Patents

Literature

298results about How to "Improve logistics efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

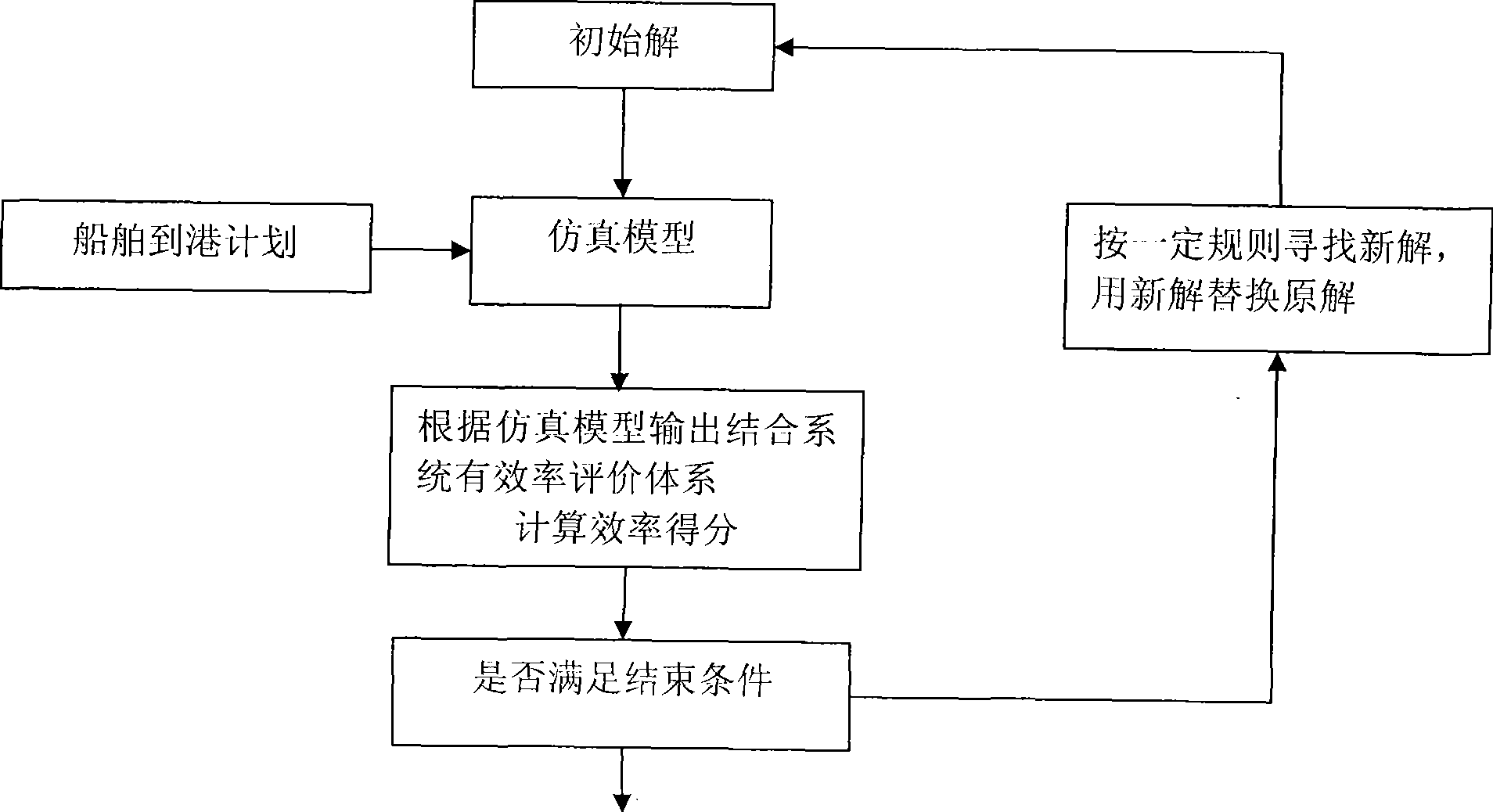

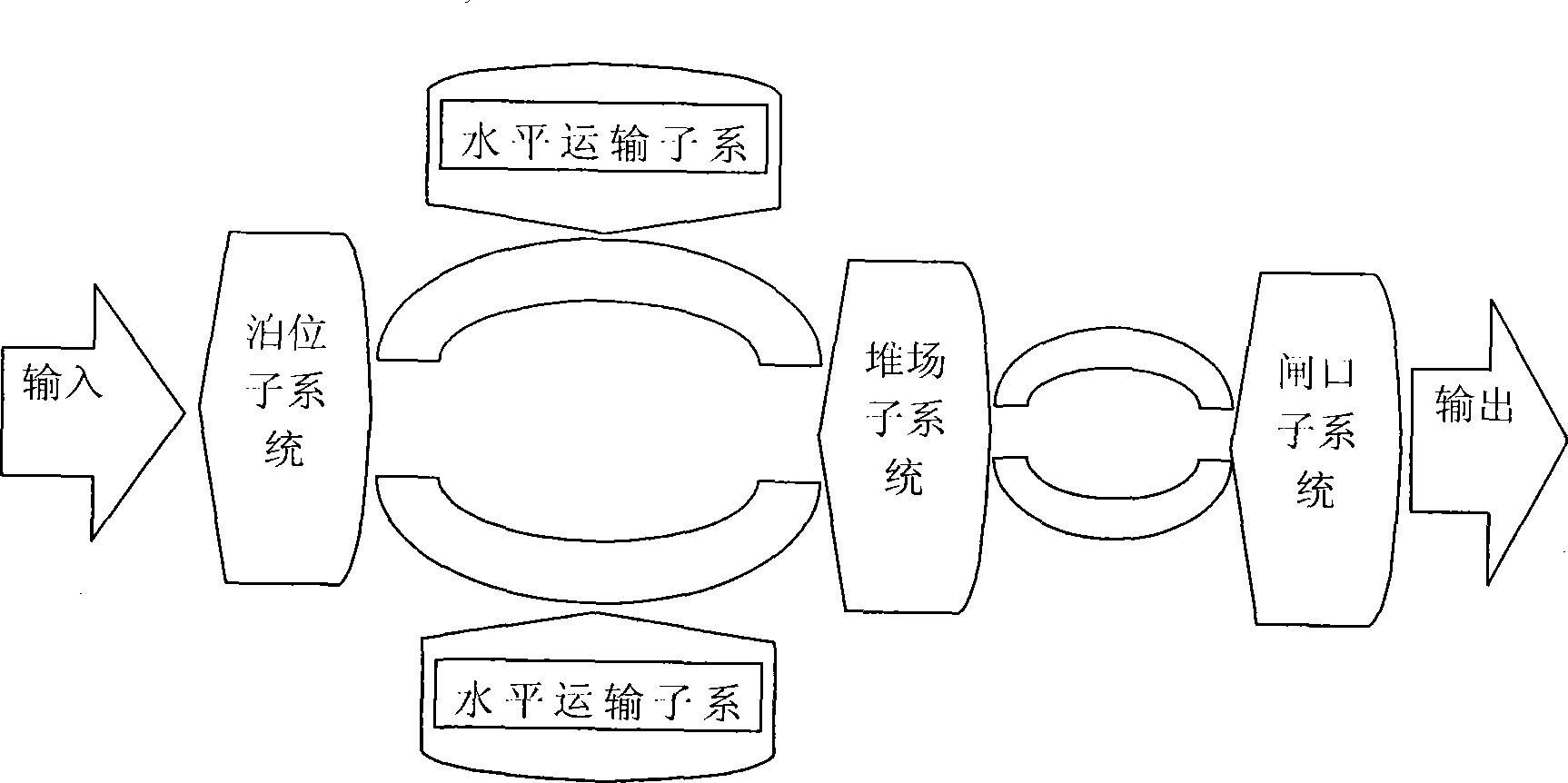

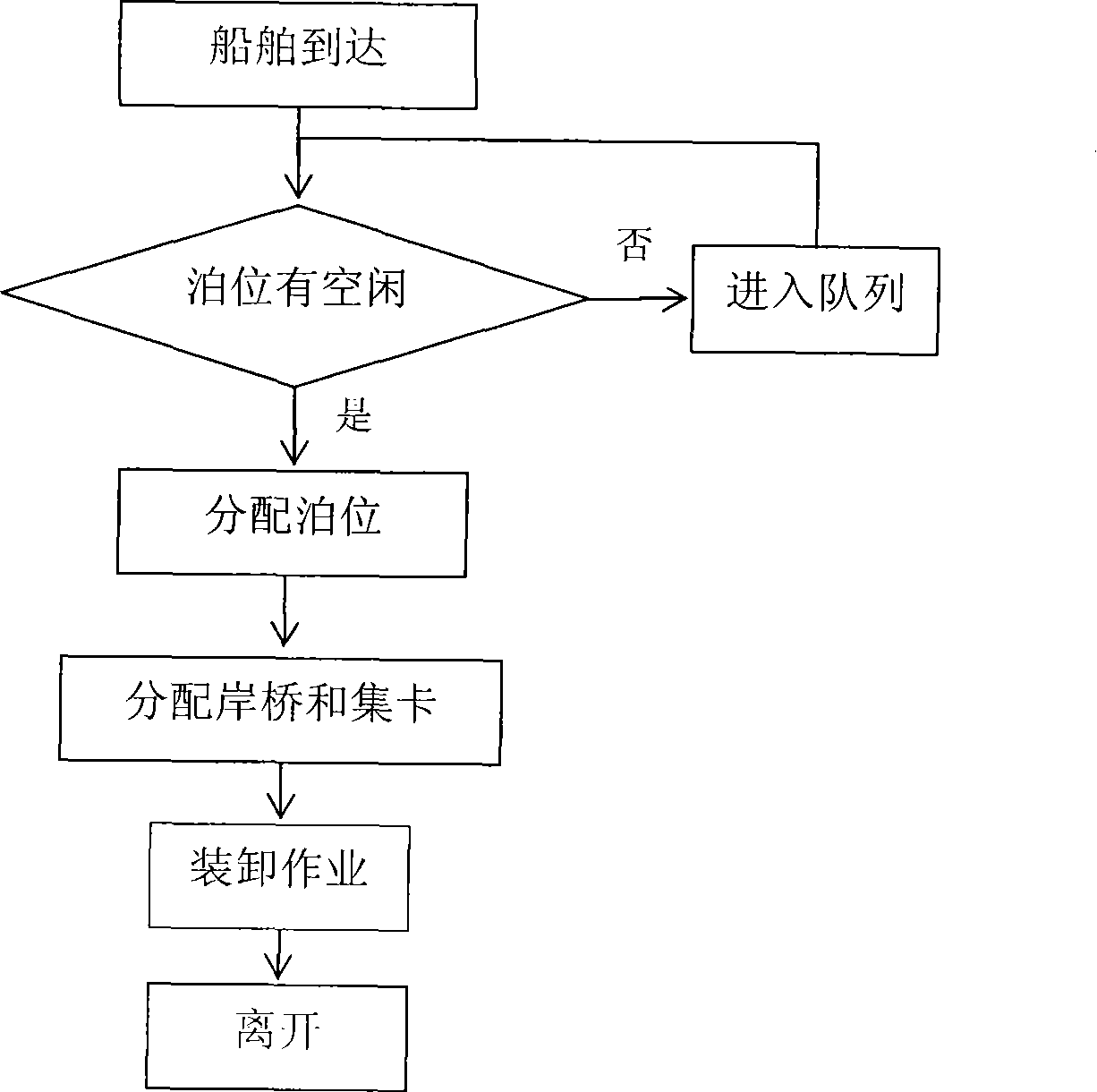

Container terminal physical distribution emulation optimizing system

InactiveCN101458788AReduce logistics costsIncreased logistics costsLogisticsDistribution controlGenetic algorithm

The invention discloses a container dock logistic simulation optimization system, which is connected with a dock logistic management system provided with a dock company logistic management data, for obtaining optimal dock resource configuration and production distribution scheme according to the ship arrival scheme. The system comprises: (1) a memory module; (2) an evaluation module for using AHP analytic hierarchy process to determine the weight value of each index, to obtain the efficiency score of a logistic system; (3) a simulation module comprising a ship arrival module, a berth distribution module, a frontier loading and unloading module, a memory operation module, a horizontal transportation module, a yard operation module, an external operation module, a lake gate check module, a distribution control module and an I / O module, building the relationship among solid properties, debugging and checking the simulation model; (4) an optimization circulation module for combining genetic algorithm and simulation technology to solve each index; (5) a simulation optimization result output module.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

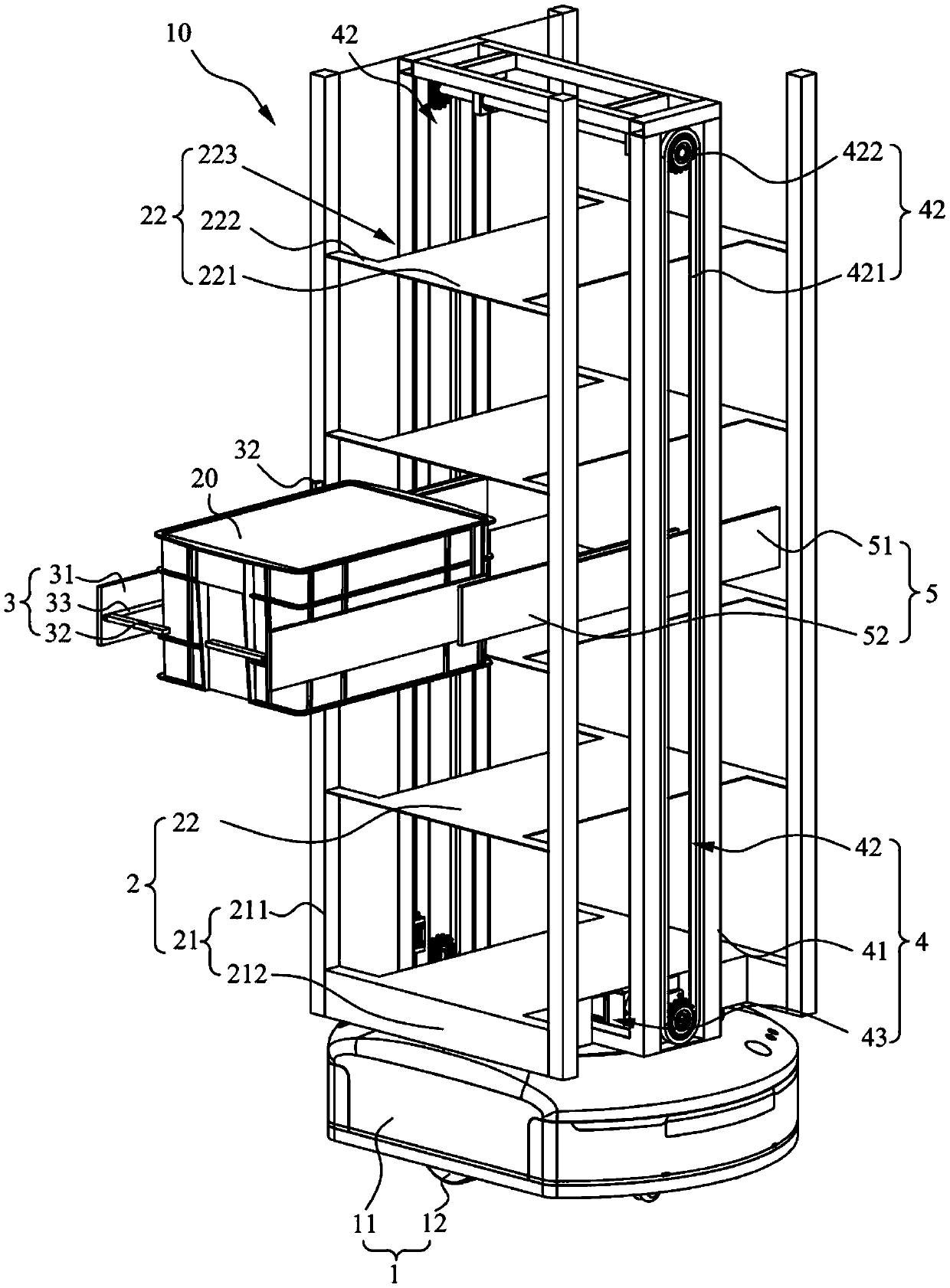

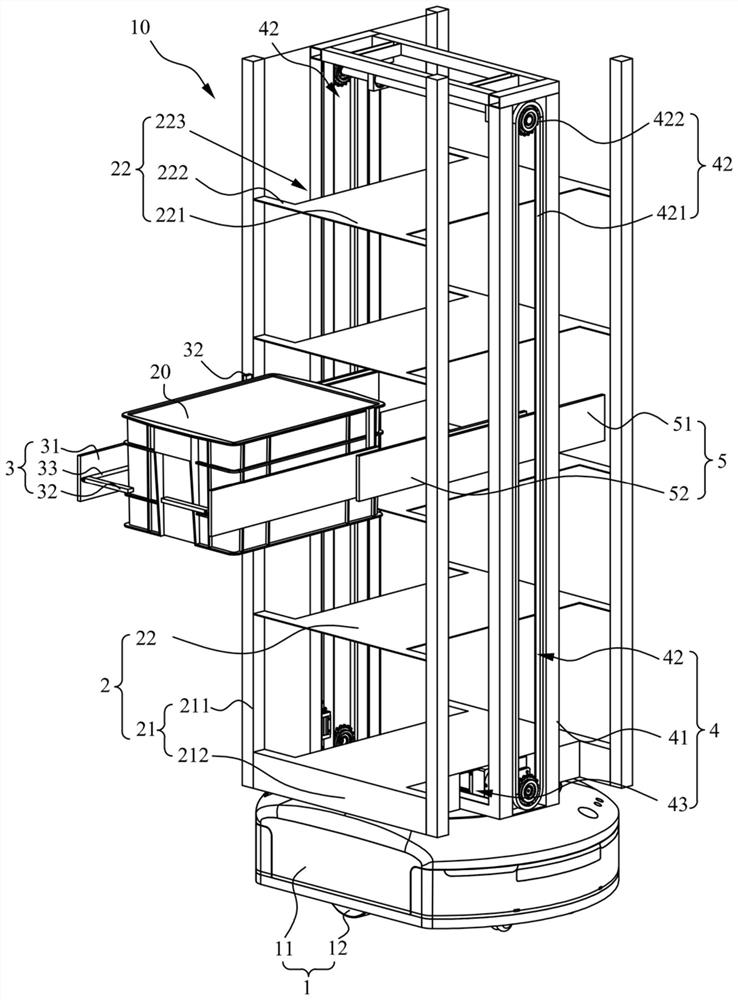

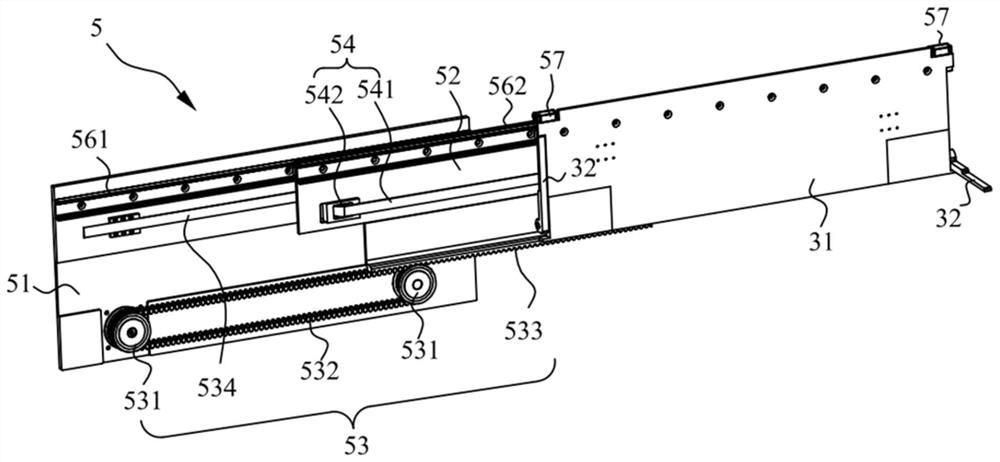

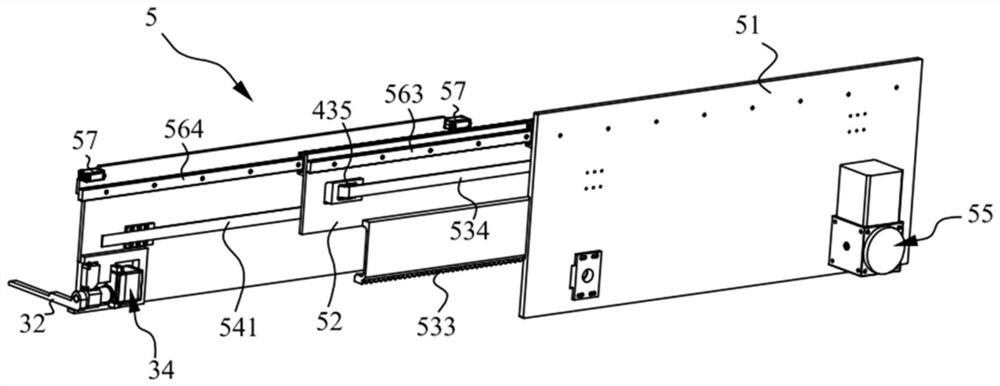

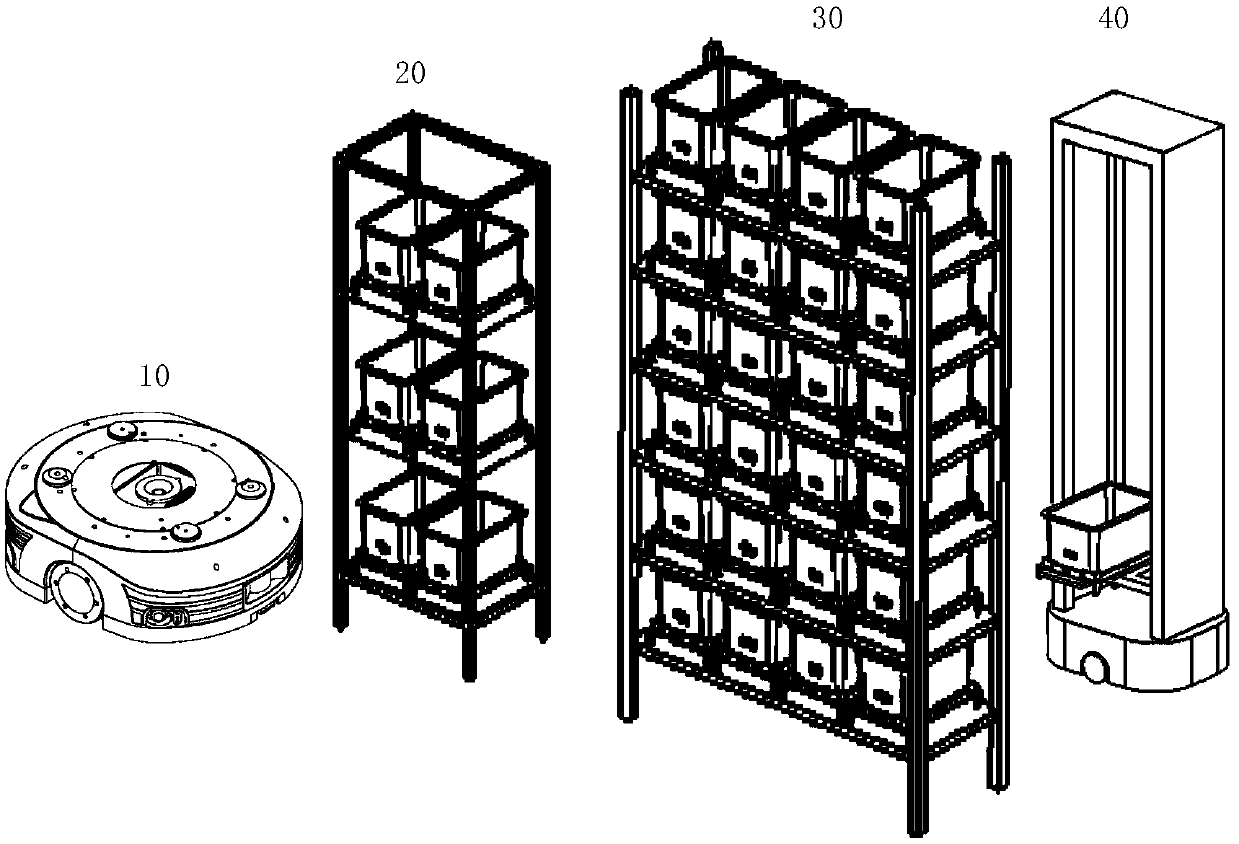

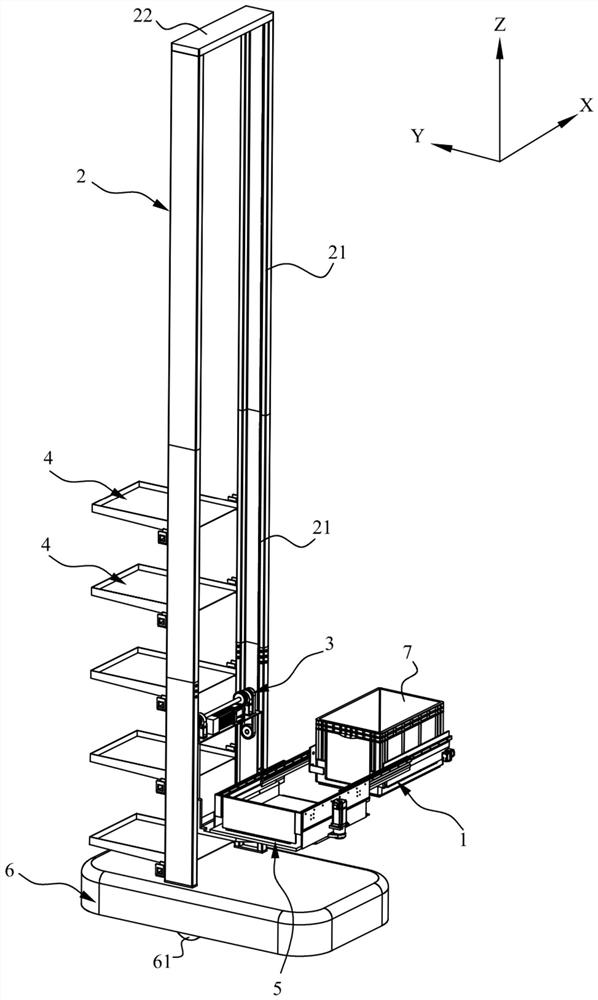

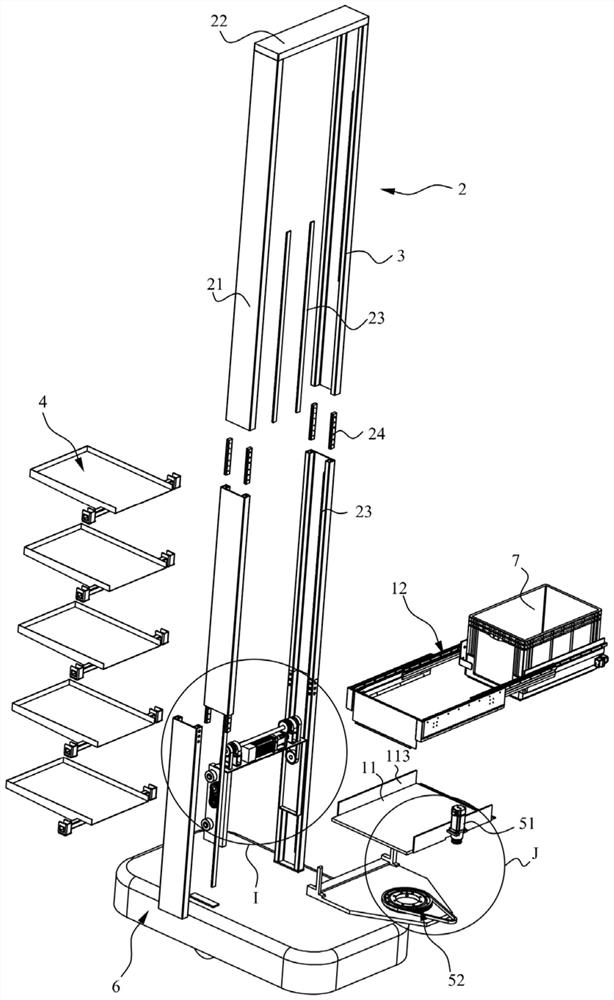

Handling robot, warehouse logistics system and packing box handling method

PendingCN109573449ALess room for movementIncrease profitStorage devicesLogistics managementMechanical engineering

The invention belongs to the technical field of warehousing logistics, and particularly discloses a handling robot, a warehouse logistics system and a packing box handling method. The handling robot comprises a movable base plate which can move along a channel between adjacent inventory containers, temporary storage racks which are arranged on the movable base plate and used for temporarily storing a target packing box, and box taking assemblies which are arranged on the movable base plate, wherein the box taking assemblies can horizontally stretch relative to the movable base plate so as to pick and place the target packing box between the inventory containers and the temporary storage racks, and the horizontal stretching direction of the box taking assemblies is perpendicular to the moving direction of the handling robot. The warehouse logistics system comprises the handling robot, and the packing box handling method adopts the handling robot to convey the target packing box. According to the handling robot, the warehouse logistics system and the packing box handling method, the occupied space of the handling robot on warehouse channels can be reduced, the utilization rate of thewarehouse can be improved, and meanwhile the handling efficiency of the packing box can be improved.

Owner:BEIJING JIZHIJIA TECH CO LTD

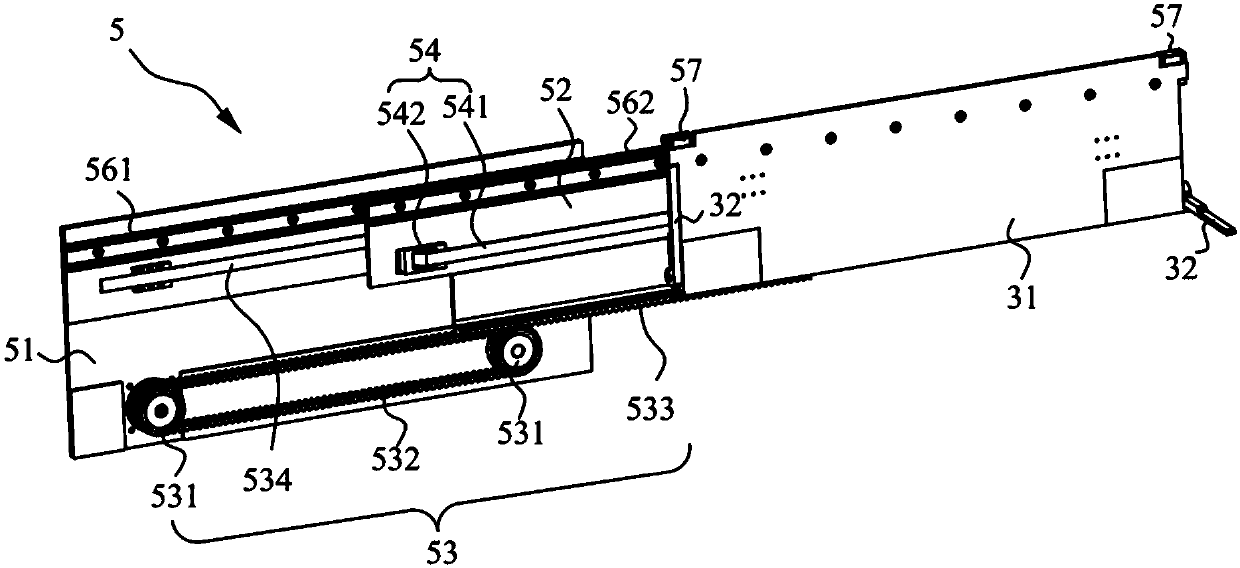

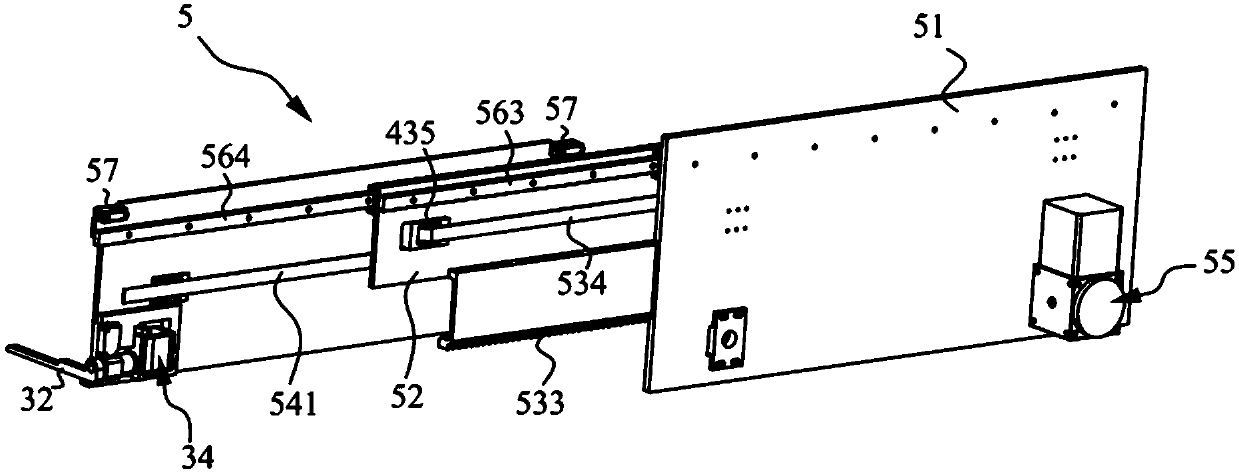

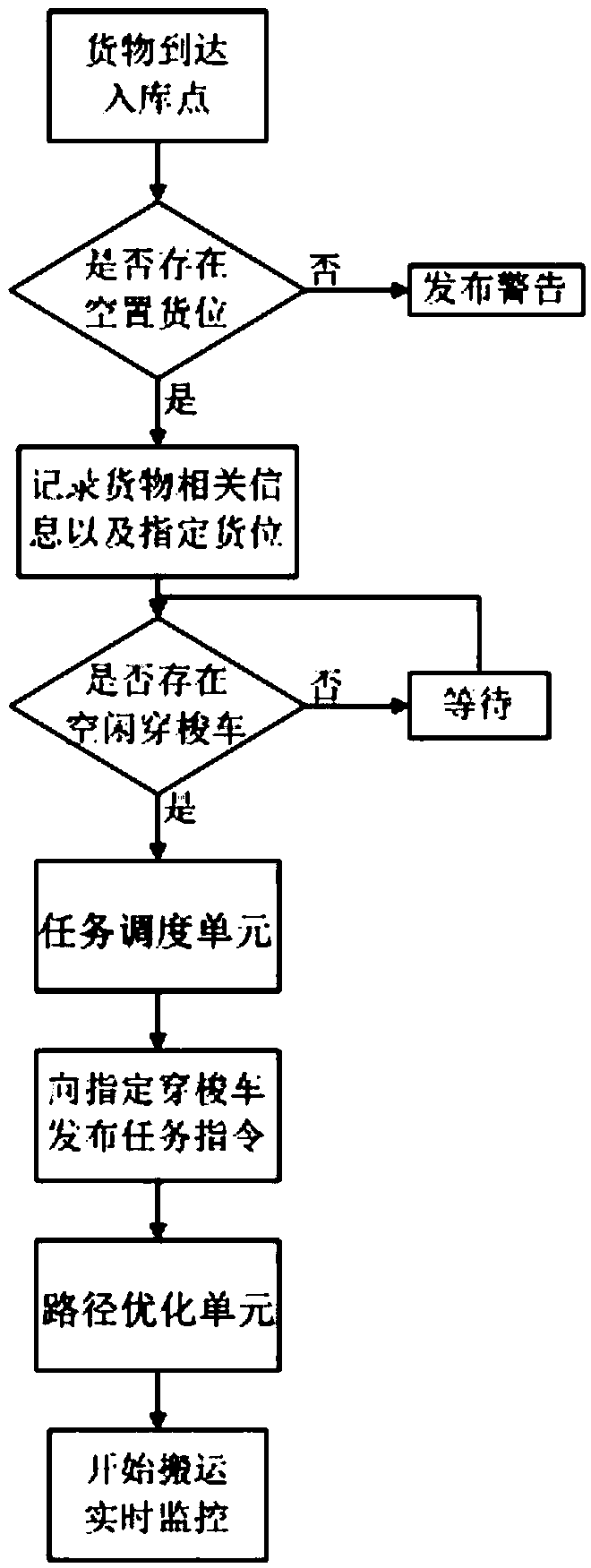

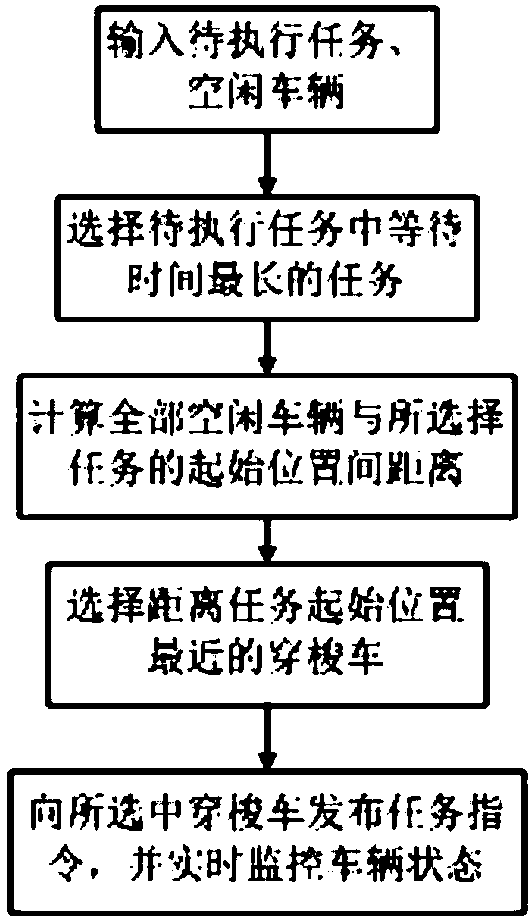

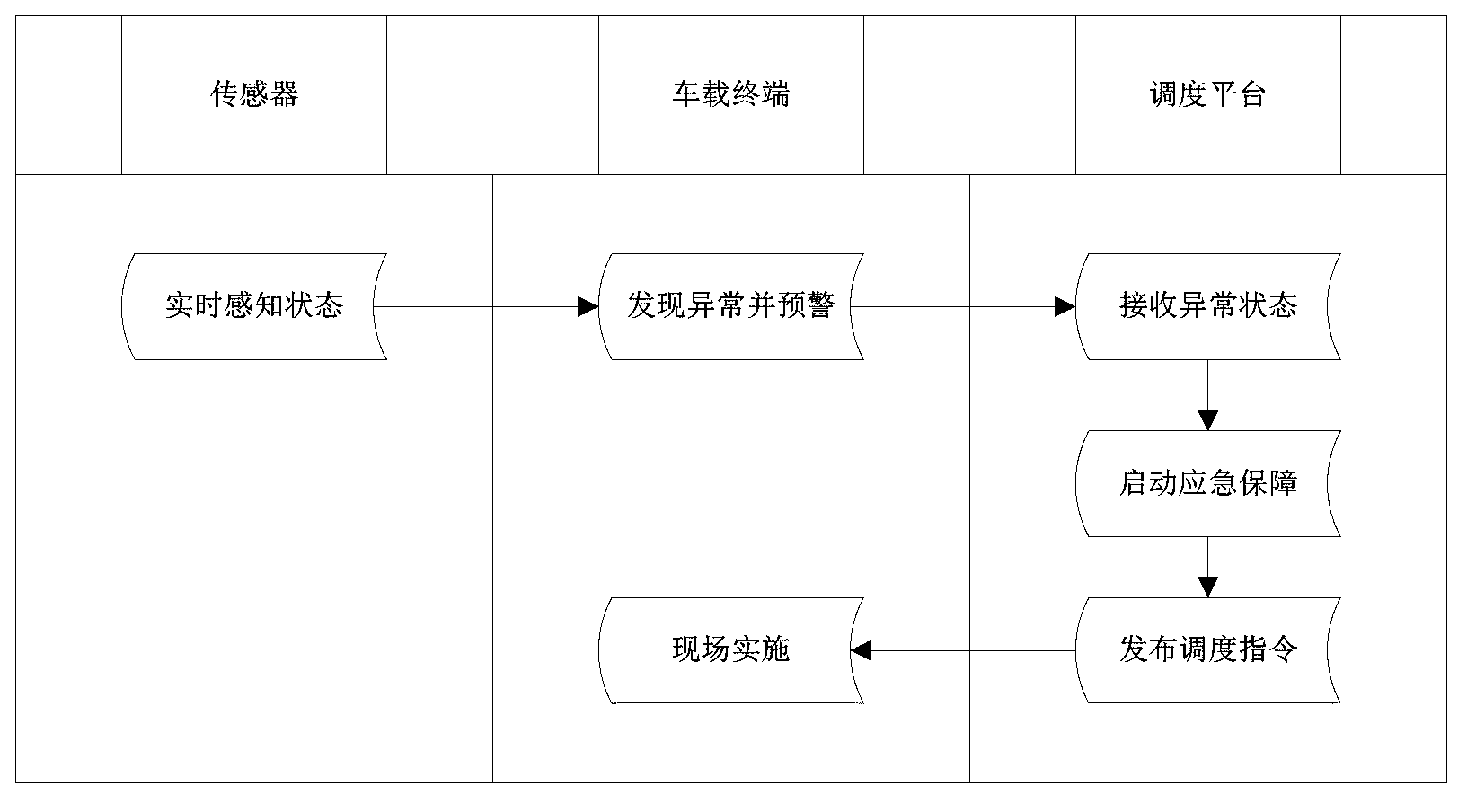

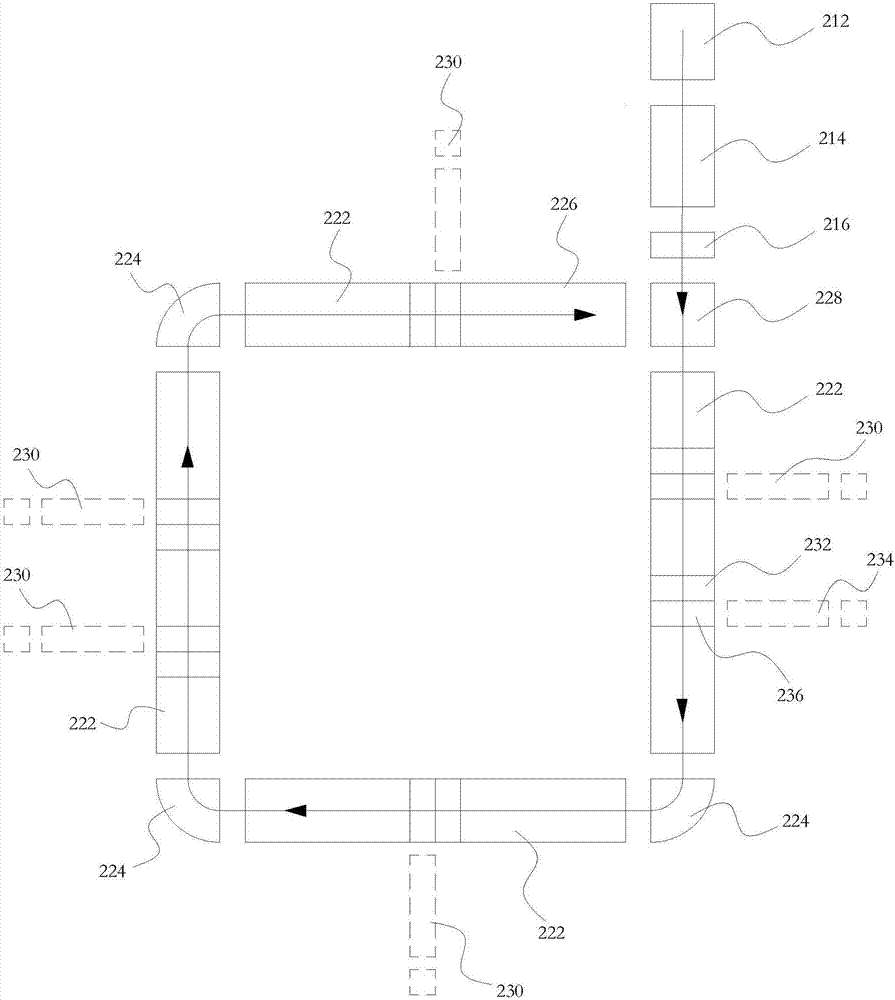

Shuttle vehicle dispatching management system and dispatching method for cold storage

InactiveCN109190840AImprove logistics efficiencyReal-time monitoring statusForecastingResourcesLogistics managementManagement system

The invention discloses a shuttle vehicle dispatching management system and dispatching method for a cold storage, belonging to the field of shuttle vehicle storage system. The system includes a shuttle vehicle management system, and a vehicle-mounted terminal arranged on the shuttle vehicle, wherein the vehicle-mounted terminal is in communication with the shuttle vehicle management system, the vehicle-mounted terminal is used for recording the working state of the shuttle vehicle itself and uploading the working state to the shuttle vehicle management system, and the working state includes the vehicle number, the remaining power, the position, the state and the task of the vehicle; the shuttle vehicle management system comprises a dispatching module which monitors and dispatches the shuttle vehicle managed in the shuttle management system and optimizes the route according to the transportation task, and sends a dispatching instruction to the corresponding shuttle vehicle through thevehicle-mounted terminal. By adopting the dispatching management system and the dispatching method of the invention, the intelligent dispatching and the path optimization of a plurality of shuttle vehicles can be realized, and the logistics efficiency can be improved.

Owner:CHINA INFORMATION & ELECTRONICSE DEV HEFEI

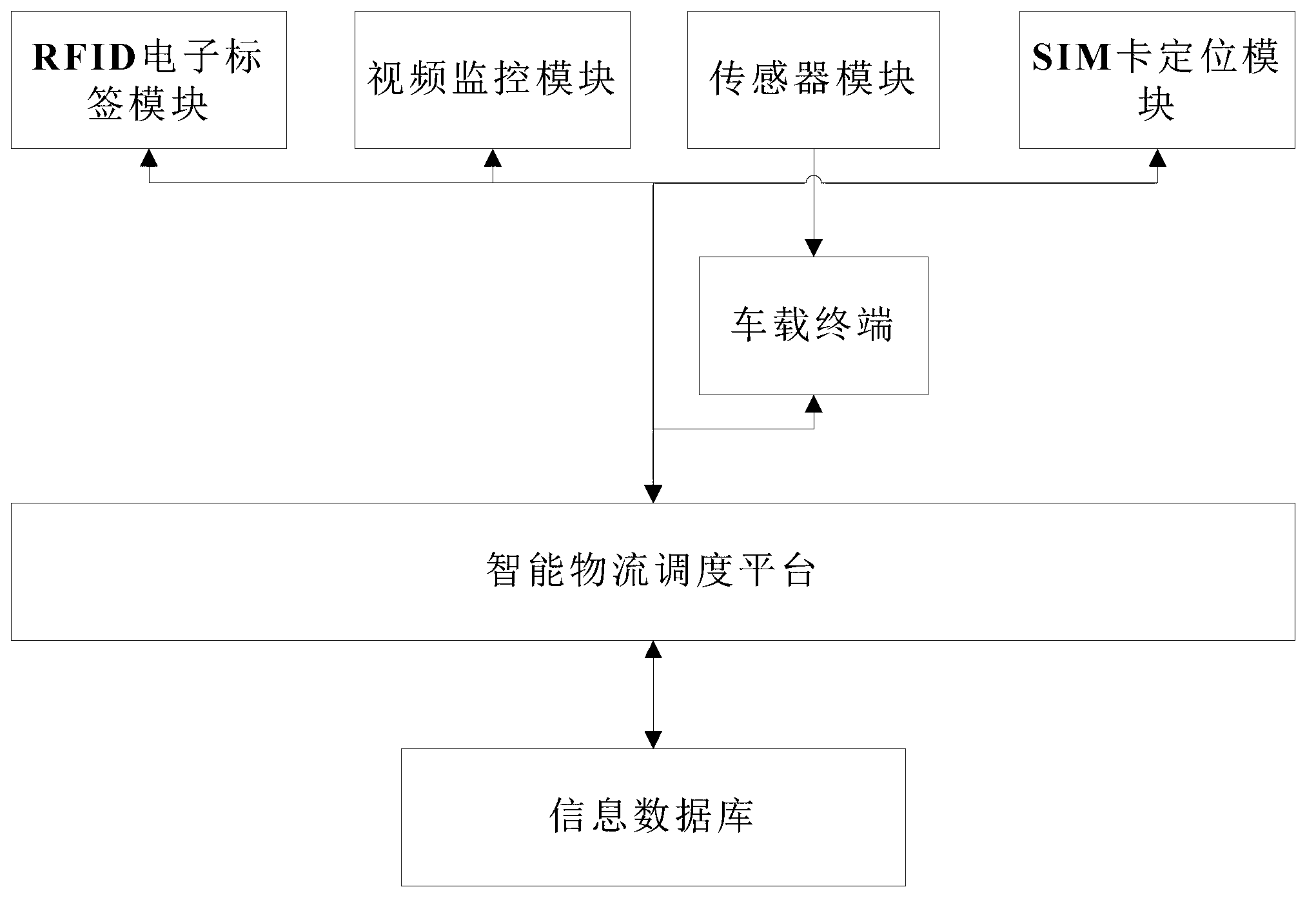

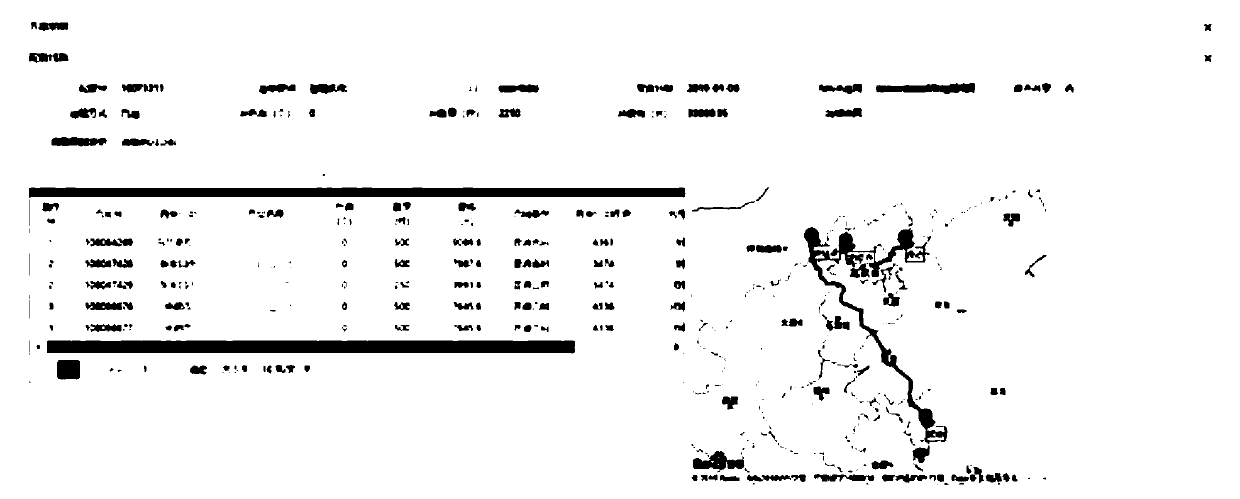

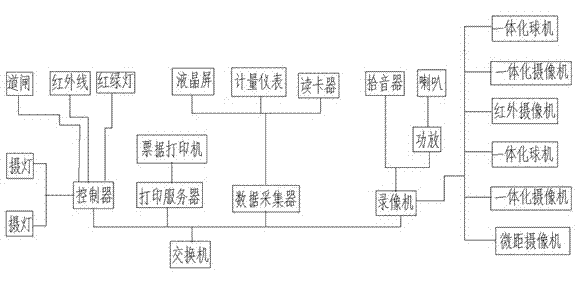

Intelligent logistics and EPC (electronic product code) network sensing system

InactiveCN103235998ALogistics status changesLearn about deliveryWireless commuication servicesLogisticsVideo monitoringLogistics management

The invention discloses an intelligent logistics and EPC (electronic product code) network sensing system used for real-time monitoring of vehicles and goods during logistics process. The system comprises video monitoring modules, SIM (subscriber identity module) card positioning modules, sensor modules, a RFID (radio frequency identification) module and an intelligent logistics scheduling platform, the video monitoring module, the SIM card positioning module and the sensor are arranged on each goods-transporting vehicle, the RFID module sends goods information to the intelligent logistics scheduling platform after reading RFID tags fixed on goods, and the intelligent logistics scheduling platform obtains positioning information of the SIM card positioning module of a vehicle transporting the goods according to information of the RFID module, obtains related vehicles transporting the goods, and monitors the vehicles and the goods in real time through the video monitoring modules and the sensor modules mounted on the related vehicles. The intelligent logistics and EPC network sensing system can realize real-time monitoring on temperature, humidity, online operating states and vehicle operating parameters of the vehicles transporting specific goods during logistics processes, can improve safety of logistics process and can reduce errors during the logistics processes.

Owner:JIANGSU TAIYUN GRP CO LTD

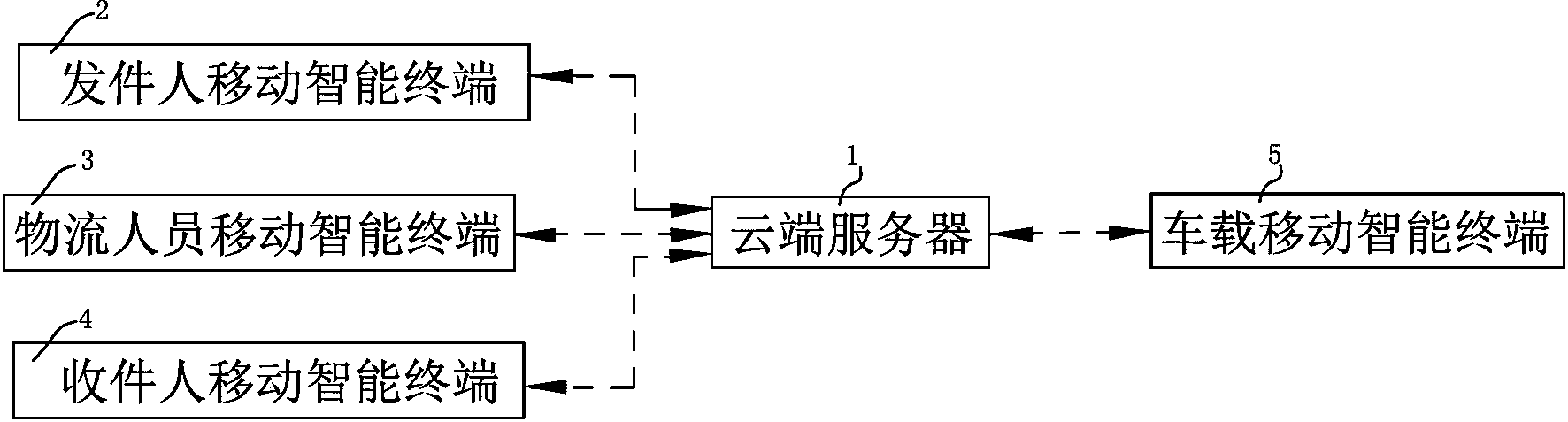

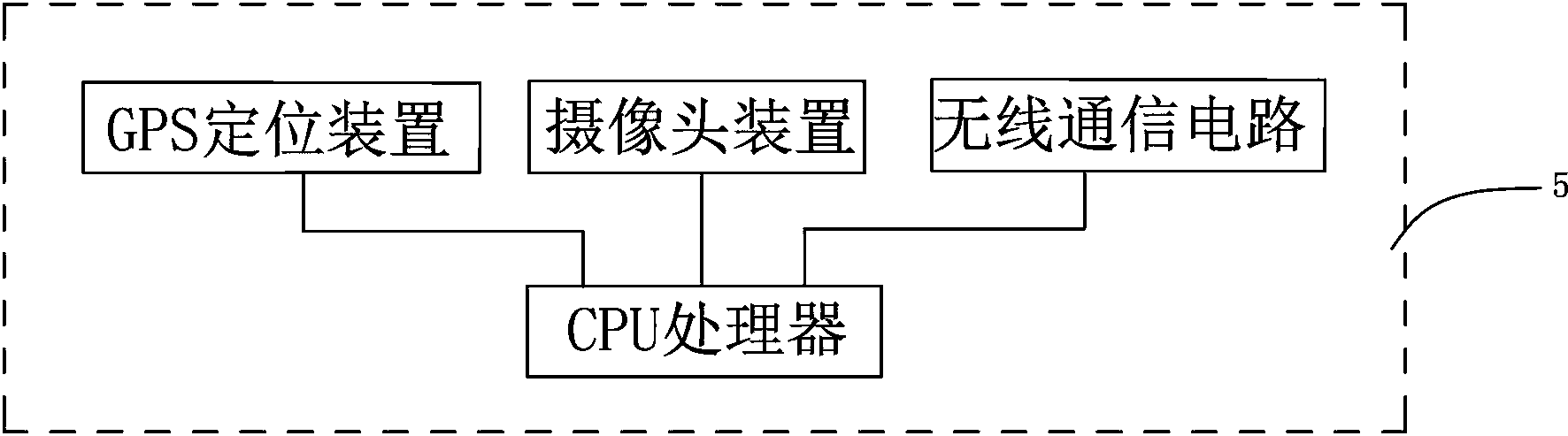

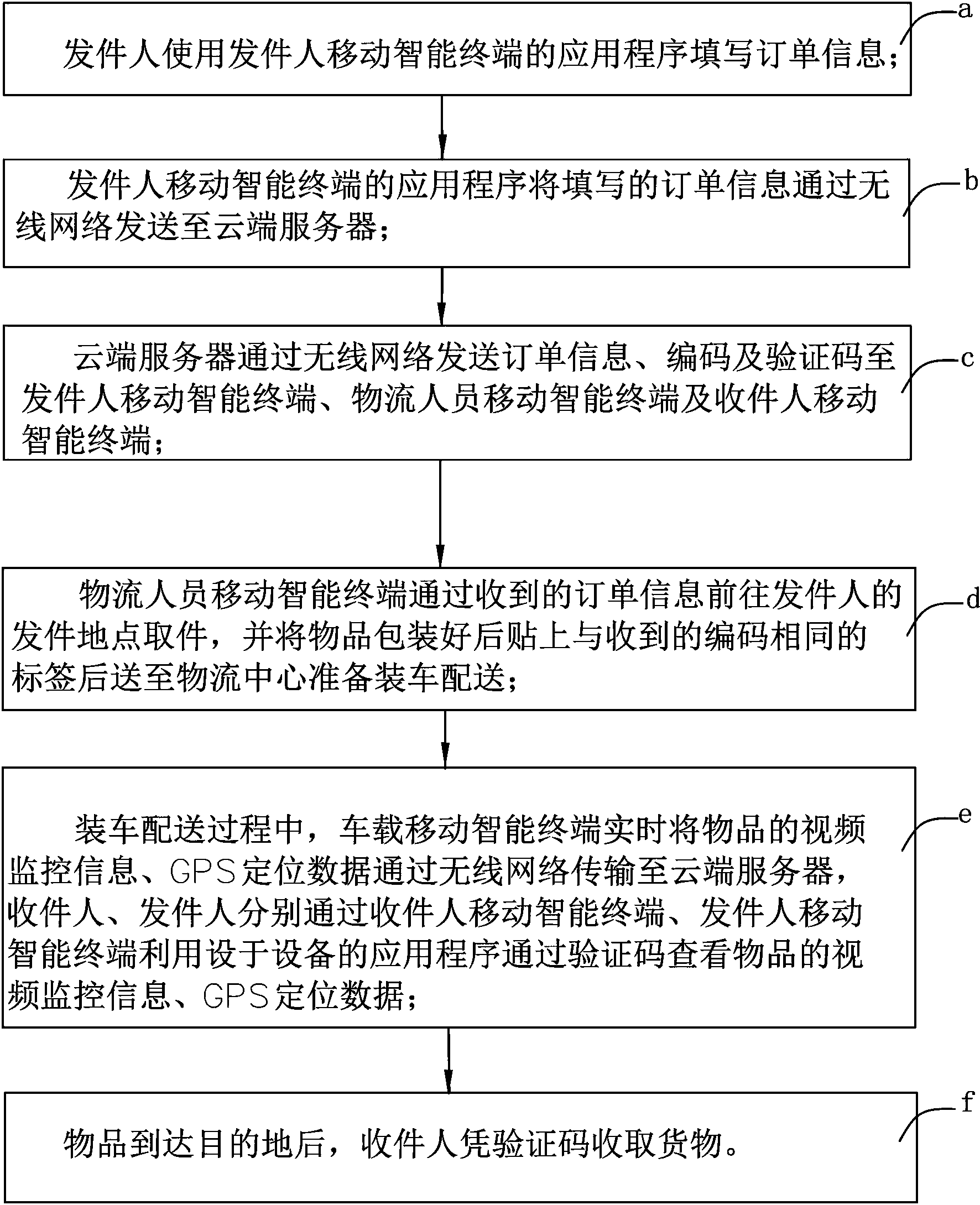

Intelligent logistics distribution system and logistics distribution method based on cloud services

InactiveCN103544591AImprove logistics efficiencyReduce wasteLogisticsTransmissionLogistics managementDistribution method

The invention relates to the technical field of logistics distribution systems and methods, in particular to an intelligent logistics distribution system and a logistics distribution method based on cloud services. Through the intelligent logistics distribution system comprising a cloud server, a vehicle-mounted mobile intelligent terminal arranged in a logistics distribution truck cargo compartment, a sender mobile intelligent terminal, a logistics personnel mobile intelligent terminal and a sender mobile intelligent terminal, the logistics efficiency of a logistics company can be effectively improved, the waste of mails is largely reduced, and therefore production cost is largely lowered. Articles can be monitored and inquired in real time when transported, clear responsibility of the person in charge of the articles is guaranteed, and the articles are prevented from being lost. A receiver and a sender can inquire the conditions such as the site and video of the articles at any time, the logistics company can effectively find out the best method of article transportation such as the placement position and a driving route, and therefore the social value is large.

Owner:东莞市艾炜特电子有限公司

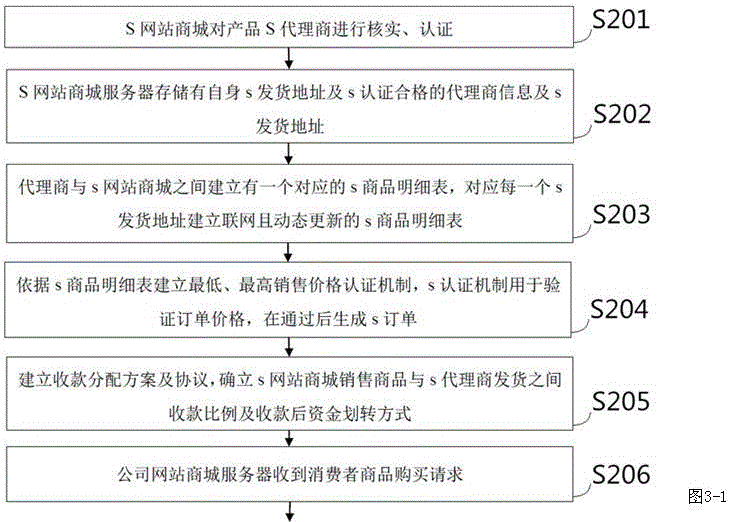

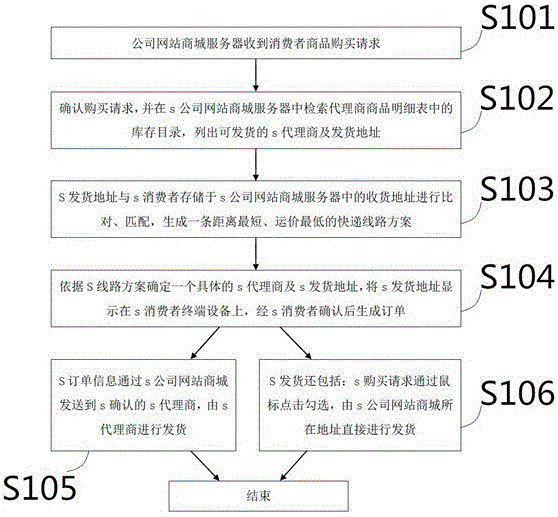

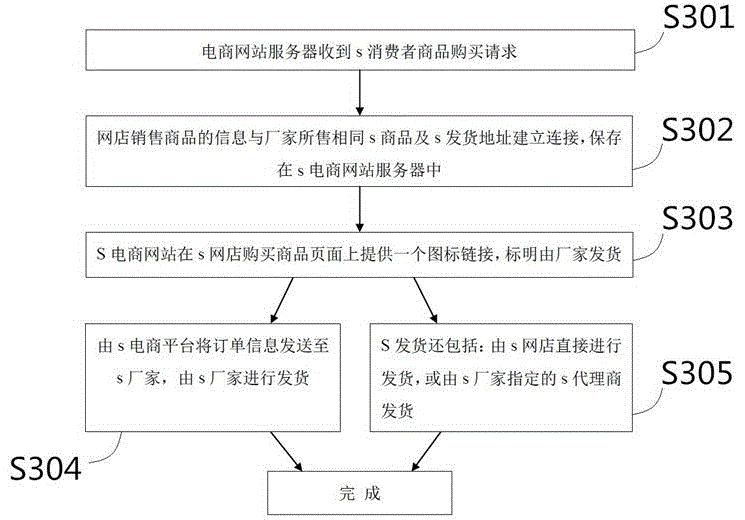

Method, device and system for delivering expresses of online marts of enterprises

InactiveCN106156884AImprove logistics efficiencyForecastingBuying/selling/leasing transactionsLogistics managementOrder form

The invention discloses a method, device and system for delivering expresses of online marts of enterprises. The method for delivering expresses of the online marts of the enterprises comprises the following steps: receiving a consumer's commodity purchasing request by using a mart server of a company website; confirming the purchasing request, searching a stock inventory in a commercial agent's commodity list in the mart server of the company website, and listing commercial agents capable of delivering commodities and ship addresses; comparing and matching the ship addresses with delivery addresses, which are stored in the mart server of the company website, of consumers to generate an express path scheme which is shortest in distance and lowest in freight rate; determining a specific commercial agent and a ship address according to the path scheme; displaying the ship address on terminal equipment of a consumer; and generating an order form after the consumer confirms; transmitting the information of the order form to the confirmed commercial agent through the mart of the company website; and delivering by the commercial agent. By the method, device and system for delivering expresses of online marts of enterprises, logistics efficiency of online shopping is greatly improved; and the rate of graded products of the online shopping commodities is increased.

Owner:刘兴丹

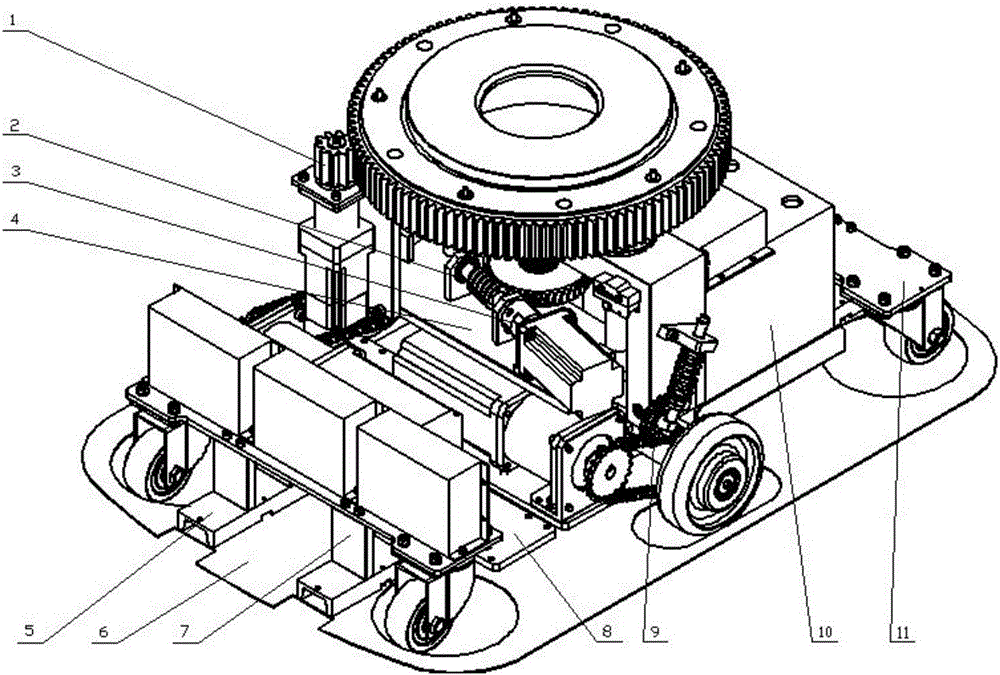

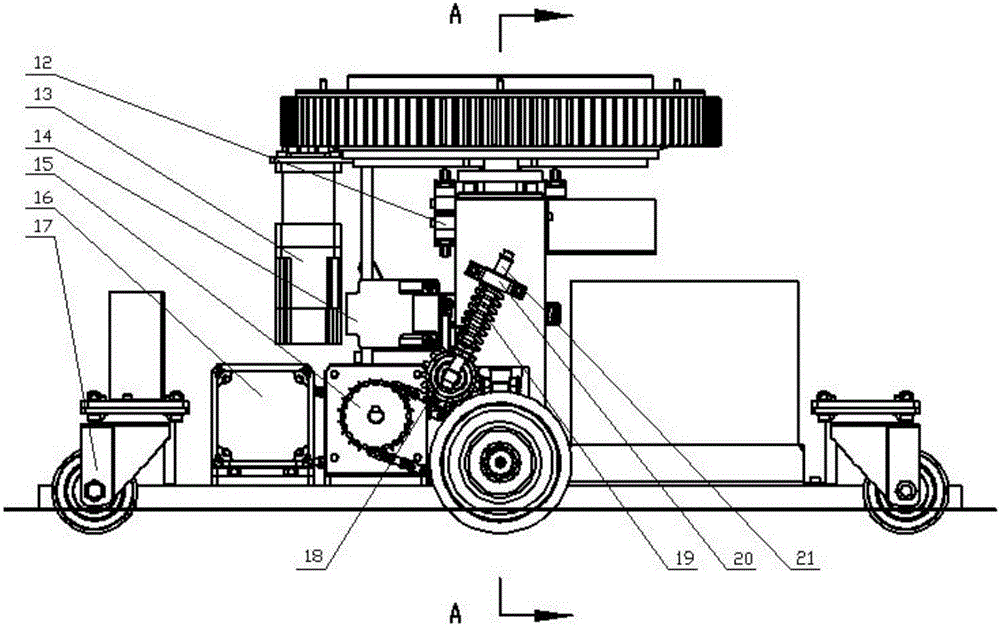

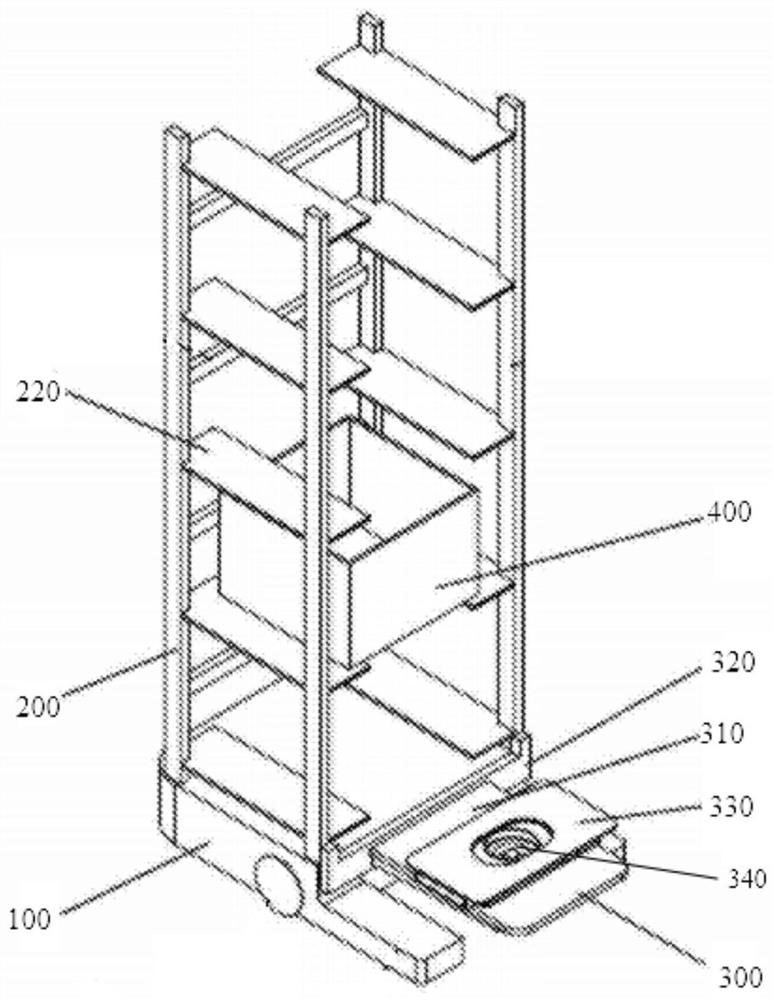

Intelligent transfer robot for warehouse

InactiveCN105947506AImprove picking efficiency and logistics efficiencyReduce tally staffStorage devicesCushionEngineering

The invention belongs to the technical field of AGV (Automatic Guided Vehicle), and relates to an intelligent transfer robot for a warehouse. The intelligent transfer robot for the warehouse comprises a trolley located on the bottom part and contacted with the ground. The trolley comprises a bottom plate, bottom frameworks, a motor base plate, universal wheel supporting plate cushion blocks, universal wheel supporting plates and universal wheels, wherein the bottom framework are fixedly arranged on the bottom plate; the motor base plate and the universal wheel supporting plate cushion blocks are fixedly arranged on the bottom framework; the universal wheel supporting plates are fixedly arranged on the supporting plate cushion blocks; the universal wheels are connected with the universal wheel supporting plates; a drive mechanism, a motor, a driver and a storage battery are sequentially arranged on the bottom framework from bottom to top; a rotatable lifting mechanism and a chain compressing mechanism are also arranged on the drive mechanism. The invention provides the intelligent transfer robot for the warehouse, which is reasonable in design, stable in performance, and applicable to the AGV and turns flexibly.

Owner:芜湖智久机器人有限公司

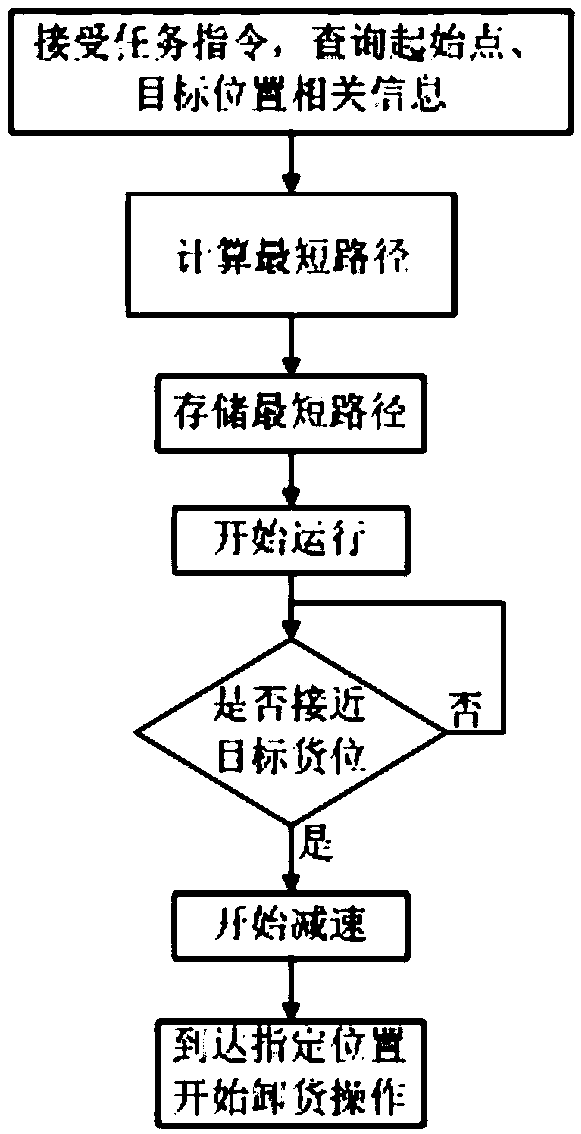

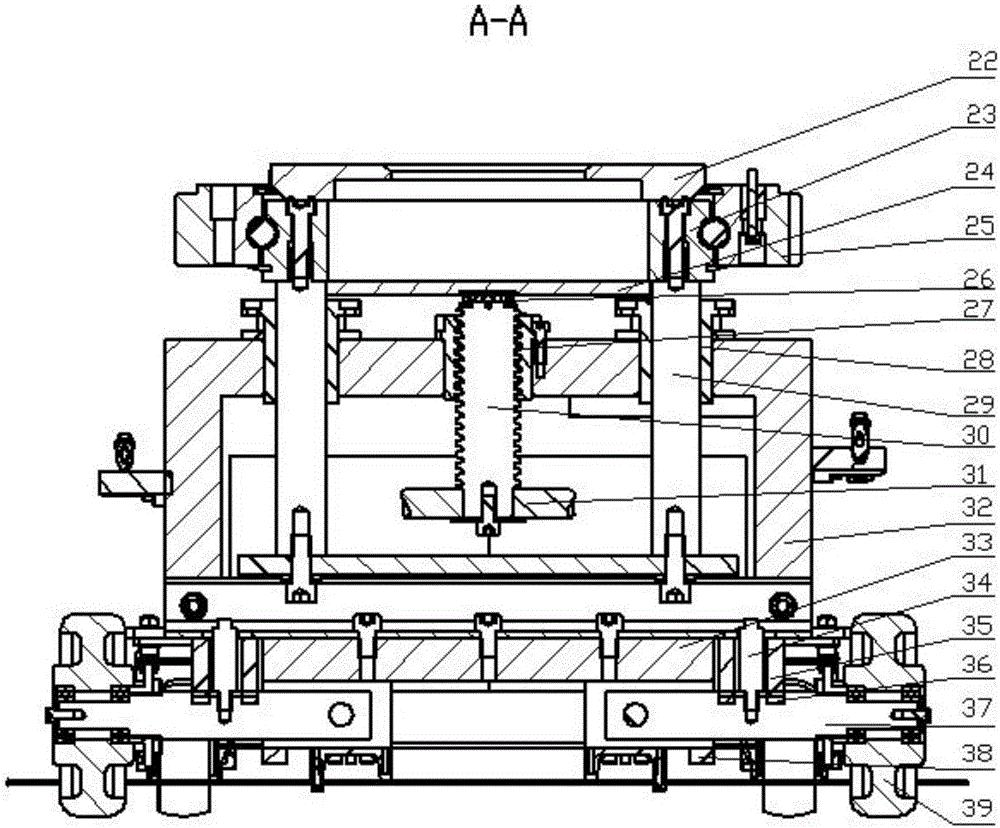

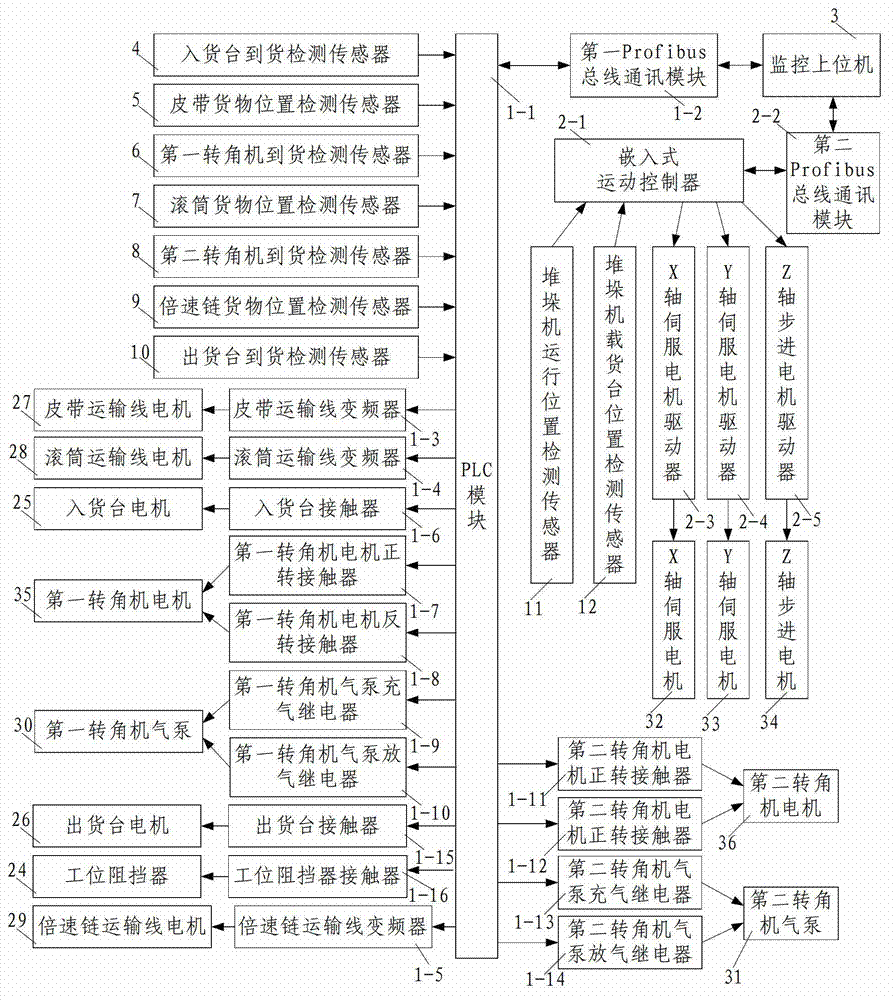

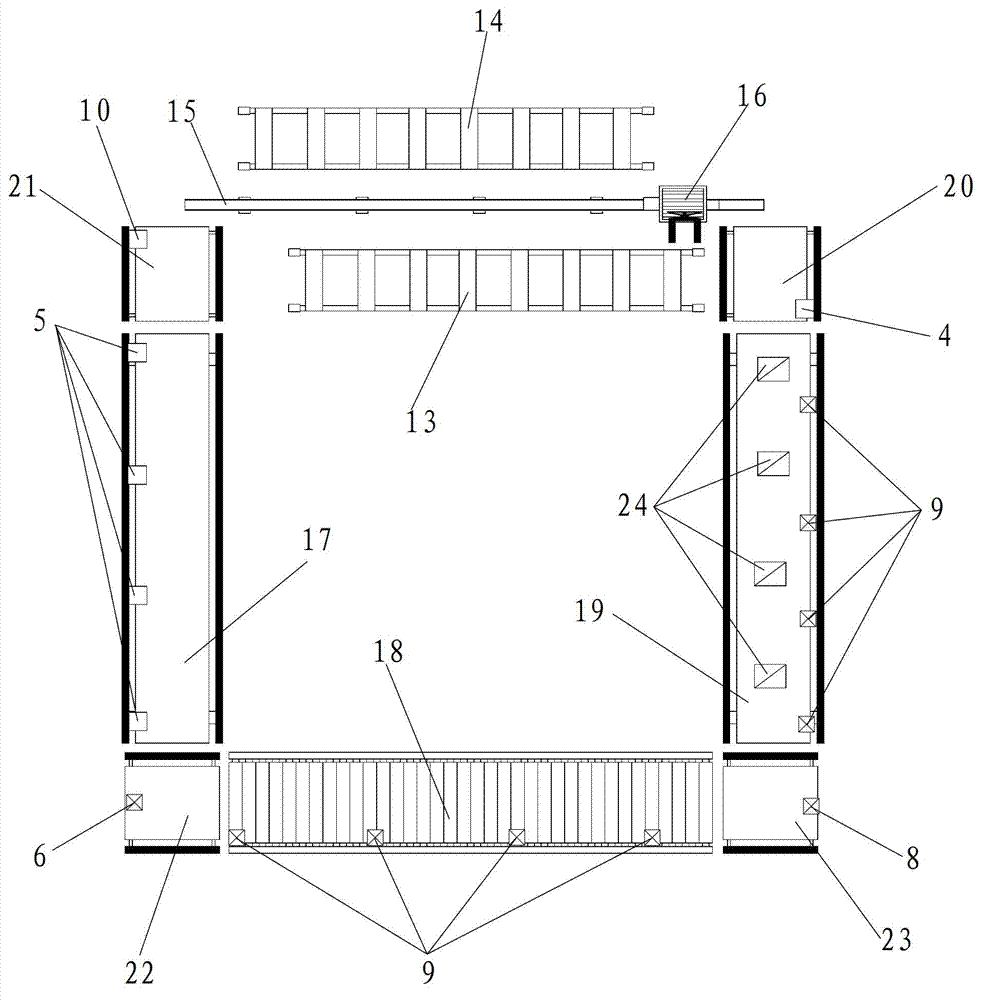

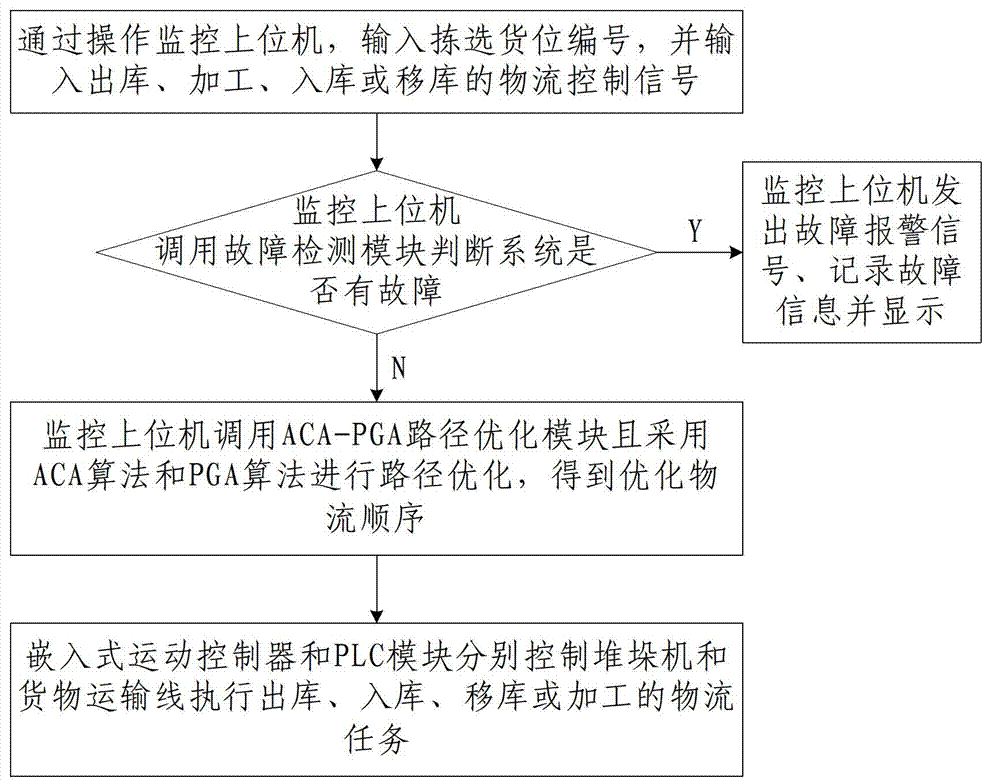

Stereo logistics system access cargo path optimization control system and method

InactiveCN103112680ASimple structureReasonable designStorage devicesLogistics managementControl system

The invention discloses a stereo logistics system access cargo path optimization control system and a method. The stereo logistics system access cargo path optimization control system comprises a monitoring upper computer, a programmable logic controller (PLC) module and an embedded motion controller, wherein an input end of the PLC module is connected with a plurality of cargo arrival detection sensors and a plurality of cargo position detection sensors, and an output end of the PLC module is connected with a plurality of frequency converters and a plurality of contactors. An input end of the embedded motion controller is connected with a piler state detection sensor, and an output end of the embedded motion controller is connected with an X-axis servo motor driver, a Y-axis servo motor driver and a Z-axis stepper motor driver. The method comprises the following steps: a logistics task signal is input, the upper computer is monitored to conduct path optimization, and the embedded motion controller and the PLC module respectively control the piler and a cargo conveying line to execute corresponding logistics tasks. The stereo logistics system access cargo path optimization control system and the method are reasonable in design, convenient and fast to use and operate, high in control precision, reliable in working reliability and stability, high in logistics efficiency, strong in practicability and high in popularization and application values.

Owner:XIAN UNIV OF SCI & TECH

Express box capable of being recycled

InactiveCN107985790AAvoid damageEasy to open and closePackage recyclingContainers to prevent mechanical damageEngineeringGarbage output

The invention discloses an express box capable of being recycled. The express box capable of being recycled comprises a box cover and a box body. The box cover is connected with the box body through aclamping and connecting structure, and two symmetrically-arranged first handles are rotationally connected to the upper end of the box cover. A screw is rotationally connected to the bottom in the box body. One end of the screw penetrates the inner wall of the box body and is provided with a flywheel in a welding manner. A bottom plate is arranged above the screw. The two ends of the bottom plateare fixedly connected with the inner walls of the two sides of the box body correspondingly. The screw is sleeved with two symmetrically-arranged clamping plates in a threaded manner. The ends, awayfrom the screw, of the clamping plates penetrate the bottom plate and extend upwards. The bottom plate is provided with sliding openings corresponding to the clamping plates. The express box is novelin structure, through the clamping and connecting structure and uniform cushion blocks, express box opening and closing are rapid and convenient, and the problems that the expressage industry efficiency is low, and the work time is long are solved; the express box is uniform in specification and can be recycled many times to be used, garbage output is reduced, resource consumption is reduced, costis reduced, the express box is more environment-friendly, and popularization is facilitated.

Owner:合肥美青工业设计有限公司

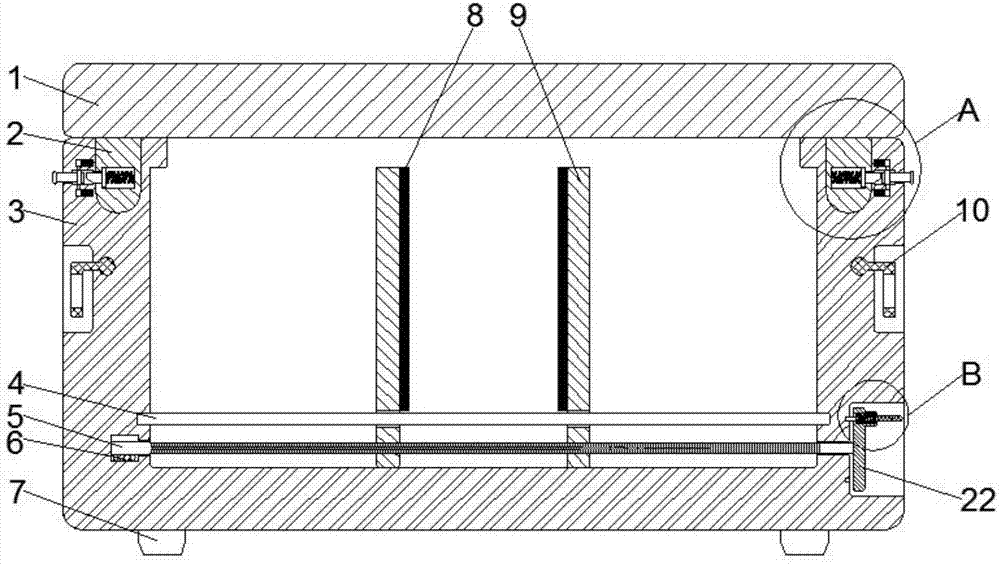

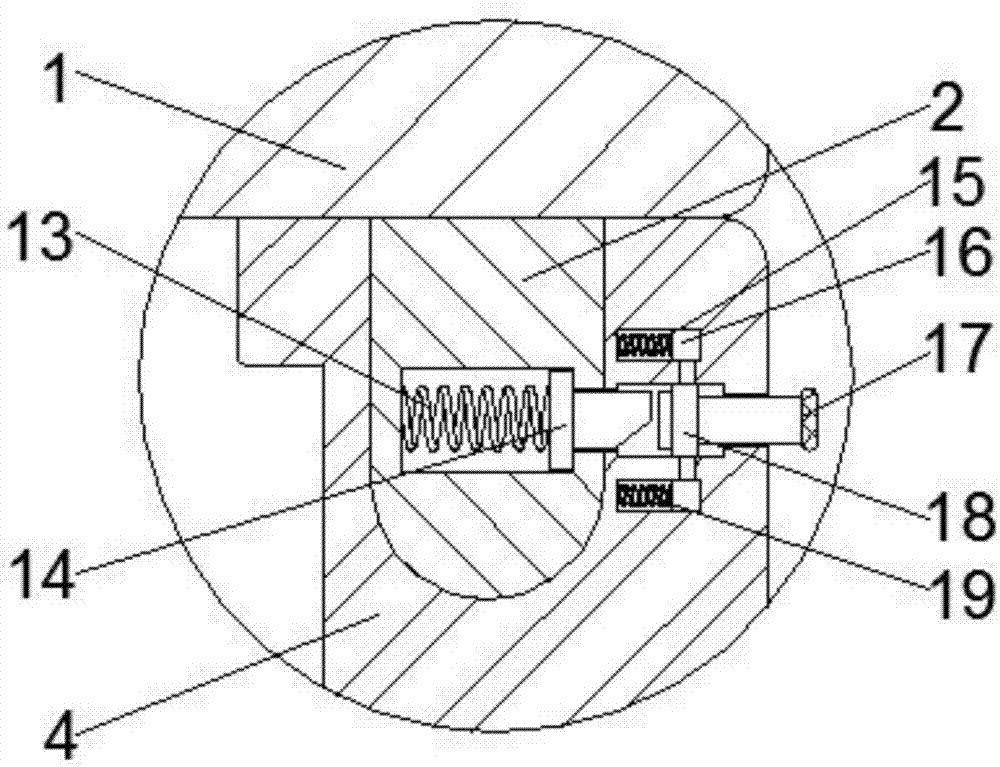

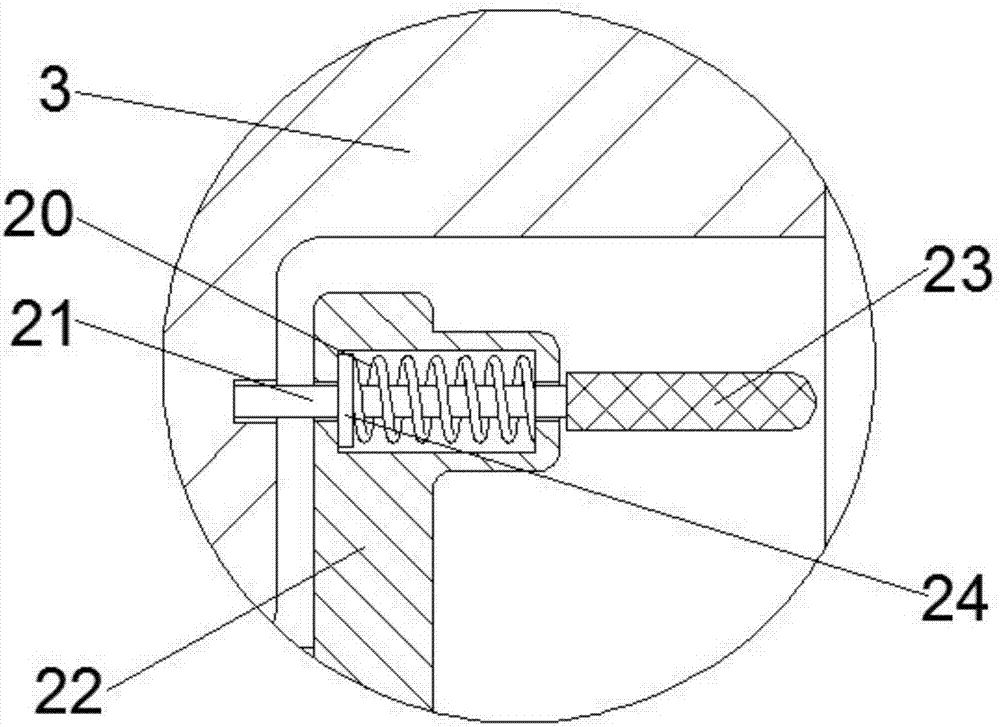

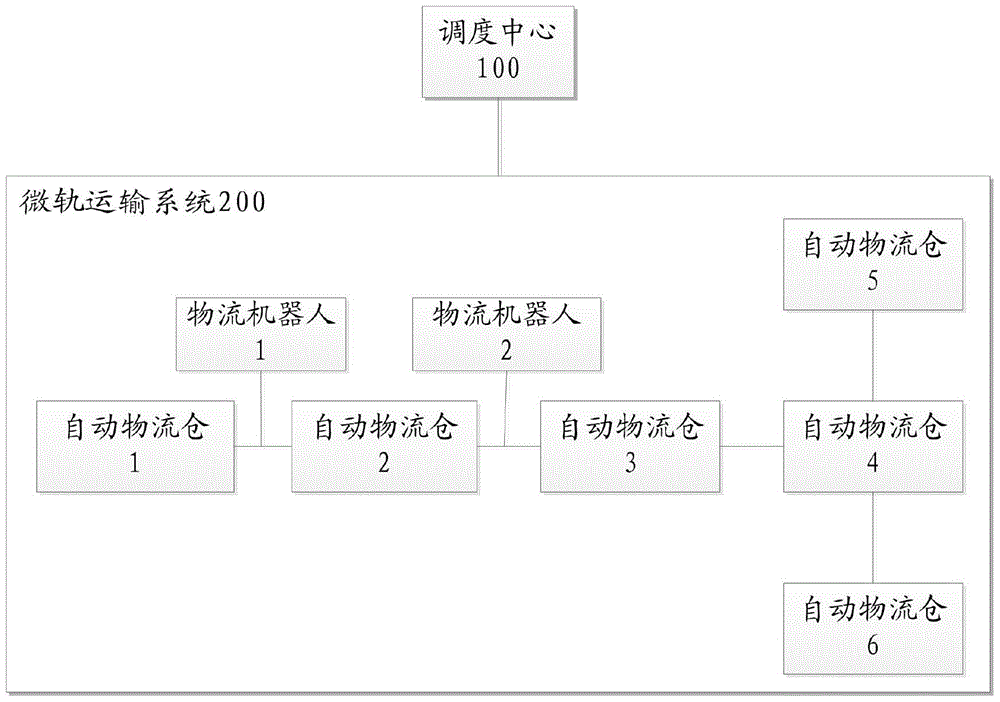

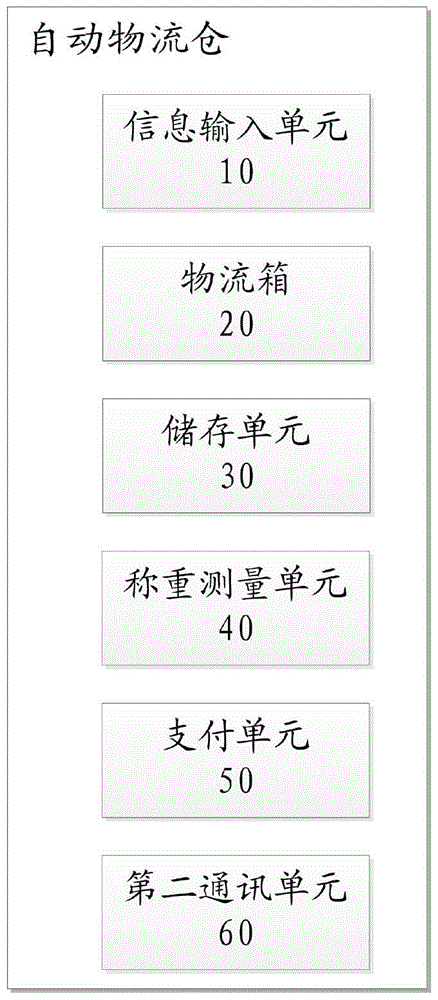

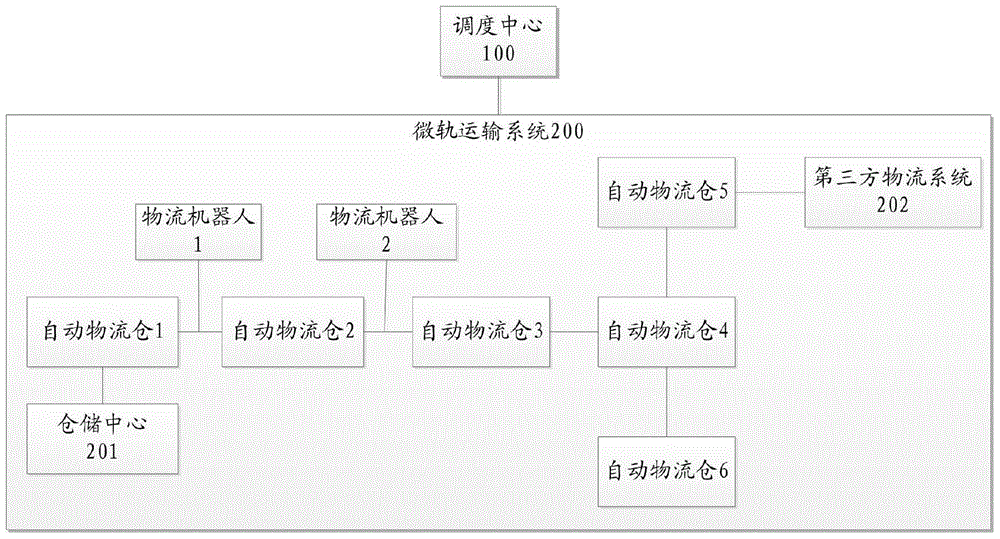

Automatic logistics system, method, and automatic logistics warehouse

InactiveCN105717892ALow costImprove logistics efficiencyTotal factory controlProgramme total factory controlLogistics managementComputer science

The invention discloses an automatic logistics system, a method, and an automatic logistics warehouse. The automatic logistic system comprises a scheduling center and a micro-rail transportation system, the scheduling center is connected with the micro-rail transportation system via a wireless network, the scheduling center receives information uploaded by the micro-rail transportation system and sends a scheduling command to the micro-rail transportation system, the micro-rail transportation system includes at least one transportation rail and a plurality of logistic robots, the logistics robots operate on the transportation rail, the automatic logistics warehouses for receiving or sending express parcels are arranged along the transportation rail, the logistics robots obtains the express parcels from the designated automatic logistics warehouses under the control of the scheduling center, and the express parcels are transported to the designated destination automatic logistics warehouses along the transportation rail. According to the system, direct point-to-point delivery of the express parcels is realized, the whole process from reception to delivery of the express parcels is automatically accomplished, the logistics efficiency is improved, and the cost is reduced.

Owner:SHENZHEN XIAODE TECH CO LTD

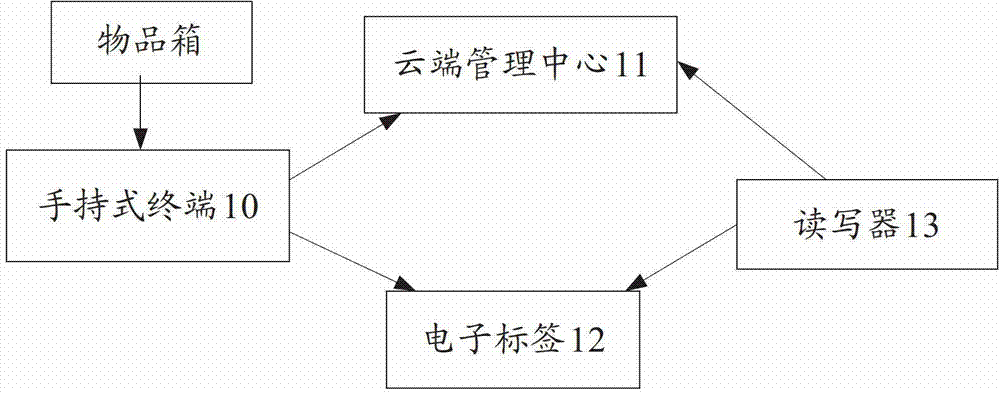

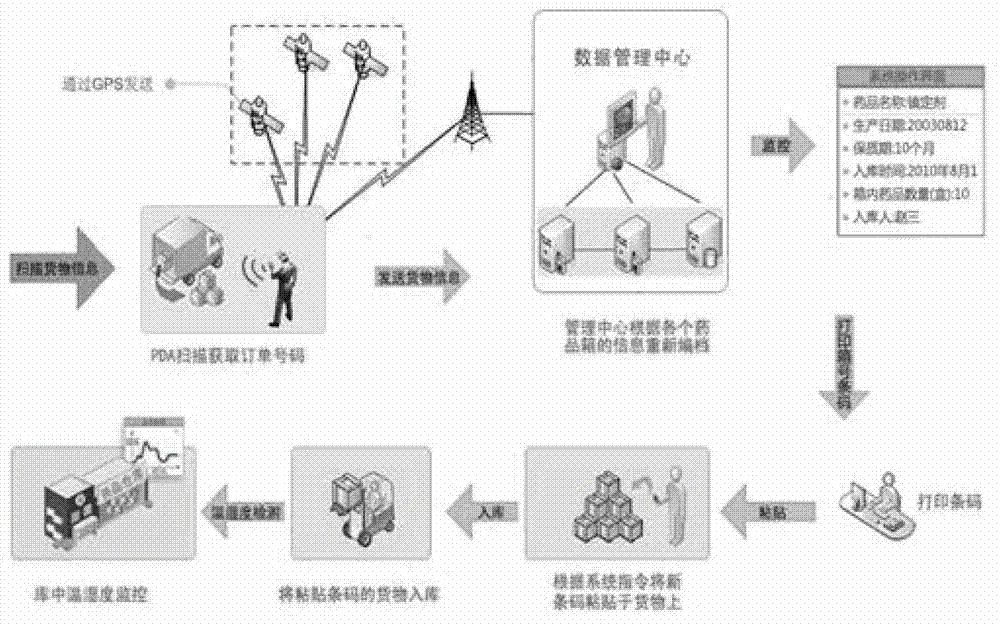

System and method for management and transportation monitoring of cold chain logistics

InactiveCN102930413AAchieve a high degree of collaborationRealize unified schedulingLogisticsCold chainLogistics management

The invention discloses a system and method for management and transportation monitoring of cold chain logistics. The management and monitoring system comprises a handheld terminal, a cloud end management center, electronic tags and a reader-writer, wherein the handheld terminal is used for acquiring order numbers on goods boxes after the arrival of goods, transmitting the data to the cloud end management center through a network, and acquiring barcode information on the goods boxes and information of temperature and humidity tags in the goods boxes when the goods are taken out of a warehouse; the cloud end management center is used for receiving the data transmitted from the handheld terminal, re-filing according to the information of each goods box, generating barcode information according to the information, outputting the barcode information, and monitoring the temperature and the humidity in the goods warehouse after the goods are warehoused; the electronic tags are used for storing all information of the goods taken out of the warehouse; and the reader-writer is used for reading the information of the electronic tags, and transmitting the information to the cloud end management center. Through the system and the method, the efficiency of the cold chain logistics can be improved, the cost is reduced, the unified scheduling and monitoring of logistics operation are realized, and timely and accurate cold chain logistics services are provided for clients.

Owner:SHANGHAI DIANJI UNIV

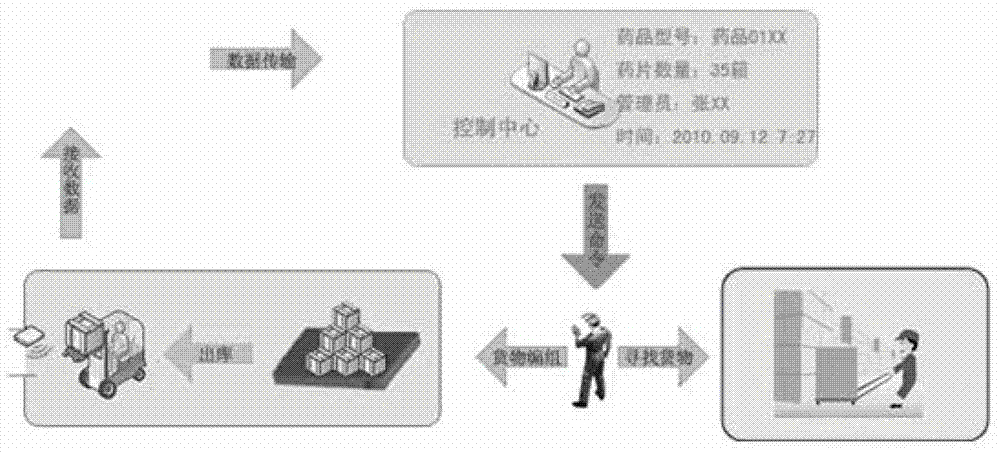

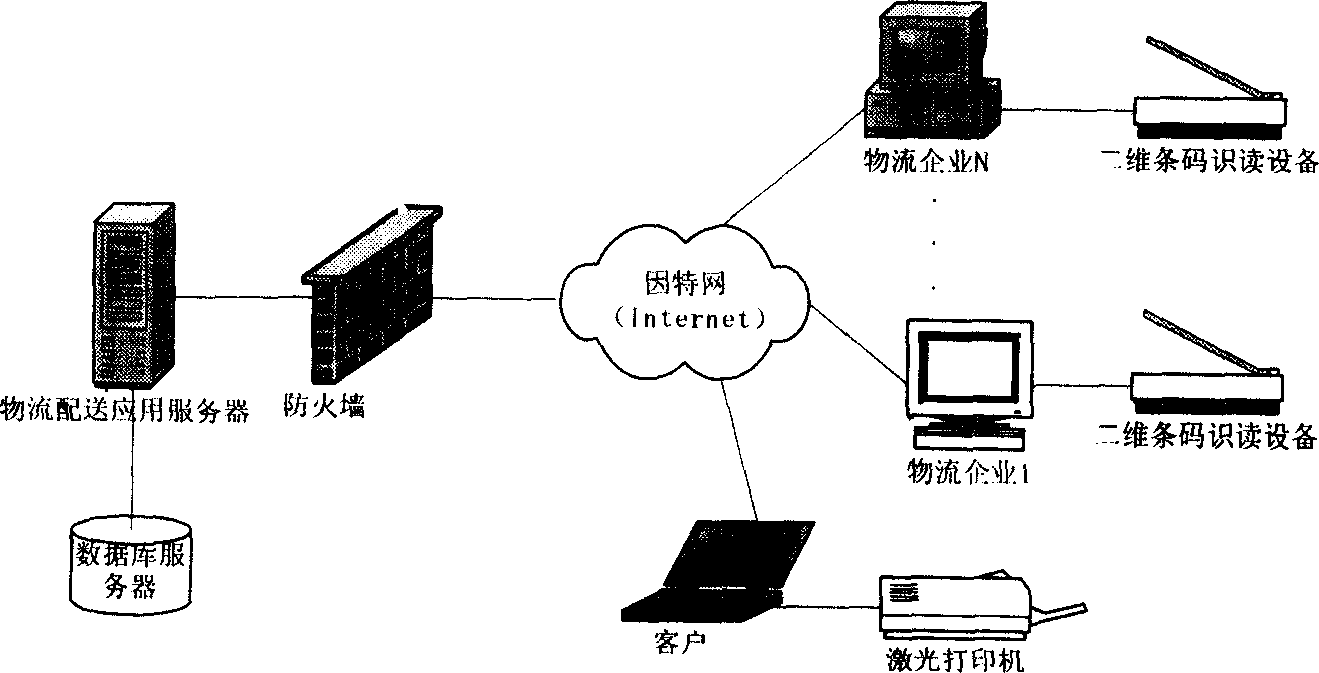

Method and system for realizing third party logistic dispensing information sharing

InactiveCN1700224AGood for secondary deliveryImprove logistics efficiencySpecial data processing applications

The invention discloses a method of achieving third party logic distribution information sharing. It provides a service operator schema so that all logic service data are stored in center database; users can generate and press object's mark or inquire the posting or receiving information of processing condition on the control of software system; logic firm website can collect object's mark information quickly and storage them into center database, it also can do object's distributing plan and service operation of logic information inquiring and statistic and so on; center database can ascertain all data form unified regulation so that different firms and different websites of one firm can share the logic information at the base of internet.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

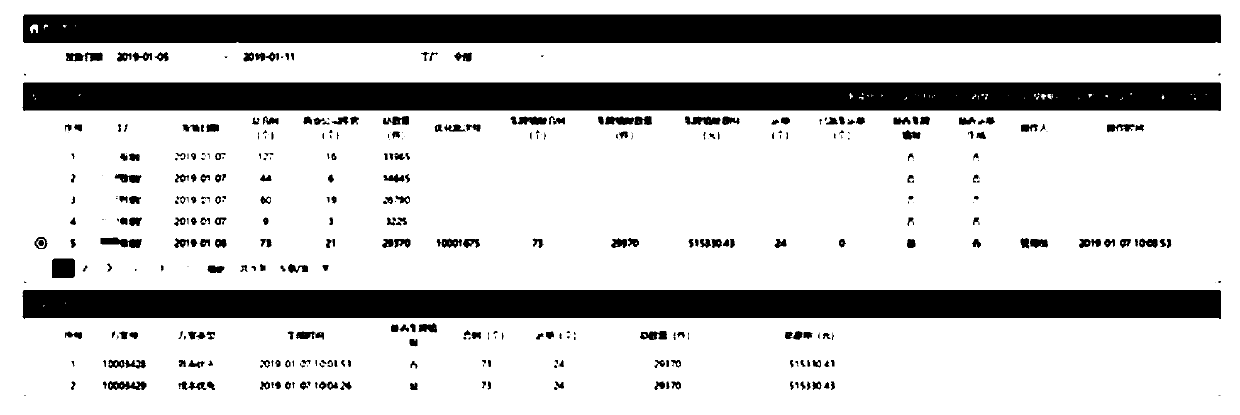

Intelligent scheduling method and system for industrial cigarette transportation

PendingCN110097234AMinimize shipping costsReduce shipping costsForecastingLogisticsLogistics managementEngineering

Aiming at the actual characteristics of industrial cigarette transportation, the path optimization method suitable for industrial cigarette transportation is constructed by considering the connectivity, the dynamic unloading time and the like of commercial companies, so that the total transportation cost of the industrial enterprises is minimized on the basis of meeting the marketing orders of thecommercial companies. The industrial cigarette pricing mode particularity is considered, through analysis and mining of historical logistics data, key factors such as actual connectivity and load sharing rules among commercial companies are objectively analyzed, the influence of artificial subjective factors is avoided, and the hidden load sharing rules in the data are discovered. According to the invention, a multi-objective intelligent evolution algorithm with a reinforcement learning capability based on a primary and secondary hierarchical framework is constructed, the transportation costof a carrier is reduced as much as possible on the premise that the logistics cost of an industrial enterprise is not improved, an intelligent scheduling system of the industrial enterprise is established, the logistics efficiency is greatly improved, and the logistics cost of the industrial enterprise is reduced.

Owner:CHINA TOBACCO JIANGSU INDAL

Carrying robot, container taking method and container placing method

ActiveCN111620024ALess room for movementIncrease profitStorage devicesLogistics managementIndustrial engineering

The invention belongs to the technical field of storage logistics, and particularly discloses a carrying robot, a storage logistics system and a container carrying method. The carrying robot comprisesa movable chassis, a temporary storage frame and a container taking assembly, wherein the movable chassis can move along a channel between adjacent inventory containers, the temporary storage frame is arranged on the movable chassis and used for temporarily storage target containers, the container taking assembly is arranged on the movable chassis, the container taking assembly can stretch and retract horizontally relative to the movable chassis so as to take and place target containers between the inventory containers and the temporary storage frame, and the horizontal stretching direction of the container taking assembly is perpendicular to the motion direction. The storage logistics system comprises the carrying robot. The container carrying method adopts the carrying robot for carrying target containers. According to the carrying robot, the storage logistics system and the container carrying method, the occupied space of the carrying robot in a warehouse channel can be reduced, the warehouse utilization rate is increased, and meanwhile the target container carrying efficiency can be improved.

Owner:BEIJING JIZHIJIA TECH CO LTD

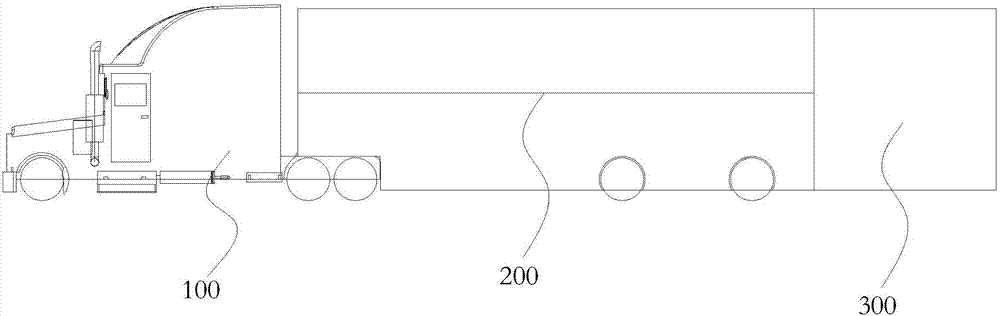

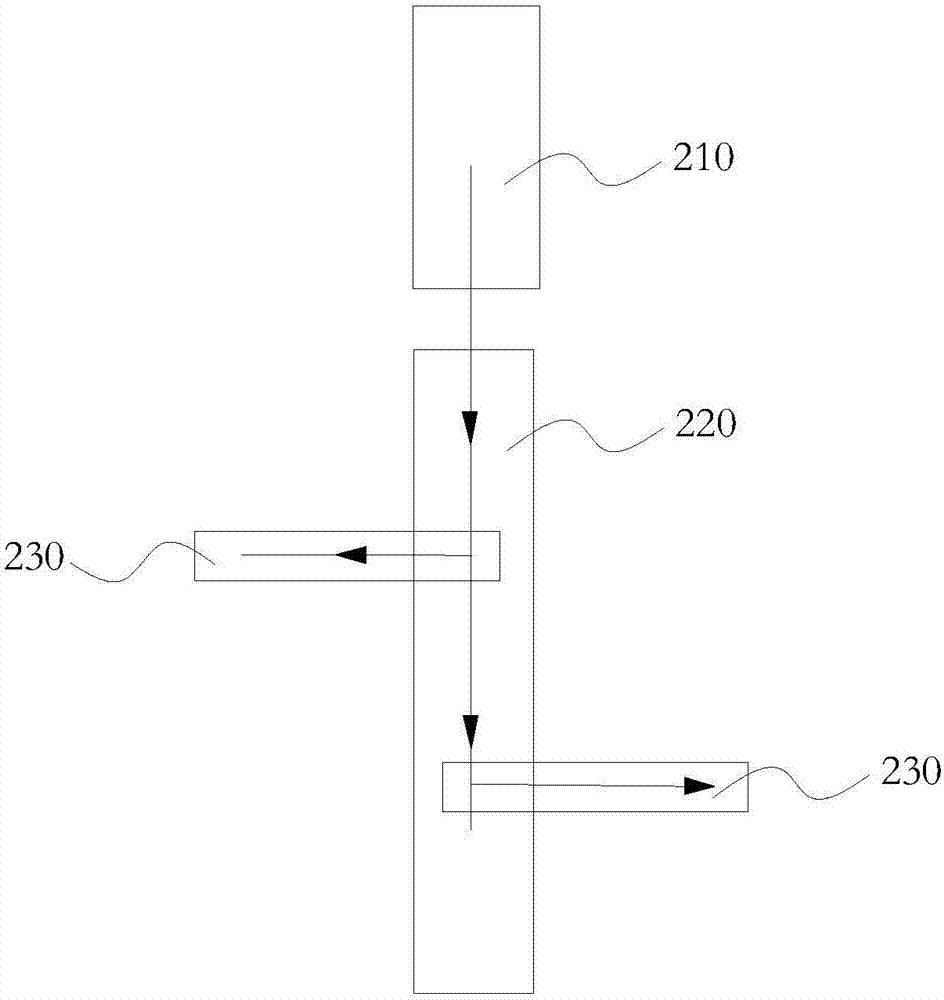

Small-region express sorting vehicle

The invention discloses a small-region express sorting vehicle. The vehicle comprises a vehicle body and a cargo sorting system arranged in the vehicle body; the cargo sorting system comprises a cargo online device arranged in the middle of the vehicle body, a cargo conveying belt connected with the cargo online device and at least one cargo sorting offline device arranged on the cargo conveying belt. According to the small-region express sorting vehicle, a fixed sorting site does not need to be used, express parcels can be automatically sorted, conveyed and delivered, the logistics cost is reduced, and the logistics efficiency is improved.

Owner:GUANGZHOU INST OF RAILWAY TECH

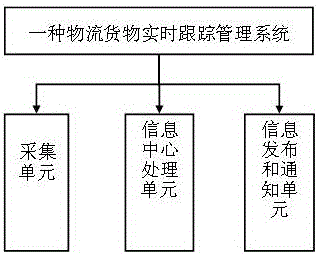

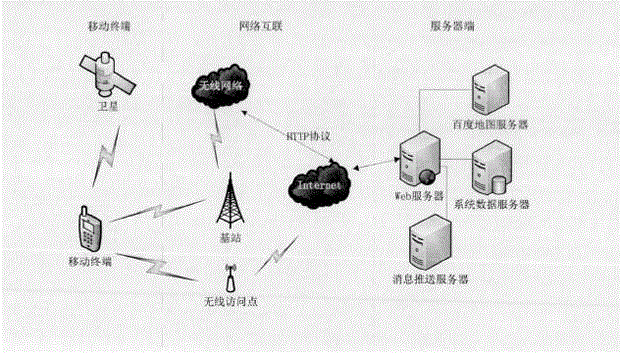

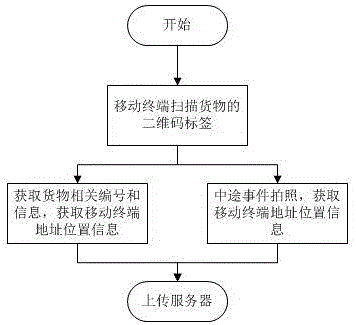

Logistics goods real-time tracking and management system based on mobile internet technology

InactiveCN105701635ARealize full tracking functionPerfect full tracking functionLogisticsMulti linkVideo recognition

The invention relates to a logistics goods whole-process real-time tracking and management system based on mobile internet technology. The system is characterized in that based on the mobile internet technology and the internet of things technology, logistics goods whole-process tracking and management are realized while investment of software and hardware does not need to be added. The logistics goods real-time tracking and management system comprises diverse handheld terminal modules, information support means such as a two-dimensional code, the GPS technology, the mobile internet technology and the video recognition and monitoring technology are adopted, multi-link cooperation between the third-party logistics, a dedicated line, a truck driver, a storage enterprise, a terminal delivery person and other working object can be realized, and under a unified frame supported by the mobile internet, whole-process visualized management and control service such as delivery notification, in-transit positioning and tracking, and electronic receipt uploading and confirmation are provided.

Owner:江苏中科今朝科技有限公司 +2

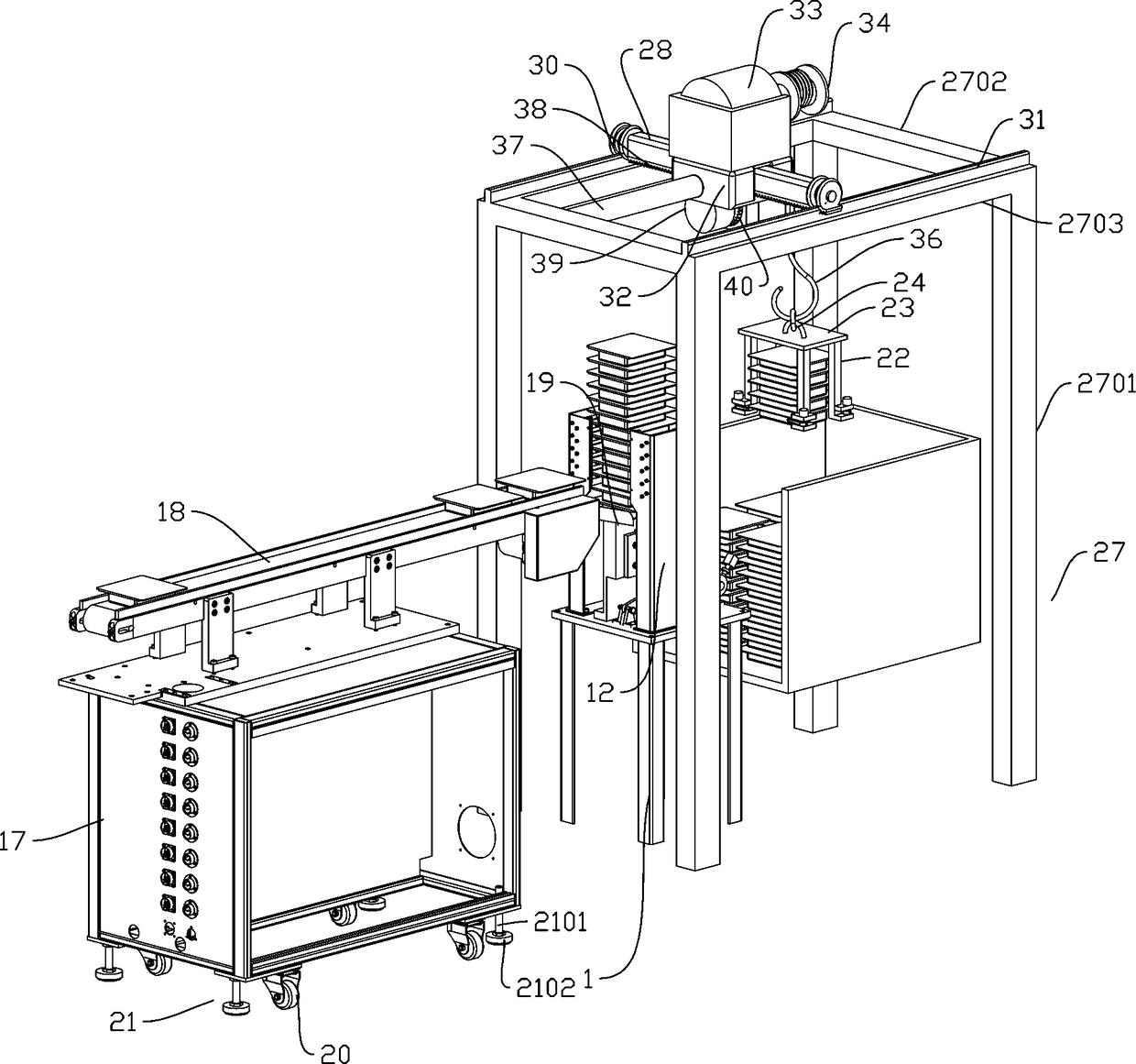

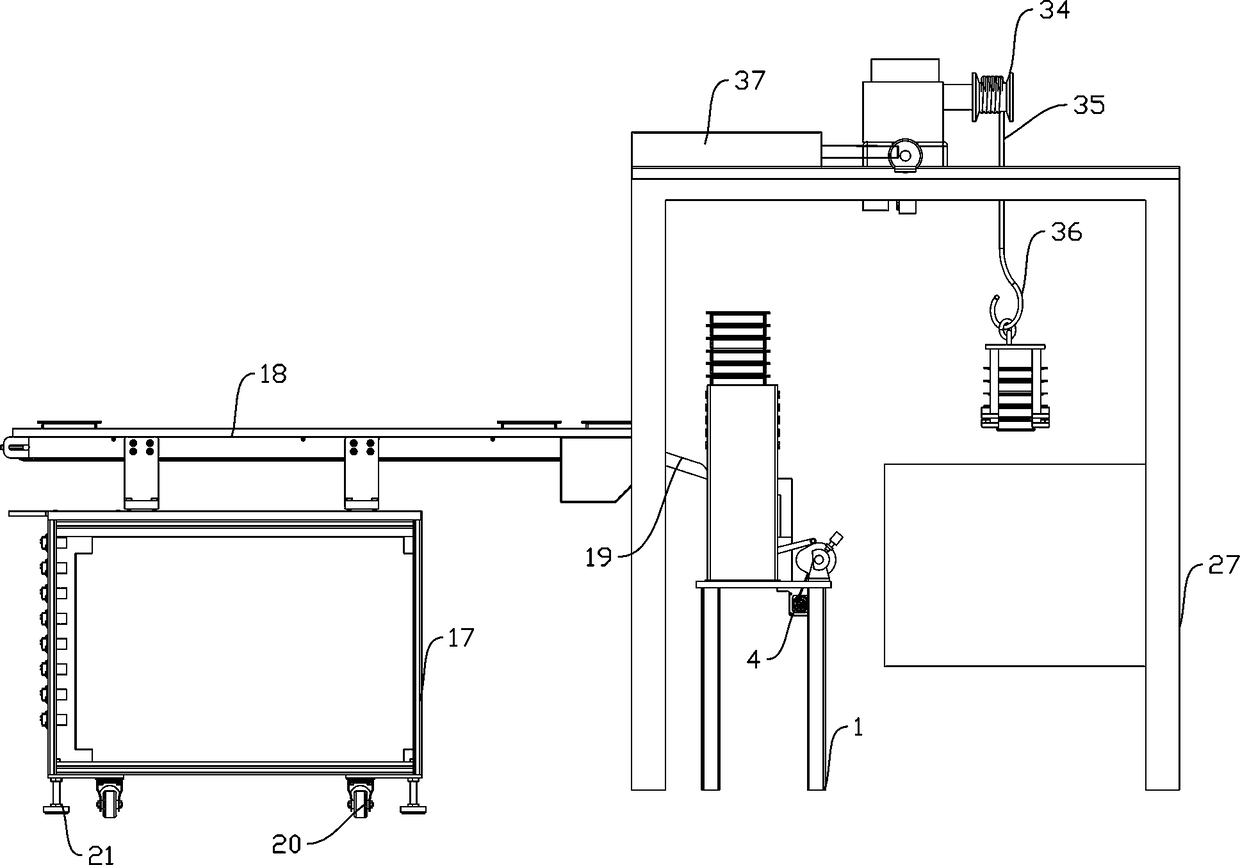

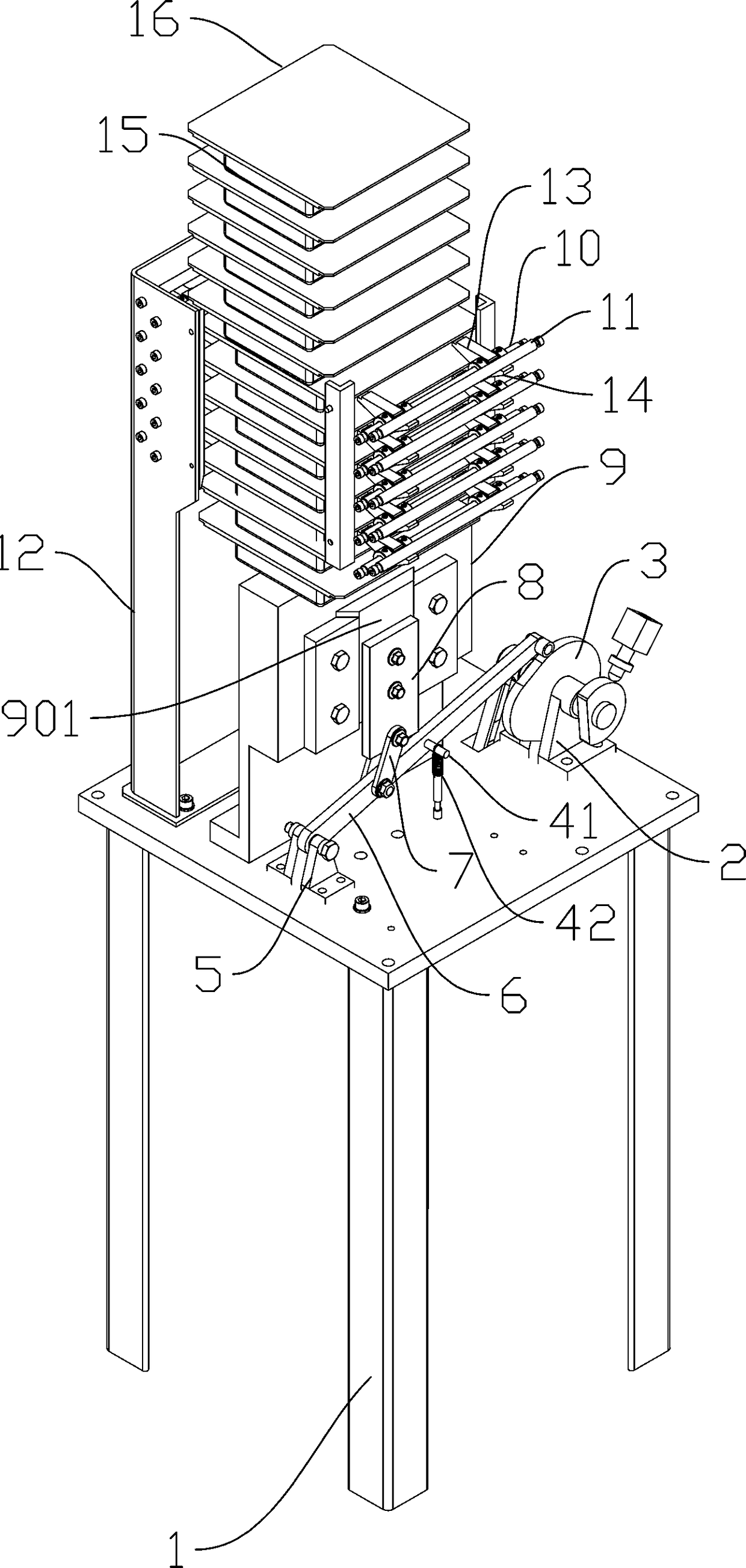

Classification logistics box automatic loading device

InactiveCN108792634ARealize automatic loadingRealize handlingConveyorsStacking articlesLogistics managementEngineering

The invention provides a classification logistics box automatic loading device. The classification logistics box automatic loading device comprises a stacking device. The stacking device comprises a supporting seat. A cam frame is arranged on the upper side of the cam frame. A rotary shaft of a cam is rotatably mounted on the cam frame and is driven through a first motor. A hinge support is arranged on the supporting seat. One end of a connecting rod is hinged to the hinge support, and the other end of the connecting rod abuts against the cam. The connecting rod is hinged to a lifting connecting rod. The upper end of lifting connecting rod is hinged to a lifting plate. The lifting plate is slidably mounted in a sliding groove of a blanking platform. A multi-layer supporting mechanism is arranged above the blanking platform. The supporting mechanism comprises rotary shafts and limiting rods, and the rotary shafts and the limiting rods are symmetrically arranged on the two sides above the blanking platform. The two ends of the rotary shafts and the two ends of the limiting rods are mounted on a support. The support is fixed to the supporting seat. Supporting jaws are rotatably mounted on the rotary shafts. The sides, far away from logistics boxes, of the supporting jaws are provided with limiting jaws. The limiting rods limit the limiting jaws to rotate upwards. Through the classification logistics box automatic loading device, automatic stacking of the logistics boxes is realized, the labor intensity is relieved, the logistics efficiency is improved, and the logistics company image is promoted.

Owner:CHINA THREE GORGES UNIV

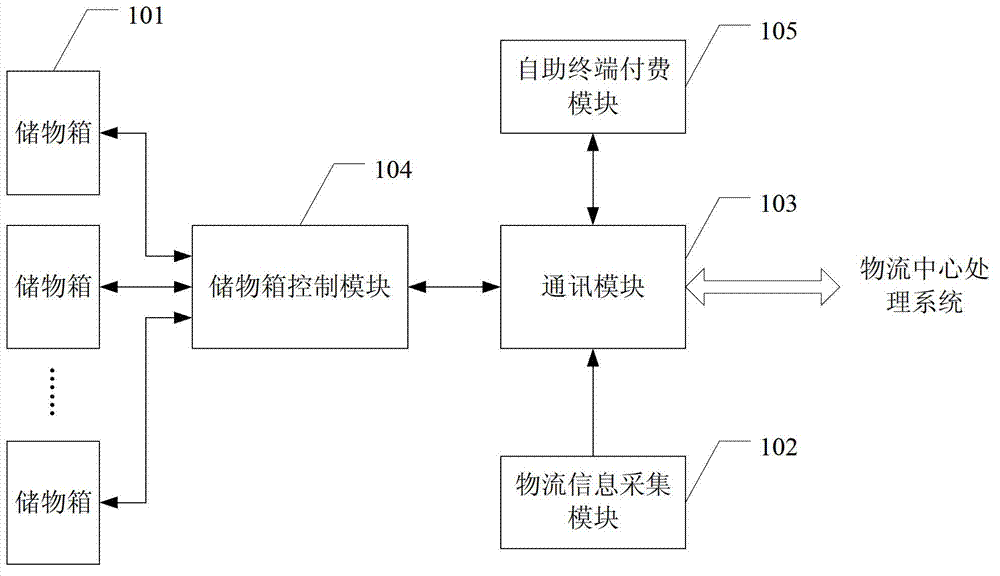

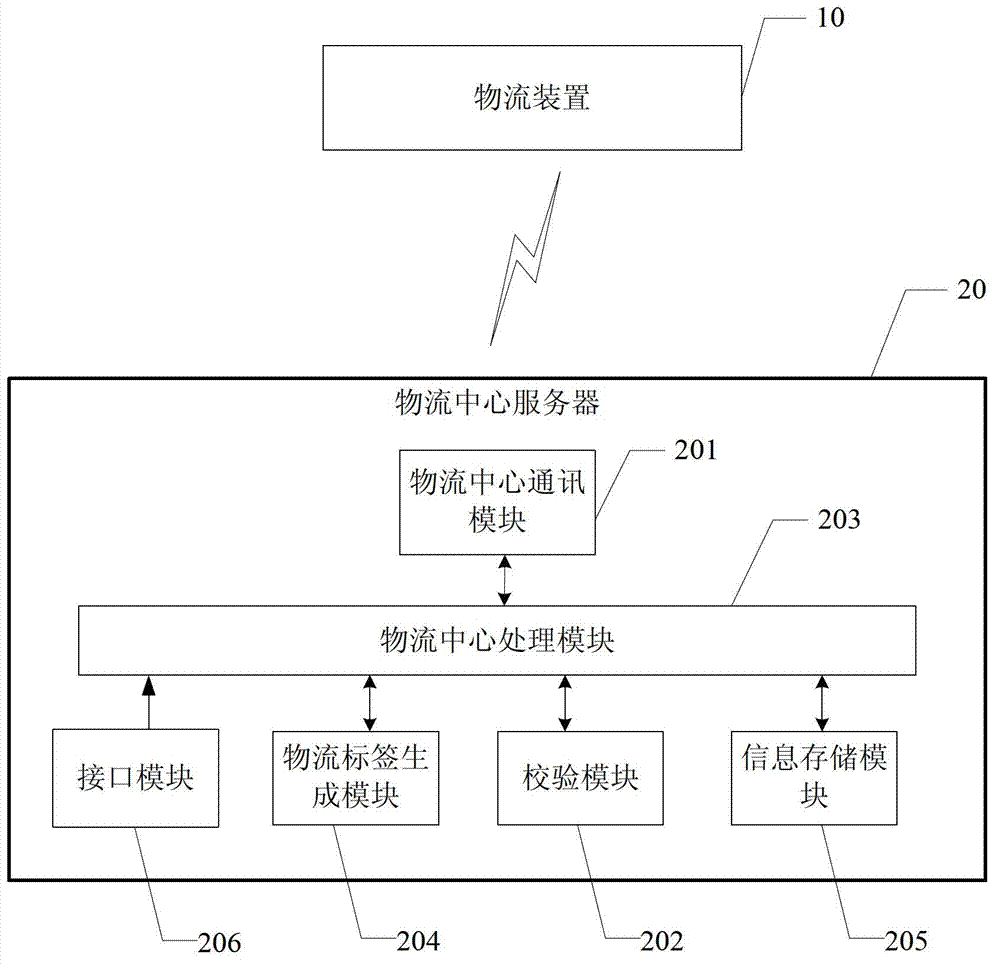

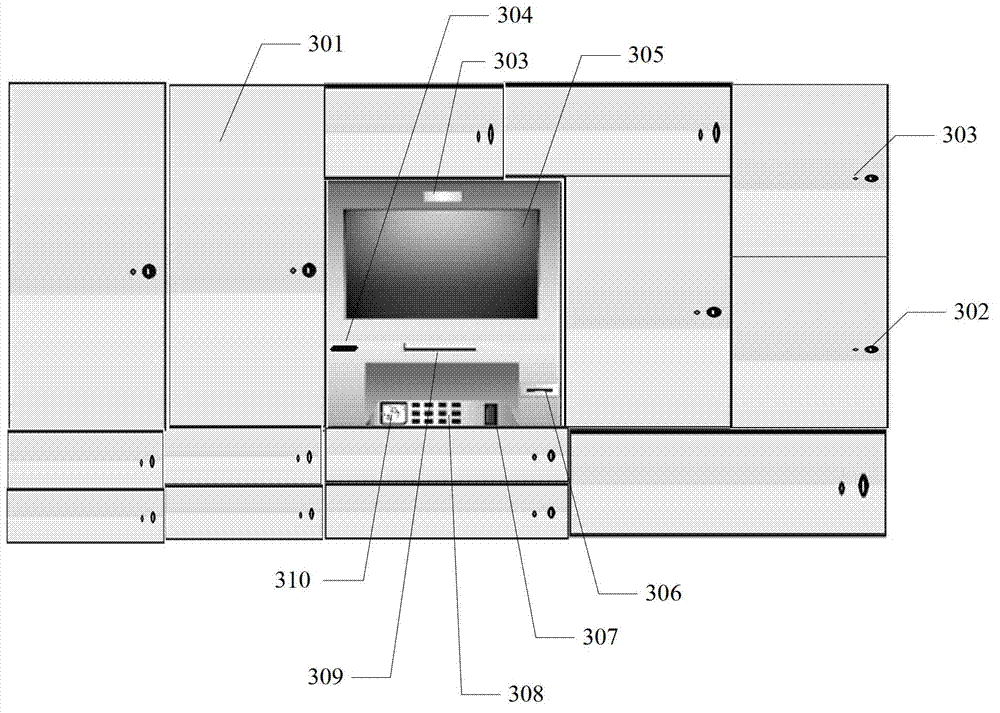

Logistics device and system

ActiveCN102968834APrivacy protectionProtection securityIndividual entry/exit registersPaymentLogistics management

The invention discloses a logistics device and a logistics system. The logistics device comprises at least one storage box, a logistics information collecting module, a communication module, and a secondary storage box array control module, wherein the at least one storage box is used for storing goods; the logistics information collecting module is used for collecting goods information, logistics personnel information and recipient information; the communication module is used for uploading the collected goods information, the logistics personnel information and the recipient information to a logistics center server, and receiving a logistics result which is generated by the logistics center server according to the goods information, logistics personnel information and recipient information; and the secondary storage box array control module is used for controlling the storage box according to the logistics result. According to the logistics device and the logistics system disclosed by the invention, logistics efficiency can be improved, privacy and safety of the recipient and the property of the recipient are protected, and a payment problem for cash on delivery is effectively solved.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

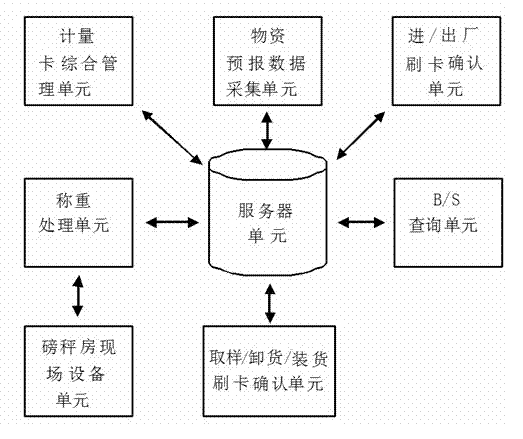

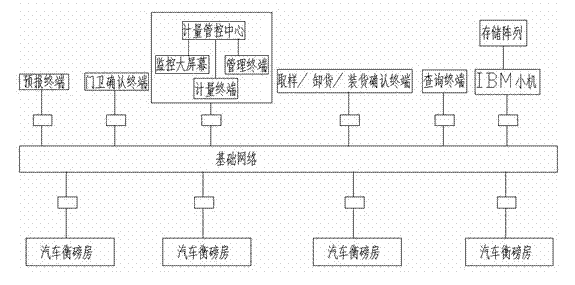

Automobile card reading measurement control system and use method

InactiveCN102496094AReduce the quantity requiredReduce the number of requirements and reduce labor costsCo-operative working arrangementsLogisticsManagement unitControl system

An automobile card reading measurement control system relates to automobile material unmanned remote centralized weighing measurement and process management, and consists of a measuring card comprehensive management unit, a material forecasting data acquisition unit, an in-factory / ex-factory card reading confirmation unit, a scale room field equipment unit, a weighing processing unit, a sampling / unloading / loading card reading confirmation unit, a B / S inquiry unit and a server unit, wherein the scale room field equipment unit is connected with the weighing processing unit; the measuring card comprehensive management unit, the material forecasting data acquisition unit, the in-factory / ex-factory card reading confirmation unit, the weighing processing unit, the sampling / unloading / loading card reading confirmation unit and the B / S inquiry unit are respectively connected with the server in a data transmission manner. By adopting the automobile card reading measurement control system, all measuring personnel are centralized in a hall, dynamic dispatching of man power and various equipment resources can be realized, the required measuring personnel quantity is greatly reduced, and the manpower cost is lowered.

Owner:WUKUN STEEL

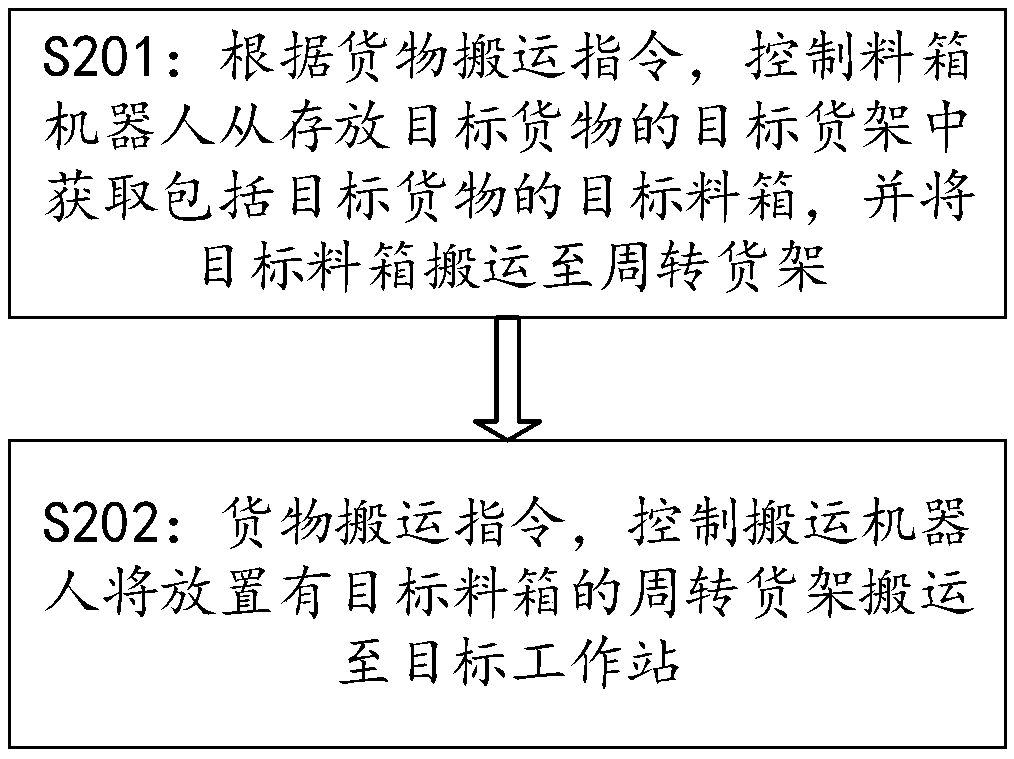

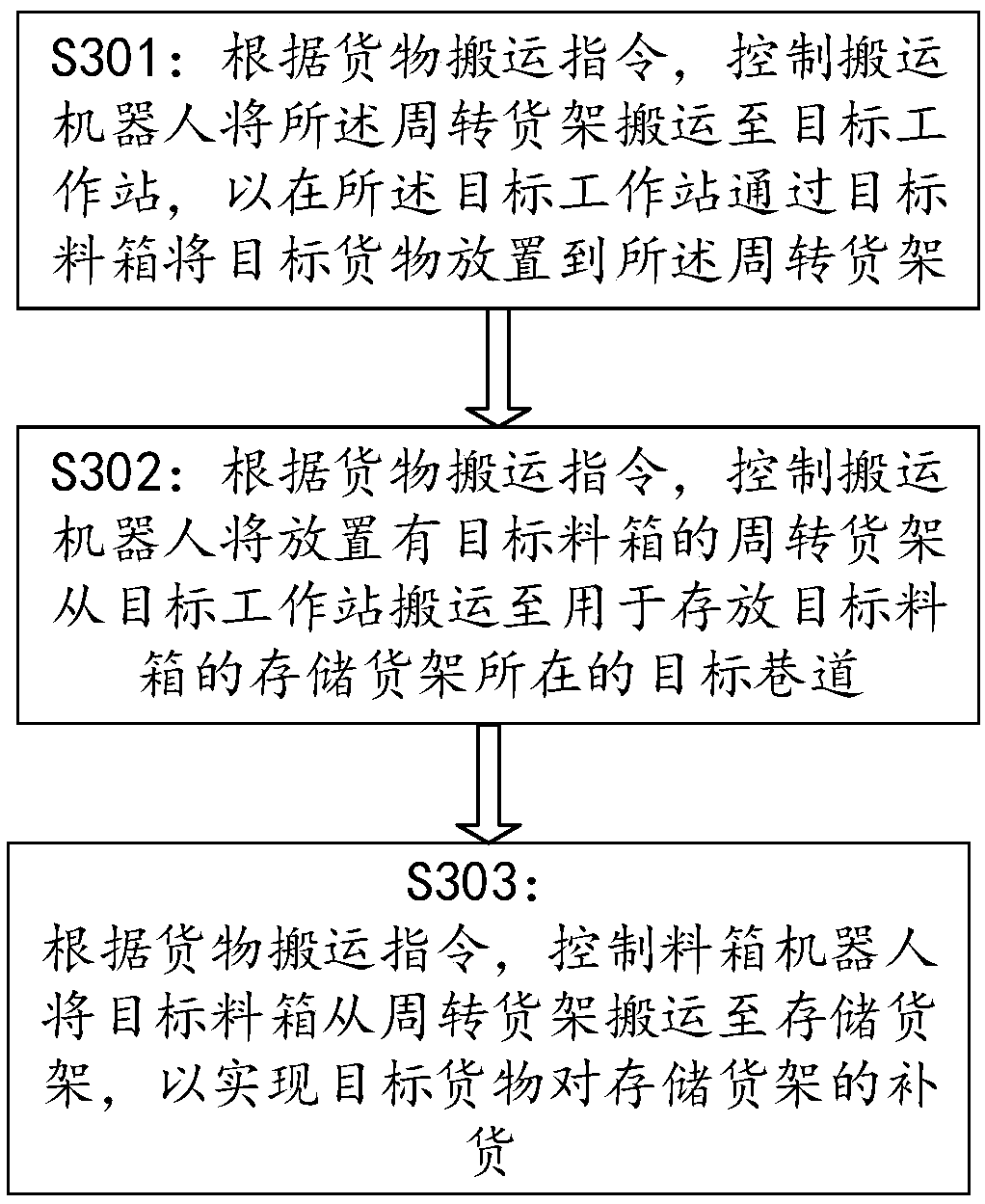

Cargo carrying method and cargo carrying system

InactiveCN109625747AImprove logistics efficiencyImprove handling efficiencyConveyorsStorage devicesWorkstationRobot

The present invention provides a cargo carrying method for a cargo carrying system and the cargo carrying system. The cargo carrying system includes a box robot, a circulation rack and a carrying robot. The cargo carrying method includes the following steps that the box robot is controlled according to cargo carrying instructions to obtain a target box containing target cargos from a target rack storing target cargos, and carry the target box to the circulation rack; and according to the cargo carrying instructions, the carrying robot is controlled to carry the circulation rack where the target box is placed to a target workstation, and therefore the target cargos or the target box are sorted out from the circulation rack.

Owner:SHANGHAI QUICKTRON INTELLIGENT TECH CO LTD

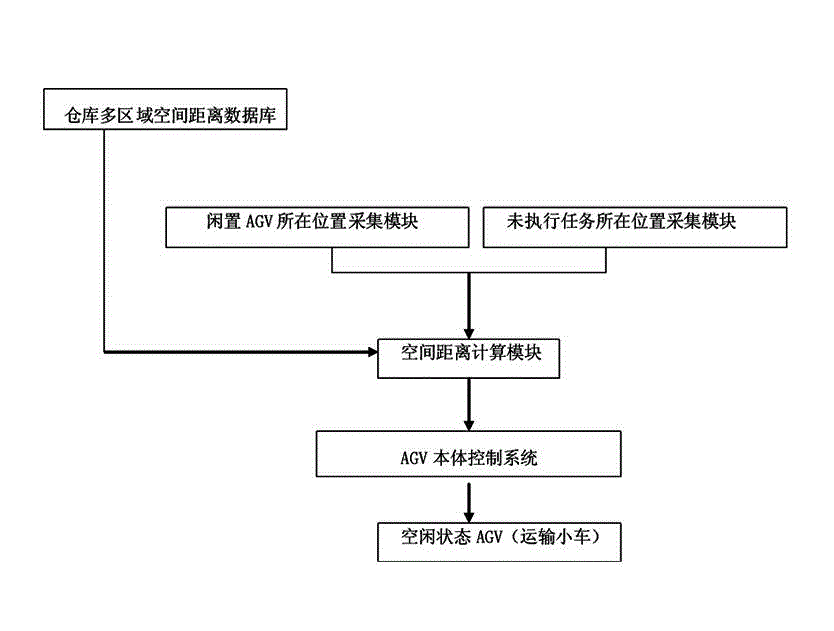

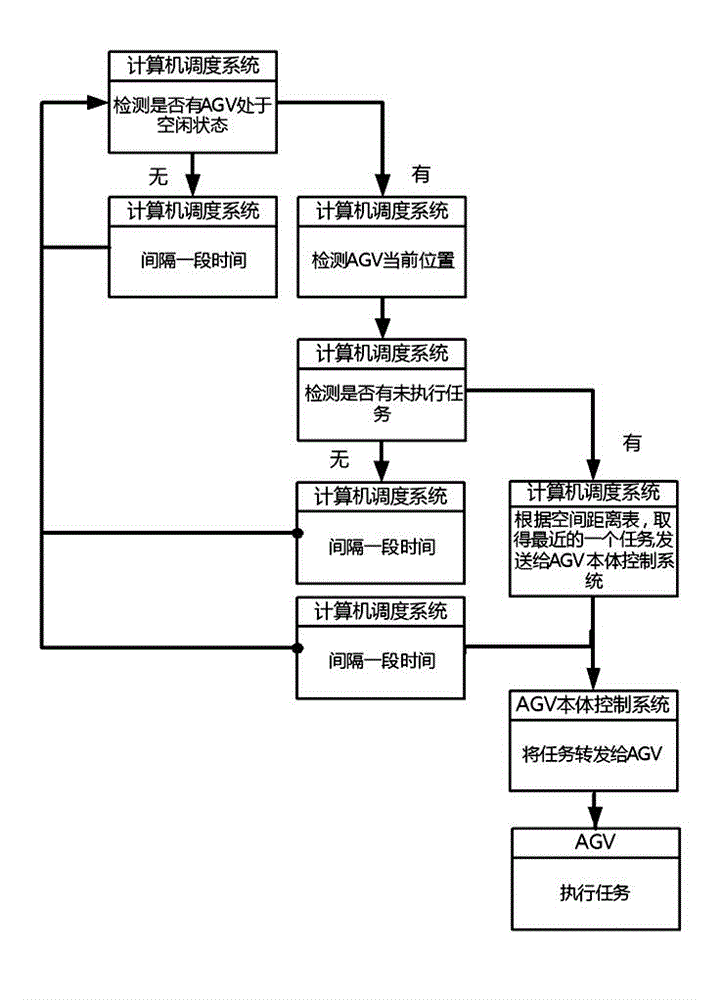

Compound circulating adjusting system of automatic guided vehicle (AVG) transfer carriage in automated logistics

InactiveCN103150640AReduce invalid operationsImprove logistics efficiencyLogisticsControl systemComputer module

The invention discloses a compound circulating adjusting system of an automatic guided vehicle (AVG) transfer carriage in automated logistics. The system comprises a computer scheduling system and an AGV body control system which controls the AVG transfer carriage. The compound circulating adjusting system is characterized in that the computer scheduling system comprises a bin multiple-area spatial distance data base, an idle AVG position collecting module, and an unexecuted task position collecting module, and further comprises a spatial distance computing module, wherein the spatial distance computing module is connected with the idle AGV position collecting module, the unexecuted task position collecting module and the AVG body control system. A close-distance execution technology is adopted in the system so that invalid operation of the AGV transfer carriage is reduced, and finally logistics efficiency is improved.

Owner:XIAMEN TOBACCO IND

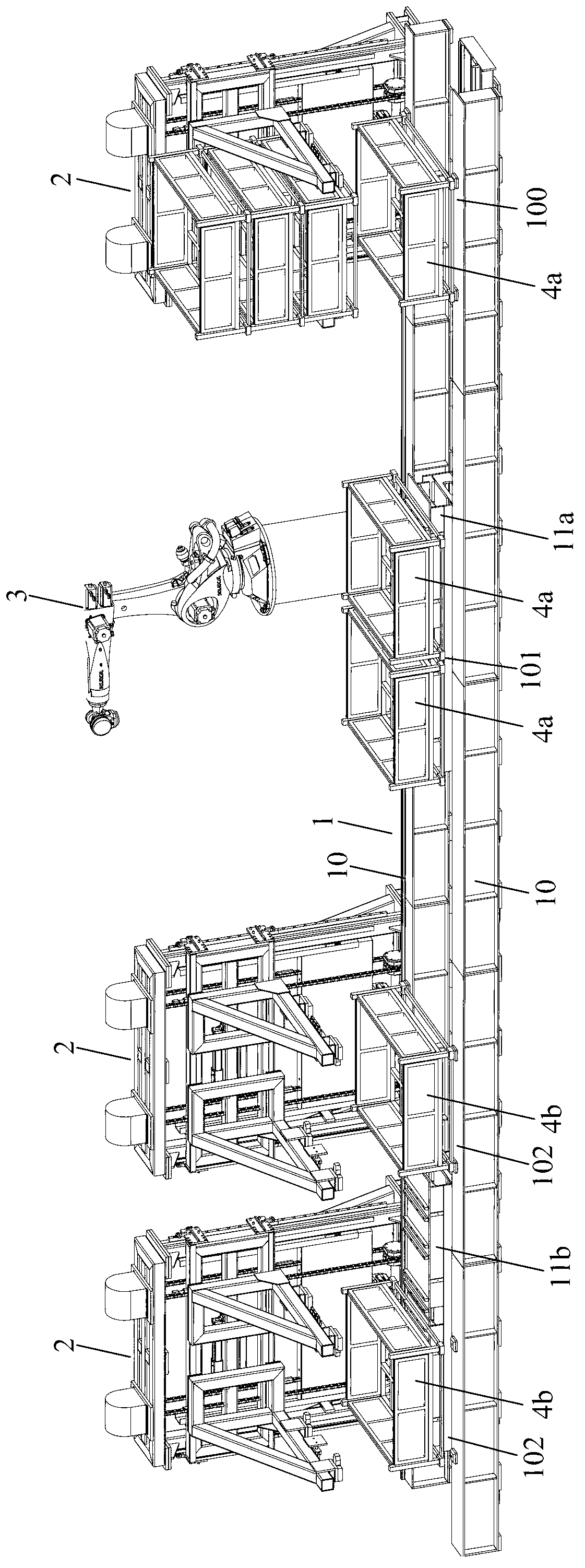

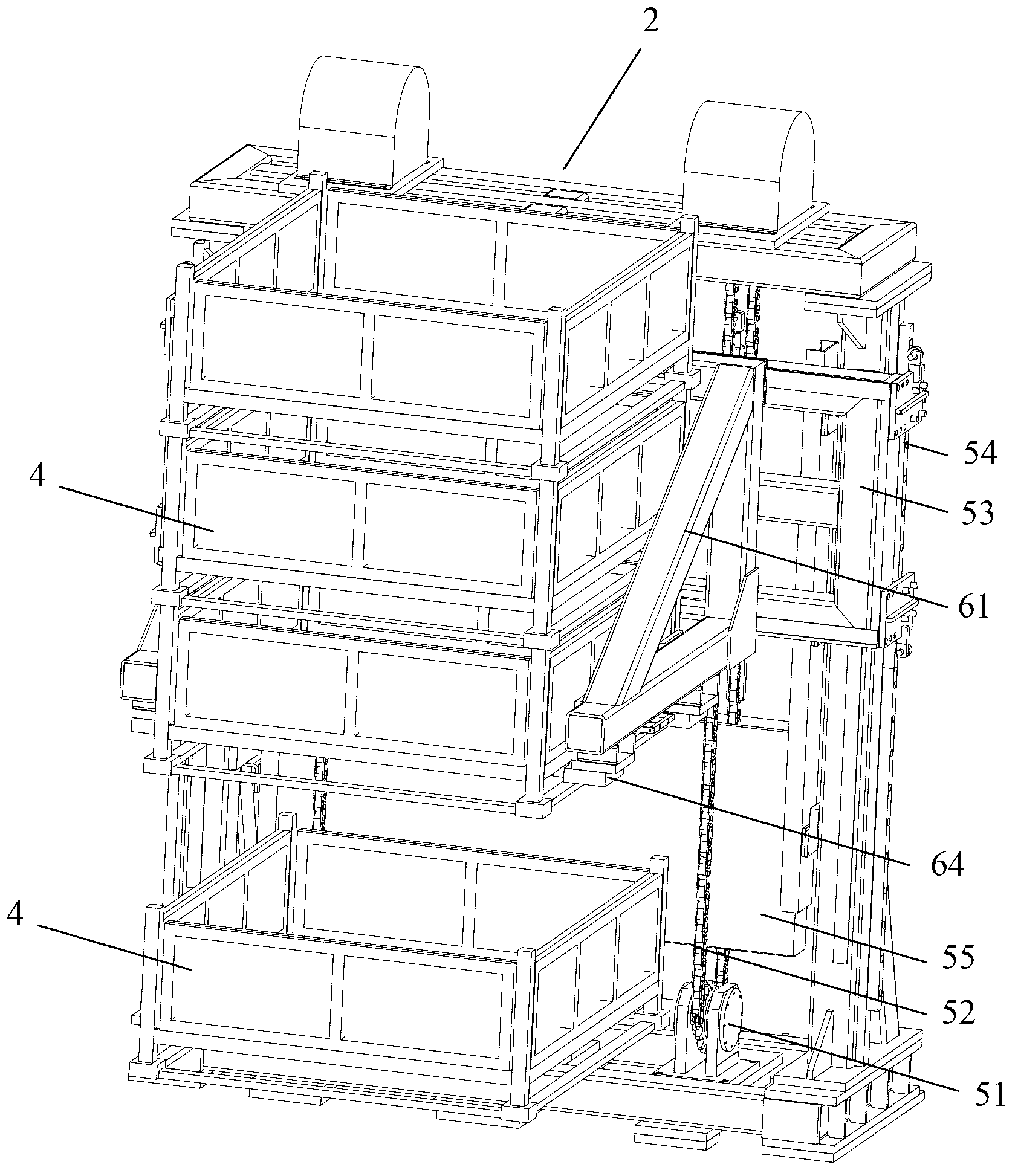

Automatic workpiece basketing and transmitting system

ActiveCN103224142AReduce the number of timesShorten the timeStacking articlesDe-stacking articlesTransport systemEngineering

The invention discloses an automatic workpiece basketing and transmitting system, relates to the technical field of automation, and can better improve the logistic efficiency. The automatic workpiece basketing and transmitting system provided by the embodiment of the invention comprises at least two stacking and splitting mechanisms and a transmission mechanism, wherein the stacking and splitting mechanisms are used for separating lower baskets from upper baskets in a group of stacked baskets or stacking a plurality of baskets into a group; the at least two stacking and splitting mechanisms are arranged on one side of the transmission mechanism in the transmission direction of the transmission mechanism; and the transmission mechanism is used for transmitting the lower baskets after separation.

Owner:精诚工科汽车系统有限公司

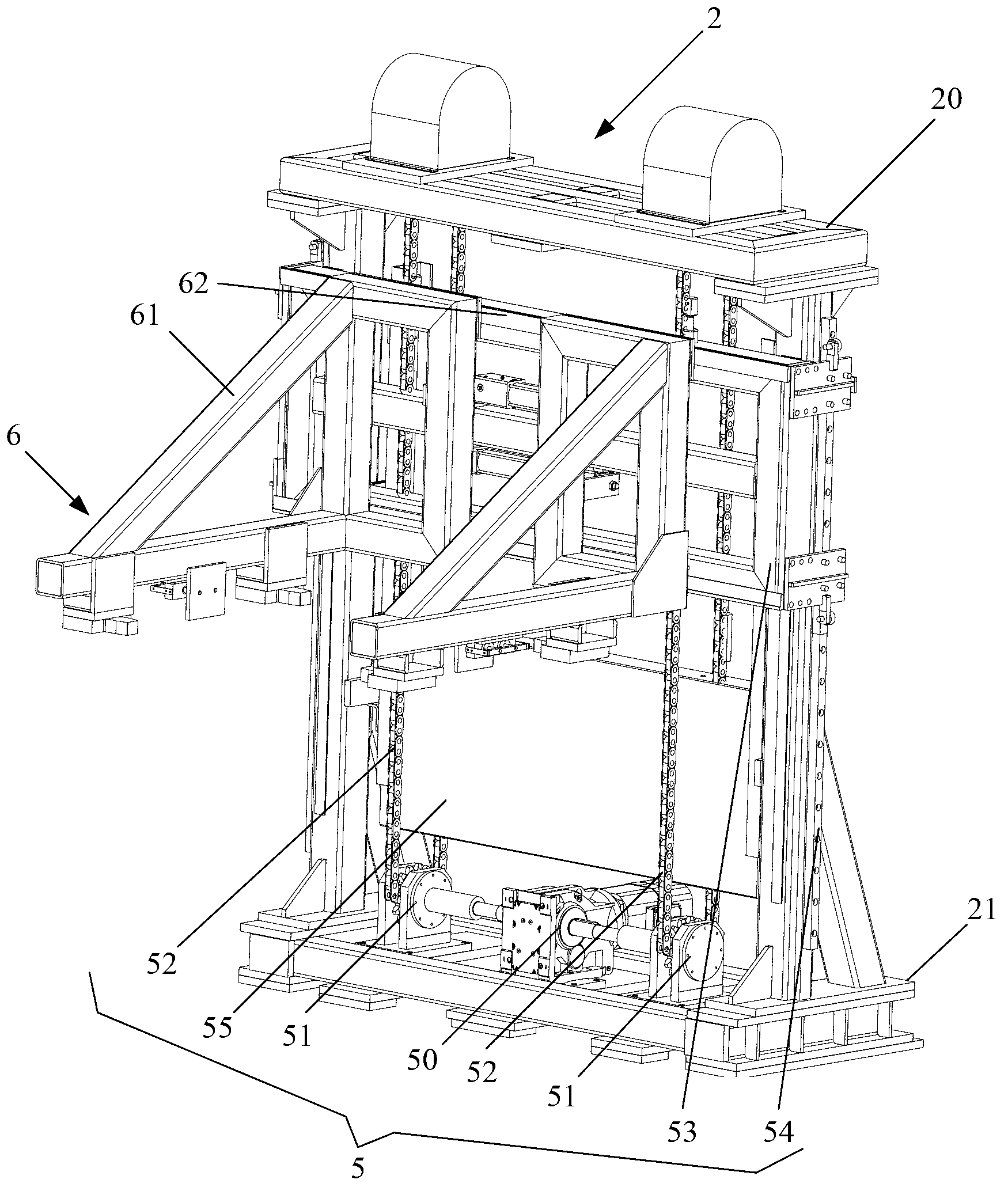

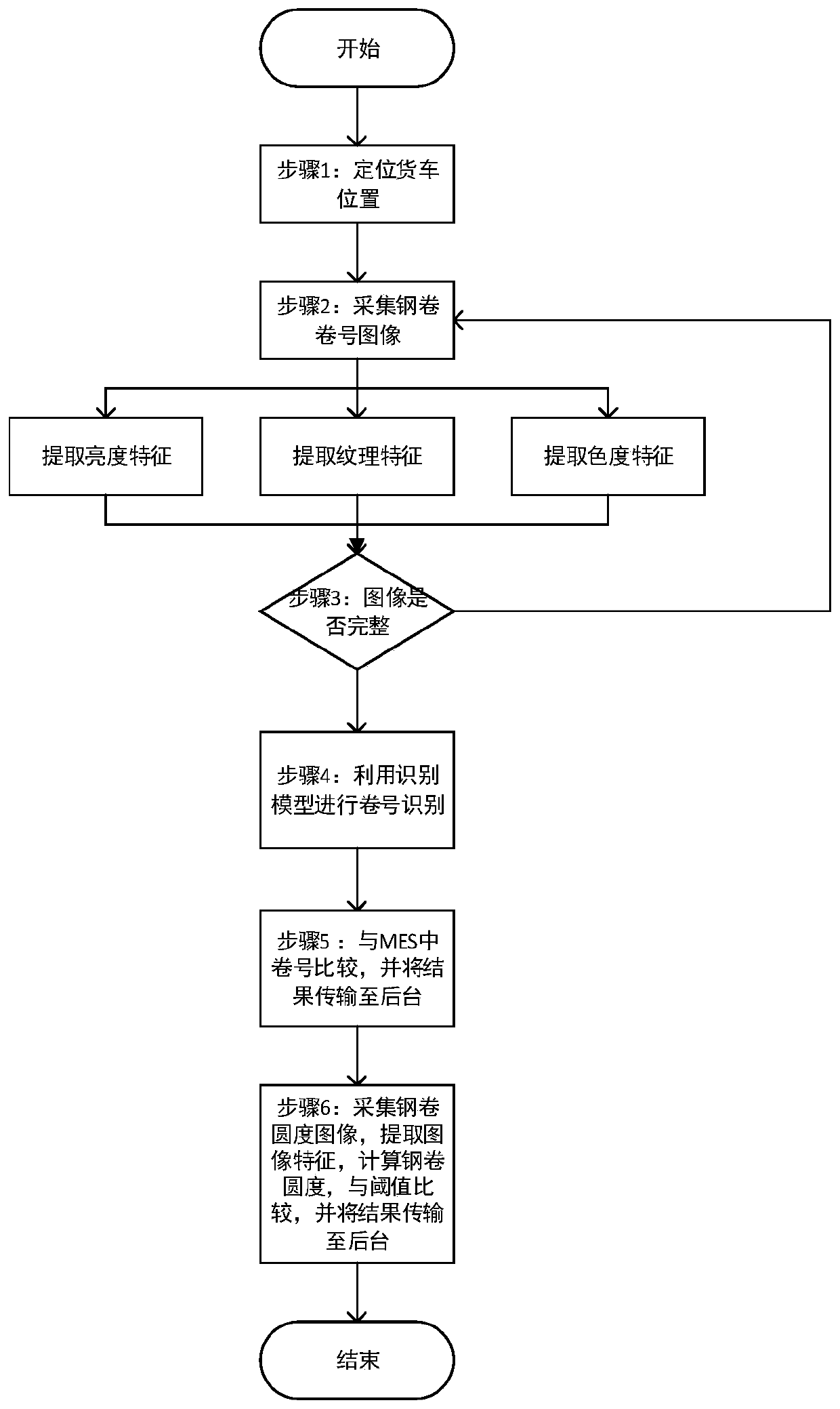

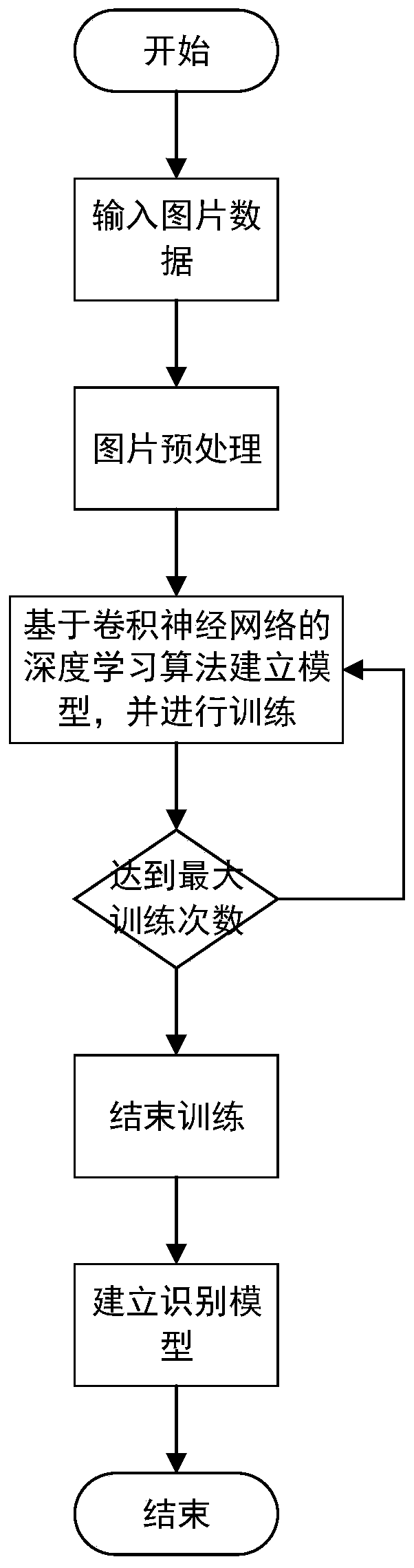

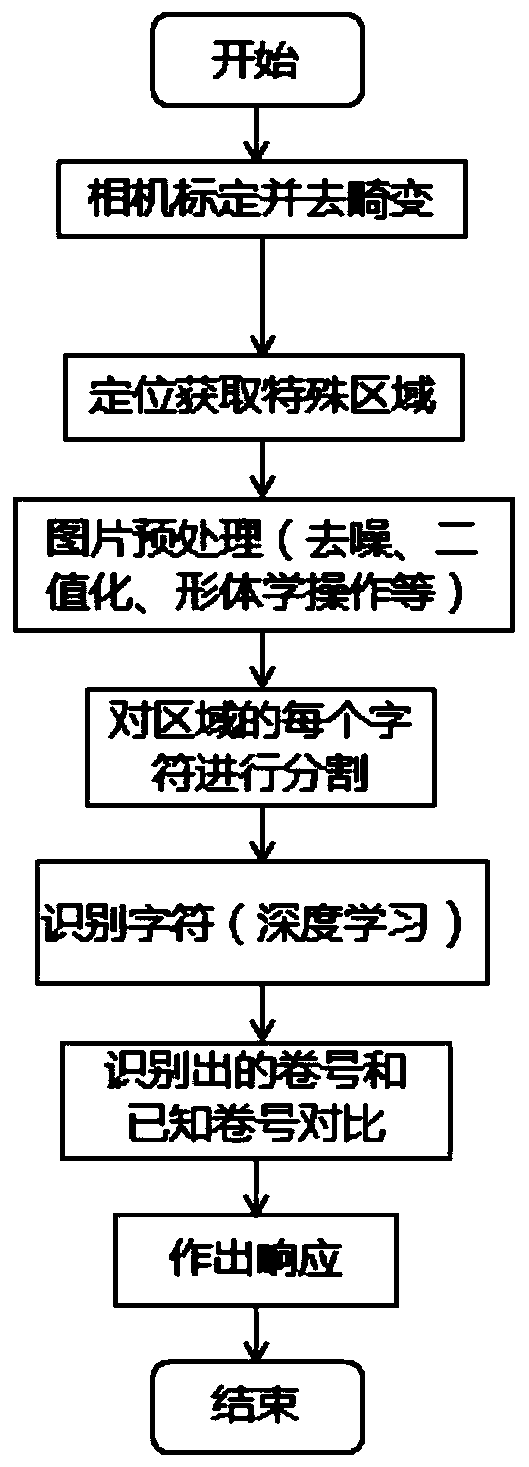

Method for identifying steel coil information

PendingCN110245663AQuick identificationThe detection process is fastImage enhancementImage analysisMinimum bounding rectangleRapid identification

The invention relates to a method for identifying steel coil information, being characterized by comprising the following steps: determining the position coordinates of a coil number in the obtained steel coil image by using a minimum bounding rectangle method, and then converting the steel coil image state characteristics at the position coordinates into character values by using a convolutional neural network-based digital character classification mode, so that the character values are the coil number of the current steel coil; and using a temperature detection module to detect the temperature of the steel coil while obtaining a side face image of the steel coil, obtained by shooting through the camera, judging whether the roundness of the steel coil reaches the standard or not through the side face image by an upper computer, and transmitting the judgment result to the background. According to the method for identifying steel coil information, rapid identification of the steel coil is achieved; the scanning period is shortened; and the logistics efficiency is improved. The method for identifying steel coil information can accurately detect the information of the steel coil, is high in the detection speed, and has the characteristic of real-time performance.

Owner:SHANGHAI ELECTRICAL APPLIANCES RES INSTGROUP +1

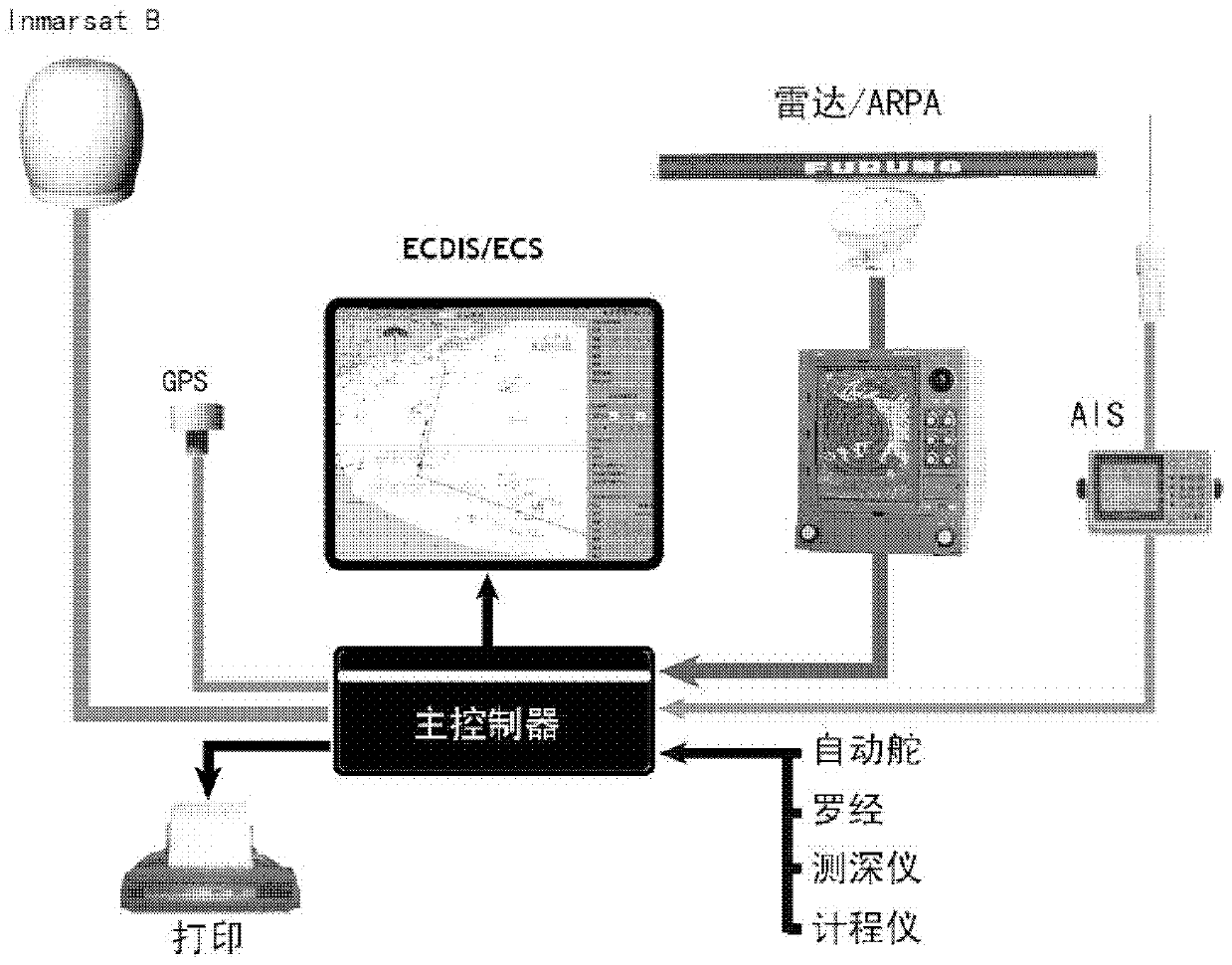

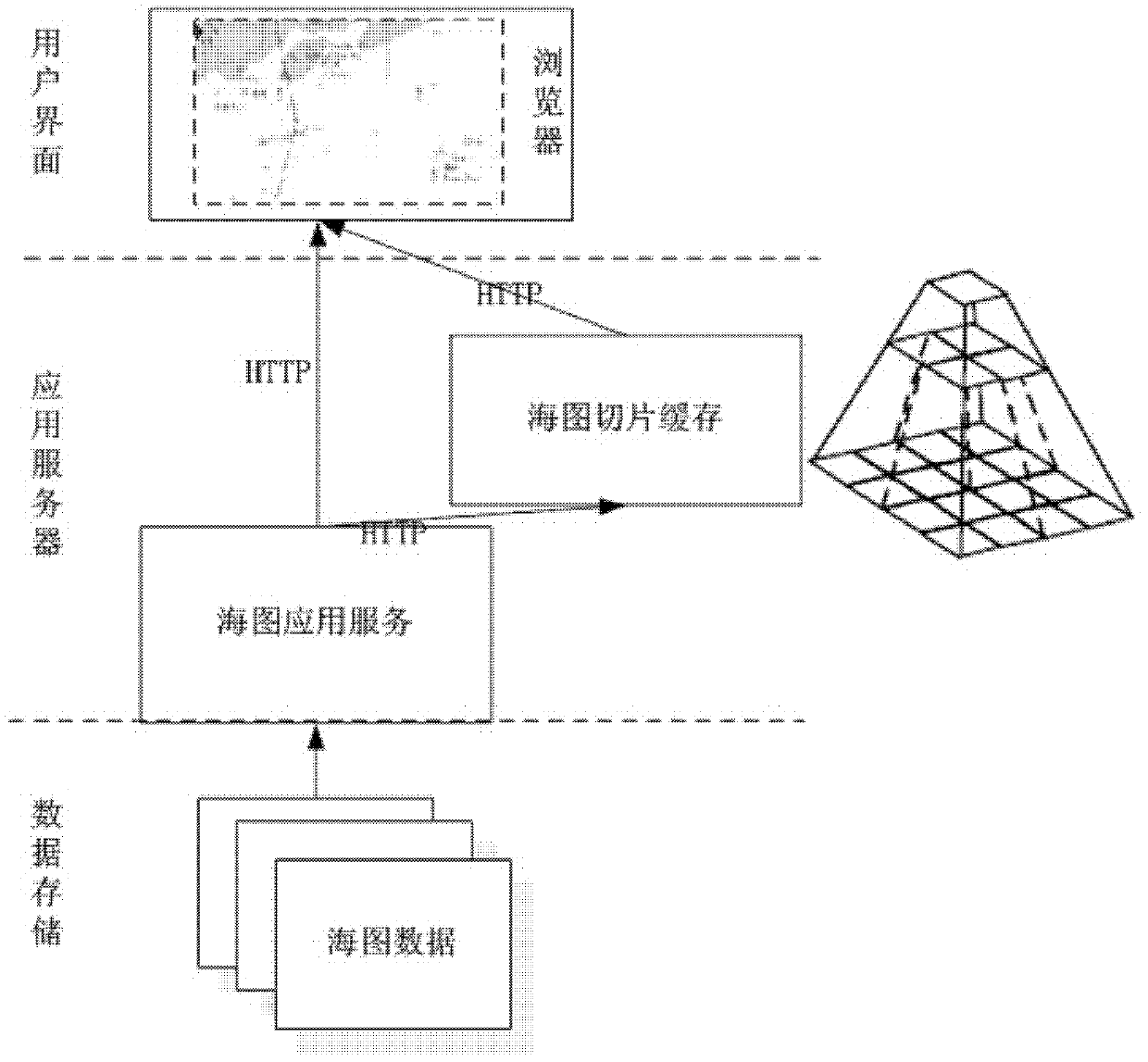

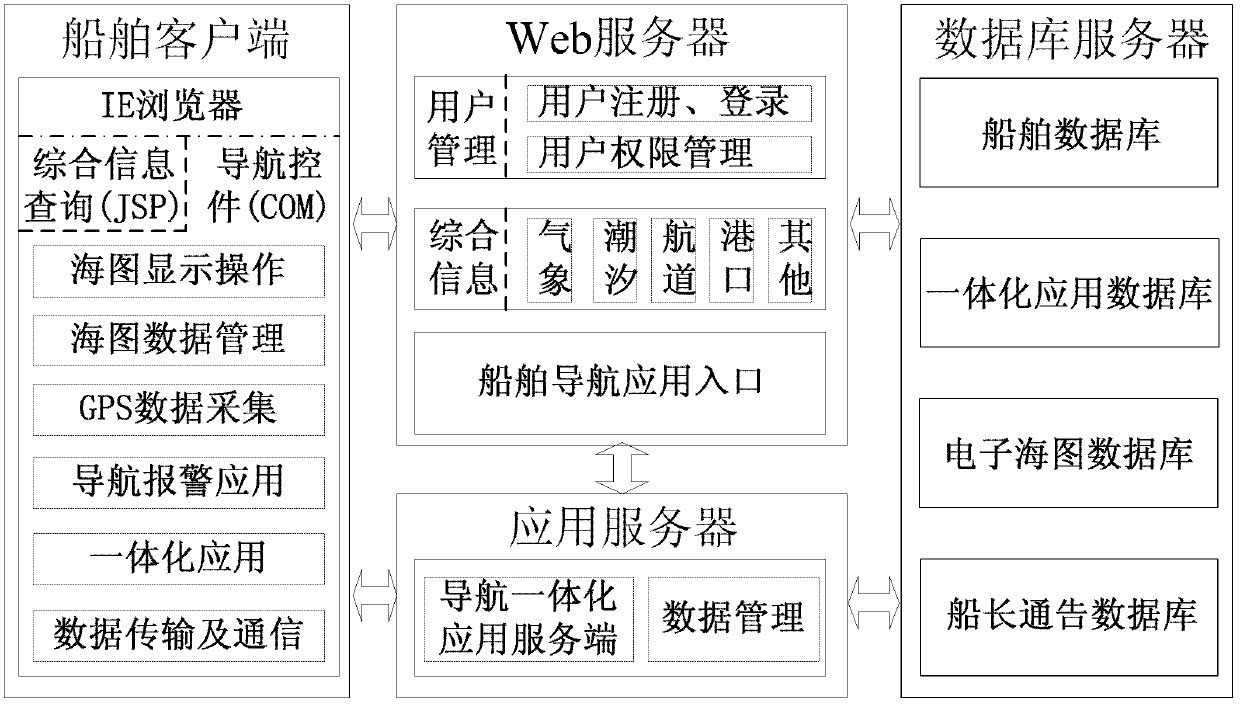

Browser-based marine navigation system

InactiveCN102636167AImprove navigation safetyComprehensive Navigation ServiceNavigation instrumentsSpecific program execution arrangementsNetwork communicationNavigation safety

The invention discloses a browser-based marine navigation system. The system is composed of three layers of network structures including a marine client, a Web server, an application server and a database server. The Web server is respectively in bidirectional connection with the marine client, the application server and the database server, and the application server is respectively in bidirectional connection with the marine client and the database server. The system adopts a mode of operating based on an IE (Internet Explorer), can avoid trouble and high cost in installation and maintenance of ECDIS (Electronic Chart Display And Information System) / ECS (Electronic Chart System) on a large number of ships in inland rivers, and the comprehensive navigation server can be obtained just with low mobile network communication cost, thus, the navigation safety of the ships is improved greatly. According to the invention, the three layers of network structures for integrated navigation service are provided, intercommunication between the browser-based marine navigation system and a shore-based system is established, and the function that the ship can obtain all-around integrated information service from one terminal is realized.

Owner:DALIAN MARITIME UNIVERSITY

Transfer robot, container taking method, container loading method and warehouse logistics system

PendingCN111703799AImprove applicabilityImprove versatilityProgramme-controlled manipulatorConveyorsLogistics managementIndustrial engineering

The invention belongs to the technical field of warehouse logistics, and particularly discloses a transfer robot, a container taking method, a container loading method and a warehouse logistics system. The transfer robot comprises a moving chassis, a door frame vertically arranged on the moving chassis, a temporary storage mechanism and a container transmission mechanism which are arranged on thedoor frame, the temporary storage mechanism is provided with a plurality of temporary spaces for temporary storage of containers, the container transmission mechanism can horizontally telescope and vertically lift relative to the door frame, so as to transmit the containers between the temporary storage spaces and an inventory vessel. The container taking method is applied to the transfer robot for container taking operation, the container loading method carries out the loading operation of the containers based on the transfer robot, and the warehouse logistics system comprises the transfer robot. According to the transfer robot, the container taking method, the container loading method and the warehouse logistics system, the efficiency of picking and logistics can be improved.

Owner:BEIJING JIZHIJIA TECH CO LTD

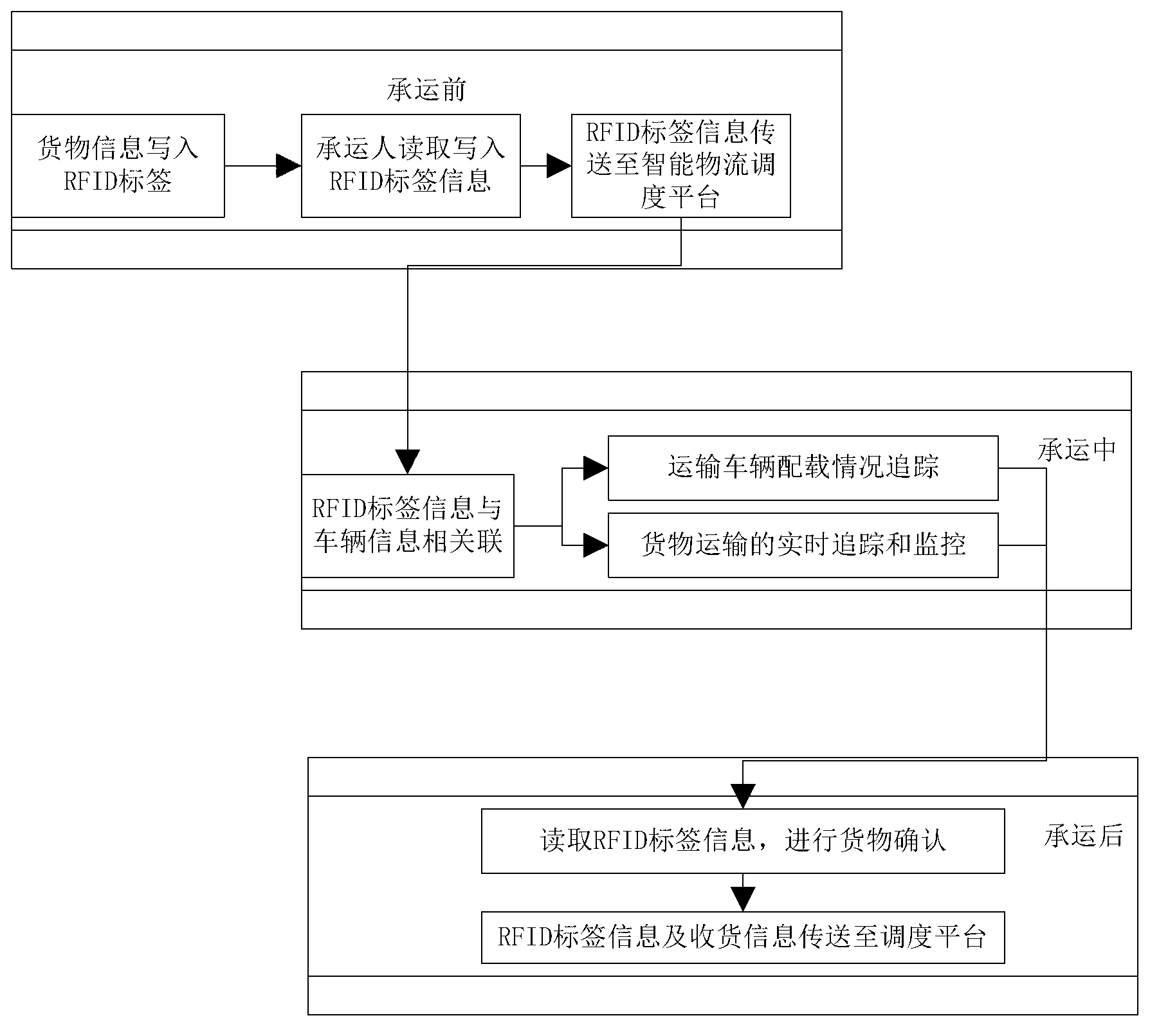

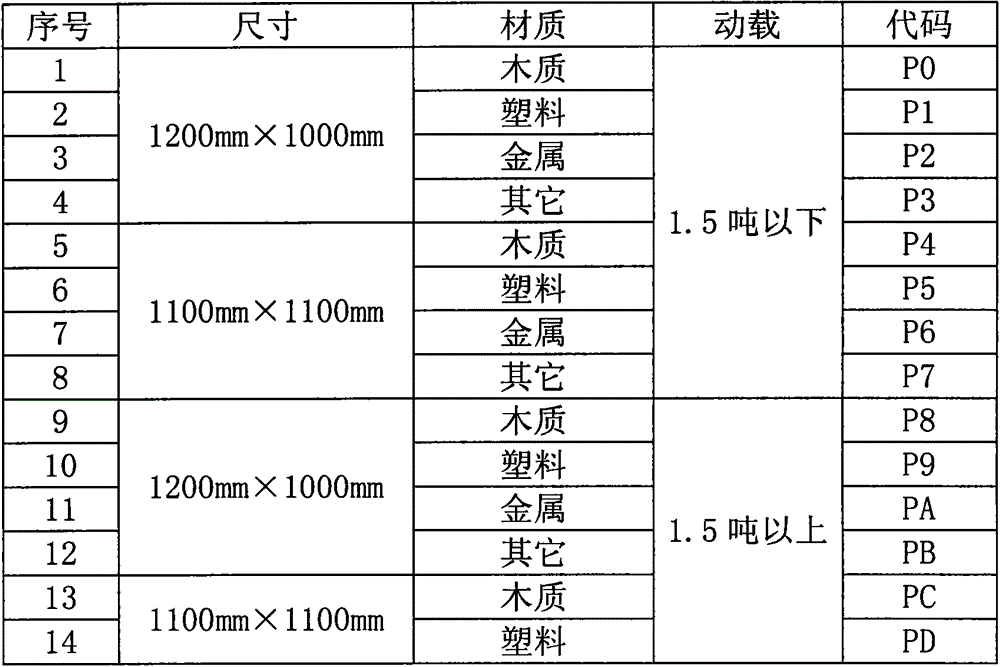

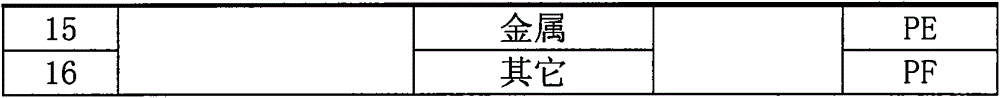

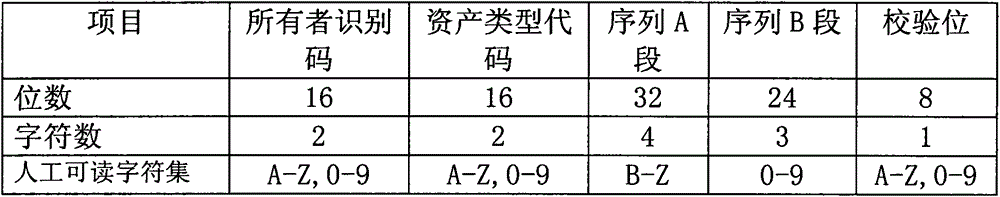

Cycle logistics packaging operation management method based on RFID (Radio Frequency Identification Devices) electronic tag

InactiveCN104680346ARealize TrackingRealize intelligent schedulingCo-operative working arrangementsLogisticsBusiness intelligenceRadio-frequency identification

The invention relates to a cycle logistics packaging operation management method based on an RFID electronic tag. The method is characterized by comprising the following steps: building an asset coding system, wherein a barcode in the asset coding system comprises independent information and shared information of a logistics package and carried goods; writing the barcode into the EPC (Electronic Product Code) area of the RFID electronic tag through data reading-writing equipment; installing the RFID electronic tag on the logistics package; installing corresponding data acquiring equipment in the asset transferring link of logistics transportation; acquiring data of the RFID electronic tag by the data acquiring equipment; transmitting the acquired data to a logistics package management platform through a wireless signal by the data acquiring equipment; performing data analyzing and processing by the logistics package management platform. According to the asset coding system based on the RFID electronic tag, an operation management platform is used for acquiring data intelligently and performing data analyzing and processing, so that tracking, real-time monitoring, intelligent scheduling, assistant decision making and business intelligence of movable assets are realized.

Owner:中包精力托盘共用系统(北京)有限公司

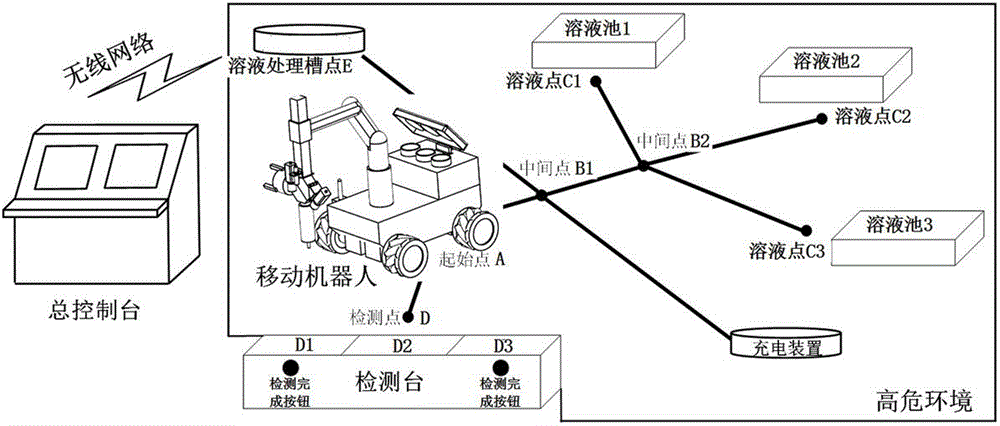

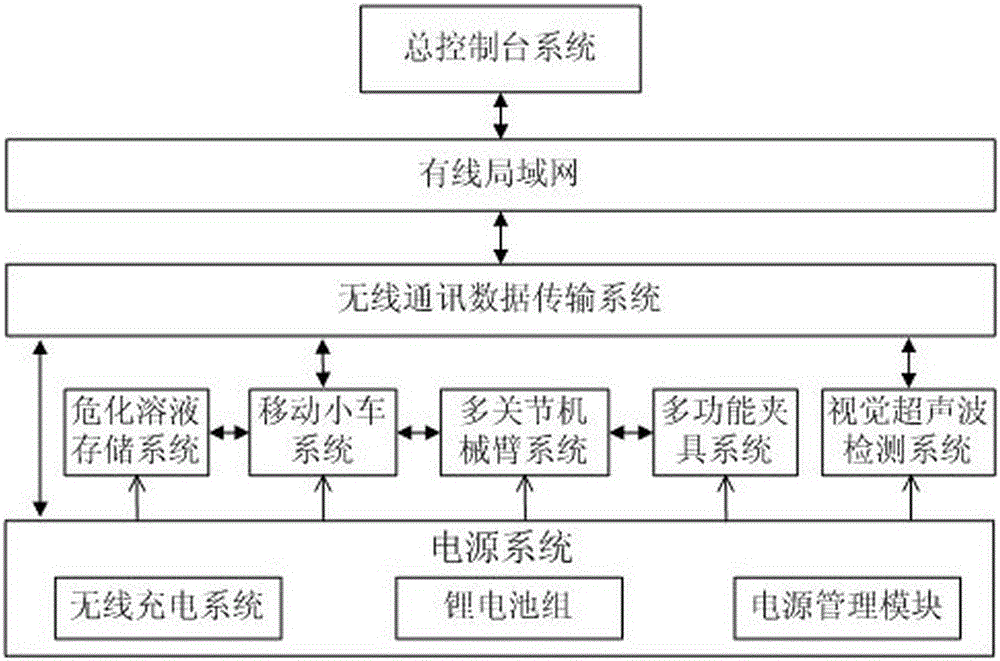

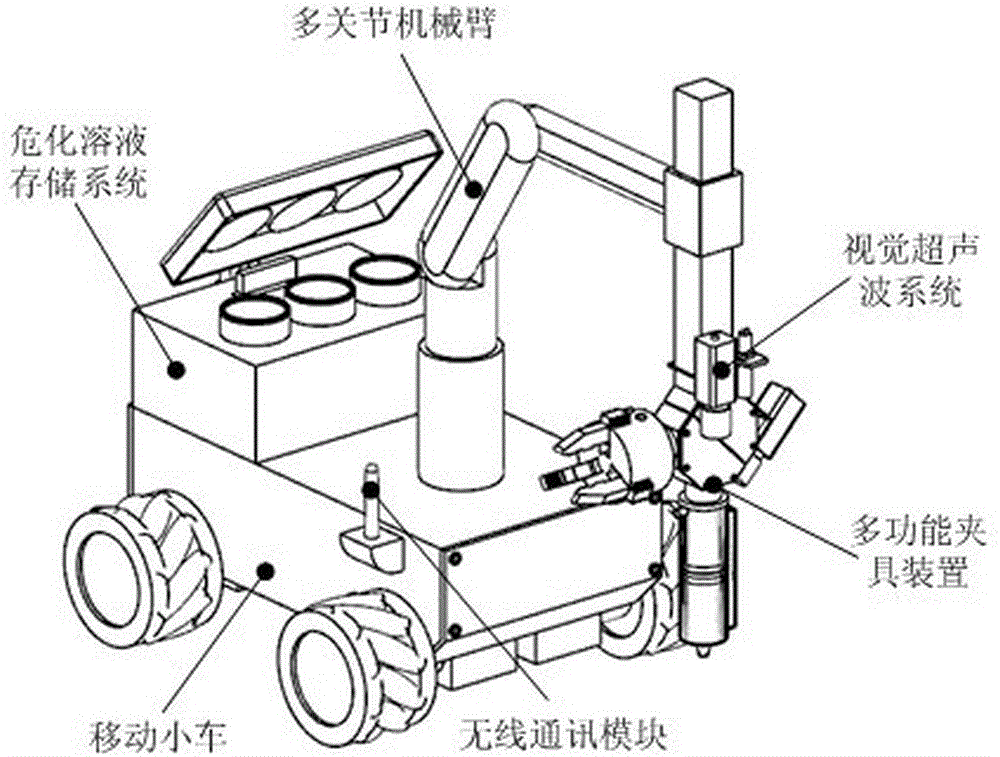

Mobile trolley system based on mobile robot

InactiveCN106584421AImprove performanceStrong radiation and corrosion resistanceProgramme-controlled manipulatorComputer moduleEngineering

The invention discloses a mobile trolley system based on mobile robot. The mobile trolley system comprises a mechanical body, a control module, a driving module, a navigation module and a communication module; the mechanical body is used for providing a physical structure for movement of the mobile robot; the control module is in communication connection with a general console system through the communication module; the control module is connected with the mechanical body through the driving module; the navigation module is connected with the control module; and the control module is connected with a multi-joint mechanical arm system. The mobile trolley provided by the invention can serve as a moving carrier of a small mechanical arm, omni-directional movement is achieved, and operating efficiency is high.

Owner:中国东方电气集团有限公司

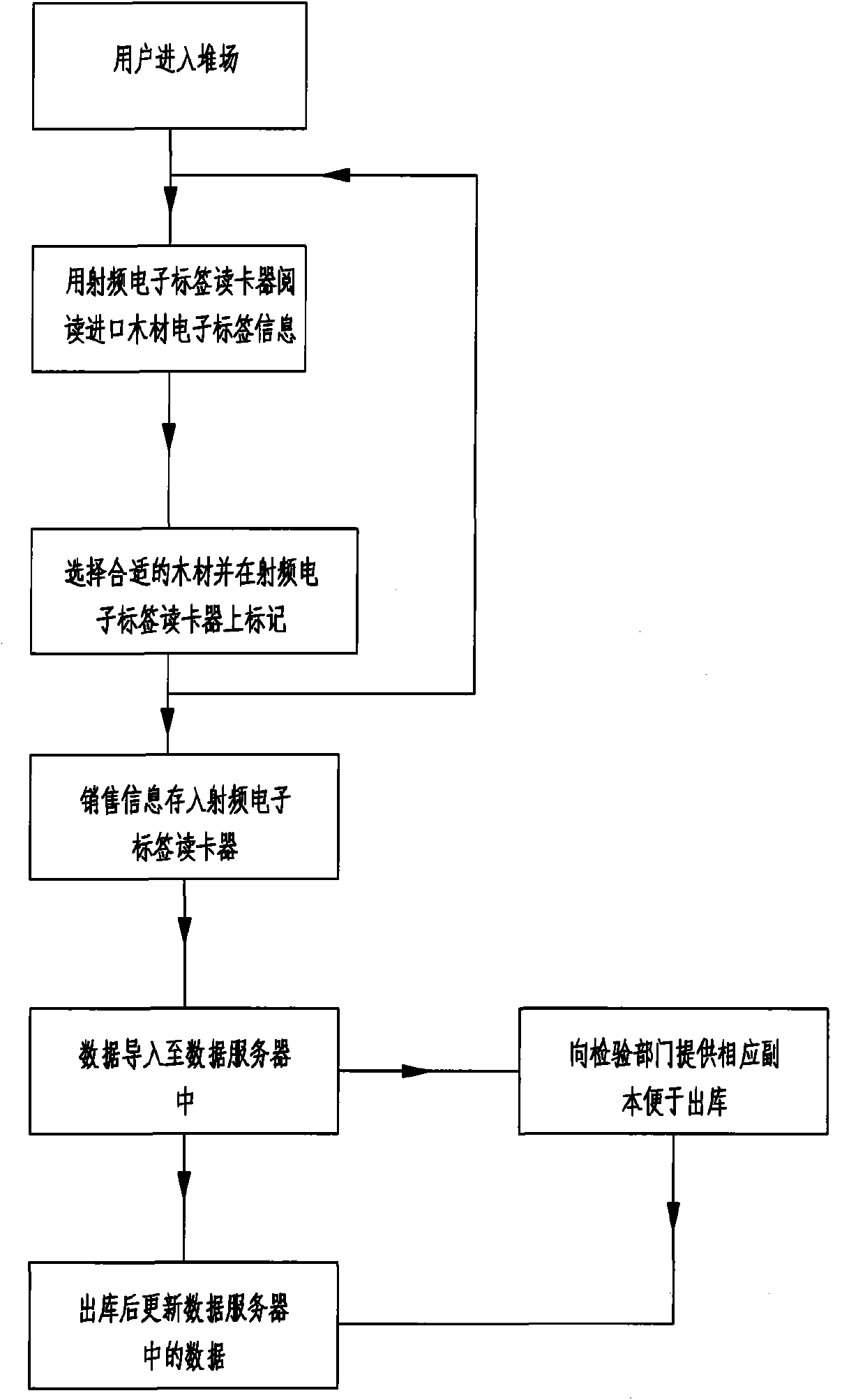

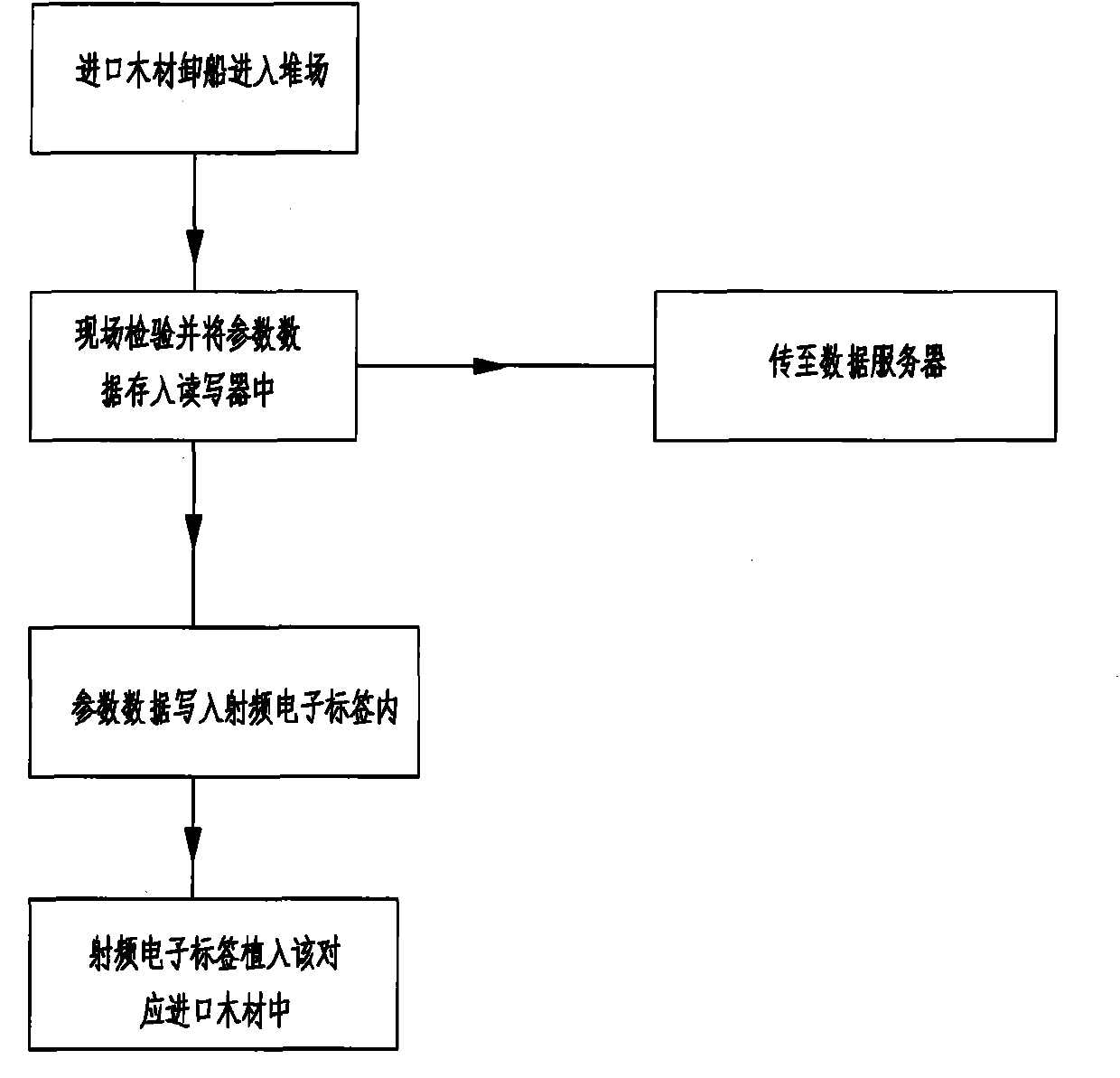

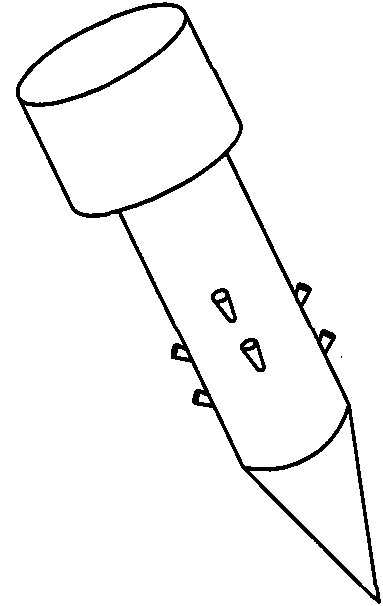

Inspection management method for imported timber

InactiveCN101950381AImprove inspection efficiencyImprove logistics efficiencyCo-operative working arrangementsResourcesLogistics managementData information

The invention relates to an inspection management method for imported timber. The method comprises the following steps of: (1) unloading imported timber and transporting the timber to a storage yard, and inspecting the imported timber by an inspector to obtain parameter data of the timber; (2) writing the parameter data information into a radio frequency electronic tag by the inspector by using the radio frequency electronic tag reader; (3) implanting each radio frequency electronic tag in which the parameter data information is written into corresponding imported timber, so that an owner of cargo, a buyer, a logistics user and the like can directly read the parameter data information of the corresponding timber by using the radio frequency electronic tag reader; and (4) establishing a data sharing platform by an inspection department to import all parameter data information of all timbers into a special server for checking, counting and analysis of the user. The inspection management method of the invention has the advantages of improving the inspection efficiency, along with more scientific and reliable management.

Owner:ZHANGJIAGANG EENTRY EXIT INSPECTION & QUARANTINE BUREAU

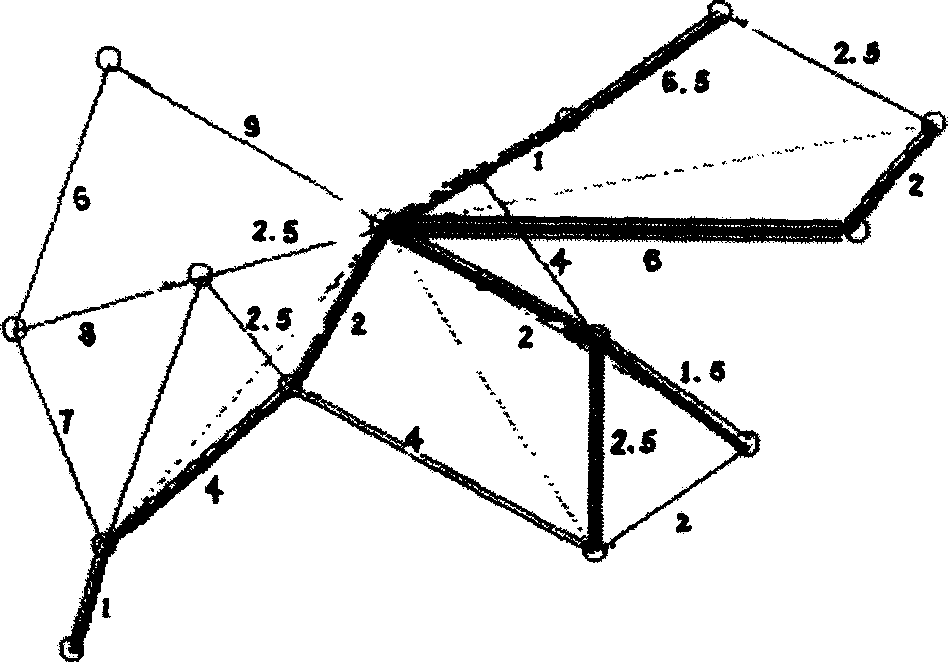

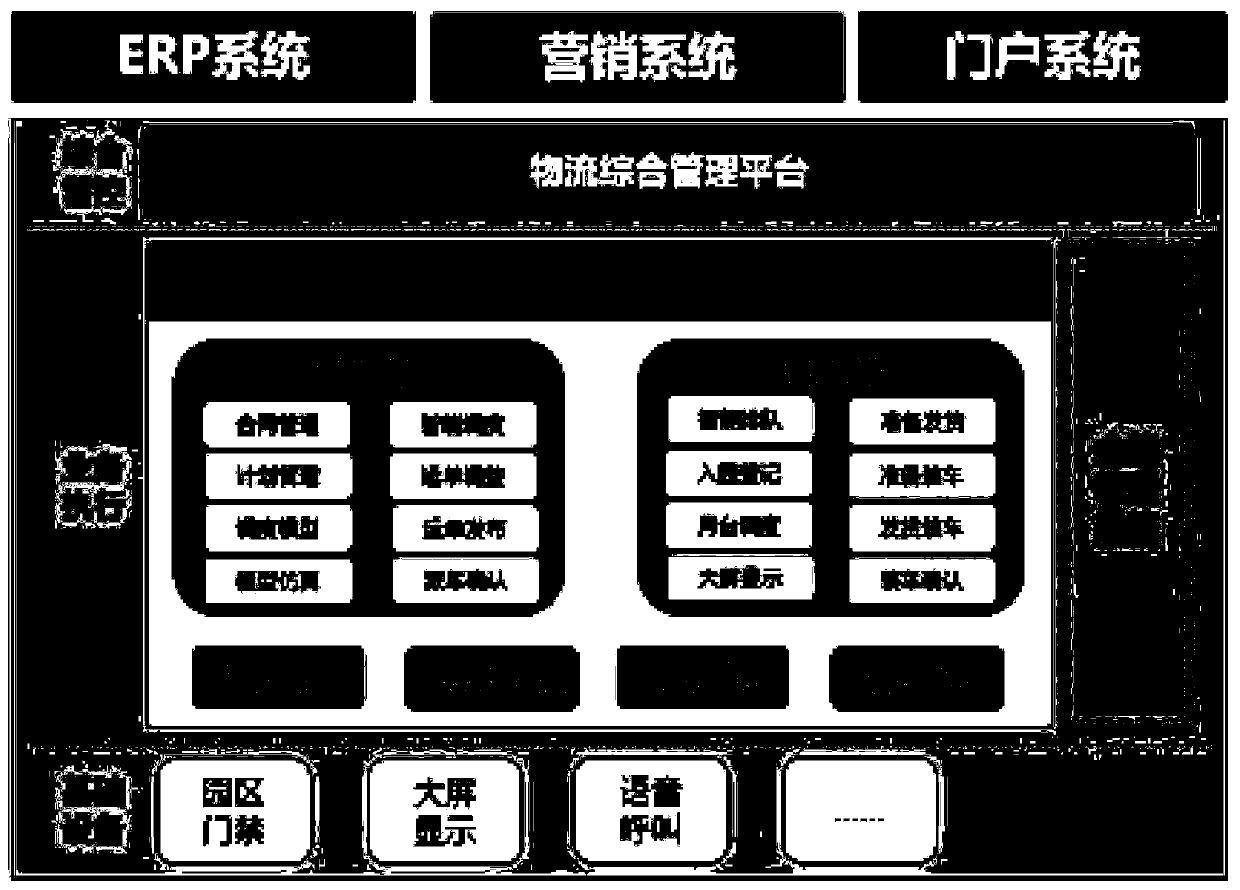

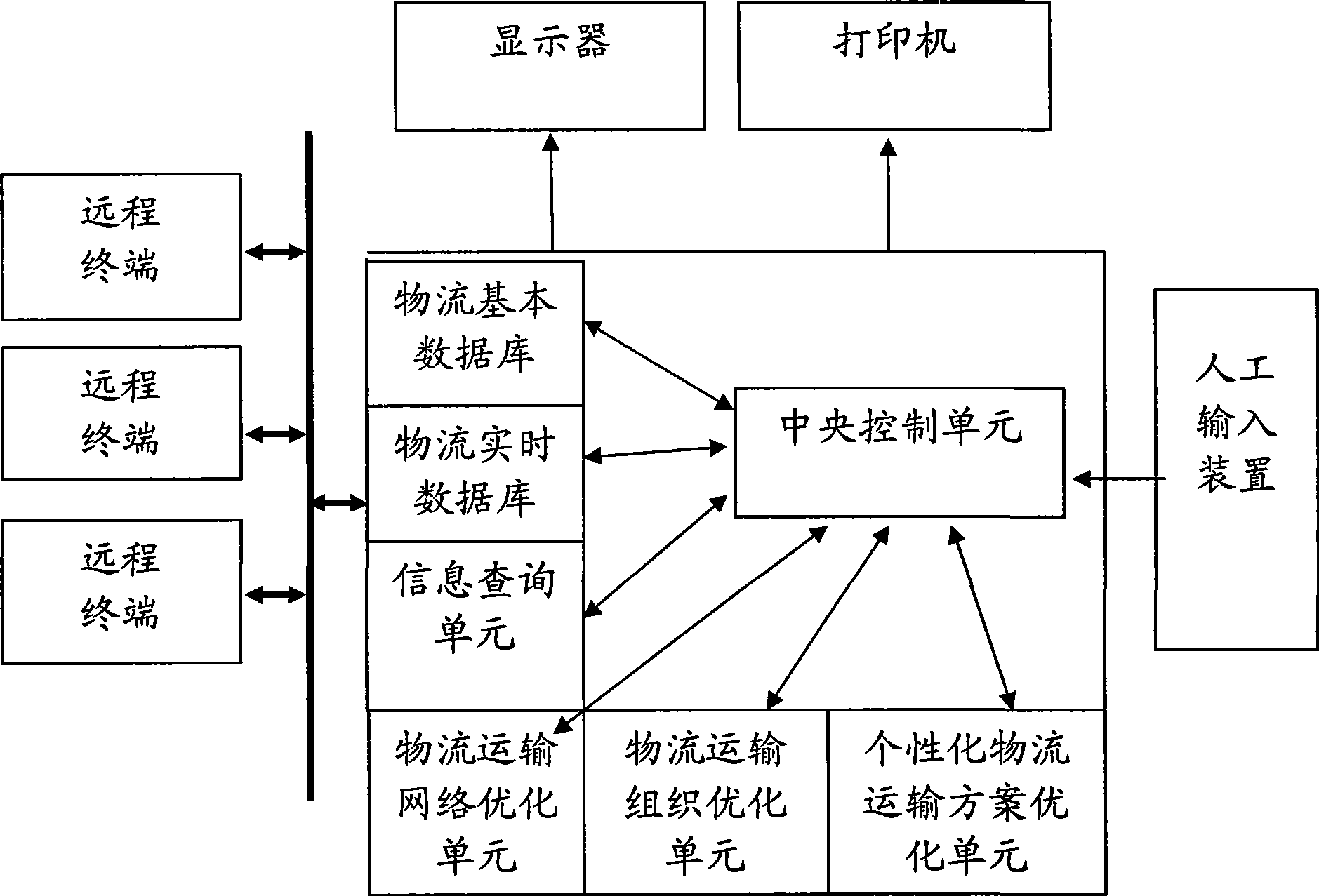

Physical distribution optimizing management system

InactiveCN101441731AImprove operational efficiencySimple designLogisticsPersonalizationLogistics management

The invention relates to a logistics optimization management system, which is provided with a logistics basic database and a real-time database, and comprises an information query unit, a logistics transportation network optimization unit, a logistics transportation organization optimization unit and an individualized logistics transportation proposal optimization unit, wherein the information query unit is used for reading data in the logistics basic database and the real-time database according to manually input query information; and the logistics transportation network optimization unit, the logistics transportation organization optimization unit and the individualized logistics transportation proposal optimization unit read the data of the logistics basic database and the real-time database according to input instructions and logistics information respectively, execute optimization operation according to preset programs, and generate corresponding optimization proposals. The system has the advantages that the system is favorable for improving logistics efficiency and reducing logistics time as well as logistics cost, and can be used for various logistics enterprises or other large-scale enterprises.

Owner:BEIJING AOTENGXUNDA SCI & TECH

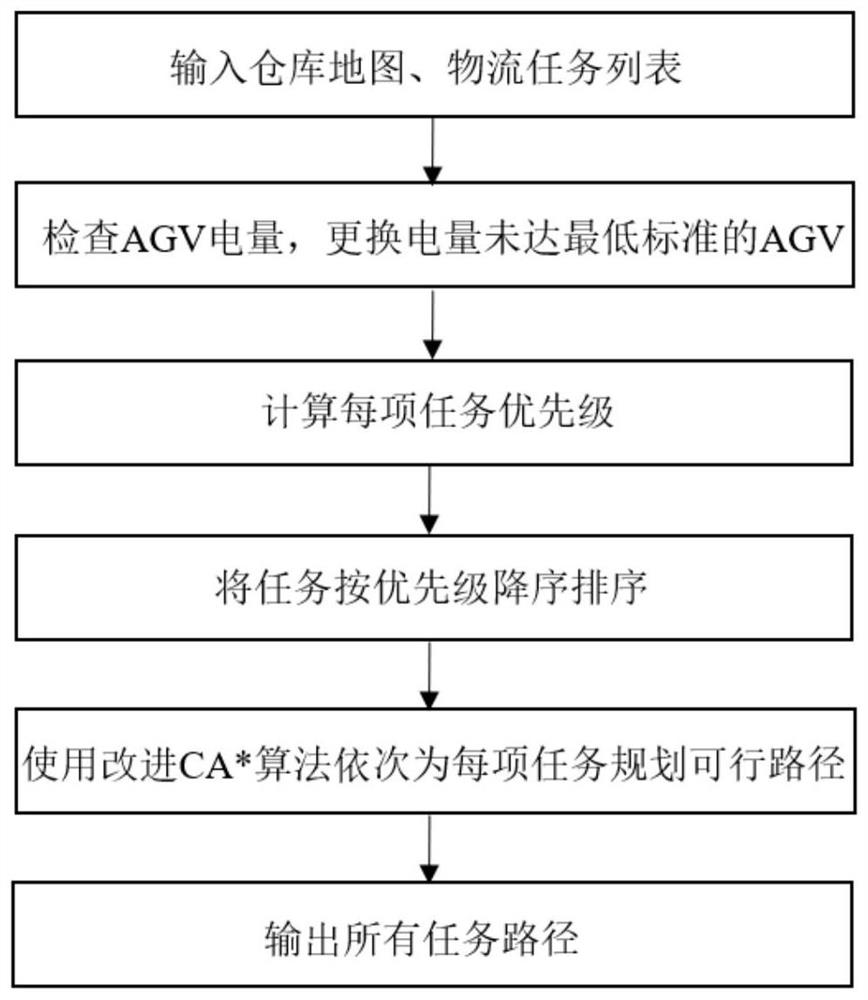

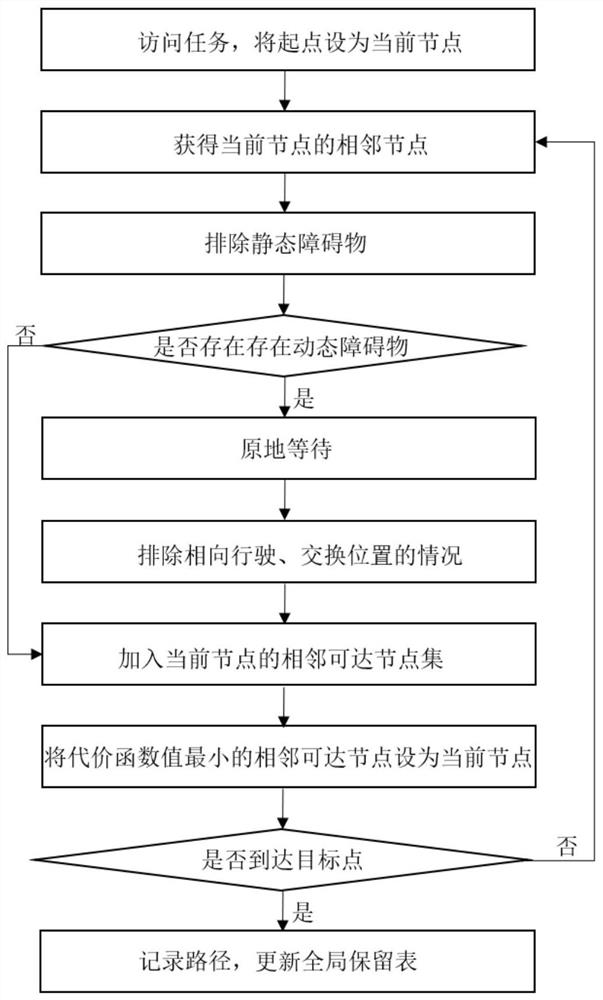

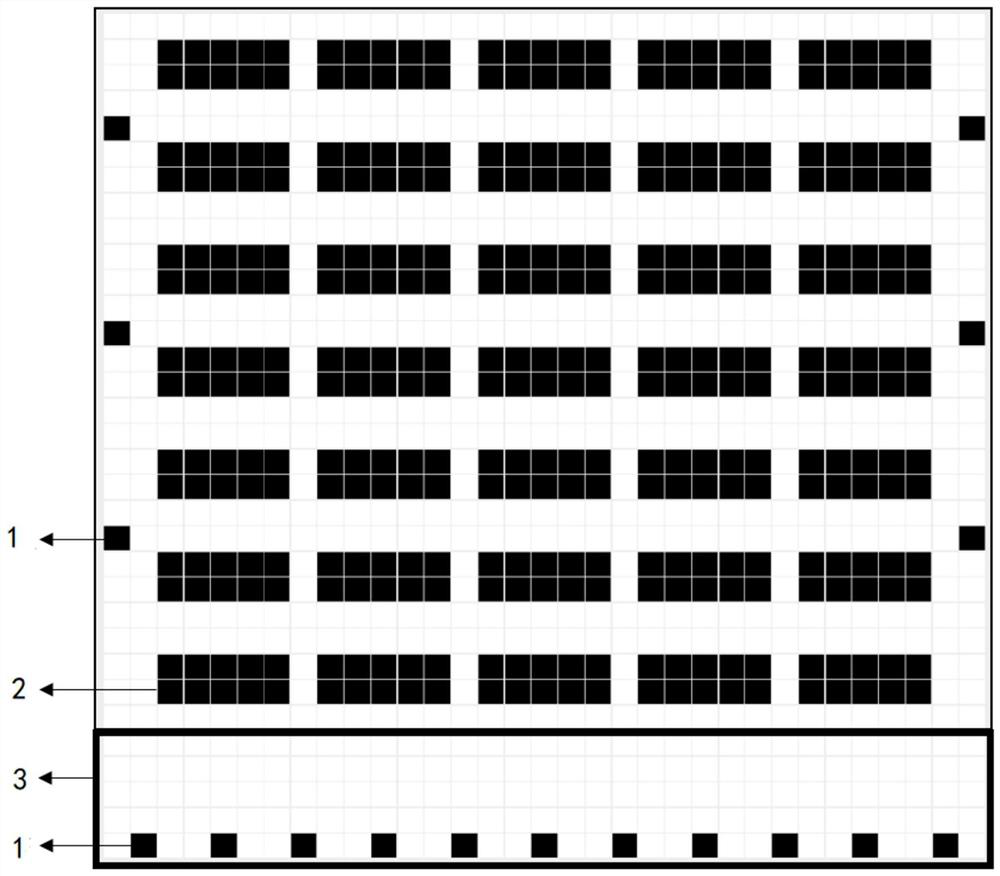

Multi-logistics robot collaborative path planning method based on task priority

ActiveCN113031603AHigh aging levelRaise priorityPosition/course control in two dimensionsVehiclesLogistics managementImproved algorithm

The invention provides a multi-logistics robot collaborative path planning method based on task priority. The method comprises the following steps of S1, inputting a warehouse map and a logistics task list; S2, calculating priority of each task in the task list, traversing the task list, and calculating priority of each task according to the aging grade of the current cargo and the residual electric quantity of the current AGV; and S3, generating an ordered task list according to priority descending sort, traversing the ordered task list by using an improved CA* algorithm, planning a feasible path for each task in sequence, and outputting all task paths. According to the method, the improved CA * algorithm is adopted, the in-situ waiting behavior of the robot is introduced during multi-machine conflict, the unnecessary detour behavior of the robot with the low priority is avoided, resources can be saved when the logistics task of the warehousing system is executed, and efficiency is improved.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com