Patents

Literature

1435 results about "Liquefied petroleum gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquefied petroleum gas or liquid petroleum gas (LPG or LP gas), also referred to as simply propane or butane, are flammable mixtures of hydrocarbon gases used as fuel in heating appliances, cooking equipment, and vehicles.

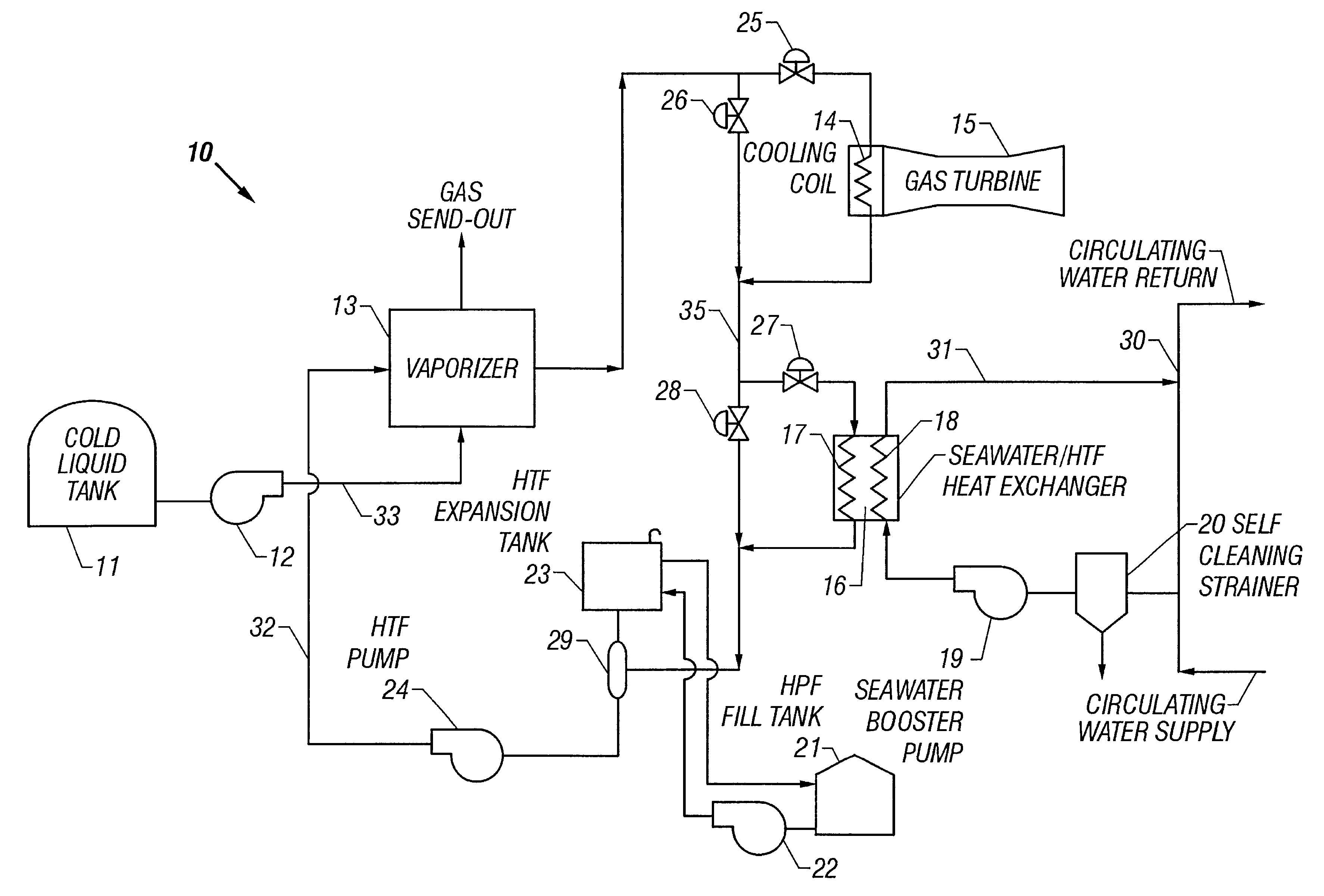

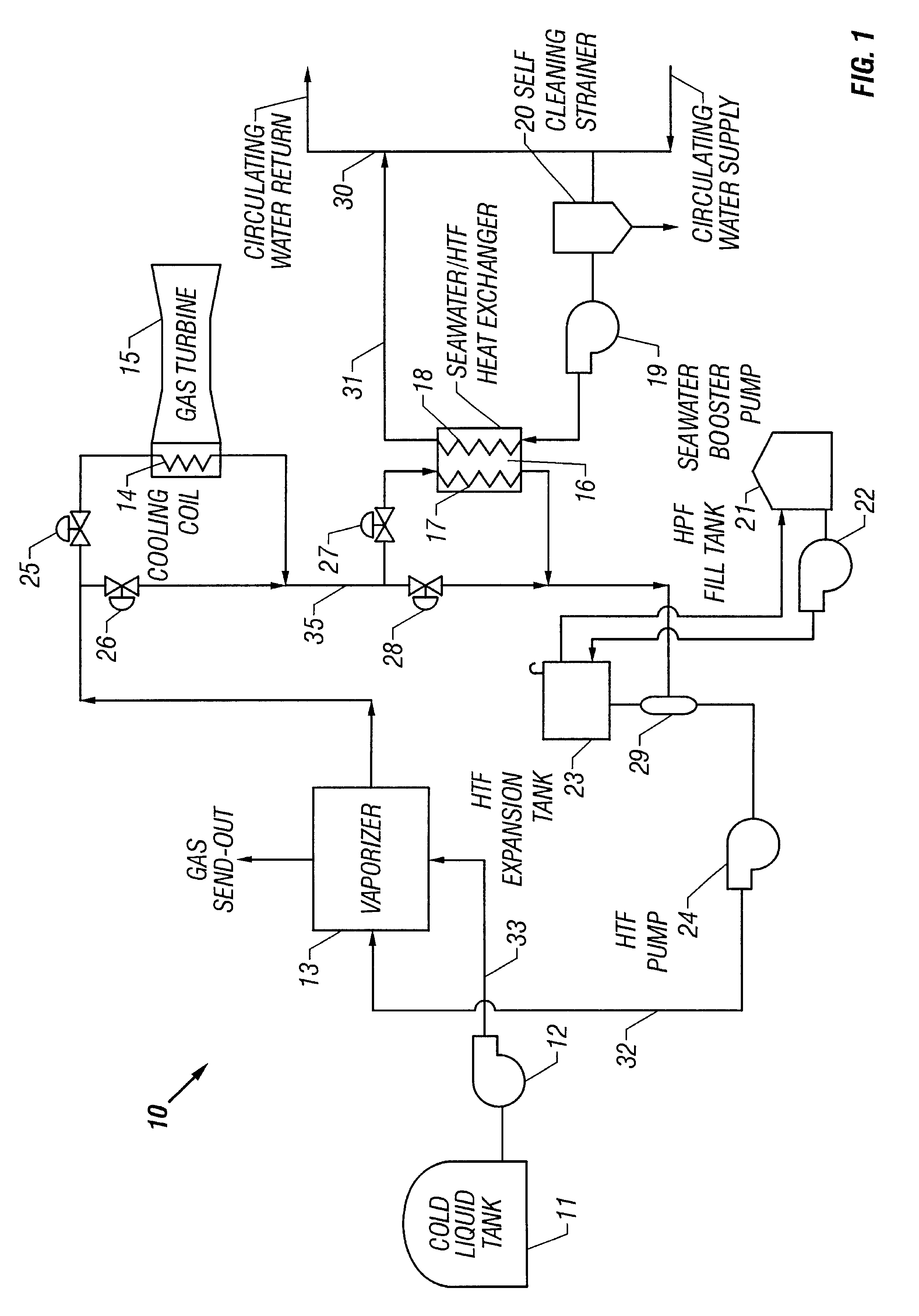

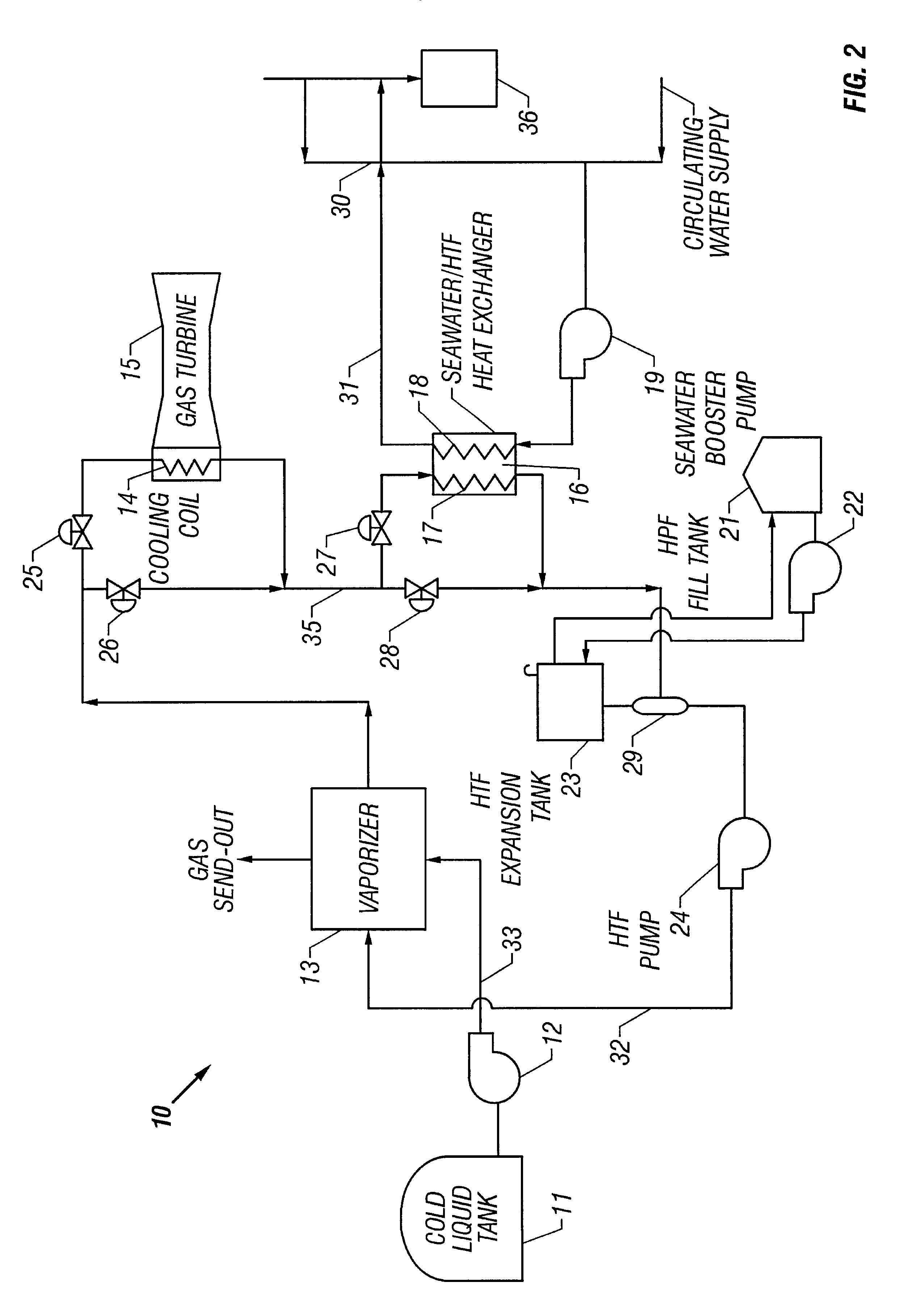

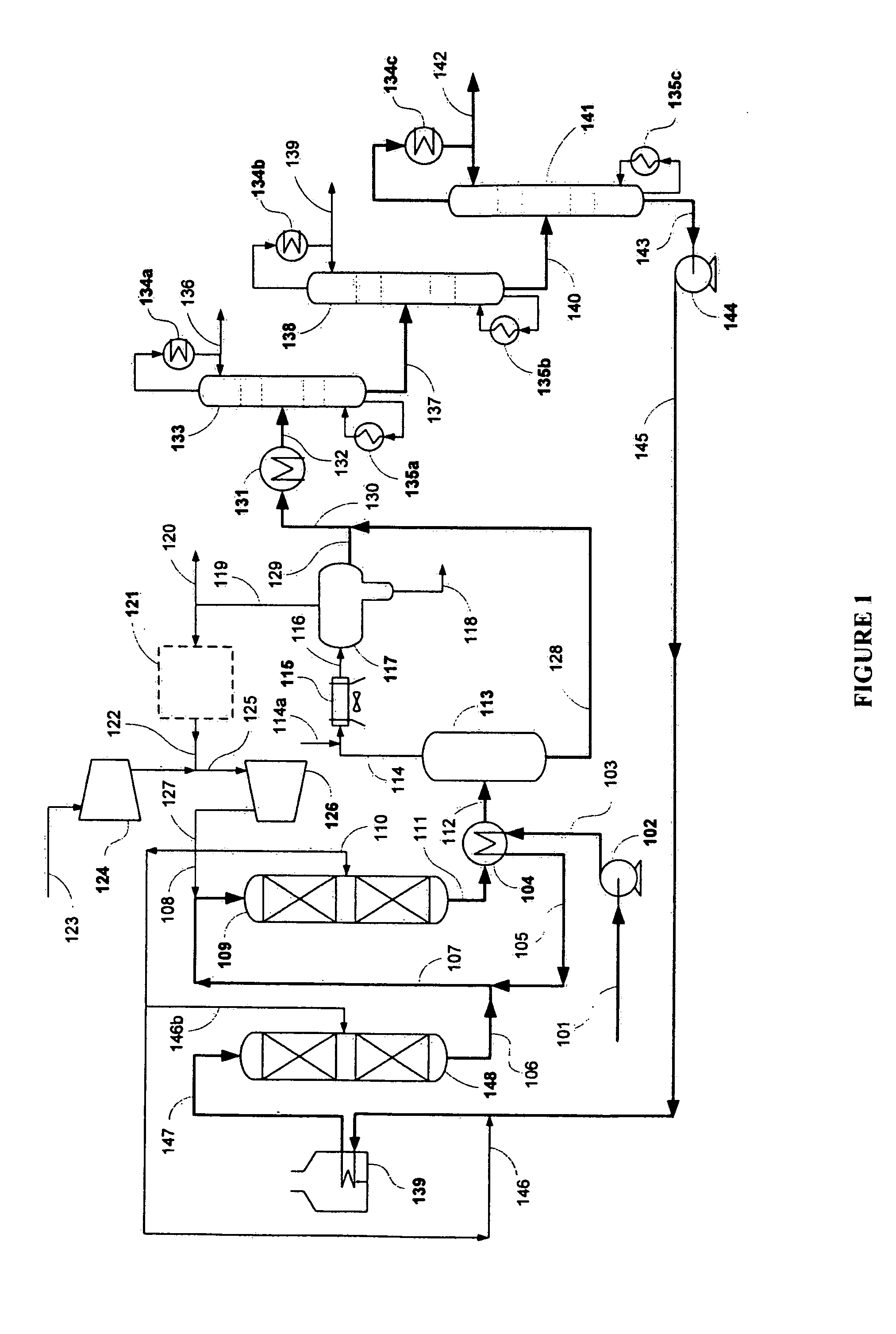

Method and apparatus for vaporizing liquid natural gas in a combined cycle power plant

InactiveUS6367258B1Turbine/propulsion engine coolingTurbine/propulsion fuel heatingPower stationProcess engineering

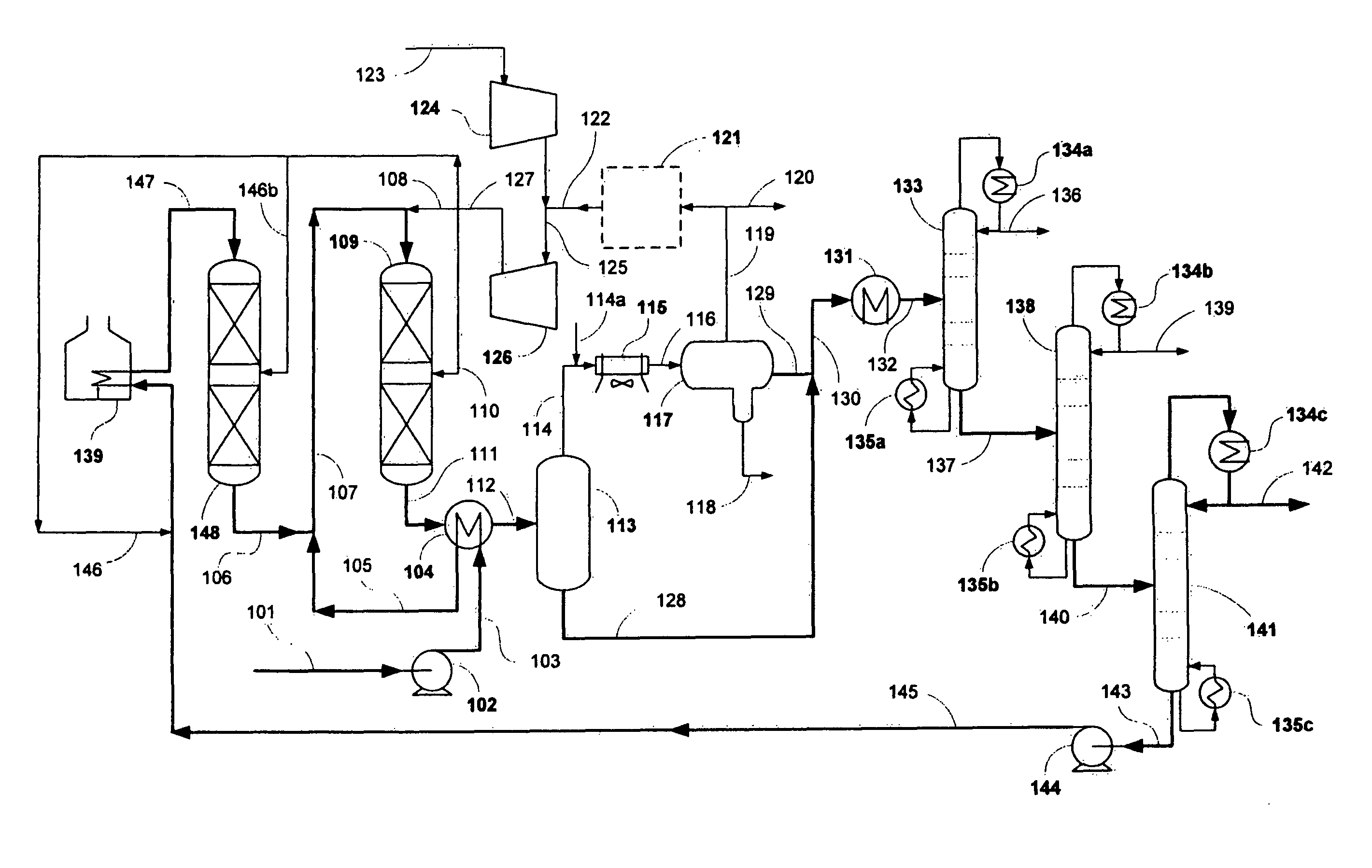

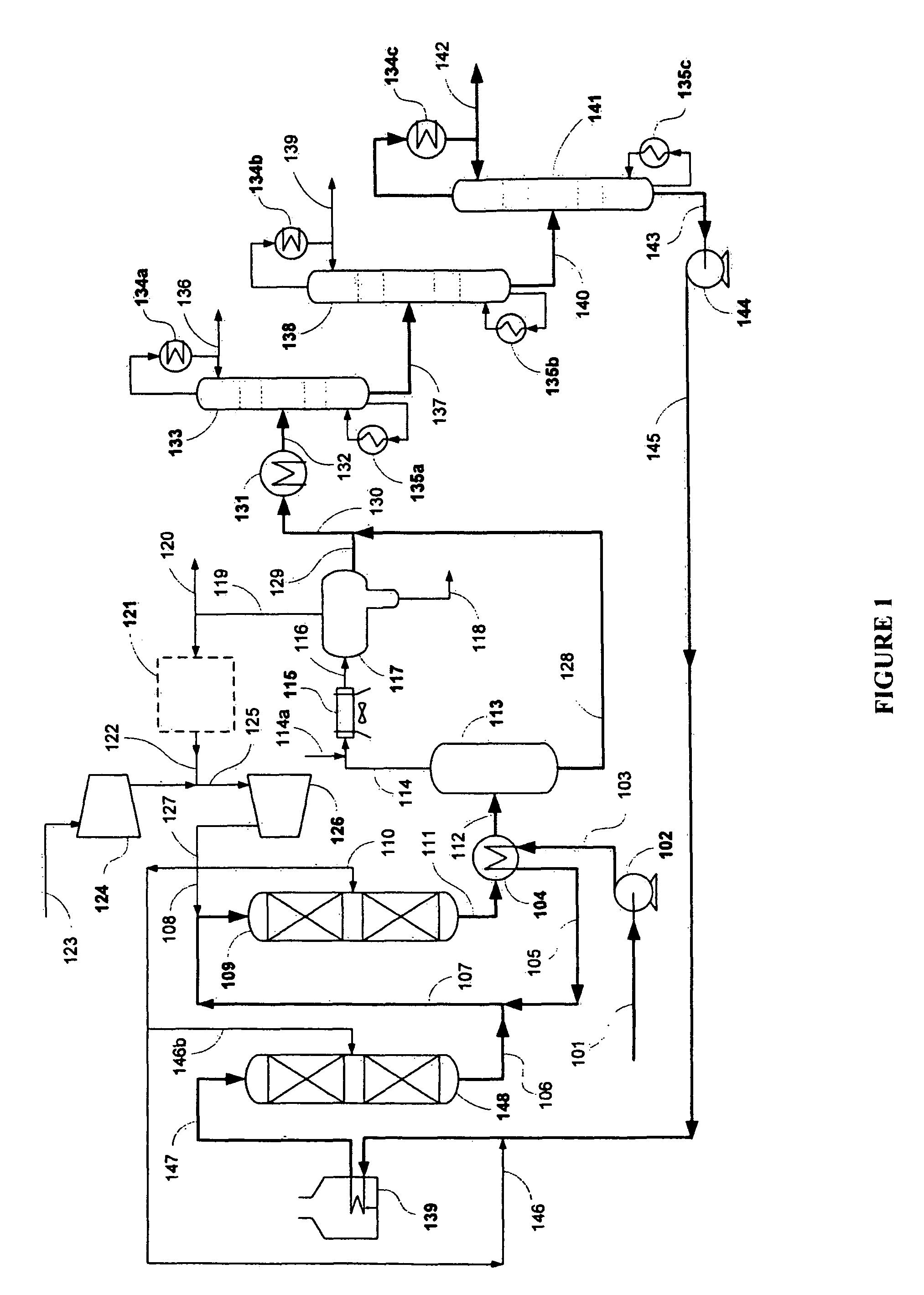

A method and apparatus for increasing the efficiency of a combined cycle generation plant by assisting the vaporization of cold liquid including liquefied natural gas ("LNG") or liquefied petroleum gas (LPG) in a combined cycle power plant. Cold liquid vaporization is assisted by circulating a warm heat transfer fluid to transfer heat to a LNG / LPG vaporizer. The heat transfer fluid is chilled by LNG / LPG cold liquid vaporization and warmed by heat from a gas turbine. The heat transfer fluid absorbs heat from the air intake of a gas turbine and from a secondary heat transfer fluid circulating in a combined cycle power plant. Chilling the gas turbine air intake densifies the air and increases the gas turbine output. Chilling the steam condenser cooling water increases steam turbine output. The effects of chill recovery is higher output and better efficiency of the combined cycle plant.

Owner:BECHTEL CORP

Process for Co-Producing Jet Fuel and LPG from Renewable Sources

ActiveUS20080244962A1Improve cold flowHydrocarbon by hydrogenationLiquid hydrocarbon mixture productionEngineeringRenewable resource

The present invention generally relates to a method for producing an isoparaffinic product useful as jet fuel from a renewable feedstock. The method may also include co-producing a jet fuel and a liquefied petroleum gas (LPG) fraction from a renewable feedstock. The method includes hydrotreating the renewable feedstock to produce a hydrotreating unit heavy fraction that includes n-paraffins and hydroisomerizing the hydrotreating unit heavy fraction to produce a hydroizomerizing unit heavy fraction that includes isoparaffins. The method also includes recycling the hydroisomerizing unit heavy fraction through the hydroisomerization unit to produce an isoparaffinic product that may be fractionated into a jet fuel and an LPG fraction. The present invention also relates to a jet fuel produced from a renewable feedstock having improved cold flow properties.

Owner:REG SYNTHETIC FUELS LLC

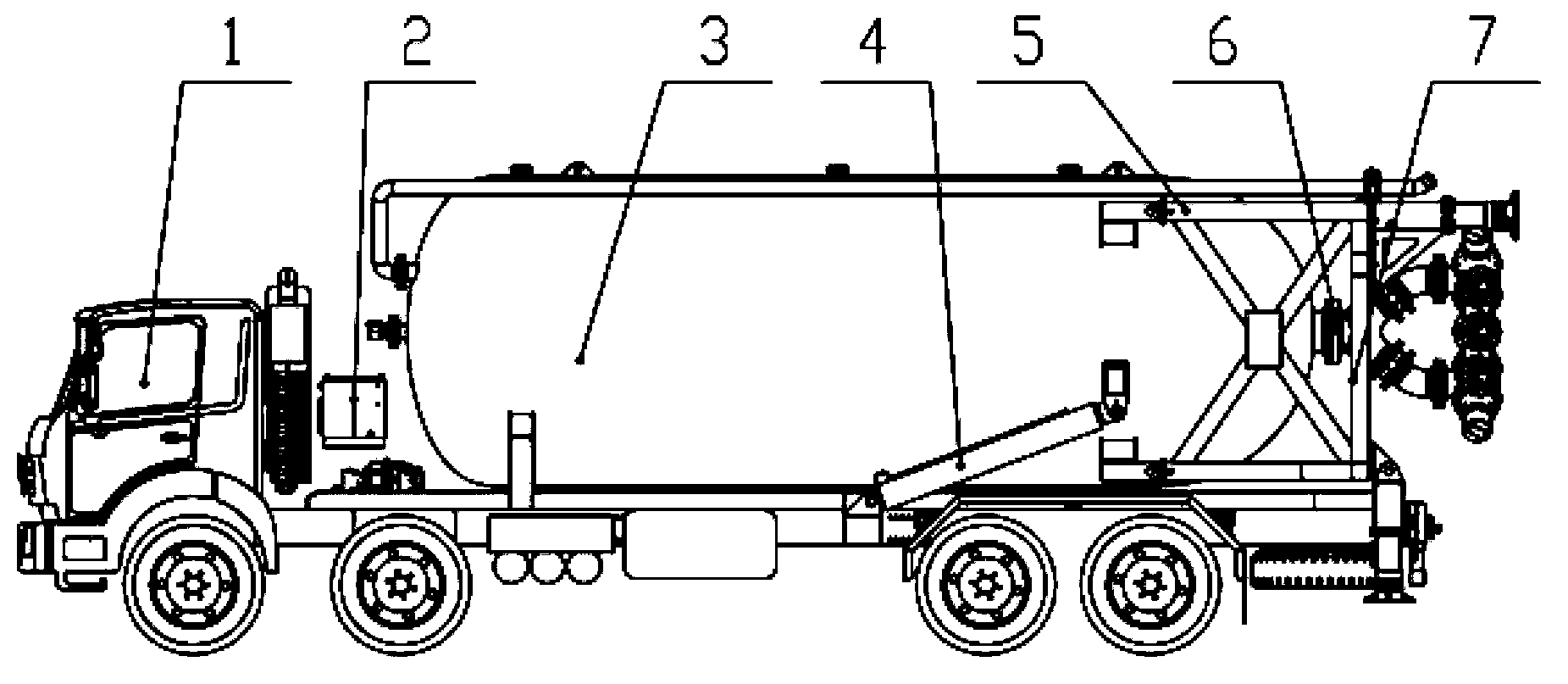

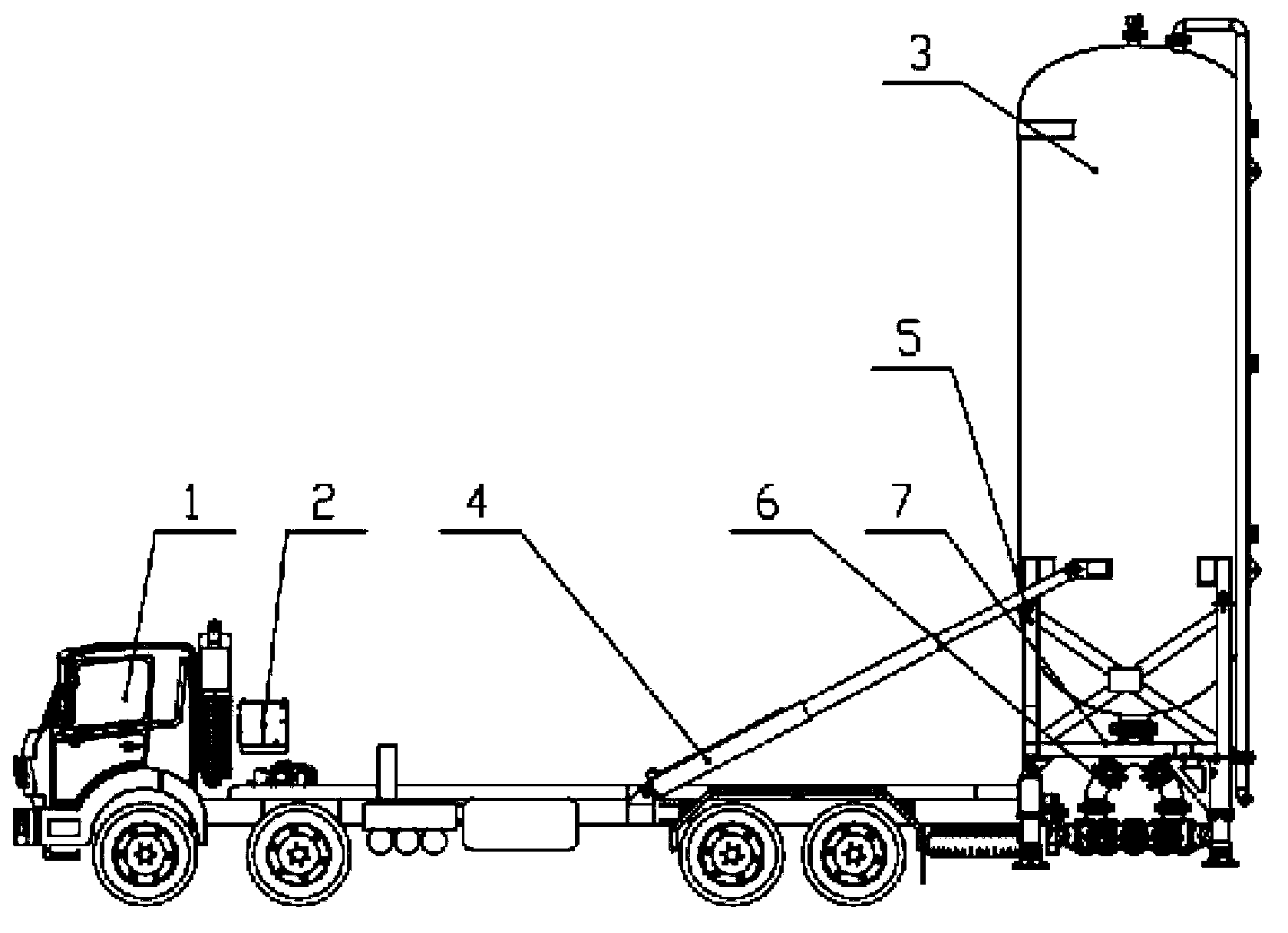

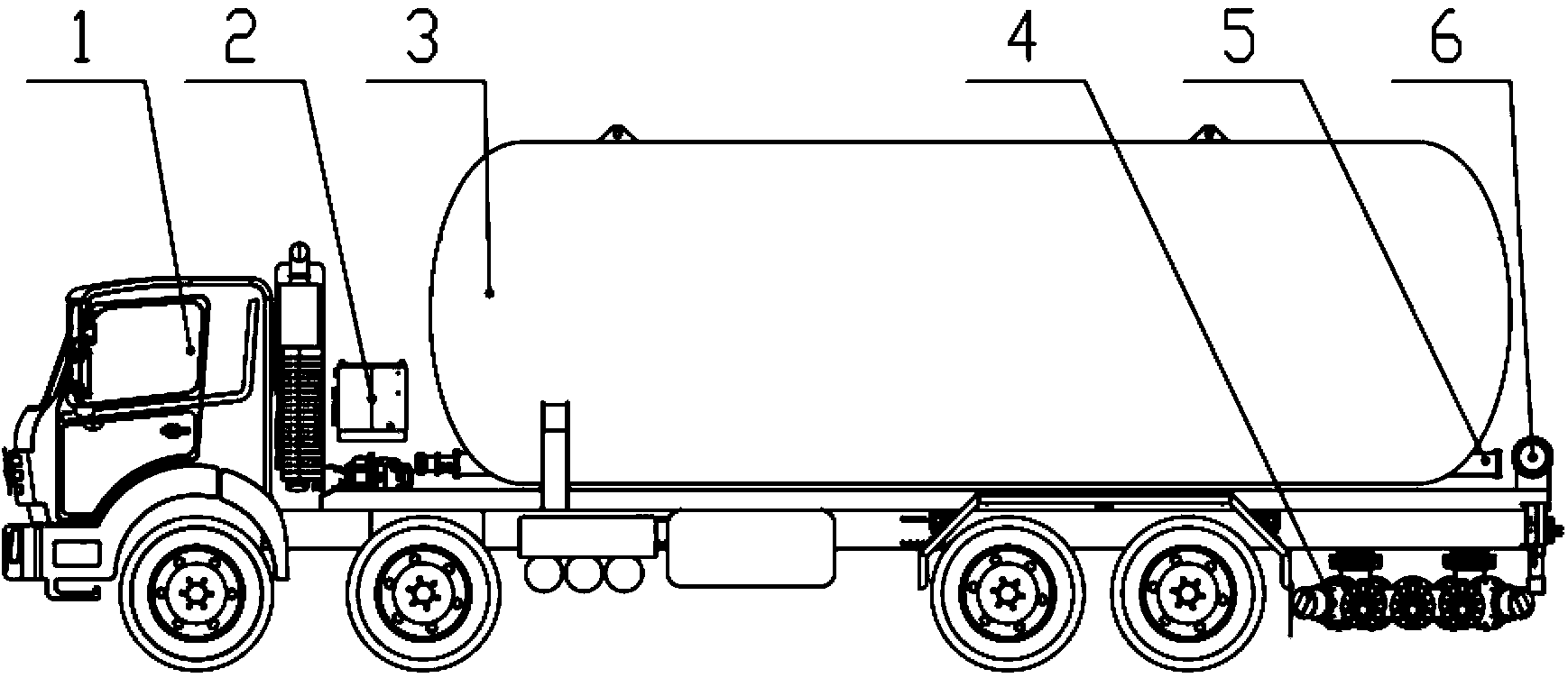

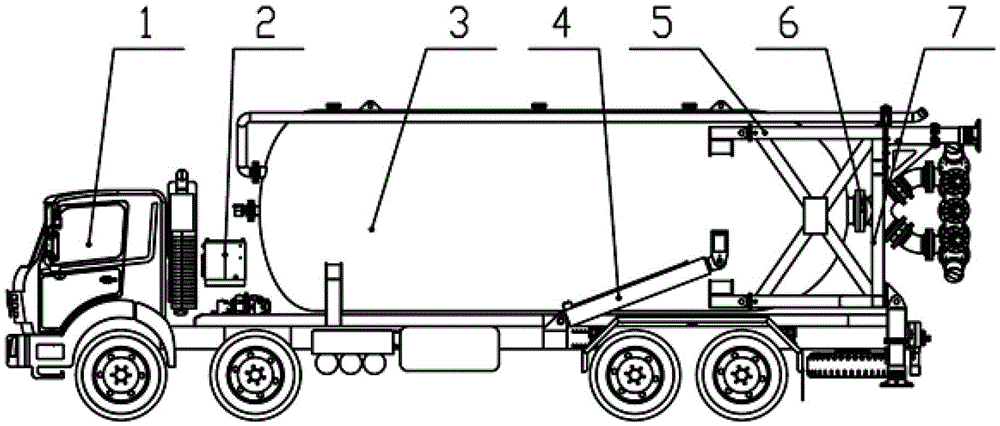

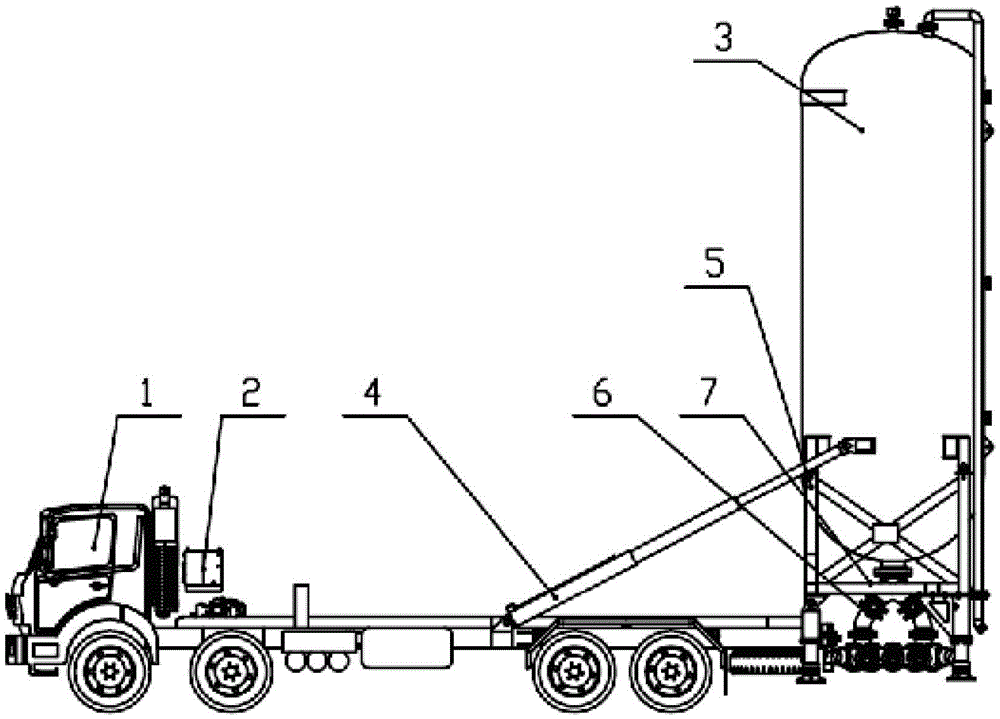

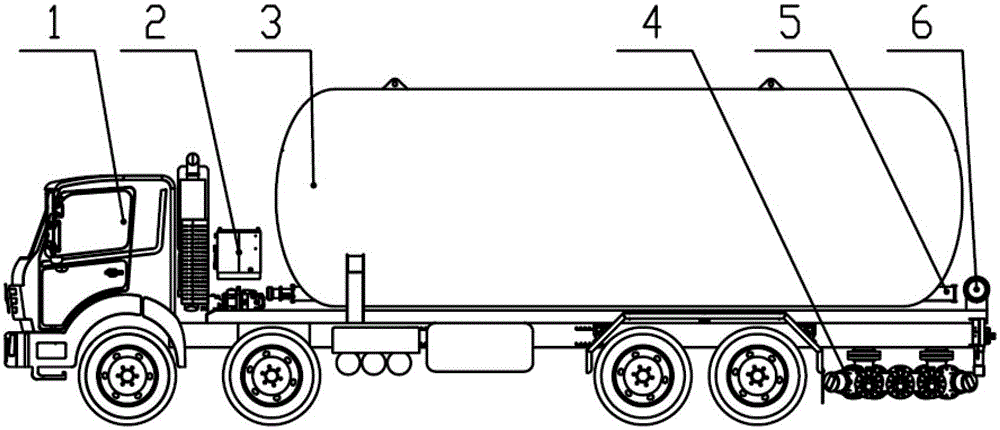

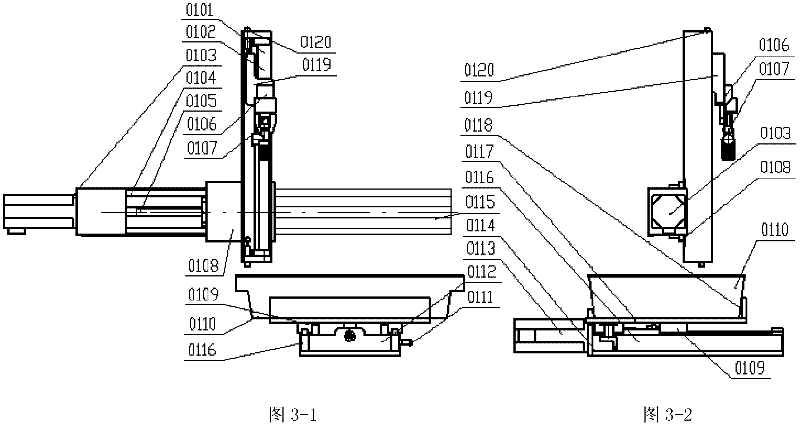

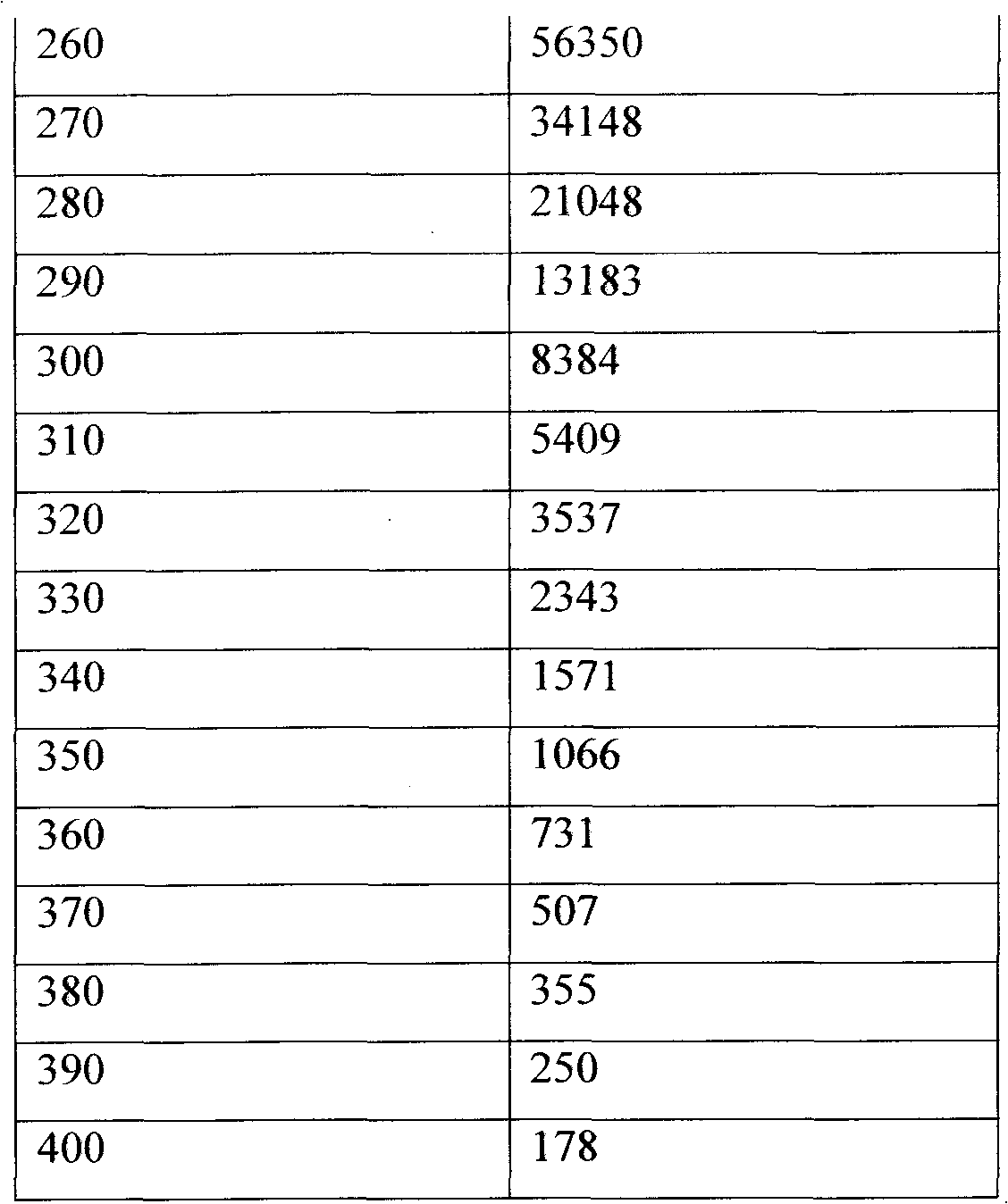

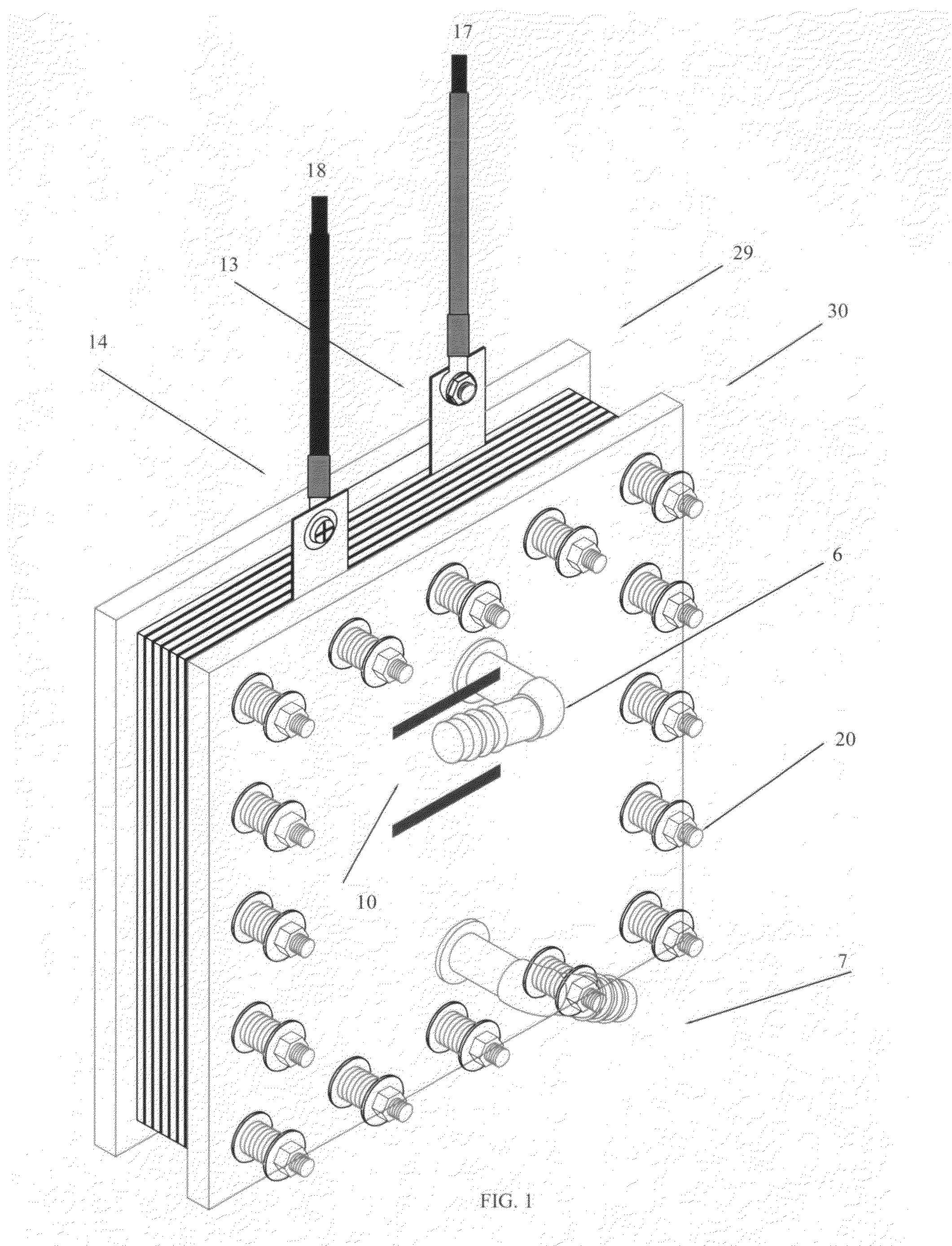

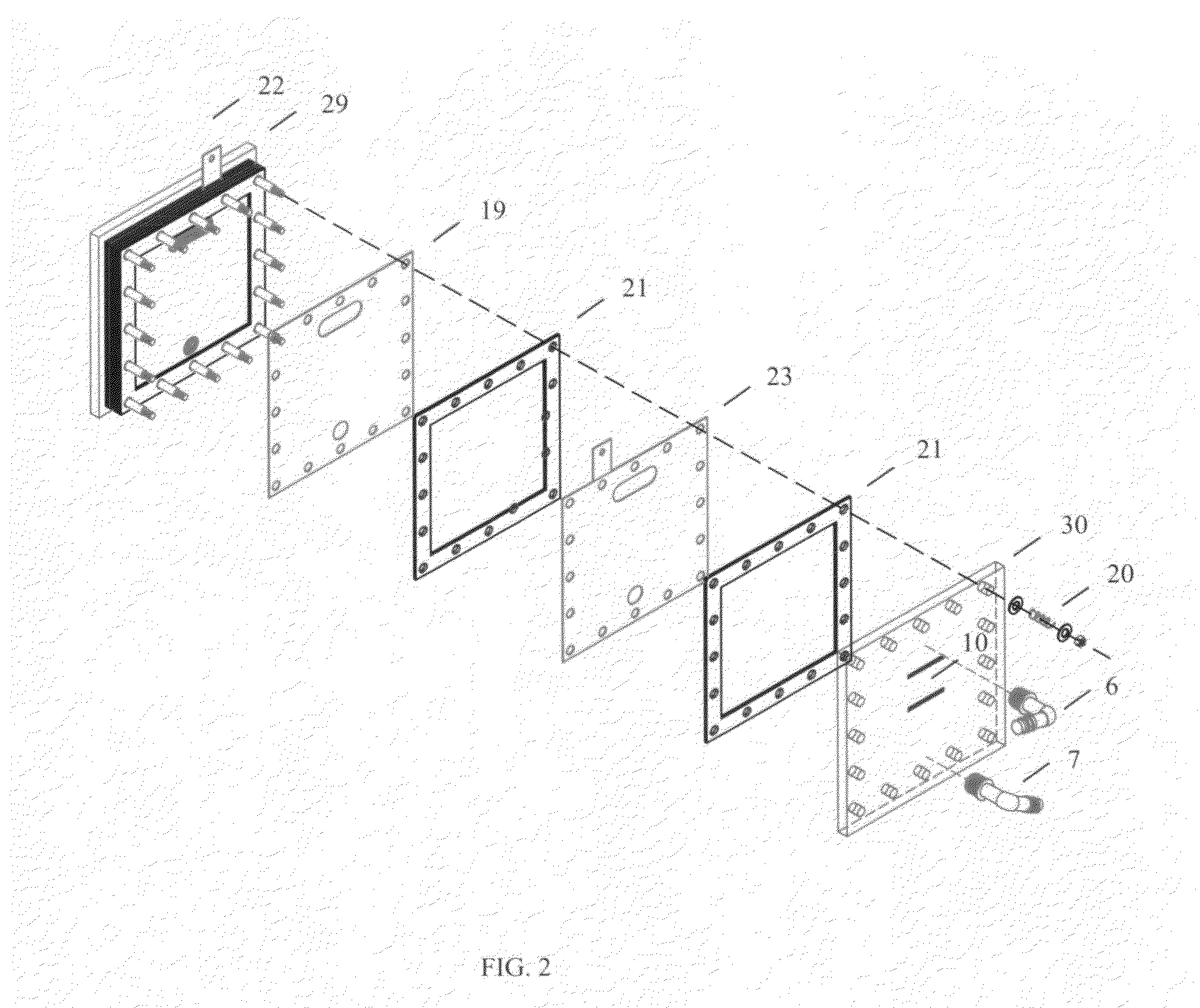

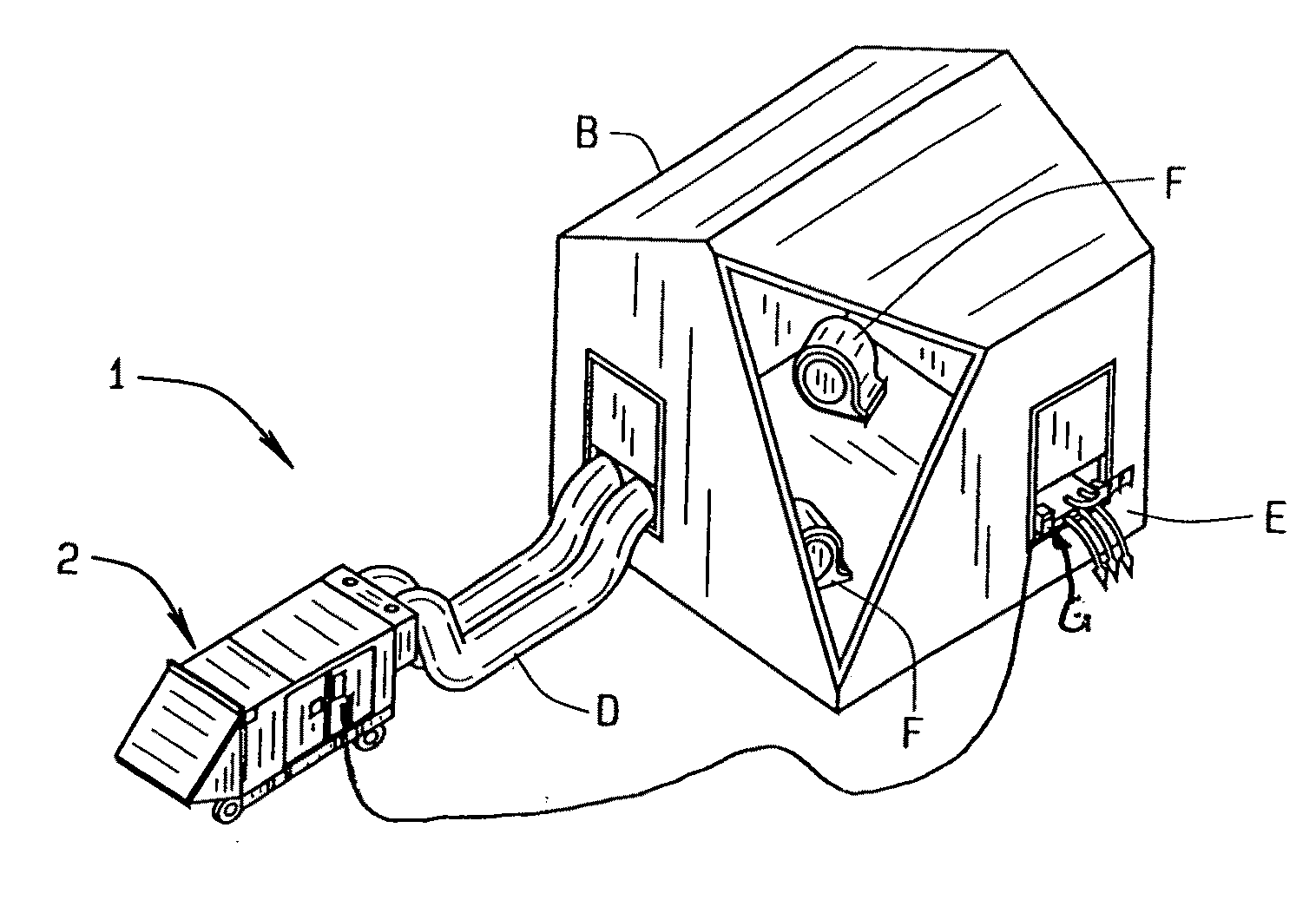

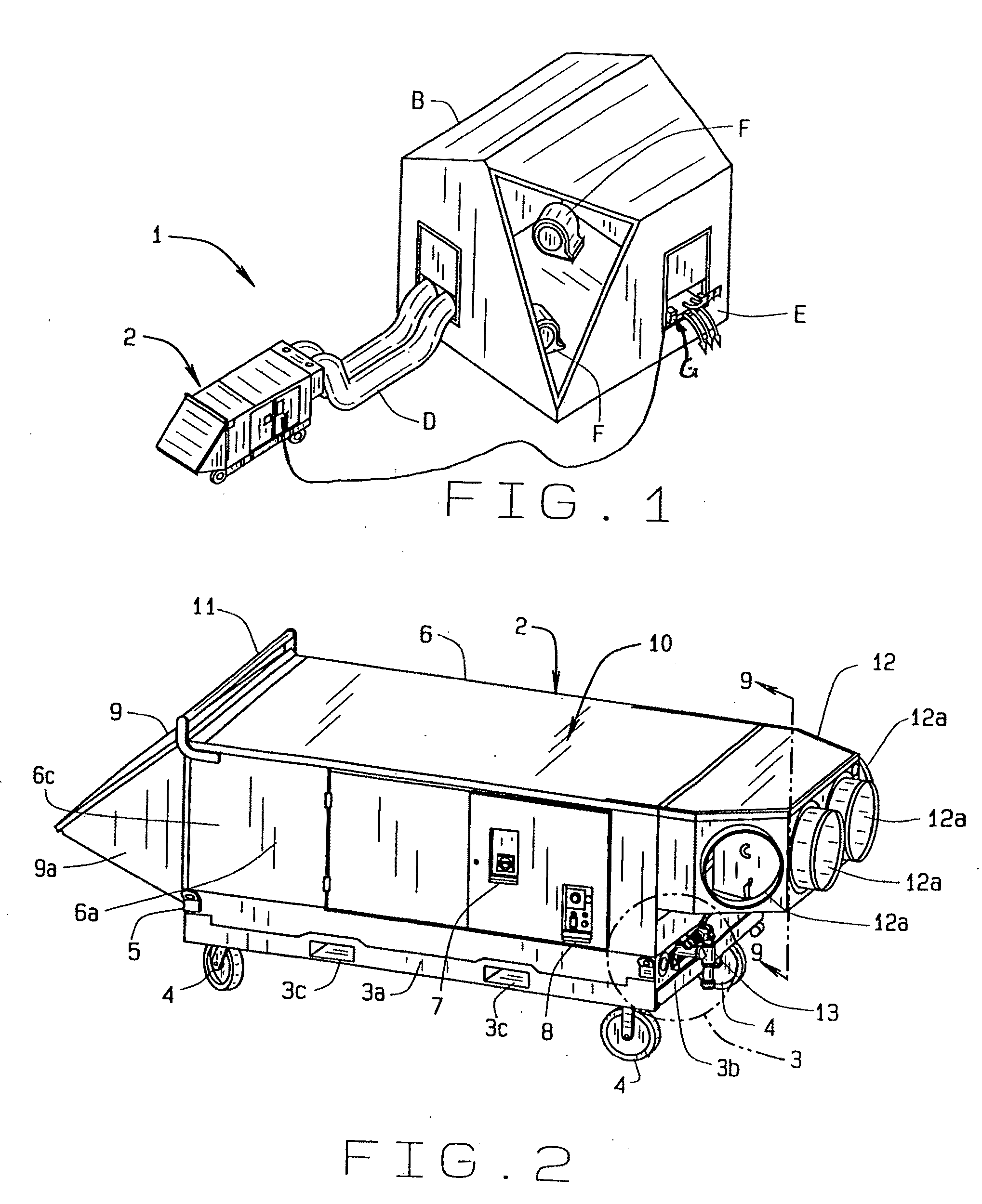

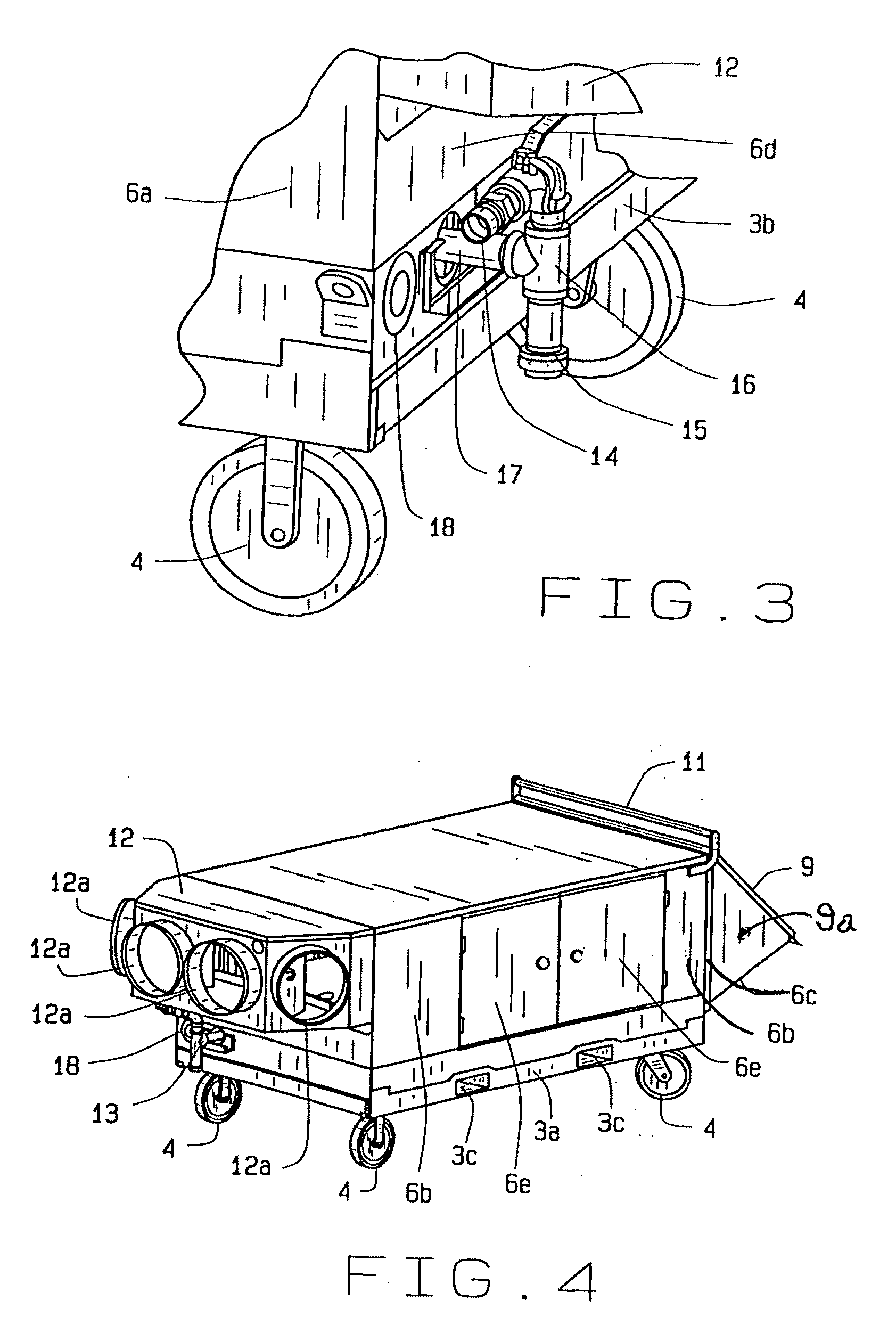

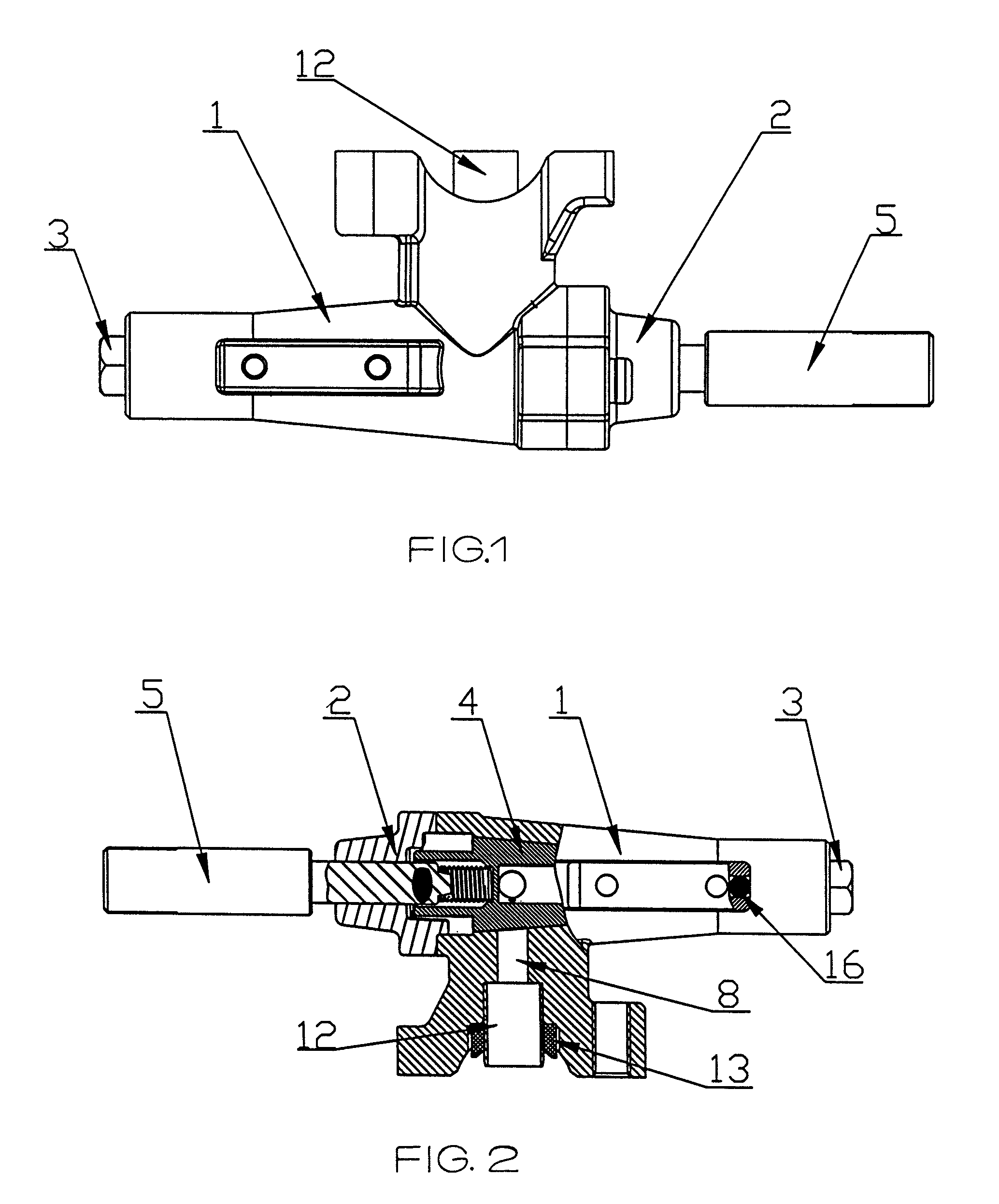

Fracturing sand mixing device

The invention provides a fracturing sand mixing device used for mixing fracturing fluid. The fracturing sand mixing device comprises a solid-liquid mixing device, and the solid-liquid mixing device is a pressure container. The solid-liquid mixing device comprises a solid lead-in port capable of leading in solid particles of the fracturing fluid, a base fluid lead-in port for leading in base fluid of the fracturing fluid, a mixing inner cavity for accommodating the solid particles and the base fluid and a solid-liquid lead-out port for leading out the fracturing fluid formed by mixing. Substances such as carbon dioxide or petroleum gas which are in a gas state under normal temperature can be kept in a liquid state by high pressure through the fracturing sand mixing device and are mixed with the solid particles to form the fracturing fluid, and the goal of preparing the fracturing fluid with liquid carbon dioxide or liquefied petroleum gas (propane) serving as the base fluid is achieved.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP

Fracturing sand mixing device

The invention provides a fracturing sand mixing device used for mixing fracturing fluid. The fracturing sand mixing device comprises a solid conveying device and a solid-liquid mixing device communicated with the solid conveying device, wherein the solid-liquid mixing device is a pressure container. The solid-liquid mixing device comprises a solid lead-in port capable of leading in solid particles of the fracturing fluid output by the solid conveying device, a base fluid lead-in port for leading in base fluid of the fracturing fluid, a mixing inner cavity for accommodating the solid particles and the base fluid and a solid-liquid lead-out port for leading out the fracturing fluid formed by mixing. Substances such as carbon dioxide or petroleum gas which are in a gas state under normal temperature can be kept in a liquid state by high pressure through the fracturing sand mixing device and are mixed with the solid particles to form the fracturing fluid, and the goal of preparing the fracturing fluid with liquid carbon dioxide or liquefied petroleum gas (propane) serving as the base fluid is achieved.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP

A fracturing sand mixing device

The invention provides a fracturing sand mixing device used for mixing fracturing fluid. The fracturing sand mixing device comprises a solid-liquid mixing device, and the solid-liquid mixing device is a pressure container. The solid-liquid mixing device comprises a solid lead-in port capable of leading in solid particles of the fracturing fluid, a base fluid lead-in port for leading in base fluid of the fracturing fluid, a mixing inner cavity for accommodating the solid particles and the base fluid and a solid-liquid lead-out port for leading out the fracturing fluid formed by mixing. Substances such as carbon dioxide or petroleum gas which are in a gas state under normal temperature can be kept in a liquid state by high pressure through the fracturing sand mixing device and are mixed with the solid particles to form the fracturing fluid, and the goal of preparing the fracturing fluid with liquid carbon dioxide or liquefied petroleum gas (propane) serving as the base fluid is achieved.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP

A fracturing sand mixing device

The invention provides a fracturing sand mixing device used for mixing fracturing fluid. The fracturing sand mixing device comprises a solid conveying device and a solid-liquid mixing device communicated with the solid conveying device, wherein the solid-liquid mixing device is a pressure container. The solid-liquid mixing device comprises a solid lead-in port capable of leading in solid particles of the fracturing fluid output by the solid conveying device, a base fluid lead-in port for leading in base fluid of the fracturing fluid, a mixing inner cavity for accommodating the solid particles and the base fluid and a solid-liquid lead-out port for leading out the fracturing fluid formed by mixing. Substances such as carbon dioxide or petroleum gas which are in a gas state under normal temperature can be kept in a liquid state by high pressure through the fracturing sand mixing device and are mixed with the solid particles to form the fracturing fluid, and the goal of preparing the fracturing fluid with liquid carbon dioxide or liquefied petroleum gas (propane) serving as the base fluid is achieved.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP

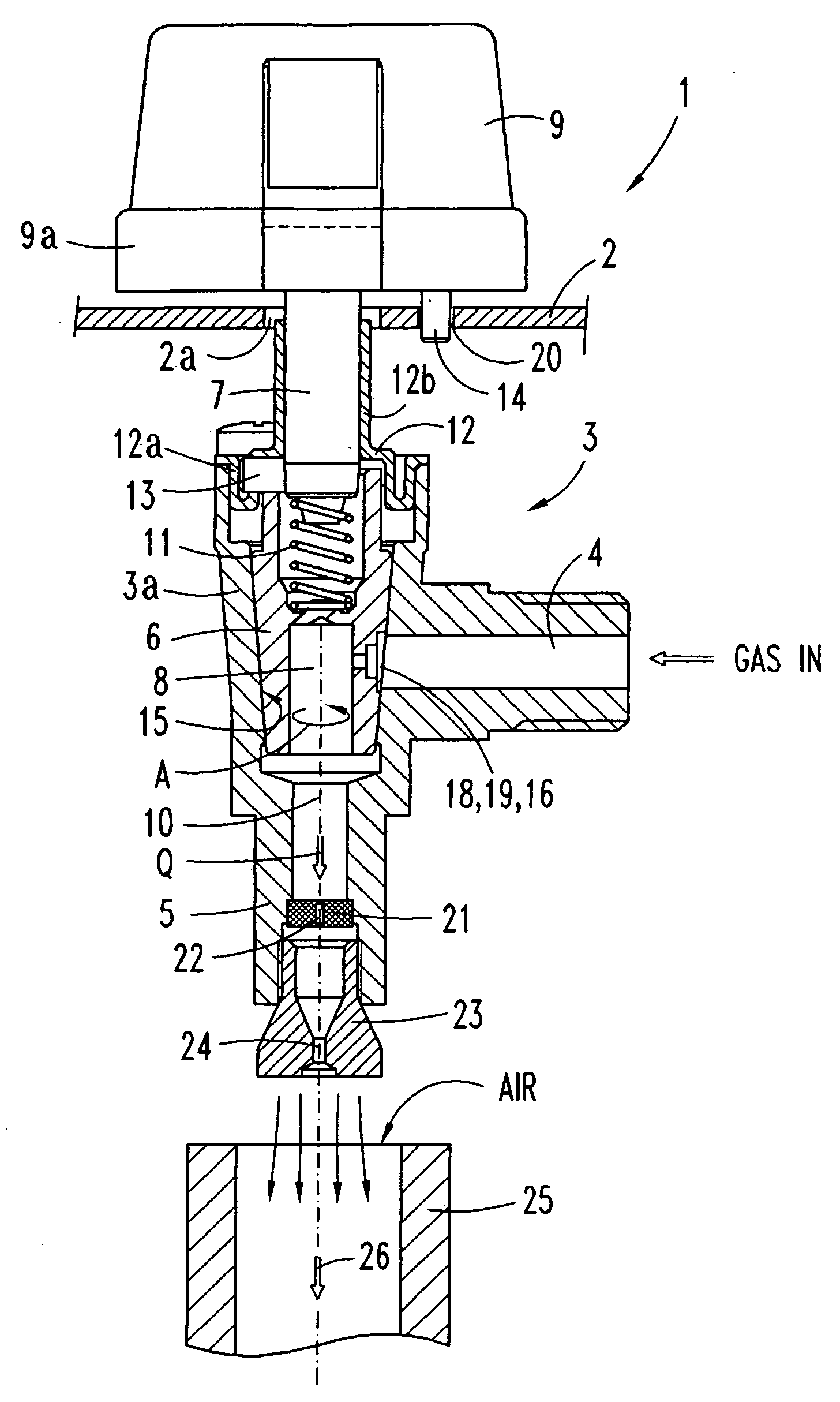

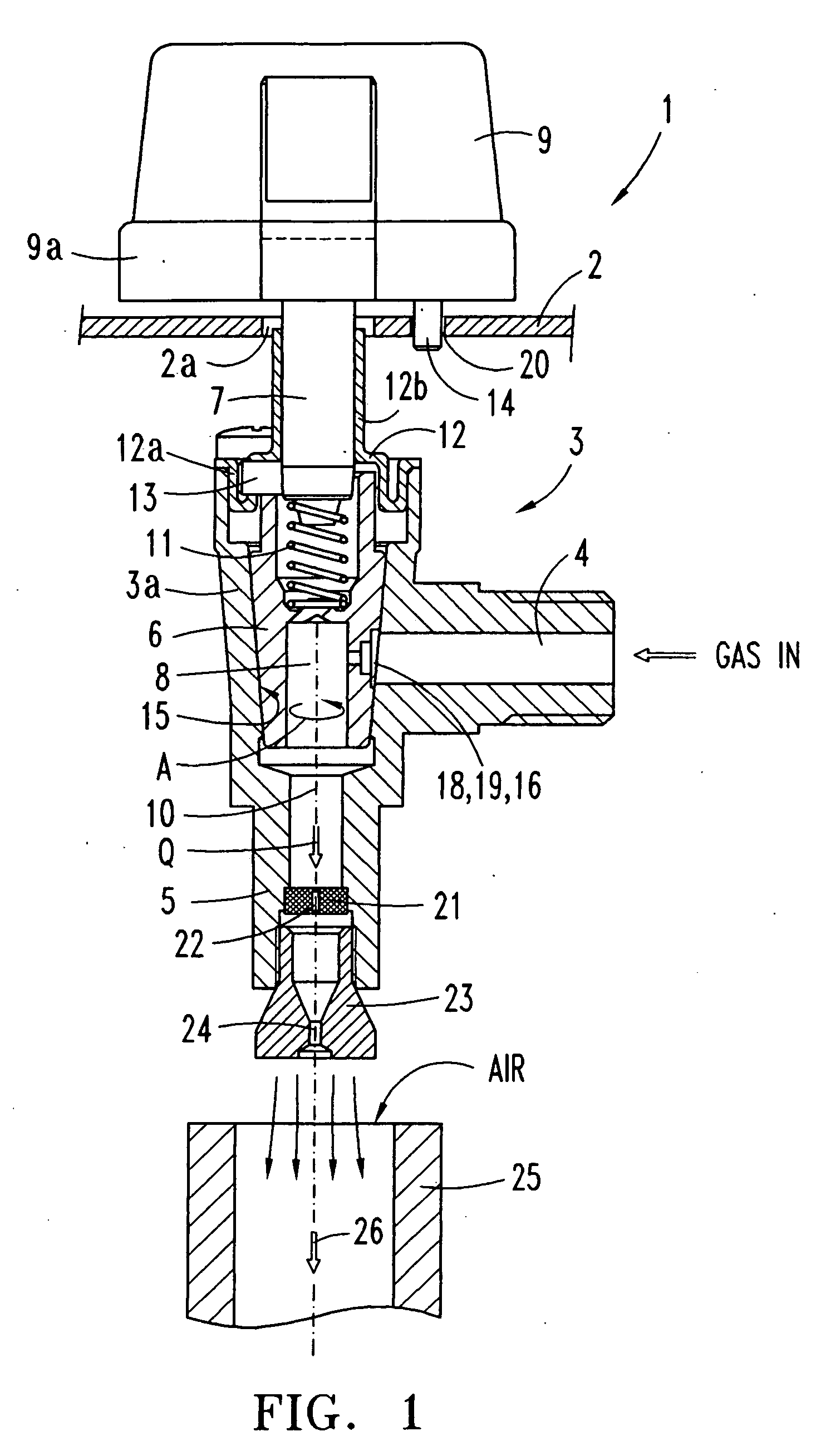

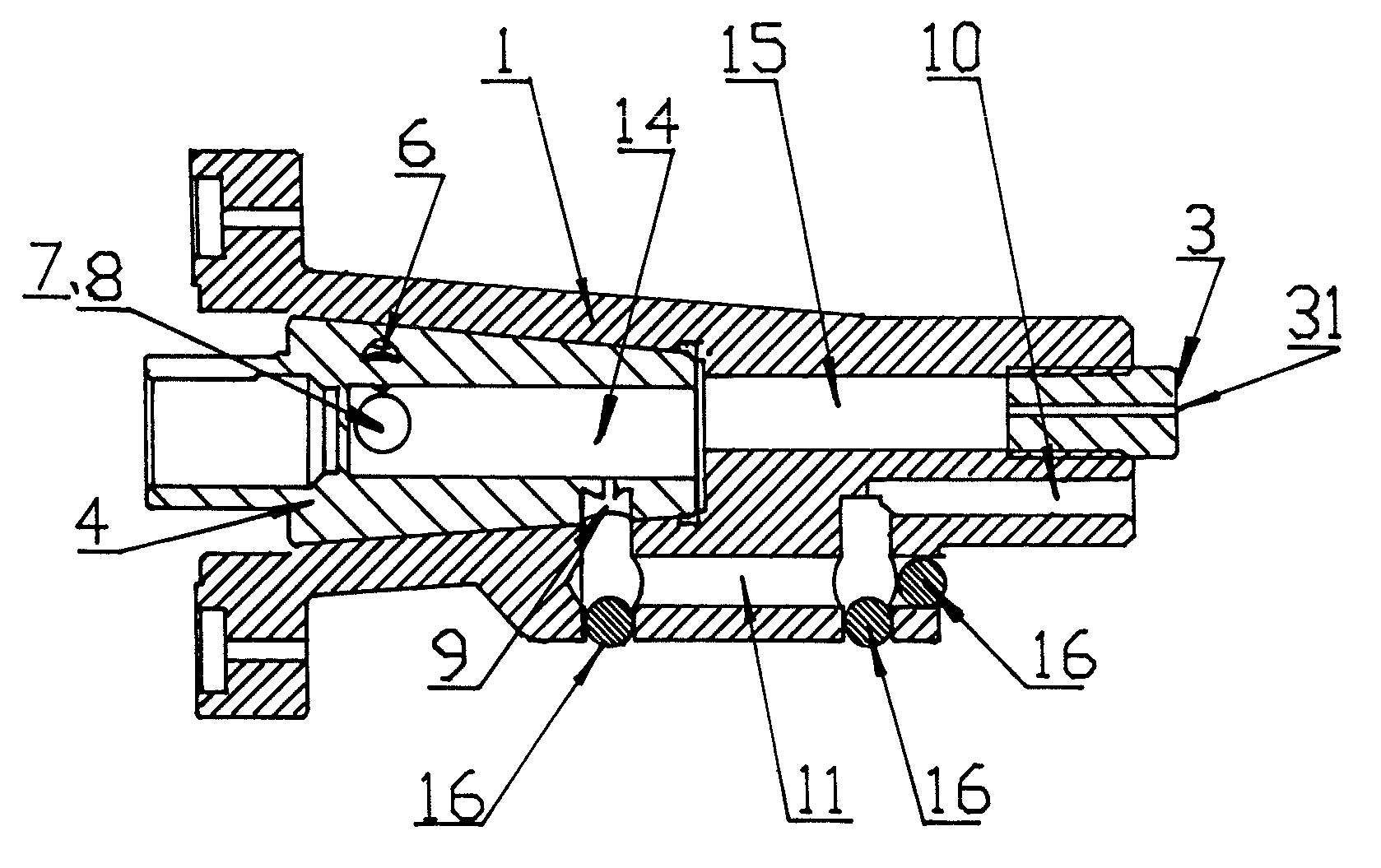

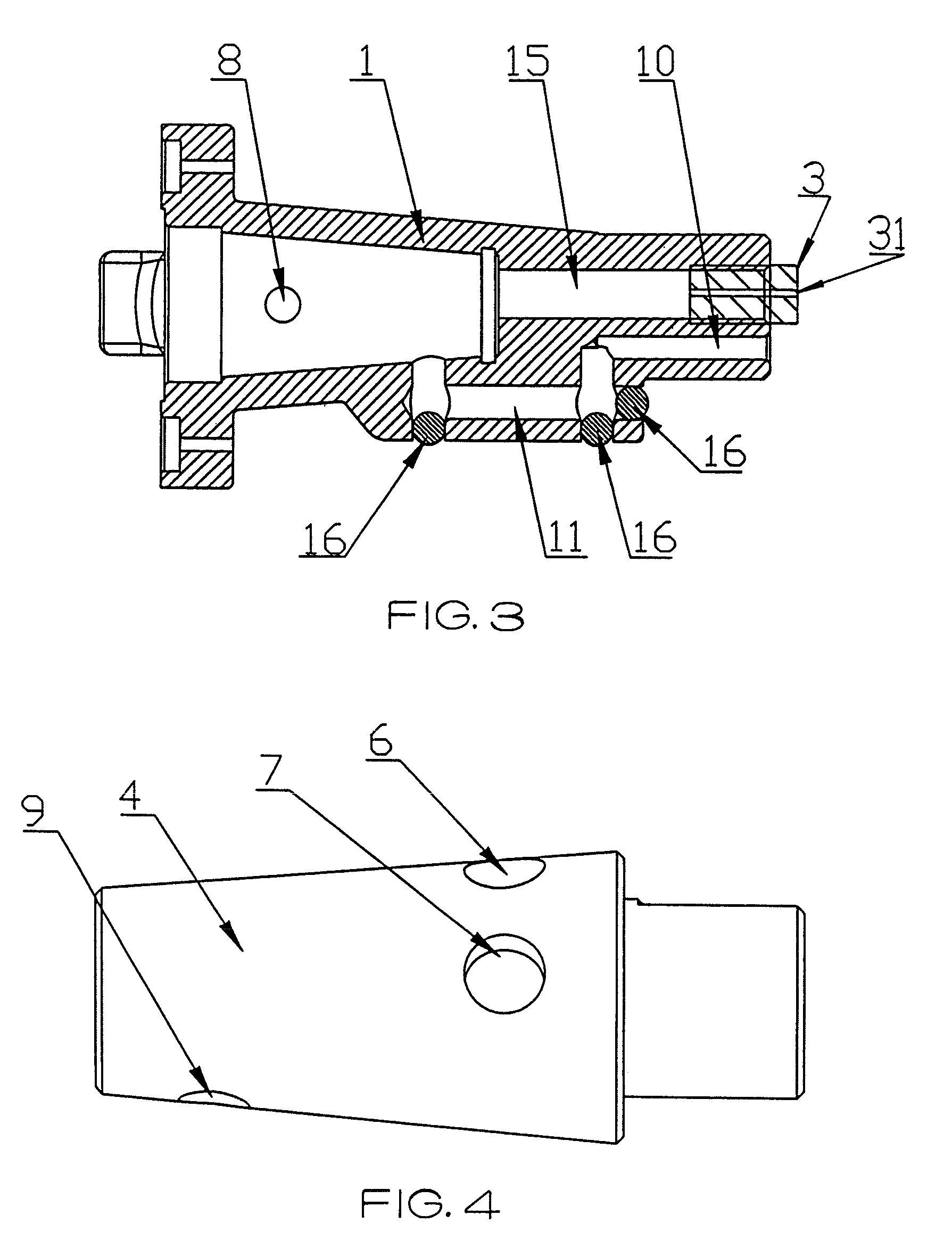

Multi-gas cooker, with a rotary valve provided with interchangeable regulating means

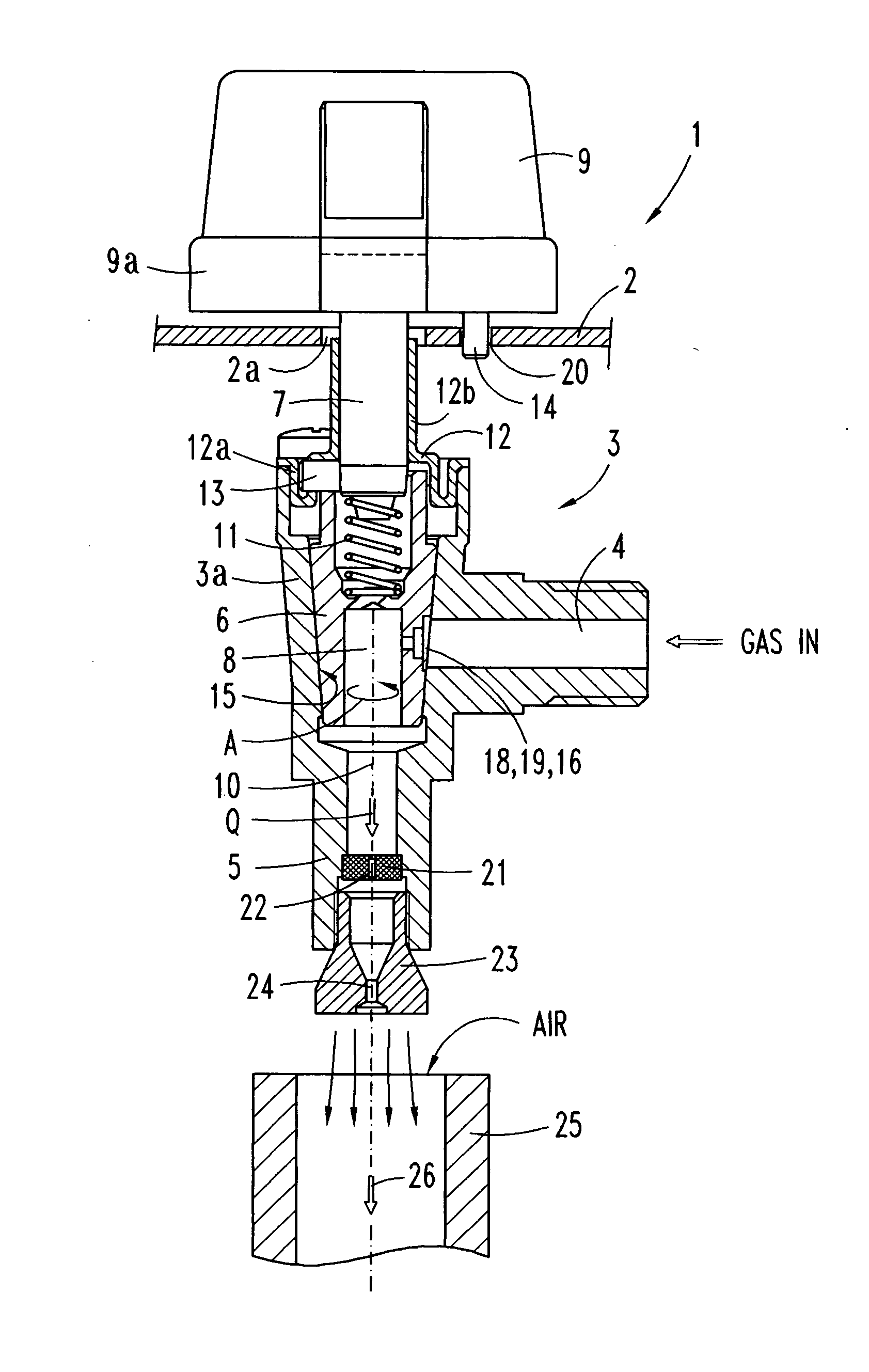

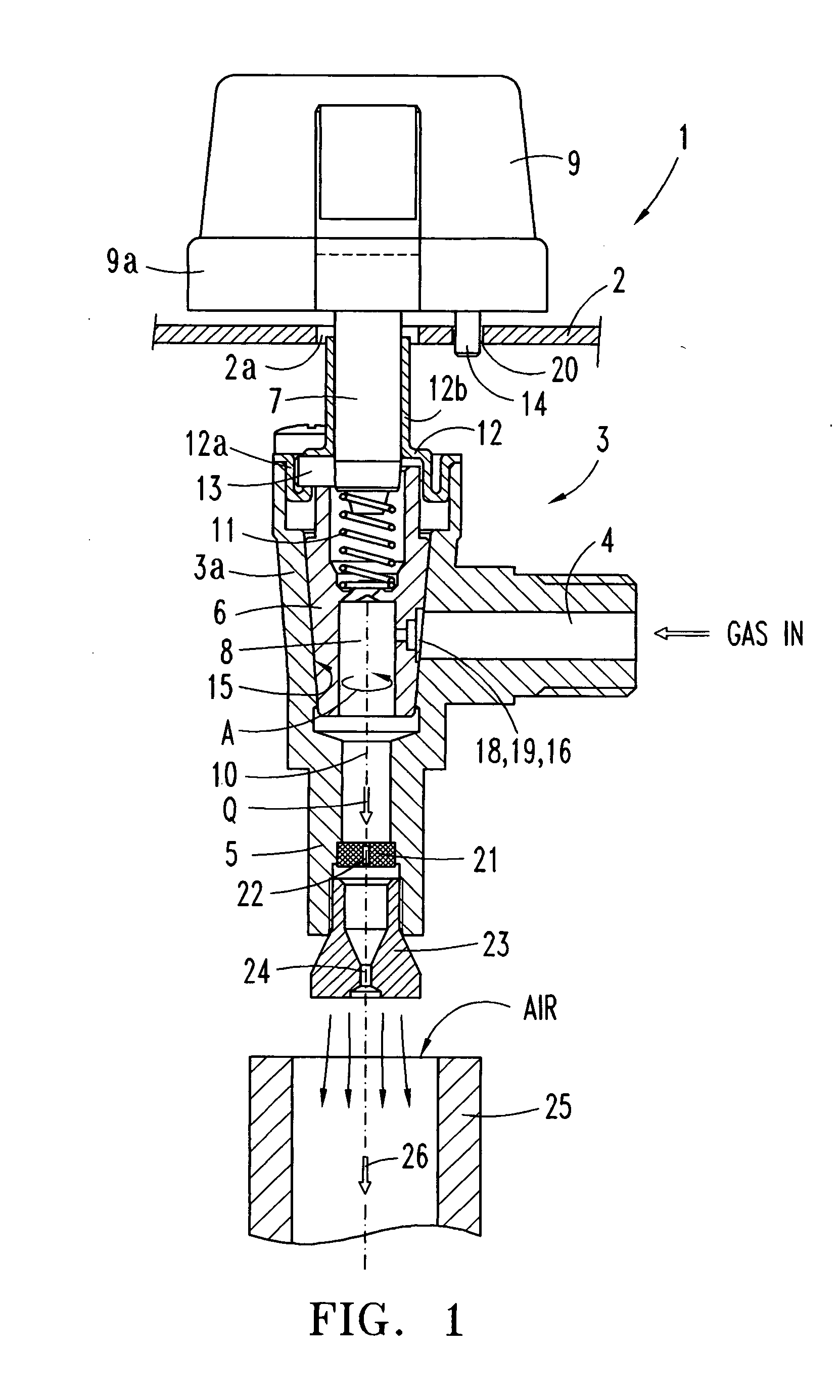

The cooking appliance (1) having a control panel (2) is equipped with one or more gas flow (Q) regulating valves, wherein the rotary regulating plug (6) is provided with various peripheral through holes (16-19). The control knob (9) being interchangeable for fitting to the actuating shaft (7), is chosen from the two units available, one and the other permitting different angular limit positions of the regulating plug (6) for the supply of a constant minimum gas flow Qmin, adjusted each one for a different type of gas N gas or LP gas. The outlet conduit (5) of the valve is equipped with a further injector nozzle (21,23) for adjusting a constant gas flow Qmax to be fed into the conduit (25) of the correspondent burner, when the cooking appliance is supplied with a LP gas.

Owner:COPRECITEC

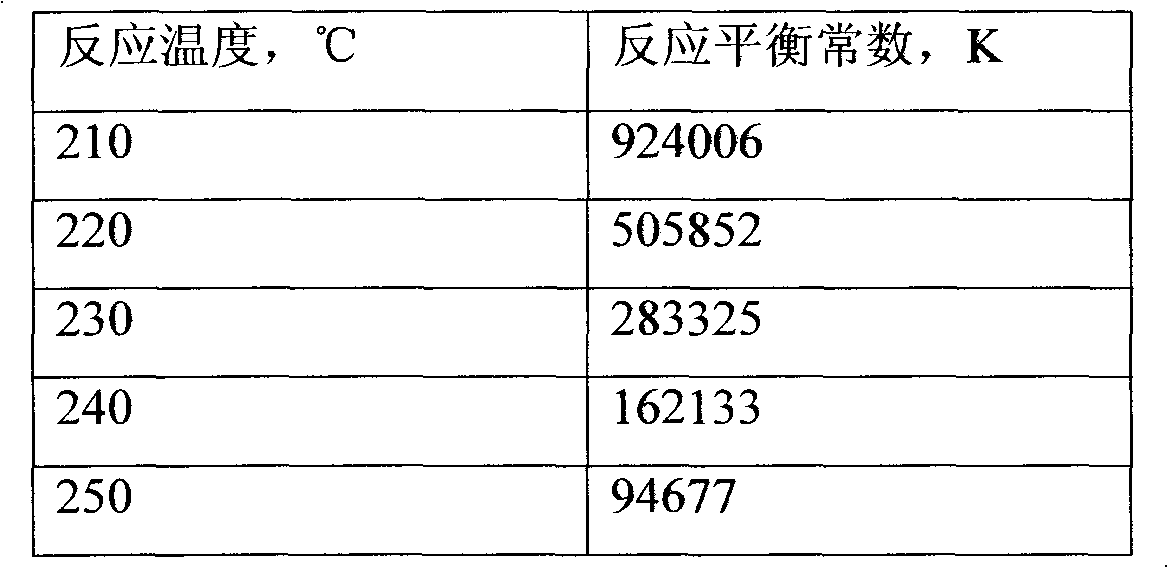

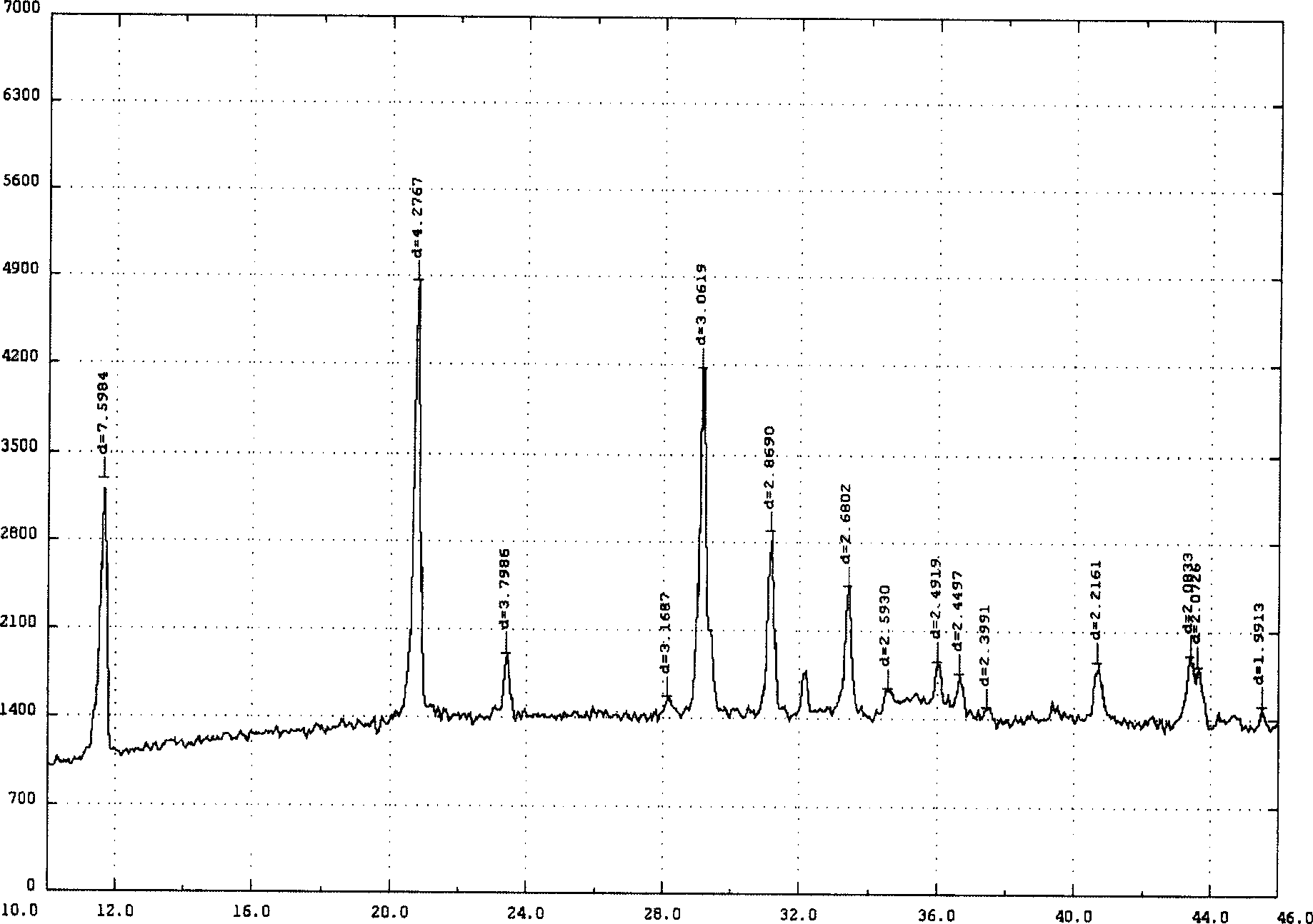

Catalyst for C4 liquefied petroleum gas aromatization and its preparing method

InactiveCN1586721ALess modification stepsLow costMolecular sieve catalystsLiquid hydrocarbon mixtures productionHigh carbonFixed bed

The present invention belongs to the field of catalyst preparation in petrochemical technology, and especially one kind of catalyst for the aromatization of liquefied C4 petroleum gas in fixed bed reactor and its preparation process. Technologically, the catalyst features that its mother substance is high-silicon zeolite with crystal granulation of 10-500 nm and the zeolite is alumina formed and prepared into the hydrogen type catalyst via conventional process, and the hydrogen type catalyst is vapor treated to regulate the acidity and acid treated to expand the pores and restore the pore passage. The catalyst is used in the aromatization of liquefied C4 petroleum gas, and has low reaction temperature, high olefin converting rate and high carbon deposition resistance.

Owner:DALIAN LIGONG QIWANGDA CHEM TECH

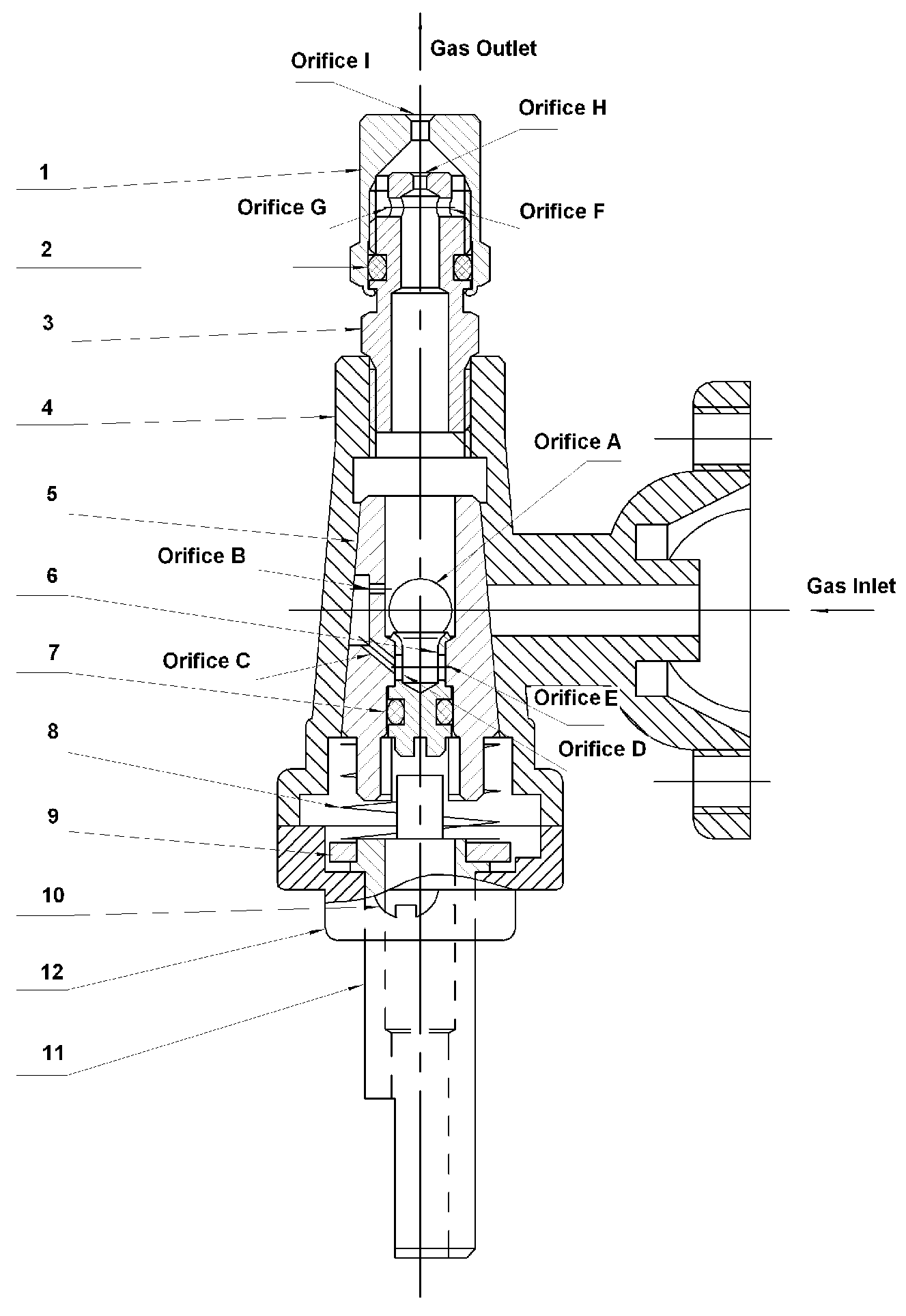

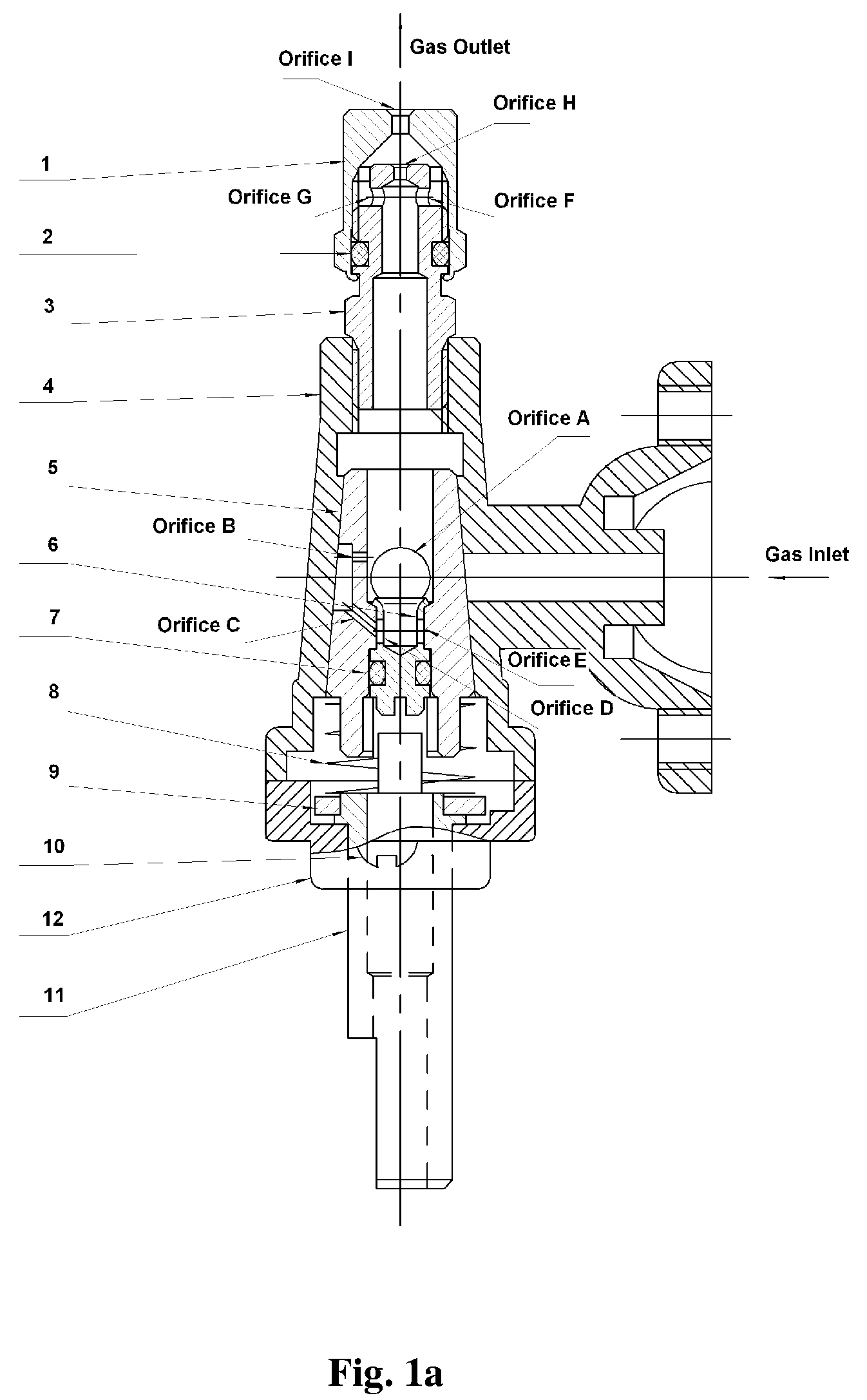

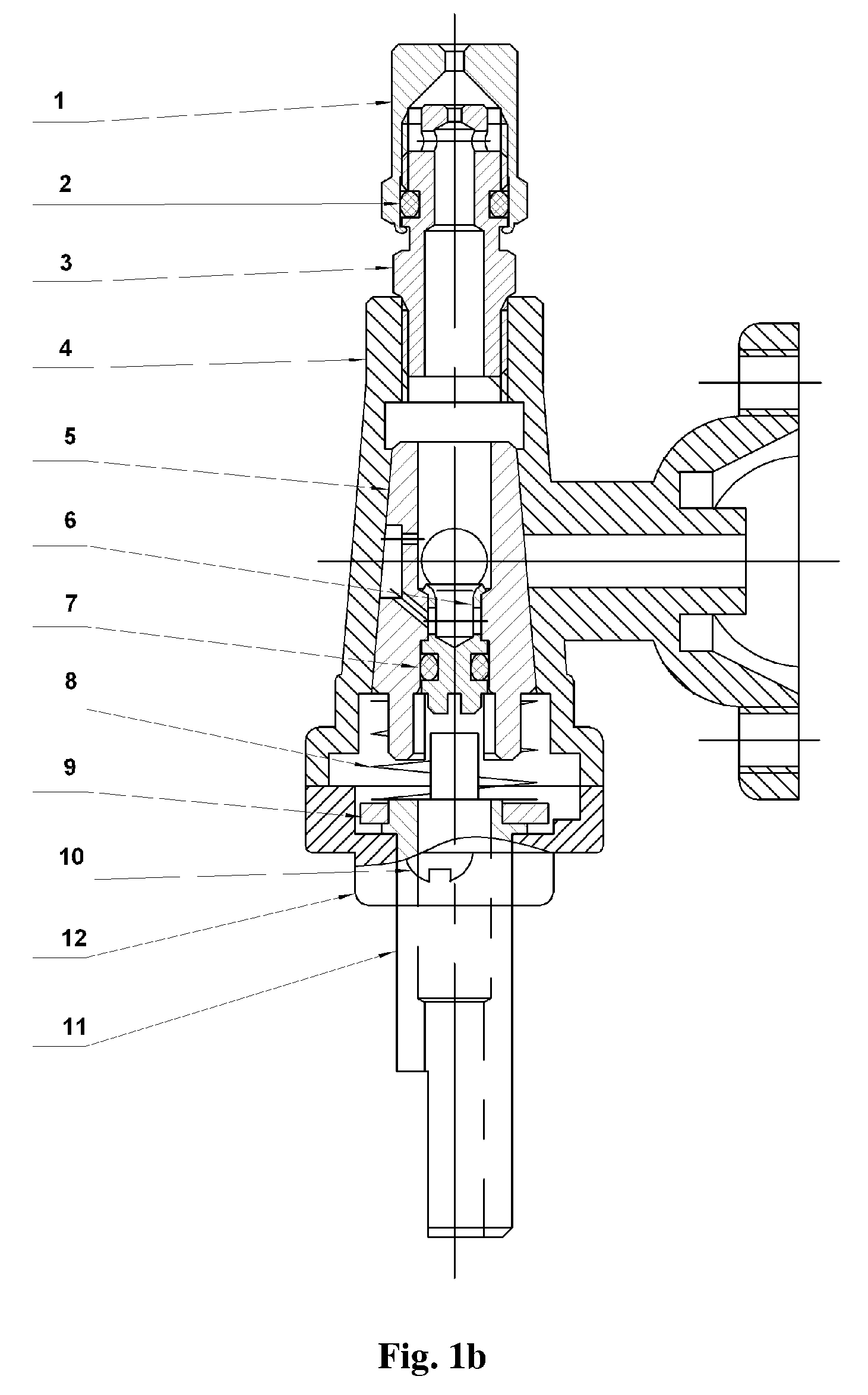

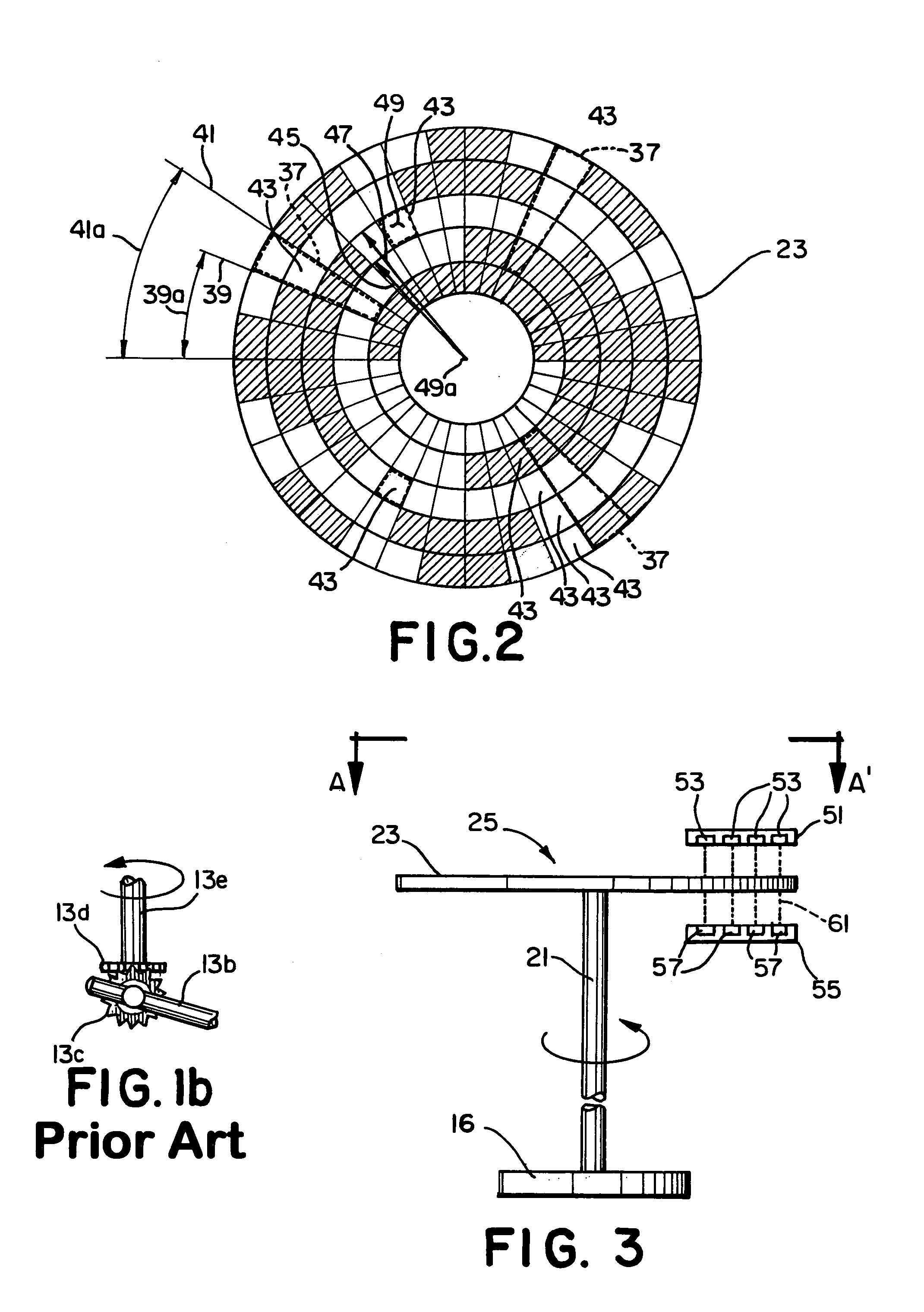

Manual gas valve with natural/LP gas conversion capability

ActiveUS7458386B2Reliable supplyEasy to operateVessel mounting detailsPlug valvesTester deviceProcess engineering

Owner:NINGBO WANAN

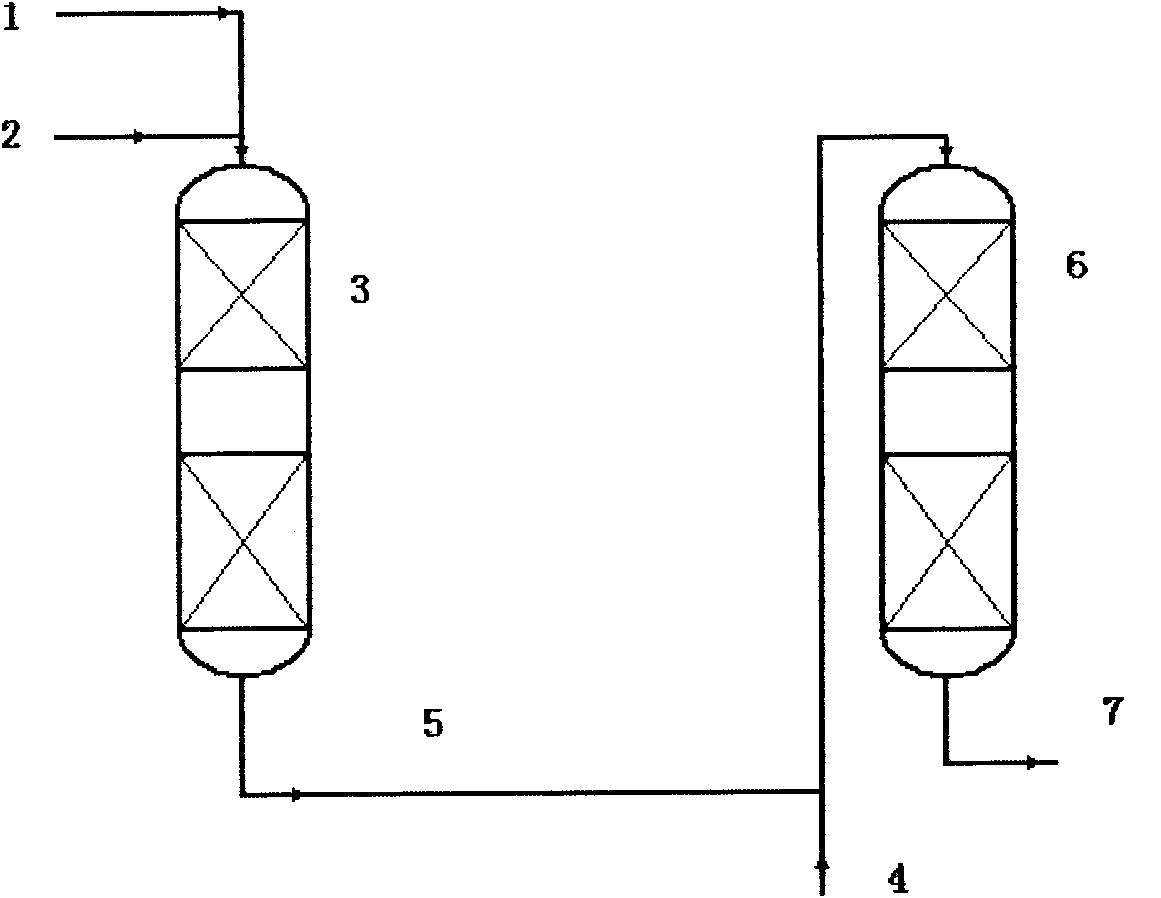

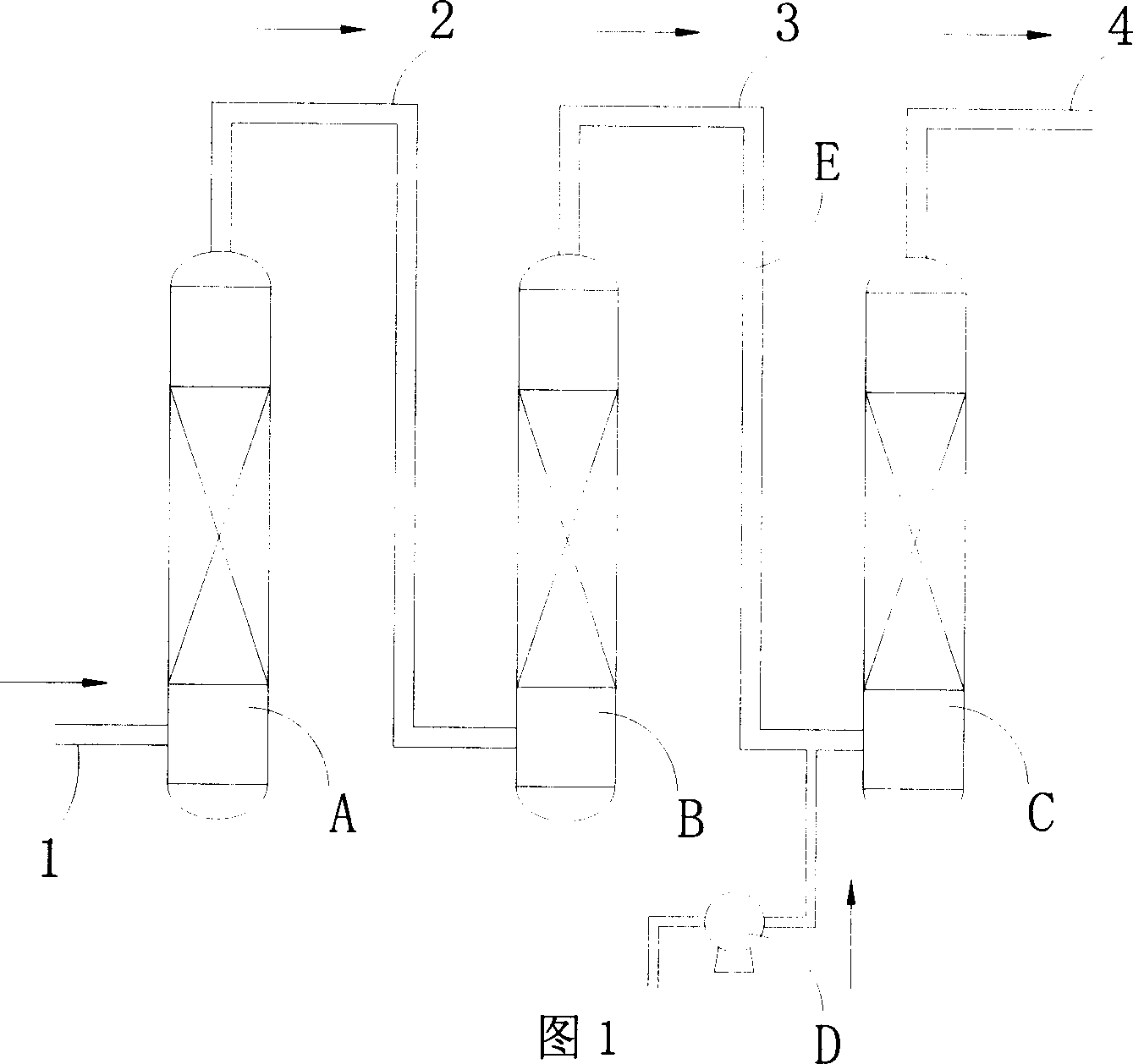

Deep desulfurization method for liquefied petroleum gas

The liquefied petroleum gas deep desulfurizing process includes the following steps: mixing alcohol amine treated liquefied petroleum gas with desulfurizer aqua, feeding the mixture into a reactor with carbonyl sulfide hydrolyzing catalyst for hydrolyzing carbonyl sulfide into hydrogen sulfide and CO2 and eliminating hydrogen sulfide, regenerating the used desulfurizer, water washing the liquefied petroleum gas to eliminate residual desulfurizer with water containing dissolved oxygen or hydrogen peroxide in a water washing tower with hydrogen peroxide decomposing catalyst in the stuffing layer, eliminating mercaptan from the liquefied petroleum gas through oxidizing mercaptan into disulfide in a mercaptan eliminating reactor with catalyst, and final rectifying in a rectifying tower to eliminate disulfide. The process is simple and practical, and can lower the total sulfide content in liquefied petroleum gas to below 5 ppm.

Owner:北京石大世通科技发展有限公司

Technology of preparing hydrocarbons produce from methanol by one-step method

ActiveCN1923770AShort processEasy to operateHydrocarbon from oxygen organic compoundsMolecular sieveGas phase

The invention discloses a preparing method of hydrocarbon based on once carbinol, which comprises the following steps: heating carbinol to reacting temperature; entering into the reactor with acid siallite zeolite molecular sieve catalyst; transmitting into hydrocarbon compound at 300-500 deg.c under 0.1-5.0 Mpa with the speed at 0.1-10.0h-1; cooling; separating the C5+ hydrocarbon product and gas phase part; entering gas phase in the compressor; making partial liquid leave system; adopting others as circulating material to blend with raw carbinol; returning to reactor to proceed next reaction.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI +2

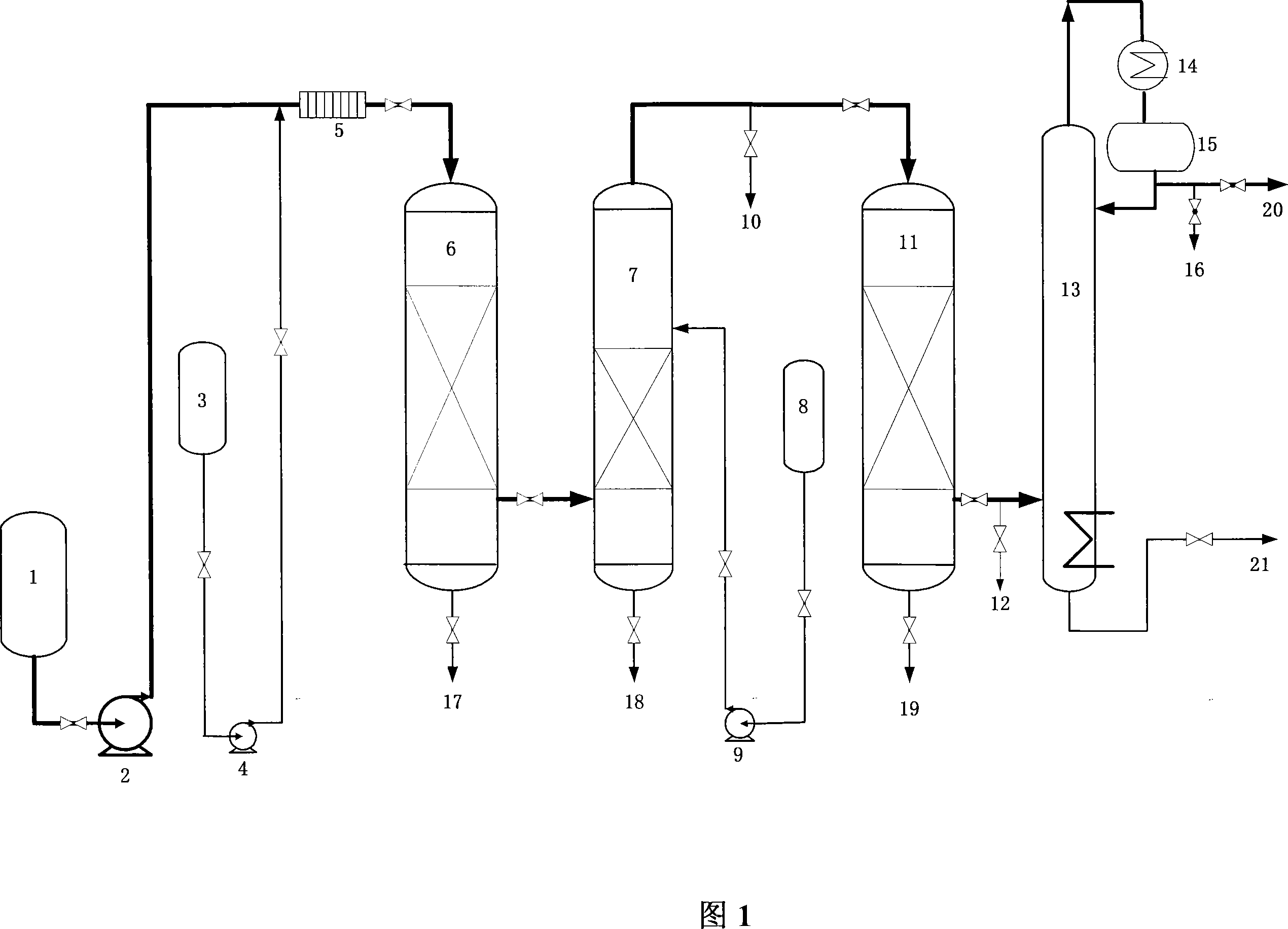

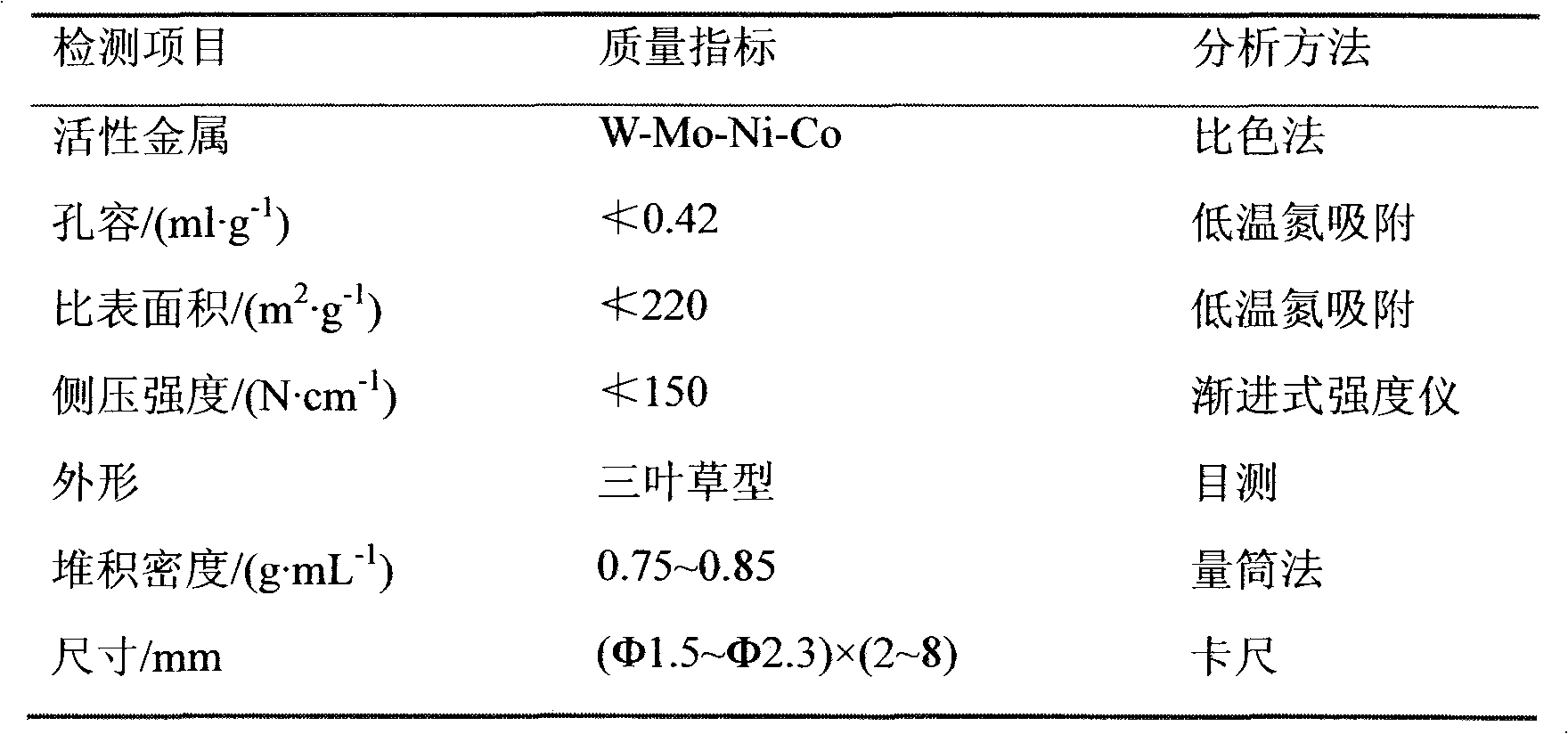

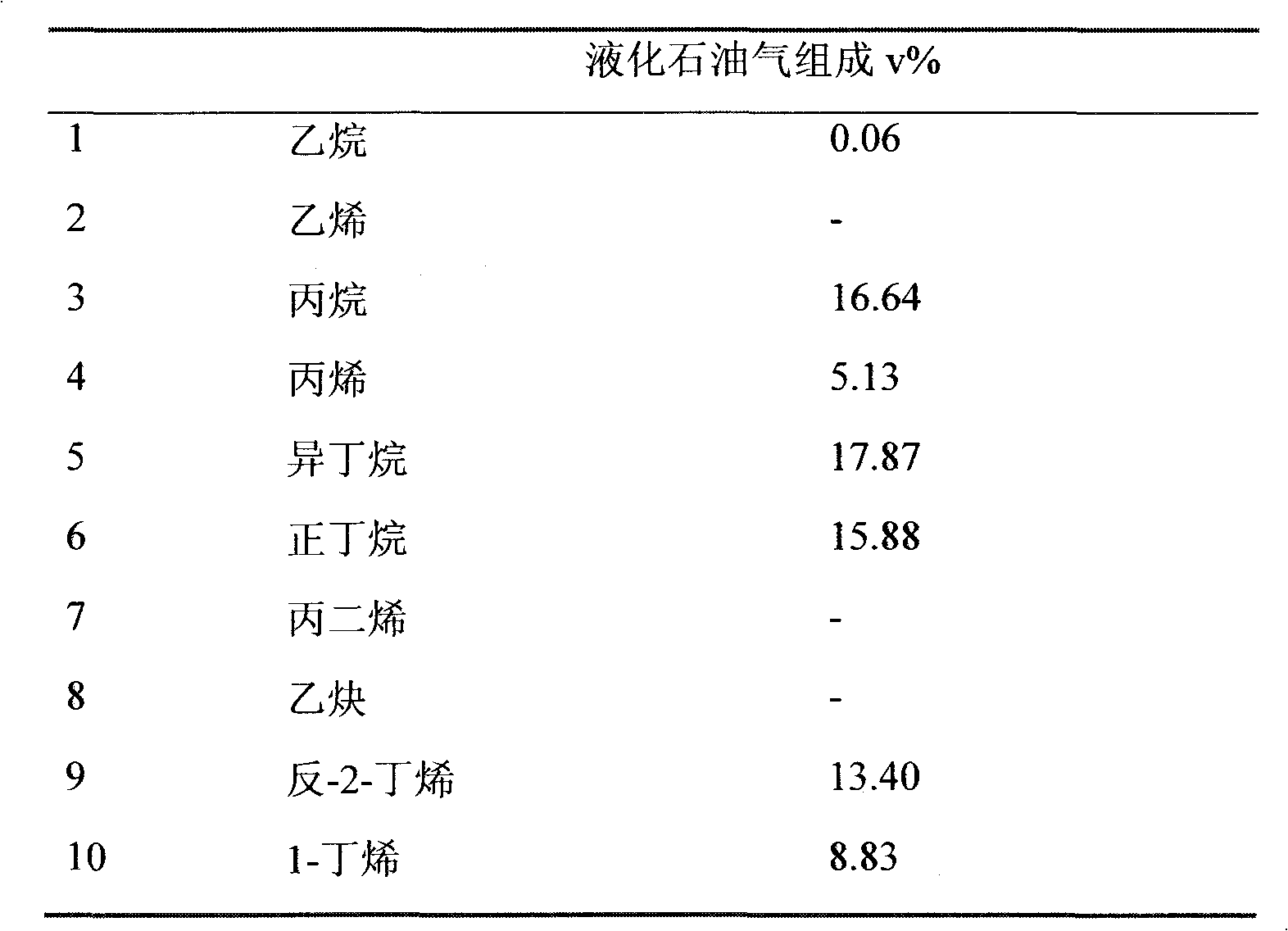

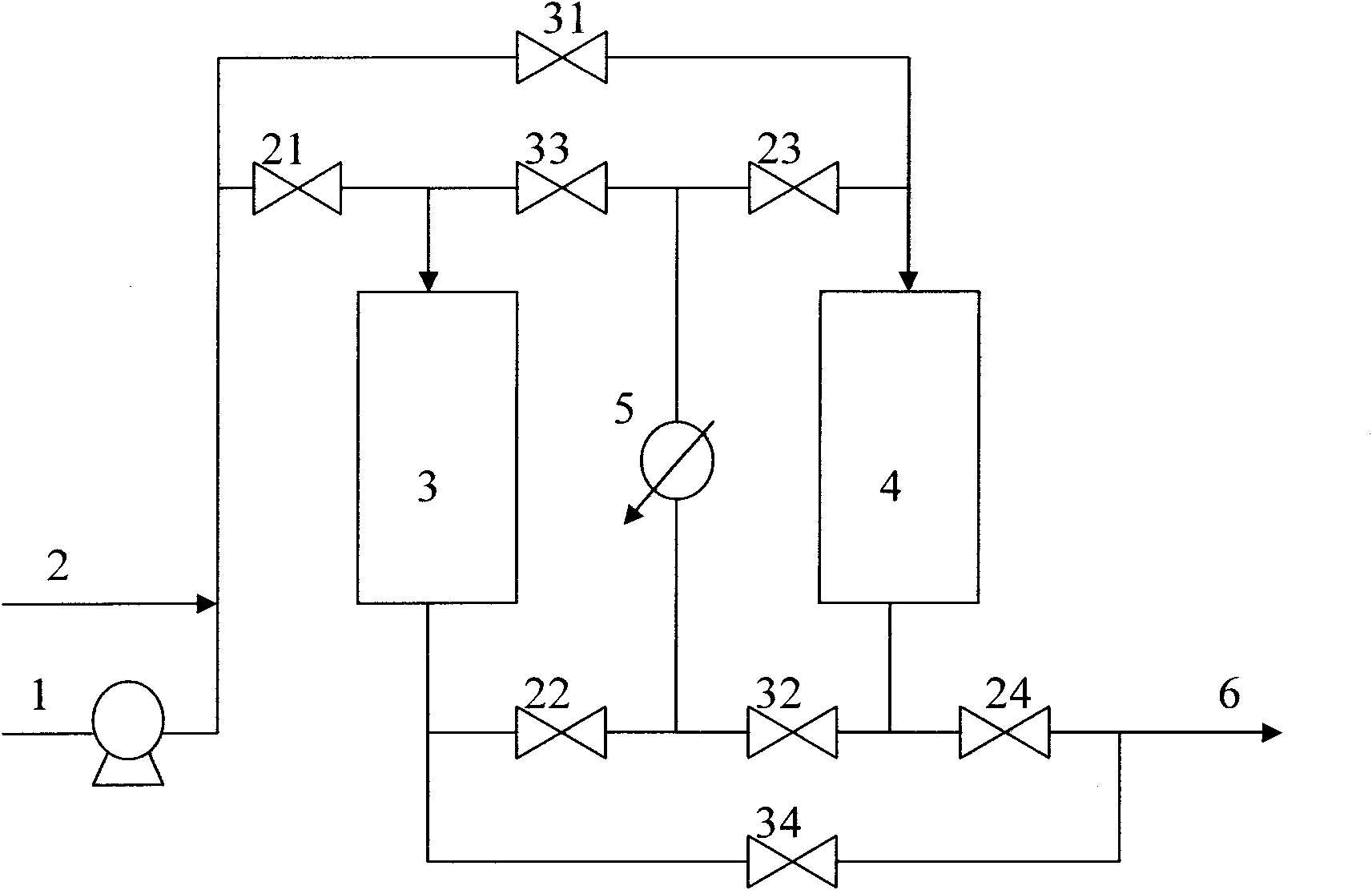

Liquefied petroleum gas-coke gasoline hydrogenation combined process method

ActiveCN102311783AFacilitated DiffusionEasy to take outTreatment with hydrotreatment processesRefining to eliminate hetero atomsHydrogenation reactionGasoline

The invention discloses a liquefied petroleum gas-coke gasoline hydrogenation combined process method, which comprises the following contents: coke gasoline undergoes a hydrogenation reaction in a coke gasoline hydrogenation reaction stage; the efflux of the coke gasoline hydrogenation reaction stage is mixed with the liquefied petroleum gas to enter a liquefied petroleum gas hydrogenation reaction stage; and the reaction efflux of the liquefied petroleum gas hydrogenation reaction stage is subjected to separation to obtain hydrogenated liquefied petroleum gas and hydrogenated coke gasoline. Compared with the prior art, the method disclosed by the invention is favorable for dissipation of reaction heat, lowers reaction temperature, reduces the influences of temperature on reaction balance and improves conversion rate; and the method reduces carbon accumulation of the catalyst, prolongs the single-pass service life of the catalyst and can obtain high-quality hydrogenated coke gasoline and hydrogenated liquefied petroleum gas at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

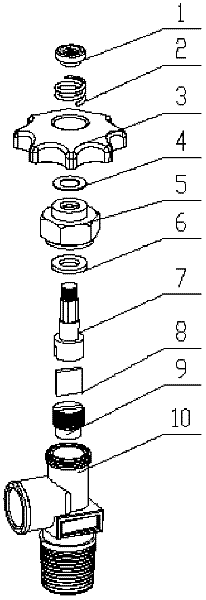

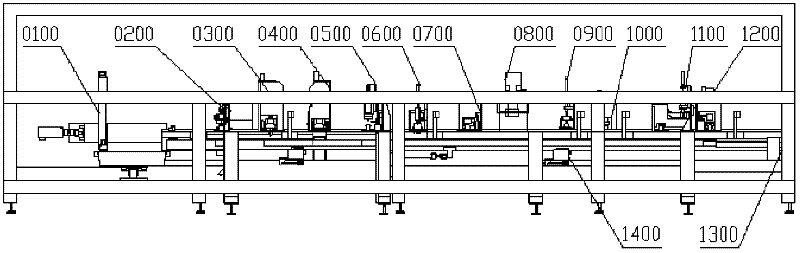

Automatic assembling line of liquefied petroleum gas cylinder valve

InactiveCN102390016AMovement precisionEffective investigationAssembly machinesGas cylinderClosed loop

The invention discloses an automatic assembling line of a liquefied petroleum gas cylinder valve and relates to an improvement on production equipment of a liquefied petroleum gas cylinder valve. The automatic assembling line is characterized by consisting of a loading working platform, a valve core assembling working platform, a connecting piece assembling working platform, a valve rod assembling working platform, a rubber pad assembling working platform, an oil coating working platform, a nut assembling working platform, a nut screwing working platform, a paper pad assembling working platform, a hand wheel assembling working platform, a spring assembling working platform, a round nut assembling working platform, a finished product blanking working platform and a line body. The automatic assembling line has the beneficial effects that a workpiece is clamped and conveyed by adopting a mode of automatic loading of a vibrating disc and stepping transmission so as to be transferred in a reciprocating manner of returning to the original position; and after the assembly of all the working platforms is finished in circulation, the blanking of the workpiece in next circulation is carried out, and the movement of the mechanism is more accurate by utilizing a cylinder and a linear guide rail. A sensor is adopted to sense whether the workpiece exists, a signal is transmitted to a PLC (programmable logic computer) and the PLC sends an instruction to execute the actions of all the working platforms and carry out closed-loop control.

Owner:CHANGCHUN UNIV OF TECH +1

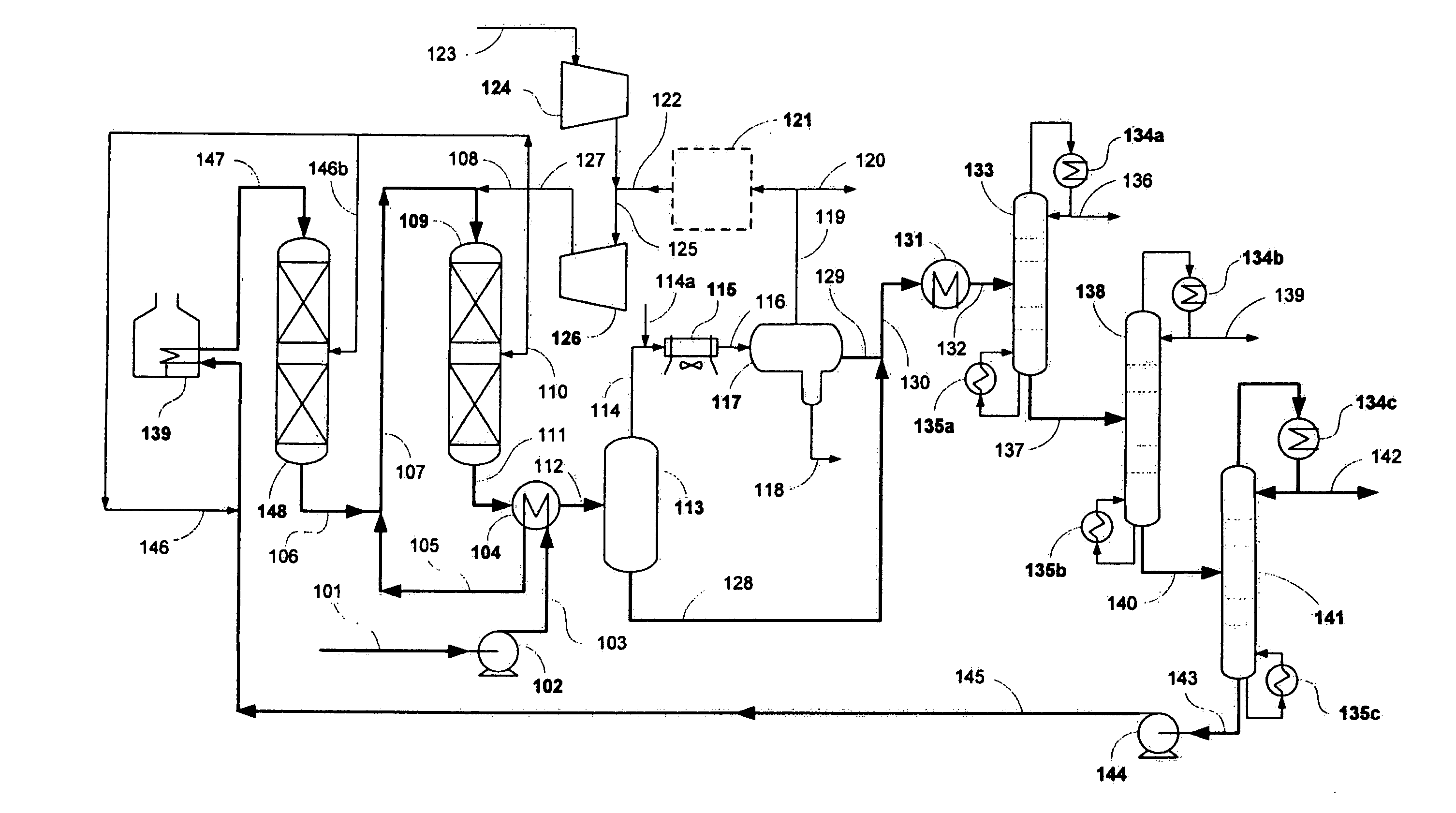

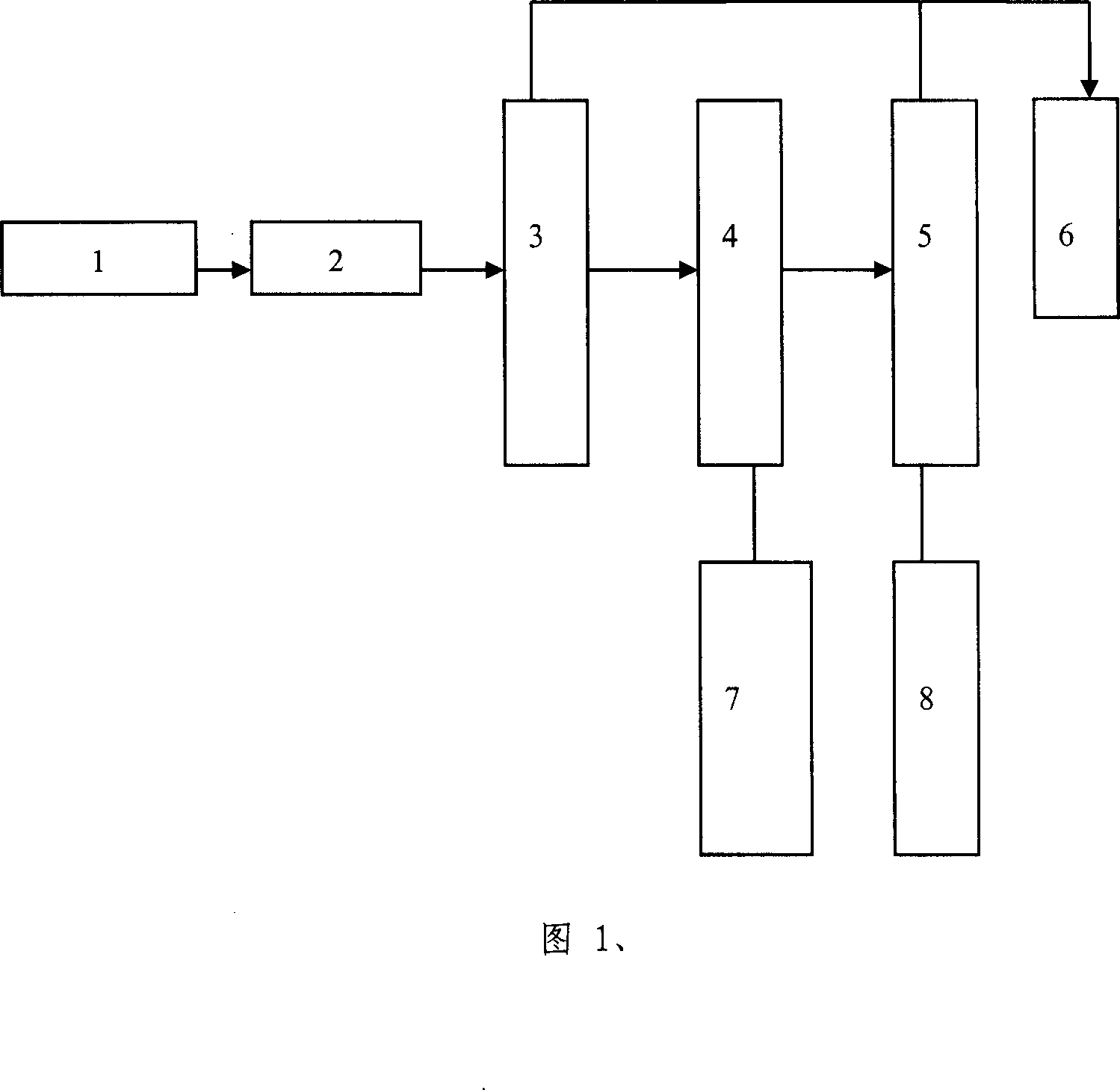

Process for co-producing jet fuel and LPG from renewable sources

ActiveUS7846323B2Improve cold flowHydrocarbon by hydrogenationLiquid hydrocarbon mixture productionEngineeringRenewable resource

The present invention generally relates to a method for producing an isoparaffinic product useful as jet fuel from a renewable feedstock. The method may also include co-producing a jet fuel and a liquefied petroleum gas (LPG) fraction from a renewable feedstock. The method includes hydrotreating the renewable feedstock to produce a hydrotreating unit heavy fraction that includes n-paraffins and hydroisomerizing the hydrotreating unit heavy fraction to produce a hydroizomerizing unit heavy fraction that includes isoparaffins. The method also includes recycling the hydroisomerizing unit heavy fraction through the hydroisomerization unit to produce an isoparaffinic product that may be fractionated into a jet fuel and an LPG fraction. The present invention also relates to a jet fuel produced from a renewable feedstock having improved cold flow properties.

Owner:REG SYNTHETIC FUELS LLC

Method of hydrogenating liquefied petroleum gas to prepare ethylene cracking feed

ActiveCN102311787AEffective temperature controlTemperature controlLiquid hydrocarbon mixtures productionTreatment with hydrotreatment processesHydrogenAlkene

The invention discloses a method of hydrogenating liquefied petroleum gas to prepare ethylene cracking feed, which is provided with two reaction sections. Reaction material cooling operation is carried out between the two reaction sections, the mixture of C4 fraction raw material and hydrogen is cooled after passing through the first reaction section, then enters the second reaction section, non-precious metal hydrofining catalysts are arranged in the two reaction sections, and a reaction material flow switching device is arranged between an inlet and an outlet of the two reaction sections to change the sequence of the reaction material flow entering the two reaction sections. The method disclosed by the invention solves the problem that the olefin content does not reach the standard due to thermodynamic control factors, simultaneously the catalysts are entirely fully utilized, and the operating cycle can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of treating biomass, fuel for fuel cell, gasoline, diesel fuel, liquefied petroleum gas, and synthetic resin

ActiveUS20110113675A1Reduce amountStable processing efficiencyCatalytic crackingBiofuelsFuel cellsContact time

In processing of biomass by catalytic cracking in a fluidized catalytic cracker having a reaction zone, a separation zone, a stripping zone, and a regeneration zone, the feedstock oil containing the biomass is processed in the reaction zone using a catalyst containing 10 to 50 mass % of ultrastable Y-type zeolite under the conditions: outlet temperature of the reaction zone 580 to 680° C., catalyst / oil ratio 10 to 40 wt / wt, reaction pressure 1 to 3 kg / cm2 G, and contact time of the feedstock oil with the catalyst in the reaction zone 0.1 to 1.0 sec, and the catalyst is then treated in the regeneration zone under the conditions: regeneration zone temperature 640 to 720° C., regeneration zone pressure 1 to 3 kg / cm2 G, and exhaust gas oxygen concentration at the regeneration zone outlet 0 to 3 mol %.

Owner:NIPPON OIL CORP

Method and apparatus for treating oil refining sewerage

ActiveCN101434443AReduce shockFacilitate deep processing and reuseWater/sewage treatmentMultistage water/sewage treatmentHigh concentrationActivated sludge

The invention relates to a treatment method and a device for refinery sewage. The refinery sewage is sent into an electrolytic catalysis oxidation reactor which is provided with an anode, a cathode and solid catalyst particles, wherein, the lower part of the reactor is provided with an oxygenation aeration device, the solid catalyst particles are filled between the anode and the cathode, and the solid catalyst particles adopts particle activated carbon loaded with metals having catalytic and oxidation function. The effluent of the electrolytic catalysis oxidation can be further treated by adopting an activated sludge process. The method is used for treating high-concentration salt-containing mixed wastewater such as the draining water of a refinery electrical desalting unit, the alkali washing waste alkali liquid of oils, liquefied petroleum gas and dry gas, and cutting water in an oils tank farm, and the like, the wastewater after treatment satisfies the requirement of direct discharging, thus alleviating impact on a wastewater treatment plant. The method put forward by the invention has the advantages that high-concentration wastewater can reach disposable treatment standard and does not need any dilution biochemical treatment, treatment effluent is not polluted secondarily by metal ions, and investment and running cost are lower, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Compositions and methods for treating subterranean formations with liquefied petroleum gas

The present invention relates to gelled fluids and methods for using liquefied petroleum gas in subterranean operations. More particularly, the present invention relates to servicing fluids that comprise gelled liquefied petroleum gas or servicing fluids that comprise a conventional gelled hydrocarbon fluid with liquefied petroleum gas and methods of using such servicing fluids in subterranean formations. One embodiment of the present invention provides a method of treating a subterranean formation comprising the steps of providing a gelled LPG fluid comprising liquefied petroleum gas and a gelling agent; and placing the gelled LPG fluid into the subterranean formation. Another embodiment of the present invention provides a method of treating a subterranean formation comprising the steps of providing a combined LPG servicing fluid comprising liquefied petroleum gas and a conventional hydrocarbon servicing fluid; and placing the combined LPG servicing fluid into the subterranean formation.

Owner:HALLIBURTON ENERGY SERVICES INC +1

On demand hydrogen enhancement system for internal and external combustion engine

InactiveUS20100206721A1Increased flame speedImprove performanceCellsInternal combustion piston enginesExternal combustion engineInternal combustion engine

The objective of this invention, on demand hydrogen enhancement system for internal and external combustion engine, is to develop a continuous non pressurized water electrolyzer from clean water (not pure water or distil water) generator system. The mixed hydrogen gas and oxygen gas called “Oxyhydrogen”. Oxyhydrogen use as catalyse for internal and external combustion engine to increase fuel flame speed. It can use with variety fuels such as Ethanol, Methanol, Gasohol, Gasoline, Diesel, Bio Diesel, LPG, CNG, and LNG. This system can reduce fuel consumption, increase fuel efficiency, increase torque, reduce emissions, and reduce engine temperatures. The system required no cooling fan and electrolytic solution circulating pump. The system has less heat loss and very low electrical consumption. Oxyhydrogen will produce on demand as the engine RPM and load of generator. The control unit detects signal frequency from the alternator. Gas production rate low at low RPM and use less current and gas production will high at high RPM and use higher current. This can save lot of energy for the electrolysis process. In the past, water electrolysis use direct current (D.C.). In this invention the inventor uses D.C. with Frequency Modulate (FM) pulse width modulator (PWM) instead of Amplitude Modulator (AM) to control the electrolyzer (FMPWM). This circuit had current detector for automatic current adjustment and over current protection.

Owner:SNIDVONGS SURAVUT

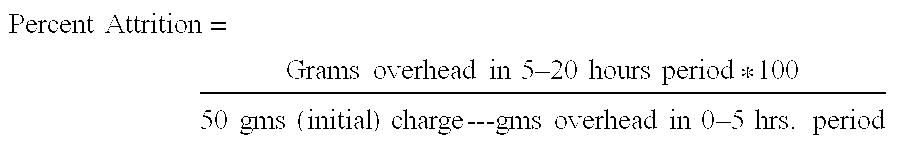

Process for preparation of bi-functional fluid catalytic cracking catalyst composition

A process for preparing bi-functional catalyst for Fluid Catalytic Cracking (FCC), that comprises molecular sieves, modified clay and semi-basic alumina and the catalyst for highly effective cracking of high boiling petroleum feedstock to provide simultaneously, enhanced yields of Liquefied Petroleum Gas (LPG) and reduction of undesirable bottoms.

Owner:INDIAN OIL CORPORATION

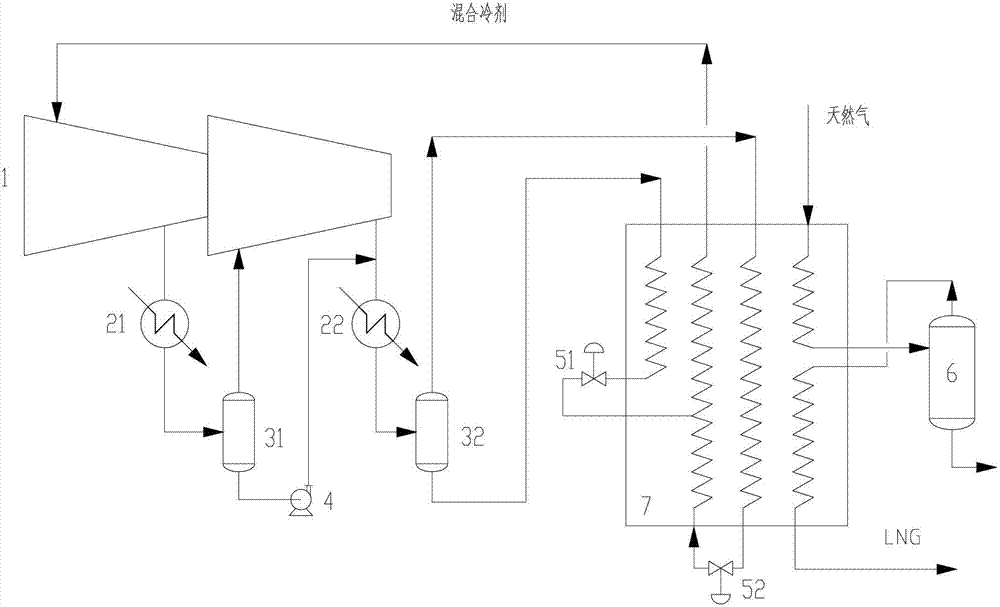

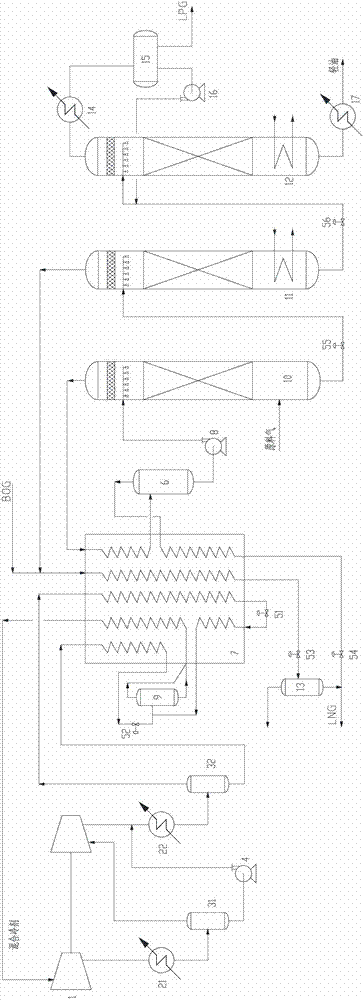

Method and device for carrying out liquefaction and heavy hydrocarbon treatment on natural gas

ActiveCN103031169AEconomical and reliableReasonable designSolidificationLiquefactionGas phaseLarge range

The invention relates to a process for carrying out liquefaction and heavy hydrocarbon treatment on natural gas, which comprises a low temperature liquefaction process and a heavy hydrocarbon treatment process. The low temperature liquefaction process comprises the following step that mixed refrigerant provides refrigerating capacity for the natural gas which is subjected to partial heavy hydrocarbon removal in the heavy hydrocarbon treatment process so as to implement cooling, complete heavy hydrocarbon removal and liquefaction on the natural gas in a cold box to obtain LNG (Liquefied Natural Gas); the heavy hydrocarbon treatment process comprises the following steps that the natural gas rich in heavy hydrocarbon is subjected to partial heavy hydrocarbon in a heavy hydrocarbon washing tower and the removed heavy hydrocarbon sequentially enters a deethanizing column and a rectifying column to be subjected to removal of light components and be separated into LPG (Liquefied Petroleum Gas) and light oil. According to the process disclosed by the invention, by-products, i.e. the LPG and the light oil, are also produced when the LNG is produced, the process route is advanced and the process is economical and reliable; the process can be suitable for the condition that raw material gas comprises aromatic hydrocarbon such as benzene and the like, the aromatic hydrocarbon such as the benzene and the like are removed along with the heavy hydrocarbon component and the cold box is prevented from being frozen and blocked; the process has large operation elasticity and can be suitable for natural gas heavy hydrocarbon content in a large range; the mixed refrigerant is adopted to circulate the flow and provide refrigerating capacity and gas-phase and liquid-phase refrigerants respectively enter the cold box to carry out heat exchange, so that heat exchange curves of cold and hot fluids are further matched; and the adopted refrigerating flow can effectively avoid liquid accumulation at the bottom of the cold box.

Owner:XINDI ENERGY ENG TECH

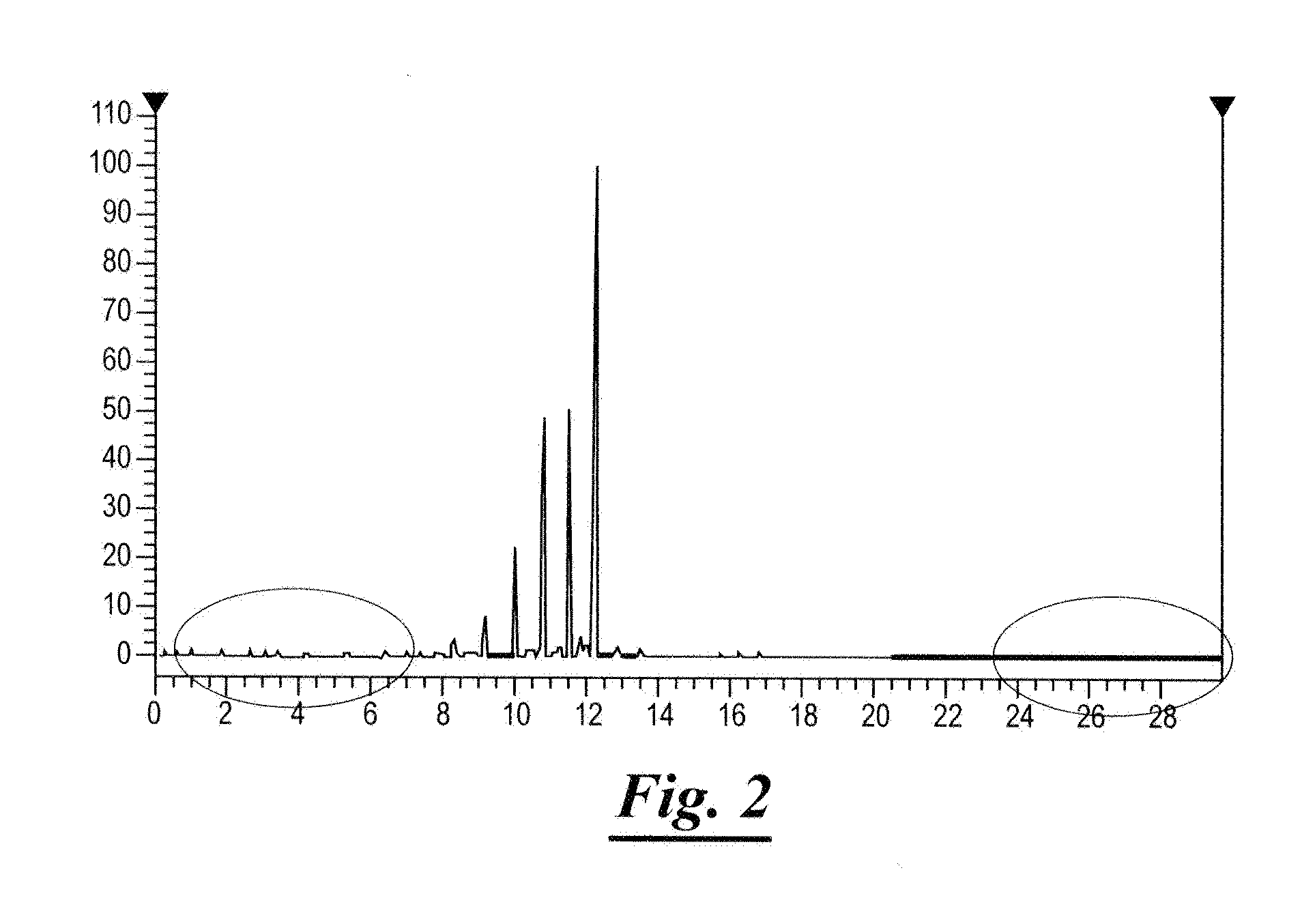

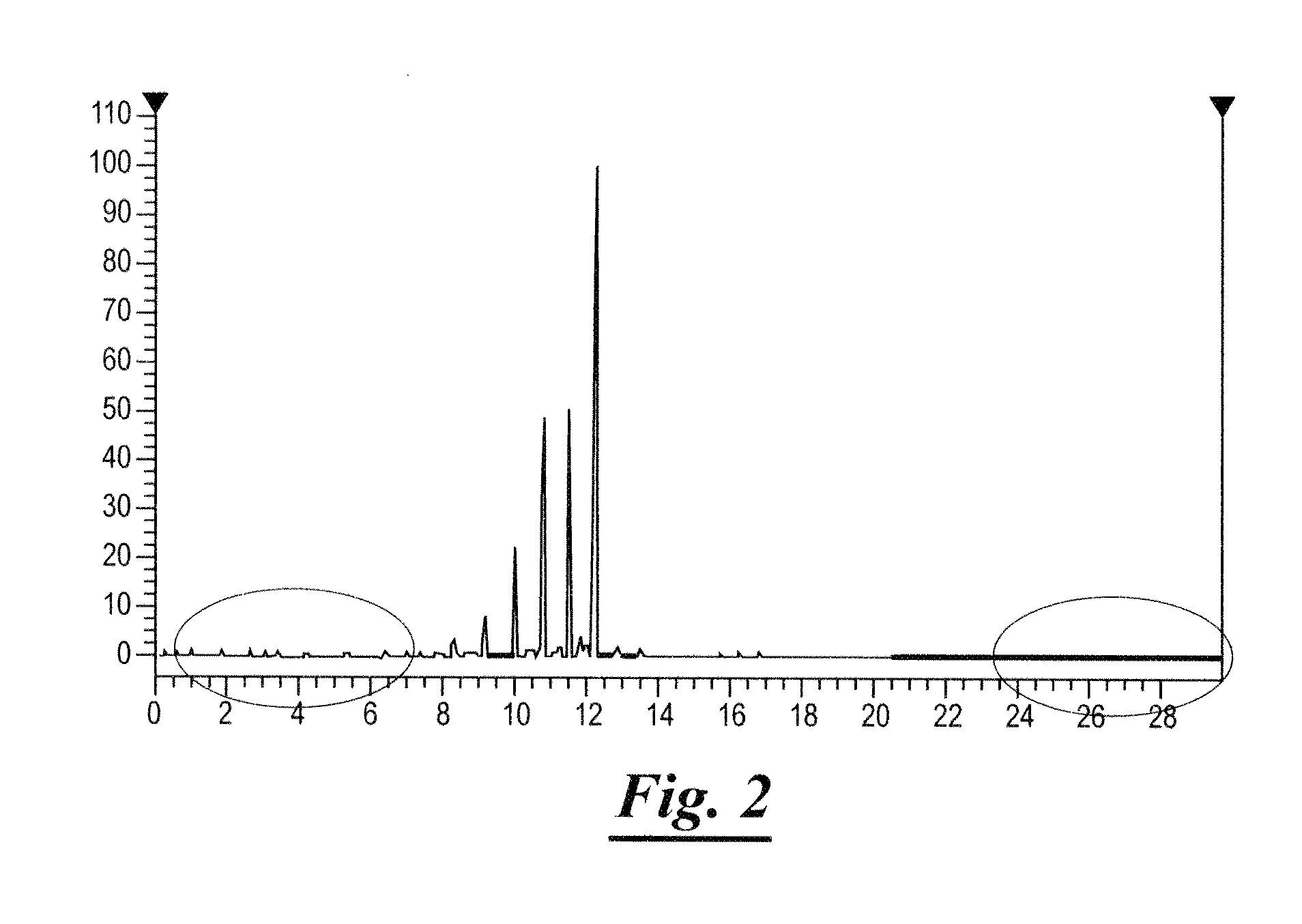

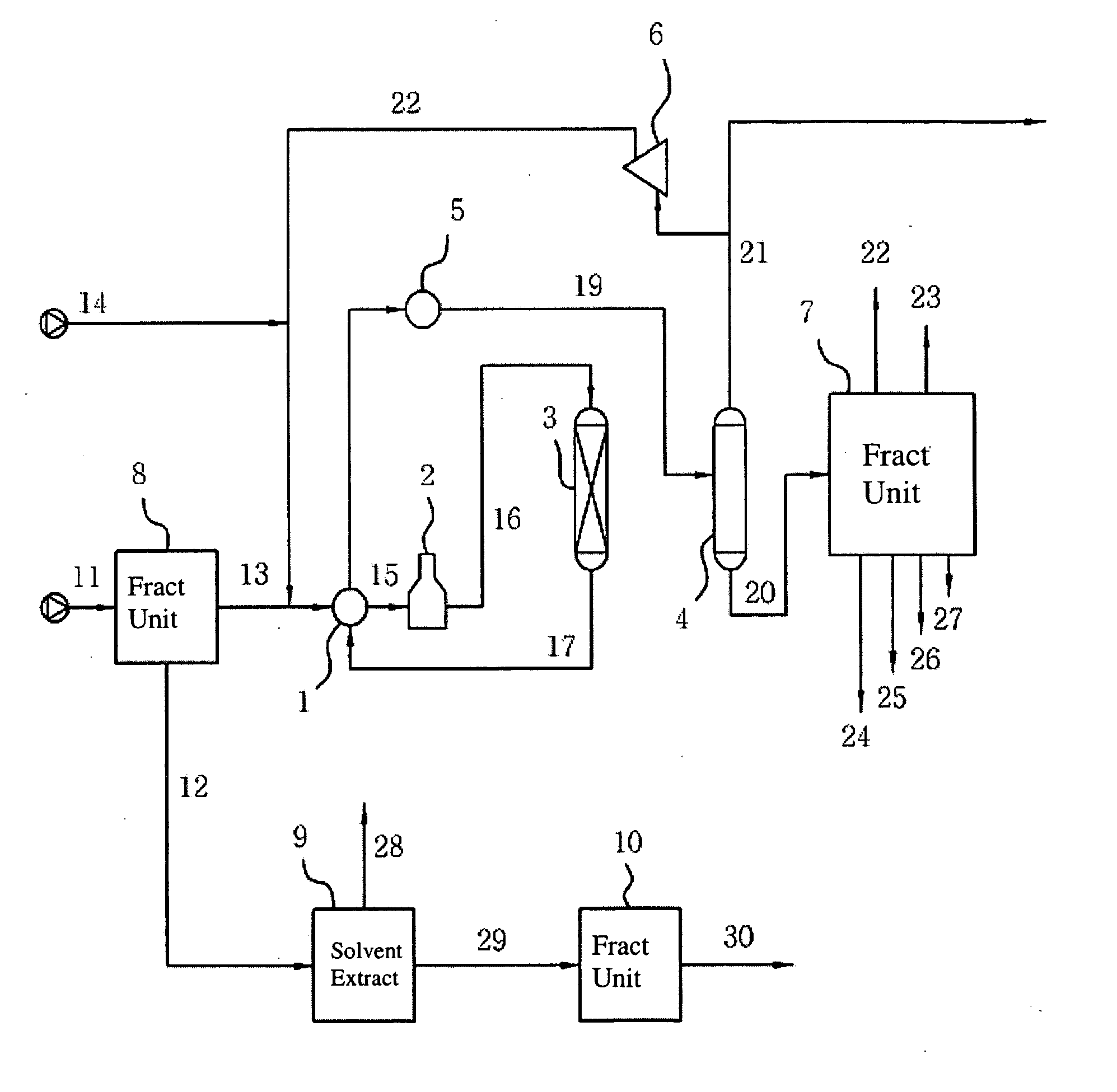

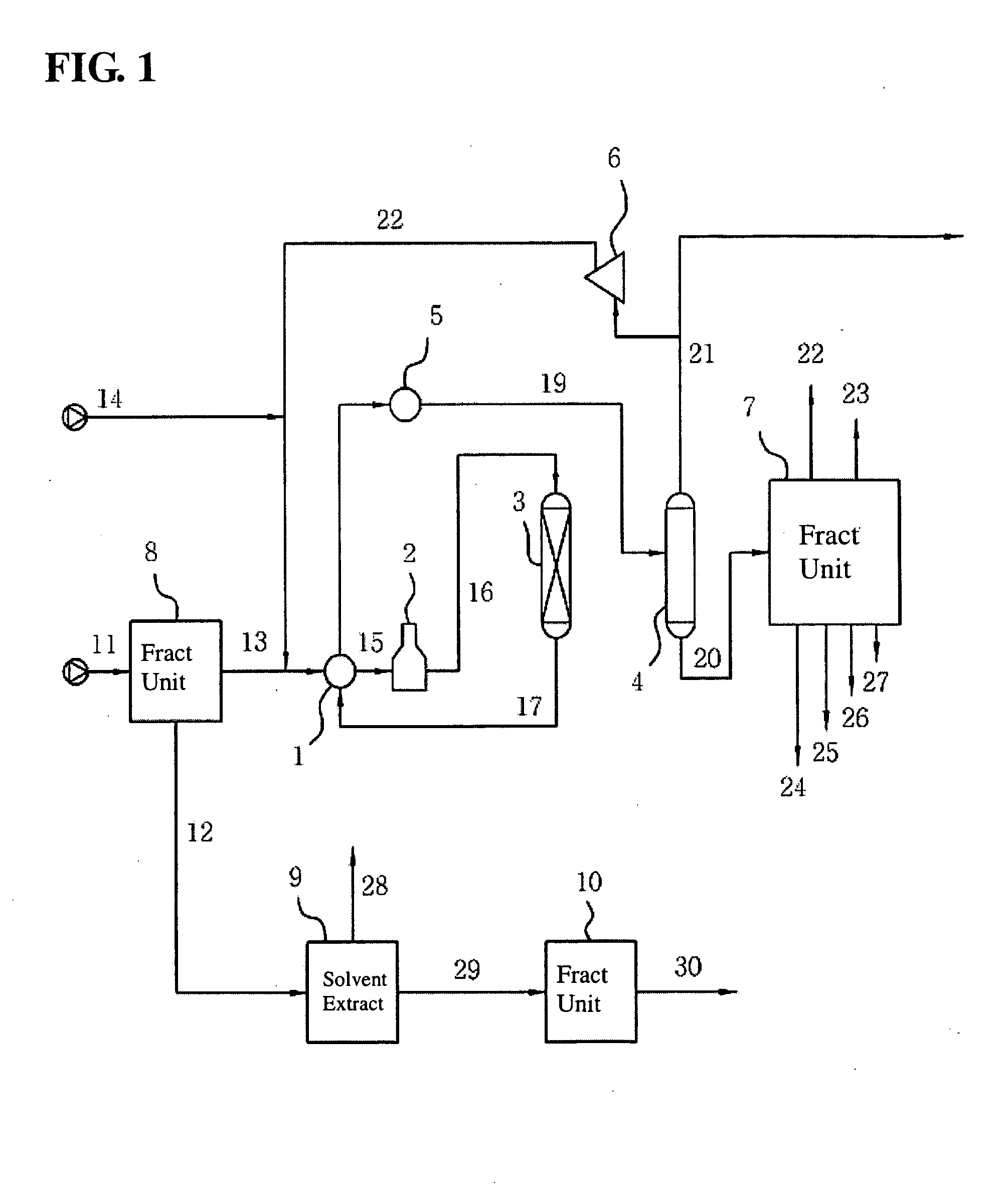

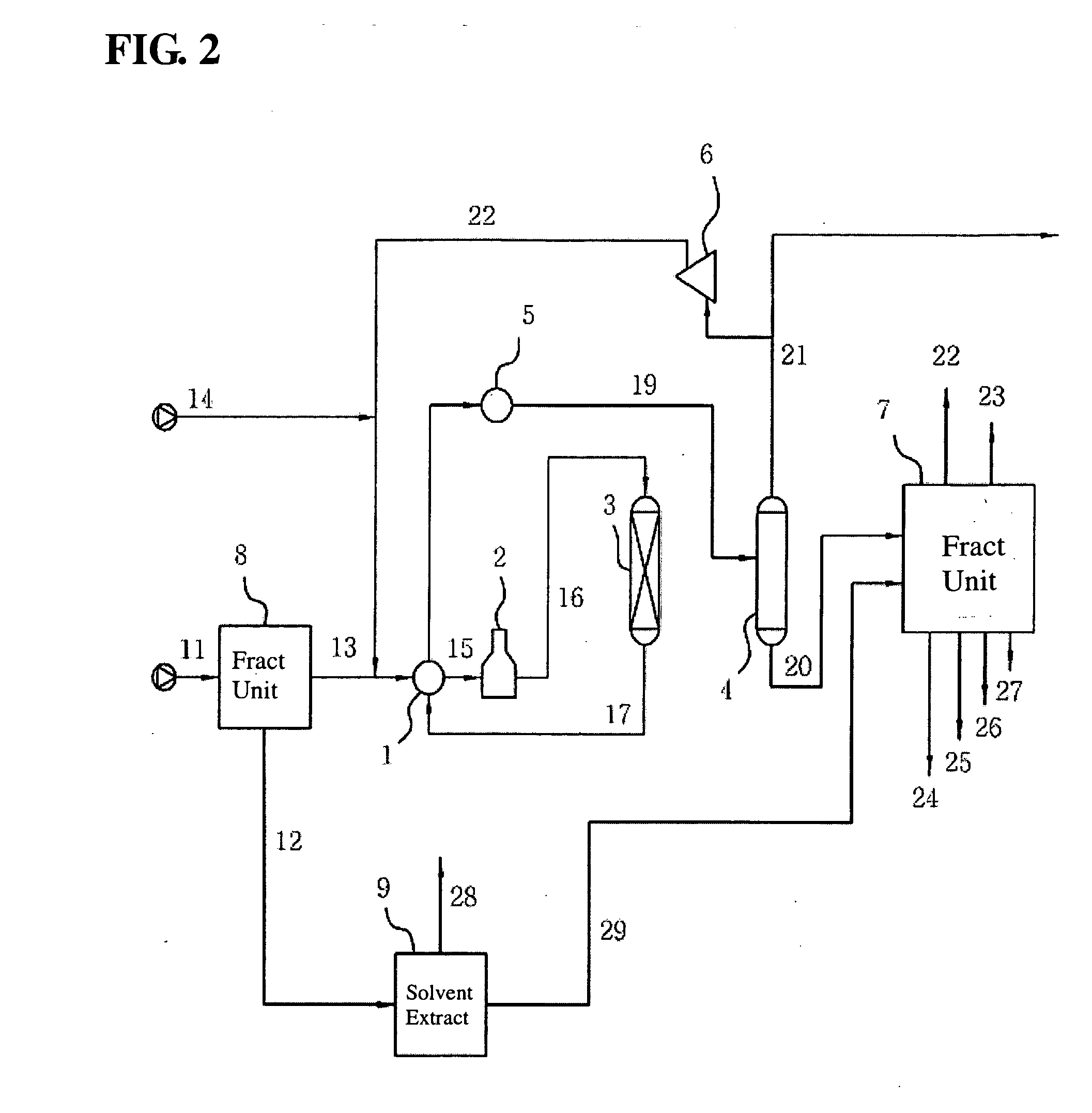

Process for increasing production of benzene from hydrocarbon mixture

ActiveUS20060287564A1Increase productivityImprove efficiencyHydrocarbon by isomerisationRefining to change hydrocarbon structural skeletonBenzeneHydrocarbon mixtures

A process for increasing the production of benzene from a hydrocarbon mixture. A process for producing an aromatic hydrocarbon mixture and liquefied petroleum gas (LPG) from a hydrocarbon mixture, and a solvent extraction process for separating and recovering polar hydrocarbons from a hydrocarbon mixture containing polar hydrocarbons (that is, aromatic hydrocarbons) and nonpolar hydrocarbons (that is, non-aromatic hydrocarbons) are integrated, thereby it is possible to increase the production of benzene.

Owner:SK INNOVATION CO LTD

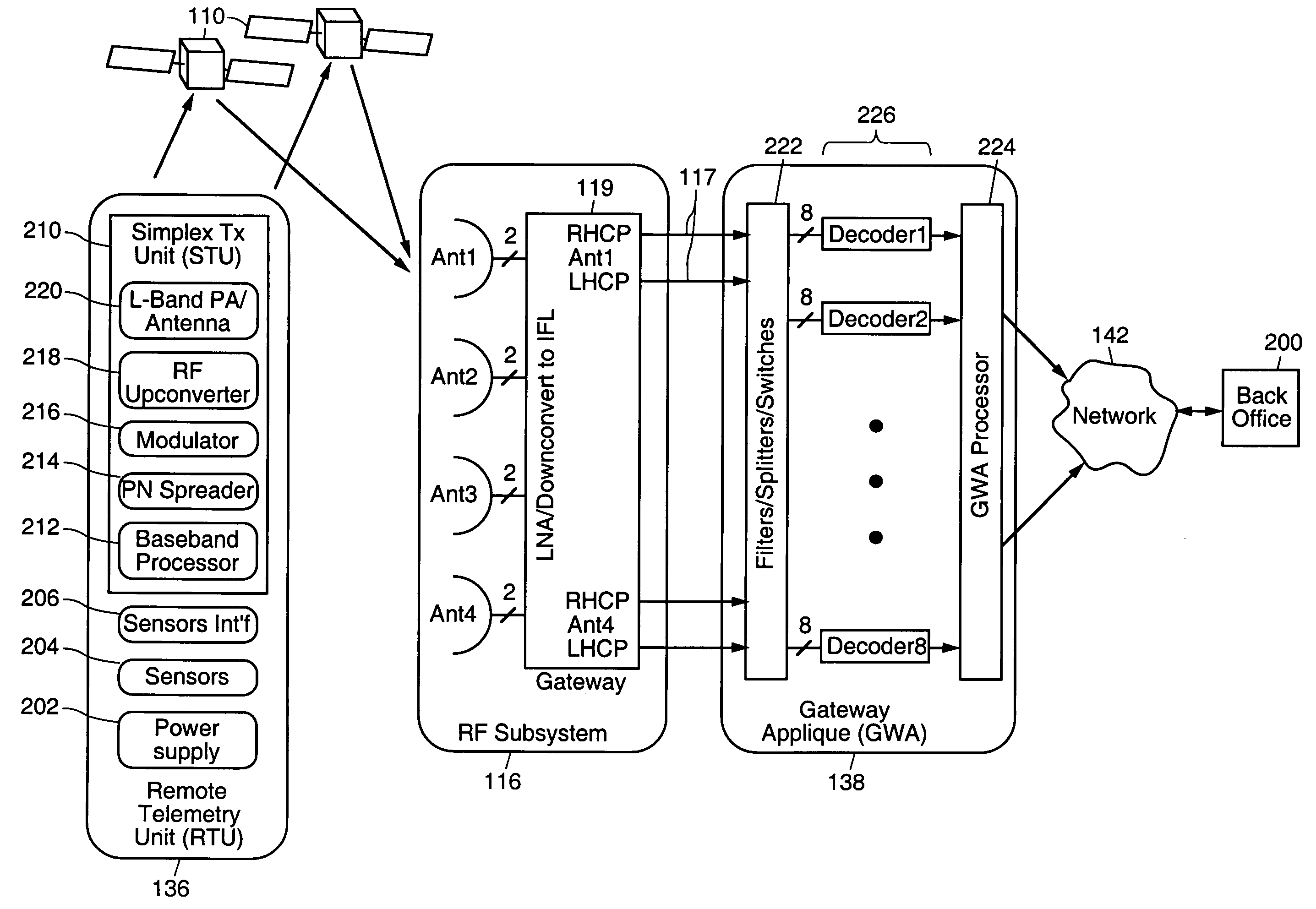

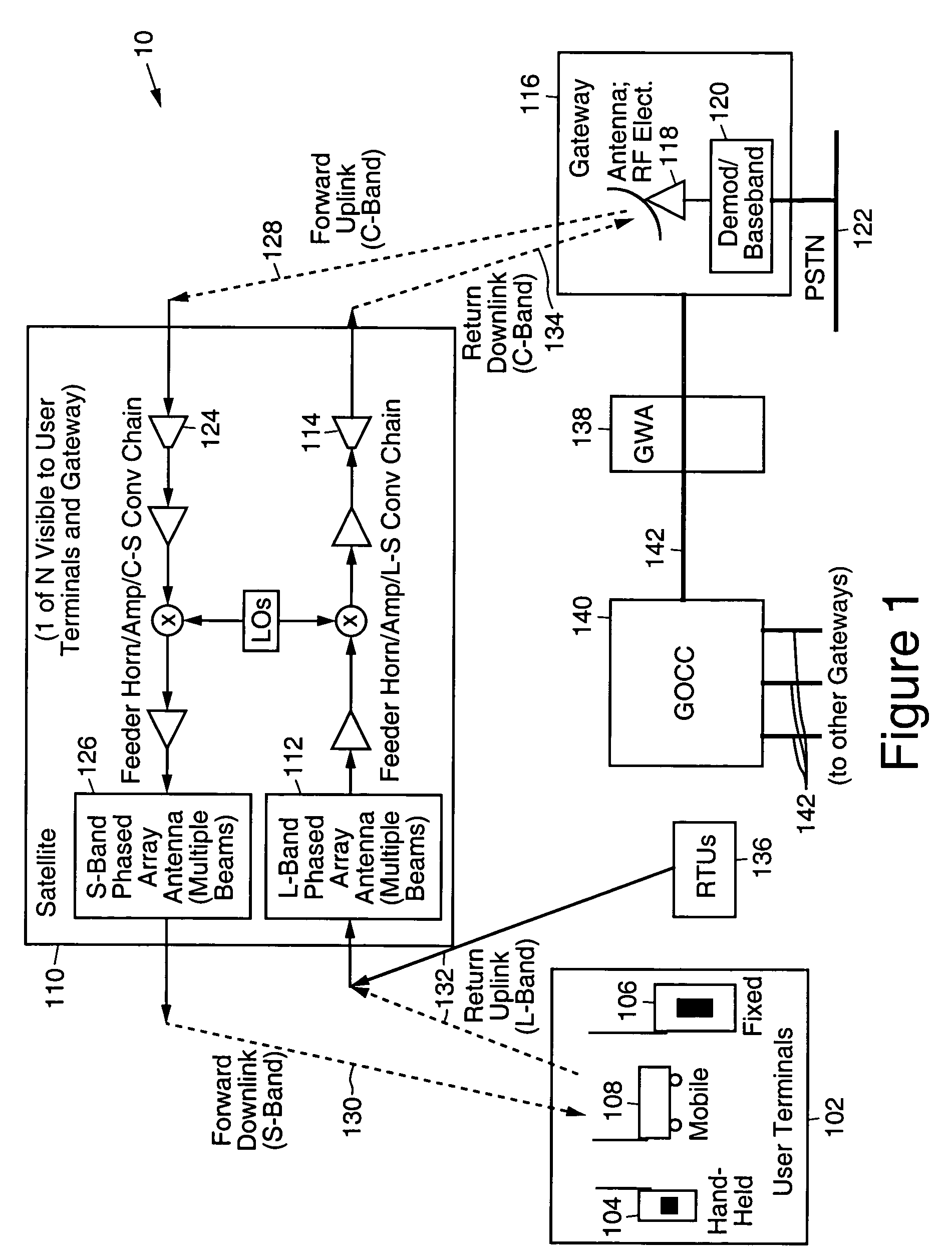

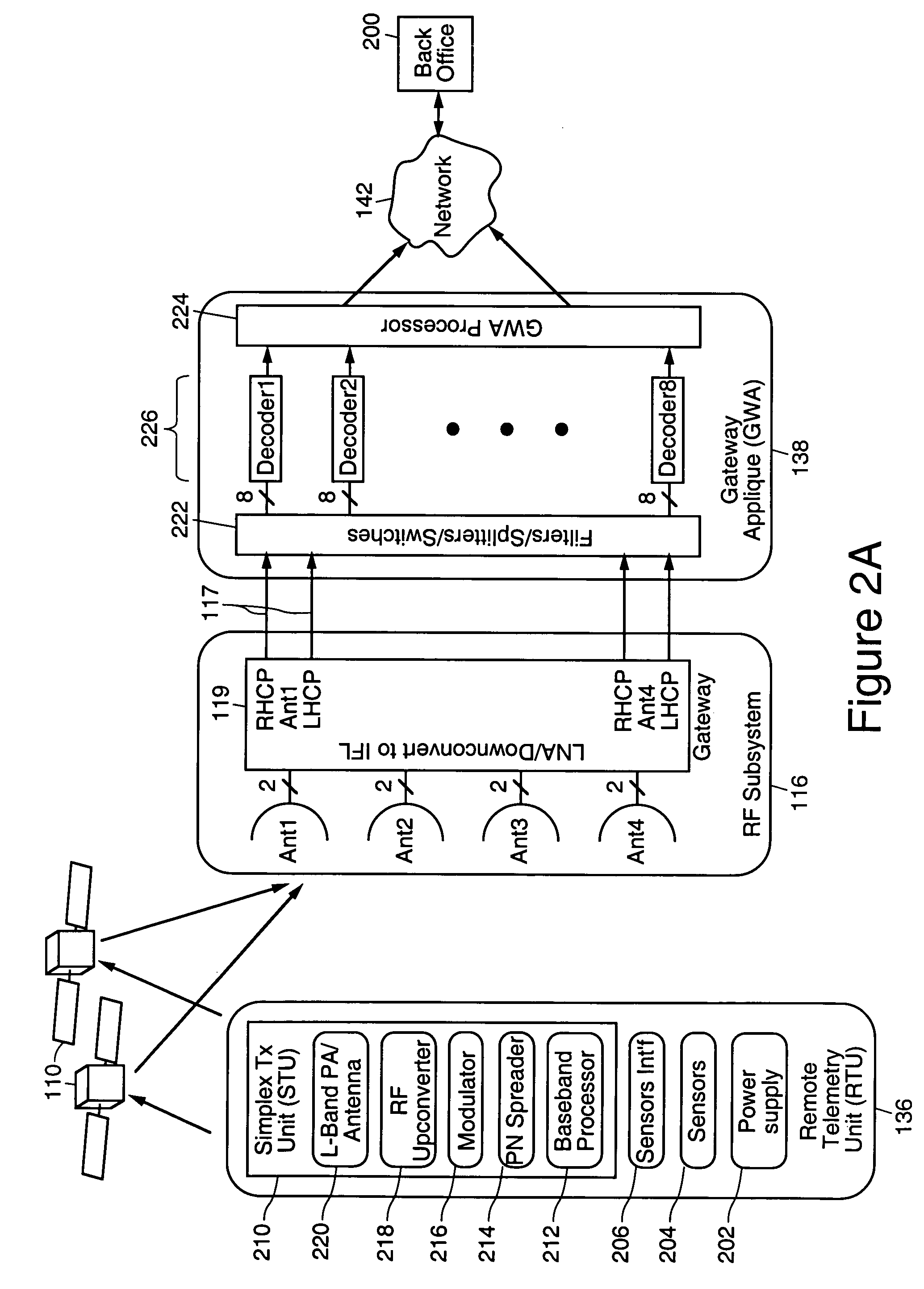

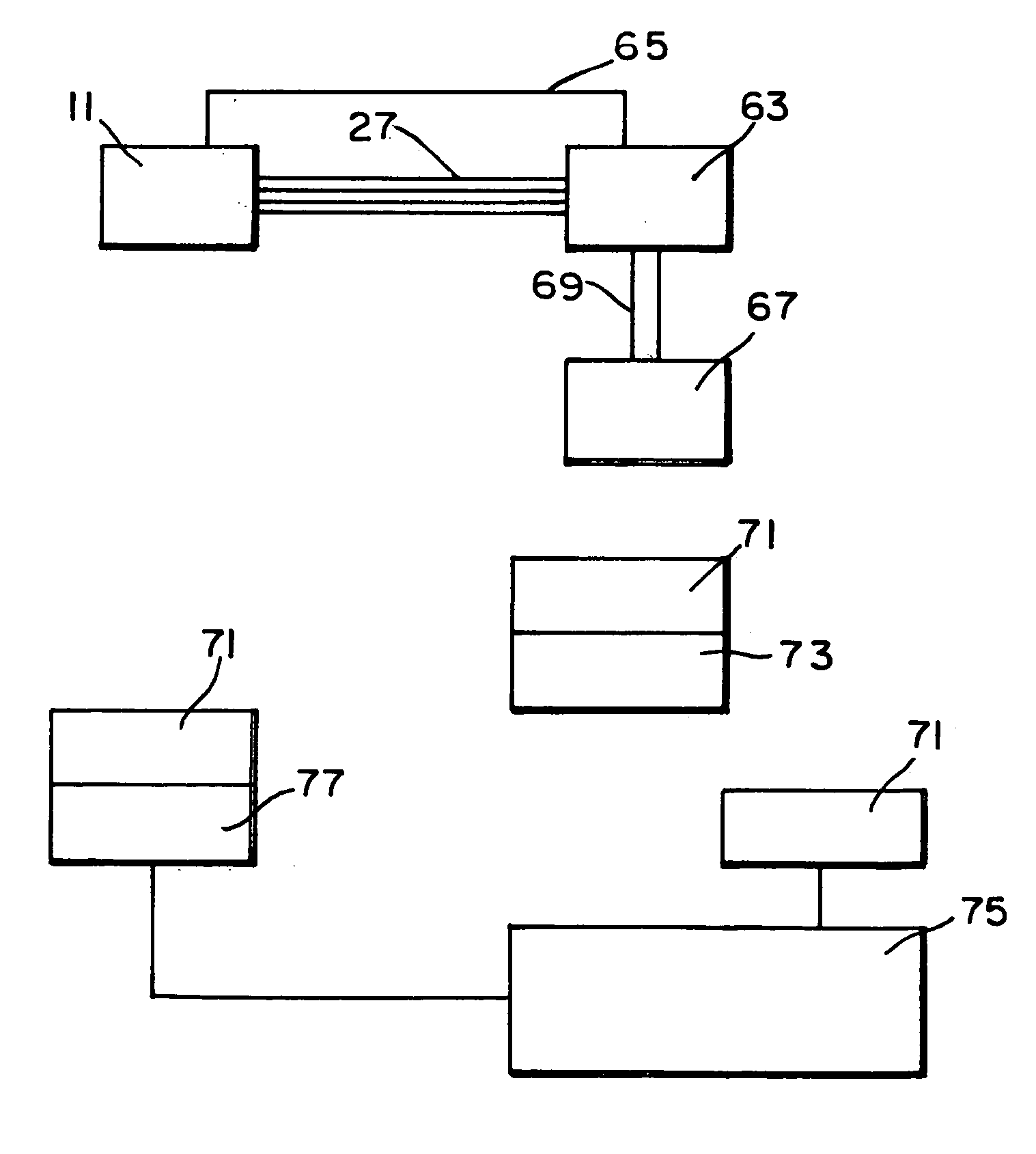

Method and system for routing telemetry in a simplex mode

ActiveUS7672639B2Cost-effective wayWireless commuication servicesRadio relay systemsCommunications systemThe Internet

A satellite based communication system in a low-earth-orbit (LEO) has multiple beams and FDM channels within each beam for voice / data communication between user terminals and multiple gateways. The satellite based communication system has two links for duplex communication, i.e., a forward link between the gateway and the user terminals through the satellites and a return link between the user terminals and the gateway through the satellites. Low volume telemetry data from remotely located assets, such as liquid petroleum gas tanks, water tanks, oil storage tanks, rail cars is gathered, processed, and transferred to a customer over an Internet link. A remote telemetry unit with a sensor and a simplex transmitting unit transmits remote telemetry data. A gateway receives data and directs the data to a gateway applique for demodulating and decoding. Resulting messages are sent to the customer via a back office over an Internet connection.

Owner:GLOBALSTAR INC

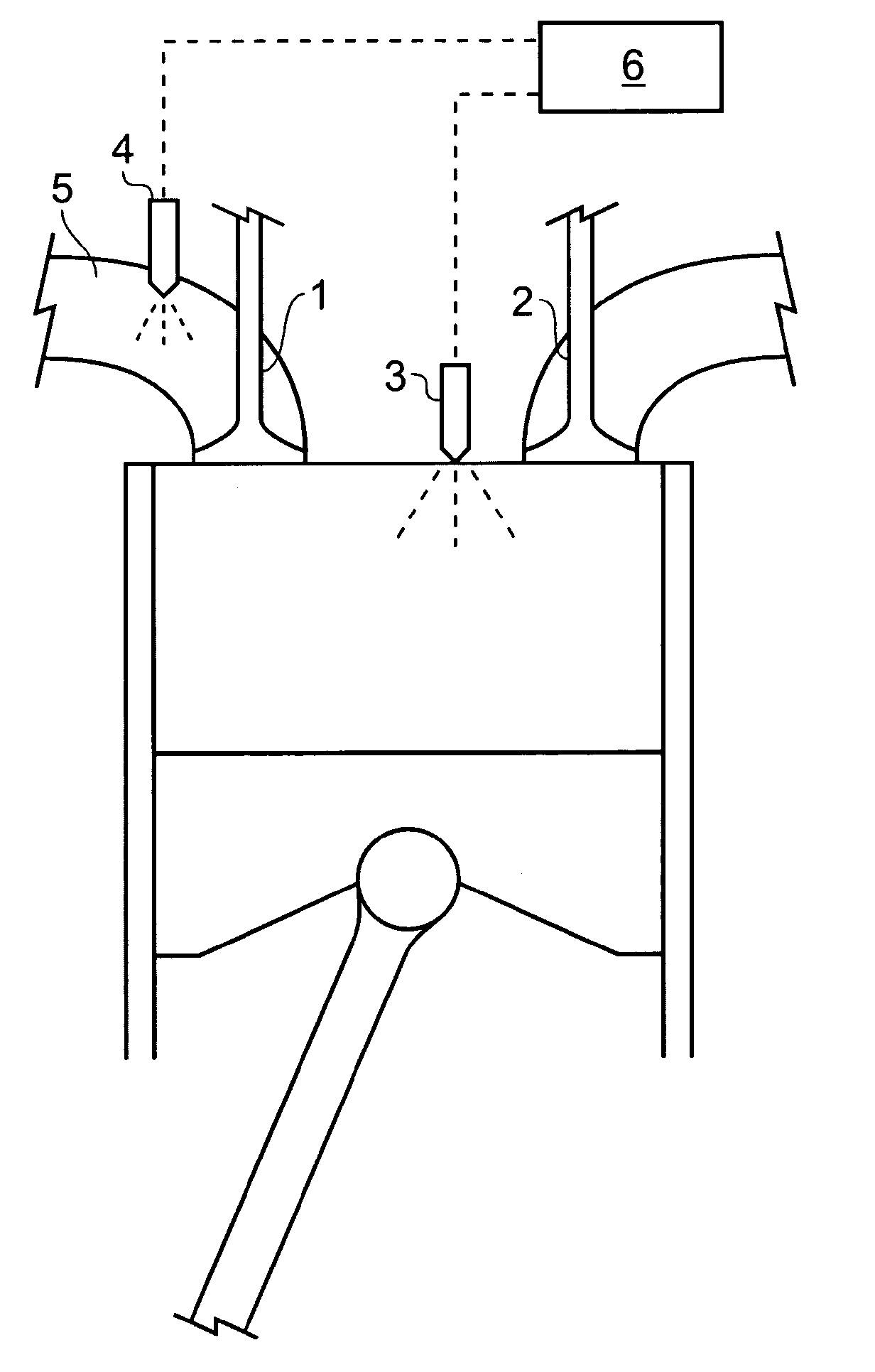

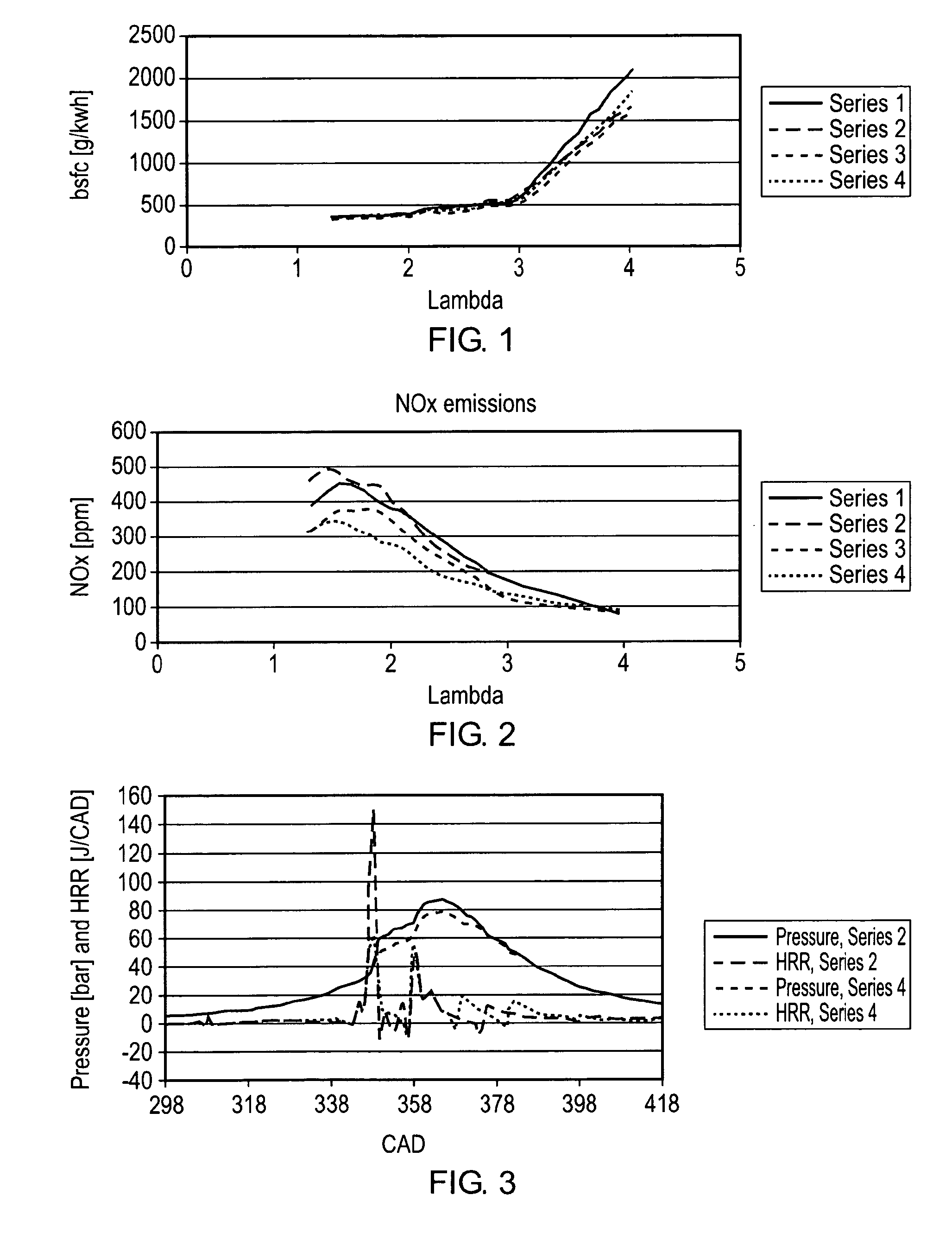

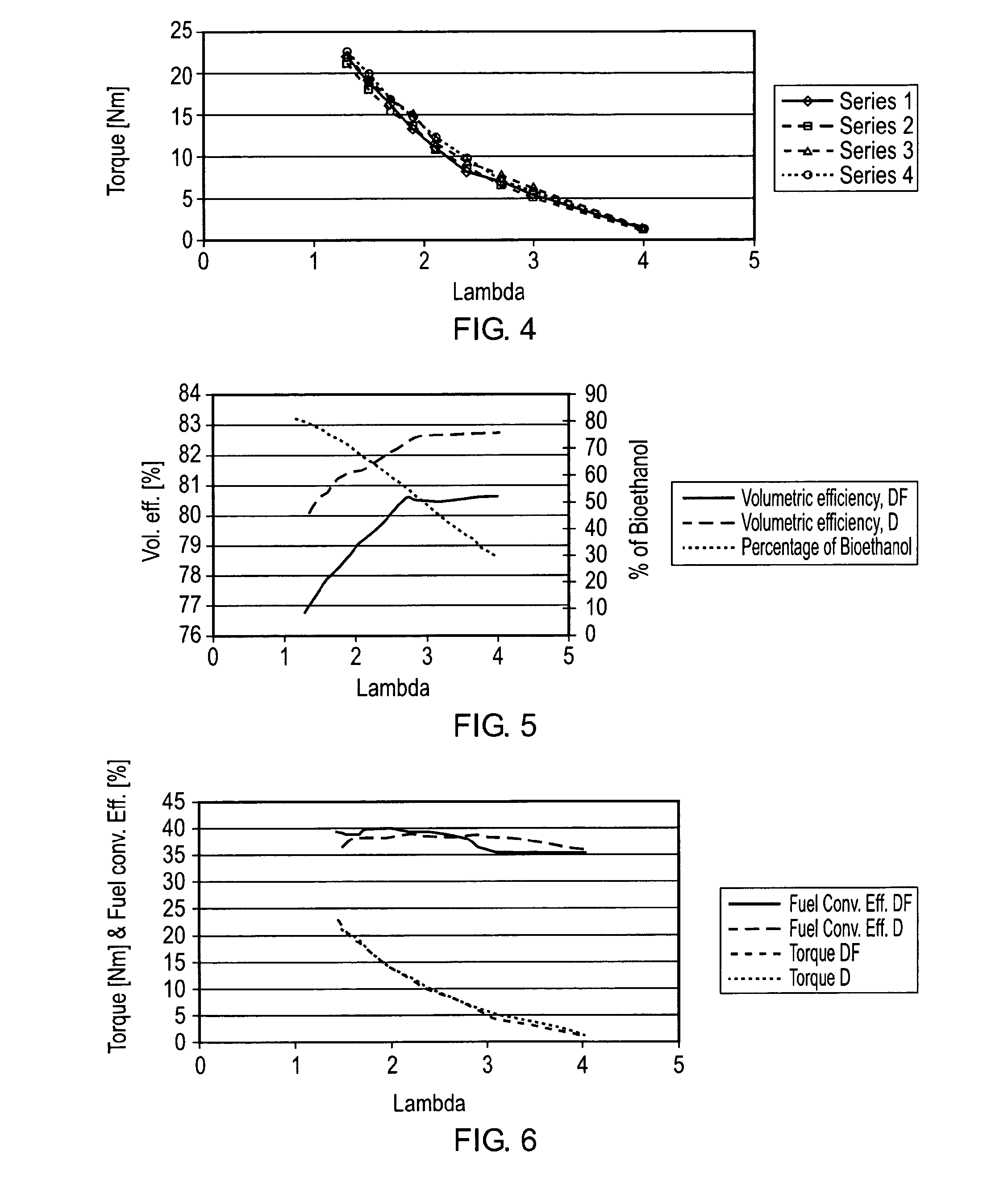

Multi-fuelling an engine

InactiveUS20110088654A1Reduce NOxReduce soot emissionsElectrical controlInternal combustion piston enginesBiodieselCombustion chamber

A compression ignition engine is supplied with a first fuel in a flow of air and a second fuel is injected into the combustion chamber. The first fuel comprises a more volatile fuel than diesel such as ethanol, LPG or other combustible gas; the second fuel comprises diesel or biodiesel; and the second fuel is injected in multiple pulses in each ignition cycle with the first pulse acting as a pilot pulse to trigger ignition, and the timing of the second pulse being such as to modify the temperature through evaporation of the second fuel and thereby reduce the combustion temperature and mitigate knock susceptibility. Preferably the pilot pulse is followed by a single further pulse of the second fuel in the ignition cycle. The engine may be controlled to operate in two different modes, one mode for light and medium load conditions when there is only a pilot pulse injection of the second fuel which reduces NOx and soot emissions, and the other mode for higher load conditions when there is a pilot pulse injection followed by a main pulse injection of the second fuel. The first fuel may comprise bioethanol and or one or more of the following: ethanol, butanol, propanol, lpg, natural gas, hydrogen.

Owner:G VOLUTION

Multi-gas cooker, with a rotary valve provided with interchangeable regulating means

InactiveUS20080138749A1Gaseous fuel feeder/distributionDomestic stoves or rangesCombustorInjector nozzle

The cooking appliance (1) having a control panel (2) is equipped with one or more gas flow (Q) regulating valves, wherein the rotary regulating plug (6) is provided with various peripheral through holes (16-19). The control knob (9) being interchangeable for fitting to the actuating shaft (7), is chosen from the two units available, one and the other permitting different angular limit positions of the regulating plug (6) for the supply of a constant minimum gas flow Qmin, adjusted each one for a different type of gas N gas or LP gas. The outlet conduit (5) of the valve is equipped with a further injector nozzle (21,23) for adjusting a constant gas flow Qmax to be fed into the conduit (25) of the correspondent burner, when the cooking appliance is supplied with a LP gas.

Owner:COPRECITEC

Heater and controls for extraction of moisture and biological organisms from structures

InactiveUS20100024244A1Tremendous ability to absorb water vaporFuel supply regulationDrying solid materials with heatGas heaterAtmospheric air

A gas heater with specialized controls allows an operator to deploy a single device to heat and to dry when extracting moisture from a structure. The heater has a fan in a blow thru arrangement ahead of a burner. The burner uses either natural gas or liquefied petroleum gas. The heater has air flow, fan motor, temperature, and ignition controls and sensors. The heater delivers high temperature air to the structure that hastens evaporation as the heated air absorbs great concentrations of water vapor. Then the moisture laden heated air exits the building as the heater draws in fresh air, ducts it into a structure, and pressurizes the structure. This moisture laden air then leaks from the building through select windows using the energy imparted from the fan and then exhausts the moisture to the atmosphere, drying the structure.

Owner:POTTER GARY J

Dual-purpose gas stove switch

A dual-purpose gas stove switch includes a valve body and a valve seat. The valve body includes an inlet passageway, an interior passageway, a nozzle having a mouth, a compensation nozzle, and a compensation passageway in communication with the compensation nozzle. A valve core is received in a chamber formed by the valve body and the valve seat. The valve core includes a blind hole in communication with the mouth via the interior passageway. The valve core includes four holes and a compensation hole. The valve core is rotatable to make the four holes to be in selective communication with the inlet passageway. The compensation hole can be in communication with the compensation passageway and the compensation nozzle. Thus, the switch can be selectively utilized with liquefied petroleum gas or natural gas.

Owner:HSIAO CHI CHEN

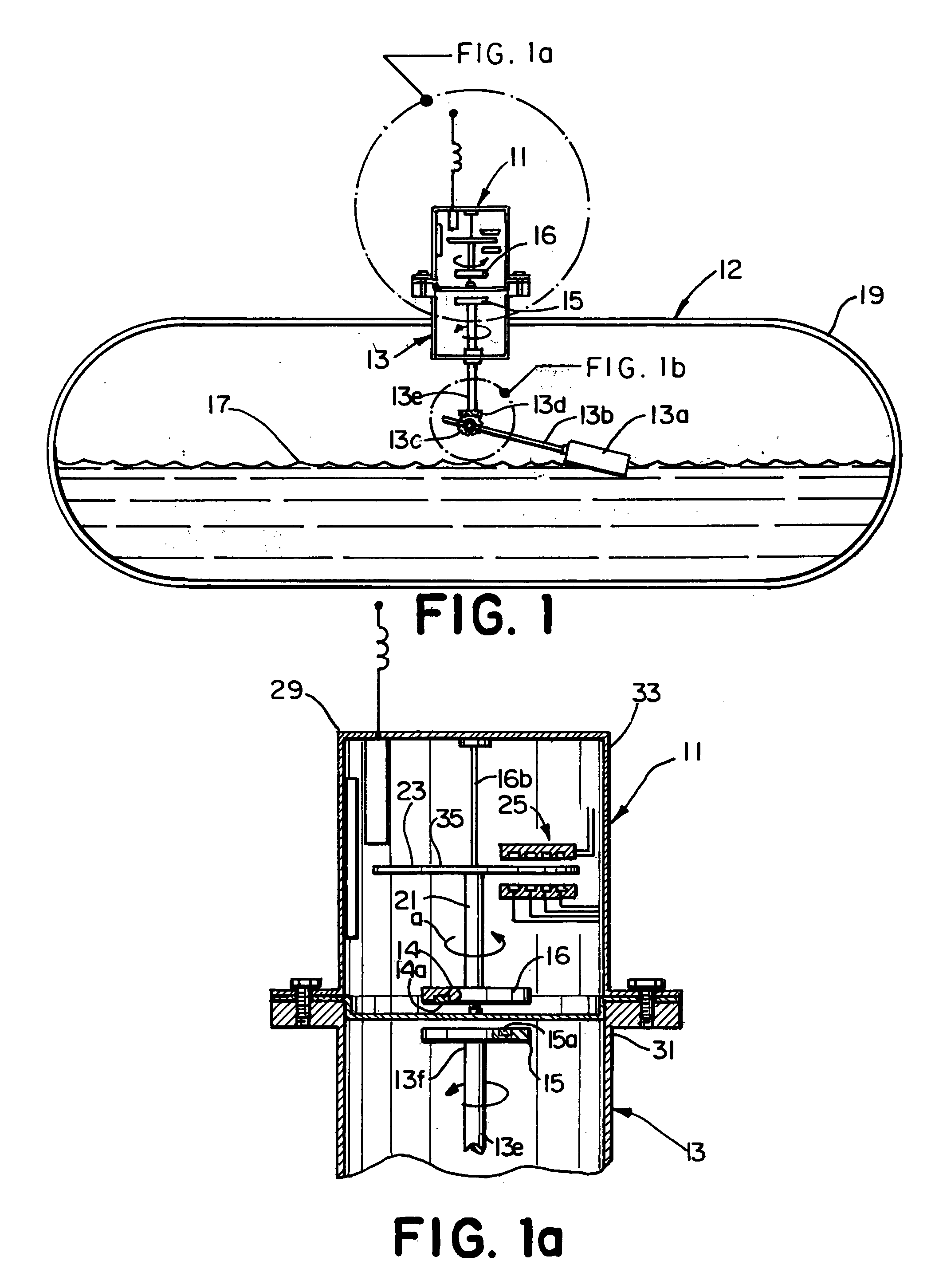

Remote liquid level gauge for remote sensing, system for employing the gauge and method of use

ActiveUS7155349B1Improving logistical inefficiencyImprove logistics efficiencyFlow propertiesFluid pressure measurement by mechanical elementsFuel oilLiquefied petroleum gas

A system, method and apparatus for improving the logistical inefficiencies associated with the delivery of liquid petroleum gas or fuel oil to remotely dispersed locations, including a gauge for detecting the level of fluid or liquid in a tank, and a transmission mechanism for transmitting the level detected by the gauge to a remote location for further evaluation and processing to facilitate delivery of the fuel.

Owner:AMERICAN WIRELESS GAUGE

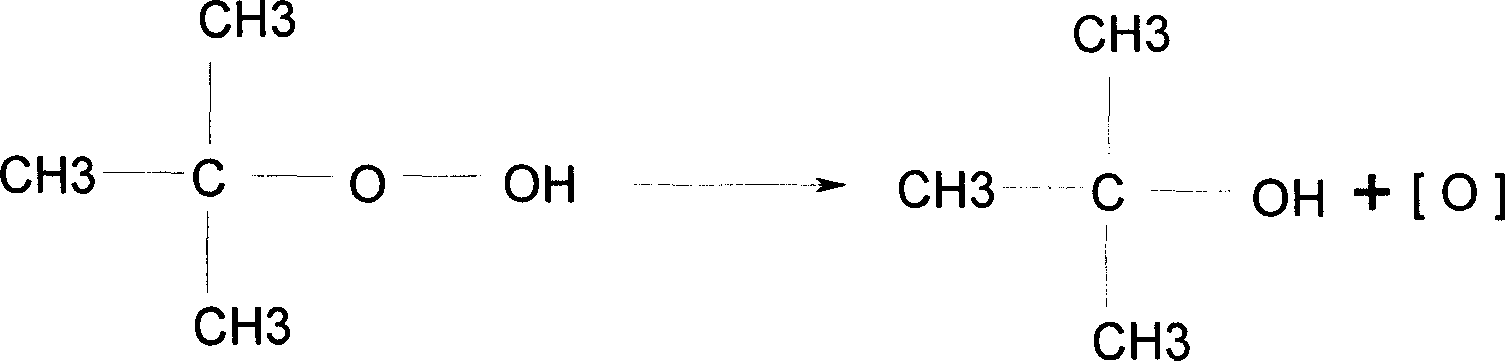

Method for refining catalytic liquefied petroleum gas

The present invention relates to a method for refining catalytic liquefied petroleum gas, in which catalyzed liquefied petroleum gas by alconol-amine method removing hydrogen sulfide process is operated by hydrolysis carbonyl sulfur process by passing through carbonyl sulfur hydrolysis activator bed layer, such that carbonyl sulfur hydrolysis generates sulfureted hydrogen and carbon dioxide; then it passes through the desulfurizer bed layer to operate hydrogen sulfide removing process, the preparation of reaction of the hydrogen sulfide and the desulfurizer is chemically absorbed on the desulfurizer; at last, liquid oxygen supplying agent having effective component of tert-butyl hydroperoxide is applied into the catalyzed liquefied petroleum gas, then it is processed by transformation mercaptan by passing through the double effects activator bed layer, under the effect of the double effects activator, the tert-butyl hydroperoxide is hydrogen peroxide decomposed to release fresh state oxygen, and the mercaptan is oxygenated to bisulfide; the activate component of the double effects activator is compound of manganic.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

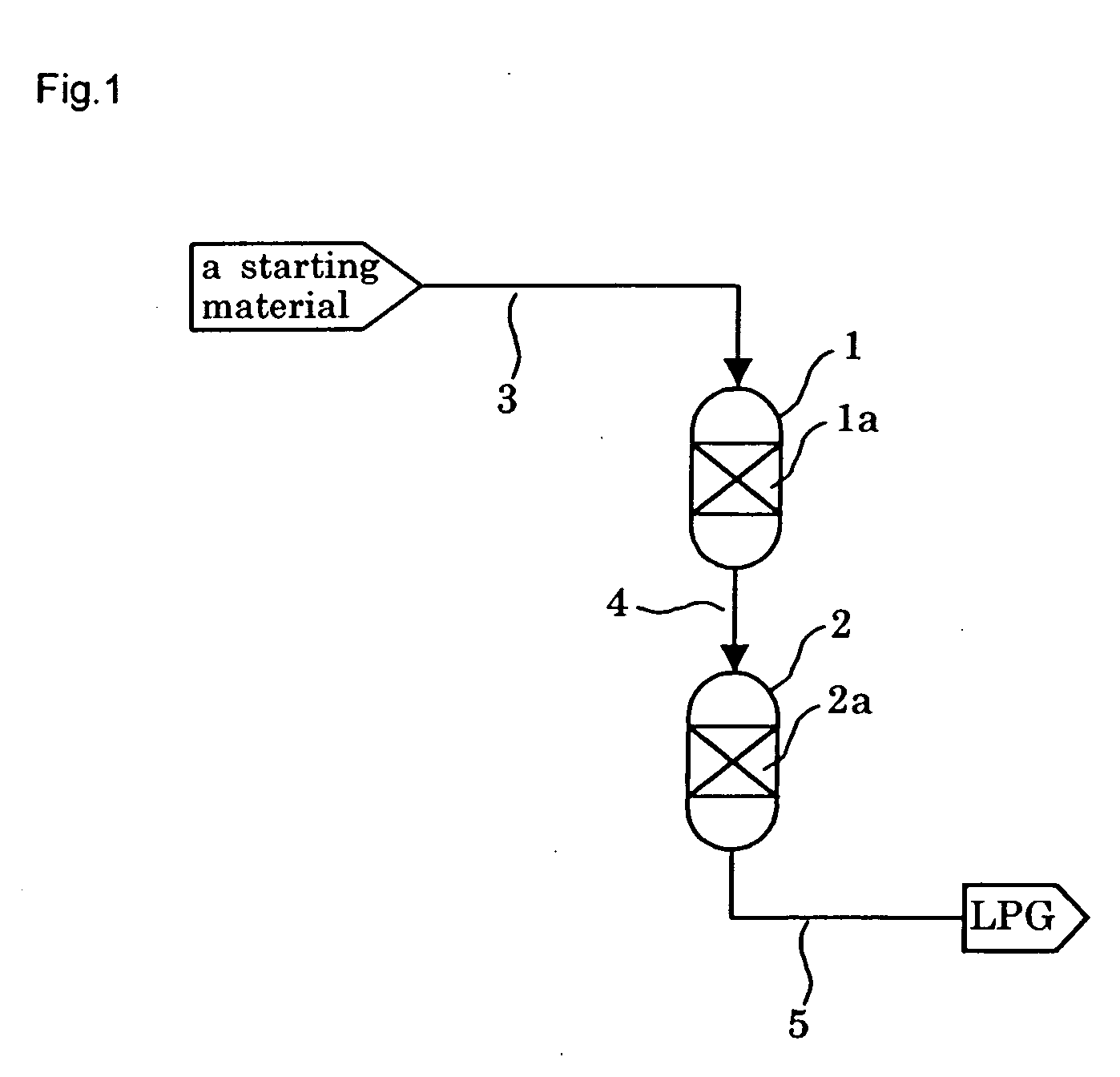

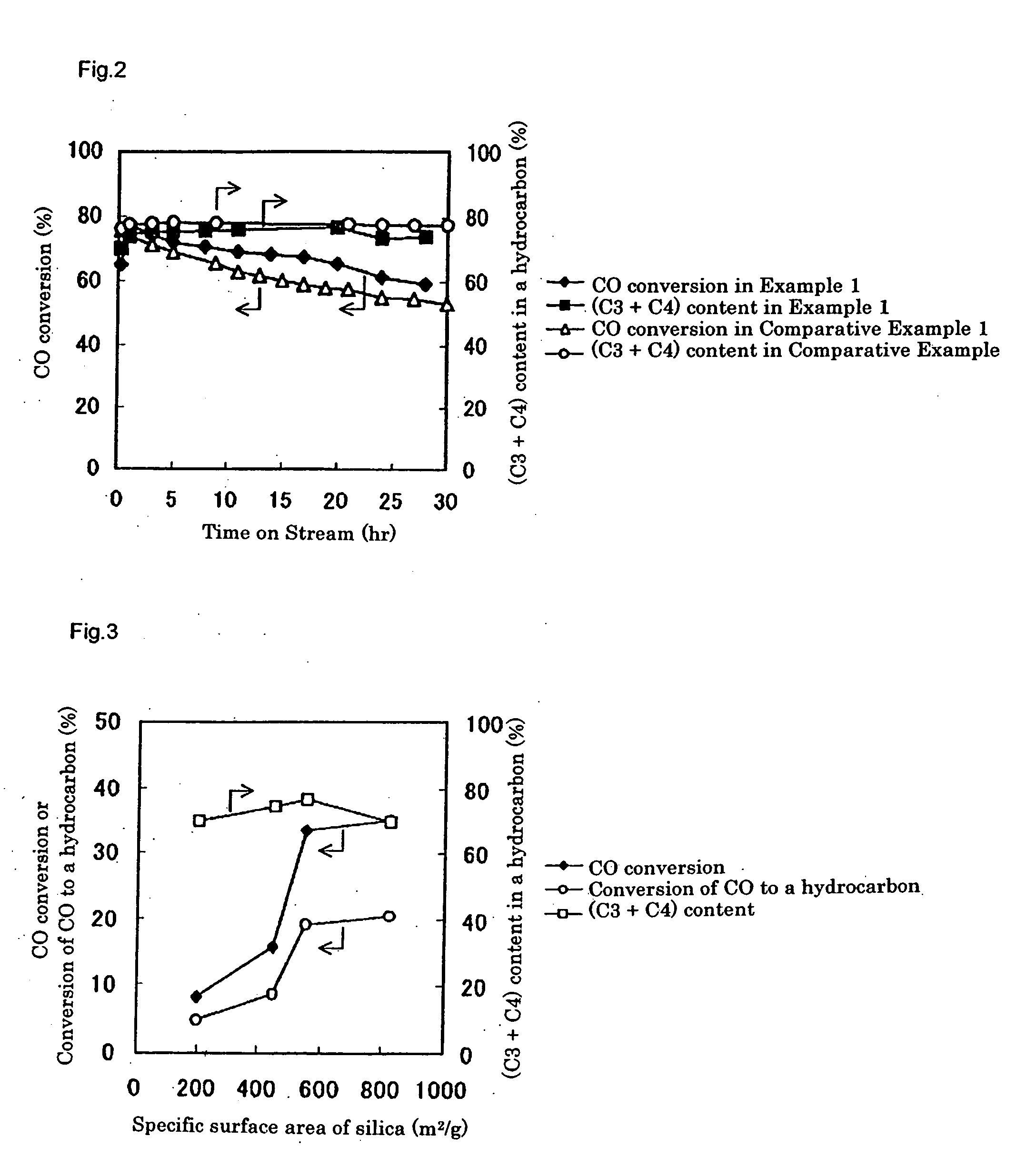

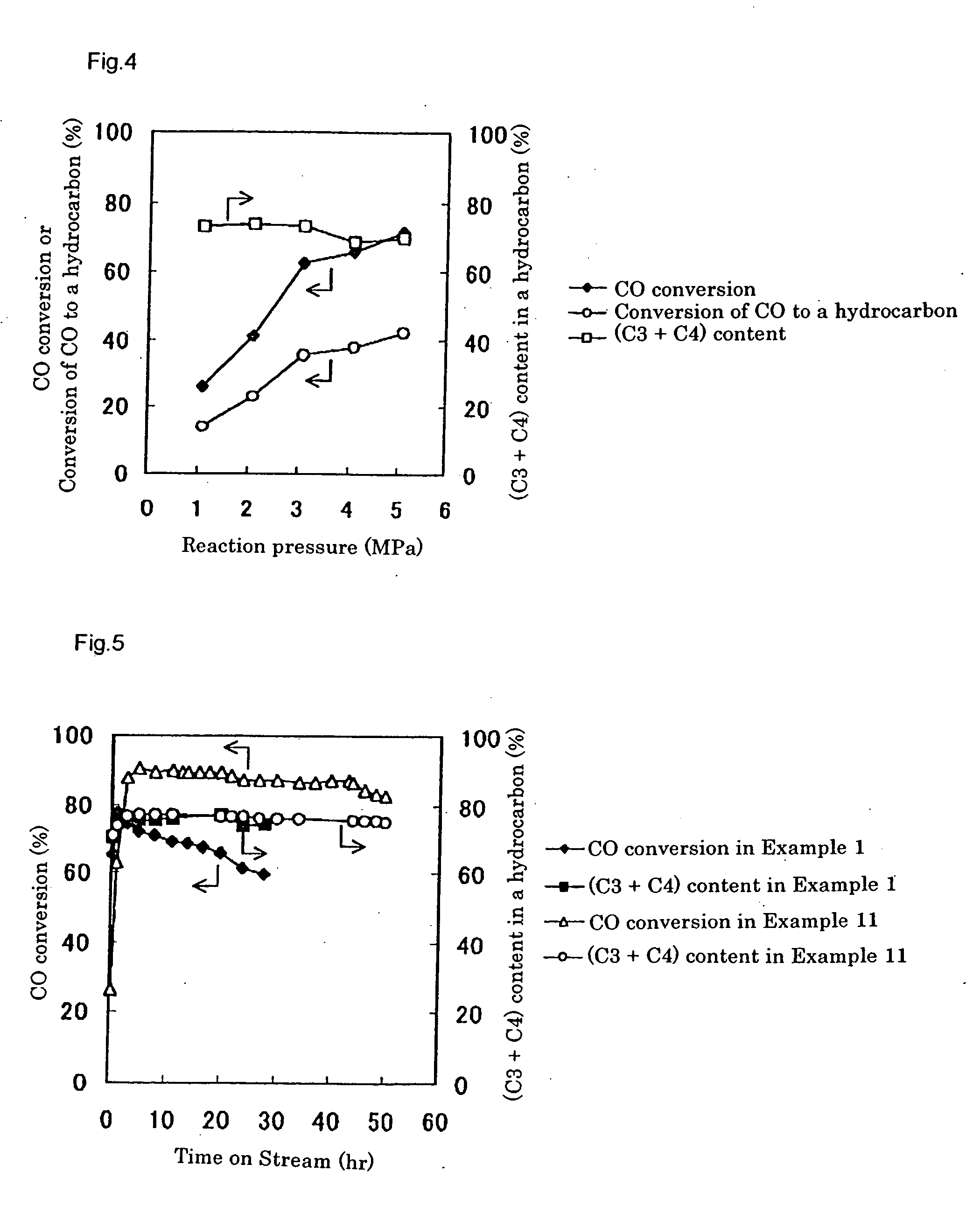

Catalyst and process for LPG production

InactiveUS20060009349A1Less deteriorationHigh activityMolecular sieve catalystsOrganic compound preparationHydrogenHigh activity

A catalyst for producing a liquefied petroleum gas according to the present invention comprises a Pd-based methanol synthesis catalyst component and a β-zeolite catalyst component. It can be used in a reaction of carbon monoxide and hydrogen to give a hydrocarbon containing propane or butane as a main component, i.e., a liquefied petroleum gas, with high activity, high selectivity and high yield. Furthermore, the catalyst has a longer catalyst life with less deterioration.

Owner:JAPAN GAS SYNTHESIZE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com