Ultralow frequency vibration isolator based on parallel connection of positive stiffness spring and negative stiffness spring

A positive and negative stiffness, ultra-low frequency technology, used in springs/shock absorbers, shock absorbers, shock absorbers, etc., can solve the problem that nonlinear vibration isolation equipment is not adjustable with mass, etc. The effect of stable and reliable vibration and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

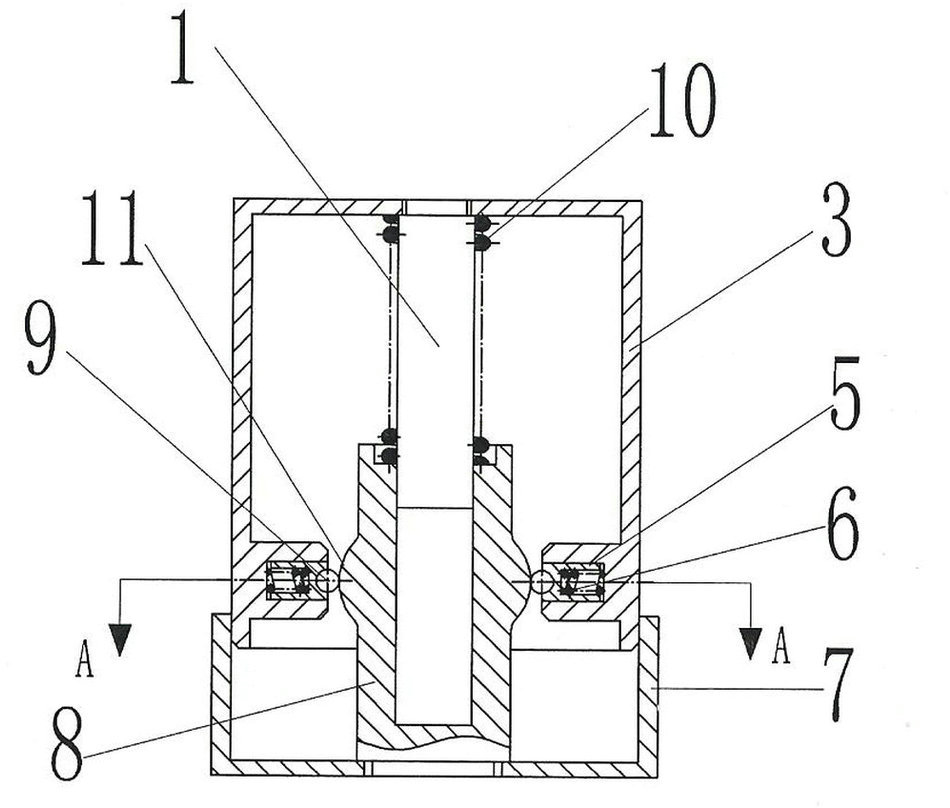

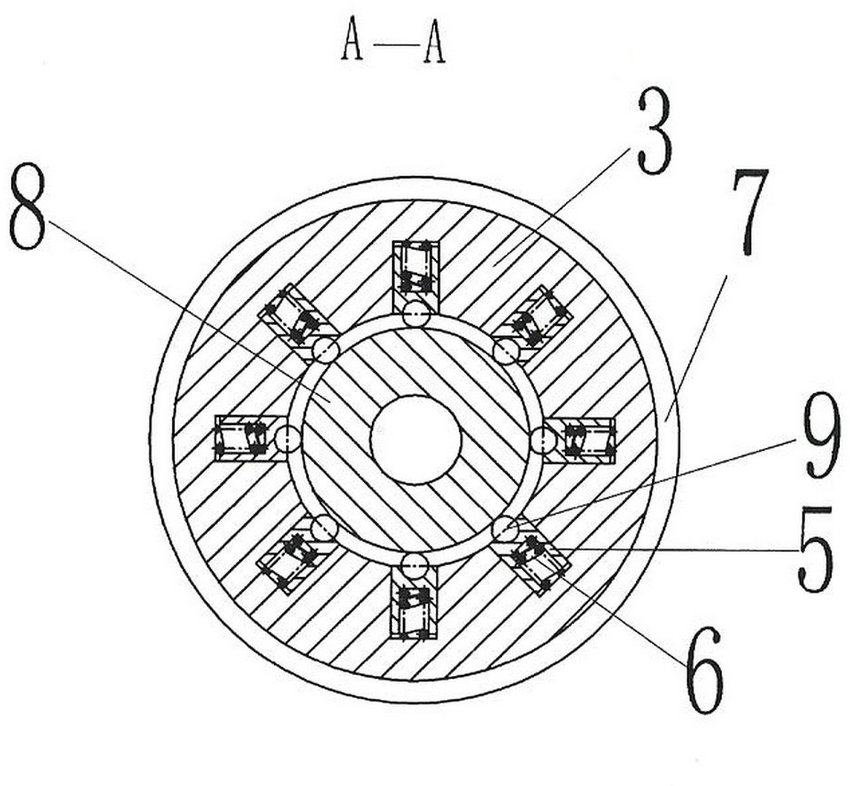

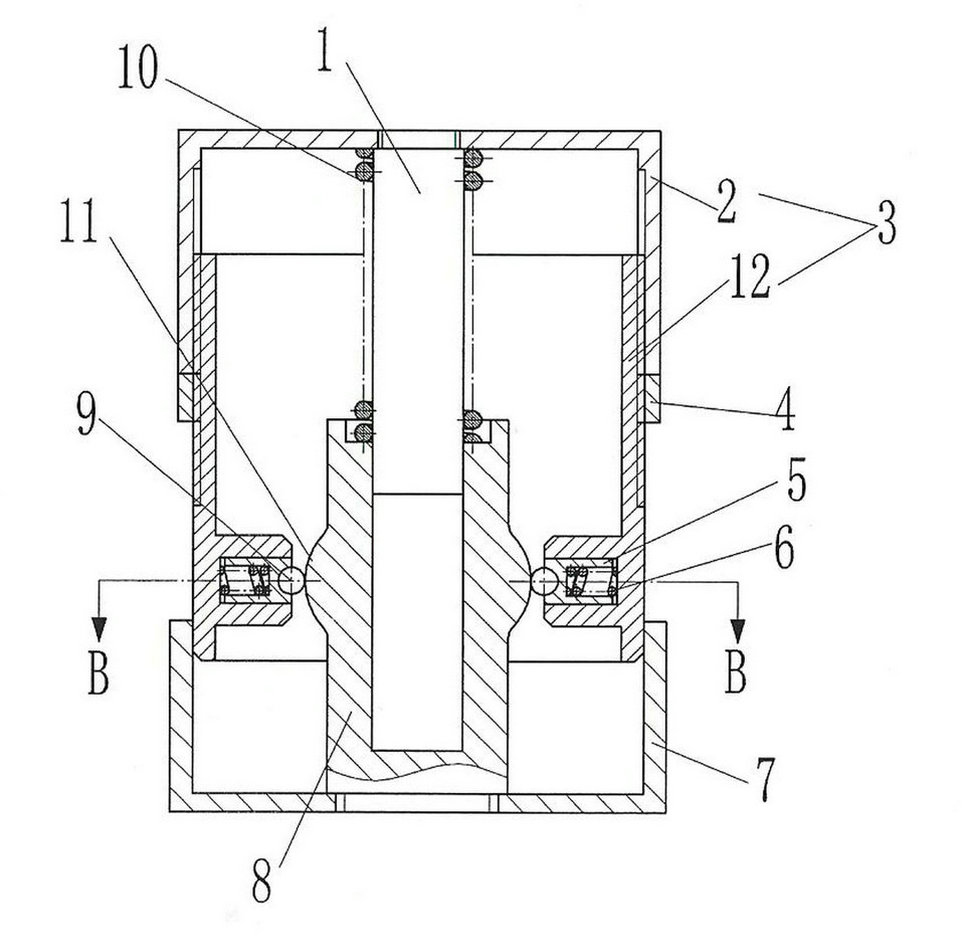

[0029] see figure 1 and figure 2 As shown, it is the first embodiment of the present invention, which is composed of guide column 1, sleeve cover 3, slider 5, negative stiffness spring 6, lower cover 7, guide seat 8, ball 9 and main spring 10, guide column 1 Threaded in the guide seat 8, the guide column 1 can slide in the guide seat 8 to play a guiding role. The main spring 10 is a positive stiffness compression spring. The main spring 10 is set outside the guide column 1. The upper and lower ends of the main spring 10 The inner surface of the top cover of the cover 3 and the groove end surface of the guide seat 8 are positioned and supported respectively, and the negative stiffness spring mechanism is formed by the cover 3, the slider 5, the negative stiffness compression spring 6 and the ball 9, and the inner circumferential direction of the cover 3 Eight cylindrical holes are evenly distributed to cooperate with eight sliders 5 respectively, such as figure 2 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com