rotating vibration suppressionSprings/dampers functional characteristicsMarine engineeringAir spring

The invention discloses a two-degree-of-freedom ultralow-frequency vibration isolator. The two-degree-of-freedom ultralow-frequency vibration isolator comprises a basic platform (10) and a load-bearing platform (30), and the basic platform (10) and the load-bearing platform (30) are connected through supporting rods. The two-degree-of-freedom ultralow-frequency vibration isolator is characterized in that the vibration isolator further comprises a positive-stiffness air spring (20) and a magnetic negative-stiffness mechanism (28) with adjustable negative stiffness, and the positive-stiffness air spring (20) and the magnetic negative-stiffness mechanism (28) form a parallel mechanism in the direction of the center axes of the basic platform and the load-bearing platform, so that the inherent frequency in the direction of the center axes of the basic platform and the load-bearing platform is decreased; and a stiffness-adjustable positive-stiffness leaf spring and a negative-stiffness inverted pendulum are arranged in the direction perpendicular to the center axes of the basic platform and the load-bearing platform and form a negative-stiffness parallel mechanism, so that the inherent frequency in the direction perpendicular to the center axes of the basic platform and the load-bearing platform is decreased. According to the vibration isolator, positive-stiffness and negative-stiffness parallel type passive structures are adopted both in the direction of the center axes of the basic platform and the load-bearing platform and in the direction perpendicular to the center axes of the basic platform and the load-bearing platform, and thus vibration of two degrees of freedom is achieved at the same time.

Owner:HUAZHONG UNIV OF SCI & TECH

Quasi-zero stiffness vibration isolator connected with magnetic spring in parallel through spiral spring

InactiveCN104747652AReduce stress concentrationLarge displacementMagnetic springsShock absorbersCoil springEngineering

A quasi-zero stiffness vibration isolator connected with a magnetic spring in parallel through a spiral spring comprises a mass supporting rod, and one end of the mass supporting rod is fixedly connected with the spiral spring through threads; a permanent magnet clamped by the spiral spring, the spiral spring and the mass supporting rod move together relative to a spiral spring clamping mechanism in the axial direction, and meanwhile the spiral spring provides positive stiffness for a system in the axial direction; two annular permanent magnets fixed through the permanent magnet clamping mechanism apply attraction to the permanent magnet clamped by the spiral spring, the three permanent magnets form the magnetic spring, and non-linear restoration force and non-linear negative stiffness are provided for the system; the relative distances between the upper permanent magnet and the permanent magnet clamped by the spiral spring and between the lower permanent magnet and the permanent magnet clamped by the spiral spring can be adjusted by rotating the permanent magnet clamping mechanism. By means of the vibration isolator, intrinsic frequency of the vibration isolation system can be effectively reduced, and the vibration isolation frequency band is widened. Meanwhile, the damping characteristic of the structure is improved, and a reliable method is provided for low-frequency vibration control.

Owner:XI AN JIAOTONG UNIV

Positive and negative stiffness parallel quasi-zero stiffness vibration isolator

ActiveCN108662055ALower natural frequencyImprove stabilityMagnetic springsArchitectural engineeringNegative stiffness

The invention discloses a positive and negative stiffness parallel quasi-zero stiffness vibration isolator which comprises an upper top plate, a lower top plate, a positive stiffness element and multiple negative stiffness elements, wherein the positive stiffness element and the multiple negative stiffness elements are located between the upper top plate and the lower bottom plate. The positive stiffness element is installed on a base plate, the base plate is fixed to the lower bottom plate and used for adjusting the height of the positive stiffness element, and the multiple negative stiffnesselements are evenly distributed on the left side and the right side of the positive stiffness element. In each negative stiffness element, an inner magnetic ring set and an outer magnetic ring set are both located in a magnetic ring sleeve, the magnetic ring sleeve is fixed to the lower bottom pate, a magnetic ring shaft is located in the axial center of the magnetic ring sleeve, the magnetic ring shaft is fixedly sleeved with the inner magnetic ring set, the inner magnetic ring set is sleeved with the outer magnetic ring set, the outer magnetic ring set is fixed to the magnetic ring sleeve,the top end of the magnetic ring shaft is connected with a metal pulling and pressing rod, the metal pulling and pressing rod is coaxial with the magnetic ring shaft, a pulling and pressing rod pressing block is fixed to the top end of the metal pulling and pressing rod and fixed to the upper top plate, and the inner magnetic ring set and the outer magnetic ring set are axially magnetized. The vibration isolator can achieve ultra-low-frequency vibration isolation.

Owner:SHANGHAI UNIV

Quasi-zero stiffness vibration isolator based on transverse groove spring

PendingCN109505918APrecise Design StiffnessSimple structureNon-rotating vibration suppressionSprings/dampers functional characteristicsDynamic stiffnessBraced frame

The invention discloses a quasi-zero stiffness vibration isolator based on a transverse groove spring, and belongs to the field of vibration isolators. An existing linear vibration isolator cannot simultaneously achieve a wide vibration isolation frequency band and small static displacement. According to the quasi-zero stiffness vibration isolator based on the transverse groove spring, a balance position adjustment structure is arranged on the upper surface of a bottom plate of a supporting frame; a positive stiffness mechanism is arranged on the upper part of the balance position adjustment structure; and the periphery of the positive stiffness mechanism is connected to the inner wall of a side face plate of the supporting frame through a set of negative stiffness mechanisms, and the twoends of the negative stiffness mechanisms are connected with the positive stiffness mechanism and the inner wall of the side face plate of the supporting frame through rotating pairs correspondingly.The dynamic stiffness at the balance position is zero, the vibration isolation performance for ultra-low frequency vibration is improved, and the effect of full frequency band isolation can further beachieved especially for basic excitation.

Owner:HARBIN INST OF TECH

Negative stiffness device and method

ActiveUS8857110B2Negative stiffnessReduce demandSprings/dampers functional characteristicsBuilding repairsSeismic protectionSpring force

A negative stiffness device and method for seismic protection of a structure is described. In one embodiment, the device has an anchor frame and a movement frame laterally translatable relative to the anchor frame. The anchor frame and movement frame have respective extension portions. A linkage is pivotably connected to the extension portion of the anchor frame. A compressed spring has a first end is attached to the extension portion of the movement frame and a second end attached to the linkage. The compressed spring has a spring force. In a rest state, the compressed spring does not apply a lateral force to the movement frame. In an engaged state, the compressed spring is configured to apply a lateral force to displace the movement frame in a lateral direction of a seismic load. The spring force is amplified by the linkage when the movement frame is laterally displaced to an amplification point.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com