Patents

Literature

48125results about "Pumps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

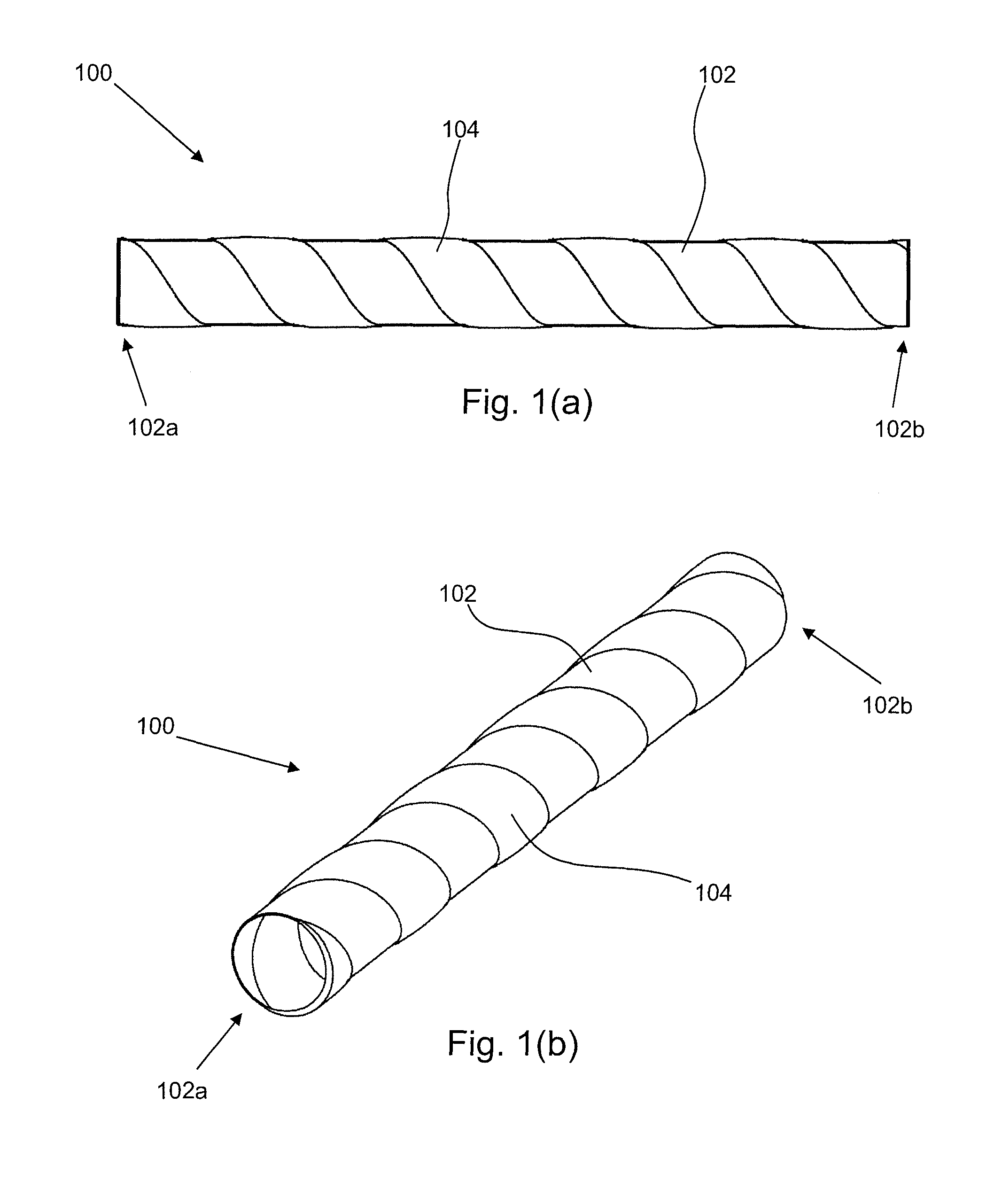

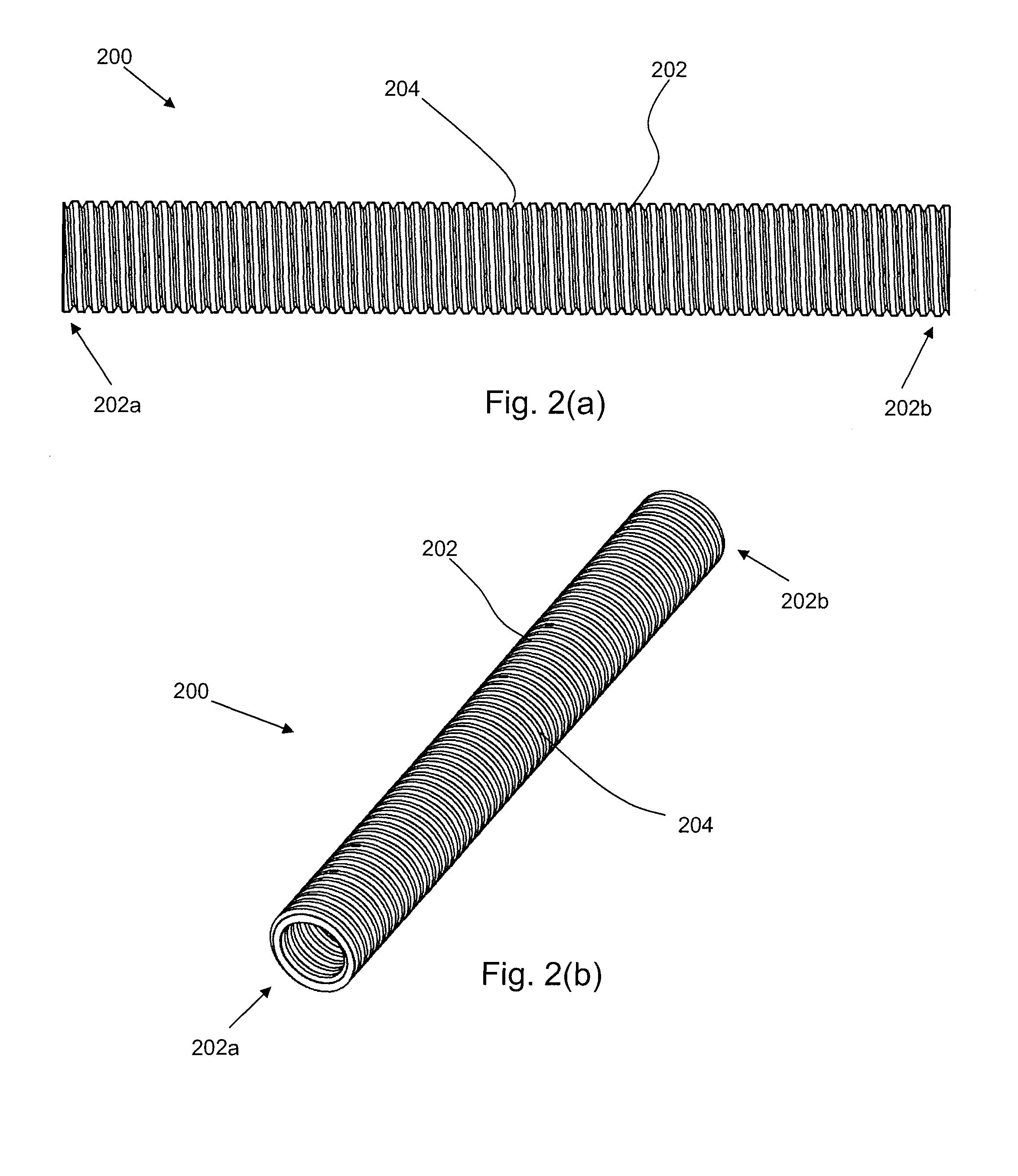

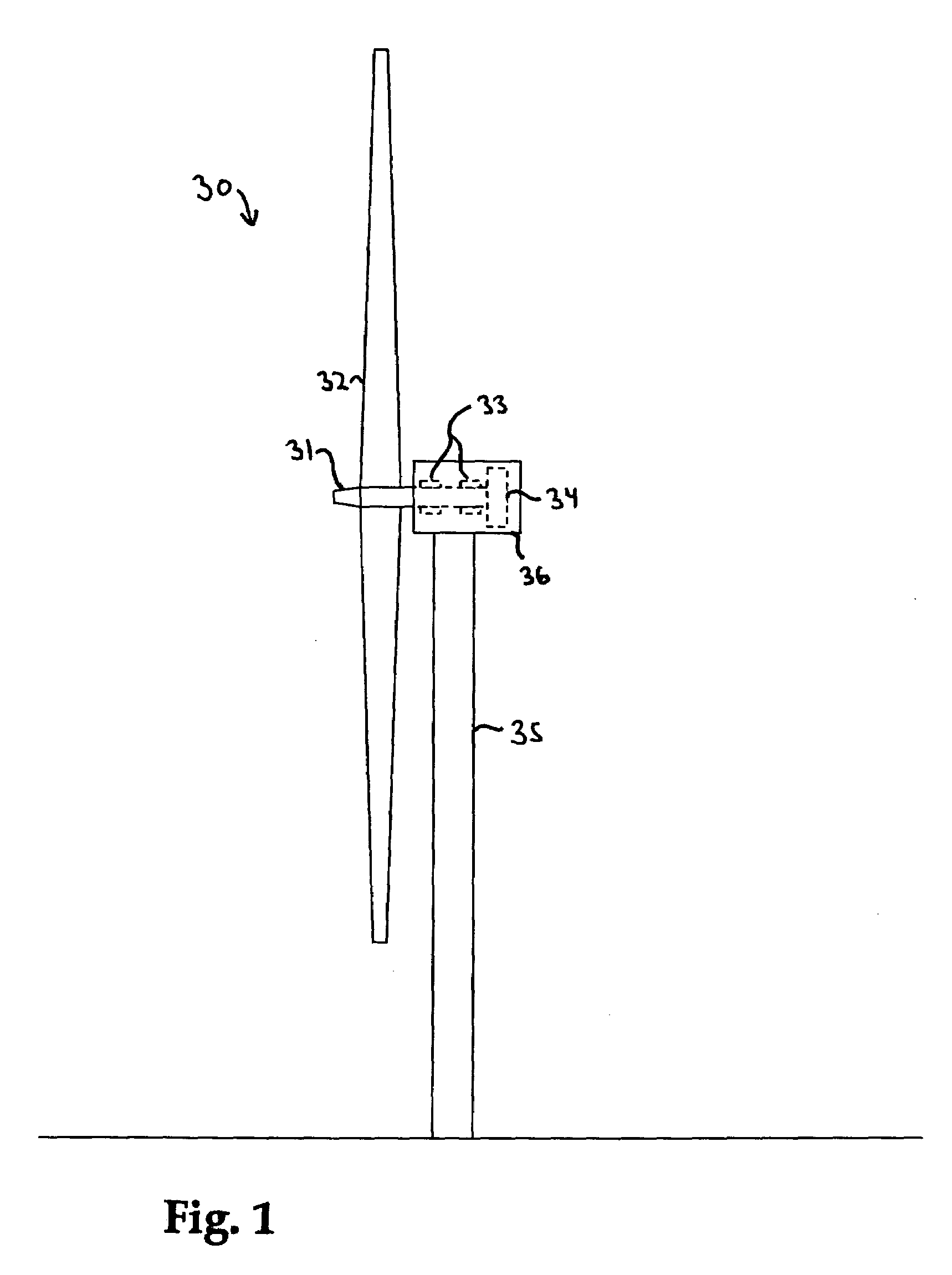

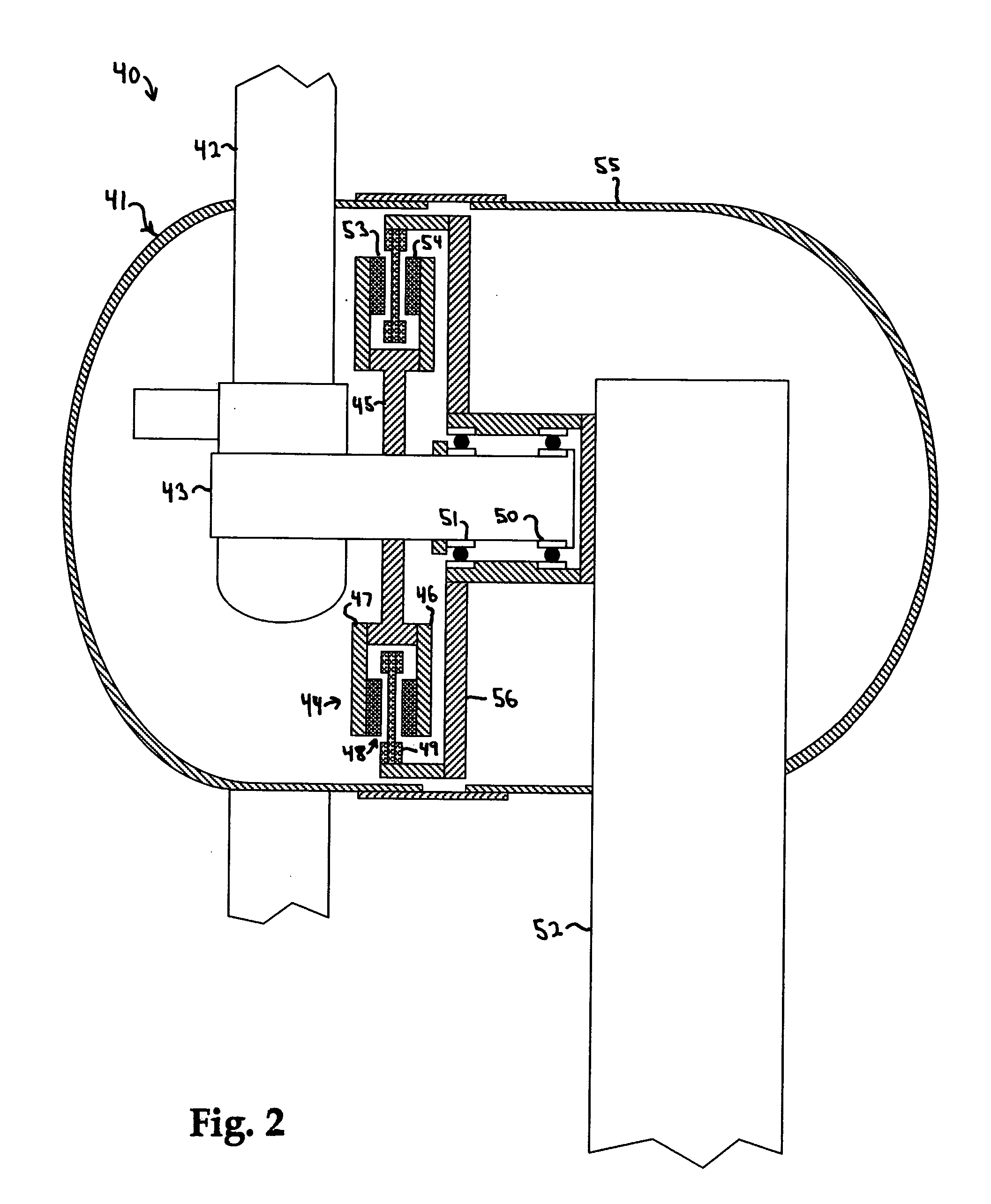

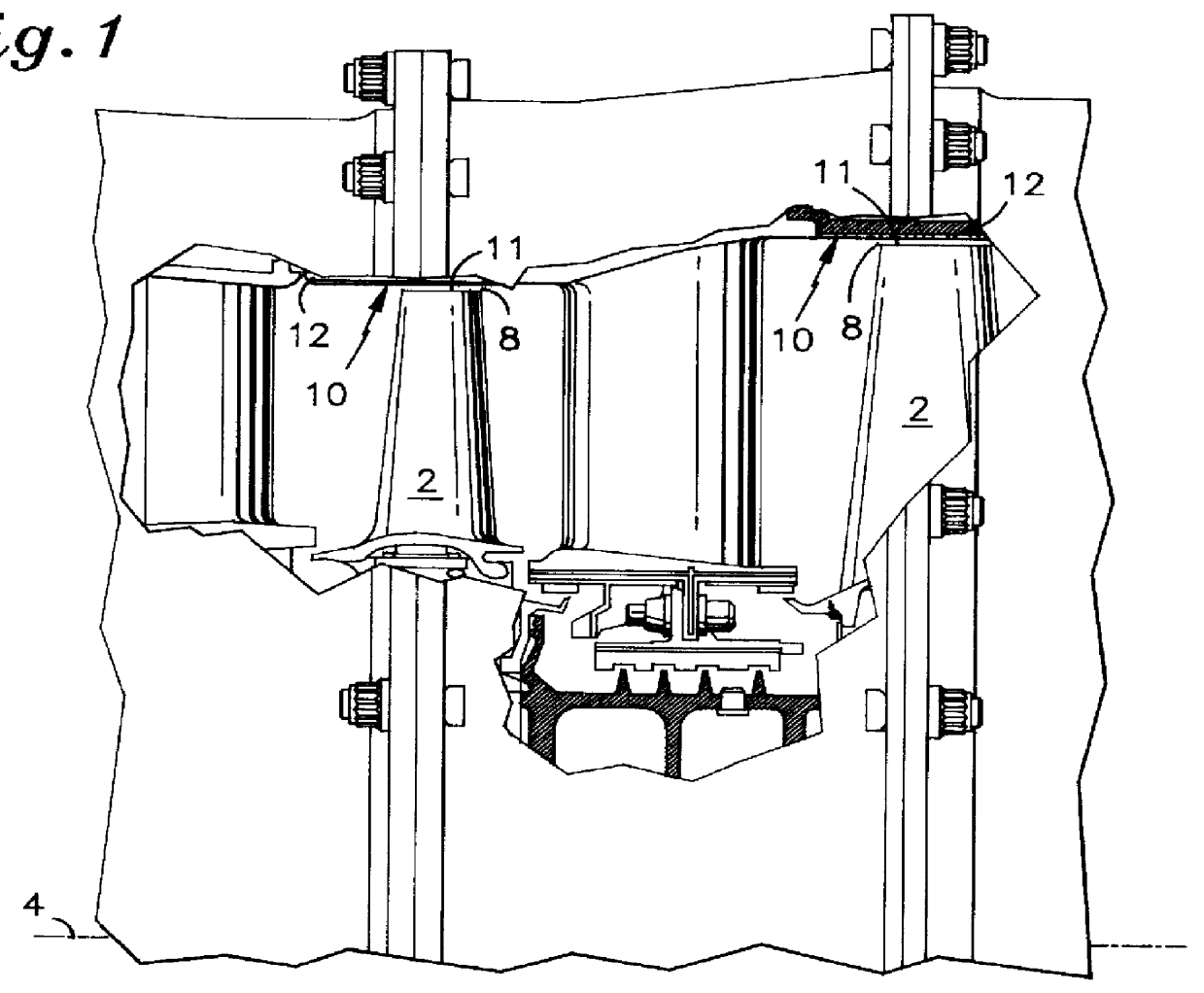

Wind turbine and a shaft for a wind turbine

InactiveUS8664792B2Little strengthImproves buckling stabilityEngine fuctionsFinal product manufactureDrive shaftTurbine

A drive shaft for a wind turbine is shaped so as to allow for increased bending of the shaft, while being suitable for transferring torque in a wind turbine system. An example of such a shaping is a drive shaft having a helical rib defined on the surface of the shaft. A wind turbine incorporating such a shaft, and a method of manufacture of such a shaft are also described.

Owner:ENVISION ENERGY DENMARK

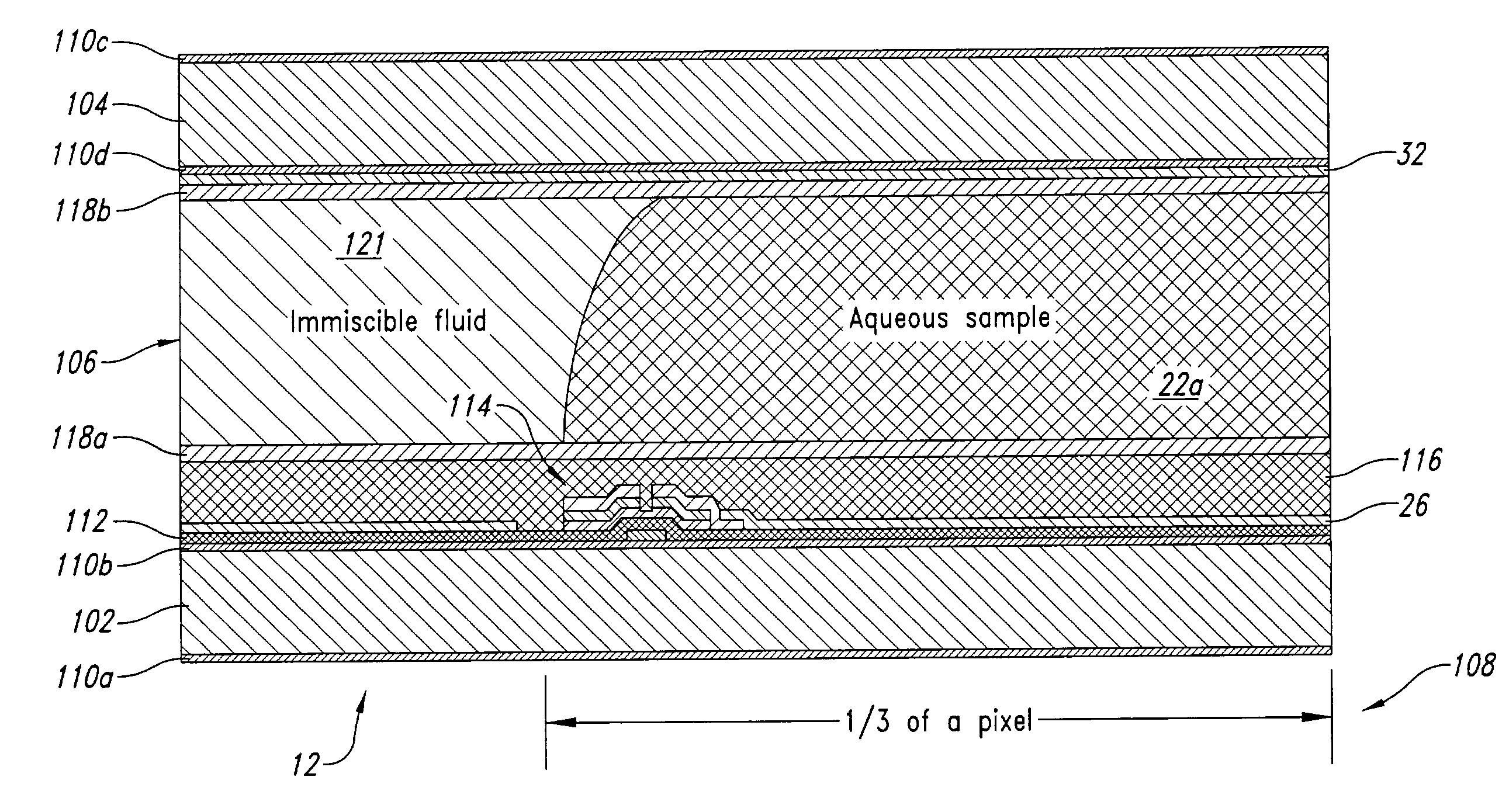

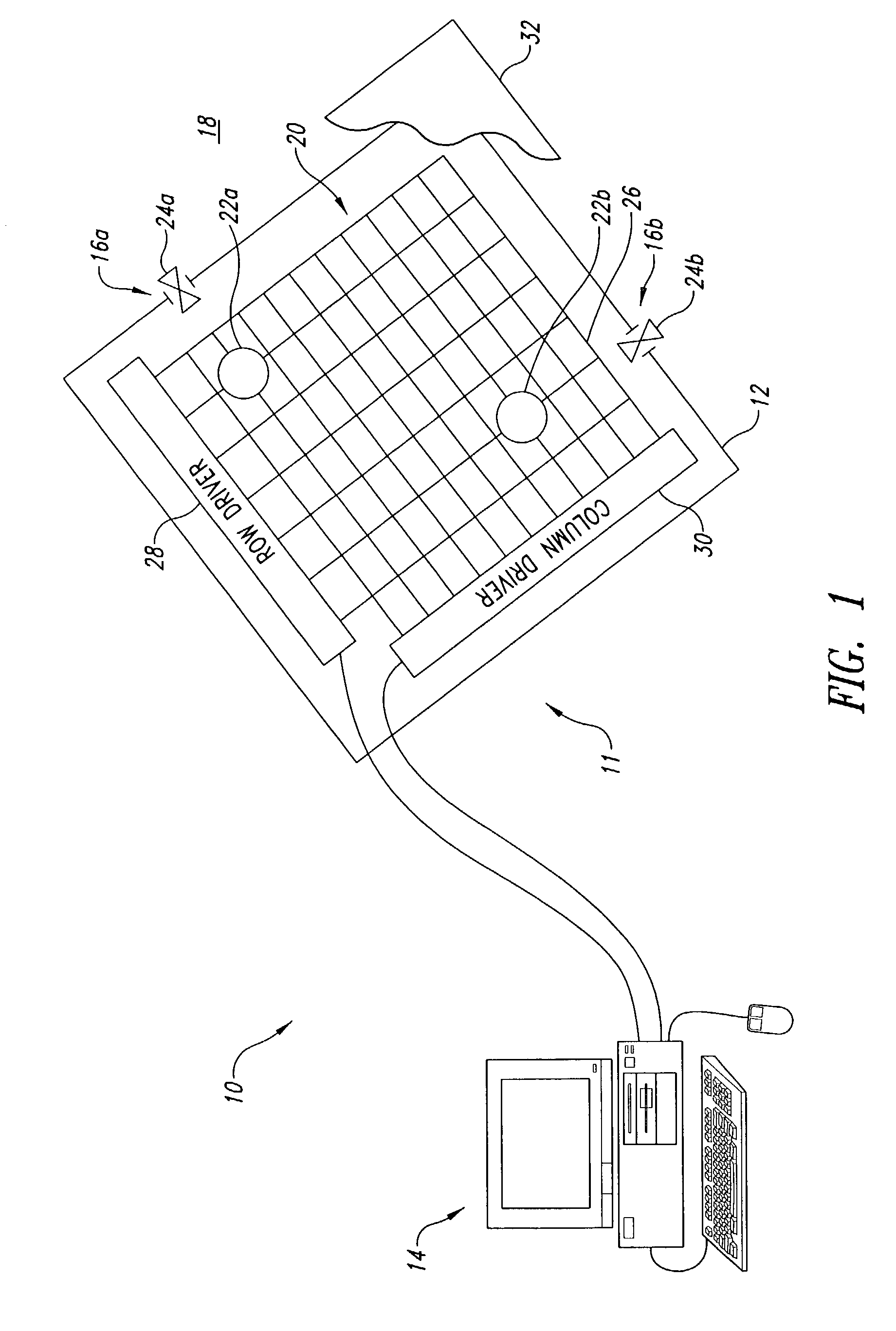

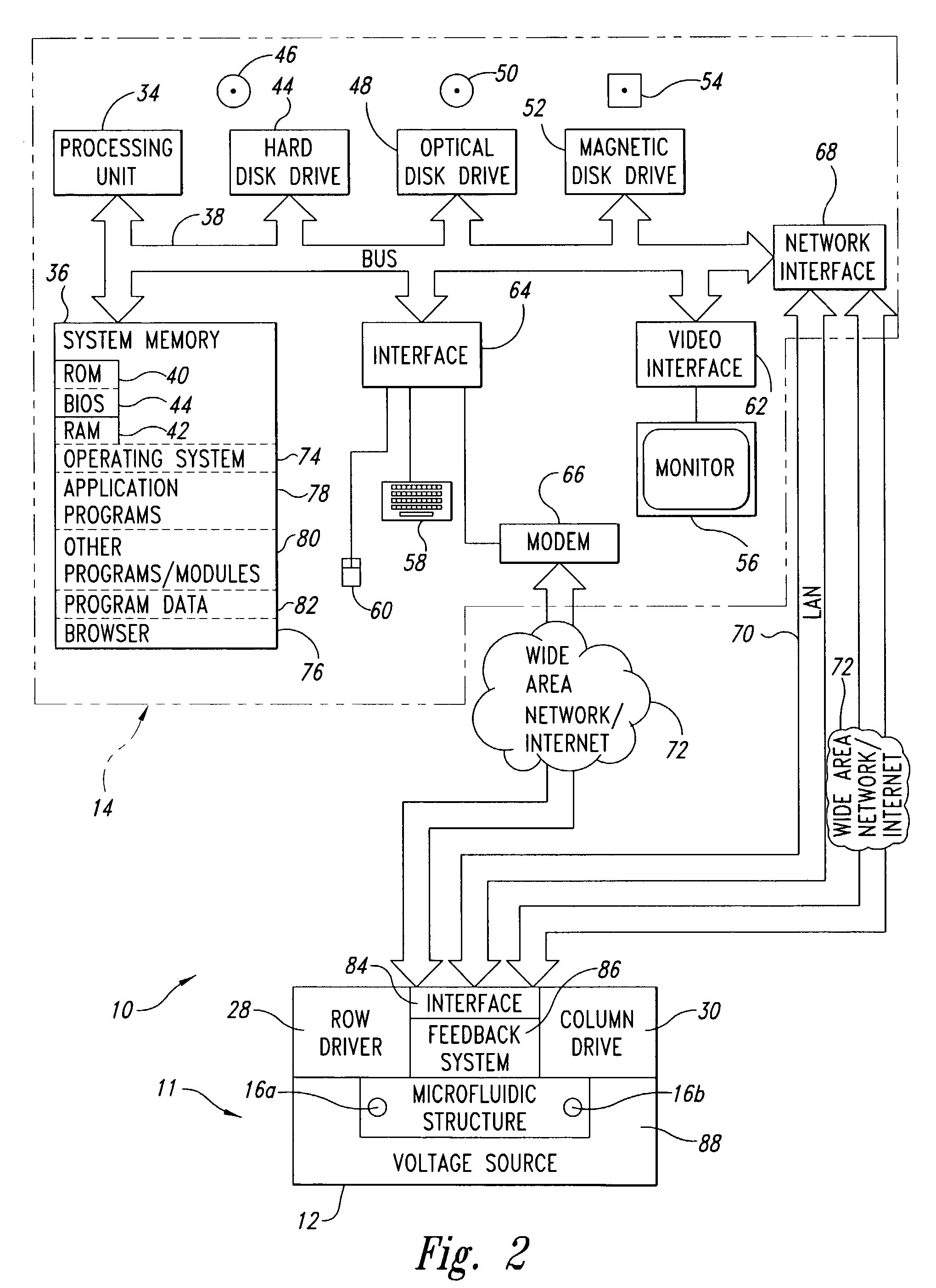

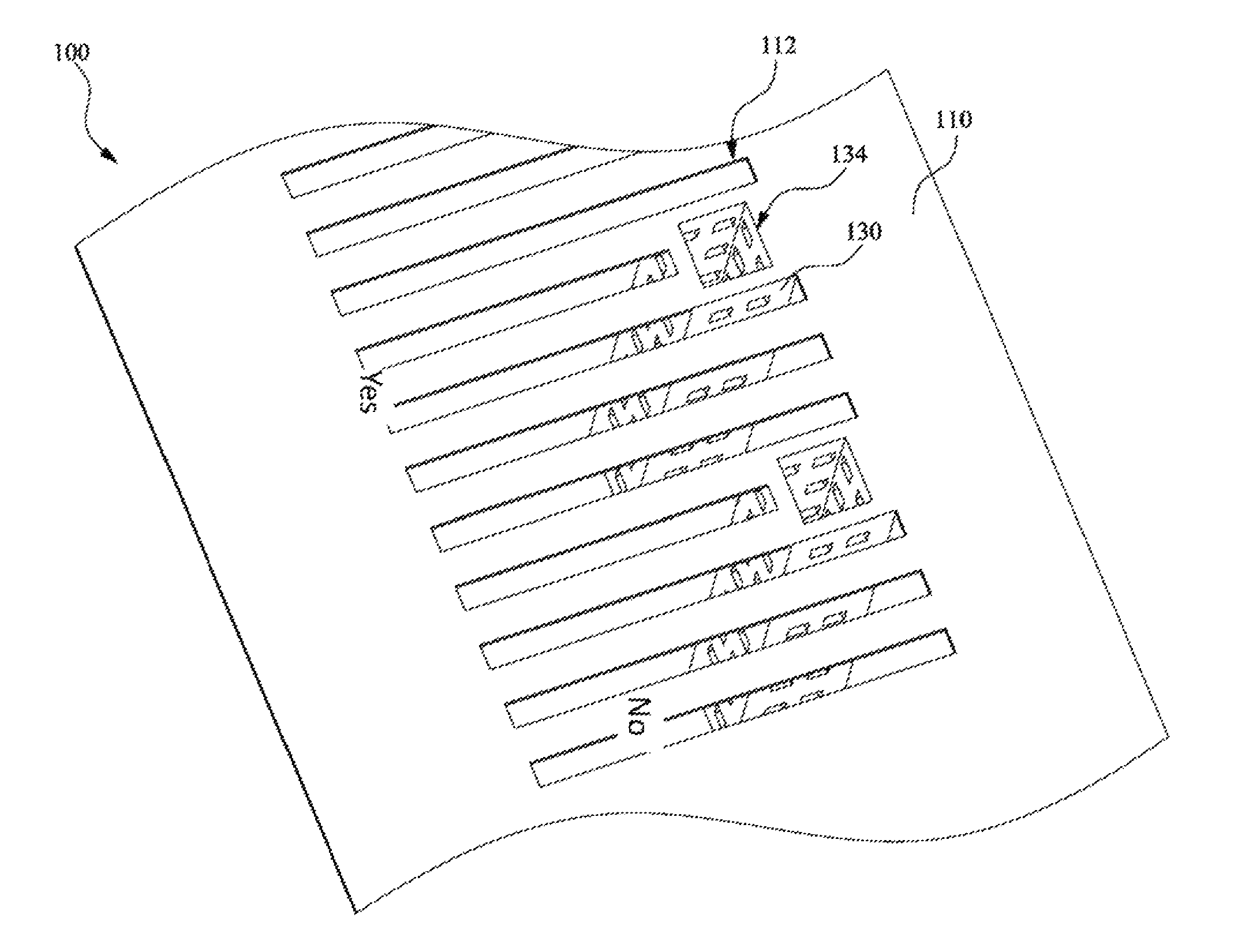

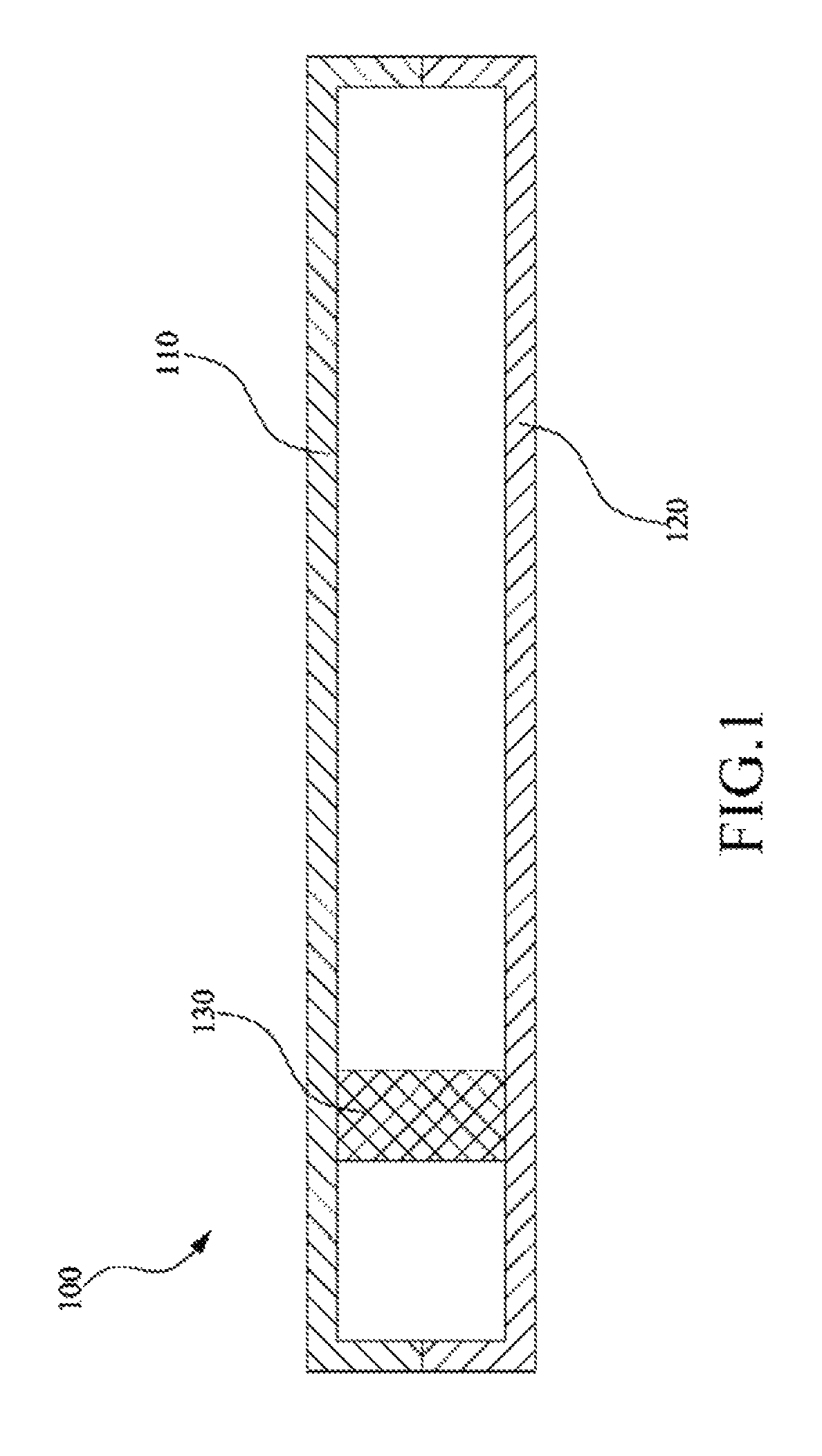

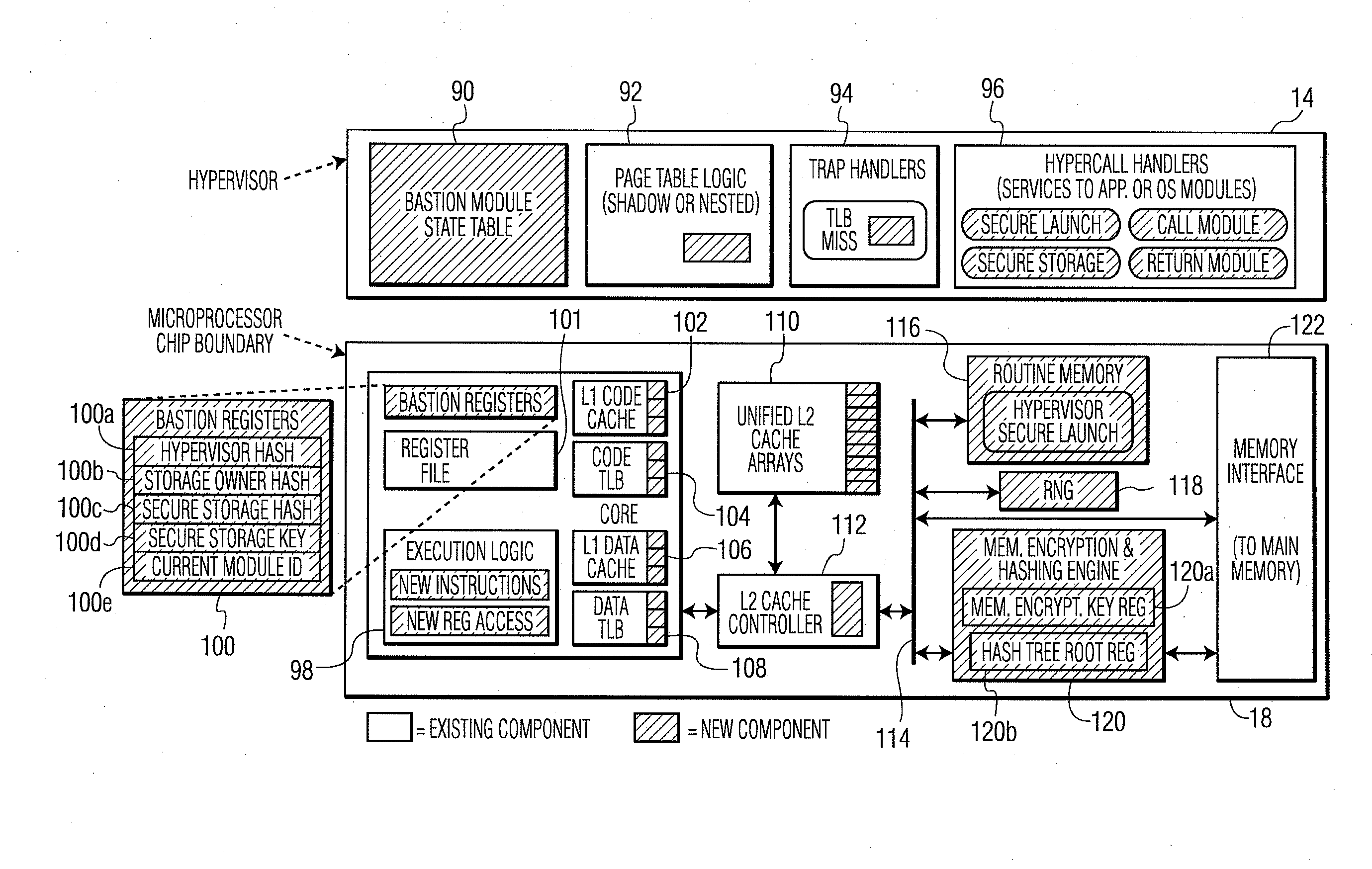

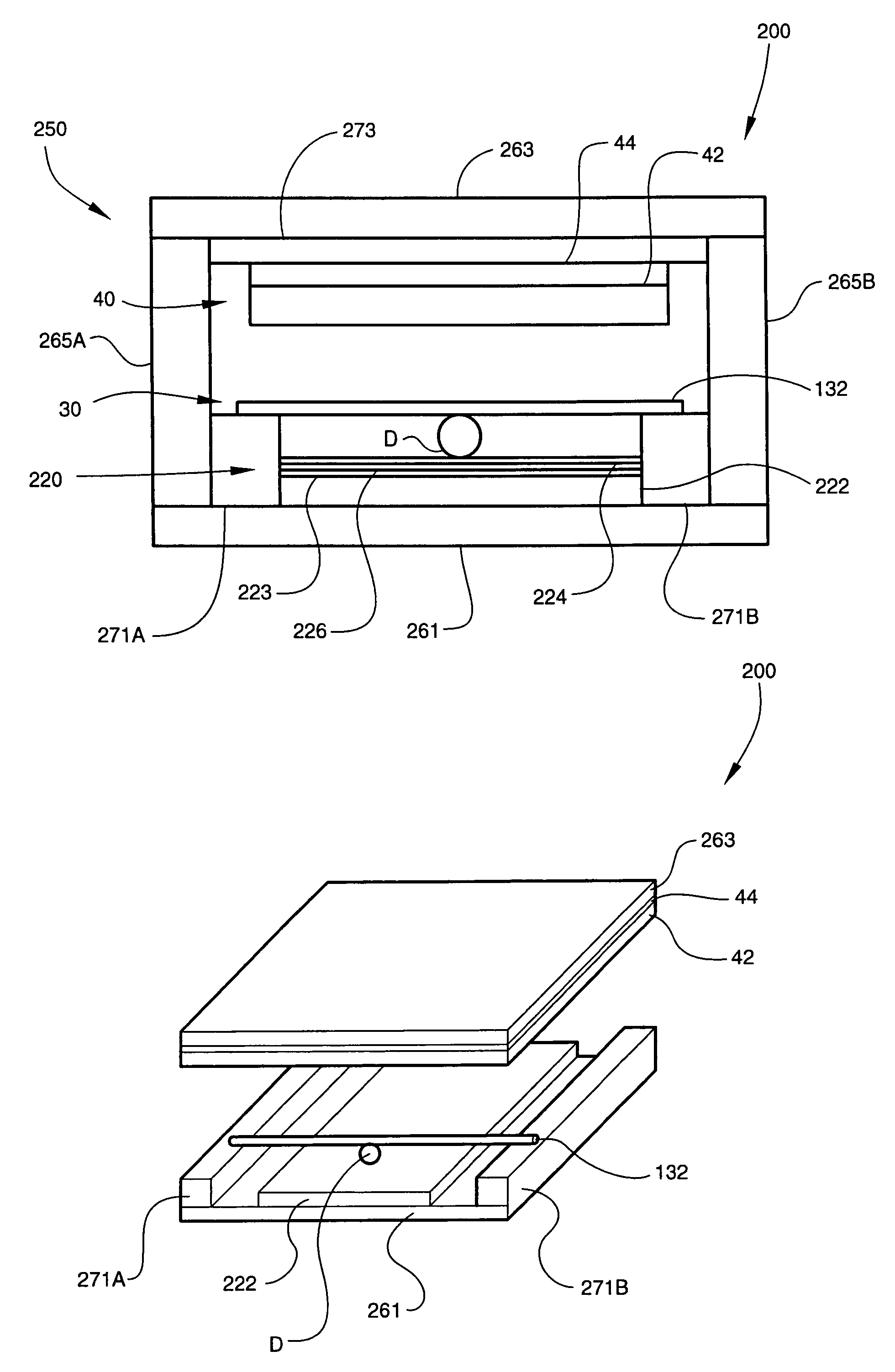

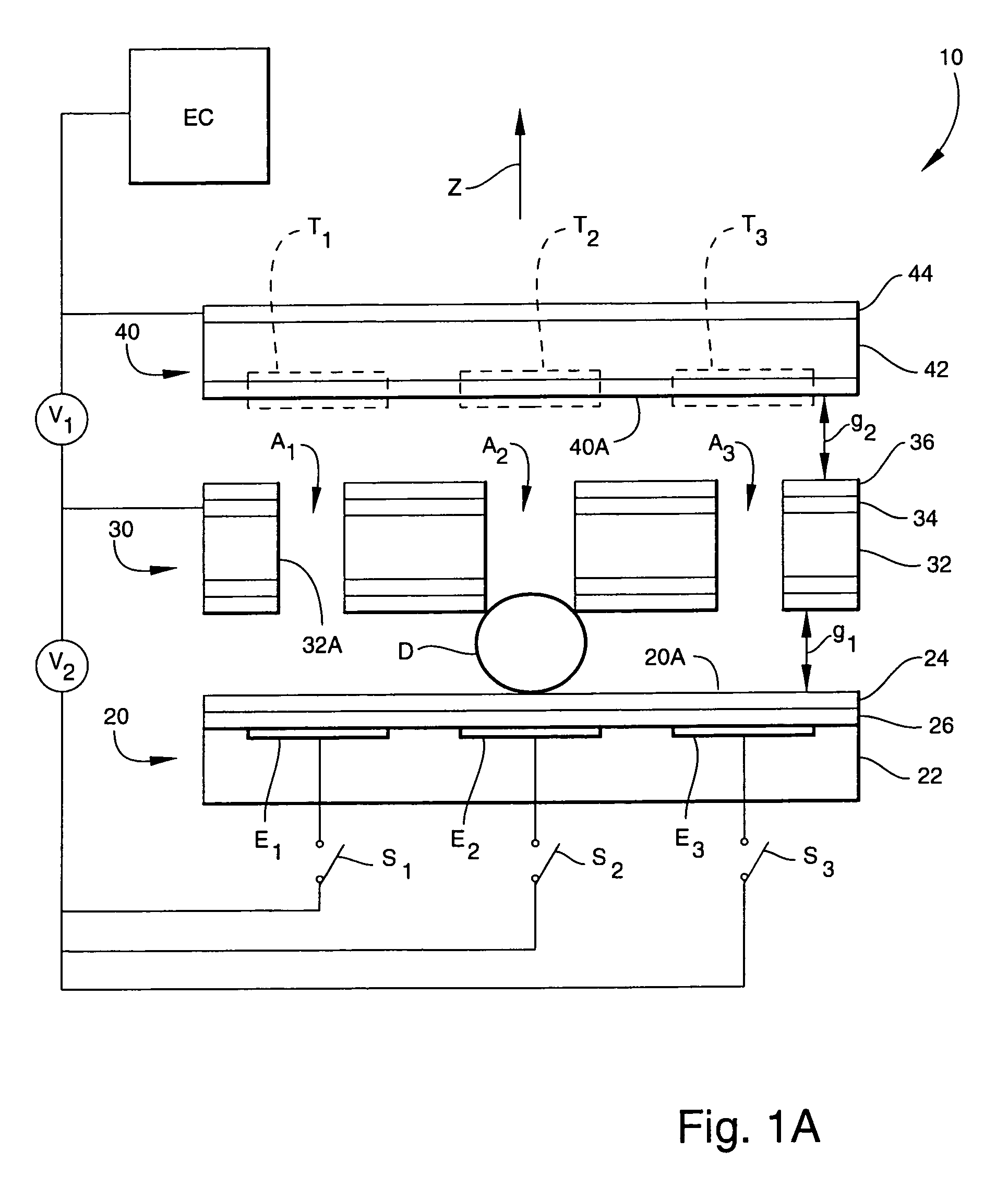

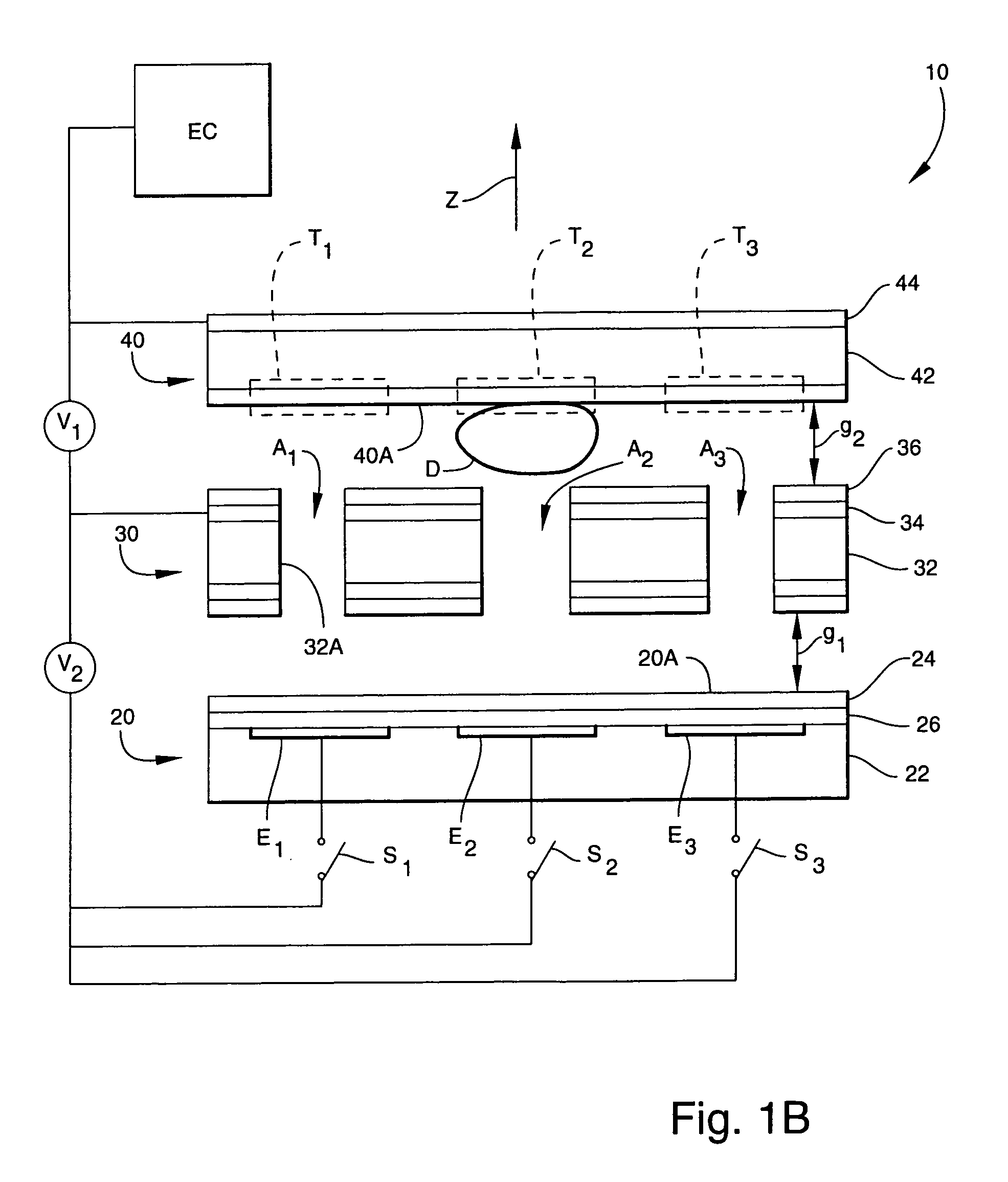

Method, apparatus and article for microfluidic control via electrowetting, for chemical, biochemical and biological assays and the like

InactiveUS7163612B2Low costElectrostatic separatorsSludge treatmentOff the shelfLiquid-crystal display

An active matrix microfluidic platform employs thin film transistor active (“TFT”) matrix liquid crystal display technology to manipulate small samples of fluid for chemical, biochemical, or biological assays without moving parts, for example, using a two-dimensional matrix array of drive electrodes. The active matrix microfluidic platform may employ existing active matrix addressing schemes and / or commercial “off-the-shelf” animation software to program assay protocols. A feedback subsystem may determine an actual location of a fluid in the microfluidic structure, and provides location information to for display, for example, on an active matrix display, and / or to control movement of one or more fluid bodies in the microfluidic structure.

Owner:KECK GRADUATE INST OF APPLIED LIFE SCI

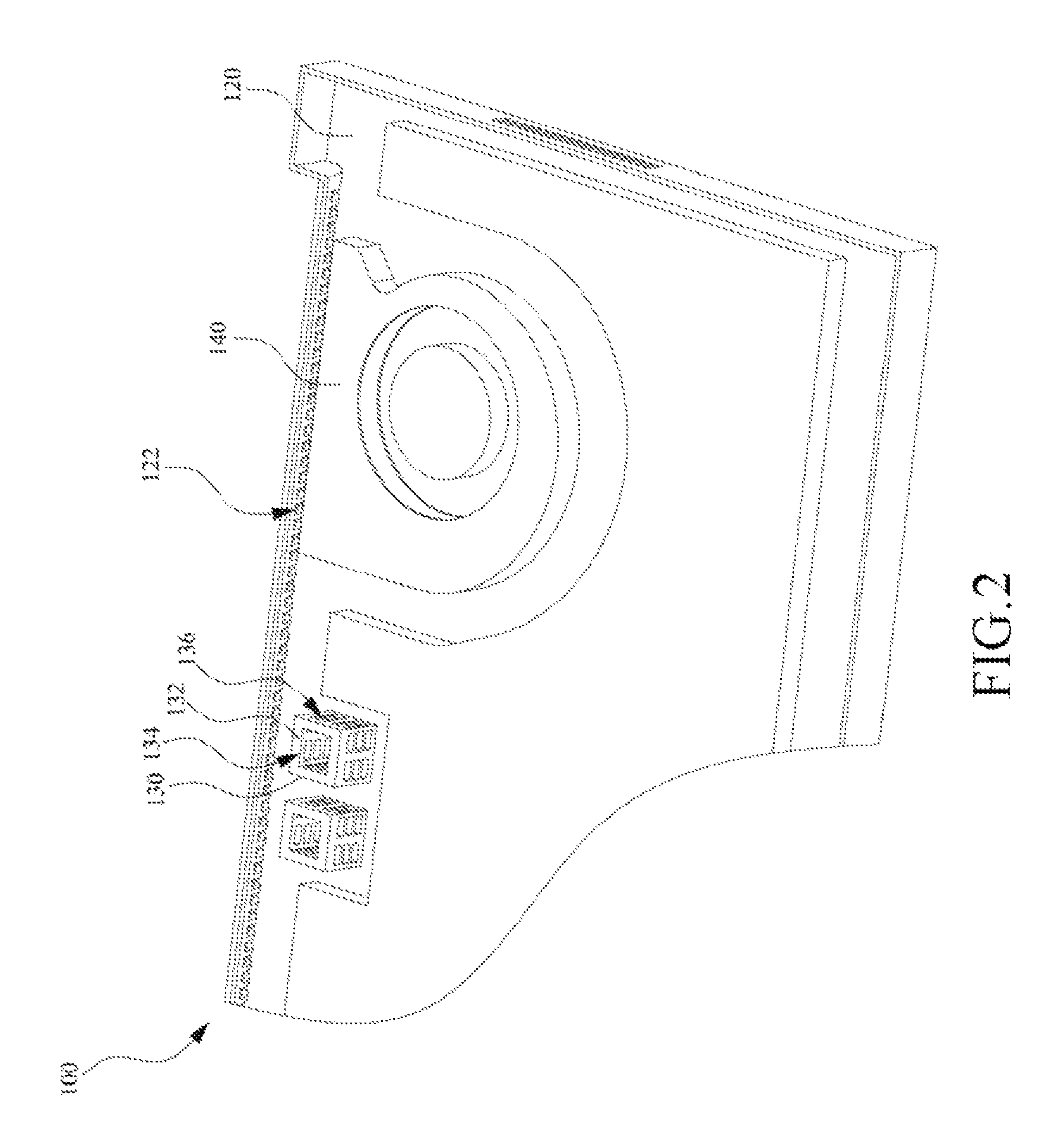

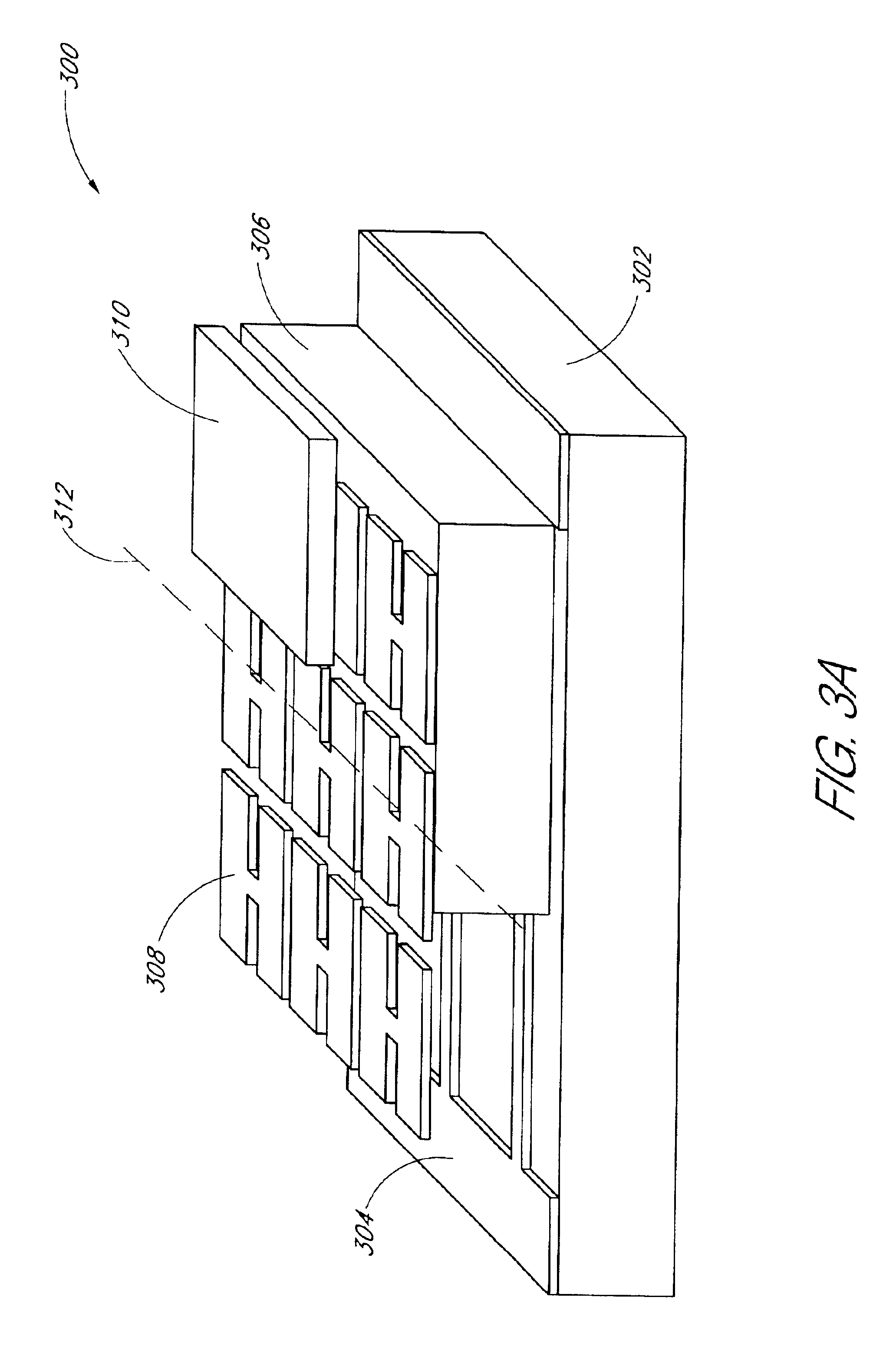

Electronic device

ActiveUS9313915B2Improve cooling efficiencyPump componentsDigital data processing detailsHeat conductingElectron device

An electronic device includes an upper cover, a lower cover combined with the upper cover, and a heat conducting pillar. An accommodating space is formed by the upper cover and the lower cover. The heat conducting pillar is disposed in the accommodating space and physically connected with the upper cover and the lower cover to balance the temperature of the upper cover and the lower cover.

Owner:ASUSTEK COMPUTER INC

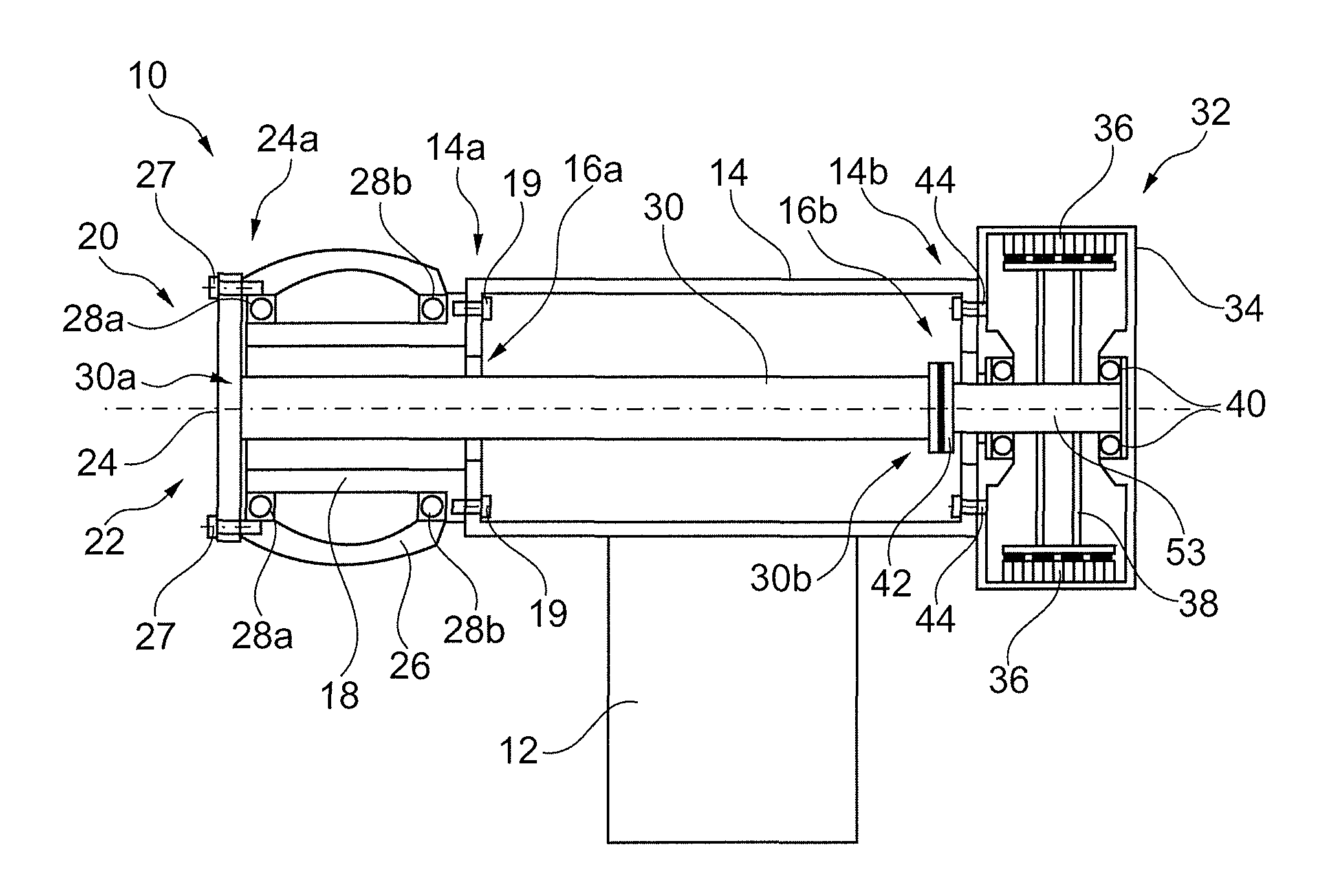

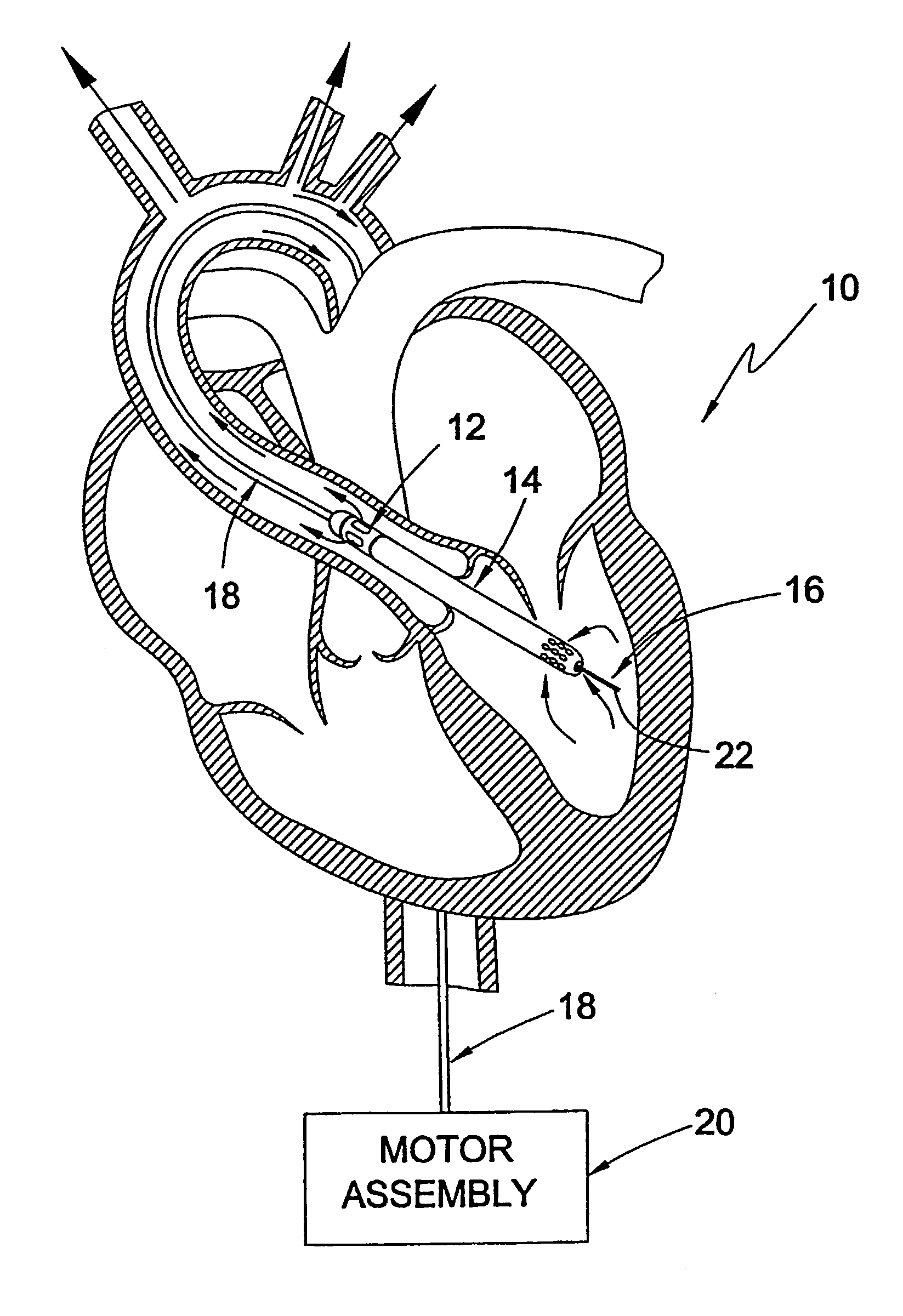

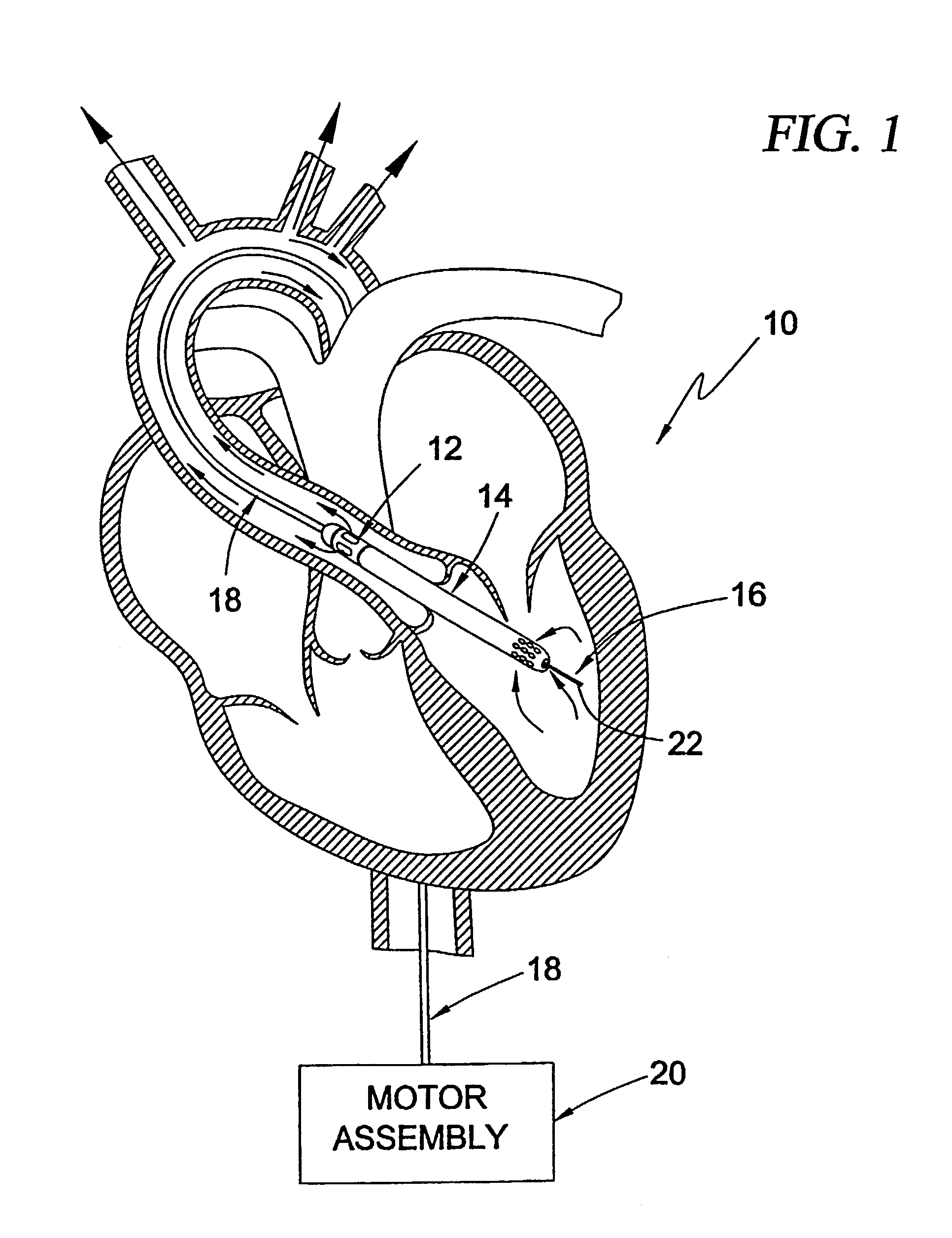

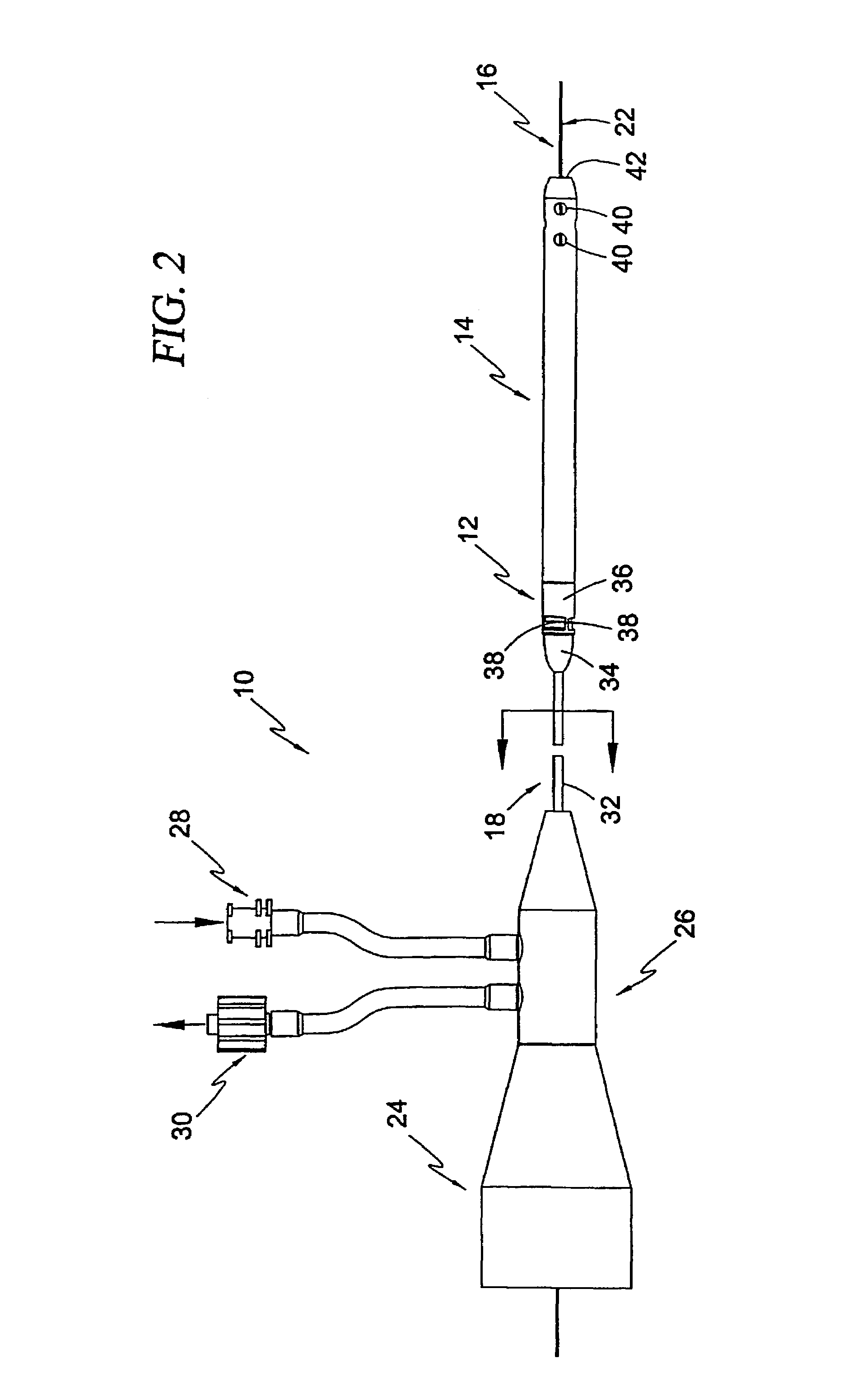

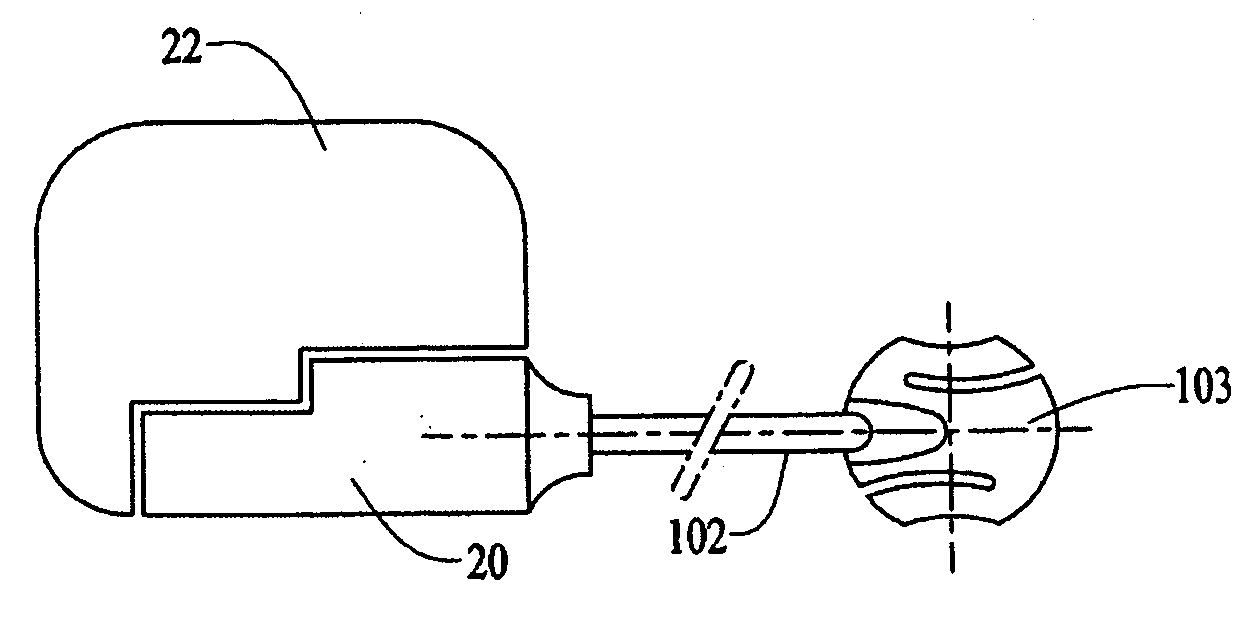

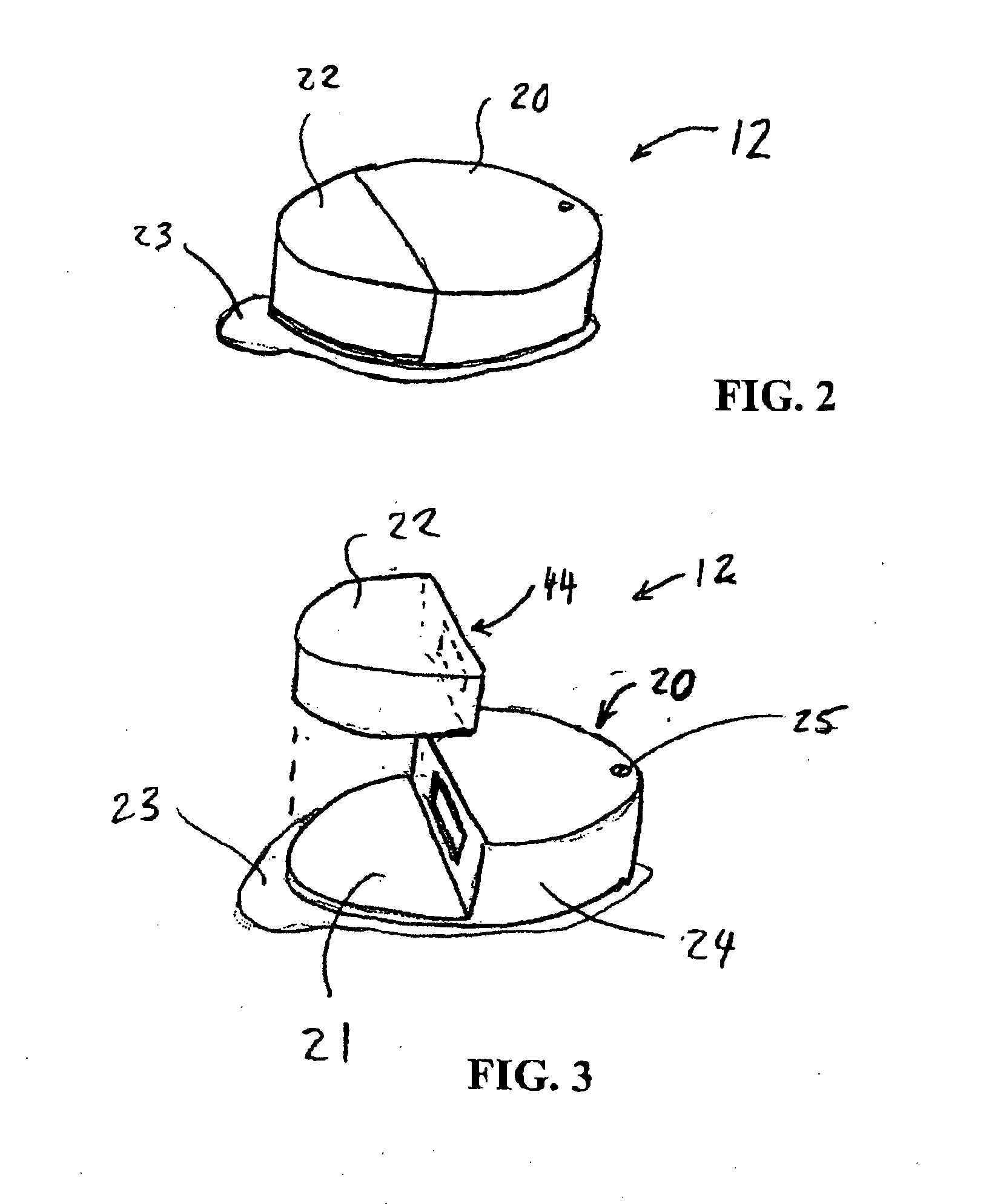

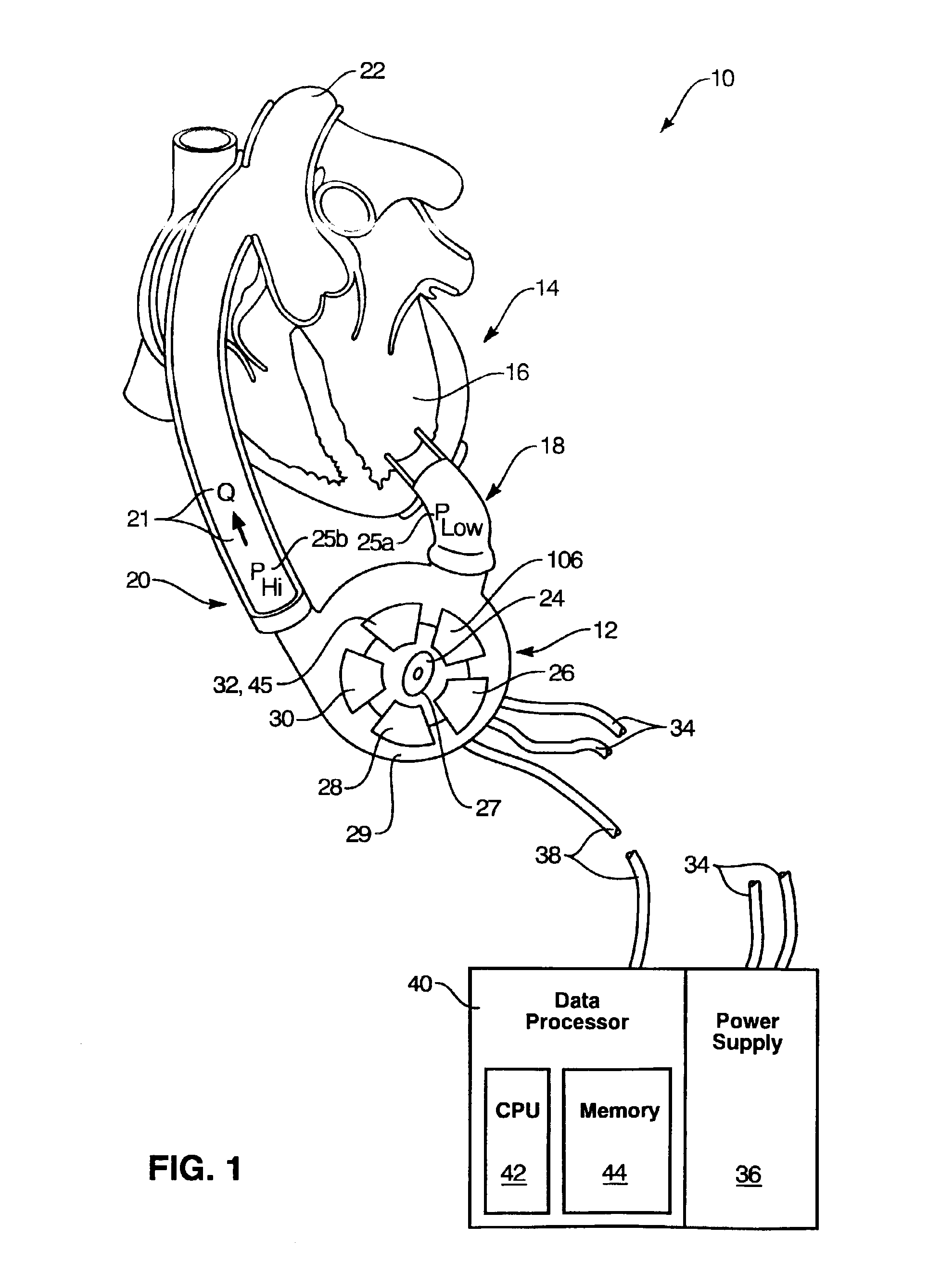

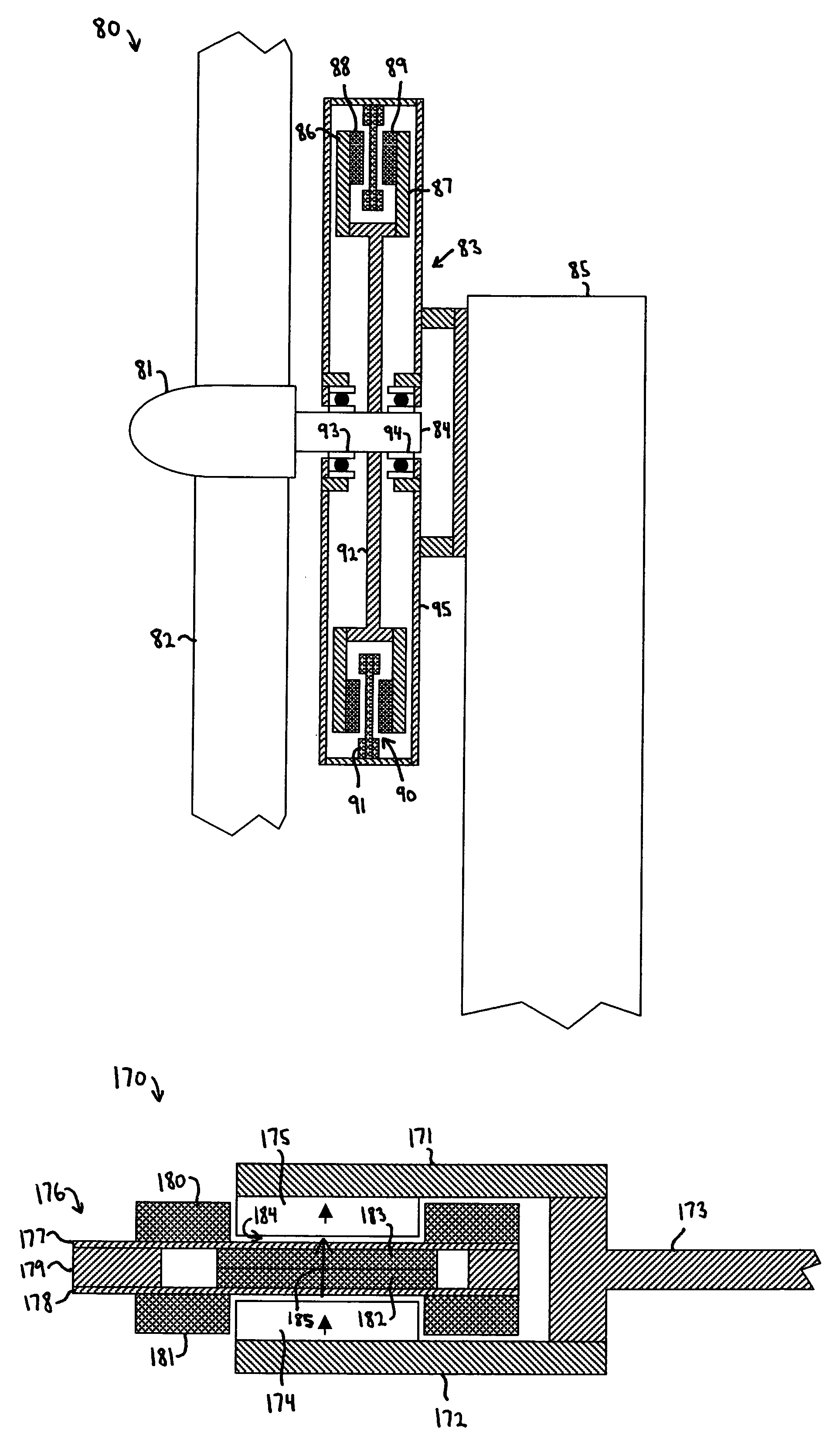

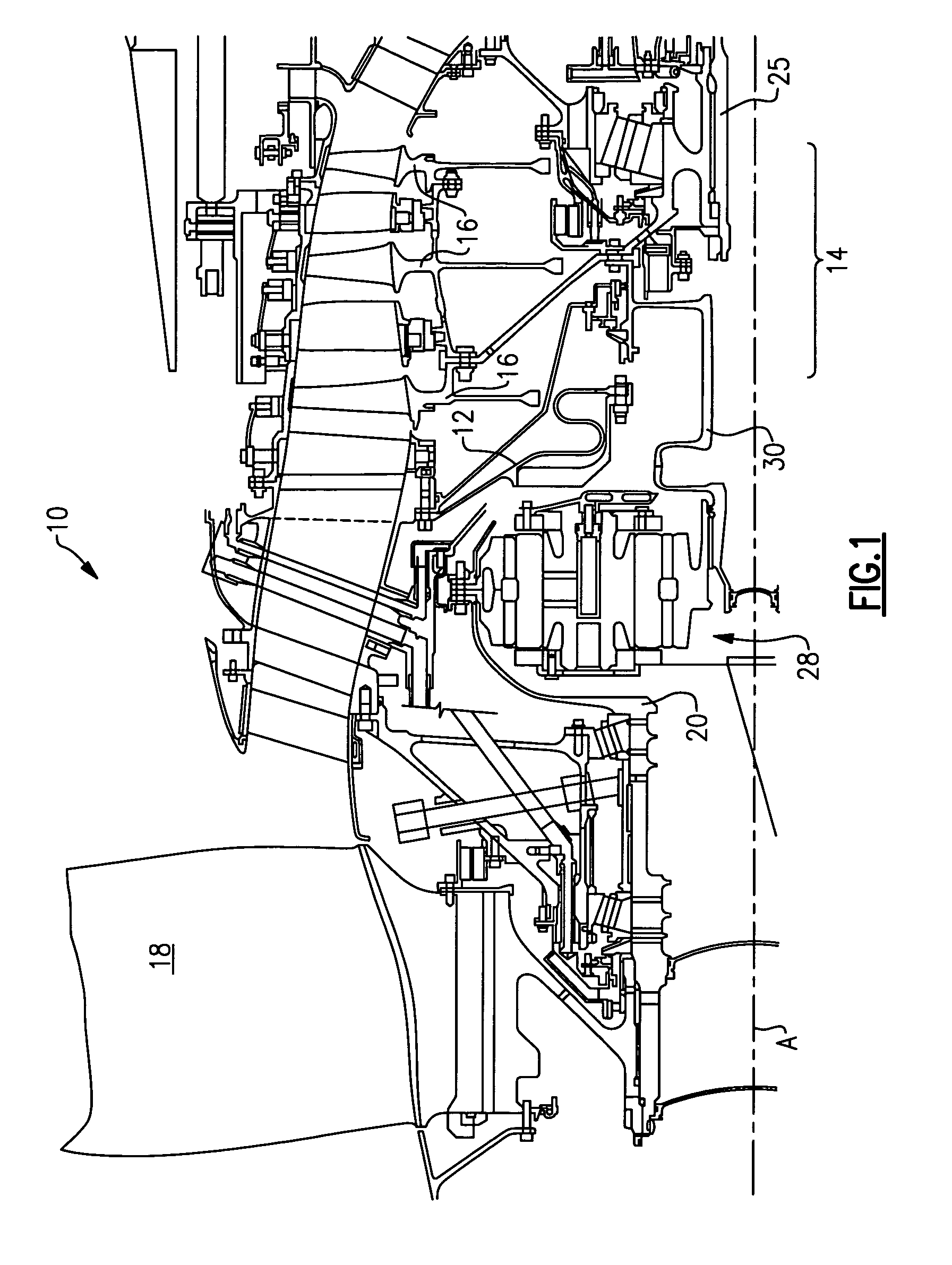

Guidable intravascular blood pump and related methods

InactiveUS7022100B1Integration of featureEliminate needGuide wiresControl devicesBlood pumpBlood vessel

An improved intravascular blood pump system (10) and related methods involving the broad inventive concept of equipping the intravascular blood pump (12) with guiding features such that the intravascular blood pump can be selectively positioned at a predetermined location within the circulatory system of a patient.

Owner:MAQUET CARDIOVASCULAR LLC

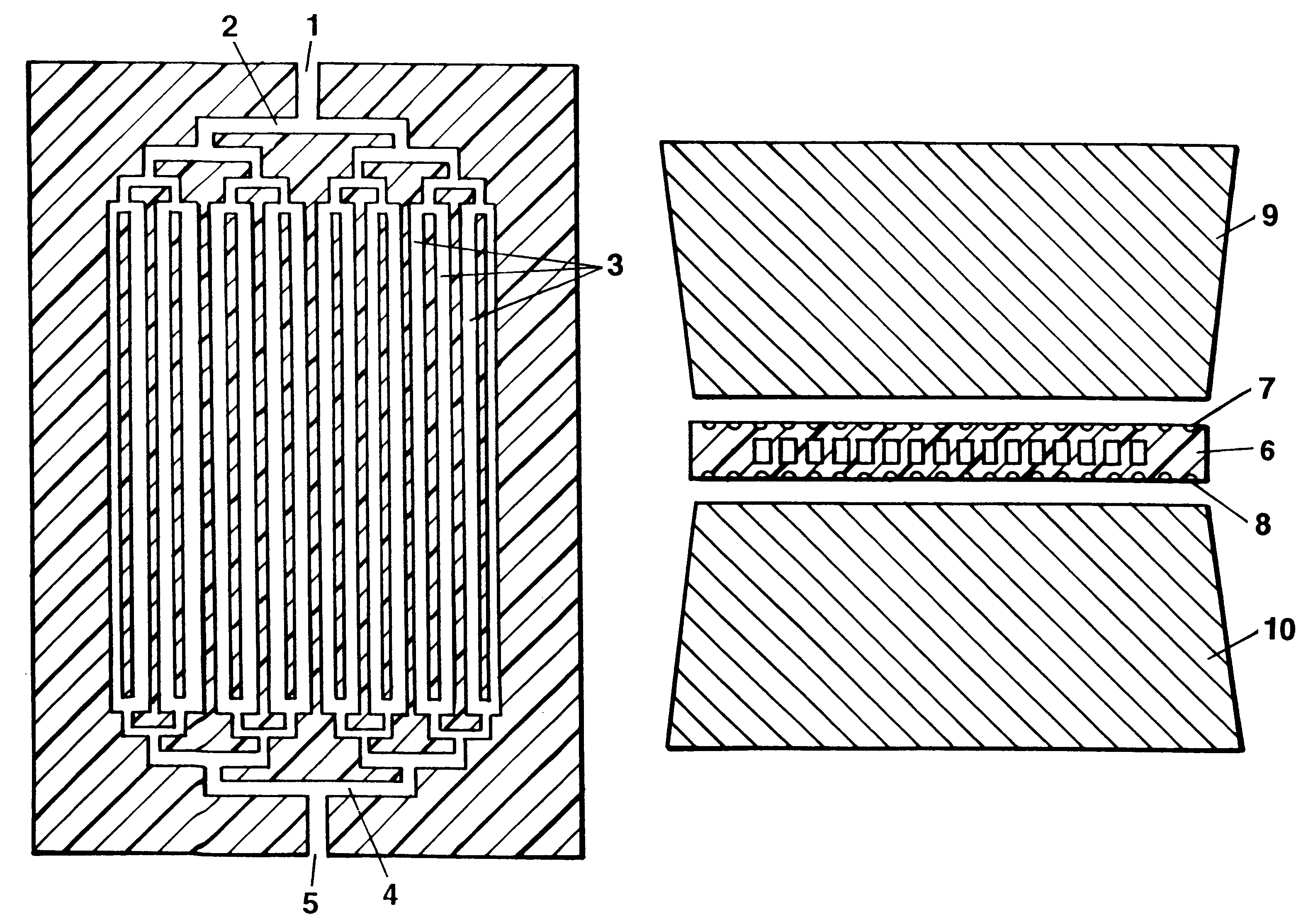

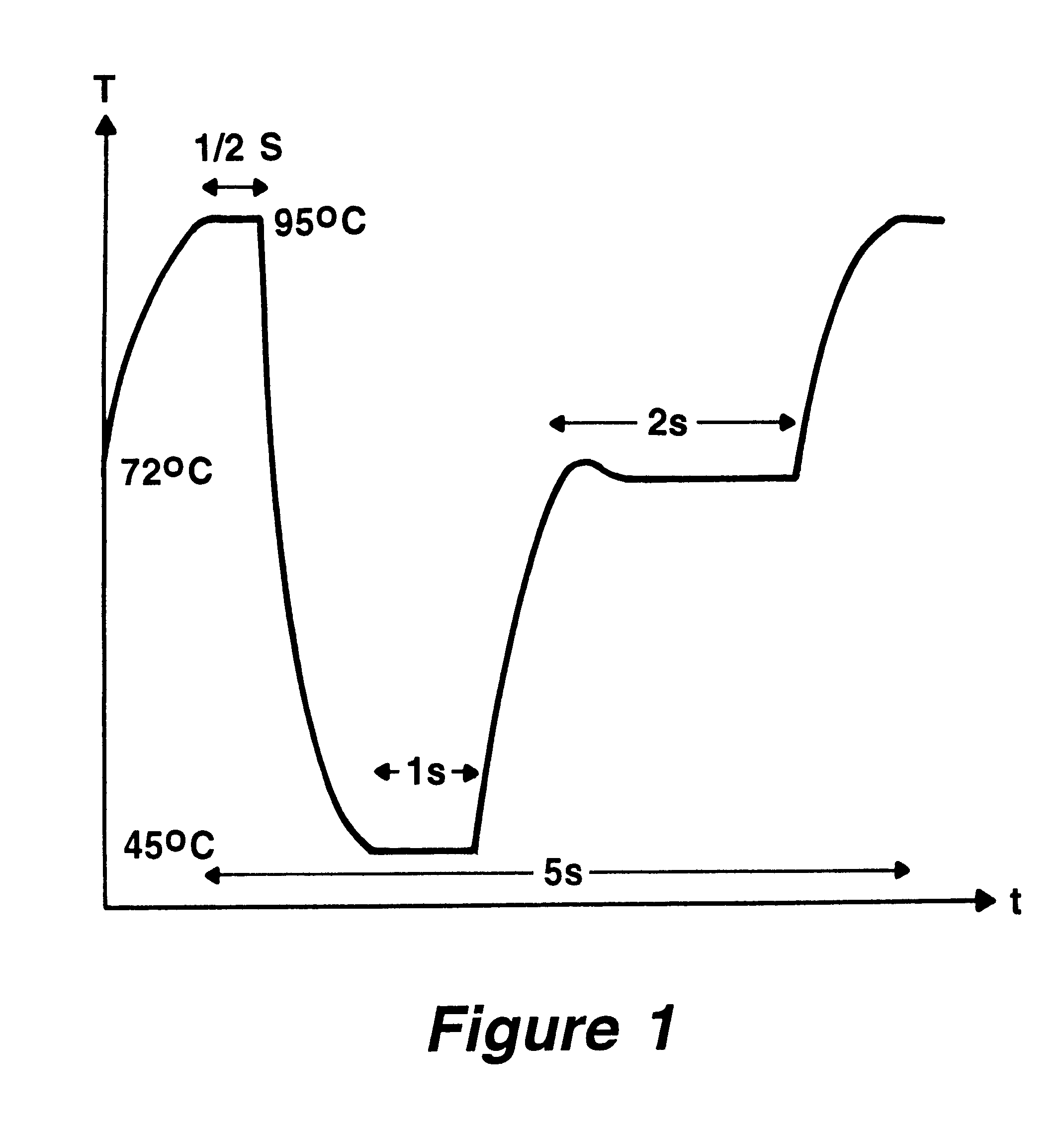

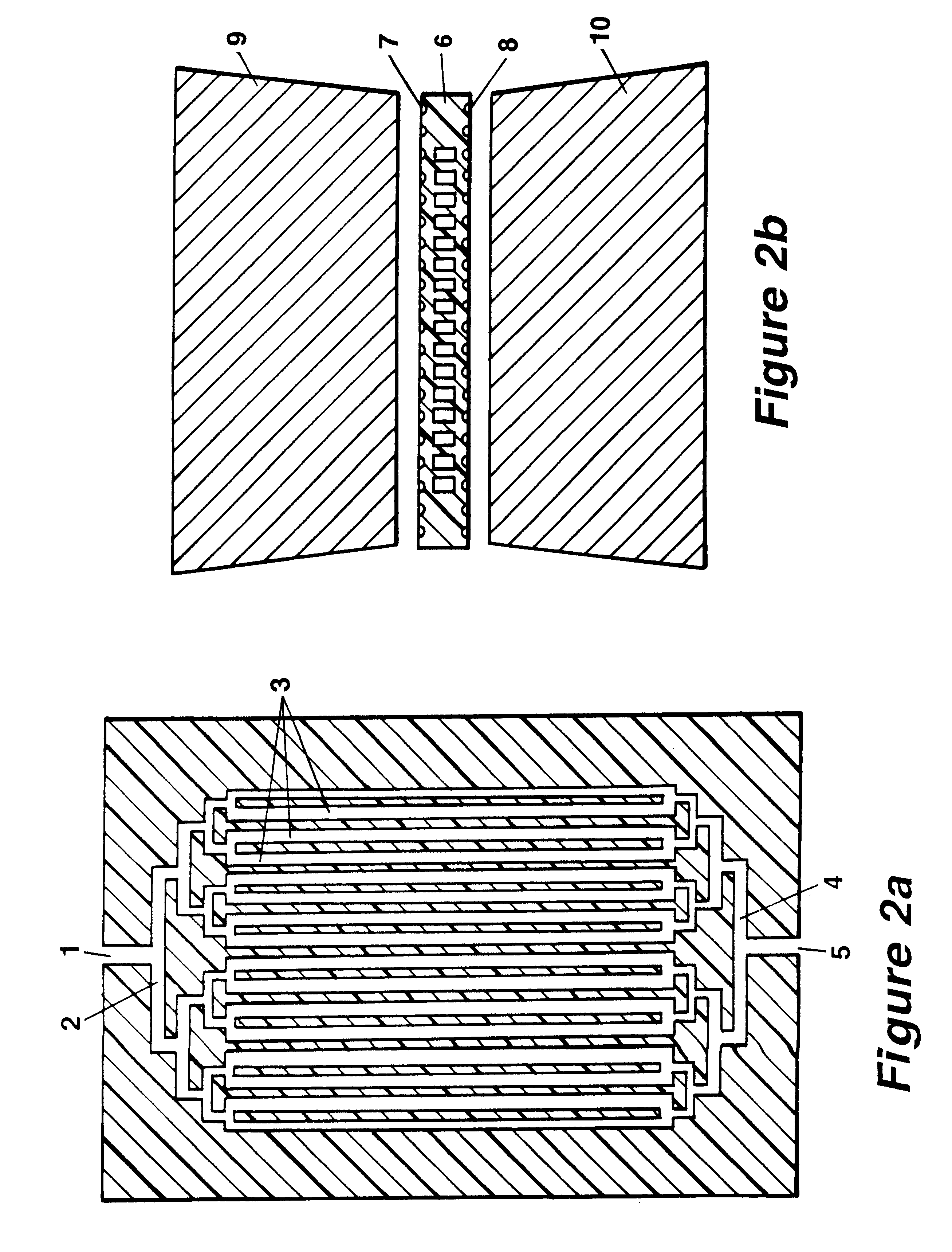

Method and devices for extremely fast DNA replication by polymerase chain reactions (PCR)

InactiveUS6180372B1Shorten cycle timeHigh sensitivityBioreactor/fermenter combinationsNanotechPolymerase LBiological materials

The invention concerns methods and instruments for fast, selective replication of deoxyribonucleic acid (DNA) from biomaterial through the known polymerase chain reaction (PCR), working in individual duplication thermocycles. The invention consists of extremely brief cycle times of only a few seconds for the PCR reactions, generated, on the one hand, by reaction chambers for the reception of the reaction solution constructed of a pattern of fine capillaries in close proximity to heating and cooling elements in order to optimally accelerate the temperature setting in the reaction solution for the three temperature phases of the PCR duplication cycles and, on the other hand, by keeping the flow rates in the capillaries to a minimum during the amplification phase so that the polymerase reaction is not disturbed. The capillary pattern can be simply produced by means of microsystern technology.

Owner:BRUKER FRANZEN ANALYTIK

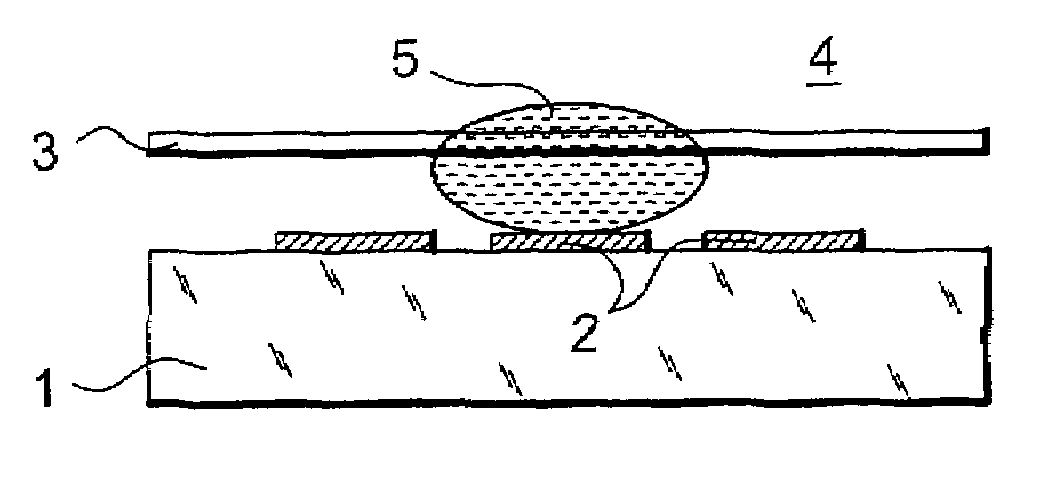

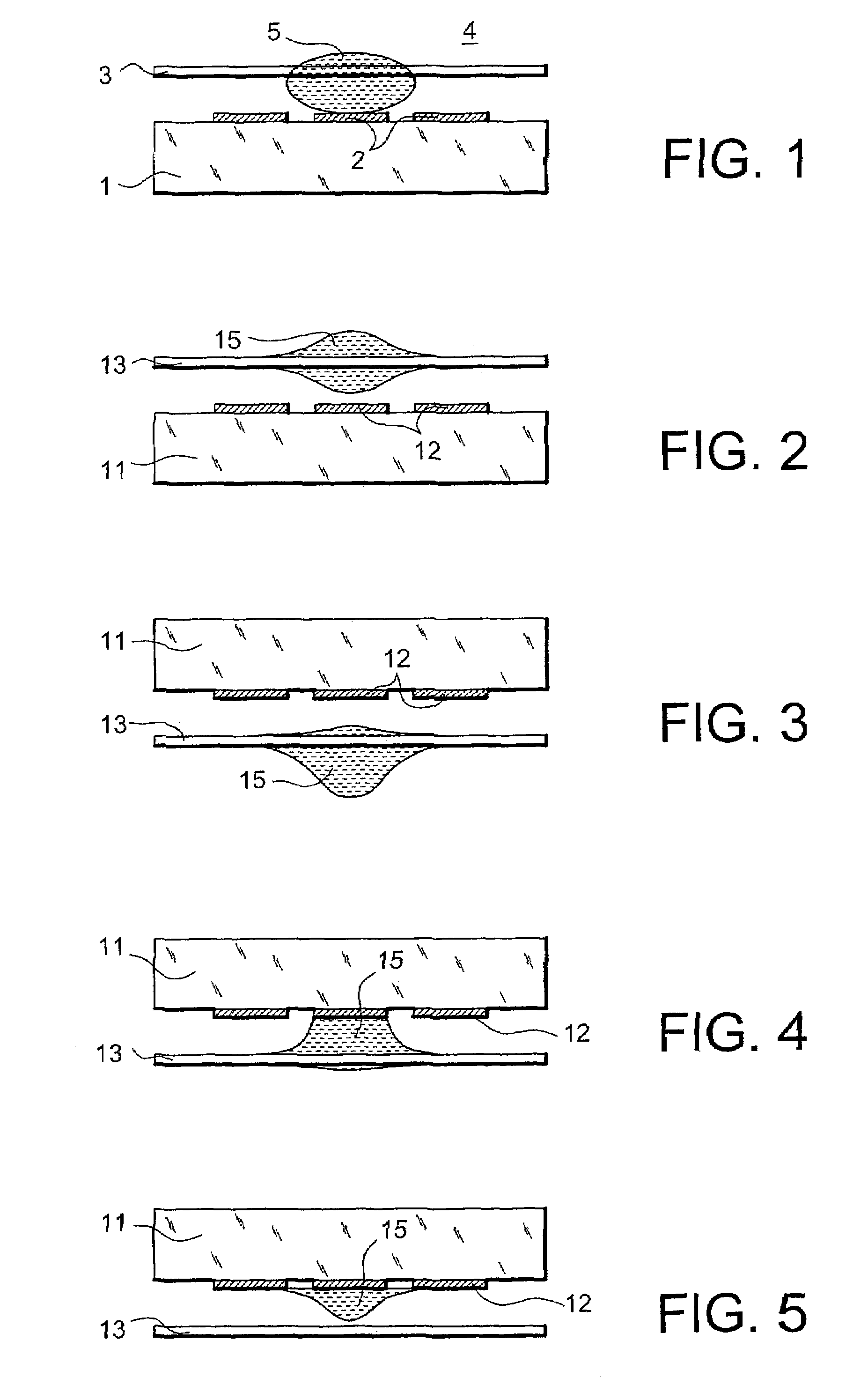

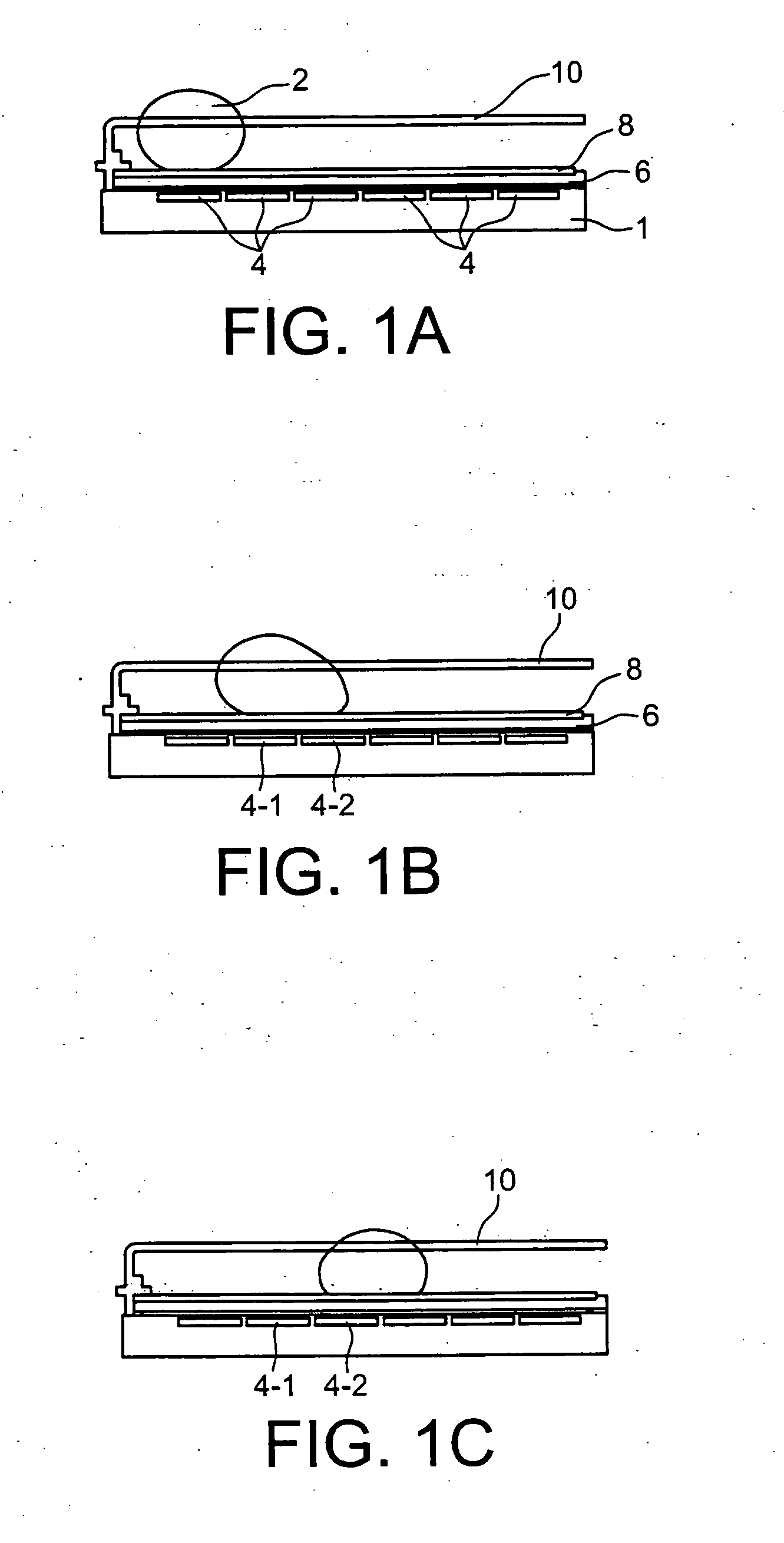

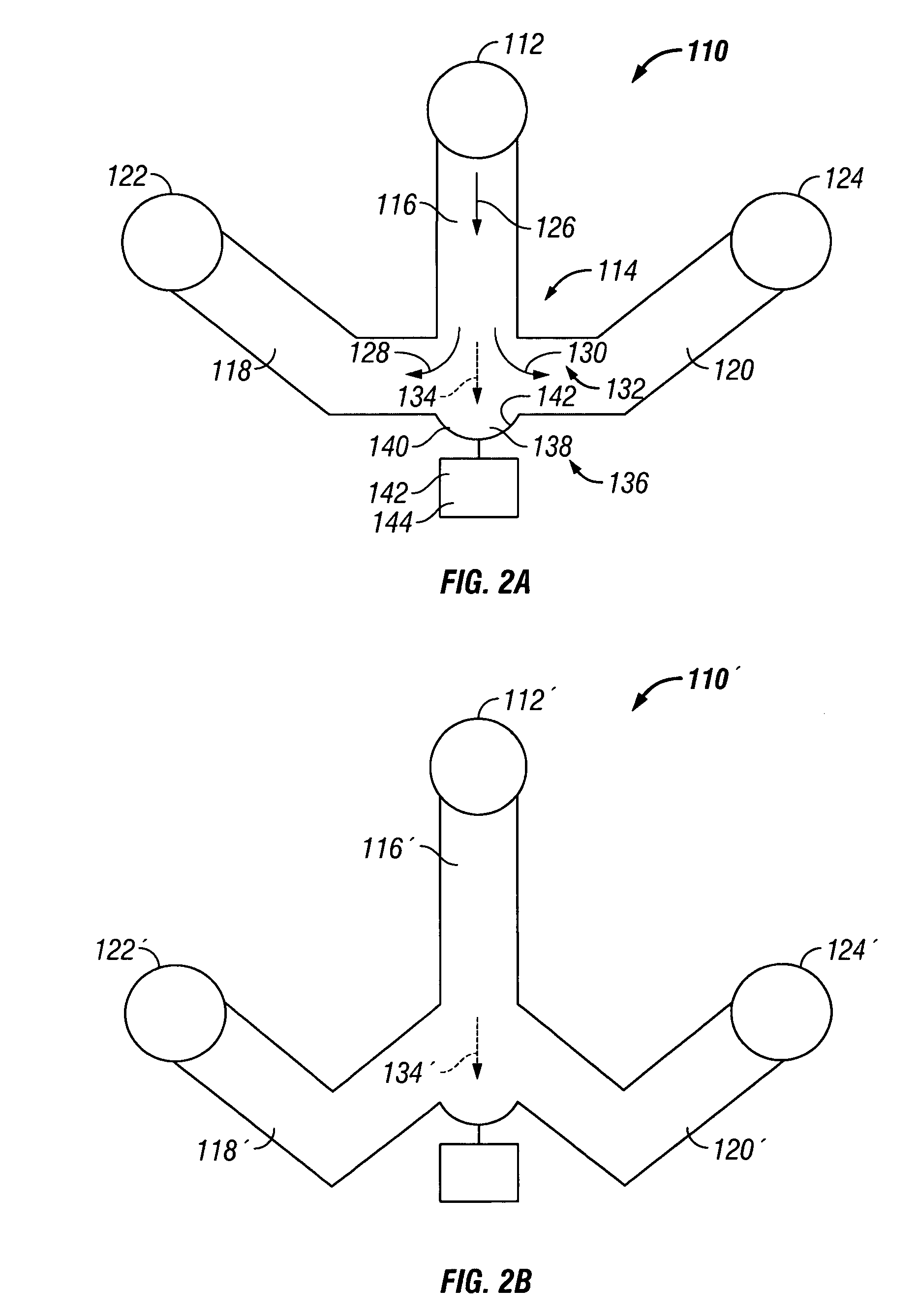

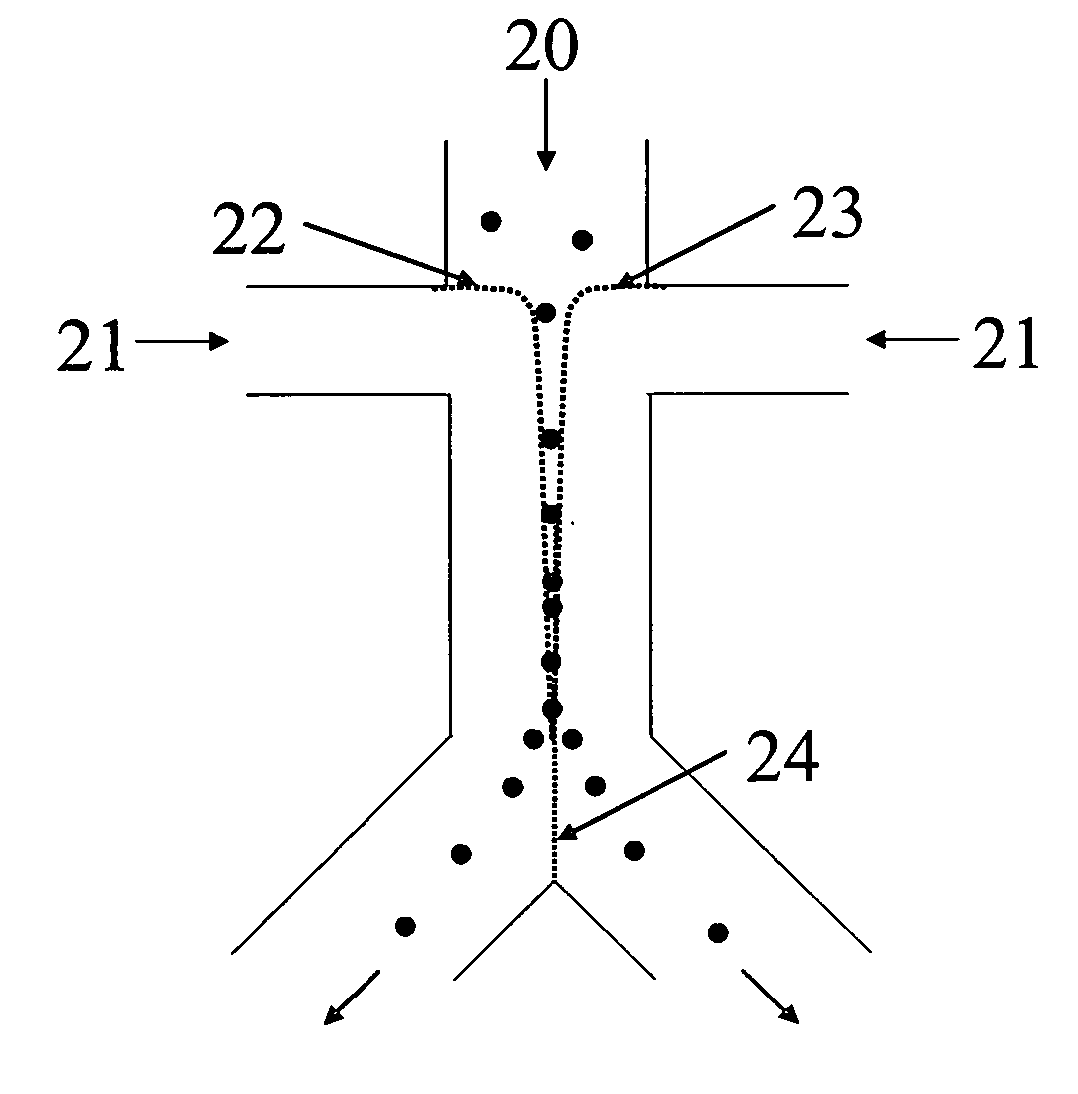

Device for displacement of small liquid volumes along a micro-catenary line by electrostatic forces

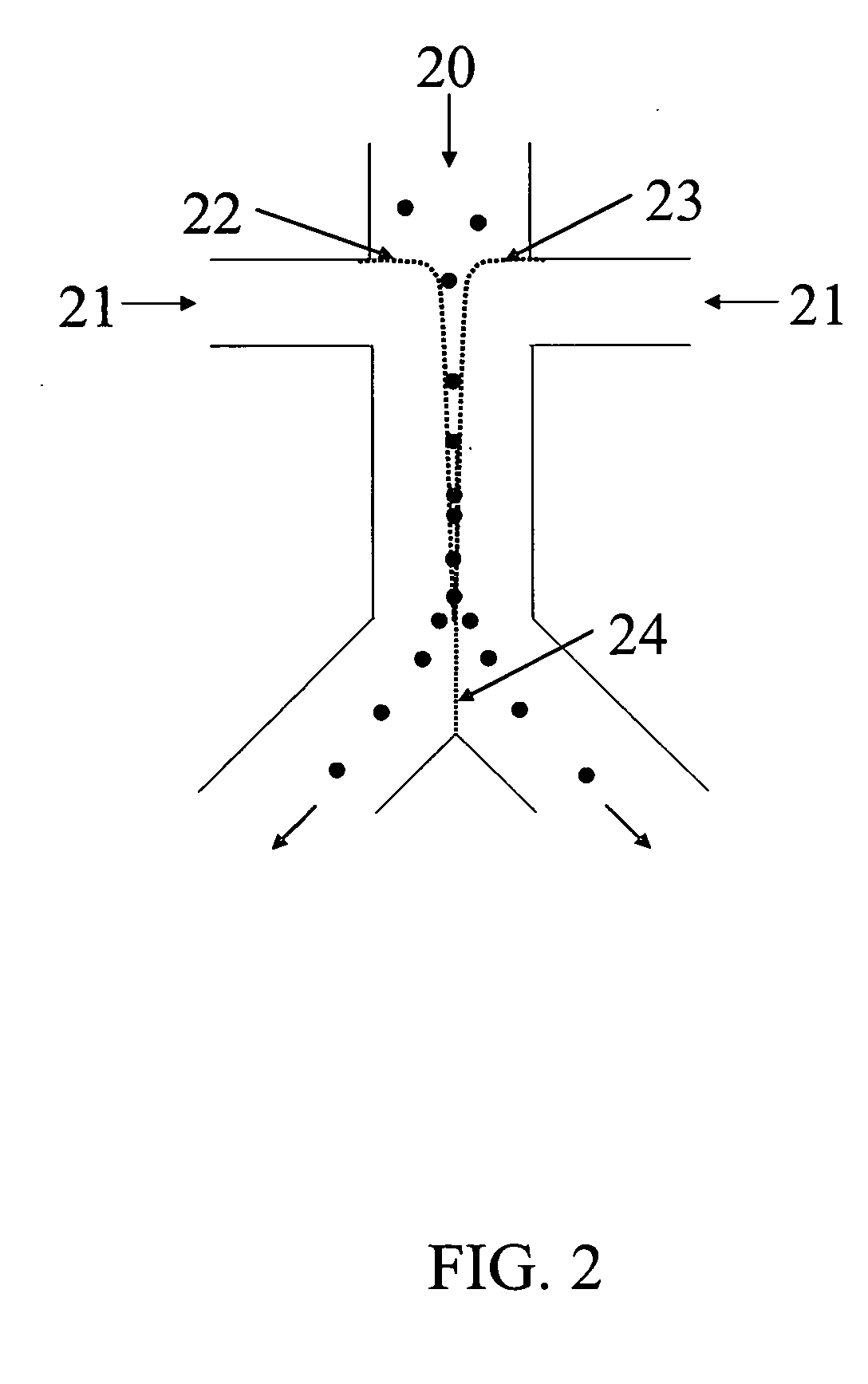

ActiveUS7052244B2Improve guidancePrevent evaporationPump componentsLaboratory glasswaresElectricityElectrical control

The invention relates to a device for displacement of at least a small volume of liquid (5) under the effect of an electrical control, including a substrate (1) provided with first electrically conducting means (2), the device also comprising second electrically conducting means (3) arranged facing the first electrically conducting means (2), the first electrically conducting means and the second electrically conducting means possibly being connected to electrical power supply means to enable the application of electrostatic forces to the small liquid volume (5). The second electrically conducting means include at least one conducting wire (3) arranged parallel to the substrate and at a fixed distance from the substrate to enable displacement of the small volume of liquid (5) along said conducting wire (3) under the effect of the applied electrostatic forces.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

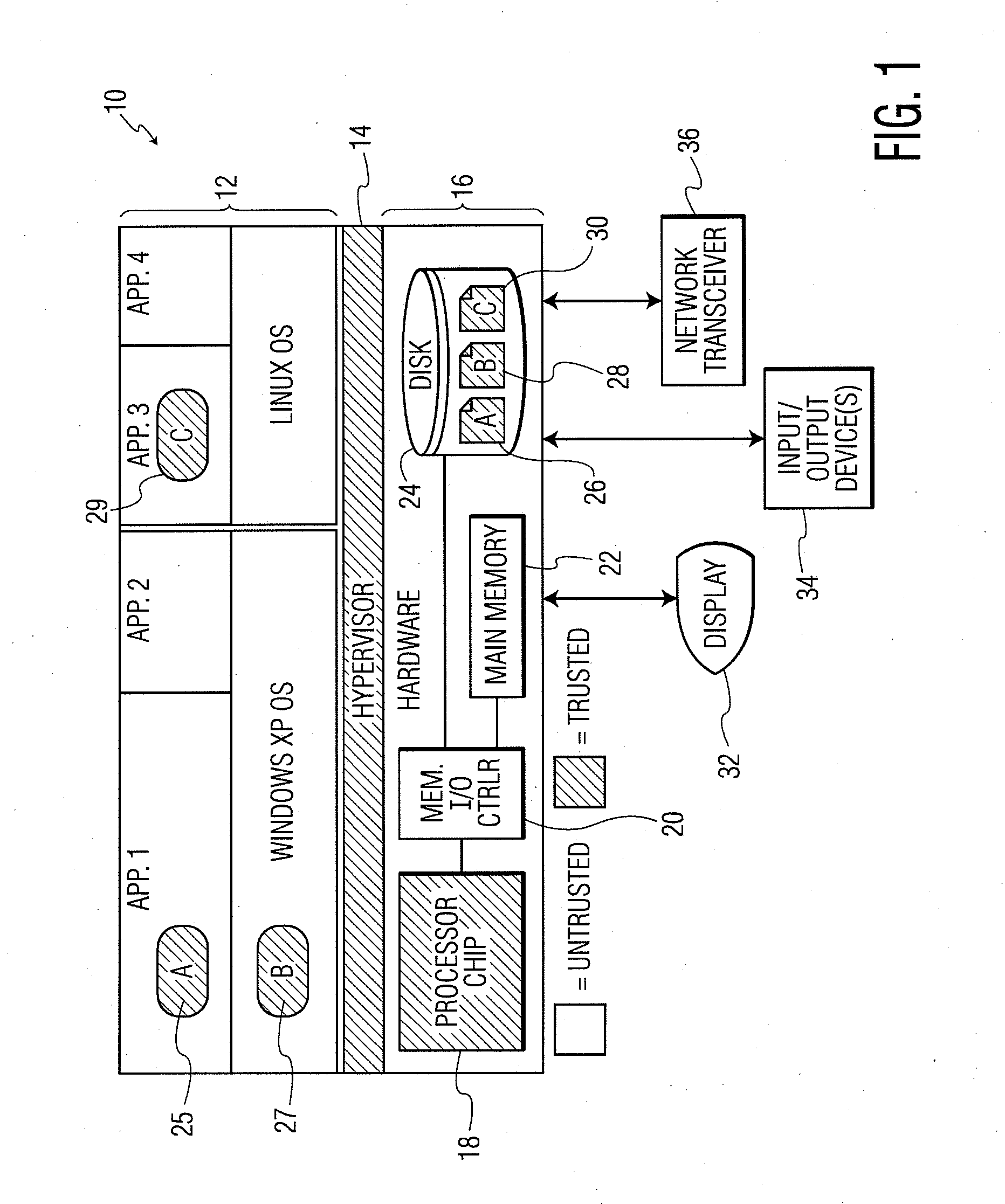

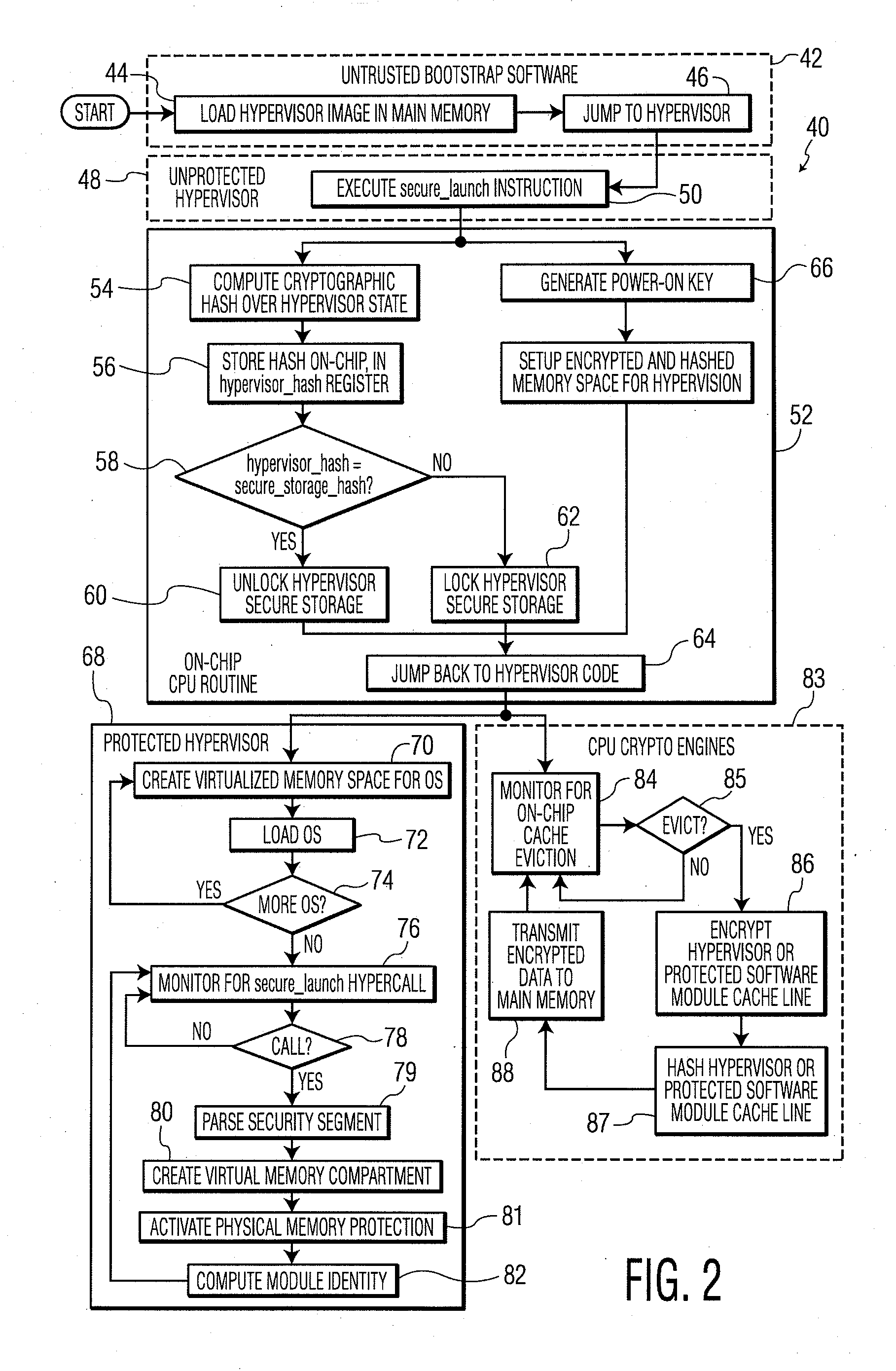

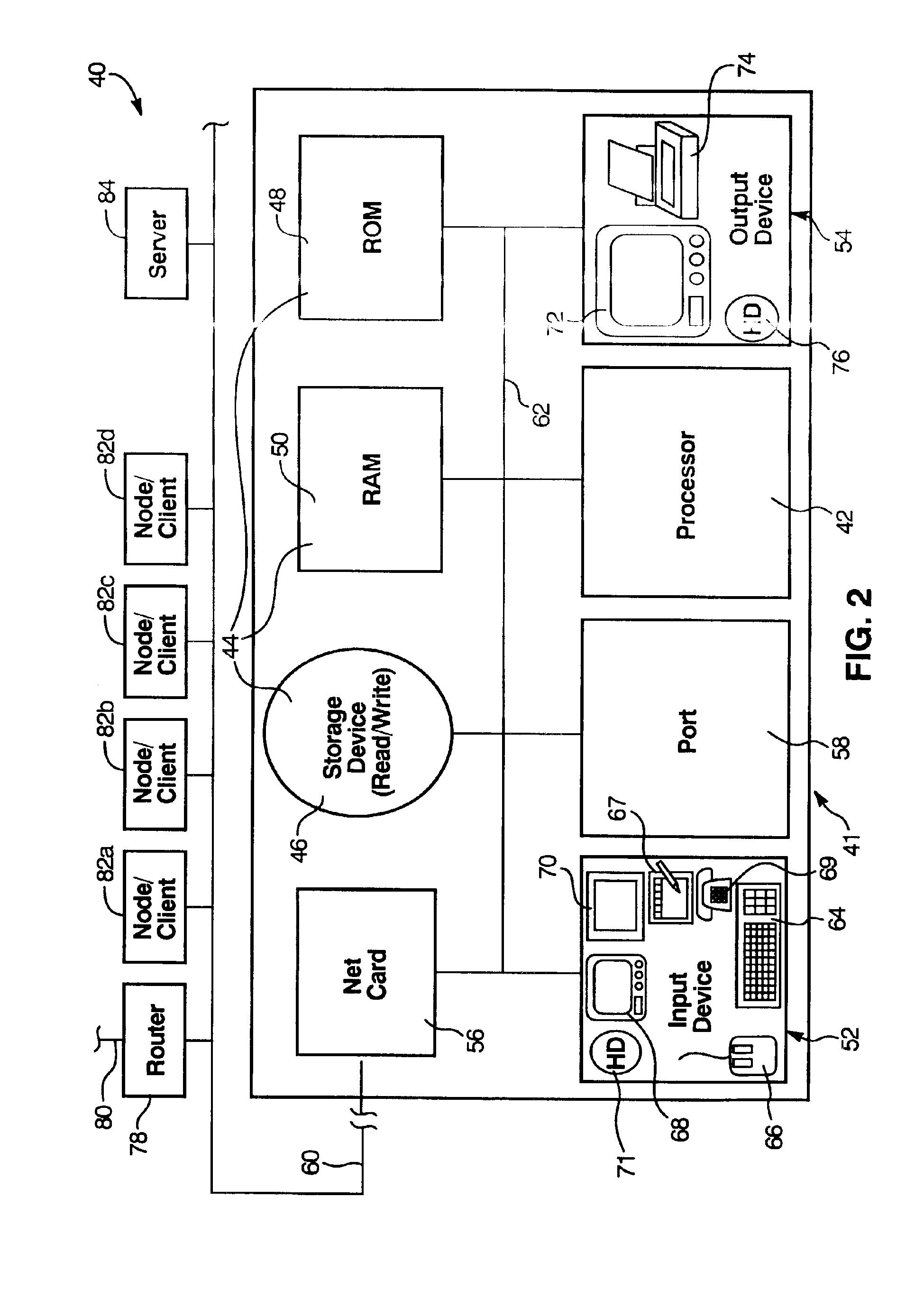

System and Method for Processor-Based Security

ActiveUS20100281273A1Avoid accessUnauthorized memory use protectionHardware monitoringExternal storageMemory interface

A system and method for processor-based security is provided, for on-chip security and trusted computing services for software applications. A processor is provided having a processor core, a cache memory, a plurality of registers for storing at least one hash value and at least one encryption key, a memory interface, and at least one on-chip instruction for creating a secure memory area in a memory external to the processor, and a hypervisor program executed by the processor. The hypervisor program instructs the processor to execute the at least one on-chip instruction to create a secure memory area for a software area for a software module, and the processor encrypts data written to, and decrypts data read from, the external memory using the at least one encryption key and the verifying data read from the external memory using the at least one hash value. Secure module interactions are provided, as well as the generation of a power-on key which can be used to protect memory in the event of a re-boot event. Lightweight, run-time attestation reports are generated which include selected information about software modules executed by the processors, for use in determining whether the processor is trusted to provide secure services.

Owner:CORESECURE TECH LLC

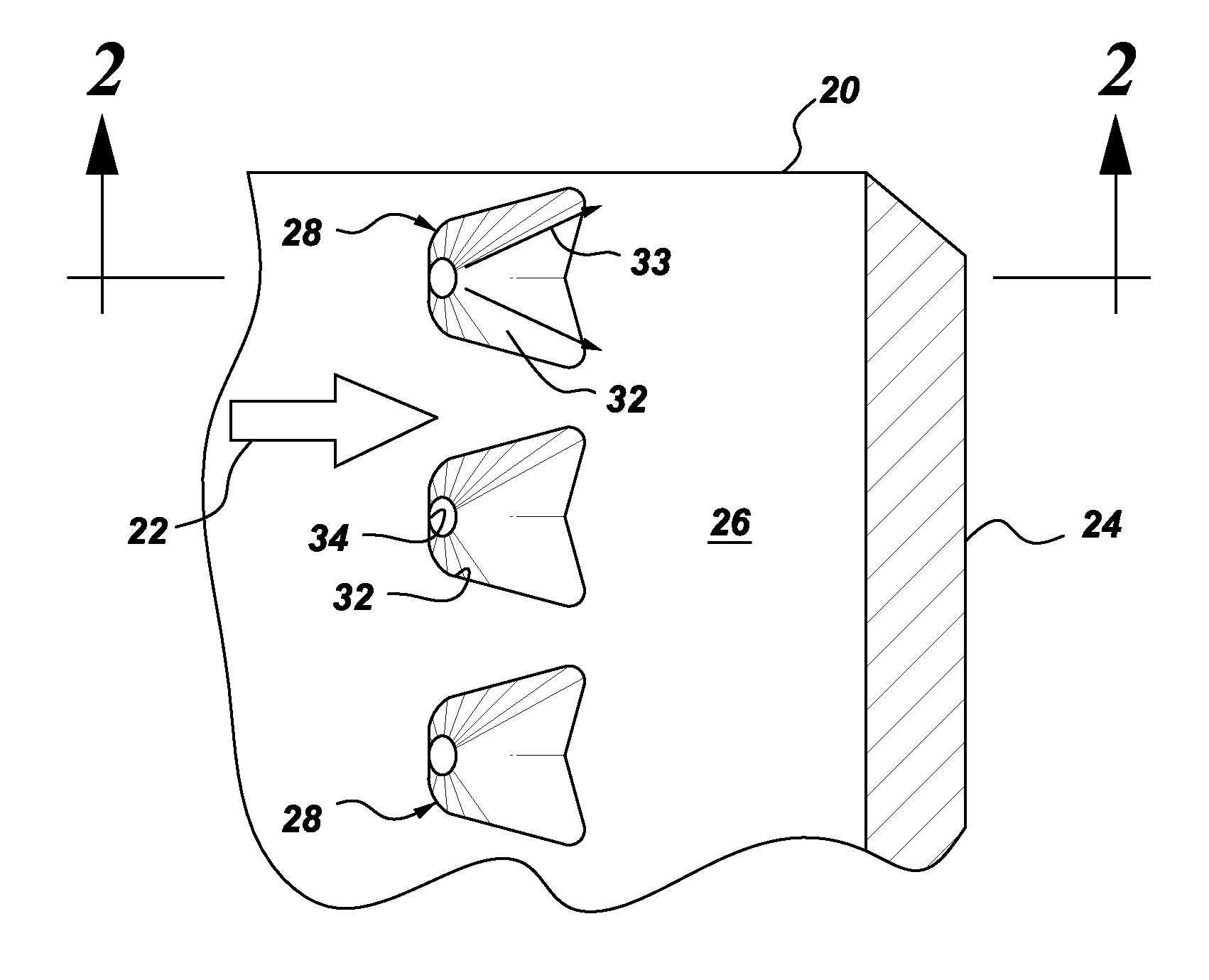

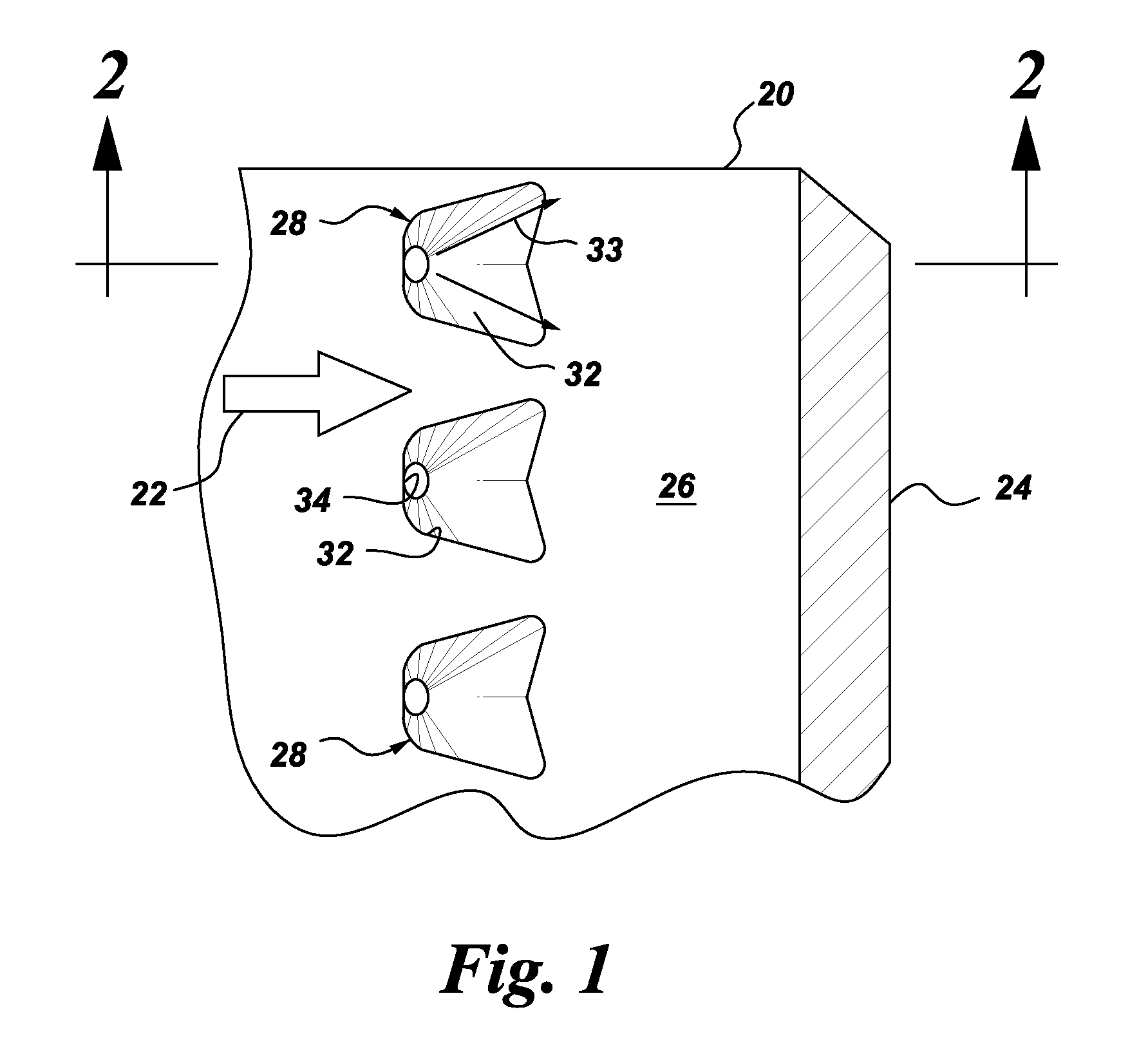

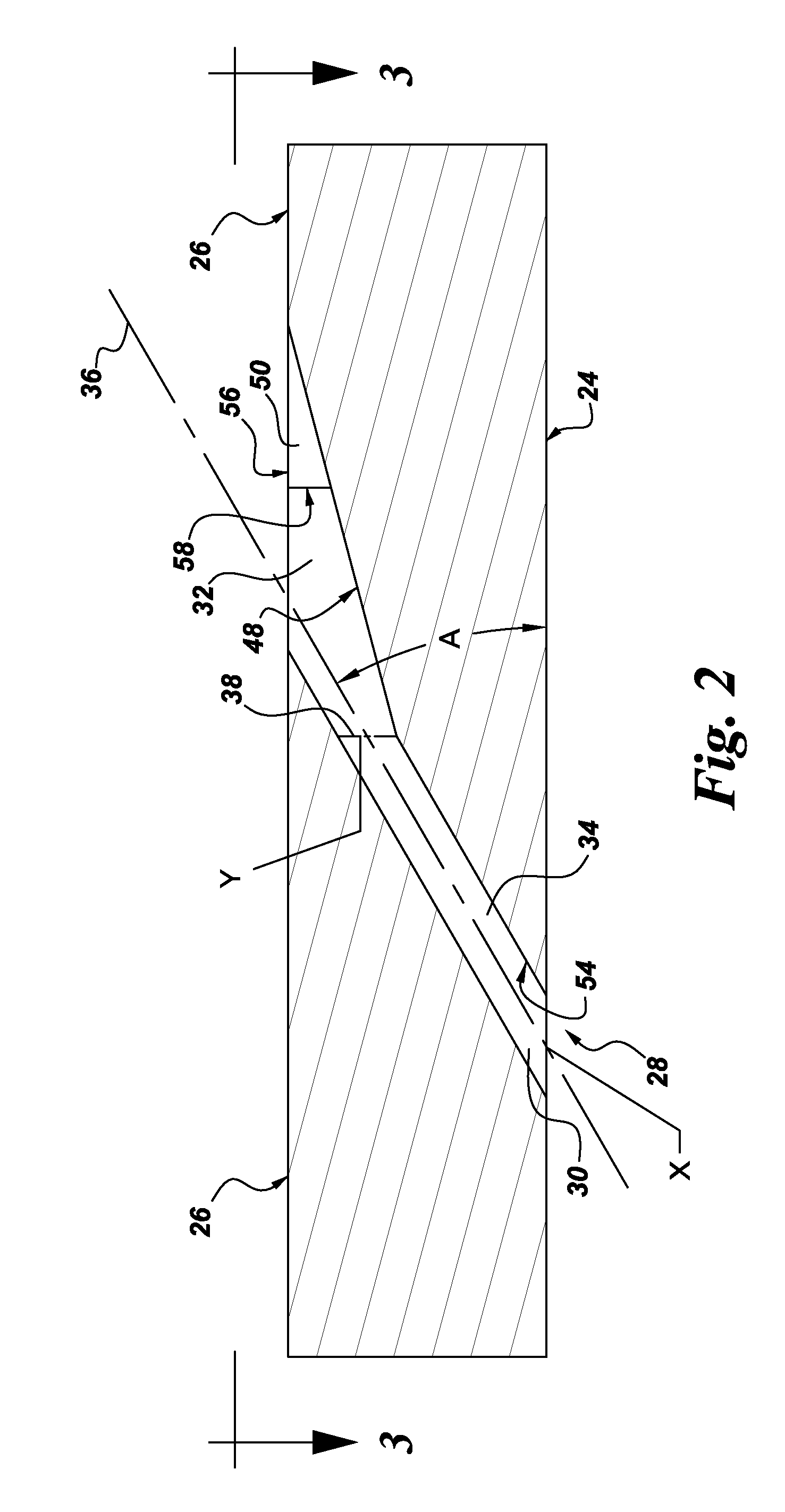

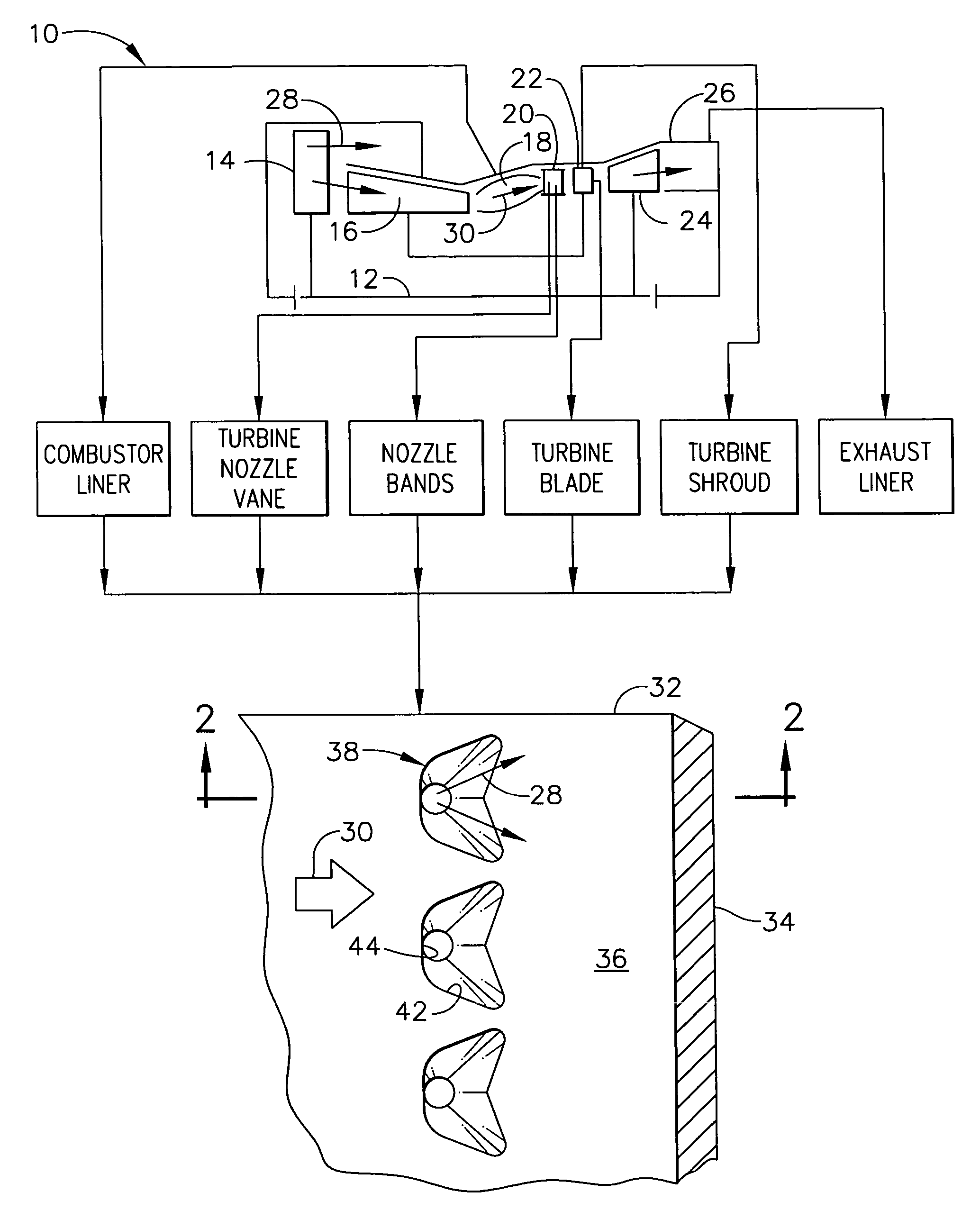

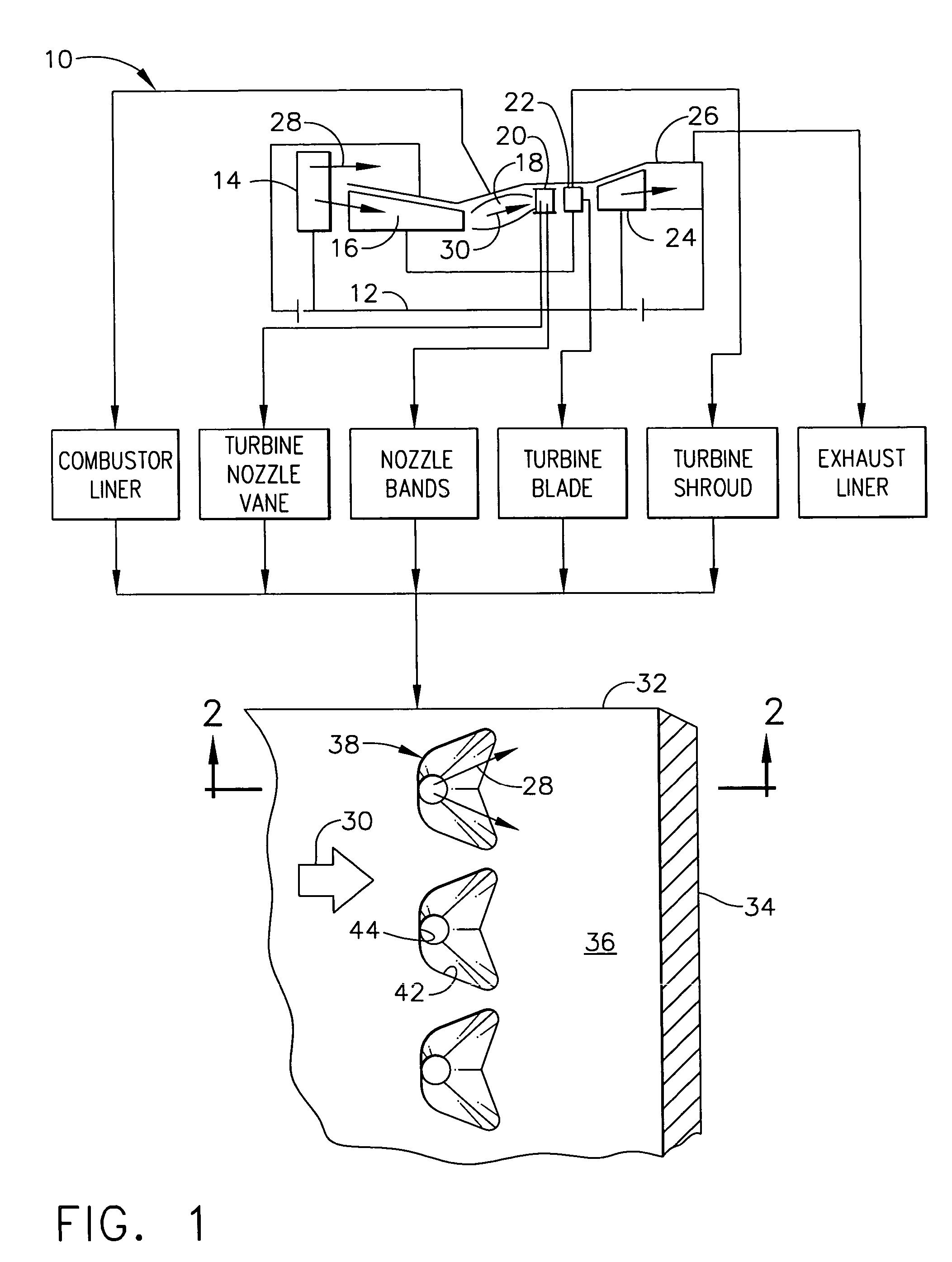

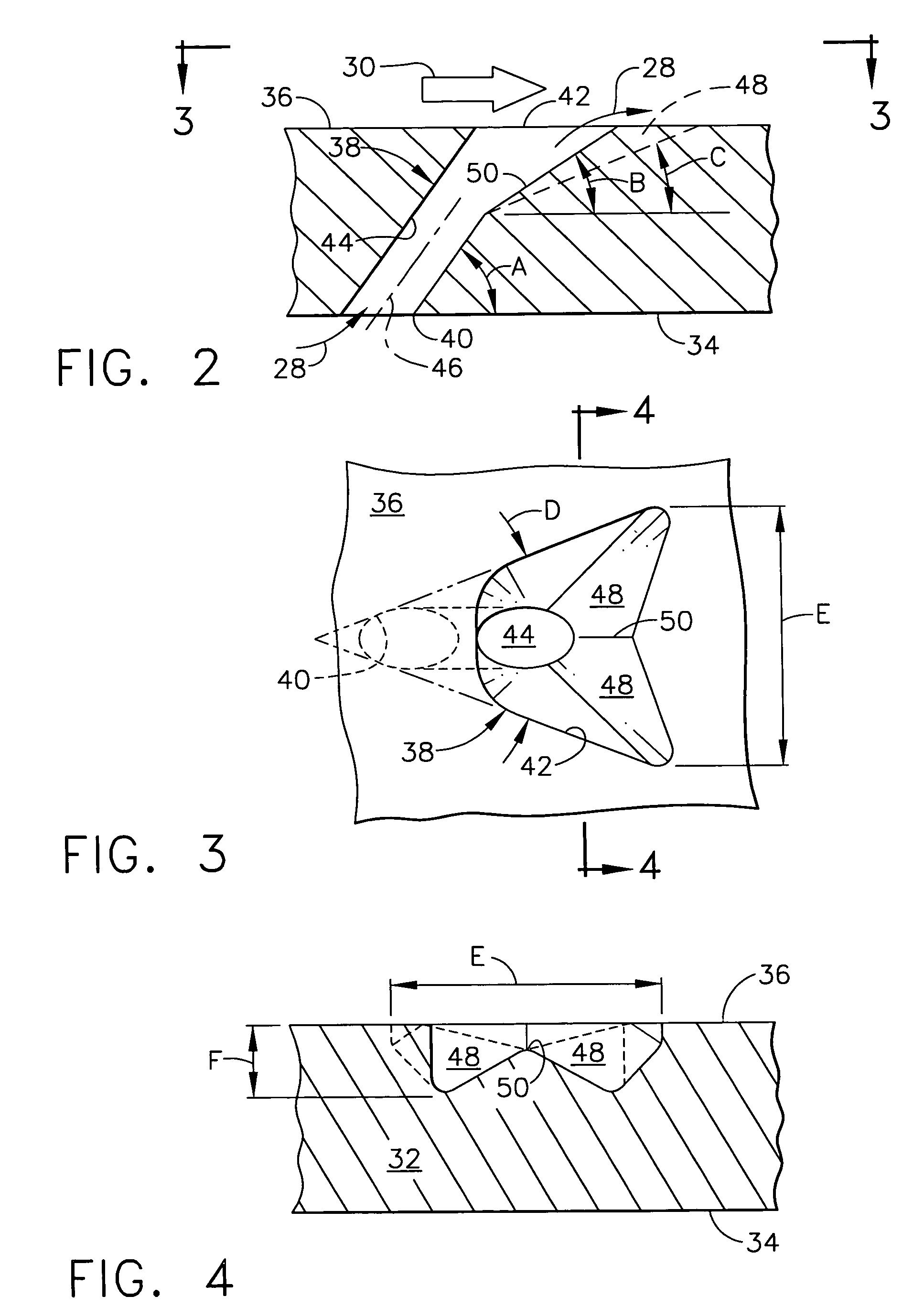

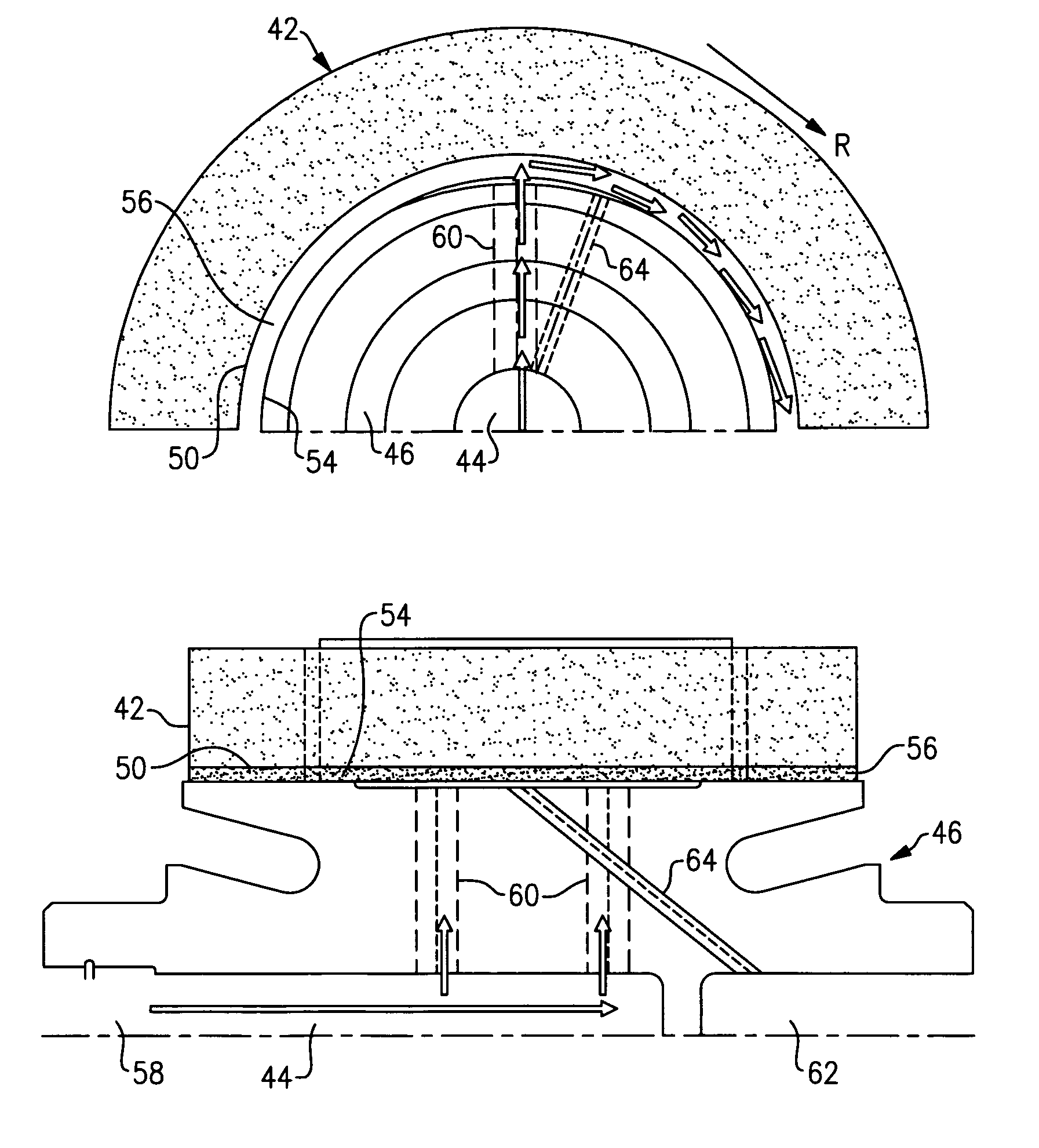

Articles which include chevron film cooling holes, and related processes

An article is described, including an inner surface which can be exposed to a first fluid; an inlet; and an outer surface spaced from the inner surface, which can be exposed to a hotter second fluid. The article further includes at least one row or other pattern of passage holes. Each passage hole includes an inlet bore extending through the substrate from the inlet at the inner surface to a passage hole-exit proximate to the outer surface, with the inlet bore terminating in a chevron outlet adjacent the hole-exit. The chevron outlet includes a pair of wing troughs having a common surface region between them. The common surface region includes a valley which is adjacent the hole-exit; and a plateau adjacent the valley. The article can be an airfoil. Related methods for preparing the passage holes are also described.

Owner:GENERAL ELECTRIC CO

Chevron film cooled wall

A wall in a gas turbine engine includes inner and outer surfaces having a row of compound chevron film cooling holes extending therethrough. The chevron holes diverge both longitudinally and laterally between an inlet at the wall inner surface and a chevron outlet at the wall outer surface.

Owner:GENERAL ELECTRIC CO

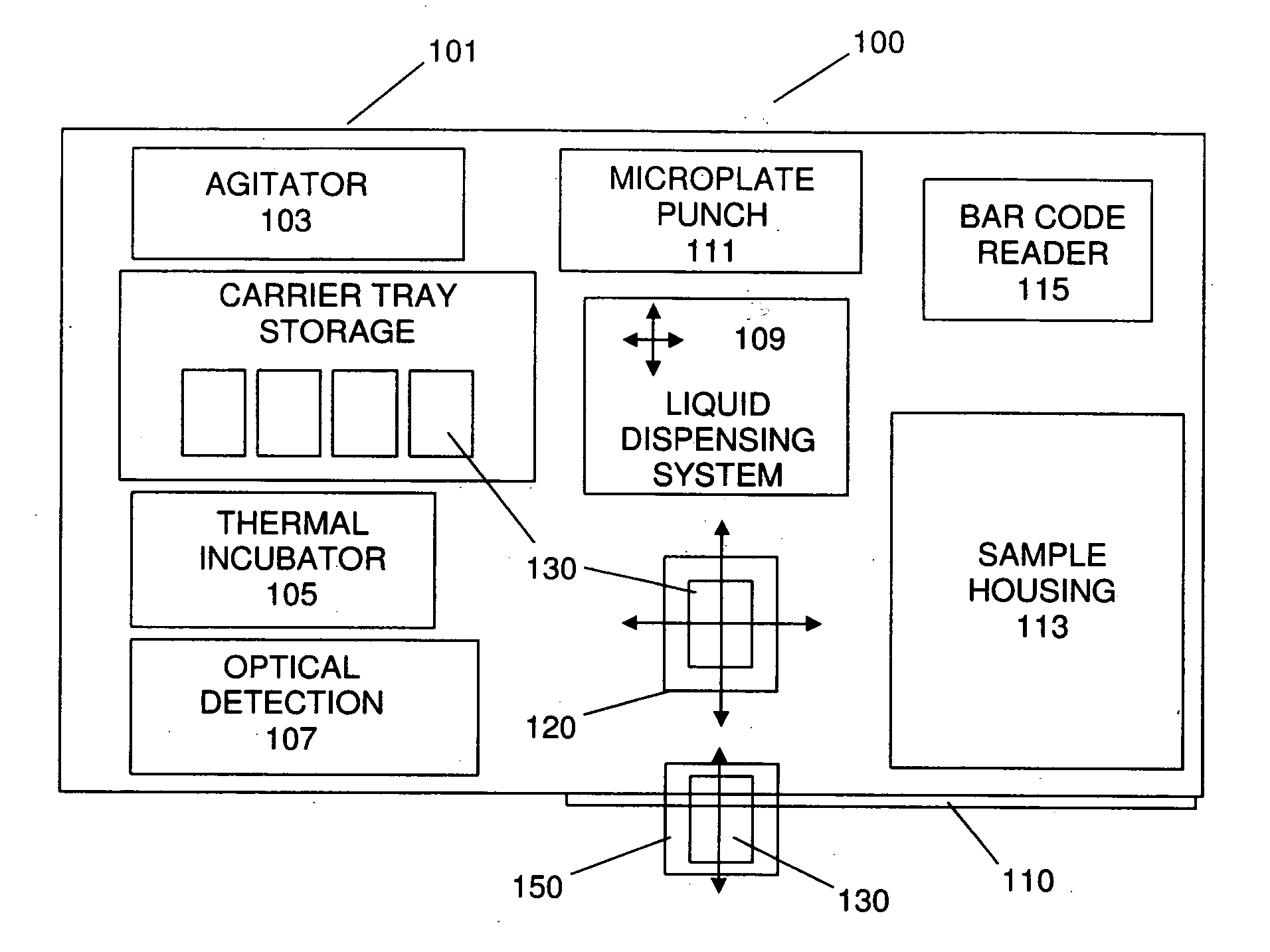

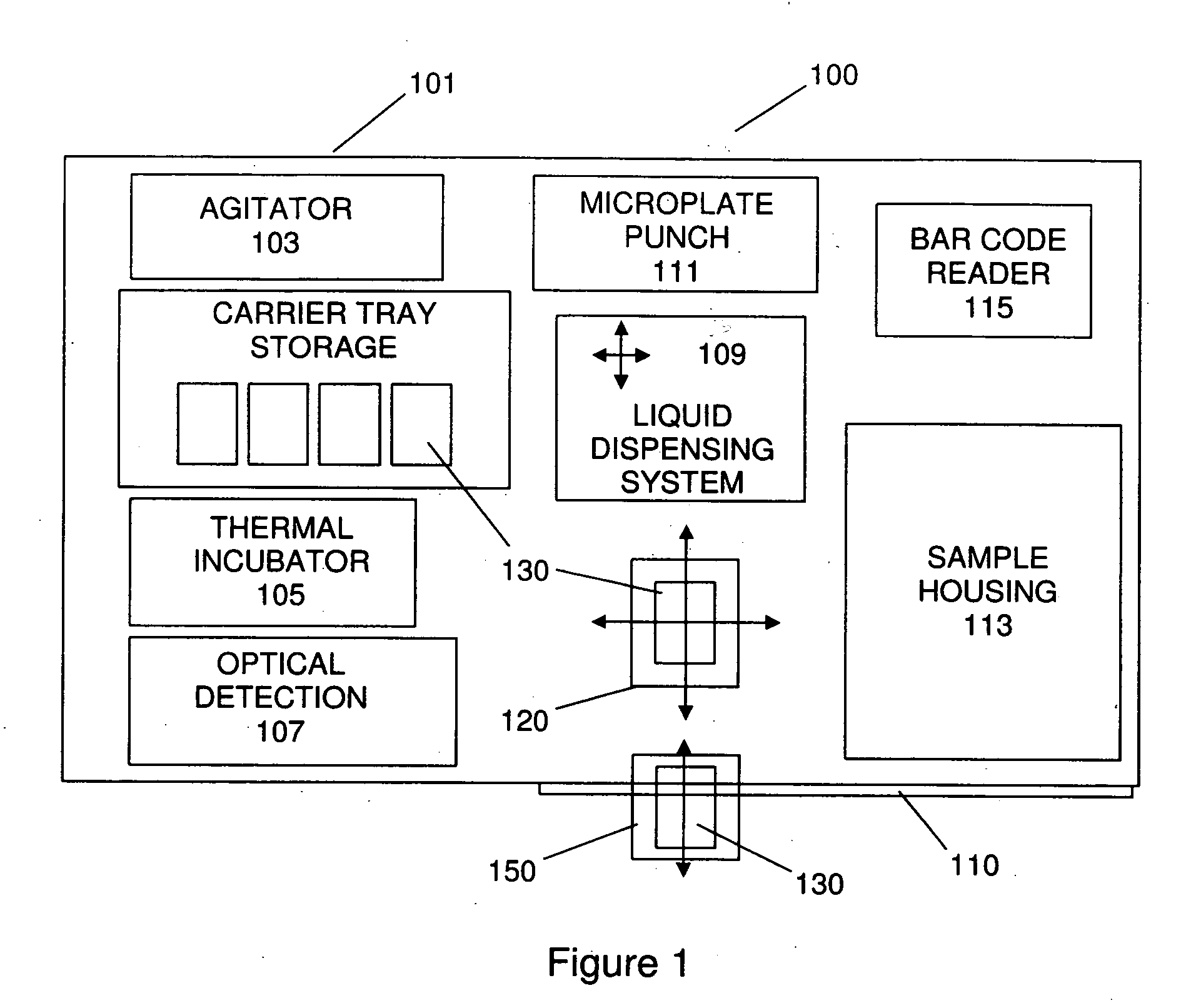

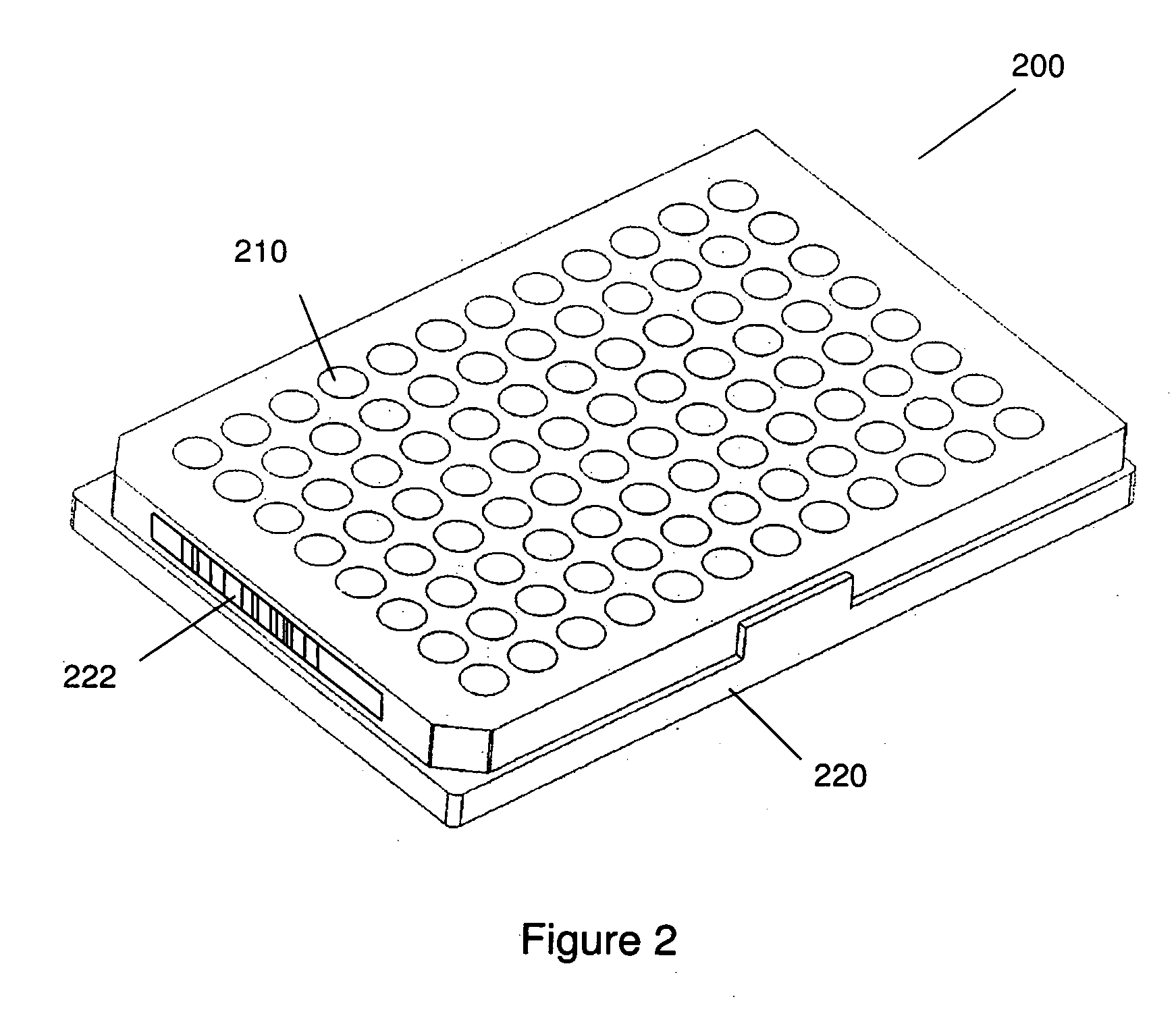

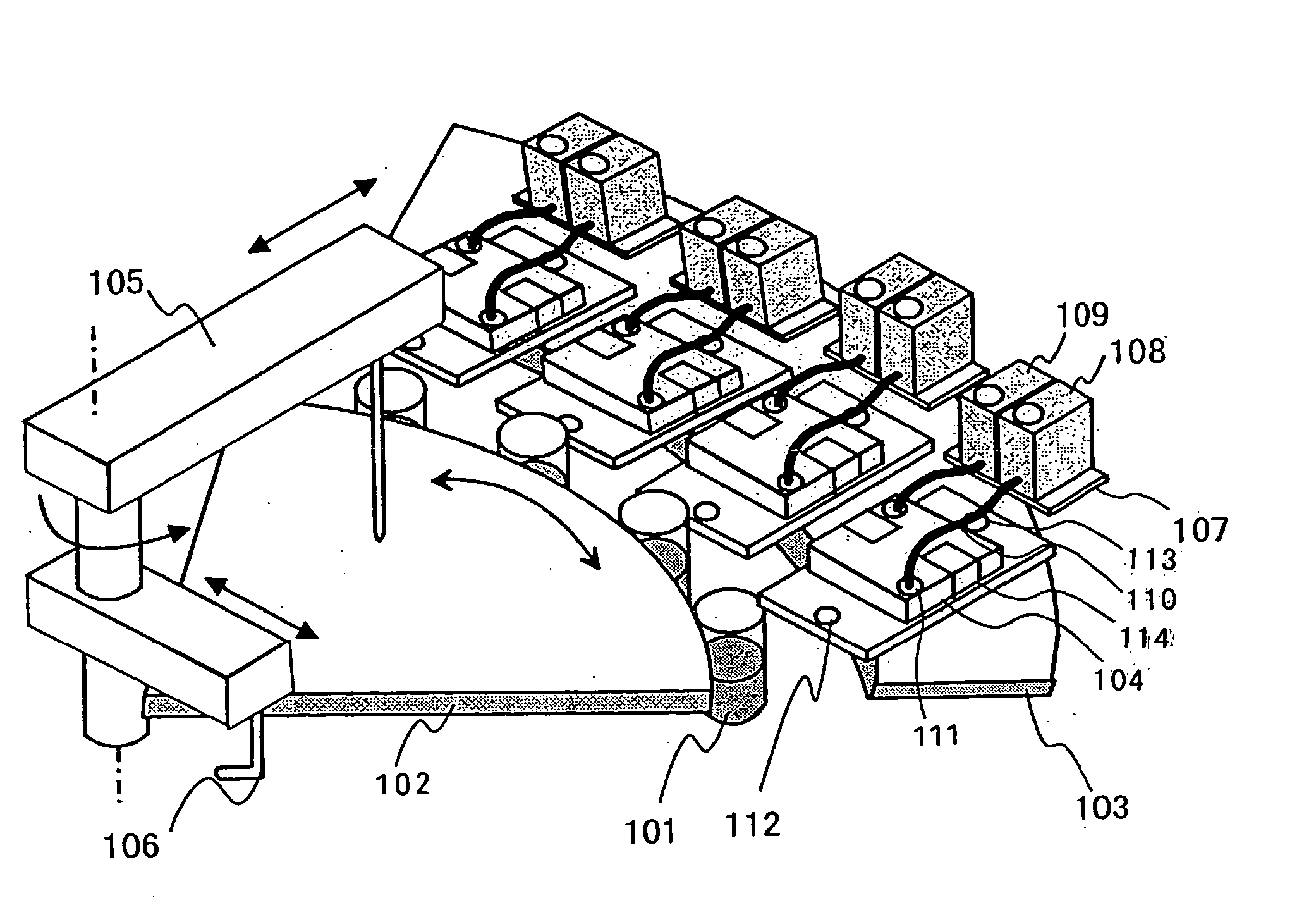

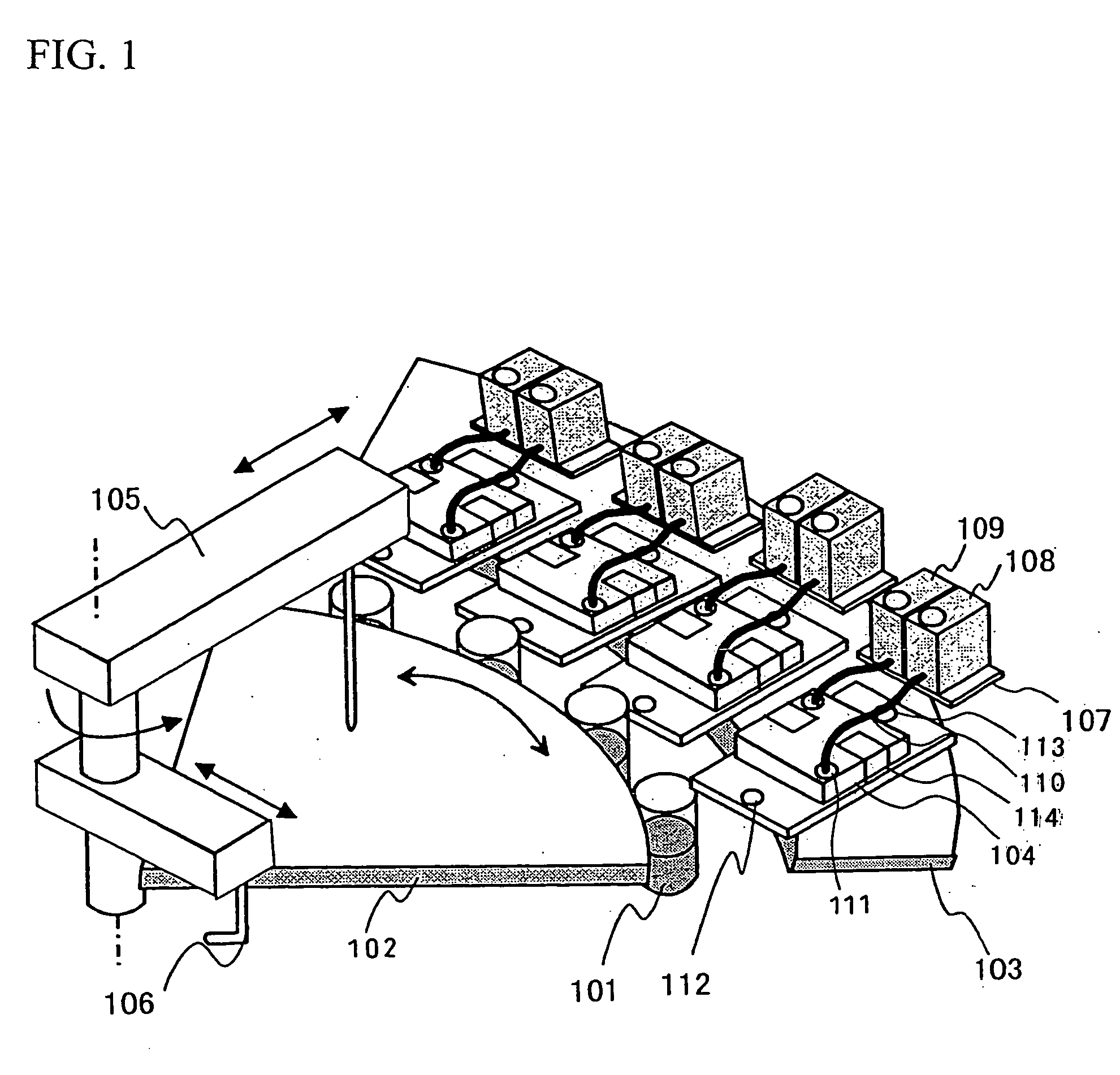

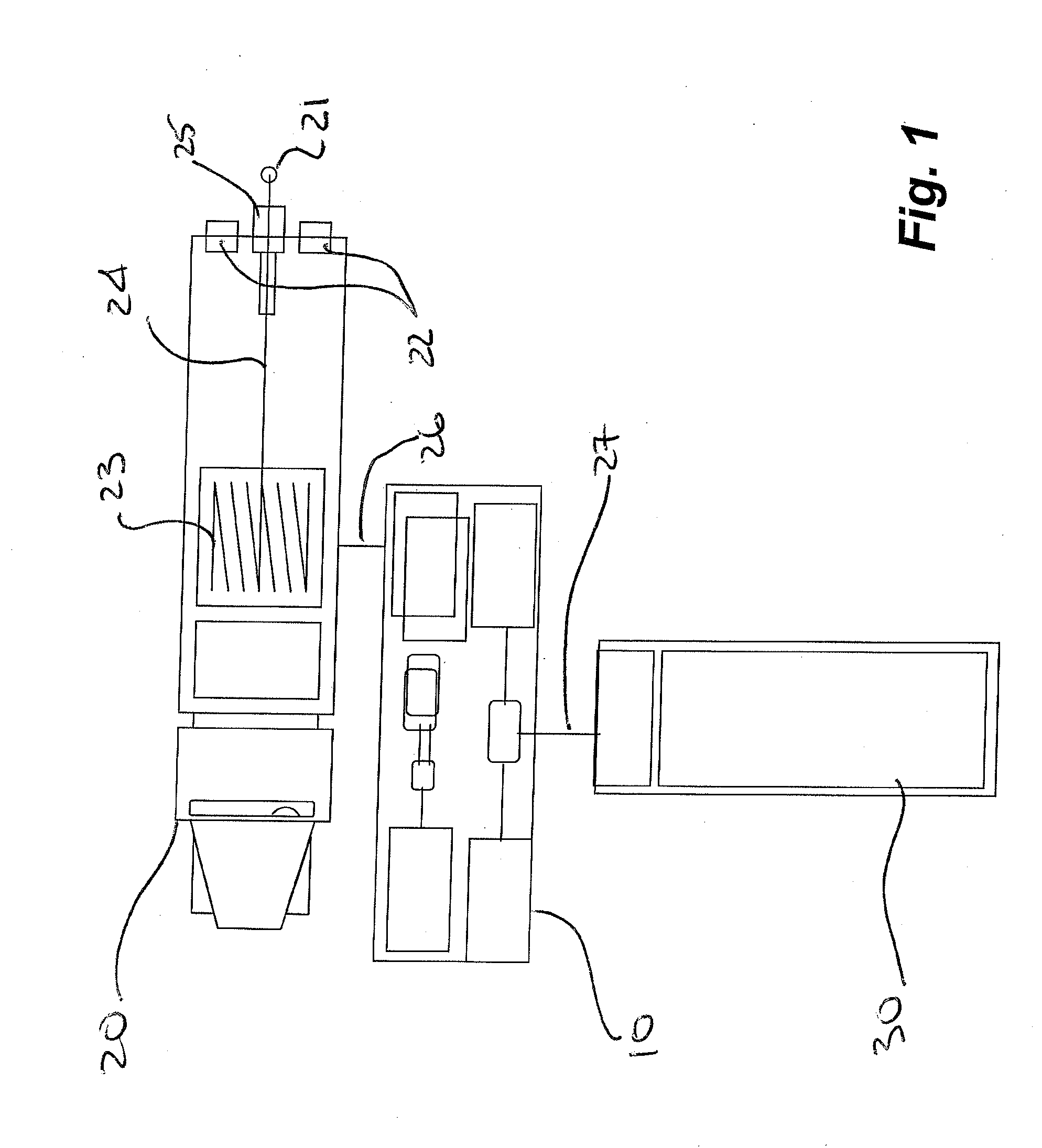

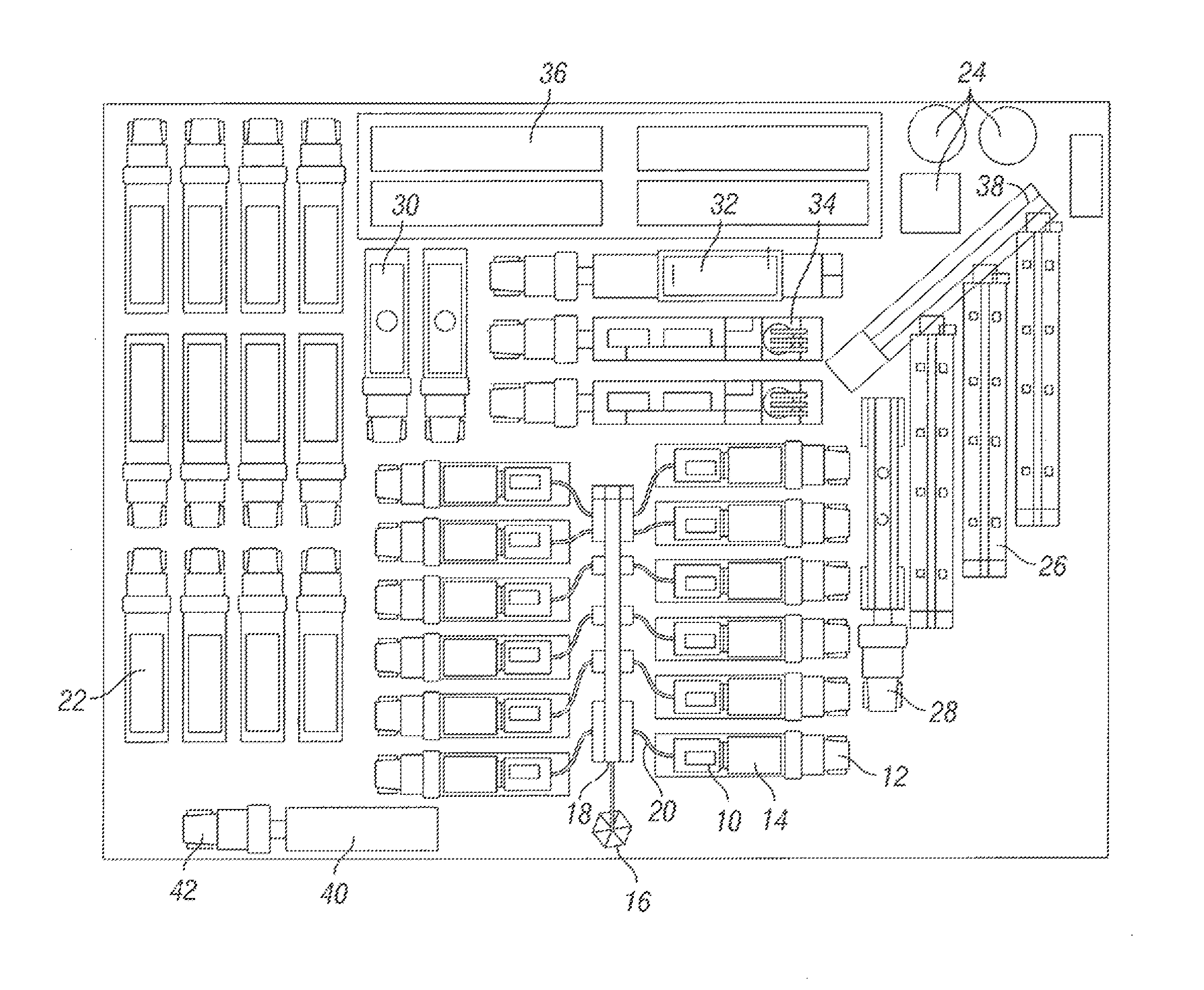

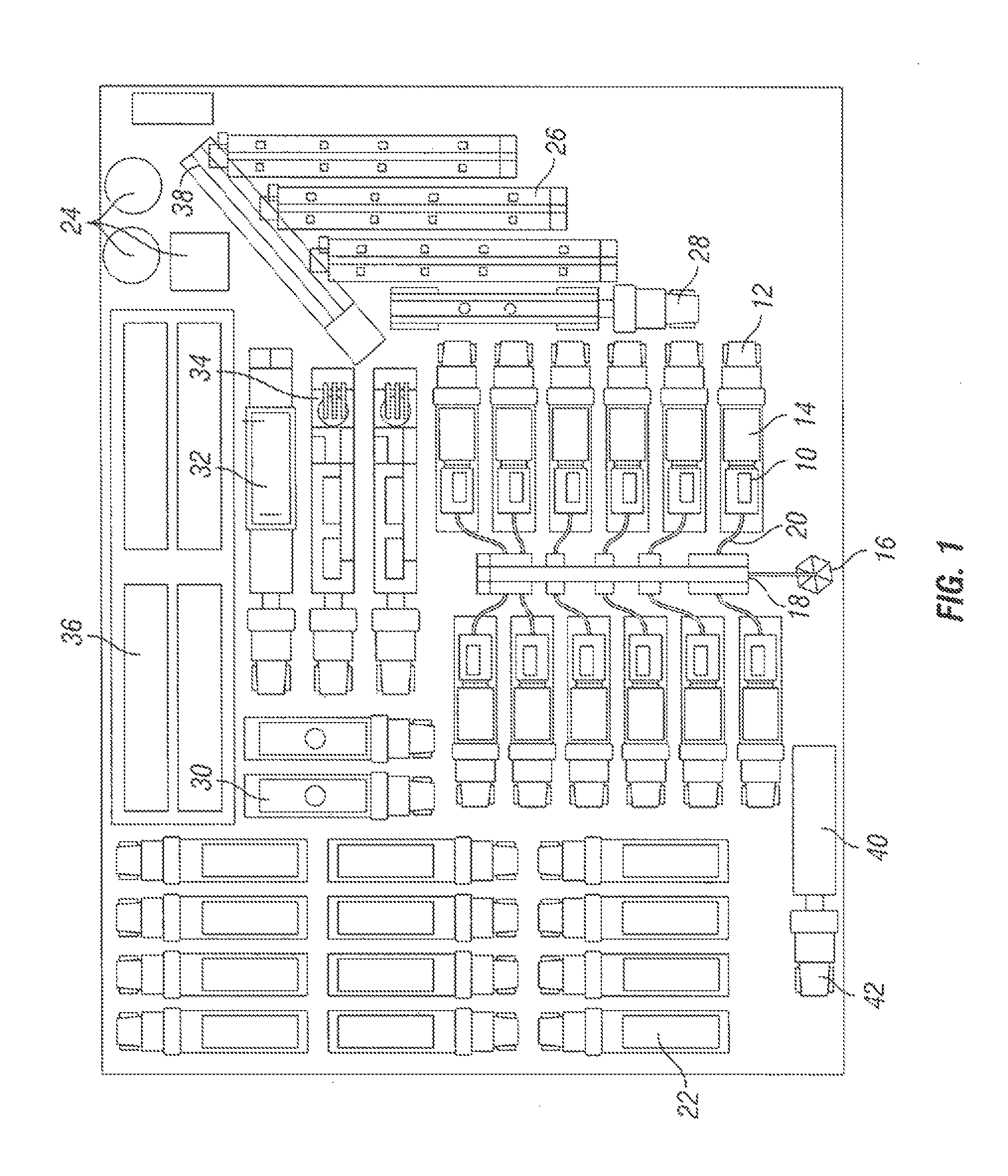

Automated analyzer

InactiveUS20060210435A1Minimal operator involvementEasy loadingBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid-crystal displayBarcode

The present invention provides a bar-code driven, completely automated, microplate-based analyzer system for performing chemical, biochemical or biological assays. The analyzer is a modular, bench-top instrument that compactly integrates subsystems for sample dispensing, liquid handling, microplate transport, thermal incubation, vortexing, solid phase separation and optical reading. An internal processor is included for automating the instrument, and a user interface to facilitate communication with the operator via a touch-sensitive liquid-crystal display (LCD), and communicating with a remote network via multiple protocols. The analyzer includes firmware resident within the processing system and the user interface allows the operator to select pre-defined assay batch protocols and the user interface is configured in such as way so as to restrict an operator from programming the firmware.

Owner:NOVX SYST CANADA

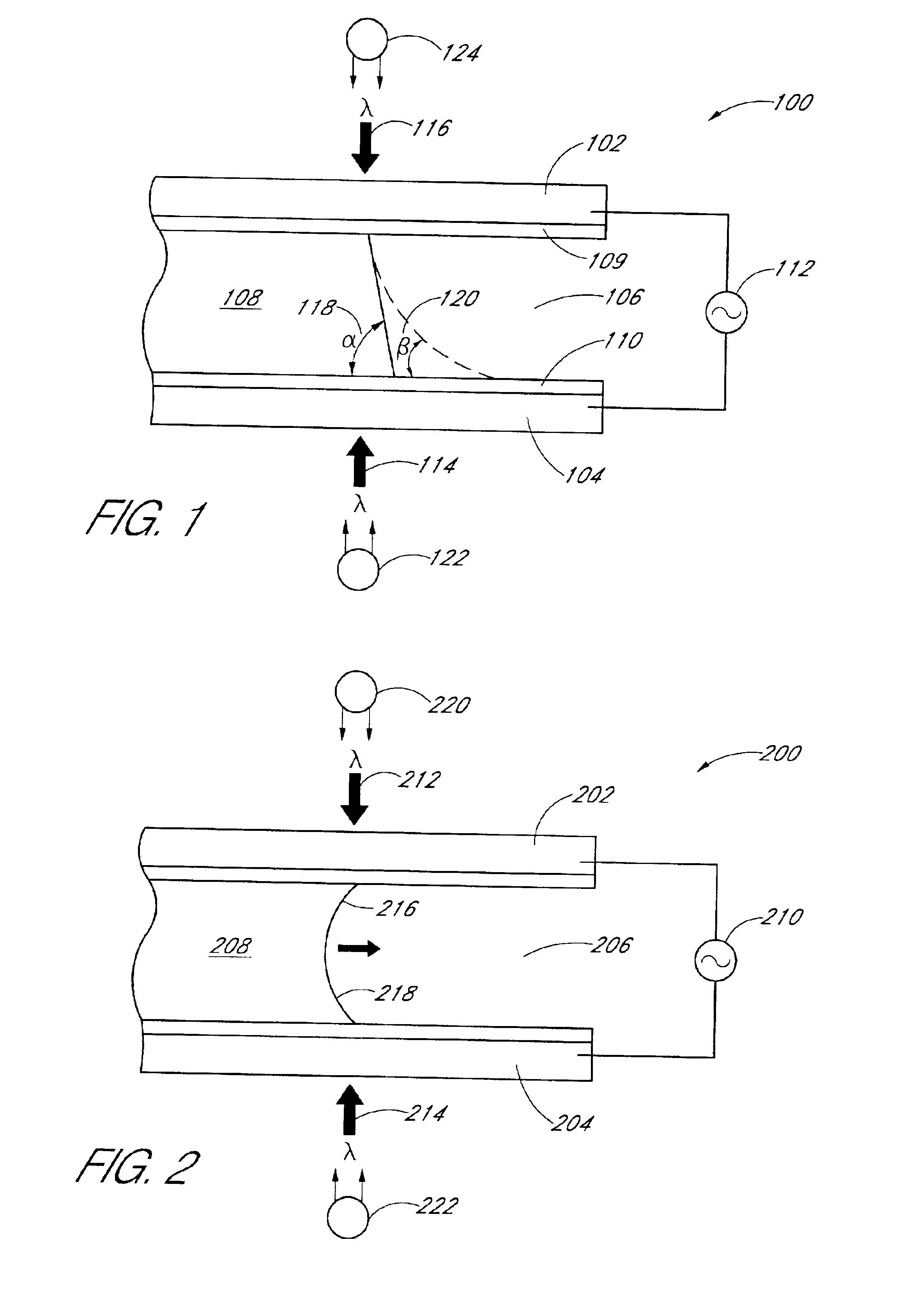

Systems and methods for optical actuation of microfluidics based on opto-electrowetting

InactiveUS6958132B2Improve performanceSludge treatmentMaterial analysis by electric/magnetic meansElectricityMicrofluidics

Owner:RGT UNIV OF CALIFORNIA

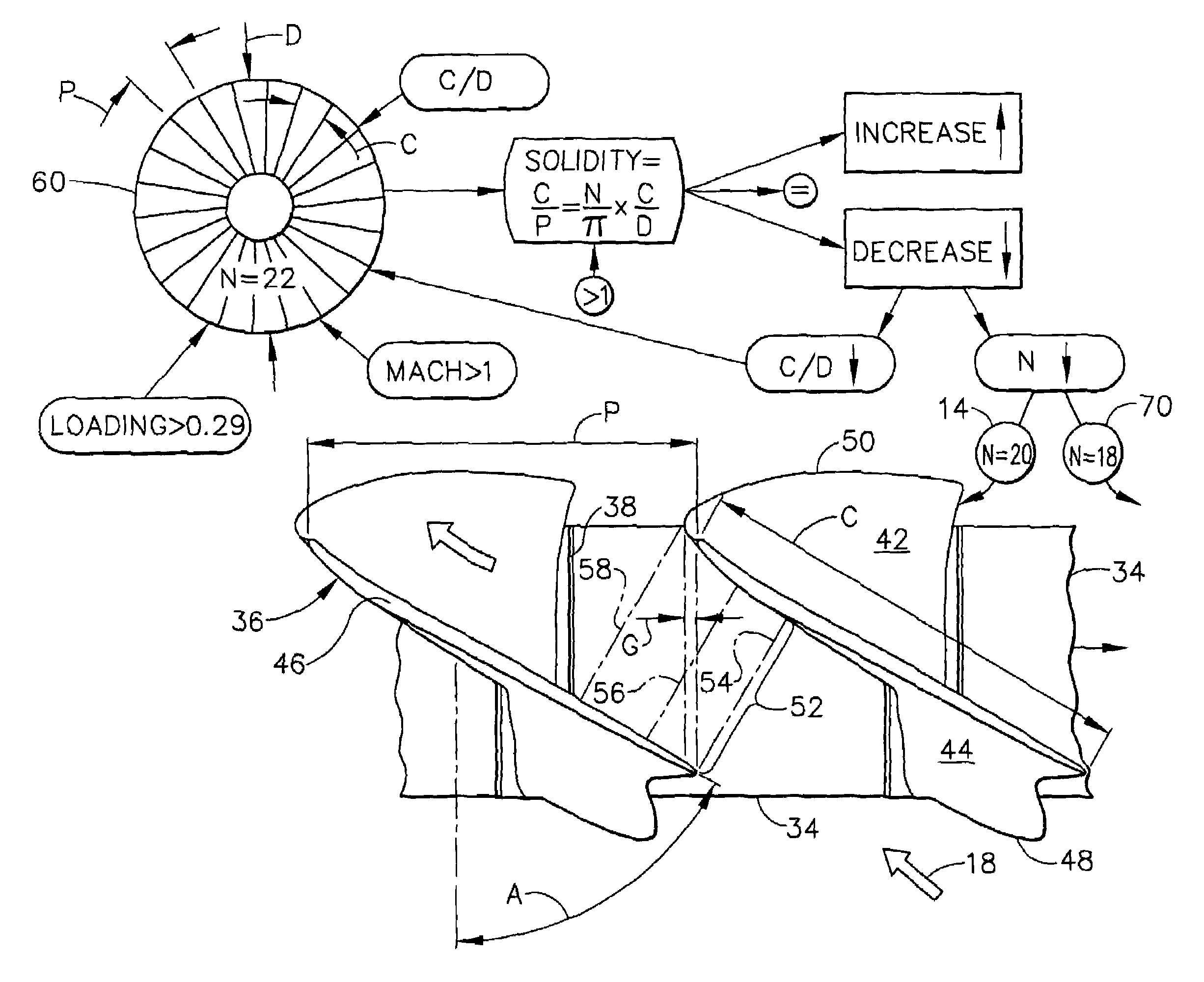

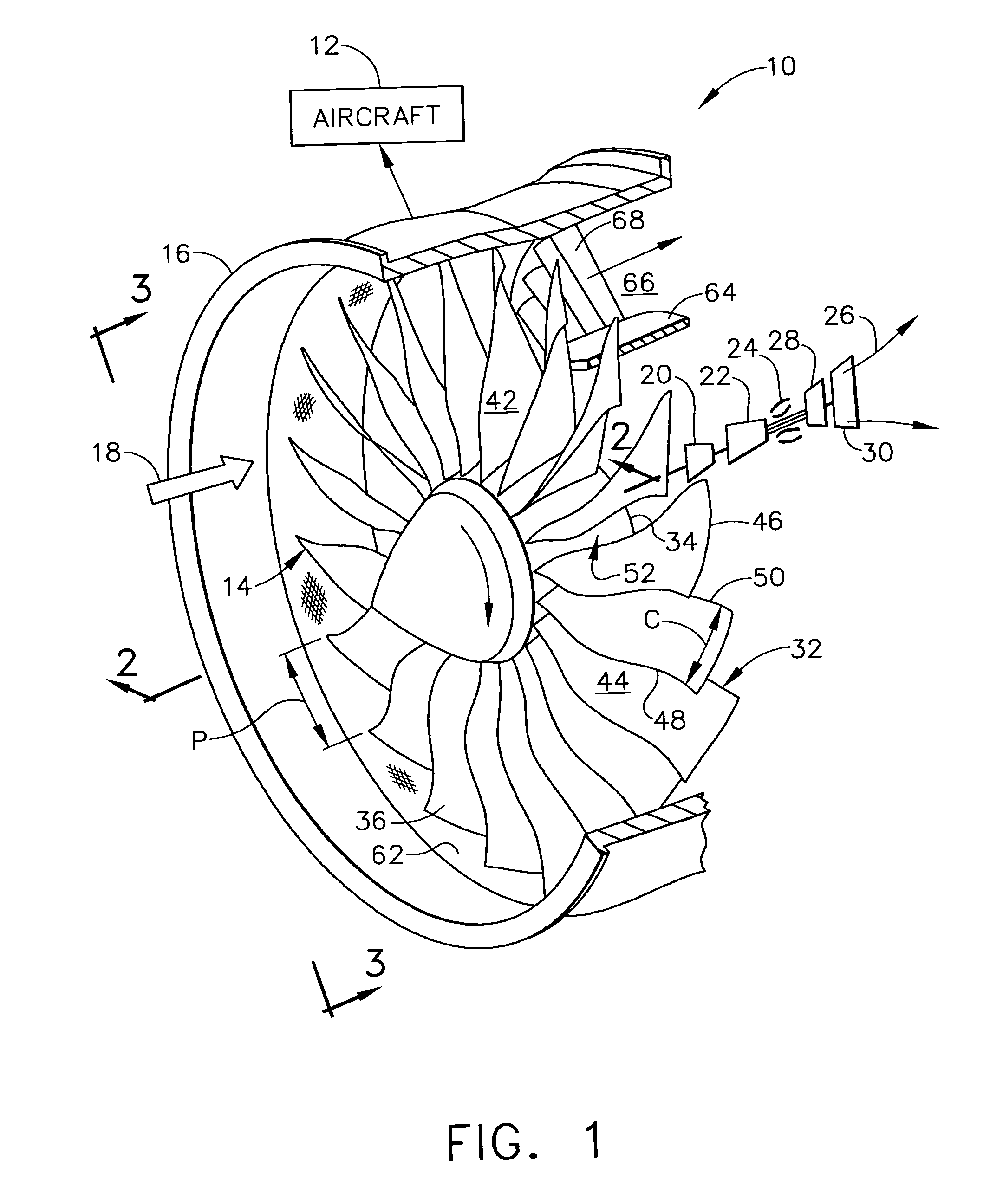

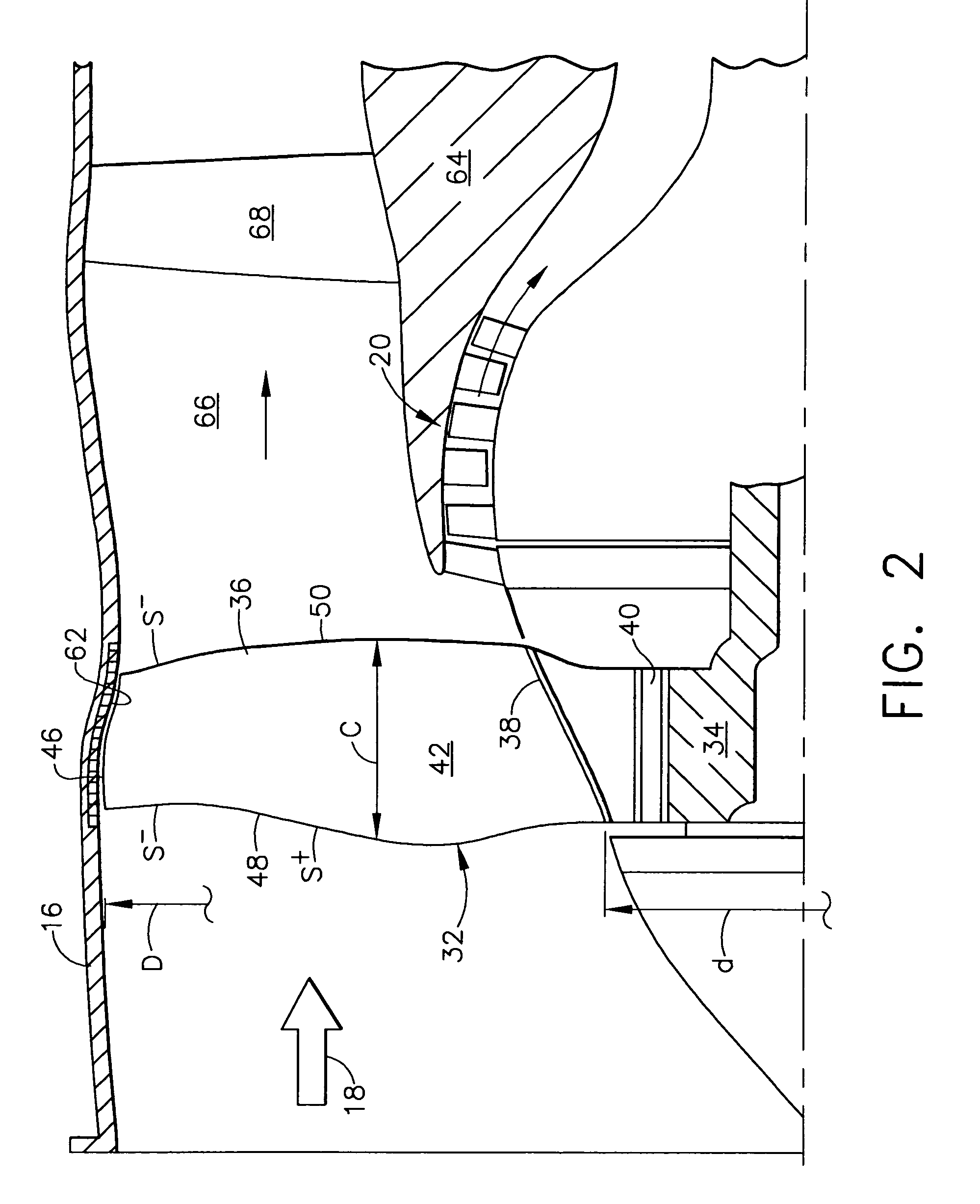

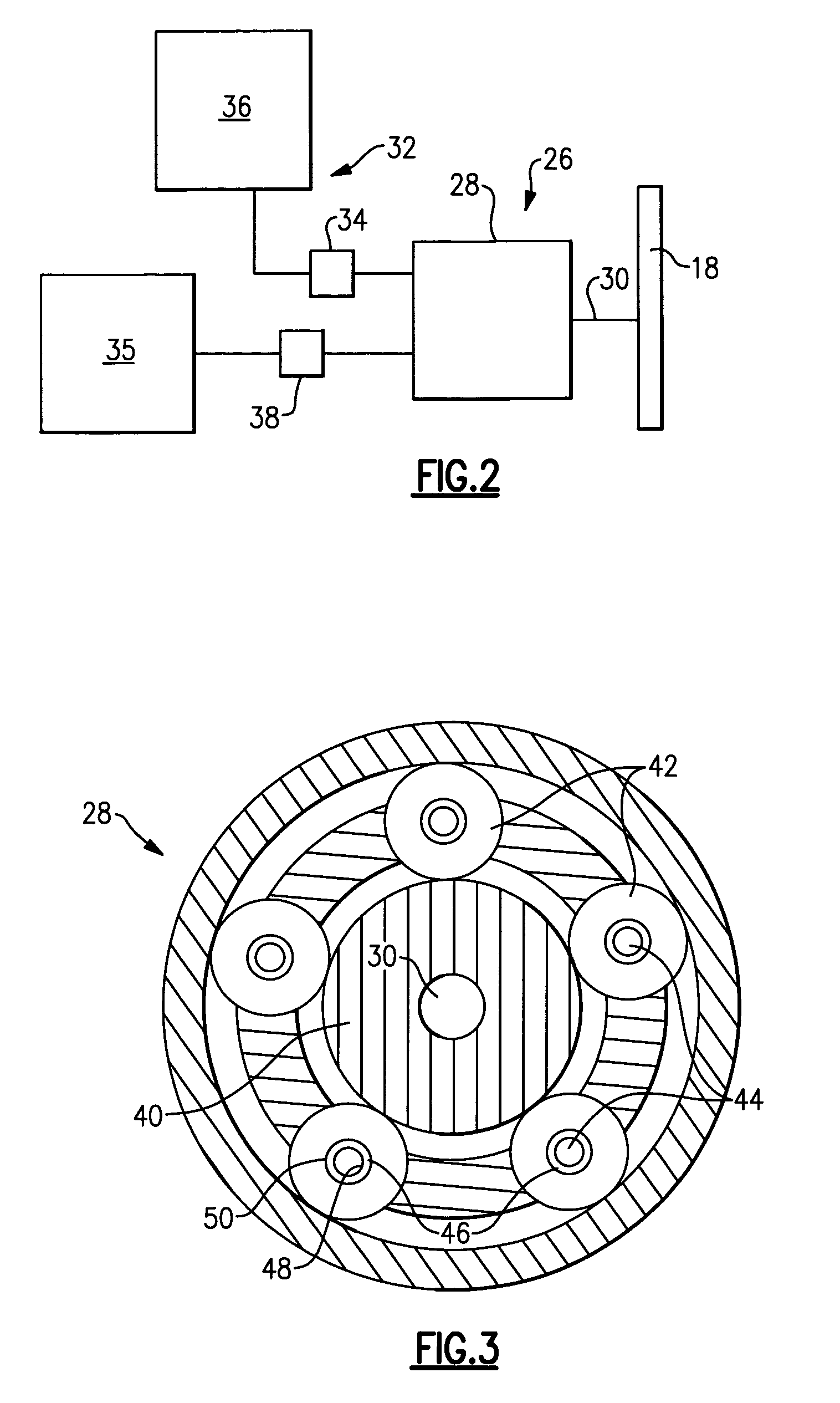

Low solidity turbofan

A turbofan includes a row of fan blades extending from a supporting disk inside an annular casing. Each blade includes an airfoil having opposite pressure and suction sides extending radially in span between a root and tip and axially in chord between leading and trailing edges. Adjacent airfoils define corresponding flow passages therebetween for pressurizing air. Each airfoil includes stagger increasing between the root and tip, and the flow passage has a mouth between the airfoil leading edge and the suction side of an adjacent airfoil and converges to a throat aft from the mouth. The row includes no more than twenty fan blades having low tip solidity for increasing the width of the passage throat.

Owner:GENERAL ELECTRIC CO

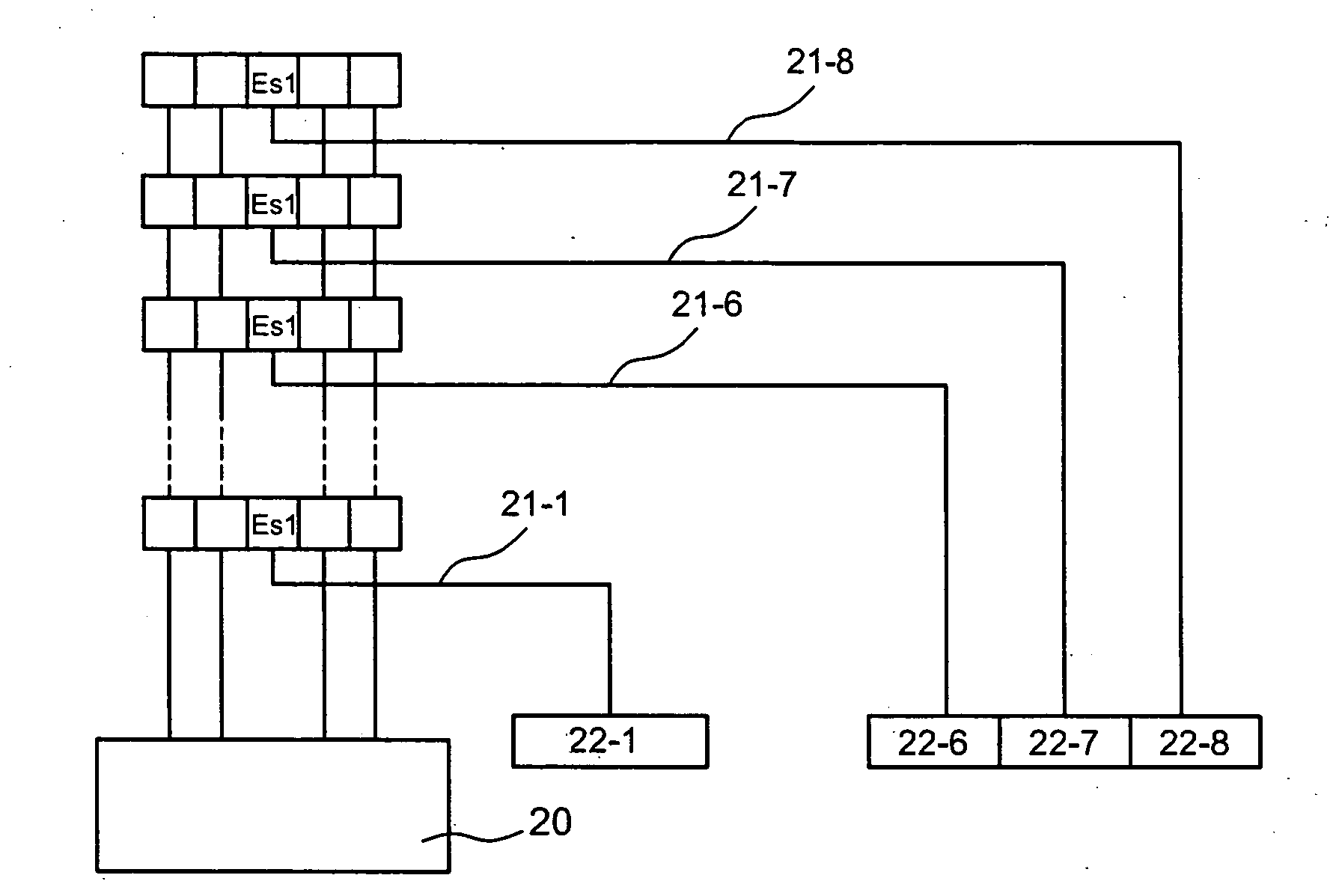

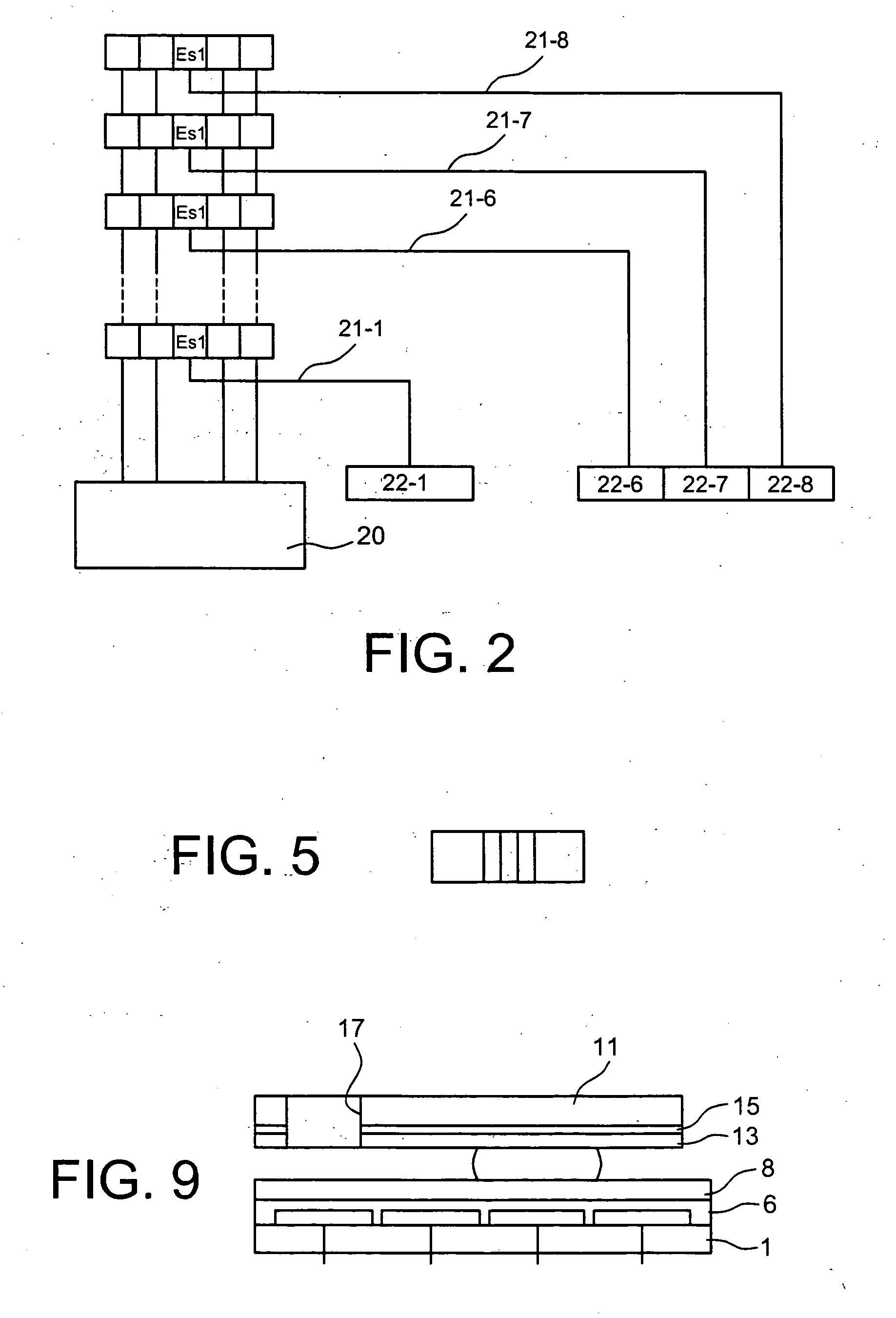

Electrode addressing method

InactiveUS20090192044A1Reduce in quantitySimplify line selection meanElectrostatic separatorsSludge treatmentElectrode arrayEngineering

A device for addressing an electrode array of 2n lines of an electro-fluidic device, each line having N electrodes (n≦N). The device includes, on each line, n selection electrodes, all of the line selection electrodes being connected to 2n line selection conductors, 2n−1 line selection electrodes of 2n−1 lines being connected to each line selection conductor, and selection devices for selecting one or more line selection conductors.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

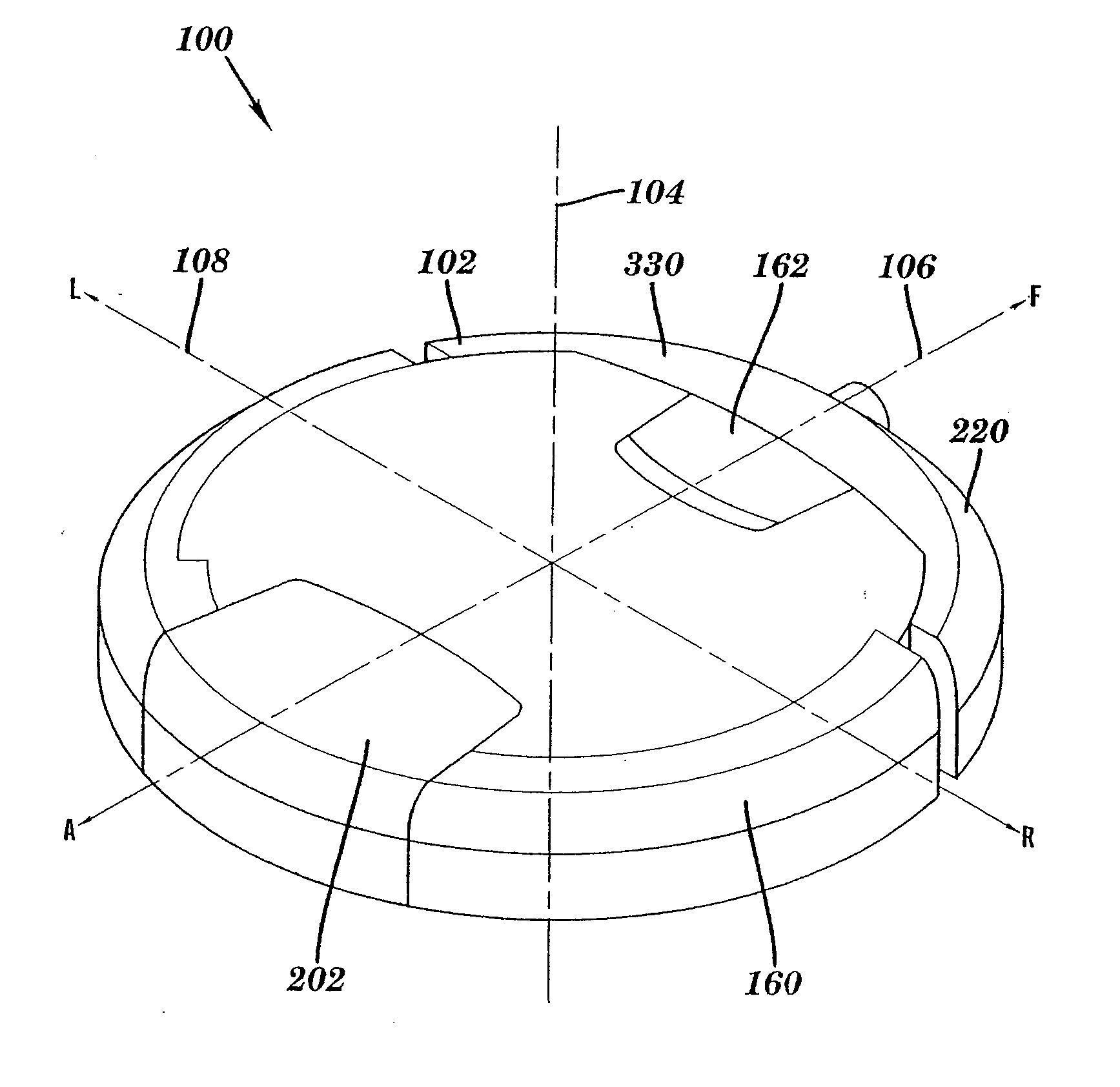

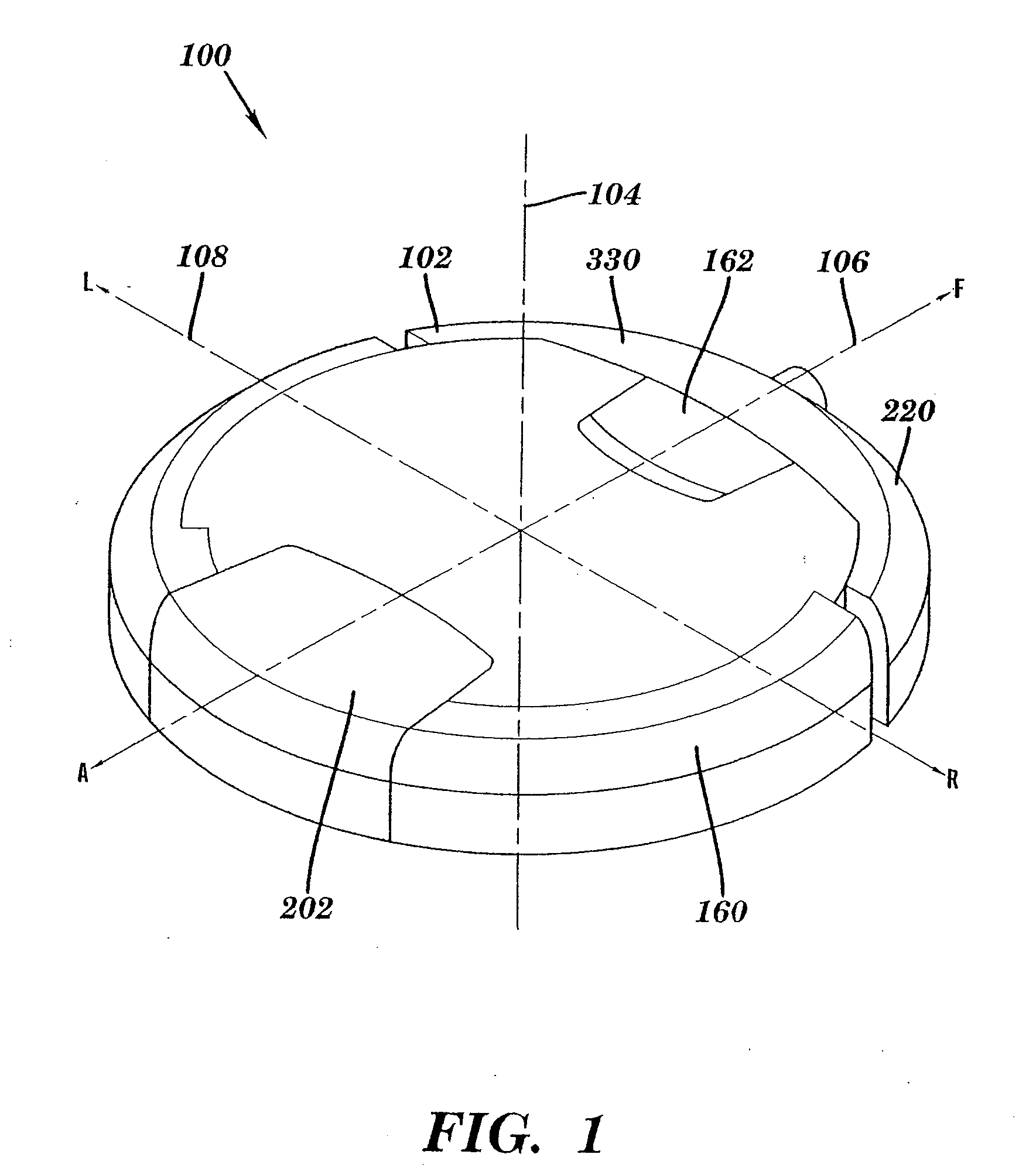

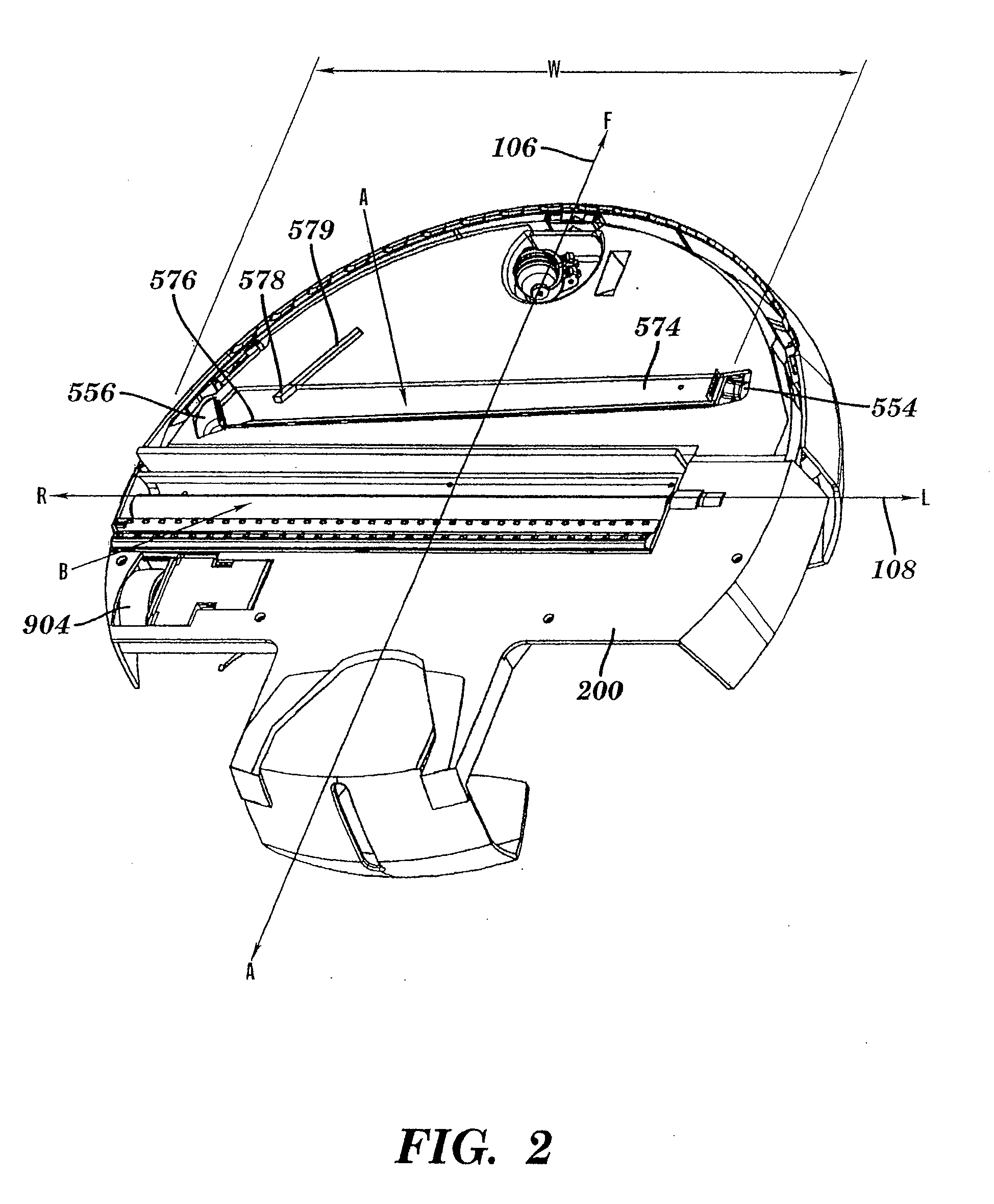

Autonomous surface cleaning robot for wet and dry cleaning

InactiveUS20080140255A1Low costWet cleaningAutomatic obstacle detectionTravelling automatic controlSurface cleaningControl system

An autonomous floor cleaning robot includes a transport drive and control system arranged for autonomous movement of the robot over a floor for performing cleaning operations. The robot chassis carries a first cleaning zone comprising cleaning elements arranged to suction loose particulates up from the cleaning surface and a second cleaning zone comprising cleaning elements arraigned to apply a cleaning fluid onto the surface and to thereafter collect the cleaning fluid up from the surface after it has been used to clean the surface. The robot chassis carries a supply of cleaning fluid and a waste container for storing waste materials collected up from the cleaning surface.

Owner:IROBOT CORP

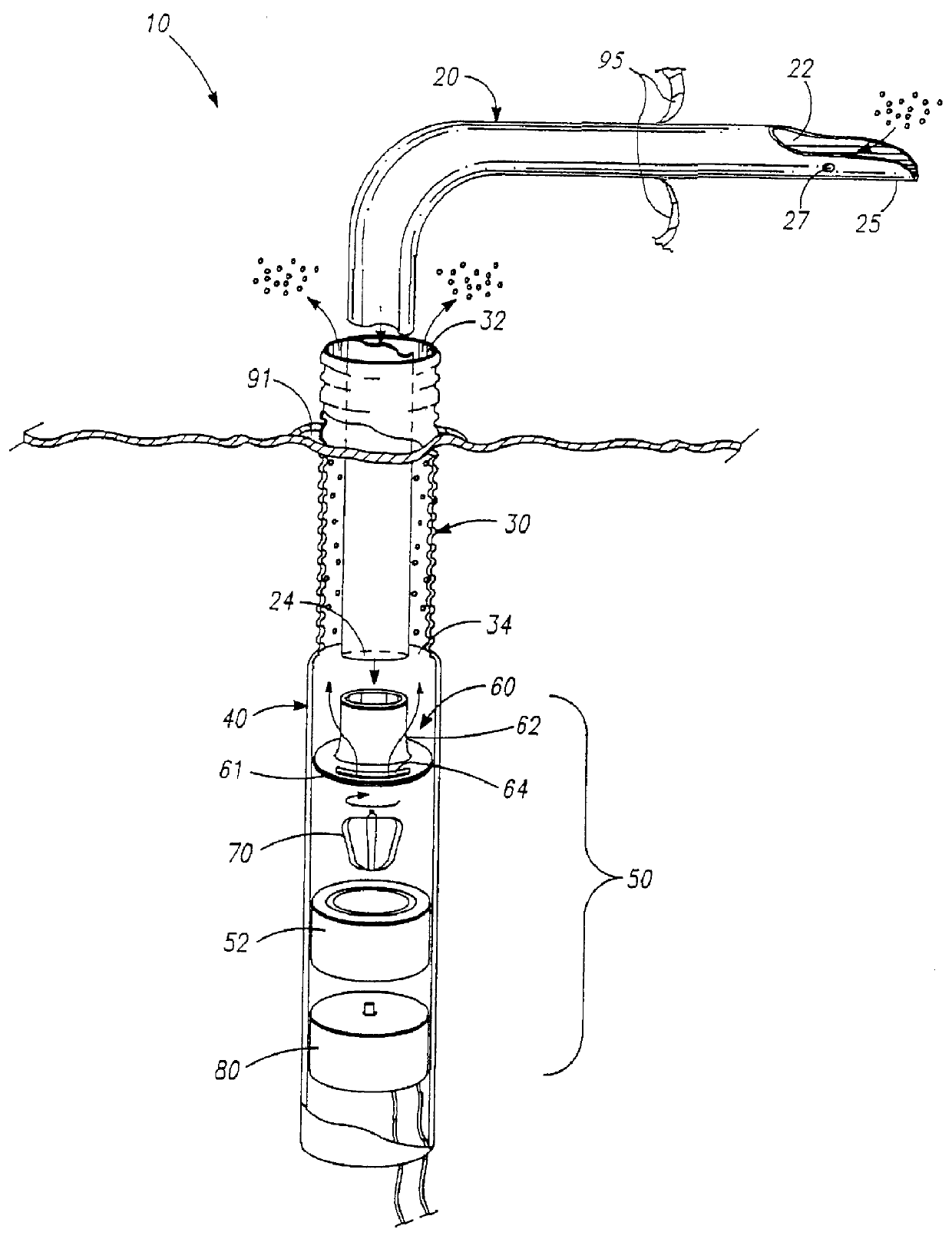

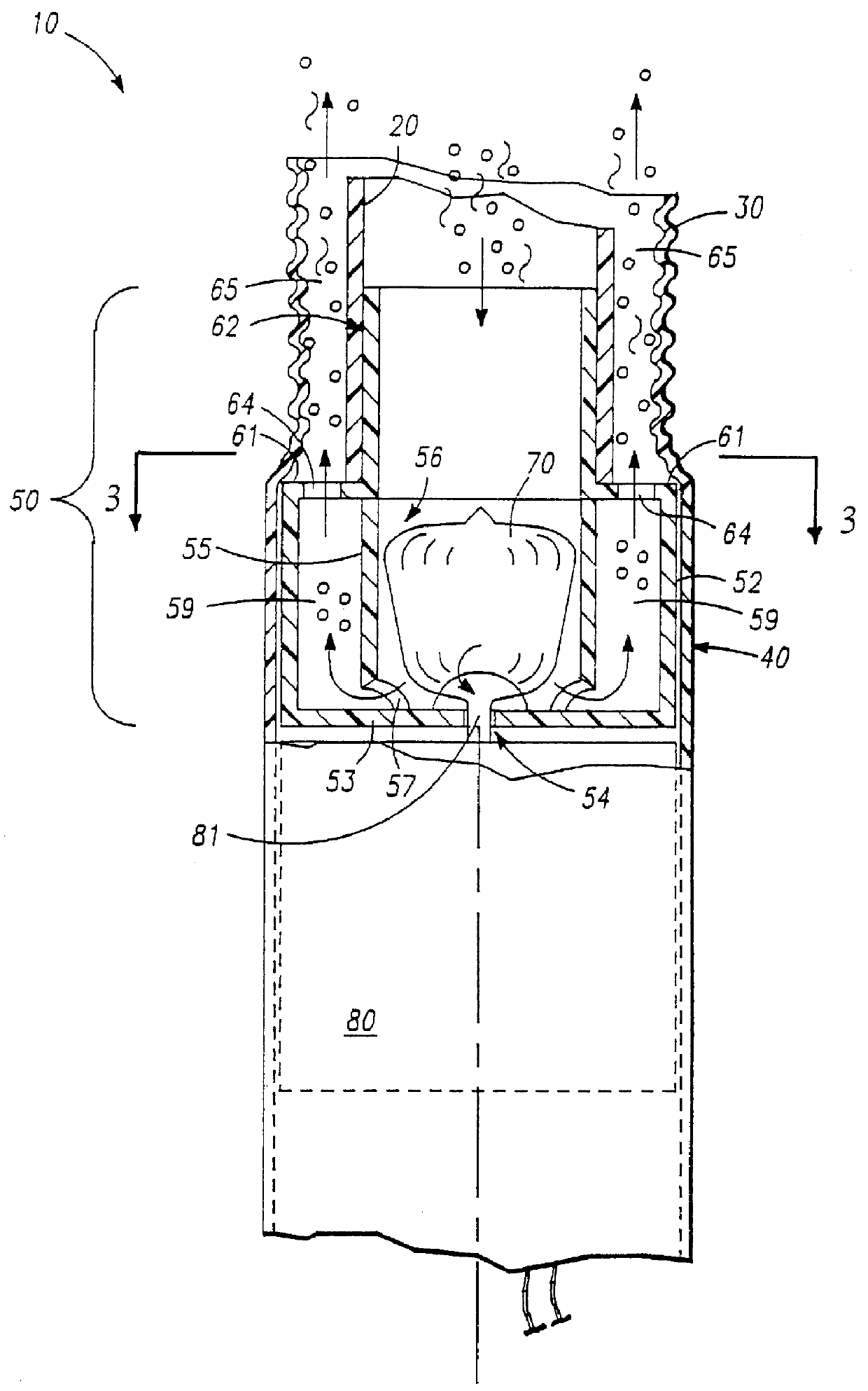

Infusion pumps and methods and delivery devices and methods with same

ActiveUS20080051716A1Reduce liquid volumeIncrease the amount of fluidContracting/expanding measuring chambersMedical devicesEngineeringInfusion pump

A delivery device includes a durable housing portion and a separable disposable portion that selectively engage and disengage from each other. The disposable housing portion secures to the patient-user and may be disposed of after it has been in use for a prescribed period. Components that normally come into contact with a patient-user or with an infusion medium, including a pump device, are supported by the disposable housing portion for disposal after the prescribed use, while the durable housing portion supports other components such as electronics for controlling delivery of the infusion medium from the reservoir and a drive device and drive linkage.

Owner:MEDTRONIC MIMIMED INC

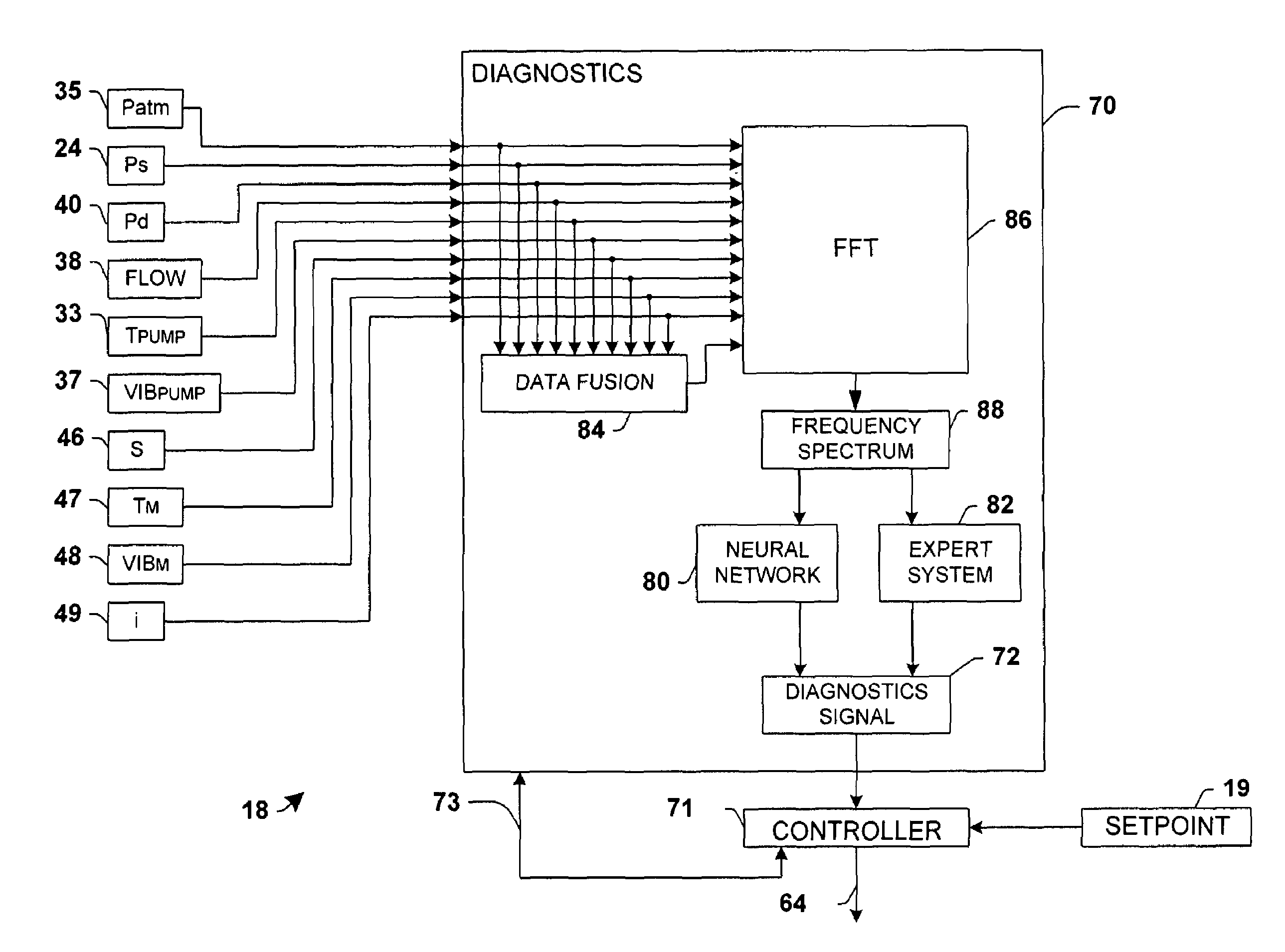

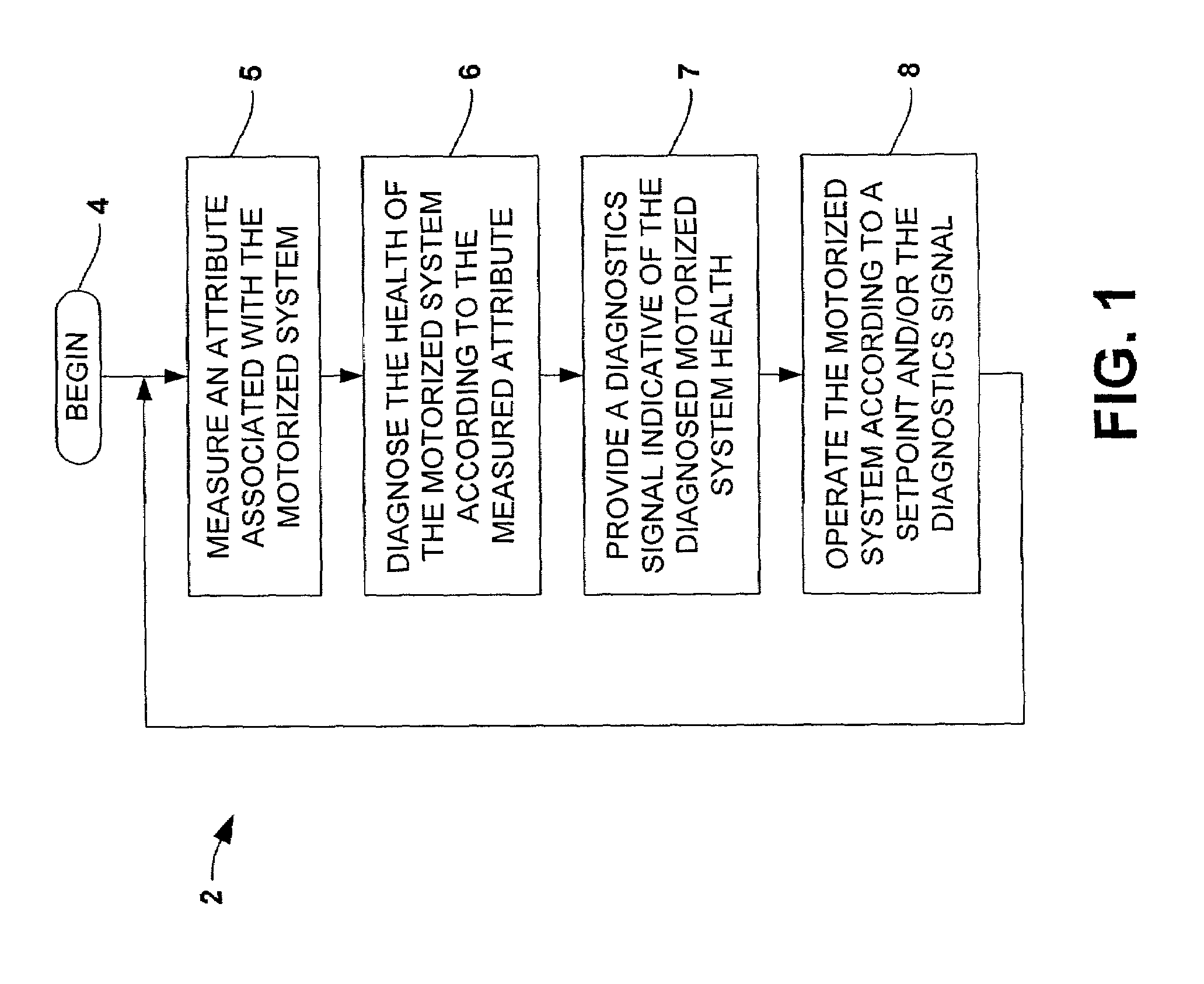

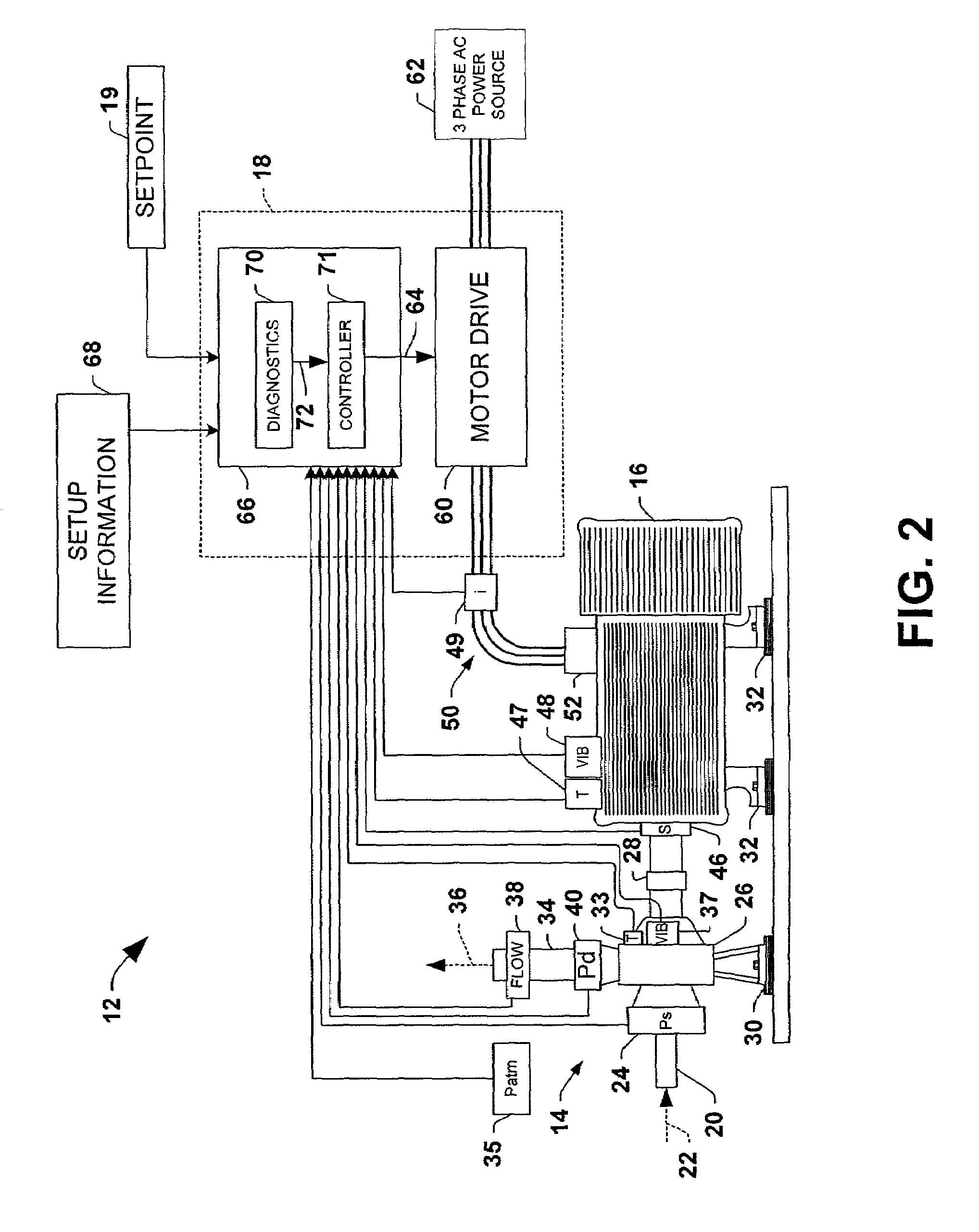

Motorized system integrated control and diagnostics using vibration, pressure, temperature, speed, and/or current analysis

InactiveUS7539549B1Condition be reduced and eliminatedAdvantageously employedPump componentsTesting/monitoring control systemsCurrent analysisDiagnostic system

Systems and methods are disclosed for controlling and diagnosing the health of a motorized system. The systems may comprise a diagnostics system and a controller, wherein the diagnostics system employs a neural network, an expert system, and / or a data fusion component in order to assess the health of the motorized system according to one or more attributes associated therewith. The controller may operate the motorized system in accordance with a setpoint and / or a diagnostics signal from the diagnostics system. Also disclosed are methodologies for controlling and diagnosing the health of a motorized system, comprising operating a motor in the motorized system in a controlled fashion, and diagnosing the health of the motorized system according to a measured attribute associated with the motorized system, wherein the motor may be operated according to a setpoint and / or the diagnostics signal.

Owner:ROCKWELL AUTOMATION TECH

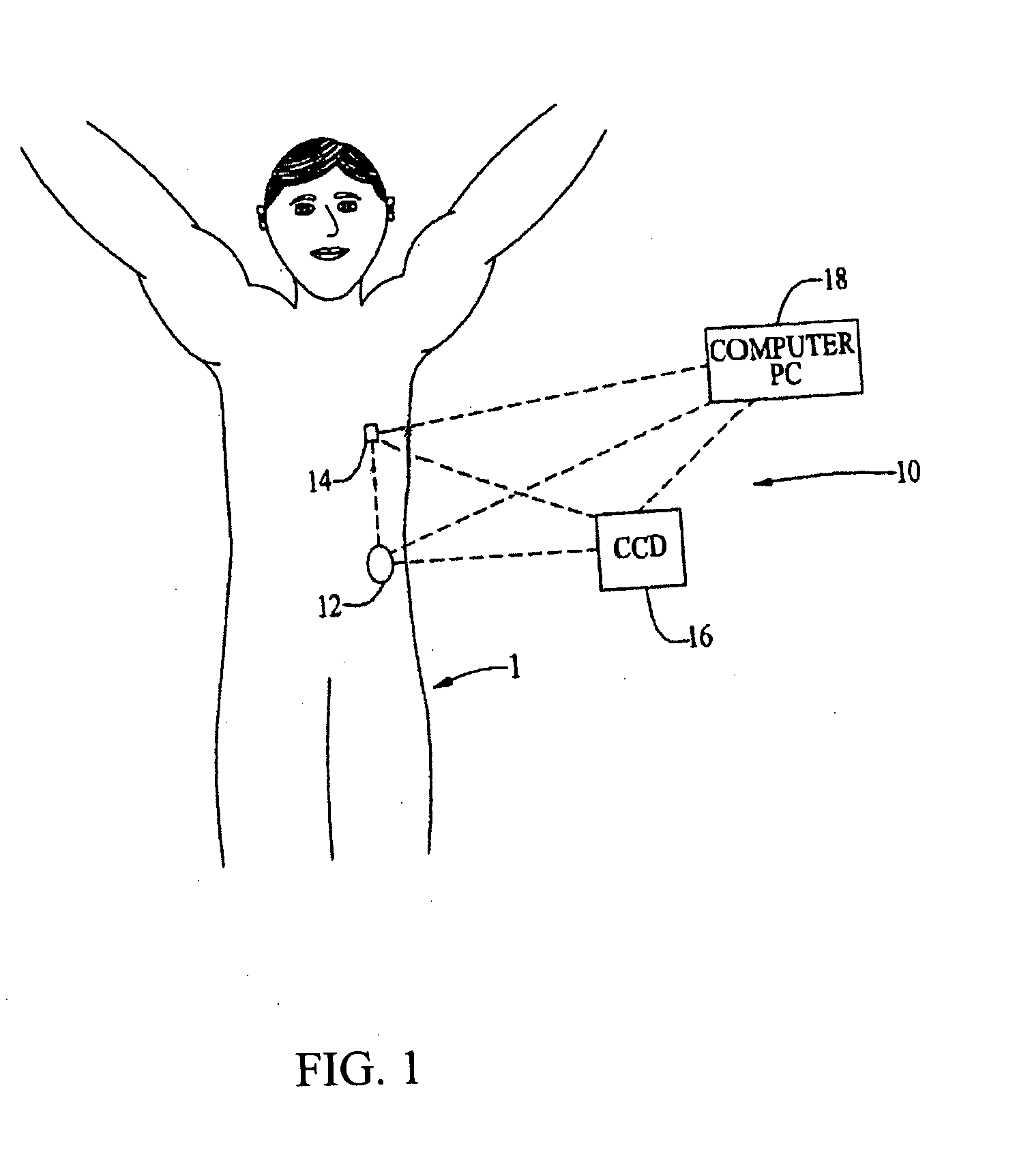

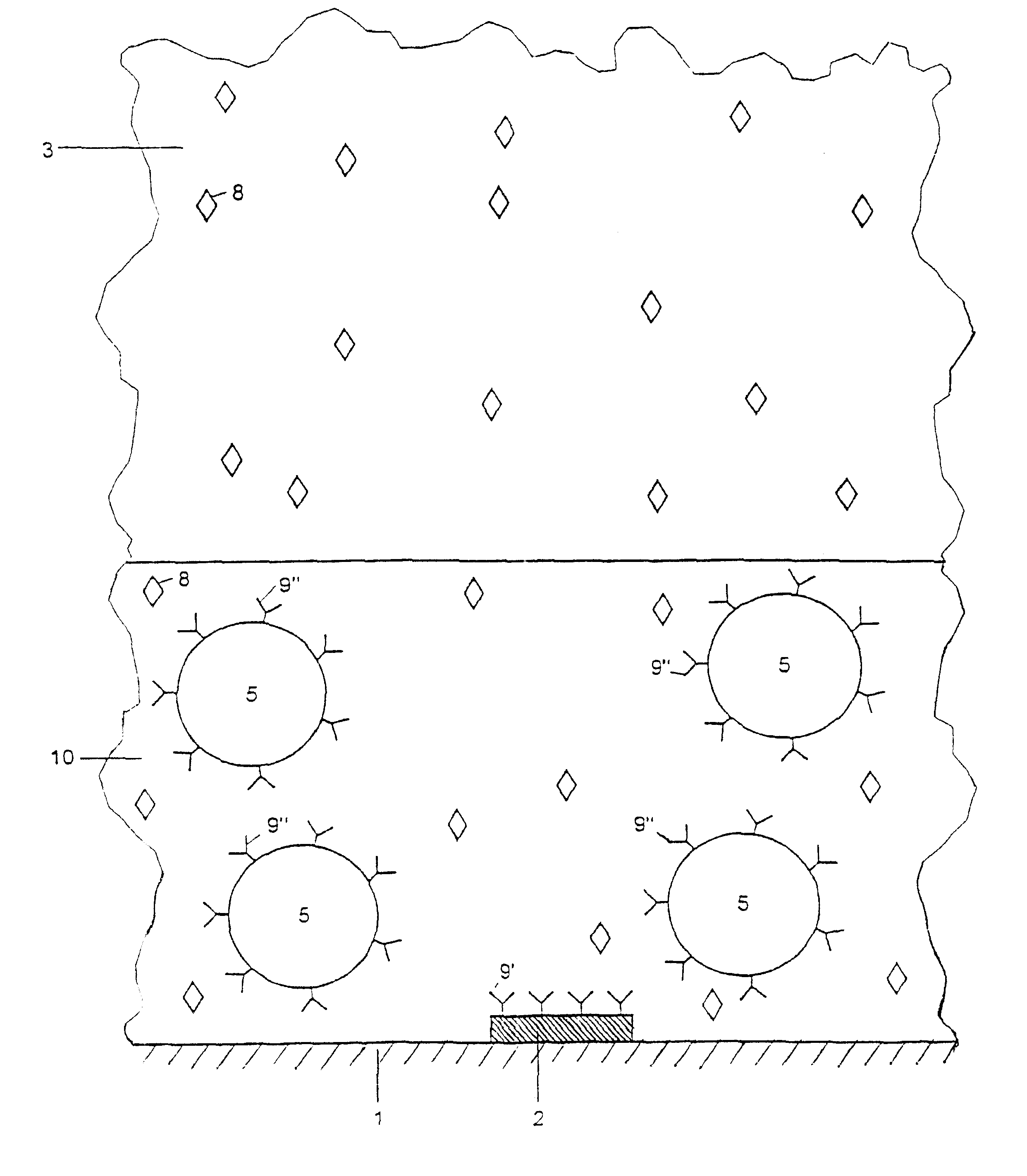

Device and method for detecting analytes

InactiveUS6548311B1Influence is negligibleRelative density is smallBioreactor/fermenter combinationsBiological substance pretreatmentsElectricityAnalyte

The invention relates to a method for detecting analytes and to a device for carrying out the method, for use for analysis or diagnosis in the fields of chemistry, biochemistry, molecular genetics, food chemistry, biotechnology, the environment and medicine. Marker particles (5) with different electrical properties or a different relative permeability to those of the measuring solution (3) surrounding them are used to detect the analytes (8). The marker particles (5) either bond specifically to the analytes (8) or to a base (2) in competition with the analyte. The analytes (8) are detected by the changes in an electrical field or an electrical current generated by electrodes (2) or in an electrical voltage applied to an electrode or in a magnetic field, said changes being caused by marker particles which have bonded with the analytes or by marker particles which have instead bonded to the base in an electrical field.

Owner:KNOLL MEINHARD

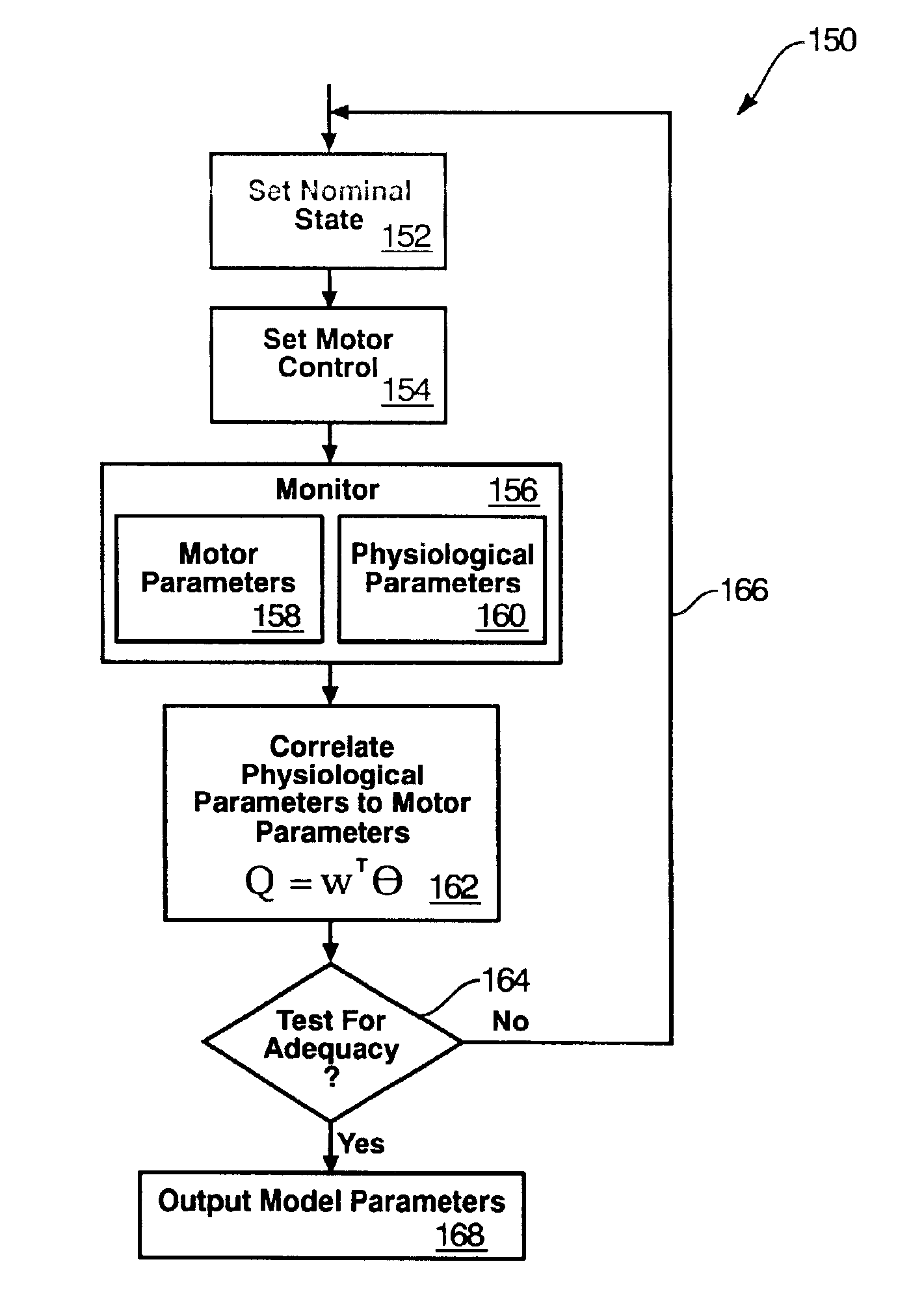

Rotary blood pump diagnostics and cardiac output controller

A method and apparatus for controlling a ventricular assist device are disclosed. The method includes the step of providing a ventricular assist device which can be defined in terms of operational parameters such as pump speed or current. Measuring at least one physiological parameter reflecting a physiological state corresponding to a patient. Correlating at least one physiological parameter measured from the patient to at least one operational parameter using an estimation method. Selecting a physiological state definable by desired values of the physiological parameters. Monitoring at least one operational parameter. Controlling input values of the operational parameter based on output from the monitoring step. The apparatus includes a pump driven by a motive drive and having an impeller. A sensor detects the value of an operational parameter of the pump. A processor provides a statistical correlation between patients physiological parameter and the operational parameter of the pump and adjusts the operational parameter to affect a predetermined optimal physiological state.

Owner:WORLD HEART

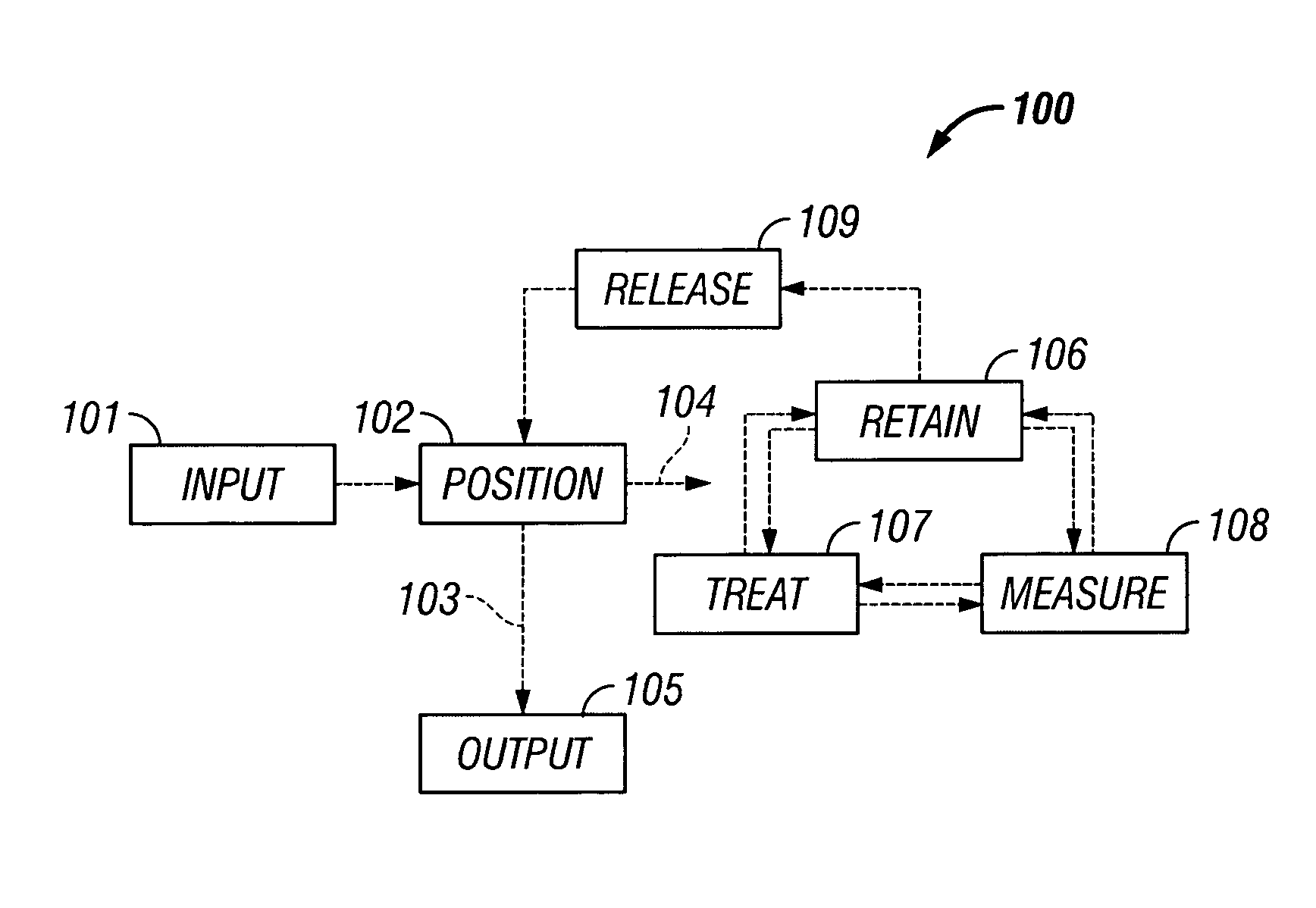

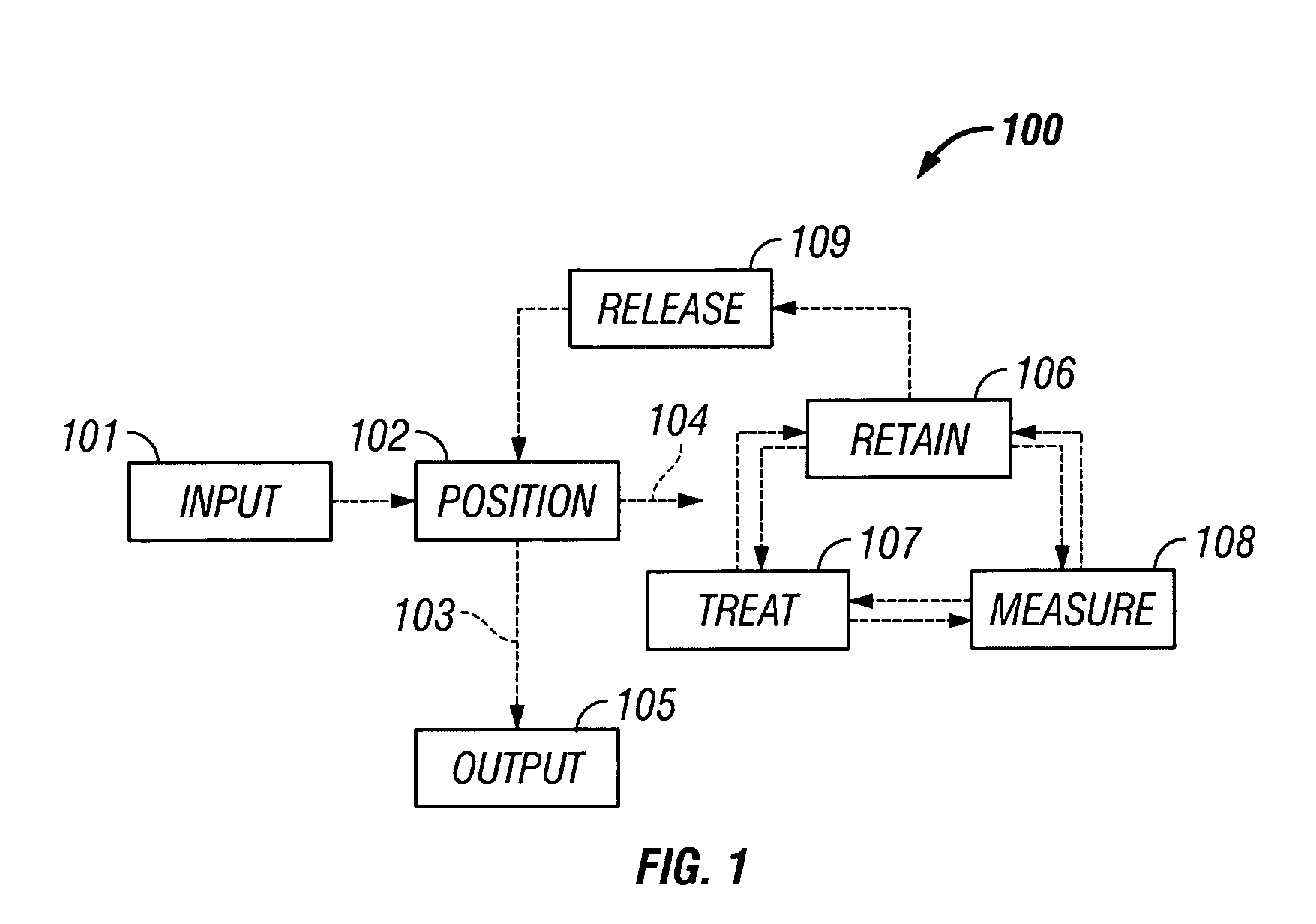

Microfluidic particle-analysis systems

ActiveUS7312085B2Bioreactor/fermenter combinationsBiological substance pretreatmentsReady to useMixed group

The invention provides systems, including apparatus, methods, and kits, for the microfluidic manipulation and / or detection of particles, such as cells and / or beads. The invention provides systems, including apparatus, methods, and kits, for the microfluidic manipulation and / or analysis of particles, such as cells, viruses, organelles, beads, and / or vesicles. The invention also provides microfluidic mechanisms for carrying out these manipulations and analyses. These mechanisms may enable controlled input, movement / positioning, retention / localization, treatment, measurement, release, and / or output of particles. Furthermore, these mechanisms may be combined in any suitable order and / or employed for any suitable number of times within a system. Accordingly, these combinations may allow particles to be sorted, cultured, mixed, treated, and / or assayed, among others, as single particles, mixed groups of particles, arrays of particles, heterogeneous particle sets, and / or homogeneous particle sets, among others, in series and / or in parallel. In addition, these combinations may enable microfluidic systems to be reused. Furthermore, these combinations may allow the response of particles to treatment to be measured on a shorter time scale than was previously possible. Therefore, systems of the invention may allow a broad range of cell and particle assays, such as drug screens, cell characterizations, research studies, and / or clinical analyses, among others, to be scaled down to microfluidic size. Such scaled-down assays may use less sample and reagent, may be less labor intensive, and / or may be more informative than comparable macrofluidic assays.

Owner:STANDARD BIOTOOLS INC

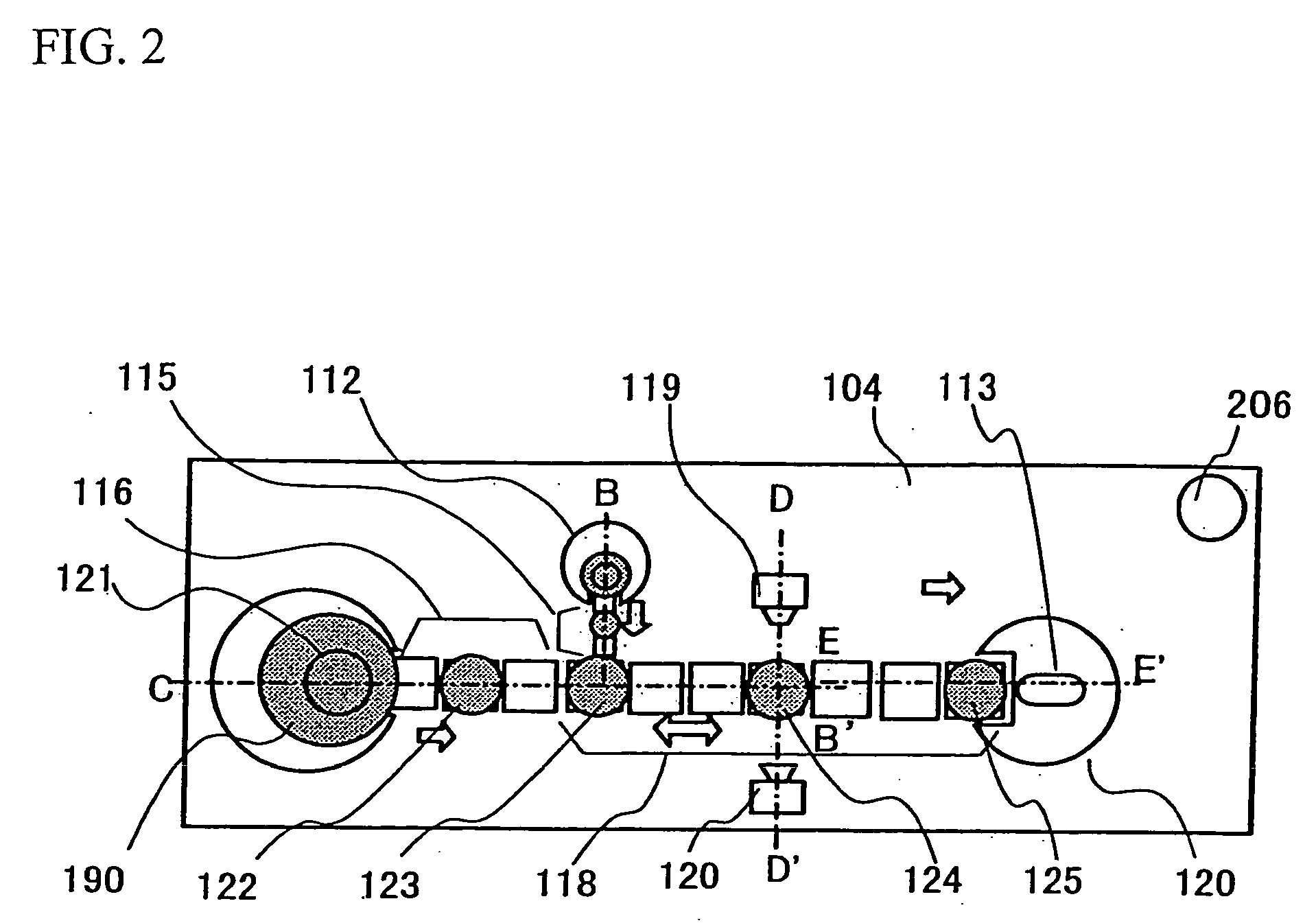

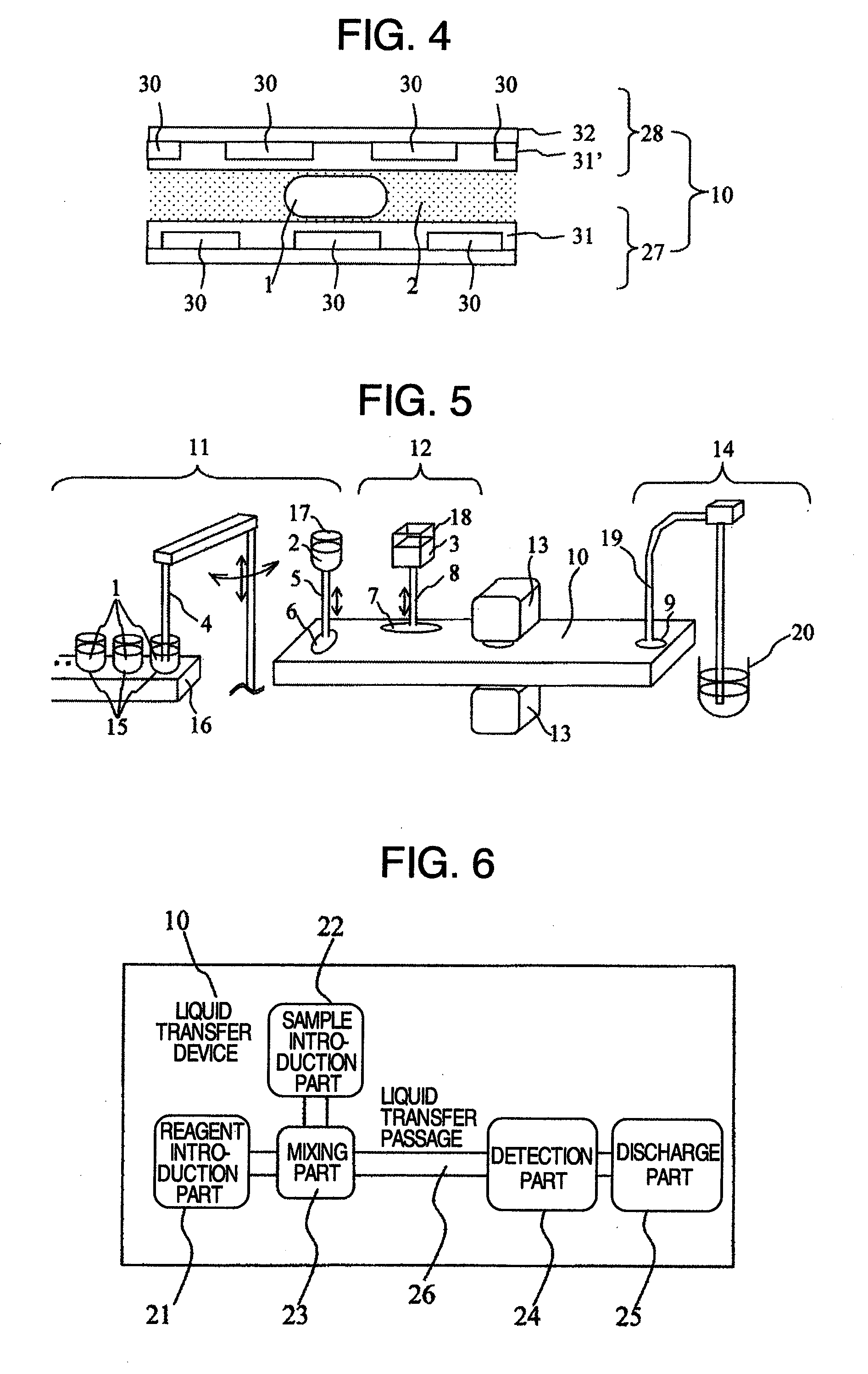

Chemical analysis apparatus

InactiveUS20060039823A1Improve accuracyHigh mixing precisionAnalysis using chemical indicatorsShaking/oscillating/vibrating mixersCompound (substance)Engineering

A chemical analysis apparatus is equipped with analysis sections having openings, means for supplying samples or reagents from the openings, means for combining and mixing samples with reagents to obtain droplets as liquids to be measured, and means for measuring the physical properties of the liquids to be measured during reaction or after completion of reaction. Furthermore, plate members are provided facing each other in analysis sections and a plurality of electrodes are provided on the plate member faces that face each other. Voltage is applied from the plurality of electrodes to the droplets of the samples and the reagents.

Owner:HITACHI HIGH-TECH CORP

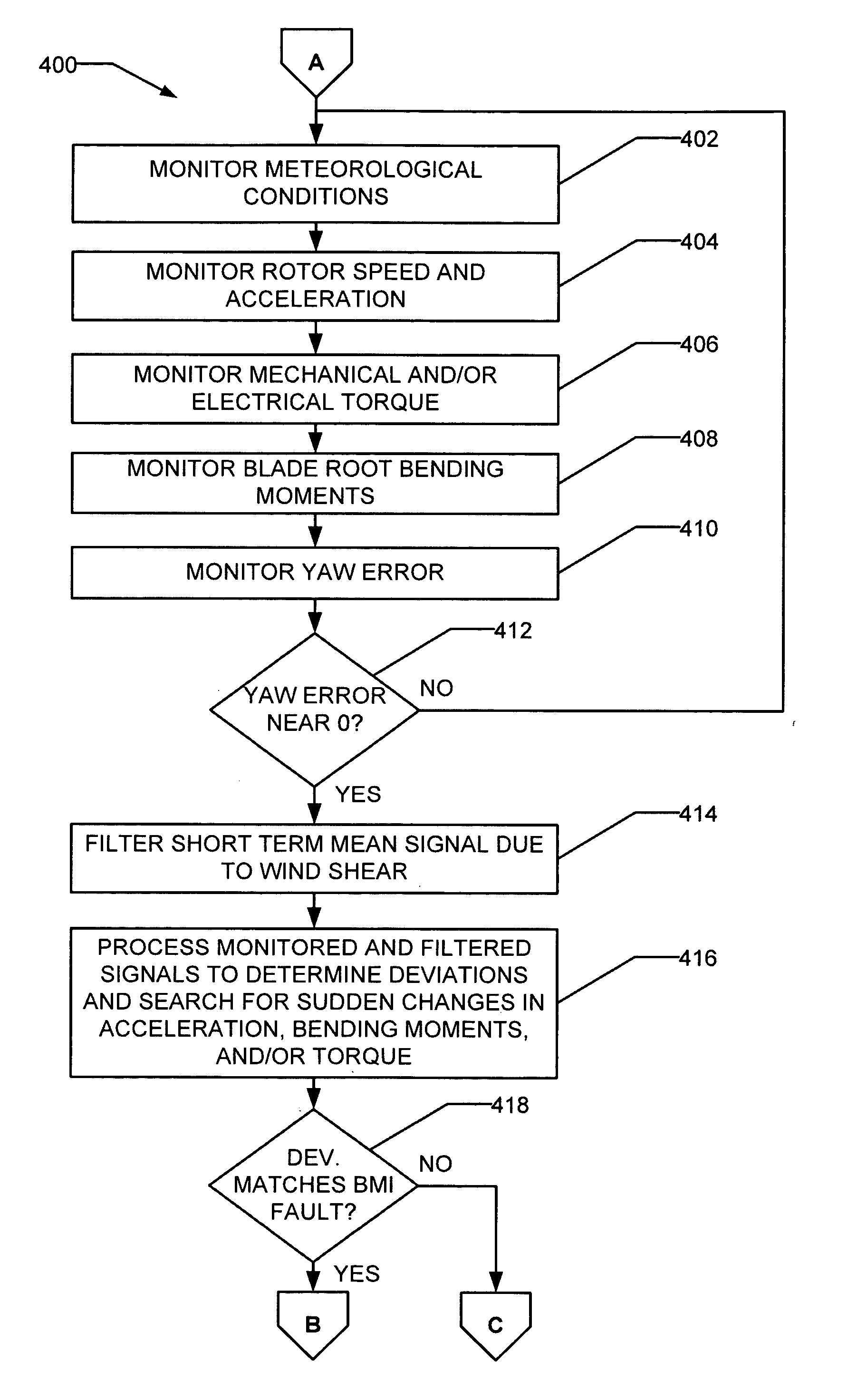

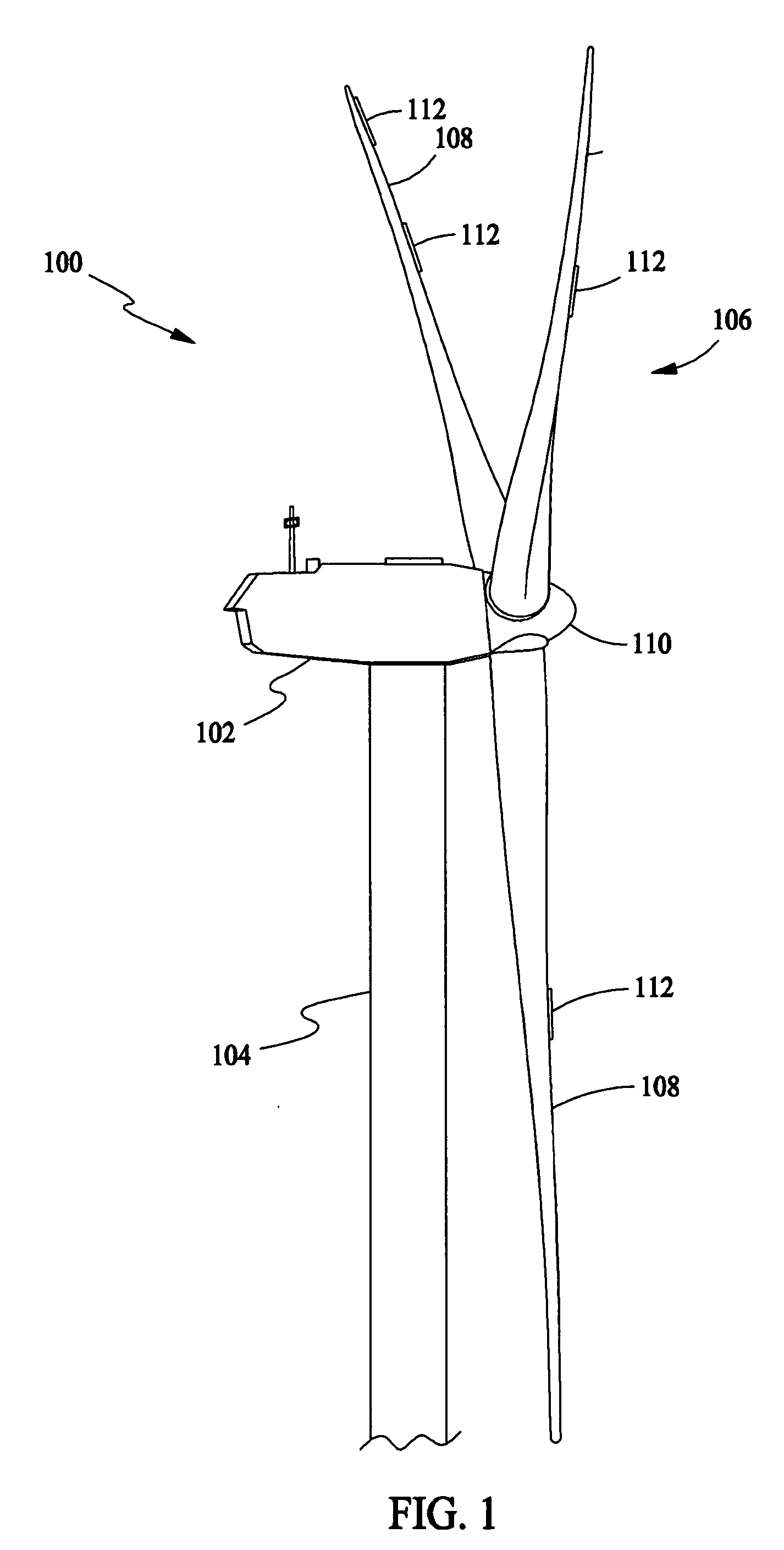

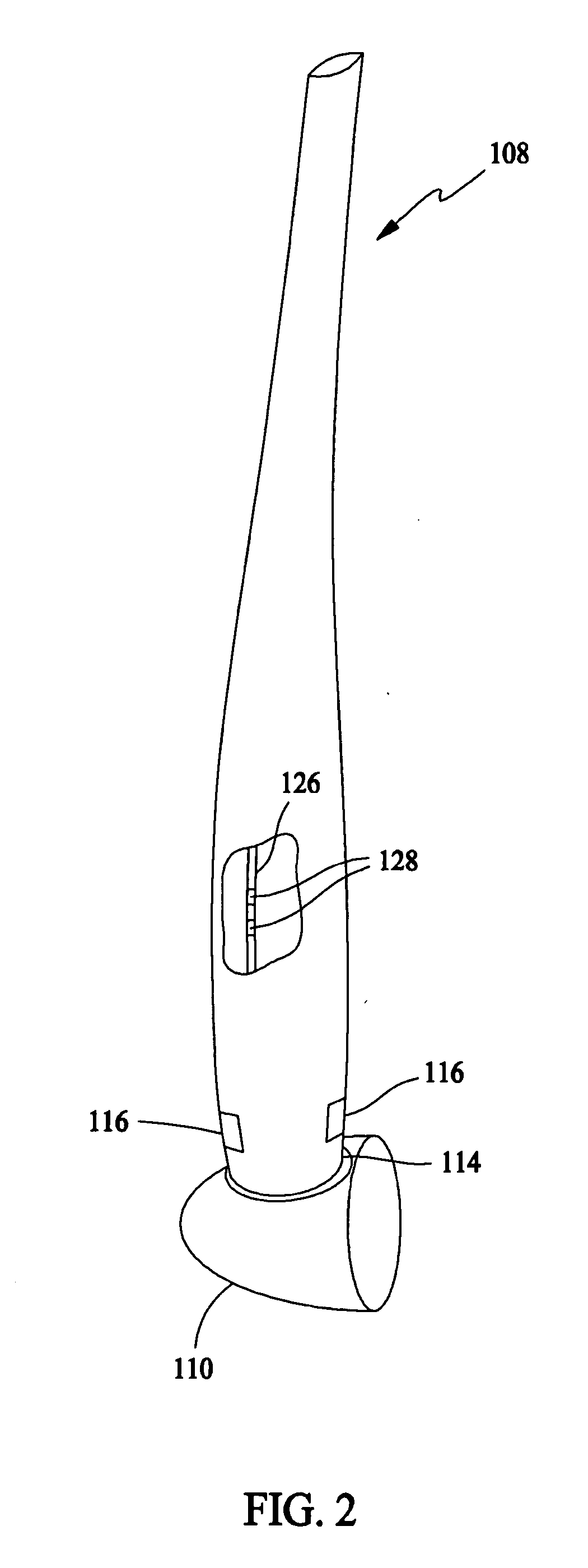

Methods and apparatus for rotor blade ice detection

ActiveUS20050276696A1Reduced lifting capabilityDiminished aerodynamic rotor blade performancePropellersWind motor controlIcing conditionsEngineering

A method for detecting ice on a wind turbine having a rotor and one or more rotor blades each having blade roots includes monitoring meteorological conditions relating to icing conditions and monitoring one or more physical characteristics of the wind turbine in operation that vary in accordance with at least one of the mass of the one or more rotor blades or a mass imbalance between the rotor blades. The method also includes using the one or more monitored physical characteristics to determine whether a blade mass anomaly exists, determining whether the monitored meteorological conditions are consistent with blade icing; and signaling an icing-related blade mass anomaly when a blade mass anomaly is determined to exist and the monitored meteorological conditions are determined to be consistent with icing.

Owner:GENERAL ELECTRIC CO

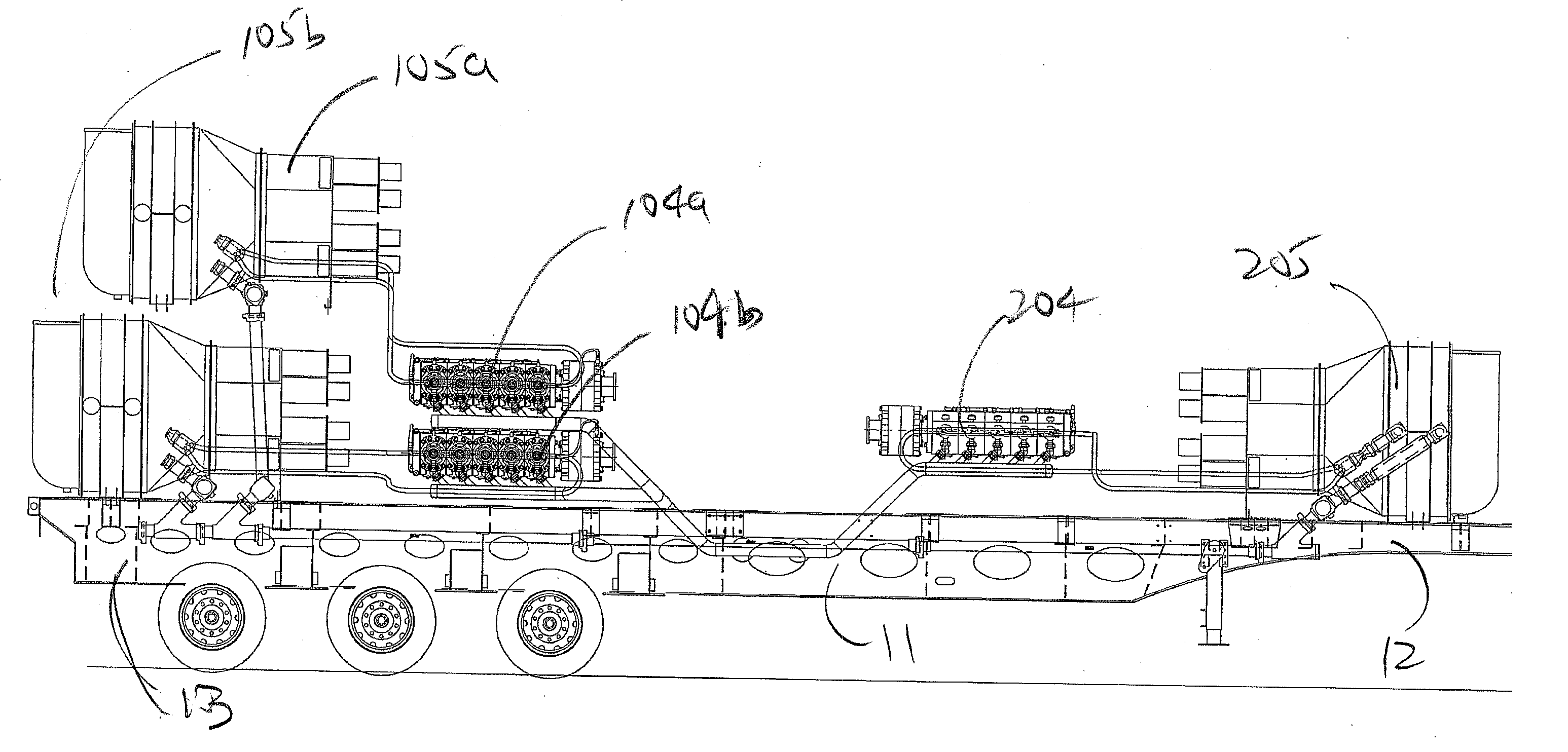

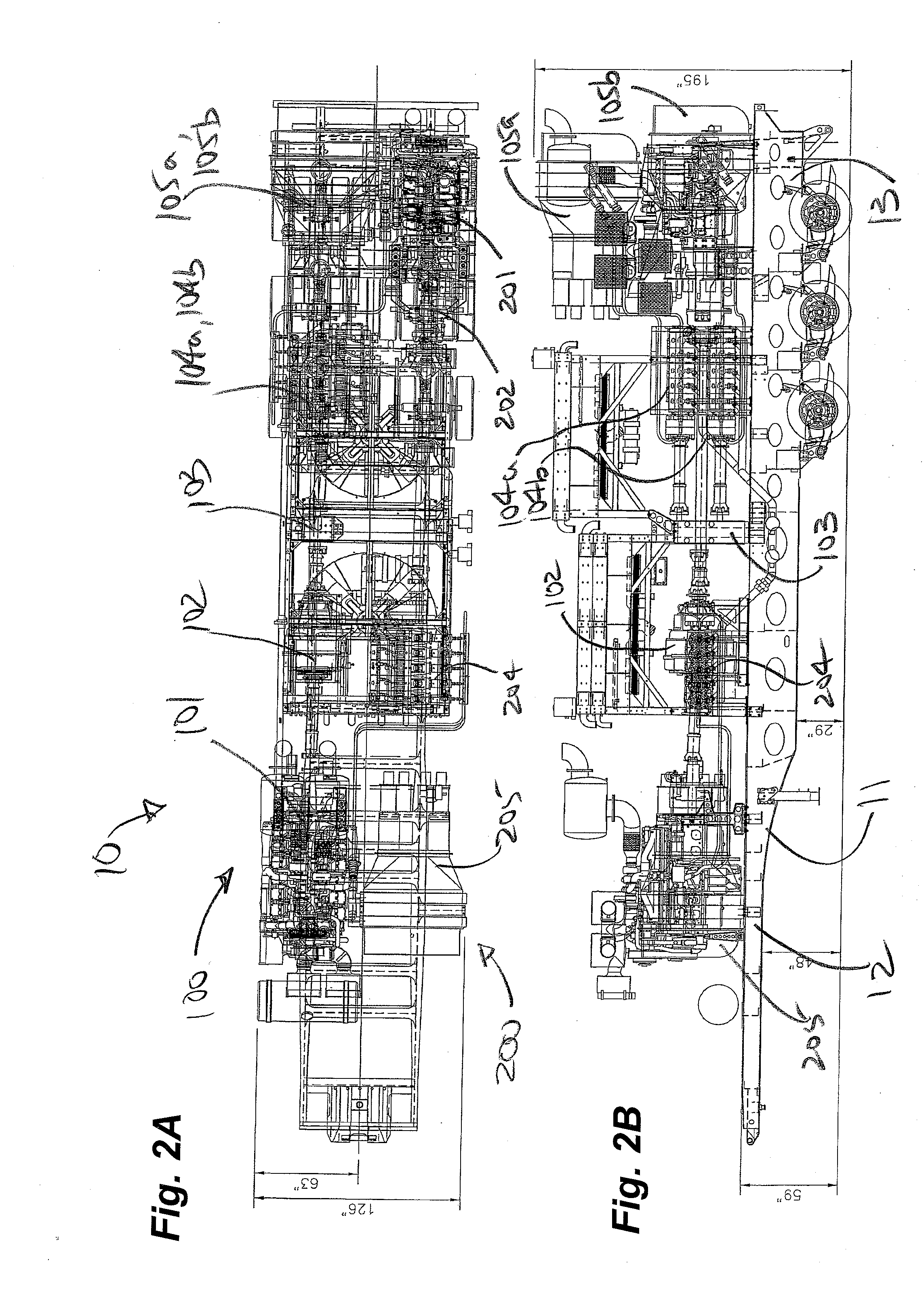

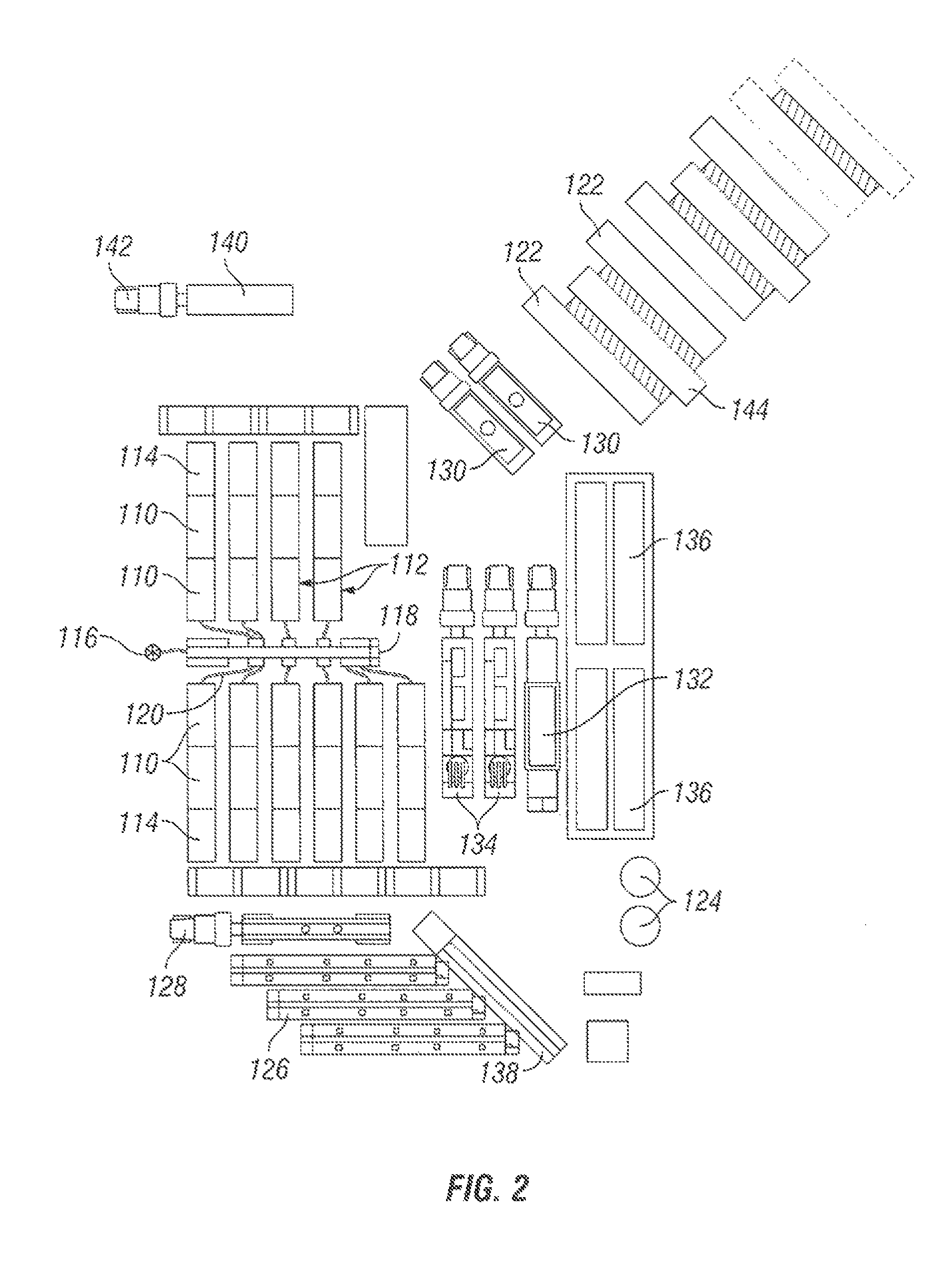

Transportable pumping unit and method of fracturing formations

InactiveUS20060260331A1Increase chanceReduced operating requirementsNon-pressured vesselsPumpsCombustorControl system

A high capacity pumper for liquefied gas incorporates multiple pumping systems distributed in a parallel arrangement and in opposing orientation on a transportable platform such as a trailer. Vaporizers incorporate a burner control system utilizing a primary set of burners operating a baseline and a secondary set of burners providing fine regulating control. A system for fracturing formations is now possible using a minimum number of components including the high capacity pumper, a coiled tubing rig and a source of liquefied gas. An improved manifold for a cryogenic plunger pump includes unions and angled connectors between a supply conduit and each of a plurality of pump heads.

Owner:CENTURY OILFIELD SERVICES

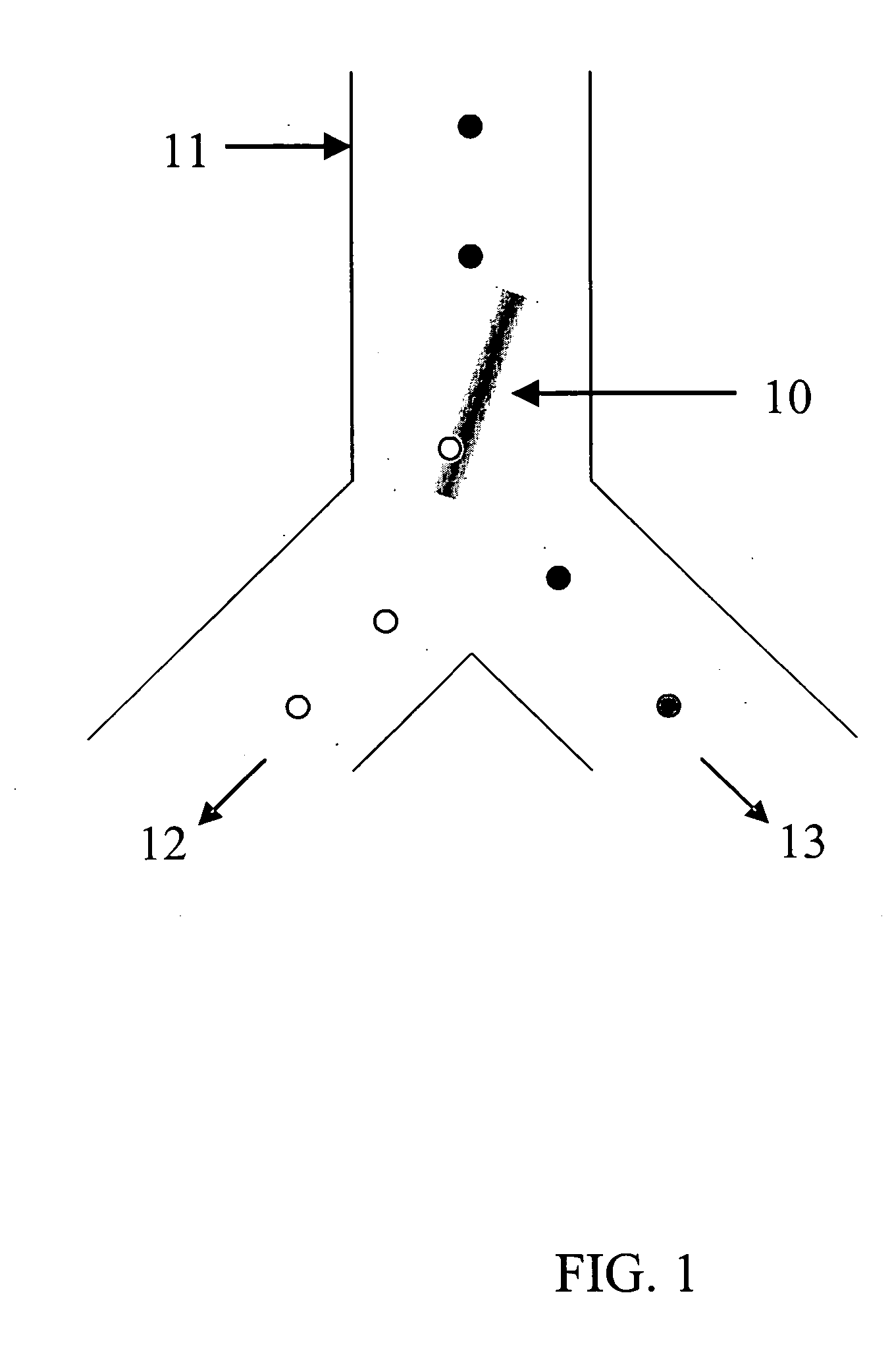

Methods and apparatus for sorting cells using an optical switch in a microfluidic channel network

InactiveUS20050207940A1Harm viabilityChemiluminescene/bioluminescenceSurgeryEngineeringMicrofluidic channel

Apparatus and Methods are provided for a microfabricated fluorescence activated cell sorter based on an optical switch for rapid, active control of cell routing through a microfluidic channel network. This sorter enables low-stress, highly efficient sorting of populations of small numbers of cells (i.e., 1000-100,000 cells). The invention includes packaging of the microfluidic channel network in a self-contained plastic cartridge that enables microfluidic channel network to macro-scale instrument interconnect, in a sterile, disposable format.

Owner:PROGENITY INC

System for pumping hydraulic fracturing fluid using electric pumps

A system for hydraulically fracturing an underground formation in an oil or gas well to extract oil or gas from the formation, the oil or gas well having a wellbore that permits passage of fluid from the wellbore into the formation. The system includes a plurality of electric pumps fluidly connected to the well, and configured to pump fluid into the wellbore at high pressure so that the fluid passes from the wellbore into the and fractures the formation. The system can also include a plurality of natural gas powered generators electrically connected to the plurality of electric pumps to provide electrical power to the pumps.

Owner:US WELL SERVICS LLC

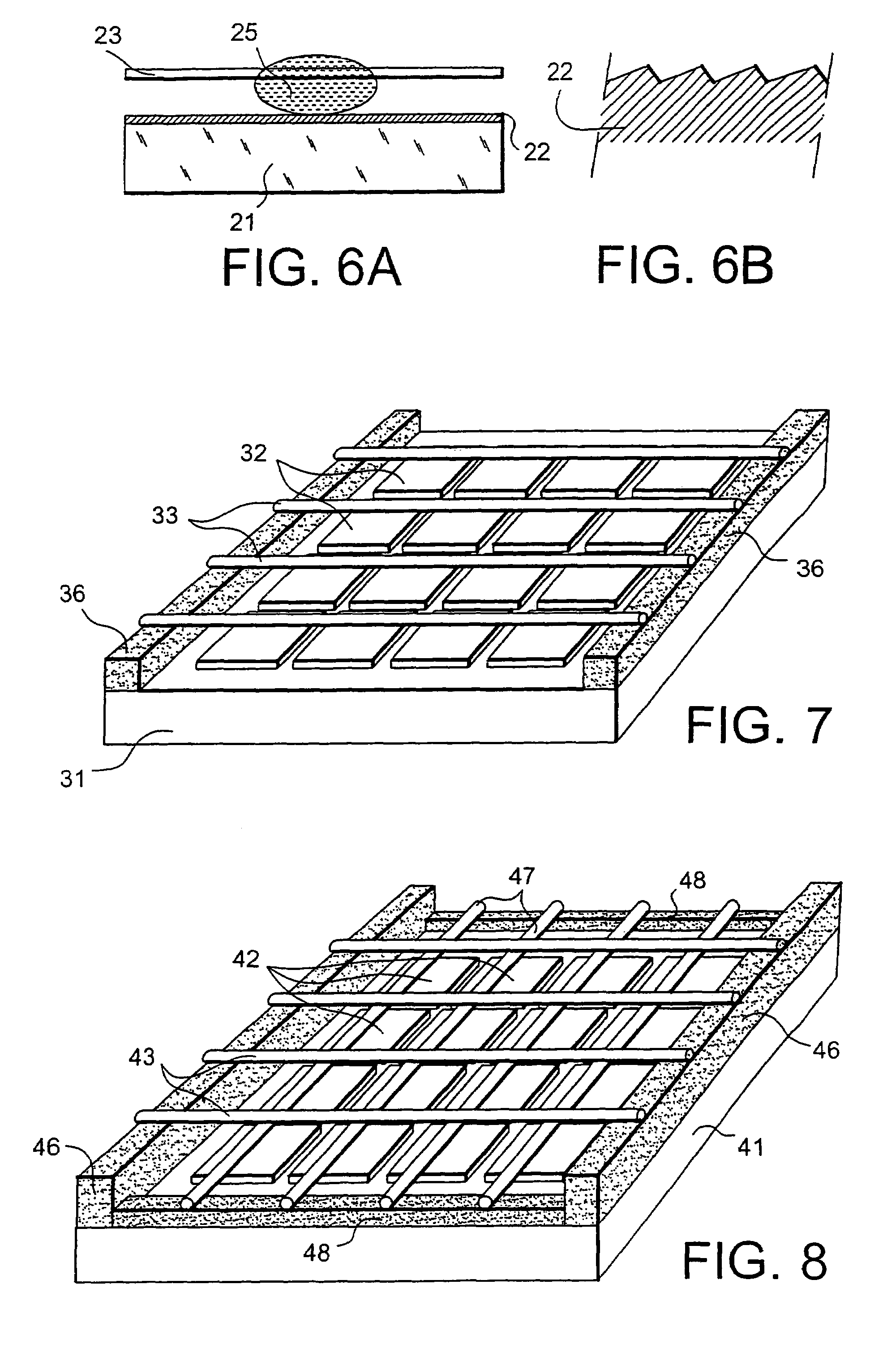

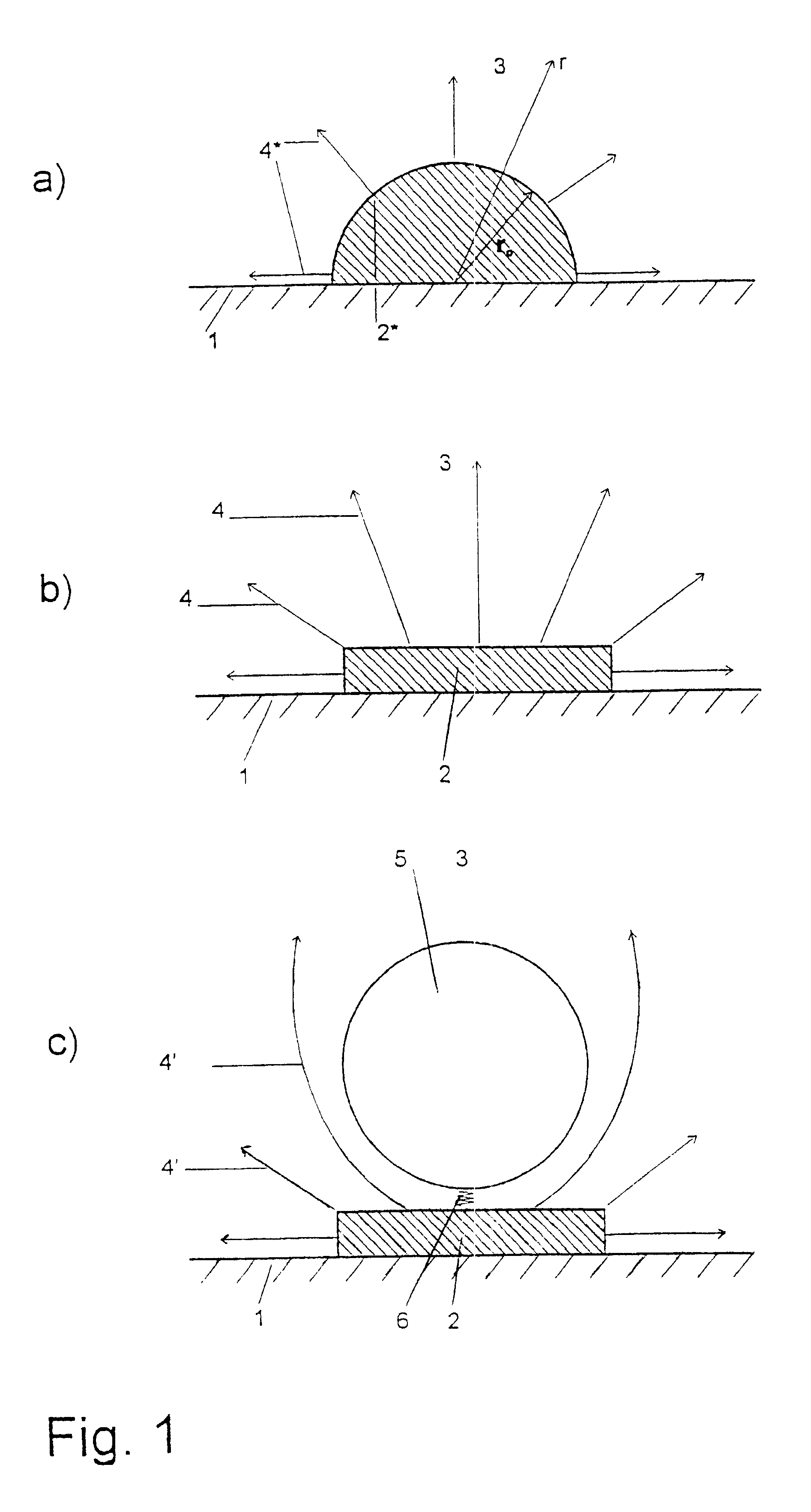

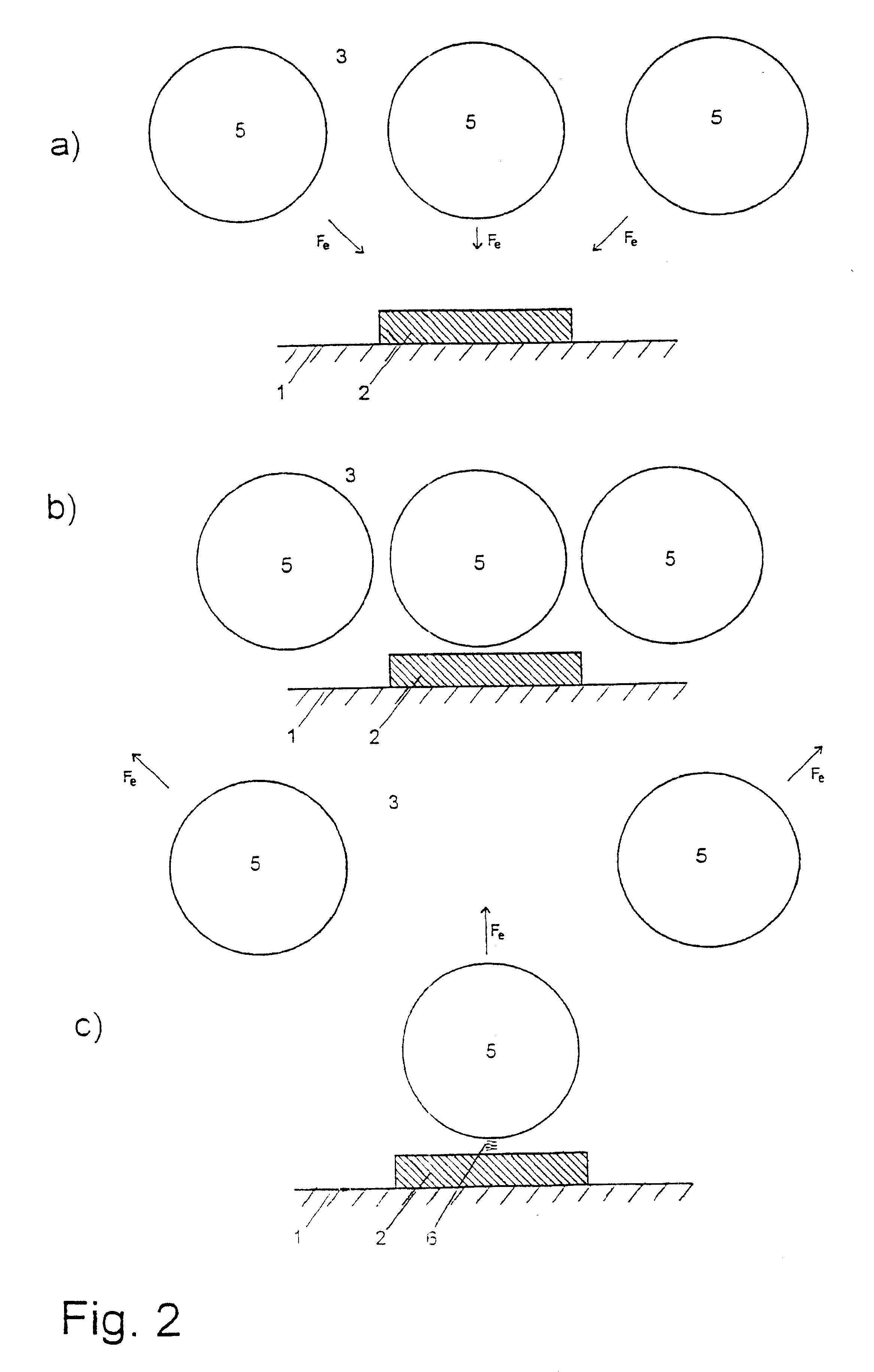

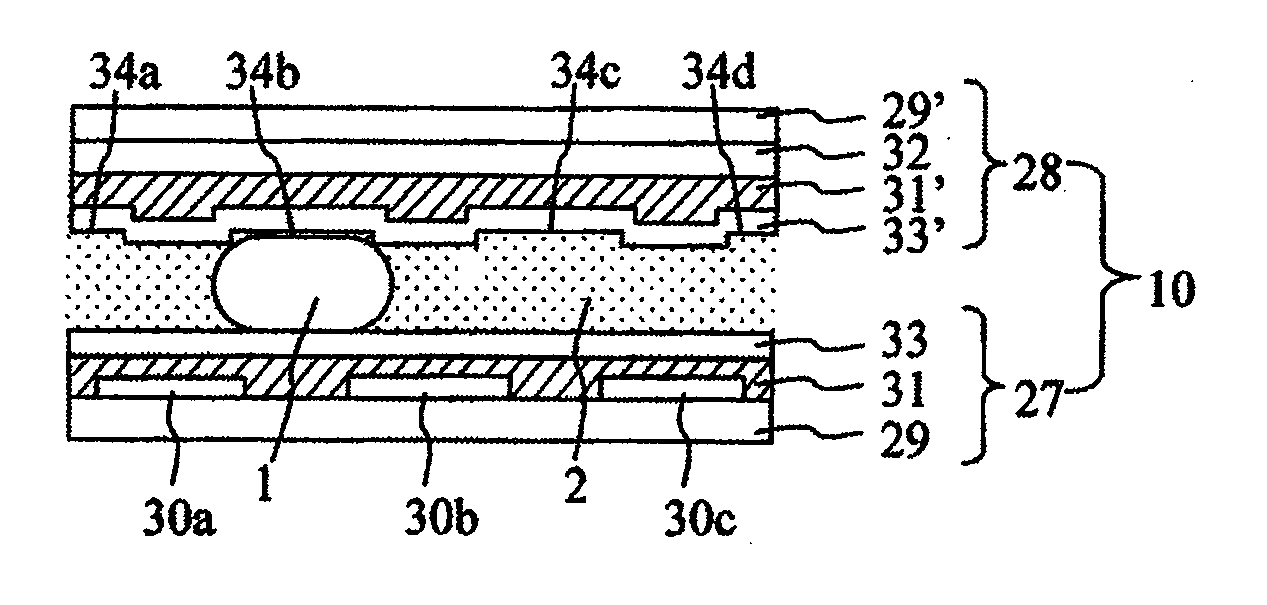

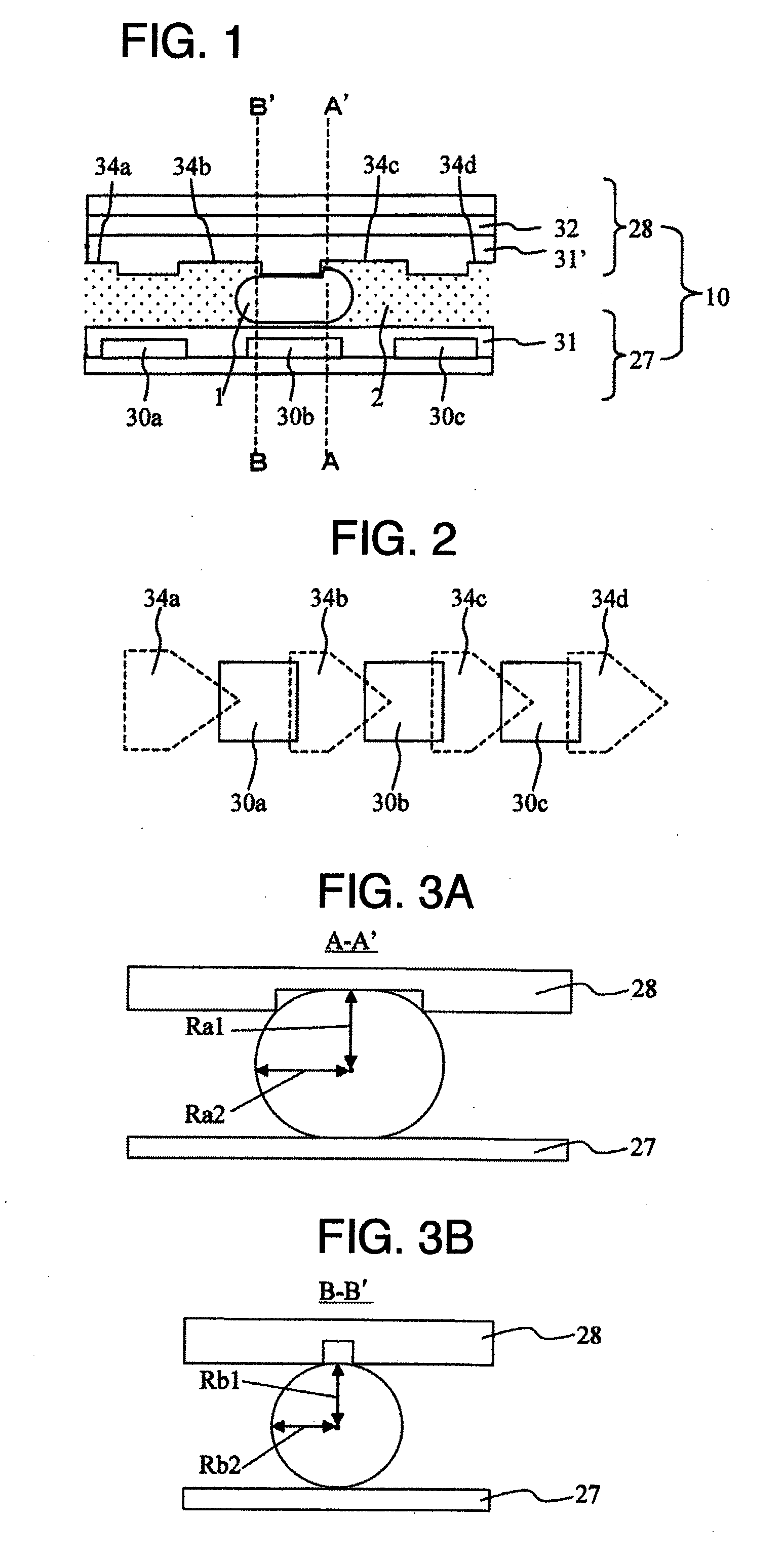

Liquid transfer device

InactiveUS20090321262A1Reduce in quantityEasy to controlSludge treatmentTransportation and packagingSpherical shapedEngineering

Provided is a liquid transfer device which controls electrically liquid position. The surface of the liquid transfer device is provided with unevenness in order to solve a problem of having a large number of electrodes for controlling voltage. The number of electrodes for controlling voltage can be halved by utilization of restoring force of liquid to a spherical shape by surface tension, in addition to electrical force.

Owner:HITACHI HIGH-TECH CORP

Wind turbine

InactiveUS7042109B2Improve efficiencyCost per unit power generationWindingsWind motor controlRotational energyAir core

A wind turbine for generating electrical power from wind energy includes a turbine rotor mounted for rotation in wind, and having multiple blades for converting energy in the wind into rotational energy. A generator is coupled with said turbine rotor such that said turbine rotor drives said generator. The generator has a stationary air core armature that is located in a magnetic airgap between two generator rotor portions. The generator rotor portions have circumferential arrays of multiple alternating polarity permanent magnets attached to ferromagnetic back irons such that the permanent magnets drive magnetic flux back and forth between each rotor portion and through the stationary air core armature. The stationary air core armature has multiple phase windings of multiple individually insulated strand conductor wire that is wound with two separate portions including an active length portion and an end turn portion. The end turn portion is located outside the magnetic airgap and traverses predominately circumferentially, and the active length portion is located in the magnetic airgap and traverses predominately non-circumferentially and perpendicular to the direction of the magnetic airgap. The end turn portion has a thickness that is greater than the thickness of said active length portion in the direction of said magnetic airgap. AC voltage is induced in the multiple phase windings as the turbine rotor rotates.

Owner:MARIAH POWER

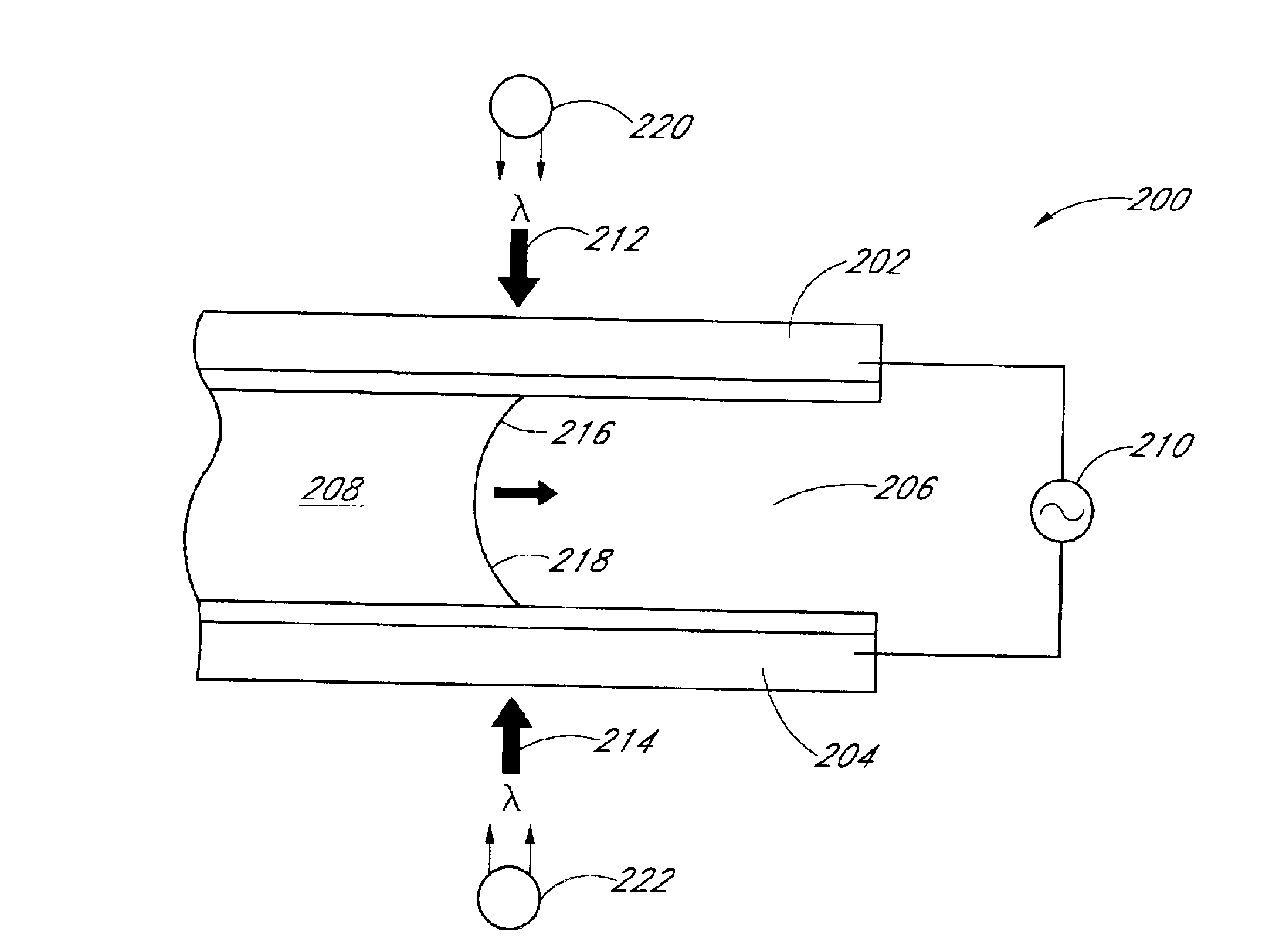

Method and apparatus for non-contact electrostatic actuation of droplets

InactiveUS6989234B2Immobilised enzymesBioreactor/fermenter combinationsHydrophobic surfacesEngineering

An apparatus for actuating a droplet comprises a first conductive layer, a second conductive layer, a conductive elongate element, and a voltage source. The first conductive layer comprises a first hydrophobic surface. The second conductive layer comprises a hydrophilic surface facing the first hydrophobic surface. The second conductive layer is axially spaced from the first conductive layer to define a gap therebetween. The conductive medial element is disposed in the gap between the first and second conductive layers, and comprises a second hydrophobic surface. The voltage source communicates with the second conductive layer and the elongate element. By applying a voltage potential between the elongate element and the second conductive layer, droplets can be electrostatically actuated so as to move from the first conductive layer into contact with the second conductive layer. The apparatus is particularly useful in the synthesis of microarrays of biological, chemical, or biochemical samples.

Owner:DUKE UNIV

Lubrication of windmilling journal bearings

A support shaft provides lubrication to a journal bearing during windmilling operation of a gear set. A primary oil pump provides oil from an oil supply during driven operation of the fan, and a secondary oil pump provides oil from an internal sump during windmilling operation of the fan. During driven operation of the fan, oil is pumped with the primary oil pump through a primary oil flow path to an outer surface of the support shaft. During windmilling fan operation, oil is pumped from an internal sump with a secondary oil pump through the secondary oil flow path. The secondary oil flow path has a smaller flow capacity, and the secondary oil pump is a smaller capacity pump.

Owner:RTX CORP

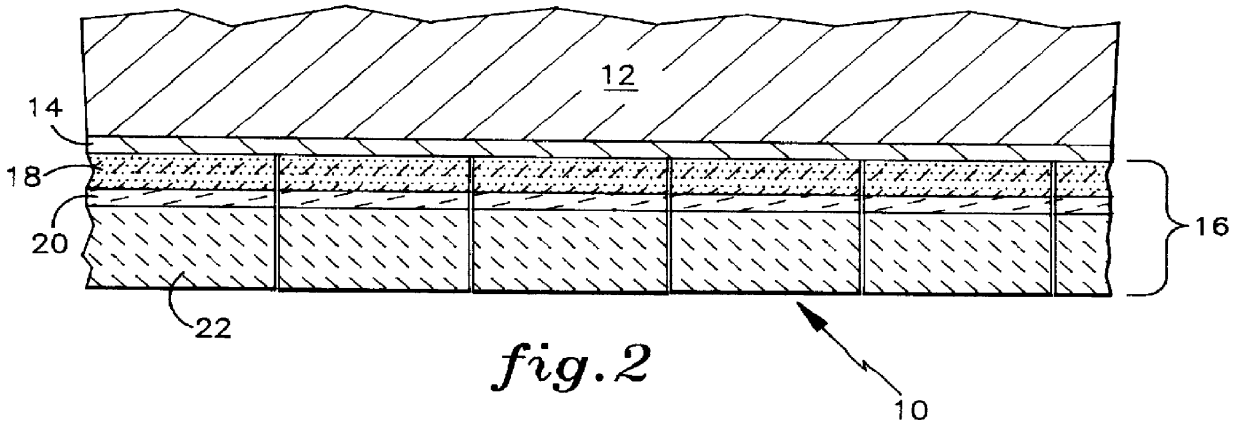

Segmented abradable ceramic coating

InactiveUS6102656AImprove wear resistanceSufficient resistanceMolten spray coatingPump componentsCeramic coatingWear resistance

A segmented abradable ceramic coating system having superior abradability and erosion resistance is disclosed. The system includes a duct segment having a metallic substrate, a MCrAlY bond coat on the substrate and a segmented abradable ceramic coating on the bond coat. The segmented abradable ceramic coating includes a base coat foundation layer, a graded interlayer and an abradable top layer for an overall thickness of preferably about 50 mils (1.270 mm). The coating is characterized by a plurality of vertical microcracks. By precisely controlling the deposition parameters, composition of the layers and layer particle morphology, segmentation is achieved, as well as superior abradability and erosion resistance.

Owner:UNITED TECH CORP

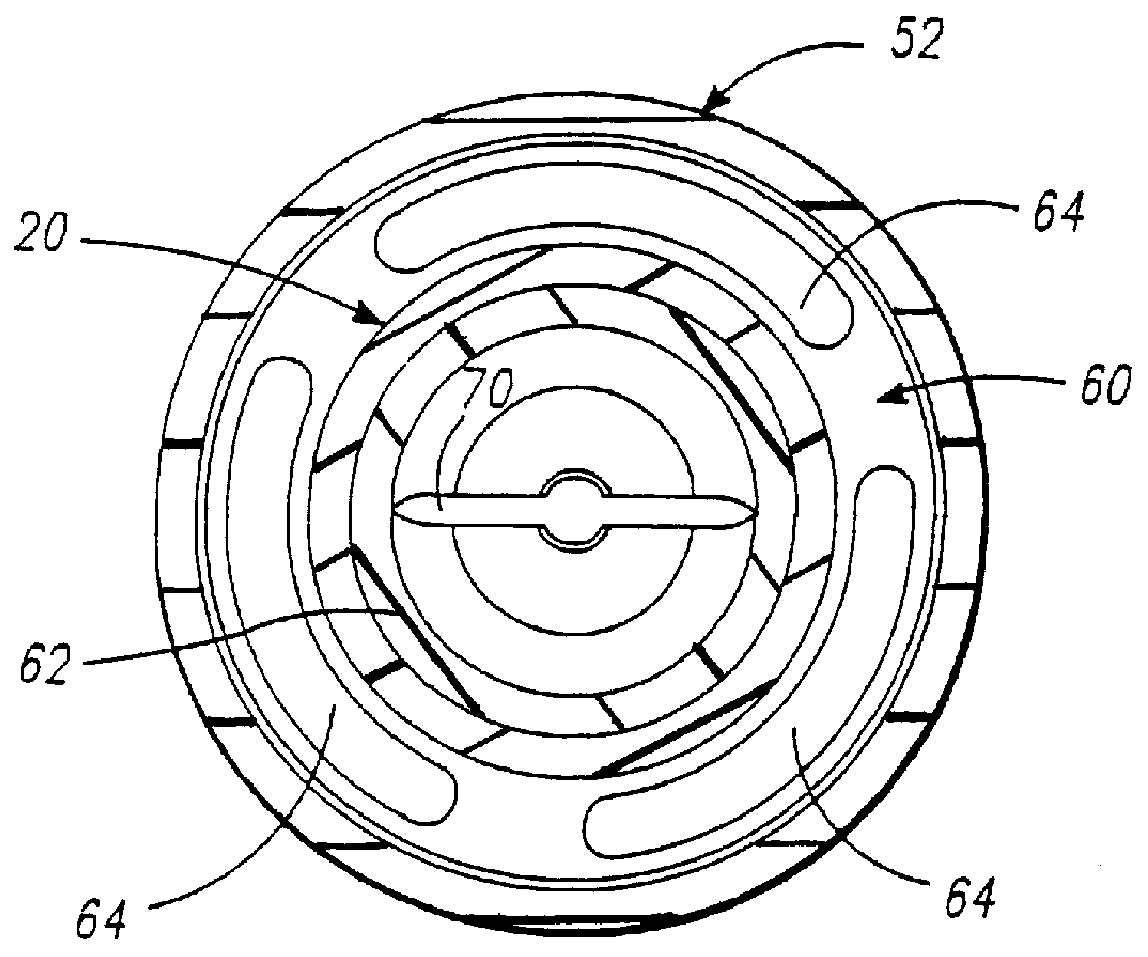

Single port cardiac support apparatus

A reverse flow pump comprising two concentric passageways and an interior compartment having cut out portions in communication with a pump passageway for the directional flow of fluid relative to the pump, and a rotor positioned within the interior compartment for reversing the directional flow of fluid through a region in communication with another pump passageway. A reverse flow pump and cannula system is further provided comprising an inner cannula adjoining a pump passageway, and an outer conduit adjoining another pump passageway for the reverse flow of fluid relative to the pump. A method of transporting fluid between body cavities is also provided comprising the steps of selecting a reverse flow pump and cannula system, forming an opening in a body passageway, positioning the outer conduit through the opening, inserting the inner cannula into the outer conduit so that the distal openings of the inner cannula and the outer conduit are positioned in separated portions of the body, connecting the inlet and the outlet passageways of the pump to the proximal ends of the inner cannula and the outer conduit, and activating the pump to transport fluid between the separated portions of the body.

Owner:MAQUET CARDIOVASCULAR LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com