Patents

Literature

543results about How to "Realize handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

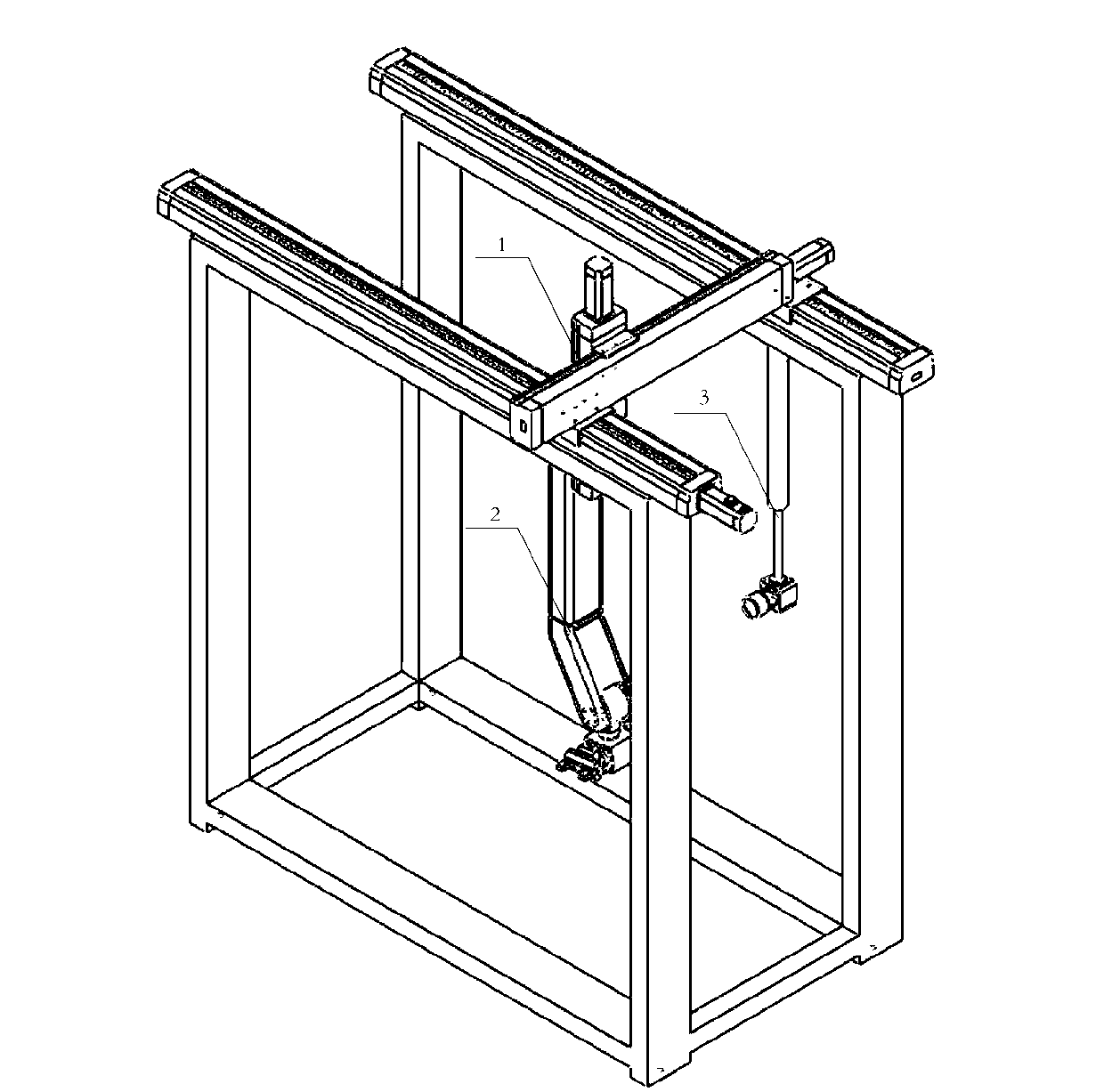

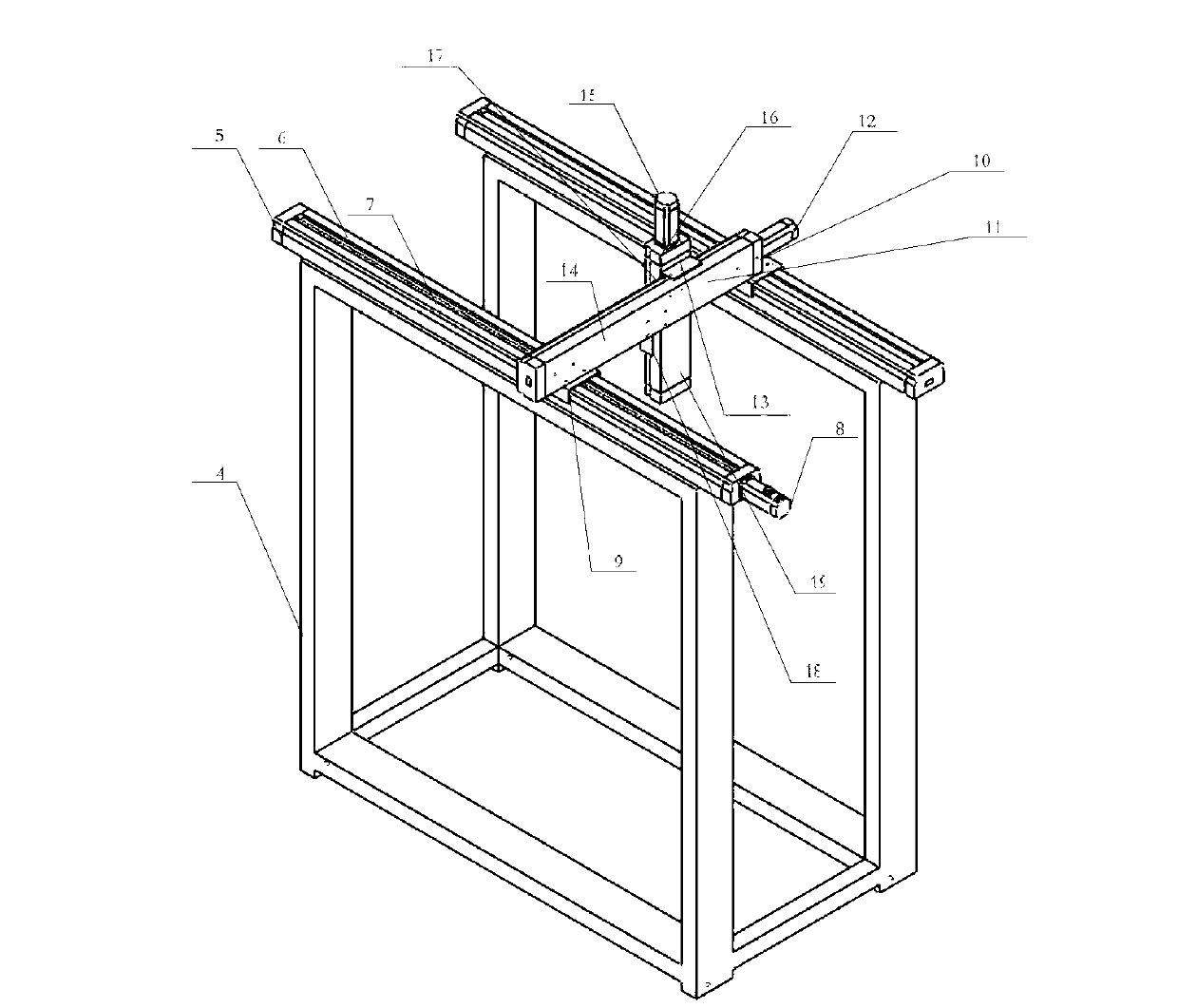

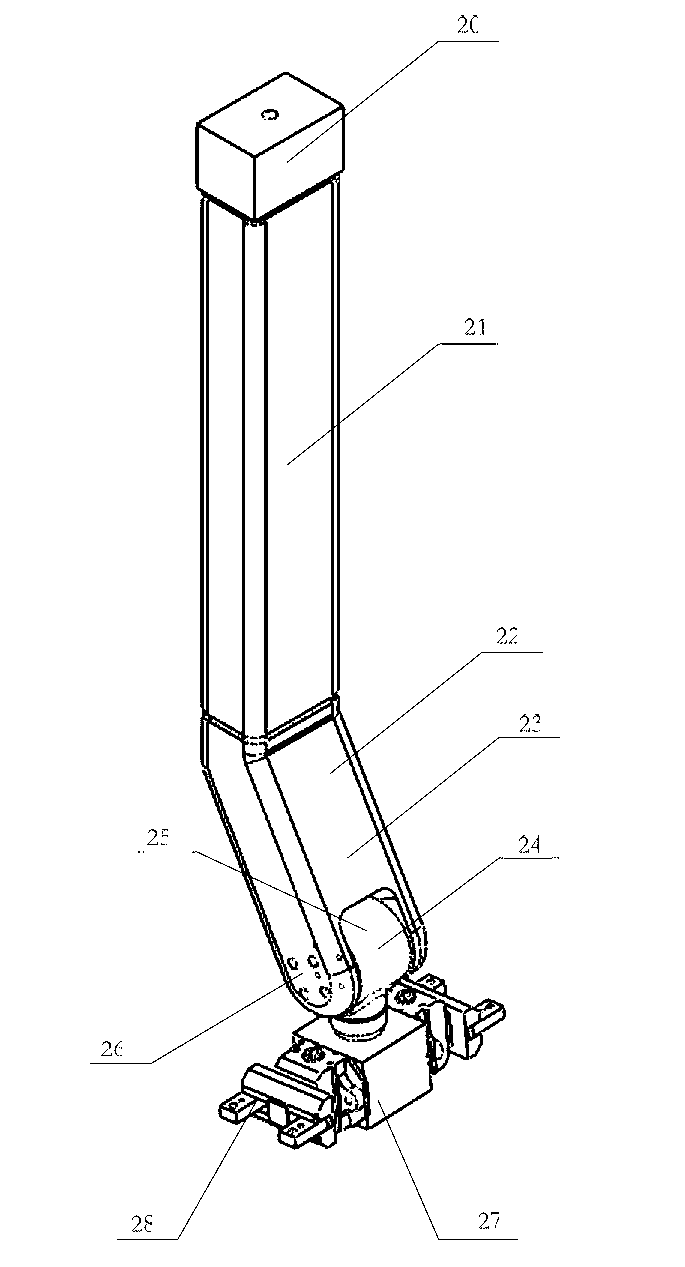

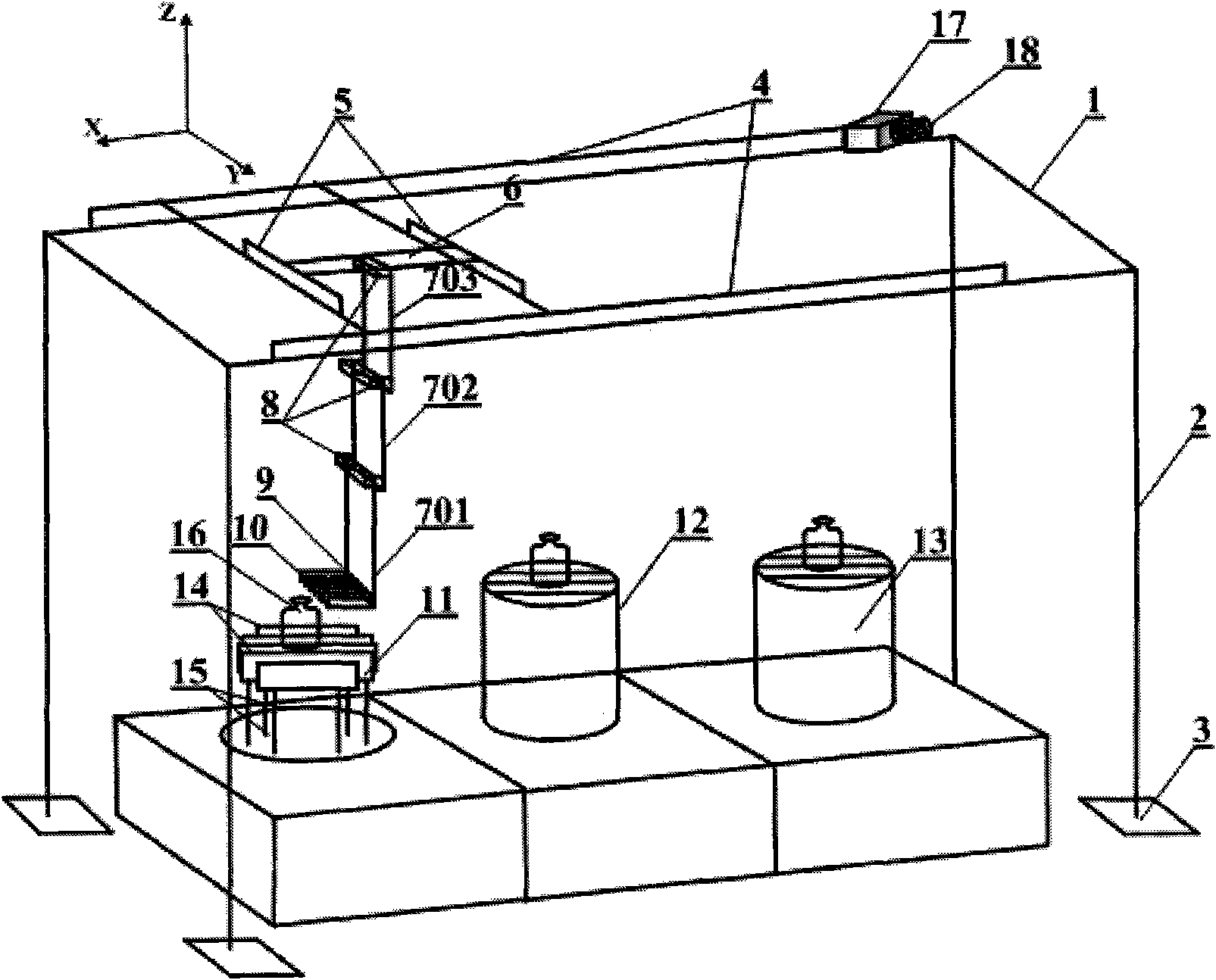

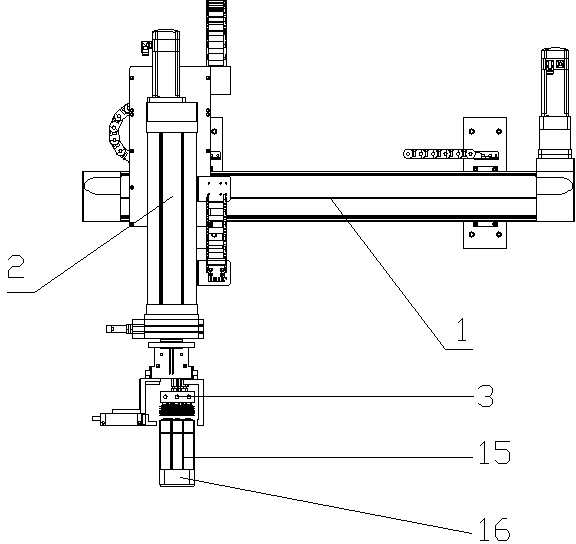

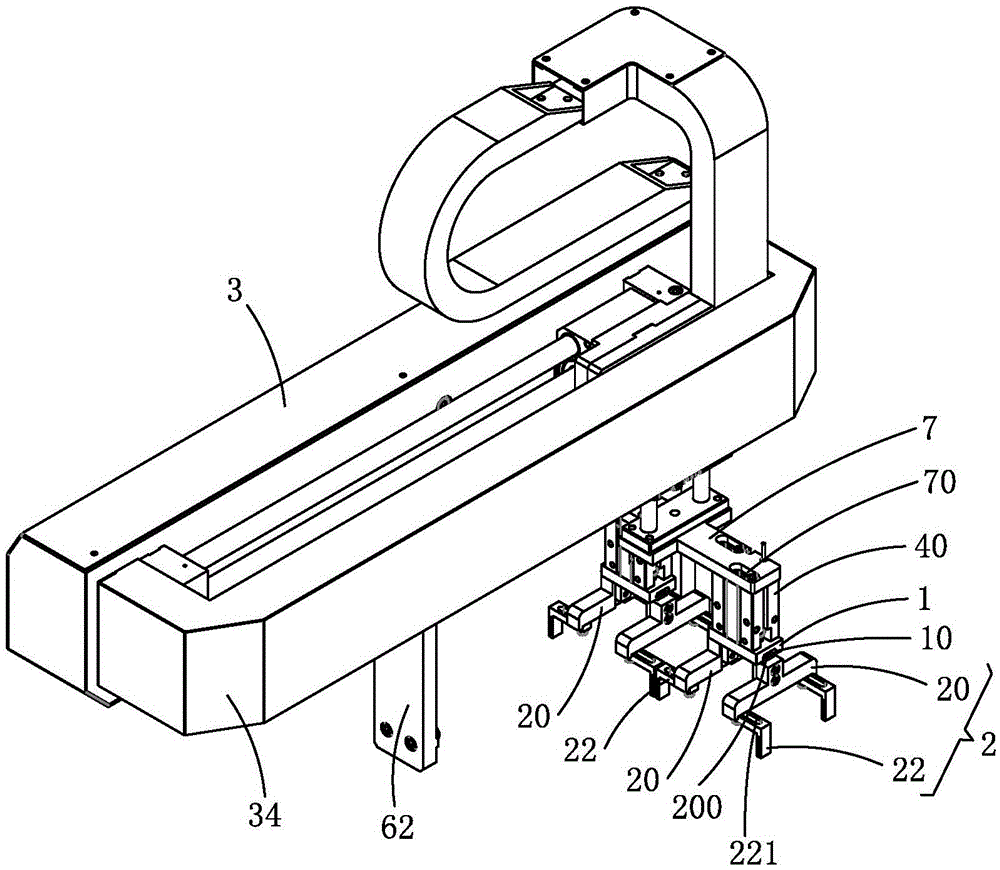

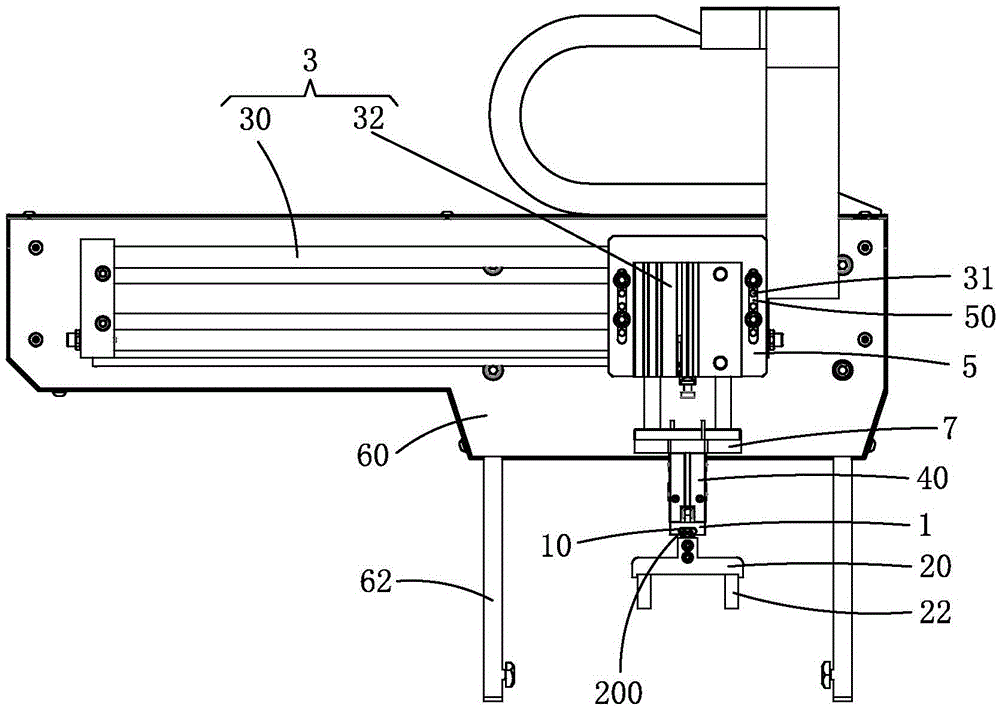

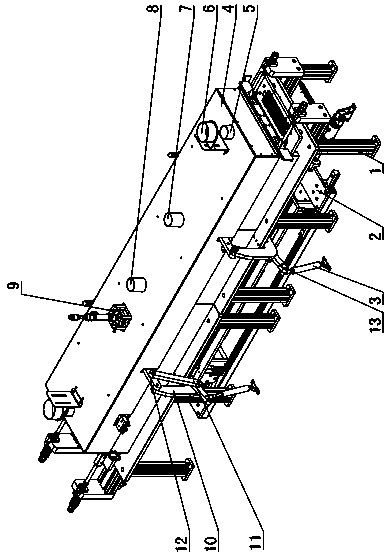

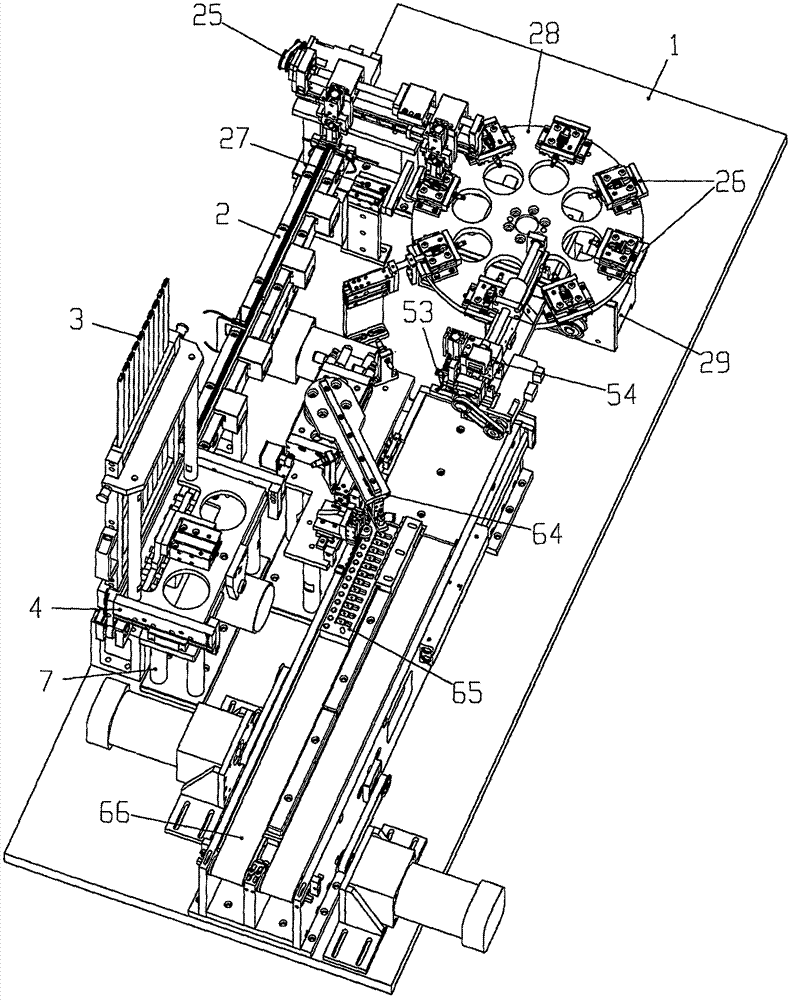

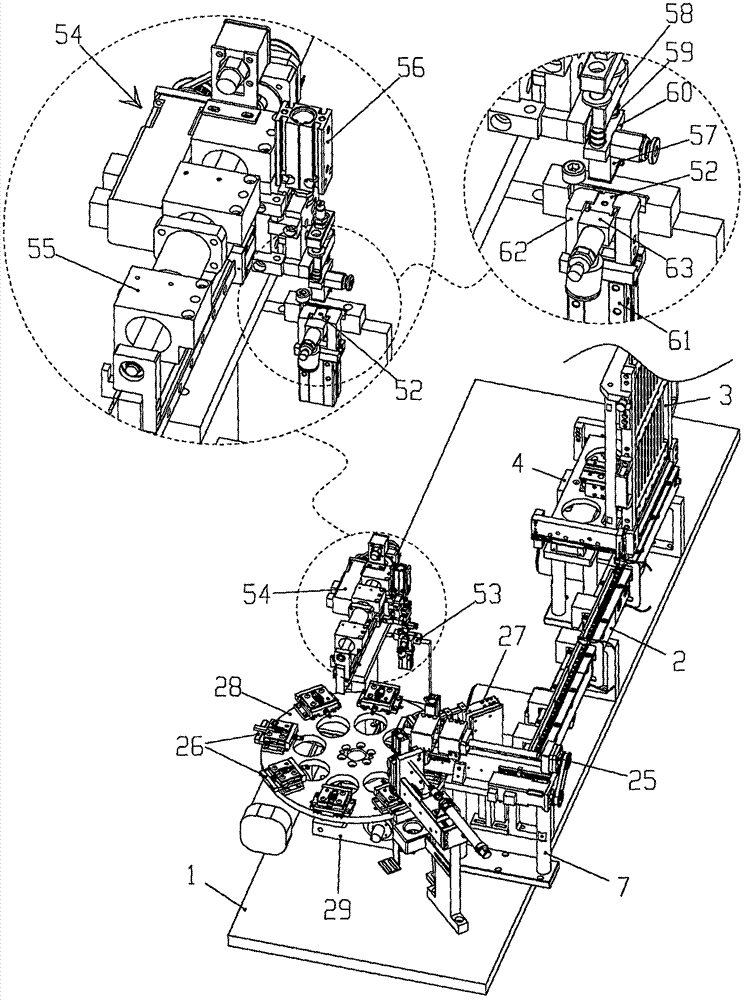

Three-dimensional automatic feeding, discharging and detecting device

ActiveCN102990458ARealize handlingPrecise handlingProgramme-controlled manipulatorMeasurement/indication equipmentsEngineeringManipulator

Owner:NORTHWESTERN POLYTECHNICAL UNIV

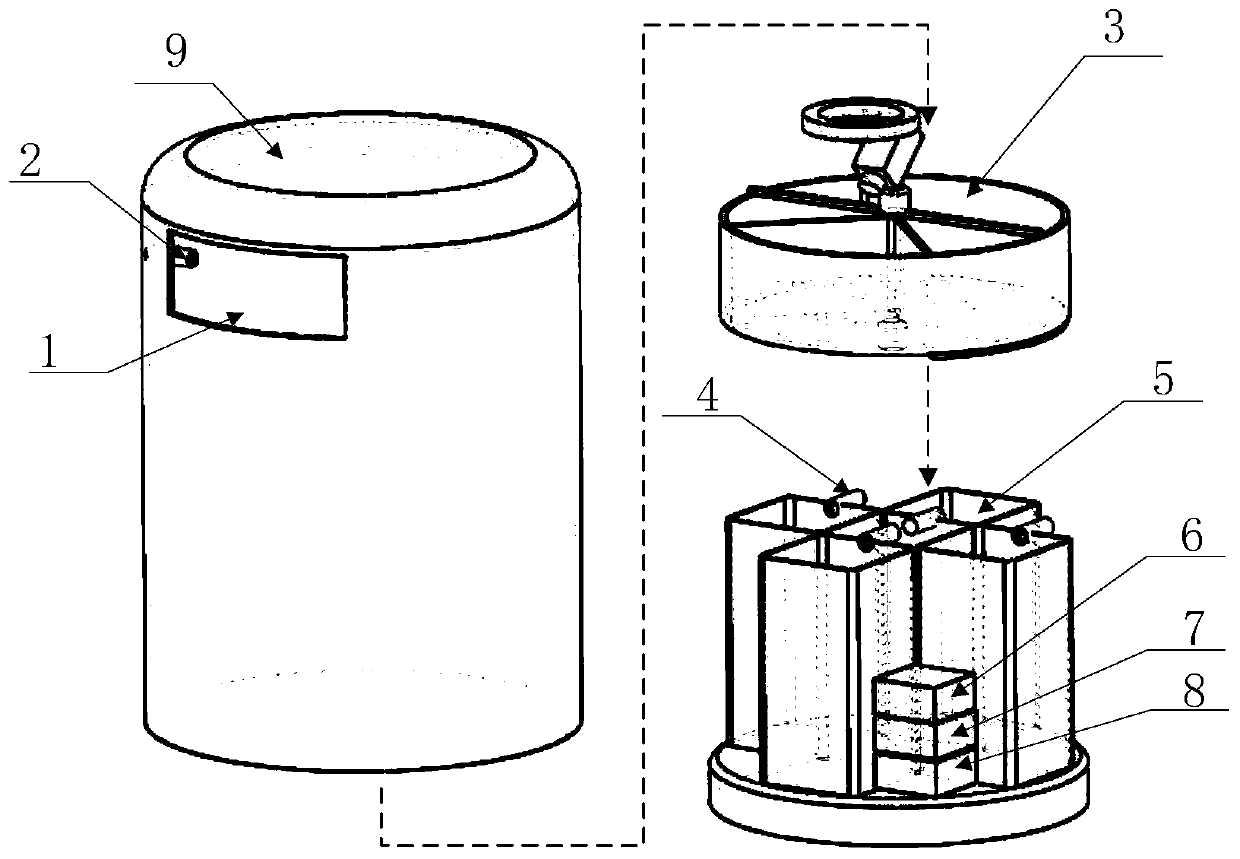

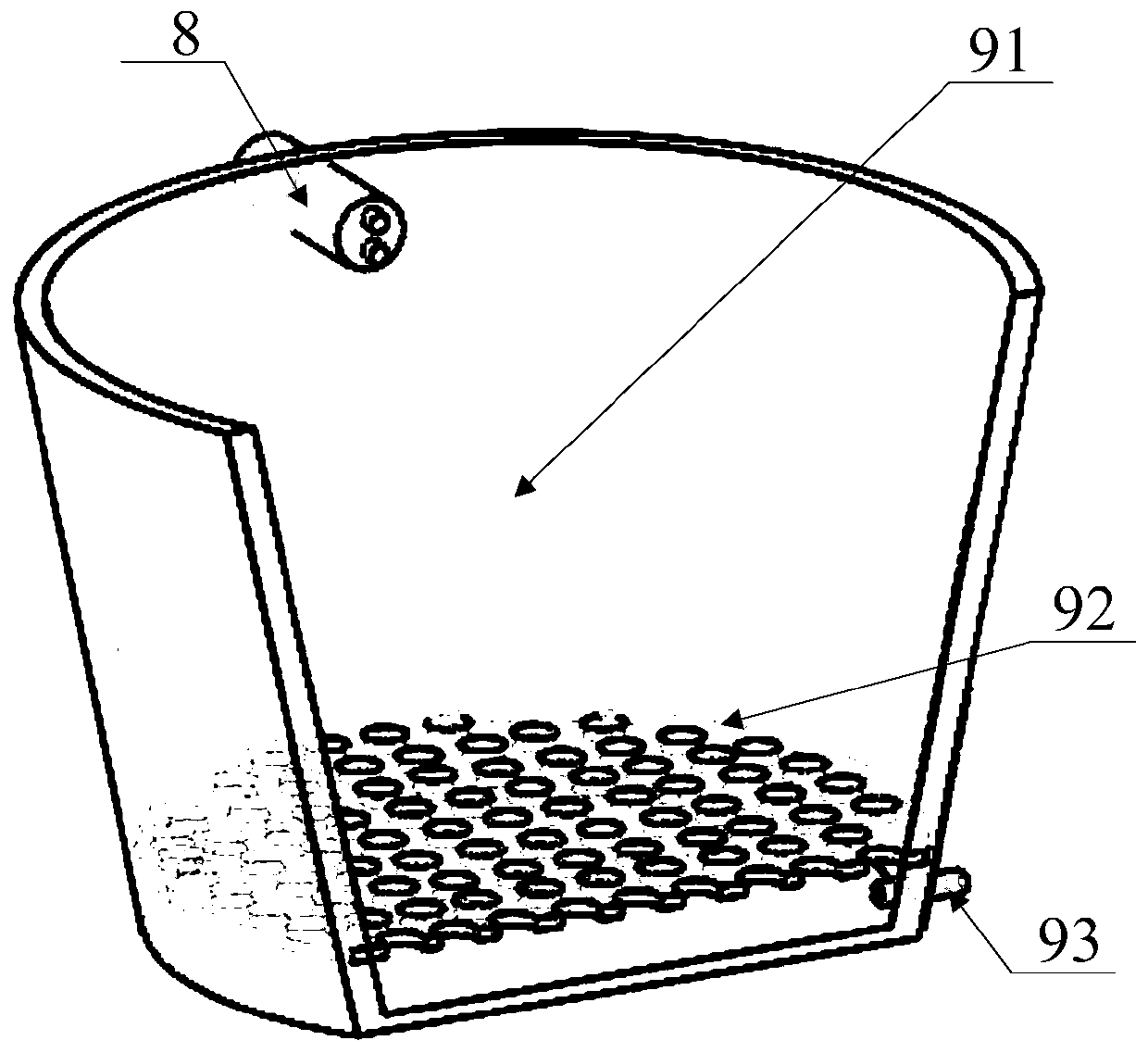

Garbage can capable of automatic classifying based on visual recognition and classifying method

InactiveCN110861852AImprove accuracyRealize handlingWaste collection and transferRefuse receptaclesComputer hardwarePhotoswitch

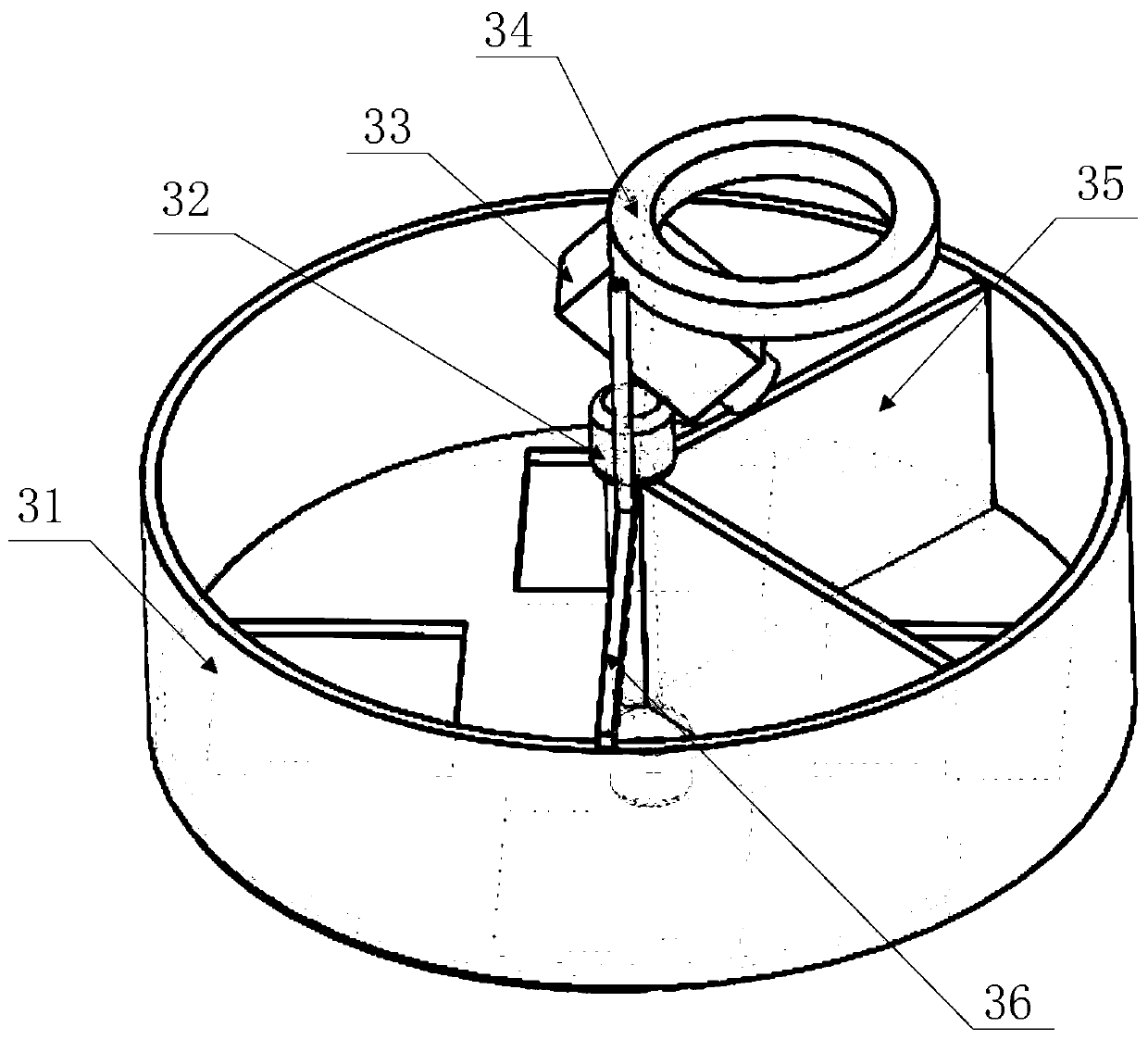

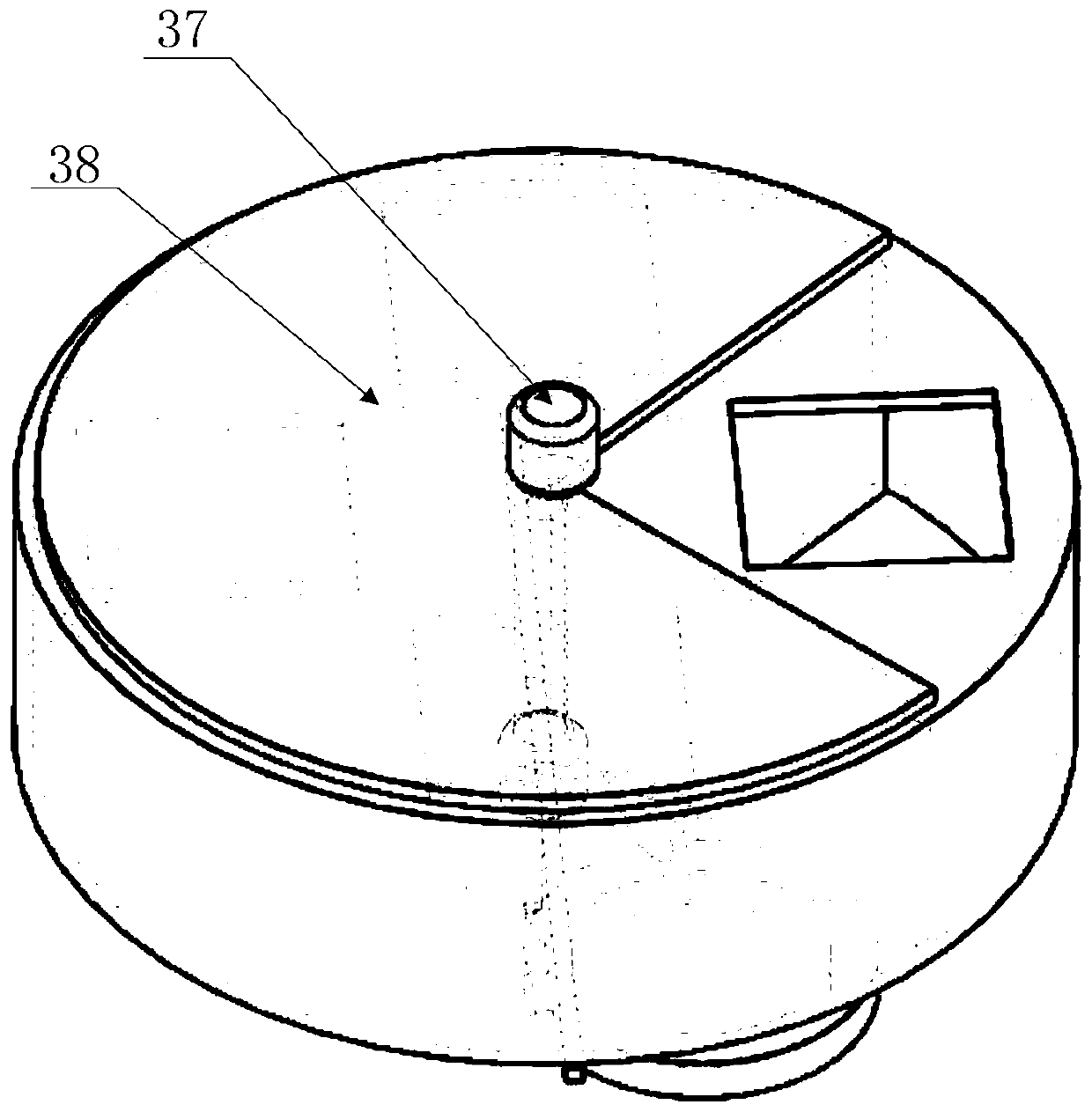

The invention discloses a garbage can capable of automatic classifying based on visual identification and a classifying method. The garbage can comprises a garbage throwing opening, a first photoelectric switch sensor, an identifying and classifying tray, second photoelectric switch sensors, sub garbage cans, an image identification component, an STM32 controller, a double-path stepping motor driver and a garbage can shell, wherein the garbage throwing opening is formed in the side wall of the garbage can shell; the first photoelectric switch sensor is arranged in the garbage throwing opening;a plurality of sub garbage cans are arranged in the garbage can shell; a second photoelectric switch sensor is mounted in a can opening position of each sub garbage can; the identifying and classifying tray is arranged in the garbage can shell and is located above the sub garbage cans; the identifying and classifying tray comprises a garbage tray, a V-shaped baffle stepping motor, a camera, a V-shaped baffle, a support frame, a rotary baffle stepping motor and a rotary baffle. According to the garbage can, the camera is used for collecting garbage images; a TensorFlow deep learning frameworkis adopted; through transfer training of a model, the accuracy rate of garbage identification is increased.

Owner:石家庄邮电职业技术学院

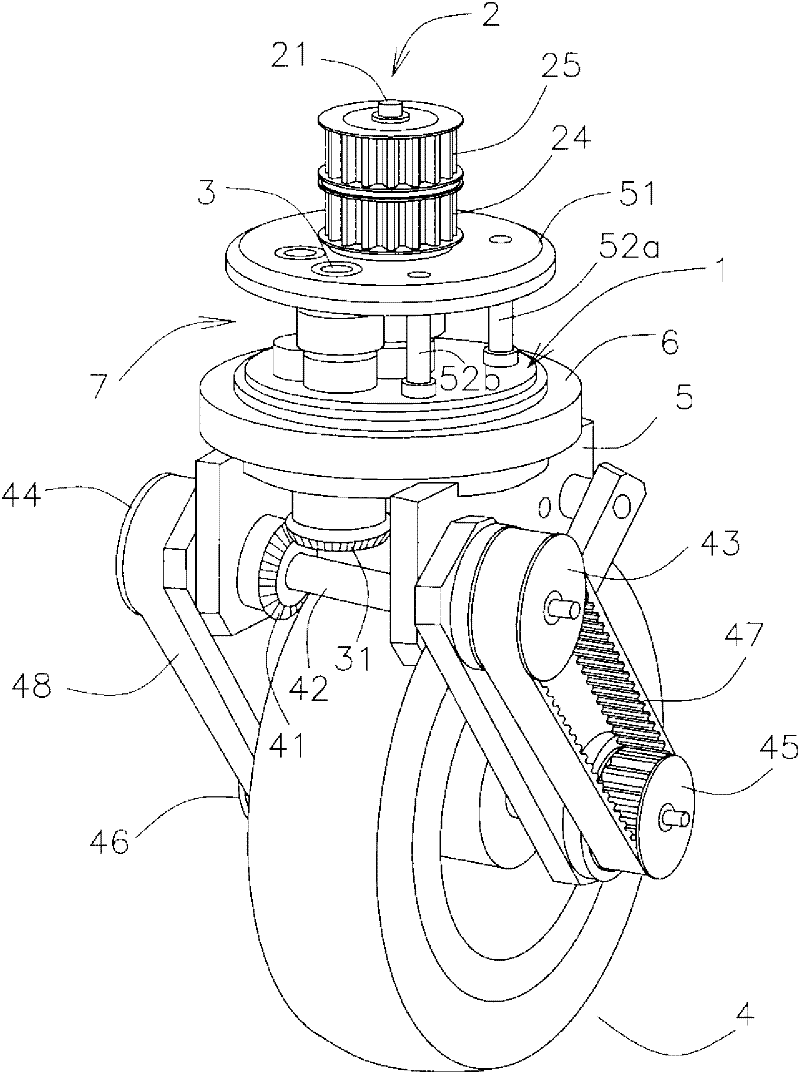

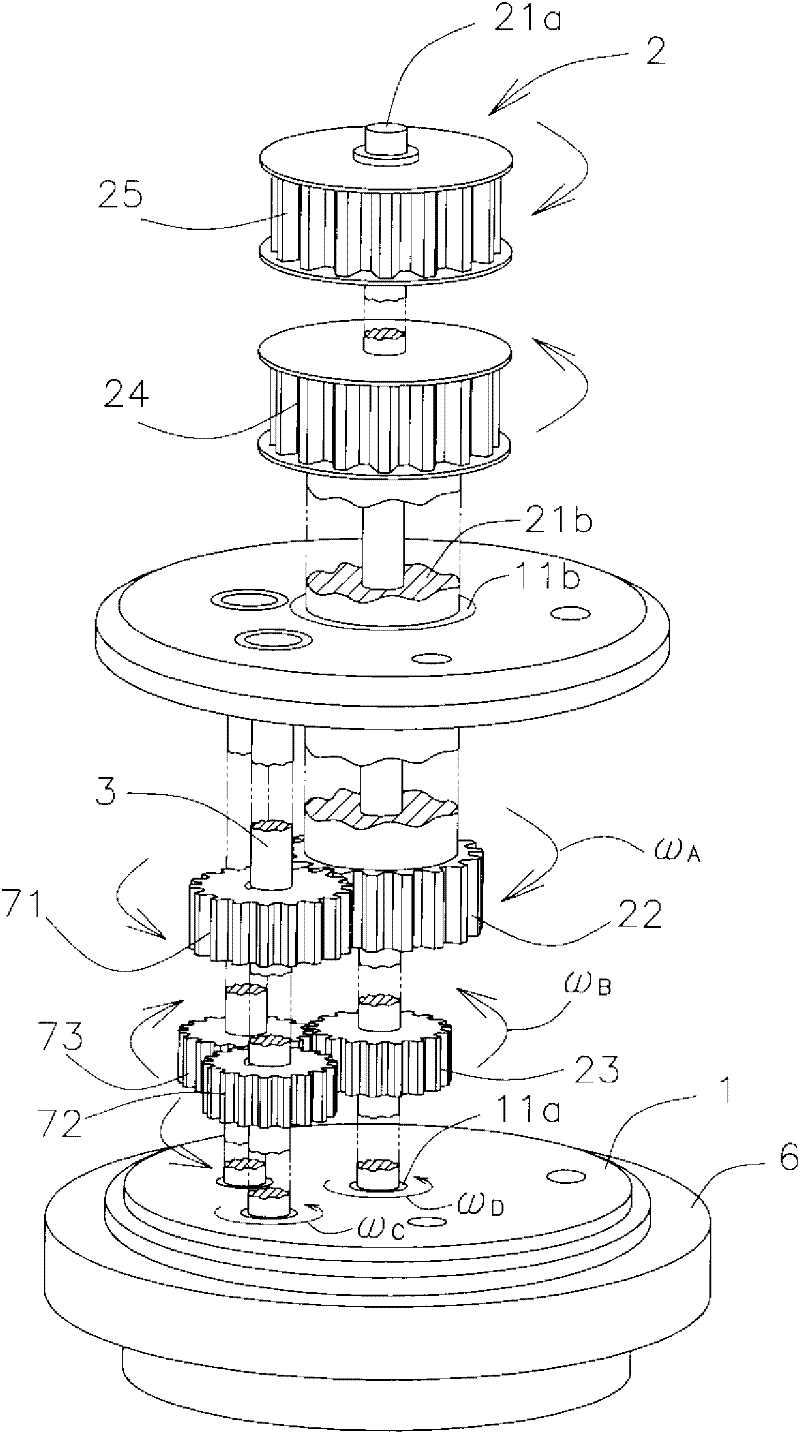

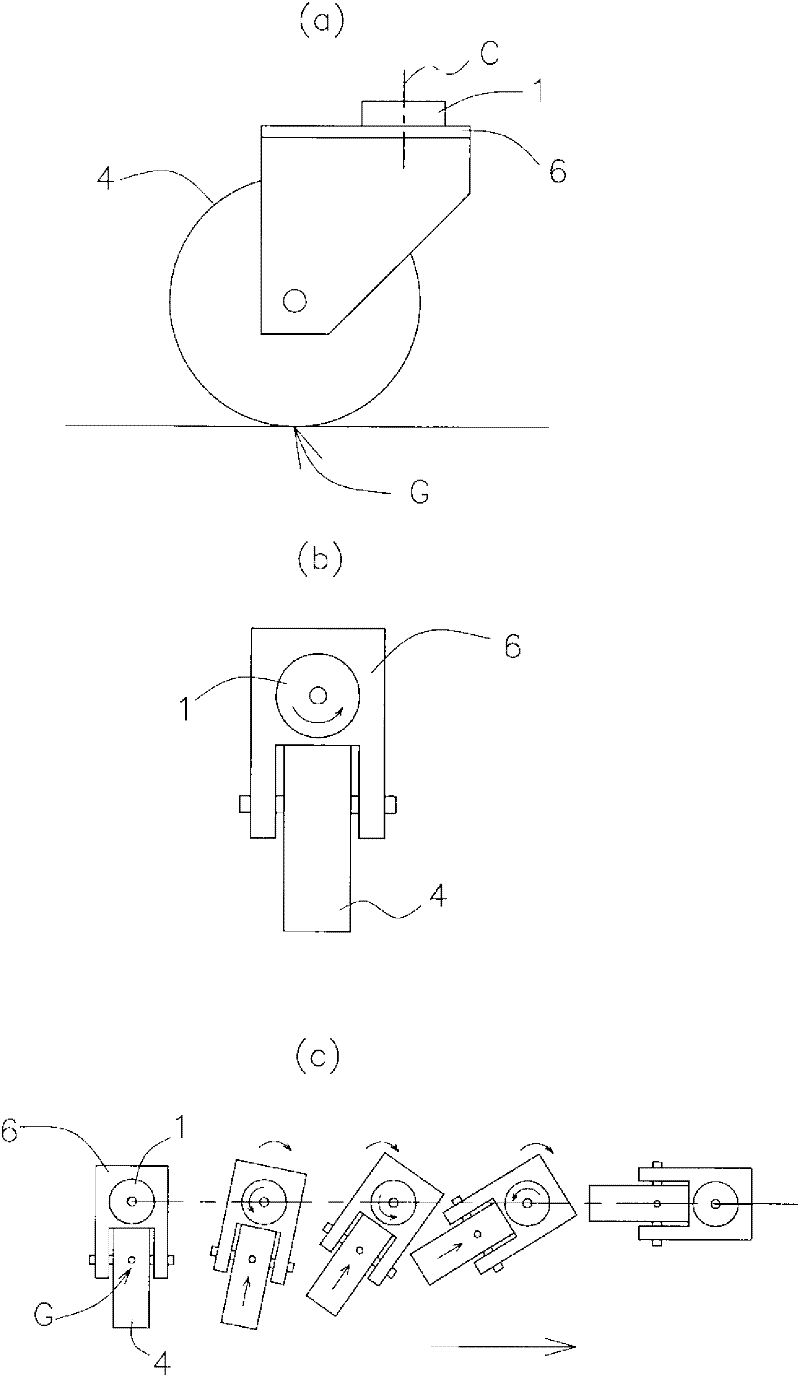

Steerable drive mechanism and omnidirectional moving vehicle

InactiveCN102458962ASteering to Environmental StabilityControl speedSteering linkagesWheelchairs/patient conveyanceControl theoryMechanical engineering

Owner:TOYOHASHI UNIVERSITY OF TECHNOLOGY

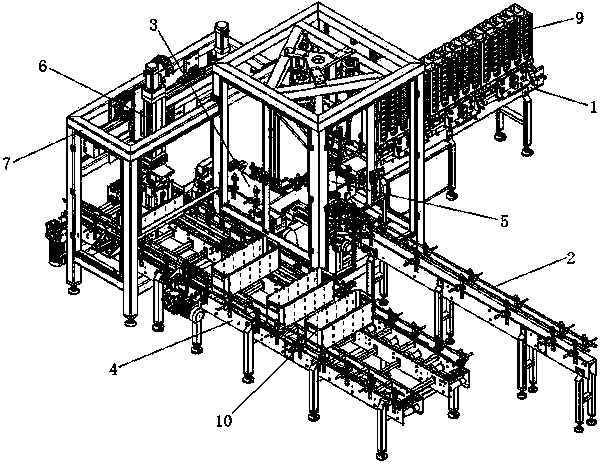

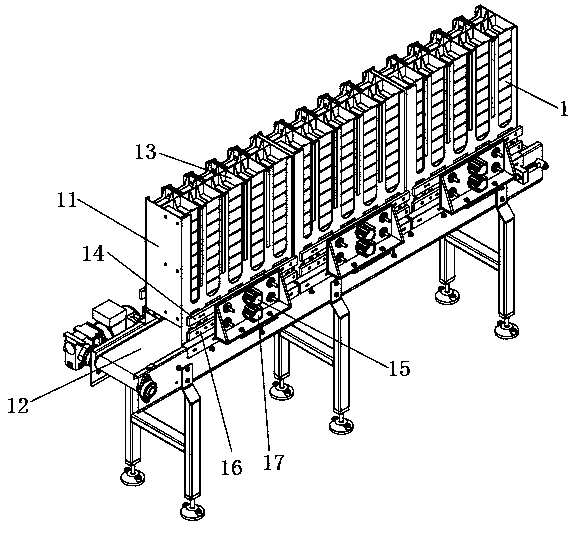

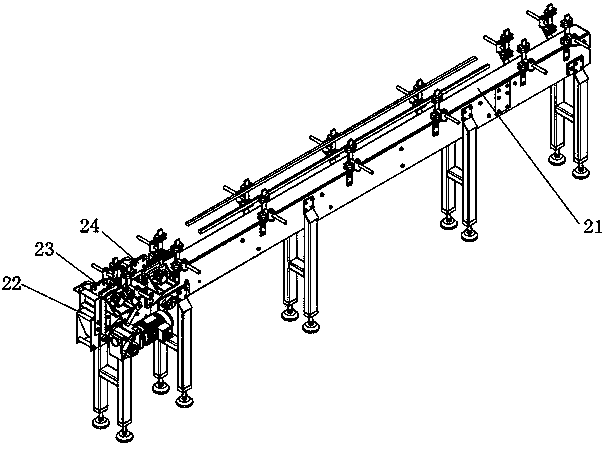

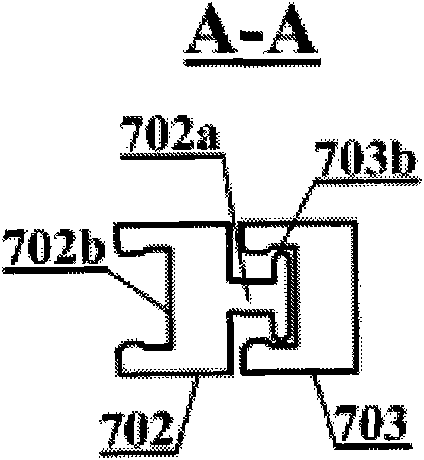

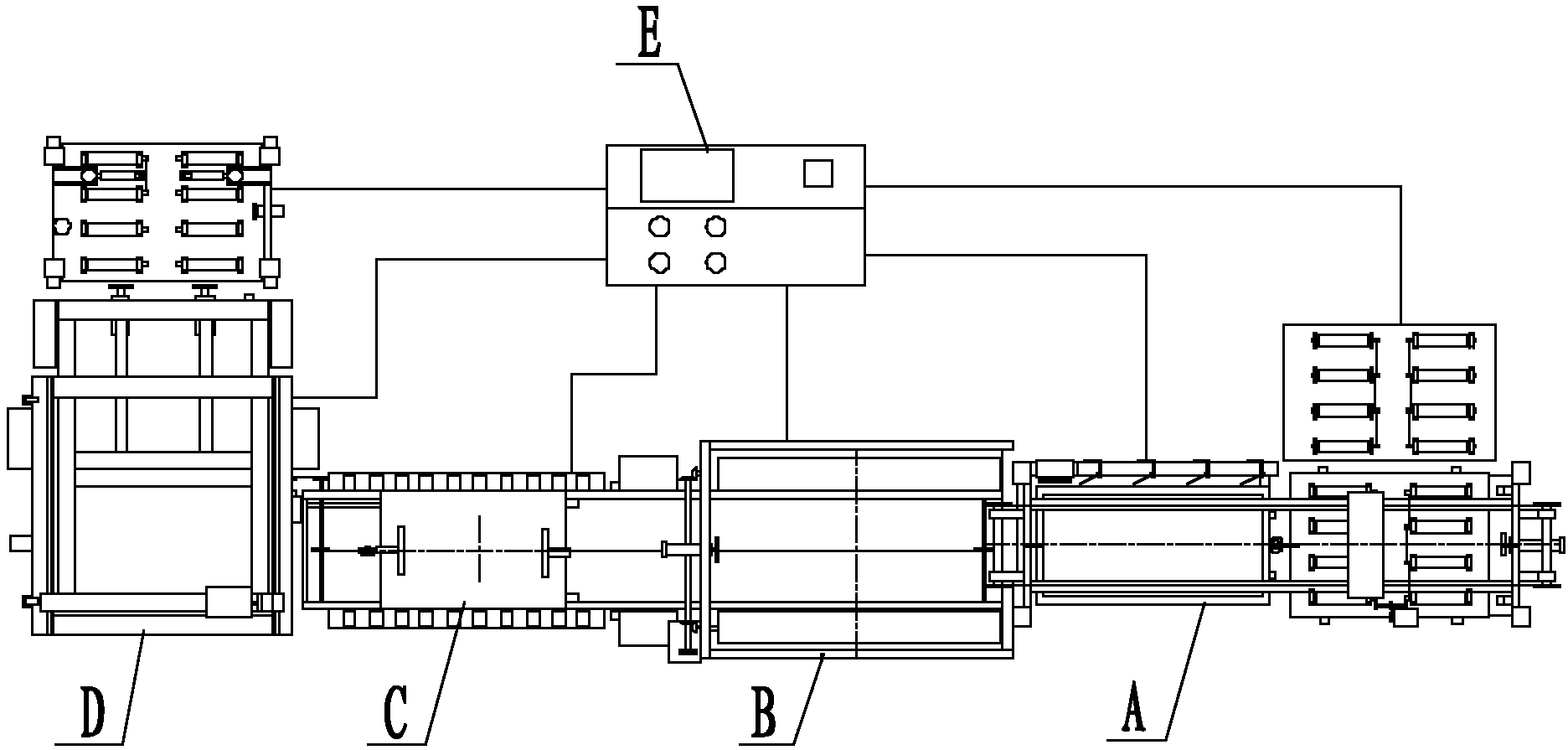

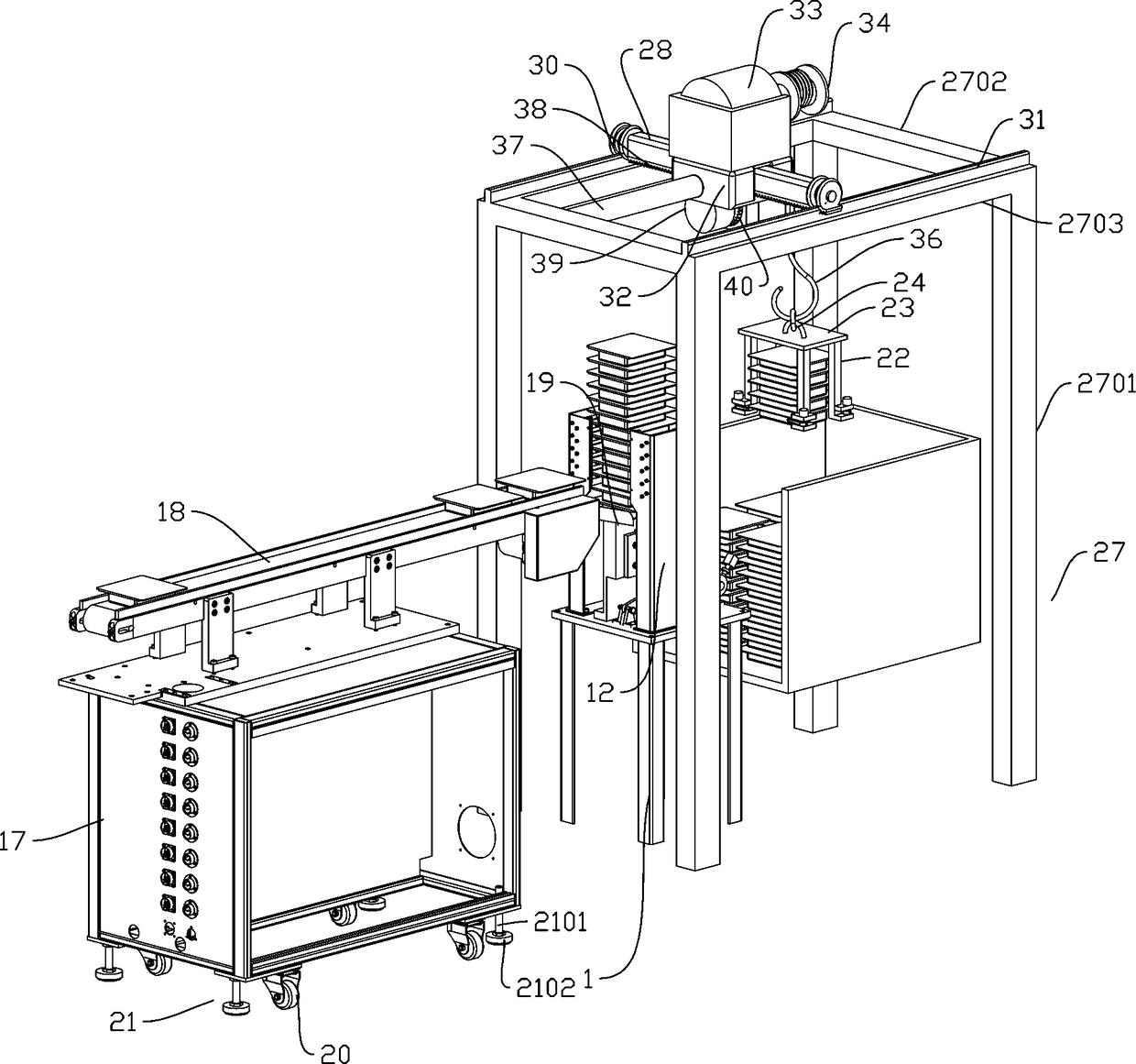

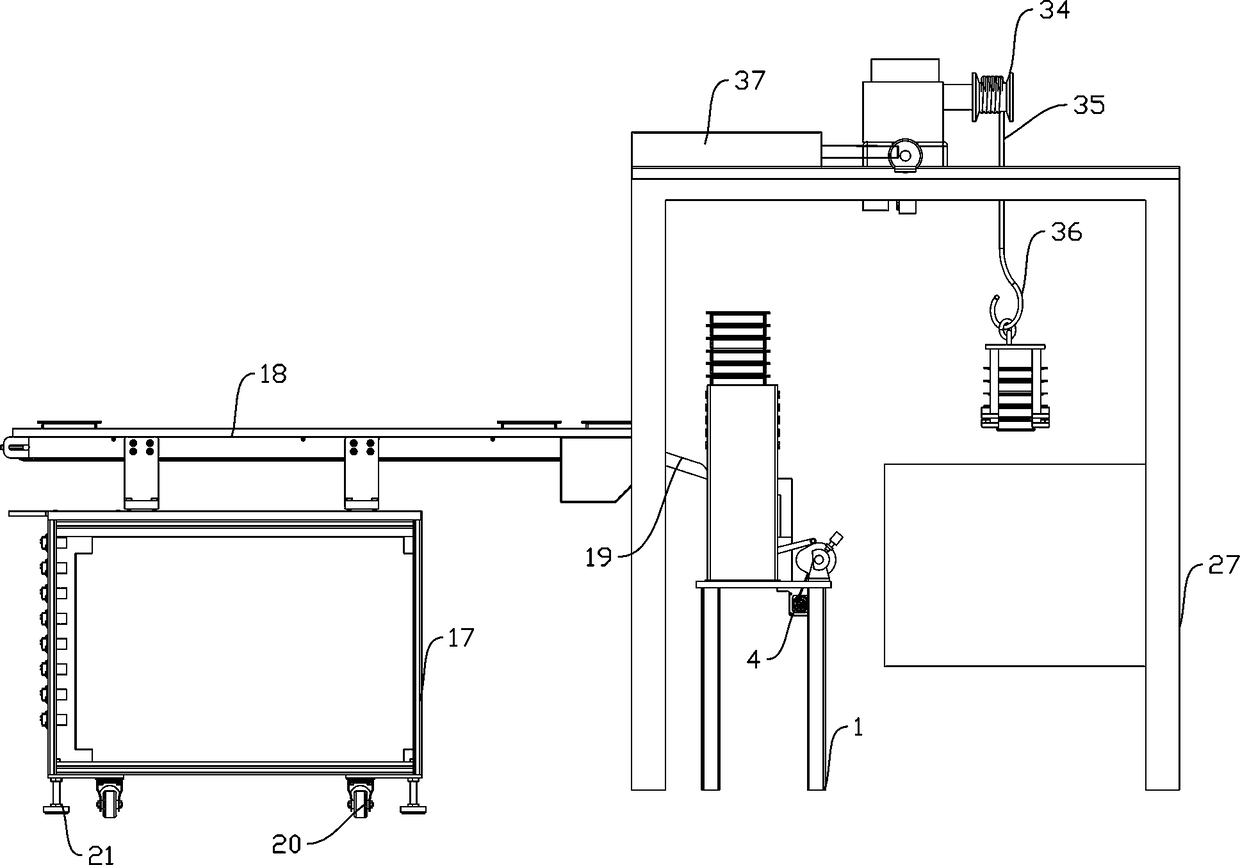

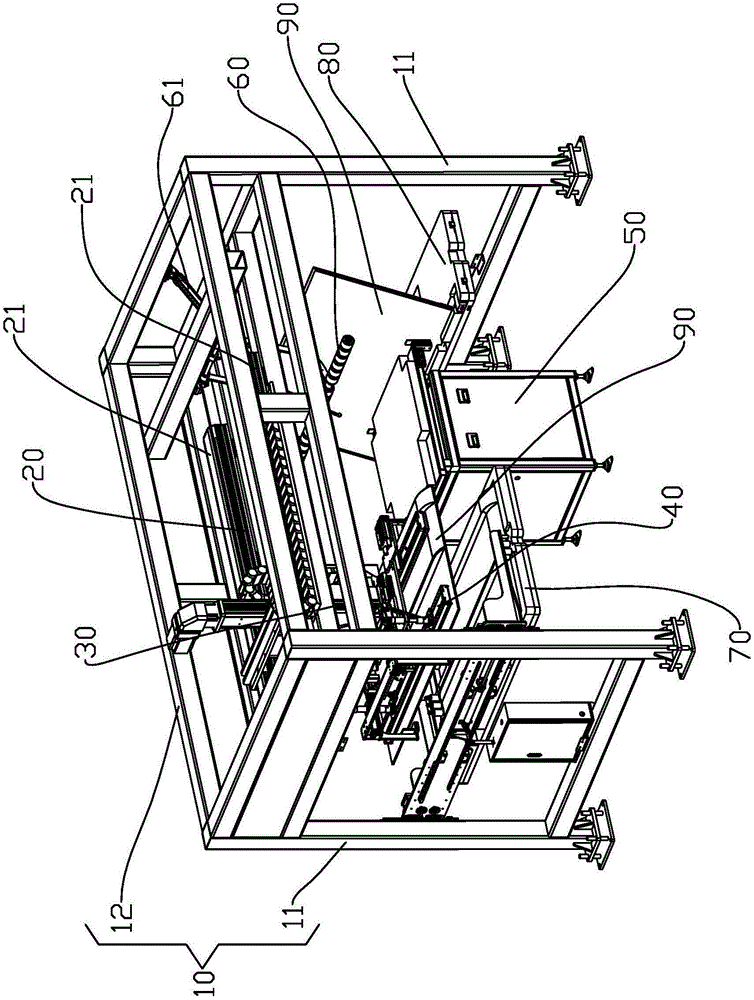

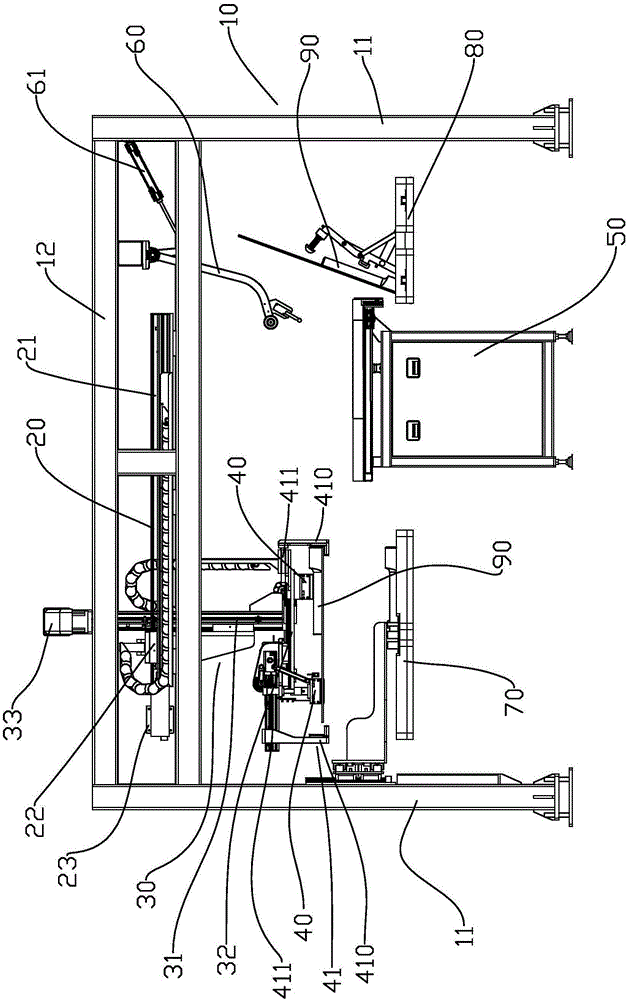

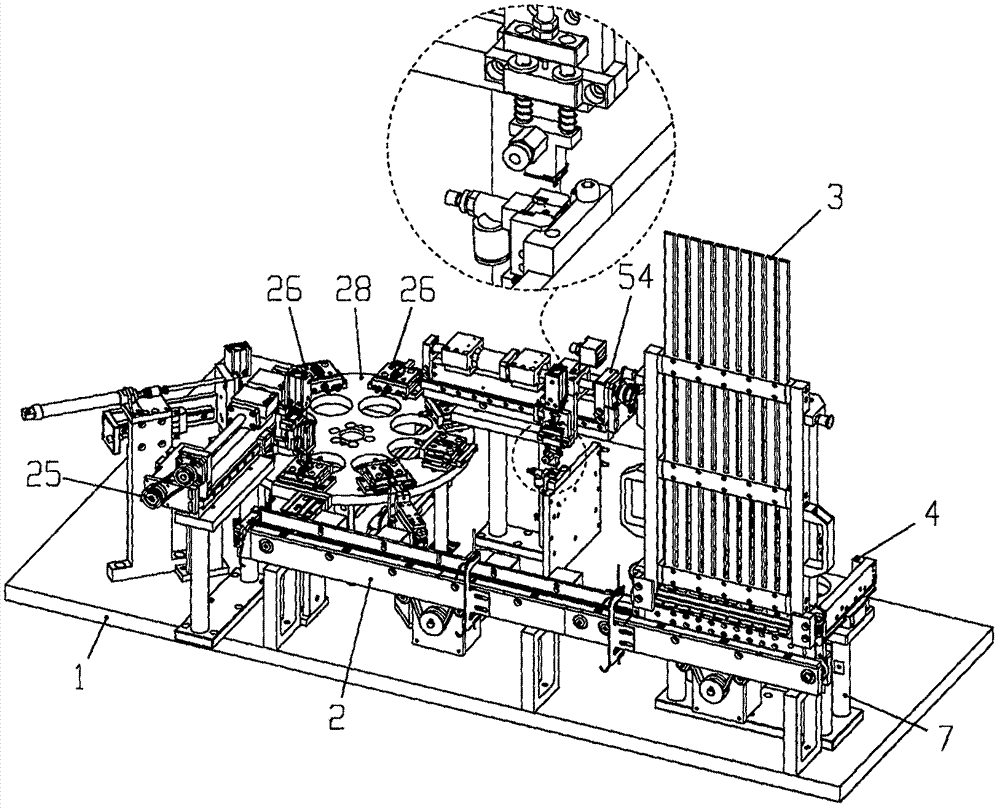

Combined box filling machine of battery assembly line

InactiveCN103419951ASafe and reliable grabbingImprove gripIndividual articlesElectricityElectrical battery

The invention discloses a combined box filling machine of a battery assembly line. The combined box filling machine comprises a controller, a cork base feeding mechanism, a battery conveying mechanism, a battery pack conveying mechanism, a battery box conveying mechanism, parallel-connection mechanical arms, an electric cylinder grasping hand and a machine frame, wherein the controller, the parallel-connection mechanical arms and the electric cylinder grasping hand are all installed on the machine frame, and the cork base feeding mechanism, the battery conveying mechanism, the battery pack conveying mechanism, the battery box conveying mechanism, the parallel-connection mechanical arms and the electric cylinder grasping hand are all electrically connected with the controller respectively. According to the combined box filling machine, batteries can be filled onto a cork base and combined into battery packs, then, the battery packs are filled into a battery box according to certain arrangement rules, automation of work for filling the batteries into the box is achieved, work efficiency is improved, and human errors are avoided.

Owner:HANGZHOU WAHAHA TECH

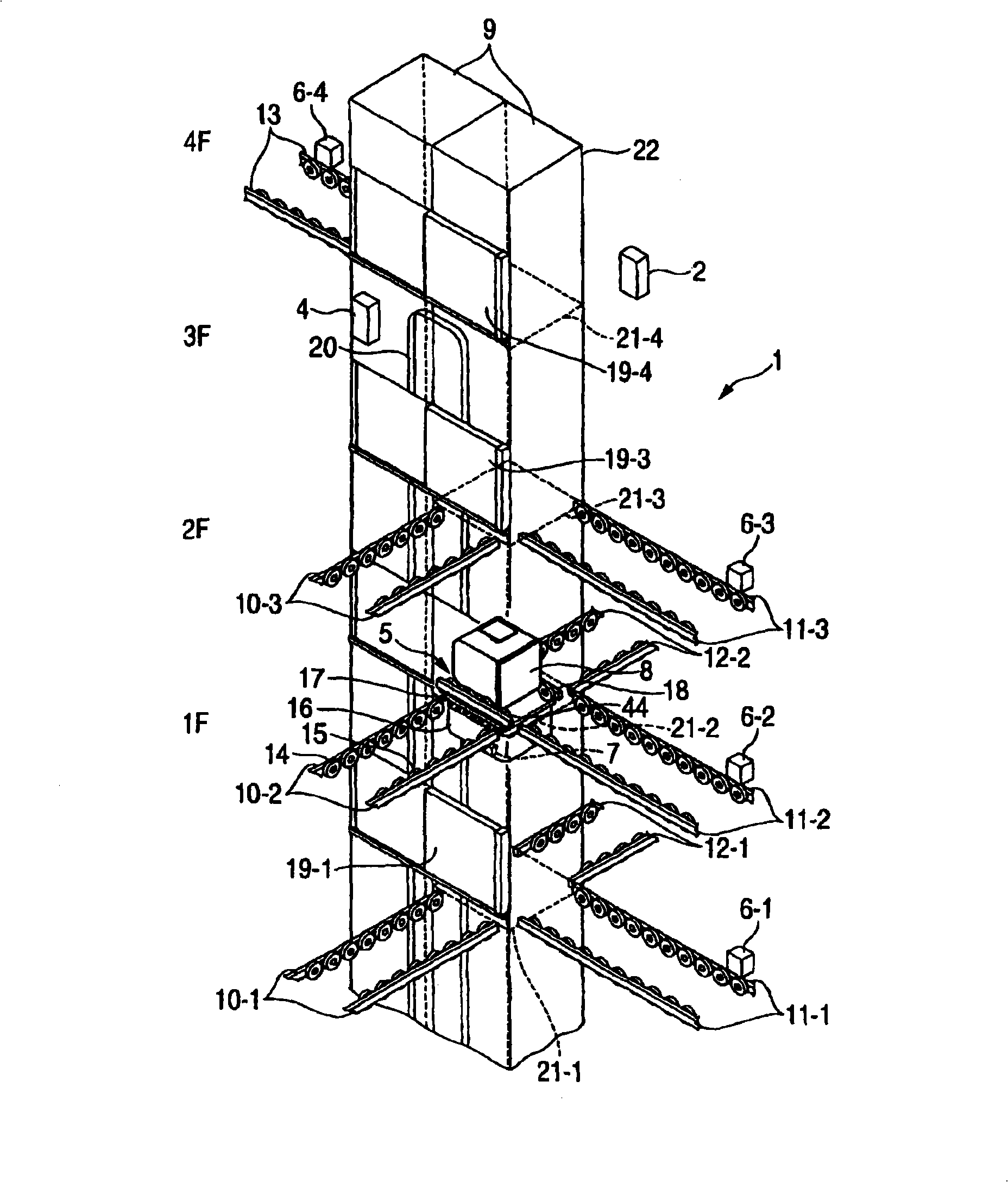

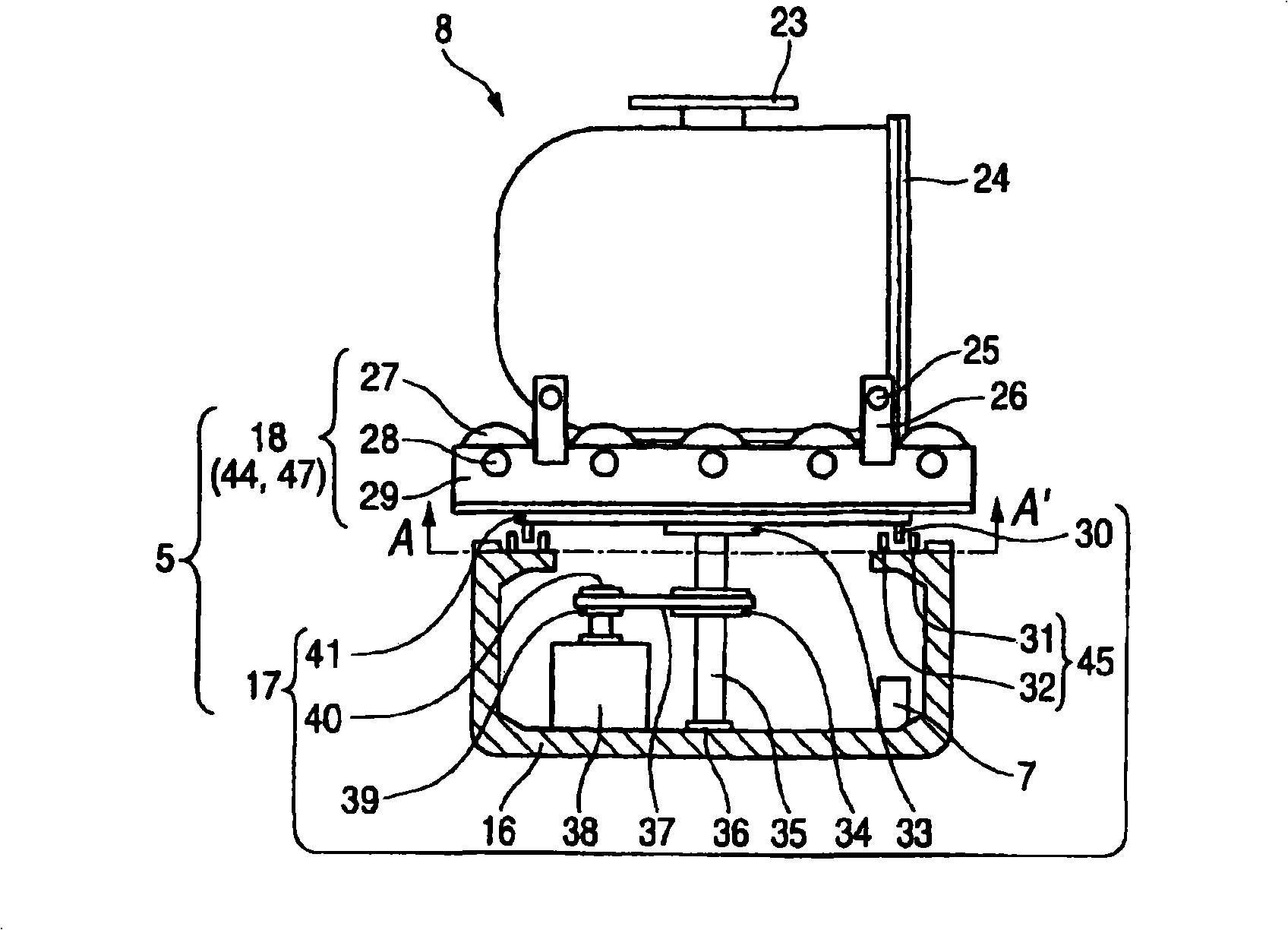

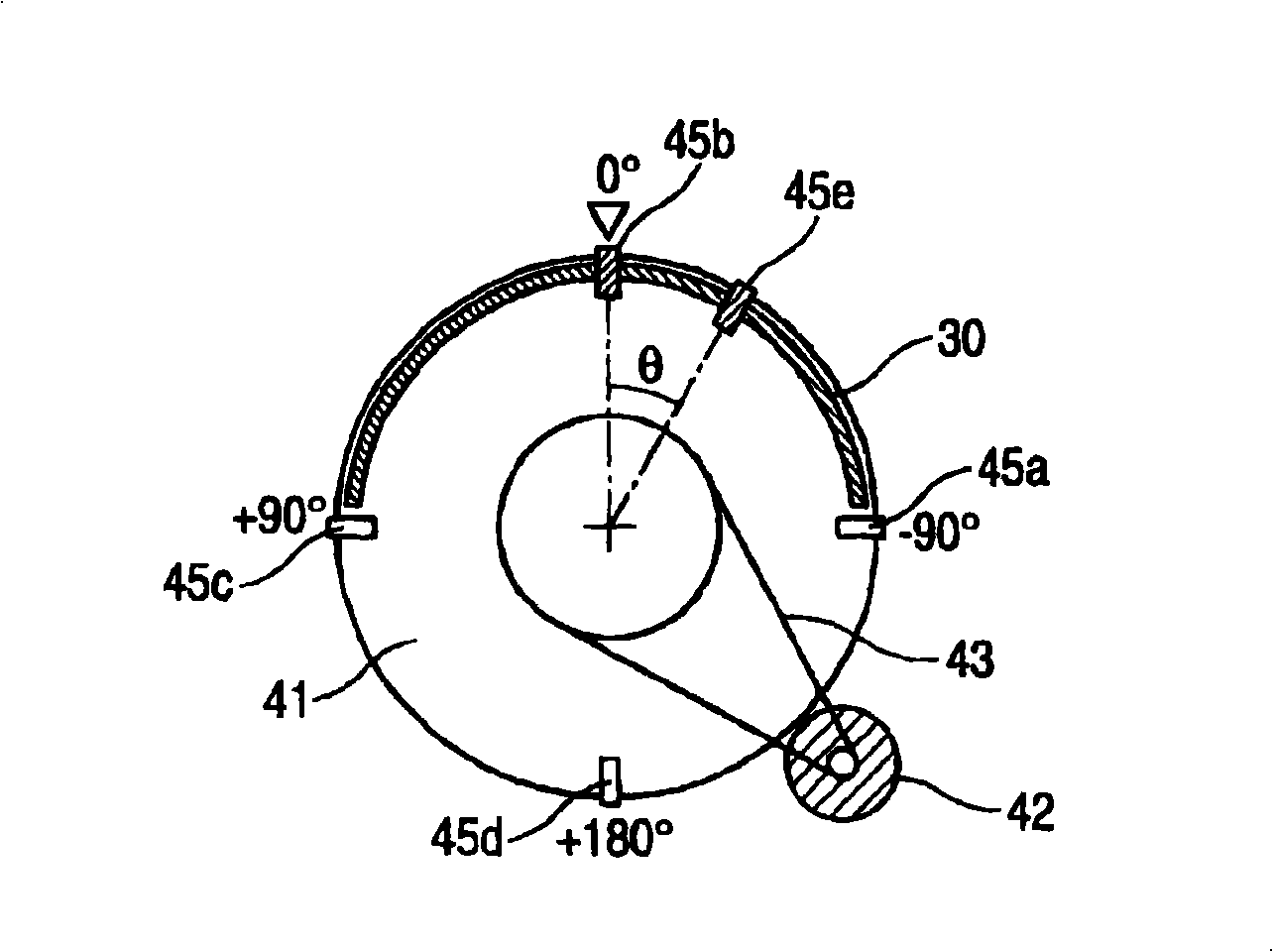

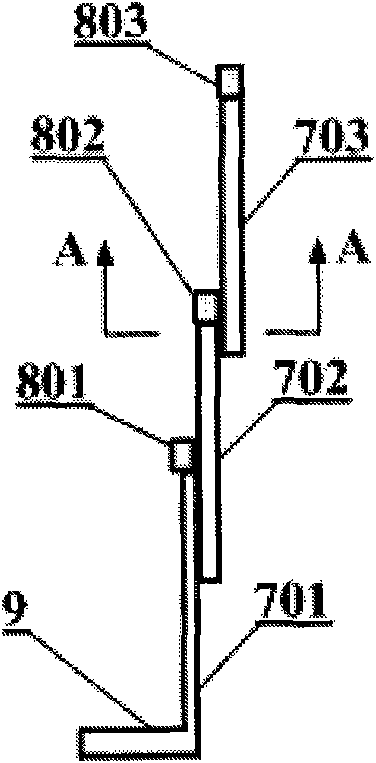

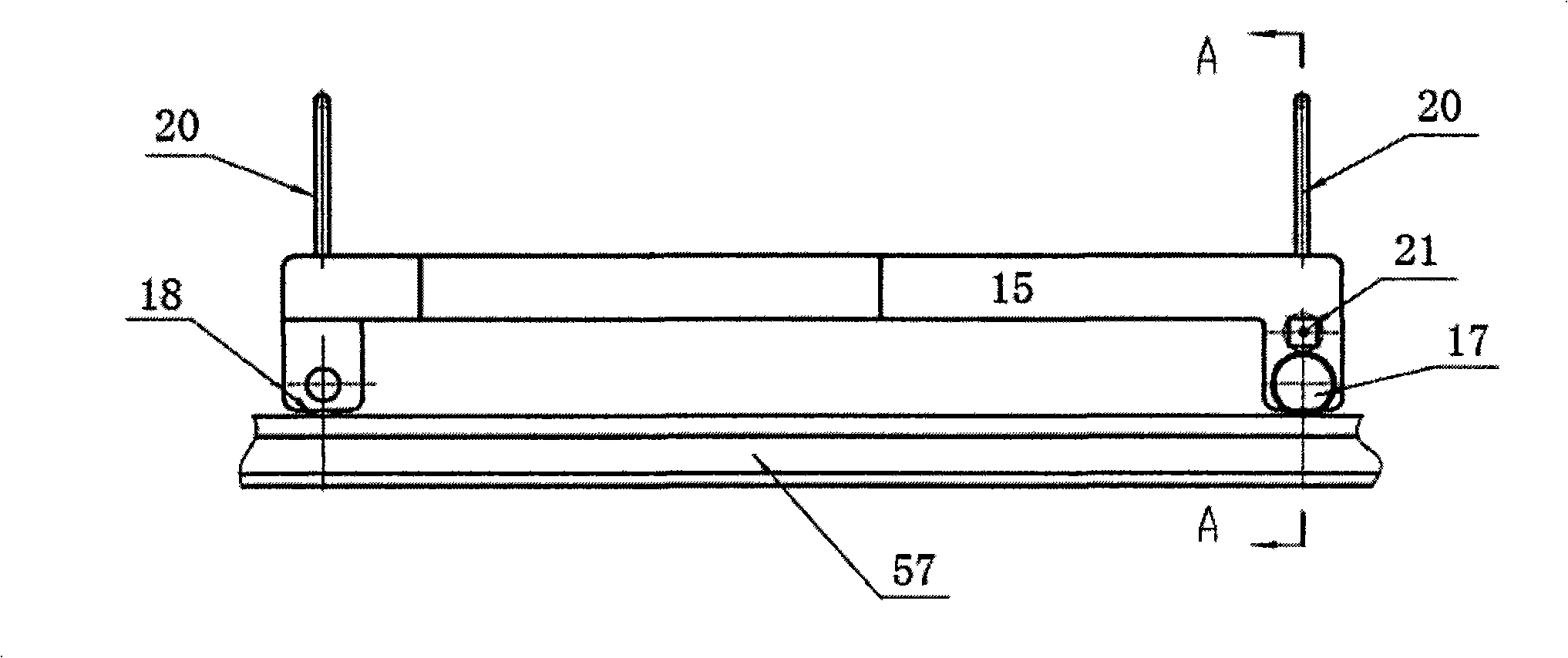

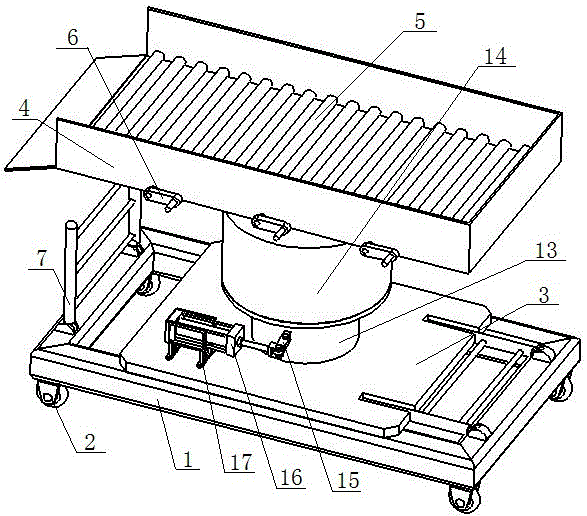

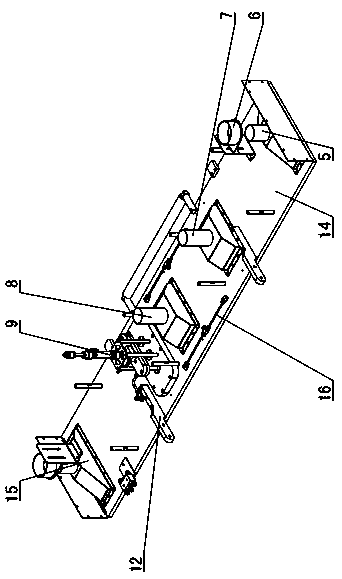

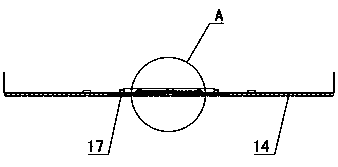

Vertical conveyance device

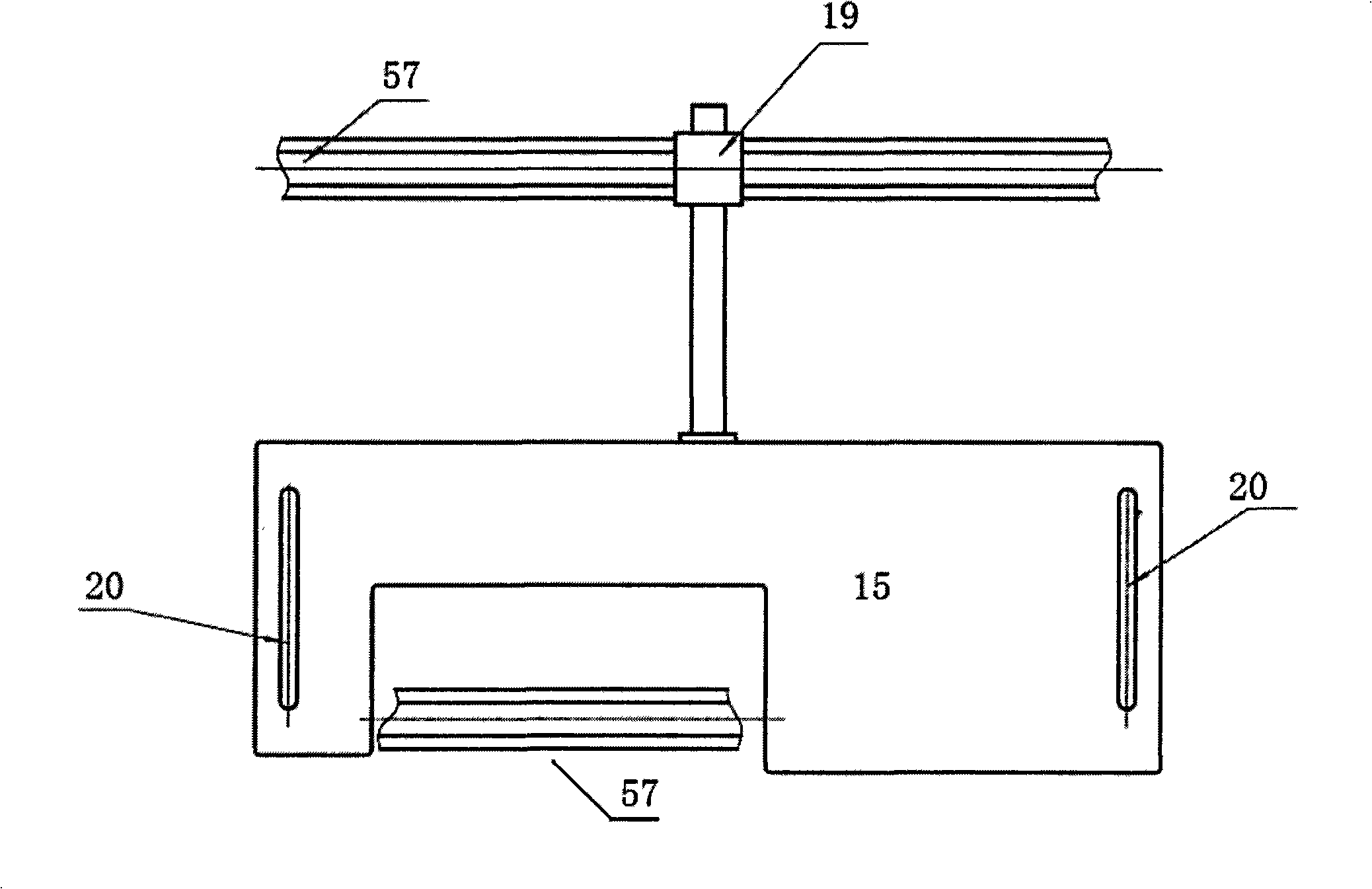

InactiveCN101331074AImprove handling efficiencyRealize handlingSemiconductor/solid-state device manufacturingThin material handlingEngineeringMechanical engineering

Provided is a vertical conveyance deivce. A lifting conveyor (5) is constructed from a turntable (17) and a roller conveyor (18). The roller conveyor (18) is supported on the turntable (17). A conveyor rail performs delivery or reception of a load. The turntable (17) is turned by a turntable controller (7) to align the conveyance direction of the conveyor rail with the roller conveyor (18), and after that, the conveyor rail and the roller conveyor (18) are driven to deliver or receive a FOUP (8). The lifting conveyor (5) is supported by a cable (20a) placed in a hoistway space (9) by a joint member (20b) of a cable bearer (20), and the cable bearer (20) is vertically circulated in a reciprocating manner by a lifting conveyor controller (4). In association with the movement of the cable bearer (20), the lifting conveyor (5) stops in a vertically movable manner at a port (21) placed at each floor.

Owner:MURATA MASCH LTD

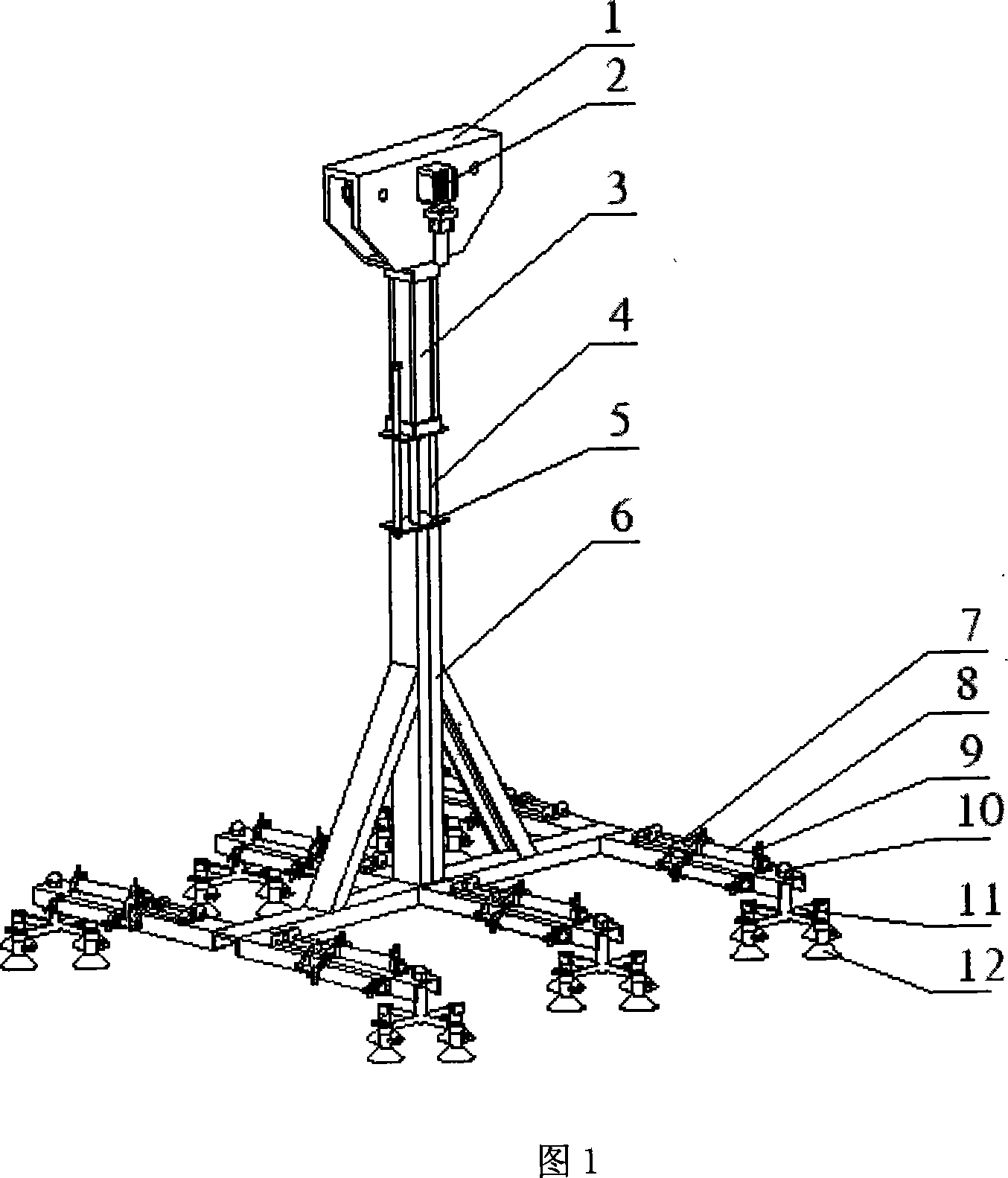

Automatic handing system of weight and application thereof

InactiveCN101806612AConvenient automatic handlingCompact structureWeighing auxillary devicesPower controlManipulator

The invention belongs to the field of weighing apparatus metering, relating to an automatic handing device of a three-dimensional weight in quality measurement. The invention discloses an automatic handing system of weight and application thereof. The system comprises the weight, a power control part, a sliding assembly, a flexible assembly and a mechanical arm, wherein the sliding assembly and the flexible assembly are matched to operate under the driving of the power control component so as to control the mechanical arm to transport the weight. The automatic handing system of a three-dimensional weight in high-accuracy quality measurement provided by the invention can conveniently and automatically transport and load cylindrical weight, has compact structure, small occupation space, high transportation and loading speed and high working efficiency, and can automatically adjust speed and realize no-impact loading, thereby bringing great convenience for operating staff to operate, saving manpower.

Owner:NAT INST OF METROLOGY CHINA

On-line laser machining apparatus for strengthening and toughening treatment of steel rail surface

ActiveCN101403030AImprove wear resistanceExtend the life cycleFurnace typesHeat treatment furnacesEngineeringHigh pressure

The invention discloses an on-line laser processing equipment used for strengthening and toughening of the surface of a steel rail, comprising a laser processing lathe and a power system container. The laser processing lathe comprises a motion actuating mechanism, a laser processing head and / or a control system and a powder feeder which are arranged on a moving cart; and the power system container comprises a power generator, a refrigerator, an air compressor, a cool drying machine and a high-voltage power supply of a laser which are arranged in the container. The laser processing head can be arranged on the motion actuating mechanism and is directly connected with the laser or connected with the laser by a light-guiding system. The invention can complete the laser surface quenching, fused quenching, alloying and cladding treatment of various steel rails which comprises a stock rail, a curve, a guide rail, a switch and the like under the premise that the steel rail is not dismounted and the normal running of trains, thus leading the wear resistance of the processed steel rail to be improved greatly and having the characteristics of simple assembly and disassembly, high processing precision and simple operation and control.

Owner:HUAZHONG UNIV OF SCI & TECH +1

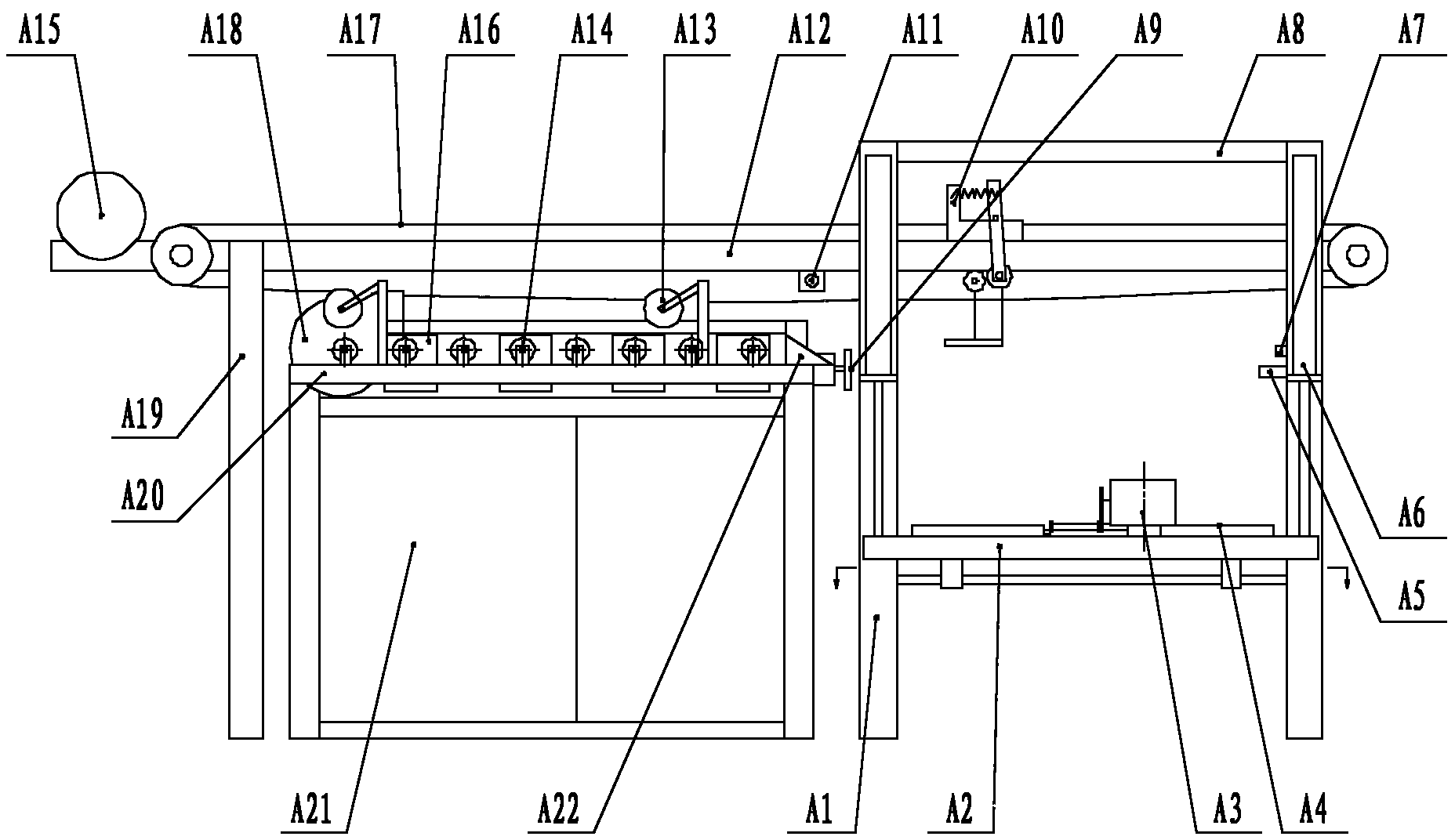

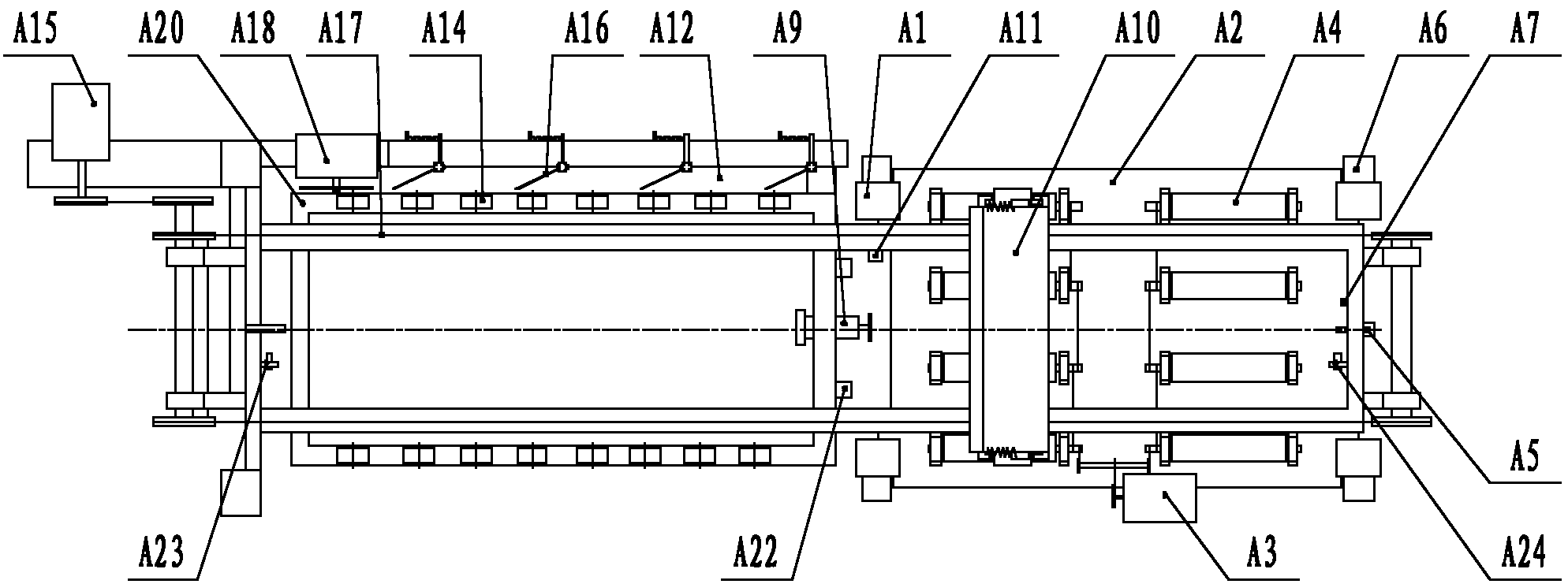

Plate edge cutting machine

InactiveCN103213173ANot easy to failImprove reliabilityFeeding devicesCircular sawsControl systemAgricultural engineering

The invention discloses a plate edge cutting machine, which belongs to the field of plate processing machinery. The plate edge cutting machine has the technical scheme that the plate edge cutting machine comprises a plate conveying machine, a plate falling machine, a longitudinal edge cutting machine, a horizontal edge cutting machine and a control system, wherein the tail part of the plate conveying machine is connected with the head part of the plate falling machine, the longitudinal edge cutting machine is connected with the plate falling machine, the other end of the longitudinal edge cutting machine is vertically connected with the horizontal edge cutting machine, the control system is respectively connected with the plate conveying machine, the plate falling machine, the longitudinal edge cutting machine and the horizontal edge cutting machine in a control mode, the plate conveying machine comprises an elevator I, a plate conveying machine rack and a positioning platform, and a push head is fixedly arranged above the plate conveying machine rack; and the push head comprises a sliding plate and a positioning and connecting device, the sliding plate is provided with a glare shield and a hook plate, and a plate propping air cylinder is arranged at the right side of the plate conveying machine rack. The invention provides the plate edge cutting machine which has better entire machine performance and higher automation degree, and is mainly used for cutting rough edges of plates.

Owner:阎育华

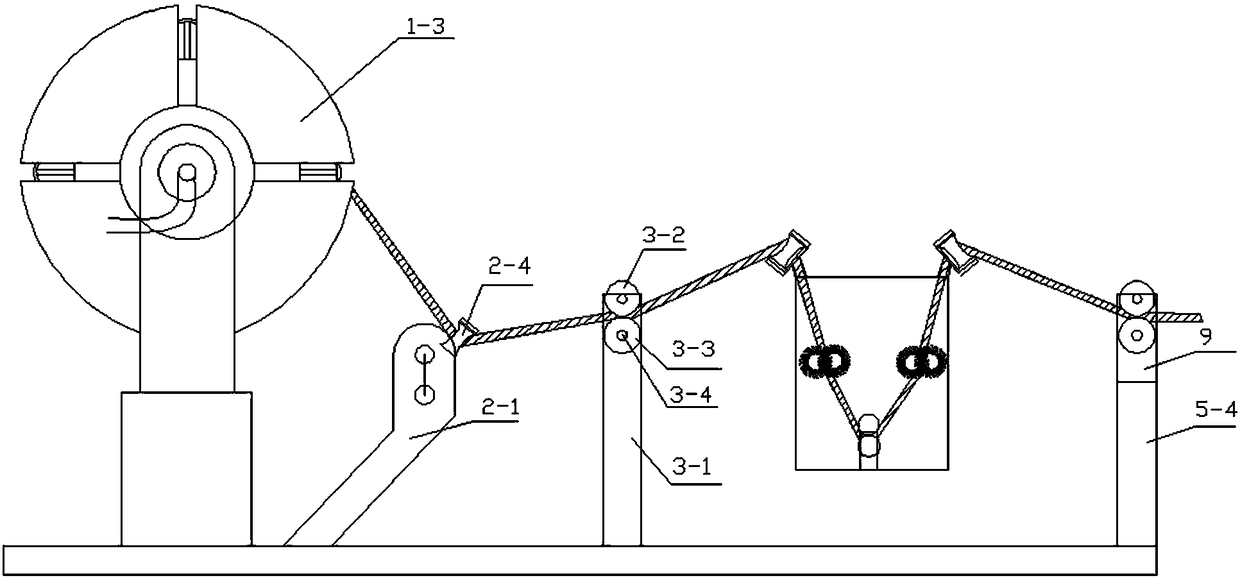

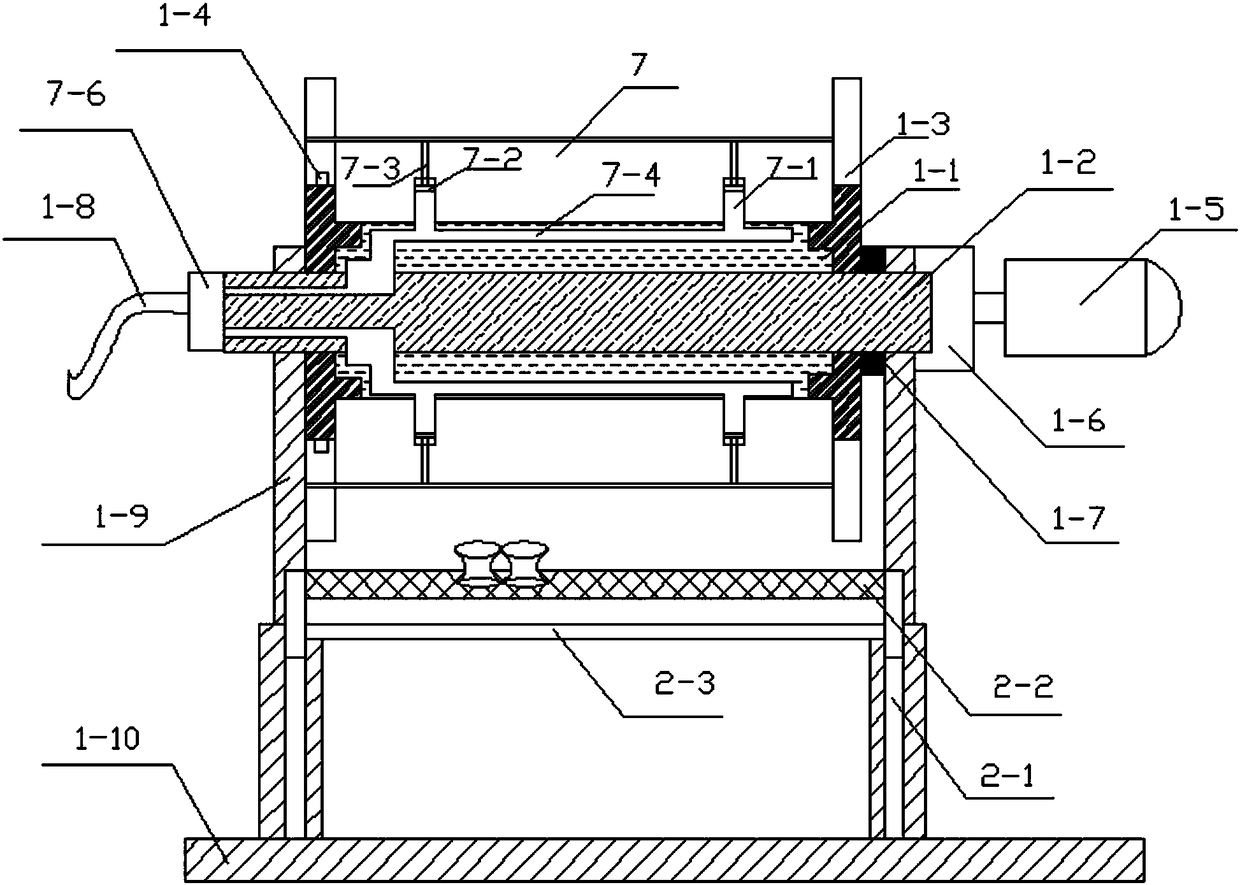

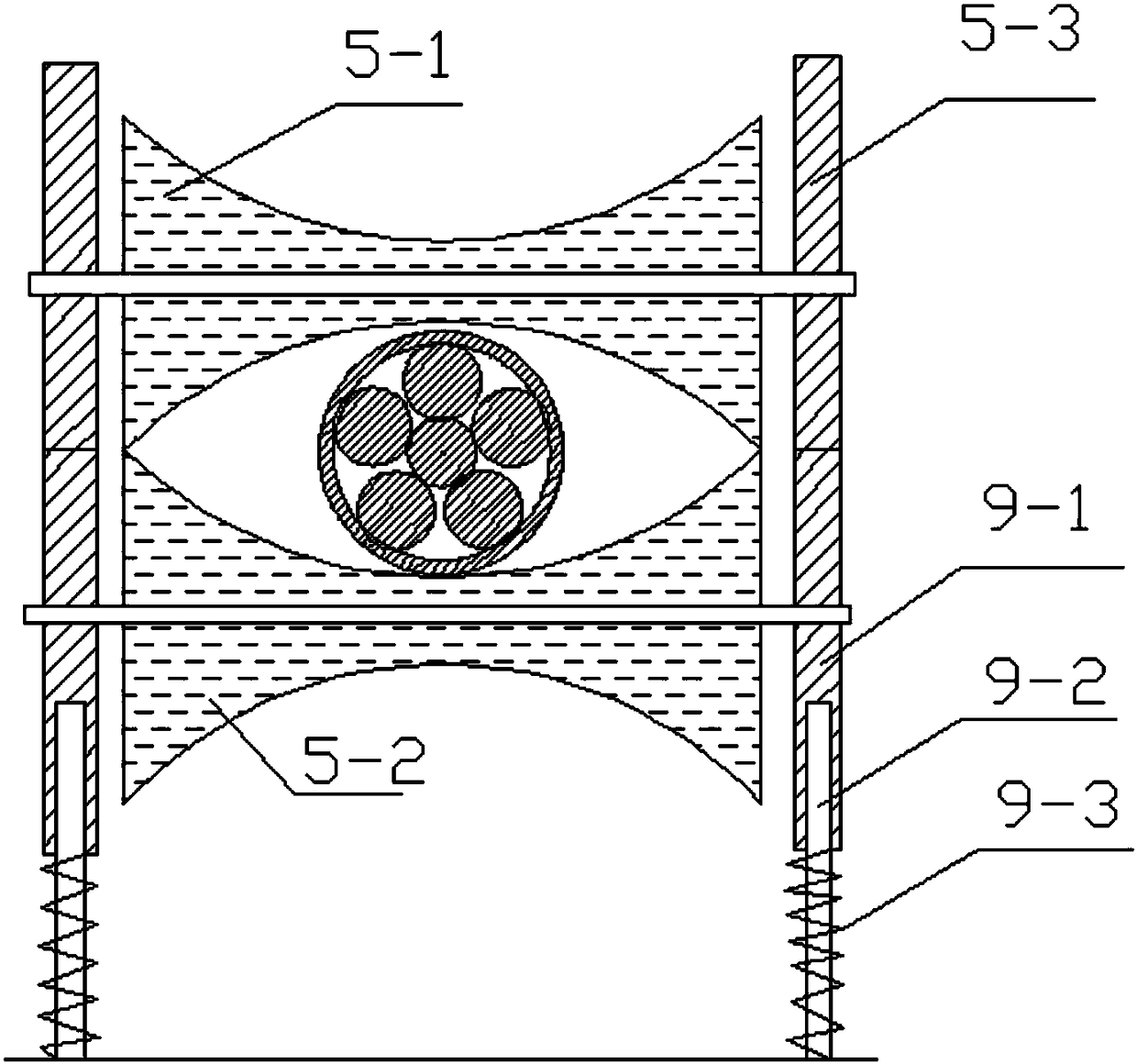

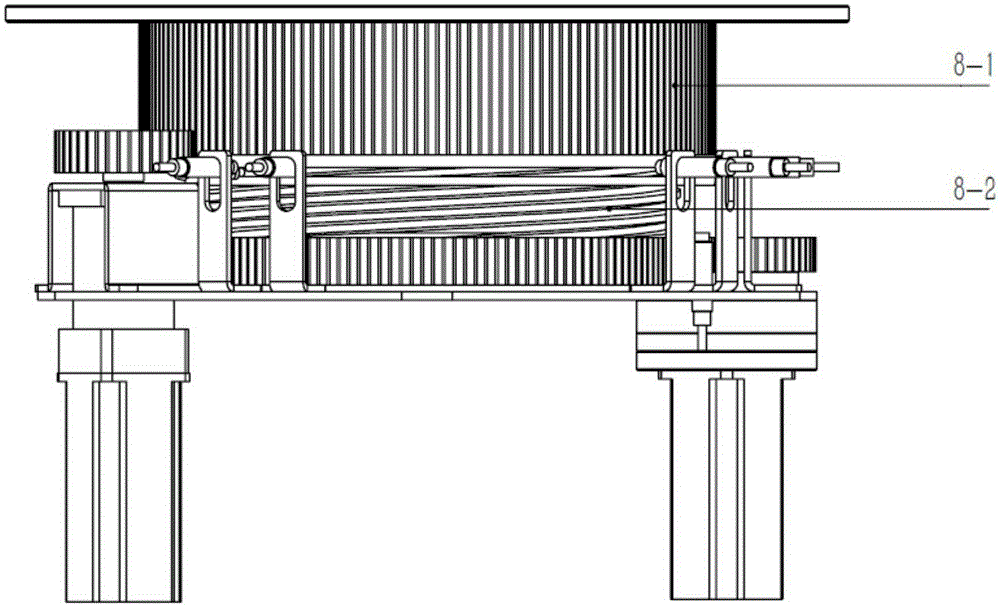

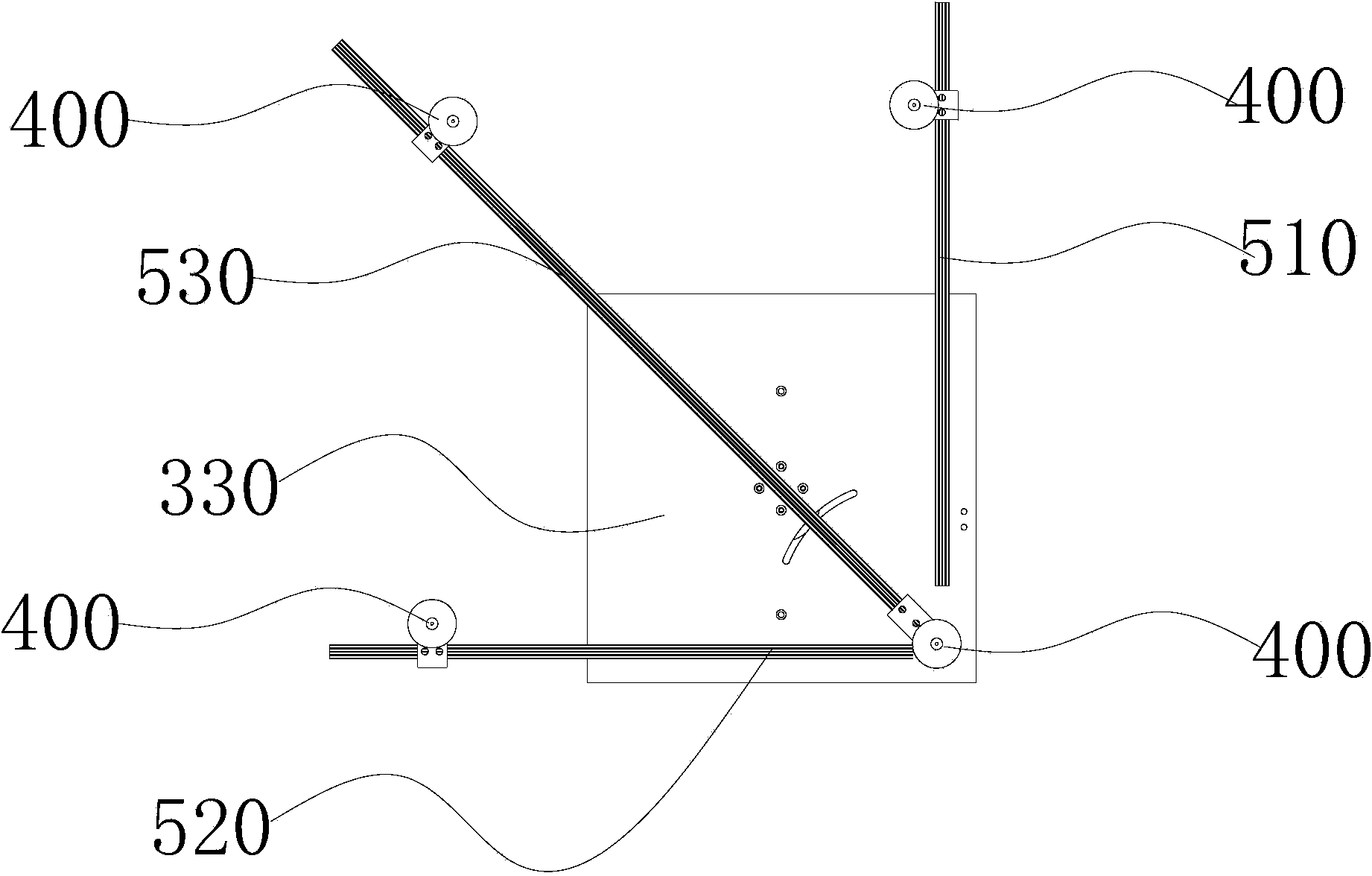

Cable winding and unwinding device and using method thereof

ActiveCN108313836AUniform and accurate retractionReduce labor wasteCable transmissionInteraction interface

The invention provides a cable winding and unwinding device and a using method thereof. The cable winding and unwinding device comprises a traction device, a cleaning device, a counting device, a cable discharging device, a reel body, a controller and a human-computer interaction interface. Cable parameters are input through the human-computer interaction interface and the cable winding and unwinding device is started, and cables are pulled to the cleaning device through the traction device. The cleaning device cleans the cables, the counting device counts the cables, and finally uniform winding is achieved. Speed data of a counting device encoder and a cable discharging motor is fed back to the controller, and determined reel motor rotational speed by calculation is compared and adjustedwith actual reel motor rotational speed to ensure the consistency of the cable discharging speed, the cable transmission speed and the reel winding speed, so that the winding quality is improved. Whenthe winding is completed, the coil discharging can be performed or the reel can be carried as required, so that the operation is simplified and the work efficiency is improved.

Owner:国网山东省电力公司嘉祥县供电公司 +1

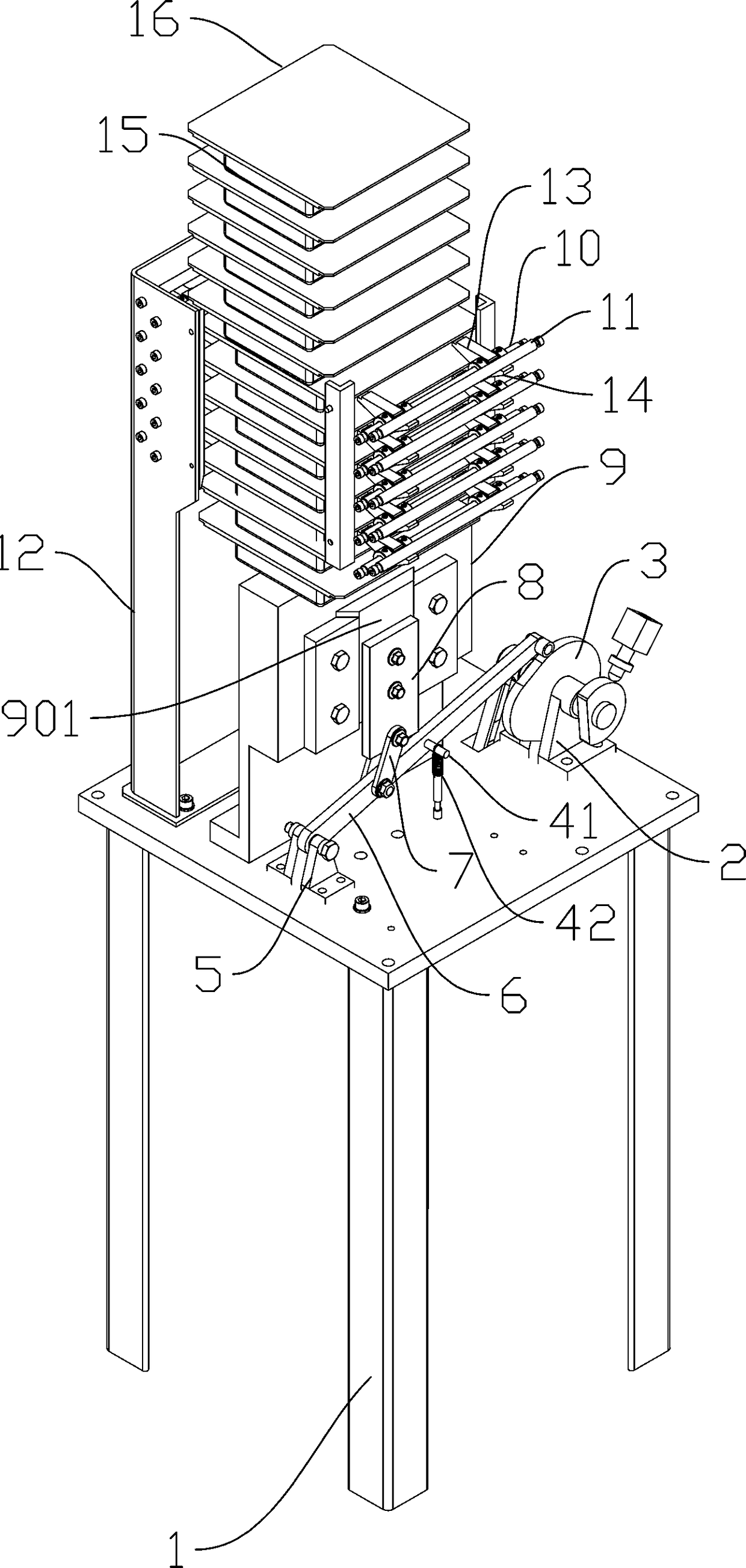

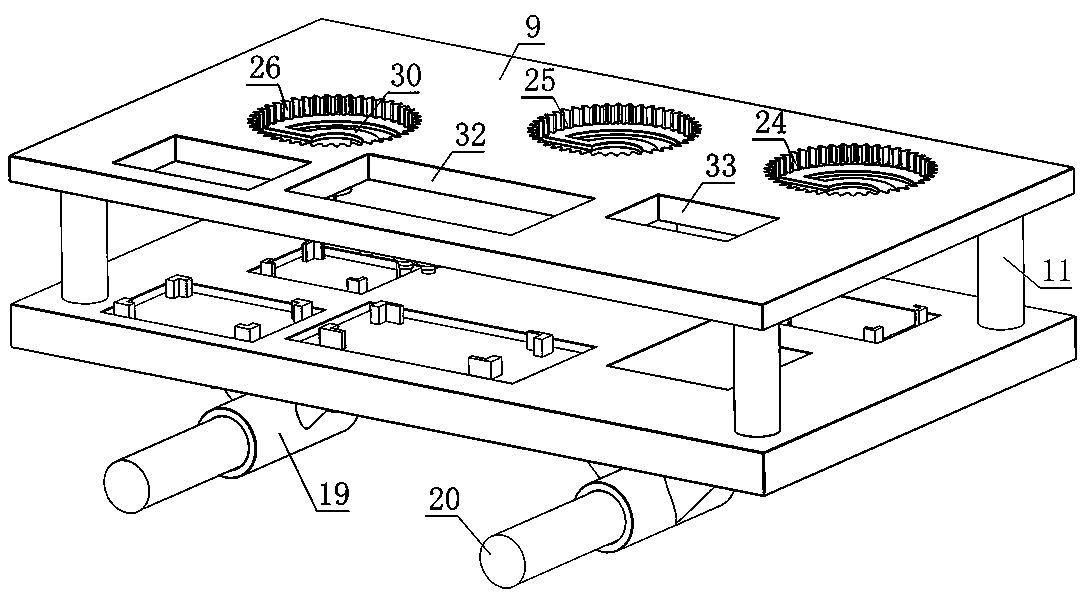

Classification logistics box automatic loading device

InactiveCN108792634ARealize automatic loadingRealize handlingConveyorsStacking articlesLogistics managementEngineering

The invention provides a classification logistics box automatic loading device. The classification logistics box automatic loading device comprises a stacking device. The stacking device comprises a supporting seat. A cam frame is arranged on the upper side of the cam frame. A rotary shaft of a cam is rotatably mounted on the cam frame and is driven through a first motor. A hinge support is arranged on the supporting seat. One end of a connecting rod is hinged to the hinge support, and the other end of the connecting rod abuts against the cam. The connecting rod is hinged to a lifting connecting rod. The upper end of lifting connecting rod is hinged to a lifting plate. The lifting plate is slidably mounted in a sliding groove of a blanking platform. A multi-layer supporting mechanism is arranged above the blanking platform. The supporting mechanism comprises rotary shafts and limiting rods, and the rotary shafts and the limiting rods are symmetrically arranged on the two sides above the blanking platform. The two ends of the rotary shafts and the two ends of the limiting rods are mounted on a support. The support is fixed to the supporting seat. Supporting jaws are rotatably mounted on the rotary shafts. The sides, far away from logistics boxes, of the supporting jaws are provided with limiting jaws. The limiting rods limit the limiting jaws to rotate upwards. Through the classification logistics box automatic loading device, automatic stacking of the logistics boxes is realized, the labor intensity is relieved, the logistics efficiency is improved, and the logistics company image is promoted.

Owner:CHINA THREE GORGES UNIV

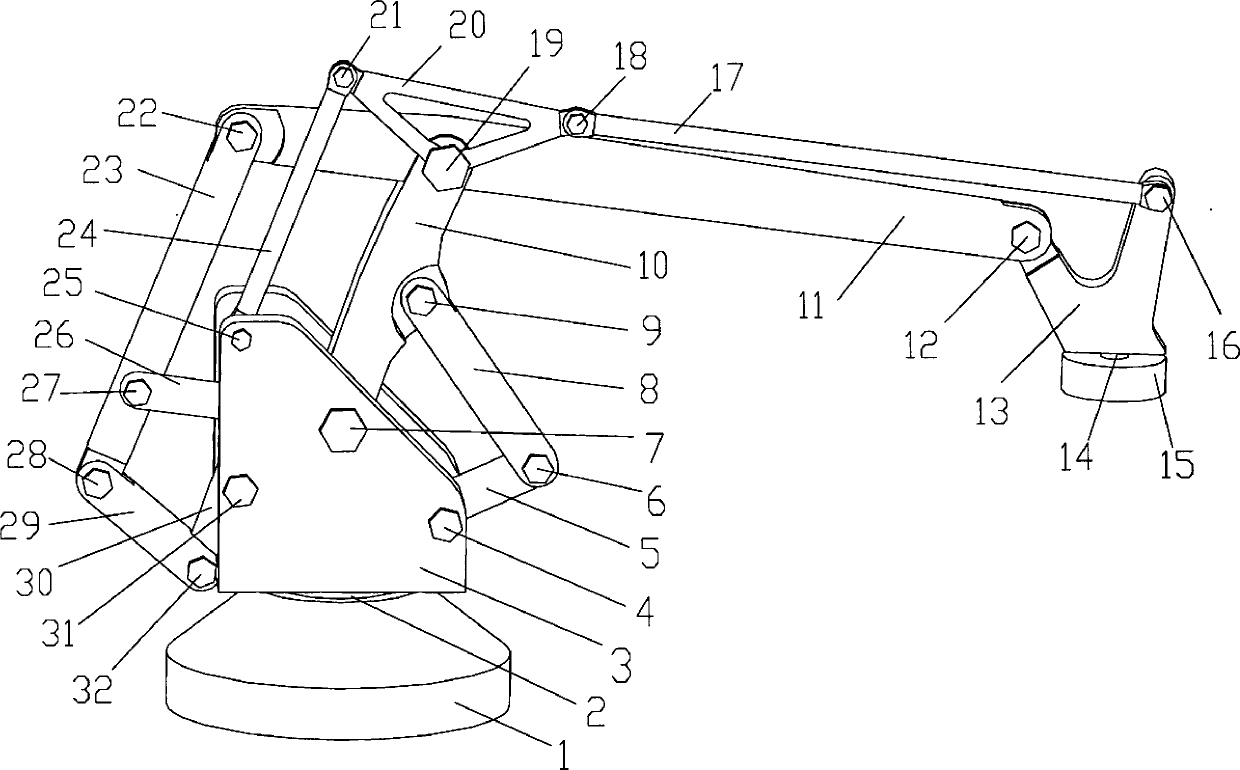

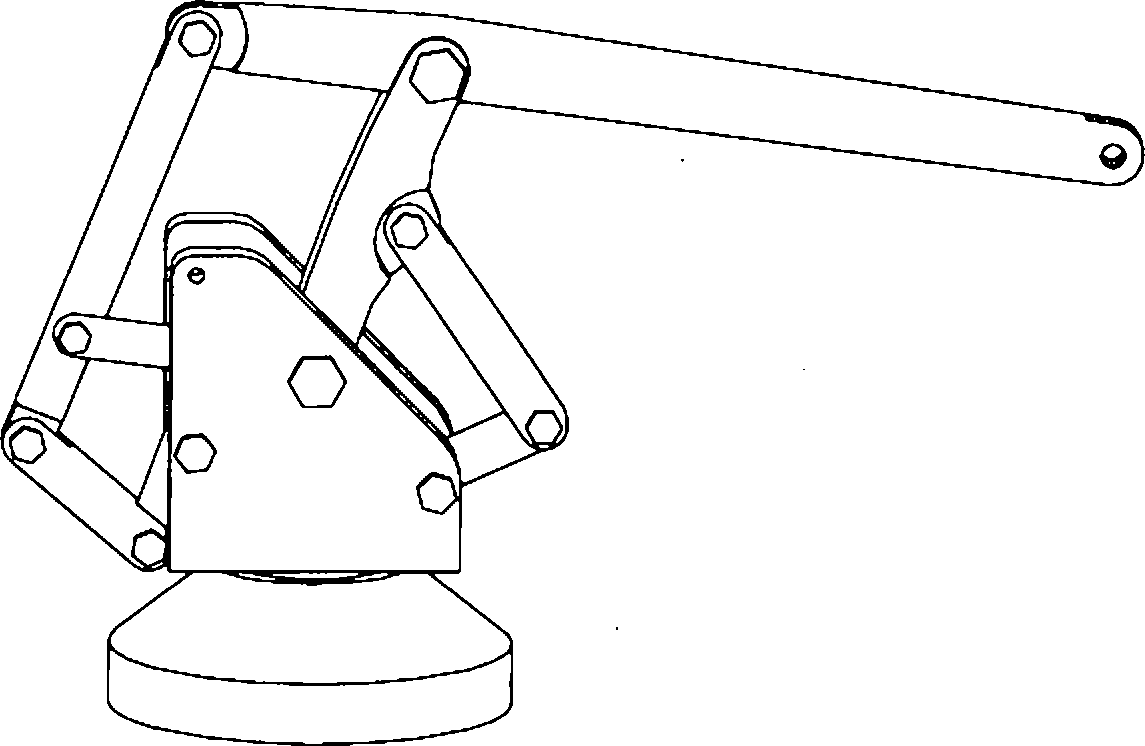

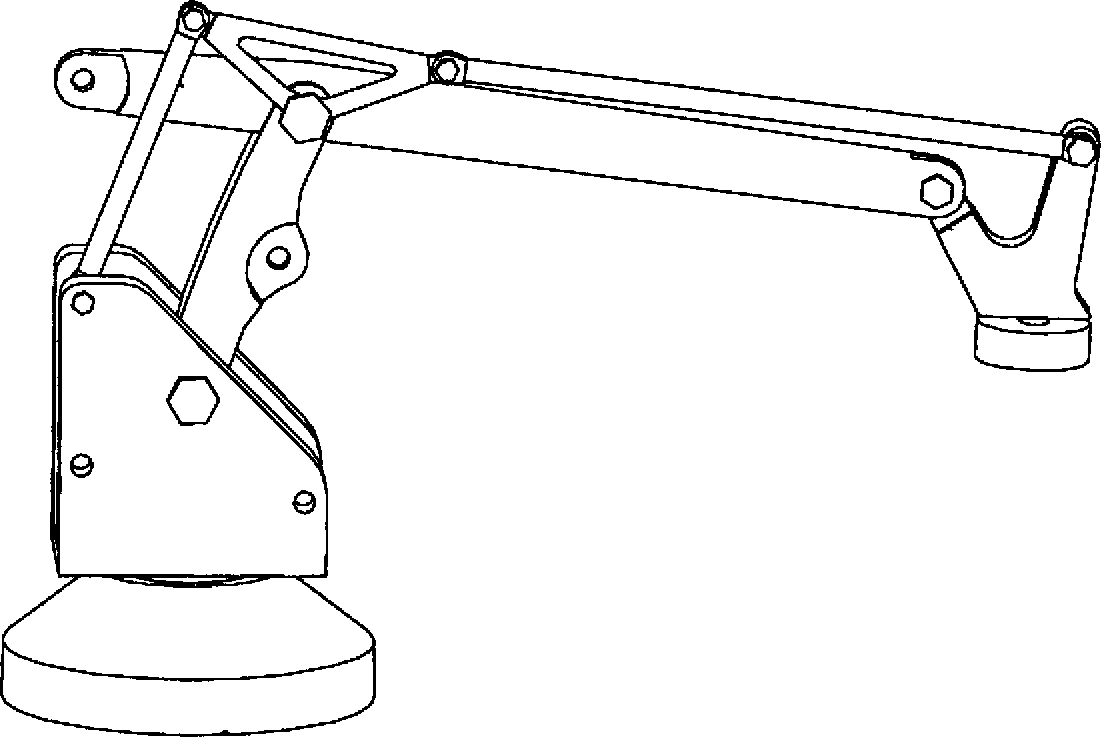

Carrying stacking mechanism

InactiveCN103121589AFlexible operationImprove flexibilityProgramme-controlled manipulatorStacking articlesNumerical controlActuator

A carrying stacking mechanism comprises a base seat, a rotary machine frame, an arm lifting mechanism, an end effector translation maintaining mechanism and a flange plate, wherein the rotary machine frame is connected on the base seat through a rotary pair, the arm lifting mechanism comprises a parallelogram mechanism, a first driving rod, a first connection rod, a second driving rod and a fourth connection rod, the parallelogram mechanism is composed of a large arm, a small arm, a second connection rod and a third connection rod, all the rod pieces are connected through hinges, the end effector translation maintaining mechanism comprises a parallelogram mechanism I and a parallelogram mechanism II, the parallelogram mechanism I is composed of a large arm, a first auxiliary connecting rod, a triangular auxiliary frame and the rotary machine frame, the parallelogram mechanism II is composed of a small arm, a second auxiliary connecting rod, a triangular auxiliary frame and an end effector translation maintaining device, all the rod pieces are connected through hinges, and the flange plate is connected on the end effector translation maintaining device through a rotary pair. The carrying stacking mechanism is simple in structure, is large in work space, is flexible to operate, is controlled through the driving of a servo motor, and can achieve intellectualization and numerical control.

Owner:GUANGXI UNIV

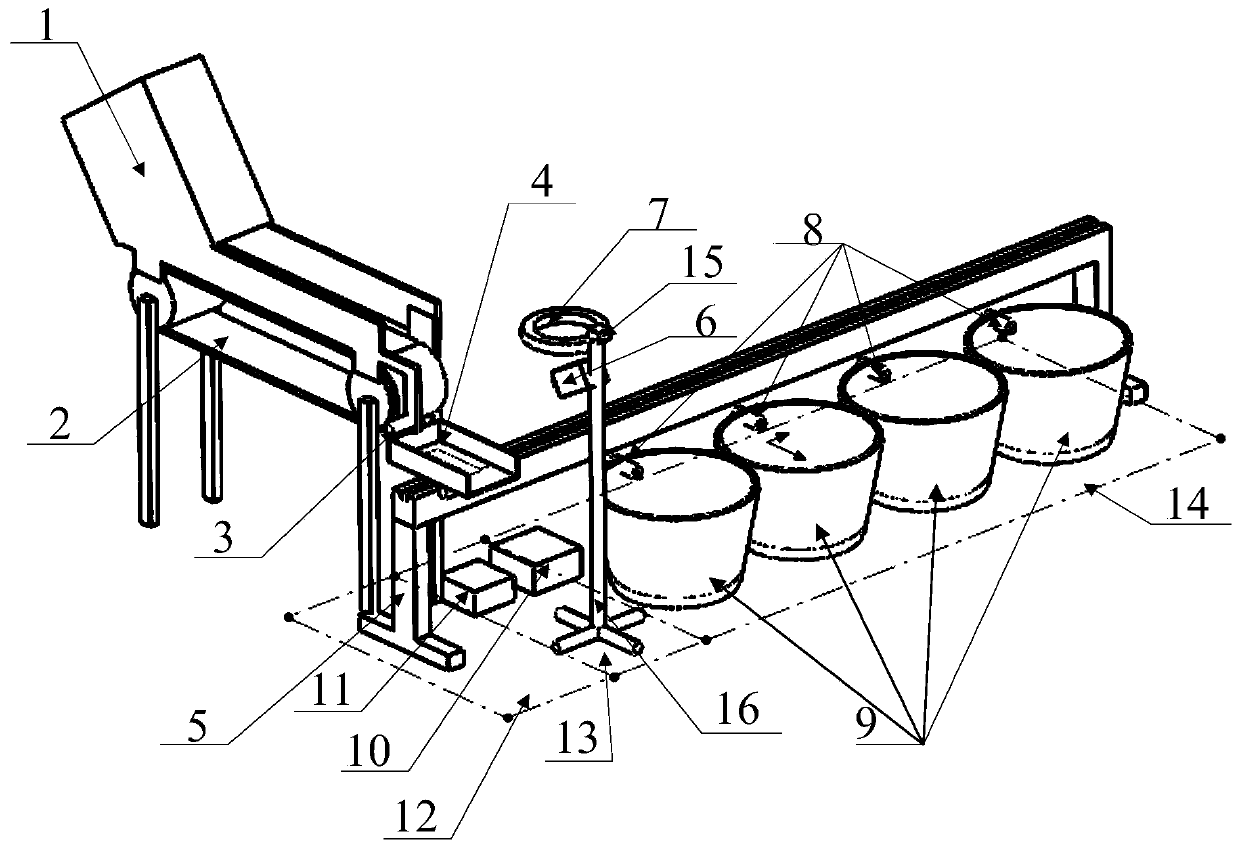

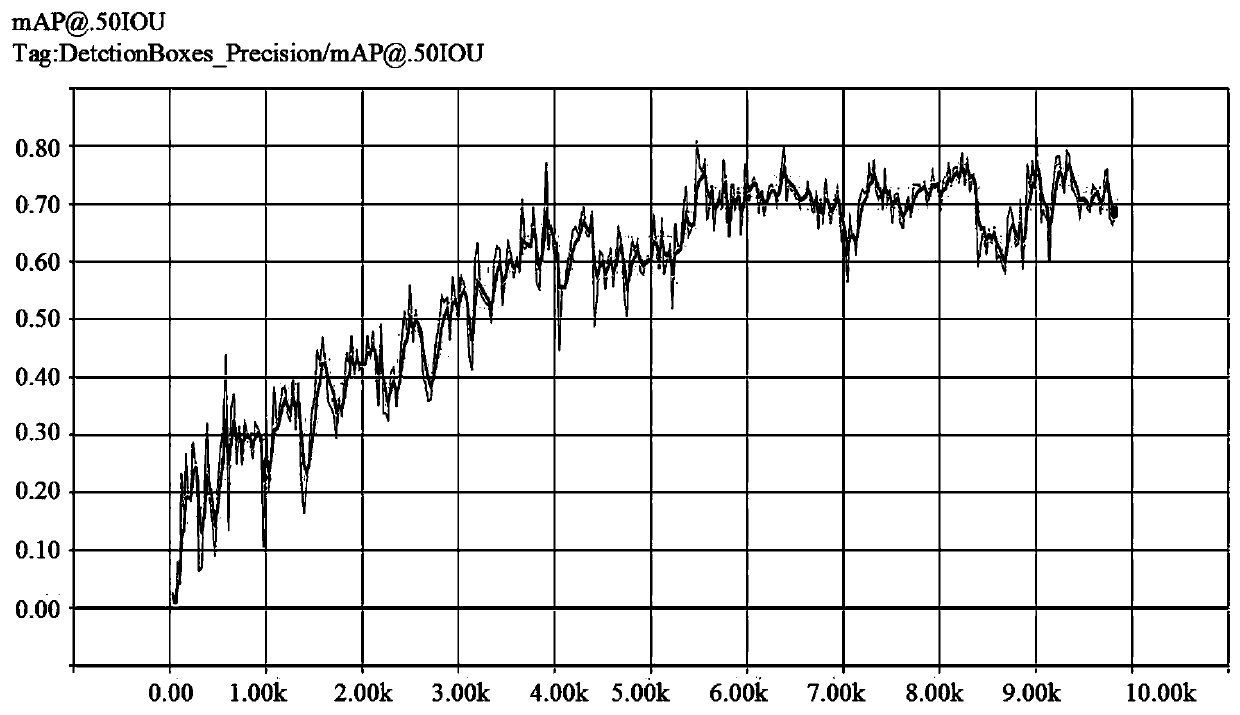

Visual garbage classification system based on TensorFlow and garbage classification method

InactiveCN110884791AImprove accuracyAchieve separationWaste collection and transferRefuse receptaclesPhotoswitchClassification methods

The invention discloses a visual garbage classification system based on TensorFlow and a garbage classification method. The system comprises a conveying belt, a first photoelectric switch sensor, a garbage tray, a slide rail, a camera, a second photoelectric switch sensor, intelligent garbage cans, an NVIDIA machine learning platform and an STM32 controller. The system applies an AI technology togarbage recognition and applies a deep learning visual classification technology to garbage sorting, acquires garbage images by the camera and adopts a TensorFlow deep learning frame, and greatly improves the garbage recognition accuracy by migration training of a MobileNet SSD. An STM32 single-chip microcomputer processes recognition results, controls the conveying belt to separate garbage and controls the slide rail to accurately put garbage into corresponding intelligent garbage cans, carrying and placement of the garbage are realized, human participation is not needed, the working efficiency and accuracy are improved, and the labor cost is greatly reduced.

Owner:石家庄邮电职业技术学院

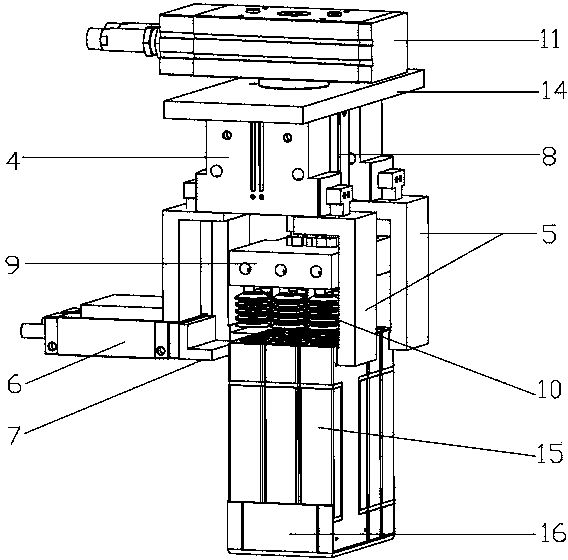

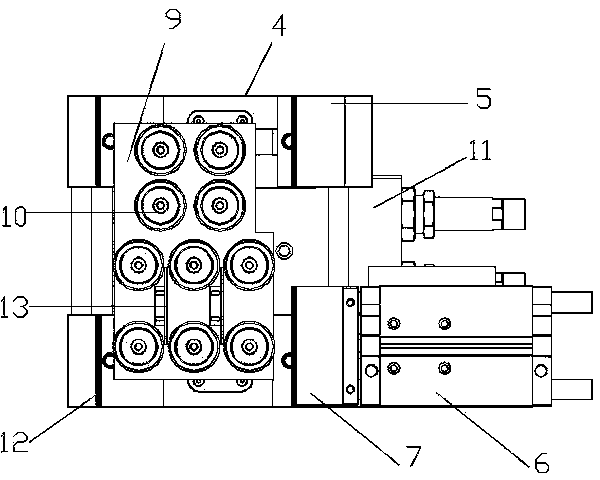

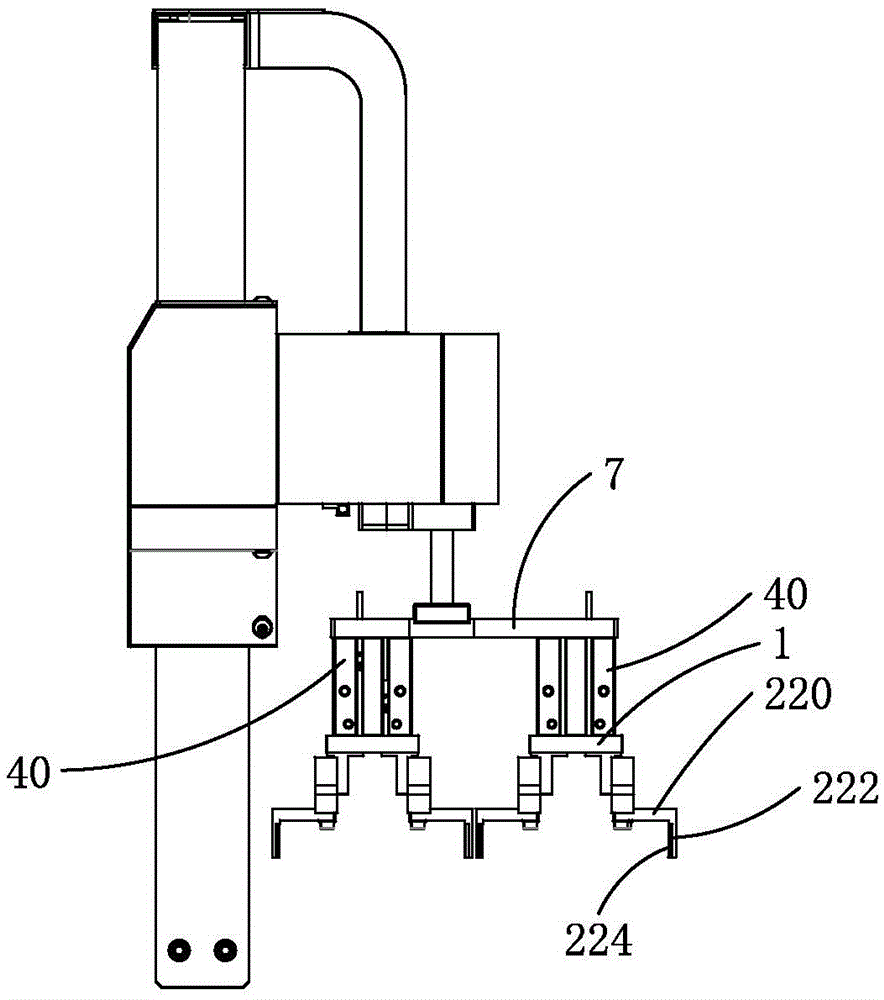

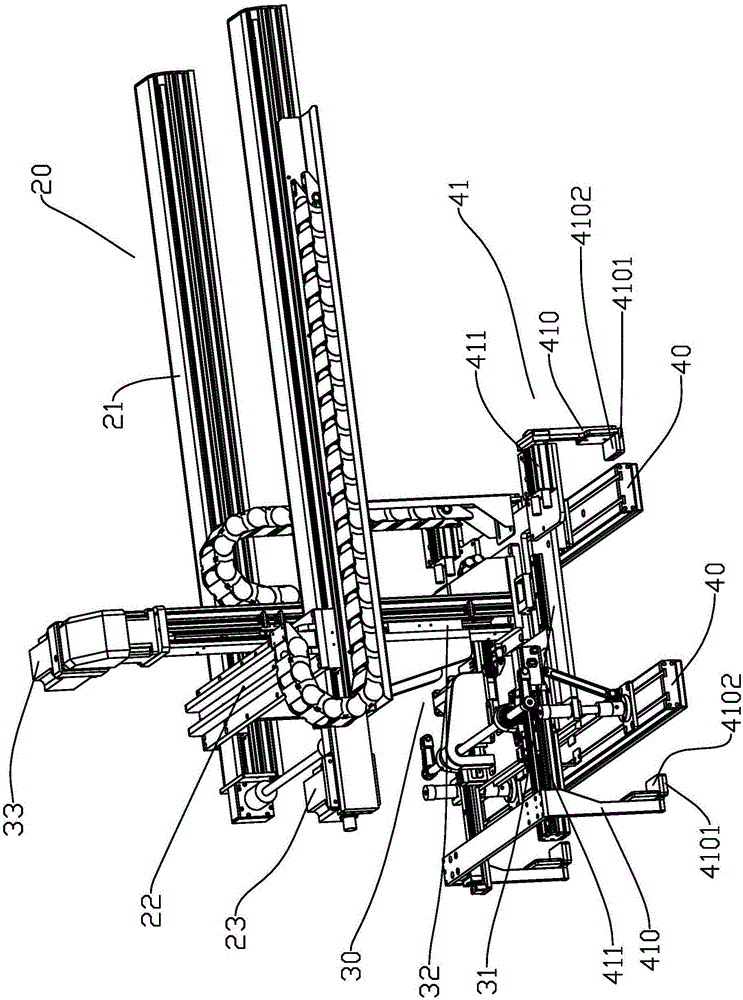

Electric cylinder hand grab used for grabbing battery pack

The invention discloses an electric cylinder hand grab used for grabbing a battery pack. The electric cylinder hand grab comprises a horizontal electric cylinder and a vertical electric cylinder connected with the horizontal electric cylinder. A hand grab body is arranged at the lower end of the vertical electric cylinder and comprises two double-end clamping air cylinders, and a clamping jaw is arranged at the stretchable end of each double-end clamping air cylinder. An auxiliary air cylinder is arranged at the head of one of the clamping jaws, and an auxiliary clamping block is arranged at the stretchable end of the auxiliary air cylinder. A vertical lifting air cylinder is arranged between the two double-end clamping air cylinders, the stretchable end of the lifting air cylinder faces downwards and is connected with a sucking disc fixing base, and a plurality of sucking discs are arranged on the lower side face of the sucking disc fixing base. The upper ends of the double-end clamping air cylinders and the upper end of the lifting air cylinder are fixedly connected through a connecting plate. A rotating air cylinder is arranged between the connecting plate and the lower end of the vertical electric cylinder. Therefore, the electric cylinder hand grab has the advantages of being capable of safely and stably grabbing the battery pack and smoothly achieving carrying and packing of the battery pack.

Owner:HANGZHOU WAHAHA TECH

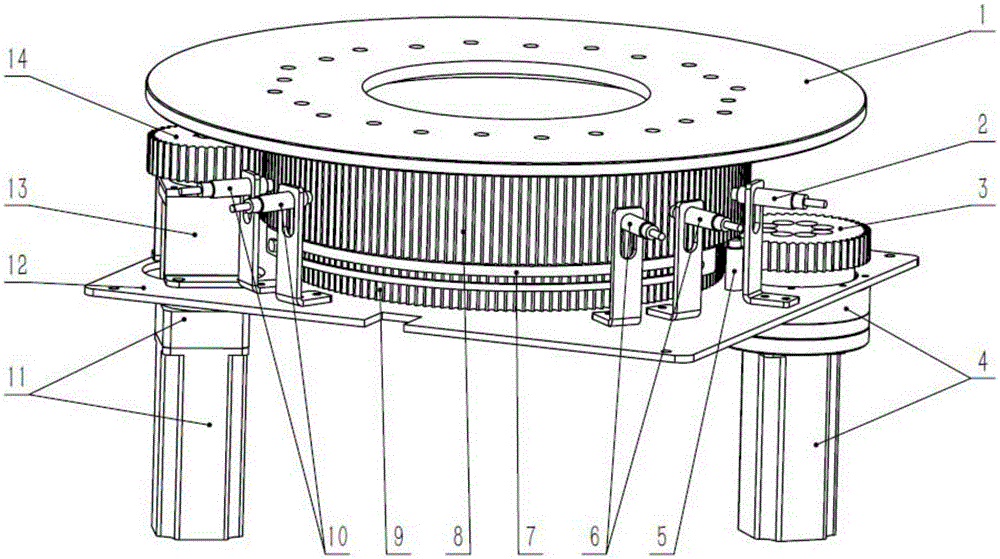

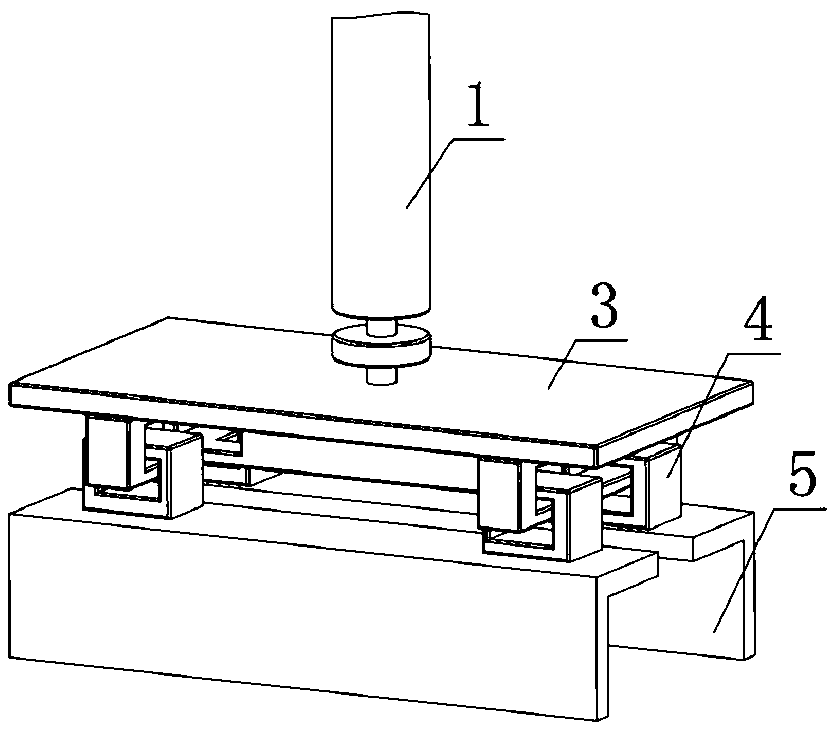

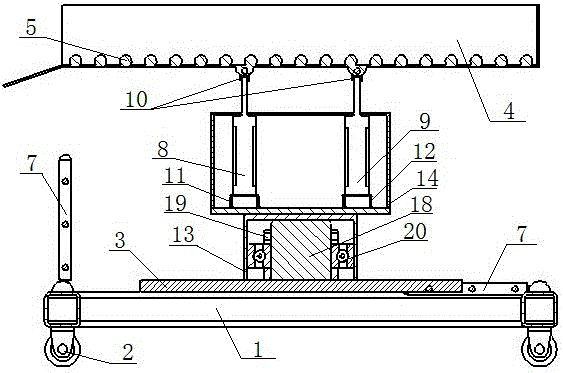

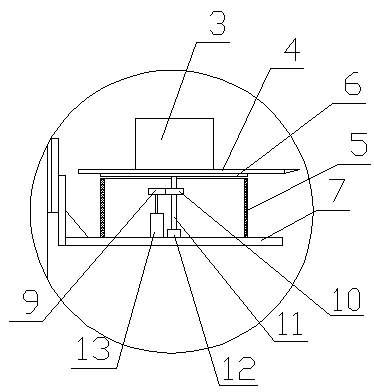

Spiral lifting mechanism and automatic guided vehicle (AGV)

The invention discloses a spiral lifting mechanism and an automatic guided vehicle (AGV). The spiral lifting mechanism comprises a jacking plate, an installation base board, a jacking mechanism and a jacking drive mechanism. The jacking mechanism comprises a thread pair and a slewing bearing, the outer ring of an outer thread part of the thread pair is a gear, the inner ring is in threaded connection with an inner thread part of the thread pair, the inner ring of the slewing bearing is fixedly connected with the installation base board, the outer ring of the slewing bearing is fixedly connected with the lower portion of the inner thread part of the thread pair, and the jacking plate is fixed to the outer thread part of the thread pair. The jacking drive mechanism comprises a lifting pinion and a lifting drive motor; the lifting pinion is fixedly connected with a motor shaft of the lifting drive motor; the lifting pinion is engaged with an outer-ring gear of the slewing bearing; the lifting drive motor is installed on the installation base board. The spiral lifting mechanism further comprises a rotary control mechanism, and the rotary control mechanism can rotate and lock the outer thread part of the thread pair.

Owner:HANGZHOU JIAZHI TECH CO LTD

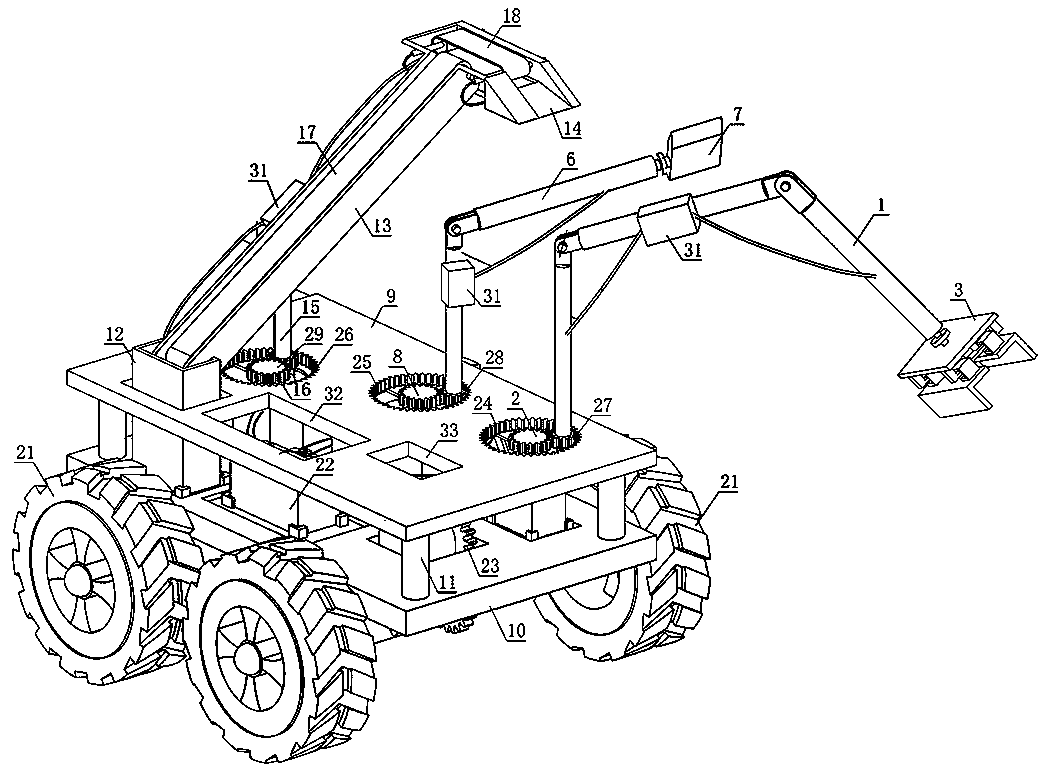

Wall building machine

InactiveCN108708560AReduce labor intensitySave time and costBuilding material handlingEngineeringMechanical engineering

The invention discloses a wall building machine, which comprises a brick grabbing mechanism, a mortar feeding mechanism and a plastering mechanism. The brick grabbing mechanism, the mortar feeding mechanism and the plastering mechanism are all arranged on an operating platform. The brick grabbing mechanism comprises a first mechanical arm and a brick clamping device; the mortar feeding mechanism comprises a mortar storage tank, a supporting frame and a conveying bucket; the plastering mechanism comprises a second mechanical arm and a plastering plate. The first mechanical arm and the second mechanical arm are both connected to the controller, and a moving mechanism is arranged under the operating platform. By integration of the brick grabbing mechanism, the mortar feeding mechanism and theplastering mechanism, a whole process of feeding, plastering and bricking is completed automatically, simulation of manual wall building action is realized, and accordingly manual participation is sharply reduced, and labor intensity is greatly relieved.

Owner:KAIFENG UNIV

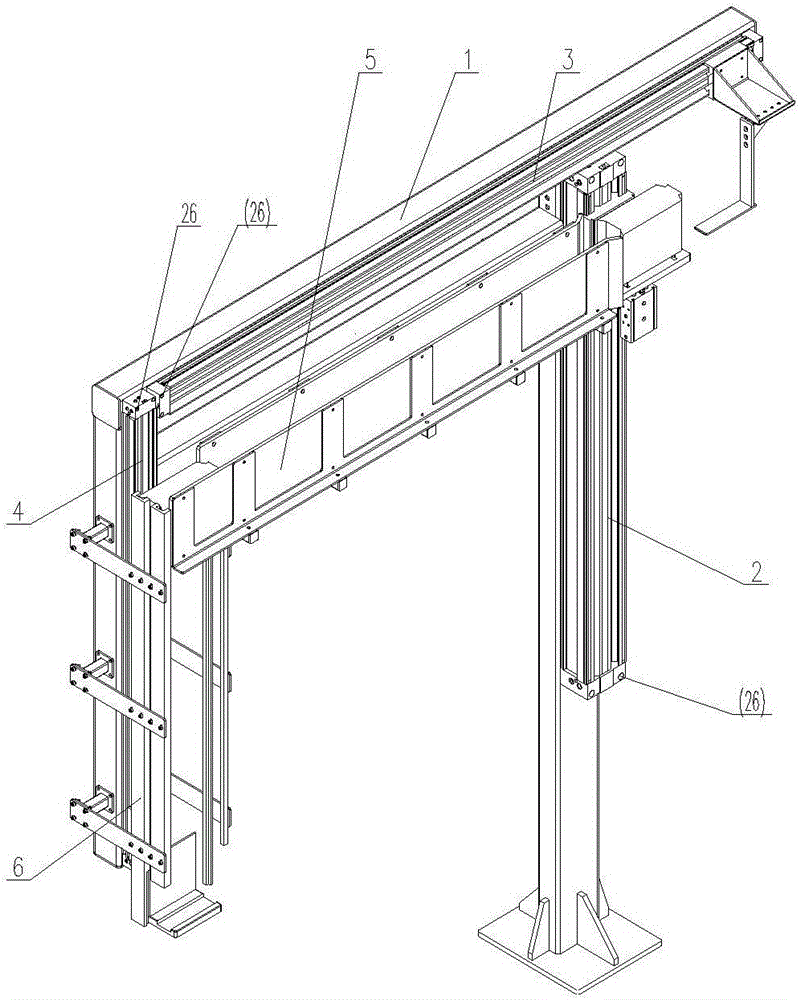

Single-portal-frame system

InactiveCN102963845AImprove work efficiencyReduce use costLifting devicesPortal framePulp and paper industry

The invention discloses a single- portal-frame system, which comprises a portal frame and a cargo fork, wherein two rolling wheels are respectively arranged at two sides of the cargo fork and are arranged in the portal frame for realizing the moving and the positioning of the cargo fork in the portal frame, the middle lower part of the portal frame is provided with a middle rib plate, in addition, the middle rib plate and the cargo fork are arranged at two sides of the portal frame, the portal frame is provided with an oil cylinder in the length direction, the bottom of the oil cylinder is fixedly arranged on a lower rib plate arranged at the bottom of the portal frame, the middle of the oil cylinder is fixedly connected with a convex block arranged on the middle rib plate through an oil cylinder hoop, the top end of the oil cylinder is provided with a chain wheel support seat, chains are respectively arranged on the chain wheels arranged at two sides of the chain wheel support seat, one end of each chain is fixedly arranged on the middle rib plate arranged at the middle lower part of the portal frame, and the other end of each chain is connected with the cargo fork. The single-portal-frame system provided by the invention has the advantages that through the driving of the hydraulic system of the oil cylinder, articles placed on the cargo fork can ascend and descend, so the article carrying is realized, the work efficiency is high, in addition, the use cost is low, and the production development of enterprises can be effectively met.

Owner:SUZHOU PIONEER MATERIAL HANDLING EQUIP & TECH

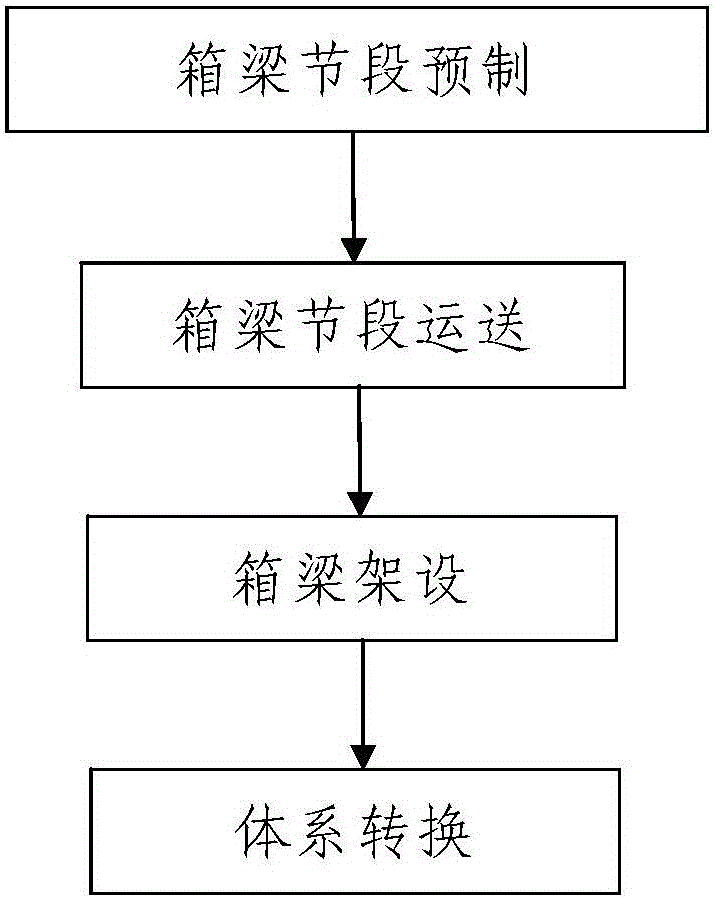

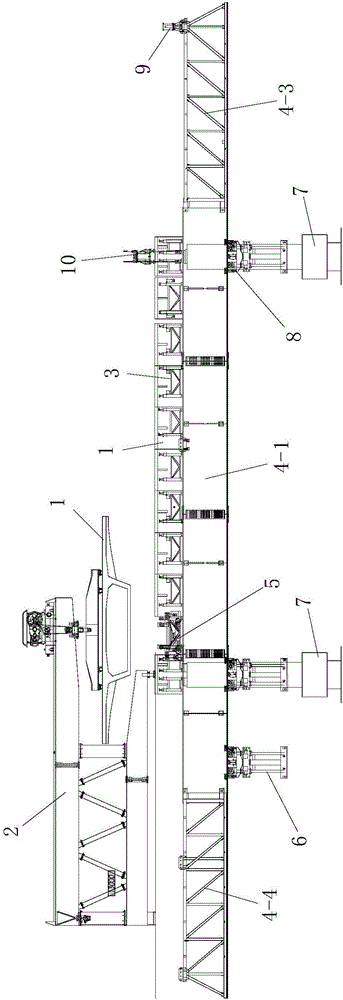

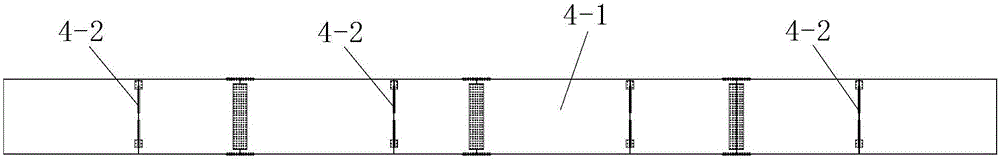

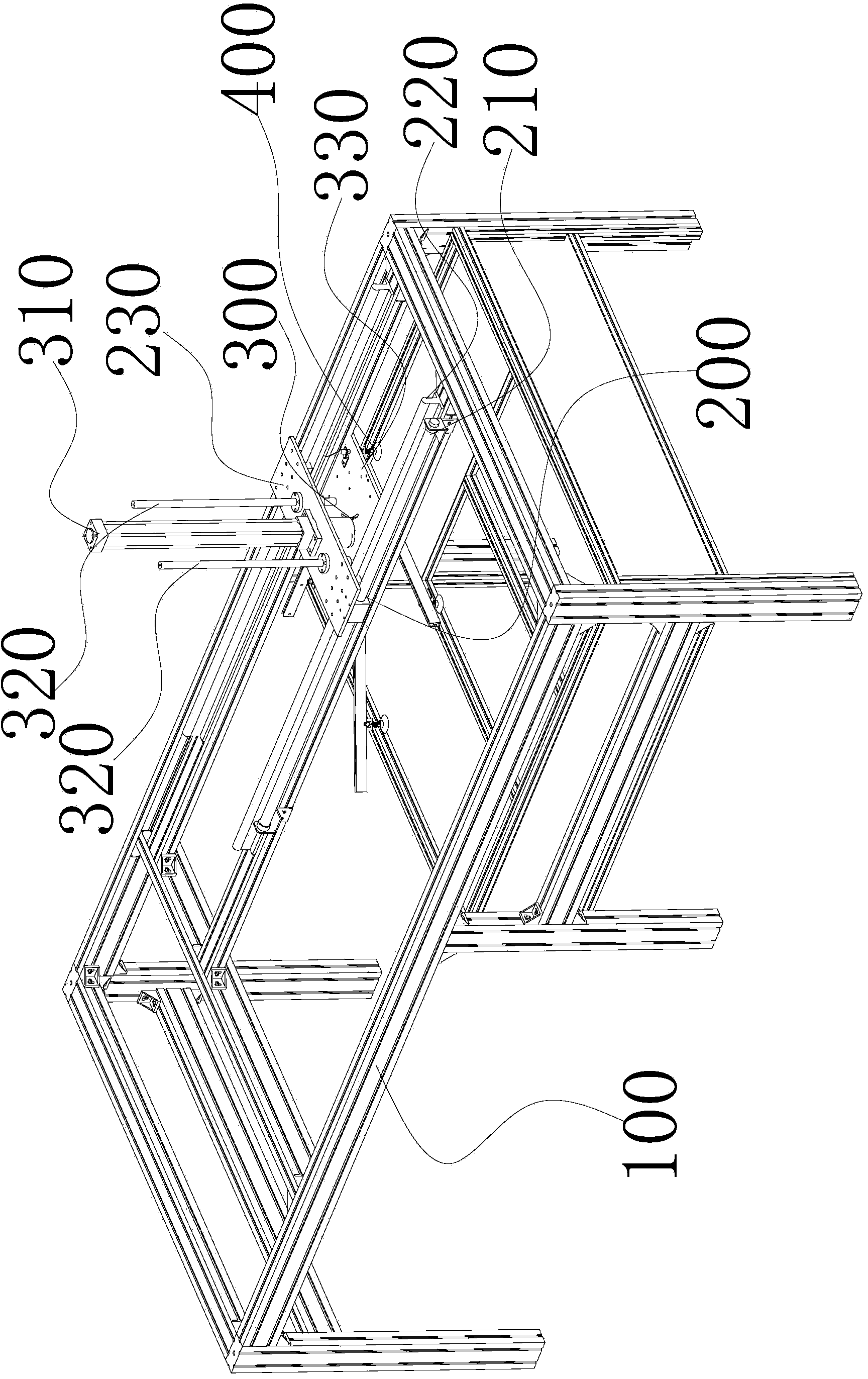

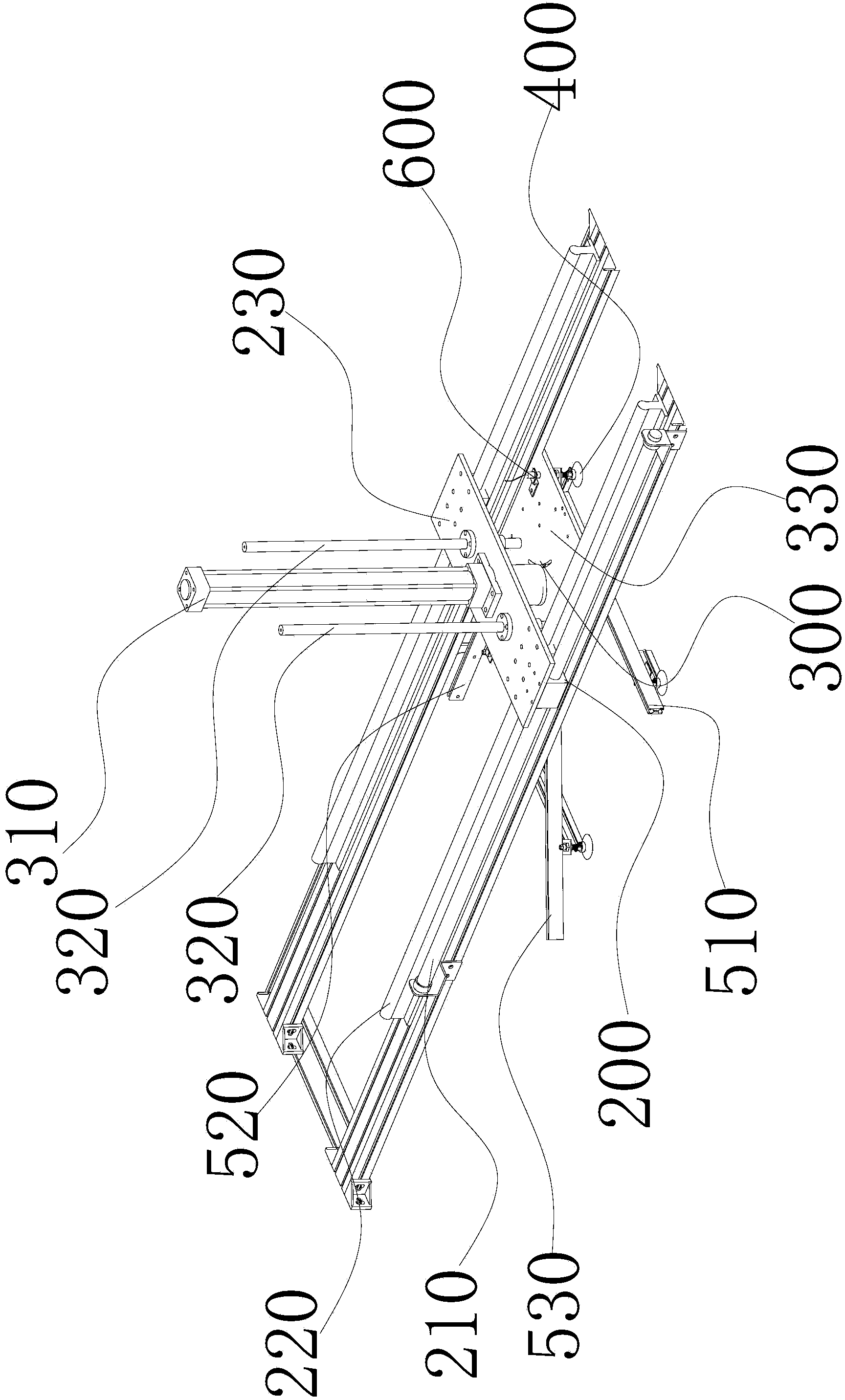

Segmental assembling box girder construction technology

ActiveCN105780660AThe construction process steps are simpleReasonable designBridge erection/assemblySupporting systemCantilever

The invention discloses a segmental assembling box girder construction technology. A constructed box girder is composed of multiple porous girders. Each porous girder is formed by assembling multiple box girder segments from back to front. When the constructed box girder is constructed, the process includes the following steps that firstly, the box girder segments are prefabricated, wherein all the box girder segments used for forming the constructed box girder are prefabricated in a prefabrication site in a concentrated manner; secondly, the box girder segments are transported, wherein all the box girder segments are transported to the erection position of the constructed box girder through a girder transport vehicle; thirdly, the box girder is erected, wherein the constructed box girder is erected and constructed through a descending bridge girder erection machine, and the descending bridge girder erection machine comprises a bottom horizontal supporting system, a main girder system, a longitudinal moving system, a cantilever crane, an assembling frame and an assembling vehicle; and fourthly, a system is converted, wherein the system is converted after the erection construction process is finished. By the adoption of the segmental assembling box girder construction technology, the technological step is simple, design is reasonable, construction is easy and convenient, a construction process is easy to control, a use effect is good, the segmental assembling box girder assembling process can be simply, conveniently and rapidly finished, and the construction quality is easy to guarantee.

Owner:CHINA RAILWAY FIRST GRP CO LTD

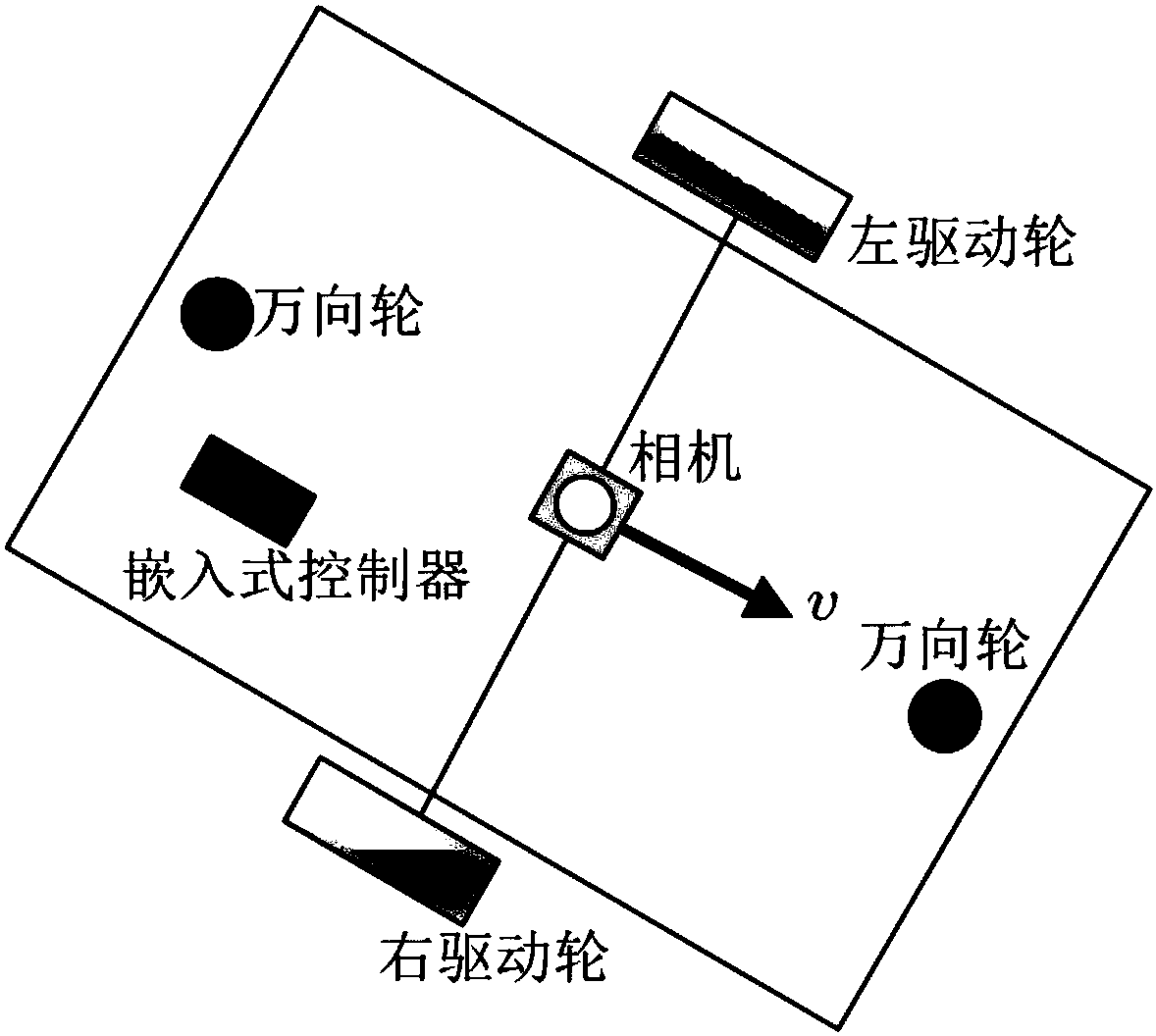

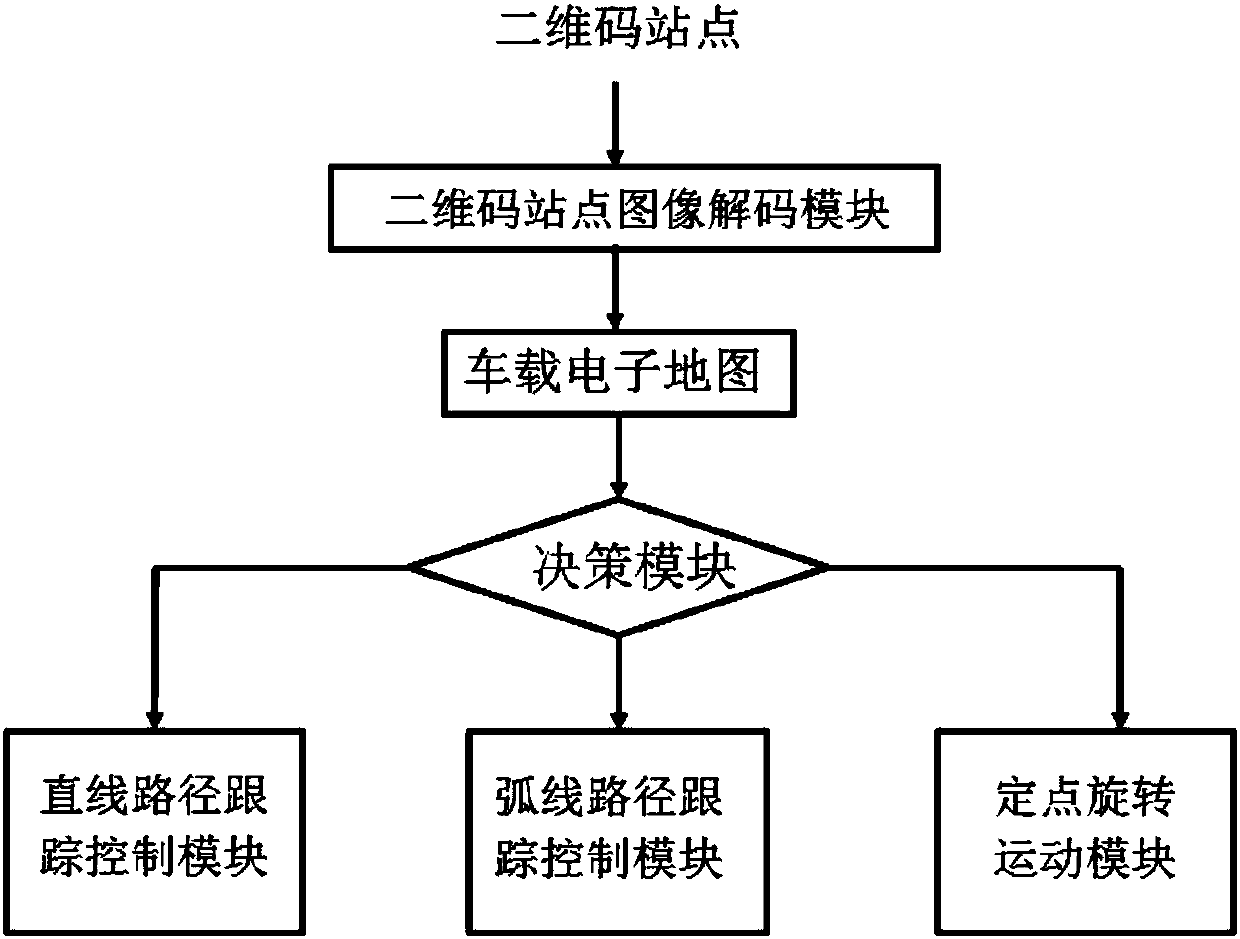

AGV composite navigation system and method integrating electronic map, two-dimensional code and colored tape

ActiveCN108088439ARealize handlingReduce post-maintenance costsNavigation instrumentsRecord carriers used with machinesStraight pathNavigation system

The invention discloses an AGV composite navigation system and method integrating an electronic map, a two-dimensional code and a colored tape. The system comprises a car-mounted device, an electronicmap and a colored tape; the colored tape is provided with a two-dimensional code site comprising at least two two-dimensional codes; each two-dimensional code site has an exclusive number and corresponds to the electronic map; the car-mounted device comprises a camera and a control unit; the control unit comprises a two-dimensional code site image decoding module, a decision module, a straight path tracking control module, an arc path tracking control module and a fixed point rotation movement module; the decision module selects a next path according to a site number and an AGV azimuth angleacquired by the two-dimensional code site image decoding module, obtains a type of the next path from the electronic map, and switches the straight path tracking control module, the arc path trackingcontrol module and the fixed point rotation movement module to respectively perform the straight movement, the arc movement and the fixed point rotation movement, so that the autokinetic movement of an AGV cart from any site to another site of a car-mounted electronic map.

Owner:浙江科钛机器人股份有限公司

Logistics tray with hydraulic ejecting wheel

The invention relates to a logistics tray with a hydraulic ejecting wheel. The inside of the logistics tray is provided with a hydraulic or wheel retracting device; one end of a support arm is provided with a nylon wheel, the other end of the support arm is connected with a hydraulic cylinder, and the middle of the support arm is connected with the logistics tray to form a rotating arm; a wheel cylinder piston can be moved by treading on a pedal to push hydraulic oil into the hydraulic cylinder from a hydraulic connecting pipe; the action of the hydraulic oil pushes the support arm through the hydraulic force so that the nylon wheel can move downwards to lift the logistics tray up away from the ground and further the entire logistics tray can move freely; when the logistics tray moves in position, the hydraulic pressure of the hydraulic cylinder can be released, so that the nylon wheel can be pressed into the logistics tray under the action of gravity of the logistics tray and goods, and further the logistics tray can be stably placed in a assigned position.

Owner:CHONGQING HANQUICK LOGISTICS

Pneumatic material taking mechanical arm

InactiveCN105563480AFlexible adjustment of spacingAchieve releaseProgramme-controlled manipulatorGripping headsEngineeringManipulator

The invention provides a pneumatic material taking mechanical arm. The mechanical arm comprises a base plate, clamping fingers, a displacement mechanism and a clamping driving mechanism for driving the clamping fingers to be opened and closed; the displacement mechanism comprises a rodless air cylinder assembly and a guide rod air cylinder assembly; the rodless air cylinder assembly is arranged in the Y axis direction, and the guide rod air cylinder assembly is arranged on a movable block of the rodless air cylinder assembly and is arranged in the Z-axis direction; the base plate and the movable block of the guide rod air cylinder assembly are relatively fixedly connected, a sliding rail is arranged on the base plate, and each pair of clamping fingers comprises two transverse supports arranged on the sliding rail in a sliding manner; a plurality of mounting holes are formed in each transverse support, two mounting holes are each provided with a clamping finger unit in a locking manner, and the transverse supports of the same pair of clamping fingers and the clamping finger units are symmetrically arranged; and the clamping driving mechanism comprises a clamping air cylinder arranged in the Z axis direction and a transmission assembly which is arranged between the tail end of a piston rod of the clamping air cylinder and the top ends of the transverse supports so as to drive the two transverse supports of each pair of clamping fingers and the clamping finger units on the two transverse supports to synchronously move in an opposite or backing manner. The pneumatic material taking mechanical arm is simple in overall structure and high in applicability.

Owner:GUANGDONG FXD INTELLIGENT EQUIP CO LTD

Porcelain brick conveying robot unit

The present invention discloses one kind of ceramic tile transporting manipulator, and aims at providing ceramic tile transporting tool with low cost and high safety. The ceramic tile transporting manipulator has the structure including a support, an upper cylinder connected through a link rod with the support, a track connected to the upper cylinder, a motor on the track, and a suction cup unit in the lower part of the support.

Owner:于复生

Simple carrying and discharging truck

InactiveCN106586890AEasy to control tilt angleRealize handlingLifting framesControl systemEngineering

The invention discloses a simple carrying and discharging truck and belongs to the field of discharging trucks. By adoption of the simple carrying and discharging truck, the technical problems that a control system in the prior art is complex, inflexible in rotation angle and prone to damaging a platform, and personal safety is endangered in the carrying and discharging processes are solved. According to the technical scheme, the simple carrying and discharging truck comprises a base, universal wheels, a support plate and a material containing tank. The support plate is installed on the base. The universal wheels are installed at the four corners of the base correspondingly. The material containing tank is connected with the support plate through a lifting mechanism and a rotation mechanism. The bottom of the material containing tank is connected with the lifting mechanism, the bottom of the lifting mechanism is connected and coaxial with the top of the rotation mechanism, and the rotation mechanism is installed at the center of the support plate.

Owner:吴学深

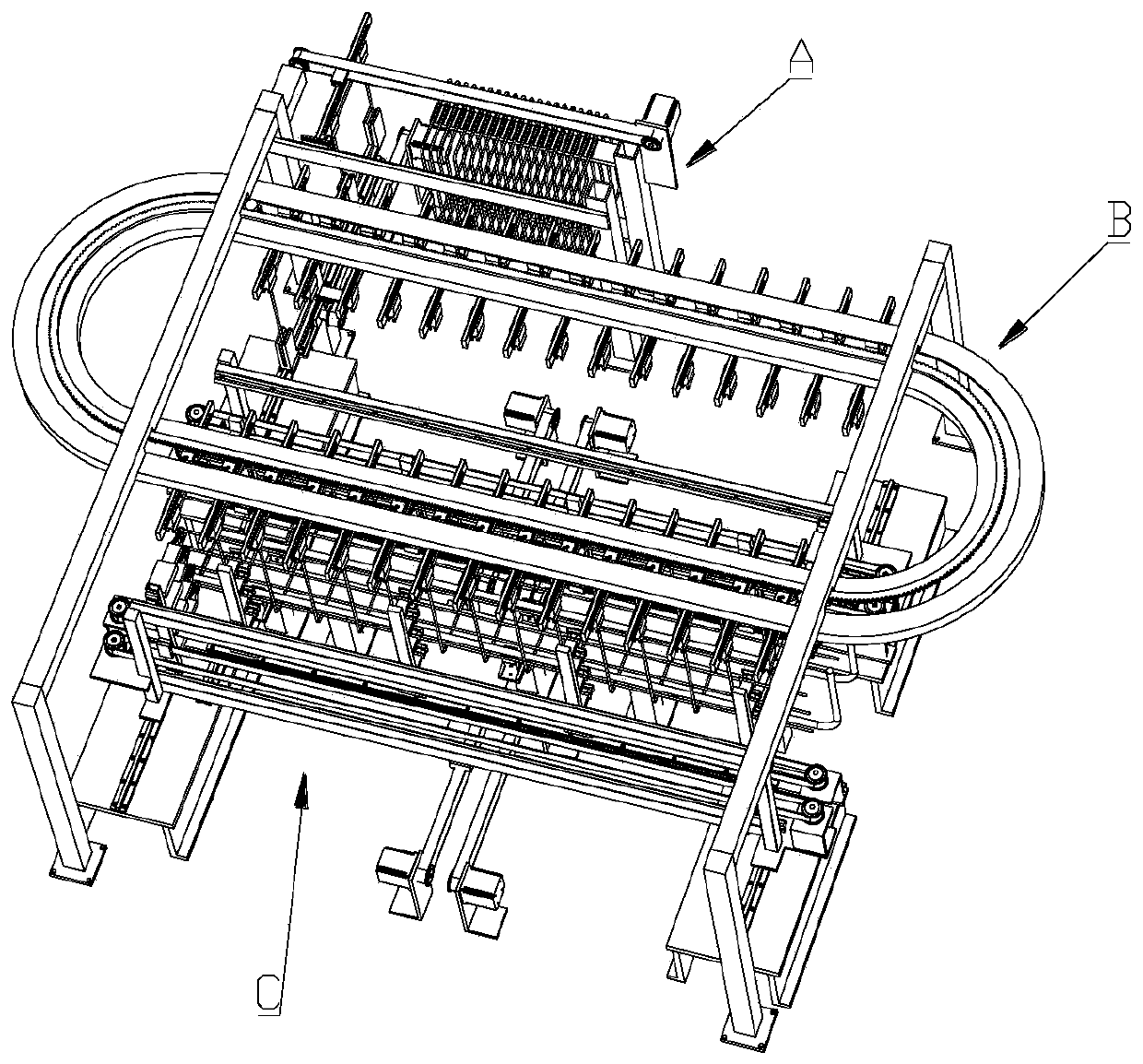

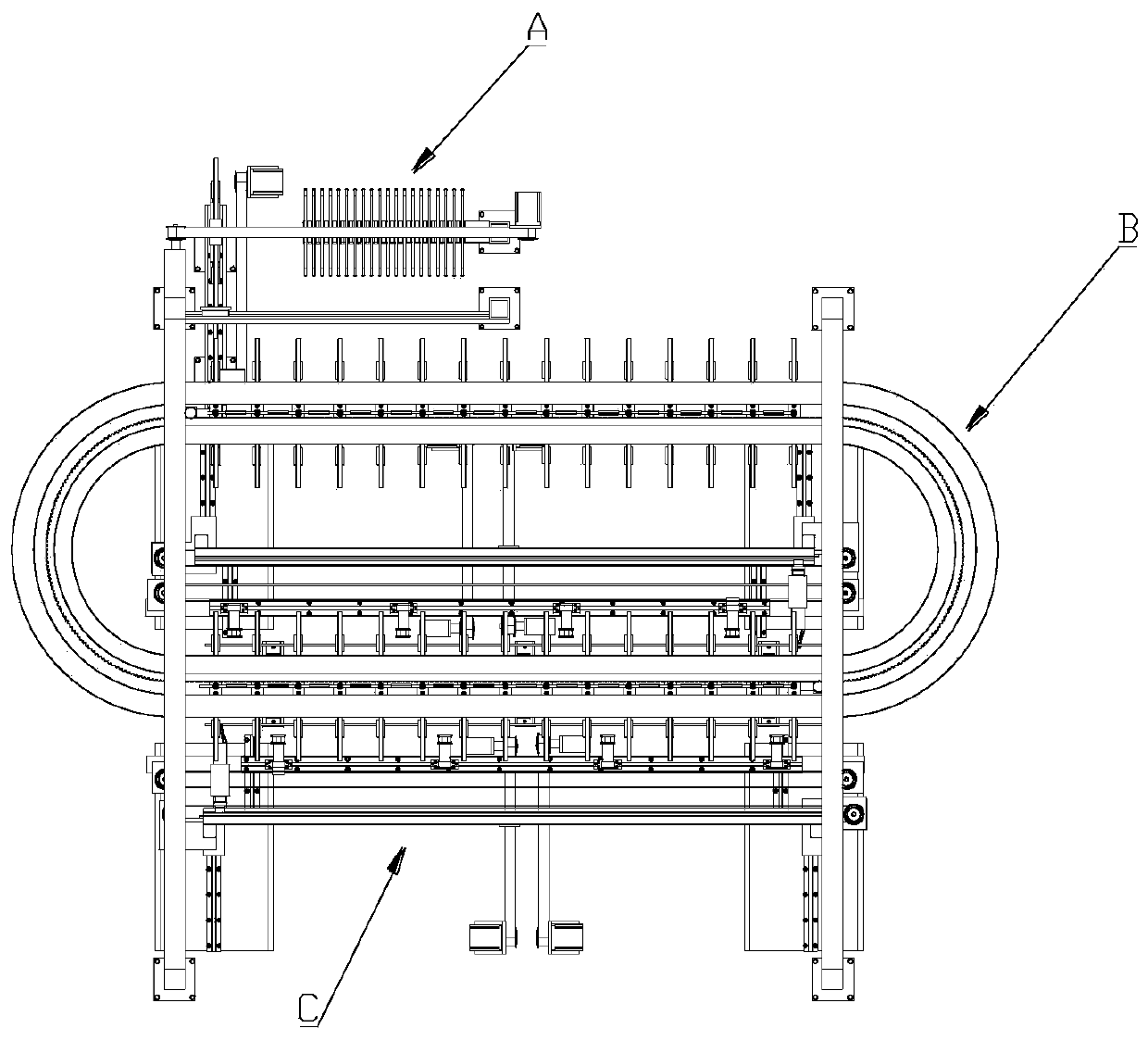

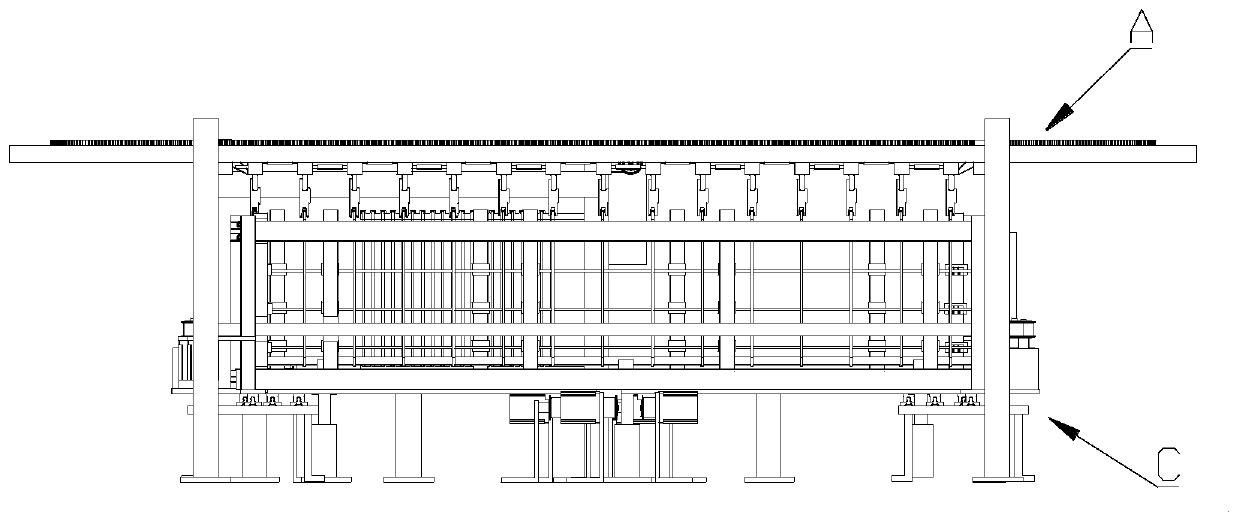

Steel reinforcement cage production equipment

InactiveCN110103334AImprove construction efficiencyReduce labor intensityCeramic shaping apparatusRebarLine segment

The invention discloses steel reinforcement cage production equipment comprising an automatic stirrup feeding device, an automatic stirrup conveyor device and a support device; the automatic stirrup feeding device comprises a stirrup storage rack, a stirrup conveyor seat, a first handling mechanism and a second handling mechanism, and the automatic stirrup conveyor device comprises a third supportframe, a conveying guide rail, a plurality of stirrup conveying parts and a stirrup conveying mechanism; the conveying guide rail is in a closed ring shape, and straight-line segments are arranged atthe positions, corresponding to the support device, of the conveying guide rail; every two adjacent stirrup conveying parts are connected through a connecting piece rotatably; and the support devicecomprises a support platform, a first support mechanism and a second support mechanism. According to the steel reinforcement cage production equipment, stirrups, longitudinal reinforcements and additional reinforcements can be conveyed onto the support device automatically, so that the construction of bed-jig is finished; in addition, the separation of the bed-jig and the support device can be further achieved, so that the bed-jig is easy to handle to a casting station through the handling device for casting.

Owner:佛山市集知汇科技有限公司

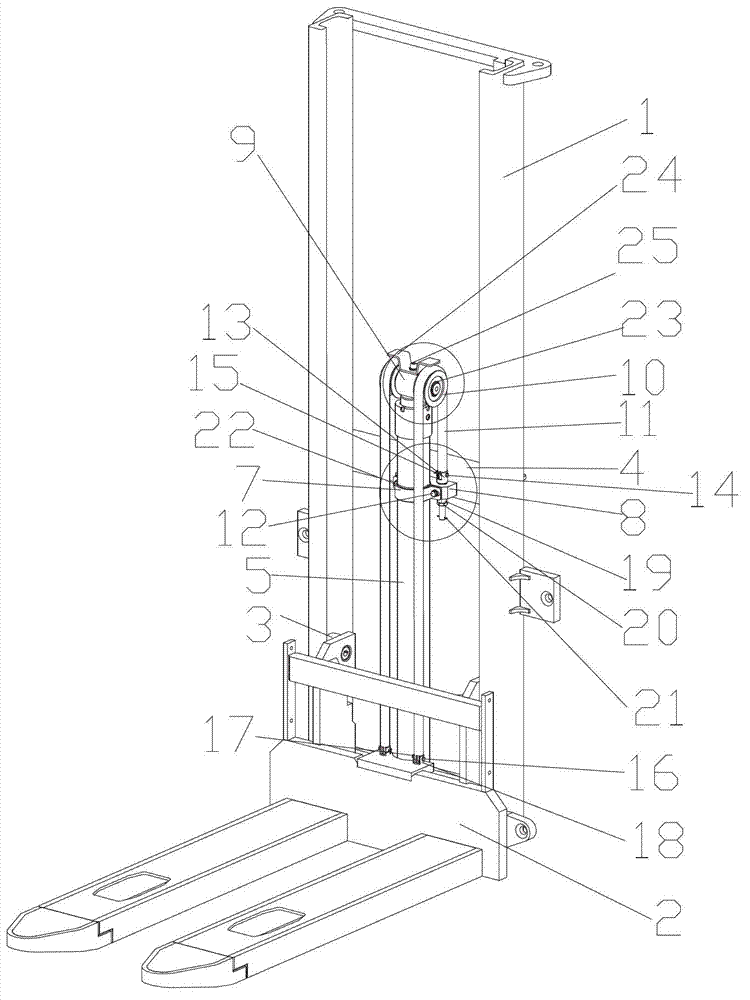

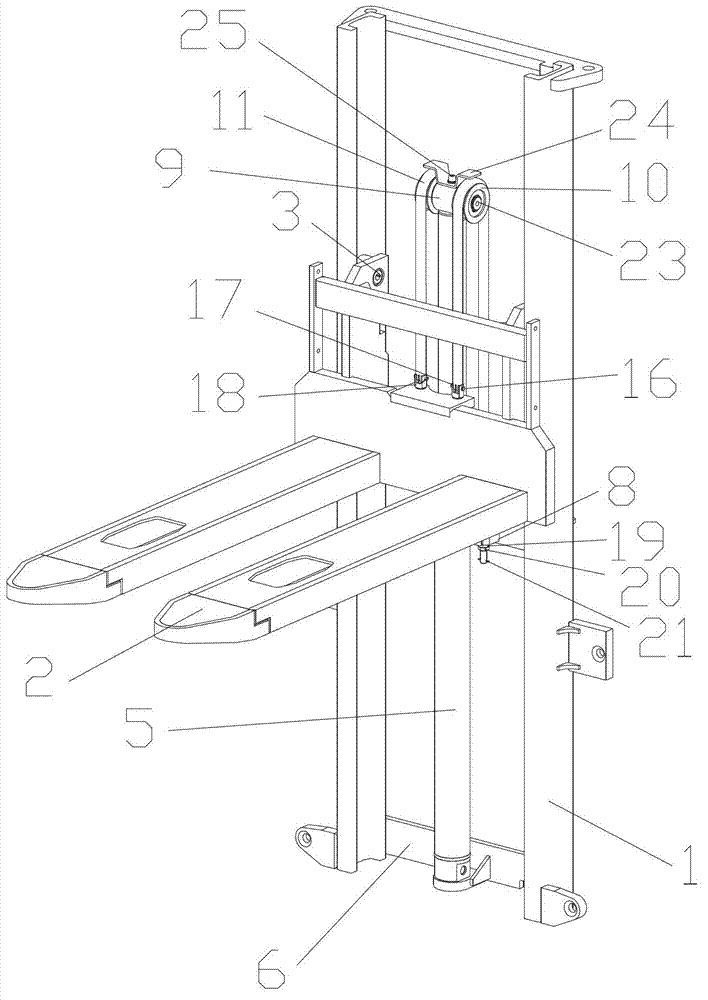

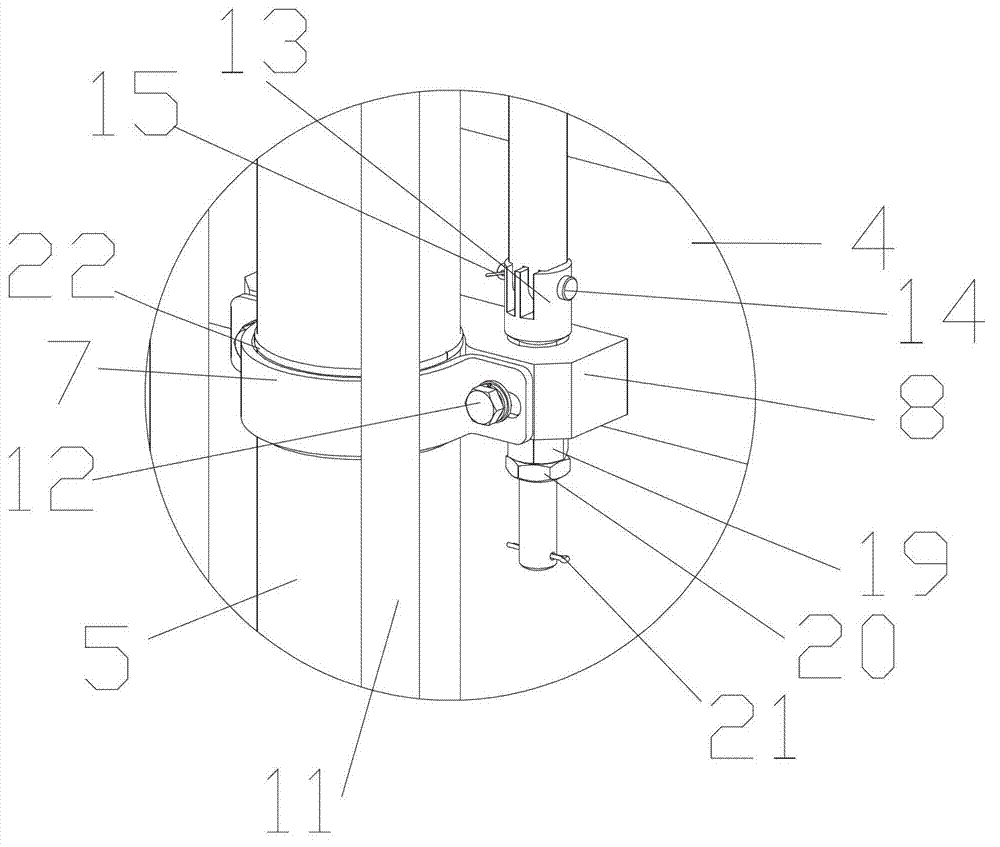

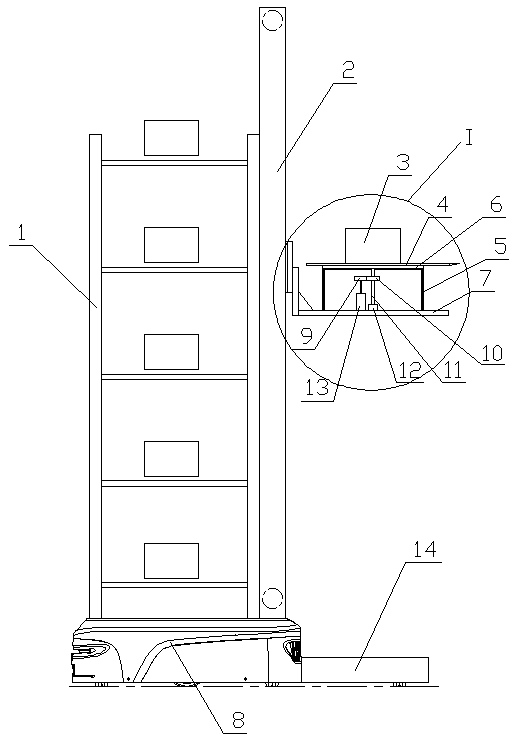

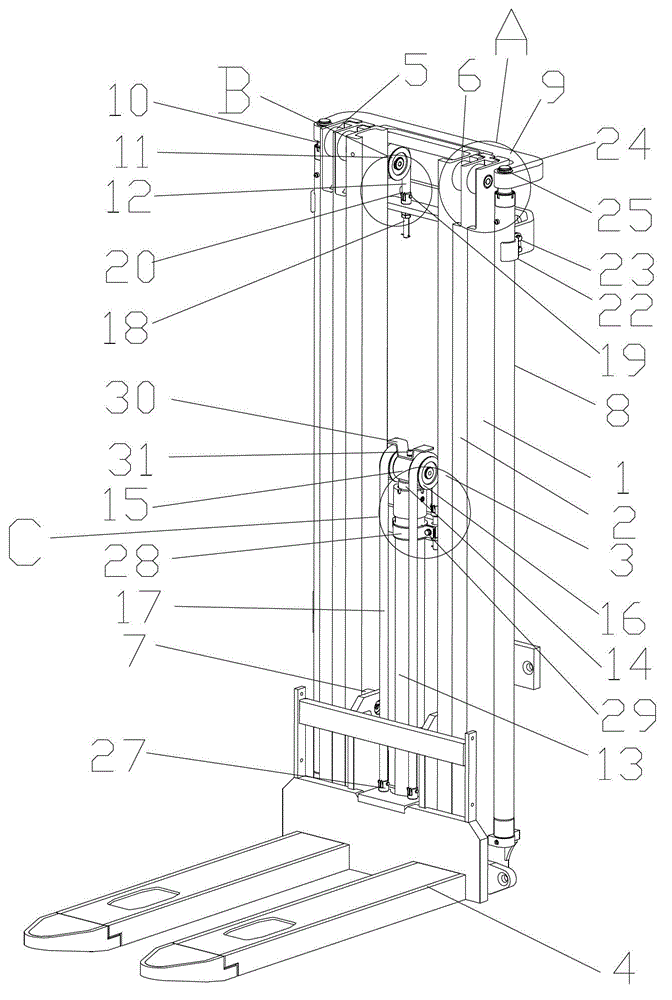

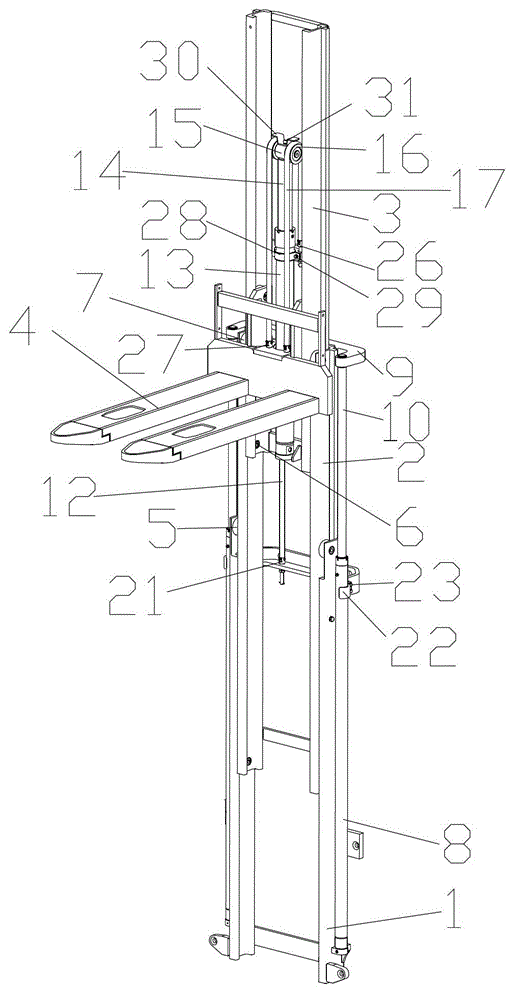

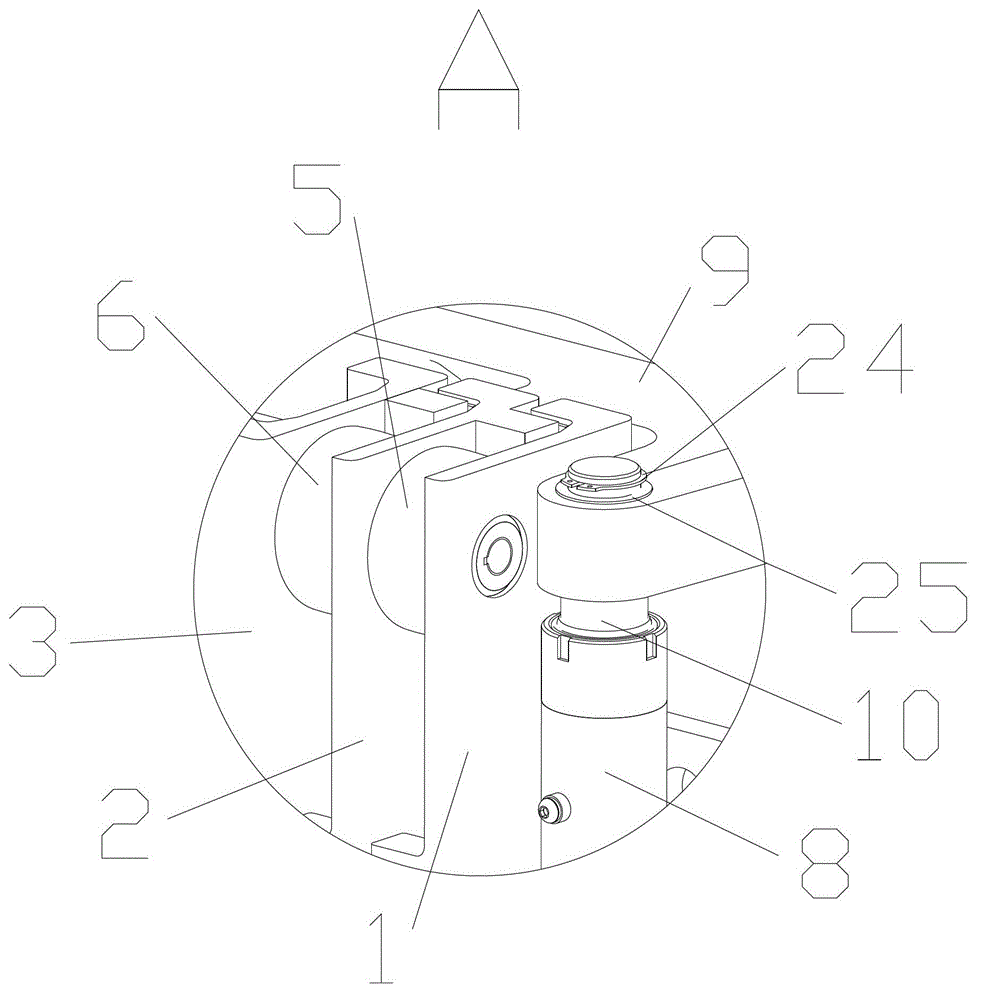

Front fork and rear rack transfer robot

PendingCN109264627ARealize handlingHigh positioning accuracyLifting devicesEconomic benefitsPallet fork

The invention relates to a front fork and rear rack transfer robot which comprises a self-propelled chassis. The front fork and rear rack transfer robot is characterized in that a rack and a fork lifting mechanism are arranged on the self-propelled chassis, and the self-propelled chassis, the rack and the fork lifting mechanism are fixedly connected together. One side of the self-propelled chassisadjacent to the fork lifting mechanism is connected with a self-balancing supporting leg. The outer side of the fork lifting mechanism is connected with a flat plate, a rotating disk capable of rotating by 90 degrees is arranged on the flat plate, and a telescopic fork capable of bidirectionally extending and retracting is arranged on the rotating disk. By the aid of the front fork and rear racktransfer robot, a dealer does not need to upgrade or rebuild warehouse racks, does not need to enlarge the distance and the walkway between the racks and does not need to invest heavily, economic benefits are greatly improved, and the front fork and rear rack transfer robot avoids the embarrassment that a backpack transfer robot transfers a whole rack once and only can finish sorting commodities with one specification, and transfer efficiency is greatly improved.

Owner:无锡弘宜智能科技股份有限公司

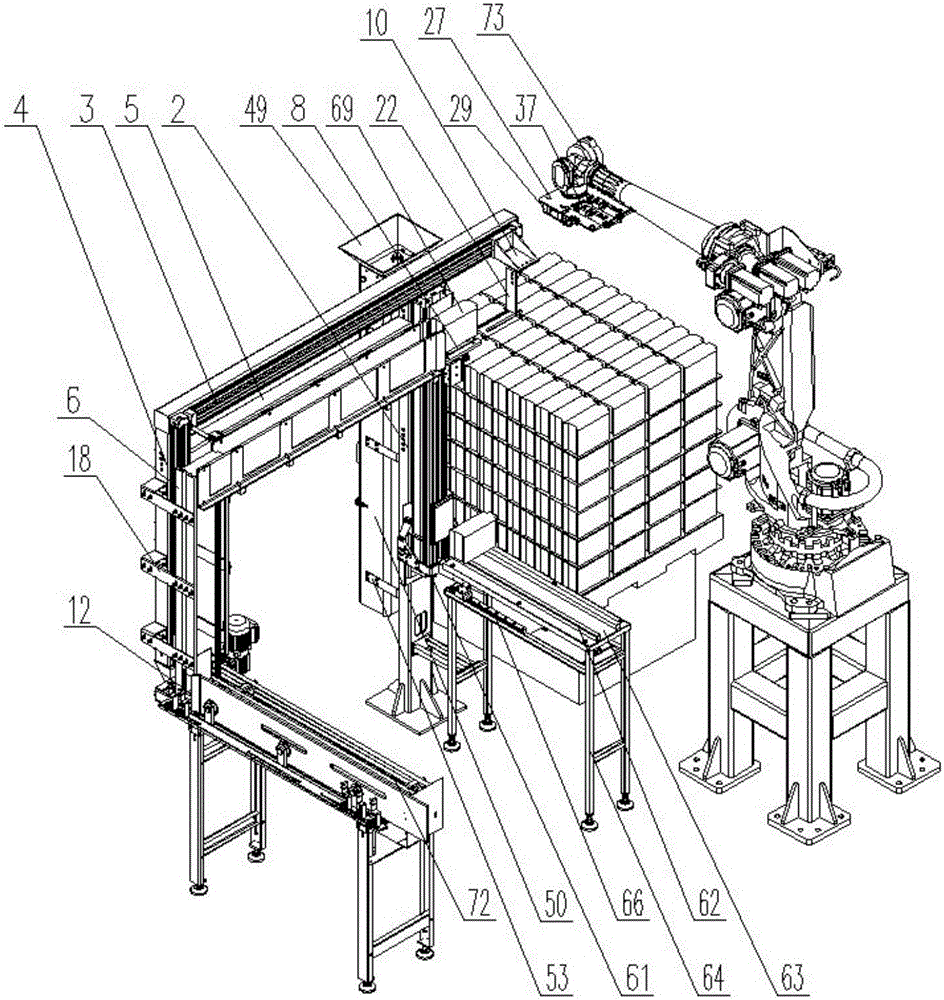

Robot-based automatic loading system for cigarette packaging square accessories

ActiveCN105883387ATimely detection of blockageIncrease falls intoConveyorsControl devices for conveyorsEngineeringAtmospheric pressure

A robot-based automatic loading system for cigarette packaging square accessories is characterized by comprising a bulk accessory conveyor system arranged on a gantry-type main support, a robot fixture close to the right side of the gantry-type main support, a bulk accessory wrapper recycling device fixed at the front end of the right side of the gantry-type main support, an automatic bulk accessory waste recycling device fixed at the rear end of the right side of the gantry-type main support, a bulk accessory wrapper withdrawal assisting mechanism arranged on a bulk accessory conveying rack, a synchronous belt conveyor connected to the left side of the gantry-type main support, and a joint robot arranged on the robot fixture, as well as a pneumatic system for providing power for a material transporting system, a material conveying system and a tool cutting system. The robot-based automatic loading system has the following beneficial effects: the production cost is effectively lowered, and the production efficiency is greatly improved; and the robot-based automatic loading system is simple in structure, good in strength and rigidity and stable and reliable in operation, and is efficient and energy-saving.

Owner:云南昆船电子设备有限公司

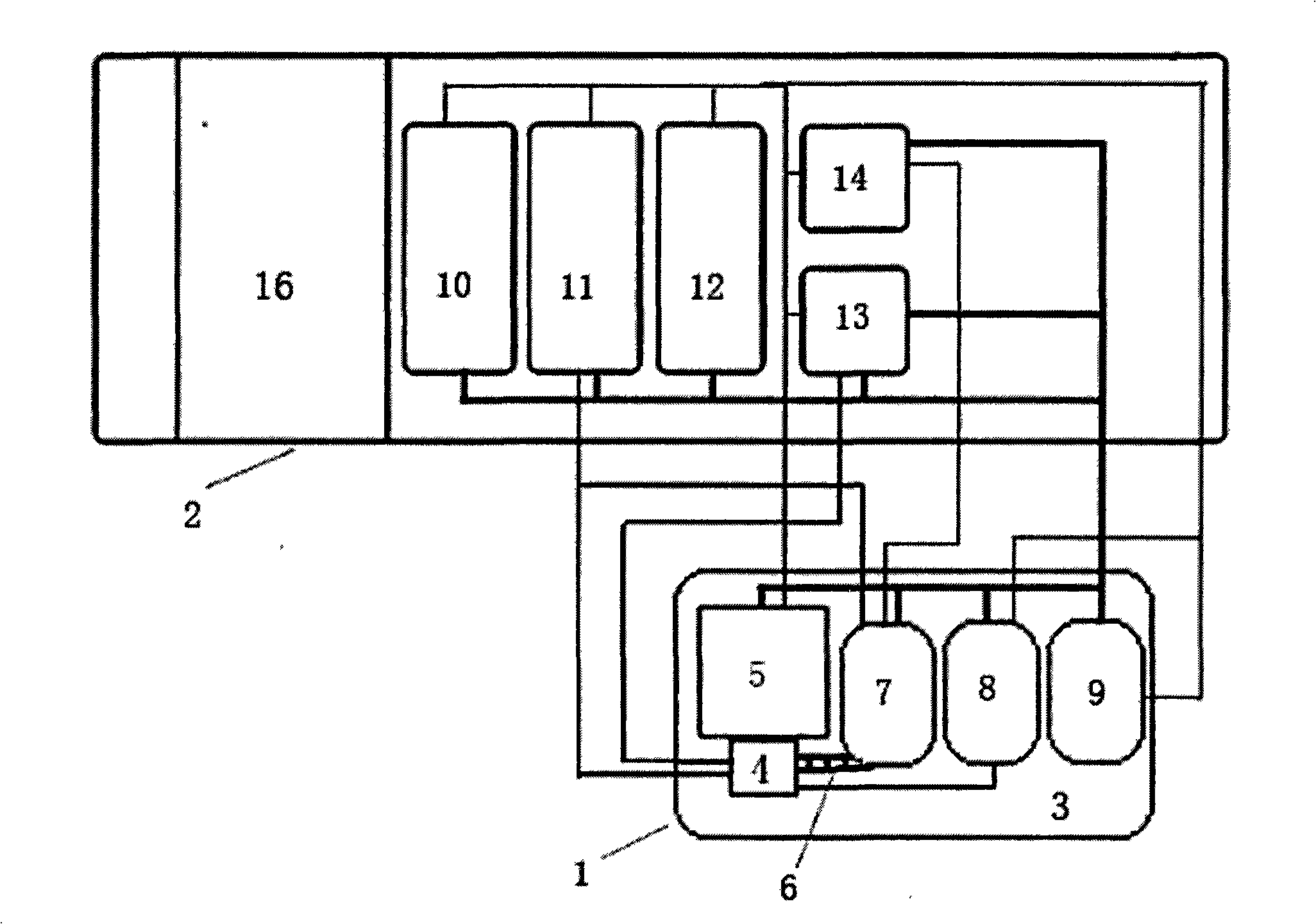

Vacuum welding furnace and welding technology

ActiveCN107931768AReduce the temperaturePrevent oxidationHeating appliancesMetal working apparatusEngineeringOxygen

The invention provides a vacuum welding furnace and a welding technology, and belongs to the technical field of vacuum welding. The vacuum welding furnace is characterized in that one end, close to the feeding end, of a welding platform (20) is used as a heating area; one side, close to the discharging end, of the welding platform (20) is used as a cooling area; a negative pressure pumping module(9) is arranged at the upper side of one end, close to the cooling area, of the heating area, and the negative pressure pumping module (9) is mounted on a furnace cover (4) by lifting; the bottom partof the negative pressure pumping module (9) and the heating area encircles a closed negative pressure chamber; a protecting gas inlet pipe is arranged on a welding chamber (18) or the furnace cover (4). According to the vacuum welding furnace, material sheets can be heated through the heating area, so that the material sheets can be quickly welded in the negative pressure chamber; protecting gasis charged, so that the material sheets are prevented from reacting with oxygen during being heated; the material sheets can be cooled and prevented from being oxidized through the cooling area. According to the welding technology, the welding time is decreased; the welding is accelerated; with the adoption of the cooling area, the material sheet can be completely cooled and is prevented from deformation caused by excessively quick cooling.

Owner:SHANDONG CAIJU ELECTRONICS TECH CO LTD

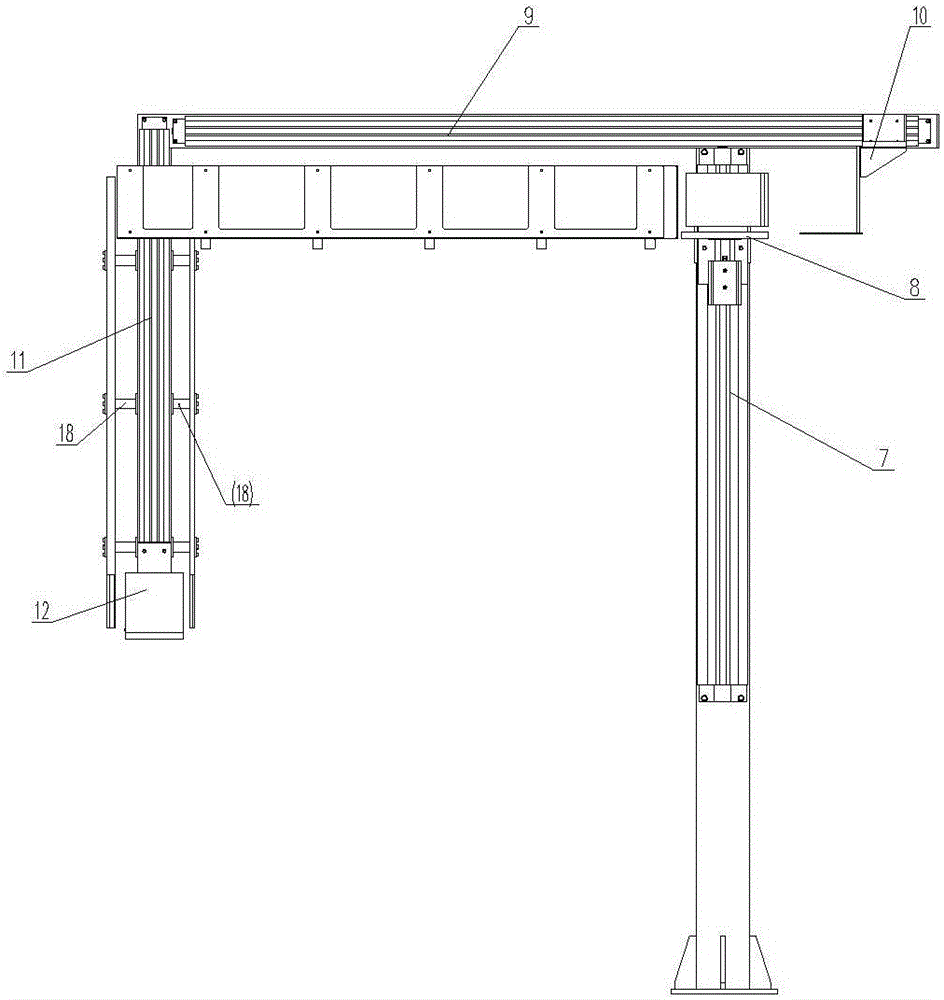

Three-gantry system

The invention discloses a three-gantry system which comprises an outer gantry, a middle gantry, an inner gantry and a fork, wherein first oil cylinders are arranged on the two sides of the outer gantry; the vertical motion of the middle gantry is driven by the ascending and descending of first stretching rods of the first oil cylinders; the inner gantry is driven to vertically move by a first chain arranged on the middle gantry, so that the fork vertically moves following the inner gantry; a second oil cylinder is arranged in the middle position of the inner gantry along the length direction; and the fork can be driven to vertically move by the ascending and descending of a second stretching rod of the second oil cylinder through a second chain. The three-gantry system provided by the invention can cause an article placed on the fork to ascend and descend by virtue of the driving of a hydraulic system, such as the oil cylinder, so that the carrying for the article is realized, the working efficiency is high, the use cost is low and the requirements of enterprise production and development are met.

Owner:SUZHOU PIONEER MATERIAL HANDLING EQUIP & TECH

Linear direction carrier for planar object

InactiveCN103552860AImprove work efficiencySo as not to damageArticle feedersConveyor partsAir pumpEngineering

The invention provides a linear direction carrier for a planar object. The linear direction carrier comprises a frame, a horizontal back-and-forth device, a vertical lifting device, N sucker heads and an air pump, wherein the air pump is used for controlling the sucker heads to extract and exhaust air. The horizontal back-and-forth device is mounted on the frame, the vertical lifting device is fixedly mounted on the horizontal back-and-forth device, the sucker heads are mounted on the lower surface of the vertical lifting device and connected with the air pump through air pipes, and N is larger than or equal to 1. The linear direction carrier for the planar object can automatically underlay paper sheets at the bottom of a pallet, and can carry the planar object to move in a linear direction.

Owner:HANGZHOU LINAN RENDA AUTOMATION EQUIP

Television carrying and turnover mechanism

InactiveCN106743568ARealize handlingPrevent accidental dropConveyor partsEngineeringMechanical engineering

The invention discloses a television carrying and turnover mechanism which comprises a vertical frame, a transverse moving mechanism, a lifting mechanism, a turnover mechanism and a falling prevention mechanism. The transverse moving mechanism is arranged on the vertical frame; the lifting mechanism is arranged on the transverse moving mechanism and provided with a grasping mechanism capable of moving up and down in the vertical direction and grasping workpieces; the turnover mechanism is arranged below the transverse moving mechanism; and the falling prevention mechanism is arranged on the lifting mechanism. By the adoption of the structure, the lifting mechanism can grasp the workpieces and put the workpieces on the turnover mechanism; the workpieces are turned over through the turnover mechanism and can slide to the target station in the turnover process, and thus carrying and turning over of the workpieces are achieved, traditional manual carrying is abandoned, the labor intensity of workers is greatly relieved, the production efficiency is improved, the situation that the workpieces are crashed or crushed by the workers by accident can also be avoided, and the yield of products is improved.

Owner:GUANGDONG HANDSOME INTELLIGENT EQUIP CO LTD

Flexible manufacturing assembly line for assembly of auxiliary insertion piece of robot

ActiveCN107196176ANo collisionNo impactContact member manufacturingContact member assembly/disassemblyAssembly lineElectronic component

The invention relates to automatic assembly equipment of an electronic component, in particular to automatic assembly line equipment for outputting an insertion piece. A flexible manufacturing assembly line for assembly of an auxiliary insertion piece of a robot comprises an automatic clamping mechanism, a large rotation disc, a carrying tool, a carrying tool conveying belt, a positioning mechanism, a swinging arm manipulator, a contact sheet correction mechanism and a contact sheet robot, wherein the automatic clamping mechanism is used for fixing the insertion piece, the large rotation disc is used for driving the automatic clamping mechanism to do circumferential rotation, the carrying tool is used for carrying a contact sheet, the carrying tool conveying belt is used for transmitting the carrying tool, the positioning mechanism is used for precisely positioning the carrying tool, the swinging arm manipulator is used for grabbing the contact sheet from the carrying tool, the contact sheet correction mechanism is used for achieving position correction of the contact sheet, and the contact sheet robot is used for picking up the contact sheet from the contact sheet correction mechanism and assembling the contact sheet onto the automatic clamping mechanism. In the flexible manufacturing assembly line for assembly of the auxiliary insertion piece of the robot, stepped feeding and accurate positioning of the contact sheet are achieved by the carrying tool conveying tool, and automatic correction and assembly of the contact sheet are achieved by the contact sheet robot.

Owner:广州博义知识产权运营有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com