Patents

Literature

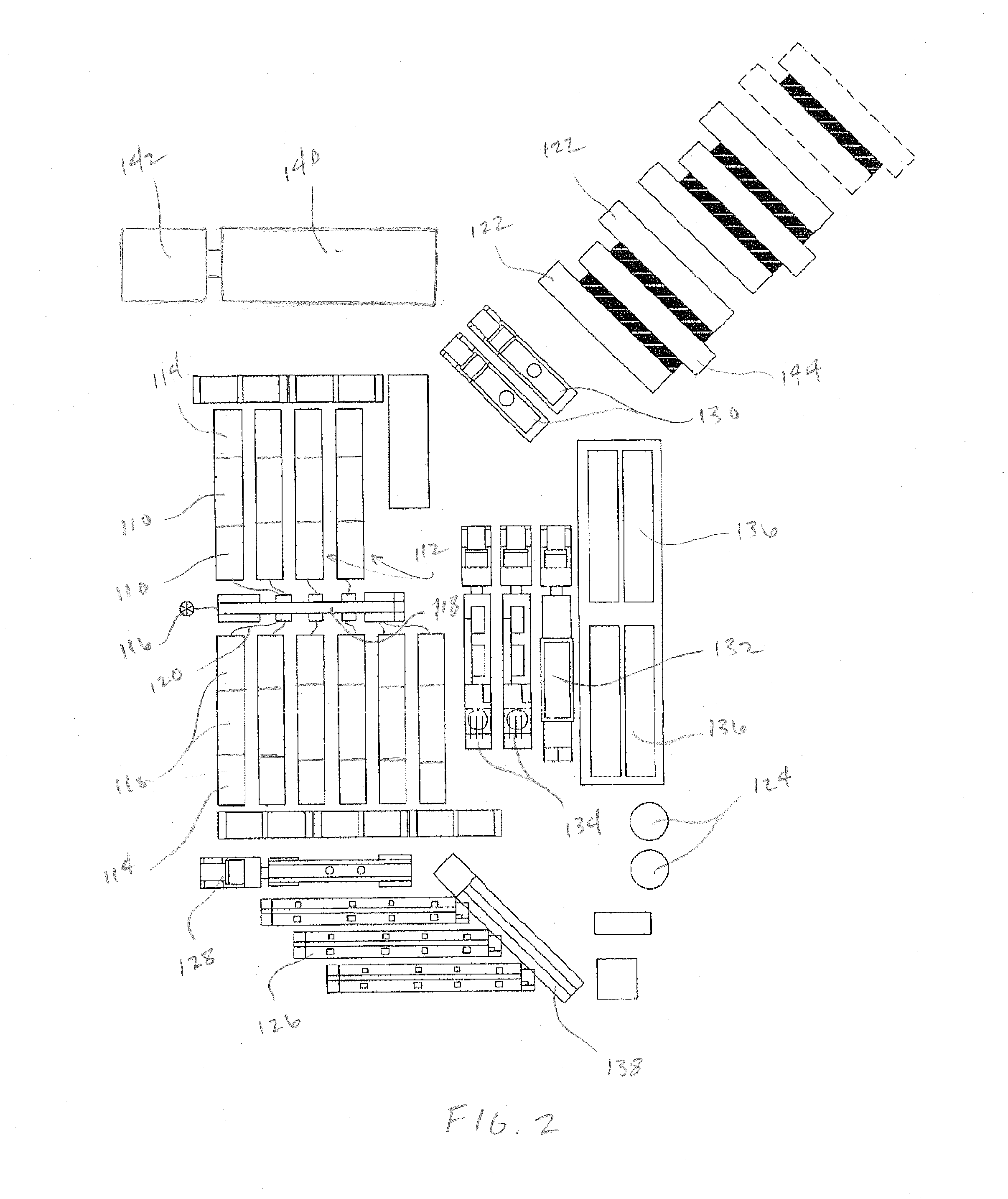

4435 results about "Fracturing fluid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fracturing Fluid. Definition - What does Fracturing Fluid mean? Fracturing fluid is a special type of fluid that is injected into a wellbore to induce fractures to facilitate access to the oil and gas resources. This fluid is mainly used in hydraulic fracturing in the petroleum industry. It is also sometimes used as an additive.

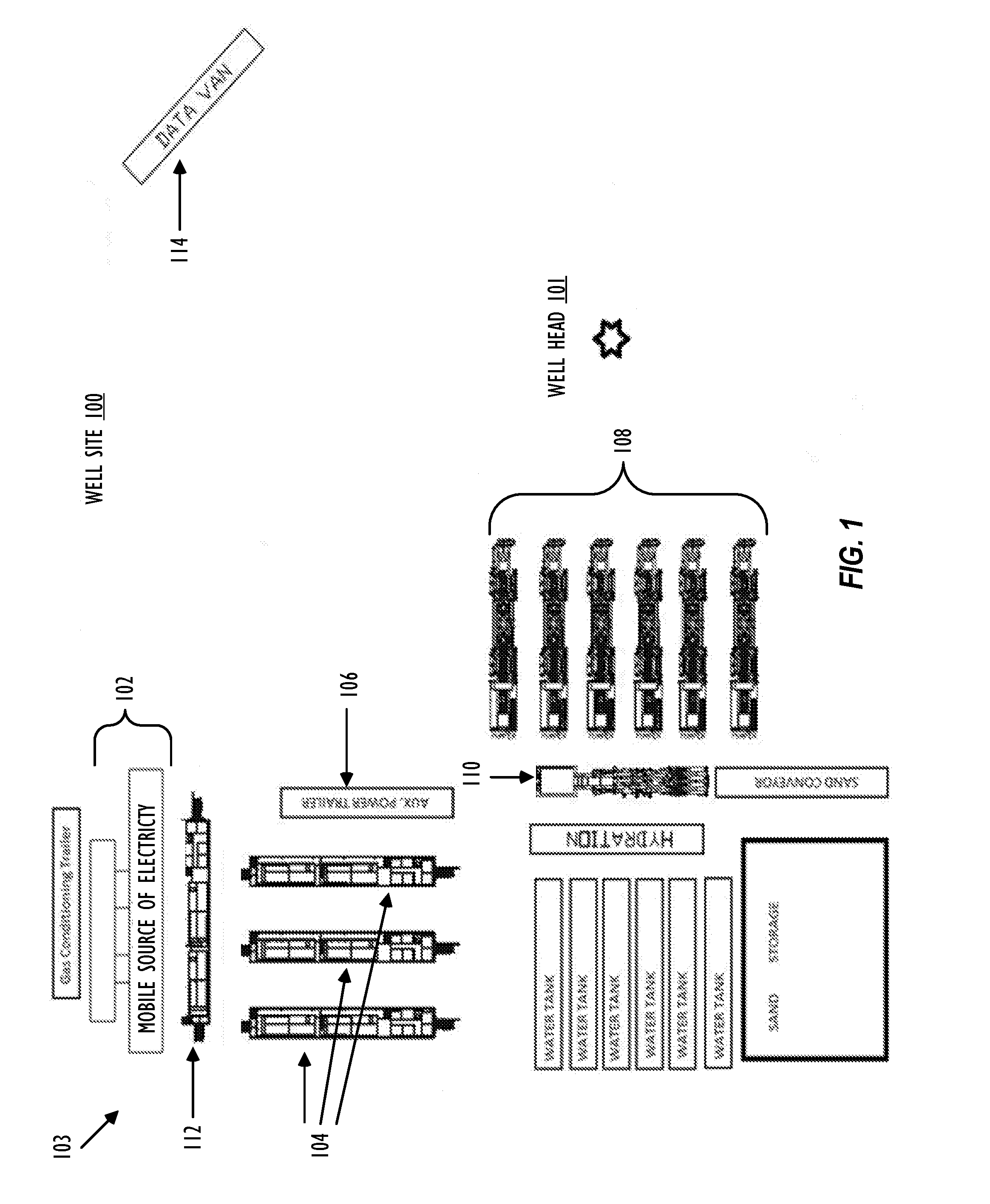

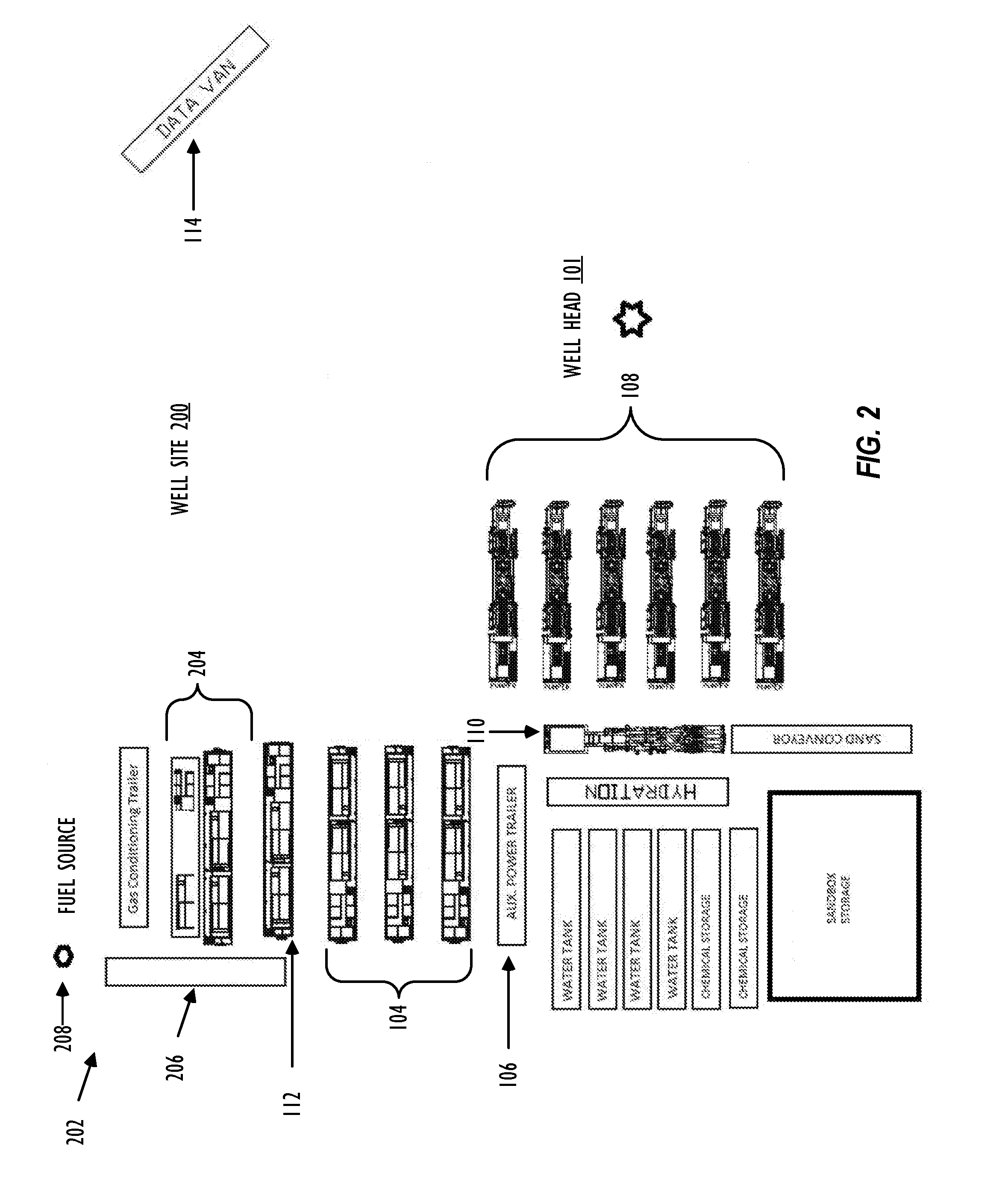

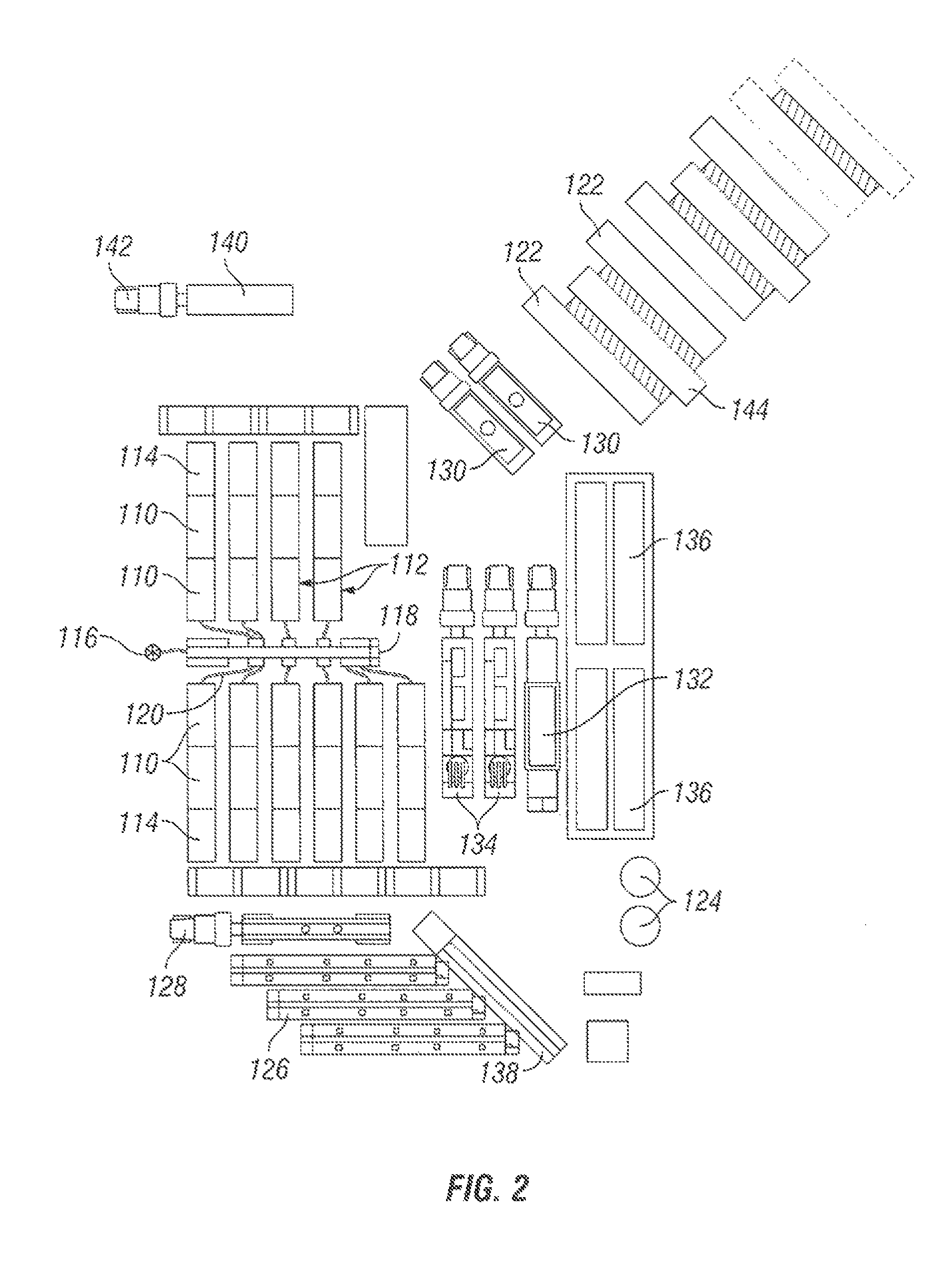

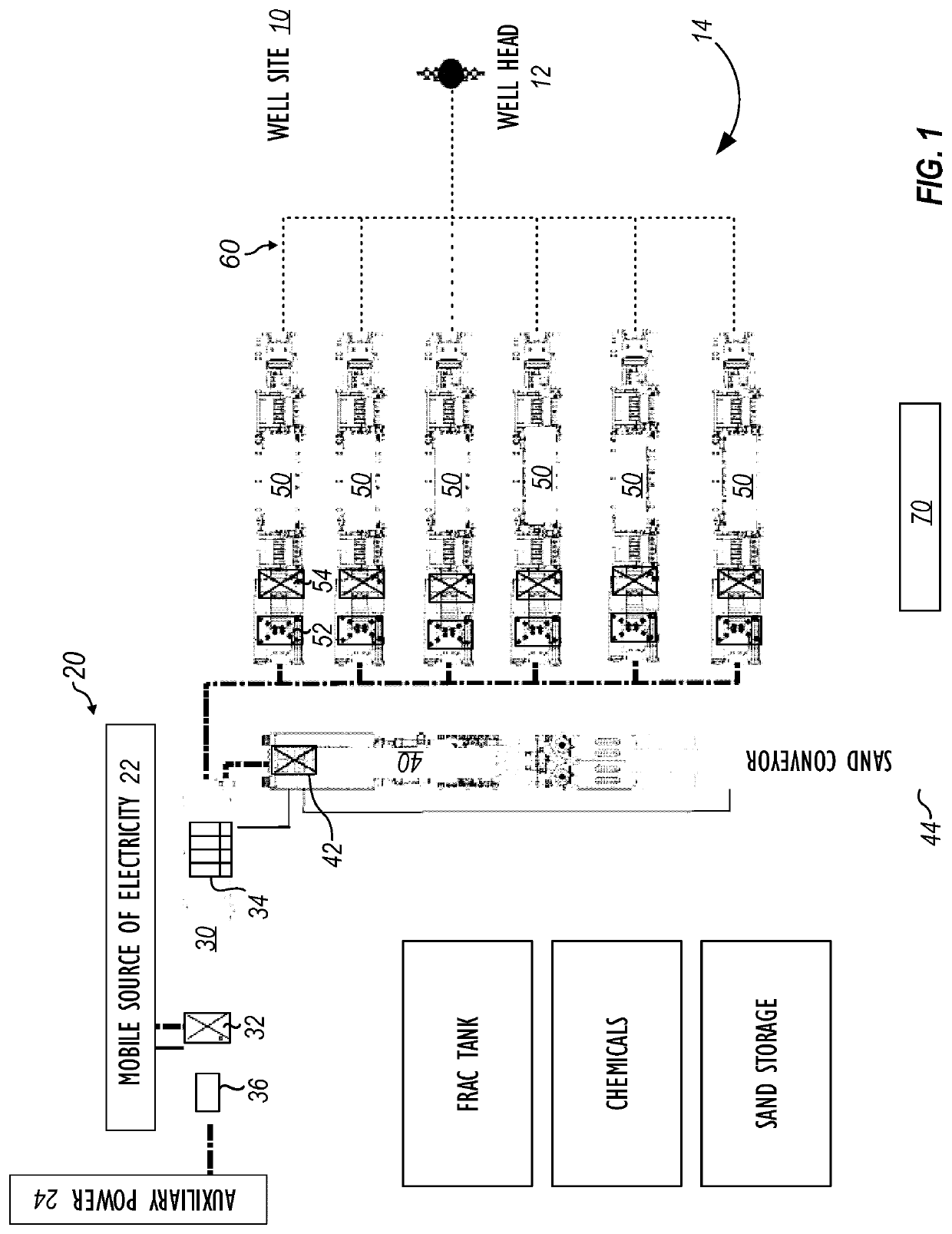

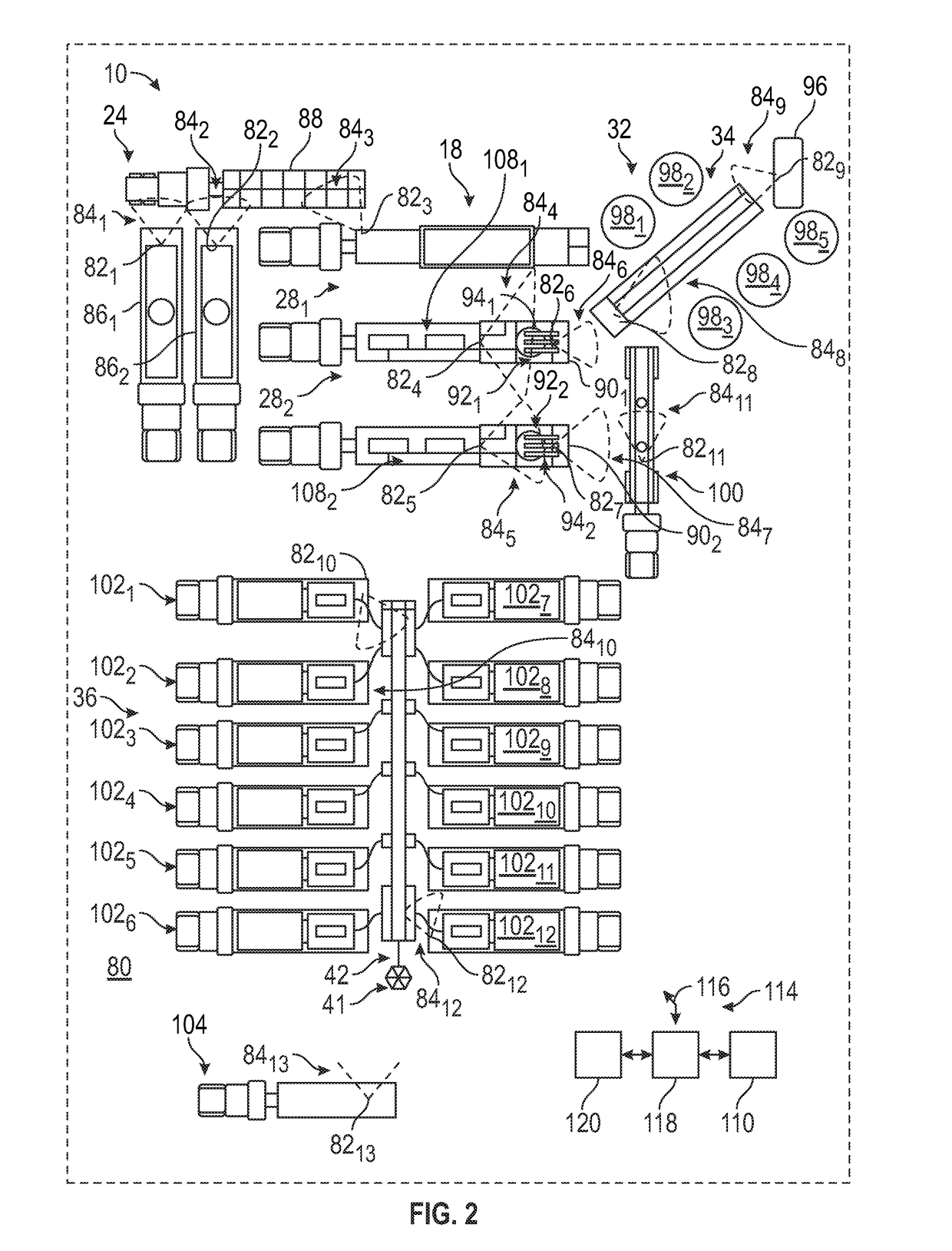

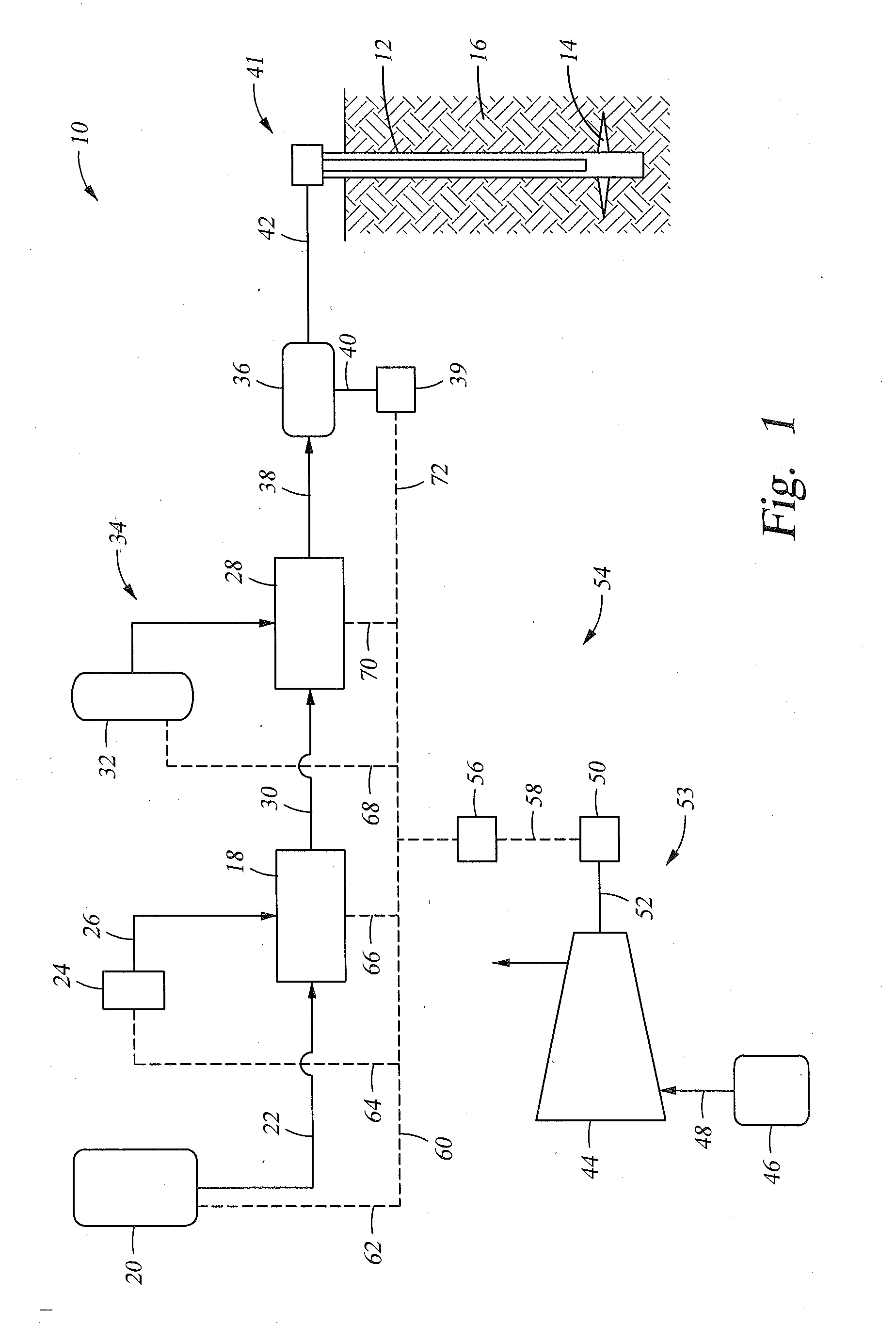

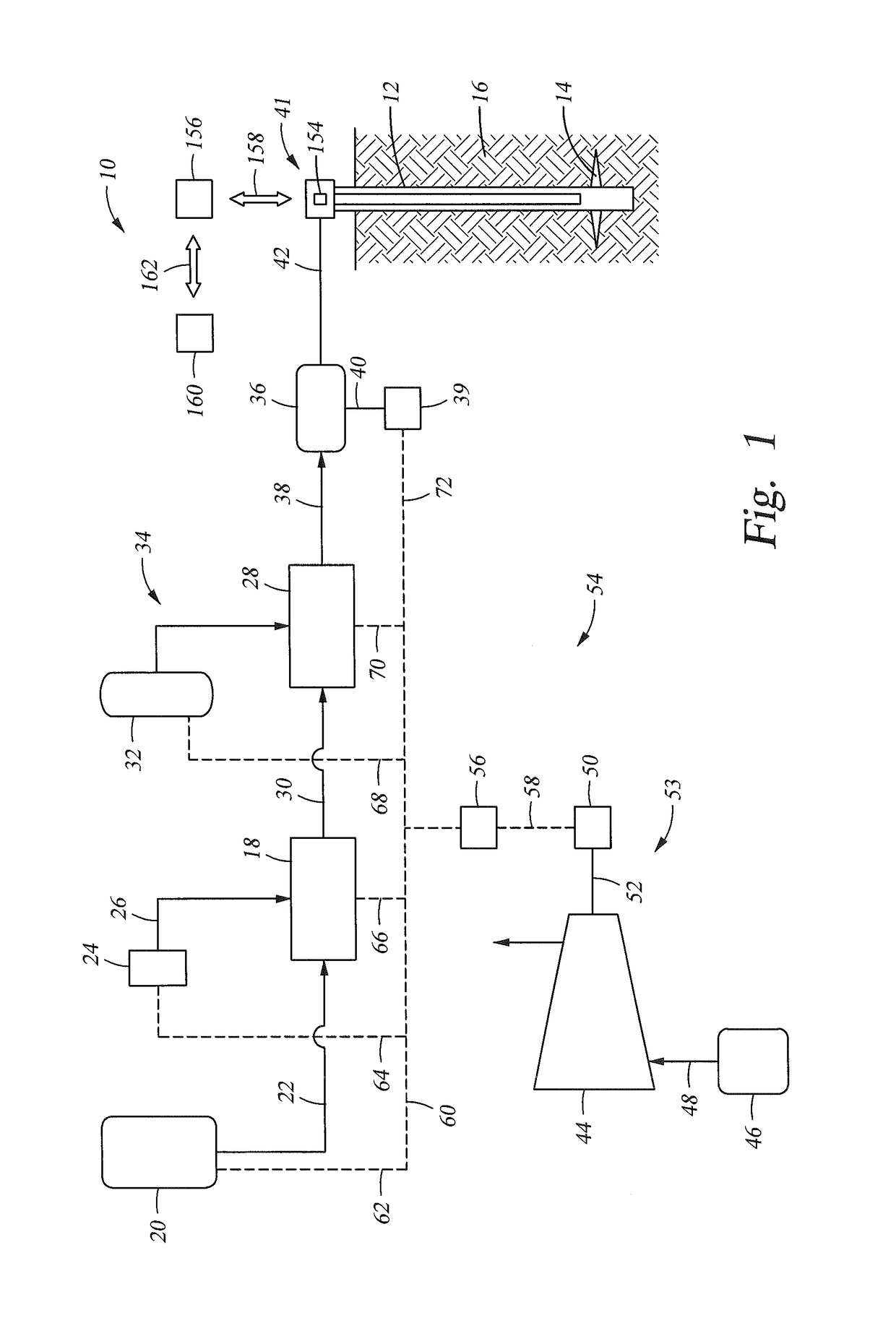

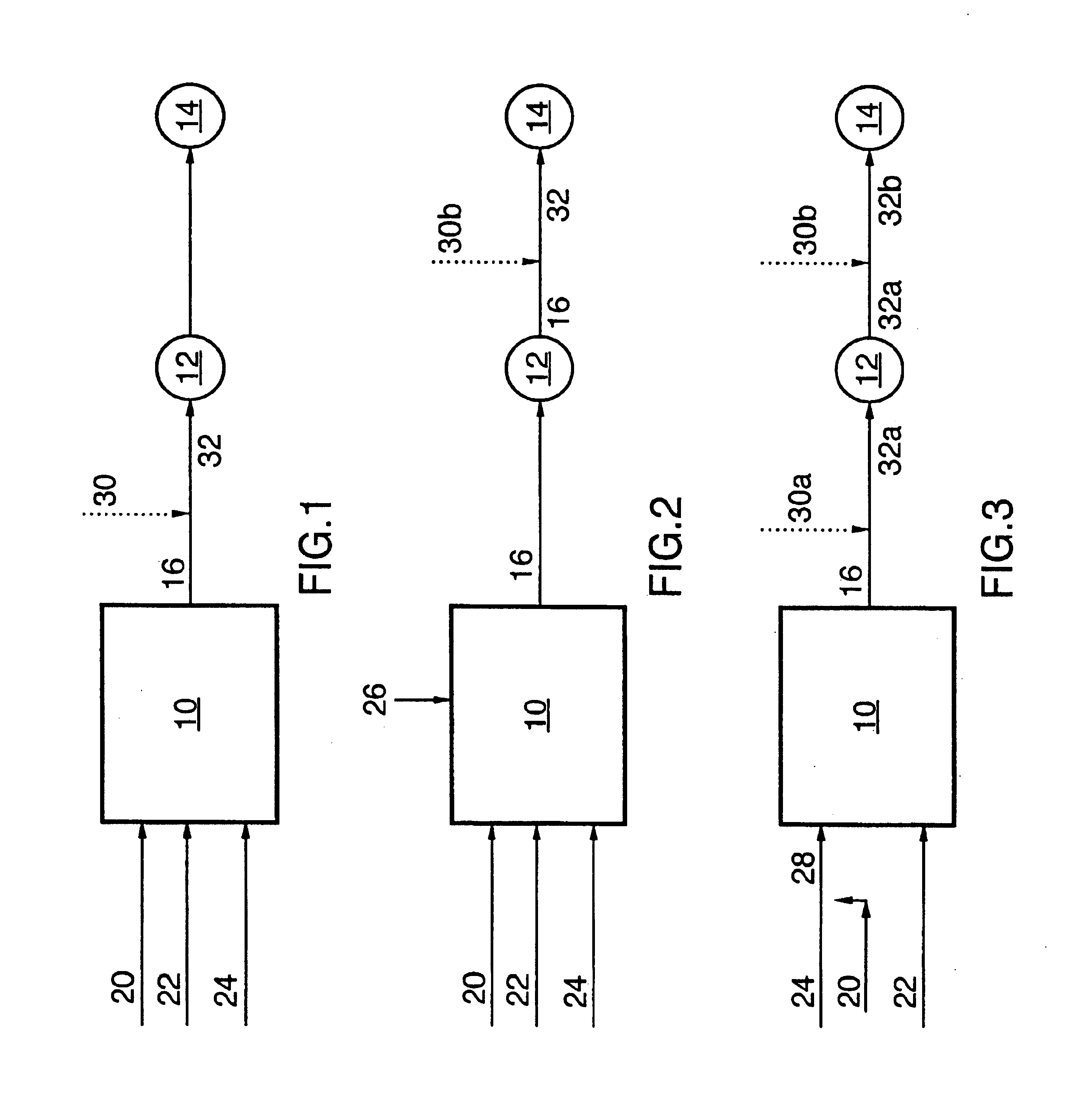

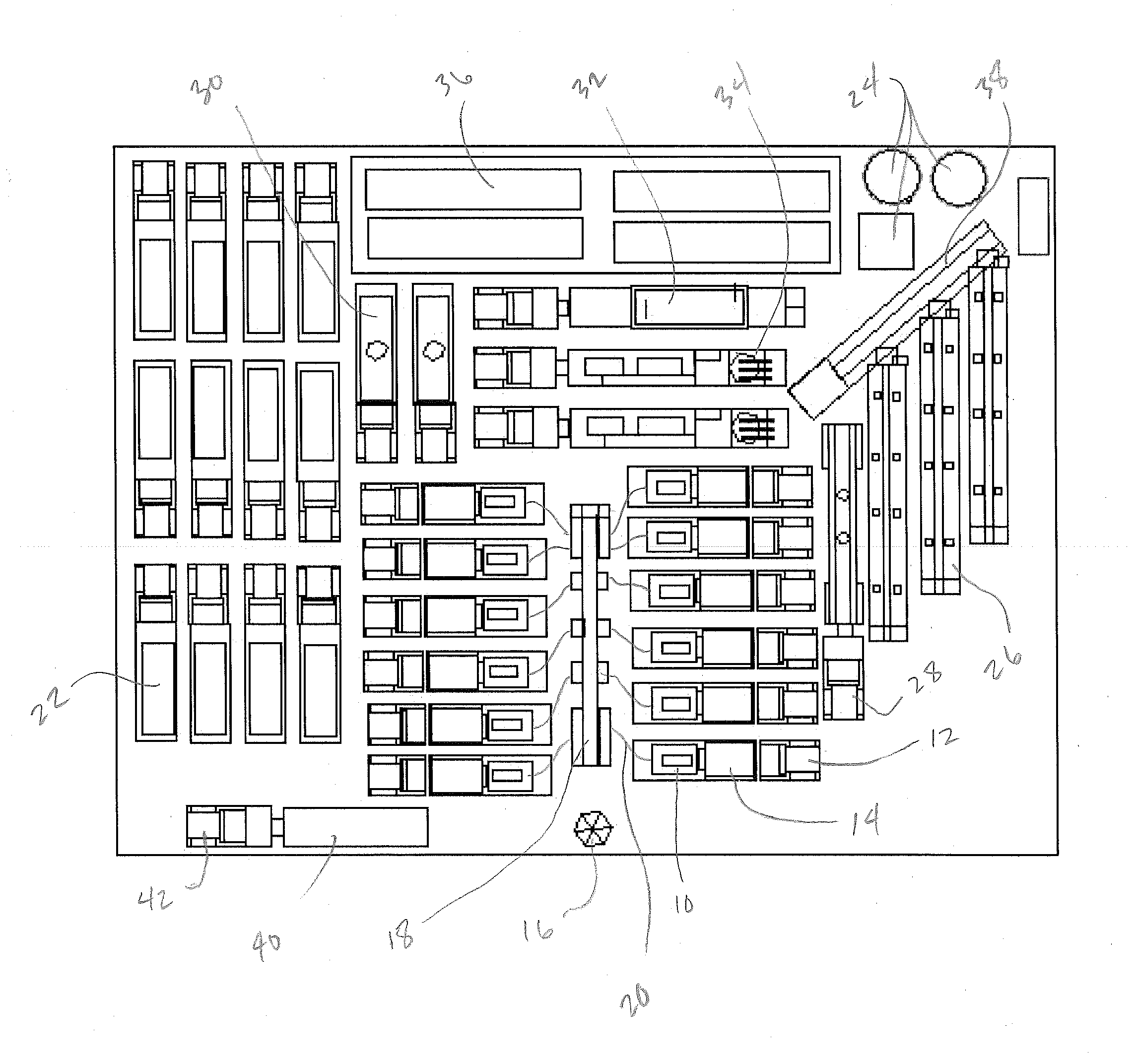

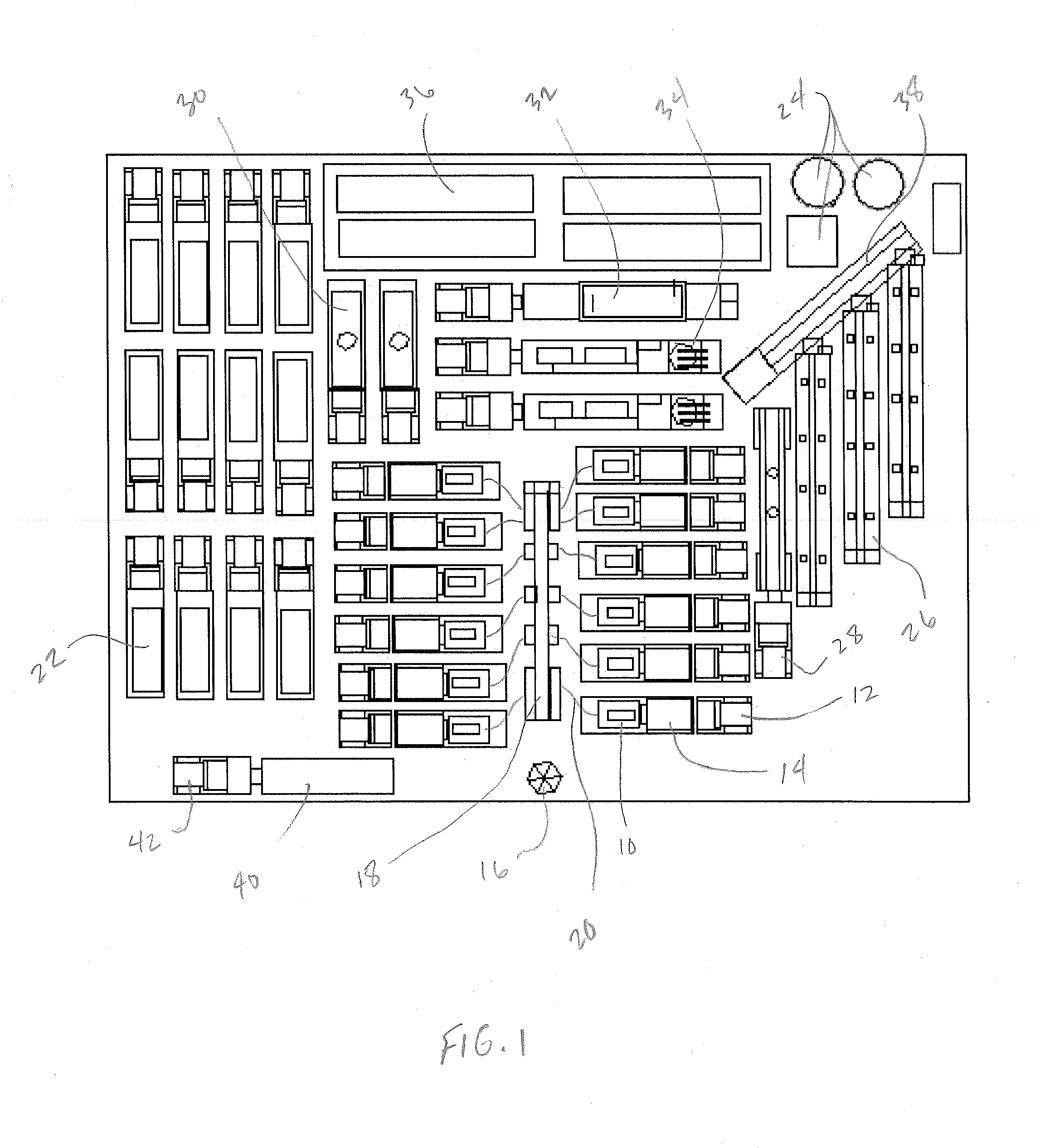

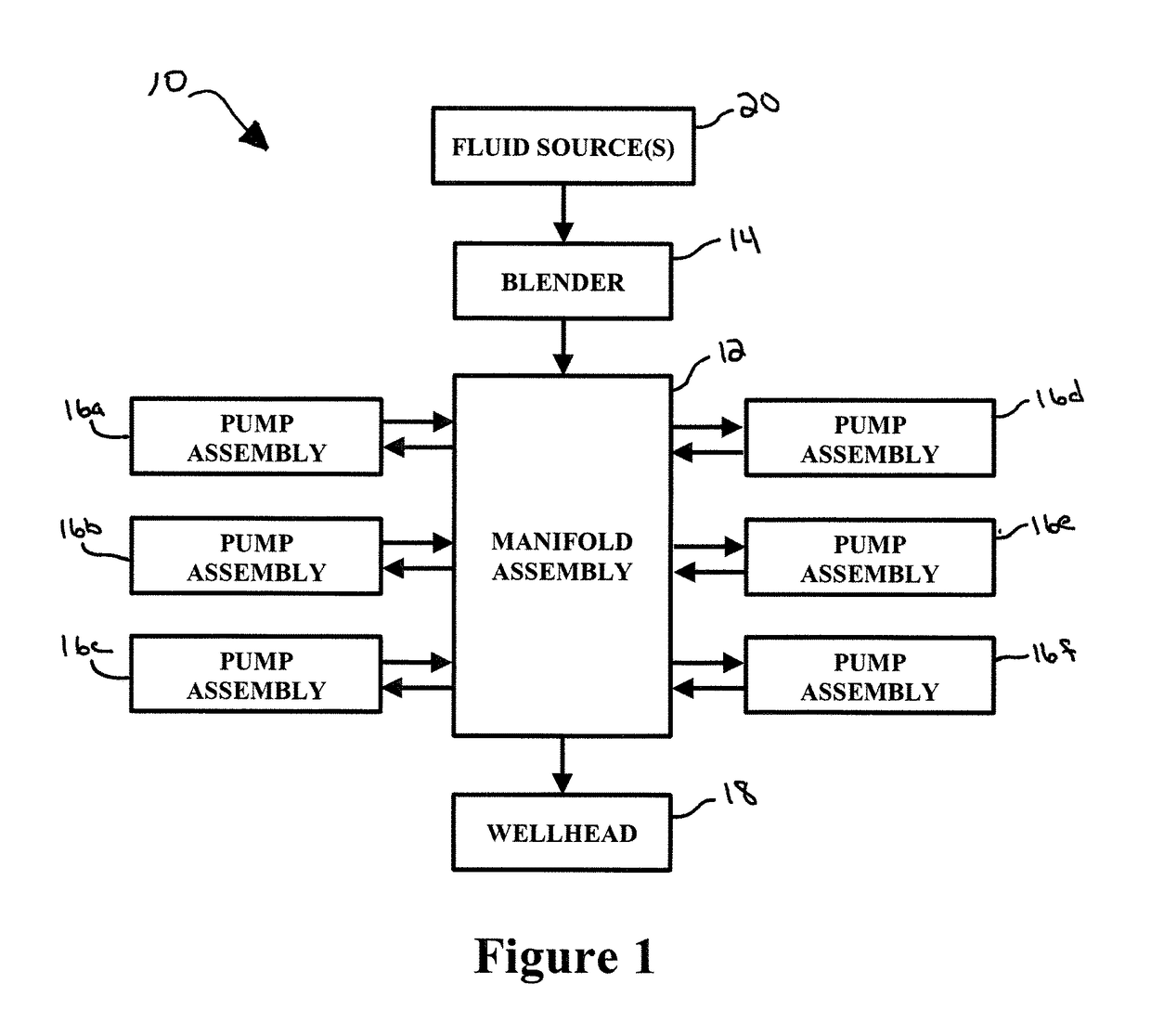

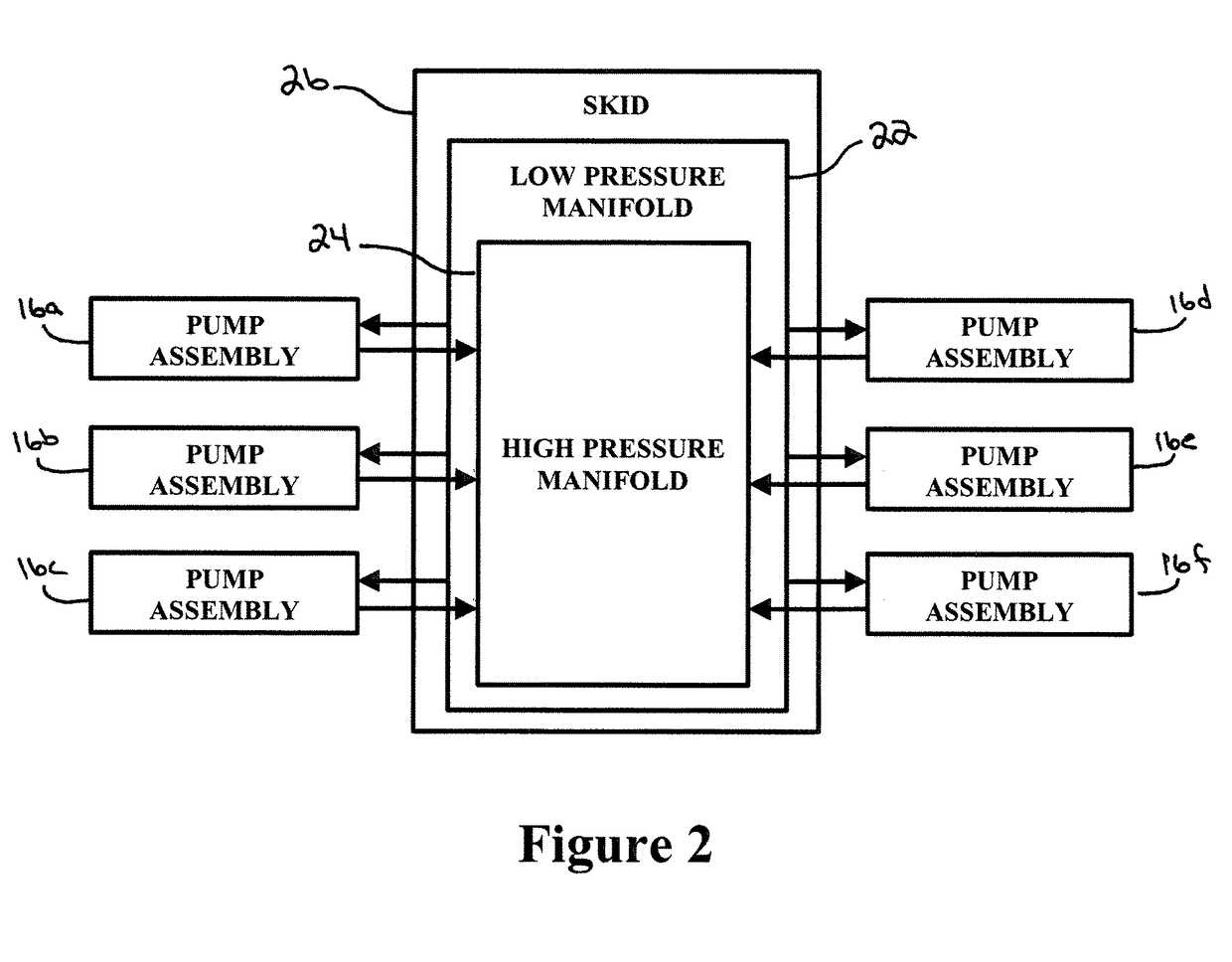

System for pumping hydraulic fracturing fluid using electric pumps

A system for hydraulically fracturing an underground formation in an oil or gas well to extract oil or gas from the formation, the oil or gas well having a wellbore that permits passage of fluid from the wellbore into the formation. The system includes a plurality of pumps powered by electric induction motors and fluidly connected to the well, the pumps configured to pump fluid into the wellbore at high pressure so that the fluid passes from the wellbore into the, and fractures the formation. The system can also include a plurality of natural gas powered generators electrically connected to the plurality of pumps to provide electrical power to the pumps.

Owner:US WELL SERVICS LLC

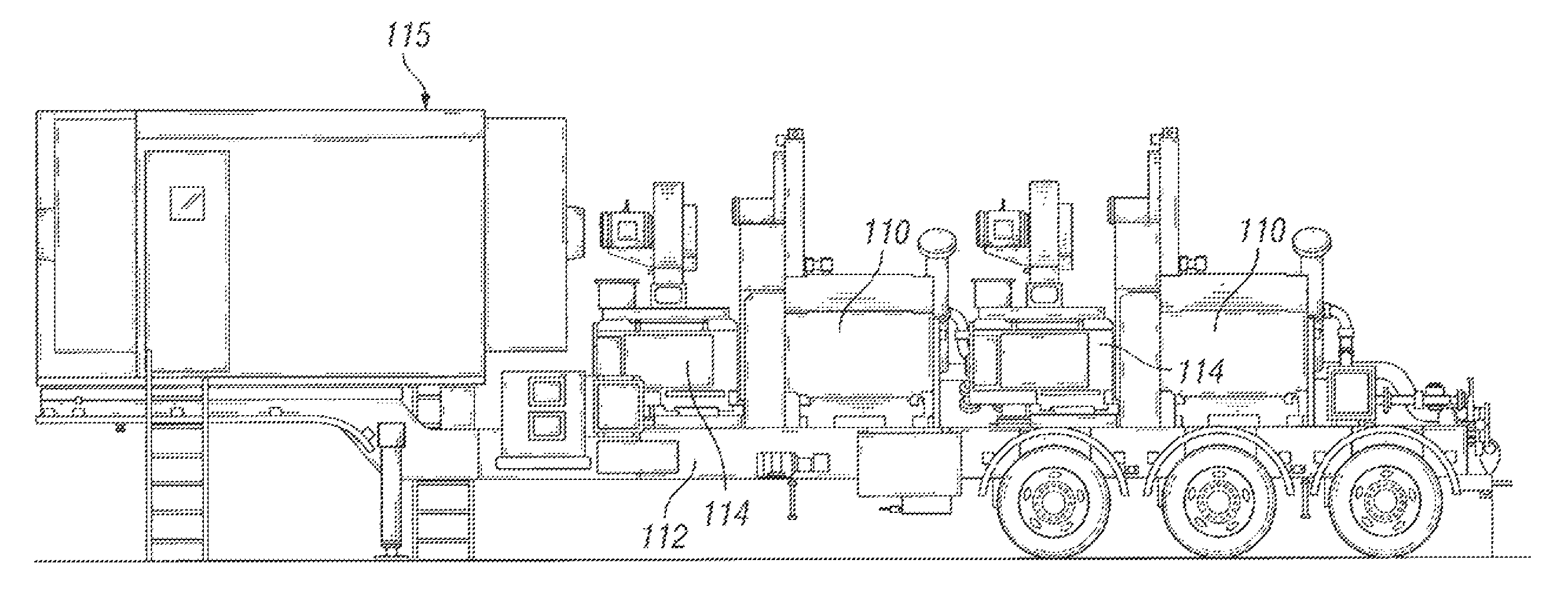

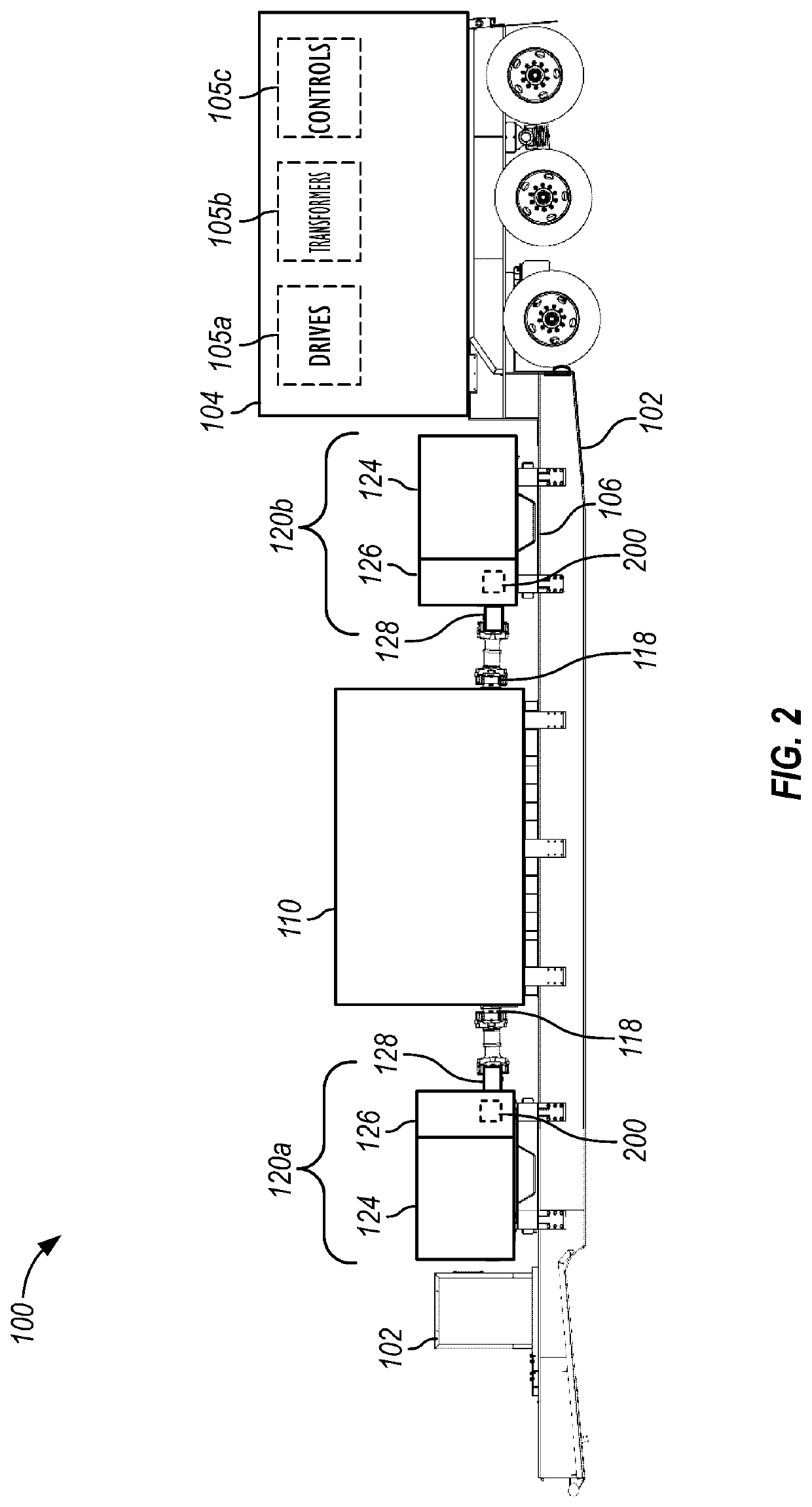

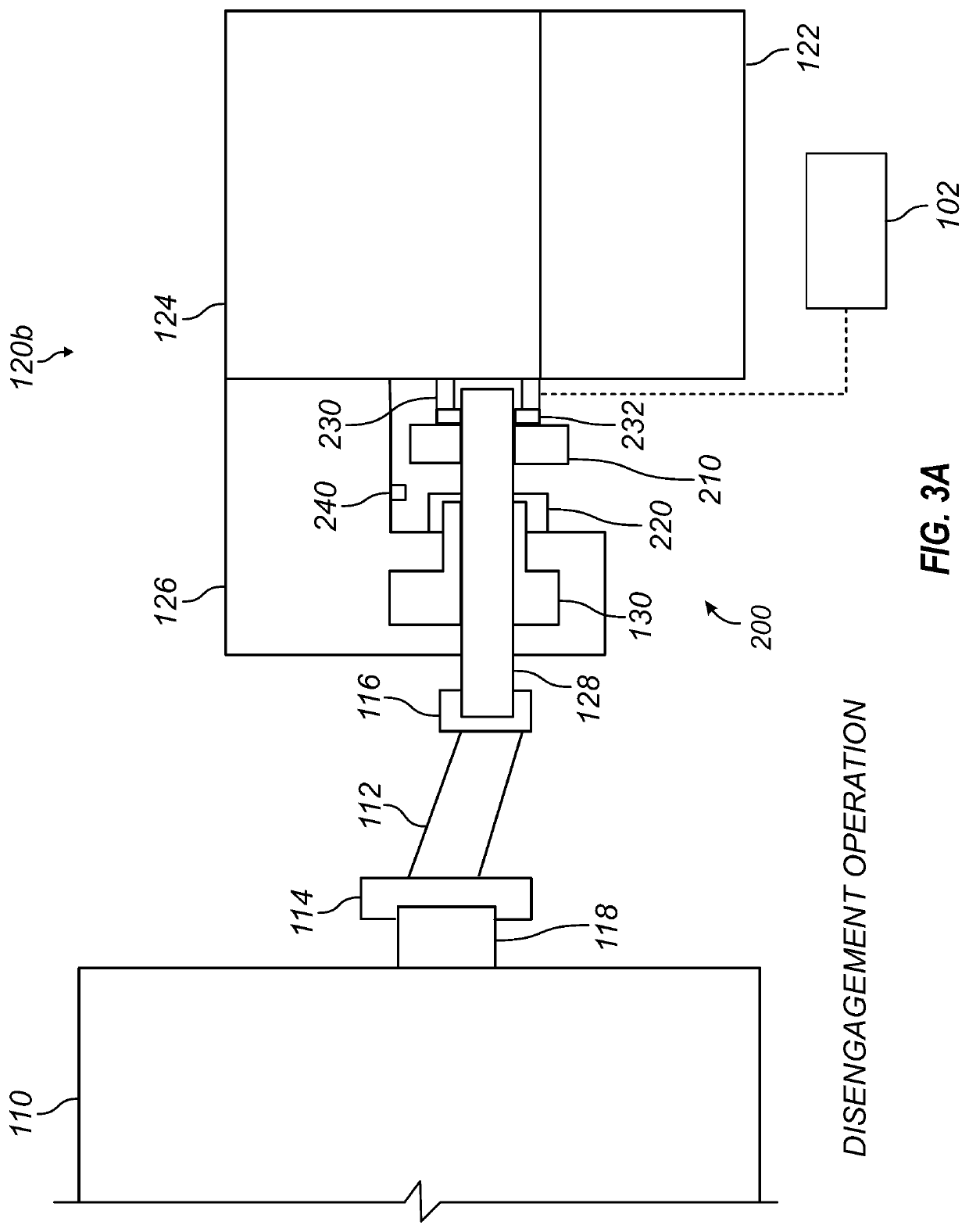

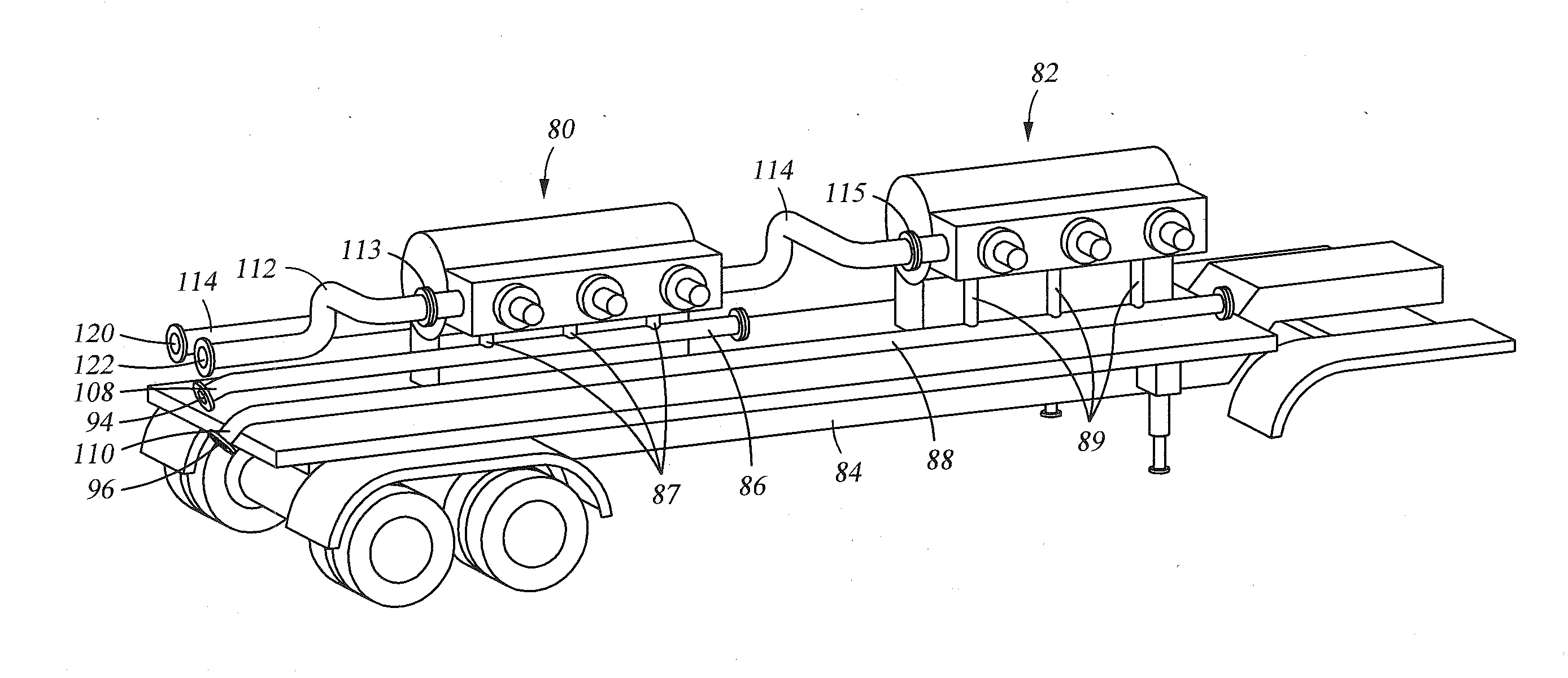

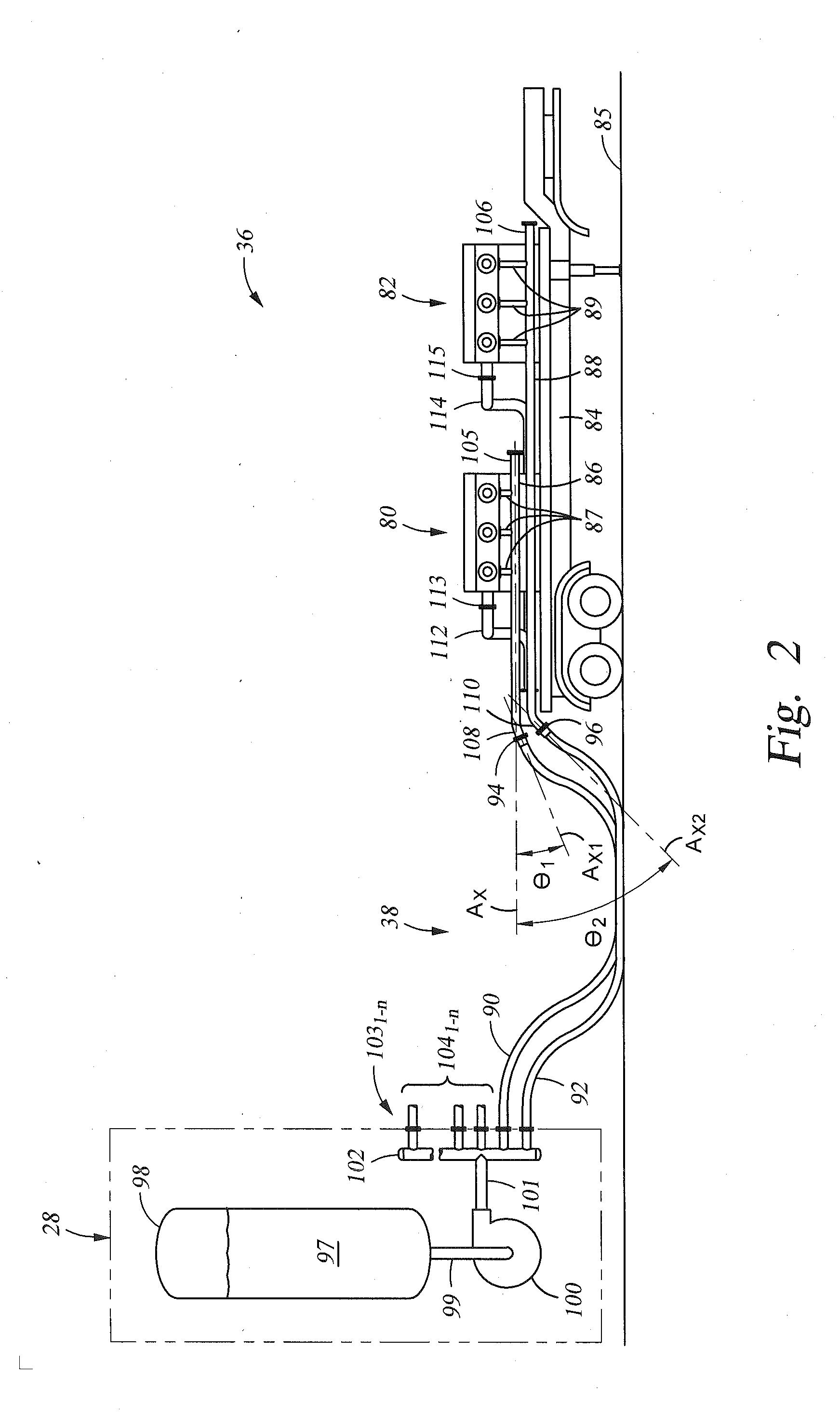

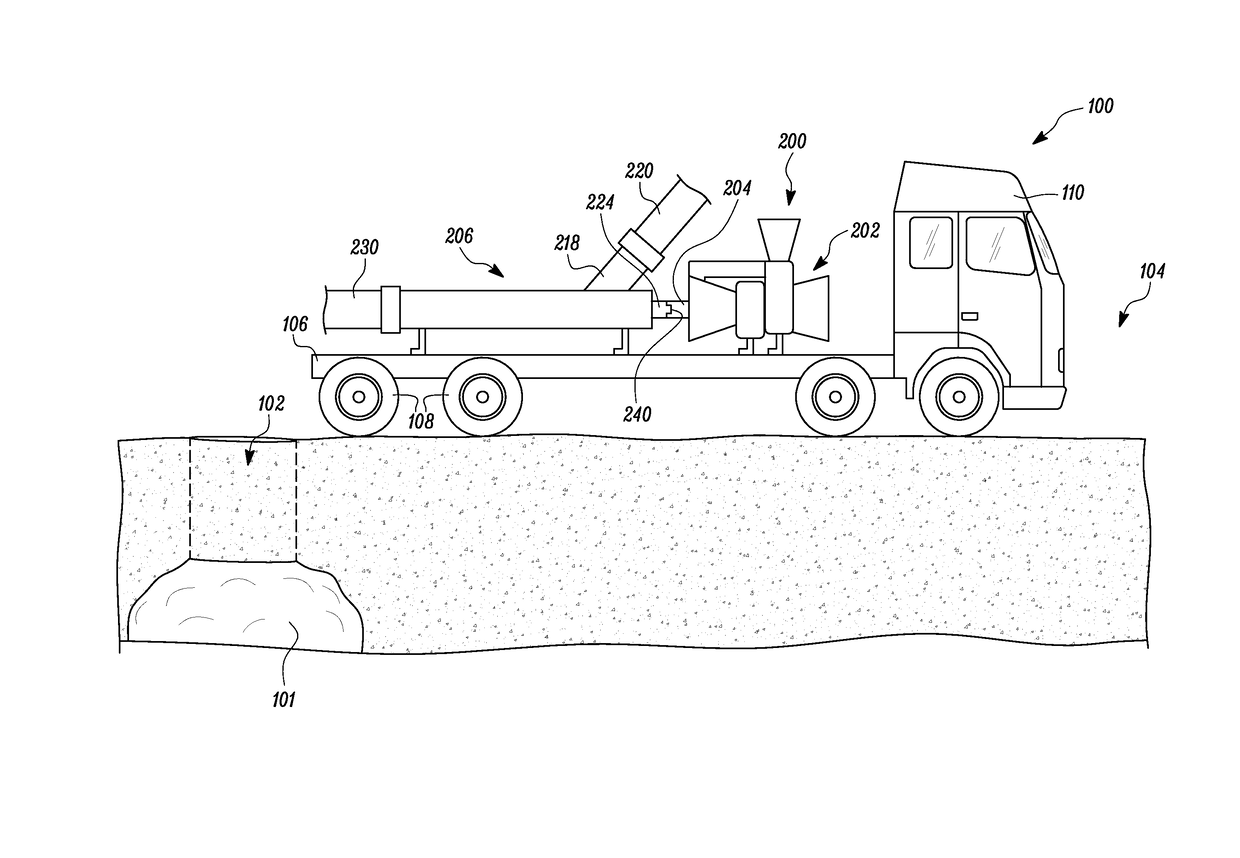

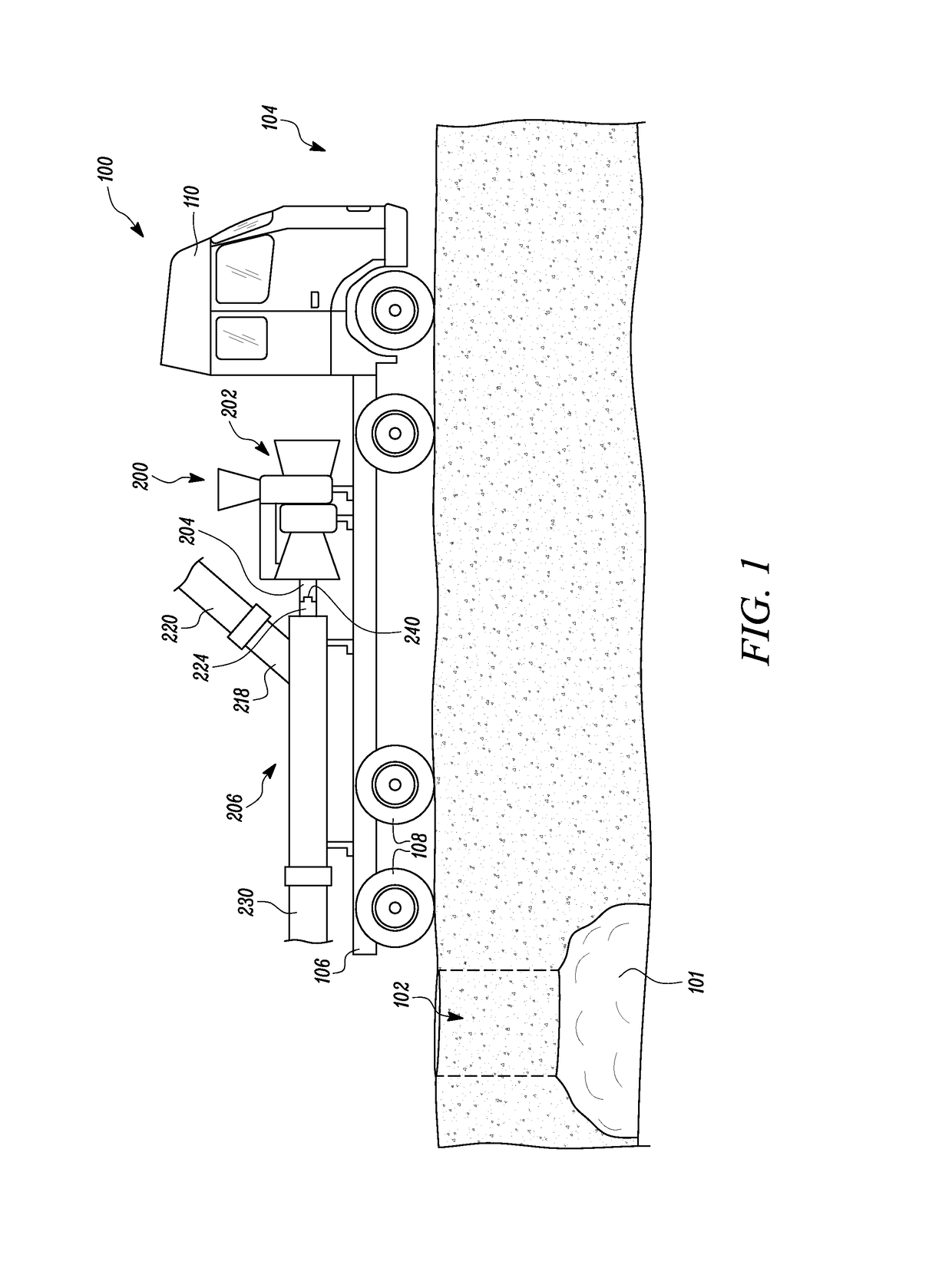

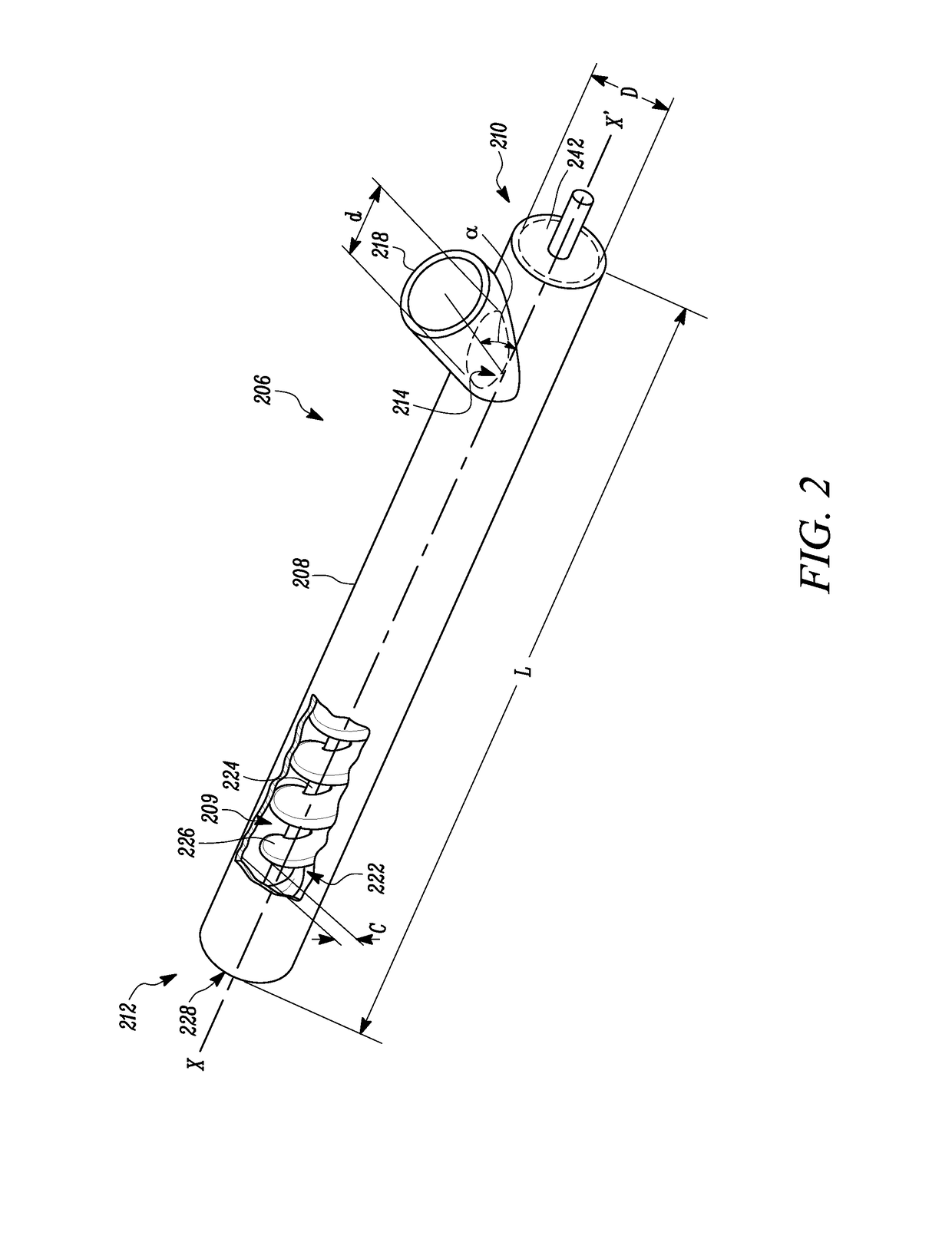

Mobile fracturing pump transport for hydraulic fracturing of subsurface geological formations

ActiveUS20160369609A1Well formedMechanical actuated clutchesGas turbine plantsCouplingFracturing fluid

Providing pressurized fracturing fluid with a fracturing pump transport comprising a first fracturing pump and a second fracturing pump that are coupled on opposite sides of a dual shaft electric motor. A first drive line assembly comprising a first engagement coupling that allows for selective engagement and / or disengagement of the first fracturing pump with the dual shaft electric motor. A second drive line assembly comprising a second engagement coupling that allows for selective engagement and / or disengagement of the second fracturing pump with the dual shaft electric motor. The fracturing pump transport also comprising an engagement panel that allows for selective engagement or disengagement at the first engagement coupling based on receiving a remote command.

Owner:TYPHON TECH SOLUTIONS (U S) LLC

System for pumping hydraulic fracturing fluid using electric pumps

A system for hydraulically fracturing an underground formation in an oil or gas well to extract oil or gas from the formation, the oil or gas well having a wellbore that permits passage of fluid from the wellbore into the formation. The system includes a plurality of electric pumps fluidly connected to the well, and configured to pump fluid into the wellbore at high pressure so that the fluid passes from the wellbore into the and fractures the formation. The system can also include a plurality of natural gas powered generators electrically connected to the plurality of electric pumps to provide electrical power to the pumps.

Owner:US WELL SERVICS LLC

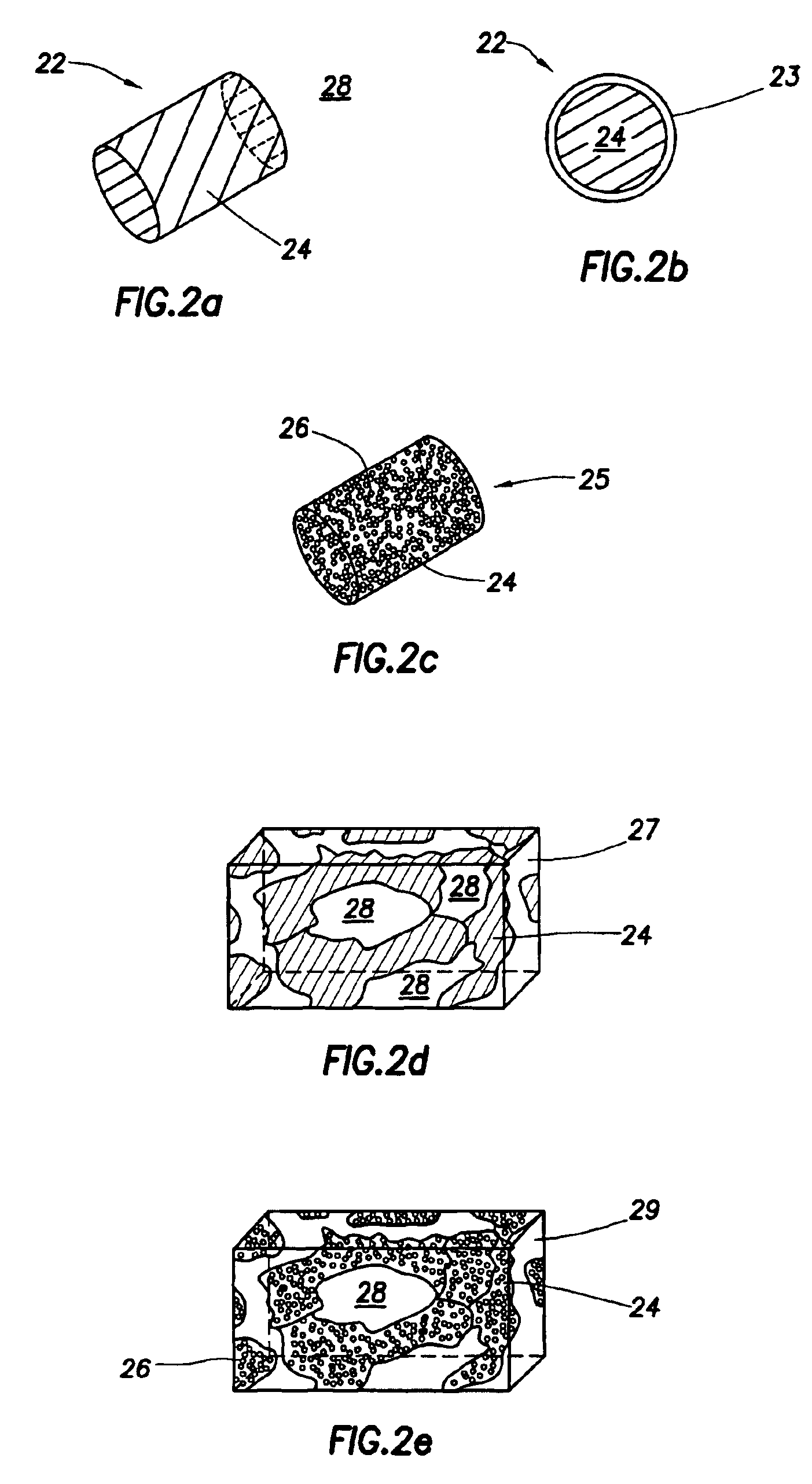

Coating and/or treating hydraulic fracturing proppants to improve wettability, proppant lubrication, and/or to reduce damage by fracturing fluids and reservoir fluids

InactiveUS20050244641A1Reduce conductivityEfficient arrangementSynthetic resin layered productsCellulosic plastic layered productsFracturing fluidCompound (substance)

Surface modified oil and gas well hydraulic fracturing proppants for improving wettability, altering chemical reactivity, altering surface topography, imparting lubricity or controlling relative permeability to flow of fluids of such proppants. The use and preparation of such coated proppants in hydraulic fracturing of subterranean formations is also described.

Owner:CARBO CERAMICS

Methods for improving proppant pack permeability and fracture conductivity in a subterranean well

ActiveUS20050059558A1Improve fluid flowIncrease productivityFluid removalFlushingParticulatesFracturing fluid

The present invention provides compositions and methods for enhancing subterranean well productivity by enhancing fracture conductivity. A method of increasing the conductivity of a fracture in a portion of a subterranean formation comprising providing a slurry comprising a fracturing fluid, a degradable material, and proppant particulates coated with a tackifying agent; allowing the degradable material to become at least temporarily attached to the tackifying agent coated onto the proppant particulates so as to avoid substantial segregation of the degradable material from the proppant particulates within the slurry; introducing the slurry to the fracture and allowing the proppant particulates and degradable material to form a substantially uniform particulate pack; and, allowing the degradable material to degrade and produce a particulate pack having voids therein.

Owner:HALLIBURTON ENERGY SERVICES INC

Methods for controlling migration of particulates in a subterranean formation

Method of treating a portion of a subterranean formation comprising: placing a pre-pad fluid into a portion of a subterranean formation wherein the pre-pad fluid comprises a low-viscosity aqueous tackifying composition that comprises an aqueous tackifier compound and an aqueous fluid; placing a fracturing fluid into the portion of the subterranean formation at a pressure sufficient to create or extend at least one fracture therein; and, activating the aqueous tackifier compound with an activator so as to consolidate the unconsolidated particulates. Method of consolidating unconsolidated particulates within a portion of a subterranean formation comprising: placing a foamed low-viscosity aqueous tackifying composition into a portion of a subterranean formation comprising unconsolidated particulates wherein the aqueous tackifying composition comprises an aqueous fluid, a foaming agent, and an aqueous tackifier compound; and, activating the aqueous tackifier compound with an activator so as to consolidate the unconsolidated particulates.

Owner:HALLIBURTON ENERGY SERVICES INC

Methods for improving proppant pack permeability and fracture conductivity in a subterranean well

ActiveUS7178596B2Improve fluid flowIncrease productivityFluid removalFlushingParticulatesFracturing fluid

The present invention provides compositions and methods for enhancing subterranean well productivity by enhancing fracture conductivity. A method of increasing the conductivity of a fracture in a portion of a subterranean formation comprising providing a slurry comprising a fracturing fluid, a degradable material, and proppant particulates coated with a tackifying agent; allowing the degradable material to become at least temporarily attached to the tackifying agent coated onto the proppant particulates so as to avoid substantial segregation of the degradable material from the proppant particulates within the slurry; introducing the slurry to the fracture and allowing the proppant particulates and degradable material to form a substantially uniform particulate pack; and, allowing the degradable material to degrade and produce a particulate pack having voids therein.

Owner:HALLIBURTON ENERGY SERVICES INC

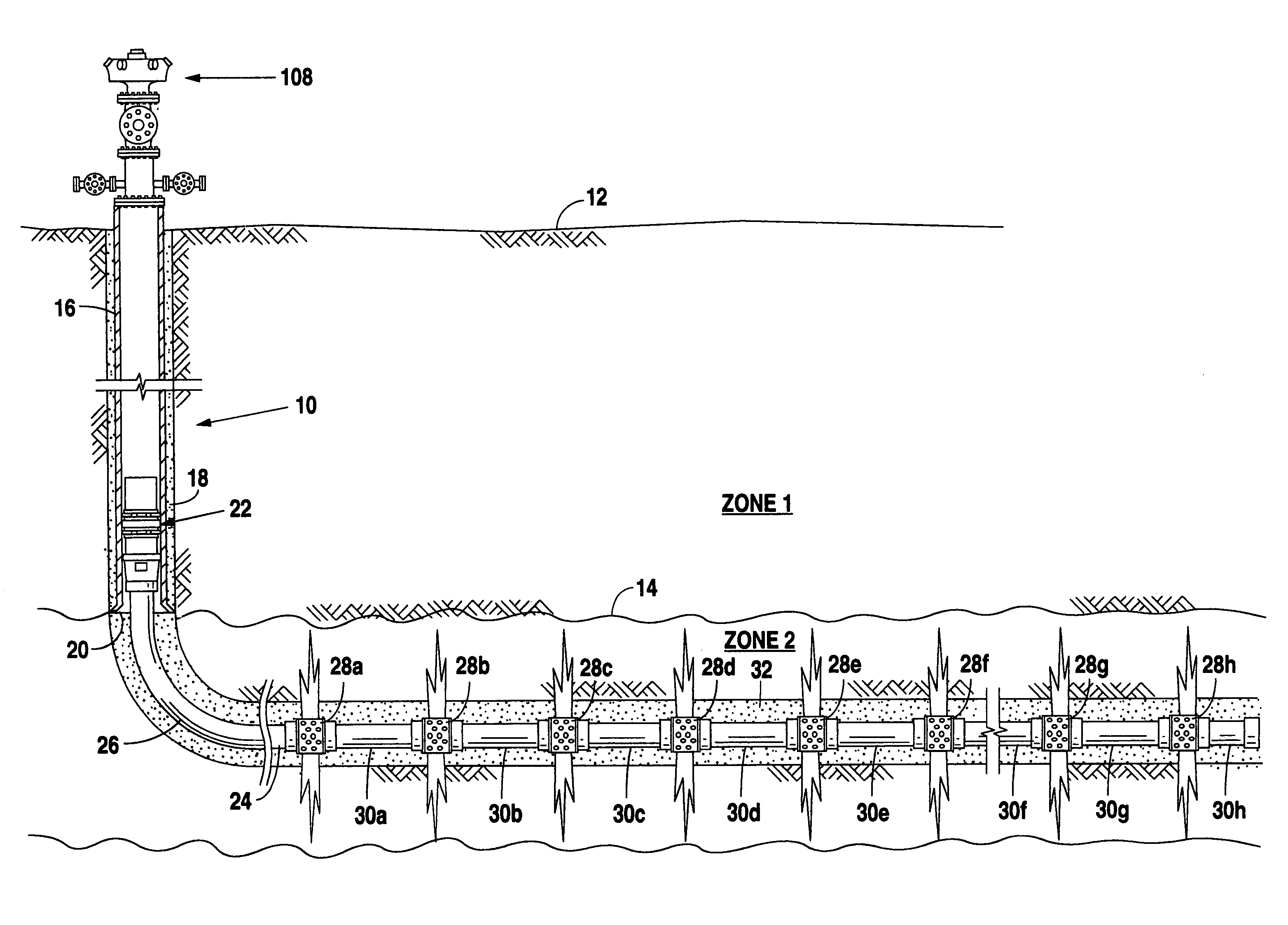

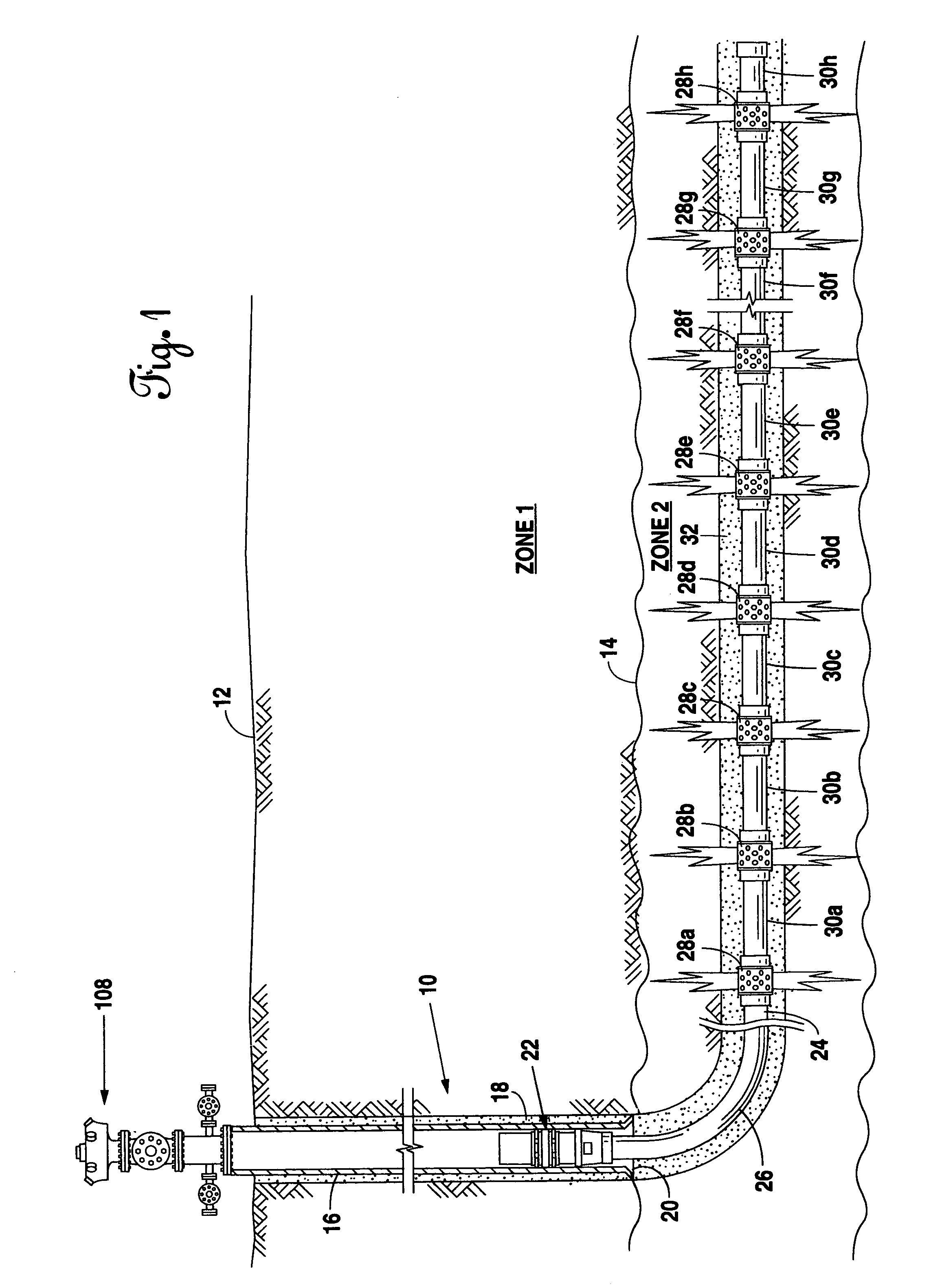

Multi-Position Valve for Fracturing and Sand Control and Associated Completion Methods

A completion tubular is placed in position adjacent the zone or zones to be fractured and produced. It features preferably sliding sleeve valves that can assume at least two configurations: wide open and open with a screen material juxtaposed in the flow passage. In a preferred embodiment the valve assembly has three positions, adding a fully closed position to the other two mentioned. After run in, the valves can be put in the wide open position in any order desired to fracture. After fracturing, the valves can be closed or selectively be put in filtration position for production from the fractured zones in any desired order. Various ways are described to actuate the valves. The tubular can have telescoping pistons through which the fracturing can take place if the application calls for a cemented tubular. Alternatively, the tubular can be in open hole and simply have openings for passage of fracture fluid and external isolators to allow fracturing in any desired order.

Owner:BAKER HUGHES INC

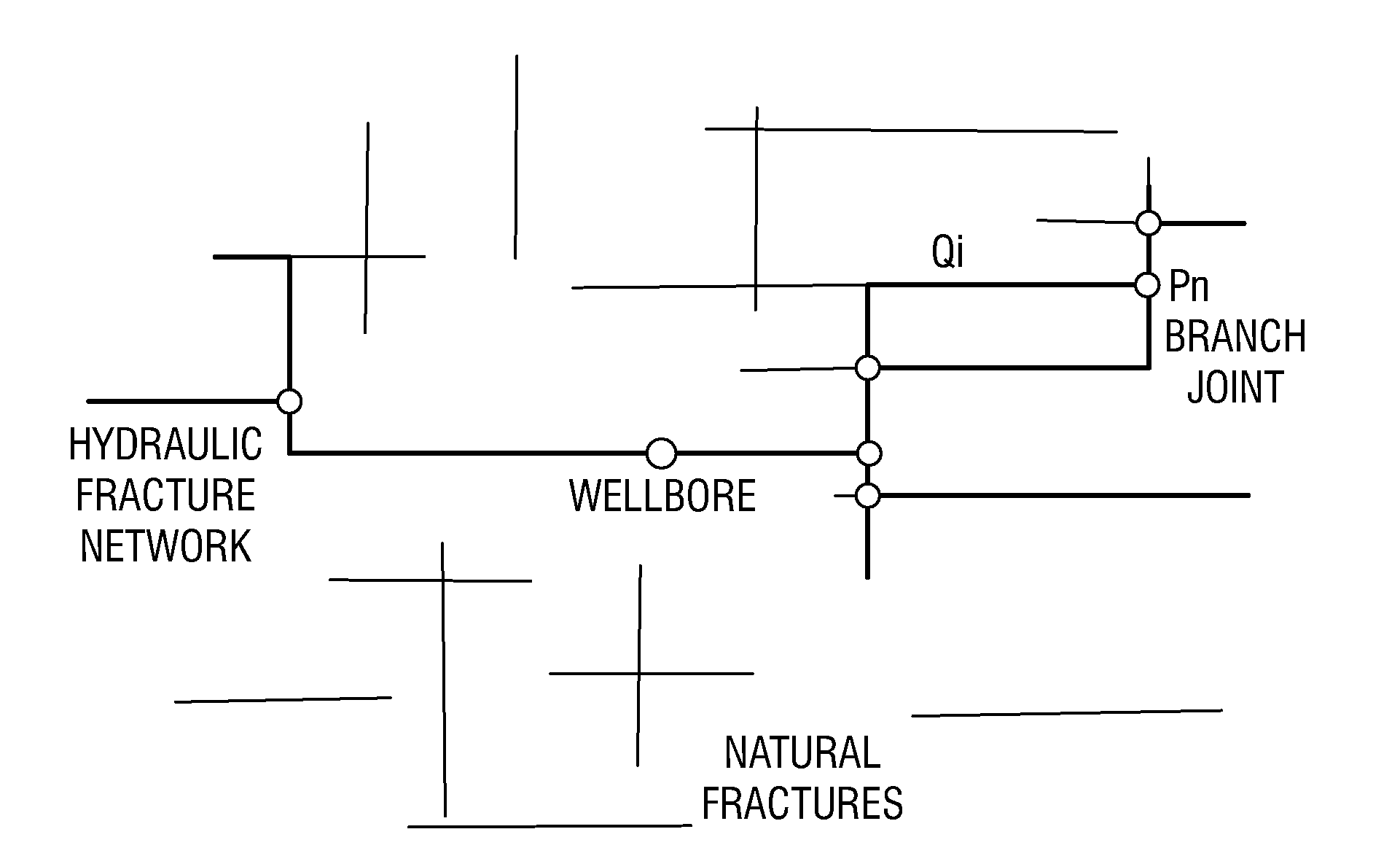

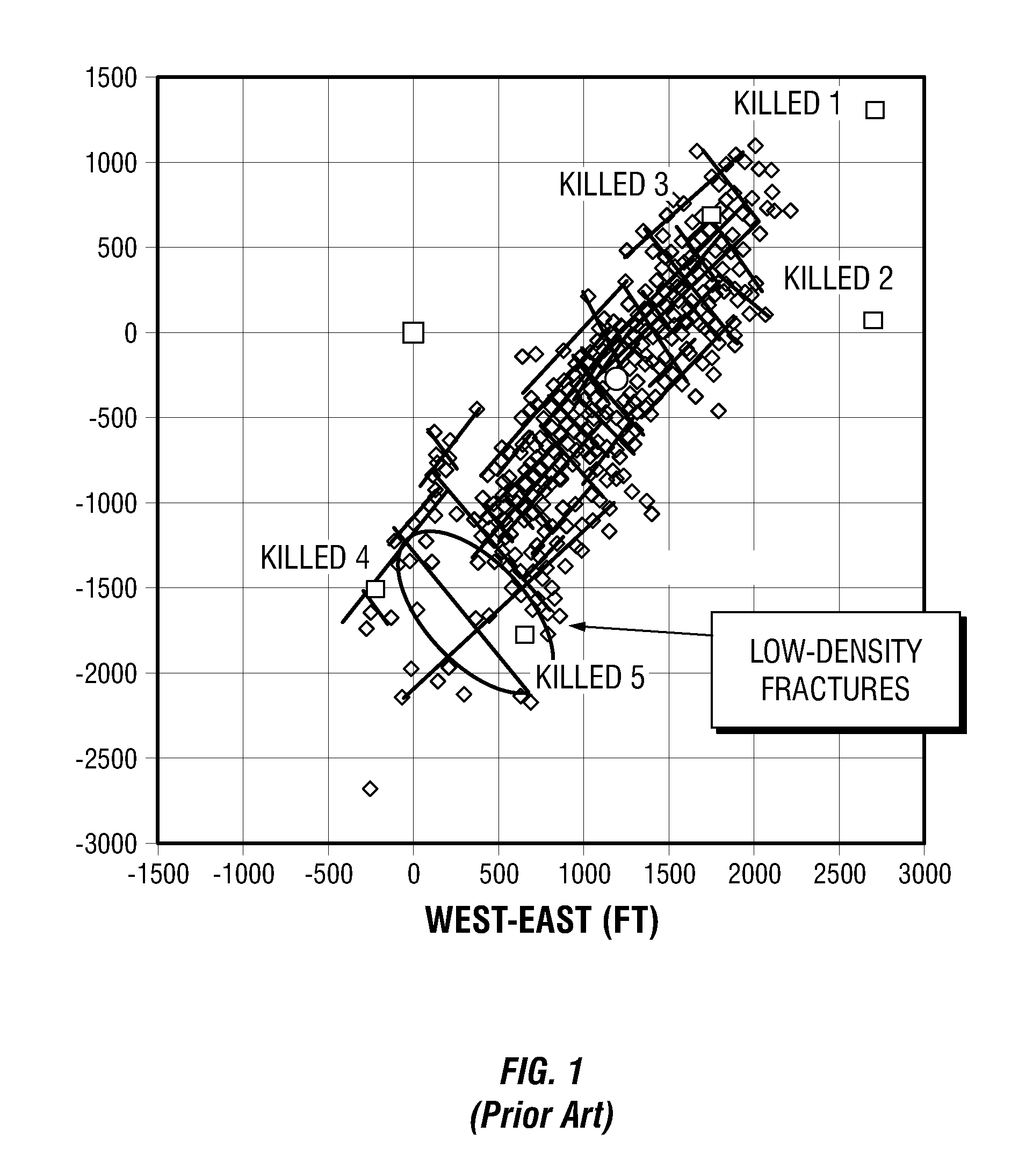

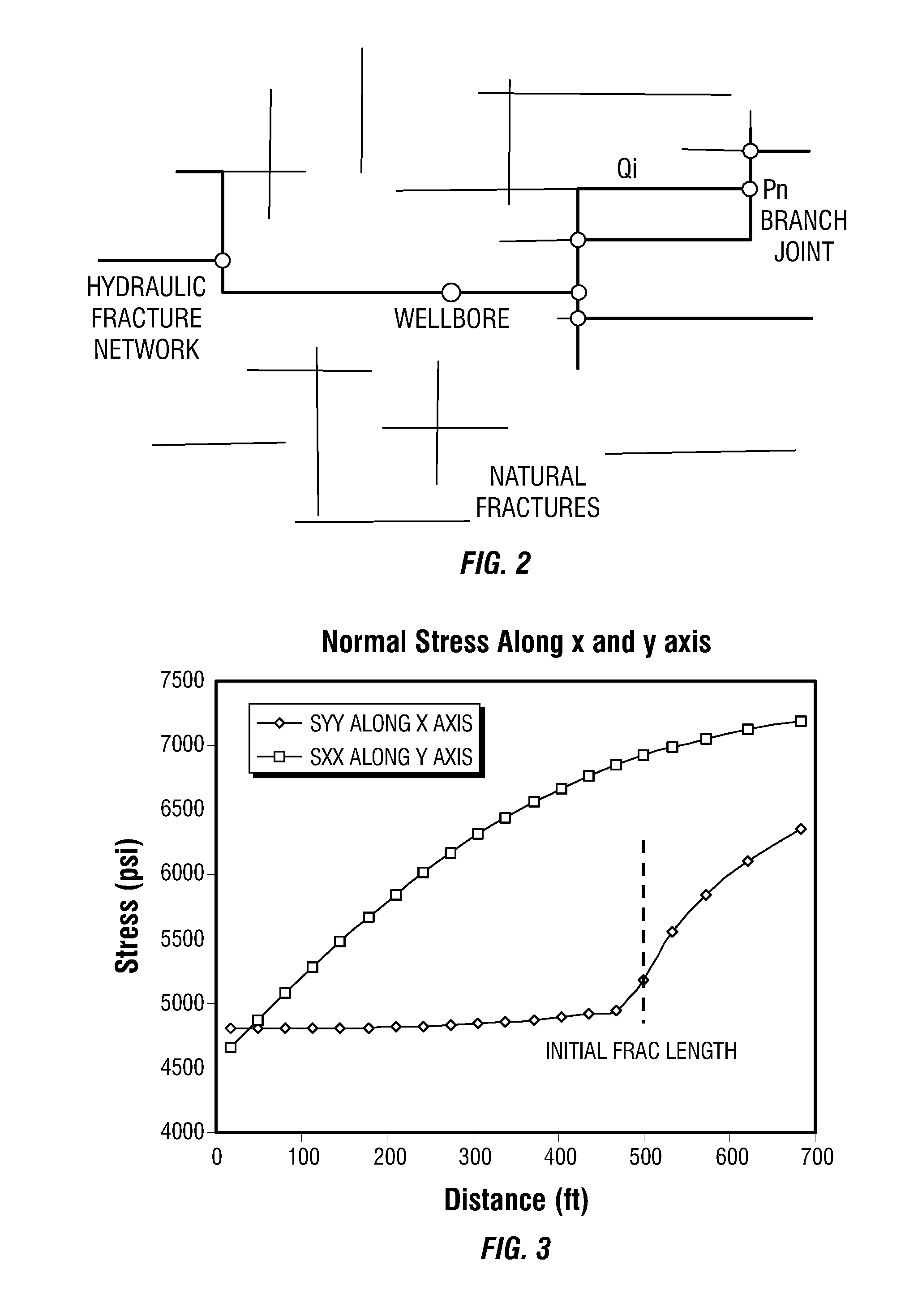

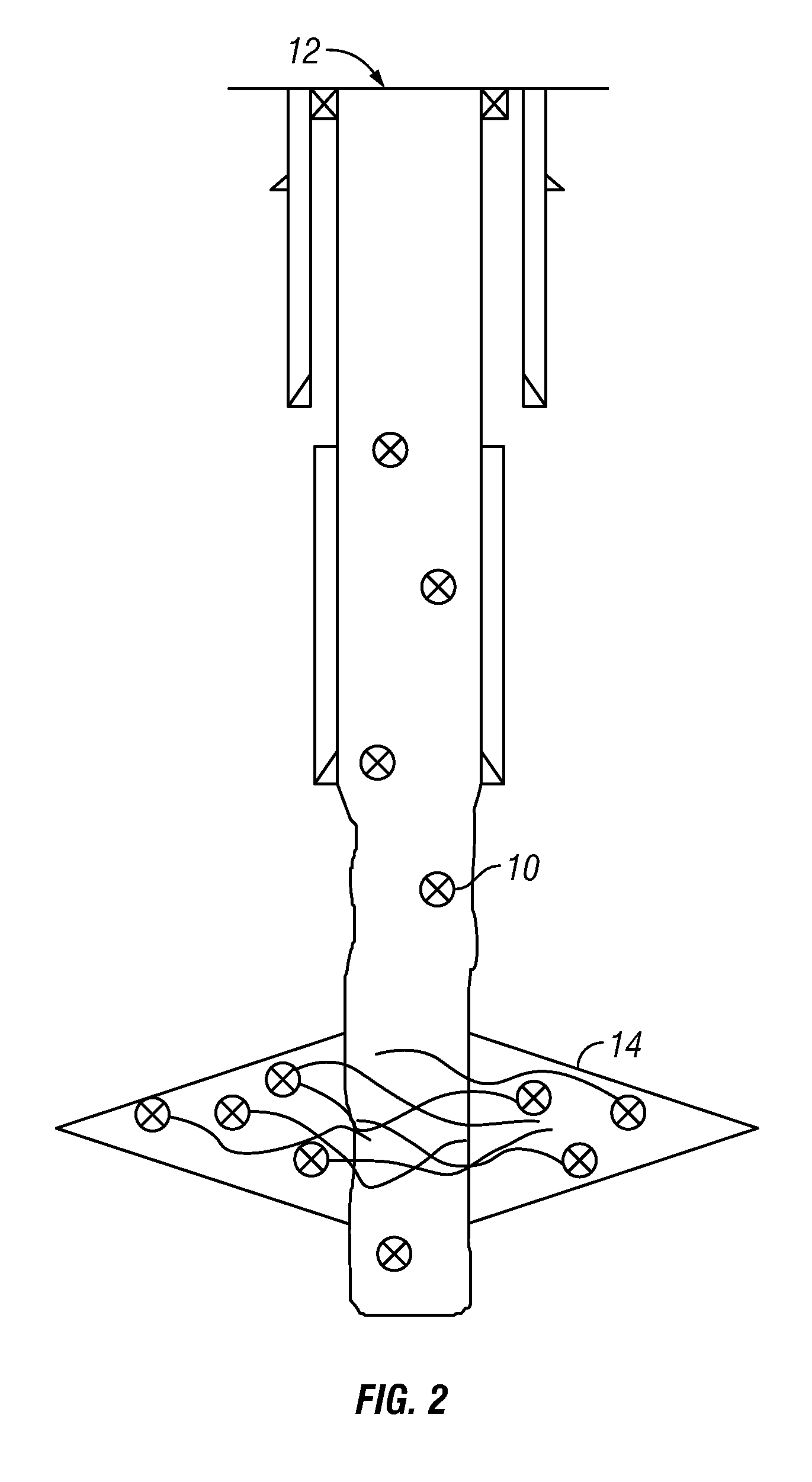

Simulations for Hydraulic Fracturing Treatments and Methods of Fracturing Naturally Fractured Formation

A hydraulic fracture design model that simulates the complex physical process of fracture propagation in the earth driven by the injected fluid through a wellbore. An objective in the model is to adhere with the laws of physics governing the surface deformation of the created fracture subjected to the fluid pressure, the fluid flow in the gap formed by the opposing fracture surfaces, the propagation of the fracture front, the transport of the proppant in the fracture carried by the fluid, and the leakoff of the fracturing fluid into the permeable rock. The models used in accordance with methods of the invention are typically based on the assumptions and the mathematical equations for the conventional 2D or P3D models, and further take into account the network of jointed fracture segments. For each fracture segment, the mathematical equations governing the fracture deformation and fluid flow apply. For each time step, the model predicts the incremental growth of the branch tips and the pressure and flow rate distribution in the system by solving the governing equations and satisfying the boundary conditions at the fracture tips, wellbore and connected branch joints. An iterative technique is used to obtain the solution of this highly nonlinear and complex problem.

Owner:SCHLUMBERGER TECH CORP

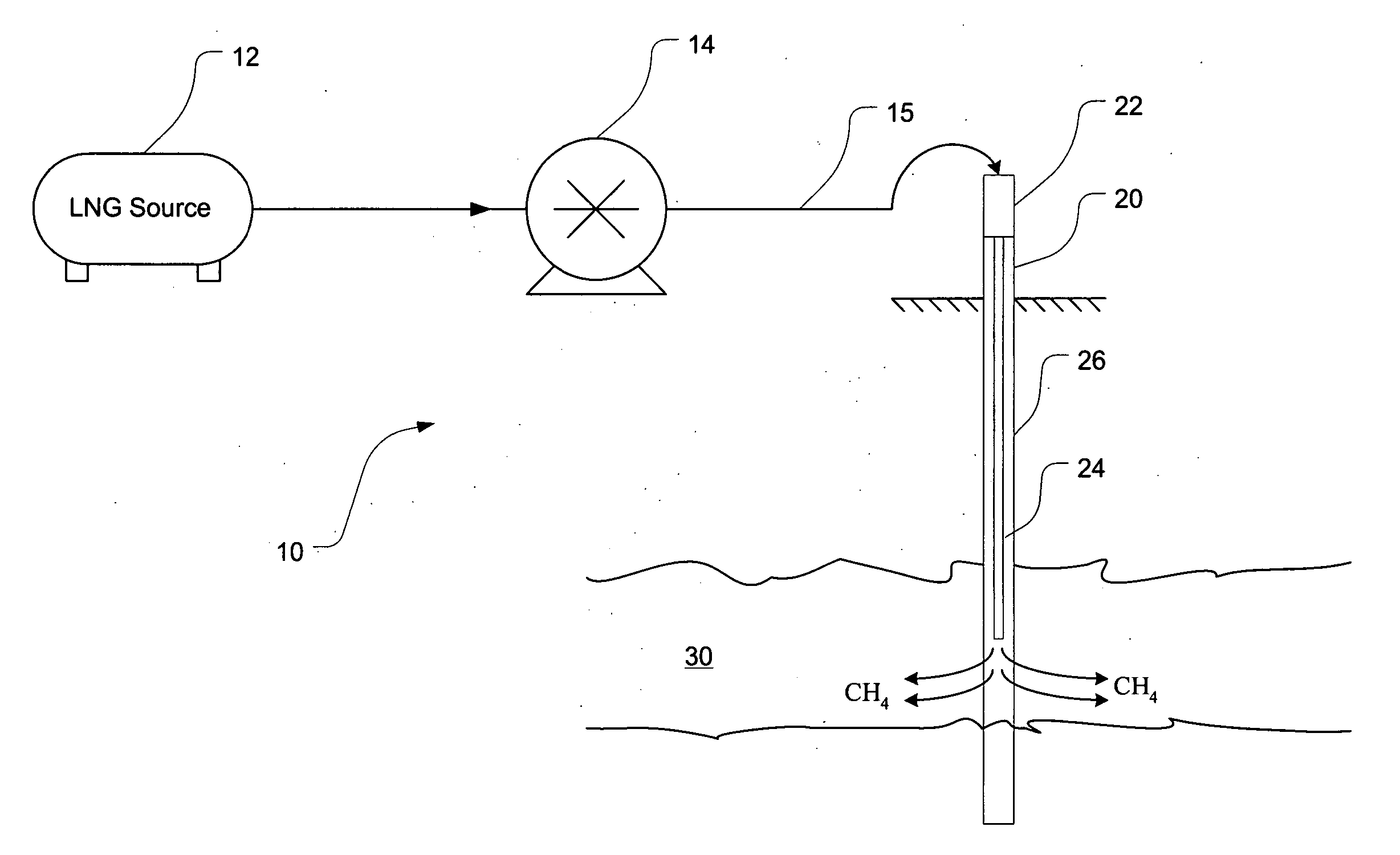

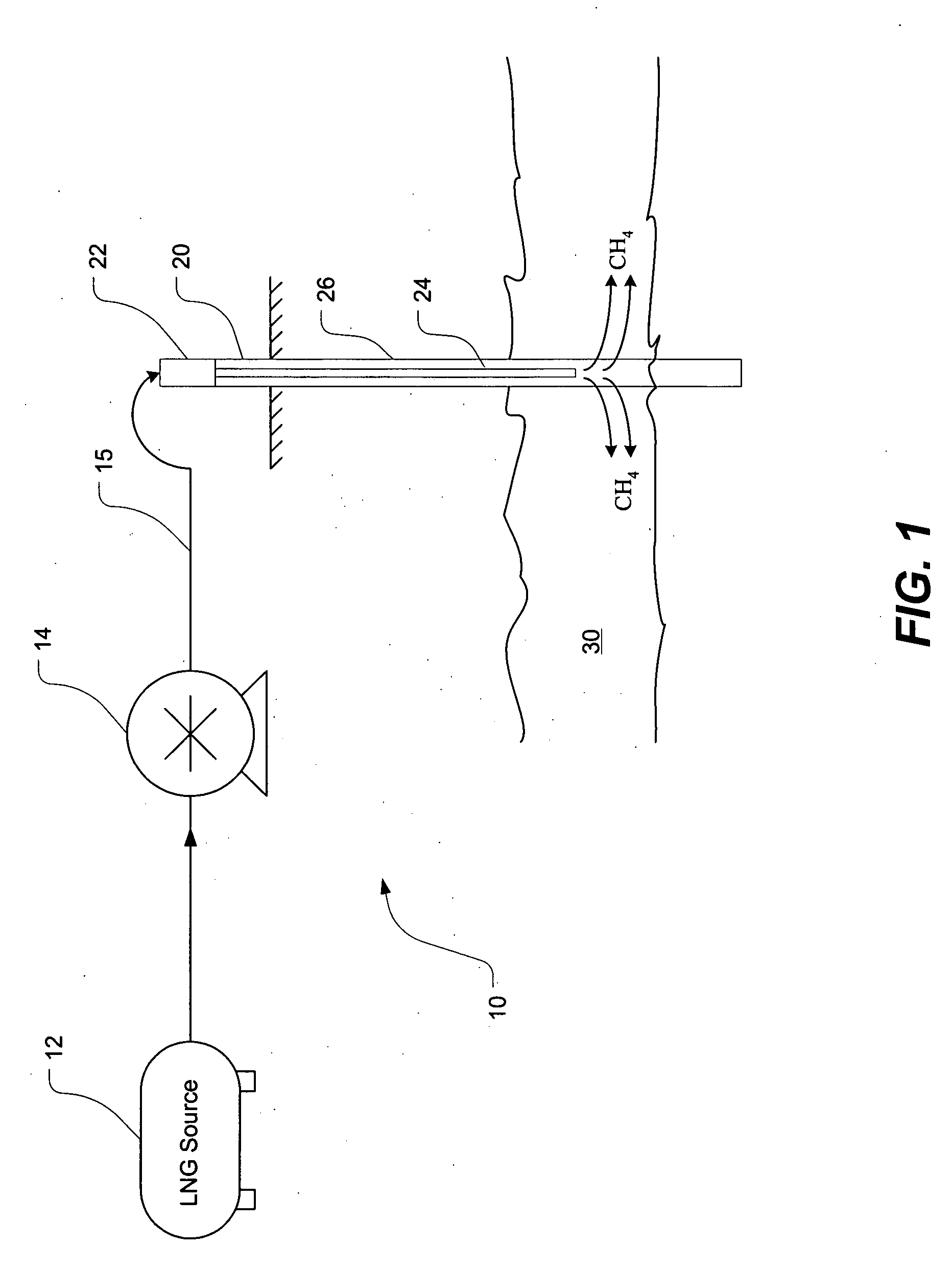

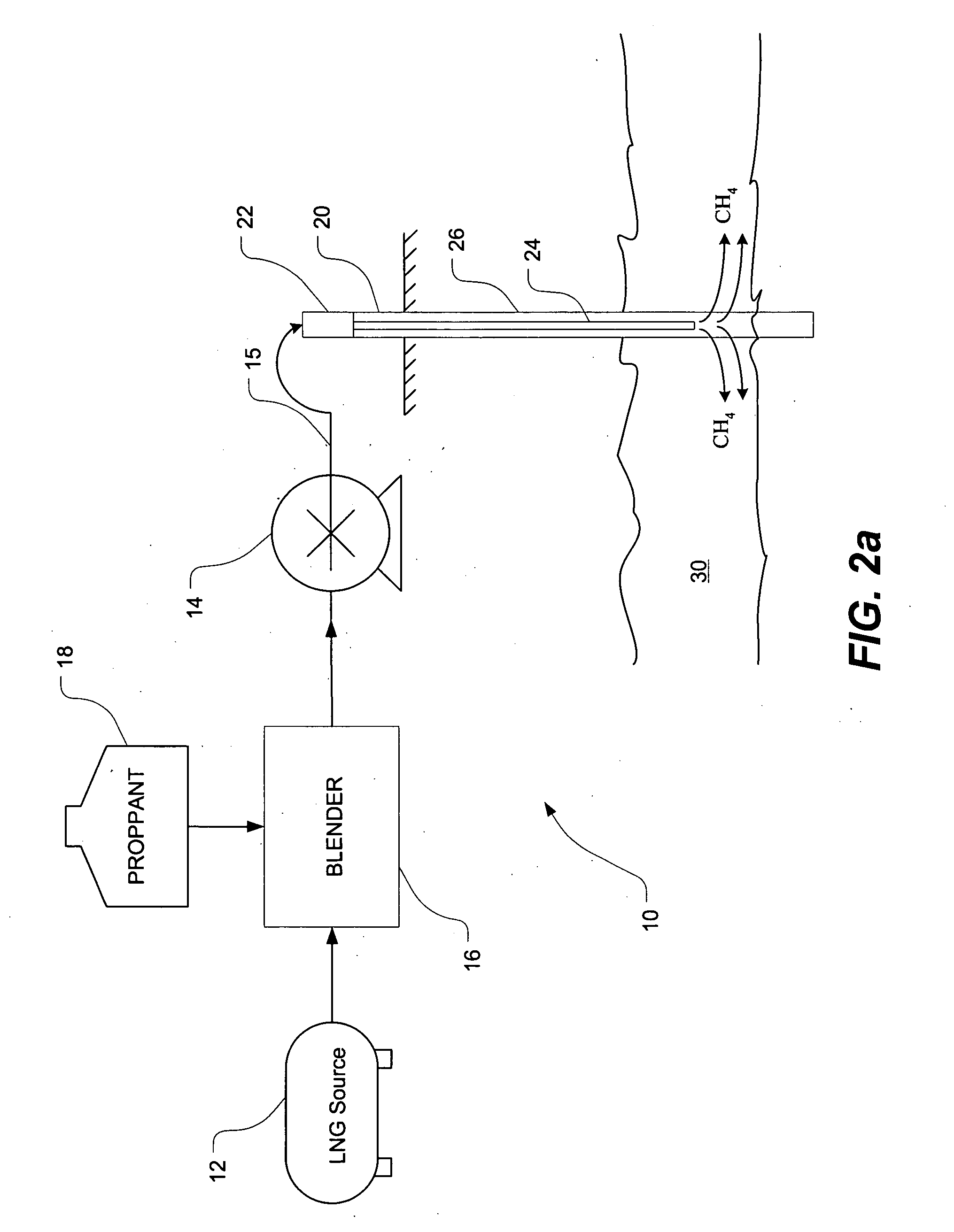

Method and apparatus for stimulating a subterranean formation using liquefied natural gas

InactiveUS20060065400A1Shorten production timeLow costSurveyFluid removalFracturing fluidHydrogen compounds

Liquefied natural gas is used as a fracturing fluid to stimulate production of hydrocarbons from and / or injectability of fluids into subterranean formations. Proppants may be blended with the LNG prior to pumping the liquefied natural gas into the well. Optionally, the liquefied natural gas is heated after it is pumped and before it is introduced into the subterranean formation.

Owner:SMITH DAVID RANDOLPH

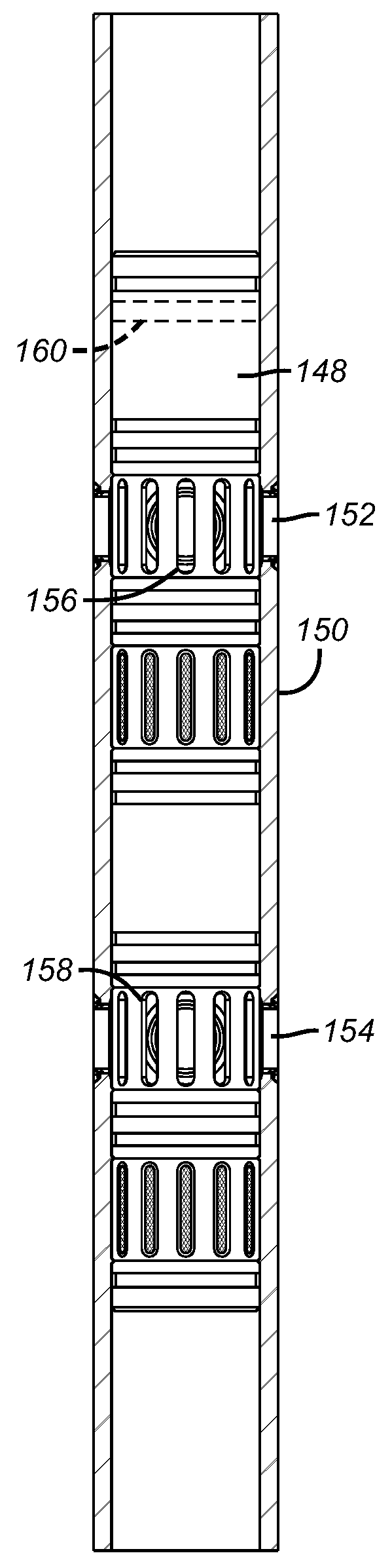

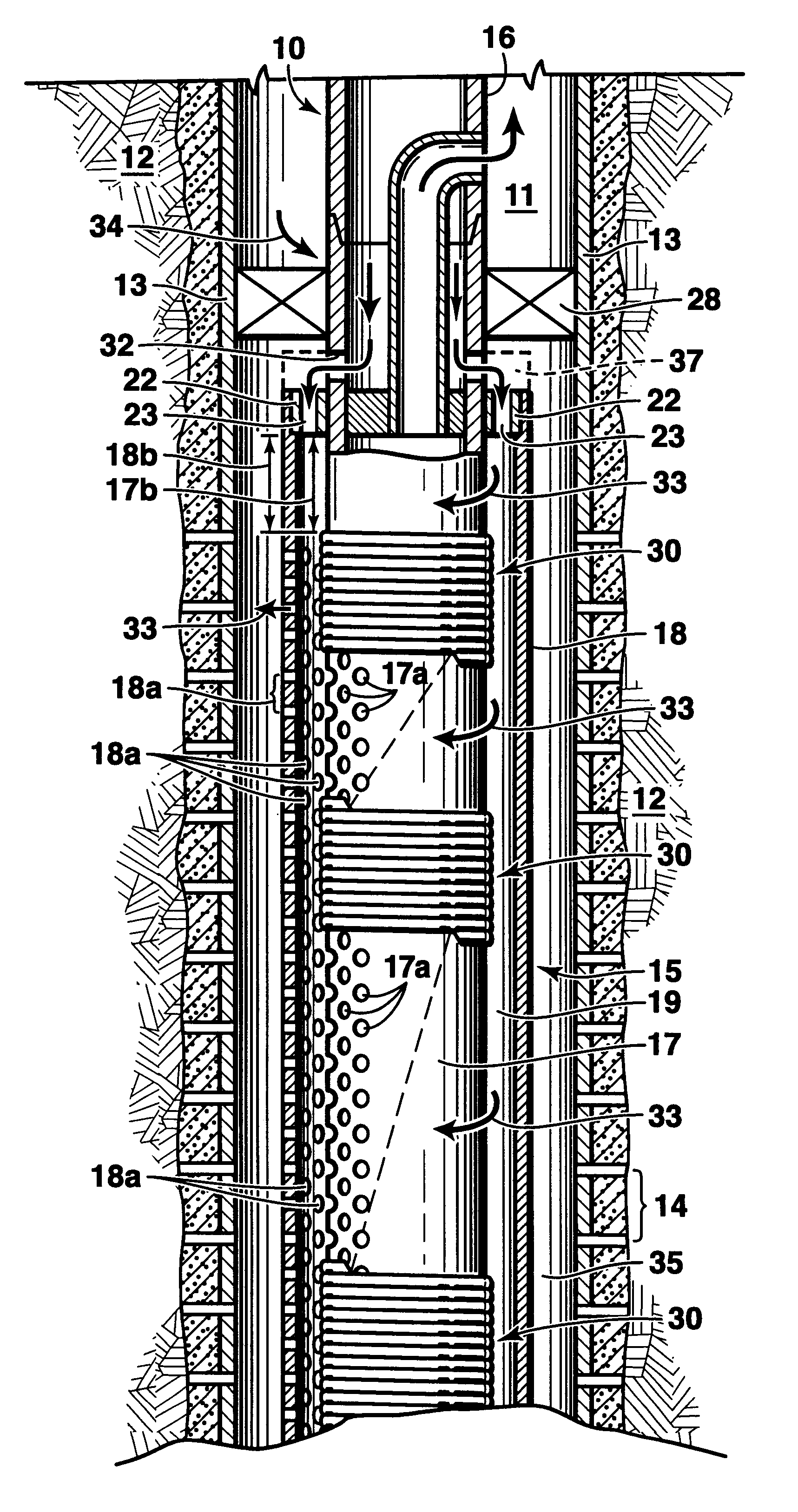

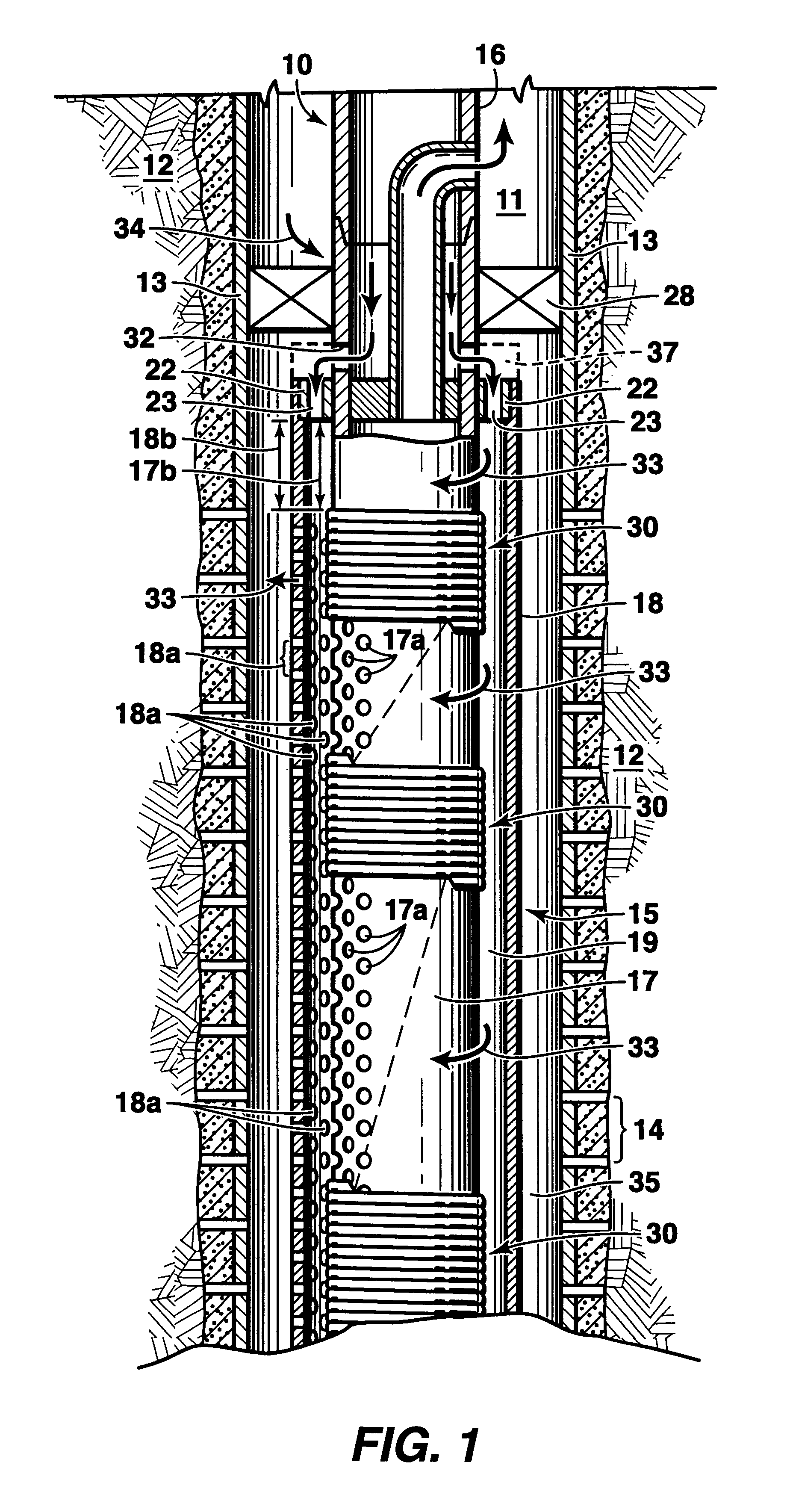

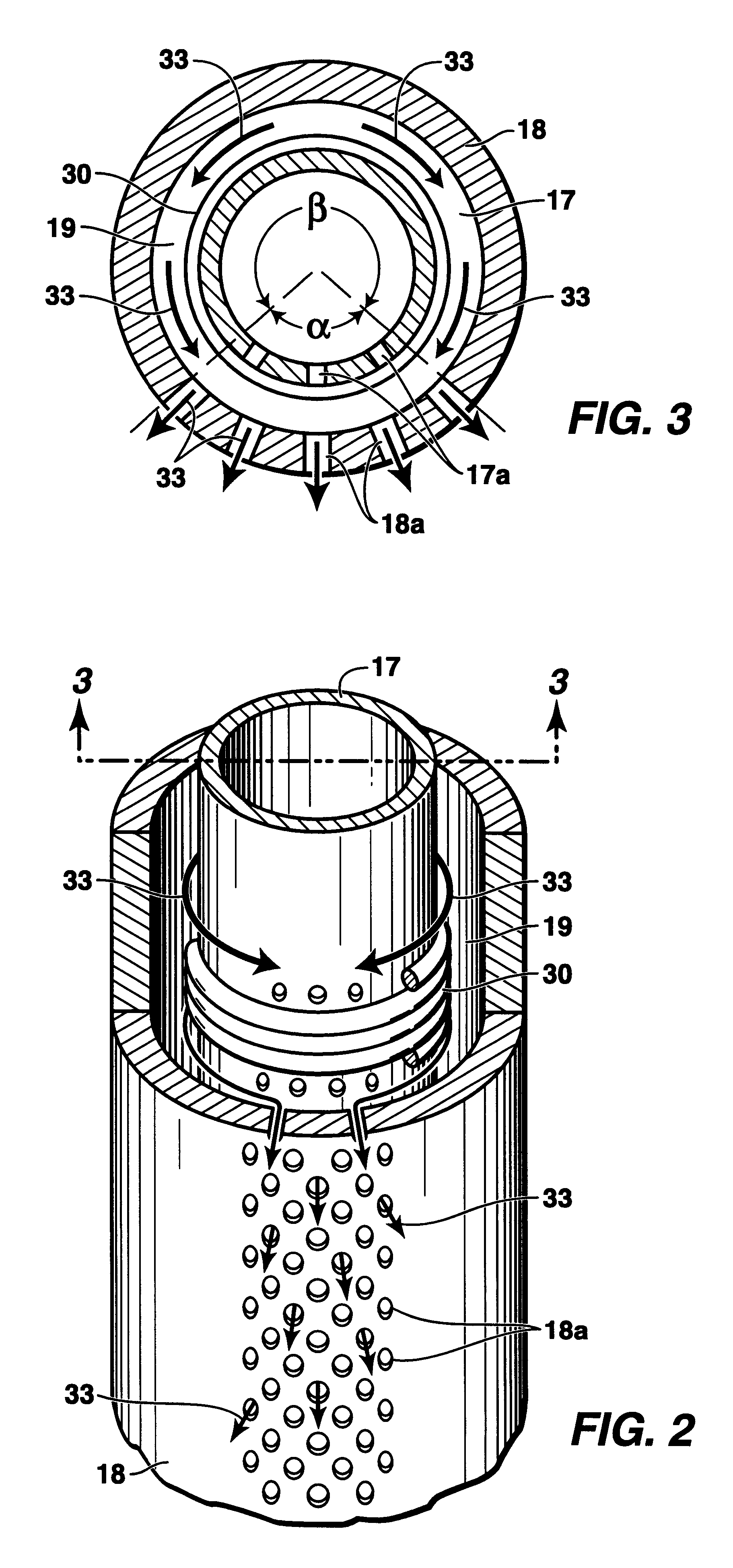

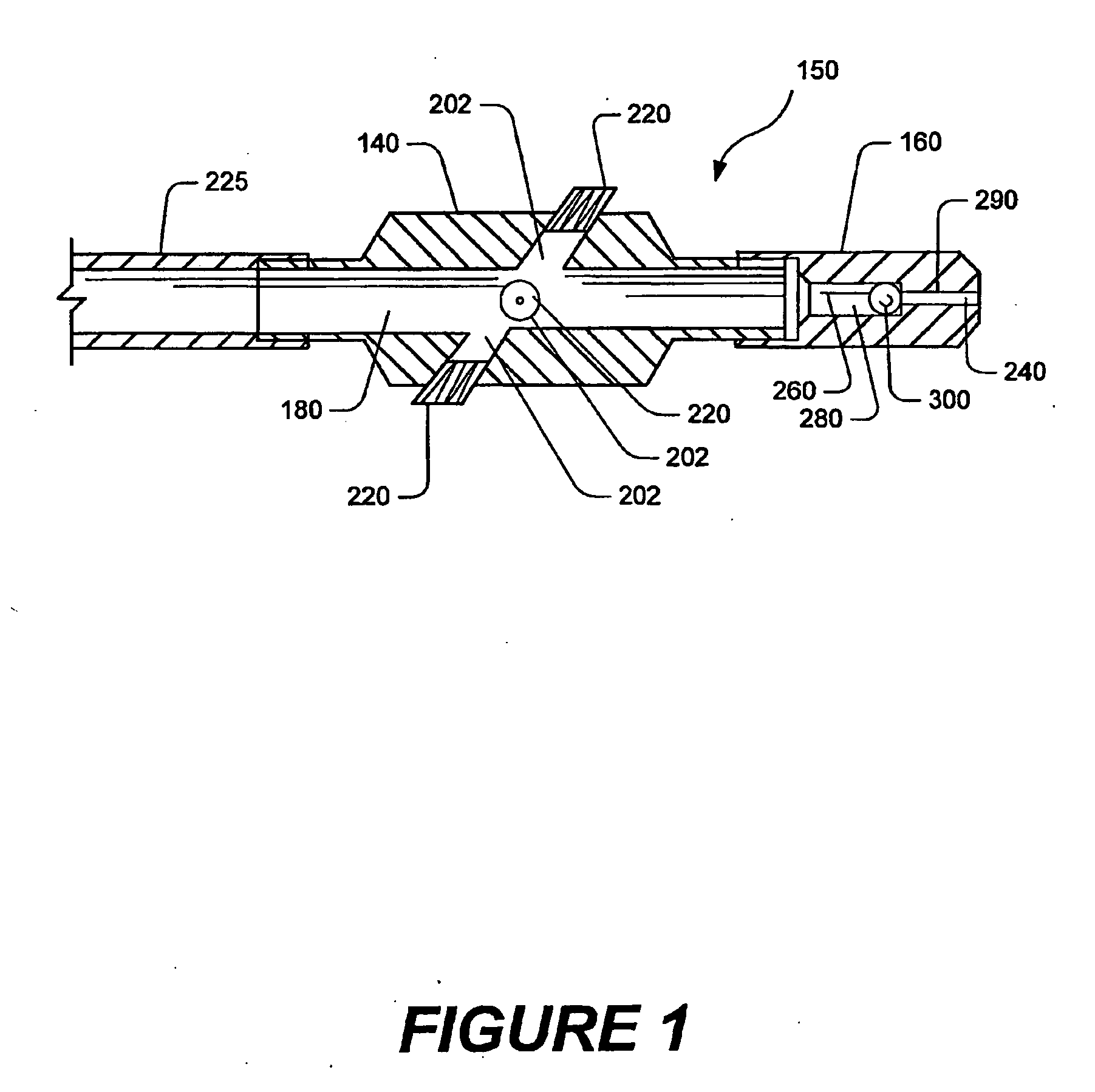

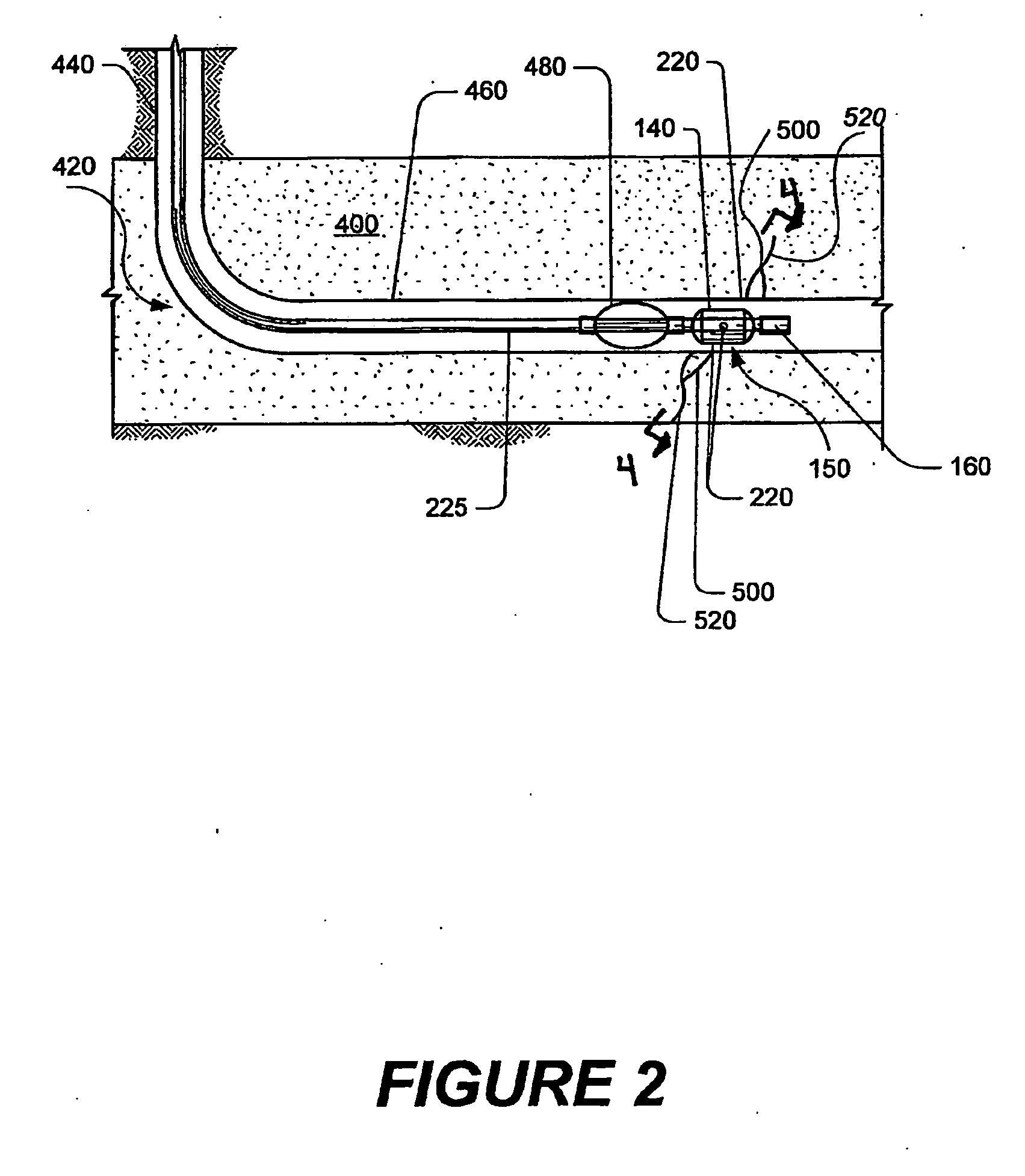

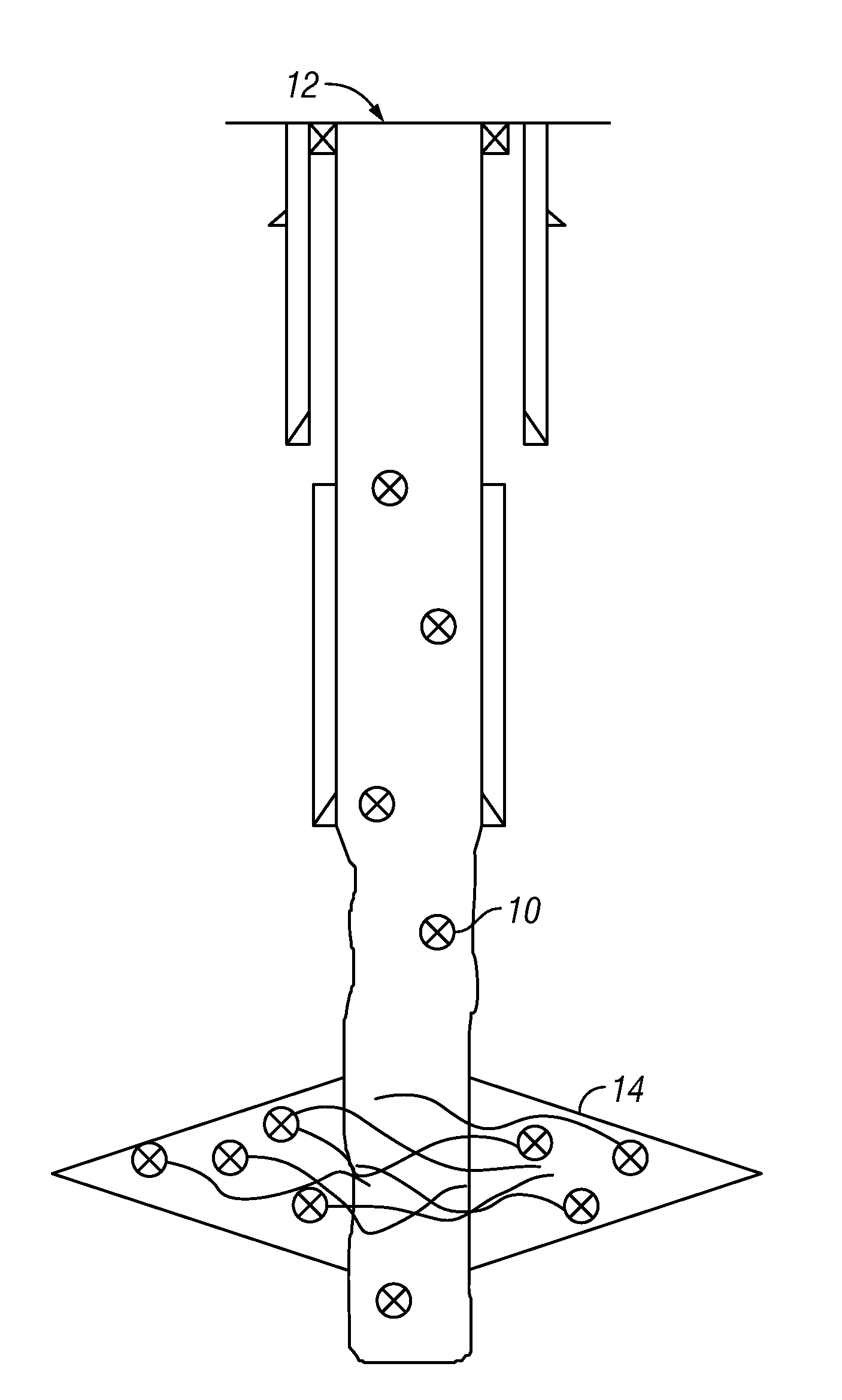

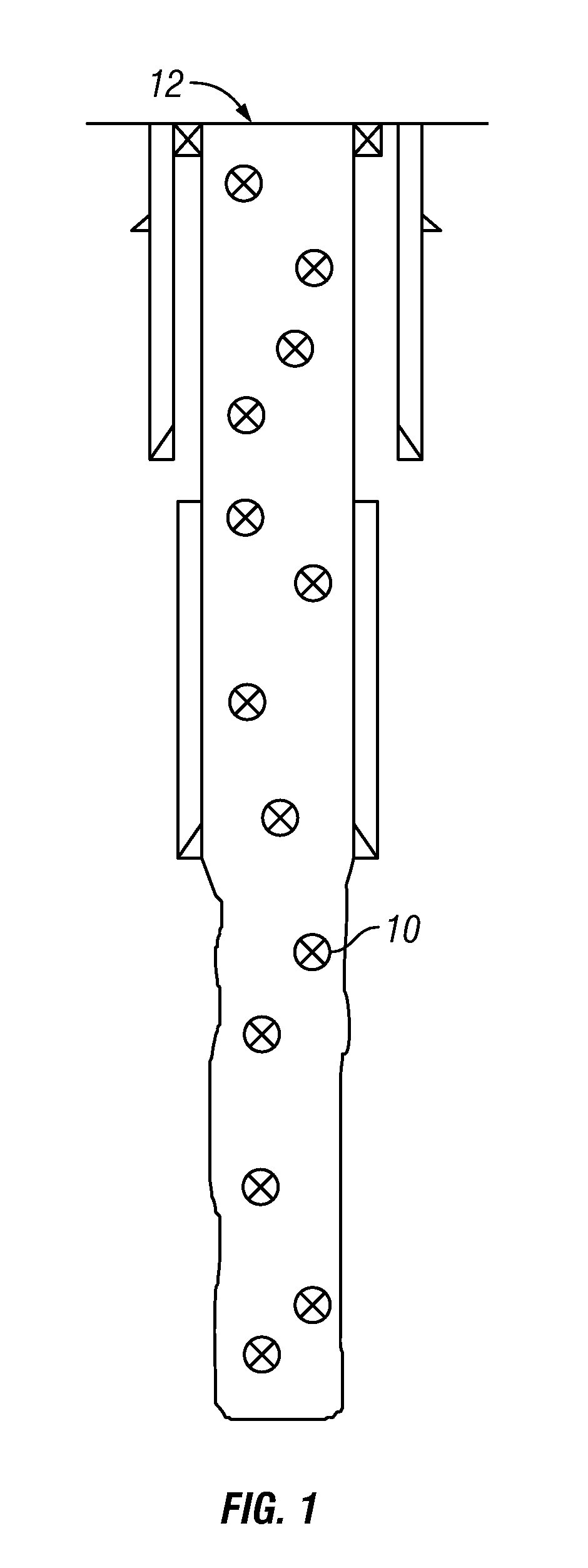

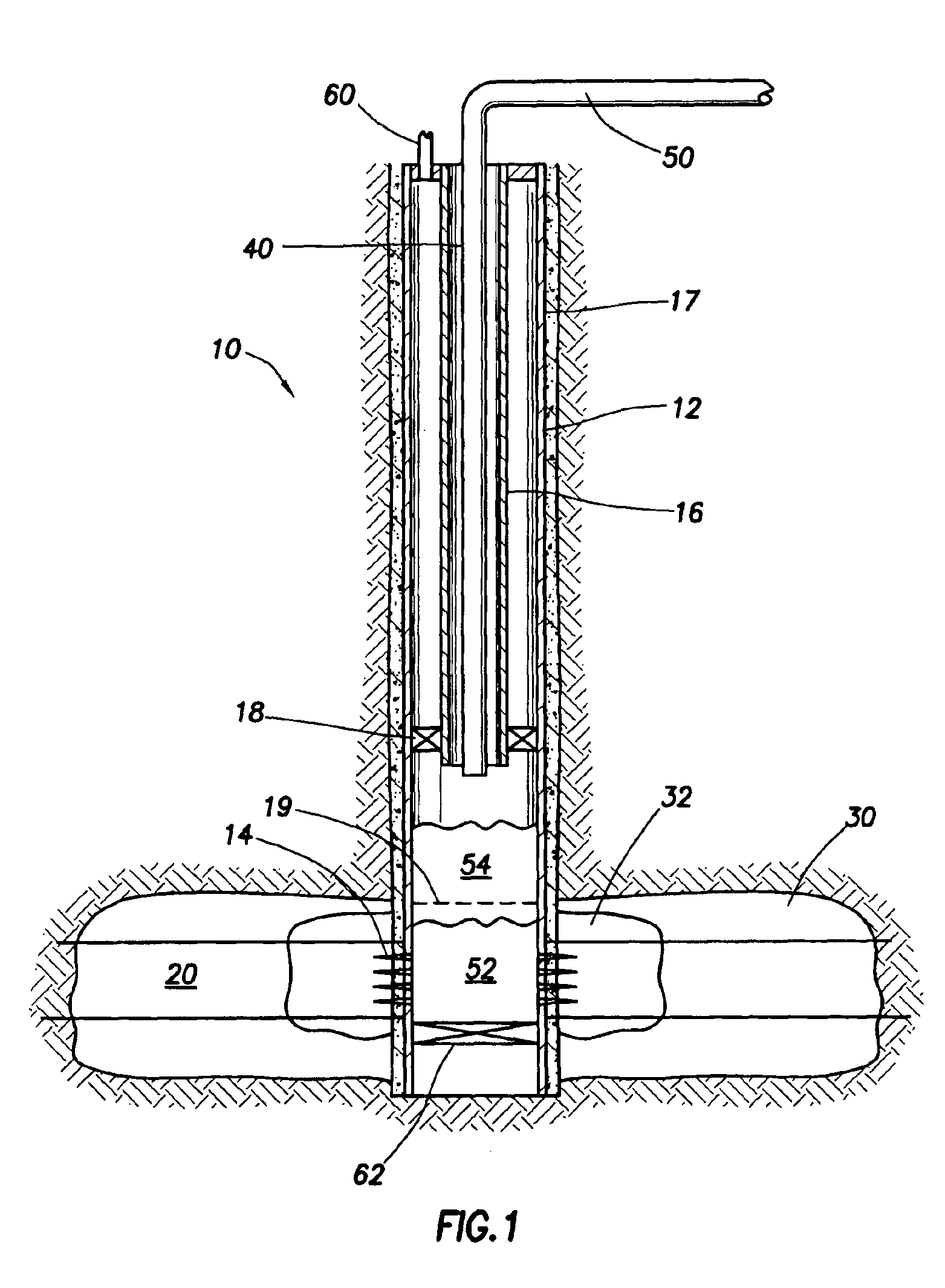

Well screen having an internal alternate flowpath

InactiveUS6220345B1High viscosityIncrease flow rateFluid removalDrinking water installationFracturing fluidEngineering

A well screen having an internal, blank alternate flowpath for delivering fracturing fluid / gravel slurry to different levels within a well annulus. The well screen includes an outer pipe which is positioned over a base pipe thereby forming an annulus therebetween. The circumference of each pipe has a perforated sector and a blank sector, both of which extend along their respective lengths. When assembled, the respective perforated sectors are aligned to form a perforated, production sector and the respective blank sectors are aligned to form the blank, alternate flowpath. The base pipe is wrapped with wire to prevent solids from flowing through the openings therein. Slurry is pumped into the annulus where it flows circumferently from the blank, alternate flowpath to exit into the well annulus through the openings in the perforated sector of the annulus.

Owner:SCHLUMBERGER TECH CORP +1

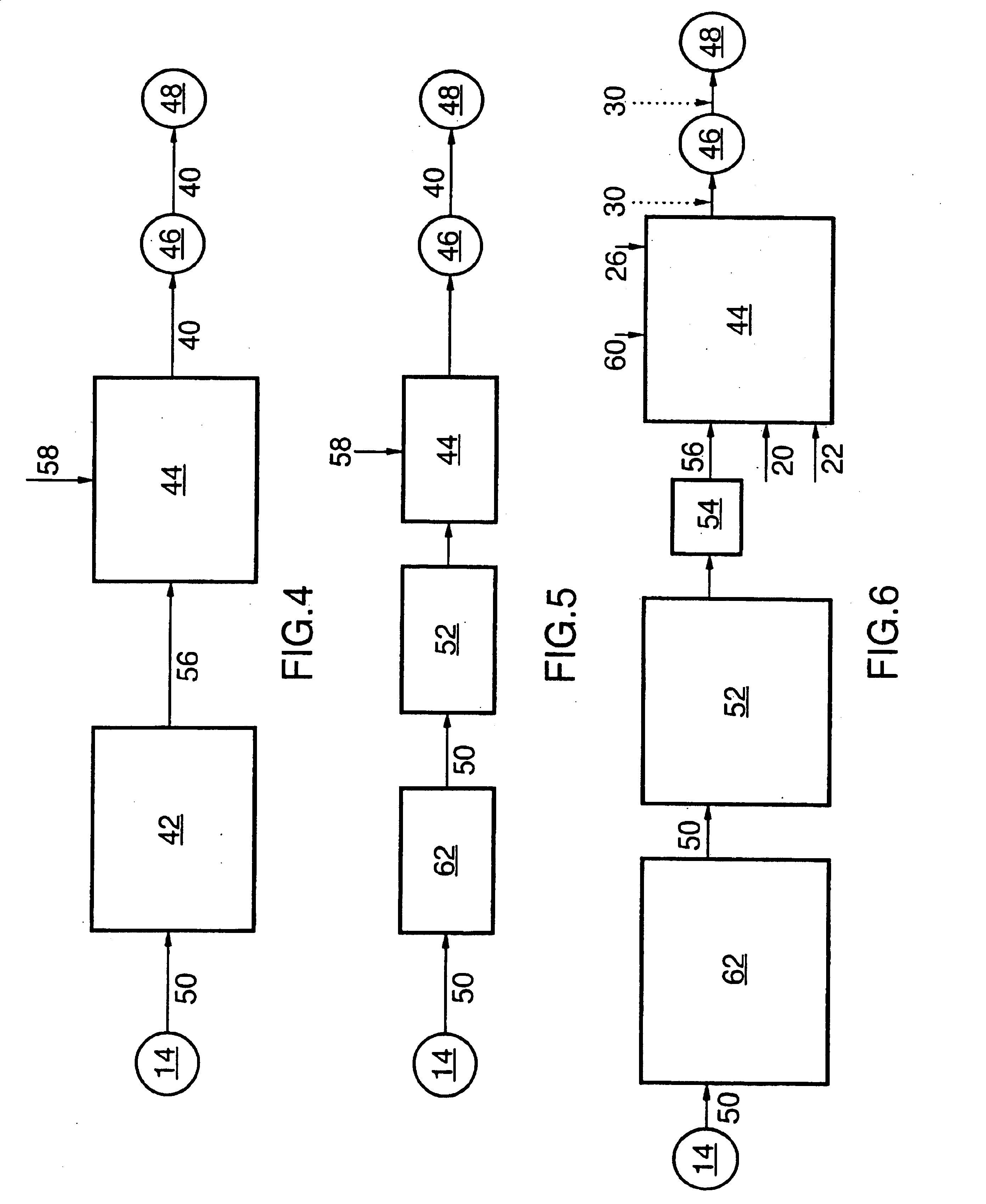

Engagement and disengagement with external gear box style pumps

A system and a method for producing fracturing fluid, comprising: engaging an engagement coupling attached to one end of a gear box dual shaft to a gear box connector of an external gear box, wherein the external gear box is part of a pump; rotating the gear box dual shaft to drive the pump after engaging the engagement coupling with the gear box connector; disengaging the engagement coupling from the gear box connector; and rotating the gear box dual shaft without driving the pump after disengaging the engagement coupling with the gear box connector.

Owner:TYPHON TECH SOLUTIONS (U S) LLC

Fracturing fluids comprising degradable diverting agents and methods of use in subterranean formations

Owner:HALLIBURTON ENERGY SERVICES INC

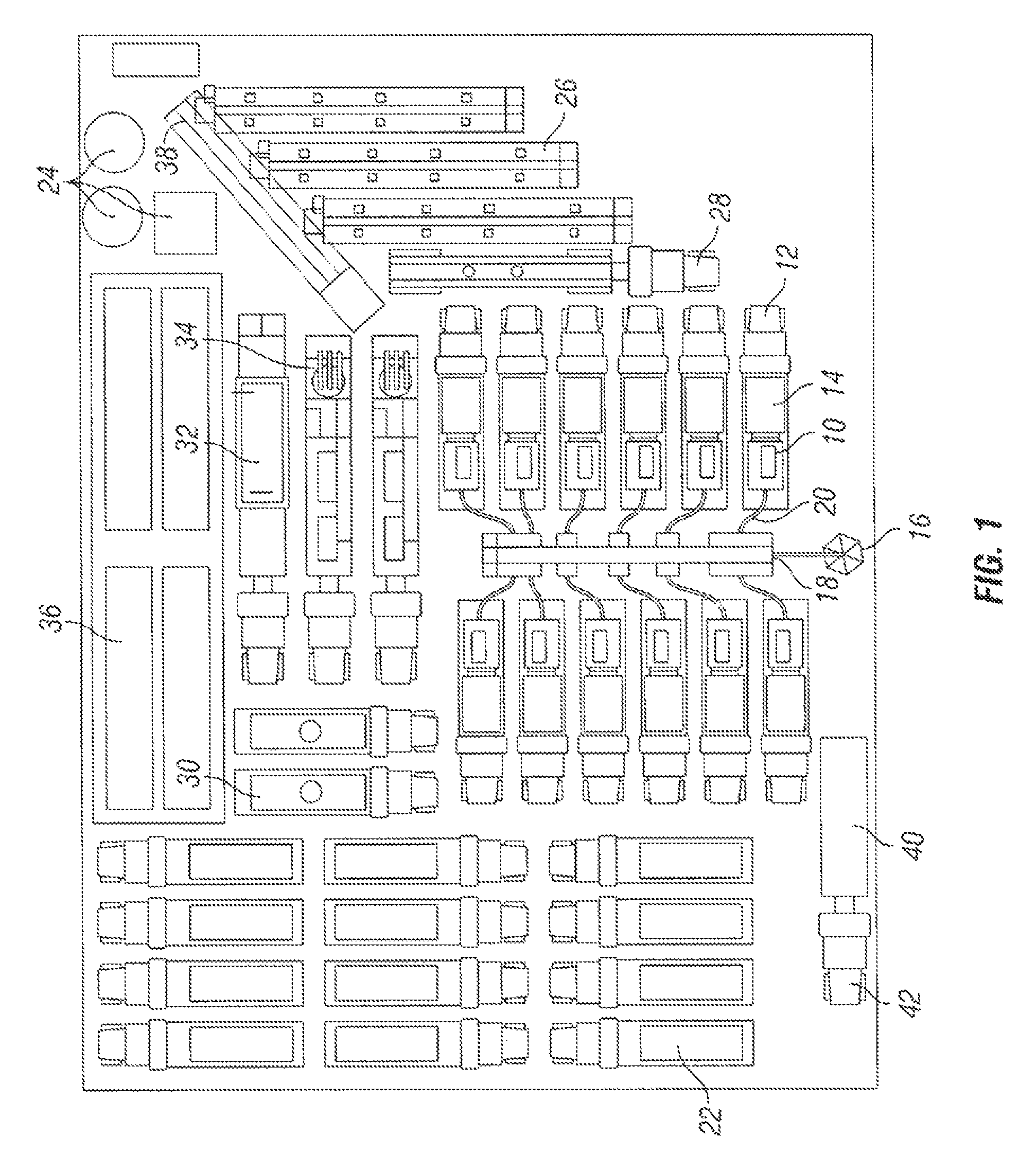

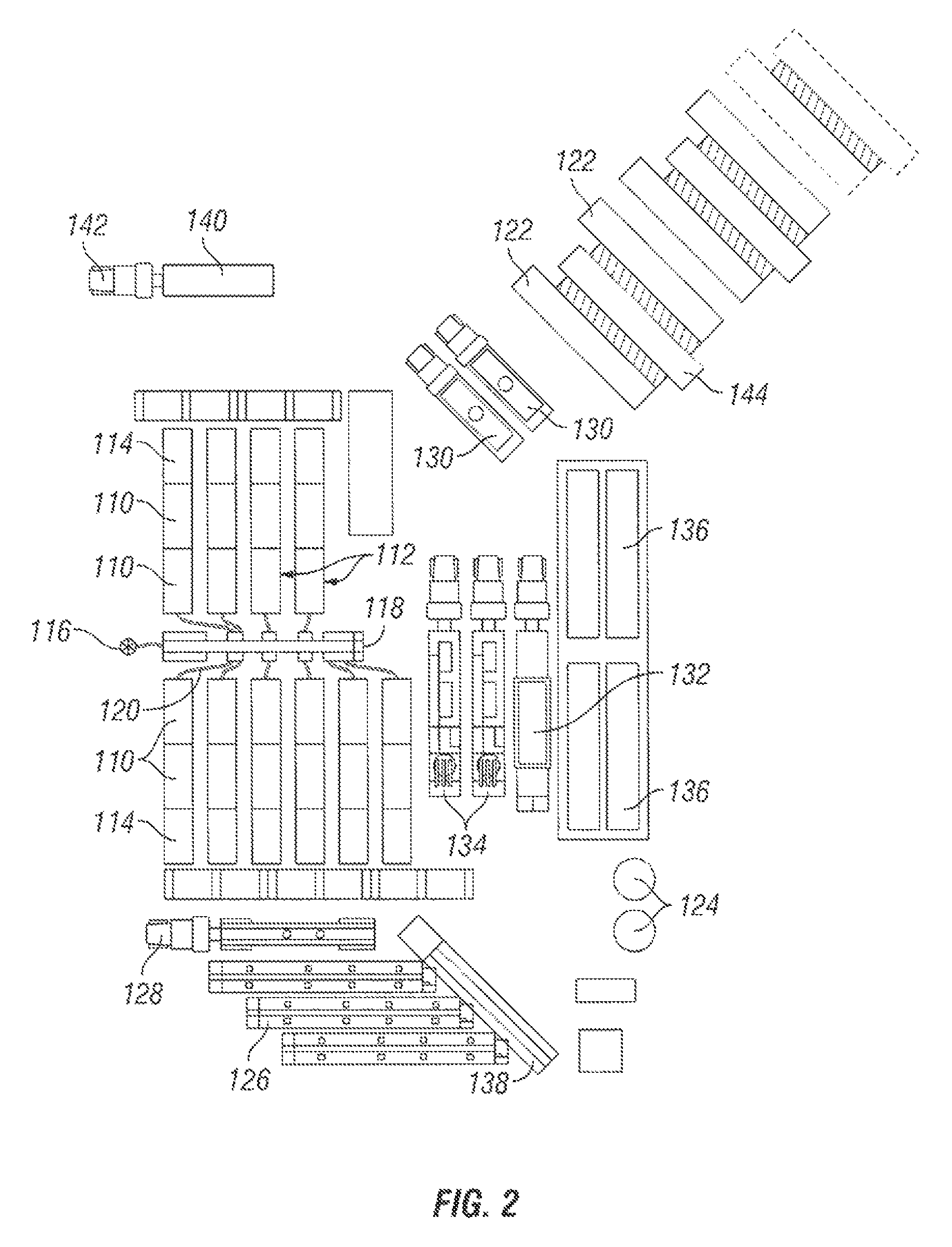

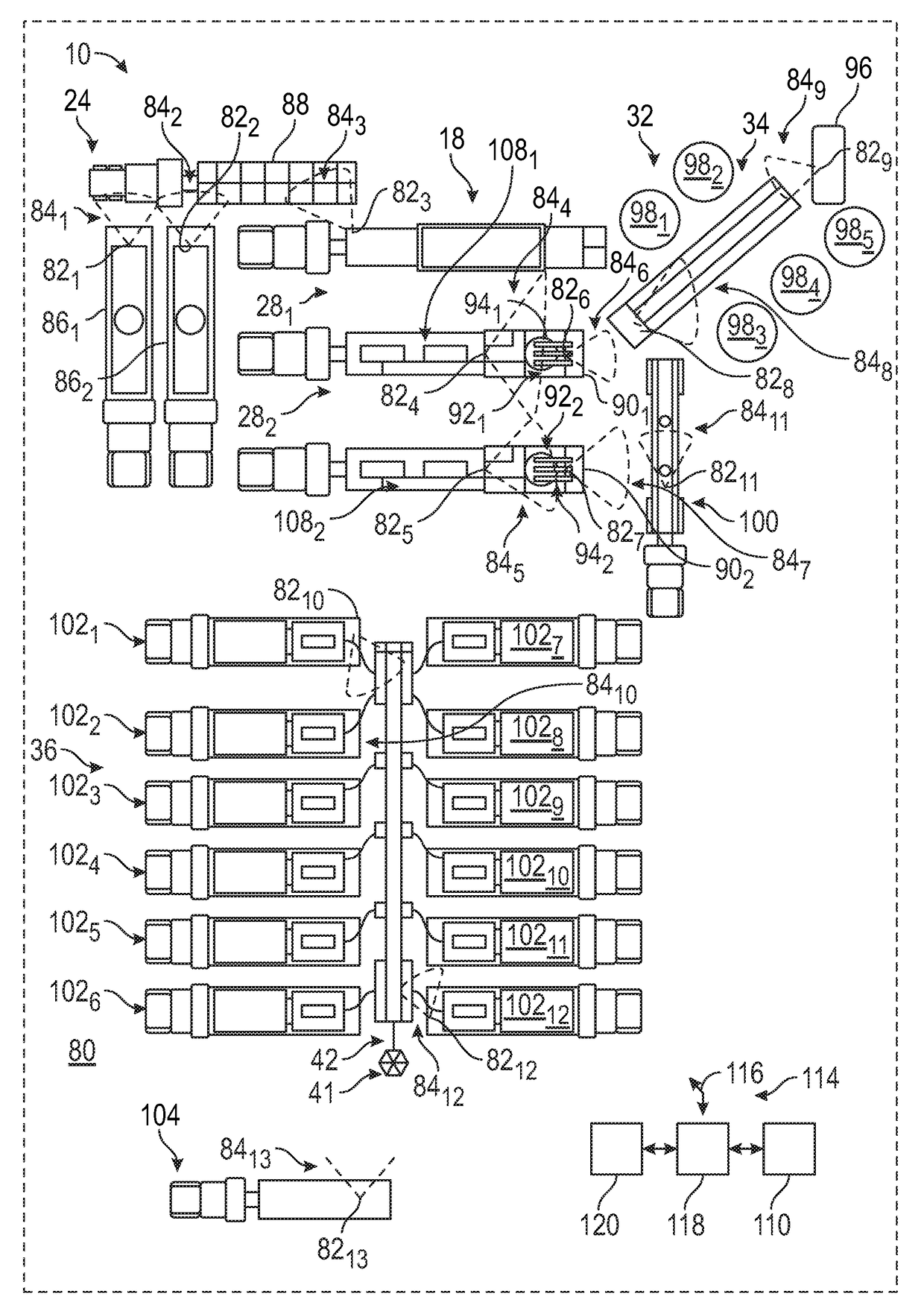

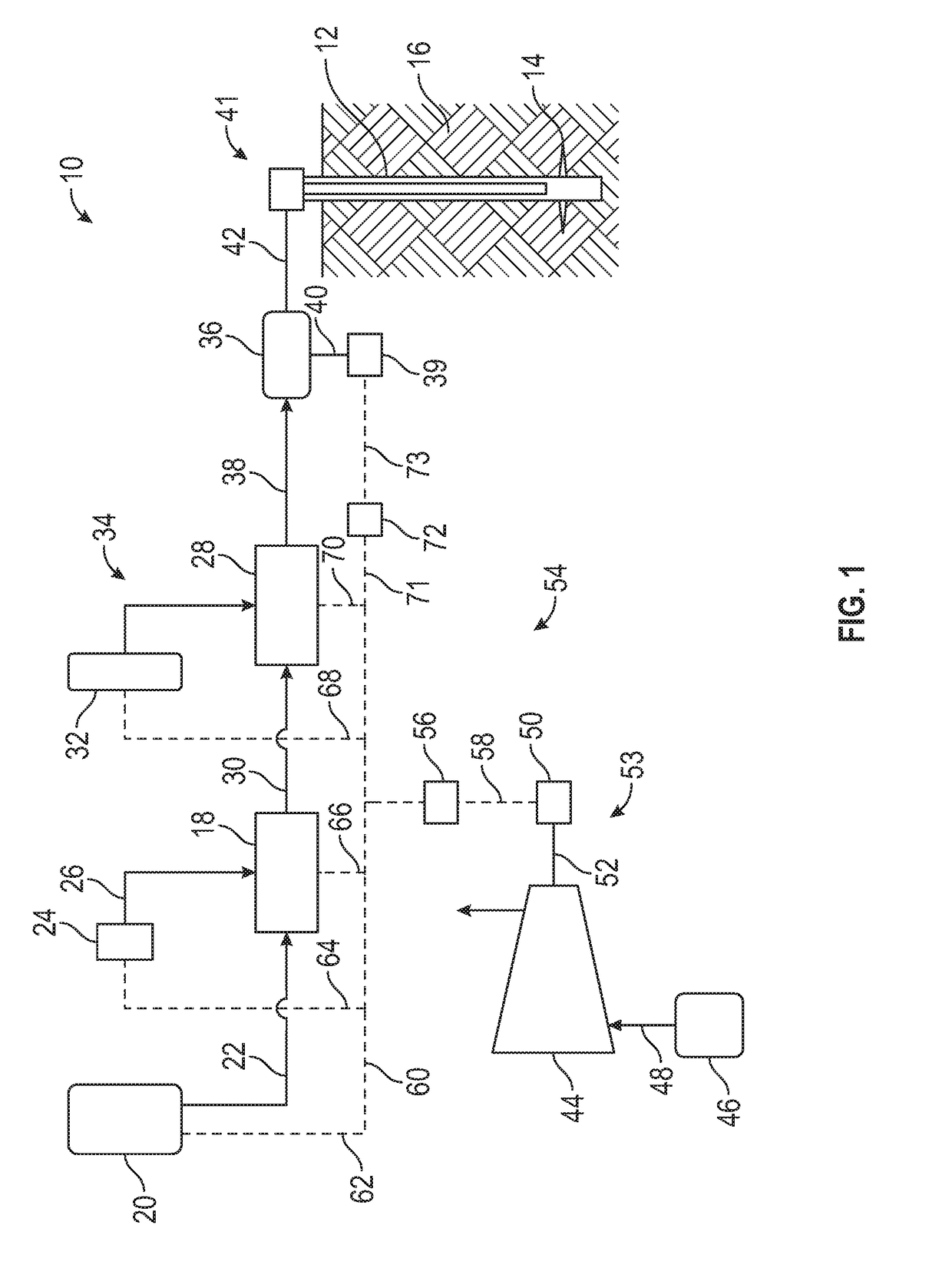

Remote monitoring for hydraulic fracturing equipment

A hydraulic fracturing system for fracturing a subterranean formation including a pump in communication via pump components with a wellbore that intersects the formation, and that pressurizes fluid in the wellbore, the fluid comprising a fracturing fluid slurry. The system further includes hydraulic fracturing system components for making the fracturing fluid slurry, and a monitoring system that selectively captures and transmits real time images of at least one of the hydraulic fracturing system components or pump components to enable remote monitoring of the at least one of the hydraulic fracturing system components or pump components.

Owner:US WELL SERVICS LLC

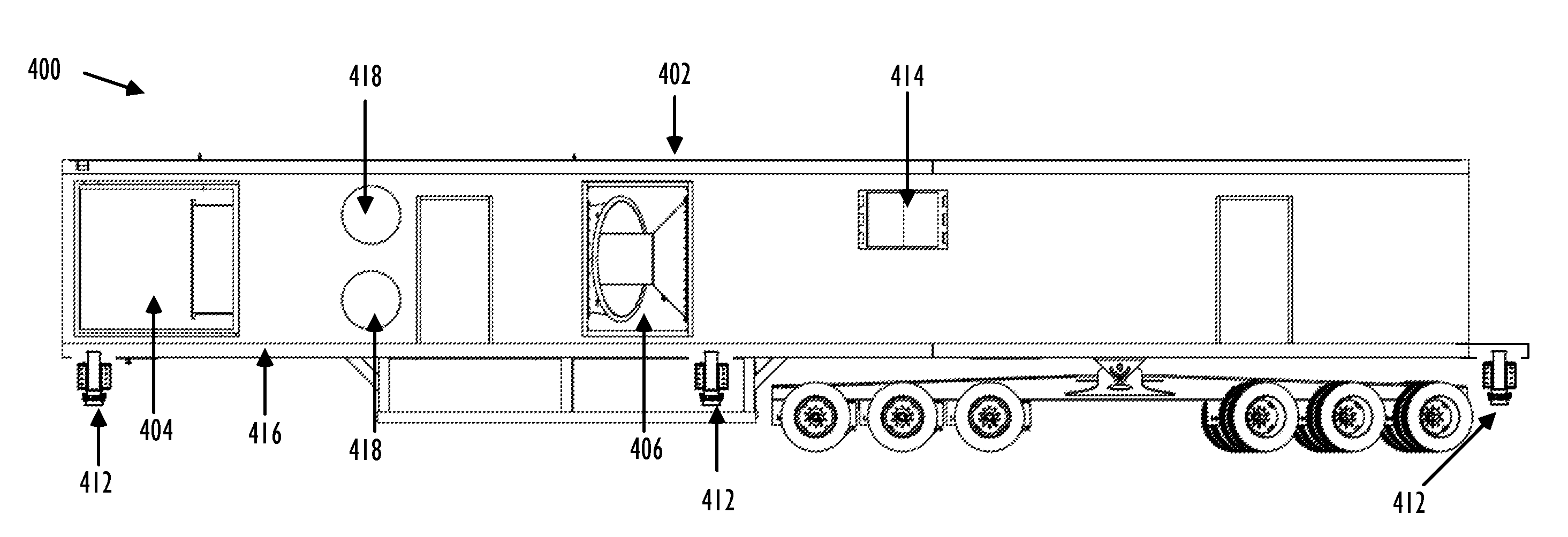

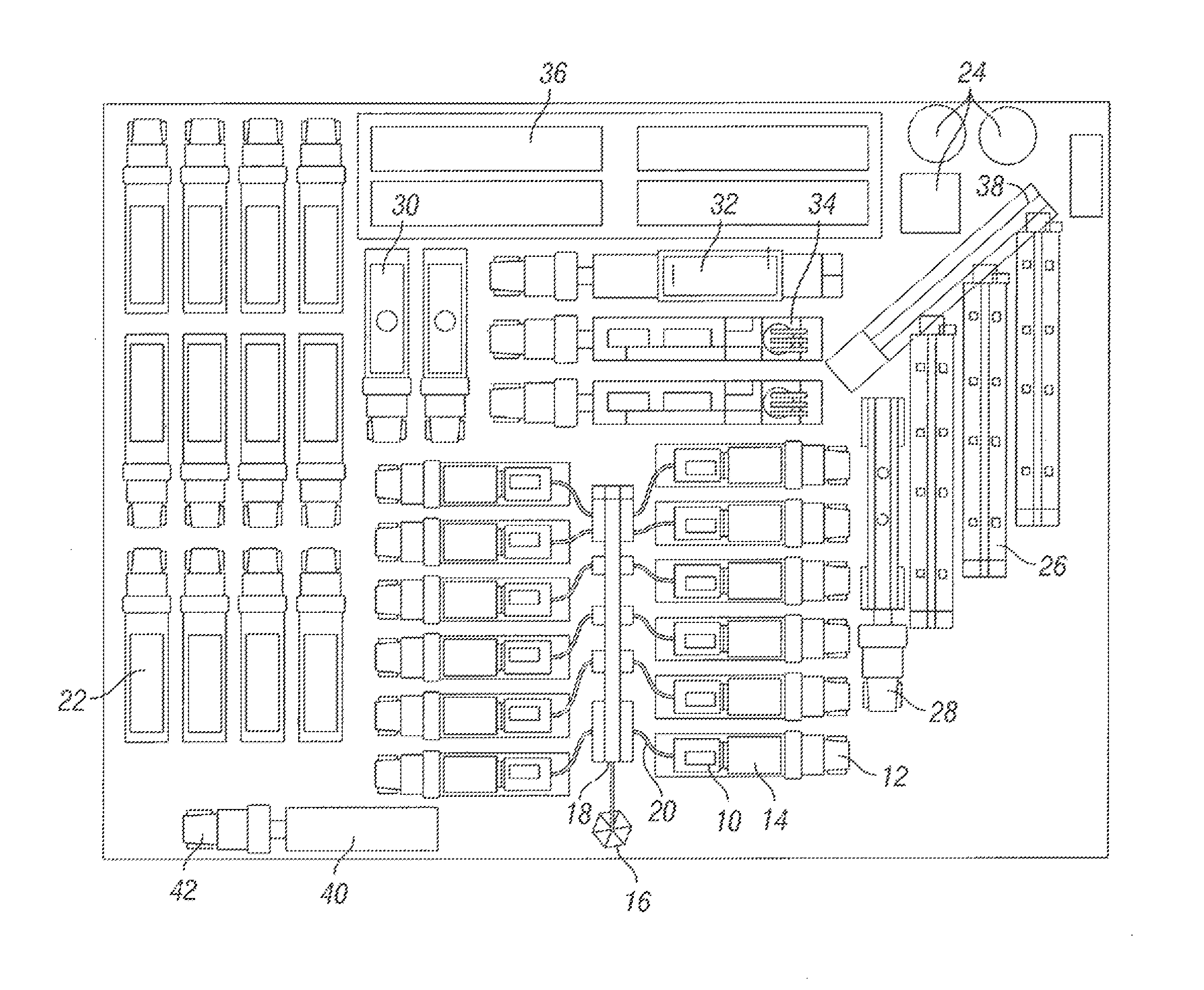

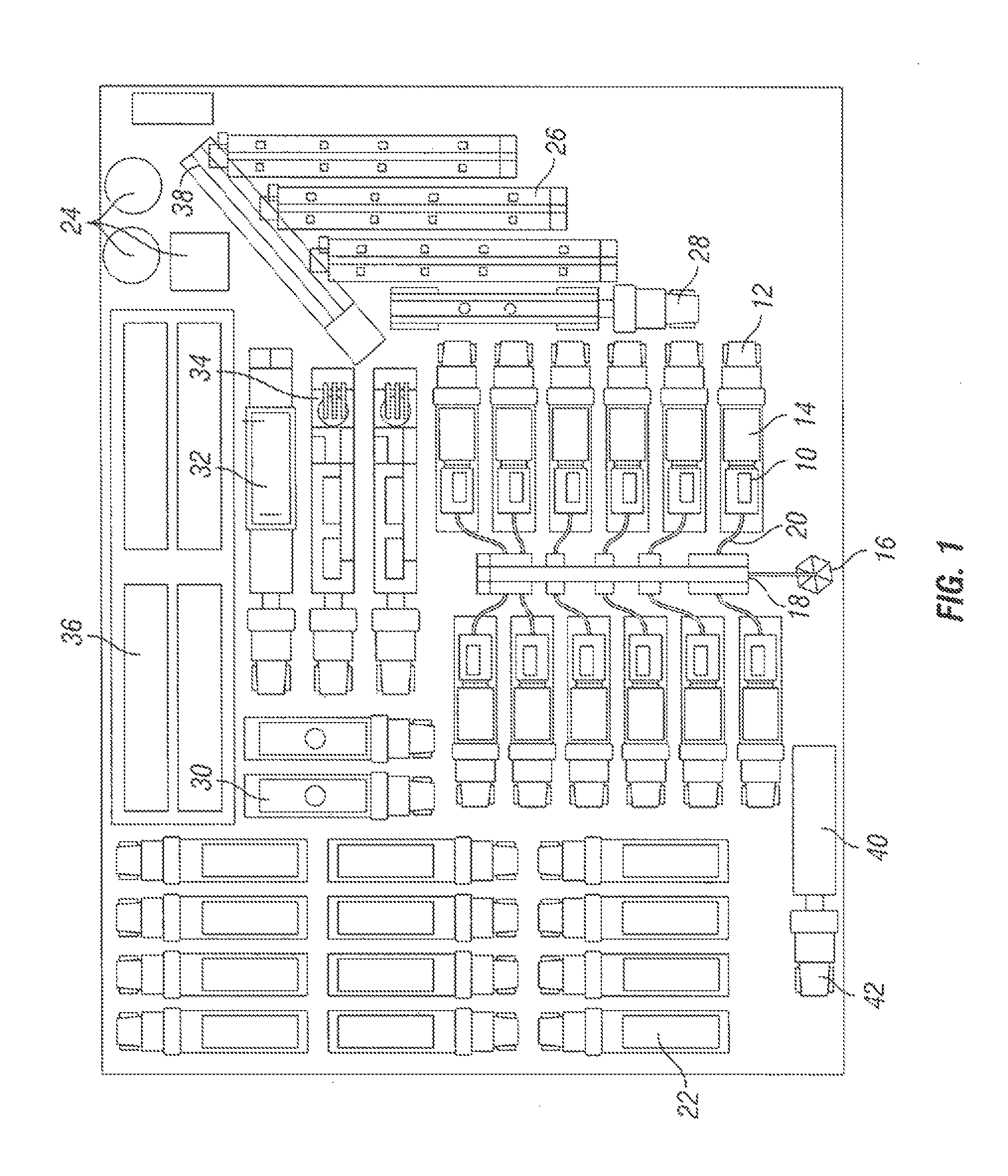

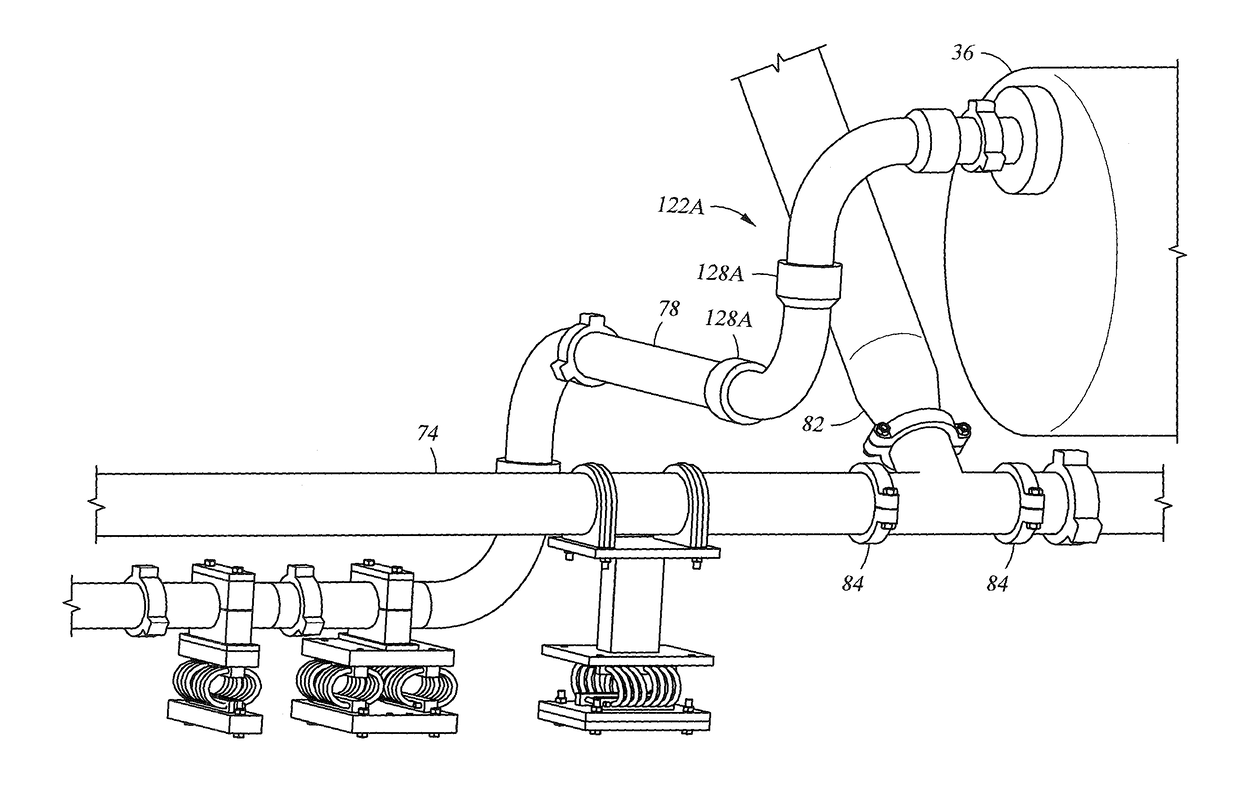

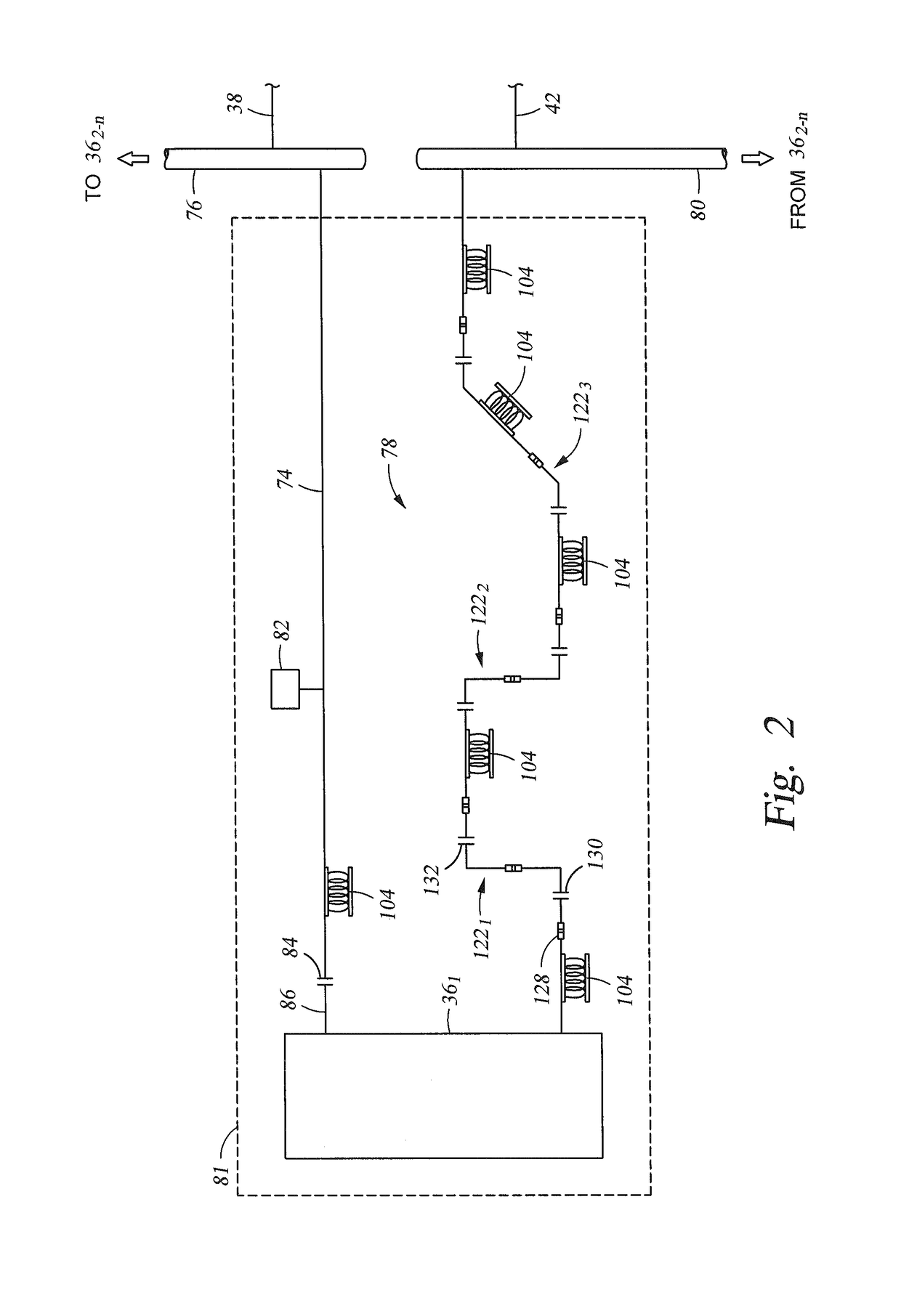

Suction and Discharge Lines for a Dual Hydraulic Fracturing Unit

An electrically powered hydraulic fracturing system includes pumps for pressurizing fracturing fluid, piping for carrying fracturing fluid, and field connections in obliquely oriented segments of the piping. The connections are between lead lines that couple directly to the pumps and lines carrying fluid to and from the pump; and are assembled and disassembled in the field. Operations personnel can more easily manipulate connections that are obliquely oriented than those that are horizontal or vertical.

Owner:US WELL SERVICS LLC

System for reducing vibrations in a pressure pumping fleet

ActiveUS10119381B2Vibration highReduce turbulenceAC motor controlPositive displacement pump componentsFracturing fluidHelical coil

An electrically powered hydraulic fracturing system having pumps for pressurizing fracturing fluid, piping for carrying fracturing fluid, and vibration reducing equipment for use with the piping. The vibration reducing equipment includes helical coils that support the piping. The coils are made of a wire rope made of strands of steel cable twisted together. Grooved fittings are provided on some piping connections, and which allow pivoting between adjacent fluid conveyance members. Swivel joints are strategically located in the piping which allow rotational flexing between adjacent sections of the piping; thereby attenuating vibration in the piping but without stressing the piping.

Owner:US WELL SERVICS LLC

Method for fracturing subterranean formations

InactiveUS6875728B2Reduce speedReduce the amount of waterFluid removalFlushingInorganic saltsFracturing fluid

A method of fracturing a formation with a fracturing fluid wherein the formation has particulate material that swells or migrates upon exposure to the fracturing fluid comprises preparing a fracturing fluid comprising (1) a thickening compound comprising a first surfactant selected from the group consisting of a cationic surfactant having only a single cationic group, an amphoteric surfactant and a mixture thereof; and, an anionic surfactant; and, (2) water, wherein no or essentially no inorganic salt is added to the fracturing fluid; and using the fracturing fluid to fracture the formation. A method for recycling a fracturing fluid is also provided.

Owner:BAKER HUGHES INC

System for Pumping Hydraulic Fracturing Fluid Using Electric Pumps

A system for hydraulically fracturing an underground formation in an oil or gas well to extract oil or gas from the formation, the oil or gas well having a wellbore that permits passage of fluid from the wellbore into the formation. The system includes a plurality of electric pumps fluidly connected to the well, and configured to pump fluid into the wellbore at high pressure so that the fluid passes from the wellbore into the and fractures the formation. The system can also include a plurality of natural gas powered generators electrically connected to the plurality of electric pumps to provide electrical power to the pumps.

Owner:US WELL SERVICS LLC

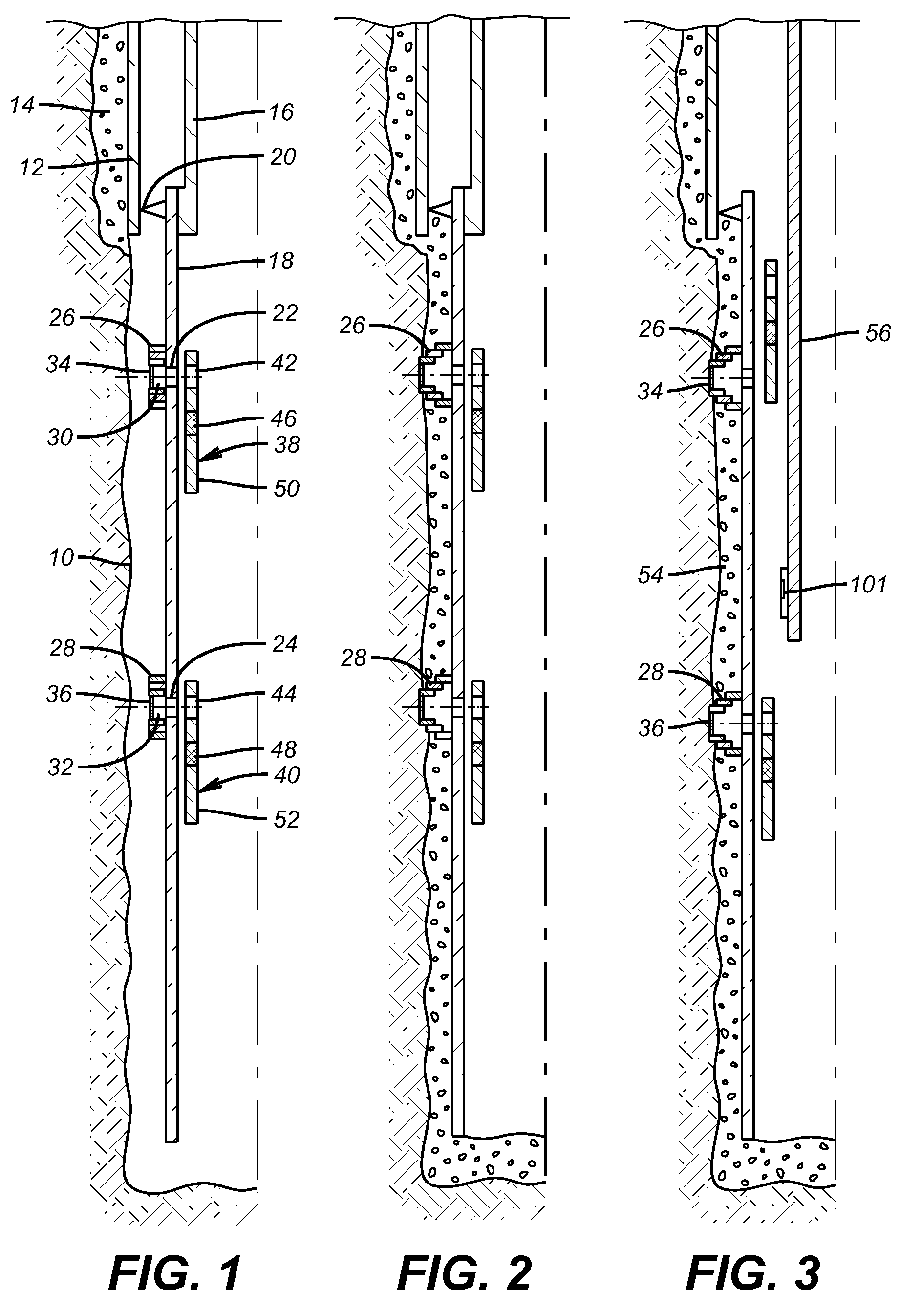

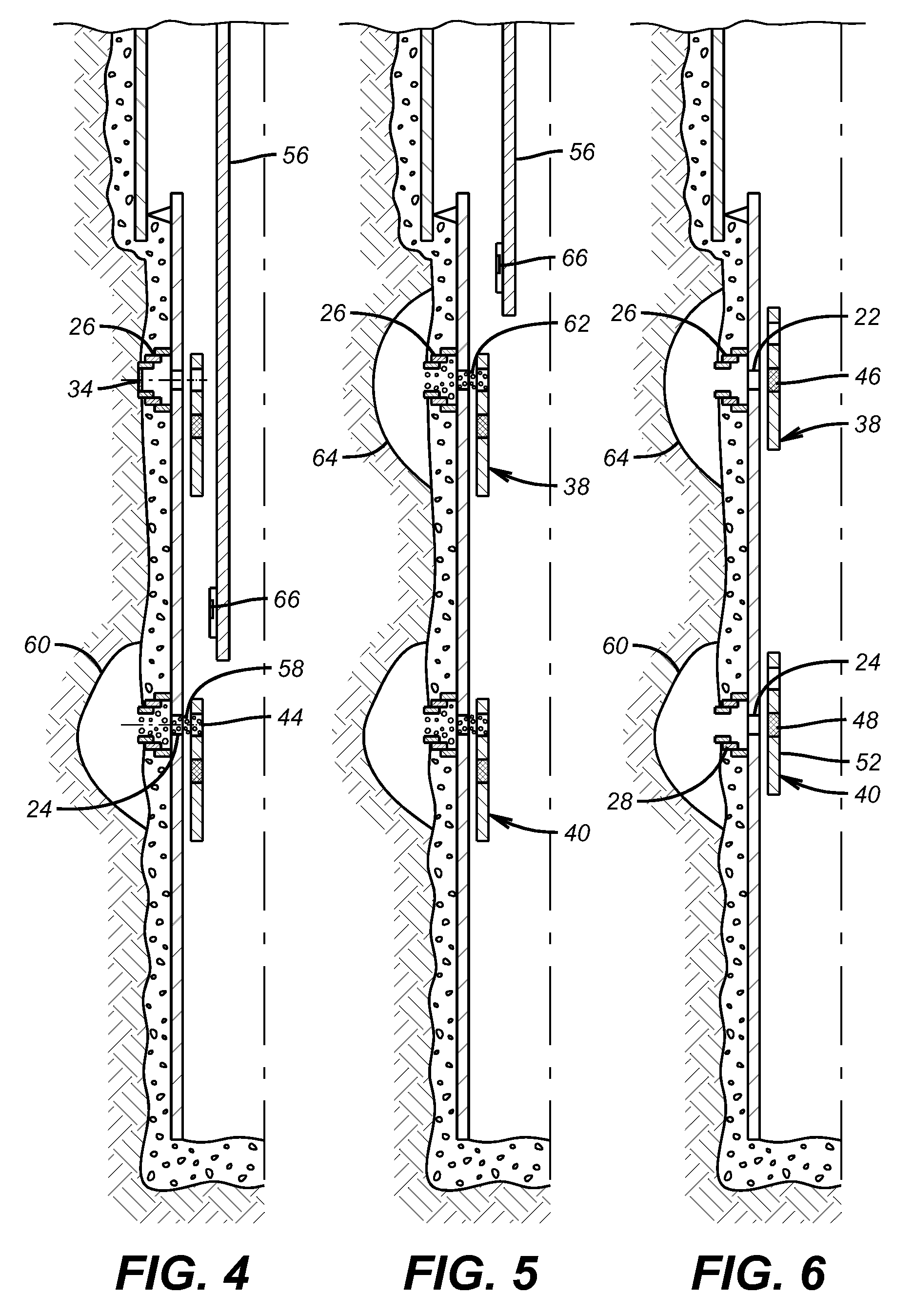

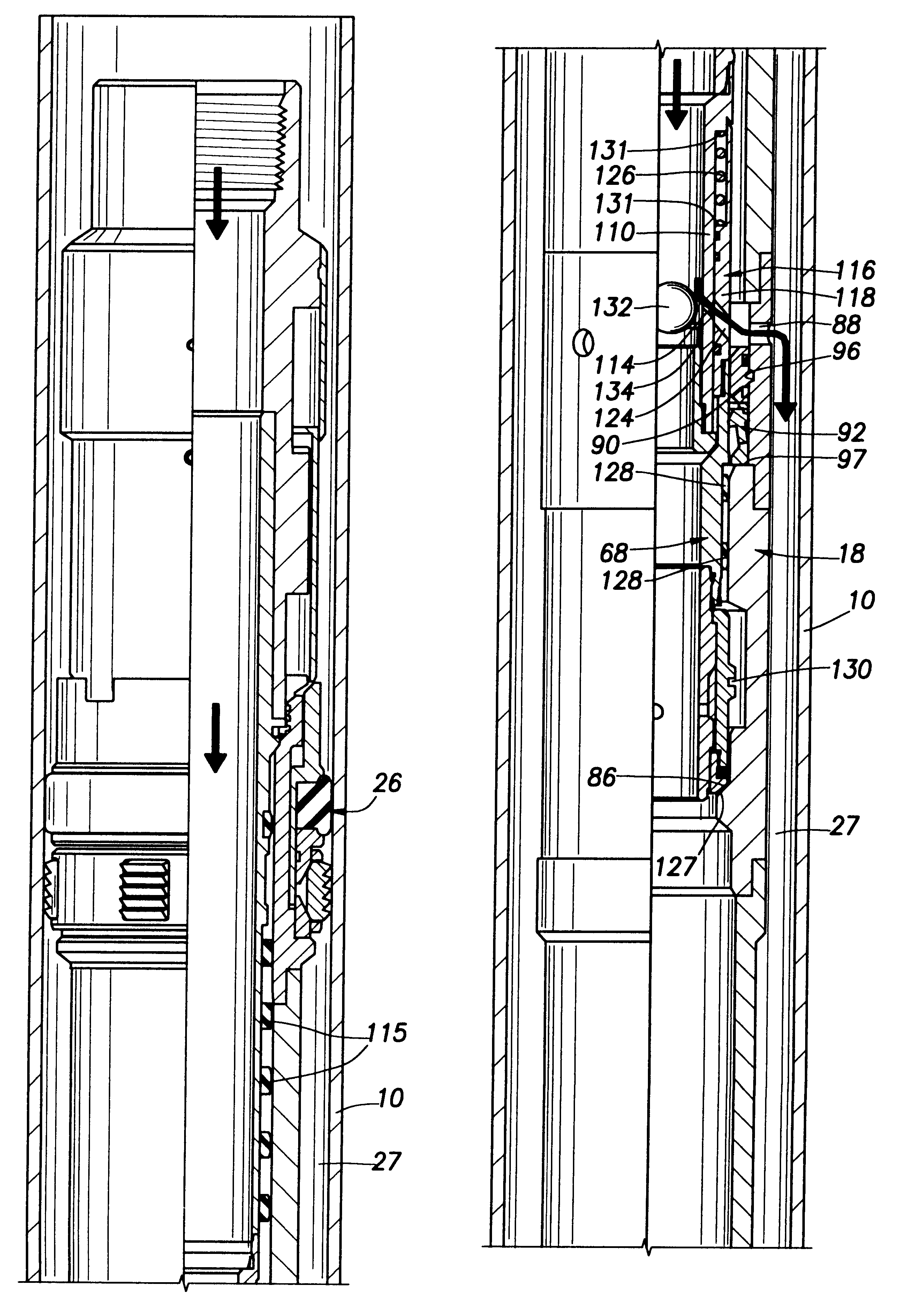

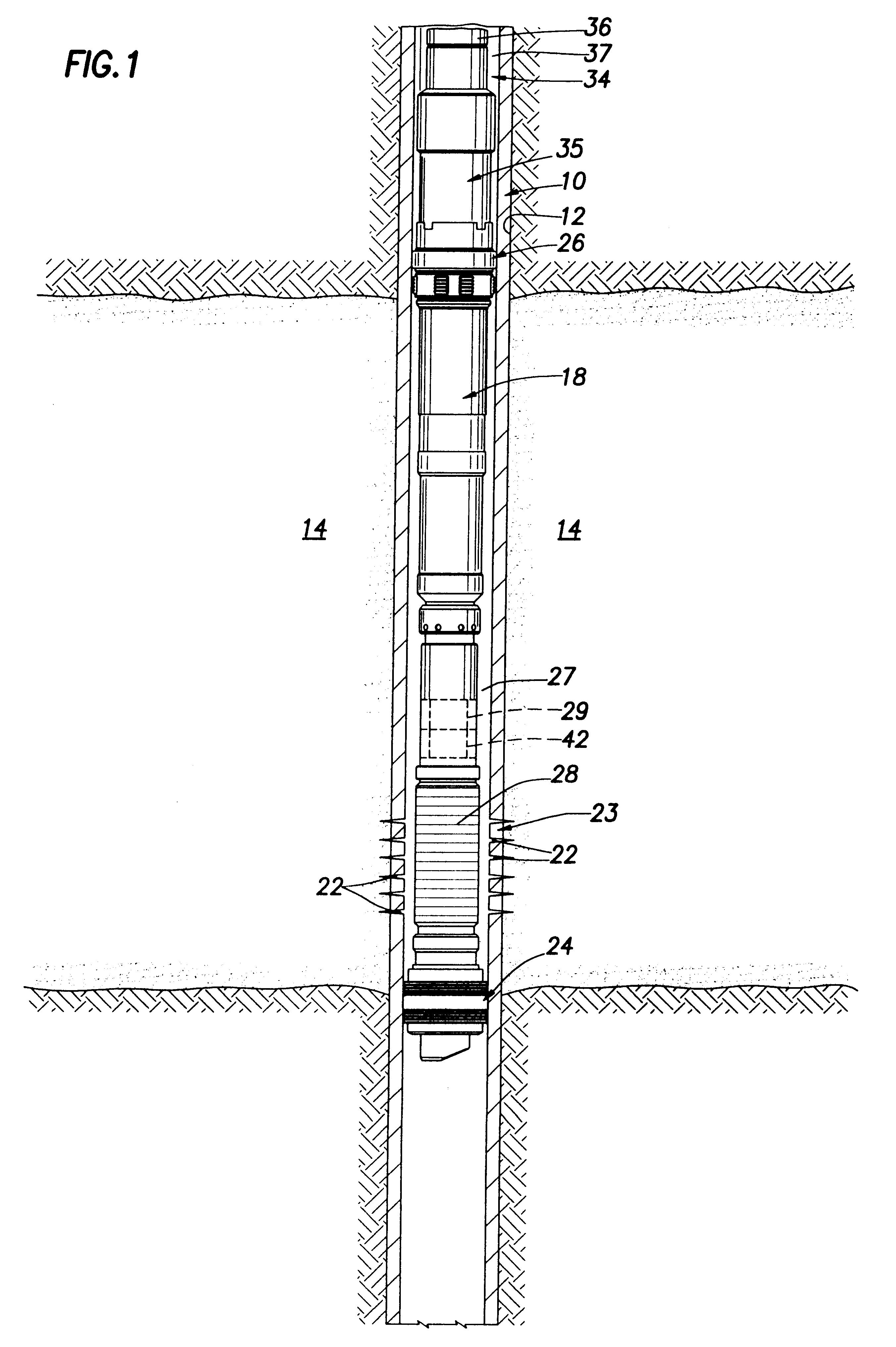

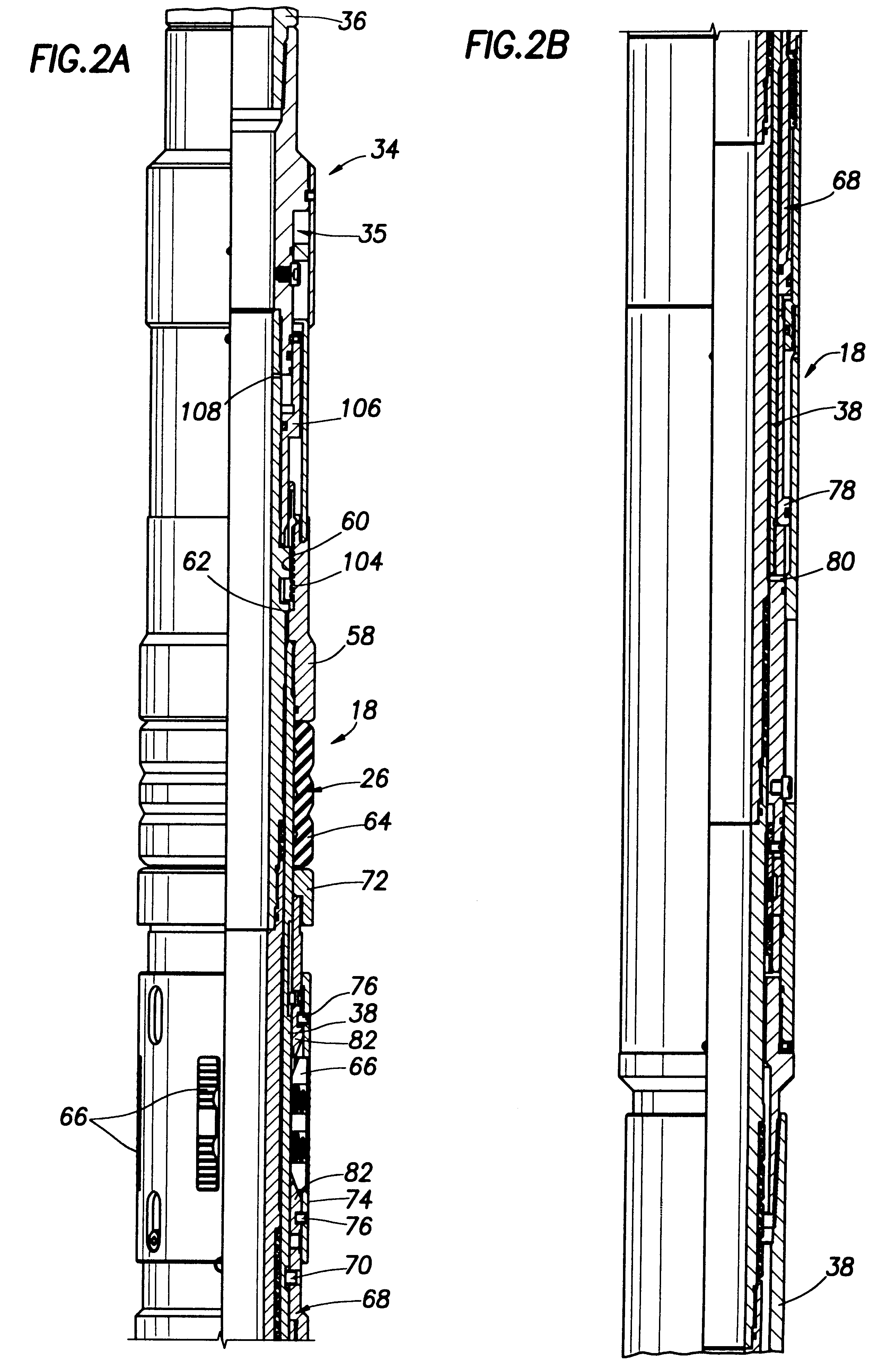

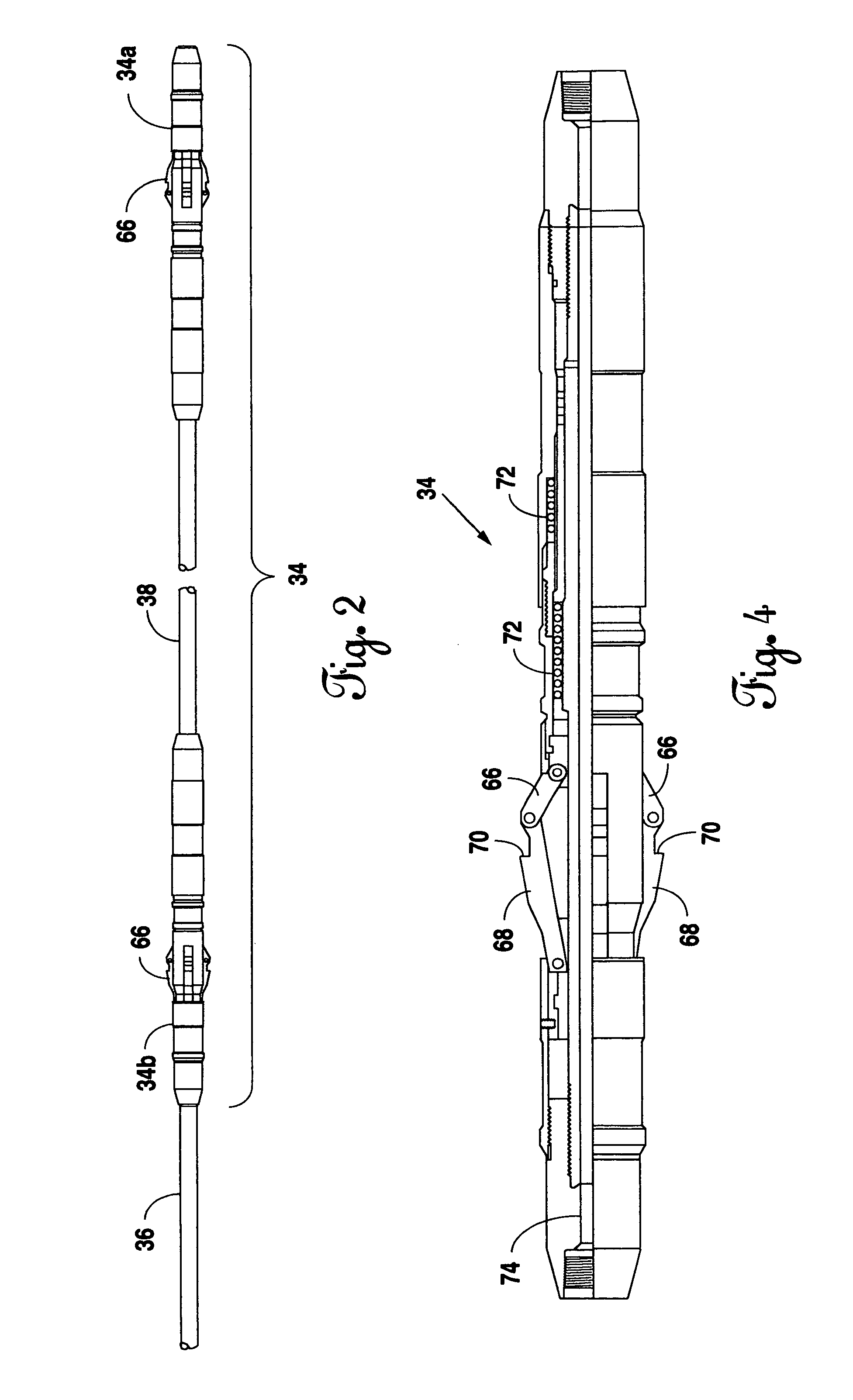

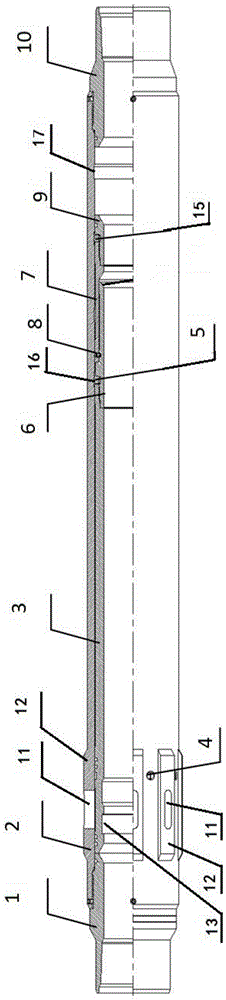

System for installation of well stimulating apparatus downhole utilizing a service tool string

A service tool string (34) is releasably attached to a bottom hole assembly (18) and forms a production string as well as a work string. The tool (35) has a mandrel (102) and a slide valve assembly (68) mounted on the mandrel for relative sliding movement. Crossover ports (114, 124) are provided in the mandrel (102) and the slide valve assembly (68). Slide valve assembly (68) moves by gravity and spring action when not contacted by the bottom hole assembly (18) to a position in which ports (114, 124) are blocked as shown in FIG. 7B. Upon contact of slidable valve assembly (68) with the bottom hole assembly (18), slide valve assembly is moved upwardly for alignment of ports (114, 124) as shown in FIGS. 5B and 6B. An equalizing valve (29) as shown in FIGS. 10-12 is effective to equalize the fluid pressure within the bottom hole assembly (18) with the fluid pressure outside the perforated casing section (23) so that in a reverse position as shown in FIG. 7B, the service tool (35) can be lifted to a position above the upper packer assembly (26) and above the bottom hole assembly (18). A diverter ball (132) seated on a ball catcher (134) is effective to divert the fracturing fluid outwardly through crossover ports (114, 124) as shown in FIG. 6B for downward flow through the annulus (27) into the formation adjacent the perforated casing section (23).

Owner:SCHLUMBERGER TECH CORP

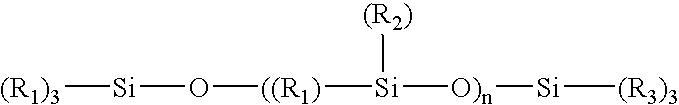

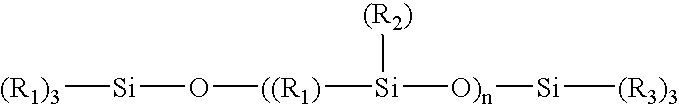

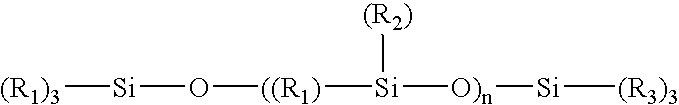

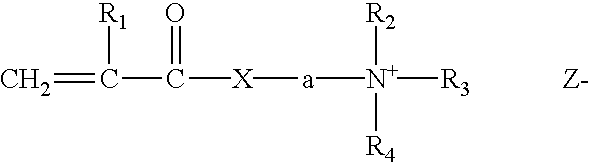

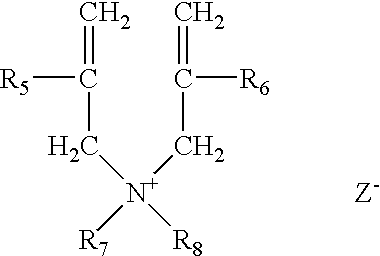

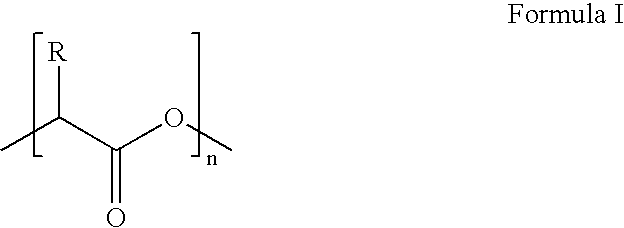

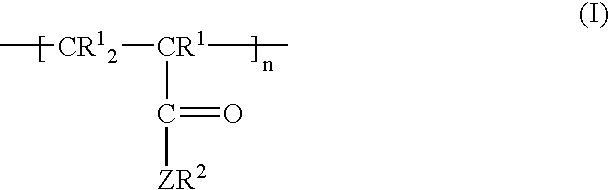

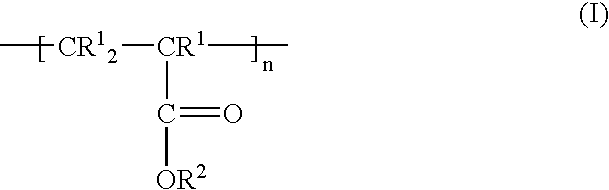

Method for making hydrophobically associative polymers, methods of use and compositions

InactiveUS6417268B1Cosmetic preparationsSludge treatment by de-watering/drying/thickeningHydrophilic monomerSludge

Method for producing an hydrophobically associative polymer is provided which is characterized by forming a monomer solution comprising a surfactant, at least one hydrophobic ethylenically unsaturated monomer, at least one hydrophilic monomer selected from nonionic ethylenically monomers, cationic ethylenically unsaturated monomers, anionic ethylenically unsaturated monomers or mixtures thereof, and water; forming a salt solution comprising a multivalent salt and water; mixing the monomer solution and salt solution to form a mixed solution; and charging the mixed solution with an initiator, thereby polymerizing the monomers to form the hydrophobically associative polymer in a dispersion. Aqueous dispersion containing the hydrophobically associative polymer formed by the method. The aqueous dispersion containing the hydrophobically associative polymer may be used in a paint formulation, in a mobility control fluid useful in enhanced oil recovery, in a secondary or tertiary oil recovery system, in an enhanced oil recovery method, in a cementious composition, in an oil well drilling mud formulation, in a fracturing fluid formulation, in a wastewater treatment system, or in a dewatering sludge system.

Owner:SOLENIS TECH CAYMAN

Permeable cement and methods of fracturing utilizing permeable cement in subterranean well bores

Owner:HALLIBURTON ENERGY SERVICES INC

WirelessTag Tracer Method and Apparatus

A fluid can be tracked in a wellbore utilizing at least one WID tag, such as an LW tag or an RFID tag, entrained in the fluid. A WID tag reader can be disposed and / or displaced in the wellbore, for example, on a drill string or a casing string. A reader can be utilized to locate the at least one WID tag in the wellbore. A reader can be housed in a drill string sub. A fluid entrained with at least one WID tag can be utilized as a tracer fluid. A WID tag can be entrained in cement or a drilling or fracture fluid.

Owner:VERRET ROBIN JAMES

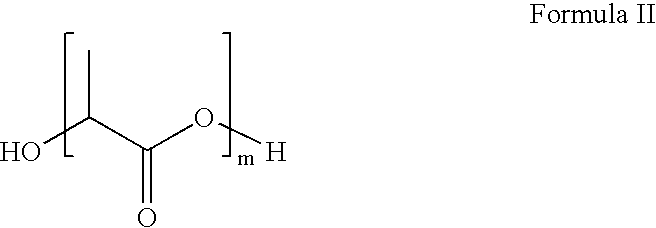

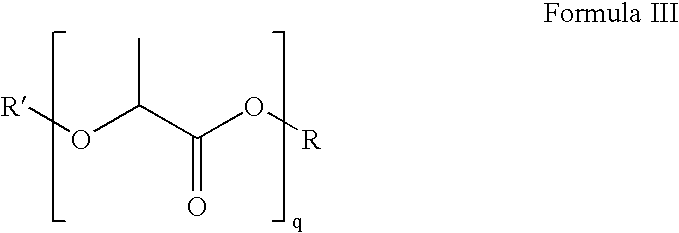

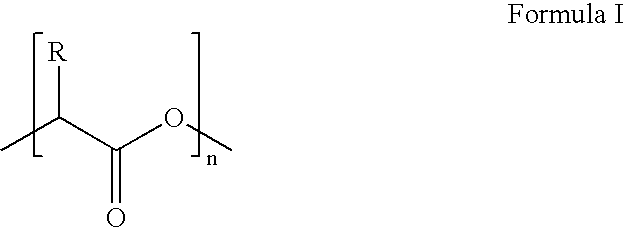

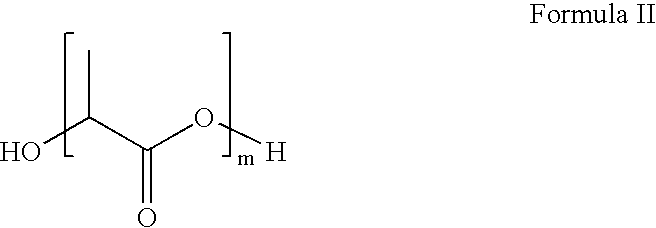

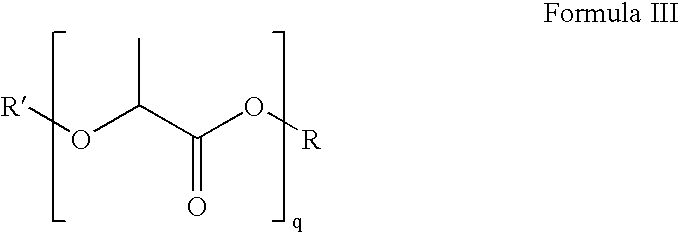

Method and materials for hydraulic fracturing of wells

InactiveUS6949491B2Increase effective viscosityRestrict pressure lossFluid removalFlushingFracturing fluidCarrier fluid

Hydraulic fracturing of wells by injecting a degradable polymer phase as a fracturing fluid is provided. Composition and degree of polymerization of the degradable polymer and the selection of additives may be varied to adjust the viscosity, degradation time and other properties of the fracturing fluid. Viscous degradable fluid or pellets of degradable polymer may be placed in a wellbore as an internal phase in a low viscosity carrier fluid. A polymer-continuous liquid phase may be formed at a selected location in the wellbore, usually near perforations, before the polymer phase is pressured into a formation to form a hydraulic fracture.

Owner:ENERPOL LLC

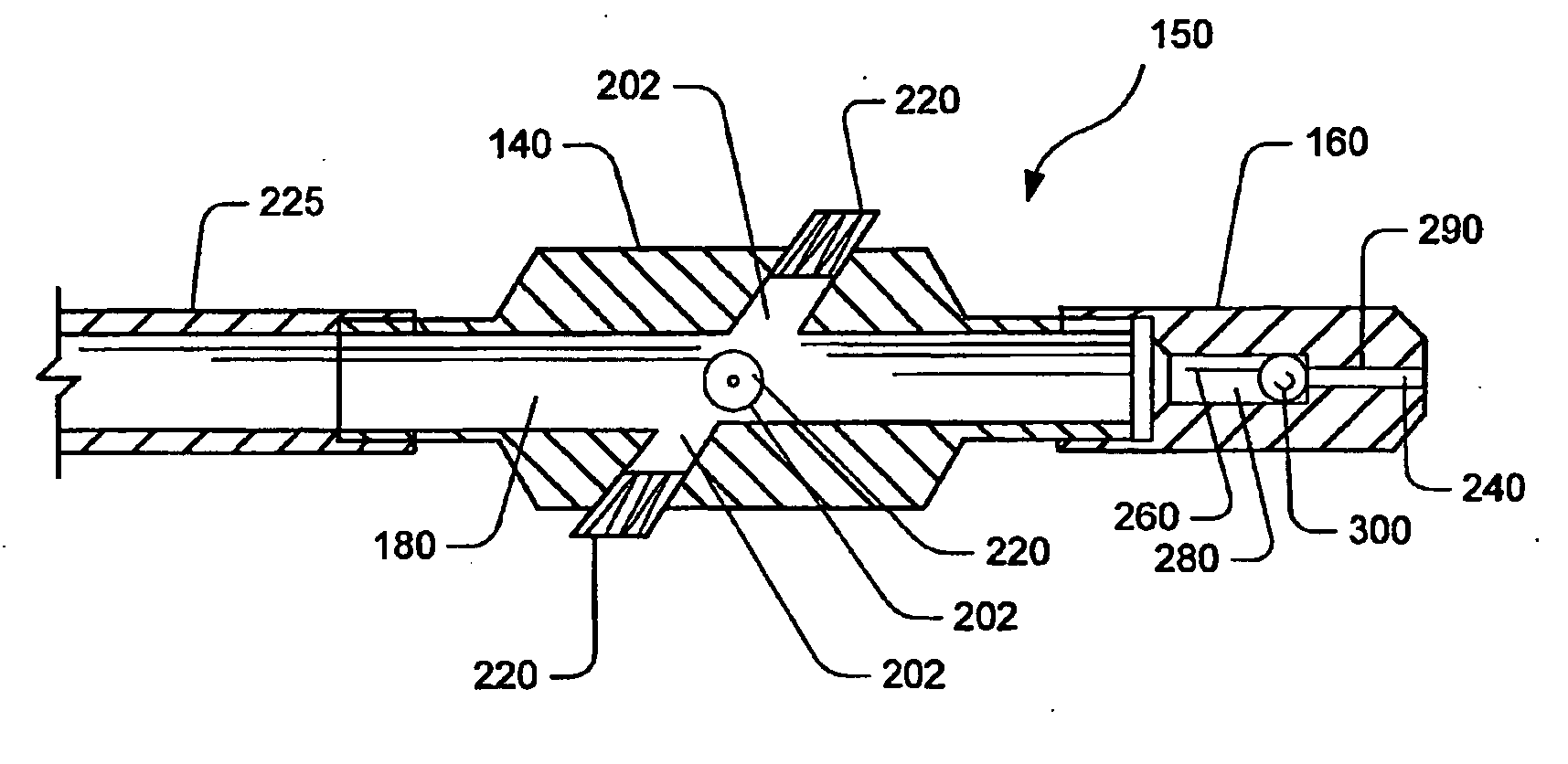

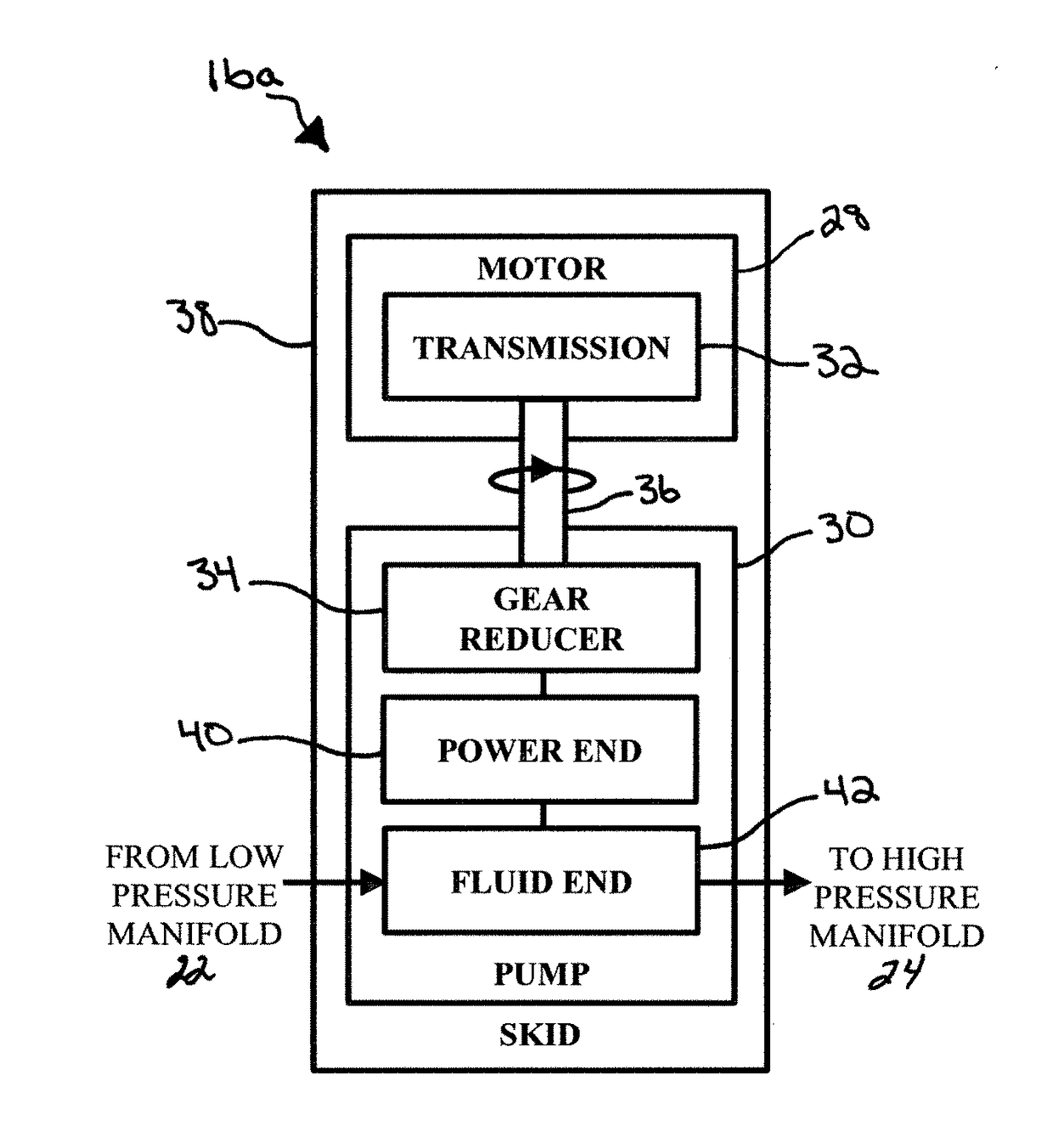

Transmission for pump such as hydraulic fracturing pump

InactiveUS20170234308A1Positive displacement pump componentsFlexible member pumpsAngular velocityFracturing fluid

An apparatus and method according to which a fluid, such as a fracturing fluid, is pressurized. The apparatus includes a motor that produces a first rotational output including a first angular velocity, a pump operably coupled to the motor, the pump comprising a fluid end and a power end operably coupled to the fluid end, and a transmission operably coupled between the motor and the pump. The transmission receives the first rotational output as a first rotational input, the first rotational input including the first angular velocity, and converts the first rotational input into a second rotational output, the second rotational output including a second angular velocity. The power end receives the second rotational output as a second rotational input, the second rotational input including the second angular velocity. In some embodiments, the transmission is directly connected to, or part of, the pump and the motor.

Owner:S P M FLOW CONTROL

Cemented open hole selective fracing system

A cemented open hole selective fracing system is shown. In the producing zone, an open hole is drilled therein and a production tubing is cemented in place. At preselected locations along the production tubing, the production tubing will have sliding valves located there along. The sliding valves may be selectively opened by a shifting tool, and the cement around the sliding valve dissolved. Thereafter, the formation may be fraced immediately adjacent the opened sliding valve. By selectively opening different combinations of sliding valves, fracing can occur in stages with more fracing pressure and more fracing fluid being delivered deeper into the formation. Just as the sliding valves can be selectively opened with a switching tool, the sliding valves can also be selectively closed to protect the production of the well.

Owner:PEAK COMPLETIONS TECH INC

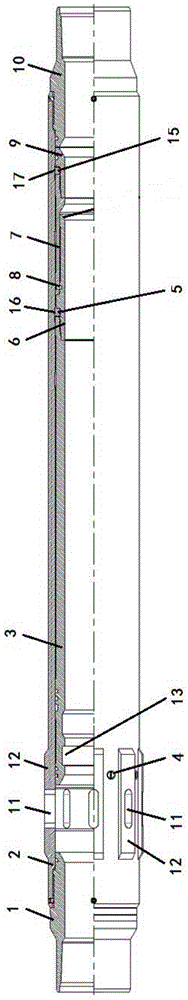

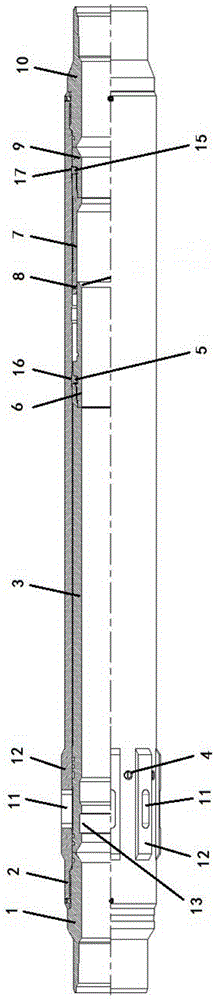

Switchable well cementation sliding sleeve based on fracturing of separate layers and construction method thereof

A switchable well cementation sliding sleeve based on fracturing of separate layers comprises an outer barrel, an upper joint and a lower joint are installed at the upper end and the lower end of the barrel respectively, a fracturing port is formed in the side wall of the upper portion of the outer barrel, and an upper center pipe, an upper connection sleeve, a lower center pipe and a lower connection sleeve are installed inside the outer barrel. The switchable well cementation sliding sleeve based on fracturing of the separate layers is not provided with a ball seat, so a full bore of the inner wall can be maintained, fracturing fluid can flow back in time, and the construction period is shortened. The well cementation sliding sleeve is set in the upper center pipe through a bottom packer, downward pushing force big enough can be generated in the process of annular or continuous tubing pressing, so the upper center pipe can overcome shearing force of corresponding shearing dowels and move downwards, and therefore the fracturing port of the well cementation sliding sleeve can be opened.

Owner:JEREH ENERGY SERVICES

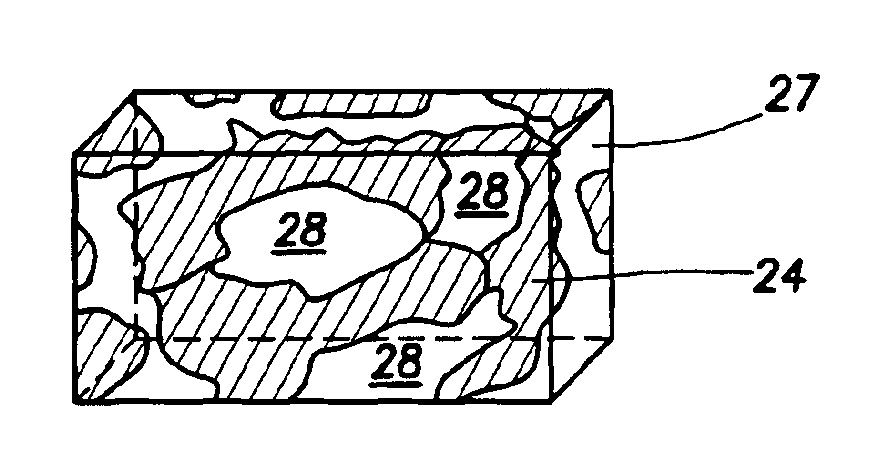

Permeable cement and methods of fracturing utilizing permeable cement in subterranean well bores

InactiveUS20040261999A1Reduce hydrostatic pressureDesirable efficiencyAlkali metal silicate coatingsFluid removalFracturing fluidMaterials science

The present invention relates to methods of stimulating a subterranean formation. More particularly, but not by way of limitation, the present invention relates to methods of fracturing subterranean formations utilizing a fracturing fluid comprising a permeable cement composition that may be used as a propping agent. One method of stimulating a subterranean formation of the present invention comprises the following steps: preparing a permeable cement composition comprising a hydraulic cement, water, and a degradable material capable of undergoing an irreversible degradation downhole; injecting the permeable cement composition into the subterranean formation at a pressure sufficient to create a fracture in the subterranean formation; and allowing the permeable cement composition to form a proppant matrix having voids in the fracture.

Owner:HALLIBURTON ENERGY SERVICES INC

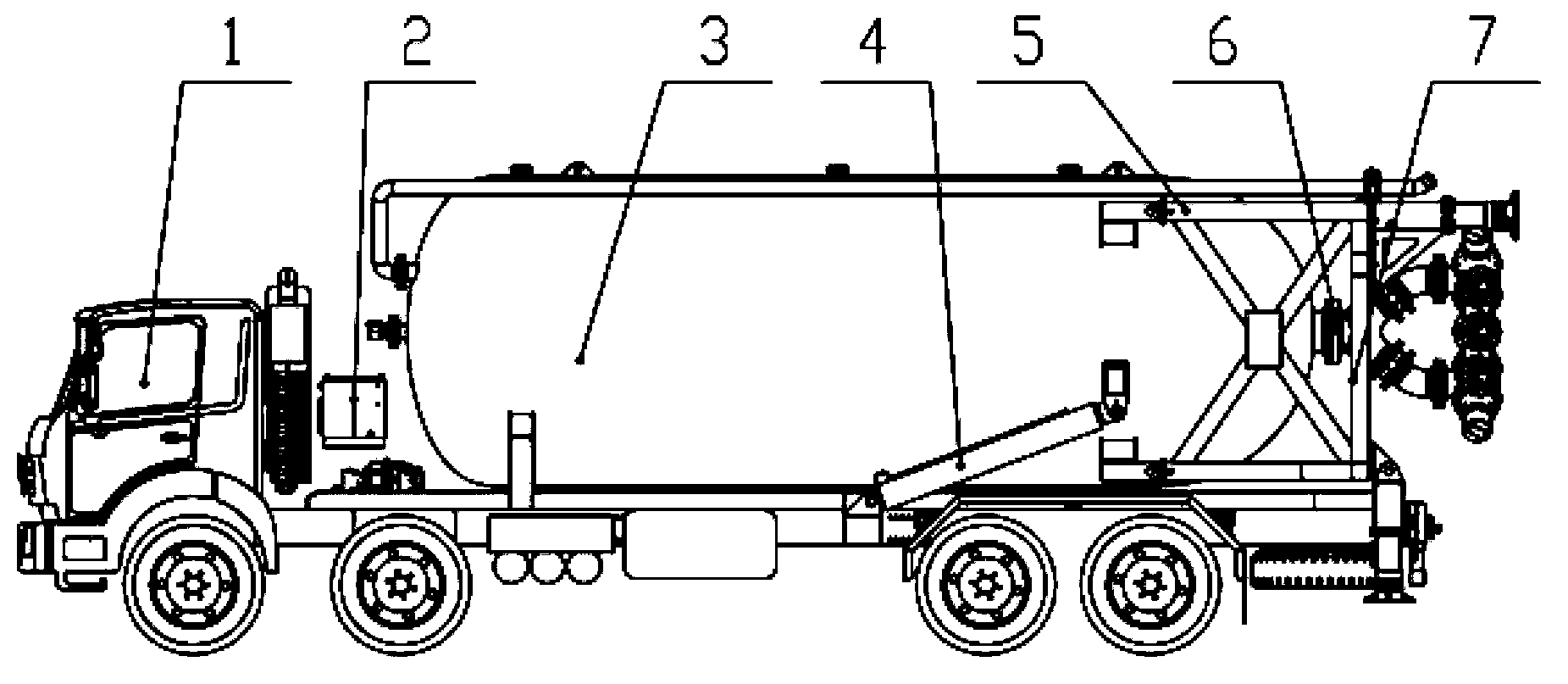

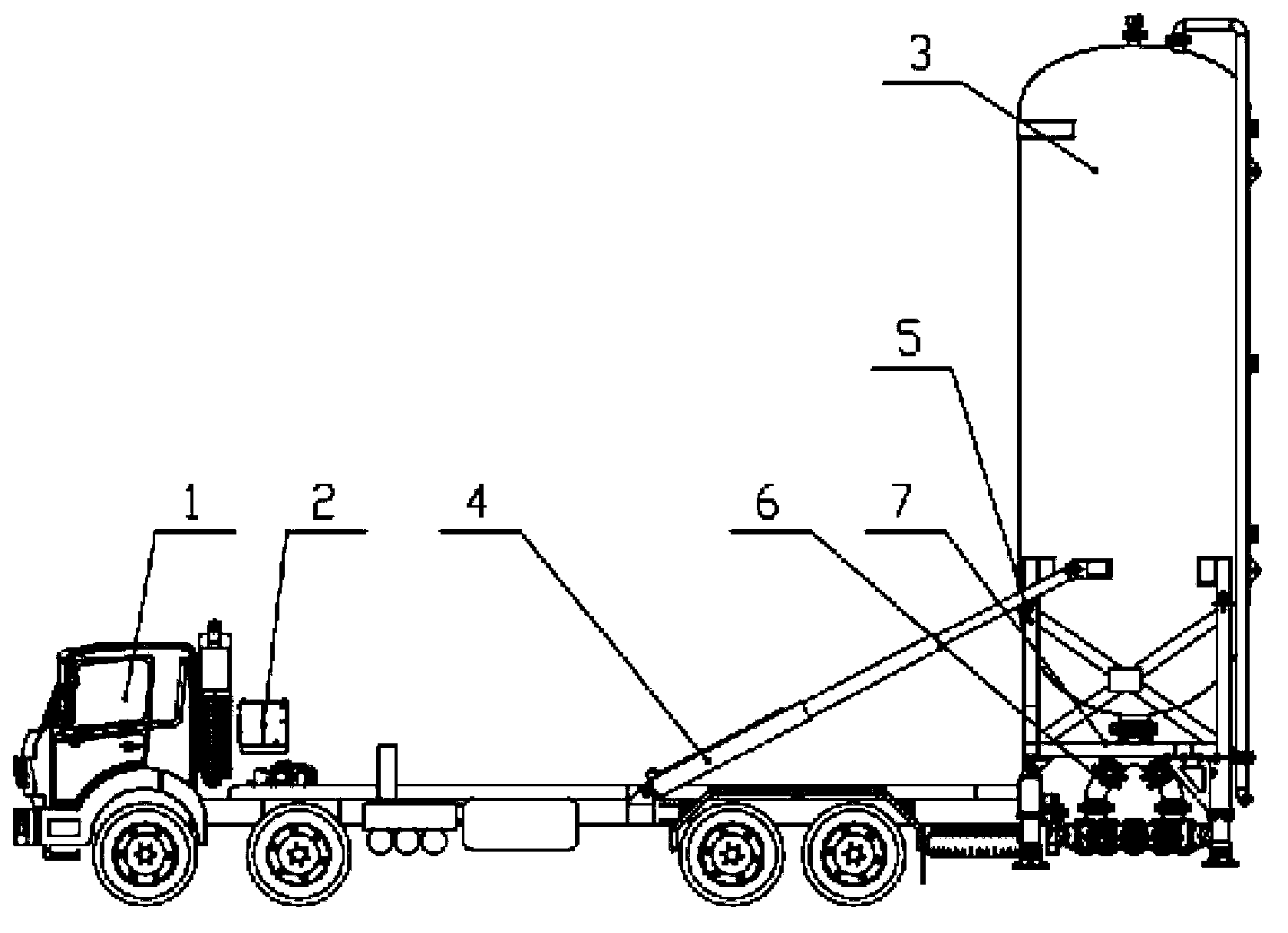

Fracturing sand mixing device

The invention provides a fracturing sand mixing device used for mixing fracturing fluid. The fracturing sand mixing device comprises a solid-liquid mixing device, and the solid-liquid mixing device is a pressure container. The solid-liquid mixing device comprises a solid lead-in port capable of leading in solid particles of the fracturing fluid, a base fluid lead-in port for leading in base fluid of the fracturing fluid, a mixing inner cavity for accommodating the solid particles and the base fluid and a solid-liquid lead-out port for leading out the fracturing fluid formed by mixing. Substances such as carbon dioxide or petroleum gas which are in a gas state under normal temperature can be kept in a liquid state by high pressure through the fracturing sand mixing device and are mixed with the solid particles to form the fracturing fluid, and the goal of preparing the fracturing fluid with liquid carbon dioxide or liquefied petroleum gas (propane) serving as the base fluid is achieved.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP

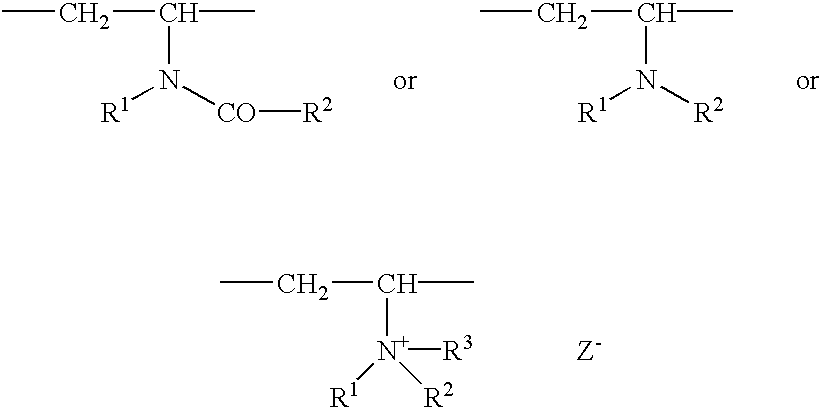

Method of fracturing subterranean formations utilizing emulsions comprising acrylamide copolymers

InactiveUS7482310B1Predictable and convenient and efficient preparationSufficient amountOther chemical processesMixing methodsPolymer scienceFracturing fluid

A method of treating a subterranean formation penetrated by a well bore including:(a) preparing a fracturing fluid containing a mixture resulting from:(I) providing a water-in-oil emulsion composition that includes:(i) 5% to 99% by weight of a water-in-oil emulsion polymer comprising a polymer or copolymer containing repeat units from an acrylamide monomer;(ii) 0.5% to 90% by weight of a carrier solvent; and(iii) 0 to 90% by weight of a fluidizing agent; and adding(iv) 0.1% to 10% by weight of one or more inorganic microparticles, where the total of all components is 100% by weight; and(II) adding the water-in-oil emulsion composition to water; and(b) contacting the subterranean formation with the fracturing fluid.

Owner:KROFF CHEM +1

System and method for fracturing formations in bores

A system for fracturing a formation in a bore at a worksite is disclosed. The system includes a turbine. The system also includes a pump coupled to the turbine. The pump includes a housing member that is adapted to receive a fracturing fluid. The pump also includes an auger rotatably disposed within the housing member. The auger pressurizes the fracturing fluid at a desired pressure based on a speed of the turbine to supply a pressurized fracturing fluid to the bore. The auger includes a shaft coupled to the turbine and rotatable about a rotational axis. The auger also includes a helical blade disposed around the shaft.

Owner:CATERPILLAR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com